SECTION 12B - LIGHTING SYSTEM

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL DESCRI PTI O N

With the introduction of the VX Series models, the following lighting components have been restyled:

• Front headlamp assemblies.

• Fog lamp assemblies.

• Sedan rear lamp, reflector and licence plate lamp assemblies.

Accord ingly, c ertain s ervice proc edures and s pecif ications f or thes e item s ar e specif ic to VX Series m odels and are

detailed in this Section.

All models continue to be fitted with dual pock et homofocal headlamps with halogen bulbs. However, all headlam p

assemblies now use the latest headlamp reflector technology.

Clear outer lens with complex reflector optics are used on high and low beam lamps for all models, providing a

significant improvement to overall headlamp performance. A bulb shield is permanently attached to the low beam

reflector to reduce glare and enhance the headlamp appearance.

Executive, Acclaim, S and SS models ar e fitted with a ‘teardrop’ style headlam p assem bly. Headlam ps fitted to SS

models have an additional styling feature in that the high/low beam separation bezel is blacked out. Berlina and

Calais models retain a revised slim line style headlamp assembly .

Headlamp adjusters are now integral with the headlamp assembly and are not a serviceable item.

Fog lam p assem blies on SS m odels are now of a circular appearance and are mounted in the front bum per facia.

Circular blanking covers are fitted in place of fog lamp assemblies on S models. Fog lamps on Calais models

rem ain as a rec tangular design m ounted onto the bumper s upport beam behind bumper facia m ounted oval bezels.

However the beam adjustment method and the bulb servicing procedure have changed. The aiming specification

has also been revised.

Rear lamp assemblies on sedan models now have turn signal lamps mounted above the stop/tail lamps and the

back-up lamps have been relocated from the decklid decor panel to the rear lamps. Berlina and Calais models

retain the additional stop/tail light assembly mounted in the revised design decor panel.

On all sedan m odels excluding Berlina and Calais, an ellipse style reflex reflector is fitted into a recess on the left

and right sides of the rear bum per facia. On Berlina and Calais models, the reflex reflector is mounted in the rear

tail lamp assembly.

Licence plate lam ps on all sedan m odels, excluding Berlina and Calais, are mounted into the body coloured decor

panel with clip-in tab holders. On Berlina sedan and Calais models the globe holders are attached to the decor

panel and the globes are accessed by removing the lens cover screws and covers from the decor panel.

Tail lamp as semblies on station wagon models remain unchanged. All inter ior lighting and lighting switches rem ain

unchanged on all models.

For all other information relating to the lighting system refer to Section 12B LIGHTING SYSTEM of the

VT Series I Service Information and of the VT Series II Service Information.

Techline

Techline

2. SERVICE OPERATIONS

2.1 AIMING OF HEADLAMPS AND FOG LAMP S

CAUTION: During headlamp aiming procedures,

do not use cloth or similar material to cover lens

of headlamp assembly not being adjusted.

Damage to headlamp assembly will result if

headlamp beam is obstructed in this manner.

The headlamps and fog lamps (if fitted) must be

correc tly aim ed in order to obtain the m aximum road

illumination and safety that has been built into the

vehicle lighting system. The headlamps and fog

lamps must be checked for correct aim whenever a

bulb or headlamp/fog lamp assembly is replaced,

and after any adjustments or repairs to the f ront end

sheet metal.

Headlamp aiming machines are in general use.

W hen us ing one of these mac hines, ensure that it is

in good condition and car efully follow the instr uctions

of the manufacturer.

Regardless of the method used for checking

headlamp and fog lamp aim, the vehicle must be at

kerb weight, that is, with full fuel level, oil, water and

spare tyre but no passengers. The tyres must be

uniformly inflated to their specified pressure.

NOTE: If the vehicle will regularly carry an unusual

load in the rear compartment or tow a trailer, these

loads should be on the vehicle when the

headlamps/fog lamps are checked.

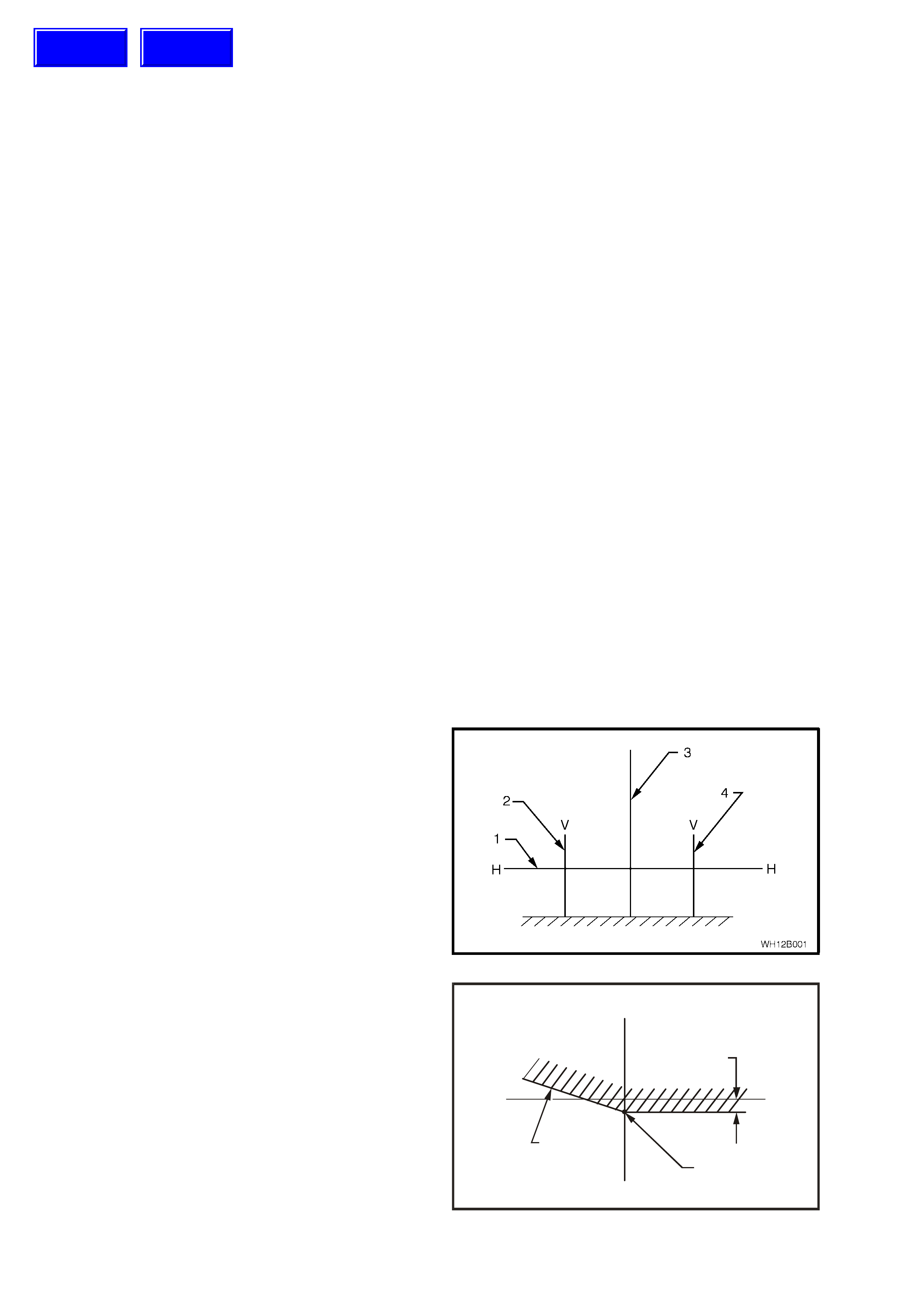

HEADLAMP AIM

1. If suitable test equipment is not available, set

up a screen or use a vertical wall, in

conjunction with a flat horizontal floor. Park

vehicle im m ediately in front of scr een and mark

horizontal (1) and vertical c entre lines of left ( 2)

and right (4) headlamps (corresponding to the

centre of the low beam bulb) and vehicle centre

line (3) on the screen or wall.

2. Park vehicle 10 metres in front of screen or

wall ensuring that the vehicle is aligned with

vehicle centre line mark on screen.

Figure 12B-1

3. Individually aim each headlamp to a point (1)

on its vertical centre line, 110 mm below the

headlamp horizontal centre line. Item 2 is the

cut-off line.

WH12B002

V

HH

V

110 m m

2

1

Figure 12B-2

Techline

Techline

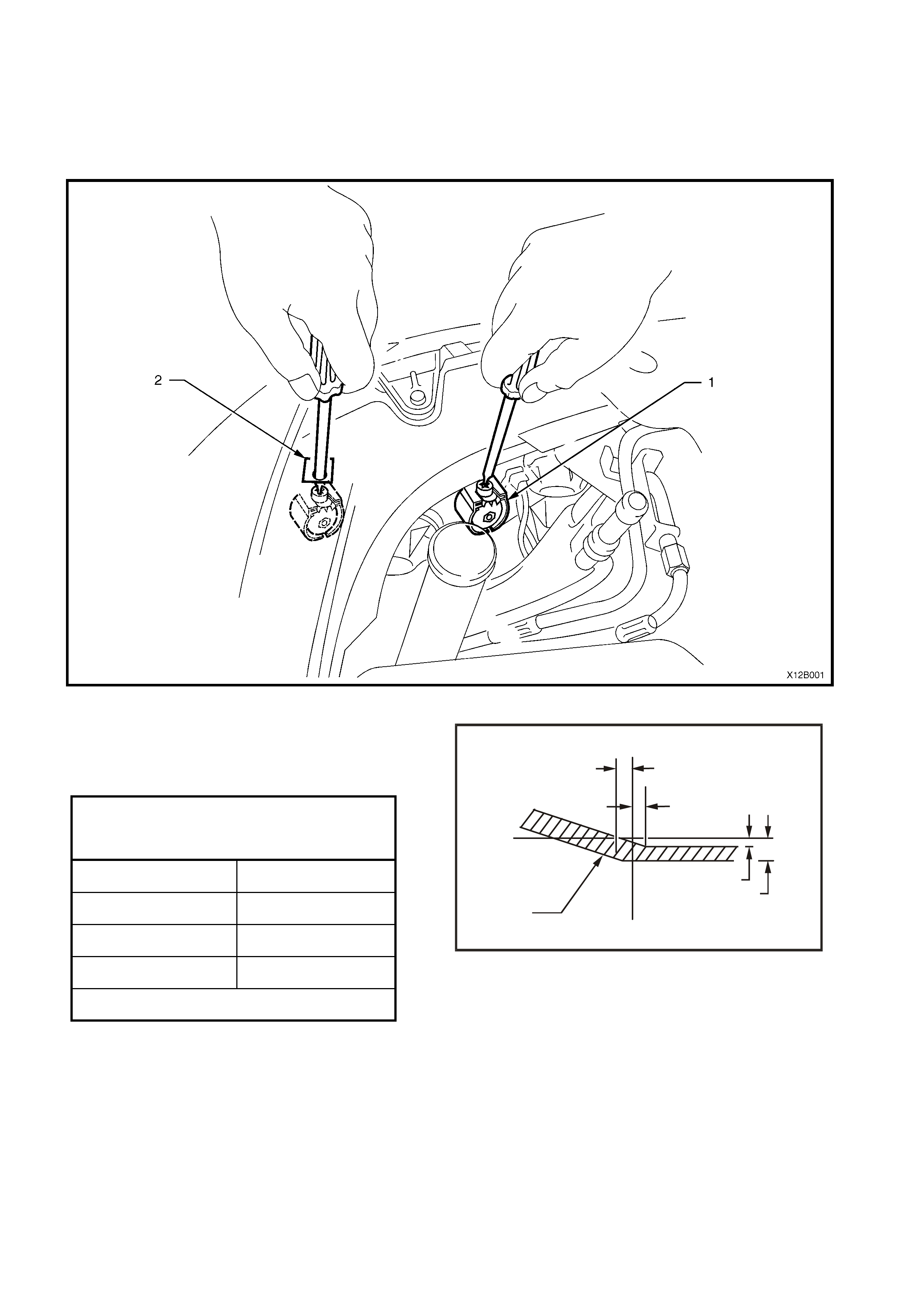

a. Adjust inboard adjuster (1) to achieve

correct vertical beam height.

b. Adjust outboard adjuster (2) to centralise

beam.

Aiming directions for each adjuster are visible

on the headlamp assembly.

Figure 12B-3

4. The allowable variations on headlamp aiming

point settings shown in Fig. 12B-1 are

specified as follows:

NOTE:Cut-off line must be within zone (1).

WH12B004

V

H

H

V

1V2

V1

HL

HR

Figure 12B-4

HEADLAMP AIMING

Acceptable Variations In Headlamp

Aiming Points

HL 100 mm

HR 0 mm

V1 100 mm

V2 120 mm

Maximum allo wable vertical vari ati on between any

pair of headlamps i s not to exceed 20 mm

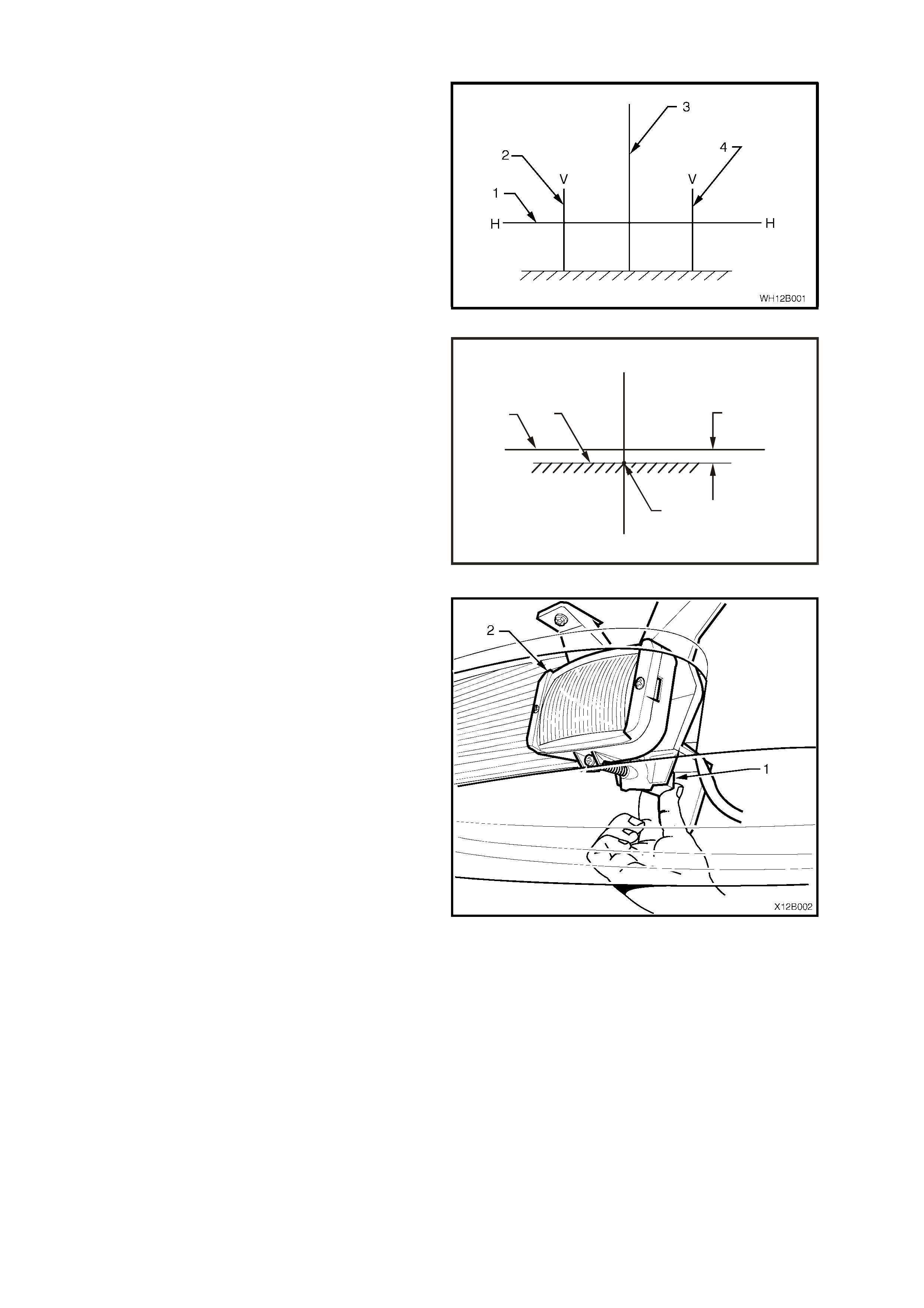

FOG L AMP AIM

1. If suitable test equipment is not available, set

up a screen or use a vertical wall, in

conjunction with a flat horizontal floor. Park

vehicle im m ediately in front of scr een and mark

horizontal (1) and vertical c entre lines of left ( 2)

and right (4) fog lamps, and vehicle centre

line (3) on the screen.

2. Park vehicle 10 metres in front of screen,

ensuring the vehicle is aligned with centre line

mark on screen.

Figure 12B-5

3. Turn fog lamps on. Individually aim each fog

lamp to a point on its vertical centre line (2),

with the cut off line ( 3) 200 m m below fog lamp

horizontal centre line (1).

WH12B005

200 m m

2

3

1

V

HH

V

Figure 12B-6

NOTE: There is no provision for horizontal

adjustment. Fog lamps are fixed to vertical centre

line.

On Calais models , adjustm ent is carried out by

rotating the adjuster knob (1) located below the

lamp housing (2). W hen facing the front of the

vehicle, turning the adjuster anti-clockwise

lowers the beam, turning clockwise raises the

beam. The adjustment can be carried out by

reaching under the bumper facia and rotating

the adjuster by hand.

Figure 12B-7

On SS models, fog lamp aim adjustment is

carried out by rotating the adjuster screw (1)

located above the lamp housing (2). Turning

the adjuster screw anti-clockwise lowers the

beam, turning clockwise raises the beam. The

adjustm ent can be car ried out by using a No. 2

Phillips head screw driver.

Figure 12B-8

2.2 HEADLAMP BULB

REPLACE

1. Open engine compartment.

Right-hand side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

Left-hand side only (with GEN III V8 engine)

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Right and left-hand sides

2. From inside engine compartment, remove dust

cap (1) from rear of headlamp housing

assembly (2) by turning dust cap anti-

clockwise, and pulling away from housing. If

dust cap seal stays on headlamp housing,

remove seal and install onto cap.

3. Carefully pull wiring harness connector (3) from

rear of bulb (4).

Figure 12B-9

4. Depres s and unc lip bulb spring retainer (1) and

pivot clear of bulb. Remove bulb (2) from

reflector.

NOTE: Do not handle quartz envelope of headlamp

bulb. If touched accidentally, wipe imm ediately with

methylated spirits or bulb performance will

deteriorate.

5. Install new bulb (2) into reflector, ensuring

correct mating of bulb base locating tangs with

reflector cut-outs. Install spring retainer (1) and

wiring harness connector.

NOTE: The different sized locating tangs on the

bulb base and mating c ut-outs in the ref lector allow

the bulb to seat correctly into the reflector in one

location only. This ensures correct relationship of

the bulb to the reflector.

6. Inspec t rubber seal in dust c ap to ensure that it

is not dam aged and that it is s eated corr ectly in

cap. Replace seal if damaged.

7. Install cap onto rear of headlamp housing with

cap tang located facing down. Lock cap into

place by turning clockwise.

Right-hand side only

Position battery in correct location and install

battery retaining clamp. Secure battery

retaining clamp and reconnect battery

terminals.

Right and left-hand sides

8. Check headlamp operation and re-aim

headlamps (headlamp aim varies from bulb to

bulb), refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS in this Section.

Left-hand side only (with GEN III V8 engine)

Install air inlet snorkel into air cleaner housing

by aligning s nork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

Figure 12B-10

2.3 PARKING LAMP BULB

REPLACE

1. Open engine compartment.

Right-hand side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

Left-hand side only (with GEN III V8 engine)

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Right and left-hand sides

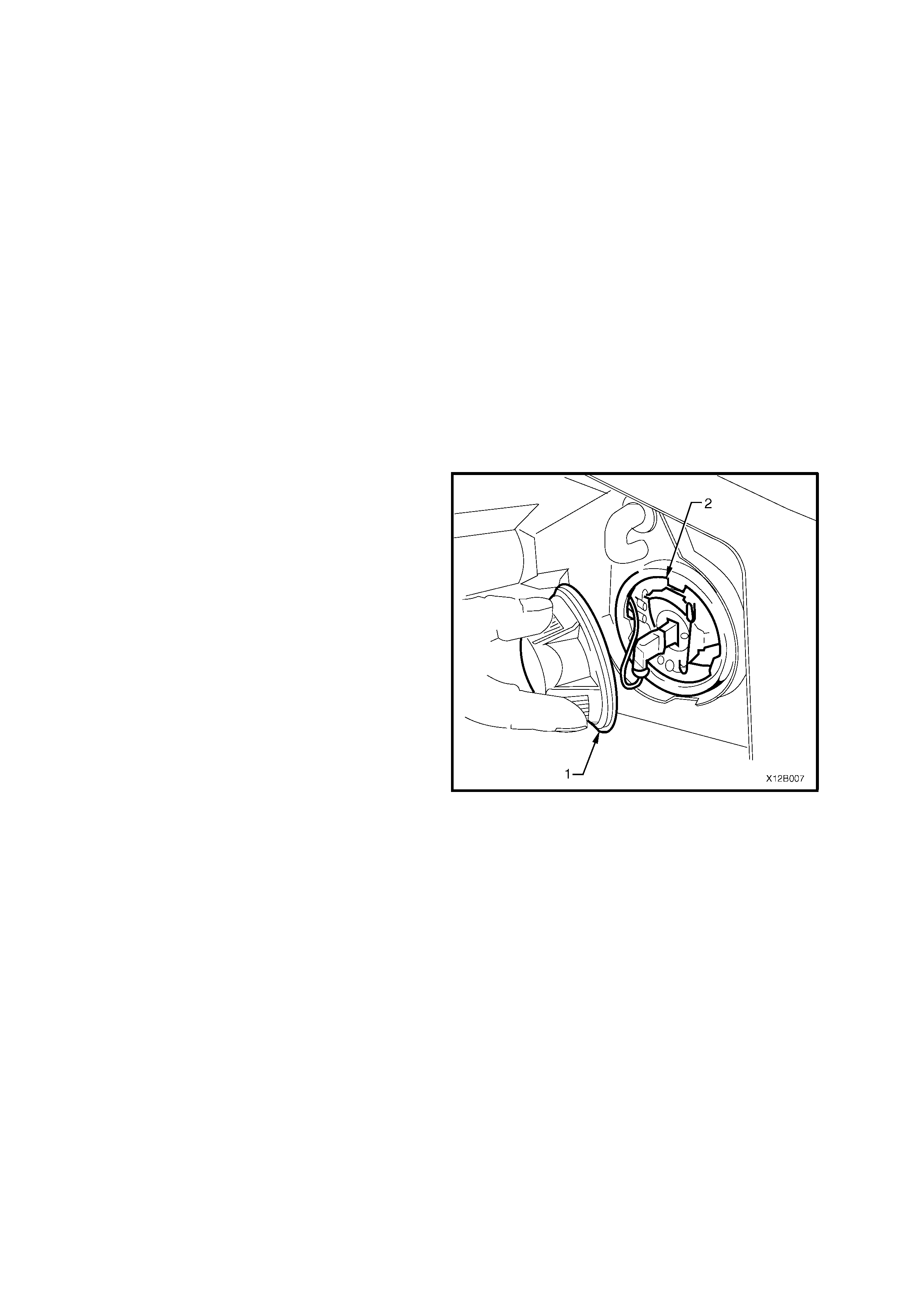

2. From inside engine compartment, remove dust

cap (1) from rear of headlamp housing

assembly (2) by turning dust cap anti-

clockwise, and pulling away from housing. If

dust cap seal stays on headlamp housing,

remove seal and install onto cap.

Figure 12B-11

3. Rem ove par k ing lam p sock et (1) from ref lector.

Alternatively, if access is difficult, remove the

headlamp bulb, and use index finger to

carefully push the bulb and holder from the

parking lamp socket. Pull bulb (2) from socket.

4. Insert new bulb into socket and install socket

into reflector.

5. Inspec t rubber seal in dust c ap to ensure that it

is not dam aged and that it is s eated corr ectly in

cap.

Install cap onto rear of headlamp housing and

lock cap into place by turning clockwise.

Right-hand side only

Position battery in correct location and install

battery retaining clamp. Secure battery

retaining clamp and reconnect battery

terminals.

Right and left-hand sides

6. Check parking lamp operation.

Left-hand side only (with GEN III V8 engine)

Install air inlet snorkel into air cleaner housing

by aligning s nork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

Figure 12B-12

2.4 INBOARD HIGH BEAMLAMP BULB

REPLACE

1. Open engine compartment.

Right-hand side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to headlamp dust cap.

Left-hand side only (with GEN III V8 engine)

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Right and left-hand sides

2. From inside engine compartment, remove

inboard high beam dust cap (1) from rear of

headlamp hous ing ass em bly (2) by tur ning dust

cap anti-clockwise, and pulling away from

housing. If dust cap seal stays on headlamp

housing, remove seal and install onto cap.

Figure 12B-13

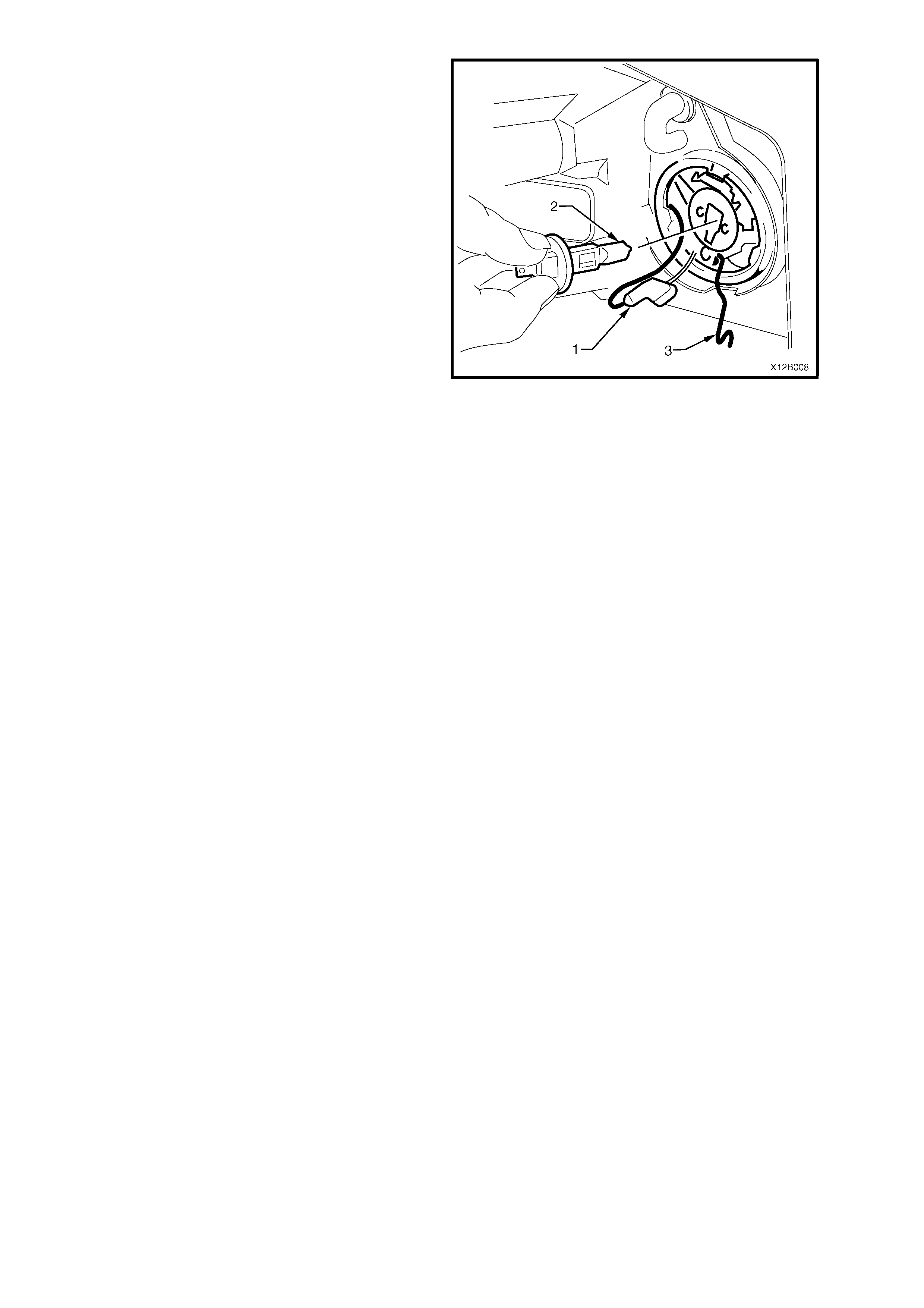

3. Disconnect harness connector (1) from

bulb (2). Depress and unclip bulb retaining

clip (3) to release, and allow to fall clear of

bulb.

NOTE: Do not handle quartz envelope of inboard

high beam bulb. If touched accidentally, wipe

immediately with methylated spirits or bulb

performance will deteriorate.

4. Pull out bulb. Install new bulb into reflector,

ensuring that locating lug on bulb housing

aligns with square edge on bulb and locating

lugs on bulb mate with holes on bulb housing.

Connect bulb retaining clip. Connect bulb

harness connector.

5. Inspec t rubber seal in dust c ap to ensure that it

is not damaged and that it is seated correctly.

Install dust cap onto rear of headlamp housing

and lock into place by turning clockwise.

Right-hand side only

Position battery in correct location and install

battery retaining clamp. Secure battery

retaining clamp and reconnect battery

terminals.

Figure 12B-14

Right and left-hand sides

6. Check inboard high beam lamp operation.

Left-hand side only (with GEN III V8 engine)

Install air inlet snorkel into air cleaner housing

by aligning s nork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

2.5 FRONT TURN SIGNALLAMP BULB

REPLACE

NOTE: If replacing a front turn signal lamp bulb,

ensure the correct type is fitted. For all models, the

bulb glass is coloured orange and has offset locating

pins.

1. Open engine compartment.

Right-hand side headlamp only

V6 engine models:

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to turn signal bulb socket.

GEN III V8 engine models:

Remove four scrivets securing upper radiator

support cover and remove cover.

Disconnect battery terminals, remove battery

retaining clamp and manoeuvre battery to gain

access to turn signal bulb socket.

Left-hand side only (with GEN III V8 engine)

Remove air inlet snorkel from air cleaner

housing by pulling snorkel straight out from air

cleaner housing.

Right and left-hand sides

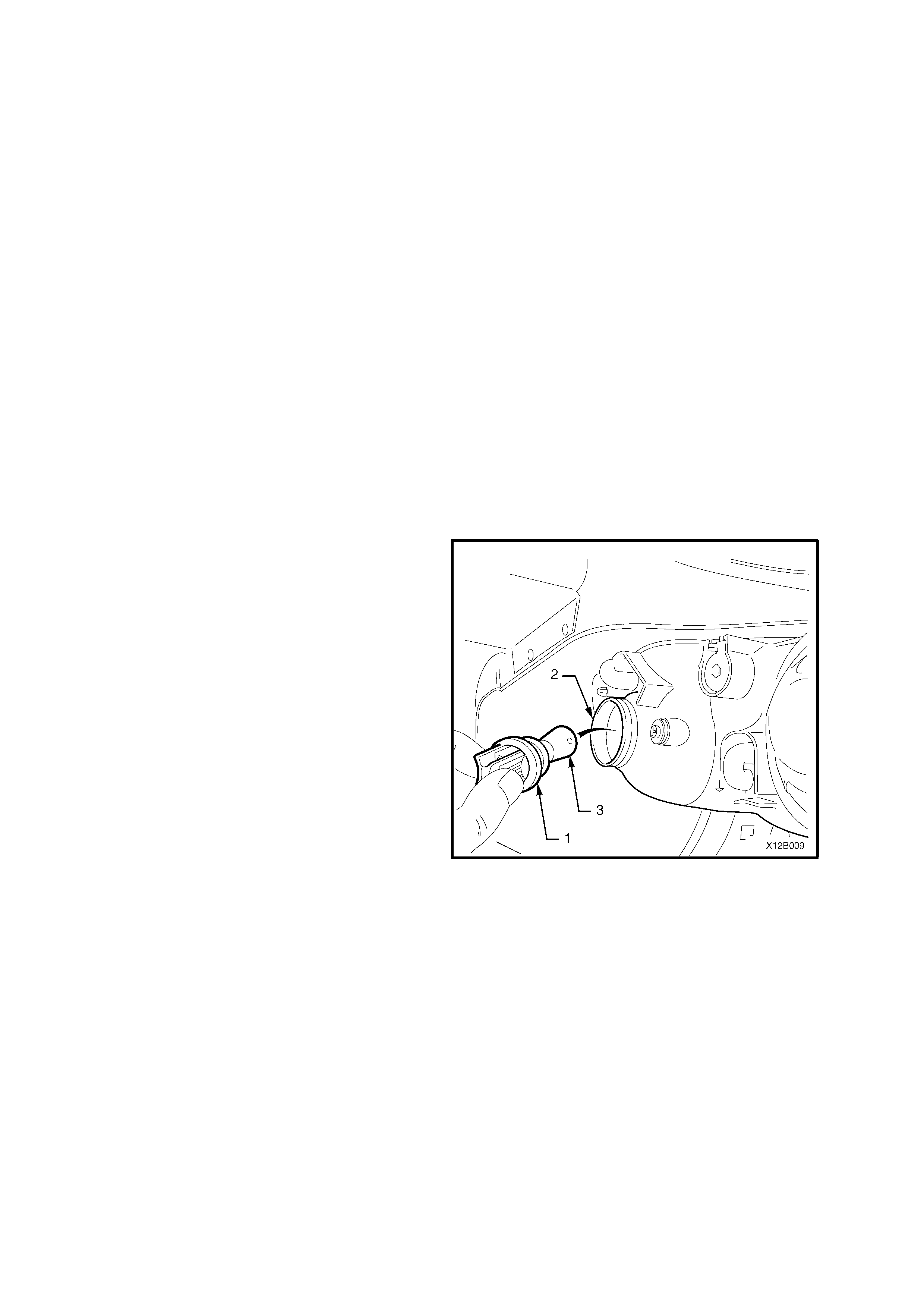

2. From inside engine compartment, twist to

release bulb socket (1) from behind headlamp

assembly (2).

3. Depress bulb into socket and rotate to remove.

4. Inspect O-ring on bulb socket for damage and

correct seating. Replace O-ring if necessary.

5. Install new bulb (3) into socket, install socket

into housing and twist to lock into position.

Right-hand side only

Position battery in correct location and install

battery retaining clamp. Secure battery

retaining clamp and reconnect battery

terminals.

Right and left-hand sides

6. Check turn signal lamp operation.

Left-hand side only (with GEN III V8 engine)

Install air inlet snorkel into air cleaner housing

by aligning s nork el with air cleaner housing and

pushing firmly into place.

Position upper radiator support cover and

install four scrivets to secure cover.

Figure 12B-15

2.6 HEADLAMP AND TURN SIGNAL/PARKING LAMP ASSEMBLY — EXECUTIVE,

ACCLAIM, S AND SS MODELS

REMOVE

1. Open engine compartment.

Right-hand side headlamp only

Disconnect the negative terminal from battery and move negative battery cable clear of battery. Remove the

screw sec ur ing engine cooling f an f us ible links holder to upper radiator s upport panel and move the holder clear

of the headlamp assembly.

Right and left-hand sides

2. F rom inside engine c om partm ent, disc onnect wiring harness c onnector f rom headlam p as sem bly. Remove turn

signal lamp bulb socket from headlamp assembly.

3. Remove the two scrivets from behind number plate, refer to Fig. 12B-16 (Executive and Acclaim) or Fig. 12B-17

(S and SS).

4. SS Model: From behind the bumper facia assembly, disconnect the fog lamp wiring harness connectors (one

place for each lamp).

5. Remove screws securing facia sides to front fender wheel arch opening and front panel assembly.

6. With the facia supported, pull the facia side members out, disconnect the facia side supports, then slide the

facia forward removing the facia assembly.

7. Place the front bumper bar facia assembly face down on a clean protective surface.

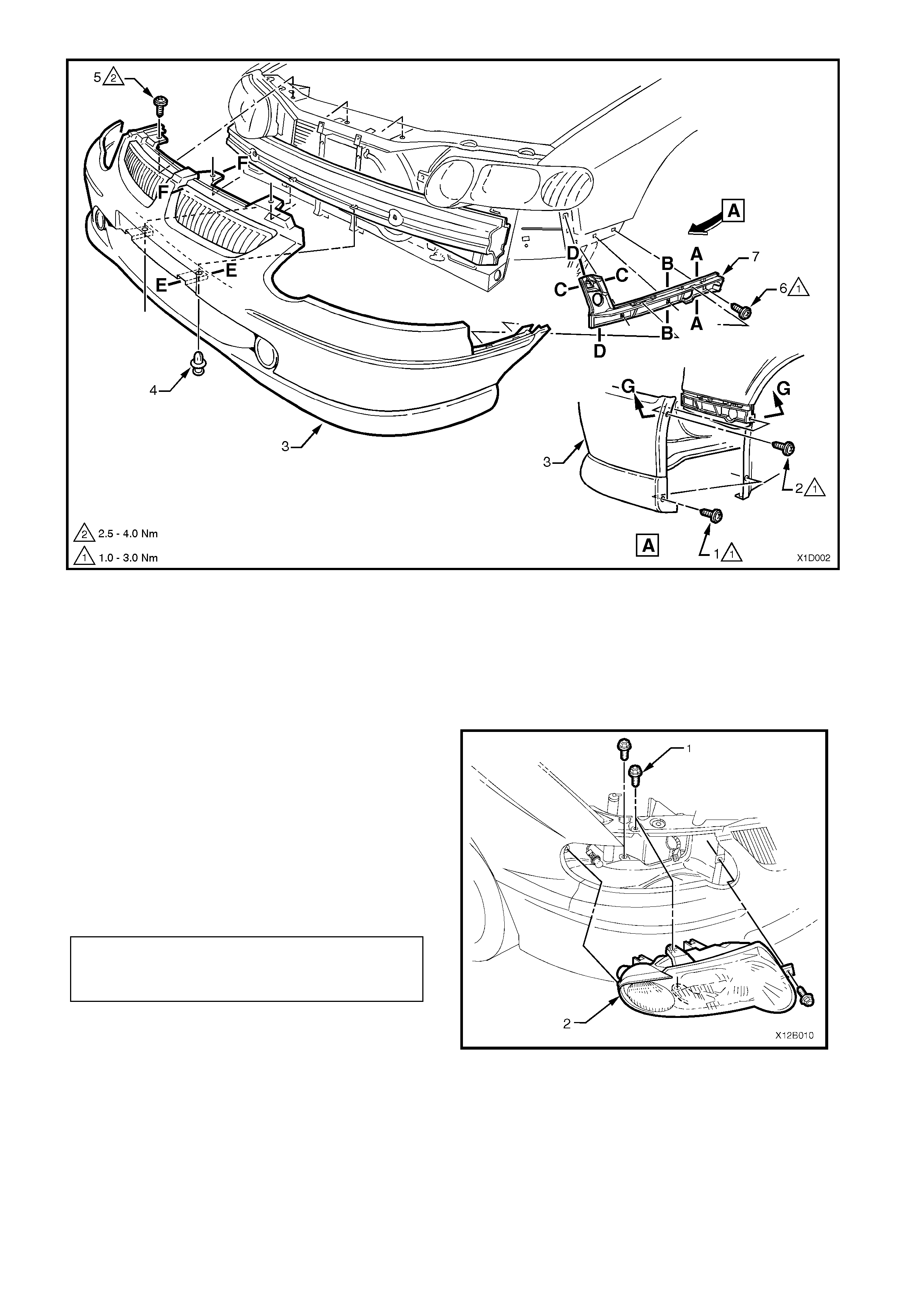

Figure 12B-16 FRONT BUMPER FACIA – EXECUTIVE and ACCLAIM

1. Screw (1 place each side)

2. Screw (1 place each side)

3. Facia assembly

4. Scrivet (2 places)

5. Screw (3 places)

6. Screw (3 places each side)

7. Front bumper guide rail assembly

NOTE: For Sectional views A-A to G-G,

refer to Section 1D BUMPER BARS in

the VX Series Service Information.

Techline

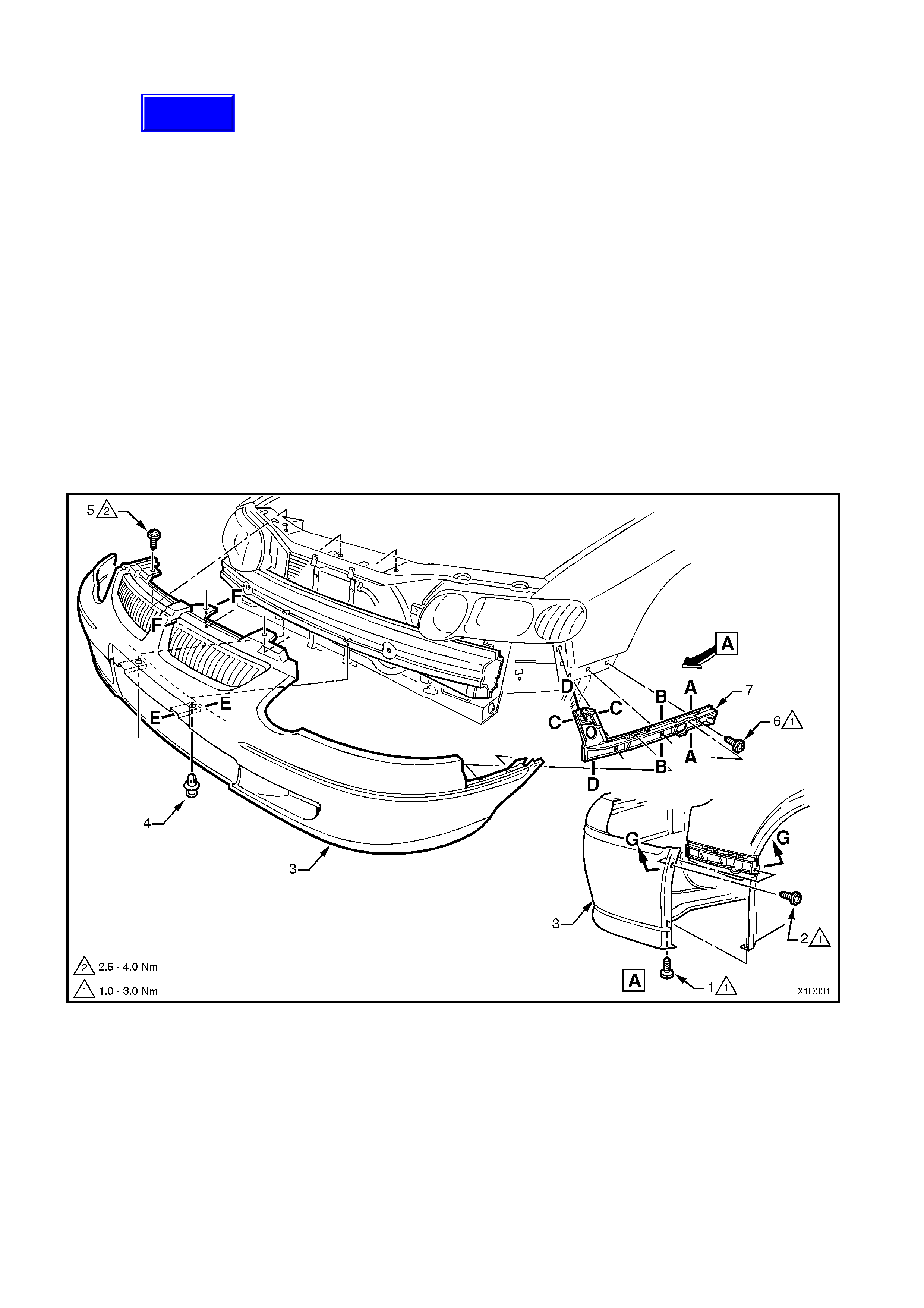

Figure 12B-17 FRONT BUMPER FACIA – S and SS

1. Screw (1 place each side)

2. Screw (1 place each side)

3. Facia assembly

4. Scrivet (2 places)

5. Screw (3 places)

6. Screw (3 places each side)

7. Front bumper guide rail assembly

NOTE: For Sectional views A-A to G-G,

refer to Section 1D BUMPER BARS in

the VX Series Service Information.

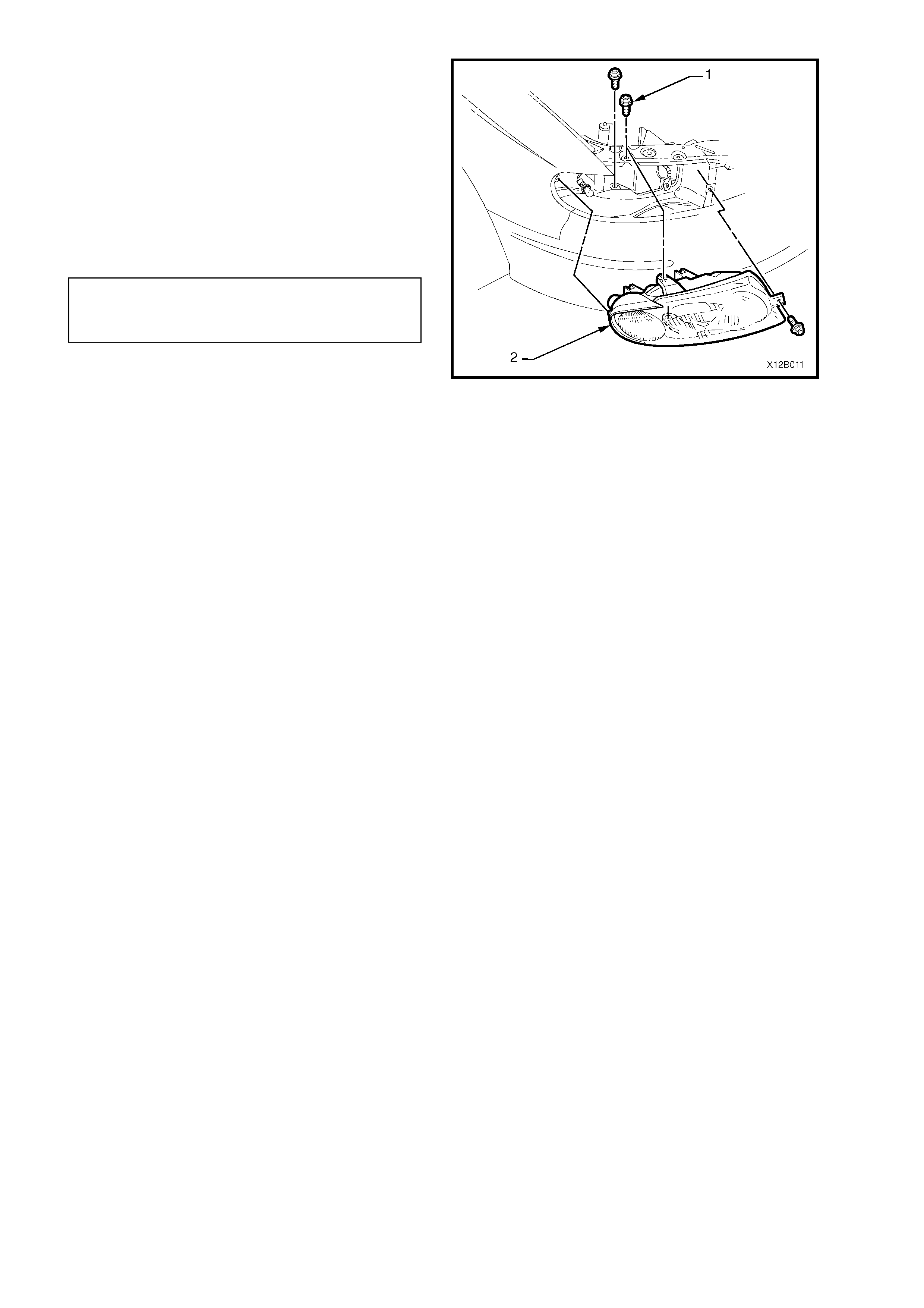

8. Remove three headlamp retaining screws (1)

and remove headlamp and turn signal/parking

lamp assembly (2).

REINSTALL

Installation of the headlam p and turn s ignal/parking

lamp assembly is the reverse of removal

procedure, noting the following points:

1. Install headlamp and turn signal/parking lamp

assembly (2) and tighten retaining screws (1) to

the correct torque specification.

2. Install front bumper facia assembly by

snapping the facia onto the retainers at guide

rails, one side at a time.

3. Ensure correct fender, hood and headlamp

clearance, adj ust f acia if nec essar y, refer to VX

Series Body Structure Repair Supplement.

4. Reconnect all wiring harness connectors and

check operation of headlamp and turn

signal/parking lamps and fog/cornering lamps.

Check headlamp (and fog lamps) aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

in this Section.

Figure 12B-18

HEADLAMP AND TURN

SIGNAL /PARKING LAMP

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION

2 – 5 Nm

2.7 HEADLAMP AND TURN SIGNAL/PARKING LAMP ASSEMBLY — BERLINA AND

CALAIS MODELS

REMOVE

1. Open engine compartment.

Right-hand side headlamp only

Disconnect the negative terminal from battery and move negative battery cable clear of battery. Remove the

screw sec ur ing engine cooling f an f us ible links holder to upper radiator s upport panel and move the holder clear

of the headlamp assembly.

Right and left-hand sides

2. F rom inside engine c om partm ent, disc onnect wiring harness c onnector f rom headlam p as sem bly. Remove turn

signal lamp bulb socket from headlamp assembly.

3. Remove the grille insert, refer to Section 1C RADIATOR GRILLE in the VX Series Service Information.

4. Remove the three scrivets securing the bumper facia assembly to the support beam, refer to Fig.12B-19.

5. Remove screws securing facia sides to front fender wheel arch opening and front panel assembly.

6. With the facia supported, pull the facia side members out, disconnect the facia side supports, then slide the

facia forward removing the facia assembly.

7. If necessary, lift off the front centre support assembly.

8. Place the front bumper bar facia assembly face down on a clean protective surface.

Figure 12B-19 FRONT BUMPER FACIA – BERLINA and CALAIS

1. Screw (1 place each side)

2. Screw (1 place each side)

3. Facia assembly

4. Scrivet (3 places)

5. Support assembly – centre

6. Screw (3 places each side)

7. Front bumper guide rail assembly

NOTE: For sectional views A-A to F-F,

refer to Section 1D BUMPER BARS in

the VX Series Service Information.

Techline

9. Remove three headlamp retaining screws (1)

and remove headlamp and turn signal/parking

lamp assembly (2).

REINSTALL

Installation of the headlam p and turn s ignal/parking

lamp assembly is the reverse of removal

procedure, noting the following points:

1. Install headlamp and turn signal/parking lamp

assembly (2) and tighten retaining screws (1) to

the correct torque specification.

2. Install front bumper facia assembly by

snapping the facia onto the retainers at guide

rails, one side at a time.

3. Ensure correct fender, hood and headlamp

clearance, adjust facia if necessary, refer to

VX Series Body Structure Repair Supplement.

4. Reconnect all wiring harness connectors and

check operation of headlamp and turn

signal/parking lamps and fog/cornering lamps.

Check headlamp (and fog lamps) aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG LAMPS

in this Section.

Figure 12B-20

HEADLAMP AND TURN

SIGNAL/PARKING LAMP

ASSEMBLY RETAINING SCREW

TORQUE SP ECIFICATION 2 – 5 Nm

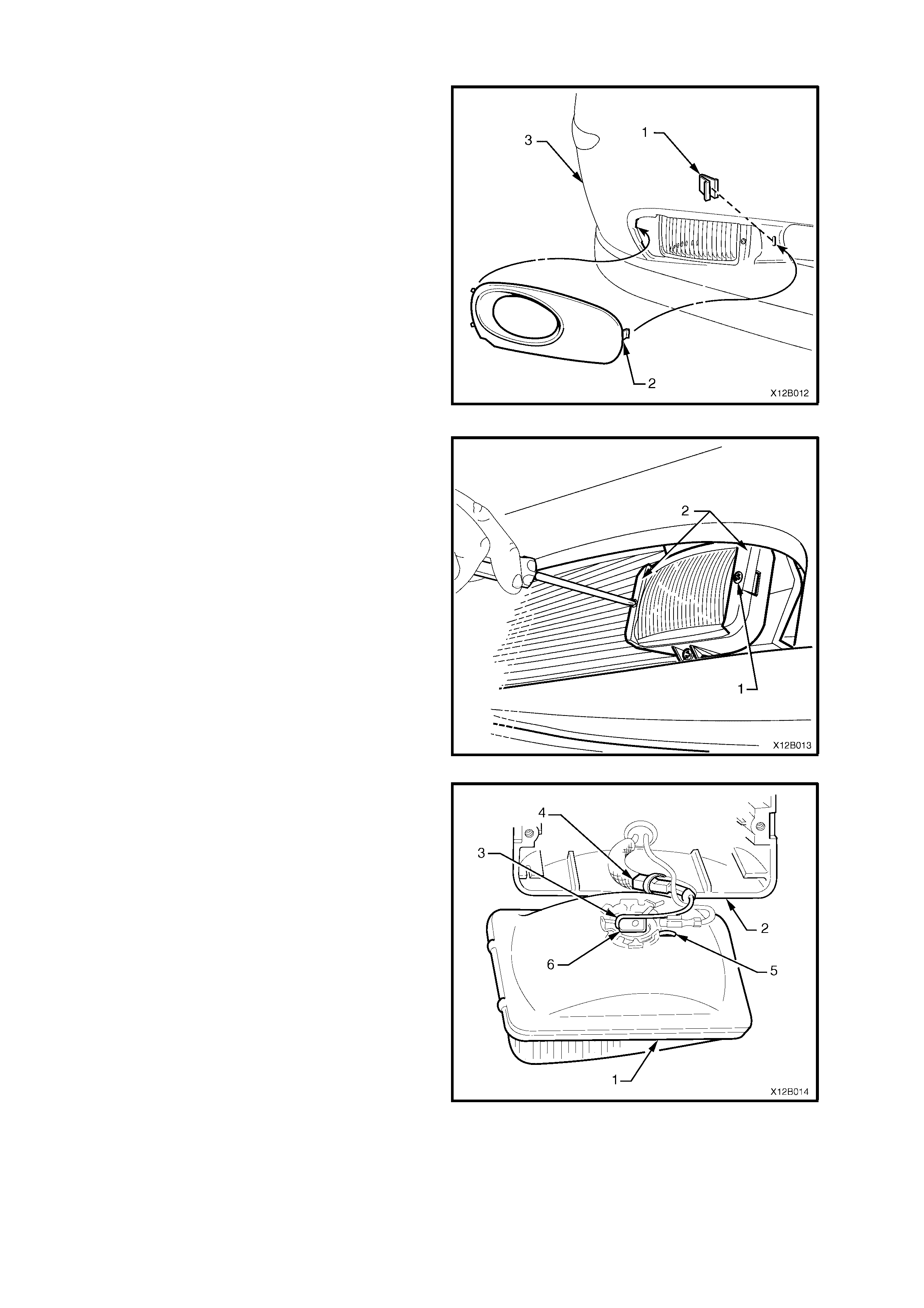

2.8 FOG LAMP BULB — CALAIS MODEL

REPLACE

1. Remove the clip (1) s ec uring fog lam p bezel (2)

to facia (3) and remove bezel.

Figure 12B-21

2. Remove lens and reflector assembly to housing

end cap retainer screws (1), remove end caps

(2).

Figure 12B-22

3. Pull lens and reflector assembly (1) out from

housing (2).

4. Disconnect bulb lead (3) from wiring harness

connector (4) located inside insulating sheath.

5. Squeeze halves of spring retainer (5) together

and pivot spring back ward clear of bulb. Lif t out

bulb (6) and remove.

NOTE: Do not handle quartz envelope of bulb. If

touched, wipe immediately with methylated spirits

or bulb performance will deteriorate.

6. Connect new bulb lead to wiring harness

connector, install bulb into correct locating

notches in reflector and reconnect spring

retainer.

7. Install lens and ref lector as sembly into housing.

Install end caps and screws, tighten screws.

8. Install fog lamp bezel and securing clip.

9. Check fog lamp operation and aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS in this Section.

Figure 12B-23

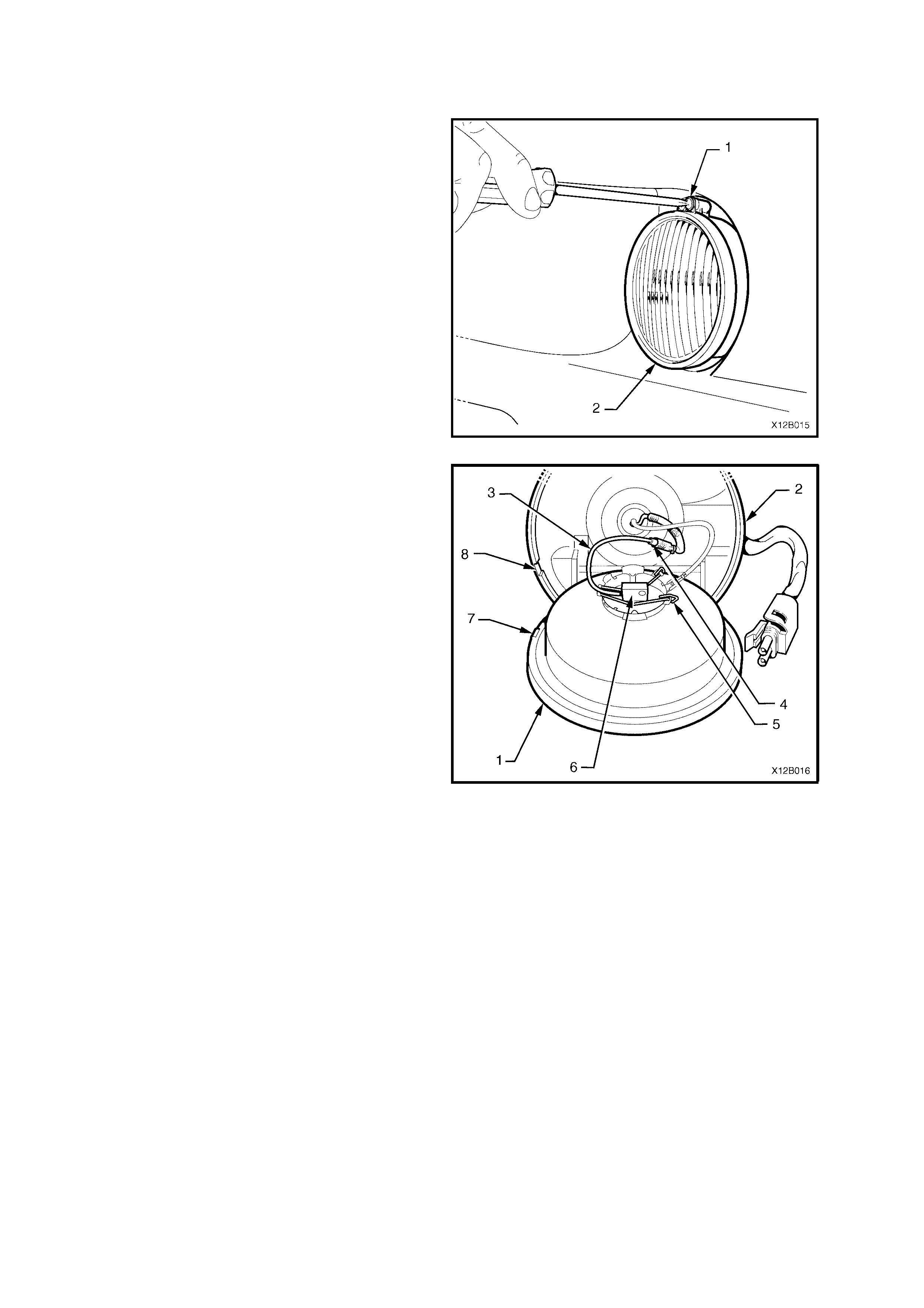

2.9 FOG LAMP BULB — SS MODEL

REPLACE

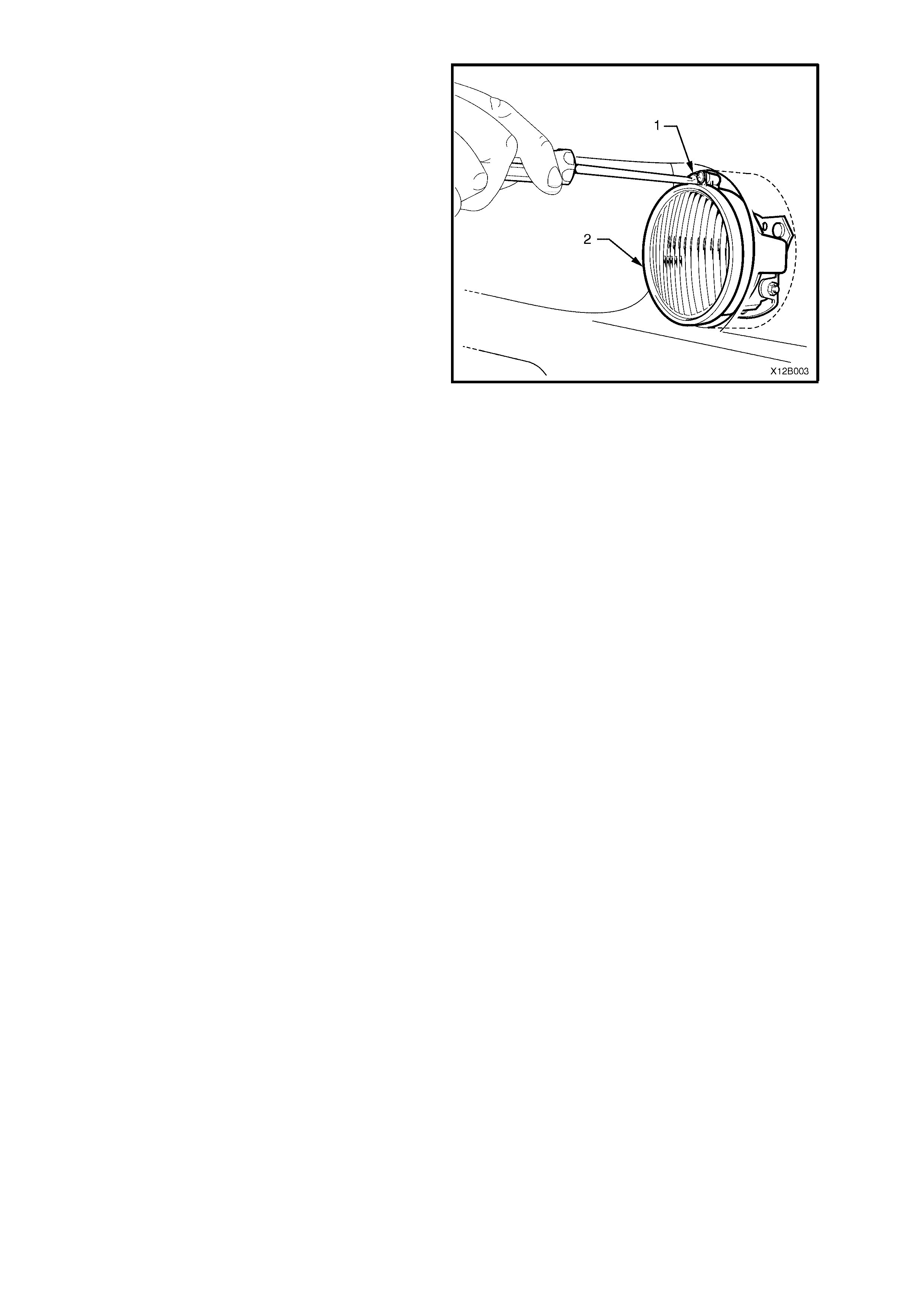

1. Remove screw (1) securing lens, reflector and

clamp ring assembly to fog lamp housing and

remove clamp ring (2).

Figure 12B-24

2. Pull lens and reflector assembly (1) out from

housing (2).

3. Disconnect bulb lead (3) from wiring harness

connector (4) located inside insulating sheath.

4. Squeeze halves of spring retainer (5) together

and pivot spring back ward clear of bulb. Lift out

bulb (6) and remove.

NOTE: Do not handle quartz envelope of bulb. If

touched, wipe immediately with methylated spirits

or bulb performance will deteriorate.

5. Connect new bulb lead to wiring harness

connector, install bulb into correct locating

notches in reflector and reconnect spring

retainer.

6. Install lens and reflector assem bly into housing

ensuring that protrusion (7) on rim of lens and

reflector assembly aligns correctly with cut-out

on rim of housing (8). Install clamp ring and

screw, tighten screw.

7. Check fog lamp operation and aim, refer to

2.1AIMING OF HEADLAMPS AND FOG

LAMPS in this Section.

Figure 12B-25

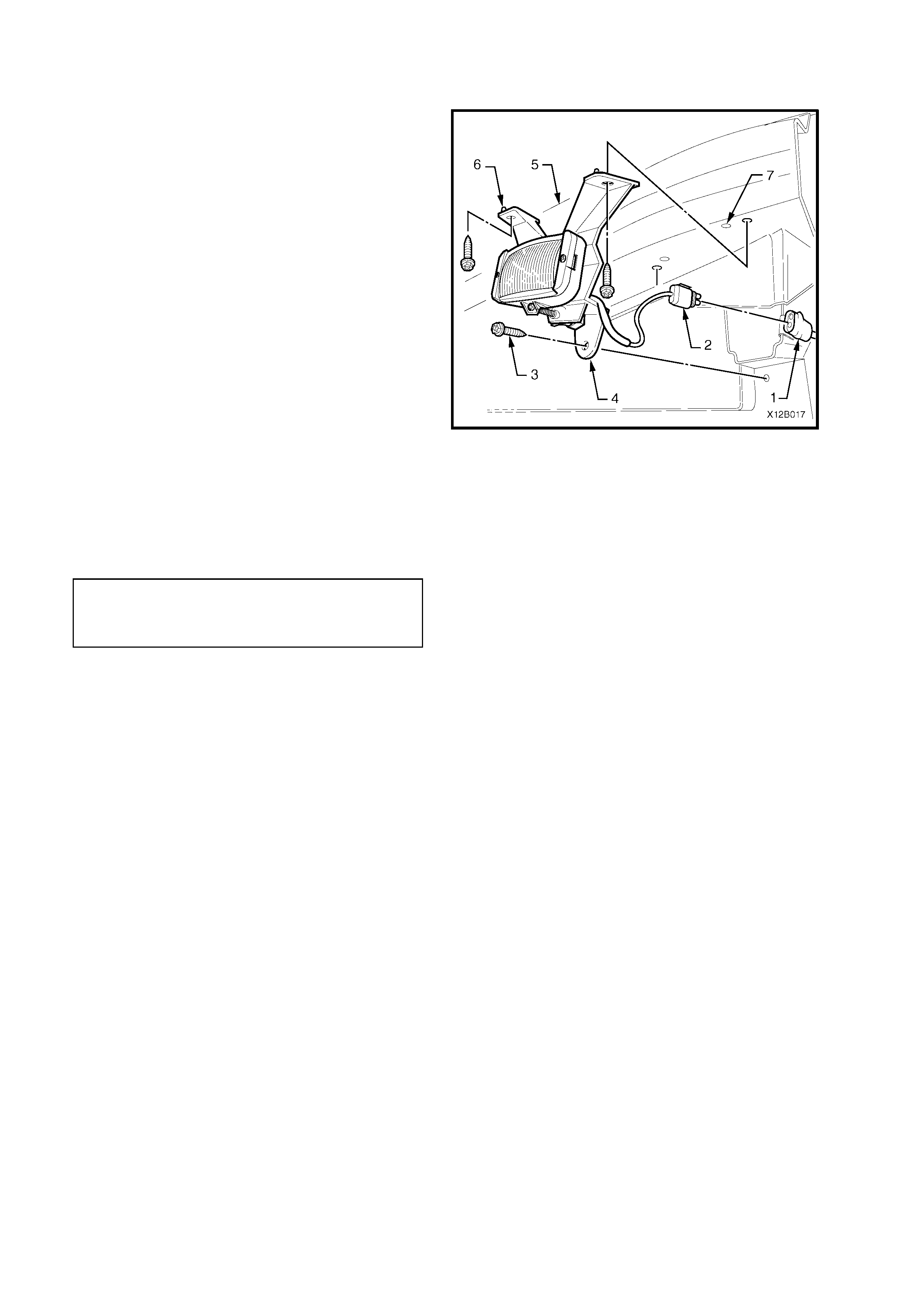

2.10 FOG LAMP ASSEMBLY — CALAIS MODEL

1. Remove the font bumper bar facia, refer to

2.7 HEADLAMP AND TURN

SIGNAL/PARKING LAMP ASSEMBLY —

BERLINA AND CALAIS MODELS in this

Section.

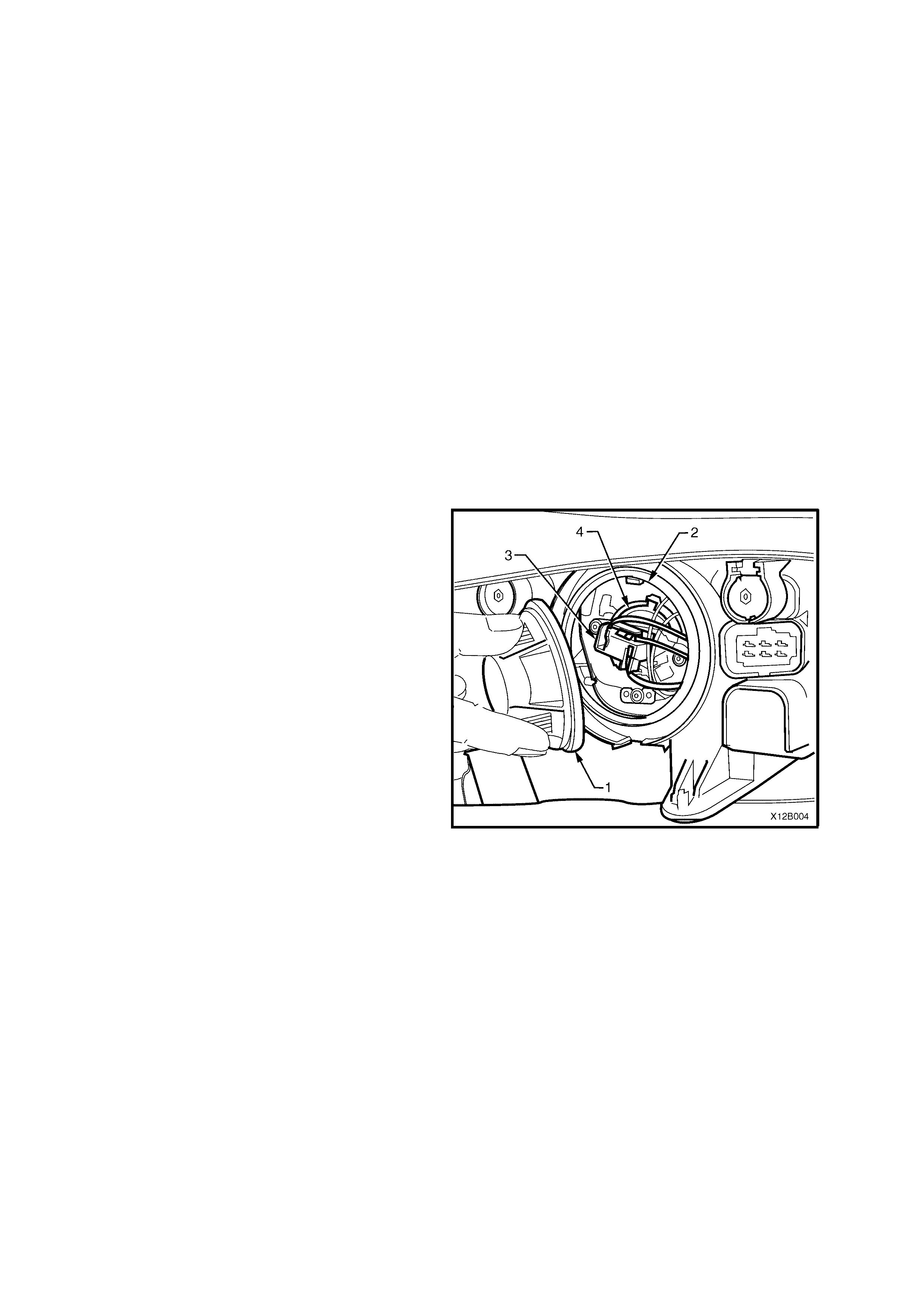

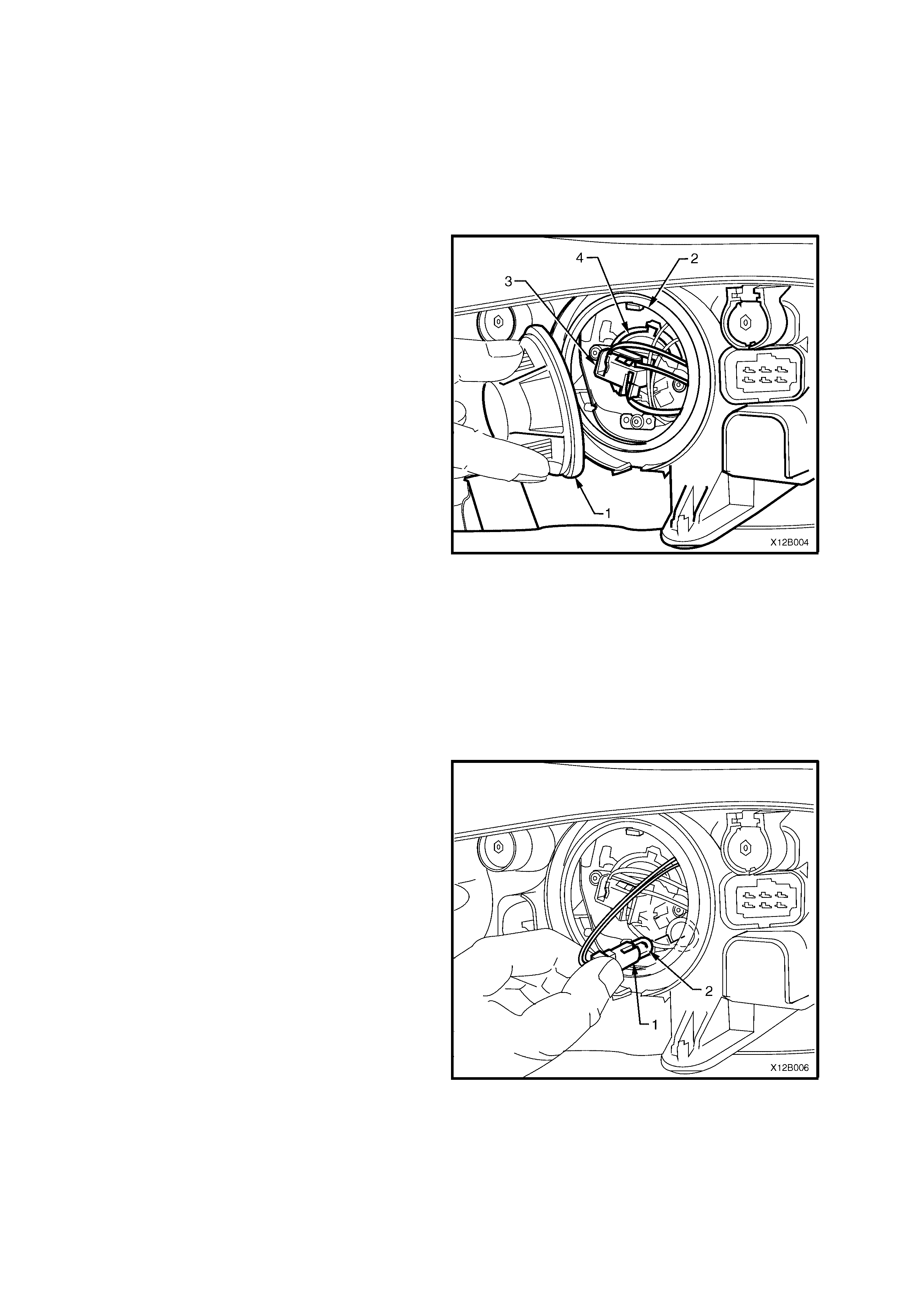

2. From inside wheelhouse, disconnect main

wiring harness connector (1) from fog lamp

harness connector (2).

3. From behind bumper bar, remove three

mounting bracket to bumper bar beam screws

(3), remove fog lamp assembly (4) from

bumper bar beam (5).

REINSTALL

Installation of the fog lam p assem bly is the re verse

of removal procedures, noting the following points:

1. Install fog lamp assembly onto bumper bar

beam, ensuring that locating lugs (6) on lamp

mounting br acket f it correc tly in the lug location

holes (7) in the bumper bar beam.

2. Tighten lamp mounting bracket to bumper bar

beam and facia screws to the correct torque

specification.

3. Check fog lamp operation and aiming, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS in this Section.

Figure 12B-26

REMOVE

FOG LAMP MOUNTING BRACKET

TO BUMPER BAR BEAM

AND FACIA SCRE W

TORQUE SPECIFICATION

2 – 5 Nm

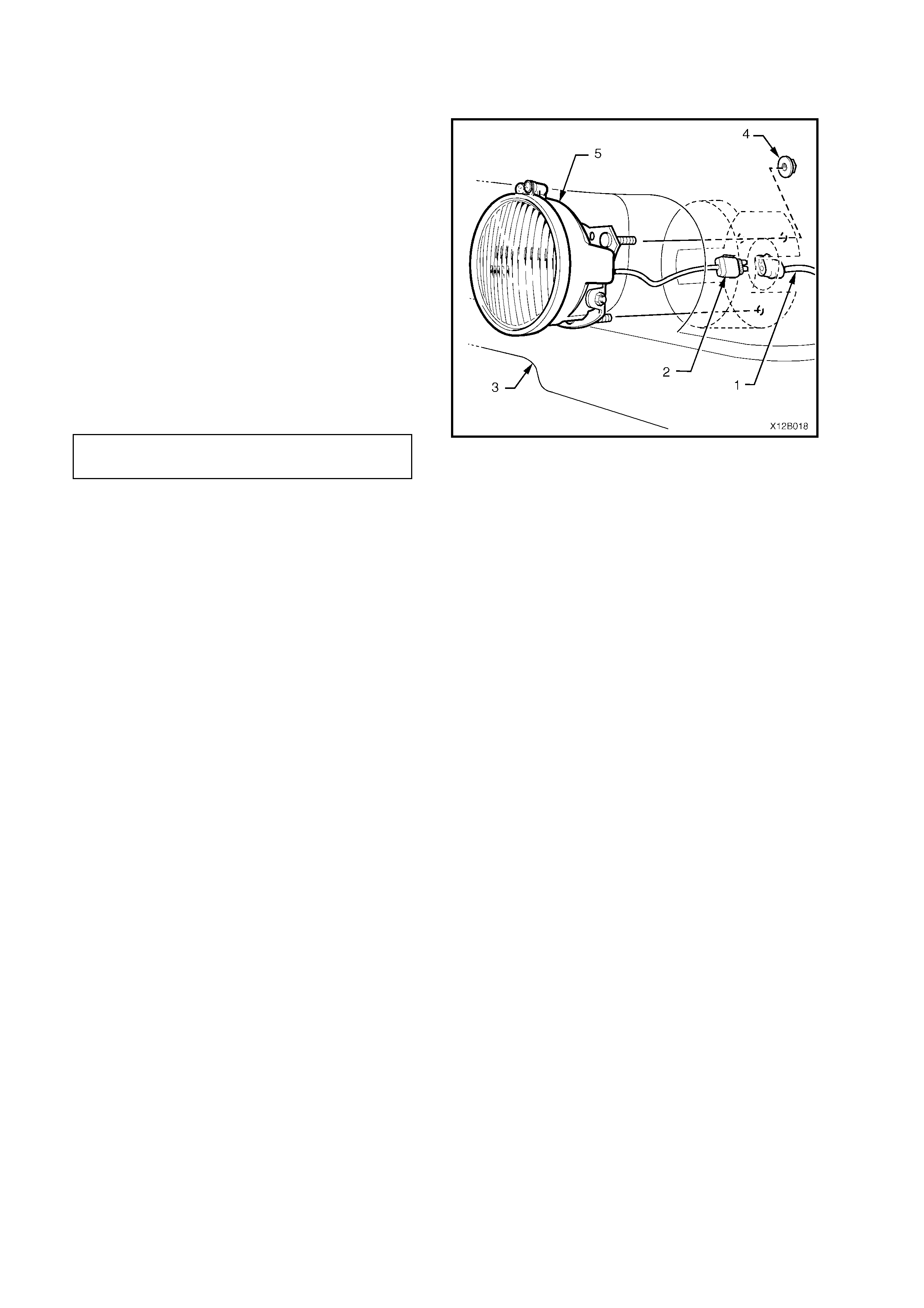

2.11 FOG LAMP ASSEMBLY — SS MODEL

REMOVE

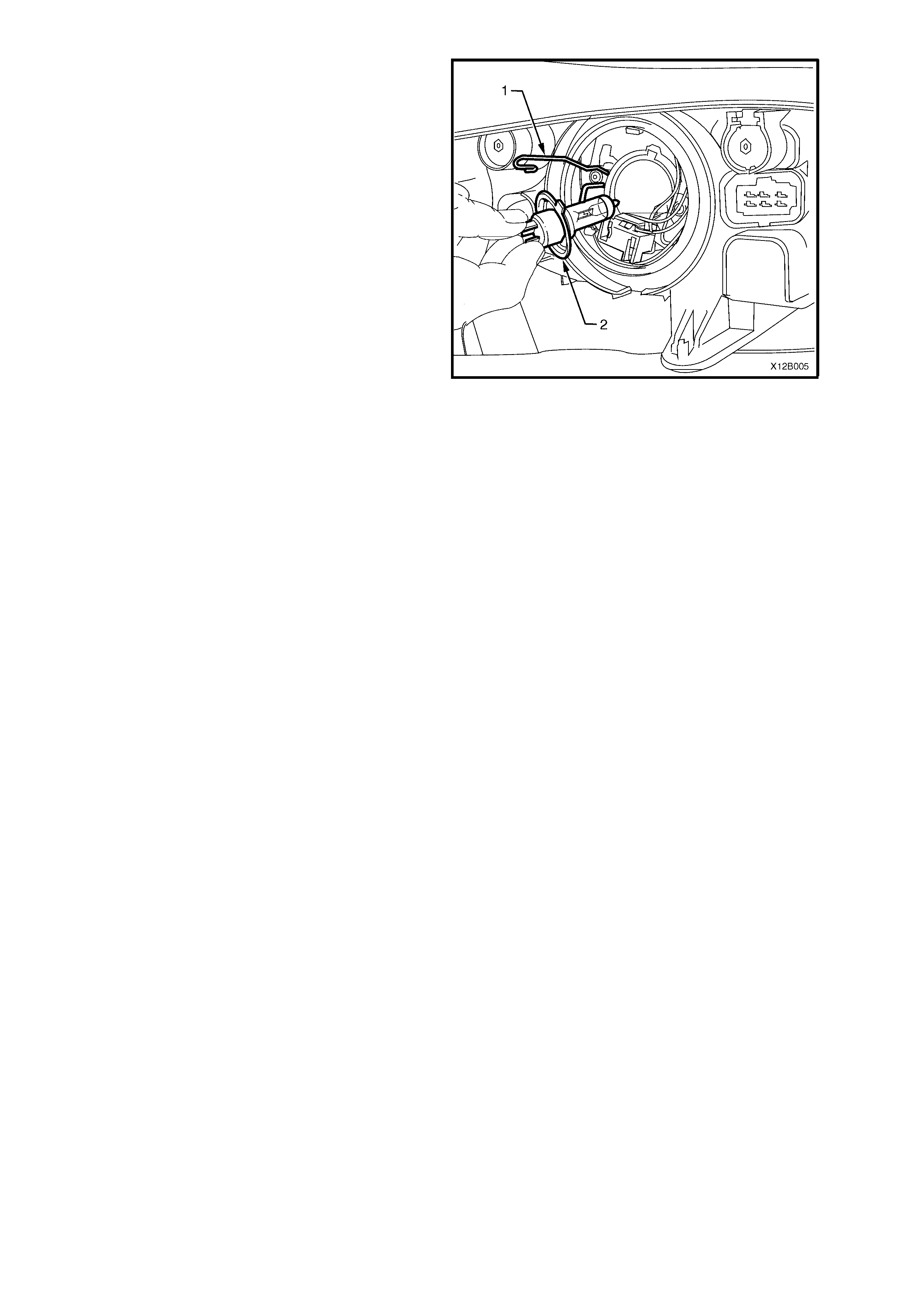

1. From inside wheelhouse, disconnect main

wiring harness (1) from fog lamp harness

connector (2).

2. From behind bumper bar facia (3), remove

three nuts (4) securing fog lamp assembly (5)

to bumper bar facia remove fog lamp

assembly.

REINSTALL

Installation of the fog lam p assem bly is the re verse

of removal procedures, noting the following points:

1. Ensure that the fog lamp assembly is correctly

orientated with the beam adjustment screw

located to the top.

2. Tighten fog lamp housing to bumper bar facia

nuts to the correct torque specification.

3. Check fog lamp operation and aiming, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS in this Section.

Figure 12B-27

FOG LAMP HOUSING TO BUMPER

BAR FACIA NUT

TORQUE SPECIFICATION 2 – 2.5 Nm

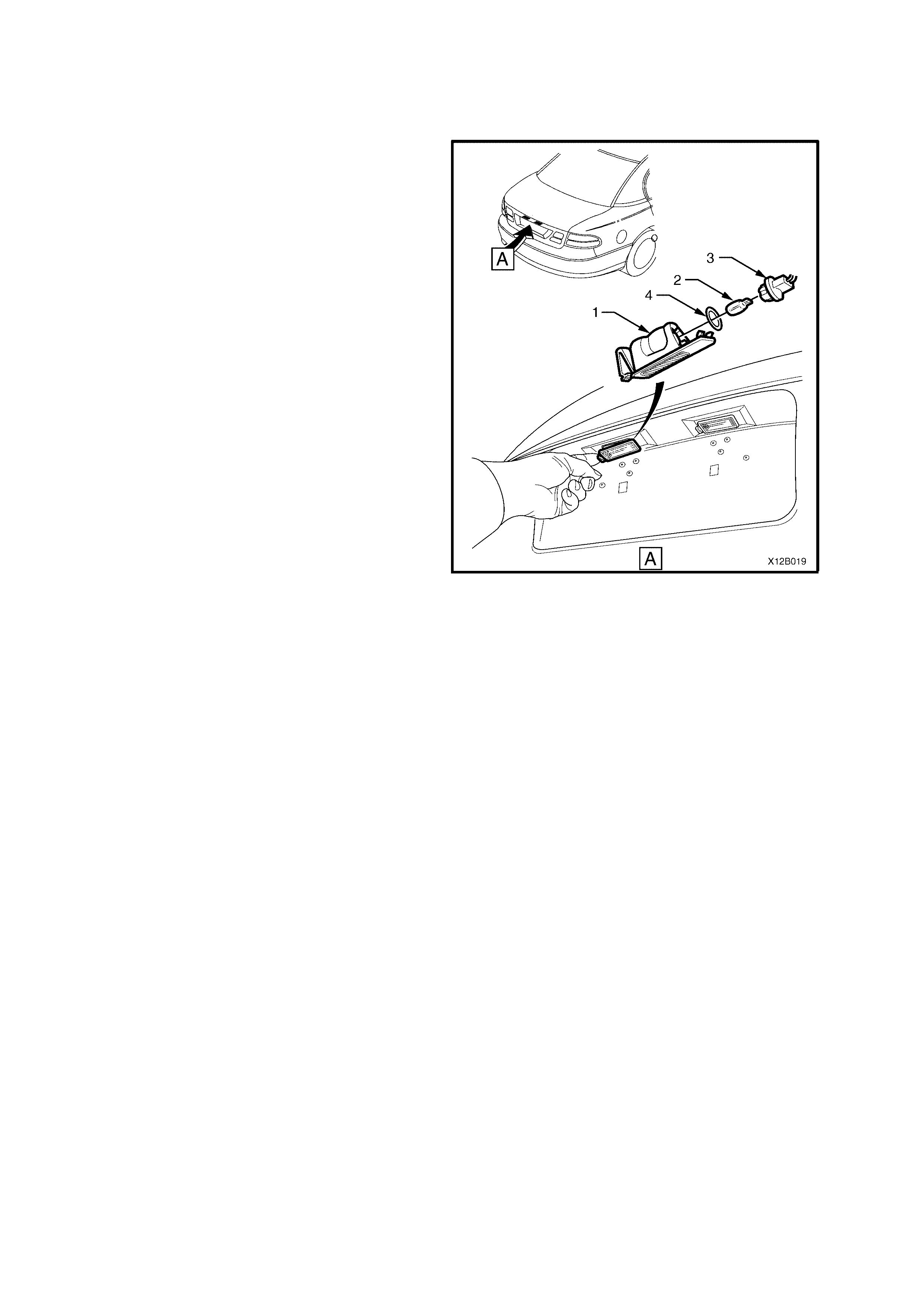

2.12 LICE NCE PLATE LAMP/BULB —EXECUTIVE AND ACCLAIM SEDAN,

S AND SS MODELS

REMOVE

1. Push locking tang located at end of lamp

holder (1) towards lamp and pivot lamp holder

assembly down to remove from decor panel

aperture.

2. Withdraw socket and bulb assembly from

holder.

3. Pull bulb (2) from socket (3).

4. Ins pect bulb sock et sealing ring (4) for damage

and replace if required.

REINSTALL

1. Push new bulb into bulb socket.

2. Install socket and bulb assembly into lamp

holder.

NOTE: Lamp holder will assemble to decor panel in

one direction only.

3. Install holder assembly into decor panel.

4. Check licence plate lamp operation.

Figure 12B-28

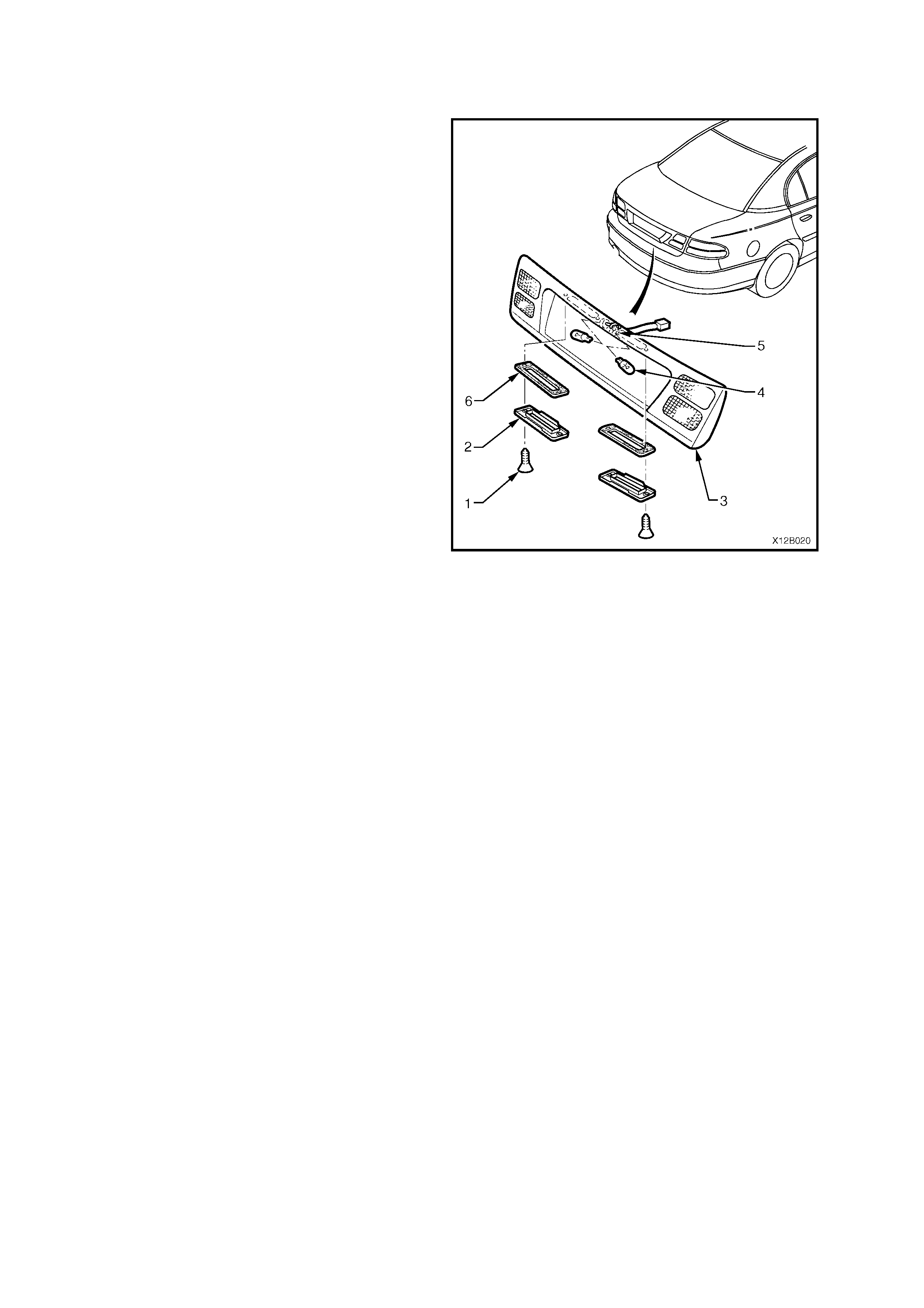

2.13 LICE NCE PLATE LAMP/BULB —BERLINA SEDAN AND CALAIS MODELS

REMOVE

1. Remove screws (1) securing lamp lens (2) to

decor panel (3) and remove lamp lens.

2. Pull bulb (4) from socket (5).

3. Inspect lens seal (6) for dam age and replace if

required.

REINSTALL

1. Push new bulb into bulb socket.

2. Check licence plate lamp operation.

3. Install lens onto decor panel.

Figure 12B-29

2.14 S EDAN REAR LAMP BULBS

STOP/TAIL LA MP BULBS (DECOR PANEL MOUNTED) — BERLINA AND CALAIS MODELS

REPLACE

1. Open rear compartment.

2. Through left or right access hole in decklid,

remove bulb socket by turning socket

anti-clockwise and removing socket.

3. Remove bulb from socket by depressing bulb

into its socket and then rotate to remove.

4. Insert new bulb into socket and install socket

into decor panel assembly, ensuring socket

locks securely into place.

5. Check rear lamp operation.

STOP/TAIL (REA R LAMP MOUNTED), BACK-UP AND TURN SIGNAL LAMP BULBS

REPLACE

1. Open rear compartment.

2. Remove rear lamp assembly refer to

2.15 REAR LAMP ASSEMBLY — SEDAN in

this Section.

3. Remove appropriate bulb socket by turning

socket anti-clockwise and removing socket,

refer to Fig.12B-30.

4. Remove bulb from socket by depressing bulb

into its socket and then rotate anti-clock wise to

remove.

5. Inspect bulb socket to lamp housing seals for

damage, replace if necessary.

6. Insert new bulb into socket and install socket

into lamp housing, ensuring socket locks

securely into place. Note that stop/tail lamps

and turn signal lam p sock ets ar e both coloured

white but have differing number of lugs to

prevent installation to incorrect rear lamp

location.

7. Check rear lamp operation.

Techline

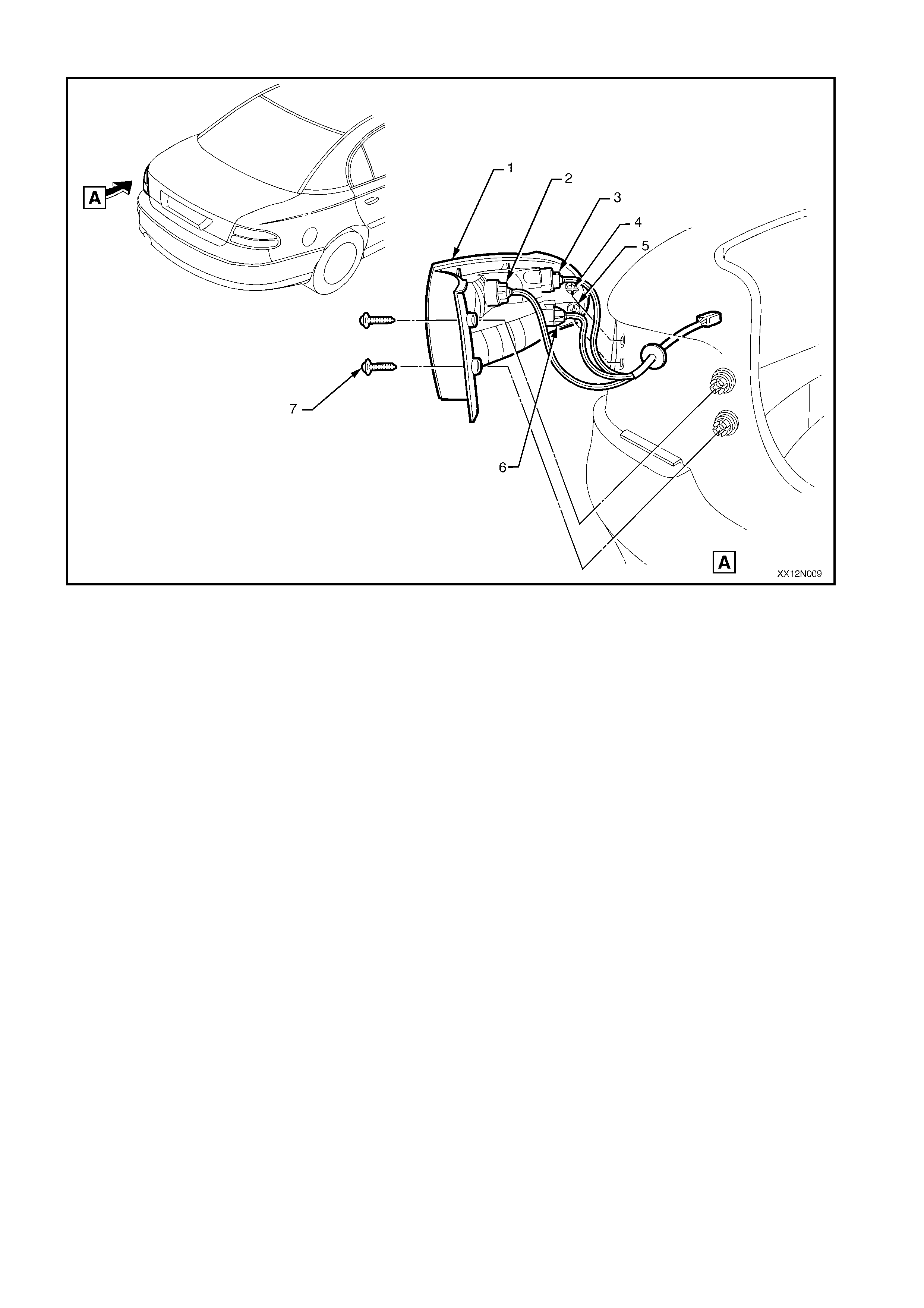

Figure 12B-30

1. Tail light housing

2. Back-up light socket (black – 4 lug)

3. Turn signal bulb socket (white – 4 lug)

4. Integral plastic guide peg (1 place each

side)

5. Metal locating peg (1 place each side)

6. Stop/tail light bulb socket (white – 3

lug)

7. Screw (2 places each side)

NOTE: Harness length will allow back-up

light socket and turn signal bulb socket to

be fitted to correct locations only.

2.15 REAR LAMP ASSEMBLY — SEDAN

REAR QUARTER LAMP ASSEMBLY

REMOVE

1. Open rear compartment.

2. Remove rear quarter lamp assembly to body

attaching screws, refer to Fig.12B-30.

3. Pull rear quarter lamp housing sideways out from

panel so that loc ating peg on s ide of lamp ass embly

snaps free from retainer.

4. While supporting lamp housing, remove back-up

light bulb socket, turn signal bulb socket and

stop/tail light bulb socket by turning socket

anti-clockwise and removing.

REINSTALL

1. Insert bulb sockets into rear quarter lamp housing,

ensuring sockets are correctly located and lock

securely into place.

2. Ensure that rear quarter lamp harness grommet is

seated correctly. Assemble lamp housing to body,

ensuring locating peg s naps into retainer and install

and tighten attaching screws to the correct torque

specification.

REAR QUARTER LAMP HOUSING T O

BODY A T T ACHING SCRE W

TORQUE SPECIFICATION

1 – 3 Nm

3. Check rear lamp operation.

Techline

DECOR PANEL ASSEMBLY

REMOVE

1. Open rear compartment.

2. From inside decklid, disconnect licence plate

wiring harness and push harness insulating

grommet through decklid panel, refer to

Fig.12B-31.

3. From inside decklid on Berlina and Calais

models, disconnect left and right stop/tail light

wiring harness from decor panel assembly.

4. Remove the two decor panel assembly to

decklid attaching nuts.

5. Remove the three decor panel assembly to

decklid attaching Torx head screws.

6. Remove the four decor panel assembly to

decklid attaching hexagon head screws.

7. Through access holes located inside decklid,

remove screws located in the four decor panel

mounting clips.

8. Pull decor panel assembly away from and

downward of decklid and remove from decklid.

REINSTALL

1. Check condition of decor panel to decklid

rubber sealing gasket and replace if damaged.

2. Remove the four decor panel mounting clips

from the decklid, and assemble to decor panel

with the four philips head screws.

3. Ass emble dec or panel to deck lid, ensuring that

licence plate wiring harness grommet is

correctly installed.

4. Install and tighten attac hing nuts and sc rews to

the correct torque specification.

5. Connect left and right stop/tail light wiring

harness on Berlina and Calais models.

6. Connect licence plate wiring harness.

7. Check rear lamp operation.

DECKLID DECOR PANE L A SSEMBLY

TO DECKLID ATTACHING NUT

TORQUE SPECIFICATION 1 - 3 Nm

DECKLID DECOR PANE L A SSEMBLY

TO DECKLID ATTACHING

(TORX HEAD) SCREW

TORQUE SPECIFICATION

2 - 5 Nm

DECKLID DECOR PANE L A SSEMBLY

TO DECKLID ATTACHING

(PHILLI P S HEAD) SCREW

TORQUE SPECIFICATION

2 - 3 Nm

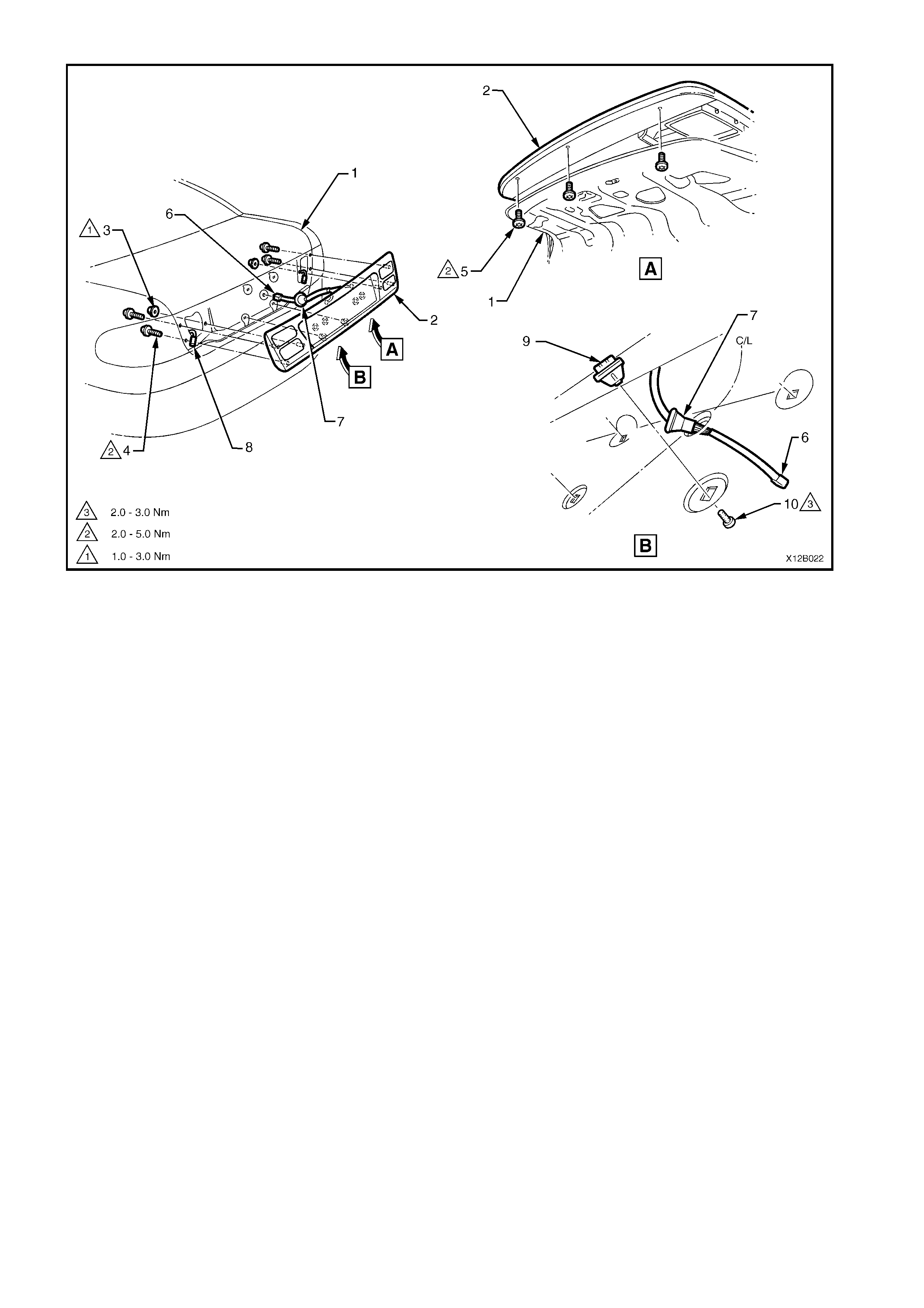

Figure 12B-31

1. Decklid

2. Decor panel assembly

3. Nut (1 place each side)

4. Screw (2 places each side)

5. Screw (3 places)

6. Licence plate wiring harness connector

7. Licence plate wiring harness grommet

8. Stop/tail light harness (1 place each

side — Berlina and Calais models

only )

9. Decor panel assembly to decklid

mounting clip (4 places)

10. Screw (4 places)

2.16 REFLECTOR LENS ASSEMBLY — EXECUTIVE AND ACCLAIM SEDAN, S AND SS

MODELS

REMOVE

1. Open the rear compartment lid.

2. Gently peel the rear compartment

weatherstrip (1) away from the upturned flange

of the rear compartment opening.

NOTE: Only partly peel the weatherstr ip away f rom

the rear compartment opening to enable access to

the four bumper bar facia scrivets and to allow for

removal of the rear compartment crossmember

cover (2).

3. Remove the four screws (3), two scrivets (4)

and prise out the four fasteners (5) securing

the rear compartment crossmember trim and

remove the trim.

4. Peel the rear compartment carpet back slightly

and remove the four nuts securing the rear

bumper assembly to the rear quarter panel

(below tail lamps), refer to Fig.12B-33.

5. Remove two screws (one each side) securing

rear bumper facia at each upper wheel arch

opening and four s crews (two each side) at the

lower wheel arch opening.

6. Remove the four scrivets at the upper edge of

facia and two scrivets at lower edge of facia.

7. With the facia supported, pull the facia side

members out to disconnect the facia side

supports, then slide the facia rearwards,

removing the facia.

8. Place the rear bumper bar facia assembly

underside face down on a clean protective

surface.

9. Remove reflector lens retaining screw and

remove reflector lens from rear facia, refer to

Fig.12B-34.

Figure 12B-32

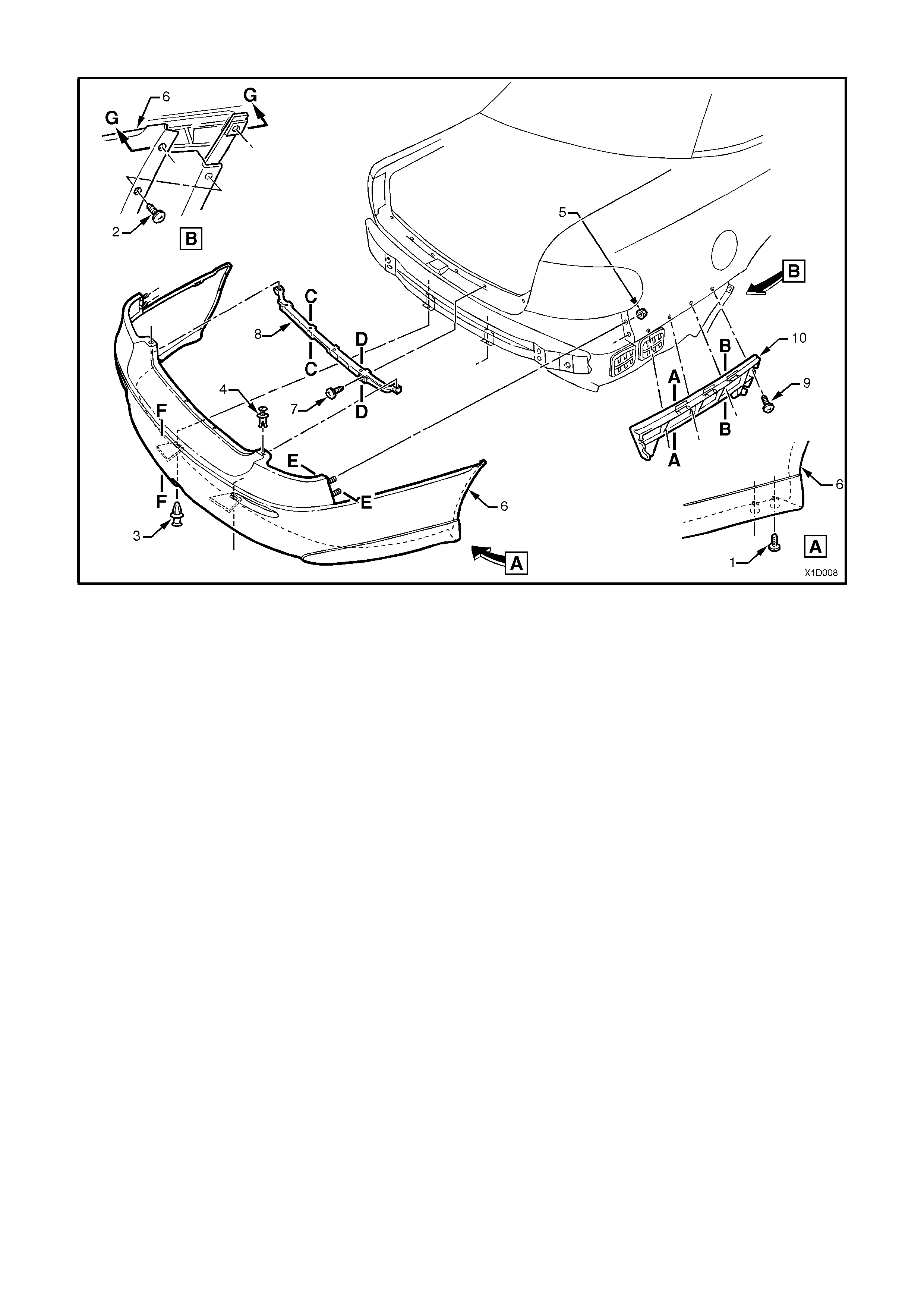

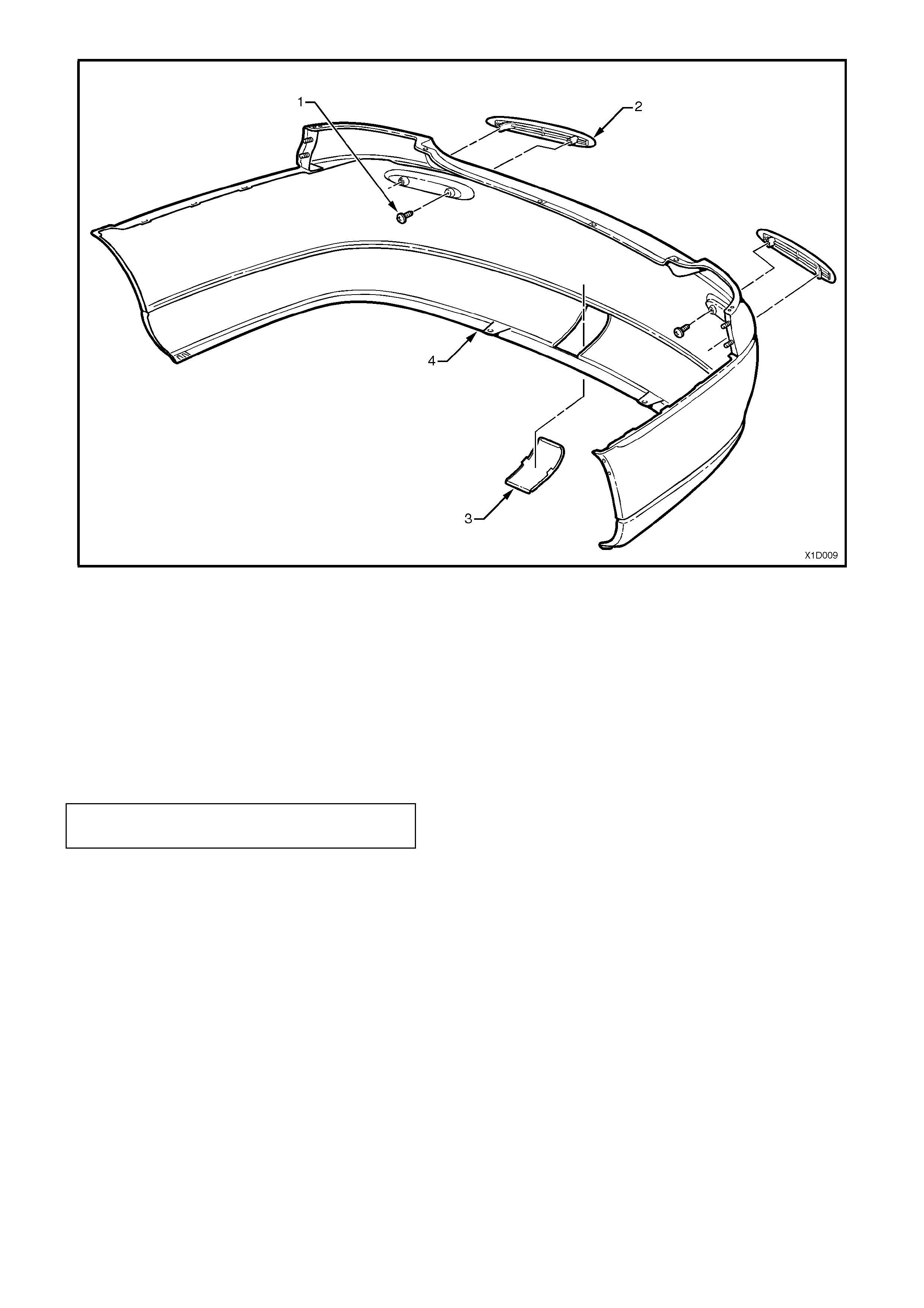

Figure 12B-33 REAR BUMPER FACIA – EXECUTIVE and ACCLAIM SEDAN, S and SS

1. Screw (2 places each side)

2. Screw (2 place each side)

3. Scrivet (2 places)

4. Scrivet (4 places)

5. Nut (2 places each side)

6. Facia assembly

7. Screw (6 places)

8. Rear facia upper centre support

9. Screw (4 places each side)

10. Rear bumper guide rail assembly (2 places)

NOTE: For sectional views of A-A to G-G, refer

to Section 1D BUM PER BARS in the VX Series

Service Information.

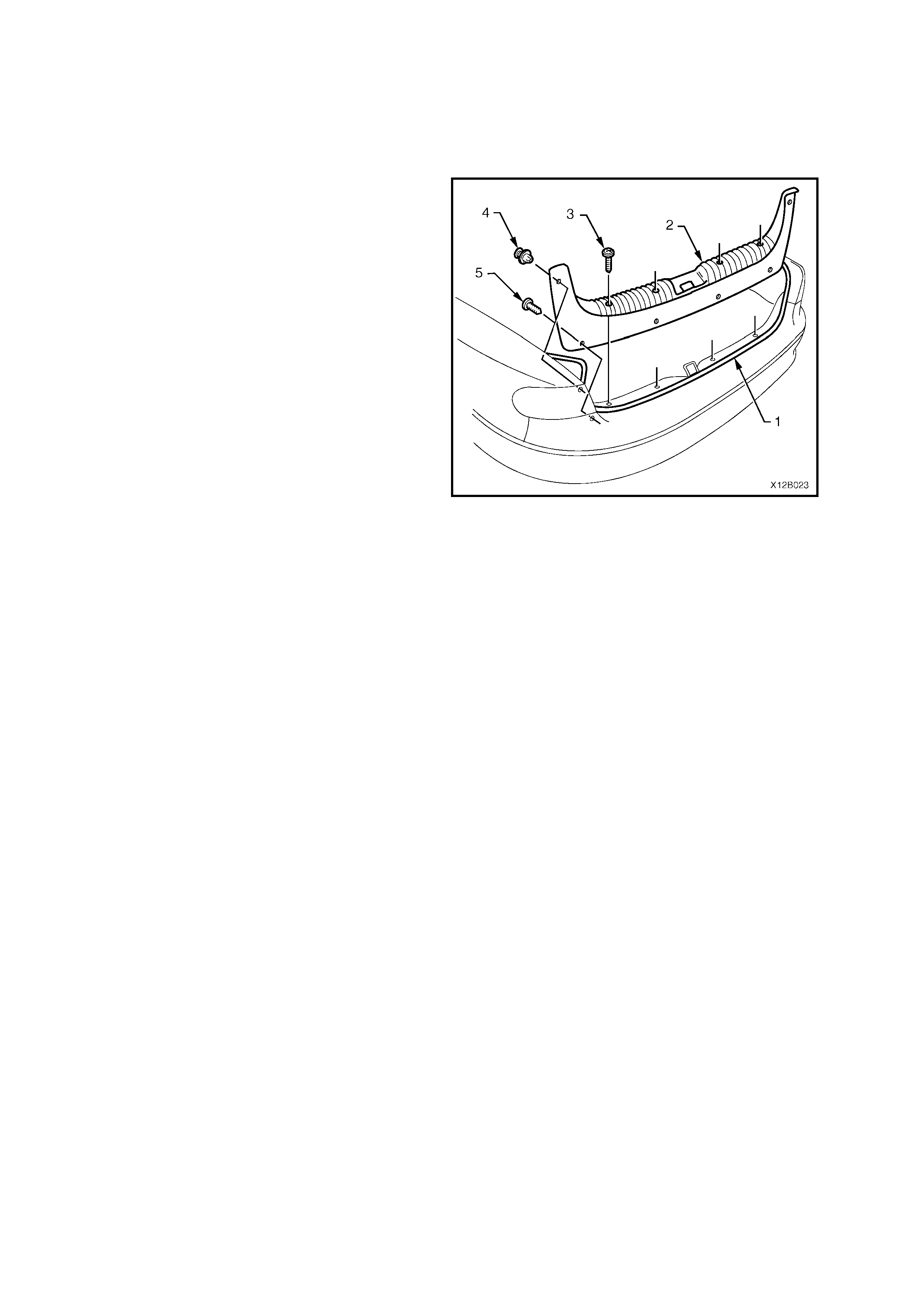

Figure 12B-34 REAR BUMPER FACIA COMPONENTS – EXECUTIVE and ACCLAIM SEDAN, S and SS

1. Screw (1 place each side)

2. Reflector lens assembly (1 place each side) 3. Blanking cover – tow bar

4. Facia assembly

REINSTALL

Installation of the reflector lens assembly is the

reverse of removal procedure, noting the following

points:

1. Install reflector lens assembly and tighten

retaining screw to the correct torque

specification.

2. Ins tall rear bum per fac ia assembly by snapping

the facia onto the retainers at guide rails, one

side at a time.

3. Ensure correct fender, and decklid clearance,

adjust rear bumper facia if necessary, refer to

VX Series Body Structure Repair Supplement.

REFLECTOR LENSE TO REAR FACIA

RETAINING SCREW

TORQUE SPECIFICATION 1 - 3 Nm

3. SPECIFICATIONS

BULB POWER RATING —

WA TTS BASE TYPE

HEADLAMPS

Hi/Lo Beam (Outboard)

Inboard High Beam

60/55

55

H4

H1

FOG LAMPS 55 H3

PARKI NG LA MPS (Front) 5 Wedge

TURN SIGNAL LA MPS (Front) 21 Offset Pin (Orange glas s)

SIDE REPEAT E R LAMPS 5 Wedge

TURN SIGNAL LAMPS

(Sedan — Rear)

21

Offset Pin (Orange glas s)

TURN SIGNAL LAMPS

(Wagon — Rear)

21

Offset Pin (Orange glas s)

BACK-UP LAMPS 21 Std. Parallel Pin

STOP AND TAIL LAMPS 21/5 Std. P aral l el P i n

LICENCE PLATE LA MPS 5 Wedge

INSTRUME NT CLUSTER

ILLUMINATION LA MPS

Executive, A cclaim, S and S S

Berlina and Calai s

3.6

5

Wedge

Wedge

INSTRUME NT CLUSTER

WARNING LAMPS

1.2

Wedge

TRIP COMPUTER ILLUMINATION

LAMPS

1.2

Wedge

REAR COMPARTMENT LAMP 10 Festoon

DOME (Courtesy) LAMP 10 Festoon

FRONT SEAT READING LAMP 5 Std. Parallel Pin

REAR SE A T RE ADING LAMP 5 Festoon

GLOVE COMPARTMENT LAMP 5 Festoon

FRONT FOOTWELL LAMPS 2.7 W edge

FRONT VANITY MIRROR LAMP 1.4 W edge

DOOR COURTESY LA MPS 5 Festoon

CONSOLE BI N LAMP 5 Festoon

HIGH MOUNTED STOP LA MP 18 Wedge

HIGH MOUNTED STOP LAMP —

(S and SS S poi l er mounted)

5

LED ass embly

FRONT AND REAR CIGAR

LIGHTER LAMPS

1.2

Wedge

IGNITION LOCK LAMP 1.4 W edge

4. TORQUE WRENCH SPECIFICATIONS

Nm

Headlamp assembly securing screws.................................. 2 – 5

Calais fog lamp mounting bracket to bumper

bar beam screws.................................................................. 2 – 5

SS fog lamp to front bumper facia nuts ............................... 2 – 2.5

Rear lamp housing retaining screw...................................... 1 – 3

Decor panel assembly attaching nuts.................................. 1 – 3

Decor panel assembly attaching screws (Torx head).......... 2 – 5

Decor panel assembly attaching screws (Phillips head)...... 2 – 3

Reflector lens to rear bumper facia retaining screw............. 1 – 3