SECTION 4C - PROPELLER SHAFT AND

UNIVERSAL JOINTS

CAUTION:

This vehicle will be equipped with a Supplemental Restraint System (SRS). A SRS will consist of either

seat belt pre-tensioners and a driver's air bag, seat belt pre-tensioners and a driver's and front

passenge r's air bags or se at belt pre-ten sioner s, drive r’s an d fron t pass enger’ s air bag and left an d rig ht

hand side air bags. Refer to SAFETY PRECAUTIONS, Section 12M, Supplemental Restraint System of

this Service Information CD before performing any service operation on, or around any SRS

components, the steering mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could

result in SRS deployment, resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC (V6

Engine) or (GEN III V8 Engine) of this Service Information CD.

1. GENERAL INFORMATION

W hile the propel ler s haf t a nd u ni vers a l j oin ts f itted t o VT Ser ies II ve hic l es remains unchanged f r om the as sem blies

fitted to VT ser ies models , the prop el ler shaf t as s embly fitte d to v ehicles with the G E N III V8 en gin e h as a cha nged

identification code.

Apart from this fact, all service operations remain as detailed in Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINT S, of this Ser vic e Inf or mation CD, exc e pt f or the ‘Important Serv ice Information ’ no te con tained

in this Section.

W ith the change in propel ler shaft ident ification c odes, an abr idged Spec ifications Section has been repro duced in

this Section.

Techline

Techline

Techline

2. SERVICE OPERATIONS

2.1 GENERAL INFORMATION

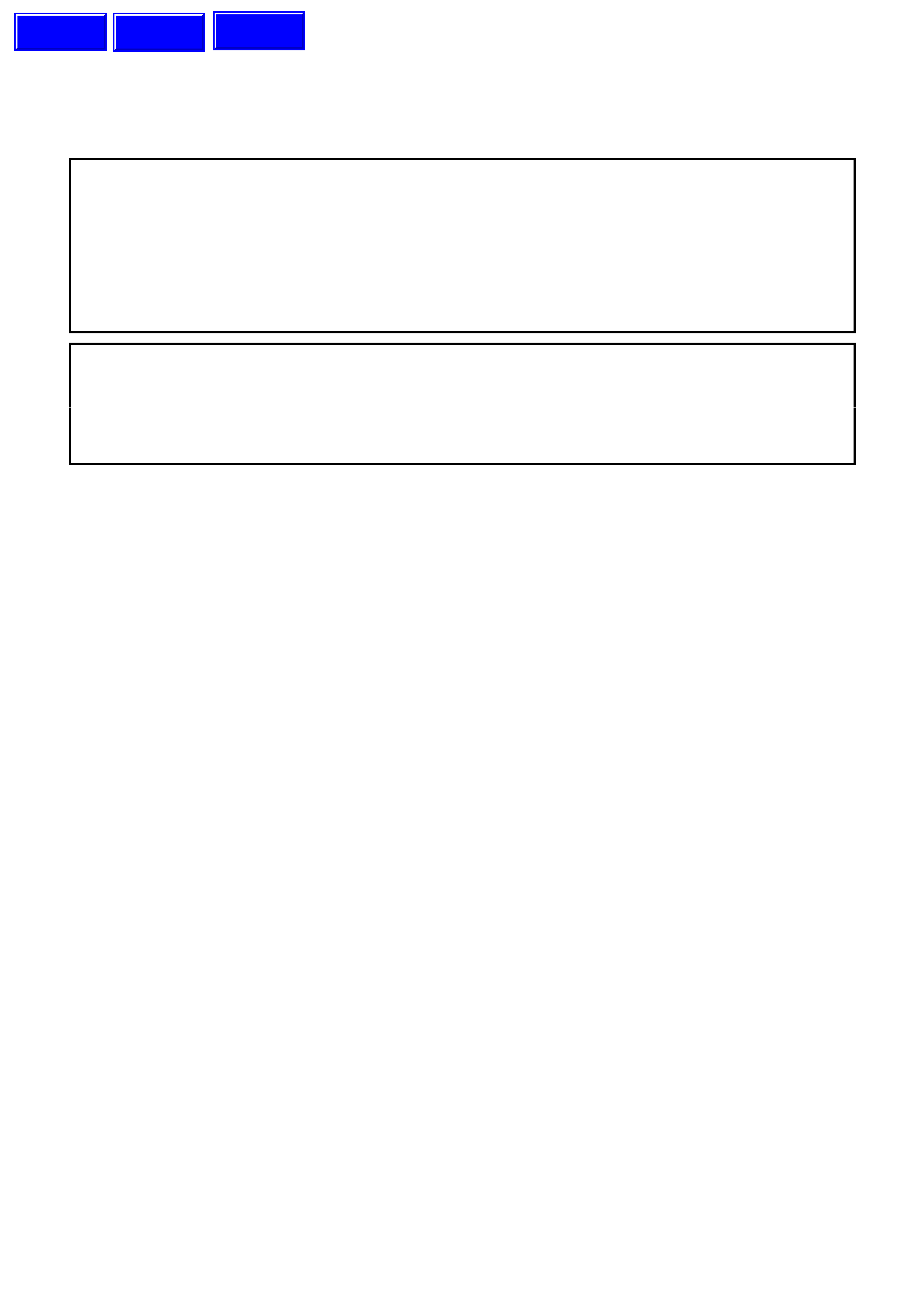

IMPORTANT SERVICE INFORMATION

In maintaining the optimum driveline angles and

phasing, a spacer has been included between the

transmission support mounting and the extension

housing on those vehicles fitted with a V6 engine.

When a GEN III V8 engine is fitted to the vehicle,

the catalytic converter bracket is used to provide

the spacer thickness required.

In addition to the transmission support spacer,

spacers (1) have also been placed between the

centre bearing carrier (3) and the centre bearing

cup guide (2), as shown.

Whenever the centre bearing carrier is separated

from the centre bearing cup guide, the original

spacers must be reinstalled in the original

positions. The spacers are NOT to be placed

between the carrier (3) and the underfloor

reinforcement (4).

NOTE 1: The spacer thickness is different for

station wagon models, compared to sedans.

NOTE 2: The centre bearing carrier (3) is offset

and the arrow symbol on the carrier must be

reinstalled, facing forward.

Apart from this information, all other service

operations remain as detailed in Section 4C

PROPELLER SHAFT AND UNIVERSAL JOINTS,

of this Service Information CD.

Figure 4C-1

Techline

3. SPECIFICATIONS

NOTE: For those specifications not included here, refer 4C PRO PEL LER SHAFT AND UNIVERSAL J OINTS, of

the VT Series I Servic e Inf or mation.

PROPELLER SHAFT IDENTIFICATION

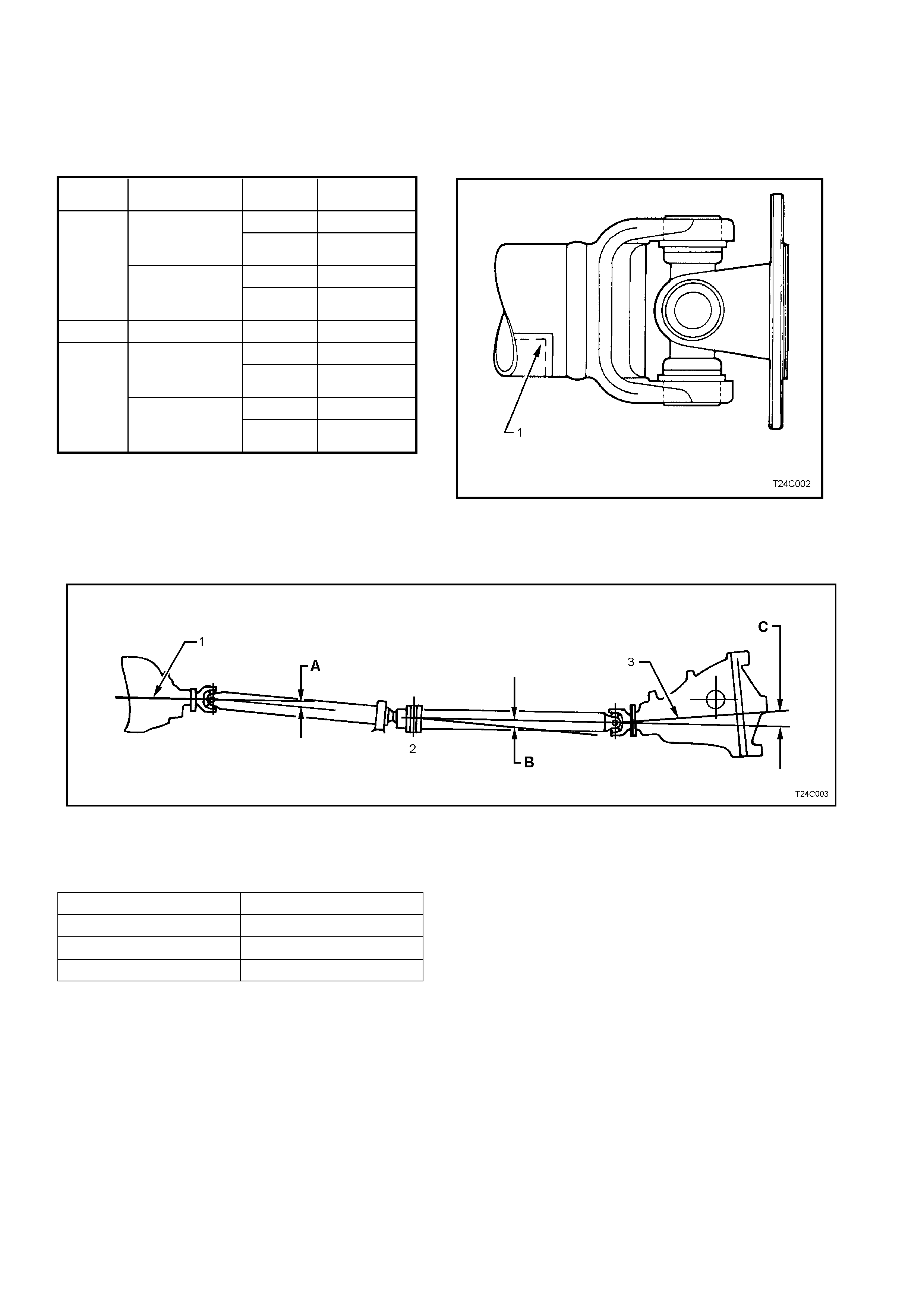

DRIVE LINE ANGLES - VEHICLE AT CURB WEIGHT

1 Engine Crankshaft Centreline 2 Centre Joint 3 Pinion Shaft Centreline

ADriveline Angle ‘A’ BDriveline Angle ‘B’ CDriveline Angle ‘C’

Figure 4C-2

Driveline Angle Degrees – All Models

‘A’ + 0.0° ± 0.5°

‘B’ Greater than ± 1.0°

‘C’ 0.0° ± 0.5°

ENGINE

TYPE TRANSMISSION

TYPE BODY

STYLE PROPELLER

SHAFT CODE

SEDAN JD

MANUAL STATION

WAGON JF

V6 SEDAN JG

AUTOMATIC STATION

WAGON JH

V6 S/C AUTOMATIC SEDAN JG

SEDAN MA

GEN III MANUAL STATION

WAGON MB

V8

SEDAN

JJ

AUTOMATIC STATION

WAGON JK

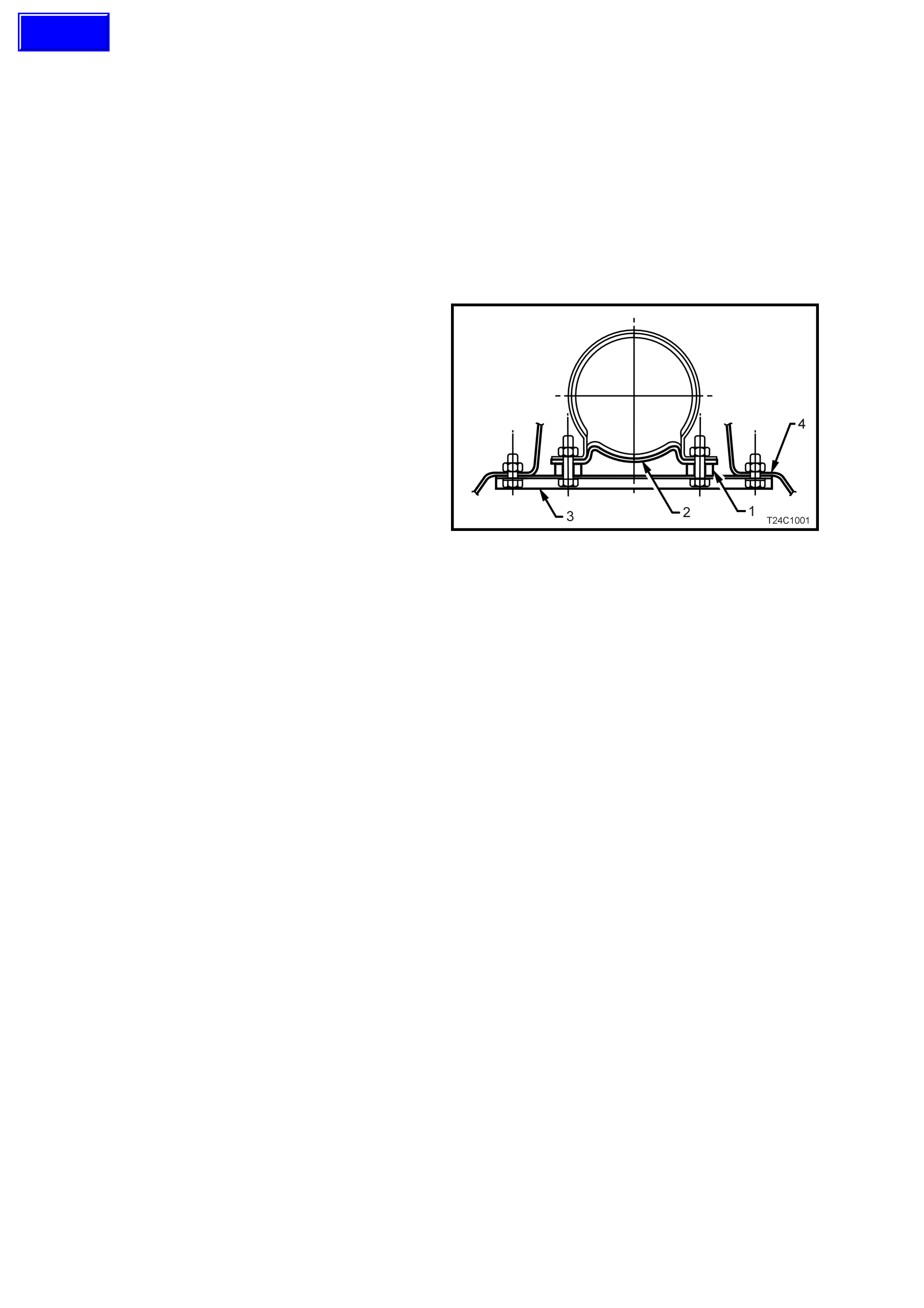

Legend:

1. Identification Code (See table above).

Positioned in line with the low imbalance

mark on the rear flange. Figure 4C-2