SECTION 6C1-3 - SERVICE OPERATIONS

V6 ENGINE

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in this VX Service Information for correct workshop practices with regards to

safety and/or property damage.

NOTE: When fastener s are rem oved, always reinstall them at the sam e location from which they were rem oved. If

a fastener needs to be replaced, use the correct part number fastener for that application. If the correct part

number fastener is not available, a fastener of equal size and strength (or stronger) may be used. Fasteners that

are not to be reused, or those requiring thread locking compound will be identified. The correct torque value must

be used when installing fasteners that require it. If the above conditions are not followed, parts or system damage

could result.

WHAT THIS SECTION CONTAINS

This Section describes the proper service procedures to repair components of the Powertrain Management

Systems. Emphasis is placed on the proper procedures and repair of components related to the systems.

Techline

Techline

3.1 SERVICE PRECAUTIONS

The following requirements must be observed when working on vehicles:

1. Before removing any PCM system component, disconnect the battery earth lead.

2. Never start the engine without the battery being solidly connected.

3. Never disconnect the battery from the on board electrical system while the engine is running.

4. When charging the battery, disconnect it from the vehicle's electrical system.

5. Never subject the PCM to temperatures above 80 degrees C i.e. paint oven. Always remove PCM first if this

temperature is to be exceeded.

6. Ensure that all cable harness plugs are connected solidly and that battery terminals are thoroughly clean.

7. The engine management system harness connectors are designed to fit in only one way; there are indexing

tabs and slots on both halves of the connector. Forcing the connector into place is not necessary if it is being

installed with the proper orientation. Failure to take care to match the indexing tabs and slots to ensure the

connector is being installed correctly can cause damage to the connector, the module, or other vehicle

components or systems.

8. Never connect or disconnect cable harness plug at the PCM when the ignition is switched "ON."

9. Before attempting any electric arc welding on the vehicle, disconnect the battery leads and the PCM

connectors.

10. When steam cleaning engines, do not direct the steam cleaning nozzle at PCM system components. If this

happens, corrosion of the terminals can take place.

11. Use only the test equipment specified in the diagnostic Tables, since other test equipment may either give

incorrect results or damage good components.

12. All voltage m easurements using a voltmeter must use a digital voltmeter with an internal impedance rating of

at least 10 million ohms per volt (10 megohm/volt).

13. When a test light is specified, a "low-power" test light must be used. Do not use a high - wattage test light.

W hile a partic ular brand of test light is not suggested, a simp le test on any test light will ensure it to be OK f or

PCM circuit testing. Connect an accurate ammeter (such as the high-impedance digital multimeter) in series

with the test light being tested, and power the test light-ammeter circuit with the vehicle battery.

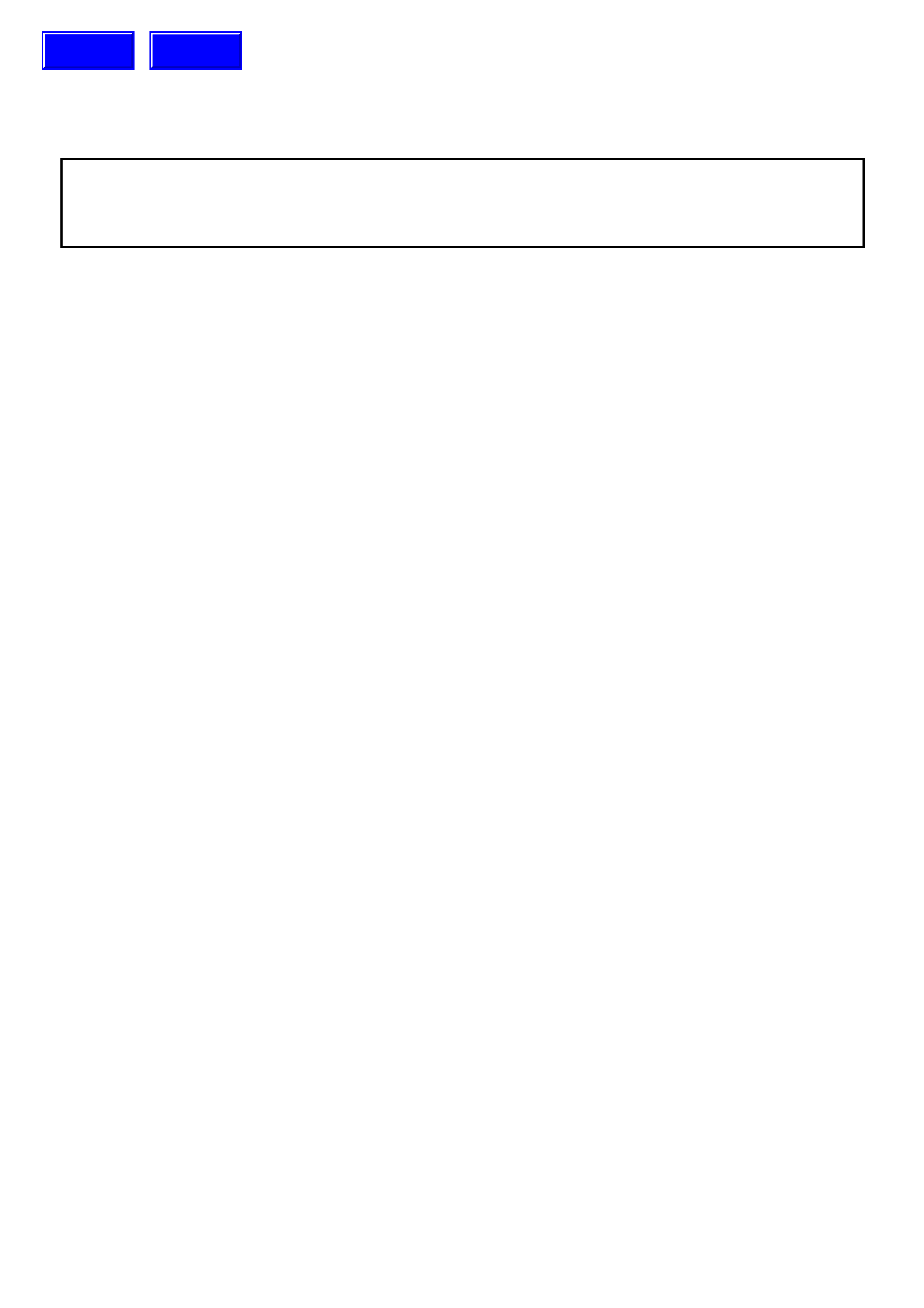

Figure 6C1-3-1 Test Light Check

If the ammeter indicates less than 3/10 amp current

flow (0.3 A or 300 mA), the test light is OK to use.

I

f

the ammeter indicates more than 3

/

10 amp current

flow (0.3 A or 300 mA), the test light is NOT OK to

use.

+

BATTERY

-

DC AMPS

Test Light

3.2 POWERTRAIN CONTROL MODULE

PCM REPLACEMENT/ PROGRAMMING

Service of the PCM should normally consist of

either replacement of the PCM or EEPROM (flash

memory) programming. If the diagnostic

procedures call for the PCM to be replaced, the

PCM should be first checked to ensure it is the

correct part. If it is, remove the faulty PCM and

install the new PCM.

IMPORTANT:

• The replacement PCM EEPROM will not be

programmed.

• DTC P0601 indicates the EEPROM is not

programmed or has malfunctioned. Refer to

Service Programming in this section for

programming procedures.

IMPORTANT:

The following must be performed anytime the PCM

is replaced:

1. Programming of the EEPROM

2. The Functional Check

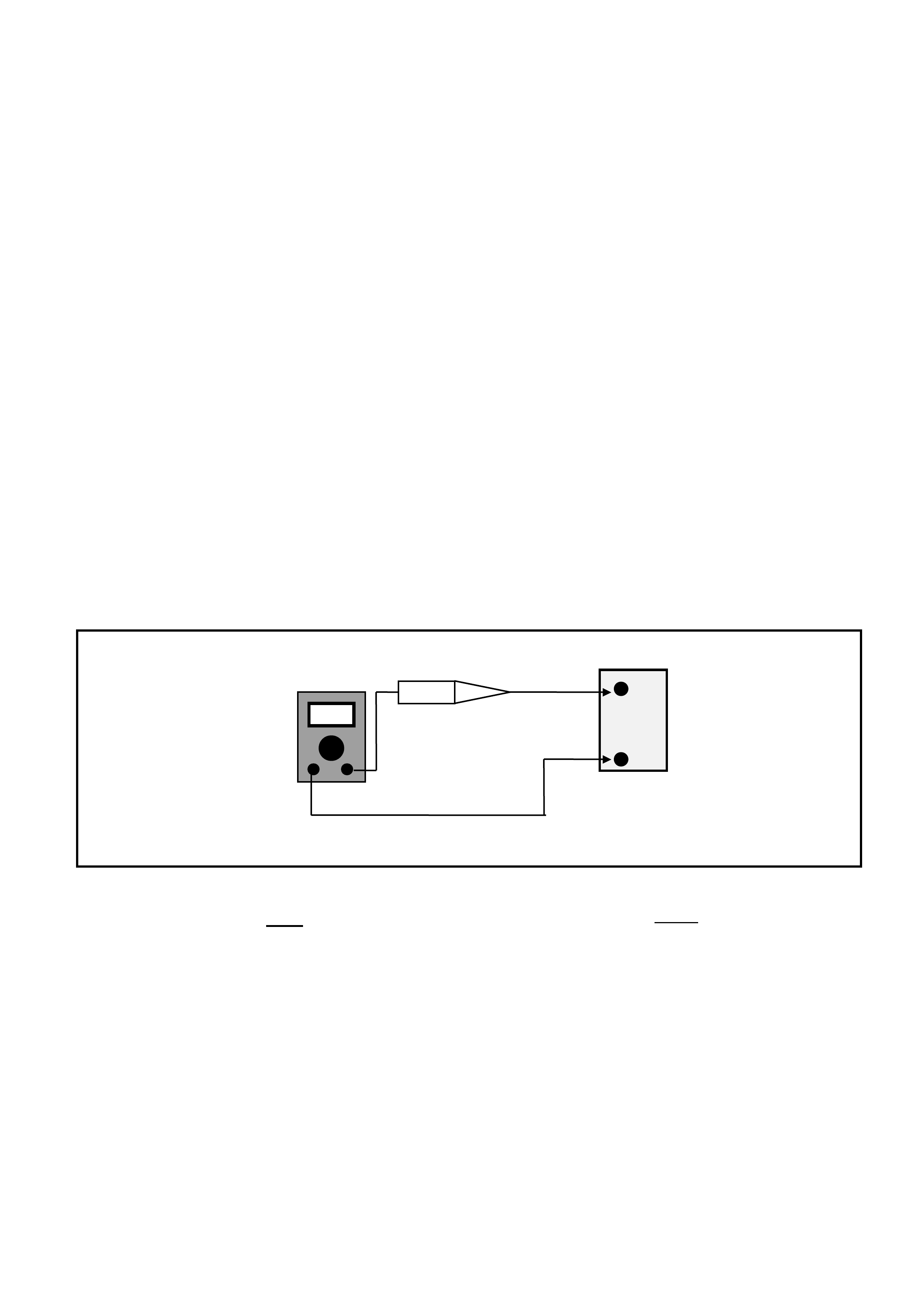

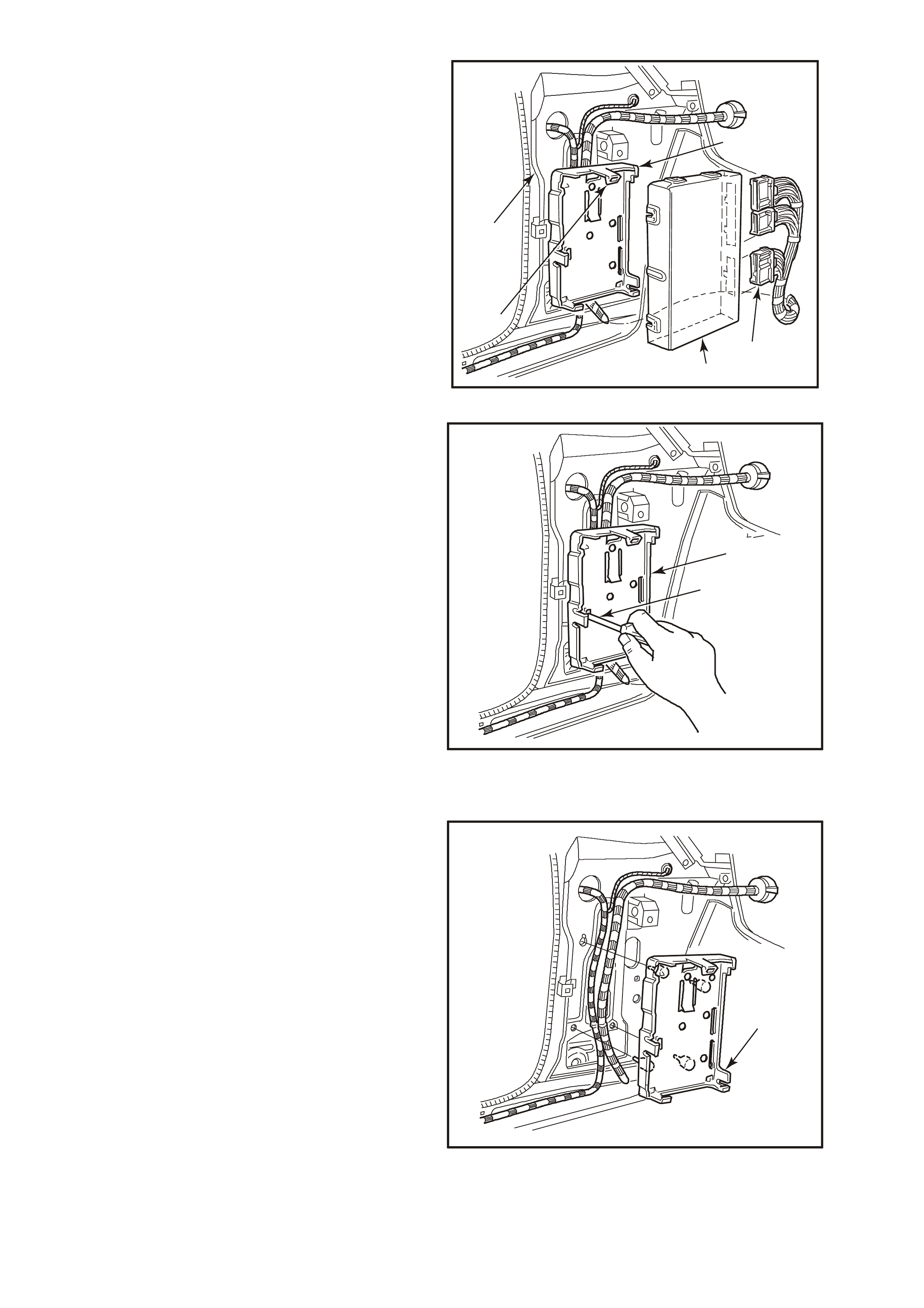

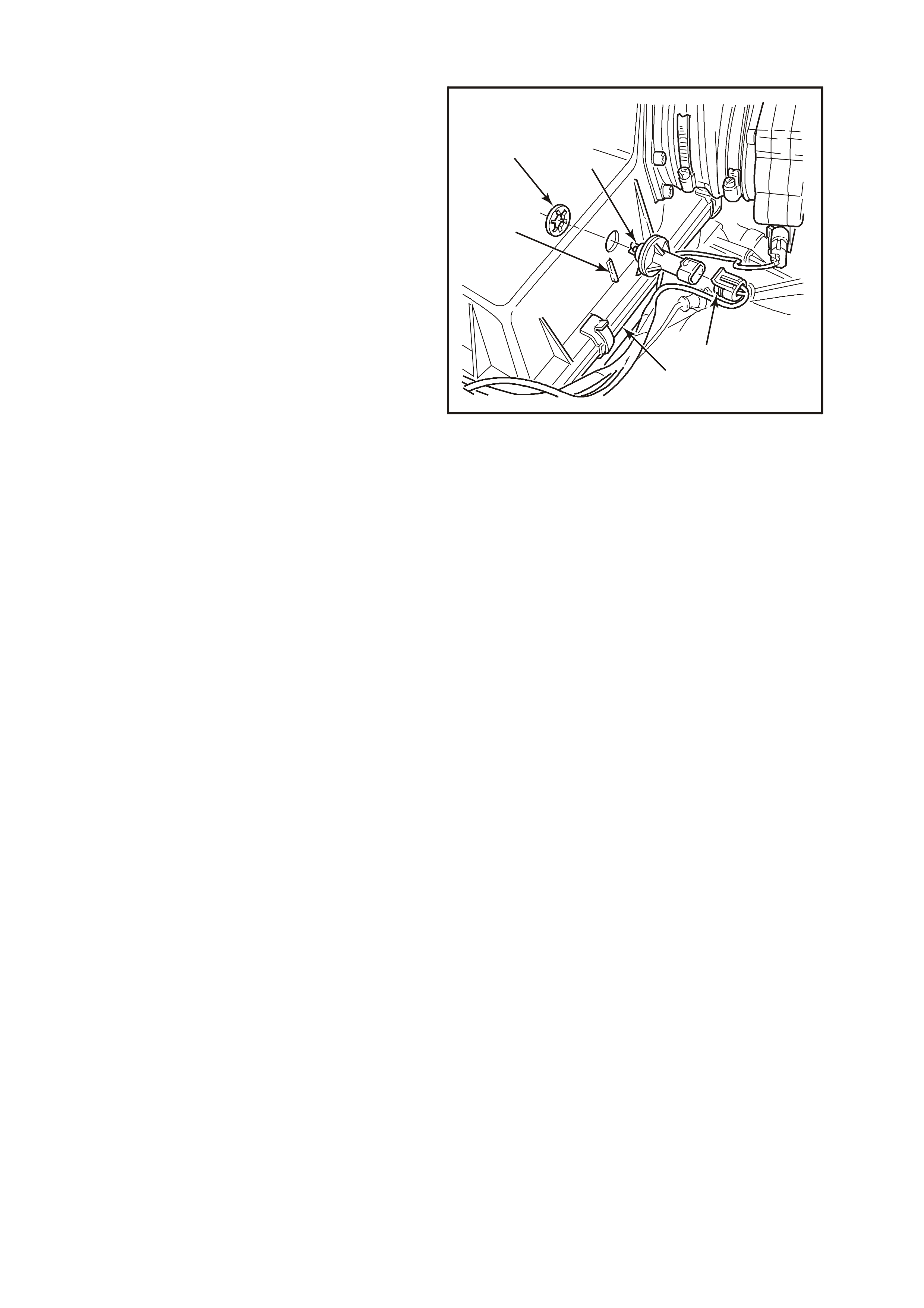

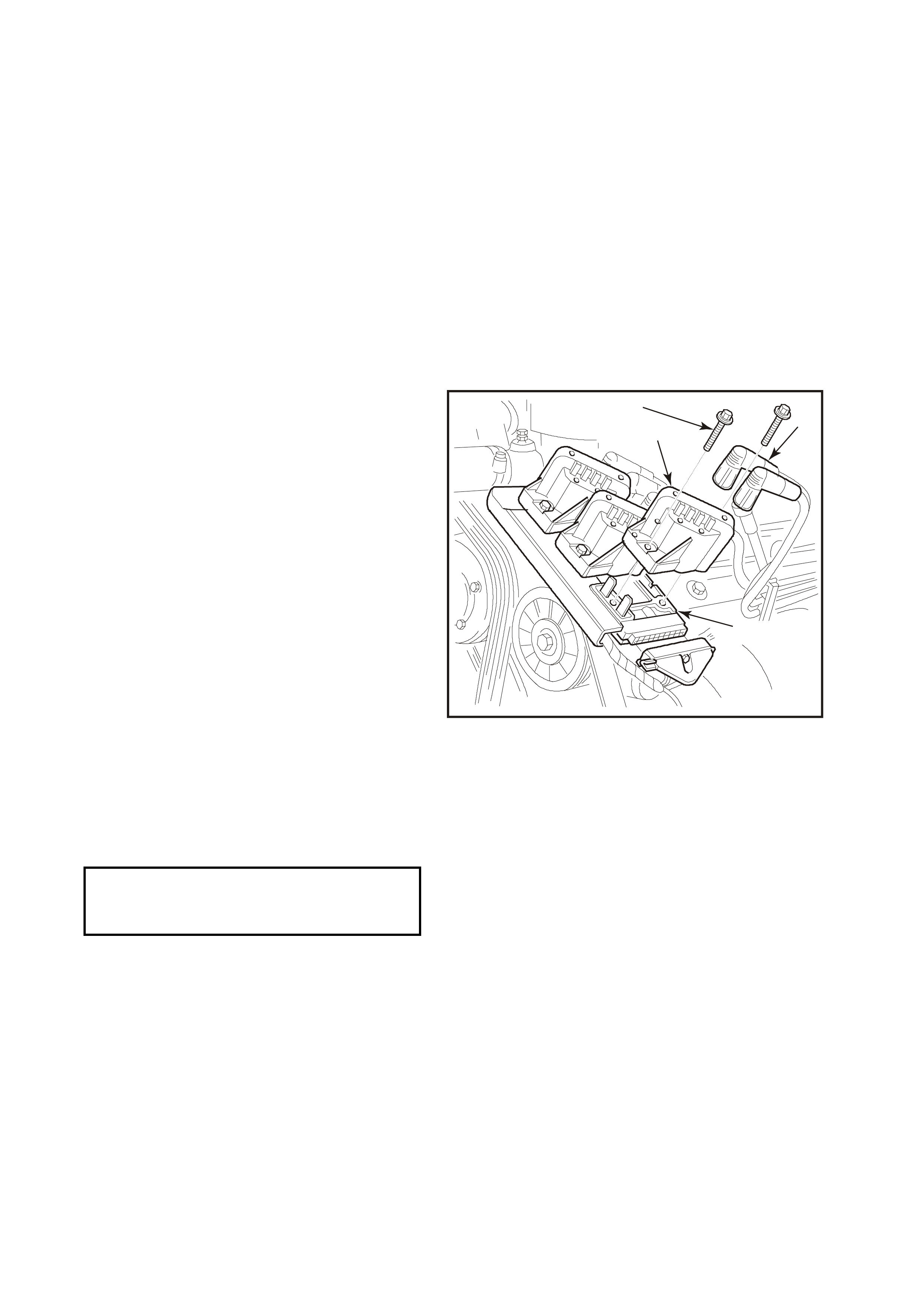

Figure 6C1-3-2 PCM Location

The f ollowing m ust be perf ormed anytime the PCM

(1) is disconnected or loses power.

1. The Functional Check.

This is described later in this section.

NOTE:

• To prevent internal PCM damage, the ignition

must be OFF when disconnecting or

reconnecting power to the PCM.

• The location of the PCM is behind the front left

hand cowl trim panel. The PCM and mounting

brackets (2) is attached to the left hand cowl

panel (3).

REMOVE

IMPORTANT:

Remove any debris from the PCM connector

surfaces before servicing the PCM.

NOTE:

Do not touch the connector pins or soldered

components on the circuit board in order to prevent

possible electrostatic discharge damage to the

PCM.

1. Disconnect battery earth lead.

2. Remove left hand front shroud panel lower

trim assembly (cowl panel trim), refer

Section 1A1, BODY in the VT Series I

Service Information.

3

2

1

4202

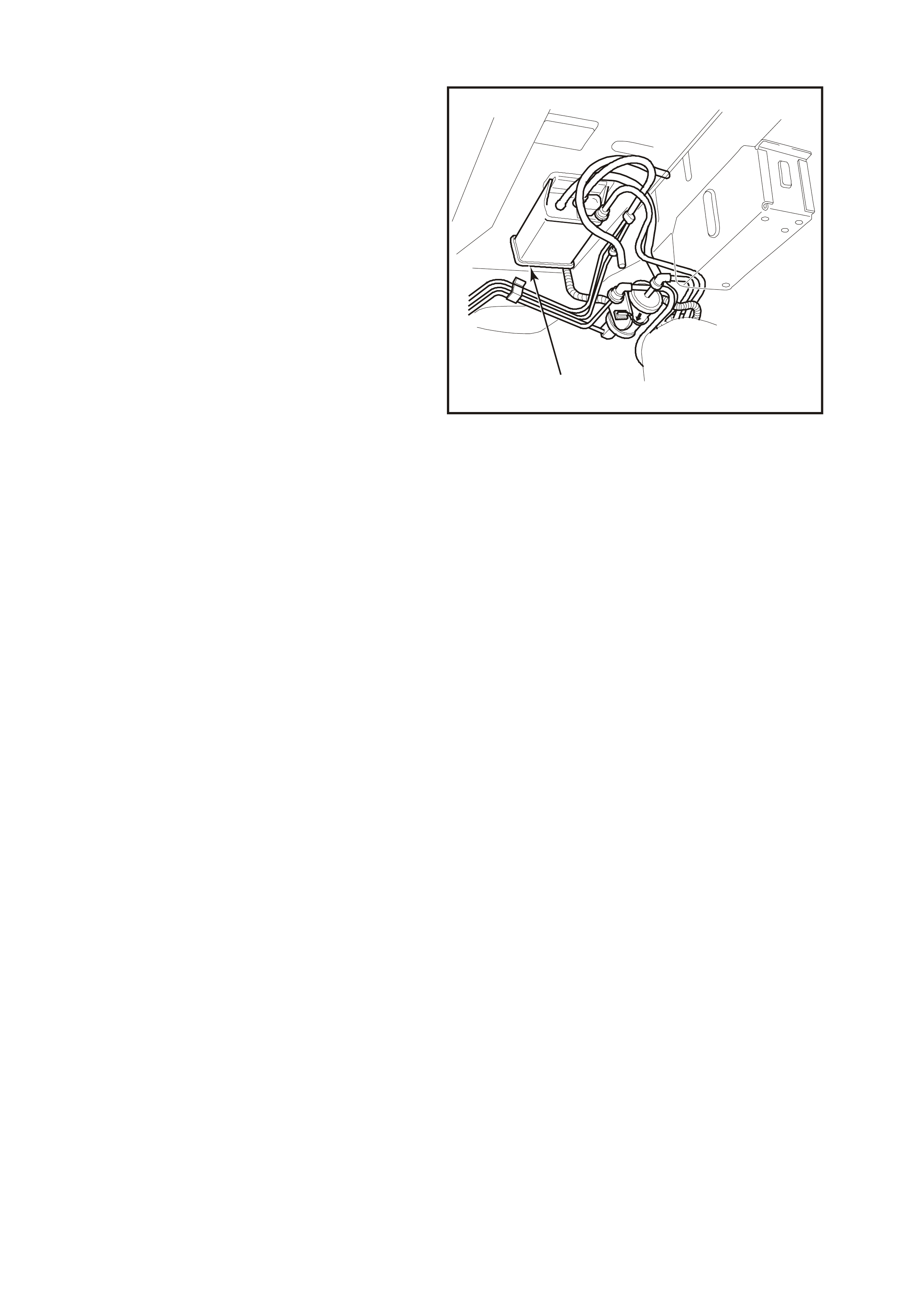

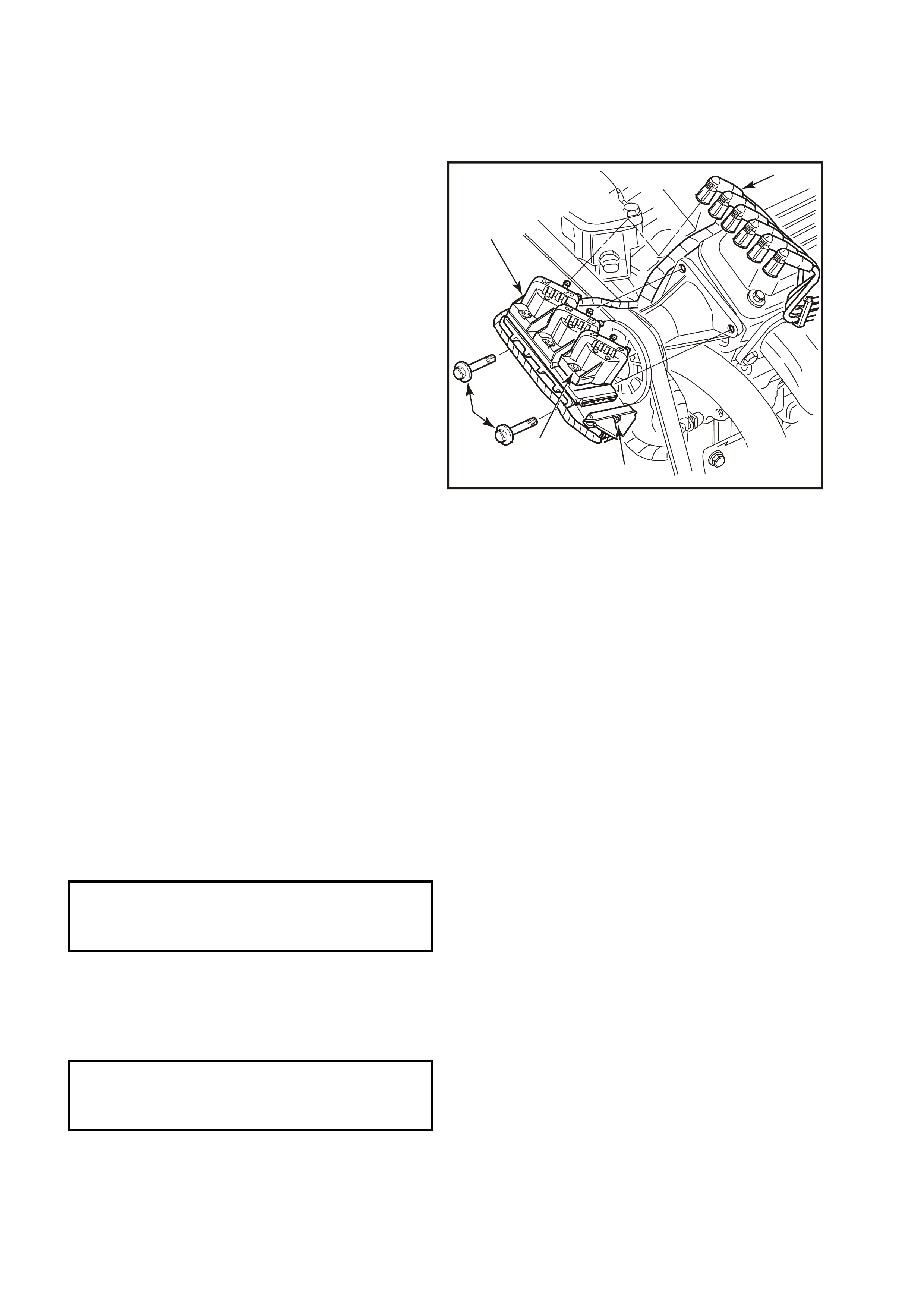

Figure 6C1-3-3 PCM Mounting

Techline

3. Lift up mounting bracket to PCM upper

retaining tang (4), pull PCM (3) out then up to

remove it from the mounting bracket (1).

4. Remove wiring harness connectors (2) from

PCM, remove PCM from vehicle.

IMPORTANT:

The replacement PCM EEPROM will not be

programmed.

1

2

4294

3

4

5

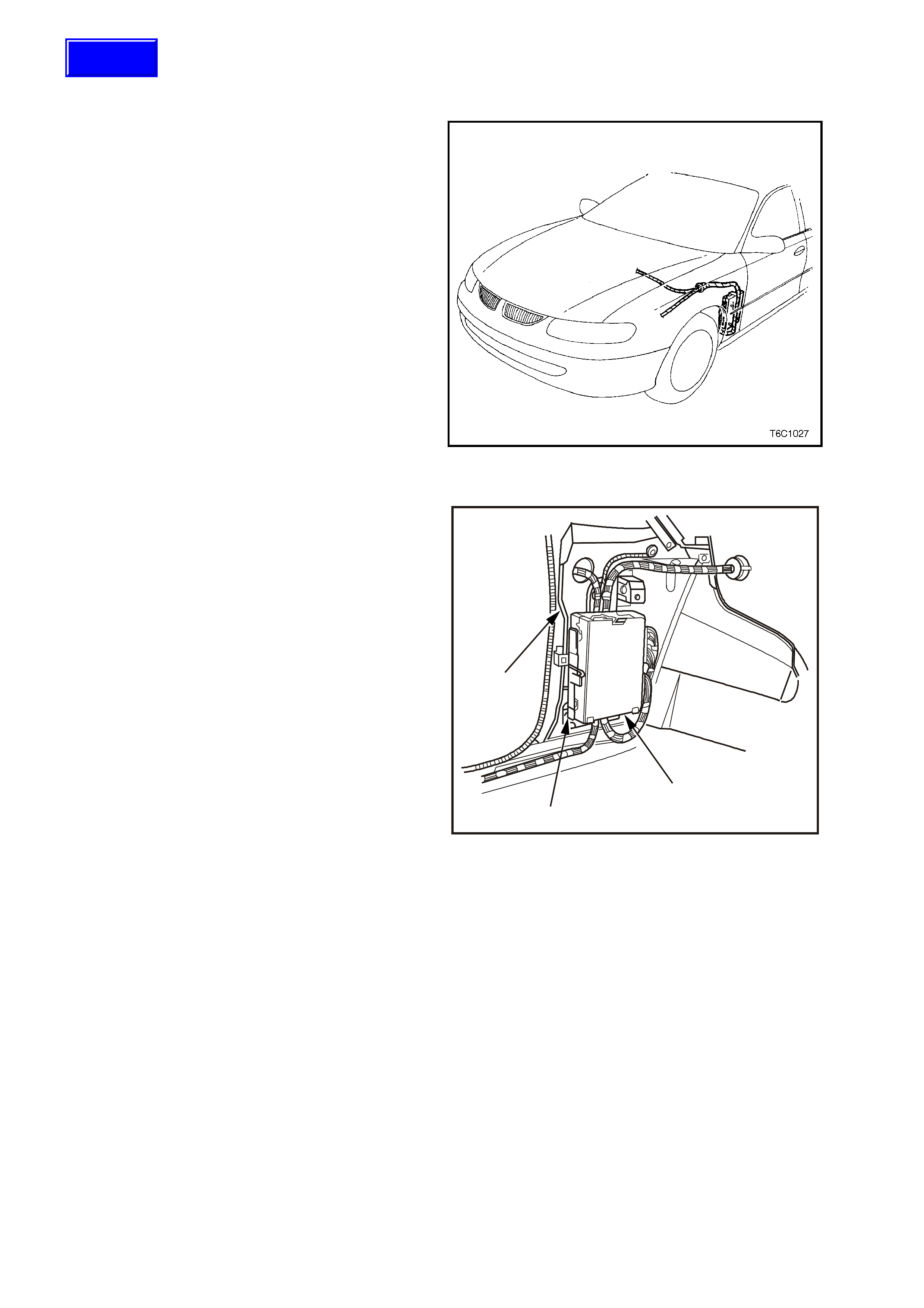

Figure 6C1-3-4 PCM Removal

5. If required, remove PCM mounting bracket (1)

by inserting a screwdriver into the retaining

tang slot (2), lever screwdriver to release tang.

Pull bracket out then down to release from the

cowl panel.

2

4295

1

Figure 6C1-3-5 PCM Mounting Bracket Removal

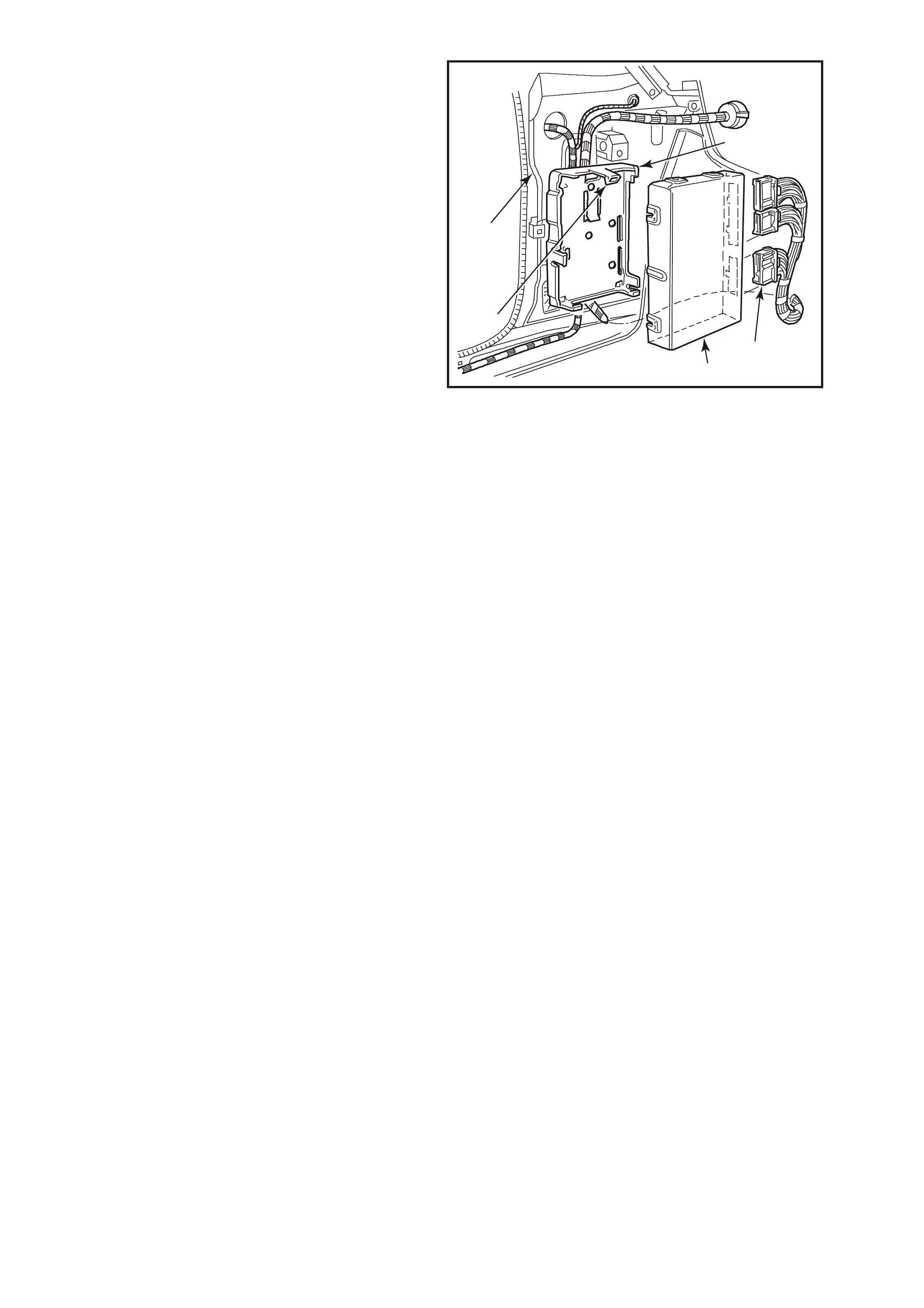

REINSTALL

1. If rem oved, r eins tall PCM mounting brac k et (1) ,

engaging bracket leg into slotted hole in cowl

panel. Lift up bracket and engage bracket

lower retainers and retaining tang into cowl

panel.

1

4296

Figure 6C1-3-6 PCM Mounting Bracket Reinstallation

2. Reconnect wiring harness connectors (2) to

PCM.

3. Assemble PCM into mounting bracket (1),

ensuring wiring harness is routed in fr ont of the

mounting bracket.

4. Reinstall cowl panel trim, Refer to

Section 1A1, BODY in the VT Series I

Service Information.

5. Reconnect battery earth lead. Perform Service

Programming if PCM was replaced with new,

refer to Service Programming in this Section

otherwise star t vehicle and allow to idle. Check

vehicle for correct operation.

1

2

4294

3

4

5

Figure 6C1-3-7 PCM Mounting Bracket Reinstallation

SERVICE PROGRAMMING

NOTE:

Follow the programming instructions completely and do not key OFF during programming unless instructed. If the

key is turned OFF during programming, possible PCM damage may occur.

IMPORTANT:

Do not disconnect tech 2 during each programming step.

1. Setup - Ensure that the following conditions have been met:

- The battery is fully charged, but not charging during programming.

- The ignition is ON.

- Ensure that all PCM connections are OK.

2. Connect TECH 2 to the vehicle and select Service Programming System (SPS) / Request Info.

3. Connect TECH 2 to a TIS terminal and download latest software matching the vehicle. Refer to TIS

terminal/equipment users instructions.

4. Connect TECH 2 to the vehicle again and select Service Programming System (SPS) / Program ECU.

5. If the PCM fails to program, proceed as follows:

- Ensure that all PCM connections are OK.

- Attempt to re-program the PCM. If the PCM still cannot be programmed correctly, replace the PCM and

program it according to this procedure.

IMPORTANT:

Once new PCM has been programmed, it must be Security Linked. Refer to PCM Security Link below for

linking procedure. If updating calibrations to the vehicle’s existing PCM hardware, no linking procedure is necessary.

PCM SECURITY LINK

Once the PCM and or BCM have been replaced, the new PCM and or BCM mus t be security link ed to each other.

If this procedure is not performed, the vehicle will not crank.

The PCM to BCM linking procedure is as follows:

Connect TECH 2 to DLC and select:

Diagnostic / (V) 20XX / VX Commodore / Body / Body Control Module / Security / BCM Link to PCM and follow

TECH 2 instructions.

For additional information regarding TECH 2 and TECH 2 test modes (including this linking procedure), refer to

TECH 2 DIAGNOSIS FOR BCM in Section 12J-1 LOW SERIES BCM or Section 12J-2 HIGH SERIES BCM in

the VX Service Information.

NOTE:

If this vehicle is also fitted with LPG, refer to Section 8A - LPG SYSTEM of the VX Service Information after the

PCM replacement and/or reprogrammed for LPG setup procedure. This must be performed whenever the PCM is

replaces or reprogrammed.

FUNCTIONAL CHECK

1. Clear the Diagnostic Trouble Codes (DTCs).

2. Perform the Powertrain OBD System Check.

3. Start the engine and idle for one minute.

4. Use the Tech 2 scan tool to check for DTCs.

3.3 CAMSHAFT POSITION SENSOR

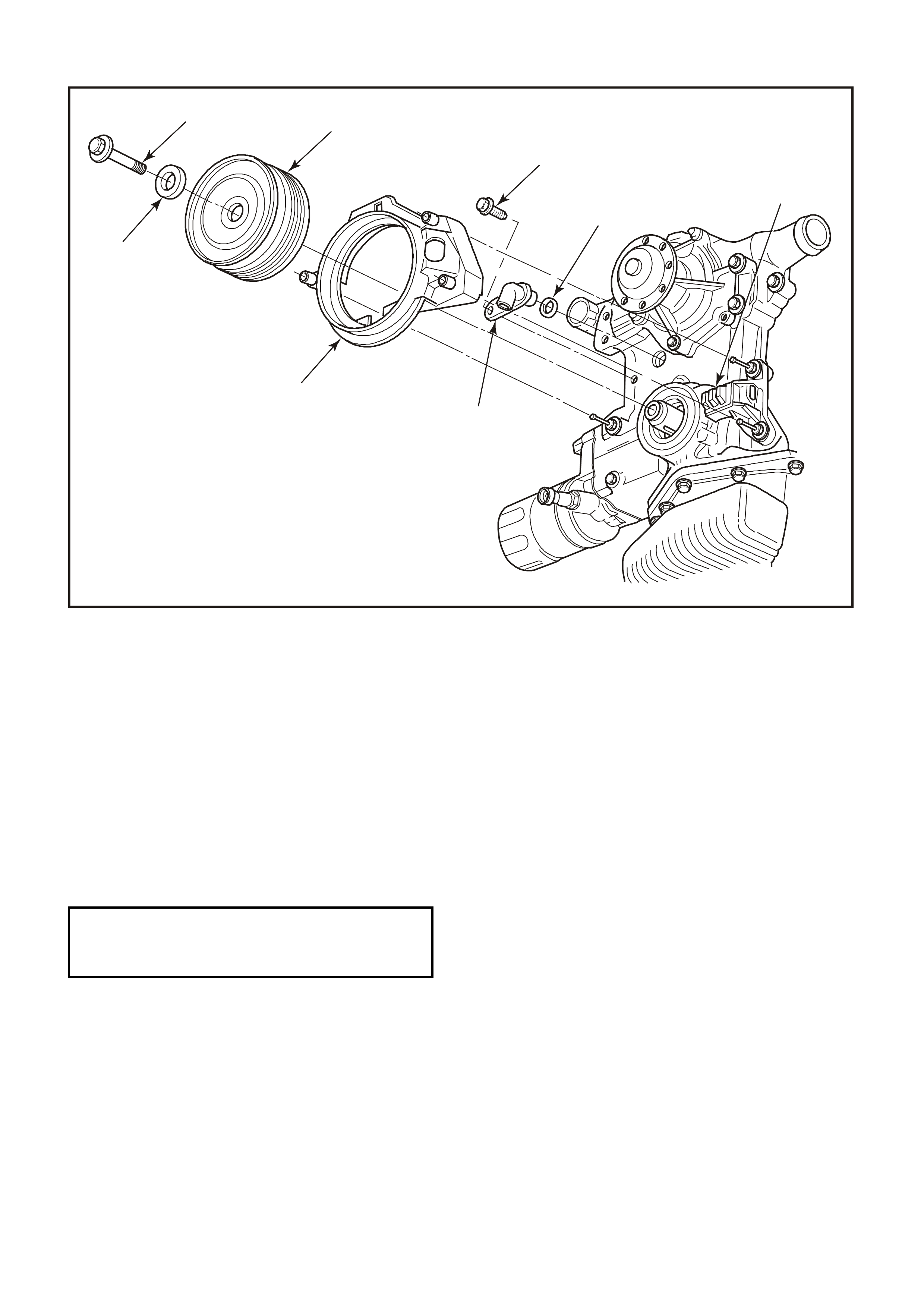

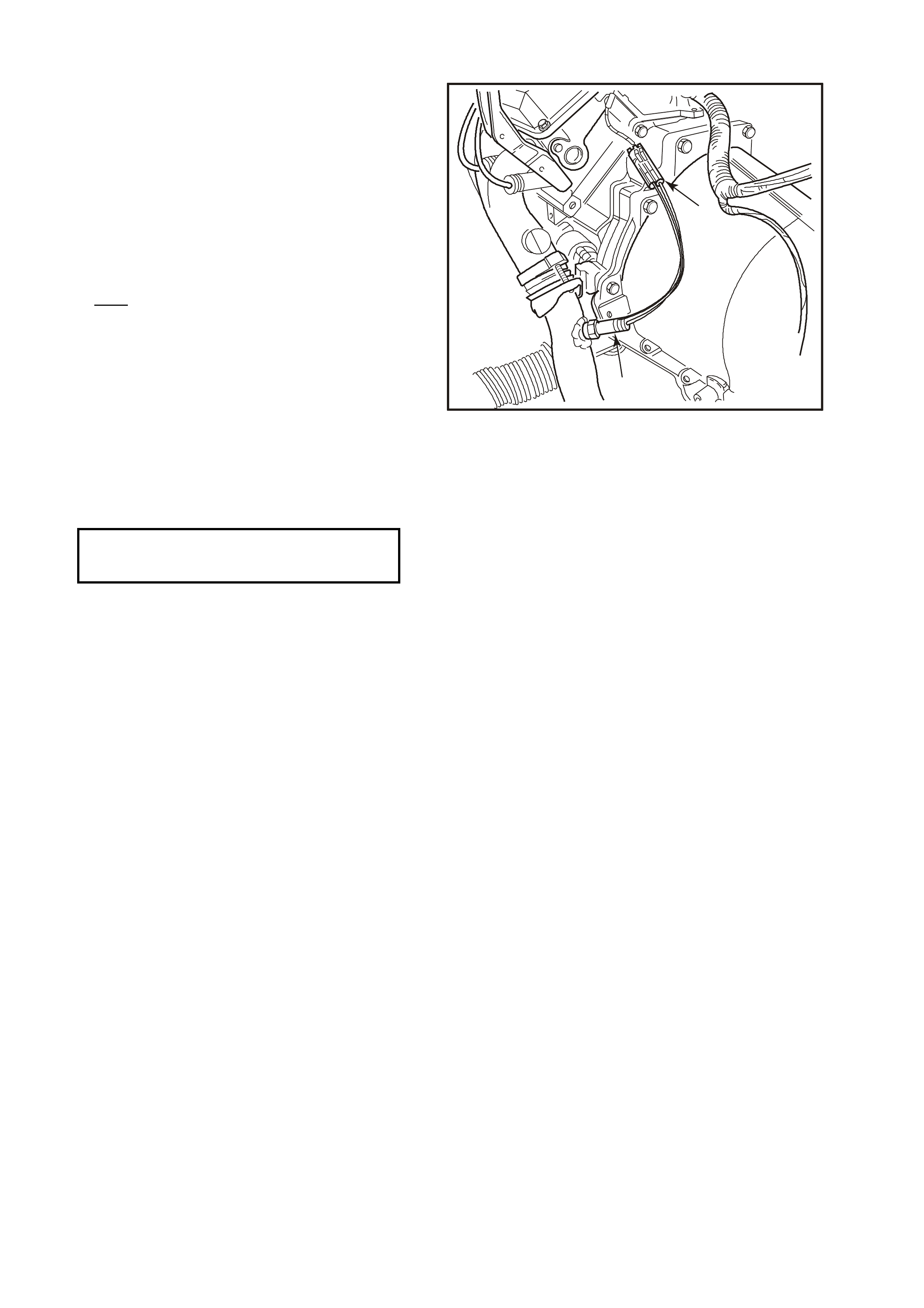

Figure 6C1-3-8 Camshaft/Crankshaft Position Sensors

REMOVE

1. Disconnect battery earth lead.

2. Lift up retaining tang and disconnect wiring harness connector from camshaft position sensor (6).

3. Remove camshaft position sensor to front cover retaining bolt (3).

4. Remove camshaft position sensor and O-ring (4) from front cover.

REINSTALL

1. Apply light engine oil to O-ring (4) on new camshaft position sensor (6).

2. Assemble camshaft position sensor (6) into front cover hole.

3. Install camshaft position sensor (6) to front cover retaining bolt (3) and tighten to the correct torque

specification.

Camshaft Position Sensor

Retaining Bolt

Torque Specification

11 N.m

4. Reconnect wiring harness connector to camshaft position sensor (6).

5. Reconnect battery earth lead.

2

3

4300

45

1

8

7

6

3.4 ENGINE COOLANT TEMPERATURE (ECT) SENSOR

IMPORTANT:

• Care must be taken when handling PCM

engine coolant sensor. Damage to sensor

will affect the operation of the engine

management system. Ensure that the

correct sensor is located before service is

attempted. There are different engine

coolant temperature sensors: for the PCM,

the instrument panel gauge, and/or warning

lights. Sensors are located in the front of

the inlet manifold below the engine

thermostat housing.

CAUTION: The Engine Coolant Temperature

(ECT) sensor (2) is installed into a "wet" engine

coolant passage (in the inlet manifold, below the

thermostat housing). Drain the engine coolant

before removing the ECT sensor from the engine.

Position a coolant drain pan appropriately, then

loosen lower radiator hose at the radiator to drain

the coolant.

REMOVE

1. Disconnect battery earth lead.

2. Depressurize engine cooling system by

removing radiator cap in two stages.

CAUTION: DO NOT REMOVE RADIATOR CAP

WHILE T HE ENGINE COOLANT TEM PERAT URE

IS ABOVE 50 DEGREES C.

4209

3

21

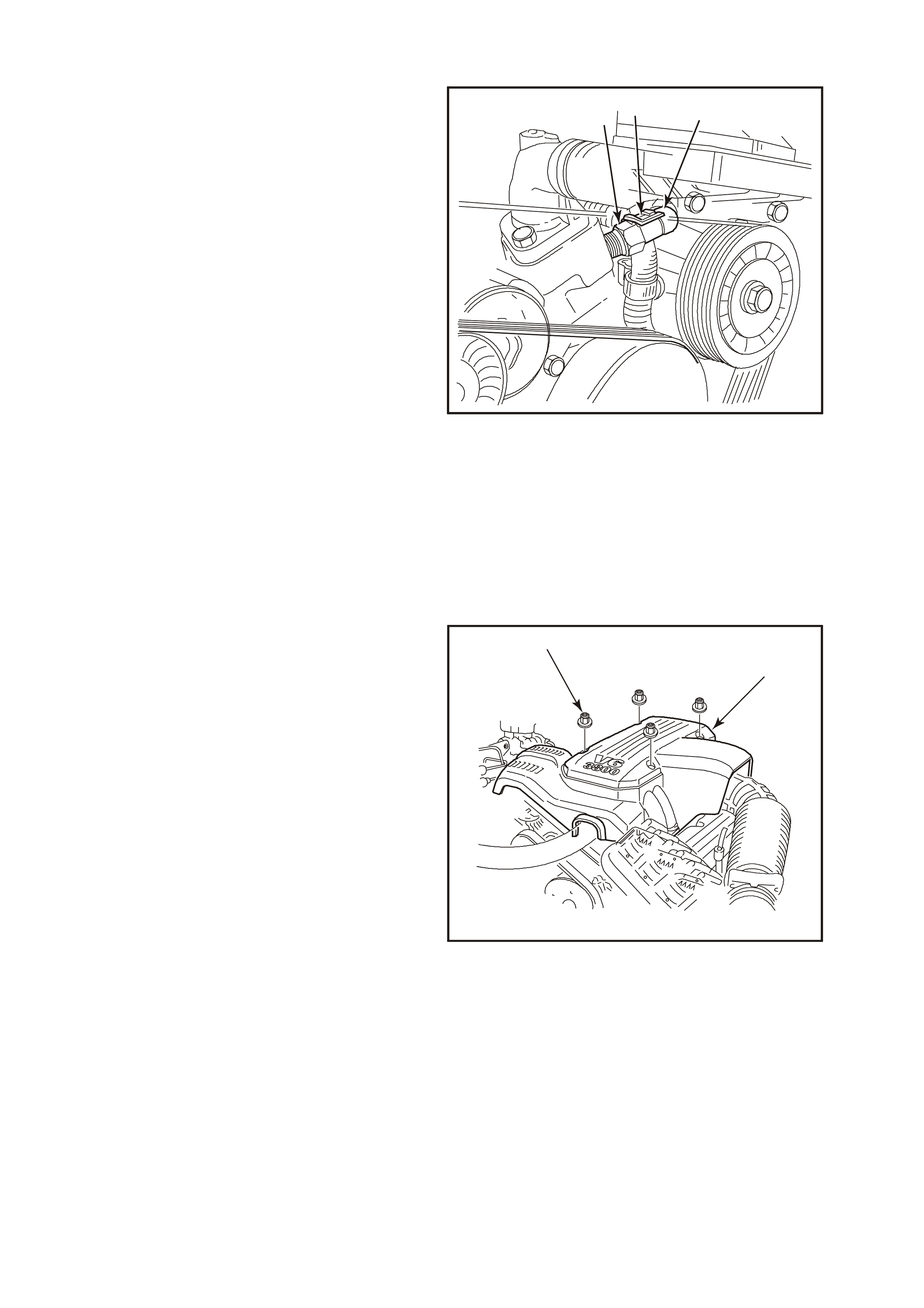

Figure 6C1-3-9 ECT Sensor Location

3. Remove four dome nuts (1) securing the

engine dress cover assembly (2) to the inlet

manifold studs, lift off and remove the cover

assembly.

4. Position a coolant drain pan appropriately

beneath the vehicle, then loosen lower radiator

hose at the radiator to drain the engine coolant.

5. Lift up retaining tang and disconnect wiring

harness connector from PCM ECT sensor. Lift

connector up away from sensor.

6. Carefully move powertrain wiring harness

down under the ECT sens or so as to allow tool

access to the sensor.

7. Using a 19 mm ring spanner, carefully loosen

and remove PCM engine coolant temperature

sensor.

2

1

4302

Figure 6C1-3-10 Engine Dress Cover V6 Engine

REINSTALL

1. Apply Loctite 242 (Holden's Specification HN1256 Class 2, Type 2) sealant to sensor threads.

2. Install ECT sensor into inlet manifold and tighten to the correct torque specification.

3. Reconnect wiring harness connector onto ECT

sensor,

NOTE:

Recheck that wiring harness connector and harness are corr ectly positioned. T he accessory drive belt passe s ver y

close to the temperature sensor connectors. Future damage to the harness could occur if not correctly positioned

now.

4. Reconnect battery earth lead.

5. Refill the engine coolant system, Ref er to Section 6B1-1, ENGINE COO LING - V6 ENGINE in the VX Ser vice

Information.

6. Reinstall engine dress cover to the inlet manifold, ens uring that stud grom mets in dres s cover rem ain in place.

Tighten securing dome nuts to the correct torque specification.

ECT Sensor To Inlet Manifold

Torque Specification 15 – 20

N.m

Engine Dress Cover Securing

Dome Nut To Inlet Manifold

Torque Specification

4 – 6 N.m

3.5 INTAKE AIR TEMPERATURE (IAT) SENSOR

IMPORTANT:

• Care must be taken when handling IAT

Sensor. Damage to IAT sensor will affect

proper operation of the fuel control system.

REMOVE

1. Disconnect battery earth lead.

2. Lift up tang on IAT sensor wiring harness

connector (1) and pull connector from sensor

(5).

3. Loosen intake air duct adapter clamp that is

located closest to air cleaner assembly.

4. Disconnect air duct, with mass air flow sensor

attached, from air cleaner upper housing.

5. Unclip 5 retaining clips holding the air cleaner

upper housing (2) in place.

6. Separate the upper and lower air cleaner

housings.

IMPORTANT:

Air filter should remain in the lower housing.

7. Remove air cleaner upper housing and place

on bench.

8. Using a pair of side cutters, cut across the IAT

sensor retainer (4) to remove it. Once

removed, discard retainer.

9. Pull out IAT sensor (5) from air cleaner upper

housing.

4215

1

2

5

4

3

Figure 6C1-3-11 IAT Sensor Removal

REINSTALL

1. Push new IAT sensor (5) into air cleaner upper housing (2), with triangular tang on the mounting flange

locating on the mating rib of the air cleaner upper housing.

2. Position the upper air cleaner housing assembly, with the IAT sensor on the work bench, pushing up into the

air cleaner upper housing.

Position new retainer (4) onto IAT sensor and then using a 20 m m sock et, push the retainer fully onto the IAT

sensor.

3. Assemble the air filter element into the air cleaner upper housing and place the upper housing onto the air

cleaner lower air cleaner housing, ensuring that air filter element remains in position.

4. Snap 5 retainer clips up into place over the top of the air cleaner upper housing.

5. Reconnect wiring harness connector (1) to IAT sensor (5).

6. Carefully assemble intake air duct and mass air flow sensor onto air cleaner upper housing.

IMPORTANT:

Align notch on air cleaner housing adapter with notch in air duct adapter and notch in clamp.

7. Tighten air duct clamp securely.

8. Check that mass air flow sensor wiring harness connector has remained firmly in place.

9. Reconnect battery earth lead.

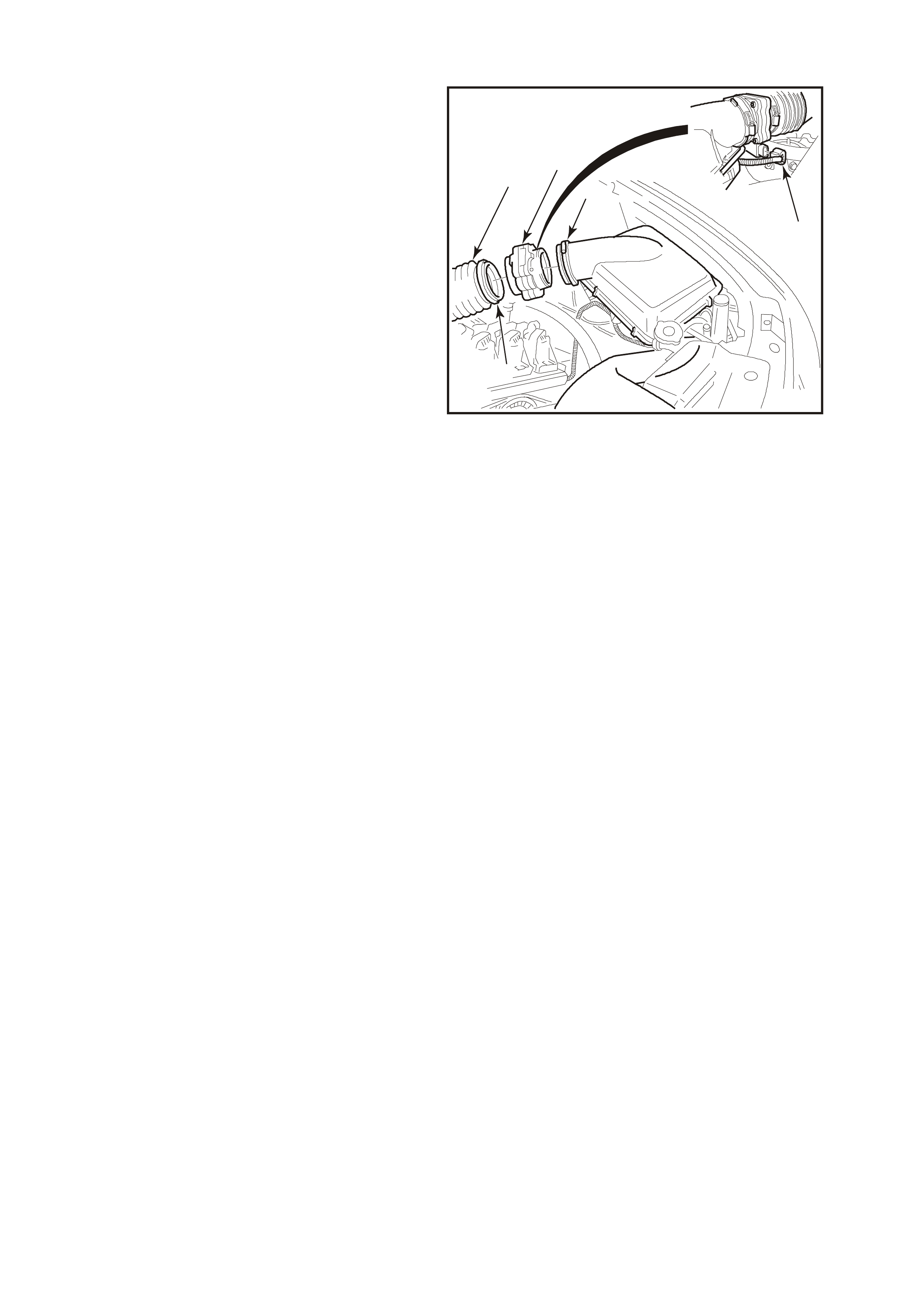

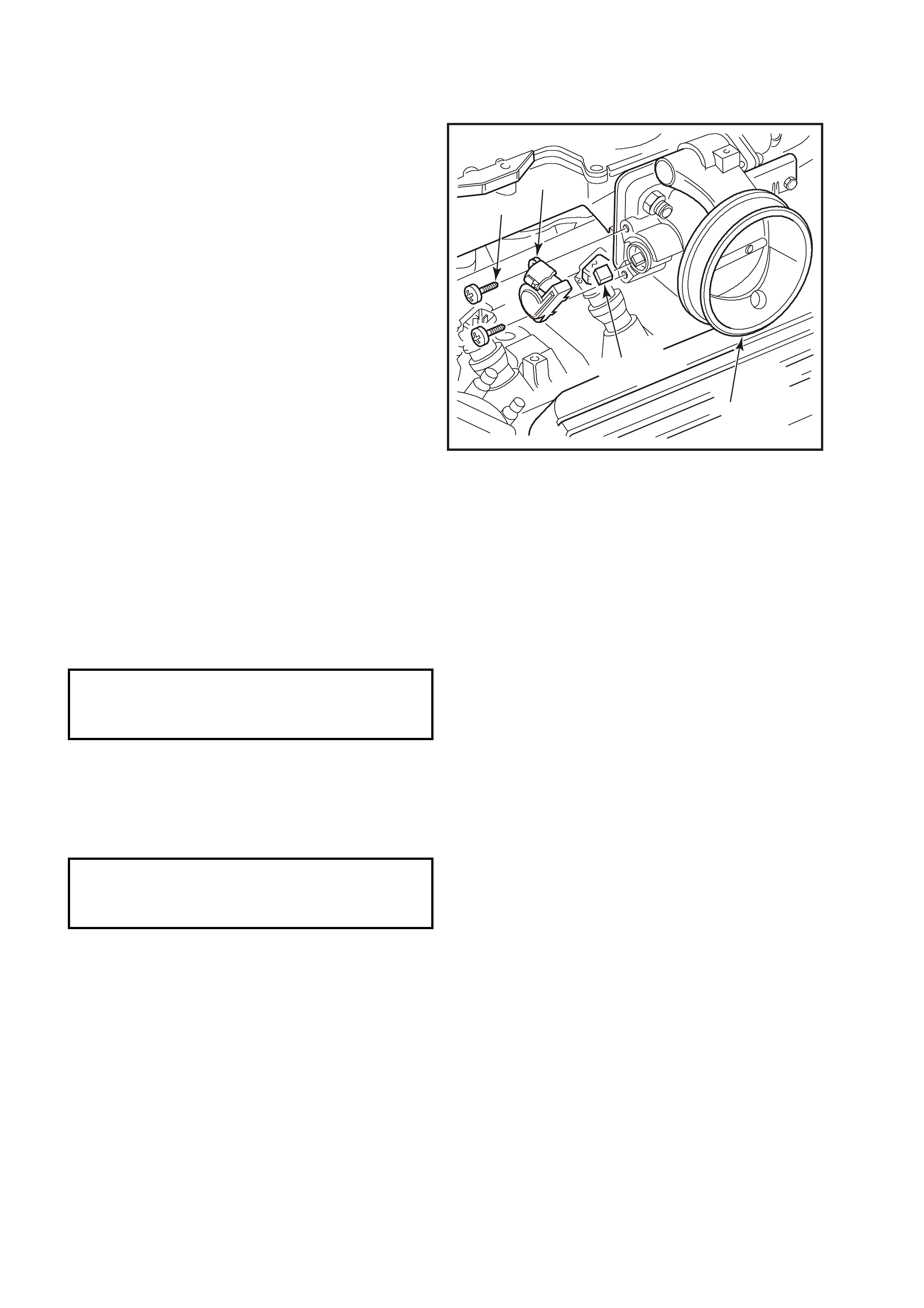

3.6 MASS AIR FLOW (MAF) SENSOR

IMPORTANT:

Care must be taken when handling MAF sensor.

Damage to MAF sensor will aff ect proper operation

of PCM control.

REMOVE

1. Disconnect battery earth lead.

2. Lift up tang on MAF sensor wiring harness

connector (3) and pull connector from

sensor (1).

3. Loosen clamp on air duct adapter, closest to

MAF sensor (1).

4. Loosen clamp ( 4) on air duc t (5) at MAF sensor

(1) and pull back air duct (5) from sensor.

IMPORTANT:

Air duct adapter (between air cleaner and MAF

sensor), both clamps, air duct and MAF sensor

itself have locating notches.

5. Remove MAF sensor (1) from air duct

adapter (5).

REINSTALL

1. Install MAF sensor (1) into air duct adapter (5)

and air duct, aligning all notches. Install

clamps, aligning notches, tighten clamps

securely.

2. Reconnect MAF sensor wiring harness

connector (3).

3. Reconnect battery earth lead.

4. Start vehicle and check for air leaks.

5

4

1

3

4303

2

Figure 6C1-3-12 MAF Sensor Removal

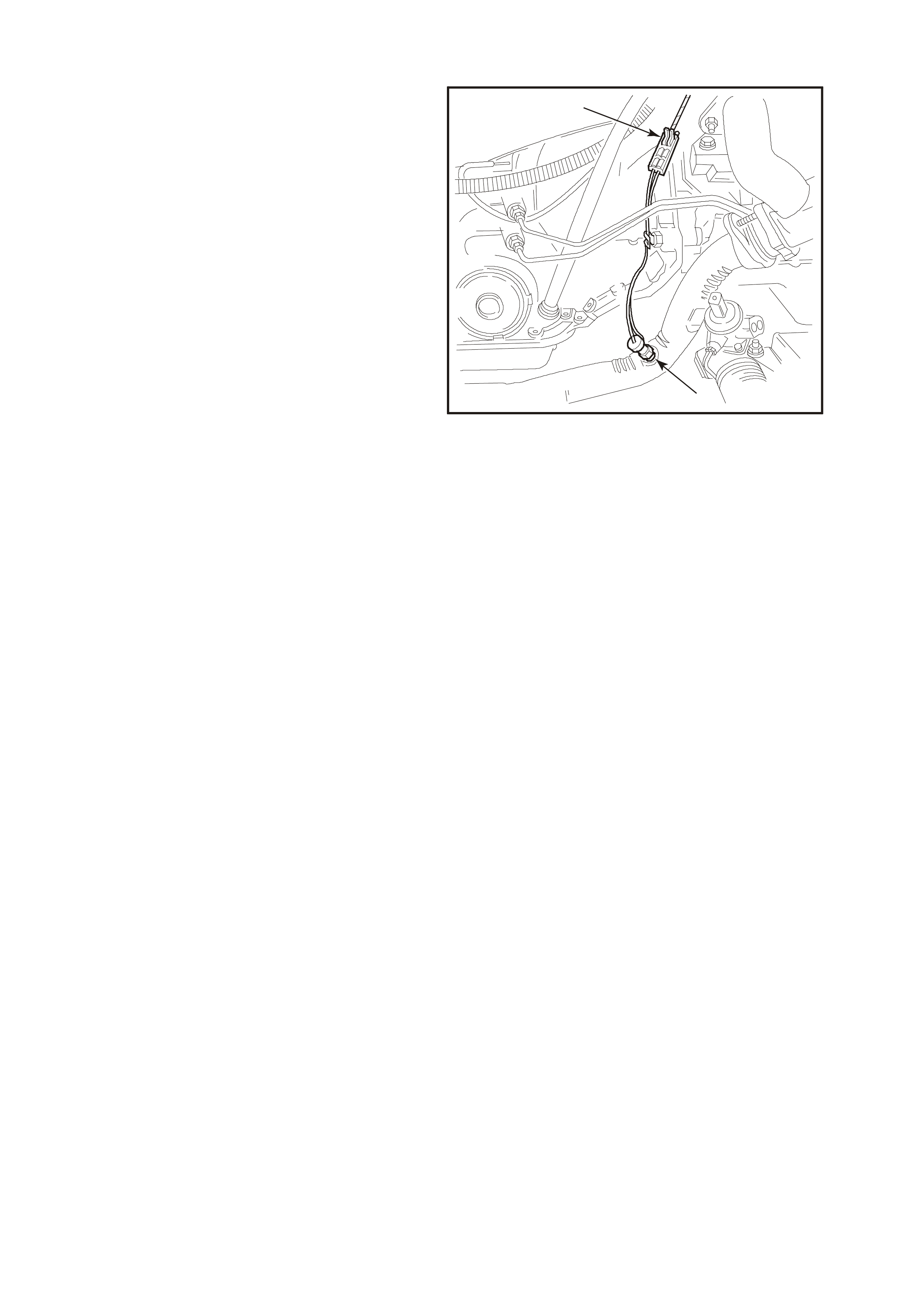

3.7 OXYGEN SENSOR

IMPORTANT:

• The oxygen sensor uses a permanently

attached pigtail and connector. This pigtail

should not be removed from the oxygen

sensor. Damage or removal of the pigtail or

connector will affect proper operation of the

oxygen sensor.

• Take care when handling the oxygen sensor.

The in-line electrical connector and louvered

end must be kept free of grease, dirt or other

contaminants. Avoid using any cleaning

solvents. Do not drop or roughly handle the

oxygen sensor.

IMPORTANT:

The oxygen sensor may be difficult to remove

when engine temperature is below 60 degrees

Celsius. Excessive force may damage threads in

exhaust pipe, or on the sensor.

REMOVE

1. Disconnect battery earth lead.

2. Lift up retaining tang on oxygen sensor wiring

harness connector (1) and pull connector from

sensor pigtail connector.

For R.H s ensor, the connector is located at the

rear of the R.H cylinder head and is accessed

from the rear of the engine compartment. The

sensor pigtail leads are further retained by a

clip attached to the torque converter housing.

For L.H sensor, the connector is located at the

rear of the L.H cylinder head and is accessed

from the rear of the engine compartment.

3. Raise vehicle and place on suitable safety

stands. Refer to Section 3, FRONT

SUSPENSION, in the VT I Service Information.

4. Carefully unscrew oxygen sensor (2) from

exhaust pipe referring to previous NOTE.

2

1

4304

Figure 6C1-3-13 R.H. Sensor Location (Two wire sensor)

REINSTALL

IMPORTANT:

• A special anti-seize compound is used on the

oxygen sensor threads. The compound

consists of a liquid graphite and very small

glass beads. The graphite will burn away, but

the glass beads will rem ain, mak ing the sens or

easier to remove.

• Genuine replacement sensors will already

have the compound applied to the threads. If a

sensor is removed from an engine, and, if for

any reason it is to be reinstalled, the threads

must have the specified anti-seize compound

applied before reinstallation.

NOTE:

Specified anti-seize compound is available from

authorized Holden Parts Outlets as part number

5613695.

1. If necessary, coat threads of oxygen sensor

with

specified anti-seize compound.

2. Ins tall oxygen sensor (2) into exhaust pipe and

tighten to the correct torque specification.

3. Remove safety stands and lower the vehicle.

4. Reconnect oxygen sensor wiring harness

connector (1).

IMPORTANT:

Ensure that the R.H sensor pigtail leads are

retained by a clip attached to the torque converter

housing

5. Reconnect battery earth lead.

2

4305

1

Figure 6C1-3-14 L.H Sensor Location (Two wire sensor)

Oxygen Sensor To Exhaust

Manifold Torque Specification 40-50

N.m

3.8 THROTTLE POSITION (TP) SENSOR

REMOVE

1. Disconnect battery earth lead.

2. Remove four dome nuts securing the engine

dress cover assembly to the inlet manifold

studs, lift off and remove the cover assembly .

Refer to Figure 6C1-3-10.

3. Lift up retaining tang on TP sensor wiring

harness connector and pull connector from

sensor (1).

4. Remove the two TP sensor to throttle body

attaching screws (4).

5. Remove sensor (1) from throttle body (2)

taking care not to lose the drive adapter (3).

NOTE:

The "drive adapter" (3) is a plastic cover that

loosely slides over the end of the throttle shaft, on

the TP sensor side of the throttle body. It is

captured in place when the T P sensor is in position

on the throttle body. The drive adapter could fall

from the throttle shaft after the TP sensor is

removed. Ensure that the drive adapter is not lost.

2

4309

3

4

1

Figure 6C1-3-15 TP Sensor Removal

REINSTALL

1. Check that the drive adapter (3) is in place on the throttle valve shaft, refer to previous NOTE.

2. With throttle valve in the norm ally closed idle position, inst all TP s ensor ( 1) on to throttle valve s haft and throttle

body at a position 30 degrees clockwise past throttle body attaching screw holes.

3. Rotate TP sensor anti-clockwise on throttle body, and install TP sensor attaching screws and tighten to the

correct torque specification.

TP Sensor To Throttle Body

Attaching Screw

Torque Specification

1 - 1.5 N.m

4. Reconnect TP sensor wiring harness connector.

5. Reinstall engine dress cover to the inlet manifold, ensuring that stud grommets in the dress cover remain in

place . Tighten securing dome nuts to the correct torque specification.

Engine Dress Cover Securing

Dome Nut To Inlet Manifold

Torque Specification

4 - 6 N.m

6. Reconnect battery earth lead.

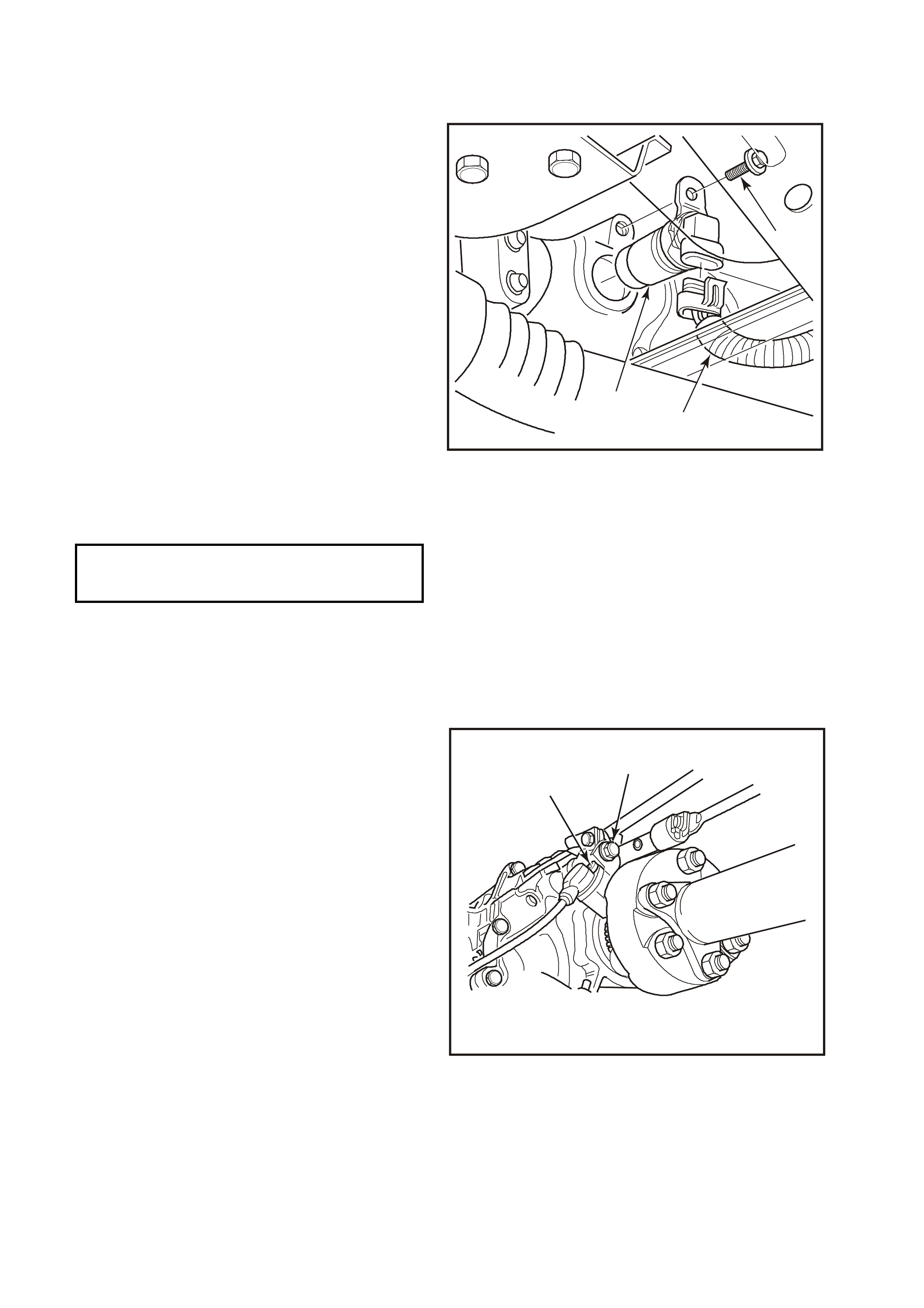

3.9 VEHICLE SPEED SENSOR

AUTOMATIC TRANSMISSIO N

REMOVE

1. Jack up rear of vehicle and support on safety

stands, Refer to Section OA, GENERAL

INFORMATION in the VT I Service Information.

2. Lift up tang on VSS wiring harness connector

(2) and pull connector from VSS (3).

3. Remove VSS to transmission extension

housing bolt (1).

4. Remove VSS and O-ring seal from extension

housing by slowly prying out sensor with a flat

screwdriver.

REINSTALL

1. Coat the VSS O-ring seal with a thin film of

transmission fluid.

2. Install new VSS and O-ring into transmission

extension housing.

3. Install retaining bolt (1) and tighten to the

correct torque specification.

4. Reconnect wiring harness connector (2) to

VSS (3).

5. Remove safety stands and lower vehicle.

1

2

4310

3

Figure 6C1-3-16 VSS Location Automatic Transmission

MANUAL TRANSMISSION

For vehicle speed sensor removal and

reinstallation, Refer to Section 7B-1 MANUAL

TRANSMISSION - V6 in the VX Service

Information.

1

2

4223

Figure 6C1-3-17 VSS Location Manual Transmission

VSS Retaining Bolt 11

Torque Specification N.m

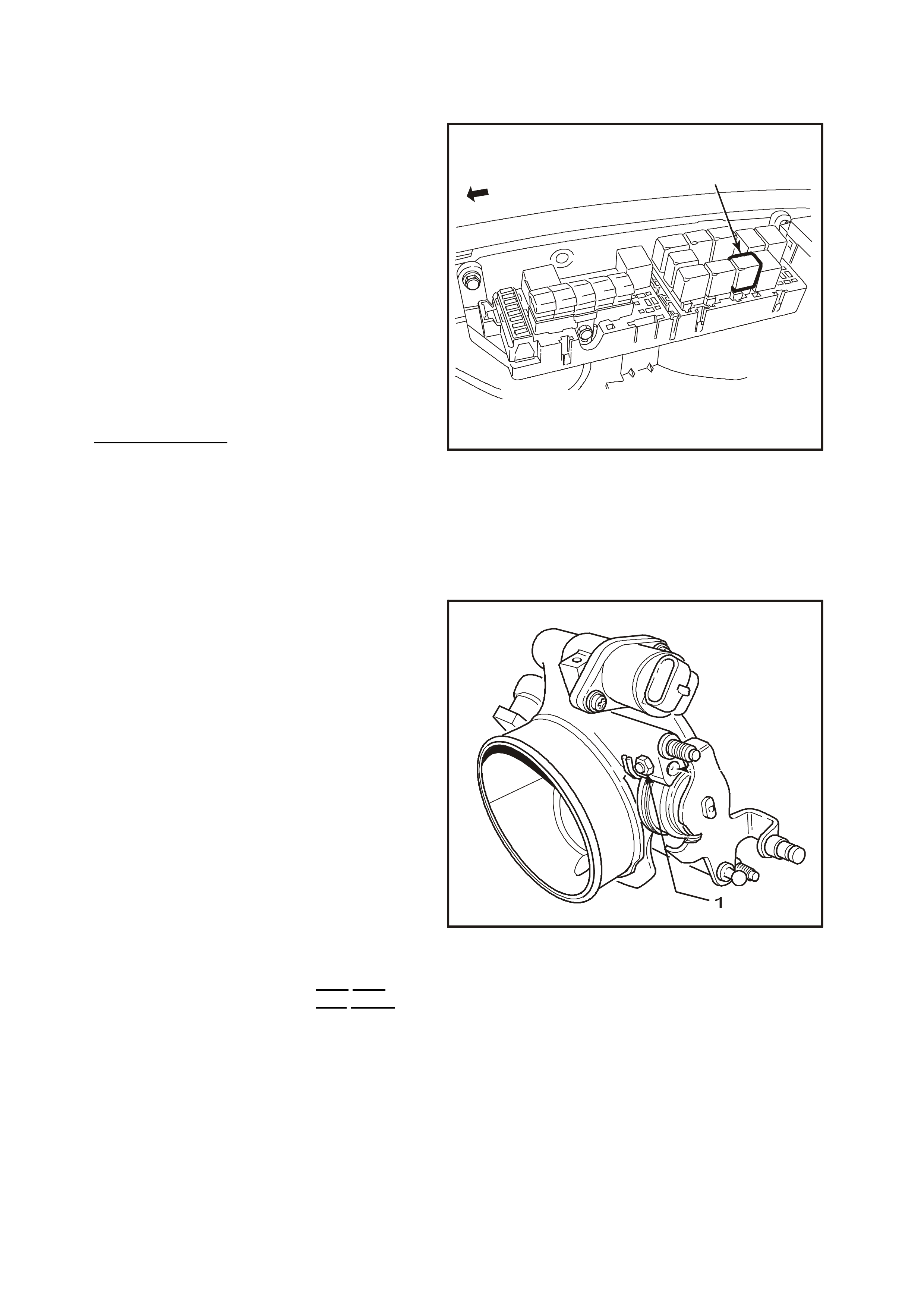

3.10 FUEL CONTROL SYSTEM

FUEL PUMP RELAY

The fuel pump relay (1) is located in a relay

housing, in the engine compartment. The relay

housing is positioned forward of the right side

(driver's side) strut tower, in front of the cooling

system coolant recovery reservoir. Other than

checking for loose connectors, the only service

possible is replacement.

FUEL PRESSURE RELIEF PROCEDURE

IMPORTANT:

UNLESS THIS PROCEDURE IS FOLLOWED

BEFORE SERVICING FUEL LINES OR

CONNECTIONS, FUEL SPRAY INTO THE

ENGINE COMPARTMENT COULD OCCUR!

1. Remove "Fuel Pump Relay" from engine

compartment relay housing.

2. With throttle closed, crank engine - engine m ay

start and idle until fuel supply remaining in fuel

line is exhausted. W hen engine stops, engage

starter again for 10 seconds to ensure

dissipation of any remaining pressure.

3. Refit fuel pump relay (1).

1

4239

Figure 6C1-3-18 Fuel Pump Relay Location

THROTTLE STOP SCREW - RESET PROCEDURE

IMPORTANT:

Engine idle for this V6 application must be check ed

every 80,000KM. If the IAC valve counts are

greater than 25 at idle, the throttle body must be

removed and cleaned. Refer to

Throttle Body Cleaning Procedure in this

Section.

The T hrottle Stop Screw (1) controls the minimum

throttle opening (nominal "Closed throttle"

position). It is preset at the factory and must not

be reset unless:

I. The s crew is known to have been inadvertently

reset,

-OR-

II. Clearly instructed to do so by a diagnostic

Table.

Engine idle speed, which will vary with engine

temperature, is PCM - controlled and is not

adjustable.

PCM - Controlled idle speed (IAC) and

Throttle stop screw setting (RPM) ARE NOT

THE SAME!

4346

Figure 6C1-3-19 Throttle Stop Screw Location

Thro ttle stop screw setting (RPM) must always be less than the PCM controlled idle s peed, and is chec ked only

after temporarily disabling the PCM's method of controlling idle speed, the Idle Air Control system. The throttle

stop screw setting is the least likely cause of an abnormal idle condition, therefore resetting the screw should

only be considered as a last resort. An incorrect setting is likely to cause a deterioration in idle stability.

IMPORTANT: - Inspect

• Before any adjustments are made, ensure that no vacuum leaks exist. Check all vacuum hoses, MAF air

ducts, inlet manifold gasket, throttle body-to-manifold attachment, and any vacuum-operated devices. The

engine must be at normal operating temperature before any checking or resetting is attempted.

WITH THIS ENGINE CONTROL SYSTEM, ANY VACUUM LEAK WILL RESULT IN A LOW/ROUGH IDLE

SPEED.

CHECK OR RESET

1. Before performing this procedure, perform the

On-Board Diagnostic System Check. Refer to

Section 6C1-2A In VX Service Information.

2. Bef ore perf orming s teps 3 - 10, ensure that the

IAC system is functioning properly. Refer

Diagnostic T ABLE A-7.1 (IAC system chec k) in

Section 6C1-2A, DIAGNOSTIC TABLES - V6

ENGINE in VX Service Information, and follow

it to the "NO TROUBLE FOUND - IAC OK"

step before proceeding.

3. Engine must be at normal operating

temperature (above 90 degrees C), preferable

achieved by driving for at least 15 minutes,

before continuing.

4. Set parking brake and block drive wheels.

Ensure transmission is in `Park' (auto) or

neutral (manual).

5. Remove four dome nuts securing the engine

dress cover assembly to the inlet manifold

studs, lift off and remove the cover assembly.

1

2

4311

Figure 6C1-3-20 IAC Valve Harness Removed

6. Verify that the throttle cable and throttle

linkage are not binding. The throttle lever

attached to the throttle butterfly shaft must be

able to open fully, and shut fully and freely

every time the accelerator pedal is fully

depressed and slowly released.

Refer "Throttle cable - adjust" in this Section if

throttle cable adjustment is required.

7. Install Tech-2 scan tool, and select

Miscellaneous tests, IAC System, Base Idle.

8. Ignition “ON”, engine running.

NOTE:

If the engine has completed less than 3,000

km, do not reset the throttle stop screw unless

the RPM is above 600. Otherwise, RPM

should be 500 - 600. If reset is necessary,

adjust throttle stop screw to obtain engine

speed of 450 - 550 RPM.

9. Using the Tech-2 scan tool, activate the Base

Idle test and follow the instructions on the

Tech-2 scan tool.

10. Adjust the base idle scr ew to obtain engine idle

speed of 450-550 RPMs.

11. Reinstall engine dress cover to the inlet

manifold, ensuring that stud grommets in the

dress cover remain in place. Tighten securing

dome nuts to the correct torque.

Engine Dress Cover Securing

Dome Nut To Inlet Manifold

Torque Specification

4 - 6 N.m

MODULAR FUEL SENDER ASSEMBLY

REMOVE

TOOL REQUIRED

J 39765, FUEL SENDER LOCKNUT WRENCH

IMPORTANT:

Do not handle the modular fuel sender assembly

by the fuel pipes.

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect battery earth lead.

3. Remove fuel tank, Refer to Section 8A, FUEL

TANK, in VX Service Information.

4. Remove the modular fuel sender retaining ring

using the J 39765 Fuel Sender Locknut

Wrench.

NOTE:

W hen removing the modular fuel sender assembly

from the fuel tank, the reservoir bucket on the fuel

sender assembly is full of fuel. The modular fuel

sender assembly must be tipped slightly during

removal in order to avoid damage to the float.

Place any remaining fuel into an approved

container once the modular fuel sender assembly

is removed from the fuel tank.

IMPORTANT:

The modular fuel sender assembly will spring-up

when the locking ring is removed.

5. Pull the modular fuel sender straight up while

draining the fuel from the reservoir.

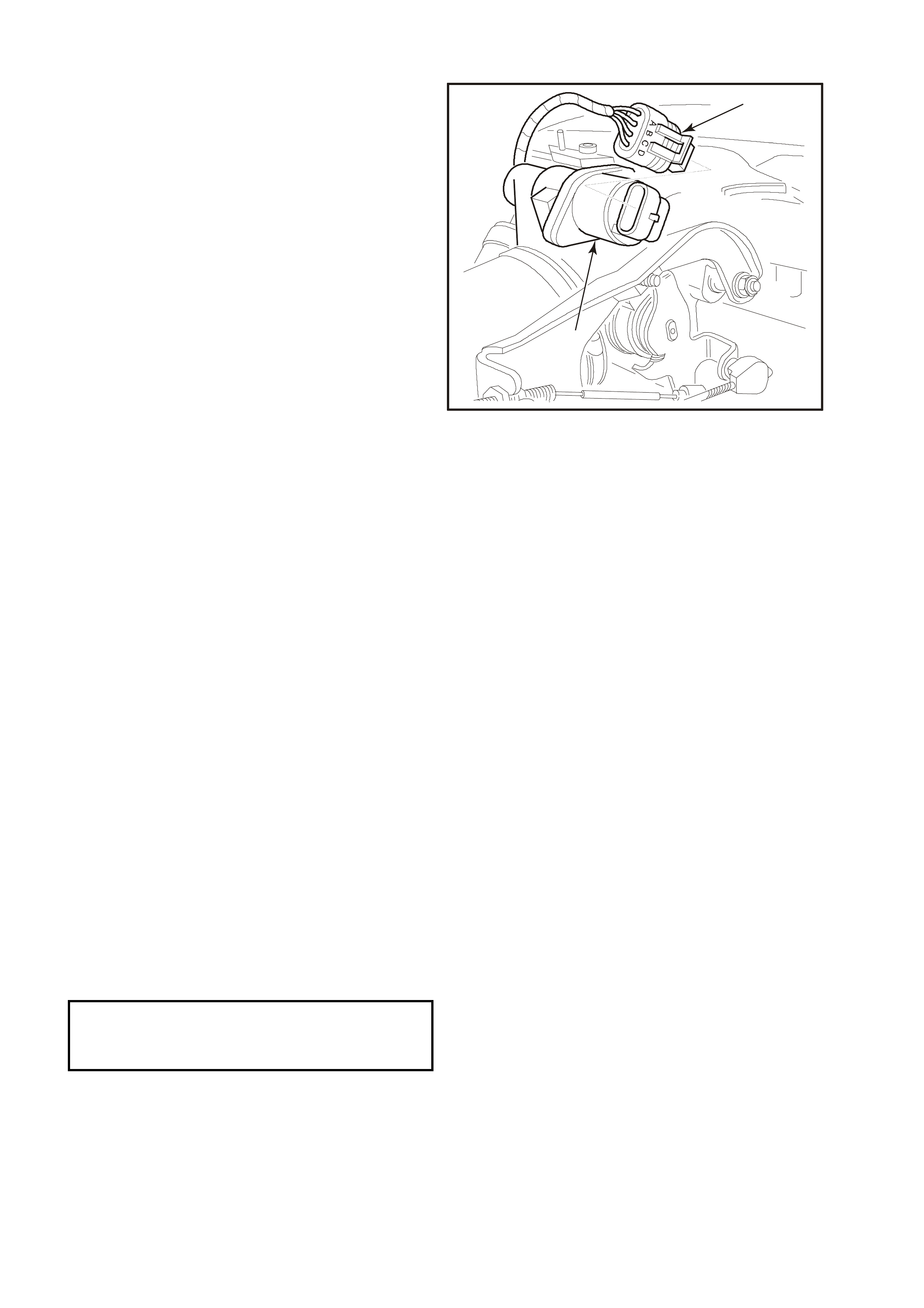

Figure 6C1-3-21 Modular Sender Assembly

6. Clean the fuel sender assembly O-ring sealing

surface.

7. Inspect the fuel sender assembly O-ring

sealing surface.

REINSTALL

IMPORTANT:

Always replace the fuel sender O-ring when

reinstalling the fuel sender assembly.

1. Position the new fuel sender assembly O-ring

on the fuel tank.

IMPORTANT:

Care should be taken not to fold over or twist the

fuel pump strainer when installing the fuel sender

assem bly, as this will restrict fuel flow. Also, assure

that the fuel pump strainer does not interfere with

full travel of float arm.

2. Install the fuel sender assembly and the fuel

sender assembly retainer ring using the J

39765 Fuel Sender Locknut Wrench.

3. Reinstall fuel tank, Refer to Section 8A FUEL

TANK, in VX Service Information.

4. Reconnect battery earth lead.

5. Inspect system for leaks.

Figure 6C1-3-22 Fuel Strainer

MODULAR FUEL SENDER ASSEMBLY (SERVICEABLE FUEL STRAINER AND FUEL LEVEL SENSOR)

REMOVE

NOTE:

Do not handle the modular fuel sender assembly

by the fuel pipes.

1. Relieve the fuel system pressure. Refer to

3.10, Fuel Control System (FUEL

PRESSURE RELIEF PROCEDURE) in this

Section.

2. Disconnect battery earth lead.

3. Remove fuel tank, Refer to

Section 8A, FUEL TANK, in VX Service

Information.

4. Remove MODULAR FUEL SENDER

ASSEMBLY. Refer to removal procedure in

this Section.

DISASSEMBLE

1. Note the position of the f uel sender strainer for

installation.

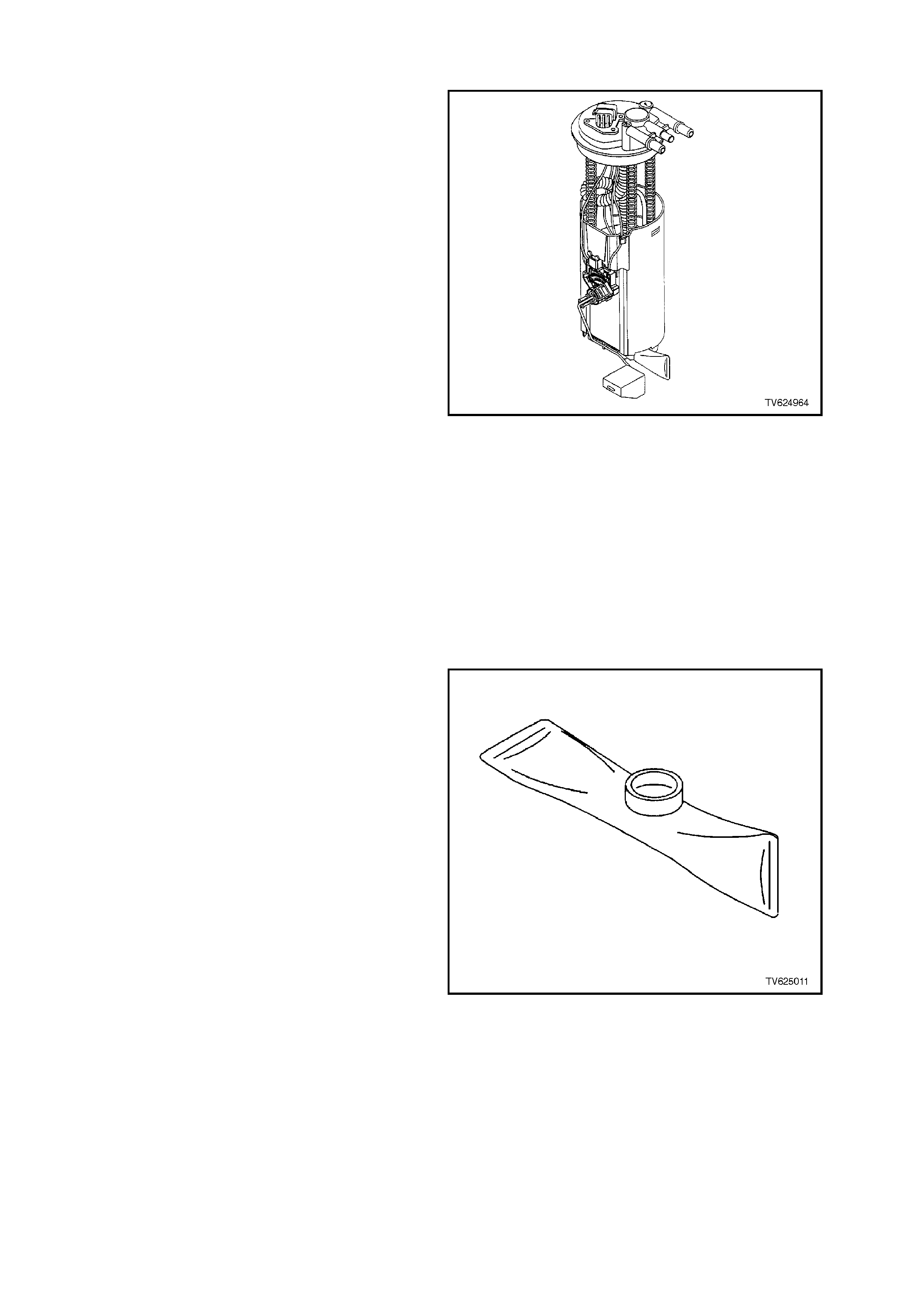

2. Support the reservoir with one hand and grasp

the fuel sender (1) strainer with the other hand.

3. Using a screwdriver (2) , pry the fuel strainer

off of the fuel sender assembly (3).

Figure 6C1-3-23 Removing Strainer

4. Inspect the fuel sender strainer. If the fuel

sender strainer is contaminated, the fuel tank

should be cleaned.

NOTE:

The Fuel Pump Strainer is NOT serviced

separately. It can only be purchased as a

pump and strainer assembly.

5. Discard the fuel sender strainer after

inspection.

6. Disassem ble the electrical connectors from the

fuel level sensor assembly of the fuel pump

and the cover assembly.

7. Disassembly the fuel level sensor assembly.

ASSEMBLE

1. Assemble the fuel level sensor assembly.

2. Assemble the electrical connectors to the fuel

pump and cover assembly.

3. Assemble the rubber pad on the bottom of the

modular fuel sender assembly.

4. Pos ition the new fuel sender s trainer and o-ring

on the modular fuel sender and push on the

outer edge of the fuel sender strainer until the

fuel sender strainer is fully seated.

Figure 6C1-3-24 Installing Strainer

REINSTALL

1. Install the fuel sender assembly. Refer to

MODULAR FUEL SENDER ASSEMBLY in

this Section for reinstallation of sender

assembly to fuel tank.

2. Reinstall fuel tank Refer to

Section 8A, FUEL TANK, in VX Service

Information.

3. Reconnect battery earth lead.

4. Inspect system for leaks.

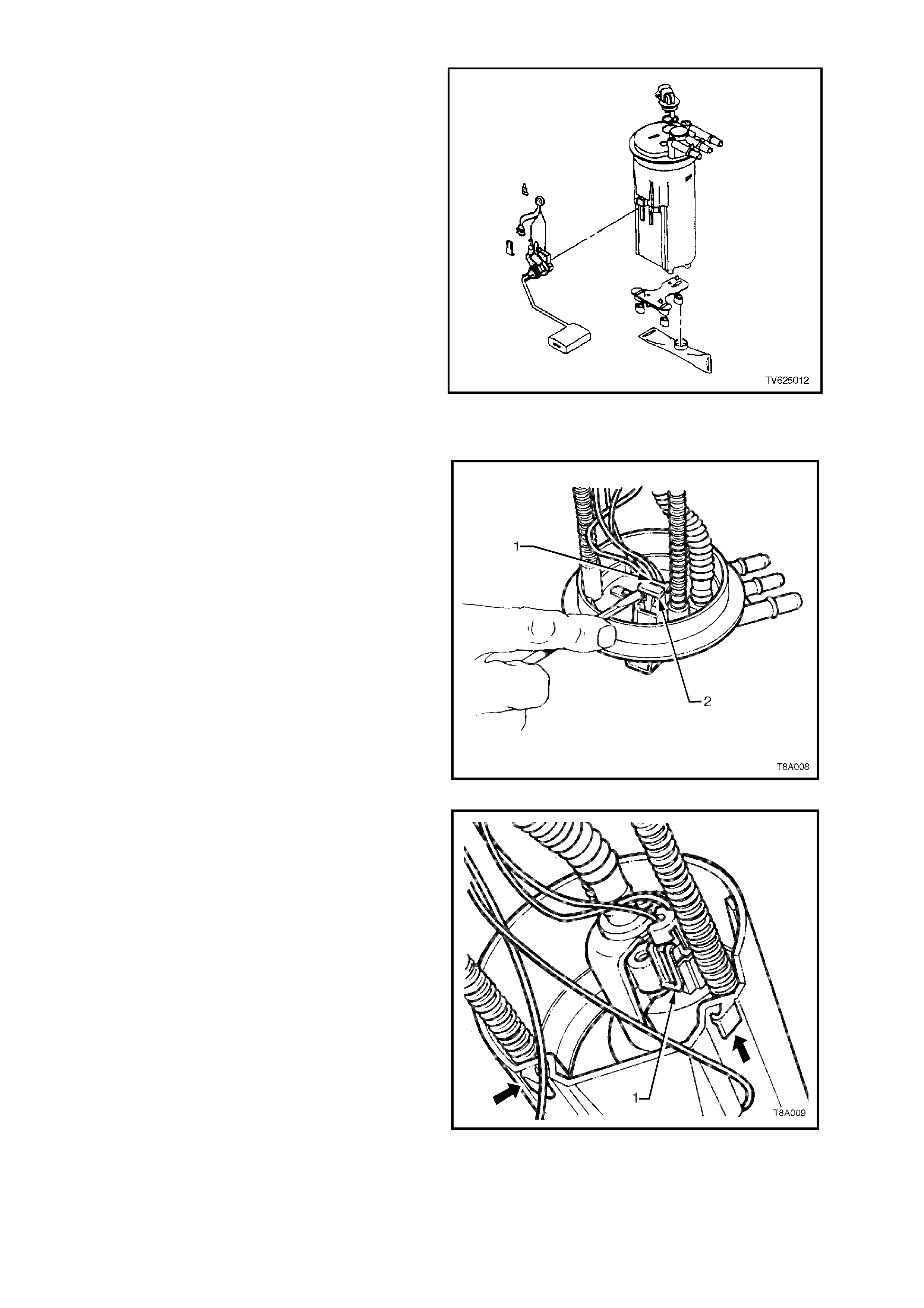

Figure 6C1-3-25 Fuel Level Sensor Assembly

MODULAR FUEL SENDER ASSEMBLY

REMOVE

1. Relieve the fuel system pressure. Refer to the

Fuel Pressure Relief Procedure in this

Section.

2. Disconnect battery earth lead.

3. Remove fuel tank, Refer to Section 8A, FUEL

TANK, in VX Service Information.

4. Remove MODULAR FUEL SENDER

ASSEMBLY. Refer to removal procedure in

this Section.

5. Remove the fuel pump/sender patch harness

connector as follows;

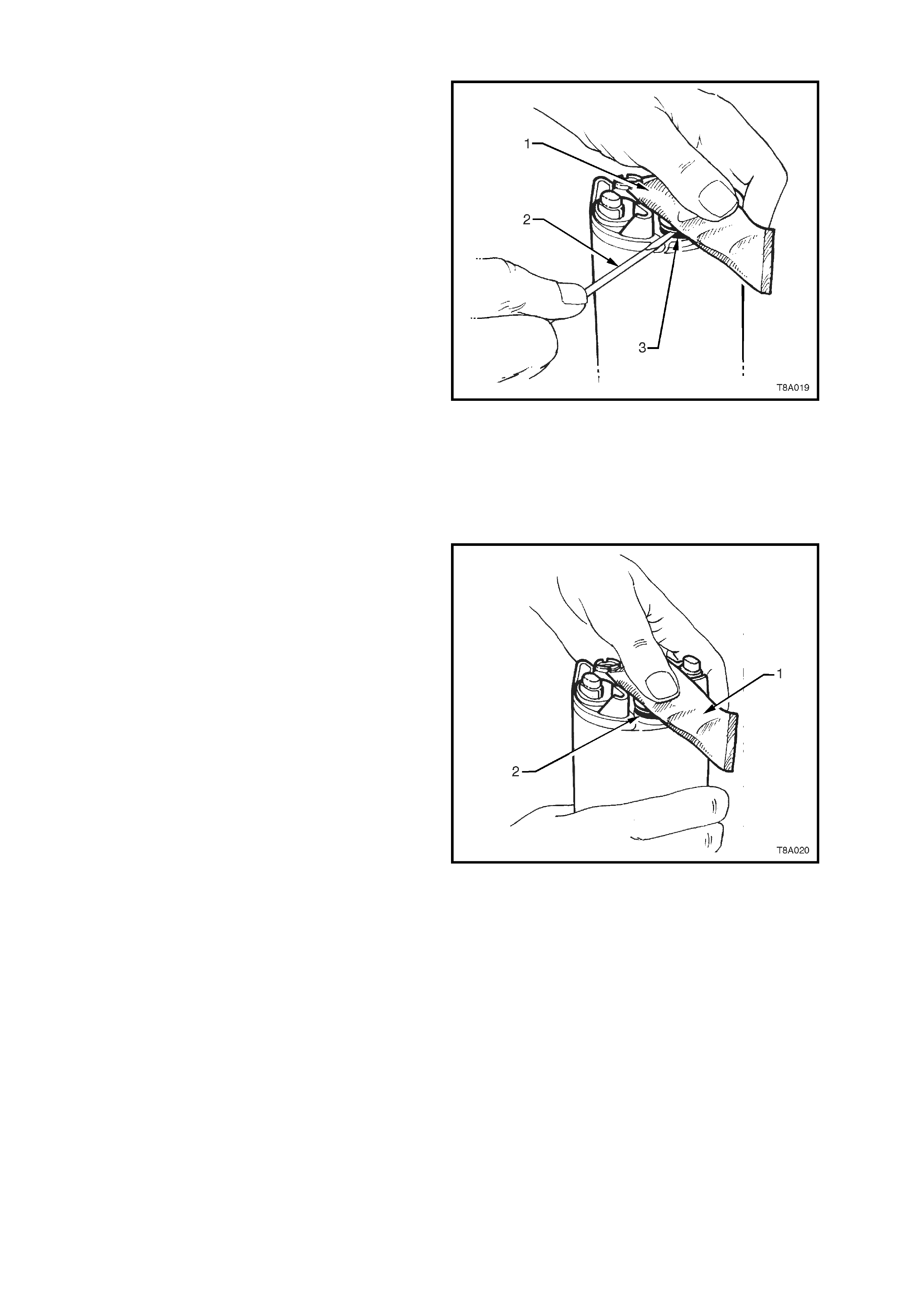

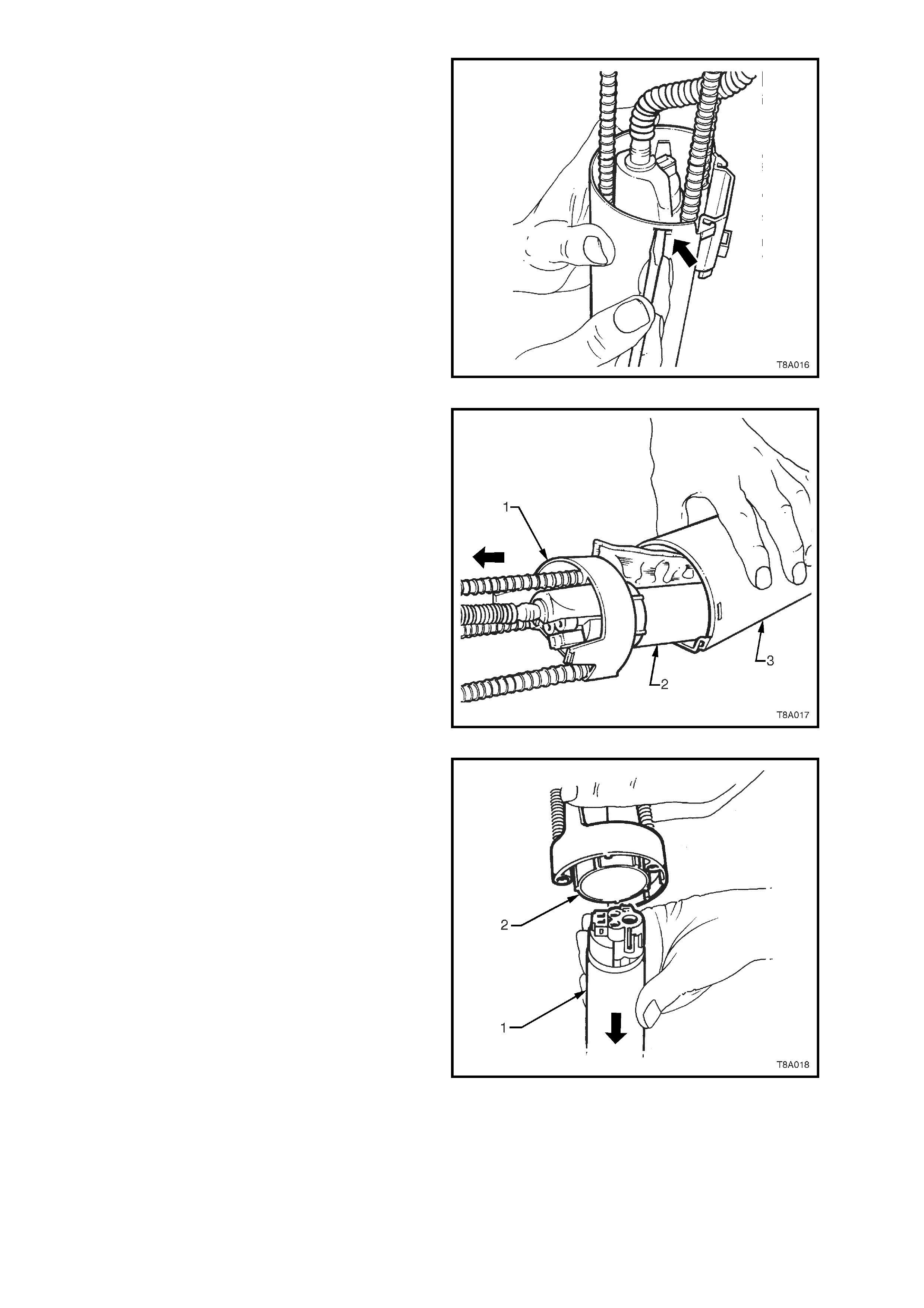

1. Using a small screwdriver, first rem ove the

red Connector Position Assurance (CPA)

locking tab (1), then the gray tap (2).

Depress the connector lock and remove

from the top cover.

Figure 6C1-3-26 Removing CPA Connector

2. Release the locking tabs on the fuel pump

harness connector and remove the

connector from the fuel pump.

Figure 6C1-3-27 Removing Connector from Fuel Pump

6. Separate the inner member from the outer

reservoir, by releasing the two tangs with a

small screwdriver as shown.

Figure 6C1-3-28 Release Tangs

7. Slide the inner member cover assembly and

fuel pump from the outer reservoir shell.

Figure 6C1-3-29 Separating pump from reservoir

8. Us ing a twisting/pulling motion, rem ove the fuel

pump and integral strainer from the inner

membe r assembly.

REINSTALL

1. Installation is the reverse of the removal

process, noting the following points:

1. Ensure that the fuel pump inlet sealing

grommet is installed in the base of the

outer reservoir shell before the pump is

installed.

2. After the fuel tank has been installed into

the vehicle, check for fuel leaks. Refer to

3.10, FUEL CONTROL SYSTEM – LEAK

TESTING, in this section.

Figure 6C1-3-30

FUEL SYSTEM PRESSURE TEST

A Fuel System Pressure Test is part of several of

the Diagnostic Tables and Symptom checks. To

perform this test, follow this procedure:

IMPORTANT:

To reduce the risk of fire or personal injury, it

is necessary to relieve fuel system

pressure before performing this test. See

"Fuel Pressure Relief Procedure" in this Section.

IMPORTANT:

At no time must the fuel inlet hose or return line

hose be clamped or bent over as this will cause a

permanent kinking of the inner section of the hose

assembly and will result in restricted fuel flow.

1. Relieve fuel pressure as described in

3.10, FUEL CONTROL SYSTEM - FUEL

PRESSURE RELIEF PROCEDURE, in this

Section. Turn ignition "OFF."

2. Remove four dome nuts securing the engine

dress c over ass em bly to the mounting brack ets

studs, lift off and remove the cover assembly.

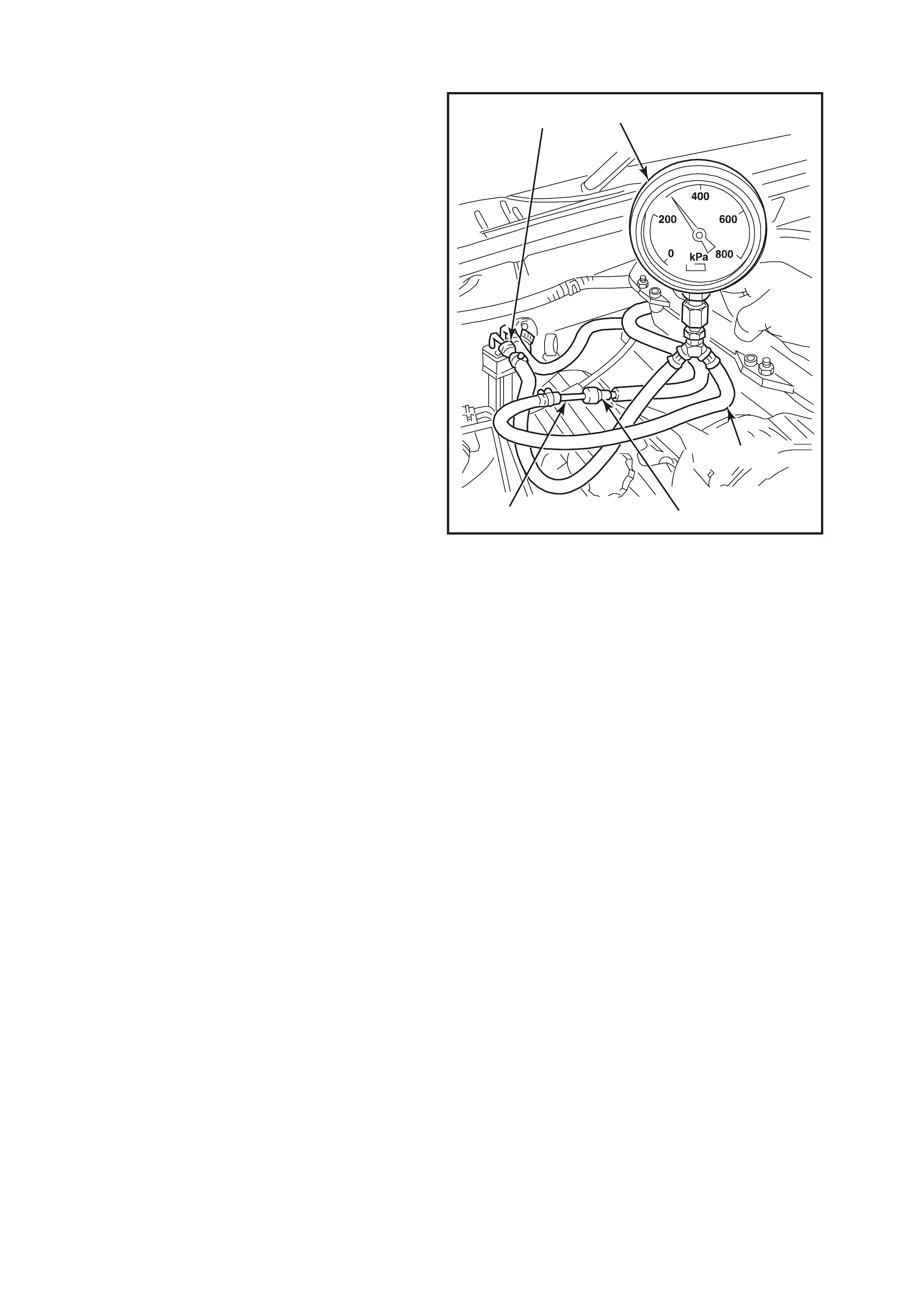

3. Open Tool No. 7370 and install over fuel inlet

line.

4. Close 7370 and pull into f uel line quic k connect

to release it f rom the f uel inlet line, pull back on

quick connect.

IMPORTANT:

Before conducting the next step, inspect tube

adapter (P/N 216812) on f uel pres sure gauge hos e

to ensure that it is free from any damage or burrs.

This is necessary so as to ensure that the tube

does not damage the sealing ring in the quick

connect. If the s ealing ring becom es dam aged, f uel

leakage will occur.

4278

1

5

43

2

Figure 6C1-3-31

5. Install fuel pressure gauge AU338 or SD28018

(1) & hose SD28057 (2) fitted with Coupler

7434 (5) and tube 216812 (4) in the pressure

line, between the fuel inlet line and the fuel

inlet hose quick connect (3).

Measure

6. Use scan tool , enable fuel pump so that the

"fuel pump" can pressurize the system.

7. Fuel gauge reading should be 270 - 350 k Pa. If

not, refer to Diagnostic TABLE A-4.1 in

Section 6C1-2A, DIAGNOSTIC TABLES - in

this Section.

8. Relieve fuel pressure as described in

3.10, FUEL CONTROL SYSTEM - FUEL

PRESSURE RELIEF PROCEDURE, in this

Section.

9. Remove fuel pressure gauge and adapter.

10. Reinstall fuel line.

11. Check for fuel leaks as described in

3.10, FUEL CONTROL SYSTEM - LEAK

TESTING, in this Section.

FUEL FILTER

REMOVE

IMPORTANT Relieve the fuel system pressure

before servicing any fuel system connection. Refer

to the Fuel Pressure Relief Procedure in

3.10, FUEL CONTROL SYSTEM in this Section.

1. Relieve fuel pressure as described in

3.10, FUEL CONTROL SYSTEM - Fuel

Pressure Relief Procedure in this Section.

2. Disconnect batter y earth lead.

3. Raise rear of vehicle and support on safety

stands, refer to Section OA, GENERAL

INFORMATION in the VT Service Information.

4. Place a drain tray beneath fuel filter.

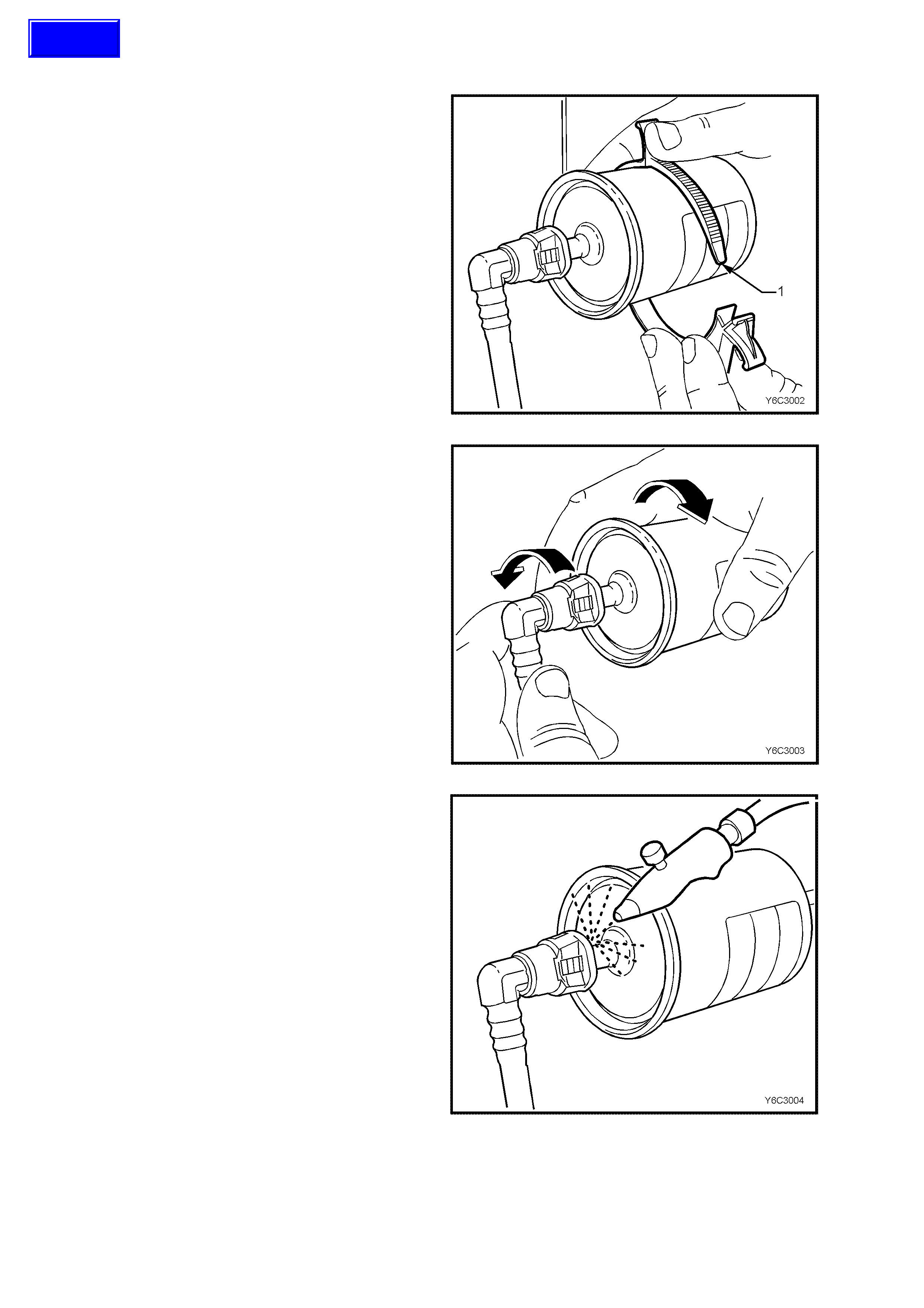

5. Remove the fuel filter from the retaining

brack et (1) with the fuel lines still connected to

the fuel filter to allow easier access.

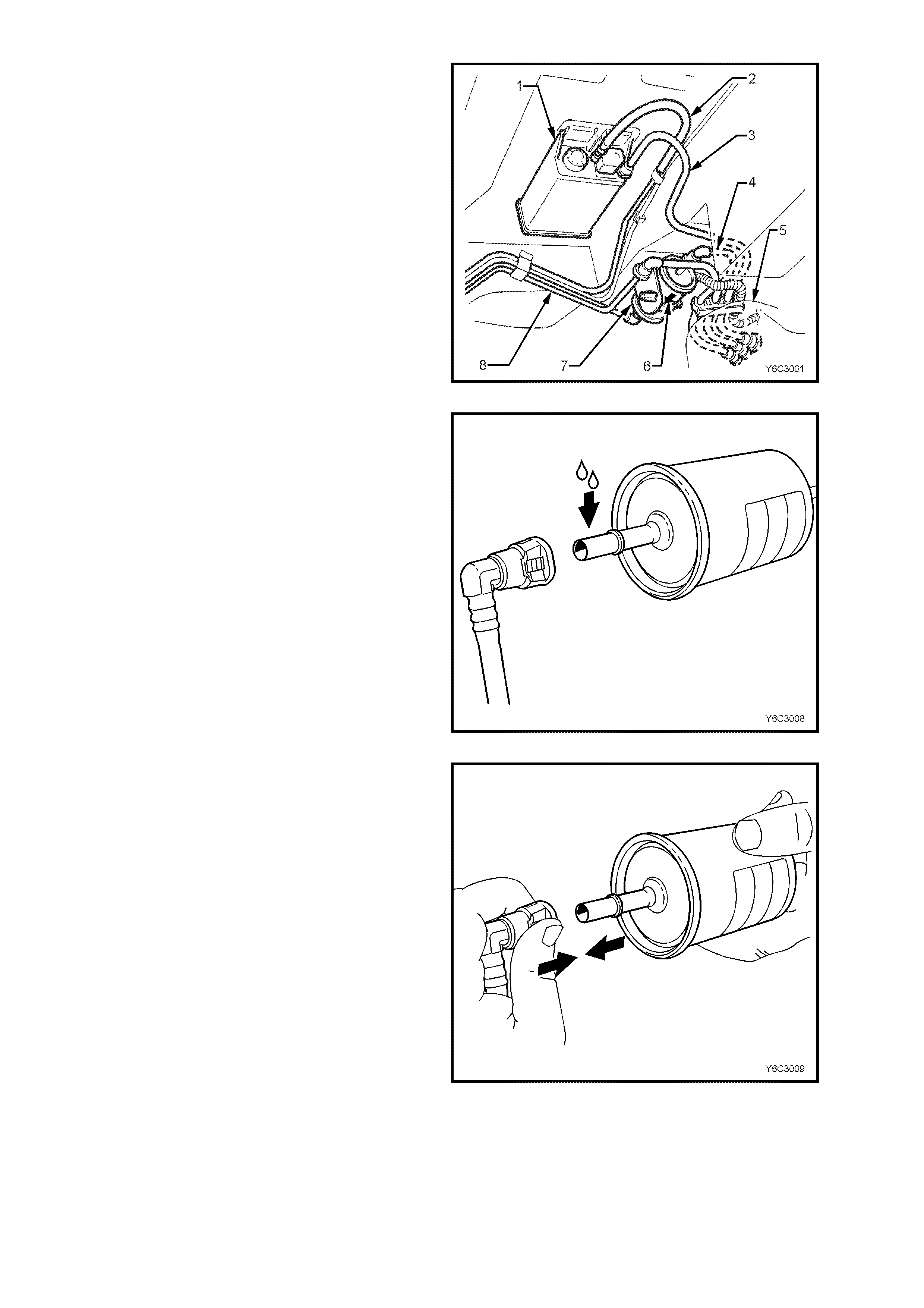

Figure 6C1-3-32

QUICK CONNECT FITTINGS

(PLAST IC COLL AR)

6. Grasp the quick-connect fittings both sides of

the fuel filter. Twist the female connectors 1/4

turn in each direction in order to loosen any dirt

within the quick-connect fitting.

Figure 6C1-3-33

7. Using compressed air, blow any dirt out of the

quick-connect fitting to aid the release of any

tension or binding on the release tabs .

IMPORTANT:

W ear safety glas ses whe n using com pres sed air in

order to prevent eye injury.

Figure 6C1-3-34

Techline

8. Hold t he fuel f ilter f irmly in one h and to support

the filter.

9. Using your other h and, grasp one of the quic k-

connect fittings.

10. Squeeze the plastic retainer release tabs (1)

on each side of the fitting while pushing the

fitting fir mly toward the fue l filter to rele ase any

tension on the release tabs.

Figure 6C1-3-35

11. With the tension release tabs still held in the

squezed position, move the complete quick-

connect fitting away from the fuel filter to

separate the connector fitting from the fuel

filter.

12. Apply the same method from step 8 to 11 for

the remaining quick-connect fitting.

Figure 6C1-3-36

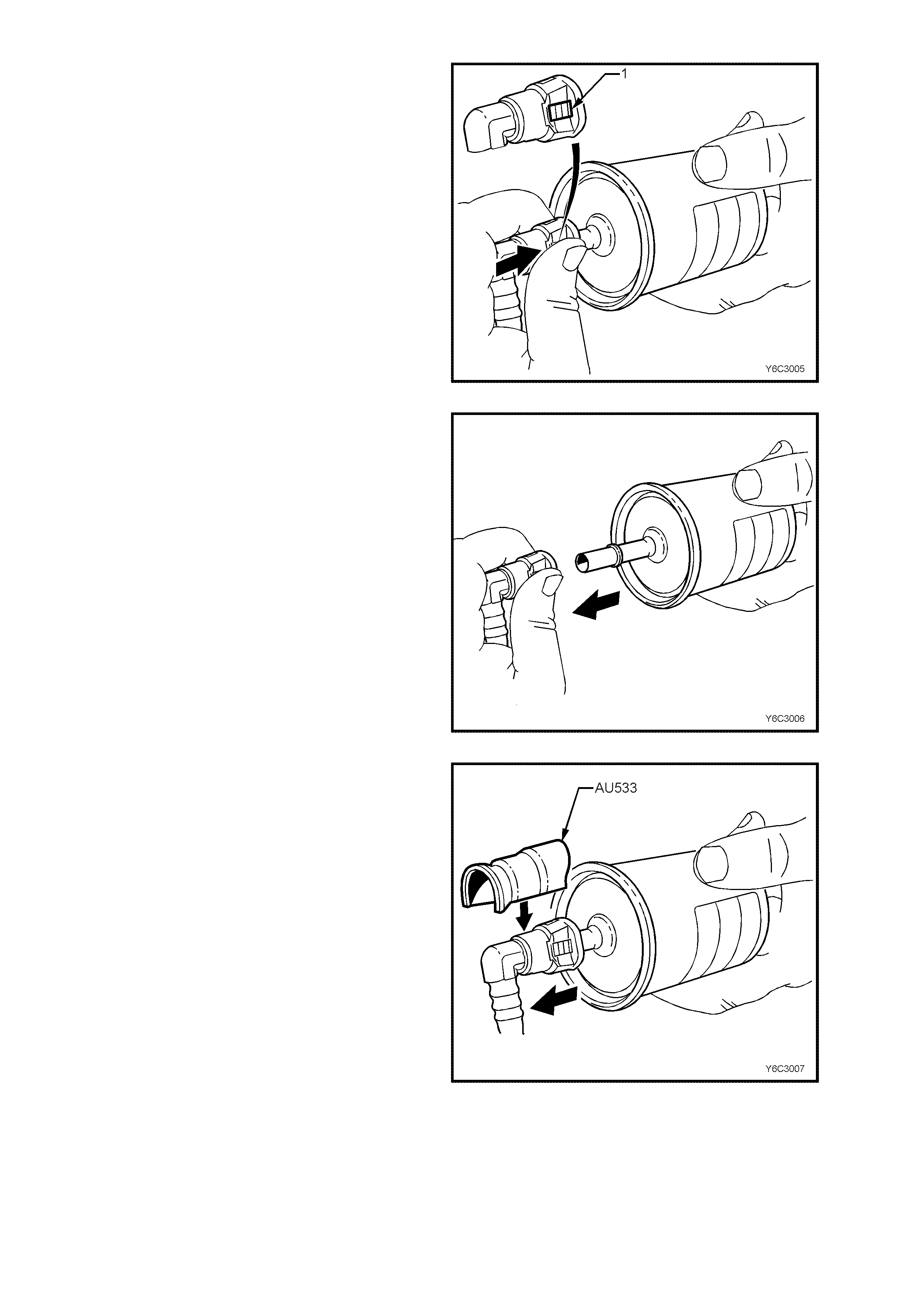

13. Alternatel y for steps 8 to 11, us e tool AU533 t o

squeeze the release tabs, release the quick

connect fittings and remove both fuel pressure

hoses from the fuel filter.

14. Remove fuel filter from vehicle and disguard

safely remembering that some fuel will still

remain in the filter.

Figure 6C1-3-37

REINST ALL

IMPORTANT The fuel filter must be installed with

the flow arrow (6) on its body pointing in the same

direction as the fuel flow to the front of the vehicle.

Figure 6C1-3-38 Fuel Filter Installation

IMPORTANT Before connecting fuel filter quick-

connect fittings, always apply a few drops of clean

engine oil to the male ends of the fuel filter.

This will e nsure proper r econnection and pr event a

possible fuel leak.

During normal operation, the O-ring located in the

fem ale connec tor will s wel l and may prevent pr oper

reconnection if not lubr icate d.

1. Apply a few drops of clean engine oil to each

male fuel filter end.

Figure 6C1-3-39

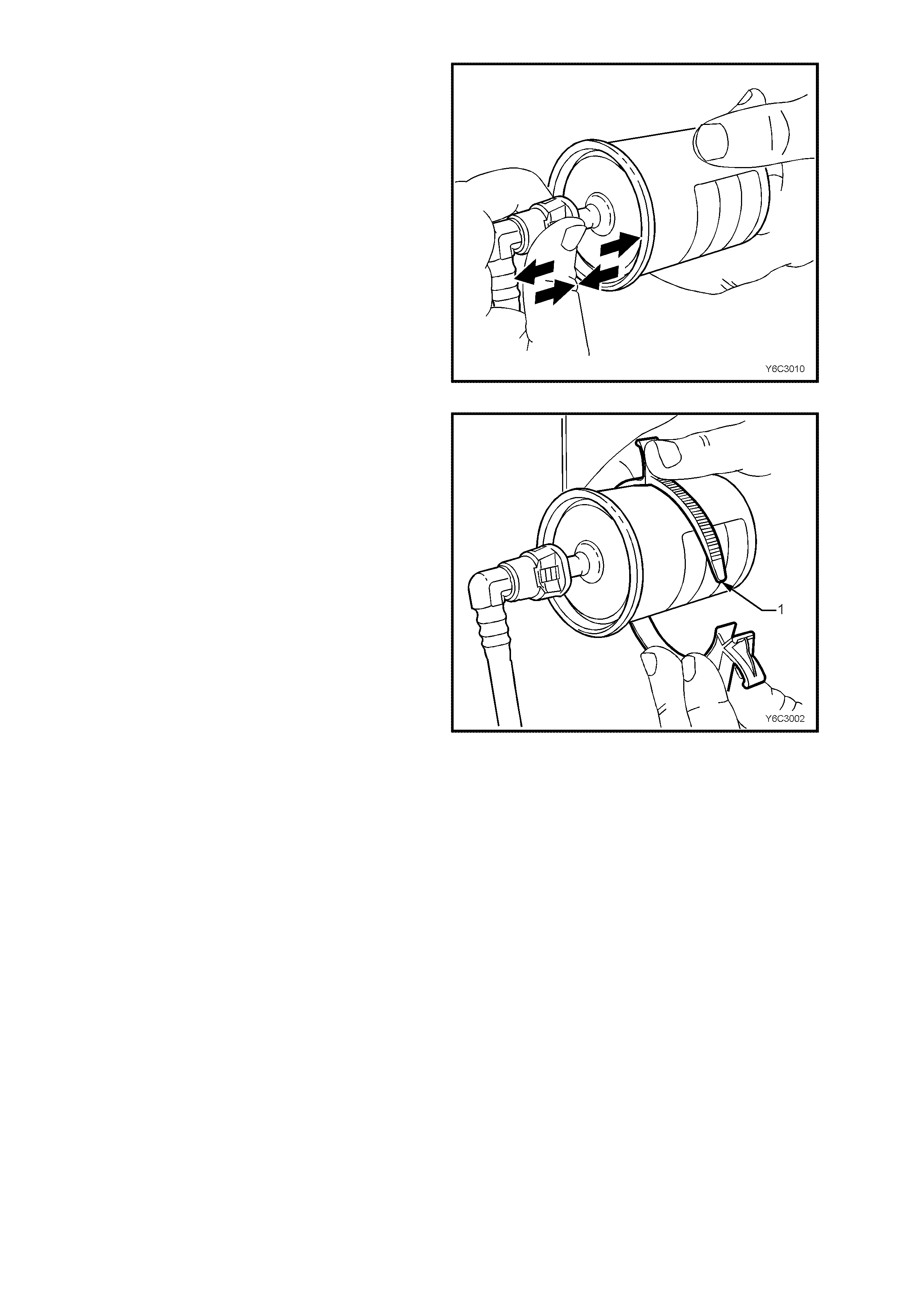

2. Push both the quick-connect fitting and the fuel

filter together in order to cause the retaining

tabs to snap into place. Apply this method to

both ends of the fuel filter and the respective

quick-connect fittings.

Figure 6C1-3-40

3. Once ins talled, pul l and pu sh on both t he quick -

connect fitting and the fuel filter in order to

make sure the connection is secure. Apply

method this to both ends of the fuel filter and

the respective quick-connect fittings.

Figure 6C1-3-41

4. Install a new fuel filter to a new retaining bracket

(1).

5. Connect battery earth lead.

6. Check for fuel leaks, refer to

3.10, FUEL CONTROL SYSTEM – Leak

Testing in this Section of the VT Service

Information.

7. Remove safety stands and lower vehicle.

Figure 6C1-3-42

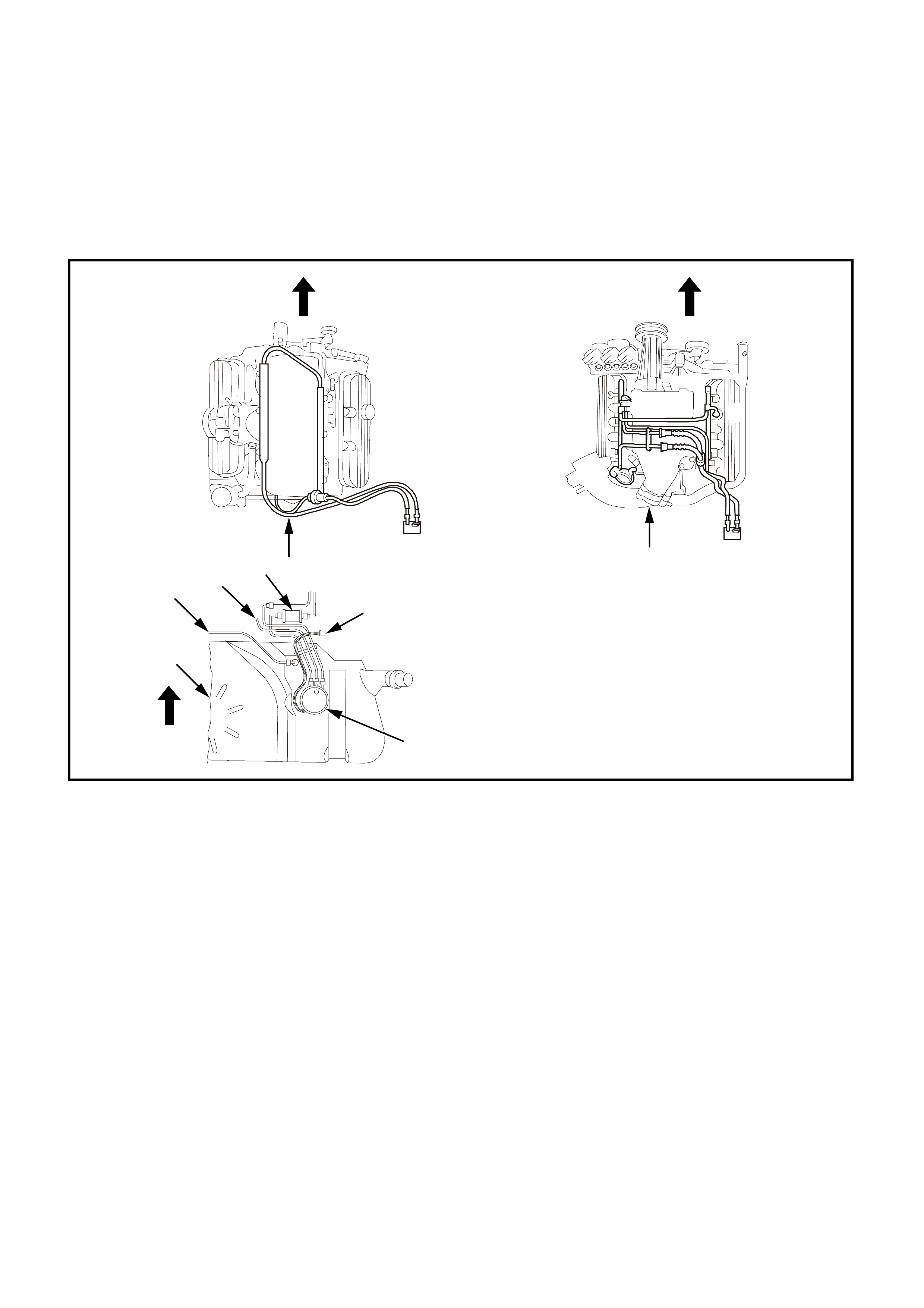

LEAK TESTING

Prior to star ting the engine, following the installation of any fuel system c omponent, c heck the f uel system f or leaks

using the following procedure:

1. Check to ensure that there is a sufficient level of fuel in the fuel tank.

2. Use sc an tool "Output Test" f or "Fuel Pump." Enabling the output tes t will activate the fuel pum p to pres surize

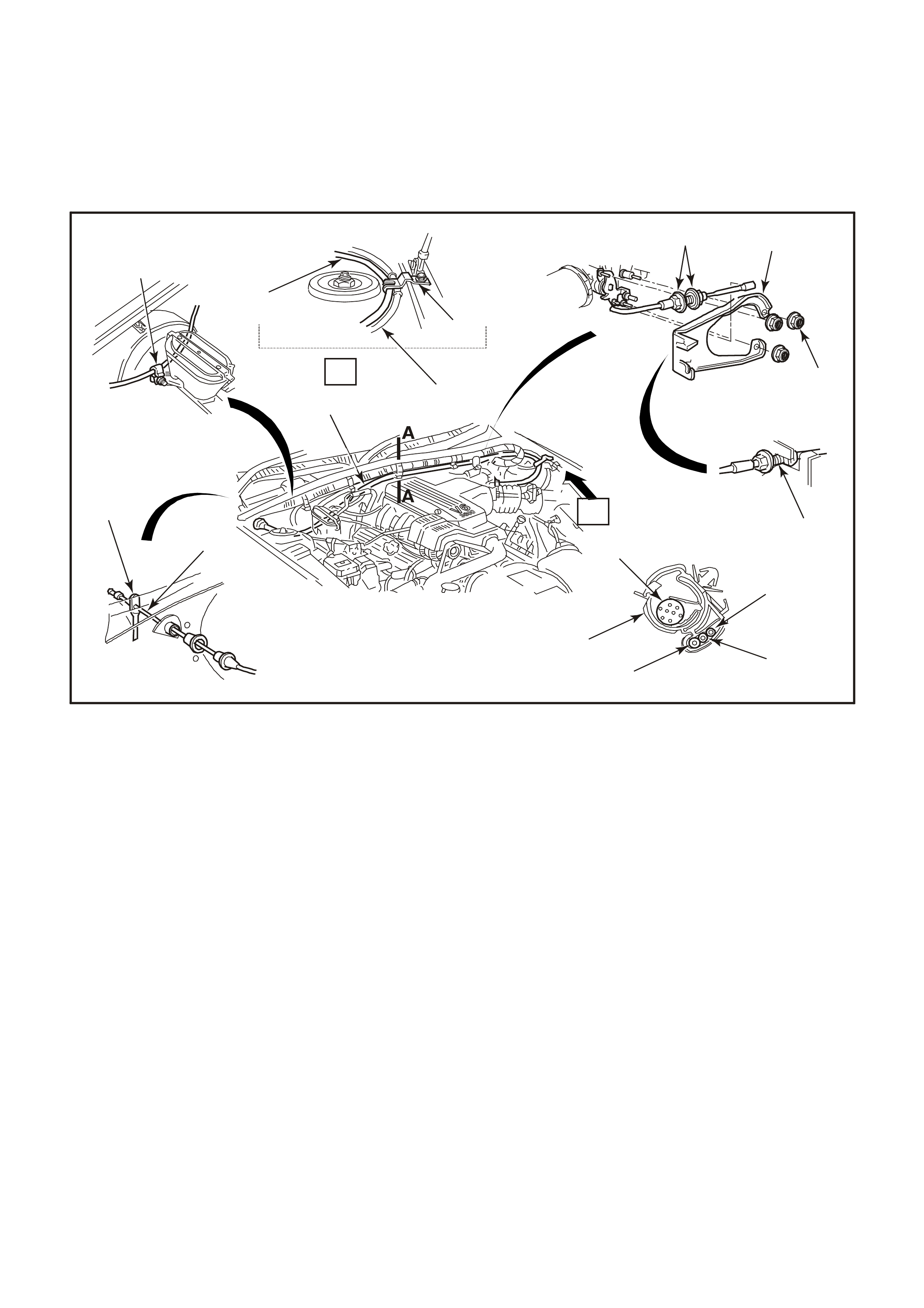

the fuel system.

3. Check fuel system for leaks, particularly at points marked in figure 6C1-3-43.

Figure 6C1-3-43 Leak Testing V6 Engine

1. V6 Supercharged Engine.

2. Fuel Pump.

3. Fuel Pump Harness Connector.

4. V6 Non-Supercharged Engine.

5. Fuel Tank.

6. Vent Tube

7. Vapour Tube.

8. Fuel Filter.

1

4

8

7

3

4229

2

6

5

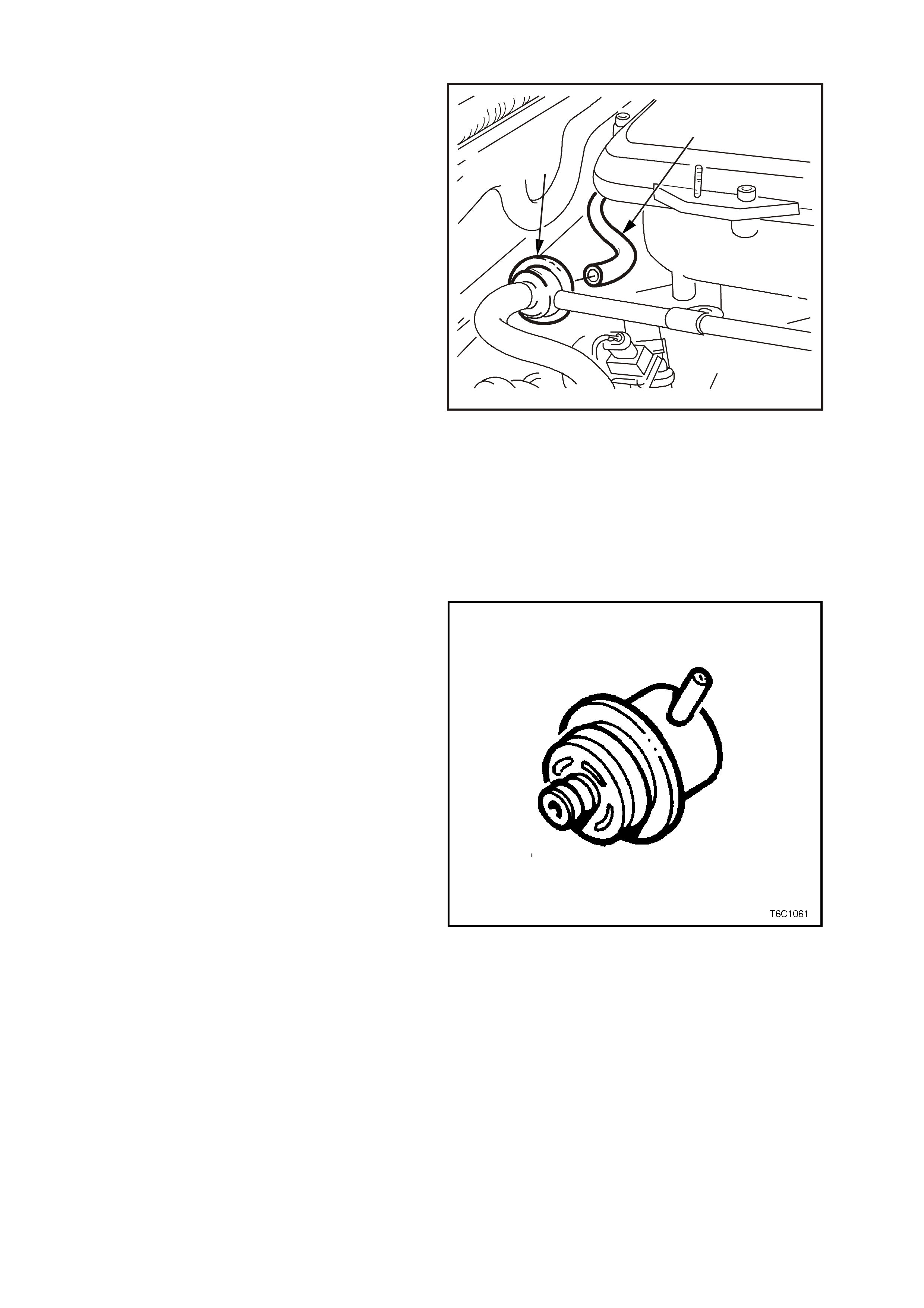

FUEL PRESSURE REGULATOR

REMOVE

1. Relieve fuel pressure as described in

3.10, FUEL CONTROL SYSTEM – (FUEL

PRESSURE RELIEF PROCEDURE) in this

Section.

2. Disconnect battery earth lead.

3. Remove four dome nuts securing the engine

dress cover assembly to the inlet manifold

studs, lift off and remove cover assembly.

Refer to Figure 6C1-3-10.

4. Remove fuel rail assembly, refer to

3.10, FUEL CONTROL SYSYTEM - FUEL

RAIL AND INJECTORS, in this Section.

5. Disconnect vacuum hose (1) from fuel

pressure regulator (2).

6. Clean any dirt from the fuel pressure regulator

retaining ring.

7. Using snap ring tool, remove snap ring from

fuel pressure regulator.

8. Us ing a shop towel to catch any spilled fuel, lift

and twist the fuel pr essure regulator in or der to

remove the fuel pressure regulator from the

fuel pressure regulator housing.

9. Cover the fuel pressure regulator housing to

prevent contamination from entering the fuel

system.

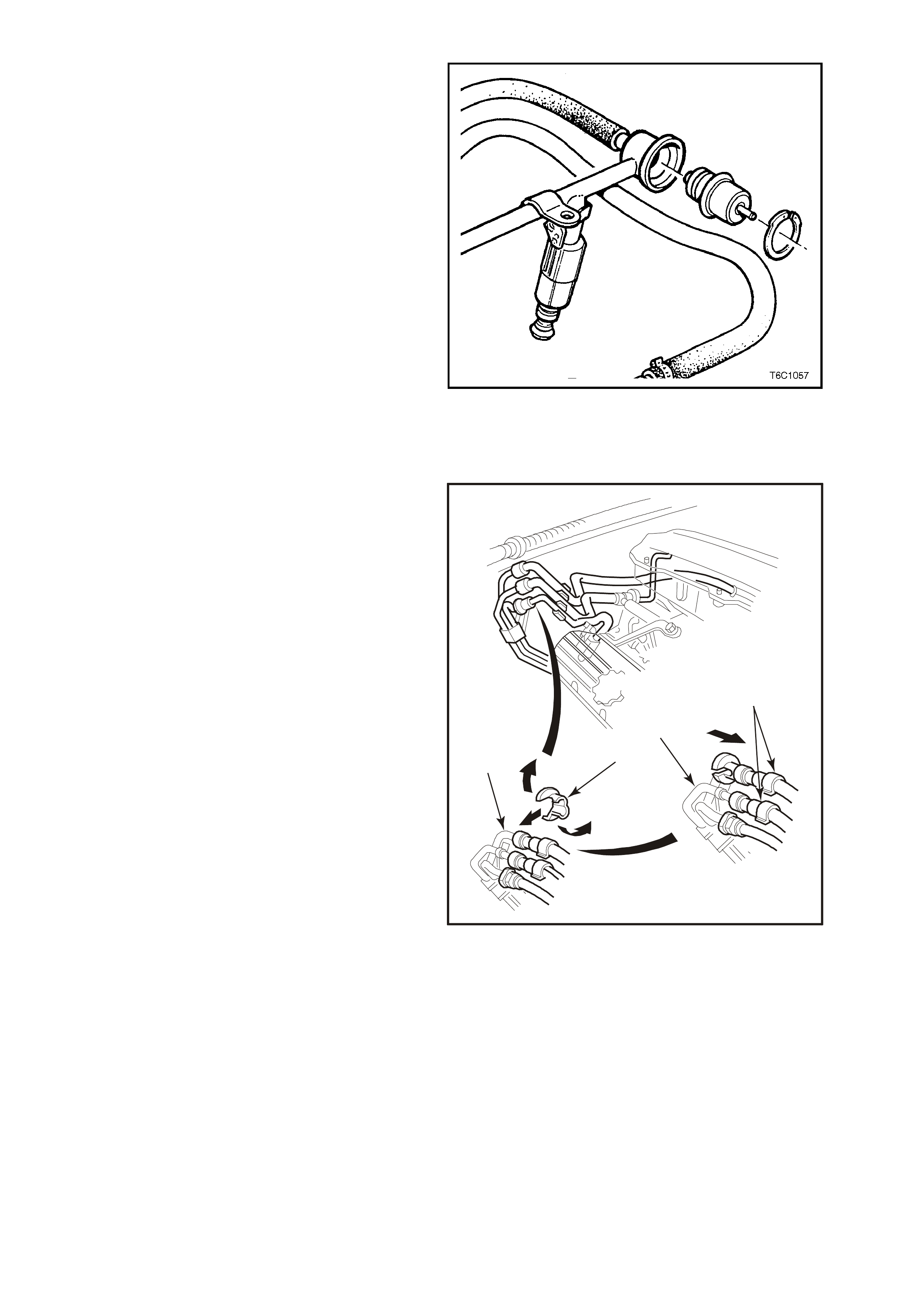

1

2

4237

Figure 6C1-3-44 V6 Engine Fuel Pressure

Regulator Location

REINSTALL

1. Install new O-rings on the fuel pressure

regulator, if a new fuel press ure regulator is not

being installed. lubricate the O-rings lightly

with clean engine oil.

2. Install the fuel pressure regulator in the fuel

pressure regulator housing.

3. Install the retaining snap ring to the fuel

pressure regulator using the snap ring tool.

4. Install the fuel rail. refer to

3.10, FUEL CONTROL SYSTEM - FUEL

RAIL AND INJECTORS, in this Section.

5. Install the vacuum hose to the fuel pressure

regulator.

7. Reconnect battery earth lead.

Figure 6C1-3-45 Fuel Pressure Regulator

8. Check for fuel leaks as described in

3.10, FUEL CONTROL SYSTEM - LEAK

TESTING in this Section.

9. Reinstall engine dress cover to the inlet

manif old, ensuring that s tud gromm ets in dr ess

cover remain in place. Tighten securing dome

nuts to the correct torque specification.

IMPORTANT:

• Compressed air must never be used to test or

clean a fuel pressure regulator, as damage to

the fuel pressure regulator may result.

• In order to prevent damage to the fuel pressure

regulator, do not immerse in solvent.

Figure 6C1-3-46 V6 Engine Fuel Pressure Regulator

Removal From Fuel Rail

FUEL RAIL

IMPORTANT:

The fuel inlet hose and return hose is an assem bly

with the fuel rail. Both components are NOT

serviced separately. For removal or replacement

of the fuel inlet hose, Refer to

3.10, FUEL CONTROL SYSTEM - FUEL RAIL

AND INJECTORS, in this Section.

1

2

3

4317

4

Figure 6C1-3-47 V6 Engine

AIR CLEANER ASSEMBLY

REMOVE

1. Loosen air duct adapter located closest to air

cleaner assembly.

2. Disconnect air duct (8) from air cleaner

assembly.

3. Pull up retaining tang on IAT sensor wiring

harness connector and pull connector from

sensor (1).

4. Unclip 5 clips holding the air cleaner upper

housing in place (3).

5. Remove air cleaner upper housing and air

cleaner element assembly.

6. Remove three studs (4) securing air cleaner

lower housing to fender inner panel insulators.

7. Disengage air cleaner lower inlet assembly (7)

from lower housing. Remove air cleaner lower

housing.

REINSTALL

1. Assemble air cleaner lower housing on to

mounting insulators.

2. Install securing studs (4) and tighten to the

correct torque specification.

5

4318

86

32

1

9

4

7

Figure 6C1-3-48 Air Cleaner Housing Removal

3. Assemble the air cleaner element into the air

cleaner upper housing and place the upper

housing onto the air cleaner lower air cleaner

housing, ensuring that air filter element

remains in position.

4. Snap 5 retainer clips up into place over the top

of the air cleaner upper housing (3).

5. Reconnect wiring harness connector to IAT

sensor (1).

6. Carefully assemble air duct adapter onto air

cleaner upper housing (8).

IMPORTANT:

Align notch on air cleaner housing adapter with

notch in air duct adapter and notch in clamp.

7. Tighten air duct clamp securely.

8. Check that mass air f low sens or wiring harnes s

connector (9) has remained firmly in place.

9. Reconnect battery earth lead.

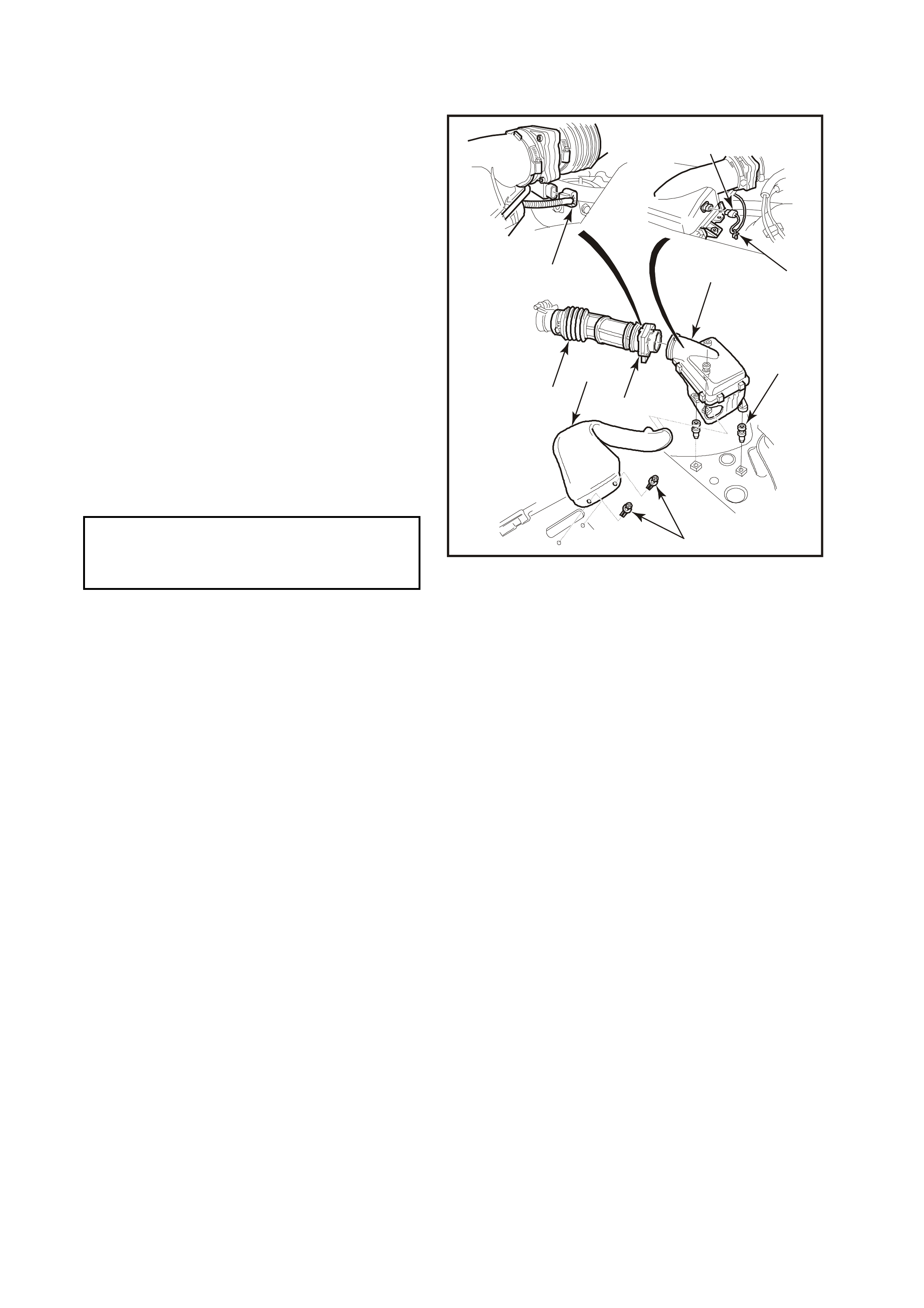

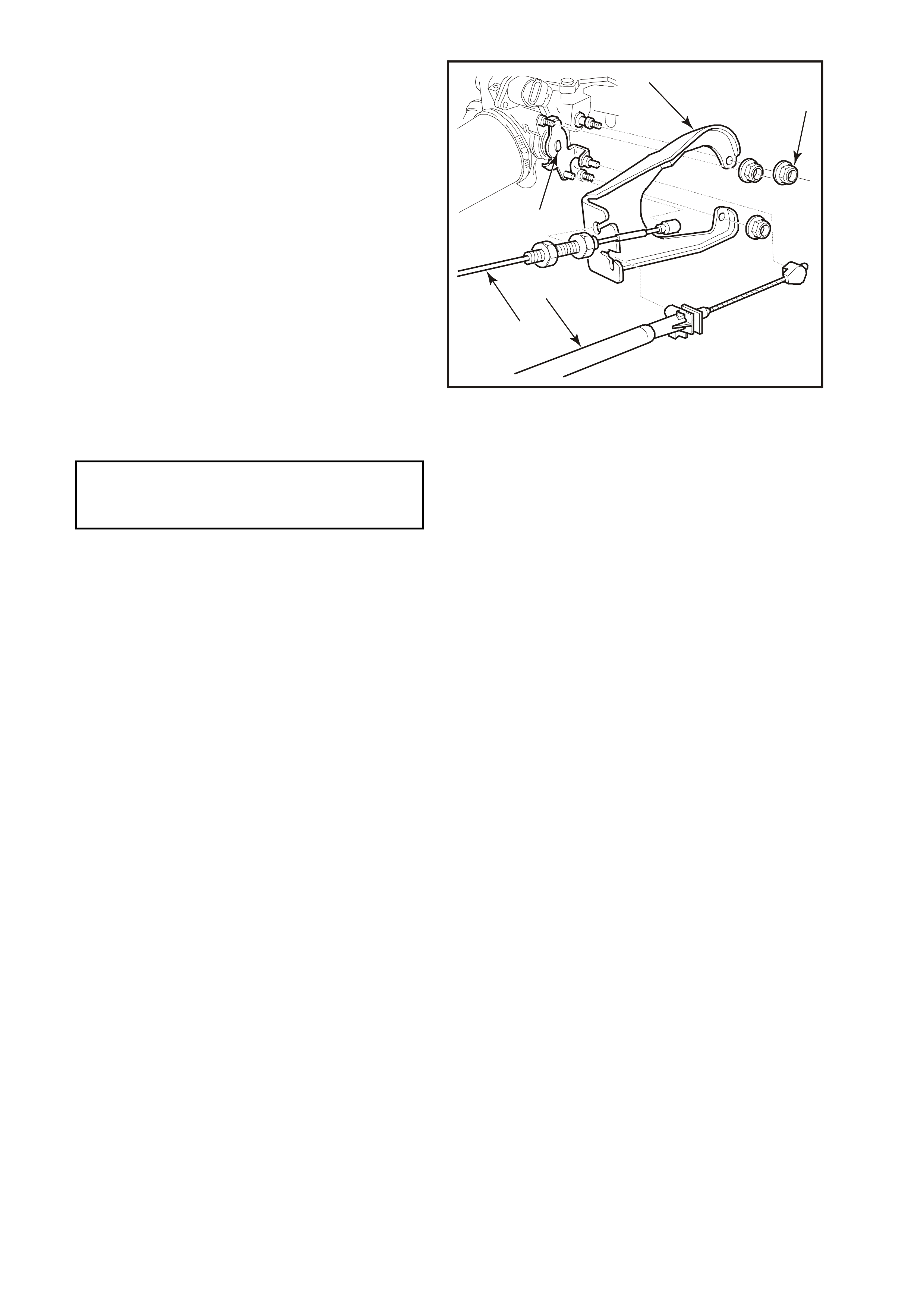

THROTTLE CABLE

REMOVE

1. Remove four dome nuts securing the engine dress cover assembly to the inlet manifold studs, lift off and

remove the cover assembly.

2. Loosen outer cable lock nuts at throttle body mounting bracket.

NOTE:

Do not detach adjusting nuts from cable.

3. Remove inner cable from throttle body linkage.

4. Disconnect outer cable from mounting bracket.

5. Remove instrument panel lower right side trim assembly retainers and lower trim, Refer to

Section 1A3, INSTRUMENT PANEL, in the VT Series I Service Information.

6. Disconnect inner cable plastic spacer from throttle pedal lever.

7. Withdraw cable assembly from engine compartment.

Air Cleaner Lower

Housing Securing Nut 5 - 7 N.m

Torque Specification

REINSTALL

1. Assemble outer cable into dash panel.

2. Attach inner cable to throttle pedal lever.

3. Install outer cable to mounting bracket.

4. Attach inner cable to throttle body linkage.

5. Adjust cable as in following instructions.

Figure 6C1-3-49 Throttle Cable V6 Engine

1. NOTE: do not detach adjusting nuts from cable. 11. Inner cable.

2. Mounting bracket. 12. Throttle pedal lever.

3. Mounting bracket nuts (3 places). 13. Throttle cable.

4. Position throttle cable in circular hole before 14. Clip.

Tightening adjustment nuts. 15. Throttle cable.

5. Rear washer hose (wagon). 16. Cruise control cable.

6. Cruise control cable. 17. Clip.

7. Throttle cable.

8. Wiring Harness Retention Clip

9. Powertrain Wiring Harness.

10. View A

16

17

15

14

13

12

11

10 4

3

2

1

9

8

5

76

4320

10

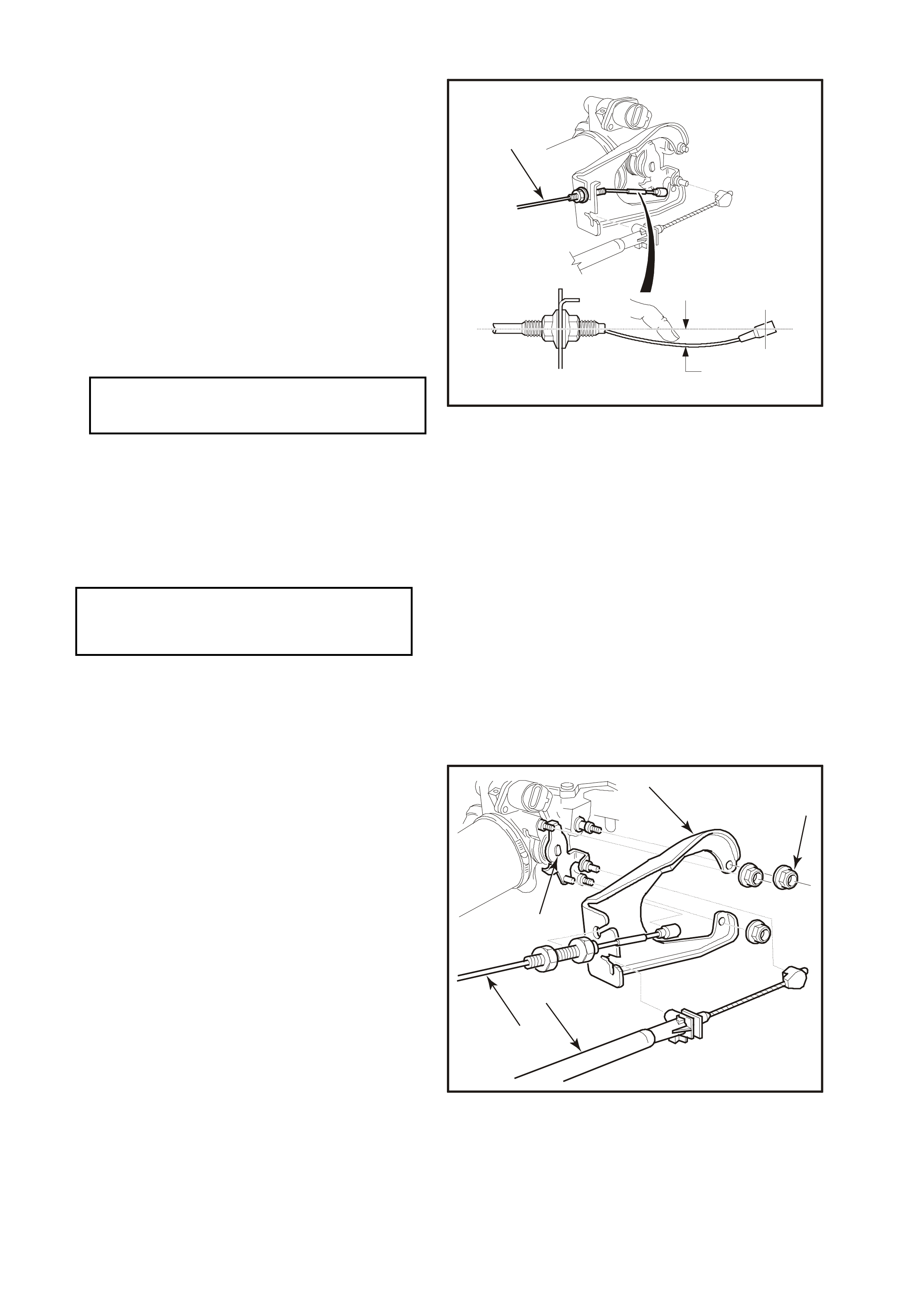

ADJUST

1. Remove instrument panel lower right side trim

(if not already removed, Refer to

Section 1A3, INSTRUMENT PANEL, of the

VT Series I Service Information.

2. Ensure throttle pedal is free to move from

closed to f ully open position. Check that throttle

pedal comes to rest at the correct closed

throttle position (against pedal stop).

3. Adjust outer cable lock nuts s o that inner cable

is tensioned with a deflection of 10 to 15 mm

(2) without moving throttle linkage from idle

stop.

4. Tighten cable lock nuts to the correct torque

specification.

5. Check for Wide Open Throttle and smooth

operation of throttle pedal.

6. Reinstall engine dress cover to the inlet

manif old, ensuring that s tud gromm ets in dress

cover remain in place. Tighten securing dome

nuts to the correct torque specification.

7. Refit instrument panel lower right side trim,

Refer to Section 1A3, INSTRUMENT PANEL

& CONSOLE, of the VT I Service Information.

1

2

4322

Figure 6C1-3-50 Throttle cable adjustment

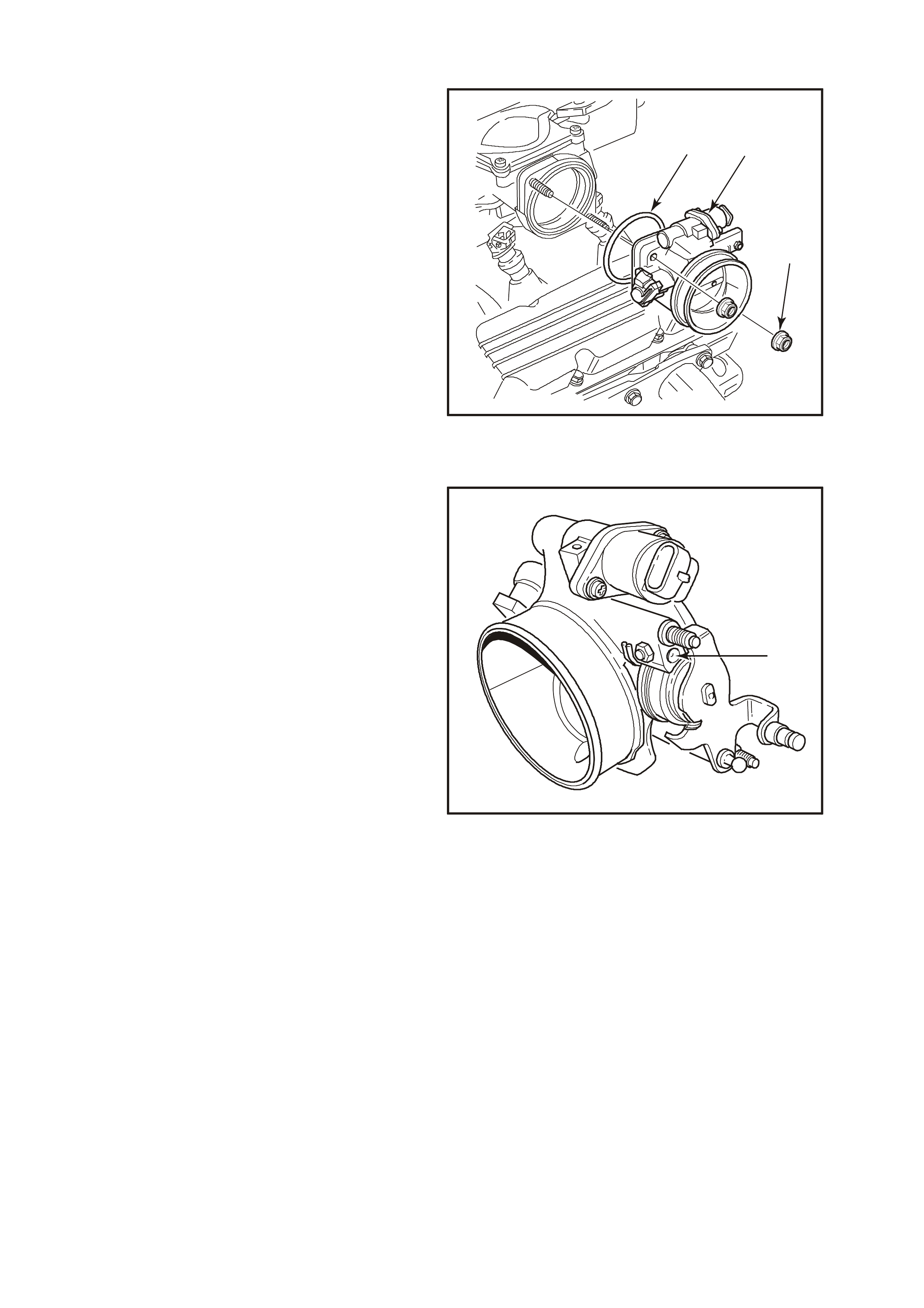

THROTTLE BODY REMOVE

1. Disconnect battery earth lead.

2. Remove four dome nuts securing the engine

dress cover assembly to the inlet manifold

studs, lift off and remove the cover assembly.

3. Disconnect wiring harness connectors from

IAC valve and TP sensor.

4. Loosen air duct clamp at throttle body.

5. Remove air flow duct from throttle body.

6. Remove engine positive crankcase ventilation

hose from throttle body union.

7. Remove canister purge hose from throttle

body.

8. Disconnect throttle cable from throttle body

linkage (5).

9. If vehicle is fitted with cruise control, remove

cruise control cable (3) from throttle body

linkage.

10. Remove throttle cable mounting bracket

attaching nut(s) (2).

1

5

4

3

2

4325

Figure 6C1-3-51

Throttle Outer Cable Lock Nut 2 – 5

Torque Specification N.m

Engine Dress Cover Securing

Dome Nut To Inlet Manifold 2 – 4 N.m

Torque Specification

11. Remove throttle body to inlet manifold

attaching nuts (3).

12. Remove throttle body (2)and gasket (1) from

manifold.

CLEAN

Gasket surfaces on throttle body and manifold.

IMPORTANT:

If reusing the old throttle body, you must perform

the throttle body Cleaning Procedure before

reinstalling.

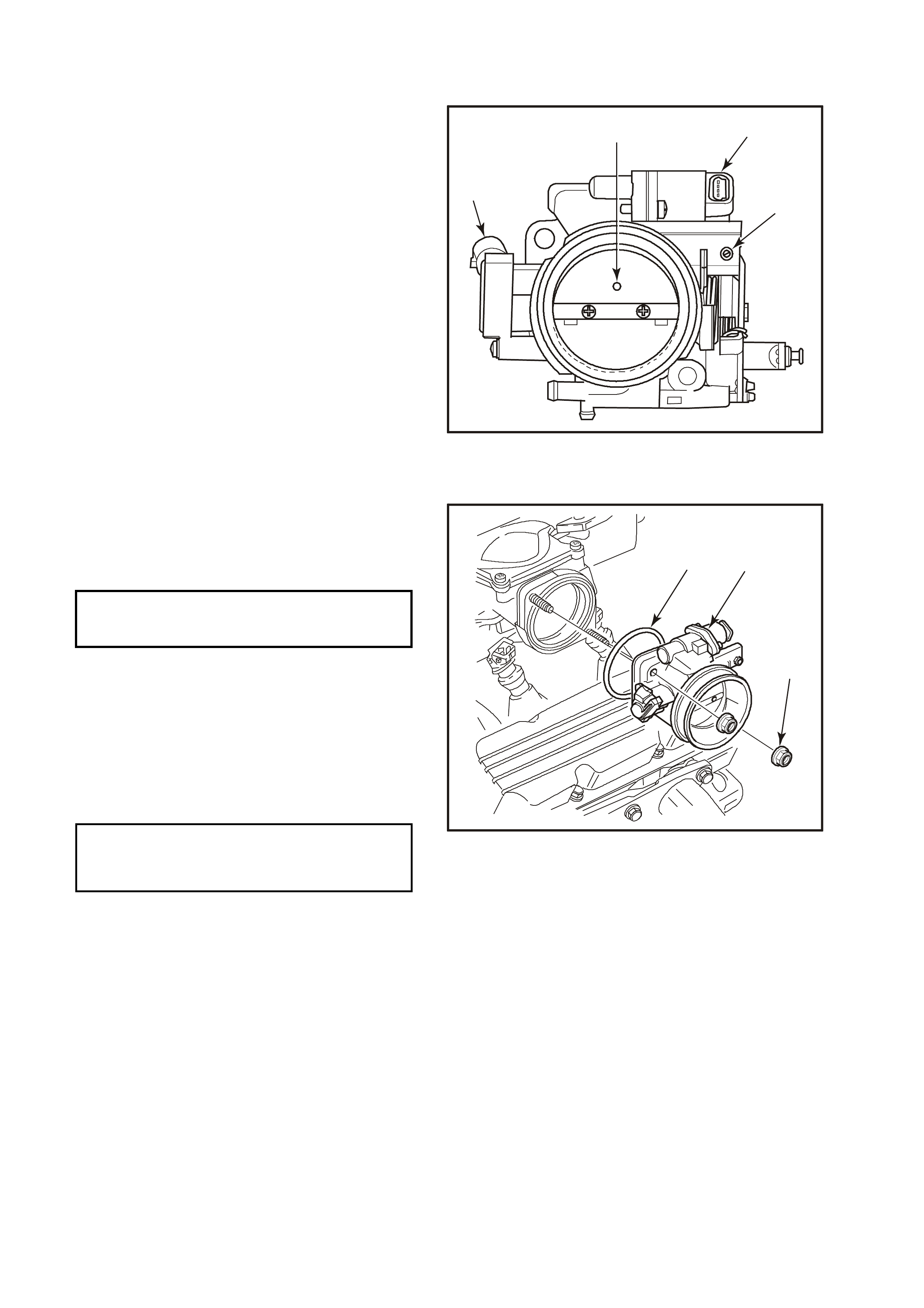

INSPECT

There is a specific throttle body assembly for the

V6 application only. Although the throttle body for

this application looks very similar to previous V6

application, the main distinctive difference is the

addition of a sm all air flow hole in the throttle blade

above the throttle blade shaft. Also, the Idle Air

Control (IAC) valve air passage has been

redesigned to allow more air flow. Refer to

Fig. 6C1-3-44.

12

3

4326

Figure 6C1-3-52

NOTE:

There are specific throttle body assemblies for

vehicles with automatic and manual transmissions.

If replacing a throttle body, ensure that the correct

type is fitted. Identification is by a drill point

marking on the throttle body used for vehicles with

manual transmission.

1

4233

Figure 6C1-3-53

THROTTLE BODY CLEANING PROCEDURE

1. Remove throttle body from vehicle.

2. Remove the TP sensor (4) and IAC valve (2)

from the throttle body.

3. Using an approved injector cleaner, clean the

carbon build up around the pintle of the IAC

valve(2).

4. On the throttle body, clean the carbon build up

around the IAC air port, throttle body bore and

Throttle Blade.

5. Reinstall TP sensor to throttle body.

6. Reinstall IAC valve to throttle body.

Continue with the reinstallation of the throttle body

to the engine.

2

1

43

4348

Figure 6C1-3-54 Throttle Body Identification and Cleaning

THROTTLE BODY REINSTALL

1. Install throttle body gasket (1) and throttle body

(2) to inlet manifold.

2. Install throttle body attaching nuts (3) and

tighten to the correct torque specification.

3. Reinstall canister purge control hose to throttle

body.

4. Reinstall engine positive crankcase ventilation

hose to throttle body union.

5. Reinstall wiring harness connectors to IAC

valve and TP Sensor.

6. Reinstall throttle cable mounting bracket

attaching nut (2).

12

3

4326

Figure 6C1-3-55

Throttle Body Attaching Nuts 15 – 20

Torque Specification N.m

Throttle Cable Mounting

Bracket Attaching Nut 2 – 4 N.m

Torque Specification

7. Reconnect throttle cable (4) to throttle body

linkage (5).

8. If vehicle is fitted with cruise control, reinstall

cruise control cable (3) to throttle body

linkage.

9. Install air duct onto throttle body, align clamp

and air duct locating notches. Tighten air duct

clamp at throttle body securely

10. Reconnect battery earth lead.

11. Start engine then look and listen for air leaks.

12. Check throttle cable adjustment, refer

3.10, FUEL CONTROL SYSTEM – Throttle

Cable Adjust in this Section.

13. Check cruise control cable adjustment, Refer

to Section 12E, CRUISE CONTROL in VX

Service Information.

14. Reinstall engine dress cover to the inlet

manifold, ensuring that stud grommets in the

dress cover remain in place. Tighten securing

dome nuts to the correct torque specification.

1

5

4

3

2

4325

Figure 6C1-3-56

THROTTLE BODY IAC VALVE COUNT CHECKING PROCEDURE

1. Start engine and run to operation temperature

85°C.

2. Transmission in Park or Neutral.

3. Turn Off all accessories (A/C, radio etc.)

4. Install Tech 2 scan tool and display Engine

Data.

5. Confirm the IAC valve counts are at 15 counts

or less at idle.

If the counts are not at 15 or less, perform the

Throttle Stop Screw Reset Procedure if the screw

has been tam pered with. If the Throttle Stop Screw

has not been tampered with, replace the throttle

body.

Engine Dress Cover Securing

Dome Nut To Inlet Manifold 4 – 6 N.m

Torque Specification

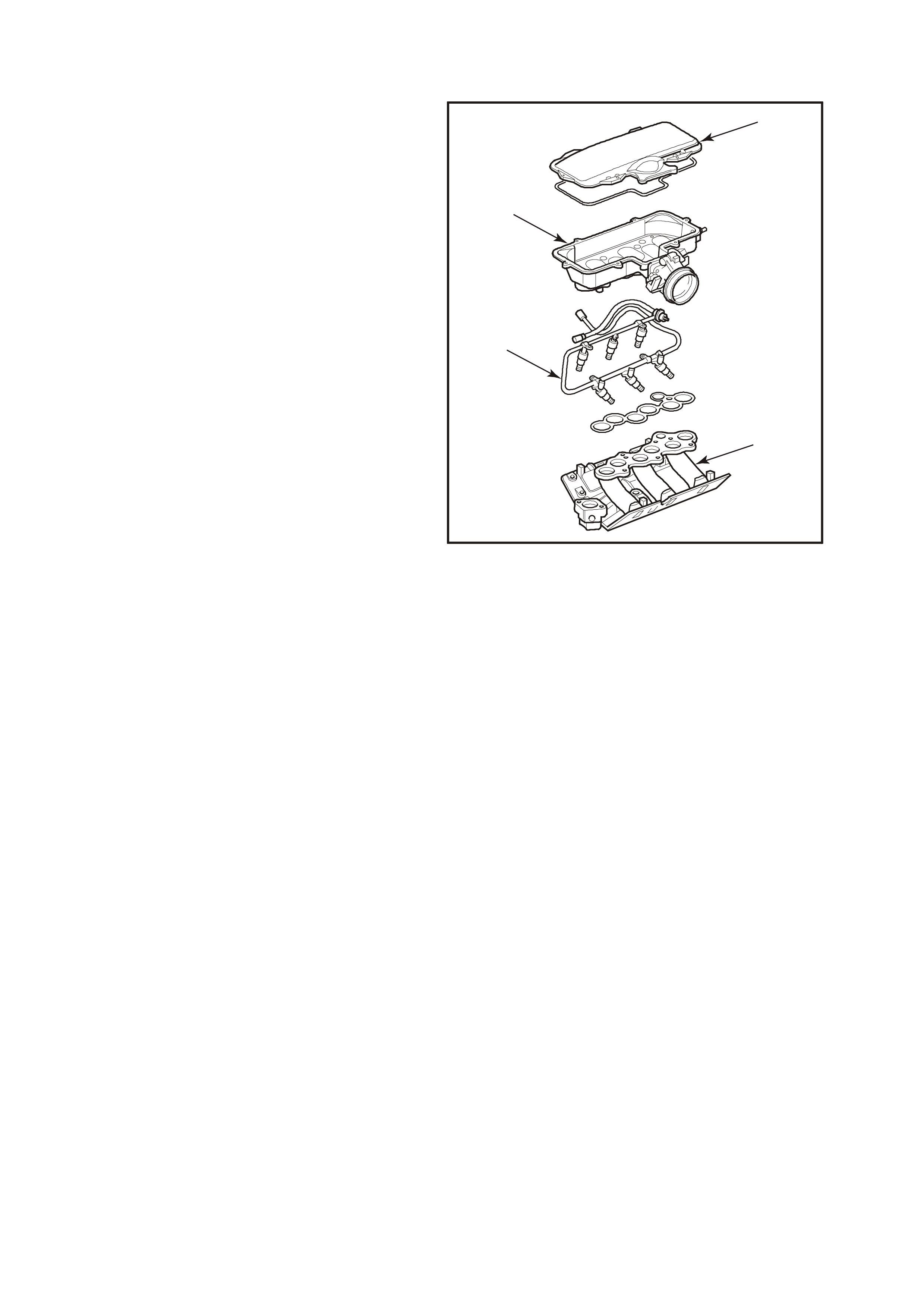

FUEL RAIL AND INJECTORS

NOTE:

The f uel inlet and return hos e are an ass em bly with

the fuel rail. Both components are NOT serviced

separately.

REMOVE

IMPORTANT:

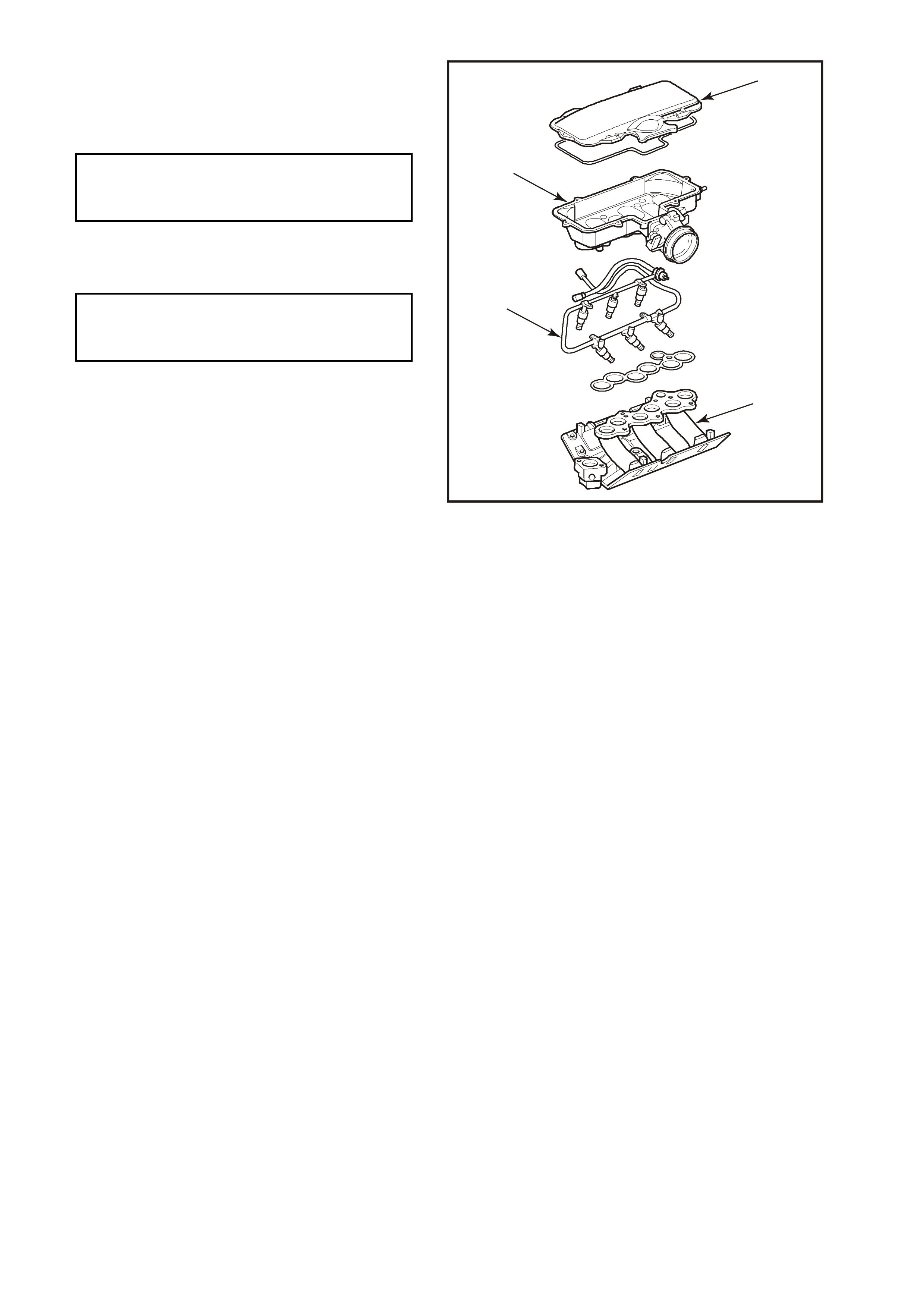

The fuel rail and injectors are attached to the

bottom of the two-piece air inlet plenum. T he top of

the air inlet plenum (1) must be removed to gain

access to the bolts that secure the inlet plenum (4)

to the inlet manifold (2). The inlet plenum is then

removed, bringing with it the attached fuel rail and

injectors.

1. Relieve fuel pressure as described in

3.10 FUEL CONTROL SYSTEM (FUEL

PRESSURE RELIEF PROCEDURE) in this

Section.

2. Disconnect battery earth lead.

3. Remove four dome nuts securing the engine

dress cover assembly to the inlet manifold

studs, lift off and remove the cover assembly.

IMPORTANT:

Thoroughly clean around injector to inlet manifold

ports.

4. Remove the intake air duct from the throttle

body.

5. Remove the purge hose and crankcase vent

hose from the throttle body.

6. Remove the brake booster vacuum hose, and

two small vacuum hoses, from the air inlet

plenum.

7. Disconnect electrical c onnectors fr om injector s,

TP sensor, and Idle Air Control valve.

8. Remove eight hex - head bolts securing

plenum cover (1) to air inlet plenum. Lift and

remove cover.

4

1

2

4328

3

Figure 6C1-3-57

NOTE:

Plenum cover uses a soft o-ring - style gasket

between the cover and the air inlet plenum . Gask et

should remain attached in the cover.

IMPORTANT:

After r emoving plenum cover, BE VERY CAREFUL

TO NOT DROP ANYTHING INTO THE EXPOSED

INLET MANIFOLD PORTS !!

NOTE:

Anything dropped into these ports can, and most

likely will, cause serious engine damage due to

foreign objects being ingested into the engine

combustion chambers through the intake valves.

9. Remove vacuum hose from fuel pressure

regulator.

10. Using Tool No. 7370 (3), disconnect fuel inlet

hose quick connect at dash panel

connection (4).

11. Disconnect fuel pressure regulator from fuel

rail. Refer to Fuel Pressure Regulator in this

Section.

12. Using T ool No. 7370 (3), disconnect f uel return

hose quick connect at dash panel

connection (4).

13. Fully loosen (but do not remove) five bolts

securing inlet plenum to inlet manifold.

14. Carefully lift air plenum (and attached fuel rail

with injectors) from inlet manifold. Carefully

rotate the front of the inlet plenum up and

towards the windscreen. Gently lower the

plenum assembly to rest on the inlet manifold,

with the fuel rail and injectors facing forward

and tilted slightly up.

IMPORTANT:

Place a clean piece of cardboard between the inlet

manifold and plenum assembly, to prevent foreign

objects from entering inlet manifold ports.

1

2

3

4317

4

Figure 6C1-3-58

15. Remove injector retaining clips (2). Withdraw

injectors (3) from fuel rail. Remove fuel rail

from air inlet plenum ONLY if replacement of

fuel rail is needed.

IMPORTANT:

When servicing the fuel rail assembly, precautions

must be taken to prevent dirt and other

contaminants from entering the fuel passages. It is

recommended that fittings be capped, and holes

plugged, during servicing.

IMPORTANT:

Any tim e the fuel system is opened f or service, the

O-ring seals used with related component(s)

should be replaced, including those used between

the air inlet plenum and inlet manifold, and

between the plenum and it's cover.

REINSTALL

1. Injec tors using new O-r ings (1&5), coat O-r ings

with engine oil.

2. Injector retaining clips (2).

3

2

1

4329

4

5

Figure 6C1-3-59

3. Air inlet plenum assembly (containing fuel rail

assembly and throttle body) (4) onto intake

manifold (2), carefully placing injectors into

intake manifold ports. Tighten five bolts to the

correct torque specification.

4. Air inlet plenum cover (1) to inlet plenum.

Tighten bolts to the correct torque

specification.

5. Vacuum hoses:

- Brake booster vacuum hose to inlet plenum.

- Crankcase vent hose to throttle body.

- Purge vacuum supply hose to bottom of

throttle body.

- HVAC vacuum hose (small hose) to back of

inlet plenum.

6. Pressure regulator to fuel rail.

7. Fuel return hose to dash quick connector.

8. Fuel inlet hose to dash quick connector.

9. Electrical connectors to fuel injectors, TP

sensor, and Idle Air Control valve.

10. Reinstall engine dress cover to the inlet

manifold, ensuring that stud grommets in the

dress cover remain in place. Tighten securing

dome nuts to the correct torque specification.

11. Negative battery cable.

12. Check for fuel leaks as described in

3.10, FUEL CONTROL SYSTEM (LEAK

TESTING) in this Section.

4

1

2

4328

3

Figure 6C1-3-60

Air Inlet Plenum Assembly

To Inlet Manifold Attaching Bolt 15 N.m

Torque Specification

Air Inlet Plenum Cover To Air Inlet

Plenum Assembly Attaching Bolt 10 N.m

Torque Specification

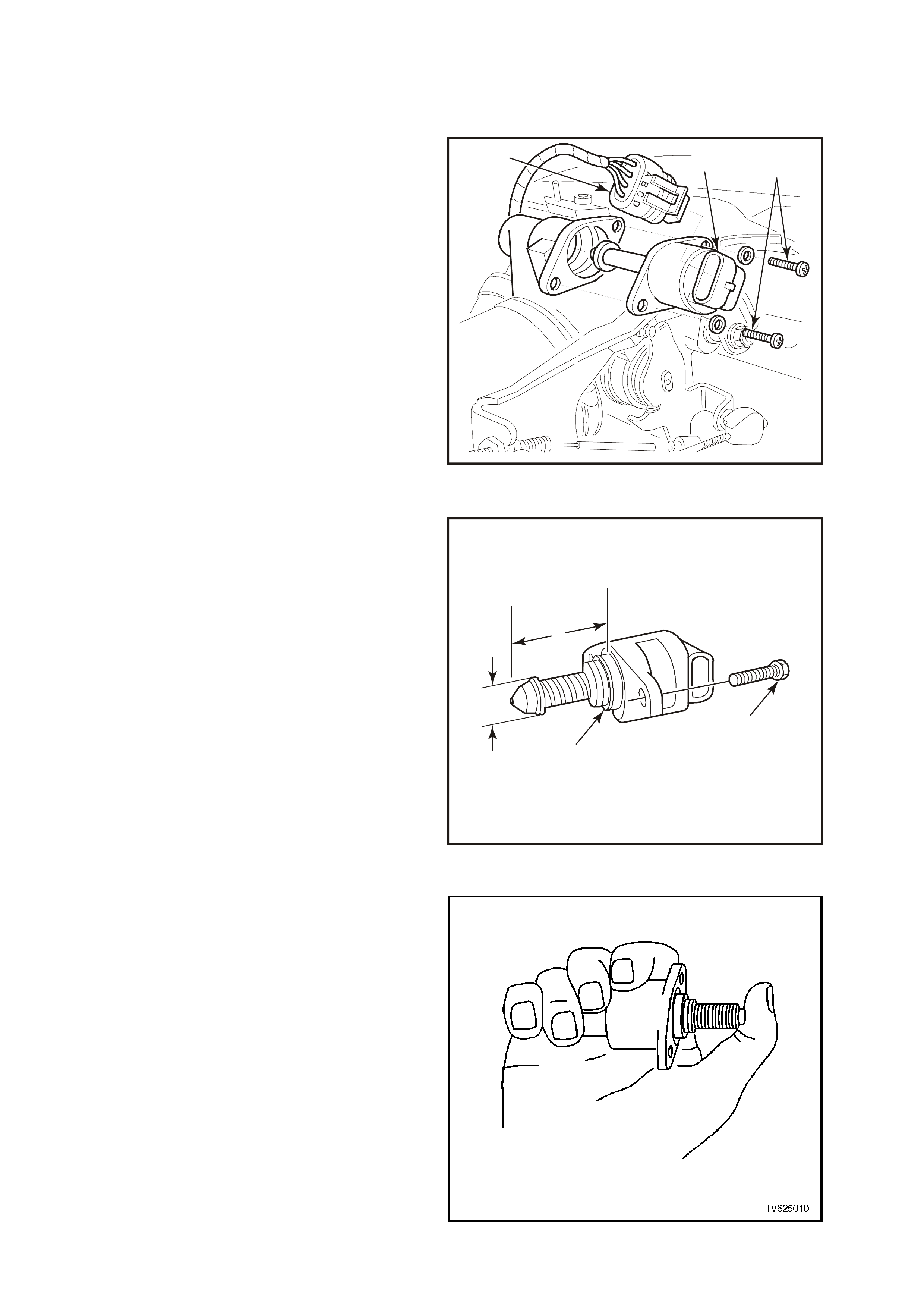

3.11 IDLE AIR CONTROL VALVE

REMOVE

1. Disconnect battery earth lead.

2. Remove four dome nuts securing the engine

dress cover assembly to the inlet manifold

studs, lift off and remove the cover assembly.

3. Lift up retaining tang on IAC valve wiring

harness connector (3) and pull connector from

valve.

4. Remove IAC valve to throttle body attaching

screws (2).

5. Remove IAC valve (1) from throttle body.

CLEAN

IAC valve sealing surfaces on throttle body, to

assure proper seal of O-ring and contact of IAC

valve flange.

IMPORTANT:

W hen installing a new IAC valve, be sure it has the

correct part number.

2

4330

1

3

Figure 6C1-3-61 IAC Valve Removal

IMPORTANT:

Before installing a new IAC valve, measure

distance "1" between tip of valve pintle and the

flange mounting surface. If it is greater than 28

mm, it must be reduced to prevent damage to the

valve when it is installed.

3

4312

2

1

4

Figure 6C1-3-62 IAC Measured Distance

Exert firm pressure on valve pintle to retract it. (A

slight side-to-side movement may be helpful).

Figure 6C1-3-63 IAC Retraction Method

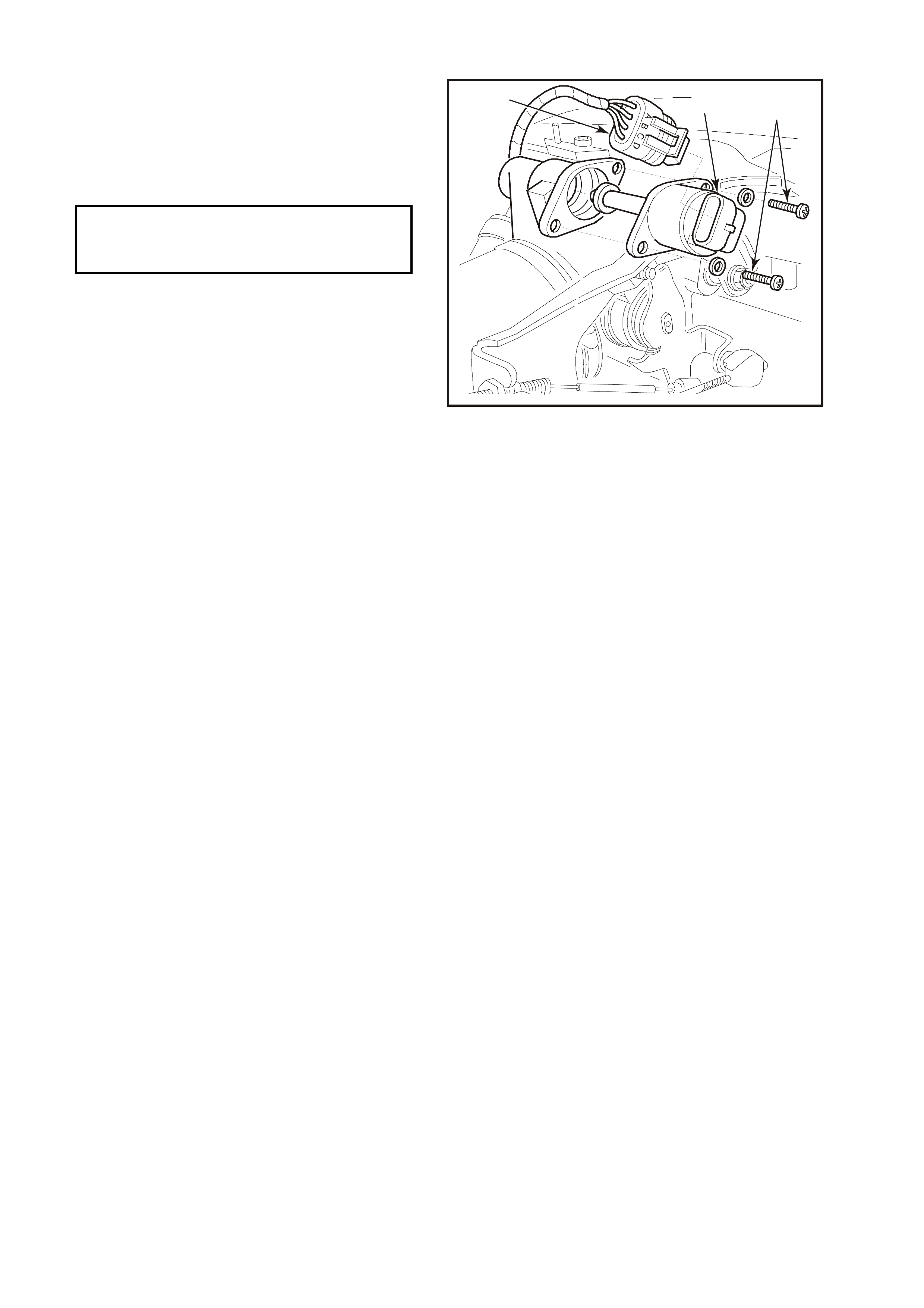

REINSTALL

1. Lubricate IAC valve O-ring with light engine oil.

If necessary, install on to valve assembly.

2. Reinstall IAC valve (1) into throttle body with

wiring harness connector (3) facing up.

3. Install IAC valve attaching screws (2) and

tighten to the correct torque specification.

4. Reconnect IAC valve wiring harness

connector (3).

5. Reconnect battery earth lead.

6. If required, clear any DTCs using scan tool.

7. Start engine, and allow engine to run for 5

seconds then turn engine "OFF" to "Reset" the

IAC valve

or

Use the Scan Tool, selec t IAC RESET to r eset

the IAC valve.

8. Reinstall engine dress cover to the inlet

manifold, ensuring that stud grommets in the

dress cover remain in place. Tighten securing

dome nuts to the correct torque specification.

2

4330

1

3

Figure 6C1-3-64

IAC Valve To Throttle

Body Attaching Screws 1-1.5 N.m

Torque Specification

3.12 DIRECT IGNITION SYSTEM (DIS)

TIMING ADJUSTMENT

The Dire ct Ignition System (DIS) system fully contr ols the spark timing. No adjustment for spar k timing is provided.

There are no timing marks on the crankshaft balancer or engine.

CHECKING EST SPARK TIMING OPERATION

The PCM will force the Electronic Spark Timing (EST) spark advance to 10 degrees BTDC when the Tech-2 is

used, and By-Pas s m ode is selected. To c heck for EST operation, run the engine with the throttle fix ed at a steady

1600-1800 RPM, then enter the "By-Pass" mode of operation with the Scan Tool. If the RPM changes (drops),

EST spark timing is operating. An EST system fault will set a DTC. Use proper DTC Table in Section 6C1-2A in VX

Service Information to correctly diagnosis the system.

IGNITION COIL (S)

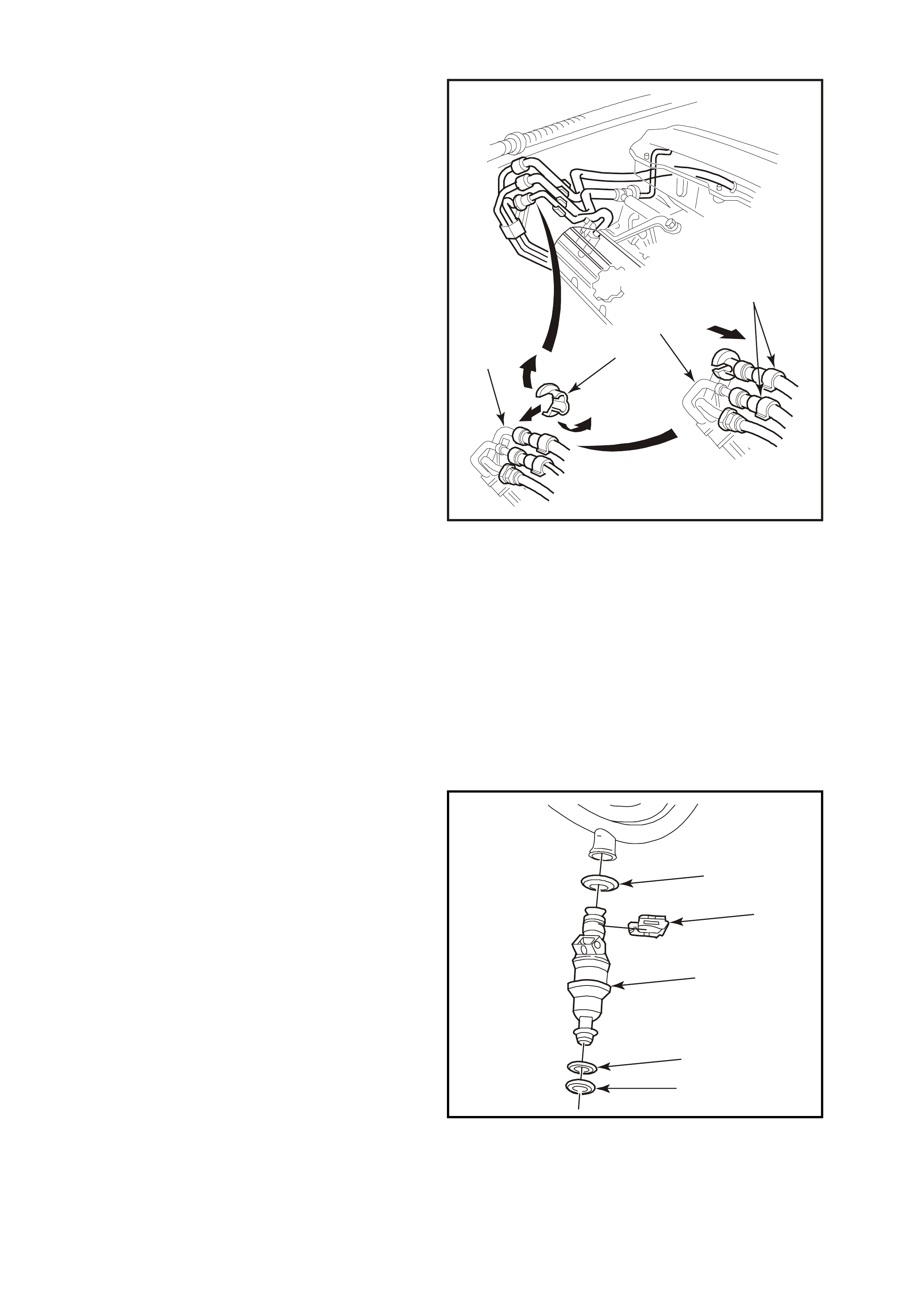

REMOVE

1. Disconnect battery earth lead.

2. Remove spark plug leads (3) from coil towers,

noting lead numbering with reference to coil

tower numbers.

IMPORTANT: 1.

Slightly twist spark plug leads before removing

from coil towers

IMPORTANT: 2.

All spark plug leads and coil terminals are

number ed to correspond to the cylinder numbering.

On service replacement coils the cylinder

numbering does not appear on top of any coil

assembly, refer to cylinder numbering on the

module.

3. Remove screws (1) securing coil(s) to module

and mounting plate.

4. Pull coil(s) (2) from m odule (4), taking care not

to bend module terminals.

REINSTALL

1. Install coil(s) (2) onto module (4), aligning

module terminals with mating slots on

underside of coil.

2. Install coil securing screws (1) and tighten to

the correct torque specification.

3. Reconnect spark plug leads (3) to coil

terminals, ensuring correct lead to coil terminal

relationship.

4. Reconnect battery earth lead, start engine and

ensure engine operates correctly.

4

4331

23

1

Figure 6C1-3-65 Ignition Coils To Module

DIS Coil To Mounting

Plate Securing Screw 4 – 5 N.m

Torque Specification

DIS MODULE

REMOVE

1. Disconnect battery earth lead.

2. Remove all spark plug leads (1) from coil

towers, noting lead numbering with reference

to coil towers numbers.

3. From beneath powertrain harness retainer at

front of coil and module assembly (5), gently

pull down on the retainer lower locating tangs

and pull retainer from coil and module

assembly.

IMPORTANT: 1.

Slightly twist spark plug leads before removing

from coil towers

IMPORTANT: 2.

All spark plug leads and coil terminals are

number ed to correspond to the cylinder numbering.

On service replacement coils the cylinder

numbering does not appear on top of any coil

assembly, refer to cylinder numbering on the

module.

4. Loosen bolt (2) attaching 14-pin wiring

harness connector to module (5) until you can

pull connector from module.

5. Remove screws securing coils (3).

6. Remove coils from module, taking care not to

bend module terminals.

7. Remove ignition module assembly (5).

1

4332

5

3

2

4

Figure 6C1-3-66 Ignition Module Removed

REINSTALL

1. When replacing module assembly, remove module to coil terminal and 14 pin wiring harness connector

terminal seals from original module. Install seals onto new module, taking care not to damage seals. If any

seal(s) is damaged in any way, install new seal(s).

2. Place coils onto module, aligning module terminals with mating slots on underside of coil.

3. Reinstall ignition module assembly (5) to mounting plate, locating raised lugs (2) on both module and plate

together.

IMPORTANT:

The lugs on the underside of the module will m ate with the mounting plate holes in one way only to ensure cor rect

assembly relationship.

4. Reinstall screws (3) securing coils and module to mounting plate and tighten to the correct torque specification.

DIS Coil To Mounting

Plate Securing Screw

Torque Specification

4 - 5 N.m

5. Reconnect spark plug leads (1) to coil terminals, ensuring correct lead to coil terminal relationship.

6. Reconnect 14-pin wiring harness connector to module assembly and tighten attaching bolt (2) to the correct

torque specification.

Wiring Harness Connector To

DIS Module Attaching Bolt

Torque Specification

0.6 - 1.2 N.m

7. Snap powertrain wiring harness retainer onto coil and module assembly and it's mounting plate.

8. Reconnect battery earth lead.

9. Start engine and ensure engine operates correctly.

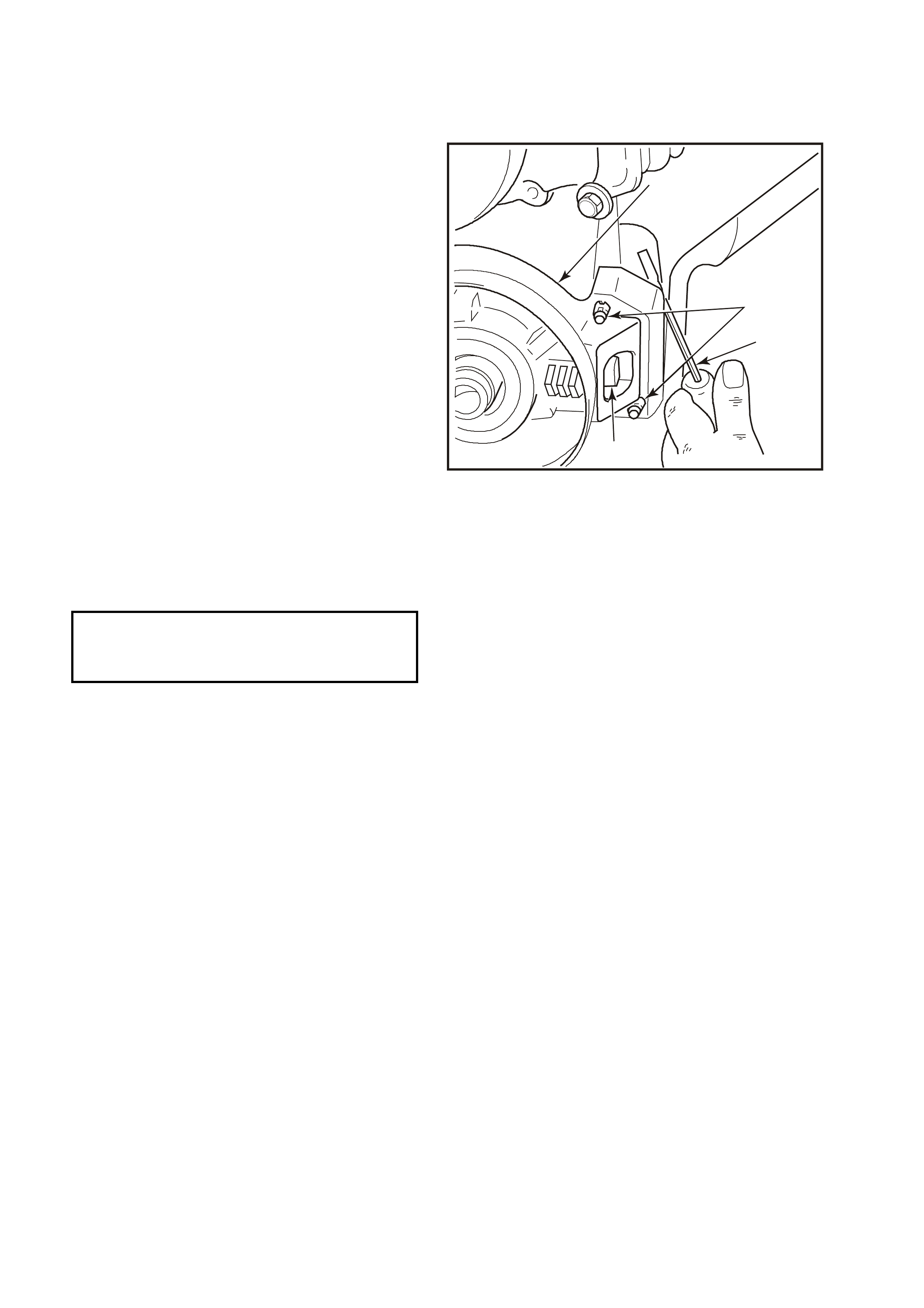

CRANKSHAFT SENSOR

REMOVE

1. Disconnect battery earth lead.

2. Using a 15 mm ring spanner on drive belt

tensioner pulley pivot bolt, rotate tensioner

pulley assembly anti-clockwise and remove

drive belt from generator drive pulley. Release

drive belt tensioner and remove drive belt.

3. Remove crankshaft balancer, Refer to

Section 6A1, ENGINE MECHANICAL - V6

ENGINE in the VT Series I Service Information.

4. Lift up retaining tang on crankshaft sensor

engine wiring harness connector and pull

connector from sensor assembly.

5. Using a prying device (3) behind crankshaft

position sensor shield (1), lever each corner of

the shield from front cover studs, remove

shield.

6. Remove crankshaft sensor bracket to front

cover attaching studs (2) and remove sensor

assembly (4).

REINSTALL

1. Install crankshaft sensor assembly (4) onto

front cover dowel pin.

2. Install and tighten sensor br acket to f ront cover

attaching studs (2) to the correct torque

specification.

Crankshaft Position Sensor

To Front Cover Attaching 20 - 30 N.m

Stud Torque Specification

3. Reinstall crankshaft position sensor shield (1)

onto front cover studs (2), ensuring deflector

retainers fully engage over ends of studs.

4. Reconnect wiring harness connector to

crankshaft sensor (4).

5. Reinstall crankshaft balancer, Refer to

Section 6A1, ENGINE MECHANICAL - V6

ENGINE in the VT Series I Service Information.

IMPORTANT:

Do not reinstall drive belt at this stage.

6. Rotate crankshaft so as to check that

interrupter rings do not contact sensor.

IMPORTANT:

If the interrupter rings contact the sensor at any

point during balancer rotation, the interrupter rings

have excessive runout and the balancer assembly

must be replaced.

7. Reinstall serpentine belt.

8. Reconnect battery earth lead.

9. Start engine and ensure engine operates

correctly.

3

4333

2

4

1

Figure 6C1-3-67

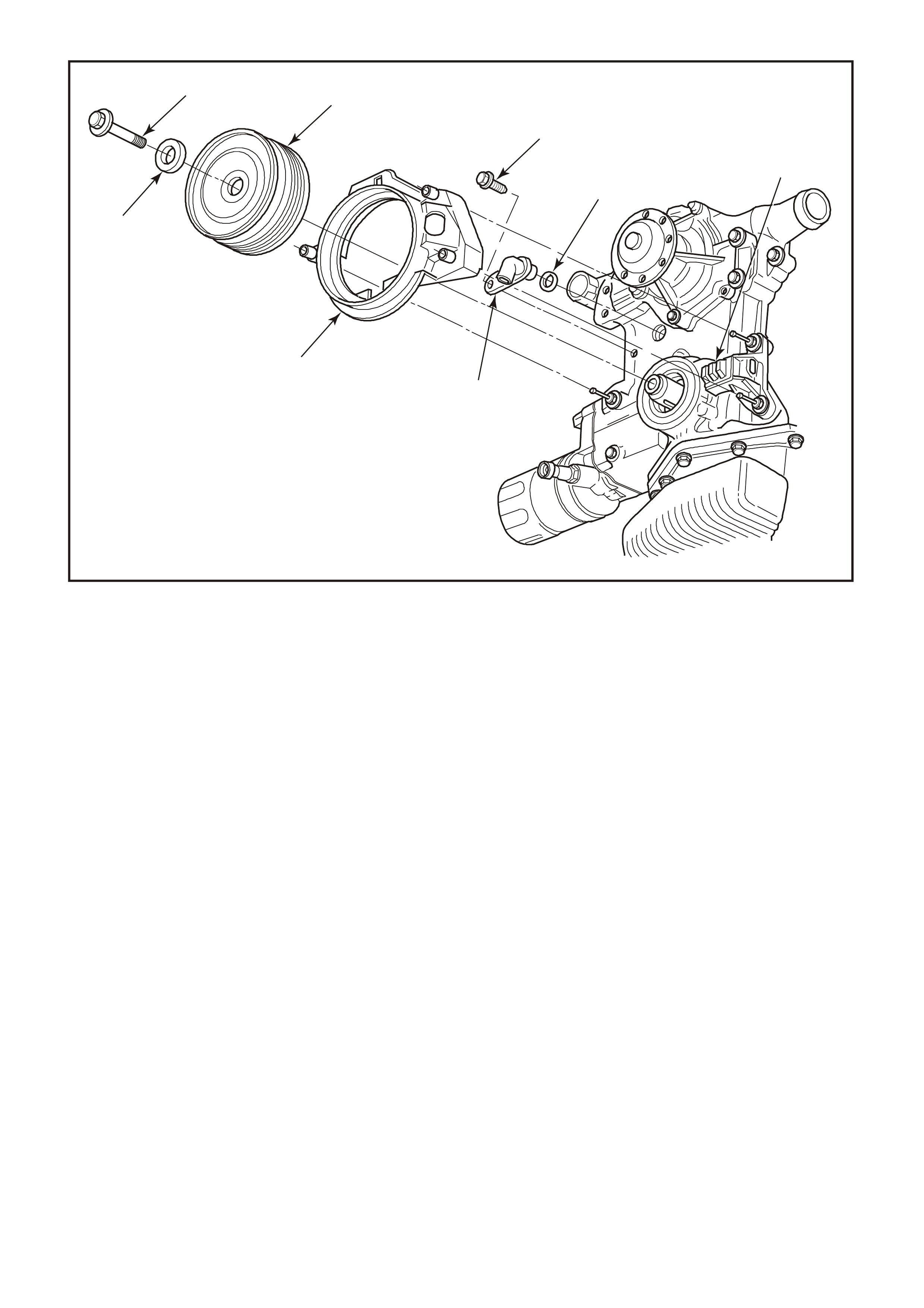

Figure 6C1-3-68 Camshaft/Crankshaft Position Sensors

1. Bolt.

2. Crankshaft Balancer.

3. Retaining Bolt.

4. O-Ring.

5. Crankshaft Position Sensor.

6. Camshaft Position Sensor.

7. Crankshaft Position Sensor Shield.

8. Washer.

2

3

4300

45

1

8

7

6

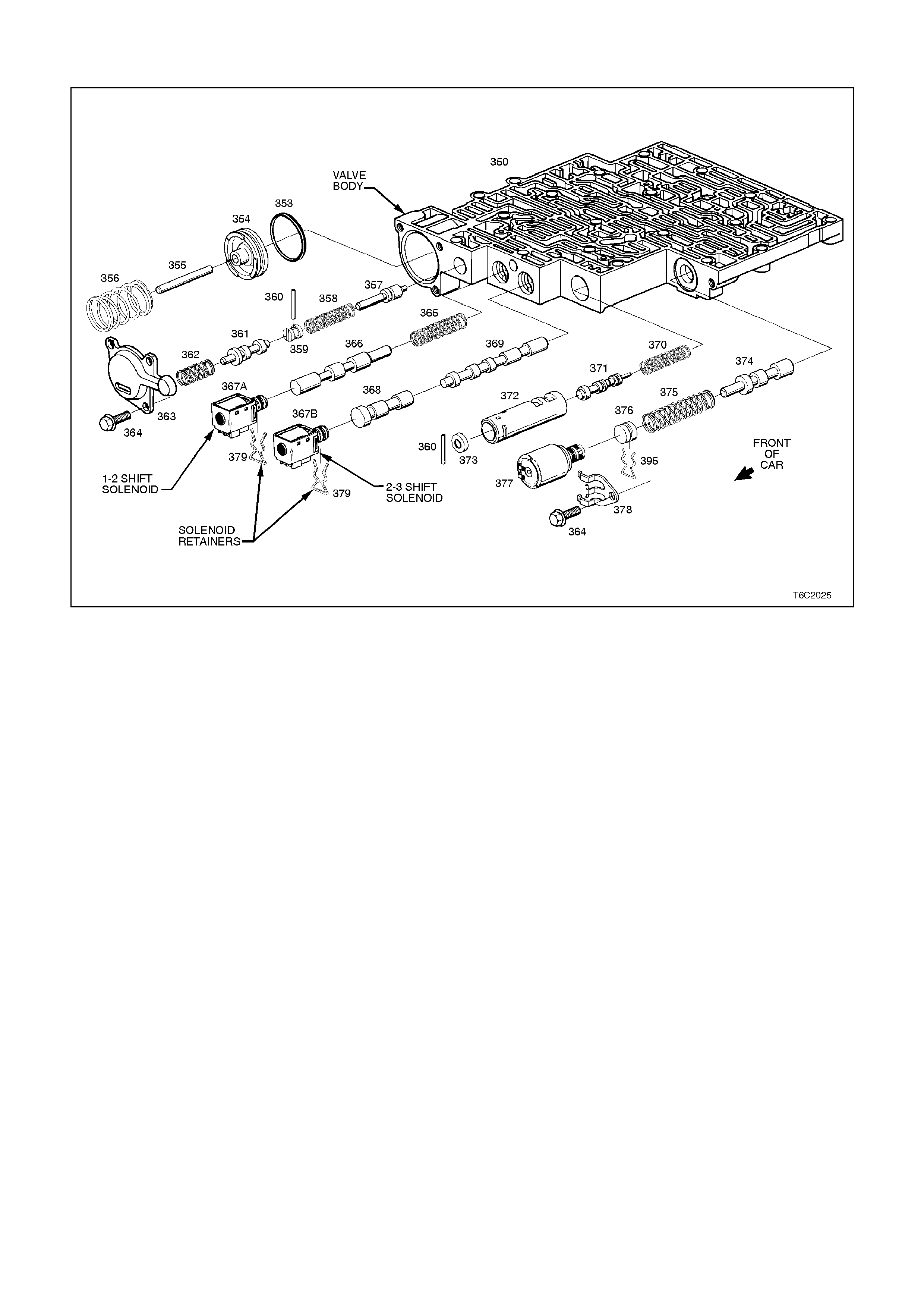

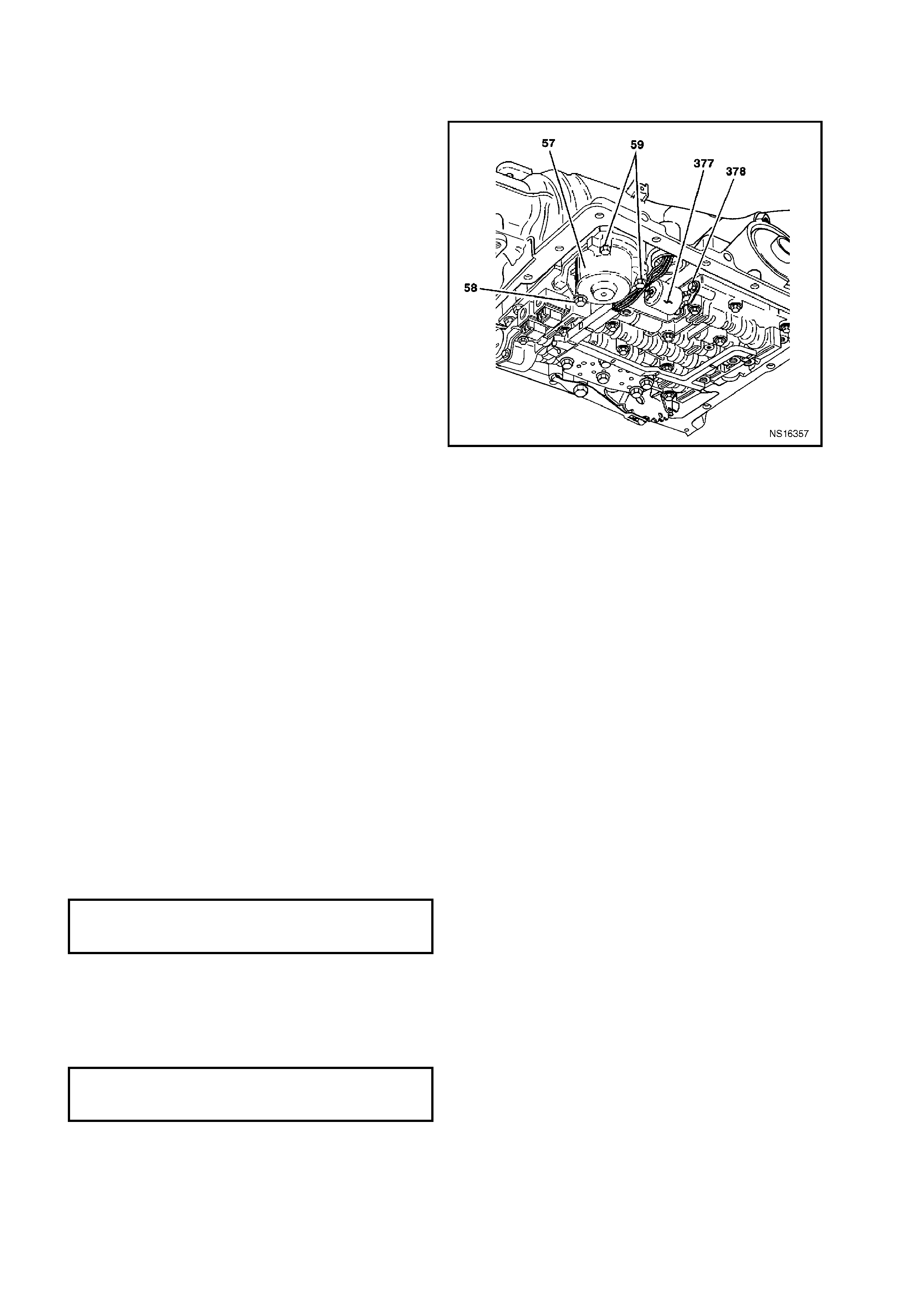

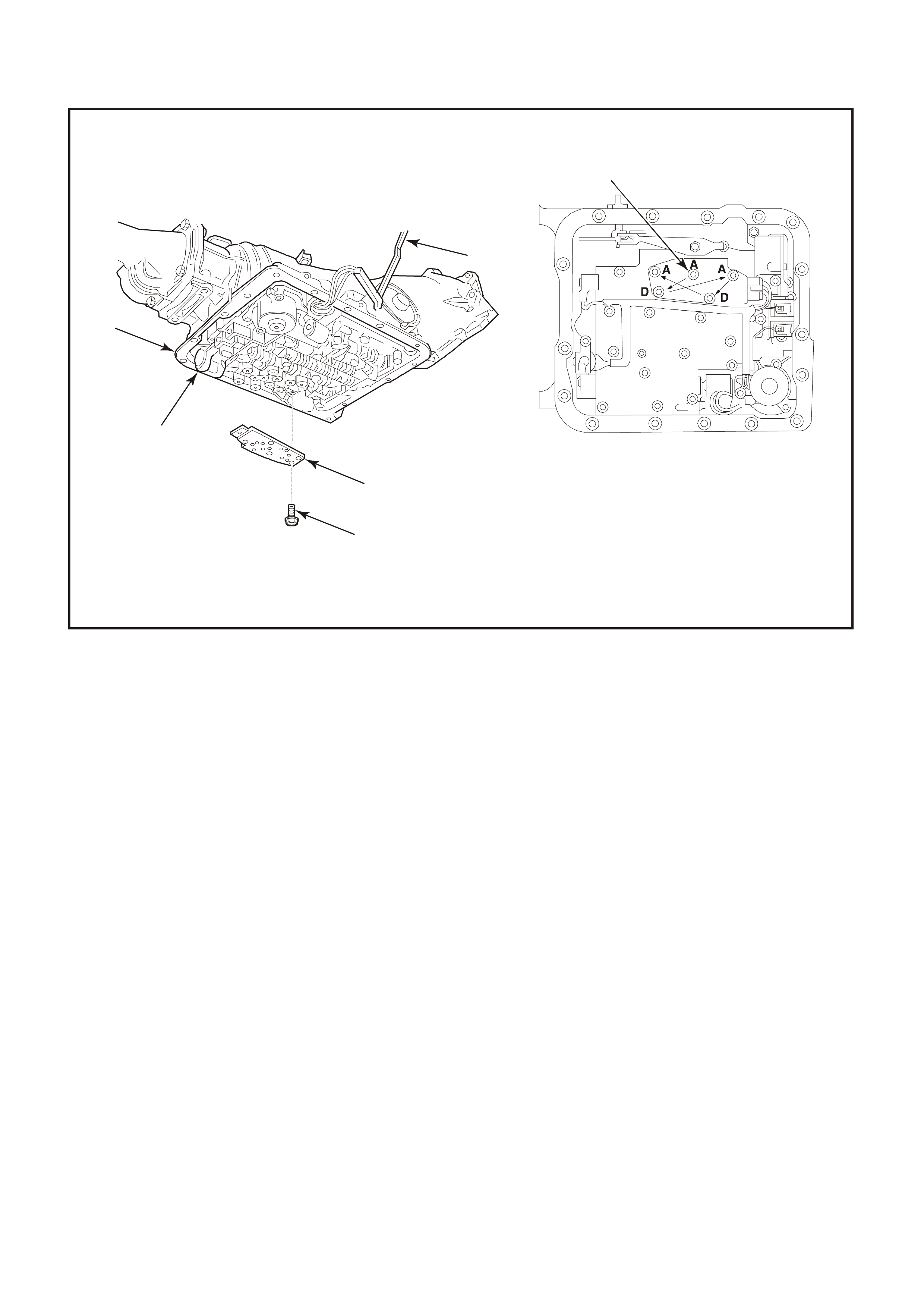

3.13 1-2 SHIFT SOLENOID

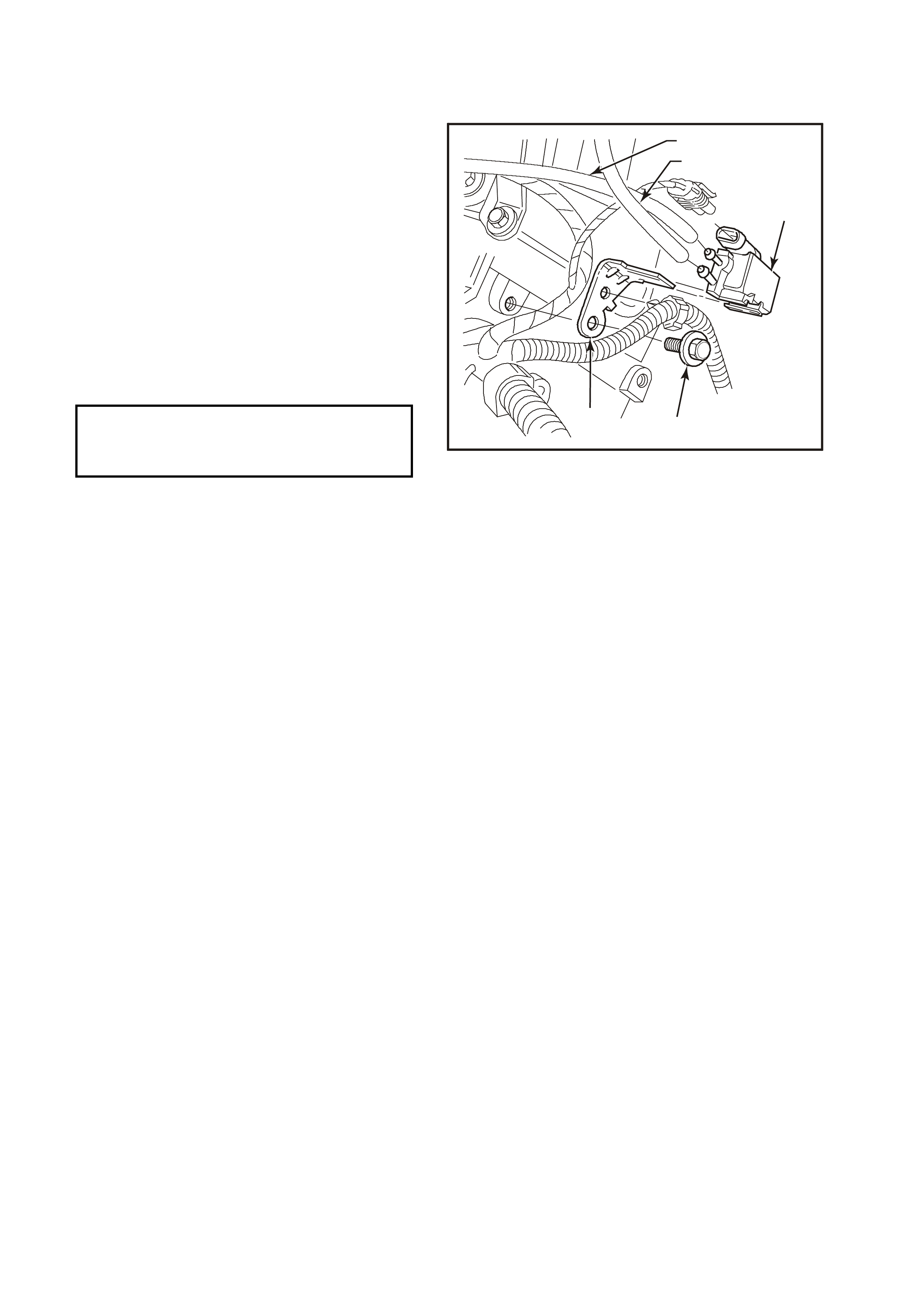

Figure 6C1-3-69 1-2 Shift Solenoid Location

REMOVE

1. Disconnect battery earth lead.

IMPORTANT:

To avoid personal injury from accidental hot oil spillage, perform fluid change only w hen transmission fluid is cold.

2. Raise vehicle and support on safety stands. Refer to Section 0A, GENERAL INFORMATION of the VT

Series I Service Information.

3. Clean all dirt from around oil pan and transmission case.

4. Place drain tray under transmission.

5. Loosen two bolts at the rear and one at the front of the oil pan. Rem ove the remaining bolts. W hile holding oil

pan, allow the front of the oil pan to drop away, emptying oil into a drain tray.

6. Remove remaining bolts, then lower pan and empty fluid from pan.

7. Remove old oil pan gasket and discard.

8. Disconnect 1-2 shift solenoid (367A) electrical connector.

9. Remove solenoid retainer (379) by using a small flat blade screwdriver. Pry the retainer down until it can be

grasped.

IMPORTANT:

Solenoid has a slight spring pressure behind it, and may pop out on its own after retainer is removed.

10. Remove solenoid assembly (367A) with O-ring seal. Ensure that 1-2 shift valve (366) remains in place.

REINSTALL

1. Push solenoid assembly (367A) into valve body.

2. Hold solenoid in place with finger pressure while installing retainer (379)

3. Reconnect 1-2 shift solenoid (367A) electrical connector.

4. Clean oil pan and case mating surfaces. Check that magnet is still magnetized, and attached to the oil pan.

5. Install new gasket and reinstall oil pan. Tighten bolts to the correct torque specification.

Transmission Oil Pan Bolt

Torque Specification 11

N.m

6. Lower vehicle and add approximately 4.8 litres of DEXRON â III automatic transmission fluid.

7. Reconnect battery earth lead.

8. Check transmission fluid level. Refer to "Fluid Checking Procedure" in Section 6C1-2A in VX Service

Information.

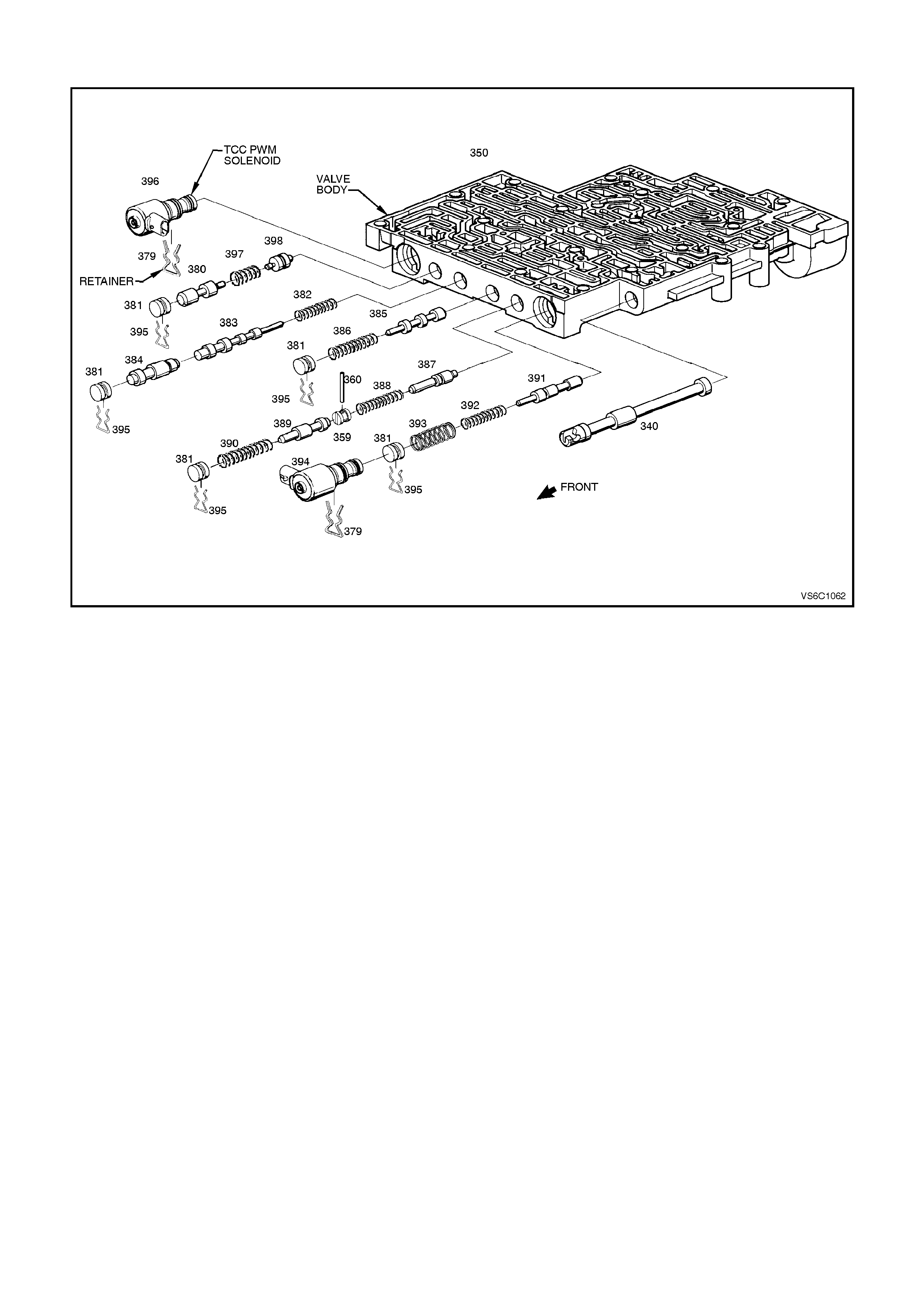

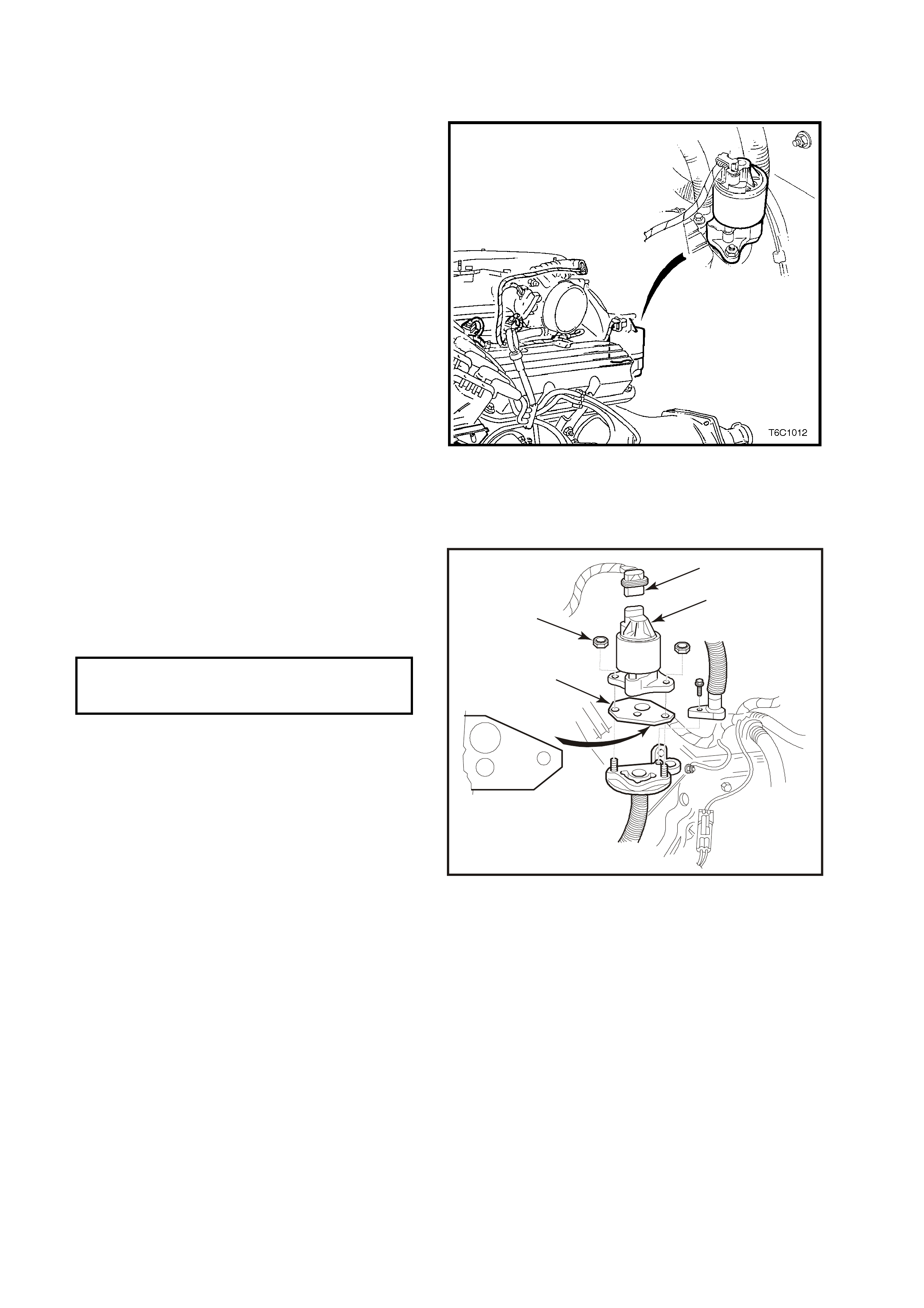

3.14 2-3 SHIFT SOLENOID

Figure 6C1-3-70 2-3 Shift Solenoid Location

REMOVE

1. Disconnect battery earth lead.

IMPORTANT:

To avoid personal injury from accidental hot oil spillage, perform fluid change only w hen transmission fluid is cold.

2. Raise vehicle and support on safety stands. Refer to Section 0A, GENERAL INFORMATION of the VT

Series I Service Information.

3. Clean all dirt from around oil pan and transmission case.

4. Place drain tray under transmission.

5. Loosen two bolts at the rear and one at the front of the oil pan. Rem ove the remaining bolts. W hile holding oil

pan , allow front of oil pan to drop away, emptying oil into a drain tray.

6. Remove remaining bolts, then lower oil pan and empty fluid from pan.

7. Remove old oil pan gasket and discard.

8. Disconnect 2-3 shift solenoid (367B) electrical connector.

9. Remove solenoid retainer (379) by using a small flat blade screwdriver. Pry the retainer down until it can be

grasped

10. Remove solenoid assembly (367B) with O-ring seal. Ensure that 2-3 shuttle valve 369 remains in place.

REINSTALL

1. Push solenoid assembly with O-ring seal (367B) into valve body

2. Install solenoid retainer (379).

3. Reconnect 2-3 shift solenoid electrical connector.

4. Clean oil pan and case mating surfaces. Check that magnet is still magnetized and attached to the oil pan.

5. Install new gasket and reinstall oil pan. Tighten bolts to the correct torque specification.

Transmission Oil Pan Bolt

Torque Specification 11

N.m

6. Lower vehicle and add approximately 4.8 litres of DEXRON â III automatic transmission fluid.

7. Reconnect battery earth lead.

8. Check transmission fluid level. Refer to "Fluid Checking Procedure" in Section 6C1-2A in VX Service

Information.

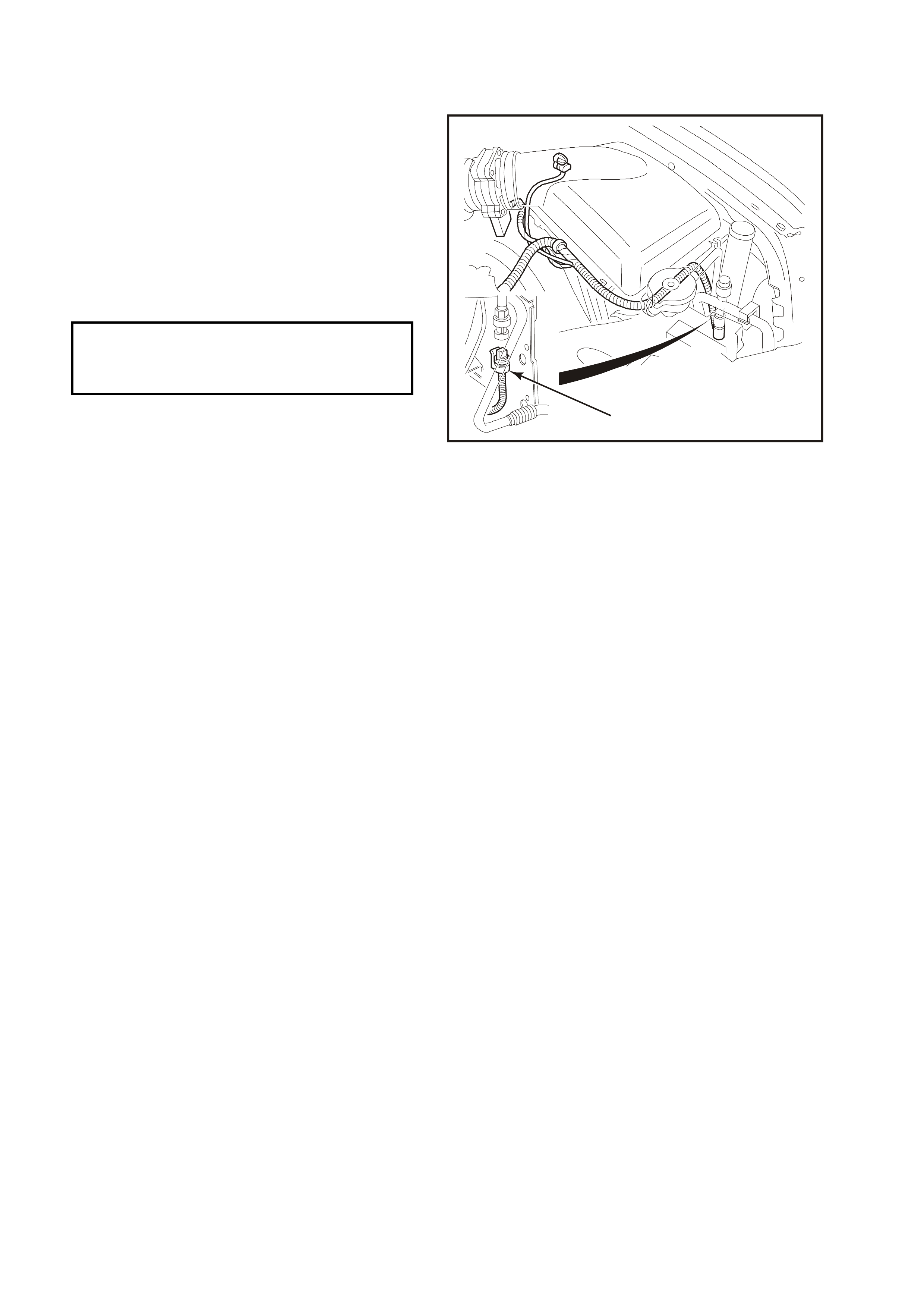

3.15 3-2 CONTROL SOLENOID

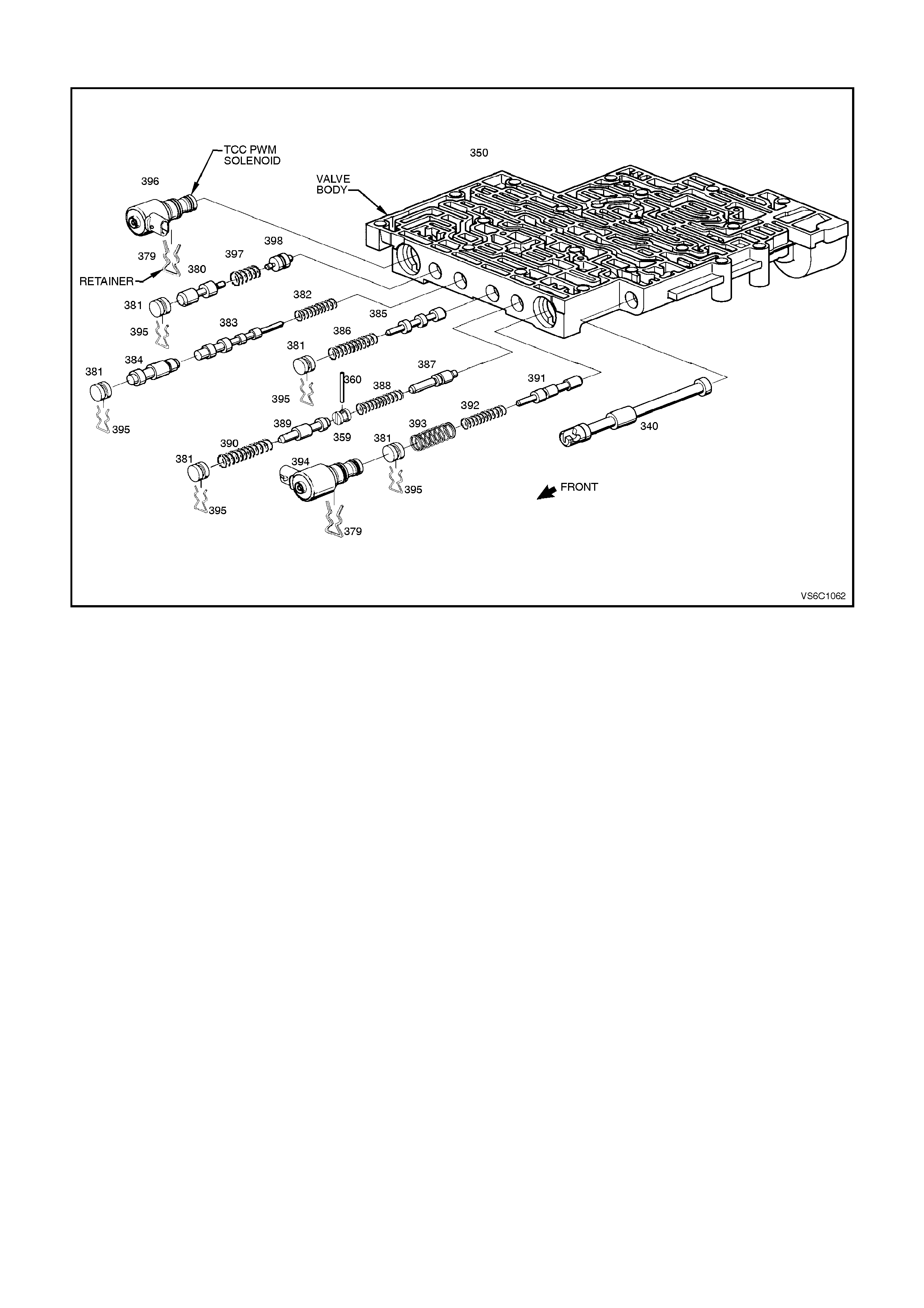

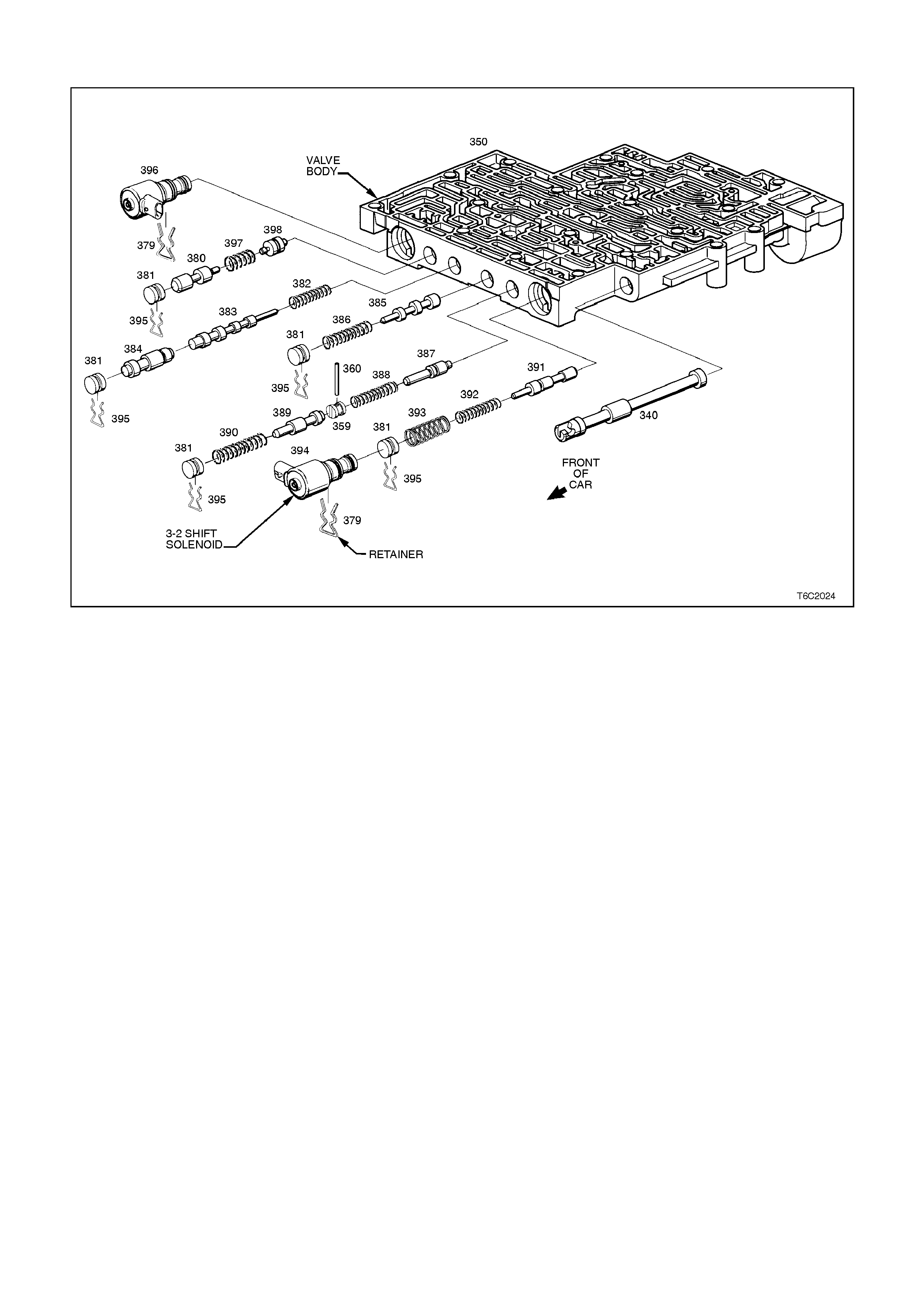

Figure 6C1-3-71 3-2 Shift Solenoid Location

REMOVE

1. Disconnect battery earth lead.

IMPORTANT:

To avoid personal injury from accidental hot oil spillage, perform fluid change only w hen transmission fluid is cold.

2. Raise vehicle and support on safety stands. Refer to Section 0A, GENERAL INFORMATION of the VT

Series I Service Information.

3. Clean all dirt from around oil pan and transmission case.

4. Place drain tray under transmission.

5. Loosen two bolts at the rear and one at the front of the oil pan. Rem ove the remaining bolts. W hile holding oil

pan, allow the front of the oil pan to drop away, emptying oil into a drain tray.

6. Remove remaining bolts, then lower pan and empty fluid from pan.

7. Remove old oil pan gasket and discard.

8. Remove strainer.

8. Disconnect 3-2 control solenoid (394) electrical connector.

9. Remove solenoid retainer (379) by using a split ring puller or similar hooked tool.

IMPORTANT:

Solenoid has spring pressure behind it and may pop out after retainer is removed.

9. Remove solenoid assembly (394) with O-ring seal.

REINSTALL

1. Push solenoid assembly with O-ring seal (394) into valve body

2. Hold solenoid firmly in place with finger pressure while installing retainer (379).

3. Reconnect 3-2 control solenoid electrical connector.

4. Install strainer.

5. Clean oil pan and case mating surfaces. Check that magnet is still magnetized, and attached to the oil pan.

6. Install new gasket and reinstall oil pan. Tighten bolts to the correct torque specification.

Transmission Oil Pan Bolt

Torque Specification 11

N.m

7. Lower vehicle and add approximately 4.8 litres of DEXRON â III automatic transmission fluid.

8. Reconnect battery earth lead.

9. Check transmission fluid level. Refer to "Fluid Checking Procedure" in Section 6C1-2A in VX Service

Information.

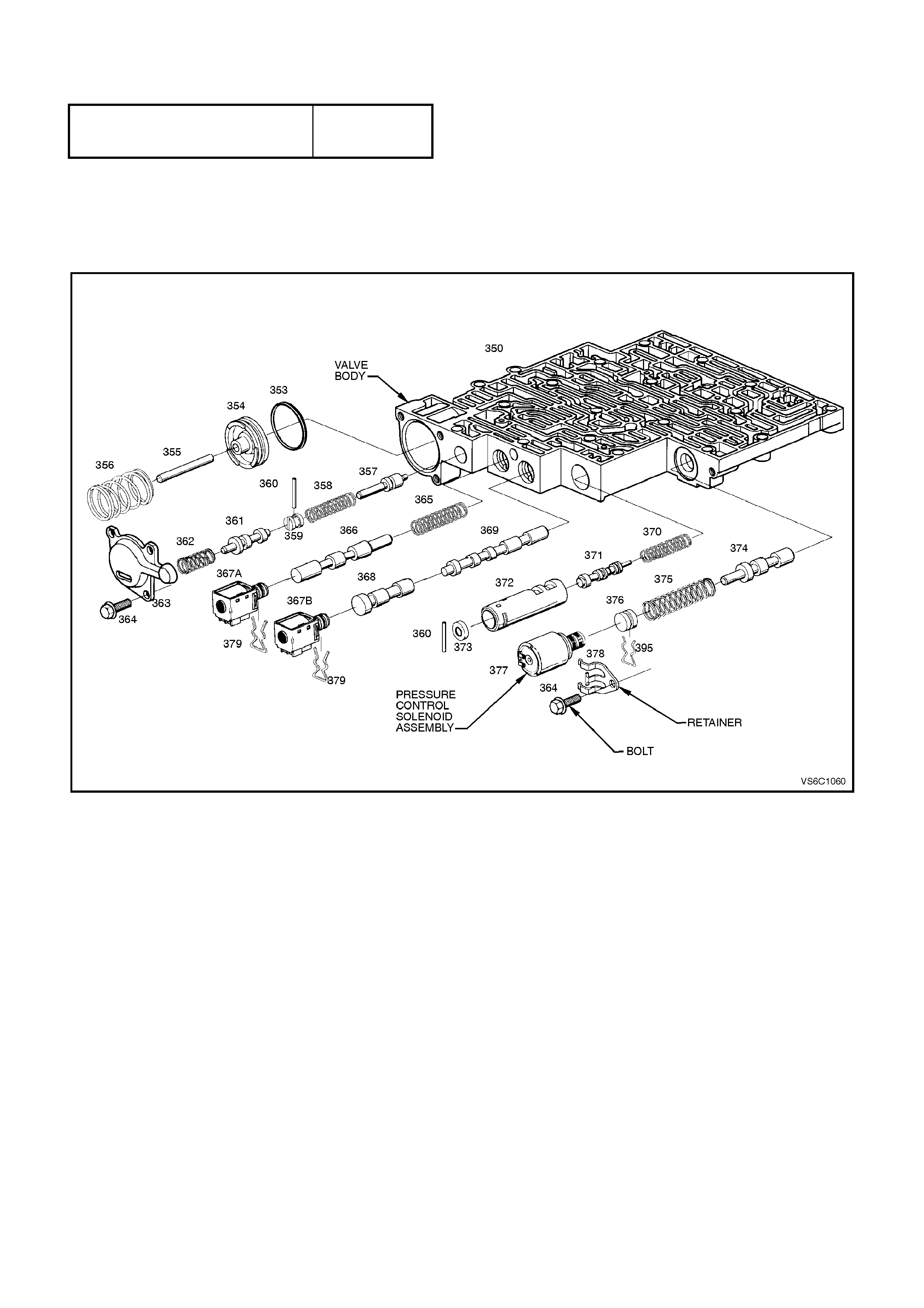

3.16 PRE S SURE CONTROL SOLENOID

REMOVE

1. Disconnect battery earth lead.

IMPORTANT:

To avoid personal injury from accidental hot oil

spillage, perform fluid change only when

transmission fluid is cold.

2. Raise vehicle and support on safety stands.

Refer to Section 0A, GENERAL

INFORMATION in the VT I Service Information.

3. Clean all dirt from around oil pan and

transmission case.

4. Place drain tray under transmission.

5. Loosen two bolts at the rear and one at the

front of the oil pan. Remove the remaining

bolts. While holding oil pan, allow the front of

the oil pan to drop away, emptying oil into a

drain tray.

6. Remove remaining bolts, then lower pan and

empty fluid from pan.