SECTION 4B - FINAL DRIVE AND DRIVESHAFTS

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1. GENERAL INFORMAT ION

The final drive assembly and driveshafts for VX Series vehicles, carries over from VT Series II, except for the

following:

1. The final drive pinion flange design has changed to suit the new propeller shaft design (refer

4C PROPELL ER SHAFT AND UNIVERSAL JOINTS of the VX Series Service Information).

The service procedure required to replace the pinion oil seal and/or the pinion flange are detailed in this

Section, to il lus trate t he method of r emoval/ reins t al lat i on of the ne w f lang e an d replac ement proc edur es for the

pinion oil seal.

Apart from this procedure, the disassembly/ reassembly procedures detailed in

4B FINAL DRIVE AND DRIVESHAFTS, in the VT Series I Service Information are still valid, despite some

illustrations showing the earlier pinion flange and the former special tools.

In these instances, use the special tools shown in this Section.

2. With the pinion flange change, the part numbers and broadcast codes have also changed. These changed

codes listed in this Section.

3. The oil manufacturer, Mobil has advised that one of their products (recommended for fitment to some of the

final dr ive assem blies fitted to Holden produc t) has ch anged it’s i dentification. An update t o reflect t his change

and all recommended final drive lubricants, is provided in this Section.

4. The source for the tapered roller bearings used in the final drive assembly is now optional. Details of this

change and the service implications that result, are detailed in this Section.

5. The final drive ratio for those VX vehicles with either of the two available manual transmissions, is 3.46:1.

Service procedures however, remain unchanged.

Apart from the service operations described here, all remaining service procedures relating to the final drive and

driveshafts remain as described Section 4B FINAL DRIVE AND DRIVESHAFTS, published for VT Series I

and Section 4B - FINAL DRIVE AND DRIVE SHAFTS - Early Production Traction Arms or

Section 4B - FINAL DRIVE AND DRIVE SHAFTS - Local Production Traction Arms in VT Series II vehicles.

Techline

Techline

Techline

Techline

Techline

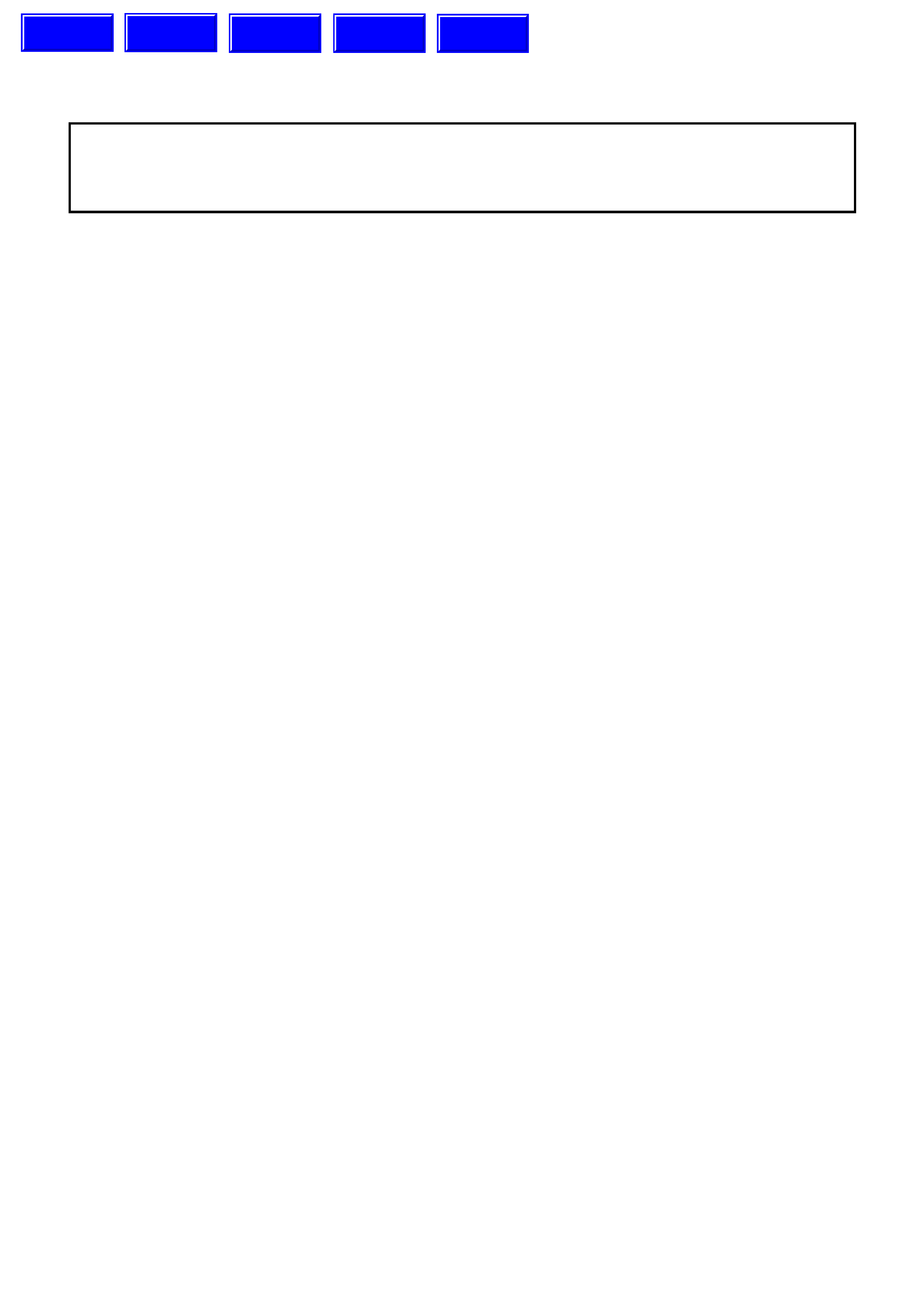

1.1 FINAL DRIVE ASSEMBLY IDENTIFICATION

Variations in the f inal dr ive as sem bly, depend u pon

the final drive ratio, whether the optional Limited

Slip Differential (LSD) and ABS is fitted or not.

NOTE: The optional LSD is also known as Slip

Resistant Differential (SRD).

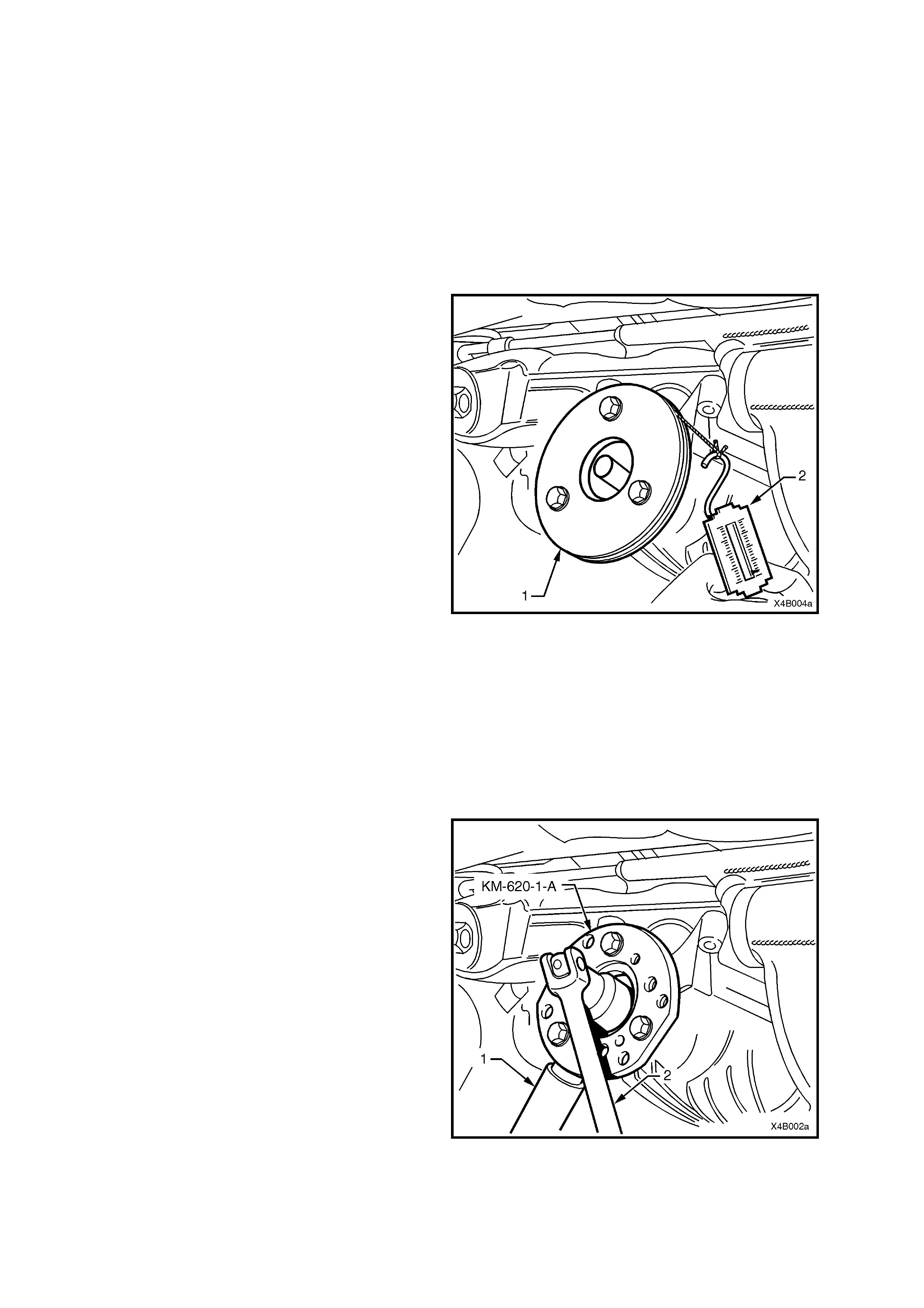

A specific variant can be identified by referring to

the identification label (1) attached to the right hand

side of the carrier housing (2).

The identification code and bar code are used for

production identification of the final drive assembly.

Figure 4B-1

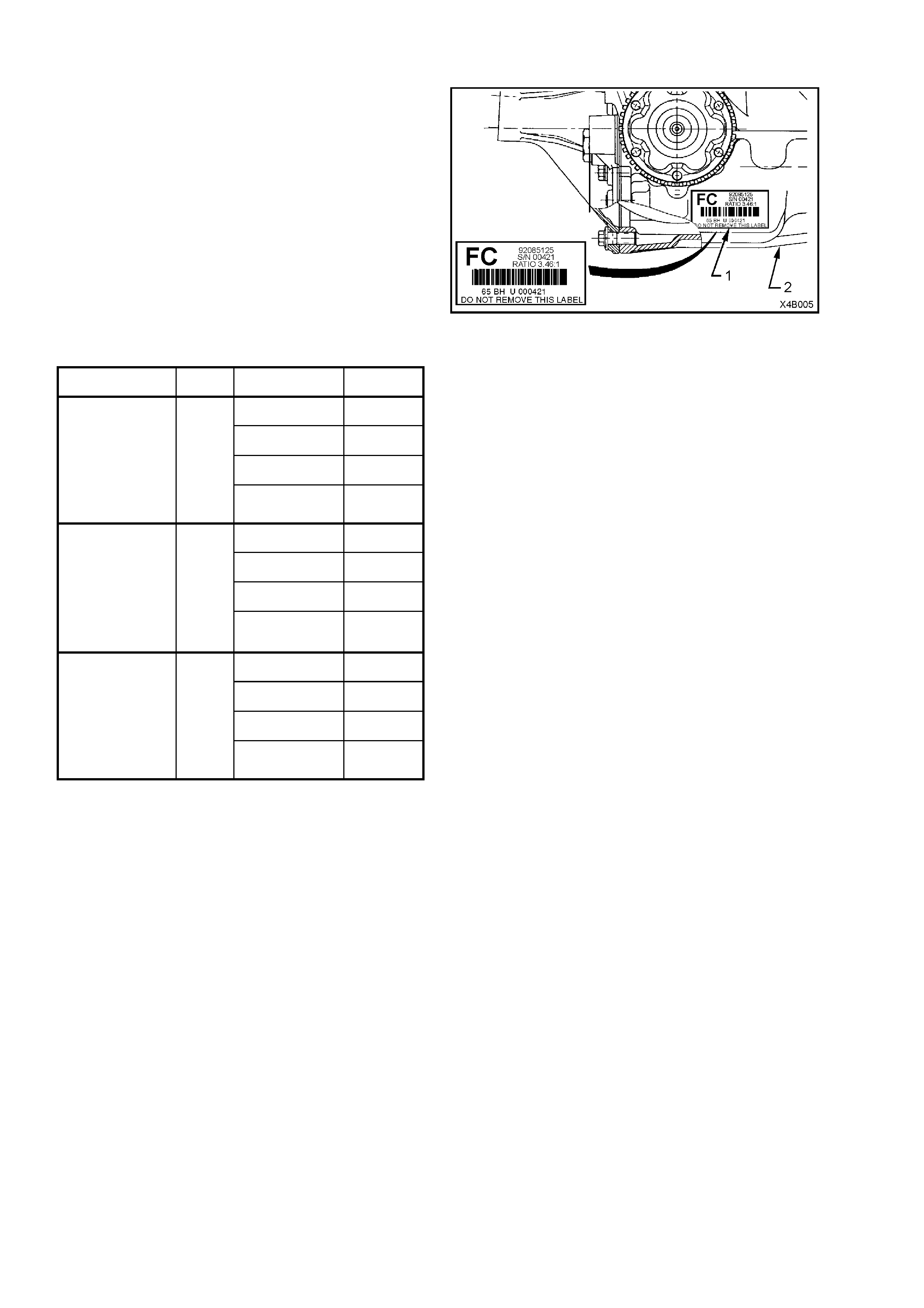

Usage Ratio Type ID Code

Standard FB

LSD FA

ABS FT

GEN II I V8 with

Manual

Transmission 3.46

LSD and

ABS FC

Standard FD

LSD FE

ABS FF

GEN II I V8

Automatic

V6 Supercharged

V6 Station Wagon

with Manual

Transmission

3.07

LSD and

ABS FH

Standard FJ

LSD FK

ABS FL

V6 Station Wagon

with Automatic

Transmission

All V6 Natu ra lly

Aspirat ed Sedans

3.08

LSD and

ABS FM

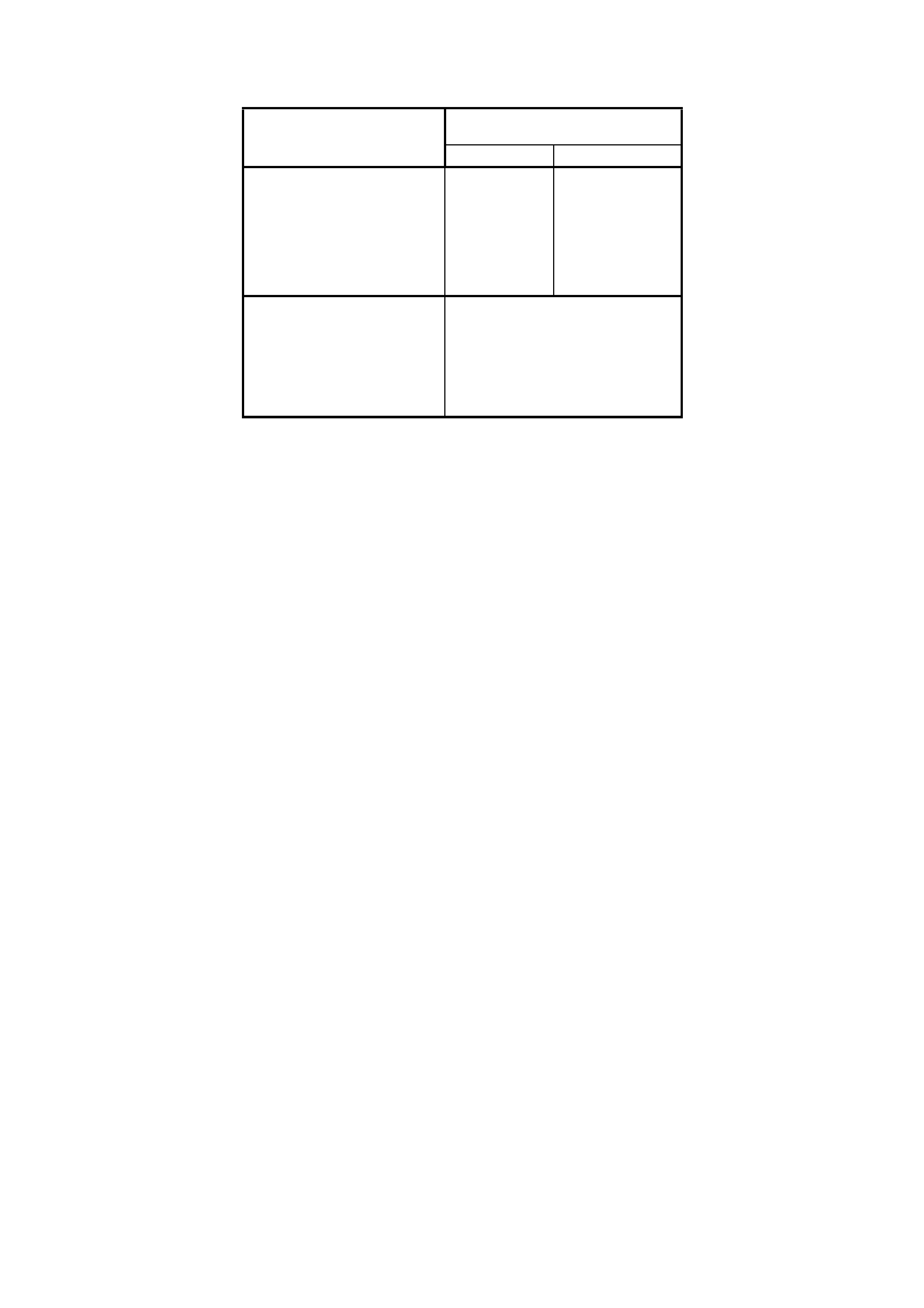

1.2 FINAL DRIVE LUBRICANT RECOMMENDATIONS

Engine & Recommended

Lubricant

Transmission Type Exc G80 LSD (G80)

All Naturally As pi rat ed V6 Sedan,

Manual Or Automatic

Transmission

V6 Station Wagon With

Automatic Transm issi on

Mineral Hypoid

Gear Oil

SAE 90

Mineral Hypoid

Gear Oil

SAE 90 LSD

Such As;

BP Limslip 90,

Castrol LSX90,

Mobil Lubrite LS90,

Shell XD90LS

All Gen III V8 W i th Manual Or

Automatic Transm iss i ons,

V6 Supercharged

V6 Station Wagon With Manual

Transmission

Synthetic Hypoi d Gear Oil

SAE 80W-140

Castrol SAF-XA

Mobil Mobilube SHC ID.

2. SERVICE OPERATION

2.1 SERVICE INFORMATION

REMOVED FINAL DRIVE ASSEMBLY

UNIT REPAIR

W ith the recent optiona l use of two sources of tapered r oller bearing m anuf acture in the as sembl y of the fin al drive

assembly, different pre-load specifications apply to each.

Apart from this change in source and that fact that some illustrations do not reflect the VX Series pinion flange

design, all remaining procedures for the repair of the removed final drive assembly, remain as detailed in

Section 4B - FINAL DRIVE AND DRIVESHAFTS VT Series I and

Section 4B - FINAL DRIVE AND DRIVE SHAFTS - Early Production Traction Arms or

Section 4B - FINAL DRIVE AND DRIVE SHAFTS - Local Production Traction Arms in VT Series II vehicles.

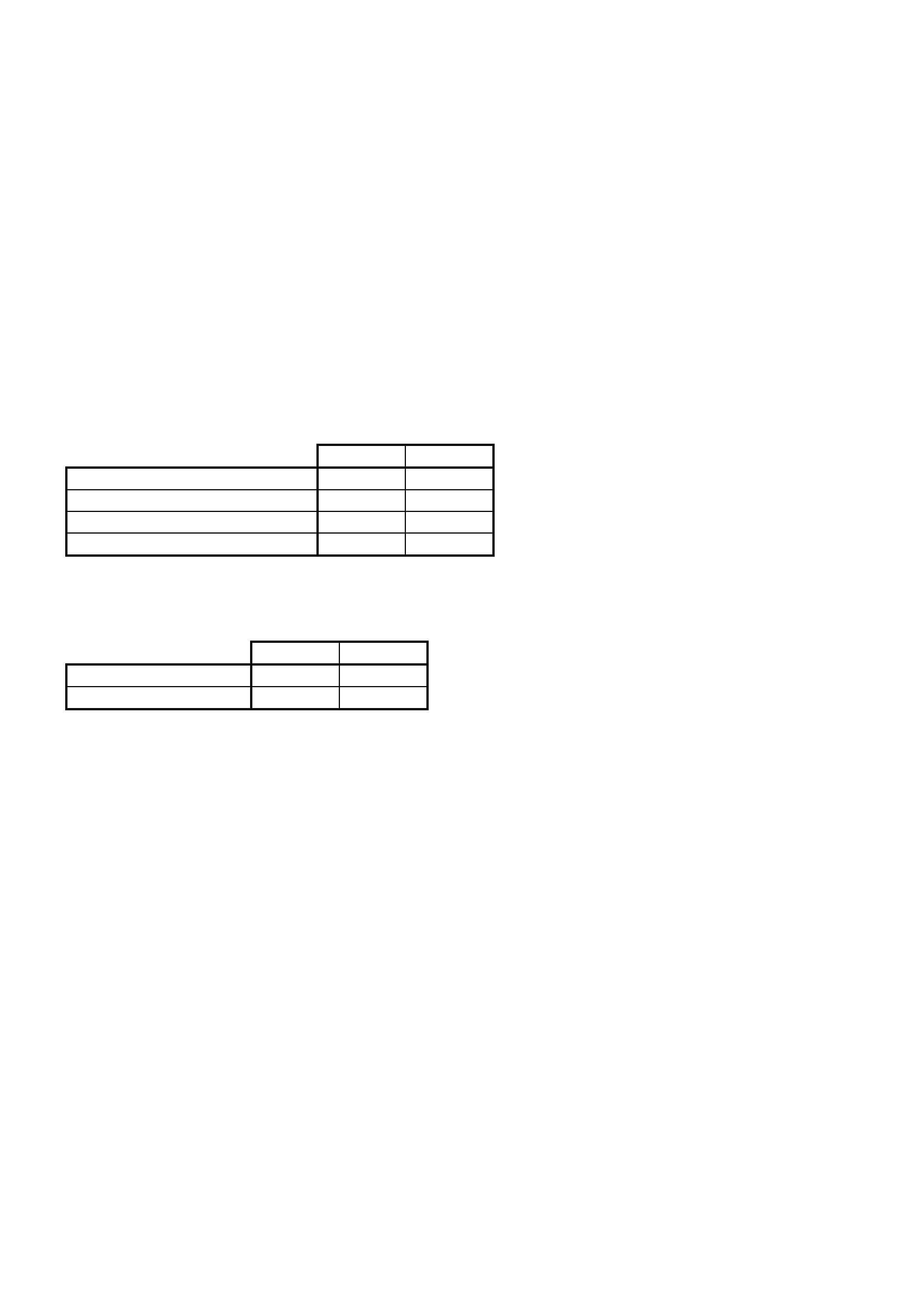

Pinion and Differential Bearings

Introduced as a running change (no breakpoint was recorded), the use of an alternative bearing supplier means

that either Timken or Koyo bearings may be used for the pinion and/or differential side applications.

Removal and fitment procedures are unchanged but the baring pre-loads differ as detailed in the following table.

1. Pinion Bear i ng Pre- l oad Sp ec ific at io ns

Timken Koyo

New bearings with pinion oil seal fitted 1.4 – 2.4 Nm 1.5 – 2.1 Nm

New bearings without pinion oil seal fitt ed 1.4 – 2.0 Nm 1.5 – 1.9 Nm

Used bearings with pinion oi l seal fitted 0.7 – 1.2 Nm 0.7 – 1.2 Nm

Used bearings without pi ni on oil seal fitt ed 0.7 – 1.2 Nm 0.7 – 1.2 Nm

NOTE: Pinion bearing pre-load is to be measured from the companion flange, without the differential assembly

installed. See Pinion Installation, in 3.3 REMOVED FINAL DRIVE ASSEMBLY, in 4B FINAL DRIVE AND

DRIVESHAFTS, in the VT Series I Service Information for the procedure.

1. Differential Bearing Preload Specifications

Timken Koyo

New bearings 15 – 35 N 8 – 24 Nm

Used bearings 8 – 18 N 5 – 13 Nm

NOTE: Preload is to be measured from the differential case flange diameter without axle shafts or the final drive

pinion installed. Refer Differential Case Side Bearing Pre-Load Setting, in 4B REAR AXLE AND DRIVESHAFTS,

in the VT Series I Service Information for the procedure.

SERVICE IMPLICATIONS

1. The front and rear pinion bearings must be a pair from the same manufacturer (i.e. both Koyo or both Timken).

2. Differential bearings must be a pair from the same manufacturer (i.e. both Koyo or both Timken).

3. The differential bearing pair may be from a different manufacturer to the pinion bearing pair.

2.2 PINION OIL SEAL

REPLACE

1. Using a floor jack under centre of differential

carrier, jack up rear of vehicle then place safety

stands under trailing arms.

2. Remove propeller shaft, refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS in the VX Series Service

Information. This operation may require partial

exhaust system removal.

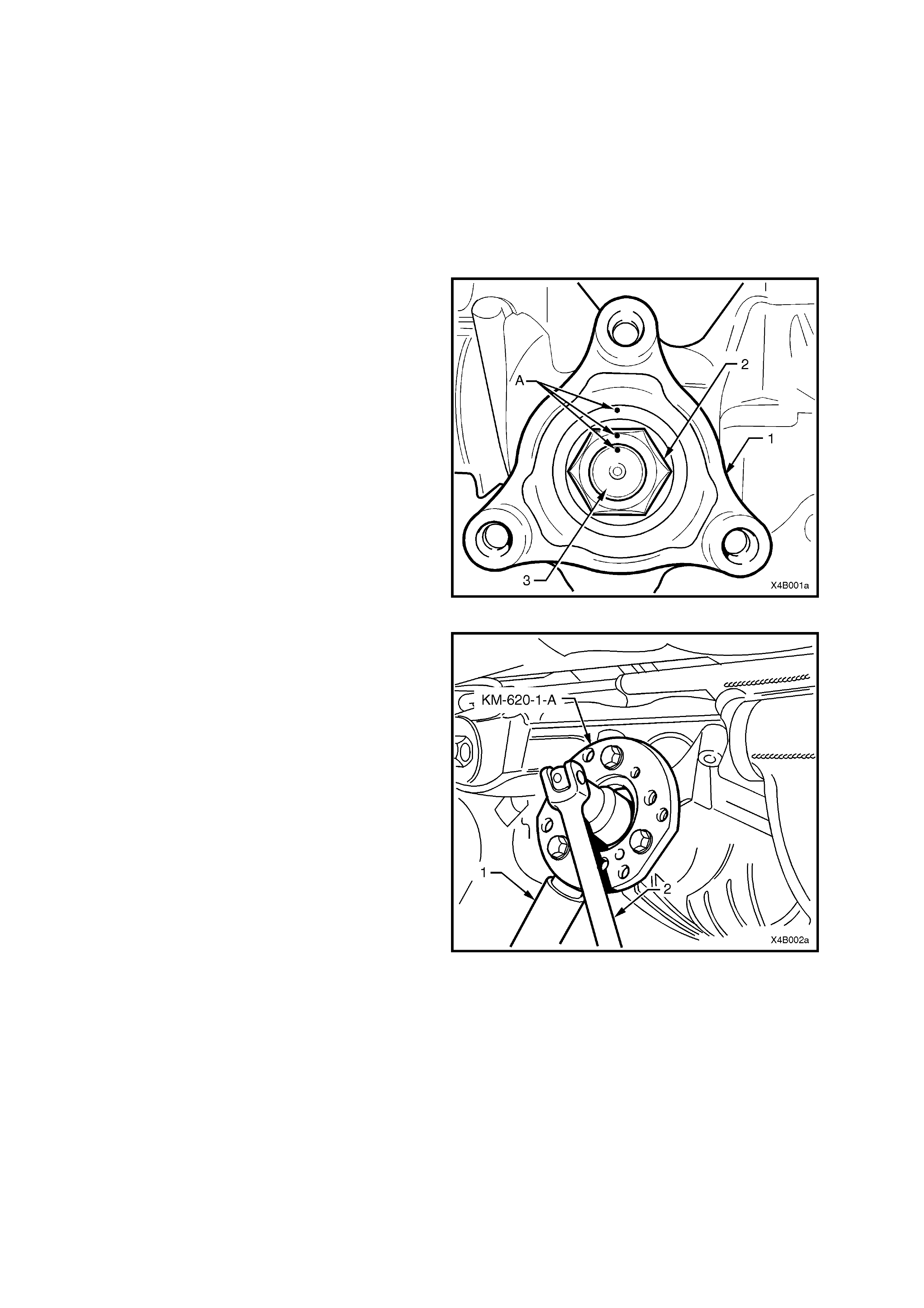

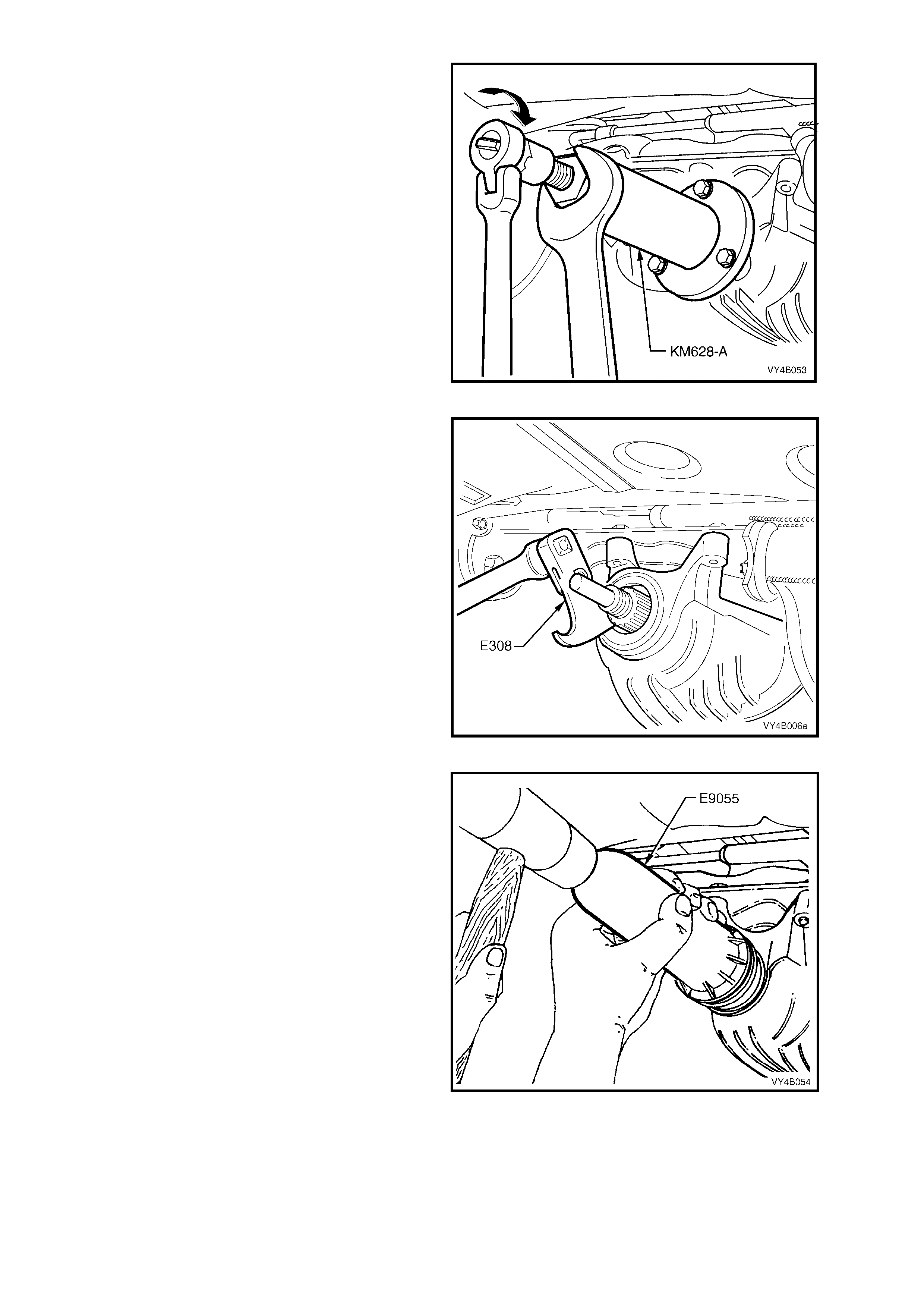

3. Lightly centre-punch alignment marks (A) on

the pinion flange (1), pinion flange nut (2) and

pinion end (3) as an aid for reassembly.

By reassembling to the original position, the

flange run-out will be m inim ised and the pinion

bearing prelo ad wi ll be m aintai ned .

Figure 4B-2

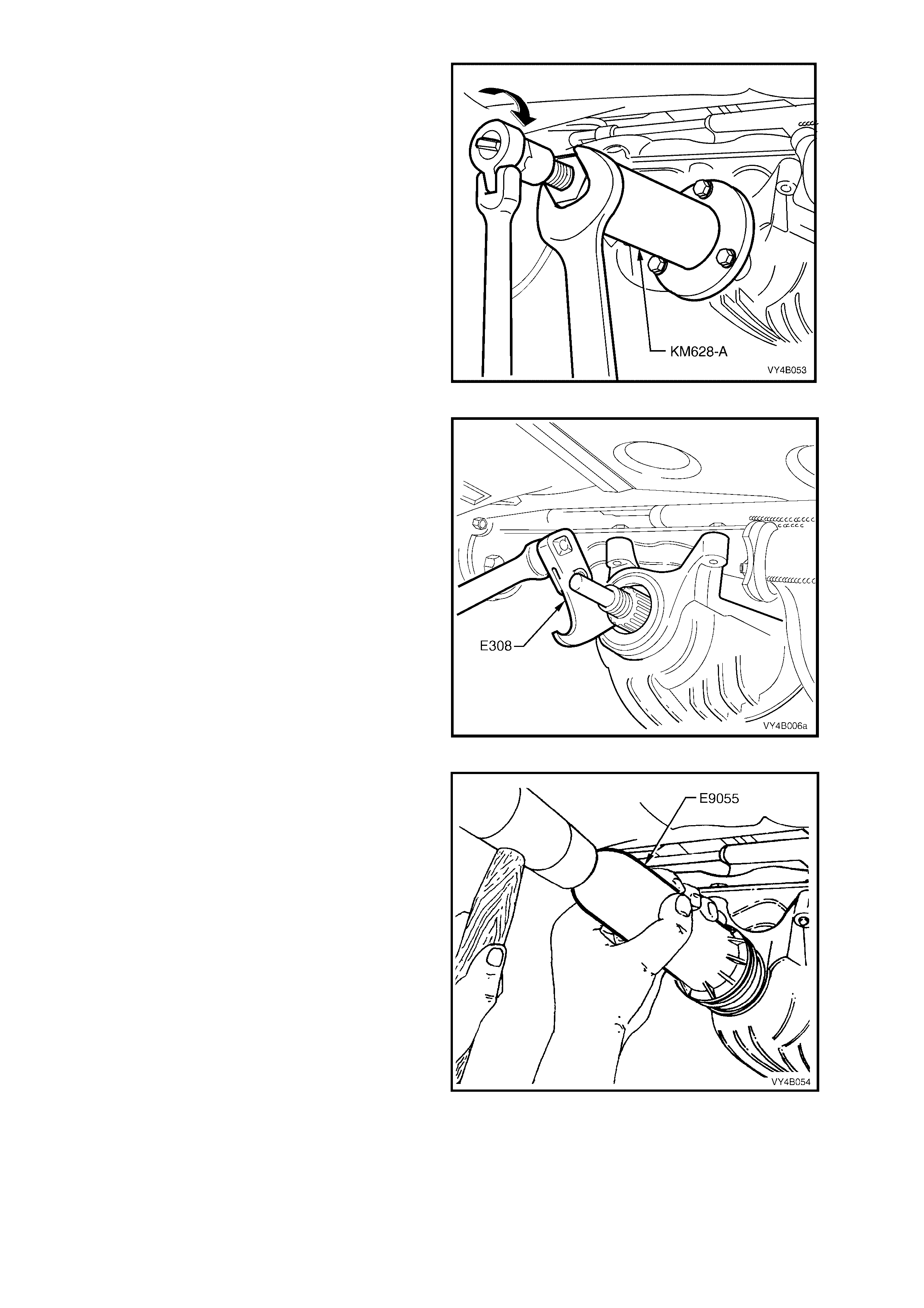

4. Attach Tool No. KM 620-1-A to the pinion

flange, using three suitable bolts and nuts to

hold pinion flange.

NOTE 1: If not previously done so, drill out holes

stamped ‘B’ on Tool No. KM620-1A to 12.5 mm.

NOTE 2: Use either the rear coupling to pinion

flange r eta in ing bo lts with a 25 m m s pac er ( e.g. f lat

washers) insta lled firs t or u se three b olts M 12 x 1.5

x 40, with the thread extending to within 12 mm of

the head.

5. Insert a suitable length of pipe (1) over the tang

of the installed tool for leverage, then remove

the pinion flange retaining nut, using a

comm erc ially ava ilabl e dee p soc ket and soc k et

bar (2).

6. Remove Tool No. KM 620-1-A.

Figure 4B-3

7. Place drain tray beneath differential carrier.

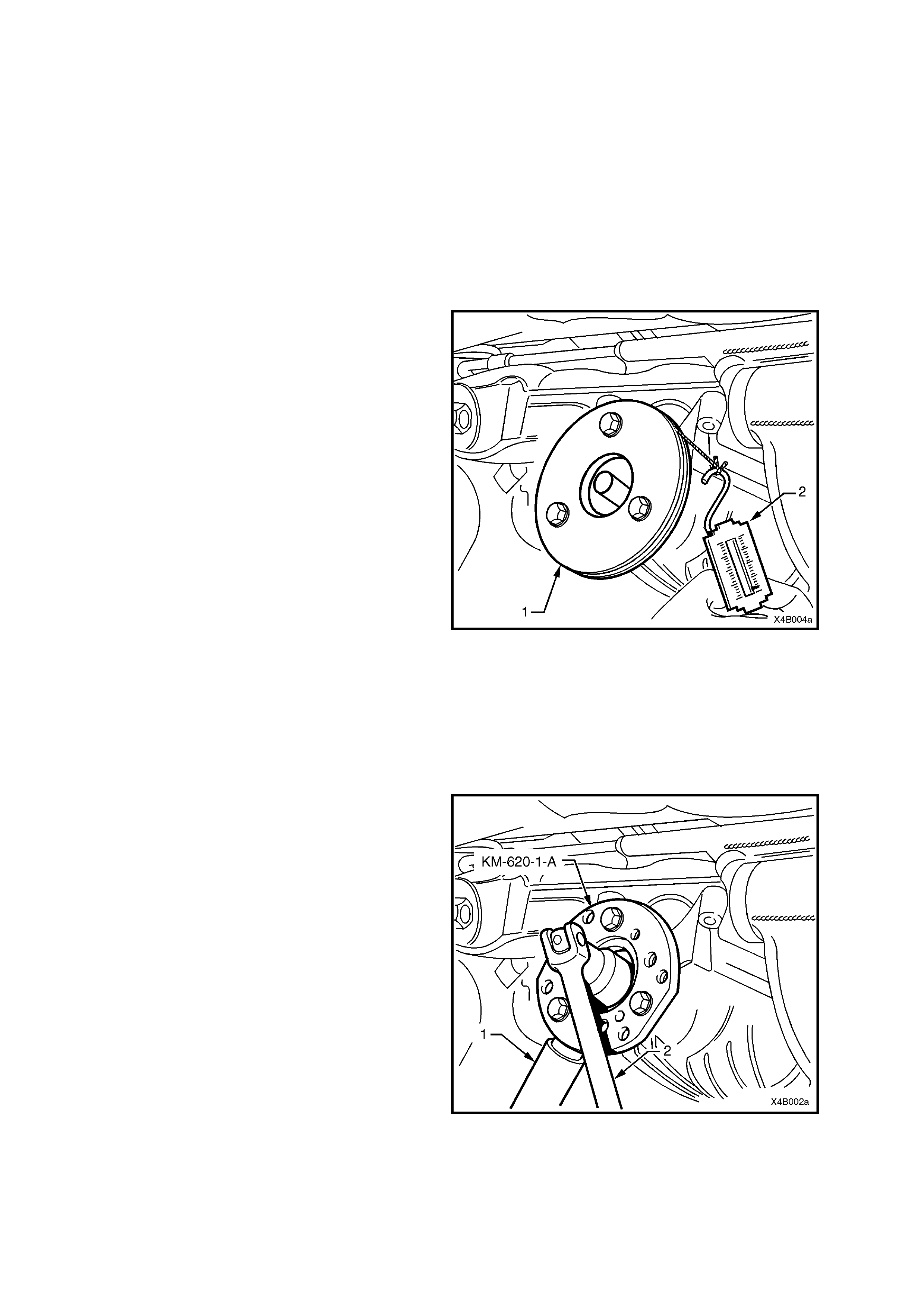

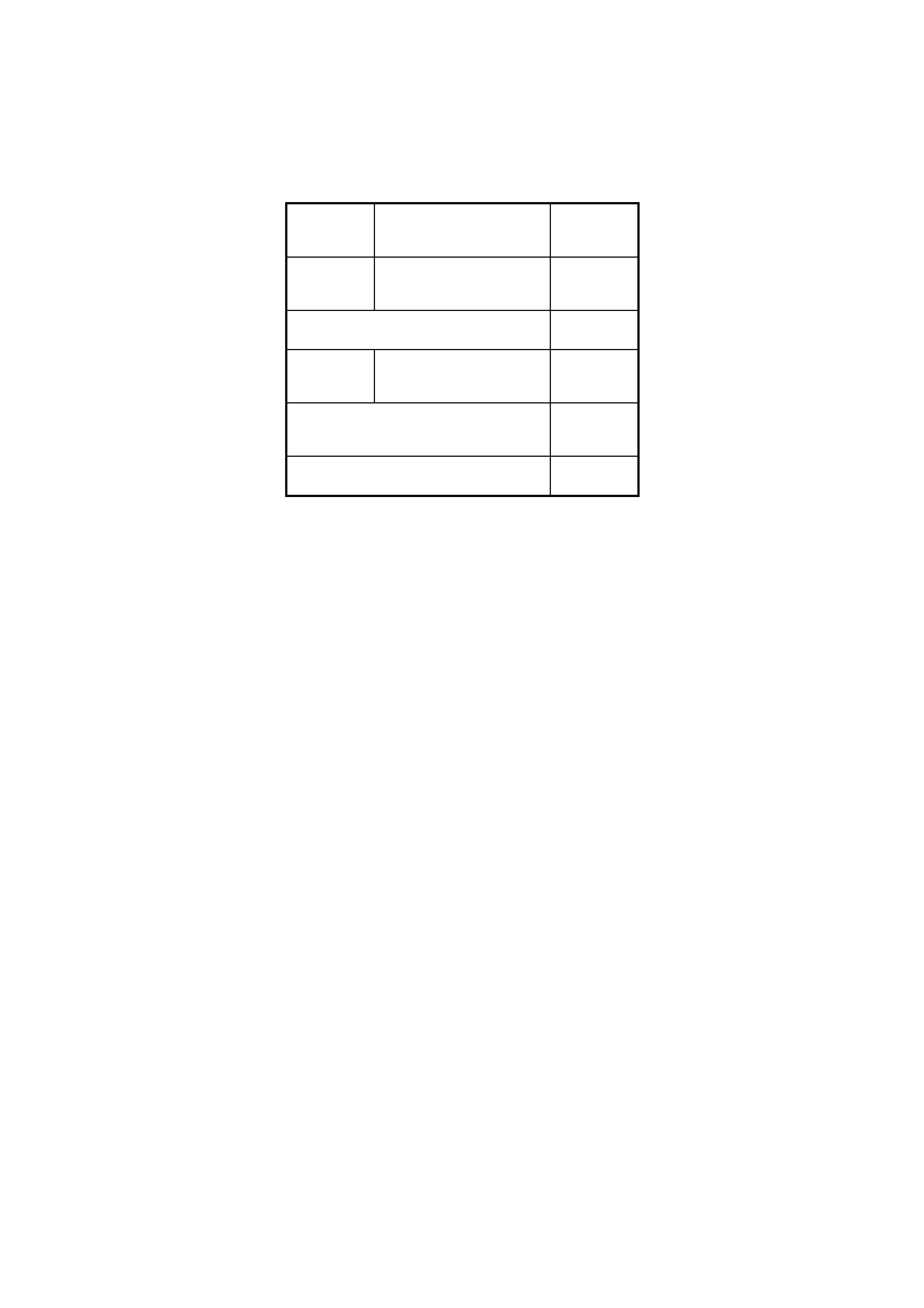

8. Install extractor, Tool No. AKM-628-A to the

pinion flange using the same three bolts and

nuts used to secure the flange holding tool,

KM-620-1-A (refer Fig. 4B-3).

NOTE: If not previo us l y done s o, dr i ll out t he f lan ge

holes on Tool No. KM628-A to 12.5 mm.

IMPORTANT: If using the original propeller shaft

coupling bolts, they must have a 25 mm spacer

fitted to each, so the tool is clamped to the pinion

flange. If this is not done, the screw thread on the

extractor Tool No. KM628-A will not be long

enough to fully remove the pinion flange.

9. While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening

the forcing screw in the direction indicated.

Figure 4B-4

10. Prise pinion oil seal from carrier bore using

Tool No. E308 or a universal seal removing

tool.

Figure 4B-5

11. Lubricate new pinion oil seal lips a nd the outer

diameter with the recommended rear axle

lubricant.

12. Start oil seal into differential carrier housing

and dri ve seal squ arel y into pos iti on usin g T ool

No. E9055. Seal fits flush to 0.25 mm below

carrier housing surface.

13. Ensure that pinion shaft is free from burrs and

that flange oil seal surface is free from

damage.

14. Clean the threads of the pinion shaft and the

flange retaining nut, removing any oil, dirt or

grease.

Figure 4B-6

15. Coat spl ines and seal s urface of pinion f lan ge with dif ferenti al g ear lu bric ant , and ins ta ll f lang e onto pinio n s haf t

splines. Ensure that centre-punch marks are aligned.

16. Reinstall holding tool KM620-1-A to the pinion flange.

17. Apply a thread locking compound such as Loctite 243 or equivalent, to the threads of the pinion flange retaining

nut, then reinstall the nut.

18. Tighten the flange retaining nut until all centre-punch marks align. Then carefully tighten the nut to a position

not more than 5° past the aligned setting.

NOTE: The pinion flange is an interference fit on pinion shaft splines and should only be pulled into place by

tightening the retaining nut. DO NOT, UNDER ANY CIRCUMSTANCES, USE FORCE OR HAMMER FLANGE

DURING INSTALLATION ONTO PINION FLANGE.

CAUTION: Should the retaining nut be ov ertightened and pre-lo ad ex ce ede d, it w ill be nece ssa ry to r emove

the pinio n f rom th e ca rri e r and inst al l a new collap sib le sp acer. Unde r n o ci r cu mstan ce s must t he retaining

nut be backed off to decrease the pre-load reading.

19. Reinstall propeller shaft rear coupling to the pinion flange, refer Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS in the VX Series Service Information.

20. If removed previously, reconnect exhaust system, in the reverse to the removal procedure. Refer to

3.2 FINAL DRIVE ASSEMBLY, in the VT Series II Service Information, for details.

21. Remove safety stands and lower vehicle.

22. Check lubricant level and t op up as necessar y. Refer 2.1 CHECKING DIFFER ENTIAL CARRIER LUBRIC ANT

LEVEL in the VT Series I Service Information.

23. Start vehicle and check for exhaust leaks.

2.3 PINION FLANGE

REPLACE (USING OLD OIL SEAL)

NOTE: Due to production tolerances in the length of the pinion flange, it is essential that the following method be

used when installing a new pinion flange. A new retaining nut must always be used when a pinion flange is

replaced.

1. Using a floor jack under centre of differential carrier, jack up rear of vehicle then place safety stands under

trailing arms.

2. Remove prope ller shaf t, ref er 2.1 PROP ELLE R SH AFT in Sec tion 4C PRO PELL ER SHAFT AND UNIVE RSAL

JOINTS in the VX Series Service Information.

3. Remove both dr ive shaf ts, refer 2.6 DRI VE SH AFTS in S ECTION 4B - FINAL DRIVE AN D DRIVE SHAFT S of

the VT Series I Servic e Inf ormation.

4. Check and record pre-load at pinion flange as follows:

a. Fit a pulley (1) to pinion flange and attach

a cord around pulley and to a spring scale

(2).

NOTE 1: Use either the rear coupling to

pinion flange retaining bolts with a 25 mm

spacer (e.g. flat washers) installed first or

use three bolts M12 x 1.5 x 40,with the

thread extending to within 12 mm of the

head.

NOTE 2: For details of the fabricated

pulley , refer 3. SPECIAL TOOLS at end of

this Section.

b. Start rotation of pulley and whilst in m otion

(approxim atel y 50-60 rpm ) note and r ecord

reading of spring balance.

This pre-load reading includes pinion

bearings, side bearings, meshing effect of

gear set and pinion oil seal.

To determine pre-load, multiply reading on

spring balance by radius of pulley.

EXAMPLE: W ith a pulley diam eter of 152 mm, the

radius is 76 mm, which equals 0.076 m. With a

spring balance reading of 25 N, the pre-load equals

0.076 m x 25 N = 1.9 Nm.

5. Remove pulley from pinion flange.

Figure 4B-7

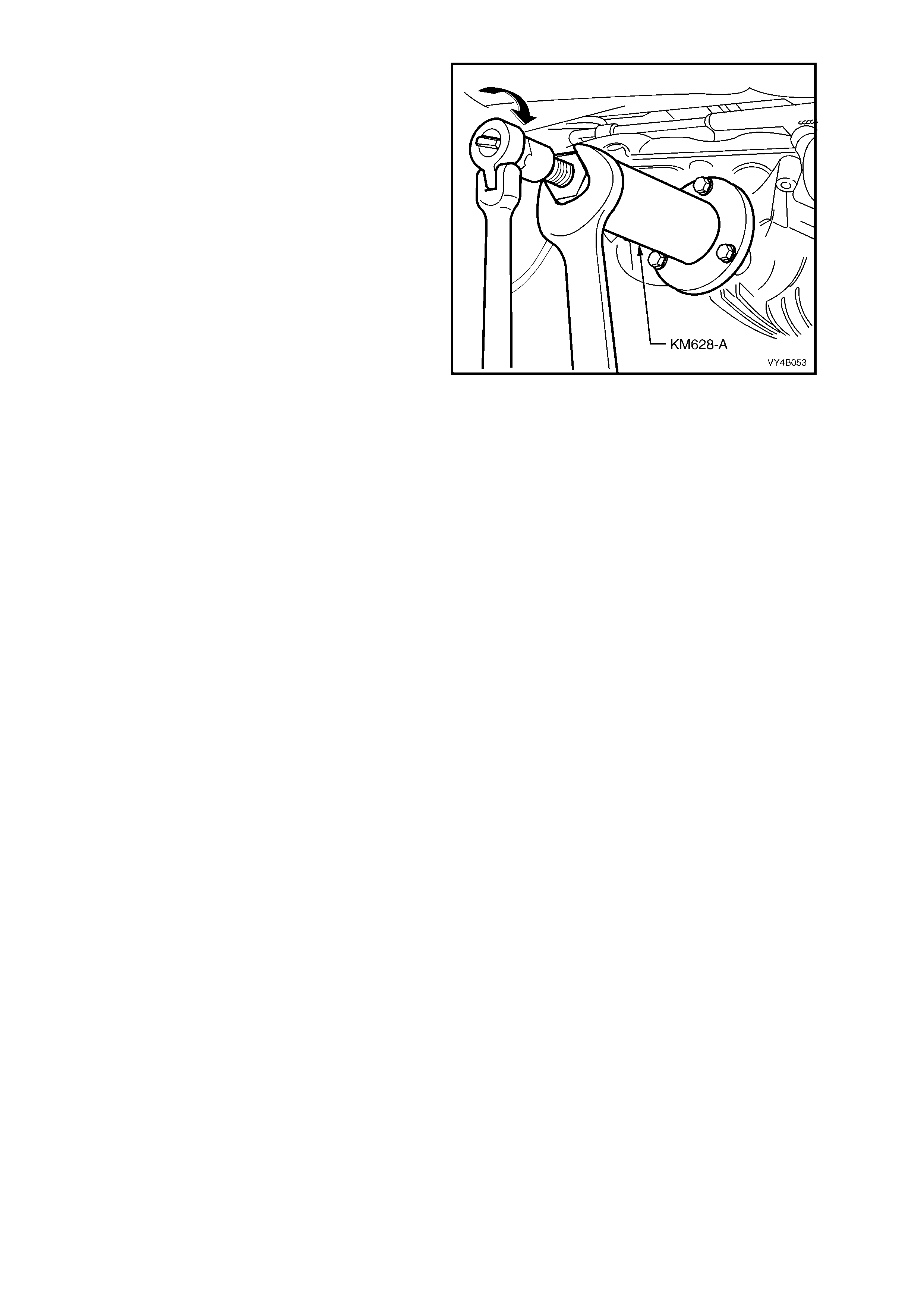

6. Attach Tool No. KM 620-1-A to the pinion

flange, using three suitable bolts and nuts to

hold pinion flange.

NOTE 1: If not previously done so, drill out

holes stamped ‘B’ on Tool No. KM620-1A to

12.5 mm.

NOTE 2: Use either the r ear coup ling to pini on

flange retaining bolts with a 25 mm spacer

(e.g. flat washers) installed first or use three

bolts M12 x 1.5 x 40,with the thread extending

to within 12 mm of the head.

7. Insert a suitable length of pipe (1) over the tang

of the installed tool for leverage, then remove

the pinion flange retaining nut, using a

comm erc ially ava ilabl e dee p soc ket and soc k et

bar (2).

8. Remove Tool No. KM 620-1-A from the pinion

flange.

Figure 4B-8

9. Place drain tray beneath differential carrier.

10. Install extractor, Tool No. AKM-628-A to the

pinion flange using the same three bolts and

nuts used in step 6.

NOTE: If not previo us l y done s o, dr i ll out t he f lan ge

holes on Tool No. KM628-A to 12.5 mm.

IMPORTANT: If using the original bolts, they must

have the 25 mm spacers fitted so the tool is

clam ped to the pinion f lang e. If this is not don e, the

screw thread on the extractor Tool No. KM628-A

will not be long enough to fully remove the pinion

flange.

11. While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening

the forcing screw in the direction shown.

Figure 4B-9

12. Ensure that pinion shaft thread is free from burrs, then coat splines and seal surface of pinion flange with the

recom m ended rear ax le lub r icant.

13. Reinstall the new pinion flange and retaining nut.

NOTE: The new flange will be an interference fit on pinion shaft splines and should only be pulled into place by

tightening retaining nut. DO NOT, UNDER ANY CIRCUMSTANCES, USE FORCE OR HAMMER FLANGE

DURING INSTALLATION ONTO PINION FLANGE.

14. Tighten flange retaining nut gradually until pinion shaft end play is reduced to approximately 0.50 mm.

15. Attach pulley to pinion flange and using spring balance, check pre-load. Continue tightening nut while

alternatively turning pinion to seat bearings, until the pre-load figure recorded previously (Step 4b) is reached.

Further increase this original pre-load reading by 0.5 Nm.

ROTATE PINION AN EXTRA 30-40 TURNS AND RE-CHECK THE PRE-LOAD TO ENSURE THAT NO

CHANGE HAS OCCURRED.

CAUTION: Should the retaining nut be overtightened and the pre-load exceeded, it will be necessary to

remove the differential carrier assembly and install a new collapsible spacer. Under no circumstances

must the retaining nut be backed off to decrease the pre-load setting.

16. Reinstall drive shafts, refer to 2.6 DRIVE SHAFTS in SECTION 4B - FINAL DRIVE AND DRIVE SHAFTS of

the VT Series I Servic e Inf ormation.

17. Reinstall propeller shaft, refer to Section 4C PROPELLER SHAFT AND UNIVERSAL JOINTS in the VX

Series Service Information.

18. If removed previously, reconnect exhaust system, in reverse to the removal procedure. Refer to 3.2 FINAL

DRIVE ASSEMBLY in SECTION 4B – FINAL DRIVE AND DRIVE SHAFTS - Local Trailing Arms of the VT

Series II Service Information, for details.

19. Remove safety stands and lower vehicle.

20. Check lubricant level and top up as necessary with the recommended lubricant, refer to

2.1 CHECKING DIFFERE NTI AL CARRIER LUBRIC ANT LEVEL in SECTION 4B - FINAL DRI VE AND DRI VE

SHAFTS of the VT Series I Service Information.

21. Start vehicle and check for exhaust leaks.

REPLACE (USING NEW OIL SEAL)

1. Using a floor jack under centre of differential

carrier, j ack up r ear of vehic le then place s afety

stands under trailing arms.

2. Remove propeller shaft, refer to

Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS in the VX Series Service

Information.

3. Remove both drive shafts, refer to

2.6 DRIVE SHAFTS in SECTION 4B - FINAL

DRIVE AND DRIVE SH AF TS of the VT Series I

Service Information.

4. Check and record pre-load at pinion flange as

follows:

a. Fit a pulley (1) to pinion flange and attach

a cord around pulley and to a spring

balance (2).

NOTE 1: Use either the rear coupling to

pinion flange retaining bolts with a 25 mm

spacer (e.g. flat washers) installed first or

use three bolts M12 x 1.5 x 40,with the

thread extending to within 12 mm of the

head.

NOTE 2: For fabr icated pul le y details, r efer

to 3. SPECIAL TOOLS at end of this

Section.

b. Star t rotation of pulle y and whilst in m otion

(approximately 50-60 rpm), note and

record the spring balance reading.

This pre-load reading includes pinion

bearings, side bearings, meshing effect of

gear set and pinion oil seal.

To determine pre-load, multiply reading on

spring balance by radius of pulley.

EXAMPLE: W ith a pulley diam eter of 152 mm, the

radius is 76 mm which equals 0.076 m. With a

spring balance reading of 25 N, the pre-load equals

0.076 m x 26 N = 1.9 Nm.

5. Remove pulley from pinion flange.

Figure 4B-10

6. Attach Tool No. KM 620-1-A to the pinion

flange, using three suitable bolts and nuts to

hold pinion flange.

NOTE 1: If not previously done so, drill out holes

stamped ‘B’ on Tool No. KM620-1A to 12.5 mm.

NOTE 2: Use either the rear coupling to pinion

flange r eta in ing bo lts with a 25 m m s pac er ( e.g. f lat

washers) insta lled firs t or u se three b olts M 12 x 1.5

x 40,with the thread extending to within 12 mm of

the head.

7. Insert a suitable length of pipe (1) over the tang

of the installed tool for leverage, then loosen

the pinion flange retaining nut, using a

comm erc ially ava ilabl e dee p soc ket and soc k et

bar (2) until end play can be felt in the pinion

shaft.

8. Check the oil seal and differential side bearing

pre-load using the spring scale and pulley, as

detailed in steps 4a and 4b, Record oil seal

and side bearing pre-load for later use.

9. Remove Tool No. KM 620-1-A from the pinion

flange.

Figure 4B-11

10. Place drain tray beneath differential carrier.

11. Install extractor, Tool No. AKM-628-A to the

pinion flange using the same three bolts and

nuts used previously.

NOTE: If not previo us l y done s o, dr i ll out t he f lan ge

holes on Tool No. KM628-A to 12.5 mm.

IMPORTANT: If using the original bolts, they must

have the 25 mm spacers fitted so the tool is

clam ped to the pinion f lang e. If this is not don e, the

screw thread on the extractor Tool No. KM628-A

will not be long enough to fully remove the pinion

flange.

12. While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening

the forcing screw in the direction shown.

Figure 4B-12

13. Prise pinion oil seal from carrier bore using

Tool No. E308 or a universal seal removing

tool.

Figure 4B-13

14. Examine carrier seal bore and remove any

nicks or burrs.

15. Lubricate new pinion oil seal lips with the

recommended rear axle lubricant. Lightly coat

outside of seal shell with a non-hardening

gasket cement.

16. Start oil seal in differential carrier and drive

seal squarely into position using Tool No.

E9055. Se al fits flush to 0. 25 mm below carr ier

seal bore leading surface.

17. Ensure that pinion shaft threads are free from

burrs, then coat splines and seal surface of

pinion flange with differential gear lubricant.

18. Reinstall flange on pinion shaft splines.

NOTE: The ne w flang e will be an int e rf er enc e f it on

pinion shaft splines and should only be pulled into

place by tightening the retaining nut. DO NOT,

UNDER ANY CIRCUMSTANCES, USE FORCE

OR HAMMER FLANGE DURING INSTALLATION

ONTO PINION FLANGE.

19. Tighten flange retaining nut gradually until

pinion shaft end play is reduced to

approximately 0.5 mm.

Figure 4B-14

20. Check new oil seal and differential assembly pre-load using spring balance as previously outlined in steps 4a

and 4b. Record pre-load for reassembly reference.

21. T he pre-load re ading for differential assembl y obtain ed in step 8, is su btracted f rom pre- load reading obt ained

in step 20. The difference between these figures represents extra lip tension of new seal expressed as a Nm

pre-load figure. The difference between the pre-load readings obtained in steps 8 and 20 must be added to

pre-load reading obtained in step 4b to obtain a total pre-load reading.

THEOR ETICAL EXAMPLE

STEP 20 NEW OIL SEA L AND SIDE

BEARIN G PR E- L OAD

SETTING

1.47 Nm

STEP 8 OLD OIL SEAL AND SIDE

BEARING

PRE-LOAD READING

1.02 Nm

SUBTRACT STEP 8

FROM STEP 20

0.45 Nm

STEP 4b COMPLETE

DIFFEREN TI AL AS SEM BLY

PRE-LOAD READING

1.47 Nm

THE PRE-LOAD READING

COMBINATION WILL BE

THE SUM OF:-

.47 Nm plus

0.45 Nm

WHICH GI VE S A T O TAL

PRE-LOAD READING OF:-

1.92 Nm

CAUTION: Should the retaining nut be overtightened and the pre-load exceeded, it will be necessary to

remove the differential carrier assembly and install a new collapsible spacer. Under no circumstances

must the retaining nut be backed off to decrease the pre-load setting.

22. Continue tightening retaining nut while alternately turning pinion to seat bearings until total pre-load figure

obtained in step 21 is achieved, then increase this pre-load reading by 0.11 to 0.34 Nm. Further rotate pinion

an extra 30-40 turns and recheck pre-load to ensure that no change has occurred.

NOTE: It must be realised that the pre-load readings in the example are only theoretical. In practice, the figures

could differ greatly, so the readings obtained when performing the actual operations, are the ones to use.

23. Reinstall drive shafts, refer to 2.6 DRIVE SHAFTS in SECTION 4B - FINAL DRIVE AND DRIVE SHAFTS of

the VT Series I Servic e Inf ormation.

24. Reinstall propeller shaft, refer to Section 4C PROPELLER SHAFT AND UNIVERSAL JOINTS in the VX

Series Service Information.

25. If removed previously, reconnect exhaust system, in the reverse to the removal procedure. Refer to

3.2 FINAL DRIVE ASSEMBLY in S ECTIO N 4B – FI NAL DR IVE AND DRI VE S HAFT S - Loc al Tr ailing Ar m s of

the VT Series II Service Information, for details.

26. Remove safety stands and lower vehicle.

27. Check lubricant level and top up as necessary, refer to 2.1 CHECKING DIFFERENTIAL CARRIER

LUBRICANT LEVEL in SECTION 4B - FINAL DRIVE AND DRIVE SHAFTS of the VT Series I Service

Information.

28. Start vehicle and check for exhaust leaks.

3. SPECIAL TOOLS

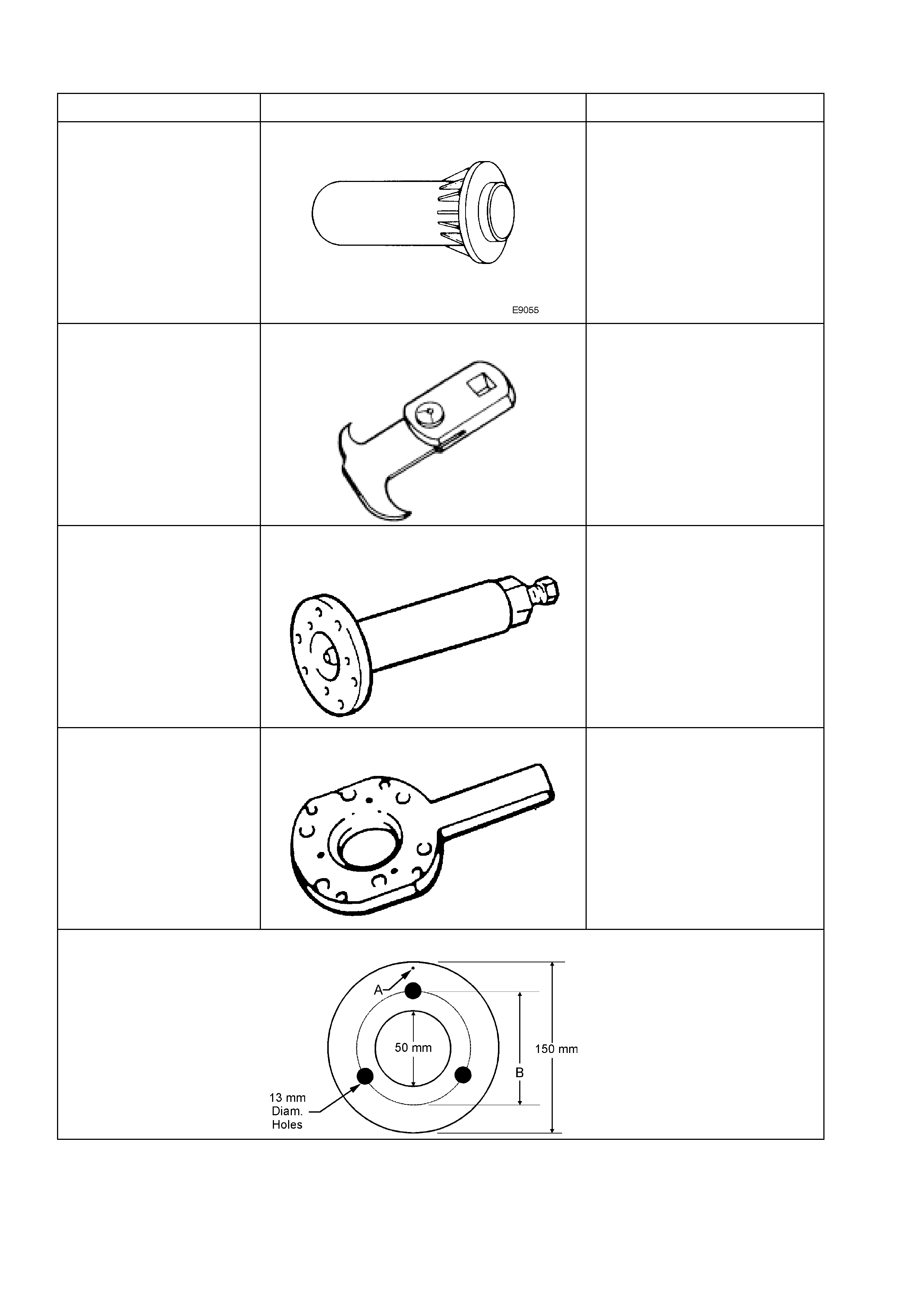

TOOL No. REF. IN TEXT TOOL DESCRIPTION COMMENTS

E9055 PINION OIL SEAL INSTALLER

Also released as 17-010A.

E308 SEAL REMOVER Also released as 56750.

KM 628-A EXT RACTOR TOO L Previously released for the VT,

V6 Manual T ransmis sion.

KM 620-1-A FLANGE HOLDING TOOL

Previously released for the VT,

V6 Manual T ransmis sion.

If not modified, drill out the

holes stamped ‘B’ on the tool,

to 12.5 mm

PINION FLANGE PULLEY DETAILS Fabricated:

1. From a 13 mm thick piec e of

wood.

2. Drill a small hole at ‘A” an

attach a one metre length of

string at this point.

3. Drill t hr ee 13 m m holes , on a

pitch circle diameter (B) of

96 mm, 120° apart, as

shown.