SECTION 0A - GENERAL INFORMATION

IMPORTANT:

Before p erf orming any Service O p eratio n o r ot her p roced ure describ ed in t his Sect ion , refer t o Sect ion

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1.GENERAL I NFORMATION

The VU Series Utility is a new body design based on the VX Series Commodore featuring new headlamps,

sheet metal and tail lamps. The load compartment has been revised with replaceable rails on high wear areas

surrounding the load compartment and a new design tonneau cover. Independent rear suspension is standard

on all models.

A four speed, electronically controlled automatic transmission is optional equipment.

NOTE: VU Series Models must be operated only on unleaded fuel with a minimum research octane rating

of 91.

The following charts provide model availability, power train combinations, transmission ratios, engine data and

exterior dimensions for VU Series Models.

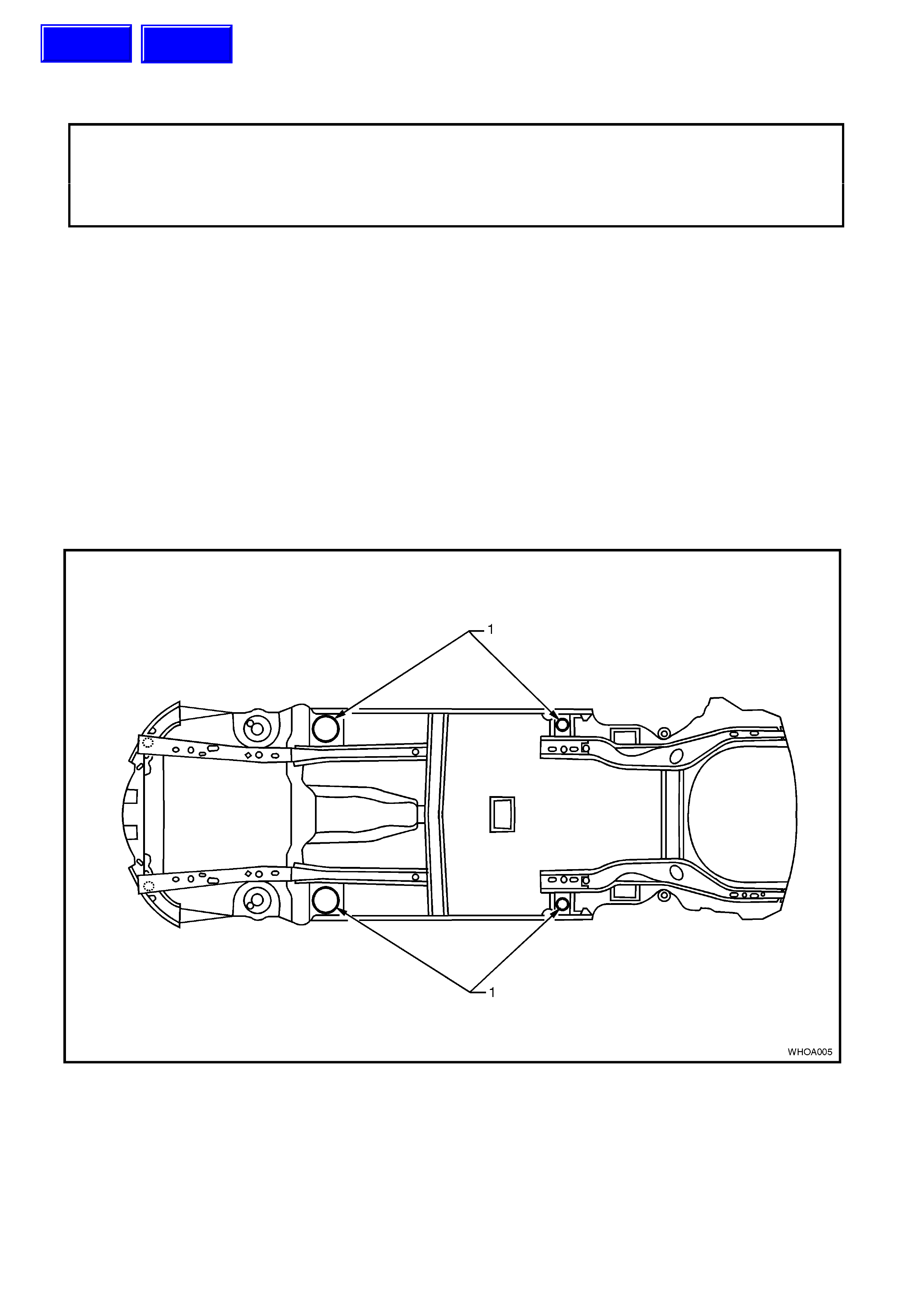

NOTE: When using a trolley jack to raise the vehicle it is important that the jack be positioned under the

suspens ion cross m em ber or hoist pad locations (1). Do not j ack under the s uspension c ontrol arm . T he vehicle

should always be supported by jack stands at the hoist pad locations when raised.

Figure 0A-1

Techline

Techline

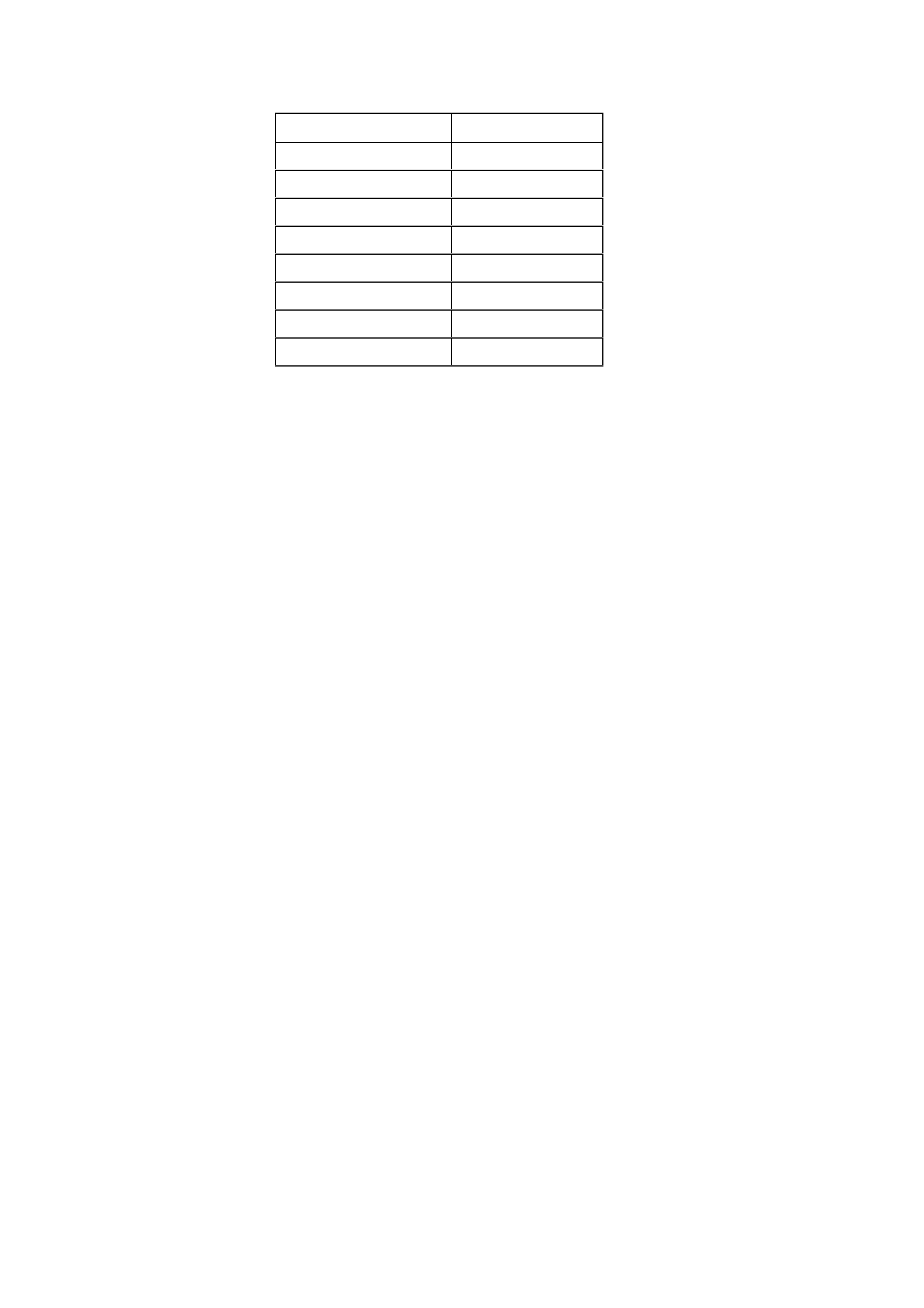

2. MODEL AVAILABILITY AND BASE EQUIPMENT

TRANSMISSION BODY

STYLE MODEL

NO. MODEL

NAME NO.OF

DOORS ENGINE

TYPE SHIFT

LOC.

FINAL

DRIVE

RATIO

TYRES WHEELS

Utility 8VK80

Utility

S

SS

2

3.8 PFI

3.8 PFI

5.7 PFI

5 Speed

Manual

5 Speed

Manual

6 Speed

Manual

Floor 3.46:1

205/65

R15 95H

225/55

R16 95V

235/45

R17 93V

7 x 15

Steel

7 x 16

Alloy

8 x 17

Alloy

3. POWERTRAIN COMBINATIONS

ENGINE TRANSMISSION

TYPE MODEL

AVAILABILITY FIRST GEAR

RATIO FINAL DRIVE RA TIO

3.8 LITRE

PFI 5 Speed

Manual UTILITY, S 3.83:1 3.46:1

4 Speed

Automatic UTILITY, S 3.06:1 3.08:1

5.7 LITRE

PFI 6 Speed

Manual S, SS 2.66:1 3.46:1

4 Speed

Automatic S, SS 3.06:1 3.08:1

4. TRANSMISSION RATIOS

5 SPEED

MANUAL 6 SPEED

MANUAL 4 SPEED

AUTOMATIC

V6 GEN III V8 V6 & GEN III V8

1ST 3.829:1 2.66:1 3.06:1

2ND 2.199:1 1.78:1 1.63:1

3RD 1.401:1 1.30:1 1.00:1

4TH 1.00:1 1.00:1 0.70:1

5TH 0.809:1 0.74:1 -

6TH - 0.50:1 -

REV 3.456:1 2.90:1 2.29:1

5. ENGINE DATA

ENGINE

DESIGNA TION 3.8 LITRE

V6 5.7 LITRE

GEN III V8

Piston Displacement

Nom.cm3

3791

5667

Compression Ratio 9.4:1 10.1:1

Number of Cylinders 6 8

Bore x Stroke mm 96.5 X

86.3 99 X

92

Taxable H.P.

RAC OR SAE

34.7

48.6

Power kW

DIN @ RPM 152 kW

@ 5200 225 kW

5200

Torque Nm

DIN @ RPM 305Nm

@ 3600 460 Nm

@ 4400

6. EXTERIOR DIM ENSIONS

BODY DIMENSIONS

VEHICLE LENGTH 5049

VEHICLE WIDTH 1845

VEHICLE HEIGHT 1484

WHEELBASE 2939

OVERHANG - FRONT 933

OVERHANG - REAR 1178

TREAD - FRONT 1569

TREAD - REAR 1587

7. VEHICLE WEIGHTS

VU SERIES MODELS

VEHICLE

WEIGHTS

UTILITY

(MANUAL)

UTILITY

(AUTO)

'S'

(MANUAL)

'S'

(AUTO)

'SS'

(MANUAL)

'SS'

(AUTO)

Kerb Mass V6 1494 1519 1524 1549 N/A N/A

Kerb Mass GEN III V8 1557 1567 1587 1597 1610 1620

Rear Axle Load V6 1350 1350 1260 1260 N/A N/A

Rear Axle Load

GEN III V8 1350 1350 1260 1260 1260 1260

Payload V6

(2 Pass. + Cargo) 780 830 735 710 N/A N/A

Payload GEN III V8

(2 Pass. + Cargo) 790 780 670 660 665 655

NOTE: All figures are estimates only.

Payload figures must include luggage, goods,

passengers and a full tank of fuel. If you are towing,

then the weight on the tow bar ball must also be

included.

Maximum Rear Axle Load is maximum for all

conditions.

8. SERIAL NUMBERS

The complete vehicle and various components of the vehicle are identified by number plates or numbers

stam ped into the par t. It is ess ential that when compiling warranty claims or product and field reports, the vehicle

identification number (VIN) is quoted in conjunction with the identification number of the component affected.

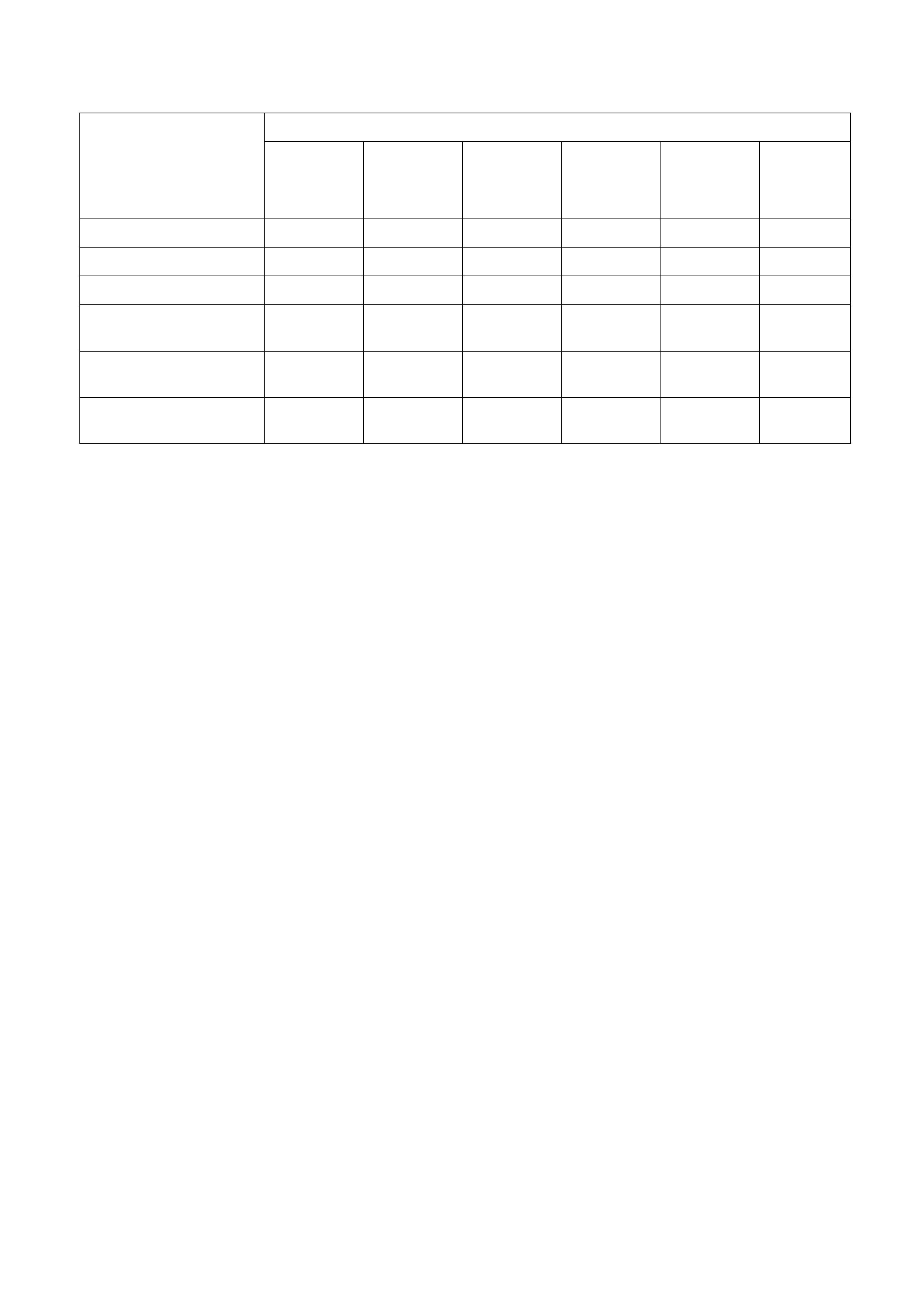

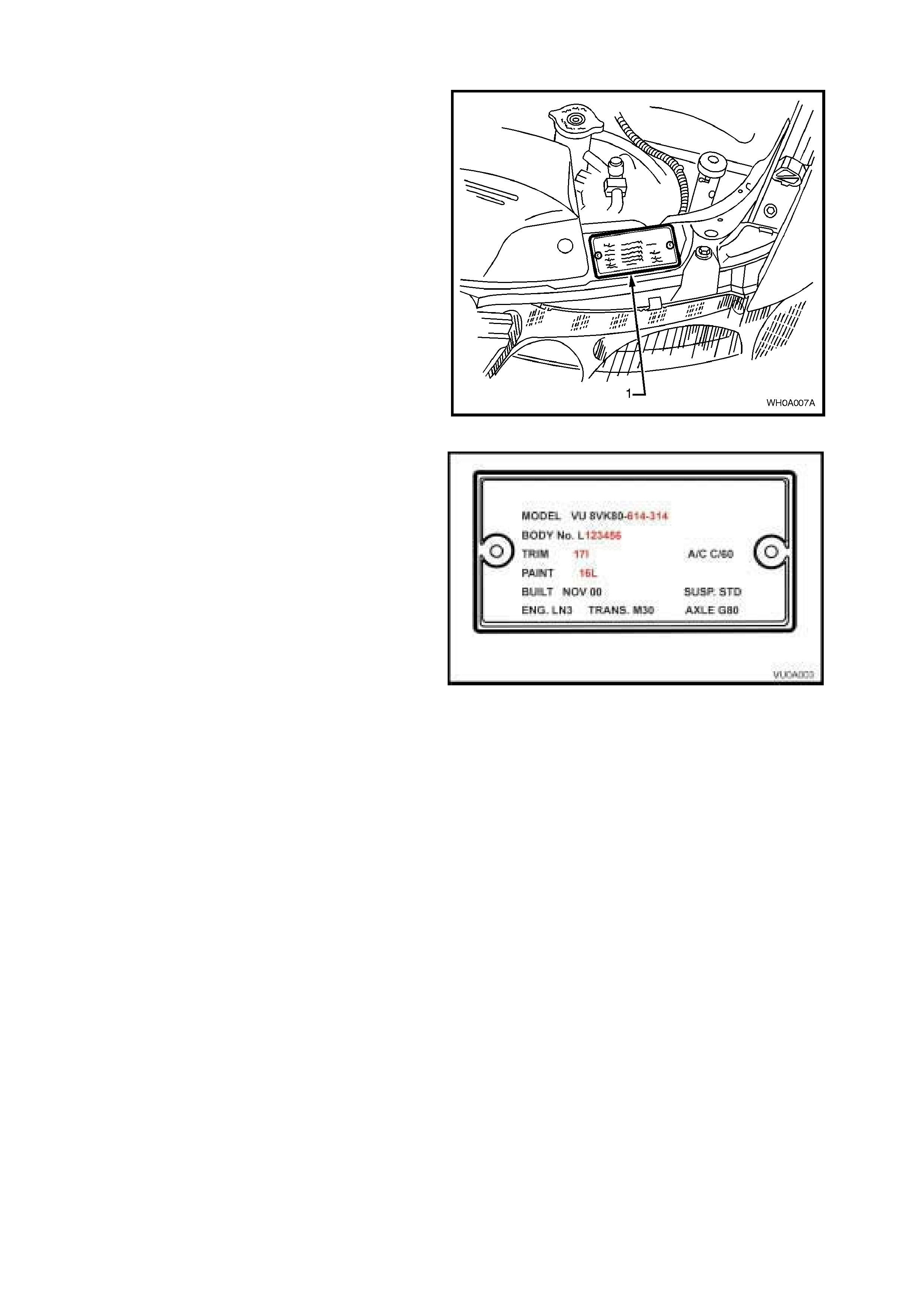

8.1 LOCATION OF IDENTIFICATION PLATES

Identification plates ar e attached to the upper lef t s ide of the das h panel, f ront r adiator suppor t panel, behind the

bumper facia and under the windshield lower left corner, refer to Fig. 0A-2.

NOTE: Stam ping of the VIN into the sheetm etal under the RH f ront seat will be introduced in VU Series Models

with a build date on or after Januar y 2001. The build date is stam ped on the body and option identification plate,

refer to Fig 0A-6.

Figure 0A-2

Legend

1. Carpet flap (under RH seat)

2. Vehicle Identification Number

(stamped under RH seat)

3. Body and Option Identification Plate

(front upper panel)

4. Vehicle Identification Number Plate (under facia)

5. Safety Compliance Plate

(engine side of dash panel)

6. Vehicle Identification Number Plate

(under windscreen)

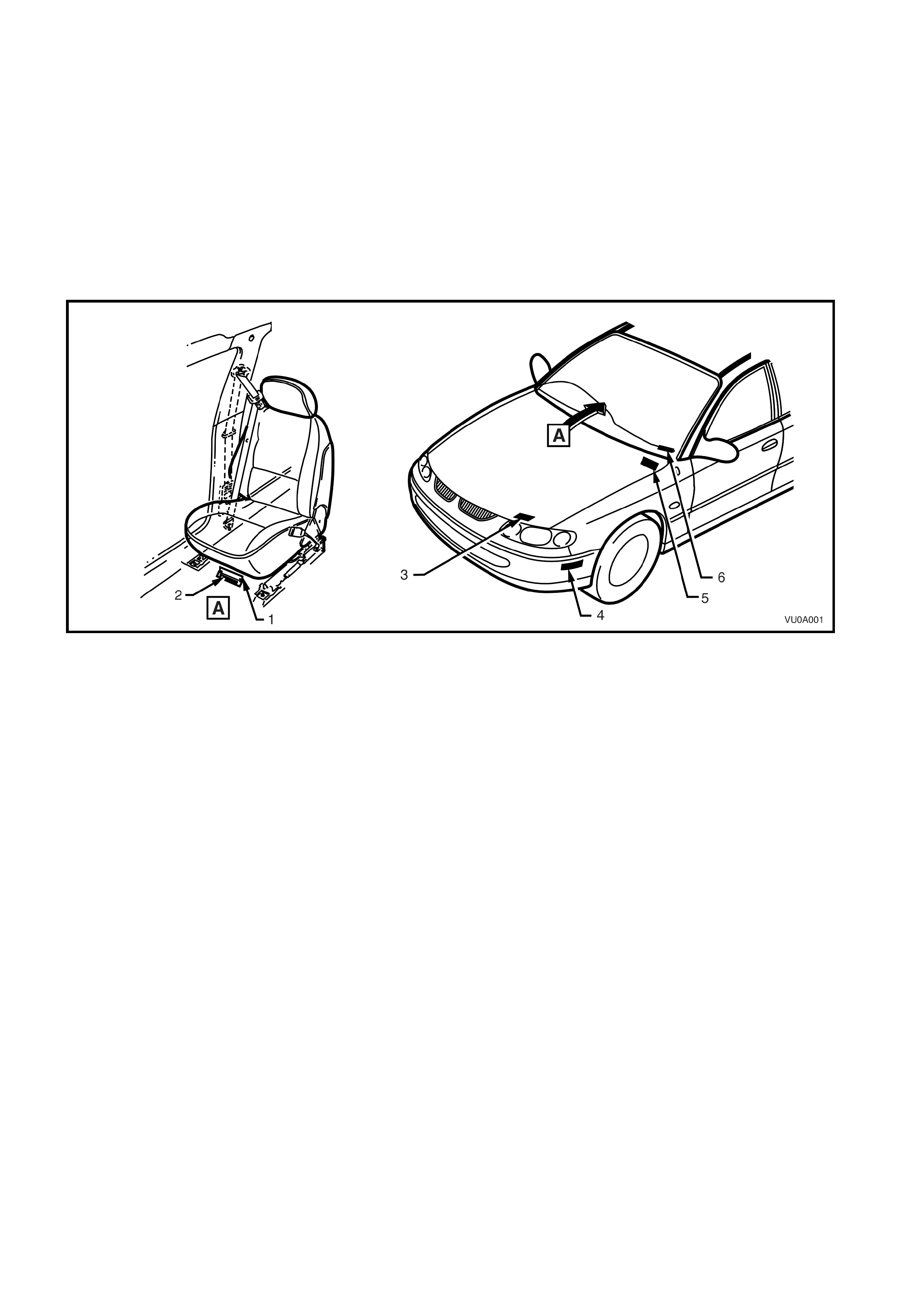

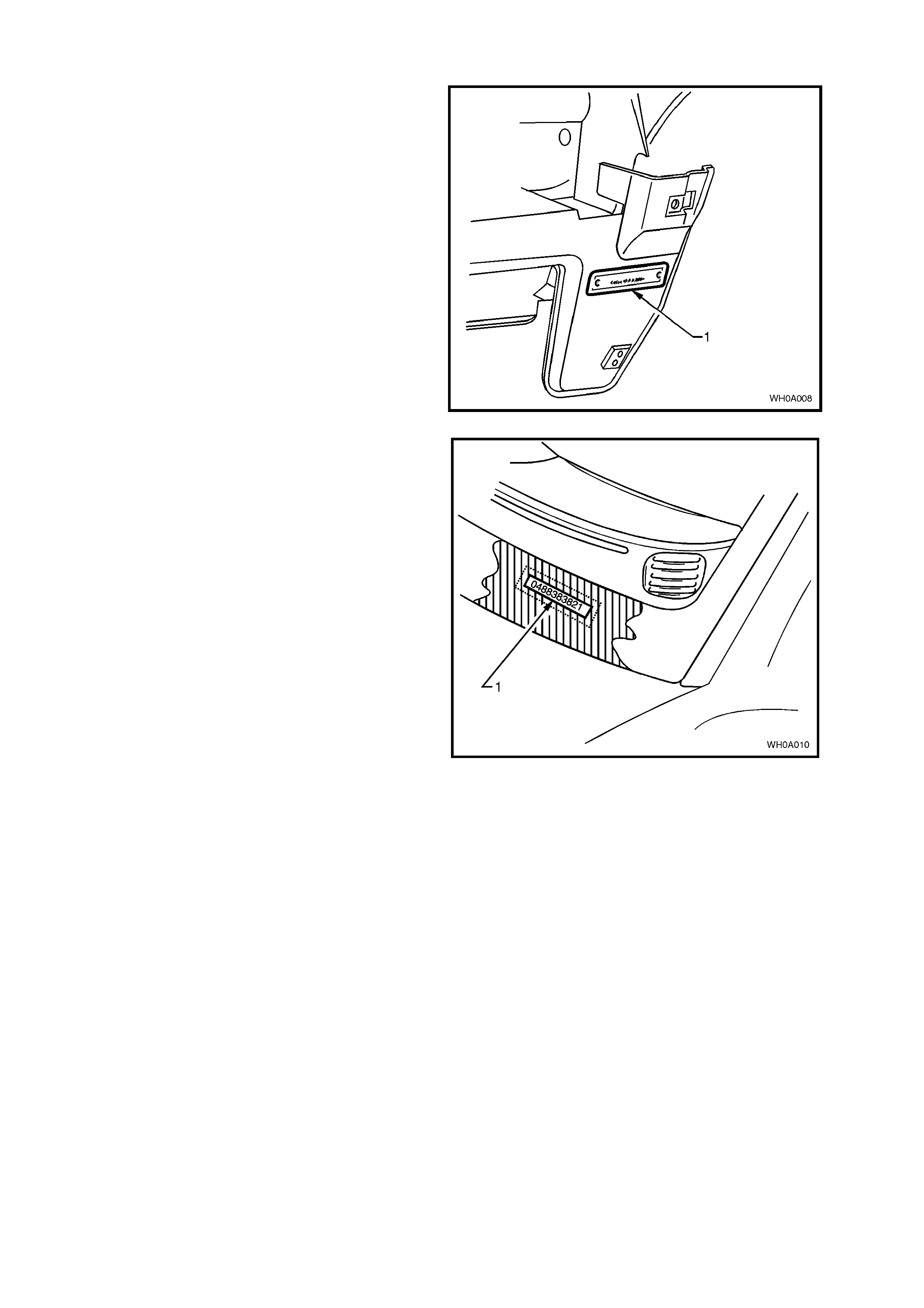

8.2 SAFETY COMPLIANCE PLATE (NOT APPLICABLE TO EXPORT)

Plate stamped with the following inform ation, Refer

to Fig. 0A-3:

COMPLIANCE PLATE APPROVAL NUMBER.

VEHICLE CATEGORY CODE.

NAME APPEARING ON COMPLIANCE PLATE

APPROVAL.

MAKE/MODEL.

SEATING CAPACITY.

DATE OF MANUFACTURE (* Variable

information).

VEHICLE IDENTIFICATION NUMBER (* Variable

information).

Figure 0A-3

Legend

1. Safety Compliance Plate.

Figure 0A-4

8.3 BODY AND OPTION IDENTIFICATION PLATE

The body and option identification plate (1) is

stamped with the following information, refer to

Fig. 0A-6.

Figure 0A-5

MODEL

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

NOTE: A listing of Production Option num bers and

Smart Pack Option numbers can be found by

referring to the latest spare parts information

(Partfinder) for the applicable model.

BODY

Production build number, in continuous sequence

regardless of model, body type and series.

TRIM

Trim combination.

PAINT

Exterior paint material and colour identification.

BUILT

The date of manufacture by calendar month and

year in which the body shell and power train are

conjoined and the vehicle is driven or moved from

the production line.

SUSP

Suspension option code identification number, i.e.

FE2.

ENGINE, TRANSMISSION AND AXLE

Identification option codes for specific engine,

transmission and final drive.

A/C

Identification option code C60 identifies vehicles

fitted with air conditioning.

Figure 0A-6

8.4 FUEL CONSUMP TION LABEL

ADR 81/00 requires that from 1st January 2001, a

label similar to that shown in Fig.0A–7 is attached

to the windscreen of any new vehicle which is

displayed for sale.

The f uel c onsumption f igur es quoted are the results

of tests carried out in accordance with an

Australian standard for fuel consumption testing.

Each vehicle is tested under identical conditions.

The results therefore enable a comparison to be

made between vehicles.

This label should be removed from the windscreen

immediately prior to the vehicle being delivered to

the owner.

Figure 0A-7

8.5 VEHICLE IDENTIFICATION NUMBER PLATE LOCATION (BODY LOCATION)

One of the body mounted Vehicle Identification

Number (VIN) plates (1) is located under the front

bumper on the left hand side.

NOTE 1: This plate will be deleted following the

introduction of the stamping of the VIN into the floor

sheetmetal under the front RH seat, refer to

8.1 LOCATION OF IDENTIFICATION PLATES in

this Section.

NOTE 2: Stamping of the VIN into the sheetmetal

under the RH front seat will be introduced in VU

Series Models with a build date on or af ter January

2001. The build date is stamped on the body and

option identification plate, refer to Fig 0A-6.

Figure 0A-8

The second body mounted Vehicle Identification

Number plate (1) is located under the windscreen

and is viewed through the windscreen aperture.

The VIN plate is secured to the body by unique

rosette headed rivets.

Figure 0A-9

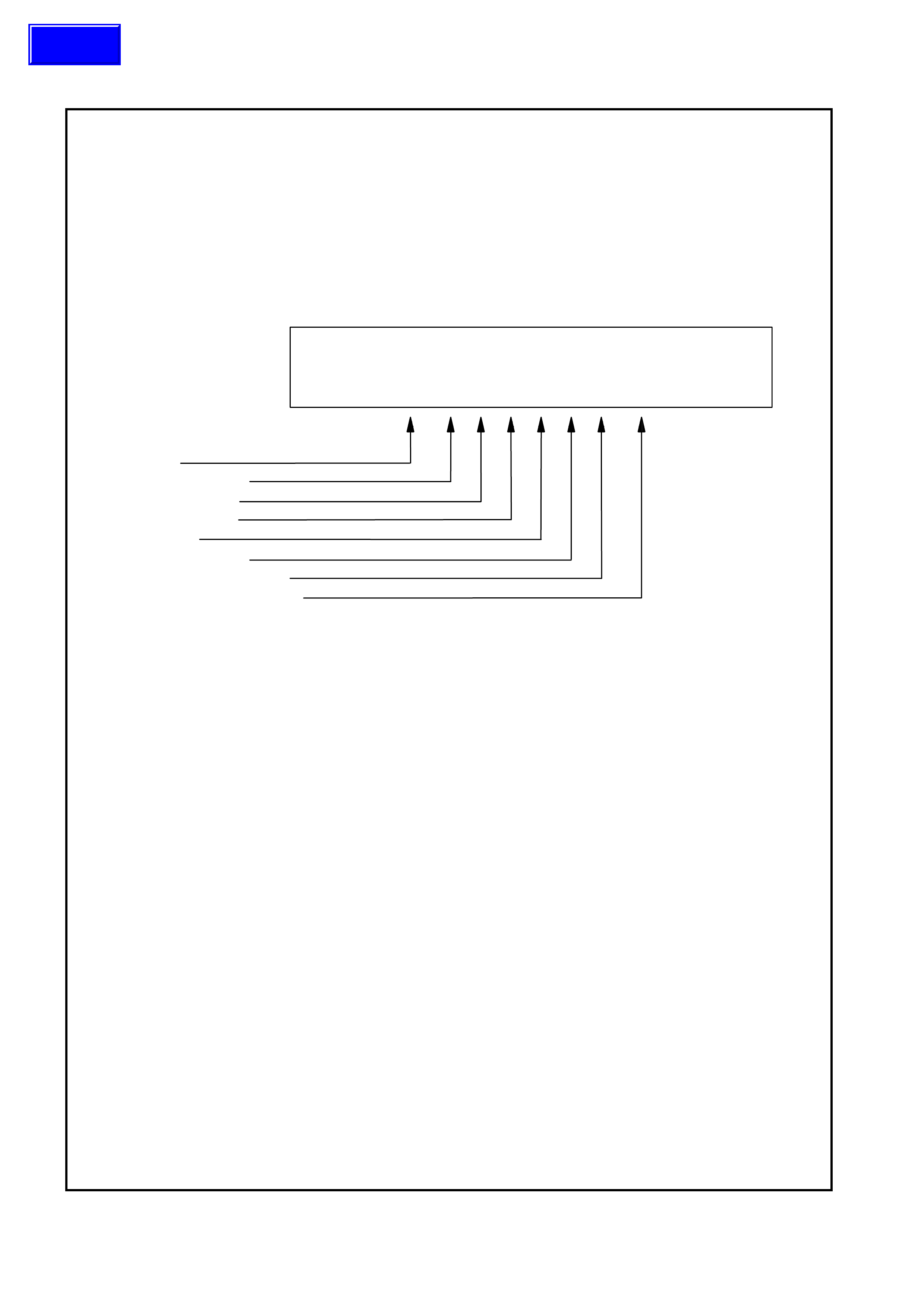

8.6 VEHICLE IDE NTIFICATION NUMBERING SYSTEM

For details of Vehicle Identification Numbering (VIN) system, refer to Fig. 0A-10.

VEHICLE IDENTIFICATION NUMBERING SYSTEM

The Vehicle Identification Numbering (VIN) system is based on the uniform Car Model Designation

System. The reason for this is to identify the vehicle in one coded series of characters.

The significance of these characters or blocks of characters are explained below, using as an example

identification number 6H8 VU K 80 A Y L 123456.

MODEL DESIGNATION

WMI Code

Model Series Code

Degree of Luxury

BODY STYLE CODE

ENGINE CODE

MODEL YEAR CODE

ASSEMBLY PLANT CODE

SERIAL SEQUENCE NUMBER

6H8 VU K 80 A Y L 123456

MODEL DESIGNATION

WMI Code – 6H8 – World manufacturer’s identifier allocated to Holden

Model Series Code - VU = VU Series

Degree of Luxury - K – UTILITY

Body Style Code - 80 – Utility

ENGINE CODE

Engine Identification Code A – signifies 3.8 litre V6 engine,

F – signifies 5.7 litre GEN III V8 engine)

MODEL YEAR CODE

Y – Identifies Model Year Y = 2000

1 = 2001

This Letter relates to GM Internal Operation Only.

ASSEMBLY PLANT CODE

Australian Assembly Plant Identification Code:-

L – Adelaide (Elizabeth)

SERIAL (Sequence ) NUMBER

123456 – Sequential Production Serial Number

NOTE: This designates the Serial Unit Number at the Vehicle Plant, starting at

(00001) and continues in Numerical Sequence regardless of vehicle type.

Figure 0A-10

Techline

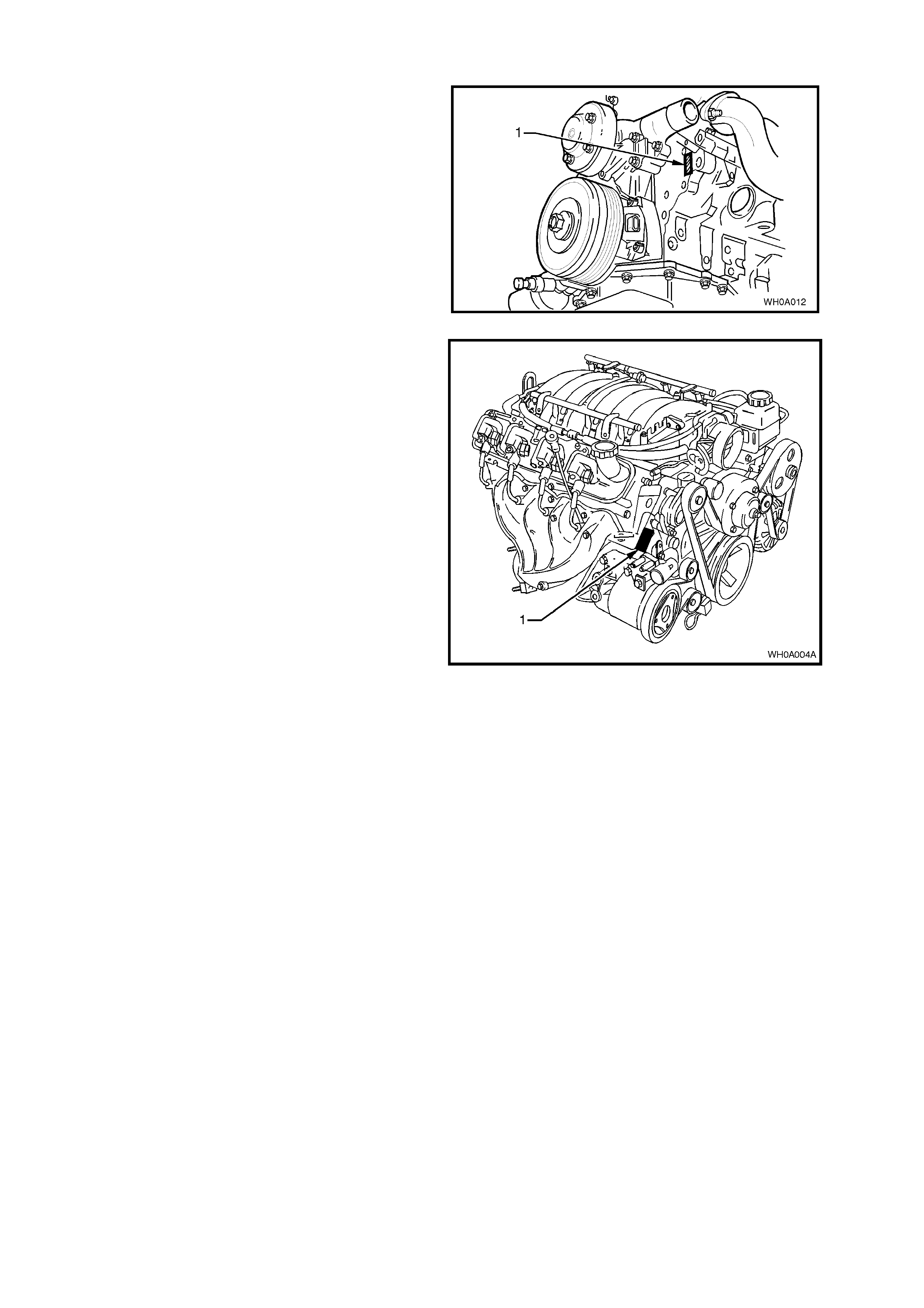

8.7 ENGINE SERIAL NUMBER

The engine number (1) for the 3.8 V6 engine is

stamped on the front face of the engine, below the

ignition coil as illustrated in Fig.0A-11.

Figure 0A-11

The 5.7 litre GEN III V8 engine number (1) is

stamped on a pad located adjacent to the engine

coolant outlet pipe, refer to Fig. 0A-12.

The engine number is prefixed by the letters 'VF'.

Figure 0A-12

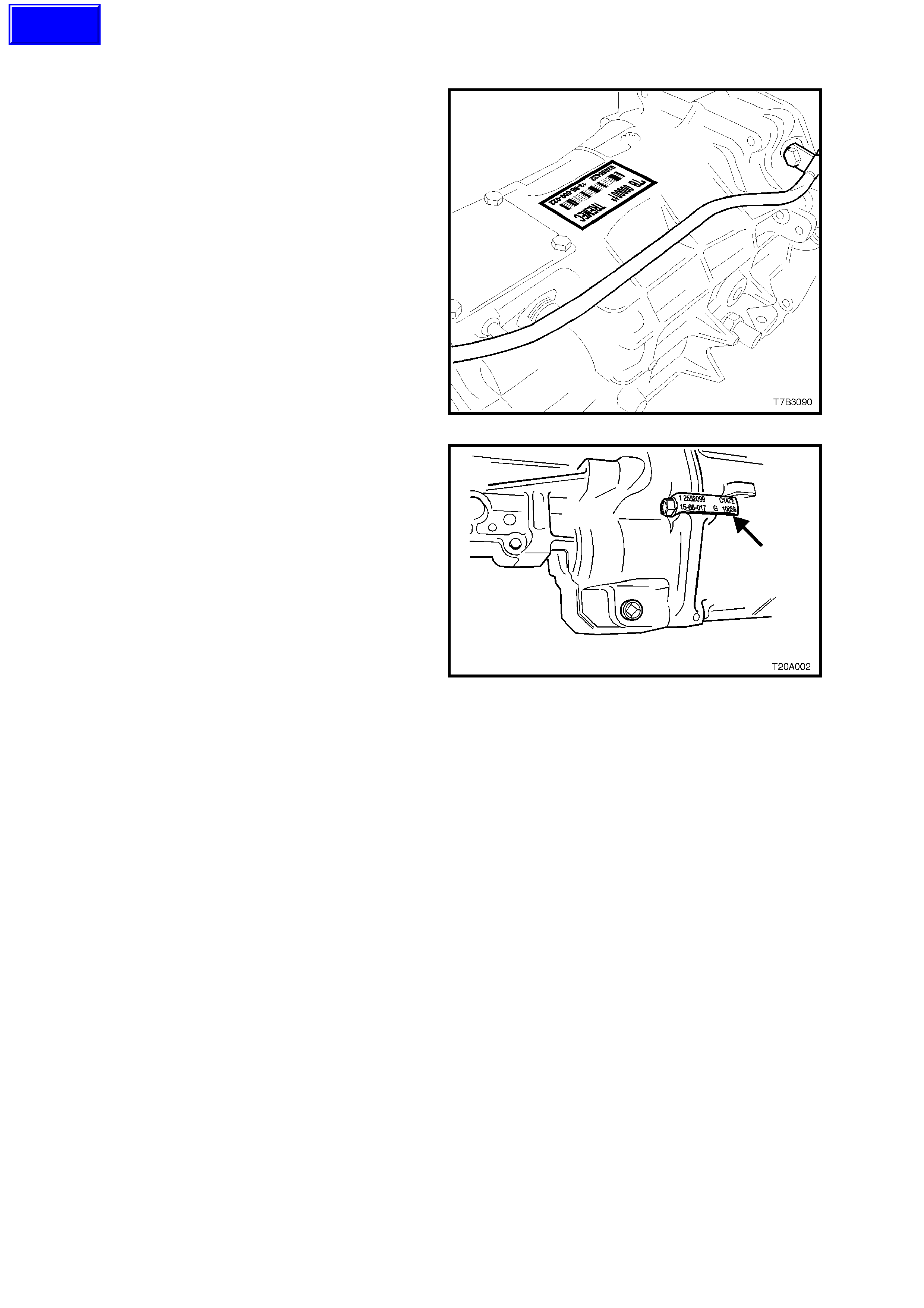

8.8 MANUAL TRANSMISSION SERIAL NUMBER

The Borg-W arner (Tremec) T56 six speed manual

transmission serial number is located on a self-

adhesive decal attached to the top of the

transmission case, refer to Fig. 0A-13.

This number provides coded information which

could be significant to parts interpretation and

should be referred to when ordering replacement

parts.

Figure 0A-13

In addition, an identification tag is attached to the

transmission under an extension housing bolt, on

the right-hand side, refer to Fig 0A-14.

Figure 0A-14

Techline

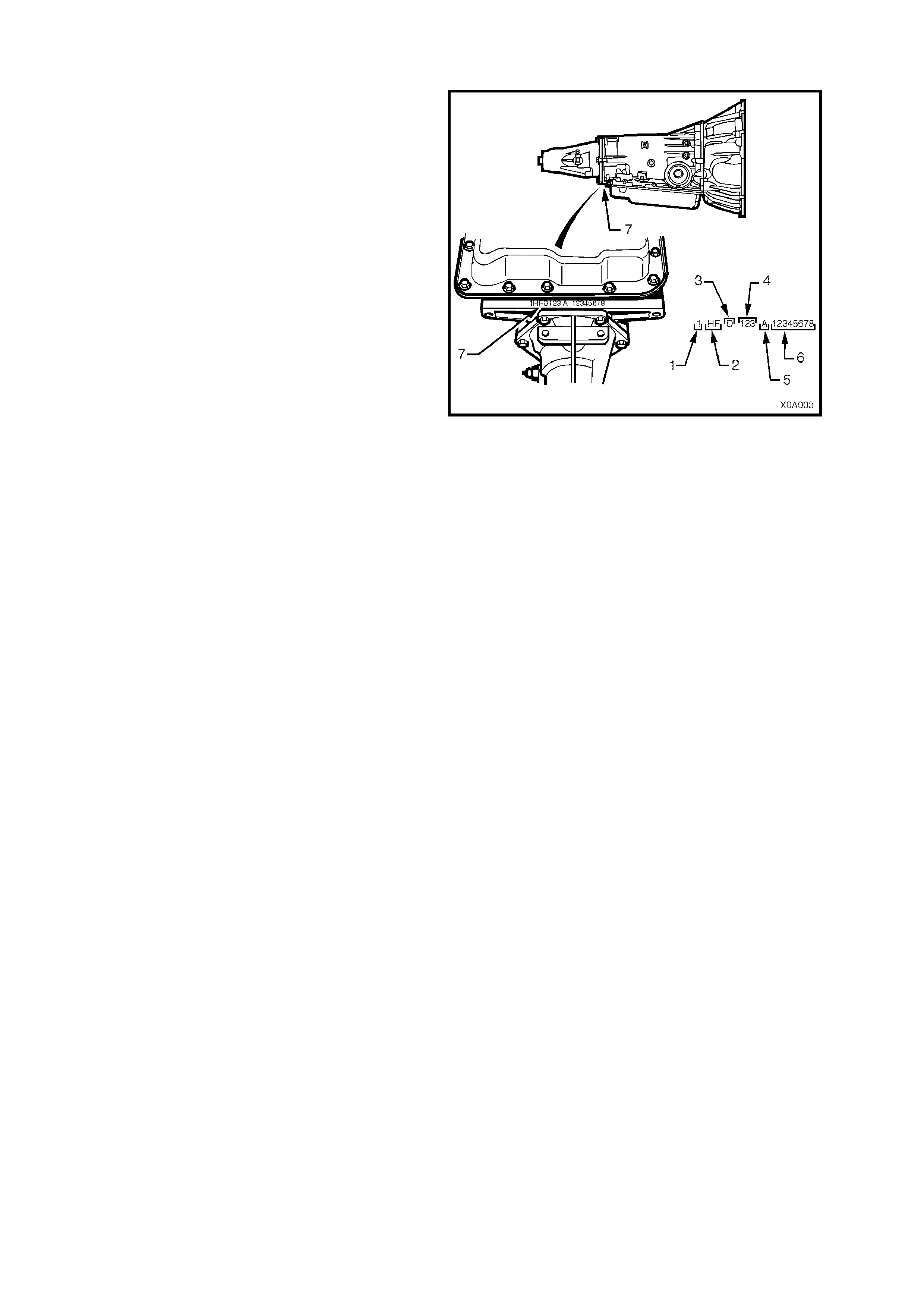

8.9 AUTOMATIC TRANSMISSION SERIAL NUMBER

The automatic transmission serial number is

stamped into a machined surface at the rear

underside of the transmission centre case, refer to

Fig. 0A-15.

1. Model Year (‘0’ = 2000 ‘1’ = 2001)

2. Model: V8 – 5.7 litre...................... HP

V6 – 3.8 litre ..................... HF

3. Transmission Model Identifier (D = 4L60-E).

4. Julian Date (or day of year).

5. Shif t Built (A, B, J = f irst s hift; C, H, W = second

shift).

6. Individual Transmission Serial Number.

7. Transmission Identification Number Location.

Figure 0A-15

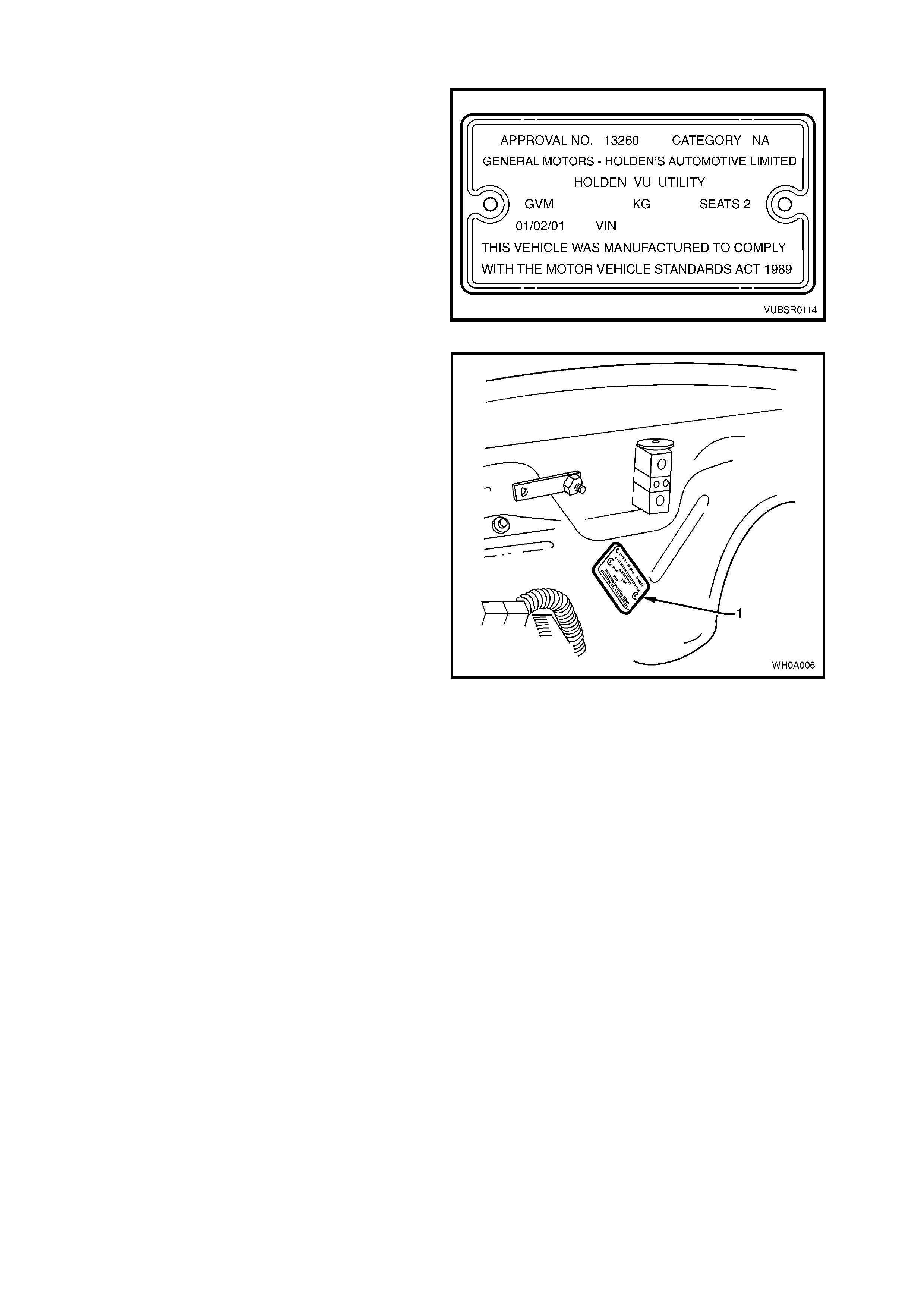

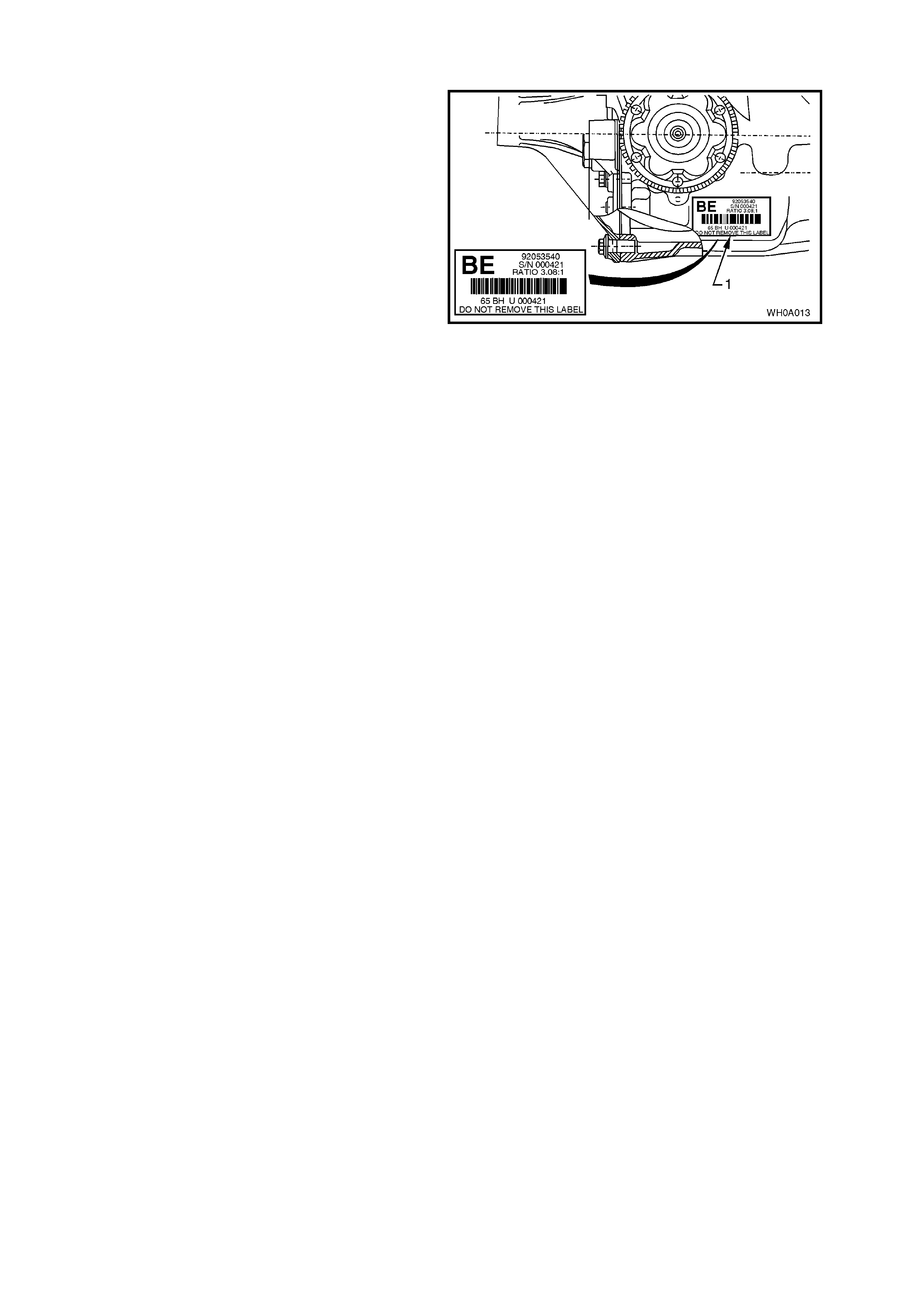

8.10 FINAL DRIVE IDENTIFICATION

An identification tag ( 1) is adhered to the final drive

assembly to the RHS of the carrier housing, ref er to

Fig. 0A-16. T he tag car ries the Holden part num ber

for the final drive ass embly, the final drive ratio and

the serial number of the final drive assembly.

Figure 0A-16

9. ADDI TIONAL GENERAL INFORMATIO N

9.1 ELE CTRICAL TRANSIENTS AND RADIO FREQUENCY INTERFERENCE

Electronic circuits are used in VU Series Models to perform a number of functions associated with electronic

cruise control, electronic engine and transmission control systems etc. These circuits can be damaged or

malfunction as a result of electrical transients or excessive Radio Frequency (RF) radiation.

ELECTRICAL TRANSIENTS

Electrical transients are high voltage spikes produced by the sudden switching or interruption of electric currents.

Older style timing lights and battery chargers can produce serious transients, hence, it is important to use only

good quality equipment suitable for use with electronic systems.

It is also good practice to ensure that the battery is disconnected before using a battery charger.

Indiscriminate fitting of solenoids, indicators or relays can also cause transients.

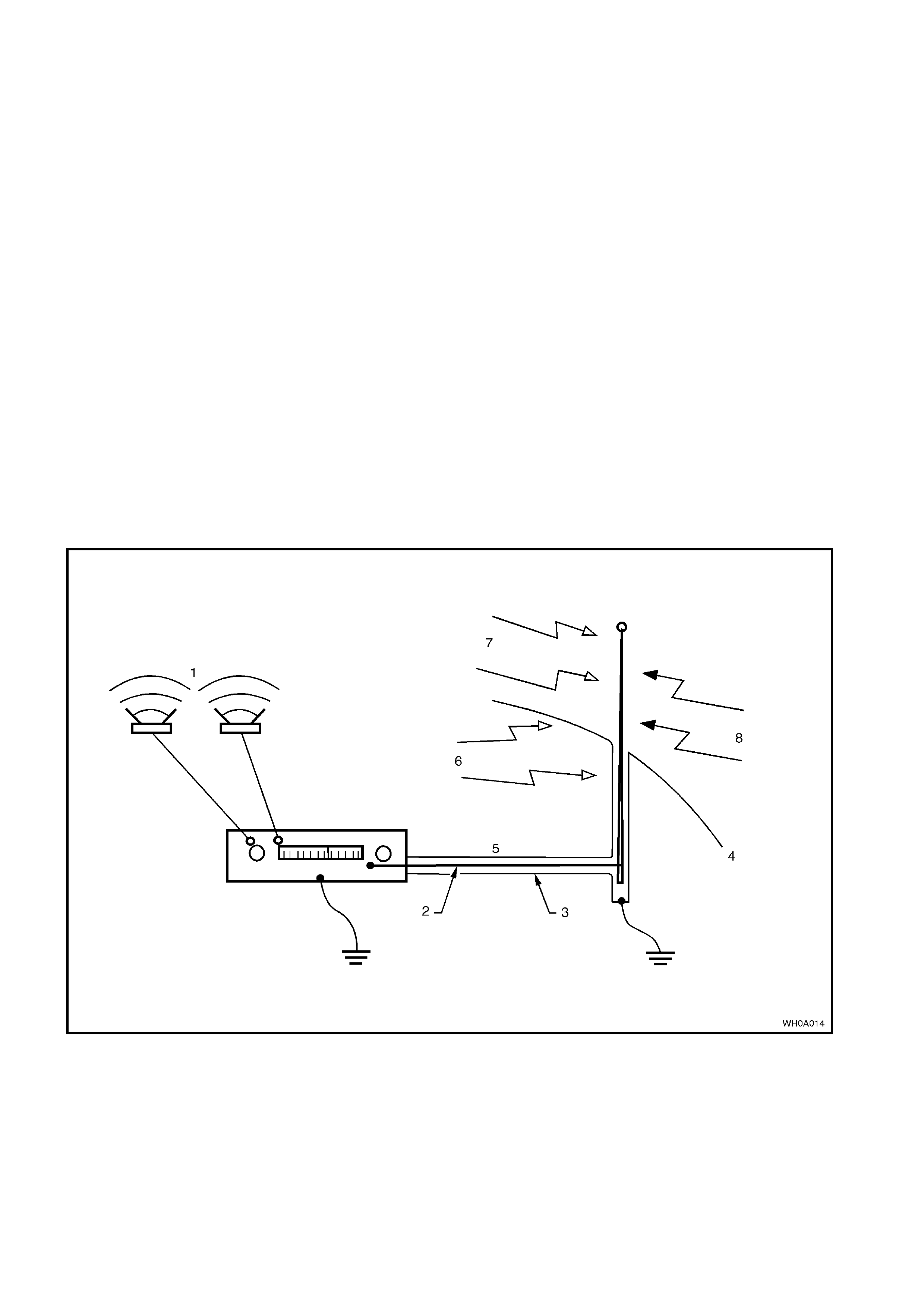

RADIO FREQUENCY INTERFERENCE

One of the chief sources of RF interference is the ignition system. Other sources include CB radio and radio

telephones. The following are normally used to suppress RF interference.

Resistors eg. High Tension Cables and Connectors.

Capacitors and Choke Coils.

Metal Braid for screening leads or suppression covers made from conductive material for screening equipment.

To prevent damage to equipment:

Do not replace interference suppressed high tension ignition cables or connectors with unsuppressed types.

Do not remove or reposition interference suppression filters or capacitors.

Figure 0A-17

Legend

1. Music

2. Core

3. Braid

4. Body

5. Antenna cable

6. Internal Interference

7. Signal from station

8. External interference

9.2 STATIC ELECTRICITY

Care should be exercised when handling electronic equipment e.g. the powertrain control module (PCM), to

avoid touching the terminals unnecessarily. Static electricity, which is present on every person, can cause

damage to some electronic components.

9.3 PUSH OR TOW STARTING

Do not push or tow start VU Ser ies Models. Pus h or tow starting can result in unburned f uel passing through the

exhaust to the catalytic converter, causing damage to the converter.