SECTION 1A7 - SEAT & SEAT BELT ASSEMBLIES

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air bag s or seat belt pre- tensio ners, d riv er’s and fron t p asseng er’s air bag and lef t and rig ht

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Section of this Service Information CD for more

specific servicing information.

1. GENERAL DESCRIPTI ON

Since the VT Series Service Information CD was first published, there have been several changes to the seats. The

information contained in this Section provides a summary of these changes, together with any relevant Service

Operations, Diagnostic Procedures and Specifications.

Noting the following Cautions, information, including General Description, Service Operations, Diagnosis,

Specifications and Special Tools, that is not covered in this Section, refer to Section 1A7 SEAT & SEAT BELT

ASSEMBLIES of the VT Series I Service Information.

Thes e following Cautions apply to Service Operations detailed in both this Sec tion and thos e pr eviously published in

Section 1A7 SEAT A ND SEAT BELT ASSEMBLIES of the VT Series I Service Information.

CAUTION: Before performing any Service Operation on a front seat assembly, ensure the SRS is disabled.

Refer to Section 12M SUPPLEMENTAL RESTRAINT SYSTEM of the VT Series I Service Information.

CAUTION: Accessory and after market seat covers MUST NOT be fitted to a vehicle with side impact air

bags unless approved by Holden Ltd. Seat covers that are not approved by Holden Ltd. could greatly inhibit

the performance of the side impact air bag and occupants safety in the event of side impact air bag

deployment.

SUMMARY OF CHANGES

In August 1998, side impact air bags became available as an option to VT Series Models. With the availability of this

option, a revised procedure for disassembling and reassembling the front seat has been developed.

For additional information, including the removal and reinstallation of a side impact air bag module assembly,

refer to Section 12M SUPPLEMENTAL RESTRAINT SYSTEM of the VT Series I Service Information.

New lumbar support knob for vehicles with side impact air bags.

NOTE: If a lumbar support knob requires replacement, and the vehicle is equipped with side impact air bags,

only install this new type lumbar support knob which has been modified to suit side impact air bag applications.

New seat fabrics / colours for VT Series II Models.

Since the start of VT Ser ies vehicle production, var ious fas tener types and tor que wrench s pecifications have been

revised. Therefore, 4. TORQUE WRENCH SPECIFICATIONS in this Section has been revised to reflect these

changes and re-published in full. Whenever tightening a seat or seat belt fast ener on a VT Series Model, referenc e

to this Section should be made.

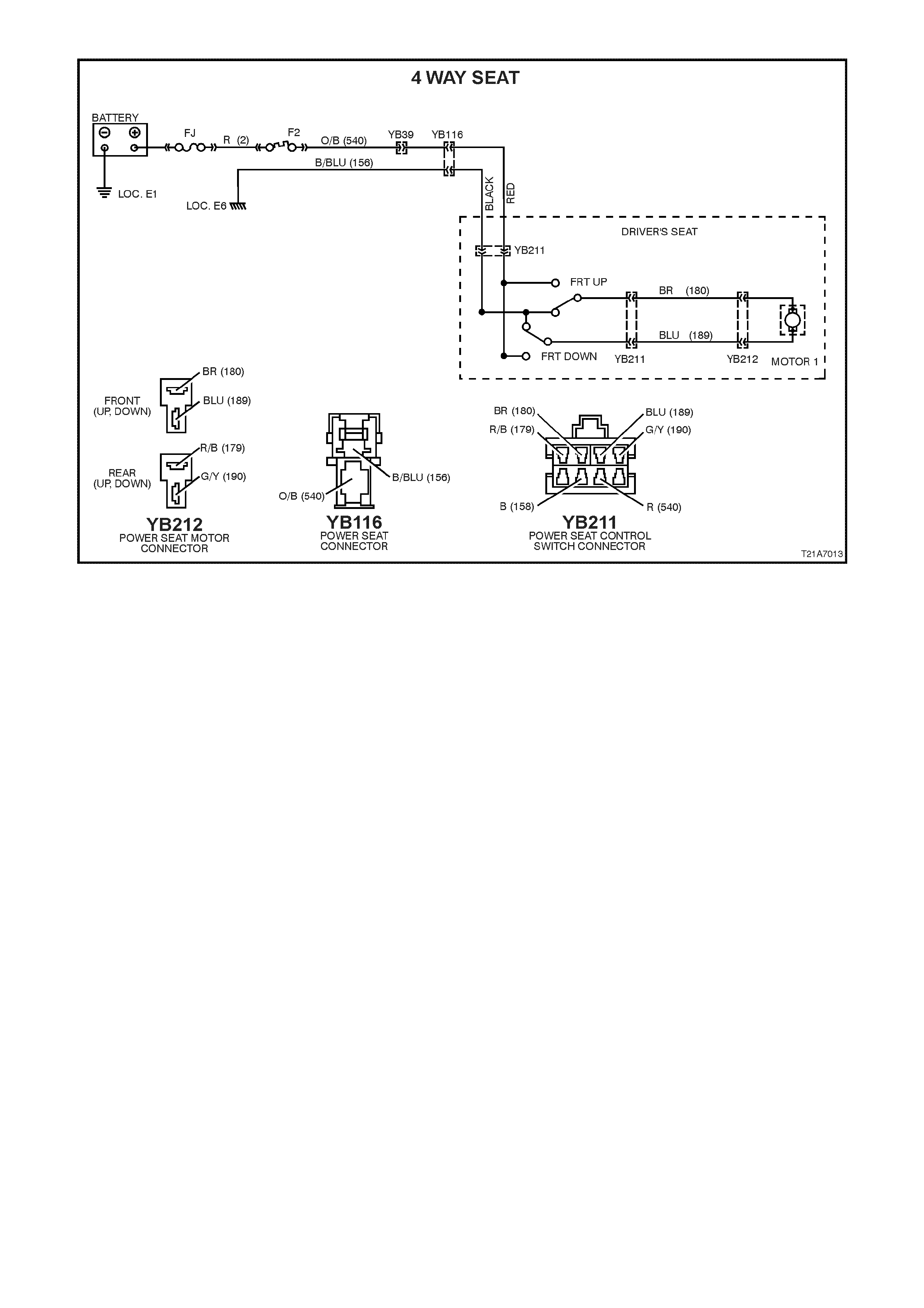

From vehicle Tag Number L423680 there was a revision to the wiring on the four way seat electric motors.

Previously, the electric seat motors were constantly supplied with power and connected to earth to activate. With

this wiring revision, the seat m otors ar e constantly earthed and connected to battery voltage to activate. As a result

of this change, there have been some revisions to the diagnostic procedures, refer to 3. DIAGNOSTICS in this

Section.

NOTE: The wiring of the eight way electric seat remains unchanged. Eight way electric seat m otors are constantly

earthed and connected to battery voltage to activate.

Techline

Techline

Techline

Techline

2. SERVICE OPERATIONS

2.1 FRONT BUCKET SEAT ASSEMBLY

REMOVE

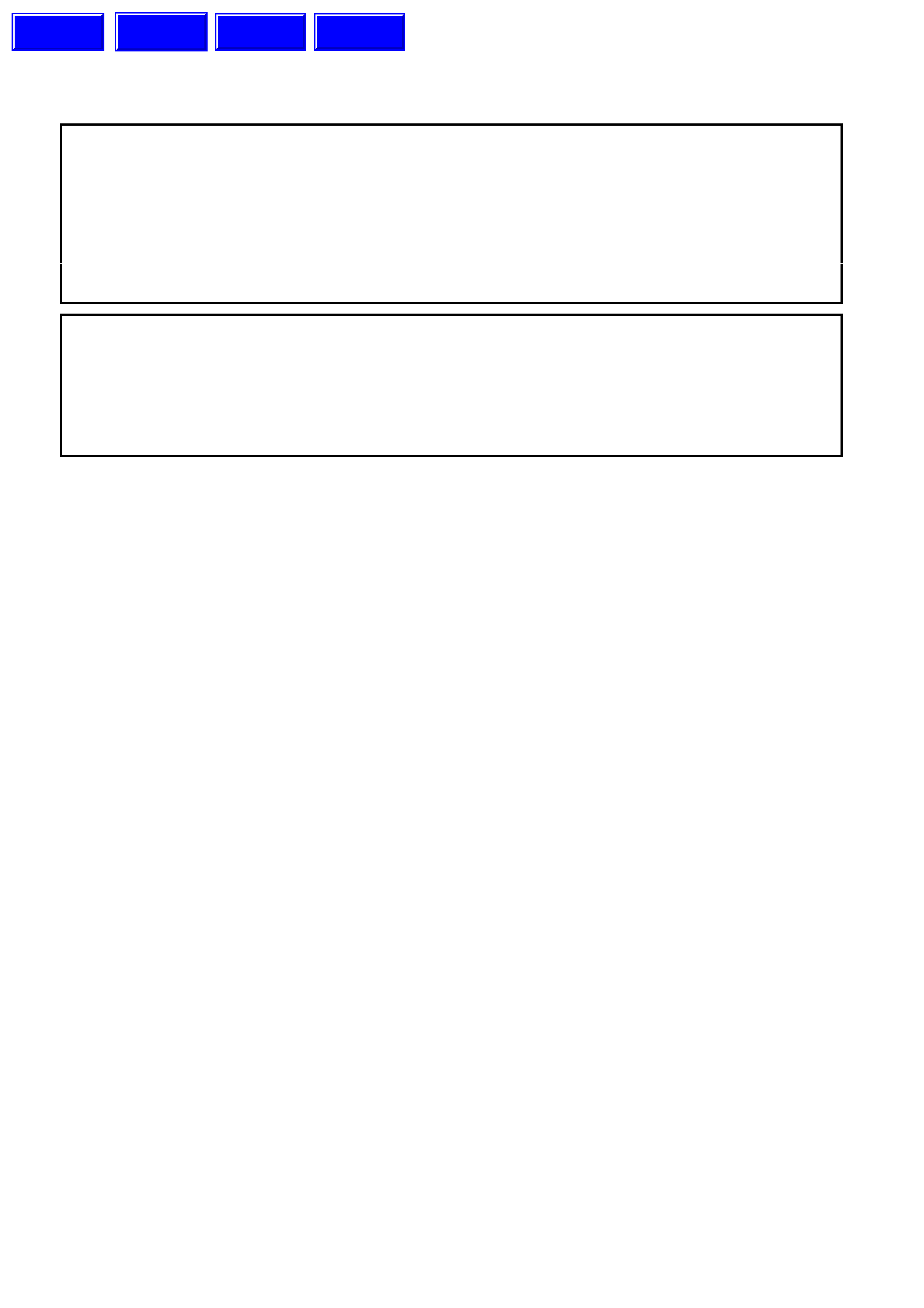

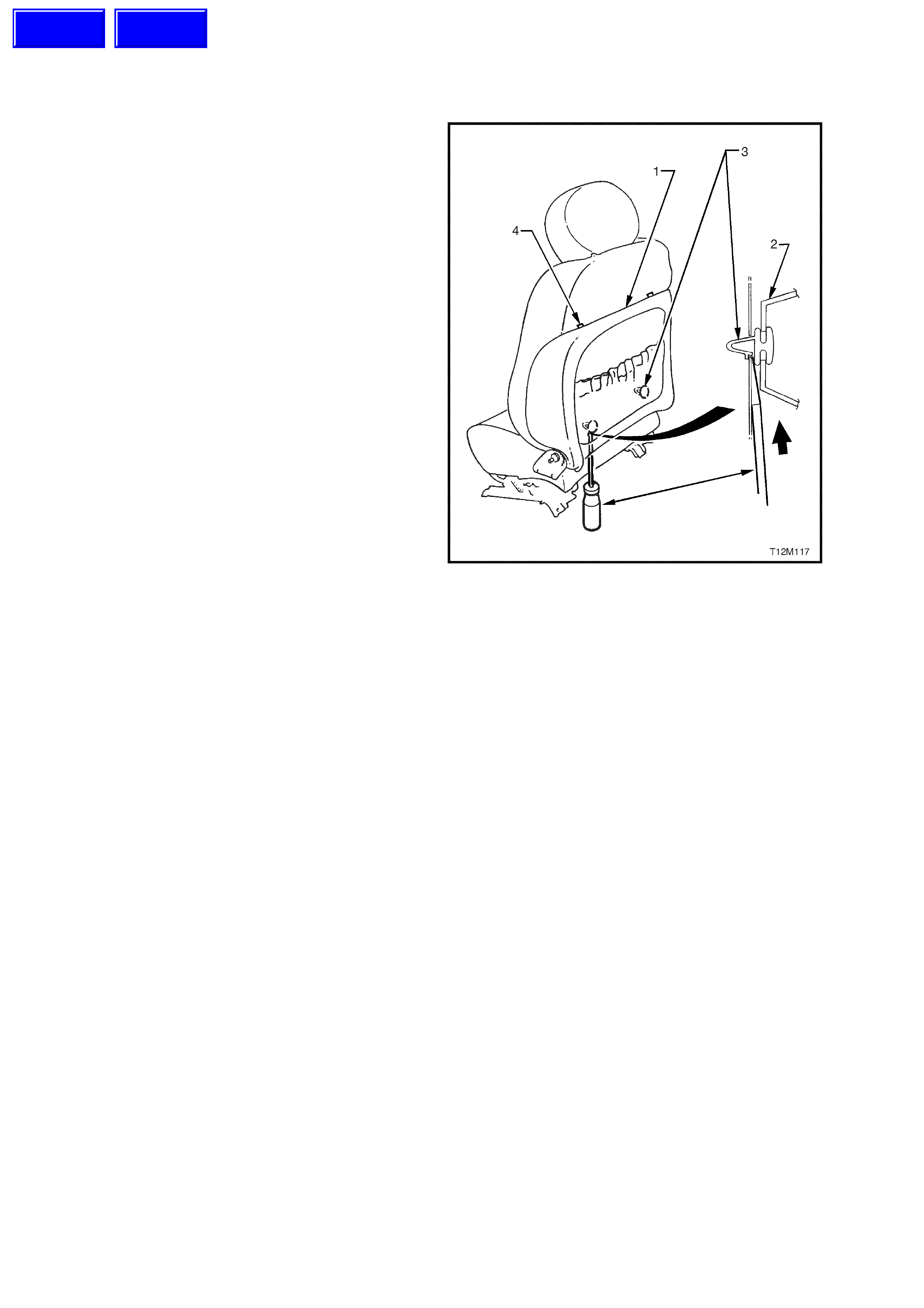

1. Position the relevant front seat to obtain the

easiest access to the seats four retaining bolts

and, if possible, the seat should be fully raised

and the seat back tilted forward.

2. Disable the SRS, refer to Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of

the VT Series I Service Information.

3. If removing the driver’s seat, remove the

retaining screw (1) from the driver’s side outer

front guide rail cover.

4. Using a small screwdriver, push in the centre of

the front (3) and rear (2) outer seat guide rail

covers where the two parts meet.

5. Remove the front outer guide rail covers by

lifting the outer edge of the front cover up and

pulling it forward. Lift driver’s outer front seat

guide rail cover over fuel filler door release

lever.

6. Lift the two rear guide r ail covers up and off the

guide rails.

2

1

T12M111

3

4

Figure 1A7-1

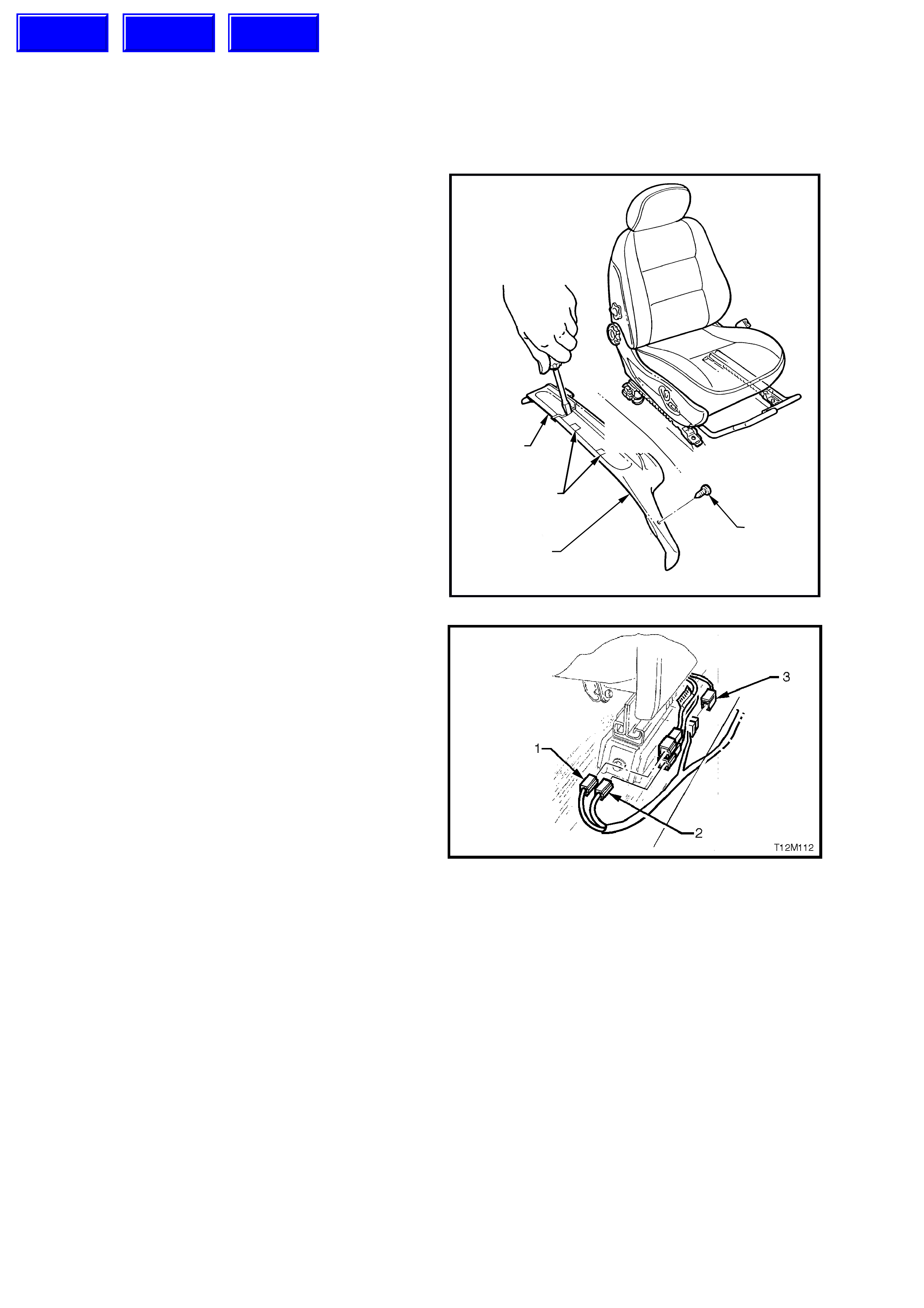

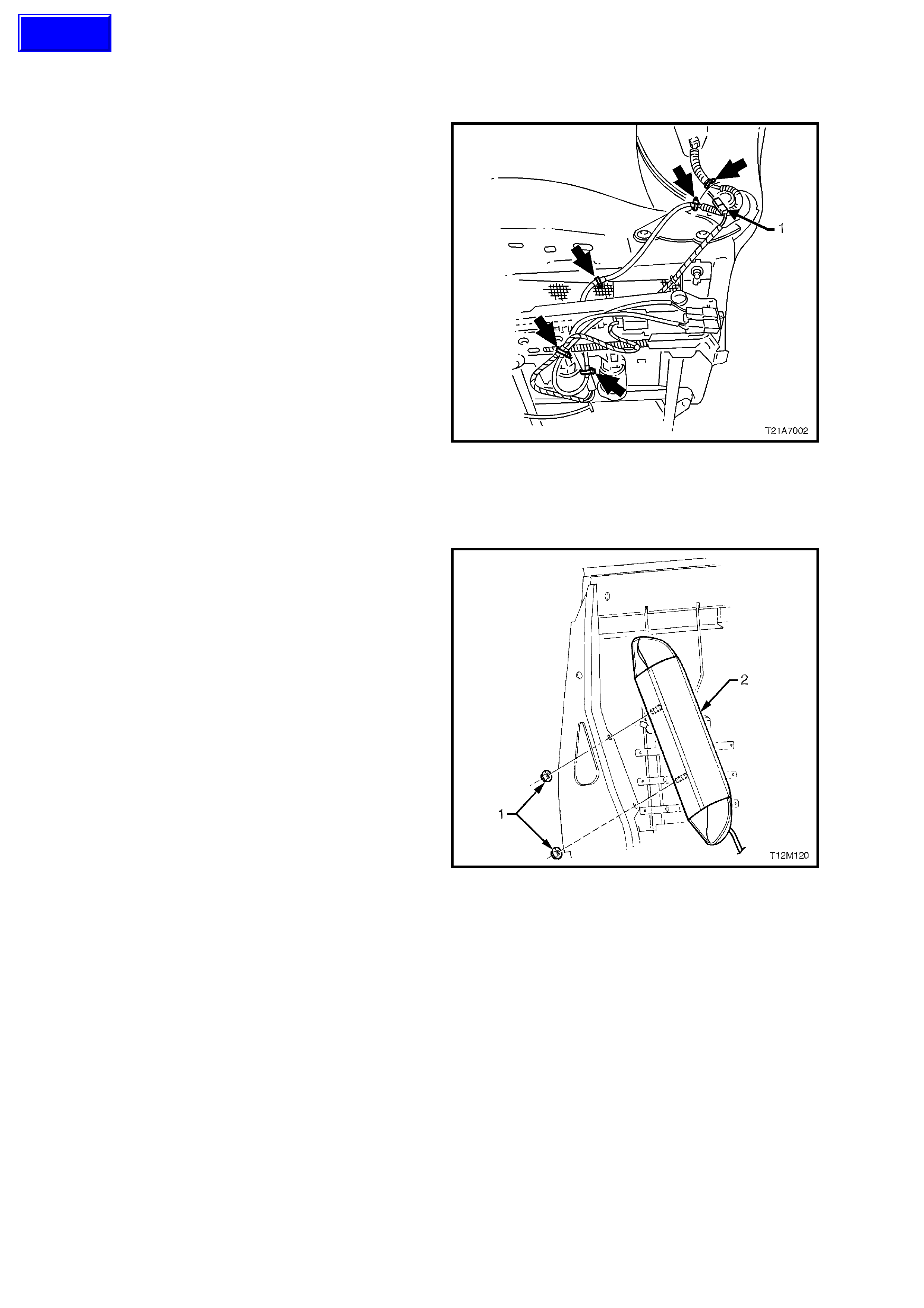

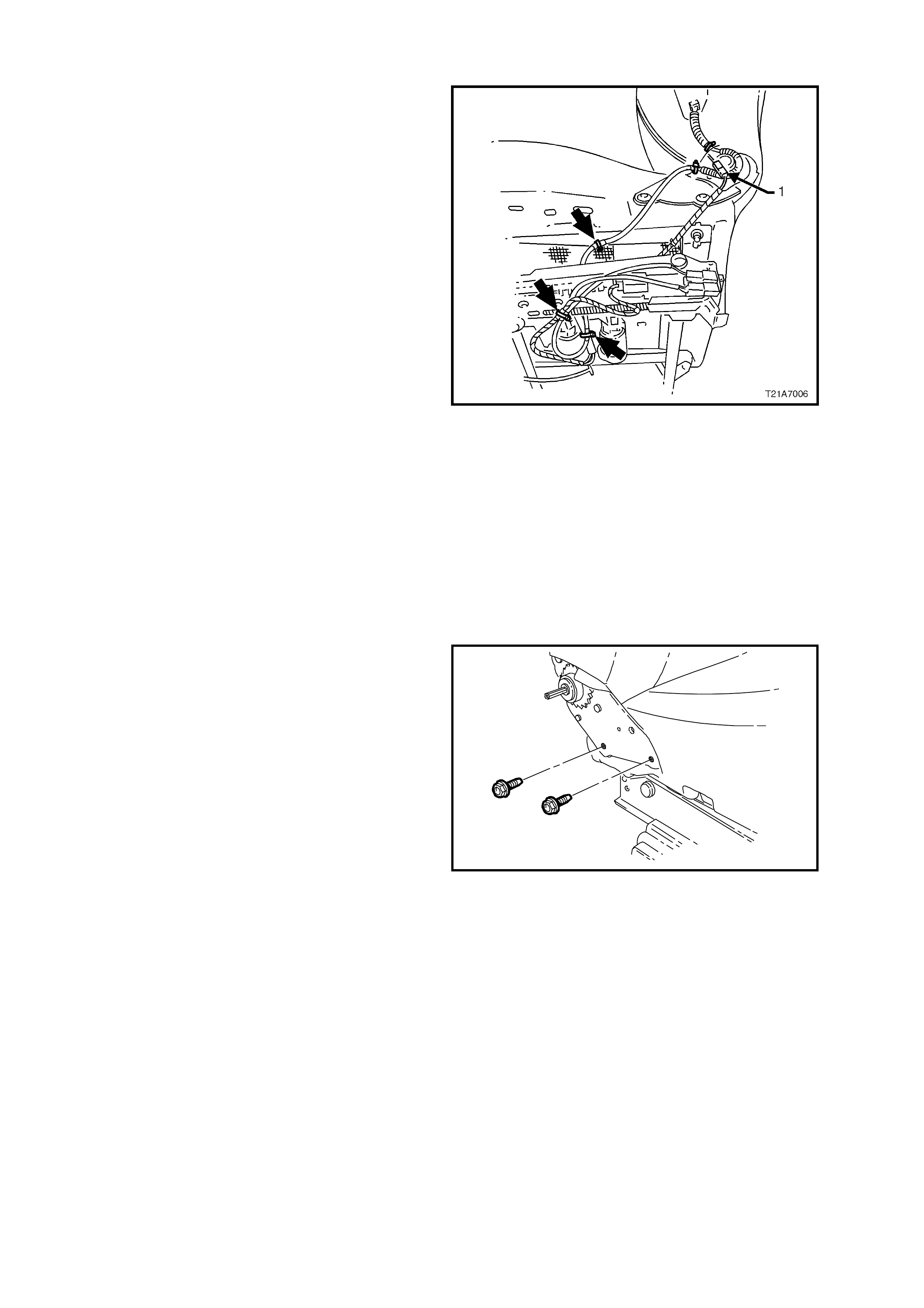

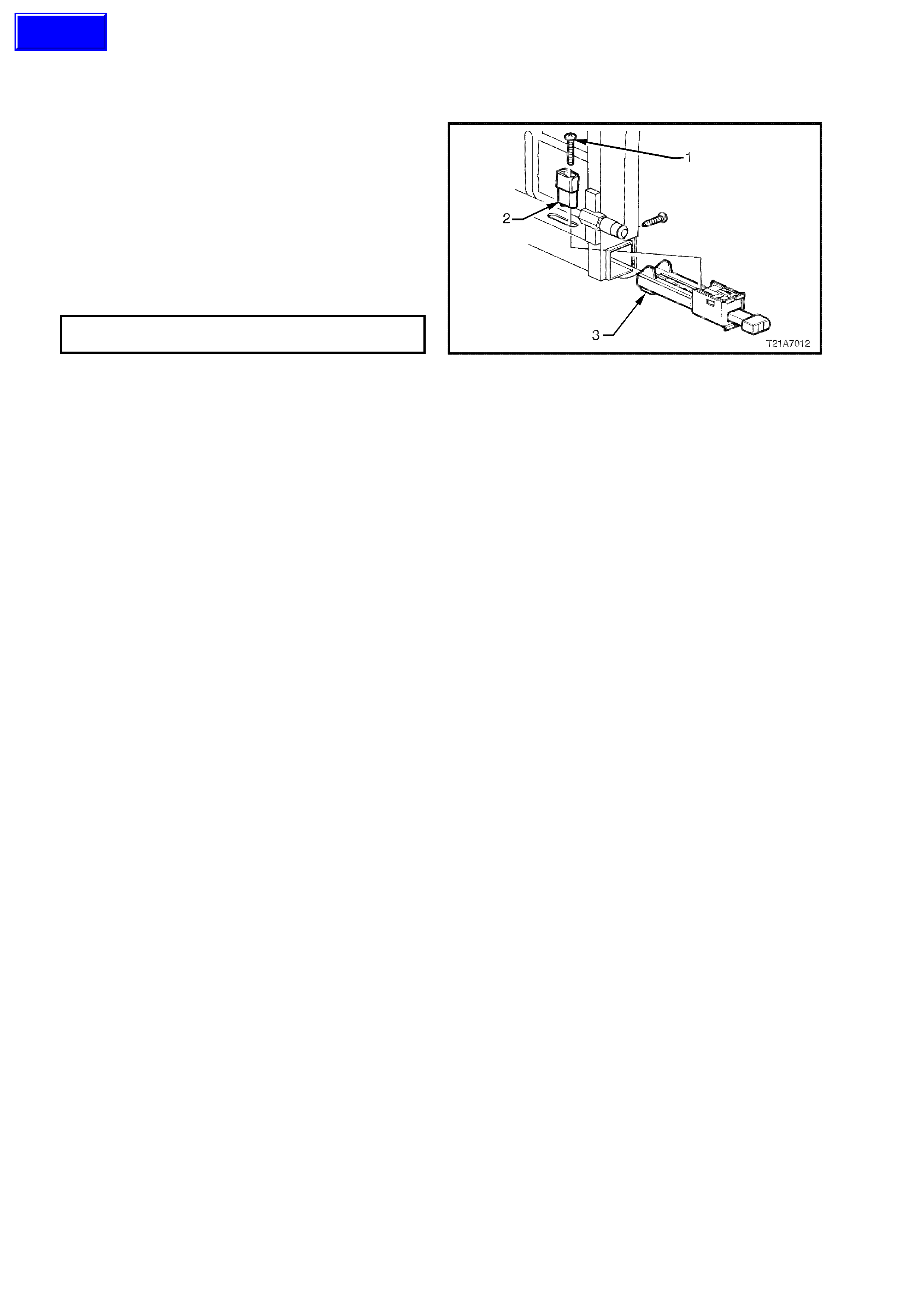

7. Disconnect seat (3), seat belt pre-tensioner (2)

and, if fitted, the side air bag m odule (1) wiring

harness connectors from outer side of the

relevant seat.

8. Remove the four bolts securing the front seat

to the floor and remove seat.

Figure 1A7-2

Techline

Techline

Techline

REINSTALL

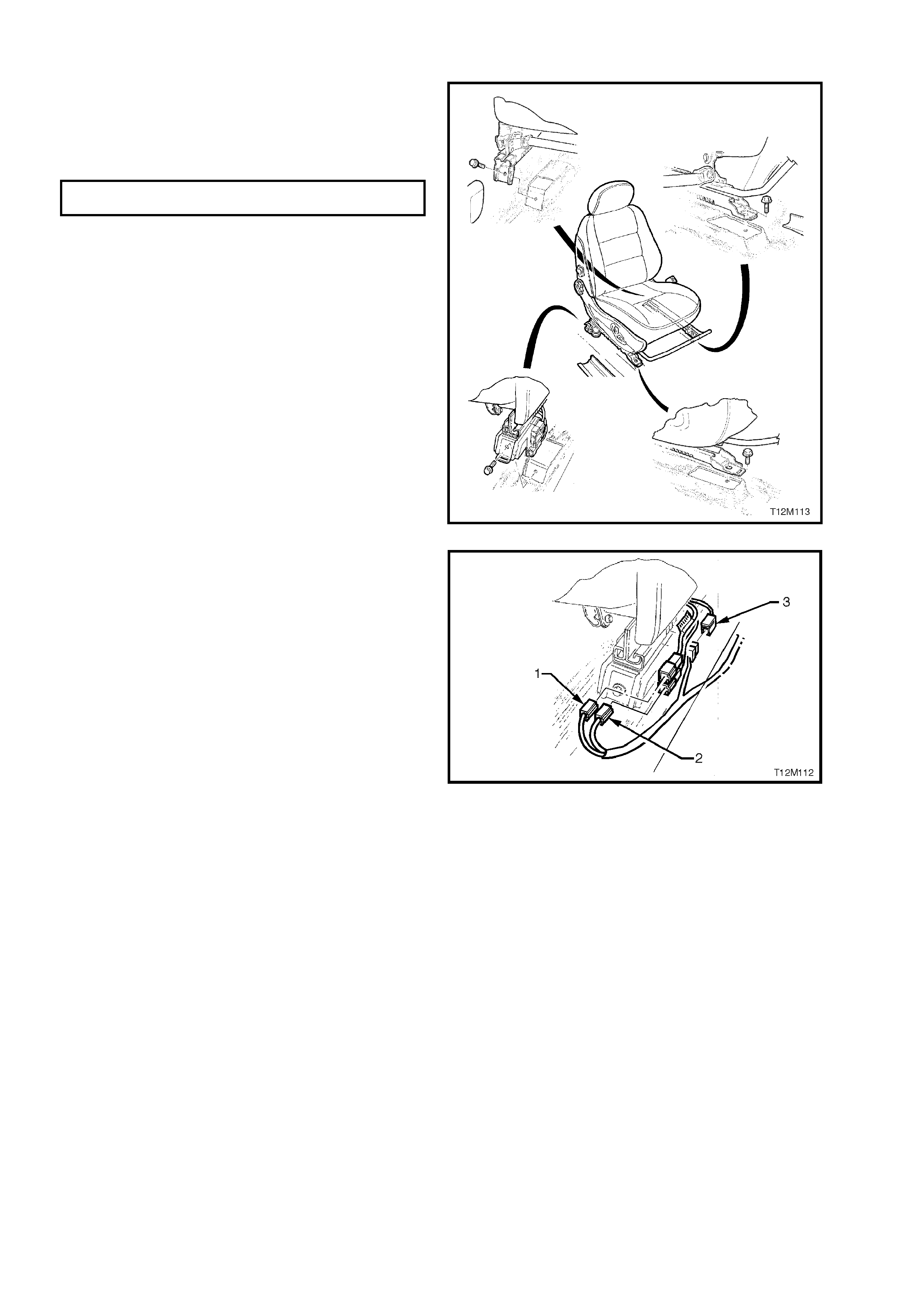

1. Position the front seat assembly into the

vehicle.

2. Install the four bolts securing the front seat to

the floor and tighten to the correct torque

specification.

FRONT SEAT TO FLOOR SECURING 35 - 50

BOLT TORQUE SPECIFICATION Nm

Figure 1A7-3

3. Connect seat (3), pre-tensioner (2) and, if

fitted, side air bag module (1) wiring harness

connectors.

4. Align the front outer seat guide rail cover’s two

retaining clips and push firmly to engage.

NOTE: The two retaining clips can be aligned by

using the alignment marks on the upper side

of the cover, refer to Fig. 1A7-1, (4) in this

Section.

5. Push the front of the outer seat guide rail

cover down to engage cover with front of seat

rail.

6. If installing the driver’s side outer seat guide

rail cover, install the screw at the front of the

front outer seat guide rail cover.

7. Install the rear outer seat guide rail cover

lower rear retainer over the seat guide r ail and

push rear outer seat guide rail cover forward to

engage with front outer seat guide rail cover.

8. Enable the SRS, refer to Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of

this Service Information CD.

Figure 1A7-4

9. If the vehicle is equipped with side impact air

bags, switch ignition on, and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approxim ately five seconds. During this period

the SDM performs a wiring and system self

check.

If no system faults are detected, the SRS

warning lamp will be switched off. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates two seconds after it was originally

switched off, an SRS fault is present. Refer to

Section 12M SUPPLEMENTAL RESTRAINT

SYSTEM of this Service Information CD.

10. Check operation of front seat mechanical and

electrical adjustments / operation. While

check ing the seat adjustm ent / operation, also

check to ensure that the seat wiring harnesses

do not foul with any of the seats moveable

components (ie. seat motor drive shafts, etc.).

2.2 LUMBAR SUPPORT ADJUSTER KNOB - VEHICLES WITHOUT

SIDE IMPACT AIR BAGS

REMOVE

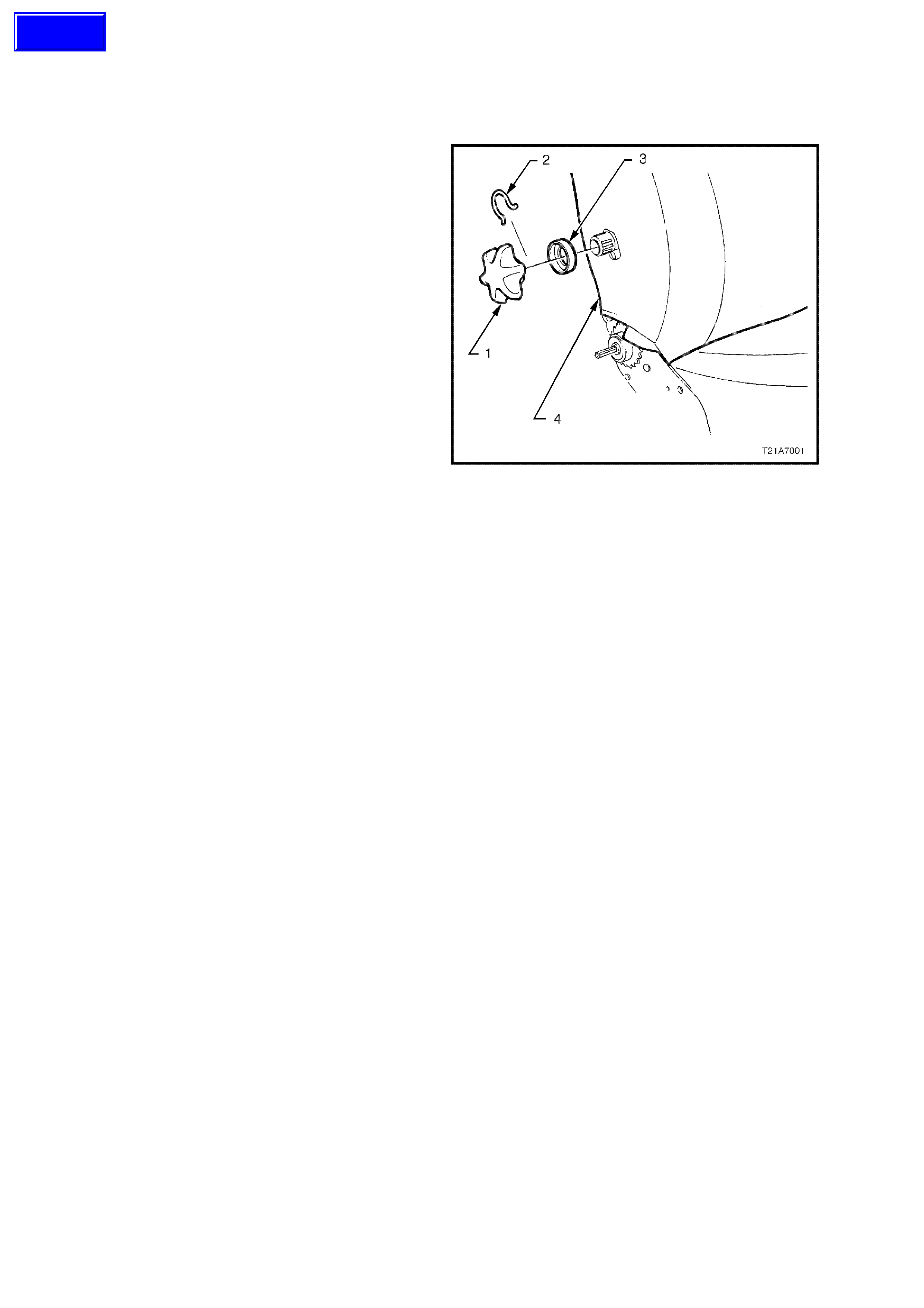

Remove lumbar support knob (1) by pushing seat

back cover (4) in far enough to expose circlip (2),

using a suitable pair of pliers or a small screw

driver, remove circlip and remove lumbar support

adjusting knob and spacer (3), refer Fig. to 1A7-5.

REINSTALL

1. Install circlip onto lumbar support adjusting

knob.

2. Ensure splines of lumbar support are correctly

aligned and push adjusting knob onto lumbar

adjuster shaft until circlip locks adjusting knob

into place.

Figure 1A7-5

Techline

2.3 FRONT SEAT BACK COVER- VEHICLES WITHOUT SIDE IMPACT AIR BAGS

REMOVE

1. Remove lumbar support adjusting knob, refer

to 2.2 LUMBAR SUPPORT ADJUSTER

KNOB in this Section.

2. Insert a screwdriver between the seat back

cover (1) and seat back (2) and push up on the

retaining clip (3) (2 places) while pulling the

bottom of the back cover out, away from seat,

to release lower retaining clips, and then pull

back cover down to release top retainers (4).

Remove seat back cover.

REINSTALL

Reinstallation of the front seat back cover is the

reverse of the removal operation.

Figure 1A7-6

Techline

Techline

2.4 LUMBAR SUPPORT ADJUSTER KNOB & FRONT SEAT BACK

COVER ASSEMBLY - VEHICLES WITH SIDE IMPACT AIR BAGS

REMOVE

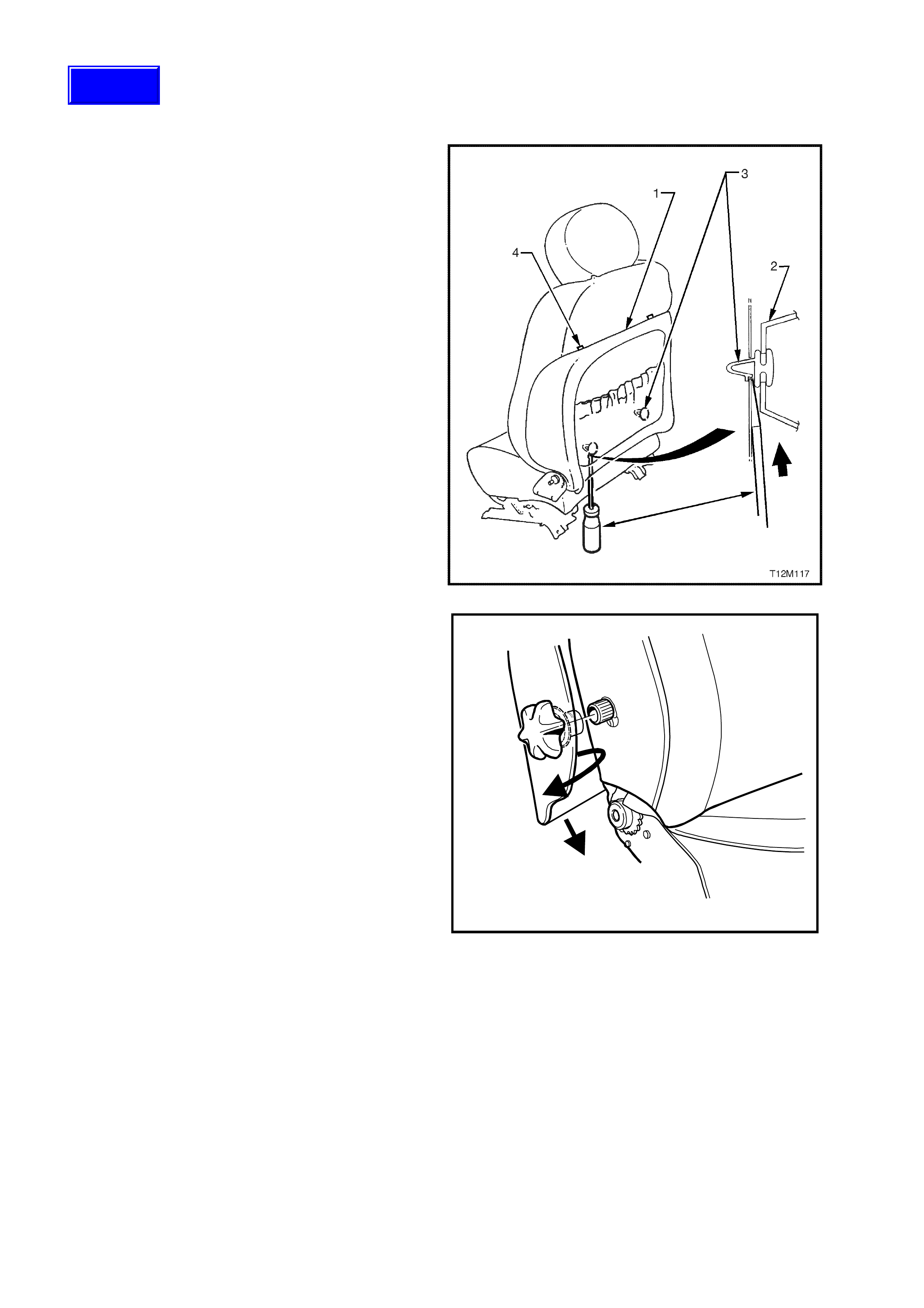

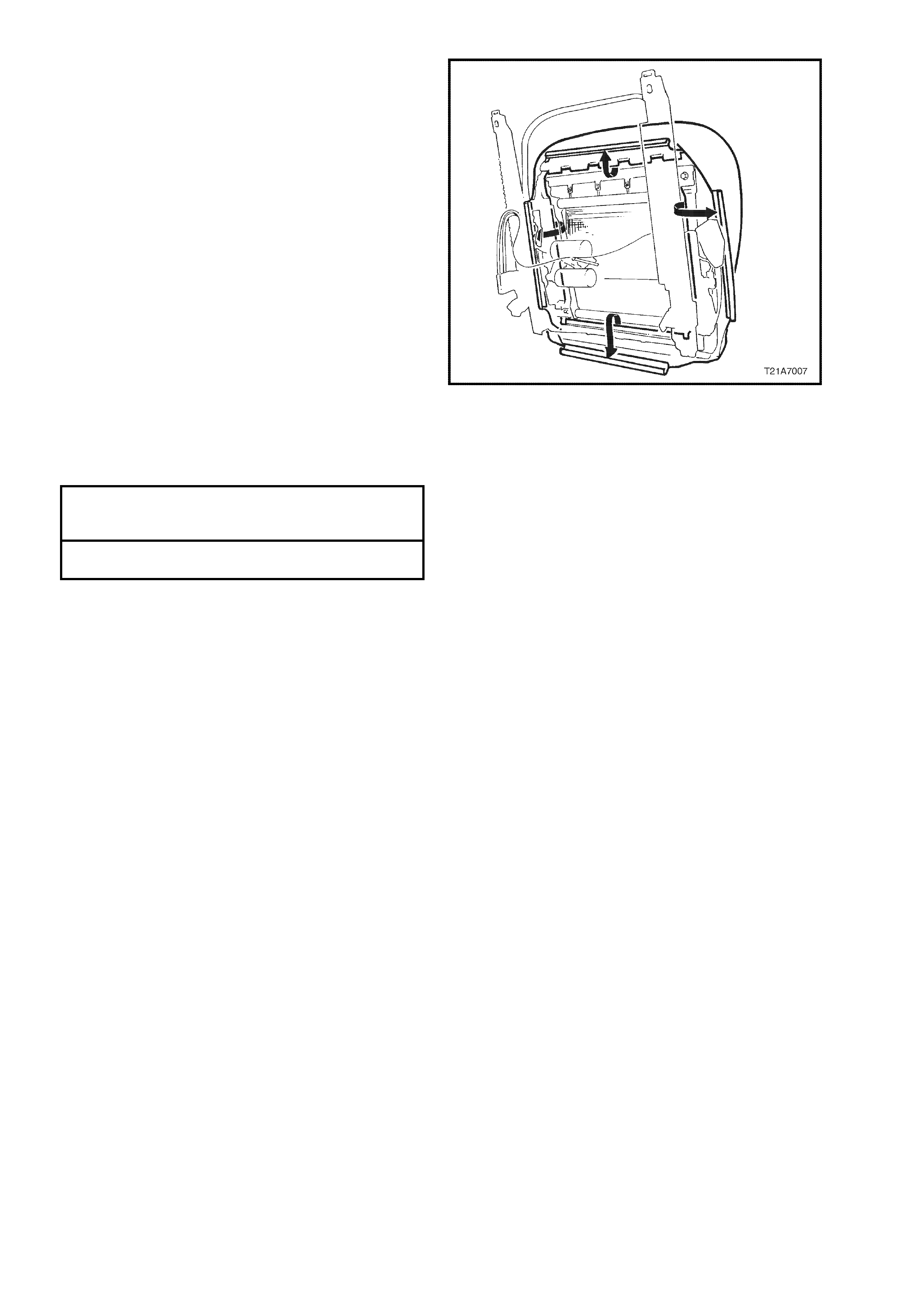

1. Insert a screwdriver between the seat back

cover (1) and seat back (2) and push up on

the lower retaining clip (3) (2 places) while

pulling the bottom of the back cover out, away

from seat, to release lower retaining clips.

Figure 1A7-7

2. From the front side of the seat back cover, in

front of the lumbar support knob, pull the seat

back cover outwards from the seat assembly

to disengage the lumbar support knob.

While holding the side of the seat back cover

out, pull the seat back cover down to release

the top seat back cover retainers, refer (4) in

Fig. 1A7-7. Remove seat back cover and

lumber support knob assembly.

NOTE: It is recommended not to remove the

lumbar support knob from the seat back cover

unless either the knob or the seat back cover is to

be replaced.

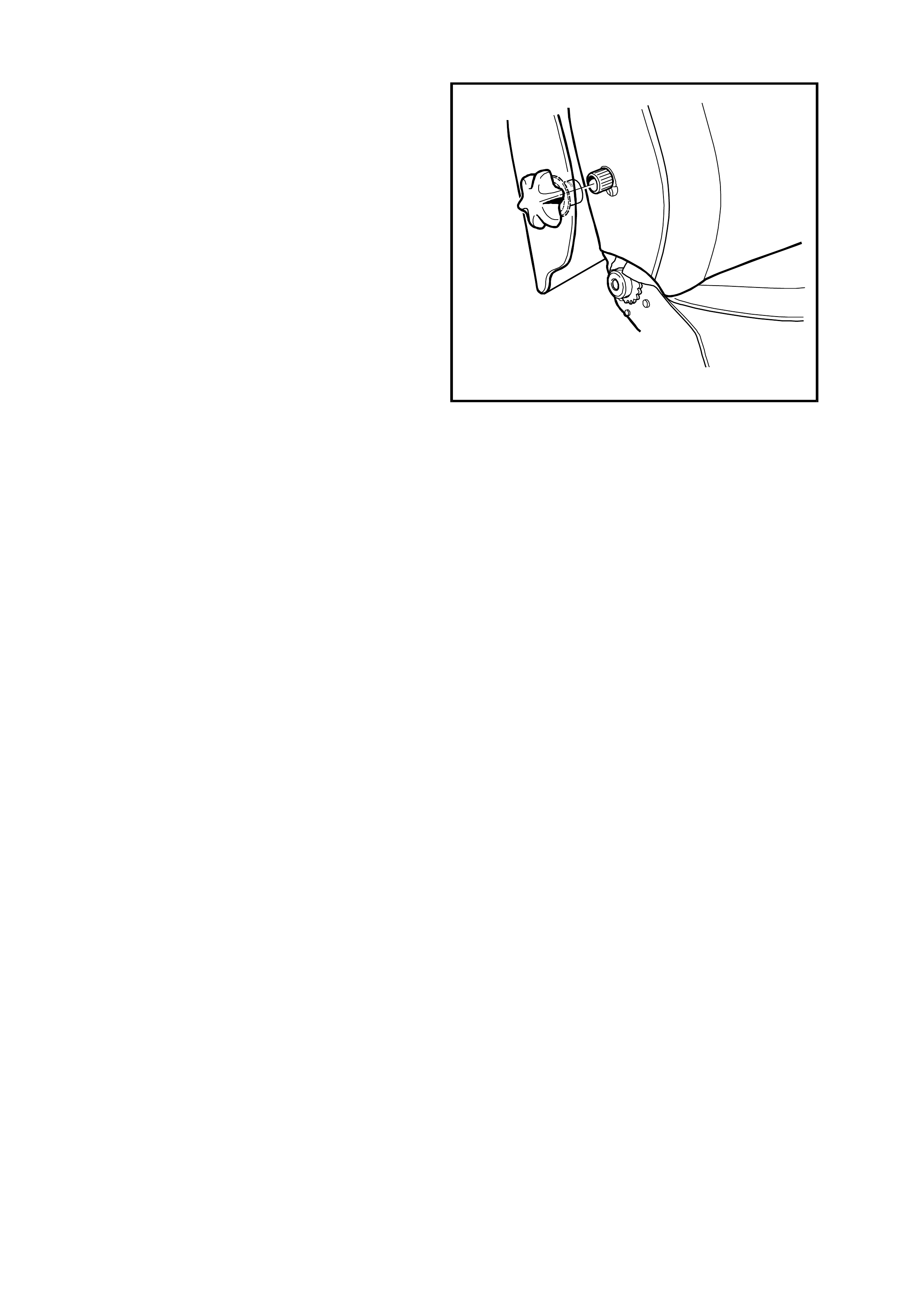

3. Remove the lumbar suppor t knob fr om the s eat

back cover by, shining a light between the

lumbar knob and the boss to locate two

retaining tangs.

4. Insert a flat blade screwdriver between the

lumbar knob and boss and disengage the two

tangs. Separate the lumbar knob and boss.

T12M137

Figure 1A7-8

Techline

REINSTALL

NOTE: If a lumbar support knob requires

replacem ent on a vehicle with side im pact air bags,

do not fit a non side impact air bag lumber

support knob (circlip type). Always refer to the

latest VT Series spare parts information for the

correct part number.

1. If removed, install lumbar knob and boss onto

seat back cover and push the lumbar knob

onto the boss until the two retaining tangs

engage.

2. locate the two upper retaining clips (4) on the

seat back cover (1) with the seat back (refer

Fig. 1A7-7 in this Section).

3. Pull the side of the seat back cover out, align

the splines on the lumbar support knob and

adaptor with the splines on the lum bar s upport

shaft. Push lumbar support knob and adaptor

onto lumbar support shaft.

4. Push the seat back cover into the seat back,

to engage the two lower retaining clips (refer

Fig. 1A7-7 in this Section).

T12M136

Figure 1A7-9

2.5 FRONT SEAT BACK PAD AND COVER ASSEMBLY

REMOVE

1. Disconnect the battery earth and positive

leads.

NOTE: If the vehicle is equipped with side impact

air bags, wait at least 10 seconds before

performing any work on the vehicle.

2. Remove front seat assembly, refer to 2.1

FRONT BUCKET SEAT ASSEMBLY in this

Section.

3. Remove inner and outer side cover

assemblies, refer to Section 1A7 SEAT &

SEAT BELT ASSEMBLIES of this Service

Information CD.

4. Remove lumbar support knob and seat back

cover, refer 2.4 LUMBAR SUPPORT

REMOVE and 2.5 SEAT BACK COVER (with

or without side impact air bags) in this Section.

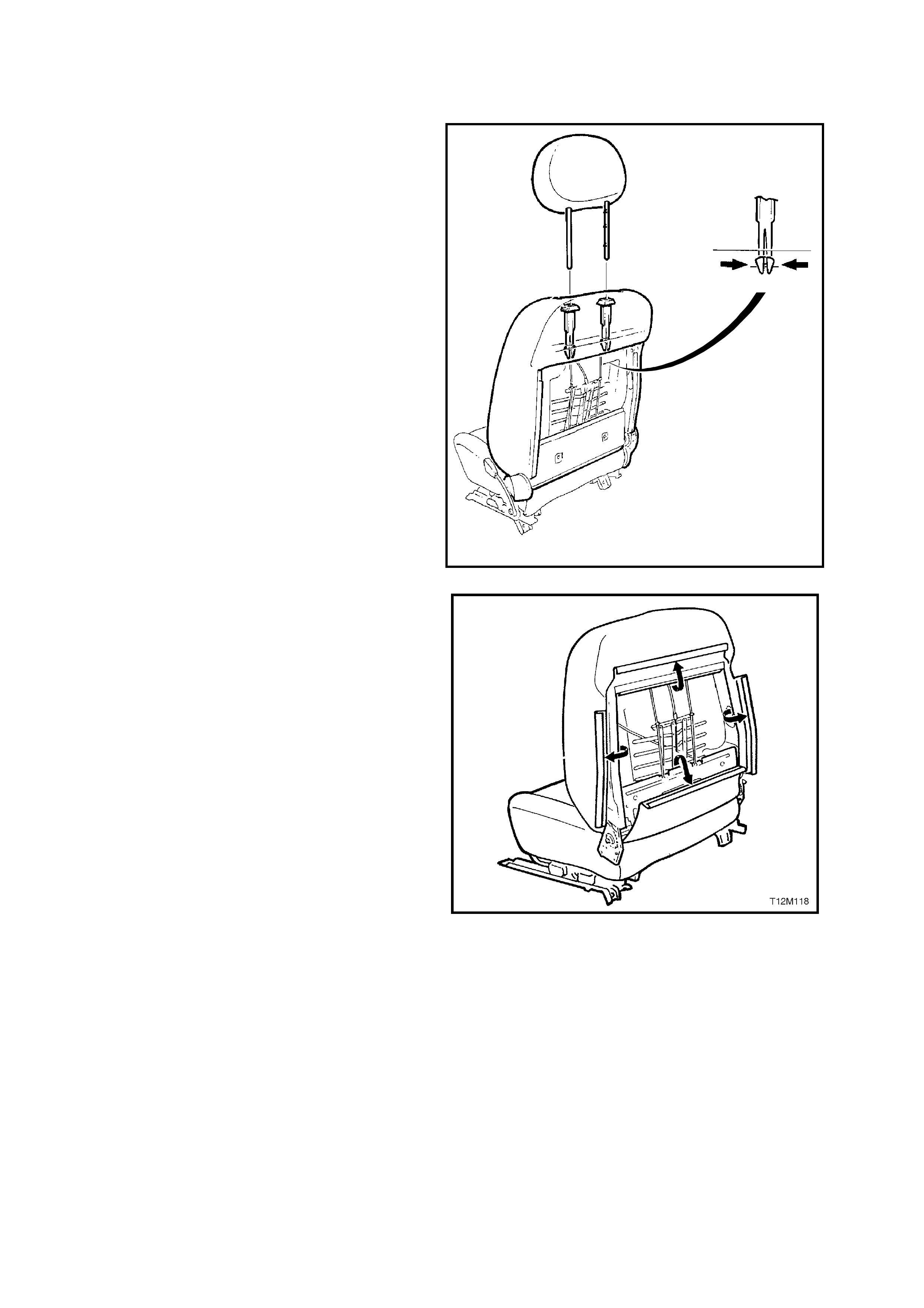

5. While holding head restraint height adjuster

lock in, pull head restraint completely out of

guide.

6. From the back of front seat, squeeze the

lock ing prongs of head r estr aint guide together

while pulling top of guide out of seat back

assembly, refer to Fig 1A7-10

T12M110

Figure 1A7-10

7. Pull the four ‘J’ strips away from the seat

frame.

8. Lift cover and pad assembly away from seat

back frame.

REINSTALL

Reinstallation is the reverse of the removal

operation, noting the following:

1. Ensure the head restraint guide with adjusting

lock is installed on the correct side, ie. side

with notches on the head restraint.

2. Ensure all fasteners are tightened to the

correct torque specification.

Figure 1A7-11

2.6 FRONT SEAT BACK FRAME, LUMBAR SUPPORT AND ADJUSTER ASSEMBLY

REMOVE

NOTE: The lumbar support is part of the seat back

frame and can only be replaced as an assembly.

1. Disconnect the battery earth and positive

leads.

2. Remove front seat back cover and pad

assembly, refer to 2.5 FRONT SEAT BACK

PAD AND COVER ASSEMBLY in this

Section.

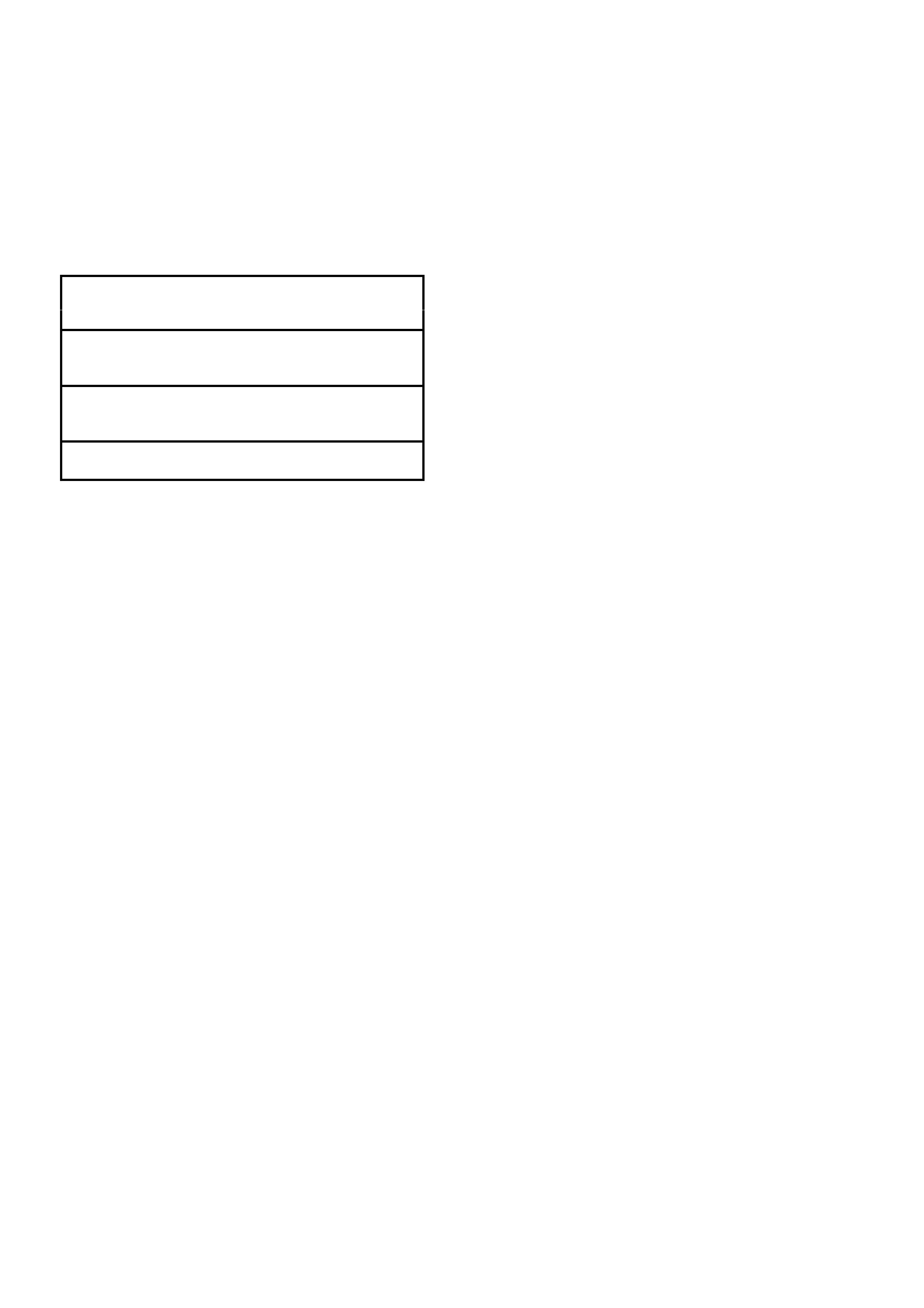

3. On seats with side impact air bags c ut the wire

ties (five places) securing the side air bag

module ‘pigtail’ wiring harnes s to the f ront seat

assembly, taking care not to damage the

wiring harness.

4. On seats with electric seat recliner

assemblies, disconnect the wiring harness

connector for the recliner motor (1).

NOTE: Fig 1A7-12 shows a seat with an electric

seat recliner assembly and side impact air bags.

On seats with out an electric seat recliner

assembly, the conduit around the recliner (as

shown) is not fitted.

Figure 1A7-12

5. Loosen and remove the two nuts securing the

side air bag assembly to the front seat back

frame.

Remove side air bag module and ‘pigtail’

wiring harness assembly from front seat back

frame.

CAUTION: When carrying a live (undeployed)

side air bag inflator module assembly, make

sure the bag opening is pointed away from you.

Never carry the side air bag inflator module

assembly by the wiring harness or connectors.

In case of an accidental deployment, the bag

will then deploy with minimal chance of injury.

When placing a live side air bag inflator module

assembly on a bench or other surface, always

face the air bag opening up, away from the

surface. Never rest the air bag inflator module

assembly with the opening face down. This is

necessary so that a free space is provided to

allow t he air b ag t o exp and in t he u nlikely ev ent

of accidental deployment. Otherwise, personal

injury may result.

6. If necessary, remove the two nuts retaining the

front seat foam block insert to the seat frame

and remove foam block insert.

Figure 1A7-13

Techline

7. Remove the four bolts (two on each side)

securing the seat back assembly to the seat

height adjuster and cushion frame assembly,

remove the seat back frame assembly.

T21A7003

Figure 1A7-14

8. From the rear of the front seat back frame,

disengage the lumbar support adjuster cable

wire tie clip (3) by squeezing the tangs on the

wire tie retaining clip together and pushing

wire tie retaining clip through seat back frame

(1).

9. Push down the top of the lumbar support to

disengage the two retainers ( 2) from the guide

rails (4) on the seat back, allowing lumbar

support to swing freely.

10. While slightly compressing lumbar support

assembly by hand to release cable ( 5) tens ion,

disengage cable from the top of the lumbar

support.

11. Unclip lower cable retainer from lower lumbar

bracket.

T21A7004

42

31

5

Figure 1A7-15

12. Remove adjusting cable (1) from adjuster (2)

by unclipping outer casing (3) of cable from

adjuster and removing cable assembly.

Remove the two screws (4) securing the

lumbar support adjuster to the seat back

frame (5) and remove adjuster.

Figure 1A7-16

REINSTALL

Reinstallation of the front seat back frame, lumbar

support and adjus ter ass embly is the reverse of the

removal operation, noting the following:

1. Align hole in adjuster for adjusting cable ball

by turning the adjuster until access hole lines

up, insert cable into adjuster and push outer

casing of cable into locking seat of adjuster

until it clicks.

2. Ensure all fasteners are tightened to the

correct torque specification.

SEAT BACK TO SEAT ADJUSTER AND

GUIDE RAIL ASSEMBLY SECURING 30 - 45 Nm

BOLT TORQUE SPECIFICATION

FRONT SEAT FOAM BLOCK INSERT

TO FRONT SEAT BACK RETAINING 5.0 - 6.0 Nm

NUT TORQUE SPECIFICATION

SIDE IMPACT AIR BAG ASSEMBLY TO

FRONT SEAT BACK RETAINING 5.0 - 6.0 Nm

NUT TORQUE SPECIFICATION

FRONT SEAT TO FLOOR SECURING

BOLT TORQUE SPECIFICATION 35 - 50 Nm

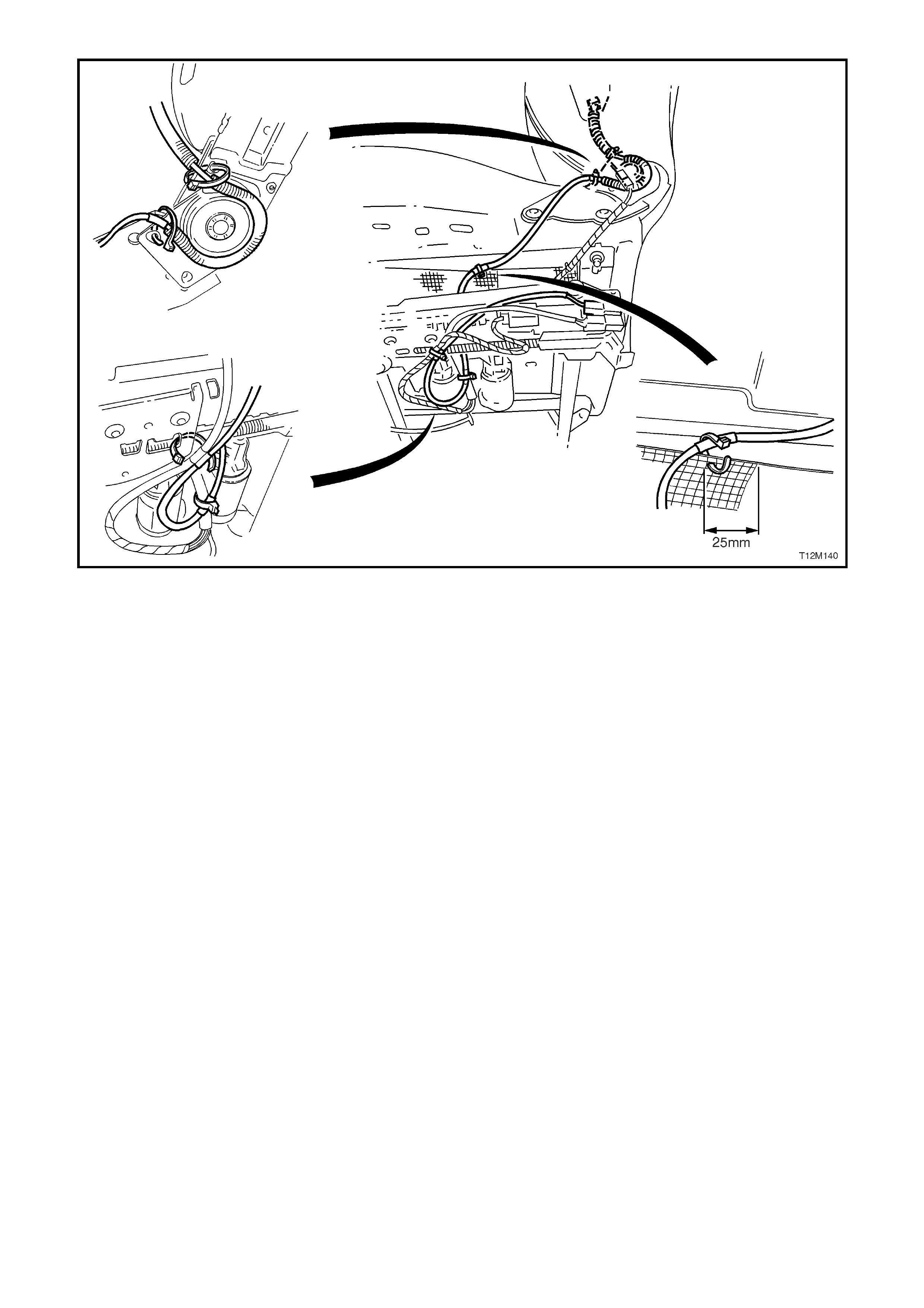

3. Route the side impact air bag wiring harness

through to the side of the seat rail assembly

and secure with new wire ties as per Fig. 1A7-

17.

NOTE 1: On seats without an electric seat recliner

assembly, the conduit around the recliner (as

shown in Fig. 1A7-17) is not fitted.

NOTE 2: If the side impact air bag modules

wiring harness is not routed correctly, damage

to the harness may occur, resulting in the side

impact air bag becoming inoperative and

setting a Diagnostic Trouble Code (DTC) (SRS

warning lamp on).

NOTE 3: The wiring harness that connects to the

side impact air bag module, and runs through the

front seat down to the seat rail, is not serviced

separately from the side air bag inflator module due

to the design of the anti-back-out connector on the

module assembly.

If this wiring harness, as with any other SRS

‘pigtail’ type wiring harness becomes damaged no

wire, connector or terminal repairs are to be

attempted. REPLACE THE SIDE AIR BAG

MODULE AND PIGTAIL WIRING HARNESS

ASSEMBLY.

Figure 1A7-17

4. Reconnect batter earth and positive leads,

switch ignition on, and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approximately five seconds. During this period

the SDM performs a wiring and system self

check.

If no system faults are detected, the SRS

warning lamp will be switched off. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates two seconds after it was originally

switched off, an SRS fault is present. Refer to

3 DIAGNOSTICS in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of

this Service Information CD to rectify fault.

5. Check operation of front seat mechanical and

electrical adjustments / operation. While

checking the seat adjustment / operation, also

check to ensure that the side air bag harness

does not foul with any of the seats moveable

components (ie. seat motor drive shafts, etc.).

2.7 FRONT SEAT CUSHION PAD AND COVER ASSEMBLY

REMOVE

1. Disconnect the battery earth and positive

leads.

NOTE: If the vehicle is equipped with side impact

air bags, wait at least 10 seconds before

performing any work on the vehicle.

2. Remove front seat assembly, refer to 2.1

FRONT BUCKET SEAT ASSEMBLY in this

Section.

3. Remove inner and outer side cover

assemblies, refer to Section 1A7 SEAT &

SEAT BELT ASSEMBLIES of this Service

Information CD.

4. On seats with side impact air bags, taking care

not to damage the wiring harness, c ut three of

the five wire ties (m arked with an arrow in Fig.

1A7-18) securing the side air bag module

‘pigtail’ wiring harness to the front seat

assembly.

5. On seats with electric seat recliner

assemblies, disconnect the wiring harness

connector for the recliner motor (1 ).

NOTE: Fig. 1A7-18 shows a seat with an electric

seat recliner assembly and side impact air bags.

On seats without an electr ic s eat r ec liner as s embly,

the conduit around the recliner (as shown) is not

fitted.

Figure 1A7-18

6. Remove the four bolts (two on each side)

securing the seat back assembly to the seat

height adjuster and cushion frame assembly,

remove the seat back frame assembly.

T21A7003

Figure 1A7-19

7. From under seat cushion, pull the front and

side ‘J’ strips away from the seat frame.

8. Lift cover and pad assembly away from seat

frame and then release the rear ‘J’ strip.

REINSTALL

Installation of the f ront seat cushion pad and cover

assembly is the reverse of the removal operation,

noting the following:

1. W hen installing the seat back assembly to the

seat adjuster and guide rail assembly, ensure

there is a metal to metal contact of parts (no

trim material caught between).

2. Ensure all fasteners are tightened to the

correct torque specification.

Figure 1A7-20

SEAT BACK TO SEAT ADJUSTER AND

GUIDE RAIL ASSEMBLY SECURING 30 - 45 Nm

BOLT TORQUE SPECIFICATION

FRONT SEAT TO FLOOR SECURING

BOLT TORQUE SPECIFICATION 35 - 50 Nm

3. Route the side impact air bag wiring harness

through to the side of the seat rail assembly

and secure with new wire ties as per Fig. 1A7-

17 in this Section.

NOTE 1: If the side impact air bag module

wiring harness is not routed correctly, damage

to the harness may occur, resulting in the side

impact air bag becoming inoperative and

setting a Diagnostic Trouble Code (DTC) (SRS

warning lamp on).

NOTE 2: The wiring harness that connects to the

side impact air bag module, and runs through the

front seat down to the seat rail, is not serviced

separately from the side air bag inflator module due

to the design of the anti-back-out connector on the

module assembly.

If this wiring harness, as with any other SRS

‘pigtail’ type wiring harness, becomes damaged no

wire, connector or terminal repairs are to be

attempted. REPLACE THE SIDE AIR BAG

MODULE AND PIGTAIL WIRING HARNESS

ASSEMBLY.

4. Reconnect battery earth and positive leads,

switch ignition on, and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approxim ately five seconds. During this period

the SDM performs a wiring and system self

check.

If no system faults are detected, the SRS

warning lamp will be switched off. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates two seconds after it was originally

switched off, an SRS fault is present. Refer to

3. DIAGNOSTICS in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEMS of

this Service Information CD to rectify fault.

5. Check operation of front seat mechanical and

electrical adjustments / operation. While

check ing the seat adjustm ent / operation, also

check to ensure that the side air bag harness

does not foul with any of the seats moveable

components (ie. seat motor drive shafts, etc.).

2.8 FRONT SEAT CUSHION FRAME ASSEMBLY

REMOVE

1. Remove front seat cushion cover and pad

assembly, refer to 2.7 FRONT SEAT

CUSHION PAD AND COVER ASSEMBLY in

this Section.

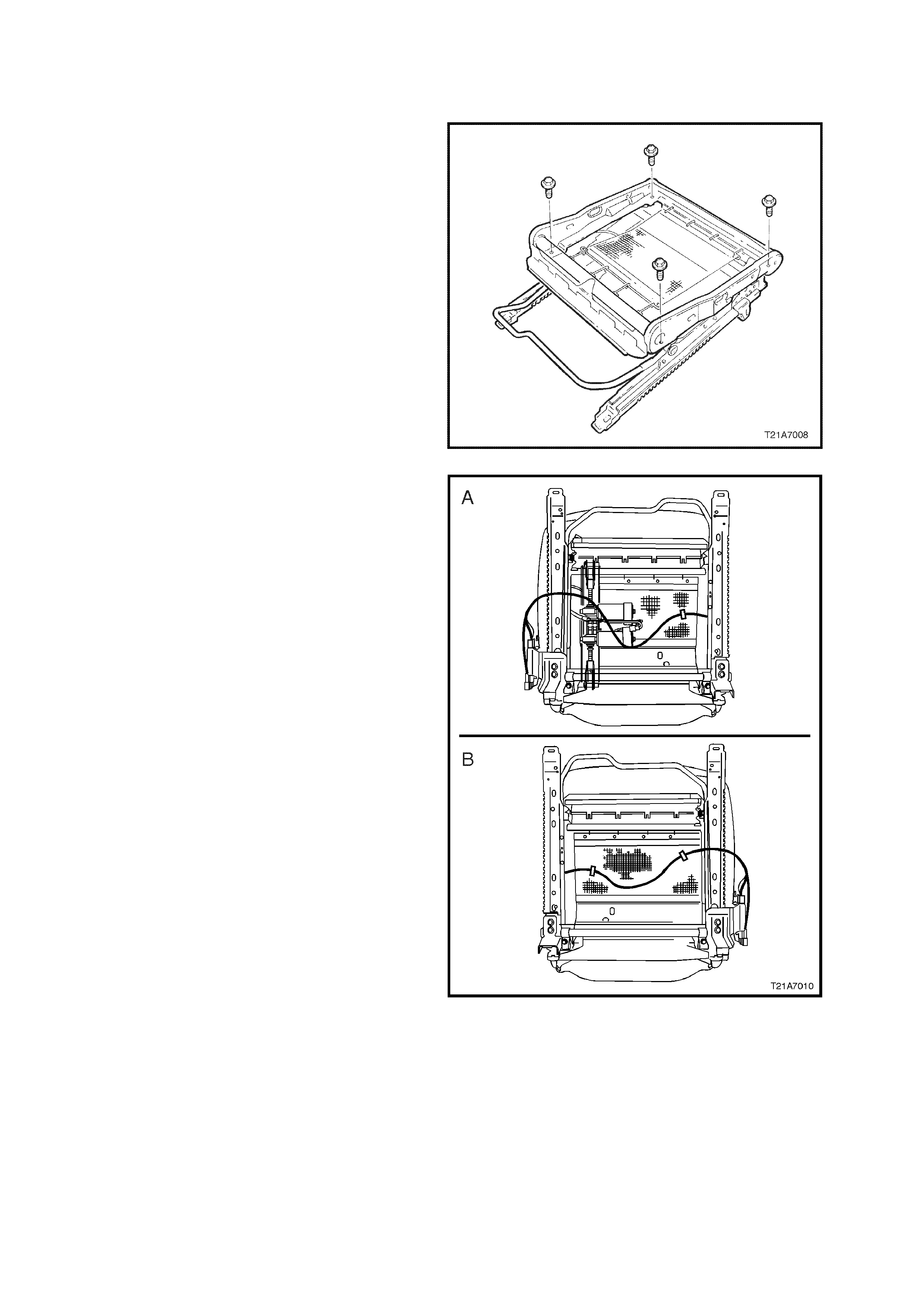

2. Remove the four bolts securing the front seat

cushion frame to adjuster and guide rail

assembly.

Figure 1A7-21

NOTE: Before disconnecting pre-tensioner wiring

harness connector, take note of wiring harness

routing.

3. Tak ing care not to damage the wiring harness,

cut the wire ties (two on non electric seats;

View B, and one on 4 and 8 way electric seats;

View A) securing the seat belt pre-tensioner

wiring harness to the front seat suspension

mat.

4. By squeezing the retaining tangs on the seat

belt pre-tensioner wiring harness connector

retaining clip at the outer s ide of the front s eat

adjuster and guide rail assembly, disconnect

the connector from the pre-tensioner

assembly.

Figure 1A7-22

5. Remove bolt securing seat belt buckle and

pre-tensioner assembly to frame and remove

seat belt buckle and pre-tensioner assembly.

Figure 1A7-23

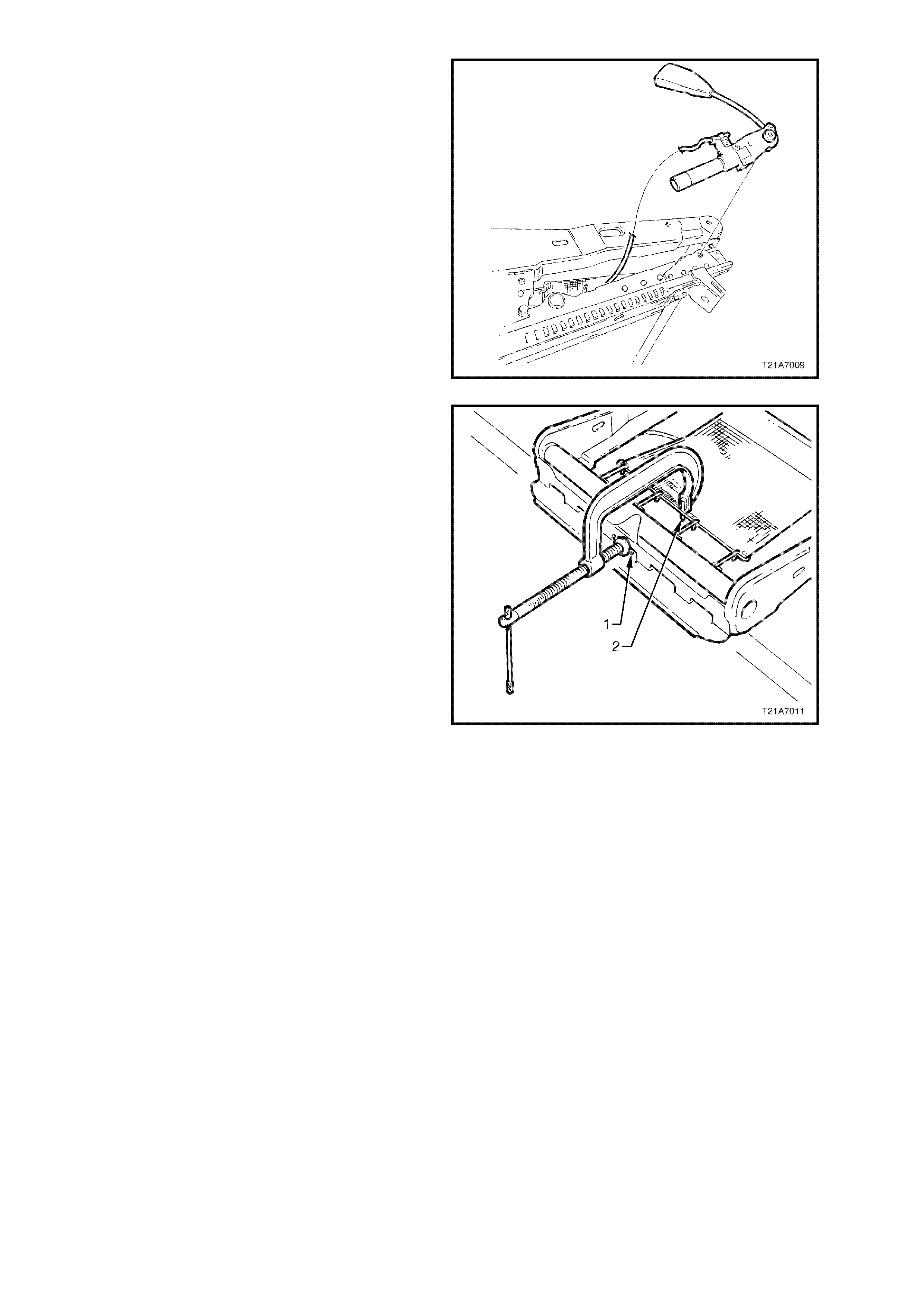

6. Using a pre-fabricated tool:

‘G’ clamp with a 5mm diameter metal dowel

(1) welded to one end, approximately 40mm

long and with a 2mm diameter pin (2)

approximately 20mm long welded to the other

end.

Using the pre-fabricated tool, stretch the

suspension mat far enough to allow for

webbing clamps to be removed from seat

frame. Back ‘G’ clamp load off and remove

suspension mat.

NOTE: When using pre-fabricated tool, use

existing holes in s us pens ion mat to ensur e that mat

deformation does not occur.

Figure 1A7-24

REINSTALL

Reinstallation of the front seat cushion frame

assembly is the reverse of the removal operation,

noting the following:

1. Ensure all fasteners are tightened to the

correct torque specification.

SEAT BACK TO SEAT ADJUSTER AND

GUIDE RAIL ASSEMBLY SECURING 30 - 45 Nm

BOLT TORQUE SPECIFICATION

FRONT SEAT TO FLOOR SECURING

BOLT TORQUE SPECIFICATION 35 - 50 Nm

SEAT BELT BUCKLE AND PRE-

TENSIONER ASSEMBLY BOLT 45 - 50Nm

TORQUE SPECIFICATION

FRONT SEAT CUSHION FRAME TO

SEAT GUIDE RAIL AND ADJUSTER 24 - 32 Nm

BOLT TORQUE SPECIFICATION

2. Ensure the pre-tens ioner, seat adj uster m otor,

and (if fitted) side impact air bag wiring

harnesses are routed correctly and retained by

wiring ties at each red spot tape loc ation, ref er

Figs. 1A7-17 & 1A7-22 in this Section.

3. When installing seat belt buckle and pre-

tensioner assembly ensure that the front

locating pin on the pre-tensioner assembly

aligns with seat frame.

NOTE 1: If the side impact air bag module or

seat belt pre-tensioner wiring harnesses are

not routed correctly, damage to the harness

may occur, resulting in the side impact air bag

or seat belt pre-tensioner becoming inoperative

and setting a Diagnostic Trouble Code (DTC)

(SRS warning lamp on).

NOTE 2: The wiring harness that connects to the

side impact air bag module, and runs through the

front seat down to the seat rail, is not serviced

separately from the side air bag inflator module due

to the design of the anti-back-out connector on the

module assembly.

If this wiring harness, as with any other SRS

‘pigtail’ type wiring harness, becomes damaged no

wire, connector or terminal repairs are to be

attempted. REPLACE THE SIDE AIR BAG

MODULE AND PIGTAIL WIRING HARNESS

ASSEMBLY.

4. Reconnect battery earth and positive leads,

switch ignition on, and observe the SRS

warning lamp in the instrument cluster. The

warning lamp should be illuminated for

approxim ately five seconds. During this period

the SDM performs a wiring and system self

check.

If no system faults are detected, the SRS

warning lamp will be switched off. If the

warning lamp remains illuminated and an

audible alarm chimes, or the warning lamp

illuminates two seconds after it was originally

switched off, an SRS fault is present. Refer to

3. DIAGNOSTICS in Section 12M

SUPPLEMENTAL RESTRAINT SYSTEM of

this Service Information CD to rectify fault.

5. Check operation of front seat mechanical and

electrical adjustments / operation. While

check ing the seat adjustm ent / operation, also

check to ensure that the side air bag harness

does not foul with any of the seats moveable

components (ie. seat motor drive shafts, etc.).

2.9 FRONT SEAT RECLINING MOTOR AND GEARBOX ASSEMBLY

REMOVE & REINSTALL

The removal and installation procedure f or the f ront s eat r ec lining motor and gearbox as s embly remains unc hanged

from that detailed in Section 1A7 SEATS AND SEAT BELT ASSEMBLIES of this Service Information CD, noting

the following:

To remove and reinstall the front seat back pad and cover assembly, reference to 2.5 FRONT SEAT BACK PAD

AND COVER ASSEMBLY in this Section should be made.

Techline

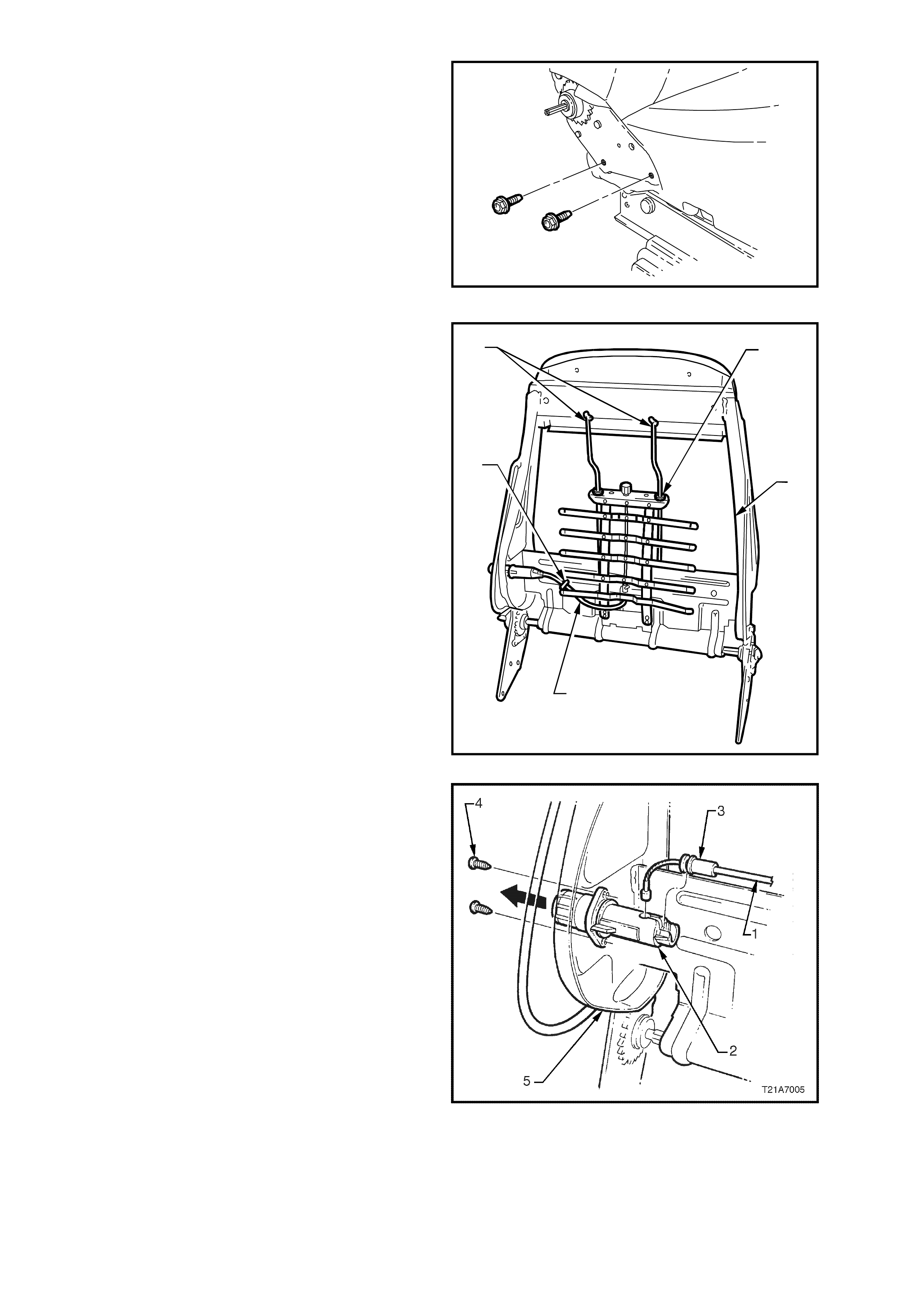

2.10 RE AR SEAT BACK LOCK, ACTUATOR, CABLE AND RELEASE BUTTON - WAGON

REMOVE & REINSTALL

The rem oval and installation procedure for the rear

seat back lock, actuator, cable and release button

remains unchanged from that detailed in Section

1A7 SEATS AND SEAT BELT ASSEMBLIES of

this Service Information CD, noting the following:

W hen reinstalling the seat back release handle (2)

to lock assembly (3), apply Loctite 262 or

equivalent, to Holden Specific ation HN 1256, to the

threads of the retaining s c rew ( 1) and tighten s c rew

to the correct torque specification.

SEAT BACK LOCK HANDLE RETAINING 3.0

SCREW TORQUE SPECIFICATION Nm

Figure 1A7-25

Techline

3. DIAGNOSTICS

NOTE: The following diagnsotic procedures only relate to vehicles built after Tag Number L423680 fitted with the

four way electric seat.

3.1. PREREQUISITES TO DIAGNOSIS AND TROUBLE SHOOTING

PRELIMINARY SYSTEM REQUIREMENTS

The prerequisites before proceeding with system checks are:

• Fusible link FJ and circuit breaker F2 must be checked before any electrical diagnostic checks are performed.

• Ensure no moisture is present in the main wiring harness to body wiring harness or seat harness connections.

• Ensure that sound earth connections are available for all functioning components.

• Ensure the battery is in good condition and adequately charged (above 11.5 Volts) before carrying out any

electrical checks.

SAFETY REQUIREMENTS

Disconnect the battery when carrying out work which involves the risk of an electrical short circuit.

Do not touch mechanical components during function checks, to avoid the risk of a hand being caught in the

mechanism.

If the vehicle is equipped with side im pact air bags, bef ore removing any components on or around the front seats ,

disable the SRS, refer to Section 12M SUPPLEMENTAL RESTRAINT SYSTEM of this Service Information CD.

CHECKING EQUIPMENT

An unpowered testlamp with a current draw of less than three Amps.

A digital multimeter, with a minimum 10 Megohm impedance MUST be used when undertaking any electrical

checks on these systems.

Exercise care when taking readings from wiring harness connectors. It is preferred that the back probing method

with individual connectors is employed wherever possible, to avoid terminal damage and subsequent connection

failure.

When carrying out wiring chec k s as directed to by the diagnostic c harts , r ather than pr obe terminals and c onnec tors

with incorrect sized m ultimeter connec tions, use the adaptors contained in c onnector test adaptor kit KM-609. This

will prevent any possibility of spreading or damaging wiring harness terminals.

IMPORTANT:

• When checking, the exact order of the test steps should be observed.

• If the required nominal value is not achieved in any stage, then the problem must be rectified before proceeding

further.

• Unless the multimeter being used has an auto ranging function, check that the correct range, as specified, is

selected before the test is carried out.

3.2 VISUAL INSPECTION

When investigating any complaint of an elec tr ic s eat pr oblem or malf unc tion, s tart diagnos is with a vis ual inspec tion

of the system.

The visual inspection procedure may quickly identify the cause and illuminate the need for additional diagnosis, in

particular if the problem is a mechanical fault.

If the complaint condition can not be resolved by the visual inspection, proceed to the appropriate diagnostic chart in

this Section.

NOTE: Diagnostic Chart 3.3, Diagostic Chart 3.4 and Diagnostic Chart 3.5 in this Section relate to electrical

faults only and assume there are no mechanical faults.

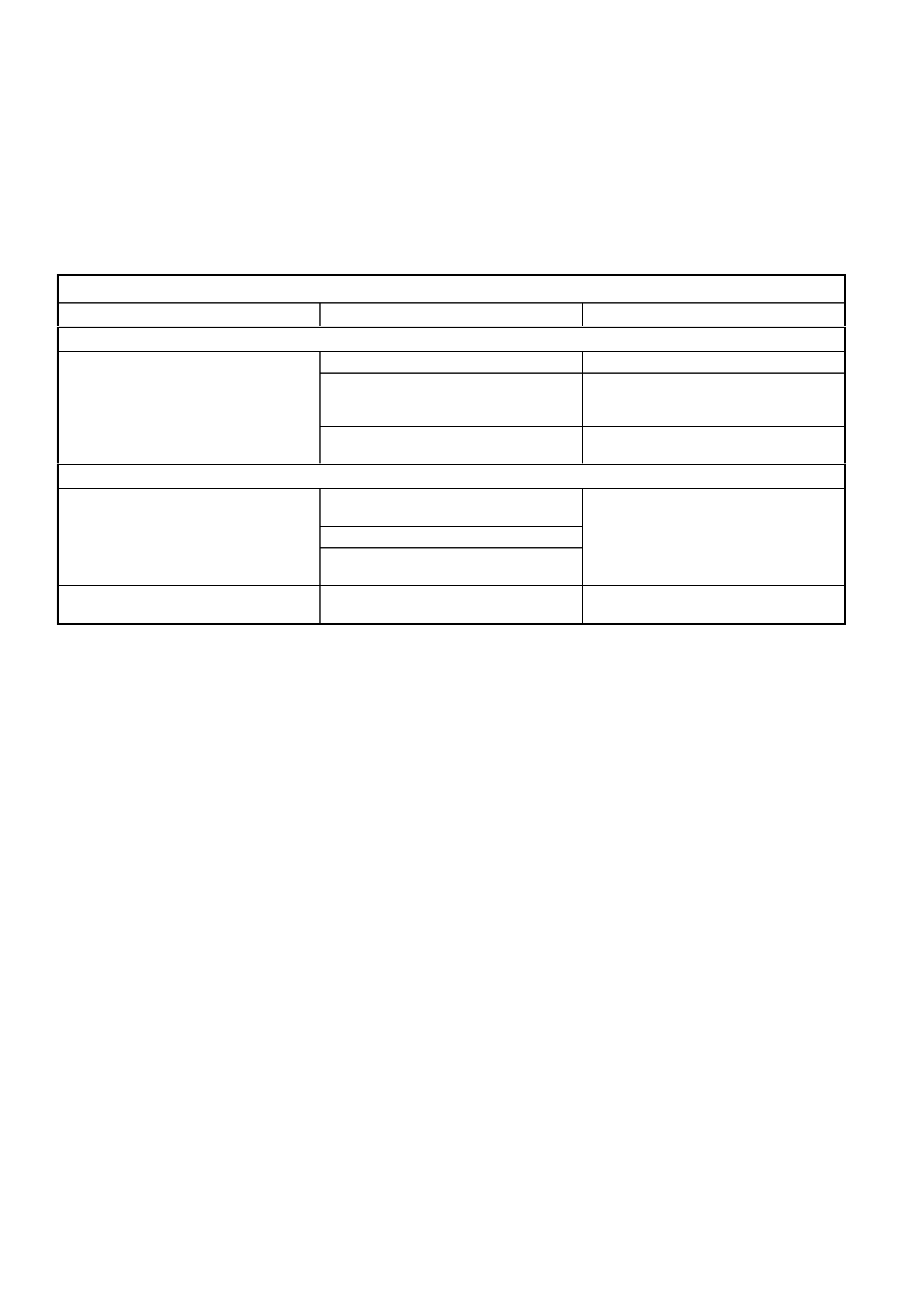

ELECTRIC SEAT VISUAL INSPECTION

ITEM INSPECT FOR CORRECTIVE ACTION

GENERAL

Operation of seat (noisy, slow or no Foreign material causing seat to bind. Remove foreign material.

operation at all). Dry components, build up of dirt on

moving components. Clean and apply Lithium based grease

(to Holden specification HN 2073) to

noisy component.

Bent, loose or physically damaged

components. Repair or replace faulty components.

WIRING CONNECTIONS & CIRCUIT BREAKER

Seat and switch wiring harness

connectors. Loose connections at individual

motors. Ensure secure connections.

Loose connections at control switch.

Loose connection at power supply

connector at side of seat assembly.

Circuit breaker F2. Loose connection or not fitted. Ensure secure connection or supply

new circuit breaker.

3.3 ELECTRIC SEAT DOES NOT MOVE IN ANY DIRECTION

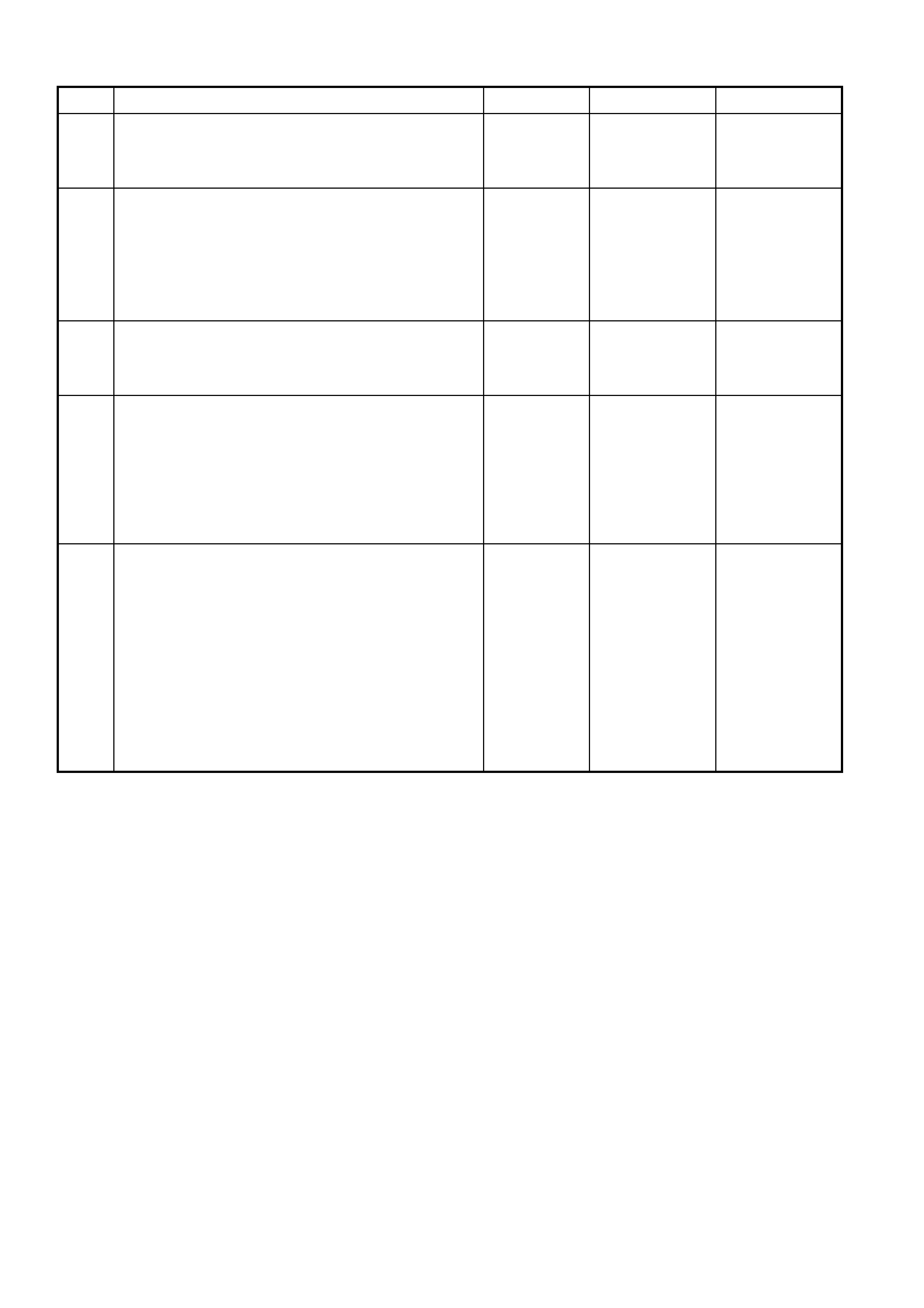

STEP ACTION VALUE YES NO

1. • At the side of the front seat assembly, back probe

power seat connector YB116, circuits 540 and 156

with a test lamp.

• Does the test lamp illuminate ?

Go to Step 4. Go to Step 2.

2. • Disconnect body harness from connector YB116.

• Using a voltmeter, measure voltage at Orange/Black

wire connection and a sound earth connection.

• Is voltage as specified ?

Battery + Go to Step 3. Check and repair

open or short in

circuit 540

(including fusible

link FJ and circuit

breaker F2),

recheck and

verify repair.

3. • With body harness connector YB116 disconnected,

check for continuity between Black/Blue wire

connection and earth location E6.

• Does continuity exist ?

Circuit OK. Check and repair

earth circuit 156,

recheck and

verify repair.

4. • Back probe seat switch connector YB211, Red and

Black wire connections with a test lamp.

• Does the test lamp illuminate ?

Go to Step 5. Check and repair

open in either

Red or Black

wire circuits

between seat

switch connector

and body

harness

connector YB116

5. • From under front seat assembly, back probe any one

of the seat adjusting motors wiring harness

connectors (YB212) with a test lamp connected to

both sides of the connector.

• Operate the selected seat adjusting motor.

• Does the test lamp illuminate ?

Replace seat

adjusting motors,

refer to the

appropriate

Service

Operation in 2.

SERVICE

OPERATIONS in

Section 1A7

SEAT & SEAT

BELT

ASSEMBLIES of

this Service

Information CD.

Replace seat

adjusting switch

assembly, refer

to 2. SERVICE

OPERATIONS in

Section 1A7

SEAT & SEAT

BELT

ASSEMBLIES of

this Service

Information CD.

Figure 1A7-26

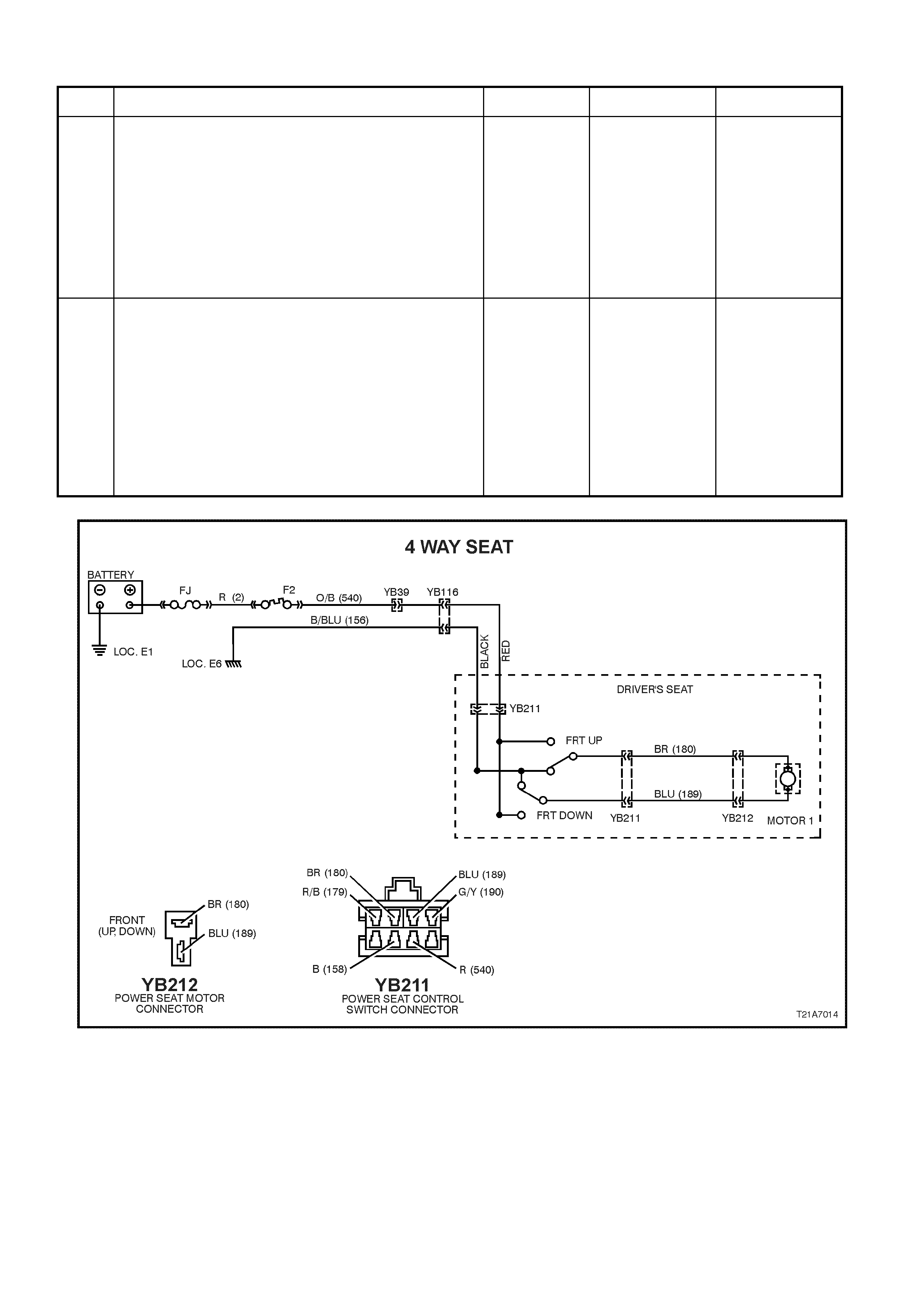

3.4 ELECTRIC SEAT FRONT UP AND DOWN OPERATION INOPERATIVE

STEP ACTION VALUE YES NO

1. • From under front seat assembly, back probe the seat

front lift motor wiring harness connector YB212,

between circuit 180 (Brown wire) and circuit 189

(Blue wire) connections with a test lamp.

• Operate the seat front lift motor.

• Does the test lamp illuminate ?

Replace the seat

front lift motor

assembly, refer

2. SERVICE

OPERATIONS in

Section 1A7

SEAT & SEAT

BELT

ASSEMBLIES of

this Service

Information CD.

Go to Step 2.

2. • Back probe seat switch connector YB211, between

circuit 180 (Brown wire) and circuit 189 (Blue wire)

connections with a test lamp.

• Operate the seat front lift motor.

• Does the test lamp illuminate ?

Check and repair

open in circuits

180 (Brown wire)

or circuit 189

(Blue wire)

between seat

adjusting switch

connector and

seat front lift

motor connector.

Recheck and

verify repair.

Replace seat

adjusting switch,

refer to

2. SERVICE

OPERATIONS in

Section 1A7

SEAT & SEAT

BELT

ASSEMBLIES of

this Service

Information CD.

Figure 1A7-27

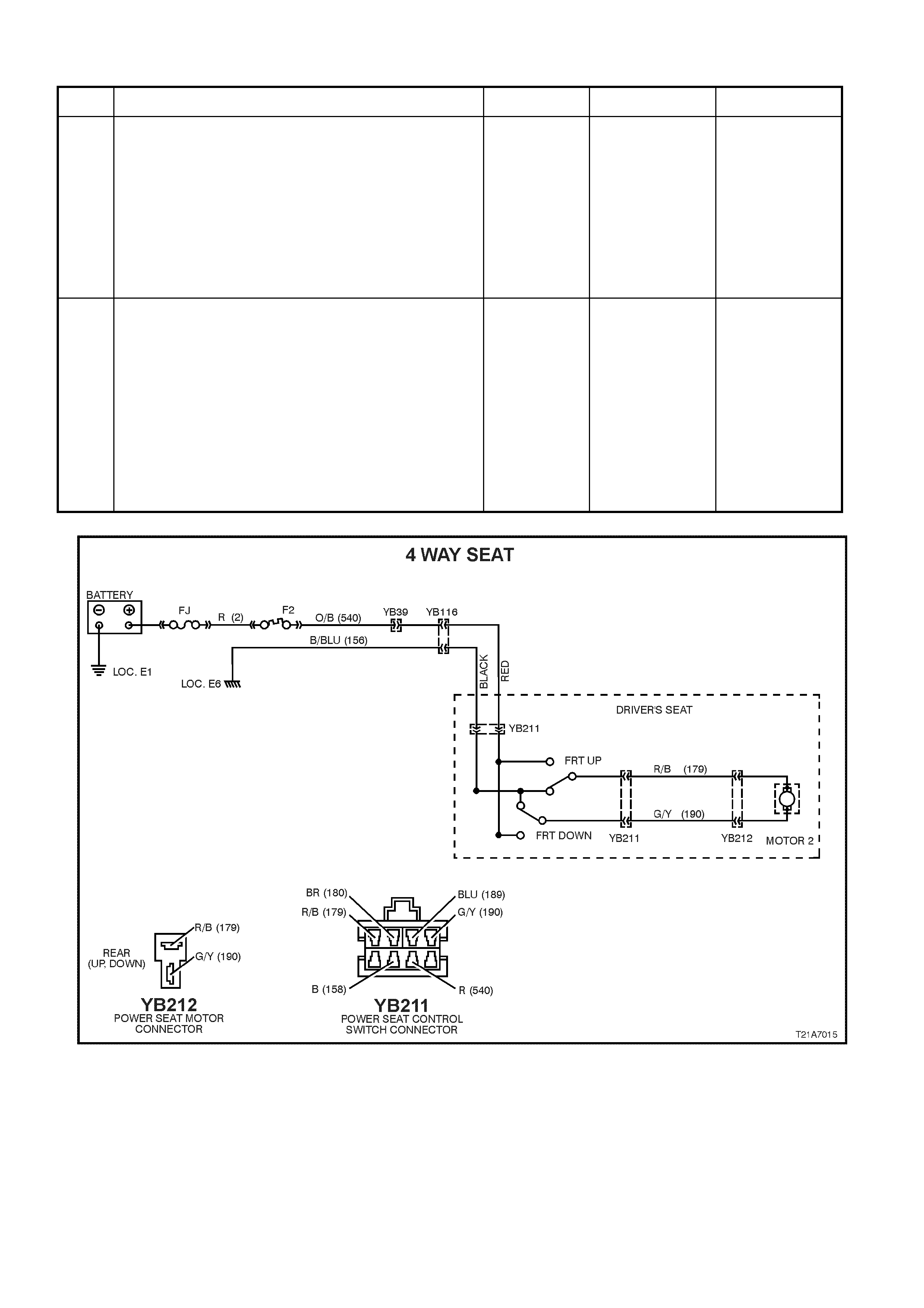

3.5 ELECTRIC SEAT REAR UP AND DOWN OPERATION INOPERATIVE

STEP ACTION VALUE YES NO

1. • From under front seat assembly, back probe the seat

rear lift motor wiring harness connector YB212,

between circuits 179 (Red/Black wi re) and circuit 190

(Green/Yellow wire) connections with a test lamp.

• Operate the seat rear lift motor.

• Does the test lamp illuminate ?

Replace the seat

rear lift motor

assembly, refer

to 2. SERVICE

OPERATIONS in

Section 1A7

SEAT & SEAT

BELT

ASSEMBLIES of

this Service

Information CD.

Go to Step 2.

2. • Back probe seat adjusting switch connector, YB211

circuits 179 (Red/Black wire) and circuit 190

(Green/Yellow wire) connections with a test lamp.

• Operate the seat rear lift motor.

• Does the test lamp illuminate ?

Check and repair

open in circuits

179 (Red/Black

wire) or circuit

190 (Green/

Yellow wire)

between seat

adjusting switch

connector and

seat rear lift

motor connector.

Recheck and

verify repair.

Replace seat

adjusting switch,

refer to 2.

SERVICE

OPERATIONS in

Section 1A7

SEAT & SEAT

BELT

ASSEMBLIES of

this Service

Information CD.

Figure 1A7-28

4. TORQUE WRENCH SPECIFI CATIONS

Nm

Armrest Bracket to Frame Retaining Screw ......................... 4.0

Armrest to Bracket Retaining Screw..................................... 4.0

Armrest to Bracket Securing Bolt - Sedan............................ 7 - 10

B pillar Upper Trim Retaining Screw..................................... 1.0 - 3.0

Bracket to Seat Back Retaining Bolt..................................... 15 - 25

Centre Cover to Frame Retaining Screw.............................. 2.5

Centre Hinge Lower Securing Bolt........................................ 35 - 50

Centre Hinge Upper Securing Bolt........................................ 25 - 35

Child Seat Anchor Bolt.......................................................... 14 - 21

Front Seat Belt Guide Retaining Screw ................................ 2.4 - 3.4

Front Seat Cushion Frame to Seat Guide Rail

and Adjuster Assembly Bolt.................................................. 24 - 32

Front Seat to Floor Securing Bolt.......................................... 35 - 50

Garnish Retaining Screw ...................................................... 2.0

LHR Seat Back Lock Retaining Screw.................................. 3.0

Outer Front Seat Guide Rail Cover....................................... 1.0 - 3.0

Rear Seat Back to Floor Retaining Bolt................................ 25 - 30

Rear Seat Back Lock Handle Retaining Screw..................... 3.0

Seat Back to Height Adjuster Assembly Securing Bolt......... 30 - 45

Seat Back to Seat Adjuster & Guide Rail Assembly

Securing Bolt......................................................................... 30 - 45

Seat Belt Buckle and Pre-tensioner Asm Bolt....................... 45 - 50

Seat Belt Buckle Anchor Securing Bolt................................. 35 - 50

Seat Belt guIde Bracket Securing Bolt.................................. 20 - 22

Seat Belt Retractor Retaining Nut......................................... 35 - 50

Seat Belt Securing Bolt......................................................... 40 - 54

Side Inner Cover Retaining Screw........................................ 1.0 - 3.0

Striker Retaining Bolt - Wagon Seat Back............................ 25 - 35

Striker Retaining Screw - Sedan Seat Back Lock................. 25 - 35

Side Impact Air Bag Assembly to Front Seat Back

Frame Retaining Nut............................................................. 5.0 - 6.0

Front Seat Foam Block Insert Retaining Nut........................ 5.0 - 6.0