SECTION 2C - AIR CONDITIONING -

SERVICING AND DIAGNOSIS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bag s or seat belt pre- tensio ners, d riv er’s and fron t p asseng er’s air bag and lef t and rig ht

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Sections of this Service Information CD for more

specific servicing information.

1. GENERAL INFORMATION

With the introduction of the GEN III V8 engine, and in particular the acc ompanying Harrison V7 Com pres s or, c omes

some minor changes to how the air conditioning system should be diagnosed.

For this reason, the diagnosis procedures of the previously published Section 2C AIR CONDTIONING –

SERVICING AND DIAGNOSIS for VT Series I has been updated and republished in full in this Section. As such,

these diagnosis procedures supersede those previously published, and can be used on all VT Series Models.

For all Servicing procedures, including; safety precautions, discharging, evacuation and charging the air

conditioning system, refer to Section 2C AIR CONDITIONING - SERVICING AND DIAGNOSIS of this Service

Information CD.

Techline

Techline

Techline

Techline

Techline

Techline

2. DIAGNOSIS

2.1 PREREQUISITES AND PRELIMINARY CHECKS FOR DIAGNOSIS AND

TROUBLESHOOTING

The following list are the prerequisites and prelim inar y checks that s hould be perf orm ed bef ore proc eeding with any

system diagnosis.

1. Perform a visual inspection of all interior and under-hood components. Many problems can be detected by a

thorough inspection of system components without having to perform any system diagnosis. Repair system as

necessary.

2. If the vehicle is equipped with ECC, ensure this system is functioning correctly, refer to Section 2D AIR

CONDITIONING - ECC - DESCRIPTION AND OPERATION of this Service Information CD.

3. Ensure air conditioning fuses are okay.

4. Ensure the blower fan is operating correctly.

5. Ensure the temperature controls / door is moving freely from hot to cold.

6. Ensure the condenser air flow is not restricted by foreign matter.

7. Ensure the clutch coil and pressure switch connections are okay.

8. Engine cooling fans are operating correctly. (At idle, the cooling fans must be on at any A/C mode and cooling

fans must be operating in the correct direction; drawing ambient air through the condenser toward engine).

9. If the air conditioning system is noisy, particularly from or around the compressor, check for (and repair as

necessary):

• Damaged or slipping compressor drive belt.

• Idler pulleys for bearing roughness or damage.

• Drive belt tensioner.

• Loose compressor mounting bolts.

• Ensure air conditioning pipes do not contact the vehicle body work.

Techline

Techline

Techline

2.2 GENERAL AND SPECIFIC SYSTEM CONDITION CHARTS

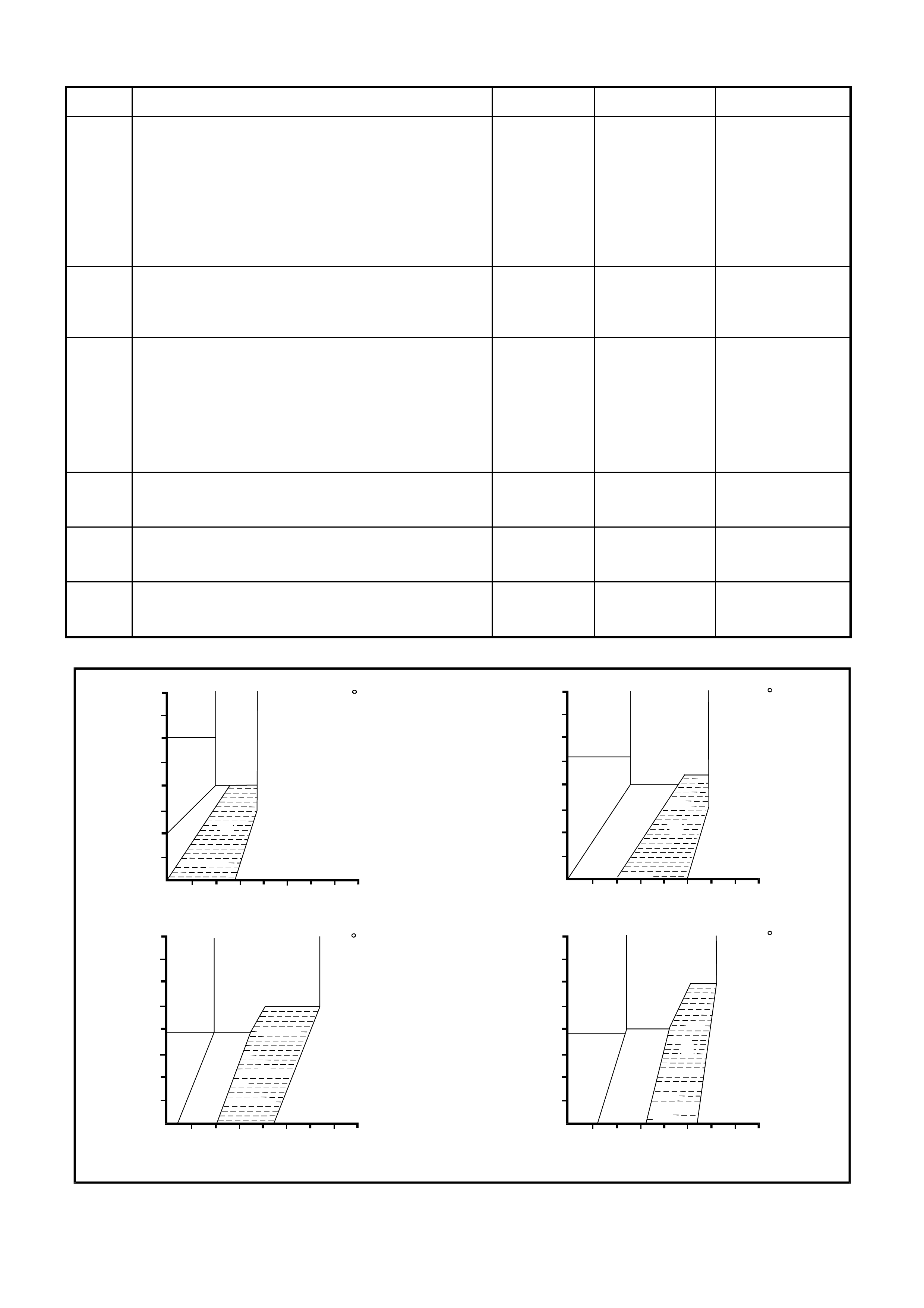

The charts and graphs in this Section were developed in a climatic controllable wind tunnel by producing known

system problems and recording pressures at various am bient temperatures. Results were then validated using the

same vehicle set up in a service environment.

The air conditioning diagnosis chart is the starting point for verifying and diagnosing all air conditioning and HVAC

control related complaints. The chart represents the correct path to follow from a customer complaint or condition

through delivery of the vehicle back to the customer.

In general, there are some variances in the readings between systems of different vehicles; however the target

areas have been developed to accommodate these changes.

2.3 AIR CONDITIONING DIAGNOSIS CHART

STEP ACTION VALUE YES NO

1. • Ensure all the preliminary checks been performed

as per 2.1 PREREQUISITES AND PRELIMINARY

CHECKS FOR DIAGNOSIS AND

TROUBLESHOOTING in this Secti on.

• Have all the checks and prerequisites been

preformed and met?

Go to Step 2 Perform checks

and ensure

prerequisites are

met as per 2.1

prerequisites and

preliminary checks

for diagnosis and

troubleshooting in

this Section.

2. • Check performance of the air conditioning system

as per 2.4 PERFORMANCE TEST in this Section.

• Is the air conditioning system operating as

specified in this test ?

System OK Go to Step 3.

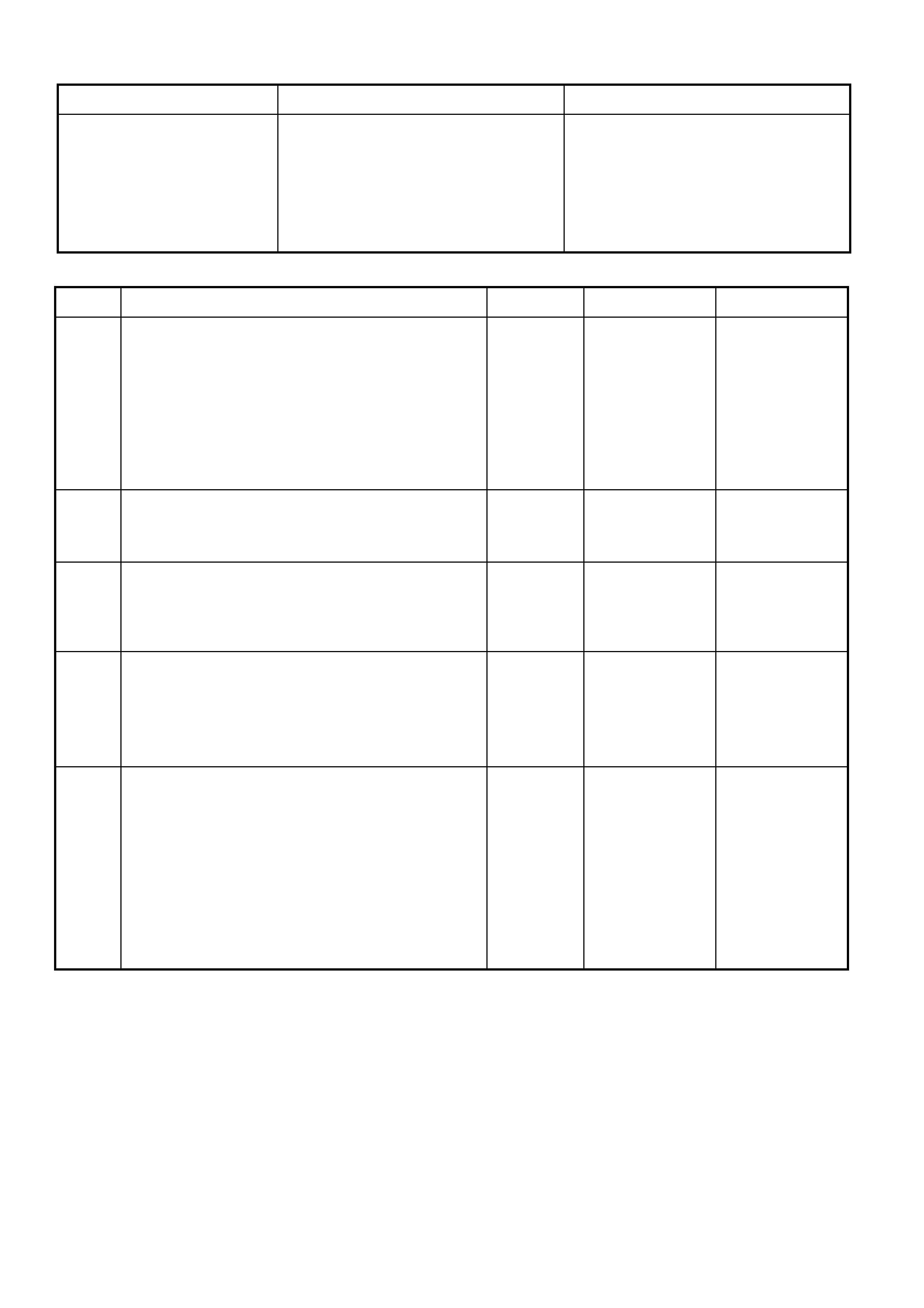

3. • Compare the gauge readings and ambient

temperature recorded in the performance test with

the following diagnostic chart graphs, refer Fig. 2C-

1. Read the high and low pressures and note

where they intersect in the graph.

• Do pressure readings intersect within area A of the

diagnostic chart graph (refer Fig. 2C-1) for the

relevant ambient temperature?

System OK Go to Step 4.

4. • Do pressure readings intersect areas B or D of the

diagnostic chart graph (refer Fig. 2C-1) for the

relevant ambient temperature?

Refer to Repair

Procedure 1 in

this Section

Go to Step 5.

5. • Do pressure readings intersect area C of the

diagnostic chart graph (refer Fig. 2C-1) for the

relevant ambient temperature?

Refer to Repair

Procedure 2 in

this Section

Go to Step 6.

6. • Do pressure readings intersect area E of the

diagnostic chart graph (refer Fig. 2C-1) for the

relevant ambient temperature?

Refer to Repair

Procedure 3 in

this Section

Refer to Repair

Procedure 4 in this

Section

D

F

B

E

C

A

21 C

560

490

420

350

280

210

140

1400 2100 2800

700

70

HI GH SIDE P RESSURE

LOW SIDE PRESSURE

(kpa)

(kpa)

D

F

B

E

C

A

26.5 C

560

490

420

350

280

210

140

1400 2100 2800700

70

HI GH SIDE PRESSURE

LOW SIDE PRESSURE

(kpa)

(kpa)

D

F

B

E

C

A

32 C

560

490

420

350

280

210

140

1400 2100 2800

700

70

HI GH SIDE P RESSURE

LOW SIDE PRESSURE

(kpa)

(kpa)

D

F

B

E

C

A

37.5 C

560

490

420

350

280

210

140

1400 2100 2800700

70

HI GH SIDE PRESSURE

LOW SIDE PRESSURE

(kpa)

(kpa)

T22C001

Figure 2C-1 Diagnostic Chart Graphs

REPAIR PROCEDURE 1 (Areas B and D pressure reading in Fig.2C-1)

CONDITION / COMPLAINT POSSIBLE CAUSE ACTION

Discharge Air:- Slightly cool to

warm.

Thermal expansion valve

sweating or has a frost build up

on it.

Low Side Gauge Reading:- Low

(or vacuum)

High Side Gauge Reading :-

Low

Thermal expansion valve remains closed

or blocked.

Thermal expansion valve jammed closed

causing insufficient refrigerant flow to the

suction side of the compressor. This is

normally related to the thermal expansion

valve sensing bulb malfunction or from

being disconnected from the tube, foreign

material in thermal expansion valve or

moisture entry causing rust formations.

Confirm by thorough physical inspection of

all tubes, hoses and components. In

normal operation, the evaporator inlet

temperature is hot. If the inlet pipe is cool,

check for high side restriction. If the inlet

pipe is room temperature, confirm thermal

expansion valve is blocked by running

engine at 2000 RPM - neither high or low

pressure should change by more than 140

kPa.

If the thermal expansion valve proves to be

blocked, replace thermal expansion valve.

Verify repair by repeating the performance

test as detailed in 2.4 AIR CONDITIONING

PERFORMANCE TEST in this Section.

Discharge Air:- Slightly cool to

warm.

High pressure side tubes are

cool and showing signs of

sweating or moisture build up at

a point after a restriction

Low Side Gauge Reading:- Low

High Side Gauge Reading :-

Low

Restriction in high side of system or faulty

compressor control valve.

Foreign material causing blockage

between the compressor outlet and

evaporator inlet (high side).

Very little or no refrigerant flow to suction

(low) side of compressor.

Test compressor control valve by running

engine at 1500 rpm for 10 minutes with air

conditioning controls set to; maximum/full

cold with lowest blower fan speed. Close

doors and windows, open engine hood.

If the low side gauge reads less than

200kPa, replace the compressor control

valve.

If the compressor control valve is okay,

check system for blockages and repair as

necessary.

Verify repair by repeating the performance

test as detailed in 2.4 AIR CONDITIONING

PERFORMANCE TEST in this Section.

Discharge Air:- Slightly cool to

warm.

Low Side Gauge Reading:- Low

High Side Gauge Reading :-

Low

Refrigerant undercharged.

Refrigerant leak from system. Evacuate and leak test the air conditioning

system, refer 2.1 SYSTEM CHARGING

AND EVACUATION in Section 2C AIR

CONDITIONING - SERVICING AND

DIAGNOSIS of this Service Information

CD.

Verify repair by repeating the performance

test as detailed in 2.4 AIR CONDITIONING

PERFORMANCE TEST in this Section.

REPAIR PROCEDURE 2 (Area C pressure reading in Fig.2C-1)

CONDITION / COMPLAINT POSSIBLE CAUSE ACTION

Discharge Air:- Slightly cool to

warm.

Compressor clutch may

continually cycle on the high

pressure switch. Compressor

may also be noisy when

operating.

Low Side Gauge Reading:- Low

to normal

High Side Gauge Reading :-

high to very high

Refrigerant overcharged, restricted filter

drier receiver, blocked or obstructed

condenser fins (air flow), cooling system

overheating, faulty cooling fan operation,

or drive belt slippage.

Referring to the appropriate Sections of

this Service Information CD, check, and

repair as necessary, the following:

• Ensure cooling fans are operating

correctly.

• Check cooling system operation.

• Physically check for blocked or

restricted condenser fins, clean or

remove obstruction.

• Check compressor drive belt for

damage, slippage or incorrect

operation.

• Touch the filter drier receiver inlet and

outlet pipes; if there is a temperature

difference between these two pipes,

replace the filter drier receiver.

If all the above are okay, recharge the air

conditioning system with refrigerant, refer

to 2.1 SYSTEM CHARGING AND

EVACUATION in Section 2C AIR

CONDITIONING - SERVICING AND

DIAGNOSIS of this Service Information

CD.

Verify repair by repeating the performance

test as detailed in 2.4 AIR CONDITIONING

PERFORMANCE TEST in this Section.

REPAIR PROCEDURE 3 (Area E pressure reading in Fig.2C-1)

CONDITION / COMPLAINT POSSIBLE CAUSE ACTION

Discharge Air:- May perform

normally, but on an extended

journey the air temperature may

go warm temporarily and then

correct itself after vehicle shut

down.

Compressor may produce a

‘slugging’ noise.

Low Side Gauge Reading:-

High.

High Side Gauge Reading :-

normal to high.

Thermal expansion valve stuck open To check the thermal expansion valve;

• Run blower fan on high.

• Air conditioning on.

• Fast idle engine for 2 minutes, then

turn engine off for 3 minutes.

• Restart engine and turn air conditioner

off and let RPM stabilise.

• Turn blower fan to low speed, turn air

conditioner on.

• With engine hood closed, listen for a

‘slugging’ sound.

If a ‘slugging’ noise can be heard, replace

thermal expansion valve.

If thermal expansion valve is okay, check

for a faulty compressor control valve, refer

Repair Procedure 1 in this Section.

Verify repair by repeating the performance

test as detailed in 2.4 AIR CONDITIONING

PERFORMANCE TEST in this Section.

REPAIR PROCEDURE 4 (Area F pressure reading in Fig.2C-1)

CONDITION / COMPLAINT POSSIBLE CAUSE ACTION

Discharge Air:- warm; outlet

temperature will be the same

as ambient air temperature.

Low Side Gauge Reading:-

High.

High Side Gauge Reading :-

Low.

Compressor faulty or possible

blockage in the suction. Test compressor as per the following

compressor diagnostic chart.

Verify repair by repeating the

performance test as detailed in 2.4 AIR

CONDITIONING PERFORMANCE

TEST in this Section.

Compressor Diagnostic Chart

STEP ACTION VALUE YES NO

1. • With refrigerant recovery unit manifold pressure

gauges connected to the high and low service

valves, start the engine and run engine at 3000 rpm.

• Set the air conditioner controls to; blower speed

high, temperature setting on maximum cold and

fresh (outside) air mode.

• Close the vehicles windows and doors.

• Run vehicle under these conditions for 5 minutes.

• Are the high and low pressure gauge readings

within 210kPa of each other.

Go to Step 2. Go to Step 5.

2• Turn engine off.

• With compressor disengaged, turn the compressor

clutch front plate (not the drive belt pulley) by hand.

• Does the compressor clutch front plate turn freely?

Go to Step 5. Go to Step 3.

3• Replace compressor and recharge air conditioning

system.

• Repeat performance test as detailed in this Section

to verify repair.

• Has fault been rectified ?

System OK. Go to Step 4.

4• Leak test air conditioning system, refer 2.1 SYSTEM

CHARGING AND EVACUATION in Section 2C AIR

CONDITIONING - SERVICING AND DIAGNOSIS, in

VT Series I Service Information.

• Was a leak found?

Repair leak as

necessary. Verify

repair by

repeating the

performance test

as detailed in this

Section.

Go to Step 5.

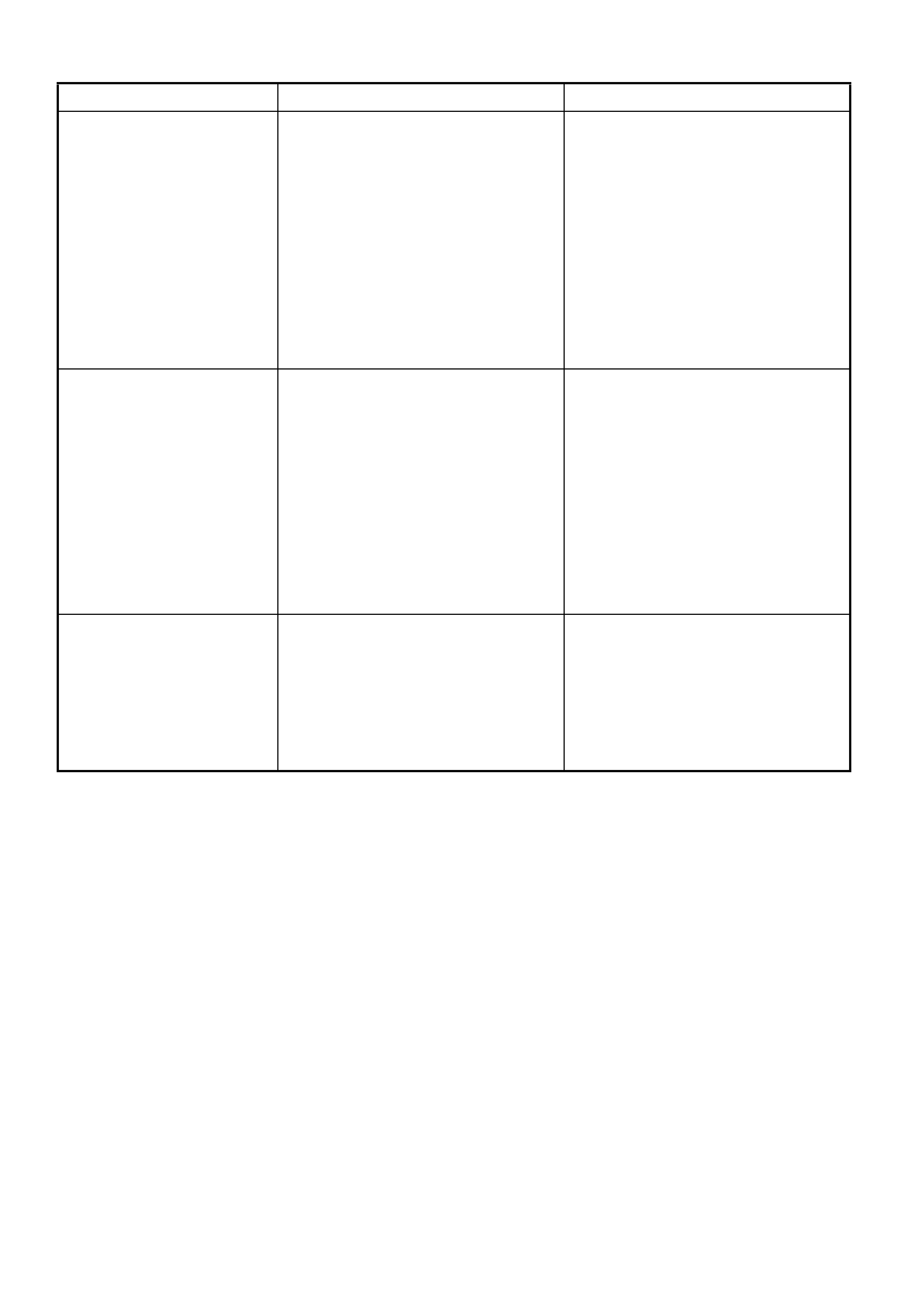

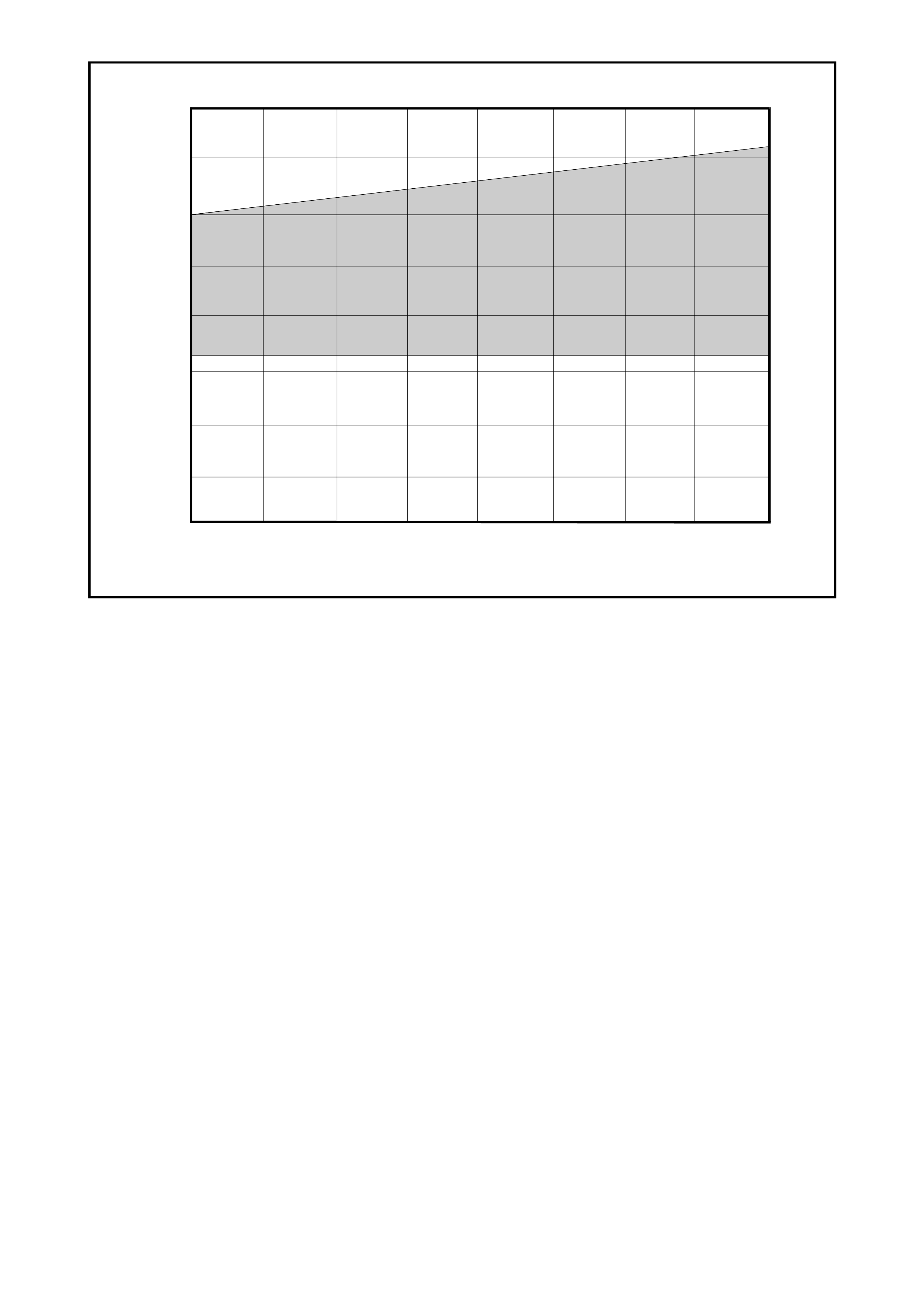

5• With refrigerant recovery unit manifold pressure

gauges connected to the high and low service

valves, start the engine and run engine at 1500 rpm.

• Set the air conditioner controls to; blower speed low,

temperature setting on maximum cold and

recirculated air mode.

• Close the vehicles windows and doors.

• Run vehicle under these conditions for 5 minutes.

• Do the high and low pressure gauge readings

intersect within the shaded area of the following

compressor control valve test specification graph,

refer Fig. 2C-2 ?

System OK. Replace

compressor

control valve.

Verify repair by

repeating the

performance test

as detailed in

2.4 AIR

CONDITIONING

PERFORMANCE

TEST in this

Section.

500 1000 1500 2000 2500

0

50

100

150

200

250

300

350

400

HIGH PRESSURE SIDE (kPa)

LO W PR ESSURE SIDE (kPa)

T22C002

Figure 2C-2 Harrison V5 and V7 compressor control valve test specification

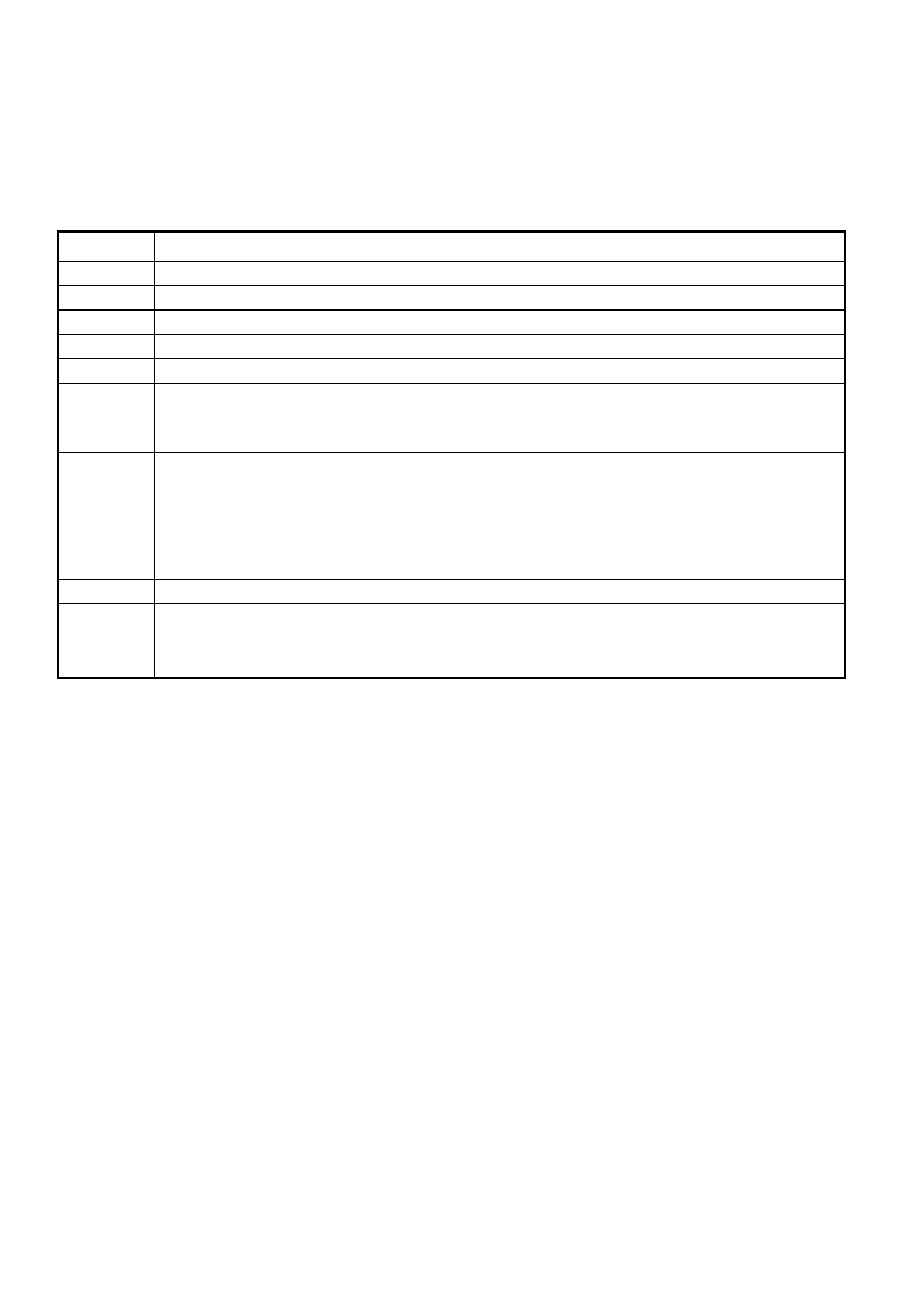

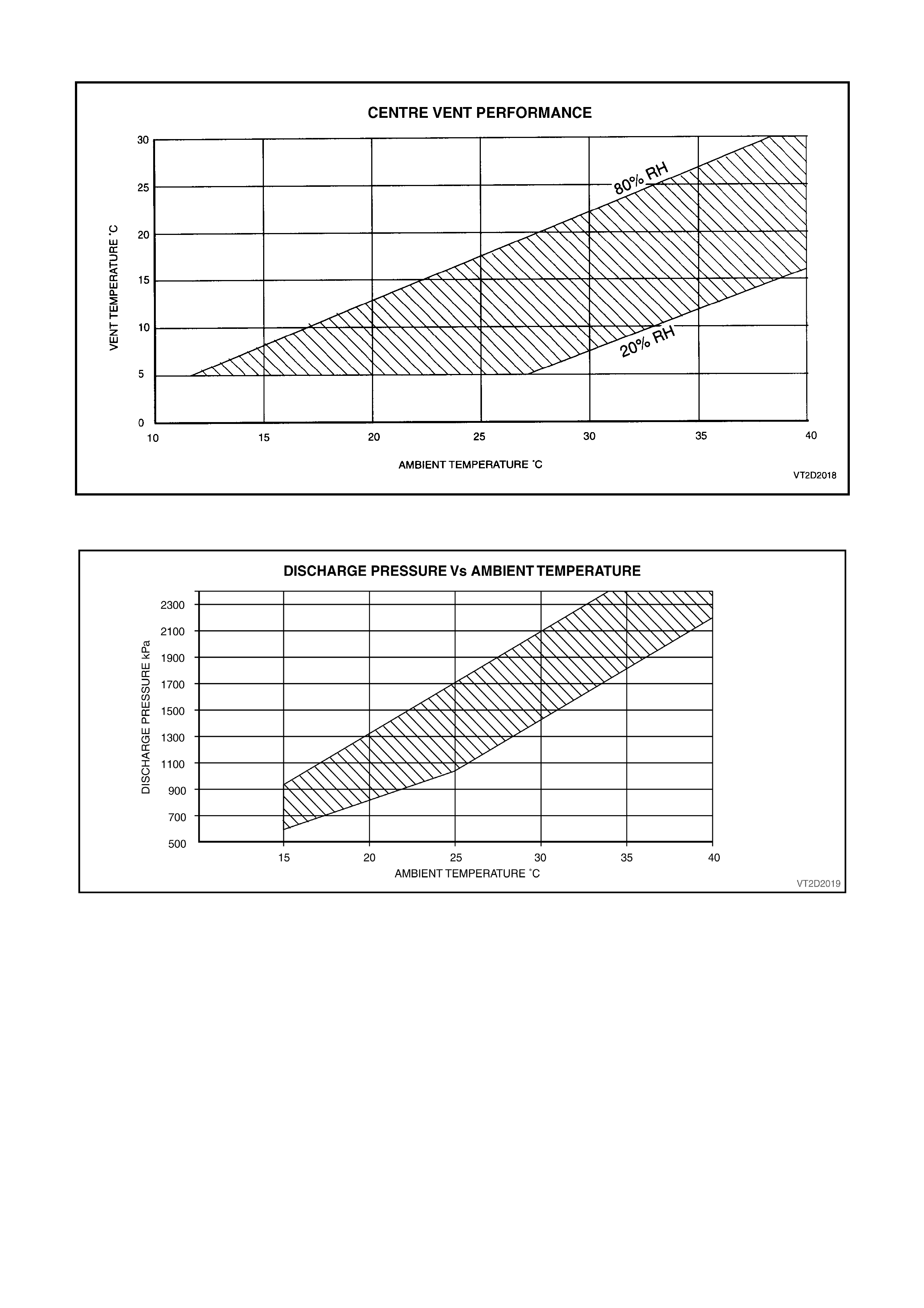

2.4 AIR CONDITIONING PERFORMANCE TEST

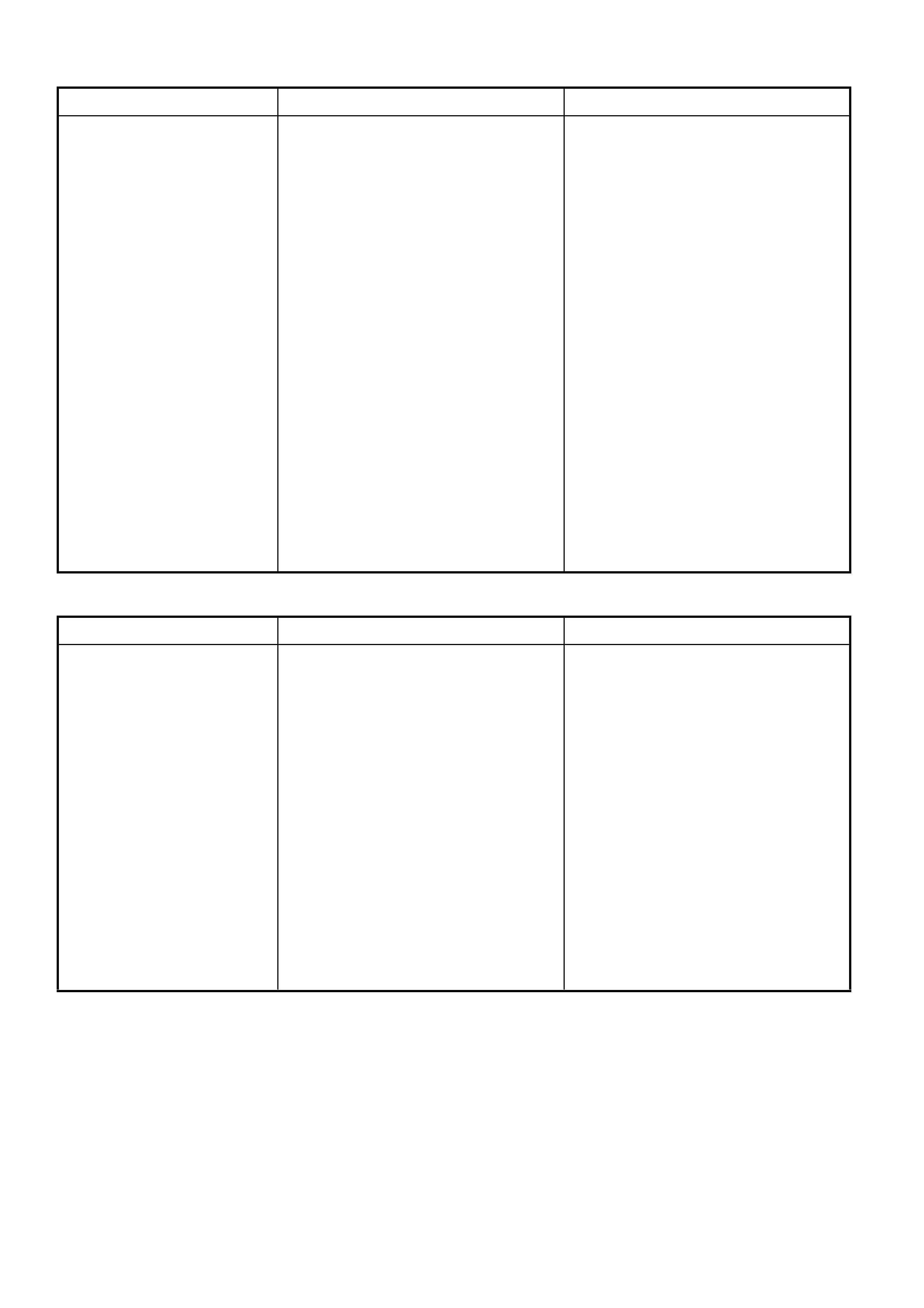

NOTE: The f ollowing perfor m ance test is designed to put the air c onditioning system under an increased load. If an

air conditioning system can perform to the manufacturers specifications under these loads, in normal driving

situations, engine hood down, windows clos ed and possibly a lower blower speed, the centre vent tem peratures will

be lower.

If the air conditioning system performs outside the specified range, as detailed in Fig. 2C-3 and 2C-4, refer to 2.3

AIR CONDITIONING DIAGNOSIS CHART in this Section.

STEP No. ACTION

1Park vehicle in a shaded area.

2Measure and record the ambient temperature.

3Open both front windows and engine hood.

4Connect both high and low pressure service hose coupling valves to the system filling ports.

5Open all dash louvres and adjust to the straight ahead position.

6Insert thermometer probe approximately 50mm into the centre vent louvre.

NOTE: If the vehicle has an ECC dual zone system, ensure both sides of the centre vent are

checked to ensure temperature performance is correct.

7Set air conditioning controls to:

a. Fresh air position

b. Face vent mode

c. Maximum cooling (ECC system select C maximum cooling)

d. A/C on

e. Highest blower speed

8Start engine and bring engine speed to 1700rpm. Allow pressure gauge needles to stabilise.

9Tak e pressur e and centre vent tem per ature readings. Com par e the recor ded values of the vehicle

against the performance charts in Figures 2C-3 and 2C-4.

NOTE: Only take pressure and temperature readings when the compressor is engaged.

Figure 2C-3 Performance Chart A

Figure 2C-4 Performance Chart B