SECTION 4C - PROPELLER SHAFT AND

UNIVERSAL JOINTS

IMPORTANT:

Before p erforming any Serv ice Operation or o ther procedure described in this Section, ref er to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

1. GENERAL DESCRI PTI O N

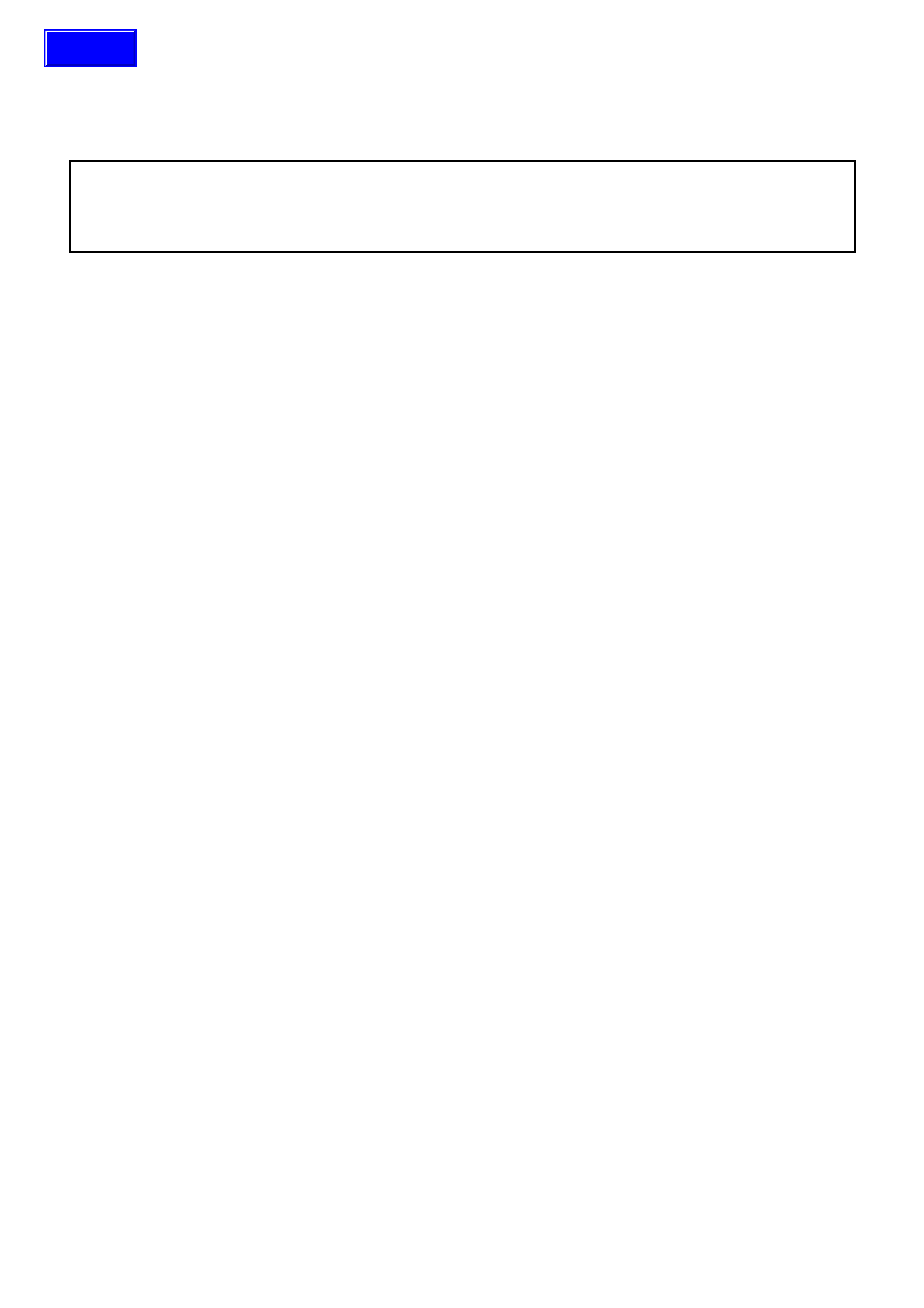

The propeller shaft assembly fitted to the VX range of vehicles is a new, two piece tubular design (refer Fig. 4C-1).

The new design features a rubber coupling at the front, connected to a slip yoke at the transmission end (V6 and

automatic transmission and GEN III V8 with manual and automatic transmission) and a second coupling bolted to

the pinion f lange at the f inal drive end. The pr opeller shaft ass embly fitted to those VX vehicles with the V6 engine

and manual transmission, continues to have a rubber coupling bolted to a flange splined to the transmission

mainshaft.

Drive is transmitted between the two halves of the propeller shaft through a centre universal joint, that is of the

conventional cross design (Hooke’s joint), located and secured in each of the two propeller shaft yolks by peening.

A fully sealed ball bearing, m ounted in a reinforced rubber cup, supports the propeller shaft assem bly in the centre

location. This centre bearing rubber cup is supported in a cup guide and attached to a carrier, which in turn, is

bolted to the vehicle underbody brace.

The centre universal joint and centre bearing are lubricated for life and do not require any periodic lubrication.

Techline

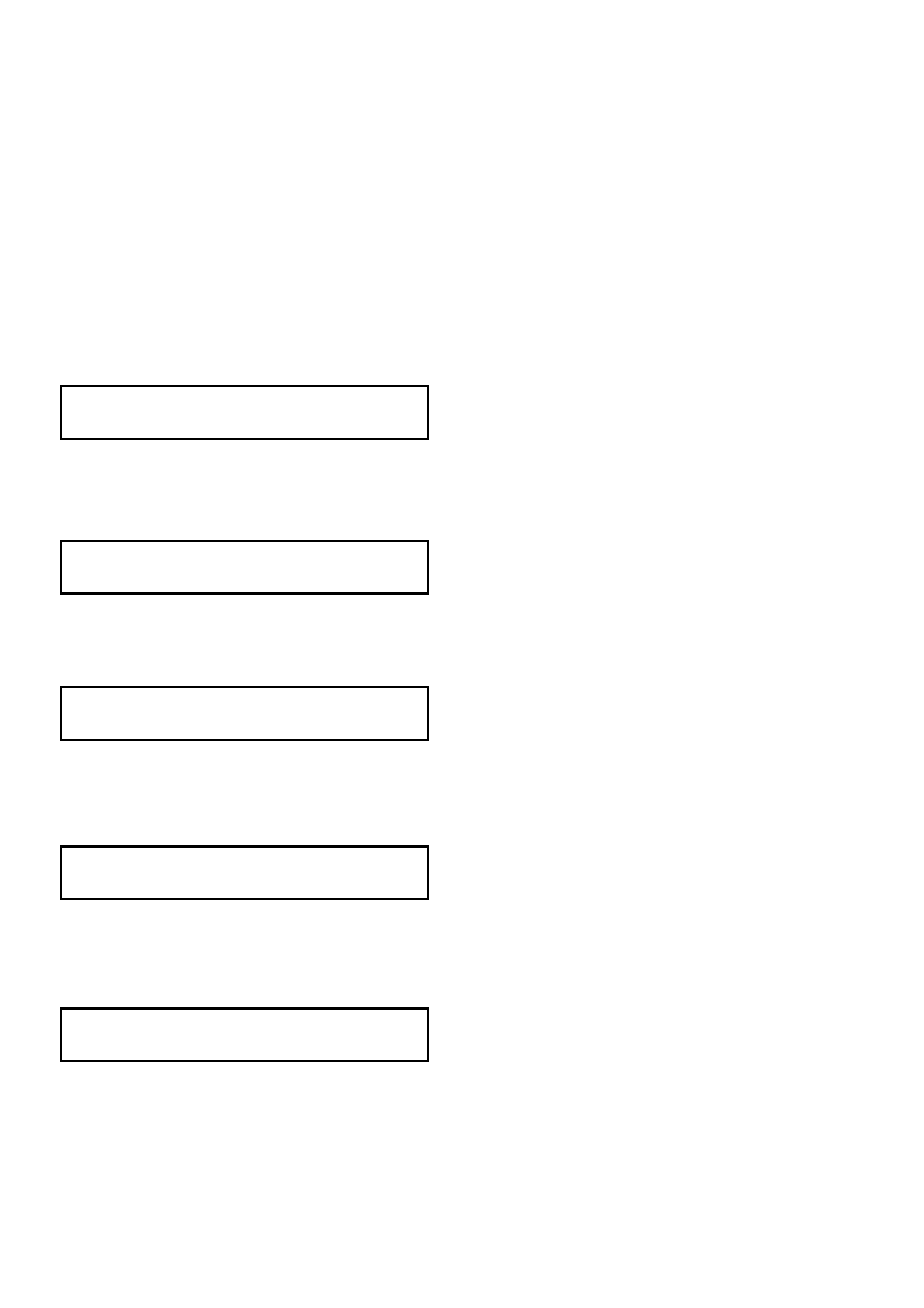

Figure 4C-1

1. Nut – Front Coupling to Transmission Flange Stud – 3 pl aces 3. Bolt – Cent re B eari ng Cup Gui de to Underfloor Brace

2. Guide – Centre Bearing Cup 4. Torx Bolt – Rear Coupling to P i ni on Fl ange – 3 pl aces

1.1 SERVICE INFORMATION

The only serviceable components in the propeller shaft assembly are the two rubber couplings and the centre

bearing assembly in the unit fitted to V6 engined, manual transmission models. The reasons for this situation can

be summarised as:

a. The centre univer sal joint bearing c ups are set and retained by stak ing which requires sophis ticated equipm ent

to ensure concentric reassembly of the universal joint. Should the centre universal joint require servicing, then

the propeller shaft assembly must be replaced.

b. In order to separ ate the two propeller shaft halves, the interference f it of the splined j oint requires the use of an

hydr aulic pr ess and ex pensive tools. As this oper ation would also require the r e-balancing of the propeller s haft

assembly, the centre bearing assembly and/or slinger are also non-serviceable.

c. By using two rubber couplings and having an interfer ence f it between the two propeller shaft halves , m easuring

the driveline angles and propeller shaft phasing is no longer required.

2. SERVICE OPERATIONS

2.1 PROPELLER SHAFT

REMOVE

CAUTION: Whenever any component that forms part of the ABS is disturbed during Service Operations, it

is vital that the complete ABS system be checked, using the procedure as detailed in DIAGNOSIS, ABS

FUNCTION CHECK, in Section 12L ABS & ABS/ETC.

1. Using a floor jack under the centre of the final drive housing, jack up rear of vehicle and place safety stands

under body rear jacking points. Refer to Section 0A GENERAL INFORMATION for location of jacking points.

CAUTION: After raising the rear of the vehicle, release the park brake (if applied) to relax any ‘wind-up’ in

the flexible rubber couplings. Otherwise, when the propeller shaft bolts are released from the final drive

pinion flange, personal injury may r esult!

FOR VX MODELS WITH THE V6 ENGINE AND MANUAL TRANSMISSION.

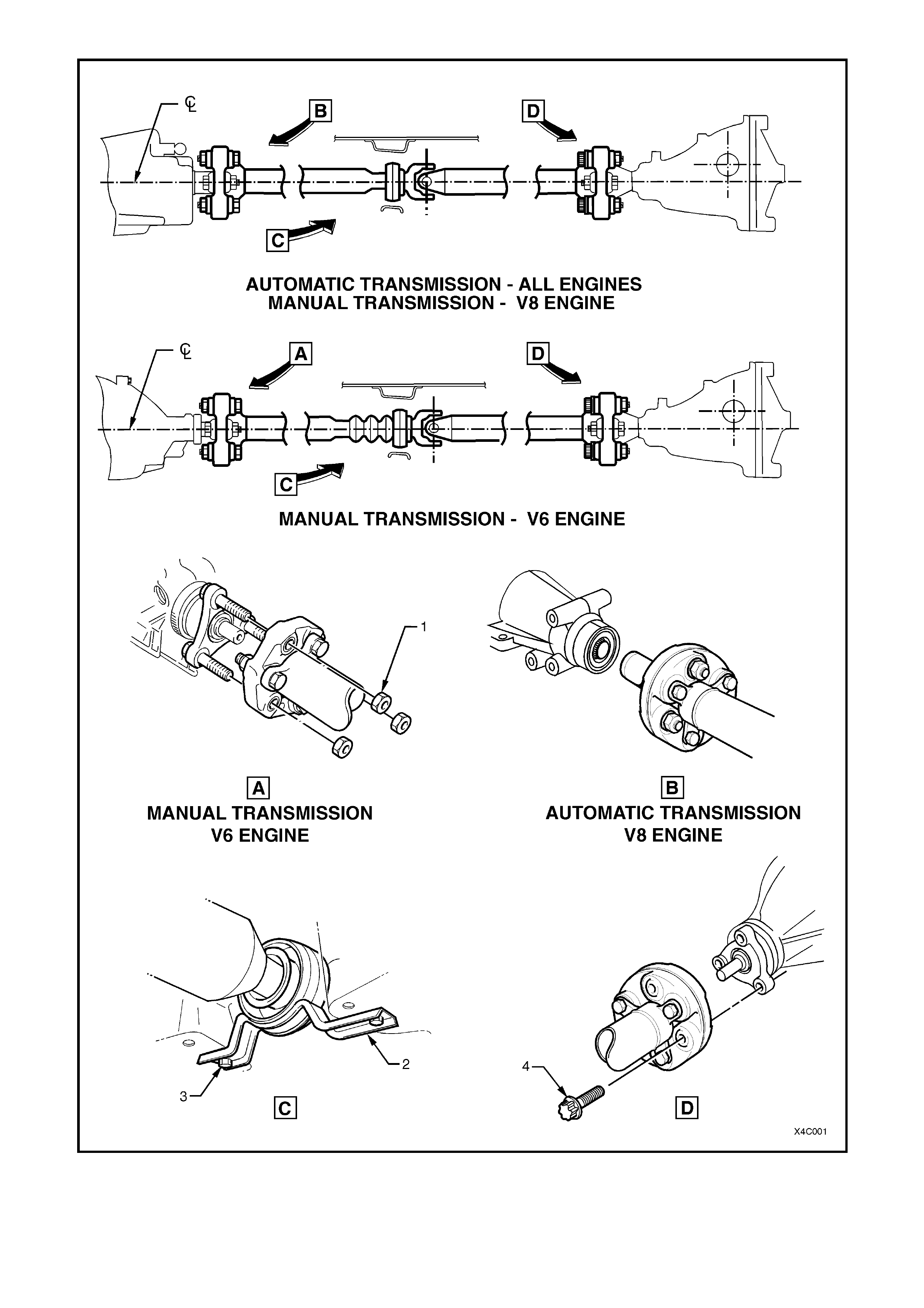

NOTE: To provide access to the f ront of the propeller shaft, it is recom mended that the twin exhaust pipe/catalytic

converter assembly be removed.

2. Disconnect the wiring harness connector s from

each of the two oxygen sensors (1).

Figure 4C-1

3. Remove the intermediate pipe to catalytic

converter bolts (1), springs (2) and sealing ring

(3). Set the removed components to one side.

4. Remove the exhaust pipe flange to exhaust

manifold nuts fr om each side (not s hown in Fig.

4C-3).

5. W hile supporting the twin exhaust pipe (5) and

catalytic converter assembly (4), remove the

support rubber (6) from the rear of the

transmission.

6. Carefully lower and remove the exhaust pipes

from the vehic le, taking c are not to dam age the

exhaust gas oxygen sensors, in the process.

Figure 4C-2

Techline

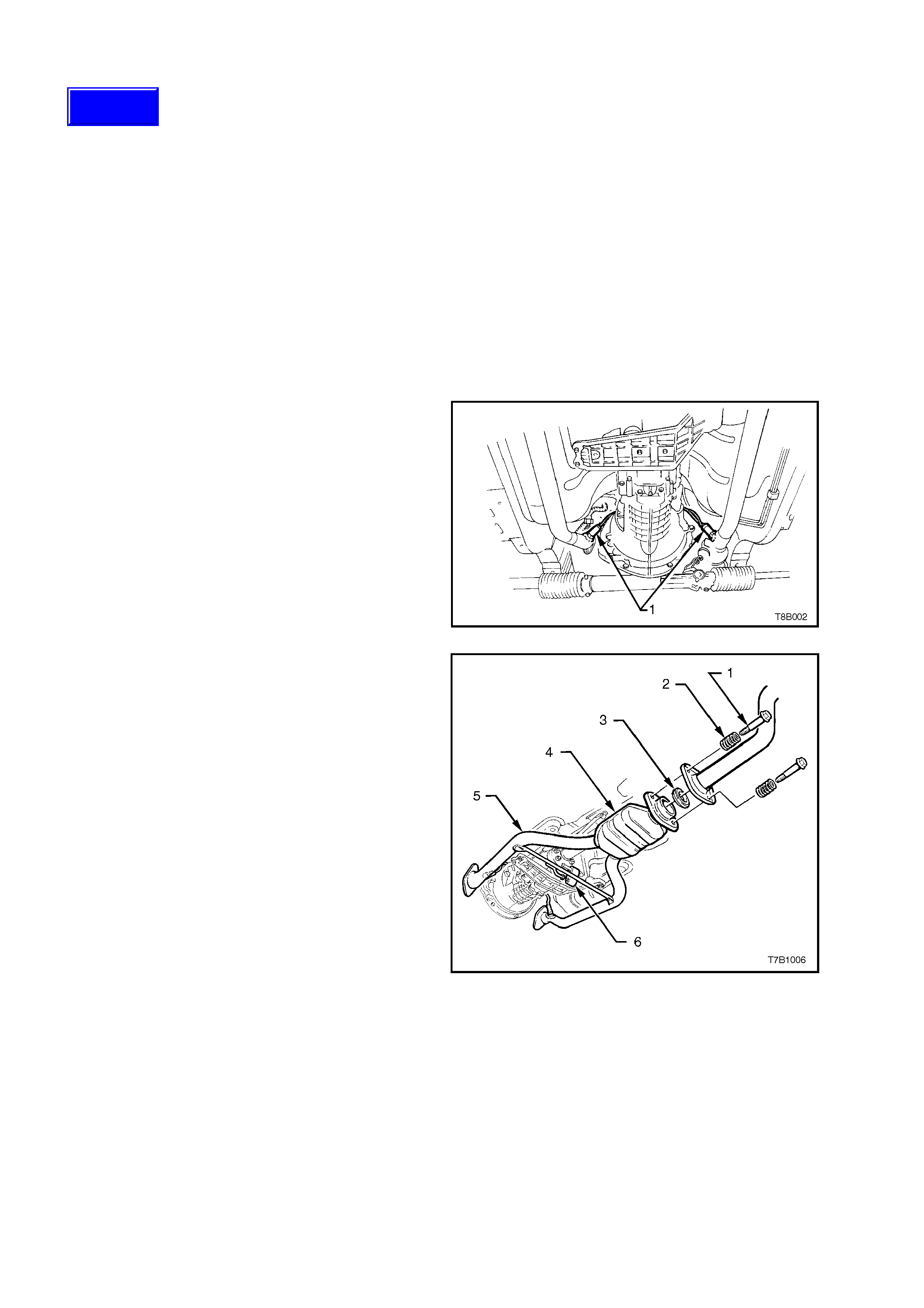

FOR VX MODELS WITH THE V6 SUPERCHARGED OR GEN III V8 ENGINE.

NOTE: To gain access to the propeller shaft

fasteners, it will be necessary to remove the

intermediate and rear sections of the exhaust

system.

7. Disconnect the intermediate exhaust pipe to

catalytic converter bolts (1) from the rear of

each catalytic converter. Discard the flange

gaskets (2).

NOTE: Only one side of the V6 Supercharged and

GEN III V8 exhaust system is shown in Fig. 4C-4.

Figure 4C-3

8. Remove the two retainers (1) from the top

support posts and discard.

9. Disconnect exhaust system support rings (2)

from rear hanger of the rear muffler.

Figure 4C-4

10. Remove the four muffler support to rear

crossmember retainers (1).

11. While supporting the intermediate section of

the exhaust system, remove the four

intermediate muffler support rubbers (2).

12. Remove the intermediate and rear sections of

the exhaust system from the vehicle.

Figure 4C-5

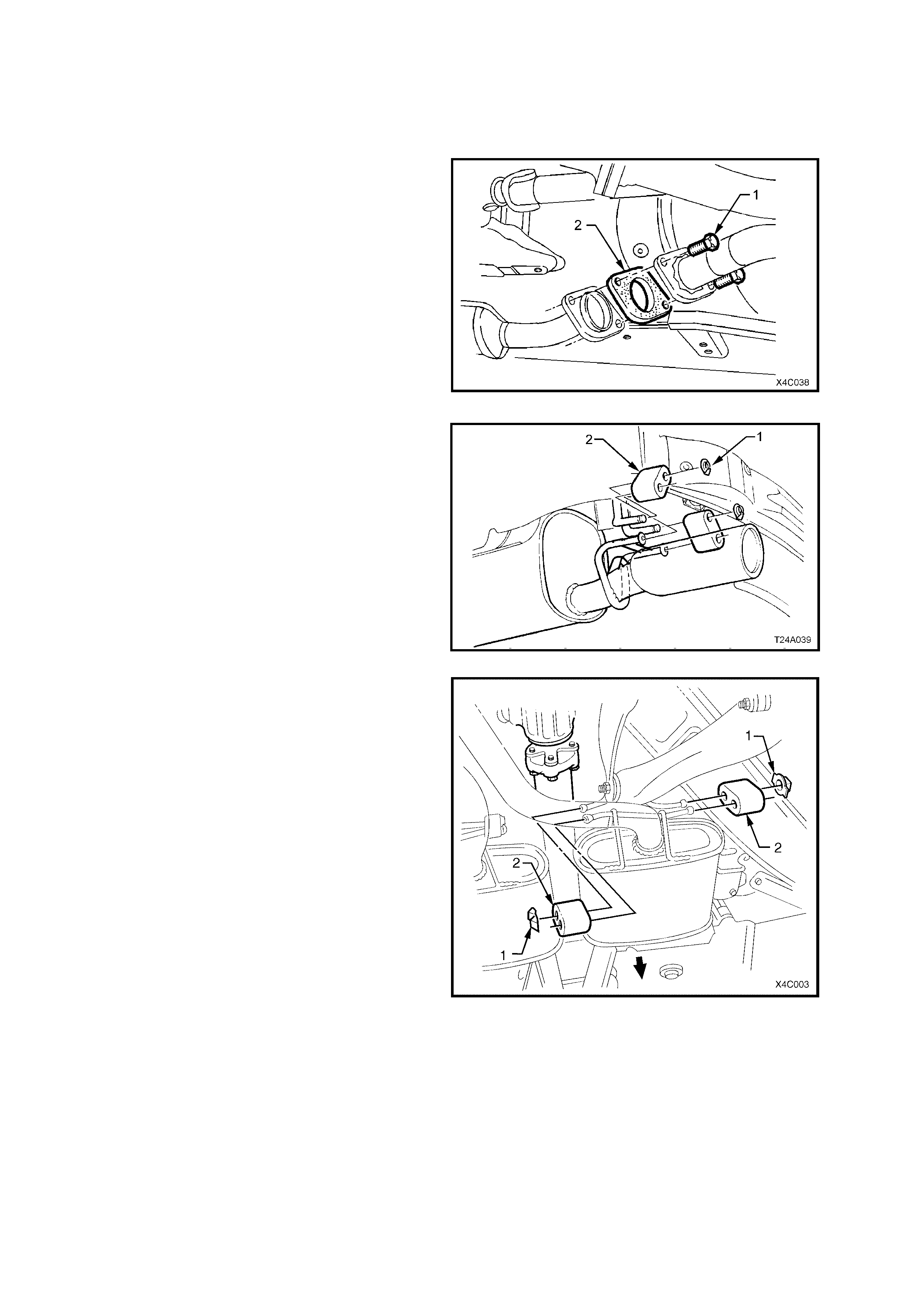

FOR VX MODELS WITH THE V6 ENGINE AND MANUAL TRANSMISSION

13. Remove propeller shaft rubber coupling (4) to

transmission output flange (1) attaching nuts

(3). Discard removed nuts (3).

Figure 4C-6

ALL VX MODELS

14. With the transmission in the ‘Park’ position

(automatic transmission) or in first gear

(m anual transm ission and the park brak e firm ly

applied, use Torx socket K04425E20 or a

commercially available E20 Torx socket to

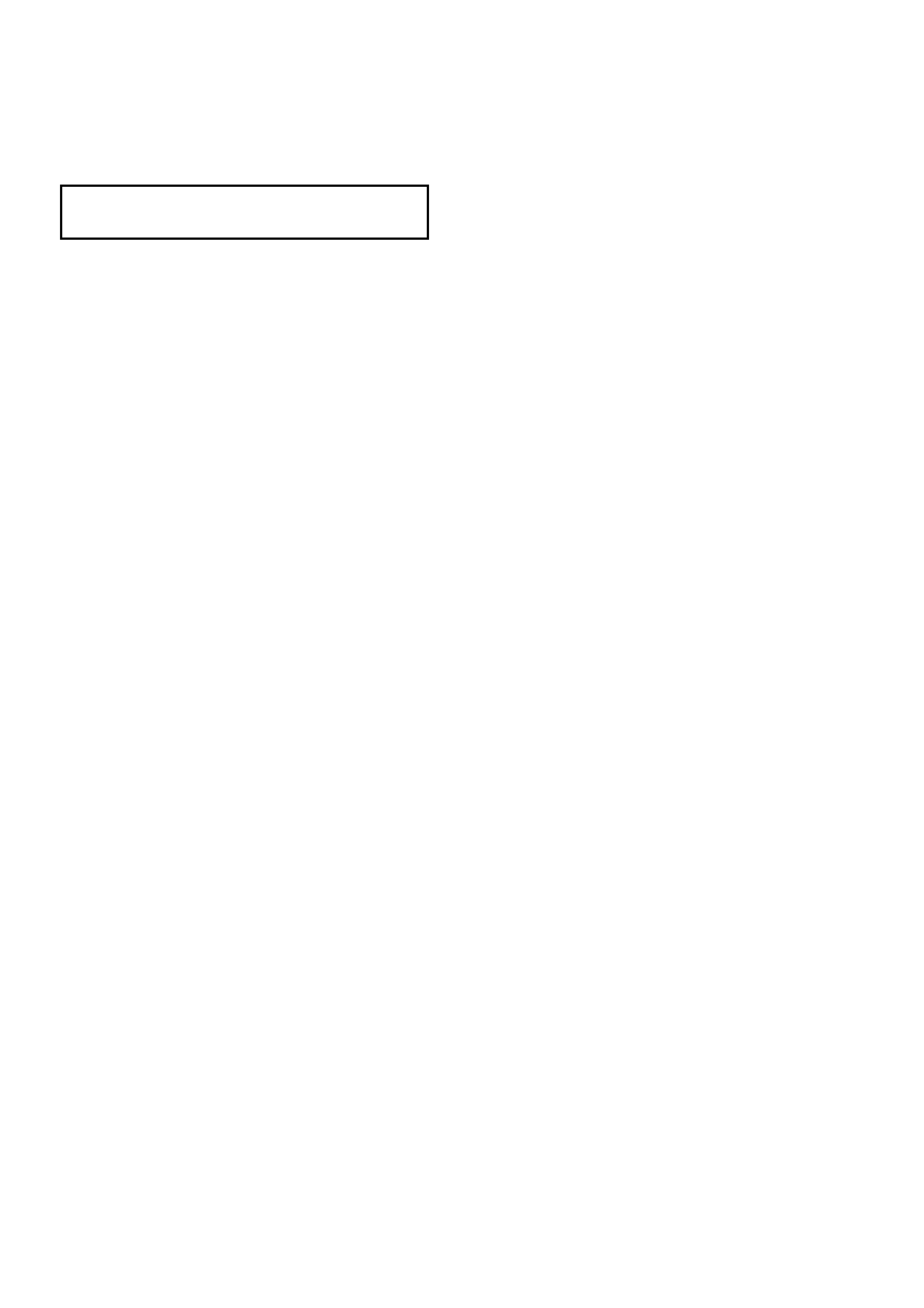

loosen the three T or x headed bolts (1) secur ing

the propeller shaft rear rubber coupling (2) to

the pinion flange (3).

15. Release the park brake to relieve any torque

loading on the rubber coupling, then remove

the three Torx headed bolts (1)

NOTE: To enable the pr opeller shaft to be ins talled

in the original position relative to the pinion flange,

use a felt tipped pen or similar to identify the

relationship (‘A’) of the two com ponents before bolt

removal.

Figure 4C-7

16. Remove the two centre bearing carrier (1) to

underbody reinforcement bolts (2).

17. While supporting the centre bearing section,

slide the propeller shaft assembly forward to

disengage from the final drive pinion support

pin, then lower the ass em bly at the rear, sliding

rearward to remove from the vehicle.

FOR VX MODELS WITH A SLIDING FRONT

YOKE

NOTE 1: Take car e to protec t the outer diameter of

the front yoke. Nicks or abrasions will damage the

transm ission extens ion seal during reas sembly and

result in subsequent lubricant leakage from this

area.

NOTE 2: Insert a suitable plug in the end of the

transmission rear extension to prevent loss of

transmission lubricant.

Figure 4C-8

REINSTALL

Reinstallation is the r everse of rem oval proc edures

noting the following:

GENERAL PROCEDURE:

1. Lubricate both the trans m ission output shaf t (V6 engine and m anual tr ansm ission) and final drive pinion spigots

with molybdenum disulphide grease to Holden Specification HN1271.

2. For those VX models with a sliding front yoke, remove any foreign matter that may have adhered to the front

universal joint yok e and lubricate with tr ans mission lubricant. Ins er t yoke on to trans mission m ains haf t, index ing

the splines.

3. Clean threads of centre bearing carrier to underbody reinforcement bolts and underbody weld nuts.

4. Reinstall the front of the propeller shaft assembly first, supporting the centre and rear sections.

5. While still supporting the centre bearing area, slide the propeller shaft assembly forward to allow engagement of

the rear spigot, then slide rearward to fully engage.

6. Raise the centre bearing assembly and reinstall the bolts and washers to secure to the underbody

reinforcement. Tighten both bolts to the correct torque specification.

CENTRE BEARING CARRIER TO

UNDERBODY REINFORCEMENT 20 – 35 Nm

BOLT TORQUE SPECIFICATION

7. Before reinstalling the attaching bolts and washers to the propeller shaft rear coupling and pinion flange, align

marks on pinion flange and rear coupling (or marks made on removal), refer to Fig. 4C-8.

8. Provided no thread damage is evident, reinstall the original rear propeller shaft coupling to final drive pinion

flange bolts and washers, tightening to the correct torque specification.

PROPELLER SHAFT REAR

COUPLING TO PINION FLANGE 105 – 125 Nm

BOLT TORQUE SPECIFICATION

VX MODELS WITH V6 ENGINE AND MANUAL TRANSMISSION

9. Install NEW r ubber coupling to transm ission output flange retaining nuts bef ore tightening to the correct tor que

specification.

RUBBER COUPLING TO TRANSMISSION

OUTPUT SHAFT FLANGE RETAINING 50 – 85 Nm

NUT TORQUE SPECIFICATION

10. Reinstall the exhaust system as follows;

V6 ENGINED MODELS (MANUAL TRANSMISSION ONLY)

a. Reinstall the twin exhaust pipes to the exhaust manifolds, then reinstall the retaining nuts and tighten the

nuts to the specified torque.

EXHAUST PIPE FLANGE TO

EXHAUST MANIFOLD NUT 18 – 35 Nm

TORQUE SPECIFICATION

b. Reinstall the support rubber to the transmission mount bracket post.

c. Reconnect both wiring harness connectors to the oxygen sensors.

d. Check that the catalytic converter to intermediate exhaust pipe bolts, springs and sealing ring are all in a

serviceable c ondition. Reinstall the sealing ring, springs and bolts , tightening the bolts to the cor rect torque

specification.

INTERMEDIATE EXHAUST PIPE

TO CATALYTIC CONVERTER 40 – 50 Nm

BOLT TORQUE SPECIFICATION

V6 SUPERCHARGED AND GEN III V8 ENGINED MODELS

e. Ensure the catalytic converter flange is clean and free from any gasket material.

f. Reinstall exhaust system, using a new gasket at the catalytic converter and new hanger retainers for the

muffler supports to rear crossmember.

g. Reinstall the catalytic converter to intermediate exhaust pipe bolts and tighten to the correct torque

specification.

INTERMEDIATE EXHAUST PIPE

TO CATALYTIC CONVERTER 40 – 50 Nm

BOLT TORQUE SPECIFICATION

All VX Models

h. Check exhaust clearances as detailed in Section 8B EXHAUST SYSTEM in the VT Series I and

VT Series II Service Information.

ALL VT MODELS WITH A SLIDING YOKE

11. If transm ission lubricant leak ed from the rear of the transm ission when the propeller shaf t was rem oved, check

transm iss ion lubricant level and top up as nec essar y. Refer to Section 0B LUBRICATION AND SERVICE in the

VT Series I and VT Series II Service Information for lubricant specifications and procedure.

2.2 RUBBER COUP LING

REPLACE

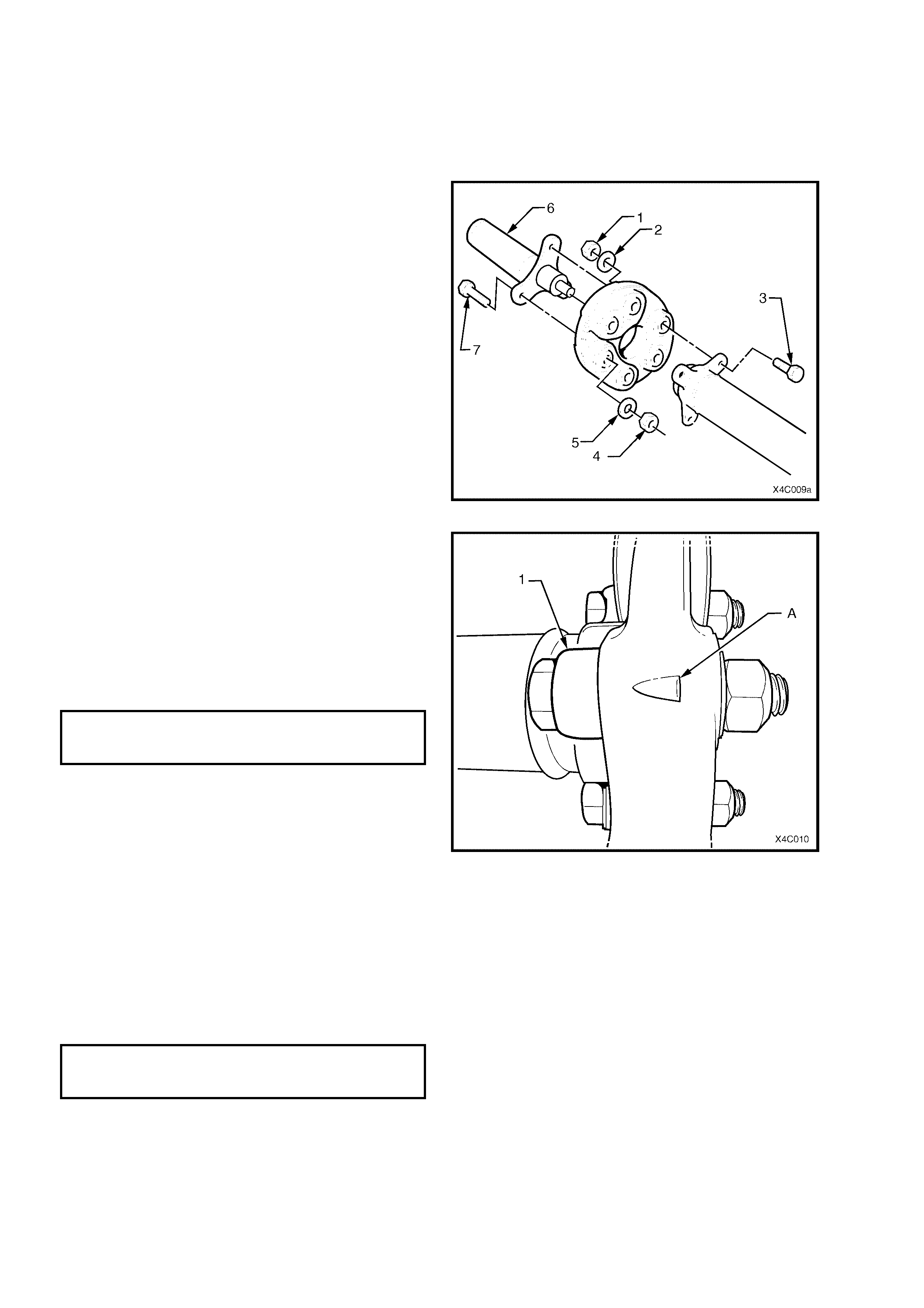

NOTE: While the front coupling is shown for this

operation, the replacement of either coupling is

similar.

1. Remove propeller shaft. Refer to

2.1 PROPELLER SHAFT, in this Section.

2. Using a back-up spanner on each of the three

propeller shaft sliding yoke bolts (7), loosen

then remove the nuts (4) and washers (5).

Discard the removed bolts and nuts. Remove

the sliding yoke from the coupling.

3. Using a back-up spanner on each of the three

propeller shaft to coupling bolts (3), loosen then

remove the nuts (1) and washers (2). Discard

the removed bolts and washers. Remove the

coupling from the front of the propeller shaft.

Figure 4C-9

4. Reinstall a replacement rubber coupling to the

end of the propeller shaft, aligning the holes in

such a way that the triangular shape (‘A’) on

the coupling ‘points’ to the propeller shaft

flange (1), as shown.

5. Install NEW bolts, washers and nuts to secure

the coupling to the propeller shaft flange and

tighten to the correc t torque specif ication, using

a back-up spanner on the bolt head.

PROPELLER SHAFT TO

RUBBER COUPLING NUT 74 – 80 Nm

TORQUE SPECIFICATION

6. Install 0.5 gm of molybdenum disulphide

grease (to Holden Spec ific ation HN1271) to the

spigot bush in the propeller shaft end of the

sliding yoke.

7. Reinstall the sliding yoke spigot to the bush on

the f ront end of the propeller s haft, aligning the

bolt holes. If the rear bolts were placed

correctly (refer step 4), then the triangular

shape will ‘point’ to the sliding yoke flange bolt

holes.

8. Install new bolts, washers and nuts to secure

the coupling to the sliding yoke flange and

tighten to the correc t torque specif ication, using

a back-up spanner on the bolt head.

PROPELLER SHAFT TO

SLIDING YOKE NUT 74 – 80 Nm

TORQUE SPECIFICATION

9. Reinstall the propeller shaft, as detailed in

2.1 PROPELLER SHAFT Reinstall, in this

Section.

Figure 4C-10

2.3 CENTRE BEARING ASSEMBLY

NOTE 1: T his oper ation is only to be carried out on

propeller shafts fitted to those VX models fitted w ith

the V6 engine and manual transmission.

The reasons for this are detailed in

1.1 SERVICE INFORMATION, in this Section.

NOTE 2: The centre bearing and housing are an

integral part and are not serviced separately

NOTE 3: During the removal process described,

the rubber bearing support will be damaged,

requiring the complete centre bearing assembly to

be replaced.

REMOVE

1. Remove propeller shaft. Refer to

2.1 PROPELLER SHAFT in this Section.

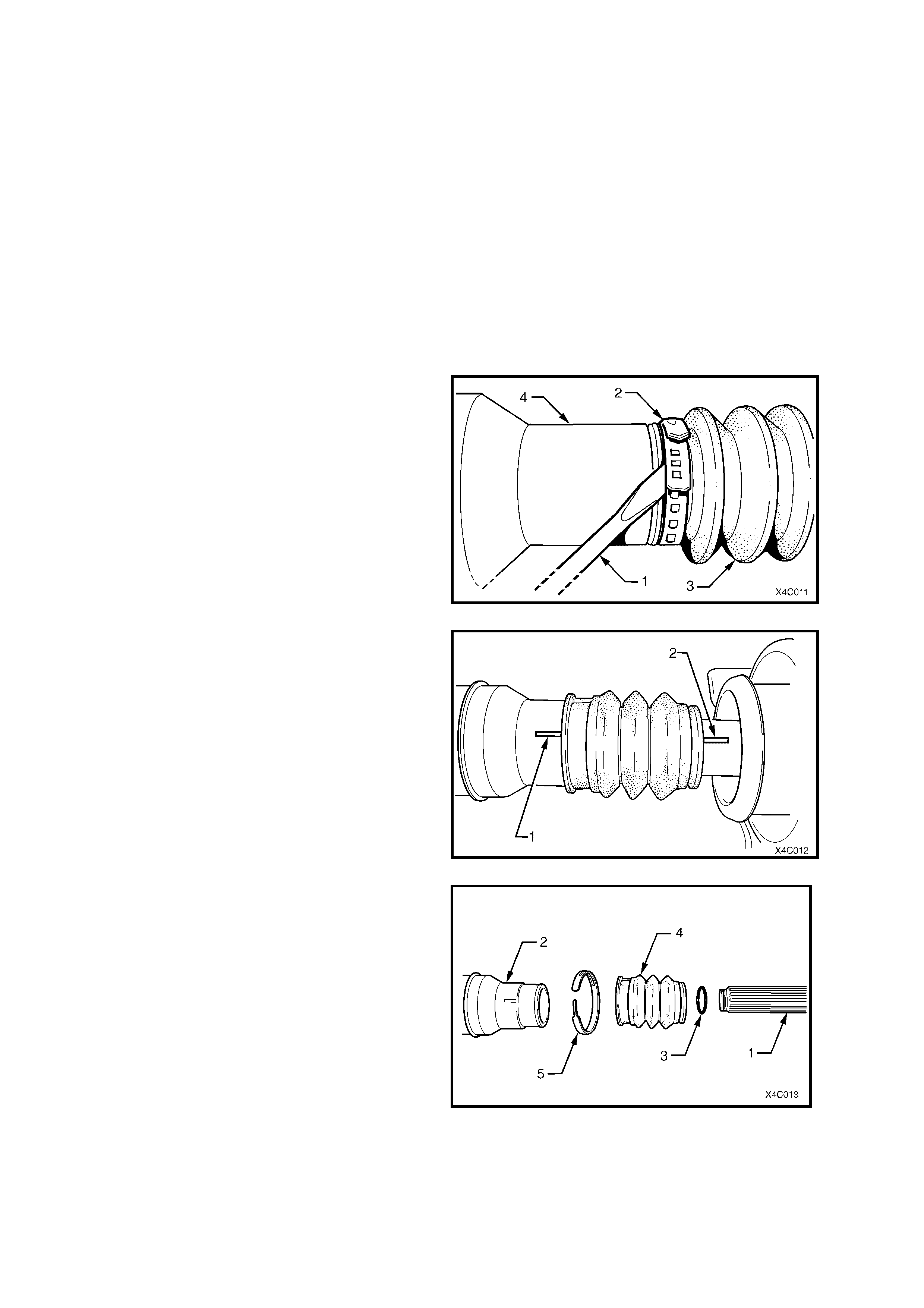

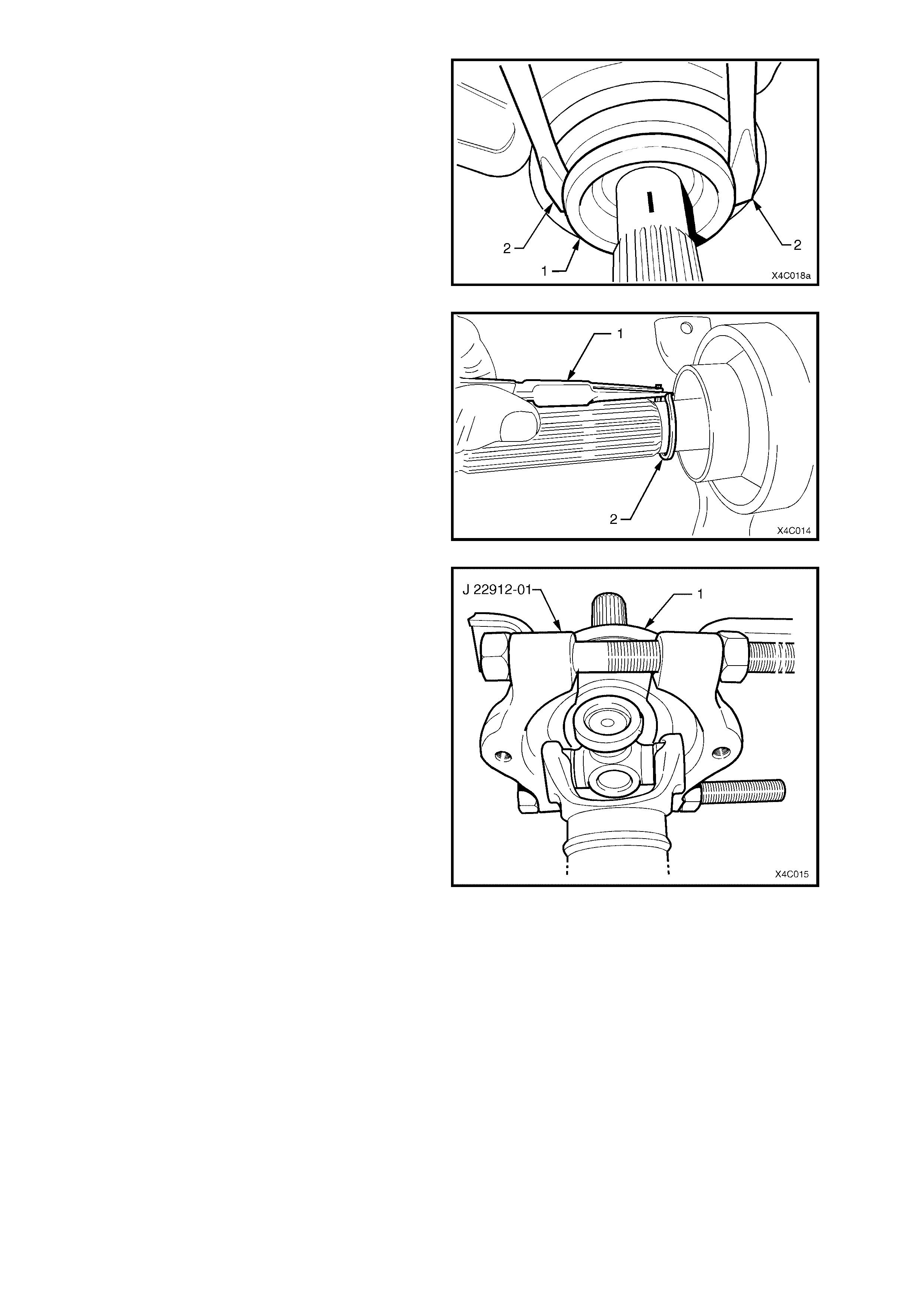

2. W ith the propeller shaft assembly (4) laying on

a bench, use a screwdriver (1) or similar and

lever up on the boot clamp (2) releasing the

tension.

Figure 4C-11

3. Extend the sliding joint until resistance is felt,

then use a felt tipped pen or similar to mark

alignment marks on the front propeller shaft

section (1) and the rear (2)

Important: This is a critical operation, as propeller

shaft phasing and balance will be affected if the two

propeller shaft halves are not aligned correctly on

reassembly.

Figure 4C-12

4. W ith the two propeller s haft halves extended, a

snap action is required to separate them,

because of the O-ring seal (3) mounted on the

end of the rear shaft (1).

5. Once separated, the ribbed boot (4) and O- ring

seal (3) are released.

NOTE: Once s eparated, the O- ring seal (3) may be

retained in the fr ont half (2). Retrieve by inserting a

hooked piece of wire.

Figure 4C-13

6. Remove the slinger (1), by levering off, using

two similar sized screwdrivers (2) or similar, as

shown.

NOTE: Removal of the slinger is required to gain

access to a circlip underneath.

Figure 4C-14

7. Using suitable, commercially available circlip

pliers (1), remove the circlip (2) securing the

centre bearing.

Figure 4C-15

8. Install s uitable pr ess plates s uch as J 22919-01

under the centre bear ing, carrier (1) and rubber

support, with the flat face towards the bearing

and carrier (1).

9. T ighten the clamp nuts on the pres s plates until

the two halves are firmly secure around the

bearing.

10. Support the press plates on the bed of an

hydraulic press and press the rear propeller

shaft, splined shaft from the centre bearing.

NOTE: This operation will damage the rubber

bearing support, requiring the centre bearing,

rubber and carrier assembly to be replaced.

Figure 4C-16

11. Fig. 4C-18 shows the relationship of the centre

bearing as semb ly ( 3) to the rear pr opeller shaft

(4), together with the slinger (1) and the

retaining circlip (2).

Figure 4C-17

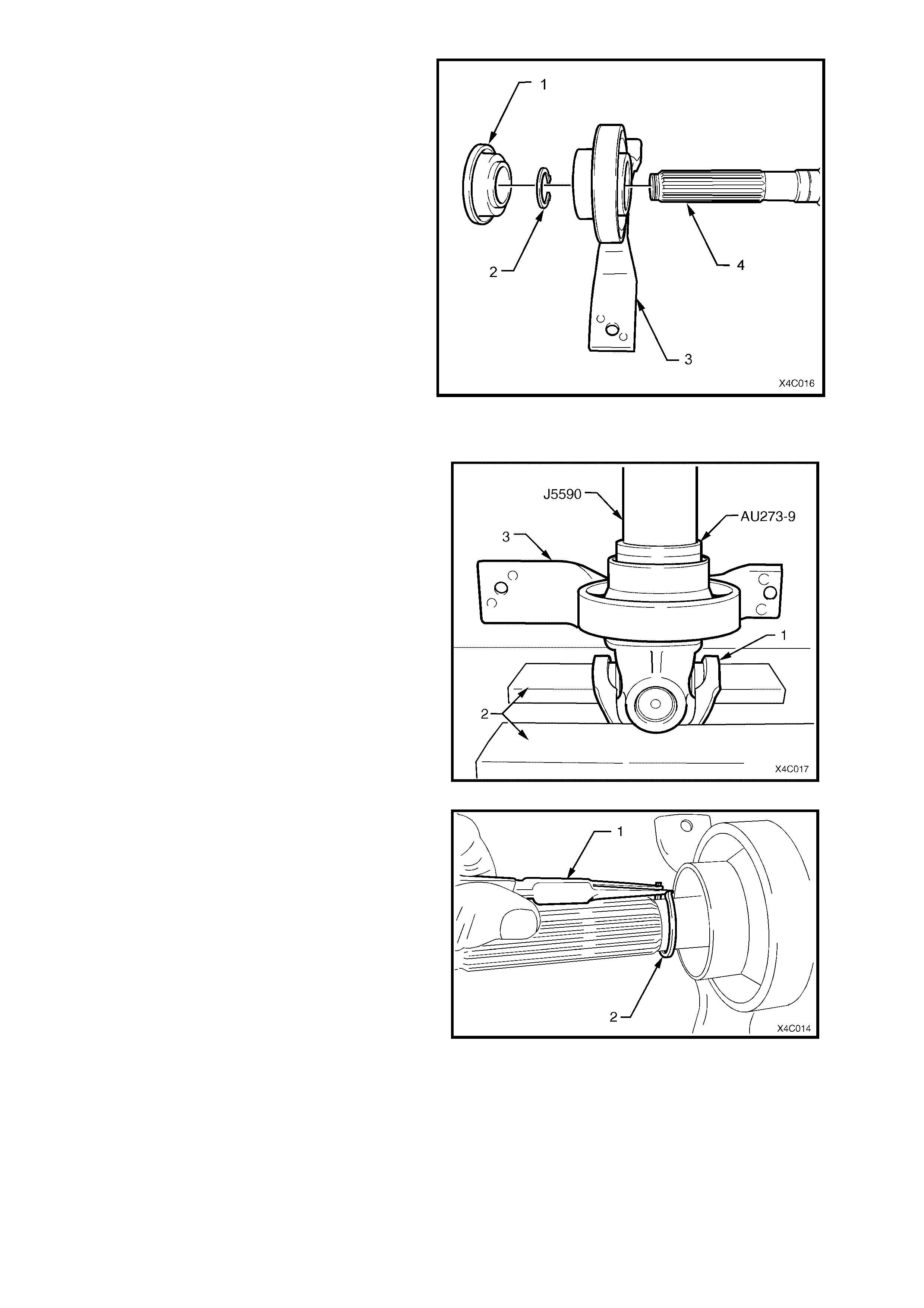

REINSTALL

1. With the front universal joint ‘ears’ (1)

supported on press plates (2), press a NEW

centre bearing assembly (3) onto the front

section of the rear propeller shaft, using press

tube J5590 and adaptor AU273-9.

NOTE: If these tools are not available, then a 150

mm length of pipe with an ID of 30 mm (wall

thickness 5 mm), can be used as a substitute.

Figure 4C-18

2. Install a NEW centre bearing retaining circlip

(2), using commercially available circlip pliers

(1), taking care not to over-stretch the circlip.

3. Install a NEW slinger, using press tool J5590.

Figure 4C-19

4. Install a NEW boot and ring assembly over the

splines of the rear propeller shaft.

5. Lubricate the splines of the rear propeller shaf t

with approximately 1 – 2 gm of molybdenum

disulphide grease (to Holden Specification

HN1271).

6. Install a NEW O-ring seal to the nose of the

rear propeller shaft.

7. Taking care to align the two propeller shaft

halves with the marks made before

disassembly (1 and 2), push the two halves

together until the O-ring seal clears the inner

splines of the front half.

NOTE: At this time it should be poss ible to slide the

two halves back and forth with little resistance.

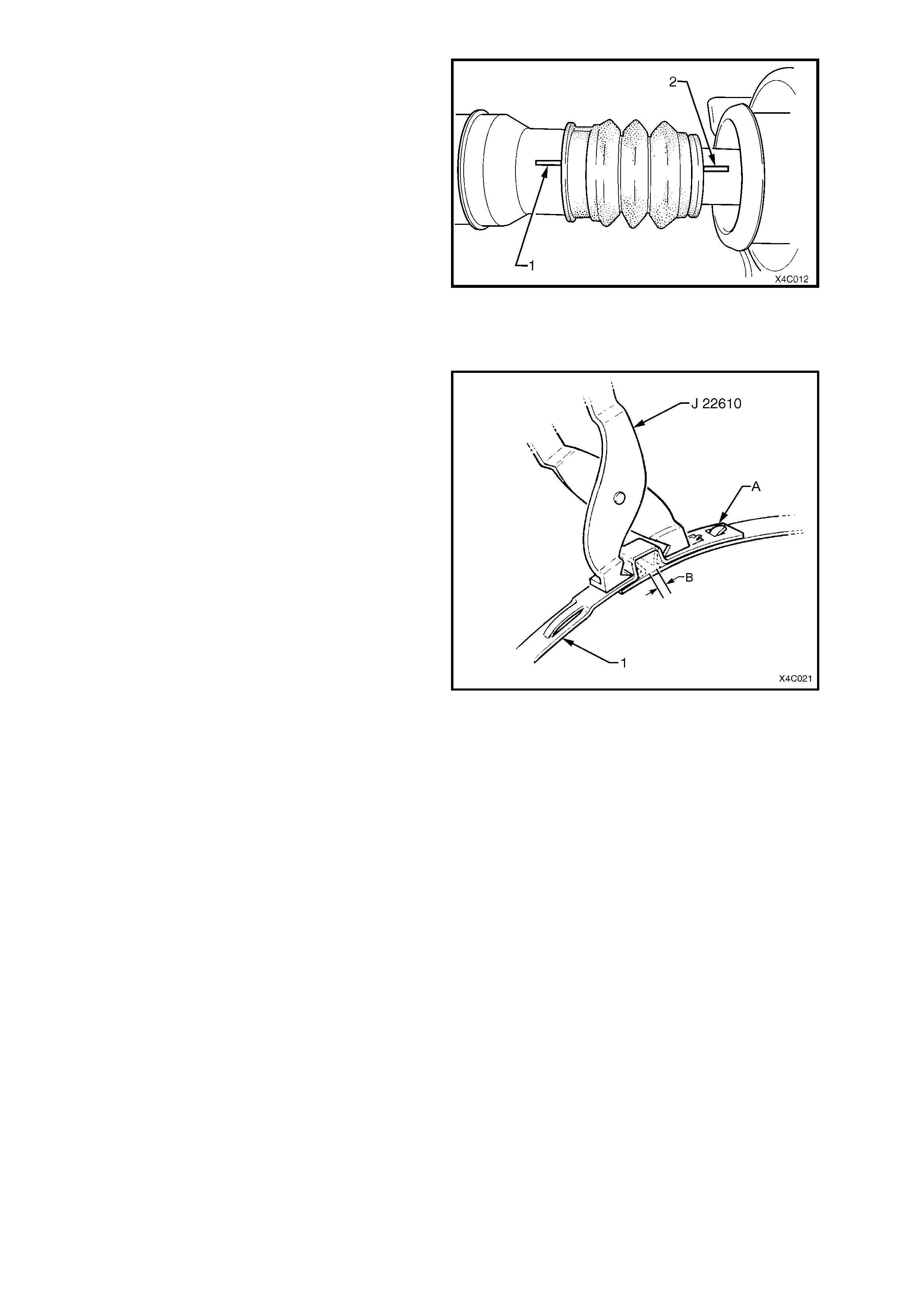

Figure 4C-20

8. With the boot and ring assembly located

correctly in the grooved section of the front

propeller shaft, install a NEW retaining clamp

to secure.

9. After installing a NEW clamp around the boot

and ring assem bly bend the tab over as shown

by ‘A’ in Fig. 4C-22.

10. Using keystone clamp pliers such as J 22610

(Also released as E1896 and 3A13) or

commercial equivalent, tighten the clamp (1)

until the gap ‘B’ is from 1 – 2 mm.

11. Reinstall propeller shaft assembly. Refer

2.1 PROPELLER SHAFT, in this Section.

Figure 4C-21

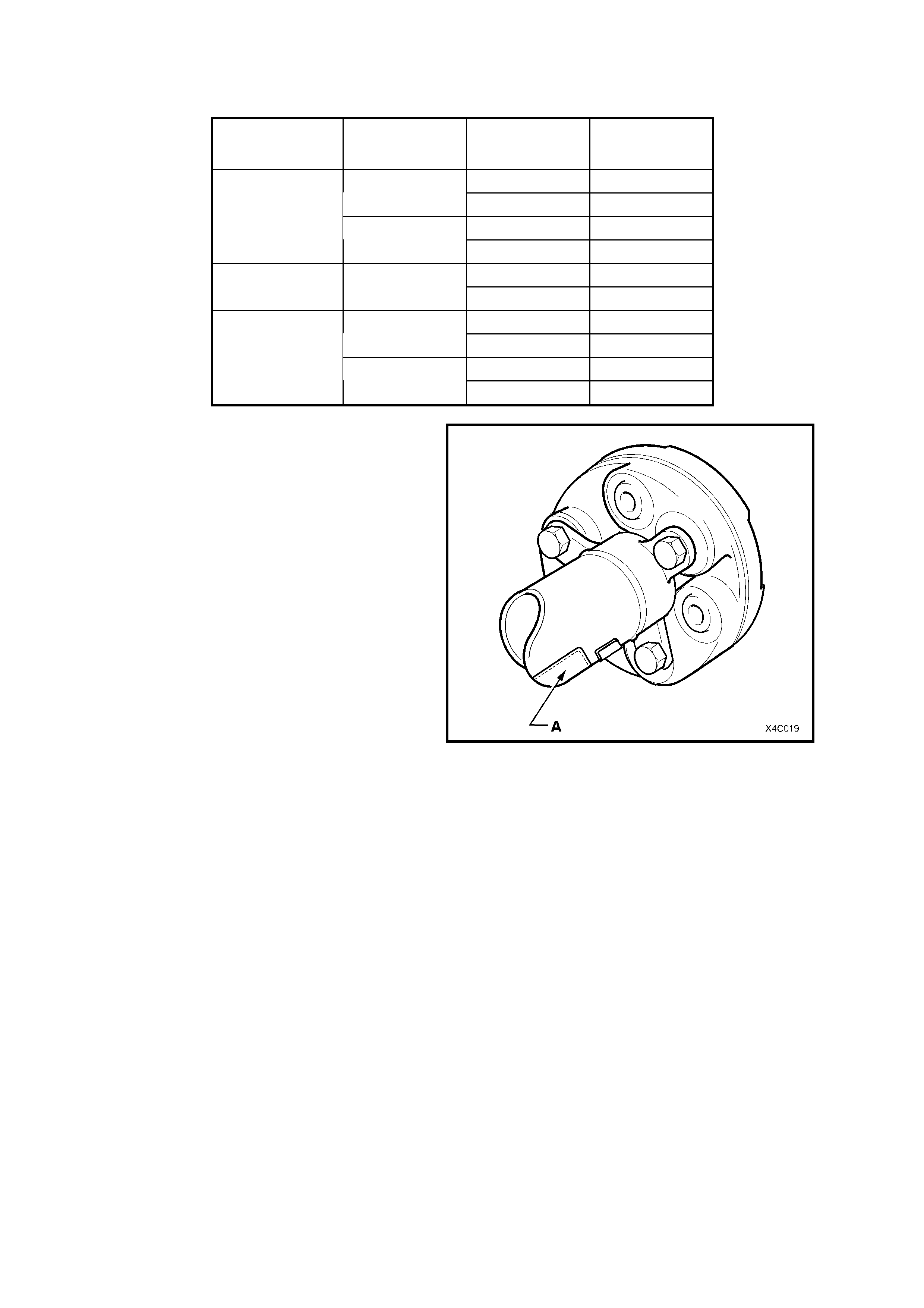

3. SPECIFICATIONS

PROPELLER SHAFT IDENTIFICATION

ENGINE TYPE TRANSMISSION

TYPE BODY STYLE PROPELLER

SHAFT

PRODUCTION I.D.

AUTOMATIC SEDAN NA

STATION WAGON NB

V6 MANUAL SEDAN NC

STATION WAGON ND

AUTOMATIC SEDAN NK

V6

Supercharged STATION WAGON

NL

AUTOMATIC SEDAN NE

STATION WAGON NF

GEN III V8 MANUAL SEDAN NE

STATION WAGON

NF

Legend:

‘A’ Location of Production Identification Label at

Rear of Propeller Shaft assembly.

Figure 4C-22

PROPELLER SHAFT:

Balance Specification.............................................. 8 g cm @ 3,500 rpm, on turn over.

Maximum permissible imbalance 12 g cm @ 5,000 rpm.

LUBRICANT:

At specified locations as detailed in text..................... Molybdenum Disulphide grease to Holden's

Specification HN1271.

4. TORQUE WRENCH SPECIFICATIONS Nm

Centre bearing carrier to underbody reinforcement bolt............................ 20 - 35

Exhaust pipe to engine manifold (V6 engine)............................................ 18 - 35

Intermediate exhaust pipe to catalytic converter attaching bolt (All) ......... 40 - 50

Propeller shaft rear coupling to pinion flange bolt ..................................... 105 - 125

Propeller shaft/sliding yoke to rubber coupling nut.................................... 74 - 80

Rubber coupling bolt to V6 manual transmission output flange nut .......... 50 - 85

5. SPECIAL TOOLS

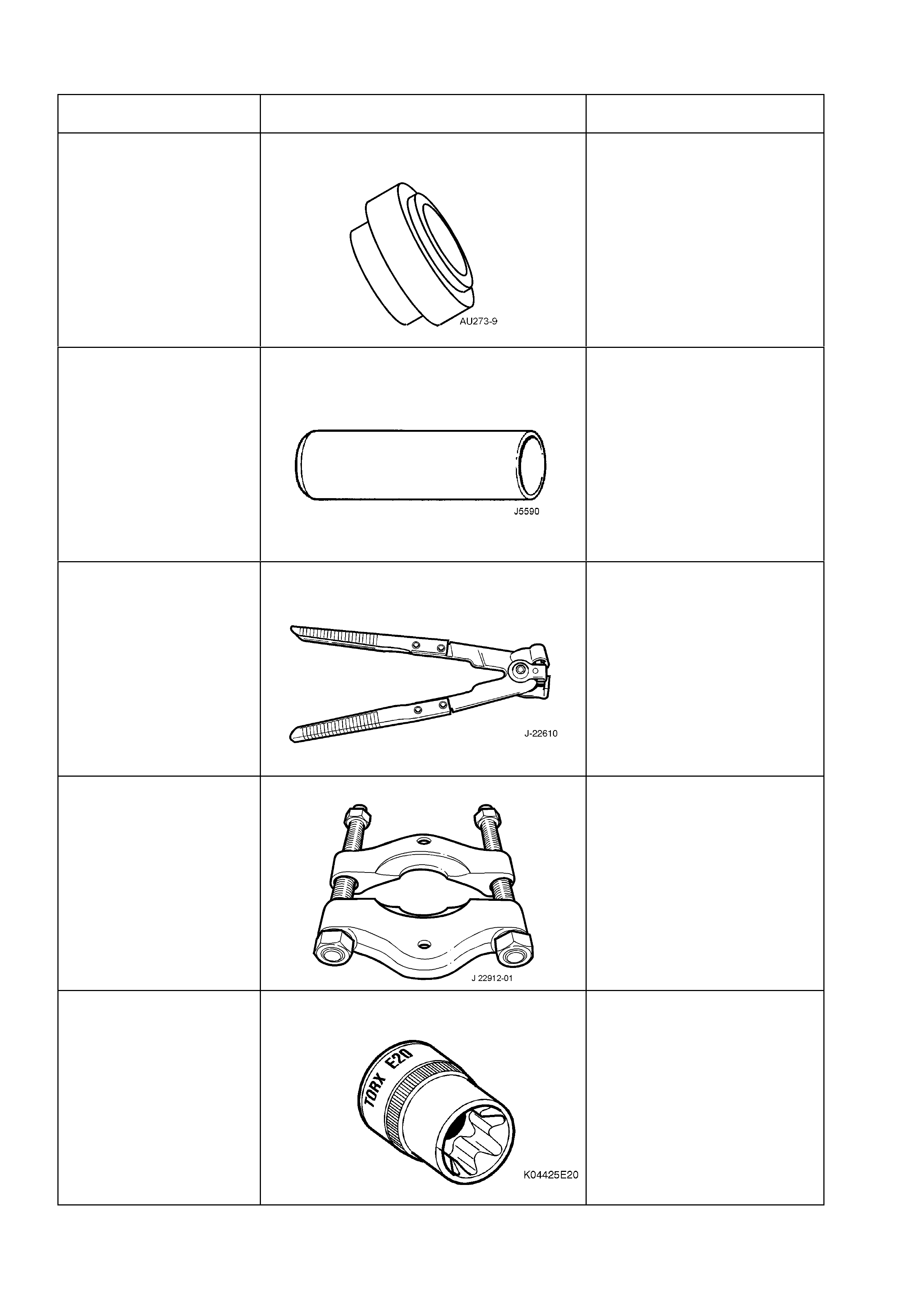

TOOL No. REF. IN TEXT TOOL DESCRIPTION COMMENTS

AU273-9 ADAPTOR

Previously released.

J 5590 PRESS TUBE

Previously released.

J 22610 KEYSTONE CLAMP PLIERS

Previously released.

Used to tighten the sliding joint

boot clamp.

Also released as E 1896 and

3A13.

J 22912-01 PRESS PLATES

Previously released.

K04425E20 E 20 TORX SOCKET

New release or use

commercially available

equivalent.