SECTION 8A1 - FUEL TANK

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1. GENERAL INFORMAT ION

The VU Ser ies Mod els f uel s ystem m aintains c omm on link s with VT Seri es II Mod els wit h chan ges to suit t he utilit y

fuel tank assembly positioning beneath the load compartment tonneau floor.

The m odular f uel s en der assembly incor pora t es a fuel s ender u nit as sembl y, pick up s tr ain er an d tur b ine f ue l pump.

The assembly is retained in the fuel tank by a circlip.

The information in this Section should be read in conjunction with Section 8A FU EL TANK of the VT Series I and

VT Series II Servic e Infor m atio n.

Techline

2. SERVICE OPERATIONS

2.1 FUEL TANK

REMOVE

CAUTION: Ensure that there are no naked flames or other sources of ignition in the vicinity.

1. Depressurise the fuel system. For V6 engines refer to Section 6C1-3 POWERTRAIN MANAGEMENT - V6

ENGINE in the VX Series Service Information.

For GEN III V8 engines refer to either Section 6A3 ENGINE MECHANICAL - GEN III V8 ENGINE or

Section 6C3-3 PO WERTRAIN MANAGEMENT - GEN III V8 ENGINE in the VX Series Service Information.

2. Disconnect the negative cable from the battery terminal.

3. Remove th e front tonneau floor, refer to Section 1 A4 LOAD COMPARTMENT AND ENDG ATE. If necessary

remove the LPG cylinder, refer to Section 8A2 LPG SYSTEM.

4. Remove the screws (2) securing the load compartment side panel inner front cover (1), refer to Fig. 8A1-1. If

necessary remove the LPG filler and service lines, refer to Section 8A2 LPG SYSTEM.

6. Disconnect modular fuel sender harness connector (3).

7. Tag the fuel feed (7) and return (8) line connections located on top of the fuel tank.

NOTE: For ident if ic atio n pu r pos es, the f u e l return hose is tagg ed with a wh ite ban d near the con nec tor at the top of

the fuel tank.

8. Tag the vent pipe (9) on top of the fuel tank and disconnect by pulling hose from fuel tank vent fitting.

9. Disengage the fuel return line (8) and fuel feed line (7) quick connect fittings using special tool No. AU533.

10. Remove th e modular fuel sender assembly (refer 2.2 MODULAR FUEL SENDER ASSEMBLY) and drain the

entire co ntents of the f uel tank by pum ping or syphoni ng the fuel through t he sender ass embly hole in the f uel

tank.

NOTE: Due to a permanent restriction (flood gate) in the lower fuel filler neck, the fuel tank can not be drained

through the filler aperture.

11. Remove the four bolts (4), steel washers (5) and rubber isolators (10), then remove the tank by manipulating

the filler neck free of the filler neck grommet then past the inner quarter panel.

CAUTION: Fuel va pour rem ains in the tank even when com pletely em pty, seal the open ings in the f uel tank using

a suitable plastic plug and avoid all sources of ignition.

Techline

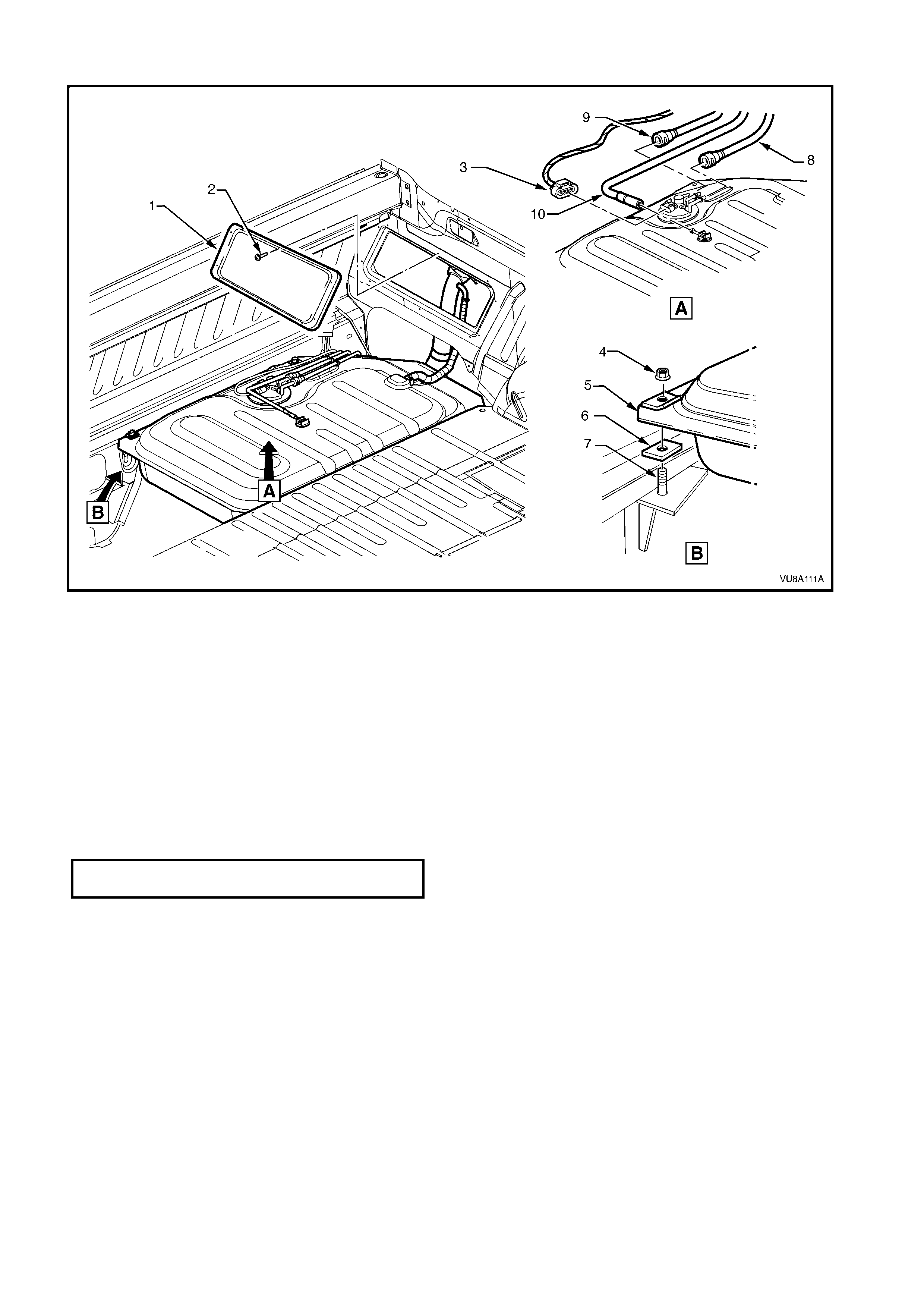

Figure 8A1-1

Legend

1. Side panel inner front cover

2. Side panel screw (10 places)

3. Fuel sender harness

connector

4. Fuel tank retaining nut

5. Fuel tank

6. Fuel tank isolator rubber

7. Fuel tank mounting stud

8. Fuel return line

9. Fuel feed line

10. Fuel tank vent hose

REINSTA LL

The reinstallation procedure for the fuel tank is the reverse of the removal procedure, noting the following:

a. Apply a bead of sealant (Holden's Specification HN1005) around the perimeter of the access covers and

tonneau floor before installation.

b. The connections for the fuel tank vent pipe is shown in view A Fig. 8A1-1.

FUEL TANK MOUNTING BOLT 25-30

TORQUE SPECIFICATION Nm

2.2 MODULAR FUEL SENDER ASSEMBLY

REMOVE

CAUTION: Ensure that there are no naked flames

or other sources of ignition in the vicinity.

1. Disconnect the negative cable from the battery

terminal.

2. Remove the front tonneau floor, refer to

Section 1A4 - LOAD COMPARTMENT AND

ENDGATE.

3. Disconnect the modular fuel sender assembly

harness connector, refer to Fig. 8A1-1.

4. Tag the fuel feed and return hoses from the

connections located on top of the fuel tank,

refer to Fig. 8A1-1.

5. Tag the vent pipe on top of the fuel tank and

disconnect by pulling hose from fuel tank vent

fitting, refer to Fig. 8A1-1.

6. Disengage th e f uel return li ne a nd fuel f eed li ne

quick connect fittings using special tool No.

AU533.

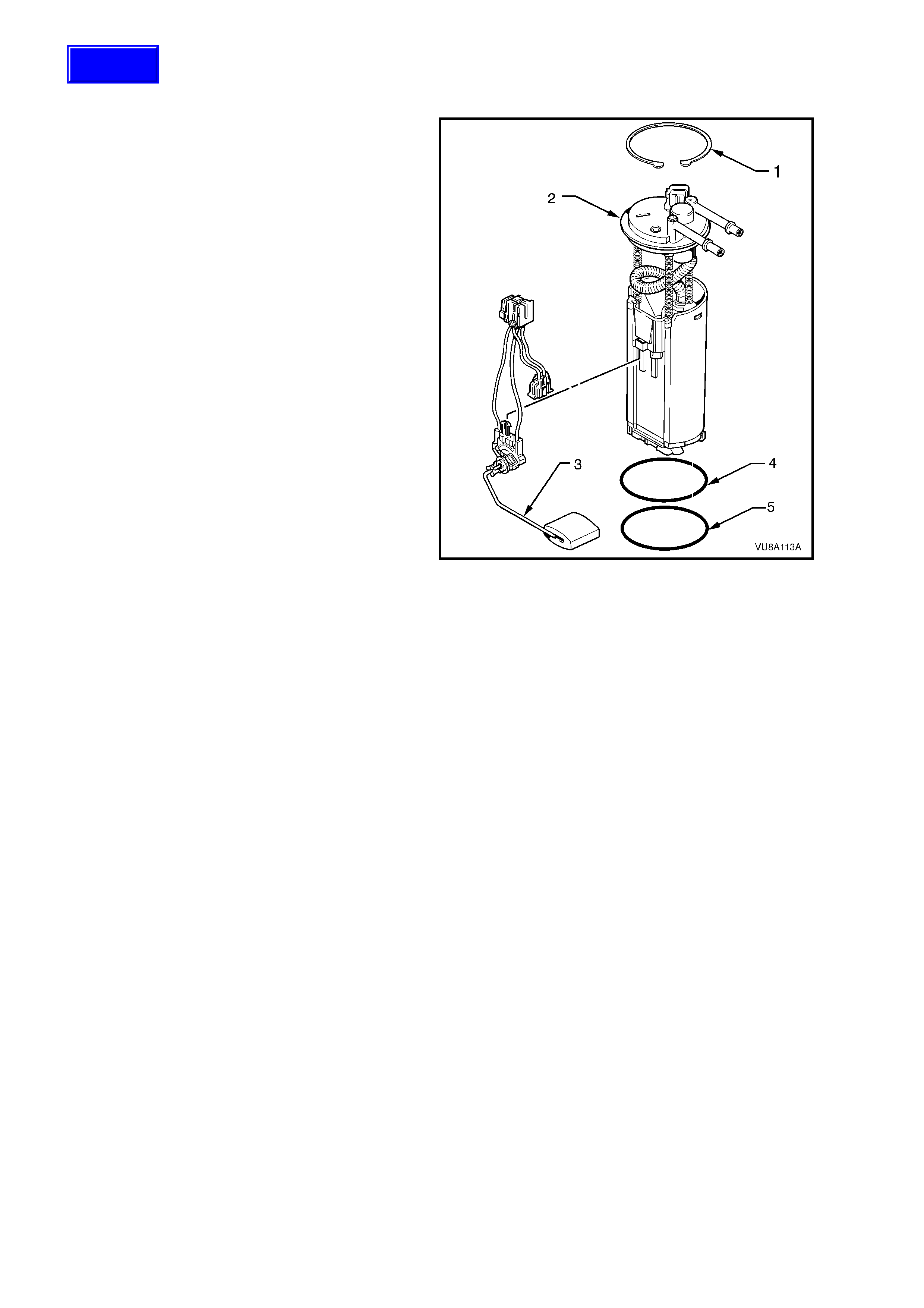

7. Remove the circlip (1) retaining the modular

fuel sender assembly (2) using circlip pliers.

8. Carefully lift the modular fuel sender assembly

from the fuel tank taking care not to damage

the fuel sender float arm (3). Take care not to

spill any fuel remaining in the reservoir.

NOTE: The fuel sender float arm for VU Series

Models is not serviced separately.

IMPORTANT: Pour any fuel remaining in the

reservoir into a suitable contai ne r.

9. Remove and discard sender assembly to fuel

tank O-ring (5).

NOTE:The modular fuel sender assembly as fitted

to VU Series Models with the Gen III V8 engine

contains a plastic spacer ring (4) between the O-

ring (5) and the top mounting face.

10. Cover all fuel tank openings to prevent foreign

matter entry.

Figure 8A1-2

REINSTA LL

The reinstallation procedure for the modular fuel

sender assembly is the reverse of the removal

procedures noting the following:

1. Install new O-ring (5) on fuel sender assembly,

refer to Fig. 8A1-2.

2. For VU Series Models with the GEN III V8,

ensure that the plastic spacer (4) is correctly

seated between the O-ring (5) and the top

mounting face of the modular fuel pump

sender assembly.

3. Install the modular fuel sender assembly into

the fuel tank.

4. Install the modular fuel sender assembly

retaining circlip (1).

5. Apply a bead of sealant (Holden's Specification

HN1005) around the perimeter of the access

covers and tonneau floor before installation.

Techline

3. TORQUE WRENCH SPECIFIC ATIONS

Nm

Fuel Tank Mounting Bolt................... ...................................... 25-30

4. SPECIFICATIONS

Fuel Tank Capacity:

All Models ................................................... 70 litres

Fuel Tank Material:

All Models ................................................... Steel

Fuel Filler Location:

All Models ................................................... RH rear quarter panel

Fuel Pump Type:

All Models ................................................... Single stage turbine with jet pump

Fuel Pump Location:

All Models ................................................... In tank

Fuel Pump Pressure:

V6 Models................................................... 350 kPa

GEN III V8 Models...................................... 400 kPa

Fuel Pump Flow Capacity:

V6 Models................................................... 1.6 litres @ 13.5 volts

GEN III V8 Models...................................... 2.5 litres @ 13.5 volts

Fuel Pump Current Draw:

V6 Models................................................... 6.7 amps maximum

GEN III V8 Models...................................... 9.6 amps maxim um

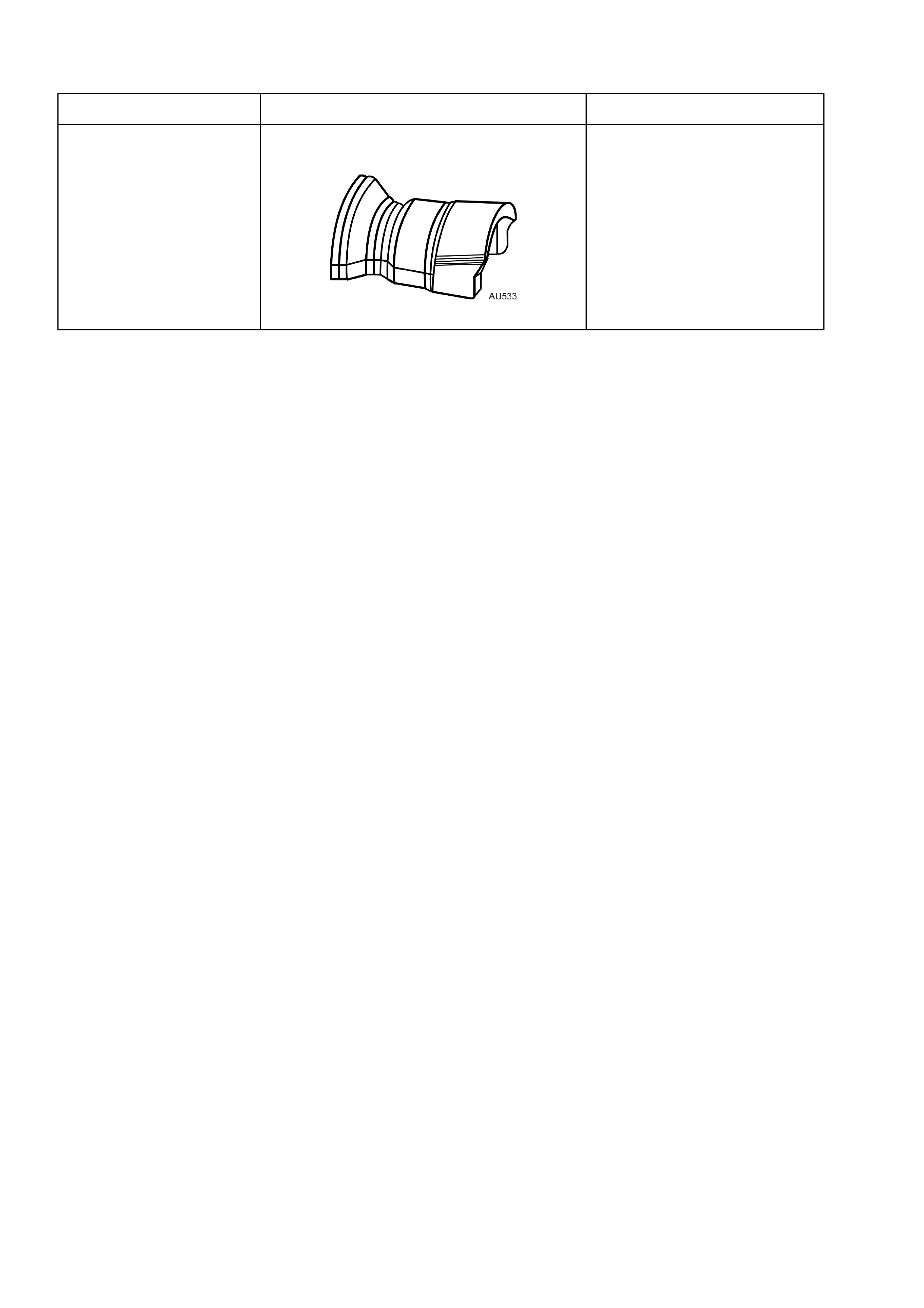

5. SPECIAL TOOLS

TOOL No. REF. IN TEXT TOOL DESCRIPTION COMMENTS

AU533 QUICK CONNECT FITTING RELEASE

TOOL

Released in two sizes;

Red for 5/16” fittings and

Blue for 3/8” fittings.

Also avai lab le com merc iall y

under P/N AUSP 45