SECTION 12J-1 - LOW SERIES BODY

CONTROL MODULE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL I NFORMATI O N

All inf ormation relating to the Low Series Body Control Module (BCM) for VX Ser ies Models is as detailed in Sec tion

12J-1 LOW SERIES BODY CONTROL MODULE of the VT Series I Service Information and of the

VT Series II Service Information, noting the following:

A minor change was made to the wiring harness connectors for the cooling fans, however, this change does not

effect the operation of the cooling fans.

Additionally, with the introduction of a new Powertrain Control Module (PCM) for VX Series Models with a V6

engine, the terminal assignment of the PCM is different to the terminal assignment of the VT Series Model PCM.

Therefore, to avoid any confusion, all BCM diagnostic procedures that are effected by this PCM change (including

the engine cooling fan diagnostics) have been updated and republished in full in this Section.

NOTE: Refer to Section 12J-1 Low Series Body Control Module, of the VT Series I Service Information and

VT Series II Service Information, which should be read in conjunction with each other.

Techline

Techline

Techline

Techline

Techline

2. DIAGNOSIS

2.1 PREREQUISITES TO DIAGNOSIS AND TROUBLESHOOTING

PRELIMINARY SYSTEM REQUIREMENTS

The prerequisites before proceeding with system checks are:

• Ensure no moisture is present in the wiring harness connections in either A-pillar.

• Ensure that sound ear th connections are available for all f unctioning com ponents, par ticularly at the body earth

connection (fender panel inner stud, adjacent to the battery).

• Ensure the battery is in good condition and adequately charged (above 11.5 volts) before carrying out any

electrical checks.

SAFETY REQUIREMENTS

Disconnect the battery when carrying out work which involves the risk of an electrical short circuit.

Do not touch mechanical components during function checks, to avoid the risk of a hand being caught in the

mechanism.

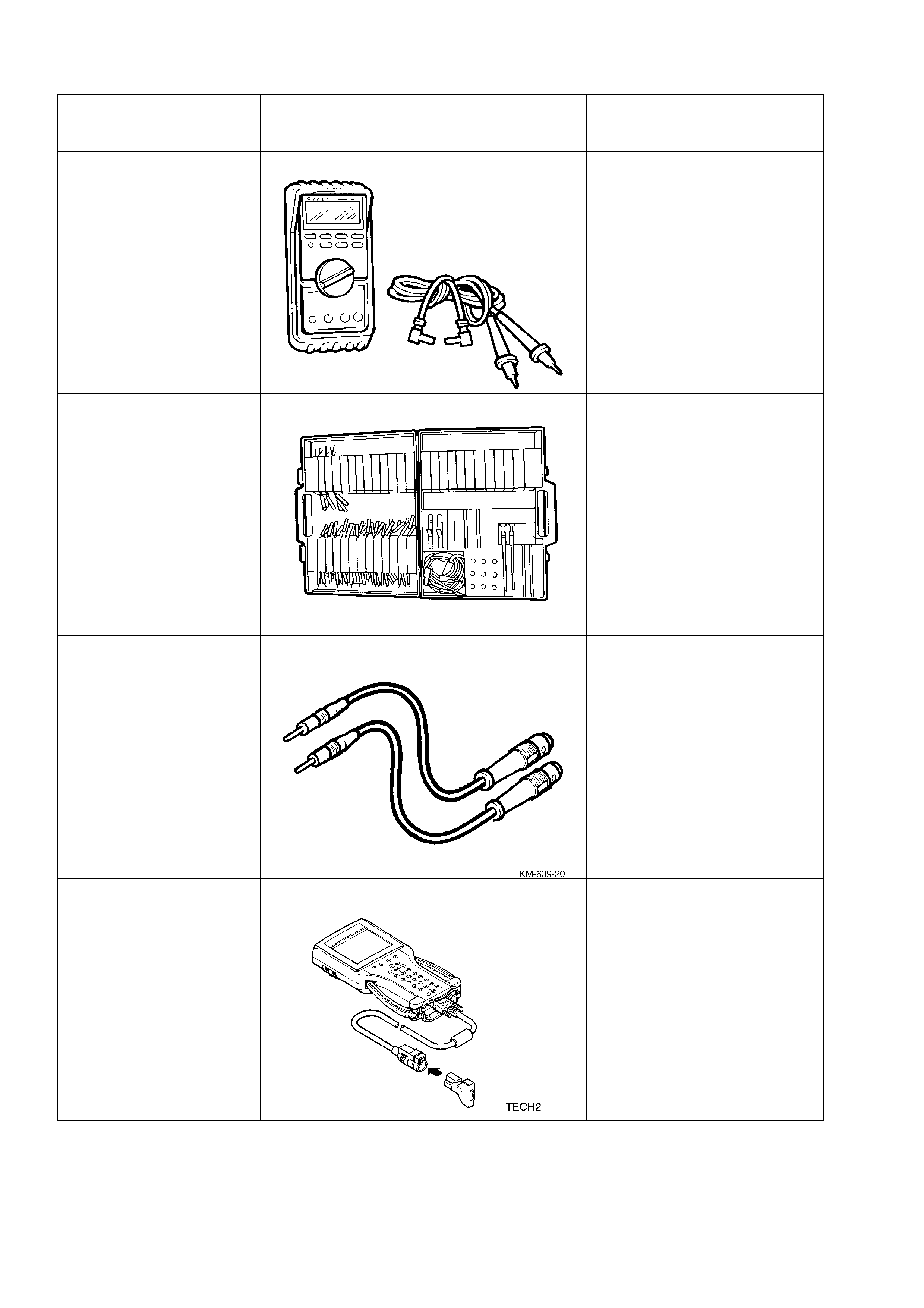

CHECKING EQUIPMENT

TECH 2 scan tool.

A digital multimeter, with a minimum 10 Megohm impedance MUST be used when undertaking any electrical

checks on these systems.

Exercise care when taking readings from wiring harness connectors. It is preferred that the back probing method

with individual connectors is employed wherever possible, to avoid terminal damage and subsequent connection

failure.

When carrying out wiring chec k s as direc ted to by the diagnostic charts, rather than probe terminals and connectors

with incorrect sized multimeter connections, use the adaptors contained in suitable connector test adaptor kit such

as KM-609. This will prevent any possibility of spreading or damaging wiring harness terminals.

IMPORTANT:

• ENSURE THAT THE IGNITION IS TURNED OFF AND THE BATTERY EARTH LEAD IS DISCONNECTED

BEFORE ANY TEST THAT REQUIRES DISCONNECTION OR RECONNECTION OF ANY OF THE BCM

CONNECTORS.

• When checking the complete system, the exact order of the test steps should be observed.

• If the requir ed nominal value is not ac hieved in any stage, then the problem must be rec tif ied before proc eeding

further.

• Unless the multimeter being used has an auto ranging function, check that the correct range, as specified, is

selected before the test is carried out.

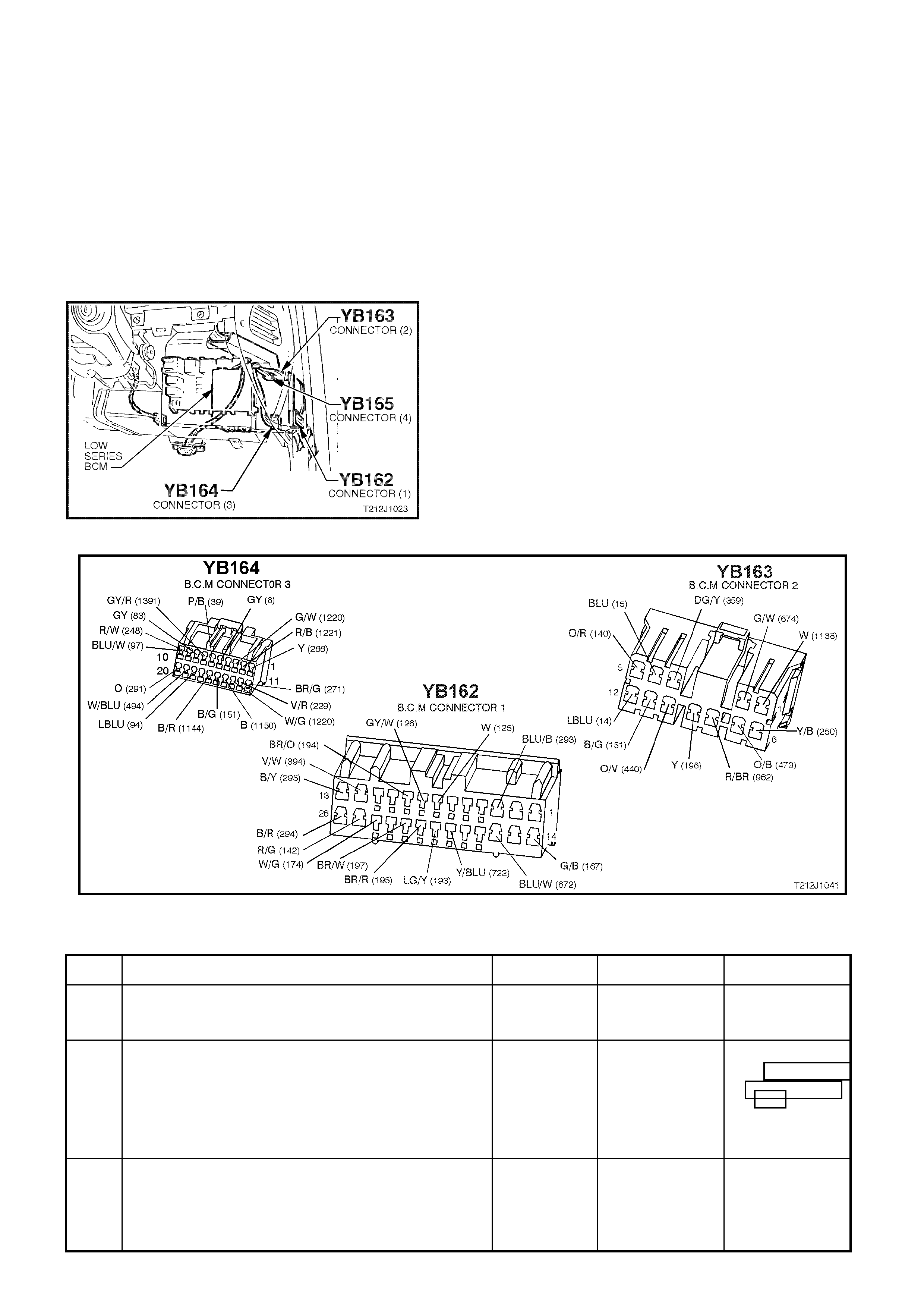

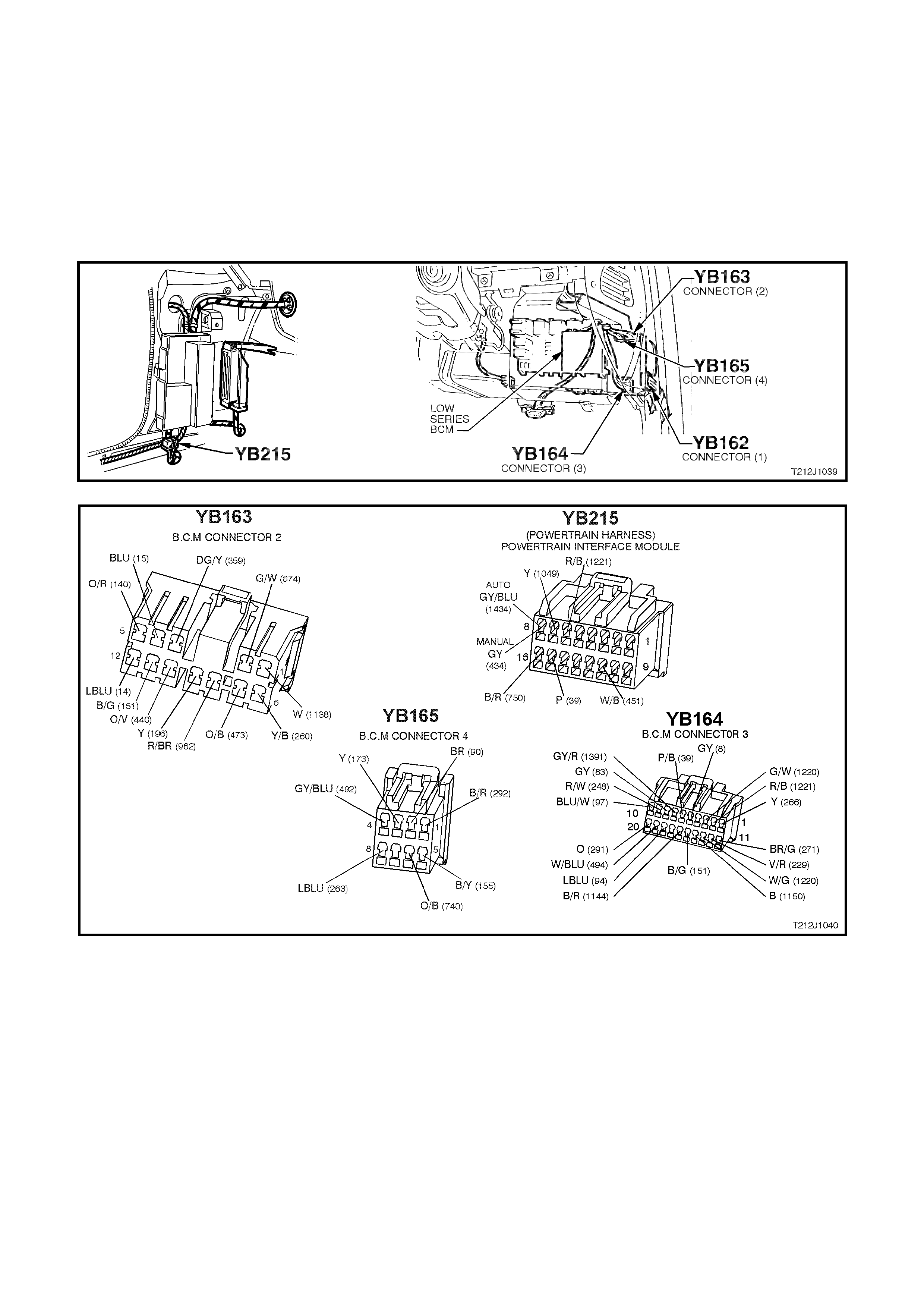

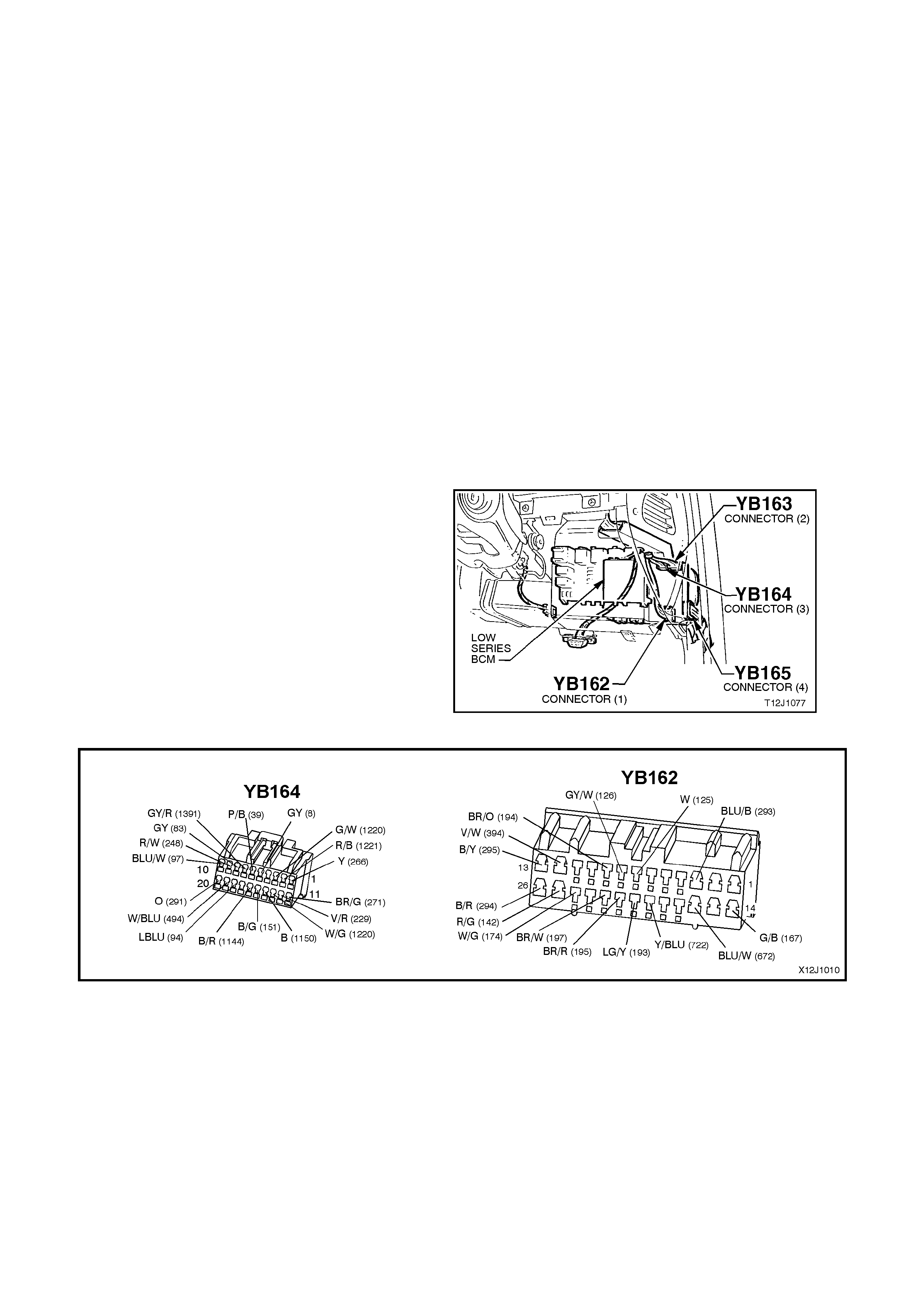

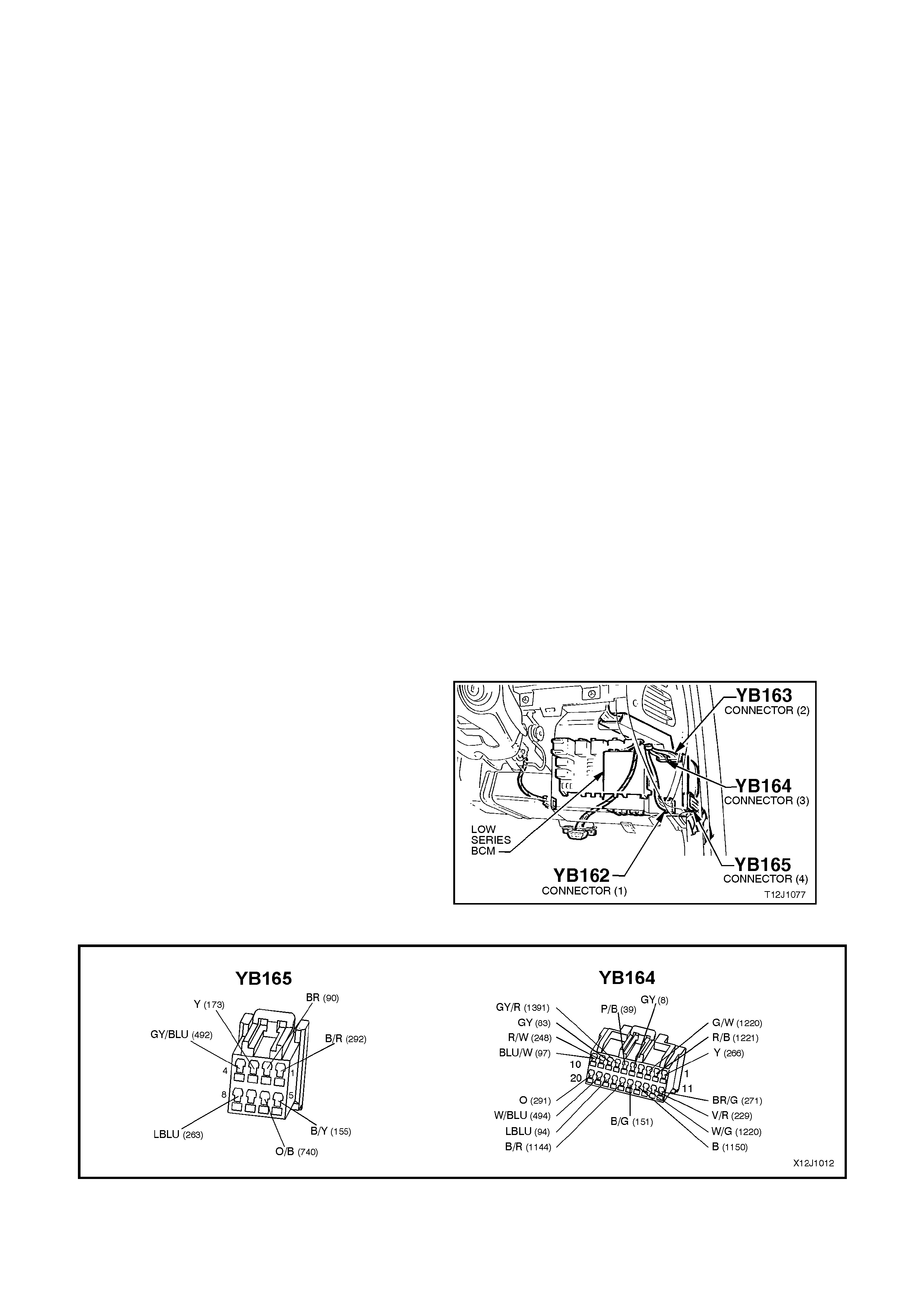

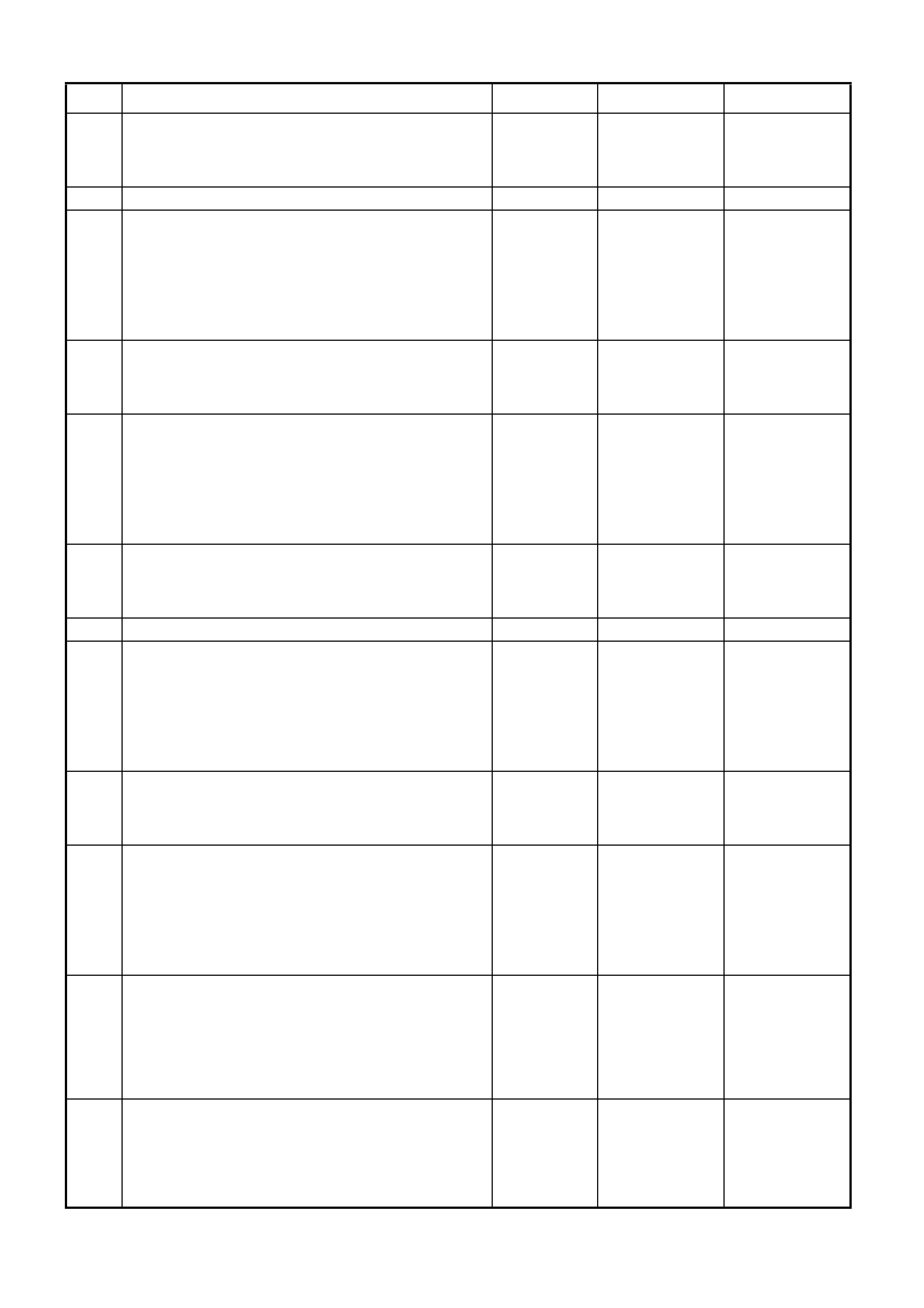

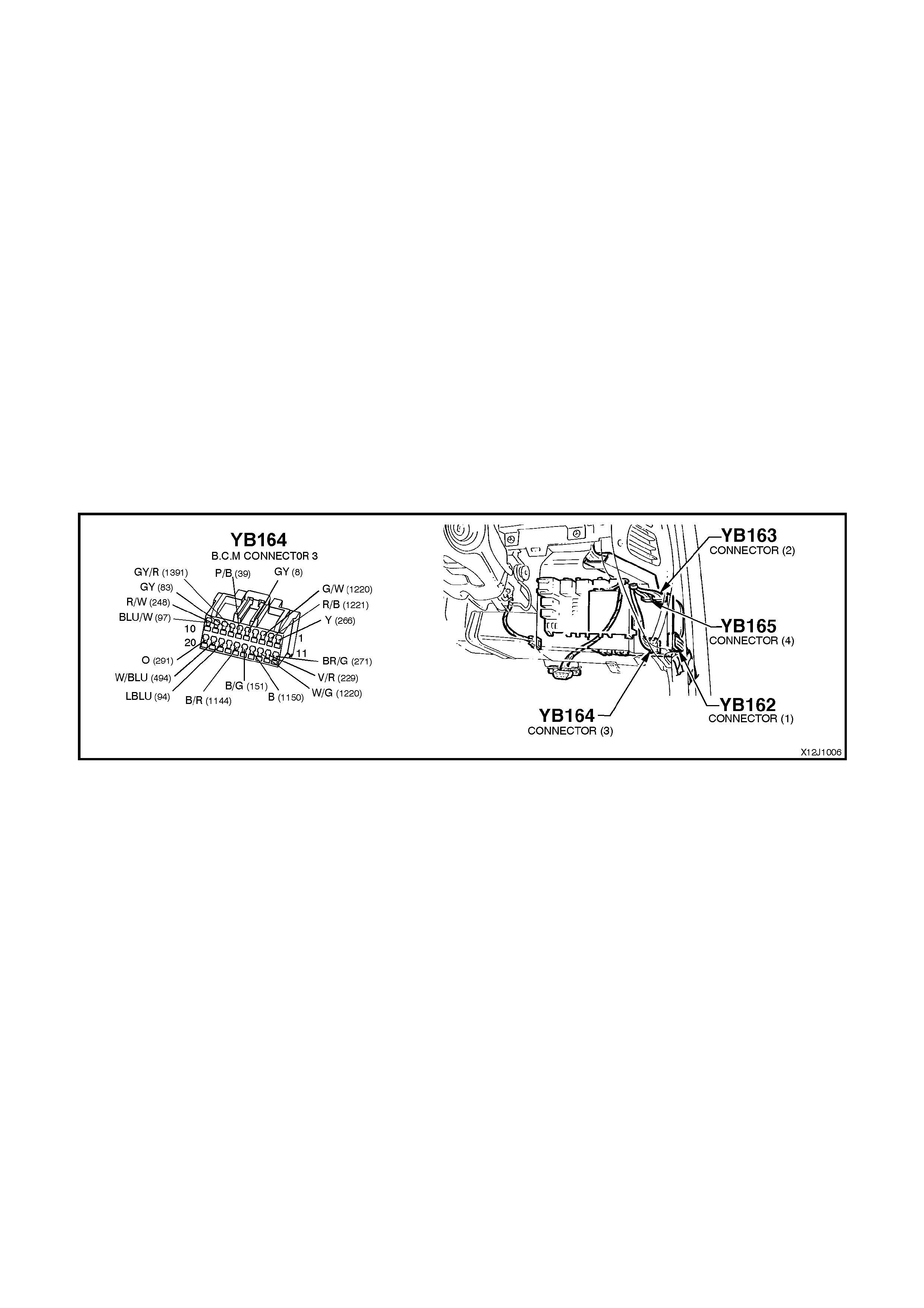

• It will be necessary to lower the BCM down to gain access to BCM wiring harness connectors, refer to

2.2 LOW SERIES BCM in Section 12J-1 LOW SERIES BCM in of the VT Series II Service Information.

• Testing of the various systems will involve gaining access to specific wiring harness connectors. For the

location of these connectors, refer to Section 12N FUSES AND WIRING HARNESSES of the

VT Series I Service Information and of the VT Series I Service Information.

Techline

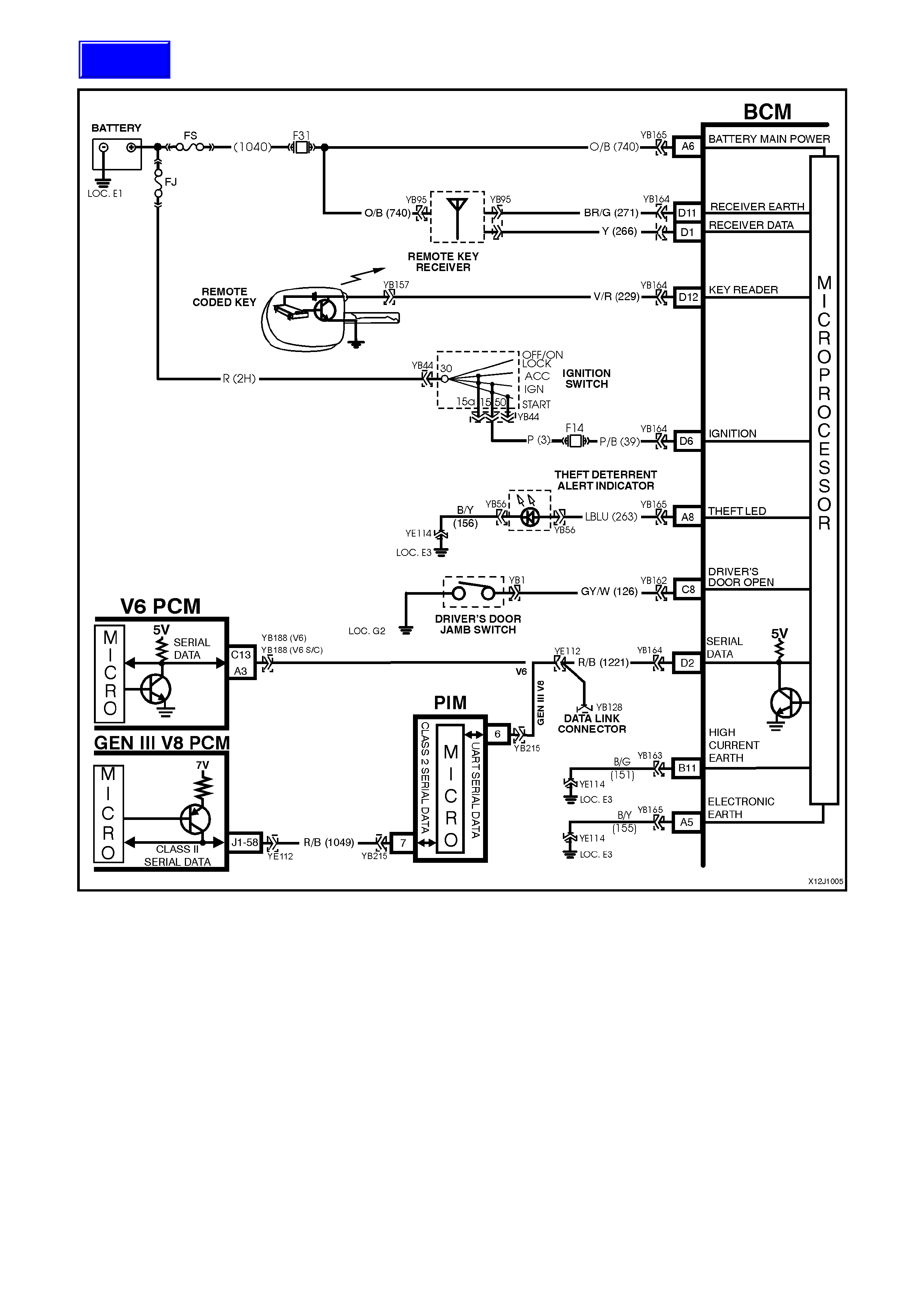

2.2 SERIAL DATA COMMUNICATION

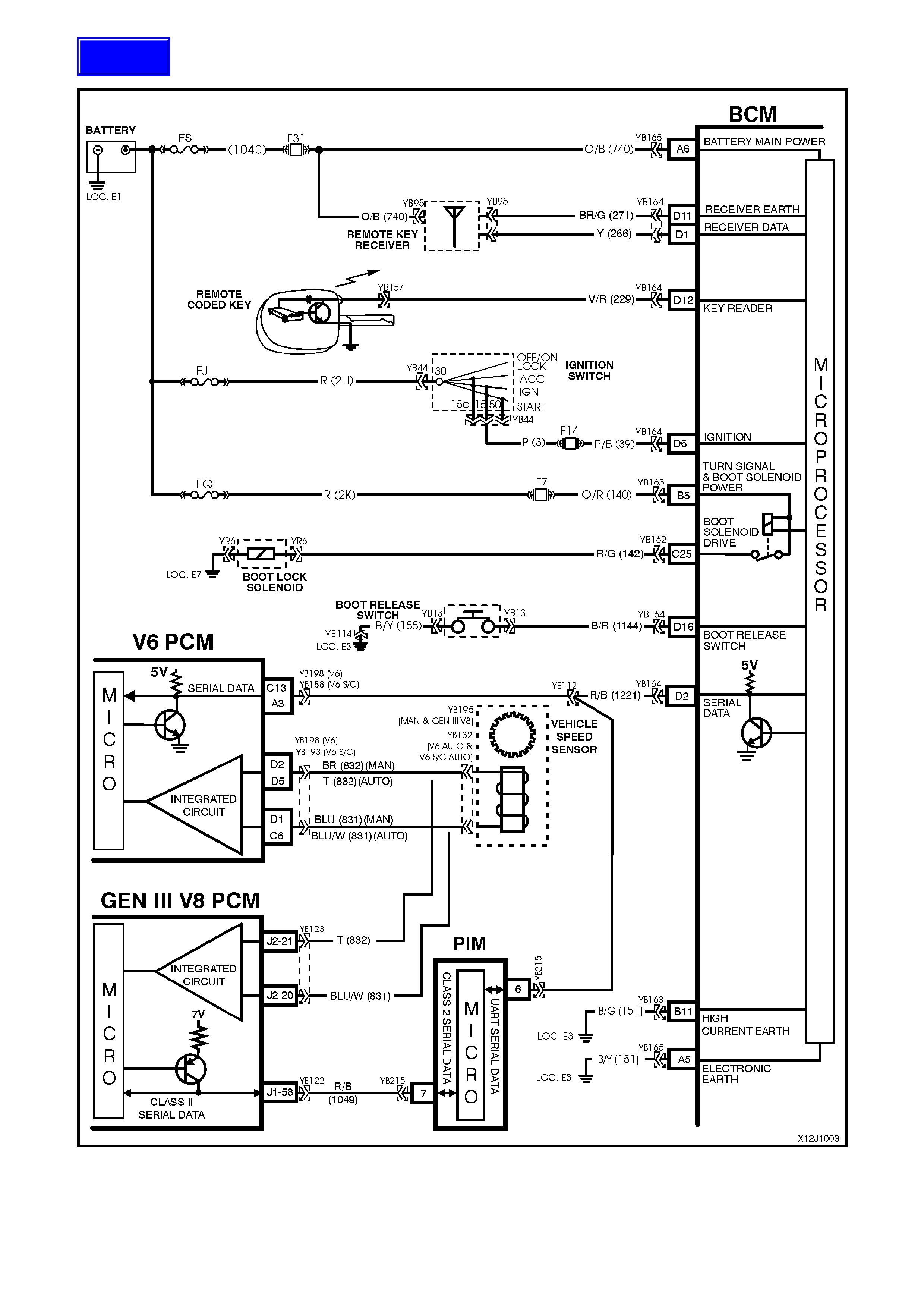

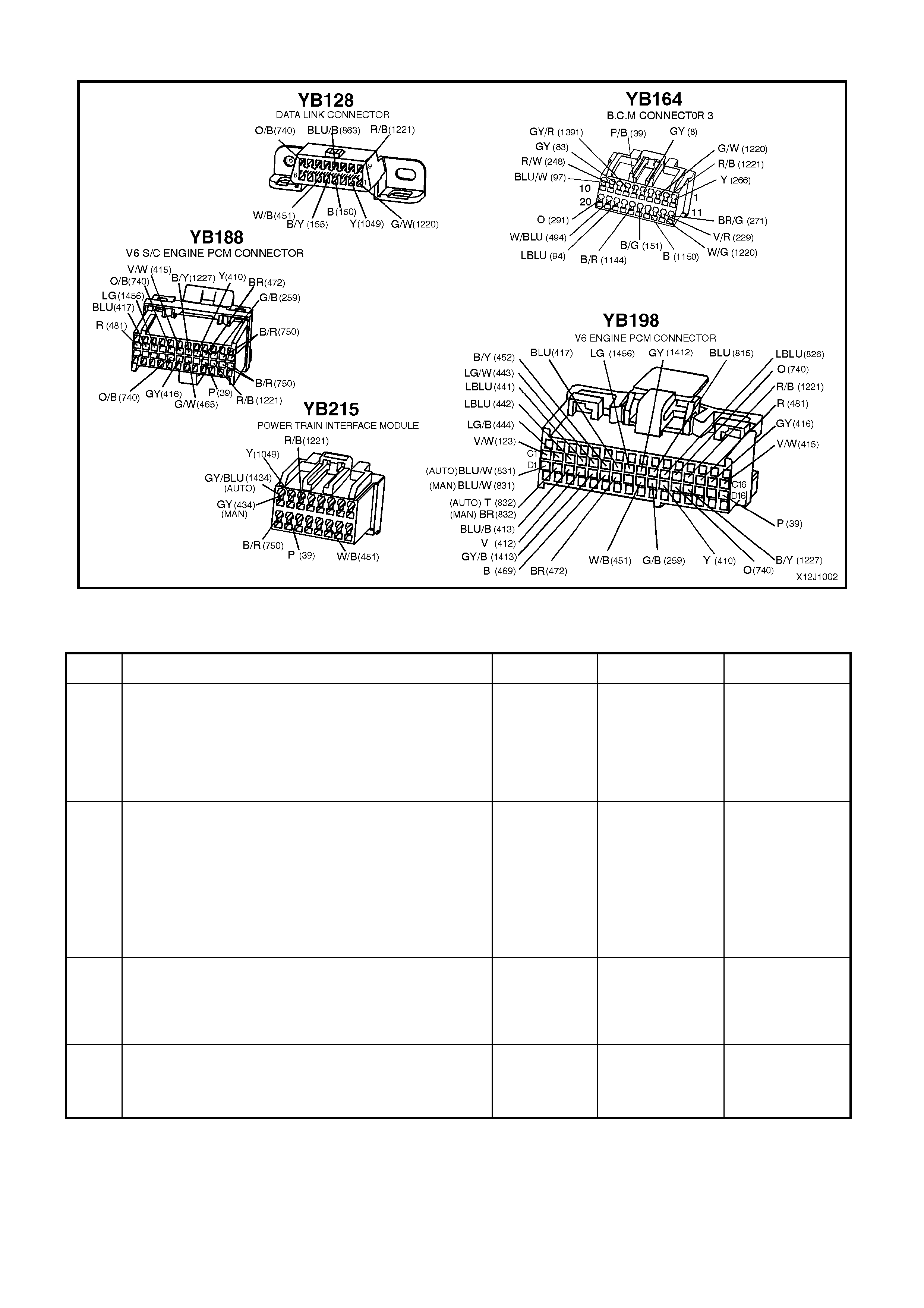

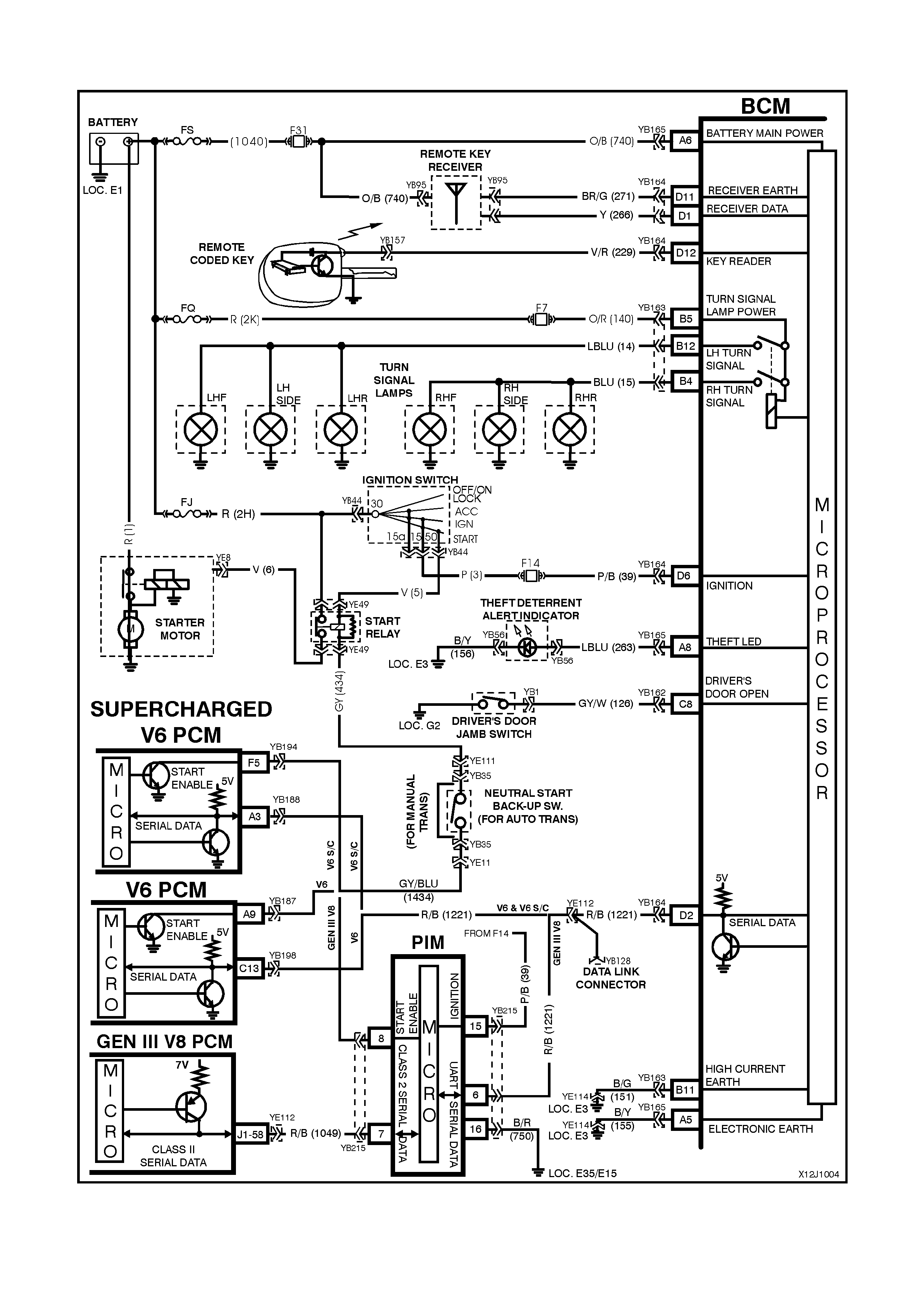

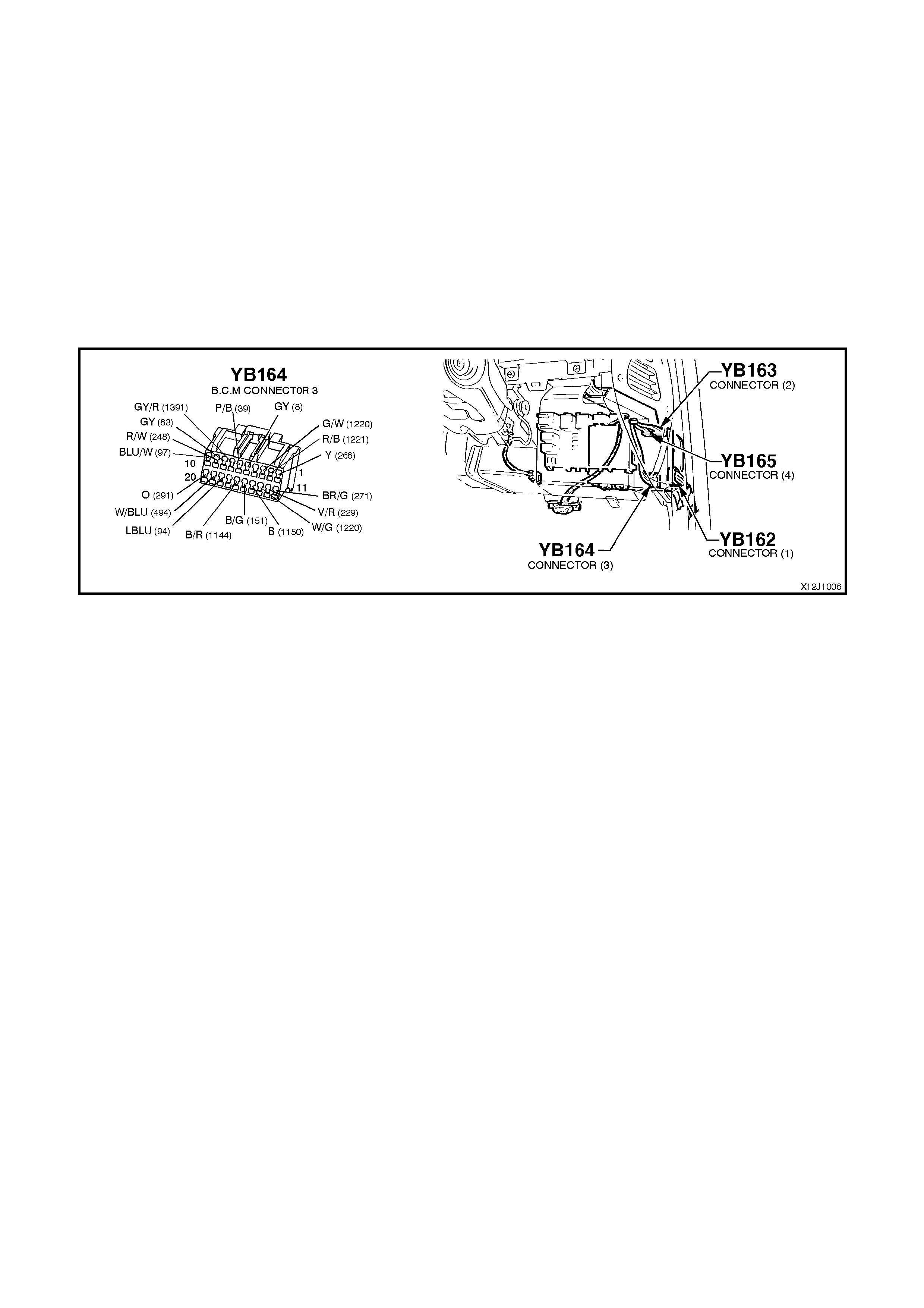

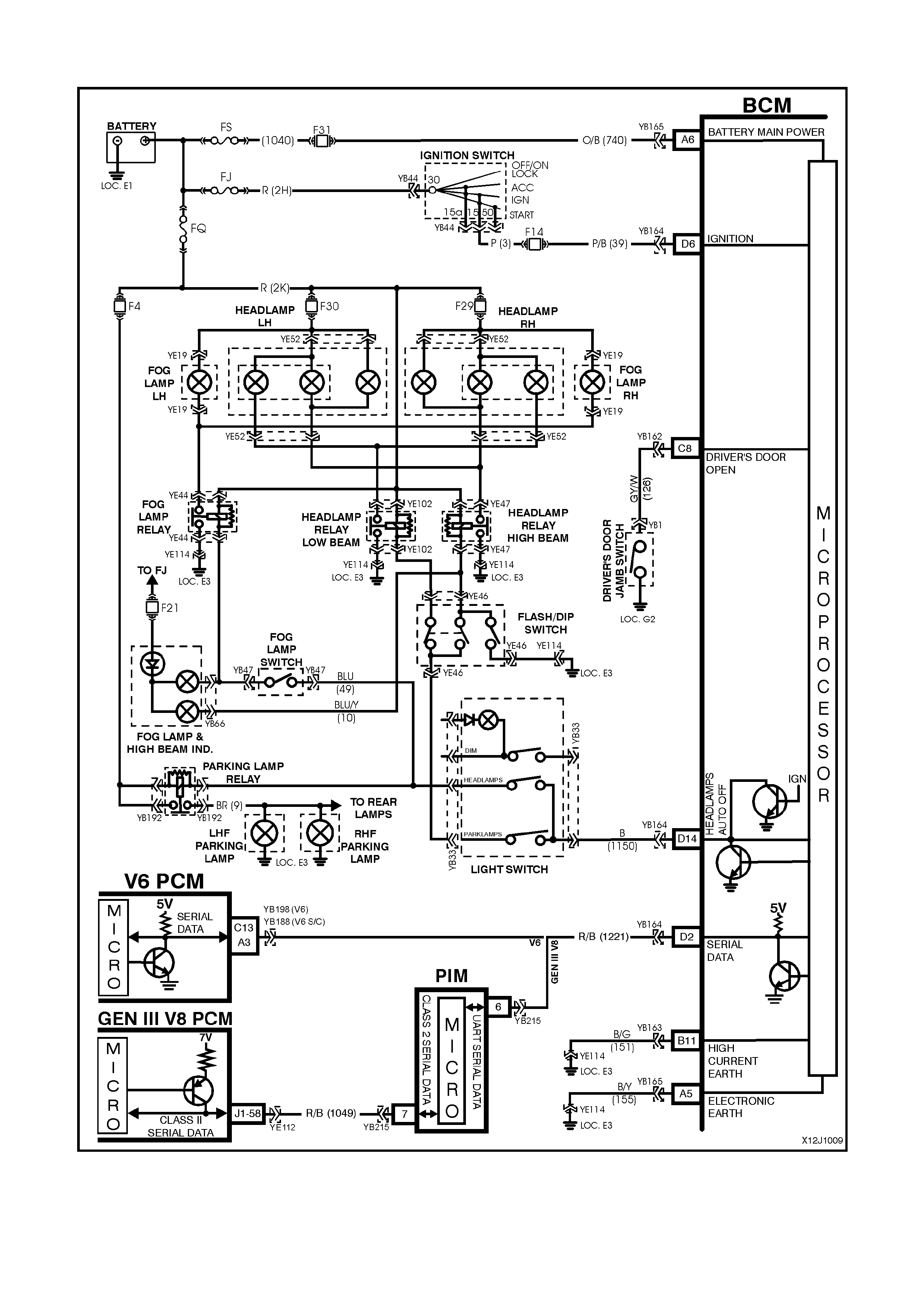

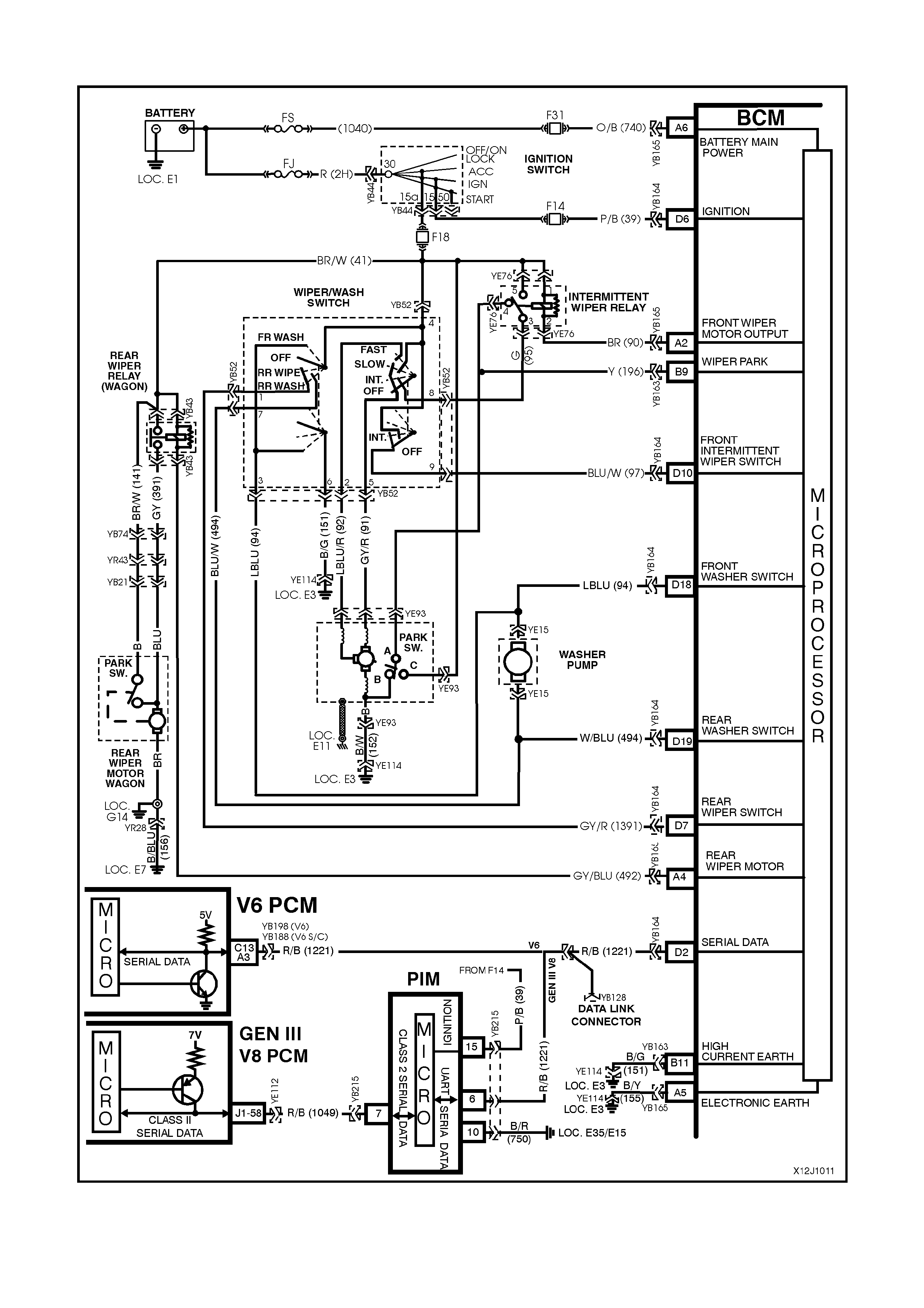

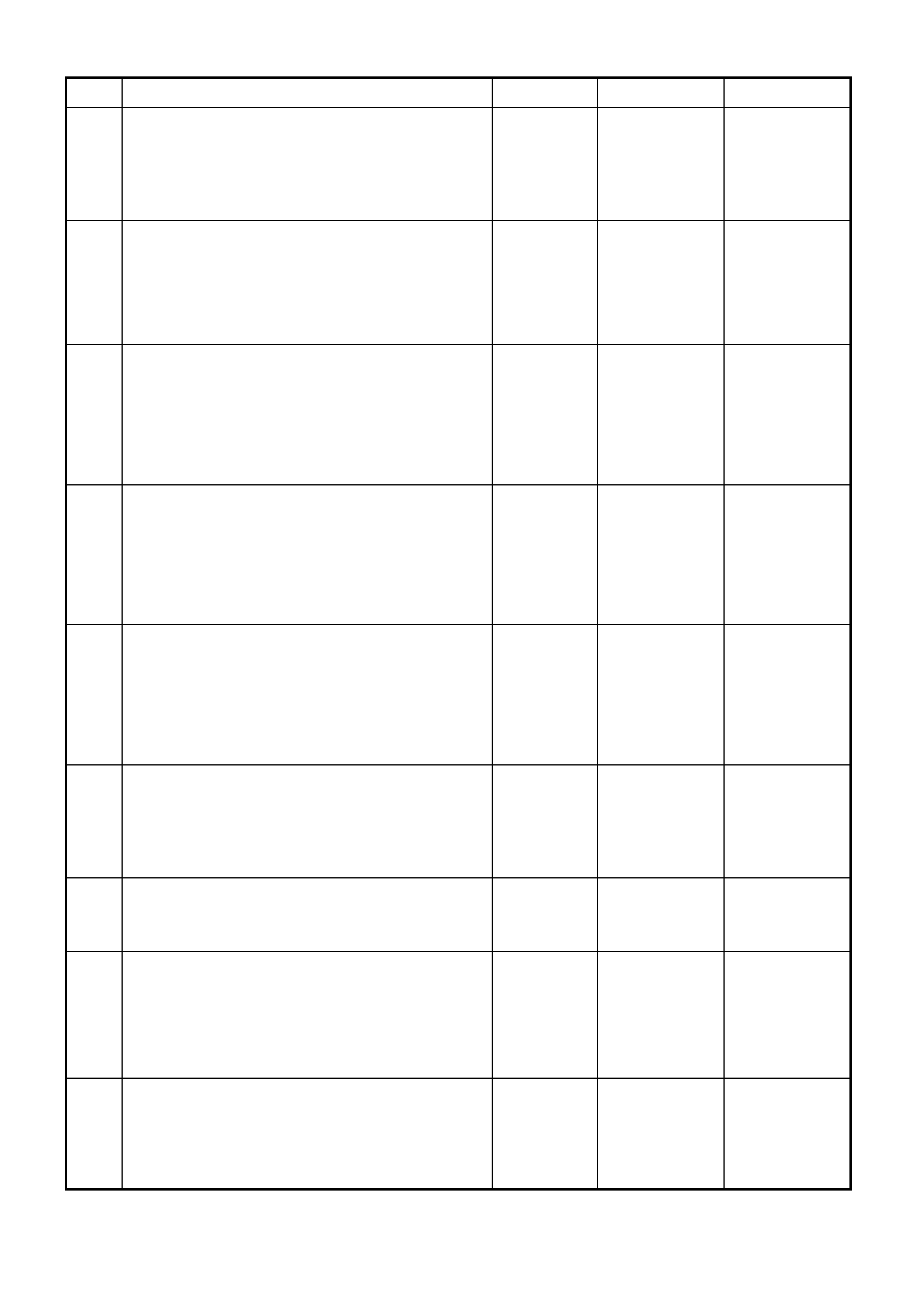

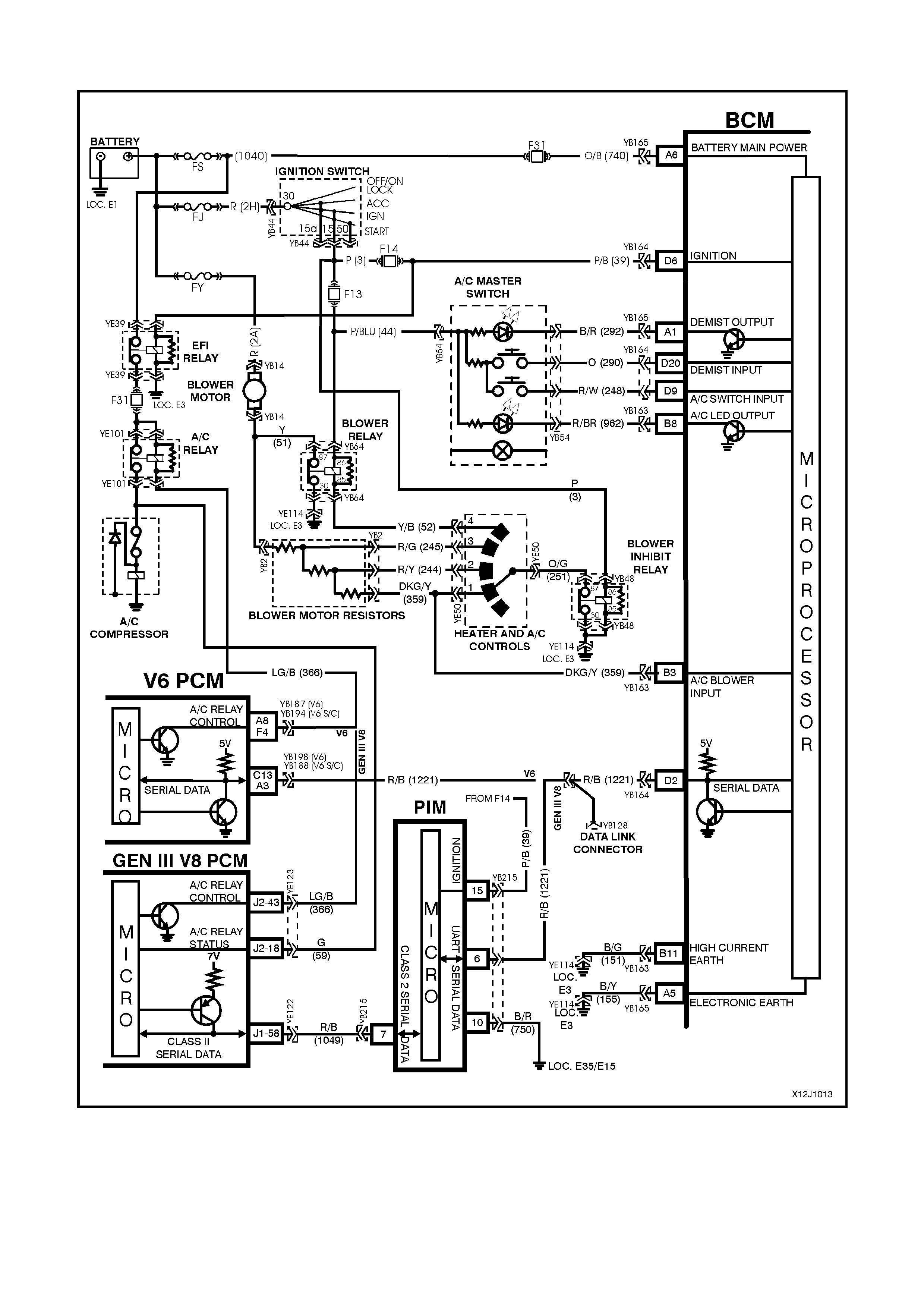

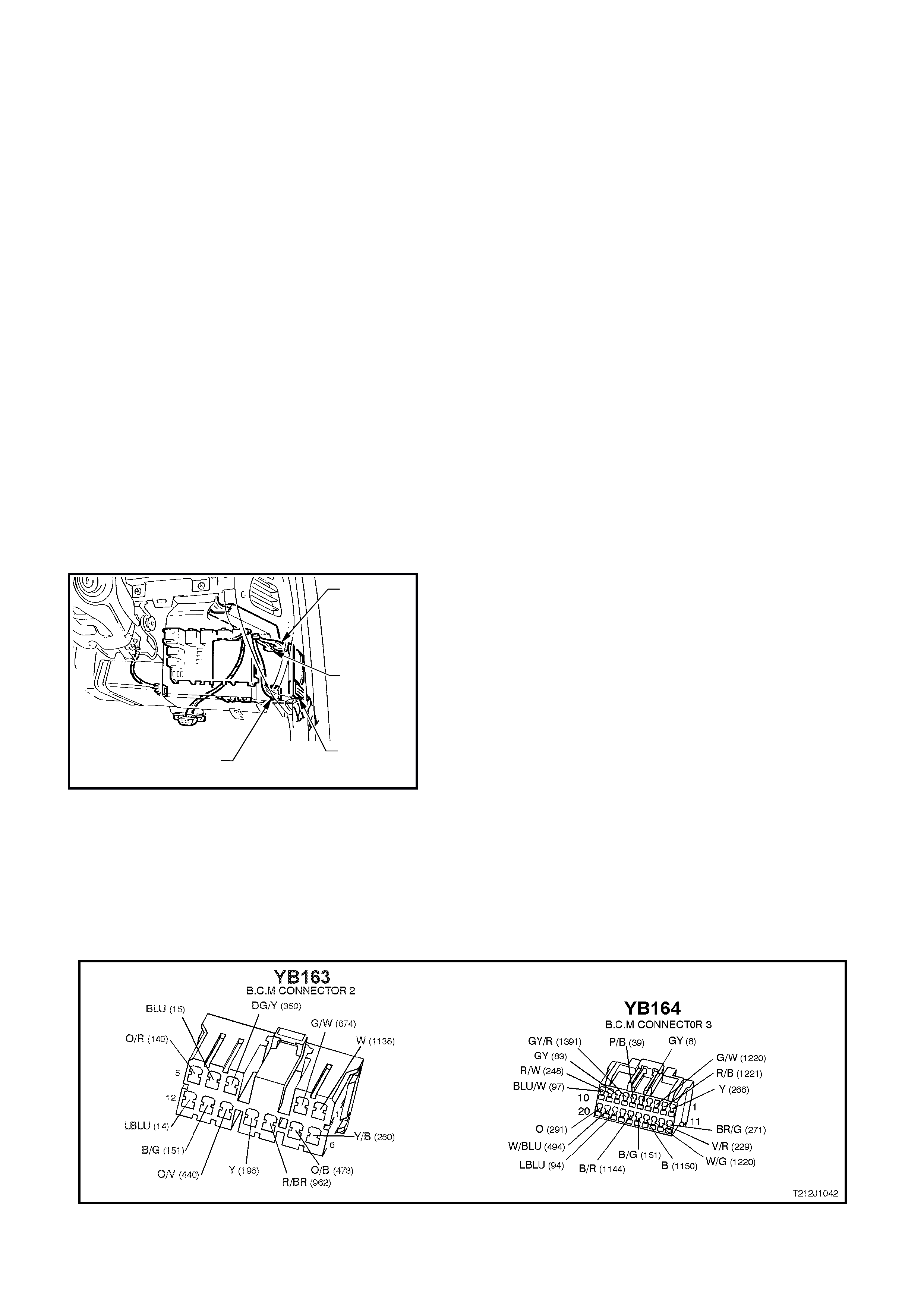

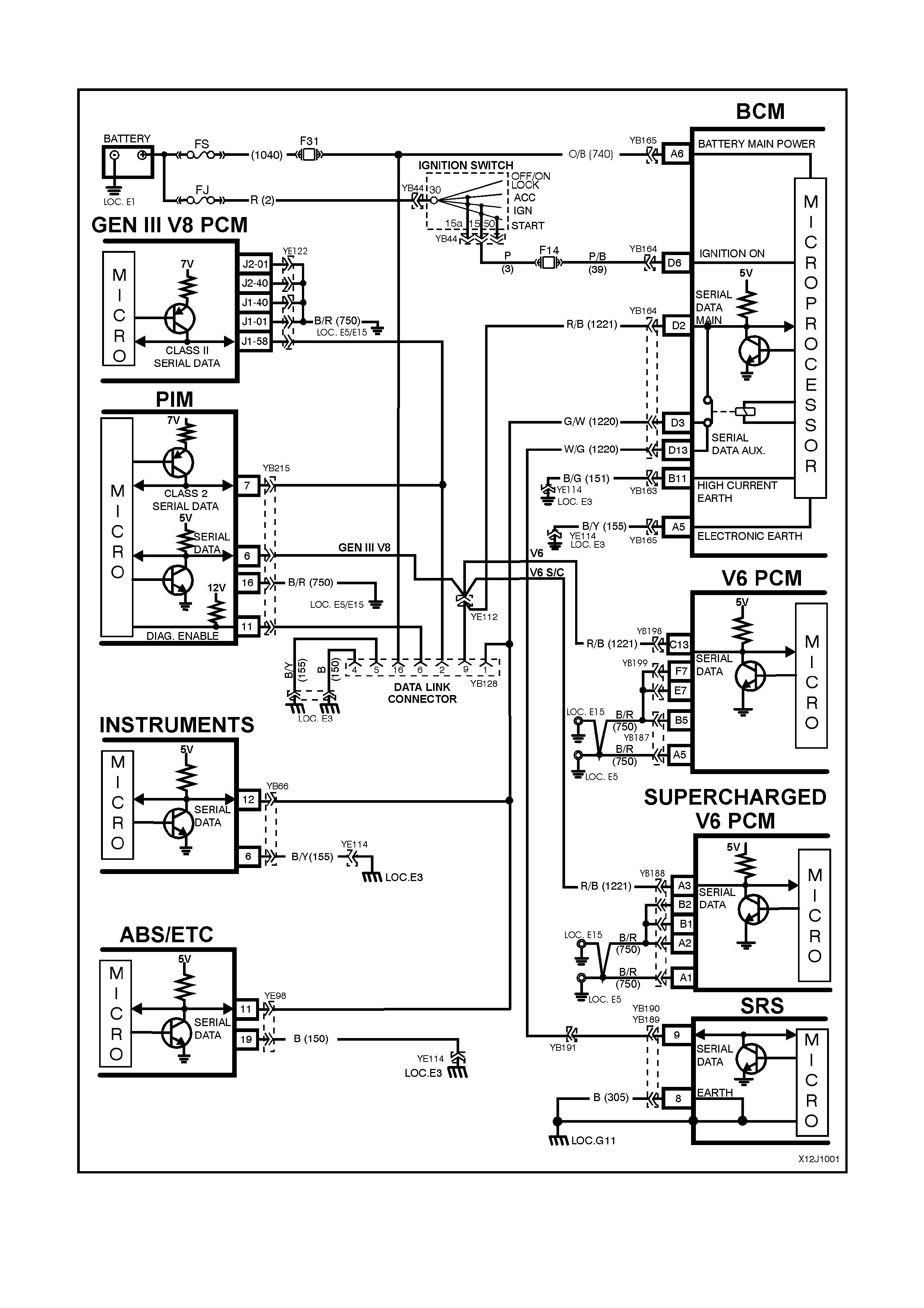

Figure 12J-2-1

GENERAL INFORMATION

VT and VX Series Model use a bus master communication system where the BCM is the bus master.

The BCM periodically polls (surveys) each device on the bus and requests status data.

NOTE: The GEN III PCM communicates using a Class 2 communication protocol, all other control modules,

including the new V6 PCM, communicate using UART. Due to these two different communication protocols, a

Powertrain Interf ace Module (PIM) is requir ed to convert the Class 2 data into UART . For additional inform ation on

Class 2 and UART communication protocols and the PIM, refer to 1.2 SERIAL DATA COMMUNICATION (BUS

MASTER) in Section 12J-1 LOW SERIES BCM of the VT Series II Service Information.

The devices connected to the bus are:

• Body Control Module (BCM).

• V6 and V6 supercharged engine Powertrain Control Module (PCM).

• GEN III V8 engine Powertrain Control Module (PCM) via the Powertrain Interface Module (PIM).

• Instrument cluster (INS).

• Antilock Brake System / Electronic Traction Control (ABS/ETC) module.

• Supplemental Restraint System (SRS) Sensing and Diagnostic Module (SDM).

• External diagnostic scan tool (TECH 2).

The data provided by each device may be utilised by any device connected to the bus.

Each device has a unique response “Message Identifier Word” (MIW) for ease of identification.

The bus mas ter (BCM) polls eac h device with a serial data m essage which includes that device’s MIW. The device

responds by putting a serial data m essage back onto the bus. T he device’s m essage includes its MIW and data, of

which is retrieved and utilised by any device on the bus requiring it.

The BCM polls each device for a status update, once every 300 millisec onds. The ex ception to this being the PCM

(V6) and PIM (GEN III V8) which are polled twice every 300 milliseconds.

When the ignition switch is turned from the OFF position to the ON position, the BCM will communicate with the

PCM (via the PIM on vehic les with G EN III V8 engines ) f or theft deterrent pur poses . If the BCM does not rec eive an

OK TO START message from the PCM within 0.5 seconds of ignition on, the auxiliary data bus is isolated via

switching from the BCM.

The isolation of the auxiliary data bus during this period eliminates the possibility of a device failure other than the

BCM, PCM or PIM (GEN III V8 only), causing a problem on the bus and inhibiting antitheft communications.

This period (short loop time) continues until the PCM responds with an acknowledgment or a maximum of five

seconds after which the BCM will switch to the standard polling sequence.

Following succ essful theft deterrent com munica tions, the BCM begins sequential polling of devices on the bus and

normal system operation is established.

When the ignition switch is in the OFF position, the BCM continues to poll, allowing for TECH 2 communications

and external control of the bus prior to the ignition being switched on.

TEST DESCRIPTION

The numbers below refer to step numbers on the facing pages diagnostic chart.

1. Ensures TECH 2 is functioning correctly.

2. Checks if TECH 2 can communicate with the BCM.

3. Checks if TECH 2 can communicate with the V6 or V6 supercharged PCM (vehicles with V6 or V6

supercharged engines).

4. Checks if TECH 2 can communicate with the PIM (vehicles with GEN III V8 engines).

5. Checks if TECH 2 can communicate with the GEN III V8 PCM (vehicles with GEN III V8 engines).

6. Checks if TECH 2 can communicate with all the devices (SRS, ABS/ETC, INS) on the auxiliary serial data line.

7. Checks continuity of circuit 1221 between the BCM and the DLC.

8. Check s if no BCM com munication is caused by c ontrol module interf erence connected to the m ain or auxiliary

serial data line.

9. Checks if no BCM communication is caused by a short to battery + or earth on the main and auxiliary serial

data lines.

10. Check s continuity of circuit 1221 between the BCM and PCM, and if there is a pr oblem with the PCM (vehicles

with V6 and V6 supercharged engines).

11. Checks continuity of circuit 1221 between the BCM and PIM (vehicles with GEN III V8 engines).

12. Continuation of Step 6; determines if TECH 2 can communicate with at least one of the devices (SRS,

ABS/ETC, INS) on the auxiliary serial data line.

13. Check s to establis h whether lost comm unic ation between modules on the auxiliary serial data line and TECH 2

is due to an open in circuit 1220 or the module itself.

14. Check s to establis h whether loss of com munic ation on the auxiliary s erial data line is due to an open in circuit

1220 or the BCM.

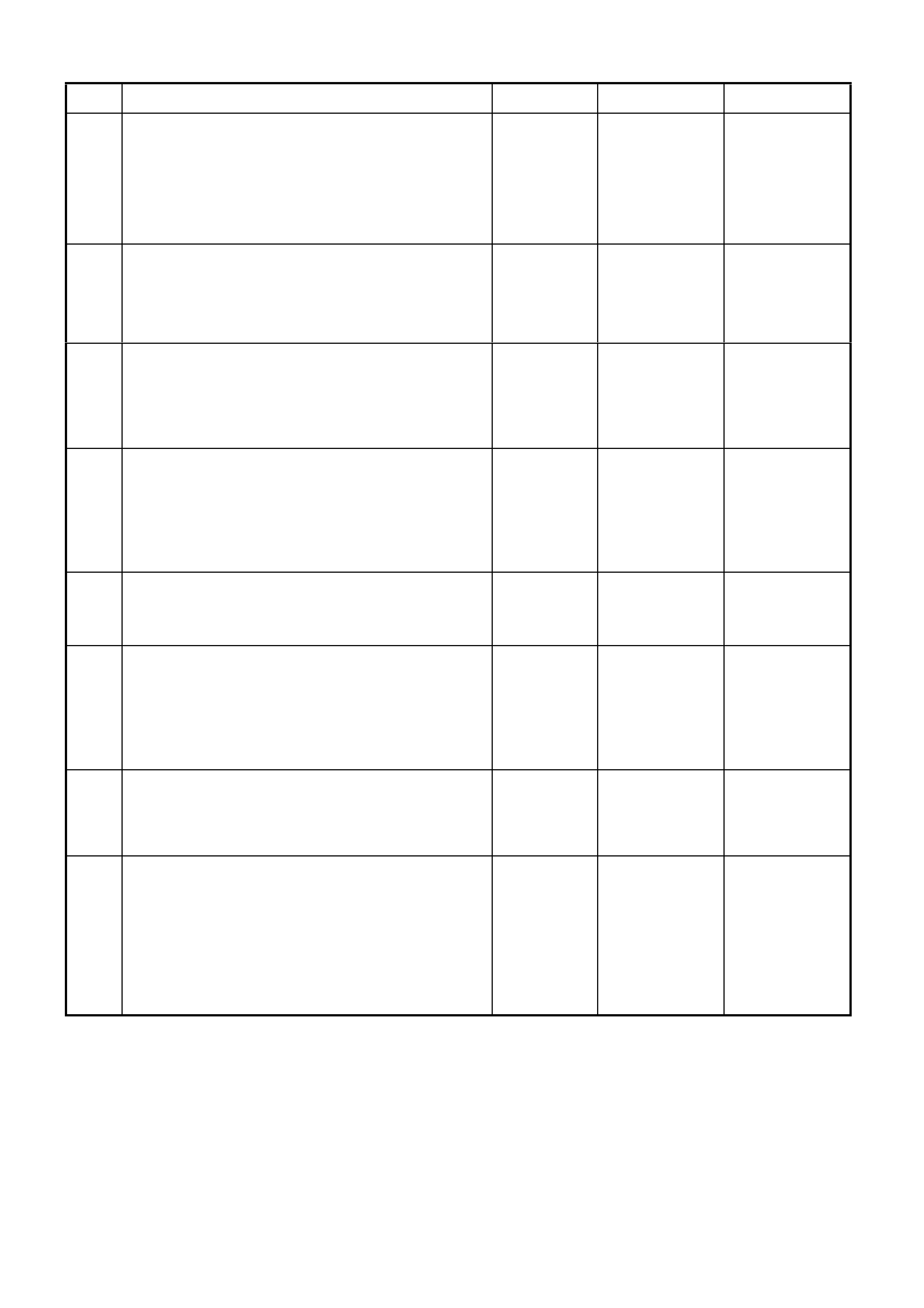

Figure 12J-2-2

SERIAL DA TA COMMUNICATION

STEP ACTION VALUE YES NO

1. • Connect TECH 2 to DLC.

• Turn ignition ON.

• Push power button on TECH 2.

• Does TECH 2 power up (screen will illuminate

display TECH 2)?

Go to Step 2. Go to TECH 2

diagnosis, refer

to Section 0C

TECH 2 of the

VT Series I

Service

Information.

2. • With TECH 2 still connected and ignition ON, select

Diagnostics / Body / Body Control Module.

• Does TECH 2 display BCM system identification

information (BCM level and type)?

Go to Step 3 -

vehicles with V6

or V6

supercharged

engines.

Go to Step 4 -

vehicles with

GEN III V8

engine

Go to Step 7.

3. • W ith TECH 2 still connected, ignition ON, exit BODY

and select Diagnostics / Engine / Engine Type (ie

V6, V6 Supercharged).

• Does TECH 2 display PCM system identification

information?

Go to Step 6. Go to Step 10.

4. • W ith TECH 2 still connected, ignition ON, exit BODY

Control Module and select Powertrain Interface

Module (PIM).

• Can TECH 2 communicate with the PIM?

Go to Step 5. Go to Step 11.

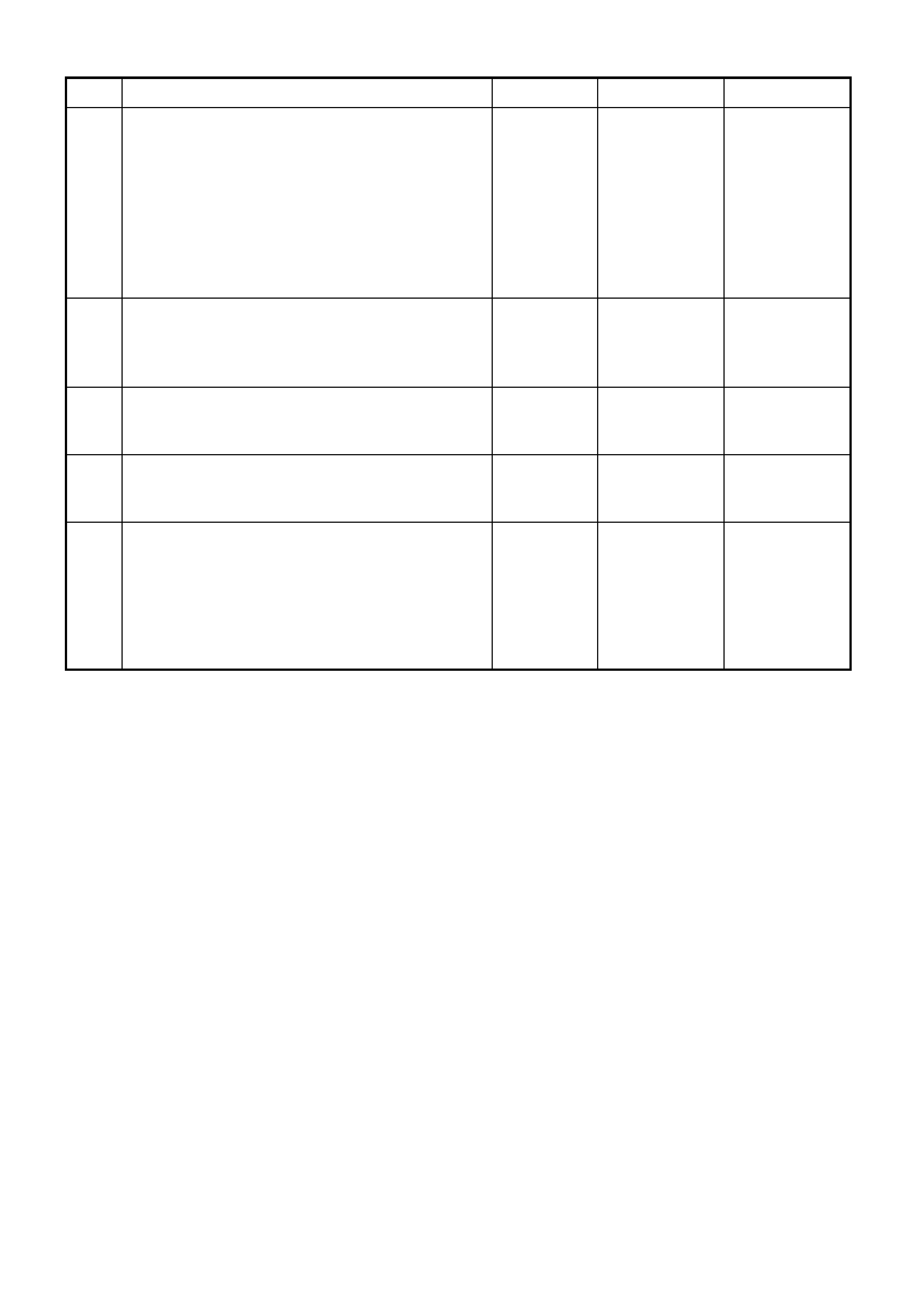

STEP ACTION VALUE YES NO

5. • W ith TECH 2 still connected, ignition ON, exit BODY

and select Diagnostics / Engine / Engine Type (ie V8

GEN III).

• Does TECH 2 display GEN III V8 PCM system

identification information?

Go to Step 6 Go to PCM

diagnostics in

Section 6C3

POWERTRAIN

MANAGEMEN T -

GEN III V8

ENGINE in the

VX Series

Service

Information.

6. • With TECH 2 still connected, ignition ON, exit Engine

Diagnostics and select Body / DTC Check / DTC

Check.

• Can TECH 2 communicate with all control modules

fitted to the vehicle (if NO DATA is displayed next to

a control module, then there is no communication

between TECH 2 and that control module)?

NOTE: If vehicle is not equipped with a particular

feature, ie. ABS/ETC, No Data will be displayed next to

this module in the TECH 2 display.

System OK. Go to Step 12.

7. • Turn ignition OFF.

• Back probe DLC connector YB128, terminal 9, circuit

1221 (Red/Black wire) and BCM connector YB164,

terminal D2, circuit 1221 (Red/Black wire) with an

Ohmmeter.

• Is value as specified?

Below 1 ohm Go to Step 8. Check and repair

open in circuit

1221 between

DLC and BCM.

Recheck and

verify repair.

8. • Disconnect control modules on auxiliary serial data

line (ABS, ABS/ETC, SRS, INS) and the PCM (V6 &

V6 Supercharged engine) or PIM (GEN III V8

engine) on the main serial data line one at a time,

checking each time if TECH 2 can communicate with

the BCM (refer to Step 2).

• Does communication between the BCM and TECH 2

resume after disconnecting any of the control

modules?

Go to suspect

control module

diagnosis refer to

the relevant

Section in the VX

Series Service

Information.

Go to Step 9.

9. • Disconnect all control modules; ABS, ABS/ETC,

SRS, INS, PCM, PIM (GEN III only) and BCM.

• Check integrity (i.e. short to battery +, short to earth)

of circuits 1221 (Red/Black wire) and circuit 1220

(Green/White – White/Green wire).

• Are circuits 1221 and 1220 OK?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Repair circuits

1221 or 1220 as

necessary.

Recheck and

verify repair.

10. • Turn ignition OFF.

• Back probe BCM connector YB164, terminal D2,

circuit 1221 (Red/Black wire) and PCM connector

YB198, terminal C13 (V6) or YB188, terminal A3 (V6

supercharged), circuit 1221 (Red/Black wire) with an

Ohmmeter.

• Is value as specified?

Below 1 ohm Go to PCM

diagnostics in

Section 6C1

POWERTRAIN

MANAGEMEN T -

V6 ENGINE in

the VX Series

Service

Information.

Check and repair

open in circuit

1221 between

PCM and BCM.

11. • Turn ignition OFF.

• Back probe BCM connector YB164, terminal D2,

circuit 1221 (Red/Black wire) and PIM connector

YB215, terminal 6, circuit 1221 (Red/Black wire) with

an Ohmmeter.

• Is value as specified?

Below 1 ohm Go to 2.4 THEFT

DETERRENT

diagnostics in

this Section.

Check and repair

open in circuit

1221 between

PIM and BCM.

12. • In Step 6, was TECH 2 able to communicate with at

least one of the control modules on the auxiliary

serial data line (ABS, ABS/ETC, INS, SRS)?

NOTE: TECH 2 will display No Data next to a control

module that it can not communicate with in the DTC

Check mode.

Go to Step 13. Go to Step 14.

STEP ACTION VALUE YES NO

13. • Check continuity between BCM and suspect control

module in circuit 1220 (Green/White – White/Green

wire).

• Does continuity exist?

Go to suspect

control module

diagnosis in the

relevant Section

in the VX Series

Service

Information.

Repair open in

circuit 1220

between suspect

control module

and the BCM.

Recheck and

verify repair.

14. • Check continuity between BCM and all control

modules on the auxiliary serial data line.

• Does continuity exist?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Repair open in

circuit 1220.

Recheck and

verify repair.

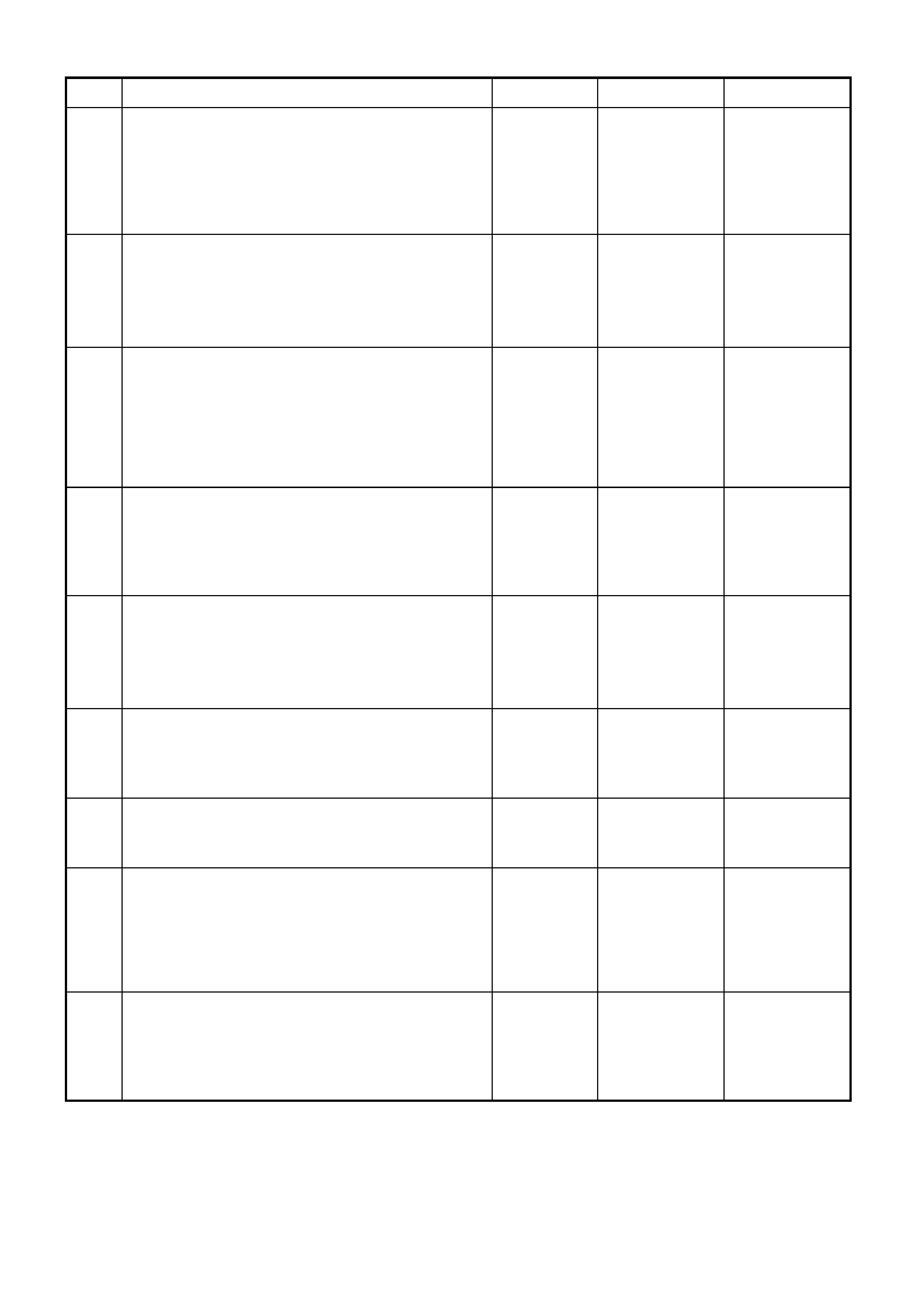

CIRCUIT DESCRIPTION

The rear compartment lock actuator is controlled by

pressing the rear compartment lock switch located

in the glove compartment. The BCM disables the

lock switch when the vehicle speed is greater than

15 km/h or the theft deterrent system is armed via

the remote coded key, drivers door microswitch or

deadlocked.

The lock switch is only enabled when the theft

deterrent system is disarm ed via the rem ote coded

key or key reader (valid security code).

Figure 12J-1-4

TEST DESCRIPTION

The num ber s below refer to step num bers in the following

diagnostic chart.

1 & 2. Functional check to determine if system is

functioning correctly or if faulty, determines if fault is

with remote receiver/key or with boot release system.

3. Uses TECH 2 to operate the rear compartment lock

actuator to establis h whether problem is with the input

or output of BCM.

4. Uses TECH 2 to check BOOT RELEASE SWITCH

ON signal at microprocessor of BCM.

5. Checks for rear compartment lock actuator drive

signal at the output of the BCM when com manded by

TECH 2.

6. Checks circuit 142.

7. Checks circuit 156 and rear compartment lock

actuator.

8. Check s f or battery voltage supply at BCM (turn signal

/ boot solenoid supply).

9. Checks for BOOT SWITCH signal at input of BCM.

10. Checks circuit 1144.

11. Checks circuit 155 and rear compartment lock switch.

Figure 12J-1-5

BOOT RELEASE

STEP ACTION VALUE YES NO

1. • Activate boot release lock switch in glove

compartment with vehicle speed below 15 km/h.

• Does the rear compartment lid open?

Go to Step 2. Go to Step 3.

2. • Close rear compartment lid.

• Press the boot release button on the remote coded

key (within two metres of the rear of the vehicle).

• Does rear compartment lid open?

System OK. Go to remote

receiver

diagnosis, refer

to 2.5 REMOTE

RECEIVER /

KEY in this

Section.

3. • Connect TECH 2, ignition ON.

• Select Body / Body Control Module / Miscellaneous

Tests / Security System / Boot Release.

• Conduct test as instructed by TECH 2.

• Does boot lid open?

Go to Step 4. Go to Step 5.

STEP ACTION VALUE YES NO

4. • With TECH 2 still connected, exit Miscellaneous

Tests, select Data Display and scroll to Boot Release

Switch.

• Press boot release button in glove compartment.

• Does the screen display change to Boot Release

Switch On?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 9.

5. • Back probe BCM connector YB162, terminal C25,

circuit 142 (Red/Green wire) with a Voltmeter to

earth.

• Repeat TECH 2 Boot Release test and press release

button in glove compartment.

• Are voltages as specified?

Test not

conducted:

0 volts

Test

conducted:

12 volts

Go to Step 6. Go to Step 8.

6. • Back probe actuator connector YR6, circuit 142

(Red/Green wire) with Voltmeter to earth.

• Repeat TECH 2 Boot Release test and press release

button in glove compartment.

• Are voltages as specified?

Test not

conducted:

0 volts

Test

conducted:

12 volts

Go to Step 7. Repair open or

short in circuit

142. Recheck

and verify repair.

7. • Back probe actuator connector YR6 circuit 156

(Black/Blue wire) with an Ohmmeter to earth.

• Is reading as specified?

Below 1 ohm Replace rear

compartment

lock actuator,

refer to Section

1A4 REAR

COMPARTMENT

LID AND

TAILGATE of the

VT Series I

Service

Information.

Repair open in

circuit 156.

Recheck and

verify repair.

8. • Back probe BCM connector YB163, terminal B5,

circuit 140 (Orange/Red wire) with a Voltmeter to

earth.

• Is voltage as specified?

Battery + Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Check and repair

open or short in

circuit 140

(including fuse

F7). Recheck

and verify repair.

9. • Back probe BCM connector YB164, terminal D16,

circuit 1144 (Black/Red wire) with an Ohmmeter to

earth.

• Activate the rear compartment lock switch.

• Is value as specified?

Below 1 ohm Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 10.

10. • Back probe rear compartment lock switch connector

YB13, circuit 1144 (Black/Red wire) with a

Ohmmeter to earth.

• Activate the rear compartment lock switch.

• Is value as specified?

Below 1 ohm Repair open or

short in circuit

1144. Recheck

circuit to verify

repair.

Go to Step 11.

11. • Back probe rear compartment lock switch connector,

YB13, circuit 155 (black/Yellow wire) with an

Ohmmeter to earth.

• Is reading as specified?

Below 1 ohms Replace rear

compartment

lock switch, refer

to Section 1A4

REAR

COMPARTMENT

LID AND

TAILGATE of the

VT Series I

Service

Information.

Repair open in

circuit 155.

Recheck and

verify repair.

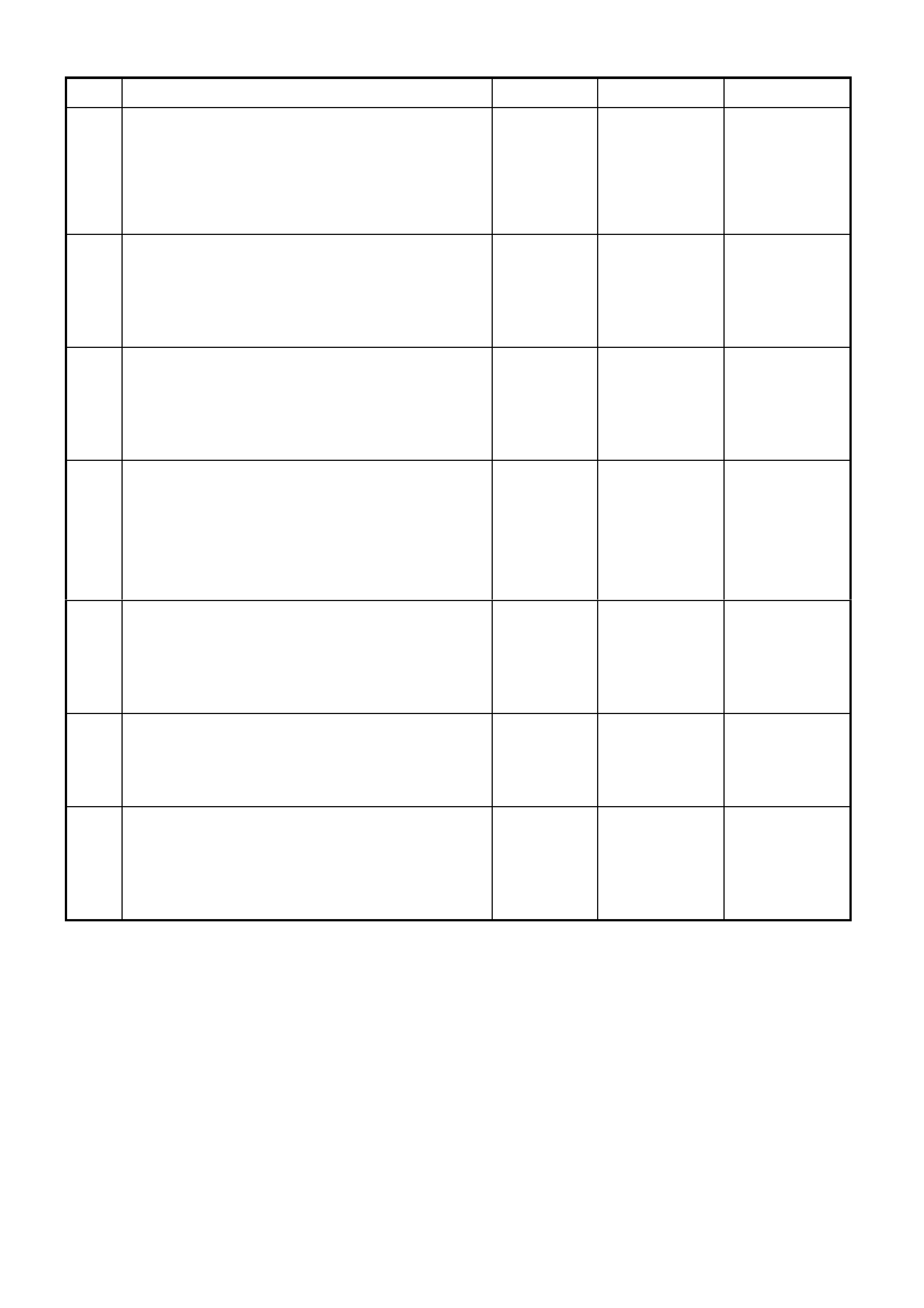

2.4 THEFT DETERRENT

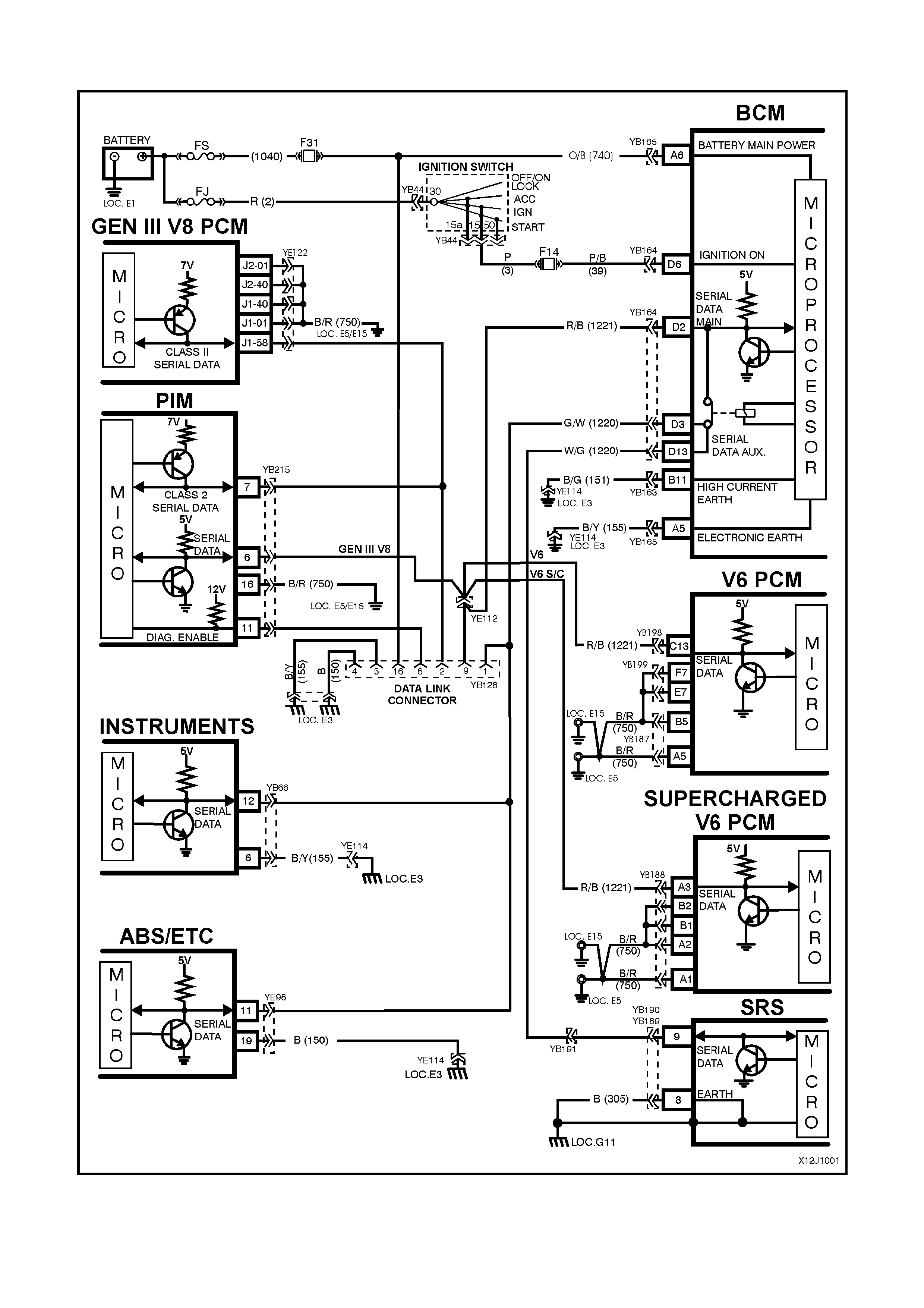

Figure 12J-1-6

CIRCUIT DESCRIPTION

The theft deterrent system can be armed by pressing the lock button on the remote coded key when the driver’s

door is clos ed or passively armed autom atically by the BCM 30 seconds after the ignition is switched off . W hen the

system is armed, the Powertrain Control Module (PCM)(V6 and V6 supercharged engine) or Powertrain Interface

Module (PIM)(GEN III V8 engine) prevents the engine from starting.

The theft deterrent system can be disarmed in two ways:-

1. By pressing the unlock button on the remote coded key. This will unlock doors, turn the interior light on and

disarm the system for 30 seconds.

2. By inserting the remote coded key into the ignition switch cylinder and turning the ignition to the ON position.

This causes the BCM to read a security code serial data output from the remote coded key contact pin, via the

remote coded key reader assembly.

Should the s ystem not disar m (thef t deterrent LED of f) when the ignition switch is turned to the ON position (ie. due

to a m is aligned or f aulty remote coded key reader or faulty remote c oded key), then press the loc k or unlock button

on the remote key to disarm the theft deterrent system.

The remote coded key is powered by it’s own internal battery. If the battery fails, the remote coded key can be

powered by the rem ote coded k ey reader once the k ey is ins erted into the ignition cylinder and turned to either the

ON or START positions.

When pressing the lock button on the remote coded key to arm the system, the indicators will flash once and the

theft deterrent alert indicator (LED) will begin to flash.

W hen pres sing the unlock button on the rem ote coded key to disarm the system, the indicators will flash twice and

the theft deterrent alert indicator (LED) will go out.

On vehic les with V6 and V6 supercharged engines, when the ignition switch is tur ned to the ON position, the BCM

polls the PCM and sends an encrypted BCM/Key sec urity code (The s ecurity code is rec eived via the BCM slip ring

or re mote receiver in the event of no slip ring com m unication). T he PCM com pares the rec eived security code with

it’s stor ed security code and if the codes m atch, the PCM will enable injector fuelling and continue engine crank ing.

The PCM will return an OK TO START message, which tells the BCM to jump from SHORT LOOP mode to the

LONG LOOP mode.

On vehicles with GEN III V8 engines, when the ignition switch is turned to the ON position, the BCM polls the PIM

and sends an encrypted BCM/Key security code (The security code is received via the BCM slip ring or remote

receiver in the event of no slip ring comm unication). The PIM compares the received security code with it’s stored

security code and if the c odes match, the PIM will continue engine cr anking and send a s eparate enc rypted security

code to the PCM. T he PCM com pares this c ode with its stored security code and if the codes m atch, the PCM will

enable injector fuelling to continue. The PIM will return an OK TO START message, which tells the BCM to jump

from SHORT LOOP mode to the LONG LOOP mode.

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1-10 . Functional check of system.

11. Checks if doors are not locking due to central door locking system or remote receiver/remote key.

12. Re-synchronisation of remote key rolling code in event of rolling code misalignment.

14. Uses TECH 2 to operate indicators (establish whether problem is with the BCM or other external problem).

15. Checks turn signal input at input to BCM.

16. Checks turn signal output at output of BCM when commanded by TECH 2.

17. Uses TECH 2 to operate the theft deterrent LED (establish whether problem is with the BCM or other

external problem).

18. Checks for theft deterrent LED output drive form the BCM when commanded by TECH 2.

19. Checks for short to earth in circuit 263 causing LED to be faulty.

20. Checks circuit 263.

21. Checks circuit 156 for open to establish if circuit is faulty or theft deterrent LED is faulty.

22. Checks if problem is confined to the key reader or remote serial data transfer.

23. Checks for poor remote coded key shaft earth contact.

24. Checks for poor contact of remote coded key pin with remote coded key reader.

25. Checks if problem is with remote coded key by trying a known good remote coded key.

26. Checks for BCM signal at remote key reader.

27. Checks ignition switch/cylinder earth.

28. Uses TECH 2 to check IGNITION ON signal at microprocessor of BCM.

29. Checks circuit 229 for open to establish if circuit is faulty or BCM is faulty.

30. Checks for short to earth in circuit 229.

31. Checks ignition ON signal at input to BCM.

32. Uses TECH 2 to check for PASSIVE MODE OFF signal at microprocessor of BCM to establish if fault is

with the BCM or PCM.

33. Continuation of functional check for vehicles with GEN III V8 engines.

34. Uses TECH 2 to check for PASSIVE MODE OFF signal at microprocessor of BCM to establish if fault is

with the BCM or PCM.

35. Using TECH 2, checks for communication with the PIM.

36. Uses TECH 2 to check for THEFT STATUS start signal at the microprocessor of the PIM.

37. Uses TECH 2 to drive the starter relay to determine if the fault is with the PIM or starter circuits.

38. Checks for ignition on (power feed) at the input to the PIM.

39. Checks circuit 750.

40. Checks circuit 1221.

41. Uses TECH 2 to check starter relay drive of PIM.

Figure 12J-1-7

Figure 12J-1-8

THEFT DETERRENT

STEP ACTION VALUE YES NO

1. • Close and lock all doors.

• Operate remote key UNLOCK button within four

meters of the driver’s side B pillar.

• Does the driver’s door unlock (two stage unlocking

programmed) or all doors unlock (single stage

unlocking programmed)?

Go to Step 2. Go to Step 11.

2. • In Step 1, did all indicator lights flash twice (both left

and right hand sides)? Go to Step 3. Go to Step 13.

3. • In Step 1, did the dome lamp illuminate? Go to Step 4. Go to dome lamp

delay diagnosis,

refer 12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

4. • In Step 1, did the theft deterrent LED go out

immediately and begin flashing 30 seconds latter? Go to Step 5. Go to Step 17.

5. • Close all doors.

• Arm theft deterrent system by operating the LOCK

button on the remote coded key within four metres of

the driver’s side B pillar.

• Did all doors lock?

Go to Step 6. Go to central

door locking

diagnosis, refer

to 12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

6. • In Step 5, did the dome lamp go out immediately

upon activating the lock button? Go to Step 7. Go to dome lamp

delay diagnosis,

refer 12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

7. • In Step 5, did all indicator lights flash once (both left

and right hand sides)? Go to Step 8. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

8. • Is the theft deterrent LED flashing? Go to Step 9. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

9. • Unlock vehicle with remote coded key and wait for

the vehicle to passively arm (theft deterrent LED

flashing).

• W ith vehicle passively armed), insert the ignition key

into ignition switch and turn to the ON position.

• Does the theft deterrent LED extinguish?

Go to Step 10. Go to Step 22.

10. • Turn the ignition key to the START position.

• Does the vehicle crank and start? System OK. Go to Step 32 -

vehicles with V6

or V6

supercharged

engines.

Go to Step 33 -

vehicles with

GEN III V8

engines

STEP ACTION VALUE YES NO

11. • Insert ignition key into driver’s door lock cylinder and

operate door unlock microswitch (turn key to unlock

position).

• Do all doors unlock?

Go to Step 12. Go to central

door locking

diagnosis, refer

to 12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

12. • Insert ignition key into ignition switch and cycle from

OFF - ON - OFF.

• Remove key and lock doors with driver’s door lock

cylinder switch.

• Operate UNLOCK button on remote key within four

metres of driver’s door B pillar.

• Does the driver’s door unlock (two stage unlocking

programmed) or all doors unlock (single stage

unlocking programmed)?

Go to Step 2. Go to remote

receiver

diagnosis, refer

to 2.5 REMOTE

RECEIVER /

KEY in this

Section.

13. • In Step 2, did at least one side of vehicle’s indicators

flash twice (either left or right hand side)? Go to Step 16. Go to Step 14.

14. • Driver’s door closed.

• Connect TECH 2 to DLC.

• Select BODY / BODY CONTROL MODULE /

MISCELLANEOUS TESTS / LAMPS / INDICATORS.

• Conduct test as instructed by TECH 2.

• Do all indicator lights illuminate?

Go to central

door locking

diagnosis, refer

to 12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

Go to Step 15.

15. • Back probe BCM connector YB163, terminal B5,

circuit 140 (Orange/Red wire) with a Voltmeter to

earth.

• Is voltage as specified?

Approx. 12

volts Go to Step 16. Check and repair

open in circuit

140 (including

fuse F7), recheck

and verify repair.

16. • Back probe BCM connector YB163, terminals B12

and B4, circuits 14 & 15 (Light Blue wire and Blue

wire respectively) with a Voltmeter to earth.

• Repeat Tech 2 Indicator Illumination test as per Step

14.

• Is voltage as specified?

Approx. 12

volts Check and repair

circuits 14 (LH

indicator) and/or

15 (RH

indicator).

Recheck and

verify repair

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

17. • Connect TECH 2 to DLC.

• Select BODY / BODY CONTROL MODULE /

MISCELLANEOUS TESTS / SECURITY SYSTEM /

SECURITY LED.

• Conduct test as instructed by TECH 2.

• Does theft deterrent LED illuminate?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 18.

18. • Back probe BCM connector YB165, terminal A8,

circuit 263 (Light Blue wire) with a Voltmeter to earth.

• Repeat Security LED test as per Step 17.

• Are voltages as specified?

Approx 5 volts

LED on

Approx 0 volts

LED off

Go to Step 20. Go to Step 19.

19. • Back probe BCM connector YB165, terminal A8,

circuit 263 (Light Blue wire) with an Ohmmeter to

earth.

• Is value as specified?

Below 1 ohm. Repair short in

circuit 263.

Recheck and

verify repair.

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

STEP ACTION VALUE YES NO

20. • Back probe theft deterrent LED connector YB56,

circuit 263 (Light Blue wire) with a Voltmeter to earth.

• Repeat Security LED test as per Step 17.

• Are voltages as specified?

Approx 5 volts

LED on

Approx 0 volts

LED off

Go to Step 21. Check and repair

open in circuit

263. Recheck

and verify repair.

21. • Back probe theft deterrent LED connector YB56,

circuit 156 (Black/Yellow wire) with a Ohmmeter to

earth.

• Is value as specified?

Below 1 ohm Replace theft

deterrent LED,

refer to 12C

INSTRUMENTS,

WIPERS /

WASHER &

HORN of the VT

Series I Service

Information.

Repair open in

circuit 156.

Recheck and

verify repair.

22. • With the ignition key in the ON position, operate the

unlock button on the remote coded key.

• Does the theft deterrent LED go out?

Go to Step 23. Go to remote

receiver

diagnosis, refer

to 2.5 REMOTE

RECEIVER /

KEY in this

Section.

23. • Remove remote key, key shaft and clean earth

contact (shaft earth).

• Reinstall key shaft and tighten screws to the correct

torque specification (0.7 - 0.9 Nm).

• With system passively armed (theft deterrent LED

flashing), insert key into ignition switch and turn key

to the ON position.

• Does the theft deterrent LED go out?

Go to Step 10. Go to Step 24.

24. • Turn ignition key to the ON position.

• Visually check to see if remote coded key contact pin

is making good contact with remote key reader (slip

ring).

• Is remote coded key contact pin making good

contact?

Go to Step 25. Check and

repair: remote

key reader or

alignment of

remote key

reader (refer step

12) or length of

key shaft or

remote key

contact pin

25. • Check function of second remote key.

• Is second key OK? Replace remote

coded key, refer

12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

Recheck and

verify repair.

Go to Step 26

26. • Isolate remote coded key contact pin (use a thick

piece of paper to cover pin).

• Insert key into ignition switch and turn key to the ON

position.

• Measure voltage at the remote coded key reader

(slip ring) to a sound earth.

• Is voltage as specified?

Fluctuates

between 4 - 6

volts - AC

Go to Step 27. Go to Step 28.

27. • Check ignition switch earth using an Ohmmeter

connected between the ignition switch housing a

sound earth point.

• Is value as specified?

Below

100 ohms Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Check and repair

open or poor

earth connection

at ignition switch.

Recheck and

verify repair.

STEP ACTION VALUE YES NO

28. • Connect TECH 2 to DLC.

• Select BODY / BODY CONTROL MODULE / DATA

DISPLAY / DATA LIST.

• Turn ignition ON as instructed by TECH 2.

• Scroll to Ignition Switch display.

• Does screen display Ignition Switch On?

Go to Step 29. Go to Step 31.

29. • Back probe BCM connector YB164, terminal D12,

circuit 229 (Violet/Red wire) with a Voltmeter to

earth.

• W ith remote coded key contact pin isolated (covered

with thick paper), insert ignition key into ignition

switch and turn ignition switch to the ON position.

• Is voltage as specified?

Fluctuates

between 4 - 6

volts - AC

Check and repair

open in circuit

229 or remote

key reader,

Recheck and

verify repair.

Go to Step 30.

30. • Check circuit 229 (Violet/Red wire) for short to earth.

• Is circuit 229 OK? Check and repair

short in circuit

229. Recheck

and verify repair.

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

31. • Back probe BCM connector YB164, terminal D6,

circuit 39 (Pink/Black wire) with a Voltmeter to earth.

• Turn ignition ON.

• Is voltage as specified?

Approx. 12

volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Check and repair

open in circuit 39

(including fuse

F14). Recheck

and verify repair.

32. • Connect TECH 2 to DLC.

• Select BODY / BODY CONTROL MODULE / DATA

DISPLAY / DATA LIST and scroll to PASSIVE

MODE.

• W ith system disarmed (theft deterrent LED off), does

the screen display Passive Mode OFF?

Go to PCM

diagnostics in

Section 6C1

POWERTRAIN

MANAGEMEN T -

V6 ENGINE in

the VX Series

Service

Information.

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

33. • Turn the ignition to the START position.

• Does the engine crank and continue to crank after 1

second?

Go to PCM

diagnostics in

Section 6C3

POWERTRAIN

MANAGEMEN T -

GEN III V8 ENG

in the VX Series

Service

Information.

Go to Step 34.

34. • Connect TECH 2 to the DLC.

• Turn ignition ON.

• Select BODY / BODY CONTROL MODULE / DATA

DISPLAY / DATA LIST and scroll to PASSIVE

MODE.

• With the theft deterrent system disarmed (theft

deterrent LED off) does the screen display Passive

Mode OFF?

Go to Step 35. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

35. • With TECH 2 still connected and ignition ON, exit

BODY CONTROL MODULE and select BODY /

POWERTRAIN INTERFACE MODULE (PIM).

• Can TECH 2 communicate with the PIM (i.e.

software version number displayed)?

Go to Step 36. Go to Step 38.

STEP ACTION VALUE YES NO

36. • Ensure the BCM has been linked to the PIM (Refer

BCM linking procedure in Section 12J-1 LOW

SERIES BCM of the VT Series II Service

Information).

• With TECH 2 still connected and ignition ON select

BODY / BODY CONTROL MODULE /

POW ERTRAIN INTERFACE MODULE / DATA LIST.

Scroll to THEFT STATUS.

• Does screen display Theft Status START?

Go to Step 37. Replace PIM,

refer Section 6C3

POWERTRAIN

MANAGEMEN T -

GEN III V8 ENG

in the VX Series

Service

Information.

37. • With TECH 2 connected and ignition ON, select

BODY / BODY CONTROL MODULE /

POWERTRAIN Interface Module /

MISCELLANEOUS TESTS / STARTER RELAY.

• Turn and hold the ignition switch in the START

position.

• Conduct starter relay test as instructed by TECH 2.

• Does the engine crank?

Replace PIM,

refer Section 6C3

POWERTRAIN

MANAGEMEN T -

GEN III V8 ENG

in the VX Series

Service

Information.

Go to Step 41.

38. • Back probe PIM connector YB215, terminal 15,

circuit 39 (Pink wire) with a voltmeter to earth.

• Turn ignition ON.

• Is voltage as specified?

12 volts Go to Step 39. Check and repair

open in circuit

39. Recheck and

verify repair.

39. • Turn ignition OFF.

• Back probe PIM connector YB215, terminal 16,

circuit 750 (Black/Red wire) with an ohmmeter to

earth.

• Is value as specified?

Below 1 ohm Go to Step 40. Check and repair

open in circuit

750. Recheck

and verify repair.

40. • Back probe BCM connector YB164, terminal D2,

circuit 1221 (Red/Black wire) and PIM connector

YB215, terminal 6, circuit 1221 (Red/Black wire) with

an ohmmeter.

• Is value as specified?

Below 1 ohm Replace PIM,

refer Section 6C3

POWERTRAIN

MANAGEMEN T -

GEN III V8 ENG

in the VX Series

Service

Information.

Check and repair

open in circuit

1221 between

PIM and BCM.

Recheck and

verify repair.

41. • Back probe PIM connector YB215, terminal 8, circuit

1434 (Grey/Blue wire) with a voltmeter to earth.

• Connect TECH 2 to the DLC and select BODY /

BODY CONTROL MODULE / POWERTRAIN

INTERFACE MODULE / MISCELLANEOUS TESTS /

STARTER RELAY.

• Turn and hold the ignition switch in the START

position.

• Conduct starter relay test as instructed by TECH 2.

• Is value as specified?

Below 1 volt Check the starter

circuits, including

fusible links,

circuits 1434,

434, 5, 6, 1,

starter relay,

neutral safety

switch and

starter motor.

Refer to the

appropriate

sections in the

VX Series

Service

Information.

Replace PIM,

refer Section 6C3

POWERTRAIN

MANAGEMEN T -

GEN III V8 ENG

in the VX Series

Service

Information..

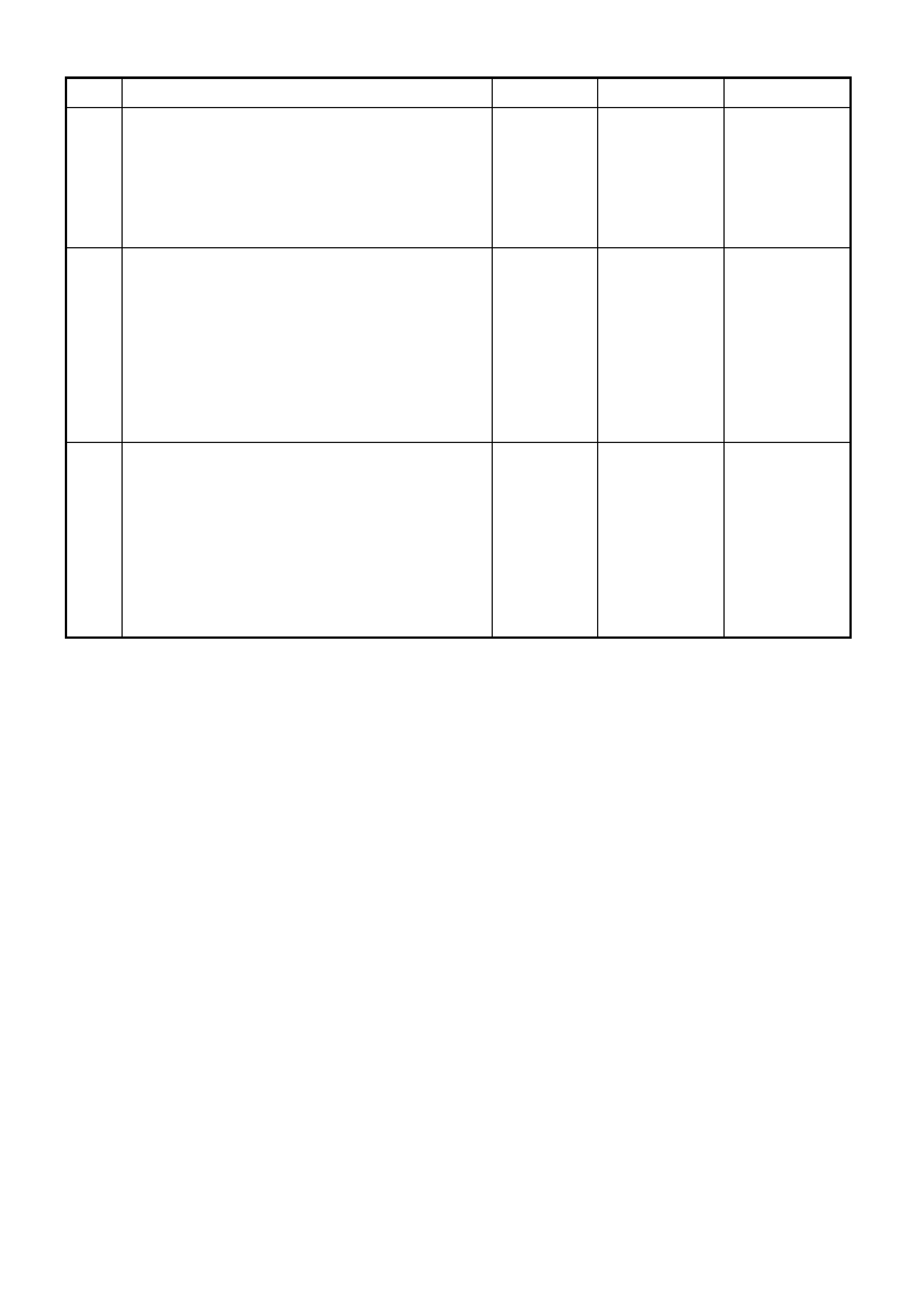

2.5 REMOTE RECEIVER / KEY

Figure 12J-1-9

CIRCUIT DESCRIPTION

When operating the UNLOCK button on the remote coded key a Radio Frequency (RF) signal is transmitted.

Provided the signal is tr ansm itted within f our m etr es of the driver’s side B pillar f or 0.25 sec onds, the BCM rec eives

this unlock reques t from the r em ote coded k ey via the remote rec eiver, located in the instrument panel between the

demist grille. The BCM then proceeds to unlock all the doors (single stage unlock) or just the driver’s door (two

stage unlock), disarms the theft deterrent sy stem, turns on the dome lamp and flashes the indicators twice.

W hen operating the LOCK button on the remote coded key within four meters of the driver’s door B pillar for 0.25

seconds, an RF signal is again transmitted. The RF signal (lock request) is received by the BCM via the remote

receiver. The BCM then proceeds to lock all doors, arm the theft deterrent system, turn the dome lamp off (if

illuminated) and flash the indicators once.

W hen oper ating the boot release button on the rem ote coded k ey within two meter s of the boot f or 0.3 s econds, an

RF signal is transmitted to the BCM via the remote receiver. The BCM then proceeds to activate the rear

compartment lock actuator (provided the vehicle speed is less than 15 km/h).

The remote coded key is powered by it’s own internal battery. If this battery fails, no RF signal will be transmitted

when operating the lock, unlock and boot release buttons. However, if the battery does lose power, the remote

coded k ey reader has the ability to power the key once it is inserted into the ignition s witch key c ylinder and turned

to the IGN or START positions. This will then enable theft deterrent disarming.

Techline

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1-7. Functional chec k to determ ine if system is f unctioning cor rect ly or if f aulty, determines if fault is with rem ote

receiver/key, central locking system or theft deterrent system.

8. Uses TECH 2 to chec k rem ote key signal - establish whether problem is with BCM or if f urther diagnosis is

required.

9. Uses TECH 2 to check for a rem ote key signal from a fully functional VT or VX Series vehicle to establish

whether problem is with remote key or if further diagnosis is required.

10. Checks for power supply to remote receiver.

11. Checks circuit 271.

12. Checks circuit 266.

13. Checks if problem is due to faulty BCM or remote receiver by swapping remote receiver with a fully

functional unit.

Figure 12J-1-10

REMOTE RECEIVER/KEY

STEP ACTION VALUE YES NO

1. Close and lock all doors.

Insert ignition key into driver’s door lock cylinder switch.

Operate unlock / lock.

Do all doors unlock and lock?

Go to Step 2. Go to central

door locking

diagnosis, refer

12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

2. Insert ignition key into driver’s door lock cylinder switch

and unlock door.

With theft deterrent LED flashing, insert ignition key into

ignition switch and turn key to the ON position.

Does the theft deterrent LED turn off?

Go to Step 3. Go to theft

deterrent

diagnosis, refer

2.4 THEFT

DETERRENT in

this Section.

3. Insert ignition key into driver’s door lock cylinder switch

and lock all doors.

Operate the UNLOCK button on the remote coded key

within two metres of the driver’s door B pillar.

Does the driver’s door only (two stage unlock) or all

doors (single stage unlock) unlock?

Go to Step 4. Go to Step 8.

4. When performing Step 3, did all of the following occur

when the UNLOCK button on the remote coded key was

pressed?

Indicators flash twice.

Dome lamp illuminate (dome lamp switch in

doors position).

Theft deterrent LED go out.

Go to Step 5. Go to theft

deterrent

diagnosis, refer

2.4 THEFT

DETERRENT in

this Section.

5. Close all doors.

Operate LOCK button on remote coded key within two

metres of driver’s door B pillar.

Do all doors lock?

Go to Step 6. Go to Step 8.

6. When performing Step 5, did all of the following occur

when the LOCK button on the remote coded key was

pressed?

Theft deterrent LED began flashing.

Indicators flashed once.

Dome lamp went out (if illuminated & with

switch in the doors position).

Go to Step 7. Go to theft

deterrent

diagnosis, refer

2.4 THEFT

DETERRENT in

this Section.

7. Press the boot release button on the remote coded key

(within two metres of the rear of the vehicle) for two

seconds.

Does rear compartment lid lock actuator solenoid

activate?

System OK. Go to Step 8.

8. Connect TECH 2 to the DLC.

Select Body / Body Control Module / Data Display.

Scroll to Remote Door Signal and Remote Boot Signal

screen display.

Operate UNLOCK, LOCK and BOOT buttons on the

remote coded key.

Does the screen display change for the remote door

signal change from Off to Unlock / Lock to Off and the

remote boot signal change from Off to Open to Off?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 9.

STEP ACTION VALUE YES NO

9. On a VT or VX Series vehicle with a fully functional

remote coded key and receiver, connect TECH 2 to the

DLC.

Select Body / Body Control Module / Data Display.

Scroll to Remote Door Signal and Remote Boot Signal

screen display.

Operate UNLOCK, LOCK and BOOT buttons on the

remote coded key.

Does the screen display change for the remote door

signal change from Off to Unlock / Lock and the remote

boot signal change from Off to Invalid to Off?

Go to Step 10. Program a new

remote coded

key, refer to

12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

Recheck and

verify repair

10. Return to original vehicle with suspected faulty remote

coded key/receiver.

Back probe remote receiver connector YB95, circuit 740

(Orange/Black wire) with a Voltmeter to earth.

Is voltage as specified?

Battery + Go to Step 11. Check and repair

open or short in

circuit 740.

recheck and

verify repair.

11. Check integrity of circuit 271 (Brown/Green wire).

Is circuit 271 OK? Below 1 ohm

Go to Step 12. Repair circuit 271

as necessary.

Recheck and

verify repair.

12. Check integrity of circuit 266 (Yellow wire).

Is circuit 266 OK? Below 1 ohm Go to Step 13. Repair circuit 266

as necessary.

Recheck and

verify repair.

13. Replace remote receiver with a known functional one

and connect TECH 2 to the DLC.

Select Body / Body Control Module / Data Display.

Scroll to Remote Door Signal screen display.

Operate UNLOCK and LOCK button on the remote

coded key.

Does the screen display change from Off to Unlock /

Lock Off?

Replace remote

receiver, refer to

12J-1 LOW

SERIES BCM of

the VT Series II

Service

Information.

Recheck and

verify repair.

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

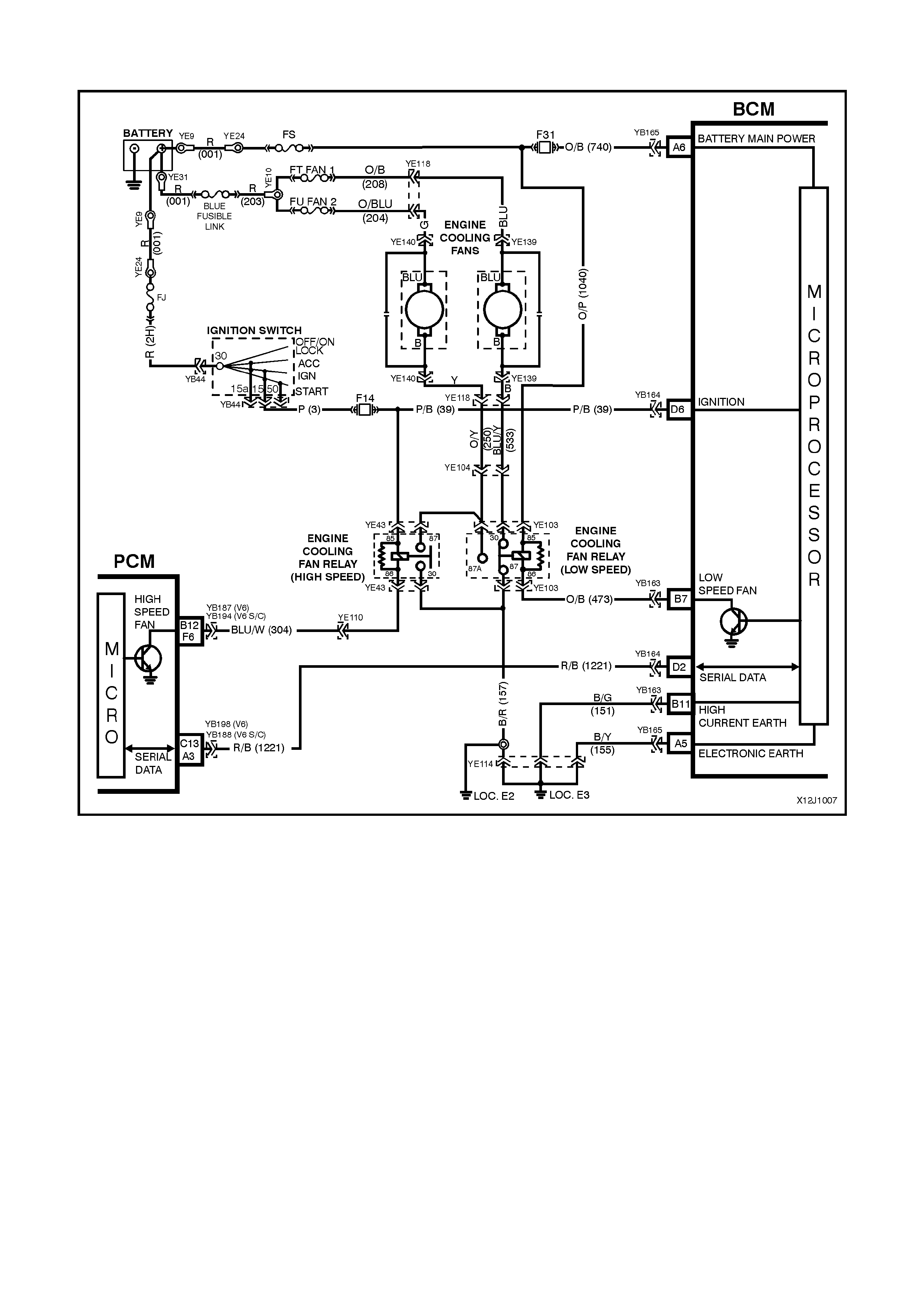

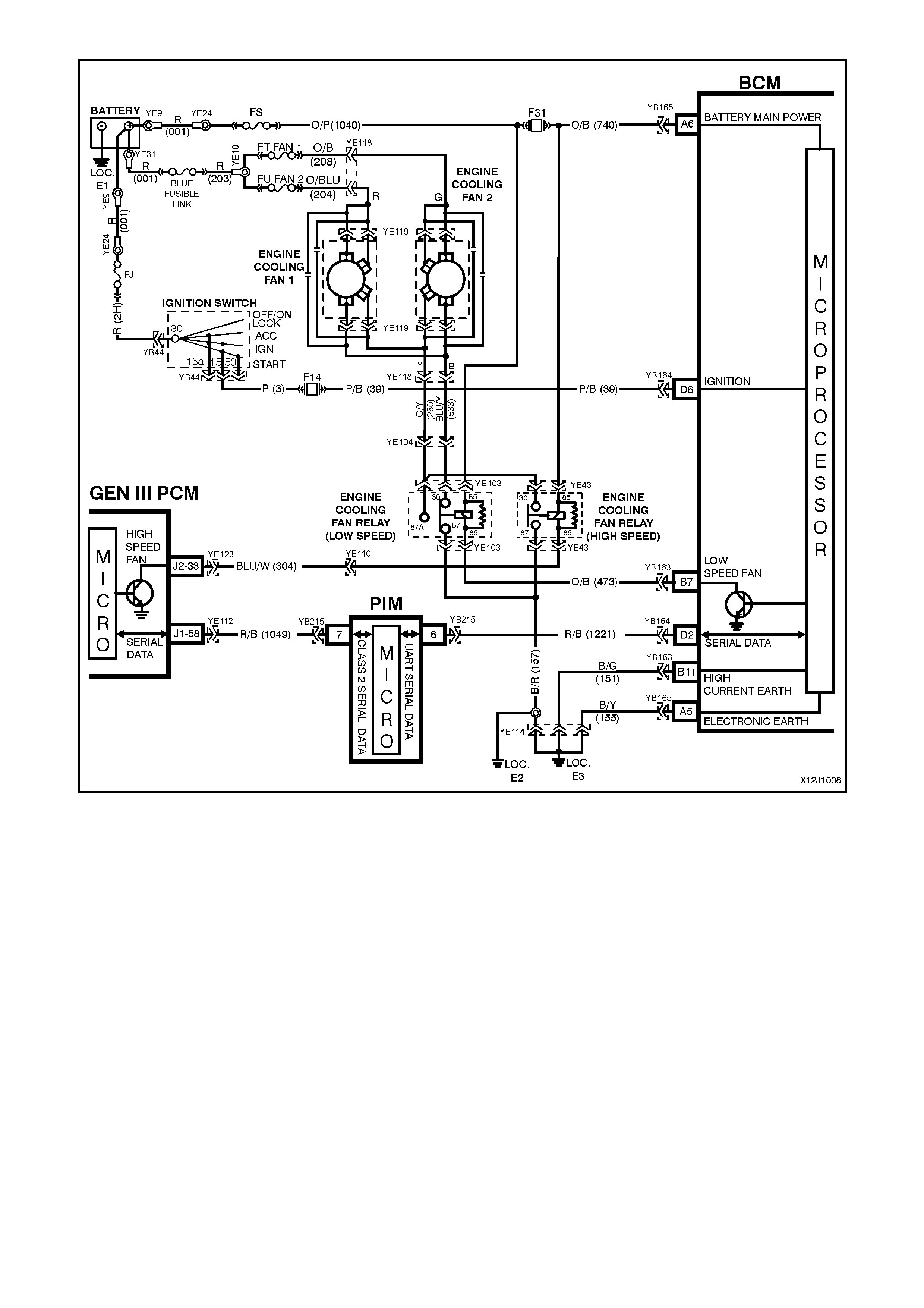

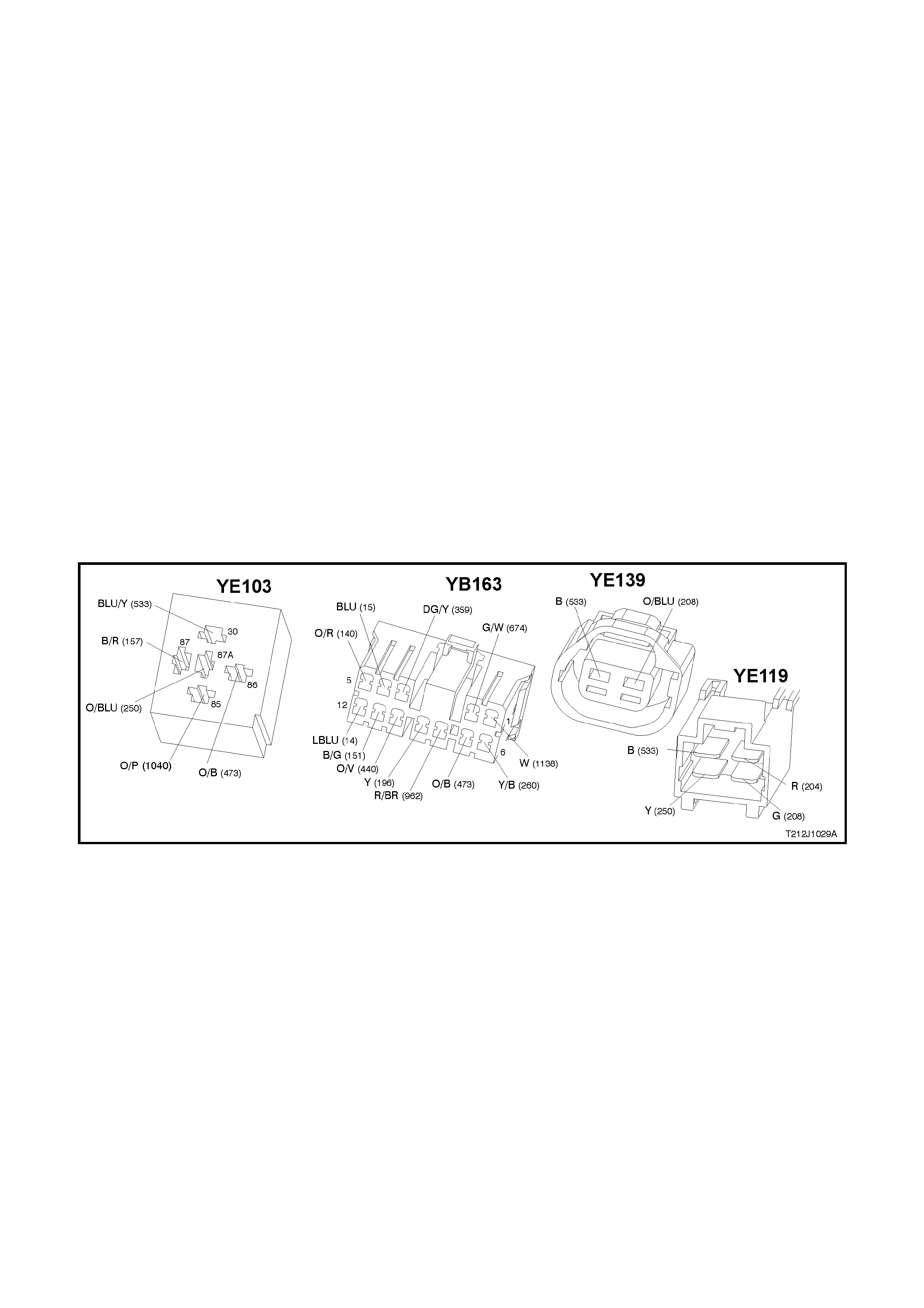

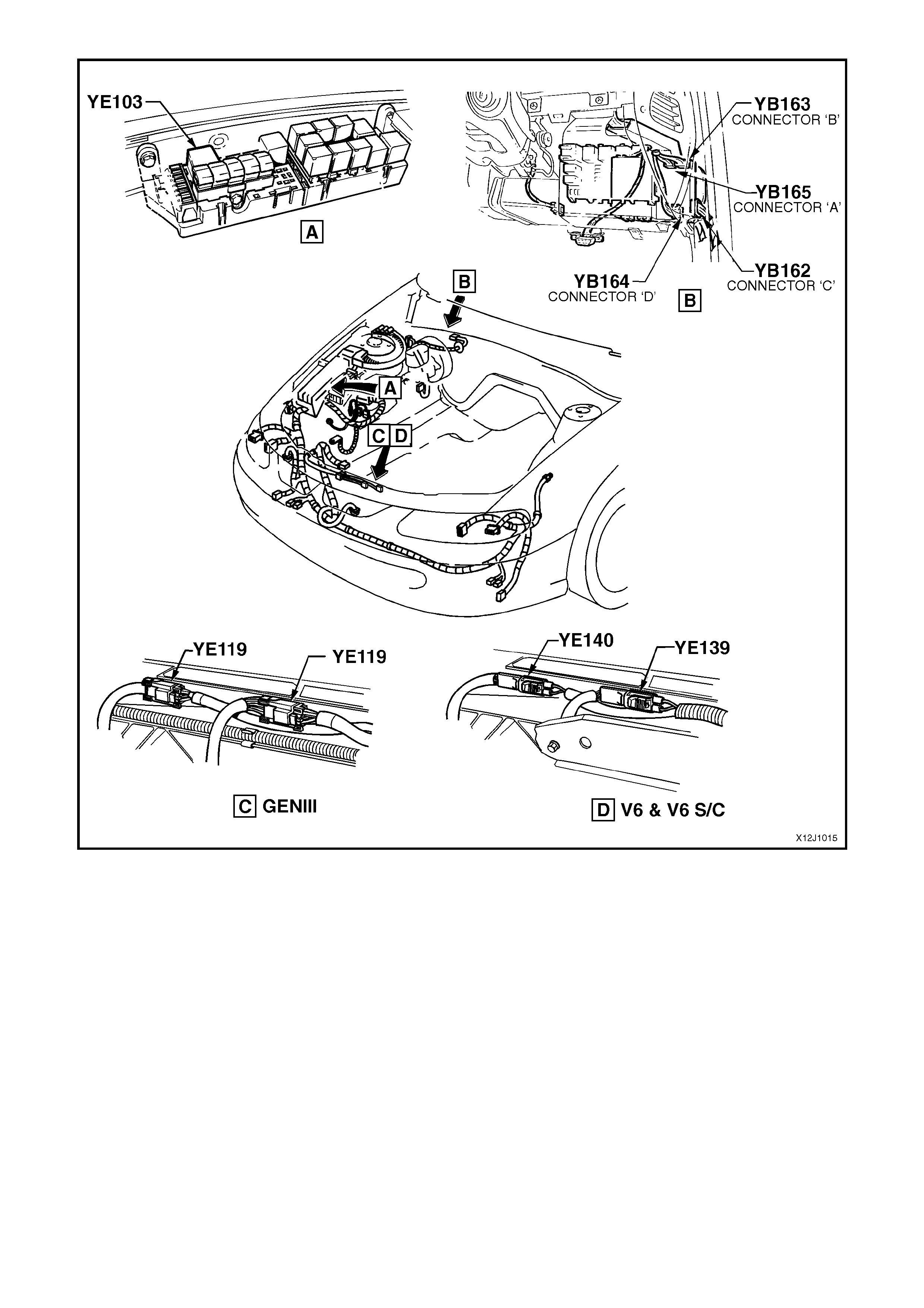

2.6 ENGINE COOLING LOW SPEED FAN CONTROL

Figure 12J-1-11 V6 AND V6 SUPERCHARGED ENGINE

Figure 12J-1-12 GEN III V8 ENGINE

CIRCUIT DESCRIPTION

Regardless of the engine configuration, the low speed c ooling fan operation is enabled when the low speed engine

cooling f an micr o r elay (located in the engine compartment relay housing, labelled Lo Fan) is ener gis ed by the Body

Control Module (BCM) via a request from the Powertrain Control Module (PCM). The PCM will request low speed

fan enable and disable via serial data communication to the BCM on circuit 1221 (Red/Black wire).

The PCM determ ines when to enable the low speed fan r elay based on inputs from the A/C request signal, Cooling

Temperature Sensor (CTS) and the Vehicle Speed Sensor (VSS).

When the ignition switch is turned from O N to OF F and the engine coolant tem peratur e is above 117°C (V6 and V6

supercharged) / 113°C (GEN III V8). The BCM will continue to energise the low speed engine cooling fan micro

relay for four minutes.

On vehicles with GEN III V8 engines, the low speed cooling fan run on time has a minimum default value of 30

seconds.

TEST DESCRIPTION

The numbers below refer to step numbers in the following diagnostic chart.

1. Functional check of low speed cooling fan operation.

2. Uses TECH 2 to command the BCM to turn the low speed fan on.

3. Checks for battery voltage supply to engine cooling fan motor.

4. Checks low speed fan drive signal at output of BCM when.

5. Checks circuit 473.

6. Checks circuit 1040.

7. Checks circuit 157.

8. Checks engine cooling low speed fan motor.

9. Checks circuit 533 and engine cooling low speed fan relay.

10.

Figure 12J-1-13

Figure 12J-1-14

ENGINE COOLING FAN LOW SPEED CONTROL

STEP ACTION VALUE YES NO

1. • With the engine coolant temperature greater than

104°C (V6 or V6 Supercharged engine) or 98°C

(GEN III V8 engine) is the low speed fan enabled?

System OK. Go to Step 2.

2. • Connect TECH 2 to the DLC.

• Select BODY / BODY CONTROL MODULE /

MISCELLANEOUS TESTS / LOW FAN.

• Conduct test as instructed by TECH 2 and enable

the low speed fan.

• Is the low speed fan enabled?

Go to PCM

Temperature

sensor diagnosis

in Section 6C1

POWERTRAIN

MANAGEMEN T -

V6 ENGINE (V6)

or 6C3

POWERTRAIN

MANAGEMENT

– GEN III V8

ENGINE in the

VX Series

Service

Information.

Go to Step 3.

3. • Back probe engine cooling fan motor connector

YE139 circuit 208 (Blue wire) on vehicles with a V6

or V6 supercharged engine or connector YE119,

circuit 208 (Green wire) on vehicles with a GEN III

V8 engine with a Voltmeter to earth.

• Is voltage as specified?

12 volts Go to Step 4. Check and repair

open in circuit

208. Recheck

and verify repair.

4. • Back probe BCM connector YB163, terminal B7,

circuit 473 (Orange/Black wire) with a jumper lead to

earth.

• Does low speed fan turn on?

0 volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 5.

5. • Back probe engine cooling fan low speed relay

connector YE103, terminal 86, circuit 473

(Orange/Black wire) with a jumper lead to earth.

• Does low speed fan turn on?

0 volts Go to Step 6. Check and repair

open in circuit

473. Recheck

and verify repair.

6. • Back probe engine cooling fan low speed relay

connector YE103, terminal 85, circuit 1040

(Orange/Pink wire) with a Voltmeter to earth.

• Is voltage as specified?

12 volts Go to Step 7. Check and repair

open in circuit

1040. Recheck

and verify repair.

7. • Back probe engine cooling fan low speed relay

connector YE103, terminal 87, circuit 157 (Black/Red

wire) with an Ohmmeter to earth.

• Is value as specified?

Below 1 ohm Go to Step 8. Check and repair

open in circuit

157. Recheck

and verify repair.

8. • Back probe engine cooling fan motor connector

YE139 (V6 and V6 supercharged) or YE119 (GEN III

V8), circuit 533 (Black wire) with a test light

connected to battery +.

• Connect TECH 2 to the DLC.

• Select BODY / BODY CONTROL MODULE /

MISCELLANEOUS TESTS / LOW FAN.

• Conduct test as instructed by TECH 2 and enable

the low speed fan.

• Does test lamp illuminate?

Replace engine

cooling fan

motor, refer to

either Section

6B1 ENGINE

COOLING - V6

ENGINE of the

VT Series I

Service

Information or

6B3 ENGINE

COOLING - GEN

III V8 ENGINE of

the VT Series II

Service

Information.

Recheck circuit

to verify repair.

Go to Step 9.

9. • With TECH 2 still connected, back probe engine

cooling fan low speed relay connector YE103,

terminal 30, circuit 533 (Blue/Yellow wire) with a test

light connected to battery +.

• Repeat TECH 2 LOW SPEED FAN test as again.

• Does test lamp illuminate?

Repair open in

circuit 533.

Recheck circuit

to verify repair .

Replace engine

cooling low

speed fan relay.

Recheck and

verify repair.

2.7 AUTOMATIC LIGHTS OFF CONTROL

Figure 12J-1-15

CIRCUIT DESCRIPTION

The automatic lights off control feature is designed

to automatically switch the headlights and parking

lights off when the driver leaves the vehicle.

In the event of a system failure, the default status

of the BCM light control output is in the ON state

when the ignition is in the ON position. This will give

direct control of the lights to the headlamp switch.

The sequence of events required to switch the

lights off automatically is as follows:

1. The vehicle road speed input to the BCM

indicates the vehicle speed is less than 10

km/h and there has not been a sudden loss of

speed (ignition being switched off with the

vehicle travelling above 10 km/h).

2. The BCM senses that the ignition switch is

turned from ON to OFF and remains in the

OFF position.

3. The headlamp switch has not been turned on

after the ignition switch was turned off.

4. The BCM senses the driver’s door has been

opened and turns the lights off.

When the ignition switch is turned back to the IGN

position, the lights will turn back on to the position

selected by the headlamp switch and mode of

headlamp operation.

Turning the headlamp switch off, deactivates the

auto lights off system.

TEST DESCRIPTION

The num ber s below refer to step num bers in the following

diagnostic chart.

1-6. Functional check of headlamp and park lamp system.

7. Tests fail safe function.

8. Tests to establish whether problem is due to no

output drive from the BCM or circuit problem beyond

the BCM.

9. Checks circuit 1150.

10. Uses TECH 2 to check for DRIVER’S DOOR OPEN

signal at microprocessor of BCM.

11. Uses TECH 2 to for false IGNITION ON signal at

microprocessor of BCM.

12. Checks for correct ignition signal level.

13. Checks DRIVER’S DOOR OPEN signal at input of

BCM.

14. Checks circuit 126.

15. Tests for false output drive from BCM or short circuit

in lamp circuits.

Figure 12J-1-16

Figure 12J-1-17

AUTOMATIC LIGHTS OFF CONTROL

STEP ACTION VALUE YES NO

1. • Turn ignition OFF.

• Turn headlamp switch from OFF position to

PARKLAMP position.

• Are the park lamps on?

Go to Step 2. Go to Step 6.

2. • Turn ignition OFF.

• Turn headlamp switch from PARKLAMP position to

HEADLAMP position.

• Are the headlamps on?

Go to Step 3. Check and repair

headlamp switch

assembly, fault in

wiring harness to

headlamp relay

and headlamp

circuits (including

fuses and

headlamp relay).

Recheck and

verify repair.

3. • Turn ignition ON.

• Driver’s door closed.

• Headlamp switch in HEADLAMP position.

• Turn ignition OFF.

• Open driver’s door.

• Do the headlamps turn off?

Go to Step 4. Go to Step 10.

4. • After headlamps have automatically be turned off

from test Step No. 3 and with the driver’s door open,

turn the ignition ON.

• Do headlamps turn ON?

Go to Step 5. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

5. • Driver’s door open.

• Following on from test Step 4, turn ignition OFF

(headlamps will turn OFF).

• Turn headlamp switch from the HEADLAMP position

to the OFF position.

• Turn headlamp switch from the OFF position to the

HEADLAMP position.

• Do headlamps turn on?

System OK.

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

6. • Turn ignition OFF.

• Turn headlamp switch to the HEADLAMP position.

• Are the headlamps on?

Check and repair

headlamp switch

assembly, fault in

wiring harness to

park lamp relay

and parking

lamps (including

fuses and park

lamp relay).

Recheck and

verify repair.

Go to Step 7.

7. • Turn ignition ON.

• Turn headlamp switch to HEADLAMP position.

• Are the headlamps on?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 8.

8. • Disconnect BCM connector YB164 and back probe

terminal D14 (harness earth) circuit 1150 (Black

wire) with a jumper wire and connect to a sound

earth point.

• Turn headlamp switch to PARKLAMP position.

• Do park lamps turn on?

12 volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 9.

STEP ACTION VALUE YES NO

9. • Reconnect BCM connector YB164 and back probe

terminal D14 circuit 1150 (Black wire) and headlamp

switch connector YB33 circuit 1150 (Black wire) with

an Ohmmeter.

• Is value as specified?

Below 1 ohm Check and repair

headlamp switch

assembly, fault in

wiring harness to

park lamp relay

and parking

lamps (including

fuses and park

lamp relay), and

headlamp

circuits. Recheck

and verify repair.

Repair open in

circuit 1150.

Recheck and

verify repair.

10. • Connect TECH 2 to DLC.

• Select Body / Body Control Module / Data Display

and scroll to Driver’s Door.

• Open driver’s door.

• Does screen display Driver’s Door Open?

Go to Step 11. Go to Step 13.

11. • With TECH 2 still connected and Data Display

selected, scroll to Ignition Switch.

• Turn ignition OFF.

• Does screen display Ignition On?

Go to Step 12. Go to Step 15.

12. • Turn ignition OFF.

• Back probe BCM connector YB165, terminal D6,

circuit 39 (Pink/Black wire) with a Voltmeter to earth.

• Is voltage as specified?

Ignition OFF

0 volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Check and repair

fault in wiring

(particularly short

to B+) in circuit

39 or faulty

ignition switch.

Recheck and

verify repair.

13. • Driver’s door open.

• Back probe BCM connector YB162, terminal C8,

circuit 126 (Grey/White wire) with a Voltmeter to

earth.

• Is voltage as specified?

Below

0.5 volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 14.

14. • Disconnect BCM connector YB162.

• Back probe BCM connector YB162, harness end,

terminal C8, circuit 126 (Grey/White wire) and

driver’s door jamb switch connector YB1, circuit 126

(Grey/White wire) with an Ohmmeter.

• Is Value as specified?

Below 1 ohm Replace driver’s

door jamb switch,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Repair open in

circuit 126.

Recheck and

verify repair.

15. • Turn ignition OFF.

• Headlamp switch in the HEADLAMP position.

• Driver’s door open.

• Disconnect BCM connector YB164.

• Do headlamps turn off?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Check and repair

short circuit in

wiring to relays

and earth end of

lamps, faulty

relays (beyond

terminal D14).

Recheck and

verify repair.

2.8 WIPER CONTROL SYSTEM

Figure 12J-1-18

CIRCUIT DESCRIPTION

This system controls the front intermittent and rear wiper function. The wiper dwell on vehicles with a low series

BCM has a fixed dwell period of approximately eight seconds and is non-adjustable. The rear wipers (on Wagon

models) are synchronised to the front wipers when the front wipers are in intermittent mode. Due to the different

wiper action between front and rear wipers, the wipers will start one quarter of a second before the front wipers. If

the option is set, the rear wiper (wagon with automatic transmission only) has the added function of wiping

continuously when the vehicle is in reverse gear and the rear wiper/washer switch is turned on

Reverse gear communication is between the PCM (and PIM – GEN III V8) and BCM via the serial data bus.

The f ront and rear wipers em ploy a “wipe after wash” function where, if the relevant was her pum p switch has been

pressed for more than 0.5 seconds, the wipers start sweeping at a low speed continuously until the washer pump

has been disengaged. Following which, the wiper will be held on for a calculated time period so that the following

number of sweeps can be completed:

• One additional sweep if washer switch pressed for less than 1 second.

• Two additional sweeps if washer switch is pressed for less than 1.5 seconds.

• Three additional sweeps if washer switch is pressed for more than 1.5 seconds

To correctly perform the number of additional sweeps, the wiper motor park switch is monitored. This allows the

wiper supply power to be transferred to the park switch at the optimum time.

NOTE: Battery Saver Mode – If the ignition switch is tur ned to the ACC position and the vehic le enters battery saver

mode, the intermittent wipers will not operate.

TEST DESCRIPTION

The numbers below refer to step numbers in the

following diagnostic chart.

1-11. Functional check of wiper control system.

12. Uses TECH 2 to operate front wiper

(establishes whether problem is with input or

output of BCM).

13 Uses TECH 2 to check for INTERMITTENT

WIPER/WASHER SWITCH ON signal at

microprocessor of BCM.

14. Checks for 12 volt supply to terminals 1 and 5

of intermittent relay.

15. Checks for BCM output drive of intermittent

wiper relay when commanded by TECH 2.

16. Checks circuit 90.

17. Checks intermittent wiper relay.

18. Checks for 12 volts at wiper motor when

commanded by TECH 2.

19. Checks circuit 152 / wiper motor.

20. Checks circuit 95.

21. Checks circuit 91 / wiper/washer switch.

22. Checks INTERMITTENT WIPER/WASHER

SWITCH ON signal at input to BCM.

23. Checks circuit 97.

24. Checks circuit 41 / wiper/washer switch.

25. Uses TECH 2 to check for WIPER PARK SW

signal at microprocessor of BCM.

26. Checks if continuous wiper operation is due to

faulty wiper/washer switch / continuous drive

from intermittent relay.

27. Checks WIPER PARK SW signal at input to

BCM.

28. Checks circuit 41.

29. Checks circuit 196 / wiper motor assembly

(internal park switch).

30 Checks for short in circuit 90, causing relay to

be always driven.

31. Checks intermittent wiper relay.

32. Checks FRONT WASHER SW signal at input to

BCM.

33 Checks circuit 94 / wiper/washer switch.

34 Uses TECH 2 to operate rear wiper (establish

whether problem is with input or output of BCM).

35 Uses TECH 2 to check REAR WIPE SWITCH ON

signal at microprocessor of BCM.

36 Checks for 12 volt supply to terminal 2 and 5 of rear

wiper relay.

37. Check s f or BCM output drive of rear wiper relay when

commanded by TECH 2 at rear wiper relay.

38. Checks rear wiper relay.

39. Checks circuit 391.

40. Checks rear wiper motor, circuit 156.

41. Checks for BCM output drive of rear wiper relay at

BCM when commanded by TECH 2.

42. Checks REAR WIPER SW signal to BCM.

43. Checks circuit 139 / wiper/washer switch.

44. Checks for short in circuit 492, causing relay to be

always driven.

45. Checks rear wiper relay.

46. Checks REAR WASHER SWITCH signal at input to

BCM.

47. Checks circuit 494 / wiper/washer switch.

48. Uses TECH 2 to check REVERSE GEAR signal at

microprocessor of PCM.

49. Uses TECH2 to check reverse gear signal on the

serial data bus.

Figure 12J-1-19

Figure 12J-1-20

WIPER CONTROL SYSTEM

STEP ACTION VALUE YES NO

1. • Turn ignition to ACC.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Does the front wiper sweep?

Go to Step 2. Go to Step 12.

2. • In Step 1, did the front wiper only sweep once? Go to Step 3. Go to Step 25.

3. • While carrying out Step 1, time the period between

each sweep.

• Is the delay period as specified?

eight seconds Go to Step 4. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

4. • Turn ignition to ACC.

• Operate the front wash switch for two seconds.

• Does the front wiper commence continuous

operation?

Go to Step 5. Go to Step 32.

5. • In Step 4, did the front wipers continue for three

additional sweeps after the front wash switch was

released?

Sedan - System

OK.

Wagon - Go to

Step 6.

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

6. • Turn ignition to ACC.

• Turn the wiper/washer switch to REAR WIPE

position.

• Does the rear wiper sweep?

Go to Step 7. Go to Step 34.

7. • In Step 6, did the rear wiper only sweep once? Go to Step 8. Go to Step 44.

8. • While carrying out Step 6, time the period between

each sweep.

• Is the delay period as specified?

eight seconds Go to Step 9. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

9. • Turn ignition to ACC.

• Operate the rear wash switch for two seconds.

• Does the rear wiper commence continuous

operation?

Go to Step 10. Go to Step 46.

10. • Turn ignition to ACC.

• Turn the wiper/washer switch to INTERMITTENT

position and REAR WIPER position.

• Are the front and rear wipers synchronised?

Go to Step 11. Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

11. • Using TECH 2, ensue the “rear wipe continuous

operation” option is active (Body / Body Control

Module / Program / Rear Wiper Control).

• Turn ignition ON.

• Turn the front intermittent wipers on.

• Do the rear wipers operate continuously when

reverse gear is selected?

System OK. Go to Step 48.

12. • Connect TECH to DLC.

• Select Body / Body Control Module / Miscellaneous

Tests / Wiper Tests / Front Wipers.

• Turn Ignition to the ACC position and conduct test as

instructed by TECH 2.

• Do front wipers sweep continuously?

Go to Step 13. Go to Step14.

STEP ACTION VALUE YES NO

13. • With TECH 2 still connected, exit Miscellaneous

Tests and select Data Display.

• Scroll to Front Wiper Intermittent Switch.

• Turn ignition to the ACC position.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Does screen display Front Wiper Intermittent Switch

On?

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 22.

14. • Turn ignition to the ACC position.

• Back probe intermittent wiper relay connector YE76,

terminal 5 and 1, circuit 41 (Brown/Green wire) with a

Voltmeter to earth.

• Is voltage as specified?

12 volts Go to Step 15. Check and repair

open in circuit 41

(including fuse

F18 and ignition

switch). Recheck

and verify repair.

15. • Back probe BCM connector YB165, terminal A2,

circuit 90 (Brown wire) with a jumper lead connected

to earth.

• Do wipers sweep?

0 volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 16.

16. • Back probe intermittent wiper relay connector YE76,

terminal 2, circuit 90 (Brown wire) with a jumper lead

connected to earth.

• Do wipers sweep?

0 volts Check and repair

open in circuit

90. Recheck and

verify repair.

Go to Step 17.

17. • Back probe intermittent wiper relay connector YE76,

terminal 3, circuit 95 (Green wire) with a Voltmeter to

earth.

• Turn ignition to the ACC position and conduct TECH

2 Front Wiper test.

• Is voltage as specified?

12 volts Go to Step 18. Replace

intermittent wiper

relay. Recheck

and verify repair.

18. • Back probe wiper motor connector YE93, circuit 91

(Grey/Red wire) with a Voltmeter to earth.

• Turn ignition to the ACC position and repeat TECH 2

Front Wiper test.

• Is voltage as specified?

12 volts Go to Step 19. Go to Step 20.

19. • Back probe front wiper motor connector YE93, circuit

152 (Black/White wire) with an Ohmmeter to earth.

• Is value as specified?

Below 1 ohm Replace front

wiper motor

assembly, refer

to 12C

INSTRUMENTS,

WIPERS /

WASHERS &

HORN of the VT

Series I Service

Information.

Check and repair

open in circuit

152. Recheck

and verify repair.

20. • Back probe wiper/washer switch connector YB52,

terminal 8, circuit 95 (Green wire) with a Voltmeter to

earth.

• Turn ignition to the ACC position and repeat TECH 2

Front Wiper test.

• Is voltage as specified?

12 volts Go to Step 21. Check and repair

open in circuit

95. Recheck and

verify repair.

21. • Back probe wiper/washer switch connector YB52,

terminal 5, circuit 91 (Grey/Red wire) with a

Voltmeter to earth.

• Turn ignition to the ACC position and repeat TECH 2

Front Wiper test.

• Is voltage as specified?

12 volts Check and repair

open in circuit

91. Recheck and

verify repair.

Replace

wiper/washer

switch, refer to

Section 12C

INSTRUMENTS,

WIPERS /

WASHERS &

HORN of the VT

Series I Service

Information

STEP ACTION VALUE YES NO

22. • Turn ignition to ACC.

• Back probe BCM connector YB164, terminal D10,

circuit 97 (Blue/White wire) with a Voltmeter to earth.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Is voltage as specified?

12 volts Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 23.

23. • Turn ignition to ACC.

• Back probe wiper/washer switch connector YB52,

terminal 9, circuit 97 (Blue/White wire) with a

Voltmeter to earth.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Is voltage as specified?

12 volts Check and repair

open in circuit

97. Recheck and

verify repair.

Go to Step 24.

24. • Turn ignition to ACC.

• Back probe wiper/washer switch connector YB52,

terminal 4, circuit 41 (Brown/White wire) with a

Voltmeter to earth.

• Is voltage as specified?

12 volts Replace

wiper/washer

switch, refer to

Section 12C

INSTRUMENTS,

WIPERS /

WASHERS &

HORN of the VT

Series I Service

Information.

Check and repair

open in circuit 41

(including fuse

F18). Recheck

and verify repair.

25. • Connect TECH 2 to DLC.

• Select Body / Body Control Module / Data Display

and scroll to Wiper Park Switch.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Does screen display Wiper Park Switch On when

wiper is in the park position and Wiper Park Switch

Off when wiper is operating?

Go to Step 26. Go to Step 27.

26. • Turn ignition to ACC.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Remove intermittent wiper relay.

• Do wipers operate continuously?

Replace

wiper/washer

switch, refer to

Section 12C

INSTRUMENTS,

WIPERS /

WASHERS &

HORN of the VT

Series I Service

Information.

Go to Step 30.

27. • Turn ignition to ACC.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Back probe BCM connector YB163, terminal B9,

circuit 196 (Yellow wire) with a Voltmeter to earth.

• Are voltages as specified?

12 volts while

operating,

0 volts in park

Replace BCM,

refer to 12J-1

LOW SERIES

BCM of the VT

Series II Service

Information.

Recheck and

verify repair.

Go to Step 28.

28. • Turn ignition to ACC.

• Back probe wiper motor connector YE93, circuit 41

(Brown/White wire) with a Voltmeter to earth.

• Is voltage as specified?

12 volts Go to Step 29. Check and repair

open in circuit

41. Recheck and

verify repair.

29. • Turn ignition to ACC.

• Turn the wiper/washer switch to INTERMITTENT

position.

• Back probe wiper motor connector YE93, circuit 196

(Yellow wire) with a Voltmeter to earth.

• Are values as specified?

12 volts while

operating,

0 volts in park

Check and repair

open in circuit

196. Recheck

and verify repair.

Replace front

wiper motor,

refer Section 12C

INSTRUMENTS,

WIPERS /

WASHERS &

HORN of the VT

Series I Service

Information.

30. • Turn ignition to ACC.