SECTION 6C1-2B - SYMPTOMS - V6 ENGINE

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in VX Service Information for correct workshop practices with regards to safety

and/or property damage.

When no diagnostic trouble codes have been set and the scan tool data values are within typical ranges, you should

diagnose the condition based on the symptoms of the complaint.

This Symptom section starts with preliminary checks that must be performed in order to diagnose by symptom.

Then, intermittent conditions are discussed. These preliminary pages provide important information to assist you

with symptom diagnosis. Next, the contents of this VX Series Service Informationpresents the various symptoms

and lists a series of checks for each.

Many of the s ymptom diagnostic s s tar t with a very important proc edur e, a visual/physical inspec tion. Always look for

the obvious first. Some situations may warrant observing the driver. Is the driver using the correct shift lever position

or riding the brake pedal? Visually check the engine, transmission and PCM connectors. Are there any

disconnected wires or incorrectly installed components? Finally, are there obvious signs that someone may have

performed incorrect repairs? These checks take very little time; they can eliminate the time spent on a broad-base

systematic diagnos is by direc ting you to the problem . If they do not reveal the pr oblem, proceed to c heck the other

suspect systems, as shown.

The last pages of this VX Series Service Information contain PCM connector symptom Tables. If you are diagnosing

a problem, scan the right-most column for the symptom(s) and check for the correct wire and voltage at the

designated connector cavity. PCM

Since the PCM can have a failure which may affect only one circuit, following the Diagnostic Procedures in this

section will determine which circuit has a problem and where it is.

If a diagnostic T able indicates that the PCM connections or PCM is the cause of a problem, and the PCM is

replaced, but does not correct the problem, one of the following may be the reason:

• There is a problem with the PCM terminal connections. The diagnostic Table will say "PCM connections or

PCM." The terminals may have to be removed from the connector in order to check them properly.

• The PCM is not correct for the application. The incorrect PCM may cause a malfunction and may or may not set

a code.

• The problem is intermittent. This means that the problem is not present at the time the system is being

checked. In this cas e, r ef er to the "Symptoms" T ables and m ake a careful physical inspection of all c omponents

of the system involved.

• Shorted solenoid, relay coil, or harness. Solenoids and relays are turned "ON" and "OFF" by the PCM, using

internal electronic switches called "Drivers." Each "driver" is part of a group of four (called "Quad drivers").

Failure of one driver may cause other drivers in the set to m alfunction. Solenoid and relay coil resis tance must

measure more than 20 ohms, in most cases. Less resistance may cause early failure of the PCM "driver."

Before replacing an PCM, be sure to check the coil resistance of all solenoids and relays controlled by the

PCM. See PCM wiring diagram for the solenoid(s) and relay(s) and the coil terminal identification.

• The replacement PCM may be faulty. After the PCM is replaced, the system should be rechecked for proper

operation. If the diagnostic Table again indicates the PCM is the problem, substitute a known good PCM.

Although this is an extremely rare condition, it could happen.

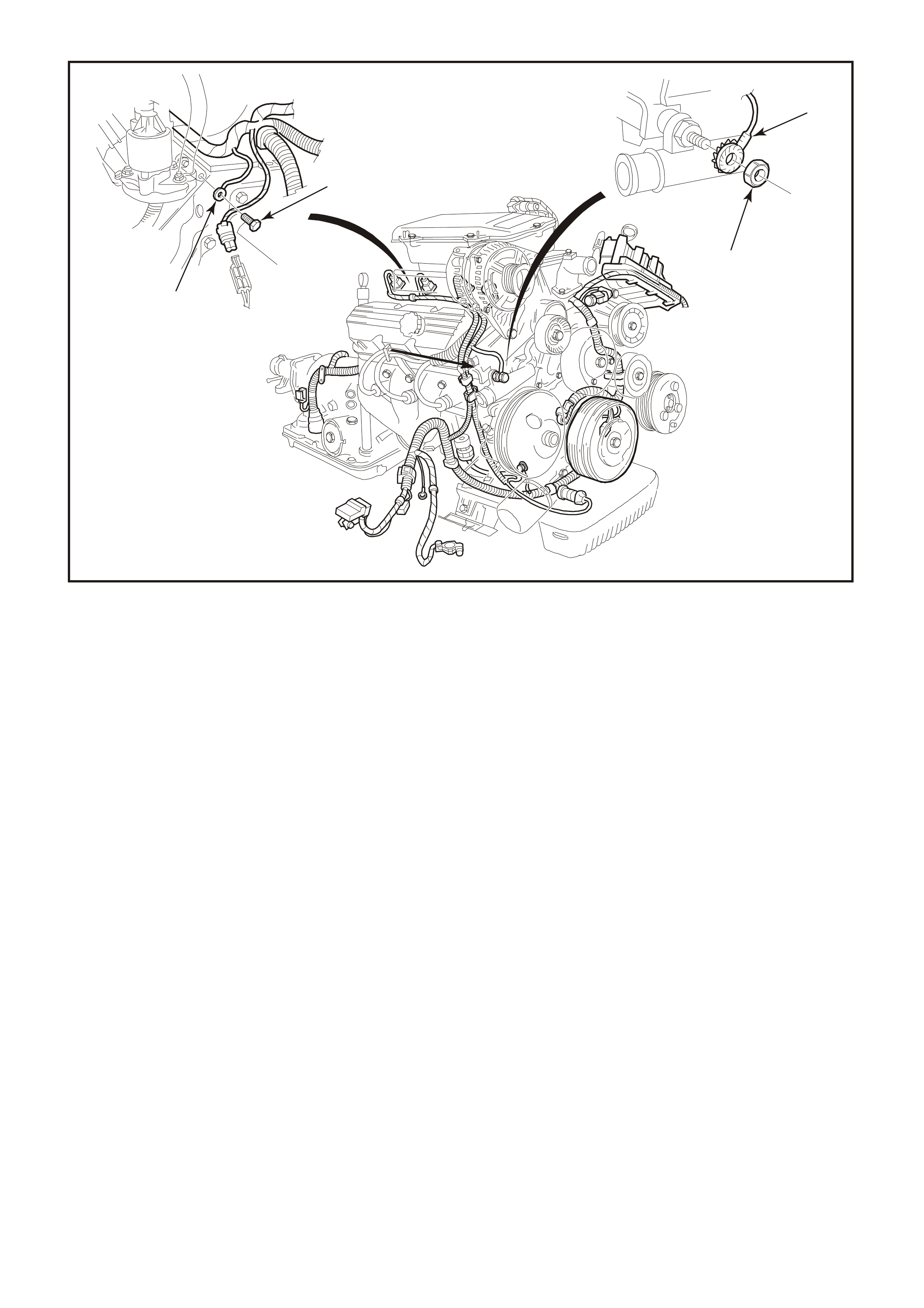

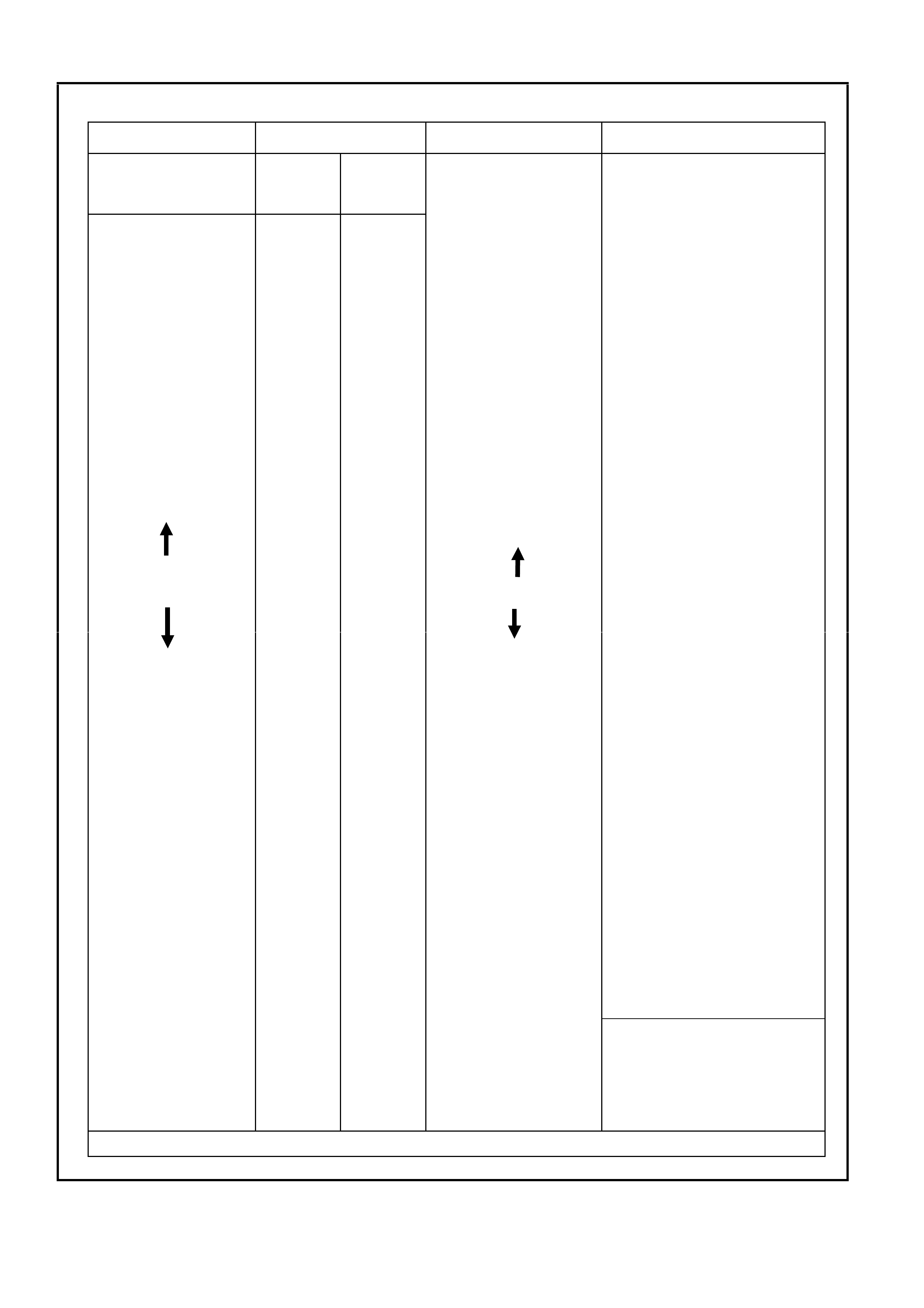

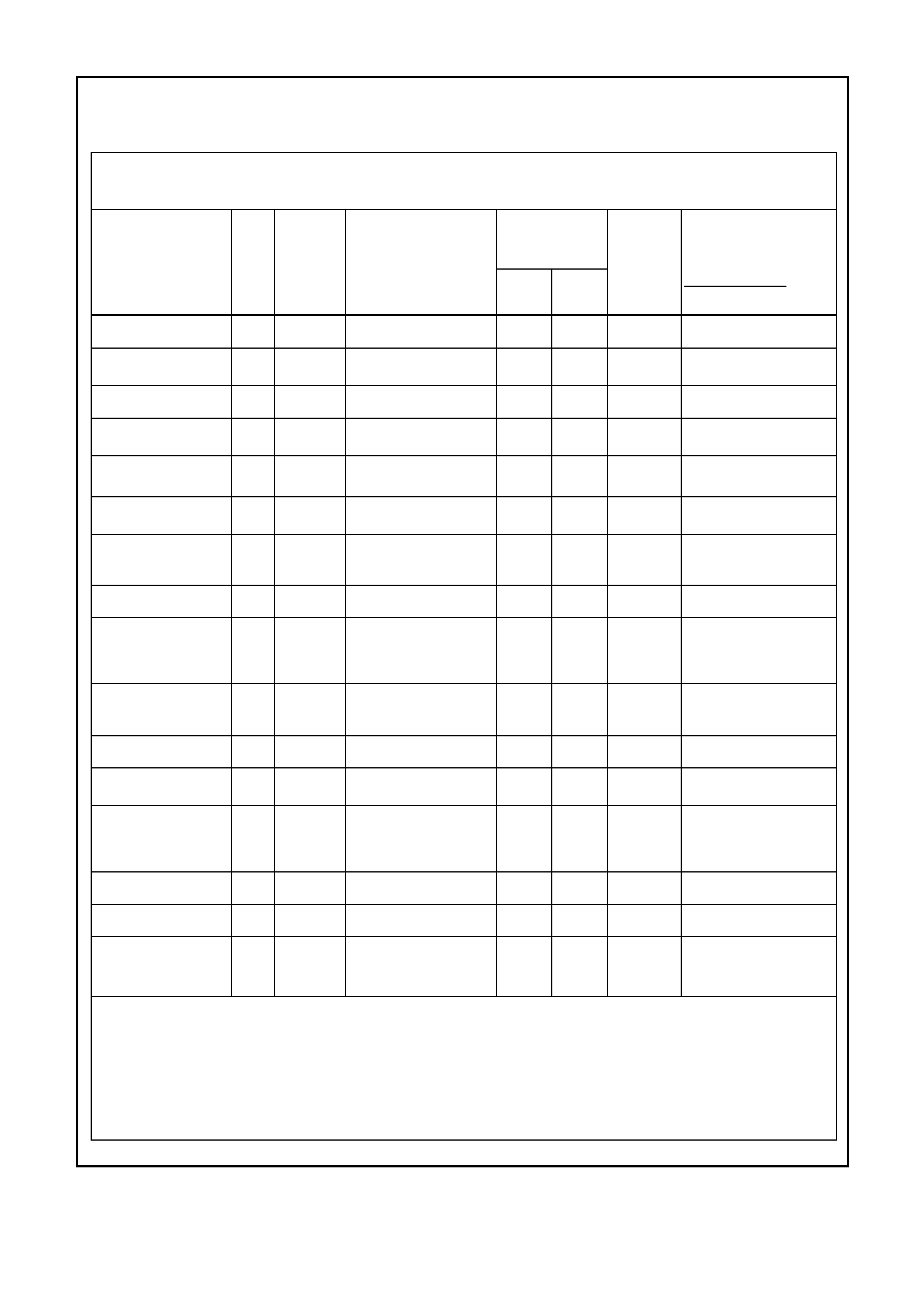

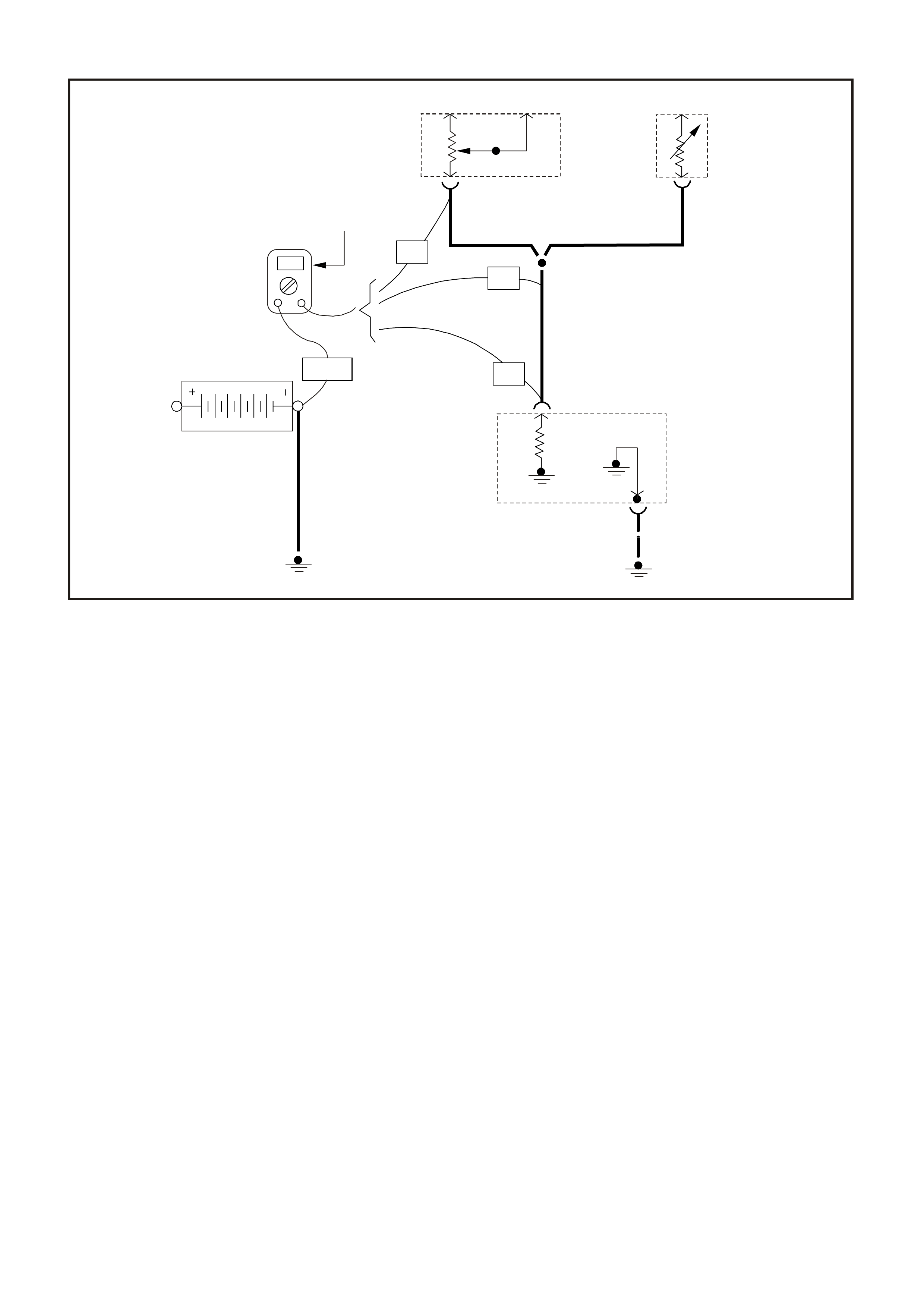

Figure 6C1-2B-1 Engine Powertrain Wiring Harness to Engine Assembly Earth Location.

1. Engine Earth Terminal.

2. Nut.

3. Earth Terminal.

4. Bolt.

3

4

1

4287

2

IMPORTANT P RELIMINARY CHECKS

BEFORE USING THIS SECTION

Before using this Symptoms Section you should have performed the "On Board Diagnostic System Check" as

detailed in Section 6C1-2A of the VX Series Service Information and determined that:

1. The PCM and "Check Powertrain" lamp are operating correctly.

2. There are no diagnostic trouble codes stored.

3. There is a diagnostic trouble code stored in the PCM memory and the "Check Powertrain Lamp is not "ON."

4. The diagnostic Table for the diagnostic trouble code indicates that the trouble is intermittent.

5. Figure 6C1-2B-1 on the previous page illustrates the Powertrain wiring harness to engine assembly earth

locations as described in the various "SYMPTOM TABLES" of this Section. You should become familiar with

these locations.

SYMPTOM

Verify the customer complaint, and locate the correct symptom in the table of contents. Check all the items

indicated under that symptom.

If the ENGINE CRANKS BUT WILL NOT RUN, refer to Table A3.1 in Section 6C1-2A of the VX Series Service

Information.

VISUAL/PHYSICAL CHECK

Several of the symptom procedur es call f or a Caref ul Visual/Physical Check . T he im portance of this s tep cannot be

stressed too strongly it can lead to correcting a problem without further checks and can save valuable time. This

check should include:

• Check service records for any recent repairs that may indicate a related problem, or the current need for

scheduled maintenance.

• PCM sensors for being in their proper location.

• PCM earth circuits term inate at 2 separ ate eyelet terminals. O n a V6 these attach to the engine at two separate

locations: the rear of the left cylinder head, and on the by-pass tube and drive belt tensioner attaching stud,

below the generator (refer figure at the beginning of the VX Series Service Information). They must be clean

and tight. Check for earth terminals that may be loose under the retaining nuts/bolts, or for terminals that m ay

have been lef t off after engine repair. Any repair of the wire to term inal connection must include soldering with

rosin core solder. (NEVER use acid core solder for any wiring repairs.)

• Vacuum hoses for splits, kinks, and proper connections. Check thoroughly for any type of leak or restriction.

• Air leaks at throttle body mounting area and inlet manifold sealing surfaces.

• Ignition wires for cracking, hardness, proper routing and carbon tracking.

• Wiring for proper connections, pinches and cuts.

• Check for any non genuine Holden's options or accessories that may have been fitted to the vehicle that may

cause or exaggerate the problem.

INTERMITTENTS

Definition: Problem may or may not turn "ON" the "Check Powertrain" lamp or store a DTC. DO NOT use the

diagnostic code Tables for intermittent problems. W hen using the code Tables the fault must be present to locate

the problem. If a fault is intermittent, use of diagnostic trouble code Tables may result in replacement of good parts.

• Most intermittent problems are caused by faulty electrical connections or wiring. Perform careful visual/physical

check as described at the start of the VX Series Service Information-

"IMPORTANT PRELIMINARY CHECKS".

Check for:

- Poor mating of the connector halves or terminal not fully seated in the connector body (backed out).

- Improperly formed or damaged terminal. All connector terminals in the problem circuit should be carefully

reformed or replaced to insure proper contact tension.

- Poor terminal to wire connection. This requires removing the terminal from the connector body to check as

outlined in service operations.

- PCM earth circuit terminals being loose at the engine. On a V6 engine these attach to the engine at two

separate locations : the rear of the lef t cylinder head, and on the by-pass tube and drive belt tensioner attaching

stud, below the generator, refer figure at the beginning of the VX Series Service Information.

• If a visual/physical check does not find the cause of the problem, the car can be driven with a voltmeter

connected to a suspected circuit. A scan tool can also be used to help detect intermittent conditions. An

abnorm al voltage, or sc an tool r eading, when the problem occur s , indicates the problem m ay be in that circuit. If

the wiring and connectors check OK, and a diagnostic trouble code was stored for a circuit having a sensor,

except for DTC's P0132 or P0152 and P0131 or P0151, substitute a known good sensor and recheck.

• Loss of diagnostic code memory. To check, disconnect TP sensor and idle engine until "Check Powertrain"

lamp c omes "O N." DTC P0122 should be stored, and k ept in mem ory when ignition is turned "OFF." If not, the

PCM is faulty.

• An intermittent "Check Powertrain" lamp with no stored diagnostic trouble code may on V6 be caused by:

- Ignition coil shorted to earth and arcing at spark plug wires or plugs.

- Intermittent short to + 12 volts on 0-5 volt input CKTs 451 (diagnostic request), 410 (ECT sensor), 792

(MAF sensor), 417 (TP sensor), and 472 (IAT sensor).

• Check for an electrical system interference caused by a defective relay, PCM driven solenoid, or switch. They

can cause a sharp electrical surge. Normally, the problem will occur when the faulty component is operated.

• Check for improper installation of non-factory installed electrical options such as lights, 2 way radios, etc.

• EST wires should be routed away from spark plug wires, ignition wires, ignition module assembly and

generator. Wire from PCM to ignition should have a good connection.

• Check for open diode across A/C compressor clutch, and for other open diodes (refer to wiring diagrams and

TABLE A-11.1 or TABLE A-11.3 facing page wiring diagrams in Section 6C1-2A of the VX Series Service

Information).

• If problem has not been found, refer to the proper symptom and perform all checks listed there.

HARD START

Definition: Engine crank s OK, but does not s tart for a long tim e. Does eventually run, or m ay start but imm ediately

dies.

PRELIMINARY CHECKS

• Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

• Make sure the driver is using the correct starting procedure. Do not depress accelerator pedal during cranking.

• TABLE A-3.1 "ENGINE CRANKS BUT WILL NOT RUN" in Section 6C1-2A of the VX Series Service

Information. Although this Table may not exactly describe the problem, most all of the causes of a "no start" can

also cause a "hard start".

• Tim e or kilometers since norm al engine tune-up has been perform ed, refer to tim e/distance intervals specified

in the Owner's Manual.

• PCM earth circuit terminals being loose at the engine. On a V6 engine these attach to the engine at two

separate locations : the rear of the lef t cylinder head, and on the by-pass tube and drive belt tensioner attaching

stud, below the

generator, refer figure at the beginning of the VX Series Service Information.

SENSORS

• CHECK: Engine Coolant Temperature (ECT) sensor using a scan tool, compare coolant temperature with

ambient temperature on cold engine.

- If coolant tem perature readings is 5 degrees greater than or less than am bient air temperature on a

cold engine, check resistance in coolant sensor circuit or sensor itself. Compare ECT resistance

value to the "Diagnostic Aids" Table on DTC P0117 Table in Section 6C1-2A of the VX Series

Service Information.

• CHECK: MAF sensor. for a shifted sensor, refer TABLE A-6.1 "MAF OUTPUT CHECK" in Section 6C1-2A of

the VX Series Service Information.

• CHECK: TP Sensor for binding or a high TP sensor voltage with the throttle closed.

IGNITION SYSTEM

• CHECK: Spark plug leads being misrouted at the coils or at the spark plugs.

• CHECK: For proper ignition voltage output with spark tester ST-125 or 7230.

• CHECK: Spark plugs. Remove spark plugs, check for wet plugs, cracks, wear, improper gap, burned

electrodes, or heavy deposits. Repair or replace as necessary.

• CHECK: Bare or shorted wires.

FUEL SYSTEM

• CHECK: Fuel pump relay operation pump should turn "ON" for 2 seconds when ignition is turned "ON." Use

TABLE A-4.1.

• CHECK: Fuel pressure, refer to TABLE A-4.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Contaminated fuel or incorrect fuel.

• CHECK: If the problem occur s worse with hotter temper atures, check for leaking injectors , refer TABLE A-4.3

in Section 6C1-2A of the VX Series Service Information.

• NOTE: A faulty in-tank fuel pump check valve will allow the fuel in the lines to drain back to the tank after

engine is stopped. T o check for this condition, per form f uel sys tem diagnosis, r efer TABLE A- 4.3 in

Section 6C1-2A of the VX Series Service Information.

ADDITIONAL CHECKS

• CHECK: Exhaust back pressure, refer TABLE A-13 "RESTRICTED EXHAUST CHECK" in Section 6C1-2A of

the VX Series Service Information.

• CHECK: IAC Operation, refer to TAB LE A-7.1 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Basic engine problem. Cam s haf t timing chain for being str ipped or slipped, causing valve timing to be

retarded.

• CHECK: Compression. Disconnect fuse F31 before performing test.

• CHECK: Service Bulletins for updates.

SURGES AND/OR CHUGGLE S

Definition: Engine power variation under steady throttle or cruise, f eels like the vehic le speeds up and slows down

with no change in the acceleration pedal.

PRELIMINARY CHECKS

• Perform the careful visual checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

• Make sure driver understands transmission torque converter clutch, and A/C compressor operation as

explained in the Owner’s Manual.

• Tim e or k ilometer s since norm al engine tune-up has been perform ed. Refer to time/dis tance intervals specif ied

in the Owner’s Manual.

SENSORS

• CHECK: Oxygen Sensor (O2S) . T he O x ygen Sensor (O2S) should r es pond quickly to different throttle position,

if it does not, c hec k the Ox ygen Sensor (O2S) f or s ilic on or other contamination’s f rom f uel, or use of

improper RTV sealant.

The sensor may have a white, powdery coating and result in a high but false signal voltage (rich

exhaust indication). The PCM will then reduce the amount of fuel delivered to the engine, causing a

severe driveability problem. Also, watch for green glycol contamination or cracking.

• CHECK: MAF sensor for proper operation, refer TABLE A-6.1 “MAF OUTPUT CHECK” in Section 6C1-2A of

the VX Series Service Information.

IGNITION SYSTEM

• CHECK: For proper ignition voltage output using spark tester ST-125 or 7230.

• CHECK: Spark plugs. Remove spark plugs, check for wet plugs, cracks, wear, improper gap, burned

electrodes, or heavy deposits. Repair or replace as necessary. Also, check spark plug wires.

• CHECK: Ignition secondary coil or wiring shorting to earth.

FUEL SYSTEM

• CHECK: Contaminated or incorrect fuel.

NOTE To determine if the condition is caused by a rich or lean system, the car should be driven at

the speed of the complaint. Monitoring block learn and integrator will help identify a problem.

- Lean - Long Term Fuel Trim near +25%. Refer to "Diagnostic Aids" on facing page of DTC P0131

or P0151 in Section 6C1-2A of the VX Series Service Information.

- Rich - Long Term Fuel Trim near - 22%. Refer to "Diagnostic Aids" on facing page of DTC P0132 or

P0152 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Fuel pressure while condition ex ists, refer TABLE A-4.3 in Section 6C1- 2A of the VX Ser ies Service

Information.

• CHECK: In line fuel filter. Replace if dirty or plugged.

• CHECK: Restricted fuel injectors.

ADDITIONAL CHECKS

• CHECK: PCM earth circuits for being clean, tight and in their proper location.

• CHECK: Vacuum lines for splits, kinks, leaks and proper connections.

• CHECK: Generator output voltage. Repair if less than 9 or more than 16 volts.

• CHECK: Speedometer reading with the speed on a scan tool are equal.

• CHECK: Service Bulletins for updates.

• CHECK: Excessive exhaust back pressure, refer TABLE A-13 "RESTRICTED EXHAUST CHECK" in

Section 6C1-2A of the VX Series Service Information.

• CHECK: TCC operation for proper operation.

LACK OF POWER, SLUGGISH, OR SPONGY

Definition: Engine delivers less than expected power. Little or no increase in speed when accelerator pedal is

pushed down part way.

PRELIMINARY CHECKS

• Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

• Compare customer's car to similar unit. Make sure the customer has an actual problem.

• Remove air filter and check air filter for dirt, or for being plugged. Replace as necessary .

• Time or kilometers since normal engine tune-up has been performed. Refer to time/distance intervals in

owner’s handbook.

SENSORS

• CHECK: MAF sensor f or proper oper ation, refer T ABLE A-6.1 "M AF OUT PUT CHECK" in Section 6C1-2A of

the VX Series Service Information.

ENGINE MECHANICAL

• CHECK: Engine valve timing.

• CHECK: Engine for correct or worn camshaft.

• CHECK: Compression. Disconnect the fuse F31 before performing test.

IGNITION SYSTEM

• CHECK: Secondary voltage using a shop oscilloscope or a spark tester ST-125 or 7230.

• CHECK: For ignition m is f ir e under heavy engine load. Check eac h s park plug lead for excessive resis tanc e (or

open circuit), or for faulty or cracked spark plugs.

FUEL SYSTEM

• CHECK: Restricted fuel filter, refer TABLE A-4.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Fuel pressure, refer TABLE A-4.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Contaminated fuel, refer TABLE A-4.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: F uel Pum p Control Module chec k. Refer to TABLE 4.1-1 in Section 6C1-2A of the VX Series Service

Information.

ADDITIONAL CHECKS

• CHECK: PCM earth circuit for being clean, tight and in their proper locations.

• CHECK: Generator output voltage. Repair if less than 9 or more than 16 volts.

• CHECK: Exhaust system for possible restriction, refer TABLE A-13 in Section 6C1-2A of the VX Series

Service Information.

- Inspect exhaust system for damaged or collapsed pipes.

- Inspect muffler for heat distress or possible internal failure.

• CHECK: Torque Converter Clutch (TCC) for proper operation.

DETONATION/SPARK KNOCK

Definition: A mild to severe ping, usually worse under acceleration. The engine m akes sharp metallic knocks that

change with throttle opening.

PRELIMINARY CHECKS

Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

NOTE: If scan tool readings are normal (refer facing page of "On-Board Diagnostic System Check" in Section

6C1-2A of the VX Series Service Information) and there are no engine mechanical faults, fill fuel tank with a

premium unleaded fuel and reevaluate vehicle performance.

IGNITION SYSTEM

• CHECK: Spark plugs for proper heat range.

ENGINE MECHANICAL

• CHECK: Combustion chambers for excessive carbon build up. Remove carbon with top engine cleaner and

follow instructions on can. If the problem recurs and top engine cleaner corrects it again, look for

possible causes of high oil consumption.

• CHECK: For excessive oil in the combustion chamber.

- Valve oil seals for leaking.

• CHECK: Combustion chamber pressure by performing a compression test. Disconnect the fuse F31 before

performing test.

• CHECK: For incorrect basic engine parts such as camshaft, heads, pistons, etc.

COOLING SYSTEM

Check for obvious overheating problems:

- Low engine coolant.

- Defective engine thermostat.

- Loose water pump belt.

- Restricted air flow to radiator, or restricted water flow through radiator.

- Inoperative electric cooling f an cir cuit, refer to TABLE A-12.1 in Section 6C1-2A of the VX Series Service

Information.

- Correct coolant solution should be a 50/50 mix of antifreeze coolant and water.

FUEL SYSTEM

• CHECK: Fuel quality and proper octane rating.

• NOTE:· To determine if the condition is caused by a rich or lean system, the car should be driven at the

speed of the complaint. Monitoring block learn will help identify the problem.

- Lean - Long Ter m F uel Trim near +25%. Refer to "Diagnostic Aids" on f acing page of DTC P0132 or

P0152 in Section 6C1-2A of the VX Series Service Information.

- Rich - Long T erm Fuel T rim near - 22%. Ref er to "Diagnostic Aids" on f acing page of DT C P0132 or

P0152 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Fuel Control Module oper ation. Refer to TABLE A-4.1-1 in Sec tion 6C1-2A of the VX Series Service

Information.

• CHECK: Fuel pressure, refer to TABLE A-4.3 in Section 6C1-2A of the VX Series Service Information.

ADDITIONAL CHECKS

• CHECK: Vacuum leaks.

• CHECK: TCC operation, TCC applying too soon.

• CHECK: Service Bulletins for updates.

HESITATION, SAG, STUMBLE

Definition: Momentary lack of response as the accelerator is pushed down. Can occur at all vehicle speeds.

Usually most sever e when fir st tr ying to mak e the c ar move, as f r om a stop s ign. May cause engine to stall if sever e

enough.

PRELIMINARY CHECKS

Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

Time or distance interval since normal engine tune-up has perform ed. Refer to time/distance intervals specified in

Owner's Manual.

• CHECK: Vacuum hoses for splits, kinks, and proper connections.

• CHECK: For vacuum leaks at throttle body mounting and inlet manifold.

SENSORS

• CHECK: TP Sensor - Check TP Sensor for binding or sticking. Voltage should increase at a steady rate as

throttle is moved toward W ide Open Throttle (W OT), refer TABLE A - 6.2 in Section 6C1-2A of the

VX Series Service Information.

• CHECK: MAF sensor, refer to TABLE A - 6.1 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Engine coolant tem perature sensor resistance. Refer to DTC P0117 – “Engine Coolant Tem perature

(ECT) Signal Voltage Low” in Sect ion 6C1-2A of the VX Series Service Infor mation for engine coolant

temperature sensor temperature - resistance table.

IGNITION SYSTEM

• CHECK: Spark plugs for being fouled, or for there being faulty secondary wiring.

• CHECK: Ignition system earth, CKT 453.

FUEL SYSTEM

• CHECK: Fuel pressure, refer use TABLE A - 4.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Contaminated or incorrect fuel.

• CHECK: Canister purge system for proper operation.

• CHECK: Fuel injectors. Perform injector balance test.

ADDITIONAL CHECKS

• CHECK: Service Bulletins for updates.

• CHECK: Exhaust system back pressure, refer TABLE A-13 "RESTRICTED EXHAUST SYSTEM TEST" in

Section 6C1-2A of the VX Series Service Information.

• CHECK: Engine thermostat functioning correctly and proper heat range.

• CHECK: Generator output voltage. Repair if less than 9 or more than 16 volts.

CUTS OUT, MISSES

Definition: Steady pulsation or jerking that follows engine speed, usually more pronounced as engine load

increases. The exhaust has a steady spitting sound at idle or under load.

PRELIMINARY CHECKS

Perform the careful visual/physical checks as described at start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

IGNITION SYSTEM

• CHECK: If ignition system is suspected of causing a miss at idle or cutting out under load.

• CHECK: If the previous checks did not find the problem;

Visually inspect ignition system fo r moistur e, dus t, cr ac ks, burns , etc . Spray plug wir es with fine water

mist to check for shorts.

Check for a misfiring cylinder at idle by:

1. Start engine, then dis connect IAC m otor . Rem ove one s park plug wire at a time us ing insulated pliers . Do

not run engine for long periods of time with any spark plug disconnected. The unburned fuel causes the

catalytic converter to be abnormally hot, and damage may occur if allowed to run this way too long.

2. If there is an rpm drop on all cylinders (equal to within 50 RPM), go to ROUGH, UNSTABLE, OR

INCORRECT IDLE, STALLING symptom. Reconnect IAC motor.

3. If there is no rpm drop on one or more cylinders, or excessive variation in drop, check for spark on the

suspected cylinder(s) with ST-125 Spark Checking Tool or equivalent. If no spark, check plug lead for

excessive resistance (or possibly `open'). If there is spark, remove spark plug(s) in those cylinders and

check for:

- Cracks - Wear

- Improper Gap - Burned Electrodes

- Heavy Deposits

ENGINE MECHANICAL

• CHECK: Compression. Perform compression check on questionable cylinder(s) found above. If compression

is low, repair as necessary. Disconnect fuse F31 before checking.

• CHECK: Base engine. Remove rocker covers. Check for bent pushrods, worn rocker arms, broken valve

springs, worn camshaft lobes and valve timing, repair as necessary .

FUEL SYSTEM

• CHECK: Fuel system - Blocked fuel filter, low pressure, refer TABLE A-4.3 in Section 6C1-2A of the VX Series

Service Information.

• CHECK: Contaminated or incorrect fuel.

• CHECK: Perf ormance of injector . If there is good spark and com pression on all cylinders, check for res tricted

or non-operating fuel injectors. To check for a non-operating injector:

With the engine idling, check for clicking sound at each injector with a stethoscope or long

screwdriver held on the body of each injector. If any injector fails to make the clicking sound,

disconnect the electrical connector, and connect a suitable test light, such as BT-8329, across the

harness connec tor ter m inals. If the test light blink s with the engine idling, replace the inj ector . If there

is no blinking light, check for an "open" wire leading to that injector. Refer to Fuel Injector Circuit

Diagnosis TABLE 3.0 in Section 6C1-2C of the VX Series Service Information.

ADDITIONAL CHECKS

• CHECK: For EMI interference. A missing condition can be caused by Electromagnetic Interference (EMI) on

the reference circuit. EMI can usually be detected by monitoring engine RPM with a scan tool. A

sudden increas e in RPM with little c hange in actual engine RPM change, indicates EMI is pr esent. If

the problem exists, check routing of secondary wires, check earth circuit.

• CHECK: Inlet and exhaust manifold passage for casting flash.

ROUGH, UNSTABLE, OR INCORRECT IDLE , STALLING

Definition: Engine runs unevenly at idle. If bad enough, the vehicle may shake. Also, the idle may vary in RPM

(called "hunting"). Either condition may be bad enough to cause stalling. Engine idles at incorrect speed.

PRELIMINARY CHECKS

Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

• CHECK: For vacuum leaks, they will cause a fast idle.

• CHECK: PCM earths for being clean, tight and in there proper location. Refer to PCM wiring diagrams.

• CHECK: Idle Air Control (IAC) s ys tem f or proper operation, refer T ABL E A-7.1 IG NIT ION SY STEM in Sec tion

6C1-2A of the VX Series Service Information.

• CHECK: For proper ignition voltage output using spark tester ST-125 or 7230.

• CHECK: Spark plugs. Remove spark plugs, checks for wet plugs cracks, wear, improper gap, burned

electrodes, or heavy deposits.

ENGINE MECHANICAL

• CHECK: Perform a cylinder compression check. Disconnect fuse F31 before checking.

• CHECK: For correct camshaft valve lift and timing or weak valve springs.

FUEL SYSTEM

• CHECK: For contaminated or incorrect fuel.

• CHECK: For injectors that are restricted or not operating.

• CHECK: For injectors leaking, or incorrect fuel pressure, refer TABLE A-4.3 in Section 6C1-2A of the VX

Series Service Information.

• NOTE: Monitoring Long term fuel trim will help identify the cause of the problem. If the system is running lean

(Long Term F uel T r im near +25%) , refer to "Diagnostic Aids " on f ac ing page of DTC P0132 or P0152

in Section 6C1-2A of the VX Series Service Information. If the system is running rich (Long Term

Fuel Trim near -22%), refer to "Diagnostic Aids" on facing page of DTC P0132 or P0152 in Section

6C1-2A of the VX Series Service Information.

• CHECK: Injector balance.

• CHECK: For fuel in pressure regulator hose. If fuel is present, replace regulator assembly.

• CHECK: T he Oxygen Sensor (O2S) should respond quick ly to different throttle positions, if it does not, check

the Oxygen Sensor (O2S) for silicon contamination from fuel, or use of improper RTV sealant. The

sensor will have a white, powdery coating, and will result in a high but false signal voltage (rich

exhaust indication). The PCM will then reduce the amount of fuel delivered to the engine, causing a

severe driveability problem.

ADDITIONAL CHECKS

• CHECK: MAF sensor, refer to TABLE A-6.1 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Throttle linkage for sticking or binding.

• CHECK: IAC operation, refer TABLE A-7.1 in Section 6C1-2A of the VX Series Service Information.

• CHECK: A/C signal to PCM, scan tool should indicate A/C is being requested whenever A/C is selected and

the blower switch is "ON." If problem exists with A/C "ON," check A/C system operation

TABLE A-11.1 or TABLE A-11.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: PCV valve for proper operation by placing finger over inlet hole in valve end several times. Valve

should snap back. If not, replace valve.

• CHECK: Service Bulletins for updates.

• CHECK: For broken motor mounts.

• CHECK: Generator output voltage. Repair if less than 9 or more than 16 volts.

• CHECK: Batter y cables and earth str aps should be c lean and secur e. Erratic voltage will caus e IAC to change

its position resulting in poor idle quality.

POOR FUEL ECONOMY

Definition: Fuel ec onomy, as measur ed by an actual road tes t, is notic eably lower than expected. Also, economy is

noticeably lower than it was on this vehicle at one time, as previously shown by an actual road test.

A misfiring engine will have excessive unburned oxygen in the exhaust, and the "Closed-Loop" fuel control

system oxygen sensor will interpret a lean exhaust. The PCM will cause an increase in fuel injector

pulsewidth in attempts to overcome the lean exhaust indication.

PRELIMINARY CHECKS

Perform the careful visual checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

Visually/physically check: Vacuum hoses for splits, kinks, and proper connections

Check owner's driving habits.

- Is A/C "ON" full time (Defroster mode "ON")?

- Are tires at correct pressure?

- Are excessively heavy loads being carried?

- Is acceleration too much, too often?

Check air cleaner element (filter) for dirty or being plugged.

Check for correct size tyres. Oversize tyres will cause speedometer/odometer to be "slow," and indicated fuel usage

may increase.

IGNITION SYSTEM

• CHECK: Spark plugs. Remove spark plugs, check for wet plugs, cracks, wear, improper gap, burned

electrodes, or heavy deposits. Repair or replace as necessary.

COOLING SYSTEM

• CHECK: Engine coolant level.

• CHECK: Engine thermostat for faulty part (always open) or for wrong heat range.

ENGINE MECHANICAL

• CHECK: Compression. Disconnect fuse F31 before checking.

ADDITIONAL CHECKS

• CHECK: TCC operation. A scan tool should indicate an rpm drop, when the TCC is commanded "ON."

• CHECK: For dragging brakes.

• CHECK: For exhaust system restriction, refer to TABLE A-13 in Section 6C1-2A of the VX Series Service

Information.

• CHECK: For proper calibration of speedometer.

• CHECK: Induction system and crankcase for air leaks.

BACKFIRE

Definition: Fuel ignites in inlet manifold, or in exhaust system, making loud popping noise.

PRELIMINARY CHECKS

Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

IGNITION SYSTEM

• CHECK: Proper ignition coil output voltage with spark tester ST-125 or 7230.

• CHECK: Spark plugs. Remove spark plugs, check for wet plugs, cracks, wear, improper gap, burned

electrodes, or heavy deposits. Repair or replace as necessary.

• CHECK: Spark plug wires for cr ossfir e, also inspect dis tributor assem bly, s park plug wires, and pr oper routing

of plug wires.

ENGINE MECHANICAL

• CHECK: Compression - Look for sticking or leaking valves. Remove fuse F31 before performing check.

• CHECK: Valve timing.

• CHECK: Inlet and exhaust manifold passages for casting flash.

FUEL SYSTEM

• CHECK: Perform "Fuel System Diagnosis Check", refer TABLE A-4.3. in Section 6C1-2A of the VX Series

Service Information.

EXCESSIVE EXHAUST EMISSIONS OR ODOURS

Definition: Vehicle fails an emission test. Vehicle has excessive "rotten egg" smell. Excessive odours do not

necessarily indicate excessive emissions.

PRELIMINARY CHECKS

Perform "On-Board Diagnostic Sy stem Check" in Section 6C1-2A of the VX Series Service Information.

IGNITION SYSTEM

• CHECK: Spark plugs. Remove spark plugs, check for wet plugs, cracks, wear, improper gap, burned

electrodes, or heavy deposits. Repair or replace as necessary.

COOLING SYSTEM

If the scan tool indicates a very high engine coolant temperature and the system is running lean:

• CHECK: Engine coolant level.

• CHECK: Engine thermostat for faulty part (always open) or for wrong heat range.

• CHECK: Cooling fan operation.

FUEL SYSTEM

• CHECK: For contaminated or incorrect fuel.

• NOTE:· If the system is running RICH (Long Term Fuel Trim near -22%) - Refer to "Diagnostic Aids" on

facing page of DTC P0132 or DT C P0152 in Sec tion 6C1-2A of the VX Ser ies Service Inf orm ation. If

the system is r unning LEAN (Long T erm Fuel T r im near +25%) - Ref er to "Diagnos tic Aids" on f acing

page of DTC P0131 or DTC P0151 in Section 6C1-2A of the VX Series Service Information.

• CHECK: For properly installed fuel cap.

• CHECK: Fuel pressure, refer TABLE A-4.3 in Section 6C1-2A of the VX Series Service Information.

• CHECK: Canister for fuel loading.

ADDITIONAL CHECKS

• CHECK: For vacuum leaks.

• CHECK: Burnt valves.

• CHECK: For lead contamination for catalytic converter (look for the removal of fuel filler neck restriction).

• CHECK: Carbon build-up. Remove carbon with top engine cleaner. Follow instructions on can.

• CHECK: For exhaust system restriction, refer TABLE A-13 in Section 6C1-2A of the VX Series Service

Information.

• CHECK: PCV valve for being plugged or stuck, or fuel in the crankcase.

• CHECK: Service Bulletins for updates.

DIESELING, RUN-ON

Definition: Engine continues to run after ignition is turned "OFF," but runs very roughly.

PRELIMINARY CHECKS

Perform the careful visual/physical checks as described at the start of the VX Series Service Information -

"IMPORTANT PRELIMINARY CHECKS".

FUEL SYSTEM

• CHECK: Injectors for leaking. Perform "Fuel System Diagnosis Check", refer TABLE A-4.3 in Section 6C1-

2A of the VX Series Service Information.

IGNITION SYSTEM

• CHECK: If engine runs smoothly, check ignition switch and adjustment.

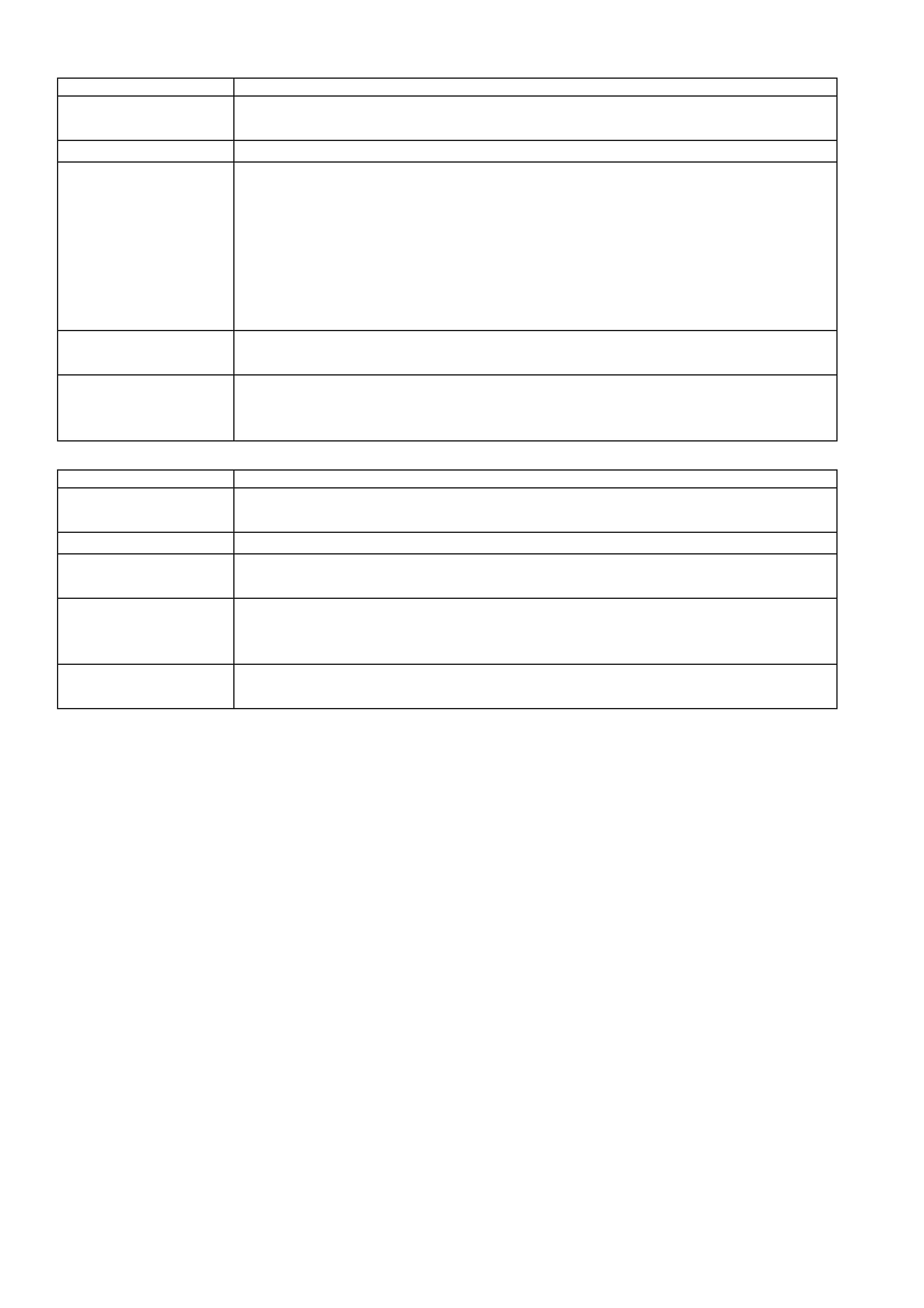

RICH/LEAN SYMPTOM TABLE

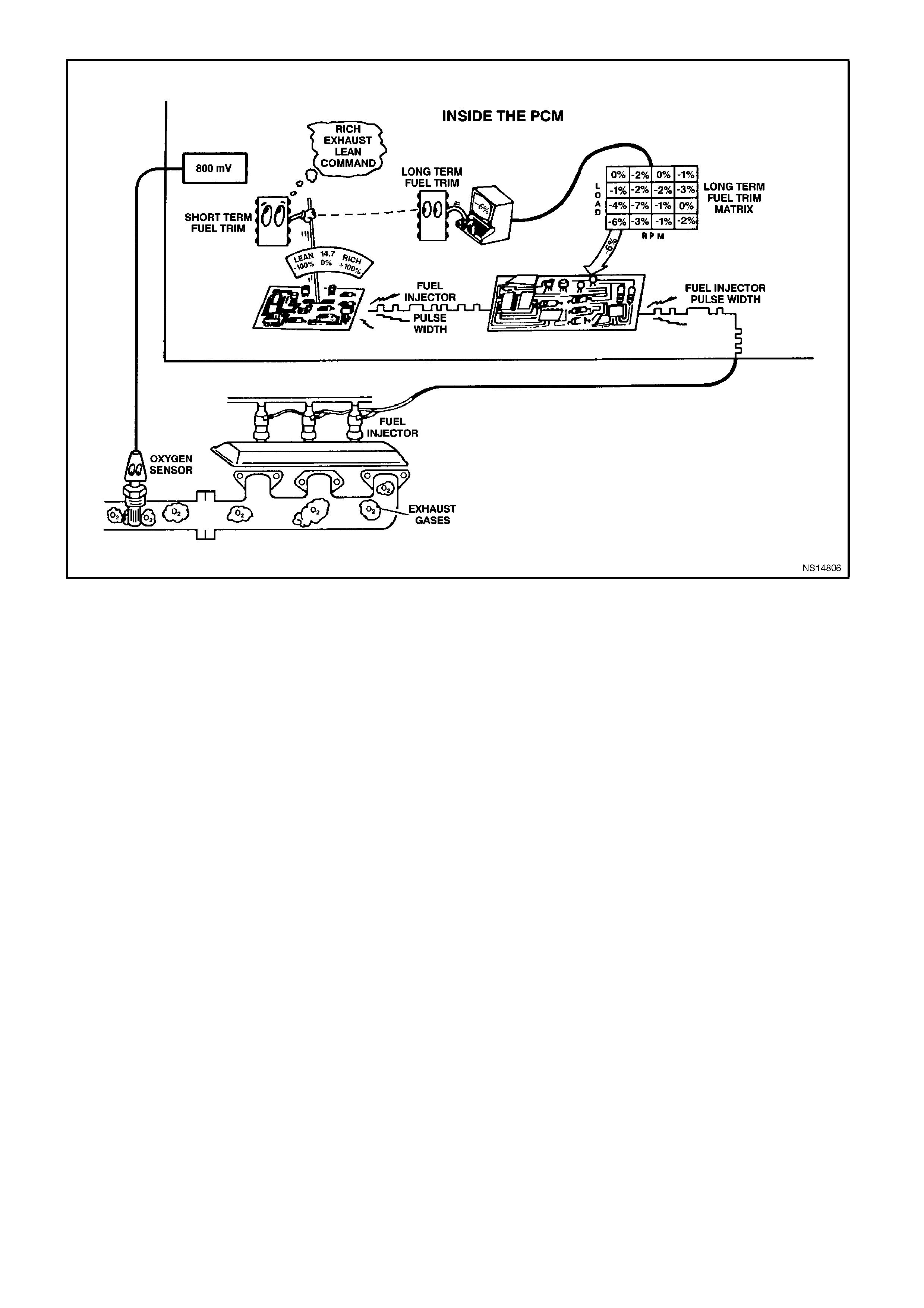

Circuit Description:

The Rich/Lean Symptom Table is an organised appr oach to identifying a dr iveability com plaint that may be caused

by an overric h or overlean oper ating condition. Unders tanding the Table and us ing it corr ectly will reduce diagnostic

time and improve customer satisfaction. Start at the left side of the Table and work to the right.

Test Description:

Numbers below refer to step number(s) on the diagnostic Table.

1. This is a partial list of possible customer complaints and what the air/fuel mixture must be to cause such a

condition.

2. A lean exhaust m eans that there is a lot of ox ygen in the ex haust str eam . Lots of oxygen in the exhaust stream

means a low oxygen sensor signal voltage. Lean=lots of oxygen=low oxygen sensor signal voltage. A rich

exhaust means that there is a lot of fuel and very little oxygen in the exhaust stream.

3. The oxygen sensor signal to the PCM determines what the PCM should do to compensate for the present

condition. Depending upon the severity of the problem , the PCM will compensate f or the condition by changing

the short term fuel trim and short term fuel trim values either higher or lower. An short term fuel trim value

above 0% m eans the PCM will add m or e f uel to the engine, by increasing the injector pulsewidth, thus mak ing a

lean engine run richer. A s hort term f uel trim value below 0% m eans the PCM will dec rease the am ount of fuel

to the engine, by decreasing the injector pulse width, thus making a rich engine run leaner.

4. This list represents areas where you should look to find the root cause of the customer complaint. Not every

cause of the symptom is listed here, however, the items listed provide a good general description of areas to

look at.

Diagnostic Aids:

Driveability complaints may be caused by the PCM, system components or electrical faults, however, a basic engine

problem may also present a symptom sim ilar to an electr ical failure. Rem em ber to check the air cleaner and all the

basic engine components, there could be worn rings, worn camshaft lobes, collapsed lifters, misaligned timing

chain, vacuum leaks etc.

RICH/LEAN SYMPTOM TABLE

RICH/LEAN SYMPTOM TABLE

VEHICLE OPERATION OXYGEN SENSOR

OPERA TION SHORT AND LONG TERM

FUEL TRIM OPERATION POSS IBLE CAUSES

CUSTOMER

DRIVEABILITY

COMPLAINT/SYMPTOM

EXHAUST

STREAM

STATUS

OXYGEN

SENSOR

VOLTAGE

LEAN Air/Fuel Mixture

Short Term Fuel Trim and Long Term Fuel

Trim are numerically increasing High

LEAN

Air/Fuel M i xture

+100

(above 0%) possible DTC P0132 or DTC

P0152.

Oxygen Sensor voltage between 450 mV

and 0 mV.

- High NoX Emissions High

Oxygen 0 mV Cause: Fuel system not in control.

Check For:

- Stumbles/Stalls Content • Poor PCM earths

- Surges • Vacuum leak, intake manifold leak

- Poor Performance LEAN

EXHAUST

+25% • Restricted fuel filter

• Low fuel pressure

RICH

COMMAND • Water contamination in fuel

• Lean (restricted flow), fuel injector(s)

ADD

FUEL Oxygen Sensor being “Tricked” Lean.

Cause: Too much air in exhaust stream

above OXYGEN SENSOR.

16 to 1

Air/Fuel M i xture • Cylinders not firing (misfire) sending

unburned air/fuel mixture into exhaust

Increase

Injector pulse width • Cracked or leaking exhaust manifold

• Oxygen sensor mounting is loose, dirty

or has no sealing washer

14.7 to 1

Air/Fuel M i xture

450 mV

0% No

Change

RICH Air/Fuel Mixture

Short Term Fuel Trim and Long Term Fuel

Trim are munerically decreasing low

Decrease

Injector Pluse Width (below 0%) possible DTC P0132 or DTC

P0152.

13 to 1

Air/Fuel M i xture

Oxygen Sensor voltage between 450 mV

and 1000 mV.

REMOVE

FUEL Cause: Fuel system not in control

Check For:

• Restricted (dirty) air filter

RICH

Air/Fuel M i xture

LEAN

COMMAND • Leaking injector(s)

• High fuel pressure

• Restricted fuel return line

- High HC, CO

Emissions • ECT temperature value low

- Black Smoke • Oxygen Sensor contaminated

(covered w/ foreign substance)

- Catalytic Converter Odor -22%

• Engine oil contaminated with fuel

- Fouled Spark Plugs RICH

EXHAUST 1000 mV

• Canister purge continuously purging

Oxygen Sensor being “Tricked” Rich.

Cause: Not enough air in exhaust.

Low • Restricted exhaust system

Oxygen

Content -100% • Oxygen Sensor earth, wire open, or has

a poor connection

• Oxygen Sensor poisoned

(impregnated w/ foreign substance)

• When using a Scan tool to observe short term fuel trim and long term fuel trim values, remember that if the system is in control, no action is required unless

there is a driveability symptom present.

AUTOMATIC TRANSMISSION SYMPTOM TABLES

Oil Pressure High or Low

Checks Causes

Oil Pump Assembly • Pressure regulator valve stuck

• Pressure regulator valve spring

• Rotor guide omitted or disassembled

• Rotor cracked or broken

• Reverse boost valve or sleeve stuck, damaged or incorrectly assembled

• Orifice hole in pressure regulator valve plugged

• Sticking slide or excessive rotor clearance

• Pressure relief ball not seated or damaged

• Porosity in pump cover or body

• Wrong pump cover

• Pump faces not flat

• Excessive rotor clearance

Oil Filter • Intake pipe restricted by casting flash

• Cracks in filter body or intake pipe

• O-ring seal missing, cut or damaged

• Wrong grease used on rebuild

Valve Body • Manual valve scored or damaged

• Spacer plate or gaskets incorrect, misassembled or damaged

• Face not flat

• 2-3 Shift valve stuck

• Checkballs omitted or misassembled

Pressure Control

Solenoid Valve Damage to pins

TFP Val Position Sw. • Contamination

• Damaged seals

Case Case to valve body face not flat

Harsh Shifts

Checks Causes

Throttle Position Sensor Open or shorted circuit

Vehicle Speed Sensor Open or shorted circuit

TFP Val Position Sw. • Contamination

• Damaged seals

Trans Fluid Temperature

Sensor Open or shorted circuit

Engine Coolant

Temperature Sensor Open or shorted circuit

Pressure Control

Solenoid Valve • Damage to pins

• Contamination

Inaccurate Shift Points

Checks Causes

Oil Pump Assembly • Stuck pressure regulator valve

• Sticking pump slide

Valve Body Assembly Spacer plate or gaskets misassembled, damaged or incorrect

Case • Porous or damaged valve body pad

• 2-4 Servo Assembly:

-2-4 accumu lator poros ity

-Damaged servo piston seals

-Apply pin damaged or improper length

• 2-4 Band Assembly:

-Burned

-Anchor pin not engaged

TP Sensor • Disconnected

• Damaged

Vehicle Speed Sensor • Disconnected

• Damaged

• Bolt not tightened

1st Gear Range Only-No Upshift

Checks Causes

Valve Body • The 1-2 Shift valve is sticking

• The spacer plate or gaskets are mispositioned or damaged

Case The case to valve body face is damaged or is not flat

Shift Solenoid Valves • Stuck or damaged

• Faulty electrical connection

2-4 Servo Assembly • The apply passage case is restricted or blocked

• Nicks or burrs on the servo pin or on the pin bore in the case

• Fourth servo pistons installed backwards

2 - 4 Band Assembly • The 2-4 band is worn or damaged

• The band anchor pin is not engaged

Slips in 1st Gear

Checks Causes

Forward Clutch

Assembly • Clutch plates worn

• Porosity or damage in forward clutch piston

• Forward clutch piston inner and outer seals missing, cut or damaged

• Damaged forward clutch housing

• Forward clutch housing retainer and ball assembly not sealing or damaged

Forward Clutch

Accumulator • Piston seal missing, cut or damaged

• Piston out of its bore

• Porosity in the piston or valve body

• Stuck abuse valve

Input Housing and Shaft

Assembly Turbine shaft seals missing, cut or damaged

Valve Body • 1-2 Accumulator valve stuck

• Face not flat, damaged lands or interconnected passages

• Spacer plate or gaskets incorrect, mispositioned or damaged

Low Roller Clutch • Damage to lugs to inner ramps

• Rollers not free moving

• Inadequate spring tension

• Damage to inner splines

• Lube passage plugged

Torque Converter Stator roller clutch not holding

1-2 Accumulator

Assembly • Porosity in piston or 1-2 Accumulator cover and pin assembly

• Damaged ring grooves on piston

• Piston seal missing, cut or damaged

• Valve body to spacer plate gasket at 1-2 Accumulator cover, missing or damaged

• Leak between piston and pin

• Broken 1-2 Accumulator spring

Line Pressure Refer to Oil Pressure High or Low

2-4 Servo Assembly 4th Servo piston in backward

Slipping or Rough 1-2 Shift

Checks Causes

Valve Body Assembly • 1-2 Shift valve train stuck

• Gaskets or spacer plate incorrect, mispositioned or damaged

• 1-2 Accumulator valve stuck

• Face not flat

2-4 Servo Assembly • Apply pin too long or too short

• 2nd servo apply piston seal missing, cut or damaged

• Restricted or missing oil passages

• Servo bore in case damaged

2nd Accumulator • Porosity in 1-2 accumulator housing or piston

• Piston seal or groove damaged

• Nicks or burrs in 1-2 accumulator housing

• Missing or restricted oil passage

2-4 Band Worn or mispositioned

Oil Pump Assembly or

Case Faces not flat

No 2-3 Shift or 2-3 Shift Slips, Rough or Hunting

Checks Causes

Valve Body Assembly • 1-2 Shift valve train stuck

• Gaskets or spacer plate incorrect, mispositioned or damaged

• 1-2 Accumulator valve stuck

• Face not flat

2-4 Servo Assembly • Apply pin too long or too short

• 2nd servo apply piston seat missing, cut or damaged

• Restricted or missing oil passages

• Servo bore in case damaged

2nd Accumulator • Porosity in 1-2 accumulator housing or piston

• Piston seal or groove damaged

• Nicks or burrs in 1-2 accumulator housing

• Missing or restricted oil passage

2-4 Band Worn or mispositioned

Oil Pump Assembly or

Case Faces not flat

2nd/3rd Gears Only or 1st/4th Gears Only

Checks Causes

Shift Solenoid Valves • Sediment is in the valves

• The electrical connection is faulty

• Damaged seal

Third Gear Only

Checks Causes

DTC 81 • The electrical connection is faulty

• Shorted or damaged

3-2 Flare or Tie-Up

Checks Causes

3-2 Shift Solenoid • Shorted or damaged

• Contamination

• Damaged Seal

No 3-4 Shift, Slips or Rough 3-4 Shift

Checks Causes

Oil Pump Assembly • Pump cover retainer and ball assembly omitted or damaged

• Faces not flat

Valve Body Assembly • Valves stuck:

-2-3 Shift valve train

-Accumulator valve

-1-2 Shift valve train

-3-2 Shift valve

• Spacer plate or gasket incorrect, mispositioned or damaged

2-4 Servo Assembly • Incorrect band apply pin

• Missing or damaged servo seals

• Porosity in piston, cover or case

• Damaged piston seal grooves

• Plugged or missing orifice cup plug

Case • 3rd Accumulator retainer and ball assembly leaking

• Porosity in 3-4 accumulator piston or bore

• 3-4 Accumulator piston seal or seal grooves damaged

• Plugged or missing orifice cup plug

• Restricted oil passage

Input Housing Assembly Refer to Slipping 2-3 Shift

2-4 Band Assembly Worn or Disassembled

No Reverse or Slips in Reverse

Checks Causes

Input Housing Assembly • 3-4 Apply ring stuck in applied position

• Forward clutch not releasing

• Turbine shaft seals missing, cut or damaged

Manual Valve Link Disconnected

Valve Body Assembly • 2-3 Shift valve stuck

• Manual linkage not adjusted

• Spacer plate and gaskets incorrect, mispositioned or damaged

• Lo overrun valve stuck

• Orificed cup plug restricted, missing or damaged

Reverse Input Clutch

Assembly • Clutch plate worn

• Reverse input housing and drum assembly cracked at weld

• Clutch plate retaining ring out of groove

• Return spring assembly retaining ring out of groove

• Seals cut or damaged

• Restricted apply passage

• Porosity in piston

• Belleville plate installed incorrectly

• Excessive clutch plate travel

• Oversized housing

Lo and Reverse Clutch • Clutch plates worn

• Porosity in piston

• Seals damaged

• Return spring assembly retaining ring mispositioned

• Restricted apply passage

No Part Throttle or Delayed Downshifts

Checks Causes

Input Housing Assembly • 3-4 Apply ring stuck in applied position

• Forward clutch not releasing

• Turbine shaft seals missing, cut or damaged

Manual Valve Link • Disconnected

Valve Body Assembly • 2-3 Shift valve stuck

• Manual linkage not adjusted

• Spacer plate and gaskets incorrect, mispositioned or damaged

• Lo overrun valve stuck

• Orificed cup plug restricted, missing or damaged

Reverse Input Clutch

Assembly • Clutch plate worn

• Reverse input housing and drum assembly cracked at weld

• Clutch plate retaining ring out of groove

• Return spring assembly retaining ring out of groove

• Seals cut or damaged

• Restricted apply passage

• Porosity in piston

• Belleville plate installed incorrectly

• Excessive clutch plate travel

• Oversized housing

Lo and Reverse Clutch • Clutch plates worn

• Porosity in piston

• Seals damaged

• Return spring assembly retaining ring mispositioned

• Restricted apply passage

Harsh Garage Shift

Checks Causes

Valve Body Assembly • Orifice cup plug missing

• Checkball missing

No Overrun Braking - Manual 3-2-1

Checks Causes

External Linkage Not adjusted properly

Valve Body Assembly • 4-3 Sequence valve stuck

• Checkball mispositioned

• Spacer plate and gaskets incorrect, damaged or mispositioned

Input Clutch Assembly • Turbine shaft oil passages plugged or not drilled

• Turbine shaft seal rings damaged

• Turbine shaft sealing balls loose or missing

• Porosity in forward or overrun clutch piston

• Overrun piston seals cut or damaged

• Overrun piston checkball not sealing

No TCC Apply

Checks Causes

Electrical • 12 Volts not supplied to transmission

• Outside electrical connector damaged

• Inside electrical connector, wiring harness or solenoid damaged

• Electrical short (pinched solenoid wire)

• Solenoid not earthed

Converter Internal damage

Oil Pump Assembly • Converter clutch valve stuck or assembled backwards

• Converter clutch valve retaining ring mispositioned

• Pump to case gasket mispositioned

• Orifice cup plug restricted or damaged

• Solenoid O-ring seal cut or damaged

• High or uneven bolt torque (pump body to cover)

Input Housing and Shaft • Turbine shaft O-ring seal cut or damaged

• Turbine shaft retainer and ball assembly restricted or damaged

TFP Val Position Switch • Contamination

• Damaged seals

Valve Body Assembly • TCC signal valve stuck

• Solenoid O-ring leaking

Solenoid Screen Blocked

TCC Solenoid Valve —

Engine Speed Sensor —

Engine Coolant

Temperature Sensor —

DTCs P0121, P0122,

P0123, P0740, P0753,

P1810, P1860

—

Automatic Transmission

Fluid Temperature

Sensor

—

Torque Converter Clutch Shudder

Checks Causes

Electrical • 12 Volts not supplied to transmission

• Outside electrical connector damaged

• Inside electrical connector, wiring harness or solenoid damaged

• Electrical short (pinched solenoid wire)

• Solenoid not earthed

Converter Internal damage

Oil Pump Assembly • Converter clutch valve stuck or assembled backwards

• Converter clutch valve retaining ring mispositioned

• Pump to case gasket mispositioned

• Orifice cup plug restricted or damaged

• Solenoid O-ring seal cut or damaged

• High or uneven bolt torque (pump body to cover)

Input Housing and Shaft • Turbine shaft O-ring seal cut or damaged

• Turbine shaft retainer and ball assembly restricted or damaged

TFP Val Position Switch • Contamination

• Damaged seals

Valve Body Assembly • TCC signal valve stuck

• Solenoid O-ring leaking

Solenoid Screen Blocked

No TCC Release

Checks Causes

TCC Solenoid Valve • Internal earth

• Clogged exhaust orifice

Converter Internal damage

Valve Body Assembly The converter clutch apply valve is stuck in the apply position

Oil Pump Assembly The converter clutch valve is stuck

PCM External earth

Drives in Neutral

Checks Causes

Forward Clutch The clutch does not release

Manual Valve Link Disconnected

Case • The face is not flat

• Internal leakage exists

2nd Gear Start

Checks Causes

Forward Clutch Sprag

Assembly The sprag assembly is installed backward

No Park

Checks Causes

Parking Linkage • Actuator rod assembly bent or damaged

• Actuator rod spring binding or improperly crimped

• Actuator rod not attached to inside detent lever

• Parking lock bracket damaged or not torqued properly

• Inside detent lever not torqued properly

• Parking pawl binding or damaged

Oil Out the Vent

Checks Causes

Oil Pump Chamber in pump body rotor pocket

Miscellaneous Fluid level - overfilled

Vibration in Reverse and Whining Noise in Park

Checks Causes

Oil Pump Chamber in pump body rotor pocket

Miscellaneous Fluid level - overfilled

Ratcheting Noise

Checks Causes

Parking Pawl The parking pawl return spring is weak, damaged, or misassembled

No Drive in All Ranges

Checks Causes

Torque Converter The converter to flex plate bolts are missing

No Drive in Drive Range

Checks Causes

Torque Converter • The stator roller clutch is not holding

• The converter is not bolted to the flex plate

Front Oil Leak

Checks Causes

Torque Converter • The welded seam is leaking

• The converter hub is damaged

Torque Converter Seal • The seal assembly is damaged

• The garter spring is missing

Delay in Drive and Reverse

Checks Causes

Torque Converter Converter drainback

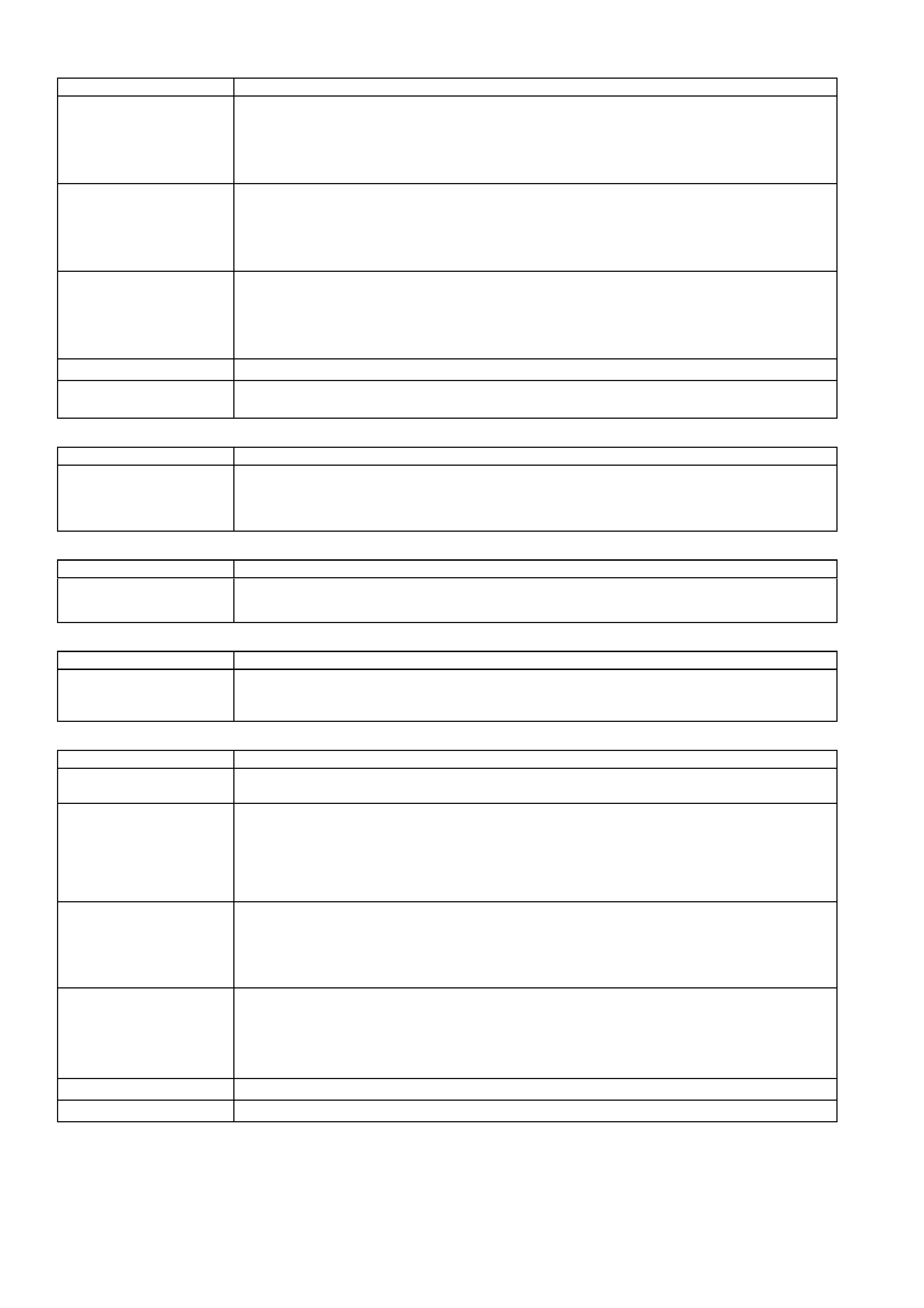

PCM CONNECTOR SYMPTOM TABLES

The following Powertrain Control Module (PCM) connector Symptoms Tables identifies the function of each pin of

the PCM connector, the c irc uit number, the wire colour , and the cavity of the component to which the wire connec ts.

The left colum n in this T able lists the PCM connec tor pins in as cending order. T he T able m ay also be entered from

the right-most column, which lists possible symptoms that may be caused by a fault in each of the circuits. If a

problem in any of these circuits will cause a Diagnostic Trouble Code to be set, the DTC's are identified in the

second column from the right edge of the Table. (However, if a DTC has been s et, you should attem pt to diagnose

the condition using Section 6C1-2A DIAGNOSTIC TABLES - V6 ENGINE of the VX Series Service Information

before diagnosing by symptom.) The expected normal voltage for each circuit is shown for two conditions. Check

the voltage with the ignition "ON" but the engine not running, and with the engine running. Both check s are r equired

for accurate diagnosis. Reference notes are made for some circuits. These notes state conditions that cause

varying voltages or mention unique characteristics of the circuit. To measure the voltages, backprobe the PCM

connector. Whenever backprobing, be careful not to damage the connector. Careless backprobing may damage the

connector seal and/or terminal. Damaged pins will provide incorrect readings and cause additional system

problems.

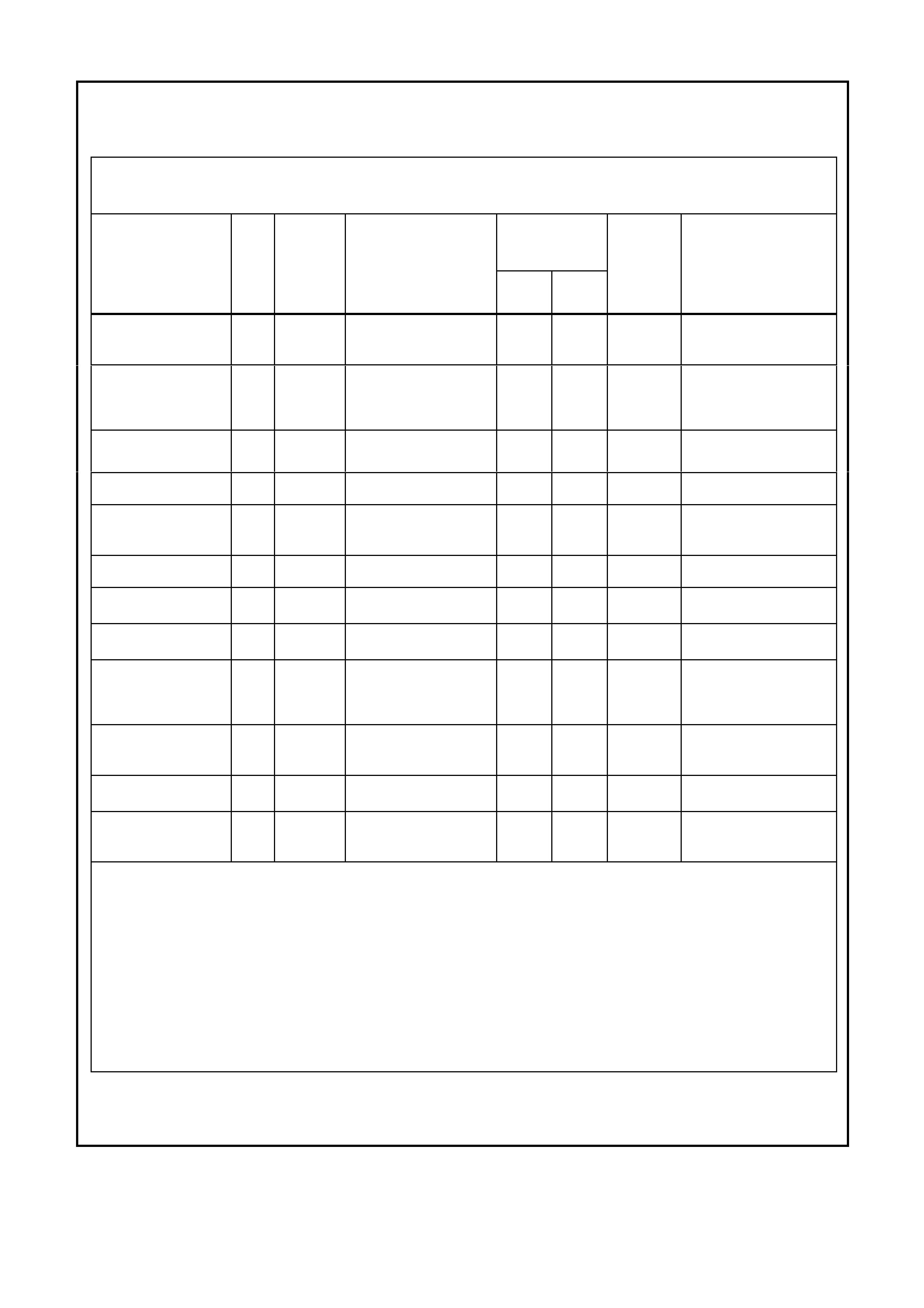

PCM CONNECTOR A

POWERTRAIN CONTROL MODULE CONNECTOR “A” SYMPTOMS TABLE

BROWN 24 PIN A - B CONNECTOR

CKT

WIRE

COMPONENT/ NORMAL

VOLTAGES

DTCS

POSSIBLE SYMPTOMS

FROM

PIN FUNCT ION # COLOUR CONNECTOR CAVITY IGN

“ON” ENG

RUN AFFECTED FAULTY CIRCUIT

A1 3-2 CONTROL

SOLENOID 897 G/W 3-2 CONTROL

SOLENOID “B” 12 * P0785 SOFT LANDING INTO

THIRD GEAR STAY IN

THIRD GEA R.

A2 2-3 SHIFT

SOLENOID

CONTROL

1223 Y/B 2-3 SHIFT SOLENOID

“B” TERMINAL “B” 12 * P0753

P0757

(9)

POSSIBLY THIRD GEAR

ONLY, NO TCC

OPERATIO N , MAXIMUM

LINE PRESSURE .

A3 LPG ENABLE

(LPG Only)

937 W/G LP G TA NK SMART UNIT 12 13 P1642 LPG SYS TE M INOP

A4 NOT USED - - - - - - -

A5 SYSTEM EARTH 750 B/R ENGINE EARTH “E ” * * NONE NO ST ART IF ALL

EARTH CIRCUITS ARE

OPEN.

A6 NOT USED - - - - - - -

A7 MAF SENSOR

INPUT 792 BR/W MASS AIR FLOW

SENSOR TERMINAL “A:” 4.8 4.2 P0101 RICH EXHAUST

A8 START RELAY

CONTROL 1434 GY/BLU START RELAY

TERMINAL “86” * * NONE NO START

A9 AIR

CONDITIONING

RELAY

CONTROL

366 LG/B A/C RELAY “1” 12 (3) NONE ROUGH IDLE, NO AI R

CONDITIONING.

A10 CANISTER

PURGE

SOLENOID

428 G/Y CANISTER PURGE

SOLENOI D TERMINAL

“B”

12 13 P0446 RICH EXHAUST

A11 TCC SOLENOID

PWM CONTROL 418 BR TCC SOLENOI D “B” 12 13 - -

A12 TCC ENABLE

SOLENOID

CONTROL

422 GR/Y TCC SOLENOI D “B ” 12 13 P0740

(9) NO T CC A ND NO

FOURTH GEAR IF IN

HOT MODE

(1)

(9)

*

**

VARIES FROM 0.10 TO ABOUT 13 VOLTS, DEPENDING ON POSITION OF DRIVE WHEELS WHEN VEHICLE IS

MOVING.

OPEN/EARTHED CIRCUIT.

LESS THA N 0. 50 V OLT.

REFER T O WIRING DI AGRAMS.

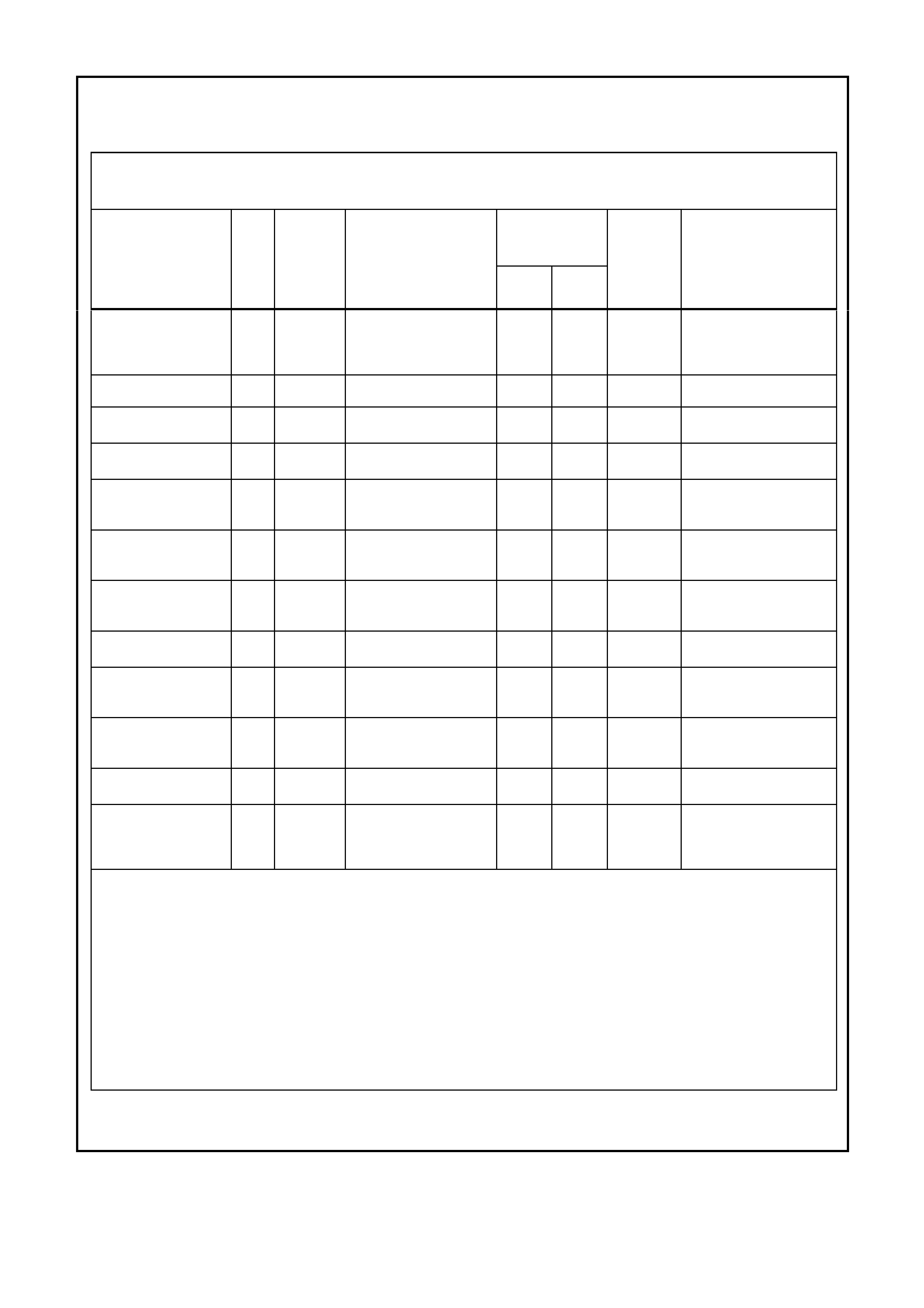

PCM CONNECTOR B

POWERTRAIN CONTROL MODULE CONNECTOR “B” SYMPTOMS TABLE

BROWN 24 PIN A - B CONNECTOR

CKT

WIRE

COMPONENT/ NORMAL

VOLTAGES

DTCS

POSSIBLE SYMPTOMS

FROM

PIN FUNCT ION # COLOUR CONNECTOR CAVITY IGN

“ON” ENG

RUN AFFECTED FAULTY CIRCUIT

B1 1-2 SHIFT

SOLENOID

CONTROL

1222 LG 1-2 SHIFT SOLENOID

TERMINAL “B” 12 * P0756

P0730

(9)

2ND AND 3RD GEAR ONLY

OR 1ST AND 4TH GEA R

ONLY AND MAXIMUM

LINE PRESSURE .

B2 NOT USED - - - - - - -

B3 EST OUTPUT 423 W IGNITION MODULE

TERMINAL “A” 0 2.0 P1351

P1361 HARD TO START,

STALL.

B4 BYPASS

CONTROL 424 T/B IGNITION MODULE

TERMINAL “B” 0 4.7 P1361 POOR PERFORMANCE.

B5 SYSTEM EARTH 750 B/R ENGI NE E ARTH “F” * * NONE NO START IF ALL

EARTH CIRCUITS ARE

OPEN.

B6 CAMSHAFT

POSITION SEN

SOR SIGNAL

630 B IGNITION MODULE

TERMINAL “F” 4.8 4.4 P0341

P0342 NO SEQUENTIAL FUEL

INJECTION.

B7 CRANKSHAFT

18X SIGNAL 647 LBLU/B IGNITION MODULE

TERMINAL “C” 5 2.7

OR

3.0

P0374

(9) NO S T A RT .

B8 TORQUE

REQUEST 1426 O/W ABS/TCS MODULE

TERMINAL “13” 4-5 4-4 - -

B9 CRANKSHAFT

REFERENCE

HIGH

430 V IGNITION MODULE

TERMINAL “D” 4.8 2.3 - NO START.

B10 CRANKSHAFT

REFERENCED

LOW

453 B/R IGNITION MODULE

TERMINAL “L” * * NONE POOR PERFORMANCE.

B11 TORQUE

ACHIEVED 1427 B/W ABS/TCS MODULE

TERMINAL “27” .9 3.6 - -

B12 ENGINE

COOLING FAN

HIGH SPEED

CONTROL

304 BLU/W HIGH SPEED COOLING

FAN RELA Y TERMINA L

“86”

12 (7) NONE HIGH ENGINE

TERMPERATURE,

OVERHEATING.

(2)

(3)

(6)

(7)

(8)

*

**

12 VOLTS WHILE ENGINE IS CRANKING. LESS THAN 0.05 VOLTS WHEN STARTER IS NOT

OPERATING.

WITH A I R CONDITIONI NG “ON’ O V O LT S , WITH A IR CONDITIONING “OFF” 13 VOLTS.

VARIES WITH TEMPERATURE.

WITH ENGINE COOLING FAN “ON” O VOLTS. WITH ENGINE COOLI NG FA N : O FF: 13 V O LTS .

OPEN.

LESS THA N 0. 50 V OLT.

REFER T O WIRING DI AGRAMS.

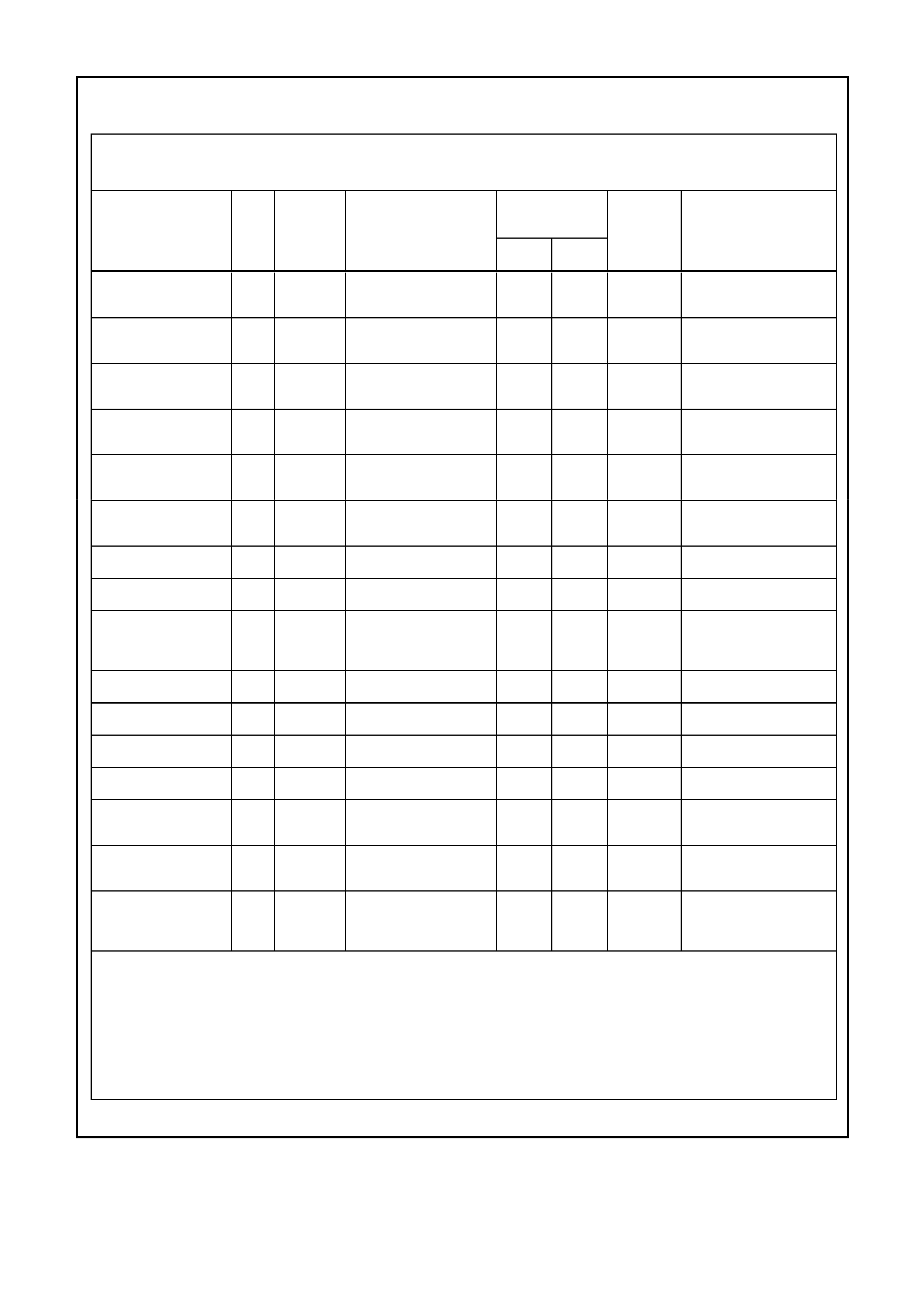

PCM CONNECTOR C

POWERTRAIN CONTROL MODULE CONNECTOR “C” SYMPTOMS TABLE

BROWN 32 PIN C - D CONNECTOR

CKT

WIRE

COMPONENT/ NORMAL

VOLTAGES

DTCS

POSSIBLE SYMPTOMS

FROM

PIN FUNCT ION # COLOUR CONNECTOR CAVITY IGN

“ON” ENG

RUN AFFECTED FAULTY CIRCUIT

C1 VEHICLE SPEED

OUTPUT TO

SPEEDOMETER

123 V/W INSTRUMENT

CONNECTOR

TERMINAL “17”

(1) (1) NONE INOPERATIVE

SPEEDOMETER.

C2 IAC COIL “B:

LOW 444 LG/B IDLE AIR CONTROL

VALVE TERMINAL “B” NOT USE-

ABLE P0506 STALLING, ROUGH,

UNSTAB LE OR

INCORRECT I DLE.

C3 IAC COIL “A”

LOW 442 LB LU/B IDLE AIR CONTROL

VALVE TERMINAL “A” NOT USE-

ABLE P0506 STALLING, ROUGH,

UNSTAB LE OR

INCORRECT I DLE.

C4 IAC COIL “A”

HIGH 441 LBLU IDLE A IR CONTROL

VALVE TERMINAL “A” NOT USE-

ABLE P0506 STALLING, ROUGH,

UNSTAB LE OR

INCORRECT I DLE.

C5 IAC COIL “B”

HIGH 443 LG/W IDLE AIR CONTROL

VALVE TERMINAL “B” NOT USE-

ABLE P0506 STALLING, ROUGH,

UNSTAB LE OR

INCORRECT I DLE.

C6 ECT/TP SENSOR

EARTH 452 B/Y ECT TE RMINAL “B ”, TP

SENSOR TERMINAL “B” * * P0118

P0123 P OOR PERFORMANCE,

HARD START,

HESITATION.

C7 TP SENSOR

SIGNAL 417 BLU TP SENSO R TE RMINA L

“C” (5) (5) P0122

P0123 P OOR PERFORMANCE,

HIGH IDLE.

C8 EGR PINTLE

POSITION 1456 LG EGR VALVE TERMINAL

“C” .7 . 7 P0405 ROUGH IDLE , STALLI NG.

C9 RH OXYGEN

SENSOR SIGNAL 1412 G/Y R.H OXYGEN SENSOR 450 mV (4) P0151

P0152

P0154

(9)

NO “CLOSED LOOP”

OPERATION.

C10 L.H KNOCK

SENSOR SIGNAL 815 BLU L.H K NOCK SENSOR 1.3 mV

A/C 25. 6 Mv

A/C P0327 ENGINE KNOCK.

C11 R.H KNOCK

SENSOR 826 LBLU R.H KNOCK S ENSOR 1. 3 mV

A/C 1.3 mV

A/C P0332 ENGINE KNOCK.

C12 BATTERY

VOLTAGE 740 O FUSE 31 12 13 NONE NO START.

C13 PRIMARY

SERIAL DATA 1221 R/B DLC TERMINAL “9”, BCM

TERMINAL “E2” “D2” 3-5 3-5 P1255 NO SERIAL DATA, NO

CRANK.

C14 INJECTOR

VOLTAGE

MONITOR LINE

481 R FUSE F34 12 13 P0200 NO START.

C15 TP SENSOR

REFERENCE

VOLTAGE

416 GY TP SENSOR TERMINAL

“A” 5 5 P0122

P0123 ROUGH I DLE.

C16 EGR/ A/C

PRESSURE

REFERENCE

VOLTAGE

415 V/W EGR TERMINAL “D”, A/C

PRESSURE SENSOR

TERMINAL “B”

5 5 P0405

P0530 NO A /C, ENGINE

DETONATION.

(1)

(4)

(5)

(9)

*

**

VARIES FROM 0.10 TO ABOUT 13 V, DEPENDING ON POSITION OF DRIVE WHEELS WHEN VEHICLE IS MOVING.

VOLTAGE SHOULD VARY B E T WEEN 100 Mv AND 1000 Mv.

0.25 – 1.25 VOLTS A T IDLE TO ABOVE 4.0 VOLTS AT WIDE OPE N THROTTLE .

OPEN/EARTHED CIRCUIT.

LESS THA N 0. 50 V OLT.

REFER T O WIRING DI AGRAMS.

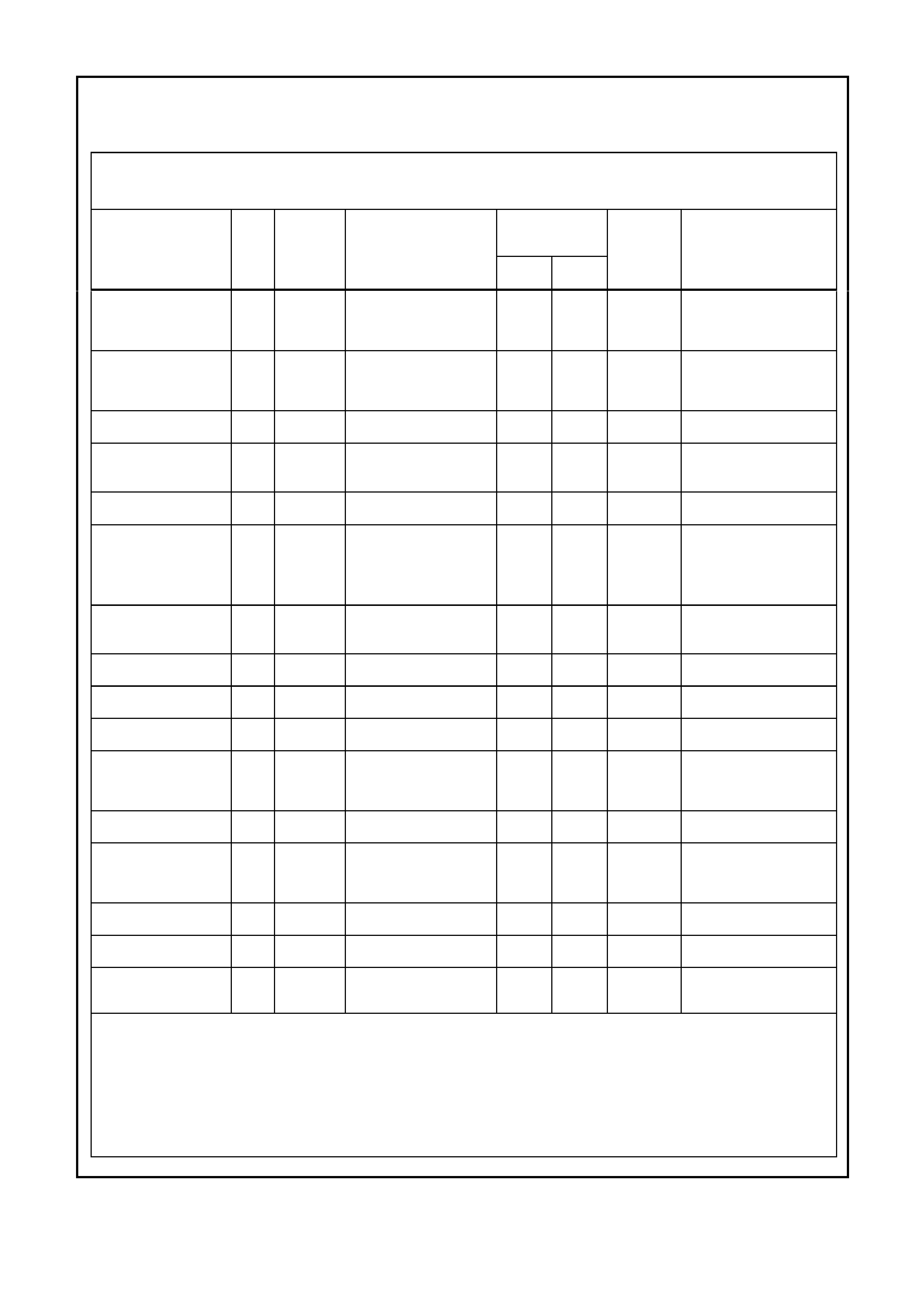

PCM CONNECTOR D

POWERTRAIN CONTROL MODULE CONNECTOR “D” SYMPTOMS TABLE

BROWN 32 PIN C - D CONNECTOR

CKT

WIRE

COMPONENT/ NORMAL

VOLTAGES

DTCS

POSSIBLE SYMPTOMS

FROM

PIN FUNCT ION # COLOUR CONNECTOR CAVITY IGN

“ON” ENG

RUN AFFECTED FAULTY CIRCUIT

D1 VEHICLE SPEED

SENSOR SIGNAL

HIGH

831 BLU/W

(AUTO)

BLU

(MANUAL)

VEHICLE SPEED

SENSOR (1) (1) P0502

P0503 SPEEDOMETER INOP,

MAXIMUM L INE

PRESSURE.

D2 VEHICLE SPEED

SENSOR SIGNAL

LOW

832 BR (AUTO)

T

(MANUAL)

VEHICLE SPEED

SENSOR * * P0502

P0503 SPEEDOMETER INOP,

MAXIMUM L INE

PRESSURE, SENCOND

GEAR ONLY.

D3 L.H. OXYGEN

SENSOR EARTH 413 B LU/B L.H OXYGEN SENS OR * * P0151

P0152 NO “CLOS ED LOOP”

OPERATION (8).

D4 L.H. OXYGEN

SENSOR SIGNAL 412 V L.H OXYGEN SENSOR 450 Mv (4) P0151

P0152

P0154

NO “CLOSED LOOP”

OPERATION (9).

D5 R.H OXYGEN

SENSOR EARTH 1413 GY/B R.H OXYGEN SENSOR * * P0131

P0132 NO “CLOS ED LOOP”

OPERATION (8).

D6 IAT, TFT, EGR,

A/C P RESSURE

SENSOR EARTH

469 B IAT SENSOR “B”, TFT

SENSOR “B”, EGR

VALVE “B”, A/C

PRESSURE SENSOR

“A”

* * P0112

P0405

P0530

P0713

(8)

SLIGHT HIGH IDLE, T CC

APPLY EARLY, A/C

INOP.

D7 INTAKE AIR

TEMPRERATURE

SENSOR SIGNAL

472 BR IAT SE NSOR TERMINAL

“B” 1.0 (6) 1.0 (6) P0111

P0112

P0113

NONE

D8 NOT USED - - - - - - -

D9 DIAGNOSTIC

TEST ENABLE 451 W/B DLC TERMINA L “6” 5 5 NONE WILL NOT FLA S H DTCs.

(8)

D10 A/C PRESSURE

SENSOR SIGNAL 259 G/B A/C PRESSURE

SENSOR TERMINAL “C” 1-2 1-2 P0530 A/C INOP.

D11 ENGINE

COOLANT

TERMERATURE

SENSOR SIGNAL

410 Y ECT S E NSOR 1.9 (6) 1.9 (6) P0116

P0117

P0118

HARD STA RT , LONG

CRANK TIME.

D12 BATTERY

VOLTAGE FEED 740 O FUSE F31 12 13 NONE NO START IF “C12”

ALSO OPEN.

D13 TRANS FLUID

TEMPERATURE

SENSOR

SIGNAL1227

B/y G/Y TRANSMISSION PASS-

THROUGH

CONNECTOR “L”, TFT

TERMINAL “A”

1.8 (6) 1.8 (6) P0712

P0713 MAXIMUM LINE

PRESSURE, TCC IN

SECOND, T HIRD, AND

FOURTH GEAR.

D14 NOT USED - - - - - - -

D15 NOT USED - - - - - - -

D16 IGNITION FEED 39 P FUSE F14 12 13 NONE NO “CHECK

POWERTRAIN” LAMP,

NO START.

(1)

(4)

(6)

(8)

(9)

(10)

*

**

VARIES FROM 0.10 TO ABOUT 8.5V, DEPENDING ON POSITION OF DRIVE WHEELS WHEN VEHICLE IS MOVING.

VOLTAGE SHOULD VARY BETWEE N 100mV - 1000 mV.

VARIES WITH TEMPERATURE.

OPEN

OPEN/EARTHED CIRCUIT.

EARTHED CIRCUIT.

LESS THA N 0. 50 V OLT.

REFER T O WIRING DI AGRAMS.

PCM CONNECTOR E

POWERTRAIN CONTROL MODULE CONNECTOR “E” SYMPTOMS TABLE

TAN 32 PIN E - F CONNECTOR

CKT

WIRE

COMPONENT/

NORMAL

VOLTAGES

DTCS

POSSIBLE SYMPTOMS

FROM

PIN FUNCT ION # COLOUR CONNECTOR CAVITY IGN

“ON”

ENG

RUN

AFFECTED FAULTY CIRCUIT

E1 NOT USED - - - - - - -

E2 FUEL INJECTOR

#2 CONTROL 842 G FUEL INJECTOR #2 12 13 NONE ROUGH IDLE, HARD

START.

E3 NOT USED - - - - - - -

E4 FUEL INJECTOR

#1 CONTROL 841 BLU FUEL INJ E CTOR #1 12 13 NONE ROUGH IDLE, HARD

START.

E5 FUEL INJECTOR

#4 845 GY FUE L I NJECTOR #4 12 13 NONE ROUGH IDLE, HARD

START.

E6 FUEL INJECTOR

#6 CONTROL 846 Y FUEL INJ E CTOR #6 12 13 NONE ROUGH IDLE, HA RD

START.

E7 SYSTEM EARTH 750 B/R ENGI NE EARTH “E” * * NONE NO ST A RT I F ALL

EARTH CIRCUITS ARE

OPEN.

E8 NOT USED - - - - - - -

E9 PRESSURE

CONTROL

SOLENOID HIGH

1228 R TRANSMISSION PASS-

THRU CONNECTOR “C”,

PRESSURE CONTROL

SOLENOID “A”.

* 1.3 P0748 MAXIMUM LINE

PRES S URE, HARD

SHIFT (8).

E10 FUEL PUMP

RELAY

CONTROL

1228 G/W FUEL PUMP RELAY

TERMINAL “2” (4) (2) 13 NONE HARD TO ST A RT , LONG

CRANK TIME.

E11 NOT USED - - - - - - -

E12 EGR CONTROL

(PWM) 435 V EGR VALVE TERMINAL

“A” 0.0% 0.0% P0400

P0405 ROUGH I DLE, SPARK

KNOCK. (9)

E13 PRESSURE

CONTROL

SOLENOID LOW

1229 GY/BLU TRANSMISSION PASS-

THRU CONNECTOR “D”,

PRESSURE CONTROL

SOLENOID “B”.

* 6.8 P0748 (9) MAXIMUM LINE

PRESSURE - HARD

SHIFT.

E14 NOT USED - - - - - - -

E15 NOT USED - - - - - - -

E16 FUEL CONTROL

VALVE

(LPG Only)

1062 B/BLU FUEL CONTROL VALVE

SOLENOID 12 13 P1643 LPG SYSTEM INOP

(2)

(4)

(6)

(8)

(9)

*

**

12 VOLTS FOR THE FIRST TWO SECONDS AFTER IGNITION IS TURNED ON W ITHOUT CRANKING.

12 VOLTS WHEN FUEL P UMP IS RUNNING.

VARIES WITH TEMPERATURE.

OPEN.

OPEN/EARTHED CIRCUIT.

LESS THA N 0. 50 V OLT.

REFER T O WIRING DI AGRAM.

PCM CONNECTOR F

PCM CONNECTOR “F” SYMPTOMS TABLE

TAN 32 PIN E - F CONNECTOR

CKT

WIRE

COMPONENT/ NORMAL

VOLTAGES

DTCS

POSSIBLE SYMPTOMS

FROM

PIN FUNCT ION # COLOUR CONNECTOR CAVITY IGN

“ON” ENG

RUN AFFECTED FAULTY CIRCUIT

F1 FUEL INJECTOR

#3 843 V FUEL INJECTOR #3 12 13 NONE ROUGH IDLE, HARD

START.

F2 FUEL INJECTOR

#4 844 BR/ Y FUE L I NJECTOR #4 12 13 NONE ROUGH IDLE, HARD

START.

F3 PRNDL “A” 771 B LU/W PRNDL SWITCH

TERMINAL “A” * * NONE IMPROPER GEAR

INDICA T E D ON

INSTRUMENT PANEL (9).

F4 FUEL MODE

SWITCH

(LPG Only)

936 BLU/O FUEL MODE WITCH * * NONE LPG SYSTEM INOP

F5 NOT USED - - - - - - -

F6 PRNDL “P” 776 W PRNDL SWIT CH

TERMINAL “c” * * NONE IMPROPER GEAR

INDICA T E D ON

INSTRUMENT PANEL (9).

F7 SYSTEM EARTH 750 B/R E NGINE EART H “E” * * NONE

NO START IF ALL

EARTH CIRCUITS ARE

OPEN.

F8 PRNDL “B” 772 Y PRNDL SWIT CH

TERMINAL “D” 12 13 NONE IMPROPER GEAR

INDICA T E D ON

INSTRUMENT PANEL (9).

F9 PRNDL “C” 773 GY PRNDL SWI T CH

TERMINAL “B” 12 13 NONE IMPROPER GEAR

INDICA T E D ON

INSTRUMENT PANEL (9).

F10 NOT USED - - - - - - -

F11 RANGE SIGNAL

“A” 1224 BR/Y

TRANSMISSION PASS-

THRU CONNECTOR “N”,

PRESSURE SWITCH

TERMINAL “C”.

12 13 P1810 MAXIMUN LINE

PRESSURE, NO

FOURTH GEAR IF IN

HOT MODE, NO TCC

OPERATION (8).

F12 RANGE SIGNAL

“B” 1225 Y

TRANSMISSION PASS-

THRU CONNECTOR “R”,

PRESSURE CONTROL

SOLENOID “E”.

0 0 P1810 (8) NONE

F13 RANGE SIGNAL

“C” 1226 GY

TRANSMISSION PASS-

THRU CONNECTOR “P ”,

PRESSURE CONTROL

SOLENOID “D”.

12 13 P1810 MAXIMUN LINE

PRESSURE, NO

FOURTH GEAR IF IN

HOT MODE, NO TCC

OPERATION (8).

F14 POWER/

ECONOMY

SWITCH

774 BLU POWER/ECONOMY

SWITCH 12 13 NONE NO POWER SHIF TING.

F15 OIL PRESSURE

INPUT SWITCH 31 DK BLU/R OIL PRESSURE

SWITCH 12 * NONE OI L LIGHT ON.

F16 IGNITION FEED

(LPG Only) 39 P

FUSE F14 12 13 NONE

NO “CHECK

POWERTRAIN” LAMP,

NO START.

(8)

(9)

*

**

OPENED CIRCUIT.

OPENED/EARTHED CIRCUIT.

LESS THA N 0. 50 V OLT.

REFER T O WIRING DI AGRAM.

TESTING EARTHS

Unusual displays in the instrument cluster, lamps

that are dim or flash unexpectedly, unexpected

readings - gremlins? Probably not; these are

classic symptoms of earth problems.

This section discusses the importance of good

earth circuits. It starts by explaining some basic

theories. Then, you are shown how to diagnose a

solid-state circuit earth condition and how, if there

is a problem, to correct it.

BASICS

For a circuit to operate properly, you need three

things - a good power supply to components, good

components, and good earths. Circuits are

complete systems; current must flow from

beginning to end as designed, not hindered by

unexpected resistance anywhere in the circuit.

Some tec hnic ians r ealis e that the power supply to a

circuit must be free of unwanted resistance, but

have difficulty visualising why an earth circuit must

also be f r ee of unwanted res istanc e. Curr ent f low is

through a complete circuit; it passes through and

out of a component like water flowing through a

tub. With a properly draining tub (no clogs), the

water can flow out as freely as it flow in. Current

mus t enter and leave c om ponents f reely, if they are

to perform as designed.

3

RI

4

4289

2

1

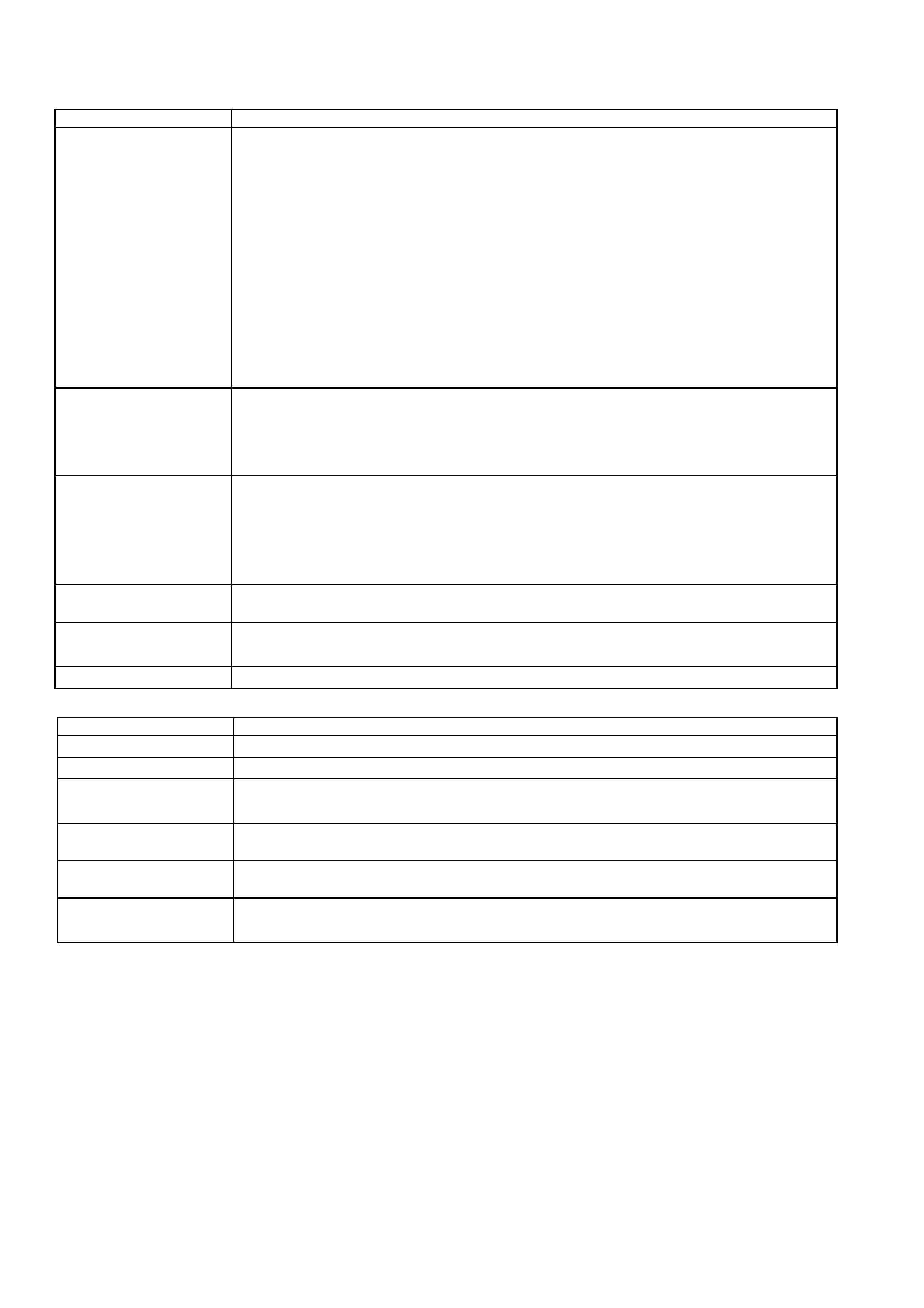

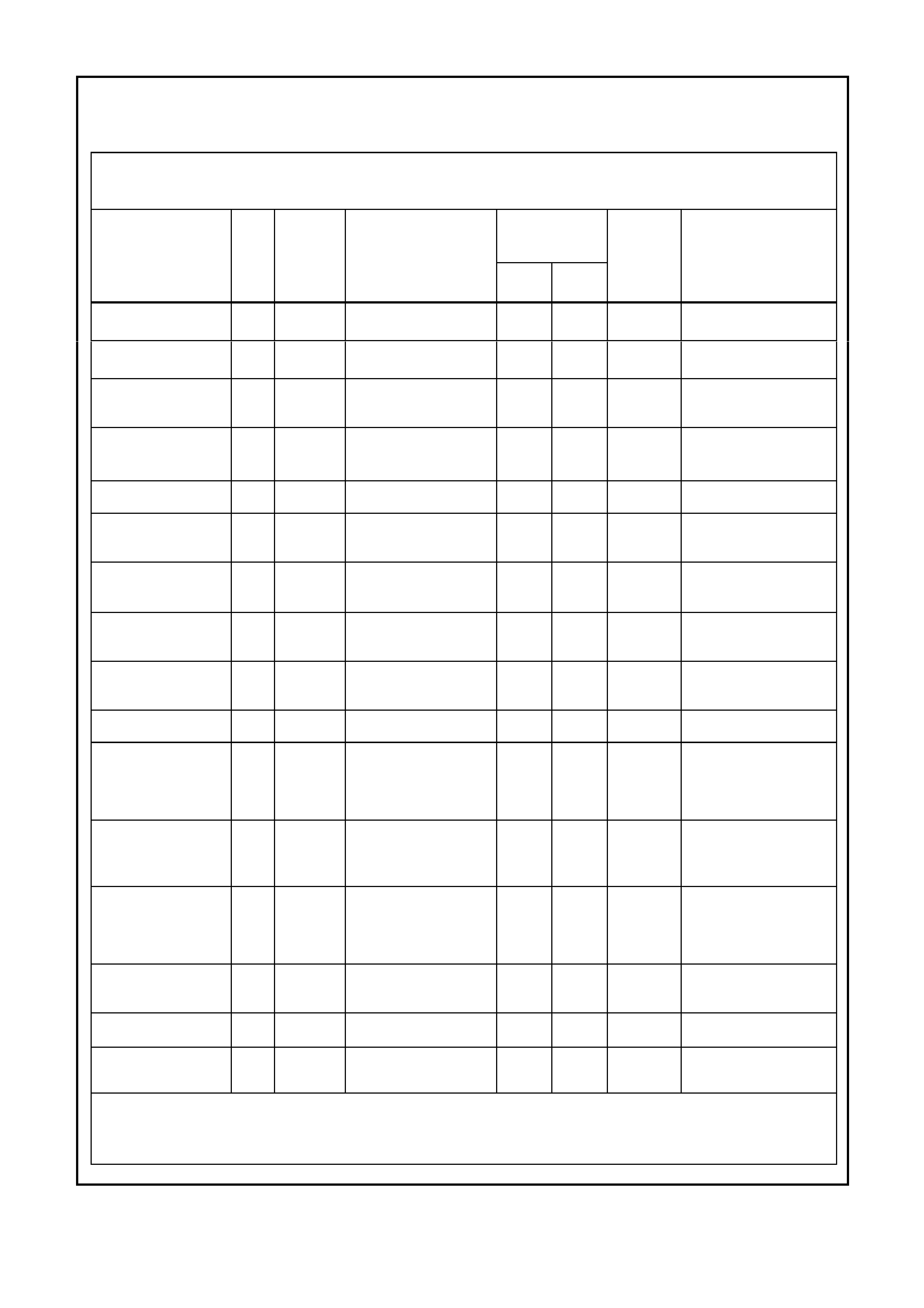

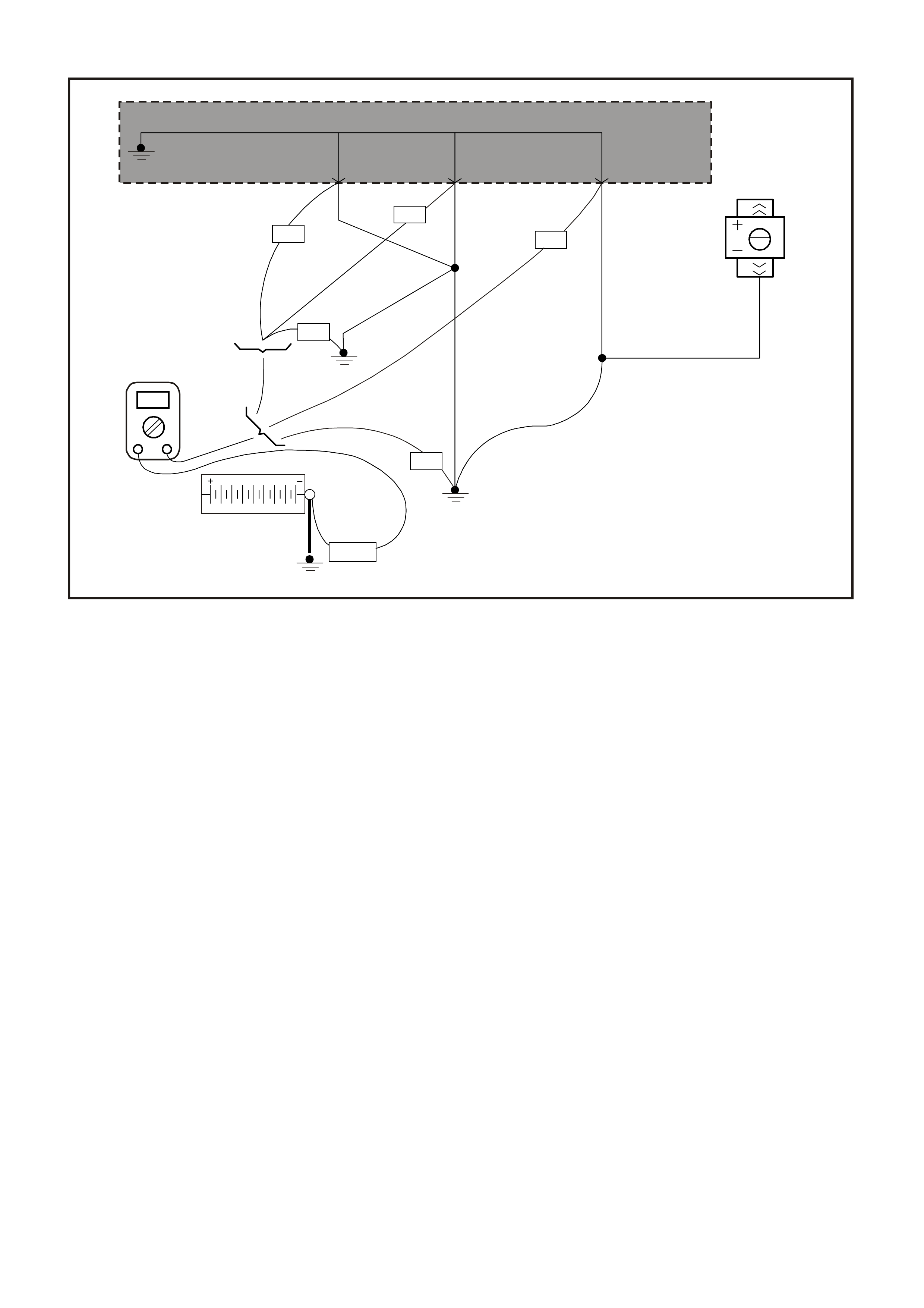

Figure 6C1-2B-2

1. Voltage = Resistance X Current V = R X I

2. Resistance = Current Relationship With Fixed Voltage

3. Large Resistance, Small Current

4. Small Resistance, Large Current

Sensitive solid-state systems have their own earths;

high cur rent devices (like m otors) do not earth at the

same location. High current devices can cause

voltage spikes (sudden changes in voltage) when

turned "ON" or "OFF." To prevent these spikes from

affecting sensitive solid-state circuits, the two

different types of systems use different earth

locations. The use of a dedicated wire to connect an

isolated earth junction block to the battery negative

terminal. This wire reduces the effect of spikes on

sensitive circuits at the earth junction block.

Solid-state circuits are particularly sensitive to poor

circuit c ontinuity becaus e in mos t cases they use low

current f low. This sec tion on earth concerns with one

solid-state device, the PCM. However, the

information included here applies to all solid-state

earth circuits.

Severe restrictions in the earth circuit can cause

resets and intermittent codes in solid-state systems.

The PCM operates devices (fuel injectors, idle air

control, etc.) and receives inputs from low voltage

sensors, manifold absolute pressure sensor,

crankshaft speed/position. These input and output

devices need good circuitry for correct operation.

Remember, that when misadjusted or imperfect

sensors cause values to shift there are usually

driveability problems. If there is excessive resistance

in the earth circ uit, the res ult will be the same; shifted

sensor outputs with corresponding driveability

conditions. These conditions may not be severe

enough to set diagnostic trouble codes, but they will

reduce vehicle efficiency and performance and may

be noticed by the customer.

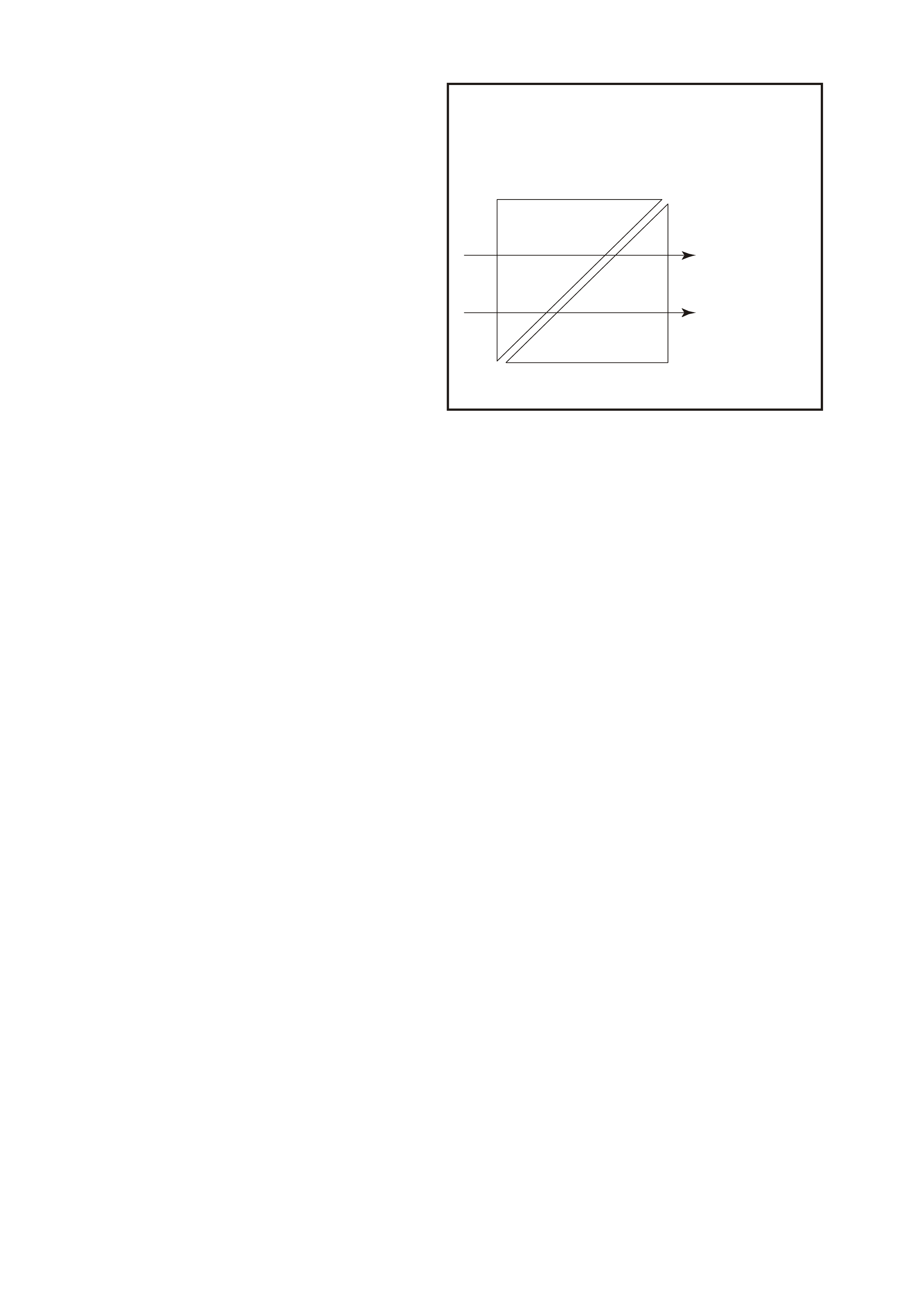

Sensor circuit earth sensitivity - an example.

Looking at the Throttle Position (TP) sensor circuit

will provide an example of how a little resistance in

the earth circuit can cause problems. The

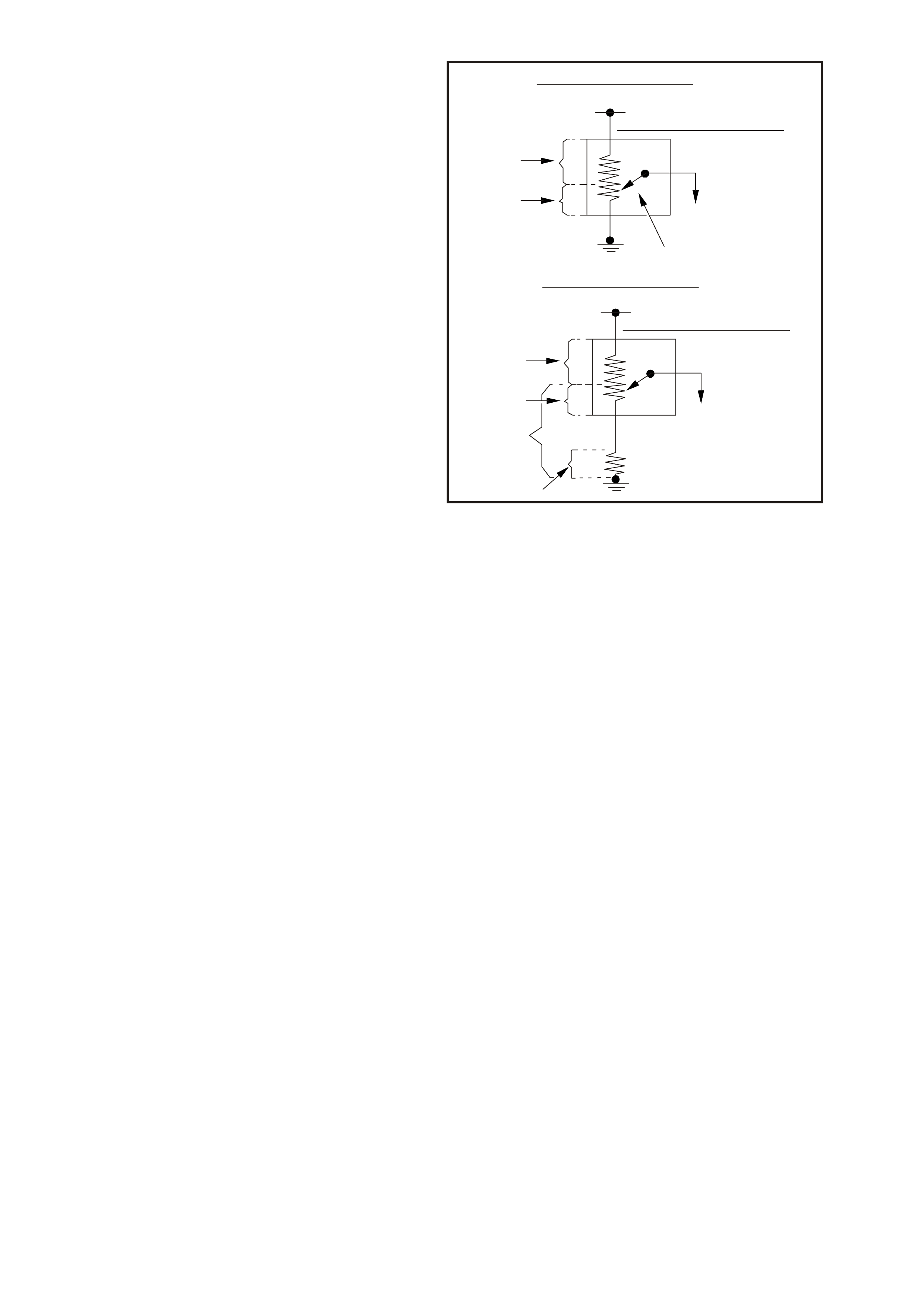

accompanying figure (Figure 6C1-2B-4) shows a

throttle position sens or first with a good earth circ uit

and then with a poor connection in the earth circuit.

Refer to this figure as you proc eed through the text

that follows.

A throttle position sensor consists of a resistor and

a wiper. One terminal of the resistor is connected to

a supply voltage and the other earth. As the wiper

moves along the resistor, the voltage of the wiper

terminal progressively changes. If the wiper is near

the supply voltage end of the resistor, the wiper

output will approach the supply voltage (over 4.5

volts at wide open throttle). As the wiper moves

toward the earthed end of the resistor the voltage

of the wiper output decreases to near zero (about

0.5 volts for the closed throttle in this example).

(The actual closed and wide open throttle voltage

specifications may vary for different engines.) The

sensor output should never be greater than

reference supply voltage or less then .20 volts.

(The PCM would set a diagnostic trouble code if

this occurs.)

The Figure 6C1-2B-4 shows voltage drops across

various points in the circuit. In the example with

good circuit earth, the T P sensor is shown with the

wiper in the closed throttle position. The total

voltage across the resistor in the TP sensor is 5

volts. The voltage drop from the resistor source

voltage terminal to the wiper is 4.5 volts. The

voltage drop from the wiper to the resistor earth

side is 0.5 volts. The wiper output is 0.5 volts - a