SECTION 12A - BATTERY & CABLES

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver’s air bag, seat belt pre-tensioners and a driver’s and front

passenger’s air bags or seat belt pre-tensioners, driver’s and front passenger’s air bags and left and

right-hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12 M Supplemental Restraint System

in the VT Series I Service Information before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SA FETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG fuel

system should be isolated by turning 'OFF' the manual service valve and then draining the LPG service

lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with the

Owner's Handbook for details or the appropriate Section of this Service Information CD for more specific

servicing information.

1. GENERAL INFORMATION

All models in the VT Series II range of vehicles are fitted with a 12 volt low maintenance battery, with a Rated

Reserve Capacity of 95 minutes and a Rated Cold Cranking Current of 400 amps minimum. This battery is the

same as that fitted to VT Series Berlina and Calais with a V6 engine, and all VT Series models with a V8 engine.

Details of this battery are contained in Section 12A BATTERY & CABLES in the VT Series I Service Information.

Details on the battery charging system are contained in Section 6D1-1 CHARGING SYSTEM — V6 ENGINE or

Section 6D3-1 CHARGING SYSTEM — GEN III V8 ENGINE in the VT Series II Service Information.

Techline

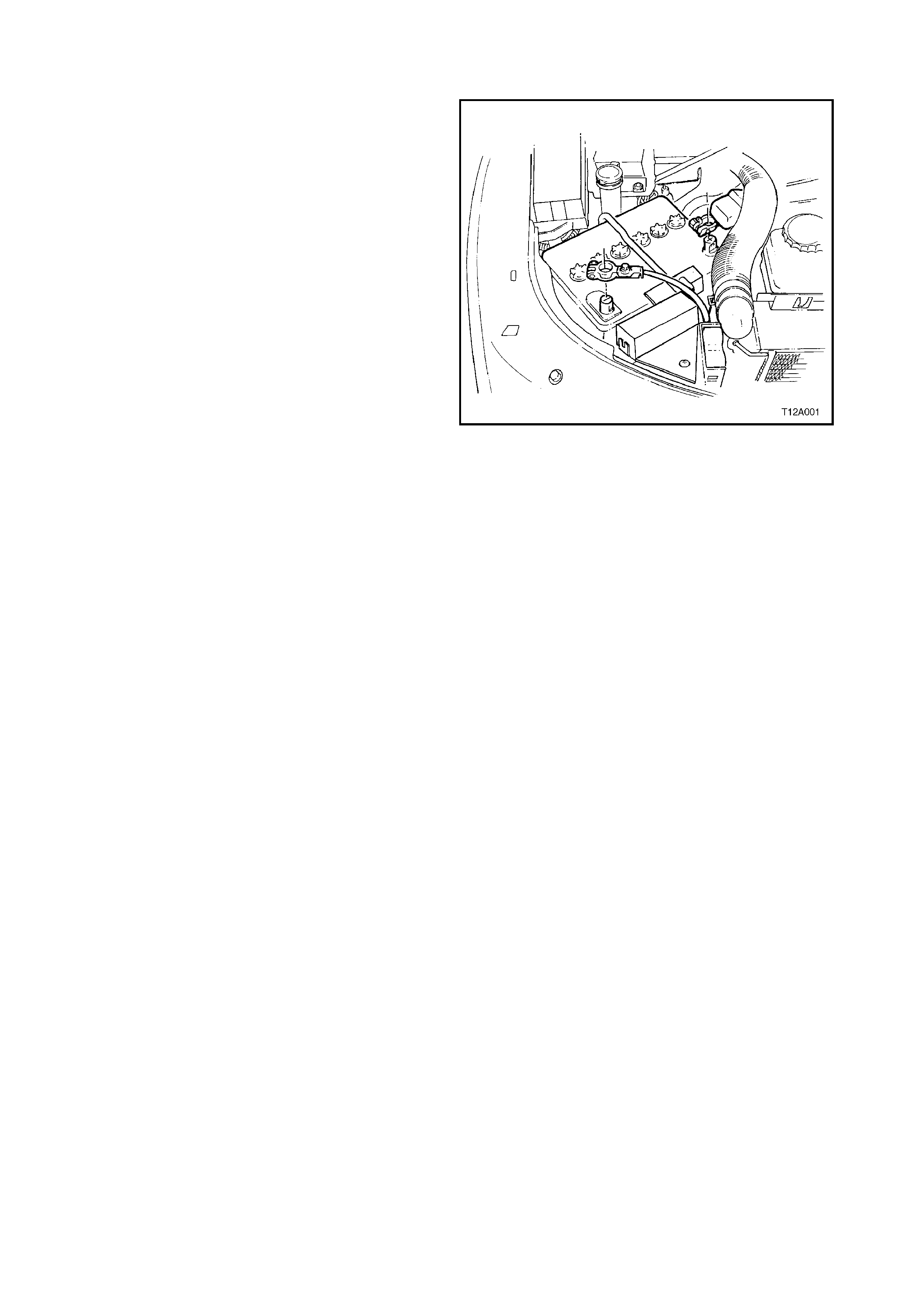

1.1 GENERAL DESCRIPTION

In all VT Series II models, the 12 volt battery is

located in the engine compartment behind the

driver’s side headlamp, refer to Fig. 12A-1. The

battery cables are attached to the battery terminals

by nut tightened clamps. The negative terminal is

earthed to the vehicle body at the fender inner

panel stud, and to the engine (at right-hand engine

mounting bracket for V6 engine and to the engine

block, forward of the right-hand engine mounting

bracket for the GEN III V8 engine).

The battery has four major functions in the vehicle

electrical system:

1. Provide a source of energy for cranking the

engine.

2. Acts as a voltage stabiliser for the electrical

system.

3. It can, for a limited time, provide energy when

the electrical load used exceeds the output of

the generator.

4. Provides power for accessories when the

engine is not running.

Figure 12A-1

2. SERVICE OPERATIONS

CAUTION: Do not allow liquid from battery to

contact eyes, skin, clothing or painted surfaces.

Battery fluid contains sulfuric acid which

causes injury and damage in the event of

contact. In the event of an accident, flush area

immediately with large amounts of water. Also,

in the case of eye contact, see a physician

immediately.

Lead acid batteries produce ex plosive gases. Keep

sparks, flames and lighted cigarettes away from

battery when charging or working around battery

area in an enclosed area. Failure to follow this

warning could cause the battery to explode.

Take care with all metal objects including items of

jewellery (rings and metal watch bands) and tools

when working near battery term inals. Metal objects

that touch a battery term inal can cause spark s and

serious heat burns to the user or wearer.

Ensure that the ignition is switched off when

connecting or disconnecting battery cables, battery

chargers or jumper cables. Failing to do so may

damage vehicle electronic components.

It is advisable to always disconnect the battery

negative cable from the battery first, and connect it

to the battery last, to avoid the possibility of shorting

to earth with the spanner while working on the

connections of the positive cable. Spanners

shorting to earth from either end of the positive

cable would carry high amperage and heat quick ly,

causing serious burns to the hand.

2.1 BATTERY INSPECTION

The battery inspection details are contained in

Section 12A BATTERY & CABLES in the VT

Series I Service Information.

If battery water usage is considered excessive and

inspection reveals that the battery case is OK, the

generator may be overcharging. Check generator

output as described in Section 6D1-1 CHARGING

SYSTEM — V6 ENGINE or Section 6D3-1

CHARGING SYSTEM — GEN III V8 ENGINE in

the VT Series II Service Information.

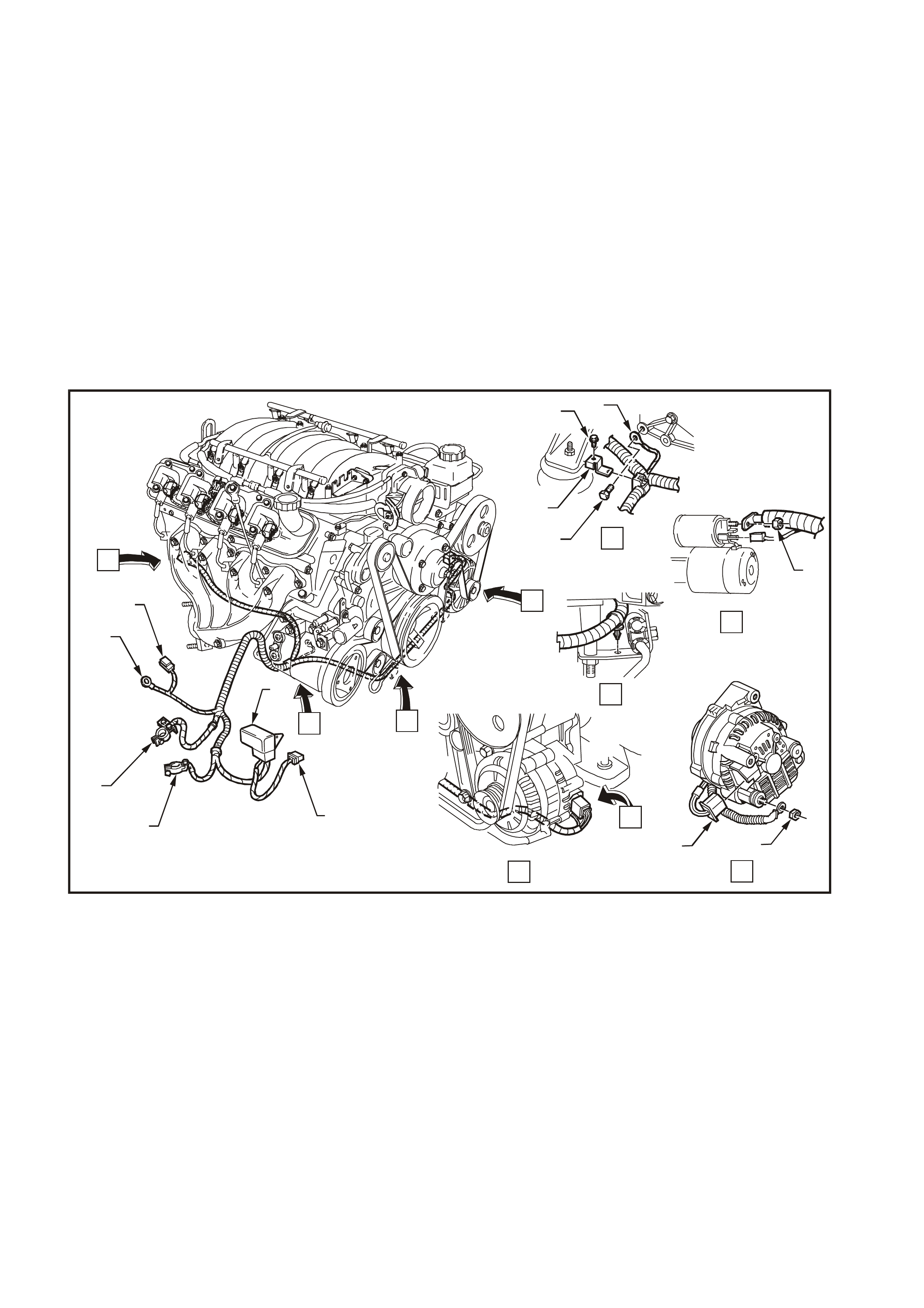

The engine battery harness installation details for

all VT Series Models with a V6 engine are

contained in Section 12A BATT ERY & CABLES in

the VT Series I Service Information. T he details for

a GEN III V8 engine are shown in Fig. 12A-2.

T212A005

13

12

11

10 9

76

8

3

4

2

1

5

A

B

C

DE

B

AC

D

E

Figure 12A-2

1. Harness bracket-to-engine mounting attaching

bolt 8. Fusible link housing

2. Engine earth 9. Engine/Condenser fan connector

3. Engine earth attaching bolt 10. Battery negative terminal harness connector

4. Harness bracket 11. Battery positive terminal harness connector

5. Harness-to-solenoid attaching nut 12. Body earth

6. Harness-to-B+ terminal attaching nut 13. Main wiring harness connector

7. Generator connector

4. SPECIFICATIONS

VT SERIES II ALL MODELS

Rated Voltage .................................................... 12 volts

Charge Acceptance............................................ 10 amps minimum

Rapid Discharge Current (RCC) ........................ 400 amps minimum

Reserve Capacity (RRC).................................... 95 minutes minimum

20 Hour Discharge............................................. 55 amp-hour minimum

5 Second Voltage @ 25°C................................. 150 amps 10.6 volts ±0.2 volt

......................................................................... 400 amps 8.4 volts ±0.2 volt

Number of Plates (per cell) ................................ 11

NOTE: Specified ratings when tested in accordance with Australian Standard AS 2149-1990