SECTION 6D1-1 - CHARGING SYSTEM -

V6 ENGINE & V6 SUPERCHARGED

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver’s air bag, seat belt pre-tensioners and driver’s and front

passenger’s air bags or seat belt pre-tensioners, driver’s and front passenger’s air bags and left and

right-hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System

of the VT Series I Service Information performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Sections of this Service Information CD for more

specific servicing information.

1. GENERAL INFORMATION

A Bosch KC-A Compact 90 Amp generator is fitted to VT Ser ies II Models equipped with the naturally aspirated V6

engine, and a Bosch KC-A Compact 100 Amp generator is fitted to models equipped with V6 supercharged

engines. Servicing inf orm ation related to the 90 Am p generator is contained in this Sec tion. For service inform ation

on the 100 Amp gener ator, refer to Sectio n 6D1-1 CHARG ING SYST EM — V6 ENGINE & V6 SUPERCHARGED

of the VT Series I Service Information.

A Mitsubishi 120 amp generator is fitted to those WH Series models with production option T82 (‘Headlamps on’).

All service information relating this generator can be found in 6D1-1 CHARGING SYSTEM – V6 ENGINE, in VT

Series Service Inforamtion.

Techline

1.1 GENERAL DESCRIPTION

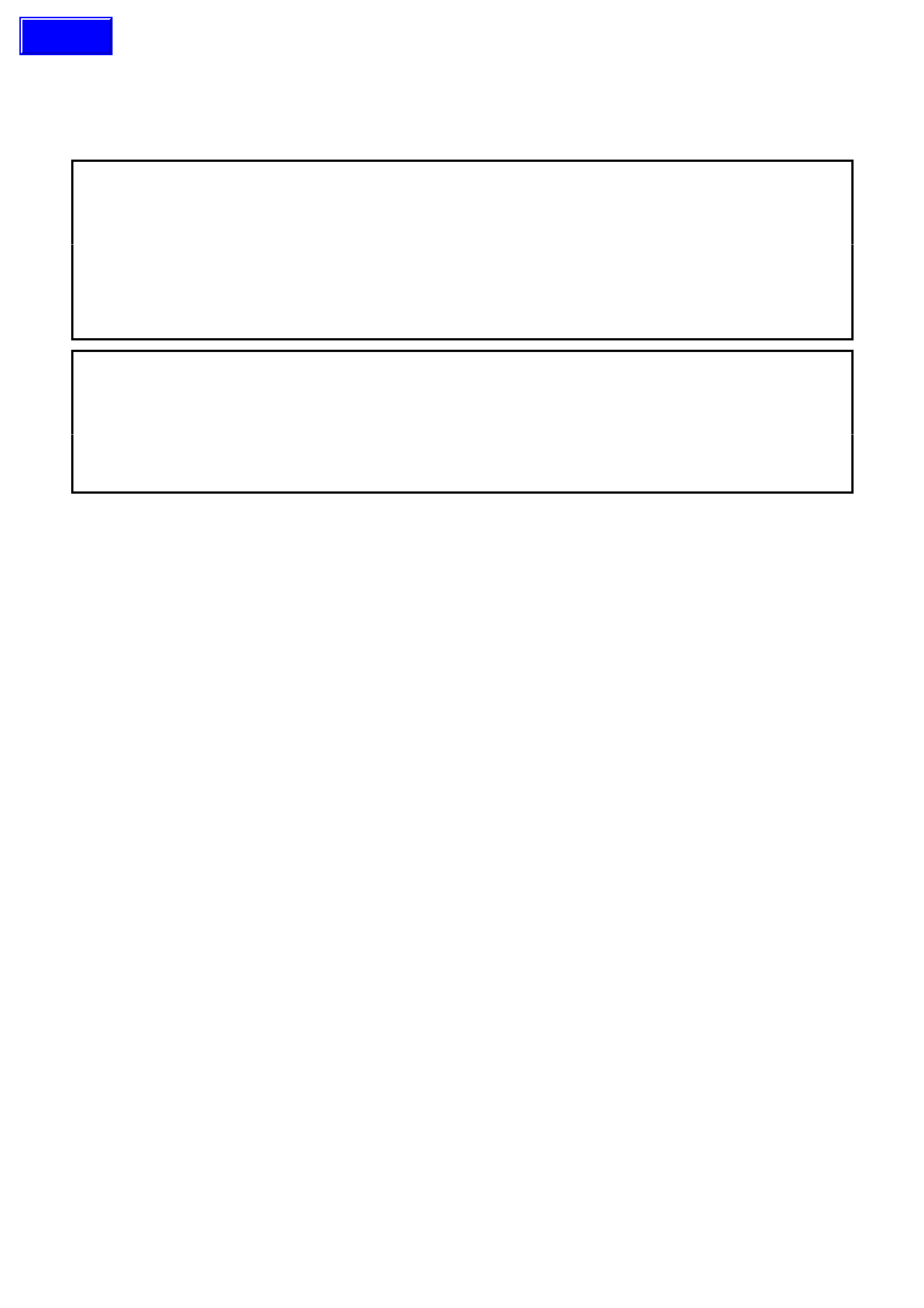

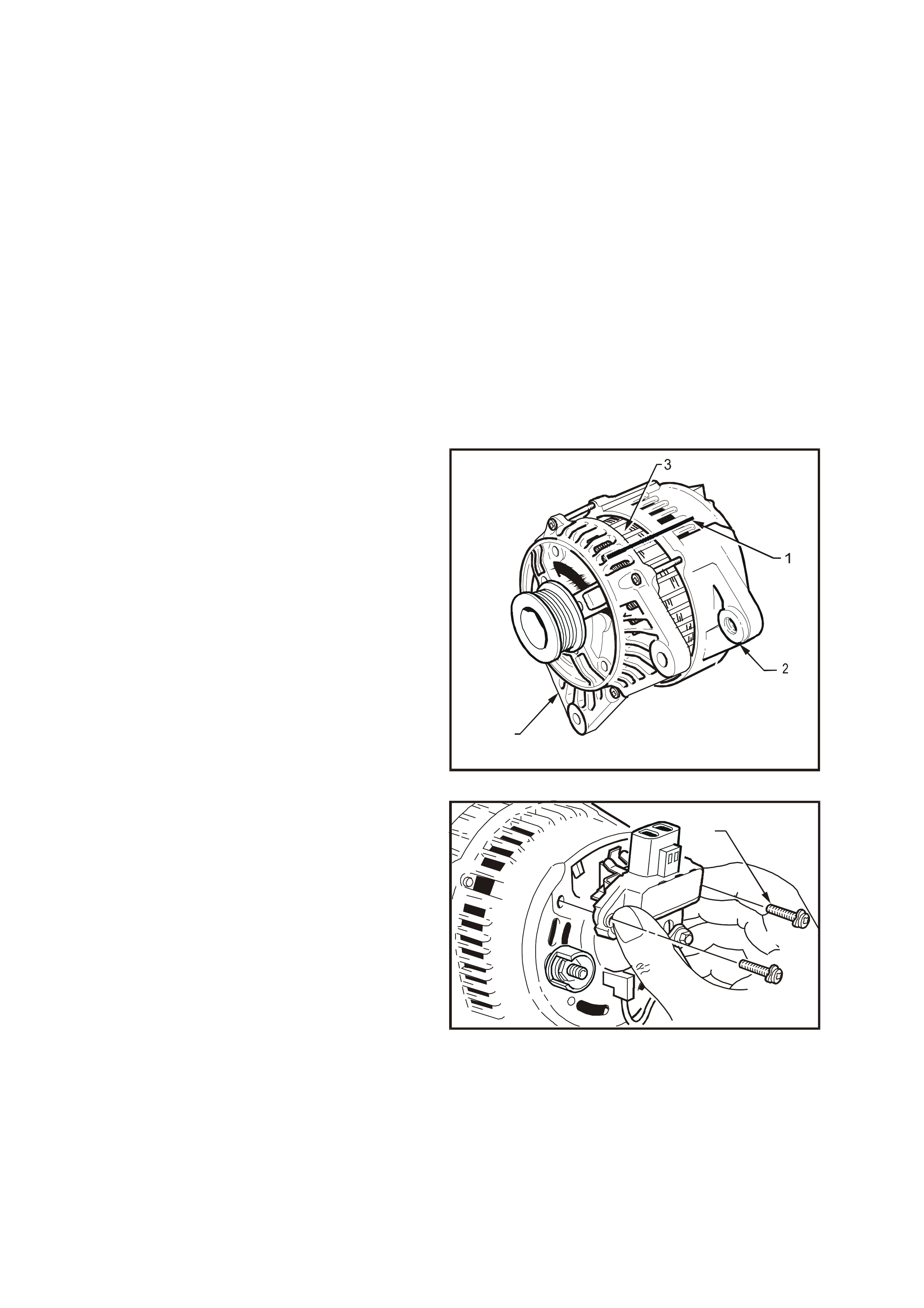

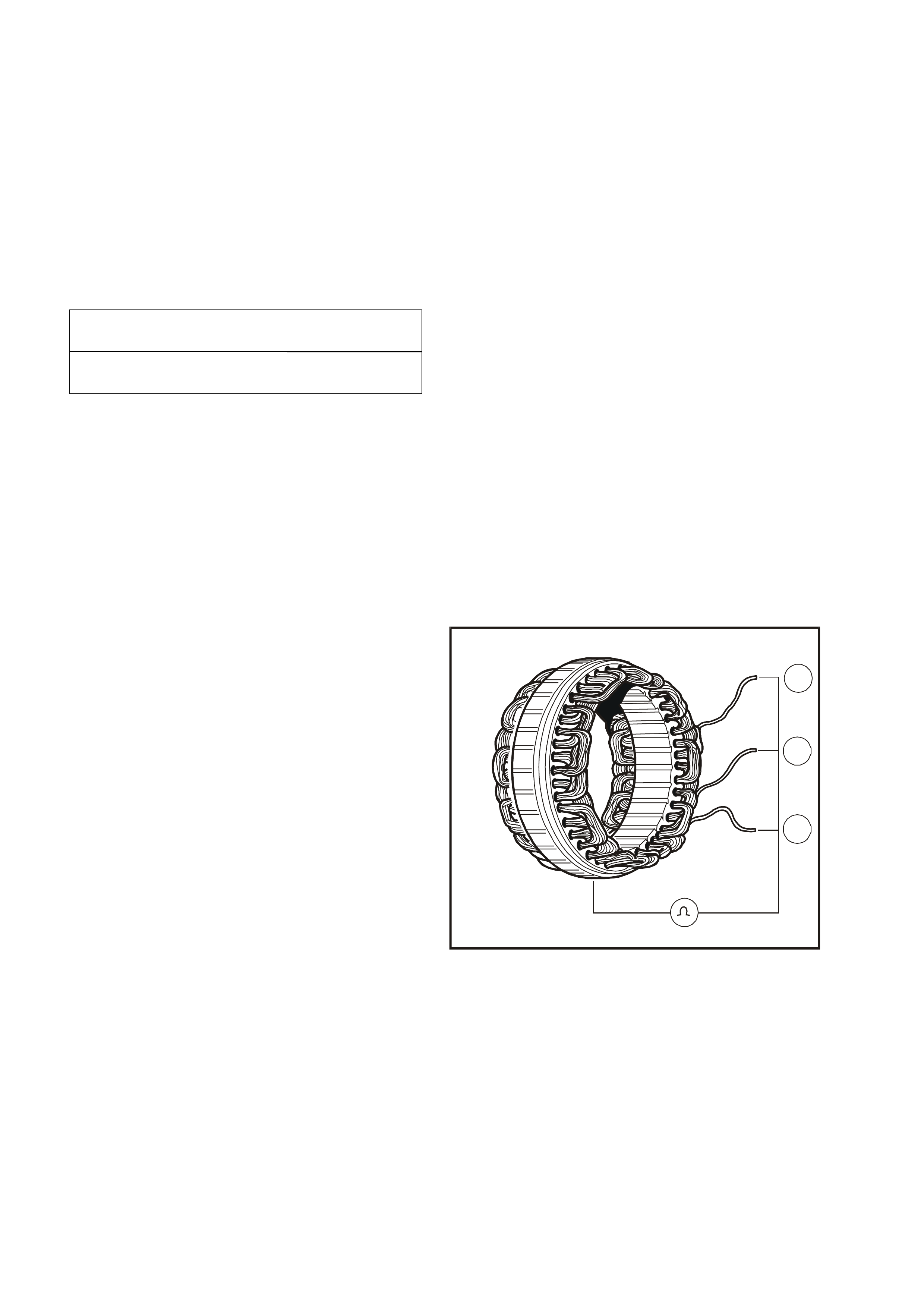

The generator as shown in Fig. 6D1-1-1 is a three-phase type, incorporating a rotor having 6 pole pairs fitted with

two cooling fans, one on the drive-end and the other on the slip-ring end. Rotor current is conveyed to the rotor

winding by a pair of slip-rings and carbon brushes via the voltage regulator. T he rotor is supported by ball bearings

in both the drive and slip-ring end housings. Surrounding the rotor is a stator, which is of a three-phase star

connected output winding construction on a ring shaped lamination pack.

The output of the stator winding is rectified by six diodes which are contained within the slip-ring end housing.

Excitation current is supplied to the rotor field coil via the voltage regulator, brushes and slip-rings. The electronic

voltage regulator requires no adjustment in service.

The generator has three external connections: the S lead (1) for battery voltage sensing, the L lead (2) to the

generator warning lamp (max. 2 watts), the B+ lead (3) to the battery positive terminal, and an earth connection,

refer Fig. 6D1-1-1.

NOTE: Do not reverse S and L connections or damage to the warning lamp circuit of the regulator will result.

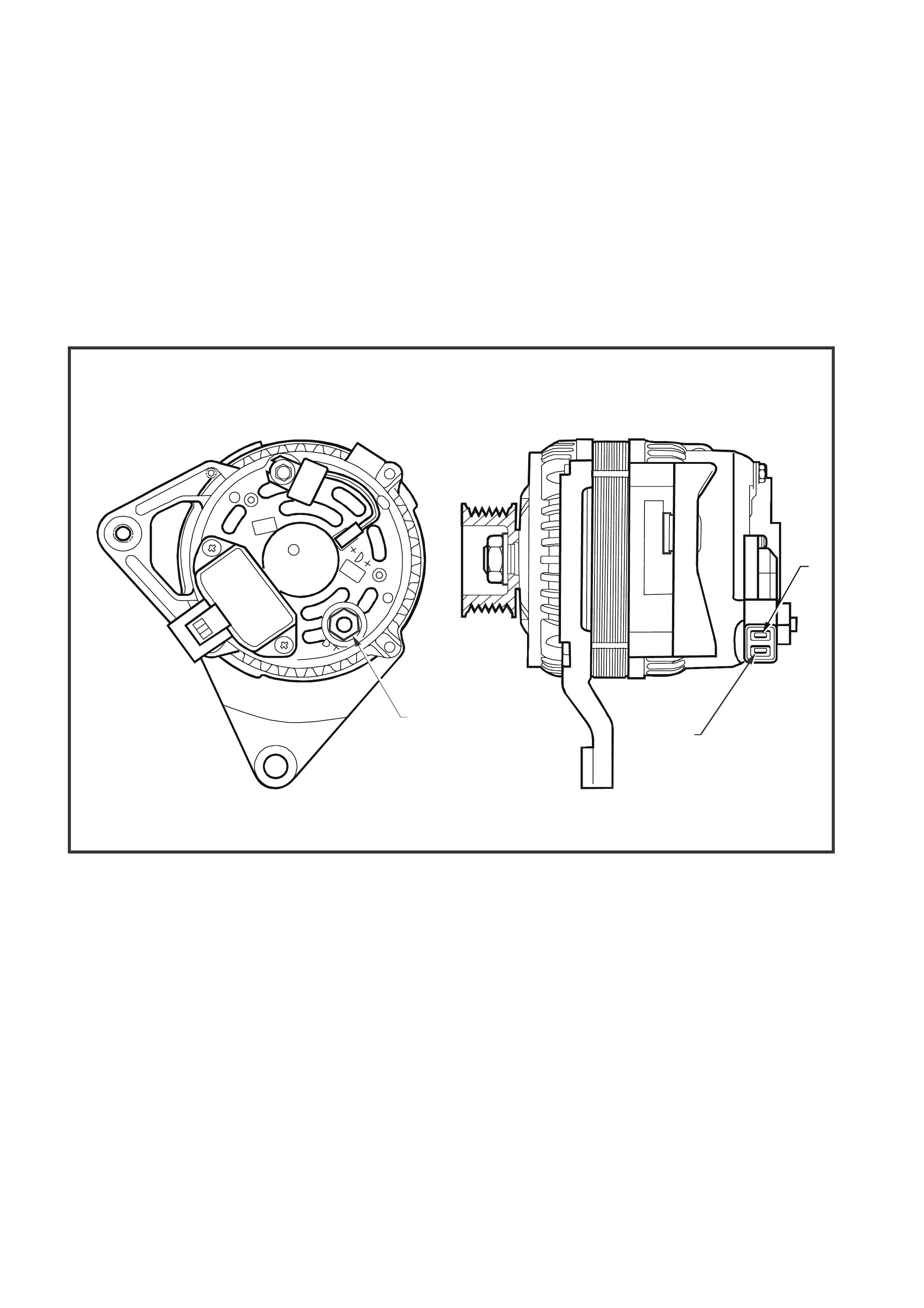

Fig. 6D1-1-2 provides an exploded view and parts identification of the 90 amp generator.

T26D1101

32

1

Figure 6D1-1-1

T26D1103

1

2

3

8

11 12

4

6

510

9

15

13

14

16

17 18

20

21 2223

27

26

24 25

Figure 6D1-1-2

1. Nut 15. Rectifier assembly

2. Lock washer 16. Mica insulating washer

3. Drive pulley 17. Insulating washer

4. Bearing retaining plate screw (4 off) 18. Spacer

5. Through bolt (4 off) 19. Slip-ring end housing lug sleeve

6. Drive end housing 20. Slip-ring end housing

7. Drive end bearing 21. Terminal cover bush

8. Bearing retaining plate 22. Flat washer

9. Rotor 23. B+ terminal retaining nut

10. Slip-ring end bearing 24. Suppressor

11. Stator 25. Suppressor attaching screw

12. Slip-ring end bearing support ring 26. Regulator and brush screws

13. Rectifier attaching screws 27. Regulator and brush assembly

14. B+ terminal bolt

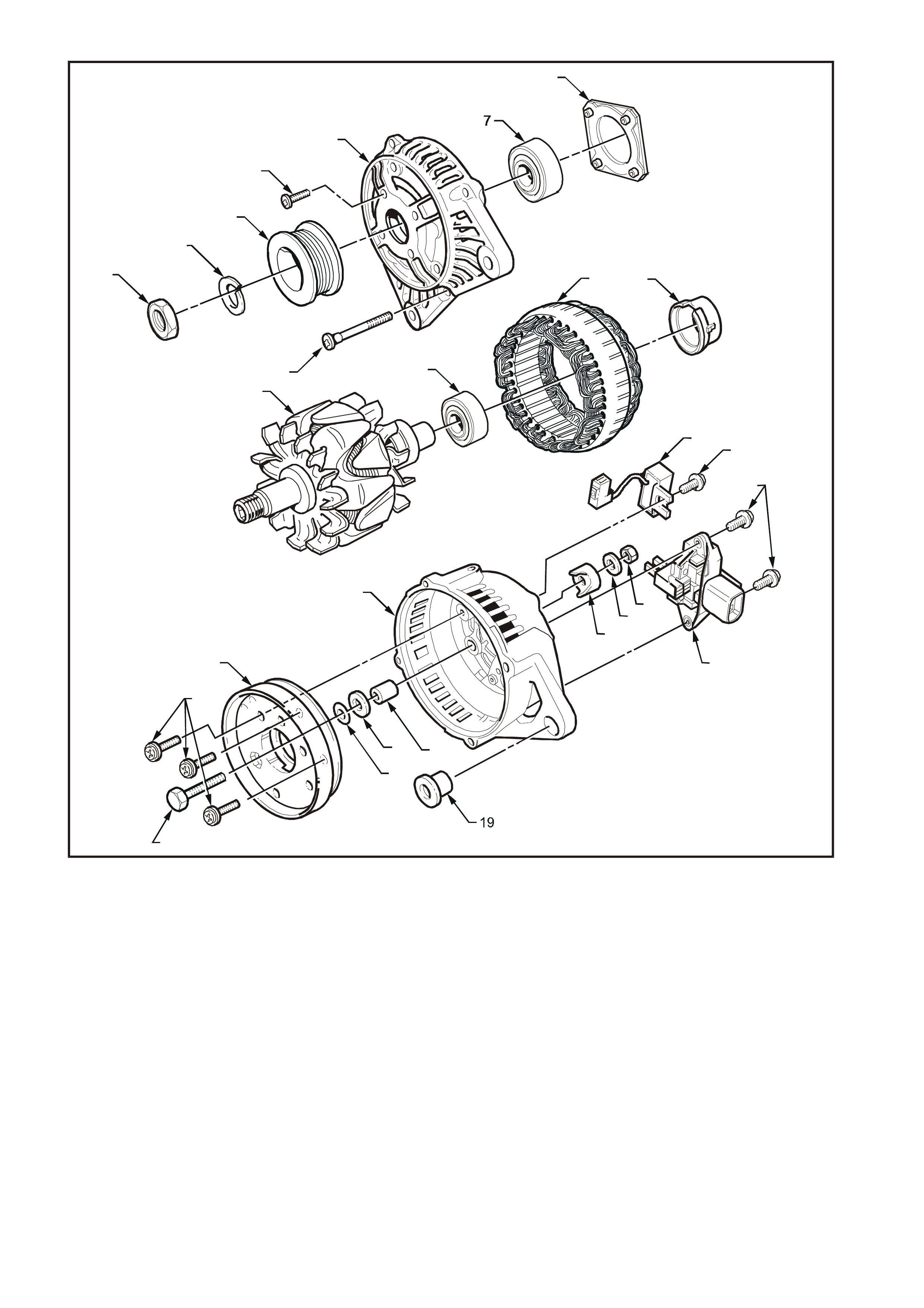

1.2 OPERATION

W ith the ignition switch turned to the ON position, current is supplied via the warning lamp to the L terminal of the

regulator. Base current from the regulator hybrid circuit is fed to the transistor T15 which turns on. Current then

flows from the B+ terminal through the rotor winding via the regulator brushes and the collector-emitter junction of

transistor T15 to earth, completing the circuit.

The curr ent in the rotor caus es a m agnetic field between adjacent poles to be created. T his f ield is rotated and c uts

the windings of the stator at right angles, inducing a voltage into them. As the speed is increased, this induced

voltage increases and results in current being rectified in the three-phase diode bridge and supplied as DC to the B+

output and hence to the battery. When the voltage at the B+ terminal to the battery reaches approximately

14.2 volts, the S terminal which is monitoring this voltage, turns off the regulator hybrid circuit base current to

transistor T15, removing rotor current. This results in a decrease in output voltage to below the regulating voltage,

transistor T15 base current is turned back on and the whole cycle is repeated very rapidly. Diode D38 protects

transistor T15 and the regulator against the back voltage developed across the rotor winding when transistor T15

tu rns off.

Should a situation arise where the main B+ cable or battery sense wire (S terminal) become disconnected, the

regulator will limit the output voltage to a safe level, approximately 1 to 3 volts above the regulator’s normal setting.

When the ignition switch is turned on and the engine is not running, the current to the rotor is reduced by switching it

on and off at a 50% duty cycle, the frequenc y is appr oximately 4 kHz and m ay be audible at tim es (this is norm al).

Once the engine is started, normal regulation commences.

Should the warning lamp fail, the generator will self excite by deriving a small current from the phase connection

allowing the voltage to build-up to regulating level.

IMPORTANT: No rotor winding current will flow when the engine is cranking.

The regulator incorporates internal diagnostics which will illuminate the warning lamp as a result of fault conditions

in the generator and/or external circuitry.

These conditions include:

1. An open circuit in the regulator battery sensing wire (S terminal).

2. An open circuit or excessive voltage drop in the B+ cable.

3. An open circuit in the generator phase connection.

4. Overcharging of the battery.

5. Regulator output stage short circuit.

6. Open circuit in the rotor winding.

The regulator compares the voltage at the B+ terminal with the voltage sensed at the S terminal connected to the

battery positive. If the voltage differential exceeds a predetermined threshold, the regulator will operate in backup

mode to limit the output voltage to a safe level. The warning lamp will remain illuminated as long as the fault

conditions prevail.

Sources of high resistance which will trigger the warning lamp are:

1. Poor contact in the wiring harness connectors.

2. Poor contact between the rectifier and the regulator.

3. High resistance in the fusible link assembly.

T26D1104

B+ 0.5 F

FIELD

D38

T15 PHASE

REGULATOR ASSEMBLY

REGULATOR

HYBRID

CIRCUIT

S

L

BATT. SENSE

IGN. SW. WARN. LAMP

1.2 WATT

300

12V BATT.

Figure 6D1-1-3

2. MI NOR SERVICE OPERATIONS

2.1 SAFETY PRECAUTIONS

Since the generator and voltage regulator are designed for use only on a negative earth system, the following

precautions must be observed. Failure to observe these precautions will result in serious damage to the generator.

1. When installing a battery, first f it pos itive (+) cable to batter y positive (+) term inal and then f it negative (–) c able

to battery negative (–) terminal.

2. W hen a slave battery is utilised for starting purposes, ensure that both batteries are connected in parallel, ie.

positive terminals together and negative terminals together.

3. When charging battery, disconnect both battery cables, thus isolating generator from battery and external

charging equipment.

4. The generator must not be operated on open circuit (this is without battery in circuit), and battery must not be

disconnected while the generator is running.

5. Do not attempt to polarise generator.

6. Always ensure that generator warning lamp glows when ignition switch is turned to ON position.

NOTE: As this circuit is related to and assists in the excitation of the rotor field windings, do not proceed until any

faults in the generator warning lamp circuit have been rectified.

7. The L terminal of the generator should never be connected to battery or ignition circuit (12 volts), as this will

damage the generator warning lamp circuit.

8. Some battery powered timing lights can produce high transient voltages when connected or disconnected. Only

disconnect or connect timing lights when the engine is switched off.

2.2 MAINTENANCE AND ON VEHICLE TESTING

At regular intervals, inspect the terminals of the generator for corrosion, loose connections and the wiring for

damaged insulation. Check the mounting bolts for tightness, check the drive belt for alignment and wear and the

drive pulley for damage. The drive belt adjustment for the engine ancillaries, such as the generator and water pump,

is provided by a spring loaded tensioner. The drive belt therefore, does not require any regular adjustment.

LUBRICATION

The ball bearings supporting the rotor shaft are prelubric ated and sealed, therefor e no lubrication is pos sible during

service.

The bearings used in this generator are high tolerance type. If the bearings are removed during the generator

disassembly, new bearings must be installed to restore the generator to original specification.

TESTING THE GENERATOR OUTPUT AND VOLTAGE REGULATOR

Testing Prerequisites

Before testing the generator output, m ake certain that the generator circuit is thoroughly check ed for loose or dirty

connections. The generator must always be connected to the battery during testing, otherwise damage to the

diodes could result.

The battery should be fully charged. Test the specific gravity of the individual cells. The readings should be within 10

points of each other. It is recommended that the average specific gravity should be 1.260 or higher.

A load test should be carried out to determ ine the ability of the battery to supply and accept current. T his is a good

indicator as to the general condition of the battery. Refer to Section 12A BAT T ERY AND CABLES of the VT Ser ies

I Service Information for details of battery testing.

The generator warning light, in addition to indic ating that the generator is charging, is also necessary for initial f ield

excitation.

Inspect drive belt and tensioner markings to determine if belt is within operating limits. Replace belt if it is

excessively worn or outside tensioner's operating range, refer to Section 6A1 ENGINE MECHANICAL — V6

ENGINE of the VT Series I Service Information for details.

Testing Generator Output

Regulating Voltage Test On The Vehicle

1. Ensure that all the electrical equipment is turned off, and the ignition switch is in the OFF position.

2. Disconnect battery earth cable at battery.

3. Disconnect the generator positive lead (red wire) from the B+ generator terminal.

4. Connect the positive lead of an ammeter

(0 - 100 amp scale) to the generator

B+ terminal, and the negative am m eter lead to

the disconnected generator positive lead (red

wire).

5. Connect positive lead of a voltmeter (0 -

20 volt scale minimum) to the generator

B+ terminal, and negative voltmeter lead to a

good earth connection on the generator

housing.

NOTE: Insulate the generator positive lead (red

wire) terminal to prevent contact with any metal

part of the vehicle. If the terminal is earthed,

damage to the charging circuit will result when the

battery is reconnected.

6. Reconnect the battery earth cable. Fit a

loading device across battery terminals, ie. an

adjustable carbon pile.

IMPORTANT: Loading device must have a

minimum power consumption of 1000 watts.

7. Note and record the voltmeter reading before

starting the engine. This reading should

increase when the engine is running,

indicating generator output.

8. Start engine, raise engine speed and adjust

load (ammeter reading) to that nominated in

the following chart. Check generator output

(voltmeter reading) against specification.

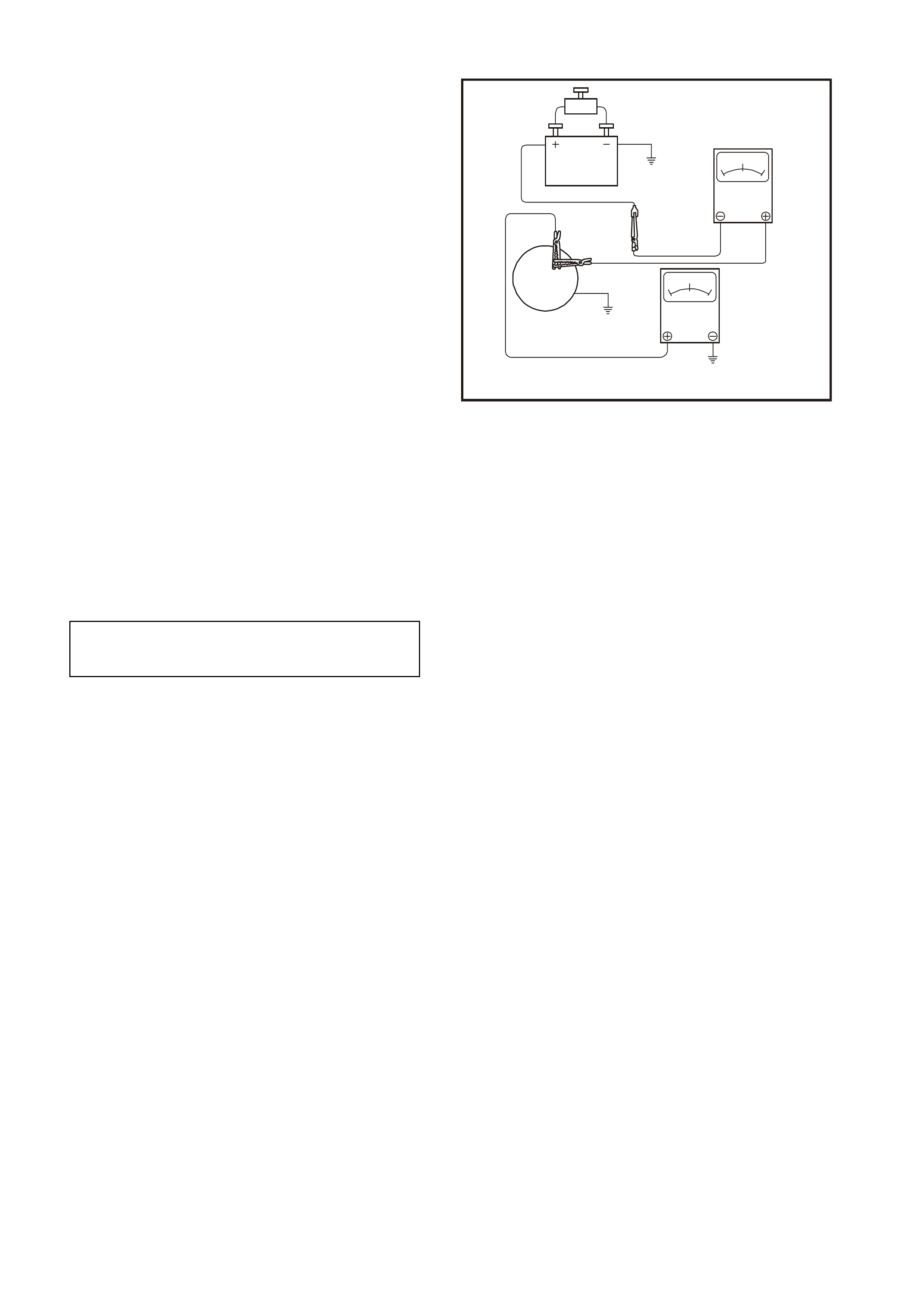

T26D1105

ADJUSTABLE LOAD

CONNECT TO

GENERATOR BODY

GENERATOR

B+

TERMINAL

BATTERY

0+100-100

AMPS

020

VOLTS

Figure 6D1-1-4

Load Regulation Test

With the voltmeter, ammeter and carbon pile

connected as in previous test, increase engine

speed to 1900 rpm (approximately 6000 generator

rpm) and increase load to approximately

76.5 amps (90% of full output). A decrease in the

regulating voltage should not exc eed 0.5 volt of the

readings obtained in the previous test.

If the decrease in the regulating voltage is greater

than 0.5 volt, the regulator is defec tive and mus t be

replaced.

ENGINE RPM

LOAD

VOLTMETER READING

1275

5 – 10 Amps

14.0 – 14.2 Volts

Generator Output Test at Full Load

With the voltmeter, ammeter and carbon pile connected as in previous tests, increase engine speed to 1900 rpm

(approximately 6000 generator rpm) and increase load until the generator output voltage drops to 13.5 volts and

note ammeter reading.

Full output should be obtained under these conditions. It m ay be necessary to adjust the throttle so as to maintain

the desired engine speed.

NOTE: Keep the time for this test to a minimum so as to avoid undue heating and high engine speeds.

If generator does not provide rated output, it should be disassembled and inspected for faults, refer to

3.1 GENERATOR in this Section.

NOTE: On com pletion of the gener ator output testing, to prevent exc essive battery discharge occurr ing, the engine

should be resumed to idle speed and the loading device disconnected from battery terminals.

Disconnect the battery earth cable at battery. Remove the volt and am meters , then rec onnec t the generator pos itive

lead (red wire) to the generator B+ terminal. Reconnect the battery earth cable to the battery.

CHARGING CIRCUIT VOLTAGE DROP TEST

With normal connections made at generator, charging circuit can be checked for voltage drop as follows:

1. Connect a low range voltmeter between generator positive terminal and battery positive post.

2. Switch on headlamps, start engine and increase engine speed to approximately 2500 rpm and note voltm eter

reading.

3. Reduce engine speed and transfer voltmeter connections, negative to generator housing and positive to battery

negative post. Increase engine speed to approximately 2500 rpm and again note voltmeter reading.

4. If readings exceed 0.5 volt on positive side and 0.25 volt on negative side, there is a high resistance in

charging circuit which must be traced and corrected.

5. Reduce engine speed and transfer voltmeter connections, negative to generator body and positive to battery

negative post. Increase engine speed to approximately 2500 rpm and again note voltmeter reading.

6. If readings exceed 0.5 volt on positive side and 0.25 volt on negative side, there is a high resistance in

charging circuit which must be traced and corrected.

3. MAJOR SERVICE OPERATIONS

3.1 GENERATOR

REMOVE

1. Disconnect battery earth lead.

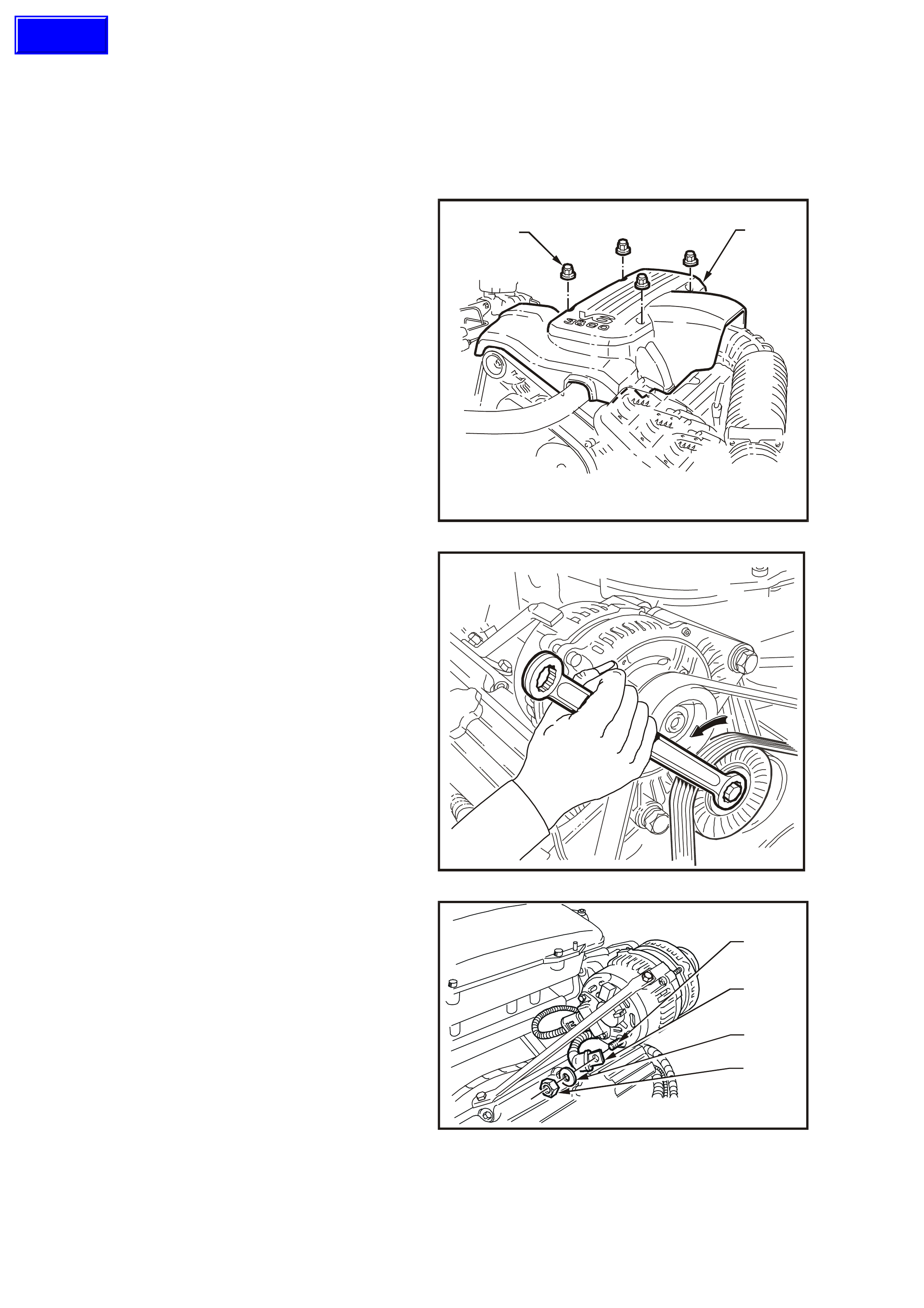

2. Remove four dome nuts (1) securing engine

dress c over (2) to intak e manif old and rem ove

engine dress cover (2).

T26D1102

12

Figure 6D1-1-5

3. Using an 15 mm ring spanner on drive belt

tensioner pulley pivot bolt, rotate tensioner

pulley assembly anti-clockwise and remove

drive belt fr om generator dr ive pulley. Release

drive belt tensioner.

T26D1106

Figure 6D1-1-6

4. Pull back battery harness cap f rom B+ term inal

(4), remove nut (1), washer (2) and positive lead

(3).

3

2

1

4

T26D1107

Figure 6D1-1-7

Techline

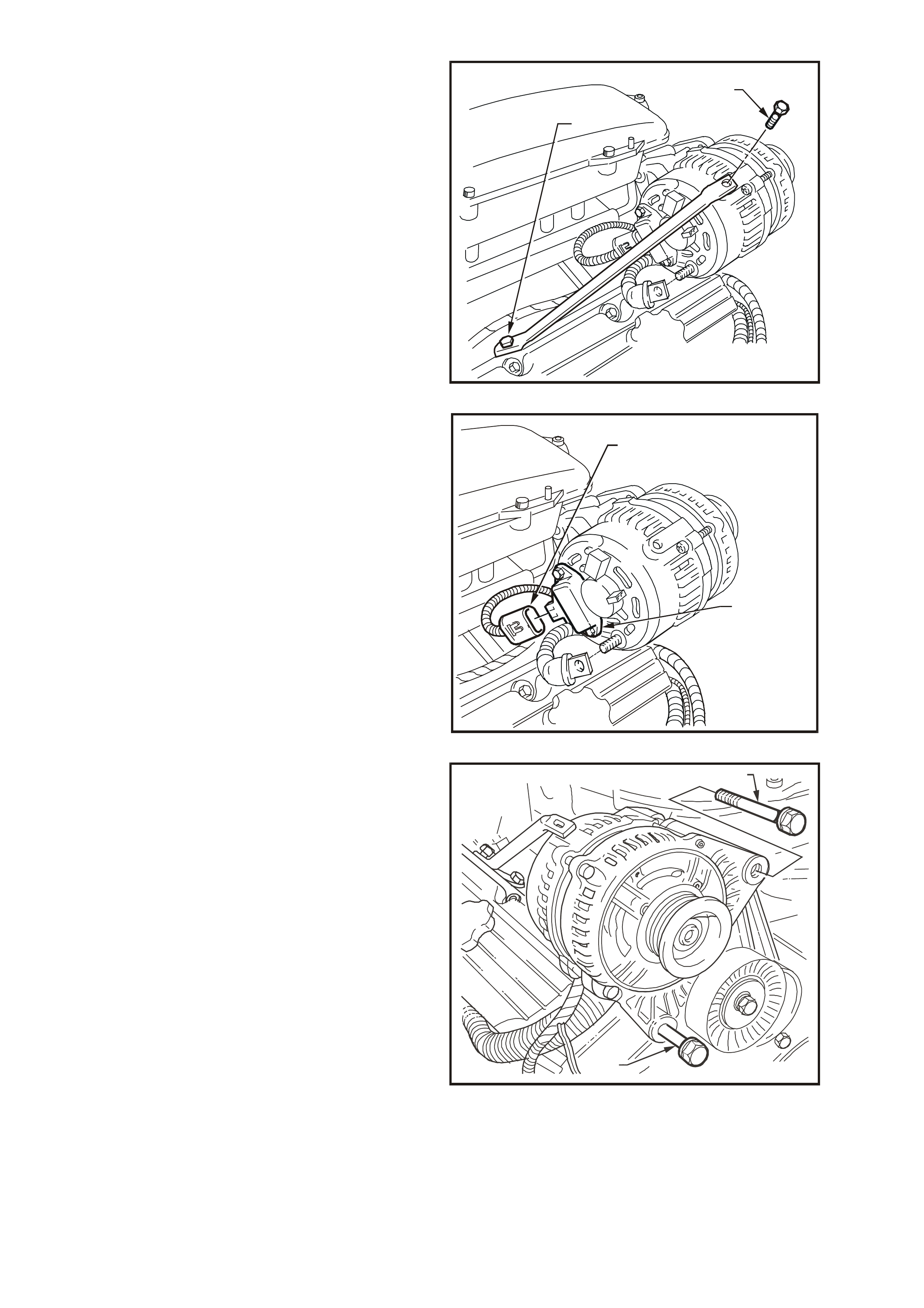

5. Remove generator brace to generator

attaching bolt (1) and loosen brace to engine

bracket attaching bolt (2).

T26D1130

1

2

Figure 6D1-1-8

6. Disconnect the generator connector (1) from

the regulator and brush assembly (2).

T26D1131

1

2

Figure 6D1-1-9

7. Remove generator mounting to drive belt

tensioner bracket attaching bolt (1).

8. Remove generator to drive belt tensioner

bracket lower bolt (2) and remove generator

assembly.

T26D1108T26D1108

2

1

Figure 6D1-1-10

REINSTALL

1. Assemble generator with drive-end housing

into support and brace mounting. Install

generator mounting bolt.

Swing generator down to drive belt tensioner

and install attaching bolt.

Tighten mounting and attaching bolts to the

correct torque specification.

2. Install battery harness positive lead (red

wire), washer and nut on B+ terminal.

Tighten nut to the correct torque

specification. Install cap ove B+ terminal

3. Connect wiring harness connector to

generator teminal block

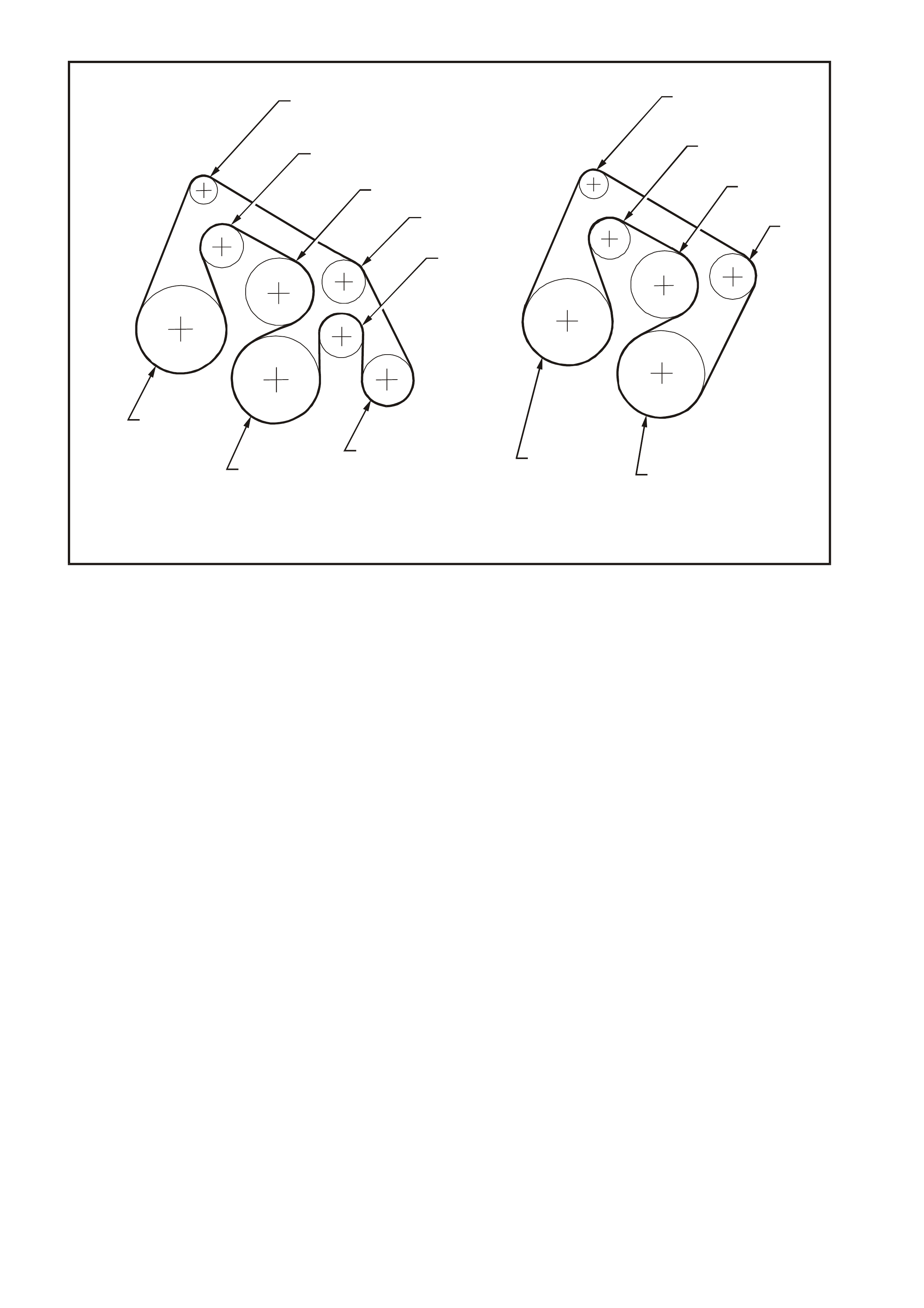

4. With aid of an 15 mm ring spanner, rotate

drive belt tensioner anti-clockwise and fit

drive belt to generator drive pulley. Ensure

that the drive belt is correctly routed, refer to

Fig. 6D1-1-11 (A for vehicles with air

conditioning or B for vehicles without air

conditioning). Release tensioner and ensure

that drive belt ribs are correctly installed into

all accessory drive pulleys and crankshaft

balancer drive belt grooves

5. Reconnect battery earth lead.

6. Start engine and check generator waring

lamp operation, drive belt alignment,

generator output and voltage regulator

operation.

B+ TERMINAL NUT

TORQUE SPECIFICATION 5 – 12 Nm

GENERATOR TO SUPPORT

AND BRACE MOUNTING BOLT

TORQUE SPECIFICATION 20 – 34 Nm

GENERATOR TO DRIVE BELT

TENSIONER BRACKET

MOUNTING BOLT

TORQUE SPECIFICATION

20 – 34 Nm

T26D1109

11

22

33

44

5

6

77

8

8

AB

Figure 6D1-1-11

1. Generator

2. Tensioner pulley

3. Water pump

4. Idler

5. Idler

6. Air conditioning compressor

7. Crankshaft

8. Power steering pump

DISASSEMBLE

The following precautions must be noted before

attempting to disassemble the generator and

checking for faulty components.

a. When testing the rectifier diodes with an AC

type tester, the RMS output must not exceed

12.0 volts. It is recommended that the stator

should be disconnected before testing the

diodes.

b. When testing diode breakdown voltage, all

diodes should have the same Zener voltage.

c. Insulation tests on the rotor and stator should

use a voltage not exceeding 110 volts for a

series test lamp. The rectifier must be

disconnected from the stator prior to testing.

d. Due to the very low resistance value of the

stator winding, it m ay not be possible to obtain

accurate readings using a conventional

ohmmeter.

1. Using a permanent marking pen, draw a line

(1) to mark relative positions of slip-ring end

housing (2), stator frame (3) and drive-end

housing (4).

T26D1110

4

Figure 6D1-1-12

2. Remove two screws (1) securing regulator and

brush assembly to slip-ring end housing.

Holding the terminal bloc k of the regulator and

brush assembly, tilt the assembly up from the

slip-ring end housing and then lift out, taking

care not to damage the brushes.

T26D1111

1

Figure 6D1-1-13

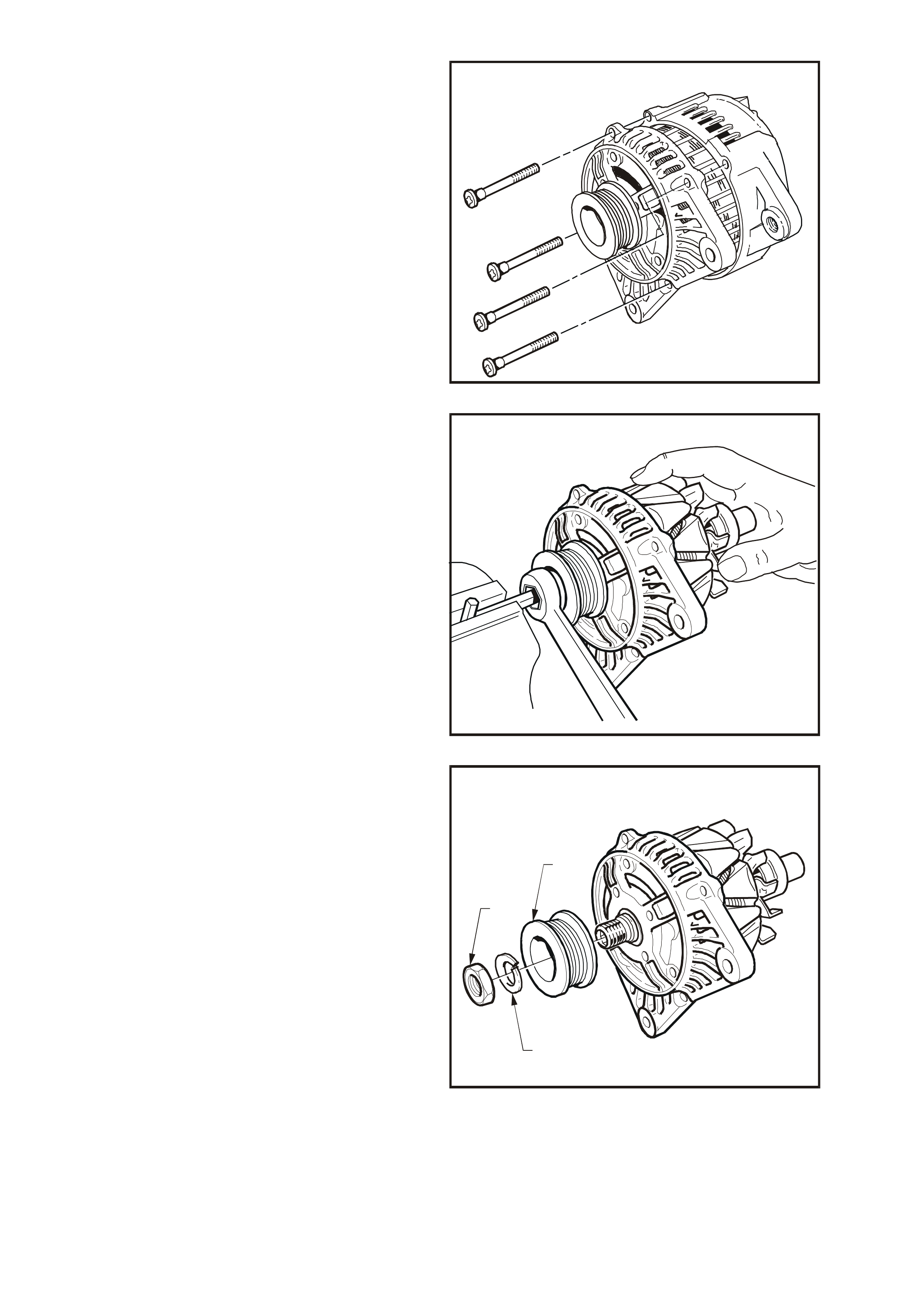

3. Remove four through bolts.

4. Carefully separate the slip-ring end housing

and stator (as an assembly) from rotor and

drive-end housing, taking car e not to put strain

on the stator.

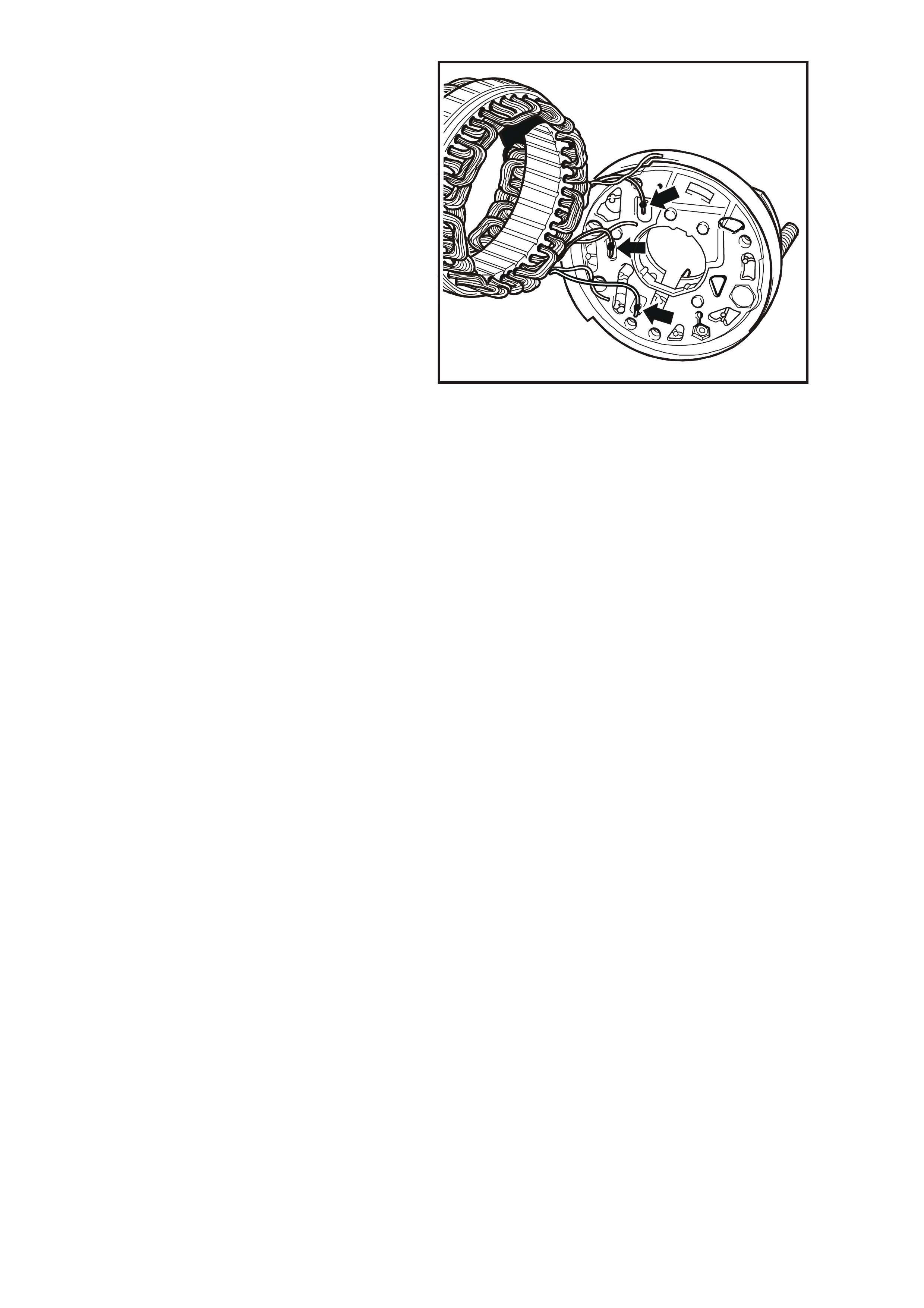

T26D1112

Figure 6D1-1-14

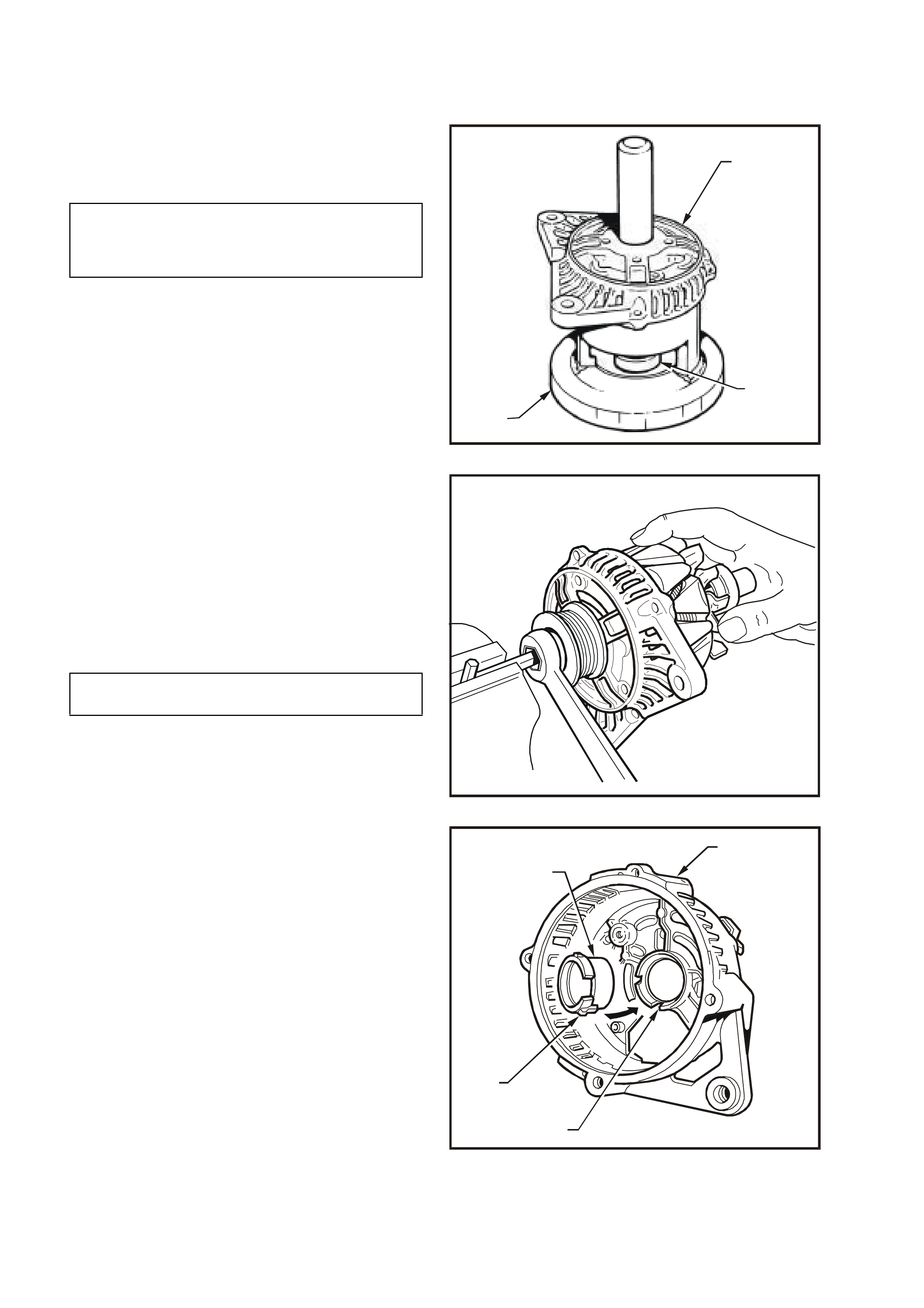

5. To remove the drive pulley, mount an 8 mm

Allen key in a vice with the long end pointing

out from the side of the vice.

Place a deep 24 mm socket with external hex

(commercially available) onto the pulley

attaching nut and place a suitable size

spanner over socket hex.

As an alternative, use a deep 24 mm socket

and weld a suitable length bar to the side of

the socket to act as a lever.

Position drive-end housing and rotor assem bly

with the internal hexagon of the rotor shaft

onto the Allen key.

Loosen drive pulley attaching nut. Remove

drive-end housing from Allen key.

NOTE: Under no circumstances is the rotor to be

mounted in the vice as the rotor and or cooling fans

will be damaged.

T26D1113

Figure 6D1-1-15

6. Remove drive pulley attaching nut (1), lock

washer (2) and drive pulley (3).

T26D1114

2

1

3

Figure 6D1-1-16

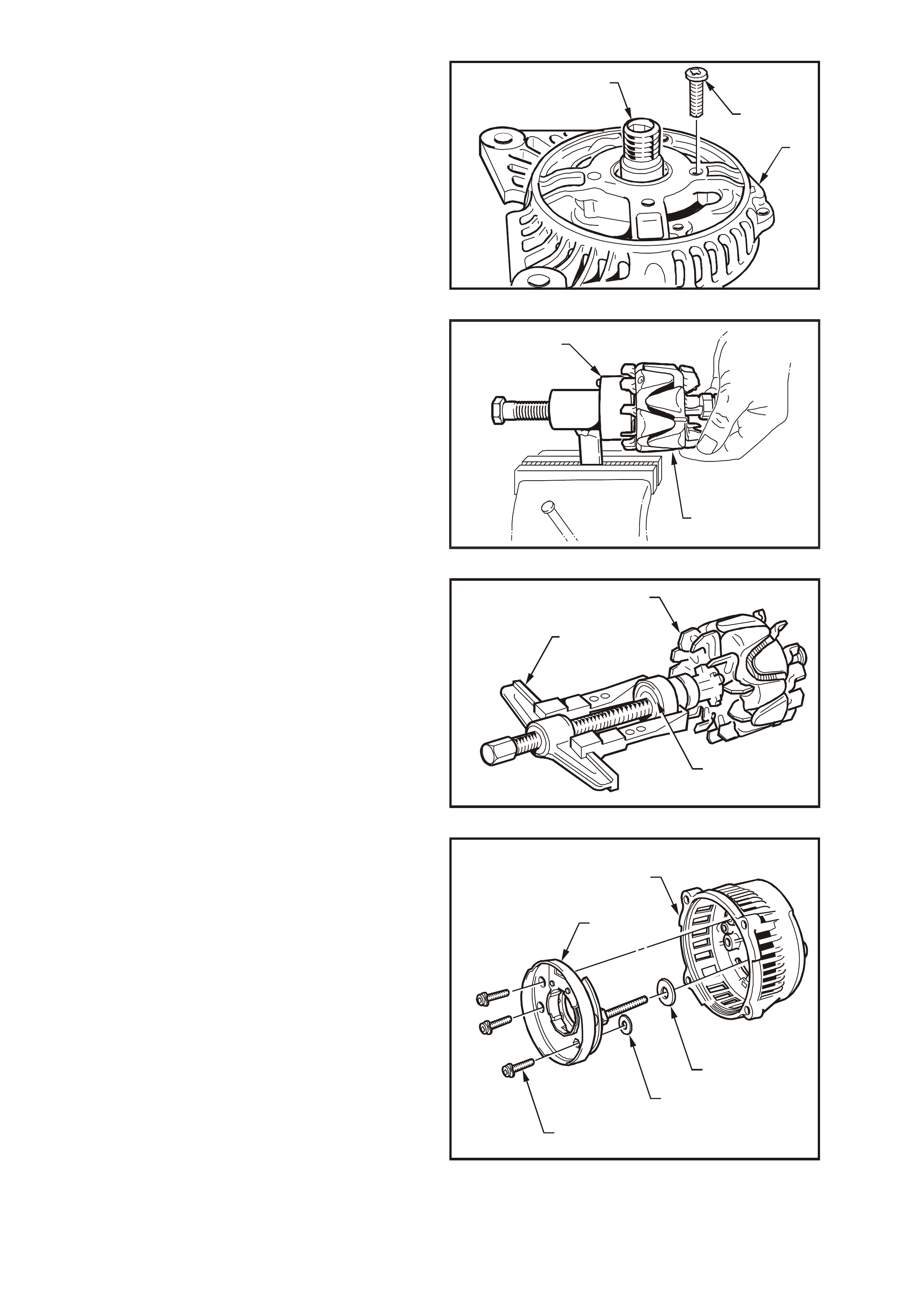

7. Remove four screws (1) securing the bearing

retaining plate to drive-end housing (3).

8. Push the rotor s haft (2) and f ront bearing f rom

the drive-end housing (3) by hand.

NOTE: The rotor must not be pressed from the

drive-end housing. If the rotor is pressed out, the

bearing retaining plate and drive-end housing will

be damaged or distorted. Parts removed in this way

MUST be replaced if the integrity of the generator

is to be maintained.

T26D1115

1

2

3

Figure 6D1-1-17

9. Using Special Tool 9981 066 601(1), remove

drive-end bearing from rotor shaft (2) taking

care not to distort the front fan during the

process.

T26D1116

1

2

Figure 6D1-1-18

10. Using the puller (1), remove slip-ring end

bearing (2) from rotor shaft, taking care not to

distort the rear fan (3) during the process.

Remove retaining plate from rotor shaft.

T26D1117

3

1

2

Figure 6D1-1-19

11. Remove nut, wave washer, flat washer and

insulating washer from the B+ terminal bolt.

12. Remove suppressor lead connection from

rectifier + terminal.

13. Remove three screws (1) attaching rectifier

assembly (2) to slip-ring end housing (3).

Remove the stator and rectifier as an

assembly. Remove spac er and mica ins ulating

washer (4) from B+ terminal bolt.

Remove second mica insulating washer (5)

from beneath rectifier positive heat sink.

(W asher may be adhered to boss on inside of

slip-ring end housing).

NOTE: Discard the two mic a insulating washers as

new washers and heat sink compound must be

used on reassembly.

T26D1118

3

4

5

1

2

Figure 6D1-1-20

14. Separate stator from rectifier assembly by

unsoldering the three stator windings to

rectifier connections.

NOTE: Use only as much heat as required to melt

the solder. Excessive heat may damage the

diodes.

To disconnect the stator from the rectifier

assembly, grasp the stator wires close to the

wire loop with a pair of pointed nose pliers.

Heat the joint with a soldering iron and when

the solder at this point starts to melt, apply a

slight twisting motion to the wires, then pull

upwards to release.

IMPORTANT: The rect ifier assembly is ser viced as

an assem bly only. Individual replacement parts are

not available.

T26D1119

1

Figure 6D1-1-21

CLEANING AND INSPECTION

With generator completely disassembled,

components should be cleaned and inspected.

Wash all components except stator, rotor, rectifier

and regulator in a suitable cleaning solvent.

Carefully clean rotor and stator with compressed

air.

NOTE: Do not clean stator or rotor windings with

cleaning solvent or damage to the insulation could

result.

CAUTION: Clean all parts other than those

previously nominated using a non-volatile or

low inflammab le agent in a well v entilated area.

It is important that all parts are thoroughly

dried before assembly, taking care not to

breath in any vapours. Observe the safety

regulations and precautions issued by the

manufacturer of the cleaning agent in use.

COMPONENT CHECKING

If brush length is less than specified, replace

brushes as follows:

Brush Gear

Check the length of the brushes protruding from

the regulator brush holder. This is measured from

the brush holder to the end of the brush, along its

centre line.

1. Unsolder brush leads from regulator brush

holder connections (1) and bend back the

retaining lugs. Remove brushes and springs.

2. Inspect brush springs for discolouration,

breakage, corrosion or loss of tension. If any

of these conditions exist, replace springs.

3. Ensure that insulating sleeves are fitted over

new brush leads. Install brush springs over

brush leads. T hread new brus h leads up br us h

holder along with springs, pull the leads

through the tabs until the brush is protruding

12 mm from the holder. Bend down the tabs

and solder the brush leads to the regulator

connections. T ake car e not to allow the s older

to run up the lead which would reduce its

flexibility.

4. Check that brushes m ove smoothly in and out

of holder by pushing on end of brushes, and

then releasing.

T26D1120

1

Figure 6D1-1-22

Diodes

IMPORTANT: The rectifier assembly is not

repairable and should be r eplaced if any diode

proves to be faulty.

The following commercially available test

equipment is essential for correctly testing the

diodes within the rectifier assembly.

a. A diode tester or multimeter with a diode test

feature where the DC output at the test probes

does not exceed 14 volts , or in the case of AC

testers, 12 volts RMS.

This is necessary to ensure that when testing

the diodes, the forward and reverse voltage

checks are completed and are not masked by

the diode turning on due to Zener breakdown

voltage.

b. A Zener diode tester with a DC output in

excess of 30 volts. The tester should also

incorporate internal current limiting set to 5 mA

to prevent high currents during testing.

MINIMUM BRUSH

LENGTH 3.8 mm

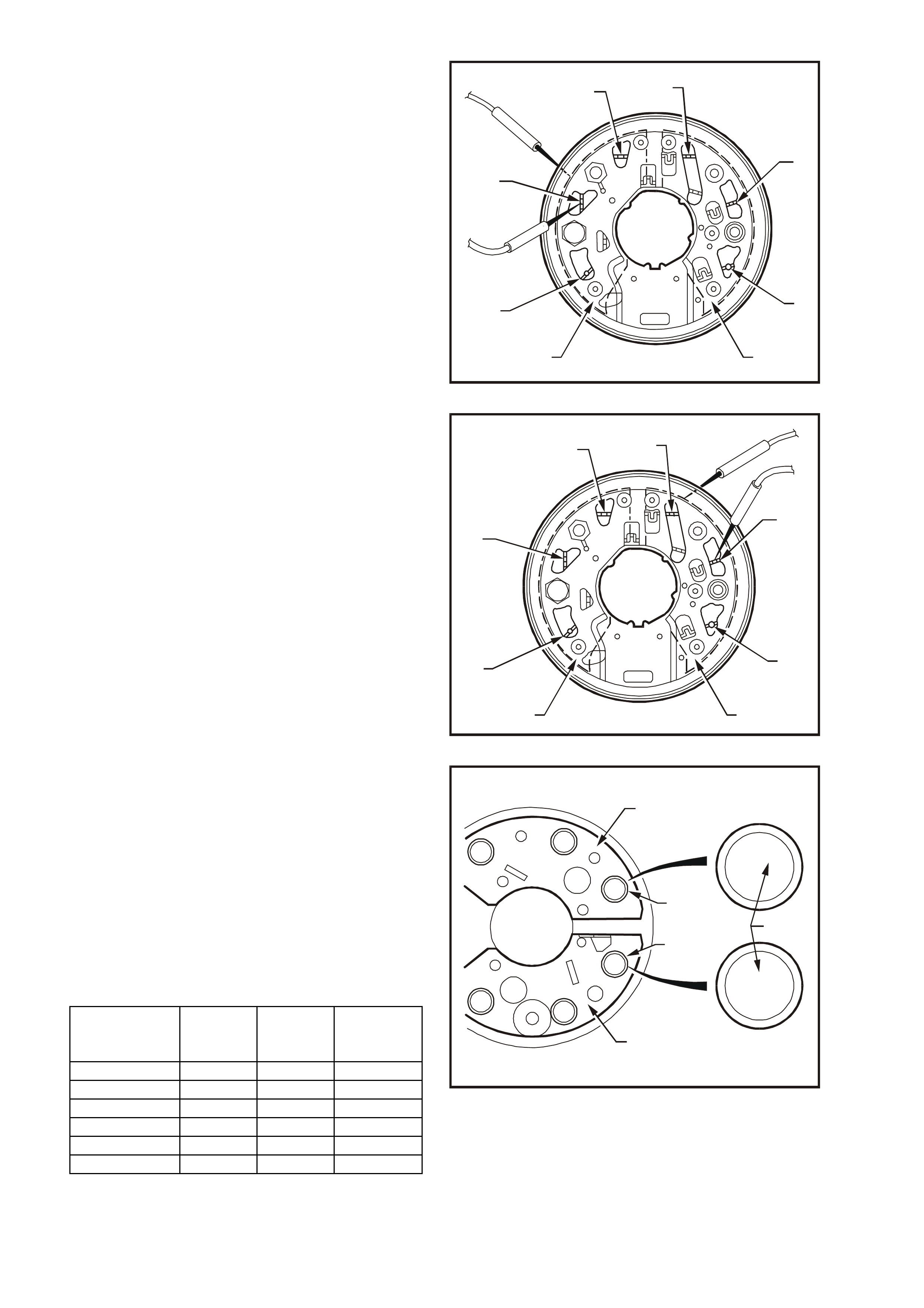

1. Attach negative test probe of diode tester or

multimeter with diode test function to the

positive heat sink (1) of the rectifier assembly

and the positive probe alternatively to positive

diode connections A, B and C shown in Fig.

6D1-1-23.

A low resistance reading, or the forward

voltage drop across the diode should be

obtained.

Reverse probe connections and repeat test to

check that current is passed in one direction

only (high resistance reading or higher reverse

voltage should be obtained).

T26D1121

CD

E

F

21

A

B

Figure 6D1-1-23

2. Repeat proc edure on negative heat sink (2) by

attaching positive test probe to the negative

heat sink (2) and the negative probe

alternatively to negative diode connections D,

E and F shown in Fig. 6D1-1-24.

A low resistance reading, or the forward

voltage drop across the diode should be

obtained.

Reverse probe connections and repeat test to

check that current is passed in one direction

only (high resistance r eading or higher r everse

voltage should be obtained).

IMPORTANT: In Steps 1 and 2, ensure that the

reverse voltage applied is less than 14 volts DC, or

12 volts RMS when using an AC tester.

T26D1122

CD

E

F

21

A

B

Figure 6D1-1-24

3. Ensure that Steps 1 and 2 are carried out before

the diodes Zener voltage is tested. The diodes

are grouped together according to their Zener

voltage, ie. all diodes within a rectifier must have

the same Zener voltage.

Figure 6D1-1-25 illustrates the underside view

of the rectifier assembly showing negative heat

sink (1), negative diode (2), positive diode (3),

positive heat sink (4) and diode number (5).

To identify the Zener voltage of the diodes, ref er

to the numbers stamped into the base of each

diode and to the following chart.

T26D1123

0 3 6

1 1 7

0 3 5

1 1 7

0 3 6

1 1 7

0 3 5

1 1 7

0 3 6

1 1 7

0 3 5

1 1 7

0 3 6

1 1 7

0 3 5

1 1 7

1

2

3

4

5

Figure 6D1-1-25

Diode Zener

Voltage at 5 mA Positive

Diode

Number

Negative

Diode

Number

Forward

Current

Rating

17.8 – 19.2 031 032 35 A

18.8 – 20.2 033 034 35 A

19.8 – 21.2 035 036 35 A

20.8 – 22.2 037 038 35 A

21.8 – 23.2 038 040 35 A

22.8 – 24.2 041 042 35 A

4. To test the positive diode Zener voltage,

connect the positive lead of the tester to the

positive heat sink and the negative lead to

diode connections A, B and C, refer to Fig.

6D1-1-23 (reverse bias of the diode). Apply

the test voltage from the Zener diode tester

(current limited to 5 mA) and read Zener

breakdown voltage.

The voltage should be a steady reading and

not increase with increased voltage from the

tester.

5. Repeat Step 4 to test the negative diode Zener

voltage but with the tester's negative lead

attached to the negative heat sink and the

positive lead to diode connections D, E and F

in turn, refer to Fig. 6D1-1-24.

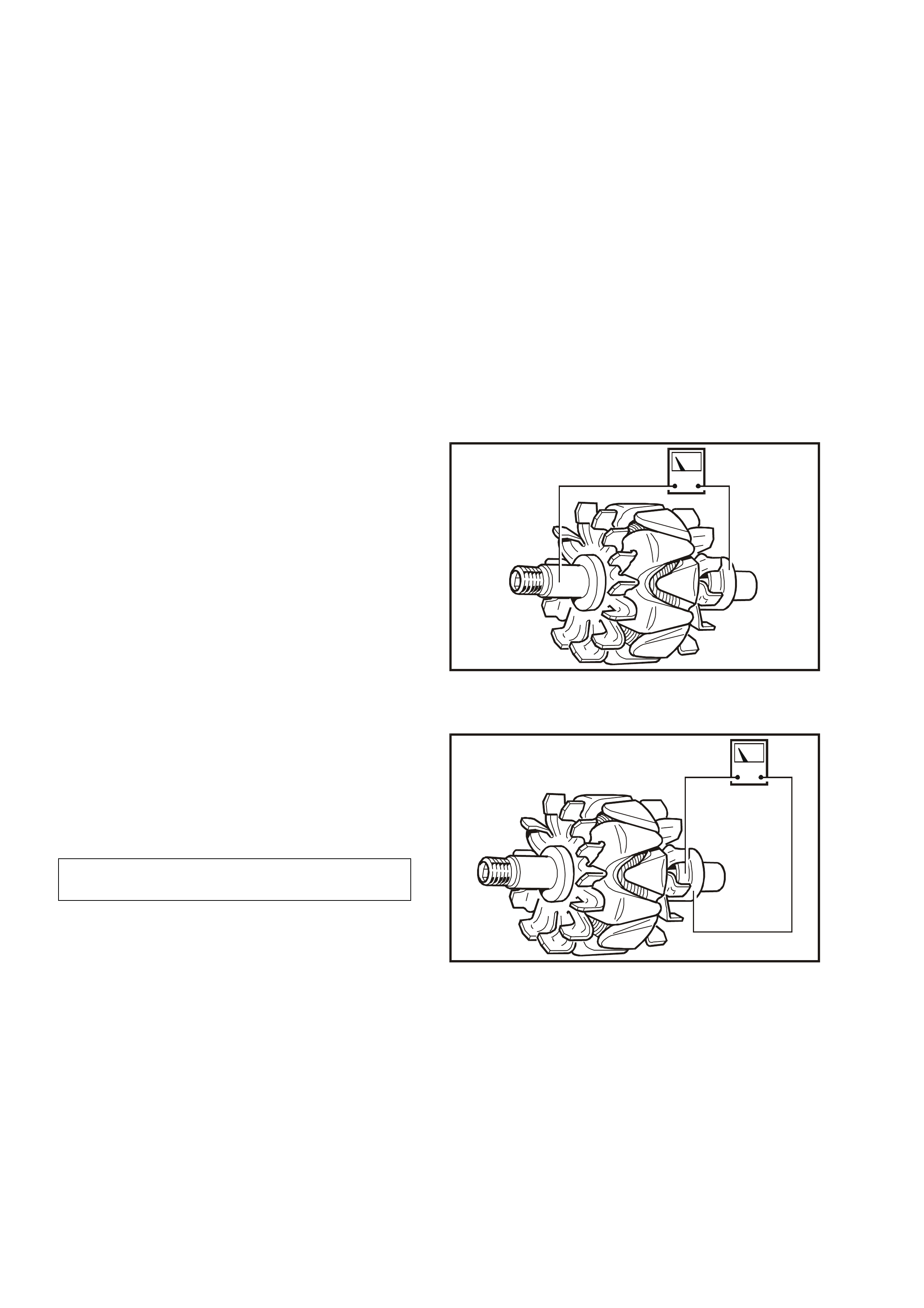

Rotor

Insulation Test

Using an insulation tester , or a series tes t lamp (up

to 110 V), check insulation between slip-rings and

rotor core or shaft. Test light should not glow or

insulation tester should indicate an open circuit

(greater than 1 Mohm). If an open circuit does not

exist replace rotor.

T26D1124

Figure 6D1-1-26

Open Circuit Test

Connect ohmmeter probes across slip-rings and

measure resistance of rotor windings.

Rotor winding resistance values are given in the

following chart.

IMPORTANT: If the resistance of the rotor winding

is not to specification, replace the rotor.

T26D1125

Figure 6D1-1-27

ROTOR WINDING

RESISTANCE @ 20° C 2.47 – 2.73 ohms

Slip-rings

Check slip-rings for wear or damage. If the slip-

rings are worn or out-of-round, they must be

machined to the minimum diameter specified as

follows and should have a run-out not exceeding

the following specification.

If the slip-ring is below these limits, the rotor must

be replaced.

NOTE: Extreme care must be exercised when

machining the slip-rings as it is possible for the

turning tool to foul the rotor's rear cooling fan.

Bearings

The bearings used in this generator are a high

tolerance type. Only genuine replacement bearings

are to be used. It is recommended that the

bearings be replaced during the reconditioning

process to restore the generator to original

specification.

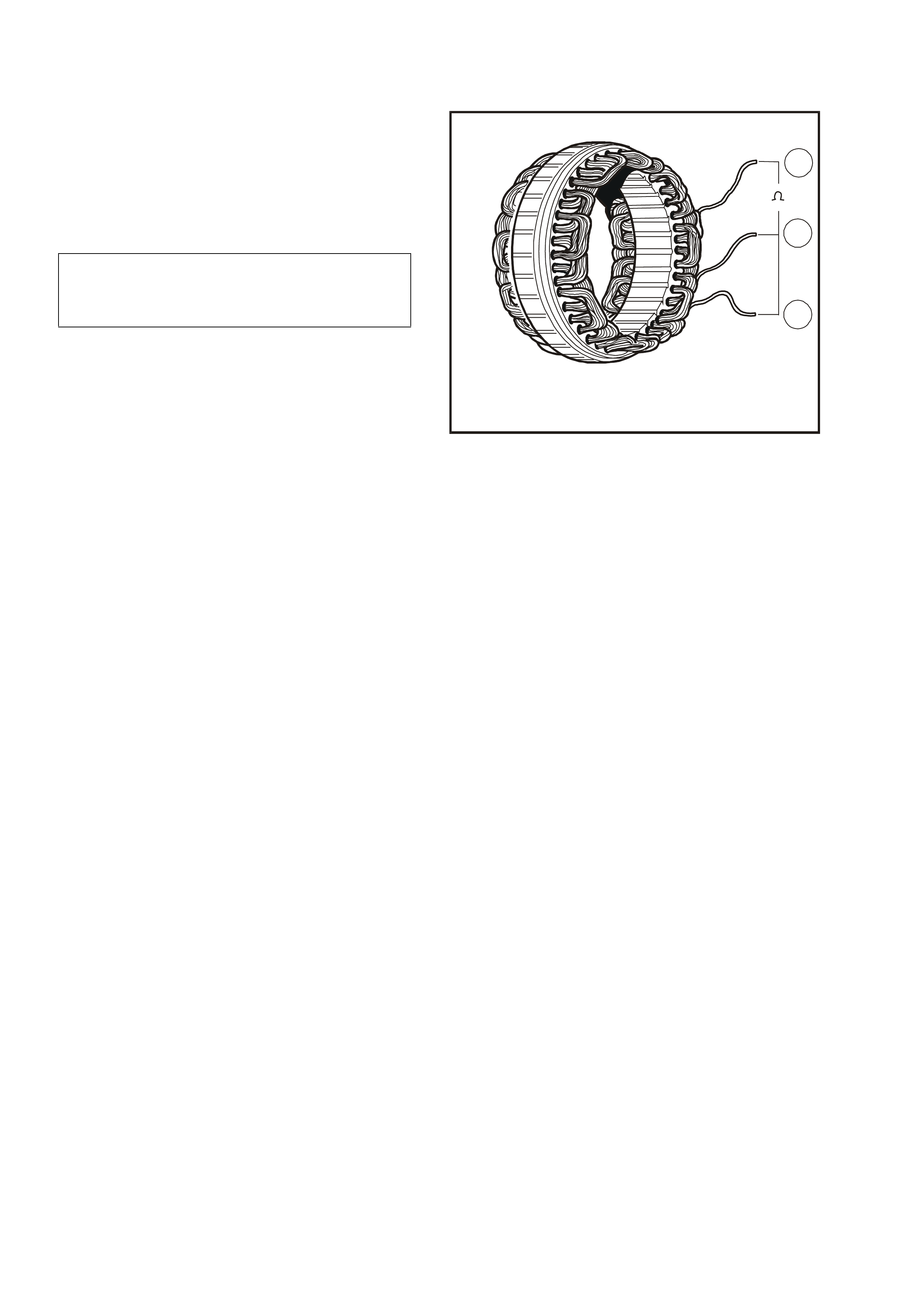

Stator

Insulation Test

Connect a powered test lamp (up to 40 V) or an

ohmmeter between any stator lead and stator

frame. If test lamp glows or ohmmeter reading is

low indicating that an open circuit does not exist,

replace stator.

T26D1126

3

2

1

Figure 6D1-1-28

SLIP-RING MINIMUM

DIAMETER 26.7 mm

SLIP-RING MAXIMUM

OUT-OF-ROUND 0.06 mm

Open Circuit Test

1. Connect ohmmeter to any two stator leads.

Ohmmeter should not register any significant

resistance.

2. Repeat test on remaining stator leads. If

resistances are high, replace the stator.

The stator winding resistance is given in the

following chart.

T26D1127

3

2

1

Figure 6D1-1-29

STATOR WINDING

RESISTANCE @ 20° C

EACH PHASE

BETWEEN PHASES 0.027 ohm + 10%

0.054 ohm +10%

REASSEMBLE

Refer to Figure 6D1-1-2 for identification of

components.

1. Install new bearing into the drive-end housing

(1). Fit bearing plate and four retaining screws.

Tighten retaining screws to the correct torque

specification.

2. Insert new slip ring bearing (2) into recess in

Special Tool 9981 066 600 (3).

3. Insert rotor into special tool so that rotor shaft

is started into slip ring bearing.

4. Place drive end housing onto special tool,

install mandrel onto drive end housing and

press bearings into position on rotor.

T26D1128

2

1

3

Figure 6D1-1-30

5. Assem ble dr ive pulley, washer and nut to rotor

shaft.

6. Mount an 8 mm Allen key in a vice with the

long end pointing out from the side of the vice.

Place socket used for pulley nut removal onto nut.

Position drive-end housing with the internal

hexagon of the rotor shaft onto the Allen key.

Tighten drive pulley attaching nut to the correct

torque specification.

NOTE: Under no circumstances is the rotor to be

mounted in the vic e as the r otor and or c ooling

fans will be damaged.

T26D1113

Figure 6D1-1-31

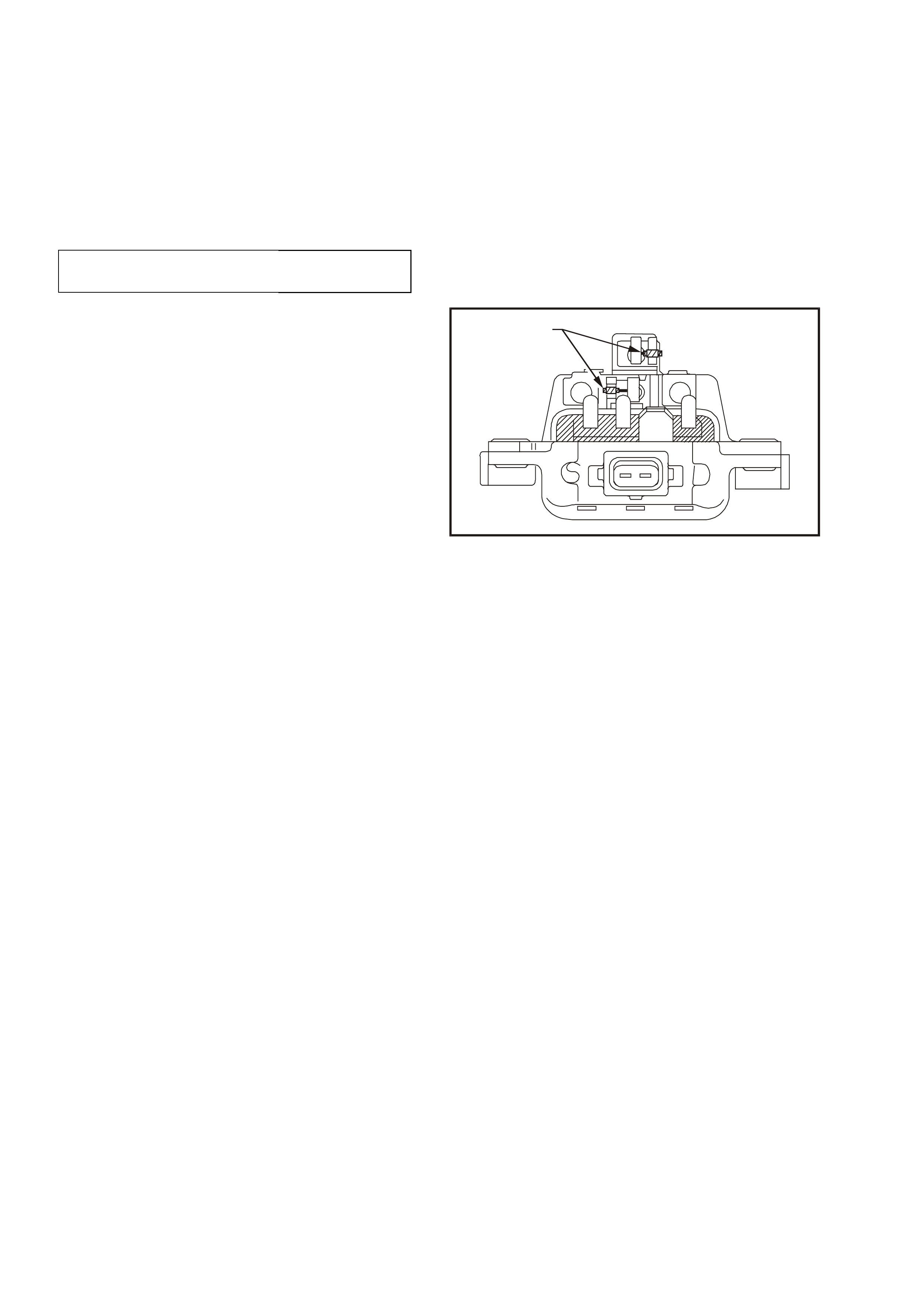

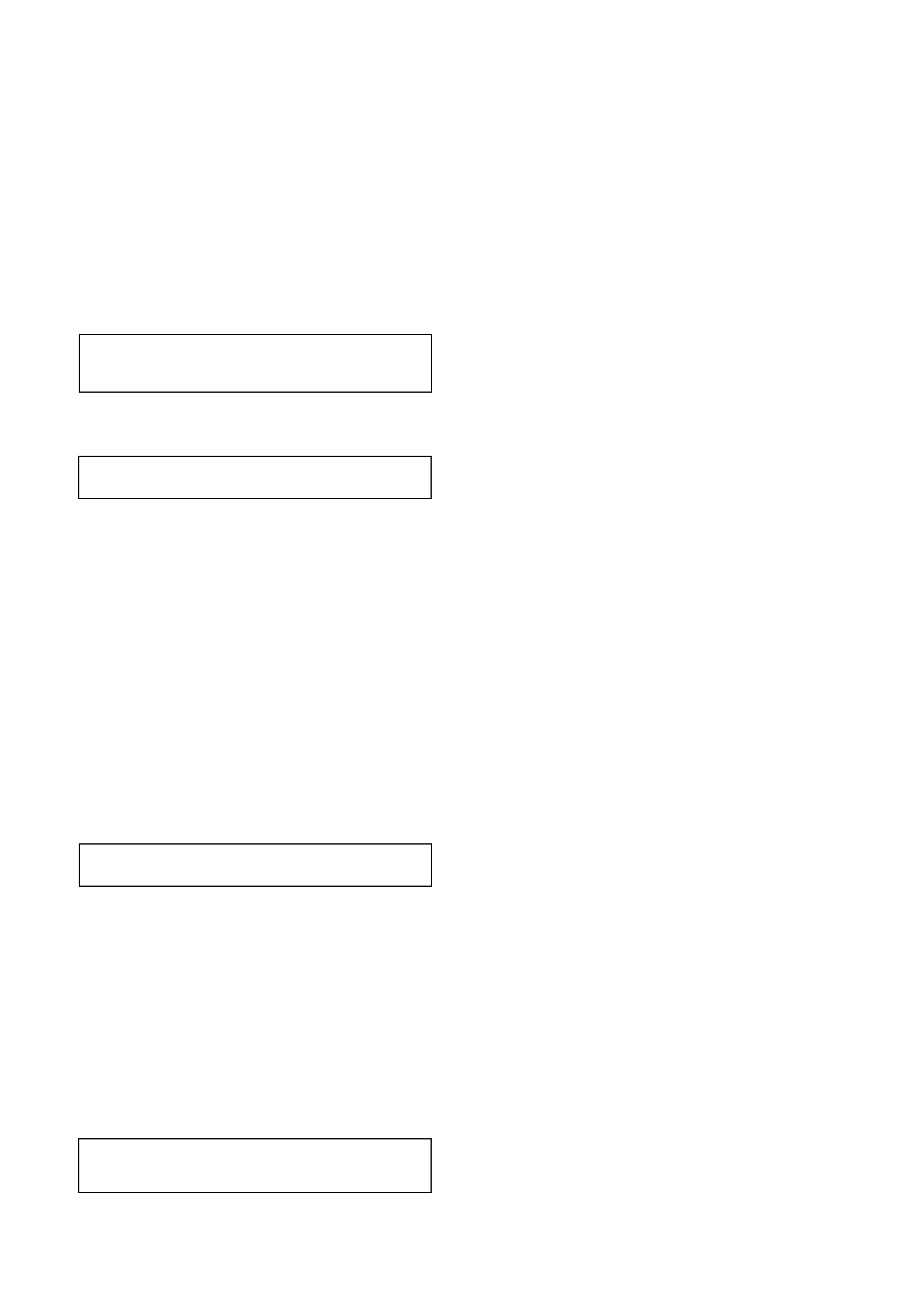

7. Inspect the slip-ring end bearing support ring

(1) for signs of damage. If in any doubt replace

the ring by pressing it into the slip-ring end

housing by hand. DO NOT USE EXCESSIVE

FORCE.

IMPORTANT: The slip-ring end bearing support

ring will only locate correctly into the slip-ring end

housing (2) in one location, ie with the long tang (3)

on its outer diameter locating into the mating slot

(4) in the slip-ring end housing (2).

T26D1129

1

2

3

4

Figure 6D1-1-32

DRIVE-END HOUSING

BEARING PLATE RETAINING

SCREW TORQUE

SPECIFICATION

2.1 – 3.0 Nm

DRIVE PULLEY ATTACHING

NUT TORQUE SPECIFICATION 54 – 68 Nm

8. Apply heat sink compound to both sides of

new rectifier positive heat sink mica washers.

Assemble mica washers to positive heat sink

with washer having largest hole fitted over the

B+ terminal bolt. The other mica washer is

fitted on the positive heat sink, around the hole

for the retaining screw.

9. Install spacer over B+ terminal bolt and

assemble rectifier into slip-ring end housing.

Install insulating washer, flat washer, wave

washer and nut on B+ terminal, leaving nut

finger tight.

10. Install and tighten rectifier retaining screws to

the correct torque specification.

Tighten B+ terminal nut to the correct torque

specification.

11. Ensure that the mating surfaces of the stator

frame, drive-end and slip-ring end housings

are clean and free from damage.

Fit the stator into the slip-ring end housing,

noting the correct lead positioning. Fit the

stator leads into the wire loops in the rectifier.

Using a pair of pointed nose pliers, squeeze

the loops to retain the stator leads prior to

soldering. Solder the leads into position using

60/40 resin cored solder.

Once completed, ensure the leads will clear the

internal fan when the rotor is assembled into

the stator.

12. Ass emble rotor and dr ive-end housing into the

stator and slip-ring end plate assembly,

aligning marks made during disassembly.

13. Install thr ough bolts and tighten evenly, and to

the correct torque specification.

IMPORTANT: Ensure that the slip-ring housing and

drive-end housing are seated squarely on the stator

frame. This ensures that the air gap between the

rotor and stator windings is equal at all points.

14. Install the regulator and brush assembly into

the slip-ring end housing, ensuring that the

regulator engages with the spring connectors

on the rectifier. Ensure the brushes are

located correctly onto the slip-rings.

Install the regulator and brush assembly

securing screws and tighten to the correct

torque specification.

15. Connect suppressor lead to rectifier + terminal.

RECTIFIER RETAINING

SCREW TORQUE

SPECIFICATION 1.6 – 2.3 Nm

B+ TERMINAL NUT

TORQUE SPECIFICATION 7.5 – 8.5 Nm

THROUGH BOLT

TORQUE SPECIFICATION 3.8 – 5.5 Nm

REGULATOR AND BRUSH

ASSEMBLY SECURING SCREW

TORQUE SPECIFICATION 1.6 – 2.3 Nm

4. DIAGNOSIS

1. UNDERCHARGED BATTERY

a. Defective battery

b. Loose connection in charging system

c. Corroded connections in charging circuit

d. Defective wiring

e. Faulty generator

f. Faulty voltage regulator

2. OVERCHARGED BATTERY

a. Shorted battery cell

b. Faulty voltage regulator

c. Short circuit in rotor winding

d. Voltage drop in sense wire

3. FAULTY INDICATOR LIGHT OPERATION

(LIGHT DOES NOT GLOW]

a. Burnt out bulb

b. Defective bulb socket

c. Defective wiring

d. Defective rectifier

e. Defective regulator

4. FAULTY INDICATOR LIGHT OPERATION

(LIGHT REMAINS ON)

a. Negative diode failure

b. Defective voltage regulator

c. Faulty generator

d. B+ cable off or broken

e. S cable off or broken

f. Battery overcharged

g. Open circuit in rotor winding

5. NOISY GENERATOR OPERATION

a. Normal magnetic hum

b. Badly discharged battery

c. Generator mount brackets loose or bolts loose

d. Worn or frayed drive belt

e. Worn bearings

f. Loose drive pulley attaching nut

g. Open or shorted diodes

h. Open or shorted stator winding

5. SPECIFICATIONS

Earth Polarity ...............................................................................Negative

Nominal Voltage...........................................................................12 V

Nominal Output.............................................................................90 Amps

Stator Phases ..............................................................................3

Stator Winding Connections ........................................................Star

Number of Rotor Poles.................................................................12

Resistance of Rotor Winding (ohms @ 20°C)..............................2.47 – 2.73 Ω

Resistance of Stator Winding

Each Phase (ohms @ 20°C)..............................................0.027 Ω + 10%

Between Phases (ohms @ 20°C) ......................................0.054 Ω + 10%

Voltage Regulator Setting.............................................................14.0 – 14.2 V

Brush Length (measured in brush holder) ...................................12 mm (new), 3.8 mm (min)

6. TORQUE WRENCH SPECIFI CATIONS

Nm

Through Bolts...............................................................................3.8 – 5.5

Drive-end Housing Bearing Retaining Plate Screws ....................2.1 – 3.0

Drive Pulley Attaching Nut ...........................................................54 – 68

Regulator and Brush Assembly Securing Screws........................1.6 – 2.3

B+ terminal Nut.............................................................................7.5 – 8.5

Battery Harness Terminal to B+ Terminal Nut..............................5 – 12

Rectifier Retaining Screw.............................................................1.6 – 2.3

Capacitor Fixing Screw.................................................................1.5 – 2.2

Generator to Support and Brace Mounting Bolt ...........................20 – 34

Generator to Drive Belt Tensioner Bracket Mounting Bolt ...........20 – 34

7. SPECIAL TOOLS

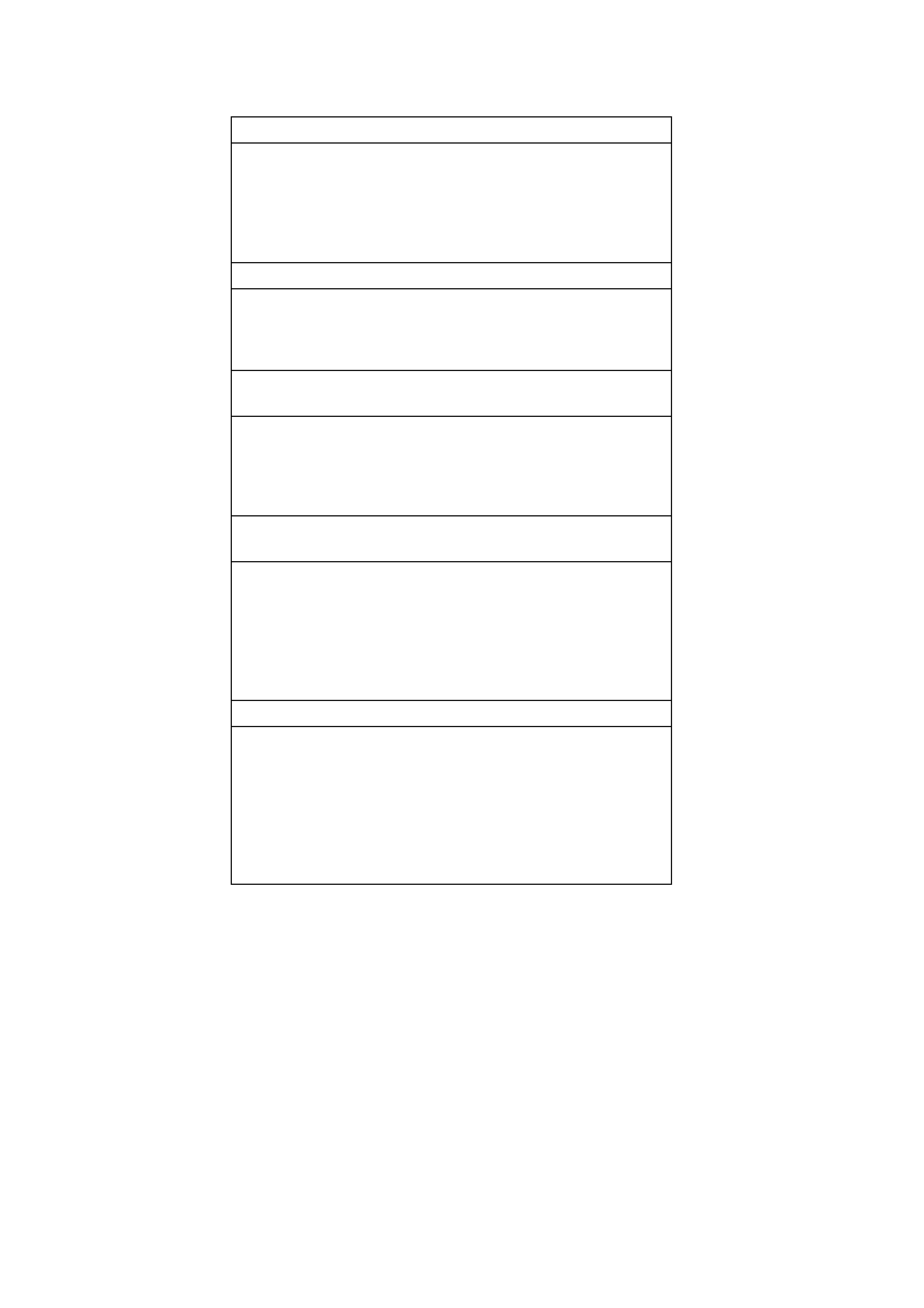

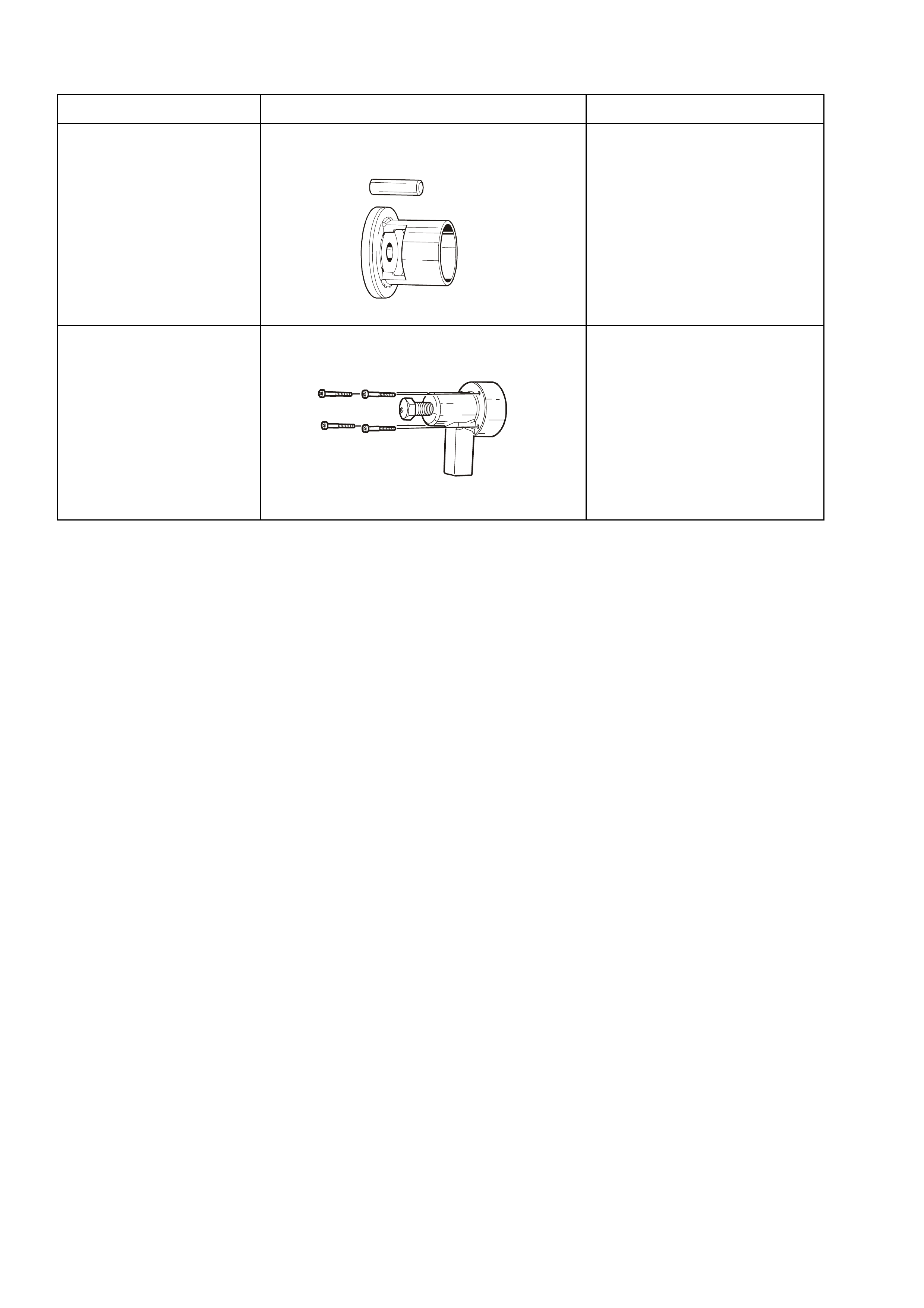

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

9981 066 600 BEARING ASSEMBLY FIXTURE

81066600

9981 066 601 ROTOR BEARING REMOVAL TOOL

81066601