SECTION 6D3-3 - IGNITION SYSTEM –

GEN III V8 ENGINE

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenge r's air bags or se at belt pre-ten sioner s, drive r’s an d fron t pass enger’ s air bag and left an d rig ht

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M, Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, VT

Series I Service Information (V6) or VT Series II Service Information (GEN III V8).

1. GENERAL INFORMATION

The electronic ignition system fitted to the GEN III V8 engine, controls fuel combustion by providing a spark to

ignite the com pressed air/fue l mixture at the cor rect tim e. To prov ide optim um engine perform ance, f uel econom y,

and contr ol of exhaust emiss ions, the Powertrain Control Mod ule (PCM) c ontrols the s park advanc e of the ig nition

system. The electronic ignition system has the following advantages over a mechanical distributor system:

• No moving parts.

• Less maintenance.

• Remote mounting capability.

• No mechanical load on the engine.

• More coil cool down time between firing events.

• Elimination of mechanical timing adjustments.

• Increased available ignition coil saturation time.

For diagnostic and servicing operations not described in this Section, refer to 6C3-2A DIAGNOSTIC TABLES -

GEN III V8 ENGINE, 6C3-2C FUNCTIONAL CHECKS - G EN III V8 ENGINE or 6C3-3 S ERVIC E OPER ATIONS –

GEN II V8 ENGINE, of the VT Series II Service Information.

Techline

1.1 GENERAL DESCRIPTION

The electronic ignition system does not use a conventional distributor and coil but consists of the following

components/circuits:

• Eight Ignition Coils/Modules

• Eight Ignition Control (IC) Circuits

• Camshaft Position (CMP) Sensor

• 1X Camshaft Reluctor Wheel

• Crankshaft Position (CKP) Sensor

• 24X Crankshaft Reluctor Wheel

• Two Knock Sensors

• Powertrain Control Module (PCM)

• Related connecting wires

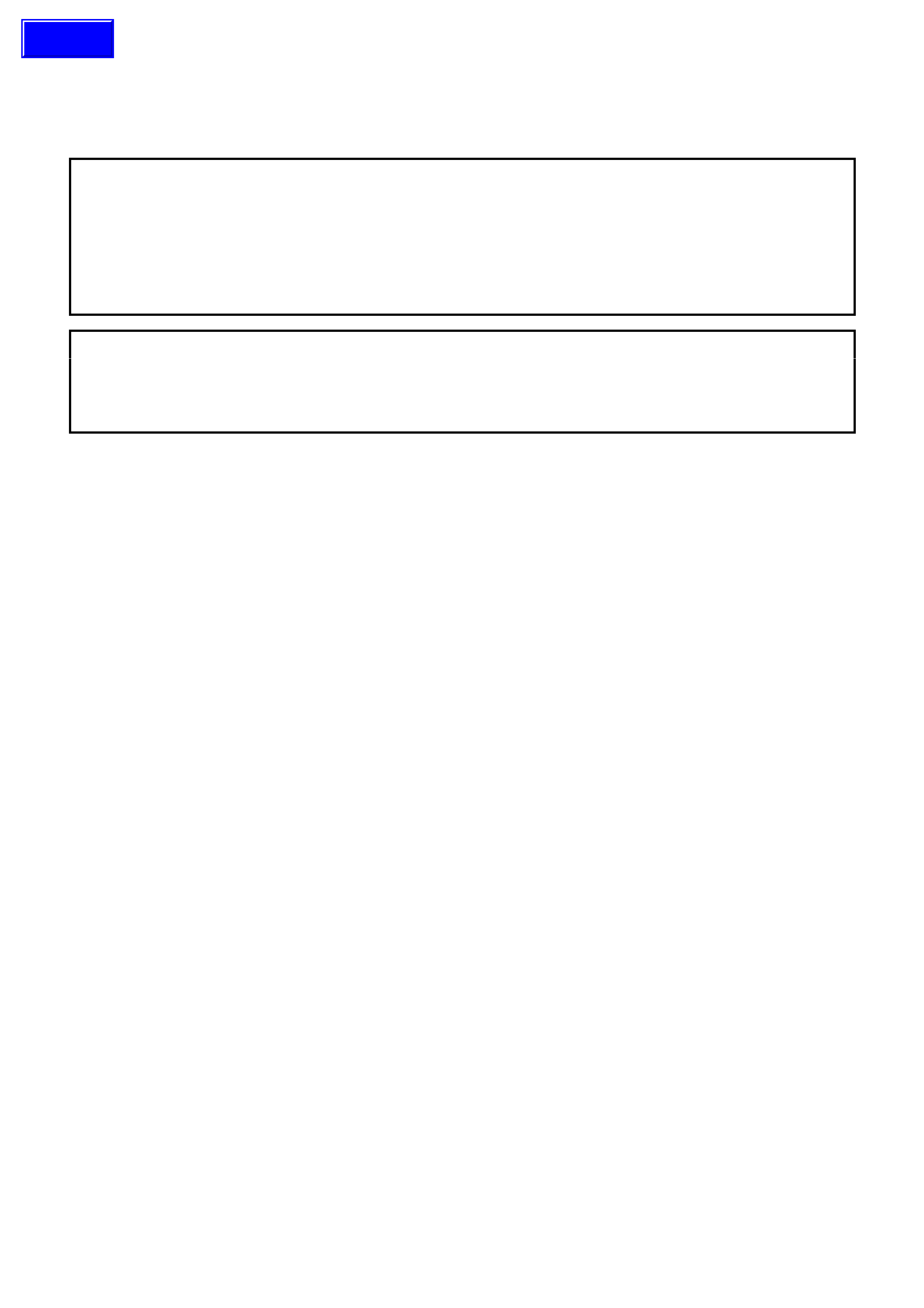

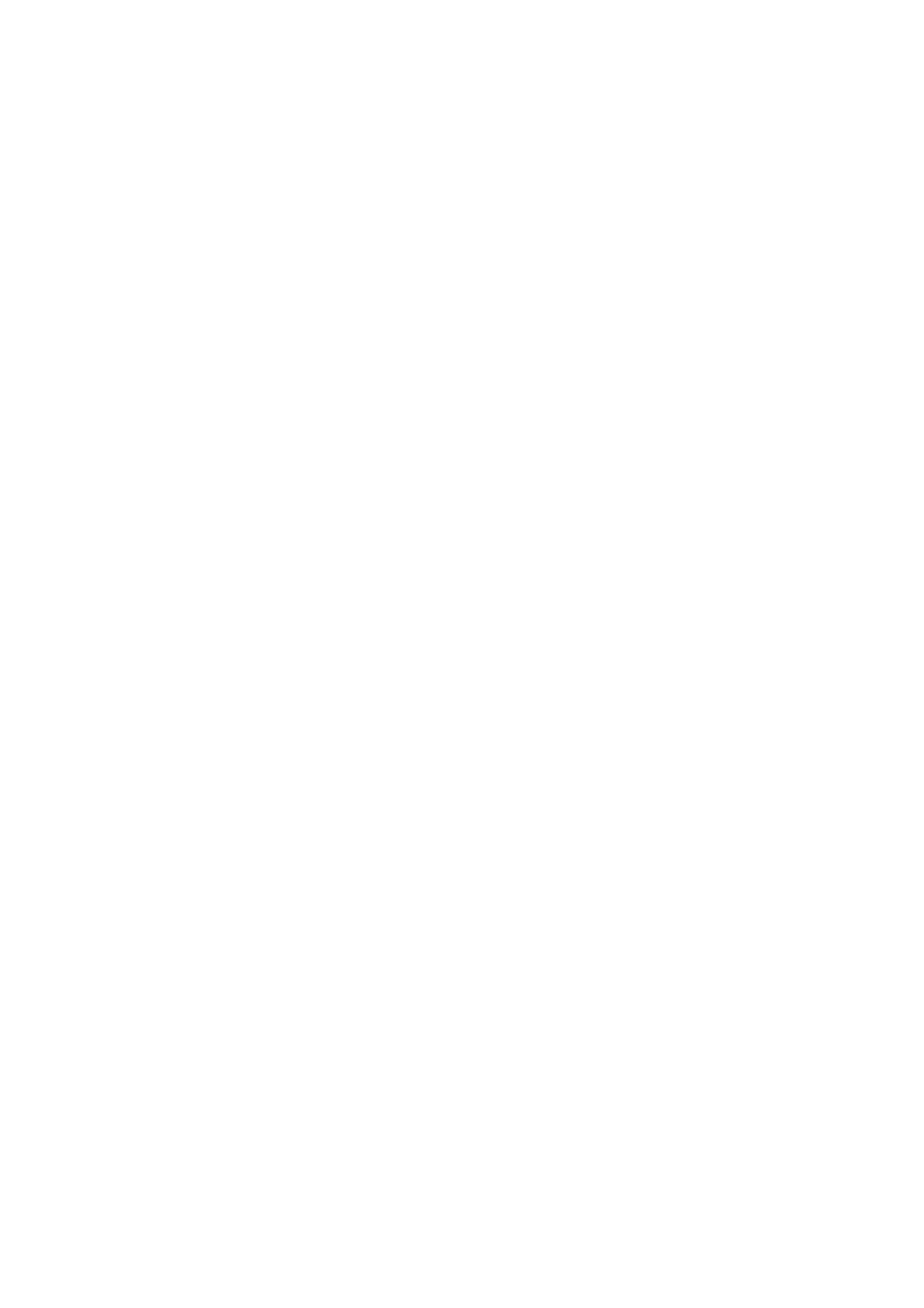

CRANKSHAFT POSITION SENSOR AND RELUCTOR WHEEL

The Crankshaft Position (CKP) sensor (2) is

located in the right rear of the engine (1), behind

the starter motor. The CKP sensor is a dual

magneto resistive type sensor and is not speed

dependent. The dual micro switches monitor both

notches of the reluctor wheel for greater accuracy.

The CKP sensor works in-conjunction with a 24X

reluctor wheel that is permanently mounted on the

rear of the crankshaft. The 24X reluctor wheel

uses two different width notches that are 15

degrees apart.

This Pulse Width Encoded pattern allows cylinder

position identification within 90 degrees of

crankshaft rotation. In some cases, cylinder

identification can be located in 45 degrees of

crankshaft rotation. This reluctor wheel also has

dual track notches that are 180 degrees out of

phase. The dual track design allows for quicker

starts and accuracy.

The PCM also receives a 4X signal from the

Crankshaft Position sensor. The PCM utilises the

4X signal for the following:

• Misfire

• Tachometer output

• Spark control

• Fuel control

• Certain diagnostics

Figure 6D3-3-1

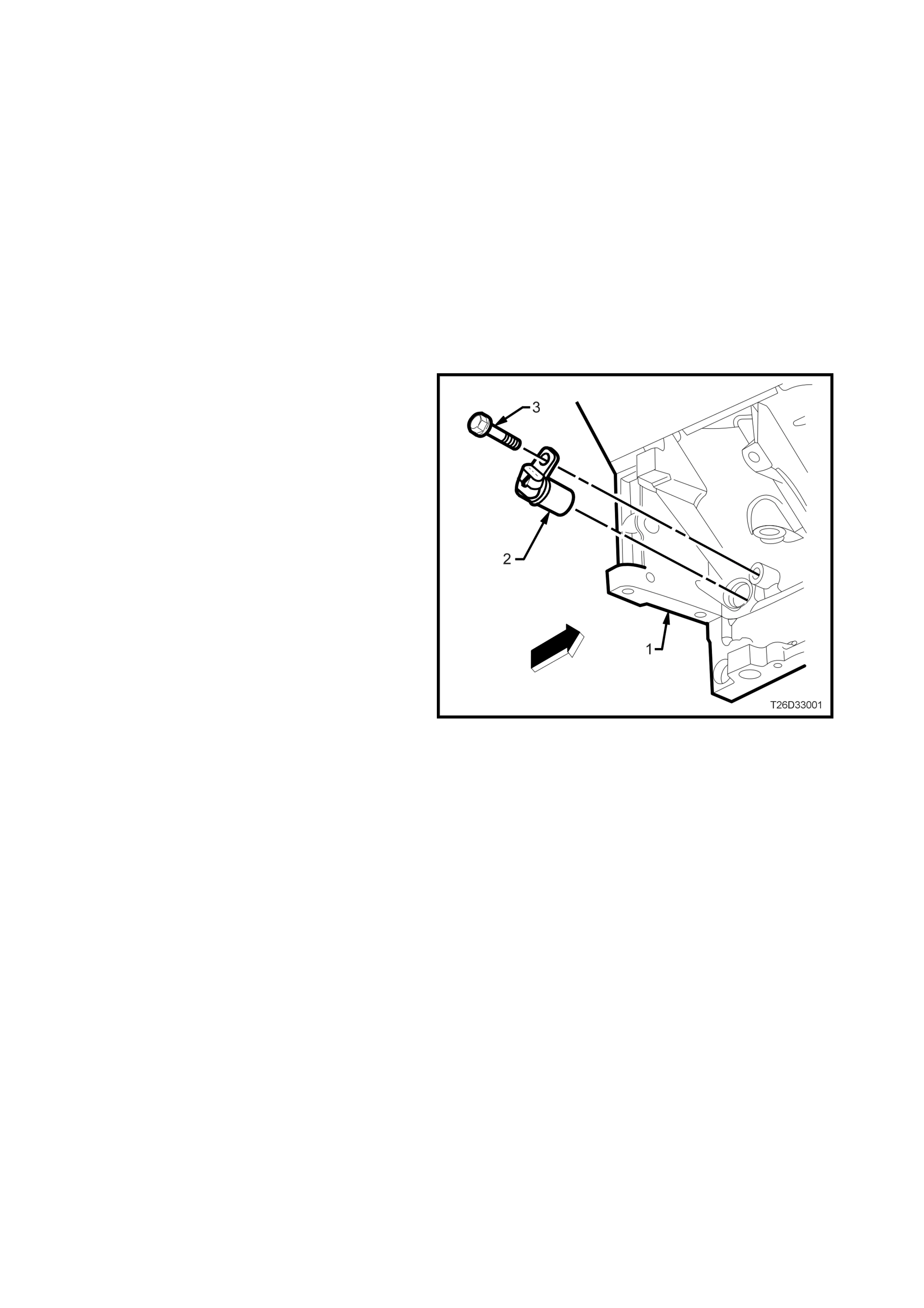

CAMSHAFT POSITION SENSOR

The Camshaft Position (CMP) sensor is mounted

through the top and at the rear of the engine

cylinder block. The CMP sensor works in-

conjunctio n with a 1X rel uctor whee l, locate d at the

rear of the camshaft. The CMP sensor is used to

determine whether a cylinder is on the firing or the

exhaust stroke.

As the camshaft rotates, the reluctor wheel

interrupts a magnetic field produced by a magnet

within the sensor. The CMP sensor internal

circuitry detects t his a nd pro duc es a s ign al wh ich is

used by the PCM. The PCM uses this signal in

combination with the CKP 24X signal to determine

crankshaft position and stroke.

While the CKP signal must be available for the

engine to start, the CMP signal is not needed to

start and operate the engine. The PCM can

determine when a particular cylinder is on either a

firing or exhaust stroke by the 24X signal. The

CMP sensor’s purpose is to determine what stroke

the engine is on. The system will attempt a

synchronised pattern and look for an increase in

the Mass Air Flow MAF signal. An increase in the

MAF signal i ndicates t he engine has starte d. If the

PCM does not detect an increase in the MAF

signal, another synchronised pattern will occur on

the opposite cam position. A slightly longer

cranking time may be a symptom of this condition.

Figure 6C3-3-2

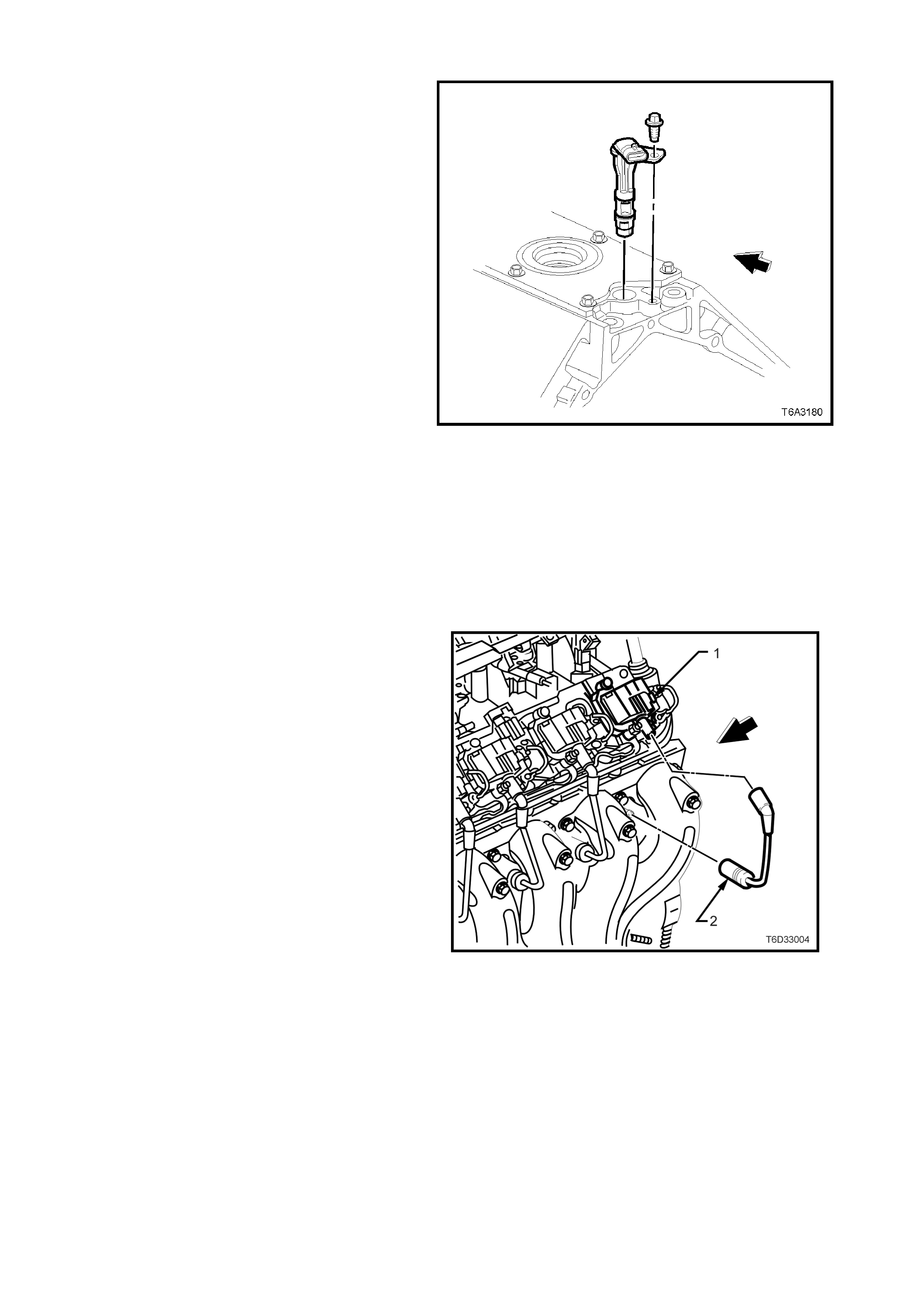

IGNITION COILS/MODULE

The ignition system on this vehicle features a

multiple coil ignition (1) and is known as “coil near

plug”. The secondary ignition wires (2) are short

compared with a distributor ignition system wire

and are all of equal len gth.

Figure 6D3-3-3

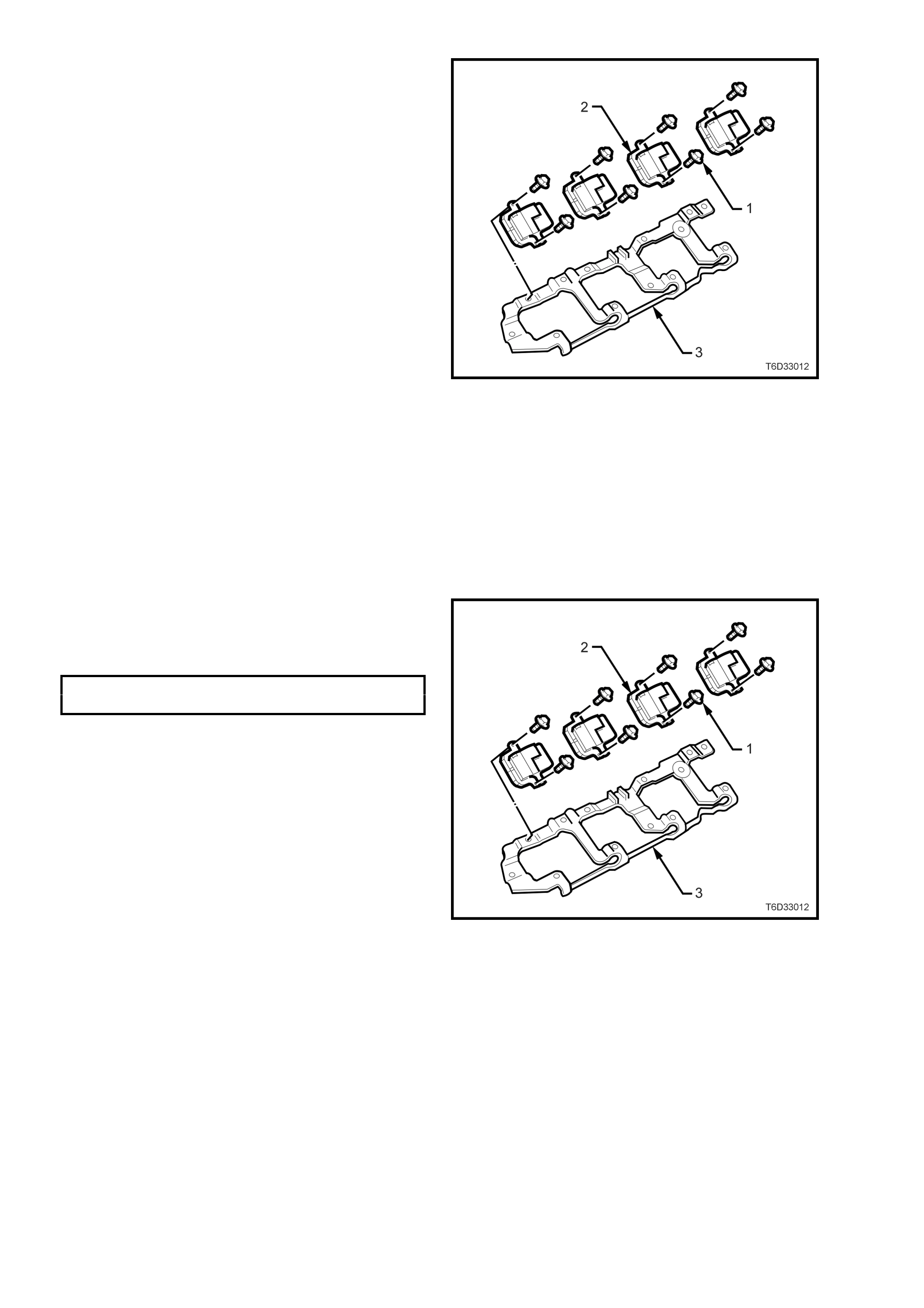

Eight ignition coils/modules (1) are individually

mounted above each cylinder on brackets (2)

attached to the rocker covers (3) by screws (4).

The coils/modules are fired sequentially.

There is an Ignition Control (IC) circuit for each

ignition coil/module and these eight ignition control

circuits are all connected to the PCM. All timing

decisions are made by the PCM, which triggers

each coil/module individually.

The ignition coil/modules are supplied with the

following circuits:

• Ignition feed circuit.

• Ignition control circuit.

• Ground circuit.

• Reference low circuit.

The ignition feed circuits are fused separately for

each bank of the engine. The two fuses also

supply the injectors for that bank of the engine.

Each coil/module is serviced separately.

This system develops a very high ignition energy

for plug firing and, because the ignition wires are

shorter, less energy is lost to ignition wire

resistance. Also, since the firing is sequential,

each coil h as seven e vents to s aturate as oppos ed

to the three in a waste spark arrangement.

Furthermore, no energy is lost to the resistance of

a waste spark system.

Figure 6D3-3-4

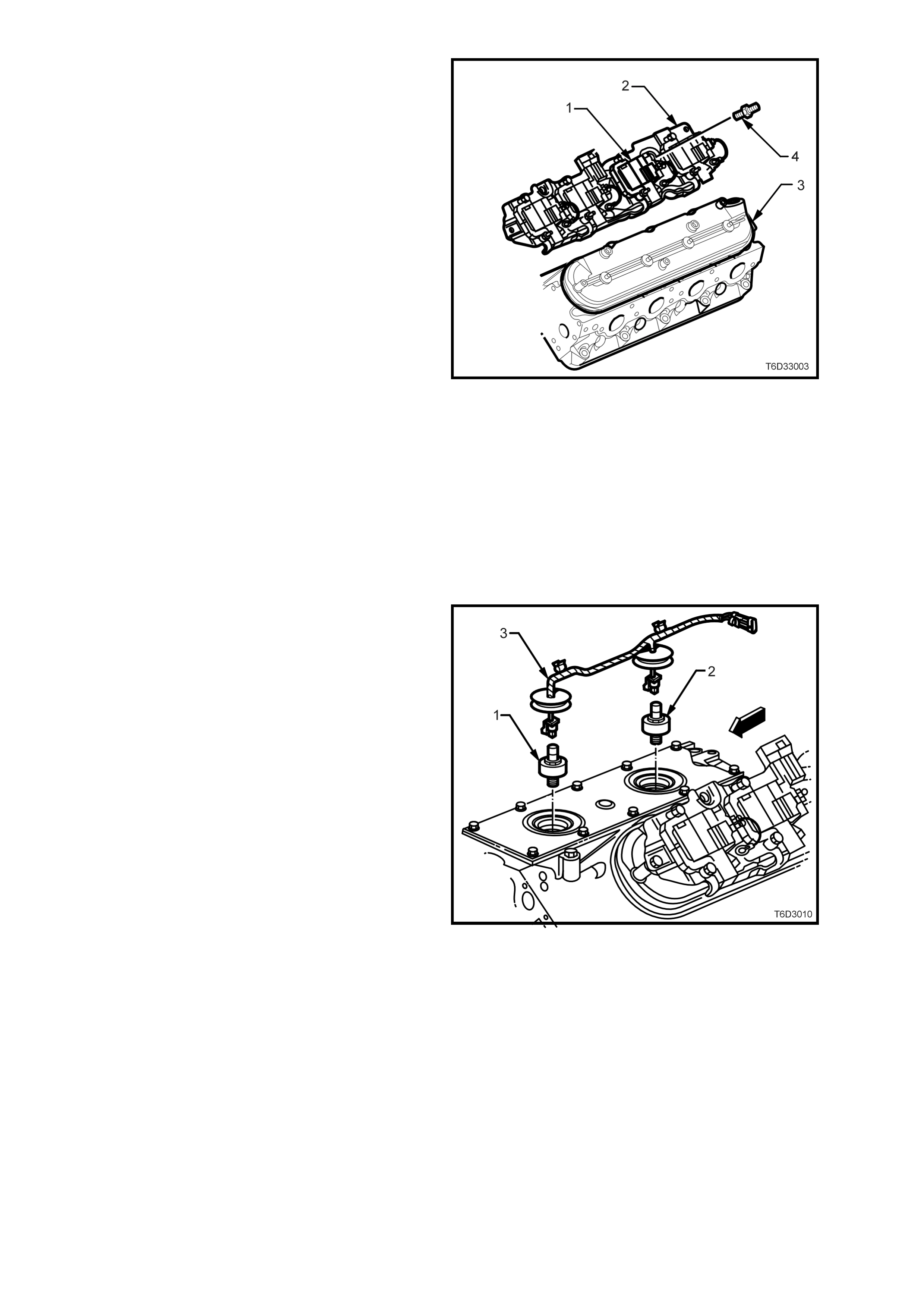

KNOCK SENSORS

A Knock Sensor (KS) system is used in order to

control eng in e spark knock .

The KS system used on the GEN III V8 engine

comprises two knock sensors (front ‘1’ and rear

‘2’), both located centrally in the engine valley

cover. A patch harness (3) connects the signals

generated by these piezo sensors with the PCM,

via the PCM wiring harness.

The GEN III V8 engine KS system is designed to

retard spark timing up to 20º in order to reduce

spark knock in the engine. This allows the engine

to use maximum spark advance to improve

driveability and fuel economy.

Figure 6D3-5

The knock sensor system is used to detect engine

detonation by the knock sensors producing an AC

voltage which is sent to the PCM. This AC signal

voltag e to the PCM is proces sed b y a Signal Nois e

Enhancement Filter (SNEF) module. The SNEF

module is used to determine if the AC signal

coming in, is noise or detonation.

This SNEF module is part of the PCM and cannot

be replaced. The PCM then adjusts the ignition

timing to r educe t he spar k adv ance. T he am ount of

timing retard is based upon the amount of time

knock that is detec ted and is lim ited to a m aximum

value of 20°.

After the detonation stops, the timing will gradually

return to it's calibrated value of spark advance.

The Knock Sensor system will only retard timing

after the following conditions are met:

• The engine run time is greater than 20 seconds.

• The engine speed is greater than 1650 RPM.

• The engine coolant temperature is greater than

70° C.

• The MAP is less than 60 kPa.

The TECH 2 scan tool has several positions for

diagnosing the KS circuit:

• Knock Retard indicates the am ount of spark the

PCM is removing from the IC spark advance in

response to the signal from the knock sensors.

• Spark indicates the amount of spark advance

being commanded by the PCM on the IC circuit.

Figure 6D3-6

CIRCUITS AFFECTING IGNITION CONTROL

To properly control ignition timing, the PCM relies

on the following information:

• Engine load (manifold pressure or vacuum)

• Atmospheric (barometric) pressure

• Engine temperature

• Intake air temperature

• Crankshaft position

• Engine speed (RPM)

• Engine detonat ion condition

The Ignition Control (IC) system consists of the

following components:

• Ignition coil/modules

• 24X crankshaft position sensor

• Powertrain Control Module (PCM)

• All connecting wires

The Ignition Control utilises the f ollowing to control

spark timing functions:

• 24X signal - The 24X crankshaft position

sensor sends a signal to the PCM. The PCM

uses this signal to determine crankshaft

position. The PCM also utilises this signal to

trigger the fuel injectors.

• Ignition Control (IC) circuits - The PC M uses

these circuits to trigger the ignition

coil/modules. The PCM uses the crankshaft

reference signal to calculate the amount of

spark advance needed.

NOTEWORTHY IGNITION INFORMATION

There are important considerations to note, when servicing the ignition system. The following information lists some

of these, to help the Technician in servicing this ignition system in a safe and efficient manner.

• Each ignition coil’s secondary voltage output capabilities is very high - more than 40,000 volts. Therefore,

avoid body contact with ignition high voltage secondary components when the engine is running, or personal

injury may result!

• The 24X crank shaf t position s ens or is th e m ost c ritical p art of the ig nition s ystem. If the sens or is d am aged s o

that pulses are not generated, the engine will not start!

• Crankshaft position sensor clearance is very important! The sensor must not contact the rotating interrupter

ring at any time, or sensor damage will result. If the interrupter ring is bent, the interrupter ring blades will

destro y the sensor.

• Ignition timing is not adjustable. There are no timing marks on the crankshaft balancer or timing chain cover.

• Be careful not to damage the secondary ignition wires or boots when servicing the ignition system. Rotate

each boot to dislo dge it from the plug or co il tower before pullin g it from either a spark plug or the ignition c oil.

Never pierce a secondary ignition wire or boot for any testing purposes! Premature failure of the leads will

result if probes or test lights are pushed through the insulation for testing purposes.

POWERTRAIN CONTROL MODULE (PCM)

The PCM is respons ible f or maintain ing prop er spark and fuel injecti on tim ing for all dr iving co nditions. To provide

optimum driveability and emissions, the PCM monitors input signals from the following components in calculating

Ignition Control (IC) spark timing:

• Engine Coolant Temperature (ECT) sensor.

• Intake Air Temperature (IAT) sensor.

• Mass Air Flow (MAF) sensor.

• Knock Sensor (KS).

• Selected automatic transmission range from the Transmission Fluid Pressure (TFP) switch assembly.

• Throttle Position (TP) sensor.

• Vehicle Speed Sensor (VSS).

RESULTS OF INCORRECT OPERATION

An ignition control circuit that is open, grounded, or shorted to voltage will set an ignition control circuit DTC. If a

fault occ urs in t he IC outpu t circuit when th e engi ne is runnin g, the e ngine will experi ence a m isf ire. DT C's P0351-

P0358 will set whe n a malfunction is detected with an Ignition Co ntrol circuit. When an Ignition contro l DTC sets,

the PCM will disable the injector for the appropriate cylinder.

The PCM uses information from the engine coolant temperature sensor in addition to RPM to calculate spark

advance va lues as follo ws:

• High RPM = more advance.

• Cold engine = more advance.

• Low RPM = less adva nc e.

• Hot engine = less adva nce.

Therefore, detonation could be caused by high resistance in the engine coolant temperature sensor circuit. Poor

performance could be caused by low resistance in the engine coolant temperature sensor circuit.

If the engine cranks but will not run or immediately stalls, refer to 6C3-2A DIAGNOSTIC TABLES - GEN III V8

ENGINE, ‘Engine Crank s But W ill Not Run’ diagnostic table of the VT Series II Service Inform ation to determ ine if

the failure is in the ignition or fuel systems.

2. SERVICE OPERATIONS

NOTE: For service information relating to ignition system components not described in this Section, refer to

Section 6C3-3 SERVICE OPERATIONS – GEN III V8 ENGINE of the VT Series II Service Information:

3.2 Powertrain Control Module.

3.3 Powertrain Interface Module

3.13 Camshaft Position Sensor.

3.17 Crankshaft Po sitio n Sen sor.

3.18 Knock Sensor/s .

2.1 SPARK PLUGS AND/OR LEADS

REMOVE

Important: The engine must be cold (below 50°

°°

° C) before removing the spark plugs. Failure to do so may

cause the spark plug/cylinder head threads to bind and result in tearing of the aluminium cylinder head

threads.

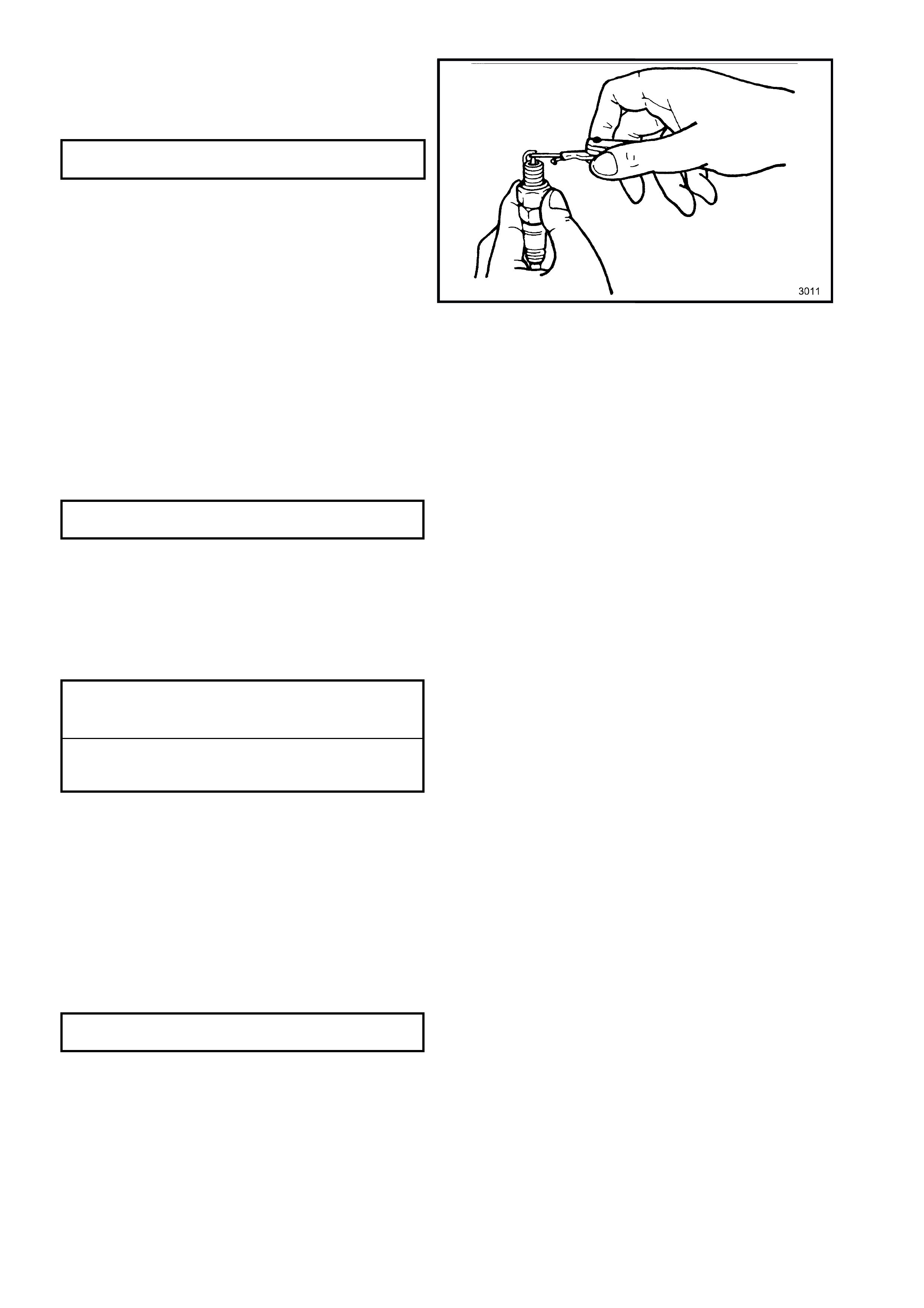

1. Remove the engine dress cover retaining nuts

(2), then remove the cover (1) from the engine

and set to one side.

Figure 6D3-3-7

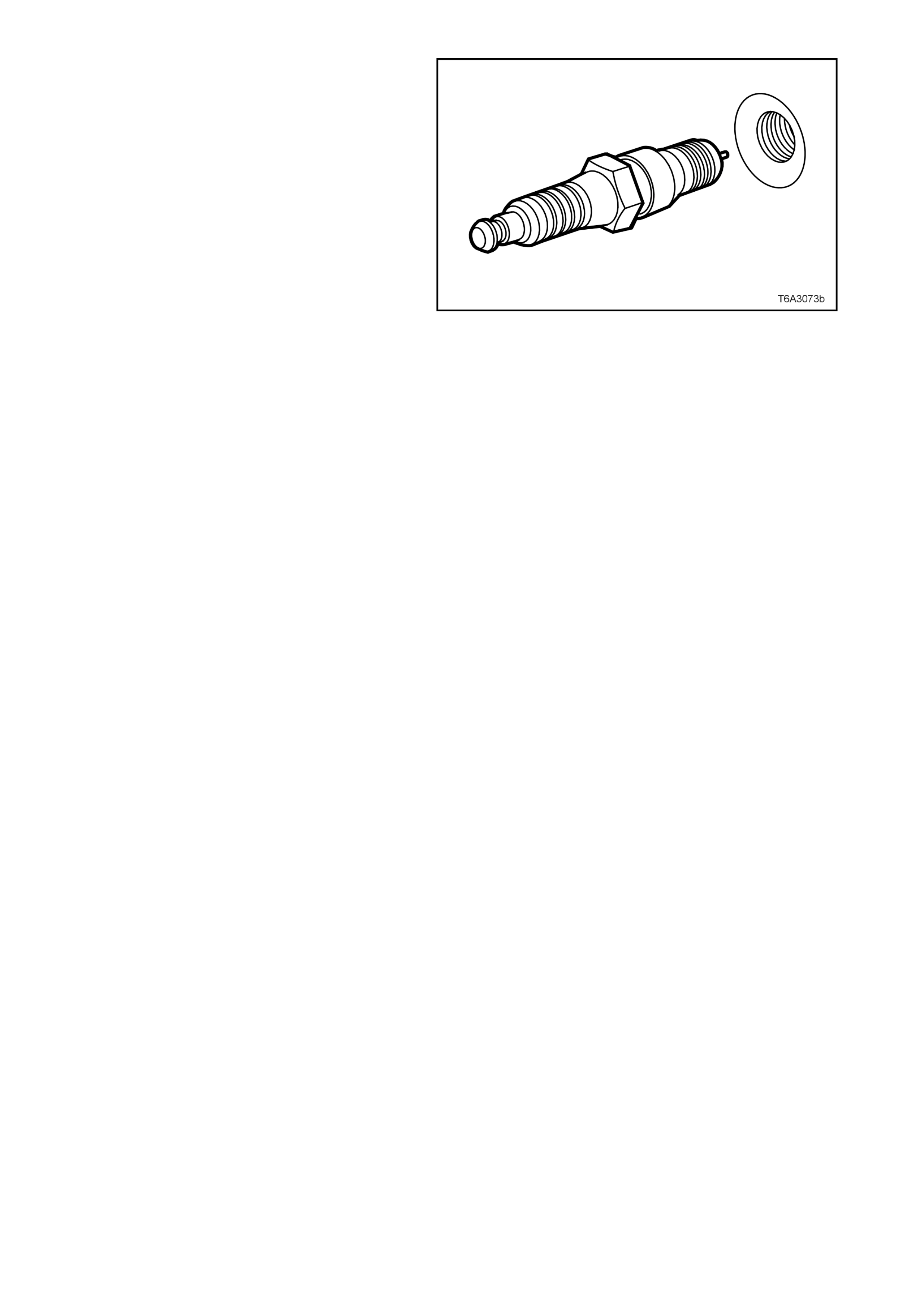

2. Remove the spark plug lead/s, noting the

following:

a. When removing spark plug lead/s, only

handle the boot on each lead, twist to

break the seal, them pull to remove. DO

NOT pull on the lead itself.

b. Unless required, it is not necessary to also

rem ove the lead from the indi vidual c oil, as

shown in Fig. 6D3-3-8.

Figure 6D3-3-8

Techline

Techline

3. Remove the spark plug/s, taking note of the

following;

a. The engine MUST be cold. If not, then the

spark plug and cylinder head threads may

bind, causing the cylinder head threads to

be torn.

b. Loosen the spark plug/s, then re-tighten to

break away any carbon deposits on the

threads.

c. Loosen the spark plug/s once again but,

this time, only one or two turns. Then use

compressed air to remove any foreign

material that may otherwise enter the

combustion chamber.

CAUTION: Wear eye protection to avoid

injury.

d. Continue to remove the spark plug/s.

NOTE: When removing spark plugs always

keep them in order of removal. This will allow

the correct cylinder identification, if a non-

standard spark plug condition is evident

following spark plug inspection.

e. Following removal, plug spark plug hole/s

with rag to prevent foreign matter entering

the combustion chambers.

Figure 9A-9

INSPECT, CLEAN AND ADJUST

Spark Plugs

1. Carefully inspect spark plug insulators and

electrodes. Replace any spark plug with

cracked or broken insulation or loose

electrodes.

NOTE: Refer to 3. DIAGNOSIS in

Section 6D2-3 IGNITION SYSTEM - V8

ENGINE, of VT Series I Service Information,

for identification of various spark plug

conditions.

2. If spark plugs are oi ly, cle an with a degre asing

agent and dry with compressed air.

CAUTION: Wear eye protection to avoid

injury.

3. If required, clean spark plugs using

commercially available sand blast type of

cleaning machine. Always follow the

manufacturer’s instructions for correct

operation of the equipment.

4. Following cleaning operations, inspect the

spark plug condition aga in, as def ects ma y not

have been previously visible.

5. Check that s park plug threads ar e clean and in

good condition. If evidence of aluminium is

seen in the threads, then use a suitable spark

plug tap to ‘chase’ the threads in the cylinder

head before reinstallation.

6. Use round wire f eeler gau ges to chec k the gap

between the spark plug electrodes.

7. Adjust the gap to the correct specification by

caref ull y bending the outer elec tr ode.

SPARK PLUG GAP 1.52 ± 0.05 mm

Figure 6D3-3-10

Spark Plug Leads

1. Carefully inspect the spark plug and ignition

coil boots on each lead for cracks, splits or

other deterioration. Replace any lead

exhibiting these conditions.

2. Connect an accurate Ohmmeter across each

spark plug lead. Replace any spark plug lead

that exceeds the specified resistance value.

SPARK PLUG LEAD 700 Ohm

RESISTANCE SPECIFICATION Maximum

REINSTALL

1. Remove rag from spark plug holes.

2. Reinstall spark plugs by hand and tighten to

the correct torq ue sp ecific ation, us ing a 16 m m

spark plug socket and a suitable torque

wrench.

SPARK PLUG TORQUE

SPECIFICATION WITH 15 Nm

ORIGINAL CYLINDER HEAD

SPARK PLUG TORQUE

SPECIFICATION WITH NEW 20 Nm

CYLINDER HEAD (‘COINING’)

3. Reinstall spark plug leads, taking note of the

following:

a. Always push each lead squarely onto both

the ignition coil and spark plug ends.

b. Ensure that the heat shield at the spark

plug end is secure and th at the connec tion

to the spark plug centre electrode is

correctly and fully engaged.

4. Reinstall the engine dress cover, install the

four decorative retaining nuts and tighten to

the correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 8.0 – 12 Nm

2.2 IGNITION COIL/MODULE

REMOVE

1. Disconnect the battery earth (negative) cable

from the battery.

2. Remove the engine dress cover retaining nuts

(2), then remove the cover (1) from the engine

and set to one side.

Figure 6D3-3-11

3. Remove the spark plug lead/s, noting the

following:

a. When removing spark plug lead/s, only

handle the boot on each lead, twist to

break the seal, them pull to remove. DO

NOT pull on the lead itself.

b. Unless required, it is not necessary to also

remove the lead from the individual spark

plug as shown in Fig. 6D3-3-12.

Figure 6D3-3-12

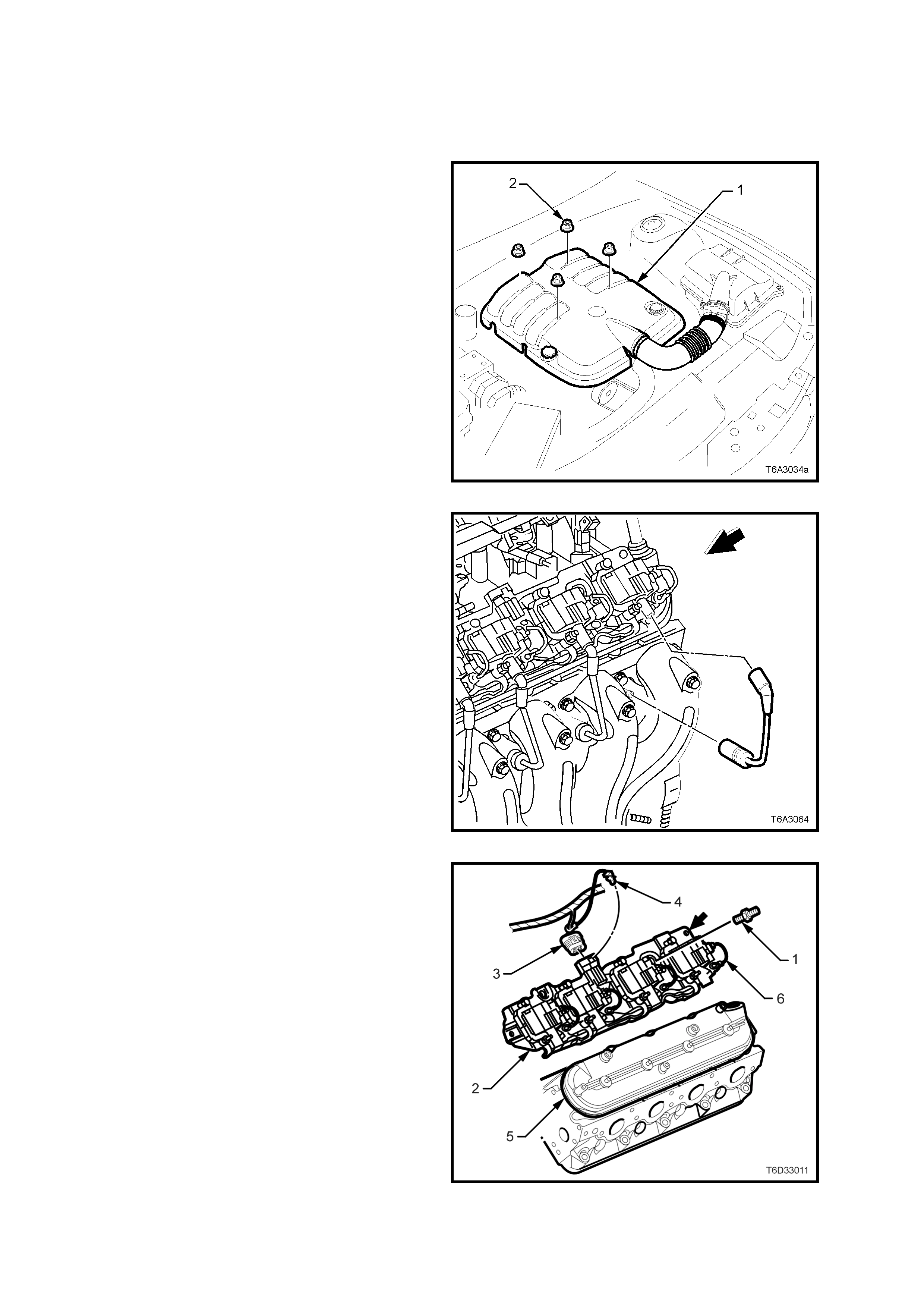

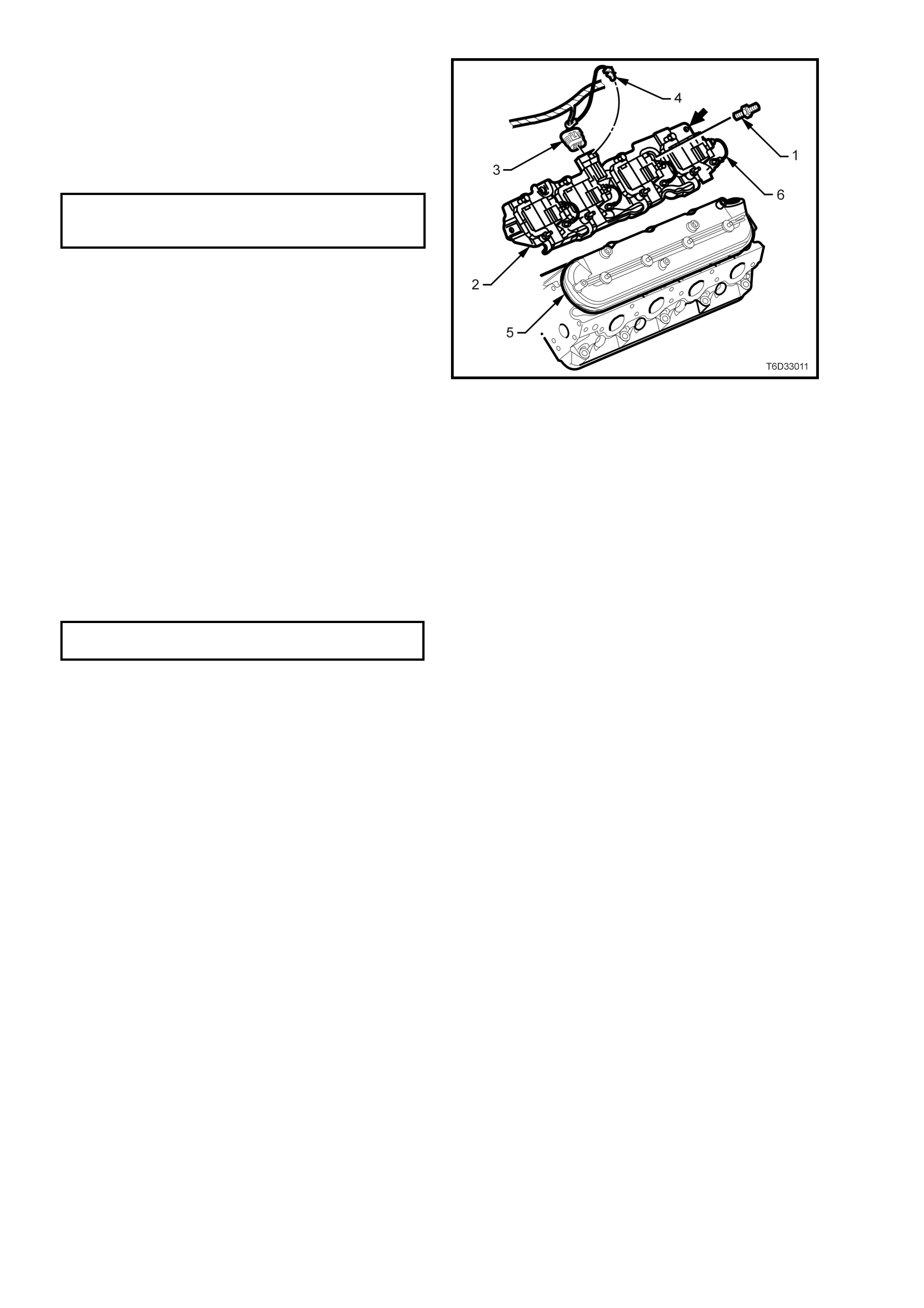

4. Rem ove the CPA lock (4) from the ign ition coi l/

module m ain connector f rom the side on which

the ignition coil/module is to be removed.

5. Remove the wiring harness connector (3).

6. Rem ove the f our s tu ds ( 1) an d o ne s c re w (bo ld

arrow), securing the coil/module mounting

bracket (2) to the valve rocker arm cover (5).

7. Lift the ignition coils/modules, wiring and

bracket from the engine.

NOTE: The rear attaching screw (bold arrow) on

each coil/module mounting bracket is a

conventional screw and not a stepped stud.

Fitment of this screw in the correct position on

reassembly is important to avoid possible chaffing.

8. Remove the CPA lock (6) from the coil/module

to be removed, then remove the coil wiring

harness connector. Figure 6D3-3-13

9. Remove the coil/module retaining screws (1)

holding the coil/module (2) to the mounting

plate (3).

10. Remove the coil/module (2) from the mounting

plate (3).

Figure 6D3-3-14

TEST

For ignition system checks, refer to

6C3-2C FUNCTIONAL CHECKS – GEN III

ENGINE, Electronic Ignition System Diagnosis, of

the VT Series II Service Information.

REINSTALL

Reinstallation is the reverse of removal operations

except for the following items.

1. Install the coil/module/s (2) to the mounting

plate (3) and secure with the retaining screws

(1), tightening to the correct torque

specification.

IGNITION COIL/MODULE RETAINING

BOLT TORQUE SPECIFICATION 12 Nm

Figure 6D3-3-15

2. Ensure that the co il wiring har n ess c onnector is

fitted cor rectl y and t hat the C PA l ock (6) is full y

installed.

3. Install the coil/module mounting bracket to the

valve rocker arm cover (5), install the four

studs (1) and one screw (bold arrow) and

tighten to the correct torque specification.

IGNITION COIL/MODULE

BRACKET STUD/SCREW 12 Nm

TORQUE SPECIFICATION

NOTE: The rear attaching screw (bold arrow) on

each coil/module mounting bracket is a

conventional screw and not a stepped stud.

Fitment of this screw in the correct position is

important to avoid possible chaffing.

4. Install the ignition coil/module main wiring

connector (3) and secure with the CPA lock

(4).

5. Reinstall spark plug leads, taking note of the

following:

a. Always push each lead squarely onto both

the ignition coil and spark plug ends.

b. Ensure that the heat shield at the spark

plug end is secure and that the connection

to the spark plug centre electrode is

correctly and fully engaged.

Figure 6D3-3-16

6. Reinstall the engine dress cover, install the

four decorative retaining nuts and tighten to

the correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 8.0 – 12 Nm

7. Reinstall the battery earth (negative) lead to

the battery.

8. Perform the ‘Idle Learn Procedure’ and the

‘Functional Check’. Refer to

Section 6C3-3 SERVICE OPERATIONS –

GEN III V8 ENGINE, 3.2 Powertrain Control

Module (PCM), of the VT Series II Service

Information.

3. DIAGNOSIS

For diagnosis of the ignition system, refer to Section 6C 3-2A D IAGNOSTIC TABLES – GEN III V8 ENG IN E, of the

VT Series II Service Information.

For diagnos is of s park plugs and /or their c ondi tion, refer to 3. DIAG NOSI S in Se ction 6D2-3 IGNIT ION SYST EM -

V8 ENGINE, of the VT Series I Service Information.

4. SPECIFICATIONS

Firing Order........................................................................... 1-8-7-2-6-5-4-3

Spark Plug Identification....................................................... AC 41-952

Spark Plug Part Number....................................................... 25171803

Spark Plug Heat Range........................................................ 2

Spark Plug Resistance ......................................................... 4 – 12 kΩ

Spark Plug Gap..................................................................... 1.52 ± 0.05 mm

Spark Plug Lead Resistance ................................................ 700 Ω maximum

5. TORQUE WRENCH SPECIFICATIONS

Nm

Engine Dress Cover Retaining Nut....................................... 8 - 12

Ignition Coil to Mounting Bracket Screw............................... 12

Ignition Coil Bracket to Rocker Cover Screw........................ 12

Spark Plugs........................................................................... 15

Spark Plugs (New Cylinder Head - ‘Coining’)....................... 20