SECTION 0A - GENERAL INFORMATION

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenger's air b ags o r seat b elt p re-t ension ers, driv er’s an d f ron t p asseng er’s air bag and left and righ t

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System

before performing any se rvice operation on, or around any S RS components, the steering mechanism or

wiring. Failure to follow the SAFETY PRECAUTIONS could result in SRS deployment, resulting in

possible personal injury or unnecessary SRS system repairs.

CAUTION:

This vehicle may be equipped with LPG (Liquefied Petroleum Gas). In the interests of safety, the LPG

fuel system should be isolated by turning 'OFF' the manual service valve and then draining the LPG

service lines, before any service work is carried out on the vehicle. Refer to the LPG leaflet included with

the Owner's Handbook for details or the appropriate Section for more specific servicing information.

1. GENERAL INFORMATION

With the release of the VT Series II Model, Production Option A9W, comes the introduction of new features and

equipment changes, including an all new 5.7 litre V8 engine.

The following information summarises these new features and changes, with additional and more detailed

information provided in the relevant Section of this Service Information CD.

New paint colours.

New and revised exterior ornamentation including; Series II and Gen III V8 badging, new decor panels, and body,

drip, belt line, rocker panel and fascia mouldings.

Various new interior trim colours and materials (dependent on Model variant).

New side repeater lamps with clear lens.

New tail lamps on all Models.

New grille inserts.

New wheels and wheel trims (depended on Model variant).

Availability of cruise control for vehicles with manual transmission.

New instrument cluster with improved diagnostic capabilities and ‘PRND321’ display.

Revised engine cooling fans for vehciles with V6 engine.

Availability of a new V8 engine, Production Option LS1, and named the GEN III V8. This engine, replacing the

Holden 5.0 litre V8 engine, is an all new 5.7 litre V8 engine, featuring an alum inium cylinder block and heads, with

cast iron sleeves cast into the cylinder block.

The Powertrain Control Module (PCM) for the GEN III V8 engine is located in the engine compartment with a

Powertrain Interface Module (PIM), located behind the left hand cowl panel trim which enables communication

between the PCM and BCM.

Also available with the GEN III engine is an optional six speed Borg-Warner (Tremec) T56 manual transmission.

Production Option L67, supercharged V6 engine, now available on Berlina Models and standard for Calais.

Electronic Traction Control (ETC) available on vehicles with GEN III V8 engine (previously not available for vehicle

with V8 engine).

Upgraded BCM; which includes:

Remote deadlocking via remote key (two lock button presses within ten seconds).

Battery saver feature; turns off all internal lamps after one hour of the ignition being switched off.

This feature inc ludes a pre- delivery mode which sets the tim er to a shorter period of three m inutes until the vehic le

has travelled above 20km/h for a cumulative period of 30 m inutes. After this period, the battery saver timer sets to

one hour.

The standing current in the BCM has also been lowered from 18mA to 4mA.

Key off courtesy lamp; courtesy lamp comes on for 30 seconds when the ignition is switched off.

Disablement of the in-vehicle boot release button when security system armed.

Techline

Techline

Techline

Techline

Techline

Techline

Approach illumination entry (High Series BCM only); headlamps and par k lamps ar e turned on f or 30 s econds when

headlamp switch in AUTO position and the vehicle is unlocked via the remote key.

HSPO aftermarket alarm compatibility (TECH 2 selectable).

Deletion of two hour override (this change was implemented as a running change in July 1998)

Front and rear power windows standard on SS Models.

Front power windows standard on Acclaim and S Models.

Power antenna, full up and down, added as standard to SS Models.

For additional General Information not covered in this Section, refer to Section 0A GENERAL INFORMATION.

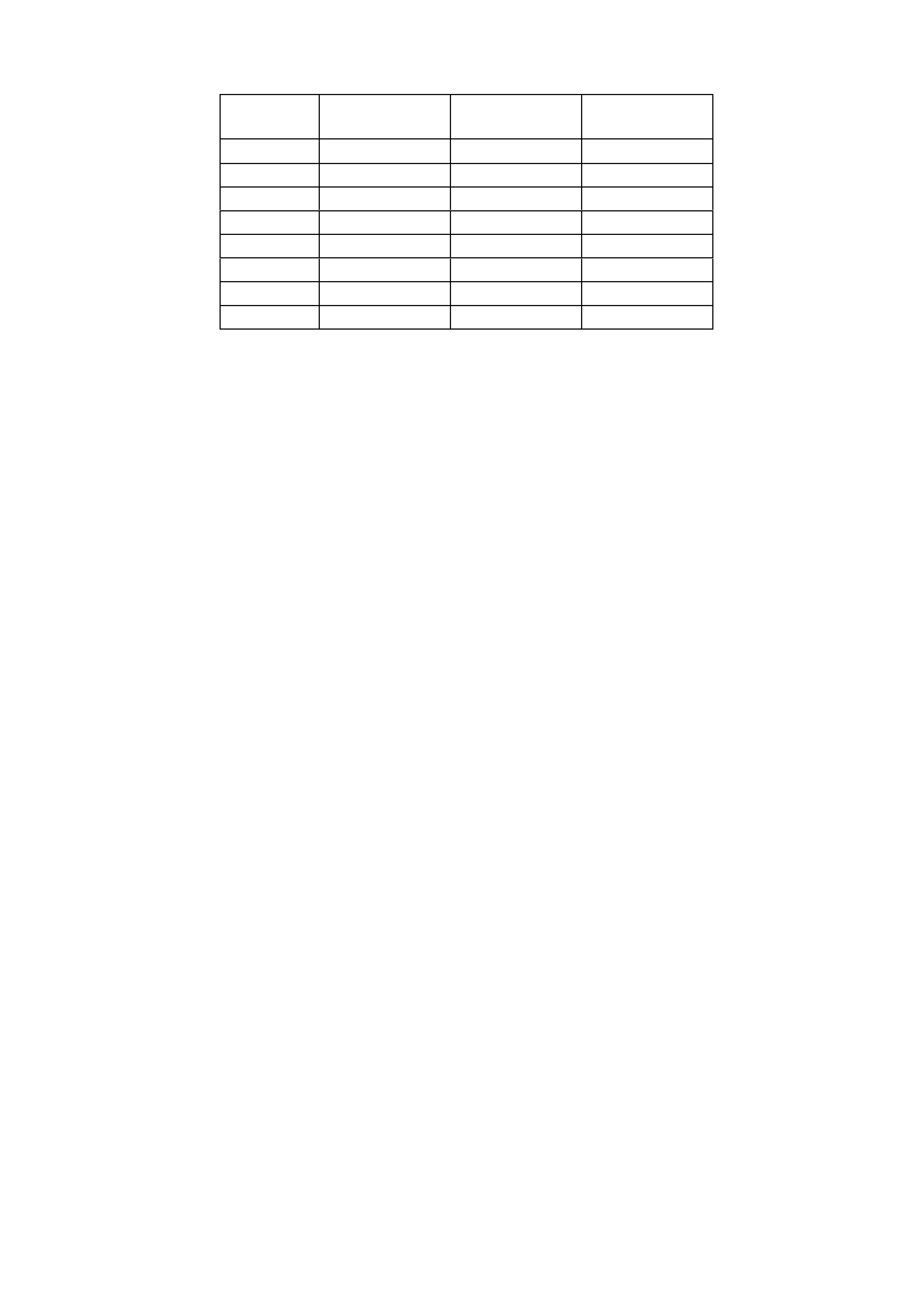

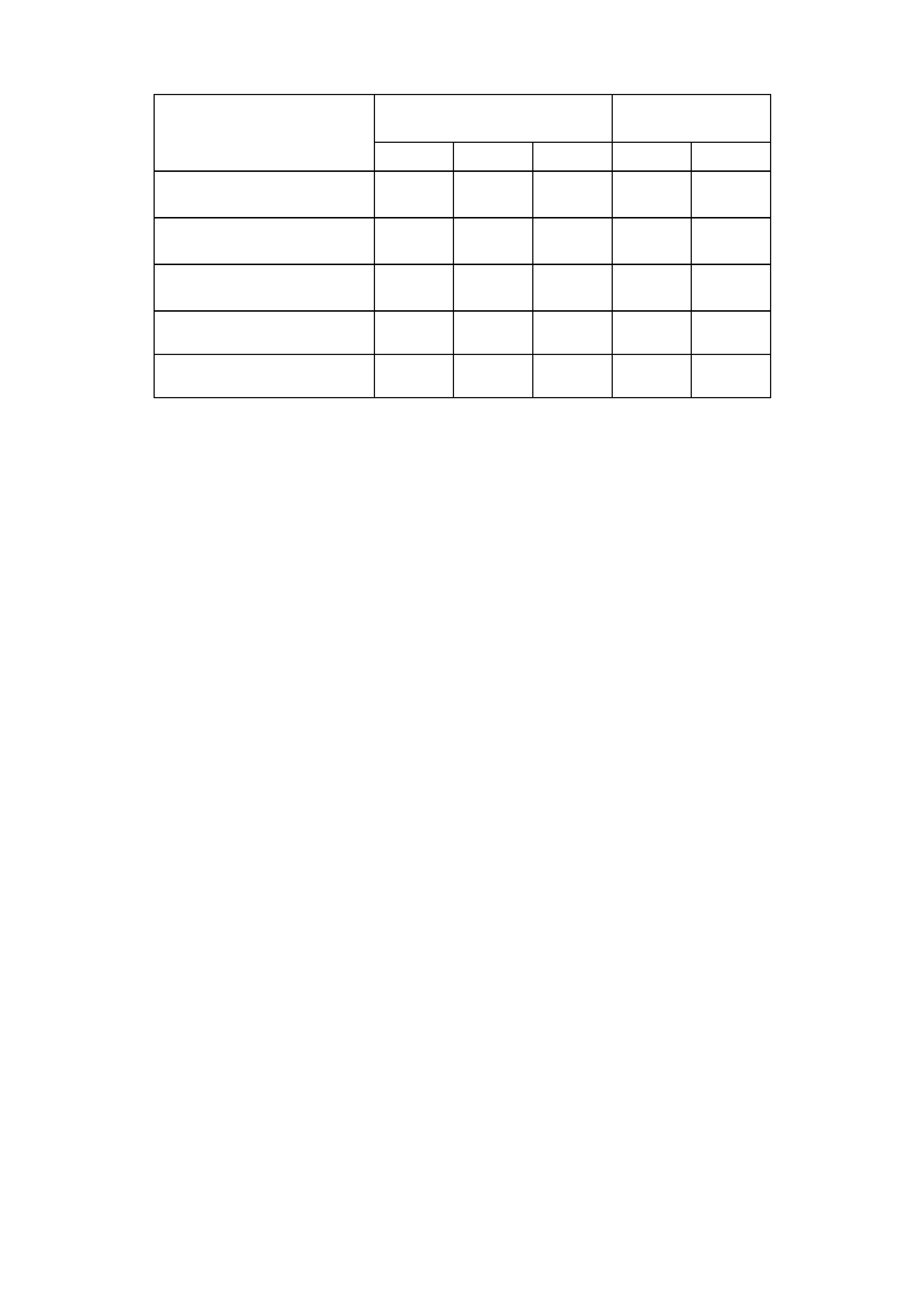

2. POWERTRAIN COMBINATIONS

ENGINE TRANSMISSION

TYPE MODEL

AVAILABILITY FIRST GEAR

RATIO REAR AXLE RATIO :1

3.8 LITRE PFI 5 Speed Manual Executive 3.829:1 3.08:1

4 Speed

Automatic Executive

Berlina

Calais

3.06:1 3.08:1

3.8 LITRE PFI

SUPERCHARGED 4 Speed

Automatic Berlina

Calais 3.06:1 3.08:1

5.7 LITRE PFI

(GEN III) 4 Speed

Automatic Executive

Berlina

Calais

3.06:1 3.08:1

6 Speed Manual Executive 2.66:1 3.46:1

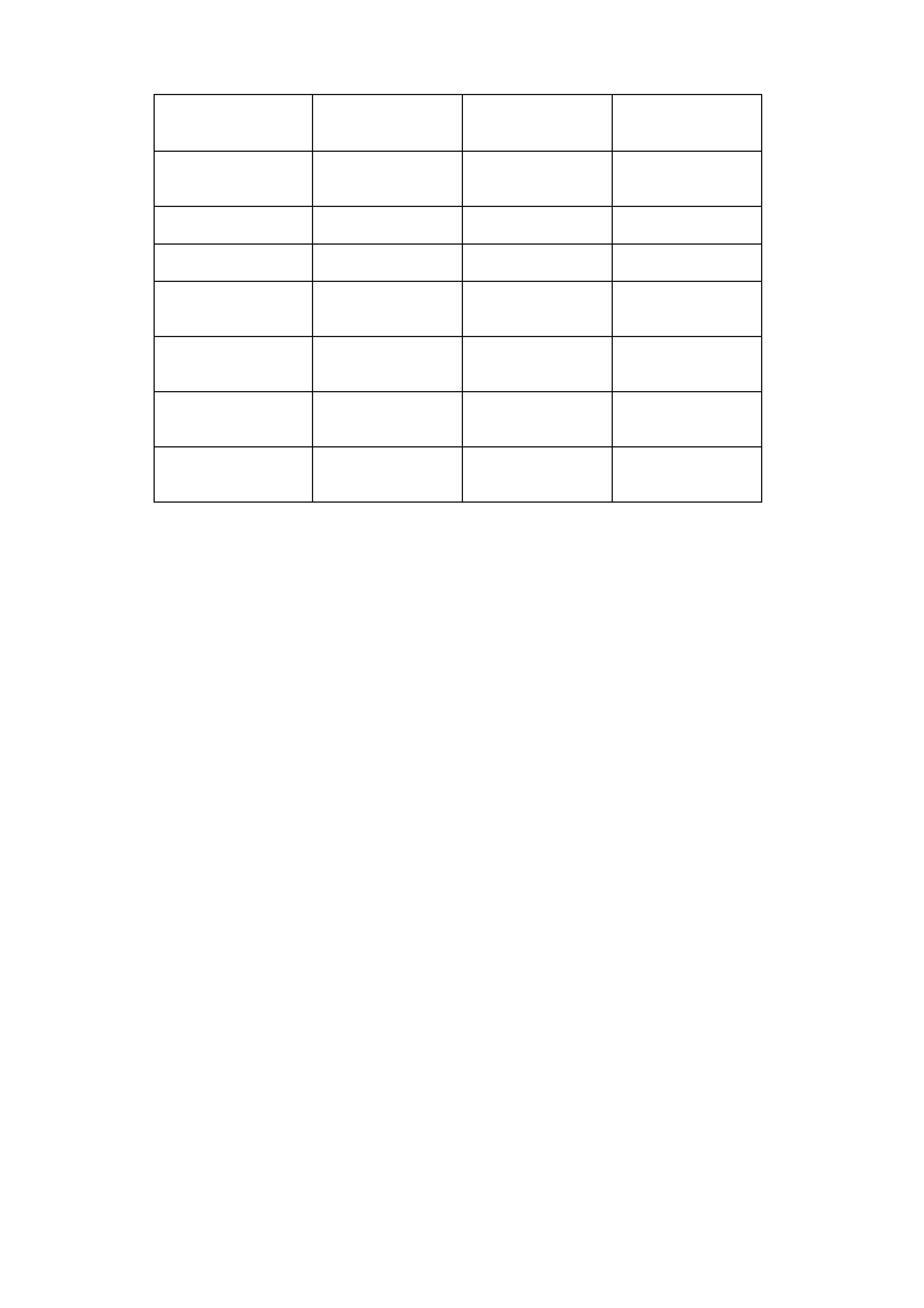

3. TRANSMISSION RATIOS

4 SPEED

AUTOMATIC 5 SPEED

MANUAL 6 SPEED

MANUAL

V6 & V8 engine V6 engine only V8 engine only

1ST 3.06:1 3.829:1 2.66:1

2ND 1.63:1 2.199:1 1.78:1

3RD 1.00:1 1.401:1 1.30:1

4TH 0.7:1 1.00:1 1.00:1

5TH - 0.809:1 0.74:1

6TH - - 0.50:1

REV 2.3:1 3.456:1 2.90:1

4. ENGINE DATA

ENGINE

DESIGNATION 3.8 LITRE PFI 3.8 LITRE

SUPERCHARGED 5.7 LITRE PFI

(GEN III)

Piston Displacement

Nom. - cm33791 3791 5667

Compression Ratio 9.4:1 8.5:1 10.1:1

Number of Cylinders 6 6 8

Bore x Stroke - mm 96.5 X

86.3 96.5 X

86.3 99 X 92

Taxable H.P.

RAC OR SAE 34.7 34.7 48.6

Power kW

DIN @ RPM 147 kW @ 5200 171 kW @ 5000

PULP* 220 kW @ 5200

Torque Nm

DIN @ RPM 304 Nm @ 3600 375 Nm @ 3200

PULP* 446 Nm @ 4000

*PULP – Premium Unleaded Petrol

5. VEHICLE WEIGHTS

VEHICLE SEDAN MODELS WAGON MODELS

WEIGHTS 8VK69 8VL69 8VX69 8VK35 8VL35

KERB MASS V6 1512 1555 1601 1572 1623

KERB MASS V8 1572 1602 1648 1632 1670

REAR AXLE LOAD V6 1140 1140 1140 1240 1240

REAR AXLE LOAD V8 1200 1200 1200 1340 1340

PAYLOAD (5 Pass. + Cargo) 408 408 408 480 480

NOTE: Figures are estimates only and measured in kg.

Payload figures must include luggage, goods, passengers, roof rack

load and a full tank of fuel. If you are towing, then the weight on the

tow bar ball must also be included.

Maximum Rear Axle Load is the maximum for all conditions.

6. SERIAL NUMBERS

The complete vehicle and various components of

the vehicle are identified by number plates or

numbers stamped into the part. It is essential that

when compiling warranty claims or product and

field reports, the vehicle identif ication num ber ( VIN)

is quoted in conjunction with the identification

number of the component affected.

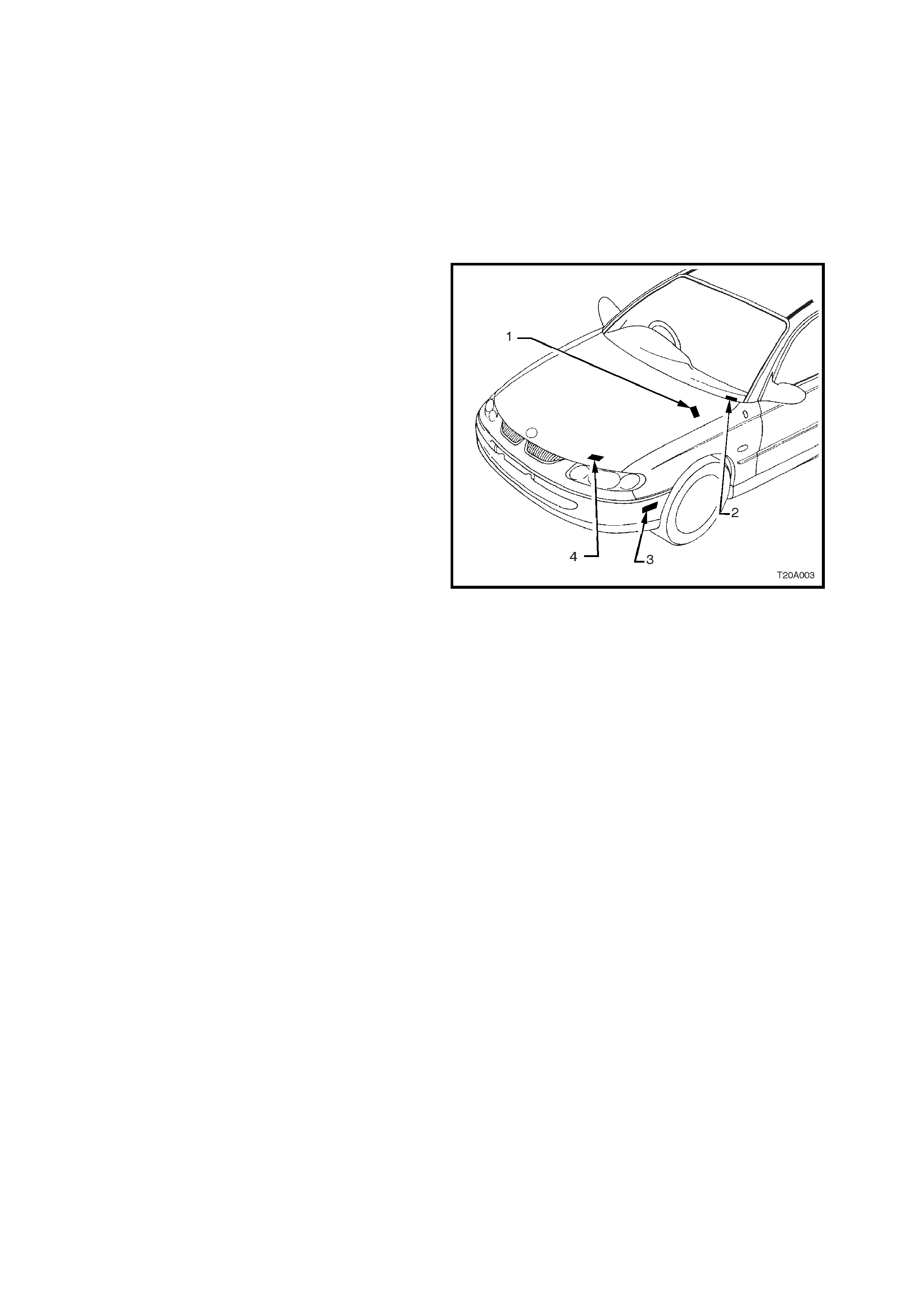

6.1 LOCATION OF IDENTIFICATION PLATES

Identification plates are attached to the upper right

side of the dash panel, front radiator s upport panel,

behind the bumper facia, and under the windshield

lower left corner, refer to Fig. 0A-.

1. Safety compliance plate

2. Vehicle Identification Number (VIN) plate

(windscreen)

3. Vehicle Identification Number (VIN) plate

(body)

4. Body and option identification plate

Figure 0A-1

6.2 SAFETY COMPLIANCE PLATE

The Safety Compliance Plate, located on the

engine com partm ent side of the coc kpit m odule, is

stamped with the following information:

COMPLIANCE PLATE APPROVAL NUMBER.

VEHICLE CATEGORY CODE.

NAME APPEARING ON COMPLIANCE PLATE

APPROVAL.

MAKE/MODEL.

SEATING CAPACITY.

DATE OF MANUFACTURE (* Variable

information).

VEHICLE IDENTIFICATION NUMBER (* Variable

information). Figure 0A-2

6.3 BODY AND OPTION IDENTIFICATION PLATE

The body option and identification plate, located to

the left hand side of the front panel upper, is

stamped with the following information:

MODEL:

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

A listing of Production Option num bers and Smark

Pack Option numbers, can be found by refering to

the latest spare parts information (Part Finder) for

the applicable model.

BODY:

Production build number; run in continuous

sequence regardless of model, body type and

series.

TRIM:

Trim combination.

PAINT:

Exterior paint material and colour identification.

BUILT:

The date of manufacture by calendar month and

year in which the body shell and power train are

conjoined and the vehicle is driven or moved from

the production line.

SUSP

Suspension option code identification, i.e. STD

(standard) or FE2 (sport).

ENGINE, TRANSMISSION AND AXLE

Identification option codes for specific engine,

transmission and rear axle.

A/C

Identification option code C60 is used for vehicles

fitted with air conditioning. C61 Identifies vehicles

fitted with Electronic Climate Control air

conditioning.

Figure 0A-3

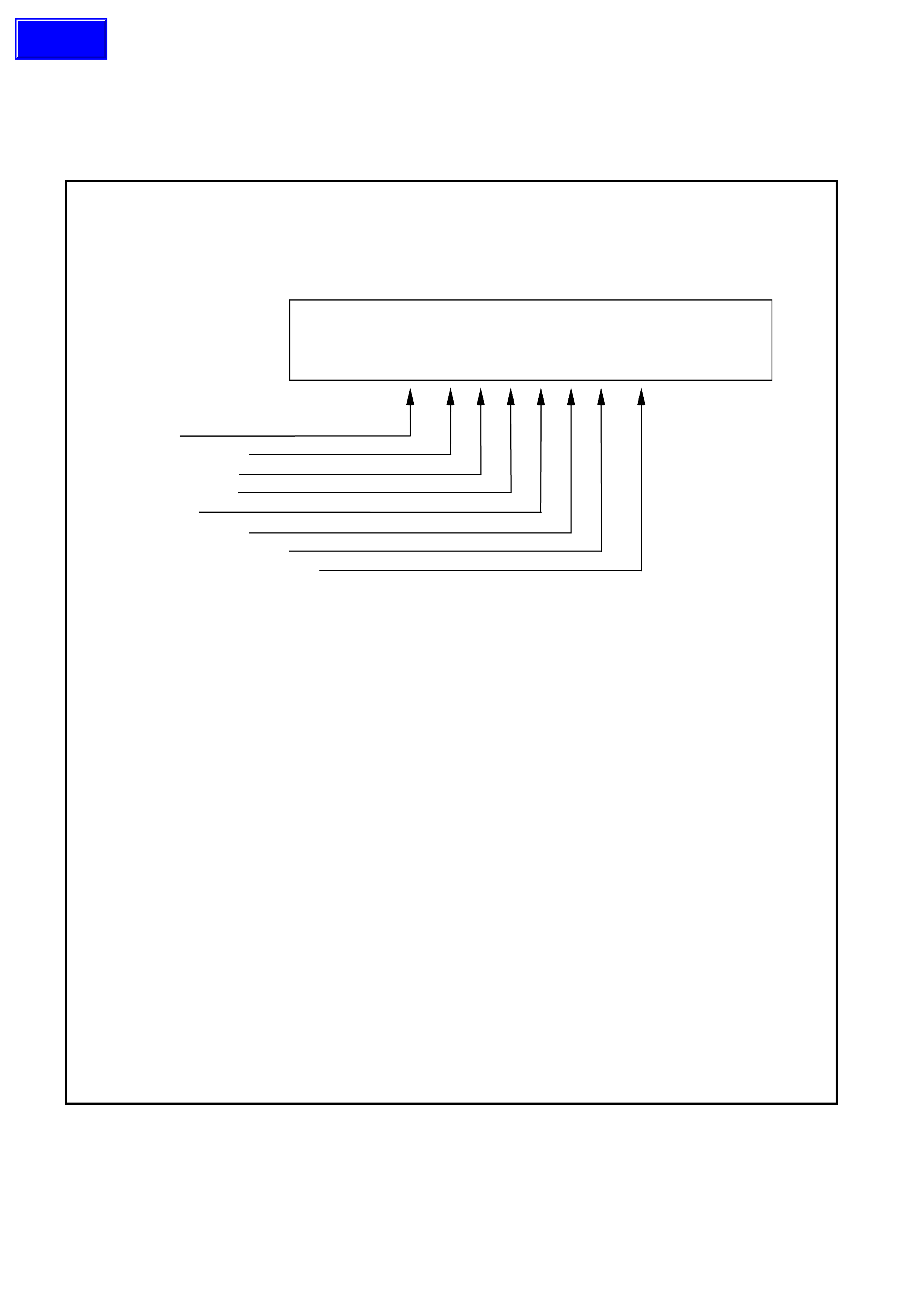

6.4 VEHICLE IDE NTIFICATION NUMBERING SYSTEM

There are two Vehicle Identification Number (VIN) plates attached to VT Series Models. The location of these plates

are: under the windscreen (viewed through the windscreen aperture) and under the front bumper on the left hand

side.

Figure 0A-4 details the vehicle identification numbering (VIN) system.

VEHICLE IDENTIFICATION NUMBERING SYSTEM

The Vehicle Identification Numbering System (VIN) is based on the uniform Car Model Designation

System. The reason for this is to identify the vehicle in one coded series of characters.

The significance of these characters or blocks of characters is explained below, using as an example

identification number 6H8 VT X 69 F X L 123456.

MODEL DESIGNATION

WMI Code

Model Series Code

Degree of Luxury

BODY STYLE CODE

ENGINE CODE

MODEL YEAR CODE

ASSEMBLY PLANT CODE

SERIAL SEQUENCE NUMBER

6H8 VT X 69 F X L 123456

MODEL DESIGNATION

WMI Code - 6H8 - World manufacturer's identifier allocated to Holden

Model Series Code - VT = VT Series

Degree of Luxury - K - EXECUTIVE

- L - BERLINA

- X - CALAIS

Body Style Code - 69 - Sedan 35 - Wagon

ENGINE CODE

Engine Identification Code (H - signifies 3.8 engine, S - signifies 3.8 supercharged engine,

F - signifies 5.7 engine)

MODEL YEAR CODE

X - Identifies Model Year W = 1998

X = 1999

This Letter relates to GM Internal Operation Only.

ASSEMBLY PLANT CODE

Australian Assembly Plant Identification Code:-

L - Adelaide (Elizabeth)

SERIAL (Sequence ) NUMBER

123456 - Sequential Production Serial Number

This designates the Serial Unit Number at the Vehicle Plant, starting at

(00001) and continues in Numerical Sequence regardless of vehicle type.

Figure 0A-4

Techline

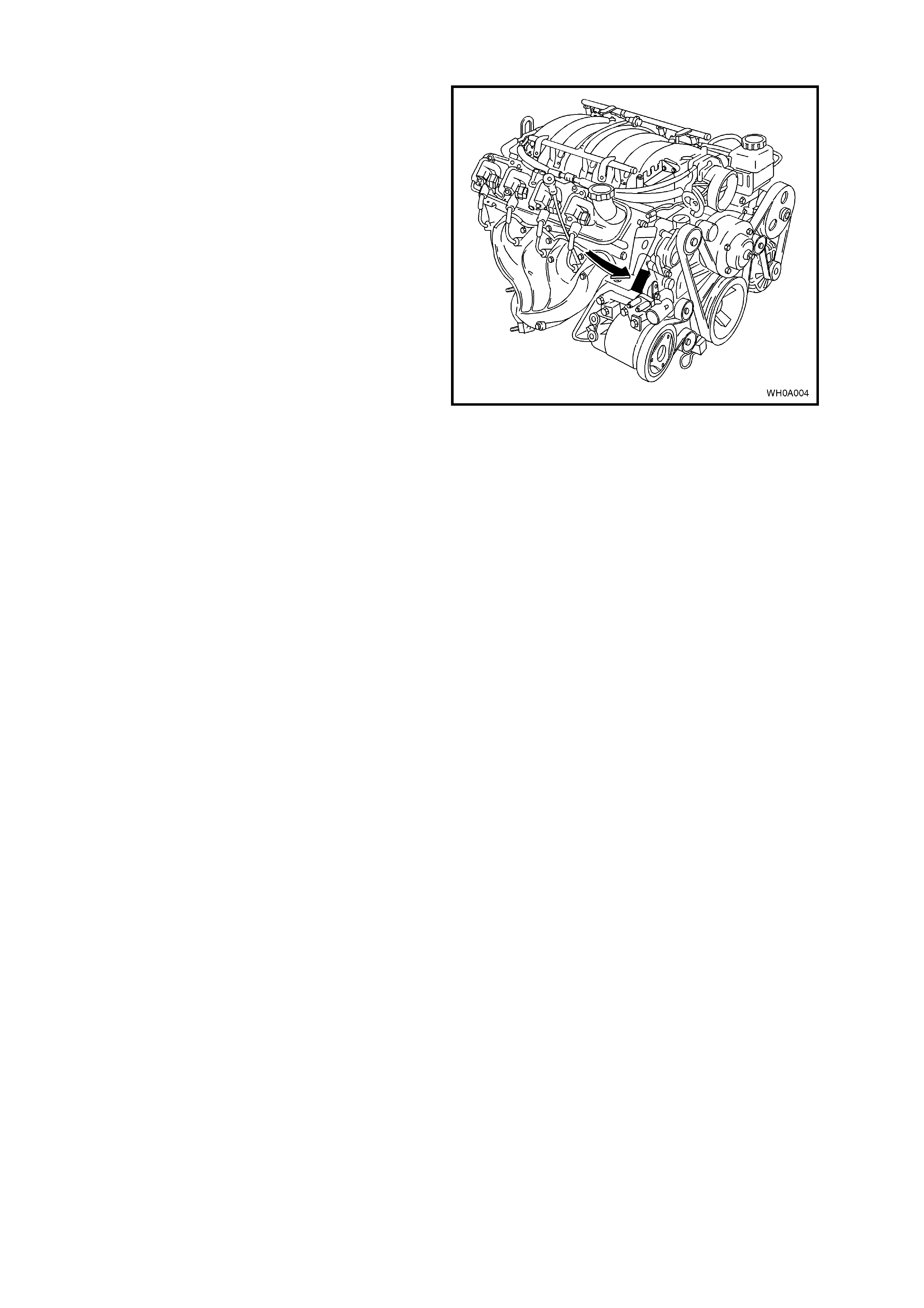

6.5 ENGINE SERIAL NUMBER

The 5.7litre Gen III V8 engine serial number is

stamped on a pad located adjacent to the engine

coolant outlet pipe, refer to Fig. 0A-5.

The engine number is prefixed by the letters ‘VF’.

Figure 0A-5

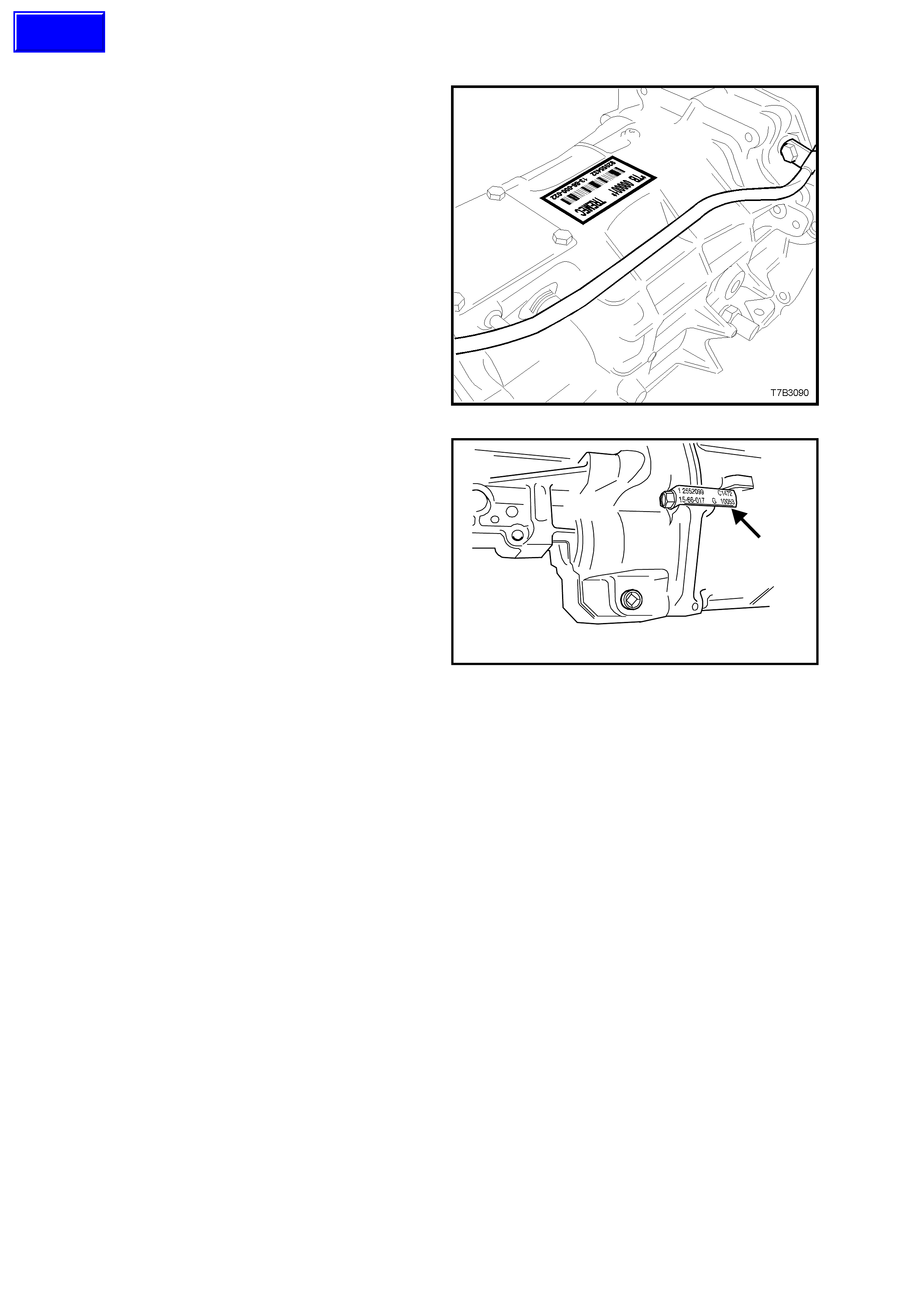

6.6 AUTOMATIC TRANSMISSION SERIAL NUMBER

The automatic transmission serial number is

stamped into a machined surface at the rear

underside of the transmission centre case, refer to

Fig. 0A-6.

1. Model Year (‘9’ = 1999)

2. Model: V8 – 5.7 litre ...................... HP

V6 – 3.8 litre ..................... HF

V6 Supercharged – 3.8 litre HN

3. Transmission Model Identifier (D = 4L60-E).

4. Julian Date (or day of year).

5. Shift Built (A, B, J = first shif t; C, H, W = second

shift).

6. Individual Transmission Serial Number.

7. Transmission Identification Number Location.

9HBD123 A 12345678

1

9 HB D 123 A 12345678

256

34

7

7

T20A001

Figure 0A-6

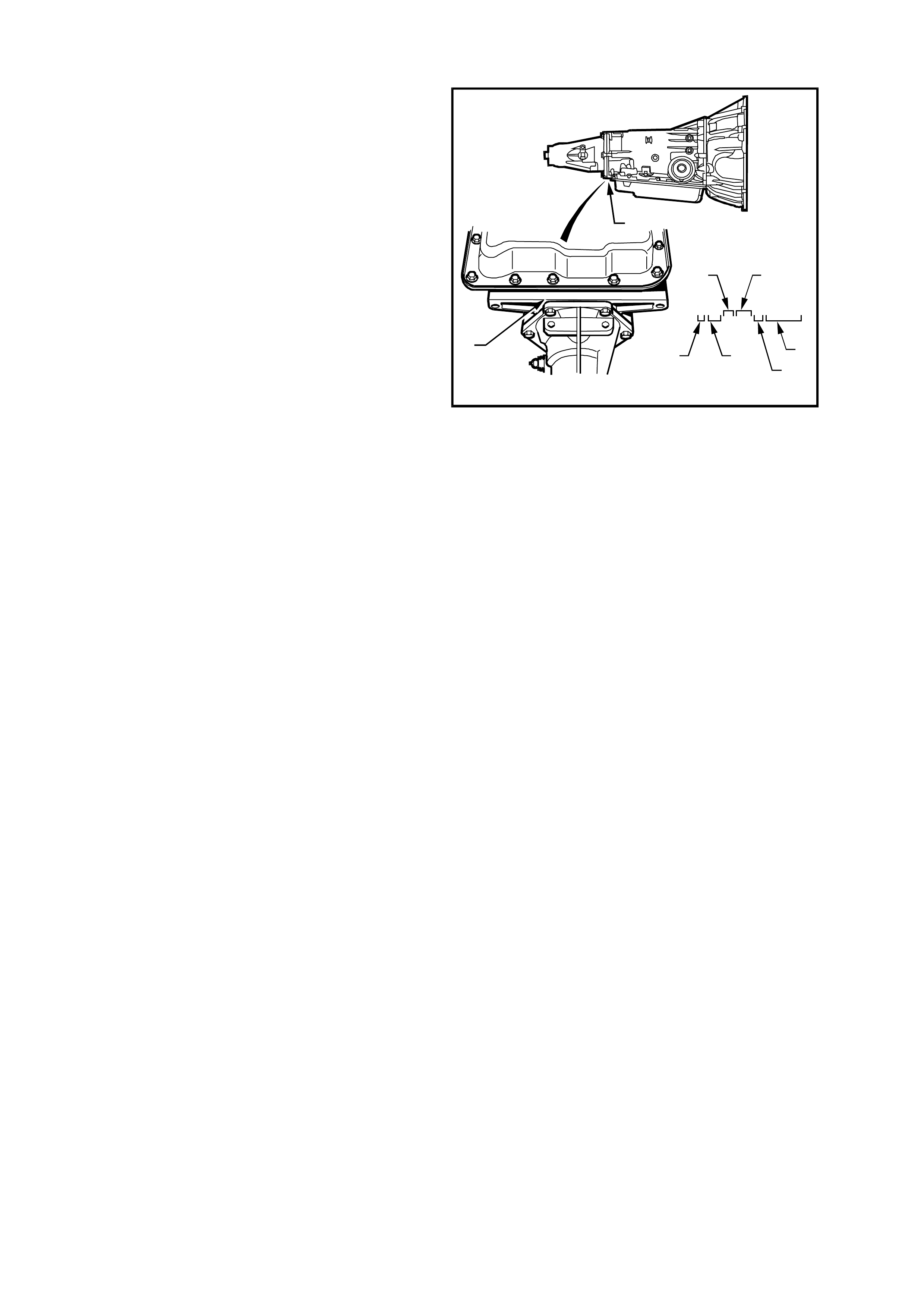

6.7 MANUAL TRANSMISSION SERIAL NUMBER

The Borg-Warner (Tremec) T56 six speed manual

transmission serial number is located on a self-

adhesive decal attached to the top of the

transmission case .

This number provides coded information which

could be significant to parts interpretation and

should be referred to when ordering replacement

parts.

In addition, an identification tag is attached to the

transmission under an extension housing bolt, on

the right hand side.

Figure 0A-7

T20A002

Figure 0A-8

Techline

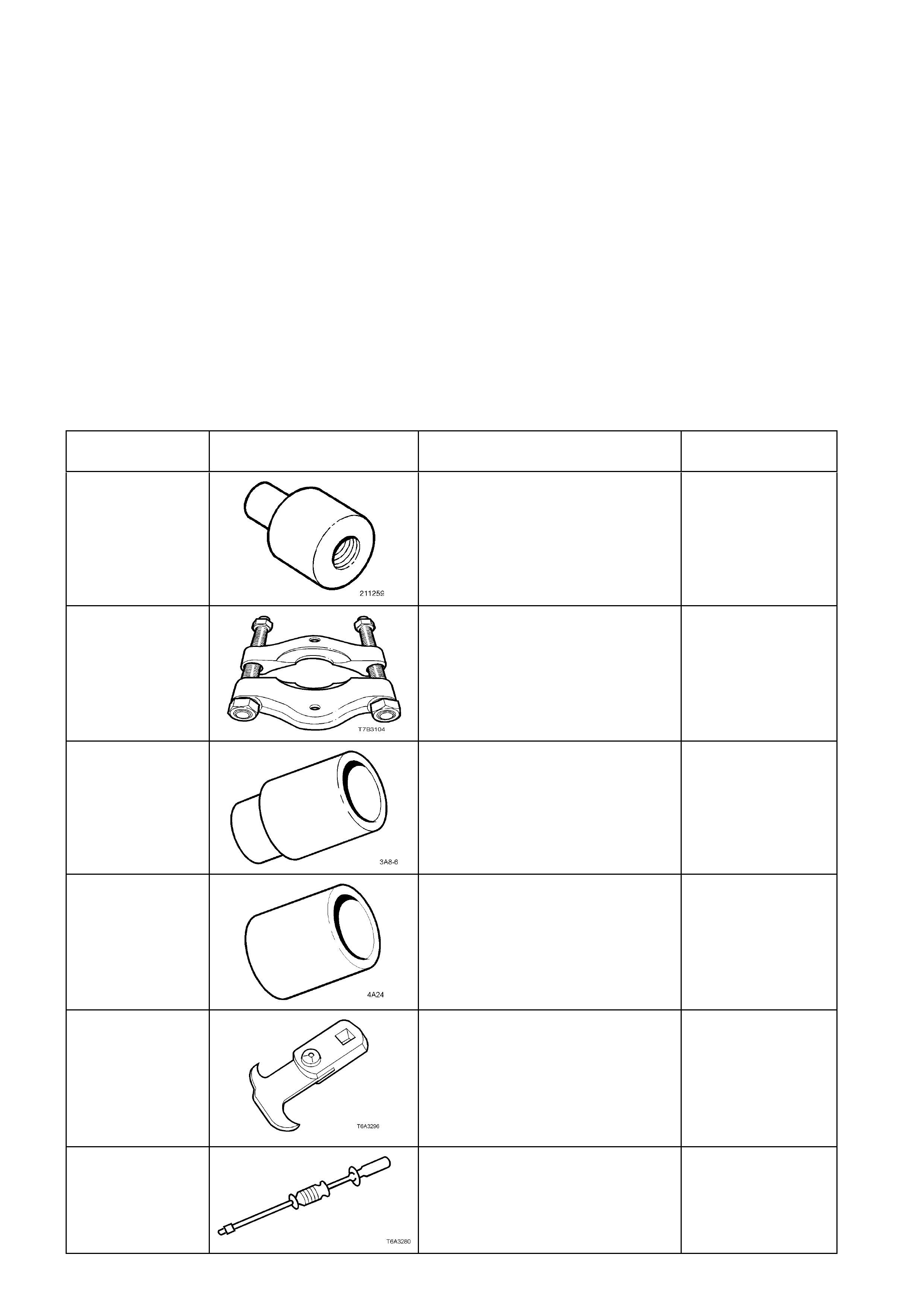

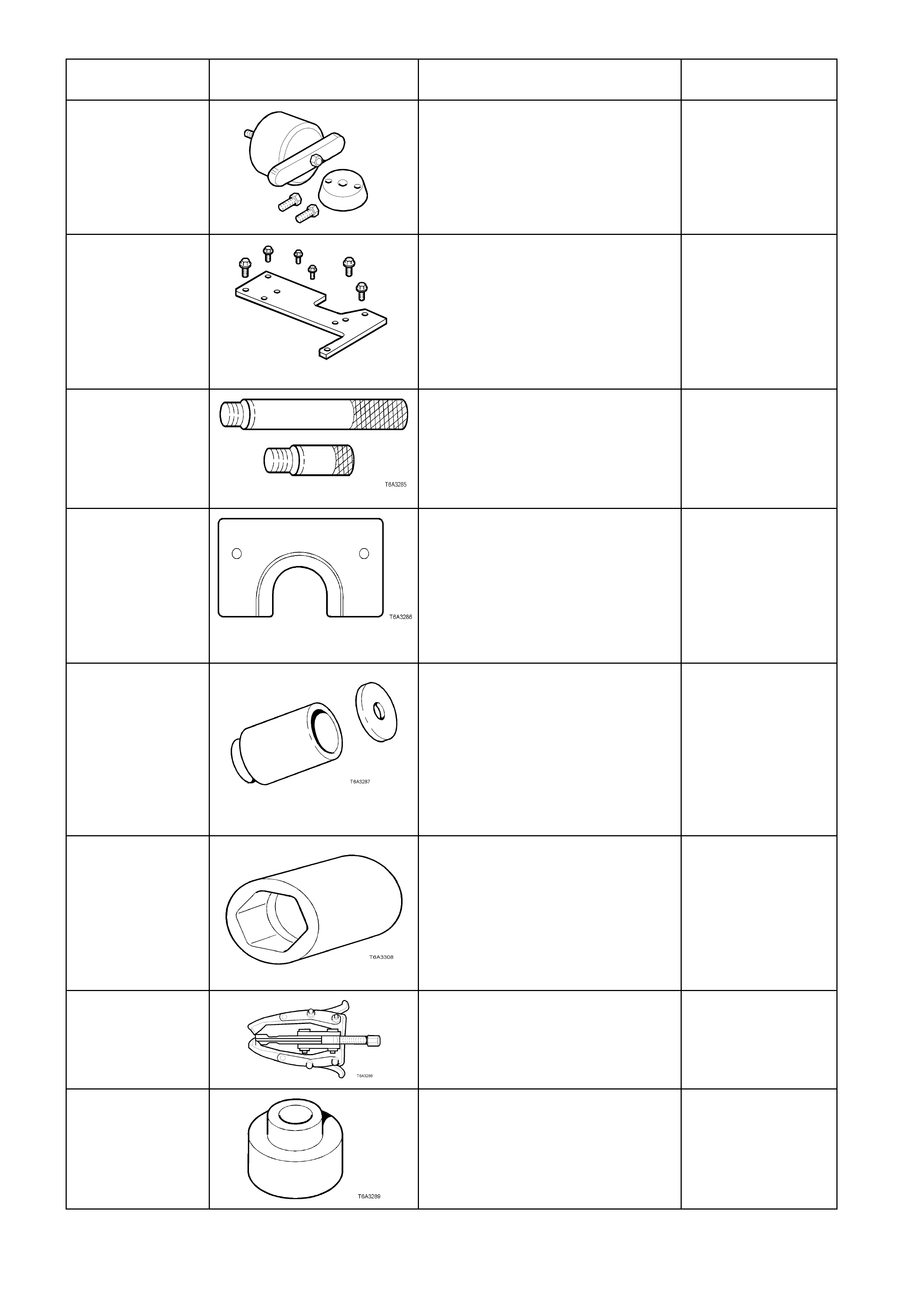

7. CONSOLIDATED TOOL LIST

The following pages list and illustrate additional special service tools required for use on VT Series II Models. This

list is to be used in conjunction with the consolidated tool list in Section 0A GENERAL INFORMATION of the VT

Series I Service Information.

NOTE: Some ser vice tools in this listing have pr eviously been published in Section 0A GENERAL INFORM AT ION

of the VT Series I Service Information.

The tools are listed in numerical / alphabetical order. The tools are also classified in accordance to the

specifications outlined in the “Holden policy and procedures manual” (unique, desirable or mandatory).

All Service Tools listed in this Section are, unless otherwise specified, available from:

SPX Australia Pty. Ltd.

OE Tool & Equipment Group

7 Expo Court

MT Waverley, Victoria 3149

Telephone: (03) 9544 6222

Facsimile: (03) 9544 5222

Email: ED@SPX.COM.AU

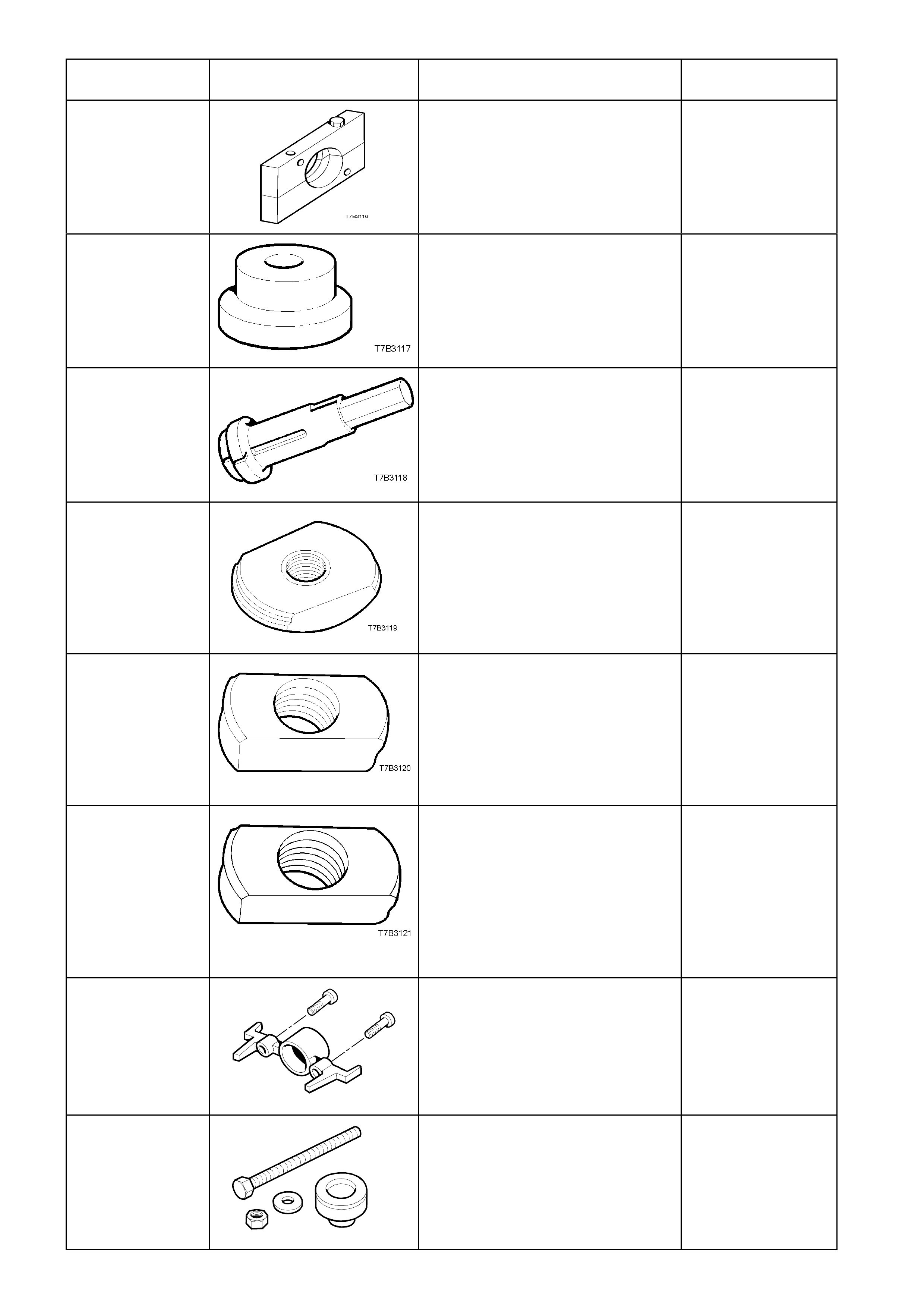

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

211-259 LOWER PINION AND BEARING

REMOVER

Used to install the lower pinion and

bearing on the VT Series II steering

gear assembly.

New release.

Unique

22912-01 PRESS PLATES

Used in a number of different

applications in removing bearings

and other transmission components

when pressing operations are

required.

Previously released.

Unique

3A8-6 SLEEVE

Used to install the 1st/2nd gear

synchromesh hub to the mainshaft

on the Tremec 6 speed manual

transmission.

Previously released.

Unique

4A24 SLEEVE

Used to install the bearing cup into

the input shaft gear on the Tremec

6 speed manual transmission.

Previously released.

Unique

56750

(or E308) SEAL REMOVER

Used for a wide range of seal

removal applications, including use

on GEN III V8 engines and Tremec

6 speed manual transmission

Previously released.

Desirable

6125-1B SLIDE HAMMER

Used in conjunction with J 41818 to

remove main bearing caps GEN III

V8 engines.

Previously released.

Unique

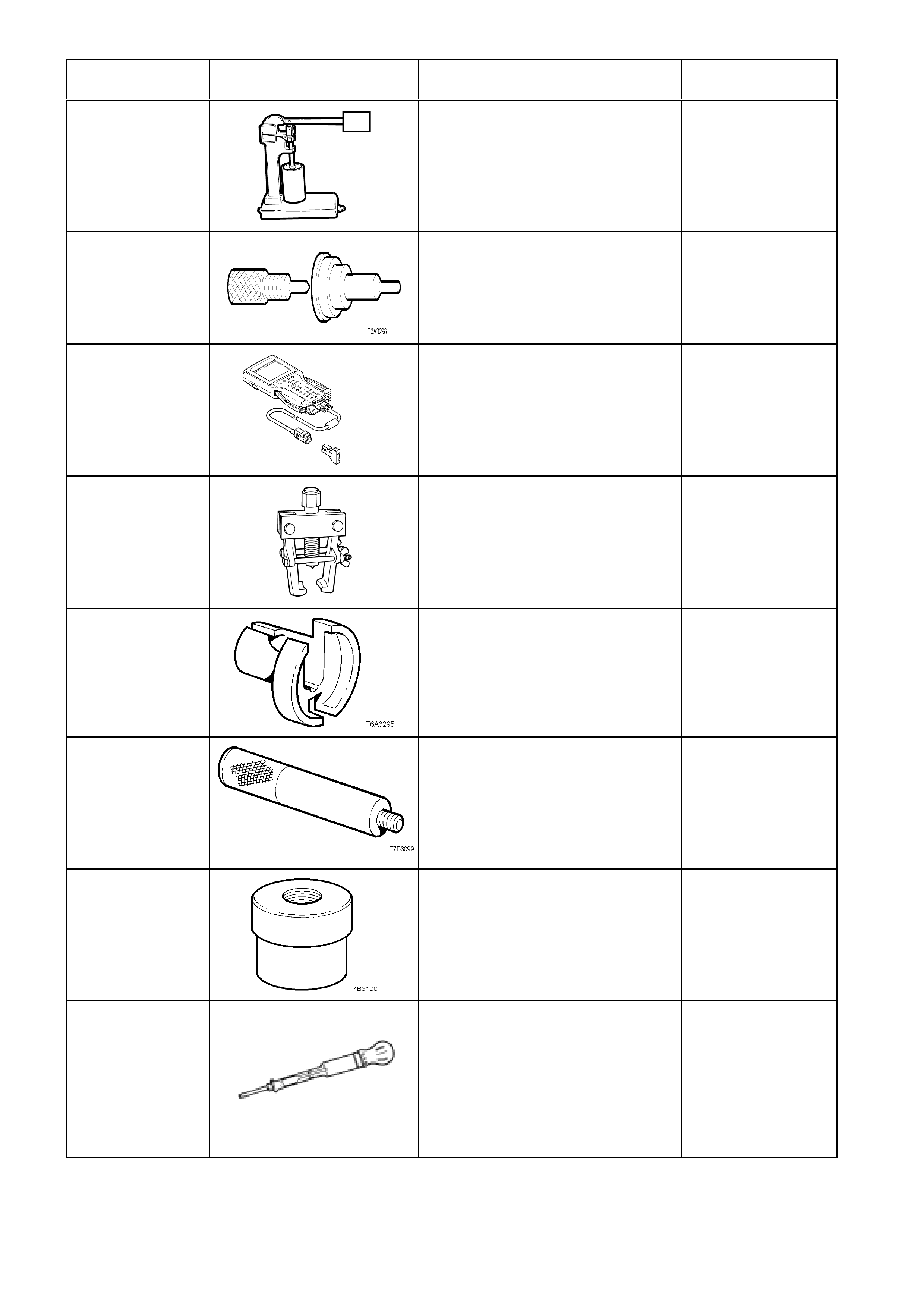

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

6A23

T6A3114b

HYDRAULIC VALVE LIFTER TESTER

Used for testing valve lifters on V6 and

GEN III V8 engines

Previously released.

Used in conjunction with testing fluid

SPX No. E1151

Unique

6A24 VALVE LIFTER ASSEMBLY TOOLS

Used to assist in assembly of the

hydraulic valve lifters on V6 and GEN

III V8 engines

Previously released.

Unique

70000861 TECH 2 DIAGNOSTIC SCAN TOOL

Used for diagnosis of vehicle electrical

systems

Mandatory

7311 TIE ROD BALL JOINT REMOVER

New release to suit new steering

knuckle.

Can also be used on earlier ‘V’ cars for

the same purpose.

Desirable

7371 QUICK CONNECT RELEASE TOOL

Previously released for releasing fuel

line quick connects on V6

supercharged engine after fuel system

has been de-pressurised.

Used on GEN III V8 engine for the

same purpose

Desirable

7AT2 DRIVER HANDLE

Used in conjunction with 7AT5 to

remove/install the slip yoke bushing in

the extension housing on the Tremec 6

speed manual transmission.

Previously released.

Unique

7AT5 SLIP YOKE BUSH

REMOVER/INSTALLER

Used in conjunction with 7AT2 to

remove/install the slip yoke bushing in

the extension housing on the Tremec 6

speed manual transmission.

Previously released.

Unique

AU435

(No longer available

use J 26568)

COOLING SYSTEM HYDROMETER

Used for testing coolant concentrate.

Previously released.

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU485

AU485

SIDE IMPACT AIR BAG

DUMMY LOAD

Used for SRS electronic diagnostic

check on side impact air bags.

Previously released.

Mandatory

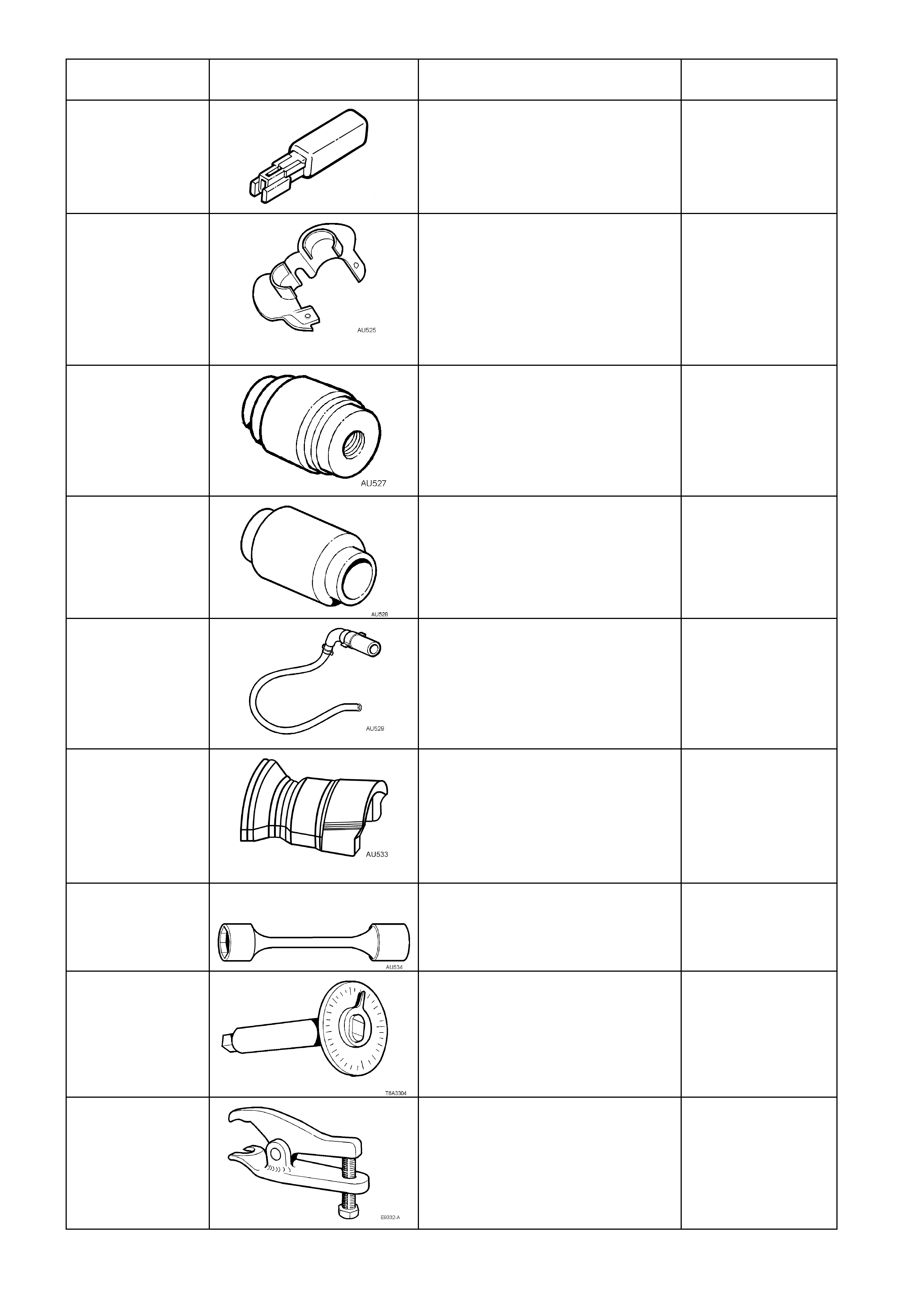

AU525 QUICK CONNECT RELEASE

TOOL

Use to release the quick connect

fittings on the automatic

transmission fluid cooler lines at the

radiator end, when the vehicle is so

equipped.

New release.

Mandatory

AU527 INTERMEDIATE BEARING AND

SEAL INSTALLER

Used to install the intermediate

bearing and seal on the VT Series

II steering gear assembly.

New release.

Unique

AU528 UPPER SEAL AND BEARING

INSTALLER

Used to install the upper seal and

bearing on the VT Series II steering

gear assembly.

New release.

Unique

AU529 CLUTCH SLAVE CYLINDER

BLEED TOOL

Used to bleed the clutch hydraulic

system on the Tremec 6 speed

manual transmission.

New release.

Desirable

AU533 QUICK CONNECT FITTING

RELEASE TOOL

Released in two sizes; Red for

5/16” fittings and Blue for 3/8”

fittings.

Also available commercially under

P/N AUSP45

Desirable

AU534 TORQUE LIMITING SOCKET

Released to allow the use of impact

gun to tighten road wheel nuts

Mandatory

E 7115 TORQUE ANGLE WRENCH

Used to accurately tighten

fasteners when an angle torque is

required.

Previously released.

Desirable

E 9332-A BALL JOINT RELEASE TOOL

Used to release the control arm ball

joint from the steering knuckle.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

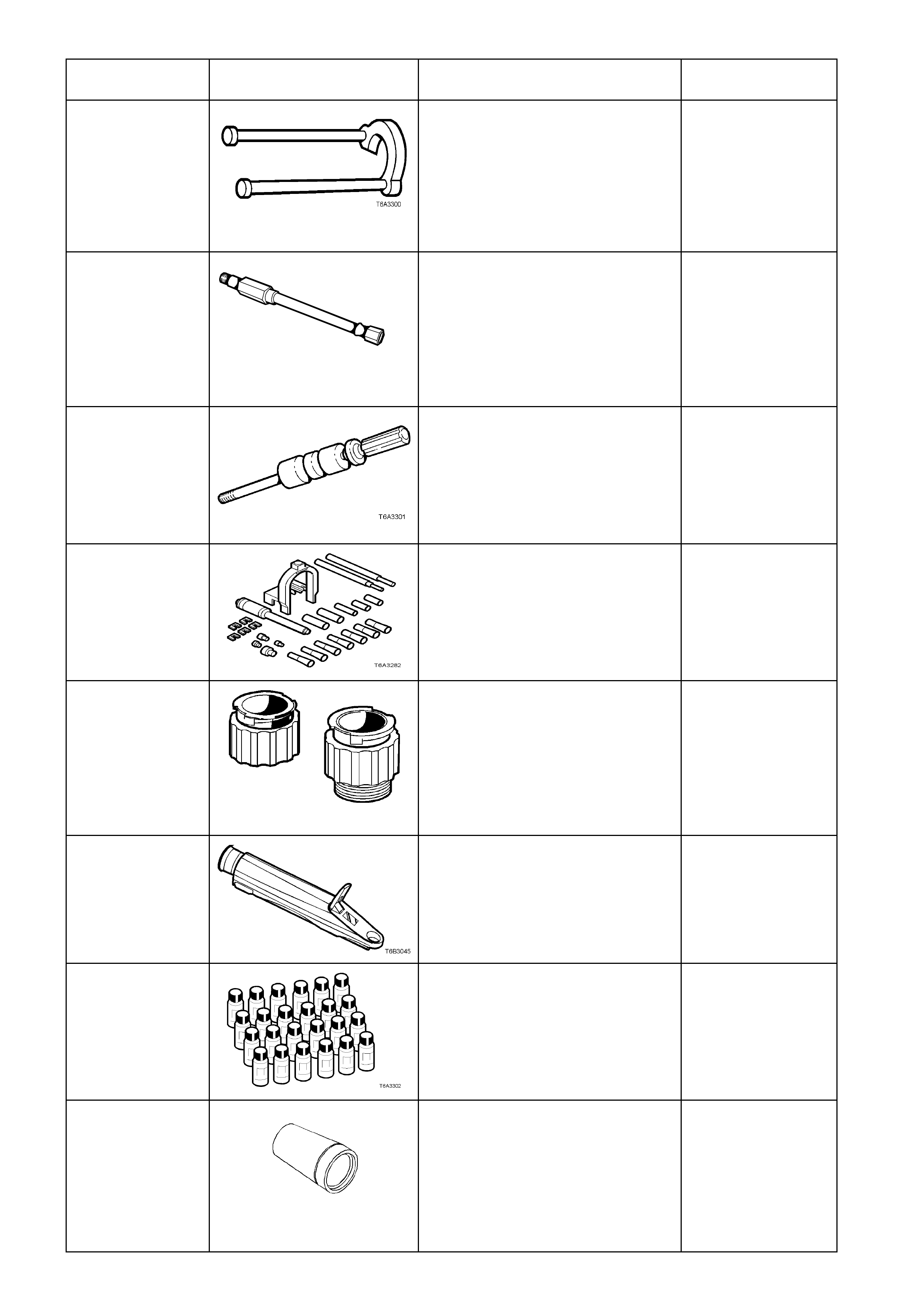

J 21427-01 PULLER ADAPTER

Used in conjunction with J 8433-1,

J 41558 and J 41816-2 to remove

crankshaft timing gear sprocket on

GEN III V8 engine.

Previously released to remove

automatic transmission speed

sensor ring.

Unique

J 22794

T6A3256a

ADAPTER

Used to facilitate the application of

air pressure to a cylinder when

replacing a valve spring or valve

stem oil seal with the cylinder head

installed.

New release.

Desirable

J 23907 SLIDE HAMMER

Used in conjunction with a number

of different pullers to remove

bushes and bearing cups in the

transmission

Previously released.

Unique

J 24086-C PISTON PIN

REMOVER/INSTALLER

Universal tool containing selective

components to suit multiple engine

applications.

New release.

Unique

J 24460-92 COOLING SYSTEM TEST

ADAPTERS

Used to pressure test the screw-on

cooling system pressure cap and

the cooling system on GEN III V8

engines.

New release.

Mandatory

J 26568 REFRACTOMETER

Used for testing coolant

concentrate.

Previously released, (replaces

AU435)

Mandatory

J 28431-B FLUID DYE

24 x 1 ounce bottles.

Used in conjunction with black light,

leak detection lamp J 42220 to

locate various types of vehicle fluid

leaks.

Previously released.

Desirable

J 28458 SEAL PROTECTOR AND

DIAPHRAM RETAINER

INSTALLER

Used to protect the power piston

seal and install the diaphram

retainer on the 4l60-E automatic

transmission

New release

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J 3289-20 BENCH HOLDING FIXTURE

Used as a bench fixture to support

a transmission.

Previously released.

Unique

J 33049 CAMSHAFT BEARING

REMOVER/INSTALLER

Universal tool containing selective

components to suit multiple engine

applications.

New release.

Unique

J 36513 PRESS PLATES

Used to press 1st/2nd speed

synchromesh assembly and 2nd

gear from the mainshaft on the

Tremec 6 speed manual

transmission.

New release.

Unique

J 36800 BUSHING REMOVER

Used to remove the shift rail

bushes in the adapter plate and

extension housing on the Tremec 6

speed manual transmission. Used

in conjunction with slide hammer

J 23907.

New release.

Unique

J 37027-A IAC MOTOR ANALYZER

Used to manualy operate and

check the idle air control valve

system operation.

New release.

Mandatory

J 37287 INLET AND RETURN FUEL LINE

SHUT-OFF ADAPTERS

Used in conjunction with the fuel

pressure gauge for restricting the

fuel supply and return lines for

testing.

New release.

Mandatory

J 38836

T6A3 189b

PILOTED DRIVER

Used to install the spigot bush in

the crankshaft on GEN III V8

engines.

New release.

Unique

J 39430 TRANSMISSION HOLDING

FIXTURE

Used to mount the Tremec 6 speed

manual transmission to the bench

for unit repair operations.

New release.

Unique

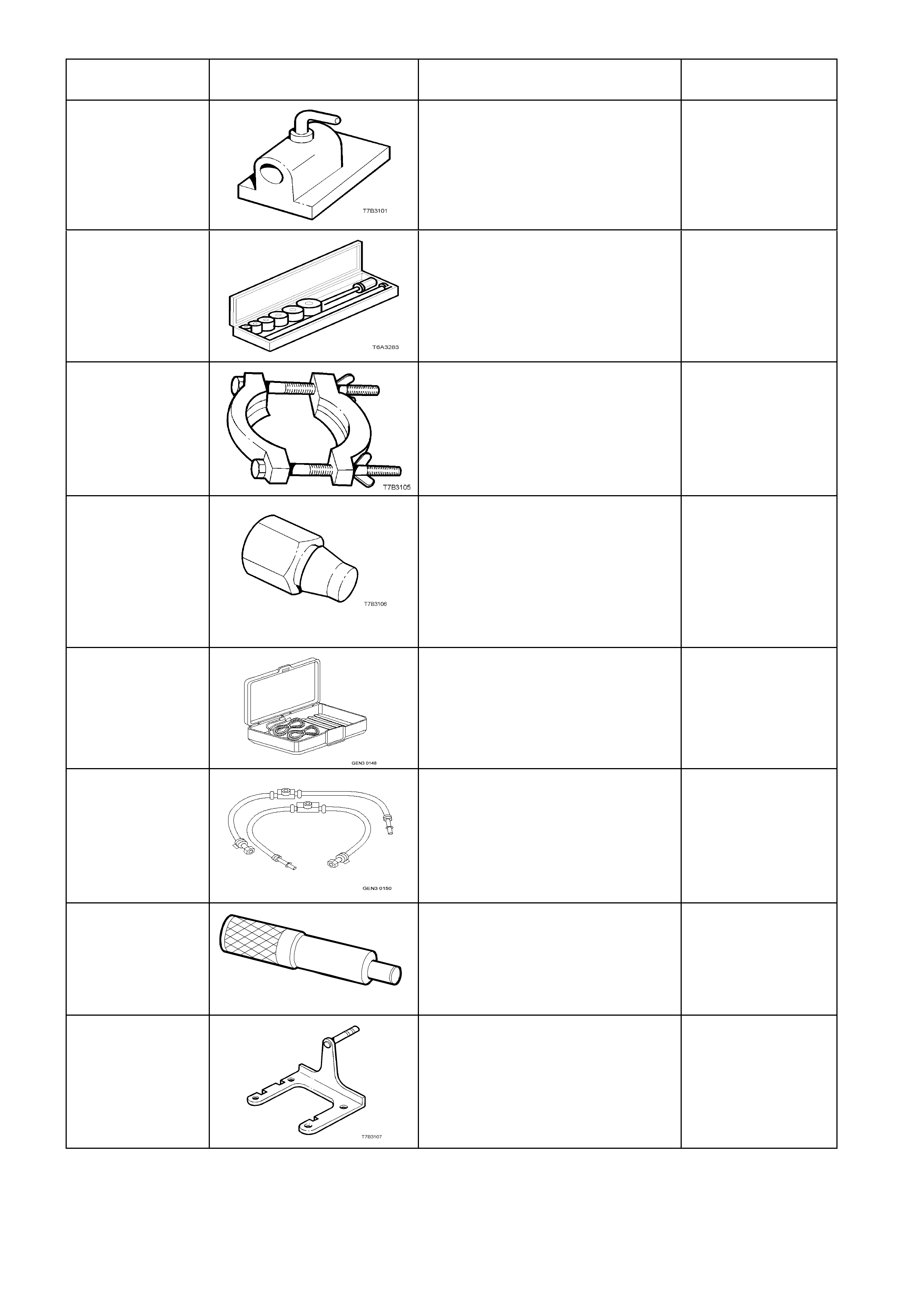

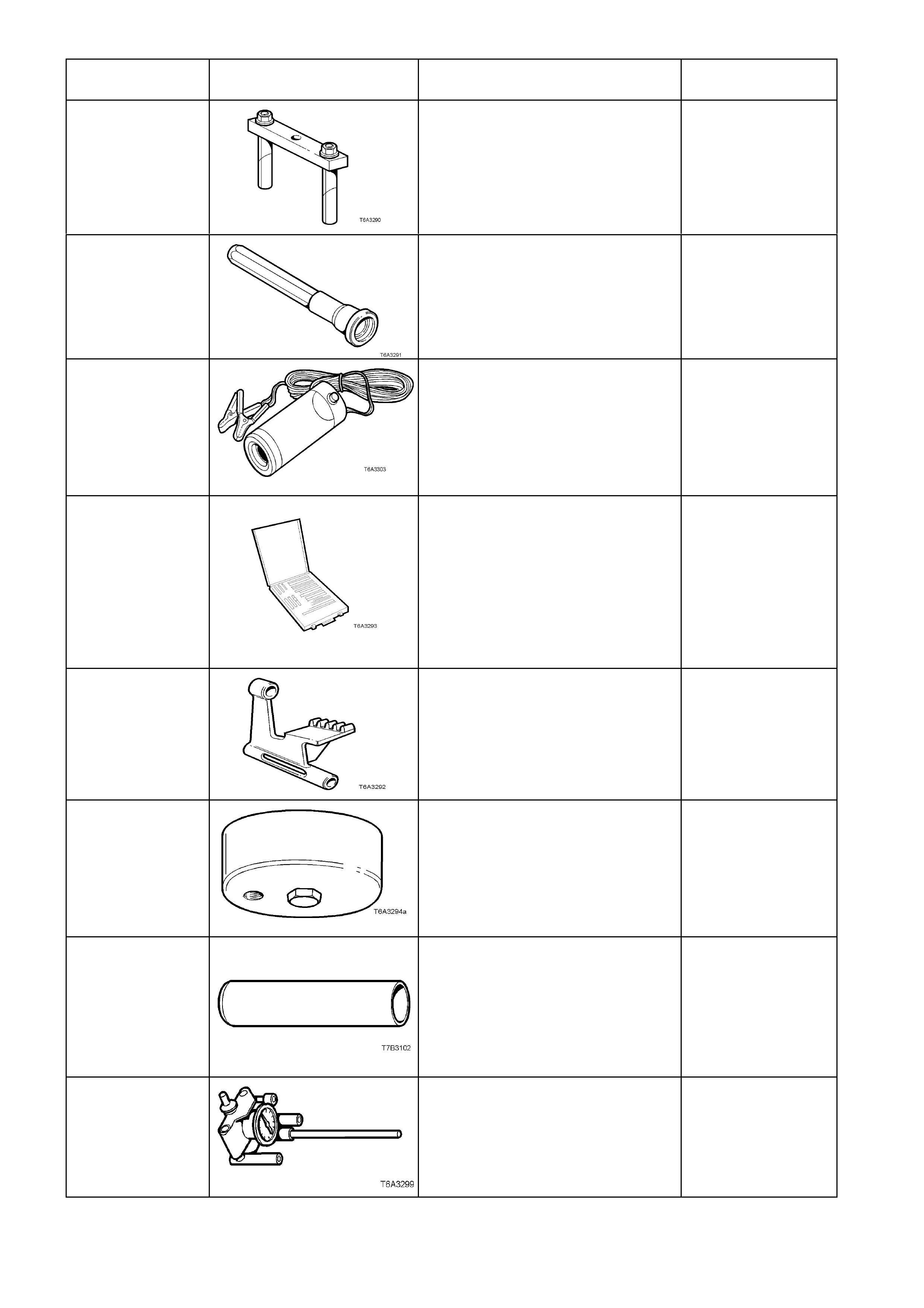

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

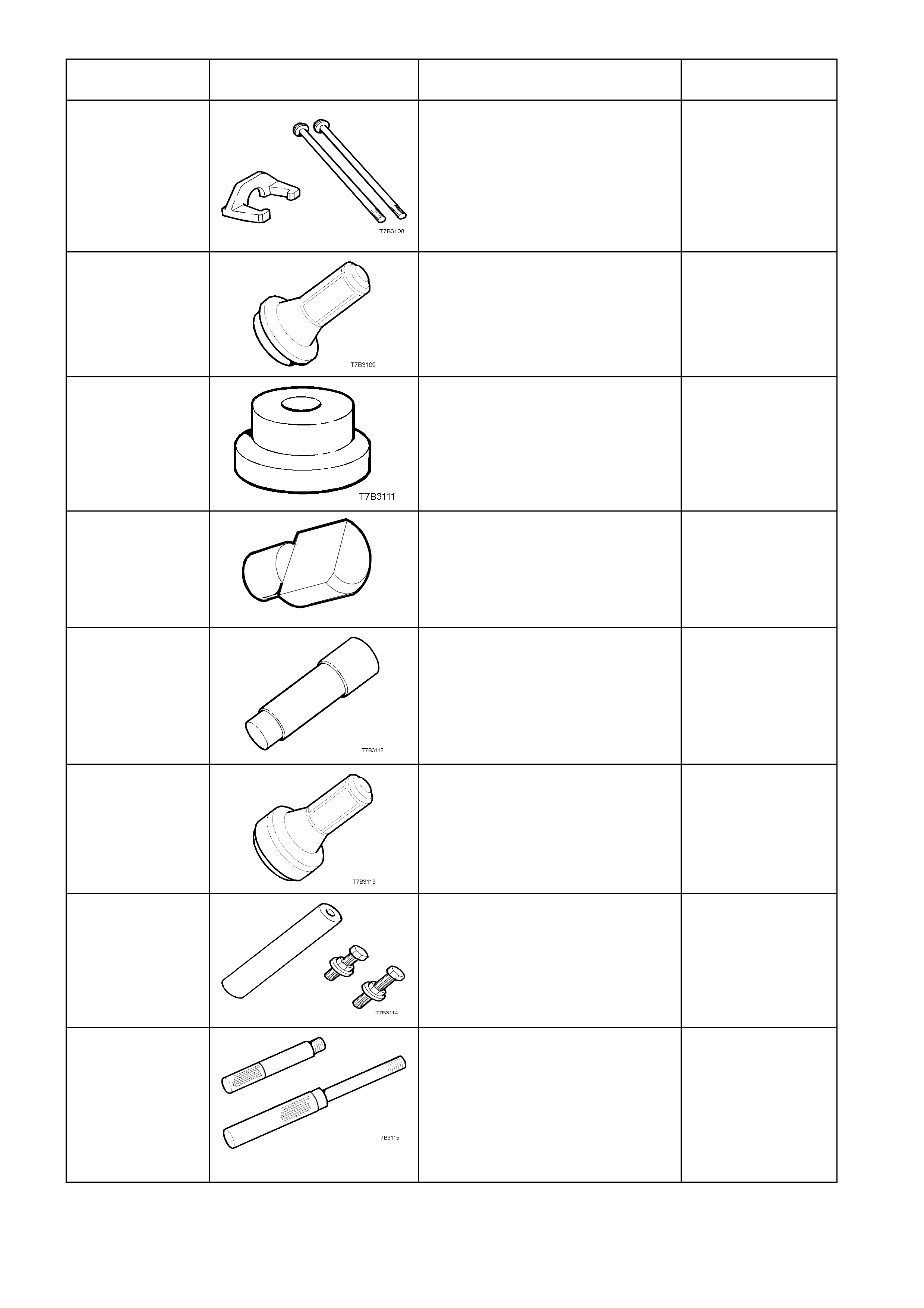

J 39431-1 & 2 REMOVER AND BOLTS

Used to remove the speedometer

pulse ring and the 5th/6th speed,

compound driven gear on the

Tremec 6 speed manual

transmission. Used in conjunction

with universal bridge puller J 8433.

New release.

Unique

J 39433 SEAL INSTALLER

Used to install the input shaft oil

seal on the Tremec 6 speed

manual transmission.

New release.

Desirable

J 39436 BEARING CUP INSTALLER

Used to install the countershaft rear

bearing cup on the Tremec 6 speed

manual transmission. Use in

conjunction with driver handle J

8092.

New release.

Unique

J 39437

J 39437

BUSHING INSTALLER

Used to install the selector shaft

bushes in the adapter plate, and

transmission case on the Tremec 6

speed manual transmission.

New release.

Unique

J 39439-1 BUSHING REMOVER/INSTALLER

Used to remove shift shaft bushes

from the transmission case and

extension housing on the Tremec 6

speed manual transmission.

New release.

Unique

J 39440 REAR SEAL AND BOOT

INSTALLER

Used to install the rear extension

seal on the Tremec 6 speed

manual transmission.

New release.

Desirable

J 39441 GEAR INSTALLER

Used to install the 5th/6th

compound driven gear and the

speedometer pulse ring on the

Tremec 6 speed manual

transmission.

New release.

Unique

J 39444-1 & 2 END PLAY RODS

Used to check the end float of the

countershaft gear (J 39444-1) and

countershaft gear extension

(J 39444-2) on the Tremec 6 speed

manual transmission.

New Releases.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J 39511 SPLIT PLATE

Used to remove the front

countershaft gear bearing on the

Tremec 6 speed manual

transmission.

New release.

Unique

J 39546 BEARING CUP INSTALLER

Used to install the rear mainshaft

roller bearing cup on the Tremec 6

speed manual transmission. Used

in conjunction with driver handle J

8092.

New release.

Unique

J 39594 BEARING CUP REMOVER

Used in conjunction with slide

hammer J 23907 to remove the

mainshaft pilot bearing cup in the

input shaft gear on the Tremec 6

speed manual transmission.

New release.

Unique

J 39789 BEARING CUP REMOVER

Used to press out the rear

mainshaft roller bearing cup from

the extension housing on the

Tremec 6 speed manual

transmission. Used in conjunction

with driver handle J 8092.

New Release.

Unique

J 39790 BEARING CUP REMOVER

Used to press out the rear

mainshaft bearing cup from the

transmission case on the Tremec 6

speed manual transmission. Used

in conjunction with driver handle J

8092

New release.

Unique

J 39791 BEARING CUP REMOVER

Used to press out the rear

countershaft bearing cup from the

transmission case on the Tremec 6

speed manual transmission. Use in

conjunction with driver handle J

8092.

New release.

Unique

J 41476

T6A3257a

FRONT AND REAR COVER

ALIGNMENT TOOL

Used to align both the front and

rear engine covers during

installation on GEN III V8 engine.

New release.

Desirable

J 41478

T6A3258a

CRANKSHAFT FRONT OIL SEAL

INSTALLER

For GEN III V8 engine; threaded

bolt, nut and washer are also used

in conjunction with J 41665 to install

the crankshaft balancer.

New release.

Desirable

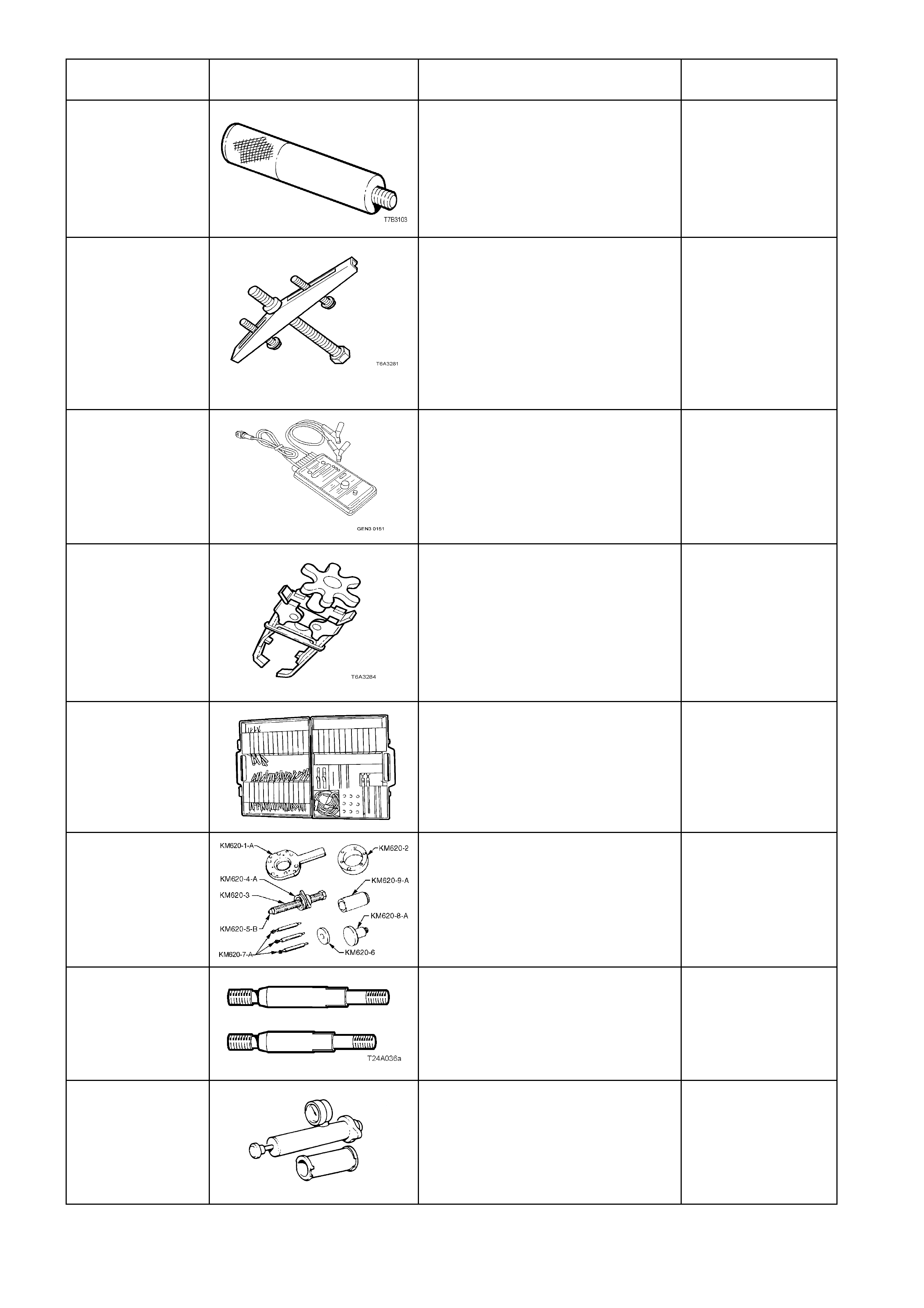

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J 41479

T6A3259a

CRANKSHAFT REAR OIL SEAL

INSTALLER

For GEN III engine.

New release

Desirable

J 41480

T6A3260a

FRONT AND REAR COVER

ALIGNMENT TOOL

Used in conjunction with alignment

tool J 41476, to correctly align the

front and rear engine covers on

GEN III V8 engines.

New release.

Desirable

J 41556 CONNECTING ROD GUIDES

Used to assist in piston and

connecting rod installation on GEN

III V8 engine.

New release.

Desirable

J 41558 CRANKSHAFT SPROCKET

REMOVER

Used in conjunction with the bolts

from J 21427-01 and pulley puller J

8433, to remove the crankshaft

sprocket on GEN III V8 engine.

New release.

Desirable

J 41665 CRANKSHAFT BALANCER

INSTALLER

Used in conjunction with the

threaded bolt, nut and washer of

Tool J 41478, to install the

crankshaft balancer and sprocket

on GEN III V8 engine.

New release.

Desirable

J 41712 OIL PRESSURE SENSOR

SOCKET

Used in conjunction with 3/8” drive

socket equipment to

remove/reinstall oil pressure sensor

on GEN III V8 engine.

New release.

Desirable

J 41816 THREE LEGGED PULLER

Used in conjunction with J 41816-2

to remove crankshaft balancer on

GEN III V8 engine.

New release.

Desirable

J 41816-2 ADAPTER

Used in conjunction with puller J

41816 to remove crankshaft

balancer on GEN III V8 engine.

New release.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J 41818 CRANKSHAFT BEARING CAP

REMOVER

Used in conjunction with slide

hammer J 6125-1B to remove main

bearing caps on GEN III V8 engine.

New release.

Desirable

J 42078 VALVE STEM OIL SEAL

INSTALLER

New release.

Desirable

J 42220 BLACK LIGHT, LEAK DETECTION

LAMP

Used with dye, Tool J 28431-B to

locate the source of various vehicle

fluid leaks.

Previously released.

Desirable

J 42385 THREAD REPAIR KIT

Comprises:

Cylinder Head/Rear Main

Bearing Cap Kit J 42385-

100

General Kit J 42385-200

Fixtures/Hardware Kit J 42385-

300 New release.

Unique

J 42386 FLYWHEEL HOLD ING TOOL

New release. Desirable

J 42907 OIL PRESSURE ADAPTER

Fitted to the oil filter adapter and

used in conjunction with a

commercially available oil pressure

gauge and hose.

New release.

Desirable

J 5590 PRESS TUBE

Used to install various components,

using a hydraulic press.

Previously released for 4L60-E

automatic transmission.

Unique

J 8087 CYLINDER BORE CHECKING

GAUGE

New release.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J 8092 UNIVERSAL DRIVER HANDLE

Used in conjunction with various

other tools for removal and

installation of various bearing cups

in the transmission.

Previously released.

Unique

J 8433 UNIVERSAL BRIDGE PULLER

Used in conjunction with J 39431-1

& 2 to remove the speedometer

pulse ring and the 5th/6th speed,

compound driven gear on the

Tremec 6 speed manual

transmission.

Previously released.

Unique

J 39021 FUEL INJECTOR COIL/BALANCE

TESTER

This tester is used in conjunction

with a digital multimeter for testing

fuel injector coils, and cylinder

injector balance testing.

New release.

Mandatory

KD 2078 VALVE SPRING COMPRESSOR

Used to remove valve springs with

cylinder head/s installed.

Used in conjunction with spark plug

adapter J 22794.

Previously released for the V6

engine.

Desirable

KM609 CONNECTOR TEST ADAPTOR

KIT

Used when carrying out electrical

diagnostic circuit checks.

Previously released.

Desirable

KM620-A REMOVER/INSTALLER

Used to remove and install trunnion

flange, rear wheel bearing and

trunnion assembly.

Desirable

KM620-7-AUS SUPPORTS

Used to support flange holding tool,

KM620-1-A when

removing/installing rear

trunnion/wheel bearing from newly

released trailing arm.

Desirable

N/A COOLING SYSTEM PRESSURE

TESTER

Commercially available.

Used in conjunction with adapters J

24460-92

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

N/A TIS CD

Only available to Holden Dealers Mandatory

N/A CLUTCH CENTRING TOOL

Commercially available. Desirable