SECTION 8B – EXHAUST SYSTEM

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenge r's air bags or se at belt pre-t ensio ners, d river’s and f ront p asseng er’s a ir bag and lef t and right

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M, Supplemental Restraint System of the

VT Series I Service Information before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DI AGNOSI S, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, in eithe r

the VT Series I Service Information (V6) or the VT Series II Service Inforamation (GEN III V8) of this

Service Information CD.

1. GENERAL DESCRIPTION

The exhaust system fitted to VT Series II vehicles, V6 and V6 supercharged engin es, carries over f rom the earlier

models. Therefore, for information and servicing procedures for these engines, refer to

Section 8B EXHAUST SYSTEM, in the VT Series I Service Information.

The engine exhaust manifolds for all engines connect to two equal length, symmetrical stainless steel front pipes.

With the GEN III V8 engine, the front exhaust pipes are of a dual wall air gap construction.

The design of the exhaust system for GEN III V8 engined VT Series II models is essentially the same as for the

earlier 5 litr e V8 engine; i.e. the s ystem features the low back pressur e exhaust s ystem and ret ains a dua l exhaust

system back to the rear of the twin intermediate mufflers. At this point, the exhaust converges into a single pipe and

rear muffler/tailpipe arrangement.

A catalytic converter is welded to each engine pipe, with a flanged, gasket joint connecting each converter to the

twin, intermediate exhaust pipes. A service catalytic converter is available for replacement purposes.

The two interm ediate exhaus t pipes are stiff ened by a welded bri dging piece an d bala nce p ipe, at points bef ore the

twin intermediate m uff ler s .

The GEN III V8 engine catalytic converters are supported by a bracket bolted to each converter and the

transm ission extensio n housing. The autom atic transm ission desig n is dif ferent to th at fitted t o the 6 sp eed m anual

transmission.

Further support for the exhaust system is provided by two rubber support rings attached to the rear suspension

crossmem ber and the re ar of eac h intermediat e muff ler . T he r ear m uff ler s uppor t is pr ov id ed by two r u bber bumper

supports att ached to br ackets welde d to the vehicl e underbod y, and brack ets attached to t he rear tail pip e, rear of

the rear muffler.

The rubber support rings are a common part for all locations and are secured by:

a. Clips at the intermediate muffler brackets, welded to the rear suspension crossmember and clips at the rear

body hanger bracket.

b. Flanged pegs at other locations .

Techline

2. SERVICE OPERATIONS

2.1 SERVICE NOTES

When installing any exhaust system component,

care must be taken to install each component in

the correct relationship to one another.

Incorrec t assem bly of exhaust s ystem c om ponents

can frequently be the cause of rattles and ‘booms'

due to incorrect alignment or clearance from body

or suspension parts.

When installing the exhaust system, ensure that

the correct assembly, installation, tightening

sequence and clearance for the system involved

are observed.

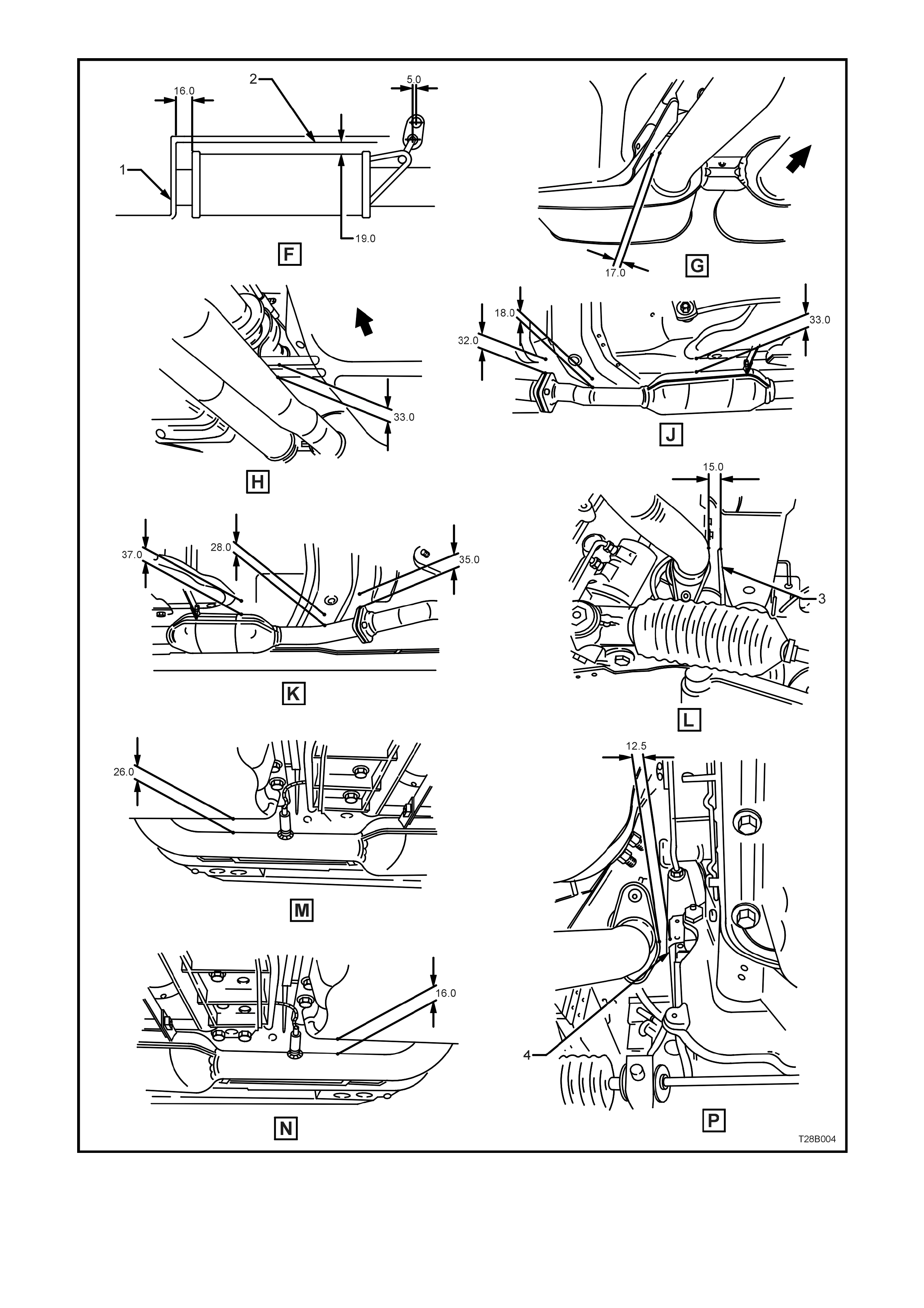

When exhaust system service work is required,

refer to the various illustrations and instructions

provided in this Section, for the necessary

information for the correct arrangement, alignment

and clearances for the GEN III V8 engine,

available in the VT Series II range of vehicles.

Step by step procedures for the replacement of

individual exhaust system components are not

included as special instructions are not required;

only normal workshop practices are necessary.

Both clearances and torque specifications for

fasteners are detailed in the illustrations included

in this Section.

A service replacement catalytic converter is

available, allowing the exhaust pipe to be welded

to the component. If removing or replacing the

converter and engine exhaust pipe, always ensure

that new sealing gaskets are installed on

reassembly.

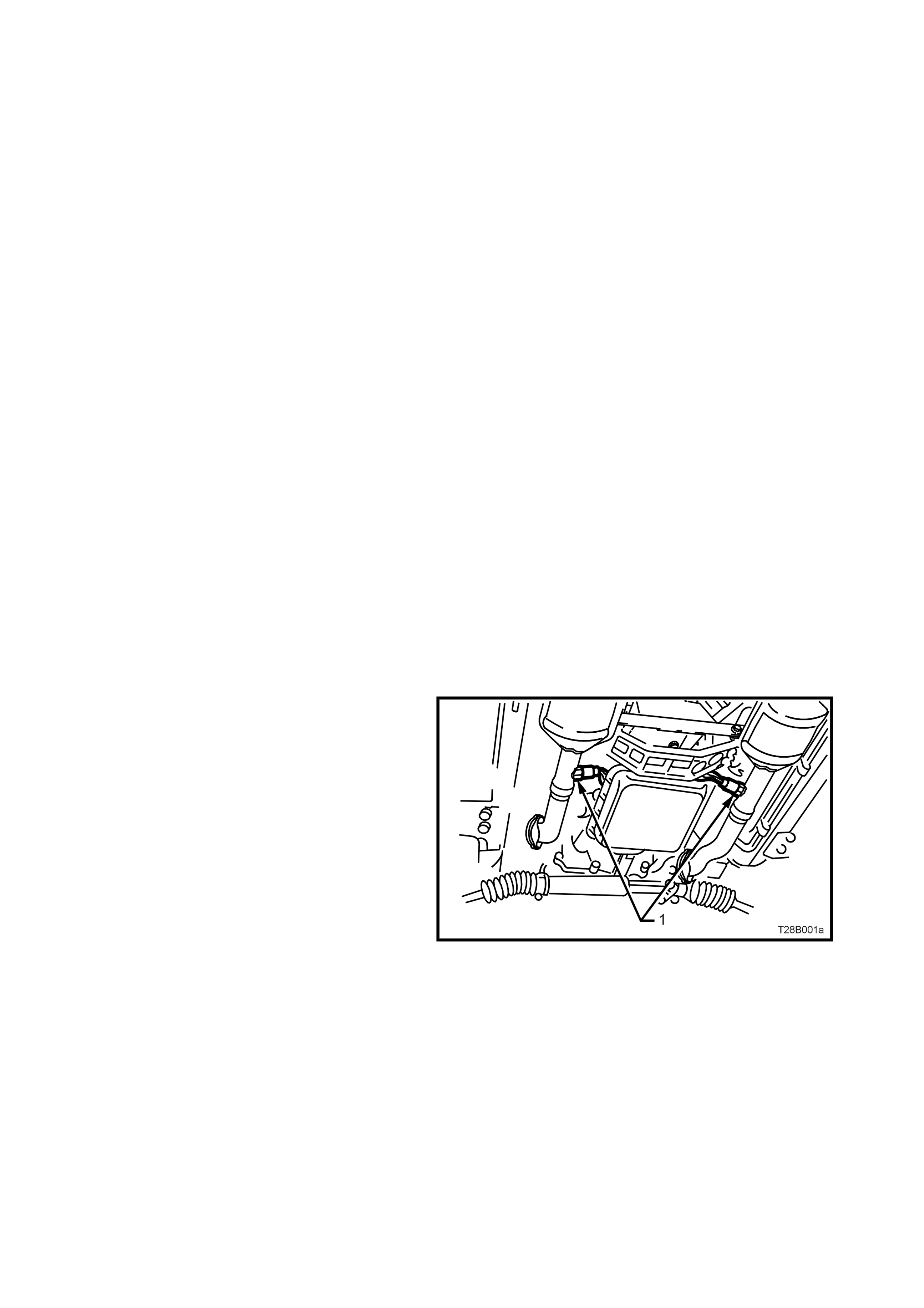

For Oxygen Sensor (1) replacement, refer to

Section 6C3 POWERTRAIN MANAGEMENT –

GEN III V8 ENGINE in the VT Series II Service

Information.

Figure 8B-1 Oxygen Sensor Location, GEN III V8 Engine

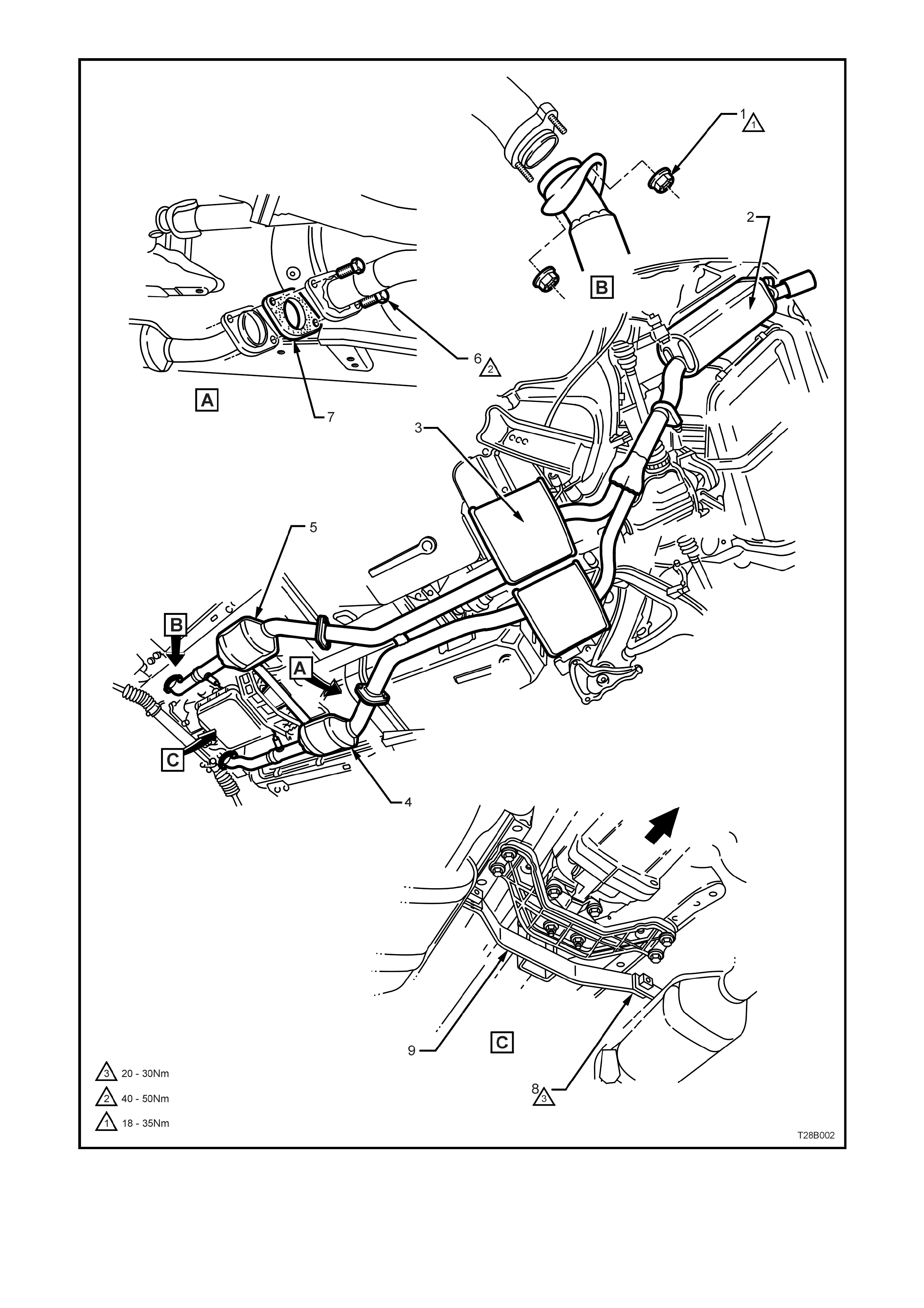

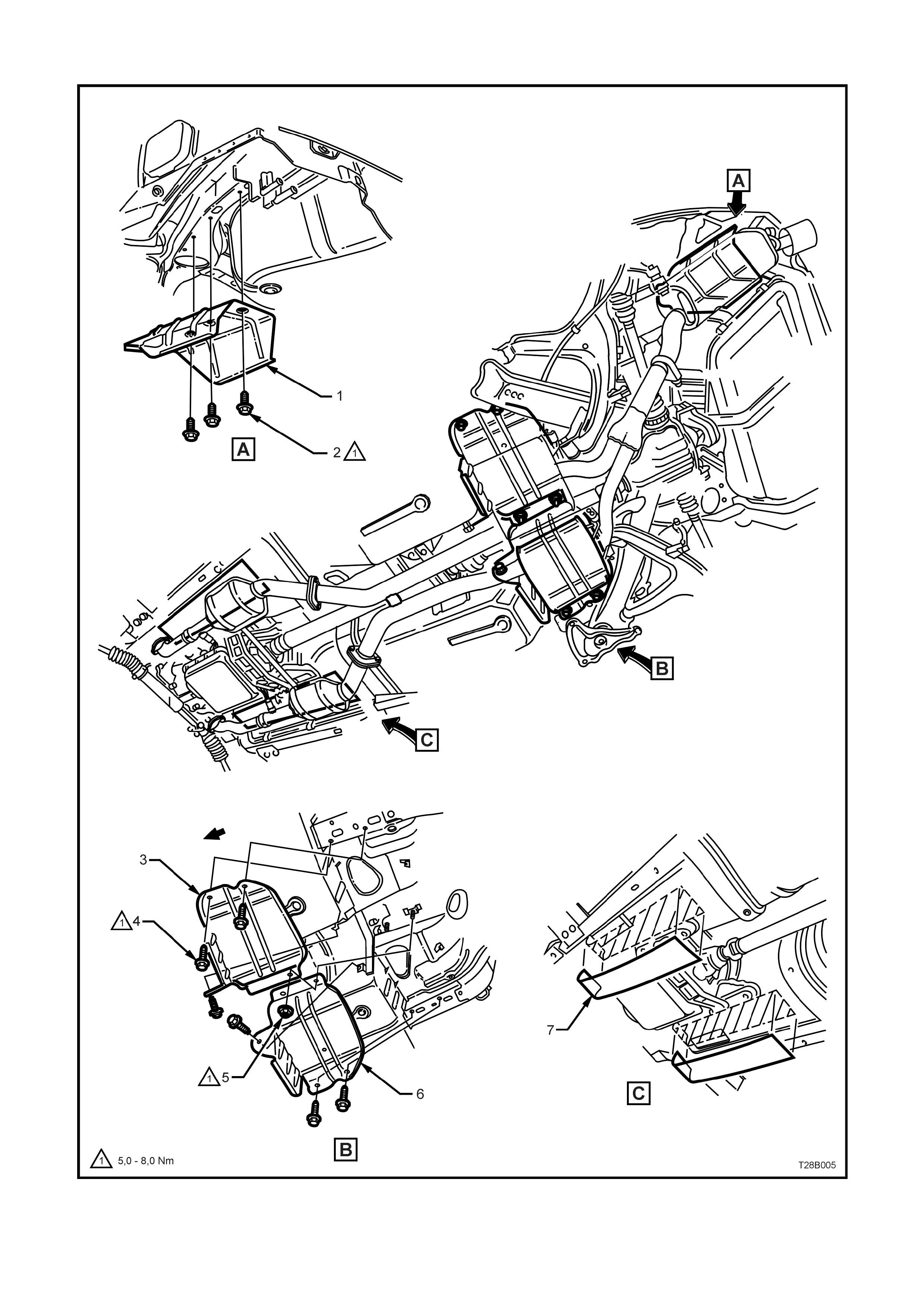

2.2 EXHAUST FITMENT AND TIGHTENING SEQUENCE - GEN III V8 E NGINE

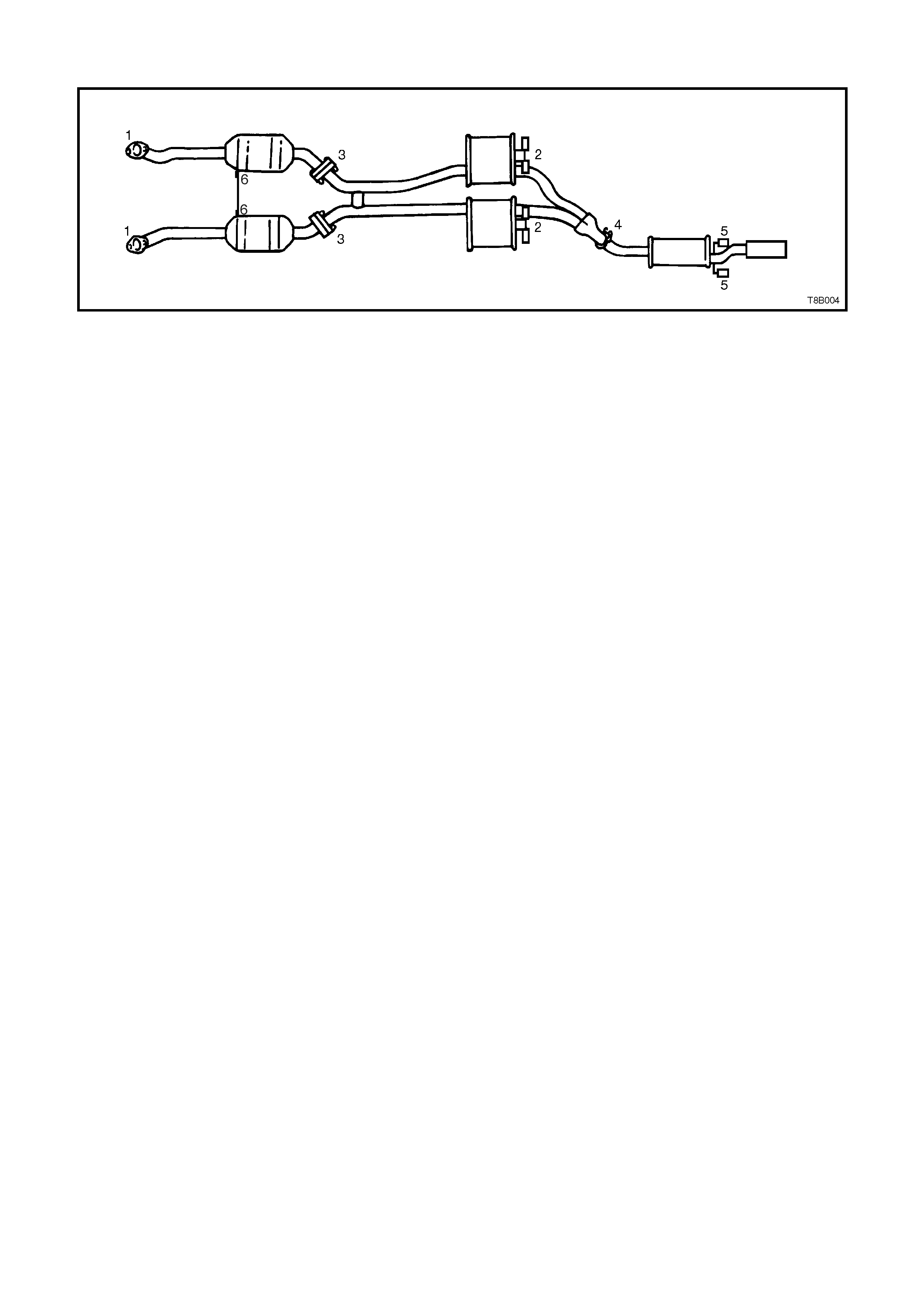

Figure 8B-2 GEN III V8 Engine Exhaus

Installation

Loosely install exhaust system as follows;

1. Attach front pipe and catalytic converter assembles, loosely to the exhaust manifolds (1).

2. Hook intermediate assembly to suspension brackets with four bum per rubbers (two per intermediate m uffler).

Fit four retaining clips to the suspension bracket ends (2).

3. Hand start bolts t o the inter m ediate exha ust pip e to c atal ytic co nverter f langes , af ter insta lling a new gas k et to

each flange (3).

4. Hand start the two bolts securing the catalytic converter bracket to the converters (6).

5. Install the intermediate muffler assembly to the rear muffler assembly and loosely install U-bolt clamp (4).

6. Attach the rear muffler assembly to the body mount hangers with two bumper rubbers (5) and retaining clips.

Tightening Sequence

1. Tighten the flange bolts at the rear of the catalytic converter (3).

2. Evenly tighten the U-bolt clamp nuts at the intermediate to rear muffler slip joint (4).

3. Tighten each of the flange nuts evenly, so that a similar amount of thread is showing on each (1).

4. Ensure that all bumper rubbers are under load (2 and 5). If this is not achieved, loosen exhaust joints in the

reverse order to the above. Load the hangers and re-tighten in the sequence described, from steps 1 to 3.

5. After all other operations have been completed, tighten the catalytic converter bracket bolts.

NOTE1: The exhaust system should be self-aligning and not require further adjustment, provided step 4 is

achieved.

NOTE 2: When tightening all fasteners related to the exhaust system, refer to

5. TORQUE WRENCH SPECIFICATIONS in this Section, for the correct values.

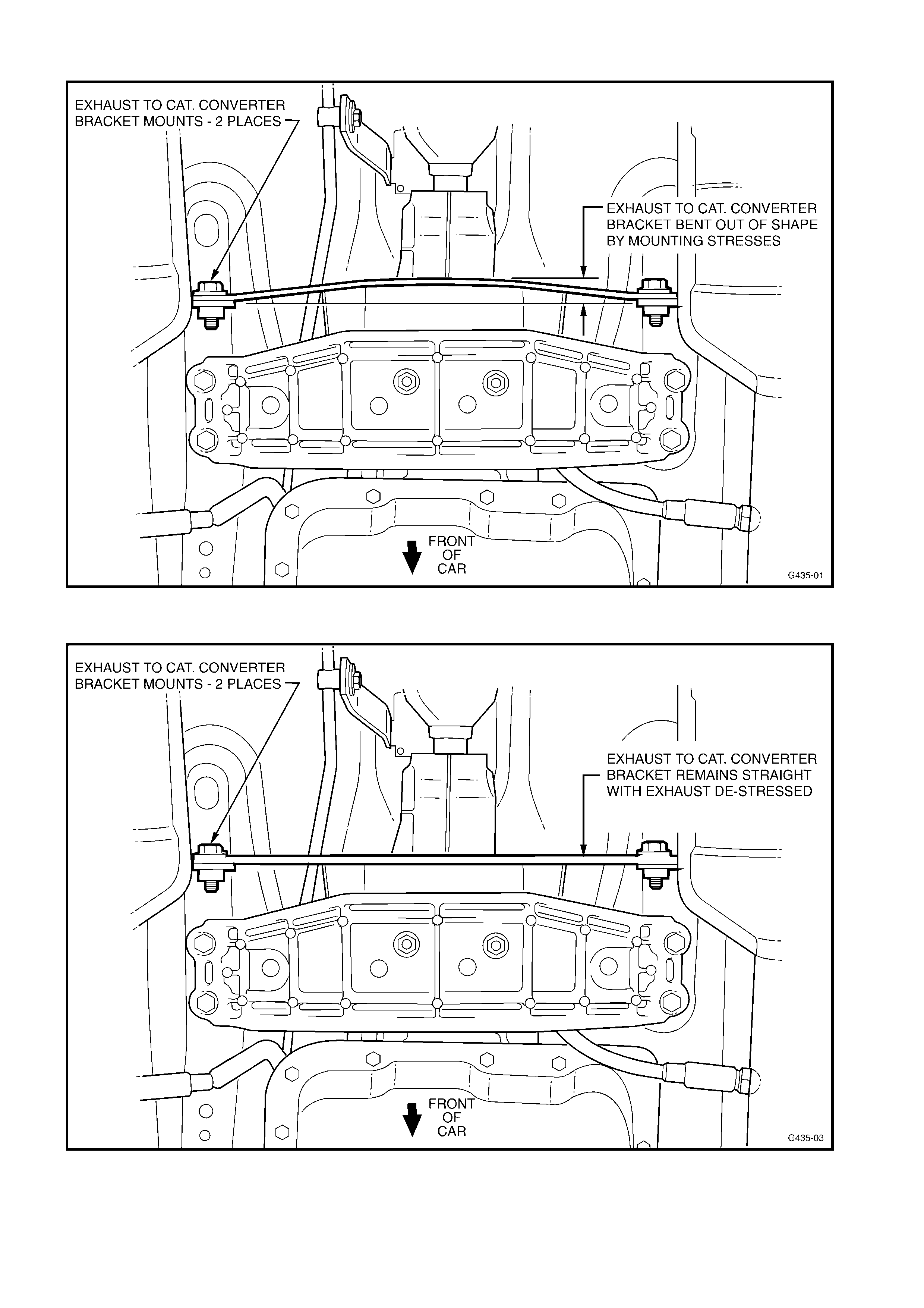

NOTE 3: An indication that the exhaust system is stressed is a bent bracket as shown in Figure 8B-3. W hen de-

stressed, the bracket will remain straight as shown in Figure 8B-4. Refer to TL101-0802

Figure 8B-3

Figure 8B-4

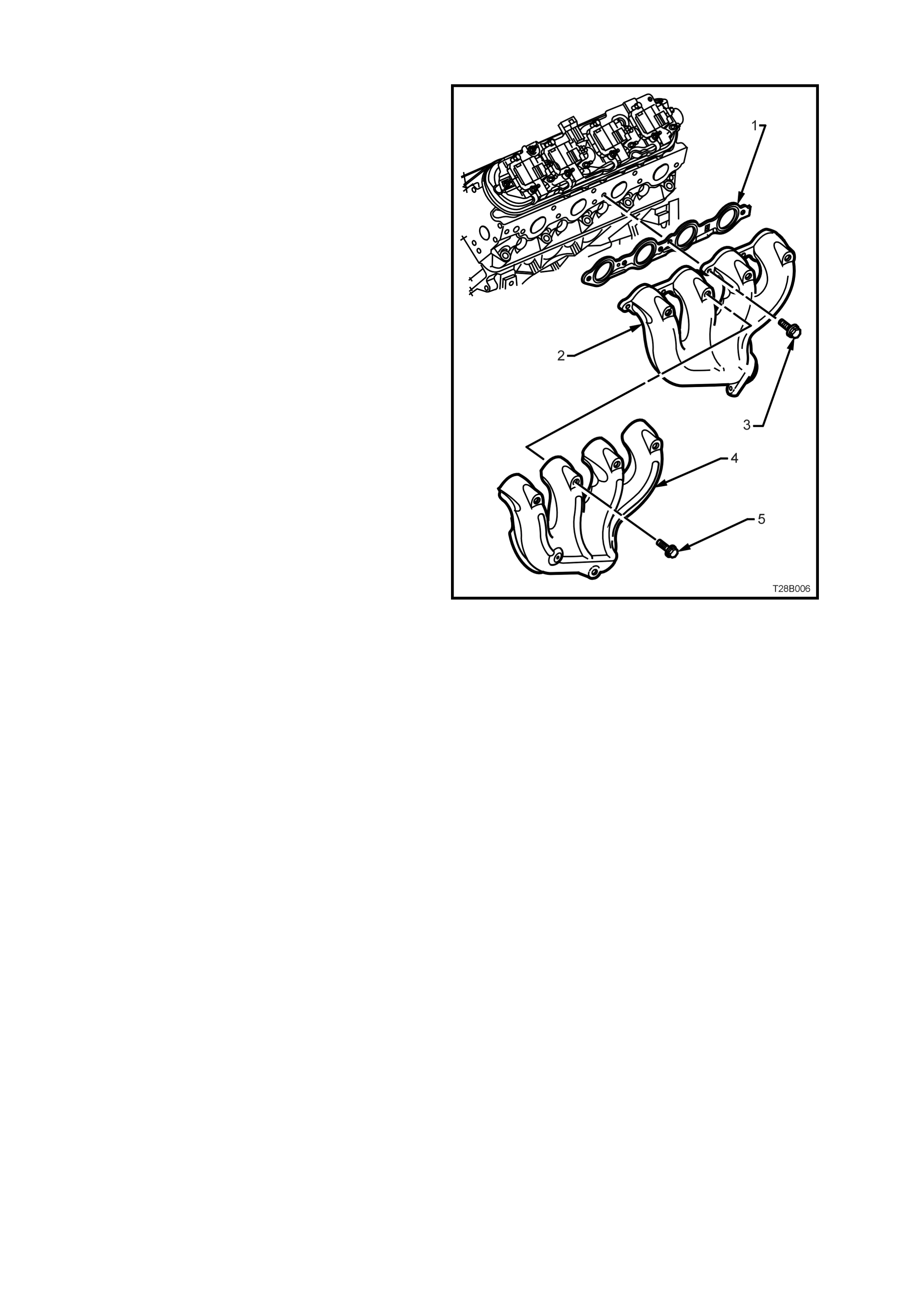

2.3 EXHAUST MANIFOLD INSTALLATIONS - GEN III V8 ENGINE

The exhaust manifolds fitted to the GEN III V8

engine, are of a one piece, high temperature

silicone molybdenum cast iron and direct exhaust

gases from the combustion chambers to the

exhaust system.

Each manifold (2) also has an externally mounted,

heat shield (4) attached, that is made from

aluminiumised steel. Each heat shield is attached

to the manifold by 5 screws (5).

NOTE: While the left hand exhaust manifold (2) is

shown, the right hand arrangement is similar.

Legend:

1. Gasket – Exhaust Manifold

2. Manifold – Exh aus t

3. Bolt – Exhaust Manifold to Cylinder Head

4. Shield – Exahust Manifold Heat

5. Screw – Heat Shiel dto Exahust Manifold (5

places).

Figure 8B-5

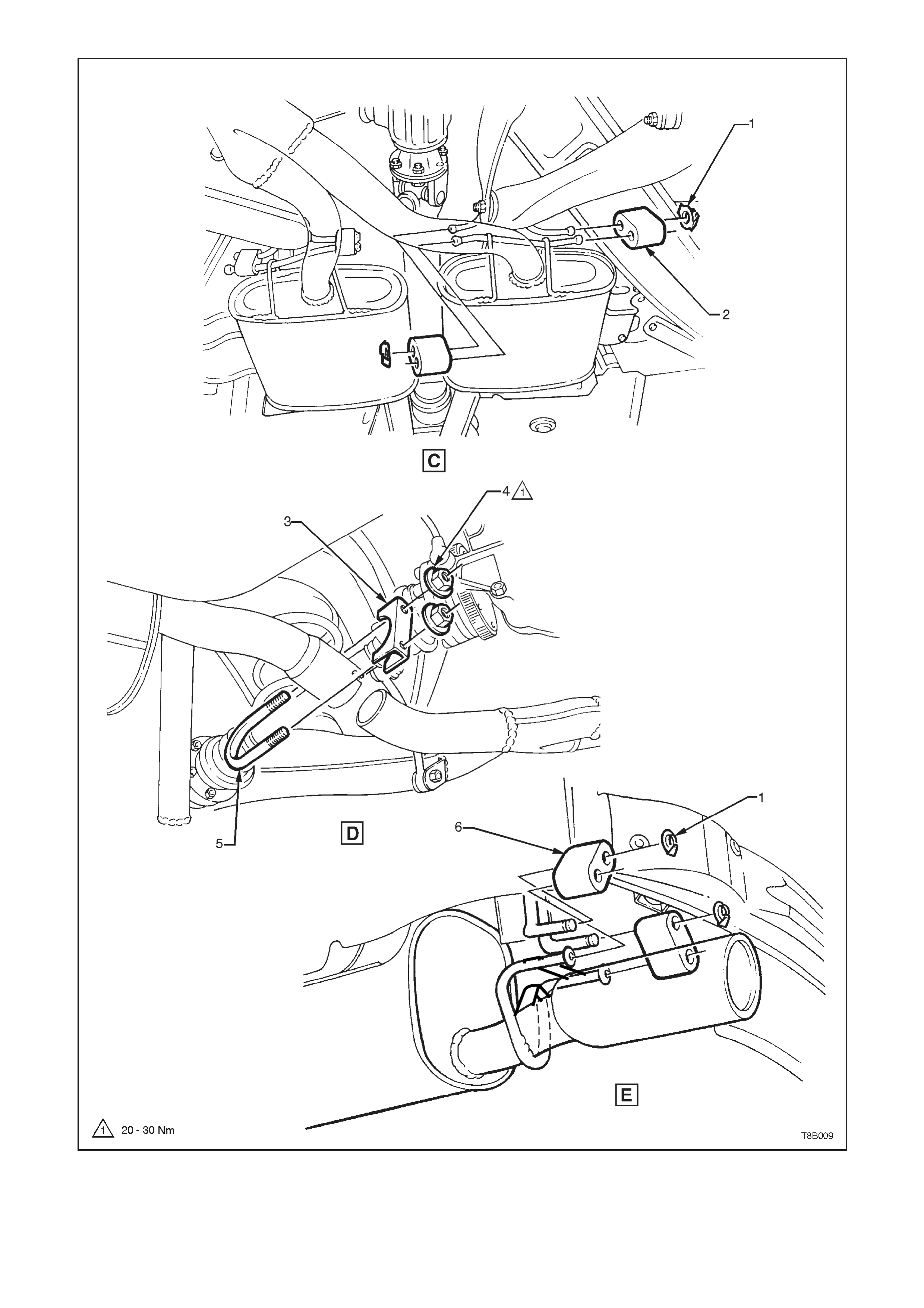

2.4 EXHAUST SYSTEM LAYOUT - GEN III V8 ENGINE

The f ollowing la yout d iagrams r elate to the exhaus t system used for the GEN II I V8 engine. T hey are arranged on

facing pages to provide maximum benefit.

1. Nut - 2 places 4. Catalytic Converter LH 7. Gasket - 2 places

2. Muffler 5. Catalytic Converter RH 8. Bolt - 2 places

3. Intermediate Mufflers - Right and Left 6. Bolt - 4 places. 9. Catalytic Converter Bracket - Man. Trans.

Figure 8B-6 Exhaust System Layout, GEN III V8 Engine (Sheet 1 of 2)

1. Retainer - 6 places 3. Clamp - U-bolt 5. U-bolt

2. Bumper Rubber - 4 places 4. Nut - 2 places 6. Bumper Rubber - 2 places

Figure 8B-7 Exhaust System Layout, GEN III V8 Engine (Sheet 2 of 2)

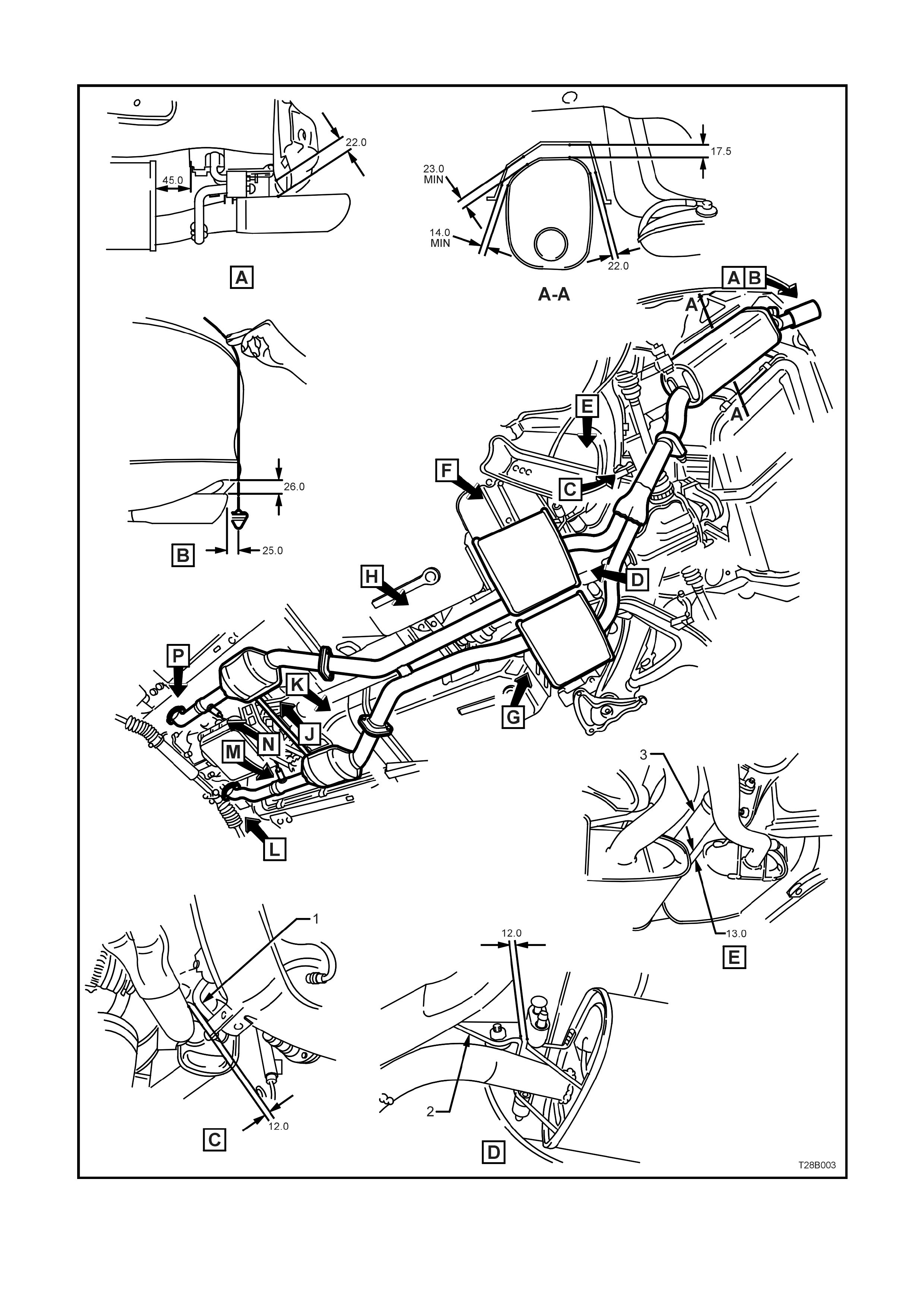

2.5 EXHAUST SYSTEM CLEARANCES - GEN III V8 ENGINE

1. Stabiliser Bar Link 2. Rear Suspension Control Arm Mount 3. Propeller Shaft

Figure 8B-8 Exhaust System Clearances, GEN III V8 Engine (Sheet 1 of 2)

1. Rear Footwell 2. Intermediate Heat Shield 3. RH Sub Frame 4. Engine Block

Figure 8B-9 Exhaust System Clearances, GEN III V8 Engine (Sheet 2 of 2)

2.6 EXHAUST SYSTEM HEAT SHIELDS – GEN III V8 ENGINE

Figure 8B-10 - Heat Shields, GEN III V8 Engine

Legend, refer Figure 8B-8

1. Heat Shield - Rear Muffler 5. Nut - 2 places

2. Screw - 3 places 6. Heat Shield - RH Intermediate Muffler (all except V6)

3. Heat Shield - LH Intermediate Muffler 7. Self-adhesive Insulators (all except V6)

4. Screw - 6 places

3. EXHAUST SYSTEM DIAGNOSIS

CONDITION PROBABLE CAUSE CORRECTION

Leaking exhaust gases Leaks at pipe joints. Tighten U-bolt nuts and joint bolts

to the correct torque

specifications.

Damaged or improperly installed

converter sealing ring/gaskets. Replace gasket as necessary.

Bu rned or rusted out exhaust pipe

or muffler/s. Replace component as necessary.

Exhaust noises Leaks at manifold or pipe

connections. Tighten clamps at leaking

connections to the correct torque

specifications. Replace gasket as

required.

Burned or blown out pipe or

muffler/s. Replace pipe/muffler assembly as

necessary.

Exhaust manifold/s cracked or

broken. Replace manifold.

Leak between manifold/s and

cylinder hea d/s . Tighten manifold to cylinder head

studs to the correct torque

specification.

Loss of engine power, hesitation,

surging, poor fuel economy,

stalling or

Clogged catalytic converter (may

result from serious engine

malfunction).

Replace catalytic converter.

hard starting Crushed pipework. Replace pipework.

Internal rattling in muffler Dislodged tubes and/or baffles in

muffler. Replace muffler.

Catalytic converter monolith has

crumbled and pieces blown into

muffler.

Replace catalytic converter

assem bl y and aff ected muffler.

Techline

4. SPECIFICATIONS

TYPE:......................................................................... Single system

MATERIAL:

Engine Pipes.............................................................. 409 stainless steel

Intermediate Muffler ................................................... 409 stainless steel

Rear Muffler................................................................ 409 stainless steel

CATALYTIC CONVERTER:

Make ......................................................................... AC Australia

Type ......................................................................... Three way monolith

Outer Steel Shell

Material ............................................................ Stainless

Inlet Diameter................................................... 57 mm

Outlet Diameter................................................ 57 mm

Monolith

Material.................................................................... Extruded Cordierite

Volume

V6 Engine ........................................................... 1.6 litres

V6 Supercharged and GEN III V8...................... 1.4 litres each

Cells/in2................................................................... 400

5. TORQUE WRENCH SPECIFICATIONS

GEN III V8 Nm

Catalytic converter bracket bolt to converter........................ 40 - 50

Engine front pipe flange to exhaust manifold flange nut....... 18 - 35

Front exhaust pipe to intermediate pipe flange bolts............ 40 - 50

Exhaust manifold to cylinder head bolts; Stage 1............... 15

Stage 2............... 25

Exhaust manifold heat shield screw ..................................... 8 - 10

Exhaust U-bolt clamp nuts.................................................... 20 - 30

Heat shield screws/nuts to underbody.................................. 5 - 8