SECTION 10 - WHEELS AND TYRES

IMPORTANT:

Before p erf orming any Service O p eratio n o r ot her p rocedu re describ ed in th is Sect ion , refer t o Sect ion

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1. GENERAL I NFORMATION

All information relating to the wheels and tyres on VU Series Models not detailed in this Section carries over

from the information published for VX Series Models. Refer to Section 10 WHEELS AND TYRES in the VX

Series Service Information.

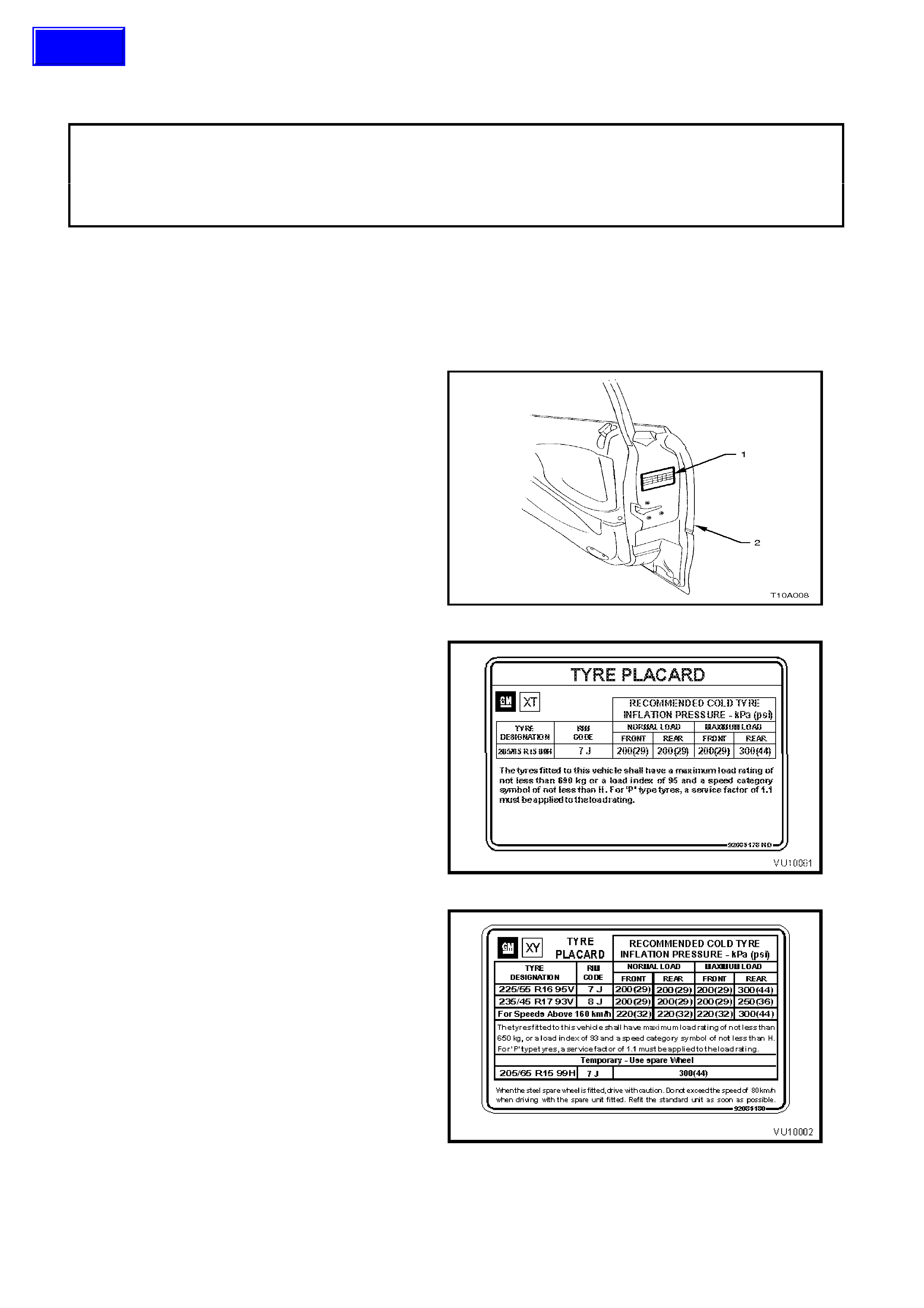

Wheel and tyre sizes, inflation pressures and load

capacity are specif ied on a tyr e placard (1), loc ated

on the end surface of the right-hand front door (2).

VU Series Models are fitted with unique tyre

placards.

For Utility, refer to Fig. 10-2.

For S and SS refer to Fig. 10-3.

Correct sizes and pressures are the subject of an

Australian Design Rule (ADR) and must be

observed at all times.

Figure 10-1

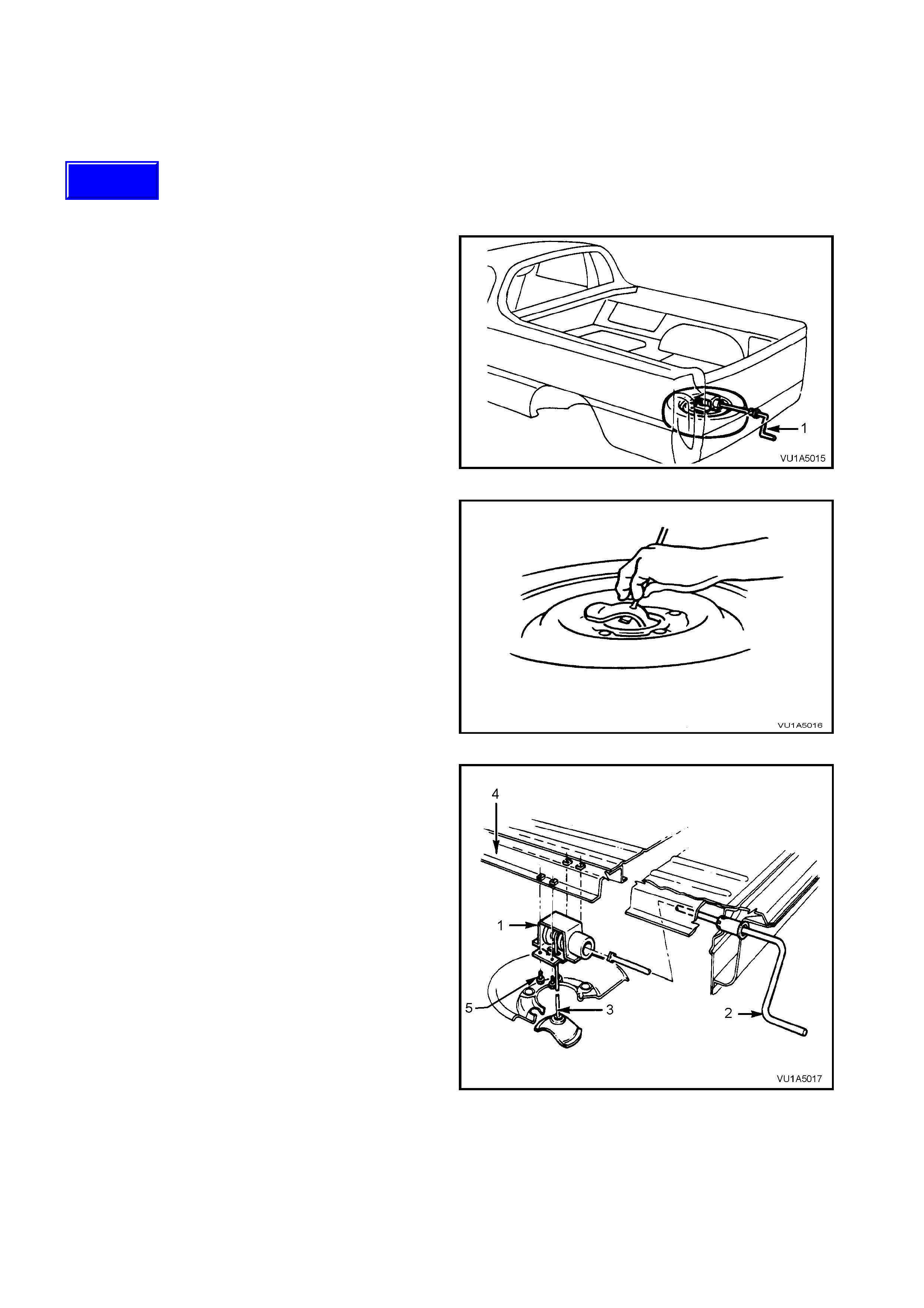

VU Series Utility Models feature 7.0J x 15 steel

wheels and centre cap with 205/65 R15 99H

tubeless tyres as used on VX Series Taxi pack

vehicles.

Fig. 10-2 illustrates tyre placard as fitted to VU

Series Utility.

Figure 10-2

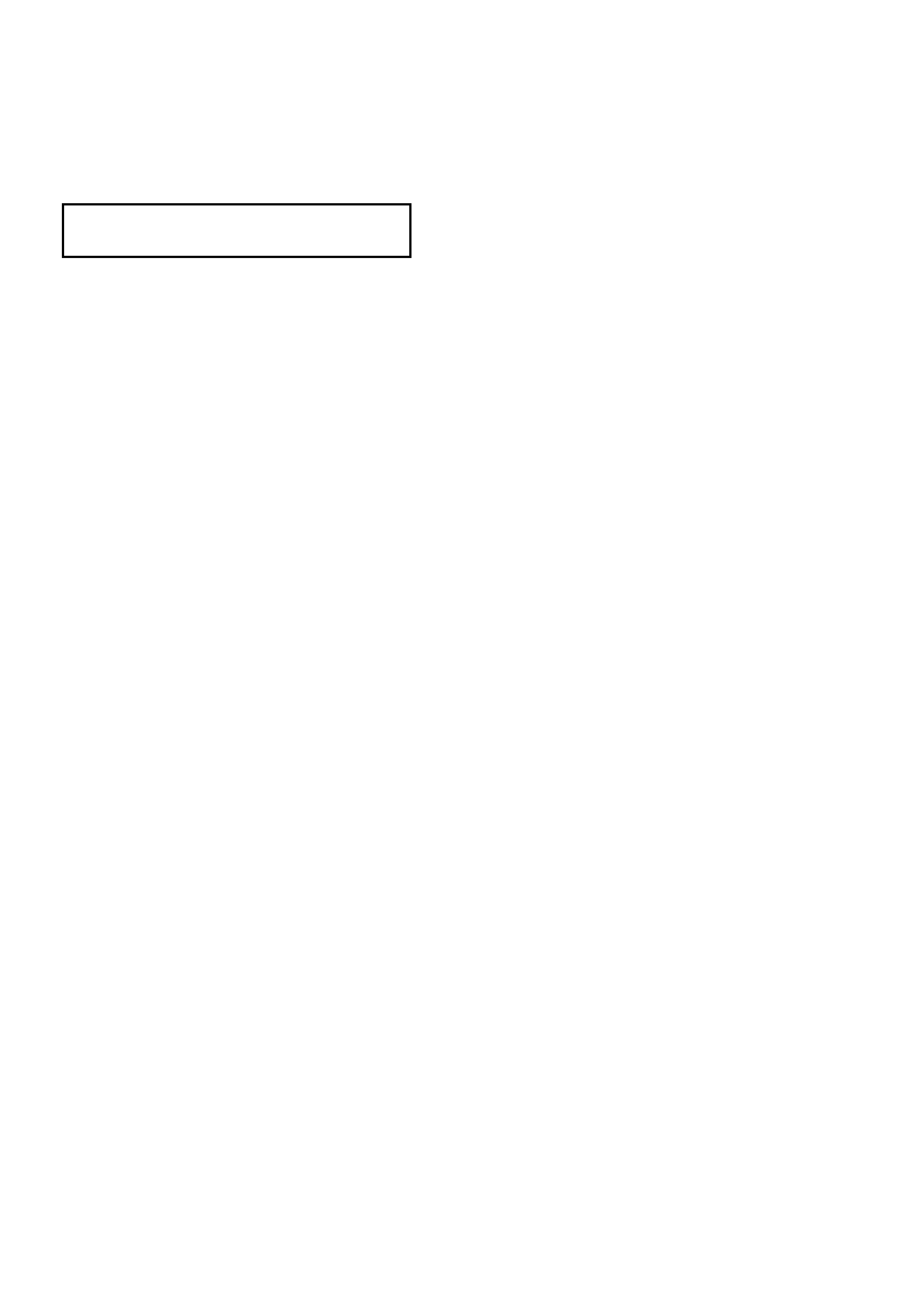

VU Series S Models are fitted with 7.0J x 16 alloy

wheels as fitted to VX Series S Models fitted with

unique 225/55 R16 95V tyres.

VU Series SS Models use the 8.0J x 17 alloy

wheels fitted with 235/45 R17 93V tyres as used on

VX Series SS models.The spare wheel and tyre

fitted to all VU Series Models use the 7.0J x 15

steel wheel fitted with 205/65 R15 99H tyres as

fitted to the Utility model.

Fig. 10-3 illustrates tyre placard as fitted to VU

Series S and SS.

Figure 10-3

Techline

2. SERVICE OPERATIONS

A new spare tyre hoist is fitted to all VU Series Models. For infor m ation regarding the service operations relating

to the Wheels and T yres as fitted to VU Ser ies models not detailed in this Sec tion, ref er to Section 10 WHEELS

AND TYRES in the VX Series Service Information.

2.1 SPARE WHEEL HOIST

REMOVE

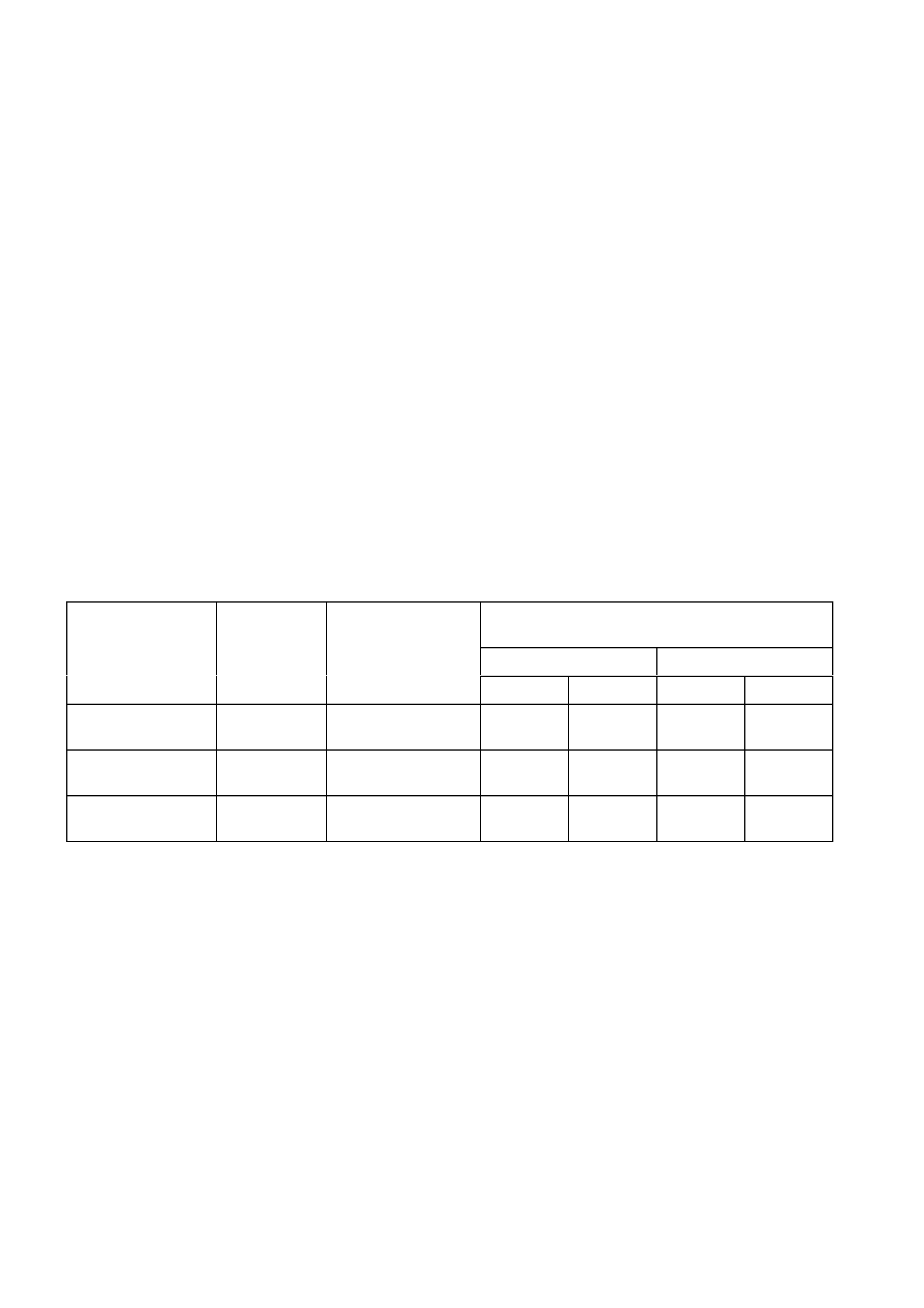

1. Insert the handle (1) into the aperture located

beside the licence plate.

Figure 1A4-4

2. Rotate the handle in a counter-clockwise

direction until the spare wheel is completely

lowered and some slack exists in the cable.

3. Support the wheel with one hand. Tilt the wheel

retainer upward, allowing the retainer to pass

through the wheel centre.

4. Remove the wheel from below the vehicle.

Figure 1A4-5

5. Remove the four screws (5) and lower the

hoist (1).

Legend

1. Hoist.

2. Handle.

3. Cable.

4. Frame.

5. Screw (four places).

Figure 1A4-6

Techline

REINSTALL

Reinstallation is the reverse of the removal

procedure.

NOTE: Ensure that the hoist is installed with the

square coupling towards the rear of the vehicle.

Tighten hoist attaching screws to the correct

torque specification.

SPARE WHEEL HOIST

ATTACHING SCREW 15-35 Nm

TORQUE SPECIFICATION

3. DIAGNOSIS

All inf ormation r egarding the diagnosis of the wheels and tyres fitted to VU Series Models carries over f rom VX

Series Models. For information regarding the diagnosis of the wheels and tyres as fitted to VU Series Models,

refer to Section 10 WHEELS AND TYRES in the VX Series Service Information.

4. SPECIFICATIONS

STEEL WHEEL

Rim Width Code...................................................... 7.0J (ISO)

Diameter Code........................................................ 15

Maximum Permissible Radial Run-out............... 0.6 mm

Maximum Permissible Lateral Run-out.............. 0.8 mm

Offset ................................................................. 43 mm (pos)

ALLOY WHEELS

Rim Width Code...................................................... 7.0J 8.0J

Diameter Code........................................................ 16 17

Maximum Permissible Radial Run-out

S......................................................................... 0.35 mm

SS ...................................................................... 0.35 mm

Maximum Permissible Lateral Run-out

All models........................................................... 0.35 mm

Offset

S......................................................................... 48 mm (positive)

SS ...................................................................... 48 mm (positive)

TYRES

Dynamic Balancing – All Models

Maximum Permissible Residual

Imbalance (Per Side) ......................................... 8 g

Maximum Tyre Load (per tyre)

Utility & Spare................................................... (205/65R15 99H) 675 kg

S....................................................................... (225/55R16 95V) 630 kg

SS .................................................................... (235/45R17 93V) 630 kg

RECOMMENDED COLD INFLATION

kPa

Normal Load Maximum Load

MODEL

WHEEL

TYRE

DESIGNATION Front Rear Front Rear

Utility 7.0J x 15

Steel 205/65 R15 99H 200 200 200 300

S 7.0J x 16

Alloy 225/55 R16 95V 200

220 (1) 200

220 (1) 200

220 (1) 300

300 (1)

SS 8.0J x 17

Alloy 235/45 R17 93V 200

220 (1) 200

220 (1) 220

220 (1) 250

300 (1)

(1) W her e vehicle is used for cons istent speed in exc ess of 160 k m /h, required cold inf lation pressur es are

to be as indicated.

5. TORQUE WRENCH SPECIFICATIONS Nm

Road Wheel Attaching Nuts.................................................. 110-140

Spare Wheel Hoist Attaching Bolts....................................... 15 - 35