SECTION 6D3-2 - STARTING SYSTEM -

GEN III V8 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver’s air bag, seat belt pre-tensioners and driver’s and front

passenger’s air bags or seat belt pre-tensioners, driver’s and front passenger’s air bags and left and

right-hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System

of the VT Series I Service Information before performing any service operation on, or around SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

1. GENERAL INFORMATION

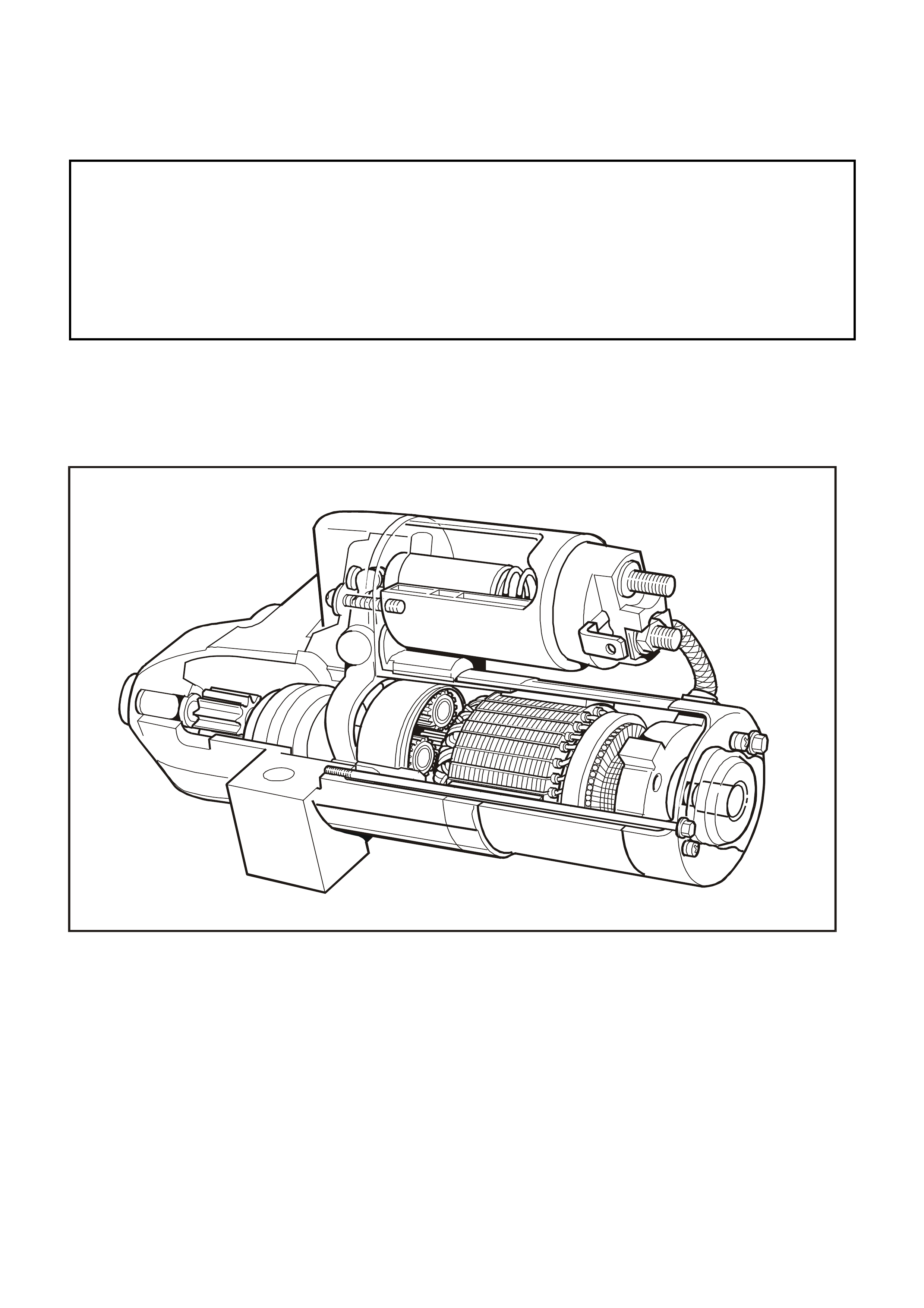

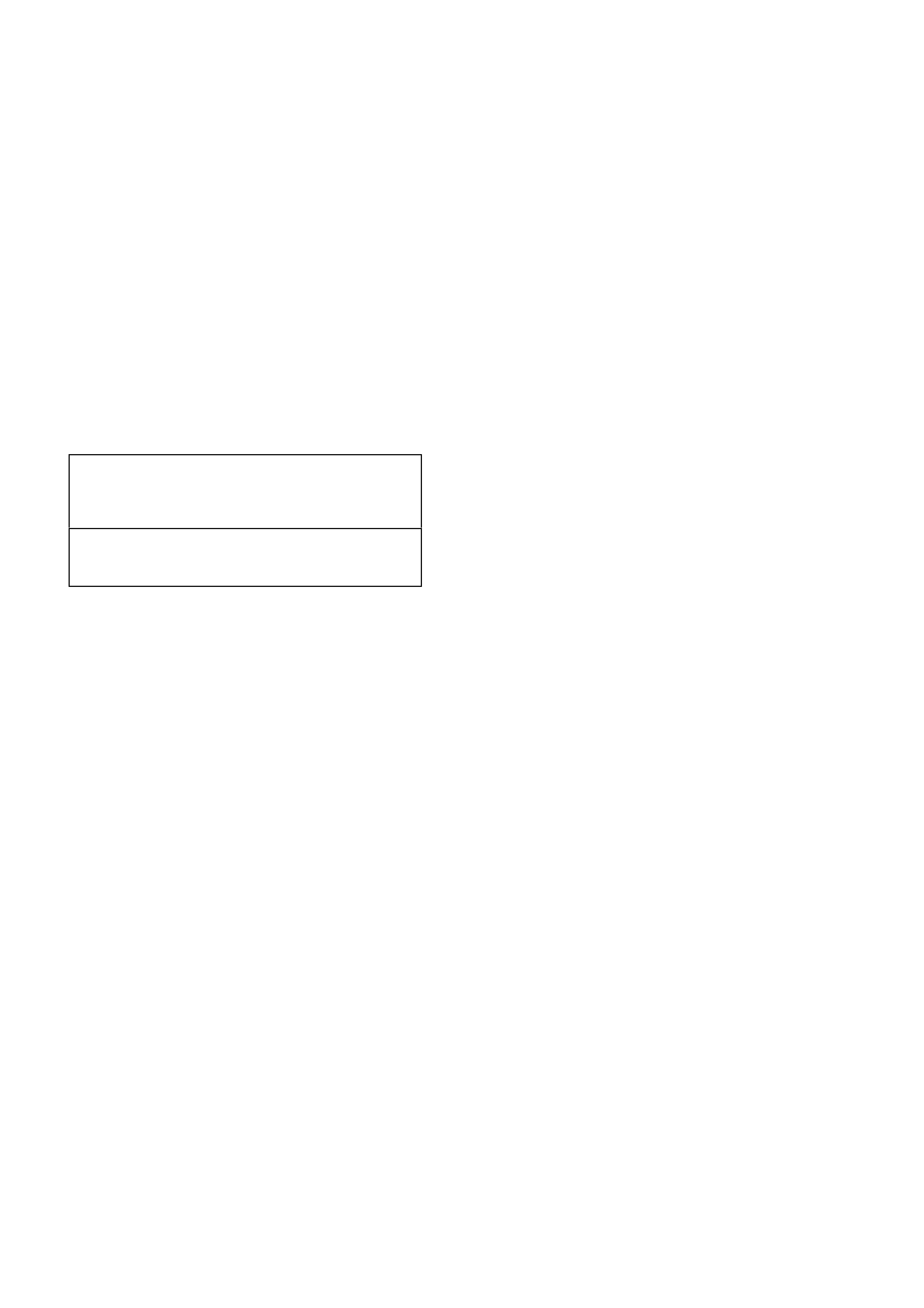

A Delco Remy, six-pole, four-brush starter motor is fitted to the VT Series II models with GEN III V8 engines. The

starter motor is a pre-engaged drive type with planetary reduction gears and is illustrated in Fig. 6D3-2-1.

T26D3228

Figure 6D3-2-1

1.1 GENERAL DESCRIPTION

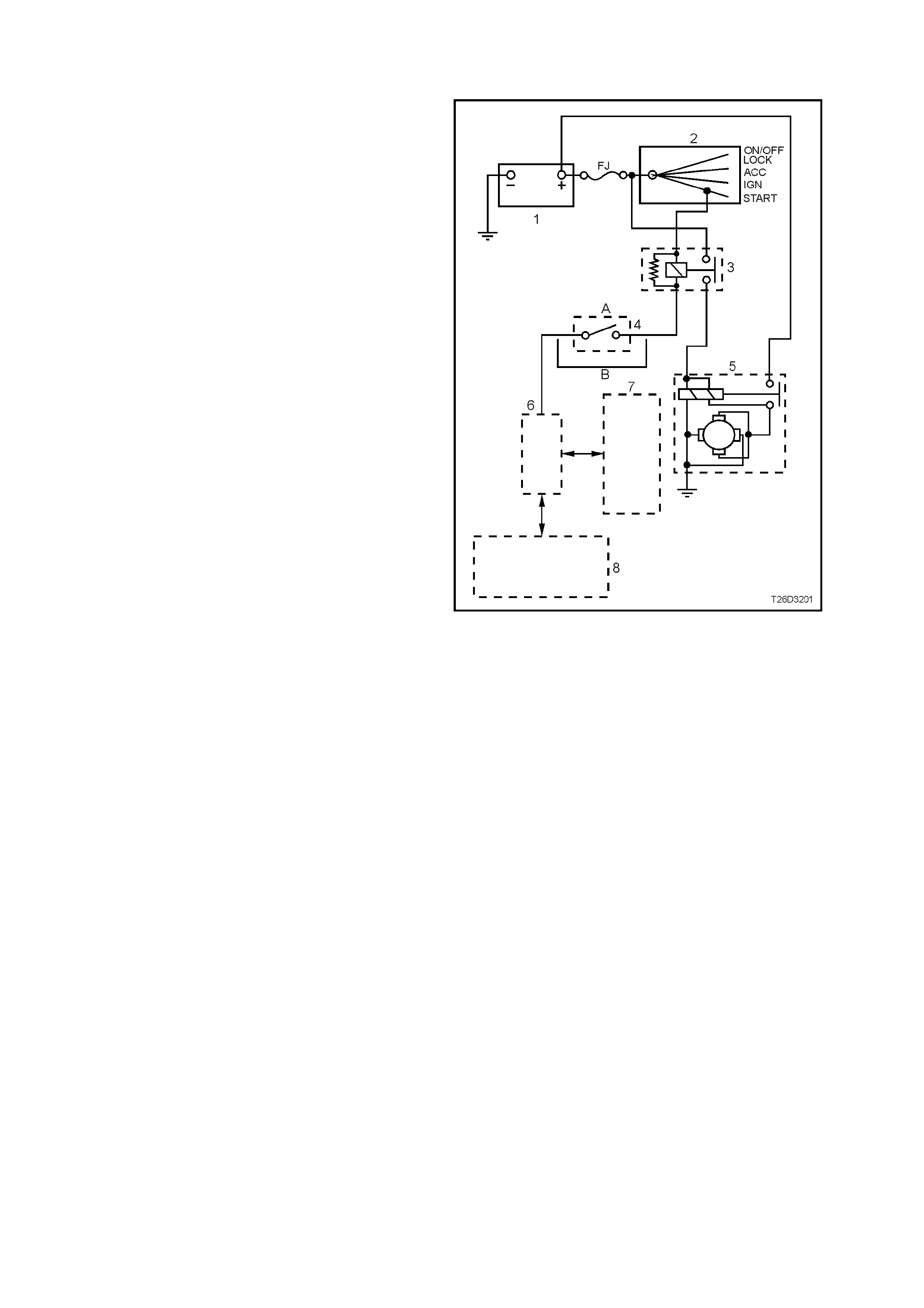

The starting system comprises the battery (1),

starter motor (5), ignition switch (2), start realay (3),

neutral/back -up switch (A - autom atic transm ission,

B – Manual transmission), Powertrain Interface

Module (PIM) (6), Powertrain Control Module

(PCM) (7), the Body Control Module (8) and related

electrical wiring. For additional infor m ation realating

to the interaction between the PIM, PCM and BCM,

refer to Section 12J-1 and Section 12J-2 of the

VT Series II Service Information

The s tarter m otor is a six pole, four brush type with

a planetary drive train. Each of the six poles is a

permanent magnet which is secured to the inside

diameter of the f ield f r ame ass embly. The armatur e

shaft which revolves centrally within the field f rame

assembly is supported at each end by metal

bushes pressed into the commutator end cover and

the inside of the planetary drive shaft.

The planetary drive train comprises a ring gear

(made from a high-grade polyamide compound with

mineral additives) with gear teeth on the inside

diameter, three planetary gear wheels and a

planetary drive shaft. When assembled, the

planetary drive shaft, which is flanged at one end

with three shafts machined onto the flange, is

positioned in the ring gear. The three gear wheels,

each m ounted on bushes, are f itted onto the shafts

on the flange of the planetary drive shaft where

they m esh with the internal teeth of the ring gear . A

metal bush is fitted into the recess in the flanged

end of the planetary drive shaft to provide a

mounting f or the end of the armature. A m etal ball,

also positioned in the recess limits the amount of

end float of the armature shaft. The cover plate is

positioned and secured over the gear end of the

assembly.

Figure 6D3-2-2

The drive assembly is installed onto the planetary drive shaft, meshed with the gear on the drive shaft and

secured to the shaft by a stop ring and ring retainer. The combined assembly is installed into position in the

starter m otor drive-end housing. The planetary drive shaft is supported by a bush in the drive-end housing, while

the ring gear is located by the drive-end housing, providing positive and secure mounting of the drive shaft and

drive assembly.

When the starter motor is assembled, the teeth of the gear on the armature shaft mesh with the teeth on the

three planetary gears wheels. W hen the s tarter m otor is oper ated, drive f rom the arm ature causes the planetary

gear wheels to rotate and revolve around the inner diameter of the r ing gear which is f ixed in pos ition. This ac tion

causes the planetar y drive shaft to rotate and impar t drive into the dr ive as sembly. During operation of the star ter

motor the armature rotates the drive assembly at a reduced speed of approximately 3.36:1.

The bushes and planetary gears require lubrication only at the time of an overhaul.

The f our brushes ar e supported by the brush holder assem bly which is s ecured to the com m utator end cover by

screws. T wo brushes are grounded to the starter m otor body, via the comm utator c over retaining sc rew, and two

are insulated from the housing and c onnected to the c ommutator. Per manent magnets are pos itioned ar ound the

inside diameter of the field frame assembly and secured by brackets.

On the drive-end housing, a polyamide fork is used to engage the drive assembly with the flexplate/ring gear.

The drive assembly transmits cranking torque to the flexplate/ring gear. To prevent the armature from being

driven at exces sive speed by the engine, an internal clutch allows the drive assem bly pinion gear to rotate fr eely

in relation to the planetary shaft and armature when the engine begins to operate.

T26D3201

1234

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

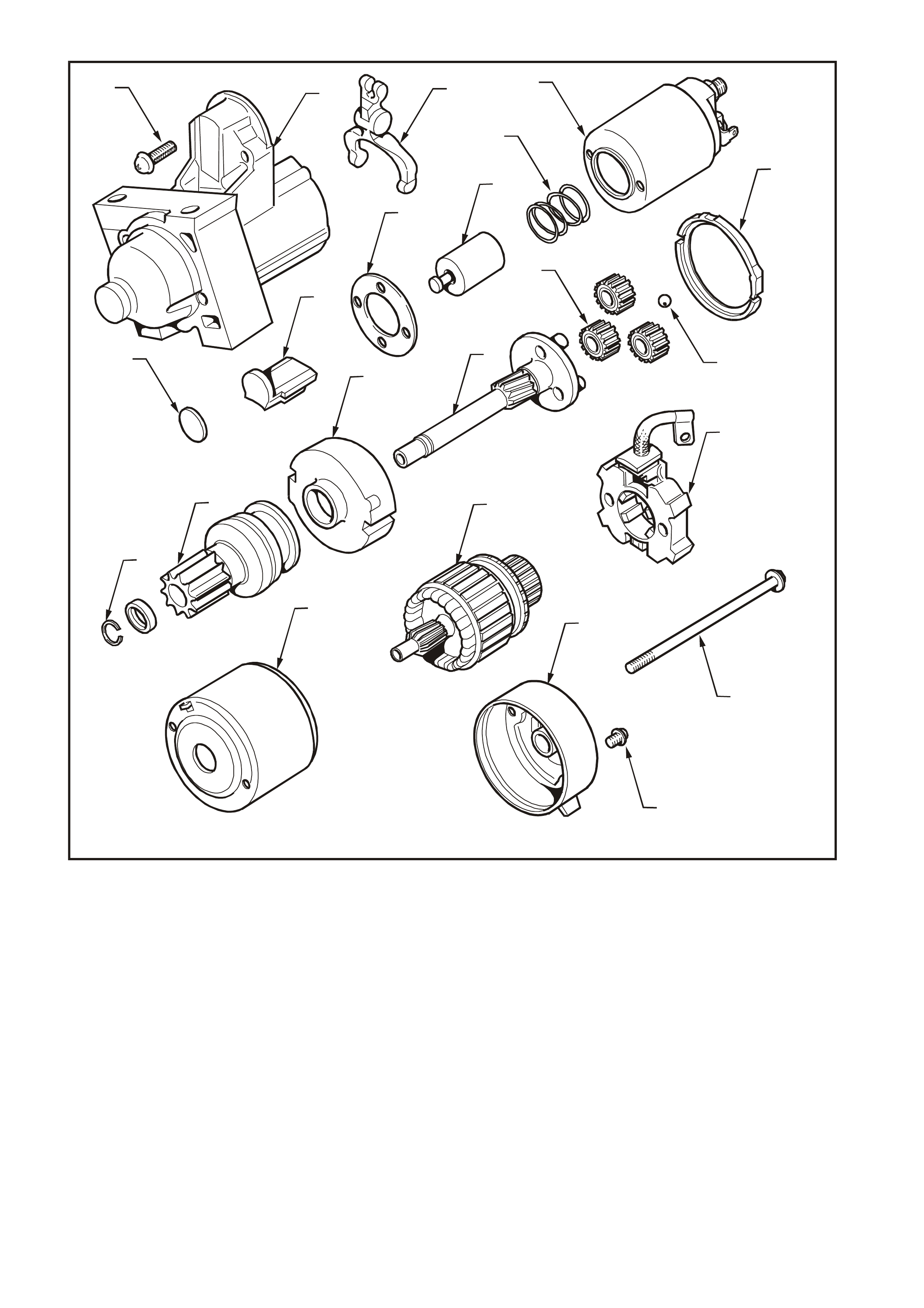

Figure 6D3-2-3

1. Solenoid switch to drive-end

housing mounting screw (2 off) 8. Rubber packing (Part of lever set) 15. Clutch gear assembly – Pinion (Part

of shaft assembly – clutch set)

2. Drive-end housing 9. Plate (Part of lever set) 16. Stopper ring and ring retainer (Part

of shaft assembly – clutch set)

3. Fork lever (Part of lever set) 10. Packing – sealing ring 17. Brush holder assembly

4. Solenoid switch 11. Ball 18. Armature

5. Return spring 12. Planetary gears (Part of shaft

assembly – clutch set) 19. Field frame assembly

6. Plunger 13. Drive shaft assembly (Part of shaft

assembly – clutch set) 20. Through bolt (2 off)

7. Solenoid switch to drive-end

housing spacer 14. Cover – gear assembly (Part of

shaft assembly – clutch set) 21. Brush holder retaining screw

22. Commutator end cover

2. SERVICE OPERATIONS

2.1 PERFORMANCE TESTING

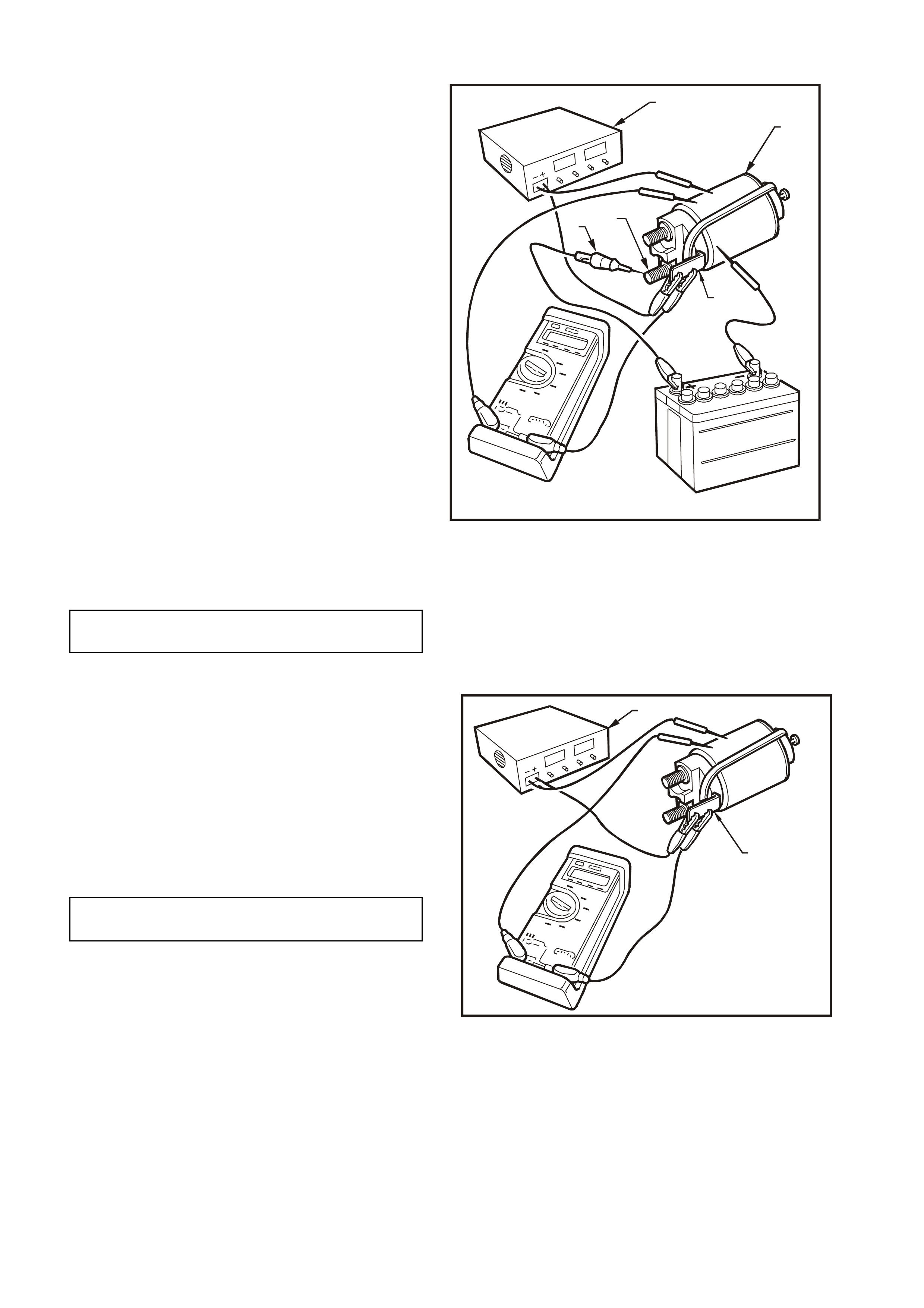

The following tests involve the starter motor being

removed from the vehicle, refer to 2.2 STARTER

MOTOR in this Section.

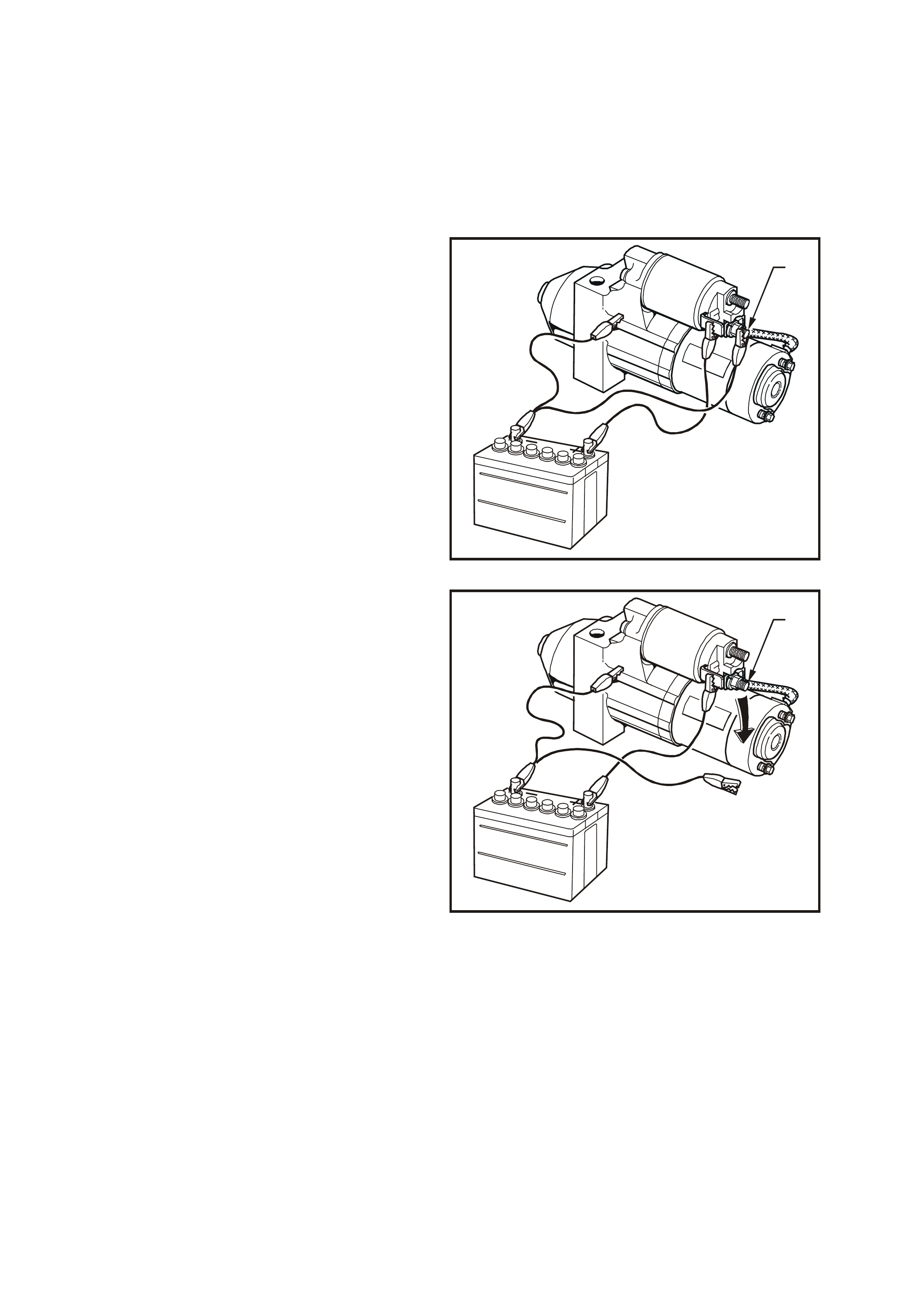

SOLENOID SWITCH TESTS

Pull-in Test

1. Remove nut and washer from solenoid switch

short threaded M terminal (1). Remove

braided cable and terminal from threaded

terminal.

2. Using suitable test leads and 12 volt battery,

connect as shown in Fig. 6D3-2-4. Check that

drive assembly moves outward.

If drive assembly does not move, replace

solenoid switch as described in this Section.

T26D3202

1

Figure 6D3-2-4

Hold-in Test

1. With battery connections to starter motor and

solenoid switch as shown for Pull-in Test,

disconnect negative lead from solenoid switch

short threaded M terminal (1).

2. Check that drive assembly remains outward.

If drive assembly returns inward, replace

solenoid switch as described in this Section.

T26D3203

1

Figure 6D3-2-5

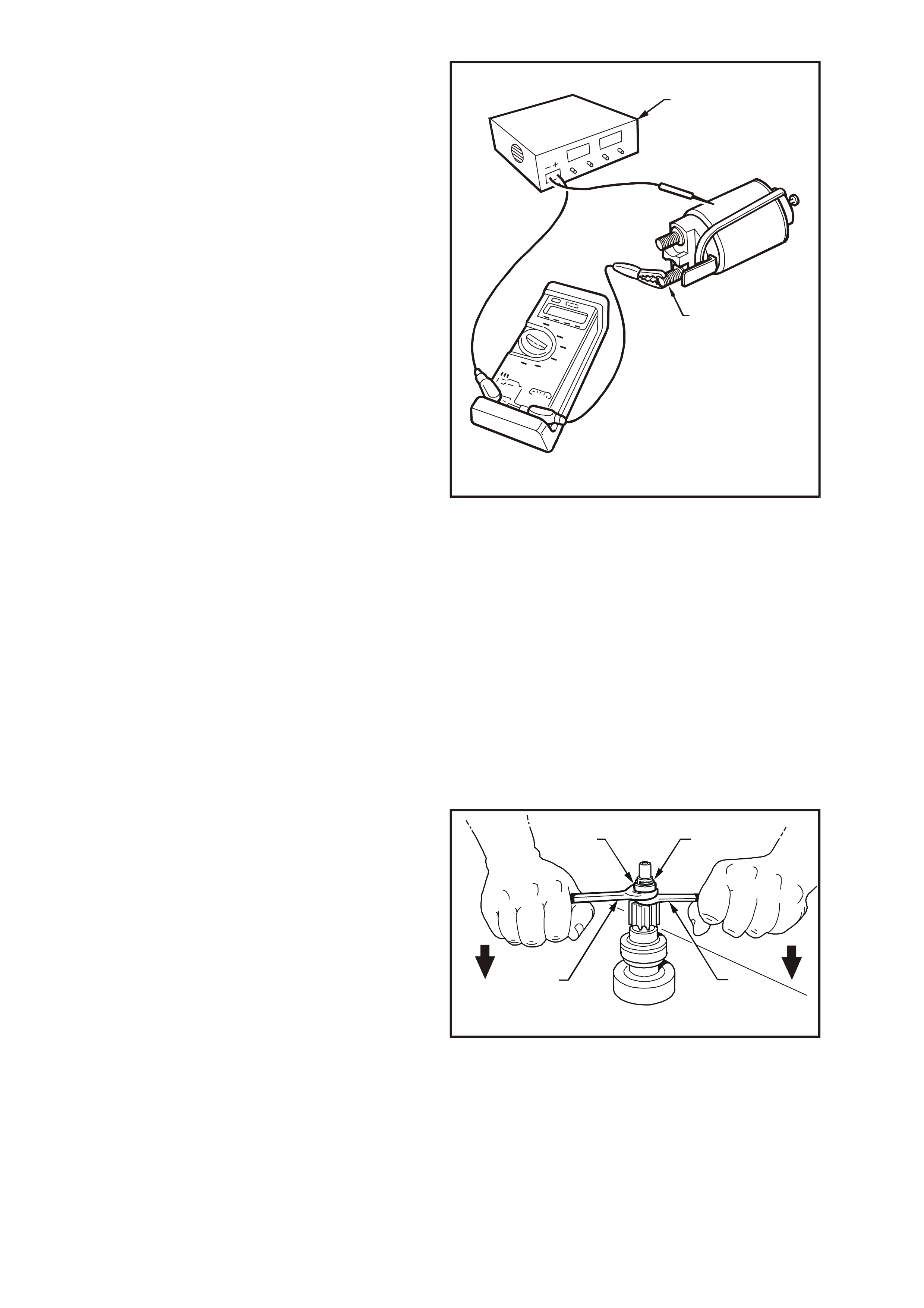

Drive Assembly Return

1. With battery and connections to starter motor

and solenoid switch as at end of Hold-in Test,

disconnect negative lead from drive-end

housing.

2. Check that drive assembly returns inward.

If drive assembly does not return, replace

solenoid switch as described in this Section.

T26D3204

1

Figure 6D3-2-6

NO LOAD TEST

The drive assembly pinion should be checked for

freedom of operation by turning it on the planetary

drive shaft. The planetary drive and armature

should be check ed f or f reedom of r otation by prying

the drive assem bly pinion with a screwdriver. If the

planetary drive and armature do not rotate freely,

the starter motor should be disassembled

immediately. However, if the planetary drive and

armature do rotate freely, the starter motor should

be given a NO LOAD test before disassembly.

Clamp starter motor securely to a test bench and

make connections as shown to terminal 30 (1), M

term inal (2), ter minal 50 (3) and to the s tar ter motor

drive-end housing. Close the switch and compare

the rpm, current and voltage readings with the

following specifications.

If the NO LOAD test indicates that the starter motor

is defective, refer to 3. DIAGNOSIS in this Section

for probable cause of starter motor fault.

T26D3205

BATTERY AMMETER VOLTMETER

CARBON

PILE

SWITCH

SOLENOID

R.P.M.

INDICATOR

1

32

STARTER

MOTOR

A

VIEW

A

1

32

Figure 6D3-2-7

STARTER MOTOR SPEED

(ARMATURE RPM) 2500 rpm

STARTER MOTOR CURRENT 90 amp s

TERMINAL VOLTAGE 11 volts

2.2 STARTER MOTOR

REMOVE

CAUTION 1: Starter motor is in close proximity

to right-hand exhaust manifold. Allow engine to

cool before attempting to remove starter motor.

CAUTION 2: When steering column is

disconnected from steering rack, do not allow

the steering wheel to spin freely as damage to

the SRS clock spring may result rendering the

SRS inoperative. Maintain the steering column

in its original position to ensure that the SRS

clock spring remains in its centred position.

Refer to Section 12M SUPPLEMENTAL

RESTRAINT SYST EM of the VT Series I Service

Information.

1. Disable the SRS in accordance with Section

12M SUPPLEMENTAL RESTRAINT

SYSTEM of the VT Series I Service

Information.

2. Jack up front of vehicle and support on safety

stands. For jacking locations, refer to Section

0A GENERAL INFORMATION of the VT

Series I Service Information.

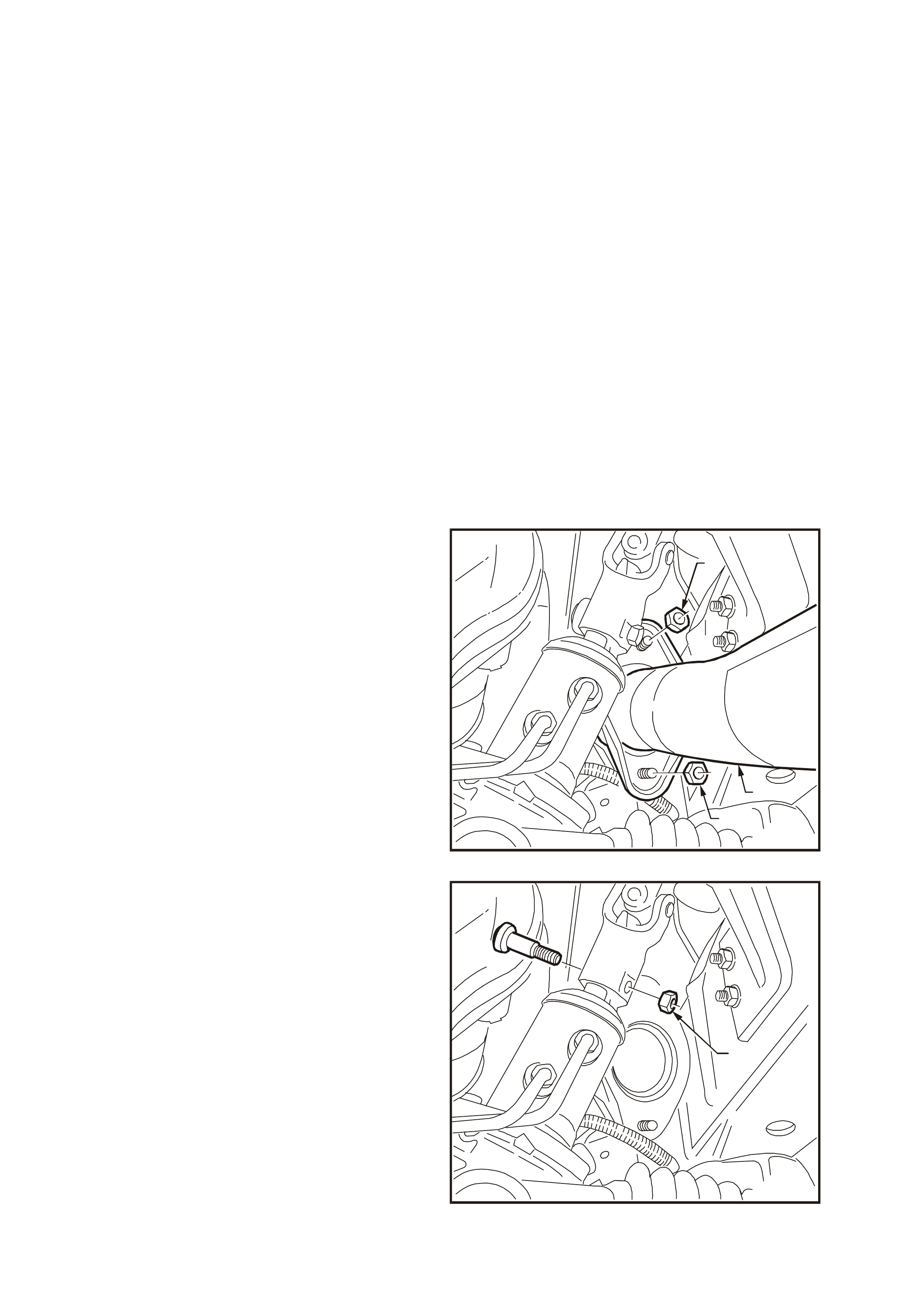

3. Remove nuts (1) securing right-hand side

exhaust engine pipe (2) to m anifold f lange and

remove bolts securing engine pipe to

intermediate pipe. Remove the engine pipe.

T26D3229

2

1

1

Figure 6D3-2-8

4. Remove nut (1) and bolt securing steering

column universal joint to steering rack input

shaft and remove universal joint from input

shaft.

T26D3230

1

Figure 6D3-2-9

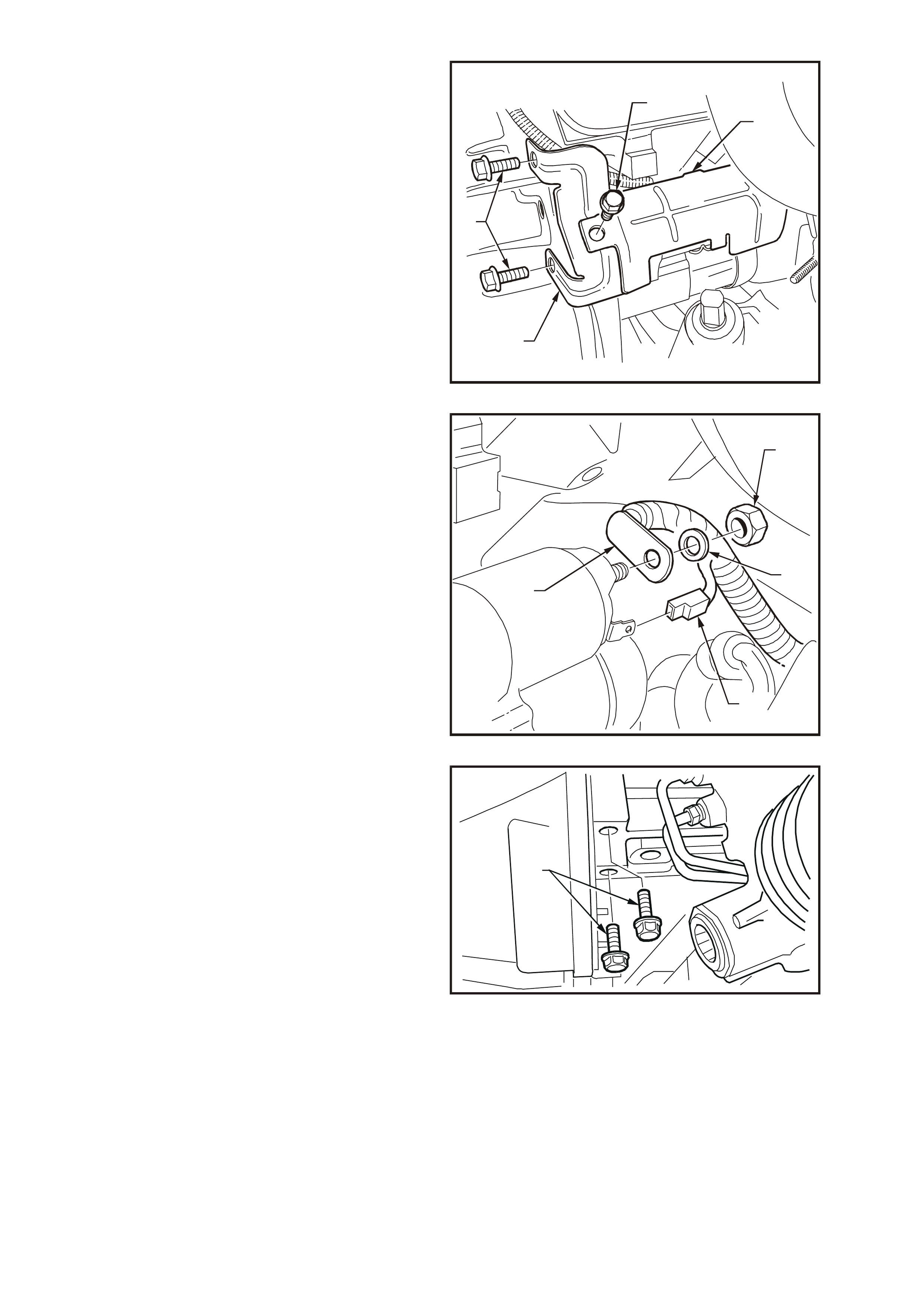

5. Remove bolt securing starter motor heat

shield to mounting bracket (1), unclip heat

shield from starter m otor solenoid and rem ove

heat shield (2).

6. Remove two bolts (3) securing starter motor

heat shield mounting bracket (4) to

transmission bell-housing and remove

mounting bracket.

T26D3231

1

4

3

2

Figure 6D3-2-10

7. Pull wiring harness connector from solenoid

switch terminal 50 (1).

8. Remove nut (2), washer (3) and battery lead

(4) from solenoid switch (B+) terminal 30.

T26D3207

2

1

3

4

Figure 6D3-2-11

9. Remove starter motor to cylinder block

mounting bolts (1).

T26D3206

1

Figure 6D3-2-12

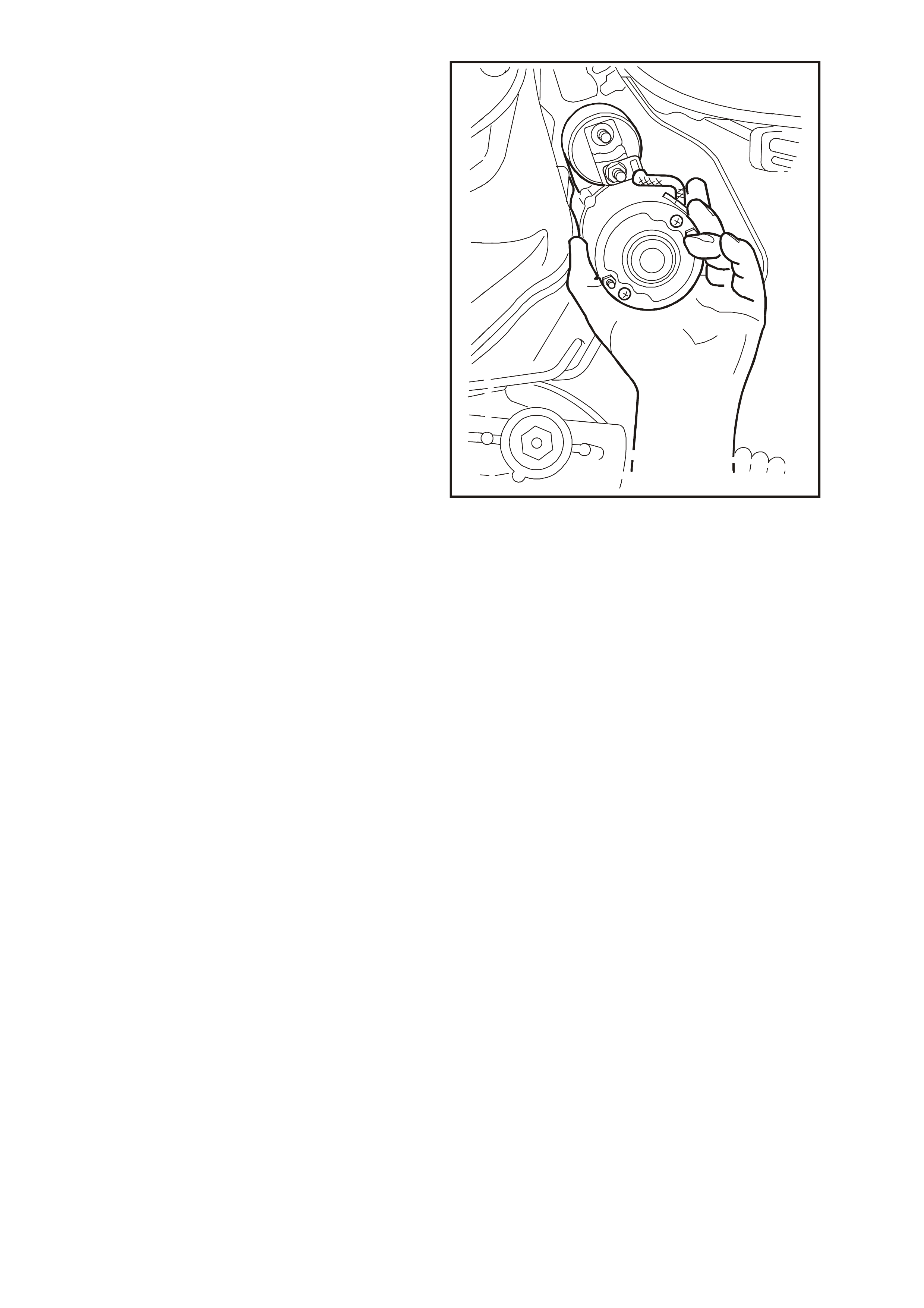

10. Manoeuvre starter motor out and down

between transmission bell-housing and body

sub-frame.

T26D3208

Figure 6D3-2-13

REINSTALL

CAUTION: When steering column is

disconnected from steering rack, do not allow

the steering wheel to spin freely as damage to

the SRS clock spring may result rendering the

SRS inoperative. Maintain the steering column

in its original position to ensure that the SRS

clock spring remains in its centred position.

Refer to Section 12M SUPPLEMENTAL

RESTRAINT SYST EM of the VT Series I Service

Information.

Installation of the starter motor is the reverse of

removal procedure, noting the following points:

1. Ensure that steering wheel and front wheels

are in straight ahead pos ition and that s teering

wheel is in mid-position from lock-to-lock.

2. Ensure that all fasteners are tightened to the

correct torque specification.

STAR TER MOTOR TO

CYLINDER BLOCK

MOUNTING BOLT

TORQUE SPECIFICATION 40 – 60 Nm

STARTER MOTOR

(B+) TERMINAL 30 NUT

TORQUE SPECIFICATION 6.0 – 10.0 Nm

3. Install exhaust engine pipe, ensuring that the

engine pipe is sufficiently clear of underbody

components. If interference with underbody

components is apparent, the exhaust system

will need to be loosened off and tightened in

correct sequence. Refer to Section 8B

EXHAUST SYSTEM of the VT Series II

Service Information.

4. Enable the SRS in accordance with Section

12M SUPPLEMENTAL RESTRAINT

SYSTEM of the VT Series I Service

Information.

5. Check starter motor operation.

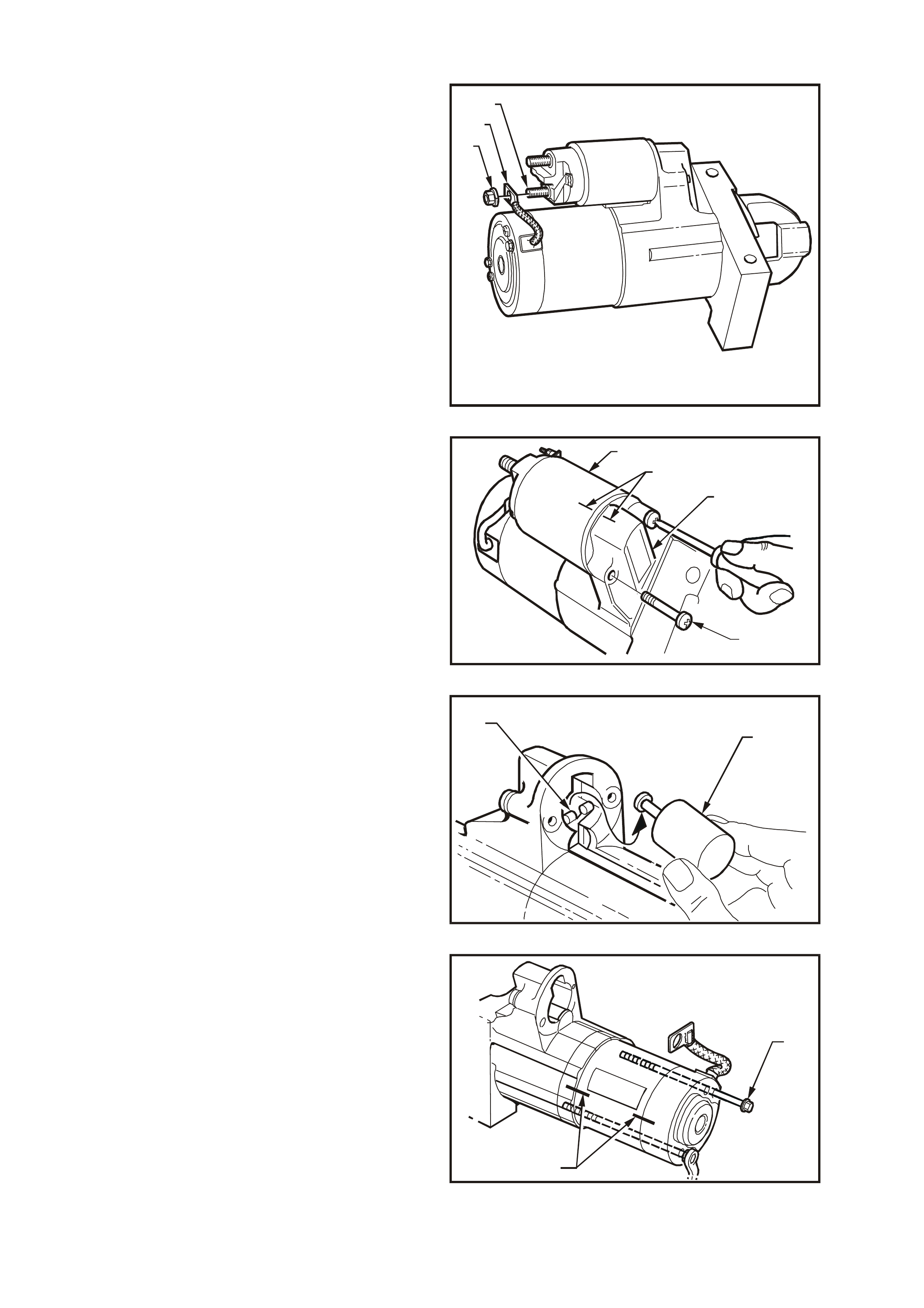

DISASSEMBLE

1. Remove nut (1) from solenoid switch short

threaded M terminal (3). Remove braided

cable and terminal (2) from solenoid terminal.

T26D3209

123

Figure 6D3-2-14

2. Scribe an aligning mark (1) on drive-end

housing (3) and solenoid switch housing (2) as

an aid for reassembly.

Remove the two solenoid switch-to-drive-end

housing mounting screws (4).

IMPORTANT: It may be necessary to loosen the

mounting screws using an impact driver. Ensure to

only lightly tap on the impact driver so as not to

damage the drive-end housing.

T26D3210

21

3

4

Figure 6D3-2-15

3. Pull solenoid switch from drive-end housing,

taking care not to lose the plunger return

spring. (Plunger may slide out from solenoid

switch and remain attached to drive assembly

fork lever).

4. Remove solenoid switch plunger (1) by lifting

up and out from drive assembly fork lever (2).

T26D3211

21

Figure 6D3-2-16

5. Scribe an aligning mark (1) on drive-end

housing, field frame assembly and

commutator end cover as an aid for

reassembly.

6. Loosen and remove the two through bolts (2)

securing the commutator end cover and field

frame assembly to the drive-end housing.

T26D3212

2

1

Figure 6D3-2-17

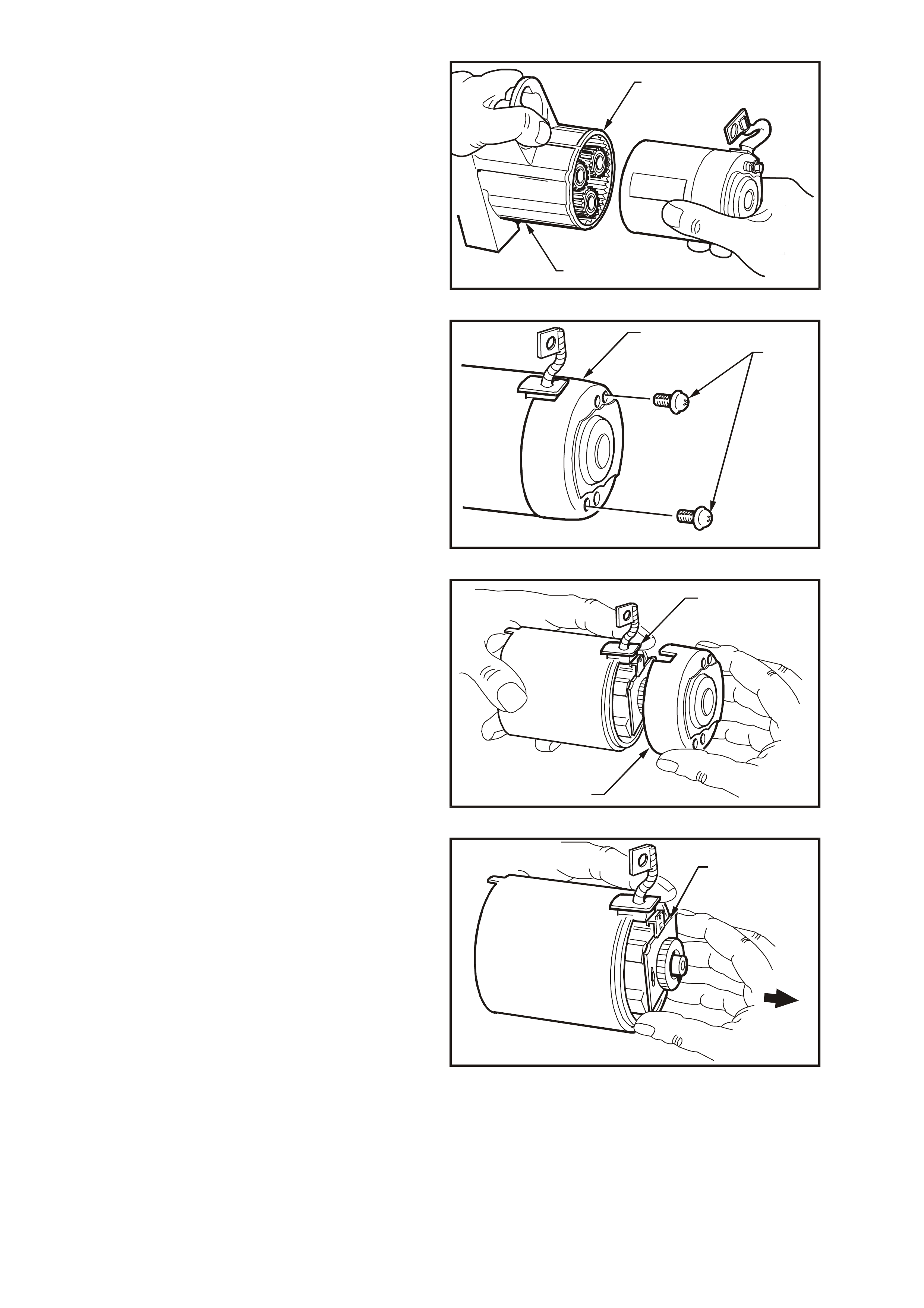

7. Keeping the sealing rubber (1) seated in the

drive-end housing ( 2), rem ove the c om m utator

end cover, field fram e assembly and armature

as an assembly from the drive-end housing.

T26D3213

1

2

Figure 6D3-2-18

8. Remove the screws (1) securing the

commutator end cover (2) to the brush holder.

T26D3214

1

2

Figure 6D3-2-19

9. While holding the braided cable and rubber

seal (1), remove commutator end cover (2).

T26D3215

1

2

Figure 6D3-2-20

10. Carefully rem ove the brush holder ( 1) from the

armature's commutator.

T26D3216

1

Figure 6D3-2-21

11. Remove the armature (1) from the field frame

assembly (2).

T26D3217

21

Figure 6D3-2-22

12. Remove the sealing rubber (1) from drive-end

housing, noting how it is installed.

13. Remove plate (2) the drive assem bly with fork

lever (3) and planetary drive assembly from

the drive-end housing.

14. Remove fork lever from drive assem bly noting

the orientation of the fork lever.

T26D3218

2

3

1

Figure 6D3-2-23

CLEANING AND INSPECTION

With the starter motor c ompletely disass embled, all

components should be cleaned and thoroughly

inspected.

Wash all components excluding the armature,

brushes, solenoid switch and drive assembly in a

suitable cleaning agent. Clean these components

with clean shop rags and compressed air.

NOTE: Do not clean armature with cleaning solvent

as damage to the insulation could occur.

Washing the drive assembly in solvent will wash

out all the lubricant, causing the drive assembly to

slip.

NOTE: Clean all parts other than those previously

nominated using non-volatile or low inflammable

agents in a well ventilated area. It is important that

all parts are thoroughly dried before assembly,

taking care not to breath in any vapours. Observe

the safety regulations and precautions issued by

the manufacturer of the cleaning agent in use.

COMPONENT CHECKING

Field Frame Assembly

Visually inspect field frame assembly for signs of

wear, breakage and/or burns (overheating). If this

condition is pres ent, the field f ram e assem bly mus t

be replaced.

Armature Insulation Test

Check armature insulation resistance to earth

using a 'meggar' or similar tester. A reading of 1

Mohm or greater should be expected.

Armature Short Circuit Test

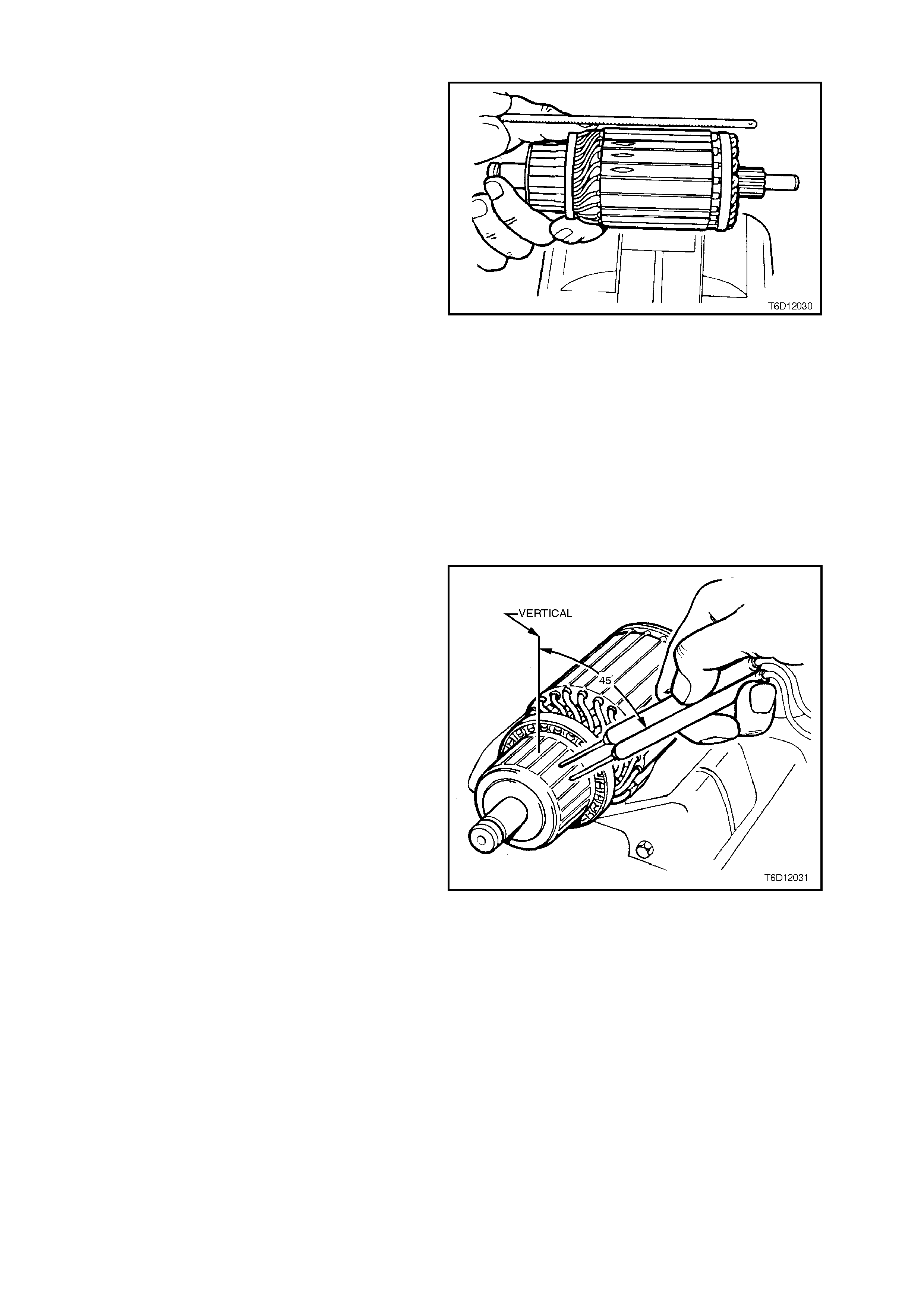

Test armature for short circuits on a growler.

1. Place the armature on a gr owler and s witch on

growler. Hold a hacksaw blade approximately

6 mm above armature core and rotate

armature.

2. If the hacksaw blade vibrates, undercut

between the commutator segments (to a depth

of approximately 0.8 mm) using a suitable

small file, then check armature again.

3. If hacksaw blade still vibrates, the armature is

short circuited and must be replaced.

Figure 6D3-2-24

Armature Continuity Test

An open circuit in the armature winding may

sometimes be detected by examining the

commutator for evidence of burnt or darkened

segments. A burnt or darkened commutator

segm ent is c aused by an arc for med every time the

segment connected to the open circuit winding

passes under the brush.

If a segment has been burnt or is darkened,

replace armature.

Test the armature for continuity on a growler.

1. Place the armature on a gr owler and s witch on

growler.

2. Using a voltmeter, measure the voltage

induced in the armature windings by touching

probes onto two adjacent commutator

segments.

IMPORTANT: T o obtain max im u m voltage r eading,

choose two segments which are approximately

45 degrees from the top of the commutator.

3. Rotate the armature in the growler so that the

next two commutator segments are in the

same position as the previous two segments

in Step 2. Measure voltage across adjacent

commutator segments.

4. Repeat Step 3 until voltage reading across all

adjacent sets of commutator segments has

been measured.

The voltage reading acr oss each adj acent pair

of commutator segments should be the same,

provided each adjacent set of segments are

positioned in the growler in the same location.

If a voltage reading ac ross any adjac ent set of

segments differs from the remainder, the

armature winding has an open circuit, and the

armature must be replaced.

Figure 6D3-2-25

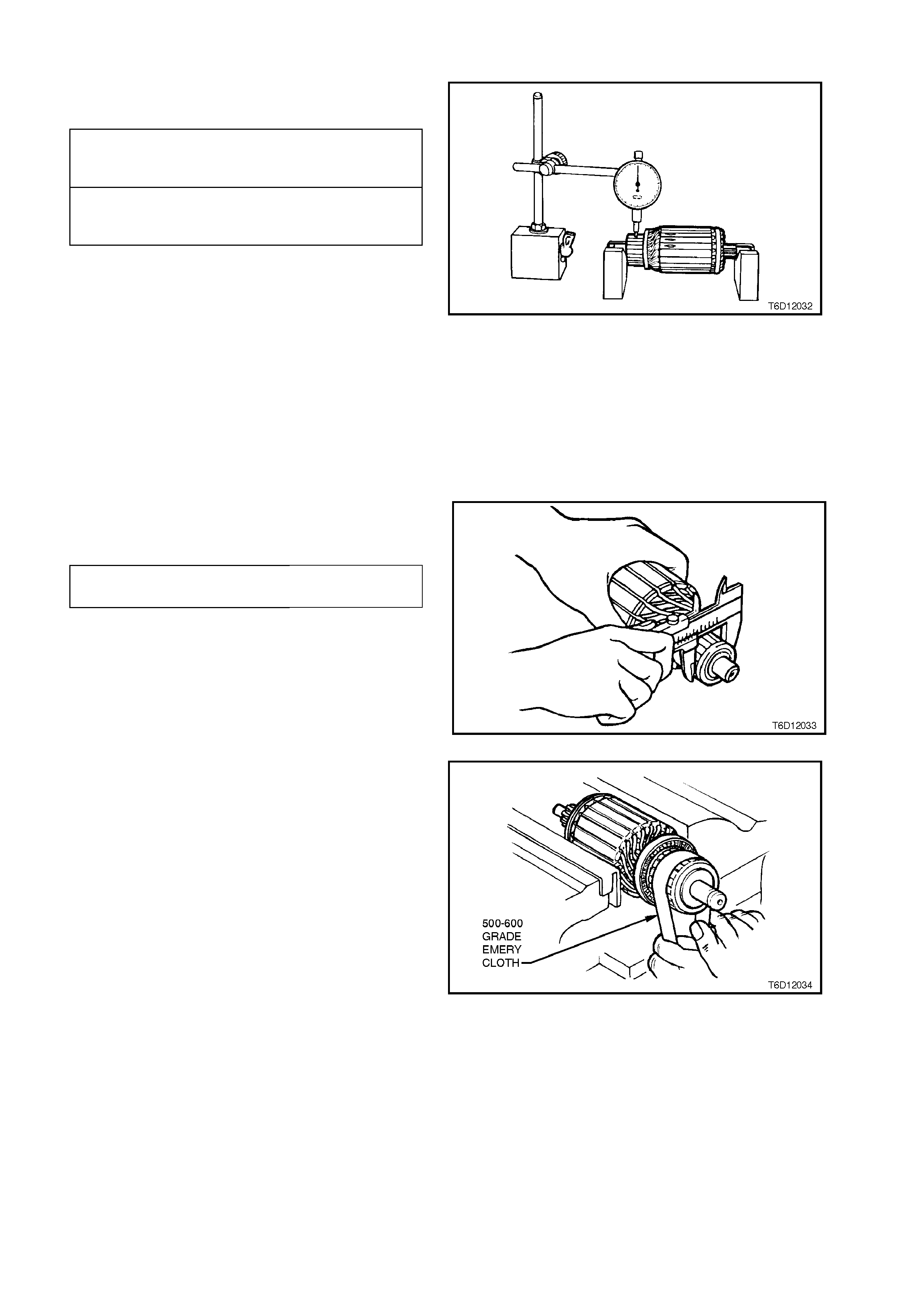

Commutator Sur face

Check commutator and armature laminations for

out-of-round.

If the armature is otherwise satisfactory but

commutator is worn, burnt, out-of round, or has

high insulation between the segments, the

commutator should be machined.

If the out-of-round check on the armature

laminations is greater than the specified value,

replace the armature.

Figure 6D3-2-26

IMPORTANT: Replace the armature if the

commutator diameter is below the dimension given

in the following chart.

When machining the armature, it must not be held

by the laminations. The armature must be held at

the drive end and supported at the c omm utator end

bearing surface.

It is recommended that the commutator be turned in

two stages, that is pre-turning and finish turning. Figure 6D3-2-27

Finish cut the armature using a fine tool. The cut

should be no more than 0.03 mm. After turning,

polish surface if necessary using 500-600 grade

emery cloth and then brush out the commutator

segment slots using a stiff brush.

Check the diameter of the c omm utator. If less than

the specified value, replace the armature.

Figure 6D3-2-28

COMMUT ATOR MAXIMUM

PERMISSIBLE

OUT-OF-ROUND 0.1 mm

MAXIMUM PERMISSIBLE

OUT-OF-ROUND OF

ARMATURE LAMINATIONS 0.1 mm

COMMUT ATOR MINI MUM

DIAMETER 28.4 mm

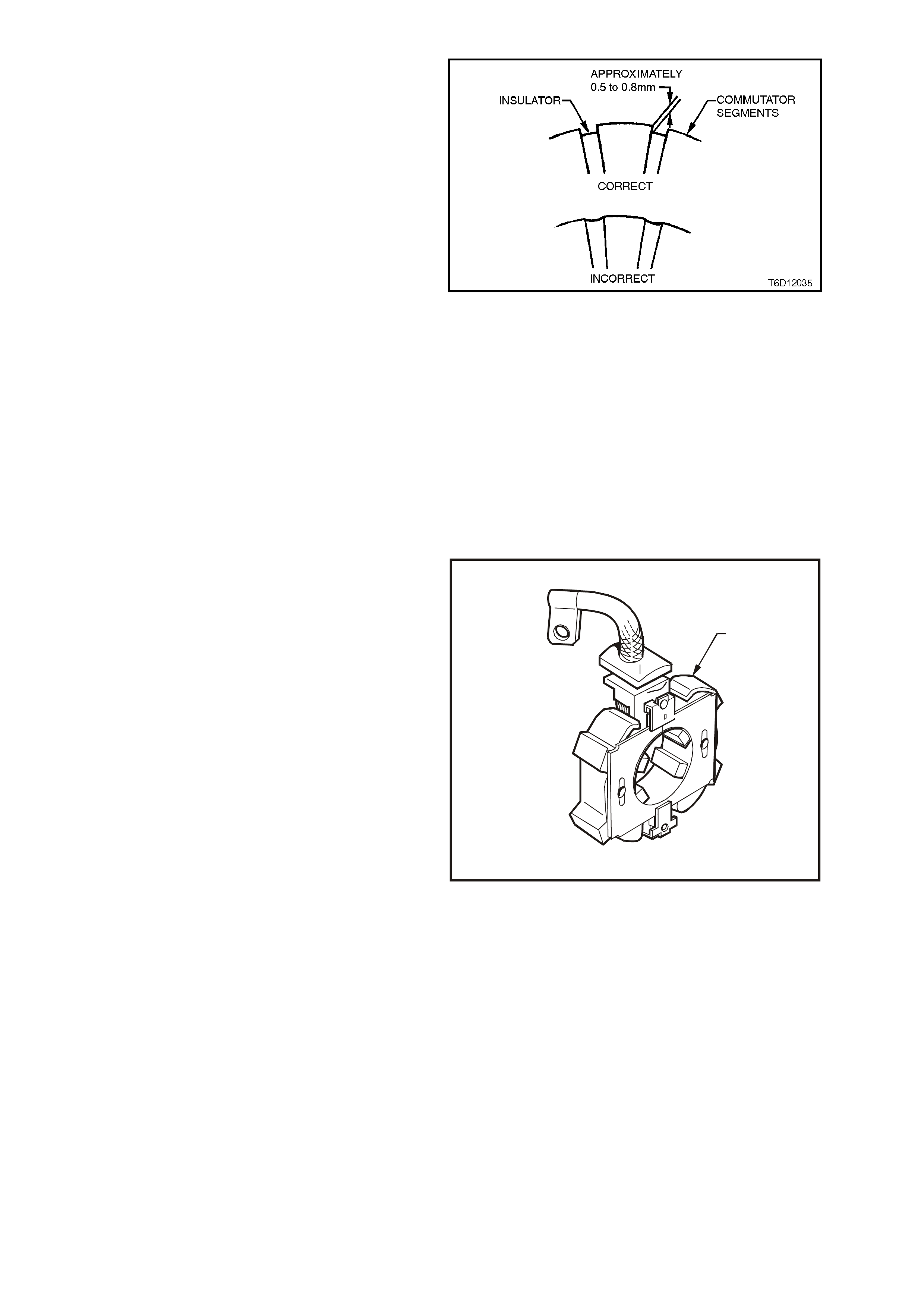

Check depth of insulating mica from commutator

surface. If depth is less than 0.2 mm, undercut

using a file to a depth of 0.5 to 0.8 mm.

CAUTION: It is important to use dust extraction

when undercutting commutators.

After under cutting, car efully clean all dirt and debr is

from commutator segment slots and lightly polish

commutator with fine emery cloth to remove any

burrs left by the undercutting operation. Clean

commutator and armature thoroughly using

compressed air.

Figure 6D3-2-29

Brushes

Check brush holder springs for breakage and

corrosion, replace as necessary.

Ensure that brushes slide sm oothly in their holders,

brush connec tions are good and brushes are clean

and not chipped.

Check brush length and spring retention. If brush

lengths vary or spring retention is uneven, replace

the complete br ush set and mac hine comm utator if

necessary.

Brush Holder Assembly

Check brush holder assembly (1) for cracks or

damage. Replace brush holder assembly as

necessary.

T26D3220

1

Figure 6D3-2-30

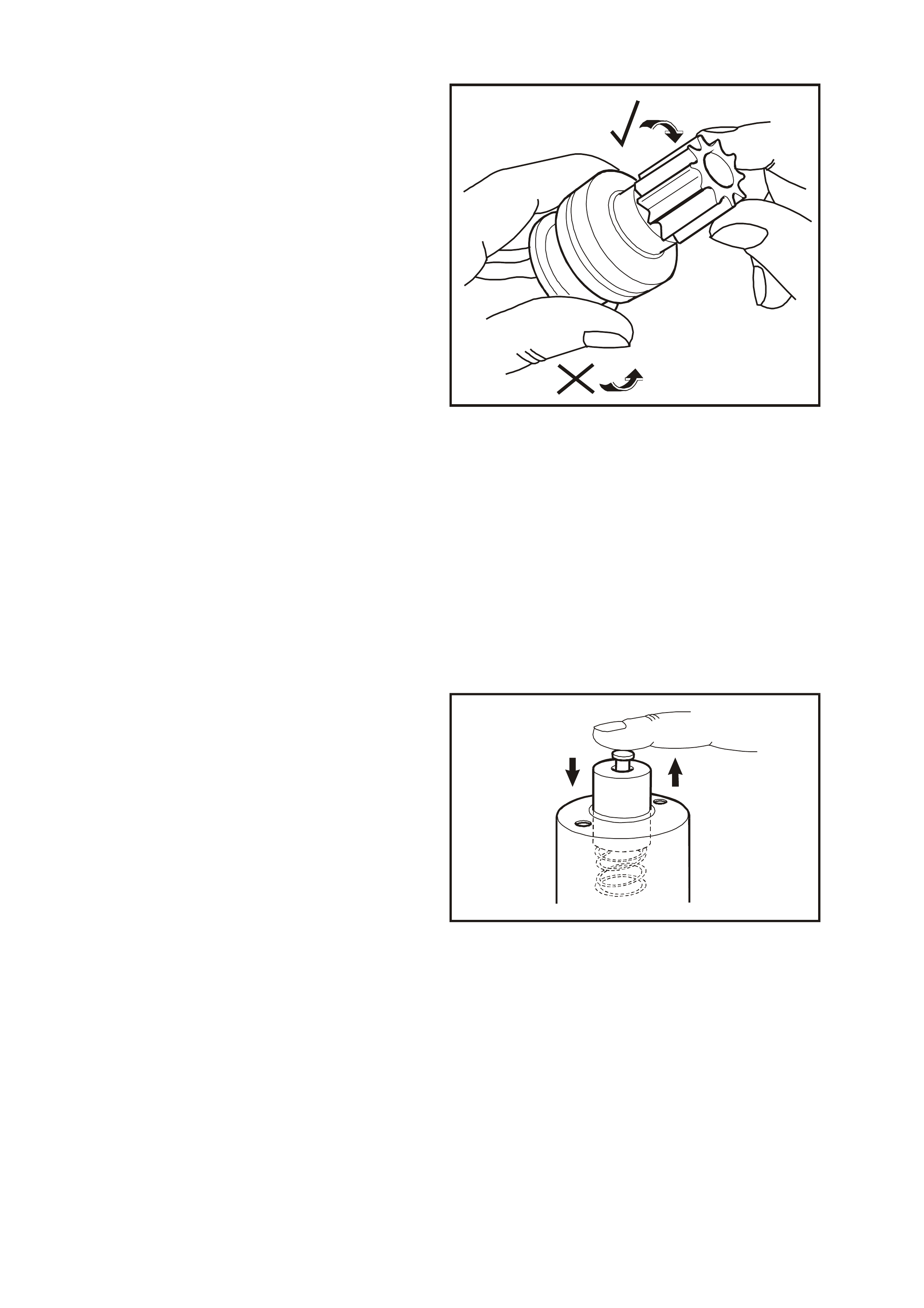

Drive Assembly Check

Inspect drive assembly pinion gear for burrs and

worn or chipped teeth.

Check the operation of the pinion. The pinion gear

should rotate free and smooth in relation to the

drive assembly pinion housing when turned in a

clockwise direction, but will not rotate when turned

in a counter-clockwise direction.

Replace the drive assembly if out of specification,

or if pinion gear is damaged or broken, inspect

flexplate/ring gear teeth and replace as necessary,

refer to Section 6A3 ENGINE MECHANICAL -

GEN III V8 ENGINE in this Service Information.

Inspect fork lever contact surfaces and pivots.

Replace fork lever if worn.

T26D3221

Figure 6D3-2-31

Bushes

Check the fit of the armature shaft in the

commutator end cover and the front end of the

planetary drive shaft in the drive-end housing.

If bushes are exc essively worn, the starter motor is

likely to operate inefficiently and/or the armature

may foul on the magnets in the field frame

assembly.

IMPORTANT: If excessive wear of the bushes is

evident, replacement of the housing in which the

bush is fitted will be necessary.

Solenoid Switch Testing

Inspect the solenoid switch for any external

damage.

Install return spring and plunger to solenoid switch.

Depress plunger and release it. T he plunger s hould

return quickly to its original position. If the plunger

sticks in the switch bore, replace solenoid switch

assembly.

T26D3222

Figure 6D3-2-32

Check the solenoid s witch windings DC res istanc es

using an ohm meter acr os s the ter minals nominated

in the following chart.

T26D3223

1

2

Figure 6D3-2-33

Replace solenoid switch if resistance readings are

not to specification.

T26D3224

1

2

Figure 6D3-2-34

PULL-IN WINDING

RESISTANCE @ 20° C 0.29 ohm

HOLD-IN WINDING

RESISTANCE @ 20° C 0.98 ohm

PULL-IN WINDING

RESISTANCE TERMINALS 50

AND M

HOLD-IN WINDING

RESISTANCE

TERMINAL 50 AND

SOLENOID

SWITCH HOUSING

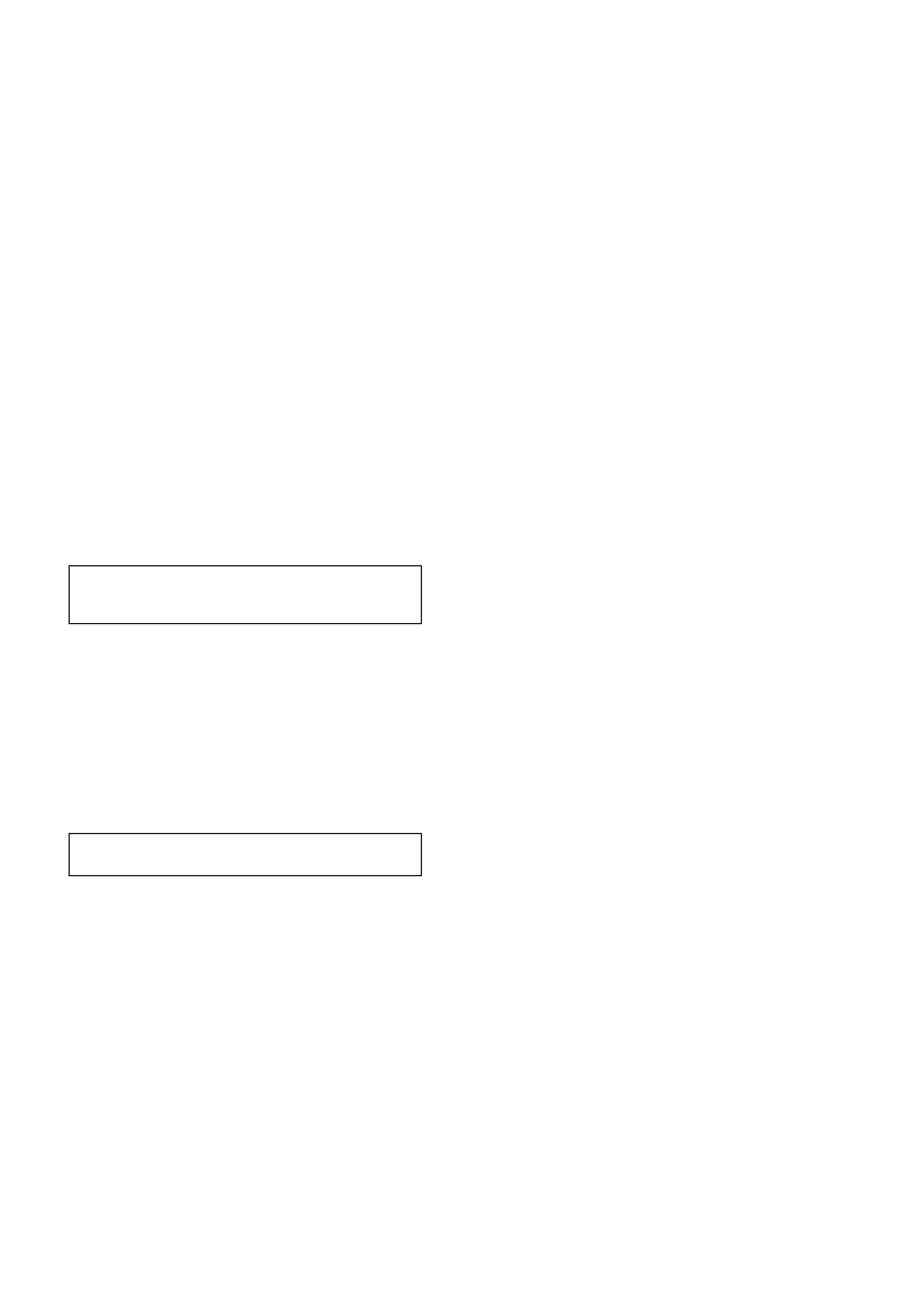

Testing Pull-in and Hold-in Voltages

During the following solenoid switch pull-in and

hold-in checks, the solenoid switch must be held

vertically, i.e. with the plunger uppermost. It is

recommended that a rubber band be fitted around

the plunger and solenoid switch housing to prevent

the plunger from flinging out during testing.

Using a power supply (1) capable of supplying 30

amps, set the voltage to 3.0 volts. A battery and a

variable resistor may also be used.

Connect the solenoid (2) to the power supply as

shown in Fig. 6D3-2-35.

Connect a 12 volt test lamp (3) between solenoid

switch terminal 30 (4) and +12 volt supply. Also,

connect a voltmeter between solenoid switch

terminal 50 (5) and earth.

Fully press in solenoid plunger until test lamp

illuminates. Allow the plunger to spring out by

approximately 8 - 10 mm and hold in this position.

IMPORTANT: The test duration for the following

pull-in voltage check should be no more than

2 seconds.

Slowly increase the voltage on terminal 50 until the

plunger pulls in, noting the voltm eter r eading. At the

same time, the test lamp must be fully illuminated

(check of solenoid switch main contact continuity).

Voltage reading should be as specified in the

following chart.

T26D3225

2

1

4

3

5

Figure 6D3-2-35

Set the power supply (1) to 12 volts and connect

the positive lead to solenoid switch term inal 50 (2).

Connect the negative lead to the solenoid switch

housing. Press the plunger in fully. It should rem ain

held in by the solenoid's hold-in winding.

Decrease the voltage until the winding will no

longer hold the plunger, noting the voltmeter

reading.

Voltage reading should be as specified in the

following chart.

Press the plunger until the solenoid switch c ontacts

close (indicated by test lamp illuminating).

It should be possible to depress the plunger into the

solenoid switch housing a further 1 mm or more. If

less than 1 mm is achieved, the solenoid switch

must be replaced.

T26D3226

1

2

Figure 6D3-2-36

HOLD-IN VOLTAGE TEST

SPECIFICATION 1.7 – 3.0 volts

@ 20°C

PULL-IN VOLTAGE TEST

SPECIFICATION 8.0 volts

A 24 volt supply (1) is required for this test.

Attach positive supply lead to solenoid switch

term inal 30 (2) and negative lead to solenoid switch

housing.

Press the plunger in fully and then release. The

plunger should return to its rest position by the

action of the return spring. If it does not, the

windings have interwinding short circuits.

W hen the solenoid switch is connected in this way,

the windings are differentially compounded, that is

their fields are in opposition to each other.

At end of solenoid switch testing, remove rubber

band retaining the plunger and return spring in the

solenoid switch housing.

T26D3227

1

2

Figure 6D3-2-37

REASSEMBLE

Reassembly of the starter motor is the reverse of

the disassembly procedure, noting the following

points:

1. Lubricate drive-end housing, commutator end

cover and drive assembly to planetary drive

bushes with clean engine oil.

2. Lightly coat helix on armature shaft, helix

inside drive assembly, inside of ring gear and

armature to commutator end cover thrust and

adjustment washers with Molybdenum

Disulphide grease (Holden Specification HN

1271 or equivalent). Pack some grease inside

of commutator end cover.

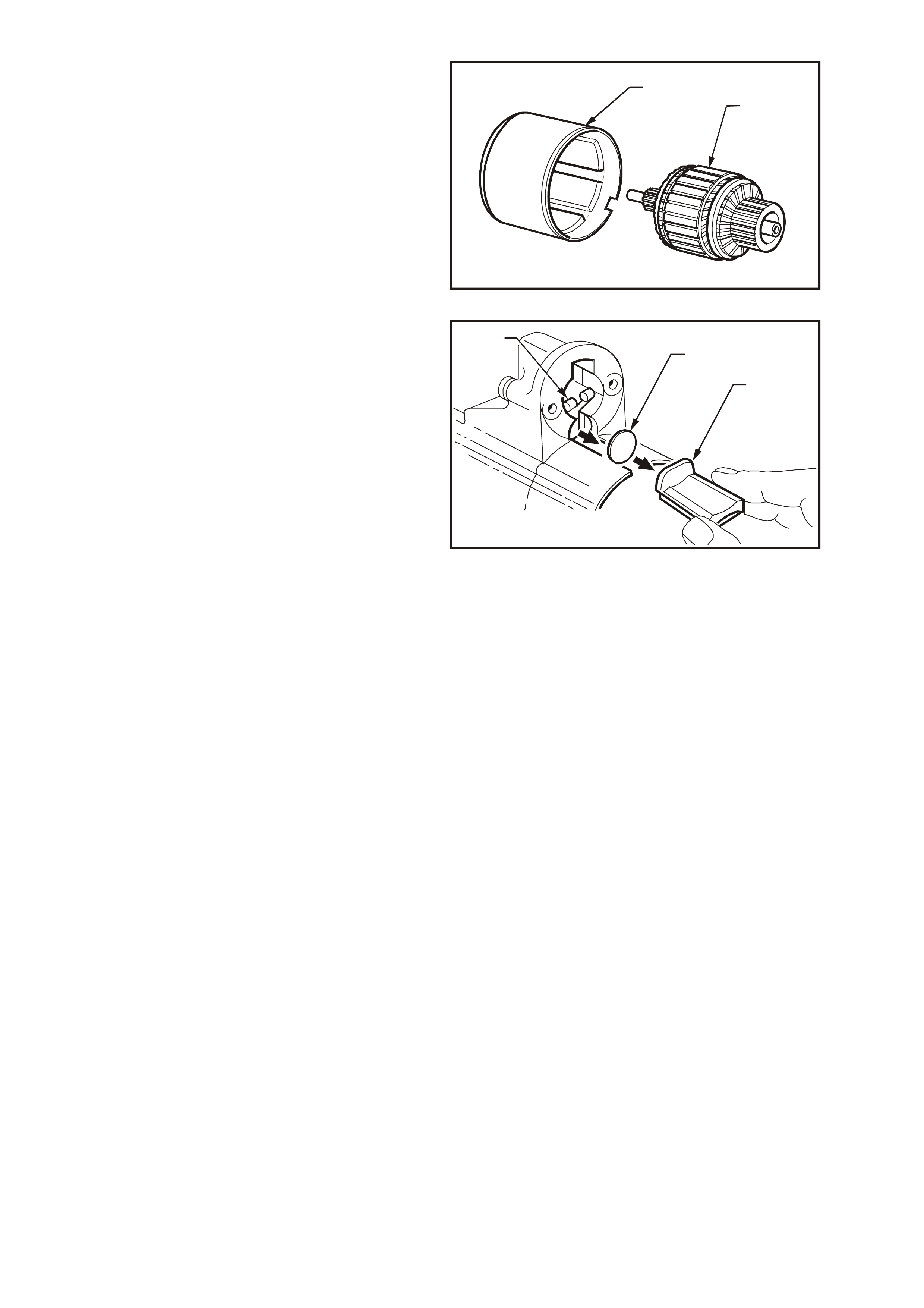

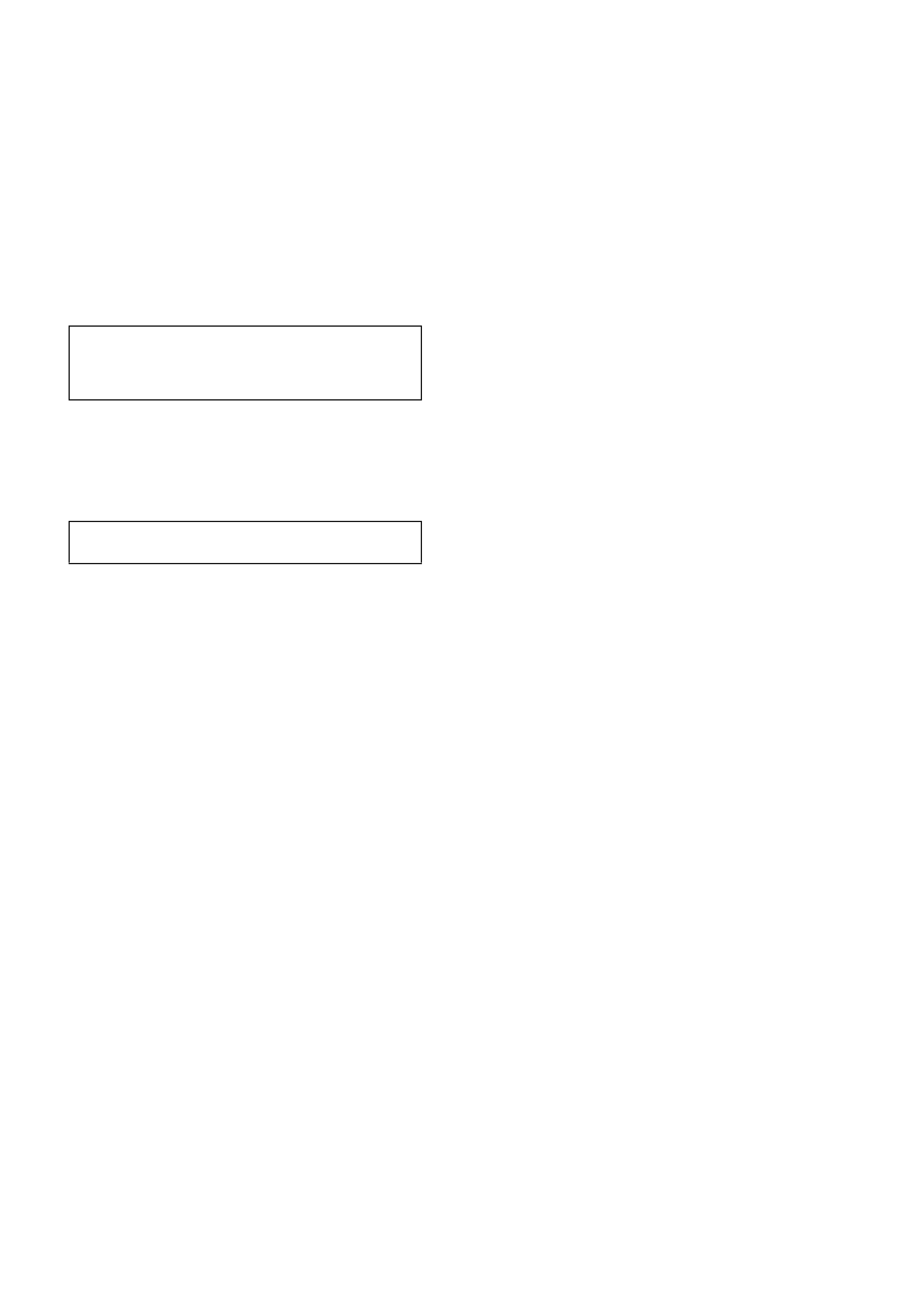

3. To install the stop ring retainer (2) over the

stop ring (1), clamp the front end of the

planetary drive shaft in a vice fitted with soft

jaws. Slide the stop ring retainer (2) up to the

stop ring (1) and f it two open end spanners ( 3)

in between the stop ring retainer and the drive

assembly gear.

4. Using a pin punch (4) and hammer, lightly tap

the stop ring (1) into the planetary drive shaft

groove. Then push down on the two spanners

(3) to force the stop ring retainer (2) over the

stop ring (1).

T26D3234

12

33

Figure 6D3-2-38

5. Slide drive assembly up and down planetary

drive shaft ensuring that it moves freely.

Check drive assembly clutch action.

6. Position fork lever on drive assembly yoke.

7. Install planetary drive shaft into the opening of

the drive-end housing, aligning the raised

sections on the planetary gear cover with the

corresponding recesses in the drive-end

housing. Slide the assembly into position

allowing the fork lever pivot to enter the drive-

end housing.

Install the plate and rubber pack ing behind the

fork lever pivot, ensuring that the rubber

packing is correctly installed in the drive-end

housing.

8. Assemble armature into the field frame

assembly with commutator exposed at rear of

housing.

Install brush holder over commutator by

angling the holder assembly onto the

commutator while pressing two adjacent

brushes into the brush holder. Press the

remaining brushes into the holder and

carefully push brush holder assembly onto

commutator. Do not use force.

Assemble end cover over brush holder and

onto commutator and align screw holes in dust

cover with brush holder. Install dust cover-to-

brush holder s crews and tighten to the corr ect

torque specification.

DUST COVER

SECURING SCREW

TORQUE SPECIFICATION 1.4 – 2.0 Nm

9. Assemble the field frame assembly to the

drive-end housing, aligning the alignment

marks. Carefully fit the armature into the

planetary drive. It may be necessary to rotate

the pinion gear slightly to enable the armature

gear to engage the planetary gears (do not

force entry).

10. Install through bolts and tighten to the correct

torque specification.

THROUGH BOLT

TORQUE SPECIFICATION 7.5 Nm

11. Lightly coat solenoid switch plunger with

Molybdenum Disulphide grease (Holden

Specification HN 1271 or equivalent).

IMPORTANT: Do not under any circumstances

allow grease on the rear f ace of the plunger. If

too much grease is applied, it may enter the

contact chamber of the solenoid switch and

cause contact problems.

12. Assemble return spring and plunger to

solenoid switch.

Pull pinion gear forward and assemble

solenoid switch assembly to drive-end

housing, ensuring that plunger is correctly

installed over drive assembly fork lever.

Align the alignment mark on the solenoid

switch housing with the corresponding mark

on the drive-end housing, ensuring that

terminal 30 is facing away from field frame

assembly. Install and tighten solenoid switch

to drive-end housing mounting screws to the

correct torque specification.

SOLENDOID SWITCH TO

DRIVE-END HOUSING

MOUNTING SCREW

TORQUE SPECIFICATION

5.5 Nm

13. Install braided cable and terminal over

solenoid switch lower threaded terminal. Install

washer and nut to threaded terminal and

tighten to the correct torque specification.

THREADED TERMINAL NUT

TORQUE SPECIFICATION 9 Nm

14. With the starter motor reassembled, a NO

LOAD test should be conducted, refer to

2.1 PERFORMANCE TESTING in this

Section.

Failure of the starter motor to perform

according to the NO LOAD specification may

be due to tight or dirty brushes or high

resistance connections. Rectify any faults

found.

3. DIAGNOSIS

Many starting problems can be categorised within the following classifications:

1. The starter motor will not crank the engine.

2. The engine will crank at normal speed, but will not start.

3. The starter cranks the engine very slowly.

If the engine is cranked over by the starter motor at the norm al speed, but will not start, the problem is in the

ignition system, fuel system or engine, rather than a fault in the starting system.

Bef ore r emoving the s tarter m otor, when investigating a starting pr oblem, f ollow the procedures outlined in the

accompanying diagnostic charts.

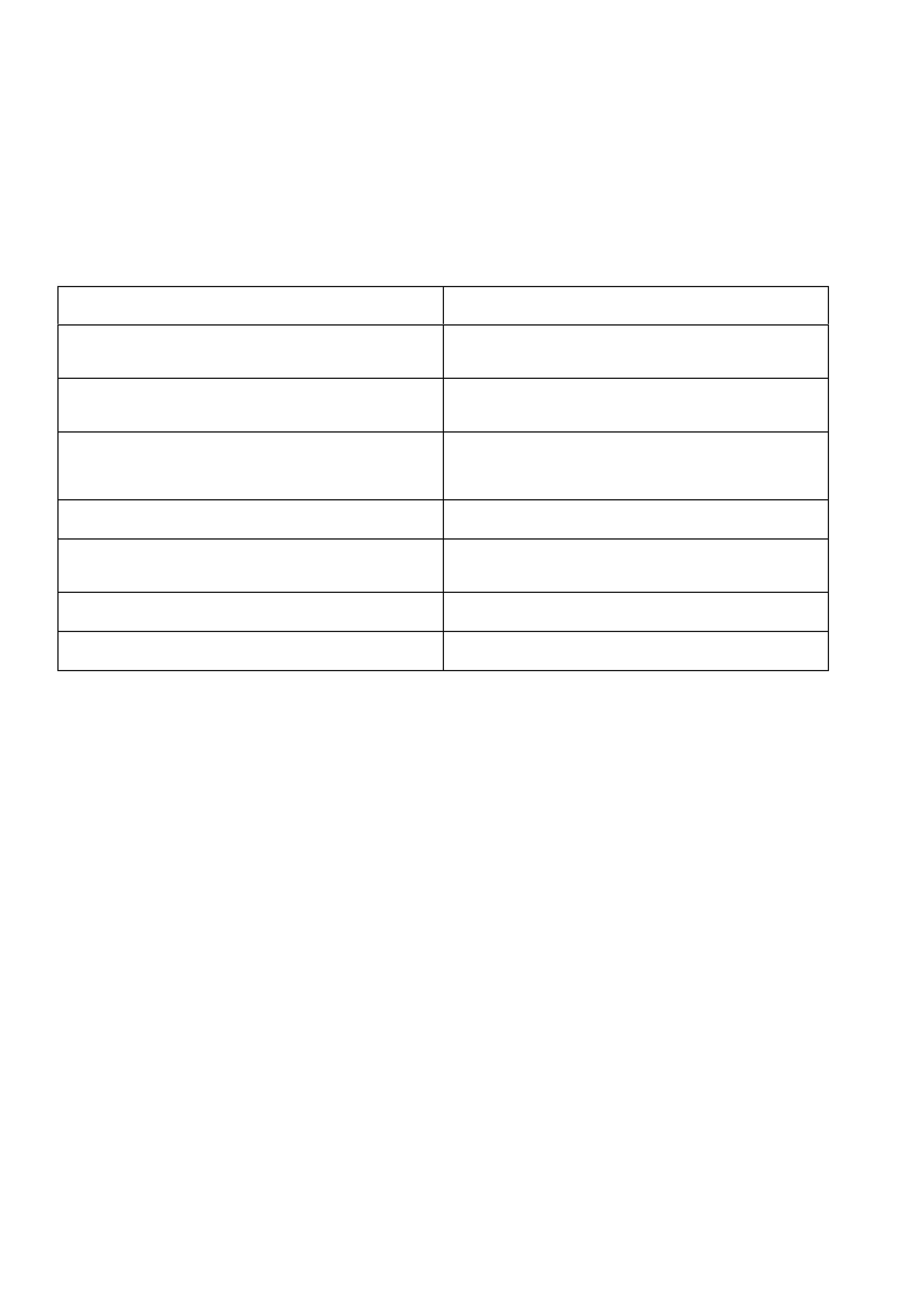

SYMPTOM PROBABLE FAULT

Speed, torque and current low. High resistance in motor. Check condition of brushes

and their connections and check for dirty brushes or

burnt comm ut a t or.

Speed and torque low, current hi gh. Tight or worn bearings, bent armature shaft,

insufficient end play, armature fouling pole shoe,

short-c i rcuit in armature, earthed arm ature.

Armature does not rotate. No current. Open circuit in arm ature or solenoid. If commutator is

badly burned, there may be poor contact between

brushes and commutator, owing to excessively worn

or sticking brus hes.

Armature does not rotate. High current. Short-circuit in solenoid switch. Armature physically

prevented from rotati ng.

Excessive brush movement causing arcing at

commutator. Low brush spring tension, worn or out-of-round

com mutator, 'thrown' or high segm ent on comm utator,

or insulat i on protruding between segm ents.

Excessive arcing at commutator. Defective armature windings, sticking brushes or dirty

commutator.

Armature rotates but pinion does not mesh with ring

gear. Pinion bearing fouled, burred, damaged flexplate/ring

gear or broken pinion t eet h.

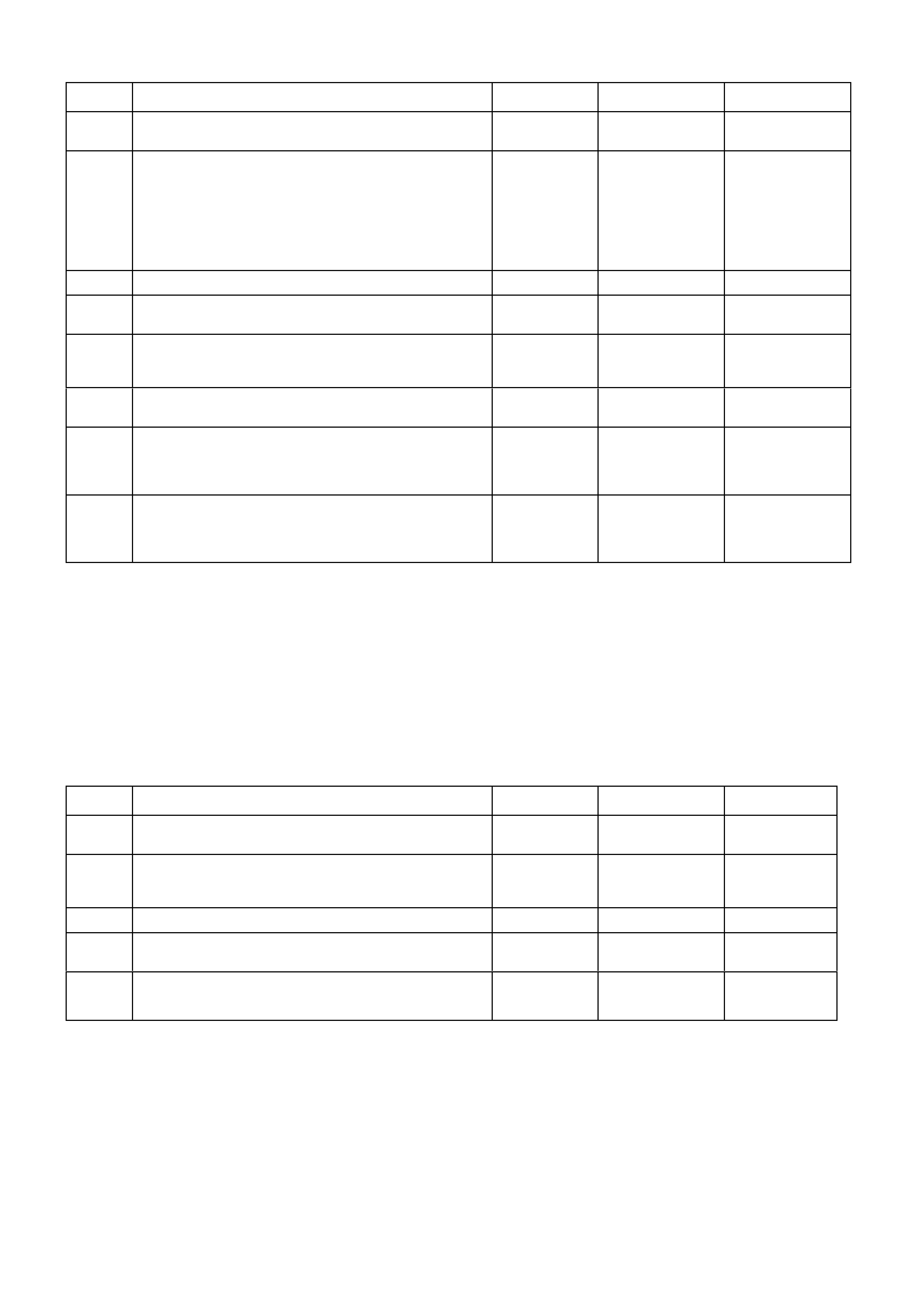

NO CRANKING, NO SOUND FROM SOLENOID

STEP ACTION RESULT YES NO

1 Turn headlam ps and dome l amps on, turn ignit i on to start

position. Lamps di m? Go to Step 2. Go to Step 3.

2 Check bat tery.

Charge battery.

Check generat or.

Check c ranking volt age at battery posts.

Check c urrent draw.

Is 9. 6 vol t s

present? Go to Step 7. Test battery.

If OK, repai r

starter.

3 Turn on radio. Operate OK? Go to Step 4. Go to Step 6.

4 Check voltage at sol enoi d switch terminal 50. Is 7. 0 vol t s

present? Repair starter. Go to Step 5.

5 With key in st art posit i on, check at ignition terminal 50. Is 7. 0 vol t s

present? Repair wiring

ignition switch to

start er motor.

Replace ignition

switch.

6 Check engine main wiring harness fusi bl e l i nk and igniti on

connections.

7 Check voltage from engi ne bl ock t o negat i ve post, with key in

start position. (Posi tive lead on block). Is 0. 5 vol t s or

more pres ent? Clean and tighten

negative cable

connect i on, and/or

replace cabl e.

Go to Step 8.

8 Check c ranking voltage at starter B terminal. Is 9. 0 vol t s

present? Check fuse and

engine to MWH

connectors.

Clean and tight en

positi ve c abl e

connect i on, and/or

replace cabl e.

SLOW CRANKING, SOLENOID CLICKS OR CHATTERS

Check: Battery state of charge. Refer to Section 12A BATTERY AND CABLES of the VT Series I Service

Information.

Visual condition of battery cables and connections.

If battery needs charging, carry out generator and battery drain check , charge battery and check cranking again. If

trouble has not been found proceed.

Remove engine fuse link from engine compartment fuse housing. This prevents fuel injection and ignition during

engine cranking. Make all voltmeter readings with ignition key in start position.

STEP ACTION RESULT YES NO

1 Measure cranki ng vol tage at batt ery termi nal posts. Is 9. 6 vol t s or

more pres ent? Go to Step 2. Go to Step 3.

2 Measure voltage from battery negative terminal to engine

block (positive lead on bl ock). Is 0. 5 vol t or

more pres ent? Repair negative

cable and

connections.

Go to Step 4.

3 Charge and load test battery. Is bat t ery OK? Repair starter. Replace battery.

4 Measure voltage at solenoid s witch 30 (B+) terminal, clean

and tighten connections at starter. Is 9. 0 vol t s or

more pres ent? Repair starter. Go to Step 5.

5 Clean and tighten positive cable connec t i ons.

If OK replace cable.

This procedure is designed for use on engines and batteries at room temperature or normal operating

temperatures. It also assumes there are no engine defects which could cause cranking problems. To use it under

other conditions might result in misdiagnosis.

4. SPECIFICATIONS

Type ......................................................................... Delco Remy . Six-pole, four brush with

planetary drive train

Rotation (drive end view)............................................ Clockwise

Number of pinion teeth............................................... 10

No load test:

Maximum current ....................................................... 90 amps at 11 volts

rpm 2500

Lock test:

Maximum current (including solenoid) ....................... 760 amps

Volts 4 volts

Torque........................................................................ 19.5 Nm

Solenoid Test Solenoid detached from starter motor:

Pull in voltage............................................................. 8 volts @ 20°C

Hold-in voltage ........................................................... 1.7 – 3.0 volts @ 20°C

Hold-in winding resistance ......................................... 0.98 ohm @ 20°C

Pull-in winding resistance........................................... 0.29 ohm @ 20°C

Armature end play...................................................... 0.5 – 2.0 mm

Armature laminations permissible

out-of-round........................................................ 0.1 mm

Commutator:

Maximum permissible out-of-round............................ 0.1 mm

Diameter - New .......................................................... 29.4 mm

Minimum diameter...................................................... 28.4 mm

Depth of undercut....................................................... 0.5 mm

Brushes:

Minimum length.......................................................... 7.0 mm

5. TORQUE WRENCH SPECIFI CATIONS

Nm

Through bolts........................................................................ 7.5

Solenoid attaching screws.................................................... 5.5

'30' terminal nut..................................................................... 6.0 – 10.0

'50' terminal nut..................................................................... 9.0

Dust cover securing screws.................................................. 1.4 – 2.0

Starter motor to cylinder block mounting bolts...................... 40 – 60