SECTION 1A6 - STATIONARY GLASS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bags or seat belt pre-tensioners, driver’s and front passenger’s air bag and left and

right-hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System

of this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Section of this Service Information for more

specific servicing information.

1. GENERAL DESCRIPTI ON

The windshield, which is laminated and features a tinted upper band, is bonded in the body opening w ith urethane.

The rear window on sedans and the tailgate glass on station wagons, both of which have a elec trically heated demist

facility, are also bonded in the body openings with urethane.

The rear quarter windows on s tation wagons utilise a s elf adhesive foam weatherstrip to seal the glass to the body

and are secured to the body opening by plastic screw on nuts.

Toughened safety glass is used for all the windows except the windshield.

For replacement of urethane bonded glasses, urethane service kits have been developed and must be used to

ma intain original installation requirem ents. Glass installed with urethane requires either par tial or com plete removal

of the urethane when replacing the glass.

Two diff erent installation methods are used when replacing the windshield, rear window and tailgate window to VT

Series II models, a ‘short method’ and a ‘long method’.

Partial rem oval of the urethane is r eferred to as the ‘s hort method’. Com plete removal of the urethane is known as

the ‘long method’.

The short m ethod is used where original urethane lef t on body opening pinch weld flanges af ter glass r emoval, c an

serve as a base for the new glass. This method would be used in cases of replacem ent of crack ed windshields or

removal of glass that is intact. The amount of urethane left in the glass opening can be controlled during glass

removal, leaving the maximum amount of original urethane intact on the body opening flange.

The long method is to be used when the original urethane left in the window opening, after glass removal, cannot

serve as a base for replacement glass. This method would be used in cases needing metal work or where paint

refinishing is required in the body opening; or in cases where the glass has been previously replaced, using the

short m ethod. In such instances, the build up of urethane could position the glass too high in the body opening. In

these cases, the original urethane is completely removed and replaced with new urethane during glass installation.

A one piece windshield moulding is now used in place of the two piece mould fitted to previous VT Series models.

For service procedures related to the rear door fixed window, refer to Section 1A5 FRONT & REAR DOOR

ASSEMBLIES of the VT Series I Service Information.

Techline

Techline

Techline

2. SERVICE NOTES

CAUTION: Safety glasses and work gloves must be worn at all times when operating with glass.

Skinning (partial curing) of the urethane commences after exposure to the atmosphere. At 23 degrees

Celsius and 50 percent relative humidity, skinning commences after 30 minutes. Complete curing of the

urethane at this temperature and humidity takes 72 hours.

Urethane service kits are available from most windshield agents. Manufacturer’s instructions should always

be followed.

Window glass should be installed in the window opening within 5 minutes of the application of urethane.

3. SERVICE OPERATIONS

3.1 WI NDSHIELD GLASS — ALL MODELS

REMOVE

The windshield glass removal procedure is the

same for both the short and long installation

methods with one exception.

If the short method installation is to be used, more

care m ust be taken during glass r emoval to ensure

that an even surface of the original remaining

urethane exists in the body opening to serve as a

base for the new urethane bead and the

replacement glass.

The windshield moulding is installed over the edge

of the windshield glass and can be removed by

pulling the moulding from the windshield opening

starting at the windshield lower corner, after

removal of the components as detailed below.

Mouldings are available for service replacement.

Refer to the VT Series parts information for details.

CAUTION: Care must be taken during any

operation involving windshield removal or

installation not to exert any load on the

windshield glass. Failure to observe this may

result in damage to the glass.

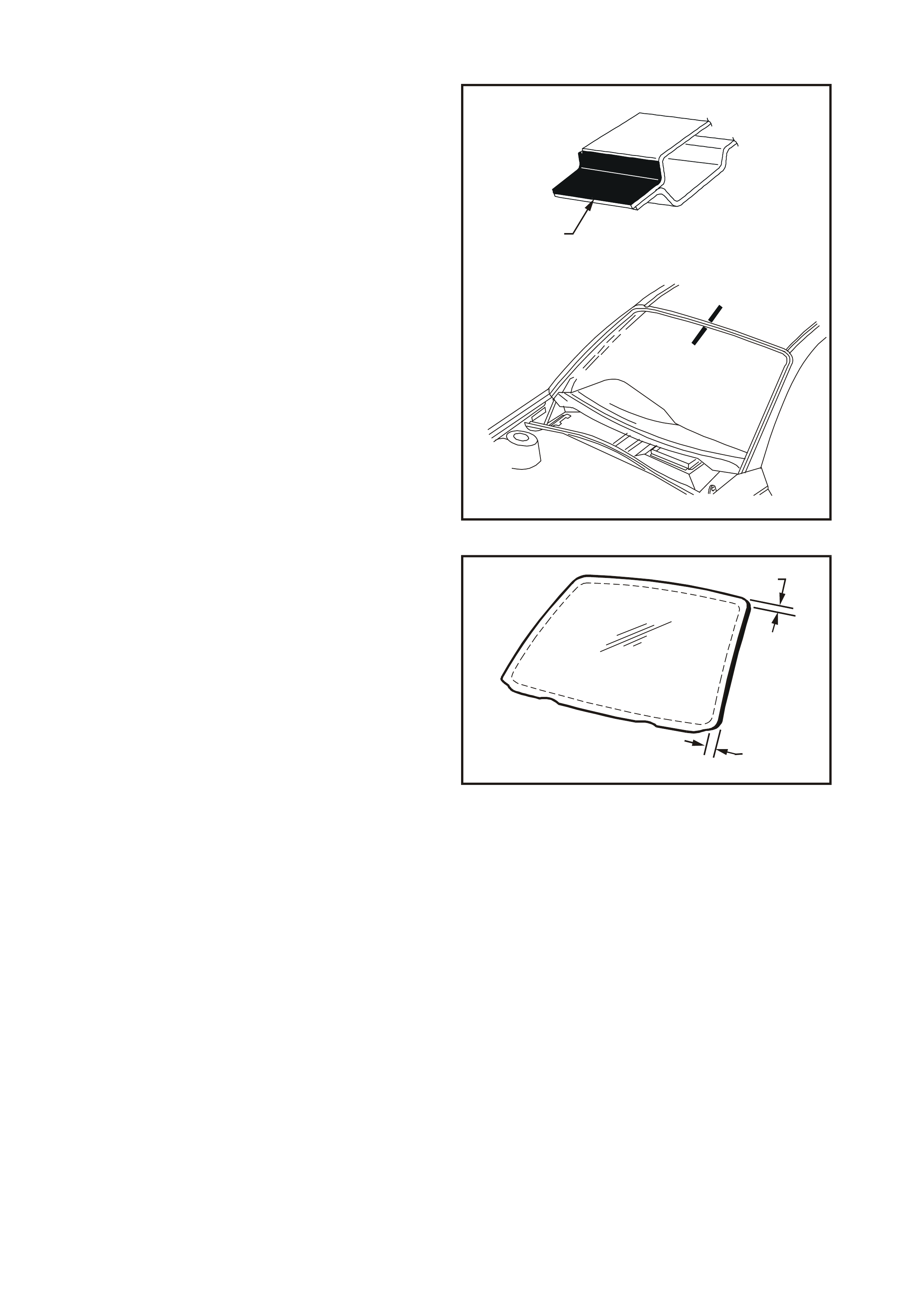

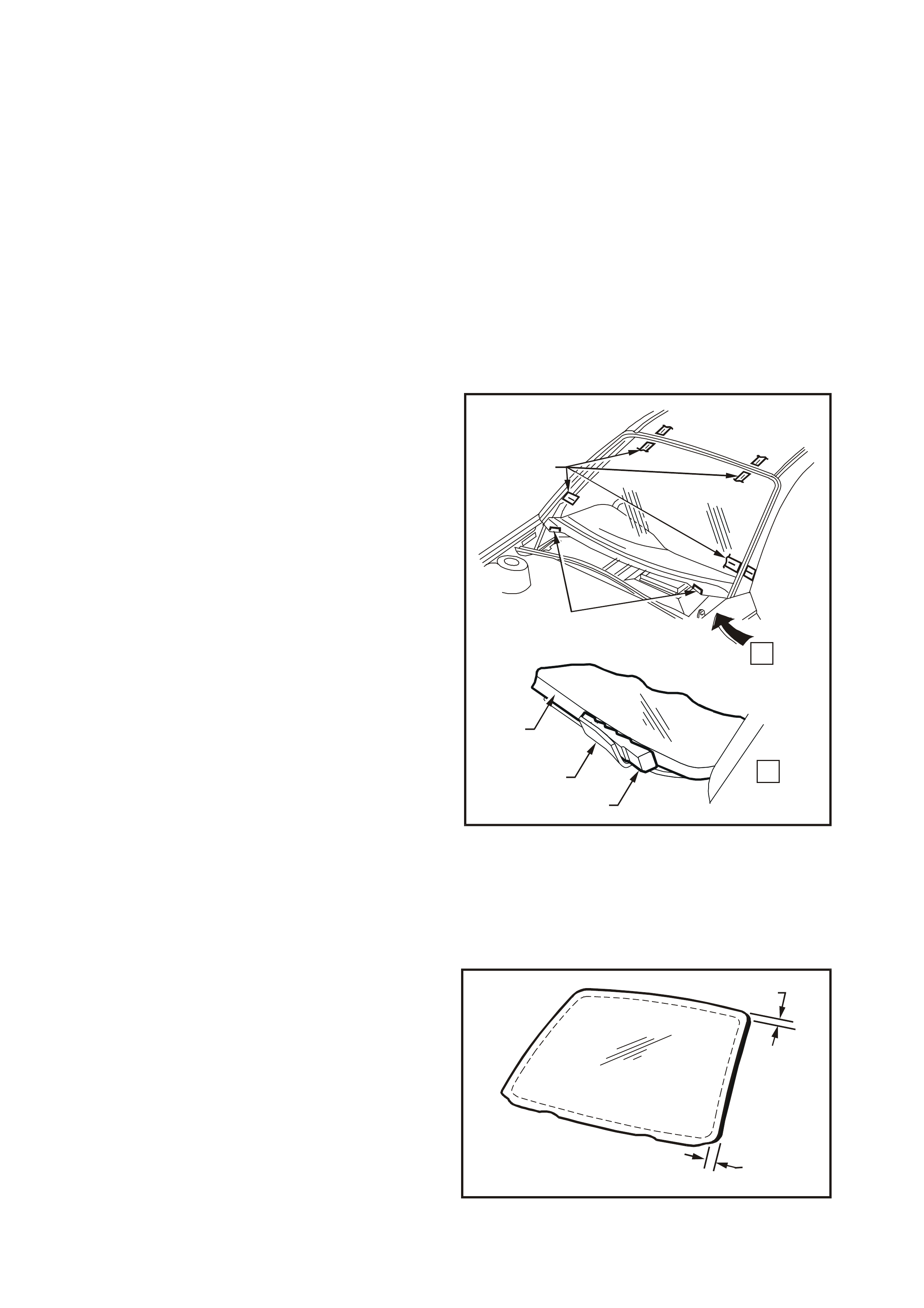

1. To prevent damage to paint f inis h and trim, and

to minimise clean up, mask-up and place

protective covers over parts adjacent to the

windshield.

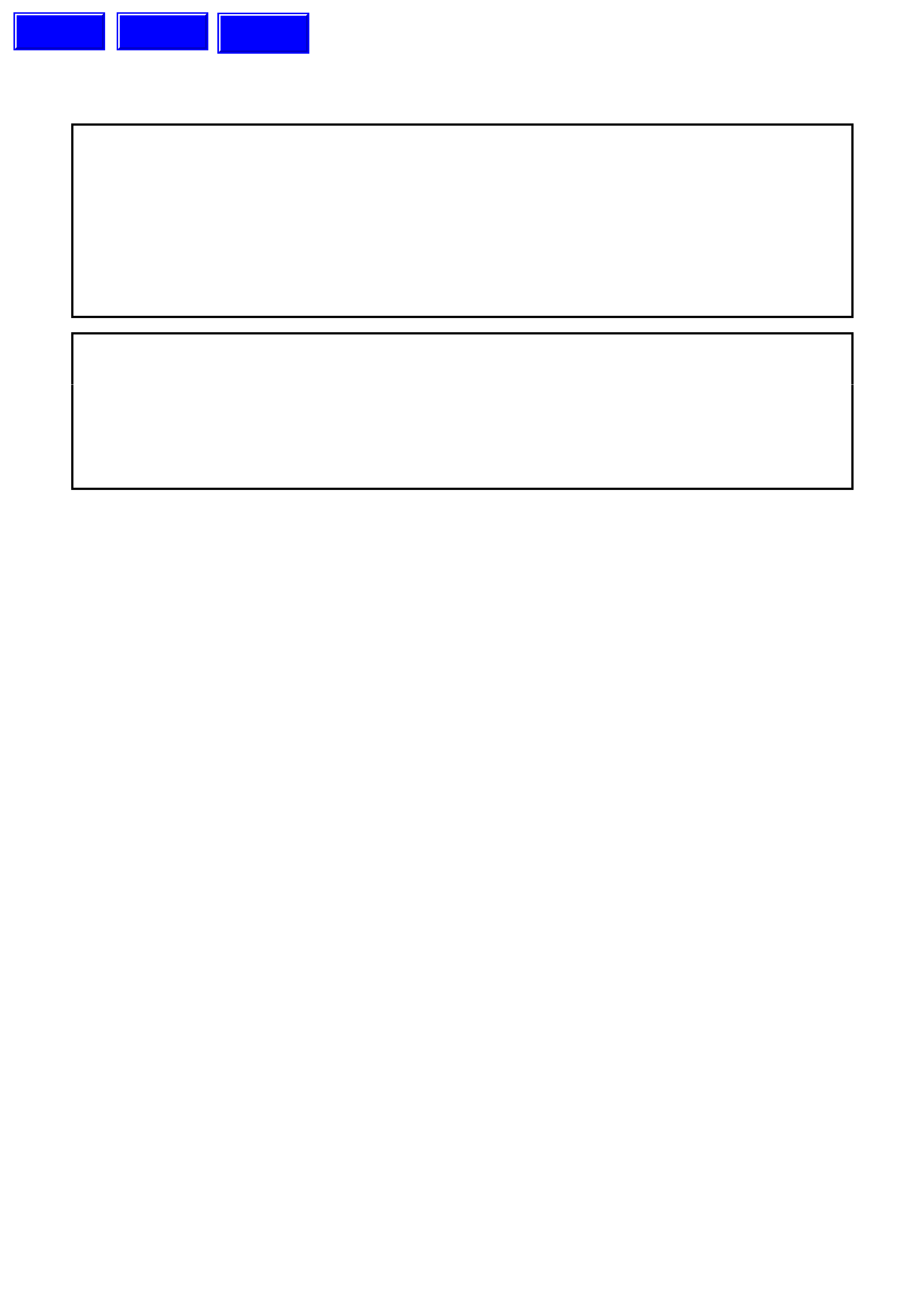

2. Prise cap (1) from wiper arm (2) and remove

wiper arm retaining nut (3) from drive spindle

(4).

31

2

T21A6001

4

Figure 1A6-1

Techline

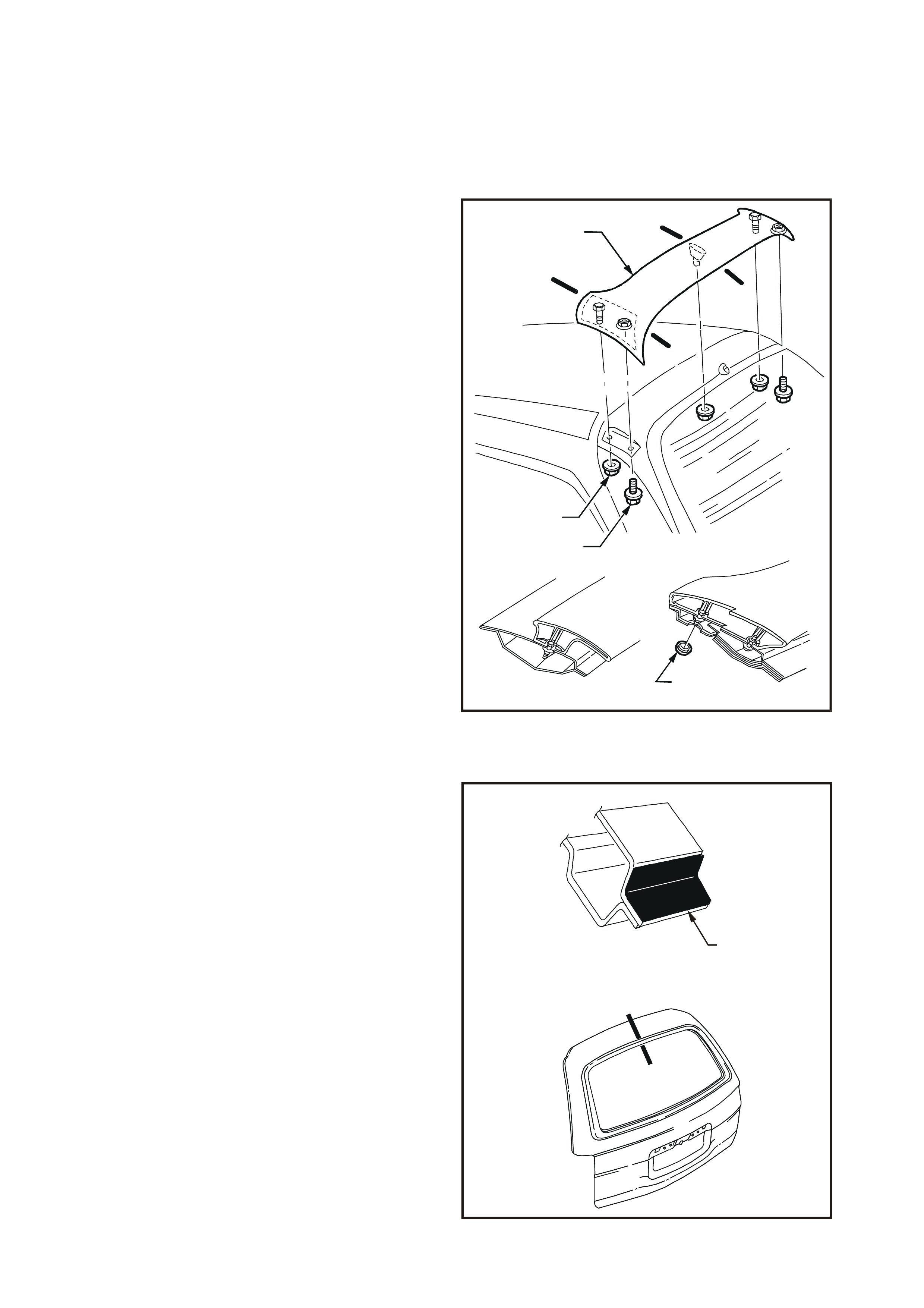

3. Remove six scrivets (1) retaining both left

plenum cover (2) and right plenum cover (3).

Remove the plenum covers, taking care not to

break the retaining lugs (4).

A

B

T21A6002

B

A

3

3

2

2

2

1

4

Figure 1A6-2

4. Remo ve six scr ivets (1) retaining plenum water

deflector (2), pull deflector towards front of

vehicle, disengaging the four retaining tabs (3)

and remove from the vehicle.

13

2

T21A6003

Figure 1A6-3

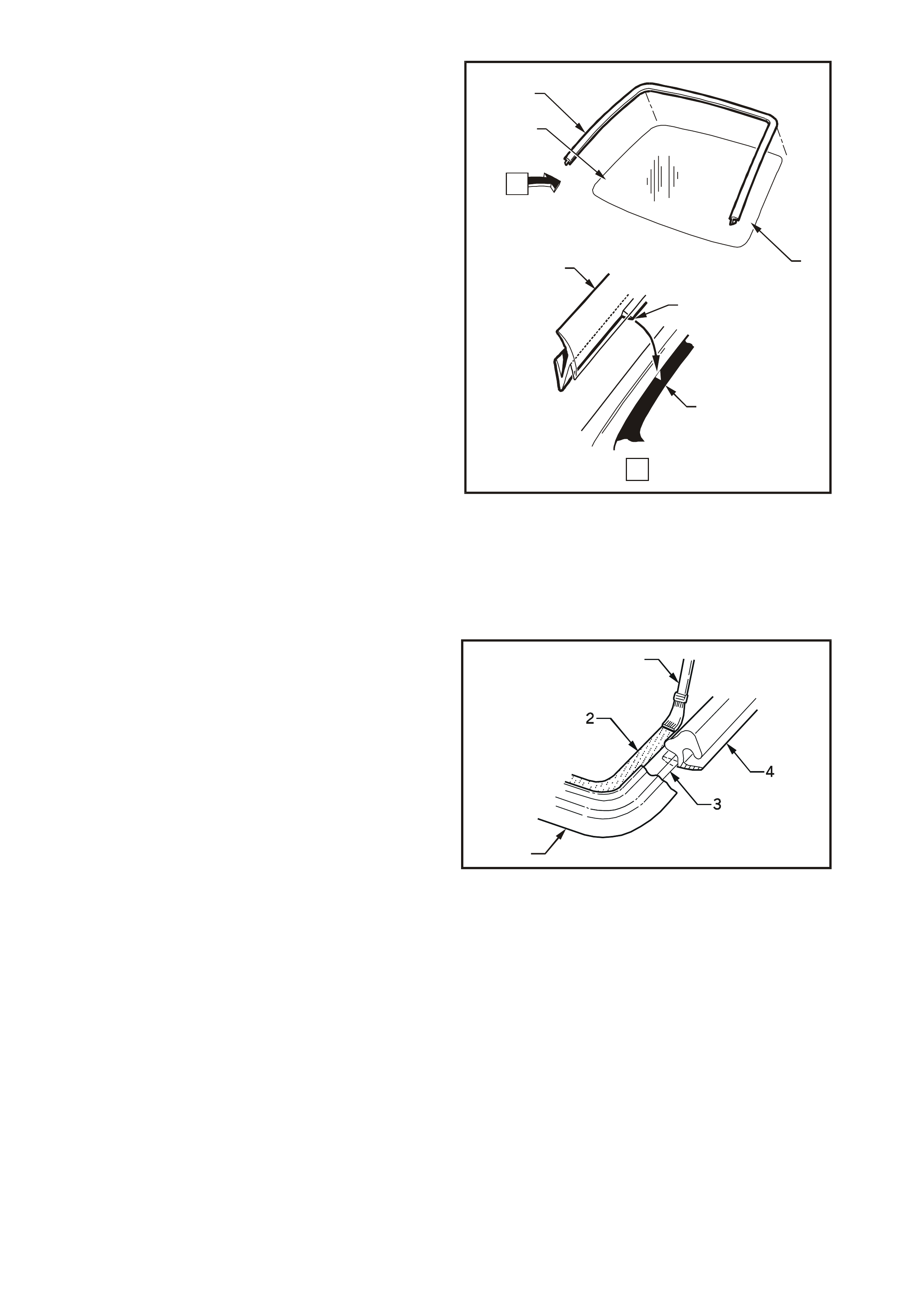

5. Remove windshield moulding (1) by pulling the

moulding from the windshield to body join (2),

starting at the windshield lower corner (3) and

working around the windshield.

1

2

3

T21A6004

Figure 1A6-4

6. From inside vehicle, remove instrument panel

end cap cover right side and left side. Refer to

Section 1A3 INSTRUMENT PANEL AND

CONSOLE of this Service Information CD.

7. Remove retaining screws (1) from the outer

ends of the demist nozzles (2).

8. Carefully disengage the horizontal retaining

lugs (3) of both demist nozzles, from the top of

the instrument panel (4) with minimum upward

movement of the demist nozzles. This is to

ensure that minimal leverage is placed on the

outer vertical retaining lugs (5).

9. Disengage the vertical retaining lugs on the end

of the demist nozzles by pulling backward and

upward, until the demist nozzles are

disengaged from the instrument panel.

T21A6005

2

3

4

4

3

5

5

1

1

Figure 1A6-5

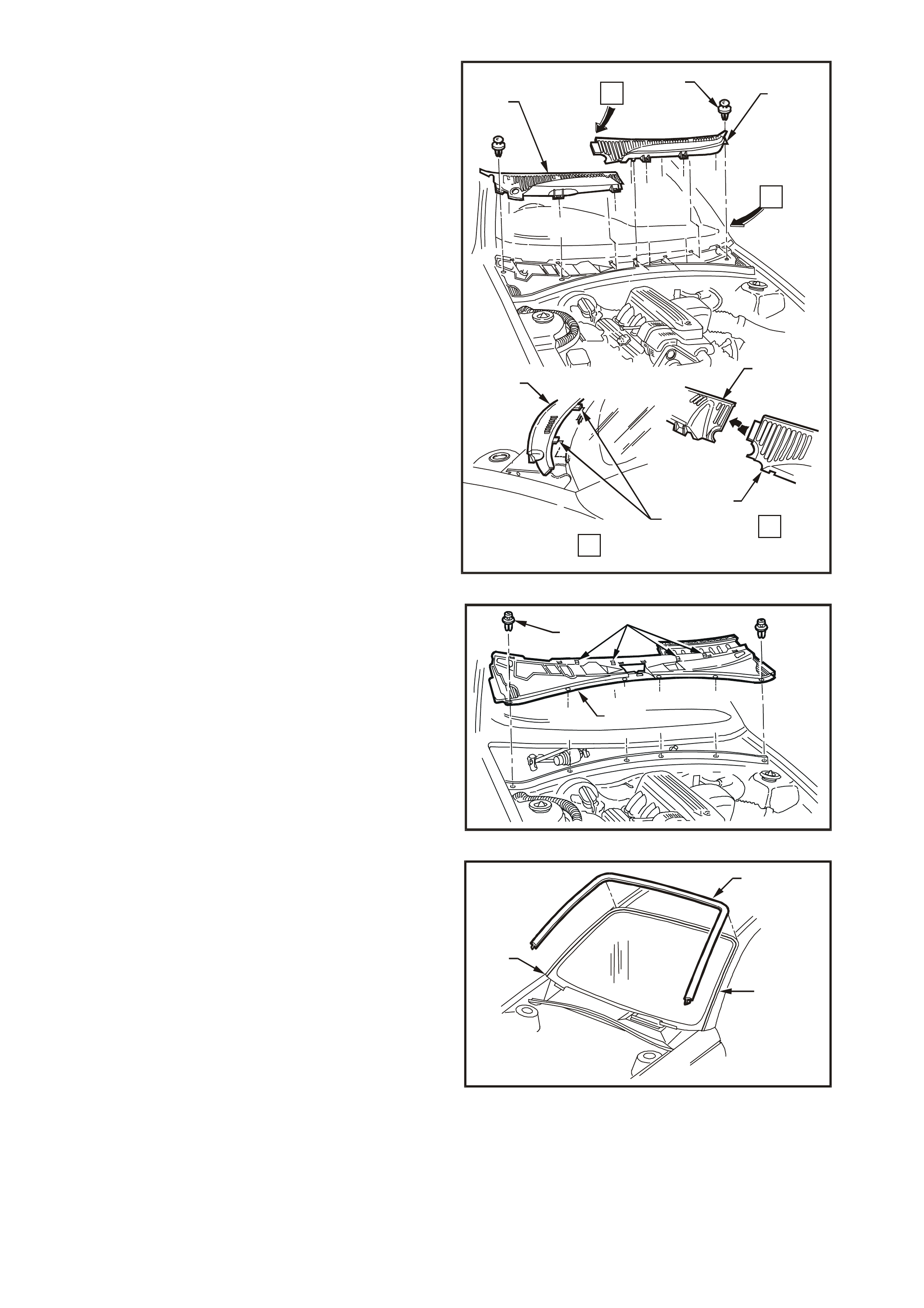

IMPORTANT: Note that on all vehicles a remote

receiver module, and on some models a solar

sensor, is installed between the left-hand and right-

hand demist nozzles on the instrum ent panel. Care

must be taken to avoid damage to the remote

receiver module (and solar sensor where fitted)

during windscreen removal procedure. It is not

necessary to remove the remote receiver module

(or solar sensor). Figure 1A6-6 illustrates:

1. Remote receiver module / solar sensor.

2. Wiring harness connector.

3. Right-hand demist nozzle.

4. Left-hand demist nozzle.

5. Wiring harness.

T21A6006

5

13

4

2

Figure 1A6-6

10. Remove interior mirror assembly by sliding

mirror base upwards.

11. Remove A-pillar trim assembly, refer to

Section 1A8 HEADLINING AND REAR END

TRIM of this Service Information CD.

12. Using piano wire and T-handles AU 390 or

equivalent (refer to Fig. 1A6-7 for dimensions),

thread one end of the piano wire through the

urethane, starting at the windshield upper

corner, pulling the end of the wire through with

pliers.

NOTE 1: Use at least 700 mm of wire between the

T-handles.

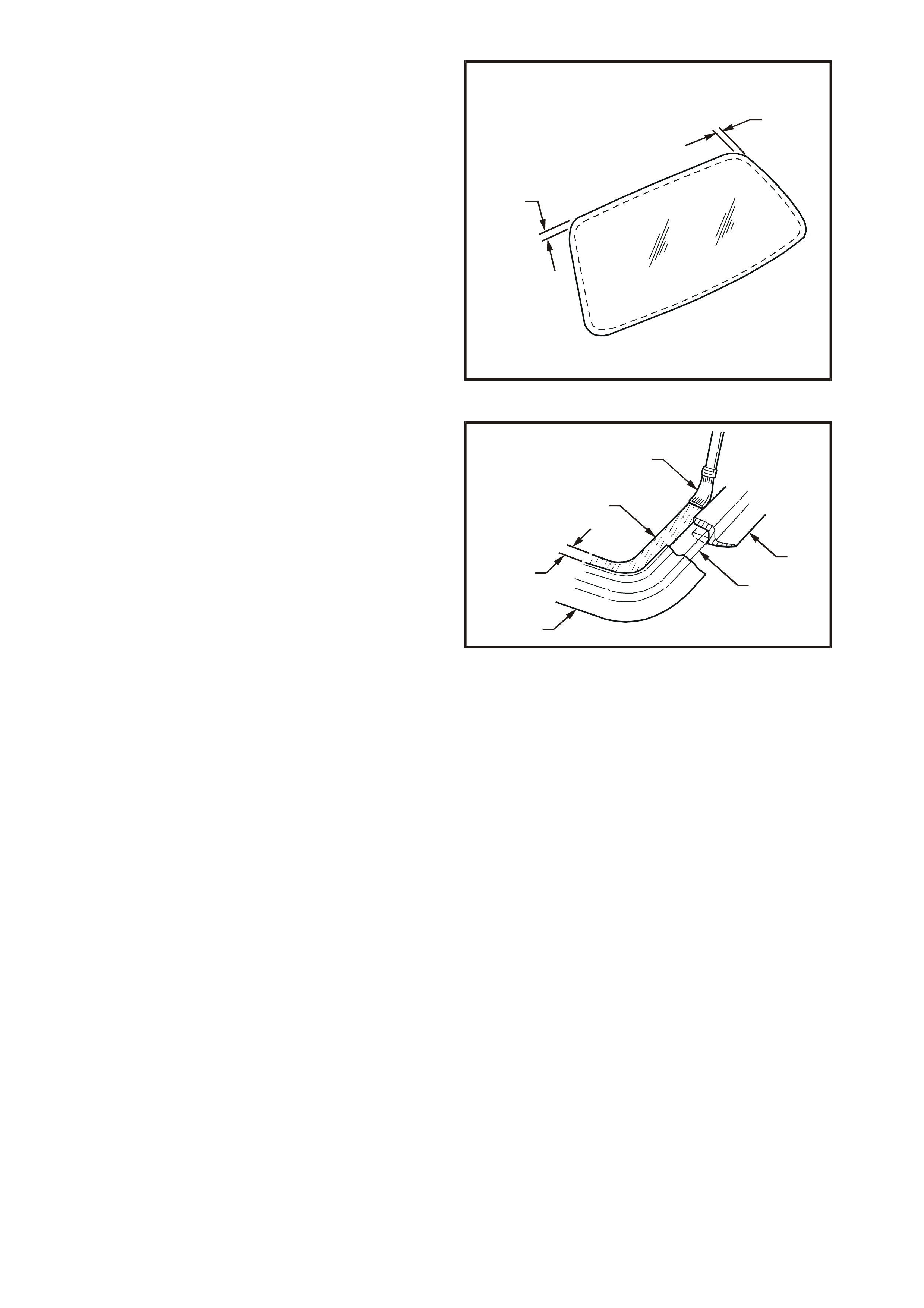

NOTE 2: Ensure that the headlining and other trim

items are not damaged.

T21A6007

100mm

10mm

100mm 2m m

Figure 1A6-7

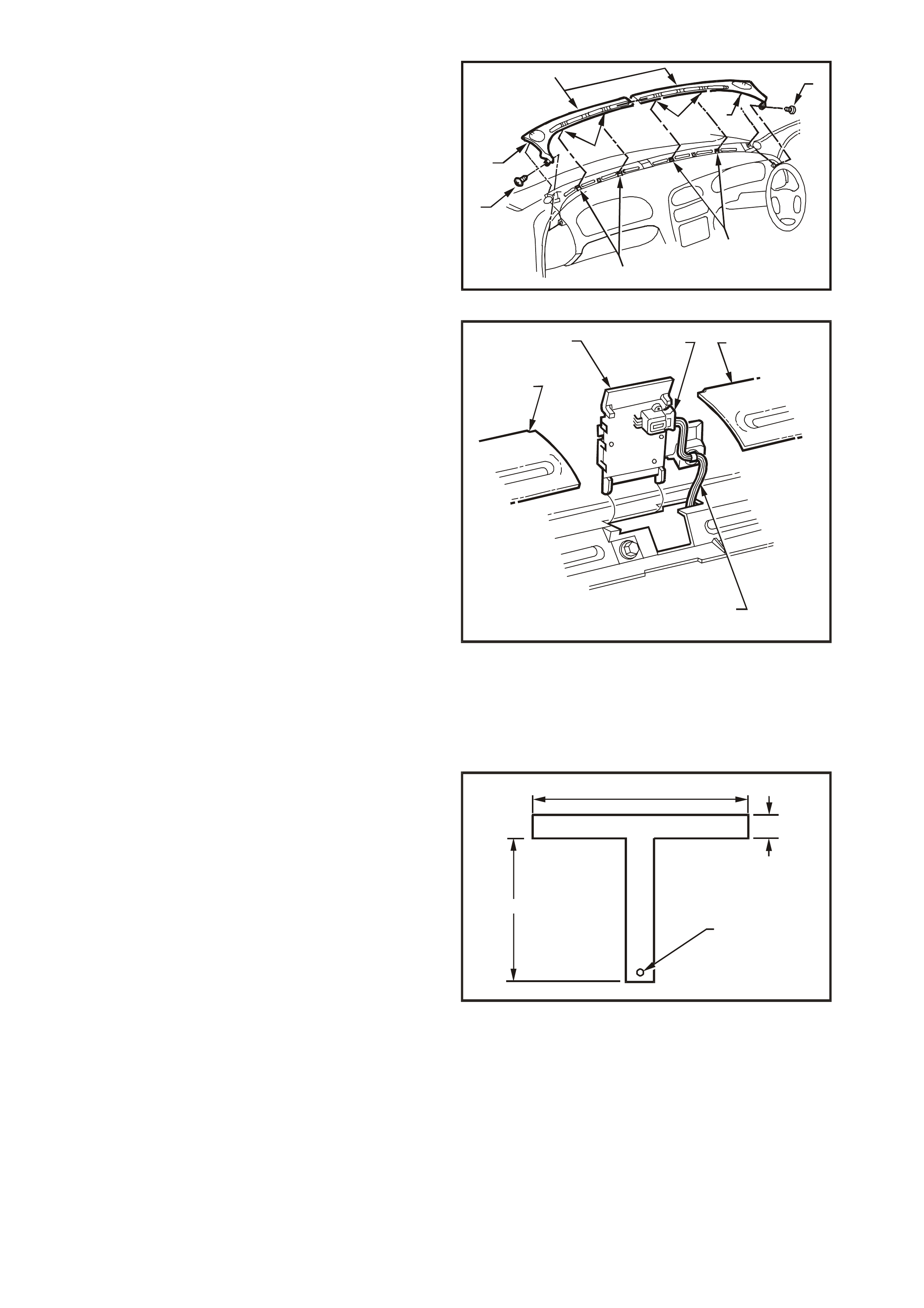

13. Connect the wire to the remaining T-handle

and with the aid of an assistant, commence

cutting the urethane bead, keeping the outside

T-handle (1) parallel to the edge of the glass

using the full length of the wire to prevent heat

build up in the wire.

NOTE: To minimise damage to the interior of the

vehicle, the operator inside the vehicle should act

as an anchor point, holding the T-handle as close

as possible to the glass at all times, especially

along the lower edge of the windshield, while the

outside operator pulls the wire up to the interior T-

handle in a ‘walking’ motion refer to Figs. 1A6-8,

1A6-9, 1A6-10, and 1A6-11.

T21A6008

1

Figure 1A6-8

T21A6009

Figure 1A6-9

T21A6010

Figure 1A6-10

T21A6011

Figure 1A6-11

14. Carefully lift the windshield out of the body

opening. If there is evidence of glass adhering

to the urethane, cut the area again with the

piano wire.

15. If the original windshield is to be installed

again, place the windshield on a clean

protected surface, holding fixture etc.

NOTE: The use of suction cups will greatly assist

any handling of the windshield.

LONG METHOD INSTALLATION

DESCRIPTION

The long method windshield replacement is used

when original urethane adhesive material cannot

serve as a base for the replacement windshield.

This method should be used on vehicles requiring

metal or paint repair to the windshield opening

when original adhesive is completely removed and

replaced with new urethane for windshield

installation.

This method is also used when the windshield has

been previously replaced, using the short method.

In such instances, the build-up of urethane could

position the windshield too high in the opening.

REPARATION

IMPORTANT: Note that on all vehicles a remote

receiver module, and on some models a solar

sensor, is installed between the lef t-hand and right-

hand demis t nozzles on the ins trum ent panel. T ake

particular care during the urethane removal

procedure to avoid damage to the remote receiver

module (and solar sensor where fitted).

CAUTION: Do not use petroleum based

solvents to clean the windshield or body

opening flange as the presence of oil will

prevent adhesion of the new urethane/silicon.

1. Using a sharp scraper, carefully remove any

original urethane from around the windshield.

Clean the windshield to be installed with a

suitable oil free cleaning agent.

2. Using a knife or sharp scraper, remove the

original urethane from around the entire

perimeter of the windshield opening flange.

Avoid the removal of paint when removing

urethane from opening flange.

Body Opening Check

1. Thoroughly check the windshield body opening

flange fo r any ir regularities before installing the

windshield.

2. Remove the A-pillar trims. Refer to Section

1A8 HEADLINING AND REAR END TRIM of

this Service Information CD.

CAUTION: Care should be taken to ensure that

glass does not strike the windshield opening.

Chipped edges can lead to subsequent

breakage of glass.

3. Place the windshield in the body opening

temporarily to check for correct alignment

between the windshield and body opening. If

necessary, reform the body opening flange to

produce a uniform flange to windshield contour.

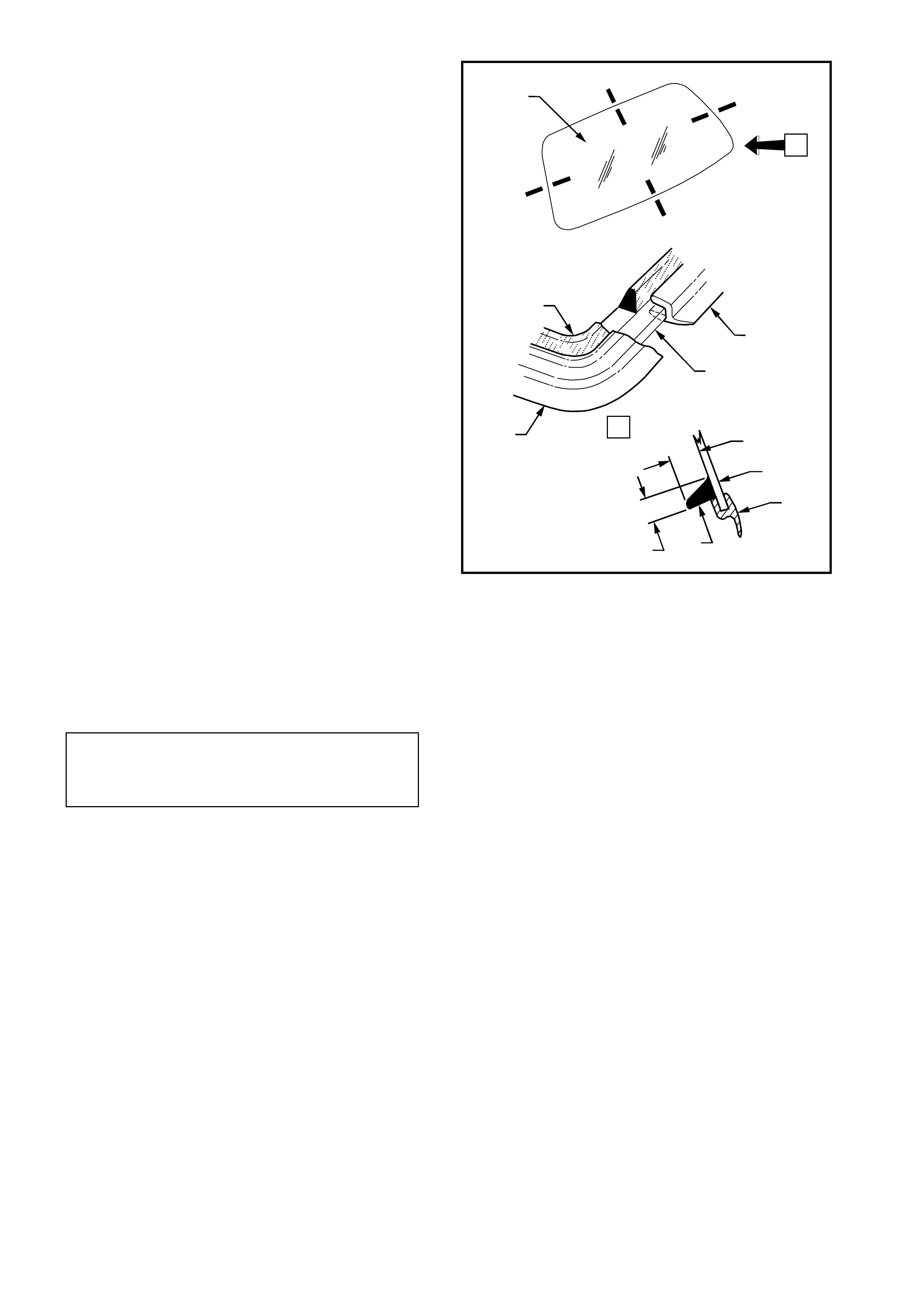

4. Using a wedge (1) placed between the lower

edge of the windshield (2) and the reinforcing

flanges (3), correctly locate the windshield in

the body opening.

5. Tape mark the outer top and side of the

windshield, pillar and roof with masking tape

(4). This procedure will assist in the alignment

of the windshield in the correct horizontal and

vertical plane during final windshield

installation.

6. Remove and place the windshield face down

on a clean protected surface or fixture.

T21A6012

4

3

1

3

2

.

.

.

..

.

.

..

..

.

.

...

...

.

.

..

.

.

.

...

.

..

..

.

.

...

...

.

.

..

.

.

.

.

..

.

..

...

...

..

..

.

..

..

.

.....

.

........

.

.

.

..

.....

.....

.

....

.

.

....

.

..

.

...

..

.

.

.

..

.

...

...

.

.

.

..

..

.

...

.

..

.

A

A

Figure 1A6-12

REINSTALL

1. Using one of the applicators in the service kit,

apply flange primer (1) to any section of the

windshield opening flange that has been

cleaned back to bare metal or to be painted.

Allow this primer to dry for 15 minutes.

IMPORTANT: Do not touch primed surfaces.

2. Thoroughly clean the inner surface and edges

of the windshield to which the urethane is to be

applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

T21A6013

1

A

-A

A

A

Figure 1A6-13

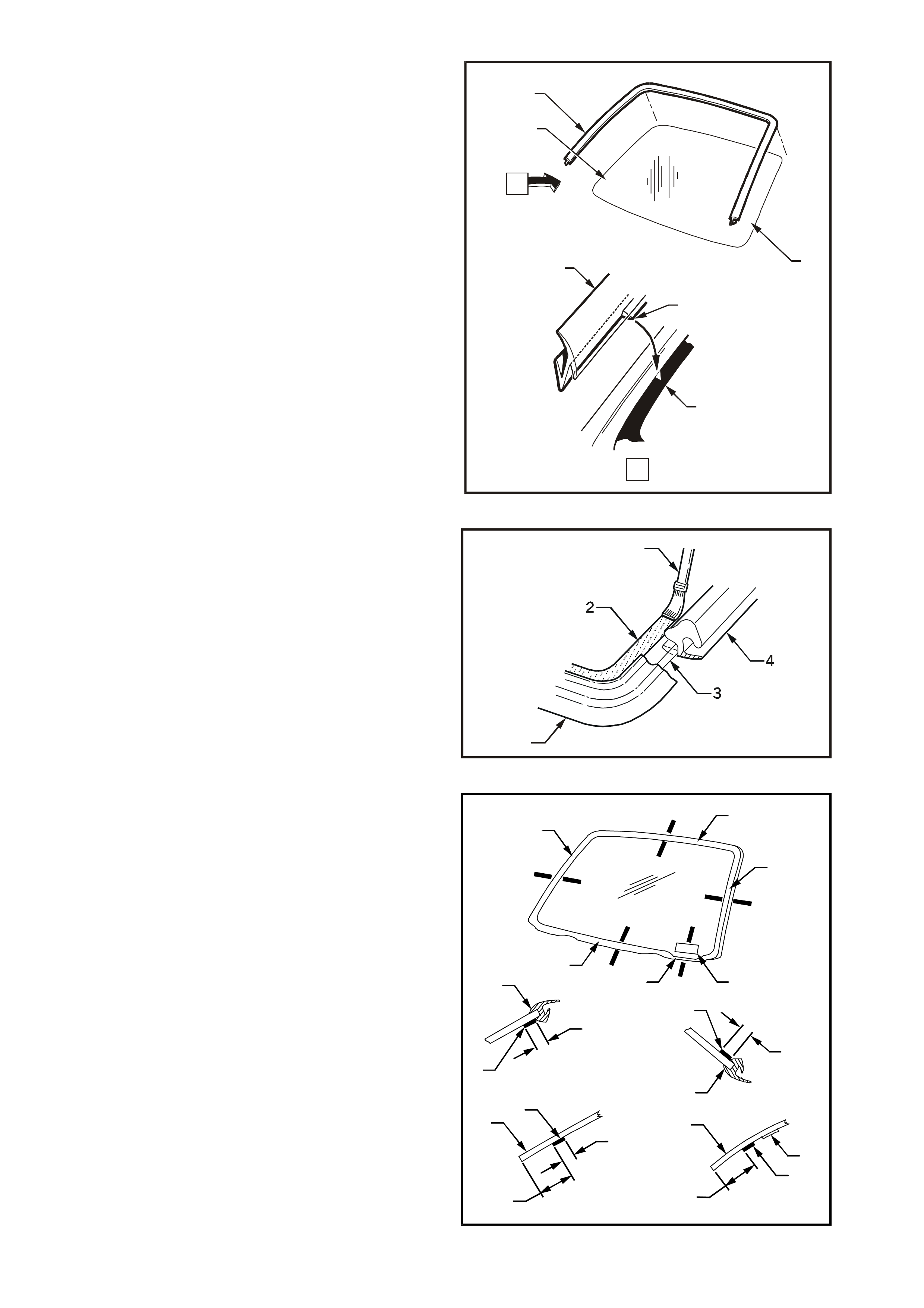

3. Apply clear glass primer to inner surface of

glass around the perimeter of the windshield

over the width of the solid black ceramic

pattern (or a width of 50 mm) and immediately

wipe off with a lint-free cloth.

4. Check the condition of the windshield

moulding. Discard and replace with new

moulding if damaged.

50mm

50mm

T21A6014

Figure 1A6-14

5. Fit windshield moulding (1) to sides and upper

section of windshield. Ensure that notch of

moulding (2) is aligned with ‘V’ locating mark

(3) on lower portion of right-hand and left-hand

side of windshield.

T21A6015

A

A

1

1

2

3

3

3

Figure 1A6-15

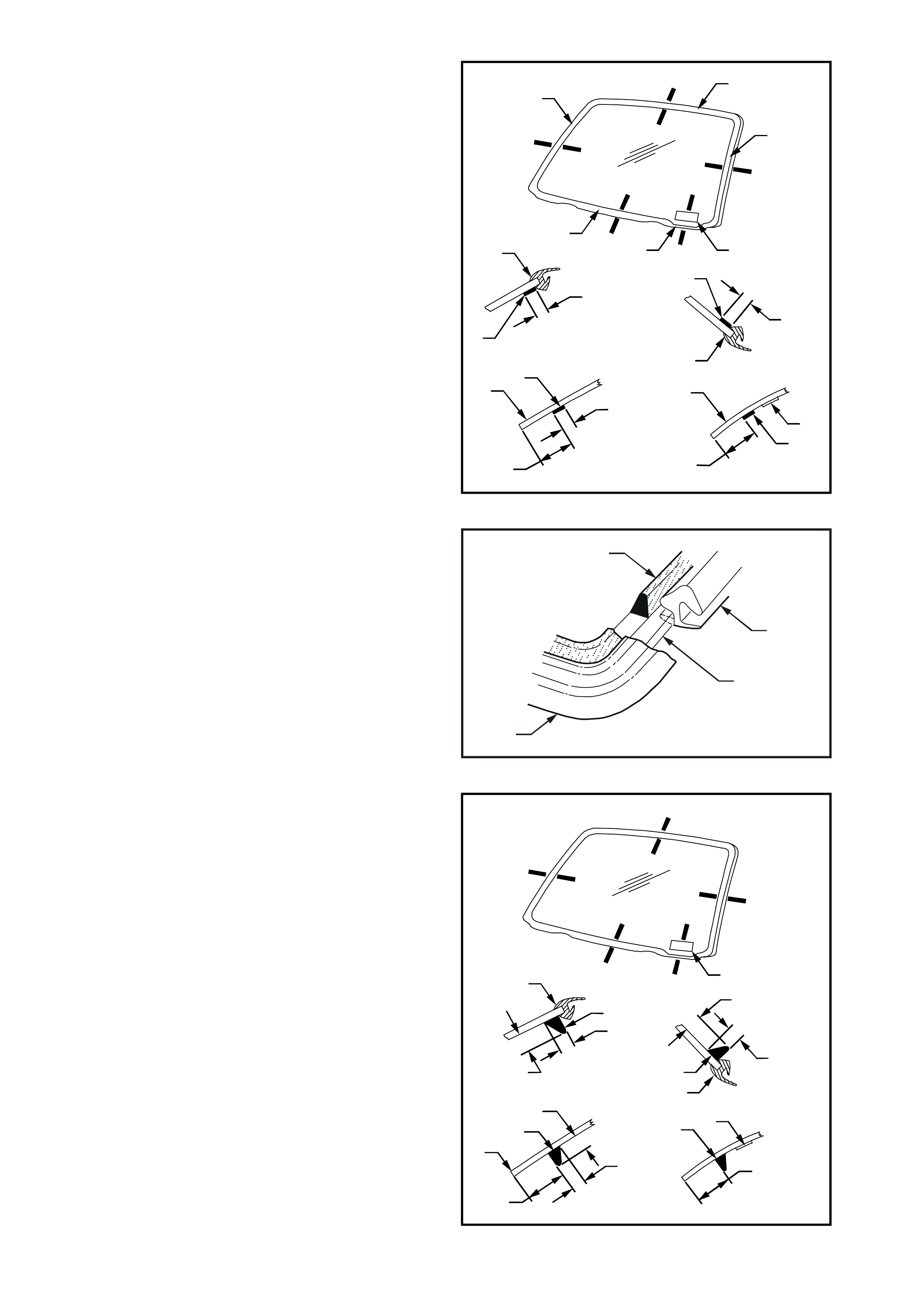

6. Using the applicator (1) included in the service

kit, apply black glass primer (2) to the

windshield (3) alongside the moulding (4).

T21A6016

4

1

Figure 1A6-16

7. Apply black glass primer (1) to the inner

surface of the upper section (2) and sides (3) of

the windshield over a width of 20 mm inboard

from the moulding (4). Repeat this process

35 mm from the lower edge (5) of the

windshield. Ensure that a suitably reduced

application of primer black glass primer (6) is

applied 15 mm from the lower edge of the

windshield (7) adjacent to the VIN plate (8).

T21A6017

A-A

1

20mm

4

A

BBB

B

C

C

D

D

A

2

3

3

87

5

B-B

1

4

20mm

C-C

20mm

1

5

35mm

D-D

8

6

7

15mm

Figure 1A6-17

8. Using a hand or automatic applicator, apply a

smooth continuous bead of urethane (1), such

as Betaseal 587.02 or equivalent, to the

windshield (2) alongside the moulding (3).

T21A6018

2

1

3

3

Figure 1A6-18

IMPORTANT: On the lower left-hand side of the

body opening, care must be taken to ensure the

urethane bead diameter is such that when

compressed by the windshield installation, the

vehicle identification number is not obscured.

9. Apply urethane (1) adjacent to the m oulding (2)

and 35 mm inboard (3) from the lower edge of

the windshield (4). A suitably reduced amount

of urethane (5) should be applied adjacent to

the VIN plate (6) to ensure that the VIN is not

obscured when the windshield is installed. All

other bead dimensions are shown in Fig. 1A6-

19.

T21A6019

A

BBB

B

C

C

D

D

A

6

D-D

6

5

15mm

B-B

1

2

14 mm

+3

–0

7 mm

+3

–0

C-C

35mm

14 mm

+3

–0

7 mm

+3

–0

3

4

A-A

1

2

14 mm

+3

–0

7 mm

+3

–0

Figure 1A6-19

NOTE: In cold weather, the placement of car tr idges

adjacent to a source of warmth will assist the flow

of urethane when using a hand applicator.

10. Install the interior mirror assembly.

IMPORTANT: For ease of installation and to avoid

unnecessary stress on related components, it is

recommended that the interior mirror assembly be

fitted to the windshield prior to installation of the

windshield to the vehicle.

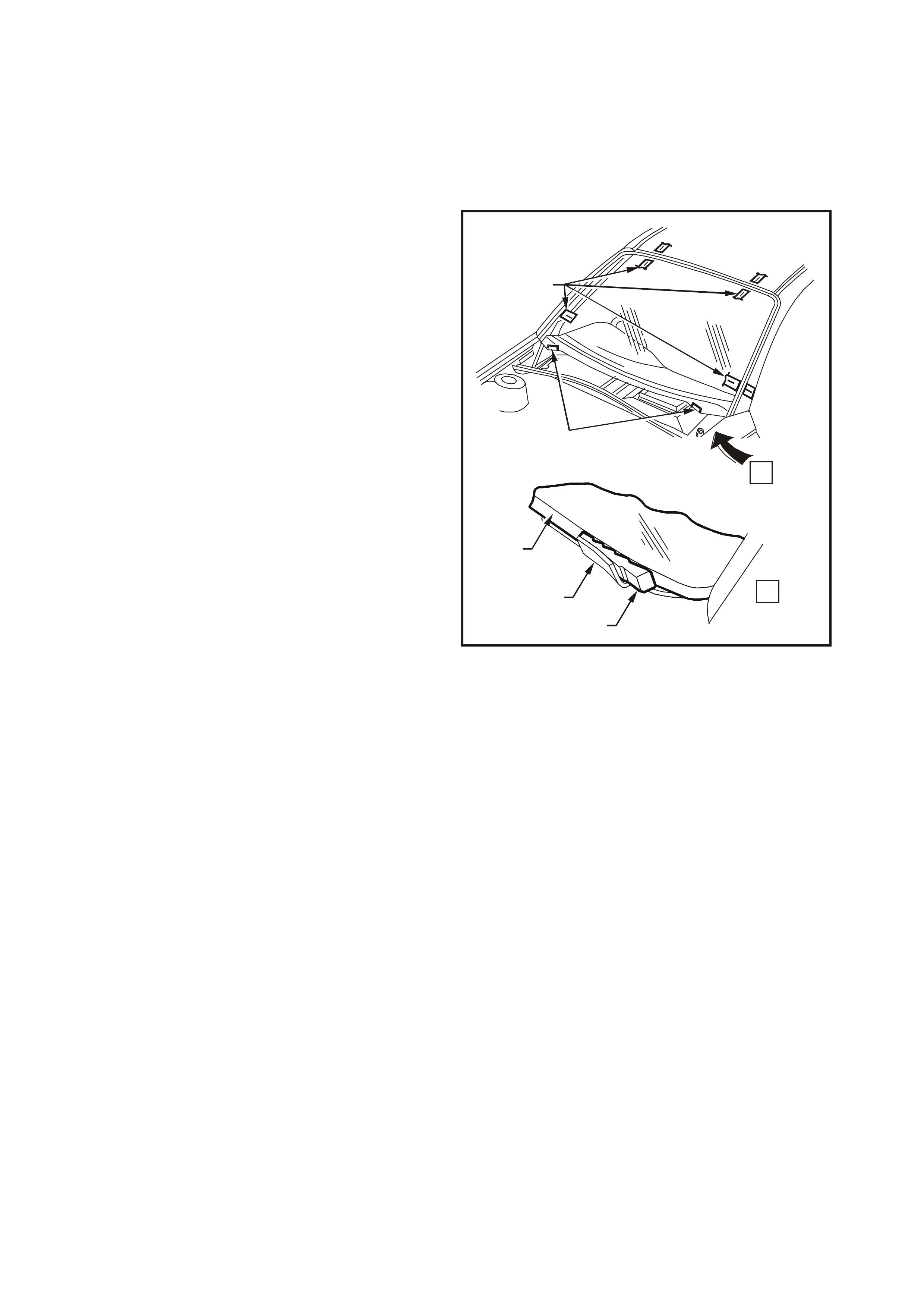

11. With the aid of an assistant, install the

windshield, using the previously attached

masking tape (1) on the roof and windshield to

ensure accurate installation. Use a wedge (2)

placed between the lower windshield edge (3)

and the reinforcing flanges (4) to locate glass

vertically in the 1windshield opening. Press

windshield firmly into position.

12. Check effectiveness of sealing from inside of

the vehicle. Should any gaps in the sealing

exist, apply additional urethane on the outside

to fill these gaps. Using a spatula, smooth the

surf ace of the urethane around the edge on the

outside of the windshield to ensure effective

sealing.

13. Water test the windshield, using a moderate

spray of water.

T21A6020

1

4

2

4

3

.

.

.

..

.

.

..

..

.

.

...

...

.

.

..

.

.

.

...

.

..

..

.

.

...

...

.

.

..

.

.

.

.

..

.

..

...

...

..

..

.

..

..

.

.....

.

........

.

.

.

..

.....

.....

.

....

.

.

....

.

..

.

...

..

.

.

.

..

.

...

...

.

.

.

..

..

.

...

.

..

.

A

A

Figure 1A6-20

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work urethane into source of leak.

IMPORTANT: If silicon is used for spot sealing,

allow a minimum of 1 hour to permit the silicon to

skin and adhere to the original urethane prior to

water testing the repair.

14. Clean off any excess urethane/silicon using

Prepsol or white spirit. Clean the windshield,

then remove the masking tape previously

installed.

15. Install the A-pillar trims. Refer to Section 1A8

HEADLINING AND REAR END TRIM of this

Service Information CD.

16. Install the demis t nozzles and retaining sc rews.

Install the instrument panel end cap covers.

Refer to Section 1A3 INSTRUMENT PANEL

AND CONSOLE of this Service Information

CD.

17. Install the plenum chamber water deflector,

right-hand and left-hand side plenum covers

and wiper arm assemblies.

CAUTION: Ensure that door windows are

partially lowered to eliminate pressure build up

which can be caused by slamming doors. A

curing time of 24 hours is recommended,

although the vehicle may be driven after

5 hours, providing it is driven only on a smooth

road at speeds not exceeding 80 km/h with the

door windows partially lowered.

SHORT METHOD INSTALLATION

DESCRIPTION

Short method installation involves the maximum

amount of the original urethane being left intact on

the body opening to form a sound base for the

replacement urethane and windshield.

This method is recommended when replacing a

cracked or broken windshield, or a leak condition

that cannot be overcom e by using minor water leak

repair procedures.

If material other than urethane has been used for

previous servicing of the windshield, the long

method installation procedure (complete removal of

adhesive) is mandatory to achieve an effective

glass to metal bond.

PREPARATION

CAUTION: Care should be taken to ensure that

glass does not strike the windshield opening.

Chipped edges can lead to subsequent

breakage of glass.

1. Using a wedge (1) placed between the lower

edge of the windshield (2) and the reinforcing

flanges (3), correctly locate the windshield in

the body opening.

2. Tape mark the outer top and side of the

windshield, pillar and roof with masking tape

(4). This procedure will assist in the alignment

of the windshield in the correct horizontal and

vertical plane during final windshield

installation.

3. Remove and place the windshield face down

on a clean protected surface or fixture.

T21A6012

4

3

1

3

2

.

.

.

..

.

.

..

..

.

.

...

...

.

.

..

.

.

.

...

.

..

..

.

.

...

...

.

.

..

.

.

.

.

..

.

..

...

...

..

..

.

..

..

.

.....

.

........

.

.

.

..

.....

.....

.

....

.

.

....

.

..

.

...

..

.

.

.

..

.

...

...

.

.

.

..

..

.

...

.

..

.

A

A

Figure 1A6-21

REINSTALL

1. Thoroughly clean the inner surface and edges

of the windshield to which the urethane is to be

applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

2. Apply clear glass primer to inner surface of

glass around the perimeter of the windshield

over the width of the solid black ceramic

pattern (or a width of 50 mm) and immediately

wipe off with a lint-free cloth.

3. Check the condition of the windshield

moulding. Discard and replace with new

moulding if damaged.

50mm

50mm

T21A6014

Figure 1A6-22

4. Fit windshield moulding (1) to sides and upper

section of windshield. Ensure that notch of

moulding (2) is aligned with ‘V’ locating mark

(3) on lower portion of right-hand and left-hand

side of windshield.

T21A6015

A

A

1

1

2

3

3

3

Figure 1A6-23

5. Check the original urethane around the

windshield opening flange for voids or

looseness. Cut away any loose pieces of

urethane and, using a suitable spatula, paddle

fresh urethane or silicon smoothly into any

voids or uneven sections.

6. Using the applicator (1) included in the service

kit, apply black glass primer (2) to the

windshield (3) alongside the moulding (4).

T21A6016

4

1

Figure 1A6-24

7. Apply black glass primer (1) to the inner

surface of the upper section (2) and sides (3) of

the windshield over a width of 20 mm inboard

from the moulding (4). Repeat this process

35 mm from the lower edge (5) of the

windshield. Ensure that a suitably reduced

application of primer black glass (6) is applied

15 mm from the lower edge of the windshield

(7) adjacent to the VIN plate (8).

T21A6017

A-A

1

20mm

4

A

BBB

B

C

C

D

D

A

2

3

3

87

5

B-B

1

4

20mm

C-C

20mm

1

5

35mm

D-D

8

6

7

15mm

Figure 1A6-25

8. Using a hand or automatic applicator, apply a

smooth continuous bead of urethane (1), such

as Betaseal 587.02, 15.685 (High Viscosity) or

equivalent (to Holden Specific ation HN2293), to

the windshield (2) alongside the moulding (3).

T21A6018

2

1

3

3

Figure 1A6-26

IMPORTANT: On the lower section of the body

opening, care must be taken to ensure the

urethane bead diameter is such that when

compressed by the windshield installation, the

vehicle identification number is not obscured.

9. Apply urethane (1) adjacent to the m oulding (2)

and 35 mm inboard (3) from the lower edge of

the windshield (4). A suitably reduced amount

of urethane (5) should be applied adjacent to

the VIN plate (6) to ensure that the VIN is not

obscured when the windshield is installed. All

other bead dimensions are shown in Fig. 1A6-

27.

T21A6019

A

BBB

B

C

C

D

D

A

6

D-D

6

5

15mm

B-B

1

2

14 mm

+3

–0

7 mm

+3

–0

C-C

35mm

14 mm

+3

–0

7 mm

+3

–0

3

4

A-A

1

2

14 mm

+3

–0

7 mm

+3

–0

Figure 1A6-27

NOTE: In cold weather, the placement of car tr idges

adjacent to a source of warmth will assist the flow

of urethane when using a hand applicator.

10. Install the interior mirror assembly.

IMPORTANT: For ease of installation and to avoid

unnecessary stress on related components, it is

recommended that the interior mirror assembly be

fitted to the windshield prior to installation of the

windshield to the vehicle.

11. With the aid of an assistant, install the

windshield, using the previously attached

masking tape (1) on the roof and windshield to

ensure accurate installation. Use a wedge (2)

placed between the lower windshield edge (3)

and the reinforcing flange (4) to locate glass

vertically in the windshield opening. Press

windshield firmly into position.

12. Check effectiveness of sealing from inside of

the vehicle. Should any gaps in the sealing

exist, apply additional urethane on the outside to

fill these gaps. Using a spatula, smooth the

surface of the urethane around the edge on the

outside of the windshield to ensure effective

sealing.

13. Water test the windshield, using a moderate

spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work urethane into source of leak.

T21A6020

1

4

2

4

3

.

.

.

..

.

.

..

..

.

.

...

...

.

.

..

.

.

.

...

.

..

..

.

.

...

...

.

.

..

.

.

.

.

..

.

..

...

...

..

..

.

..

..

.

.....

.

........

.

.

.

..

.....

.....

.

....

.

.

....

.

..

.

...

..

.

.

.

..

.

...

...

.

.

.

..

..

.

...

.

..

.

A

A

Figure 1A6-28

IMPORTANT: If silicon is used for spot sealing,

allow a minimum of 1 hour to permit the silicon to

skin and adhere to the original urethane prior to

water testing the repair.

14. Clean off any excess urethane/silicon using

Prepsol or white spirit. Clean the windshield,

then remove the masking tape previously

installed.

15. Install the A-pillar trims. Refer to Section 1A8

HEADLINING AND REAR END TRIM of this

Service Information CD.

16. Install the demis t nozzles and retaining sc rews.

Install the instrument panel end cap covers.

Refer to Section 1A3 INSTRUMENT PANEL

of this Service Information CD.

17. Install the plenum chamber water deflector,

right-hand and left-hand side plenum covers

and wiper arm assemblies.

CAUTION: Ensure that door windows are

partially lowered to eliminate pressure build up

which can be caused by slamming doors. A

curing time of 24 hours is recommended,

although the vehicle may be driven after

5 hours, providing it is driven only on a smooth

road at speeds not exceeding 80 km/h with the

door windows partially lowered.

3.2 REAR QUARTER WINDOW ASSEMBLY — STATION WAGONS

REMOVE

CAUTION: Safety glasses and work gloves

must be worn at all times when operating with

glass.

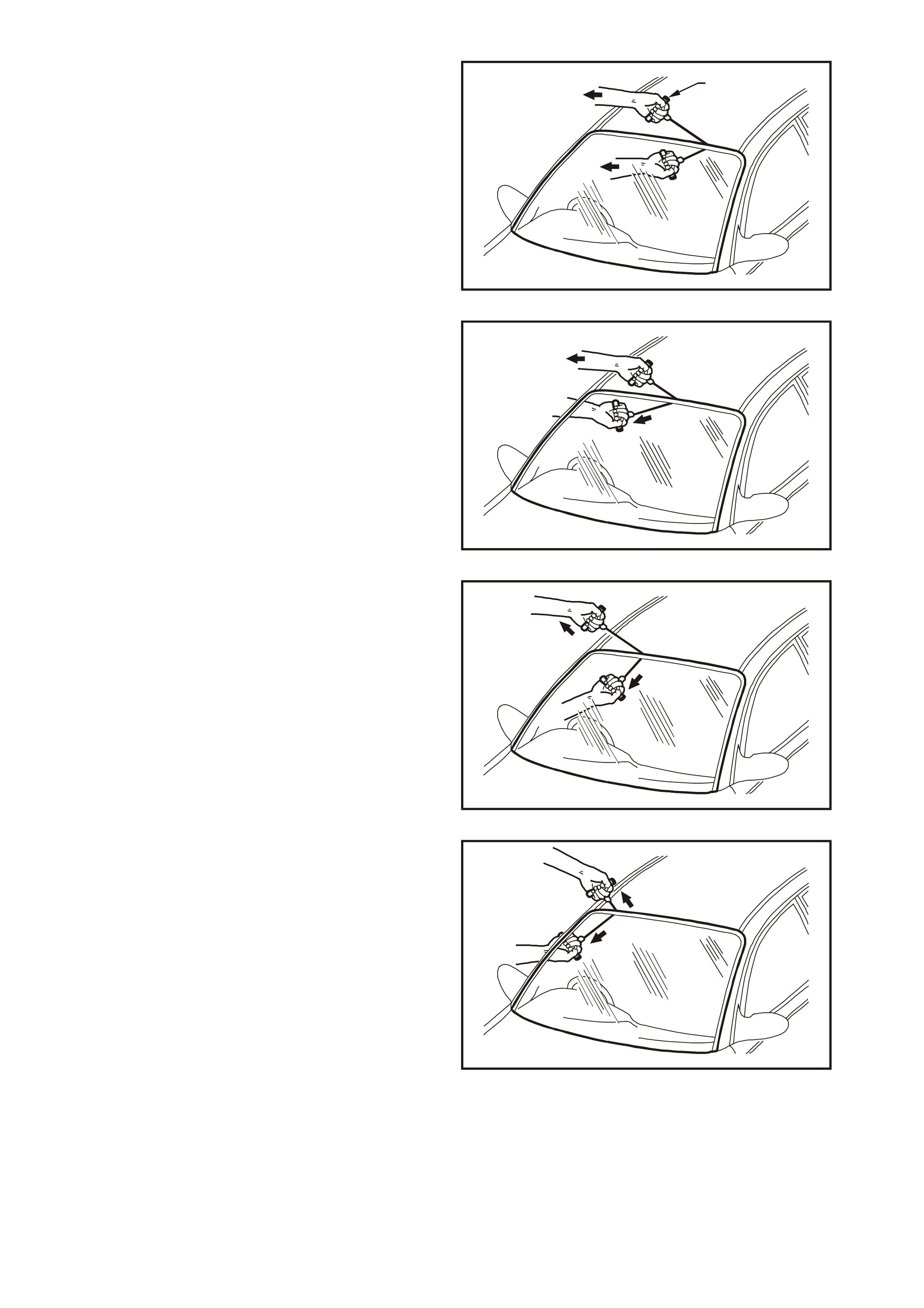

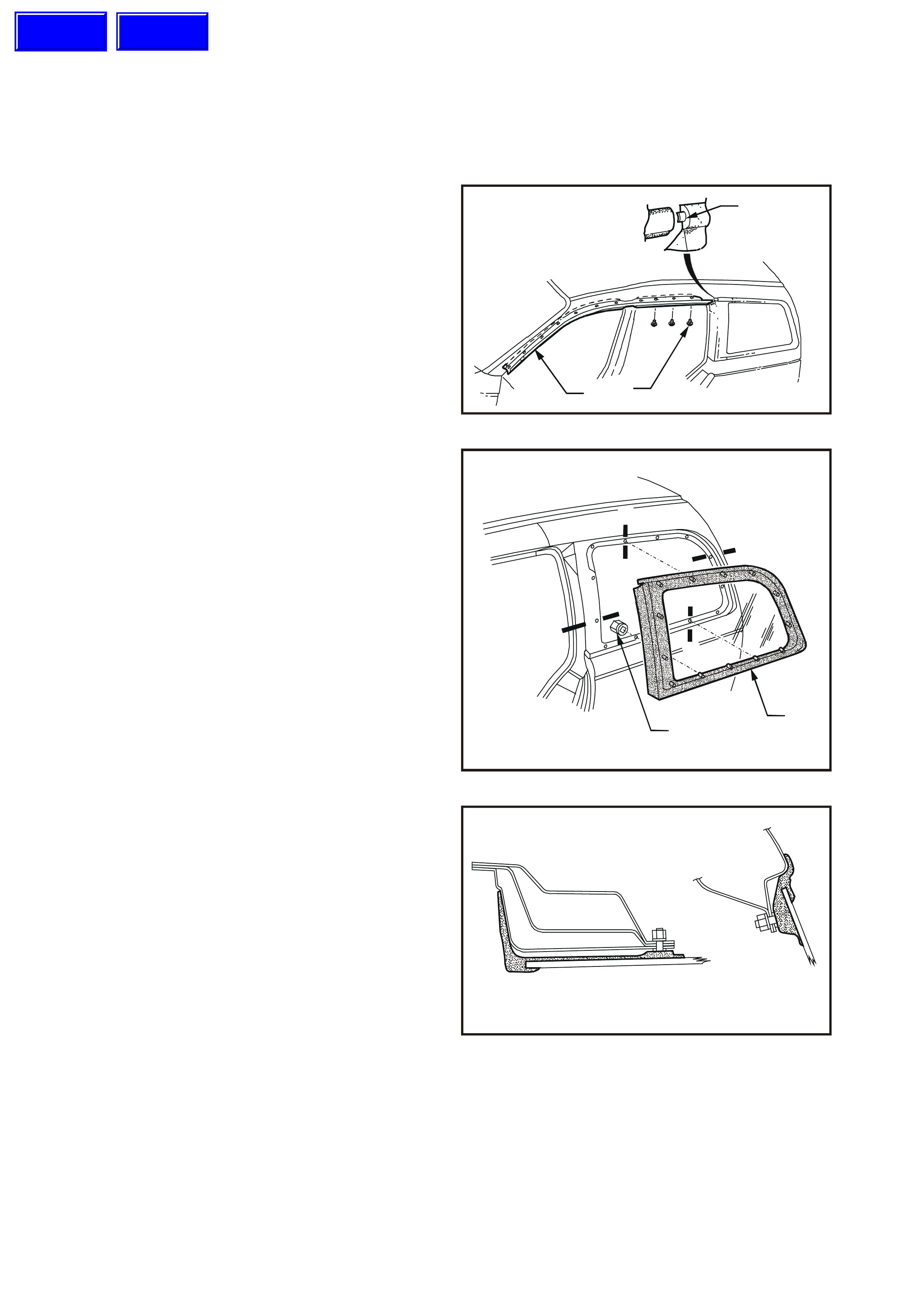

1. Partially remove the door frame opening

moulding (1) where it joins the quarter window

glass frame tab (3) by removing the moulding

screws (2) on the upper section of the

moulding, and release quarter window glass

frame tab (3). Refer to Section 1A9

EXTERIOR ORNAMENTATION of this Service

Information CD,

2. Remove the quarter window inner trim

moulding assembly, refer to Section 1A8

HEADLINING AND REAR END TRIM of this

Service Information CD.

T21A6021

1

3

2

Figure 1A6-29

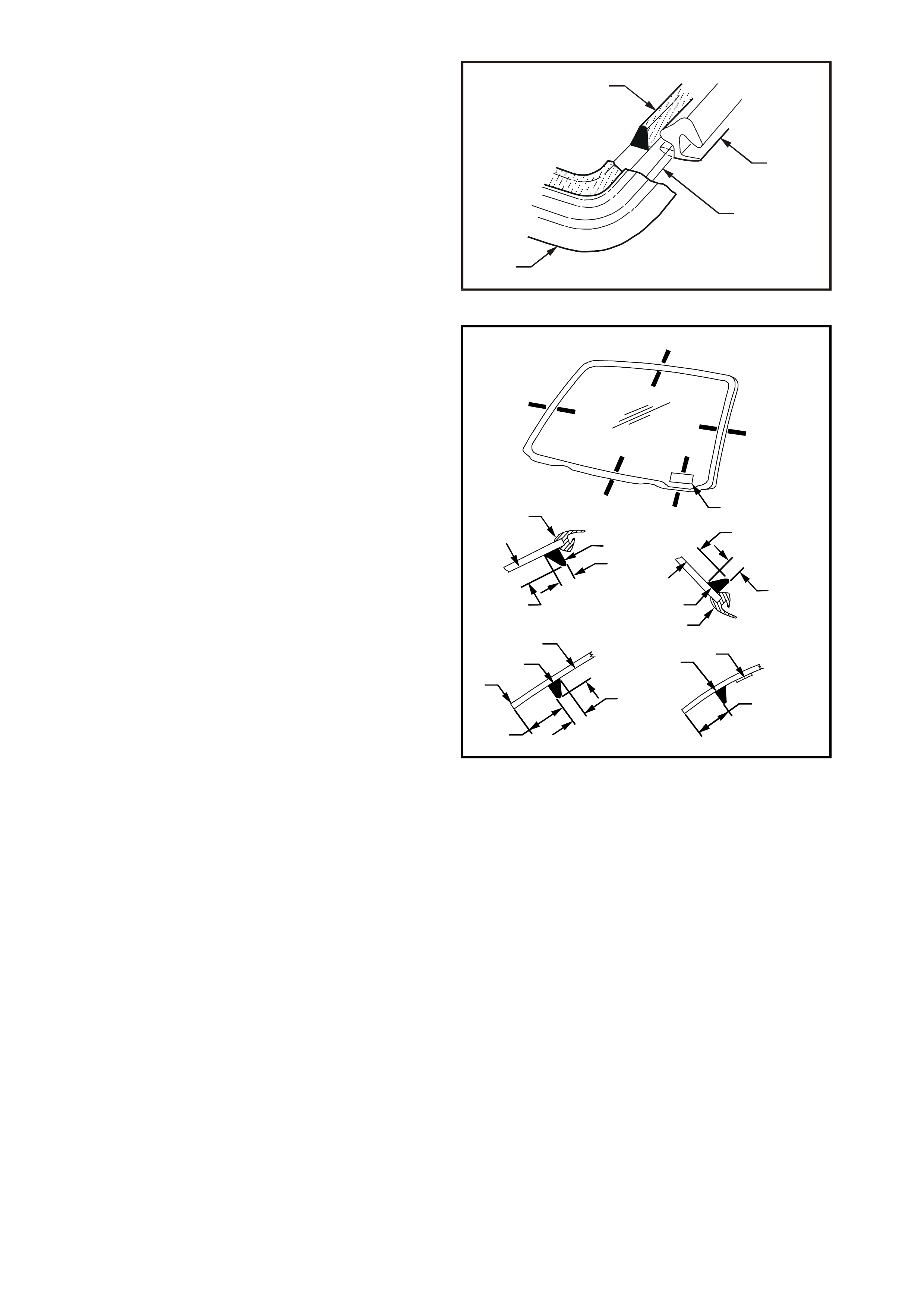

3. Remove the 13 plastic nuts (1) securing the

quarter window (2) to the body opening and

carefully lift the window from the vehicle.

For sections A-A, and B-B refer to Fig. 1A6-31.

For sections C-C, and D-D refer to Fig. 1A6-32.

T21A6022

12

A

B

A

CC

D

D

B

Figure 1A6-30

T21A6023

B-B

A-A

Figure 1A6-31

Techline

Techline

T21A6024

C-C D-D

Figure 1A6-32

REINSTALL

Reverse removal operations with the following

additional procedure.

Leave the quarter window plastic nuts loose until

door frame opening moulding is fastened in

position. Position quarter window and tighten the

quarter window plastic nuts to the correct torque

specification.

QUARTER WINDOW

PLASTIC NUTS

TORQUE SPECIFICATION 1 – 3 Nm

NOTE: Should the foam weatherstrip which seals

the window to the body opening require

replacement, sections are available. Refer to the

VT Series parts information for details.

3.3 TAILGATE WINDOW — STATION WAGONS

REMOVE

CAUTION: Safety glasses and work gloves

must be worn at all times when operating with

glass.

1. Disconnect battery ground cable.

2. Place protective covering around tailgate

opening.

3. Remove rear wiper blade and arm assembly,

refer to Section 12C INSTRUMENTS,

WIPERS, WASHERS & HORN of this Service

Information CD.

4. Remove rear window washer nozzle, refer to

Section 1A4 REAR COMPARTMENT LID

AND TAILGATE of this Service Information

CD.

5. Remove the tailgate panel upper and lower

trim, refer to Section 1A4 REAR

COMPARTMENT LID AND TAILGATE of this

Service Information CD.

6. Carefully disconnect the tailgate electrical

demister connectors.

7. Remove the two cover plugs (1), three nuts (2)

and two screws (3) securing the tailgate air

deflector and remove the assembly.

8. Should the glass be broken, carefully remove

all fragments of glass from the tailgate window

opening. Otherwise, carefully cut out the tail

gate window by following the procedure set out

in Steps 12 to 15 of 3.1 WINDSHIELD GLASS

in this Section.

NOTE: It is not necessary to remove all traces of

the original urethane. However, any original

urethane remaining must be smooth and firm.

T21A6025

1

2

4

3

A

A

-A B-B

B

B

A

Figure 1A6-33

LONG METHOD INSTALLATION

1. Using one of the applicators in the service kit,

apply flange primer (1) to any section of the

tailgate opening flange that has been cleaned

back to bare metal or to be painted. Allow this

primer to dry for 15 minutes.

IMPORTANT: Do not touch primed surfaces.

2. Thoroughly clean the inner surface and edges

of the tailgate glass to which the urethane is to

be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

T21A6035

A

A

1

A-A

Figure 1A6-34

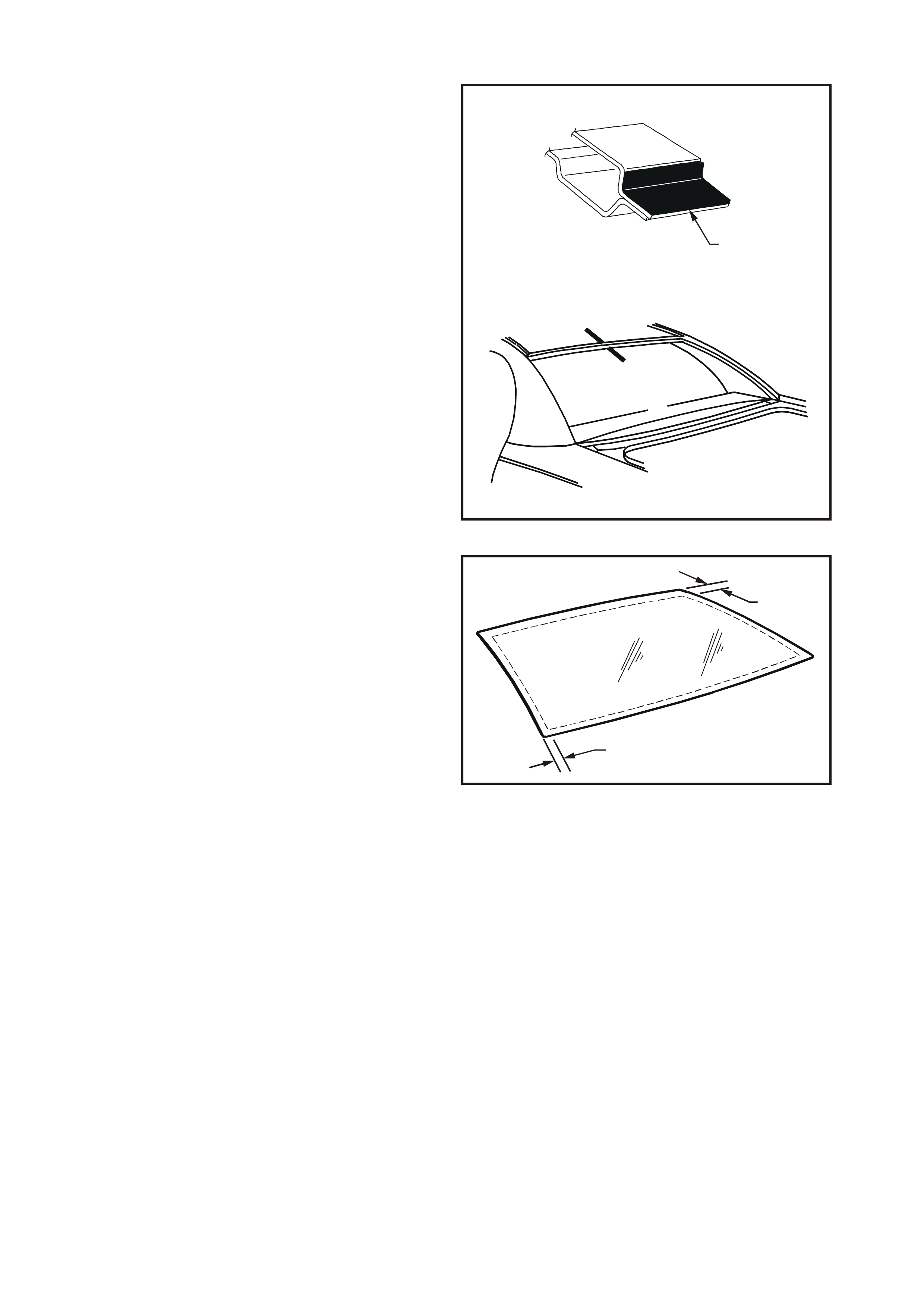

3. Apply clear glass primer to inner surface of

glass around the perimeter of the tailgate over

the width of the solid black ceramic pattern (or

a width of 50 mm) and immediately wipe off

with a lint-free cloth.

4. Check the condition of the tailgate moulding

and replace if damaged. Fit the tailgate

moulding over the edge of the glass, with

moulding joint at centre line upper side of

glass, ensure moulding is fitted correctly to

glass.

T21A6026

50mm

50mm

Figure 1A6-35

5. Using the applicator (1) included in the service

kit, apply black glass primer (2) to the tailgate

glass (3) alongside the moulding (4). Primer

application should be to a width of 20 mm

around the entire perimeter and over the

Holden logo.

T21A6027

4

3

1

2

4

20mm

Figure 1A6-36

6. Using a hand or automatic applicator, apply a

smooth continuous bead of urethane (1), such

as Betaseal 587.02 or equivalent, to the tailgate

glass (2) alongside the m oulding (3). T he bead

dimensions are shown in Fig. 1A6-37.

NOTE: In cold weather, the placement of c artr idges

adjacent to a source of warmth will assist the flow

of urethane when using a hand applicator.

7. With the aid of an assistant, install the tailgate

glass and press the glass firmly into position.

8. Check effectiveness of sealing from inside of

the vehicle. Should any gaps in the sealing

exist, apply additional urethane on the outside

to fill these gaps. Using a spatula, smooth the

surf ace of the urethane around the edge on the

outside of the tailgate to ensure effective

sealing.

9. W ater test the tailgate, using a m oderate spray

of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a leak is evident, apply

additional urethane to the leak area, using a

spatula to work urethane into source of leak.

IMPORTANT: If silicon is used for spot sealing,

allow a minimum of 1 hour to permit the silicon to

skin and adhere to the original urethane prior to

water testing the repair.

10. Clean off any excess urethane/silicon using

Prepsol or white spirit.

T21A6028

14 mm

+3

–0

2

3

1

7 mm

+3

–0

A-A

1

3

2

3

A

2

A

A

A

A

AA

A

A

A

Figure 1A6-37

11. Install the tailgate air deflector and secure with

three nuts and two screws. Tighten the nuts

and screws to the correct torque specification.

TAILGATE AIR DEFLECTOR

RETAINING NUTS

AND SCREWS

TORQUE SPECIFICATION

2 – 5 Nm

12. Connect the tailgate electrical demister

connectors, then clean the tailgate and

surrounding area.

CAUTION: Ensure that door windows are

partially lowered to eliminate pressure build up

which can be caused by slamming doors. A

curing time of 24 hours is recommended,

although the vehicle may be driven after 5

hours, providing it is driven only on a smooth

road at speeds not exceeding 80 km/h.

SHORT METHOD INSTALLATION

The short method of installation for the tailgate is

the same as that detailed in 3.1 WINDSHIELD

GLASS in this Section. Note that the clear and

black primers must follow the entire perimeter of

the tailgate glass.

3.4 BACK WINDOW — SEDANS

REMOVE

CAUTION: Safety glasses and work gloves

must be worn at all times when operating with

glass.

1. Disconnect battery ground cable.

2. Place protective covering adjacent to back

window to protect trim and paint finish.

3. Remove the right-hand and left-hand side roof

finisher mouldings, refer to Section 1A9

EXTERIOR ORNAMENTATION of this Service

Information CD.

4. Remove the rear window inner trim moulding

assembly, refer to Section 1A8 HEADLINING

AND REAR END TRIM of this Service

Information CD.

5. Carefully disconnect the back window electrical

demister connectors.

6. Should the glass be broken, carefully remove

all fragments of glass from the back window

opening. Otherwise, carefully cut out the back

window glass by following the procedure set

out in Steps 12 to 15 of 3.1 WINDSHIELD

GLASS in this Section.

NOTE: It is not necessary to remove all traces of

the original urethane. However, any original

urethane remaining must be smooth and firm.

Body Opening Check

1. Thoroughly check the back window opening

flange fo r any irregularities before inst allation of

replacement window.

CAUTION: Care should be taken to ensure that

glass does not strike the back window opening.

Chipped edges can lead to subsequent

breakage of glass.

2. Check and if necessary, re-form the body

flange to produce a uniform flange to glass

contour.

3. Correctly locate the glass in the body opening,

then tape mark the outer top of glass and roof

on the right-hand and left-hand sides. This

procedure will assist the alignm ent of the glass

in the correct horizontal plane during final

installation.

Techline

LONG METHOD INSTALLATION

1. Using one of the applicators in the service kit,

apply flange primer (1) to any section of the

back window opening flange that has been

cleaned back to bare metal or to be painted.

Allow this primer to dry for 15 minutes.

IMPORTANT: Do not touch primed surfaces.

2. Thoroughly clean the inner surface and edges

of the back window glass to which the ur ethane

is to be applied, using clean lint- free cloths and

a suitable oil free cleaning solvent.

T21A6036

1

A

A

A-A

Figure 1A6-38

3. Apply clear glass primer to the inner surface of

glass around the perimeter of the back window

edge over a width of 50 mm and immediately

wipe off with a lint-free cloth.

T21A6029

50mm

50mm

Figure 1A6-39

4. Check the condition of the back window

mouldings and replace if damaged. Install the

back window upper moulding (1) and lower

moulding (2) over the edge of the glass,

ensuring that each moulding is fitted correctly

to the glass. Refer to Fig. 1A6-40.

5. Install two roof to glass retaining m ouldings (3)

to left-hand and right-hand sides of glass.

Ensure that mouldings are positioned to

alignment marks (4), and are fitted correctly to

edge of glass.

6. Using the applicator (5) included in the service

kit, apply black glass primer (6) around the

perimeter of the back window glass bonding

surf ace over a width of 20 m m along the inside

edge of back window mouldings.

7. Using a hand or automatic applicator, apply a

smooth continuous bead of urethane (7), such

as Betaseal 587.02, 15.685 (High Viscosity) or

equivalent (to Holden Specification HN2293),

inboard of the mouldings around the entire

perimeter of the body opening. The urethane

bead should be as specified in Fig. 1A6-40.

NOTE: In cold weather, the placement of c artr idges

adjacent to a source of warmth will assist the flow

of urethane when using a hand applicator.

8. With the aid of an assistant, install the back

window glass and press the glass firmly into

position.

NOTE 1: Ensure glass is centralised in body

opening left to right by checking that the gaps

between the glass moulding and C-pillar are even

on both sides of the vehicle.

NOTE 2: Ensure windscreen glass moulding is

under-f lush with roof opening to pr event wind noise

occuring.

Figure 1A6-40

1. Upper moulding 3. Roof-to-glass

retaining moulding 5. Applicator 7. Urethane

2. Lower moulding 4. Alignment marks 6. Black glass primer

9. Engage the roof finisher moulding assembly

over side moulding as shown in Fig. 1A6-41

and slide along until roof finis her m oulding is in

position (refer to Fig. 1A6-42).

10. Engage roof finisher moulding assembly clips

along roof until r oof f inisher m oulding as sem bly

sits flush against roof, refer to Section 1A9

EXTERIOR ORNAMENTATION of this Service

Information CD. The following items are

illustrated in Fig. 1A6-41:

1. Roof finisher moulding.

2. Notch (locate over window moulding).

3. C-pillar.

4. Back window glass.

5. Back window side moulding.

6. Urethane bead.

7. Roof panel.

8. Roof finisher moulding locating clips

(seven places, ensure lead clip is installed

under roof panel flange).

NOTE: Front of roof finisher moulding must be

installed under windshield moulding cover.

IMPORTANT: Roof finisher mouldings must be

fitted within 10 minutes of installing glass.

T21A6031

21

8

5

8

3

1

1

6

7

4

3

B

B-B

A-A

B

A

A

Figure 1A6-41

NOTE: Ensure that the end cap of the roof finisher

moulding is aligned with quarter panel to roof

moulding. The following items are illustrated in

Fig. 1A6-42:

1. Roof finisher moulding.

2. C-pillar.

3. Roof finisher moulding end cap.

4. Back window lower moulding.

5. End cap of roof finisher moulding to be in

line with items 2 and 4.

11. Check effectiveness of sealing from inside of

the vehicle. Should any gaps in the sealing

exist, apply additional urethane on the outside

to fill these gaps. Using a spatula, smooth the

surf ace of the urethane around the edge on the

outside of the back window to ensure effective

sealing.

12. Water test using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a leak is evident, apply

additional urethane to the leak area, using a

spatula to work urethane into source of leak.

IMPORTANT: If silicon is used for spot sealing,

allow a minimum of 1 hour to permit the silicon to

skin and adhere to the original urethane prior to

water testing the repair.

13. Clean off any excess urethane/silicon using

Prepsol or white spirit, then remove the

masking tape previously installed.

14. Connect the electrical demist connectors, then

clean the rear window and surrounding area.

CAUTION: Ensure that door windows are

partially lowered to eliminate pressure build up

which can be caused by slamming doors. A

curing time 24 hours is recommended,

although the vehicle may be driven after 5

hours, provided it is driven only on a smooth

road at speeds not exceeding 80 km/h.

T21A6032

4

1

3

5

2

Figure 1A6-42

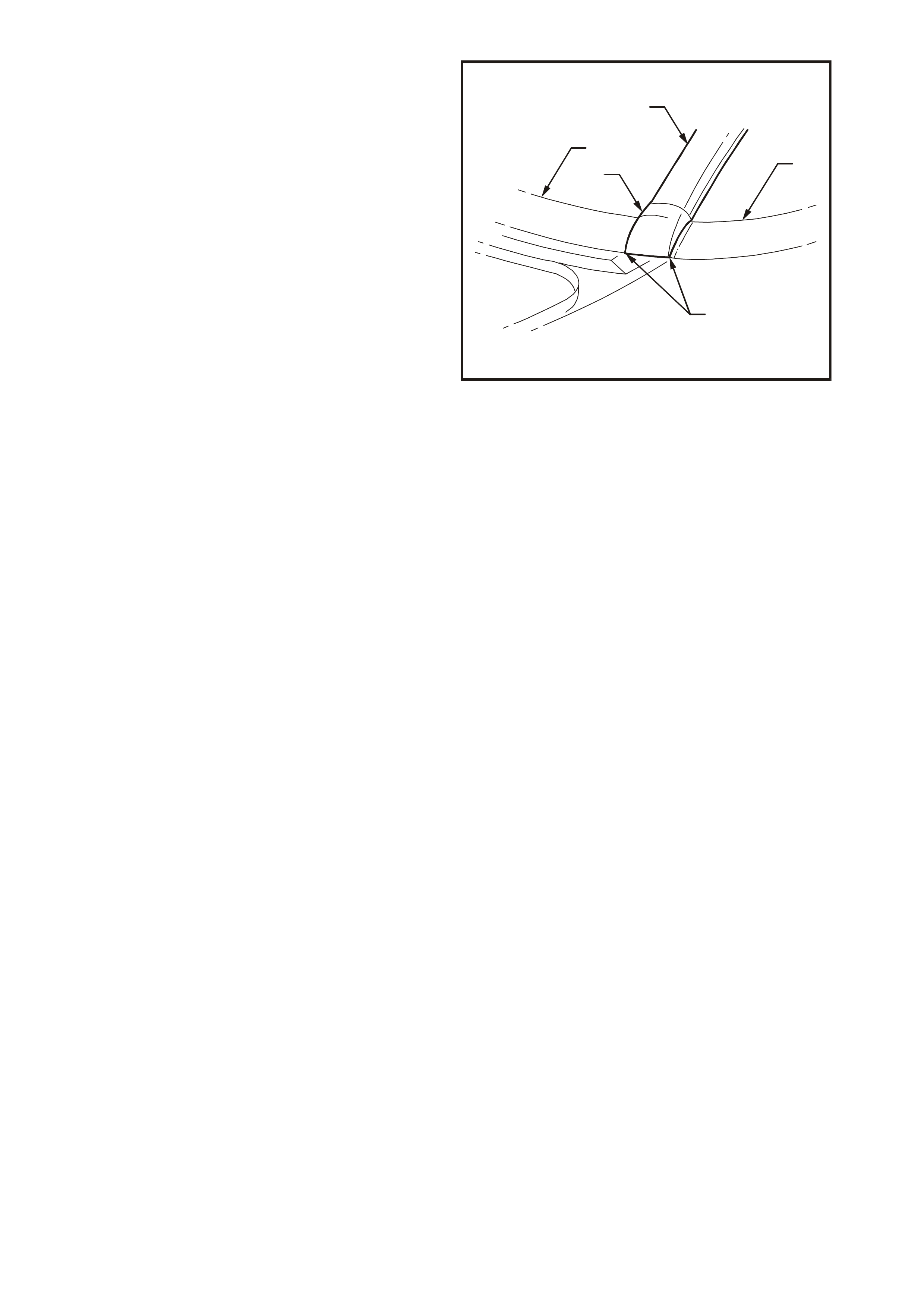

3.5 MINOR WATER LEAK CORRECTION

1. Secure protective covering with masking tape

adjacent to the leak suspect area.

NOTE: To determine the precise location of the

water leak, use the air/soap bubble leak test. The

soap/water solution can be applied with either a

spray applicator or brush as illustrated in Fig. 1A6-

43.

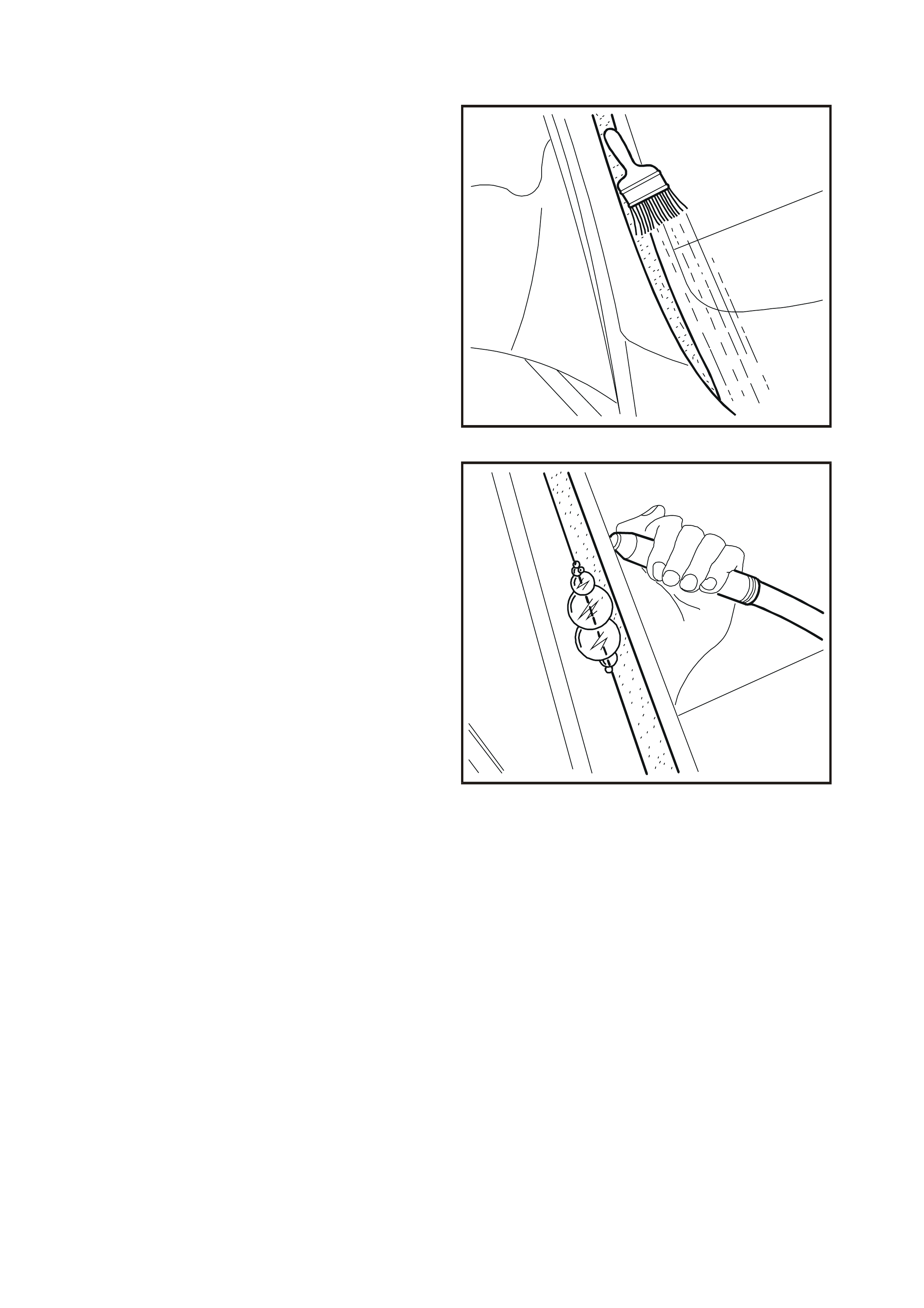

2. Locate an air hose nozzle on the inside of the

windshield as illustrated in Fig. 1A6-44. Have

an assistant outside the vehicle apply a soapy

water solution opposite the air s ource. As a low

air pressure (60 kPa) is applied, soap bubbles

will form on the outside of the windshield,

indicating the location of the leak.

3. If the suspect leak area is not obvious,

com mence the tes ting ac ros s the top and down

the sides until the leak location has been

determined.

T21A6033

Figure 1A6-43

4. It may be necessary to lift or remove moulding

covering the leak location.

NOTE 1: If silicon is to be used, thoroughly dry out

the repair area with compressed air.

NOTE 2: If urethane is to be used, it is only

necessary to remove dust, foreign matter, etc.

Water activates the curing process of urethane.

5. Using a spatula, work fresh urethane or silicon

in and around the leak area.

6. If urethane has been used, leak test the repair ,

using the air/soap bubble leak test or a non-

pressurised water leak test.

IMPORTANT: If silicon is used for spot sealing,

allow a minimum of 1 hour to permit the silicon to

skin and adhere to the original urethane prior to

testing the repair. Should the leak persist, apply

additional urethane/silicon until the leak has been

corrected.

7. Secure the section of moulding lifted or

removed to carry out the leak correction.

8. Remove the masking tape and protective

covers, then clean the glass and adjacent paint

and trim surfaces.

T21A6034

Figure 1A6-44

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Instrument Panel and Cap Cover Attachment Screws ......... 1 – 3

Demist Nozzle Securing Screws........................................... 1 – 3

Quarter Window Plastic Securing Nuts................................. 1 – 3

Tailgate Air Deflector Securing Nuts and Screws................. 2 – 5

5. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

AU390 FABRICATED T HANDLE WINDSCREEN

REMOVAL TOOL AND PIANO WIRE

AU390-1 PIANO WIRE

J39032 STATIONARY GLASS REMOVAL TOOL