SECTION 6C1-2 – DIAGNOSIS -

V6 SUPERCHARGED ENGINE

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in VX Service Information for correct workshop practices with regards to safety

and/or property damage.

GENERAL DESCRIPTI O N

This is where to start all driveability and emissions diagnosis, once you read and understand

Section 6C1-1 GENERAL INFORMATION of the VX Series Service Information. The beginning of

Section 6C1-2A contains reference material: wiring diagrams, control module terminal end views, and engine

component locations. Remember, this information is for reference; do not start diagnosis using these pages.

Always start diagnosis on the page titled Powertrain OBD System Check. This check verifies that the diagnostic

circuits are operating properly, then sends you to the correct service information for diagnosis.

If the initial steps in the Powertrain OBD System Check reveal a problem, or if the engine does not s tart, you will be

using one or more tables in Section 6C1-2A of the VX Series Service Information for diagnosis. The Powertrain

OBD System Check will s end you to the correc t table. These tables f ollow the Powertr ain OBD System Check and

problems that prevent the engine from starting.

If the Powertrain OBD System Check shows that diagnostic trouble codes have been stored, proceed to the

appropriate Diagnostic Trouble Code (DTC) diagnosis pages. If more than one diagnostic trouble code has been

stored, always start diagnostic trouble code diagnosis with the lowest diagnostic trouble code number and work

upward. Diagnostic trouble code diagnosis pages start immediately after the diagnosis tables in Section 6C1-2A.

DIAGNOSTIC PRECAUTIONS

THE FOLLOWING REQUIREMENTS MUST BE OBSERVED WHEN WORKING ON VEHICLES.

1. Before removing any PCM system component, disconnect the battery earth lead.

2. Never start the engine without the battery being solidly connected.

3. Never separate the battery from the on board electrical system while the engine is running.

4. When charging the battery, disconnect the battery from the vehicle's electrical system.

5. Never subject the PCM to temperatures above 80° C i.e. paint oven. Always remove control unit first if this

temperature is to be exceeded.

6. Ensure that all cable harness plugs are connected solidly and that battery terminals are thoroughly clean.

7. The powertrain m anagem ent s ystem harnes s connec tors ar e designed to fit in only one way; there are indexing

tabs and slots on both halves of the connector. Forcing the connector into place is not necessary if it is being

installed with the proper orientation. Failure to take care to match the indexing tabs and slots to ensure the

connector is being installed correctly can cause damage to the connector, the module, or other vehicle

components or systems.

8. Never connect or disconnect the cable harness plug at the PCM when the ignition is switched ON.

9. Before attempting any electric Arc welding on the vehicle, disconnect the battery leads and the PCM

connectors.

10. When steam cleaning engines, do not direct the steam cleaning nozzle at PCM system components. If this

happens, corrosion of the terminals can take place.

11. Use only the test equipment specified in the diagnostic tables, since other test equipment may either give

incorrect results or damage good components.

12. All voltage m easurements using a voltmeter must use a digital m ultimeter with an internal im pedance rating of

at least 10 million ohms per volt (10 mega ohms) such as the DMM J 39200.

13. When a test light is specified, a "low-power" test light must be used. Do not use a high - wattage test light.

W hile a particular brand of test light is not suggested, a simple test on any test light will ensure it to be OK f or

PCM circuit testing. Connect an accurate ammeter (such as the high-impedance digital multimeter) in series

with the test light being tested, and power the test light-ammeter circuit with the vehicle battery.

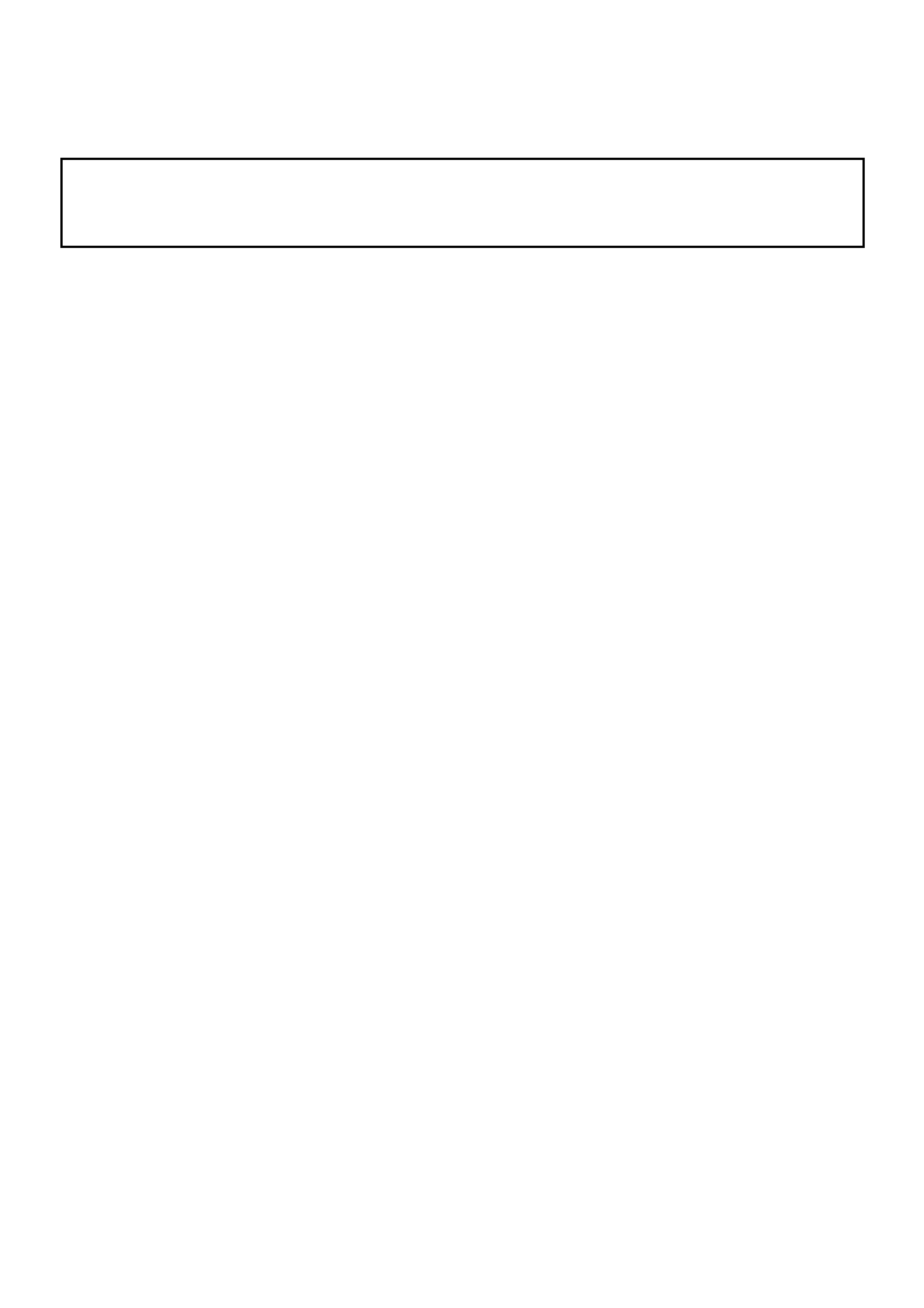

Figure 6C1-2-1

If the ammeter indicates less than 3/10 amp current flow (0.3 A or 300 ma), the test light is OK to use.

If the ammeter indicates more than 3/10 amp current flow (0.3 A or 300 ma), the test light is NOT OK to use.

+

BATTERY

-

DC AMPS

Test Li

g

ht

BLOCKING DRIVE WHEELS

The vehicle drive wheels always should be blocked and the parking brake firmly set while checking any system.

VISUAL/PHYSICAL INSPECTION

A car ef ul vis ual and physical ins pection mus t be performed as par t of any diagnostic procedur e. T his c an of ten lead

to fixing a problem without further steps. Inspect all the wires in the engine compartment for bad connections,

burned or chafed spots, pinched wires, or contact with sharp edges or hot exhaust manifolds. Also, inspect all the

wires. Check beneath the air cleaner, the compressor, the generator, etc. This visual/physical inspection is very

important. The inspection must be done carefully and thoroughly.

BASIC KNOW LE DGE AND TOOLS REQUIRED

To use this service information most effectively, a general understanding of basic electrical circuits and circuit

testing tools is required. You should be familiar with wiring diagrams, the meaning of voltage, ohms, amps, the

basic theories of electricity, and understand what happens in an open or shorted circuit.

To perform system diagnosis, the following tools are required.

• A Tech 2

• A test light

• A digital multimeter with 10 megaohms impedance

• A vacuum gauge

• A fuel pressure gauge and suitable fittings

• Fuel injector coil/ balance tester

• IAC motor analyser

Familiarise yourself with the tools and their uses before attempting diagnosis. Special tools that are required for

system service and the ones described above are illustrated in Section 6 SPECIAL TOOLS.

ELECTROSTATIC DISCHARGE DAMAGE

Electronic components used to control the systems are often designed to carry very low voltage. They are very

susc eptible to damage caus ed by electros tatic discharge. It is pos sible for less than 100 volts of static electr icity to

cause damage to some electronic components.

By comparison, it takes as much as 4,000 volts for a person to even feel the zap of a static discharge.

There are several ways for a person to become statically charged. The m ost comm on m ethods of charging are by

fric tion and by induction. An ex ample of charging by friction is a per son sliding acr oss a car seat, in which a charge

of as much as 25,000 volts can build.

Charging by induction occurs when a person with well-insulated shoes stands near a highly charged object and

momentarily touches earth. Charges of the same polarity are drained off, leaving the person highly charged with

the opposite polarity. Static charges of either type can cause damage, therefore, use care when handling and

testing the electronic components.

NOTE: To prevent possible Electrostatic Discharge damage:

Do Not touch the PCM connector pins or soldered components on the PCM circuit board.

DIAGNOSTIC INFORMATION

The diagnostic tables and functional checks in this Service Information are designed to locate a faulty circuit or

com ponent through logic bas ed on the process of elimination. The tables are prepared with the understanding that

the vehicle:

• Functioned correctly at the time of assembly.

• There are no multiple faults.

• The problem currently exists.

The PCM per form s a continual s elf- diagnosis on c ertain contr ol func tions. T his diagnos tic capability is supported by

the diagnostic procedures. The PCM indicates the source of a fault through the use of Diagnostic Trouble Codes

(DT Cs). T he DT Cs are two digit codes . When a f ault is detec ted by the PCM, a diagnostic trouble code will set and

the Check Powertrain Malfunction Indicator Lamp (MIL) lamp may illuminate.

SELF-DIAGNOSTICS

The PCM performs system self diagnostics. The PCM can detect and often isolate system faults. W hen a fault is

detected, the PCM sets a DT C that represents the ar ea of the fault. The PCM m ay or may not turn ON the "Check

Powertrain" Lamp.

CHECK POWERTRAIN MALFUNCTION INDICATOR LAMP (MIL)

The instruments receive Check Powertrain MIL

information from the PCM via the serial data bus

normal mode message.

The PCM will command the instruments to turn on

the Check Powertrain MIL for two seconds when

the ignition is first turned on and when a DTC has

been set and the DTC requires the lamp to be

illuminated.

If the instruments do not receive a normal mode

mes sage from the PCM, the MIL will be illuminated

continuously. When the Check Powertrain MIL

remains ON while the engine is running, or when a

fault is s uspected due to a driveability or emiss ions

problem, perform the "On-Board Diagnostic

System Check". Refer to POWERTRAIN OBD

SYSTEM CHECK in Section 6C1-2A of the VX

Series Service Information. These checks will help

identify faults which may not be detected if other

diagnostics are performed.

Figure 6C3-2-2 Check Powertrain Malfunction

Indicator Lamp

INTERMITTENT CHECK POWERTRAIN MALFUNCTION INDICATOR LAMP (MIL)

In the case of an "intermittent" problem, the Check

Powertrain MIL may light for ten seconds and then

go out. The corresponding Diagnostic Trouble

Code will be stored. The DTC will remain stored

until the battery voltage to the PCM has been

disconnected or until it is erased using the Tech 2

scan tool. When unexpected diagnostic trouble

codes appear, chances are that these diagnostic

trouble codes were set by an intermittent fault.

An intermittent DTC may not re-set. If an

intermittent fault occurs, do not use a Diagnostic

Trouble Code Table. Consult the "Diagnostic Aids"

on the facing page. The diagnostic table

corresponds to the intermittent diagnostic trouble

code.

Section 6C1-2B SYMPTOMS TABLES, of the VX

Series Service Information also covers the topic of

"Intermittents." A physical inspection of the

applicable sub-system most often will resolve the

problem. The Tech 2 scan tool also has several

features which can help in diagnosing intermittent

problems.

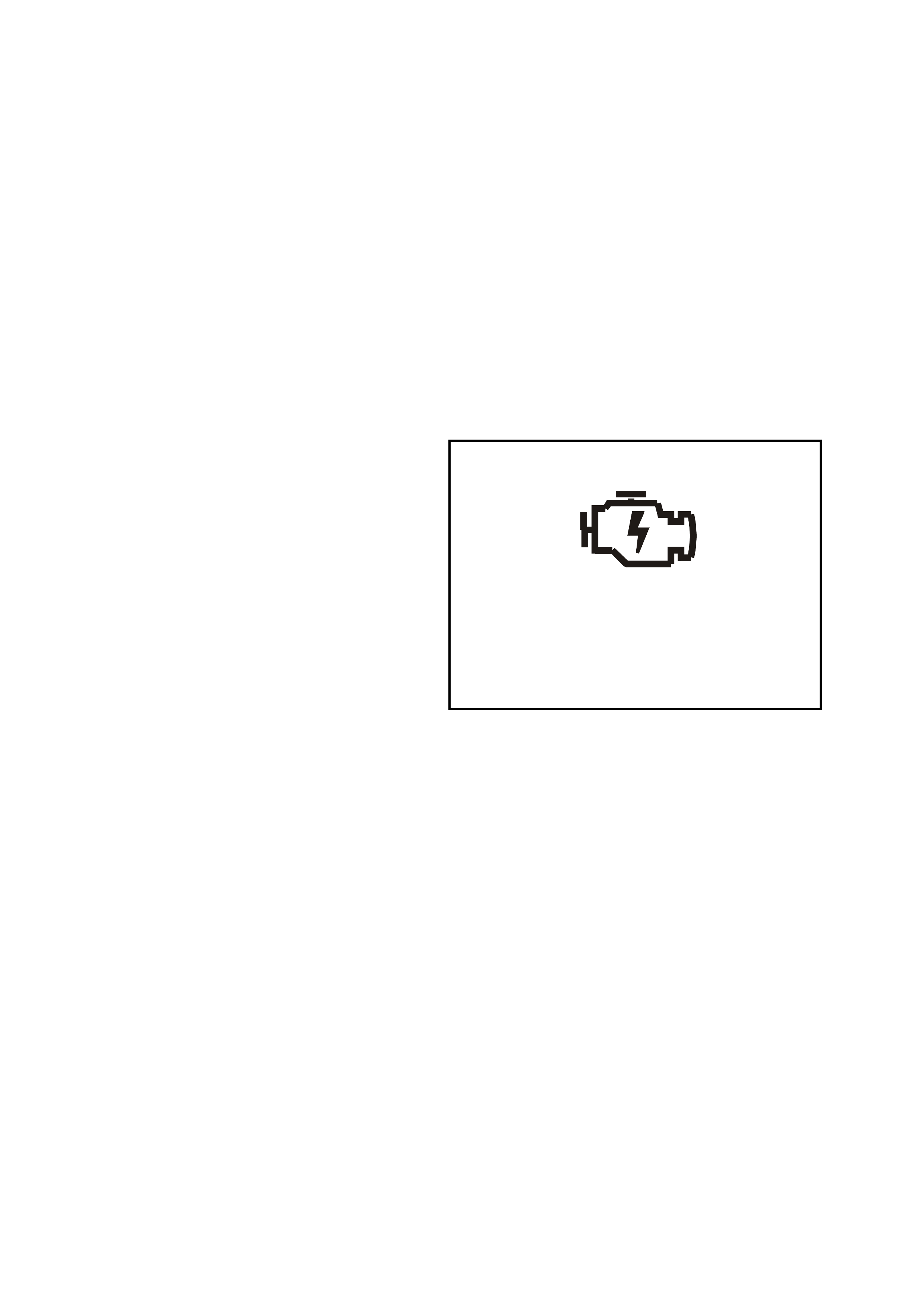

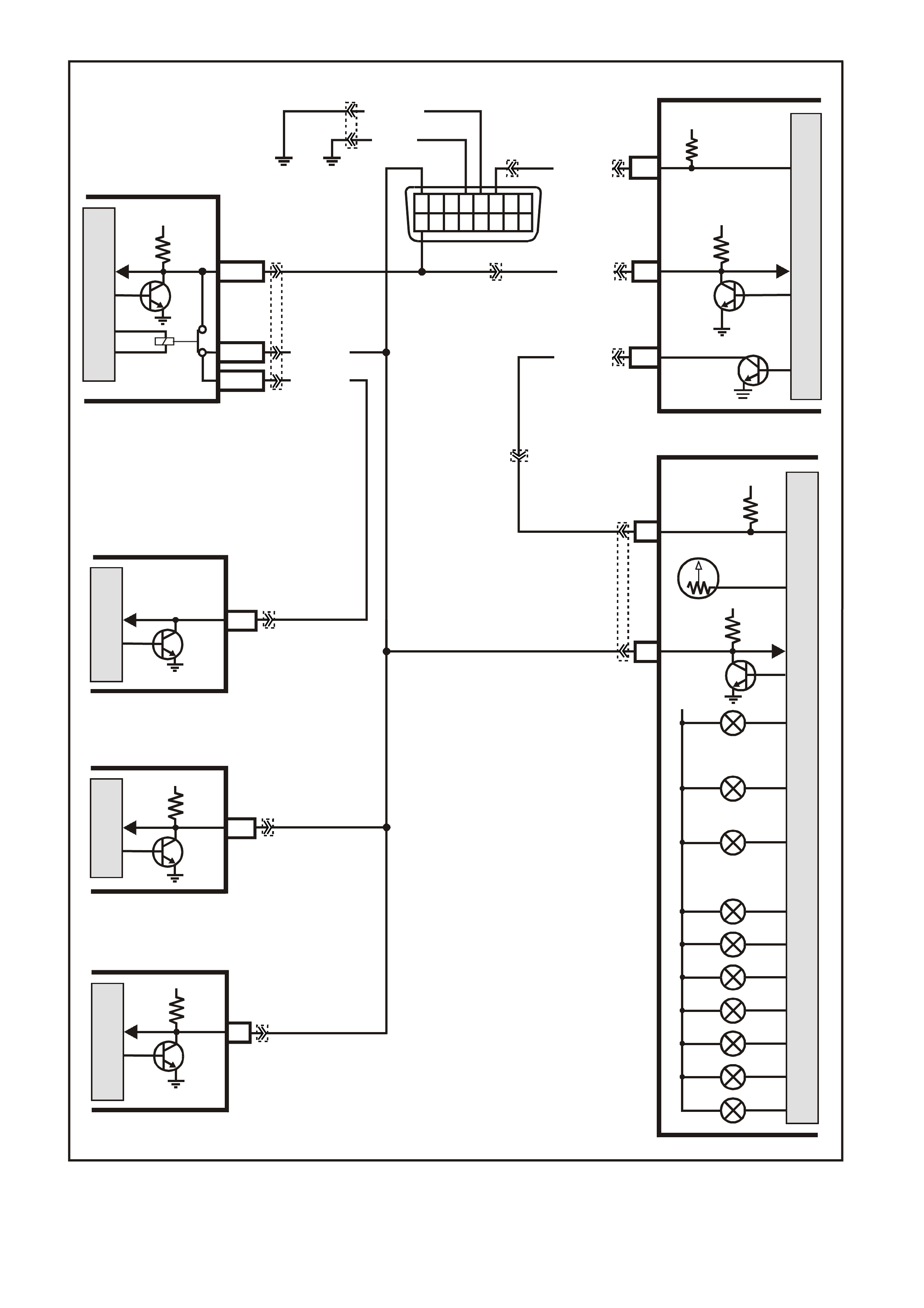

Figure 6C3-2-3 Check Powertrain Lamp Circuit

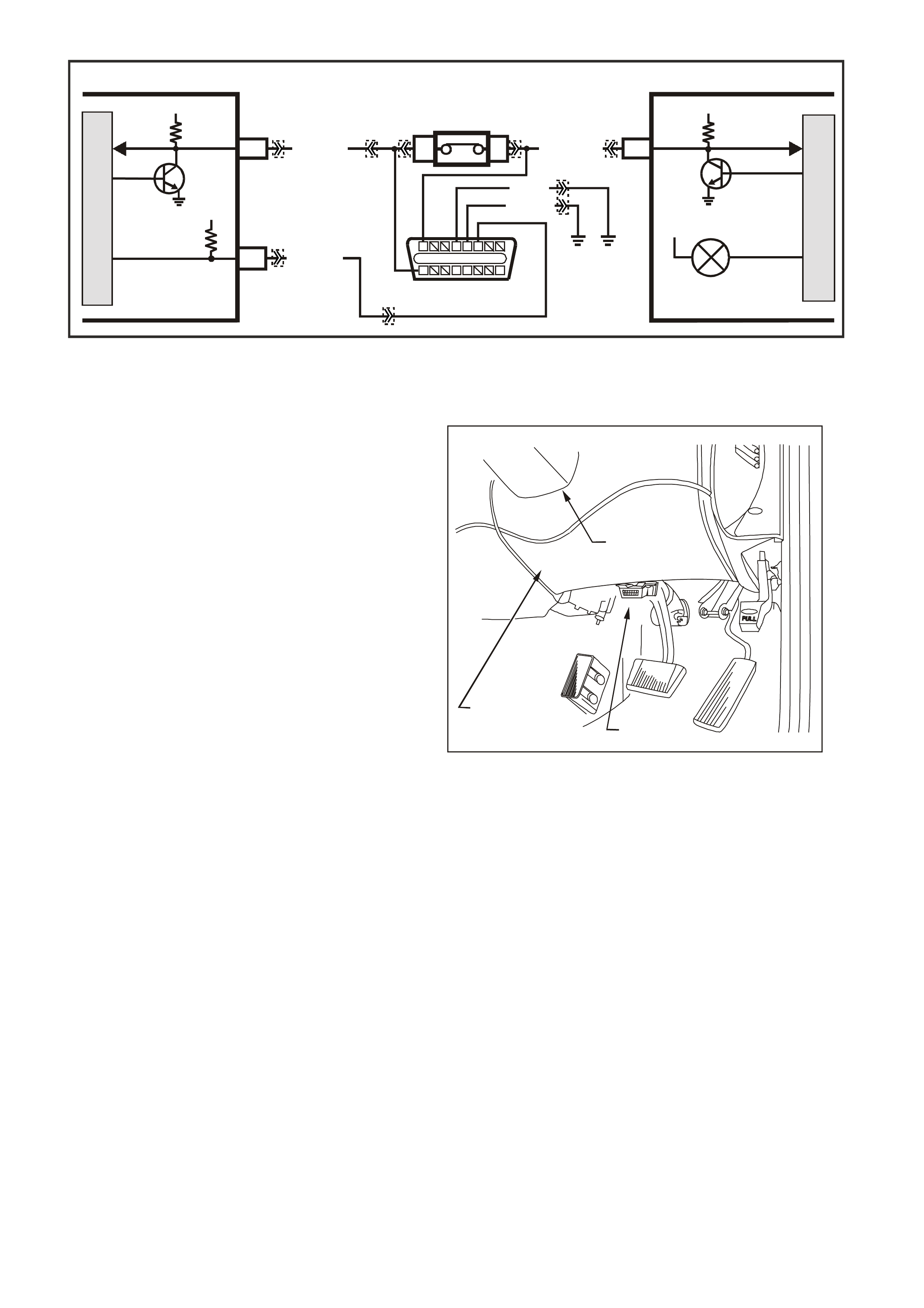

DATA LINK CONNECTOR (DLC)

The DLC is a standardised 16 way connector

located below the instruments panel and close to

the steering column.

1

3

2

Figure 6C3-2-4 Data Link Connector (DLC) Location

1. Steering Column Lower Cover

2. Data Link Connector

3. Instrument Panel Right Hand Cover Assembly

M

I

C

R

O

SUPERVX30

INSTRUMENTPCM

12 SERIAL

DATA

5V

G/W (1220)

LOC. E3

R/B (1221)

CHECK

POWERTRAIN

LAMP

12V

5V

5V

F14

A3

SERIAL

DATA

DIAGNOSTIC

ENABLE

W/B (451)

BCM

E2

D2 E9

D3

DATA LINK

CONNECTOR

1546

1613129

B (150)

B/Y (155 )

M

I

C

R

O

YB66

YE114

YE111

YE112

YB175

YB188

YB194

YB164 YB175

YB164

YB128

The DLC pin 1 is the Secondary UART serial data

circuit.

Tech 2 does not communicate with anything on

terminal 1 this is only used for engineering

purposes.

Pin 4 is the earth circuit for Tech 2, Pin 5 is an

auxiliary earth, that should be used to earth the

Diagnostic Test Enable Circuits.

The DLC pin 6 is the PCM Diagnostic Test Enable

circuit. T his circ uit when jumper ed to DLC pin 5 will

cause the PCM enter the Diagnostic Mode. The

PCM Diagnostic Mode is described later in this

section.

The DLC pin 9 is the primary UART serial data

circuit. The Tech 2 scan tool uses this circuit to

read serial data information from the PCM and

BCM, Instruments, Electronic Climate Control, and

the ABS/ETC Control Modules.

The DLC pin 12 is the ABS/ETC Diagnostic Test

Enable circuit. This circuit when jumpered to DLC

pin 5 will cause the ABS/ETC Control Module to

enter the Diagnostic Mode and flash out ABS/ECT

trouble codes.

The DLC is designed to provide battery voltage to

pin 16 from fuse F31. This circuit is used to power

the Tech 2 scan tool.

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

16

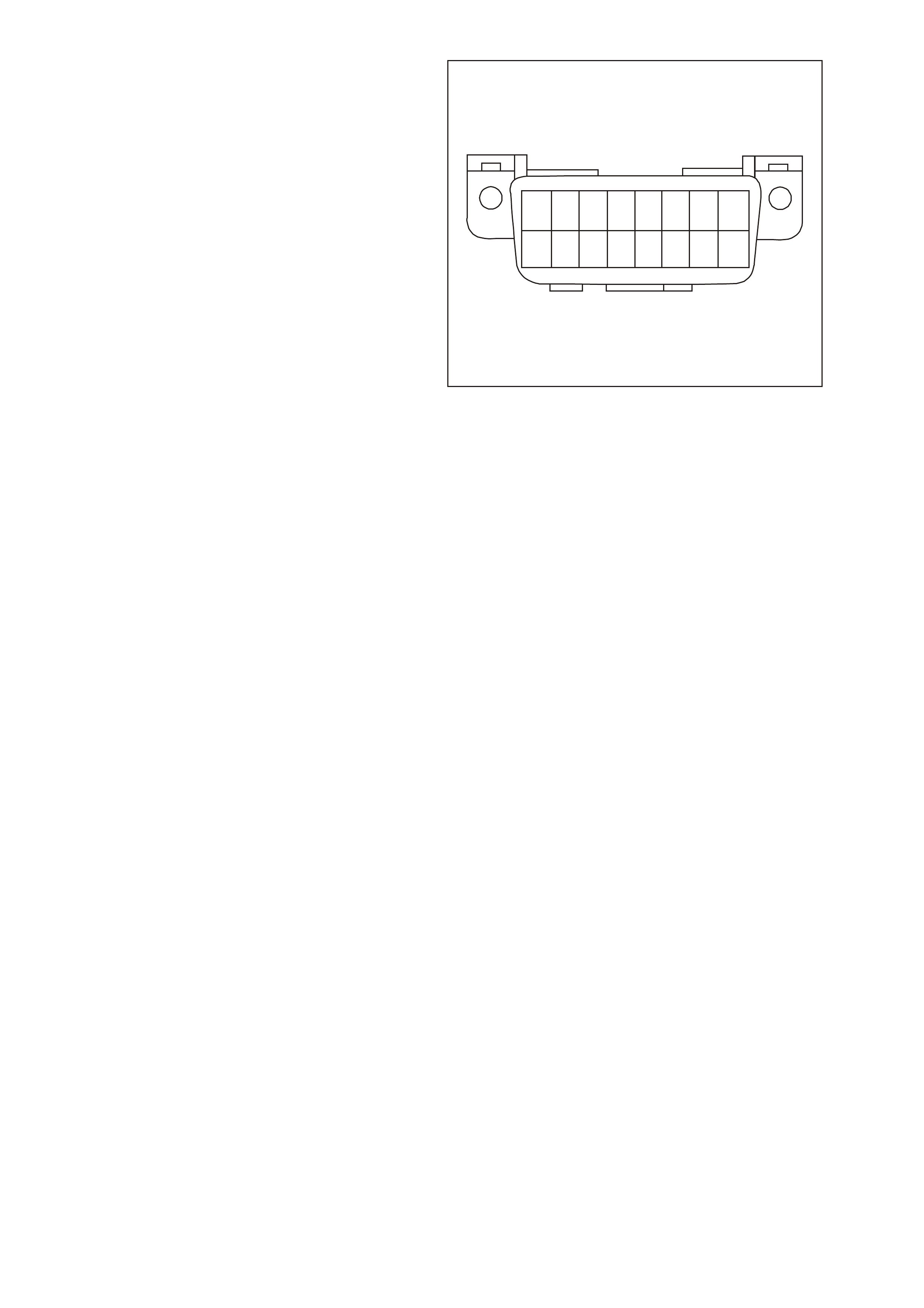

Figure 6C3-2-5 Data Link Connector (DLC)

1. Secondary Serial Data (UART)

4. Earth

5. Earth

6. Diagnostic Test Enable

9. Primary Serial Data (UART)

12. ABS Diagnostic Test Enable

16. Battery Voltage

Figure 6C3-2-6 Data Link Connector Circuits

VXSC057

PCM

A3 SERIAL

DATA

MAIN

5V

LOC. E3

BCM

E2/D2

E9/D3

E3/D13

M

I

C

R

O

SERIAL

DATA

MAIN

SERIAL

DATA AUX.

5V

G/W (1220)

W/G (1220)

HIGH SERIES

BCM TERMINALS

NOMINATED FIRST

DATA

LINK

CONNECTOR

12345678

910111213141516

5V

F14

DIAGNOSTIC

ENABLE

W/B (451)

B/Y (155)

B (150)

R/B (1221)

INSTRUMENTS

ABS/ETC

11

SERIAL

DATA

5V

12

17

SERIAL

DATA

5V

M

I

C

R

O

CHECK

POWERTRAIN

LAMP

OIL PRESSURE

WARNING LAMP

POWER

EC ONOMY LAMP

R

12V

P

N

D

3

1

2

SRS

ECC

9

6

M

I

C

R

O

M

I

C

R

O

SERIAL

DATA

SERIAL

DATA

5V

12V IGN

VEHICLE

SPEED

SPEEDOMETER

VEHICLE SPEED

C5

V/W (123)

M

I

C

R

O

M

I

C

R

O

P

R

O

C

E

S

S

O

R

YE130

YB87

YB190

YB175

YE114

YE111 YB194

YB188

YB193

YE110

YB66

YB128

YE112

YB164

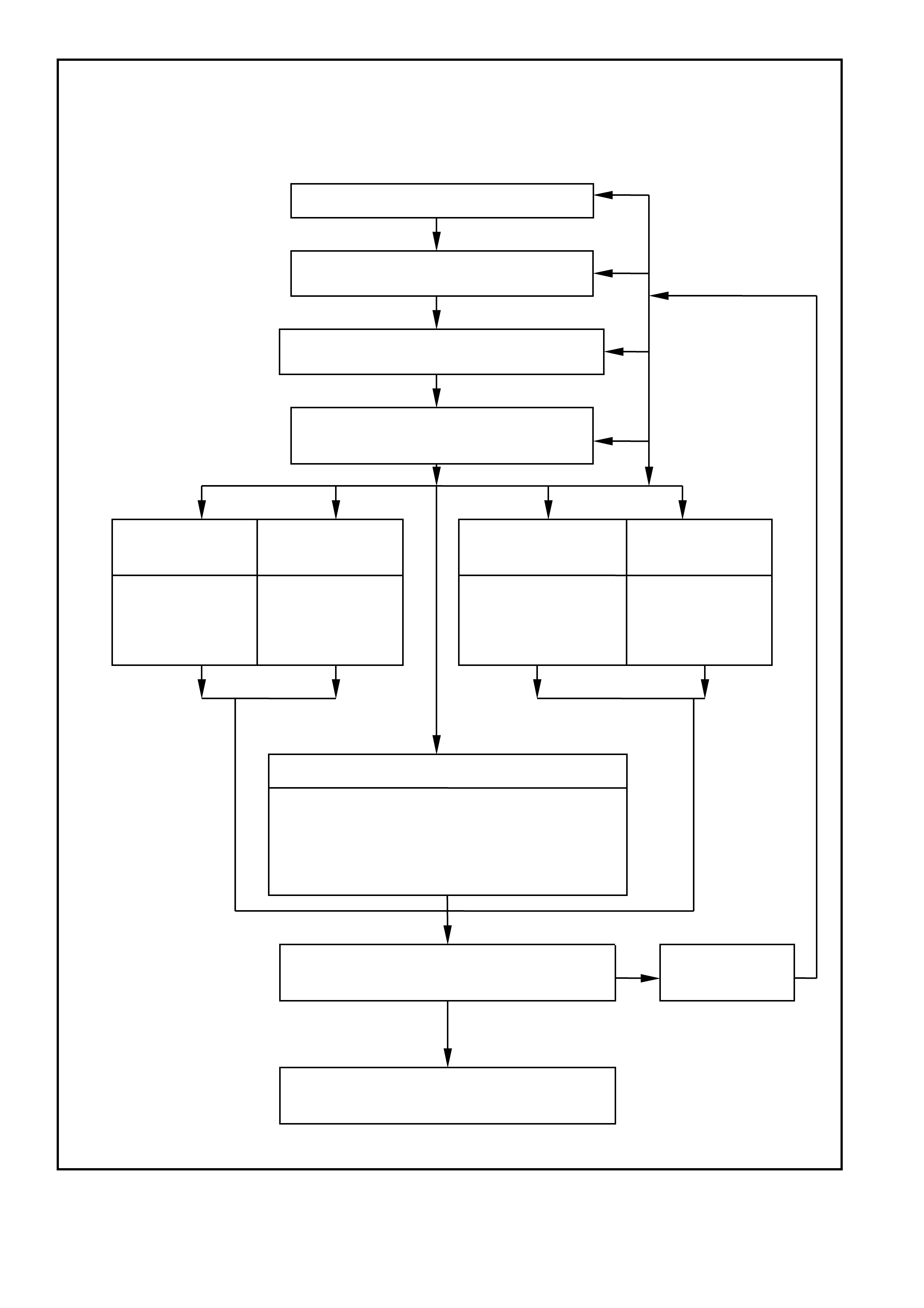

STRATEGY BASED DIAGNOSTICS

The s tr ategy based diagnos tic is a uniform approac h to repair all Elec tric al/Elec tr onic ( E/E) s ystem s . T he diagnos tic

flow can always be used to resolve an E/E s ystem problem and is a star ting point when repairs are necess ary. The

steps below are def ined to instruct the technician how to proceed with a diagnostic. Steps below also ref er to step

numbers found on the Strategy Based Diagnostic table.

1. Verify the Customer Concern: To verify the customer concern, the technician should know the normal

operation of the system.

2. Preliminary Check: Conduct a through visual and operational inspection, review the service history, detect

unusual sounds or odours, and gather diagnostic trouble code information to achieve effective repair.

3. Service information System Check(s): System checks verify proper operation of the system. This will lead

the technician in an organised approach to diagnostics.

4. Check Bulletins an d Other Service Info rmation: This should include videos, newsletters, and ser vice centre

updates.

5. Service Diagnostics (Paper/Electronic)

5.1 DTC Stored: Follow the designed DTC table exactly to make an effective repair.

5.2 Symptom, No DTC: Select the symptom from the symptom tables and follow the diagnostic paths or

suggestions to complete the repair, or refer to the applicable component/system checks in

Section 6C1-2C.

5.3 No Published Diagnostics: Analyze the complaint and develop a plan for diagnostics. Utilise the wiring

diagrams and theory of operation.

Call technical assistance for similar cases where repair history may be available. Combine technician

knowledge with efficient use of the available service information.

5.4 Intermittent: Conditions that are not always present are intermittent. To resolve interm ittents, perform the

following steps:

5.4.1 Observe history DTCs, DTC modes.

5.4.2 Evaluate the symptoms and conditions described by the customer.

5.4.3 Use a check sheet or other method to identify the circuit or electrical system component.

5.4.4 Follow the suggestions for intermittent diagnosis found in the service documentation.

The Tech 2 and DMM have data capturing capabilities that can assist in detection of intermittents.

5.5 Vehicle Operates As Designed/No Trouble Found: This condition exist when the vehicle is found to

operating norm ally. The condition described by the custom er may be nor mal. Verify against another vehic le

that is oper ating normally. The c ondition may be intermittent. Contac t T ec hnic al As sis tanc e if the c oncer n is

common. Verify the complaint under the conditions described by the customer before releasing the vehicle.

6. Re-examine the Concern: When the complaint cannot be successfully found or isolated, a reevaluation is

necessary. The complaint should be re-verified and could be intermittent or normal as per step 5.3 or 5.5.

7. Repair and Verificat ion Tests: After isolating the cause, the r epair should be m ade. Then validate f or proper

operation and verify that the symptom has been corrected. This may involve road testing or other m ethods to

verify the complaint has been resolved under the following conditions:

• Conditions noted by the customer.

• If a DTC was diagnosed, verify a repair by duplicating conditions for setting the DTC.

Figure 6C1-2-7 Strategy Based Diagnostic Table

STRATEGY BASED DIAGNOSTICS

VERIFY CUSTOMER CONCERN

PRELIMI NARY CHECKS

Visual and Operational

Perform Published

POWERTRAI N OBD SYSTEM CHECK

CHECK FOR BULLETINS

(Printed/DCS/Techline Equipment)

1

2

3

4

STORED SYMPTOM

DTC(S) NO DTC(S)

FOLLOW FOLLOW

PUBLISHED PUBLISHED

DTC SYMPTOM

DIAGNOSTICS DIAGNOSTICS

NO PUBLISHED INTERMITTENT

DIA GNOSTICS

Analyze & Develop SEE

Diagnostics or Call DIAG NO STIC

Technical DETAILS

Assistance

5.1 5.2 5.3 5.4

OPERATING AS DESIGNED

• Customer Misunderstanding of System:

Refer to Management or Zone

• Product Problem: Call Technical

Assistance

ISOLATE THE PROBLEM

REPAIR & VERI FY FIX

RE-EXA MINE

THE CONCERN

5.5

NO

Y

ES

7

6

CURRENT DIAGNOSTIC TROUBLE CODES

A current diagnostic trouble code is one that is set in the vehicle at this time. The current diagnostic trouble code

can be flashed out on the "Check Powertrain" lam p by earthing the data link connector term inal "6". The diagnostic

trouble code can also be displayed on the Tech 2 scan tool by pressing the appropriate button at the appropriate

menu. W hen the diagnostic trouble code is displayed, a code descriptor will also be listed on the Tech 2 scan tool

screen. Use of the proper diagnostic trouble code Table will find the cause of the problem.

HISTORY DIAGNOSTIC TROUBLE CODE

A histor y Diagnostic T rouble Code ( DTC ) is one that was a curr ent trouble code at s om e point previously, however,

the fault that caused the diagnostic trouble code to be logged is no longer present. The way to identify whether a

DTC is current or history is to look at the DTC history information parameter "IGN CYCLES" the number is 0 the

DTC is cur rent, any other num ber m eans it's a history DTC. The his tory diagnos tic trouble code can be f lashed out

on the "Check Powertrain" lamp by earthing the data link connector terminal "6". The diagnostic trouble code can

also be displayed on the Tech 2 scan tool by pressing the proper button at the appropriate menu. Use of the

diagnostic trouble code Tables to find the cause of the problem for the history diagnostic trouble code may lead to

replacem ent of good components. W henever a history code is set Refer to Section 6C1-2B "Symptoms" section

and also look at the "Diagnos tic Aids" listed on the diagnostic trouble codes f acing page for c riteria to set the DT C.

History diagnostic trouble codes are usually caused by intermittent conditions.

HOW DTC HISTORY WORKS

When a DTC is set, up to eleven (11) parameters will always be stored with it. The first four (4) parameters are:

1 "Engine speed" - RPM when DTC set .

2. "Times from start" - how long the engine had been running when the DTC set.

3. Times occurred, - number (#) of DTC occurrences.

4. "Ignition cycles" - since DTC last appeared.

Depending upon the DTC, up to 7 additional param eters that are related to this specific DTCs are also stored, for

example, if DTC 21 TP sensor circuit high voltage were set, the variable parameters would be: TPS signal, mass

air flow, battery voltage, reference voltage and RH LTFT.

HOW TO USE DTC HISTORY CODE INFORMATION

Based upon this information that is stored in DTC history information, the technician can obtain the DTC criteria

when the DTC set and should be able to get the DTC to become current again by repeating the criteria.

READING DTC'S

The provision for communicating with the PCM is the Data Link Connector (DLC). It is attached to the instrument

panel lower right hand trim, directly beneath the steering column. It is used in the assembly plant to receive

information in checking that the engine and transmission are operating properly before they leave the plant. The

diagnostic trouble c ode(s) stor ed in the PCM's m emory can be read either through a T ech 2 sc an tool, (a handheld

diagnostic scanner plugged into the DLC), or by counting the number of flashes of the (MIL) "Check Powertrain"

lamp when the diagnostic "test" term inal of the DLC is earthed. The DLC terminal "6" (diagnostic "test" terminal) is

the sixth terminal from the right of the DLC top row. The diagnostic "test" terminal is most easily earthed by

connecting it to term inal "5" (internal PCM earth). The ter minal "5" is to the lef t of term inal "6" on the top row of the

DLC.

Once terminals "5" and "6" have been connected, the ignition switch m ust be moved to the "ON" position, with the

engine not r unning. At this point, the (MIL) "Check Powertrain" lam p s hould flash Diagnos tic T rouble Code 12 thr ee

times consecutively. This would be the following flash sequence: "flash, pause, flash flash, long pause, flash,

pause, flash-flash, long pause, flash, pause, flash flash." Diagnostic Trouble Code 12 indicates that are no

refer ence puls es c oming to the PCM and that the PCM's diagnostic s ystem is oper ating. If Diagnostic Trouble Code

12 is not indicated, a problem is present within the diagnostic s ystem itself , and should be address ed by cons ulting

the "On Board Diagnostic System Check" Table in this section.

Following the output of Diagnostic Trouble Code 12, the (MIL) "Check Powertrain" lamp will indicate a diagnostic

trouble code three times if a diagnostic trouble code is present, or it will simply continue to output Diagnostic

Trouble Code 12. If more than one diagnostic trouble code has been stored in the PCM's memory, the diagnostic

trouble codes will be output f rom the lowest to the highest, with each diagnostic trouble code being displayed three

times.

CLEARING DTCS

To c lear the curr ent diagnostic tr ouble code f rom the m em ory of the PCM, either to determ ine if the m alfunc tion will

occur again or because r epair has been c om pleted, the PCM power feed m ust be disconnected for at least ten (30)

seconds. The PCM power feed can be disconnected by turning the ignition "OFF" and disconnecting the positive

battery terminal. The Tech 2 scan tool has a special mode that must be used to clear both history and current

diagnostic trouble codes.

NOTE: To prevent PCM damage, the ignition must be "OFF" when disconnecting or reconnecting PCM power.

CLEARING DTC HISTORY

The Tech 2 scan tool is the only tool capable of clearing the DTC history. Disconnecting the battery or removing

fuse F31 will not erase DTC history, the Tech 2 scan tool sends a special message into the PCM to erase this

memory.

IGNITION CYCLE DEFAULT

If the ignition is cycled ("OFF" and "ON") 50 times without a particular fault reappearing, that DTC will be erased

from PCM memory and the ignition cycle counter in the PCM will be reset to zero.

PCM SLEEP TEST

After the ignition switch is turned "OFF," the PCM will continue to operate for several seconds. During this shut

down, the PCM will return the IAC back to a pos ition to be used on the next star tup, de-energizing all the solenoids

and relays, then the PCM will "go to sleep". The PCM can be checked for this sleep test by monitoring the voltage

of DLC terminal "6" it should go from 5 volts to 0 volts. The Tech 2 scan tool will display updated data until the

sleep m ode is activated then the PCM will no longer send out serial data and the T ech 2 sc an tool will display DLC

DATA LOST.

DIAGNOSTIC MODE

W hen the diagnostic "test" term inal is earthed with the ignition "ON" and the engine stopped, the system will enter

what is called the Diagnostic Mode. In this mode the PCM will:

1. Display a Diagnostic Trouble Code 12 by flashing the (MIL) "Check Powertrain" lamp (indicating the system is

operating correctly). Only if there are no other stored codes in the PCMs memory.

2. Display any stored diagnostic trouble codes by flashing the (MIL) "Check Powertrain" lamp. Each code will be

flashed one at a time until all codes have been flashed, then the code flashing process starts over again.

FIELD SERVICE MODE

If the diagnostic "test" term inal is earthed with the engine running, the system will enter the Field Service mode. In

this mode, the (MIL) "Check Powertrain" lamp will flash once per second and ignition timing will be fixed."

While the system is in Field Service Mode, new DTCs cannot be stored in the PCM.

PCM LEARNING ABILITY

The PCM has a "learning" ability which allows it to make corrections for minor variations in the engine or

transmission system to improve driveability.

TRANSMISSION ADAPT FUNCTION

The HYDRA-MATIC 4L60-E uses a feedback line pressure control system which has the ability to adapt the

system's line pressure to compensate for normal wear of clutch fiber plates, seals, springs, etc. This "learning"

feature is similar to what is used for engine fuel control, short term fuel correction, long term fuel trim.

The HYDRA-MATIC 4L60-E transmission only uses the adapt function for the 1-2 upshift. The PCM monitors

engine speed to determ ine if the shif t is occur ring too fast ( harsh) or too s low (soft) and adjus t the pressur e control

solenoid to maintain the correct shift feel. The line pressure can adapt to values ranging f rom 35 kPa below, to 70

kPa above normal line pressure.

If the battery is disconnected, to c lear diagnostic trouble codes or for other repair , the "learning" proc ess res ets and

begins again. A change m ay be noted in the vehicle's perform ance. T o "teach" the vehicle, res et the IAC valve and

ensure that the engine is at operating temperature. The vehicle should be driven at part throttle, with moderate

acceleration and idle conditions until normal performance returns.

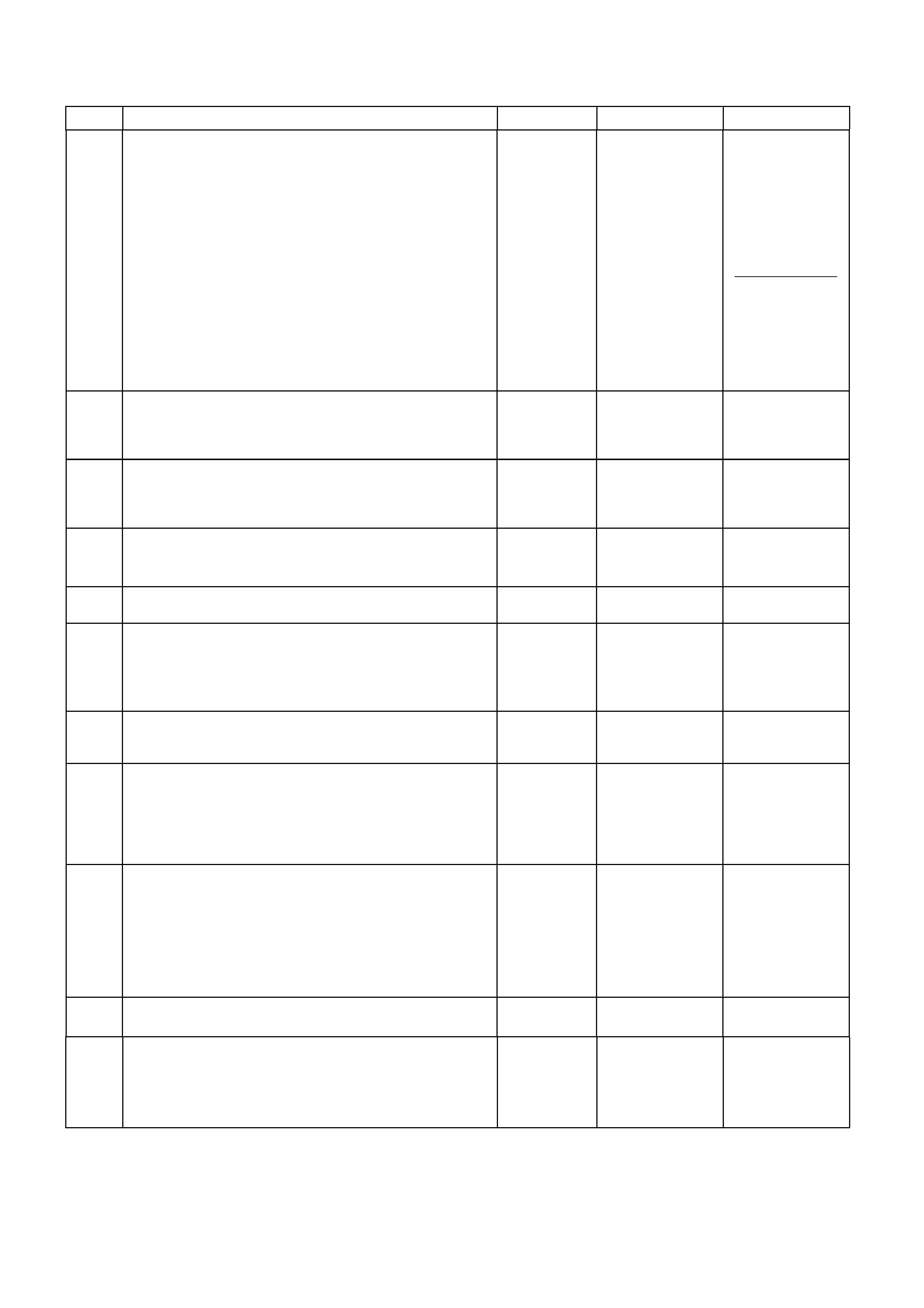

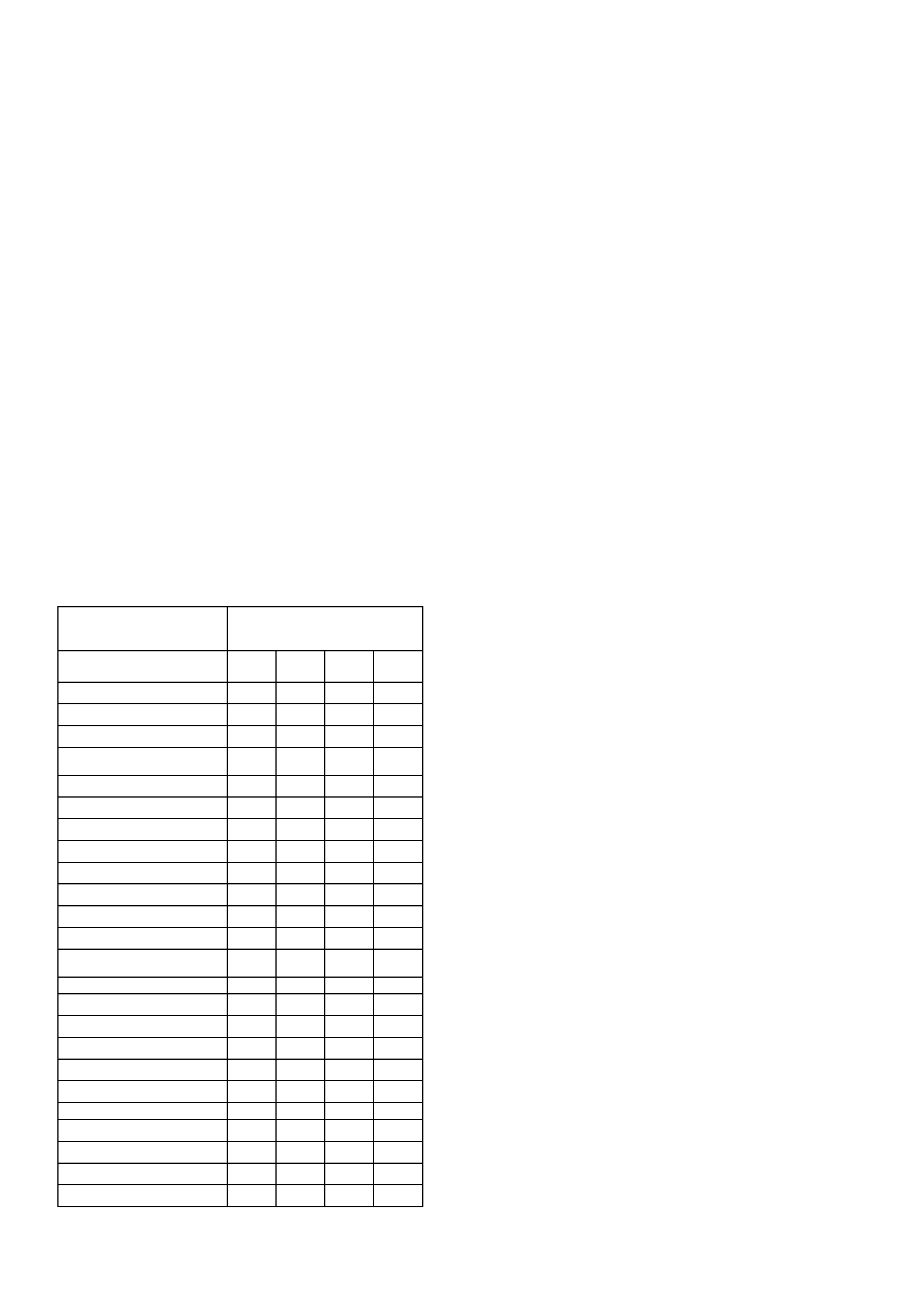

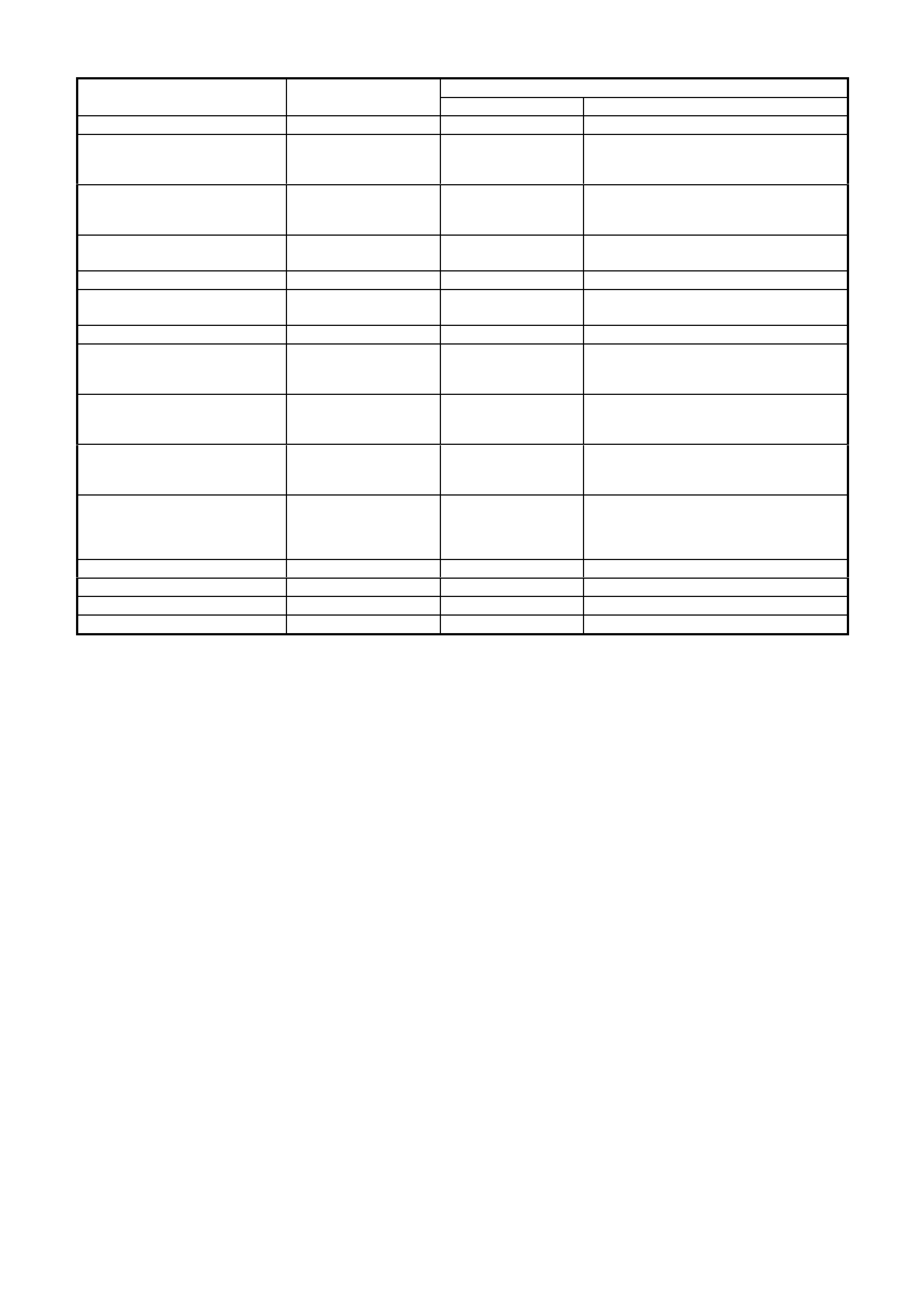

TABLE A V6 PCM

ON-BOARD DIAGNOSTIC (OBD) SYSTEM CHECK

STEP ACTION VALUE YES NO

1.

1. Ignition "ON" engine "STOPPED".

2. Observe the " CHECK POWERTRAIN" lamp (MIL).

Is the "CHECK POWERTRAIN" lamp (MIL) "ON" steady?

Go to Step 2 If

No, "CHECK

POWERTRAIN"

lamp, Go to

Table A-1 of the

VX Series

Service

Information

----------------------

If "CHECK

POWERTRAIN"

lamp is flashing

DTC 12, Go to

Step 10

2. Jumper Data Link Connector (DLC) terminal "6" To "5".

Does "CHECK POWERTRAIN" lamp flash DTC 12? Go to Step 3 Go to Table A-1

of the VX Series

Service

Information

3. 1. Disconnect Data Link Connector jumper.

2. Install scan tool to Data Link Connector.

Does scan tool display PCM serial data.?

Go to Step 4 Go to Table A-2

of the VX Series

Service

Information

4. 1. Ignition "ON".

2. Using Tech 2 scan tool, check for DTC 31.

Is DTC 31 set?

Go to DTC 31

Table Go to Step 5

5. Does engine crank? Go to Step 6 Go to

Table A-4.0

6. 1. With Tech 2 scan tool, display DTC(s).

Are any Diagnostic Trouble Codes displayed?

NOTE: Check both Current and History codes.

Refer To

Applicable DTC

Table.

Start with lowest

DTC

Go to Step 7

7. Does engine start? Go to Step 8 Go to

Table A-3.1-1

8. 1. Ignition "ON", engine "STOPPED".

2. Compare Tech 2 scan tool data with typical

values shown on scan data page.

Are values normal or within typical ranges?

Go to Step 9 Refer to indicated

"Component(s)-

System" checks

of the VX Series

Service

Information.

9. 1. Run engine until normal operating temperature is

reached.

2. Run engine at 1500 revolutions per minute for 2

minutes, then idle engine.

3. Compare Tech 2 scan data with typical values

shown on "scan data" page.

Are values normal or within typical ranges?

Refer to

"Symptom"

Diagnosis

Tables" in

Section 6C1-2B

of the VX Series

Service

Information

Refer to indicated

"Component(s)-

System "checks

of the VX Series

Service

Information

10. Check for earthed diagnostic "TEST" terminal circuit.

Was a problem found? Verify Repair Go to Step 11

11. Replace PCM.

Refer to Section 6C1-3 Service Operations of the VX

Series Service Information, for PCM Security Link

procedure.

Is action complete?

Verify Repair

Figure 6C1-2-8 Example of On-Board Diagnostic System Check

POWERTRAIN OBD SYSTEM CHECK

After the visual and physical underhood inspection, the Powertrain OBD System Check is the starting point for all

diagnostic procedures or finding the cause of an emissions test failure.

All diagnostic procedures must always begin with the Powertrain OBD System Check.

Diagnostic procedures must begin with the Powertrain OBD System Check, which represents an organised

approach for identifying system problems.

The POW ERTRAIN OBD SYSTEM CHECK mak es an initial check of the system, then will direct the technician to

other tables of this Service Inf ormation. It must be used as a st arting point for all procedur es. The entire sec tion is

set up in a specif ic or der, that is, the PO WERTRAIN O BD SYSTEM CHECK will lead the technician to other tables,

and those tables m ay lead to still other tables. THE SEQUENCE M UST BE FOLLOWED. The engine/tr ansm iss ion

control system uses many input signals and controls many output functions. If the correct diagnostic sequence is

not followed, incorrect diagnosis and replacement of serviceable parts may happen.

Diagnostic tables incorporate diagnos is proc edures us ing a T ech 2 sc an tool where possible. T his T ech 2 s can tool

is a sm all hand-held com puter in itself. Its job is to give information to a technician about what is happening in the

powertrain management system.

The Data Link Connector (DLC) is used by the assem bly plant to perform end of line tes ts. T his c onnector c an also

be used by technician to monitor certain inputs and output as seen by the electronic control module. The Tech 2

scan tool reads and displays the information (serial data) supplied to the data link connector from the Powertrain

Control Module (PCM).

The correct procedure to diagnose a problem is to follow three basic steps.

1. Are the On-Board Diagnostics working?: This is determined by performing the Powertrain OBD System

Check. Since this is the starting point for the diagnostic procedures or finding the cause of a failure, always

begin here.

If the On- Board Diagnostics ar en't working, the Powertrain O BD System Check will lead to a diagnostic table in

this section to correct the problem. If the On-Board Diagnostics are working correctly, the next step is:

2. Is there a Diagnostic Trouble Code stored?: If a diagnostic trouble code is stored, go directly to the

numbered diagnostic trouble code table. This will determine if the fault is still present. If no diagnostic trouble

code is stored, then:

3. Observe Serial Data transmitted by the PCM: This involves reading the information available on the Serial

Data Stream with a Tech 2 scan tool. Information on this tool and the m eaning of the various displays can be

found in the suc ceeding paragraphs. T ypical data readings under a particular operating condition c an be f ound

on the "Tech 2 Scan tool Data" page.

DLC TECH 2 SCAN TOOL

The PCM can communicate a variety of information through DLC connector. This data is transmitted at a high

frequency which requires a Tech 2 scan tool for interpretation.

TECH 2 SCAN TOOL EXPLANATION

To ex plain how the T ech 2 scan tool work s, let's think for a minute about how a television works . A television is an

electronic device that receives and processes information, and sends out information in a form that can be

understood by the person watching it. The television receives a signal (from a transmitting station) that is not

usable to the person.

The television processes it, then sends the signal to a screen. The person can then see the information that the

television transmitting station sent out. The Tech 2 scan tool is like the television because it also processes

information, sent to it by the PCM.

The information is sent out of the PCM to the Data Link Connector (DLC) serial data line. The Tech 2 scan tool

plugs into the data link connector, and the information is sent to the tool on its cable. The Tech 2 scan tool

processes the information, and "sends" the signal to a display screen on the tool.

Just like a television, you can select which "station" that you want to see. The difference is instead of seeing the

picture on a television, you "see" the display screen, and the "stations" that you can select on a Tech 2 scan tool

are the different input and output signals that are being processed by the PCM.

The Tech 2 scan tool has the ability to send messages back to the PCM to do different things such as switch

outputs "OFF " and "ON." This allows the technic ian to control the PCM. This c ontrol only lasts as long as the Tec h

2 scan tool is connected.

TECH 2 SCAN TOOL USES - POWERTRAIN CONTROL MODULE (PCM)

The T ech 2 scan tool is a us eful and quick way of comparing operating param eters of a poorly operating engine or

transmission with a known good one. For example, a sens or may shift its value but not s et a DT C. Comparis on with

a known good vehicle may uncover this problem.

The T ech 2 scan tool allows a quick check of sensors and switches which are inputs to the PCM. The PCM in the

vehicle sends out information to the Tech 2 scan tool at a very fast rate, and the display on the tool can update

quicker than a digital multimeter. The Tech 2 scan tool allows a technician to manipulate wiring harnesses or

components under the vehicle while observing the Tech 2 scan tool readout. This can help in locating intermittent

connections.

After you enter the proper vehicle information, the first display on the Tech 2 scan tool will ask for what type of

system to select from.

The following is a list of systems the Tech 2 will display:

F0: ENGINE

F1: TRANSMISSION

F3: CHASSIS

F4: BODY

After selecting F0: ENGINE, the scan tool will display:

V6

V6 Supercharge

V8

V8 GEN III

V6 LPG

DTC CHECK

Other

Once the c orrect engine has been selec ted, the T ech 2 sc an tool will now have s even test modes for diagnosis and

service of the PCM system. The six test modes are as follows:

• MODE F0: NORMAL MODE

In this mode, the scan tool will display various engine and transmission data and vehicle information.

The f ollowing PCM Norm al Mode controller usage table, indicates specific Control Modules using the PCM supplied

report status information:

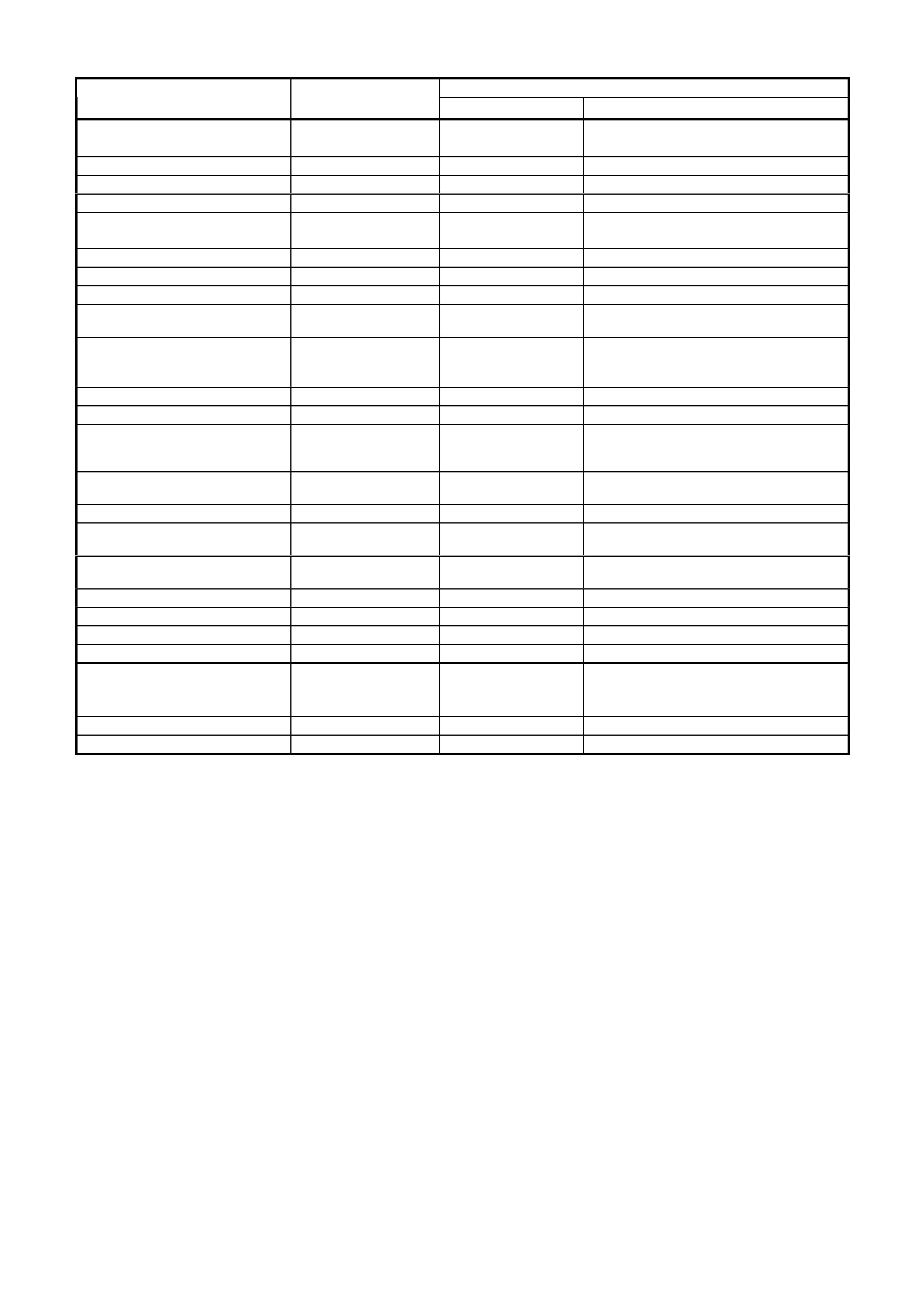

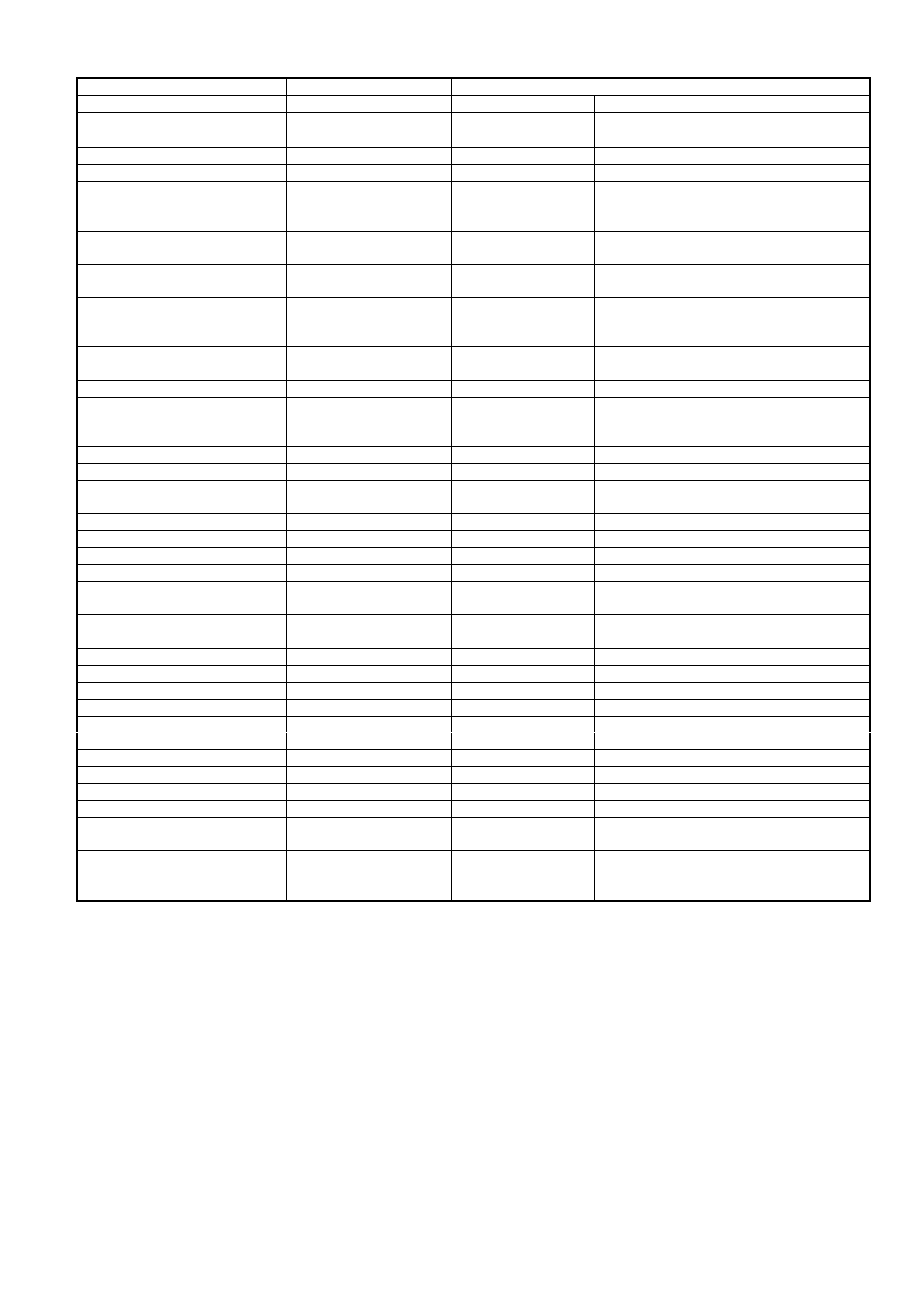

PCM NORMAL MODE CONTROLLER USAGE TABLE

PCM NORMAL MODE

SCAN TOOL

PARAMETERS

USED BY:

Scan Tool S tring BCM INST ECC ABS/

ETC

Engine Speed √

√√

√

Coolant Tem perature √

√√

√ √

√√

√

Vehicl e S peed √

√√

√ √

√√

√

A/C Clutch

A/C Pressure √

√√

√

Low Speed Fan Request √

√√

√

Low Fan Run ON √

√√

√

Theft St atus √

√√

√

PCM DTC Status √

√√

√

Check P owertrain MIL √

√√

√

Fuel Used √

√√

√

Fuel Flow Rate √

√√

√

Engine Type √

√√

√

Transmission Coding

Fuel Type √

√√

√

Engine Oil Change √

√√

√

Transm i ssion Oil Change √

√√

√

Shift Pattern √

√√

√

Torque Multiplier √

√√

√

High Coolant Temperature

Oil Pressure Switch √

√√

√

PRNDL Switc h √

√√

√

Commanded Gear √

√√

√

PCM Chim e √

√√

√

• MODE F1: DIAGNOSTIC TROUBLE CODES

In this test mode, DTCs stored by the PCM maybe displayed or cleared. When entering this mode there are four

modes:

F0. Read Current DTC

F1. Read History DTC

F2: Clear Current DTC

F4: Clear History DTC

• MODE F2: DATA DISPLAY

In this test mode, the Tech 2 scan tool continuously monitors system data, such as: engine speed data, engine

coolant temperature etc. When entering this mode, there are three modes;

F0: All Data

Displays all engine input and output data.

F1: Inputs

Displays all input data to the PCM.

F2: Outputs

Displays all output data from the PCM.

• MODE F3: SNAPSHOT

In this test m ode, the Tec h 2 scan tool captur es data before and after a snapshot triggering condition which may or

may not set a DTC.

• MODE F4: MISC. TESTS

In this test mode, the Tech 2 scan tool performs software override commands of the PCM, to assist in problem

isolation during diagnostics.

F0: OUTPUT TESTS

F0: Fuel Pump

F1: Fuel Pump Speed (Supercharge)

F2: A/C Clutch

F3: CHK PTRN LMP (Check Powertrain Lamp)

F4: High Fan

F5: Purge

F6: Starter Relay

F1: IAC SYSTEM

F0: RPM Control: used to control engine RPM from 600 RPM to 1675 RPM.

F1: IAC Reset: used to reset IAC if the IAC is lost or if IAC has been replaced.

F2: Base Idle: used to set the engine to base idle.

F2: EGR CONTROL

This test will allow for control of the EGR by increments of 10% to decrease or increase EGR flow up to

100% on time.

F3: RESET CELLS

Resets all LT Fuel Trim values to 0%

F4: BYPASS SPARK

With the engine running, this command turns on the bypass control circuit.

F5: A/F RATIO

With the engine running, forces air fuel ratio from 11.7 to 17.7.

• MODE F5: FUNCTIONS

The Functions Tests m ode perf orms func tional tests on the PCM system which help verif y proper operation. In this

mode, fault conditions are automatically logged by the Tech 2 scan tool.

The Tech 2 scan tool also has the ability to send commands to the PCM, instructing the PCM to perform various

functions or tasks. This provides a quick way to determine if a device is operational or not.

In the F5 mode, the following tests can be performed:

F0: IAC Circuit

Designed to confirm to IAC motor functions OK and is not losing track of position. Monitor the engine

speed. Repeatedly cycles the IAC motor in and out and then monitors the engine speed. If OK, then

ignition "OFF" and start repeatedly, then stabilize. If the value of final RPM - initial RPM is greater than a

calibrated threshold, then the IAC circuit has failed.

F1: O2 Sensor

Designed to confirm oxygen sensor is functioning OK and not biased or slow responding. Monitors oxygen

sensor voltages and cross counts when in "Closed Loop" and forces rich/lean "Open Loop" operation.

F2: PWR (Power) Balance

Designed to identify low power output from individual cylinders. Automatically cycles each injector "OFF"

than "ON" while monitoring and recording the RPM drop for each cylinder.

F3: Wrng ( Wiring) Harness

Designed to confirm no intermittent open or short circuits exit in selected circuits. Engine is at idle in "N".

Technician should wiggle powertrain harness. The Tech 2 scan tool monitors inputs that should remain

relatively static at idle such as: ECT, IAT, TP Sensor, VSS, CAM signal present, 18X signal present, EST

lines, injec tor voltage monitor, batter y, ignition. If disc ontinuity occurs , the T ech 2 scan tool logs f ailure and

prompts technician to check appropriate circuit.

F4: Low Fan

Designed to confirm that the PCM will send a command to the BCM to turn "ON" the low speed fan.

• MODE F6: FIELD SERVICE

In this test mode, With the ignition "ON" and the engine stopped, the Tech 2 scan tool will earth the diagnostic

"test" terminal. The system will display a Diagnostic Trouble Code 12 by flashing the (MIL) "Check Powertrain "

lamp (indicating the system is operating correctly). With the ignition "ON" and engine running, the 'Check

Powertrain" Lamp will indicate whether or not the engine system is in "Open Loop" or "Closed Loop". When the

engine is in "Closed Loop", the "Chec k Powertr ain" Lam p will indicate a rich or lean condition by the amount of tim e

the lamp is "ON".

• MODE F7: STALL DATA

Designed to capture nine (9) particular data values, when the engine is in a stall condition. This is very similar to

DTC History mode. The PCM will store the first stall condition values, then count the number of stalls after the first.

NOTE: Stall data will be erased from the PCM memory whenever DTC HISTORY DATA is cleared.

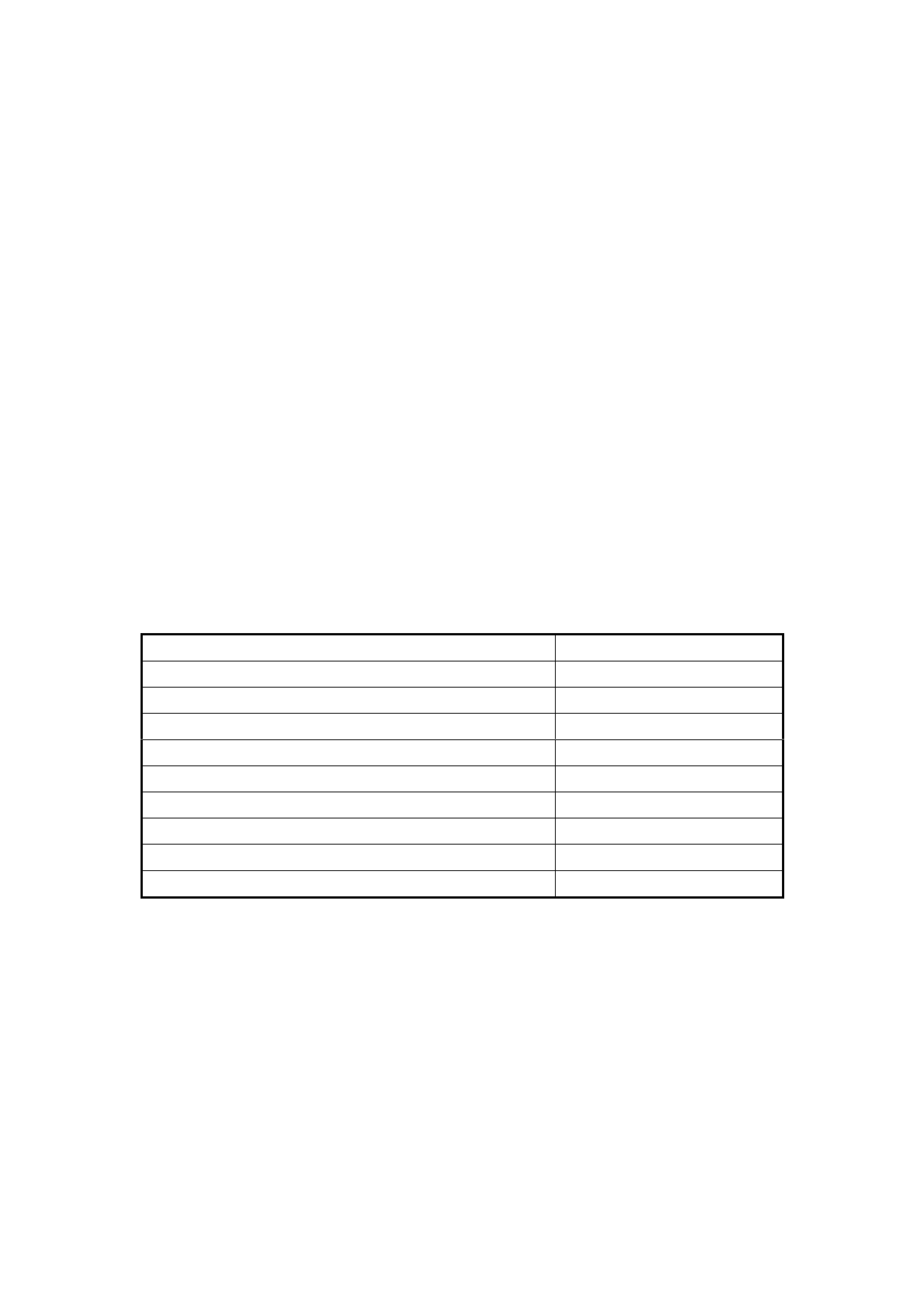

TECH 2 SCAN TOOL: STALL DATA

SCAN POSITION UNITS DISPLAYED

ENGINE SPEED RPM

TIME F ROM STAR T TIME

TIMES OCCURRED NUMBER

IGNITION CYCLES NUMBER

IDEL AIR CONTROL STEPS

VEHICLE SPEED KM/H

BATTERY VOLTAGE VOLTS

THROTTLE ANGLE 0-100%

A/C REQUEST NO/YES

TECH 2 SCAN TOOL USE WITH INTERMITTENT FAULTS

The T ech 2 scan tool allows m anipulation of wiring harnesses or c omponents under the bonnet with the engine not

running, while observing the Tech 2 scan tool readout.

The Tech 2 scan tool can be plugged in and observed while driving the vehicle under the condition when the

"Check Powertrain" lam p turns ON m omentar ily or when the engine driveability is mom entarily poor . If the problem

seems to be related to certain parameters that can be checked on the Tech 2 scan tool, they should be checked

while driving the vehicle. If there does not seem to be any connection between the problem and any specific c ircuit,

the Tech 2 scan tool can be used to monitor each parameter, watching for a period of time to see if there is any

change in the readings that indicates intermittent condition.

The Tech 2 scan tool can capture and store data when the problem occurs, so it can be played back at a slower

rate to determine what happened to the system. This is called the "SNAPSHOT" mode.

The Tech 2 scan tool is an easy way to compare the operating par ameters of a poorly operating engine with those

of a known good one. For example, a sensor may shift in value but not set a DTC. Comparing the sensor's

readings with those of a known good vehicle may uncover the problem.

The Tech 2 s can tool s aves time in diagnosis and helps to prevent the r eplac ement of s er viceable par ts. The k ey to

using the Tech 2 scan tool successfully is the technician's ability to understand the system being diagnosed, as

well as understanding the Tech 2 scan tool operation and limitations. The technician should read the Tech 2

operator’s manual to become familiar with the Tech 2 scan tool operation.

With an understanding of the data which the tool displays, and knowledge of the circuits involved, the tool can be

very useful in obtaining information which would be more difficult or impossible to obtain with other equipment.

The T ech 2 scan tool does not make the use of diagnostic tables unnecessary, nor can it indicate exactly where a

problem is in a particular circuit. Diagnostic Tables inc orporate diagnosis pr ocedures that require the use of a T ech

2 scan tool.

TECH 2 SCAN TOOL LIMITATIONS

The Tec h 2 sc an tool m ust receive the s ignal f rom the PCM in or der to display any useable inf orm ation. If the PCM

sends no signals to the data link connec tor, or the connec tion to the Tech 2 sc an tool is defec tive, the Tech 2 scan

tool will only display, "WAITING FOR DATA - NO DATA RECEIVED FROM PCM." The Powertrain OBD System

Check instructs the technician what to do if this happens.

The T ech 2 sc an tool has a few lim itations. If the T ech 2 sc an tool is displaying a PCM "output" function, it displays

only the com mand given by the PCM. That does not m ean that the desired action took place. This is s imilar to the

automatic transmission dashboard gearshift indicator. Just because the gearshift P R N D L pointer indicates the

transm ission is in DRIVE does not mean that the trans mission is actually in that gear. T o be sure, you m ust check

the linkage and adjustment at the transmission.

When using the T ech 2 s c an tool to obs erve one of the PCM "output" functions, s uc h as an idle air c ontrol motor, or

a TCC s olenoid, the technician must not assume the indic ated is the same as the actual. If the Tech 2 scan tool is

displaying TCC solenoid as being "ON," but the wire to power it is disconnected or defective, the PCM in some

cases has no way of knowing it. The display may indicate the command is "ON," but the device may not be

operating!

The Tech 2 s can tool s aves time in diagnosis and helps to prevent the r eplac ement of s er viceable par ts. The k ey to

using the Tech 2 scan tool successfully for diagnosis is the technician's ability to understand the system being

diagnosed, as well as an understanding of the Tech 2 scan tool's limitations.

With an understanding of the data the Tec h 2 scan tool dis plays, and knowledge of the circuits involved, the T ech 2

scan tool is useful in obtaining information which is difficult or impossible to retrieve with other methods.

Remem ber, the Tech 2 scan tool does NOT make using diagnostic tables unnecessary, nor can it tell you exactly

where a problem is in a circuit. Most diagnostic tables incorporate diagnosis procedures that require the use of a

Tech 2 scan tool.

TECH 2 SCAN TOOL: PCM NORMAL MODE

The Tech 2 scan Tool Normal Mode in the table may be used for comparison if a status report is being sent from

the PCM.

1. After completing the “Powertrain OBD System Check”

2. Finding the on-board diagnostics are functioning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 SCAN TOOL THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 SCAN TOOL CAN

RESULT IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed are us ed in this Section f or diagnos is. For m ore desc ription on the values and us e of the

Tech 2 scan tool to diagnosis PCM inputs, refer to the applicable diagnosis table. If all values are within the range

illustrated, refer to Section 6C1-2B SYMTOMS of the VX Series Service Information.

Test Description: The number(s) below refer to the number(s) on the Tech 2 Scan Data Engine Stream table.

1. T he Tech 2 sc an tool FO: PCM NORMAL MODE will display scan positions that will be displayed in order . T he

Tech 2 scan tool will display nine (9) scan position parameters at a time. The down arrow button will scroll

down through all of the scan positions one at a time. After TIME FROM START parameter is displayed,

pressing the down arrow button again, will display scan position parameters starting at the top of the list again.

2. UNITS DISPLAYED are the available ways of displaying what each parameter is currently operating in, or a

value that is being sensed or being issued by the PCM.

3. T YPICAL DAT A VALUE is separated into two parts. T hese displayed values are typical of a norma lly operating

vehicle. The IG NITION ON comparis on should be perform ed first as this may lead to a quick identif ication of a

failure. The ENGINE RUNNING data should be compared to the IGNITION ON data as a diagnostic check to

make sure the component or system is operating properly.

4. IGNITION ON values are the typical values that should be seen on the Tech 2 scan tool with the ignition ON

and engine stopped. Temperature sensors should be compared to the actual temperatures by allowing the

sensor to cool overnight and then comparing their values. A difference of 3-5° C from the actual temperature

may indicate a problem with the s ensor . Us e the diagnos tic aids table f or that sens or to compare the r es istanc e

to temperature values.

5. ENGINE RUNNING typical data values are an average of display values recorded from normally operating

vehicles at norm ally operating tem perature. They are intended to represent what a norm ally functioning system

would typically display.

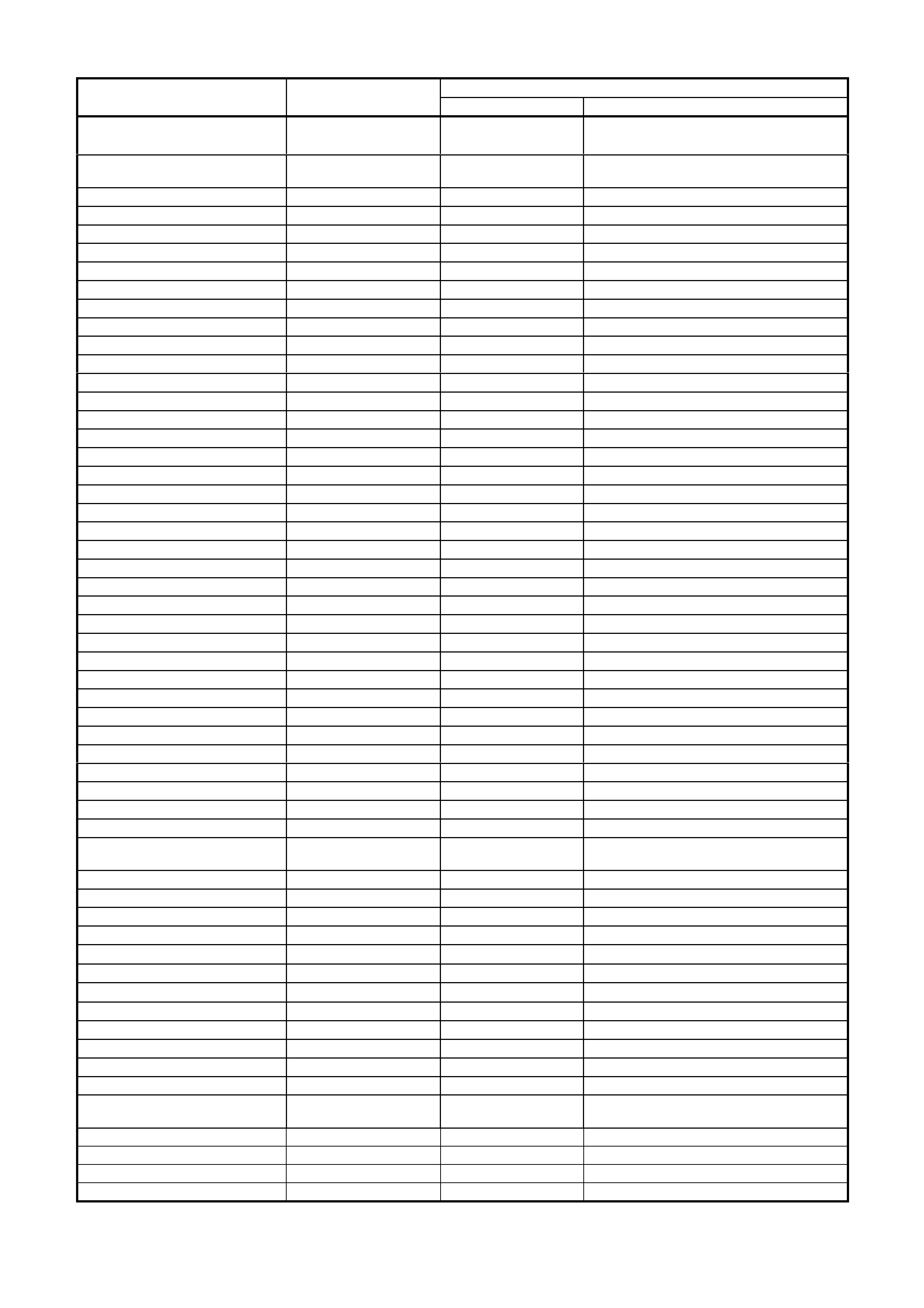

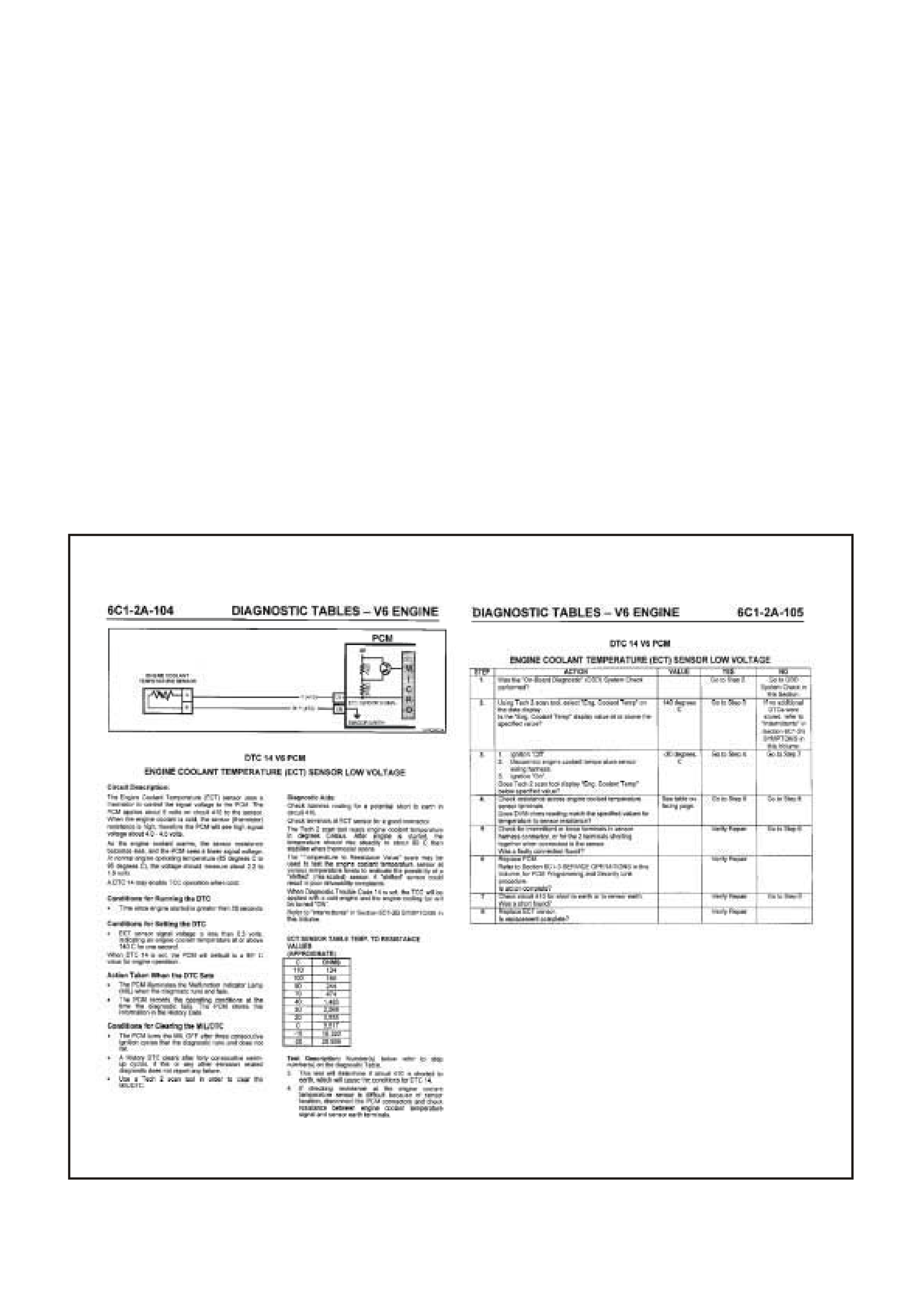

TECH 2 SCAN TOOL: PCM NORMAL MODE

TYPICAL DATA VALUE S

SCAN POSITION Q UNITS DISPLAYED R IGNITION ON T ENGINE RUNNING U

ENGINE SPEED RPM 0 RPM 600 - 650 RPM

(± 50 RPM IN DRIVE )

COOLANT TEMPERATURE DEGREES C Varies +96 C

VEHICLE SPEED km/h 0 0

A/C CLUTCH ON /OFF OFF OFF

A/C PRE S SURE kPa 896 kPa 800 - 1000 kP a A/C OFF

1600 - 1900 kPa A/C ON

LOW SPEED FAN REQUEST ON / OFF OFF OFF

LOW FAN RUN ON YES / NO NO NO

THEFT STATUS NO START / START START START

PCM DTC STATUS NO DTC(s)/DT C(s)

SET NO DTC(s) NO DTC(s)

CHECK POWERTRAIN

MALFUNCTION INDICATOR

LAMP (MIL)

OFF/ON ON OFF

FUEL USED L 00.00 1 - 2 L/Hour

FUEL FLOW RATE 00.00 1 - 2 L/Hour

ENGINE TYPE V6, V8,

V6 SUPERCHARGE,

V8 GEN 3

V8 GEN 3 V8 GEN 3

TRANSMISSION CODING MANUAL TRANS.

AUTO TRANS. MANUAL TRANS.

AUTO TRANS. MANUAL TRANS.

AUTO TRANS.

FUEL TYPE PETROL / LPG PETROL PETROL

ENGINE OI L CHANGE OKAY /

SERVICE REQUIRED OKAY OKAY

TRANSMISSION OIL CHANGE OKAY /

SERVICE REQUIRED OKAY OKAY

SHIFT PATTERN POW ER/ECONOMY ECONOMY ECONOMY

TORQUE MULTIP LI ER

HIGH COOLANT TEMPERATURE YES/NO NO NO

OIL PRESSURE SWITCH OFF/ON OFF OFF

PRNDL SWITCH INVALID /

P,R,N,D,3,2,1 INVALID

OR

GEAR SELECTED

INVALID

OR

GEAR SELECTED

COMMANDED GEAR P/N R, 1 P/N P/N

PCM CHIME YES/NO YES YES

TECH 2 SCAN TOOL: PCM NORMAL MODE DESCRIPTIONS

A list of ex planations for each data me ssage displayed on the Tech 2 s can tool is listed below. T his inform ation will

assist in diagnosing em iss ion or driveability problems . T he displays can be viewed while the vehicle is being driven.

Refer to the Powertrain OBD System Check for additional information.

ENGINE SPEED: Tech 2 Displays a range of 0 to 9999 RPM

The engine speed is computed by the PCM f rom the fuel control reference input. It should remain close to desired

idle speed under various engine loads with engine idling.

COOLANT TEMPERATURE: Tech 2 Displays a range of -39°C to 140°C (-38°F to 284°F)

The Engine Coolant Temperature (ECT) sensor is mounted in the cylinder head of the left bank. The PCM apples

5.0 volts to the ECT sensor circuit. The sensor is a thermistor which changes internal resistance as temperature

changes. W hen the sensor is cold (internal r esistance high), the PCM m onitors a high s ignal voltage and interprets

the voltage as a cold engine. As the sensor warms (internal resistance decreases), the voltage signal decreases

and the PCM interprets the lower voltage as a warm engine.

VEHICLE SPEED: Tech 2 Displays a range of 0 to 255 km/h

The vehicle speed sensor signal is converted into km/h and mph for display.

A/C CLUTCH: Tech 2 Displays "ON" or "OFF"

Represents the commanded state of the A/C clutch control relay. Clutch should be engaged when ON is displayed.

A/C PRESSURE: Tech 2 Displays a range of 0 to 3195 kPa

The kPa displayed indicates that the PCM is monitoring an A/C Refrigerant Pressure signal voltage which is too

high or too low to allow the A/C compressor clutch to engage.

LOW SPEED FAN REQUEST: Tech 2 Displays "ON" or "OFF

Indicates if the engine cooling fan low speed relay has been commanded ON or OFF.

LOW FAN RUN ON: Tech 2 Displays "NO" or "YES"

This indicates if the PCM is requesting the BCM to turn the Low Speed Fan ON at key OFF.

THEFT STATUS: Tech 2 Displays "NO START" or "START"

Indicates the status of the Theft Deterrent System.

PCM DTC STATUS: Tech 2 Displays "NO DTC(s)" or “DTC SET”

Indicates if a DTC is set. This does not indicate what DTC is set, just informs that DTC are or are not set.

CHECK POWERTRAIN MALFUNCTION INDICATOR LAMP (MIL): Tech 2 Displays "OFF" or "ON"

Indicated if the instrument panel Malfunction Indicator Lamp is ON or OFF.

FUEL USED: Tech 2 Displays a range of 0 to 1000 Litres

When the key is turned ON, and the engine is running, the PCM will calculate FUEL USED during each ignition

cycle.

FUEL FLOW RATE: Tech 2 Displays a range of 0 to 100 litres

Indicates fuel consumption per litres per hour.

ENGINE TYPE: Tech 2 Displays Engine Type

The Tech 2 uses this information for proper Tech 2 scan tool software.

TRANSMISSION CODING: Tech 2 Displays “MANUAL” or “AUTOMATIC”

The Tech 2 uses this information for proper Tech 2 scan tool software

FUEL TYPE: Tech 2 Displays “PETROL” or “LPG”

The scan tool will display what fuel type the PCM software is set up for.

ENGINE OIL CHANGE: The Tech 2 Displays “OKAY” or “SERVICE REQUESTED”

The scan tool will display the status of the engine oil change condition.

TRANSMISSION OIL CHANGE: The Tech 2 Displays “OKAY” or “SERVICE REQUESTED”

The scan tool will display the status of the transmission oil change condition.

SHIFT PATTERN: Tech 2 Displays “ECONOMY” or “POWER”

This display shows the state of the POWER/ECONOMY switch.

TORQUE MULTIPLIER: Tech 2 Displays a range of

HIGH COOLANT TEMPERATURE: Tech 2 Displays "NO" or "YES"

This is an indication to the PCM that the engine is running hot. LOW COOLANT LEVEL: Tech 2 Displays "NO"

or "YES"

This is an indication to the PCM that the coolant level is low, and the PCM will turn on the Low Coolant lamp.

* (Only with GEN III V8 Engine)

OIL PRESSURE SWITCH: Tech 2 Displays "OFF" or "ON"

This is an indication to the PCM if the oil pressure is high or low. If the oil pressure is low, the PCM will turn on a

Low Oil Warning Lamp.

PRNDL SWITCH: Tech 2 Displays “INVALID” or “P, R, N, D, 3, 2, 1”

This displays if the vehicle is not equipped with a PRNDL switch (INVALID), or if equipped, indicates what gear the

driver has selected.

COMMANDED GEAR: Tech 2 Displays “1, 2, 3, 4”

The gear that the PCM is c om m anding the transmiss ion to be in. In PARK, the Tec h 2 sc an tool will display "1", the

commanded state of the shift.

PCM CHIME: Tech 2 Displays "NO" or "YES"

This is a indication to the instrument panel allowing the instrument panel to chime if a problem or fault is detected.

TECH 2 SCAN TOOL: ENGINE DATA

The Tech 2 scan Data listed in the table may be used for comparison

1. After completing the “Powertrain OBD System Check”

2. Finding the on-board diagnostics are functioning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 SCAN TOOL THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 SCAN TOOL CAN

RESULT IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed are us ed in this Section f or diagnos is. For m ore desc ription on the values and us e of the

Tech 2 scan tool to diagnosis PCM inputs, refer to the applicable diagnosis table. If all values are within the range

illustrated, refer to Section 6C1-2B SYMTOMS of the VX Series Service Information.

Test Description: The number(s) below refer to the number(s) on the Tech 2 Scan Data Engine Stream table.

1. The Tech 2 scan tool F2: DATA LIST will display scan position's that will be displayed in order. The Tech 2

scan tool will display nine (9) scan position parameters at a time. The down arrow button will scroll down

through all of the s can positions one at a tim e. After TIME F ROM START parameter is displayed, press ing the

down arrow button again, will display scan position parameters starting at the top of the list again.

2. UNITS DISPLAYED are the available ways of displaying what each parameter is currently operating in, or a

value that is being sensed or being issued by the PCM.

3. T YPICAL DAT A VALUE is separated into two parts. T hese displayed values are typical of a norma lly operating

vehicle. The IG NITION ON comparis on should be perform ed first as this may lead to a quick identif ication of a

failure. The ENGINE RUNNING data should be compared to the IGNITION ON data as a diagnostic check to

make sure the component or system is operating properly.

4. IGNITION ON values are the typical values that should be seen on the Tech 2 scan tool with the ignition ON,

and engine stopped. Temperature sensors should be compared to the actual temperatures by letting the

sensor stabilise overnight and then comparing their values. A diff erence of 3-5° C from the actual temperature

may indicate a problem with the s ensor . Us e the diagnos tic aids table f or that sens or to compare the r es istanc e

to temperature values.

5. ENGINE RUNNING typical data values are an average of display values recorded from normally operating

vehicles at norm ally operating tem perature. They are intended to represent what a norm ally functioning system

would typically display.

TECH 2 SCAN TOOL: ENGINE DATA

TYPICAL DATA VALUE S

SCAN POSITION Q UNITS DISPLAYED R IGNITION ON T ENGI NE RUNNING U

ENGINE SPEED RPM 0 RPM ± 100 RPM FROM DESIRED RP M

(± 50 RPM IN DRIVE)

DESIRED IDLE S PEED RPM 0 RPM PCM IDLE COMMAND (VARIES WITH

TEMPERATURE)

ENG. COOLANT TEMP (ECT) VOLTS VARIES +96° C

COOLANT TEMPERATURE DEGREES C VARIES VARIES

IAT DEGREES C VARIES VARIES

MAF SENSOR FREQUENCY Hz 0 Hz 2200-2500 Hz

MASS AI R FLOW GRAM /SEC 0 g/s 5 -10 g/s

MASS AI R FLW/CYL mG/S 0.0 mG/ S 140 to 150 mG/S

TPS SI GNA L 0-100 % 0 % 0 %

THROTTLE ANGLE VOLTS 0.32 V 0.47 V

RH 02 SENSOR READY YES/NO NO YES

LH 02 SENSOR READY YES/NO NO YES

RH 02 SENSOR mV 447 mV 100-1000 mV A ND V ARYING

LH 02 SENSOR mV 447 mV 100-1000 mV AND VARYING

RH ST FUEL TRIM + 100% TO –100% +0% + 0% +10% TO –10%

LH ST FUEL TRIM + 100% TO –100% +0% + 0% +10% TO –10%

LT FUEL TRIM R + 100% to - 100 % + 0 % + 0 % + 10% to - 10%

LT FUEL TRIM L + 100% to - 100 % + 0 % + 0 % + 10% to - 10%

LTFT ENABLE YES / NO NO NO

FUELING MODE OPEN / CLOSED LOOP OPEN LOOP CLOS ED LOOP

LTFT CELL CELL # 0 0

RH O2 STATUS RICH / LEAN LEAN LEAN

LH O2 STATUS RICH / LEAN LEAN LEAN

RH O2 CROSS CNTS COUNTS 0 0

LH O2 CROSS CNTS COUNTS 0 0

STFT DELTA 0 - 100 % 0 % 0 %

LTFT DELTA 0 - 100 % 0 % 0 %

DECEL FUE L CUT OF F NO/YES NO NO

INJ. P ULS E TIME mS 27.5 mS 3.25 mS

INJECTOR V OLTA G E VOLTS 11.4 V 14.0 V

AIR / FUE L RATIO % 0.0 : 1 14.7 : 1

PURGE PWM % 0 % 10 %

EGR POS. COMMANDED % 0% 0%

EGR POS. FEEDBACK. % 0% 0%

EGR PINTLE S ENSOR VOLTS VOLTS 0.6 VOLT 0.6 VOLT

BATTERY VOLTAGE VOLTS 11.3 V 14.0 V

REFERENCE V O LTS VOLTS 4.99 V 4.99 V

CAM SIGNA L MISSING

/PRESENT MISSING PRESENT

IAC POS ITION STEPS 169 S T E PS 22 STEPS

LITERS P ER HOUR L/HR 00.00 1 - 2 L/Hour

IDLE RPM V A RIANT. RP M 0 RPM 0 RPM

SPARK MODE BYPASS/EST BYPASS EST

SPARK ADVANCE DEGREES BTDC 14 ° BTDC + 14° BTDC

KNOCK SI GNAL KNOCK/NONE NONE NONE

KNOCK RETARD # OF DEGREES 0 ° 0 °

TCC SOLENOID ON / OFF OFF OFF

VEHICLE SPEED KM / H 0 KM/H 0 KM/H

A/C REQUEST ON /OFF OFF OFF

A/C CLUTCH ON /OFF OFF OFF

A/C PRE S S. VOLTS VO LTS 1 - 2 V 1 - 2 V

A/C PRE SSURE kPa 352 kPa 600 - 700 kPa A/C OFF

800 - 1000 kPa A/C ON

HIGH SPEED FAN ON / OFF OFF OFF

LOW SPEED FAN REQUEST ON / OFF OFF OFF

THEFT STATUS NO START/START START START

STARTER RELAY OFF/ON ON ON

TECH 2 SCAN DATA ENGINE STREAM (CONTINUED)

TYPI CAL DATA VALUE S

SS

S

SCAN POSITION Q

QQ

Q UNITS DISPLAYED R

RR

R IGNITION "ON" T

TT

T ENGINE RUNNING U

UU

U

FUEL PUMP RELAY ON / OFF OFF ON

SUPERCHARGE D OP TION

(Yes or No depending on what

engine is s el ected)

YES/NO YES/NO YES/NO

PWM BOOST

(Only if Supercharged engine is

selected)

% 0% 100%

SUPERCHARGER FUEL PUMP

STATE LOW SPEED/

HIGH SPEED HIGH SPEED LOW SPEED

CRANK TIME SEC 0.0 SEC 0.5 SEC

DTC STA T US NO DTC(s )/DTC(s) SET NO DTC(s) NO DTC(s)

TIME FROM START TIME 0:00:00 VARIES

PROM I.D. FOUR DIGIT NUMBER

(VARIES WITH PROM

UPDTAES)

8808 8808

CHECK POWERTRAIN

MALFUNCTIO N INDICATO R

LAMP (MIL)

OFF/0N ON OFF

REQUESTE D TORQUE N.M 214N.M 642N.M

(N.M WILL DECREASE WITH ENGINE

LOAD)

ACTUAL TORQUE N.M 0 N.M 35-45 N. M

( N.M WILL CLOSE LY FOLLOW

REQUEST ED TORQUE ONCE E NGINE

LOAD IS DETECTED)

LPG SWITCH OFF/ON OFF OFF

LPG FUEL ENABLE NO/YES NO NO

FUEL PETROL / LPG PETROL PETROL

LPG FUEL CONTROL VA LV E 0-100 %

TECH 2 SCAN TOOL: ENGINE DATA DESCRIPTIONS

A list of ex planations for each data m essage disp layed on the Tec h 2 scan tool begins as follows. This inf ormation

will assist in tracking down em ission or driveability problems, since the displays can be viewed while the vehicle is

being driven. Refer to the "On-Board Diagnostic System Check" for additional informational.

ENGINE SPEED - Range 0-9999 RPM - Engine speed is computed by the PCM from the fuel control reference

input. It should remain close to desired idle under various engine loads with engine idling.

DESIRED IDLE - Range 0-3175 RPM - T he idle s peed that is comm anded by the PCM. The PCM will com pensate

for various engine loads to keep the engine at the desired idle speed.

ECT SENSOR VOLTS/ENG COOLANT TEMP - Range -40 degrees to 151 degrees C/ 0 - 5 VOLTS - The

Engine Coolant Temperature (ECT) sensor is mounted in the inlet manifold and sends engine temperature

information to the PCM applies 5 volts to the coolant temperature sensor circuit. The sensor is a therm istor which

changes internal resistance as temperature changes. W hen the sensor is cold (internal resistance high), the PCM

monitors a high signal voltage which it interprets as a cold engine. As the sensor warms (internal resistance

decreases), the voltage signal will increase, the voltage signal will decrease and the PCM will interpret the lower

voltage as a warm engine.

IAT SENSOR VOLTS/IAT - Range -40 degrees to 151 degrees C - The PCM converts the resistance of the

intake air temperature sensor to degrees. Intake Air Temp (IAT) is used by the PCM to adjust fuel delivery and

spark timing according to incoming air density.

MAF SENSOR FREQUENCY - Range 0-10,192 Hz - T he signal that is sent from the Mass Air Flow ( MAF) sensor

to the PCM is in the for m of a frequency output. This f requency output changes as the dem and of engine air intake

changes.

MASS AIR FLOW - Range 0-246 Grams/Sec. - The Mass Air Flow (MAF) sensor measures the change in the

intake air flow which results from engine load and speed changes. As intake air flow increases, the air in the inlet

manifold also increases and addition fuel is required.

MASS AIR FLOW/CYL - Range 0-1000 mG/S. - Calculated air flow per each cylinder.

TPS SIGNAL - Range 0 to 5.10 Volts - Used by the PCM to determine the amount of throttle demanded by the

driver. Should read 0.25 - 1.25 volt at idle to above 4 volts at wide open throttle.

TPS ANGLE - Range 0-100% - Com puted by the PCM f rom T P sensor voltage (T hrottle position) should read 0%

at idle, 100% at Wide Open Throttle (WOT).

RH/LH OXYGEN SENSOR READY - Tech 2 Displays "YES" or "NO". Indicates if the 02 sensors have reached

operating temperature.

RH/LH OXYGEN SENSOR - Range 0-1192 - Represents the exhaust sensor output voltage. Should fluctuate

constantly within a range between 100 m V (Lean exhaust) and 1000 m V (Rich exhaust) when operating in "Closed

Loop".

ST FU EL T RIM R/L - Rang e -100% -0% -+ 100% - Short Term Fuel T r im repr esents a s hort- ter m corr ec tion to f uel

delivery by the PCM in response to the am ount of time the oxygen sensor voltage spends above or below the 450

mV thres hold. If the oxygen sensor voltage has m ainly been below 450 mV, indicating a lean air/f uel m ixtur e, STF T

will increase to tell the PCM to reduce fuel delivery to compensate for the indicated rich condition. Under certain

conditions suc h as ex tended idle and high ambient tem per atur es, c anis ter pur ge may cause STF T to r ead less than

-10%.

LT F UEL TRIM R/L -100% - 0% - +100% - LT FT is derived by the PCM from the ST FT value and is used f or long-

term correction of fuel delivery. A value of 0% indicates that fuel delivery requires no compensation to maintain a

14.7:1 air/fuel r atio. A value below 0% m eans that the fuel s ystem has been rich and f uel delivery is being r educed

(decreas ed injector pulse width) to m aintain a 14.7 to 1 A/F ratio. A value above 0% indicates that a lean condition

exists and the PCM has been compensating by adding fuel (increased injector pulse width). LTFT tends to follow

STFT, a value of less than -10% due to canister purge at idle should not be considered unusual.

LTFT ENABLE - Tech 2 Displays "Y ES" or "NO". - The Long T erm Fuel Trim is enable by the PCM when a long

term fuel correction is required. A YES indicates that the LTFT is enabled, a NO indicates that is not.

FUELING MODE - Tech 2 Displays "OPEN" or "CLOSED" - "Closed Loop" displayed indicates that the PCM is

controlling fuel delivery according to oxygen sensor voltage. In "Open Loop", the PCM ignores the oxygen sensor

voltage and bases the amount of fuel to be delivered on TP Sensor, coolant and IAT sensor inputs only. "Closed

Loop" operation should begin when the 02 sensor becomes active, engine coolant temperature exceeds 50

degrees C (122 degrees F) for more than 30 seconds and the PCM has seen a RPM of 1200 or greater for 10

seconds. At extremely high temperature or when towing a trailer, it is possible for the system to remain in "Open

Loop" operation to control catalytic converter temperatures.

LONG TERM FUEL TRIM CELL (LTFT CELL) - Range 0-34 - LTFT cell is dependent upon engine speed and

ma ss air f low readings and canister pur ge. A plot of RPM vs MAF is broken into 34 cells. LTFT cell indicates which

cell is currently active.

RH/LH 02 STATUS - Tech 2 Displays "RICH" or "LEAN" - Indicates whether exhaust oxygen sensor voltage is

above (rich) or below (lean) the 450 mV oxygen sensor threshold voltage. Should change constantly indicating that

the PCM is controlling the air/fuel mixture properly.

RH/LH O2 CROSS CNTS - Range 0-255 - The number of times the oxygen sensor voltage crosses over the

rich/lean threshold during a two second interval.

STFT /LT FT DELT A - Range 0-100%. - The dif fer ence (Delta) in % of the ST FT /LT FT counts f rom eac h bank. This

value is used by the PCM to determine bank to bank fuel trim balance.

DECEL FUEL CUTOFF - Tech 2 Displays "YES" or "NO" - Yes displayed indicates that the PCM has detected

conditions appropriate to operate in deceleration fuel mode. The PCM will command deceleration fuel mode when

a sudden decrease in throttle position has been detected while the vehicle is travelling over a certain KM/H. W hile

in deceleration fuel mode, the PCM will decrease the amount of fuel delivered by entering open loop and

decreasing the injector pulse width.

INJ. PULSE WIDTH TIME - Range 0.0 - 999.9 mS. - The "ON" time of the injector as determined by the PCM.

INJECTOR VOLTAGE - Range 0 - 14.0 Volts. System voltage monitoring

AIR/FUEL RATIO - Range 0.00 : 99.99 - The reading reflects the commanded value. This should be at or near

14.7. A lower number indicates a richer commanded air fuel mixture while a higher number indicates a leaner

mixture.

PURGE PWM - Range 0 - 100% - A propor tional signal used to control EVAP Canister Purge func tion. 0% im plies

the valve is commanded fully closed, while 100% implies that the value is fully open.

EGR POSITION COMMANDED - Range 0 - 100% - Represents the EGR pintle position that the PCM is

commanding. Desired EGR position should stay close to EGR Pintle Position.

EGR POSITION FEEDBACK - Range 0% - 100% - Represents the actual position of the EGR pintle in percent.

0% displayed indicates a fully extended pintle (EGR valve closed).

EGR PINTL E SENSOR - Range 0.0 - 5.0 Volts - Represents the voltage that the PCM us es to determ ine weather

or not the EGR valve is fully closed (0% pintle position).

BATTERY VOLTAGE - Range 0-25.5 volts - This represents the system voltage measured by the PCM at its

ignition No. 1 feed.

REFERENCE VOLTS - Range 0-5.10 Volts - Indicates the voltage that is supplied to various sensors from the

PCM.

CAM SIGNAL - Range Missing or Present - Signal sent to the PCM by the Cam Sensor. This indicates

movement of the camshaft. This signal is used by the PCM to indicate if the engine is running.

IAC POSITION - Range 0-255 Counts - Displays the commanded position of the idle air control pintle in counts.

The higher the number of counts, the greater the commanded idle speed. Idle air control should respond fairly

quickly to changes in engine load to maintain desired idle RPM.

LITRES Per Hour - Range 0-100 - Indicates fuel consumption per litres per hour.

IDLE RPM VARIANT - Range 0-9999 RPM - Indicates the variation in RPM between sampling's of the engine

speed.

SPARK MODE - Tech 2 displays "BYPASS" or "EST" - Indicates what mode of ignition timing the vehicle is

operating under.

SPARK ADVANCE - Range -90 Degree to +90 Degree - T his is a display of the spark advance (EST ) calculation

which the PCM is program m ing into the ignition system. It com putes the desired spark advance using data such as

engine temperature, rpm, load, vehicle speed, and operating mode.

KNOCK SIGNAL - Tech 2 Displays "KNOCK" or "NONE" - Indicates whether or not a knock signal is being

detected by the PCM. Should read "NONE" at idle.

KNOCK RET ARD - Rang e 0 Degrees - 90 Deg rees - Indic ates the amount of s par k advanc e the PCM is removing

from EST in response to the Knock sensor (ESC) signal. Should read 0 degrees at idle.

TCC SOLENOID - Tech 2 Displays "ON" or "OFF". - Indicates if the transmission TCC Solenoid is commanded

the TCC ON or OFF.

VEHICLE SPEED - Range 0-255 km/h - The vehicle speed sensor signal is converted into kph and mph for

display.

A/C REQU EST - T ech 2 Displays "YES" or "NO" - Repr esents the state of the A/C request serial data input f rom

the BCM.

A/C CLUTCH - Tech 2 Displays "ON" or "OFF" - Represents the commanded state of the A/C clutch control

relay. Clutch should be engaged when "ON" is displayed.

A/C PRESSURE - Tech 2 Displays 0.0 - 5.10 Volts - Represents the A/C r efrigerant press ure Sensor signal. The

amount of pressure indicates the amount of load that the A/C compressor is placing on the engine.

The PCM uses this information to adjust idle speed and to control the cooling fan.

A/C PRESSURE - Range 0 - 3195 kPa - The kPa displayed indicates that the PCM is monitoring an A/C

Refrigerant Pressure signal voltage which is too high or too low to allow the A/C compressor clutch to engage.

HIGH SPEED FAN - Tech 2 Displays "ON" or "OFF - Indicates if the engine cooling fan high speed relay has

been commanded ON or OFF.

LOW SPEED FAN REQUEST - Tech 2 Displays "ON" or "OFF - Indicates if the engine cooling fan low speed

relay has been commanded ON or OFF.

THEFT STATUS - Tech 2 Displays "NO START" or "START". - Indicates the status of the Theft Deterrent

System.

STARTER RELAY - T ech 2 Displays "OFF" or "ON" - If the scan tool indic ates ON, then the vehic le will start. As

long as the Theft Deterrent System is working properly, the scan tool should indicate "ON"

FUEL PUMP RELAY - Tech 2 Displays "ON" or "OFF. - Indicates if the Fuel Pump is ON or OFF.

SUPERCHARGER OPTION - Tech 2 Displays "YES" or "NO" - Under normal driving conditions the scan tool

should indicate NO. When the vehicle is acceler ated the scan tool should indicate YES indicating the Supercharger

is being commanded ON.

PWM BOOST - T ech 2 Disp lays 0% to 100%. Under norm al driving conditions , the Tec h 2 will display 100% Boost

PWM. When in reverse gear or at a high engine load, the Tech 2 will display 0%.

SUPERCHARGER FUEL PUMP STATE - Tech 2 Displays "LOW SPEED" or "HIGH SPEED" - Under normal

driving conditions the scan tool should display Low Speed. When the vehicle is accelerated the fuel pump will

switch speeds and the scan tool should display High Speed.

CRANK TIME - Range 0 - 99.9 Seconds. - Indicates the duration of the engine crank time.

DTC ST ATUS - Tech 2 Displays "NO DTC(s)" or DT C SET - Indicates if a DTC is set. This does not indicate what

DTC is set, just informs that DTC are or are not set.

TIM E FROM START - Tech 2 Displays 0:00:00. - Indicates the hours, m inutes and seconds the engine has been

running.

CHECK POWERT RAIN MALFUNCT ION INDICAT OR LAM P (M IL) - Tech 2 Displays "OFF" or "ON" - Indicated

if the instrument panel Malfunction Indicator Lamp is "ON", or "OFF".

REQUESTED TORQUE - Tech 2 Displays 0 - 215 N.M of Torque - Indicates what N.M torque signal the

ABS/ETC module is sending to the PCM.

ACTUAL TORQUE - Tech 2 Displays 0 - 215 N.M Of Torque - Indicates the PCM N.M torque response back to

the ABS/ETC module.

TECH 2 SCAN TRANSMISSION DATA

The Tech 2 scan Data listed in the table may be used for comparison

1. After completing the "On-Board Diagnostic System Check"

2. Finding the on-board diagnostics are functioning properly and

3. No diagnostic DTCs are displayed.

A TECH 2 SCAN TOOL THAT DISPLAYS FAULTY DATA SHOULD NOT BE USED, AND THE PROBLEM

SHOULD BE REPORTED TO THE MANUFACTURER. THE USE OF A FAULTY TECH 2 SCAN TOOL CAN

RESULT IN MISDIAGNOSIS AND UNNECESSARY PARTS REPLACEMENT.

Only the parameters listed are us ed in this Section f or diagnos is. For m ore desc ription on the values and us e of the

Tec h 2 scan tool to diagnosis PCM inputs, r efer to the applicable diagnosis Table. If all values are within the range

illustrated, refer to Section 6C1-2B - SYMTOMS of the VX Series Service Information.

Test Description: Number(s) below refer to circled number(s) on the Tech 2 scan tool Transmission Date Stream.