SECTION 7B3 - MANUAL TRANSMISSION -

GEN III V8 ENGINE

CAUTION:

This v ehicle will be equipped with a Supplemental Restraint System (SRS). An SRS will consist of either

seat belt pre-tensioners and a driver's side air bag, seat belt pre-tensioners and a driver's and front

passenger's side air bags or seat belt pre-tensioners and a driver's and front passenger's side air bags.

Refer to SAFETY PRECAUTIONS, Section 12M Supplemental Restraint System, of this Service

Information CD before performing any service operation on or around any SRS components, the steering

mechanism or wiring. Failure to follow the SAFETY PRECAUTIONS could result in SRS deployment,

resulting in possible personal injury or unnecessary SRS system repairs.

CAUTION:

Whenever any component that forms part of the ABS or ABS/ETC (if fitted), is disturbed during Service

Operations, it is vital that the complete ABS or ABS/ETC system is checked, using the procedure as

detailed in 4. DIAGNOSIS, ABS or ABS/ETC FUNCTION CHECK, in Section 12L ABS & ABS/ETC, VT

Series I Service Information (V6 Engine) or VT Series II Service Information (GEN III V8 Engine) of this

Service Information CD.

1. GENERAL INFORMATION

W ith the introduction of the GEN III V8 engine, the manual transmission available for fitment to this engine, is the

six speed, Tremec, Type T56 (production option MM6).

This manual transmission is optional equipment on GEN III V8 engined Executive models and Berlina.

The ‘T56’ manual transmission is a fully synchronised unit, including reverse gear, with blocking ring type

synchronisers.

The transmission primarily consists of a four piece construction comprising a clutch housing bolted to a front

adaptor plate, transmission case and extension housing. During disassembly, the major number of gear train

components and shift mechanism remain on the transmission front adaptor plate.

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1.1 GENERAL DESCRIPTION

SYNCHRONISER ASSEMBLIES

Each of the four synchroniser hubs are splined to their respective shafts and secured by a snap ring. All

synchromesh blocking rings have a carbon fibre frictional material and are brass, except for 1st and 2nd gears.

The block ing r ings us ed on 1st and 2nd gear s are of a double c one c ons truc tion, with carbon f ibre fric tional material

on each side of the inner member. The purpose of the synchroniser assemblies is to permit clutching to the required

gear.

Synchroniser Action

During synchroniser operation, the synchroniser ring is moved into engagement by the appropriate fork, carrying

with it, three spring loaded synchroniser inserts, located in slots in the synchroniser hub.

The synchroniser ring, together with the inserts, is moved along the hub, placing a load on the three lugs of the

blocking ring.

This initial force is sufficient to seat the blocking ring and start pre-synchronisation because of the friction between

the cone on the constant mesh gear and the blocking ring.

At this stage, gear engagement is prevented as long as there is a dif ferenc e in speed between the mating s urfaces

of the blocking ring and cone of the constant mesh gear. As the speeds between the blocking ring and the gear

cone becom e synchronised, the teeth on the blocking r ing and gear c one line up with the internal splines of the ring,

allowing the ring to engage the teeth on the gear being engaged, completing gear selection.

REVERSE GEAR

The reverse idler gear is in constant mesh with the counter gear extension and the reverse gear, splined to the

mains haf t. When reverse gear is engaged, the revers e s ynchrom es h ring engages the rever se c ons tant mes h gear,

completing the selection.

BEARING SUPPORT

All shafts in the tr ansmis sion ar e suppor ted by taper roller bearings , exc ept f or a par allel roller bear ing at the rear of

the mains haft. The input shaf t gear, front counter shaft gear and rear c ountershaft gear extens ion bearing cups are

a sliding fit in their respective housings. Selective shims are located under each of the bearing cups to control

bearing pre-load or end float (for the countershaft extension).

Each of the constant mesh gears is supported by caged needle roller bearings, except for the reverse idler gear that

has a twin, caged needle roller bearing running on the reverse idler gear shaft.

LUBRICATION

Lubrication of all internal components is by splash feed, provided by the rotating countershaft gear assembly.

SELECTOR MECHANISM

The floor mounted, gearshift control lever operates through a remote lever arrangement onto a single rail

mec hanis m which extends into the tr ansmis sion r ear c as e. T he 1s t/2nd, 3rd/4th, 5th/6th and r ever se s hif t s haf t r ails

are all supported at each end, in the adaptor plate, transmission case or extension housing.

A shift interlock system, prevents engagement of m ore than one gear at a time. T he system consists of a selector

pin and interlock plate mounted on the 1st/2nd and 3rd/4th selector shaft rail.

When any gear is selec ted, the s elec tor pin is aligned with the par tic ular s hif t fork link or s hif t lever , with 5th/6th and

reverse gears. As this selector pin slides within the interlock plate, only the gear selected can be engaged.

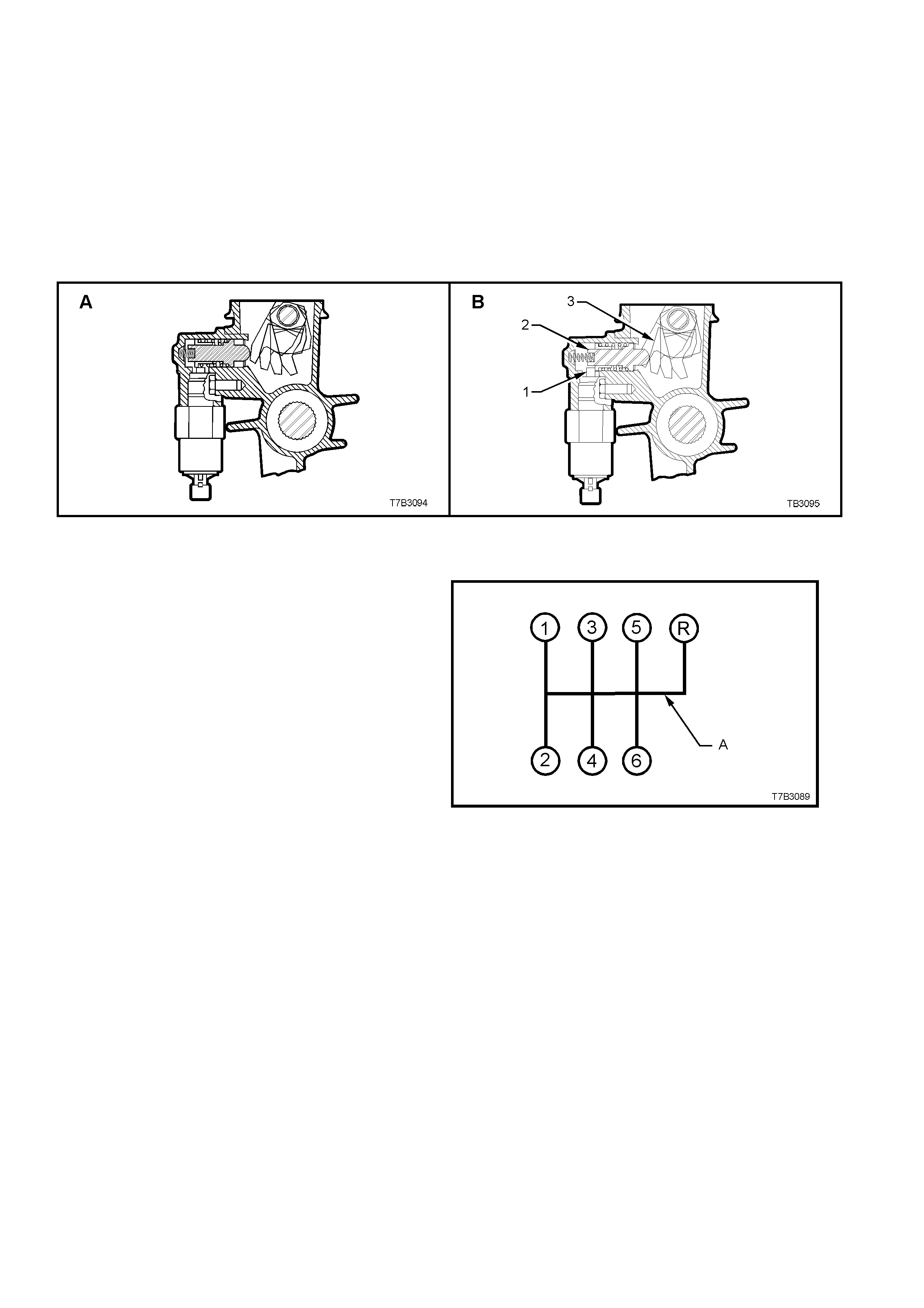

REVERSE LOCKOUT MECHANISM

The transmission is also fitted with a reverse

lockout solenoid assembly that prevents the

selection of reverse gear, above road speeds of 8

km/h. Above this speed, the Powertrain Control

Module (PCM), causes the solenoid plunger (1) to

block the movement of the spring loaded, reverse

lockout plunger (2) (See view ‘B, next).

W hen activated, the r ear offset lever (3) is blocked

from rotating to the reverse selection position.

Figure 7B3-1 - Reverse Lockout Mechanism

SHIFT PATTERN

The shif t pattern is as shown in Figure 7B3-2. Point

‘A’ indicates that reverse gear can be inhibited by

the reverse lockout solenoid assembly, just

described.

Figure 7B3-2 - Transmission Shift Pattern

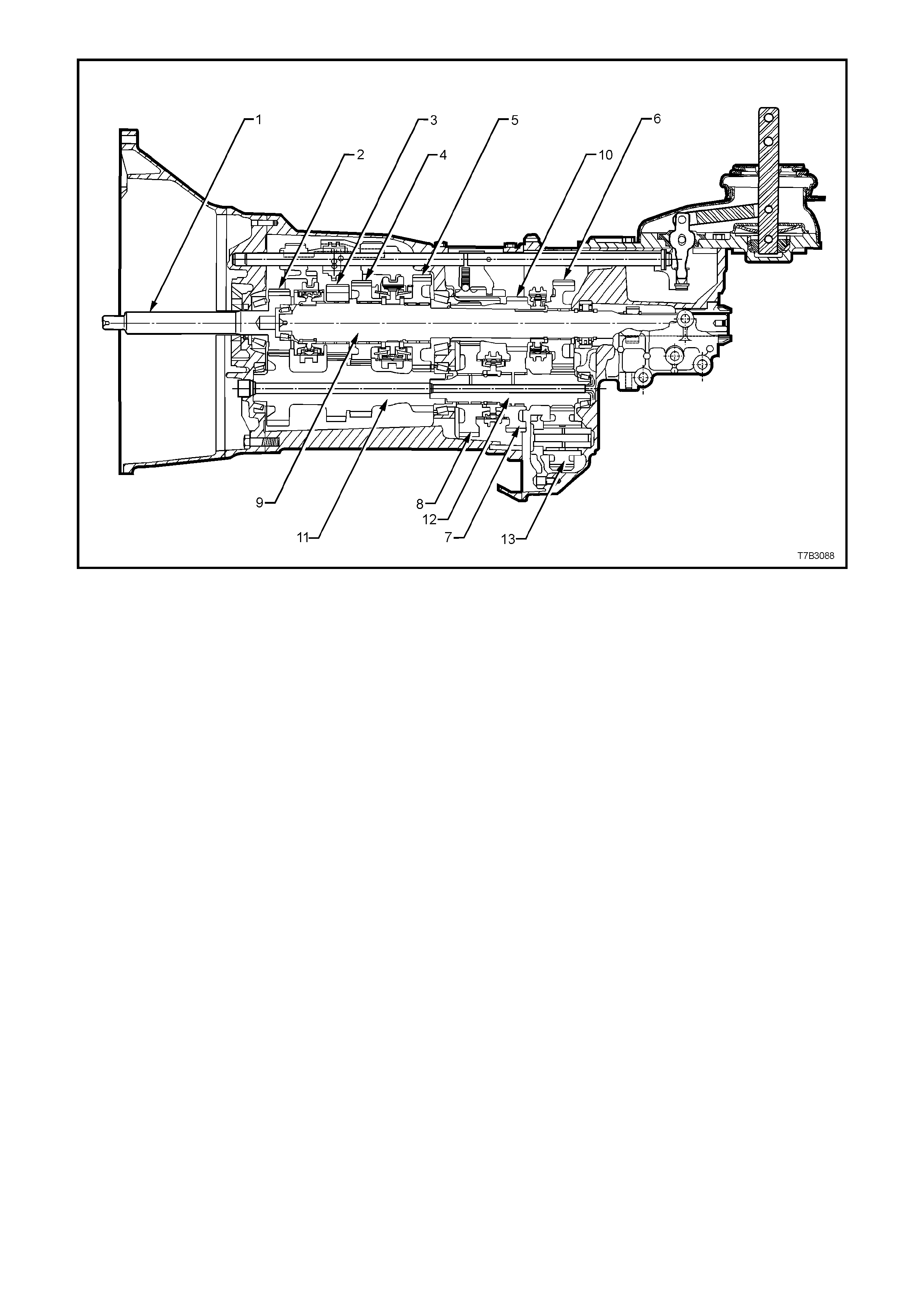

Refer F igure 7B3-3 f or a sect ioned view of the type

T56 transmission (production option MM6) and

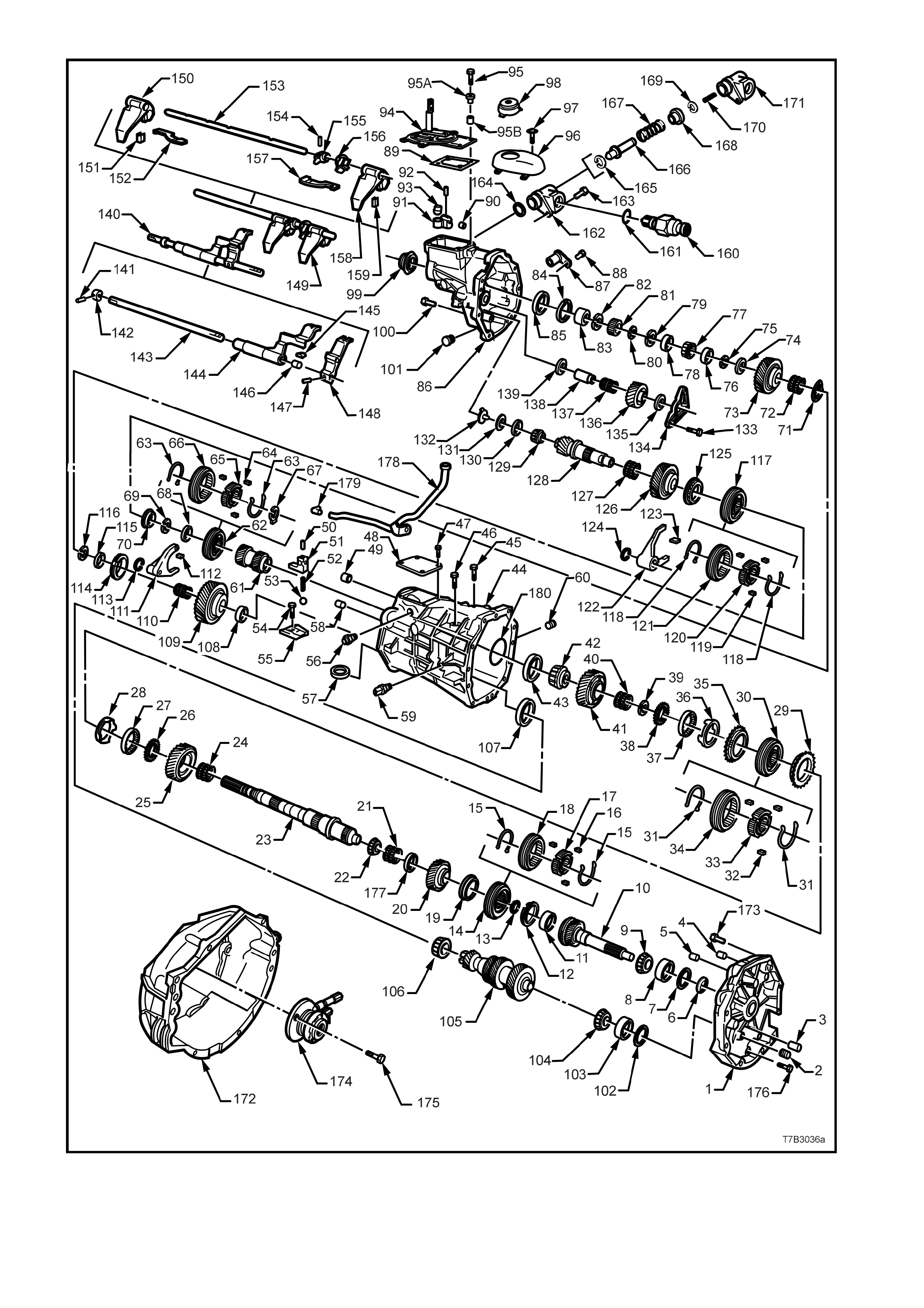

Figure 7B3-4 for an exploded view of the

transmission components.

1. Input Shaft

2. Input Shaft Drive Gear

3. Third Speed Driven Gear

4. Second Speed Driven Gear

5. First Speed Driven Gear

6. Reverse Driven Gear

7. Fifth Speed Drive Gear

8. Sixth Speed Drive Gear

9. Mainshaft

10. 5th/6th Speed Compound Gear

11. Countershaft Gear

12. Countershaft Gear Extension

13. Reverse Idler Gear

Figure 7B3-3 - Type ‘T56’ Transmission, Sectioned View

Figure 7B3-4 - Transmission Components

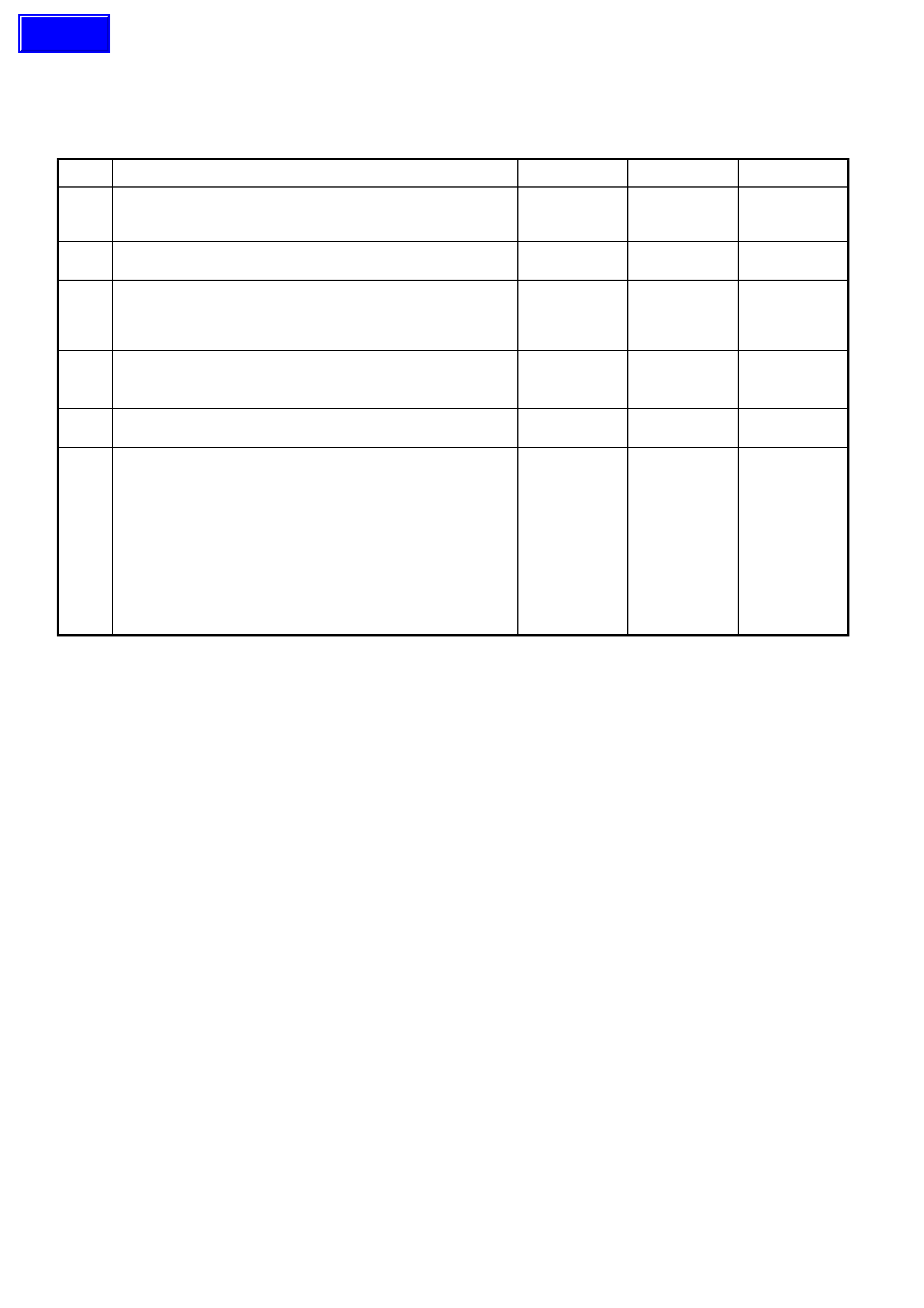

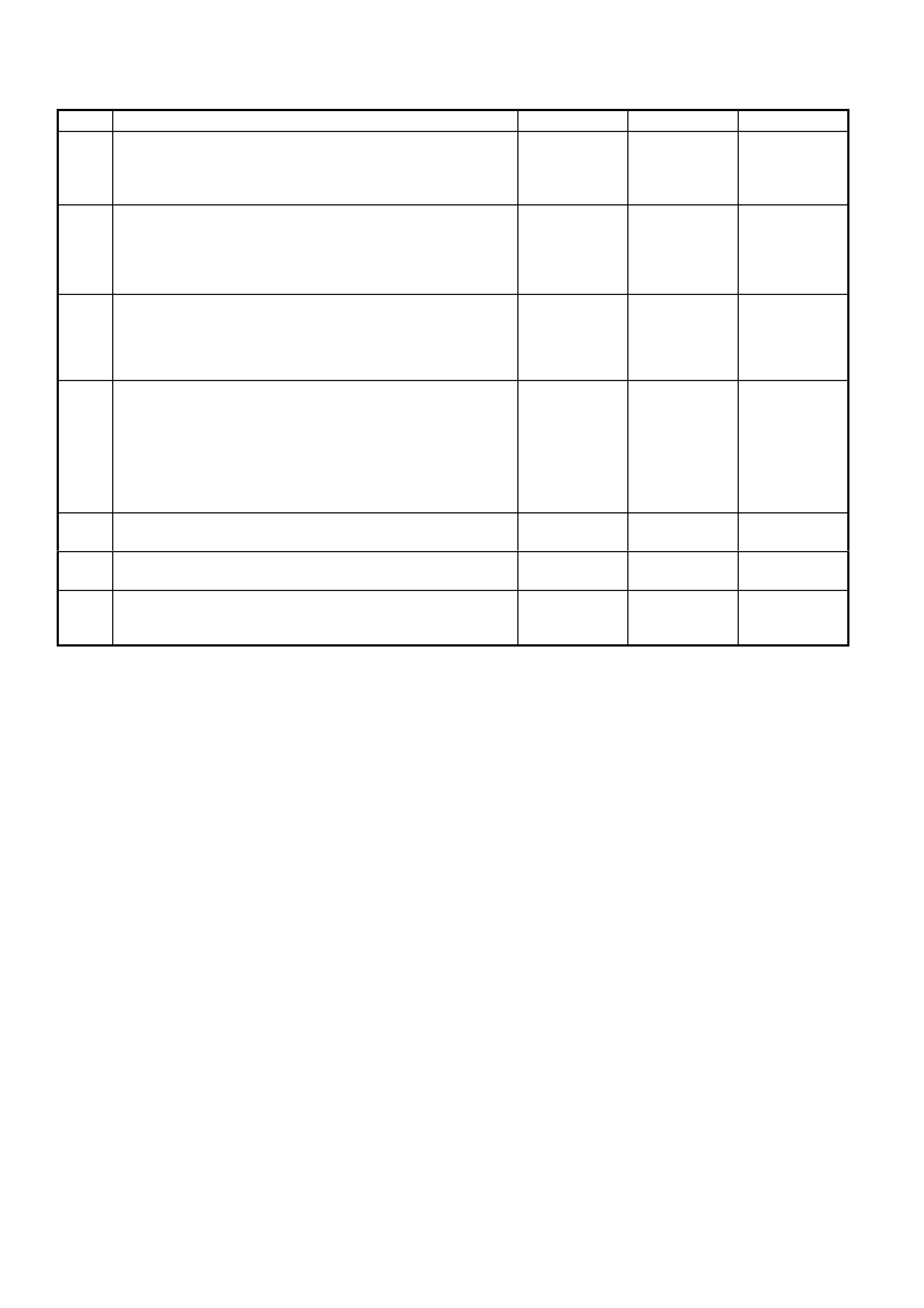

REF

No. PART NAME REF

No. PART NAME REF

No. PART NAME

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

Plate, Transmi ssion A dapt or

Plug

Pin, Dowel (2 plac es)

Pin, Dowel (2 plac es)

Bushing, Shift Rail

Seal, I nput Shaft

Shim , Input S haft

Cup, Input Shaft B eari ng

Bearing, I nput Shaft Tapered

Shaft, Input

Cup, Input Shaft B eari ng

Blocker Ring, 4t h Gear

Ring, Snap

Synchronis er Assembly, 3rd/ 4th

Spring, 3rd/ 4th Synchroniser

Key, 3rd/4th Synchroni ser

Hub, 3rd/4th Synchronis er

Ring, 3rd/4t h Synchronis er

Blocker Ring, 3rd Gear

Gear, 3rd Speed

Bearing, 3rd Gear Needle

Bearing, Mainshaft Small Tapered

Mainshaft

Bearing, 2nd Gear Needle

Gear, 2nd Speed

Washer, Thrust

Cone, Inner

Cone, Frict i on

Blocker Ring, 2nd Gear

Synchronis er Assembly, 1st/2nd

Spring, 1s t/2nd Sync hroni ser

Key, 1s t /2nd Synchroni ser

Hub, 1st / 2nd Synchronis er

Ring, 1st/2nd Sync hroni ser

Blocker Ring, 1s t Gear

Cone, Frict i on

Cone, Inner

Washer, Thrust

Ring, Snap

Bearing, 1s t Gear Needle

Gear, 1st Speed

Bearing, Mains haf t Large Tapered

Cup, Mainshaft Bearing

Case, Transmission

Bolt, Shift Lever Gui de

Bolt, Shift Lever Gui de

Bolt, Shift Detent Cover

Cover, Shift Detent

Bushing, Shift Rail

Pin, Front Offset Lever Rol l

Lever, Front Offset

Spring, S hi ft Detent

Ball, Shift Detent

Bolt, S hi ft Guide Pl ate

Plate, S hi f t Guide

Enhancer, Shift

Magnet (2 places)

Pin, Dowel (2 plac es)

Switch, B ack-up Lamp

Plug, Fill

Gear, 5th/6th Driven

Synchronis e r A ssembly, Reverse

Spring, Reverse Synchroniser

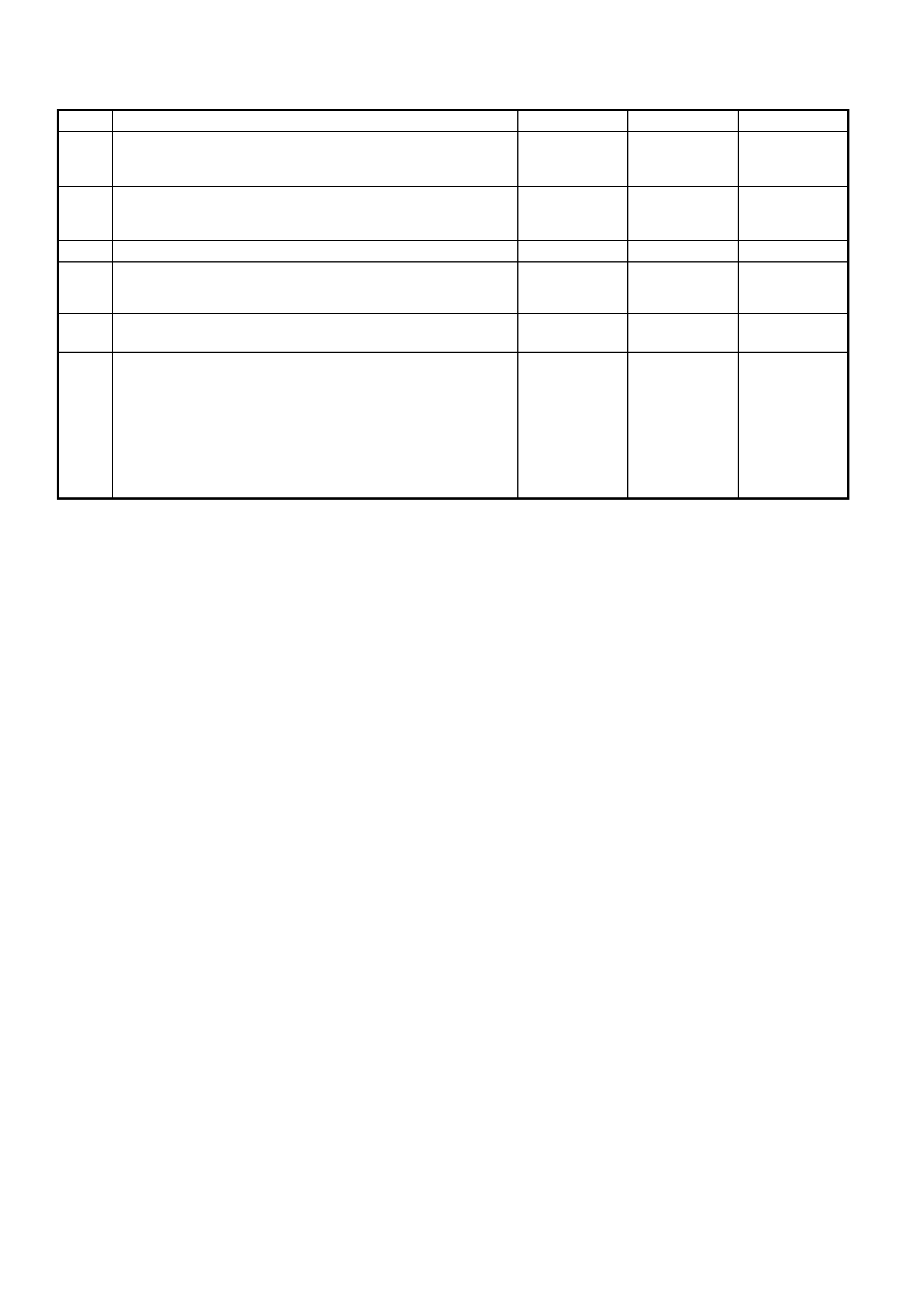

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

88.

89.

90.

91.

92.

93.

94.

95.

95a.

95b.

96.

97.

98.

99.

100.

101.

102.

103.

104.

105.

106.

107.

108.

109.

110.

111.

112.

113.

114.

115.

116.

117.

118.

119.

120.

121.

122.

Key, Revers e Synchronis er

Hub, Reverse S ync hroni ser

Ring, Reverse Synchronis er

Retainer, Reverse Synchroni ser

Key

Washer, Thrust

Ring, Snap

Blocker Ring, Revers e Gear

Washer, Wave

Bearing, Reverse Gear Needle

Gear, Reverse

Washer, Thrust

Ring, Snap

Spacer

Bearing, Rear Mains haf t Tapered

Spacer

Ring, Snap

Ring, Snap

Ring, Speedometer P ul se

Ring, Snap

Ring, Seal i ng

Ring, Snap

Cup, Mainshaft Bearing Rear

Housing, Transmi ssion E xtensi on

Sensor, Elect roni c Speed

Bolt, S peed Sensor

Gasket, Shifter Assembly Cover

Bushing, Shift Rail

Lever, Rear Offset Shi ft

Pin, Rear Of fset Shift Lever Rol l

Cup, Is ol at or

Shifter Assembly

Bolt, Shifter Assembly

Distance Piec e, Shif t Cover Bolt

Sleeve, I nsulati ng

Cover, Shifter Assembly

Screw, Shifter Assembly Cover

Boot, Shifter

Seal and Boot , Rear Output

Bolt, Transmi ssion Extens i on

Housing

Plug, Drain

Shim, Countershaft

Cup, Counters haf t Bearing

Bearing, Count ershaft Tapered

Countershaft

Bearing, Count ershaft Tapered

Cup, Counters haf t Bearing

Washer, Thrust

Gear, 6th Drive

Bearing, 6t h Gear Needl e

Fork, Reverse Shift

Pad, Reverse Shift Fork

Circlip

Blocker Ring, 6t h Gear

Spacer

Ring, Snap

Synchronis er Assembly, 5t h/6th

Spring, 5t h/6th Sync hroni ser

Key, 5th/6th Synchroniser

Hub, 5th/6th Synchroniser

Ring, 5th/ 6th Synchroniser

Fork, 5th/6th Shift

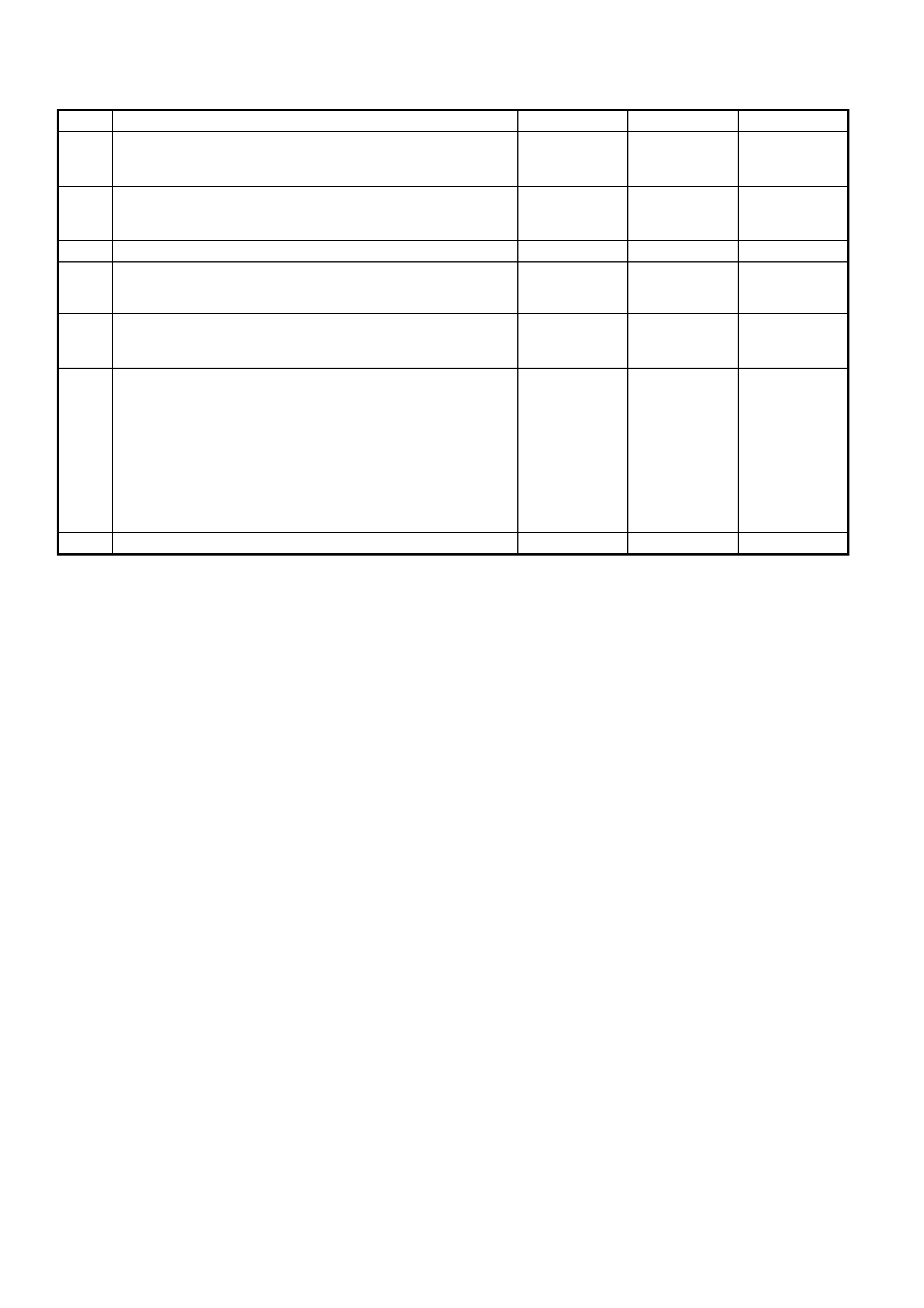

123.

124.

125.

126.

127.

128.

129.

130.

131.

132.

133.

134.

135.

136.

137.

138.

139.

140.

141.

142.

143.

144.

145.

146.

147.

148.

149.

150.

151.

152.

153.

154.

155.

156.

157.

158.

159.

160.

161.

162.

163.

164.

165.

166.

167.

168.

169.

170.

171.

172.

173.

174.

175.

176.

177.

178.

179.

180.

Pad, 5th/ 6th Shif t Fork

Circlip

Blocker Ring, 5t h Gear

Gear, 5th Drive

Bearing, 5t h Gear Needl e

Extension, Countershaft

Bearing, Count ershaft Extension

Tapered

Cup, Counters haf t Extension

Bearing

Shim , Countershaft Extens i on

Funnel, Oil

Bolt, Reverse Idler Shaft B racket

Brack et, Reverse Idler Shaf t

Washer, Reverse Idler Gear Thrust

Gear, Reverse I dl er

Bearing, Reverse Idler Gear Roll er

Shaft, Reverse Idl er Gear

Washer, Reverse Idler Gear Thrust

Rail As sem bl y, 5th/6th, Reverse

Shift

Pin, Roll

Collar

Rail, Shift

Lever, 5th/6th Shif t Rail

Pad, 5th/6th Shi f t Rail Lever

Bushing, 5th/6t h Shift Rai l Lever

Pin, Roll

Lever, Reverse S hi ft Rail

Rail As sembl y, 1st/2nd, 3rd/4th

Shift

Fork, 1s t /2nd Shift

Pad, 1st/2nd Shift Fork

Link, S hi ft

Rail, 1s t/2nd 3rd/4t h Shift

Pin, Roll

Pin, Selector

Plate, Interloc k

Link, S hi ft

Fork, 3rd/4th Shif t

Pad, 3rd/4t h Shift Fork

Solenoid, Reverse Lockout

O-Ring, Reverse Lockout Solenoid

Body Assem bl y, Reverse Lockout

Bolt, Reverse Lock out Assem bl y

O-Ring, Reverse Lockout Ass y

Circlip

Plunger, Revers e Lockout

Spring, Revers e Lockout Outer

Collar, Revers e Lockout

‘C’ Clip

Spring, Reverse Lockout Inner

Body, Revers e Lockout

Housing, Cl utch

Bolt, Cl utch Hous i ng t o Adaptor

Ass embly, Cl utch S l ave Cyl i nder

Bolt, Clutc h S l ave Cyl inder

Bolt, Transmi ssion A dapt or Plate

Spacer

Tube, Vent

Fitting, V ent Tube

O-Ring, Mainshaf t

Legend - Transmission Components

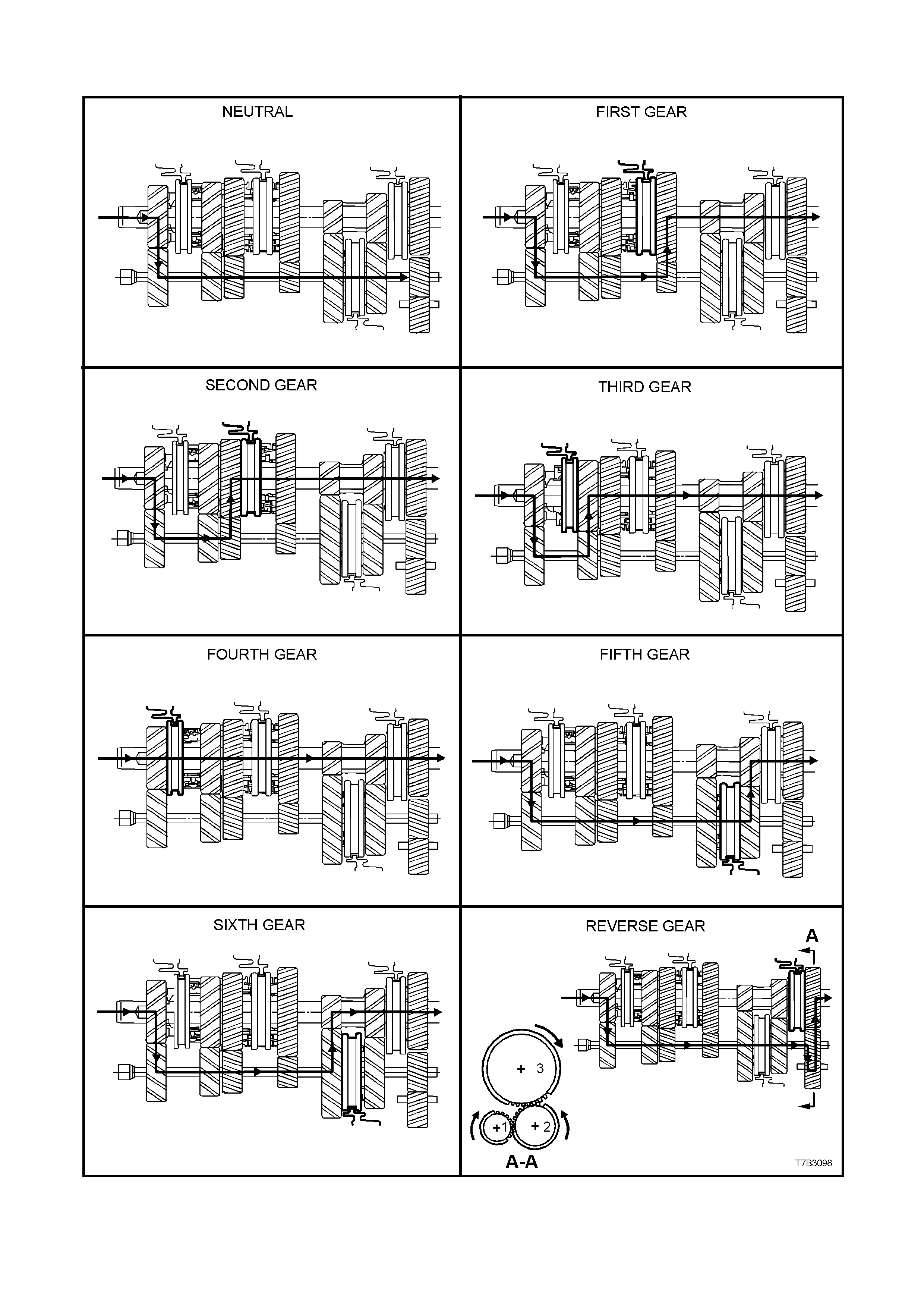

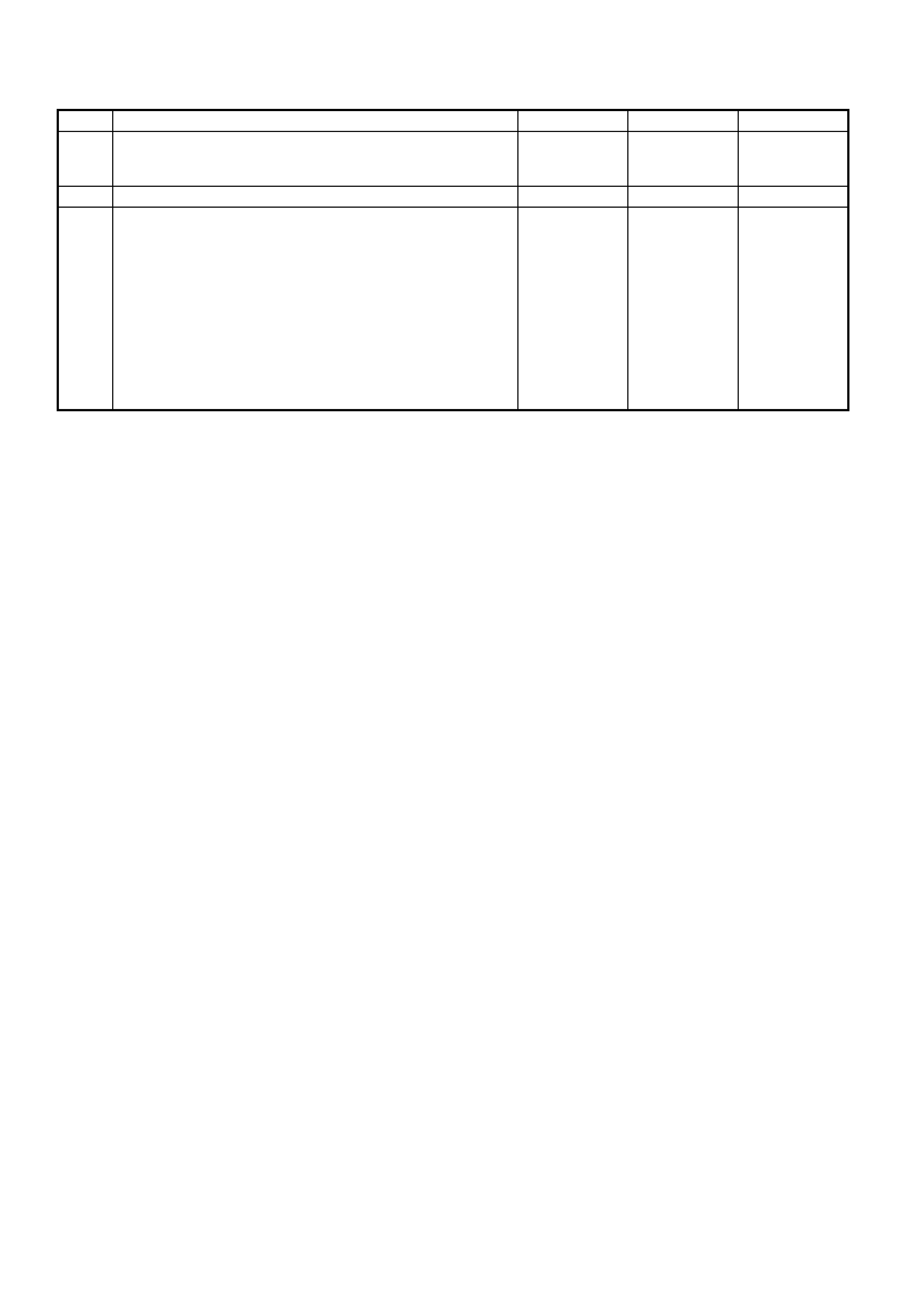

POWER FLOWS

The input s haft drive gear, third, sec ond and first speed gears ar e in constant mes h with the counters haft gear. As

the countershaf t gear extension is s plined to the end of the countershaf t gear, reverse drive gear at the end of this

extension, rotates with the countershaft gear.

Theref ore, when the engine is running with the clutch engaged, engine torque is trans ferred to the input shaf t drive

gear and through the countershaft gear to the third, second, first speed and reverse gears at all times.

The schematics in Figure 7B3-5 relate to the following descriptions:

Neutral

In neutral, with the clutch engaged, the input shaft drive gear turns the countershaft gear and countershaft

extension. The countershaft gear turns the constant mesh gears of 3rd, 2nd, 1st and reverse gears because no

synchroniser assemblies are engaged. As these constant mesh gears are supported on roller bearings, they will

also rotate with the countershaft gear.

As the 5th/6th compound gear is splined to the mainshaft, these constant mesh gears, mounted on the

countershaft extension, will remain stationery while the vehicle is stopped.

First Gear

In first gear, the first/second speed synchroniser ring is moved rearward to engage the first speed gear, which is

being turned by the counters haf t gear. Bec aus e the f irs t/s econd s peed s ynchroniser hub is splined to the mains haf t,

torque is transferred to the mainshaft from the first speed gear through the synchroniser ring and hub, at a speed

reduction of 2.66:1.

Second Ge ar

In second gear, the f ir st/s ec ond s peed synchroniser r ing is moved f or ward to engage the sec ond s peed gear , which

is being turned by the countershaft gear. Because the first/second speed synchroniser hub is splined to the

mainshaft, torque is transferred to the mainshaft from the second speed gear through the synchroniser ring and

hub, at a speed reduction of 1.78:1.

Third Gear

In selecting third gear, the first/second speed synchroniser ring moves to the neutral position and the third/fourth

speed synchroniser ring is moved rearward to engage the third speed gear. As this gear is being turned by the

countershaft gear, the engagement of the ring with the third speed gear, torque is transferred to the mainshaft

because the third/fourth speed synchroniser hub is splined to the mainshaft. The mainshaft the turns at a speed

reduction of 1.30:1

Fourth Gear

In fourth gear, the third/fourth speed synchroniser ring is moved forward to engage the input shaft drive gear.

This engagement of the input shaft drive gear with the third/fourth synchroniser ring and hub assembly, transfers

torque directly to the mainshaft.

While the countershaft gear and countershaft extension is still rotating, no torque transfer takes place but the

spinning gear continues to lubricate the internal transm ission c omponents by the ‘splash’ m ethod. As the m ainshaf t

is effectively joined to the input shaft, the drive is direct with a ratio of 1.00:1.

Fifth Gear

In fifth gear, which is the f irs t of the over drive r atios , the first/s ec ond and third/fourth s peed synchroniser r ings mus t

be in the neutral position. The fifth/s ixth speed synchroniser r ing is moved rearward to engage the f ifth speed drive

gear, supported on the countershaft extension by a caged needle roller bearing. This engagement of the ring with

the fifth speed constant mesh gear, allows torque to be transferred from the countershaft gear extension to the

mainshaft, via the splined synchromesh hub and the splined fifth/sixth speed compound driven gear. This speed

generates an overdrive ratio of 0.74:1.

Sixth Gear

In sixth gear, the fifth/sixth speed synchroniser ring is moved forward to engage the sixth speed drive gear,

supported on the countershaft extension by a caged needle roller bearing. This engagement of the ring with the

sixth speed constant mesh gear, allows torque to be transferred from the countershaft gear extension to the

mainshaft, via the splined synchromesh hub and the splined fifth/sixth speed compound driven gear. This speed

generates an overdrive ratio of 0.50:1.

Reverse Gear

In reverse gear, the reverse synchronis er ring is m oved rearward to engage the m ainshaft m ounted, rever se driven

gear. This allows torque to be transferred from the countershaft extension gear through the reverse idler gear

(revers ing direction of r otation) to the m ainshaft rever se driven gear. As the reverse synchromes h hub is splined to

the mains haft, this causes the mainshaf t to rotate in the opposite direction to the input shaf t drive gear, at a speed

reduction of 2.90:1.

MANUAL TRANSMISSION POWER FLOWS

Figure 7B3-5

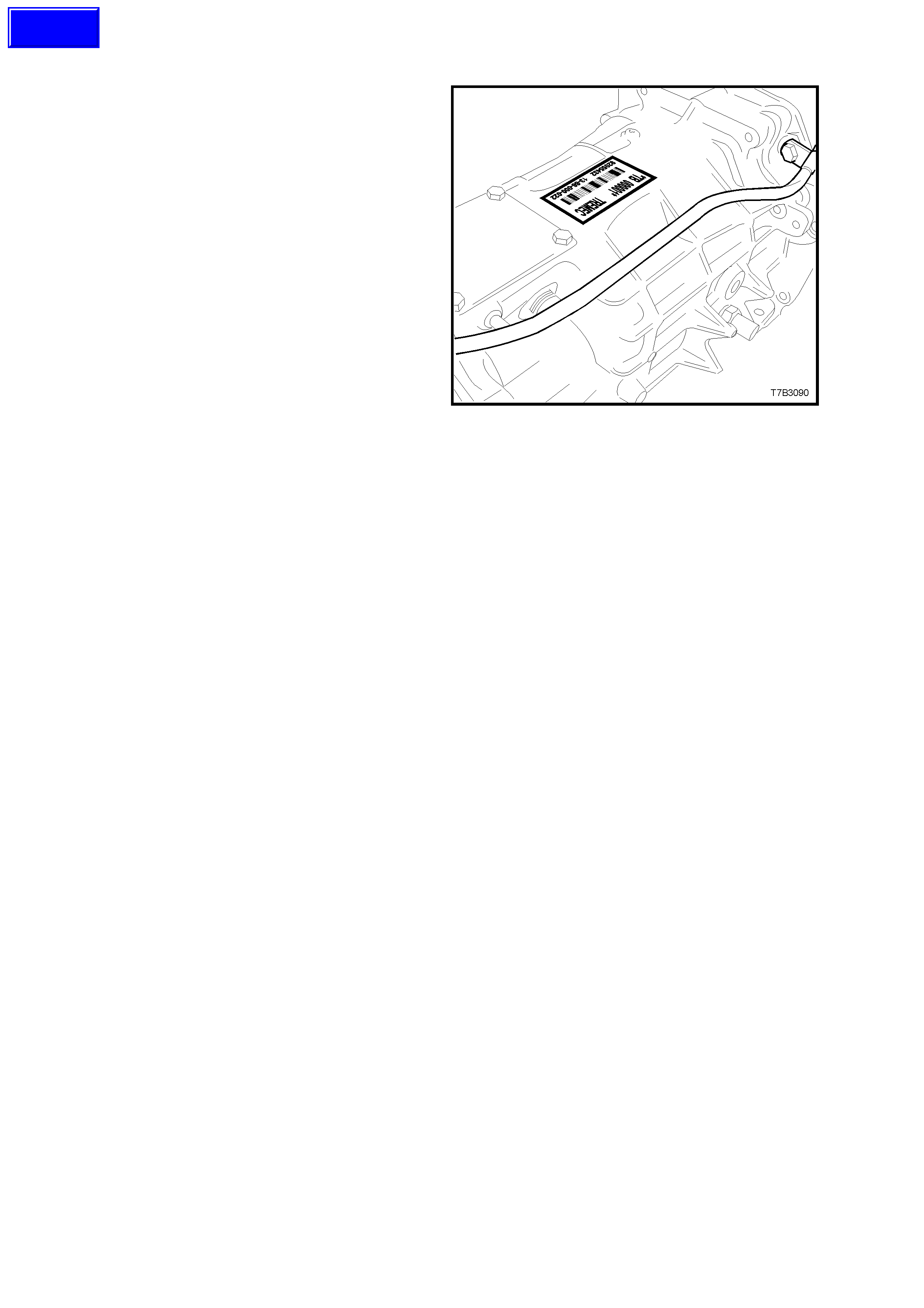

1.2 TRANSMISSION SERIAL NUMBER

The transmission serial number is located on a

self-adhesive decal attached to the top of the

transmission case.

This number provides coded information which

could be significant to parts interpretation and

should be referred to when ordering replacement

parts.

In addition, an identification tag is attached to the

transmission under an extension housing bolt, on

the right hand side. Refer Figure 7B3-8.

Figure 7B3-6

Techline

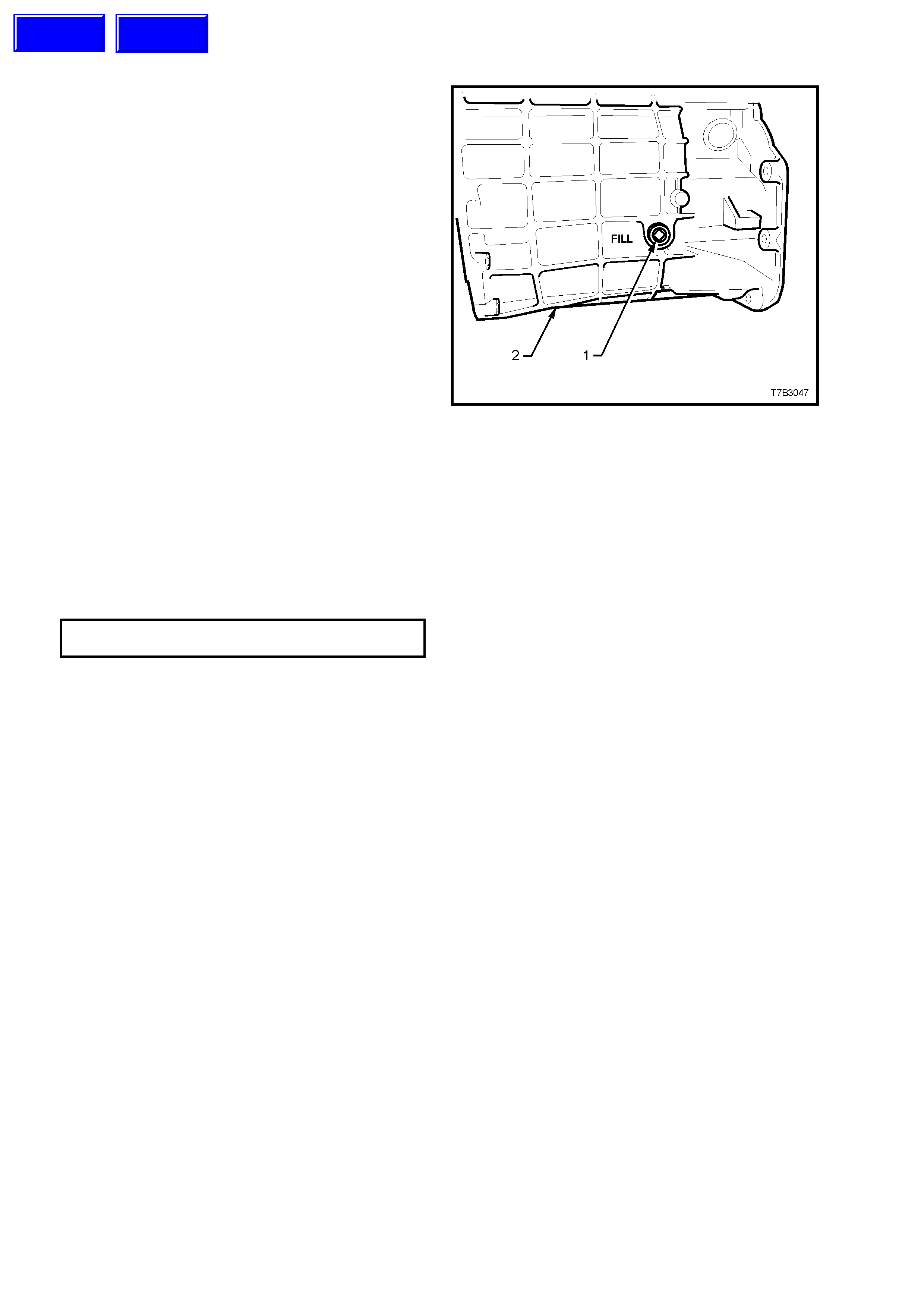

2.2 CHECKING TRANSMISSION LUBRICANT LEVEL

Important: This transmission is classified as

being a “Fill for Life” transmission and

checking the lubricant level is not

recommended.

The only time that fluid level checking would be

appropriate, would be after c orr ec tion of a f luid leak

that did not require the transmission to be fully

drained and/or removed from the vehicle.

1. Raise the vehicle f ront and r ear and support on

safety stands, ensuring that the vehicle is level.

Refer to Section 0A GENERAL

INFORMATION of the VT Series I Service

Information, for the location of jacking points.

2. Place a drain tray beneath transmission and

remove transmission filler plug (1) from left

hand side of transmission case (2), using a 3/8”

drive socket bar.

NOTE: Depending on the severity of the loss, fluid

will probably flow from the filler plug hole, following

removal.

3. Allow excess fluid to drain until flow stops. If

required, top up fluid level until it does flow out.

4. Clean the threads of the f iller plug, apply thread

sealant such as Loctite 565 or equivalent (GM

P/N 12346004), then reinstall filler plug,

tightening to the correct torque specification.

Do not apply Teflon thread tape to the plug

threads.

TRANSMISSION FILLER PLUG

TORQUE SPECIFICATION 20 - 34 Nm

5. Rem ove the back- up lam p switch as detailed in

3.1 BACK-UP LAMP SWITCH, Replace in this

Section.

6. Using commercially available fluid dispensing

equipment, add a measured, 0.5 litres of the

recommended lubric ant to the trans miss ion, via

the back-up lamp switch threaded hole in the

transmission case.

7. Reinstall the back-up lamp switch, as detailed

in 3.1 BACK-UP LAMP SWITCH, Replace in

this Section, then lower the vehicle to the

ground.

Figure 7B3-1

Techline

Techline

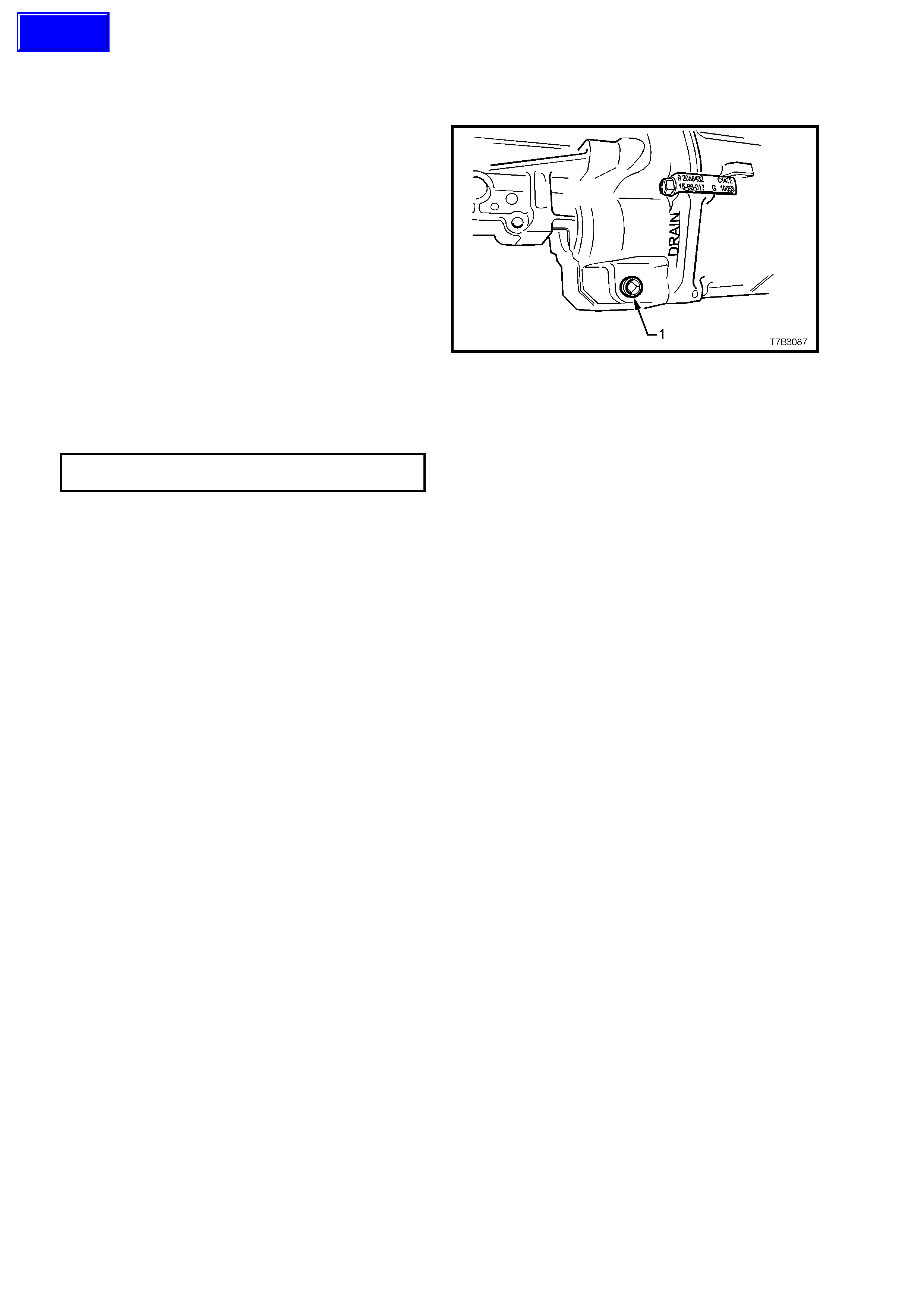

2.3 DRAINING AND REFILLING TRANSMISSION

Should a lubricant change be required, then the

following procedure should be adopted.

1. To drain transmission, jack up vehicle front

and rear and support on safety stands.

Refer to Section 0A GENERAL

INFORMATION of the VT Series II Service

Information, for the location of jacking points.

2. Place a drain tray beneath transmission and

remove filler plug (refer ‘1’ in Figure 7B3-7)

and then the drain plug from the transmission

extension housing (‘1’ in Figure 7B3-8), using

a 3/8” drive socket bar.

3. After draining, clean the threads of the drain

plug, apply thread sealant such as Loctite 565

or equivalent (GM P/N 12346004) then

reinstall, tightening to the correct torque

specification.

NOTE: Do not apply Teflon thread tape to the plug

threads.

TRANSMISSION DRAIN PLUG 20 - 34

TORQUE SPECIFICATION Nm

4. Refill transmission to correct level, refer to

2.2 CHECKING TRANSMISSION

LUBRICANT LEVEL in this Section.

Figure 7B3-8

Techline

3. MI NOR SERVICE OPERATIONS

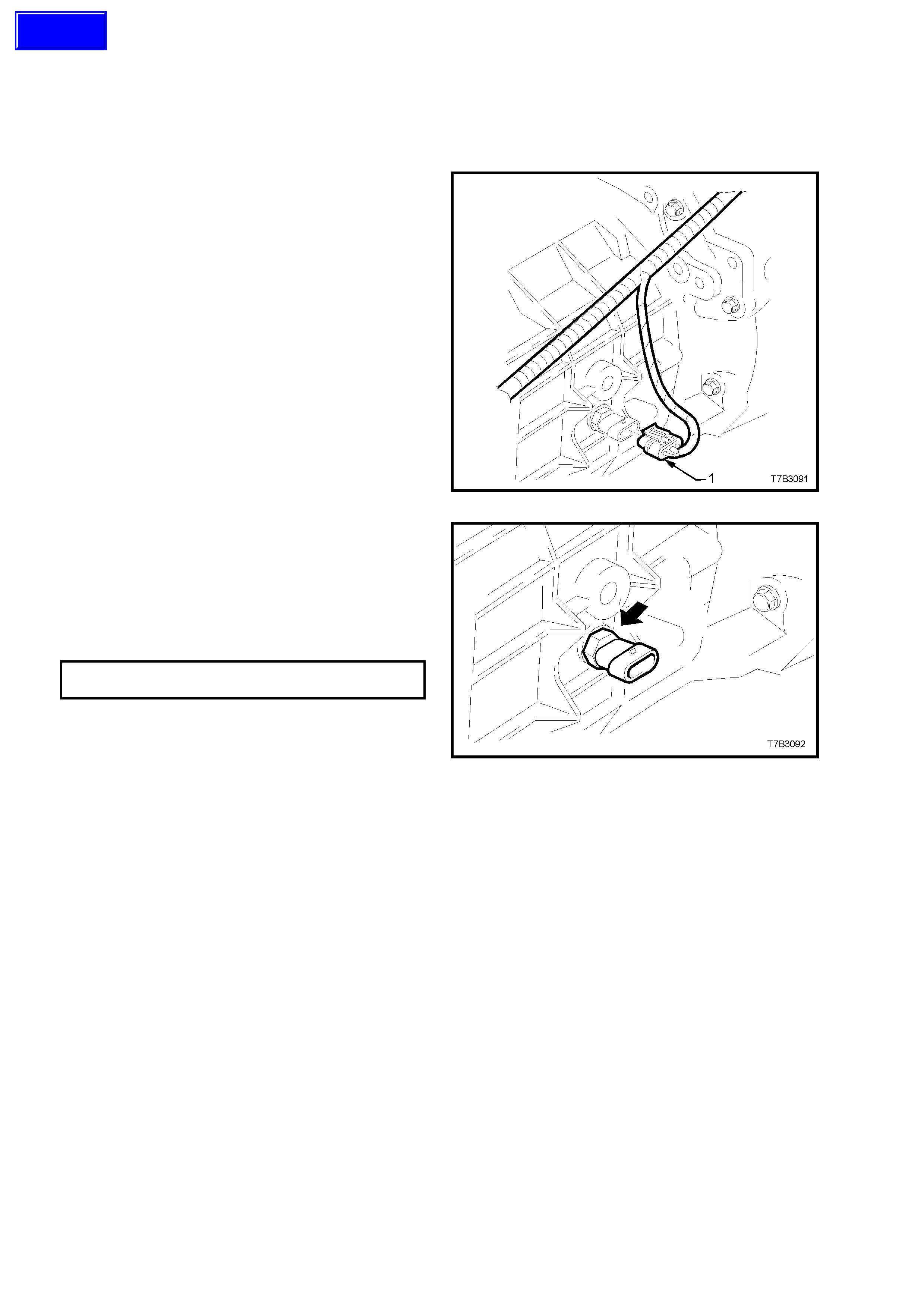

3.1 BACK-UP LAMP SW ITCH

REPLACE

1. Raise front of vehicle and support on safety

stands.

Refer to Section 0A GENERAL

INFORMATION of the VT Series II Service

Information, for the location of jacking points.

2. Remove wiring harness connector (1) from

switch, located on the right hand side of the

transmission case.

Figure 7B3-9

3. Loosen, then remove switch (arrow) from the

transmission case.

4. Apply Loctite 565 or equivalent (GM P/N

12346004), to the cleaned threads of the

back-up lamp switch.

5. Install switch to transmission case and tighten

to the correct torque specification.

BACK-UP LAMP SWITCH 20 - 34

TORQUE SPECIFICATION Nm

6. Install wiring harness connector to switch.

7. Remove safety stands and lower vehicle to

ground.

8. Check back-up lamp operation. Figure 7B3-10

Techline

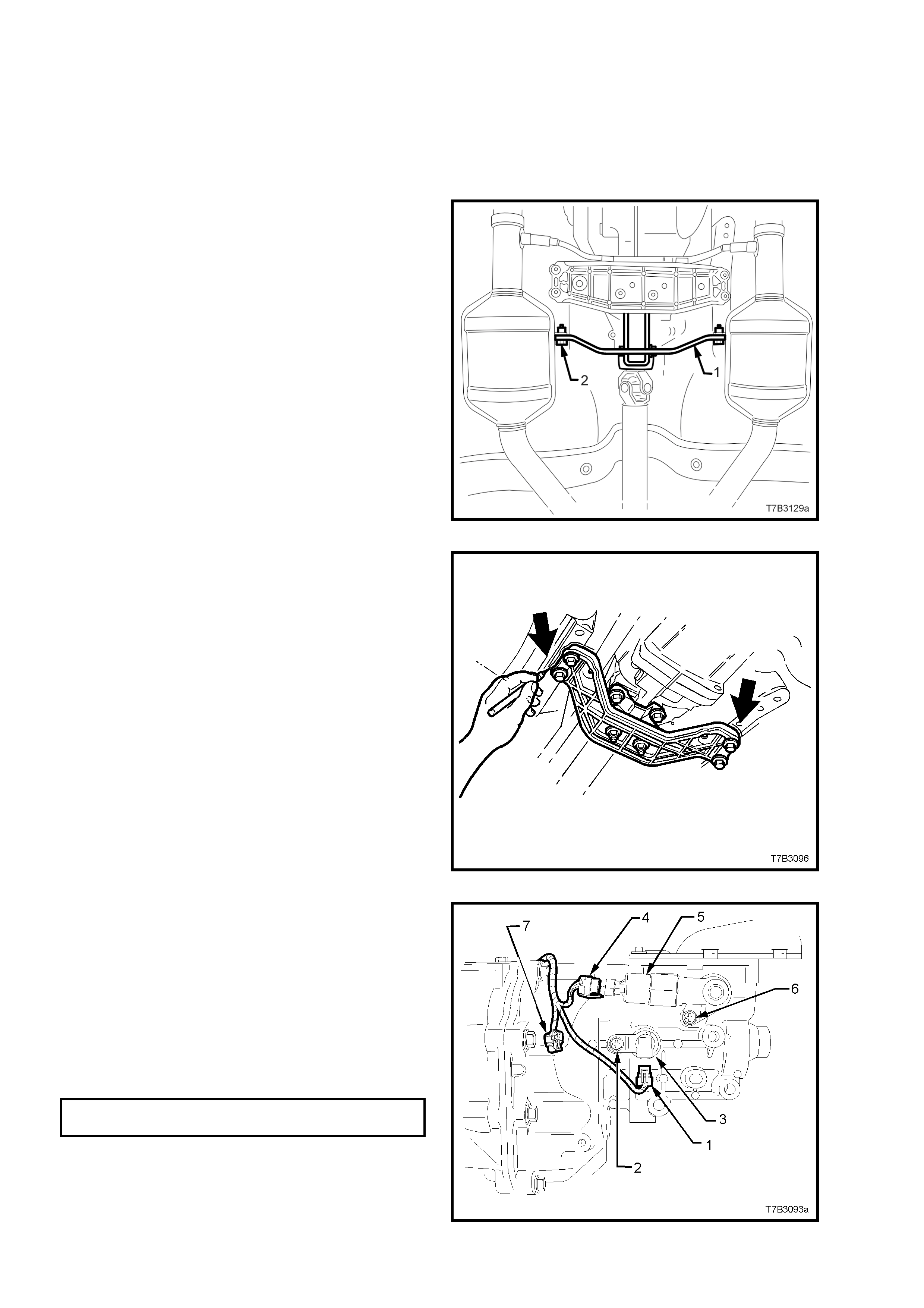

3.2 SPEED SENSOR

REPLACE

1. Jack up vehicle front and rear and support on

safety stands. Refer to Section 0A GENERAL

INFORMATION of the VT Series II Service

Information, for the location of jacking points.

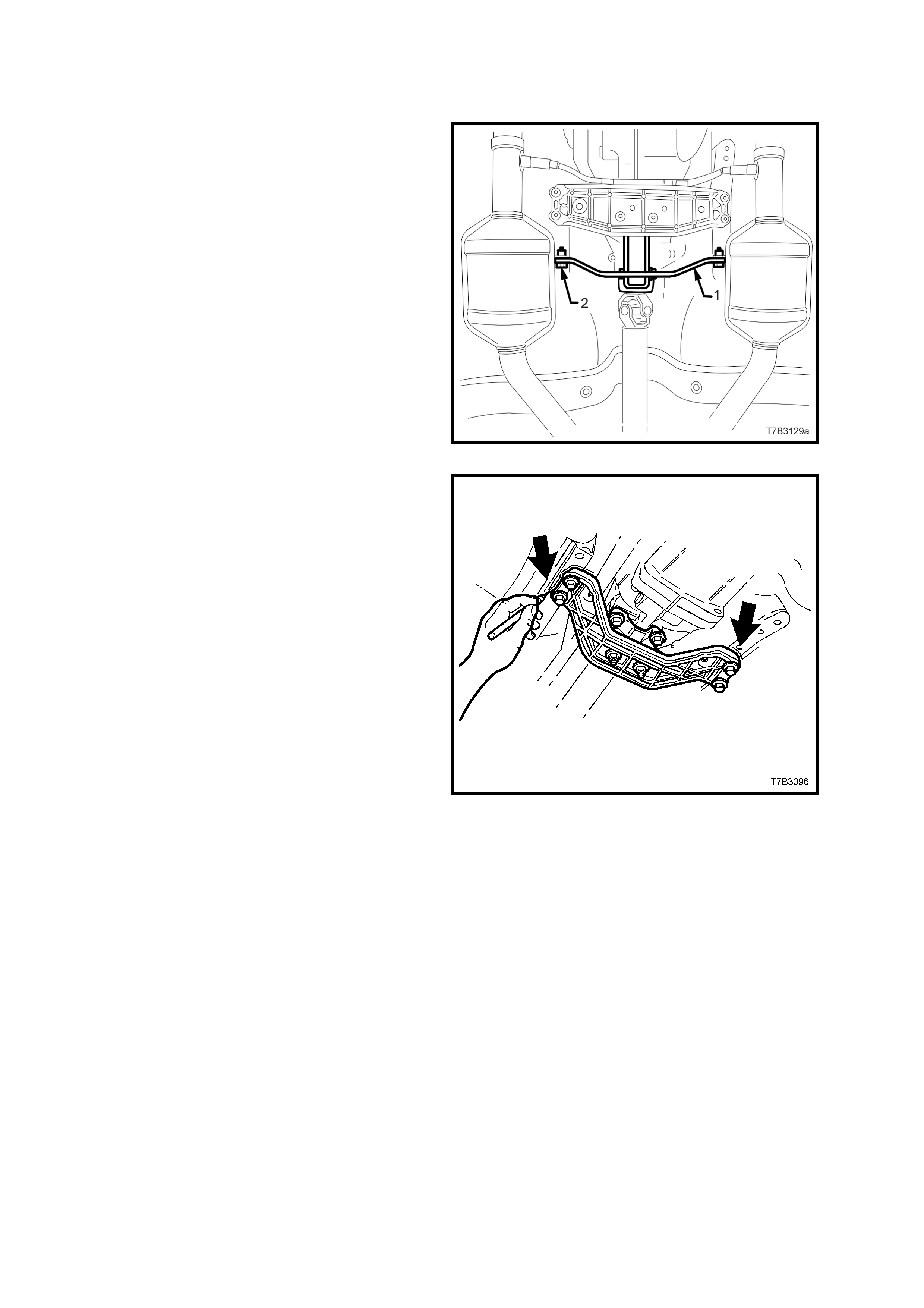

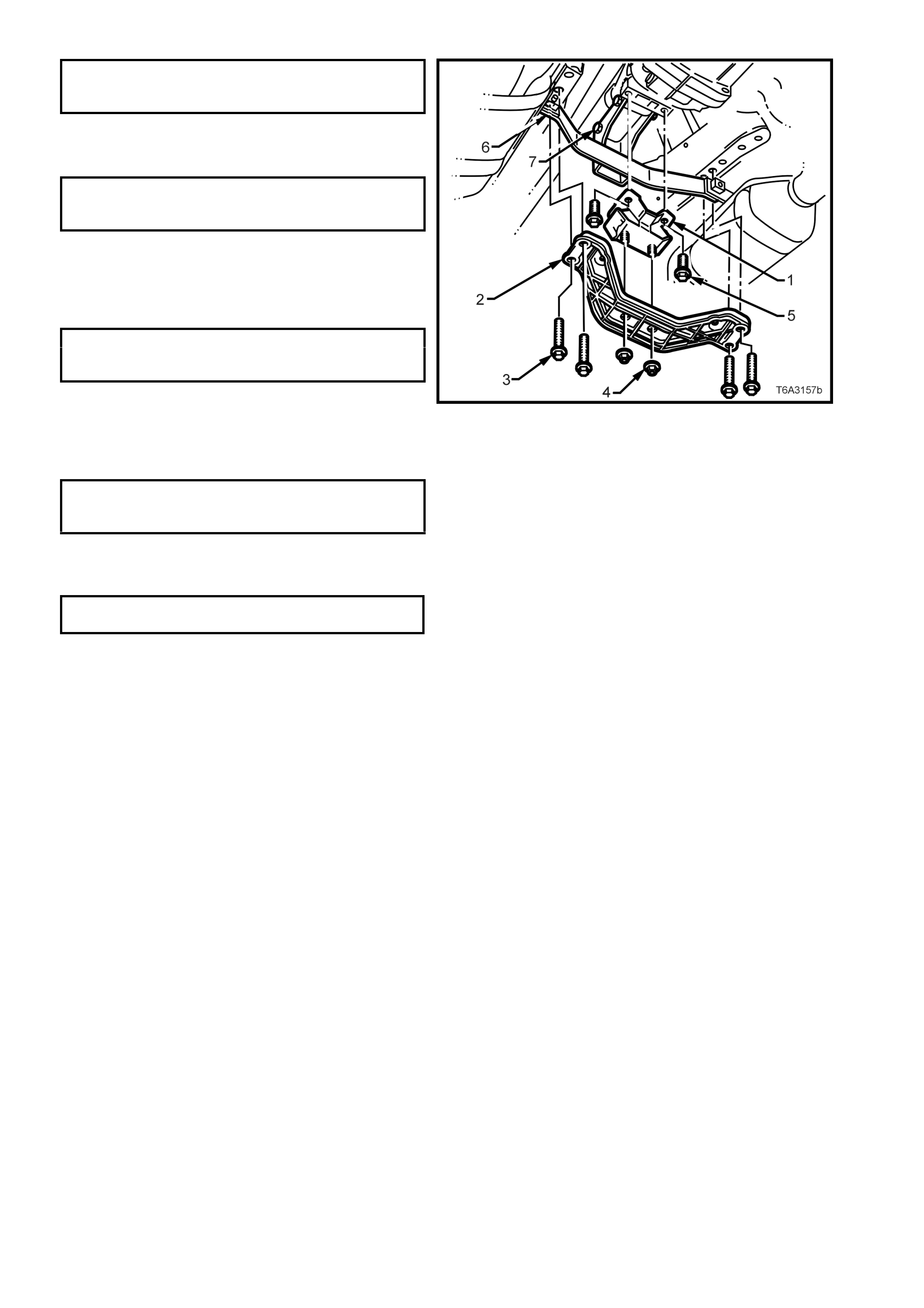

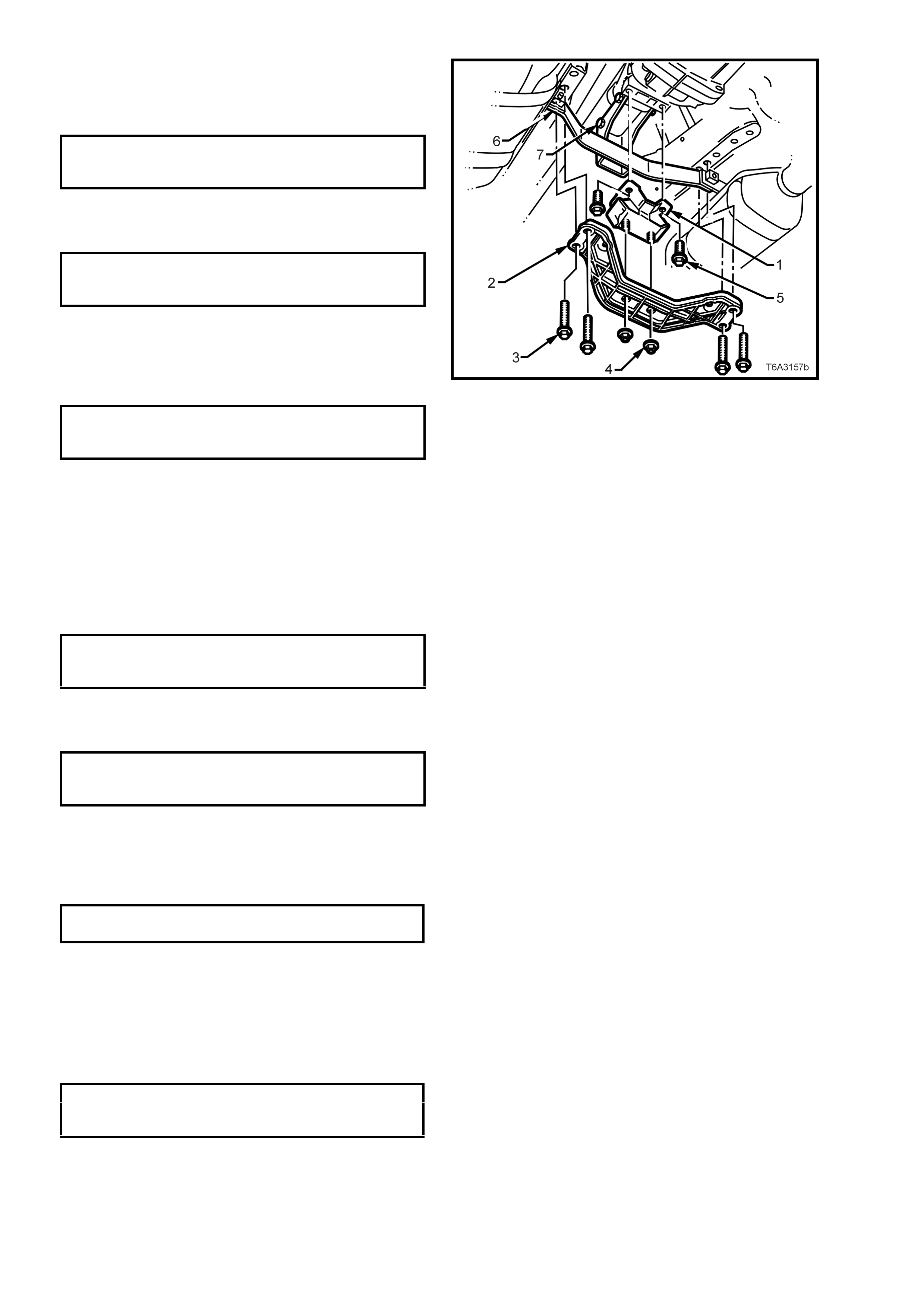

2. Remove the two bolts (2) securing the catalytic

converter bracket (1) to the catalytic

converters.

Figure 7B3-11

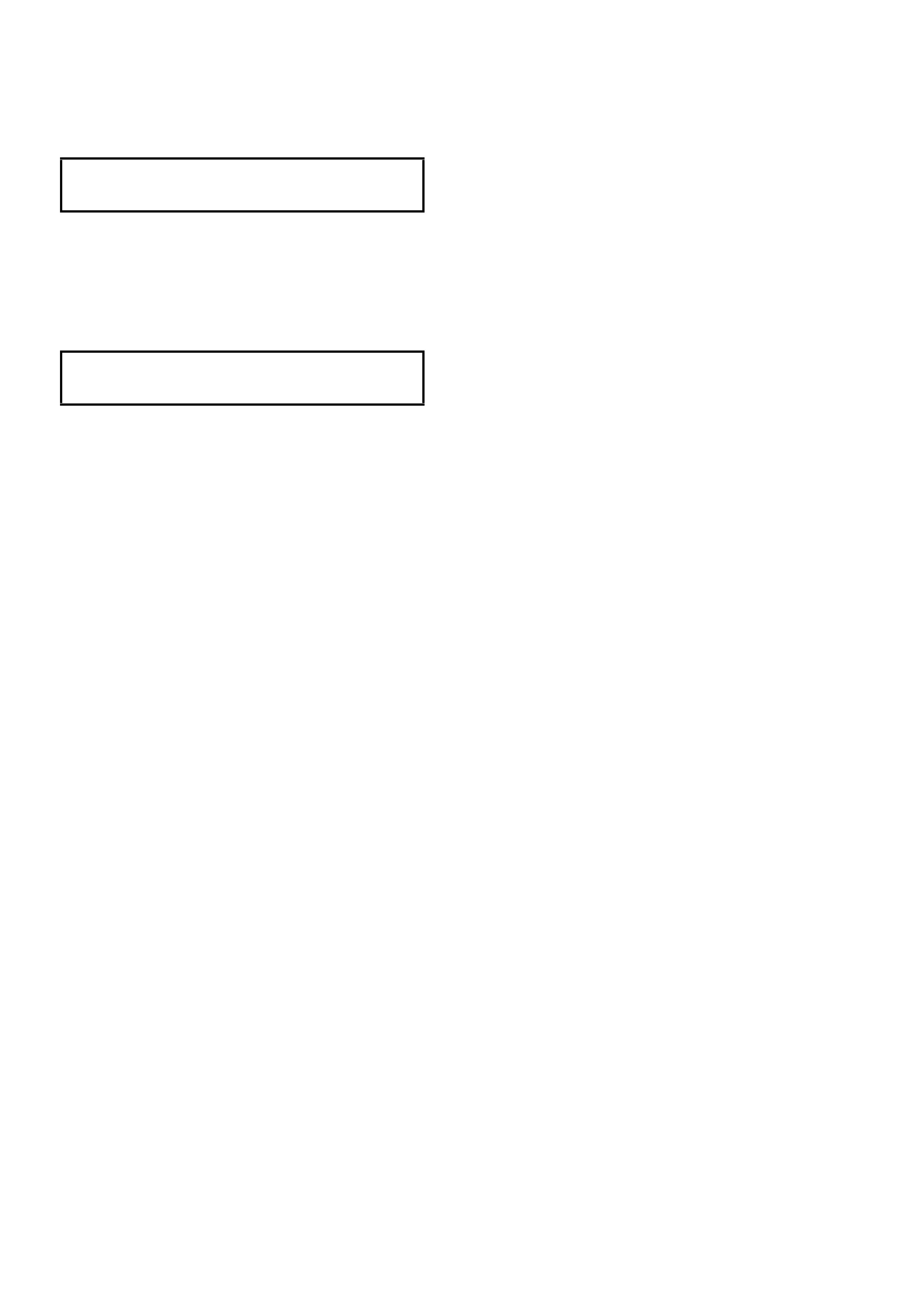

3. Scribe around each of the transmission

support crossmember mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

NOTE: Th is step is critic al to the c orrec t powertr ain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems may

result.

4. Support the transmission with a suitable lifting

device, then rem ove the four engine m ounting

crossmember bolts, followed by the two rear

mount to crossmember nuts. Set the

crossmember to one side.

5. Lower the rear of the transmission enough to

gain clear access to the sensor.

Figure 7B3-12

6. Remove the speed sensor wiring harness

connector (1) from the sensor (3).

7. Remove speed sensor mounting bracket

screw (2) from the transmission extension

housing, then remove the sensor (3).

8. Installation is the reverse of removal except for

the following points;

a. Tighten the speed sensor to mounting

bracket retaining screw (2) to the correct

torque specification.

SPEED SENSOR BRACKET 8.0 - 12.0

SCREW TORQUE SPECIFICATION Nm

b Connect the speed s ensor lead c onnector

(1) to the sensor.

Figure 7B3-13

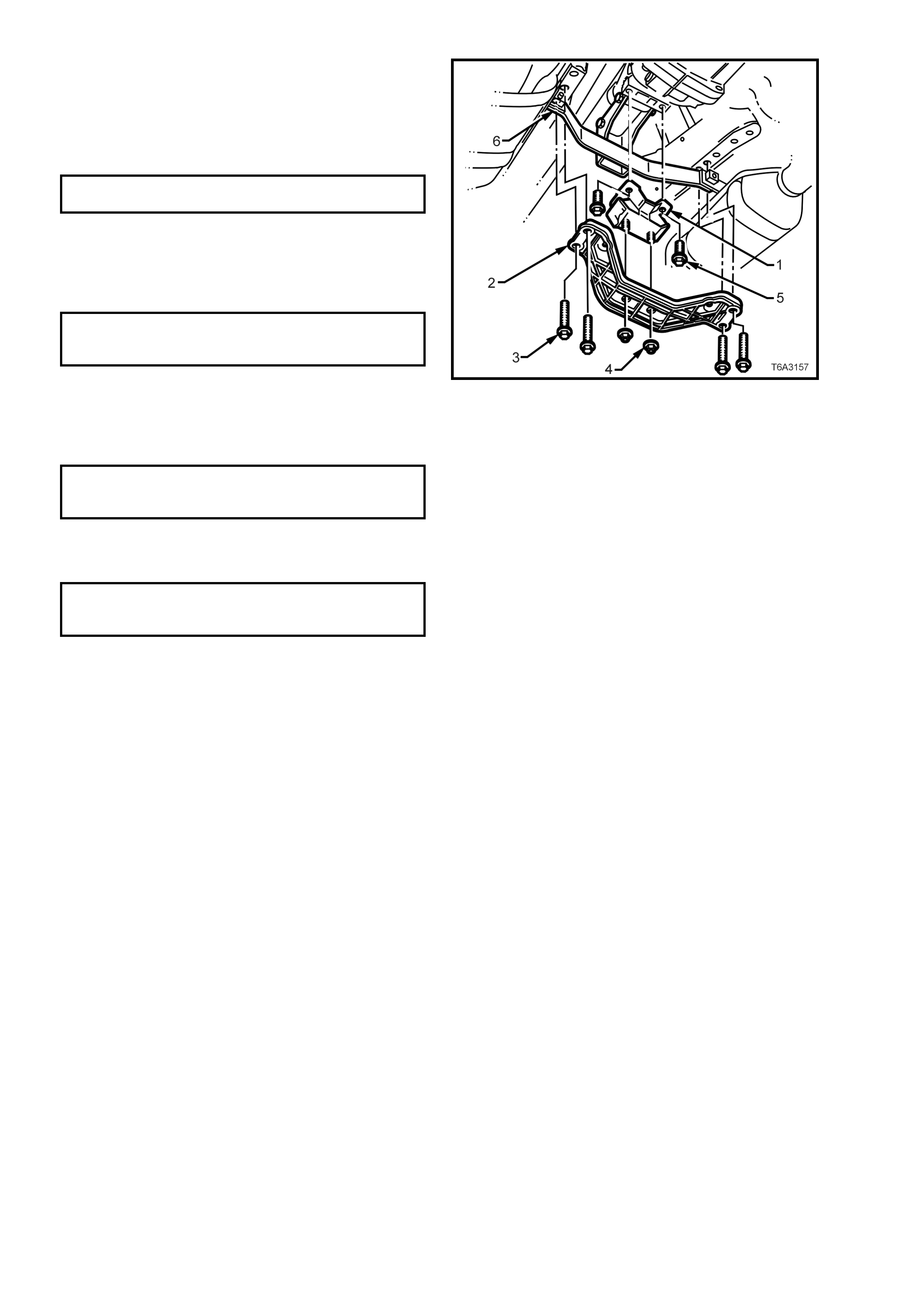

9. Raise the transmission, then install the four

crossmember to side frame bolts (3), aligning

the crossmember (2) with the scribed lines

made prior to disassembly. Tighten the bolts

(3) to the correct torque specification.

REAR CROSSMEMBER TO

SIDE FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

10. Remove the lifting device from the

transmission, centralise the rear mount studs

in the crossmember holes, then reinstall the

nuts (4), tightening to the correct torque

specification.

REAR CROSSMEMBER TO REAR

MOUNTING ATTACHING NUT 20 - 30 Nm

TORQUE SPECIFICATION

11. Reinstall the two catalytic converter bracket (6)

bolts, tightening to the correct torque

specification.

CATALYTIC CONVERTER

BRACKET BOLT 20 - 30 Nm

TORQUE SPECIFICATION.

12. Lower the vehicle and road test to check

speedometer operation.

Figure 7B3-14

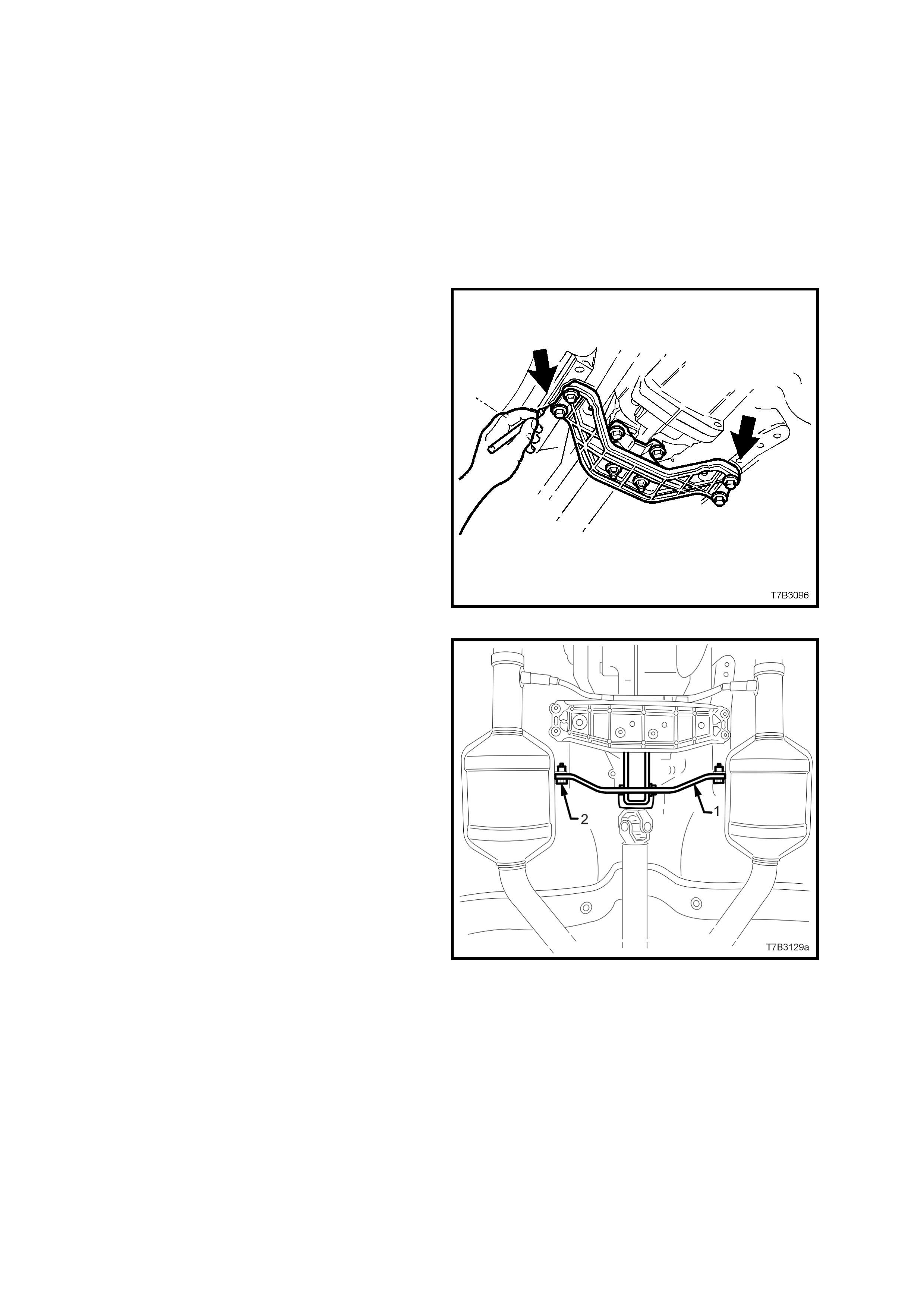

3.3 TRANSMISSION SUPPORT MOUNT

REPLACE

1. Jack up vehicle front and rear and support on

safety stands. Refer to Sect ion 0A GENERAL

INFORMATION of the VT Series II Service

Information, for the location of jacking points.

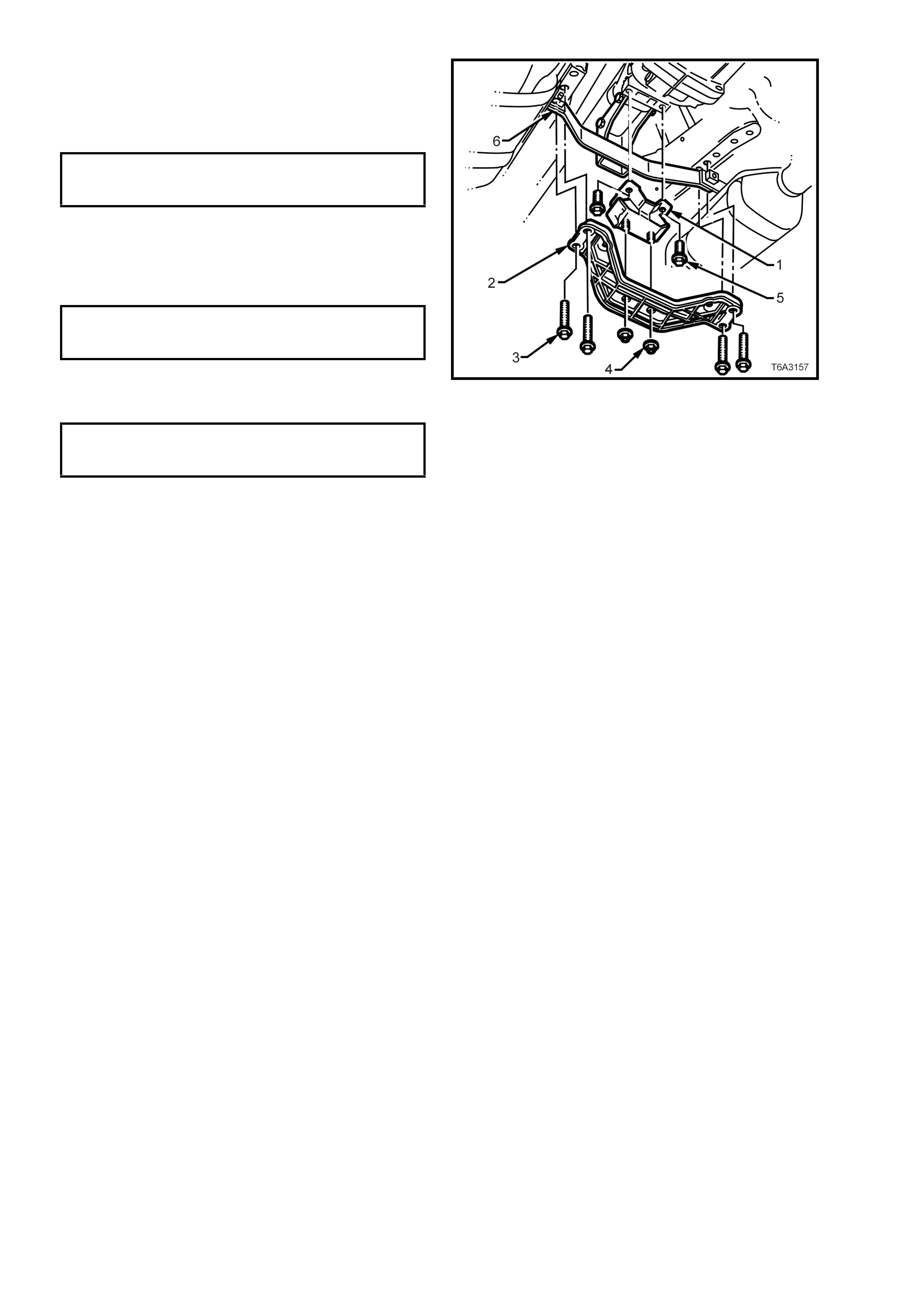

2. Remove the two bolts (2) securing the catalytic

converter bracket (1) to the catalytic

converters.

Figure 7B3-15

3. Scribe around each of the transmission

support crossmember mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

NOTE: Th is step is critic al to the c orrec t powertr ain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems may

result.

4. Support the transmission with a suitable lifting

device, then rem ove the four engine m ounting

crossmember bolts.

5. Lower the transmission slightly, then remove

the two rear mount to crossmember nuts. Set

the crossmember to one side.

Figure 7B3-16

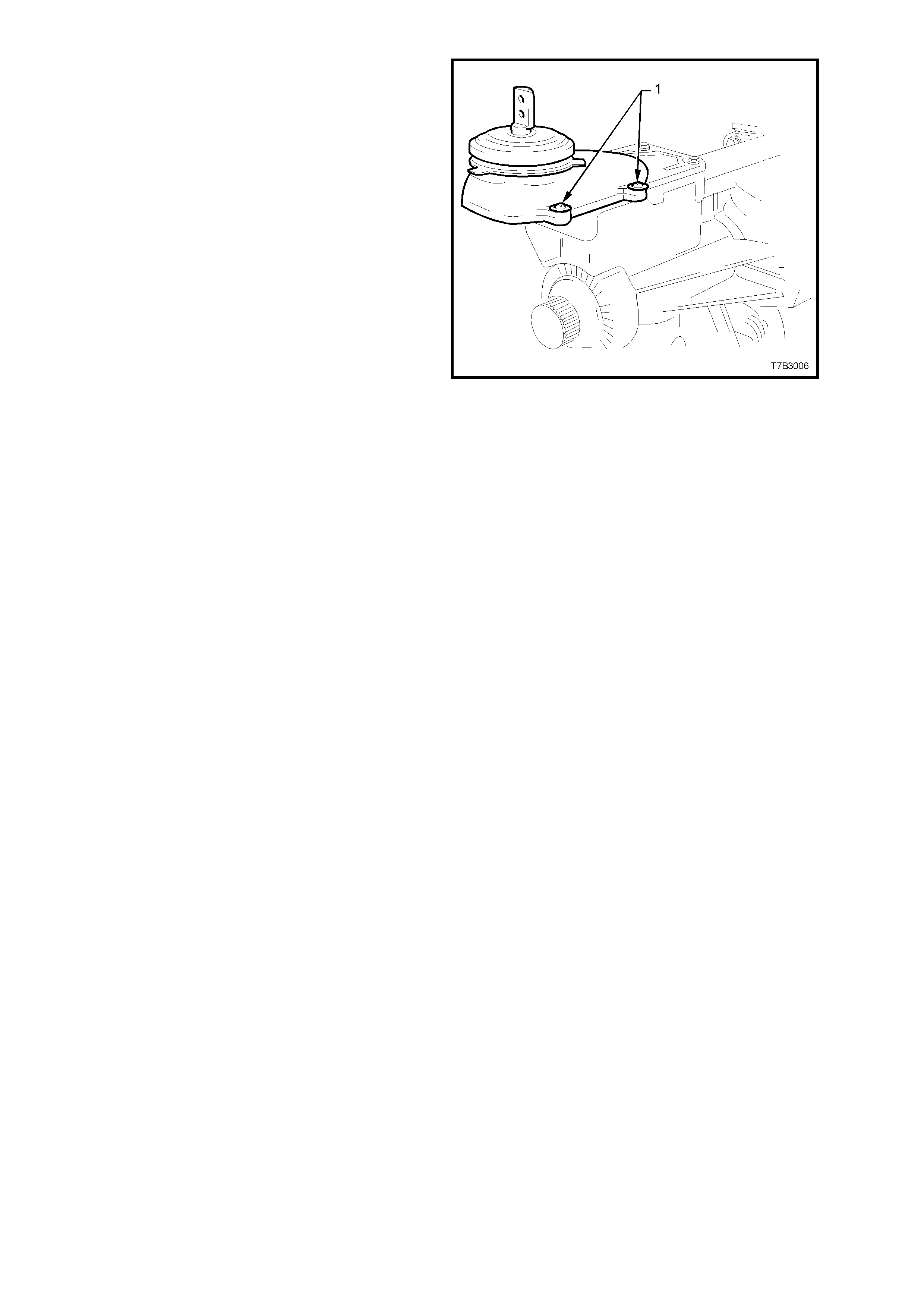

6. Remove the two bolts (5) securing the mount

(1) to the transmission extension housing,

then remove the mount from the vehicle.

7. Reinstall the mount (1) to the transmission

extension housing, ins tall the two bolts (5) and

tighten to the correct torque specification.

TRANSMISSION SUPPORT MOUNT

BOLT TORQUE SPECIFICATION 20 - 30 Nm

8. Raise the transmission slightly, then reinstall

the four crossmember to side frame bolts (3),

aligning the crossmember (2) with the scribed

lines made prior to disassembly. Tighten the

bolts (3) to the correct torque specification.

REAR CROSSMEMBER TO

SIDE FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

9. Remove the lifting device from the

transmission, centralise the rear mount studs

in the crossmember holes, then reinstall the

nuts (4), tightening to the correct torque

specification.

REAR CROSSMEMBER TO REAR

MOUNTING ATTACHING NUT 20 - 30 Nm

TORQUE SPECIFICATION

10. Reinstall the two catalytic converter bracket (6)

bolts, tightening to the correct torque

specification.

CATALYTIC CONVERTER

BRACKET BOLT 20 - 30 Nm

TORQUE SPECIFICATION.

11. Lower the vehicle and road test to check

speedometer operation.

Figure 7B3-17

3.4 REVERSE LOCKOUT SOLENOID ASSEMBLY

REMOVE

1. Jack up vehicle front and rear and support on

safety stands. Refer to Sect ion 0A GENERAL

INFORMATION of the VT Series II Service

Information, for the location of jacking points.

2. Remove the two bolts (2) securing the catalytic

converter bracket (1) to the catalytic

converters.

Figure 7B3-18

3. Scribe around each of the transmission

support crossmember mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

NOTE: Th is step is critic al to the c orrec t powertr ain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems may

result.

4. Support the transmission with a suitable lifting

device, then rem ove the four engine m ounting

crossmember bolts.

5. Lower the transmission slightly, then remove

the two rear mount to crossmember nuts. Set

the crossmember to one side.

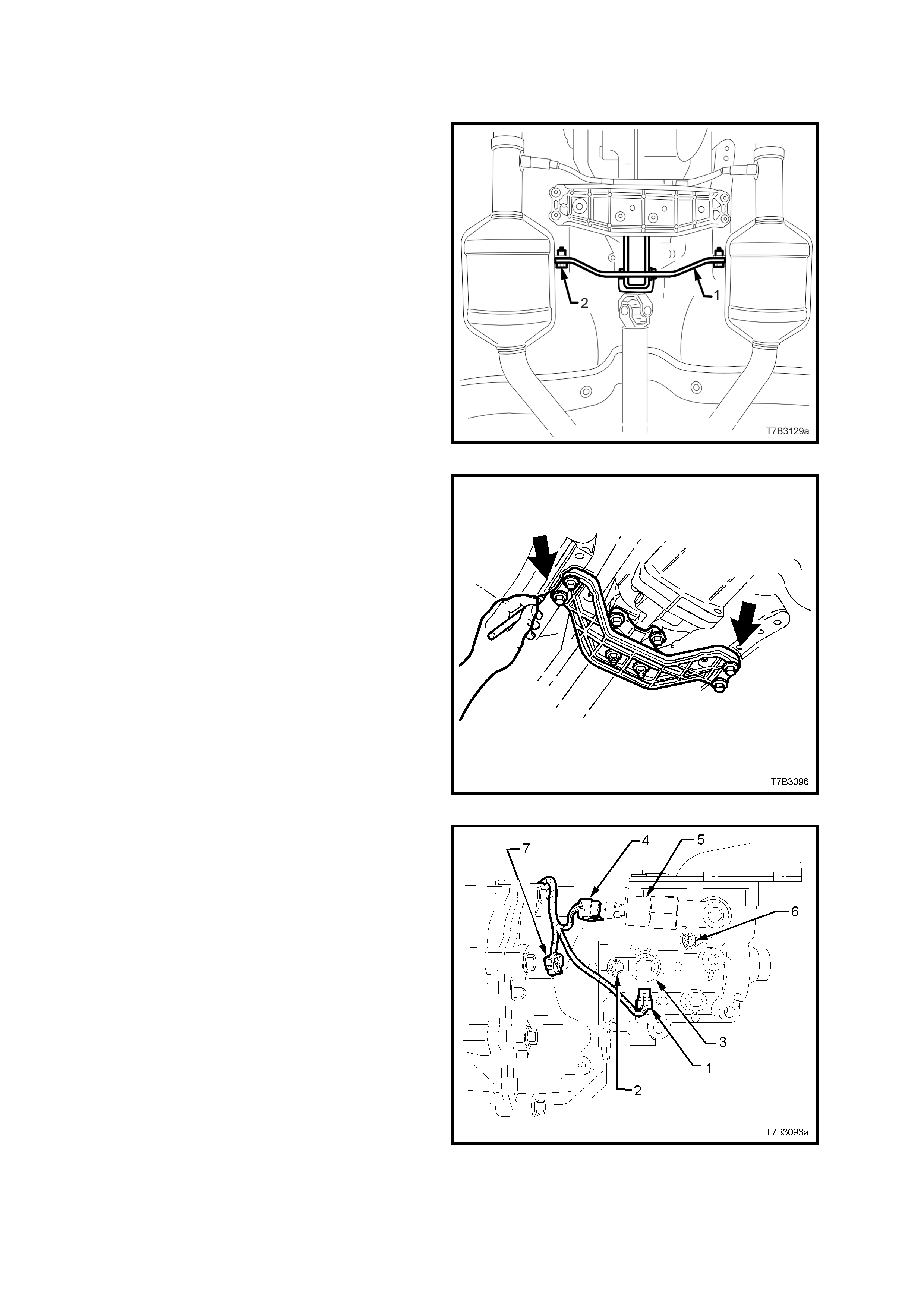

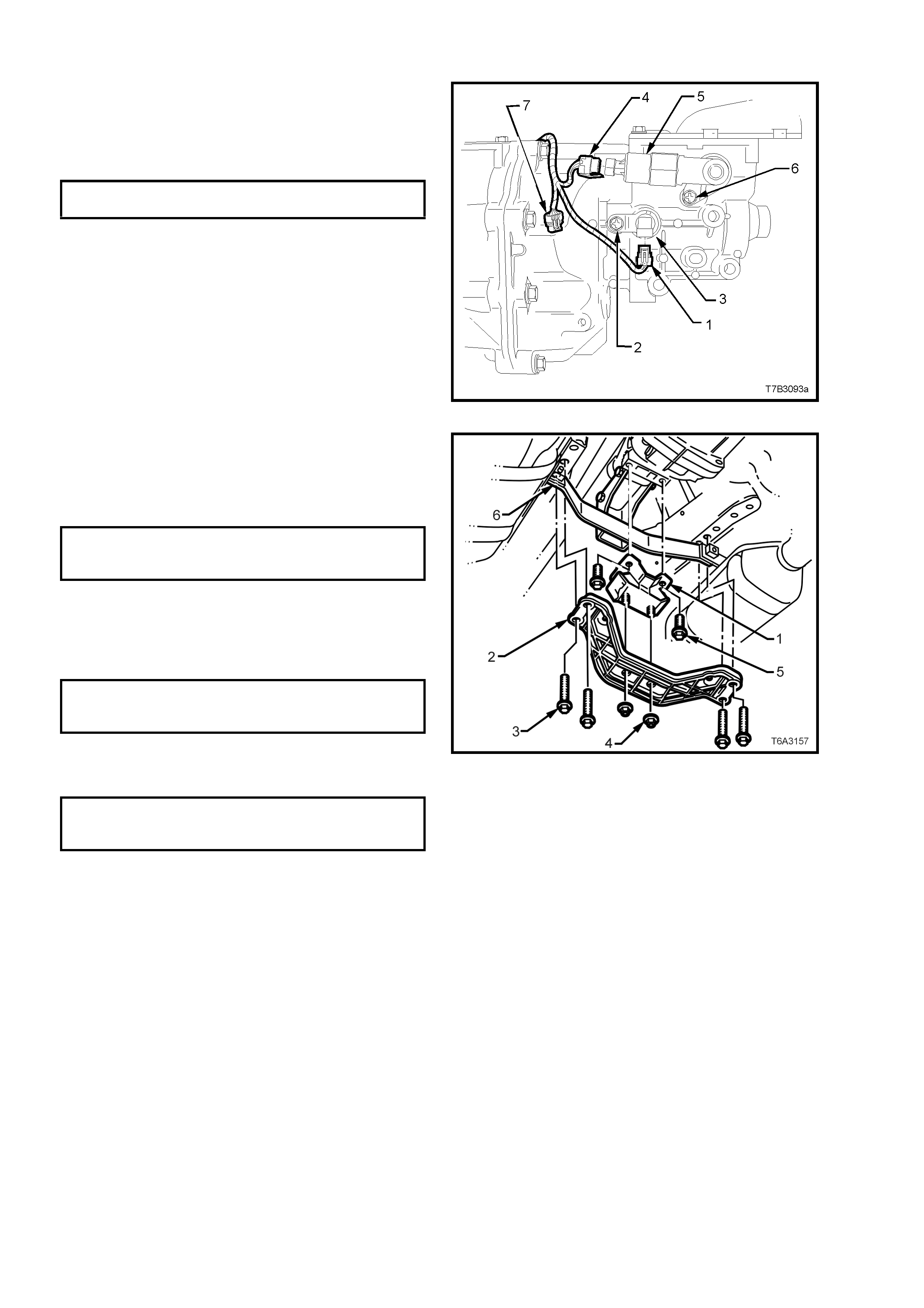

Figure 7B3-19

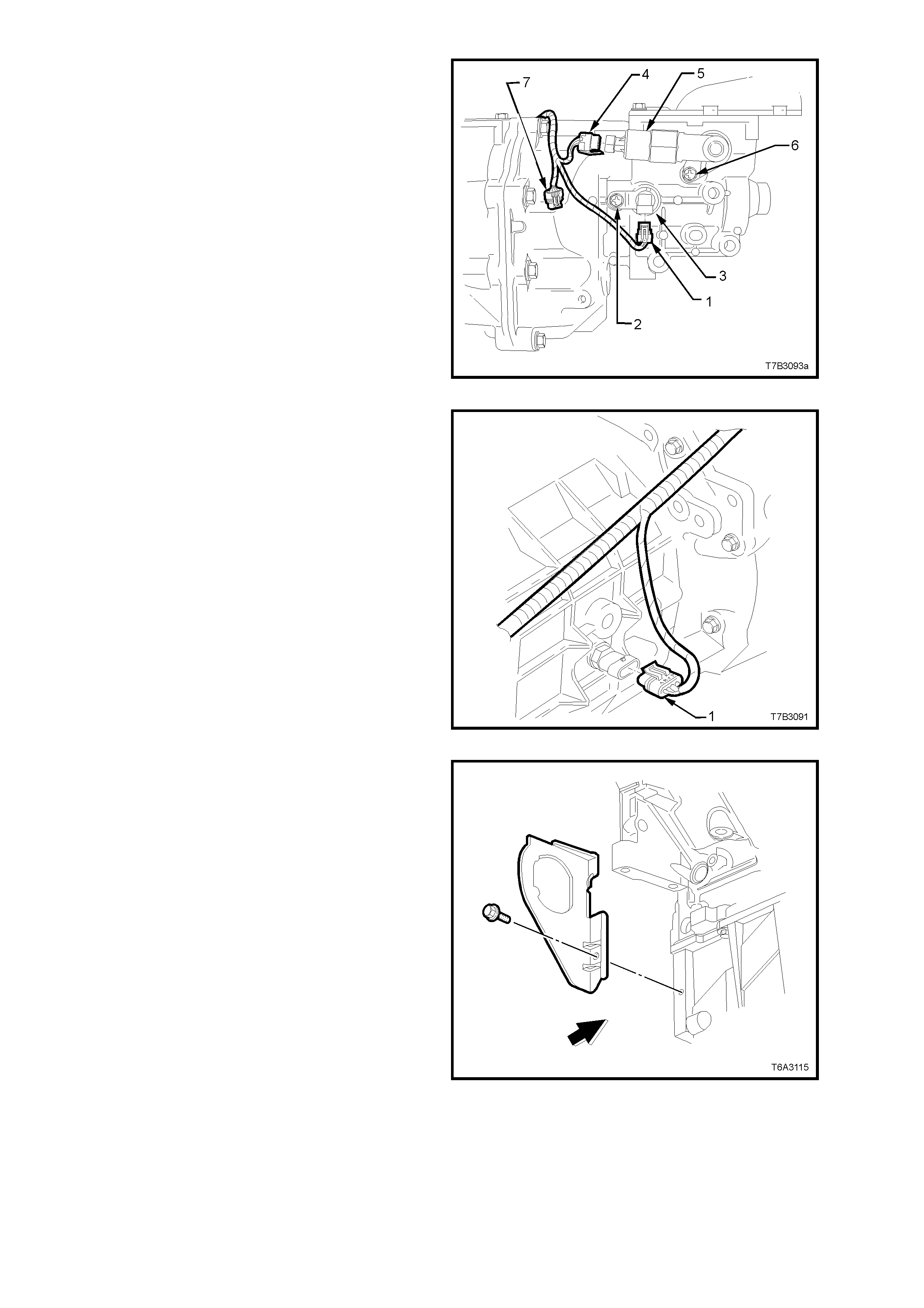

6. Lower the transmission sufficiently to gain

access to the reverse lockout solenoid

assembly (5).

7. Remove wiring harnes s c onnec tor ( 4) f rom the

reverse lockout solenoid (5), after depressing

the locking tab.

8. Remove the reverse lockout solenoid

assembly mounting screw (6), then remove

the assembly from the transmission extension

housing by rotating back and forth while pulling

on the assembly.

Figure 7B3-20

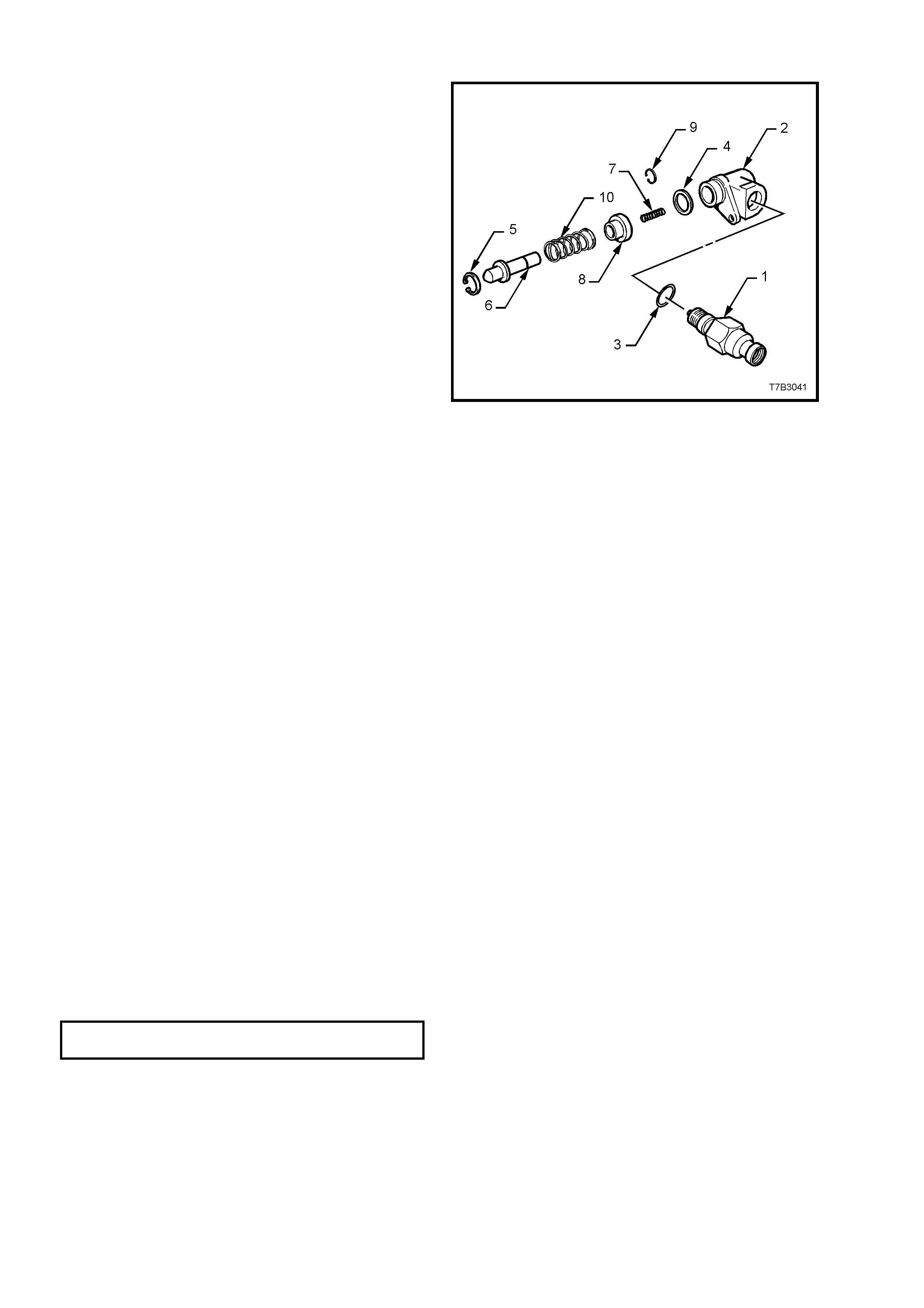

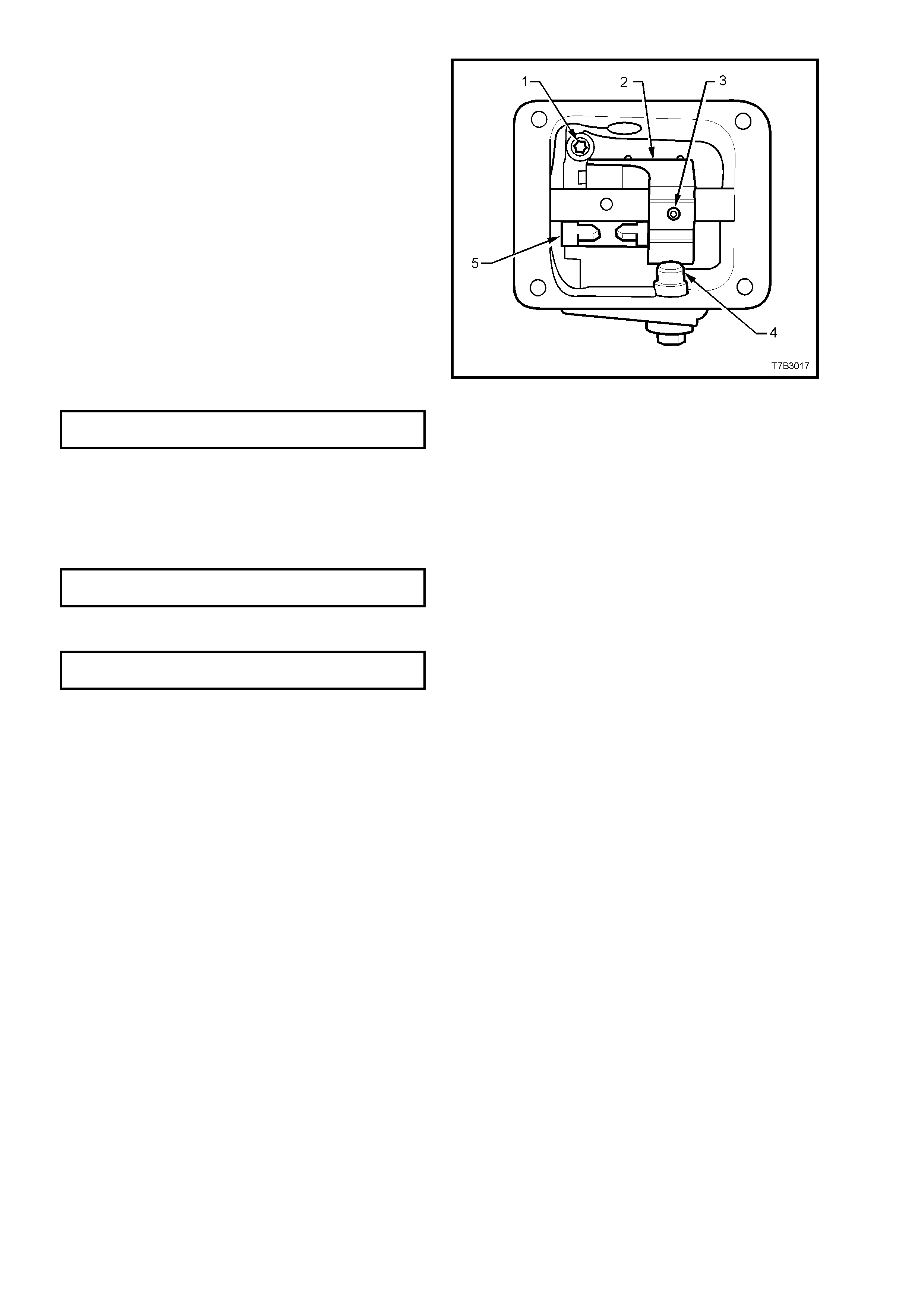

DISASSEMBLE

1. While holding the lockout body (2) in a vice

fitted with soft jaws, unscrew the reverse

lockout solenoid (1) from the body (2), then

remove the O-ring seal (3). If the O-ring seal

(3) is undamaged, it can be re-used.

2. Remove the O-ring (4) f rom the body (2). If the

O-ring seal is undamaged it can also be re-

used.

3. Remove circlip (5), using suitable pliers, from

the body (2).

4. Remove lockout plunger assembly (6) from

the body (2), then remove the inner spring (7).

5. Compress the reverse lock out plunger (6) and

collar (8) in a bench vice, then remove the ‘C’

clip (9).

CAUTION: The reverse lockout assembly is

under a strong spring force. Exercise care

when removing ‘C’ clip (9), as injury could

result.

6. Release the vice and disassemble the collar

(8) and spring (10) from the plunger (6).

7. Clean all parts in a suitable solvent and blow

dry with compressed air.

CAUTION: Wear safety glasses to avoid eye

injury.

8. Inspect all parts for damage or wear and

springs for broken or damaged coils.

9. For solenoid testing procedure, refer to

Section 6C3 POWERTRAIN MANAGEMENT

- GEN III V8 ENGINE, of the VT Series II

Service Information.

Figure 7B3-21

REASSEMBLE

NOTE: Refer Figure 7B3-21 for component

identification.

1. Compress the reverse lockout plunger (6),

spring (10) and collar (8) in a benc h vice, then

install the ‘C’ clip (9).

CAUTION: Wear safety glasses to avoid eye

injury.

2. Install the inner spring (7) into the end of the

lockout plunger assembly (6), then install the

assembly into the reverse lockout body (2).

3. Install circlip (5), using suitable pliers , to retain

the lockout plunger assembly (5).

4. Install the reverse lockout solenoid (1) and O-

ring, tightening to the correct torque

specification.

REVERSE LOCKOUT SOLENOID 34 - 48

TORQUE SPECIFICATION Nm

5. Install the O-ring (4) to the body (2).

REINSTALL

The installation process is the reverse of removal

operations except for the following:

1. After reinstalling the reverse lockout assem bly

(5), install the retaining bolt (6) and tighten to

the correct torque specification.

REVERSE LOCKOUT ASSEMBLY 15 - 20

BOLT TORQUE SPECIFICATION Nm

2. Reinstall the wiring harness connector (4) to

the reverse lockout solenoid.

Figure 7B3-22

3. Raise the transmission slightly, then reinstall

the four crossmember to side frame bolts (3),

aligning the crossmember (2) with the scribed

lines made prior to disassembly. Tighten the

bolts (3) to the correct torque specification.

REAR CROSSMEMBER TO

SIDE FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

4. Remove the lifting device from the

transmission, centralise the rear mount studs

in the crossmember holes, then reinstall the

nuts (4), tightening to the correct torque

specification.

REAR CROSSMEMBER TO REAR

MOUNTING ATTACHING NUT 20 - 30 Nm

TORQUE SPECIFICATION

5. Reinstall the two catalytic converter bracket (6)

bolts, tightening to the correct torque

specification.

CATALYTIC CONVERTER

BRACKET BOLT 20 - 30 Nm

TORQUE SPECIFICATION.

6. Lower the vehicle and road test to check

speedometer operation.

Figure 7B3-23

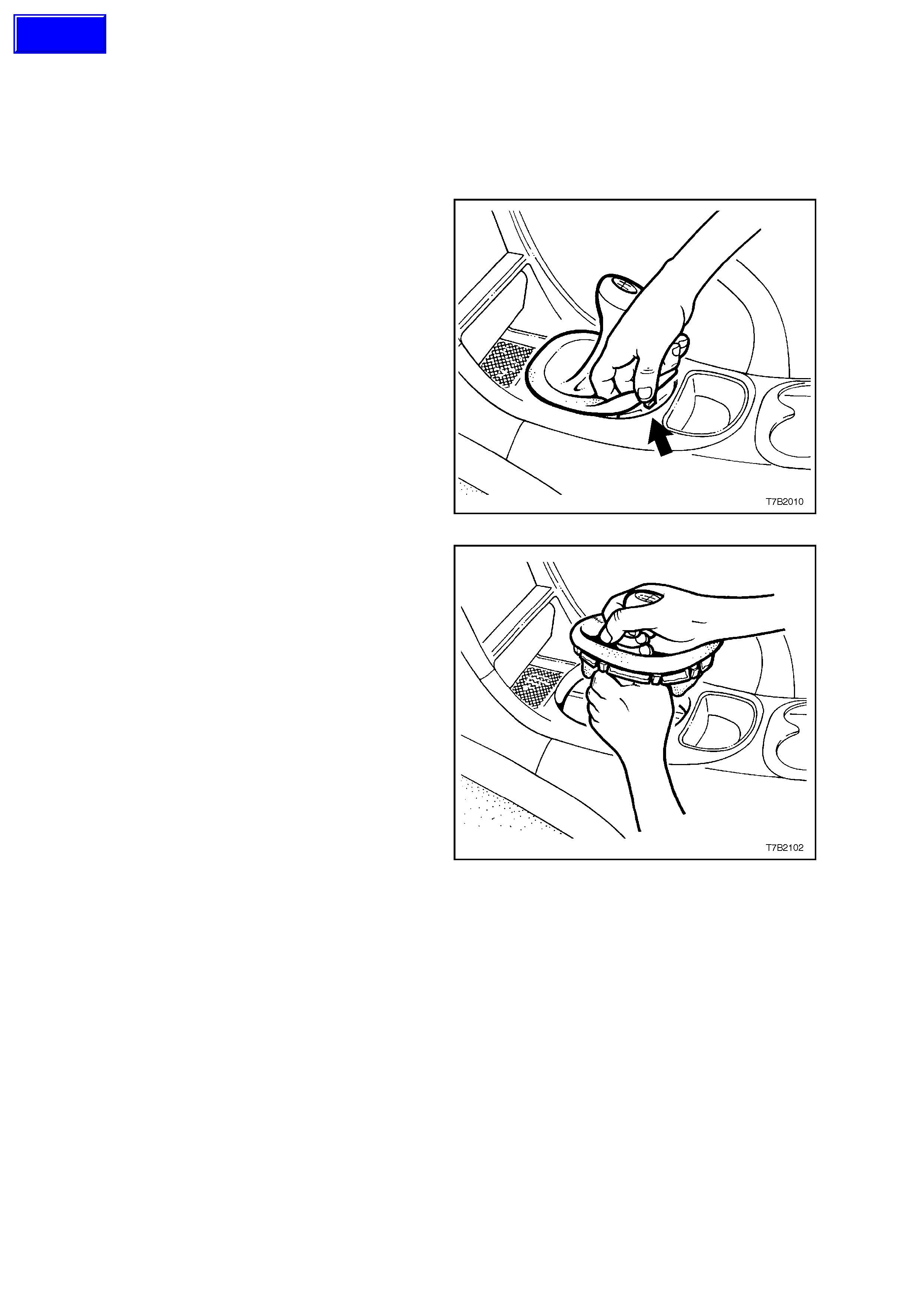

3.5 CONTROL LEVER KNOB AND BOOT ASSEMBLY

NOTE: The gearshift lever knob and console boot

are manufactured as a single component. Do not

attempt to remove the gearshift lever knob

separately to the boot.

REMOVE

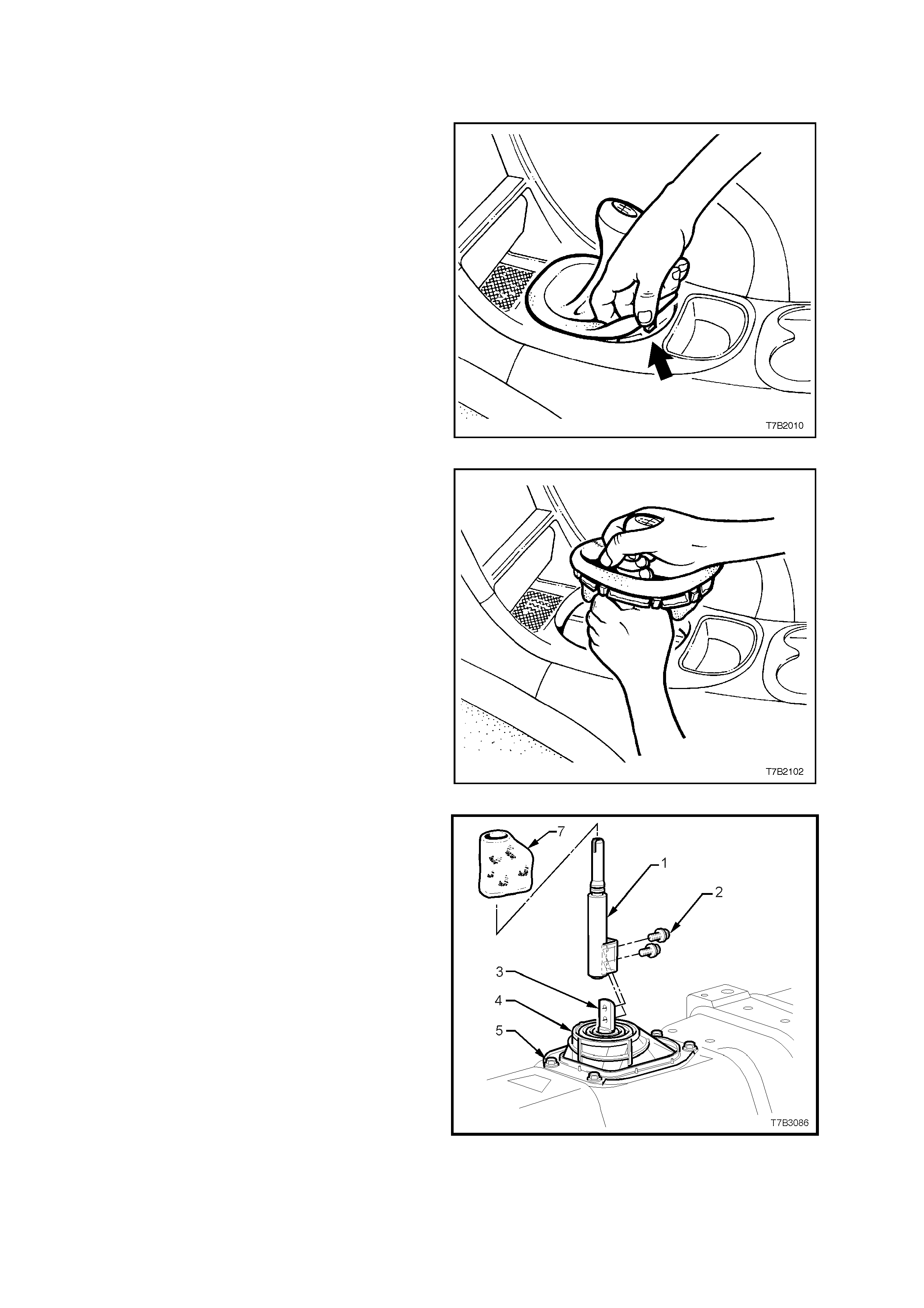

1. With the fingers of one hand hooked under the

edge of the gearshift lever boot as shown,

caref ully release each of the 8 plas tic retainer s

and free the gearshift lever boot from the

console cap.

Figure 7B3-24

2. Lift the gears hif t lever boot enough to enable a

firm grasp to be made on the gearshift lever

with the left hand, then grasp the gearshift

knob with the right.

3. W hile rocking the knob sideways, and with an

upward force applied, dislodge the knob

retaining claws from the lever.

4. Remove the gearshift lever knob and boot

assembly, from the gearshift lever.

Figure 7B3-25

REINSTALL

1. Reinstall the k nob and boot assembly over the

gearshift lever, align the knob in the correct

attitude and then bump the knob onto the

gearshif t lever until the retaining claws engage

with the groove in the lever.

2. Align the boot retaining clips with the hole in

the console cap, then carefully seat the boot

retainers into the console cap until each clip

engages correctly.

Techline

3.6 GEARSHIFT CONTROL LEVER AND REMOTE SHIFTER SHAFT BOOT

REMOVE

1. Disconnect the battery earth lead.

2. Remove the gearshift lever knob and boot

assembly, from the gearshift lever. Refer to

3.5 CONTROL LEVER KNOB AND BOOT

ASSEMBLY in this Section, f or the necessary

procedure.

3. Remove the centre console assembly,

including the console cap. Refer to

Section 1A3, INSTRUMENT PANEL AND

CONSOLE, of the VT Series I Service

Information for the necessary procedure.

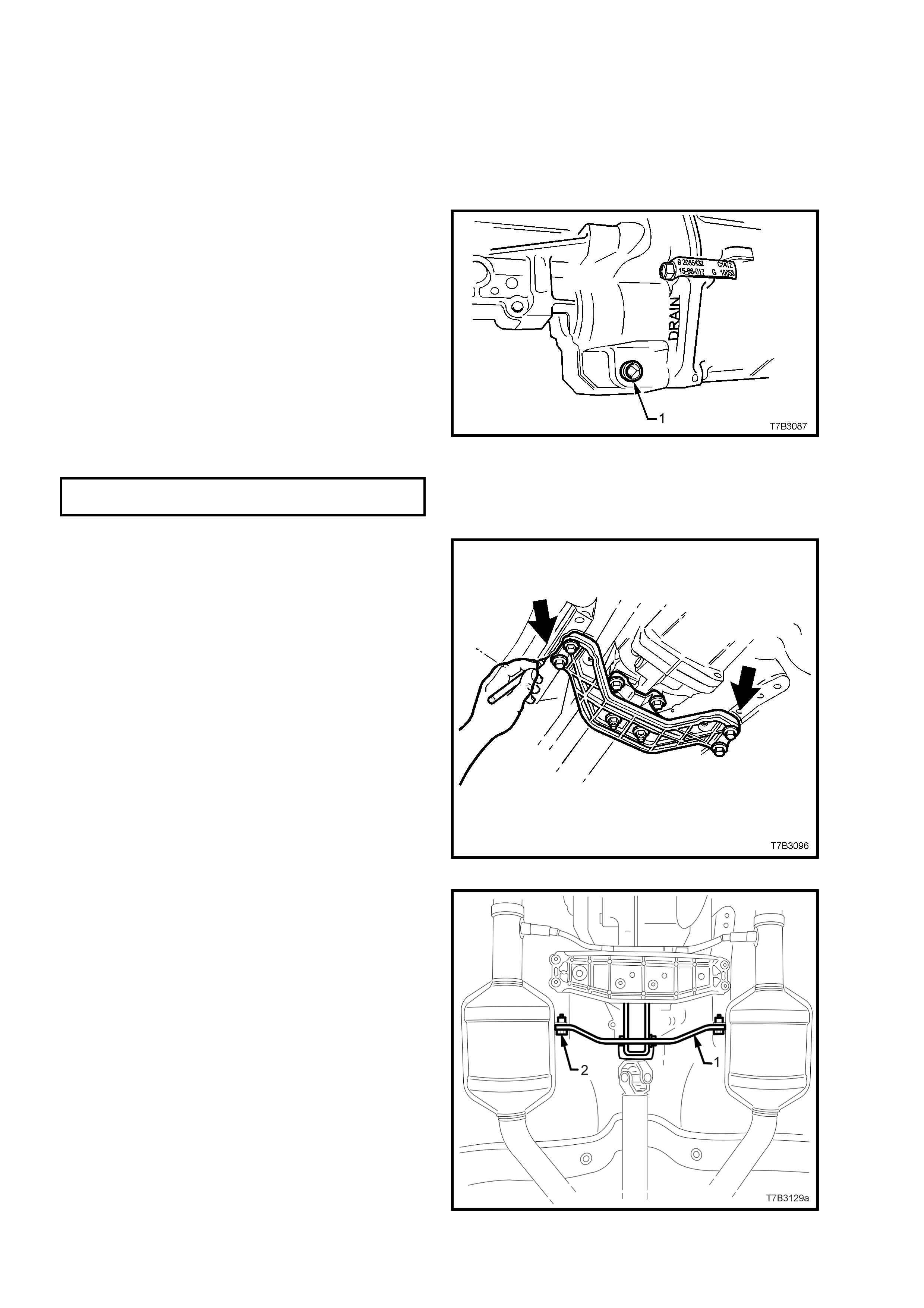

4. Slip the insulator sock (7) from the control

lever (1) and set it to one side.

5. Using a 10 mm socket, remove the two bolts

(2) securing the control lever (1) to the

gearshift remote shift lever shaft (3), then lift

the control lever free.

6. If required, remove the four bolts (5) securing

the gearshift remote shift lever boot retaining

plate (6) to the floor pan, then remove the boot

(4) and retaining plate (6).

CLEAN AND INSPECT

1. Inspect the gearshift remote shift lever boot (4)

for tears or other damage, replacing as

required.

2. Clean the threads of the control lever bolts (2)

and check for thread damage.

Figure 7B3-26

Techline

Techline

Techline

REINSTALL

1. If removed, install the gearshift remote lever

boot (4) and plate (6) and secure with the four

bolts (5), tightening to the correct torque

specification.

GEARSHIFT REMOTE LEVER

BOOT PLATE BOLT 6.0 - 14.0 Nm

TORQUE SPECIFICATION

2. Apply thread sealant such as Loctite 242 or

equivalent (to Holden’s Specification HN 1256

Class 2, T ype 2), to the cleaned threads of the

control lever retaining bolts (2).

3. Install the control lever (1) over the remote

shift lever shaft (3), install the two bolts (2),

tightening to the correct torque specification.

GEARSHIFT LEVER TO REMOTE

SHIFT LEVER SHAFT BOLT 15 - 35 Nm

TORQUE SPECIFICATION

4. Reinstall the insulator sock (7) over the

remote shift lever (1).

5. Reinstall centre console assembly, including

the console cap. Refer to

Section 1A3, INSTRUMENT PANEL AND

CONSOLE, of the VT Series I Service

Information for the necessary procedure.

6. Reinstall the gearshift knob and boot

assembly over the gearshift lever, align the

knob in the c orrect attitude and then bum p the

knob onto the gear shif t lever until the retaining

claws engage with the groove in the lever.

7. Align the gearshif t boot retaining clips with the

hole in the console cap, then c ar ef ully seat the

boot retainers into the console cap until each

clip engages correctly.

8. Reconnect battery earth lead.

9. Road test vehicle and check for correct

gearshift operations.

4. MAJOR SERVICE OPERATIONS

4.1 TRANSMISSION OUTPUT SHAFT SEAL AND BOOT

REMOVE

1. Disconnect battery earth lead.

2. Raise front and rear of vehicle, supporting on

safety stands. Refer to

Section 0A GENERAL INFORM AT ION of the

VT Series I Service Information, for the

location of jacking points.

3. Scribe around each of the transmission

support crossmember mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

NOTE: Th is step is critic al to the c orrec t powertr ain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems may

result.

Figure 7B3-27

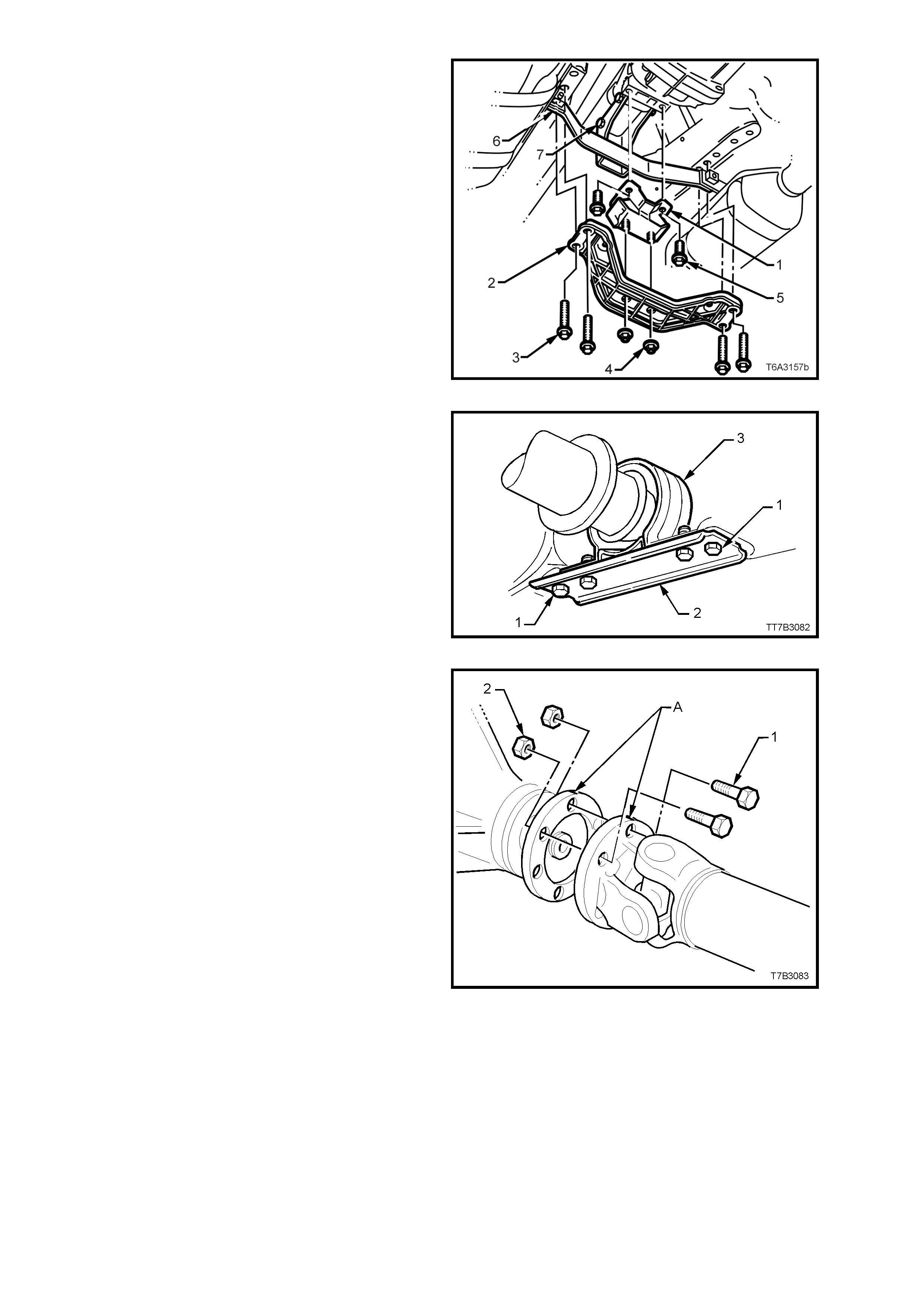

4. Remove the two bolts (2) securing the catalytic

converter bracket (1) to the catalytic

converters.

Figure 7B3-28

5. Support the transmission with a suitable lifting

device, then remove the four engine rear

crossmember to side frame attaching bolts (3).

6. Lower the transmission slightly, then remove

the two transmission mount to crossmember

nuts (4). Set the crossmember (2) to one side.

7. Remove the two bolts (5) securing the

transmission mount (1) to the transmission

extension, then remove the mount (1) and

bracket (6) from the vehicle.

NOTE: Illustration does not show transm ission j ack

in position, for clarity of the crossmember

orientation.

8. Remove the nuts from the two bolts (7)

securing the catalytic converter bracket (6) to

the transmission extension, remove the bolts

and bracket and set to one side.

9. Lower the transmission enough to provide

clearance for the propeller shaft rubber

coupling when the propeller shaft is removed.

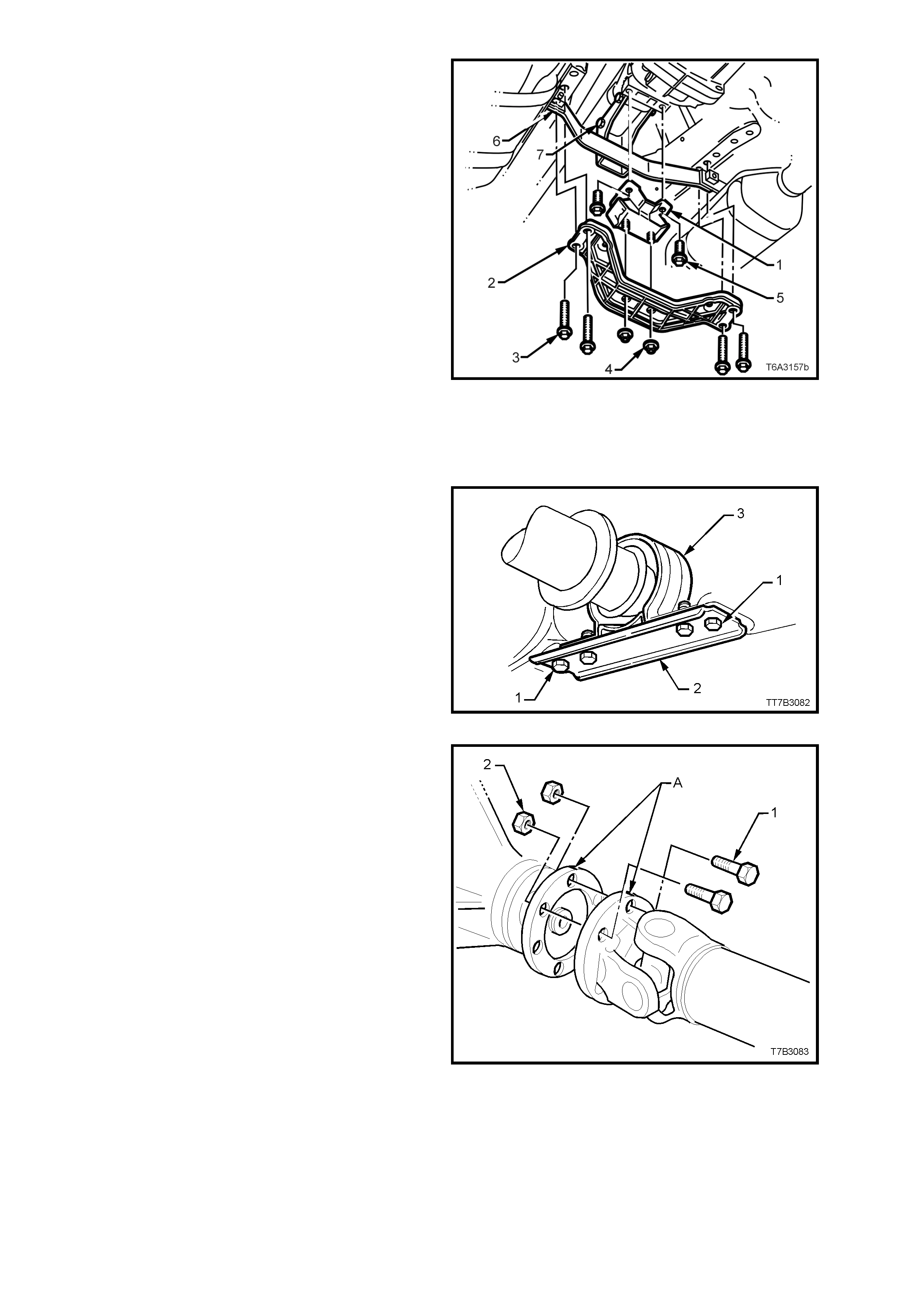

Figure 7B3-29

10. Remove centre bearing carrier to underbody

reinforcement bolts and spacers.

NOTE: For correct reassembly, take particular note

of any spacer arrangement that may be fitted,

observing any side to side variations and the

orientation of the bracket offset.

11. Support centre bearing assembly to prevent

any angular deflection of the constant velocity

joint that exceeds 8°. Should this angle be

exceeded, then damage to the boot and/or

constant velocity joint may occur.

Figure 7B3-30

12. Place a drain tray beneath transmission.

13. Remove nuts (2) and bolts (1) holding

propeller shaft rear universal joint flange to

pinion flange, then disengage rear universal

joint flange from pinion flange.

NOTE: The two flanges have paint alignment

marks (A) that are assembled as close together as

possible. If the mark s are not vis ible, scribe a mark

on both flanges so that they will be reinstalled in

their original position.

14. Disconnect the propeller shaft from the rear

flange and, moving the propeller shaft slightly

to the left hand side of the vehicle, pull the

assembly to the rear of vehicle, enough to

disengage the slip joint from the transmission

mainshaft.

Figure 7B3-31

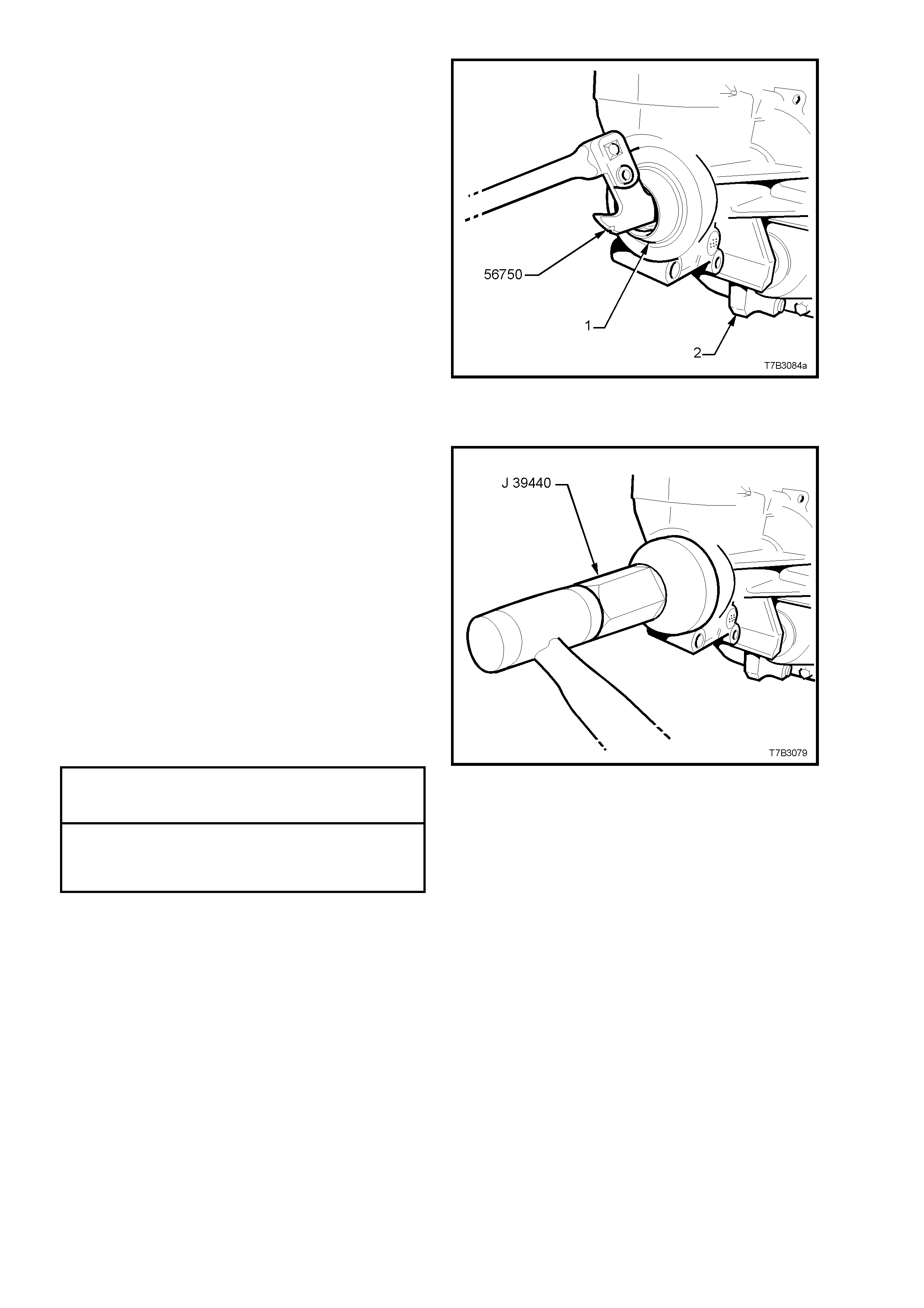

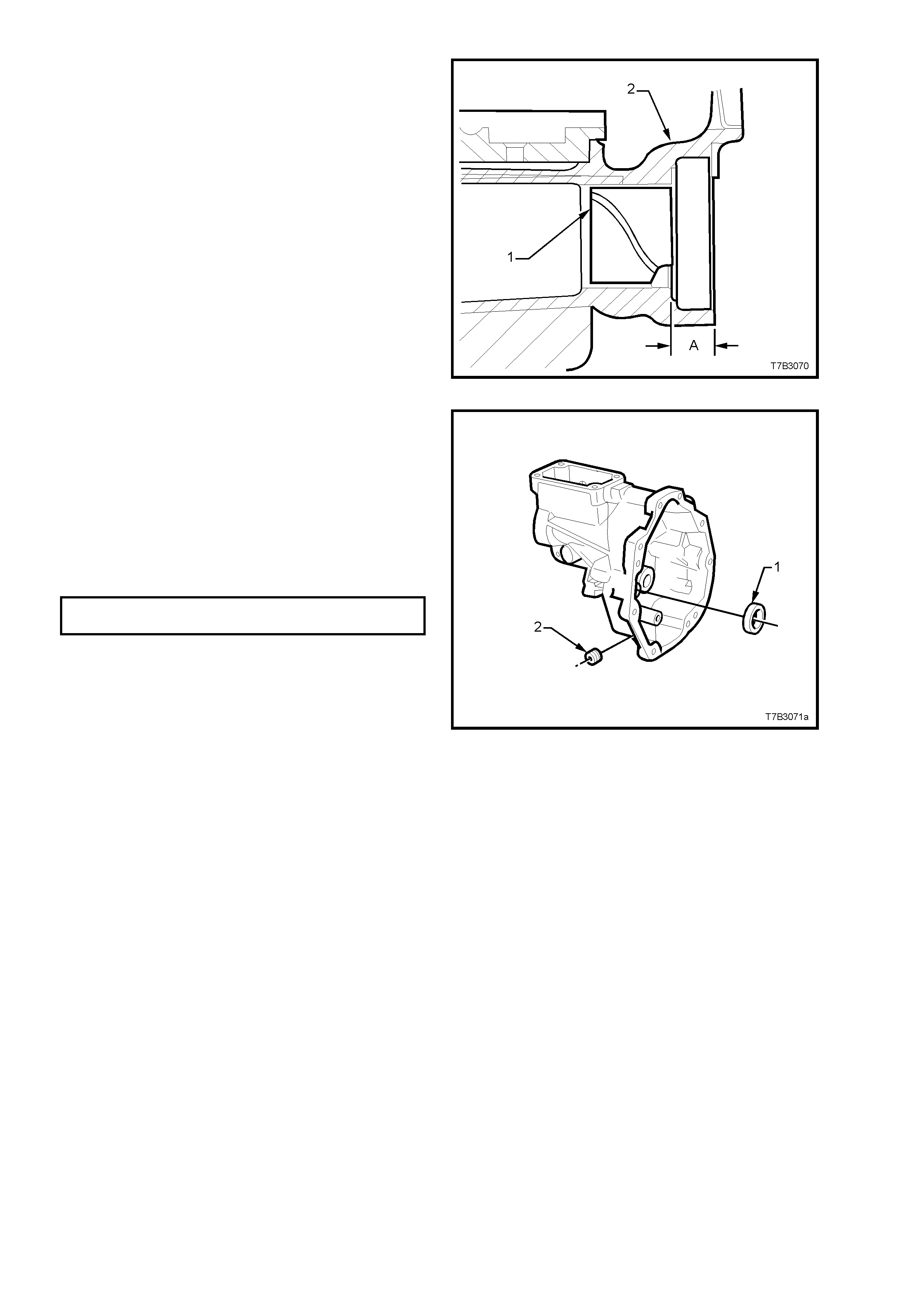

15. Using a seal rem over such as Tool No. 56750

(also released as E308), remove the seal (1)

from the transmission extension housing.

NOTE: Should Tool No. 56750 not be available,

then it will be necessary to remove the seal by

prising it from the extension hous ing with a suitable

lever such as a screwdriver. If this method is used,

take care not to scratch the bore of the extension

housing during the removal process.

Figure 7B3-32

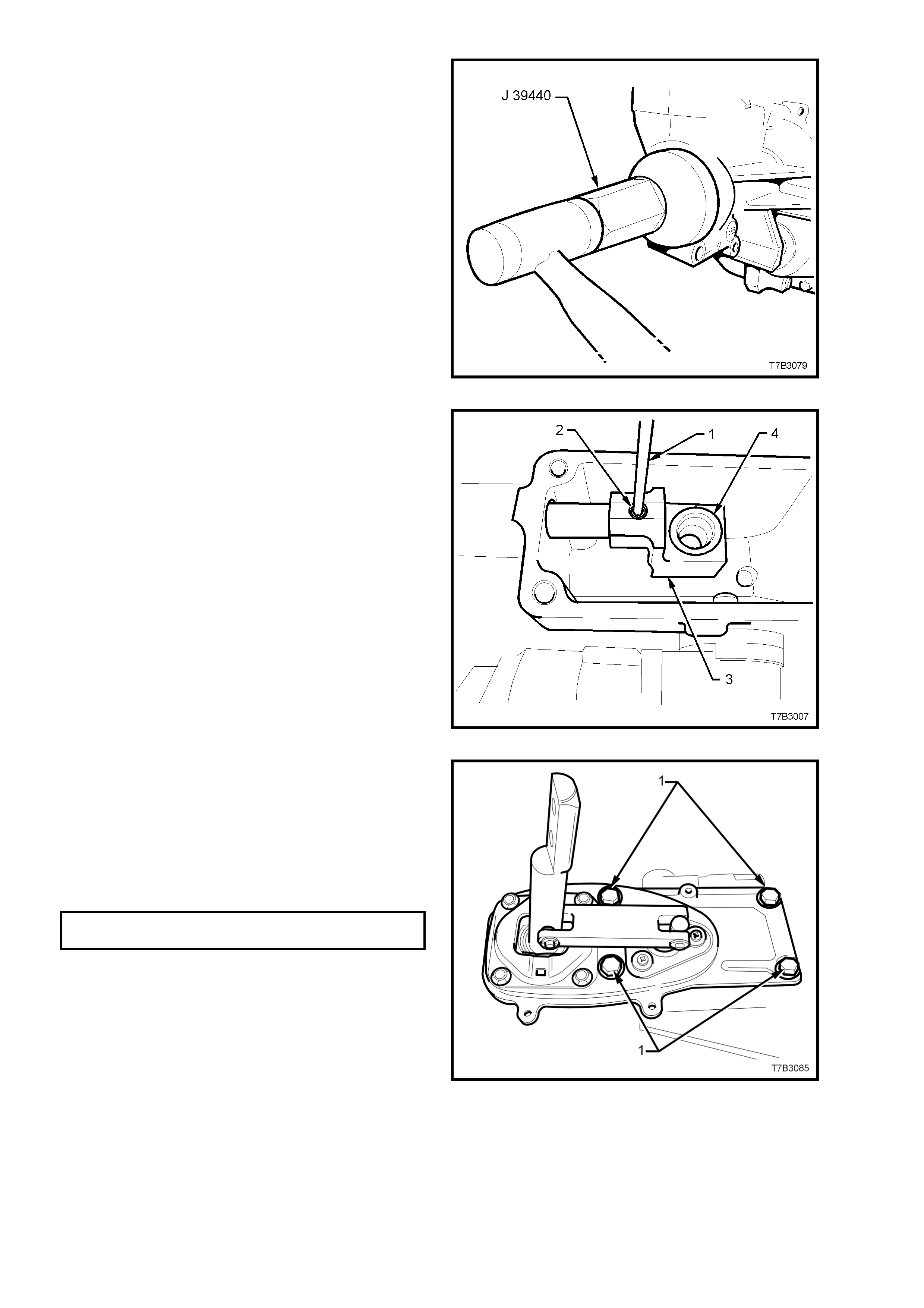

REINSTALL

1. After lubricating the seal lip with transmission

lubricant, use s eal installer J 39440 and install

the new seal into the rear of the extension

housing.

2. Install the propeller slip joint into the rear of the

transmission, then lift the propeller shaft

upward (while maintaining and angular

deflection less than 8°) and install centre

bearing carrier to underbody reinforcement.

Ensure all spacers are replaced in the same

positions, noted on removal, then install

retaining bolts.

3. Assemble propeller shaft rear universal joint

flange to pinion flange and install attaching

bolts and nuts.

4. Tighten all propeller shaft attaching bolts to the

correct torque specification.

CENTRE BEARING CARRIER TO

UNDERBODY REINFORCEMENT 20 - 35 Nm

BOLT TORQUE SPECIFICATION

PROPELLER SHAFT REAR

UNIVERSAL JOINT FLANGE TO

PINION FLANGE BOLT 55 - 65 Nm

TORQUE SPECIFICATION

5. Reinstall the catalytic converter bracket (6) to

the transm ission extension, ins tall the bolts (7)

and nuts, then tighten to the correct torque

specification.

Figure 7B3-33

CONVERTER BRACKET TO

TRANSMISSION EXTENSION BOLT 40 – 60 Nm

TORQUE SPECIFICATION

6. Reinstall the transmission mount (1) to the

transmiss ion extension, install the two bolts (5)

and tighten to the correct torque specification.

TRANSMISSION MOUNT TO

EXTENSION HOUSING BOLT 20 - 30 Nm

TORQUE SPECIFICATION

7. Raise the transmission slightly, then reinstall

the four crossmember to side frame bolts (3),

aligning the crossmember (2) with the scribed

lines made prior to disassembly. Tighten the

bolts (3) to the correct torque specification.

REAR CROSSMEMBER TO

SIDE FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

8. Remove the lifting device from the

transmission, centralise the rear mount studs

in the crossmember holes, then reinstall the

nuts (4), tightening to the correct torque

specification.

REAR CROSSMEMBER TO

TRANSMISSION MOUNT NUT 20 - 30 Nm

TORQUE SPECIFICATION

Figure 7B3-34

9. Reinstall the two catalytic converter bracket

(6) bolts, tightening to the correct torque

specification.

CATALYTIC CONVERTER BRACKET 20 - 30

BOLT TORQUE SPECIFICATION Nm

10. Check the transmission fluid level. Refer to

2.2 CHECKING TRANSMISSION

LUBRICANT LEVEL in this Section. Top up

as required.

11. Lower the vehicle reconnect battery ground

lead.

12. Lower the vehicle and road test to check

vehicle operation.

4.2 TRANSMISSION ASSEMBLY

REMOVE

1. Disconnect battery ground lead.

2. With the fingers of one hand hooked under the

edge of the gearshift lever boot as shown,

carefully release each of the 8 plastic retainers

and free the gearshift lever boot from the

console cap.

NOTE: The gearshift lever knob and console boot

are manufactured as a single component. Do not

attempt to remove the gearshift lever knob

separately to the boot.

Figure 7B3-35

3. Lift the gears hif t lever boot enough to enable a

firm grasp to be made on the gearshift lever

with the left hand, then grasp the gearshift

knob with the right.

4. W hile rocking the knob sideways, and with an

upward force applied, dislodge the knob

retaining claws from the lever.

5. Remove the gearshift lever knob and boot

assembly, from the gearshift lever.

Figure 7B3-36

6. Remove the centre console. Refer

Section 1A3 INSTRUMENT PANEL AND

CONSOLE, of the VT Series I Service

Information for the necessary procedure.

7. Slip the insulator sock (7) from the control

lever (1).

8. Using a 10 mm socket, remove the two bolts

(2) securing the control lever (1) to the remote

shifter shaft (3), then lift the control lever free.

9. Remove the f our bolts (5) securing the rem ote

shift lever boot retaining plate (6) to the floor

pan, then remove the boot (4) and retaining

plate (6).

10. Select third gear to allow the remote shifter

shaft (3) to clear the opening in the floor pan,

when the transmission is lowered for removal.

Figure 7B3-37

11. Raise vehicle, preferably on a ‘drive-on’ hoist

or a four post hoist. This preference is based

on the fact that the tr ansmiss ion is very heavy

and the use of a transmission jack will be

required for effective transmission removal

and installation.

12. Disconnect wiring harness connectors from

each of the two oxygen sensors.

13. Depending on the reason for removal, it might

be appropriate to drain the transmission

lubricant into a clean container.

Place a drain tray beneath transmission and

remove the drain plug (1) using a 3/8” drive

socket bar.

When transmission has fully drained, clean the

threads of the drain plug, apply thread sealant

such as Loctite 565 or equivalent (GM P/N

12346004), then reinstall, tightening to the

correct torque specification, using a 3/8” drive

adaptor and a torque wrench.

NOTE: Do not apply Teflon thread tape to the plug

threads.

TRANSMISSION DRAIN PLUG 20 - 34

TORQUE SPECIFICATION Nm

Figure 7B3-38

14. Scribe around each of the transmission

support crossmember mounting points to the

vehicle underbody, to provide an alignment

reference for reassembly.

NOTE: Th is step is critic al to the c orrec t powertr ain

alignment on reassembly. If not carried out, then

vehicle vibration and/or handling problems may

result.

Figure 7B3-39

15. Remove the two bolts (2) securing the catalytic

converter bracket (1) to the catalytic

converters.

Figure 7B3-40

16. Support the transmission with a suitable lifting

device, then remove the four engine rear

crossmember to side frame attaching bolts (3).

17. Lower the transmission slightly, then remove

the two rear mount to crossmember nuts (4).

Set the crossmember (2) to one side.

18. Remove the two bolts (5) securing the rear

mount (1) to the transmission extension, then

set the mount to one side.

19. Remove the two nuts and bolts (7) securing

the catalytic converter bracket (6) to the

transmission extension, then remove the

bracket (6) from the vehicle.

NOTE: Illustration does not show transm ission j ack

in position, for clarity of the crossmember

orientation.

Figure 7B3-41

20. Remove centre bearing carrier (2) to

underbody reinforcement bolts (1) and

spacers, if fitted.

NOTE: For correct reassembly, take particular note

of any spacer arrangement that may be fitted,

observing any side to side variations and the

orientation of the bracket (2) offset.

21. Support centre bearing assembly (3) to

prevent any angular deflection of the constant

velocity joint that exceeds 8°. Should this

angle be exceeded, then damage to the boot

and/or constant velocity joint may occur.

Figure 7B3-42

22. Place a drain tray beneath transmission or

insert a plug into the rear of the extension

housing.

23. Remove nuts (2) and bolts (1) holding the

propeller shaft rear universal joint flange to

pinion flange, then disengage rear universal

joint flange from pinion flange.

NOTE: The two flanges have paint alignment

marks (A) that are assembled as close together as

possible. If the mark s are not vis ible, scribe a mark

on both flanges so that they will be reinstalled in

their correct position.

24. Disconnect the propeller shaft from the rear

flange and, moving the propeller shaft slightly

to the left hand side of the vehicle, pull the

assembly toward the rear of vehicle, sufficient

to disengage the slip joint from the

transmission mainshaft. Figure 7B3-43

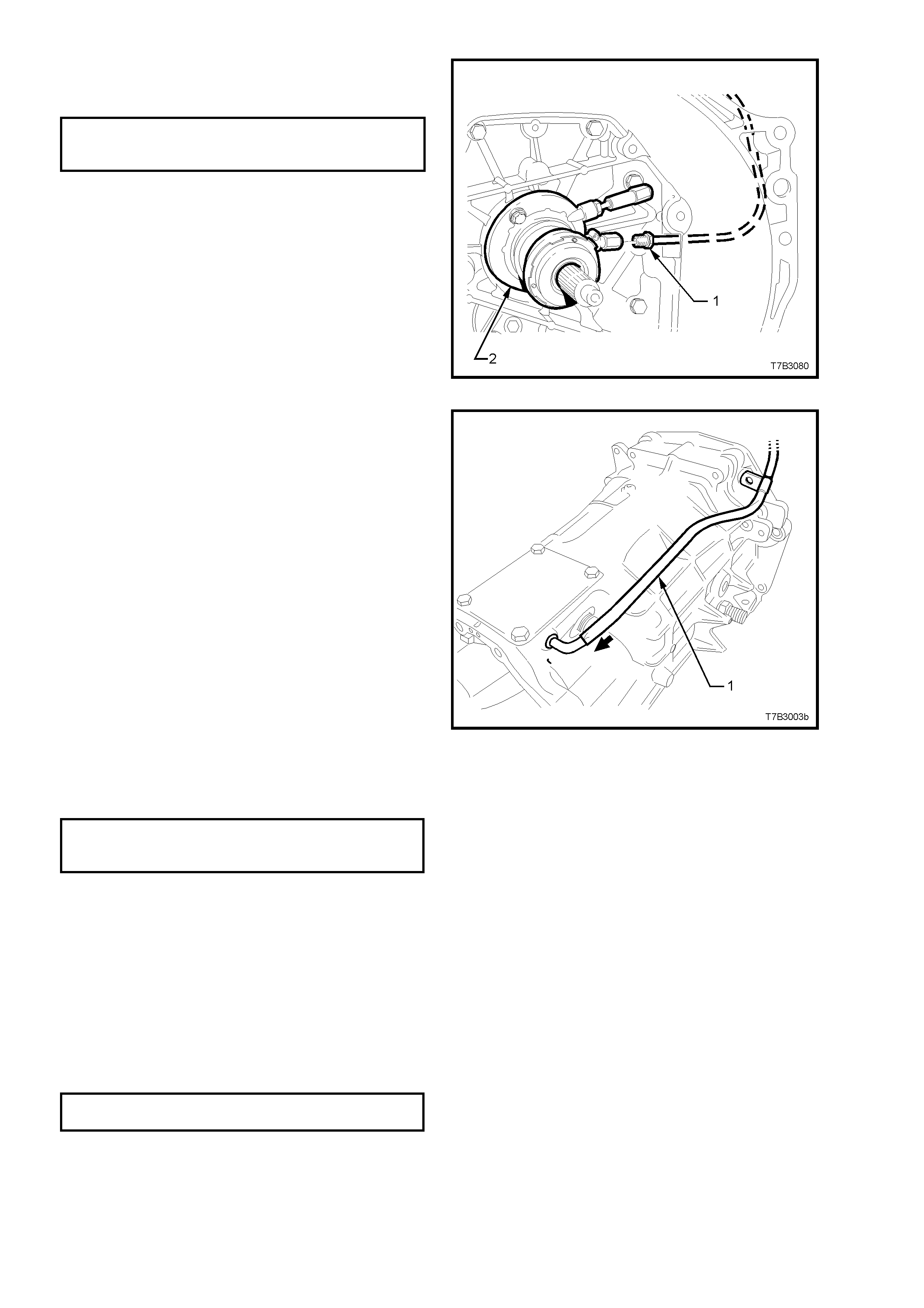

25. Remove the speed sensor wiring harness

connector (1) and the connector (4) from the

reverse lockout solenoid. (5).

Figure 7B3-44

26. Remove the wiring harness connector from

the back-up lamp switch, located on the right

hand side of the transmission.

27. Cut the tie strap securing the powertrain

harness to the breather pipe (not shown),

remove the harness from the clip under the

right hand top extension housing bolt and

secure to one side.

Figure 7B3-45

28. Remove the starter motor. Refer to

Section 6D3-2, STARTING SYSTEM - GEN

III V8 ENGINE, of the VT Series II Service

Information, for the necessary procedure.

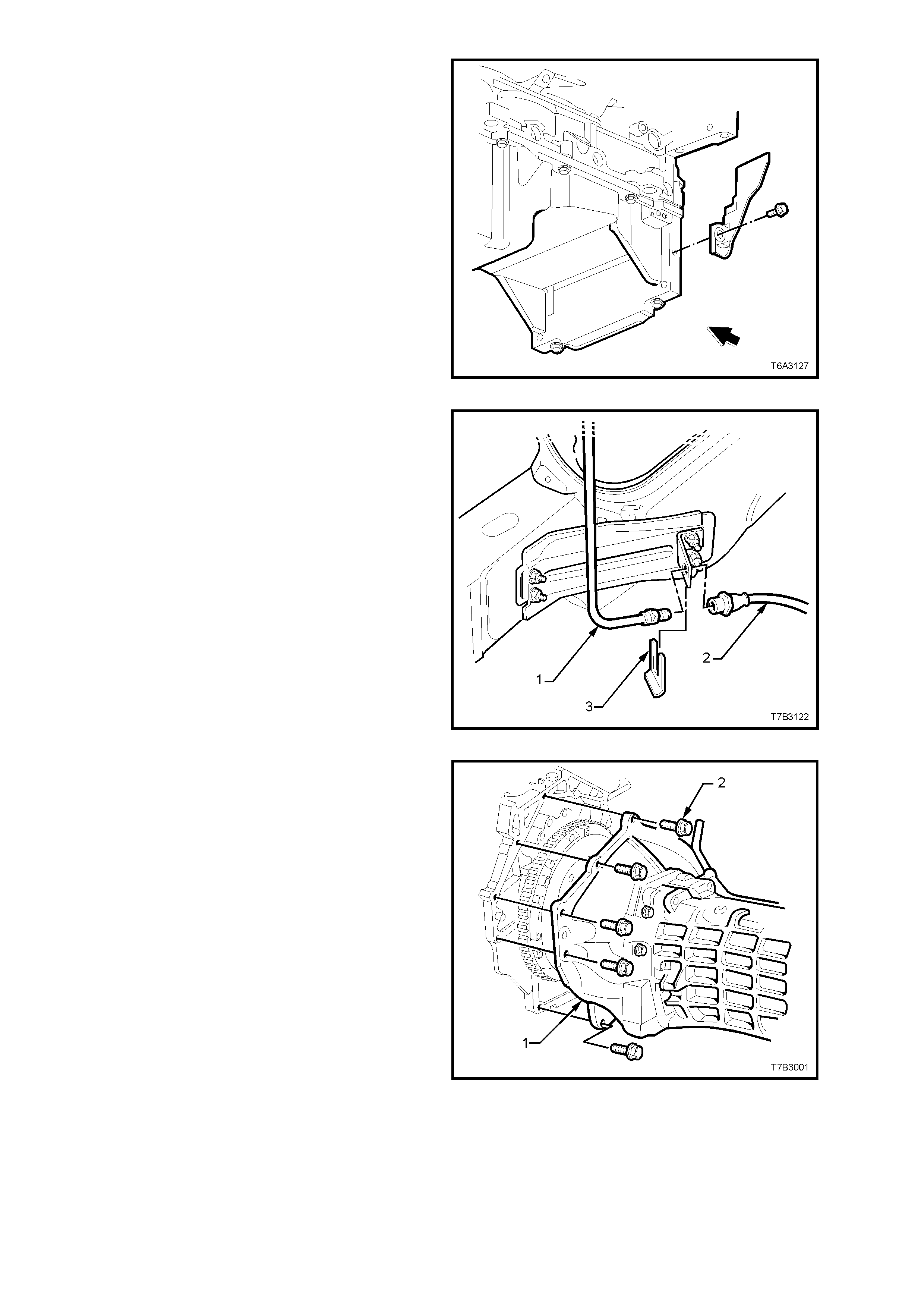

29. Remove the right close-out cover and bolt.

Figure 7B3-46

30. Remove the left close-out cover and bolt.

Figure 7B3-47

31. Place a suitable container under the clutch

hydraulic hose area, then disconnect the

hydraulic pipe (1) from the hydraulic hose (2),

at the bracket attached to the vehicle sub-

frame.

NOTE: Use a back-up spanner on the hydraulic

hose (2) when loosening the pipe fitting.

32. Remove the hose retaining clip (3) using

com bination plier s , then remove the hos e f r om

the bracket.

NOTE: Plug the hydraulic hose (2) and master

cylinder pipe (1) open ends to stop fluid loss and

dirt entry.

Figure 7B3-48

33. Lower the transmission enough to gain access

to the bolts (2) f astening the c lutch housing (1)

to the rear of the engine.

34. Progressively loosen then remove six of the

eight clutch housing to engine bolts (2).

Figure 7B3-49

35. After removing the two remaining bolts (1) that

also secure the starter motor heat shield (2),

unclip the heat shield from the starter motor

and set to one side.

36. Pull the transmission rearward, just enough to

clear the locating dowels, then rotate the

transmission through 90° to the right to gain

clearance at the floor pan.

37. With the transmission supported by the

transmission jack, continue to withdraw the

transmission, taking care not to place any

loading on the clutch driven plate centre

splines that could cause driven plate distortion.

NOTE: It is most important to prevent permanent

distortion of the driven plate, because replacement

would then be required.

38. When the transmission input shaft is clear of

the clutch pres sur e plate, the trans miss ion can

be lowered and removed from the vehicle.

NOTE: Take particular care when lowering the

transmission, that damage to the oxygen sensors

does not occur.

Figure 7B3-50

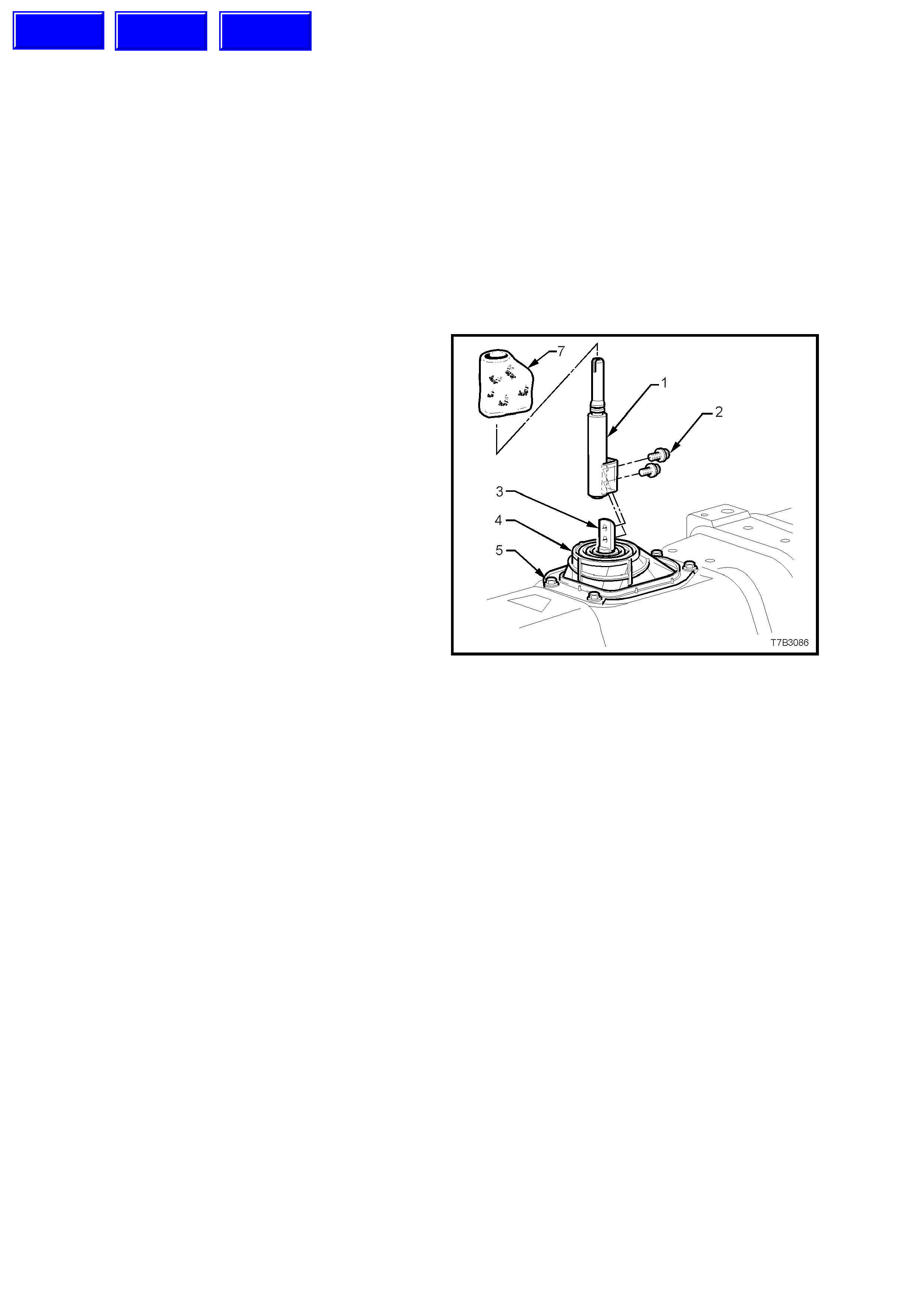

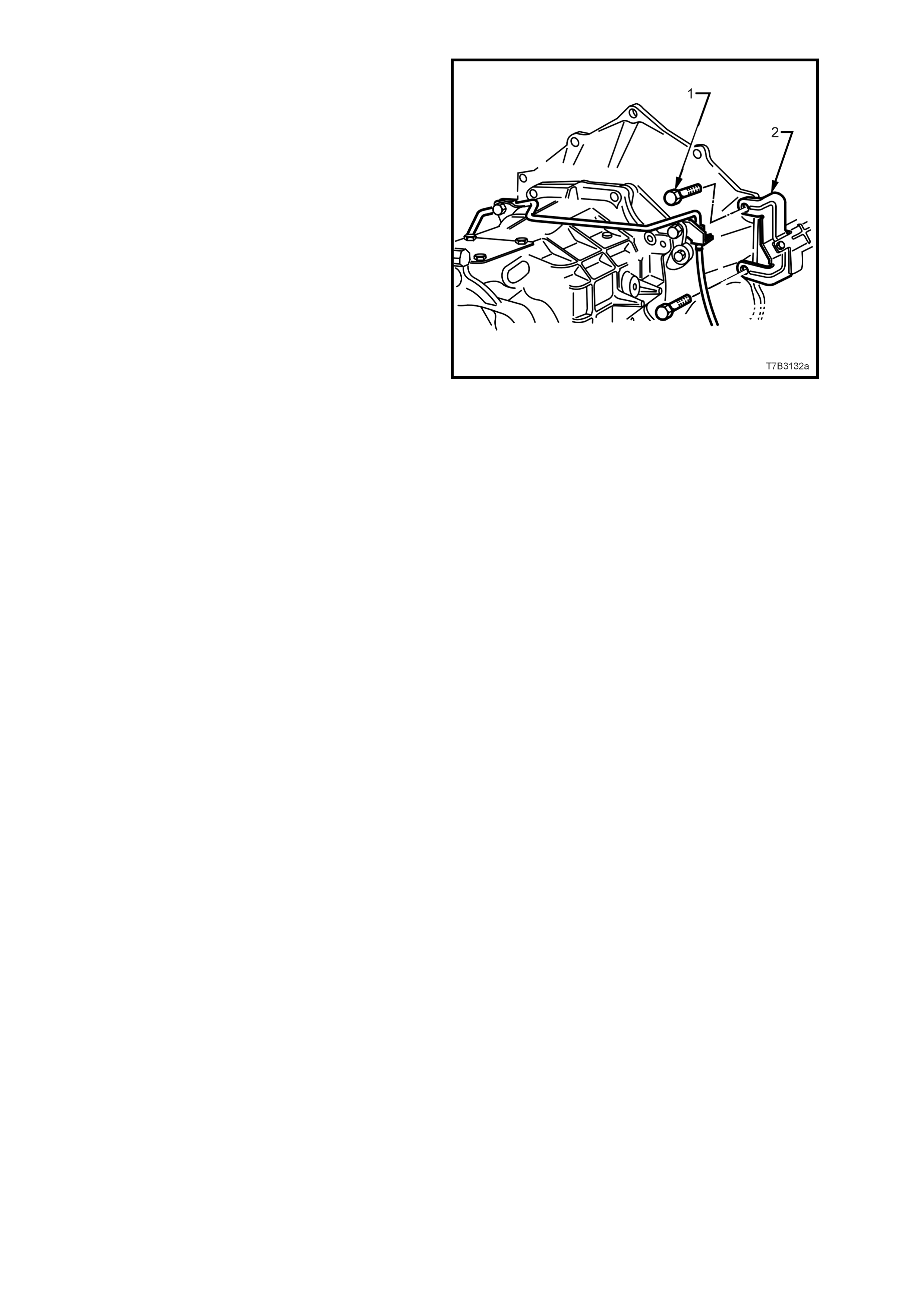

REINSTALL

1. Select 3rd gear.

2. If removed, install the clutch slave cylinder

pipe (1) to the slave cylinder (2), and tighten to

the correct torque specification.

CLUTCH FLUID PIPE FITTING TO

SLAVE CYLINDER 12 - 14 Nm

TORQUE SPECIFICATION

3. Sparingly apply 10% molybdenum disulphide

grease, such as Molybond GA 10 (or

equivalent to Holden’s Specification HN 1271)

to the bearing face of the clutch throwout

bearing, mounted to the slave cylinder (2), the

splines and spigot of the input shaft.

4. With the transmission on its side, with the top

surface facing the right hand side of the

vehicle, use a transmission jack to raise the

transmission and install input shaft into the

splines of clutch driven plate.

5. Push transmission in toward engine block. It

may be necessary to rotate the m ainshaf t after

temporarily installing the propeller shaft, to

assist in spline alignment.

Figure 7B3-51

6. When installed up to the locating dowel pins,

rotate the transmission counter-clockwise 90°,

then push fully home.

7. Clip the heat shield (2) onto the starter motor,

then install two clutch housing to engine block

bolts (1), to retain.

Figure 7B3-52

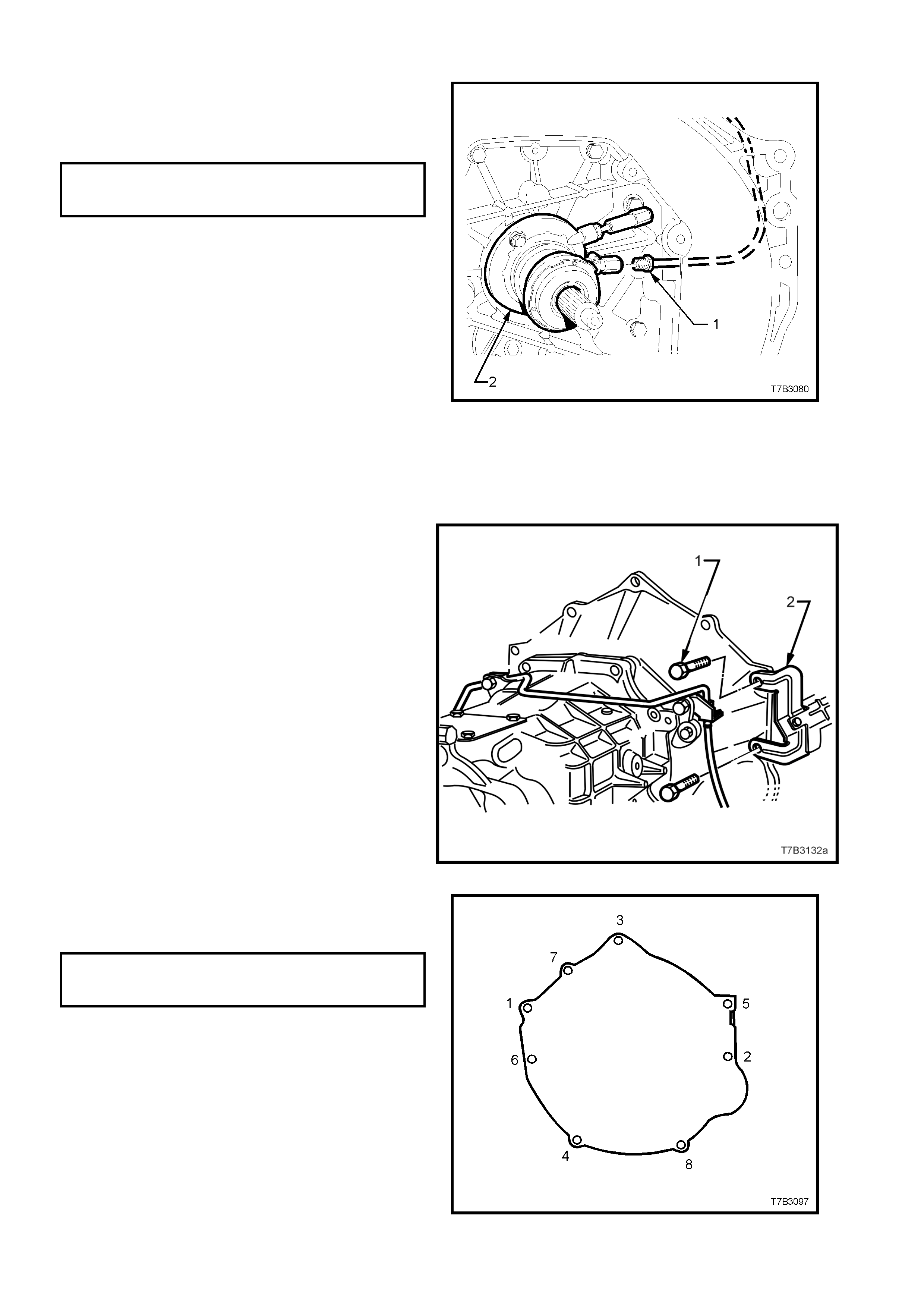

8. Install the remaining six clutch housing to

engine block bolts and tighten all bolts in the

sequence shown, to the specified torque.

CLUTCH HOUSING TO

ENGINE BLOCK BOLT 40 - 60 Nm

TORQUE SPECIFICATION

Figure 7B3-53

9. Reinstall wiring harness connectors to the

back up lamp switch, reverse lockout solenoid,

speed sensor and each of the oxygen

sensors.

10. Secure the powertrain wiring harness to the

transmission vent pipe, using a cable tie.

11. Reinstall propeller shaft slip joint into the

transm ission m ainshaft, s upporting the centre,

constant velocity joint at an angle not

exceeding 8°, to avoid damage to the joint

and/or boot.

12. Lift propeller shaft upward and install centre

bearing carrier to underbody reinforcement,

ensuring that all spacers are replaced in the

same positions, noted on removal. Install

retaining bolts.

13. Assemble propeller shaft rear universal joint

flange to pinion flange, aligning marks noted

on removal. Install attaching bolts and nuts.

14. Tighten all propeller shaft attaching bolts to

the correct torque specification.

CENTRE BEARING CARRIER TO

UNDERBODY REINFORCEMENT 20 - 35 Nm

TORQUE SPECIFICATION

PROPELLER SHAFT REAR

UNIVERSAL JOINT FLANGE BOLT 55 - 65 Nm

TORQUE SPECIFICATION

15. Reinstall the catalytic converter bracket (6) to

the transmission extension, reinstall the bolts

(7) and nuts, then tighten to the c orrect torque

specification.

CONVERTER BRACKET TO

TRANSMISSION EXTENSION BOLT 40 – 60 Nm

TORQUE SPECIFICATION

16. Reinstall the rear mount (1) to the

transmiss ion extension, install the two bolts (5)

and tighten to the correct torque specification.

TRANSMISSION MOUNT TO

EXTENSION HOUSING BOLT 20 - 30 Nm

TORQUE SPECIFICATION

17. Raise the transmission slightly, then reinstall

the four crossmember to side frame bolts (3),

aligning the crossmember (2) with the scribed

lines made prior to disassembly. Tighten the

bolts (3) to the correct torque specification.

REAR CROSSMEMBER TO

SIDE FRAME MEMBER BOLT 50 - 65 Nm

TORQUE SPECIFICATION

Important: This step is critical to the correct

powertrain alignment. If not carried out, then

vehicle vibration and/or handling problems may

result.

18. Remove the lifting device from the

transmission, centralise the rear mount studs

in the crossmember holes, then reinstall the

nuts (4), tightening to the correct torque

specification.

REAR CROSSMEMBER TO

TRANSMISSION MOUNT NUT 20 - 30 Nm

TORQUE SPECIFICATION

19. Reinstall the two catalytic converter bracket (6)

bolts, tightening to the correct torque

specification.

CATALYTIC CONVERTER

BRACKET BOLT 20 - 30 Nm

TORQUE SPECIFICATION.

20. Install clutch hydraulic hose to the bracket on

the sub-frame rail, then install the pipe fitting,

tightening to the correct torque specification.

Use a back-up spanner on the hydraulic hose

end fitting.

Figure 7B3-54

CLUTCH HYDRAULIC PIPE TO 12 - 14

TORQUE SPECIFICATION Nm

21. If transmission fluid was drained during the

removal operation, then refill, as described in

2.3 DRAINING AND REFILLING

TRANSMISSION, in this Section.

22. Reinstall the right and left close-out covers,

secure with a bolt in each and tighten to the

correct torque specification.

LEFT AND RIGHT CLOSE-OUT

COVER RETAINING BOLT 10 - 14 Nm

TORQUE SPECIFICATION

23. Reinstall the starter motor. Refer to

Section 6D3-2, STARTING SYSTEM - GEN

III V8 ENGINE of the VT Series II Service

Information, for the necessary procedure.

24. Lower vehicle to the ground.

25. Reinstall the remote shift lever boot and

retainer. Install the four bolts and tighten to the

correct torque specification.

REMOTE SHIFT LEVER BOOT PLATE 6.0 - 14

BOLT TORQUE SPECIFICATION Nm

26. Reinstall the gearshift control lever. Secure

with bolts that have Loctite 242 or equivalent

(to Holden’s Specification HN 1256 Class 2,

Type 2), applied to cleaned threads. Tighten to

the correct torque specification, then reinstall

the insulator over the control lever.

GEARSHIFT CONTROL LEVER BOLT 15 - 35

TORQUE SPECIFICATION Nm

27. Reinstall centre console assembly, including

the console cap. Refer to

Section 1A3, INSTRUMENT PANEL AND

CONSOLE, of the VT Series I Service

Information for the necessary procedure.

28. Reinstall the gearshift knob and boot

assembly over the gearshift lever, align the

knob in the c orrect attitude and then bum p the

knob onto the gear shif t lever until the retaining

claws engage with the groove in the lever.

29. Align the gearshif t boot retaining clips with the

hole in the console cap, then c ar ef ully seat the

boot retainers into the console cap until each

clip engages correctly.

30. Reconnect battery earth lead.

31. Road test vehicle and check transmission,

clutch and gearshift operations.

4.3 TRANSMISSION DISASSEMBLE

1. Remove transmission assembly from vehicle.

Refer 4.2 TRANSMISSION ASSEMBLY -

REMOVE, in this Section.

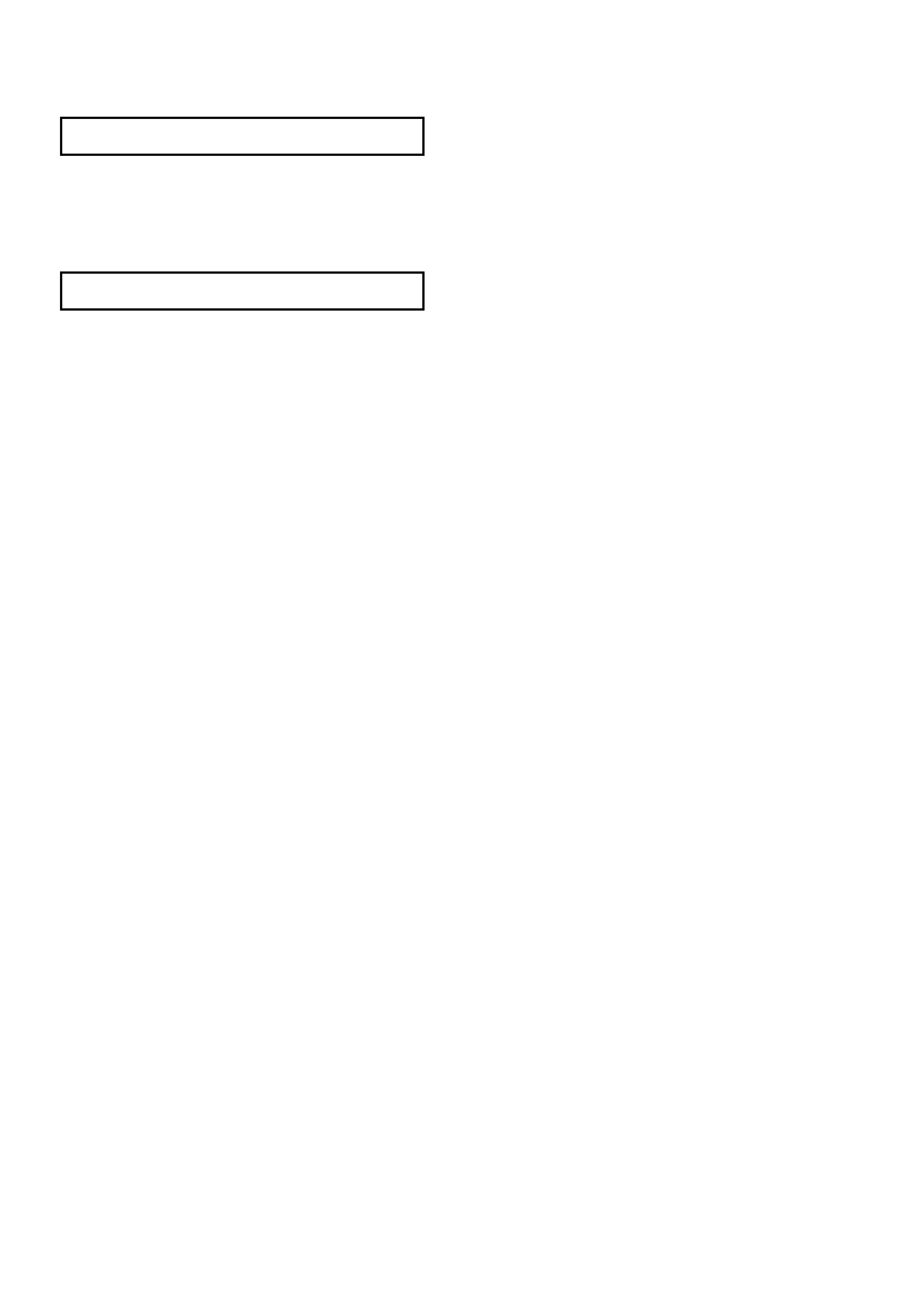

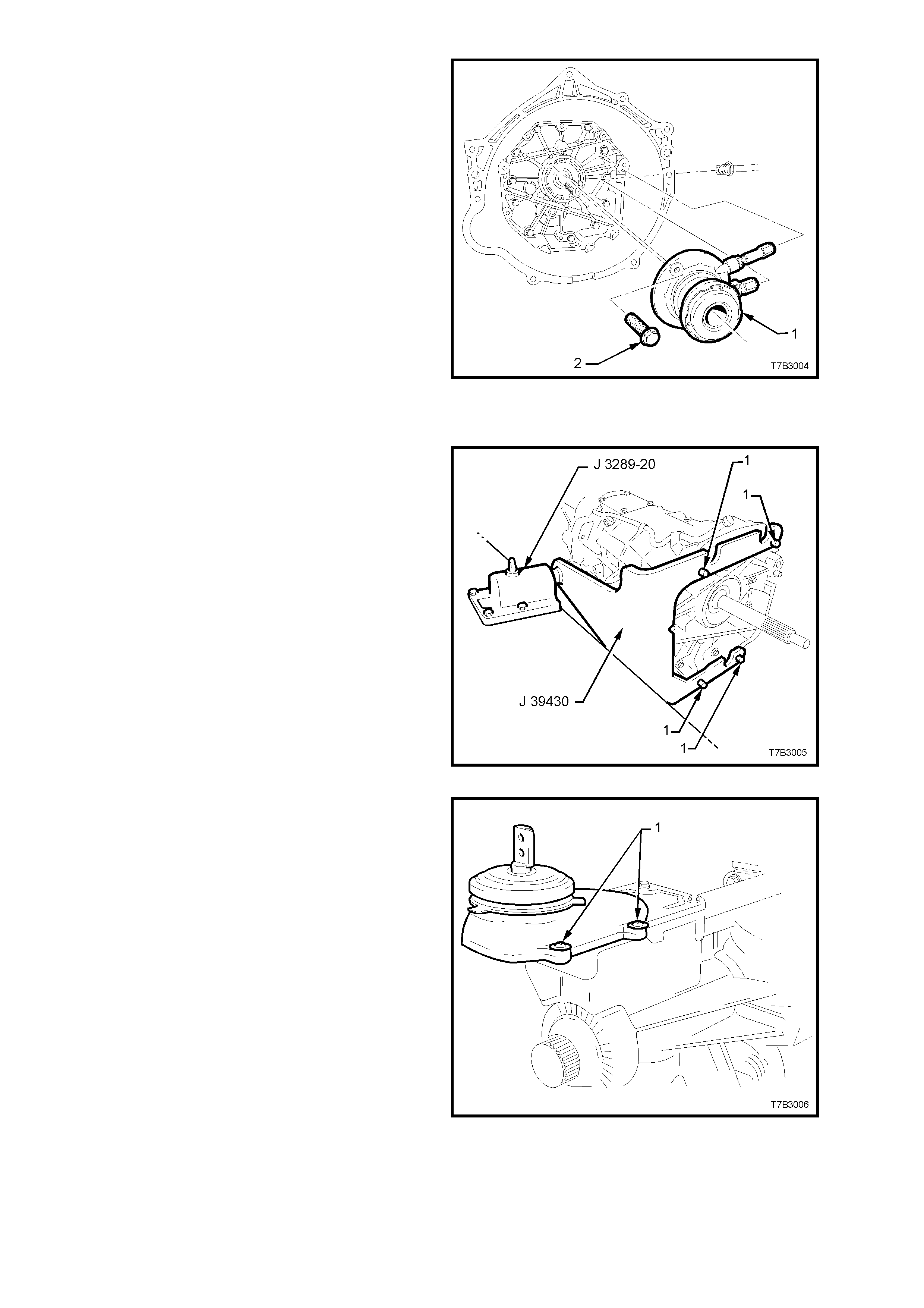

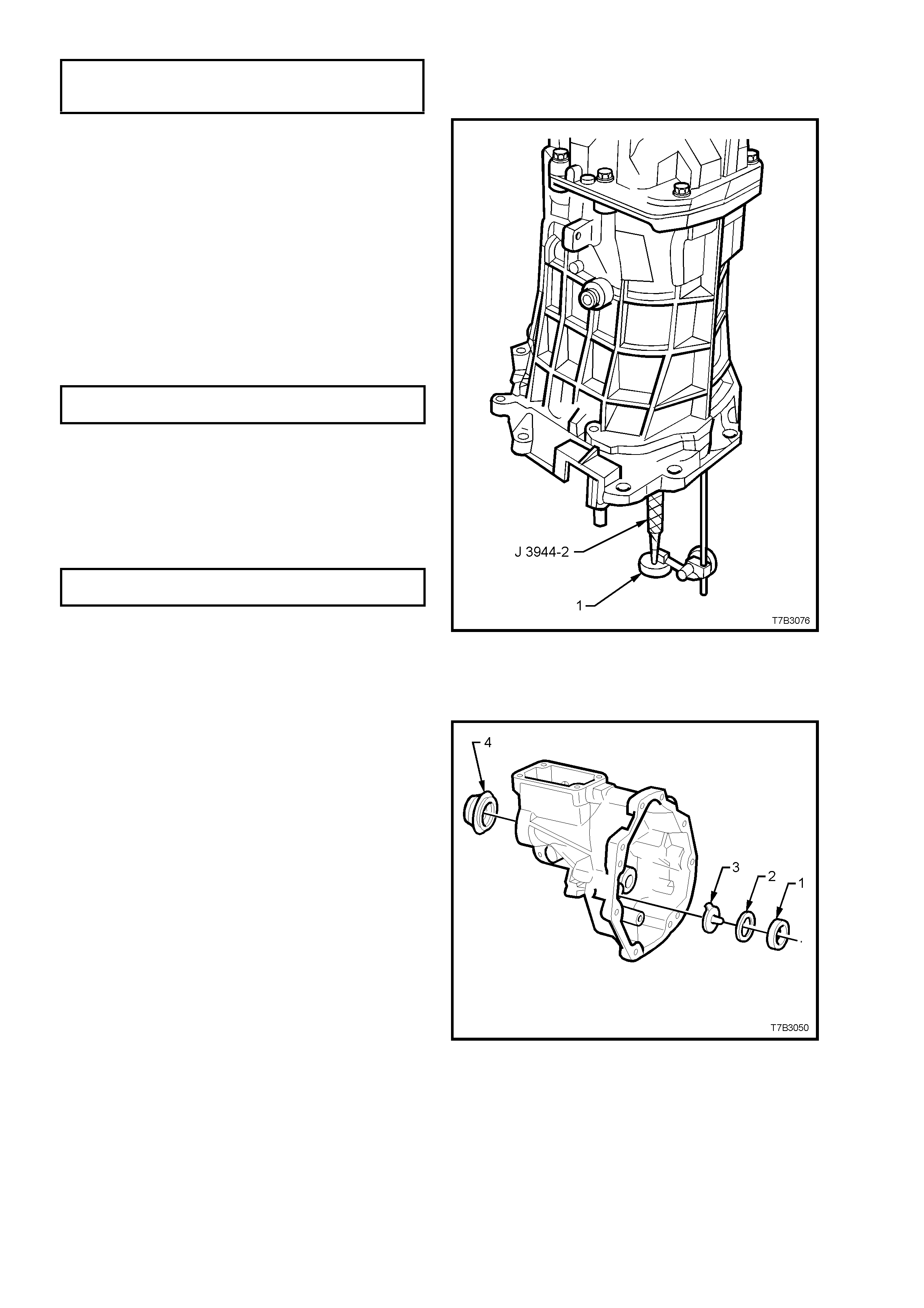

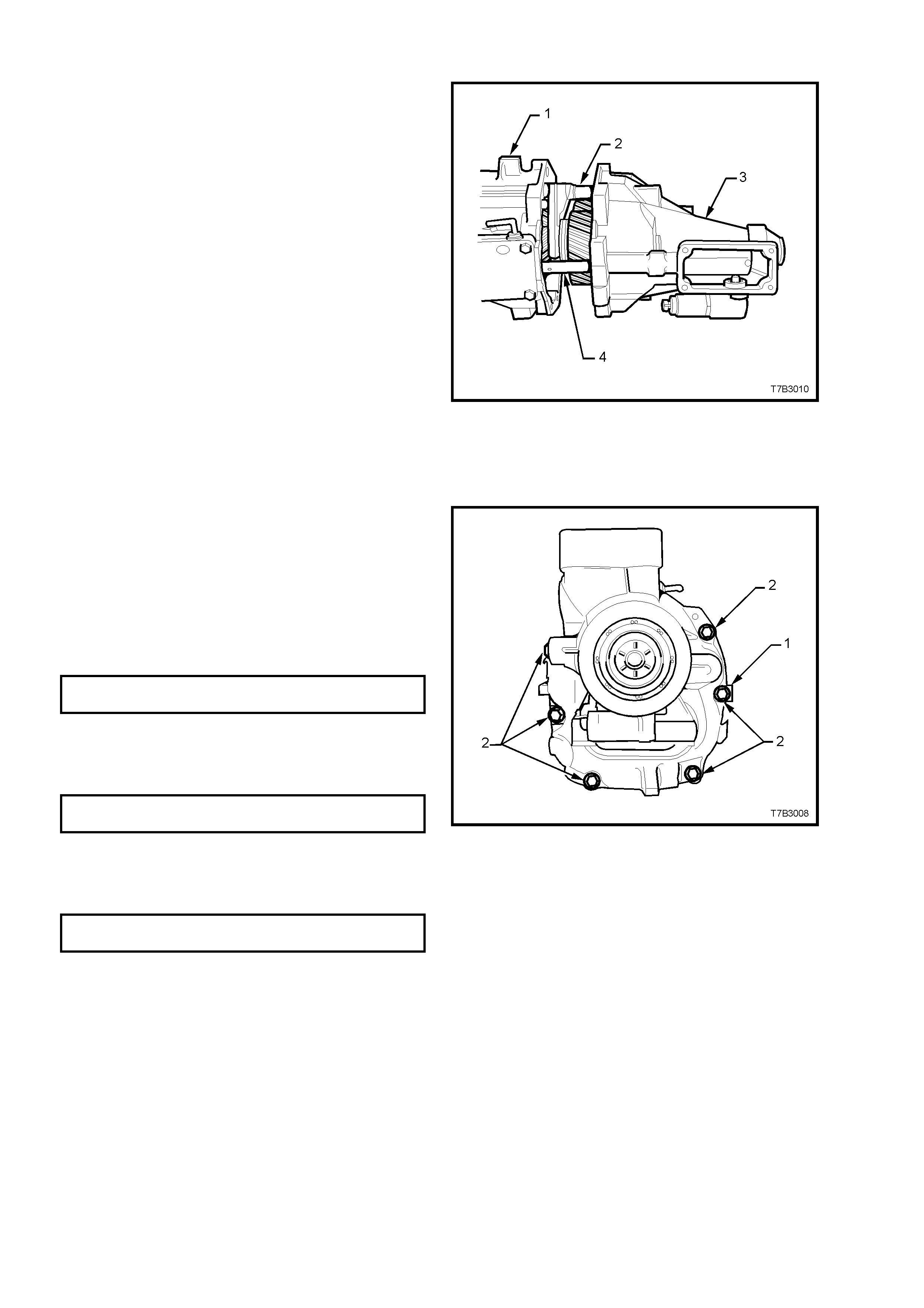

CLUTCH HOUSING AND SLAVE CYLINDER

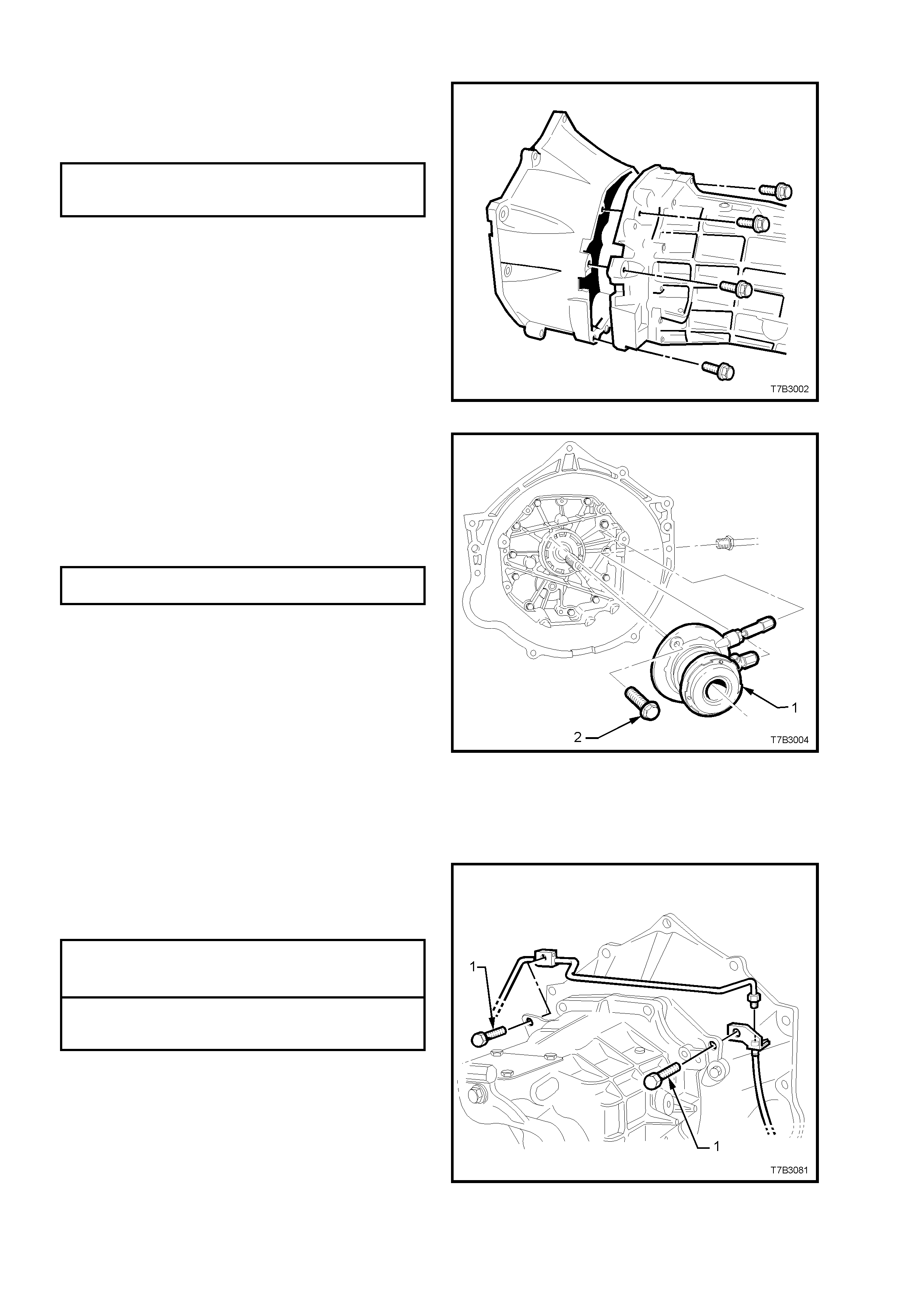

2. Remove the two bolts (1) securing the clutch

slave cylinder pipe to the transmission,

unscrew the fitting from the slave cylinder and

remove the pipe and brackets from the

transmission.

Figure 7B3-55

3. Remove the 8 bolts holding the c lutch housing

to the transmission, then remove the housing.

Figure 7B3-56

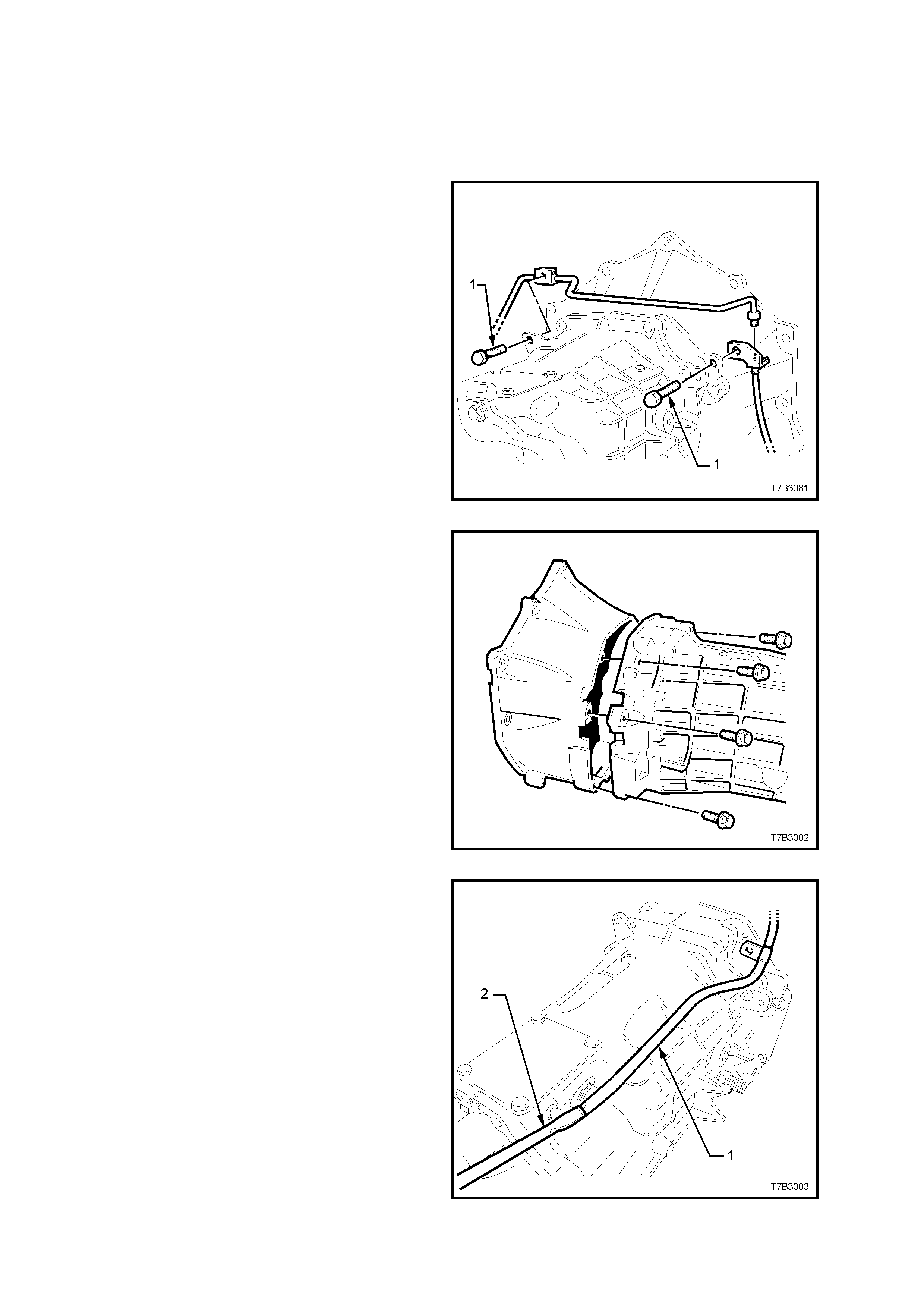

4. Remove the plastic vent tube (1), by pushing

on the end of the tube with the flat blade of a

screwdriver (2), to s lide the tube from the vent

tube fitting, then set the pipe to one side.

Figure 7B3-57

5. Remove the 2 bolts (2) securing the clutch

slave cylinder (1) to the transmission adaptor

plate, then set the slave cylinder assembly (1)

to one side.

Figure 7B3-58

EXTENSION HOUSING

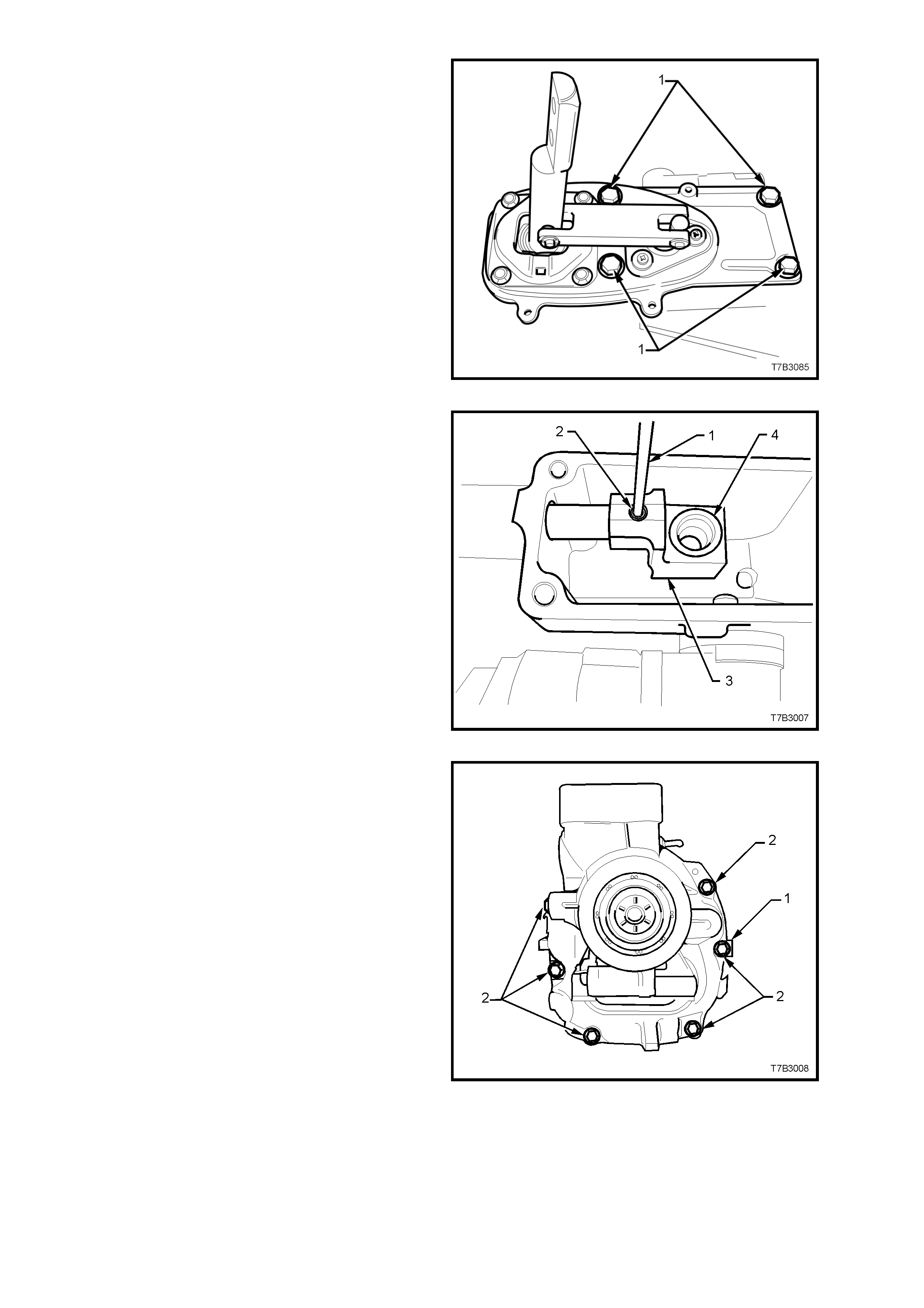

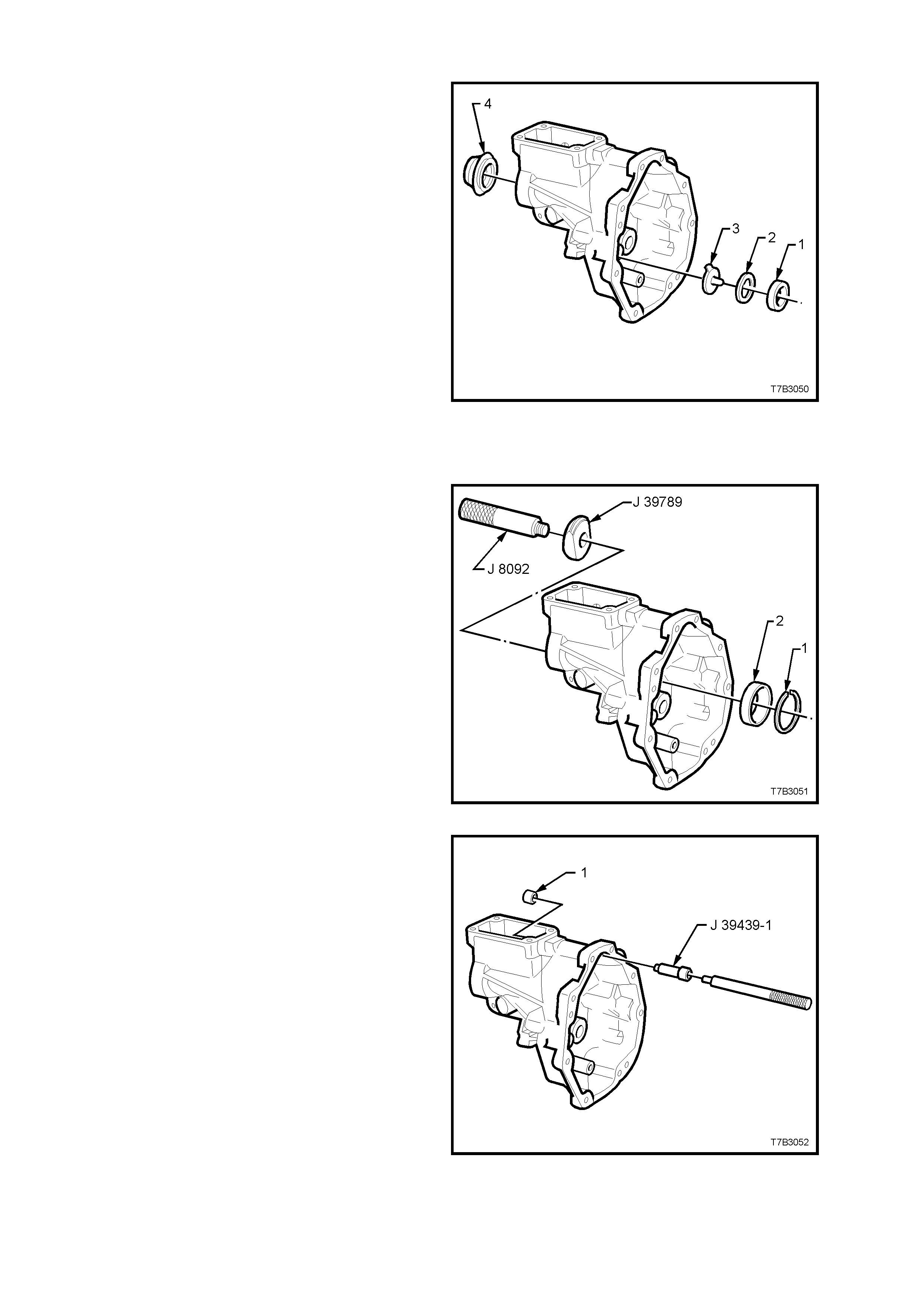

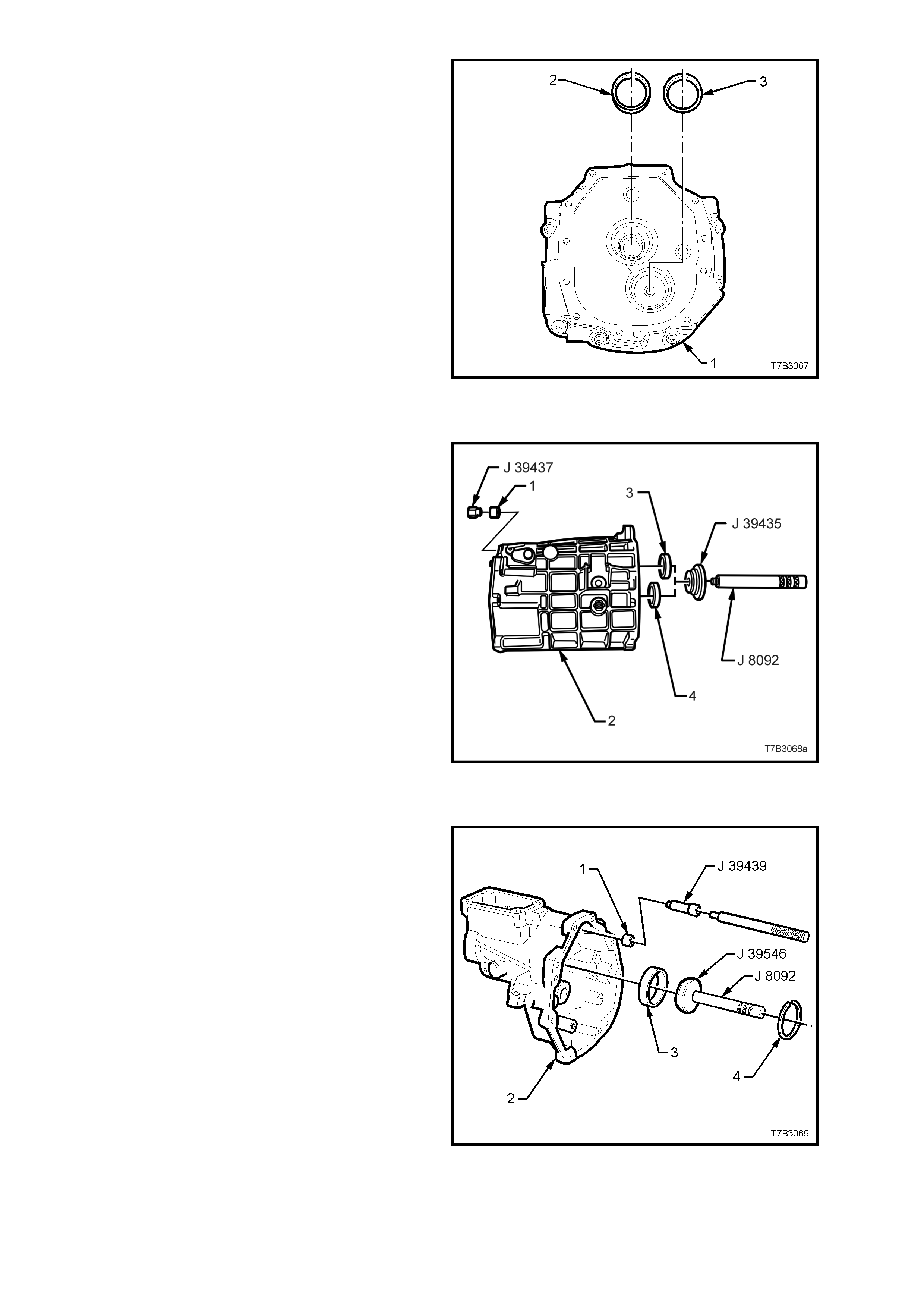

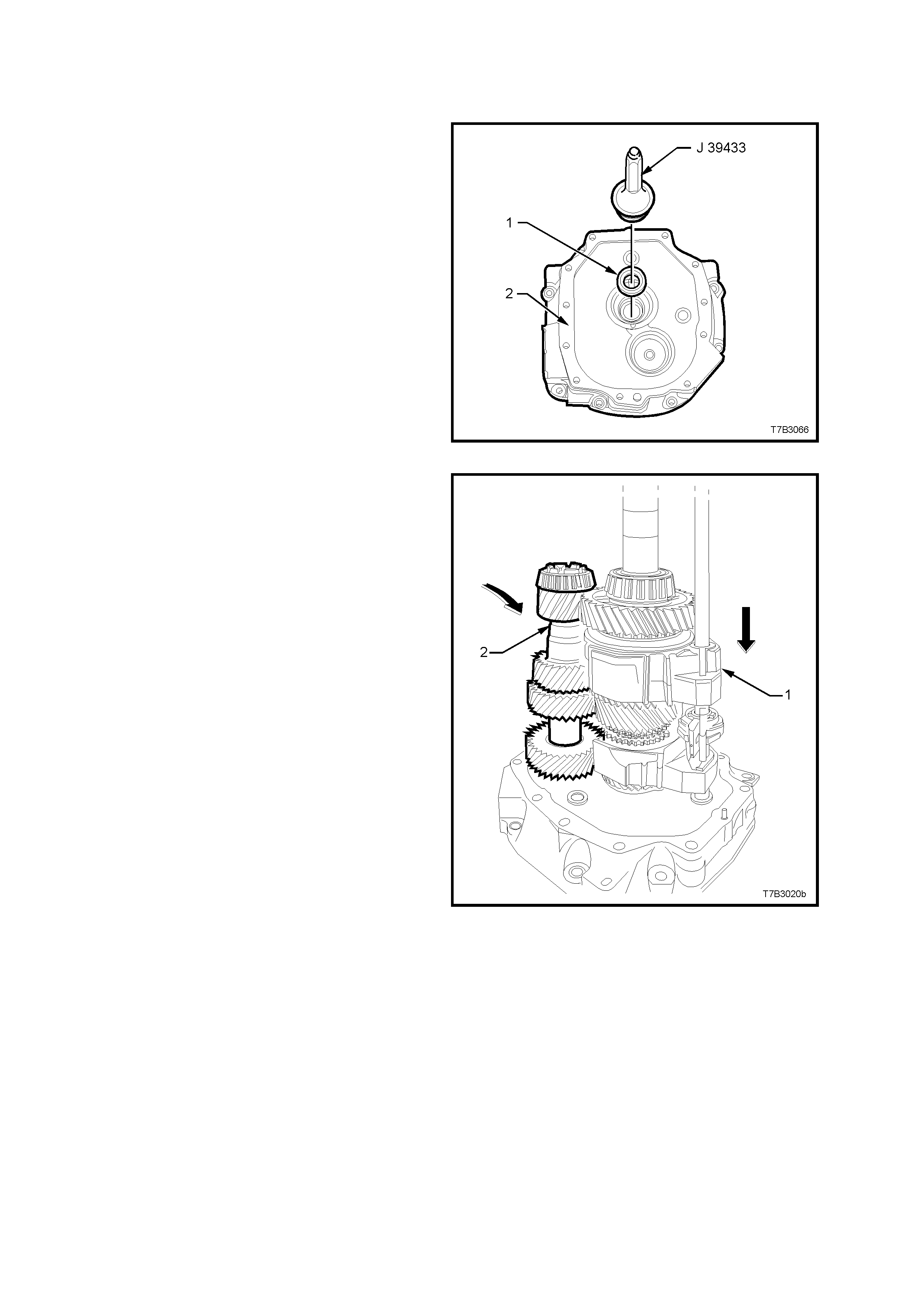

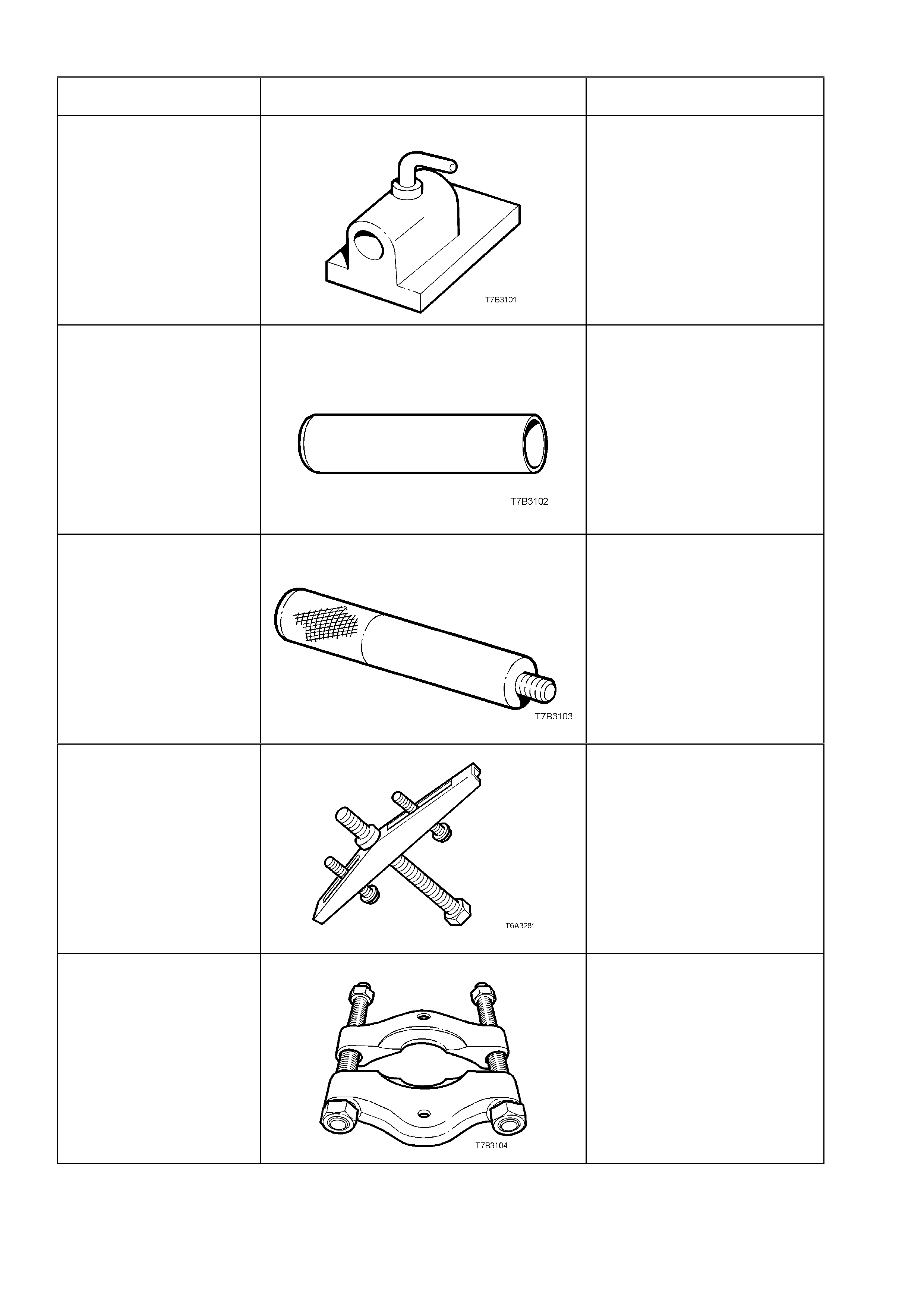

1. Install holding tool J 39430 to the front of the

transmission, using 4 of the clutch housing

bolts (1).

2. Install holding tool J 39430 into the bench

holding fixture J 3289-20.

Figure 7B3-59

3. With the transmission in a horizontal position

with the shift lever up, drain the transmission

fluid (if not carried out previously).

4. Remove the four screws securing the shift

lever cover, prise the cover loose, then

remove.

Figure 7B3-60

5. Select either 2nd or 4th gear.

6. Remove the 4 bolts (1) holding the shifter

assembly to the extension housing. If requir ed,

tap with a rubber or plastic hammer to break

the seal, then remove the assembly and

rubber seal from the extension housing.

Figure 7B3-61

7. Using a suitable pin punch (1), remove the

rear offset lever roll pin (2).

NOTE: Selecting 2nd or 4th gear shortens the shift

rail overhang, providing m or e support dur ing the roll

pin removal.

8. Remove the rear offset lever (3) and check

that the isolator cup (4) is secure in the lever.

If loose, discard both the isolator cup and the

rear offset lever.

Figure 7B3-62

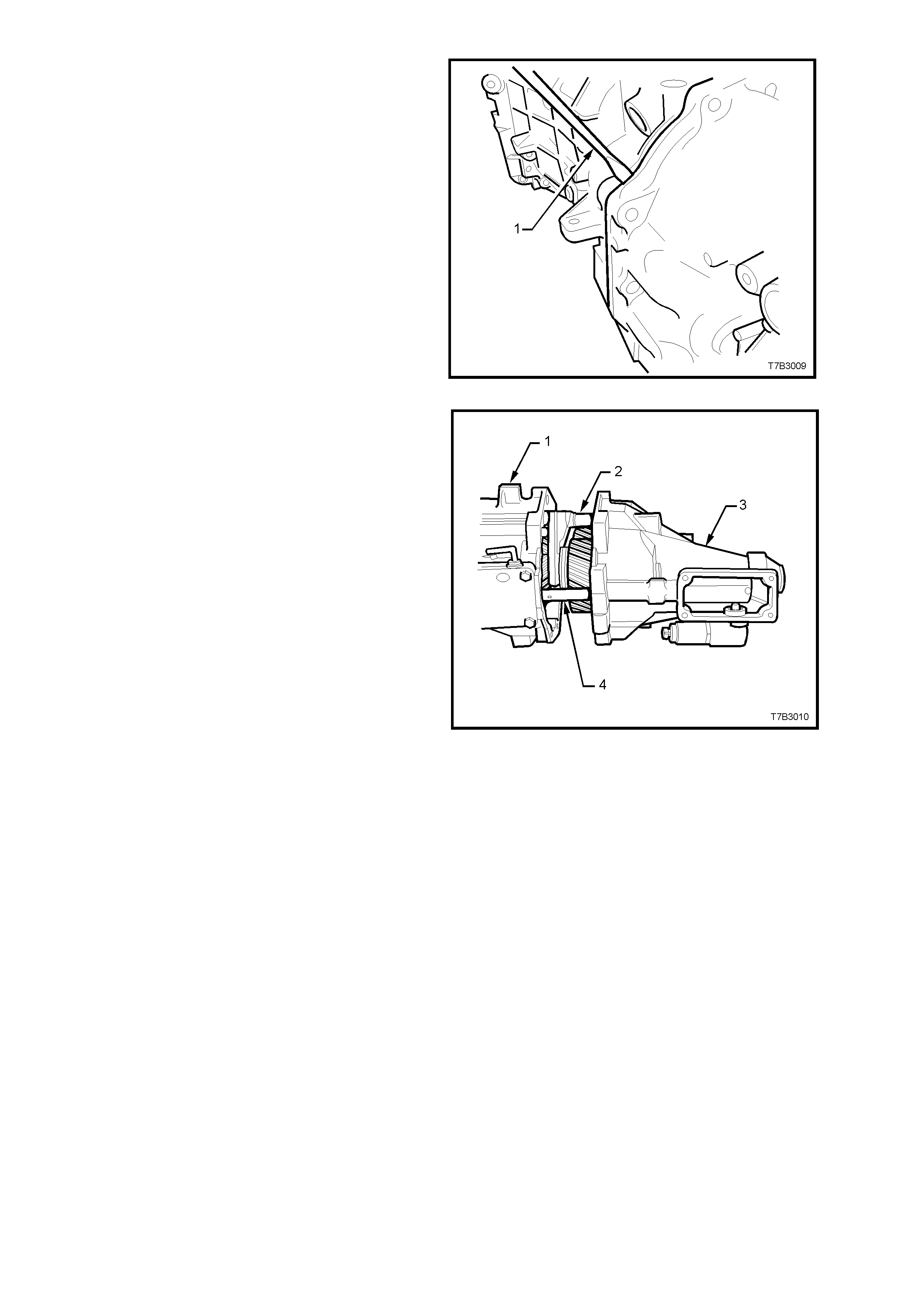

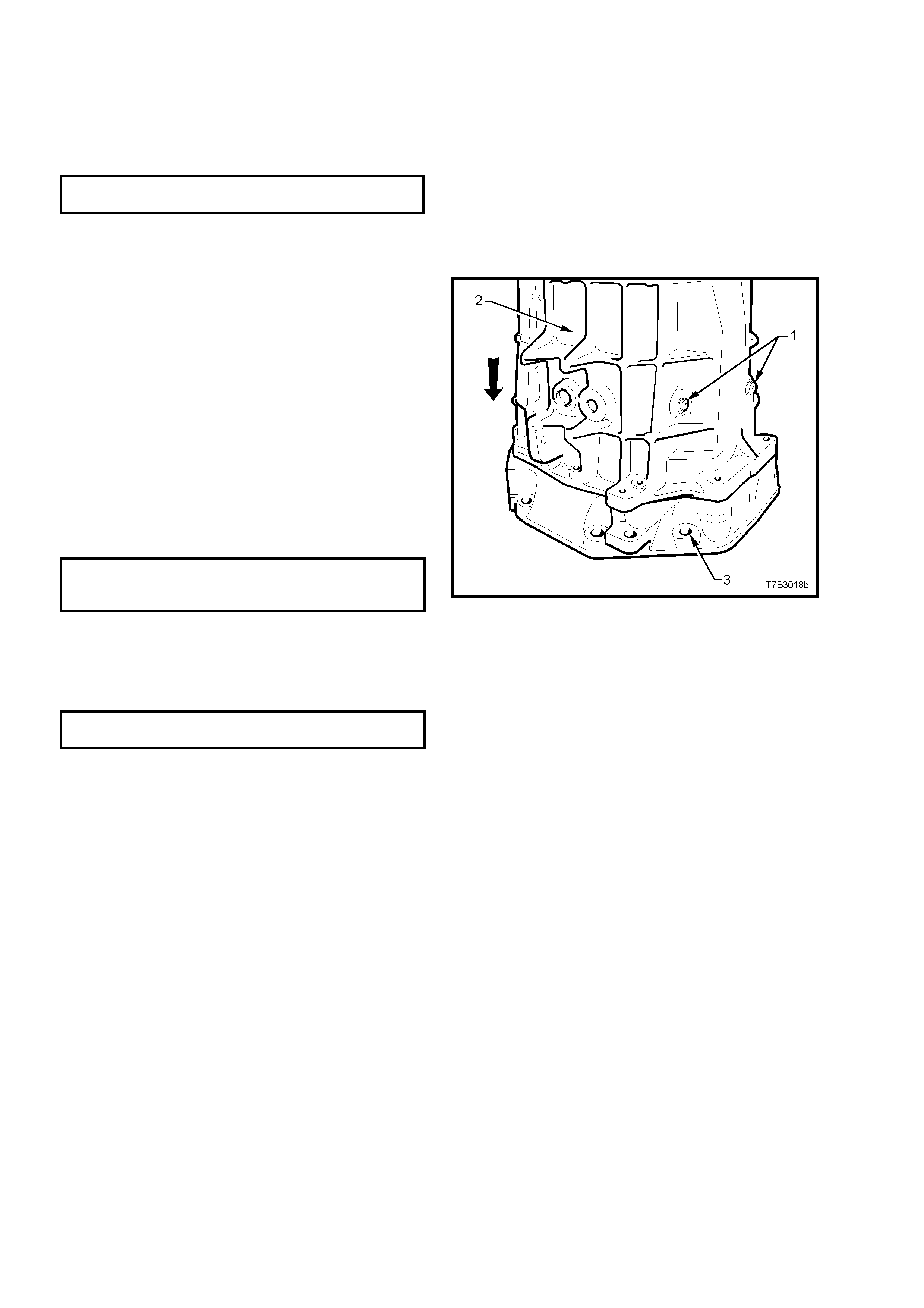

9. Remove the 8 bolts (2) holding the extension

housing, noting the position of the

identification tag (1).

NOTE: The two top bolts (not shown) have sealant

applied to the threads.

Figure 7B3-63

10. With the transmission in a horizontal position,

break the sealant seal by levering in the point

provided, using a flat bladed screwdriver (1).

11. Tap the extension housing rearward, using a

plastic or rubber hammer to remove the

housing from the 2 locating dowel pins.

Figure 7B3-64

12. Slide the housing (3) f rom the s hift rails (2 and

4) and remove from the transmission case (1).

13. Remove both circular magnets located in the

recess in the rear of the transmission case

and set to one side.

Figure 7B3-65

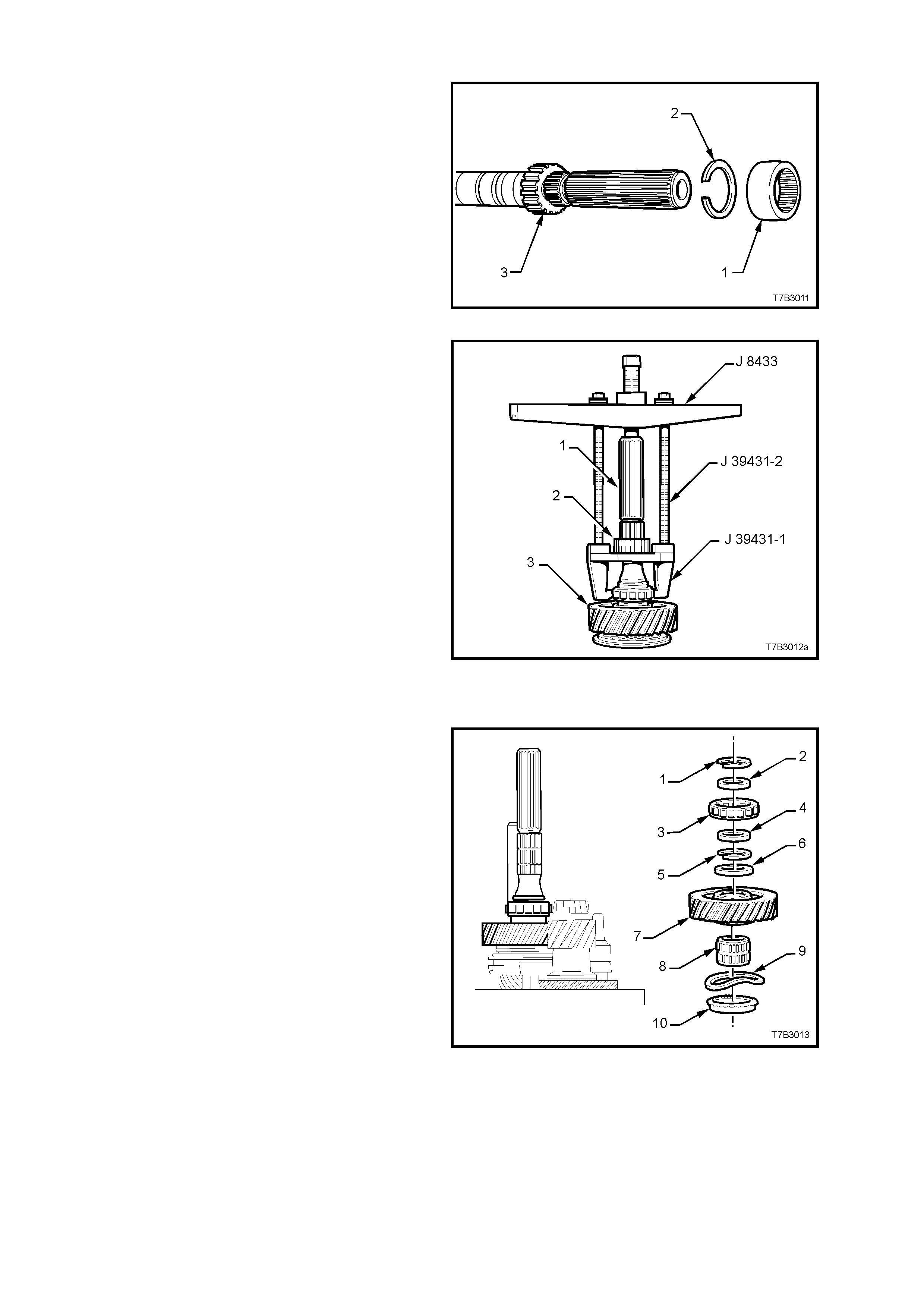

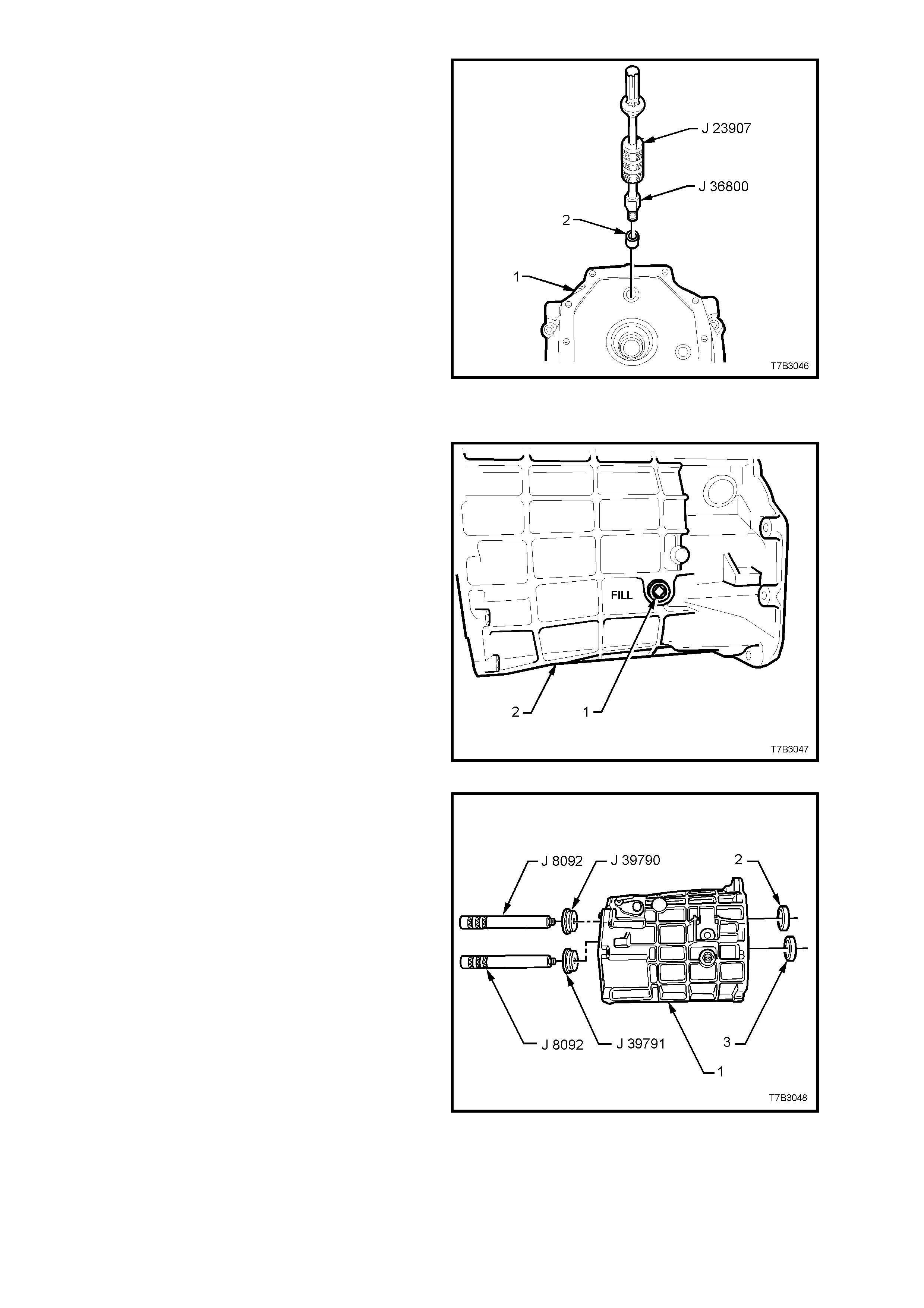

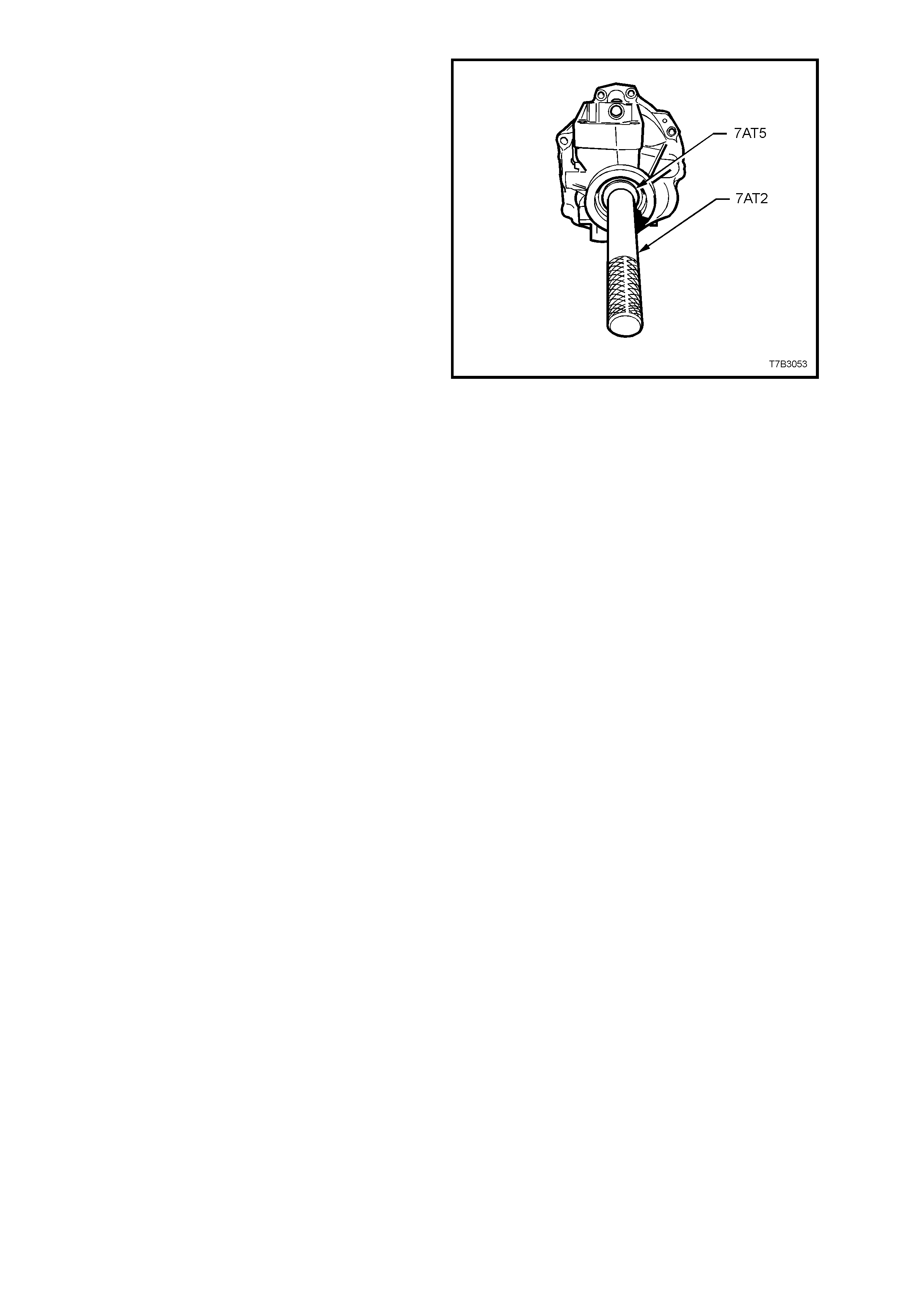

SPEEDOMETER PULSE RING

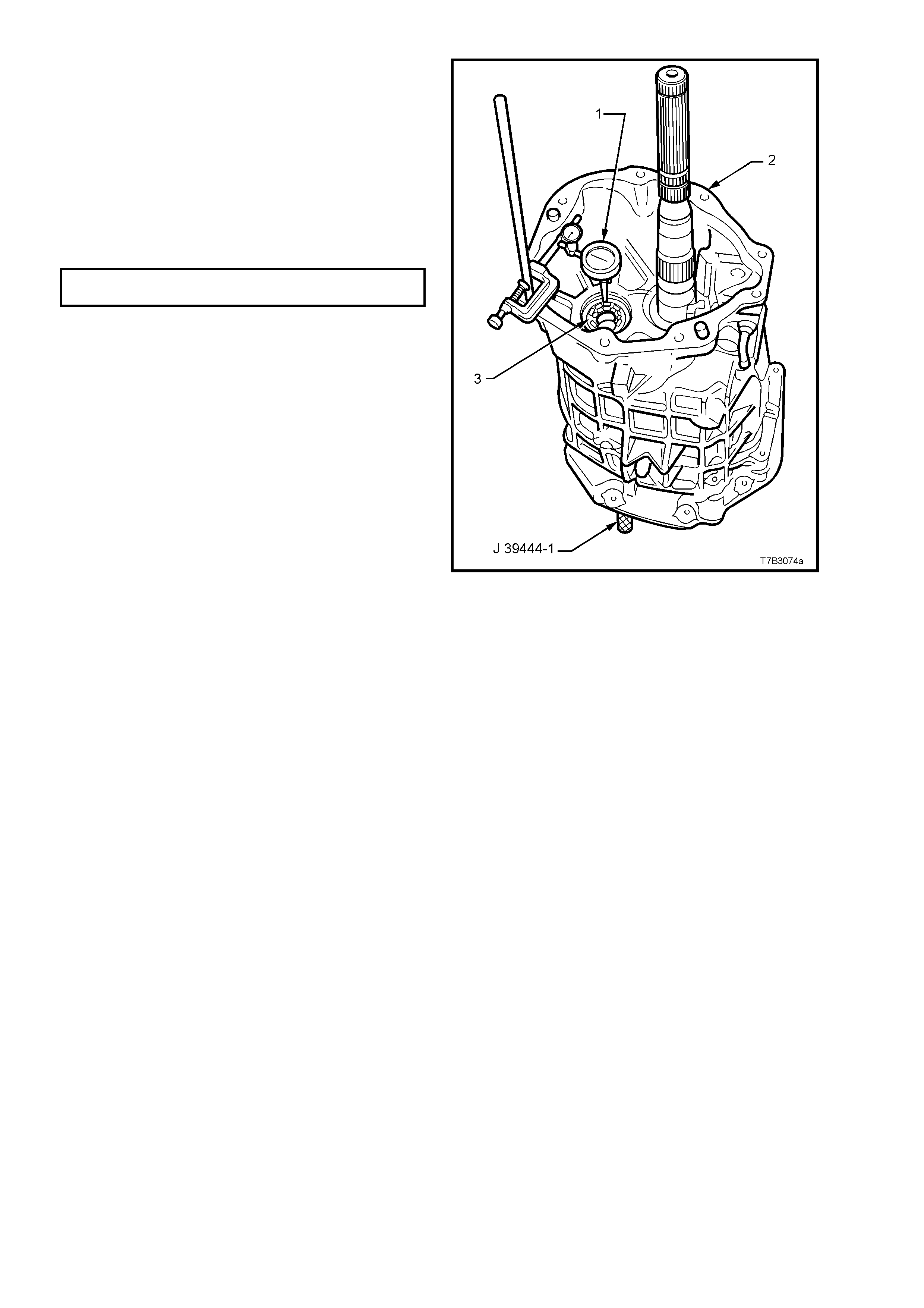

1. Slide the sealing ring (1) from the mainshaft.

2. Using suitable snap ring pliers, remove the

snap ring (2) from the speedom eter pulse ring

(3).

Figure 7B3-66

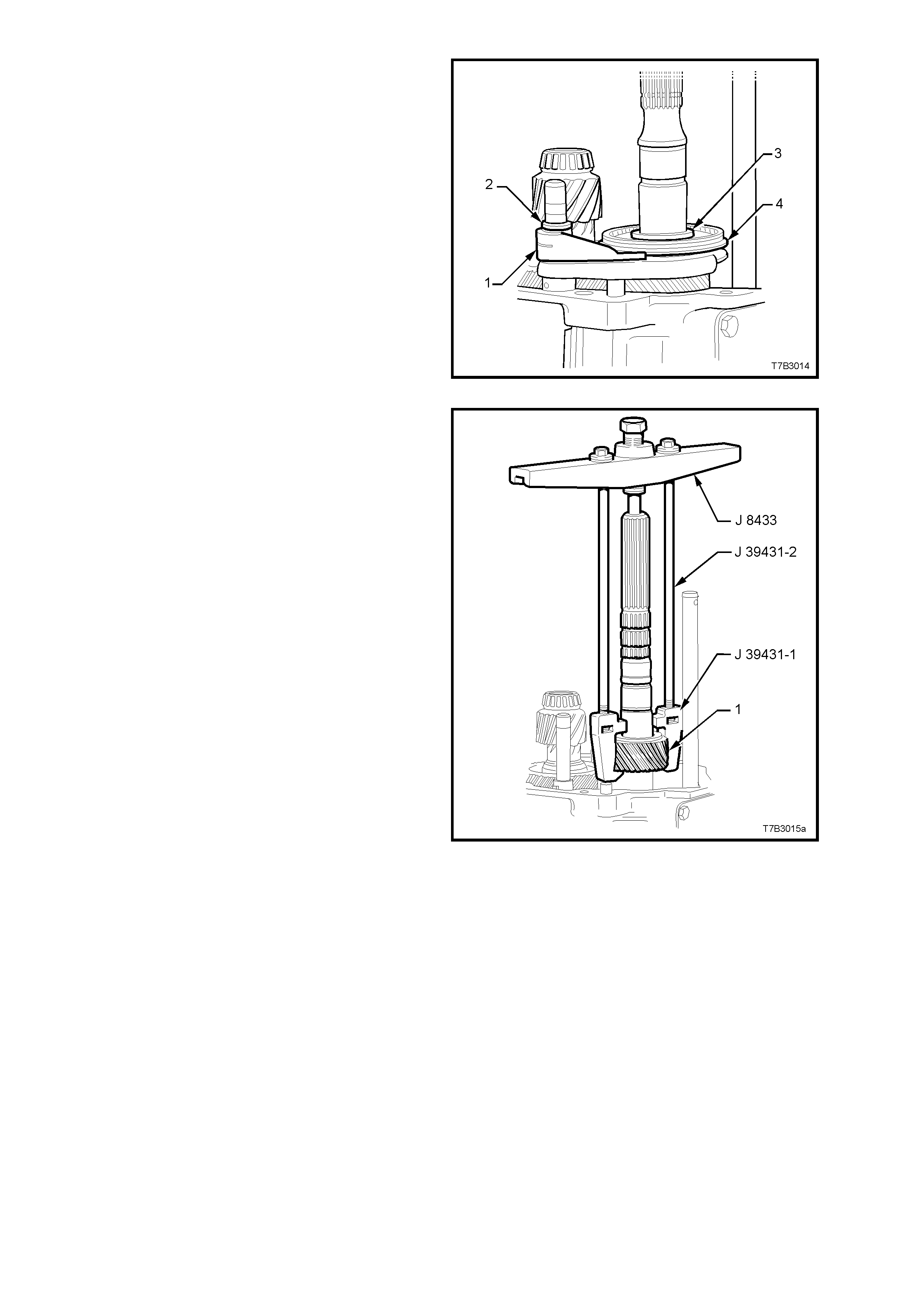

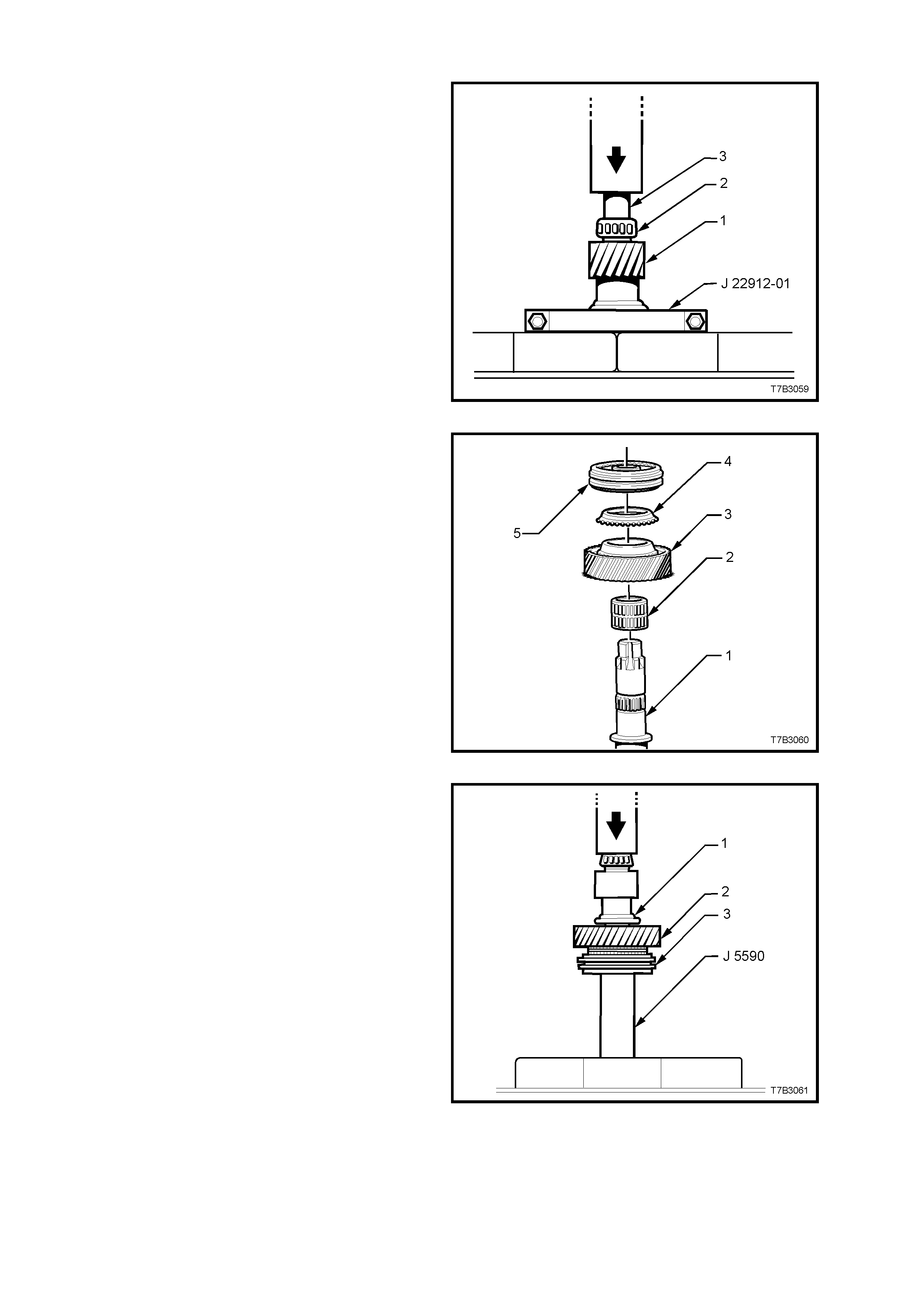

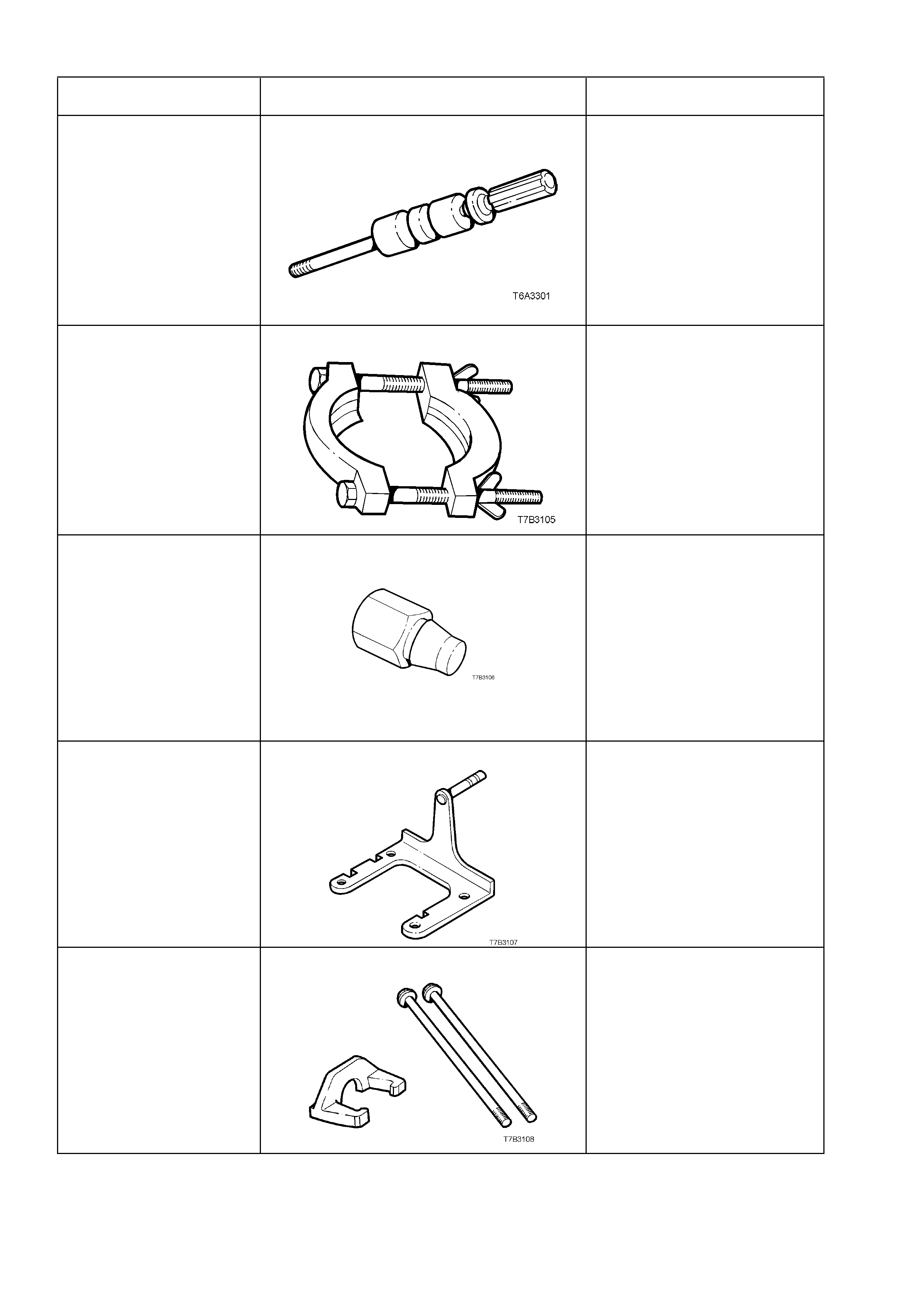

3. Assemble universal bridge puller J 8433 and

puller J 39431-1 using bolts J 39431-2, as

shown.

4. Remove the speedometer pulse ring (2) from

the mainshaft (1), then disassemble the tools.

5. Remove the second speedometer pulse ring

snap ring, using suitable snap ring pliers.

Figure 7B3-67

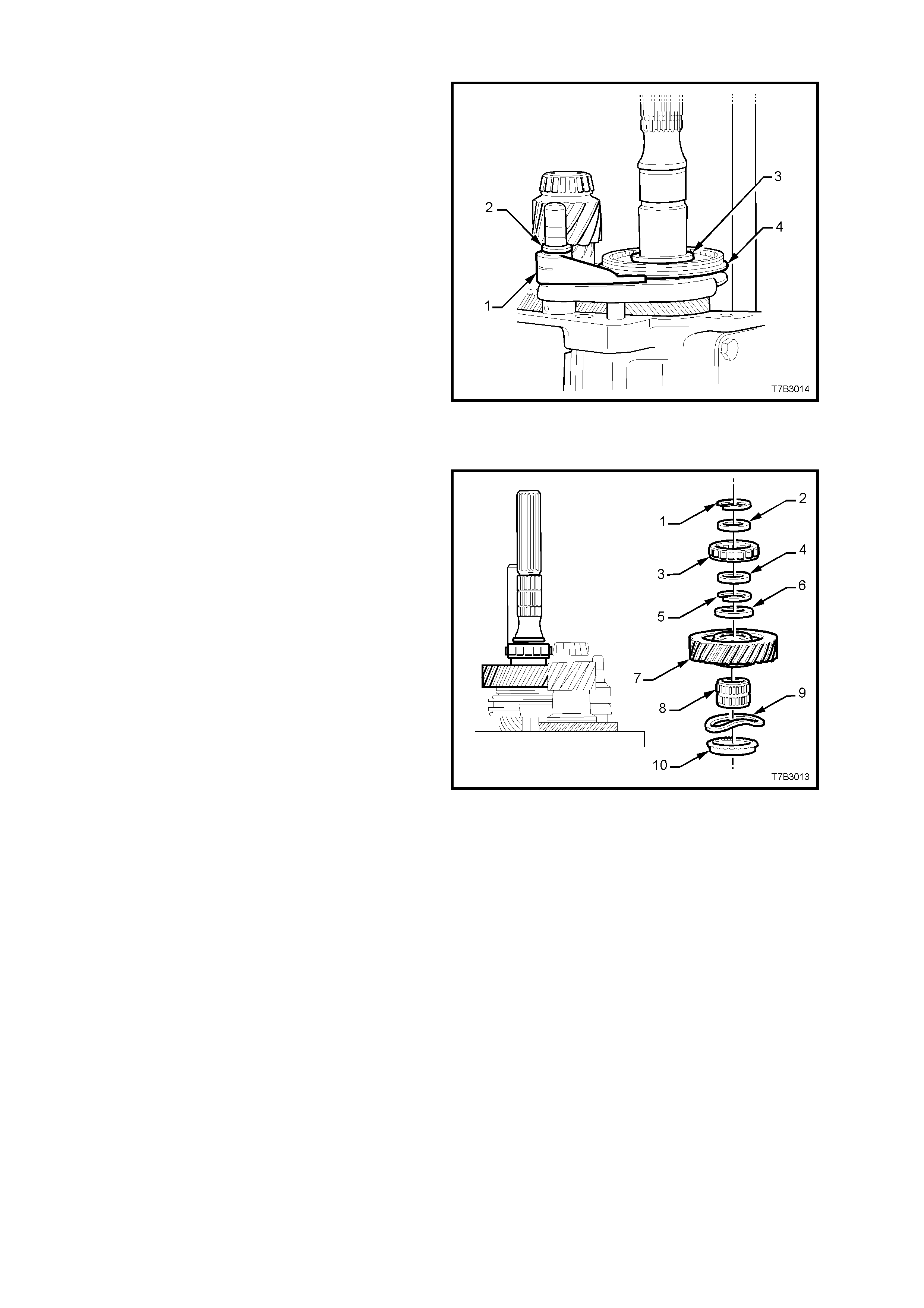

REVERSE AND 5TH/6TH DRIVEN GEAR

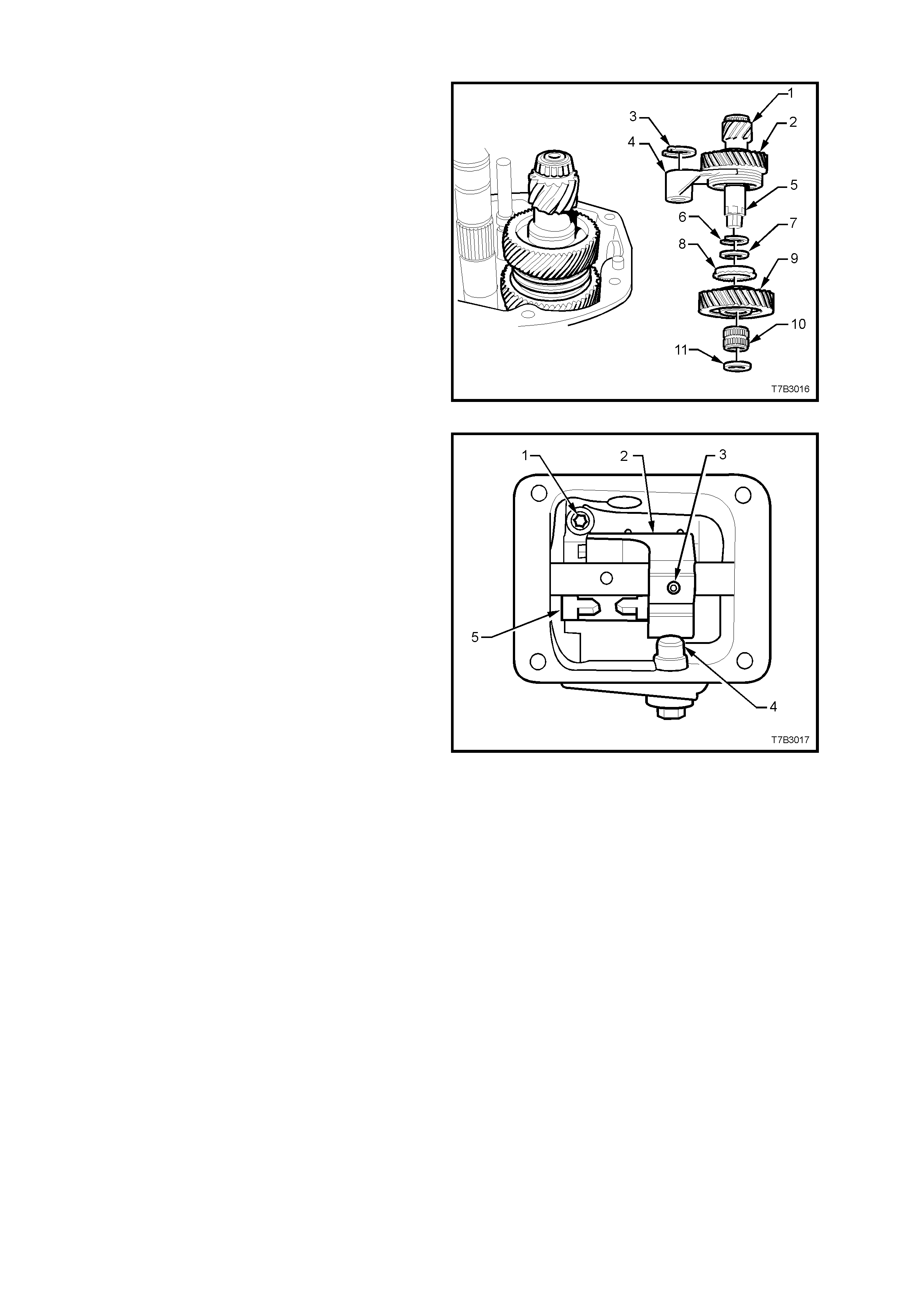

1. Remove the following components from the

mainshaft:

a. Snap ring (1).

b. Spacer (2).

c. Rear mainshaft roller race (3).

d. Spacer (4).

e. Snap ring (5).

f. Thrust washer (6).

g. Reverse gear (7).

h. Reverse gear, caged roller bearing (8).

i. Wave washer (9).

j. Reverse gear blocker ring (10).

Figure 7B3-68

2. Remo ve reverse synchromes h assembly snap

ring (3).

3. Remove circlip (2) from the reverse shift rail

and discard.

4. Remove the reverse synchromesh assembly

(4), thrust washer (not shown) and reverse

shift fork (1), as an assembly.

NOTE: The synchromesh hub (4) is a sliding fit to

the mainshaft splines.

Figure 7B3-69

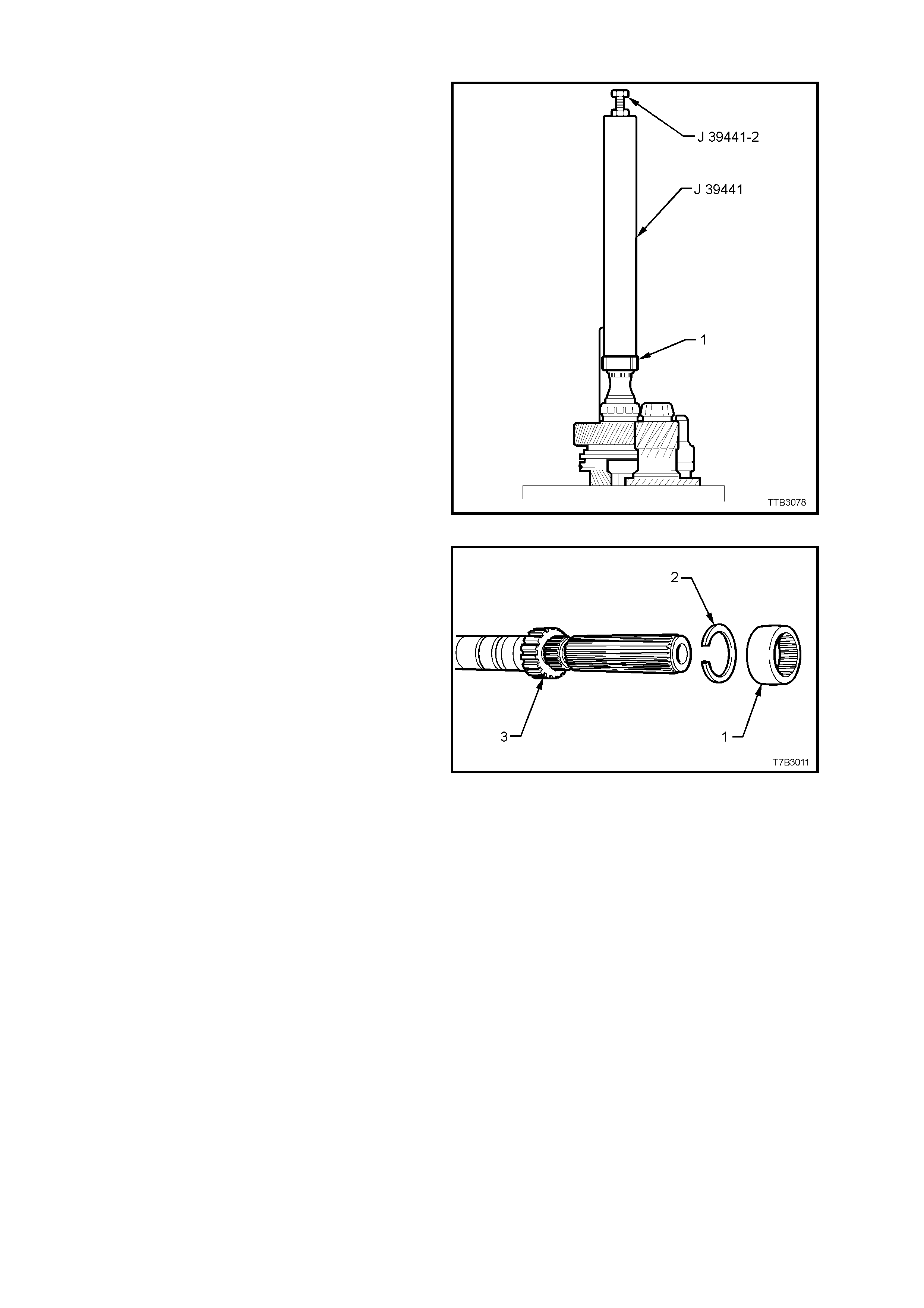

5. Assemble universal bridge puller J 8433 and

puller adaptor J 39431-1 using bolts J 39431-

2, as shown.

6. Remove 5th/6th driven gear (1), then

dismantle tools.

Figure 7B3-70

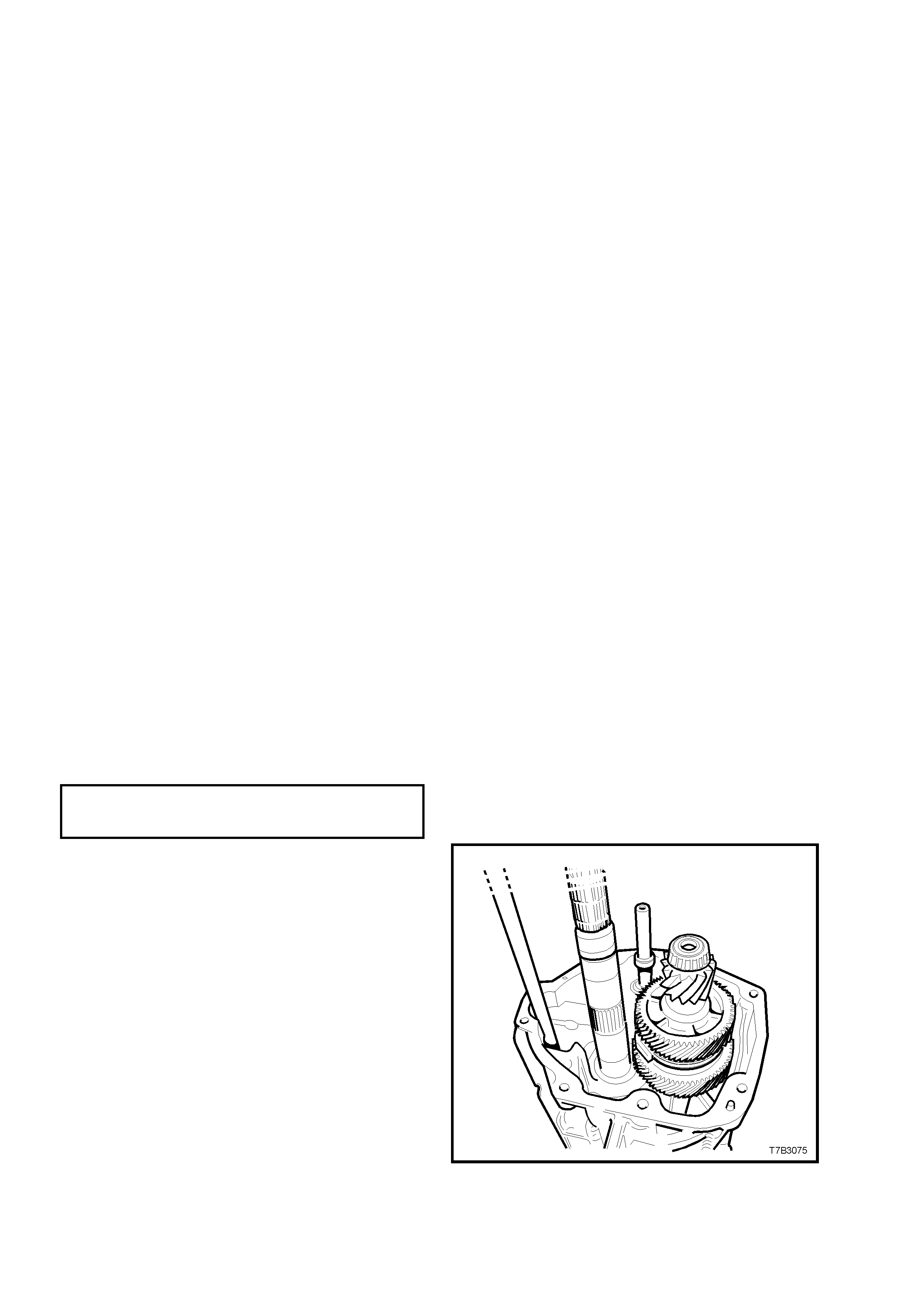

COUNTERSHAFT EXTENSION ASSEMBLY

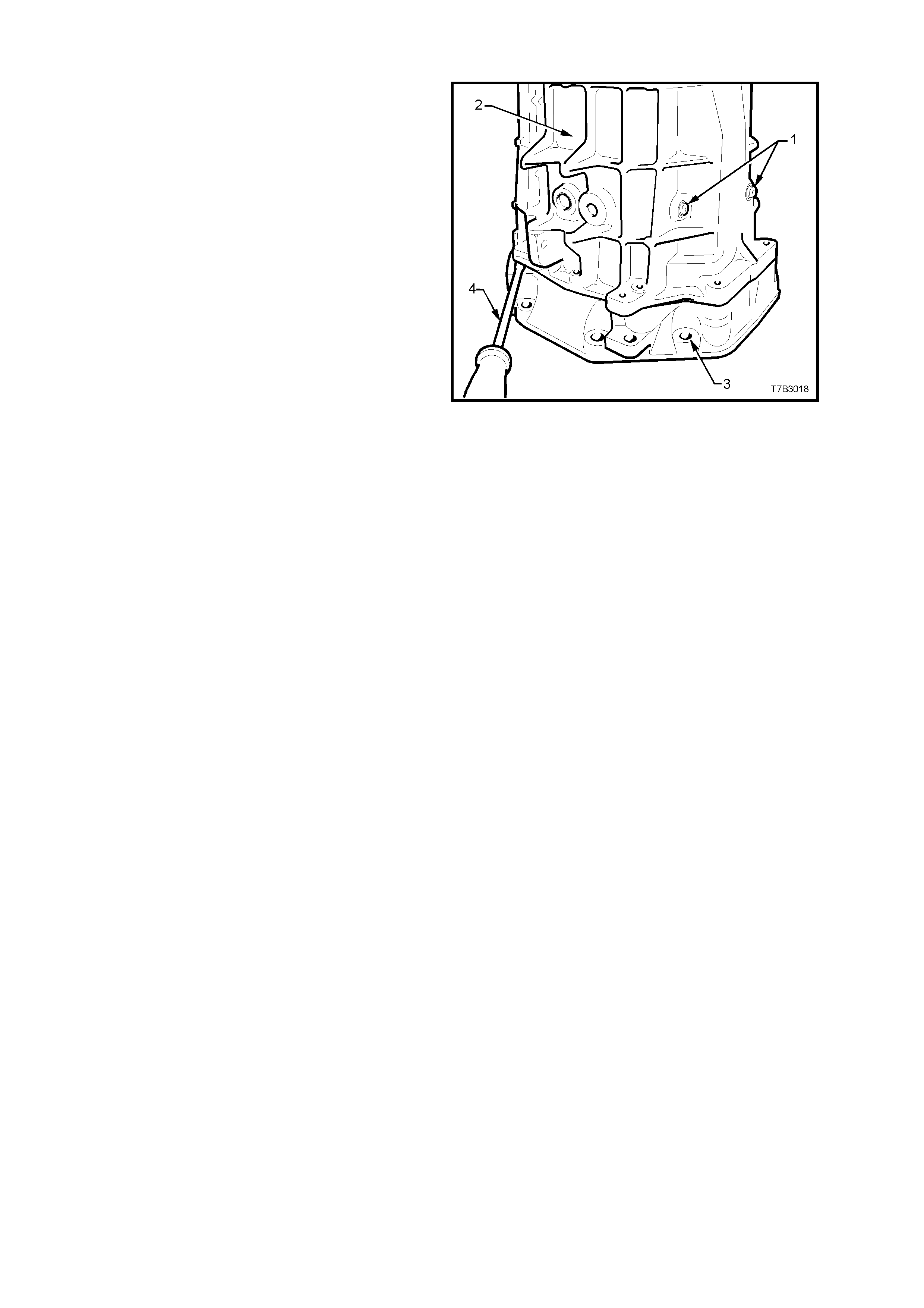

1. Remove the circlip (3) from the 5th/6th shift

rail, then rem ove the following components as

an assembly; countershaft extension (1) with

the 5th drive gear (2), selector fork (4) and

synchromesh assembly (2), all secured by the

snap ring (6).

2. Remove the following components;

a. Spacer (7).

b. 6th gear, blocker ring (8).

c. 6th drive gear (9).

d. 6th drive gear, caged needle roller

bearing (10).

e. Thrust washer (11).

Figure 7B3-71

3. Remove the 4 bolts securing the guide plate

cover to the transmission case. Use a flat

bladed screwdriver and plastic hammer to

dislodge the cover sealant, then remove the

cover.

NOTE: Be careful not to bend the cover when

breaking the sealant grip.

4. Remove the shift enhancer (4) from the

transmission case using a suitable sized

socket.

5. Using a suitable sized pin punch, remove the

roll pin (3), from the front offset lever (2).

Figure 7B3-72

TRANSMISSION CASE

1. Remove the two T40 Torx bit screws securing

the shift lever guides (1).

NOTE: Both of these screws have thread sealant

applied and will be extremely difficult to remove

unless a hot air gun is used to soften the thread

sealant prior to loosening and during removal.

2. Remove the r ever se lamp s witch f r om the s ide

of the transmission case.

3. Remove the 10 adaptor plate to transmission

case bolts from the front of the transmission

(not shown).

4. Carefully rotate the transm ission into a vertical

position, then lever the transmission case (2)

from the adaptor plate (3), using a flat bladed

screwdriver (4) in the space pr ovided, to break

the sealant seal and clear the two dowel pins.

5. Lift the transmission case upward from the

gear train and shift rail components, while

supporting the front offset lever during the

process.

NOTE: Holding the front offset lever against the

guide plate during case removal, will reduce the

possibility of the detent ball and spring from being

dislodged.

6. Referring to Figure 7B3-70, use a T40 Torx

bit, to remove the 2 screws (1) from the guide

plate (5).

NOTE: In Figure 7B3-70, the front offset lever (2)

covers the second guide plate screw.

7. Remove the guide plate (5) from the

transmission case .

Figure 7B3-73

GEAR TRAINS AND SHIFT RAILS

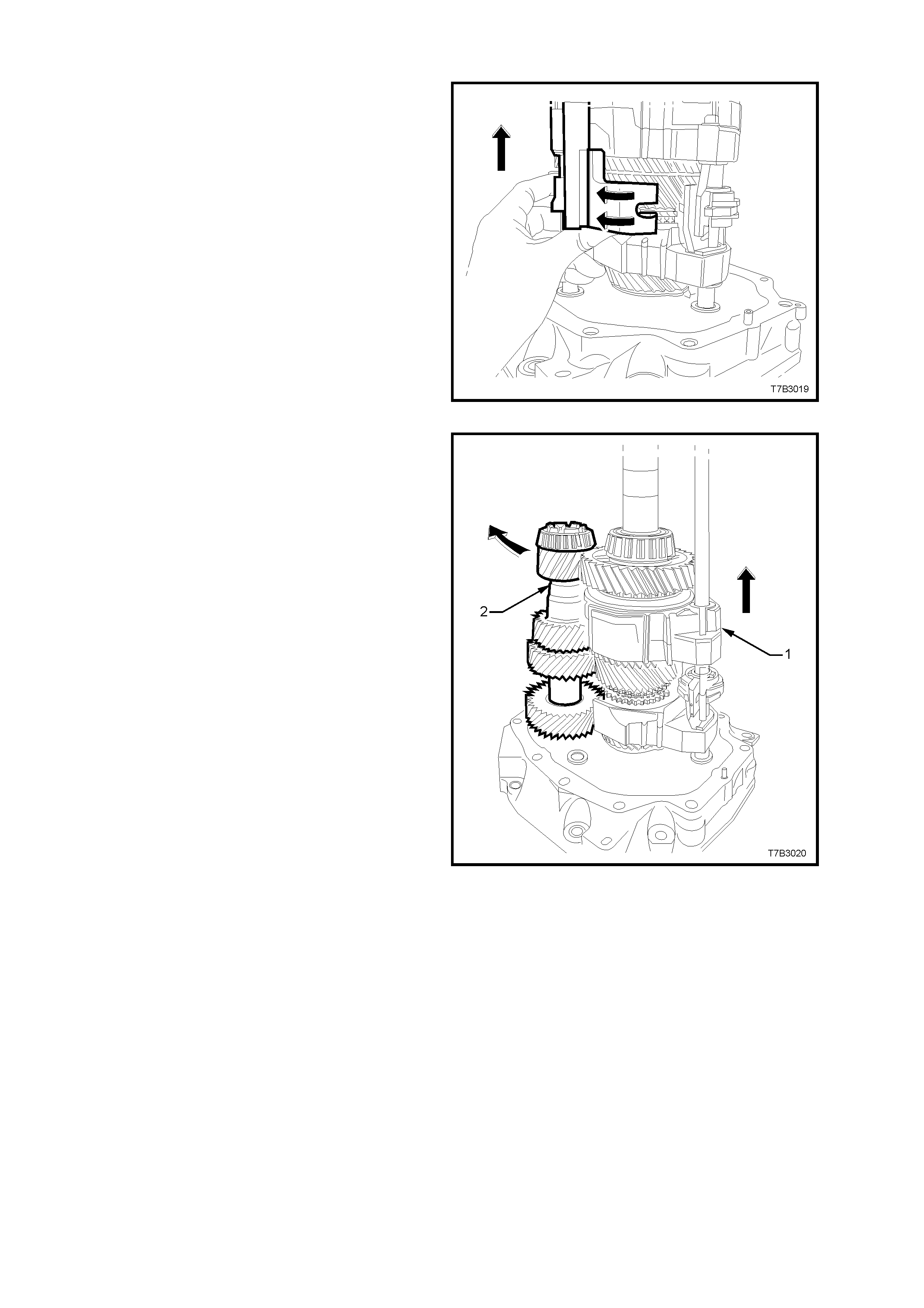

1. Rotate the 5th/6th and Reverse shift levers

from the interlock plate (curved arrows), then

lift both shift rail assemblies from the adaptor

plate.

Figure 7B3-74

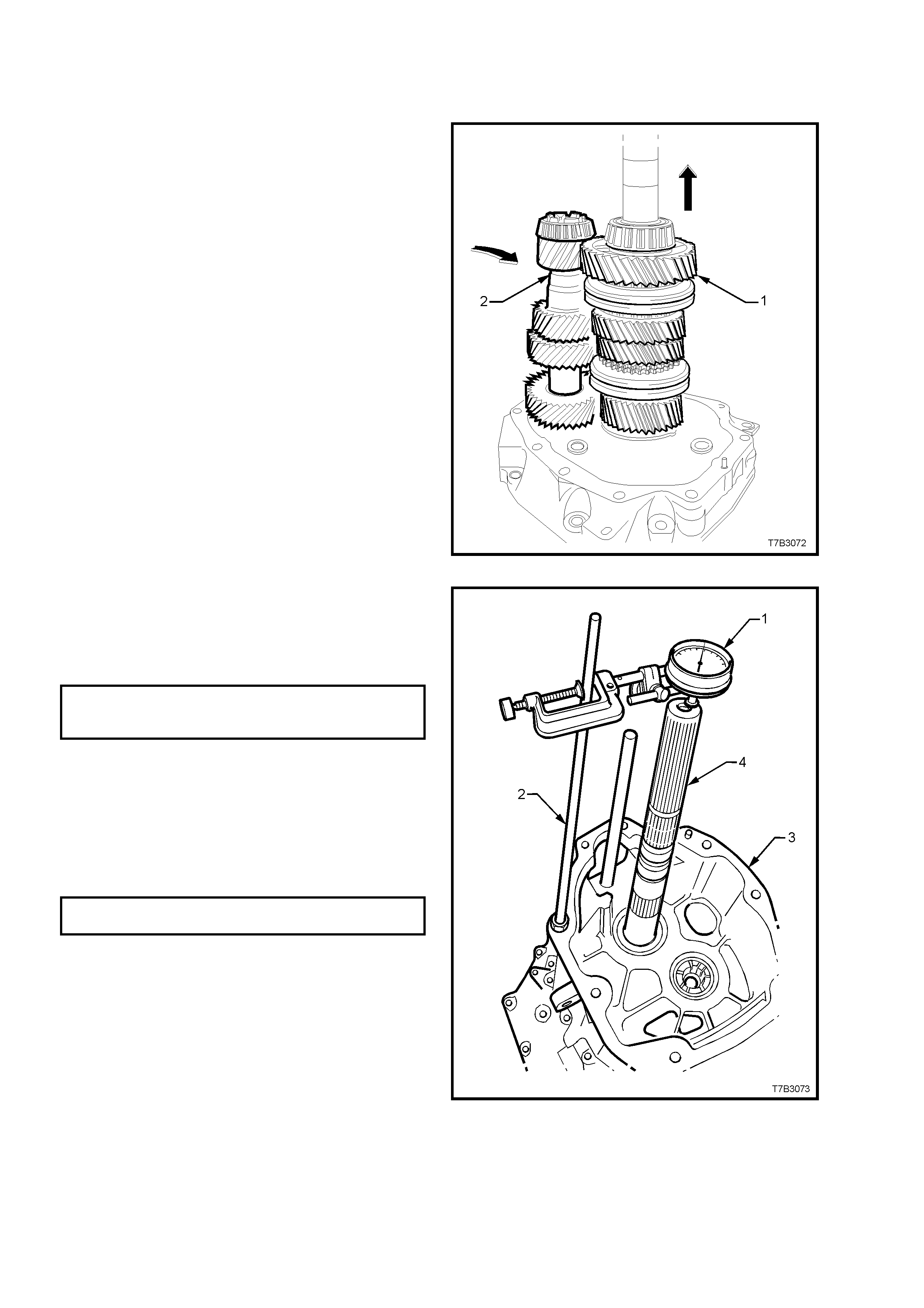

2. Lift the mainshaft and shift forks (1) to allow

counter gear (2) removal.

3. Carefully lift the mainshaft assembly with the

shift forks in place, from the input shaft and

set to one side.

4. Lift the input shaft from the adaptor plate and

set to one side.

Figure 7B3-75

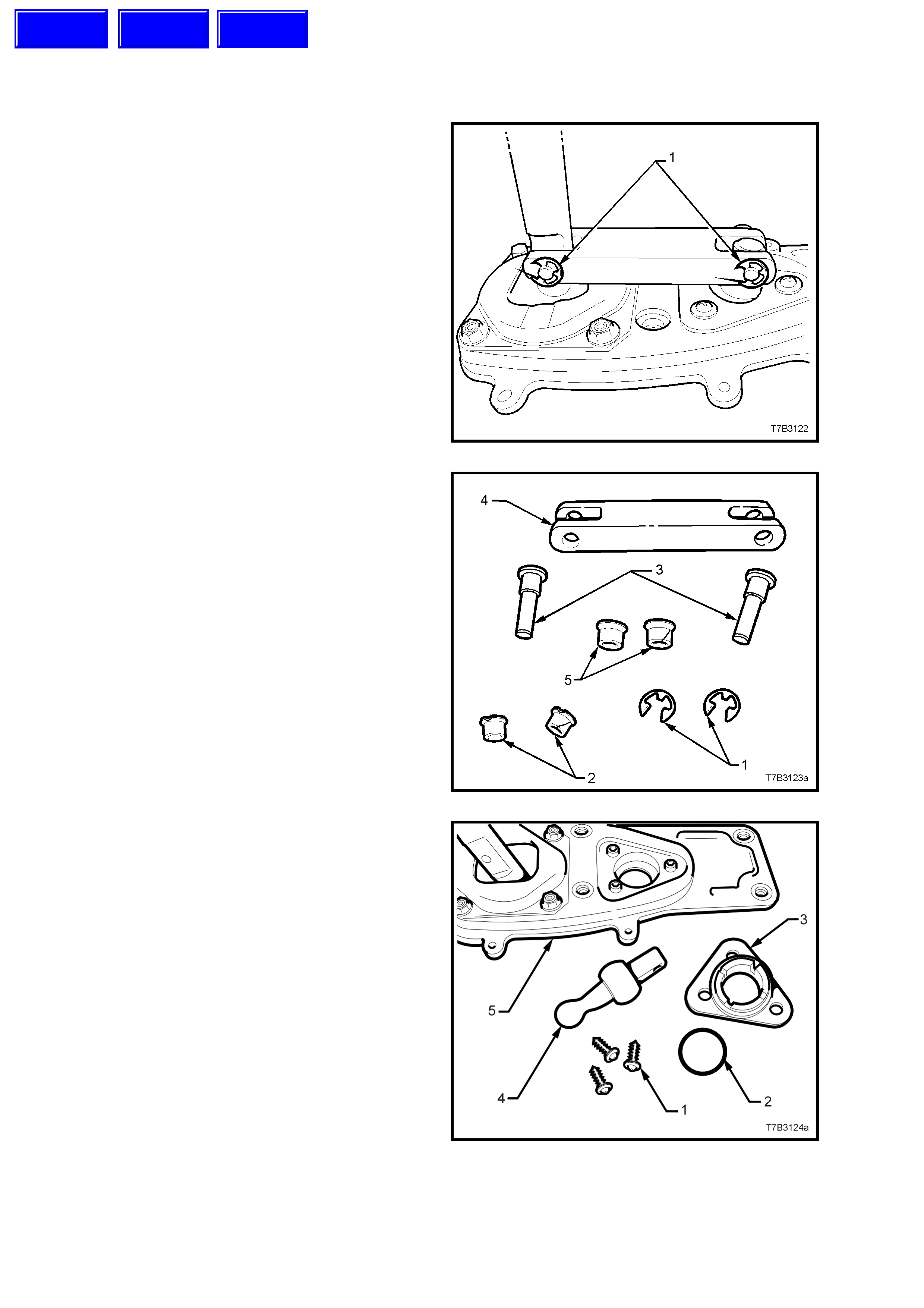

4.4 REMOTE CONTROL SHIFT MECHANISM

DISASSEMBLE

1. With the boot and dust cover removed, use a

small screwdriver to remove both ‘E’ clips (1).

CAUTION: Wear safety glasses to avoid

possible eye injury.

Figure 7B3-76

2. Tap the two pins (3) free from the bridging

piece (4). These two pins are an interference

fit into each of the two pivot pieces and must

be replaced after removal.

3. Remove both the smaller (2) and larger (5)

bushes from the bridging piece (4).

Figure 7B3-77

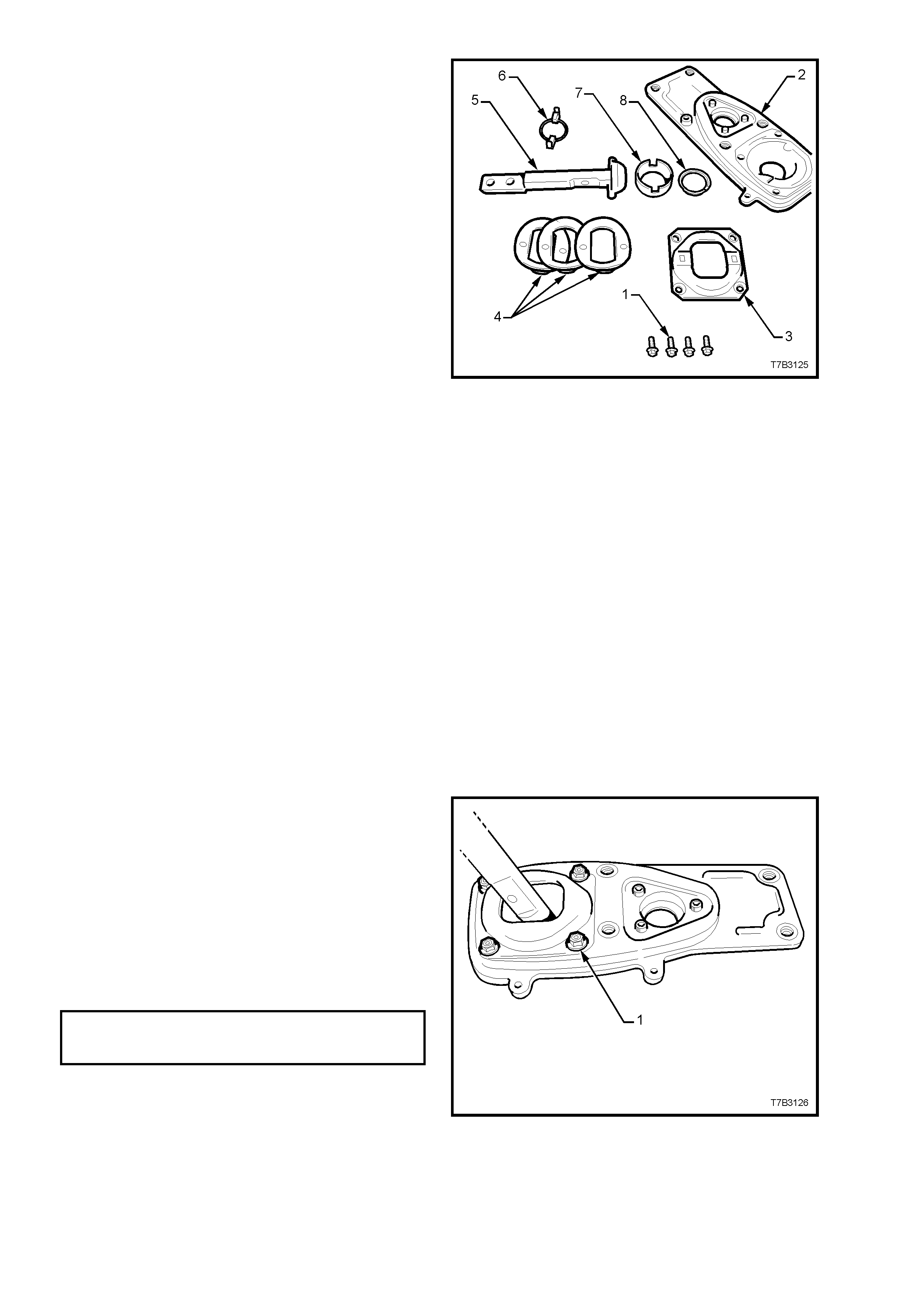

4. To disassemble the front pivot assembly,

unscrew the three self tapping screws (1),

using a Phillips No. 2 screwdriver.

5. By grasping the remote selector pivot (4), pull

the pivot (4) and seat assembly (3) from the

baseplate (5).

6. Remove the O-ring seal (2) from the seat (3).

7. Separate the selector pivot (3) from the seat

assembly (2) by supporting the seat assembly

over the open jaws of a vice assembly, then

tap the ball end of the selector pivot (3) free

from the seat (2).

Figure 7B3-78

Techline

Techline

Techline

8. The rear remote shifter assembly can be

disassembled by first removing the four plate

(3) retaining bolts (1) from the baseplate (2).

9. Remove the wave springs (4), remote shifter

shaft (5) and guide (6), from the base plate

(2).

10. Finally, remove the ball seat (7) and seat

support ring (8) from the base plate (2).

Figure 7B3-79

CLEAN AND INSPECT

Clean

After removing rubber insulating bushes and seal

to the extension housing, thoroughly wash all

components in a suitable cleaning solvent. Dry all

parts with clean, dry compressed air.

CAUTION: Wear safety glasses to avoid eye

injury.

Inspect

1. Inspect pins, bushes, ball seats and other

com ponents for wear or damage, replac ing as

required.

2. Inspect the O-ring seal at the front pivot

assembly, the cover plate insulating rubber

bushes and seal to the extension housing, for

deterioration or damage, replacing as

required.

REASSEMBLE

While reassembly is the reverse to disassembly,

there are some specific procedures such as;

1. Apply 10% molybdenum disulphide grease

such as Moybond GA 10 or equivalent (to

Holden’s Specification HN 1271) to all moving

parts in the rear remote shifter assembly.

2. Reassemble all parts in the reverse order of

disassembly.

3. Install the four bolts (1) securing the plate to

baseplate, tightening to the correct torque

specification.

REAR REMOTE SHIFT LEVER

COVER BOLT 10 - 12 Nm

TORQUE SPECIFICATION

Figure 7B3-80

4. Apply NLGI No. 4 EP greas e to the ball s ock et

of the front pivot, then reassemble by tapping

the front remote pivot into the plastic socket.

5. Install the O-ring seal to the socket, replacing

with a new part if the original is damaged.

6. Reinstall the assembly (1) to the baseplate,

install the three retaining screws and tighten

securely.

Figure 7B3-81

7. Install the bridging piece to the two remove

lever assemblies.

8. Install new bushes to the bridging piece after

lubricating with NLGI No. 4 EP grease.

9. Install NEW pivot pins to each location and tap

home with a hammer.

NOTE: These pins are designed to be an

interference fit to the front and rear remote shifter

levers and not be free floating.

10. Fit new ‘E’ clips (1) to secure each pin.

CAUTION: Wear safety glasses to avoid eye

injury.

NOTE: the dust cover and boot assembly will be

installed after the remote shifter assembly is

installed to the transmission extension housing.

Figure 7B3-82

4.5 TRANSMISSION SUB-ASSEMBLIES

DISASSEMBLE

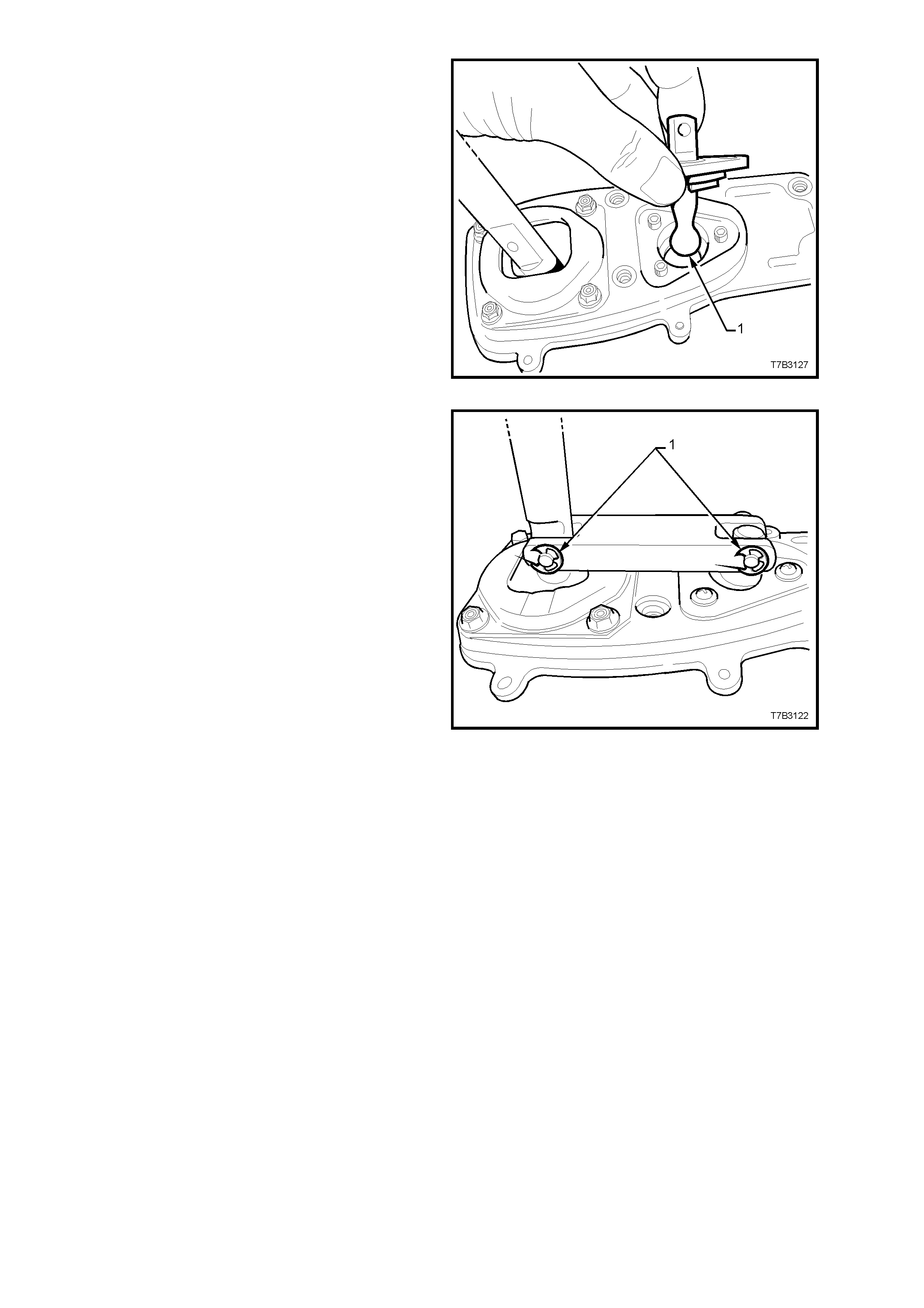

Mainshaft

NOTE: Do not mix any synchrom esh block er rings,

or any synchromesh components.

1. Remove the O-ring (1) behind the rear

mainshaft bearing (2).

2. Grasp the 1st speed gear (3) and slide from

the mainshaf t, rem oving the r ear tapered roller

bearing (2) in the process.

3. Remove the 1st speed gear, caged needle

roller bearing (4) from the mainshaft.

Figure 7B3-83

4. Remove the snap ring (1) s ecuring the 1st/2nd

synchromesh assembly (6).

5. Remove the thrust washer (2), inner cone (3),

friction cone (4), and blocker ring (5) from the

1st/2nd synchromesh assembly (6).

Figure 7B3-84

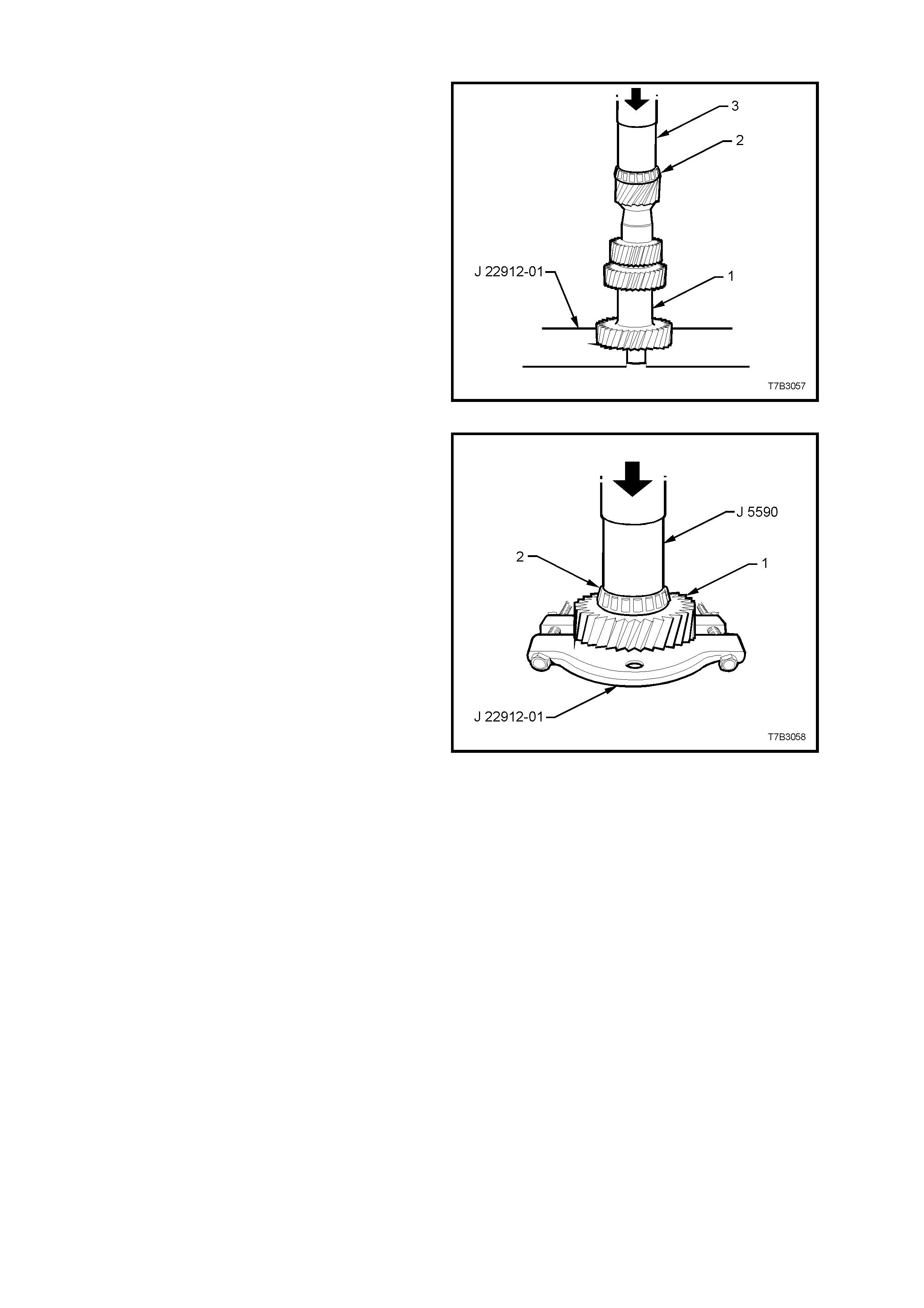

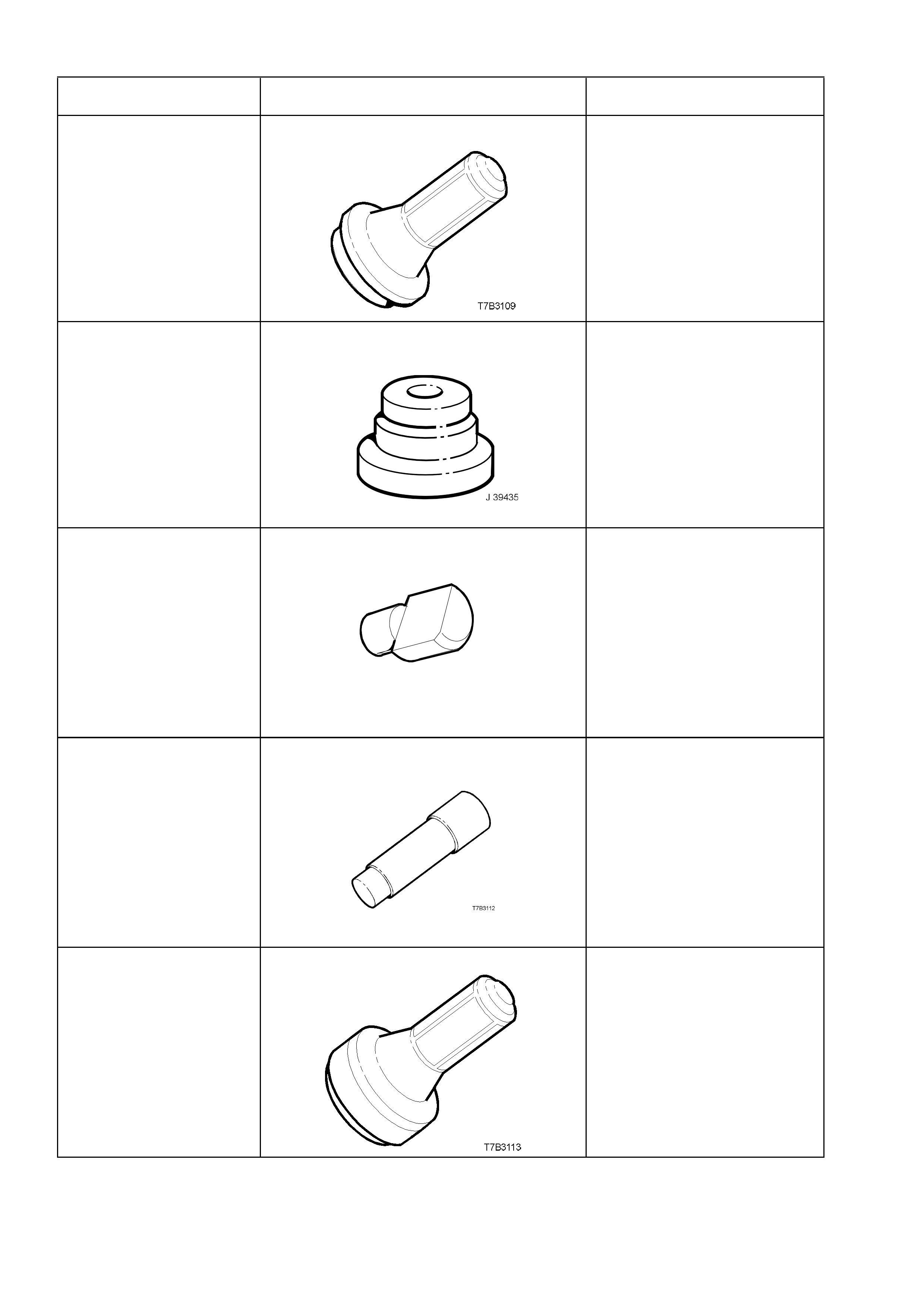

6. Install split press plates J 36513, with the flat

side (side A) against the 2nd speed constant

mesh gear (3).

7. Press the mainshaft (1) from the 2nd speed

constant mesh gear (3) and synchromesh

assembly (2). The components of the 2nd

speed synchromesh unit (2nd speed blocker

ring, friction cone, 2nd speed inner cone and

thrust washer), will also be removed in this

operation.

8. Remove the 2nd speed gear caged needle

roller bearing from the mainshaft.

Figure 7B3-85

9. Remove the snap ring securing the 3rd/4th

synchromesh assembly.

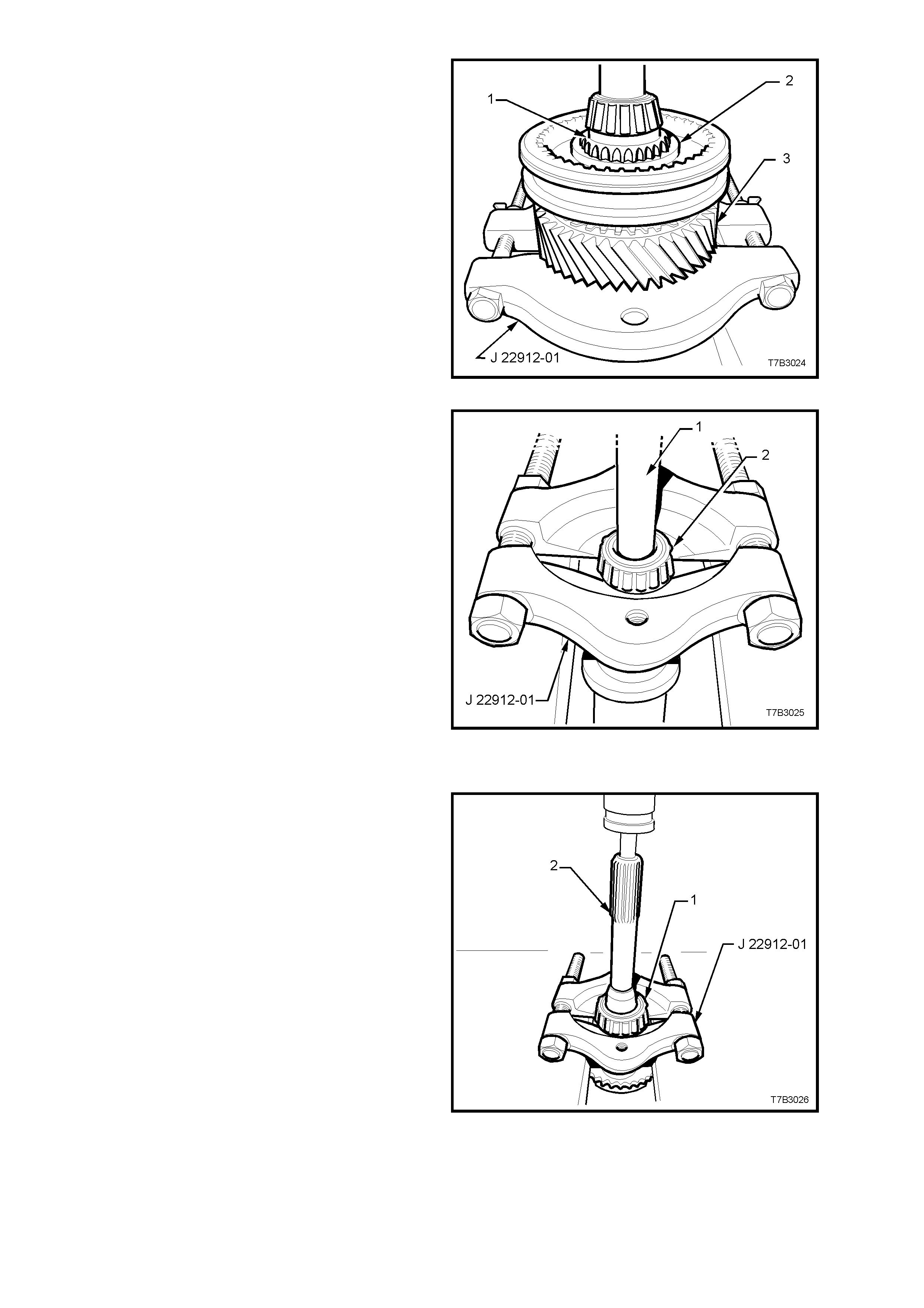

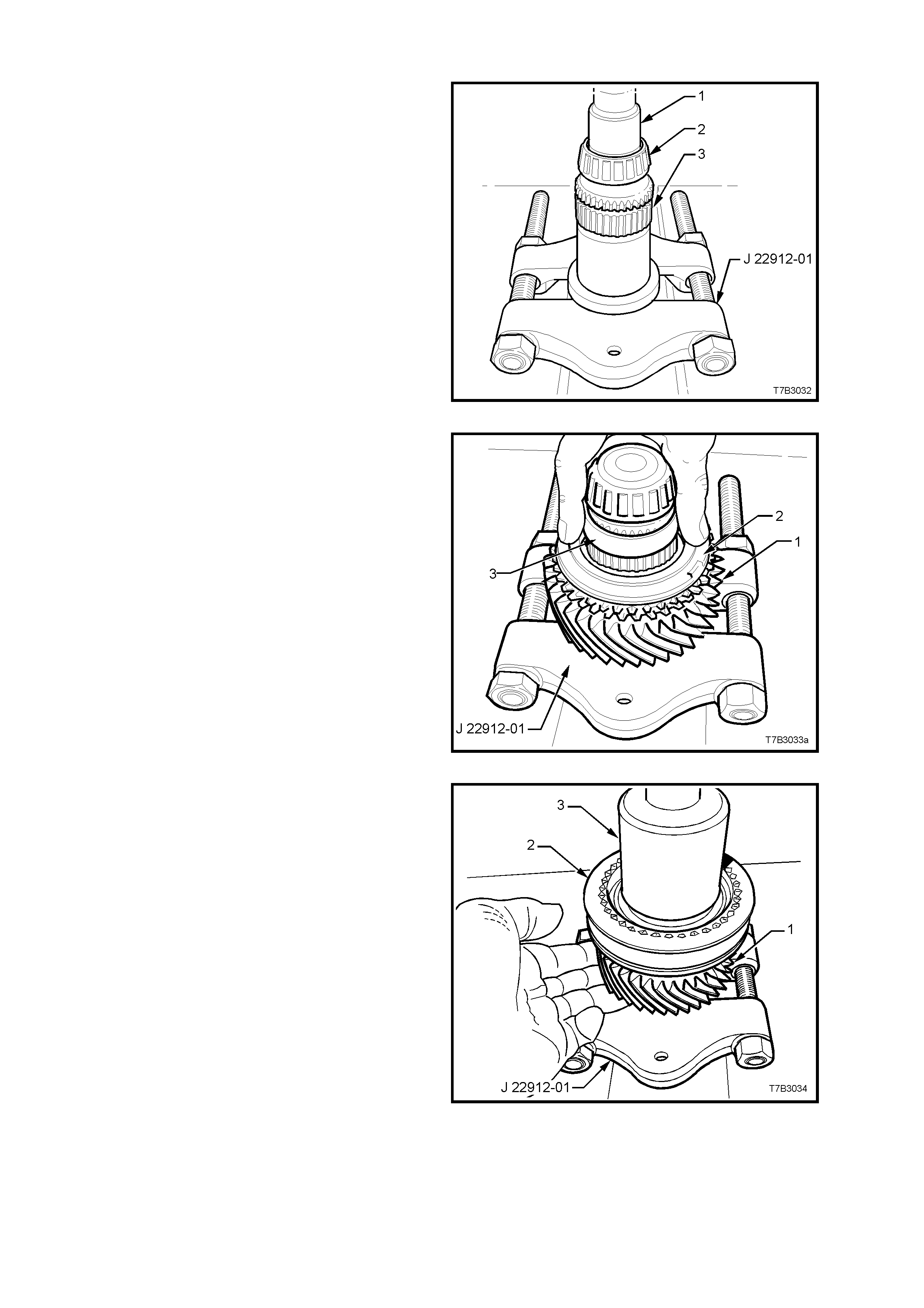

10. Install split press plates J 22912-01 with the

flat side against the 3rd speed constant mesh

gear (3). Press the mainshaft (1) from the

3rd/4th synchromesh assembly (2). In the

process, the 3rd speed constant mesh gear

(3), 3rd speed blocker ring, friction cone, inner

cone and thrust washer will also be removed.

11. Remove the 3rd speed gear caged needle

roller bearing from the mainshaft.

Figure 7B3-86

12. Install split press plates J 22912-01 under the

pilot bearing (2) installed on the nose of the

mainshaft, tightening the bolts to secure.

Press the bearing (2) from the mainshaft,

using a suitable sized drift (1) (or socket

extension). Discard the bearing.

NOTE: Only remove this bearing if it is to be

replaced, as damage to the bearing during the

removal process will most likely occur.

Figure 7B3-87

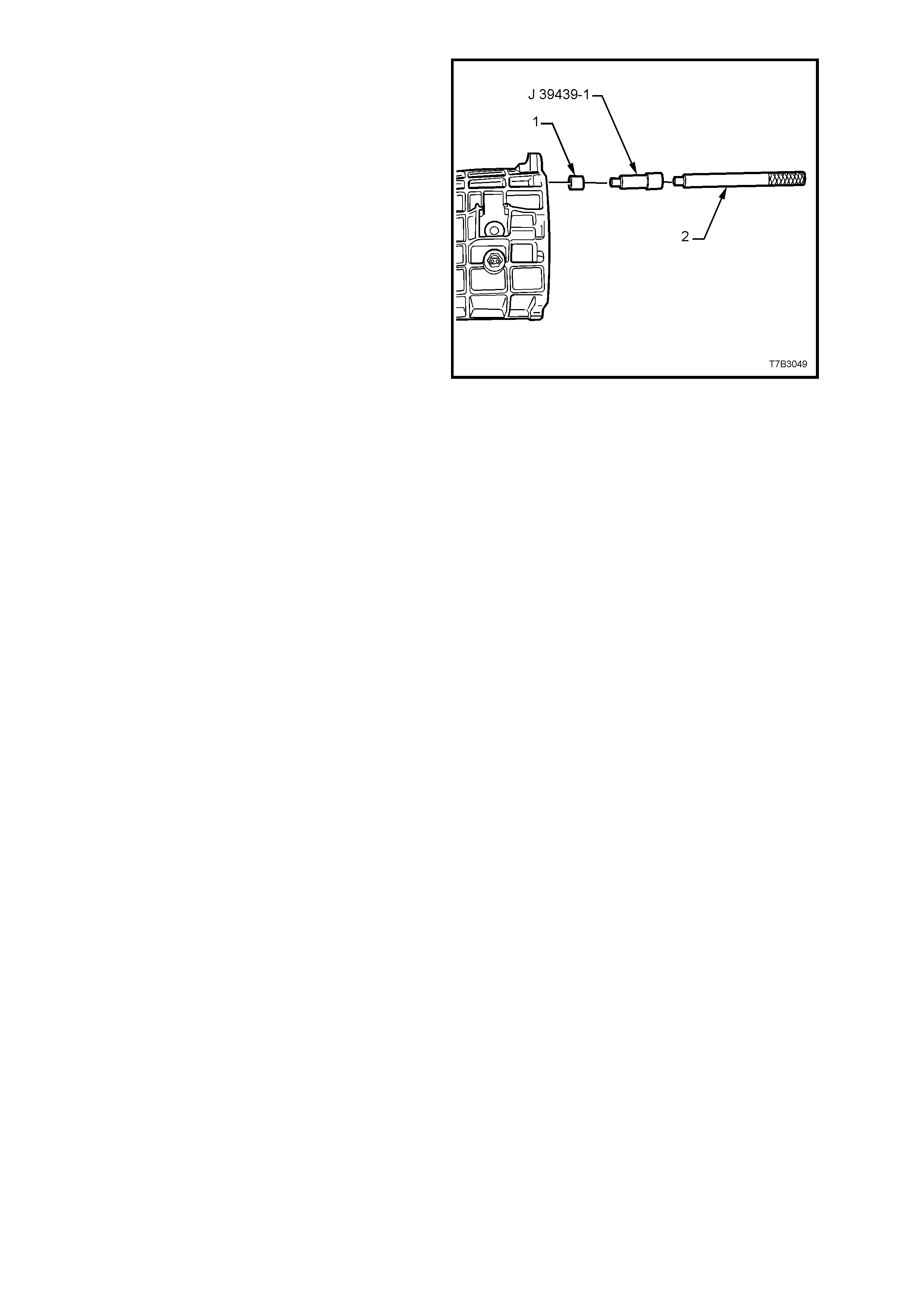

Input Shaft

NOTE: Only remove the input shaft bearing or the

pilot bearing cup, if these components are to be

replaced.

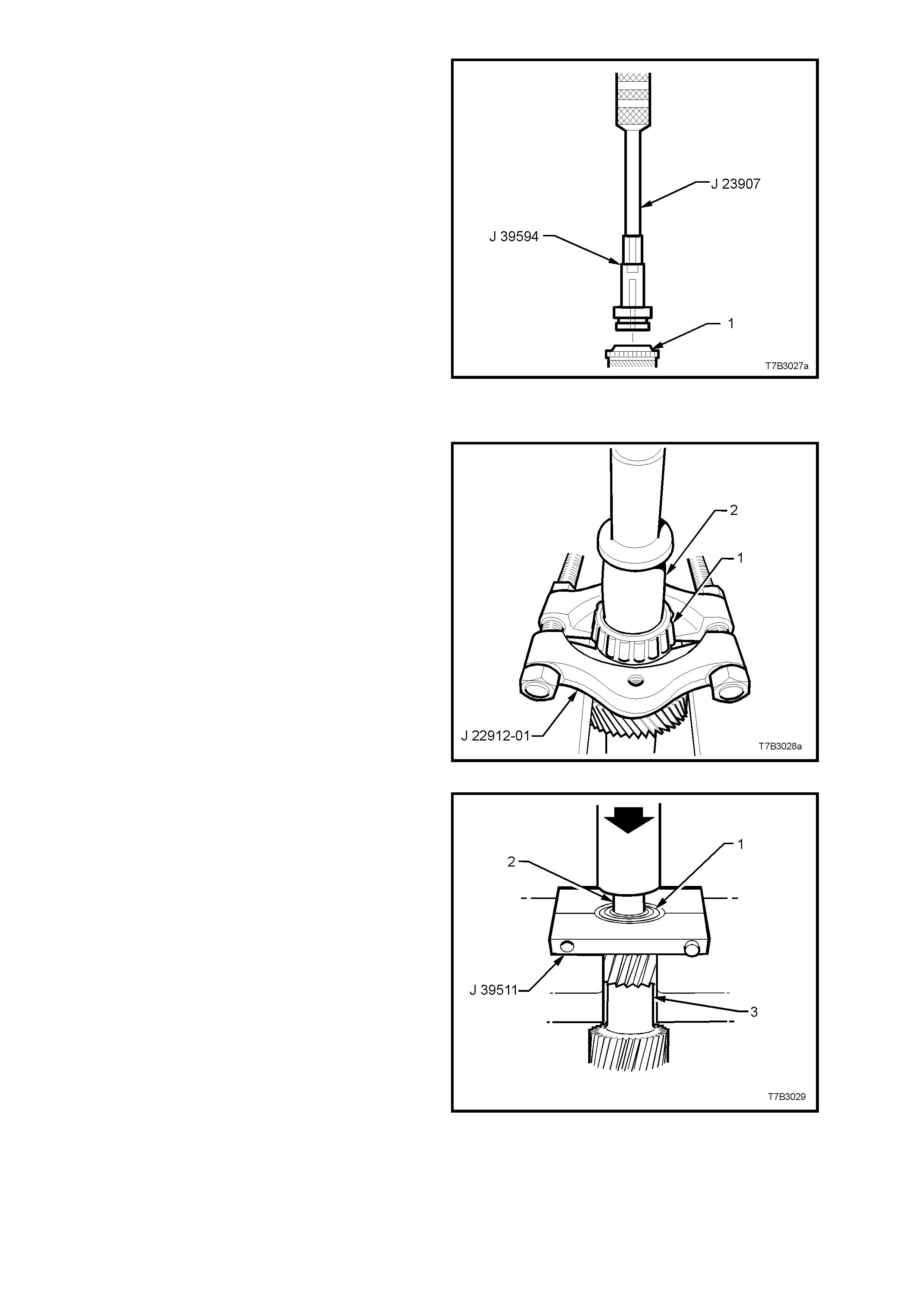

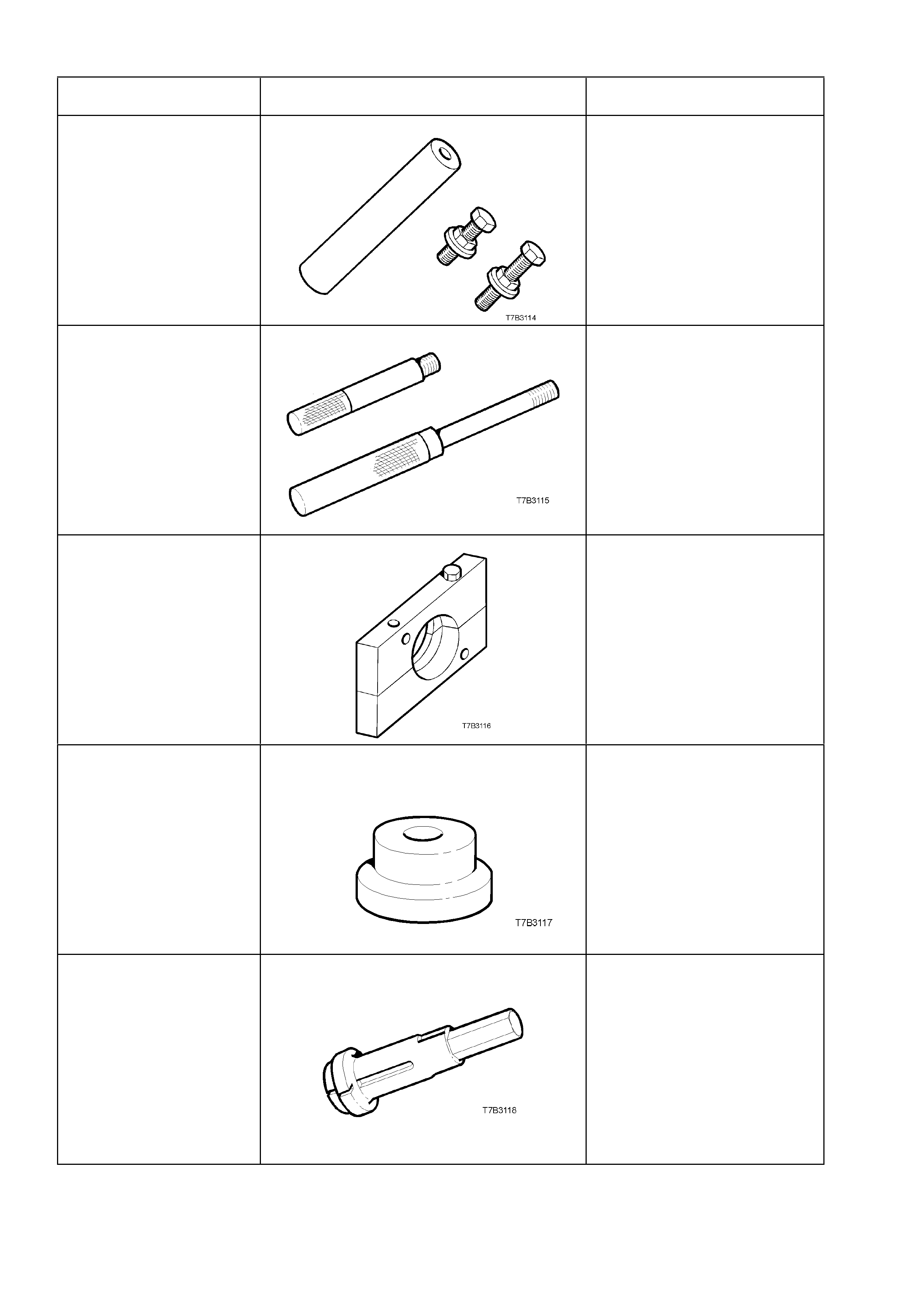

1. Install split press plates J 22912-01 under the

input shaft bearing (1), tightening the bolts to

secure.

2. Press the bearing (1) from the input shaft (2).

3. Discard the removed bearing (1).

Figure 7B3-88

4. After assembling bearing remover J 39594 to

slide hammer J 23907, remove the front

mains haft bear ing cup f rom the input shaf t ( 1).

Discard the removed bearing cup.

Figure 7B3-89

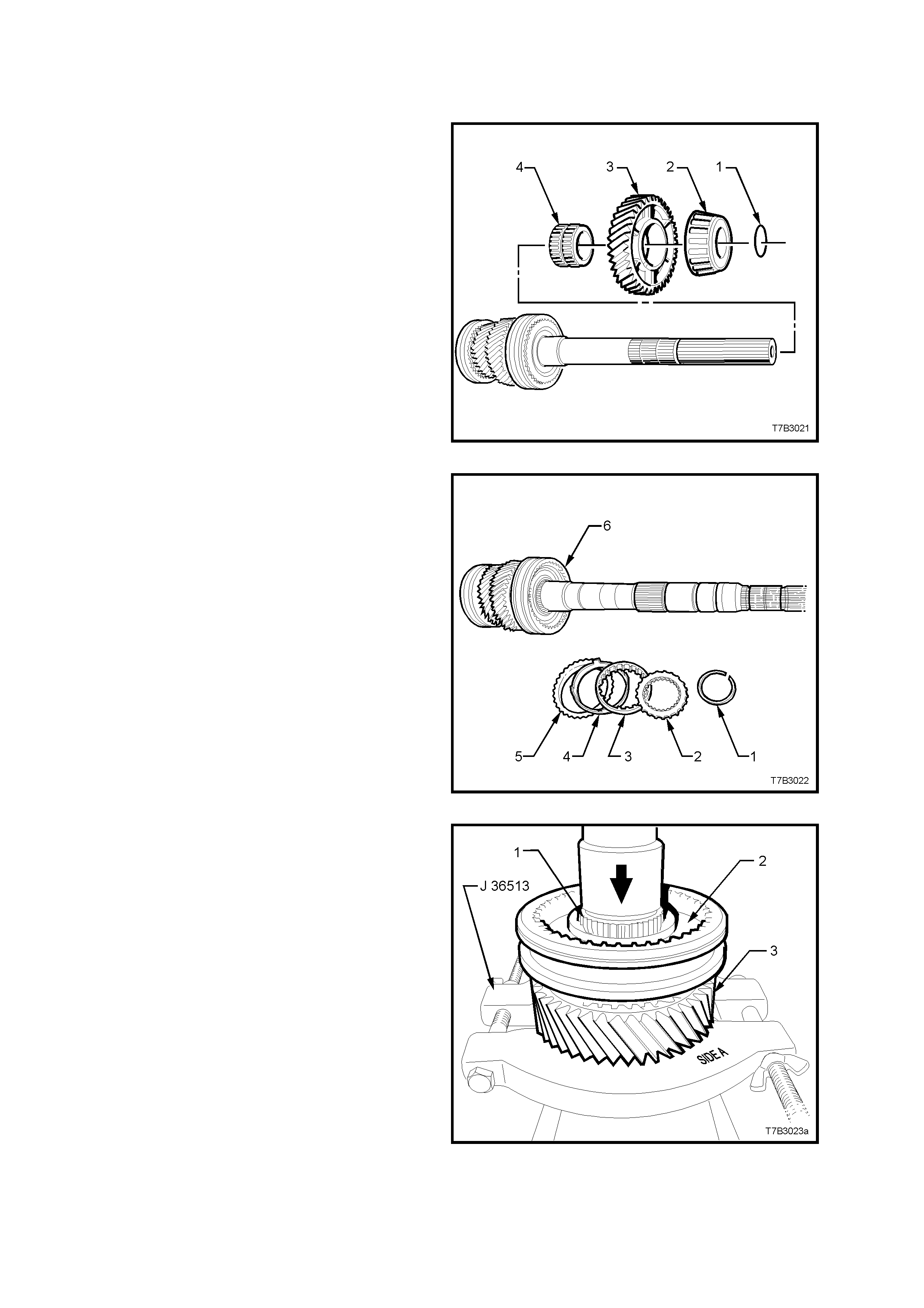

Countershaft Gear

NOTE: Only remove either or both of the

countershaft bearing/s if replacement is required,

as damage will result from the removal procedure.

1. For the rear taper roller bearing (1);

a. Install press plates J 22912-01 under the

taper roller bearing (1), tightening the

bolts to secure.

b. Press the bearing (1) from the

countershaft gear, using a suitable size

drift (2) (or socket).

c. Discard the removed bearing.

Figure 7B3-90

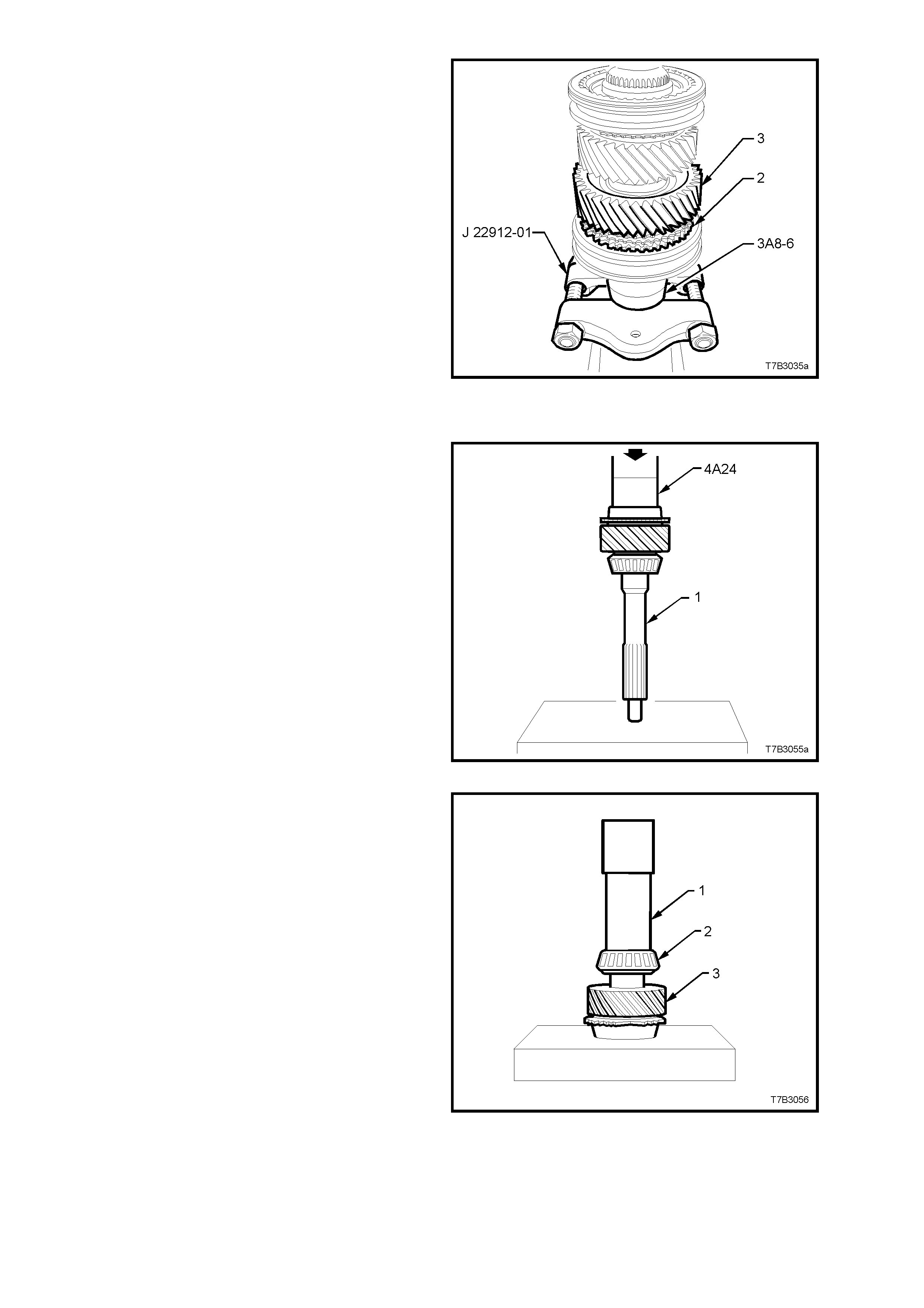

2. For the front taper roller bearing;

a. Install split press plates J 39511 under

the front countershaft gear bearing (1),

tightening the bolts to secure.

b. Press the bearing (1) from the

countershaft gear (3), using a suitable

size drift (2) (or socket).

c. Discard the removed bearing.

Figure 7B3-91

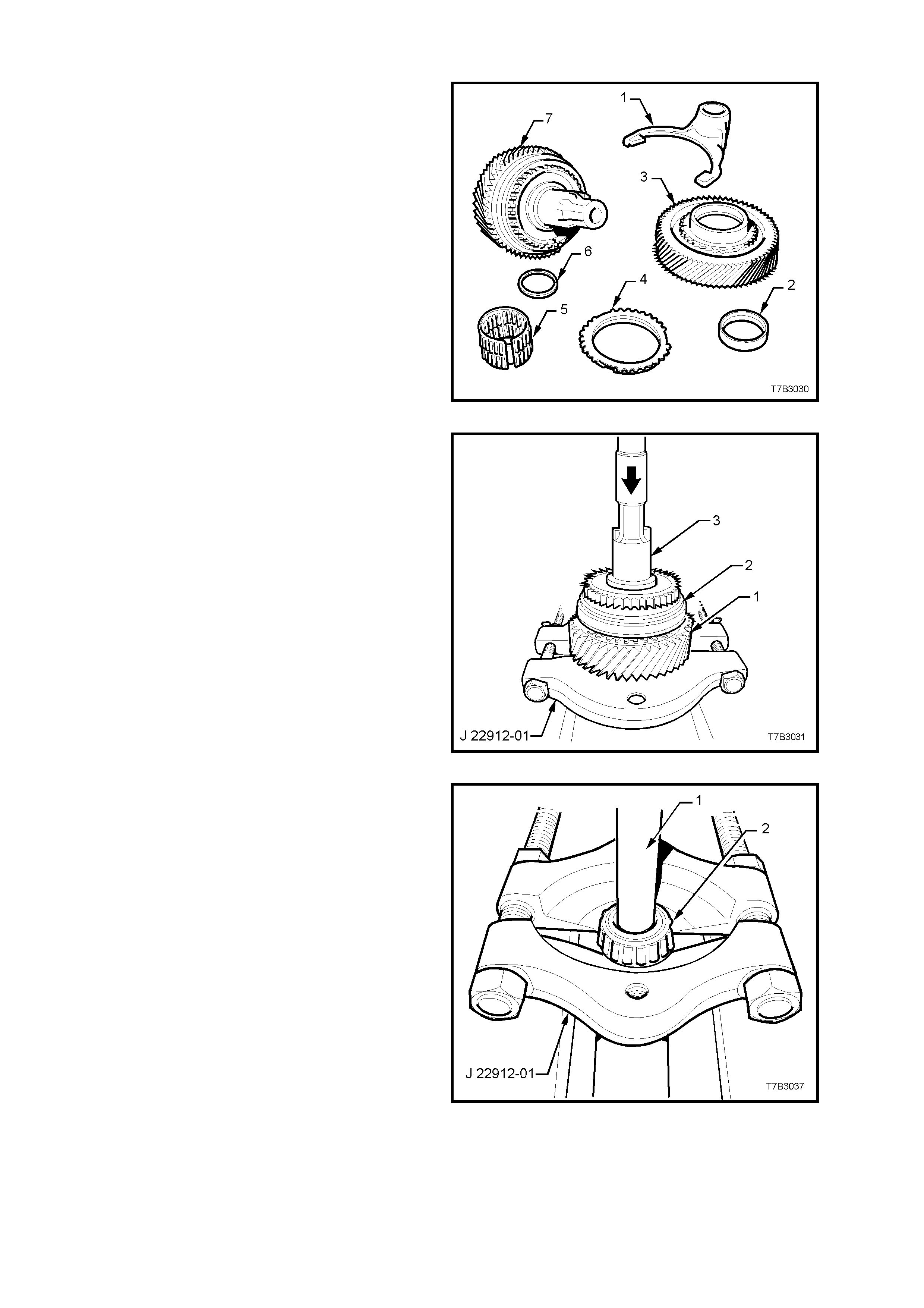

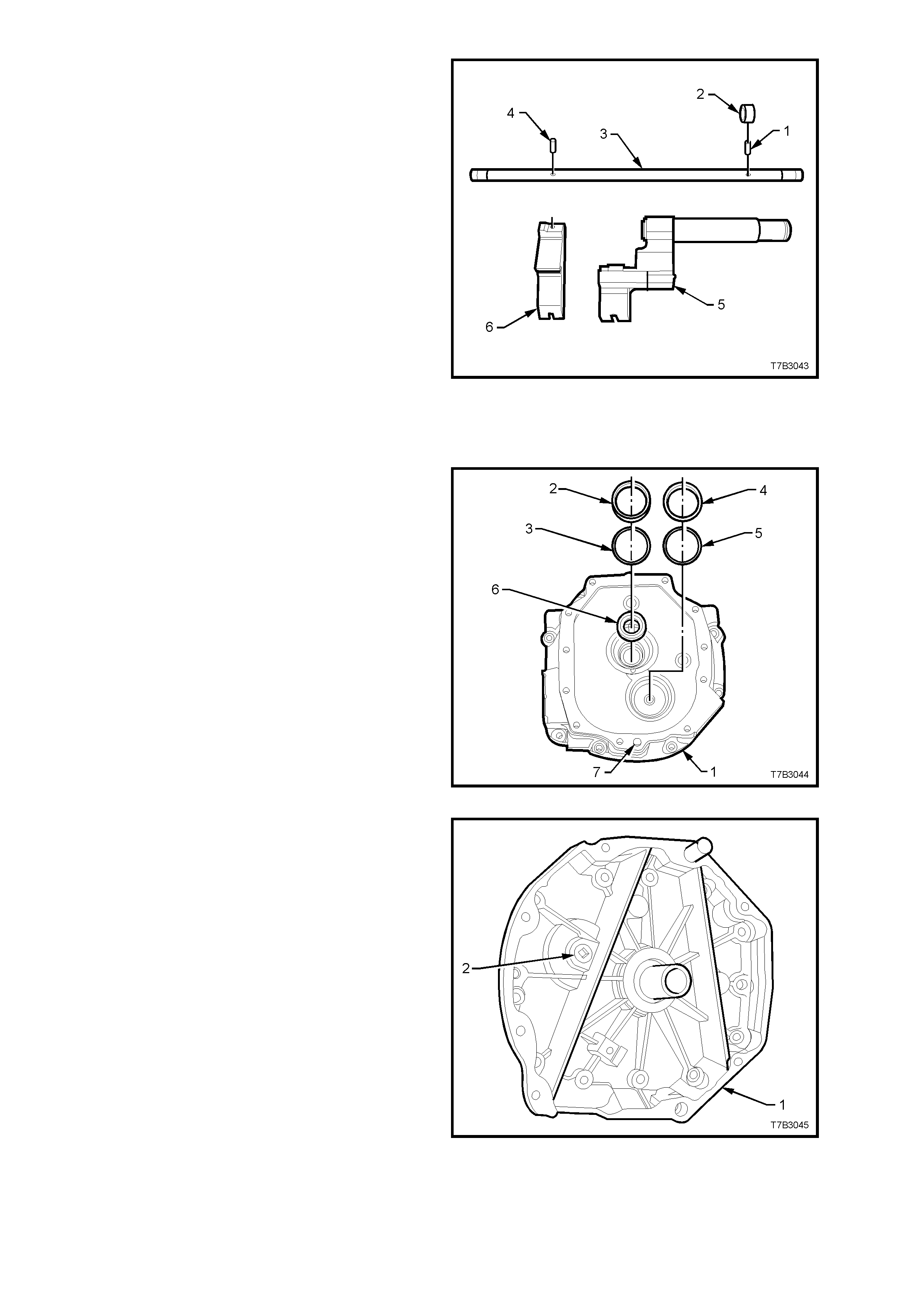

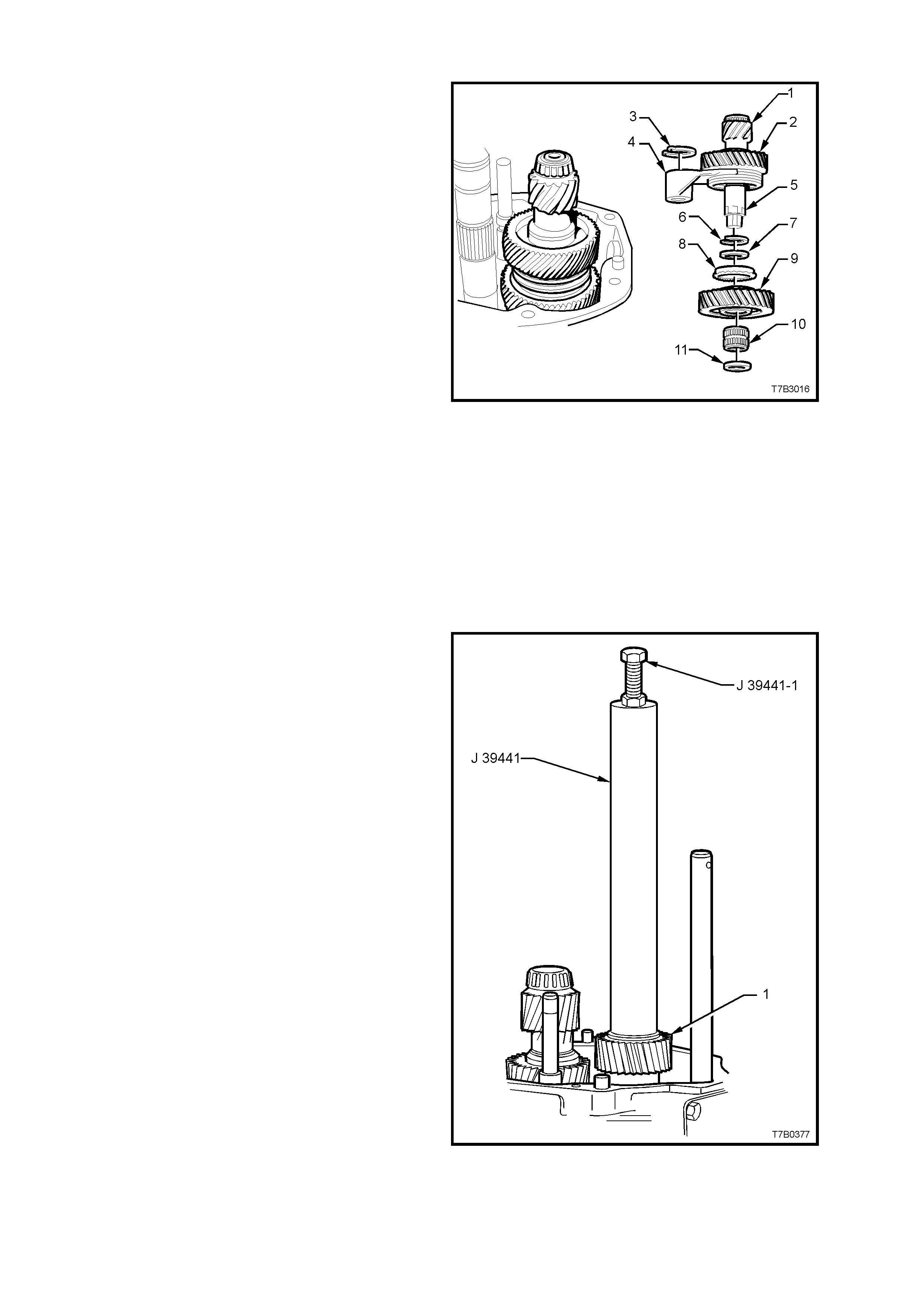

Countershaft Extension

1. Remove the following components from the

countershaft gear extension (7);

a. 5th/6th gear shift fork (1)

b. Thrust washer (may be retained on

countershaft gear) (2).

c. 6th speed drive gear (3).

d. Synchromesh blocking ring (4).

e. Caged needle roller bearing (5).

f. Spacer (6).

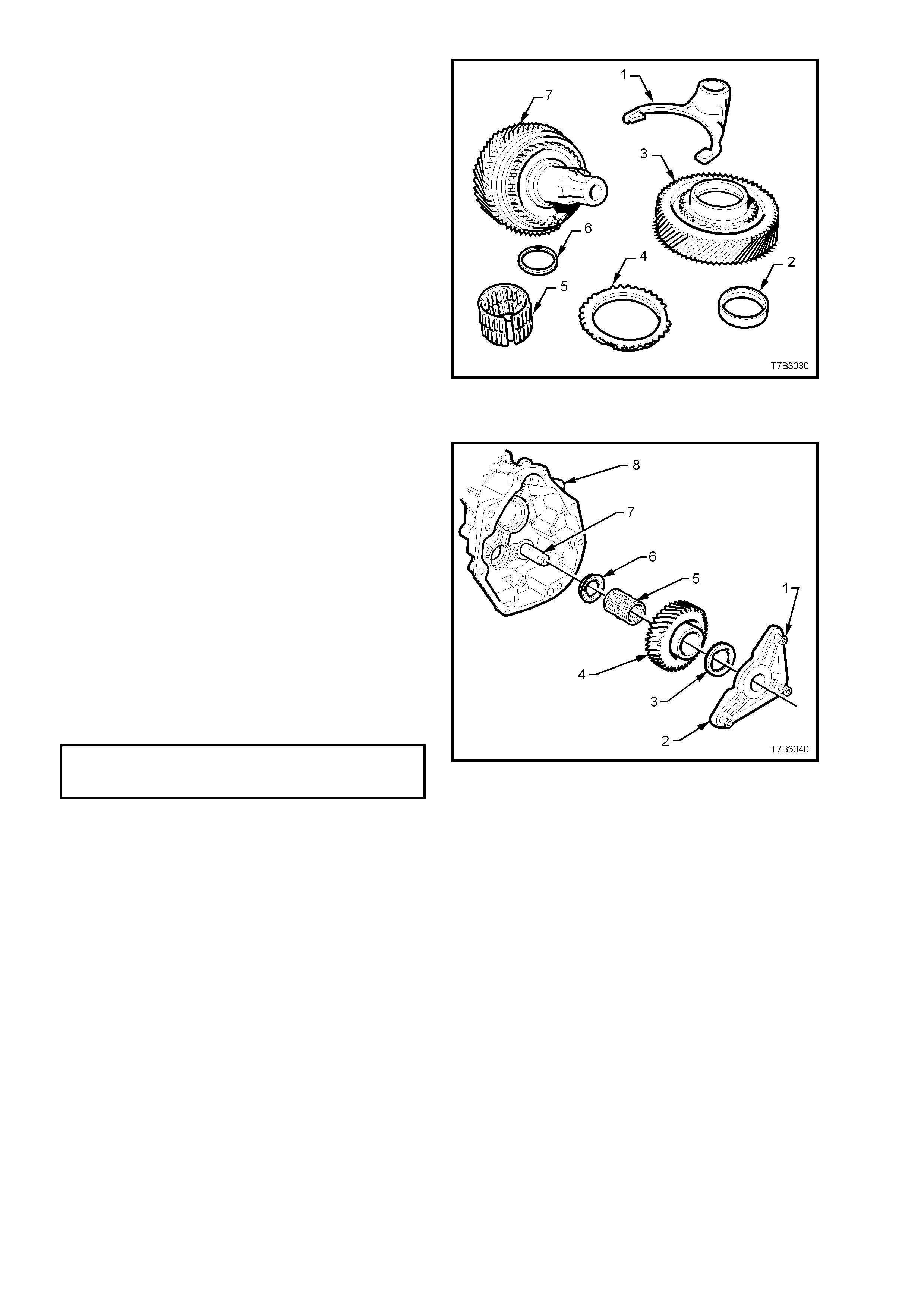

Figure 7B3-92

2. Remove 5th/6th gear synchromesh assembly

snap ring.

3. With the flat sides of press plates J 22912-01

under the 5th speed drive gear (1), press the

gear and synchromesh assembly (2) from the

countershaft extension shaft (3), using a

suitable size drift.

Figure 7B3-93

4. Install split press plates J 22912-01 under the

tapered roller bearing (2), tightening the bolts

to secure.

5. Press the bearing (2) from the countershaft

extension, using a suitable sized drift (1) (or

socket extension). Discard the removed

bearing.

NOTE: Only remove this bearing if it is to be

replaced, as damage to the bearing during the

removal process will occur.

Figure 7B3-94

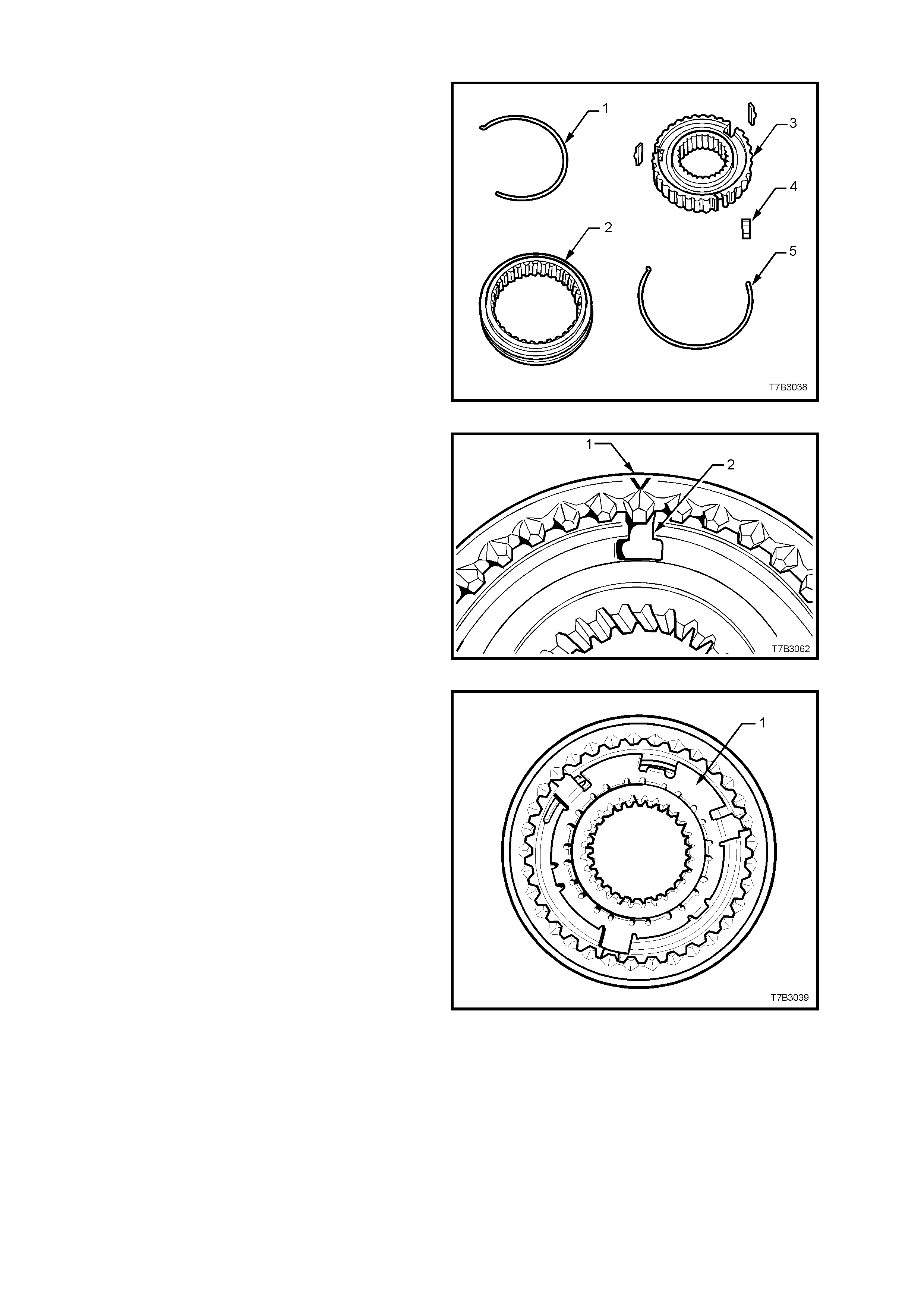

Synchromesh Assemblies

NOTE: Th is operation is not recom mended, unles s

considered to be absolutely necessary. If

disassembly is required, then extreme care must

be taken to identify each component and it’s exact

location, using liquid paper or a felt tipped pen for

the purpose.

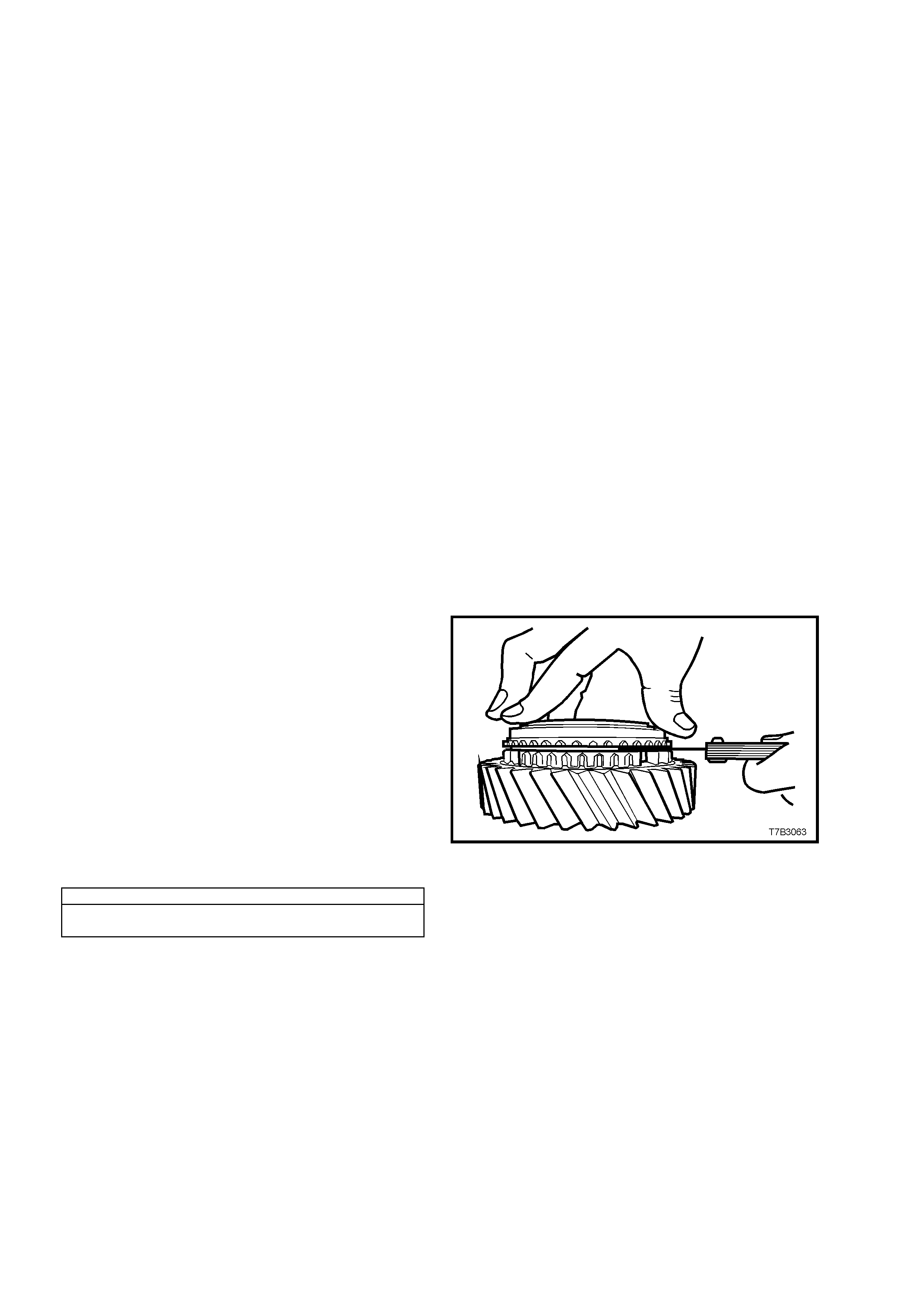

All Assemblies Except Reverse Gear

1. Using a small screwdriver, remove the

synchroniser springs (1 and 5).

CAUTION: Wear safety glasses to avoid eye

injury.

Figure 7B3-95

2. Note the location of the synchromesh

assembly ring ‘V’ mark (1) to the key location

in the hub (2), then slide the ring from the hub.

Figure 7B3-96

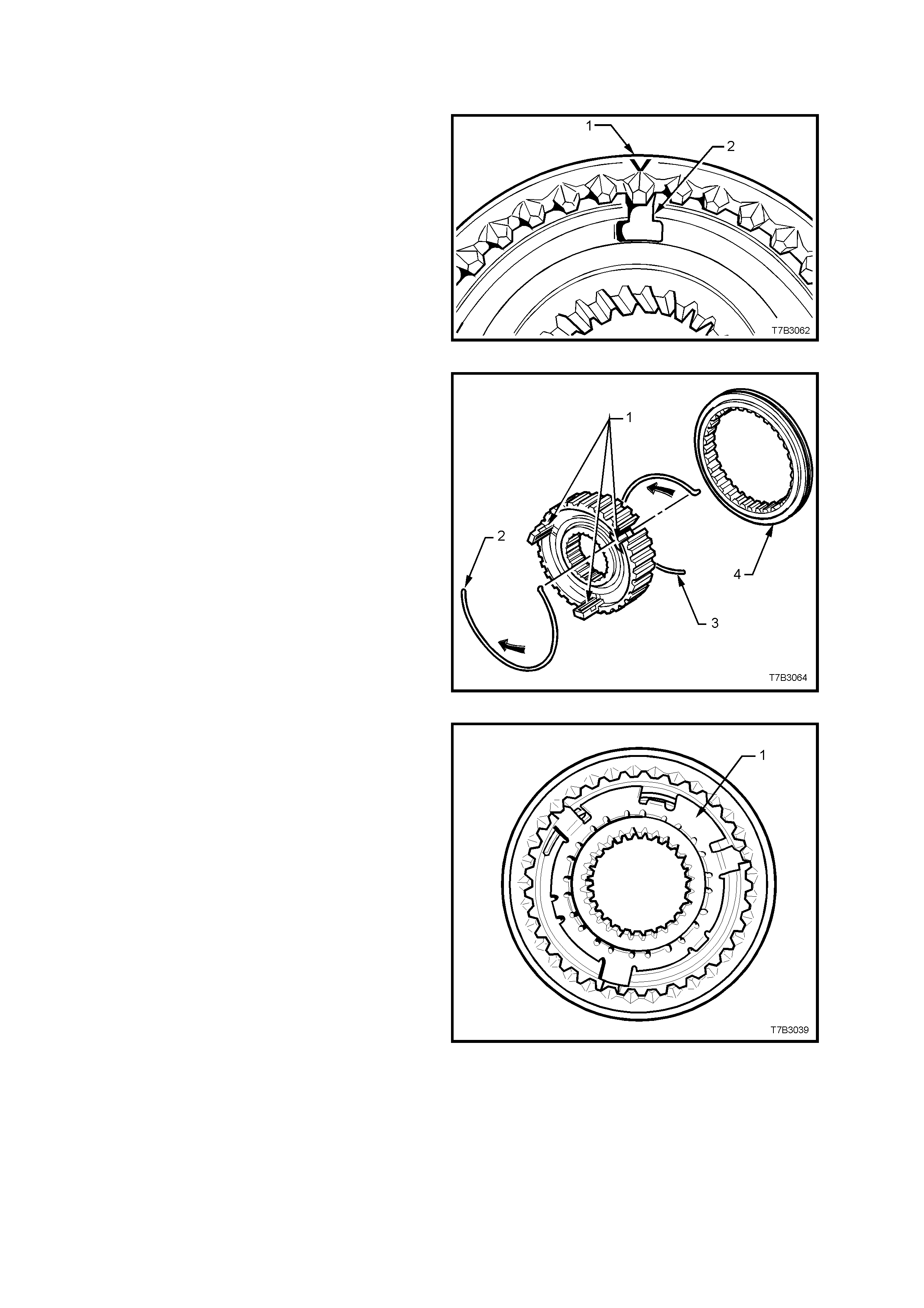

Reverse Gear Synchromesh Assembly

1. Using a small screwdriver, remove the

synchroniser spring from the reverse gear

side, taking care to avoid eye damage.

2. Note the location of the sy nchromesh

assembly ring mark (‘V’) to the key location in

the hub, then slide the ring from the hub.

3. Remove the three keys.

4. Remove the synchromesh key retainer (1),

using a pin punch through the hub key slots.

Discard the retainer.

5. Remove the second synchroniser spring,

using a small bladed screwdriver.

Figure 7B3-97

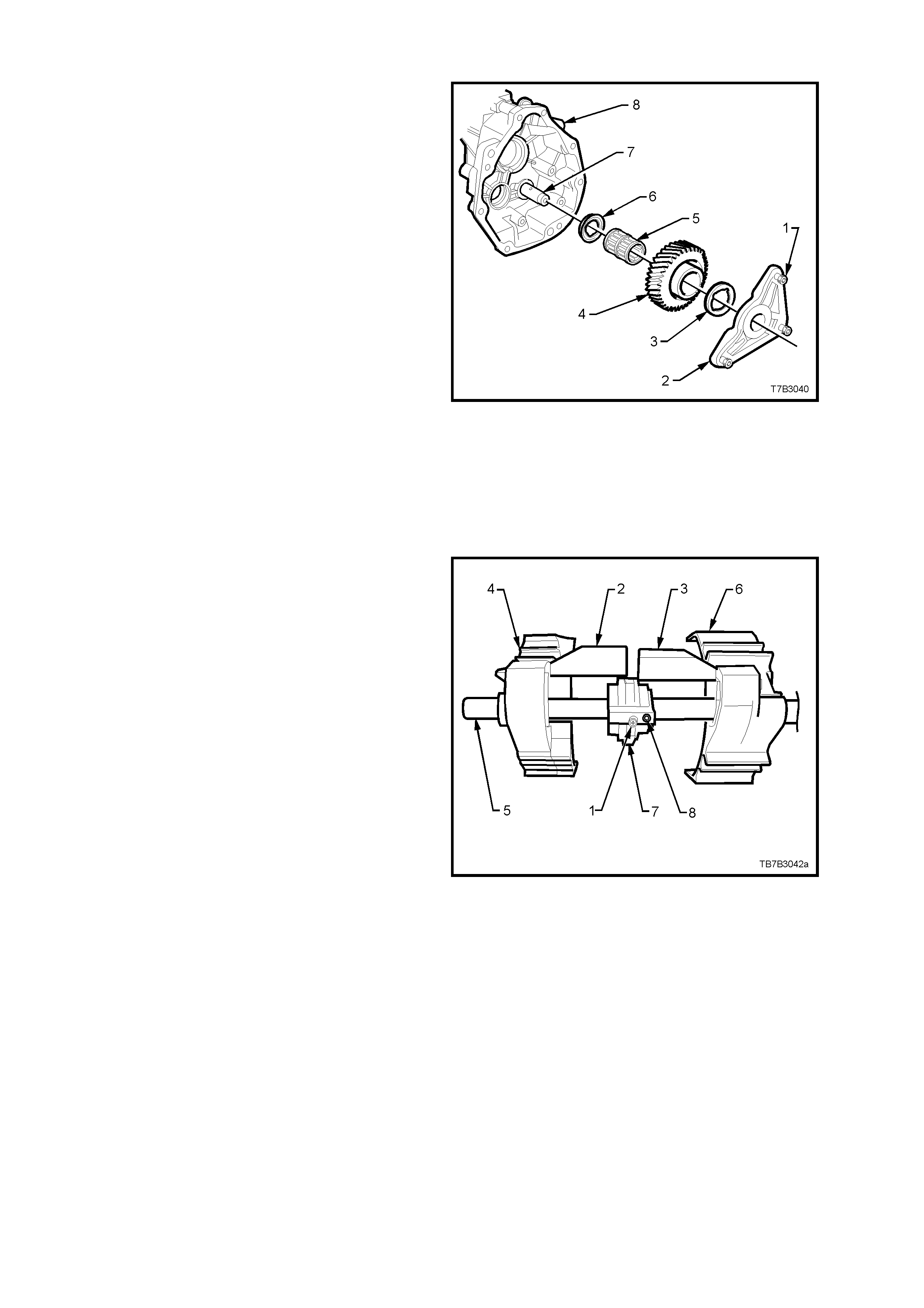

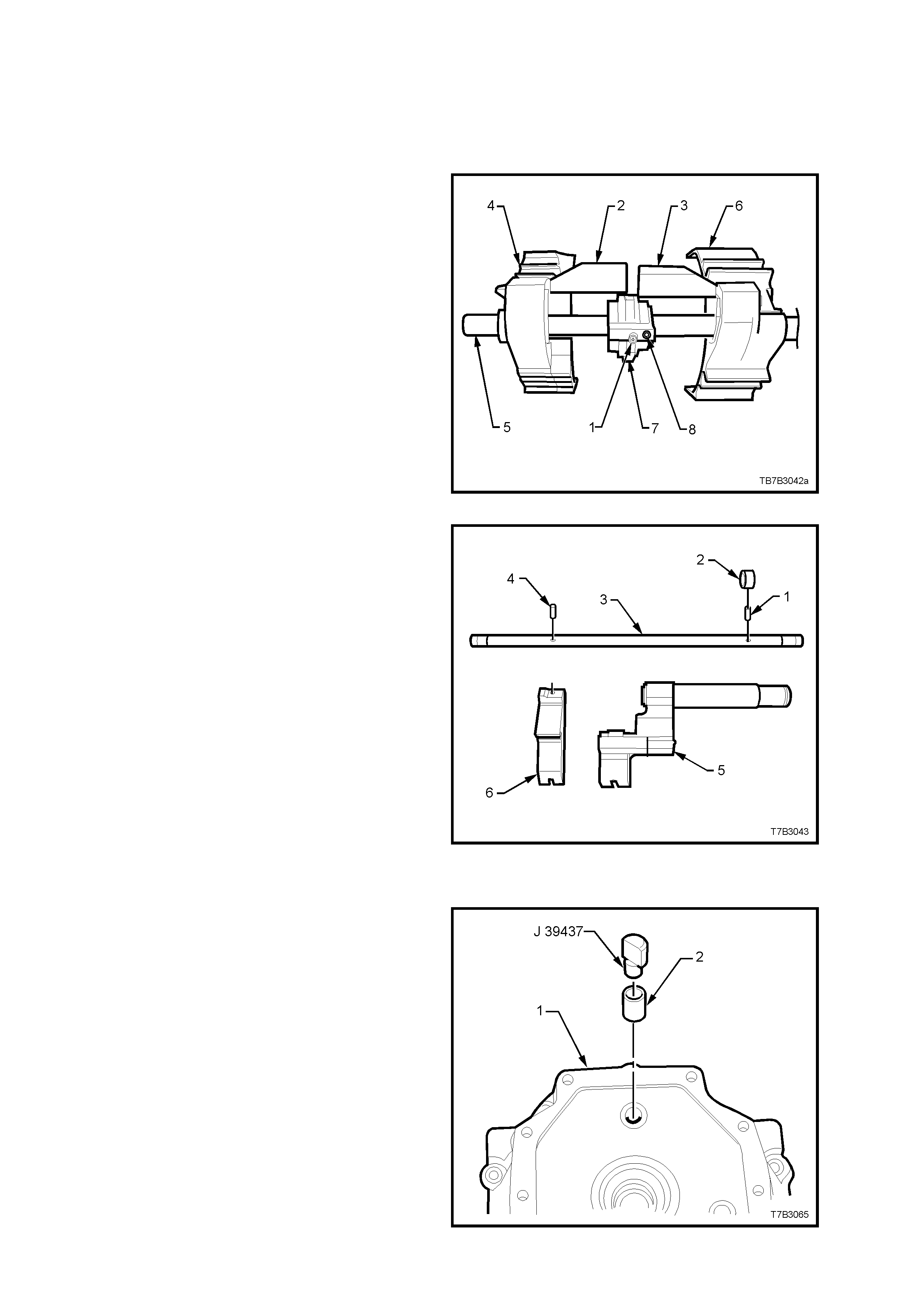

Reverse Idler Gear

1. Using Torx bit T40, remove the three screws

(1) securing the reverse idler gear shaft

support plate (2).

2. Remove the support plate (2), reverse idler

gear thrust washer (3), reverse idler gear (4),

caged needle roller bearing (5), the second

reverse idler gear thrust washer (6), and idler

gear shaft (7) from the extension housing (8).

Figure 7B3-98