SECTION 6C1-2C - FUNCTIONAL CHECKS -

V6 SUPERCHARGED ENGINE

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in VX Service Information for correct workshop practices with regards to safty

and/or property damage.

The following pages are to be used when there is a customer complaint but there are no diagnostic trouble codes

set, but one or more of the Tech 2 scan tool data values are not within typical values. Before using these Tables you

should use the symptoms Tables that may lead you to using this VX Service Information.

The purpose of these Tables is to diagnosis Powertrain Control Module (PCM) controlled components or

subsystems that do not have diagnostic trouble codes assigned to them. Another purpose of these Tables is for

technicians who feel confident that a particular part of the subsystem is not operating properly and wants to only

check that particular item for proper operation without going through lengthy diagnostic procedures.

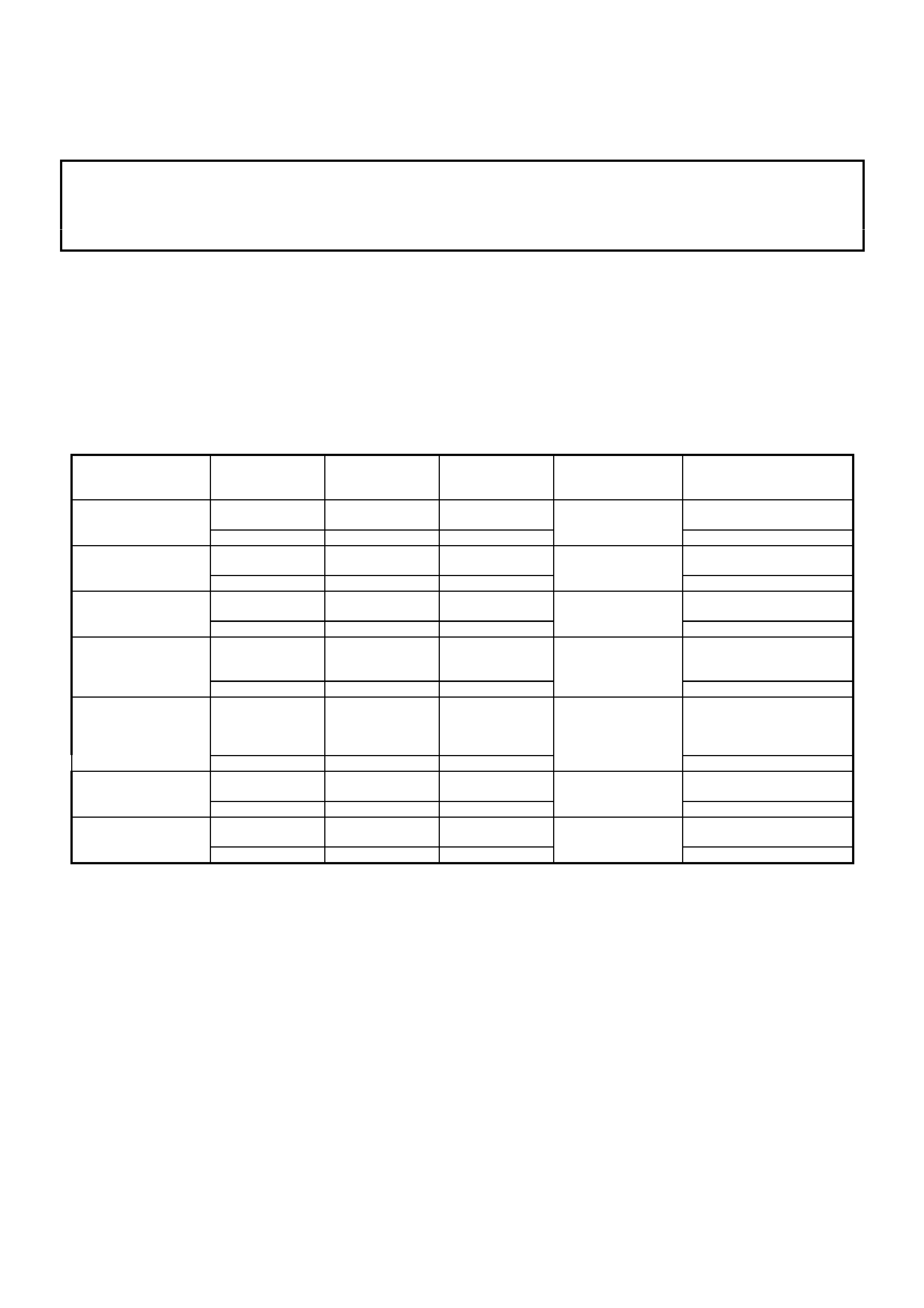

4L60 E COMPONENT RESISTANCE TABLE

COMPONENT TERMINAL WIRE COLOUR PASS-THRU

CONNECTOR

TERMINAL

RESISTANCE AT

20 DEGREES C CIRCUIT NO.

1-2 SHIFT

SOLENOID VALVE B R E* 19-24 OHMS 339

A LG A 1222

2-3 SHIFT

SOLENOID VALVE A R E* 19-24 OHMS 339

B Y B 1223

3-2 CONTROL

SOLENOID VALVE A R E* 20-24 OHMS 339

B W S 897

PRESSURE

CONTROL

SOLENOID VALVE

A V C 3-5 OHMS 1228

B LBLU D 1229

TRANSMISSION

FLUID

TEMPERATURE

SENSOR (TFT)

A BR L 3088 - 3942 OHMS 1227

B GY M 469

TCC "PWM"

SOLENOID VALVE A R E* 9 - 14 OHMS 339

B BR U 418

TCC ENABLE

SOLENOID VALVE A R E* 21-26 OHMS 339

B B T 422

• Spliced internally to pin E

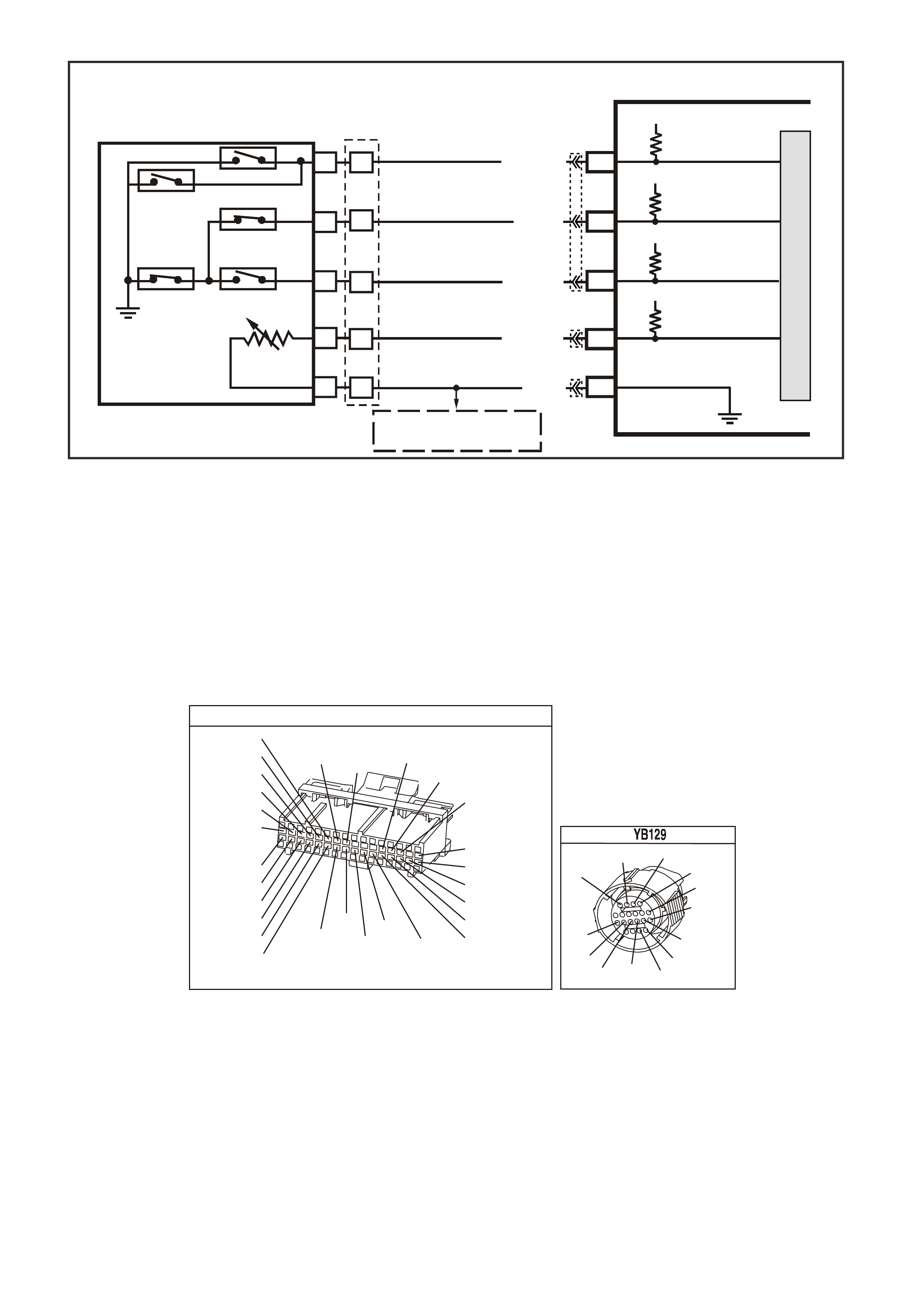

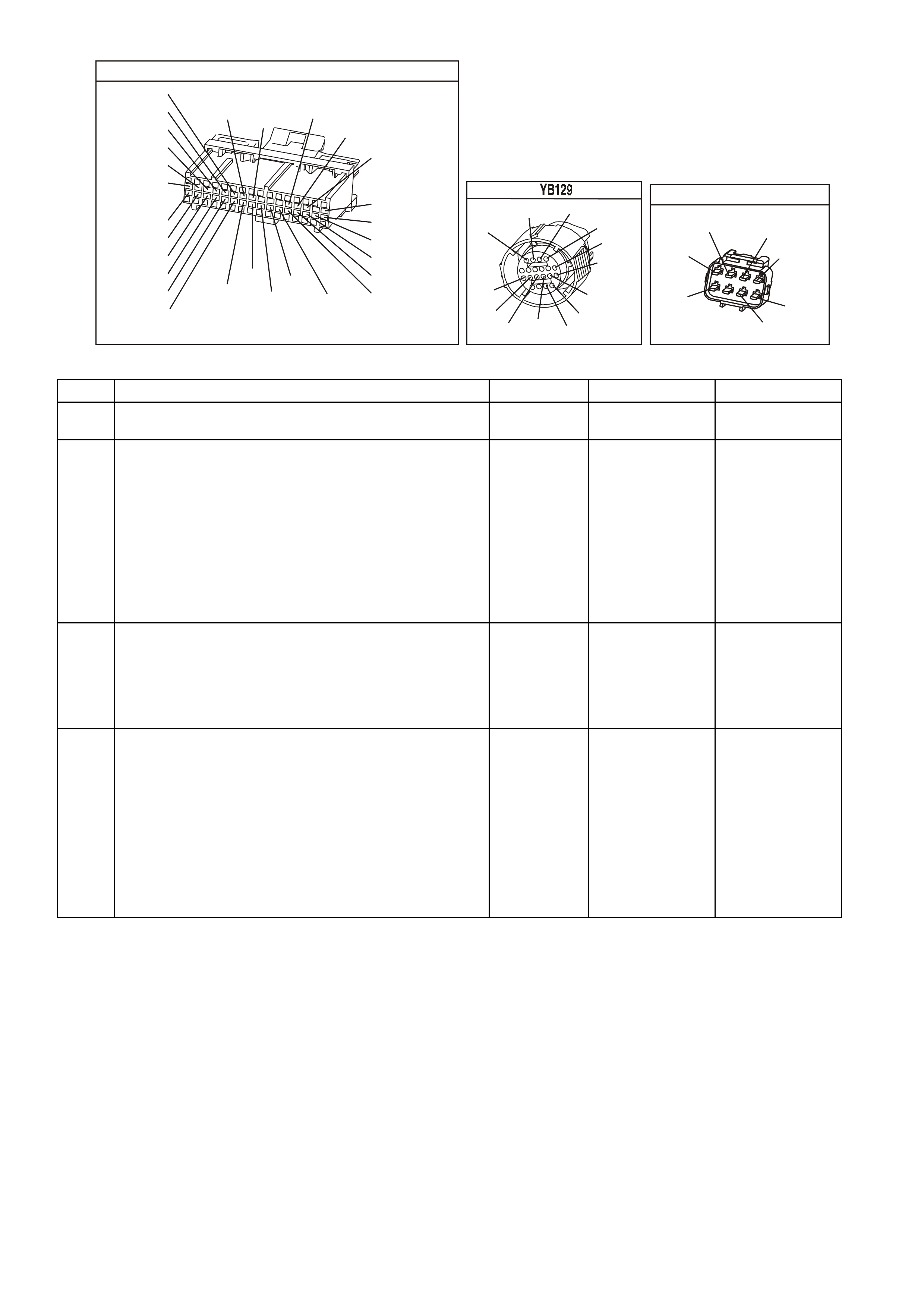

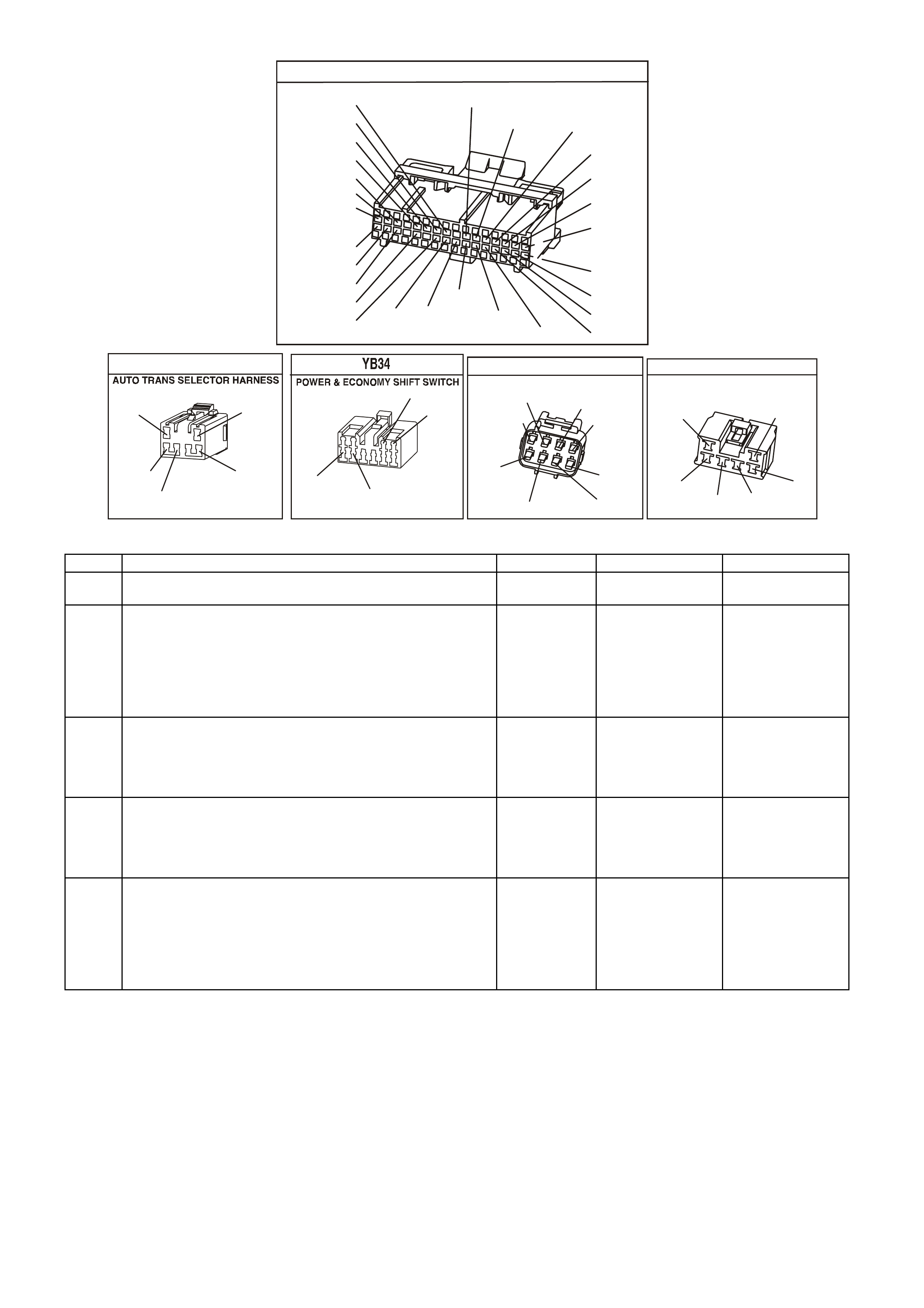

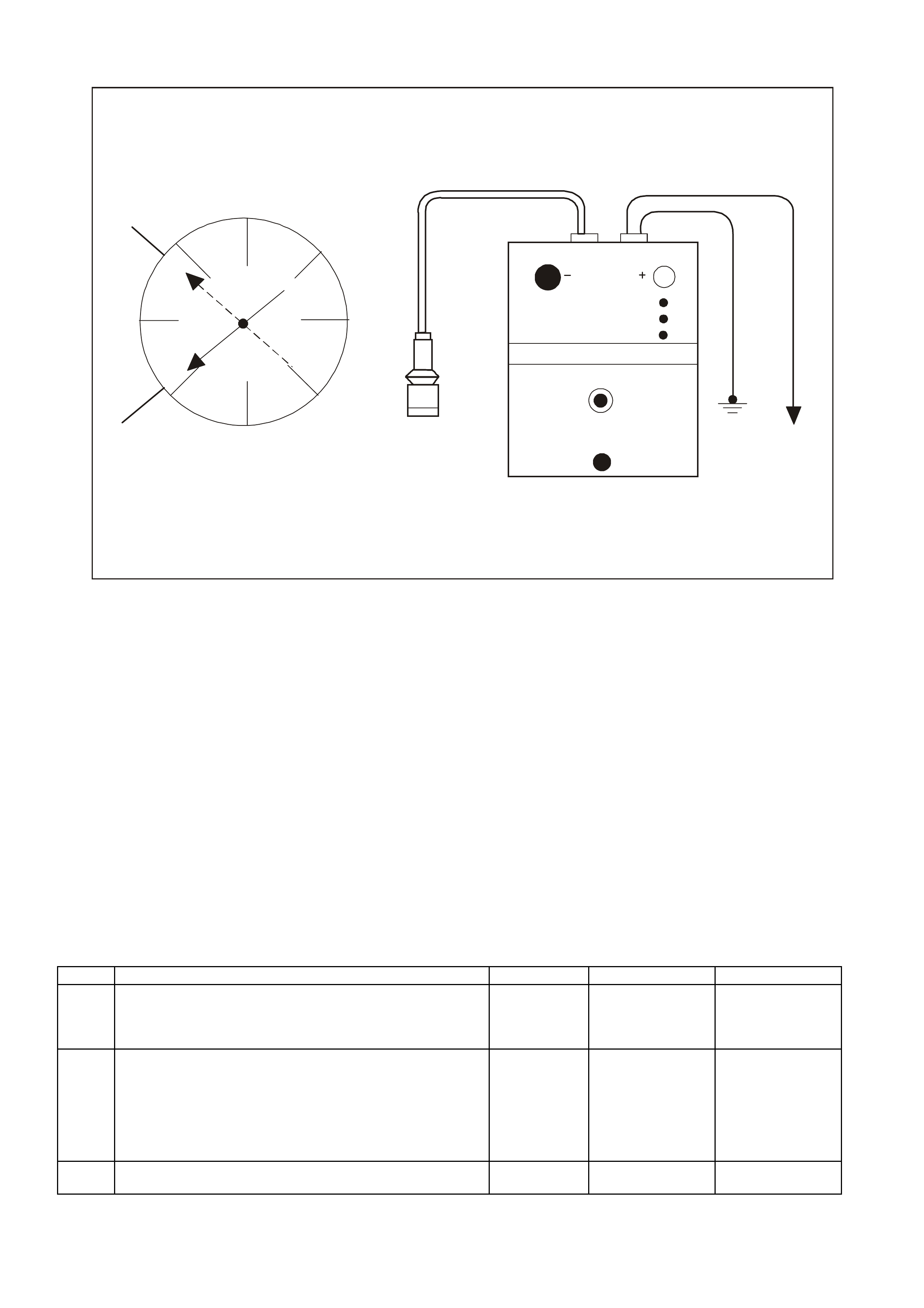

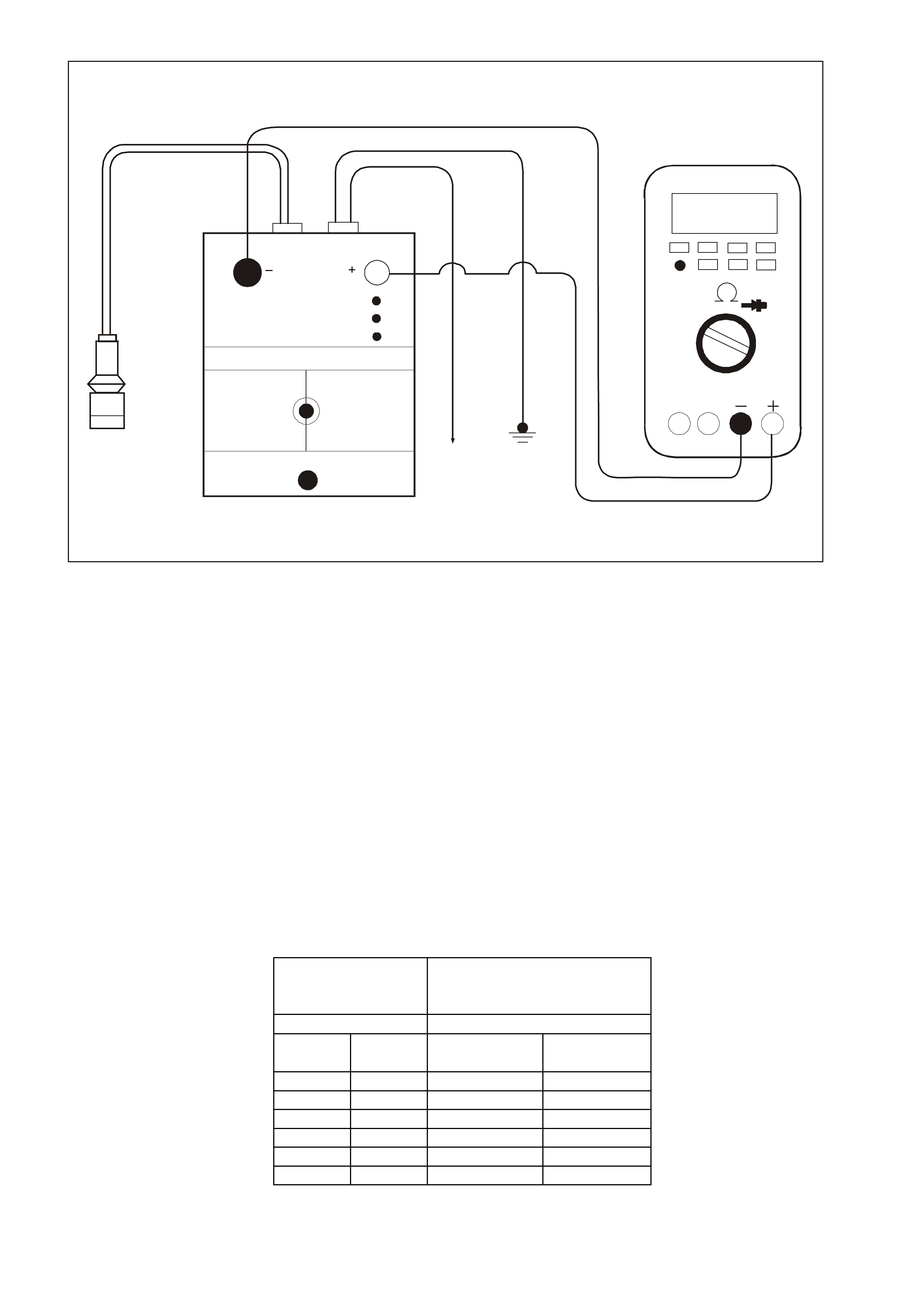

TABLE 2.1 V6 PCM AUTOMATIC TRANSMISSION WIRING

HARNESS ASSEMBLY CHECK

Tools Required:

J 39775 4L60-E Jumper Harness

J 39200 Digital Volt Multimeter (DVM)

J 35616 Connector Test Adapter Kit

IMPORTANT:

This procedure cannot be used for checking the Automatic Transmission Fluid Pressure Manual Valve Position

Switch (TFP Val. Position Sw.) circuit, or the

Automatic Transmission Fluid Temperature (TFT) Sensor circuit. Refer to TFP Valve Position Switch Assembly

Resistance Check, for those circuits.

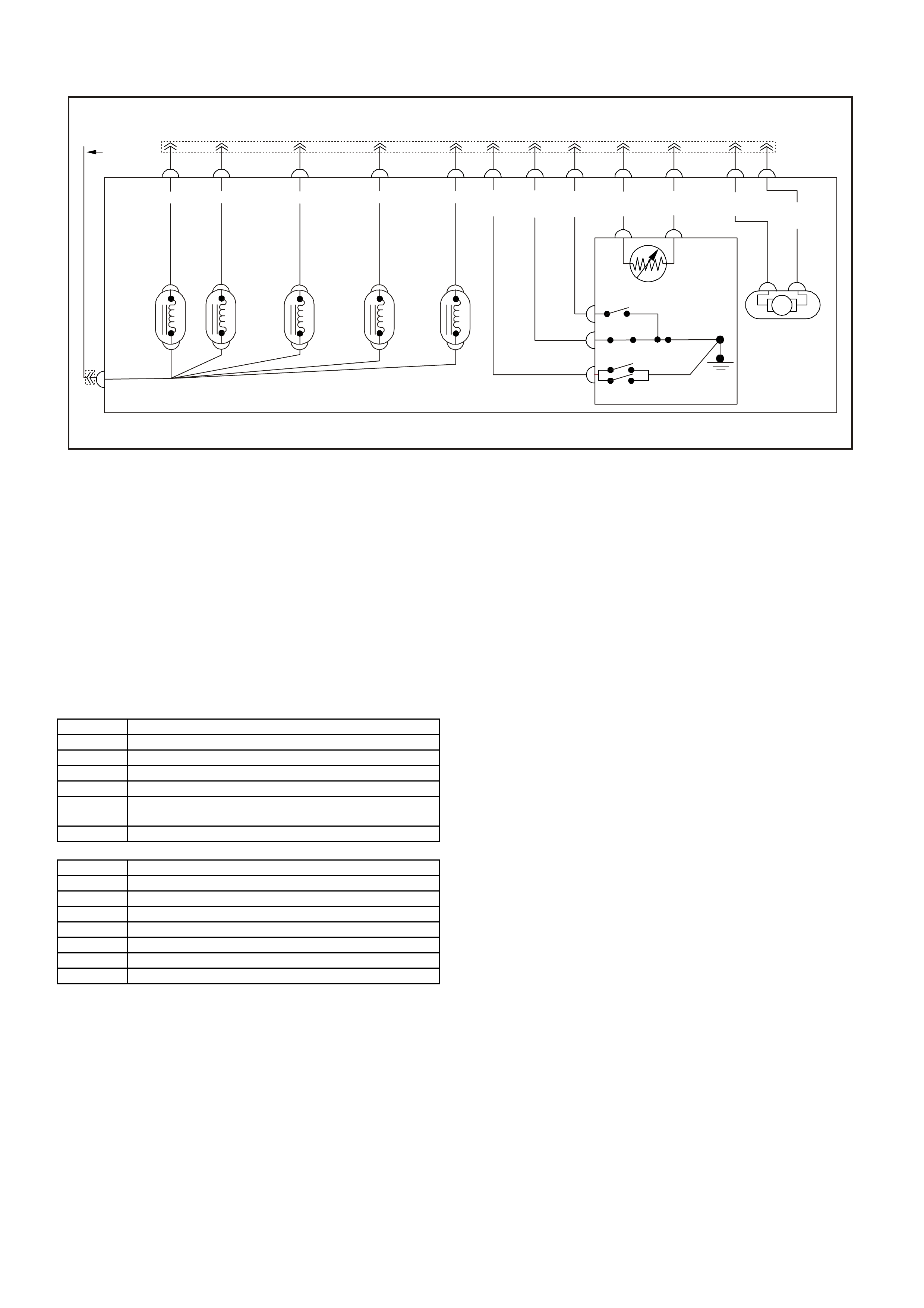

Powertrain Harness Terminal Identification

CAVITY FUNCTION

A 1-2 SHI FT SOLENOID (LOW)

B 2-3 SHI FT SOLENOID (LOW)

C PRESS URE CONTROL SOLENOID (HIGH)

D PRESS URE CONT ROL SOLENOID (LOW)

E BOTH SHIFT SOLENOIDS , TCC SOLENOID, AND

3-2 CONTROL SOLENOID (HIGH)

L TRANSMISSION FLUID TEMPERATURE HIGH

CAVITY FUNCTION

M TRANSMISSION FLUID TEMPERATURE (LOW)

N RANGE SIGNAL "A"

P RANGE SIGNAL "C"

R RANGE SIGNAL "B"

S 3-2 CONTROL SOLENOID (LOW)

T TCC SOLENOI D (LOW)

U TCC PWM SOLENOID

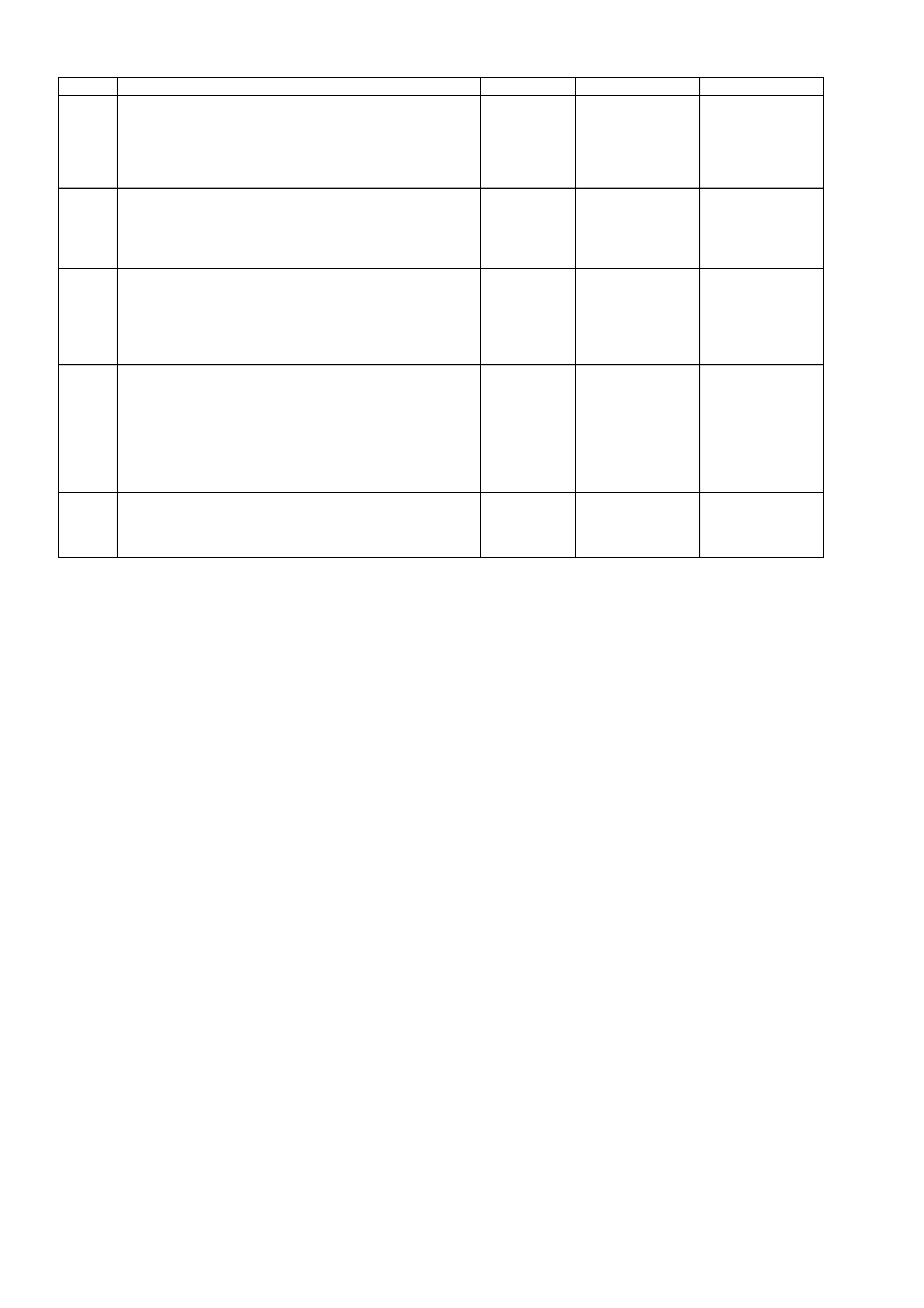

W (897)

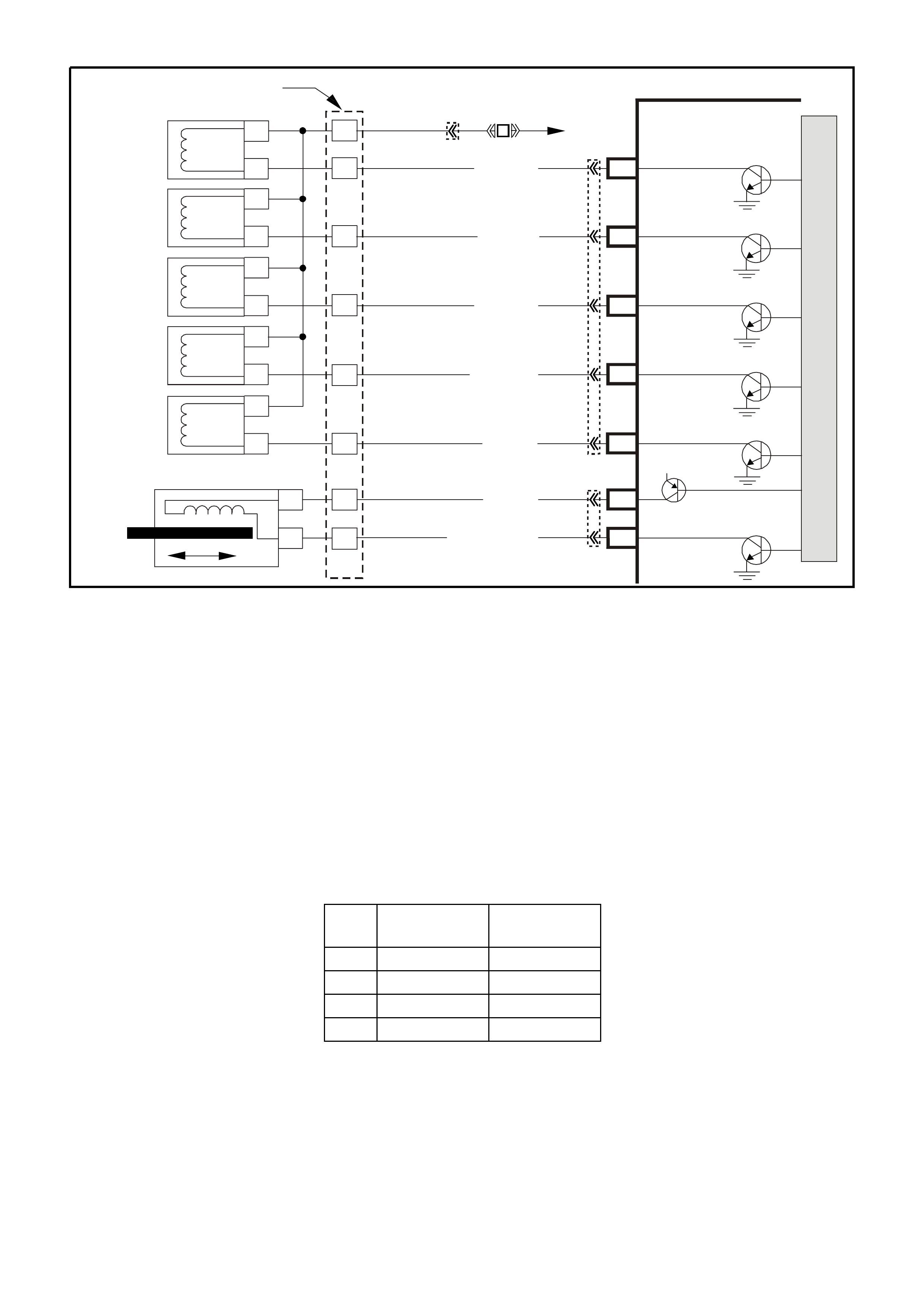

3–2

Control

Solenoid

TCC

PWM

Solenoid TCC

Solenoid

1–2

Shift

Solenoid

2–3

Shift

Solenoid

339 S

B

R (339)

A

EAAAA

BBBB D

D4 N. O.

D2 N. C.

4344

D3 N. C.

LO N. O.

Rev N. O.

E

C

B (418)

UT ABNRPM

BA

L

Range A Range B Range C

YB129

YB129

Trans.

Temp.

Sensor

Pressure

Control

Solenoid

Pressure

Switch

Assembly

CD

AB

B (422) LG (1222) Y (1223) P

(1224) BLU

(1225) O

(1226) GY

(452) BR

(1227) V

(1228) L BLU

(1229)

YE1 94

P.C.M. C ONNECTOR 3

LG/B

(366)

G

(843)

B/W

F16

B/Y

BR/Y

(1228)

(469)

Y

(451)

F1

P

(841)

BLU

V

E1

LBLU

(845)

BLU

B

(1226)

W/B

BLU/W

V

R

(435)

(31)

(1229)

GY

(1224)

Y

(846)

GY

(842)

(452)

(774)

(304)

BR/Y

(411)

(439)

GY/BLU

BLU

(1225)

E16

(1427)

(429)

(844)

B/O

(434)

OR AUTO

GY/BLU

GY

(1434)

MAN

(776)

W

BLU/W

Y

GY

(771)

(772)

(773)

YB193

(413)

(412)

(1413)

(1412)

(430)

(453)

(815)

V/B

GY/B

V

GY

V

B/R

W/R

(897)

(897)

G/W

G/W

(418)

(418)

BR

BR

(1426)

O/W

C16

D16

WT/B

(832)AUTO

(647)

(630)

BR

T

(832) MAN

LBLU/B

B

(424)

(423)

C1

D1

(792)

(422)

(1222)

(1223)

(428)

(123)

BR/W

GY/R

LG

Y/B

G/Y

V/W

BLU/W

BLU

(831) Man

(443)

LG/W

(442) (831)AUTO

(441)

LBLU

LBLU/B

(444)

LG/B

P.C.M. CONNECTOR 1

ENGINE CONNECTOR 1

YE110

O/W

(304)

(1426)

BLU/W

G/W

(339)

P/BLU

(465)

(123)

V/W

(1427)

B/W

Y

(1049)

TRANSMISSION CONNECTOR

GY/BLU

(1229)

R

(1228)

Y/B

(1223)

LG

(1222)

P/BLU

(339)

(1227)

B/Y

(1230)

B/W

GY/R

(422)

BR

(418)

BR/Y

(1224)

(1226)

GY

Y

(1225)

(897)

G/W

(V8)

B

(469) (V6)

OR

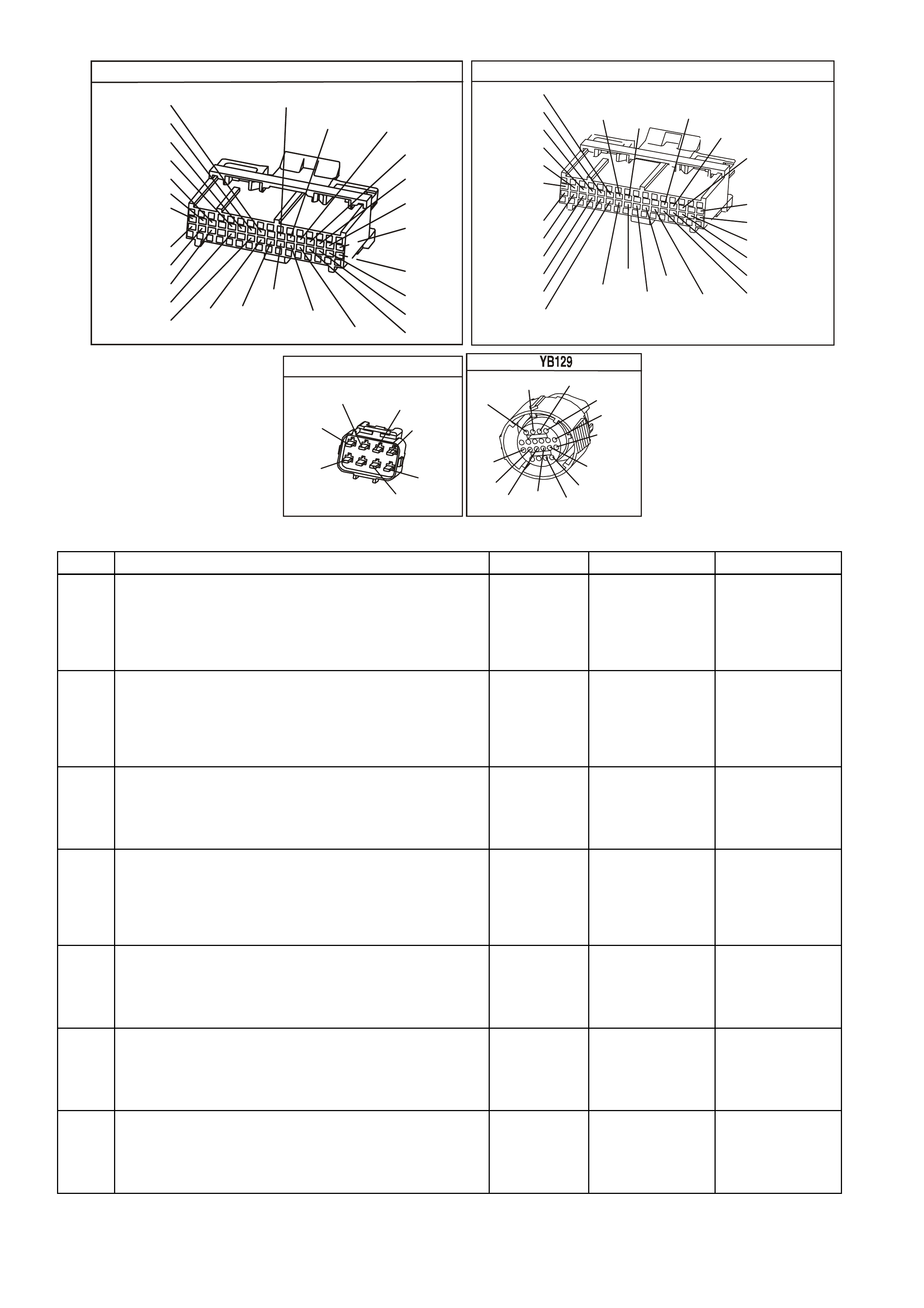

TABLE 2.1 V6 PCM AUTOMATIC TRANSMISSION WIRING HARNESS ASSEMBLY CHECK

STEP ACTION VALUE YES NO

1 1. Install the J 39775 Jumper Harness on the

transmission pass-thru connector.

2. Using a J 39200 DVM and a J 35616 Connector Test

Adapter Kit, measure the resistance between

terminals A and E (1-2 Shift Solenoid Valve).

Is the resistance within the specified range?

19-24 Ω

@ 20° C

24-31Ω

@ 100° C

Go to Step 3 Go to Step 2

2 1. Disconnect the 1-2 Shift Solenoid Valve (1-2 SS

Valve) from the Automatic Transmission Wiring

Harness Assembly.

2. Using the J 39200 DVM, measure the resistance of

the 1-2 SS Valve.

Is the resistance within the specified range?

19-24 Ω

@ 20° C

24-31Ω

@ 100° C

Go to Step 14 Go to Step 16

3 Measure the resistance between terminals B and E

(2-3 Shift Solenoid Valve).

Is the resistance within the specified range?

19-24 Ω

@ 20° C

24-31Ω

@ 100° C

Go to Step 5 Go to Step 4

4 1. Disconnect the 2-3 Shift Solenoid Valve (2-3 SS

Valve) from the Automatic Transmission Wiring

Harness Assembly.

2. Using the J 39200 DVM, measure the resistance of

the 2-3 SS Valve.

Is the resistance within the specified range?

19-24 Ω

@ 20° C

24-31Ω

@ 100° C

Go to Step 14 Go to Step 16

5 Measure the resistance between terminals T and E

(Torque Converter Clutch Solenoid Valve).

Is the resistance within the specified range?

21-26 Ω

@ 20° C

26-33 Ω

@ 100° C

Go to Step 6 Go to Step 14

6 Measure the resistance between terminals U and E

(Torque Converter Clutch Pulse Width Modulation

Solenoid Valve).

Is the resistance within the specified range?

10-11 Ω

@ 20° C

13–15 Ω

@ 100° C

Go to Step 8 Go to Step 7

7 1. Disconnect the TCC PWM Solenoid. Valve from the

Automatic Transmission Wiring Harness Assembly.

2. Using the J 39200 DVM, measure the resistance of

the TCC PW M Solenoid. Valve.

Is the resistance within the specified range?

10-11 Ω

@ 20° C

13–15 Ω

@ 100° C

Go to Step 14 Go to Step 16

STEP ACTION VALUE YES NO

8 Measure the resistance between terminals S and E (3-2

Shift Solenoid Valve assembly).

Is the resistance within the specified range?

20-24 Ω

@ 20° C

29-32 Ω

@ 100° C

Go to Step 10 Go to Step 9

9 1. Disconnect the 3–2 Shift Solenoid Valve Assembly

(3-2 SS Valve Assy.) from the Automatic

Transmission Wiring Harness Assembly.

2. Using the J 39200 DVM, measure the resistance of

the 3-2 SS Valve Assy.

Is the resistance within the specified range?

20-24 Ω

@ 20° C

29-32 Ω

@ 100° C

Go to Step 14 Go to Step 16

10 Measure the resistance between terminals C and D

(Pressure Control Solenoid Valve).

Is the resistance within the specified range?

3-5 Ω

@ 20° C

4-7 Ω

@ 100° C

Go to Step 12 Go to Step 11

11 1. Disconnect the Pressure Control Solenoid Valve (PC

Sol. Valve) from the Automatic Transmission Wiring

Harness Assembly.

2. Using the J 39200 DVM, measure the resistance of

the PC Sol. Valve.

Is the resistance within the specified range?

3-5 Ω

@ 20° C

4-7 Ω

@ 100° C

Go to Step 14 Go to Step 16

12 Using the J 39200 DVM and the J 35616 Connector Test

Adapter Kit, measure the resistance from each of the

terminals A, B, C, D, E, S, T and U of the A/T Wiring

Harness Assembly at the transmission pass-thru

connector to the transmission case.

Is the resistance more than the specified value?

250k Ω System OK, exit

the table Go to Step 13

13 1. Disconnect the A/T Wiring Harness Assembly from all

the components.

2. Measure the resistance from each of the component

terminals to the transmission case.

Is the resistance more than the specified value?

250k Ω Go to Step 14 Go to Step 16

14 Inspect for high resistance or a short.

Inspect the A/T Wiring Harness Assembly at the

transmission pass-thru connector, and the component

connectors for the following conditions:

• Poor electrical connections

• Bent, backed-out, or damaged terminals

• Weak terminal tension

• A chafed wire that could short to bare metal or

other wiring

• A broken wire inside the insulation

• Moisture intrusion

• Corrosion

If diagnosing for a possible intermittent condition, move

or massage the A/T Wiring Harness Assembly while

observing the test equipment for a change.

Did you find and correct the high resistance or a short?

Verify the repair

Go to Step 1 Go to Step 15

15 Replace the Automatic Transmission Wiring Harness

Assembly. Refer to Service Operations in Section 7C-5

in VX Service Information.

Is the action complete?

Verify the repair

Go to Step 1

16 Replace the faulty component. Refer to Service

Operations in Section 6C1-3 of the VX Series Service

Information.

Is the action complete?

Verify the repair

Go to Step 1

TABLE 2.2 V6 PCM TRANSMISSION FLUID PRESSURE

MANUAL V ALVE POSITION SWITCH CHECK

Tools Required:

J 39775 4L60E Jumper Harness

J 39200 Digital Volt Multimeter

J 35616 Connector Test Adapter Kit

IMPORTANT:

W henever the transmission pass-thru connector is disconnected and the engine is running, m ultiple DTCs will set.

Be sure to clear these codes when you are finished with this procedure.

IMPORTANT:

This procedure tests the Automatic Transmission Fluid Pressure Manual Valve Position Switch (TFP Val. Position

Sw.) circ uits and the Autom atic T ransm is sion Fluid T em perature (TFT) Sens or circ uit. Do not use this pr ocedure to

test other Automatic Transmission circuits, refer to 4L60–E Automatic Transmission Internal Wiring Harness check.

YB193

(413)

(412)

(1413)

(1412)

(430)

(453)

(815)

V/B

GY/B

V

GY

V

B/R

W/R

(897)

(897)

G/W

G/W

(418)

(418)

BR

BR

(1426)

O/W

C16

D16

WT/B

(832)AUTO

(647)

(630)

BR

T

(832) MAN

LBLU/B

B

(424)

(423)

C1

D1

(792)

(422)

(1222)

(1223)

(428)

(123)

BR/W

GY/R

LG

Y/B

G/Y

V/W

BLU/W

BLU

(831) Man

(443)

LG/W

(442) (831)AUTO

(441)

LBLU

LBLU/B

(444)

LG/B

P.C.M. CONNECTOR 1

TRANSMISSION CONNECTOR

GY/BLU

(1229)

R

(1228)

Y/B

(1223)

LG

(1222)

P/BLU

(339)

(1227)

B/Y

(1230)

B/W

GY/R

(422)

BR

(418)

BR/Y

(1224)

(1226)

GY

Y

(1225)

(897)

G/W

(V8)

B

(469) (V6)

OR

SUPERVX034

PCM

F9

F10

B6

F16

TFP SIGNAL A

TFP SIGNAL B

TRANSMISSION FLUID

TEMPERATURE (TFT)

SENSOR SIGNAL

SENSOR EARTH

N

C

R

E

D

A

B

P

L

M

TRANSMISSION FLUID

TEMPERATURE

(TFT) SENSOR

AUTOMATIC TRANSMISSION FLUID

PRESSURE SWITCH ASSEMBLY

BR/Y (1224)

Y (1225)

GY (1226)

B/Y (1227)

B (46 9 )

12V

12V

5V

F11 TF P SIGNAL C

12V

M

I

C

R

O

TO

A/C PRESSURE SENSOR

AND IAT SENSOR

YB194

YB129

YB188

YB194

TABLE 2.2 V6 PCM TRANSMISSION FLUID PRESSURE MANUAL VALVE POSITION SWITCH CHECK

STEP ACTION VALUE YES NO

1 1. Install the J 39775 Jumper Harness on the

transmission side of the pass-thru connector.

2. Using the J 39200 DVM and the J 35616 Connector

Test Adapter Kit, measure the resistance from

terminal N to the transmission case.

Is the resistance greater than the specified value?

50 k Ω Go to Step 3 Go to Step 2

2 1. Disconnect the TFP Value Position Switch from the

A/T W iring Harness Assembly.

2. Measure the resistance from terminal C of the TFP

Value Position Switch to the switch housing.

Is the resistance greater than the specified value?

50 k Ω Go to Step 16 Go to Step 19

3 Measure the resistance from terminal R to the

transmission case.

Is the resistance less than the specified value?

200 Ω Go to Step 5 Go to Step 4

4 1. Disconnect the TFP Value Position Switch from the

A/T W iring Harness Assembly.

2. Measure the resistance from terminal E of the TFP

Value Position Switch to the switch housing.

Is the resistance less than the specified value?

200 Ω Go to Step 16 Go to Step 19

5 Measure the resistance from terminal P to the

transmission case.

Is the resistance greater than the specified value?

50 k Ω Go to Step 7 Go to Step 6

6 1. Disconnect the TFP Value Position Switch from the

A/T W iring Harness Assembly.

2. Measure the resistance from terminal D of the TFP

Value Position Switch to the switch housing.

Is the resistance greater than the specified value?

50 k Ω Go to Step 16 Go to Step 19

7 1. Start the engine.

2. Allow the engine to idle.

3. Set the parking brake.

4. Place the gear selector in Reverse.

5. Measure the resistance from terminal N to the

transmission case.

Is the resistance less than the specified value?

200 Ω Go to Step 8 Go to Step 16

8 1. Place the gear selector in Low (D1).

2. Measure the resistance from terminal N to the

transmission case.

Is the resistance less than the specified value?

200 Ω Go to Step 9 Go to Step 16

9 1. Place the gear selector in Manual Third (D3).

2. Measure the resistance from terminal R to the

transmission case.

Is the resistance greater than the specified value?

50 k Ω Go to Step 10 Go to Step 16

10 1. Place the gear selector in Drive (D4).

2. Measure the resistance from terminal P to the

transmission case.

Is the resistance less than the specified value?

200 Ω Go to Step 11 Go to Step 16

11 1. Place the gear selector in Manual Second (D2).

2. Measure the resistance from terminal P to the

transmission case.

Is the resistance greater than the specified value?

50 k Ω Go to Step 12 Go to Step 16

12 1. Turn the ignition OFF.

IMPORTANT: The resistance of the TFT Sensor is

temperature dependent, and therefore varies far

more than any other device.

2. Measure the resistance from terminal L to terminal M

(TFT Sensor) of the Jumper Harness.

Is the resistance within the specified range?

3088-3942 Ω

@ 20° C

159-198 Ω

@ 100° C

Go to Step 13 Go to Step 14

13. 1. Measure the resistance from terminal L to the

transmission case.

2. Measure the resistance from terminal M to the

transmission case.

Are both resistance’s greater than the specified value?

10 M Ω No problem

found. Exit the

table.

Go to Step 14

14 1. Disconnect the TFP Value Position Switch from the

A/T.

2. Wiring Harness Assembly.

IMPORTANT: The resistance of the TFT Sensor is

temperature dependent, and therefore varies far

more than any other device. Refer to Transmission

Fluid Temperature Sensor in Section 6C1-1 General

Information of the VX Series Service Information.

3088–3942Ω

@ 20° C

159-198 Ω

@ 100° C

Go to Step 15 Go to Step 19

STEP ACTION VALUE YES NO

3. Using the J 39200 DVM, measure the resistance

between terminal A and terminal B of the TFP Value

Position Switch (TFT Sensor).

Is the resistance within the specified range?

15 1. Measure the resistance from TFP Value Position

Switch terminal A to the transmission case.

2. Measure the resistance from TFP Value Position

Switch terminal B to the transmission case.

Are both resistance's greater than the specified value?

10 M Ω Go to Step 16 Go to Step 19

16 1. Inspect for high resistance or a short.

2. Inspect the A/T Wiring Harness Assembly for poor

electrical connections at the A/T pass-thru

connector, and at the TFP Value Position Switch

Look for the following problems:

• A bent terminal

• A backed out terminal

• A damaged terminal

• Poor terminal tension

3. If diagnosing for an intermittent problem, massage

the wiring harness while watching the test equipment

for a change.

Did you find and correct the high resistance or a short?

Verify the repair

Go to Step 1 Go to Step 17

17 1. Disconnect the TFP Value Position Switch from the

A/T W iring Harness Assembly.

2. Inspect the following circuits for an open or short:

• Circuit 1224

• Circuit 1225

• Circuit 1226

• Circuit 1227 (TFT Hi)

• Circuit 469 (TFT Lo)

Did you find a problem?

Go to Step 18 Go to Step 19

18 Replace the A/T Wiring Harness Assembly.

Refer to Automatic Transmission Wi ring Harness

Assembly Replacement, in Service Operations Section

7C-5 in VX Service Information.

Is the action complete?

Verify the repair

Go to Step 1

19 Replace the TFP Value Position Switch.

Refer to Automatic Transmission Fluid Pressure Manual

Valve Position Switch Replacement. Refer to Service

Operations in Section 6C1-3 of the VX Series Service

Information.

Is the action complete?

Verify the repair

Go to Step 1

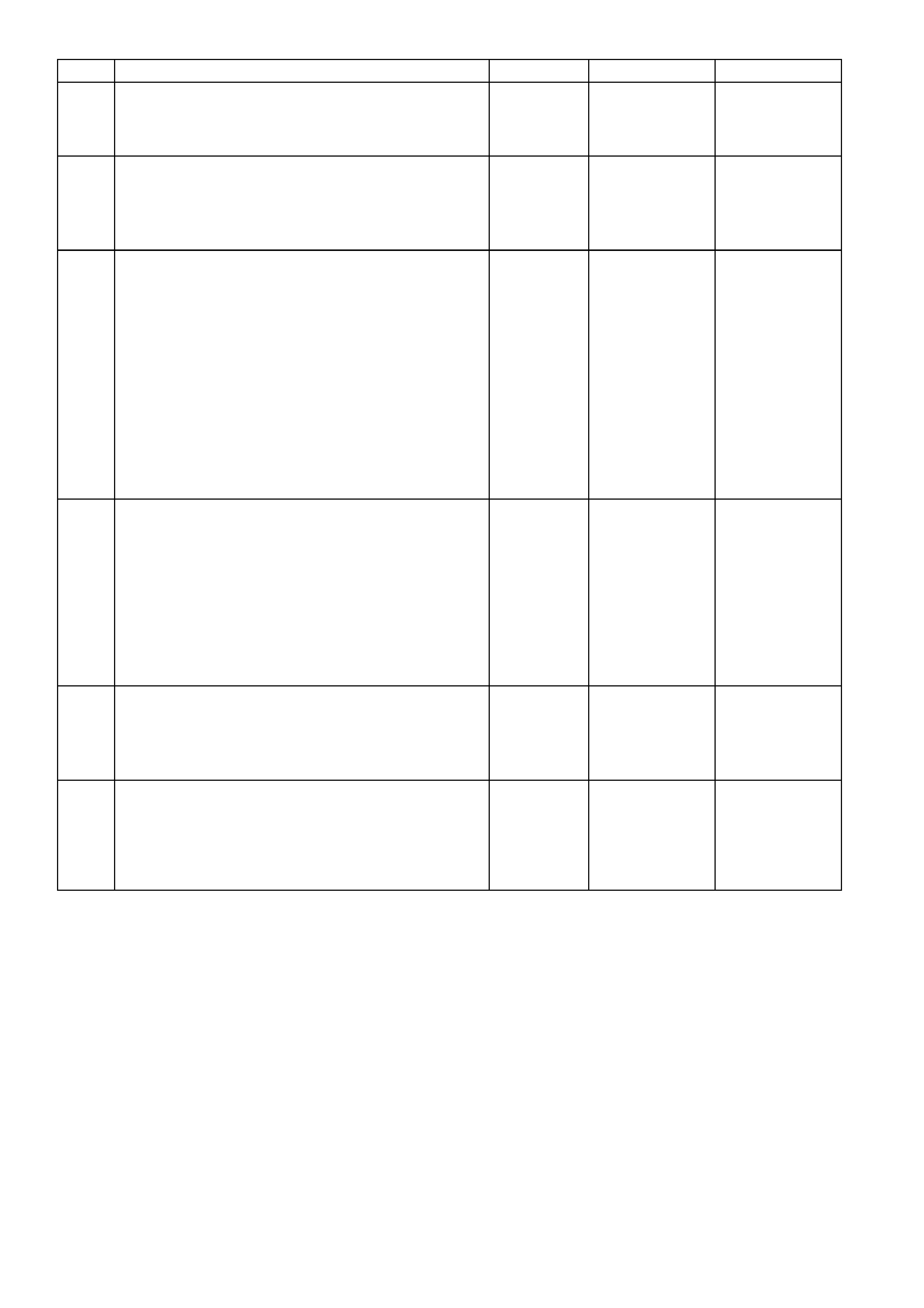

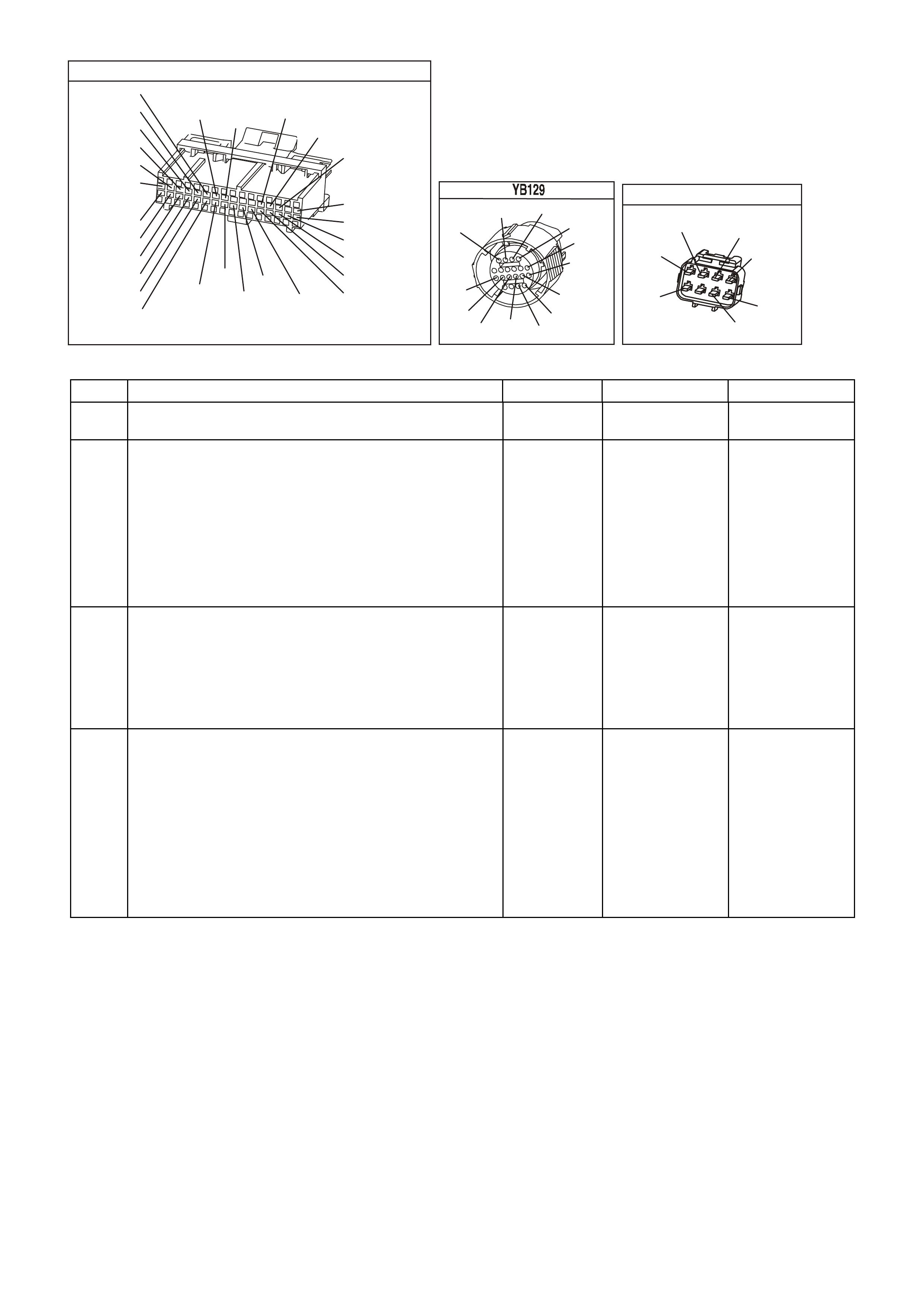

TABLE 2.3 V6 PCM 1-2 S HIFT S OLENOID PERFORMANCE CHE CK

Circuit Description:

The 1-2 Shift Solenoid Valve (1-2 SS Valve) controls the fluid flow acting on the 1-2 and 3-4 shift valves. T he 1-2

SS Valve is a norm ally-open exhaus t valve that is used with the 2-3 Shift Solenoid Valve ( 2-3 SS Valve), in or der to

allow four different shifting combinations.

This functional check is useful for diagnosing unusual shift patterns that result from a mechanical fault of the 1-2

shift s olenoid or the s hif t valve. A 1-1- 4- 4 shift pattern indica tes that the s hif t s olenoid or the shif t valve is stuck ON.

The stuck ON condition could be caused by the solenoid not exhausting fluid or the shift valve remaining in the

applied position. Similarly, a 2-2-3-3 shift pattern indicates that the shift solenoid or the shift valve is stuck OFF.

The stuck OFF condition could be caused by the solenoid exhausting fluid or the shift valve remaining in the non-

applied position.

Diagnostic Aids:

• Verify that the transmission shift speeds are within specifications.

• Other internal transmission faults may cause more than one shift to occur.

• Refer to the following Table for the correct On and Off states of the shift solenoids.

Gear 1-2 Shift

Solenoid 2-3 Shift

Solenoid

1 ON ON

2 OFF ON

3 OFF OFF

4 ON OFF

Test Description:

The numbers below refer to the step numbers on the diagnostic Table.

2. This step tests that the sc an tool c omm anded all shif ts and all shif t solenoid valves res ponded correct ly, but all

the shifts did not occur. Refer to the table below.

3–2 Down shift

Control

Solenoid

1–2 Shift

Solenoid A

2–3 Shift

Solenoid B

YB 12 9 Trans mis sion

Pass-Thru Connector

Torque

Converter

Clutch (TCC)

(PWM)

Solenoid

Torque

Converter

Clutch (TCC)

Enable

Solenoid

Pressure

Control

Solenoid A

B

A

B

SUPER4284-1

A

B

A

B

EF32 EFI

Relay

P/BLU

(339)

G/W (897)

LG (1222)

Y/B (1223)

GY/R (422)

BR (418)

R (1228)

GY/BLU (1229)

C13 3–2 Control

Solenoid

1–2 Shift

Solenoid

2–3 Shift

Solenoid

TCC Enable

Solenoid

TCC PWM

Solenoid

Pressure Control

Solenoid High

Pressure Control

Solenoid Low

C2

C3

C1

C15

E15

E14

S

A

B

T

U

C

D

A

B

A

B

PCM

M

I

C

R

O

P

R

O

C

E

S

S

O

R

12V

YB194

YB110

YB193

YB193

(413)

(412)

(1413)

(1412)

(430)

(453)

(815)

V/B

GY/B

V

GY

V

B/R

W/R

(897)

(897)

G/W

G/W

(418)

(418)

BR

BR

(1426)

O/W

C16

D16

WT/B

(832)AUTO

(647)

(630)

BR

T

(832) MAN

LBLU/B

B

(424)

(423)

C1

D1

(792)

(422)

(1222)

(1223)

(428)

(123)

BR/W

GY/R

LG

Y/B

G/Y

V/W

BLU/W

BLU

(831) Man

(443)

LG/W

(442) (831)AUTO

(441)

LBLU

LBLU/B

(444)

LG/B

P.C.M. CONNECTOR 1

TRANSMISSION CONNECTOR

GY/BLU

(1229)

R

(1228)

Y/B

(1223)

LG

(1222)

P/BLU

(339)

(1227)

B/Y

(1230)

B/W

GY/R

(422)

BR

(418)

BR/Y

(1224)

(1226)

GY

Y

(1225)

(897)

G/W

(V8)

B

(469) (V6)

OR

ENGINE CONNECTOR 1

YE110

O/W

(304)

(1426)

BLU/W

G/W

(339)

P/BLU

(465)

(123)

V/W

(1427)

B/W

Y

(1049)

TABLE 2.3 V6 PCM 1-2 SHIFT SOLENOID PERFORMANCE CHECK

STEP ACTION VALUE YES NO

1 Was the On-Board Diagnostic (OBD) System Check

performed? — Go to Step 2 Go to OBD

System Check

2 1. Install the scan tool.

2. With the engine OFF, turn the ignition switch to the

RUN position.

3. While the engine is operating, raise the drive

wheels.

4. With the transmission in D4 range, use the scan tool

to command 1st, 2nd, 3rd and 4th gears while

accelerating the vehicle. Road testing the vehicle

may be necessary.

Did you detect a 1-1-4-4 or a 2-2-3-3 only shift pattern?

— Go to Step 3 Go to “Diagnostic

Aids” on facing

page

3 Check the shift solenoid/hydraulic circuit for:

• An internal malfunction.

• Damaged seals on the shift solenoid valves.

Refer to the symptom diagnosis Tables.

Did you find and correct a problem?

— Go to Step 4 Go to “Diagnostic

Aids”

on facing page

4 In order to verify your repair, perform the following

procedure:

1. Select DTC.

2. Select Clear Info.

3. Operate the vehicle under the following conditions

(only if traffic and road conditions permit):

• With the transmission in D4 range, use the scan

tool to command 1st, 2nd, 3rd and 4th gears

while accelerating the vehicle.

Did you detect a 1-1-4-4 or 2-2-3-3 only shift pattern?

__ Begin the

diagnosis again.

Go to Step 1

Repair Verified,

exit table

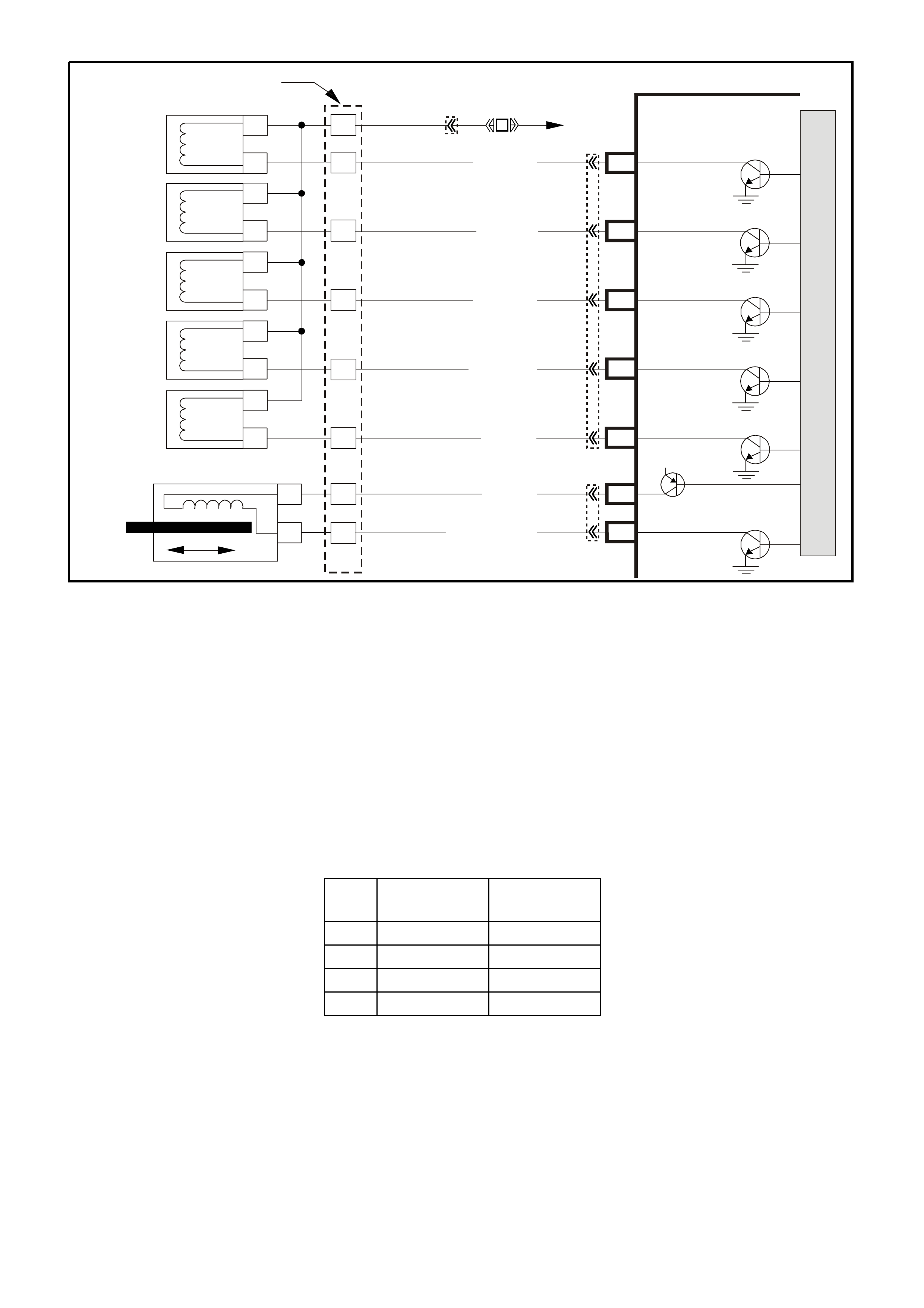

TABLE 2.4 V6 PCM 2-3 S HIFT S OLENOID PERFORMANCE CHE CK

Circuit Description:

The 2- 3 Shift Solenoid Valve (2-3 SS Valve) contr ols the fluid flow acting on the 2-3 s hift valves. The 2-3 SS Valve

is a norm ally-open exhaust valve that is used with the 1-2 Shif t Solenoid Valve (1-2 SS Valve) in order to allow four

different shifting combinations.

This functional check is useful for diagnosing unus ual shift patterns that res ult from a mechanic al failure of the 2-3

shift s olenoid or the s hif t valve. A 1-2- 2- 1 shift pattern indica tes that the s hif t s olenoid or the shif t valve is stuck ON.

The stuck ON condition could be caused by the solenoid not exhausting fluid or the shift valve remaining in the

applied position. Similarly, a 4-3-3-4 shift pattern indicates that the shift solenoid or the shift valve is stuck OFF.

The stuck OFF condition could be caused by the solenoid exhausting fluid or the shift valve remaining in the non-

applied position.

Diagnostic Aids:

Verify that the transmission shift speeds are within specifications.

Other internal transmission faults may cause more than one shift to occur.

• Refer to the following Table for the correct On and Off states of the shift solenoids.

Gear 1-2 Shift

Solenoid 2-3 Shift

Solenoid

1 ON ON

2 OFF ON

3 OFF OFF

4 ON OFF

Test Description:

The numbers below refer to the step numbers on the diagnostic Table.

2. This verif ies that the scan tool com manded all the s hifts, and all the shif t solenoids responded cor rectly, but all

the shifts did not occur. Refer to the table below.

3–2 Down shift

Control

Solenoid

1–2 Shift

Solenoid A

2–3 Shift

Solenoid B

YB 12 9 Trans mis sion

Pass-Thru Connector

Torque

Converter

Clutch (TCC)

(PWM)

Solenoid

Torque

Converter

Clutch (TCC)

Enable

Solenoid

Pressure

Control

Solenoid A

B

A

B

SUPER4284-1

A

B

A

B

EF32 EFI

Relay

P/BLU

(339)

G/W (897)

LG (1222)

Y/B (1223)

GY/R (422)

BR (418)

R (1228)

GY/BLU (1229)

C13 3–2 Control

Solenoid

1–2 Shift

Solenoid

2–3 Shift

Solenoid

TCC Enable

Solenoid

TCC PWM

Solenoid

Pressure Control

Solenoid High

Pressure Control

Solenoid Low

C2

C3

C1

C15

E15

E14

S

A

B

T

U

C

D

A

B

A

B

PCM

M

I

C

R

O

P

R

O

C

E

S

S

O

R

12V

YB194

YB110

YB193

YB193

(413)

(412)

(1413)

(1412)

(430)

(453)

(815)

V/B

GY/B

V

GY

V

B/R

W/R

(897)

(897)

G/W

G/W

(418)

(418)

BR

BR

(1426)

O/W

C16

D16

WT/B

(832)AUTO

(647)

(630)

BR

T

(832) MAN

LBLU/B

B

(424)

(423)

C1

D1

(792)

(422)

(1222)

(1223)

(428)

(123)

BR/W

GY/R

LG

Y/B

G/Y

V/W

BLU/W

BLU

(831) Man

(443)

LG/W

(442)

(831)AUTO

(441)

LBLU

LBLU/B

(444)

LG/B

P.C.M. CONNECTOR 1

TRANSMISSION CONNECTOR

GY/BLU

(1229)

R

(1228)

Y/B

(1223)

LG

(1222)

P/BLU

(339)

(1227)

B/Y

(1230)

B/W

GY/R

(422)

BR

(418)

BR/Y

(1224)

(1226)

GY

Y

(1225)

(897)

G/W

(V8)

B

(469) (V6)

OR

ENGINE CONNECTOR 1

YE110

O/W

(304)

(1426)

BLU/W

G/W

(339)

P/BLU

(465)

(123)

V/W

(1427)

B/W

Y

(1049)

TABLE 2.4 V6 PCM 2-3 SHIFT SOLENOID PERFORMANCE CHECK

STEP ACTION VALUE YES NO

1 Was the On-Board Diagnostic (OBD) System Check

performed? Go to Step 2 Go to OBD

System Check

2 1. Install the scan tool.

2. With the engine OFF, turn the ignition switch to the

RUN position.

3. While the engine is operating, raise the drive wheels.

4. With the transmission in D4 range, use the scan tool

to command 1st, 2nd, 3rd, and 4th gears while

accelerating the vehicle. Road testing the vehicle

may be necessary.

Did you detect a 1-2-2-1 or 4-3-3-4 only shift pattern?

Go to Step 3 Go to “Diagnostic

Aids” on facing

page

3 Check the shift solenoid/hydraulic circuit for:

• An internal malfunction

• Damaged seals

Refer to the symptom diagnosis Tables in Section 6C1-

2B of the VX Series Service Information.

Did you find and correct a problem?

Go to Step 4 Go to “Diagnostic

Aids” on facing

page

4 In order to verify your repair, perform the following

procedure:

1. Select DTC.

2. Select Clear Info.

3. Operate the vehicle under the following conditions

(only if traffic and road conditions permit):

• With the transmission in D4 range, use the scan

tool to command 1st, 2nd, 3rd and 4th gears

while accelerating the vehicle.

Did you detect a 1-2-2-1 or a 4-3-3-4 only shift pattern?

Begin the

diagnosis again

Go to Step 1

Repair Verified,

exit table

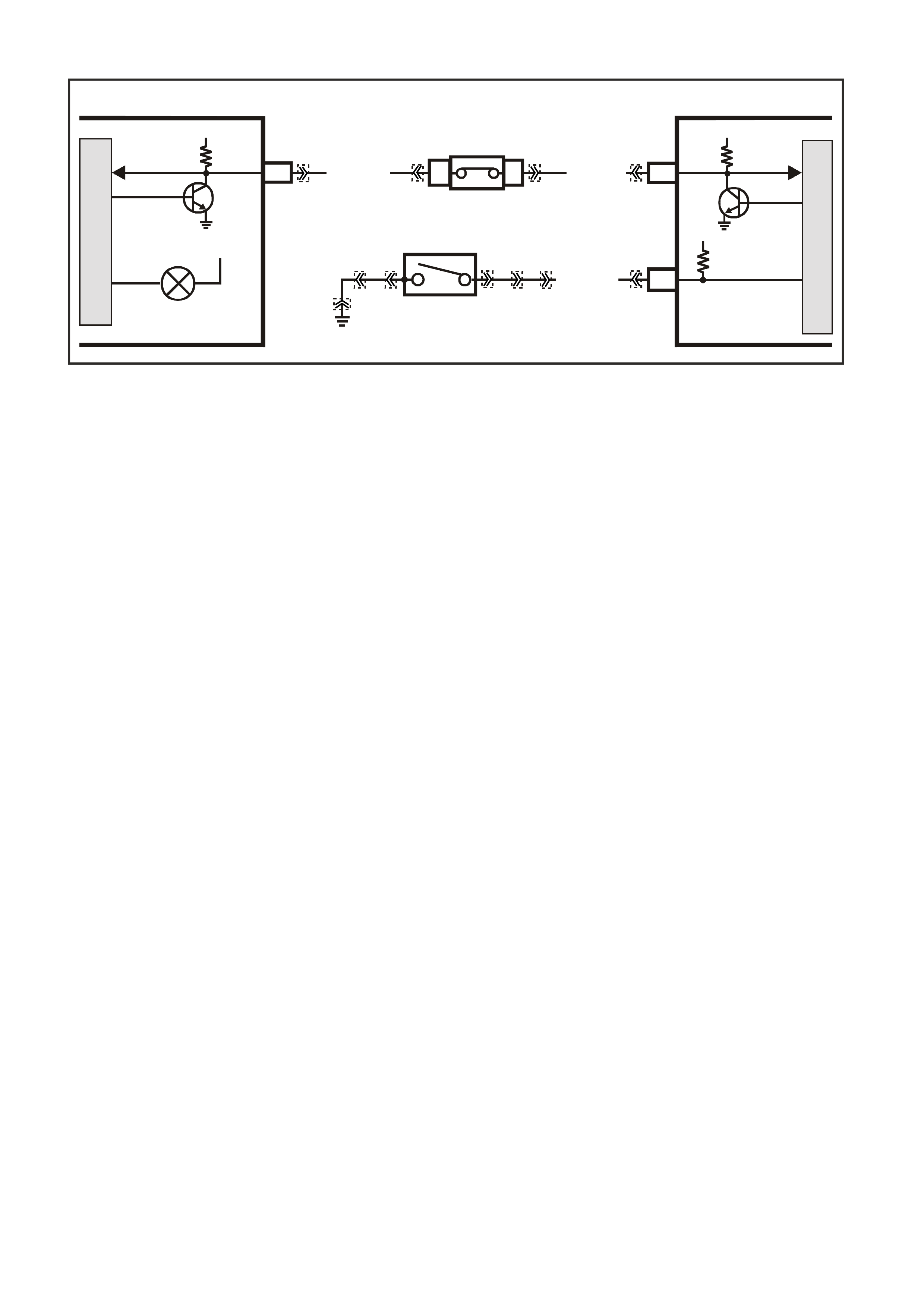

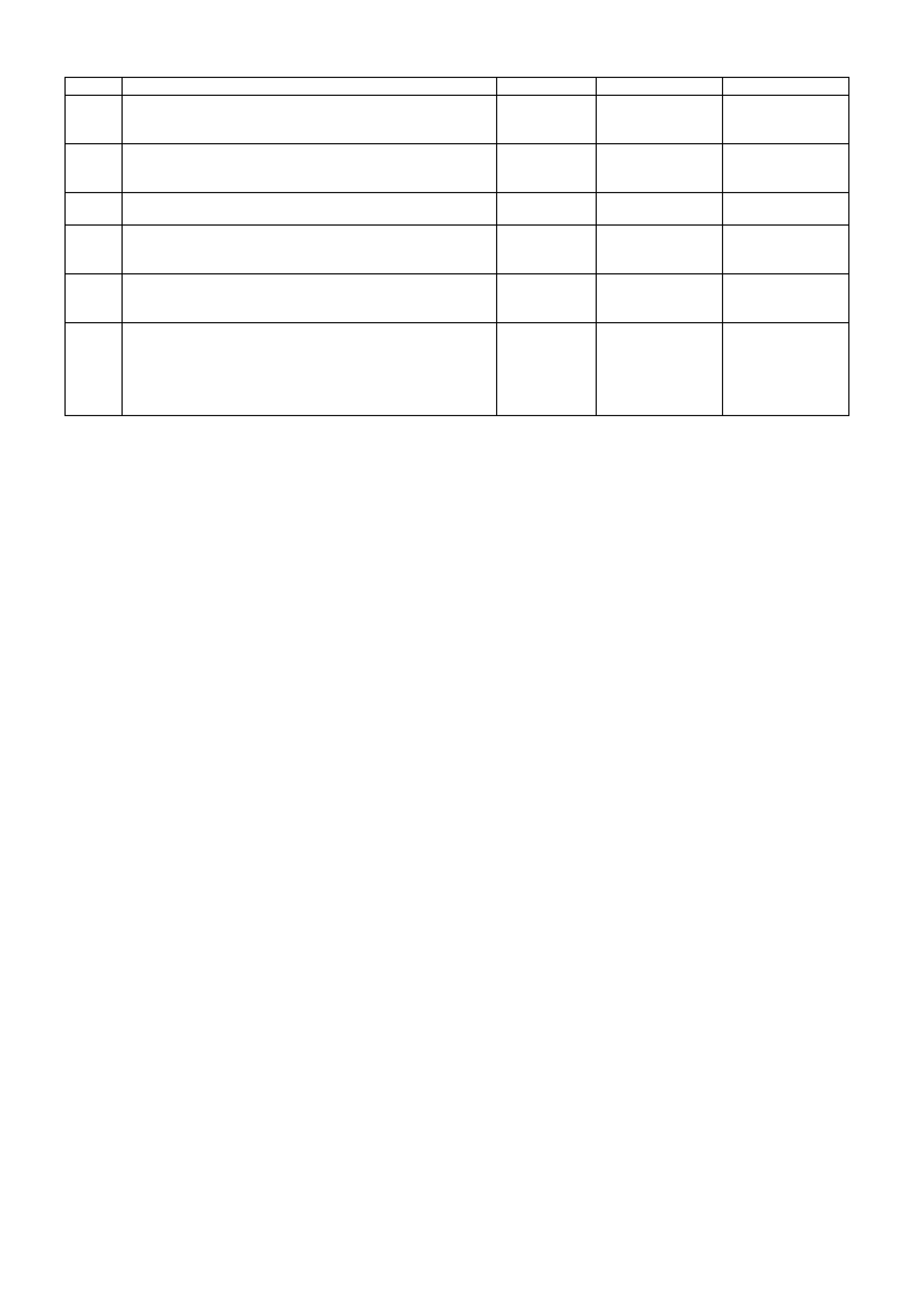

TABLE 2.5 V6 PCM TRANSMISSION POWER/ECONOMY SWITCH

CIRCUIT DESCRIPTION:

The driver can select three transmission shift modes, ECONOMY or POWER or CRUISE using a dash or centre

console mounted switch for Economy/Power, and a cruise switch located on the steering column. The

Economy/Power switch is wired to the PCM and allows the driver to choose the Economy mode, for the best fuel

econom y in all driving conditions through the incr eased use of T CC. Power m ode provides later upshif ts and higher

line pressure in the transmission.

The PCM s ends out a buf f er ed voltage s ignal, about 12 volts, and monitors the s tatus of this cir cuit. O nc e the driver

selects Power, the switch momentarily pulls low the buffered 12 volts, and the PCM will interpret this as a Power

selection and adjust the transmission shift pattern accordingly, and instructs the instrument panel to turn ON the

Power lamp. If while driving, the driver selects the Economy position, again the buffered 12 volts is momentarily

pulled low, and the PCM will adj ust the transm ission shift pattern and ins truct the instrum ent panel to turn OFF the

Power lamp.

When the key is turned ON, the PCM shift mode is set to the last mode that was previously selected

(Economy/Power). The cruise control is set to OFF at every key ON cycle.

In cruise mode operation, when the driver activates the cruise control, the Power lamp and power mode will turn

OFF (if vehicle was in power mode) and the transmission shift pattern will switch to cruise shift pattern. When in

cruise mode the PCM will modify the transmission calibration so that earlier downshift and later upshift points are

provided.

For replacement of the Economy/Power switch, refer to Section 7C4 Automatic Transmission - On Vehicle

Servicing in VX Service Information.

TEST DESCRIPTION:

The numbers below refer to step numbers on the diagnostic Table.

2. This step tests for proper operation of the transmission POWER switch, the wiring and the PCM.

3. This step tests for proper POWER lamp illumination.

5. This step determins if the switch is faulty.

8. Some interior parts must be removed to disconnect and replace the transmission switch, Refer to

Section 1A2, "Body Dimensions" in VX Service Information.

M

I

C

R

O

SUPERVX006A1

INSTRUMENT

M

I

C

R

O

PCM

12

SERIAL

DATA

5V

12V IGN

G/W (1 220) R/B (1221)

POWER

POWER/ECONOMY

SWITCH

12V

F12

A3 SERIAL

DATA

5V

BLU (774)

BCM

E2

D2 E9

D3

YB188

YB194YE112

YE30

YB34

YB175

YB164 YB175

YB164

YB34

YB66

YB30

YE114

YE194

P.C.M. CONNECTOR 3

LG/B

(366)

G

(843)

B/W

F16

B/Y

BR/Y

(1228)

(469)

Y

(451)

F1

P

(841)

BLU

V

E1

LBLU

(845)

BLU

B

(1226)

W/B

BLU/W

V

R

(435)

(31)

(1229)

GY

(1224)

Y

(846)

GY

(842)

(452)

(774)

(304)

BR/Y

(411)

(439)

GY/BLU

BLU

(1225)

E16

(1427)

(429)

(844)

B/O

(434)

OR AUTO

GY/BLU

GY

(1434)

MAN

(776)

W

BLU/W

Y

GY

(771)

(772)

(773)

YB30

(774)

(8)

BLU

GY

(1429)

BR/W

(151)

B/G

(19)

R/W

BLU

(774)

B/G

(151)

(19)

(8)

BR/W

GY ENGINE CONNECTOR 3

YE112

(1221)

(42)

(121)

BR/BLU

BR/R

R/BO/B

LG

P/B

BLU

(740)

(24)

(39)

(774)

LBLU

(411)

S/C ONLY

LOCATION E3 EARTH CONNECTOR

RIGHT HAND INNER FENDER

YE114

(151)

B/G

(157)

B/R

(150) (155)

BB/Y

(152)

B/W

(157)

B/R

TABLE 2.5 TRANSMISSION POWER/ECONOMY SWITCH

STEP ACTION VALUE YES NO

1 Was the On-Board Diagnostic (OBD) System Check

performed? Go to Step 2 Go to OBD

System Check

2 1. With the engine OFF, turn the ignition switch to the

RUN position.

2. Install the scan tool.

3. Depress the Transmission POWER switch and

observe the scan tool display.

Does the scan tool display change between the Power

or Economy mode?

Go to Step 3 Go to Step 5

3 Is the POWER lamp ON, when the scan tool displays

POWER? Go to Step 4 Go to

Instruments in

Section 12C in

VX Service

Information.

4 Does the POWER lamp go off, when the scan tool

displays ECONOMY? No Problem

found with switch

operation.

Go to

Instruments in

Section 12C in

VX Service

Information.

5 1. Disconnect the POWER switch from the wiring

harness connector.

2. Using a fused jumper wire, connect the two terminals

of the POWER switch wiring harness connector

together.

Does the scan tool display change between the Power

or Economy mode?

Go to Step 7 Go to Step 6

STEP ACTION VALUE YES NO

6 Using a fused jumper wire, connect circuit 774 to earth.

Does the scan tool display change between the Power

or Economy mode?

Go to Step 10 Go to Step 9

7 Check the POWER switch connector for a poor terminal

connection.

Was a problem found?

Verify the Repair Go to Step 8

8 Replace the faulty POW ER/ECONOMY switch.

Is the action complete? Verify the Repair

9 Check for an open or short to Earth in circuit 774, or a

faulty PCM connection for circuit 774.

Was a problem found?

Verify the Repair Go to Step 11

10 Repair open in Earth circuit 151at Power/Economy

switch.

Is action complete?

Verify the Repair

11 Replace PCM.

Refer to Section 6C1-3 Service Operations of the VX

Series Service Information, for PCM Programming and

Security Link procedure.

Is action complete?

Verify the Repair

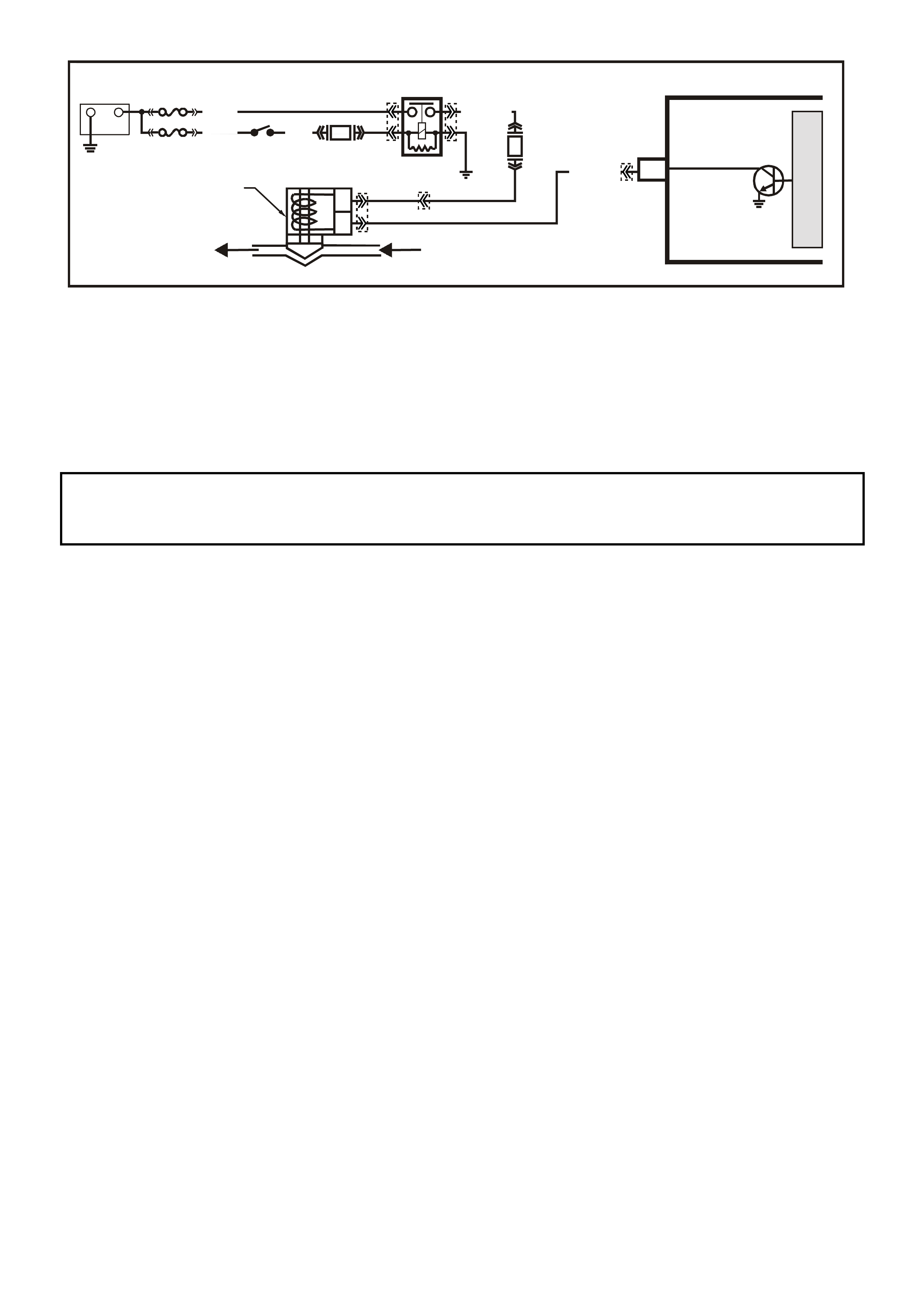

TABLE 2.6 V6 PCM SUPERCHARGED ENGINE BOOST

CONTROL SYSTEM FUNCTIONAL CHECK

Circuit Description:

Under most conditions, the PCM commands the Boost Control Solenoid to operate at 100% duty cycle ("ON") to

allow full boost pres sure upon demand. However, if reverse gear is selected or the PCM detects rapid dec eleration

or engine load is ex tremely high, reduc ed boost press ure is des ir ed. Under thes e 3 c onditions, the PCM c ommands

the Boost Control Solenoid to operate at a 0% duty cycle ("OFF"), which opens the bypass valve. W ith the bypass

valve open, boost pressure is reduced by recirculating intake air back through the supercharger inlet.

NOTICE:

When performing this diagnostic Table, make certain that the drive wheels are blocked and the parking

brake is firmly set.

Diagnostic Aids:

If this Table has been performed and no electrical or vacuum related fault is noted, check for the following

conditions:

• Misadjusted or sticking Bypass Valve Actuator.

• Binding Bypass Valve or Bypass Valve linkage.

Refer to Section 6C1-3 SERVICE OPERATIONS of the VX Series Service Information for bypass valve actuator

service and adjustment procedure. If no problem is found and a driveability symptom still exists, refer to

Symptoms Section 6C1-2B of the VX Series Service Information.

An intermittent may be caused by a poor connection, rubbed through wire insulation, or a wire broken inside the

insulation. Check for the following conditions:

Poor connection or Damaged Harness - Inspect PCM harness connector for backed out terminals, improper mating,

improperly formed or damaged terminals, poor terminal to wire connection and damaged harness.

Intermittent Test - Disconnect PCM and install a DVM to monitor voltage between the Boost Control Solenoid driver

circuit at the PCM connector and earth. W ith the key "ON", observe voltage while manipulating related connectors

and wiring harness. If the failure is induced, the voltage display will change. This may indicate the location of the

fault.

Test Description:

Number(s) below refer to step number(s) on the diagnostic Table.

2. Verifies ignition feed to the Boost Control Solenoid.

3. The Boost Control Solenoid should be commanded "OFF" (0% duty cycles) with the ignition "ON", engine not

running. If the system is functioning properly, the test light should be "OFF".

4. Ensures that the PCM can control the ODM output for the Boost Control Solenoid and Boost Control Solenoid

driver circuit is not open.

5. Checks for a faulty Boost Control Solenoid (sticking open or leaking).

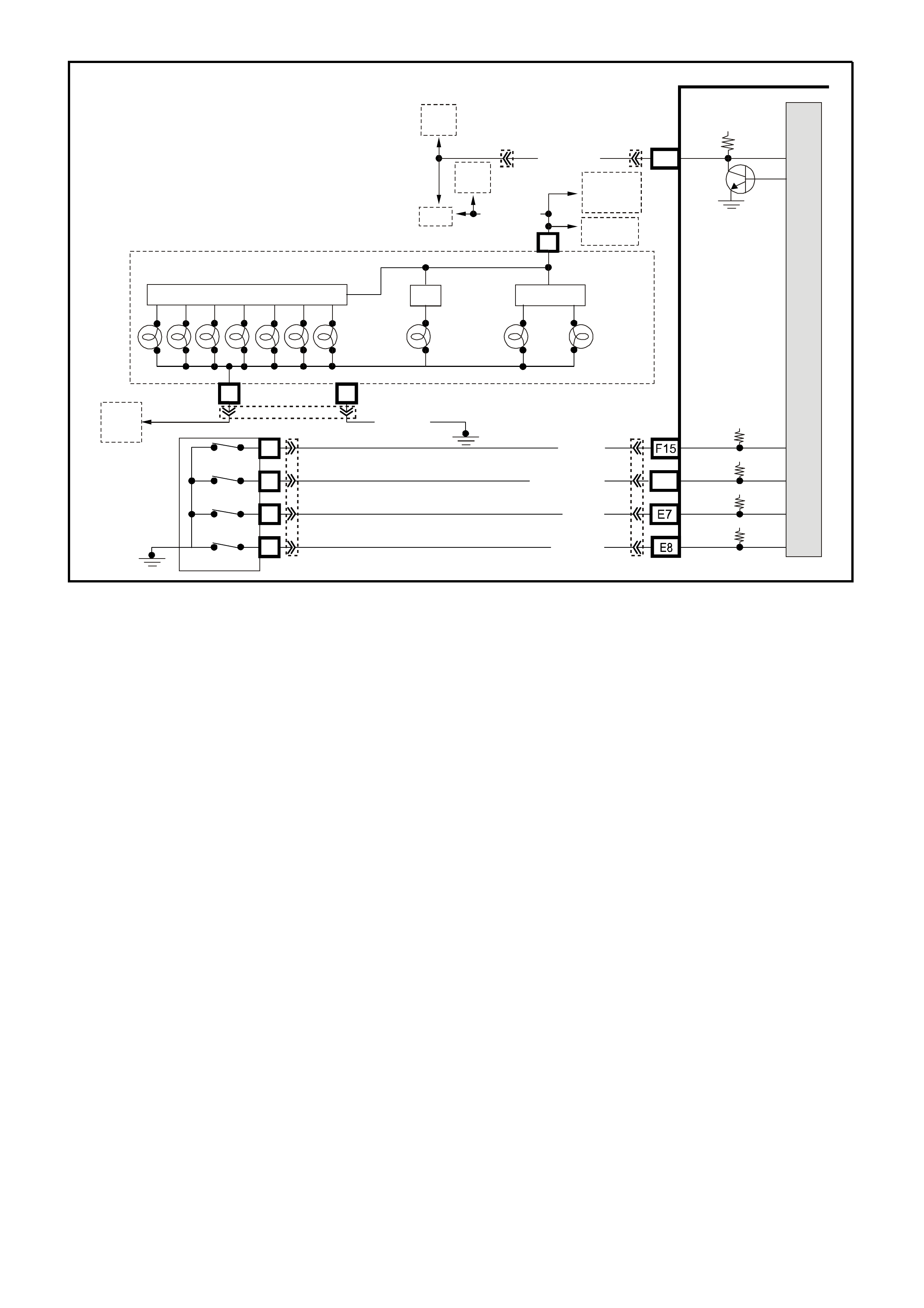

A

B

BOOST CONTROL

SOLENOID

PCM

BOOST CONTROL

SUPERVX000

E1

B/O (429)

MANIFOLD

VACUUM

TO BYPASS V ALVE

ACTUATOR

B/W

(152)

LOC. E3

M

I

C

R

O

F33

F14

IGN SW

EFI

RELAY

+

-

BATTERY

FS

FJ

P (3) P/B

(39)

(1040) O/Y (479)

R (2H)

YE39

YE111

YE115

YB194

YE39

YE194

P.C.M. CONNECTOR 3

LG/B

(366)

G

(843)

B/W

F16

B/Y

BR/Y

(1228)

(469)

Y

(451)

F1

P

(841)

BLU

V

E1

LBLU

(845)

BLU

B

(1226)

W/B

BLU/W

V

R

(435)

(31)

(1229)

GY

(1224)

Y

(846)

GY

(842)

(452)

(774)

(304)

BR/Y

(411)

(439)

GY/BLU

BLU

(1225)

E16

(1427)

(429)

(844)

B/O

(434)

OR AUTO

GY/BLU

GY

(1434)

MAN

(776)

W

BLU/W

Y

GY

(771)

(772)

(773)

S/C BOOST CONTROL SOLENOID

(429)

B/O

(439)

P

YE111

ENGINE CONNECTOR 2

(482)

(481)

R

LG

GY

G

(434)

(129)

P

(439)

(59)

(366)

LG/B

GW/B

(451)

TABLE 2.6 V6 PCM SUPERCHARGED ENGINE BOOST CONTROL SYSTEM FUNCTIONAL CHECK

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed? Go to Step 2. Go to OBD

System Check of

the VX Series

Service

Information.

2. 1. Unbolt Boost Control Solenoid from engine, to gain

axis to solenoid.

2. Disconnect the Boost Control Solenoid electrical

connector.

3. Ignition "ON".

4. Install a test light between the ignition feed circuit

at the Boost Control Solenoid harness connector

and engine earth.

Is the test light "ON"?

Go to step 3 Go to step 11

3. Connect the test light between the Boost Control

Solenoid harness connector terminals.

Is the test light "ON"?

Go to step 14 Go to step 4

4. 1. Ignition "ON", engine idling.

2. Set vehicles parking brake.

3. With the test light still connected to the Boost

Control Solenoid, observe the test light.

Is the test light "ON" while the engine is running?

Go to step 5 Go to step 16

5. 1. Reconnect the Boost Control Solenoid electrical

connector.

2. Disconnect the boost signal hose between the

Boost Control Solenoid and the Bypass Valve

Actuator.

3. Connect a vacuum gauge to read the boost signal

from the Boost Control Solenoid.

4. Start the engine and idle in park.

5. Observe the vacuum gauge reading.

Does the vacuum gauge indicate near the specified

value?

0 cm

0 in.Hg Go to step 6 Go to step 17

6. 1. With engine still idling, shift vehicle into reverse

gear.

2. Observe the vacuum gauge.

Does the vacuum gauge indicate greater than the

specified value with the Boost Control Solenoid turned

"OFF when vehicle is shifted into reverse gear"?

38 cm

15 in.Hg Go to step 7 Go to step 10

7. 1. Check for a restriction in the boost signal hose

between the Boost Control Solenoid and the

Bypass Valve Actuator.

2. If a problem is found, repair as necessary.

Was a problem found.

Go to step 21 Go to step 8

STEP ACTION VALUE YES NO

8. 1. Reconnect the boost signal hose between the

Boost Control Solenoid and the Bypass Valve

Actuator.

2. Connect the vacuum gauge to read the inlet

vacuum signal to the Bypass Valve Actuator.

3. Start the engine and idle in park.

4. Observe the vacuum gauge reading.

Does the vacuum gauge indicate greater than the

Specified value?

38 cm

15 in.Hg Refer to

Diagnostic Aids Go to step 9

9. Repair the restriction in the inlet vacuum signal hose to

the Bypass Valve Actuator or blocked inlet vacuum

source.

Is action complete?

Go to step 21

10. 1. Check for a restriction in the boost source hose to

the Boost Control Solenoid.

2. If a problem is found, repair as necessary.

Was a problem found?

Go to step 21 Go to step 18

11. Check the fuse for the Boost Control Solenoid ignition

feed circuit.

Is the fuse blown?

Go to step 12 Go to step 13

12. Locate and repair short to earth in the ignition feed

circuit.

Is action complete?

Go to step 21

13. Locate and repair open in the ignition feed circuit to the

Boost Control Solenoid .

Is action complete?

Go to step 21

14. 1. Ignition "OFF", disconnect the PCM .

2. Ignition "ON", observe the test light.

Is the test light "ON"?

Go to step 15 Go to step 20

15. Locate and repair short to earth in Boost Control

Solenoid driver circuit.

Is action complete?

Go to step 21

16. 1. Ignition "OFF", disconnect the PCM.

2. Ignition "ON".

3. Check the Boost Control Solenoid driver circuit for

an open or a short to voltage.

4. If a problem is found, repair as necessary.

Was a problem found?

Go to step 21 Go to step 19

17. 1. Check for poor terminal connections at the Boost

Control Solenoid .

2. If a problem is found, repair as necessary.

Was a problem found?

Go to step 21 Go to step 18

18. Replace the Boost Control Solenoid .

Is action complete? Go to step 21

19. 1. Check the Boost Control Solenoid driver circuit for

a poor terminal connection at the PCM.

2. If a problem is found, repair as necessary.

Was a problem found?

Go to step 21 Go to step 20

STEP ACTION VALUE YES NO

20. Replace PCM.

Refer to Section 6C1-3 Service Operations of the VX

Series Service Information, for PCM Security Link

procedure.

Is action complete?

Go to step 21

21. 1. Ignition "ON", engine idling in park.

2. Disconnect inlet vacuum signal hose to Bypass

Valve Actuator.

Bypass valve Actuator linkage should move when the

signal hose is removed, does it?

Go to step 22 Go to

Diagnostic Aids

22. 1. Ignition "OFF".

2. Connect a vacuum gauge to the Boost Control

Solenoid.

3. Ignition "ON, engine idling in park.

Does the vacuum gauge indicate near the specified

Value?

0 cm

0 in.Hg Go to step 23 Go to step 17

23 1. Set vehicle parking brake.

2. Ignition "ON", engine idling in park.

3. With vacuum gauge still connected to Boost

Control Solenoid, shift transmission into reverse

gear.

Does the vacuum gauge now read at or above the

specified value when the transmission is shifted into

reverse gear?

38 cm

15 in.Hg Go to step 24 Go to step 10

24 1. Reconnect vacuum hose to Boost Control

Solenoid.

2. Reinstall Boost Control Solenoid to engine.

Is action complete?

System is

working properly

Refer to

Diagnostic Aids

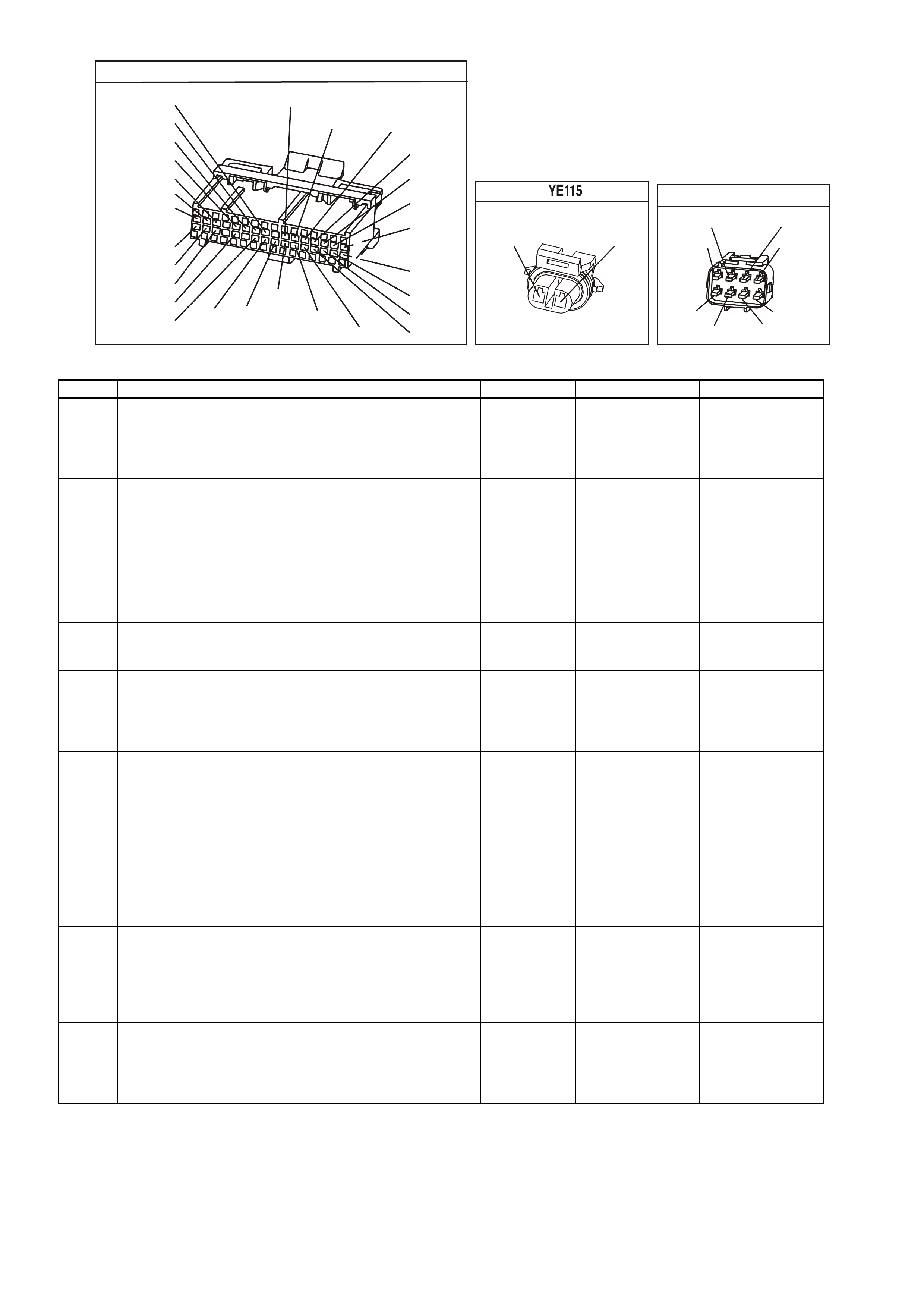

TABLE 2.7 V6 PCM INSTRUMENT P ANEL GEAR INDICATOR CHECK

Circuit Description:

The transmission PRNDL module is a mulit-signal switch which sends a signal to the PCM to indicate gear

selection. The PCM will then determine the signal from the PRNDL module and send a command vie serial data

com m unication to the instr um ent panel cluster to turn "O N" the proper gear indicator lam p for the gear that is being

selected.

The PRNDL module uses four (4) discrete circuits to pull four (4) PCM voltages low in various combinations to

indicate each gear range. The voltage level of the circuits is represented as LOW = earthed, and HIGH = open

circuit. The four (4) states display ed represents decoder P, A, B, and C inputs.

The s can tool will display all four circuits ( P, A, B, C ) and the appr opriate HIGH's and LOW's to represent the gear

selected. If the gear selected does not match the HIGH LOW Table as displayed below on the scan tool, or the

instrument panel cluster gear lamp does not light up for the gear selected, there is a fault in the PRNDL select

circuit or in the instrument panel (IP) cluster.

Diagnostic Aids:

• Monitor a scan tool while moving related connectors and wiring harness. If a f ailure is indicated, the scan data

will change states f rom either Low to High, or from High to LOW. Moving the gear selector slowly through each

gear while monitoring the scan tool may also help isolate the problem.

• Any circuitry that is suspected as causing the interm ittent complaint, should be thoroughly checked for backed

out term inals, im proper m ating, brok en lock s, impr operly for med or dam aged terminals , poor terminal to wiring

connection or physical damage to the wiring harness.

• When a fault has occurred, the PCM defaults to the 3rd gear until a correct combination is received by the

PCM. Therefore, some selected gear positions may not be possible until the fault is repaired.

PCM

To

DLC

To

DLC To

ABS/ETC

Module

To ECC

Module

A3

5V

Serial

Data

Main

BCM G/W (1220)

R/B (1221)

12

6

19

C

A

D

B

P/BLU

(44) B/Y (155)

W (776) Range

Signal P

12V

SUPERVX4293

12V

12V

12V

Range

Signal B

Range

Signal C

Range

Signal A

BLU/W (771)

Y (772)

GY (773)

E6

PRNDL

Switch

Sw itch P

Sw itch A

Sw itch B

Sw itch C

SDISDI

Ge ar In dicator Lamps (Opt ion)

Instrument Panel Cluster

SDI

To

Fuse

F13

Power/

Economy

LAmp

Check

Powertrain

Lamp (Mil)

Oil

Warning

Lamp

RNPD321

M

I

C

R

O

YB194

YB20

YB66

YE112 YB188

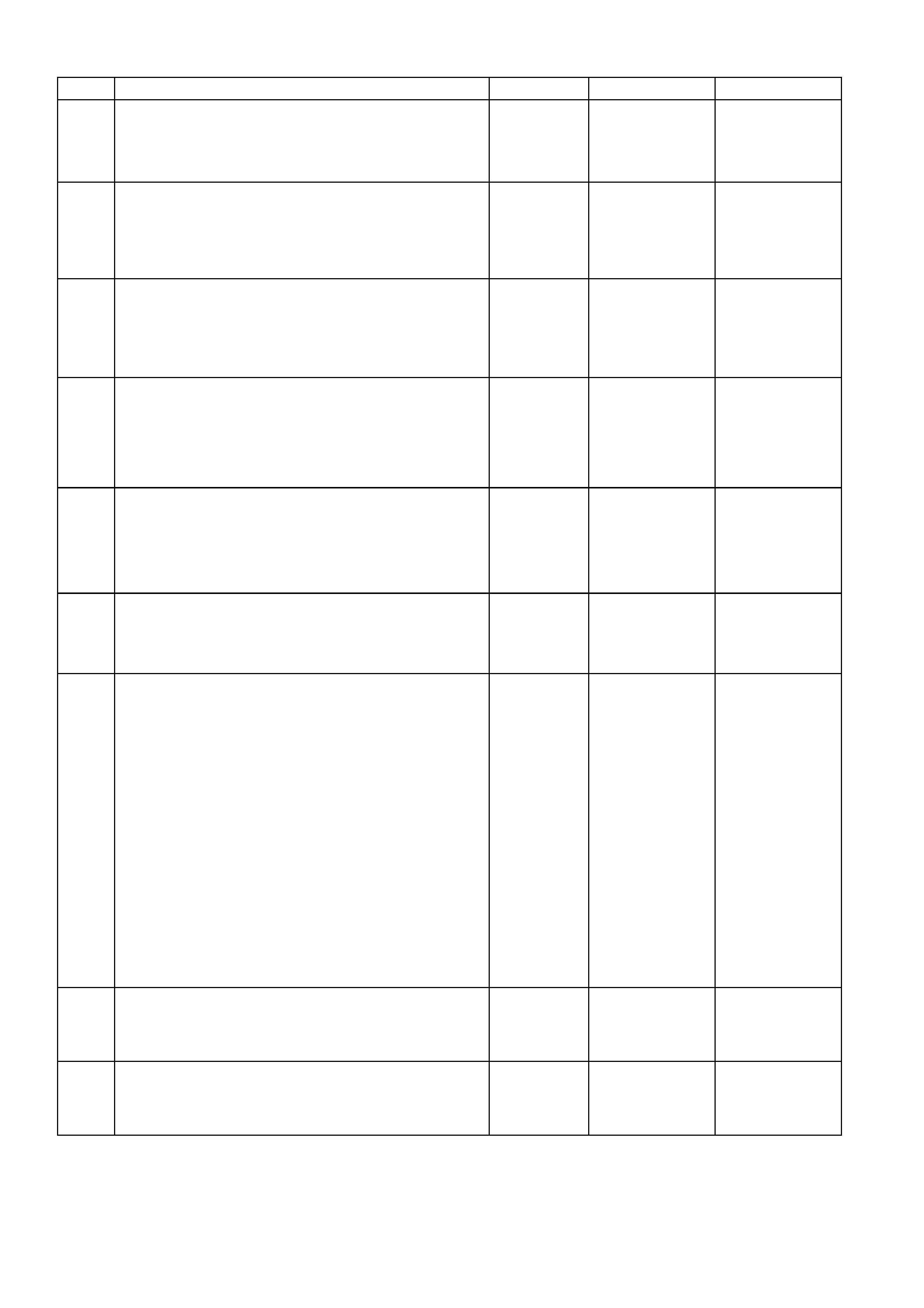

TRANSMISSION RANGE / PRNDL SWITCH

VALID INPUT COMBINATIONS

GEAR POSITION

SELECTED

SCAN TOOL PRNDL DISPLAY

(P, A, B, C)

P A B C

PARK (P) LOW

(0) LOW

(0) HIGH

(12) HIGH

(12)

REVERSE (R) HIGH

(12) LOW

(0) LOW

(0) HIGH

(12)

NEUTRAL (N) LOW

(0) HIGH

(12) LOW

(0) HIGH

(12)

DRIVE 4 (D) HIGH

(12) HIGH

(12) LOW

(0) LOW

(0)

DRIVE (3) LOW

(0) LOW

(0) LOW

(0) LOW

(0)

DRIVE 2 (2) HIGH

(12) LOW

(0) HIGH

(12) LOW

(0)

DRIVE 1 (1) LOW

(0) HIGH

(12) HIGH

(12) LOW

(0)

Test Description:

The numbers below refer to the step numbers on the diagnostic Table.

4. Any circuitry that is suspected as causing the intermittent com plaint, should be thoroughly checked for back ed

out term inals, im proper m ating, brok en locks , improperly form ed or damaged ter minals, poor ter minal to wiring

connection or physical damage to the wiring harness.

5. An invalid c ircuit will c ause the PRNDL display to go out. Jum pering each circ uit to earth sim ulates the PRNDL

module s witch operation and checks the circuitry and PCM. W hile the PRNDL m odule is disconnec ted and the

circuits are not jum per ed to earth, the sc an tool should indicate a HIGH value. A value that is indicated as LOW

with no jumper to earth indicates a earthed circuit or faulty PCM.

YE1 94

P.C.M. C ONNECTOR 3

LG/B

(366)

G

(843)

B/W

F16

B/Y

BR/Y

(1228)

(469)

Y

(451)

F1

P

(841)

BLU

V

E1

LBLU

(845)

BLU

B

(1226)

W/B

BLU/W

V

R

(435)

(31)

(1229)

GY

(1224)

Y

(846)

GY

(842)

(452)

(774)

(304)

BR/Y

(411)

(439)

GY/BLU

BLU

(1225)

E16

(1427)

(429)

(844)

B/O

(434)

OR AUTO

GY/BLU

GY

(1434)

MAN

(776)

W

BLU/W

Y

GY

(771)

(772)

(773)

YB193

(413)

(412)

(1413)

(1412)

(430)

(453)

(815)

V/B

GY/B

V

GY

V

B/R

W/R

(897)

(897)

G/W

G/W

(418)

(418)

BR

BR

(1426)

O/W

C16

D16

WT/B

(832)AUTO

(647)

(630)

BR

T

(832) MAN

LBLU/B

B

(424)

(423)

C1

D1

(792)

(422)

(1222)

(1223)

(428)

(123)

BR/W

GY/R

LG

Y/B

G/Y

V/W

BLU/W

BLU

(831) Man

(443)

LG/W

(442) (831)AUTO

(441)

LBLU

LBLU/B

(444)

LG/B

P.C.M. CONNECTOR 1

PRNDL SWITCH

(772)

(776)

Y

W

(773)

(771)

BLU/W

GY

YB 66

INSTRUMENTS

T

BLU/B

BR/W

(234)

(25)

(14)

(10)

(875)

(155)

(1340)

G/W

(44)

(121)

(8)

(30)

BLU/Y

G

O/Y

P/BLU

BR/R

V/W

(33)

(946)

(1220)

(88)

(15)

(123)

(85)

(19)

GY

W

V/R

BR

BR/O

Y/R

B/Y

LBLU

BLU

ENGINE CONNECTOR 1

YE110

O/W

(304)

(1426)

BLU/W

G/W

(339)

P/BLU

(465)

(123)

V/W

(1427)

B/W

Y

(1049)

TABLE 2.7 V6 PCM INSTRUMENT PANEL GEAR INDICATOR CHECK

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed? Go to Step 2. Go to OBD

System Check.

2. 1. Ignition "ON", engine "OFF".

2. Install a scan tool.

3. Move the gear selector through all it's ranges.

Does the scan tool indicate an INVALID in any of the

Ranges?

Go to Step 3 Go to Step 10

3. Compare the scan tool values with the Transmission

Range Switch Valid Input Combinations table.

Are all the circuit indicated as HIGH?

Go to Step 4 Go to Step 5

4. Check the transmission PRNDL module switch earth

Circuit for an open or poor connection and repair if

Necessary.

Was a problem found?

Verify Repair Go to Step 5

5. 1. Moving the gear selector through all it's ranges and

note which circuit did not correspond with the

Transmission Range Switch Valid Input

Combination table.

2. Disconnect the PRNDL module electrical

connector.

3. Jumper the circuit with the incorrect value to earth.

Does the jumpered circuit go from a HIGH value to a

LOW value?

Go to Step 8 Go to Step 6

6. Check the affected circuit for an open or short to earth

and repair as necessary.

Was a problem found?

Verify Repair Go to Step 7

7. Check for a poor connection at the PCM connector and

Repair as necessary.

Was a problem found?

Verify Repair Go to Step 9

8. Replace the PRNDL module.

Is action complete? Verify Repair

9. Replace PCM.

Refer to Section 6C1-3 Service Operations of the VX

Series Service Information, for PCM Programming and

Security Link procedure.

Is action complete?

Verify Repair

10. Does the scan tool indicate the same gear as the IP

Cluster? System OK,

refer to Diagnostic

Aids

Go to step 11

11. Remove IP cluster and inspect indicator lamp for being

Burnt.

Was a problem found?

Verify Repair Go to Step 12

12. Replace IP cluster.

Is action complete? Verify Repair

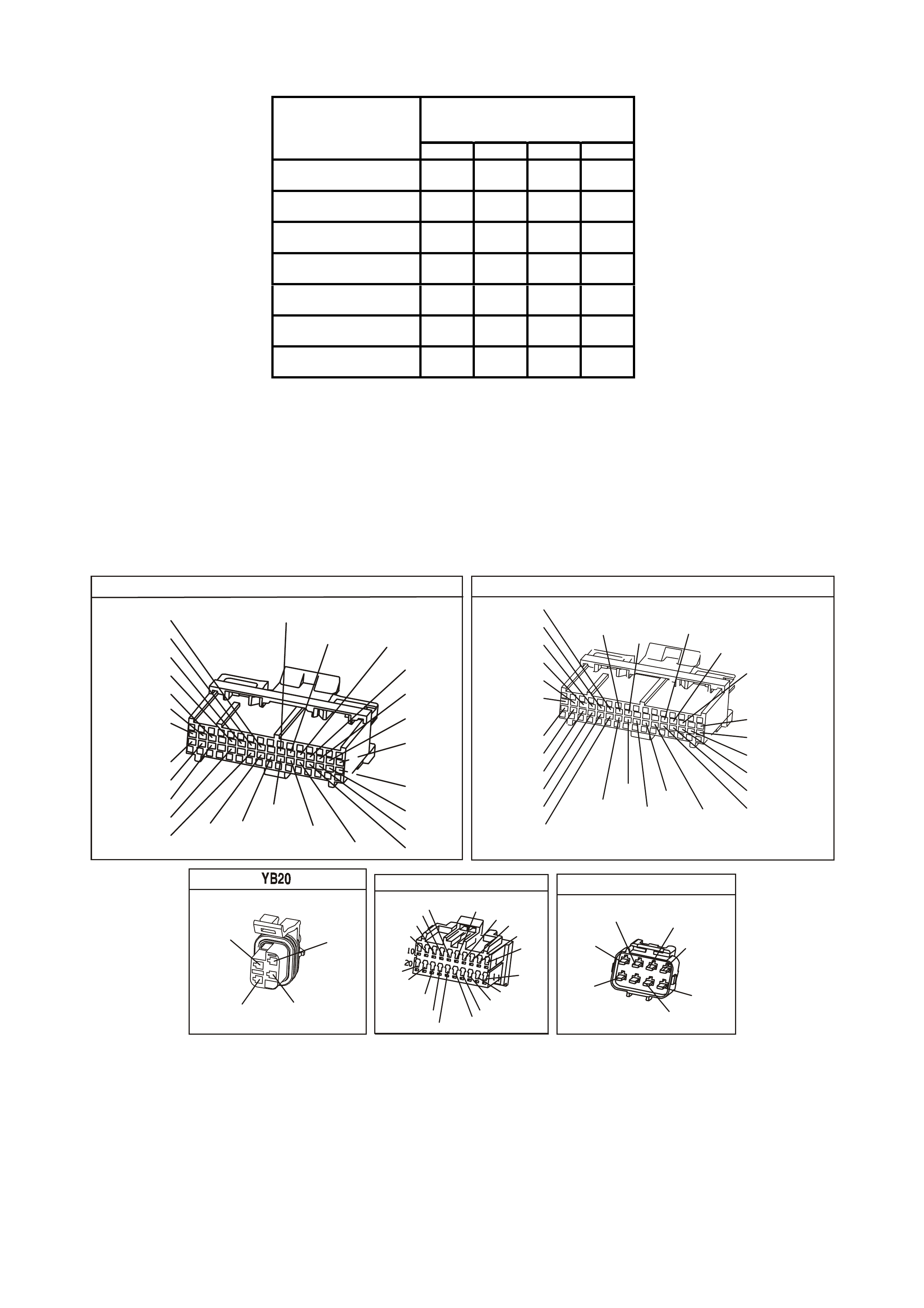

GEN3 0101

FUEL INJECTOR

TESTER

LOW VEHICLE BATTERY

READY TO TEST

TEST IN PROGRESS

AMPERAGE SUPPLY SELECTOR SWITCH

PUSH TO START TEST

Coil Test

4 amp

2.5 amp

0.5 amp

Balance Test

4 amp

0.5-2.5

amp

1

2

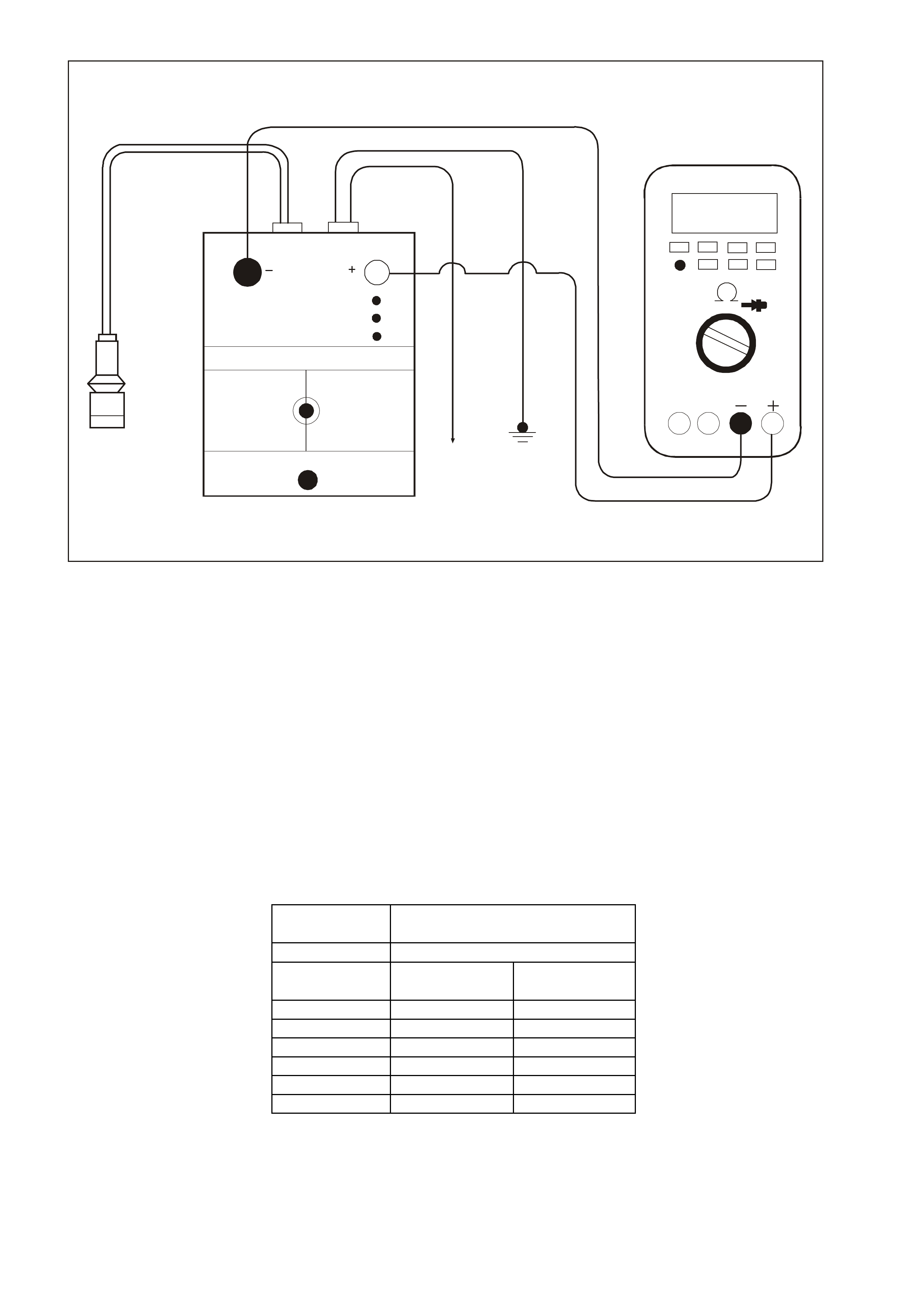

TABLE 2.8 V6 PCM FUEL INJECTOR BALANCE TEST

1. First Reading

2. Second Reading

Test Description

Caution: Wrap a shop towel around the fuel pressure connection in order to reduce the risk of fire and

personal injury. The towel will absorb any fuel leakage that occurs during the connection of the fuel

pressure gauge. Place the towel in an approved container when the connection of the fuel pressure gauge

is complete.

4. The engine coolant temperature must be below the operating temperature in order to avoid irregular fuel

pressure readings due to Hot Soak fuel boiling.

5. The fuel pressure should be within the specified range. If the fuel pressure is not within the specified range, go

to Fuel System Diagnosis in Section 6C1-2A.

6. The fuel pressure should reach a steady value. If the fuel pressure does not reach a steady value, go to Fuel

System Diagnosis.

7. If the pressure drop value for each fuel injector is within 10 kPa (1.5 psi) of the average pressure drop value, the

fuel injectors are flowing properly. Calculate the pressure drop value for each fuel injector by subtracting the

second pressure reading from the first pressure reading. Refer to the illustration above.

Running the engine after each injector test will prevent the engine from flooding.

TABLE 2.8 V6 PCM FUEL INJECTOR BALANCE TEST

Step Action Value(s) Yes No

1 Did you perform the Powertrain On-Board Diagnostic

(OBD) System Check? Go to Step 2 Go to Powertrain

OBD System

Check Table in

Section 6C1-2A

2 Did you perform the Fuel Injector Coil Test Procedure? Go to Step 3 Go to Fuel Inj.

Coil Test - EC T

Between

10-35°C of the

VX Series

Service

Information

3 Is the engine coolant temperature above the specified

value? 94°C (201°F) Go to Step 4 Go to Step 5

Step Action Value(s) Yes No

4 Allow the engine to cool below the specified value.

Is the engine coolant temperature below the specified

value?

94°C (201°F) Go to Step 5

5 Caution: Wrap a shop towel around the fuel pressure

connection in order to reduce the risk of fire and

personal injury. The towel will absorb any fuel

leakage that occurs during the connection of the fuel

pressure gauge. Place the towel in an approved

container when the connection of the fuel pressure

gauge is complete.

1. Connect the Fuel Gauge Schrader Fitting Adapter

AU453 to the fuel rail and connect SD28018 fuel

pressure gauge to the Schrader Fitting Adapter.

2. Energise the fuel pump using the scan tool.

3. Place the bleed hose of the fuel pressure gauge into

an approved petrol container.

4. Bleed the air out of the fuel pressure gauge.

5. Observe the reading on the fuel pressure gauge.

Is the fuel pressure within the specified limits?

270-350 kPa

(55-62 psi) Go to Step 6 Go to

Fuel System

Diagnosis in

Section 6C1-2A

6 Turn the fuel pump OFF.

Does the fuel pump remain constant? Go to Step 7 Go to

Fuel System

Diagnosis in

Section 6C1-2A

7 1. Connect the J 39021 fuel injector tester to a fuel

injector.

2. Set the amperage supply selector switch on the fuel

injector tester to the Balance Test 0.5-2.5 amp

position.

3. Turn the fuel pump ON then OFF in order to

pressurise the fuel system.

4. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure stabilises. This

is the 1st pressure reading (refer to (1) in the

illustration).

5. Energise the fuel injector by depressing the Push to

Start Test button on the fuel injector tester.

6. Record the fuel pressure indicated by the fuel

pressure gauge after the fuel pressure gauge needle

has stopped moving. This is the 2nd pressure reading

(refer to (2) in the illustration).

7. Subtract the 2nd pressure reading from the 1st

pressure reading for one fuel injector. The result is the

pressure drop value.

8. Run the engine after each test to clear the residual

fuel from the cylinder.

Was test completed?

Go to Step 8

8 1. Repeat Steps 1 through 7 for each fuel injector.

2. Obtain a pressure drop value for each fuel injector.

3. Add all of the individual pressure drop values. This is

the total pressure drop.

4. Divide the total pressure drop by the number of fuel

injectors. This is the average pressure drop.

Does any fuel injector have a pressure drop value that is

either higher than the average pressure drop or lower

than the average pressure drop by the specified value?

10 kPa

(1.5 psi) Go to Step 9 Go to Symptoms

9 NOTE: Do not repeat any portion of this test before

running the engine in order to prevent the engine from

flooding.

Re-test any fuel injector that does not meet the

specification. Refer to procedure in Step 7.

Does any fuel injector still have a pressure drop value

that is either higher than the average pressure drop or

lower than the average pressure drop by the specified

value?

10 kPa

(1.5 psi) Go to Step 10 Go to Symptoms

10 Replace the faulty fuel injector(s). Refer to Fuel Injector

Replacement in Section 6C1-3.

Is the replacement complete?

System OK

GEN3 0102

FUEL INJECTO R

TESTER

AMPERAG E SUPPLY SELECTOR SWITCH

PUS H TO START TEST

LOW VEHICLE BATTER Y

READY TO TEST

TES T IN PROGR E SS

J 39021

B+

J 39 2 00 DM M

V-DC mA

V-AC A

OFF µ A

mV

Coil Test

4 amp

2.5 amp

0.5 amp

Balance Test

4 amp

0.5-2.5

amp

TABLE 2.9 V6 PCM FUEL INJECTOR COIL TEST - ECT BETWEEN 10 - 35°C

Test Description

Caution: Wrap a shop towel around the fuel pressure connection in order to reduce the risk of fire and

personal injury. The towel will absorb any fuel leakage that occurs during the connection of the fuel

pressure gauge. Place the towel in an approved container w hen the connection of the fuel pressure gauge

is complete.

2. The engine coolant tem perature aff ects the ability of the fuel injector tes ter to detect a f aulty fuel injector. If the

engine coolant temperature is NOT between 10°C and 35°C (50°F and 95°F), go to Fuel Inj. Coil Test - ECT

Outside 10-35°C.

3. The first second of the voltage displayed by the DMM may be inaccurate due to the initial current surge.

Therefore, record the lowest voltage displayed by the DMM after the first second of the test. The voltage

displayed by the DMM should be within the specif ied range ( refer to the exam ple). T he voltage dis played by the

DMM m ay increase throughout the test as a fuel injector windings warm and the resistance of the fuel injector

windings changes. An erratic voltage reading (large fluctuations in voltage that do not stabilise) indicates an

intermittent connection within the fuel injector.

Examples

Resistance

Ohms Voltage Specification at

10°C-35°C (50°F-95°F)

11.4- 12.6 5.7 - 6.6 V

Fuel Injector

Number Voltage

Reading

Pass/Fail

1 6.3 P

2 5.9 P

3 6.2 P

4 6.1 P

5 4.8 F

6 6.0 P

TABLE 2.9 V6 PCM FUEL INJECTOR COIL TEST - ECT BETWEEN 10 - 35°C

Step Action Value(s) Yes No

1 Did you perform the Powertrain On-Board Diagnostic

(OBD) System Check? Go to Step 2 Go to Powertrain

OBD System

Check Table in

Section 6C3-2A

2 1. Connect the Tech 2 scan tool.

2. Check the engine coolant temperature.

Is the engine coolant temperature within the specified

value?

10°C - 35°C

(50°F - 95°F) Go to Step 3 Go to Fuel Inj.

Coil Test - EC T

Outside 10-35°C

of the VX Series

Service

Information

3 1. Turn the ignition ON

Note: In order to prevent flooding of a single cylinder and

possible engine damage, relieve the fuel pressure before

performing the fuel injector coil test procedure.

2. Relieve the fuel pressure. Refer to the Fuel Pressure

Relief Procedure.

3. Access the fuel injector electrical connectors as

required.

4. Connect the J 39201 fuel injector tester to B+ and

earth.

5. Set the amperage supply selector switch on the fuel

injector tester to the Coil Test 0.5 amp position.

6. Connect the leads from the J 39200 Digital Multi-

Meter (DMM J 39200) to the fuel injector tester. Refer

to the illustration associated with the test description.

7. Set the DMM to the tenths scale (0.0).

8. Connect the fuel injector tester to a fuel injector.

IMPORTANT: Check the engine coolant temperature

again in order to ensure that the correct Table is being

used.

9. Press the Push to Start Test button on the fuel

injector tester.

10. Observe the voltage reading on the DMM.

IMPORTANT: The voltage reading may rise during the

test.

11. Record the lowest voltage observed after the first

second of the test.

12. Repeat Steps 8 through 11 for each fuel injector.

Did any fuel injector have an erratic voltage reading

(large fluctuations in voltage that do not stabilise) or

voltage readings outside of the specified value?

5.7-6.6 V Go to Step 4 Go to Fuel

Injector Balance

Test of the VX

Series Service

Information

4 Replace the faulty fuel injector(s). Refer to Fuel Injector

Replacement in Section 6C1-3 of the VX Series Service

Information.

Is the replacement complete?

Go to Fuel

Injector Balance

Test of the VX

Series Service

Information

GEN3 0102

FUEL INJECTO R

TESTER

AMPERAGE SUPPLY SEL ECT OR SWITCH

PUS H TO START TEST

LOW VEHICLE BATTER Y

READY TO TEST

TES T IN PROGR E SS

J 39021

B+

J 39 2 00 DM M

V-DC mA

V-AC A

OFF µ A

mV

Coil Test

4 amp

2.5 amp

0.5 amp

Balance Test

4 amp

0.5-2.5

amp

TABLE 3.0 V6 PCM FUEL INJECTOR COIL TEST - ECT OUTSIDE 10 - 35°C

Test Description

Caution: Wrap a shop towel around the fuel pressure connection in order to reduce the risk of fire and

personal injury. The towel will absorb any fuel leakage that occurs during the connection of the fuel

pressure gauge. Place the towel in an approved container w hen the connection of the fuel pressure gauge

is complete.

2. The engine coolant tem perature affec ts the ability of the f uel injector tester to detect a f aulty fuel injector. If the

engine coolant temperature is NOT outside 10°C and 35°C (50°F and 95°F), go to Fuel Inj Coil Test - ECT

Between 10-35°C of the VX Series Service Information.

3. The first second of the voltage displayed by the DMM may be inaccurate due to the initial current surge.

Therefore, record the lowest voltage displayed by the DMM after the first second of the test. The voltage

displayed by the DMM may increase throughout the test as the f uel injector windings warm and the resistance

of the fuel injector windings changes. An erratic voltage reading (large fluctuations in voltage that do not

stabilise) indicates an intermittent connection within the fuel injector.

From the voltages rec orded, identify the highest voltage, excluding any voltages above 9.5 volts. Subtract each

voltage that is not above 9.5 volts from the highest voltage. Record each subtracted value (refer to the

Exam ple) . T he s ubtr act ed value f or any fuel injec tor with a subtr acted value that is greater than 0.6 volt is faulty.

Replace the fuel injector. A fuel injector with a recorded voltage above 9.5 volts is also faulty. Replace the fuel

injector. Examples

Highest Voltage

Reading Acceptable Subtracted

Value Above/Below

10°C-35°C (50°F-95°F)

7.1 V 0.6 V

Injector

Number

Voltage Subtracted

Value

Pass/Fail

1 9.8 -- F

2 6.6 0.5 P

3 6.9 0.2 P

4 5.8 1.3 F

5 7.0 0.1 P

6 7.1 0.0 P

TABLE 3.0 V6 PCM FUEL INJECTOR COIL TEST - ECT OUTSIDE 10 - 35°C

Step Action Value(s) Yes No

1 Did you perform the Powertrain On-Board Diagnostic

(OBD) System Check? Go to Step 2 Go to Powertrain

OBD System

Check Table in

Section 6C3-2A

2 1. Connect the Tech 2 scan tool.

2. Check the engine coolant temperature.

Is the engine coolant temperature outside the specified

value?

10°C - 35°C

(50°F - 95°F) Go to Step 3 Go to Fuel Inj

Coil Test - EC T

Between

10-35°C of the

VX Series

Service

Information

3 1. Turn the ignition off.

Note: In order to prevent flooding of a single cylinder and

possible engine damage, relieve the fuel pressure before

performing the fuel injector coil test procedure.

2. Relieve the fuel pressure. Refer to the Fuel Pressure

Relief Procedure in Section 6C1-3 of the VX Series

Service Information.

3. Access the fuel injector electrical connectors as

required.

4. Connect the J 39201 fuel injector tester to B+ and

earth.

5. Set the amperage supply selector switch on the fuel

injector tester to the Coil Test 0.5 amp position.

6. Connect the leads from the J 39200 Digital Multi-

Meter (DMM J 39200) to the fuel injector tester. Refer

to the illustration associated with the test description.

7. Set the DMM to the tenths scale (0.0).

8. Connect the fuel injector tester to a fuel injector.

IMPORTANT: Check the engine coolant temperature

again in order to ensure that the correct Table is being

used.

9. Press the Push to Start Test button on the fuel

injector tester.

10. Observe the voltage reading on the DMM.

IMPORTANT: The voltage reading may rise during the

test.

11. Record the lowest voltage observed after the first

second of the test.

12. Repeat Steps 8 through 11 for each fuel injector.

13. Identify the highest voltage reading recorded from the

highest voltage reading recorded.

14. Subtract any other voltage reading recorded from the

highest voltage reading recorded.

15. Repeat Step 14 for all the remaining fuel injectors.

Is any value that resulted from subtracting greater than

the specified value?

0.6 V Go to Step 4 Go to Fuel

Injector Balance

Test of the VX

Series Service

Information

4 Replace any fuel injector that had any of the following:

• A subtracted value exceeding 0.6 volts.

• An initial reading above 9.5 volts.

• An erratic reading.

Refer to Fuel Injector Replacement in Section 6C1-3 of

the VX Series Service Information.

Is the replacement complete?

Go to Fuel

Injector Balance

Test of the VX

Series Service

Information

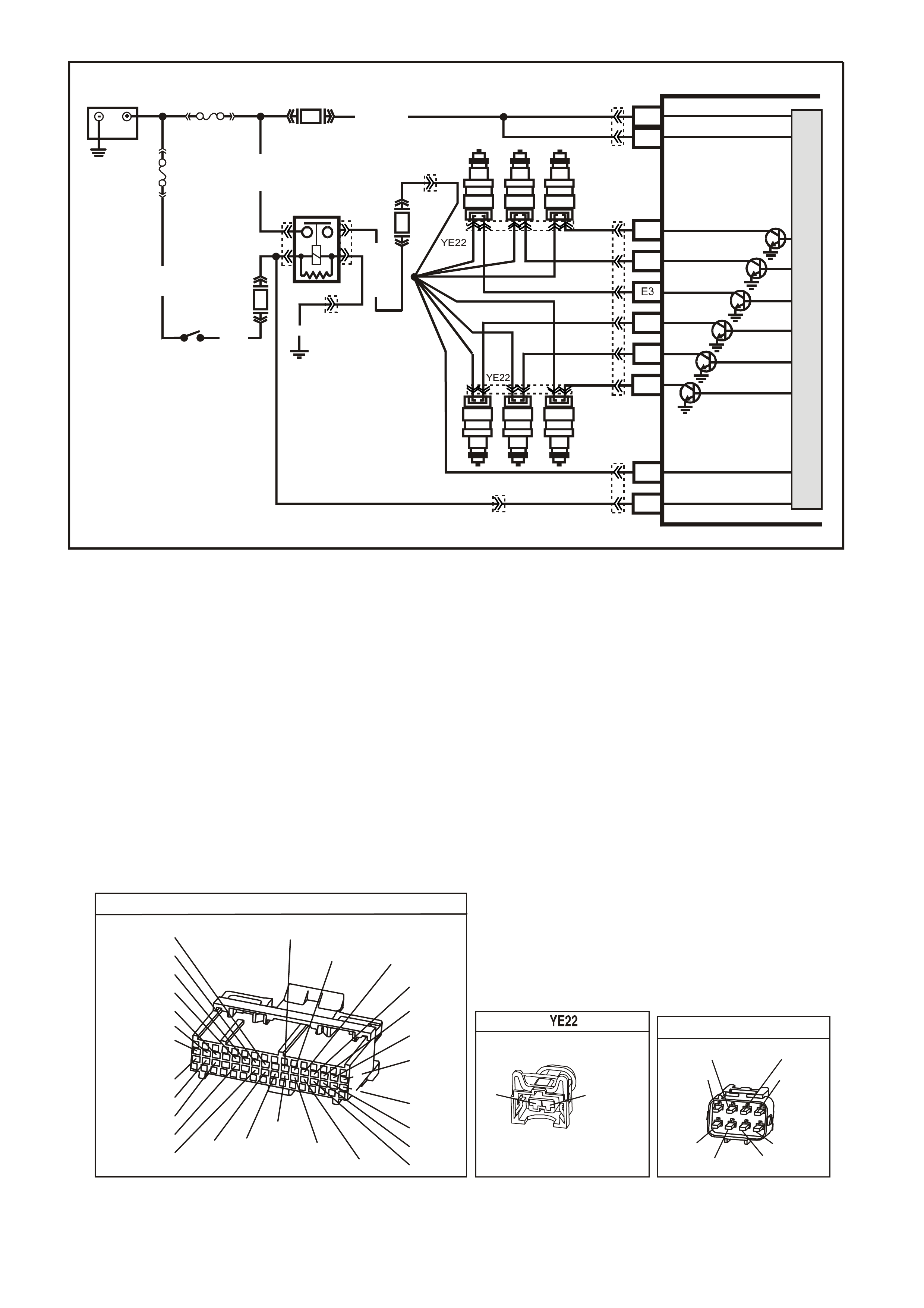

TABLE 3.1 V6 PCM FUEL INJECTOR CIRCUIT DIAGNOSIS

Circuit Description

The PCM will enable an injector on the intake stroke of each cylinder. Individual cylinder fuel control is referred to as

Sequential Multiport Fuel Injector (SFI).

Battery voltage is supplied directly to the fuel injectors. The PCM controls each injector by earthing the control circuit

via an internal switch called a driver. The primary function of the driver is to supply the earth for the component

being controlled.

Diagnostic Aids

• If an injector is disconnected while the engine is operating the injector driver will be disabled for the entire

ignition cycle.

• When the injector driver is disabled, an engine misfire will be apparent.

• For an intermittent condition, refer to Section 6C1-2B Symptoms of the VX Series Service Information.

Test Description

The numbers below refer to the step numbers on the diagnostic table.

4. This step checks to see if each injector electrically is functioning properly.

6. This step checks to see if there is a short to earth in the injector ignition feed circuits.

9. This step checks for an open or short the earth in the injector driver circuit.

YE1 94

P.C.M. C ONNECTOR 3

LG/B

(366)

G

(843)

B/W

F16

B/Y

BR/Y

(1228)

(469)

Y

(451)

F1

P

(841)

BLU

V

E1

LBLU

(845)

BLU

B

(1226)

W/B

BLU/W

V

R

(435)

(31)

(1229)

GY

(1224)

Y

(846)

GY

(842)

(452)

(774)

(304)

BR/Y

(411)

(439)

GY/BLU

BLU

(1225)

E16

(1427)

(429)

(844)

B/O

(434)

OR AUTO

GY/BLU

GY

(1434)

MAN

(776)

W

BLU/W

Y

GY

(771)

(772)

(773)

INJECTORS

GY

(1)

(842)

(481)

Y

V

BLU

(6)

(4)

(2)

(846)

(843)

G

R

(845)

(841)

(5)

(844)

BR/Y

(3)

YE111

ENGINE CONNECTOR 2

(482)

(481)

R

LG

GY

G

(434)

(129)

P

(439)

(59)

(366)

LG/B

GW/B

(451)

SUPERVX017

# 2 # 4 # 6

# 1 # 3 # 5

PCM

A8

B8

F3

F1

F2

E2

E4

B12

A4

BATTERY FEED

BATTERY FEED

O

(740)

O

(740)

BLU

(841)

V

(843)

GY

(845)

INJECTOR CONTROL

IN JECTOR VOLTAGE

MONITOR LINE

IGNITION FEED

O/Y (479)

EFI REL AY

B/W (152)

LOC. E4

P (3 )

O/B (740)

IGN SW

M

I

C

R

O

R

(481)

P

(39)

Y

(846)

BR/Y

(844)

G

(842)

F31

F14

F34

BATTERY

FS

FJ

R (2)

(1040)

YE112

YE114

YE111

YB194

YB188

YE39 YE39

YB188

TABLE 3.1 V6 PCM FUEL INJECTOR CIRCUIT DIAGNOSIS

Step Action Value(s) Yes No

1 Did you perform the Powertrain On-Board Diagnostic

(OBD) System Check? Go to Step 2 Go to Powertrain

OBD System

Check Table in

Section 6C3-2A

2 Is the injector fuse F34 OK? Go to Step 3 Go to Step 6

3 1. Turn OFF the ignition.

2. Disconnect all the injector harness connectors.

3. Turn ON the ignition leaving the engine OFF.

4. Using a test lamp J 34142-A connected to earth,

probe each injector harness ignition feed circuits.

Does the test lamp illuminate for all injectors?

Go to Step 4 Go to Step 8

4 1. Turn OFF the ignition.

2. Connect the injector test lamp (ST 8329) to isolate the

injector harness to each of the injectors one at a time.

3. Start the engine and idle.

Does the test lamp flash for all injectors?

Go to Step 5 Go to Step 9

5 1. Inspect the injector harness terminals for correct

terminal tension.

2. Replace terminal as necessary.

Was a repair necessary?

System OK Go to Step 13

6 1. Turn OFF the ignition.

2. Disconnect the injector harness connectors.

3. Using a test lamp J 34142-B connected to earth,

probe the injector harness ignition feed circuit at each

injector.

Does the test lamp illuminate?

Go to Step 11 Go to Step 7

7 Measure the resistance of each injector that is powered

by the fuse that is open using a DMM J 39200.

Does any injector measure less than the specified value?

11.4Ω Go to Step 13 Go to Step 12