SECTION 9B - SPEED SENSITIVE POWER STEERING

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). An SRS

will consist of either seat belt pre-tensioners and a driver's side air bag, or seat belt

pre-tensioners and a driver's and front passenger's side air bags. Refer to

CAUTIONS, Section 12M, before performing any service operation on or around any

SRS components, the steering mechanism or wiring. Failure to follow the CAUTIONS

could result in SRS deployment, resu lting in possible perso nal in jury or u nnecessary

SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of

safety, the LPG fuel system should be isolated by turning ‘OFF’ the manual service

valve and then draining the L PG service lines, before any service w ork is carried out

on the vehicle. Refer to the LPG leaflet included with the Owner's Handbook for

details or LPG Section 2 for more specific servicing information.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is

disturbed during Service Operations, it is vital that the complete ABS or ABS/ETC

system is checked, using the procedure as detailed in 4. DIAGNOSIS, ABS or

ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

1. GENERAL INFORMATION

Fitted to VT Calais as standard equipment, this power steering design provides variable assistance, depending on

vehicle speed. During low speed and/or parking manoeuvres, maximum assistance is provided, while minimal boost

with maximum feel is retained for high speed driving and cornering.

To achieve this variable assistance from a mechanical viewpoint, when compared to the power steering fitted to

other VT models, some minor changes to the power steering pumps and the steering rack assemblies are required.

1.1 GENERAL DESCRIPTION - RACK AND PINION ASSEMBLY

Apart from a design change to the upper end of the pinion assembly, the components in this steering system are

similar to the unit fitted to the remainder of the VT range of vehicles, with the standard power steering system.

With the exception of the servicing operations contained in this Section, all other servicing procedures for the

steering rack and associated components are the same as detailed in Section 9A STEERING.

Because the operation of the steering rack itself is as described in Section 9A STEERING, the following

description of the Speed Sensitive Rack and Pinion Assembly operation is restricted to the rotary valve only.

Techline

Techline

1.2 SPEED SENSITIVE ROTARY VALVE

GENERAL DESCRIPTION

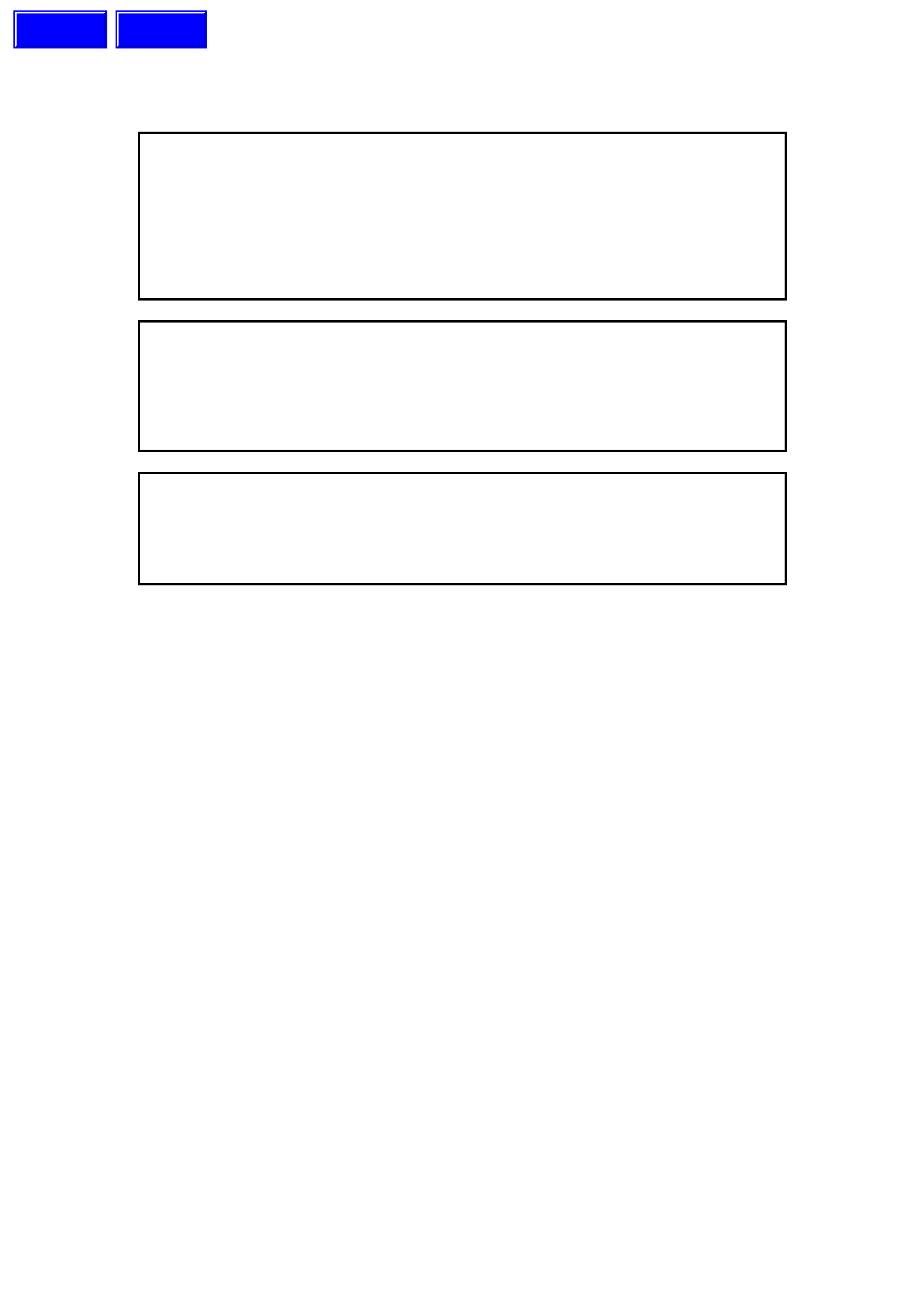

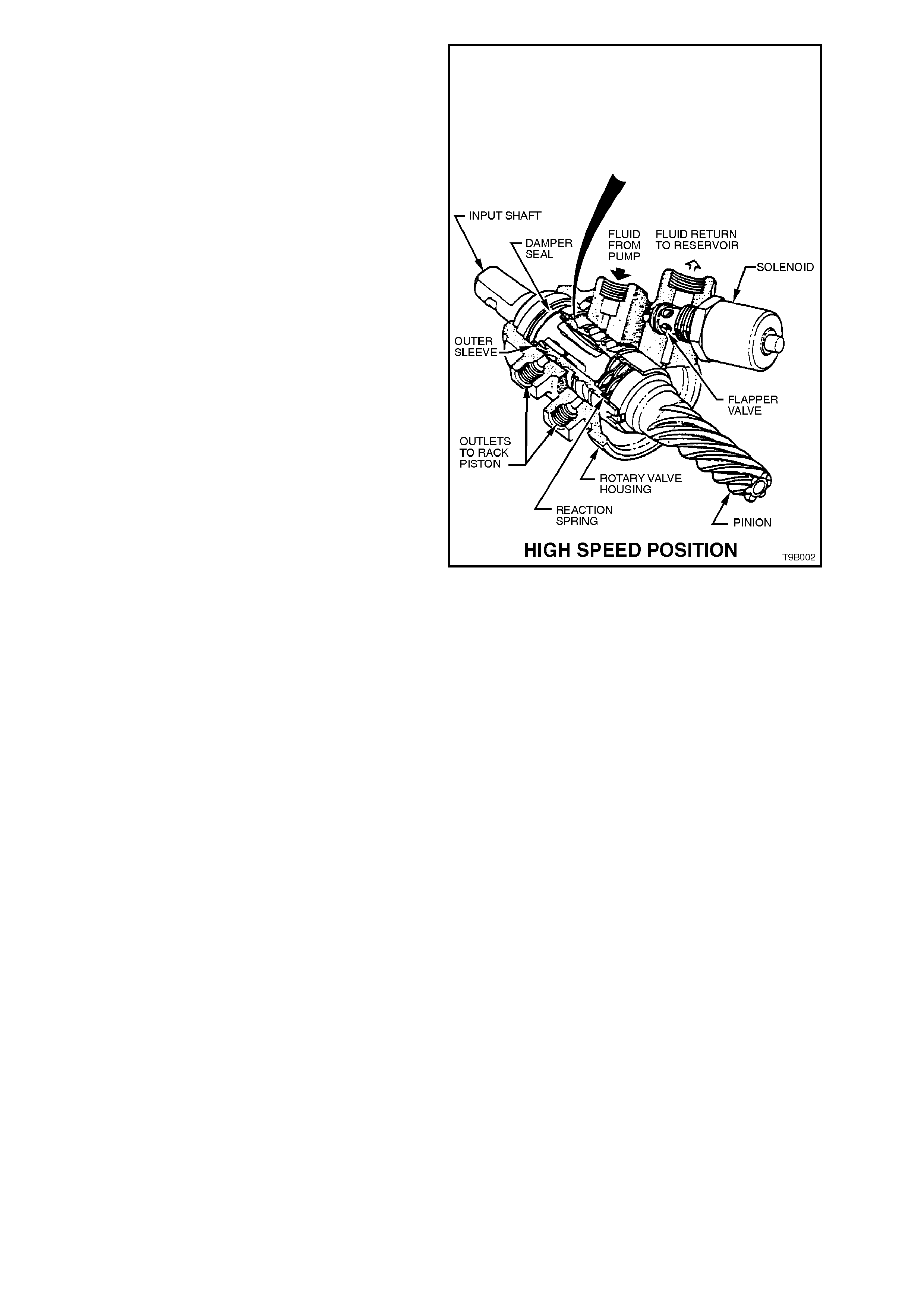

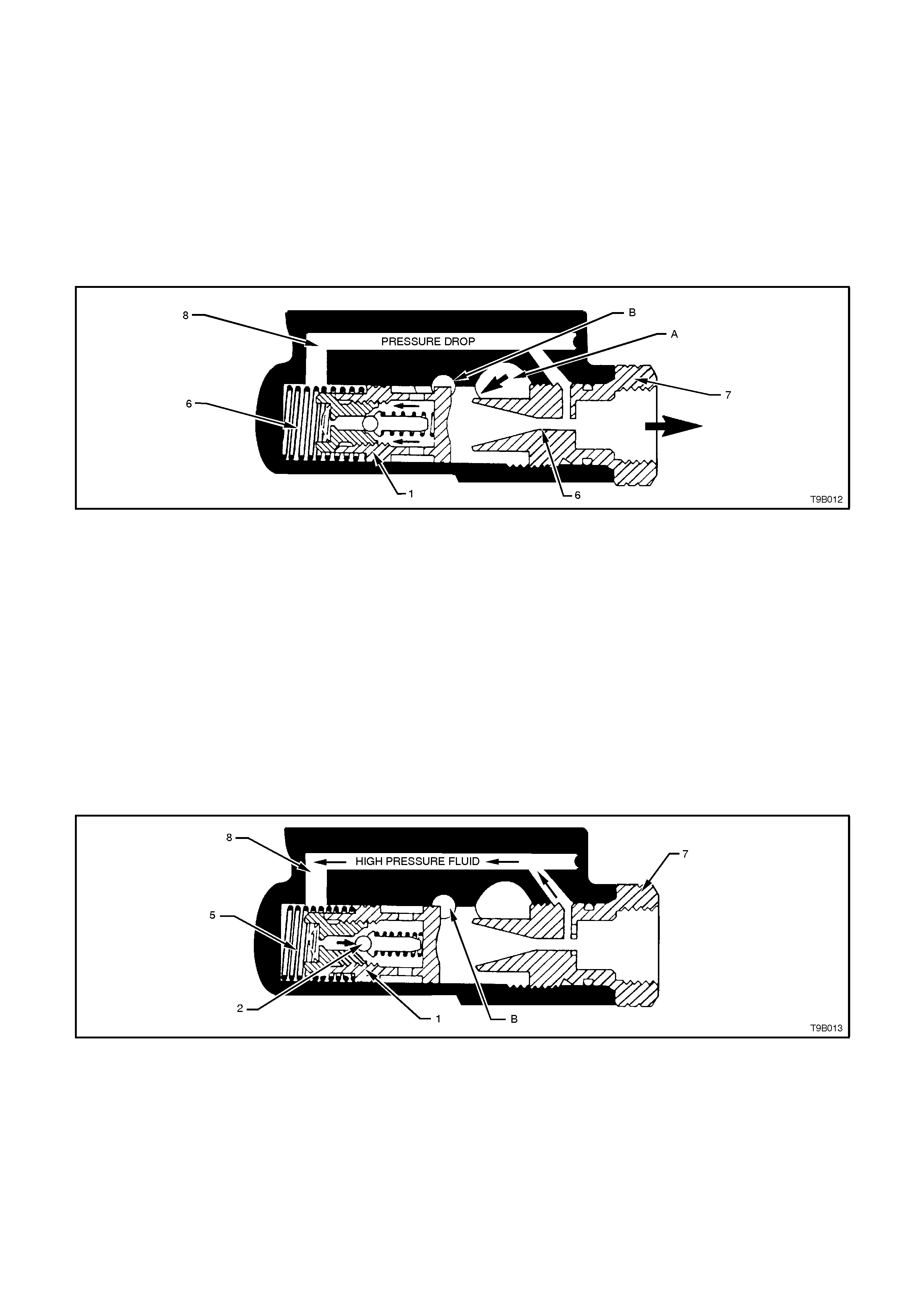

Sectioned views of the rotary control valve and

pinion assem bly are illustrated in F igures 9B-1, 9B-

2 and 9B-3, and it can be seen that the as s embly is

a modular design which provides some

interchangeability between the two different power

steering systems.

The vehicle speed related boost characteristic, is

caused by the outer sleeve member moving along

the inner input shaft member by approximately 4

mm. This outer sleeve movement alters the

quantity of fluid that is diverted to the rack piston,

varying the power assistance required. The outer

sleeve movement is controlled by a solenoid

operated 'flapper' valve, located in the fluid return

side of the valve. The solenoid operation is

controlled by the Body Control Module which

supplies a variable, pulse width, pulsed signal,

providing a variable pulse width (or "ON" time),

which is inversely proportional to road speed.

The outer sleeve's 'back and forth' movement

causes the slots in the internal bor e of the sleeve to

mask off pocketed regions machined in the inner

valve member of the input shaft, indicated in

Figures 9B-1 and 9B-2 as the 'High Speed Edge'.

The relative position of the inner valve and outer

sleeve has the effect of changing the fluid flow

characteristic and system pressure, inversely with

vehicle speed.

At low vehicle speeds, so lenoid valve activity raises

hydraulic pressure on the return side of the valve,

moving the sleeve against a reaction force provided

by a 'balancing' or reaction spring. Having raised

the system pres sure, the volum e of f luid diverted to

the steering rack will now be dependent upon the

twisting of the inner valve member, relative to the

outer sleeve.

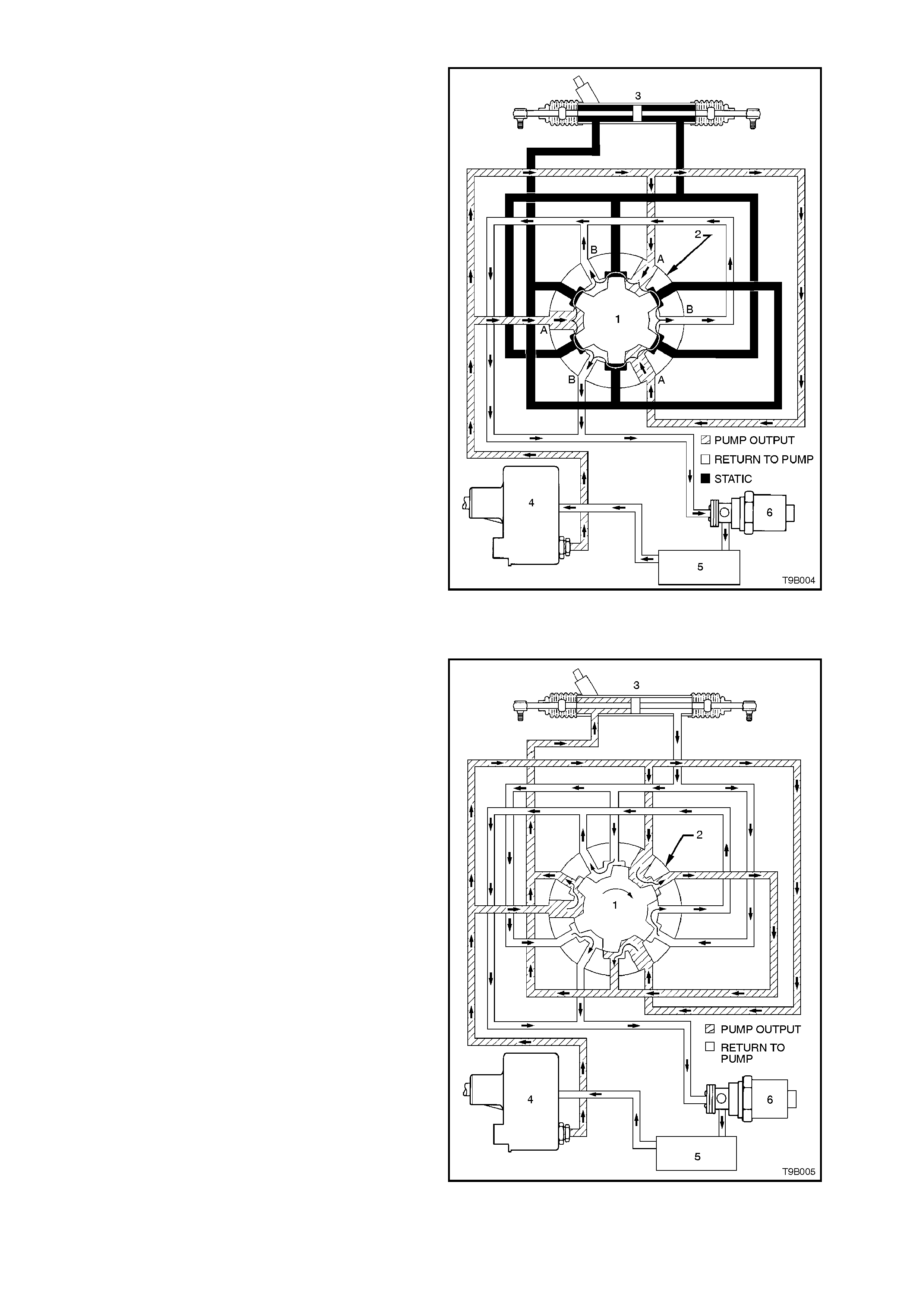

Figure 9B-1

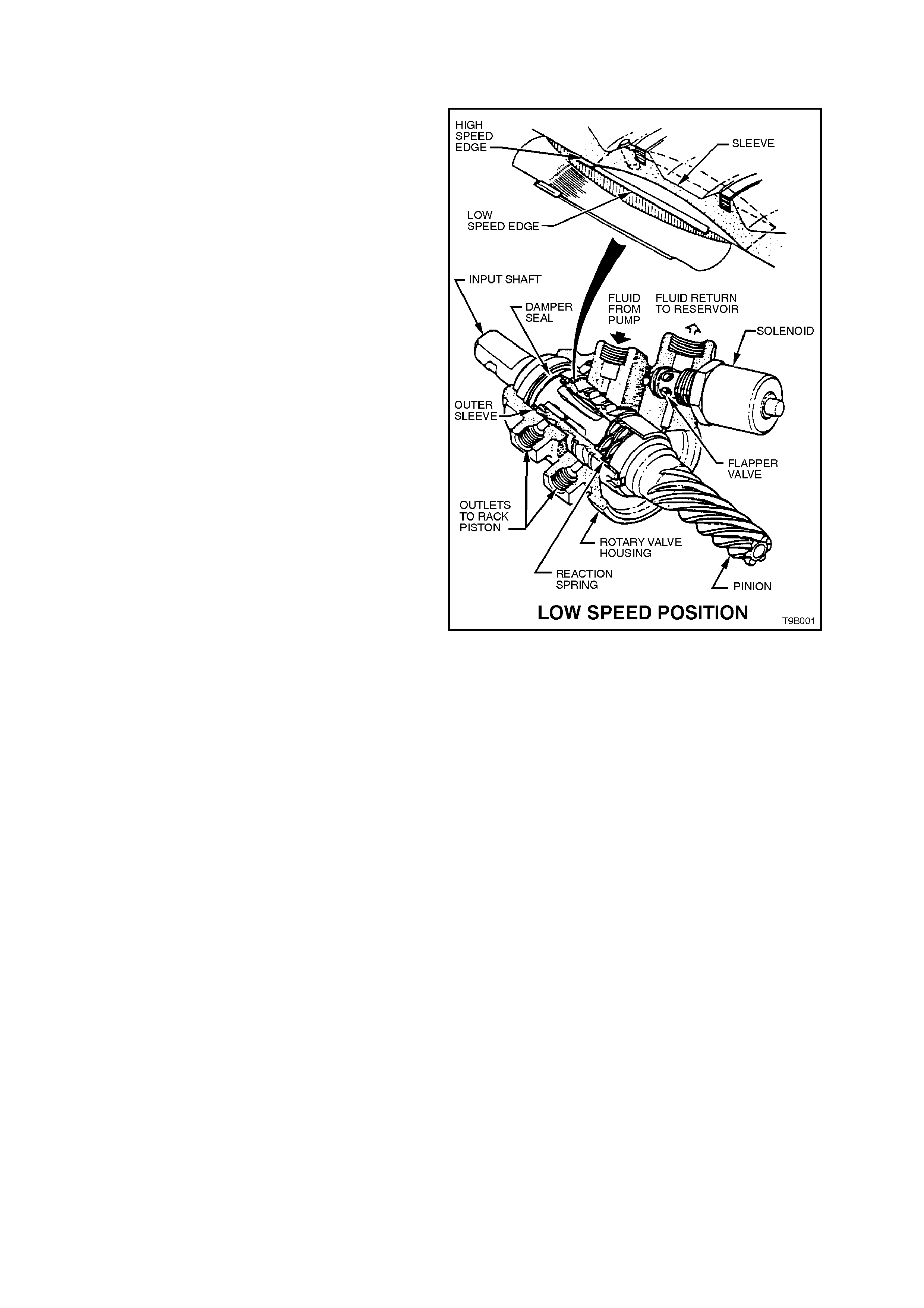

During high speed driving, when minimum boost is

required, the solenoid is not activated (above

approximately 80 km/h) and the reaction spring

moves the sleeve to its maximum point of travel.

This action effectively reduces the hydraulic

assistanc e provided to the steering rack . As vehic le

speed reduces, the solenoid is progressively

activated by the Body Control Module (BCM) and

the sleeve position is determined by the relative

balance between the return fluid pressure and the

reaction spring.

During slow speed parking manoeuvres, the

solenoid is fully activated, allowing the increased

return f luid pres sur e to move the s leeve agains t the

reaction spr ing, providing m axim um boos t pres sure

to the steering rack assembly, thereby requiring

minimum driver steering effort to turn the steering

wheel.

In the unlikely event of an electronic/electrical

failure, the control spring will move the sleeve to

the 'high speed' (or high effort) mode.

When the engine is stopped, the outer sleeve

member is pushed to the high speed (minimum

boost) position by the reaction spring. If this

situation continues f or a lengthy period of tim e (e.g.

overnight), cold, viscous fluid will have collected

behind the sleeve, at the reaction spring end. To

avoid a time delay on start up for the sleeve to be

positioned into the maximum boost position, an

orifice or bleed hole (refer to Figure 9B-3) is

provided, that allows the collected fluid to by-pass

the solenoid flapper valve and be exhausted to the

fluid reservoir.

A damper seal located at the fluid end of the

sleeve, is used to reduce sleeve oscillation that

could occur under some engine and vehicle

operating conditions. With these changing fluid

pressure levels, fluid is able to force past the seal

lip and, with a controlled leakage factor

incorporated into the seal design, effective damping

of the sleeve is achieved.

Figure 9B-2

Figure 9B-3 - Speed Sensitive Rotary Valve - Sectioned View

NEUTRAL POSITION (STRAIGHT AHEAD) - LOW SPEED METERING EDGE EXPOSED

With vehicle speeds less than approximately 18

km/h, the solenoid is fully activated, causing the

increased return fluid pressure to move the sleeve

against the reaction s pring, expos ing the low speed

metering edge. In the straight ahead position, the

fluid flow is directed into the inner valve assembly

through a number of drilled holes in the outer

sleeve. In this steering position, the inner valve

allows fluid to pass equally to both sides of the rac k

piston and also to return to the fluid reservoir,

through holes drilled in the longitudinal grooves of

the inner valve. With equal pressure applied to both

sides of the rack piston, no power assistance is

available.

Figure 9B-4

TURNING RIGHT - LOW SPEED METERING EDGE EXPOSED

When turning right with the low speed metering

edge exposed, as soon as slight relative rotation

between the input shaft (inner rotating valve) and

outer sleeve occurs, fluid is restricted in its free

return to the pump and is directed to the driver's

side of the piston. At the same time, fluid on the

other side of the piston is directed to the return

circuit, leading to the reservoir and pump. This

action is slight at first so that only a small amount of

assistance is provided, but becomes progressively

greater as the torsion bar flexes and the driver

requires more assistance.

Figure 9B-5

TURNING LEFT - LOW SPEED METERING EDGE EXPOSED

When turning left with the low speed metering edge

exposed, as soon as slight relative rotation

between the input shaft (inner rotating valve) and

outer sleeve occurs, fluid is restricted in its free

return to the pump and is directed to the

passenger's side of the piston. At the same time,

fluid on the other side of the piston is directed to

the return circuit, leading to the reservoir and

pump. This action is slight at first so that only a

small amount of assistance is provided, but

becomes progressively greater as the torsion bar

flexes and the driver requires more assistance.

Figure 9B-6

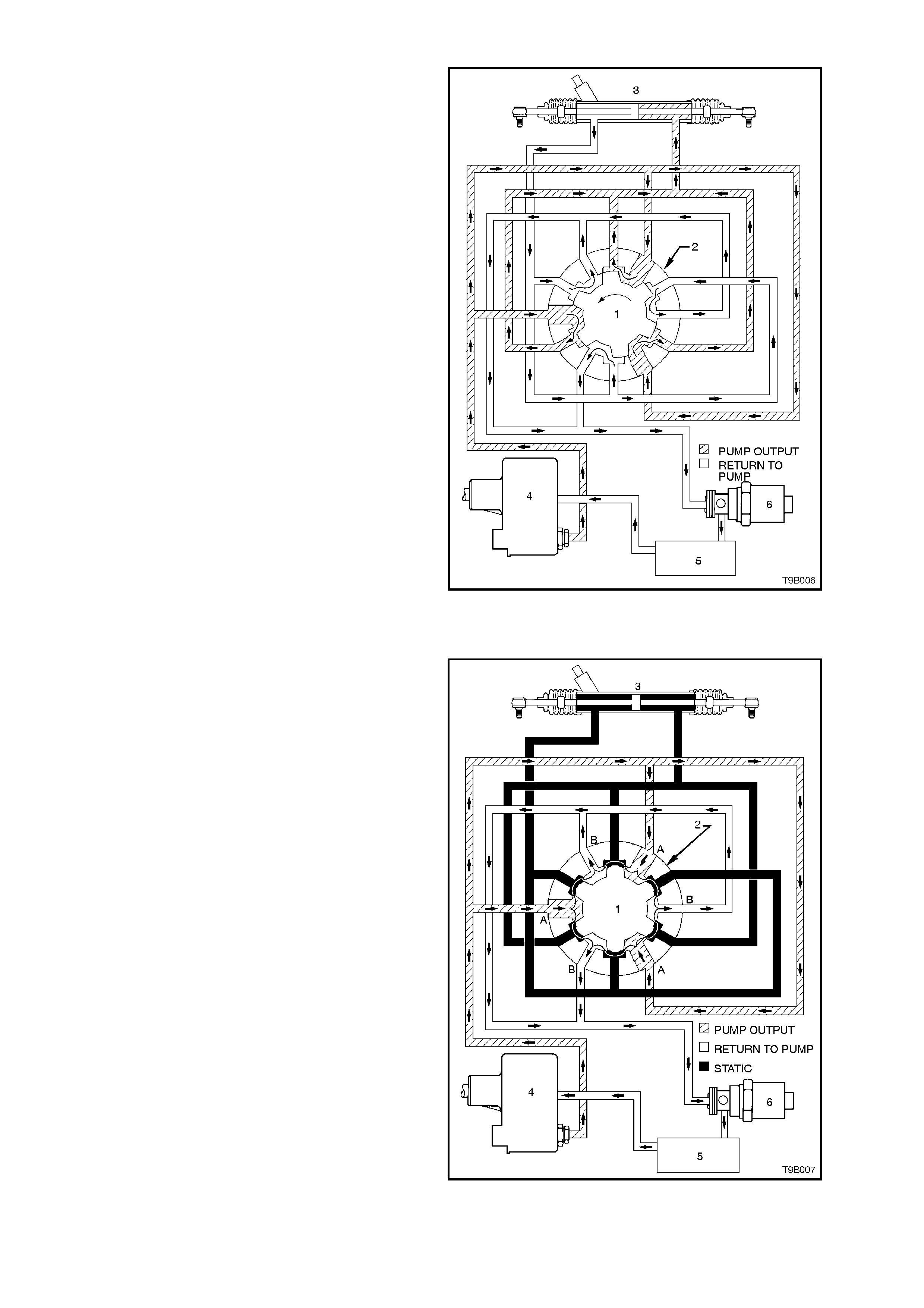

NEUTRAL POSITION (STRAIGHT AHEAD) - HIGH SPEED METERING EDGE EXPOSED

With vehicle speed above approximately 80 km/h,

the solenoid is not ac tivated at all, and the reac tion

spring moves the outer sleeve to it's maximum

point of travel, exposing the high speed metering

edge. In the straight ahead position, the f luid f low is

directed into the inner valve assembly through a

number of drilled holes in the outer sleeve. In this

steering position, the inner valve allows fluid to

pass equally to both sides of the rack piston and

also to return to the fluid reservoir, through holes

drilled in the longitudinal grooves of the inner valve.

With equal pressure applied to both sides of the

rack piston, no power assistance is available.

Figure 9B-7

TURNING RIGHT - HIGH SPEED METERING EDGE EXPOSED

When turning right with the high speed metering

edge exposed, increased relative rotation is

required between the input shaft (inner rotating

valve) and outer sleeve, before the fluid is

restricted in its free return to the pump and is

directed to the driver's side of the piston. This

means that little or no assistance is provided with

norm al steering m anoeuvres at these road s peeds.

At the sam e time, f luid on the left s ide of the piston

is directed to the return circuit, leading to the

reservoir and pump.

Figure 9B-8

TURNING LEFT - HIGH SPEED METERING EDGE EXPOSED

When turning left with the high speed metering

edge exposed, increased relative rotation is

required between the input shaft (inner rotating

valve) and outer sleeve, before the fluid is

restricted in its free return to the pump and is

directed to the passenger's side of the piston. This

means that little or no assistance is provided with

norm al steering m anoeuvres at these road s peeds.

At the same time, fluid on the right side of the

piston is directed to the return circuit, leading to the

reservoir and pump.

Figure 9B-9

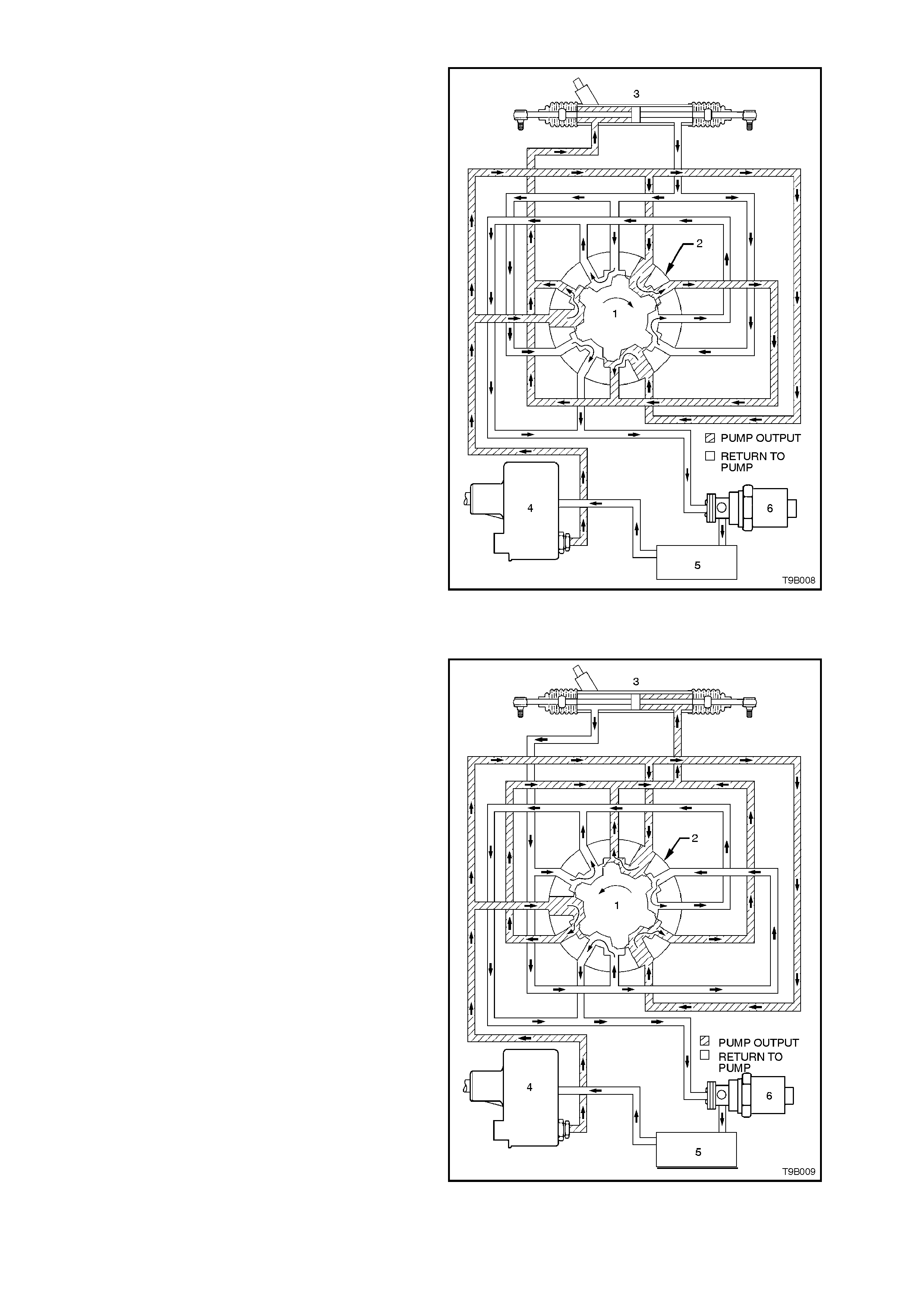

1.3 POWER STEERING PUMPS

GENERAL DESCRIPTION

The power steering pumps fitted to vehicles with

speed sensitive power steering are of the constant

flow type. However, servicing procedures are

essentially the same as those for the droop flow

design, fully detailed in Section 9A STEERING.

The only exception is the outlet fitting, which does

not feature a m etering needle valve as in the dr oop

flow design.

If a power steering pump r equires r eplacement, it is

essential that the correct type is selected. Refer to

the following table and the diagram shown, for

identification details of the available power steering

pumps for the complete range of VT Series

vehicles, regardless whether the system is the

standard or speed sensitive design.

The location of the part number (1 or 3) is as

shown, while the last 5 digits (2) of the V6 pump is

also provided.

PUMP APPLICATION PART NUMBER

V6 ENGINE:

STANDARD 26056053

SPEED SENSITIVE 26056054

V8 ENGINE

STANDARD 26056055

SPEED SENSITIVE 26056056

Because the pumps used for the speed sensitive

power steering, have a constant flow outlet fitting,

the operation is slightly different to the droop flow

design. Figure 9B-10

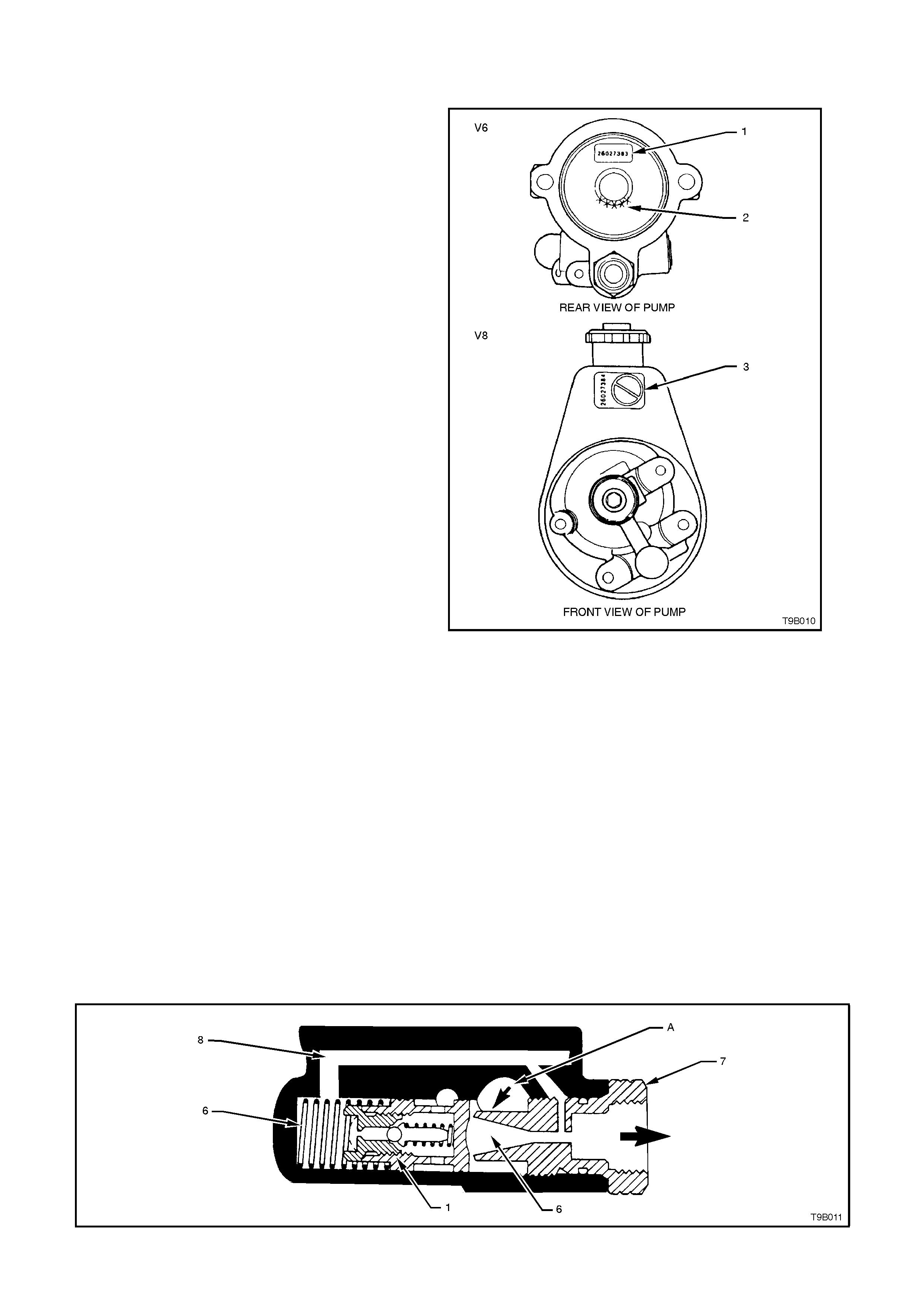

CONSTANT FLOW CONTROL VALVE OPERATION

Slow Cornering

Pump speeds during slow cornering or parking are normally low, as are demands for fluid flow volume, due to

slower steering manoeuvres.

With reasonably high relative movem ent of the inner valve and outer sleeve in the s teering rac k control valve at this

time, the fluid is pressurised to approximately 3,400 kPa to 4,800 kPa and directed to the high pressure cavity

behind the pressure plate. Discharge ports direct this fluid to the outlet fitting (7) and then on to the steering gear.

The discharge fluid pressure from the outlet fitting, is slightly lower in pressure than the internal high pressure (A),

coming from the pump ring.

This drop in pressure, due to venturi action, occurs as the fluid flows through the orifice (6) in the outlet fitting (7).

This lower pres sur e is trans mitted to the spr ing (6) end of the c ontr ol valve (1) by a fluid pas s age (8) c onnec ting the

control valve (1) to the outlet fitting (7).

This results in a pressure unbalance at each end of the control valve (1), causing it to move away from the outlet

fitting (7). Owing to the force of the control valve spring (6), the valve (1) remains closed to the fluid by-pass hole.

Because suf ficient fluid is allowed to circulate through the system, fluid pressure does not build up high enough to

cause the pressure relief ball check in the valve (1).

Figure 9B-11

MODERATE TO HIGH SPEED OPERATION

System press ure in this m ode is norm ally low (approx imately 260 kPa) due to the lac k of steering manoeuvr es and

high fluid flow rates. W hen the steering is in the straight ahead position, fluid is discharged f rom the high pressure

cavity (A), through the outlet fitting (7) to the steering gear and back to the pump reservoir.

When this flow exceeds a preset level, fluid is by-passed within the pump, as follows:

Fluid passing through the outlet fitting (7), causes a pressure reduction to occur in the orifice (6) by venturi action.

This reduced press ure is trans mitted to the spr ing (6) end of the c ontrol valve (1), via the f luid by-pass pass age (8)

connecting the control valve (1) and the outlet fitting (7), as shown.

This pressure difference on each side of the control valve, causes the valve to move against spring (6) force,

opening the fluid by-pass passage (B) to the pump inlet. Depending on vehicle road speed, pump speed and the

steering requirements needed by the driver, this valve (1) will modulate, controlling the fluid flow rate through the

steering system.

Figure 9B-12

CORNERING AGAINST WHEEL STOPS

When the steering wheel is turned to full lock and held in that position, the steering rack power piston chamber

becomes fully pressurised and fluid flow stops.

NOTE:

This full lock condition should not be maintained for long periods of time (in excess of five minutes) due to

excessive fluid temperature rise.

The resulting high pressur e is then transm itted to the spring (5) end of the control valve (1) through the connec ting

fluid passage (8) from the outlet fitting (1).

When the pressure builds up high enough, the relief ball check (2) within the control valve (1) opens, allowing a

small amount of fluid to pass through the pressure relief orifice, causing a pressure drop that results in a lower

pressur e acting on the spring (5) end of the contro l valve (1). The c ontrol valve then m oves against spr ing (5) forc e

and opens up the fluid by-pass passage (B) so that fluid is returned to the pump inlet. Pre-determined relief

pressure is thus maintained while the steering gear is turned and held on full lock.

Figure 9B-13

1.4 SOLENOID VALVE

GENERAL DESCRIPTION

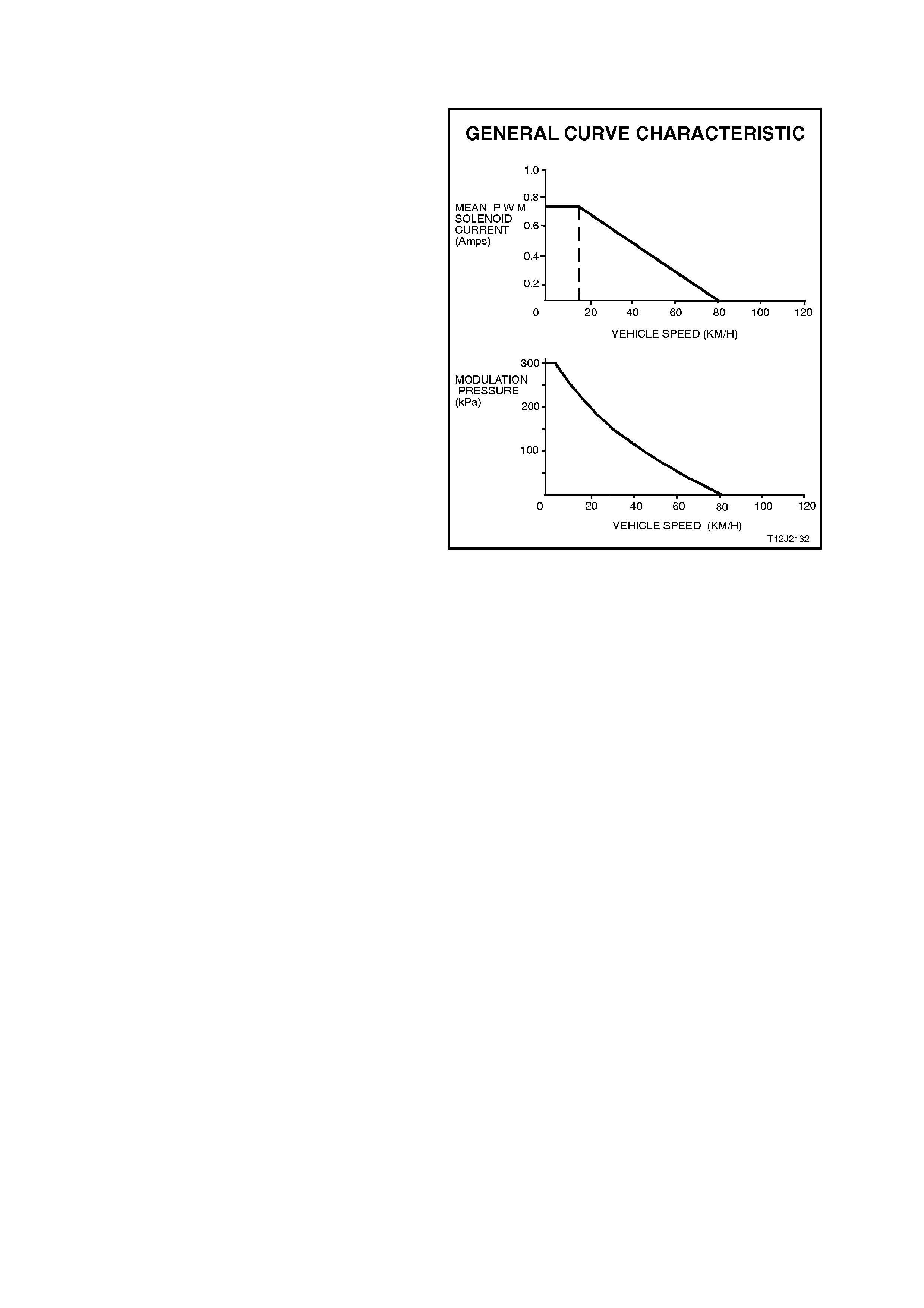

When activated, the solenoid receives a Pulse

Width Modulated (PWM) current flow from the

Body Control Module (BCM), that varies inversely

with vehicle road speed. By changing the pulse

width of the BCM current flow (i.e. the "ON" time),

pressure control within the power steering system

is maintained. As illustrated by the 'typical'

diagrams shown, the average PWM solenoid

current is controlled by the BCM's programming to

provide the m odulated pressures shown. Max imum

modulation pressure is only applied during parking

and up to a low speed of a few km/h.

From this speed, the modulated pressure falls as

road speed increases until, at approximately 80

km/h, the solenoid receives no further current

pulses fr om the BCM and modulation pres sure f alls

to 0 kPa.

Reference to the following table and the graphs, the

PWM current flow relative to road speed and

modulation pressure, is shown.

CURRENT (Amp.) ROAD SPEED (km/h)

0.75 0 - 12

0.45 40

0.0 80+

NOTE:

Do not disassemble the solenoid or attempt to

adjust it. If a problem with this component is

suspected, the whole solenoid assembly must be

replaced.

Figure 9B-14

2. SPEED SENSITIVE POWER STEERING SERVICE OPERATIONS

With the exception of operations detailed in this

Section, speed s ensitive power steering operations

are the same as for standard power steering, as

detailed in Section 9A STEERING.

2.1 POWER STEERING GEAR

Important:

NOTE 1:

Remove the ignition key from the ignition lock and

ensure that the steering column is locked. If this

operation is not carried out and the steering wheel

is spun while the steer ing gear is r emoved f r om the

vehicle, the clock spr ing coil in the upper end of the

steering column will be destroyed!

NOTE 2:

If the ignition switch is not in the "OFF" position

when this procedure is c arr ied out, the BCM will log

a fault situation and a total BCM reset will have to

be carried out. Refer to Section '12J-2 HIGH

SERIES BCM' for the necessary procedure.

REMOVE

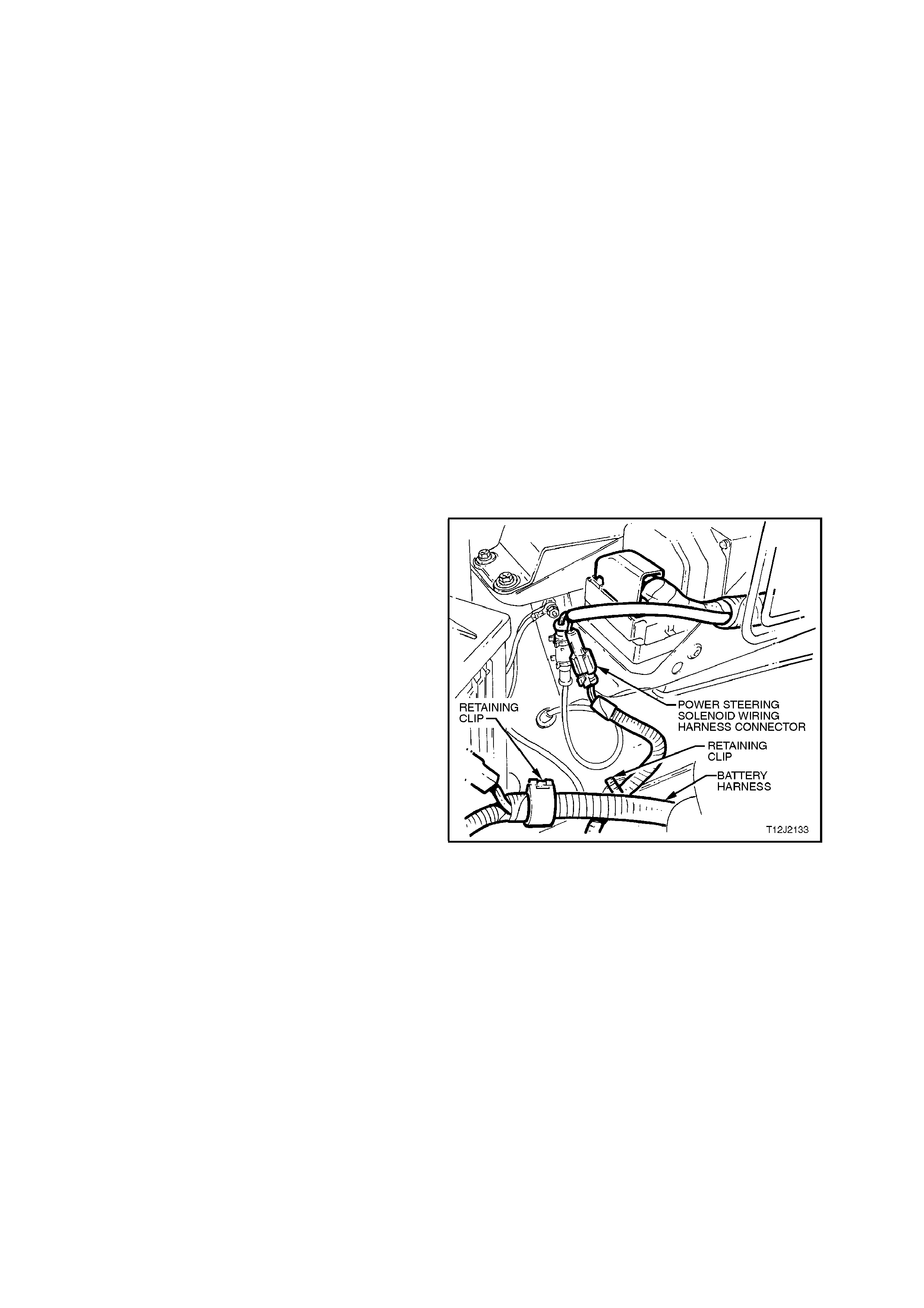

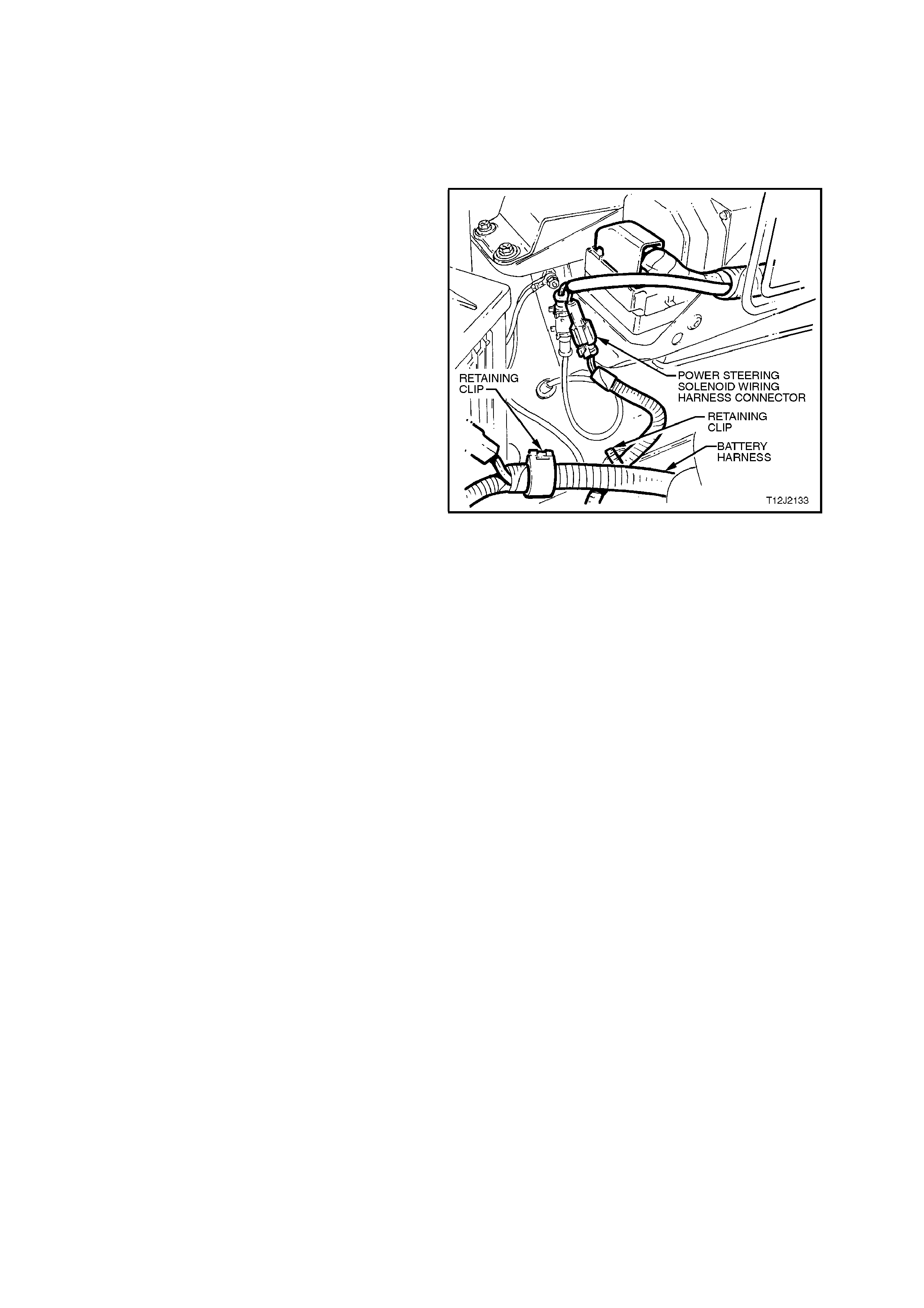

1. Disconnect power steering solenoid wiring

harness connector by lifting the locking tab

and pulling on the connector halves.

Do not pull on the wiring.

2. Disconnect the retaining clips securing the

solenoid wiring, in two places.

For all other removal operations, refer to the

procedure outlined in 3.6 POWER STEERING

GEAR in Section 9A STEERING.

Figure 9B-15

REINSTALL

With the exception of the following operations,

reinstall the power steering, as detailed in

Steering 9A STEERING.

1. Reconnect the power steering solenoid wiring

harness connector, ensuring that the two

connector halves lock together.

2. Reconnect the retaining clip to secure the

solenoid wiring harness.

2.2 SOLENOID ASSEMBLY

REMOVE

1. Disconnect wiring harness connector by lifting

the locking tab and pulling on the connector

halves.

DO NOT pull on the wiring.

NOTE:

The ignition switch MUST be turned 'OFF'.

2. Remove the retaining clips securing the

solenoid wiring, in two places.

Figure 9B-16

3. Using a 1 1/8" set spanner, loosen, then

remove the solenoid from the rotary valve

body.

IMPORTANT:

Do not disassemble the solenoid or attempt to

adjust the flapper valve seat. It is pre-set during

manufacture and is not to be tampered with. If a

problem with the solenoid is suspected, the

complete solenoid assembly must be replaced.

TEST

Because the temperature of the solenoid has a

marked effect on its resistance, the temperature

must be taken into account when checking the

following resistance readings.

1. Using a digital Ohmmeter, check the

resistance between each of the two solenoid

wires and the body of the solenoid.

Each reading should be infinity (Open Circuit).

2. The resistance between the two wires at the

harness connector will change with solenoid

temperature. The resistance reading therefore,

should be within the ranges detailed in the

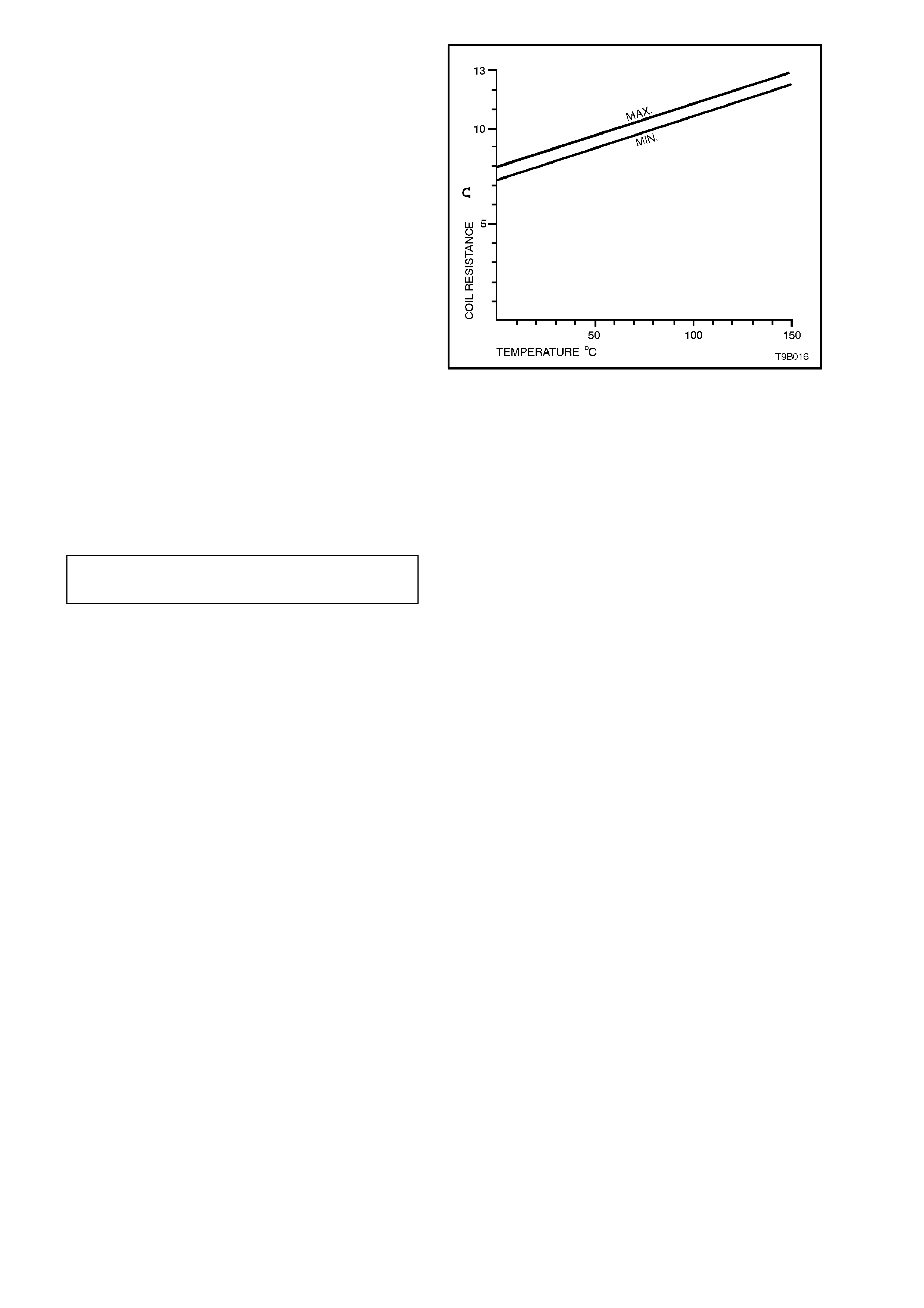

following table or as indicated in the graph.

RESISTANCE (W) TEMPERATURE (° C)

7.6 0

9.2 50

10.9 100

12.3 150

Figure 9B-17

REINSTALL

1. Replace both the O-ring on the solenoid stem

and the sealing ring around the threaded

section.

2. Apply petroleum jelly to the O-ring, install the

solenoid and tighten to the specified torque.

SOLENOID ASSEMBLY 35 - 40

TORQUE SPECIFICATION Nm

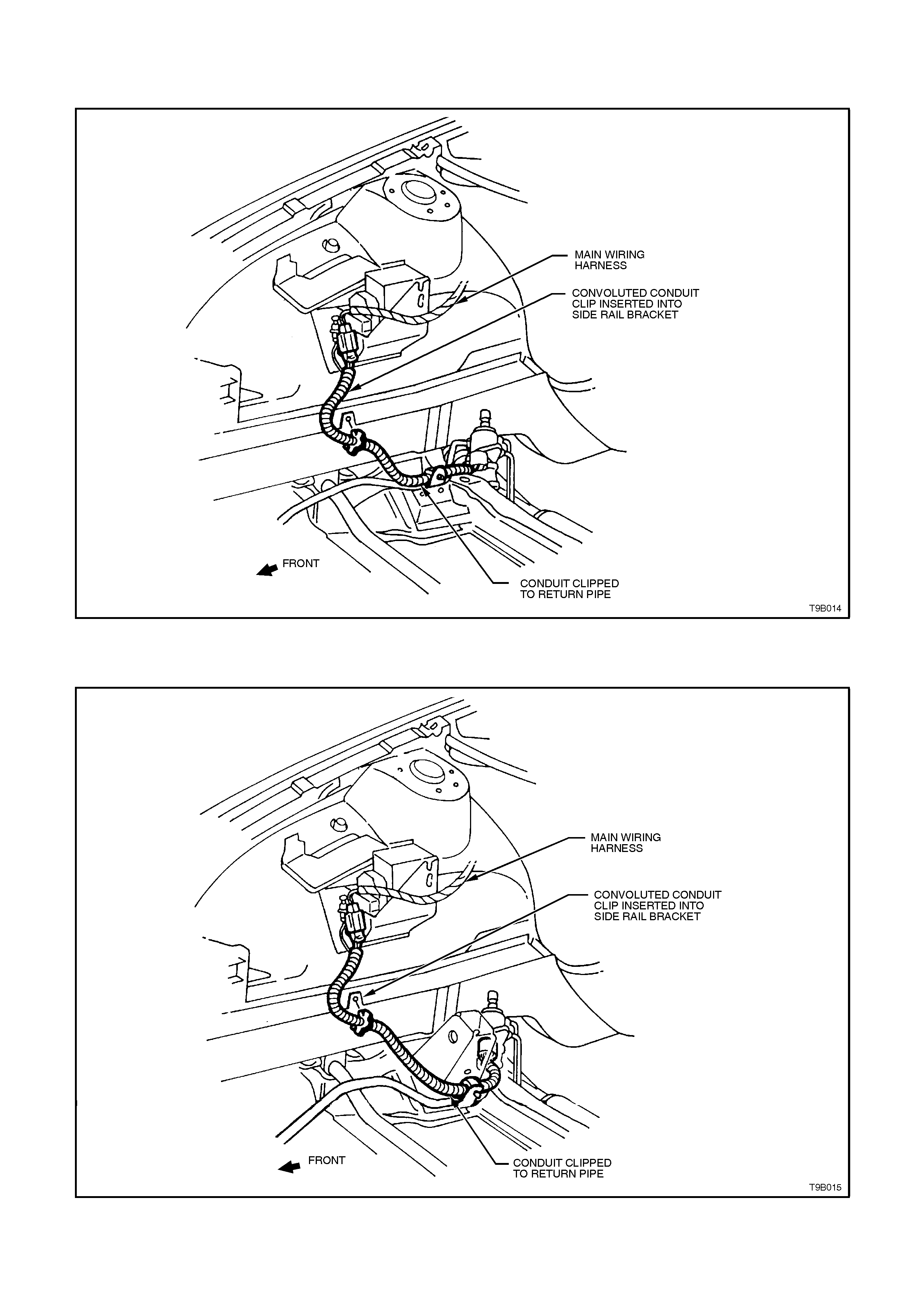

2.3 SOLENOID WIRING ROUTING

V6 ENGINE

Figure 9B-18 - V6 Engine

V8 ENGINE

Figure 9B-19 - V8 Engine

3. DIAGNOSIS

Diagnosis of the Speed Sensitive Power Steering System relies on a series of different tests to determine the

component/s causing the problem.

For example, pressure testing is required to isolate power steering pump from steering rack malfunctions, while

electrical testing of the solenoid and its circuit is needed to establish correct functioning of this component.

3.1 GENERAL DIAGNOSTIC INFORMATION

Faulty steering can be caused by problems in areas other than the pump or steering gear. Areas of the steering

system which can be easily checked and quickly corrected without disassembly and overhaul of any major

components should be attempted first.

Problem s such as hard or loose steering, road shoc k or vibrations ar e not always due to the steer ing gear or pum p,

but are often related to such factors as low tyre pressure or front end alignment. These items should be checked

and corrected before any adjustment or disassembly of the steering gear or pump is attempted.

Other factors which may affect correct operation of the steering system, are:

1. Loose component mountings.

2. Drive belt tension.

3. Fluid level and condition.

These factors must be checked and corrected before making any further diagnosis of the steering system.

After the source of the problem has been located, the cause of the problem can be diagnosed and corrected.

For exam ple, if the fluid level in the reservoir is found to be low, refill and c heck the entire hydraulic s ystem for fluid

leaks. Refilling the reservoir will not necessarily correct the problem.

Techline

Techline

3.2 SPEED SENSITIVE POWER STEERING DIAGNOSIS

For power steering pump noise and/or leaks, refer

to 4. DIAGNOSIS, in Section 9A STEERING.

STAGE 1. PRESSURE CHECKS

1. Check high pressure s ide of hydraulic s ystem ,

as detailed in 3.4 HYDRAULIC SYSTEM -

CHECK in Section 9A STEERING.

NOTE:

Constant Flow pump pressure specifications are

the same as Droop Flow pumps. Therefore, refer

to Section 9A STEERING for these details.

Results:

This pressure test is designed to assist in the

diagnosis of a pressure related hydraulic problem,

either in the power steering pump or steering rack

assembly. It will not assist in the diagnosis of

vehicle speed related problems within the steering

system.

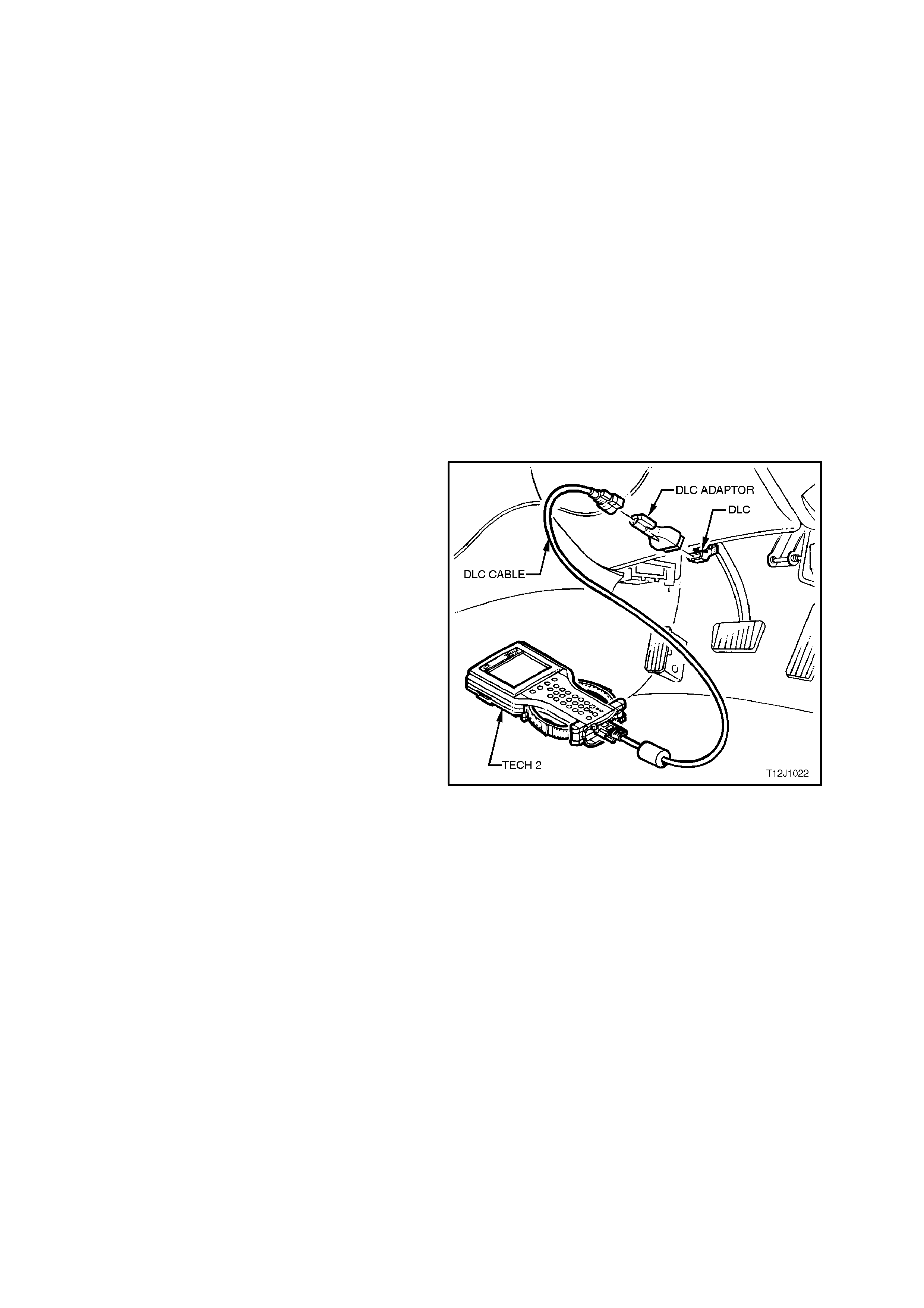

STAGE 2. ELECTRICAL CHECKS

Because of the risk of damage to electronic

components and the possibility that a BCM reset

condition may occur, the method recommended to

check the electrical components of the speed

sensitive power steering system is to use the TECH

2 Diagnostic Tool.

When connected to the Data Link Connector (DLC)

with the appropriate software, c ables and adaptors,

TECH 2, is capable of reading serial data relative to

the speed sensitive power steering solenoid.

The DLC is connected to the instrument panel

lower right hand trim, to the right of the steering

column.

For additional general information on connecting

and operating TECH 2, refer to

Section 0C, TECH 2.

Figure 9B-20

4. SPECIFICATIONS

STEERING GEAR

Steering Gear Type

Speed Sensitive Power Steering Rack and Pinion with integral power

cylinder and rotary control valve

mechanism - variable ratio with variable assist.

Steering Gear Ratio

On-Centre 17.2:1

Toward Lock 11.8:1

No. of Steering Wheel Turns Lock to Lock 3.0

Nominal Rack Travel Total 164 mm

POWER STEERING PUMP

Make Saginaw

Type V6 'N' Series: Constant Flow Type

V8 'P' Series: Constant Flow Type

Pressure Relief (at engine idle speed)

V6 7,580 - 8,270 kPa

V8 8,270 - 8,960 kPa

Drive Pulley

Lubrication (Power Steering) DEXRONÒ III Automatic Transmission Fluid.

Fluid Capacity Approximately 650 ml

Note: Use fluid level indicator as a final check

to ensure correct refill quantity.

Drive Belt Tension

V6 Belt Self Adjusting

V8 -New Belt 57 kg

Used Belt 34 kg (A belt is considered "used" after

10 minutes of operation).

GENERAL SPECIFICATIONS

Front Toe Specification (All VT Models)

Toe-in Total 0° 10' ± 0° 10'

Toe-in (per Wheel) 0° 5' ± 0° 5'

Specified Grease EP Semi Fluid Lithium Base O-Grease

Specified Thread Locking Compound Loctite 242 or equivalent to Holden

Specification HN 1256 Class 2, Type 2

5. TORQUE WRENCH SPECIFI CATIONS

NOTE:

Only those torque wrench specifications relating to service operations described in this Section, are included here.

For the remainder of torque specifications applicable to power steering components, refer to

6. TORQUE WRENCH SPECIFICATIONS, in Section 9A, STEERING.

POWER STEERING GEAR Nm

Solenoid 35 - 40

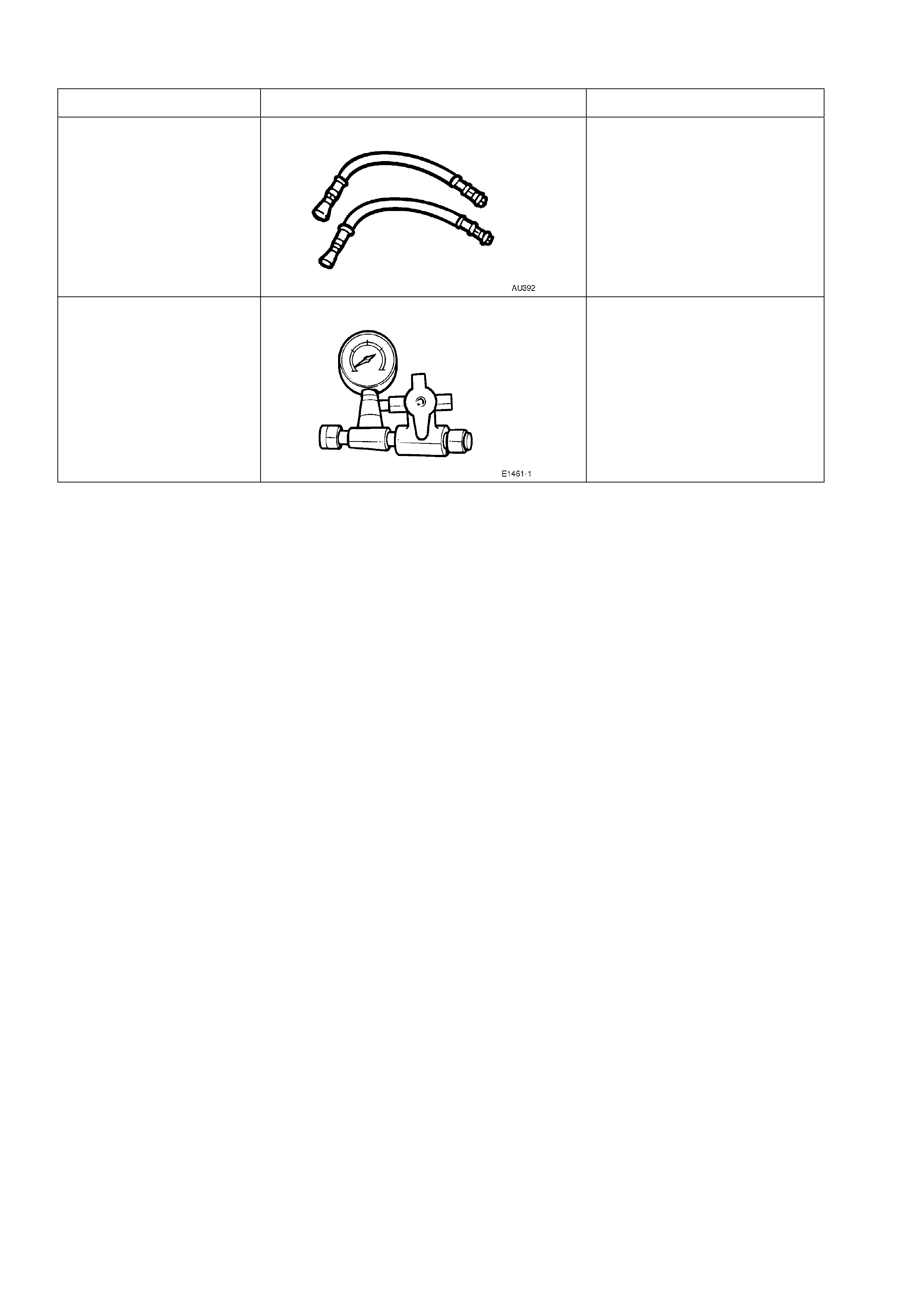

6. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

AU392 PRESSURE HOSE SET PREVIOUSLY RELEASED.

COMPRISES:

AU392-1, HOSE WITH MALE

END FITTING.

AU392-2, HOSE WITH

FEMALE END FITTING.

E1461-1 PRESSURE GAUGE ASSEMBLY PREVIOUSLY RELEASED AS

J22912-01