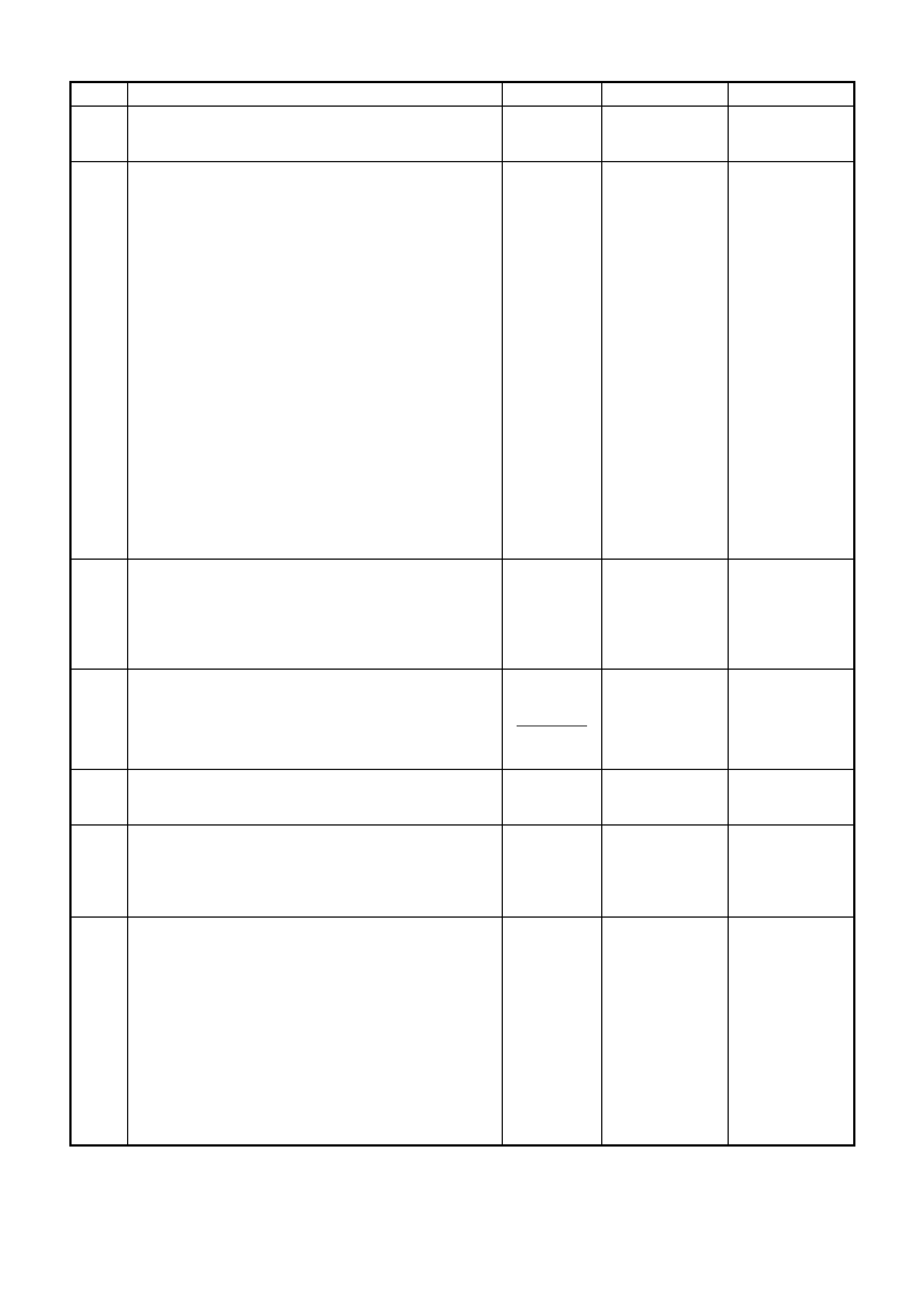

SECTION 6C3-2A - DIAGNOSTIC TABLES -

GEN III V8

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in this VX Service Information for correct workshop practices with regards to

safety and/or property damage.

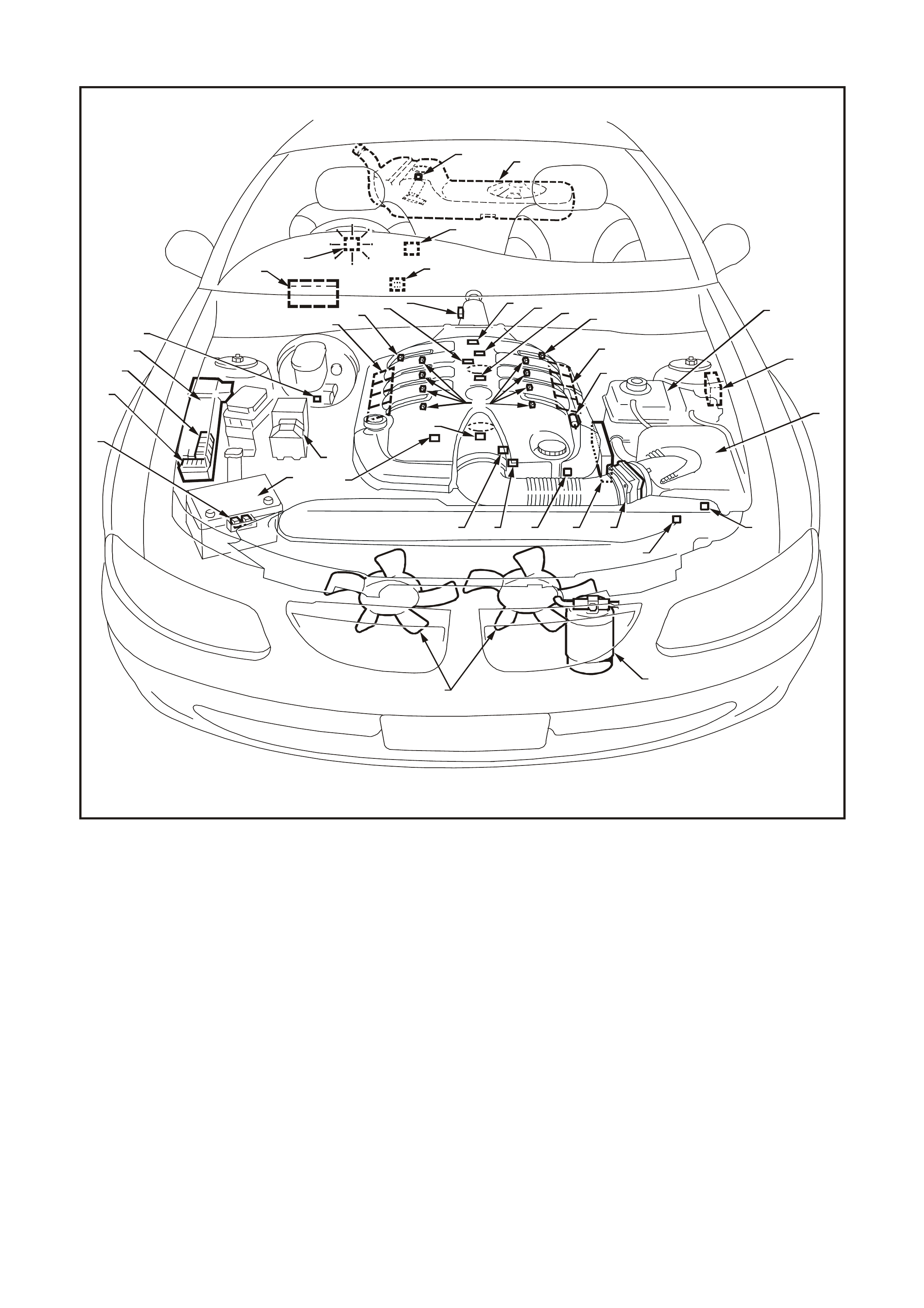

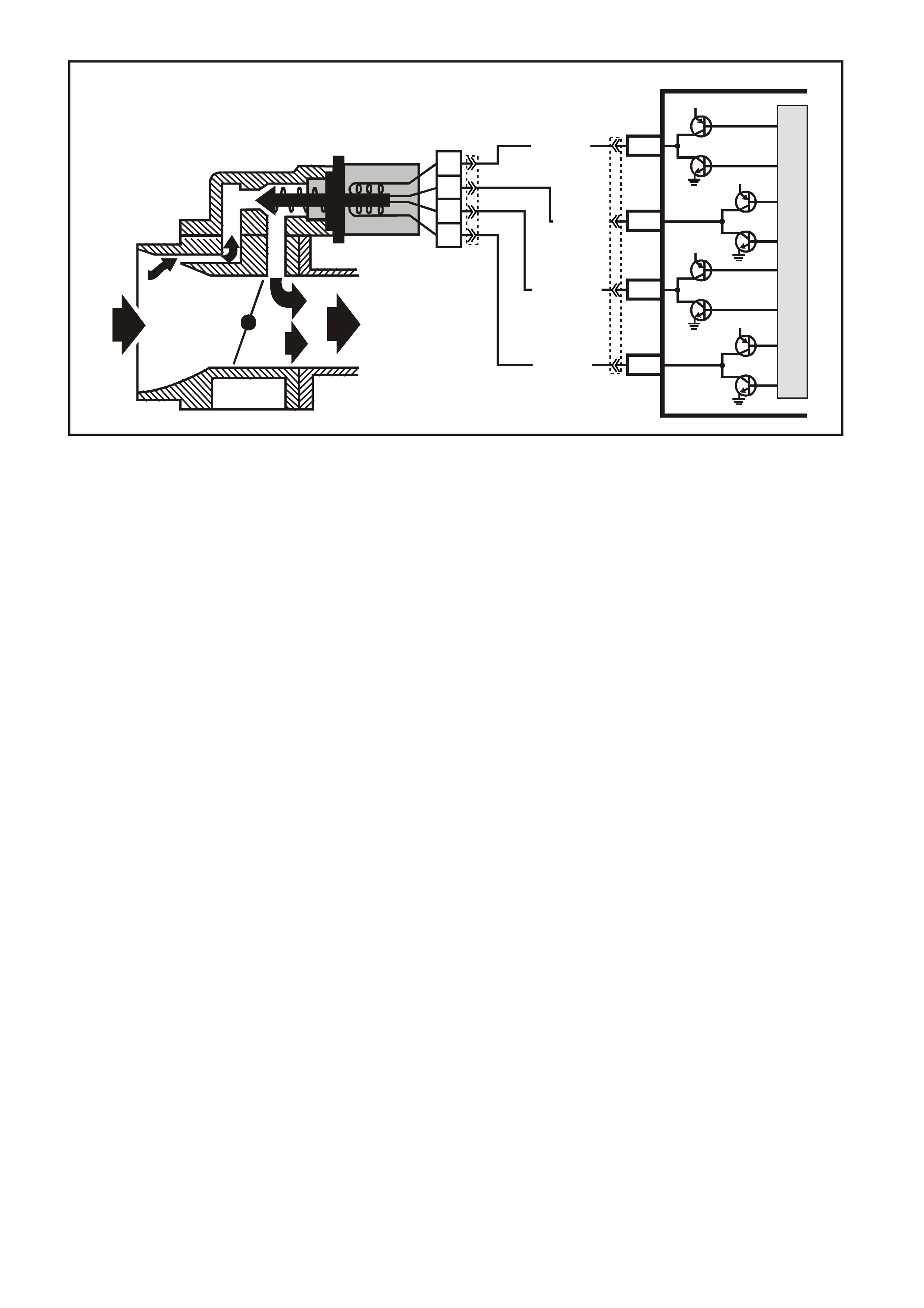

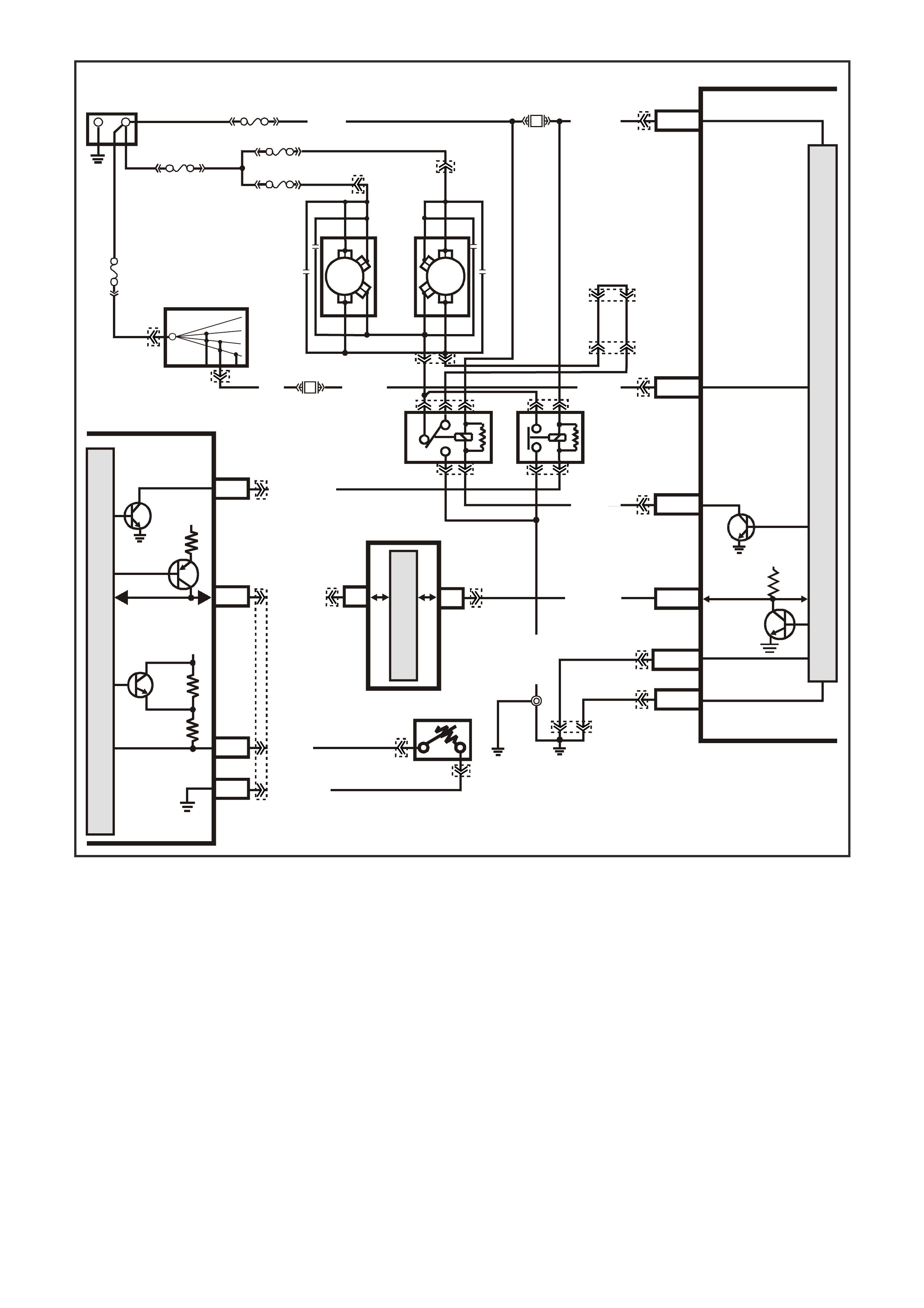

SYSTEM COMPONENT LOCATIONS

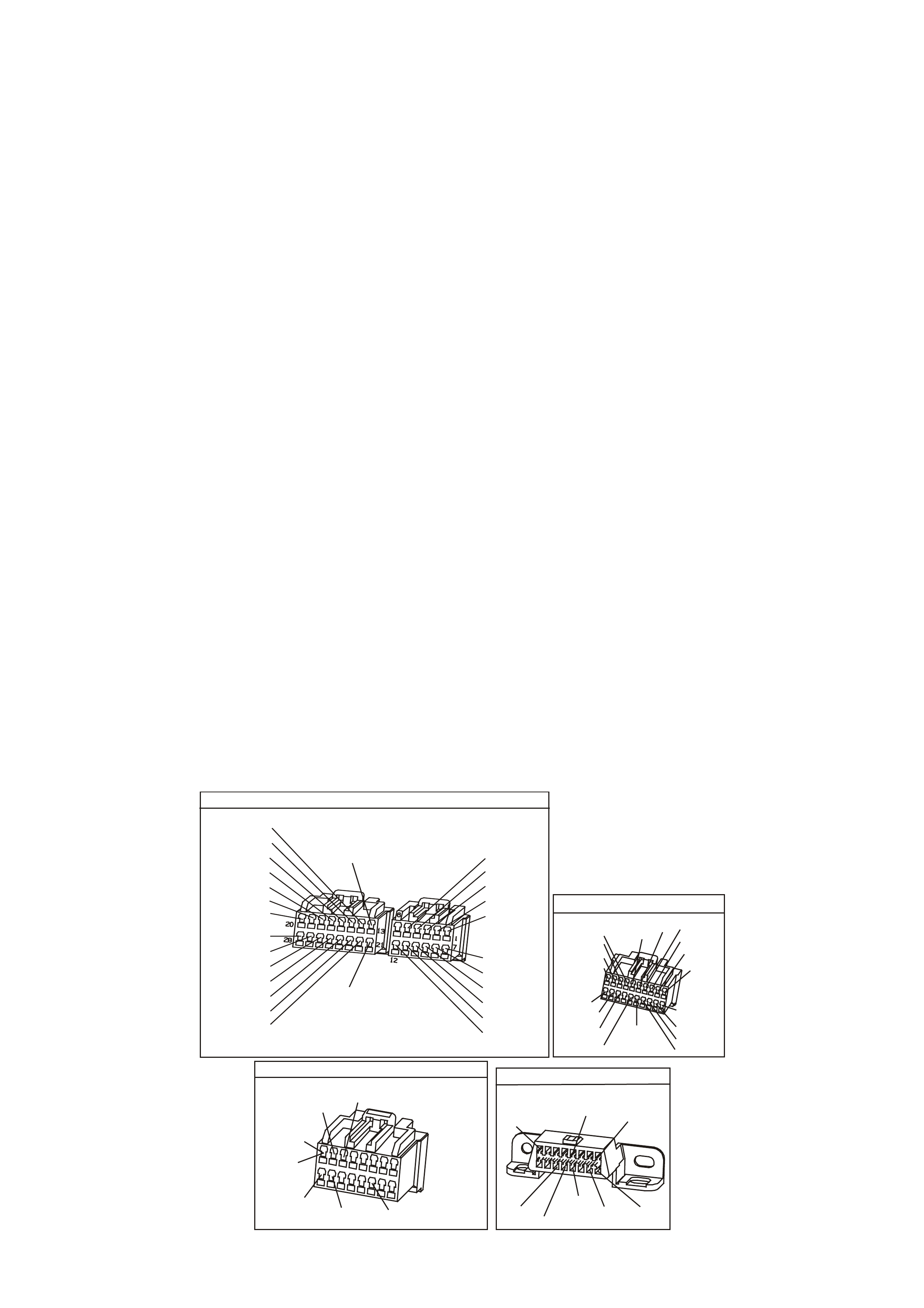

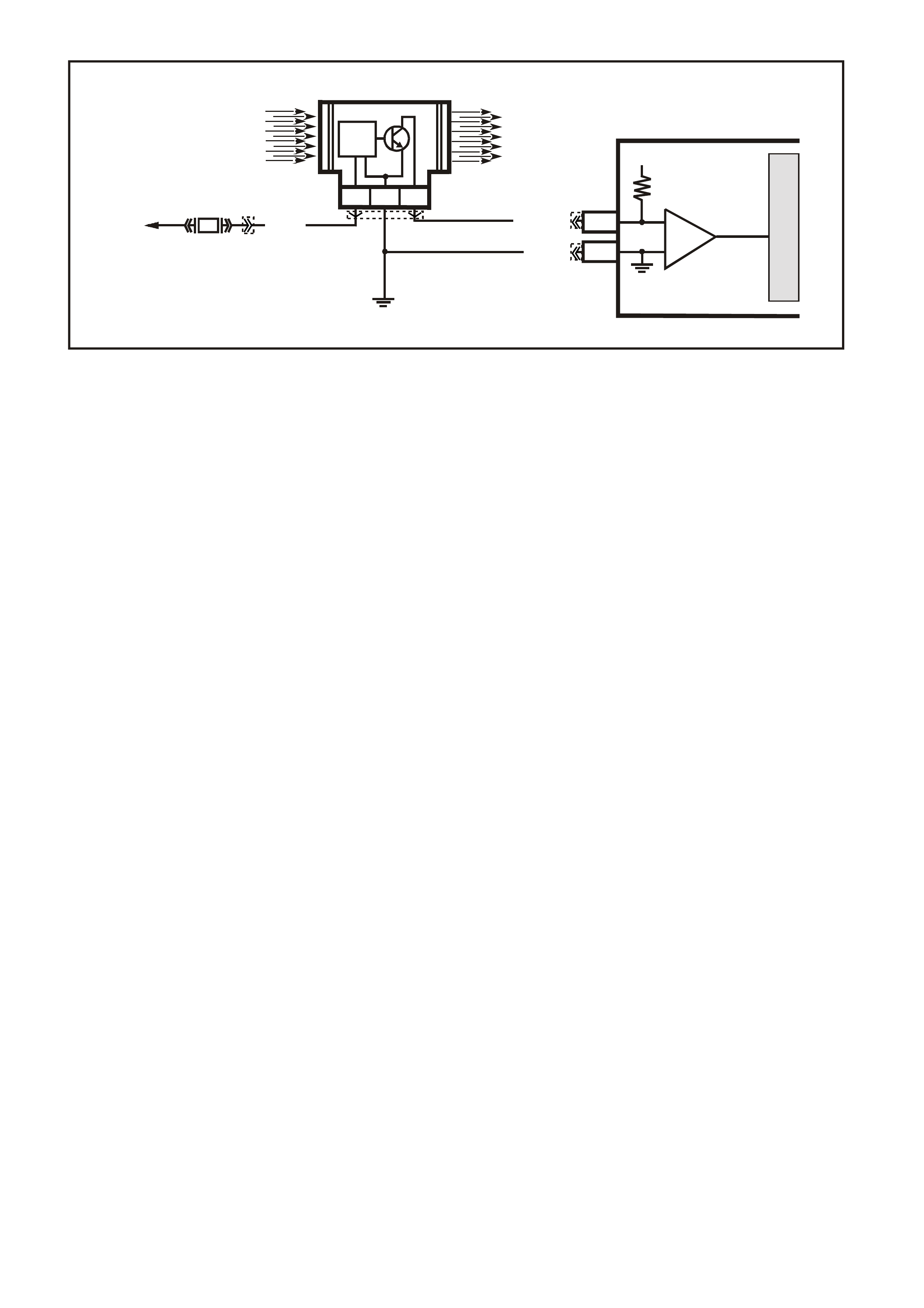

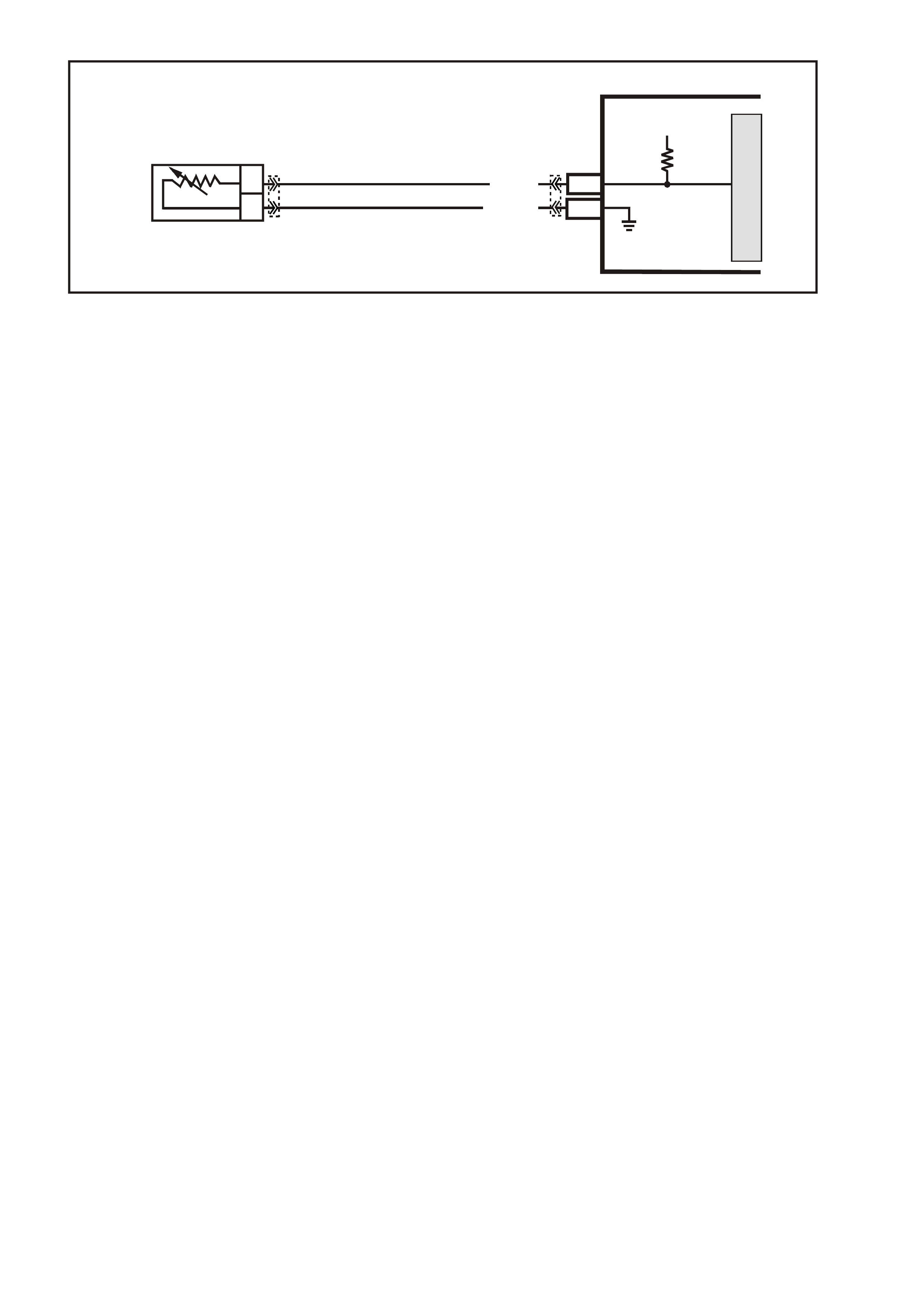

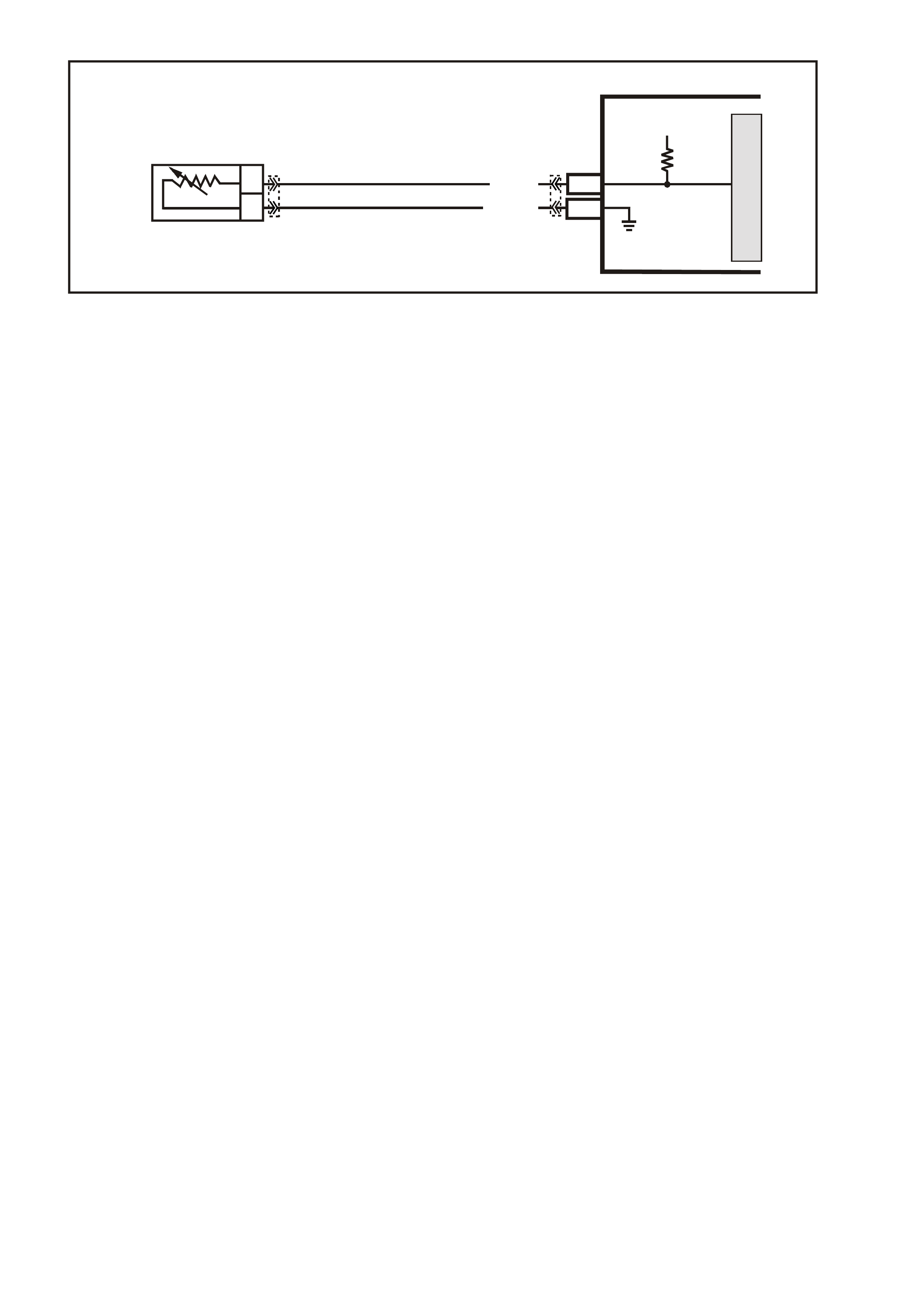

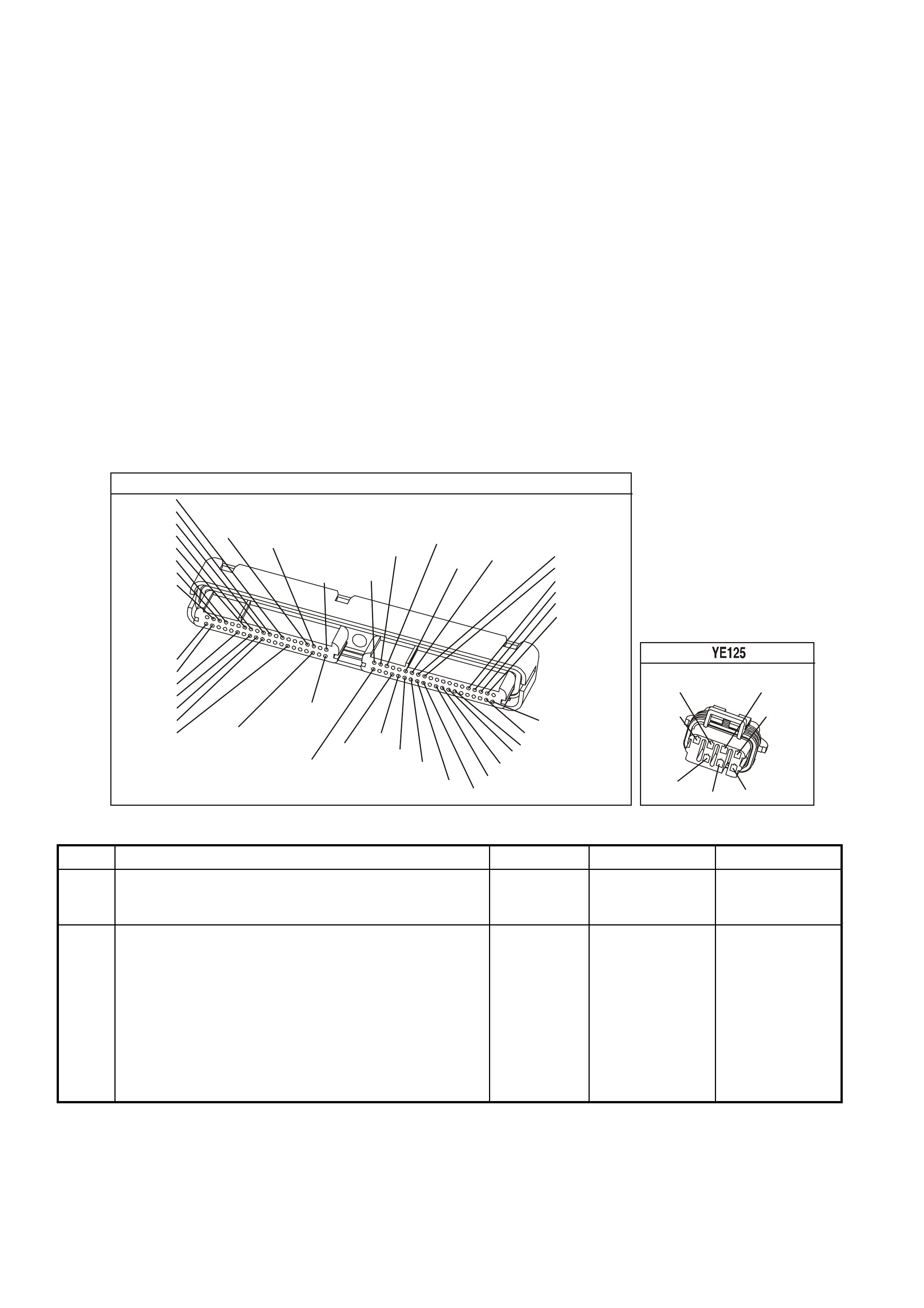

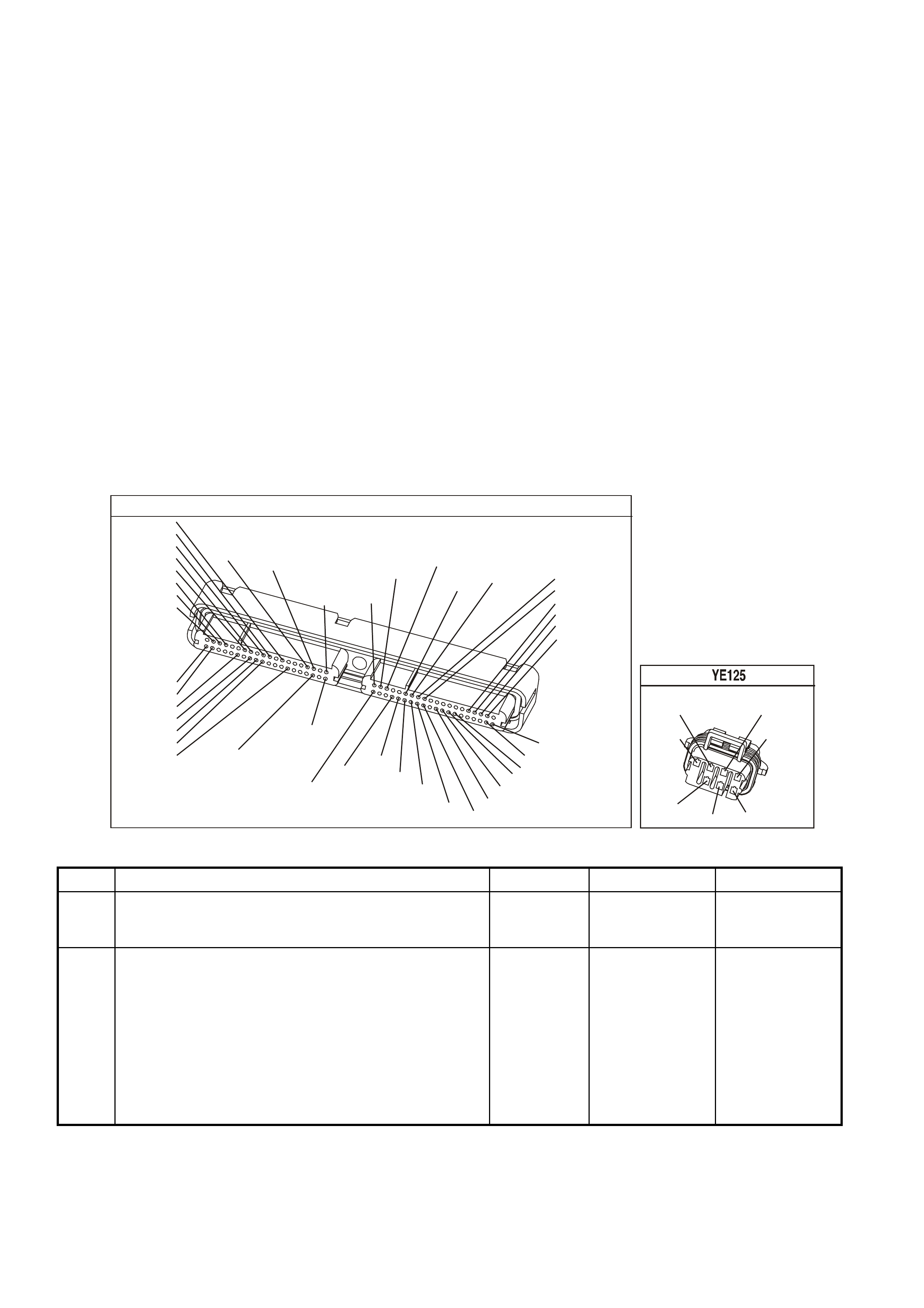

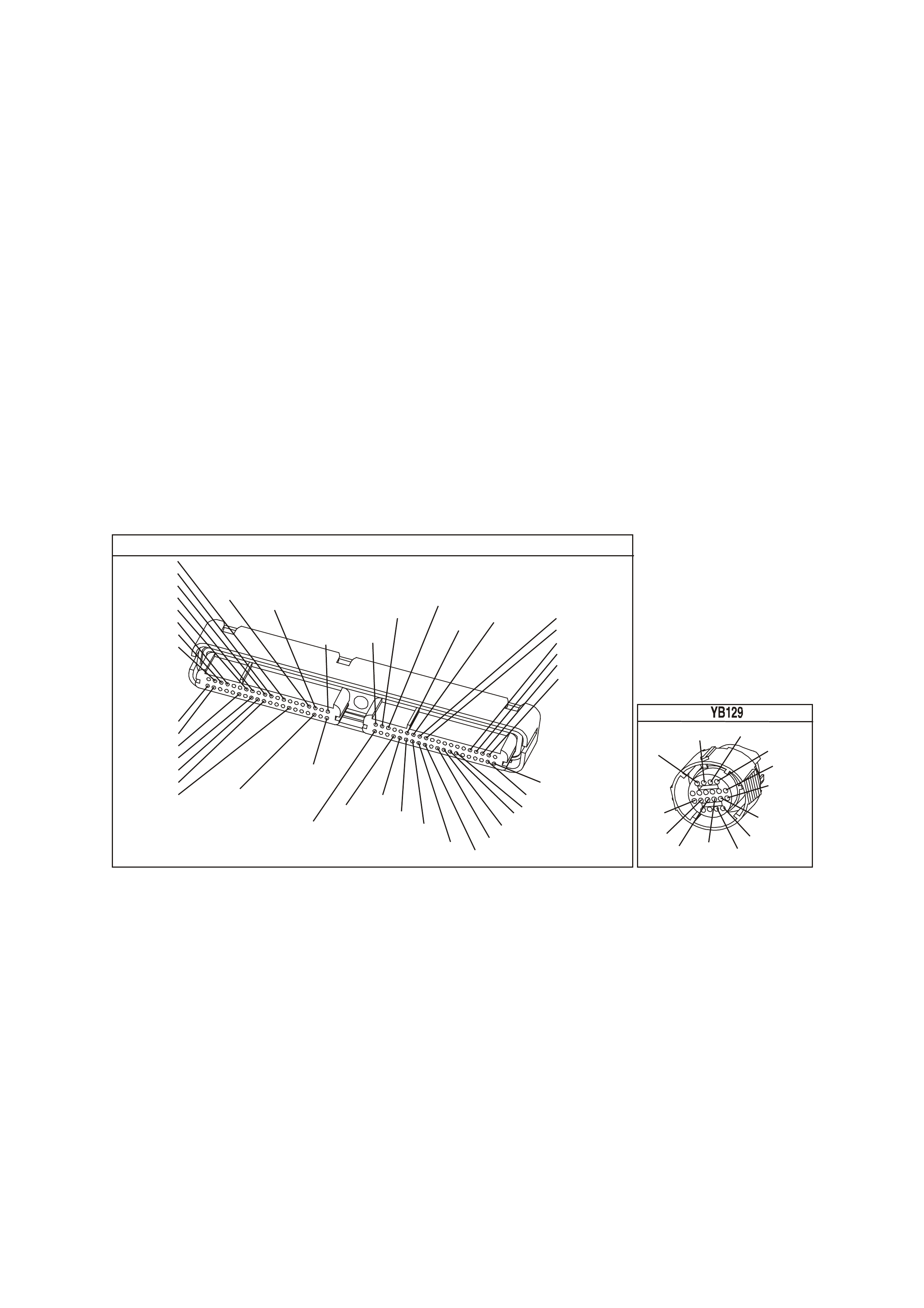

T26C3001

1

2

3

4

5

6

7

9

10

11

12

13

14

151617 18

19

20 21

21

23

23

22

24

25

26

27

28

29

30

AB

C

D

F

E

8

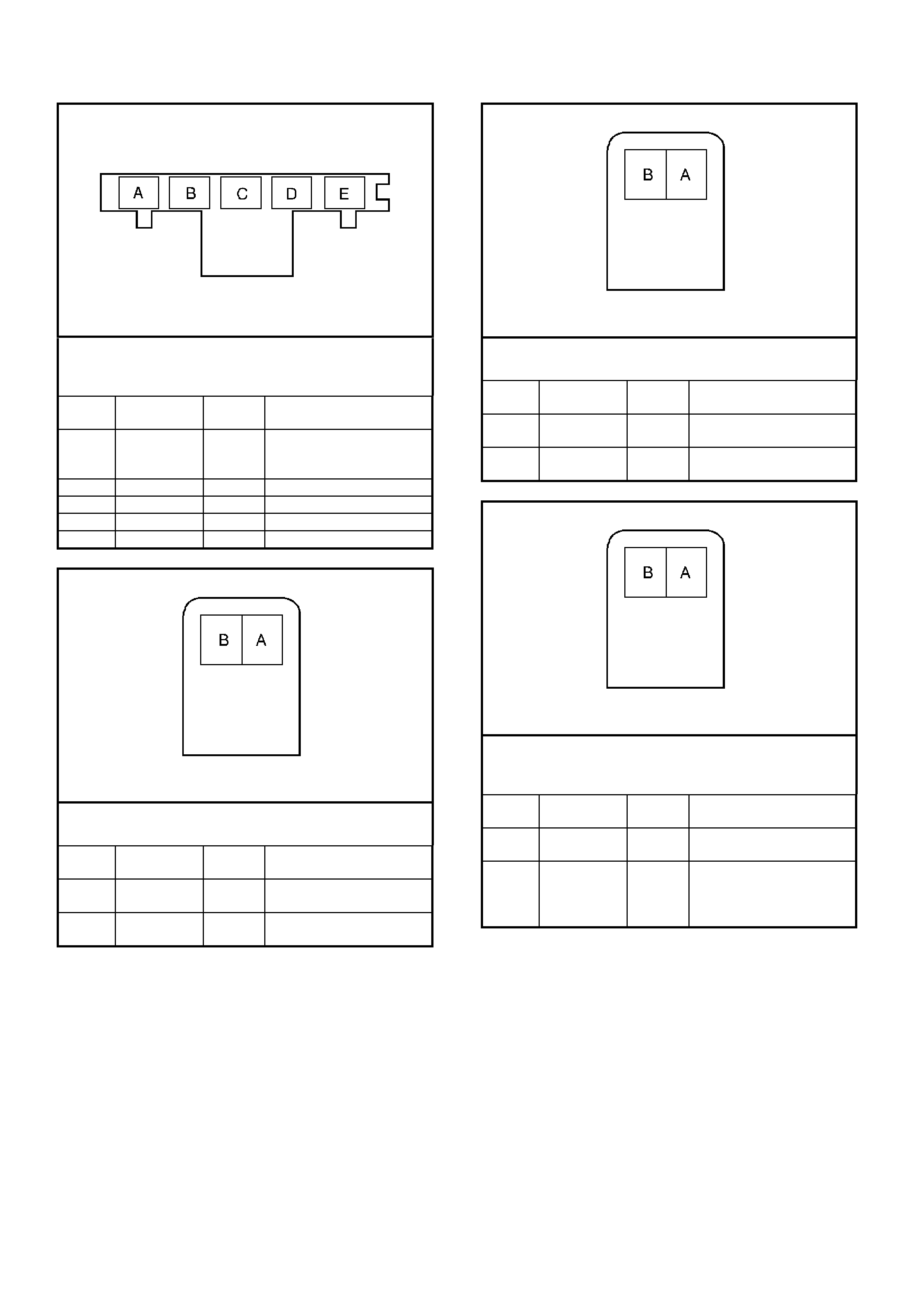

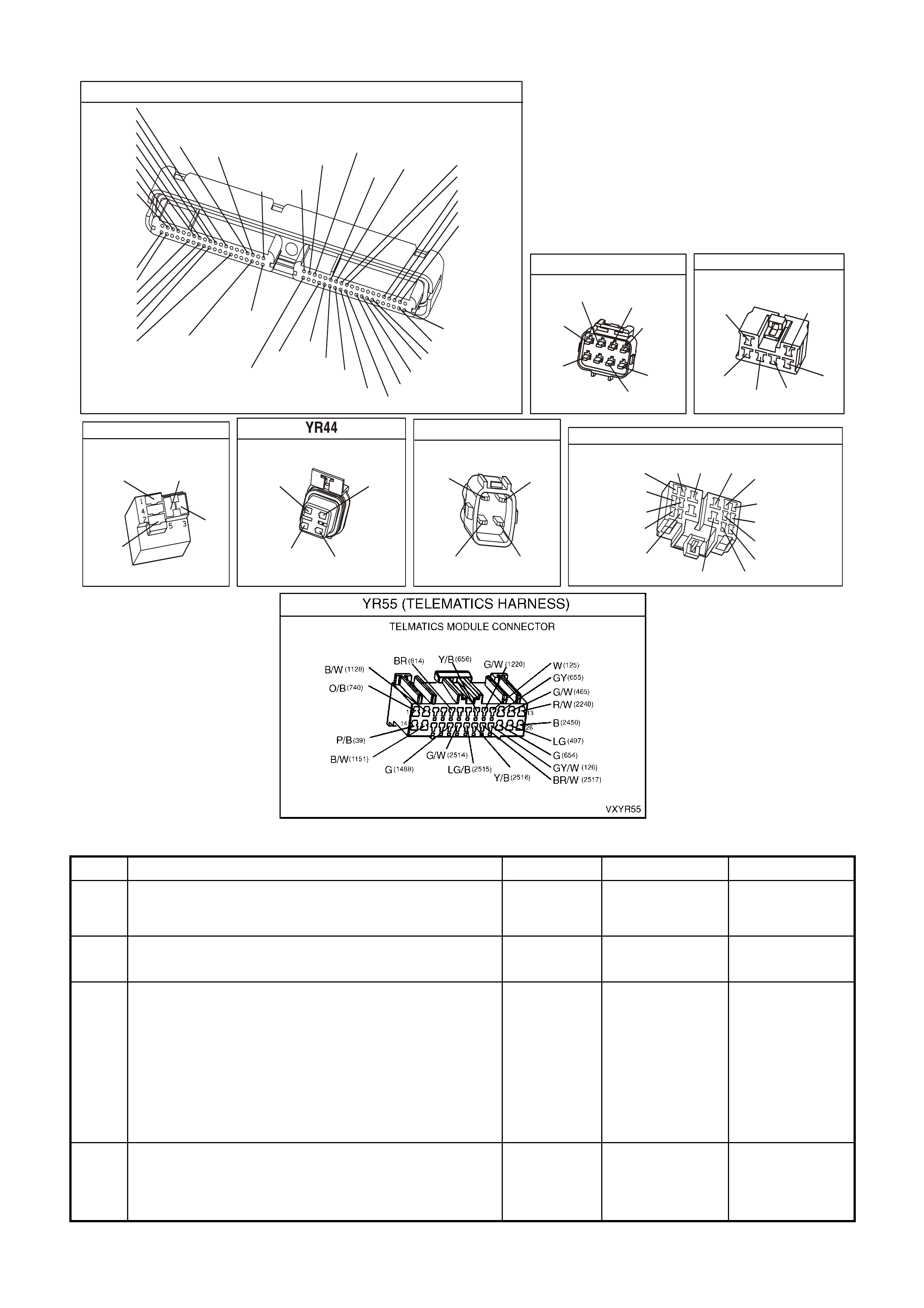

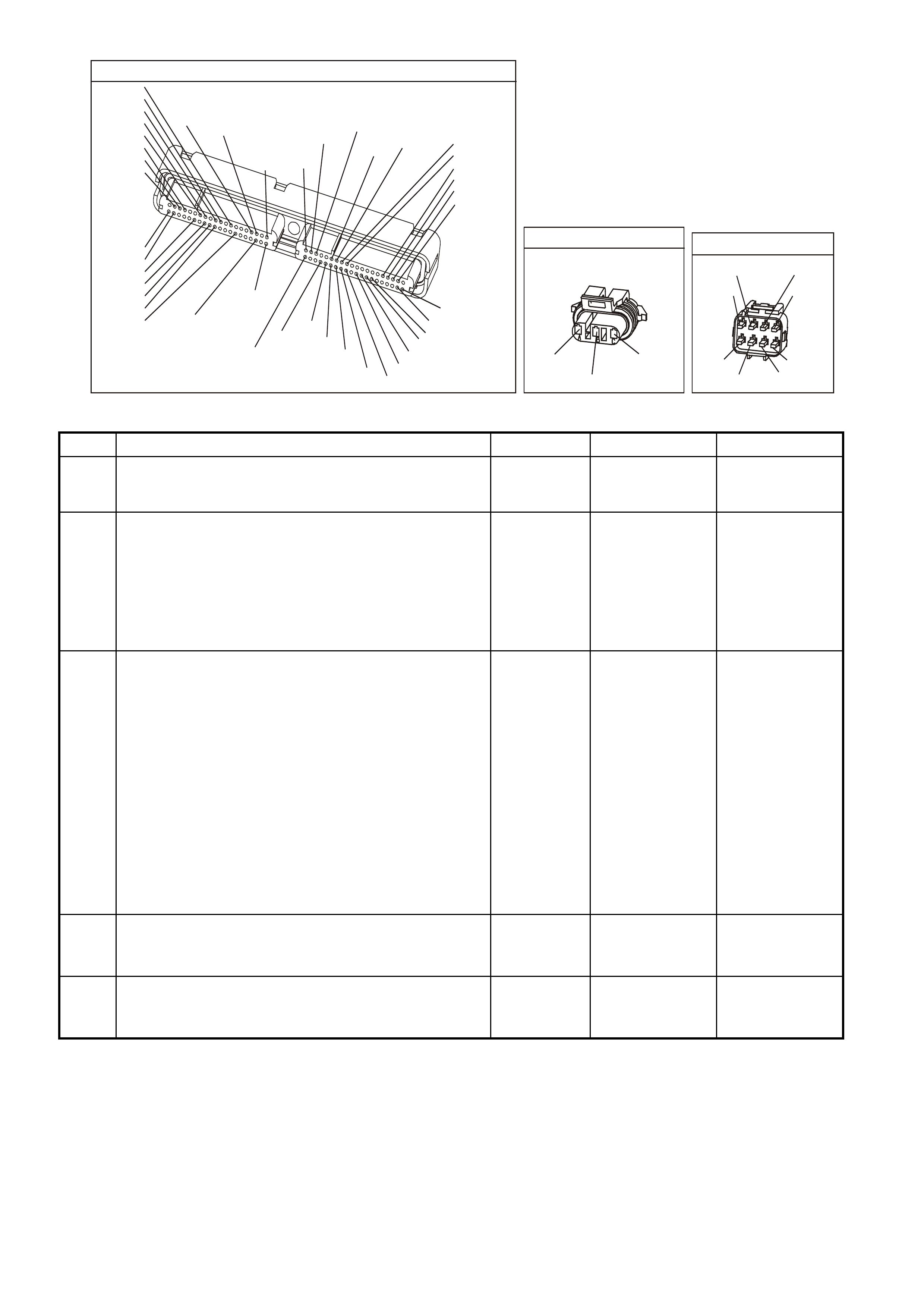

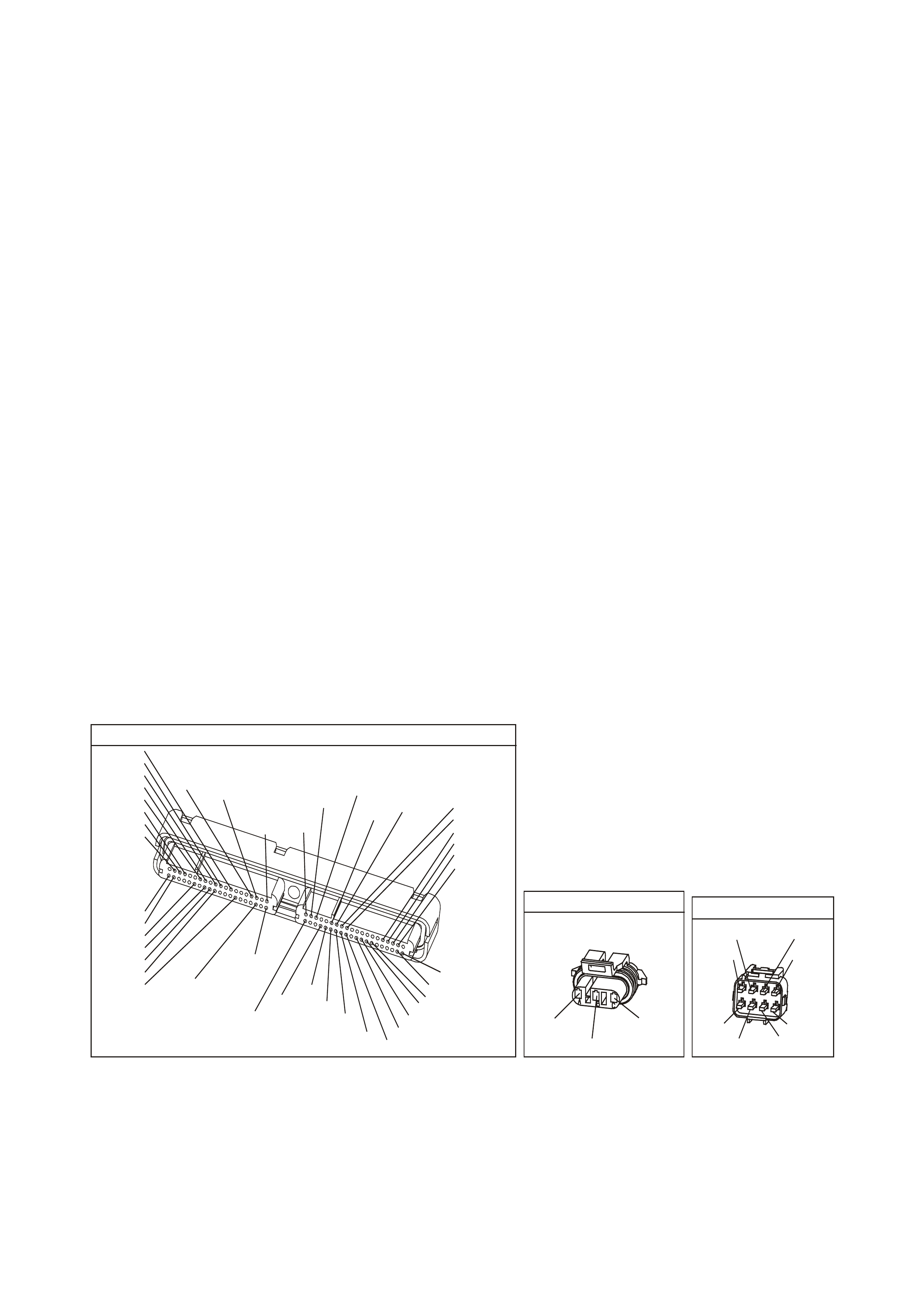

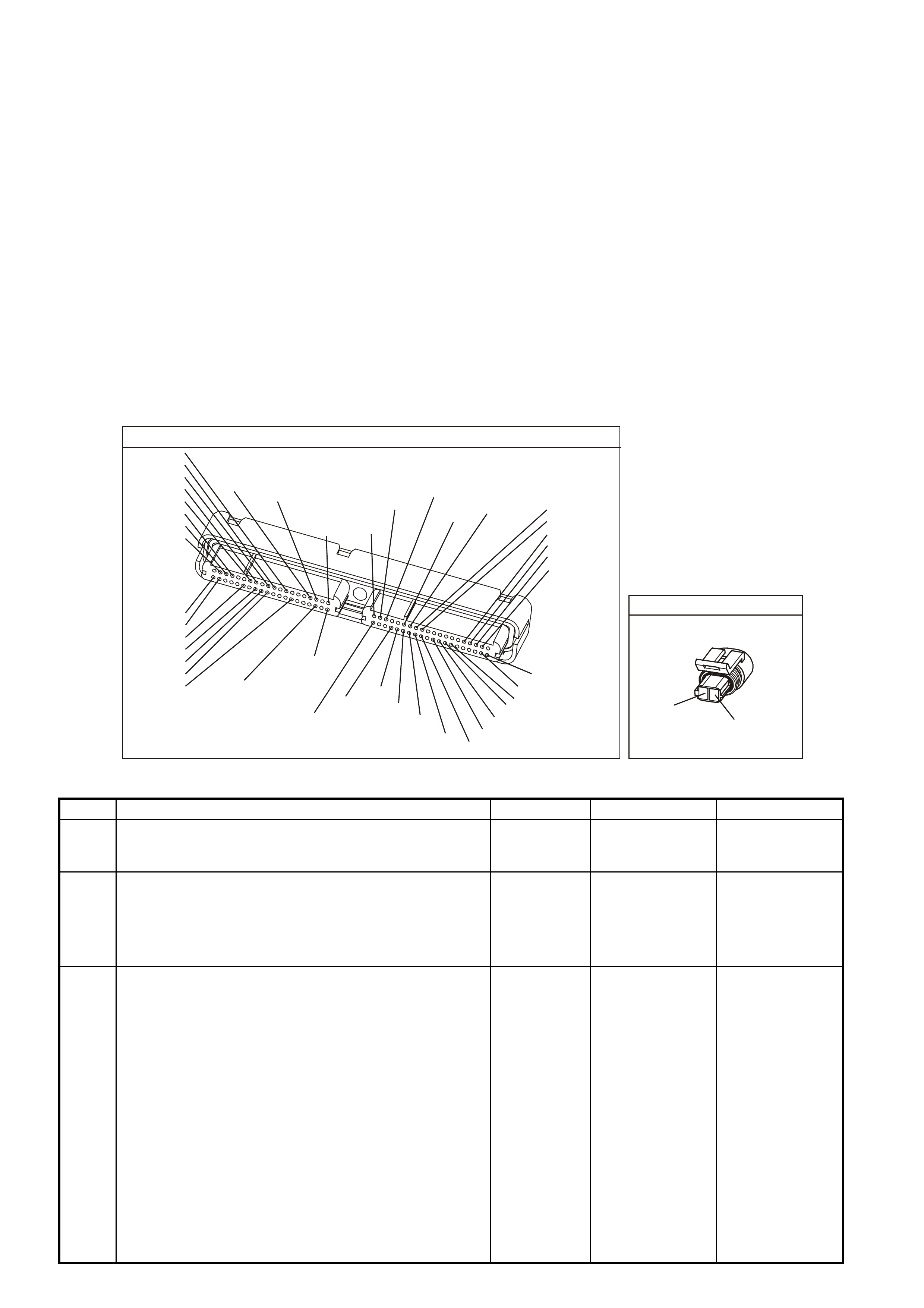

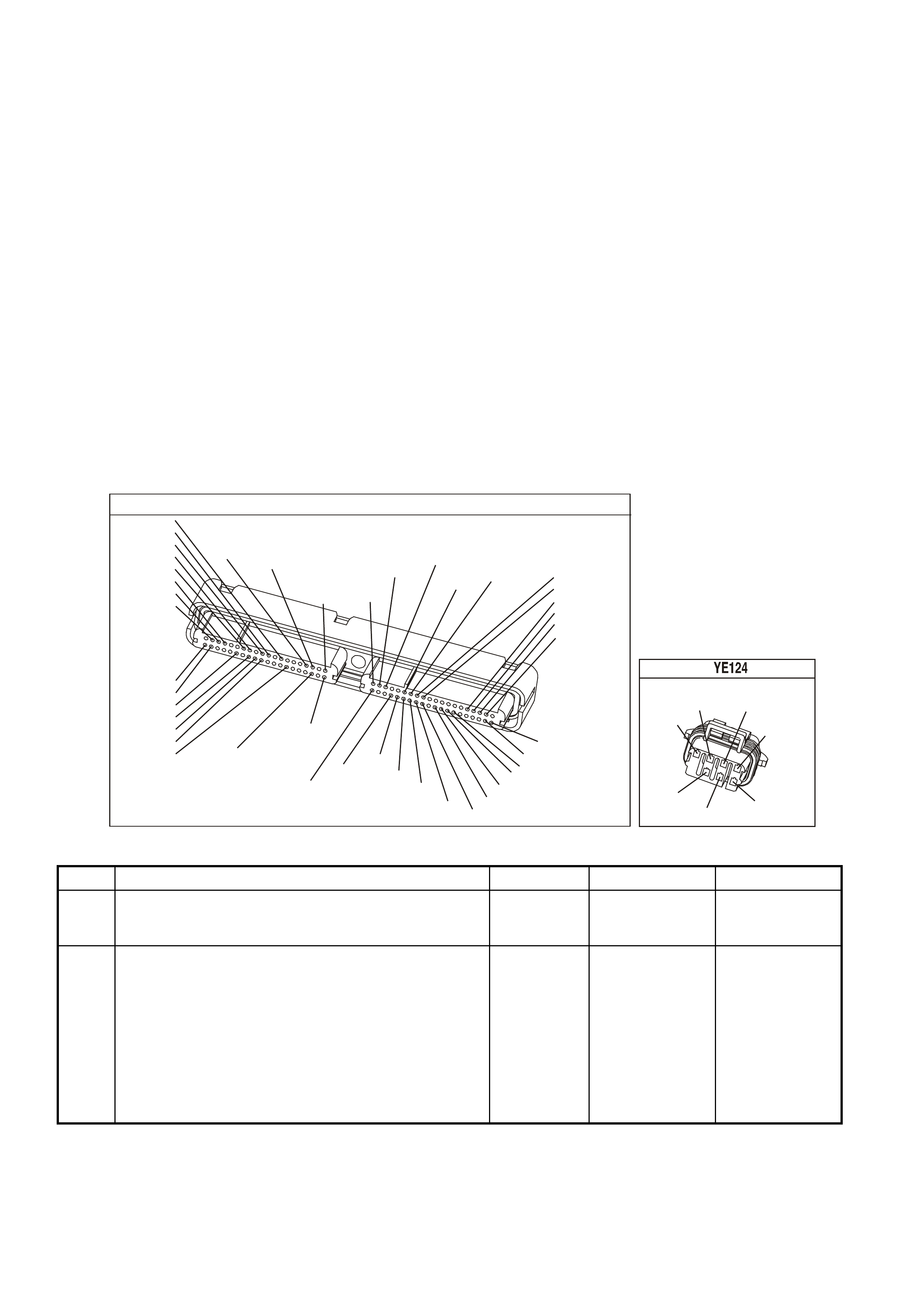

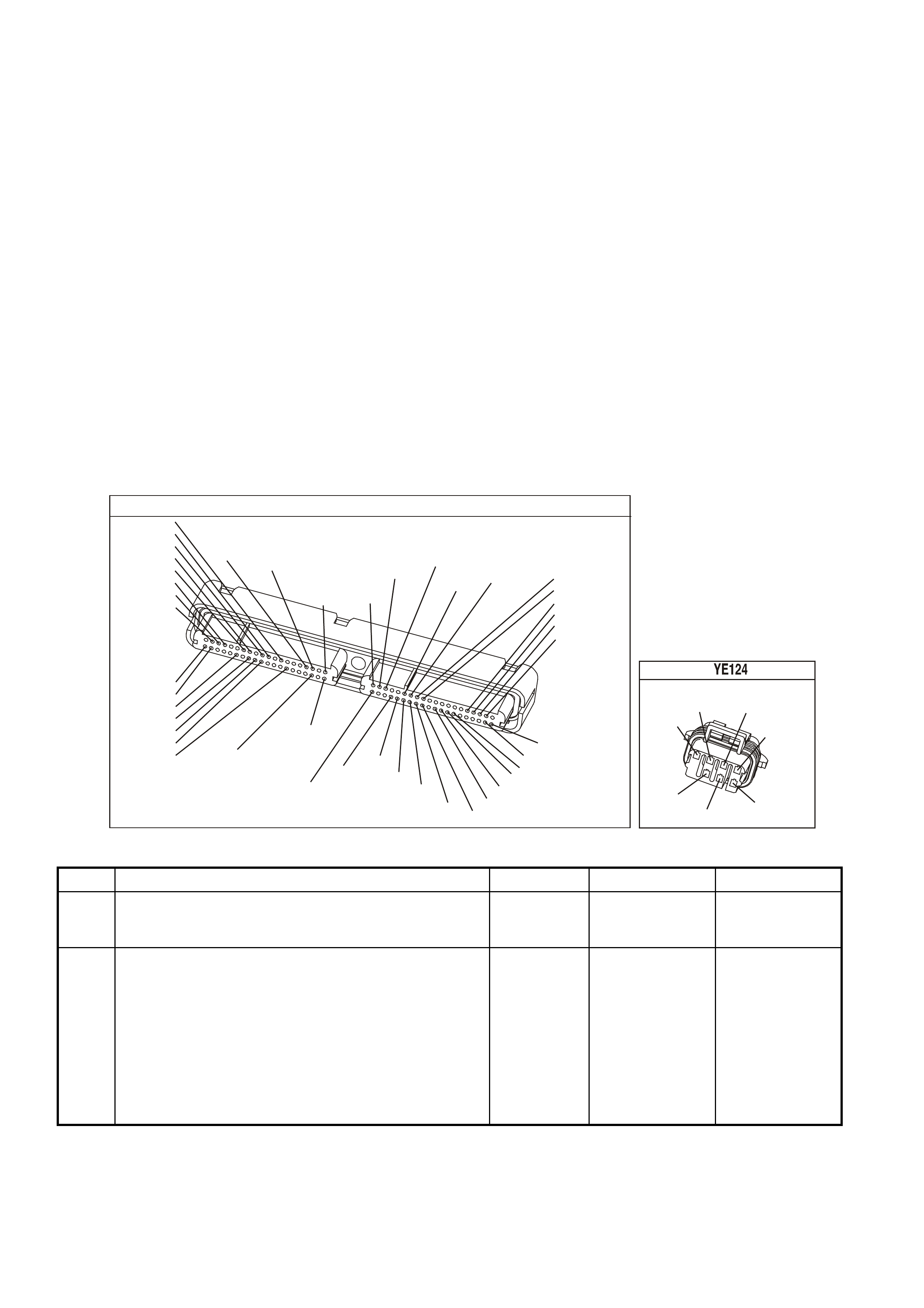

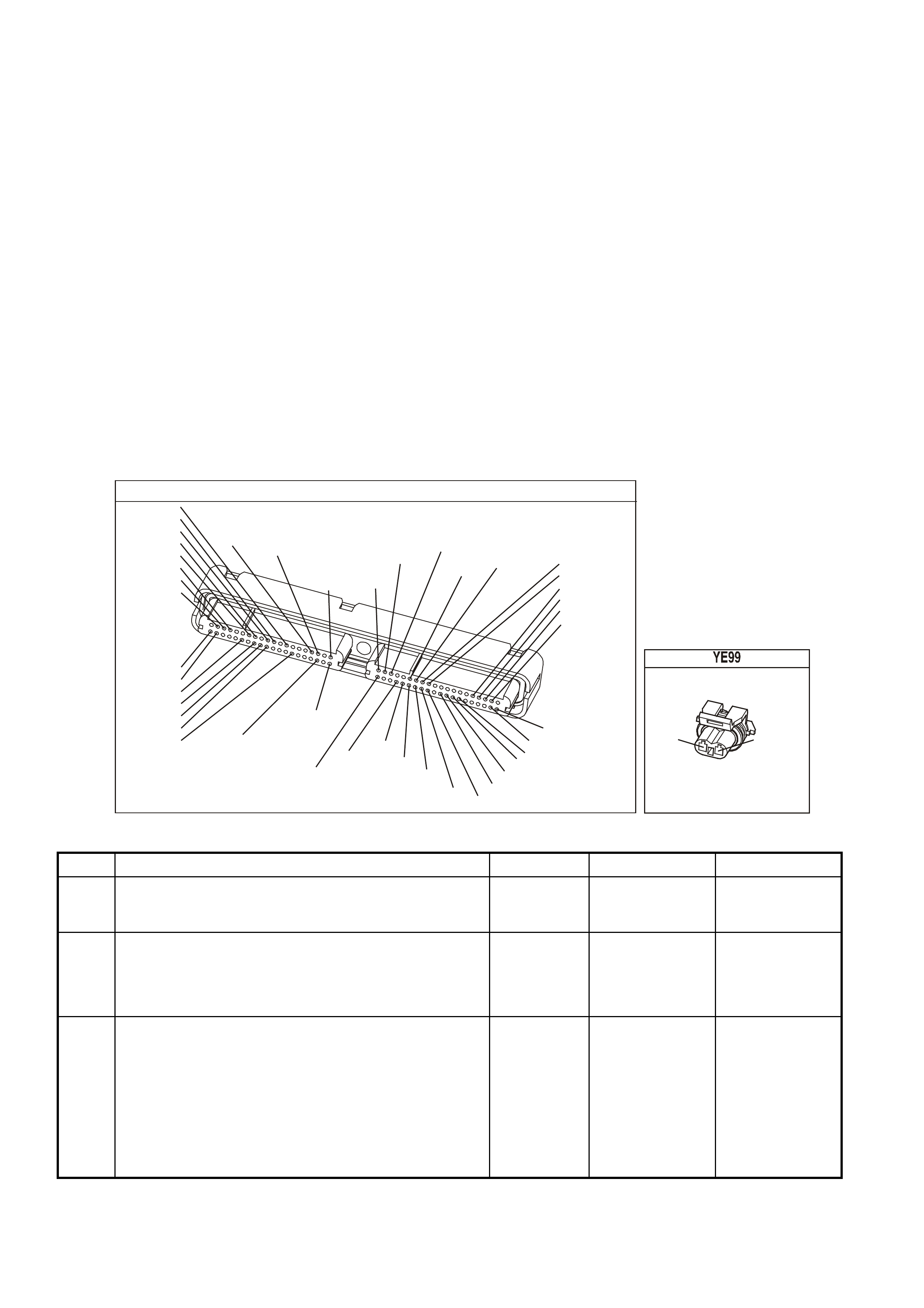

Figure 6C3-2A-1 Gen III V8 Engine Compartment Component Locations

1. Engine Compartment Fusible Link Housing 2. Battery Harness Fusible Link Housing

3. Engine Compartment Relay Housing 4. Engine Compartment Relay Housing

5. Fuel Pressure Regulator (in Fuel Tank) 6. A/C Accumulator Tank

7. Brake Hydraulic Failure Switch 8. Fuel Injectors (8)

9. Idle Air Control (IAC) Valve 10. Check Powertrain Lamp (CPL)

11. Ignition Coil/Module Right Bank 12. Ignition Coil/Module Left Bank

13. Engine Fans (2) 14. Canister Purge Solenoid

15. Mass Air Flow (MAF) Sensor 16. Engine Coolant Temperature (ECT) Sensor

17. Throttle Position (TP) Sensor 18. Intake Air Temperature (IAT) Sensor

19. Vehicle Speed Sensor (VSS) 20. Camshaft Position (CMP) Sensor

21. Heated Oxygen (HO2S) Sensor (2) 22. Crankshaft Position (CKP) Sensor

23. Knock Sensors (KS) (2) 24. ECC In - Car Air Temperature Sensor

25. A/C Refrigerant Pressure Sensor 26. Powertrain Control Module (PCM)

27. Powertrain Interface Module (PIM) - Inside

vehicle behind left kick panel 28. Diagnostic Link Connector (DLC)

29. Oil Pressure Sensor 30. Manifold Absolute Pressure (MAP) Sensor

A Battery B ABS

C BCM D Fuel Tank

E Surge Tank (With Low Coolant Level Switch) F Air Cleaner

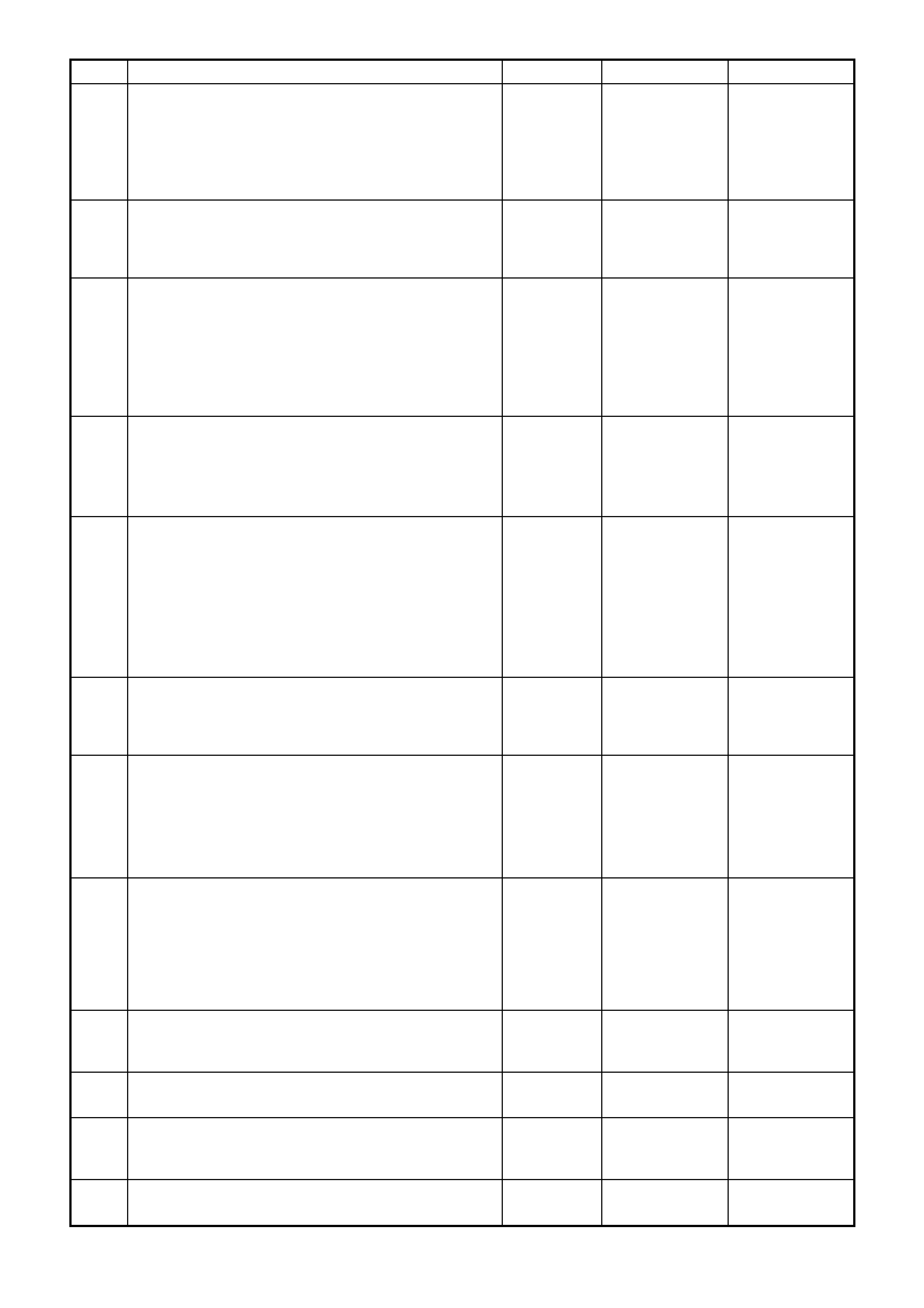

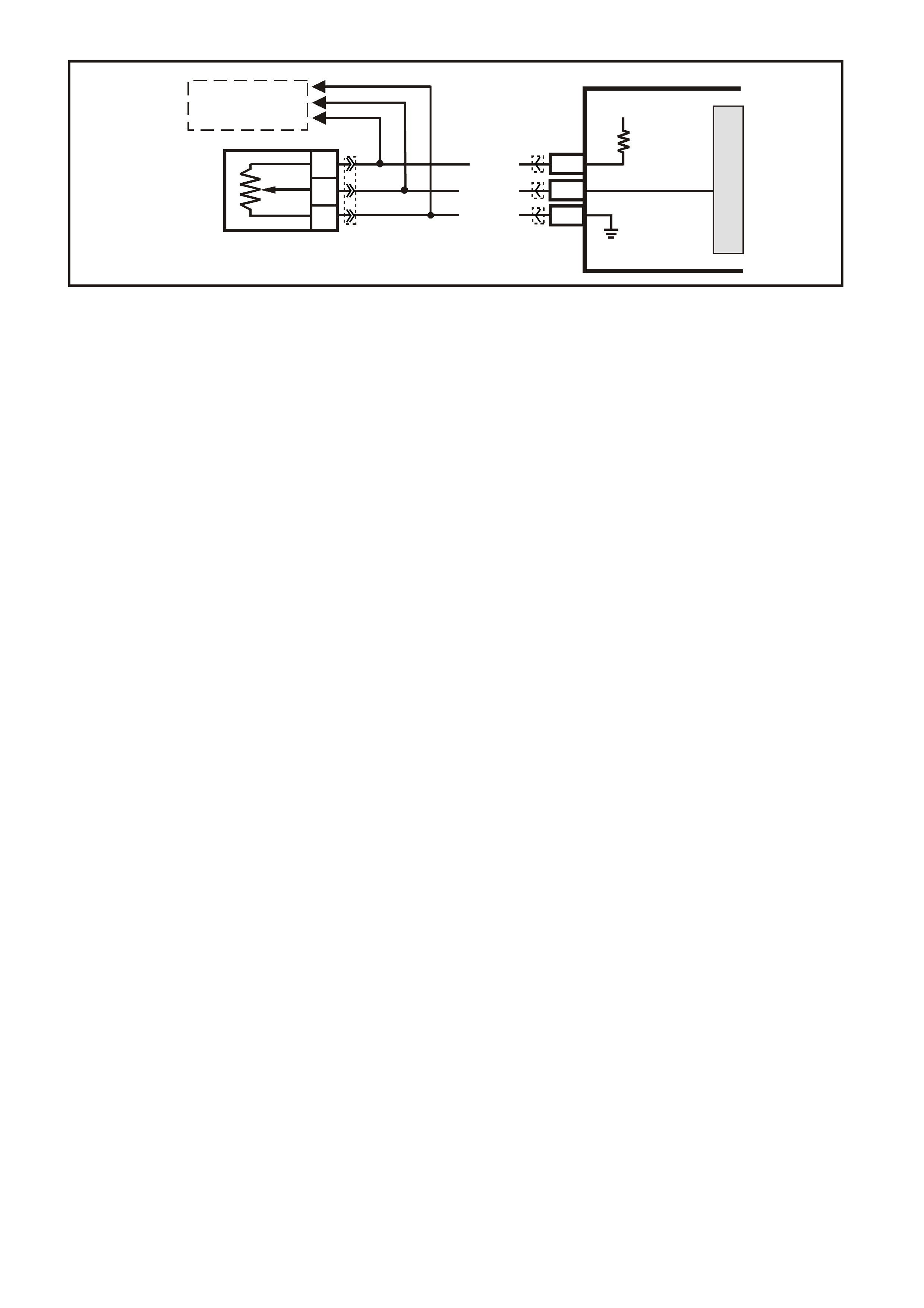

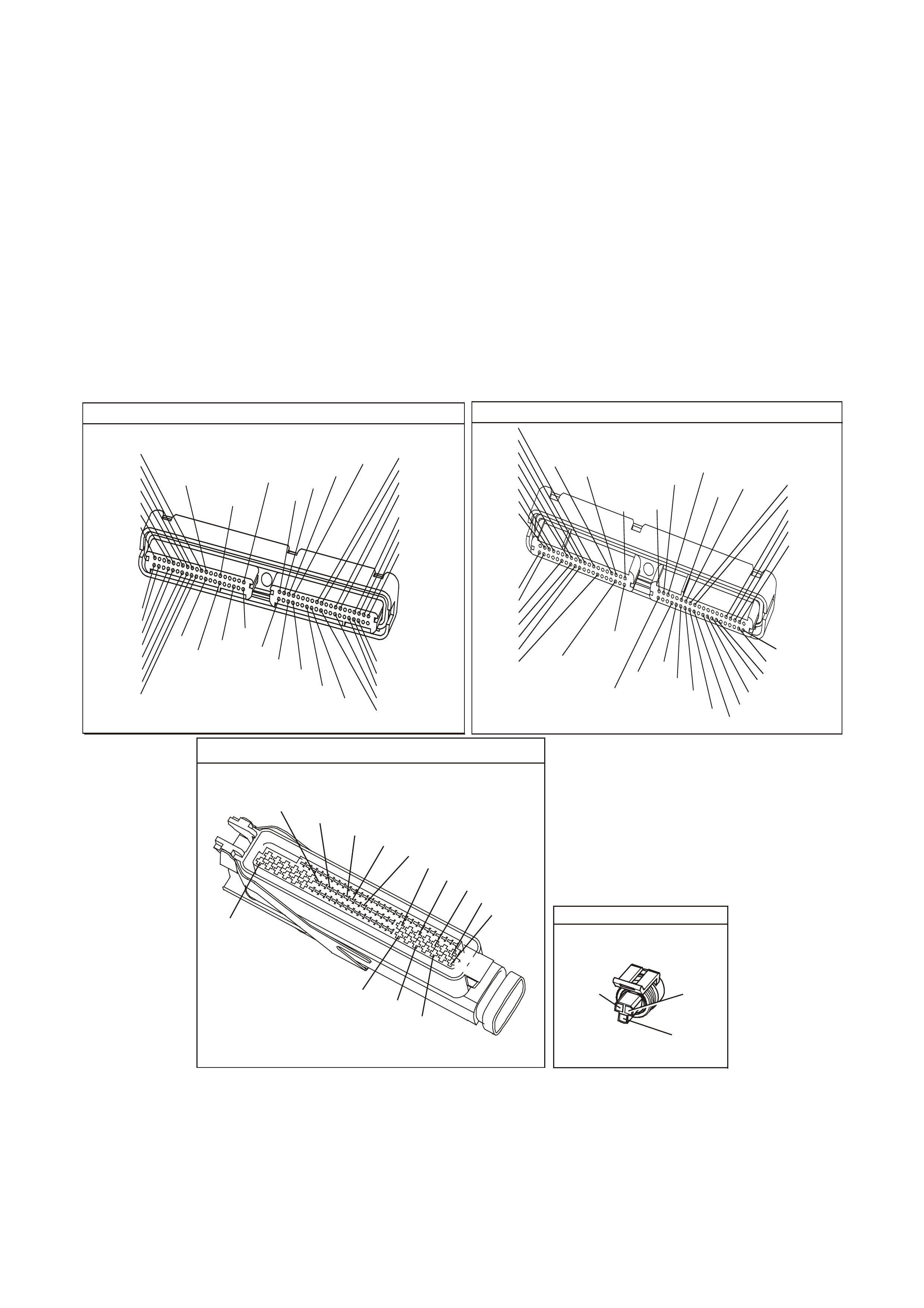

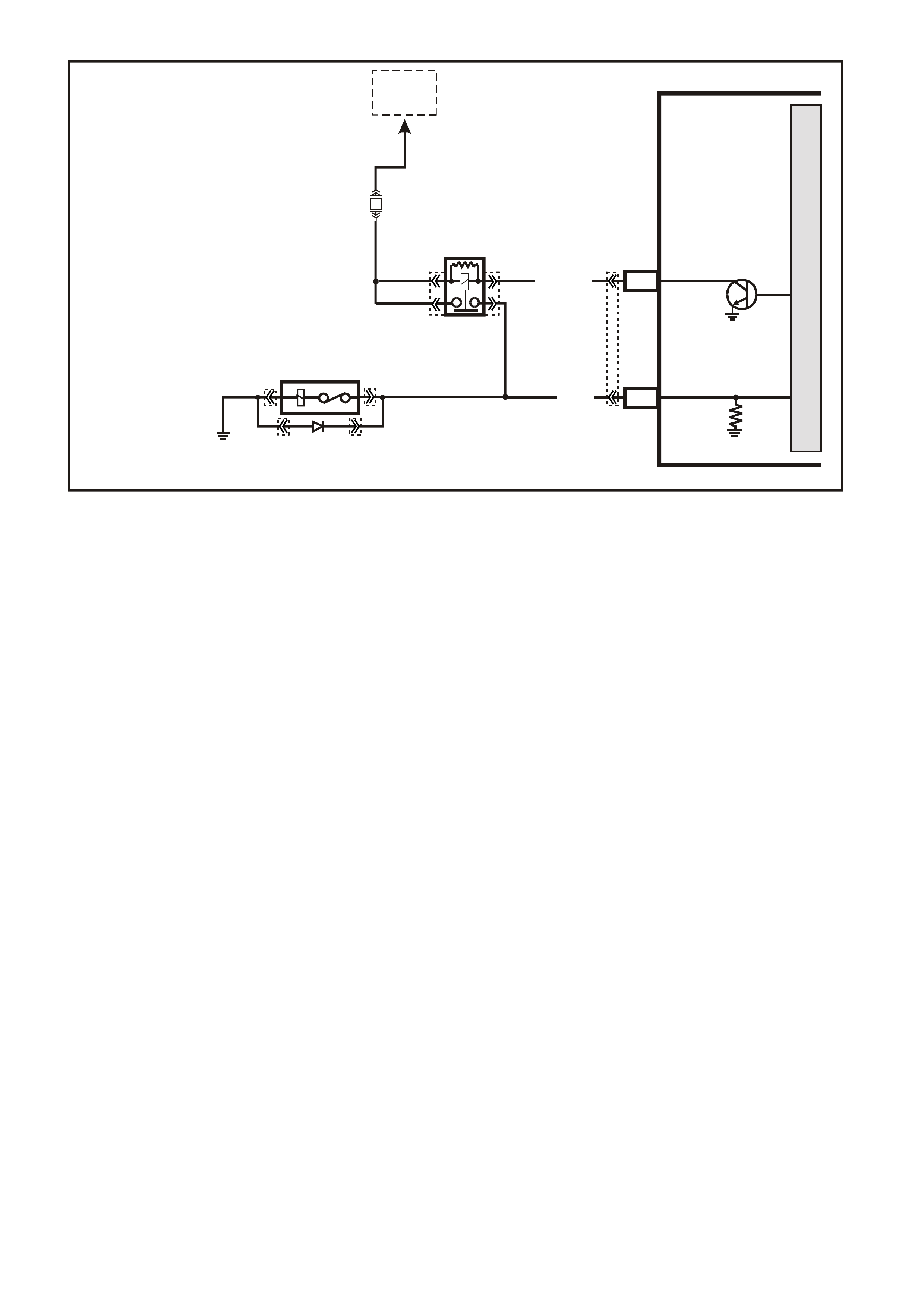

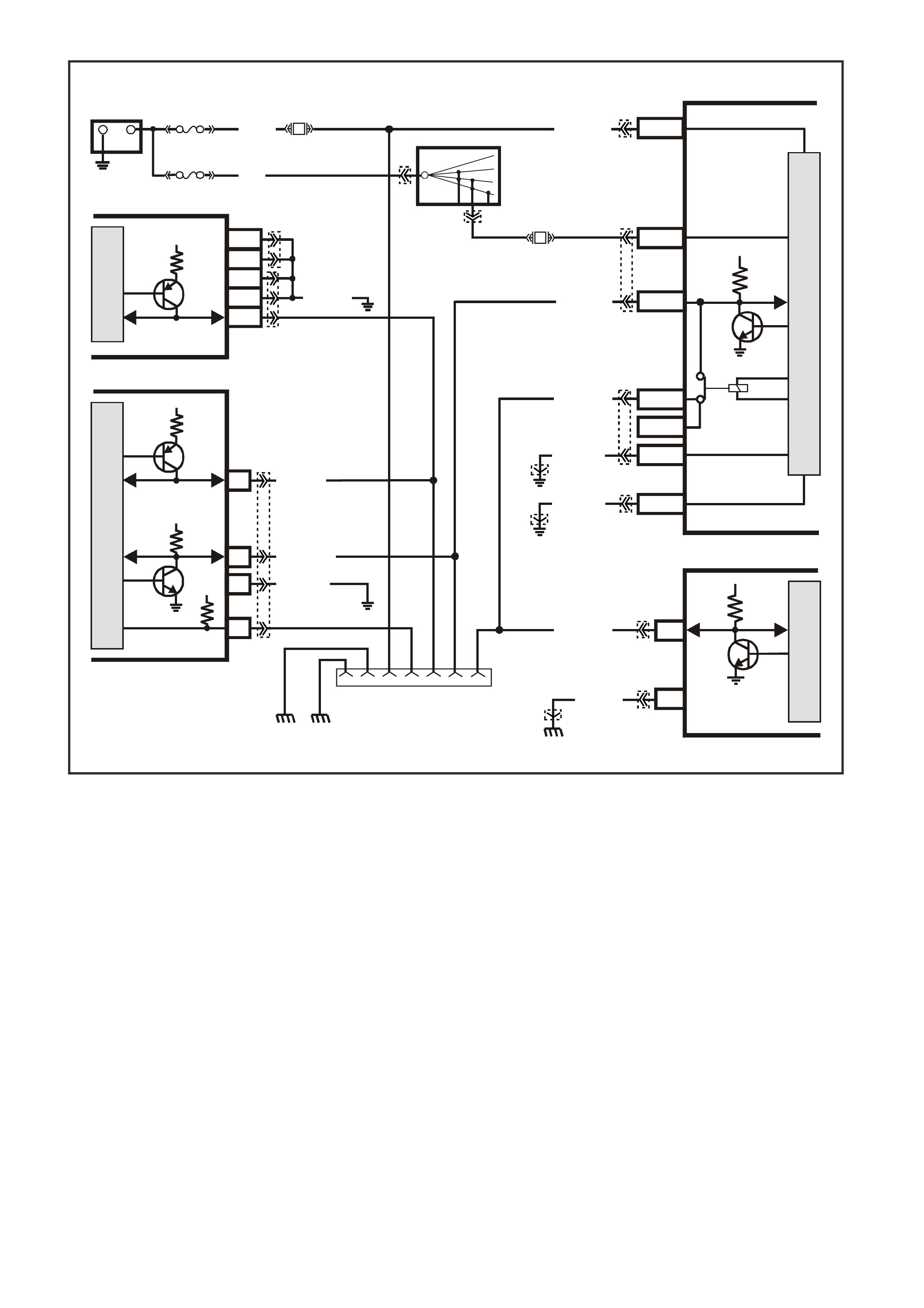

Figure 6C3-2A-2GEN. III V8 Engine View LH

1. Right Hand Ignition Coils/Modules 7. Engine Coolant Temperature (ECT) Sensor

2. Fuel Pulse Dampener 8. Fuel Pressure Gauge Test Connector

3. Fuel Rail with Injectors 9. Throttle Position (TP) Sensor

4. EVAP Canister Purge Solenoid 10. Idle Air Control (IAC) Valve

5. Crankcase Vent 11. Throttle Body

6. Left Hand Ignition Coils/Modules

GEN3 0002

4

12

3

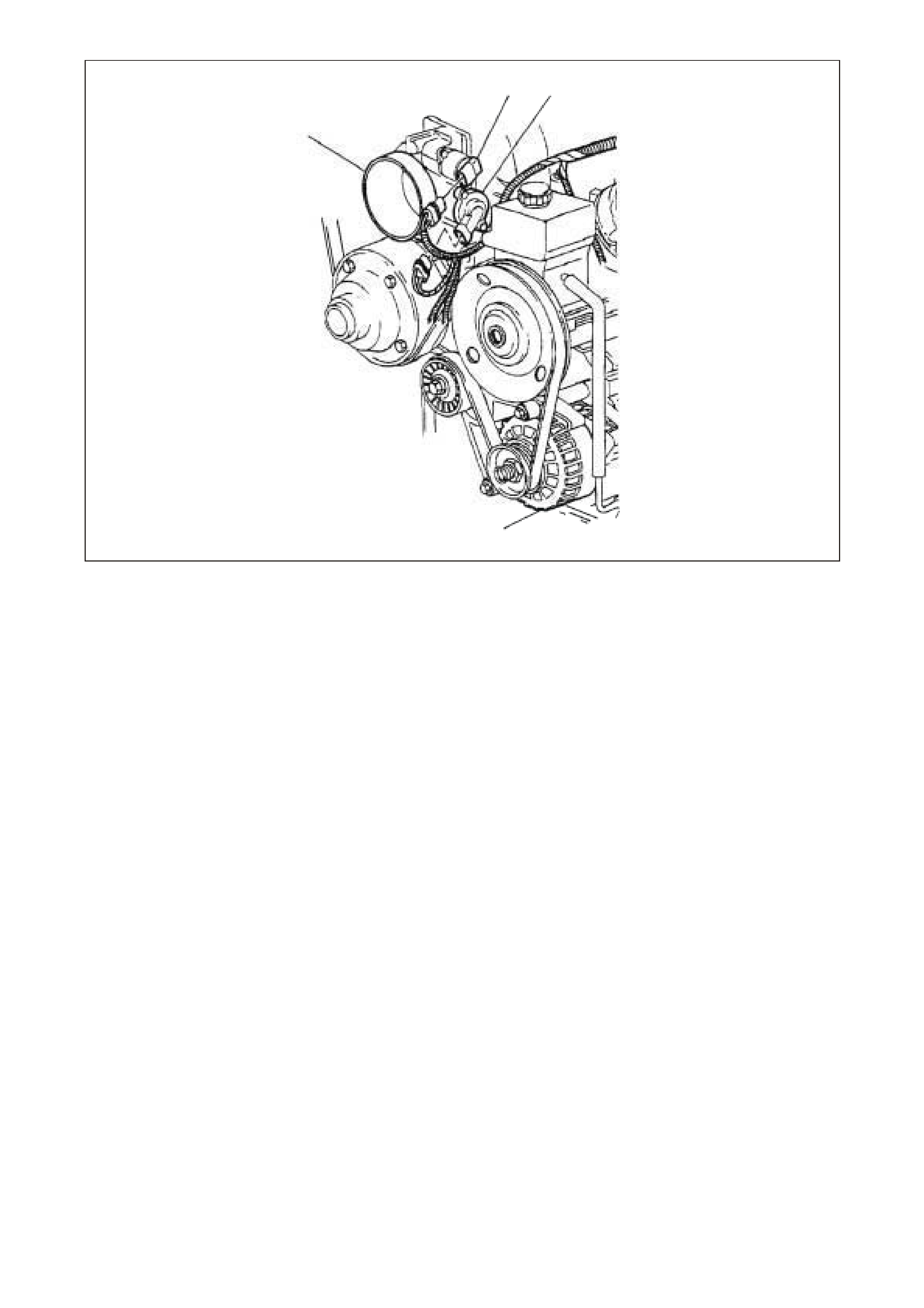

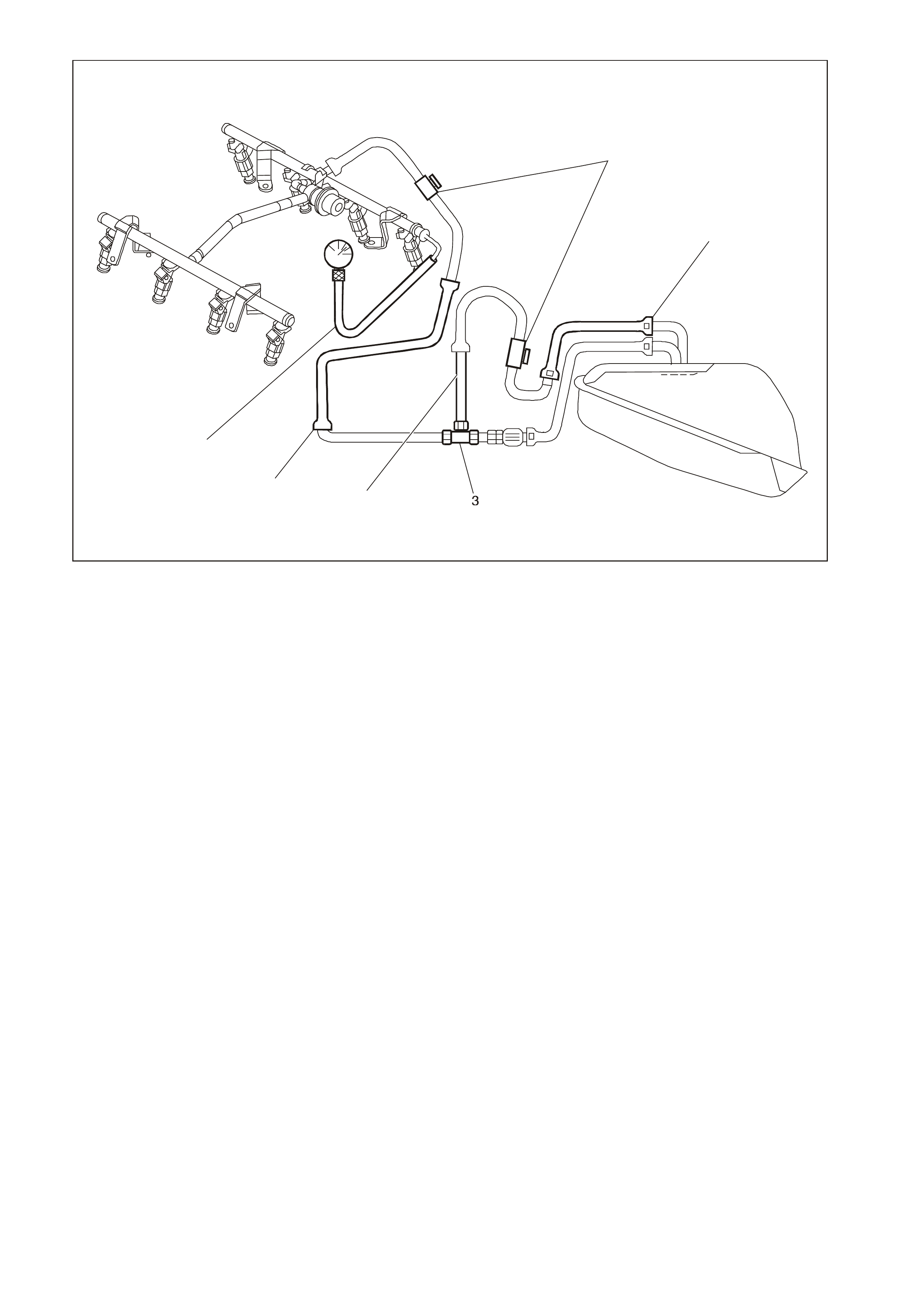

Figure 6C3-2A-3 GEN. III V8 Front of Engine View

1. Idle Air Control (IAC) Valve 3. Generator

2. Throttle Position (TP) Sensor 4. Throttle Body

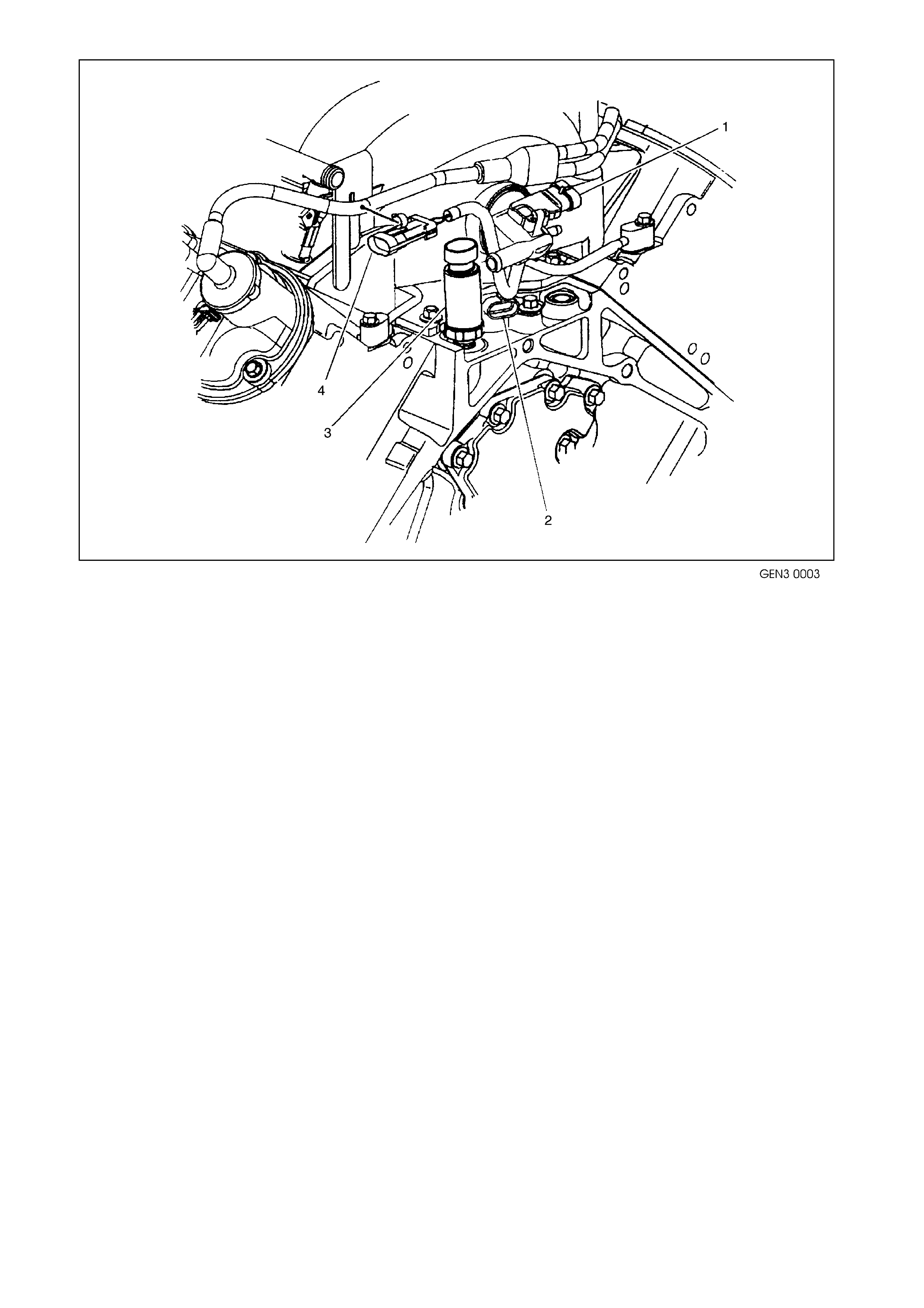

Figure 6C3-2A-4 GEN. III V8 Rear of Engine View

1. Manifold Absolute Pressure (MAP) Sensor 3. Oil Pressure Sensor

2. Camshaft Position (CMP) Sensor 4. Connector to Knock Sensor Jumper Harness

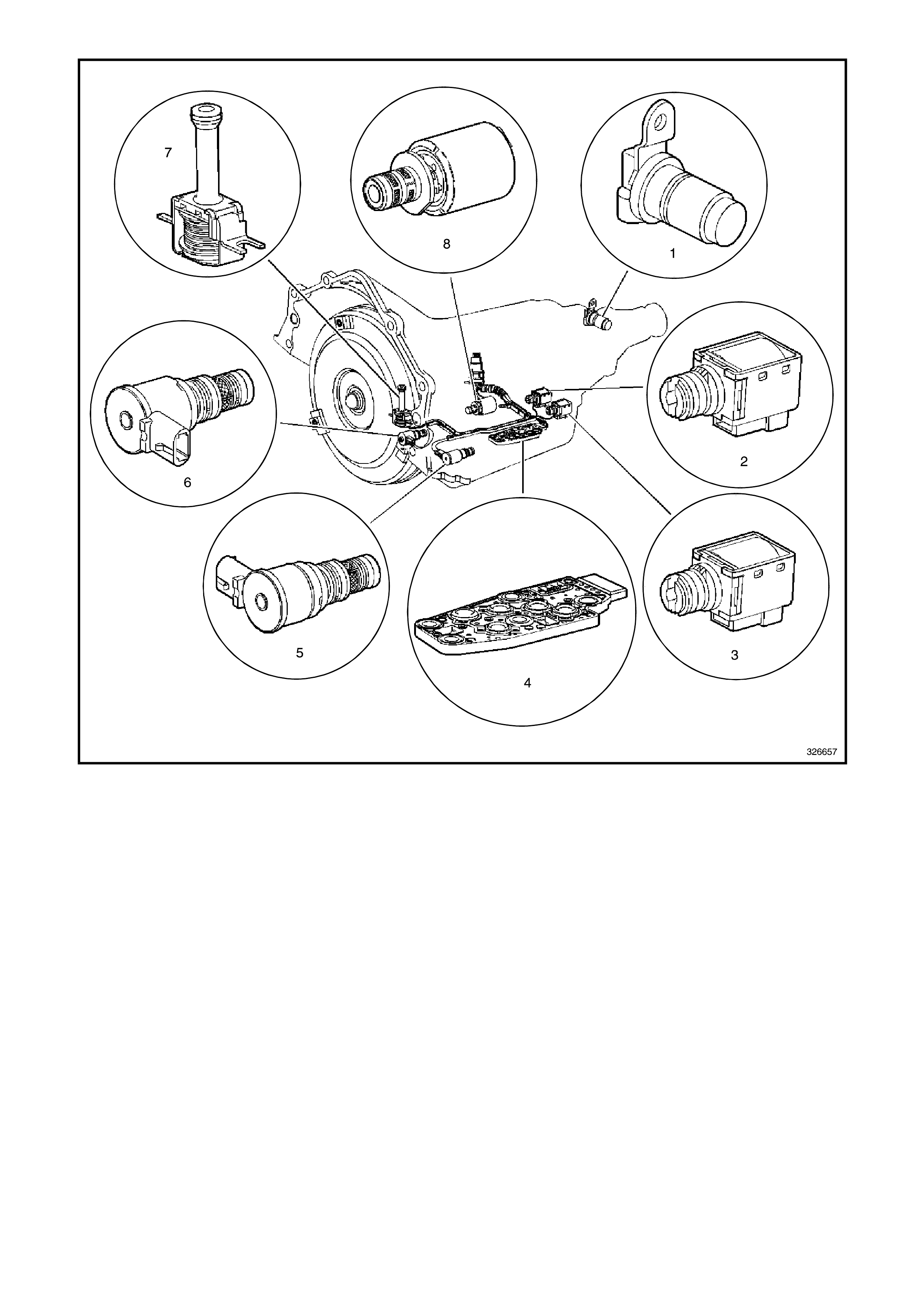

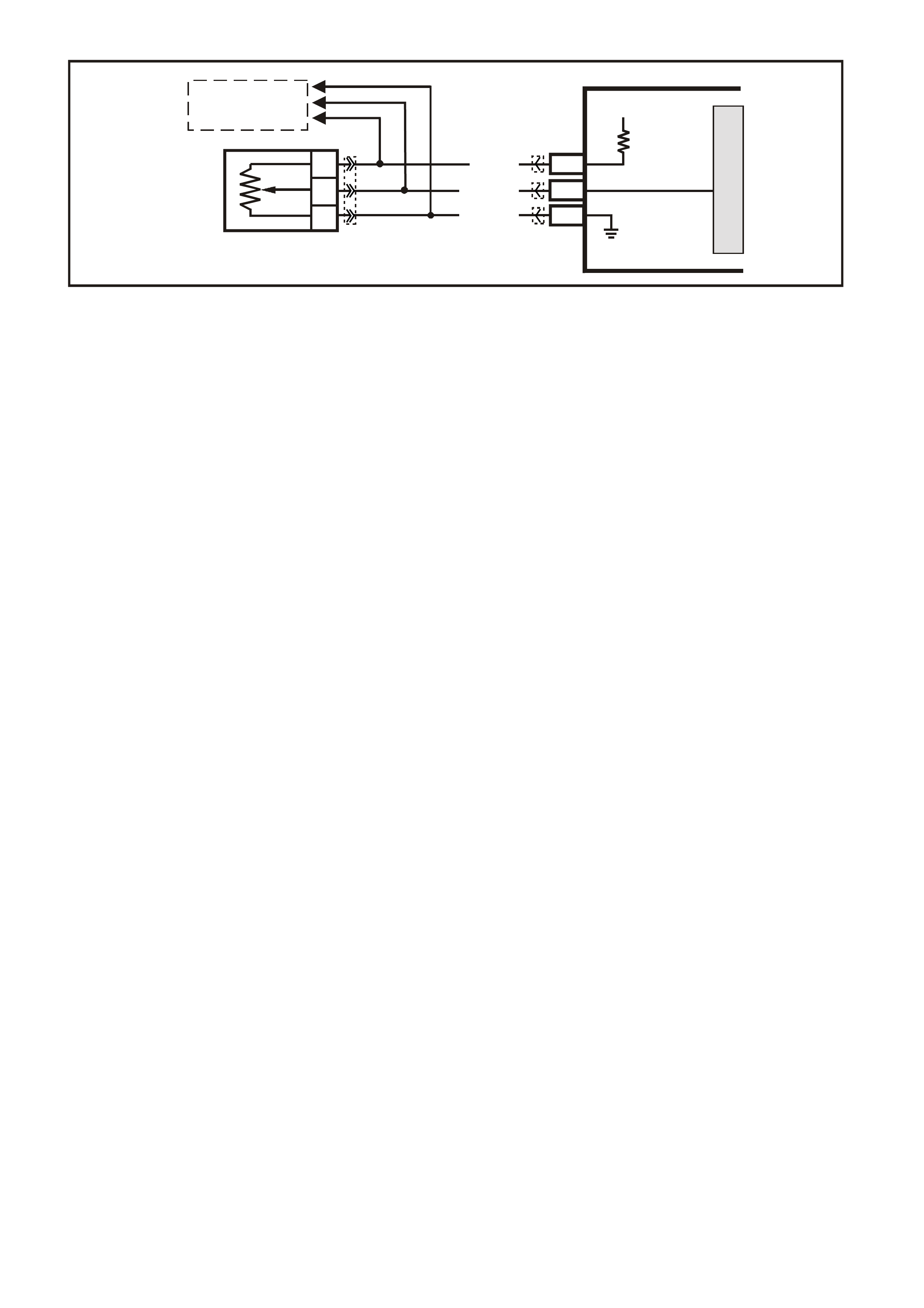

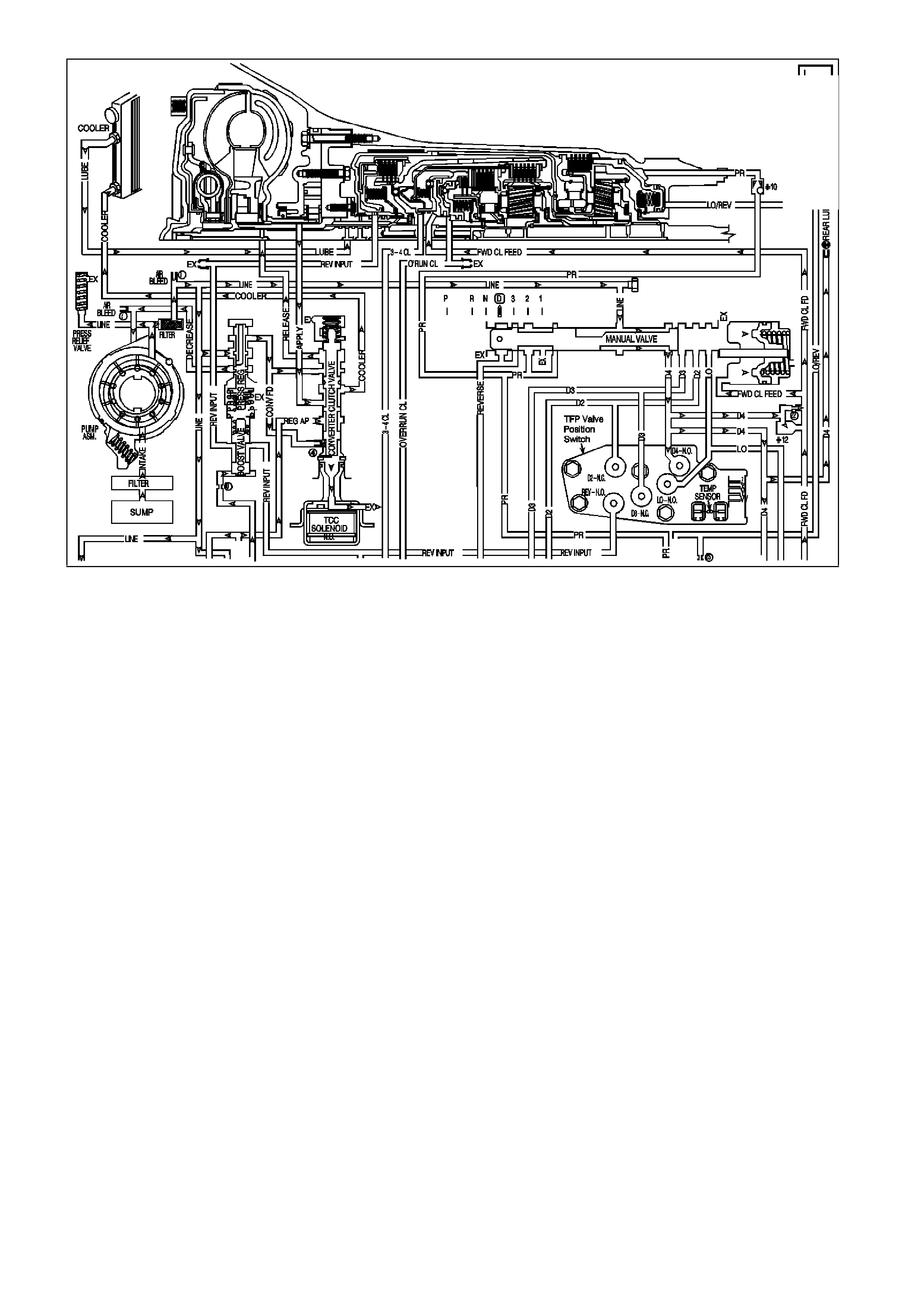

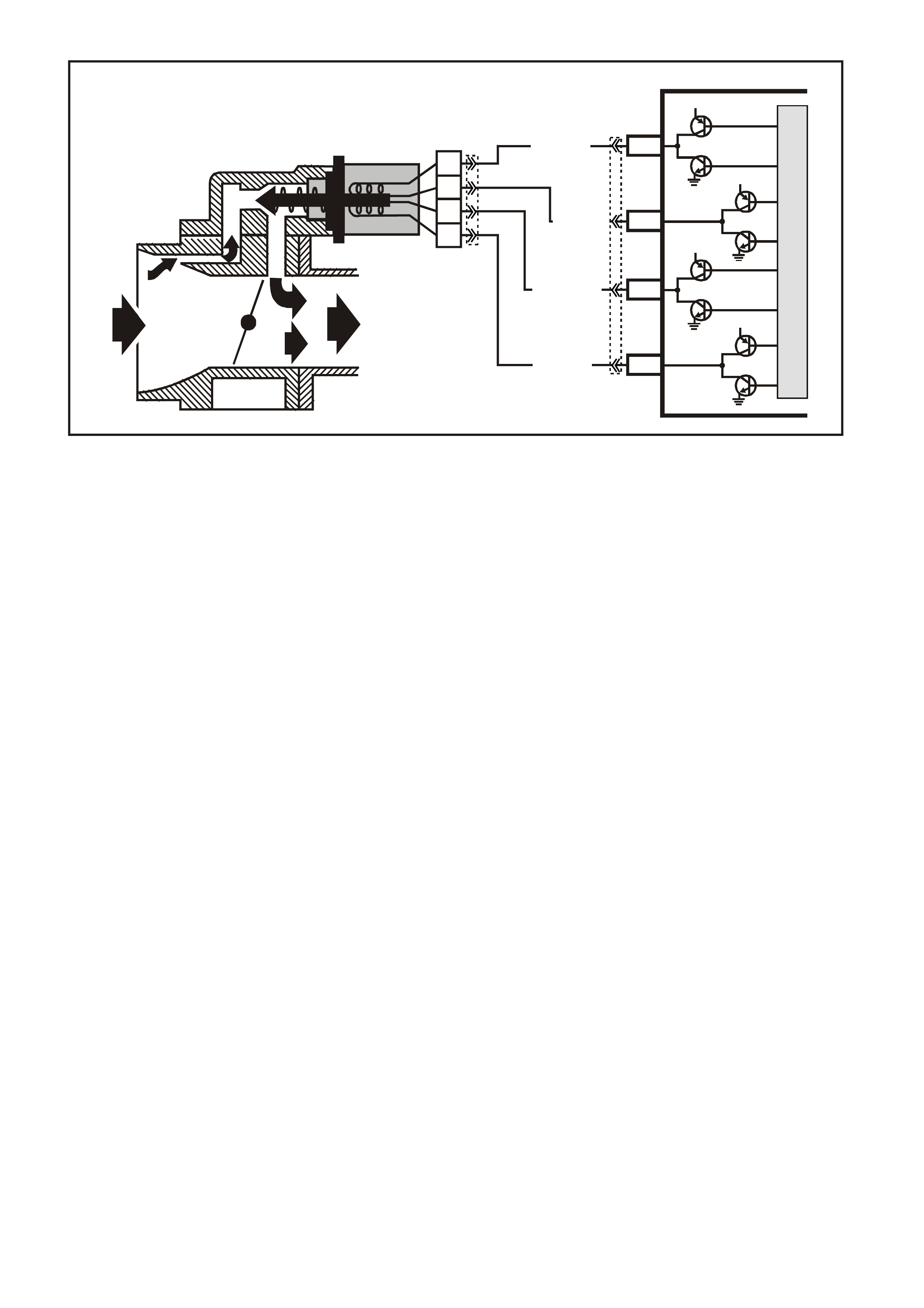

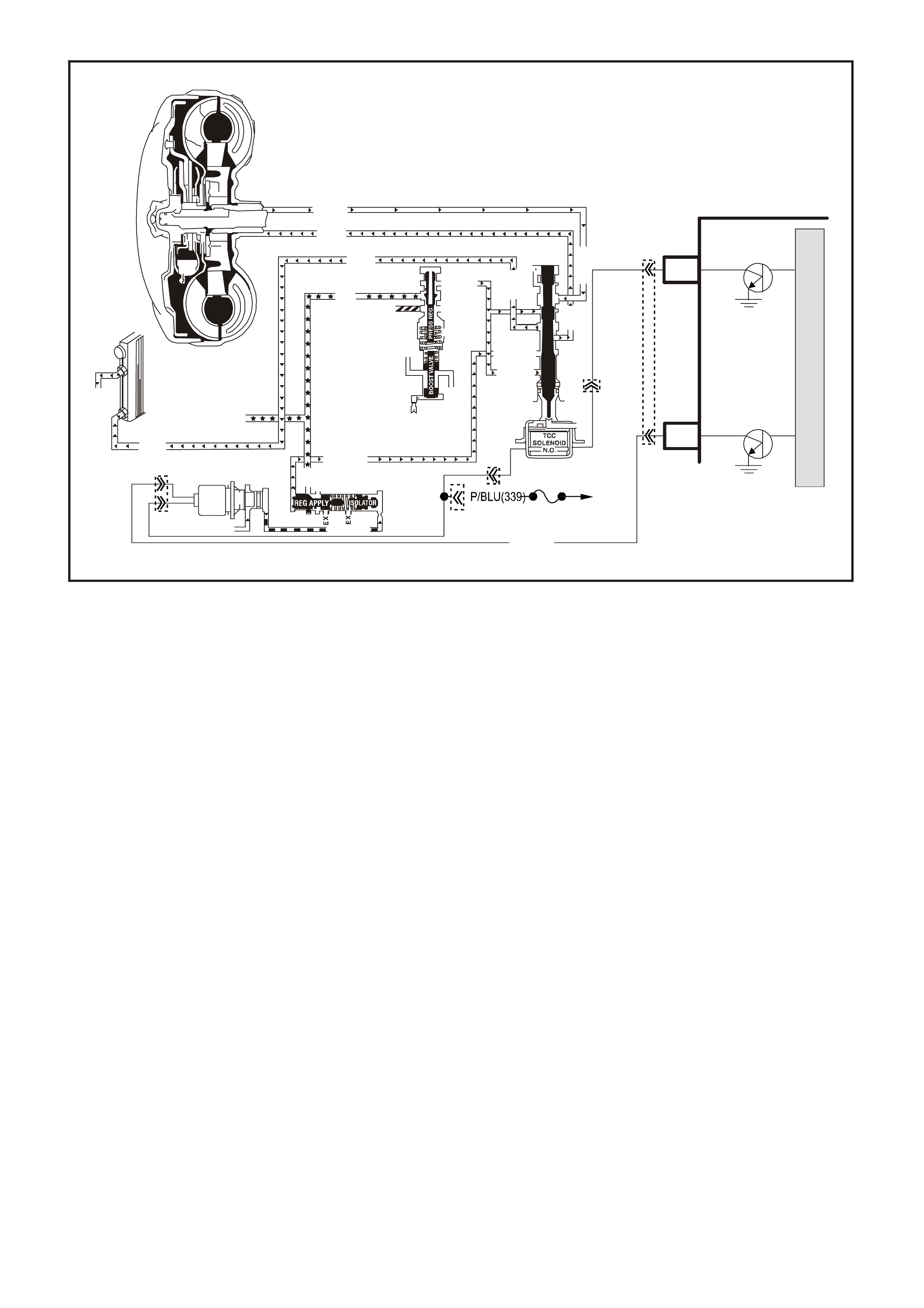

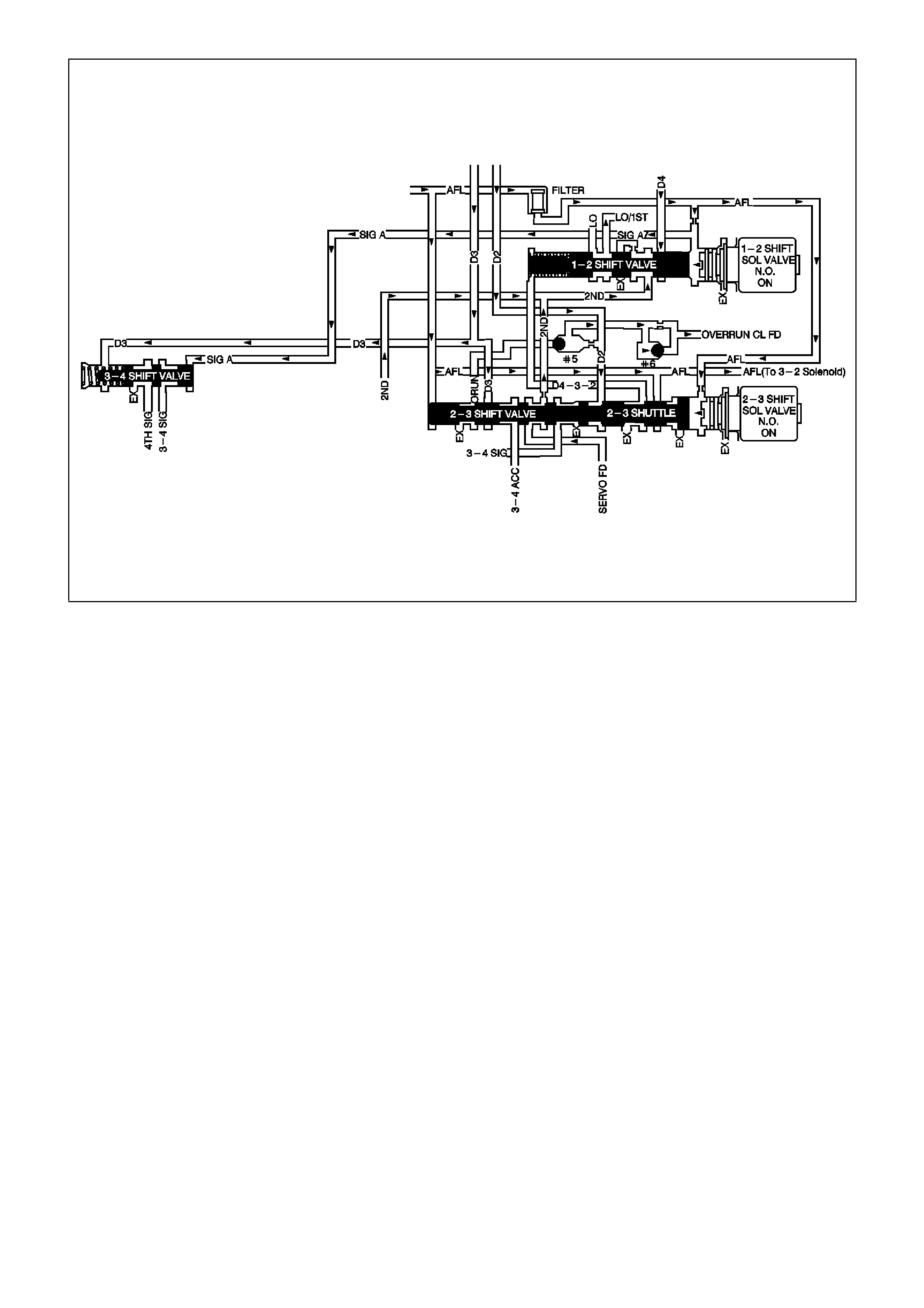

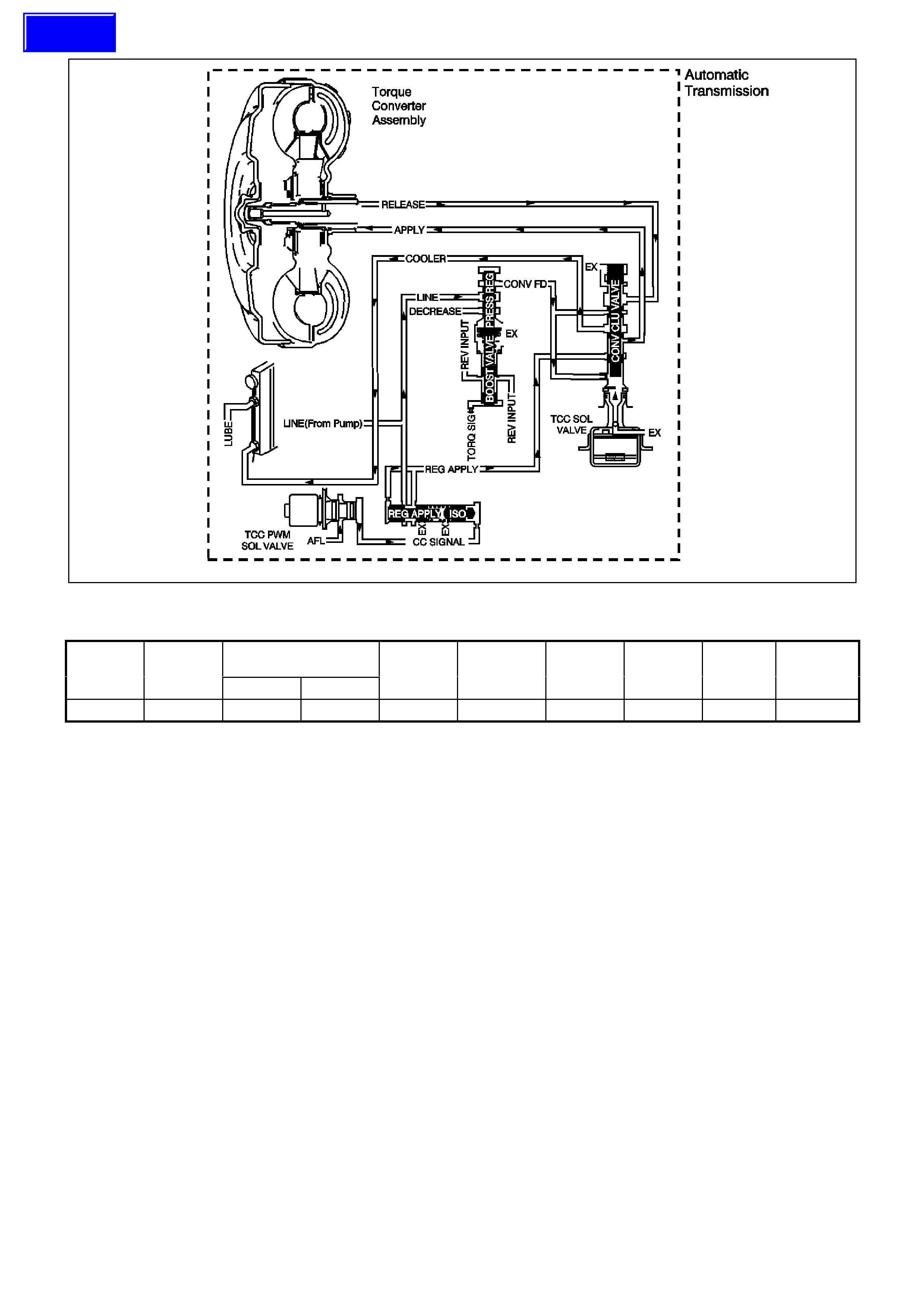

Figure 6C3-2A-5 Automatic Transmission Internal Electronic Component Locations

1. Vehicle Speed Sensor 5. Shift Solenoid (SS) Valve Assembly

2. Shift Solenoid B (SS) Valve 6. Torque Converter Clutch Pulse Width Modulation (TCC

PWM) Solenoid Valve

3. Shift Solenoid A (SS) Valve 7. Torque Converter Clutch (TCC) Solenoid Valve

4. Automatic Transmission Fluid Pressure (TFP) Manual

Valve Position Switch 8. Pressure Control Solenoid (PCS) Valve

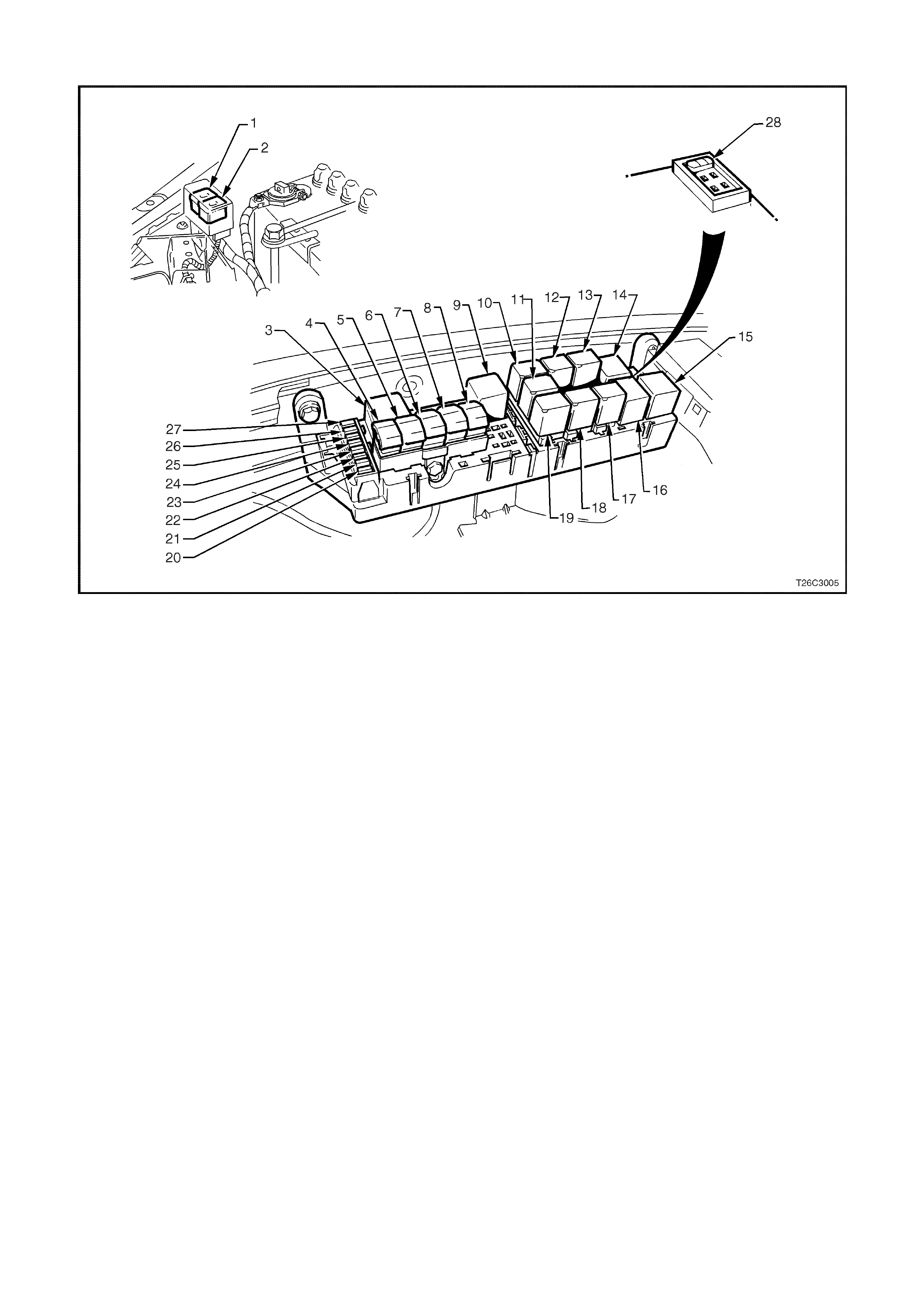

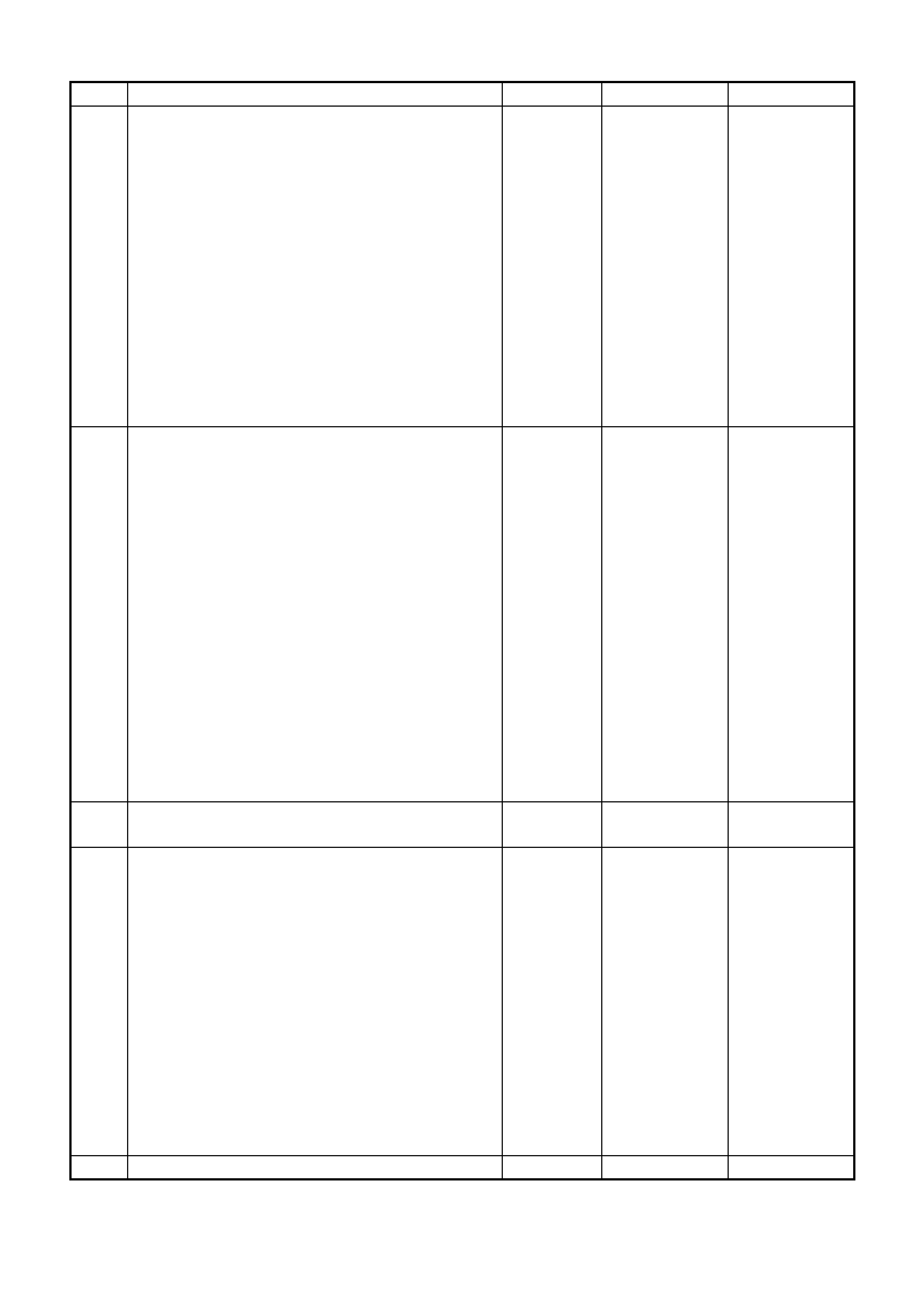

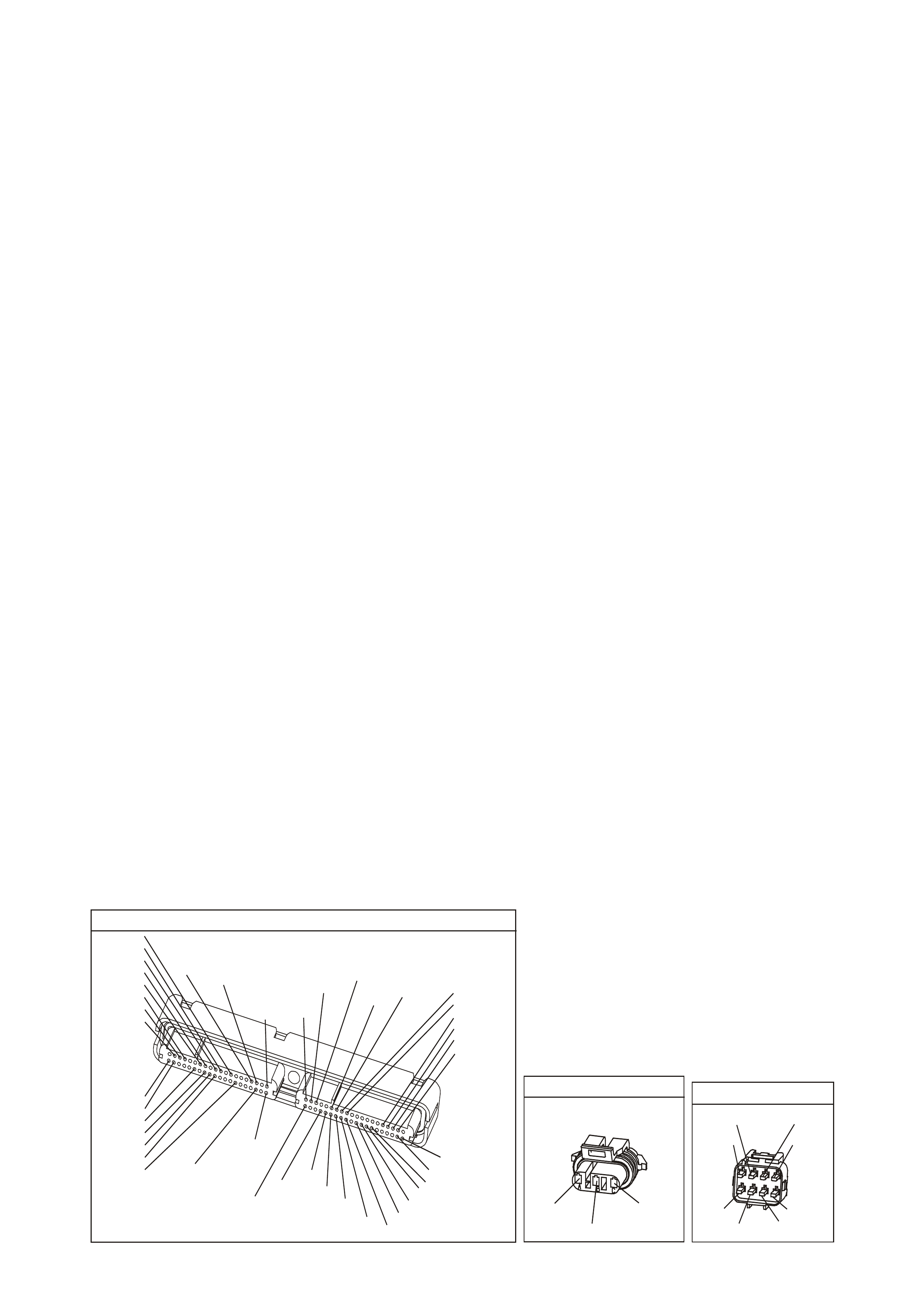

Figure 6C3-2A-6 Engine Compartment Fuse/Relay Panel

1. Fan 1 Fusible Link FU 15. Start Relay

2. Fan 2 Fusible Link FT 16. Headlamp High Beam Relay

3. Engine Fan Relay (Low Speed) 17. Fuel Pump Relay

4. Lighting Fusible Link FQ 18. Front Wiper Relay

5. ABS Fusible Link FR 19. Headlamp Low Beam Relay

6. Engine Fusible Link FS 20. Injectors/Ignition Fuse F35

7. Main Fusible Link FJ 21. Injectors/Ignition Fuse F34

8. Blower Fusible Link FY 22. Engine Sensors Fuse F33

9. Engine Cont. (EFI) Relay 23. Automatic Transmission Fuse F32

10. Horn Relay 24. Engine Control/BCM Fuse F31

11. A/C Relay 25. LH Headlamp Fuse F30

12. Theft Horn Relay 26. RH Headlamp Fuse F29

13. Fog Lamp Relay 27. Fuel Pump Fuse F28

14. Engine Fan Relay (High Speed) 28. Throttle Relaxer Control Module Fuse F36

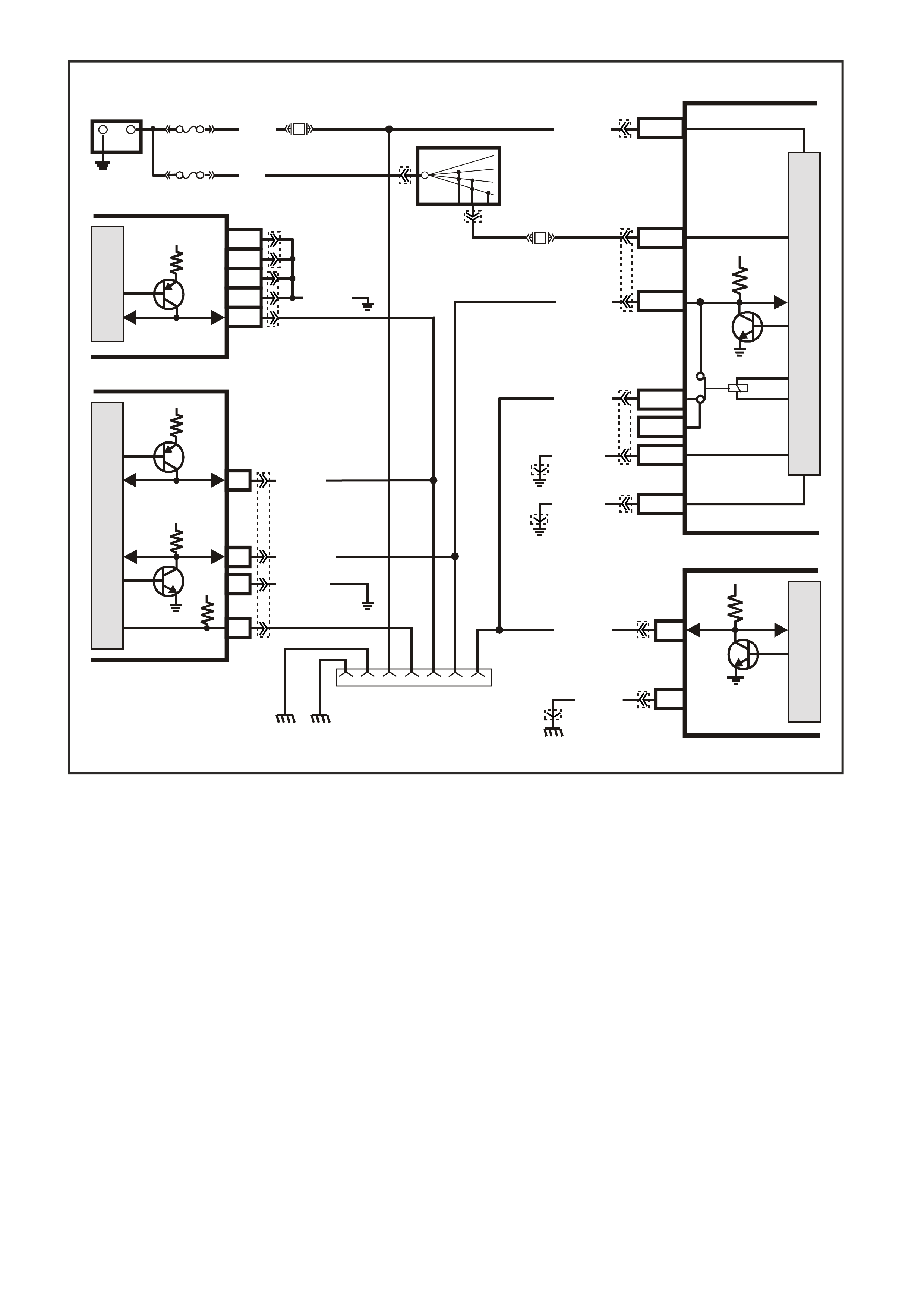

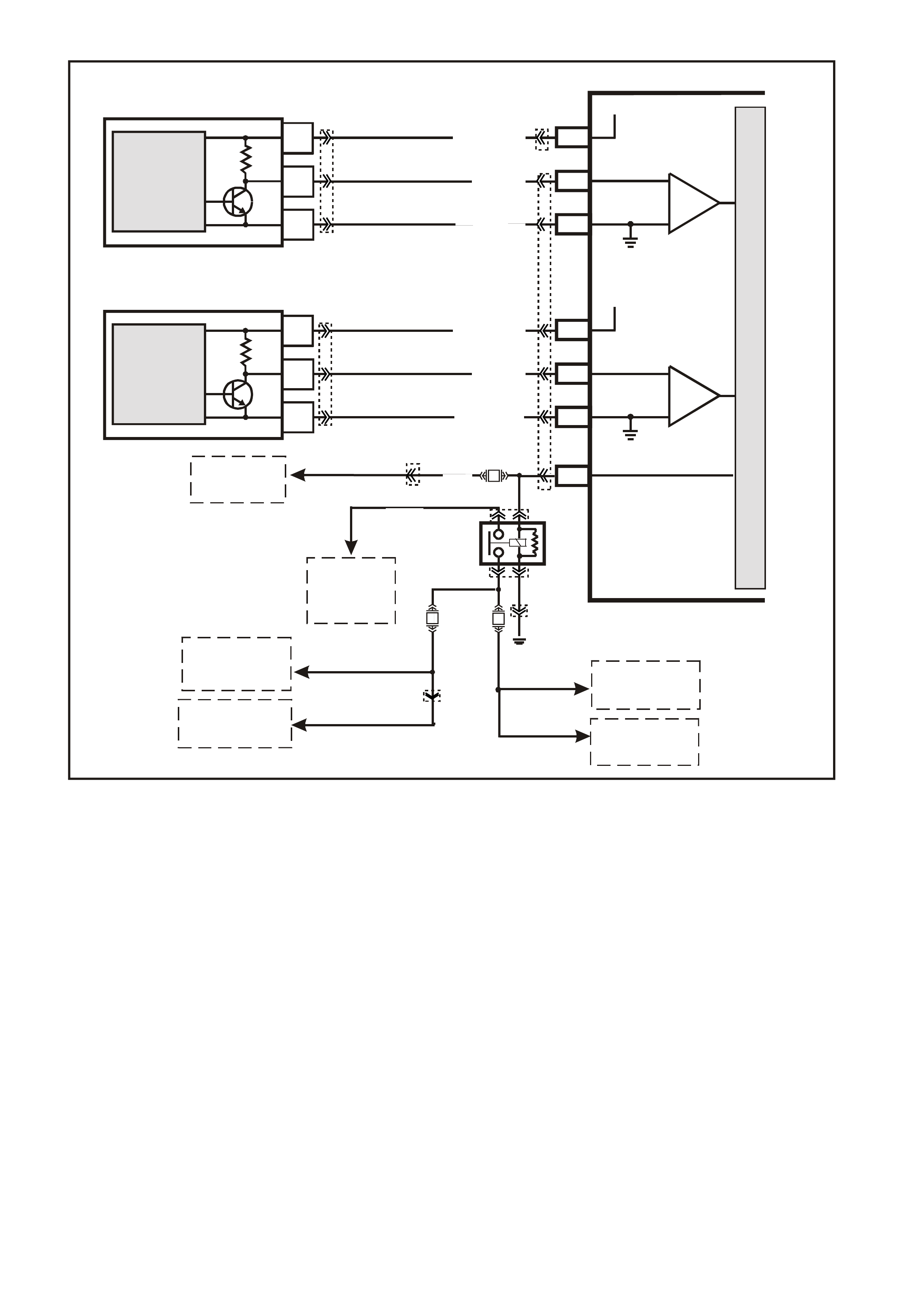

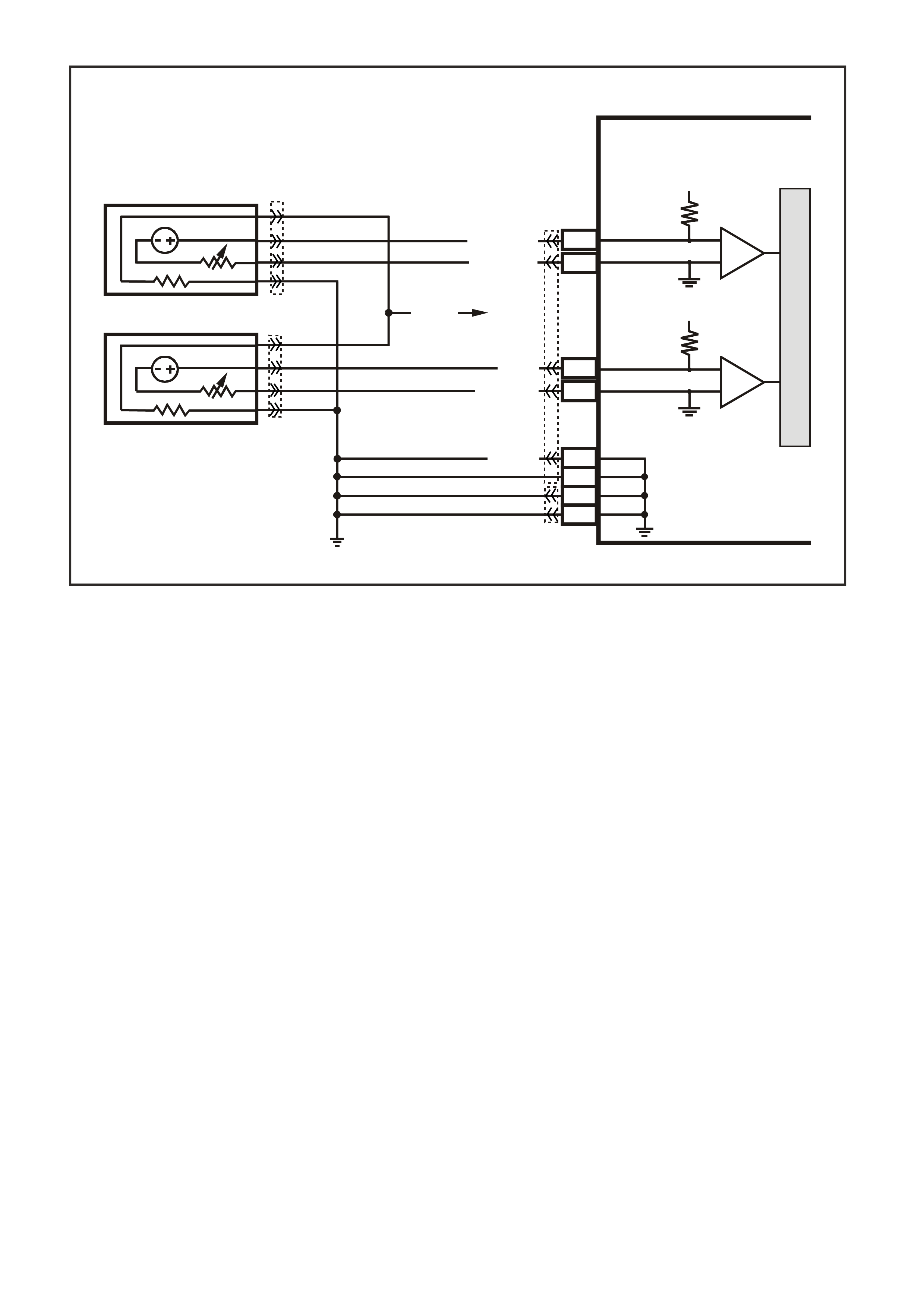

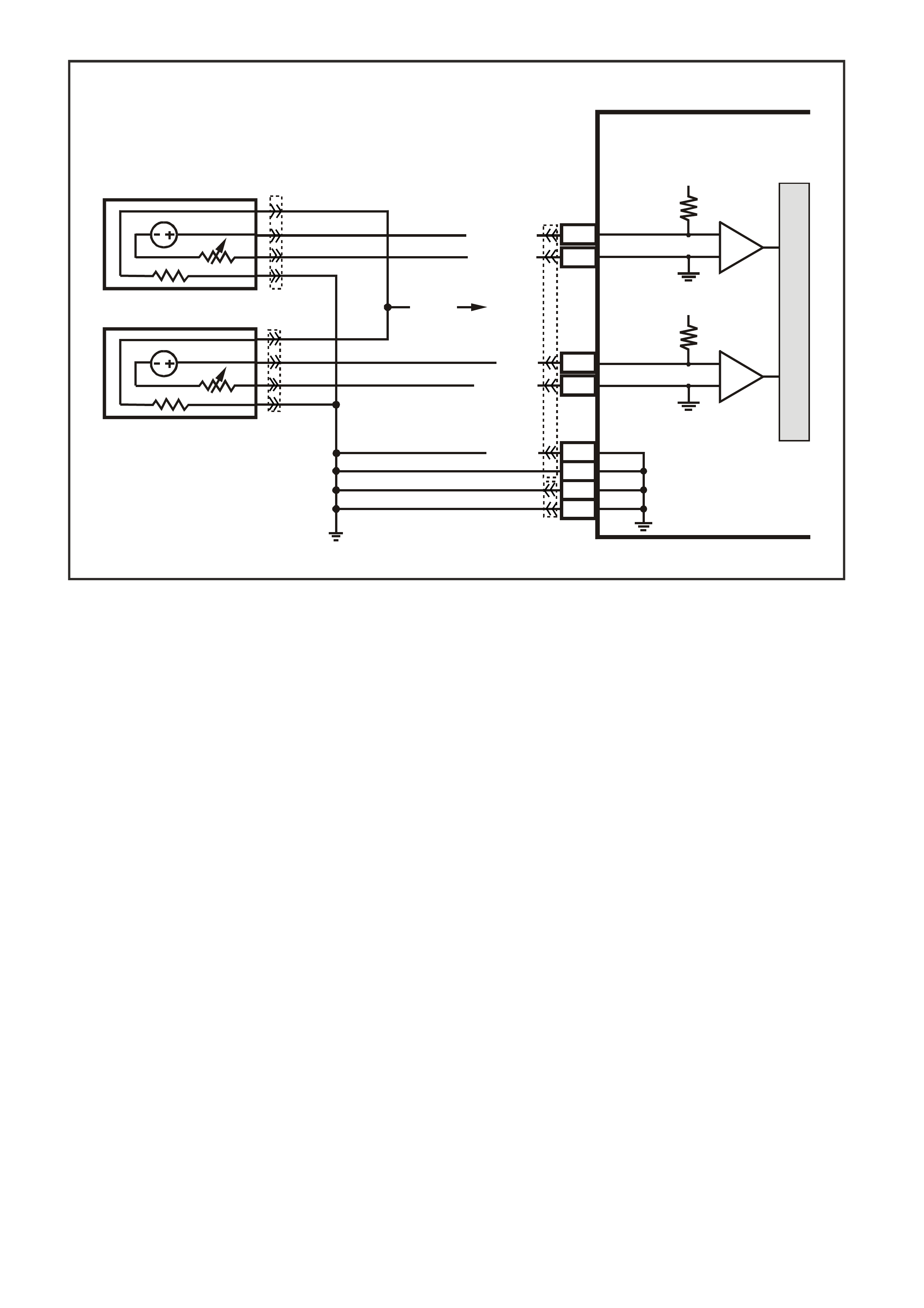

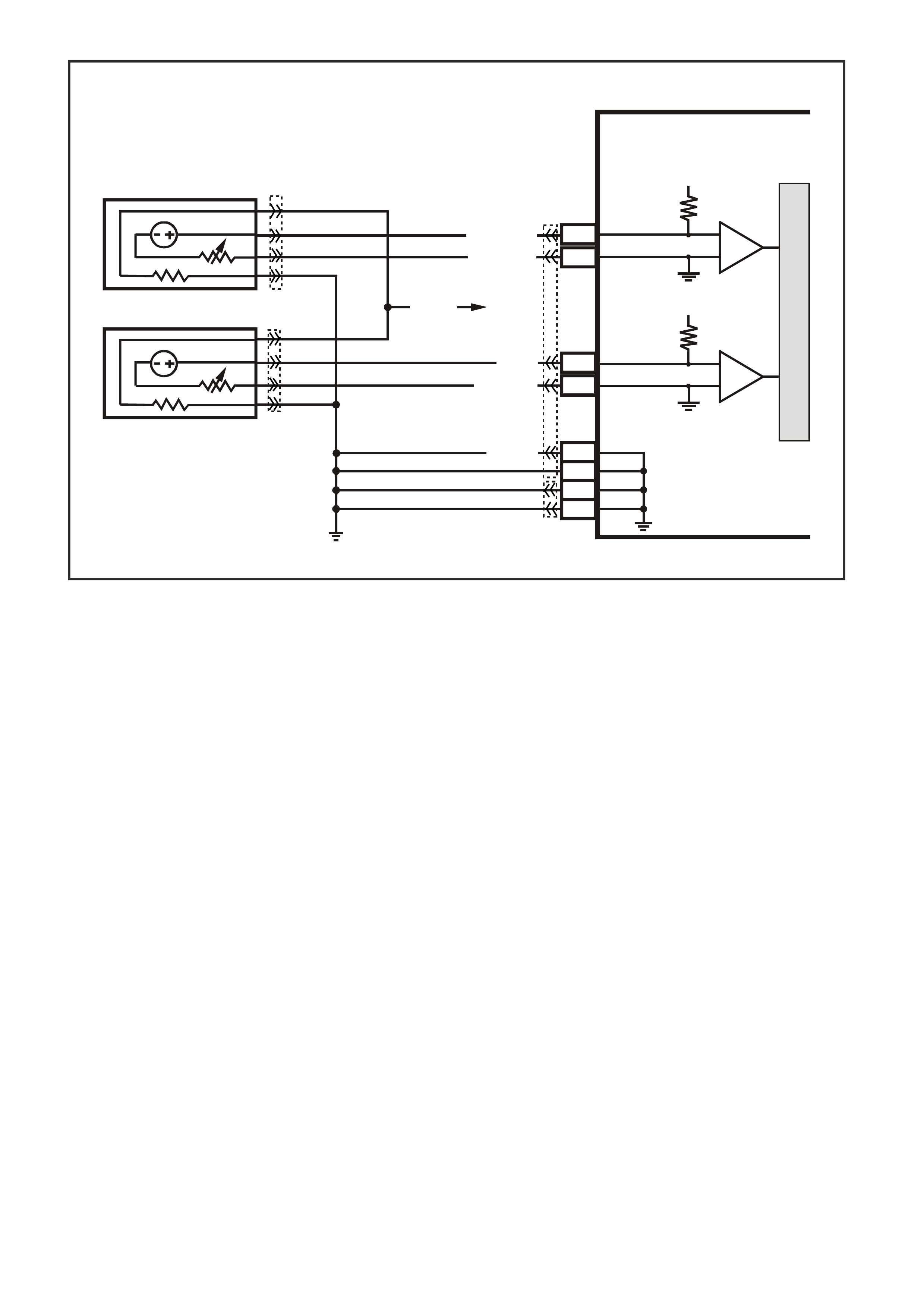

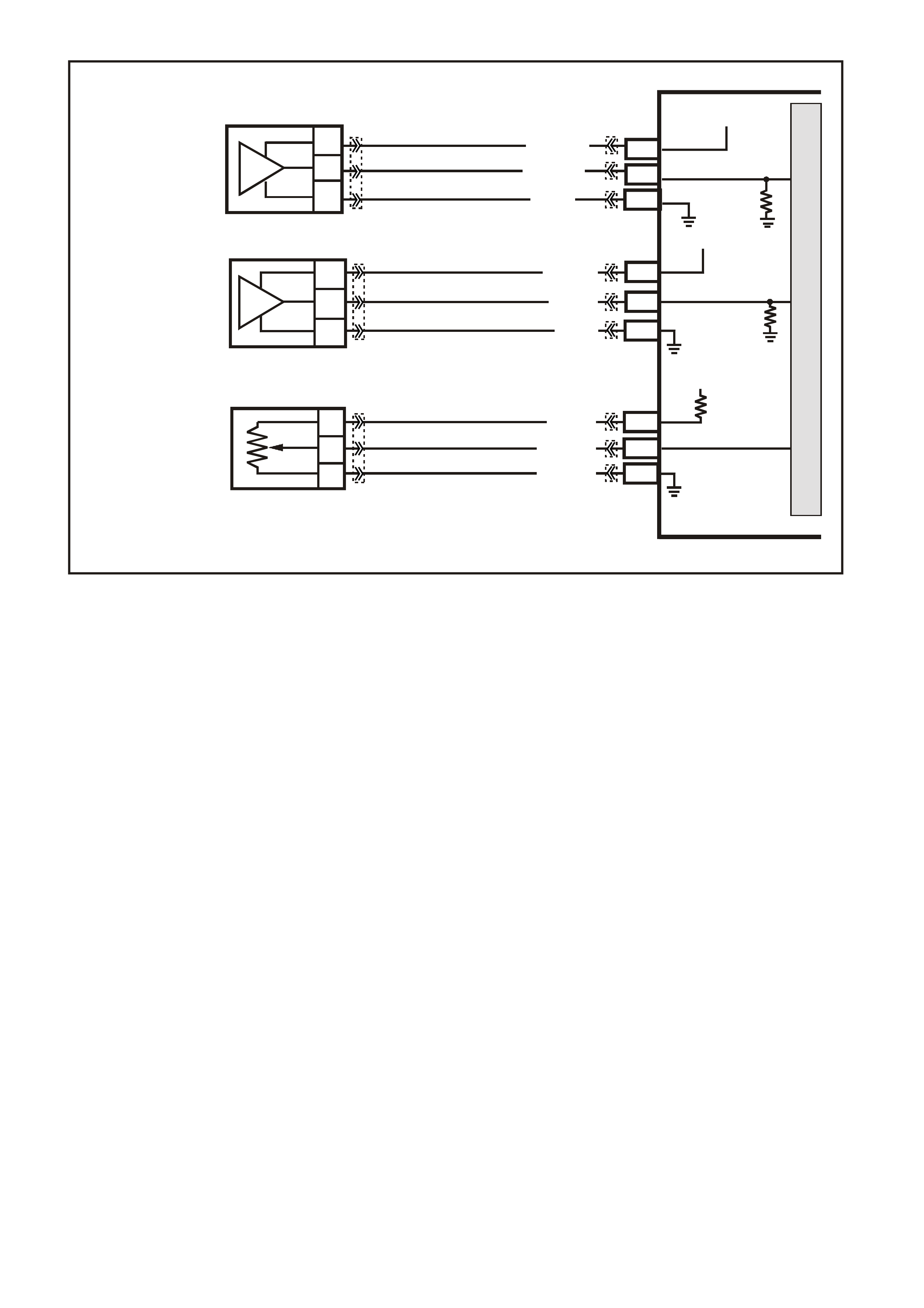

PCM WIRING DIAGRAMS

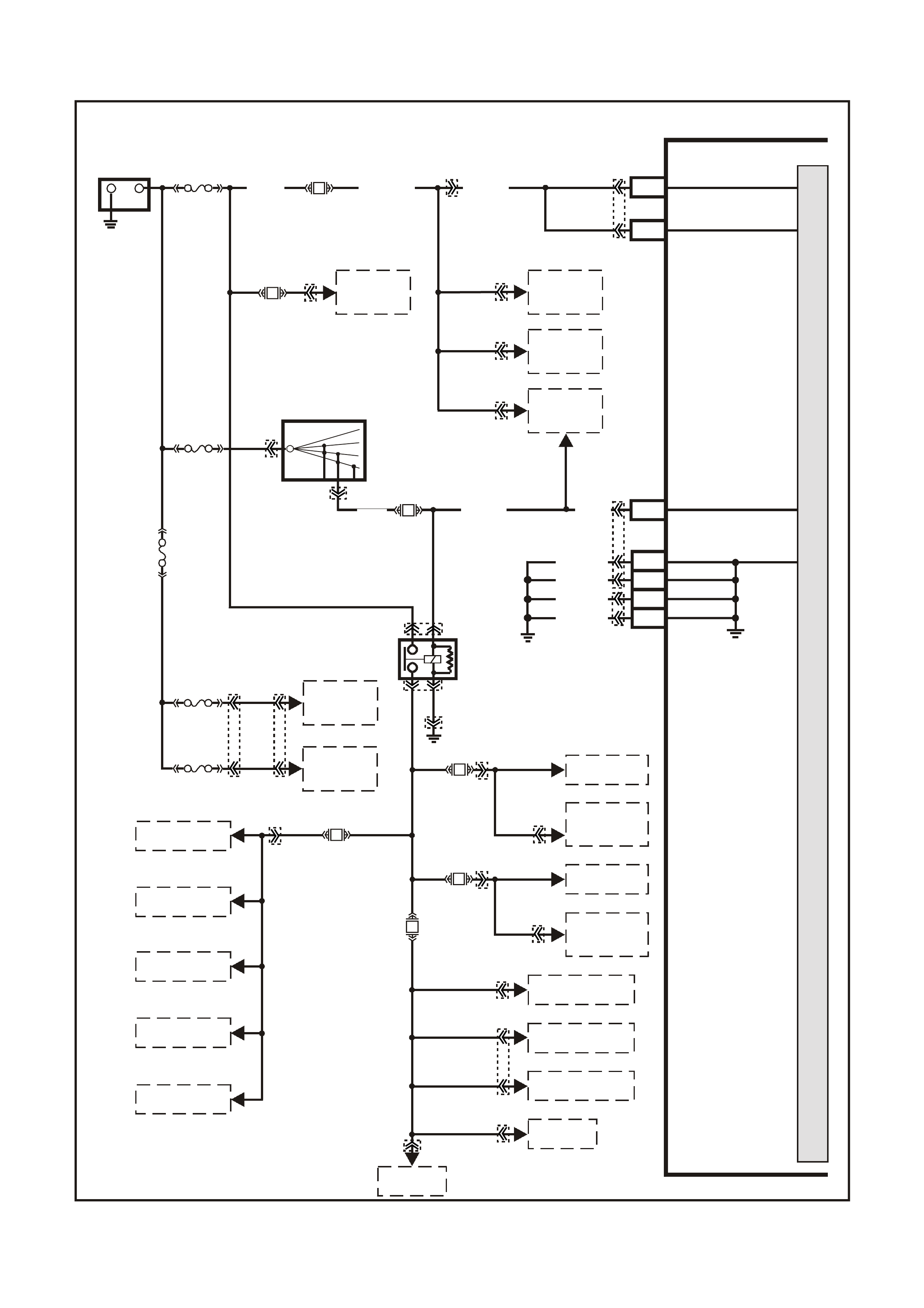

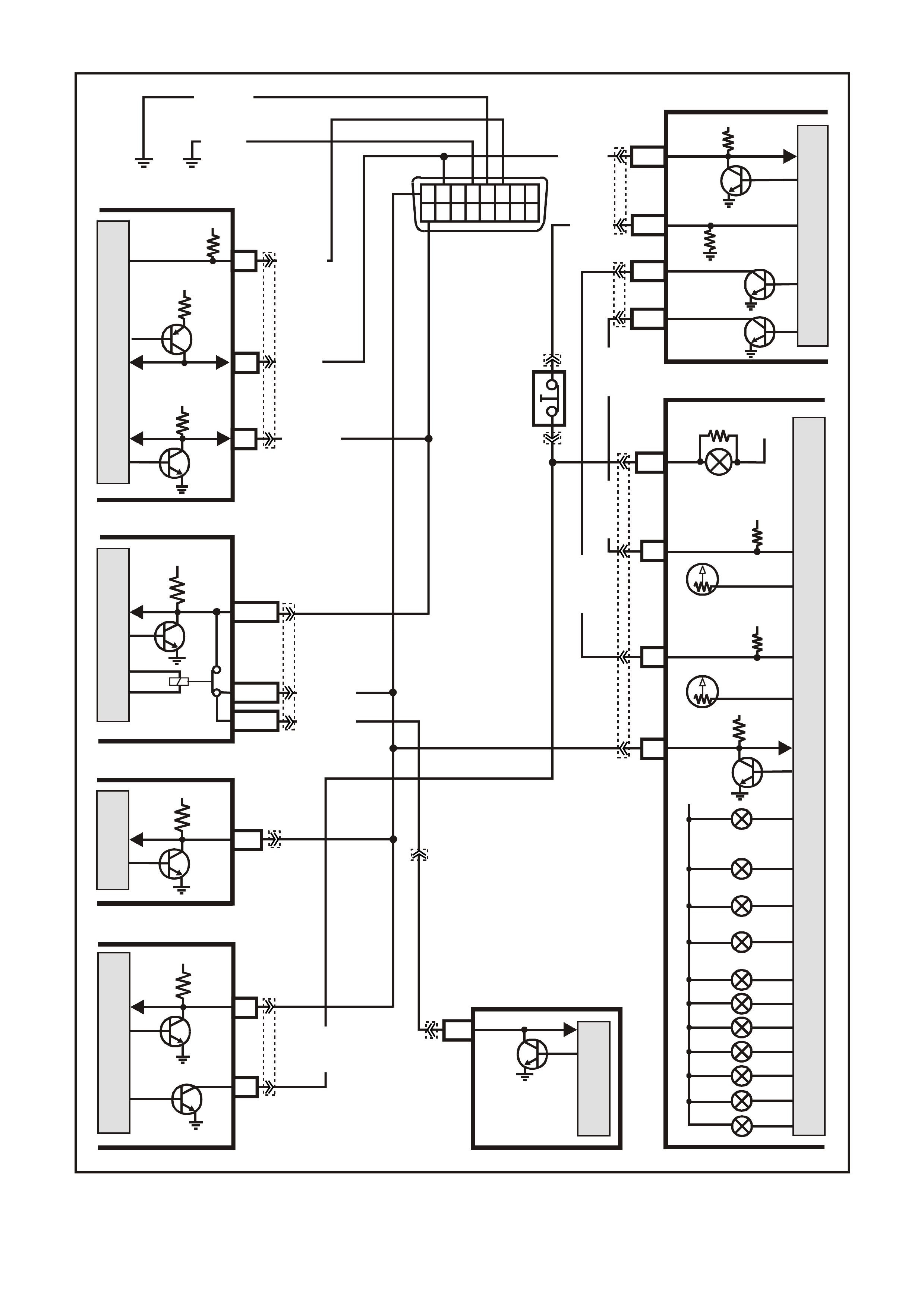

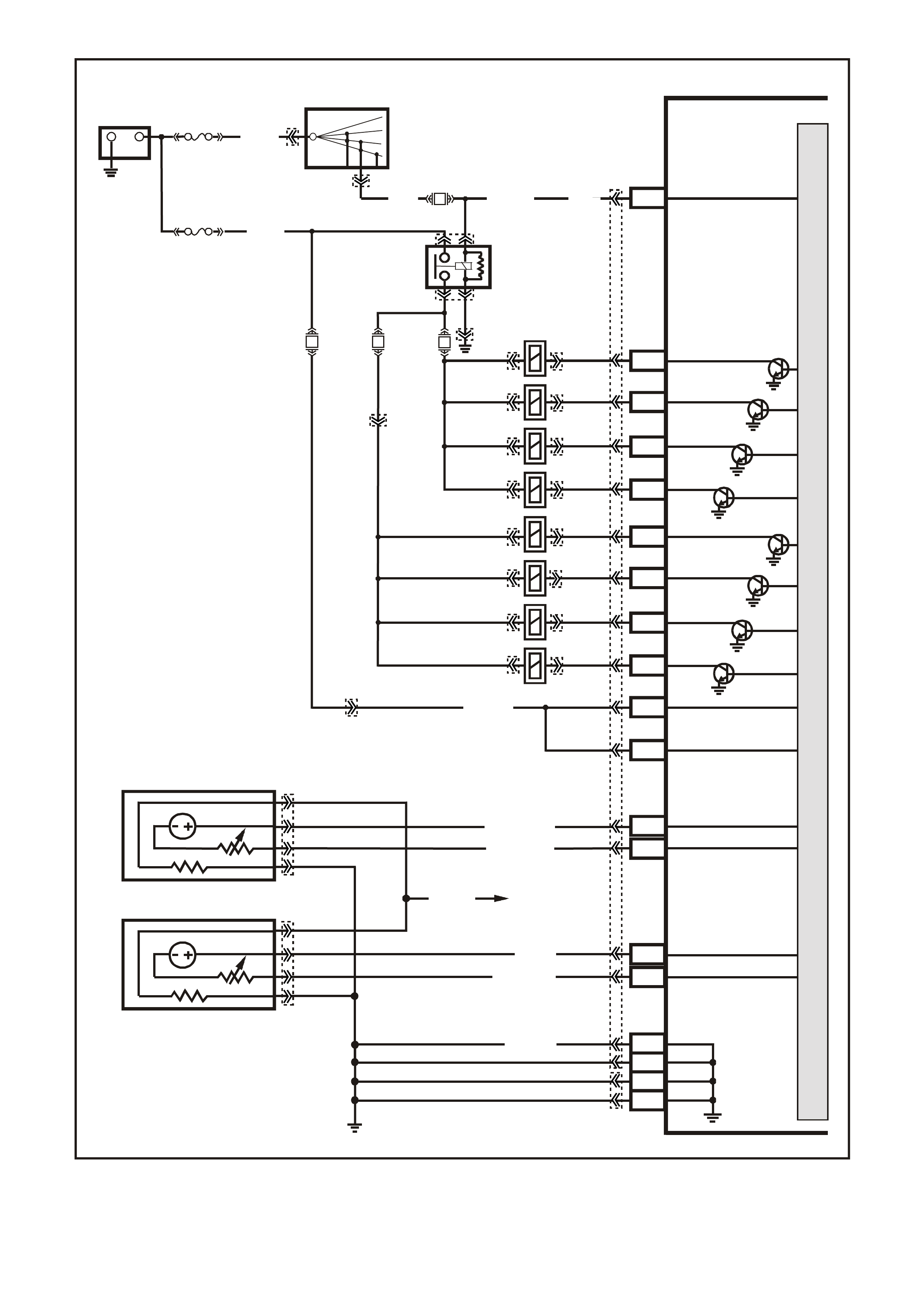

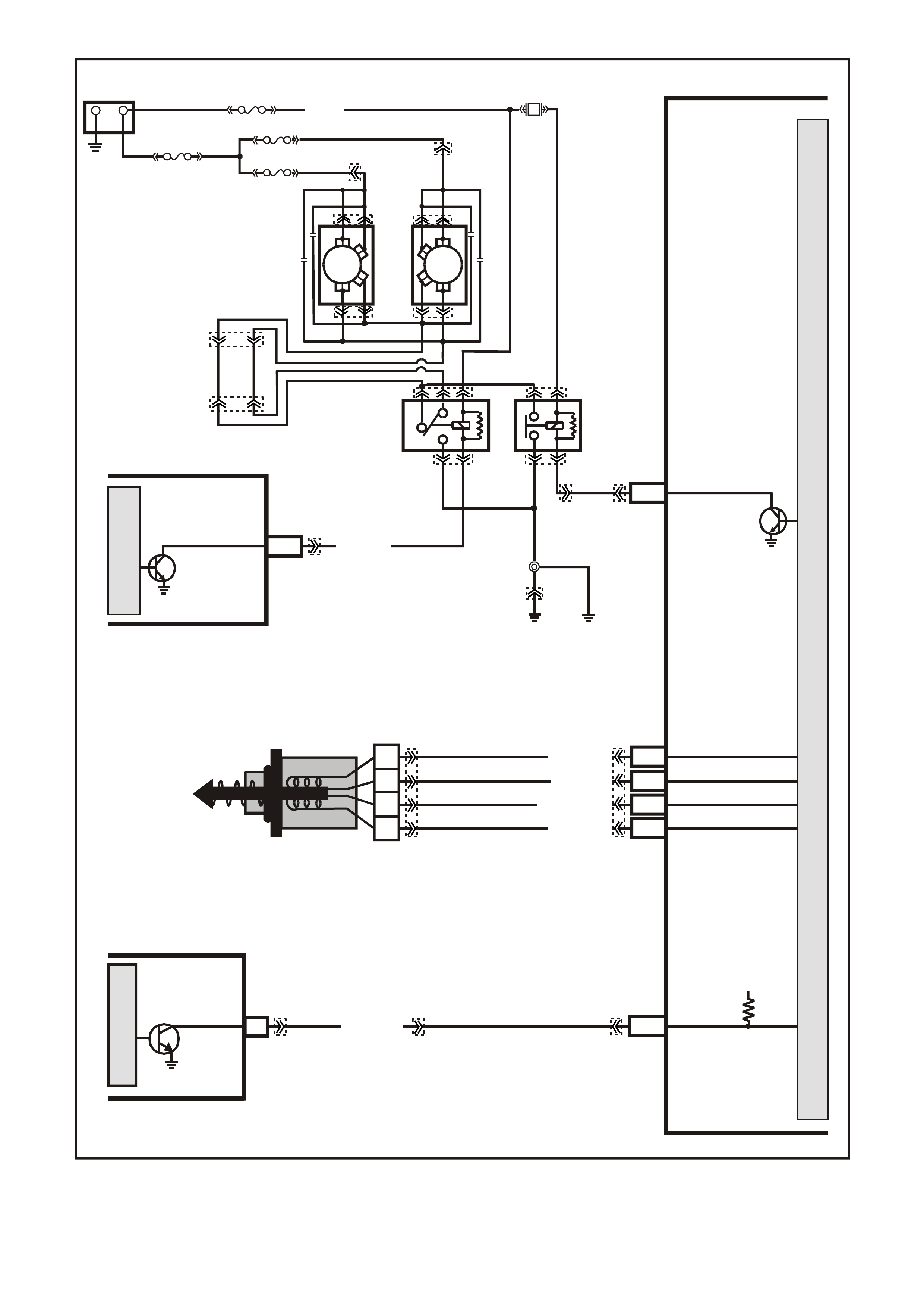

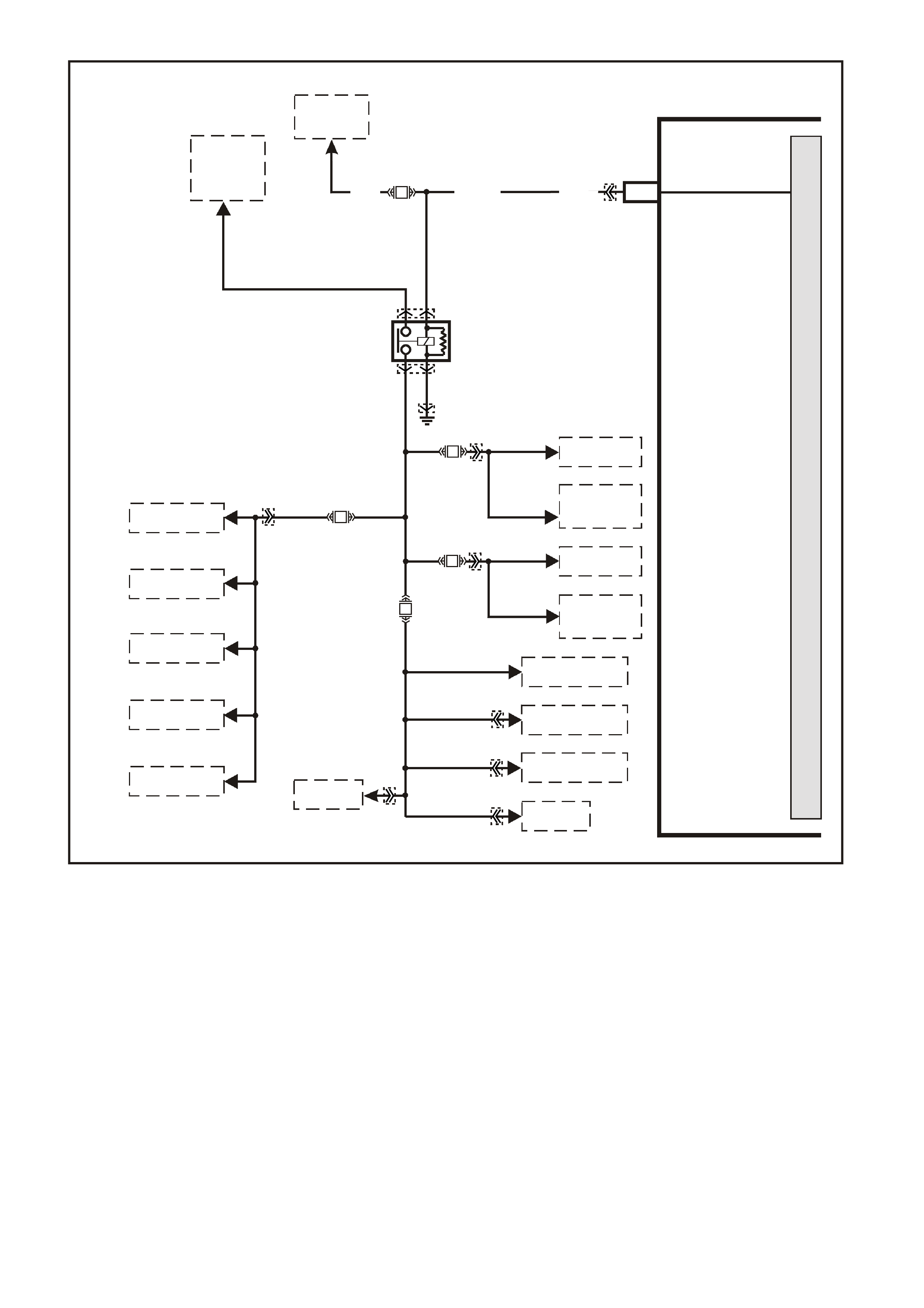

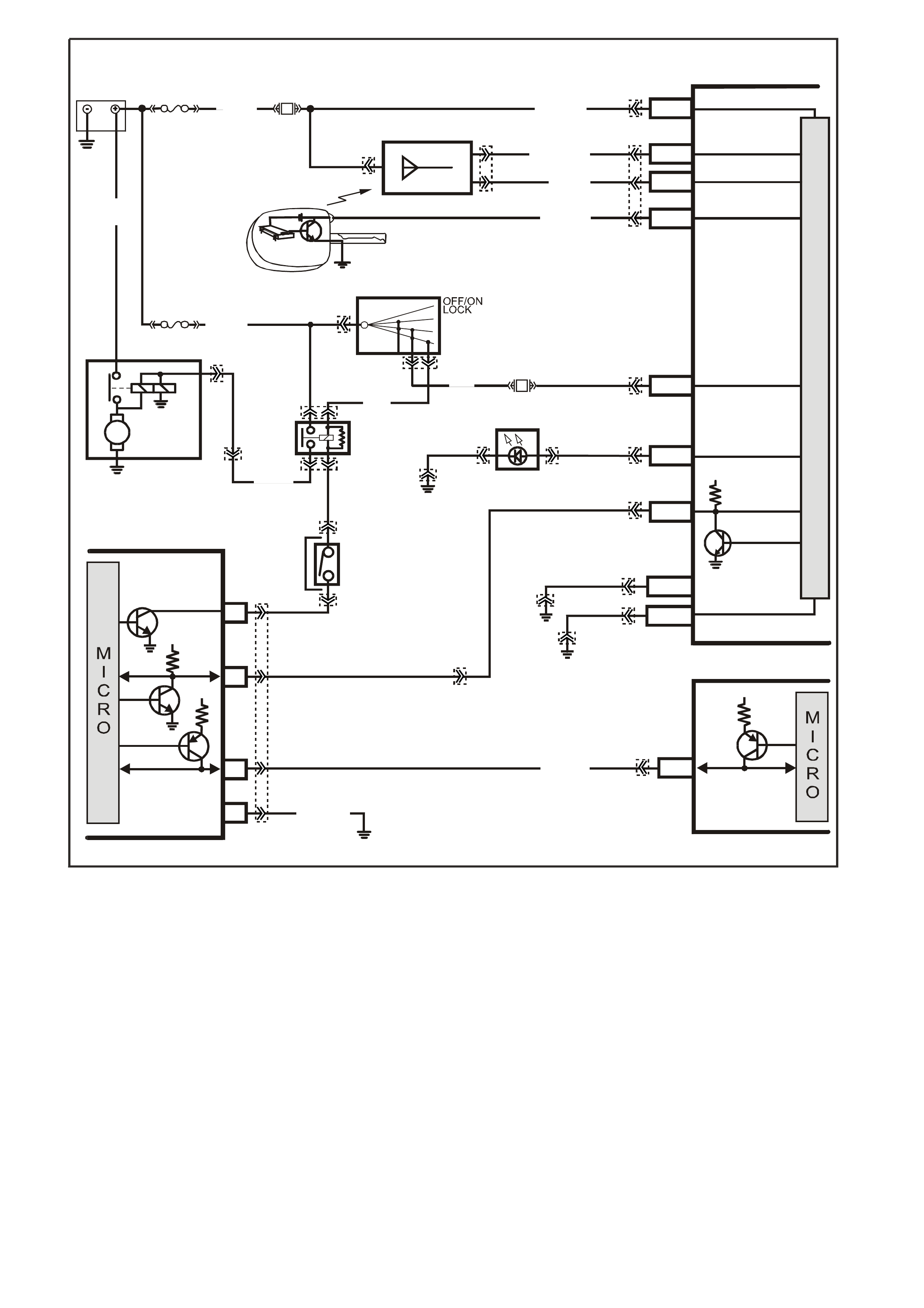

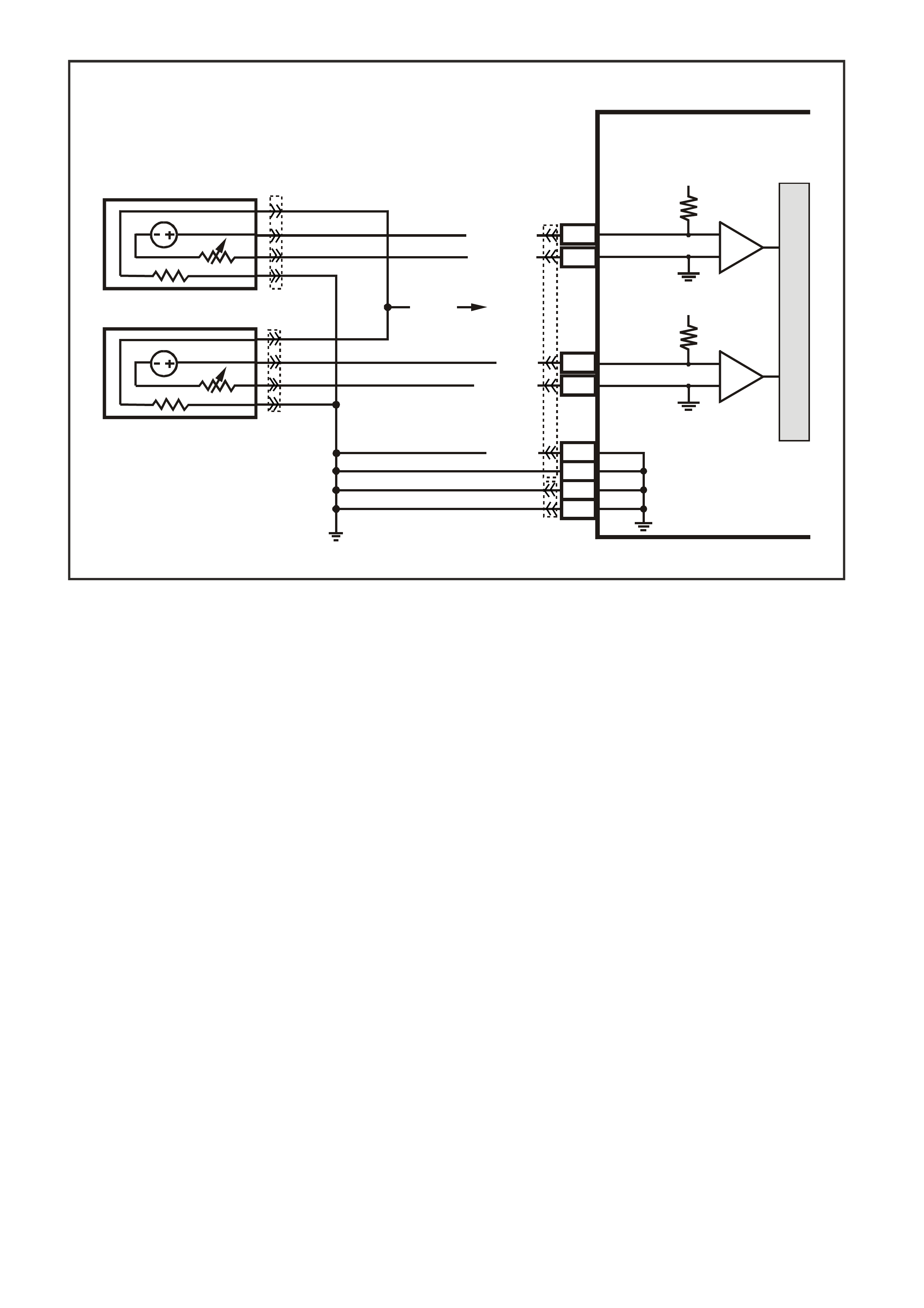

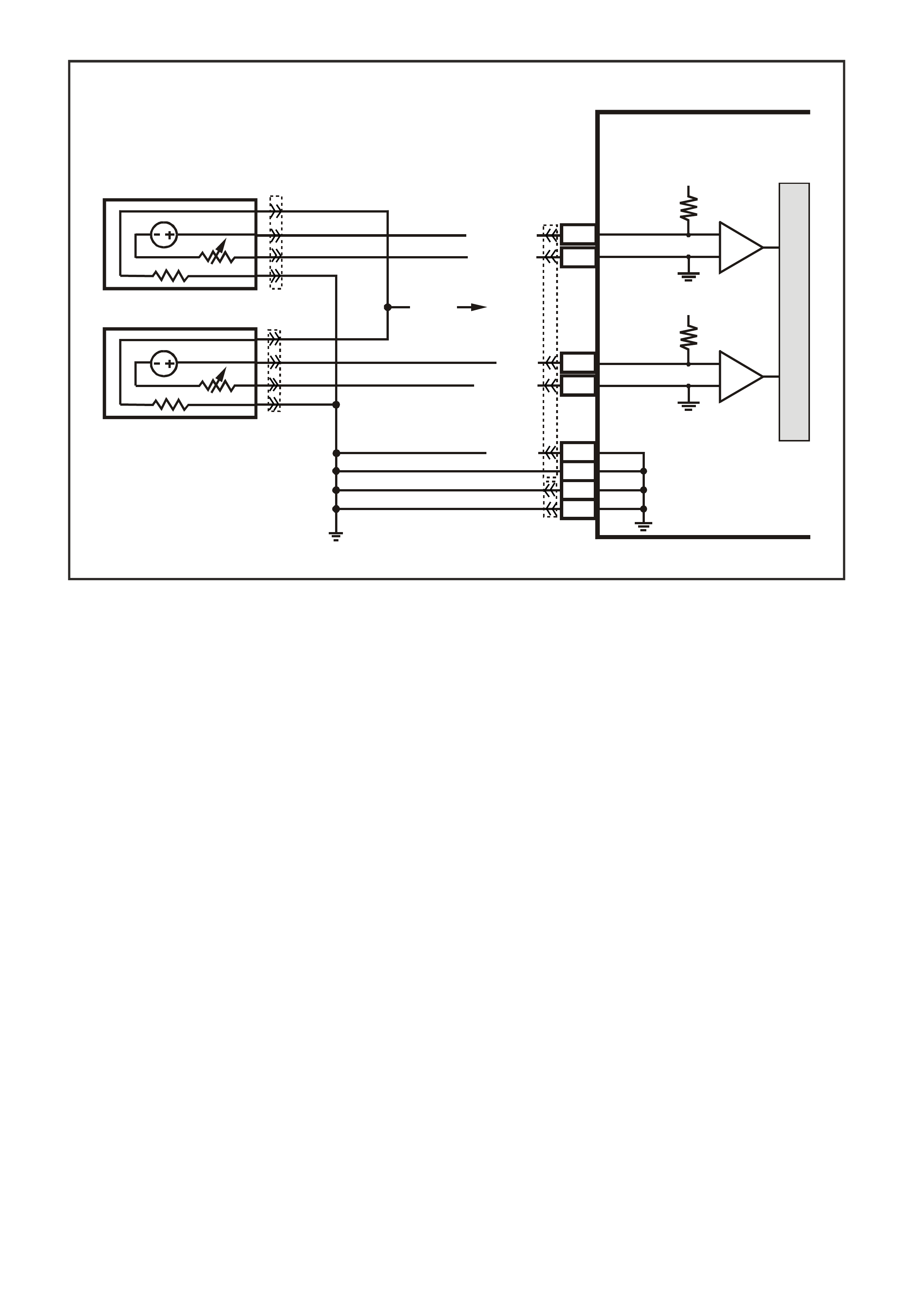

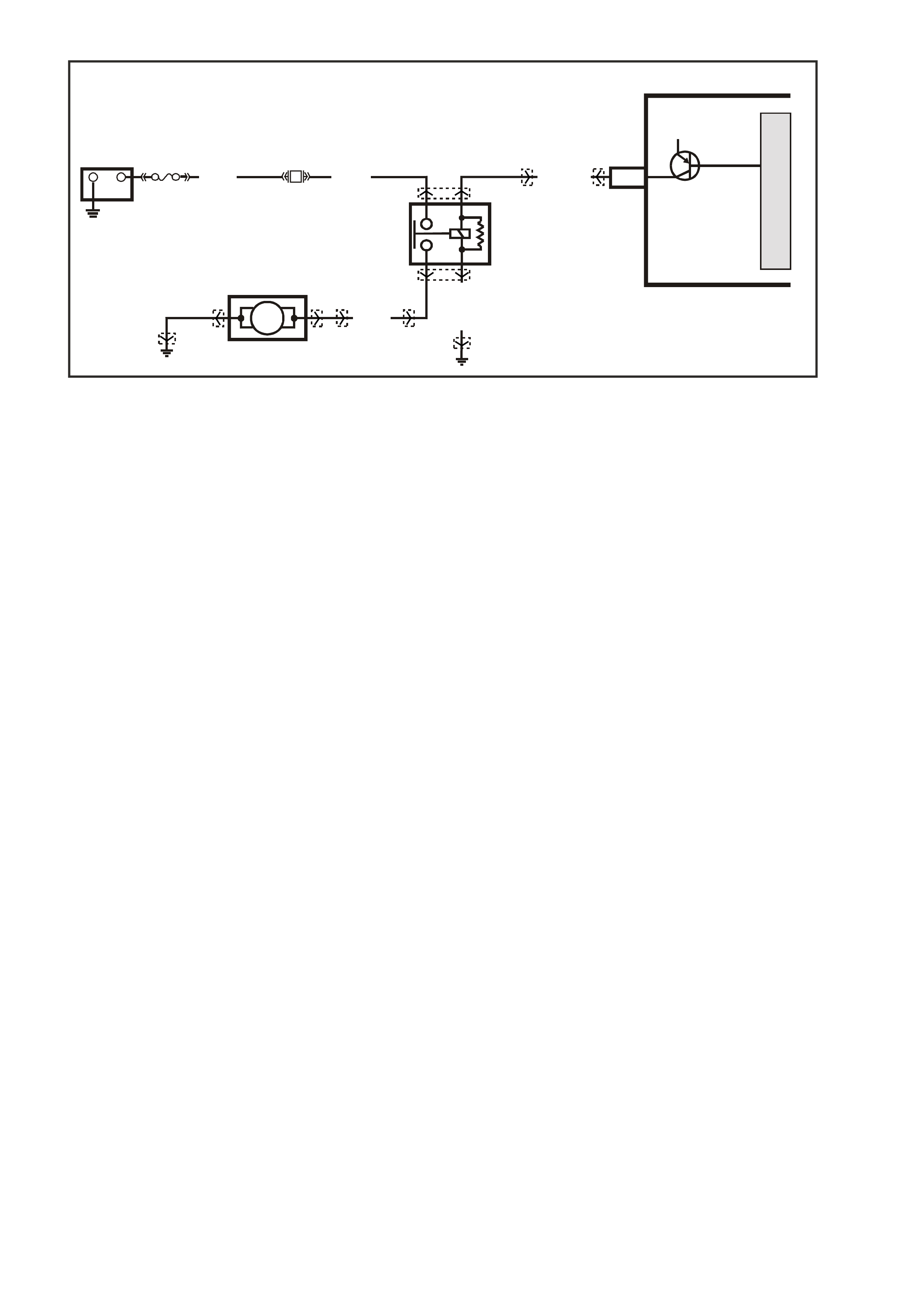

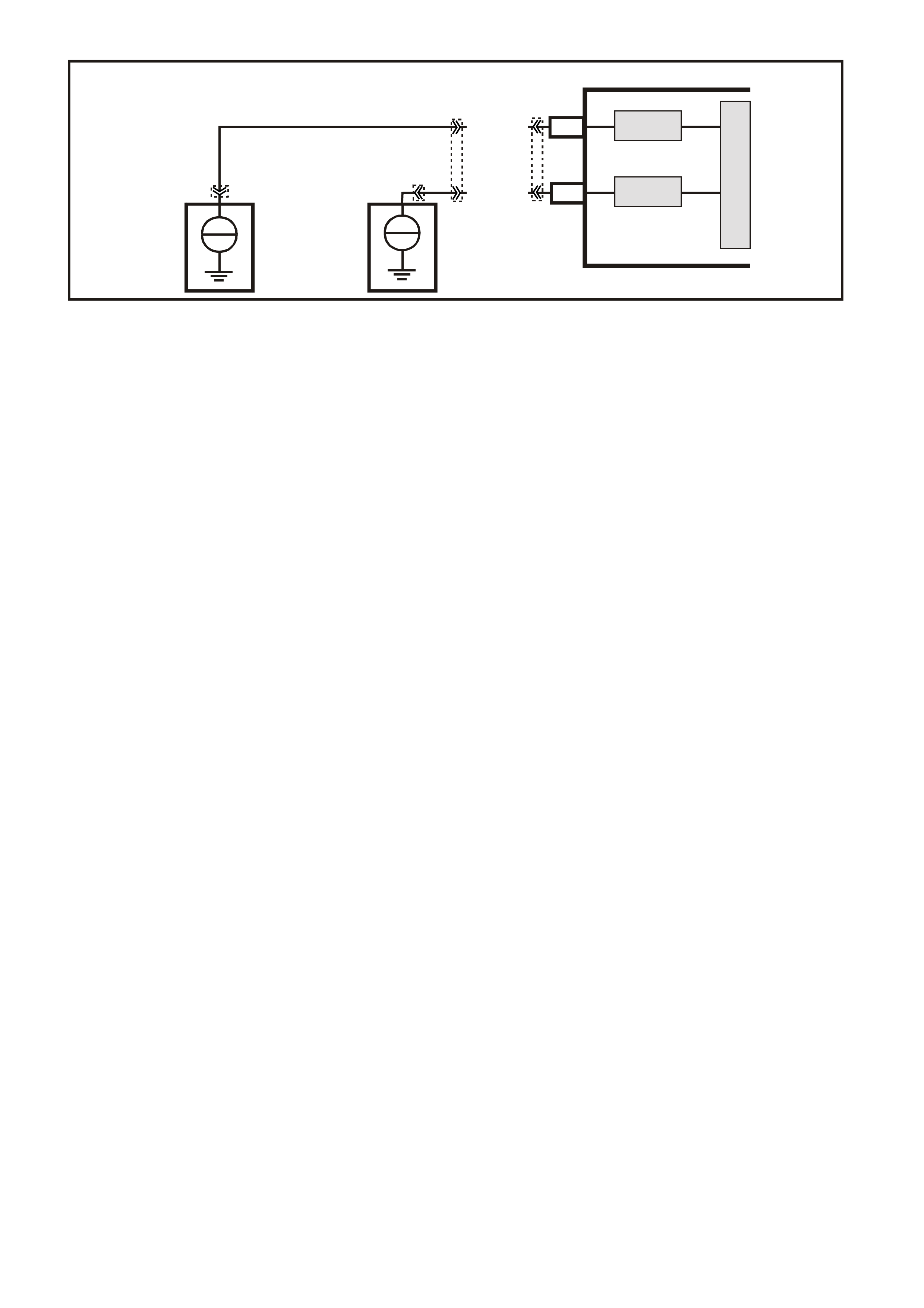

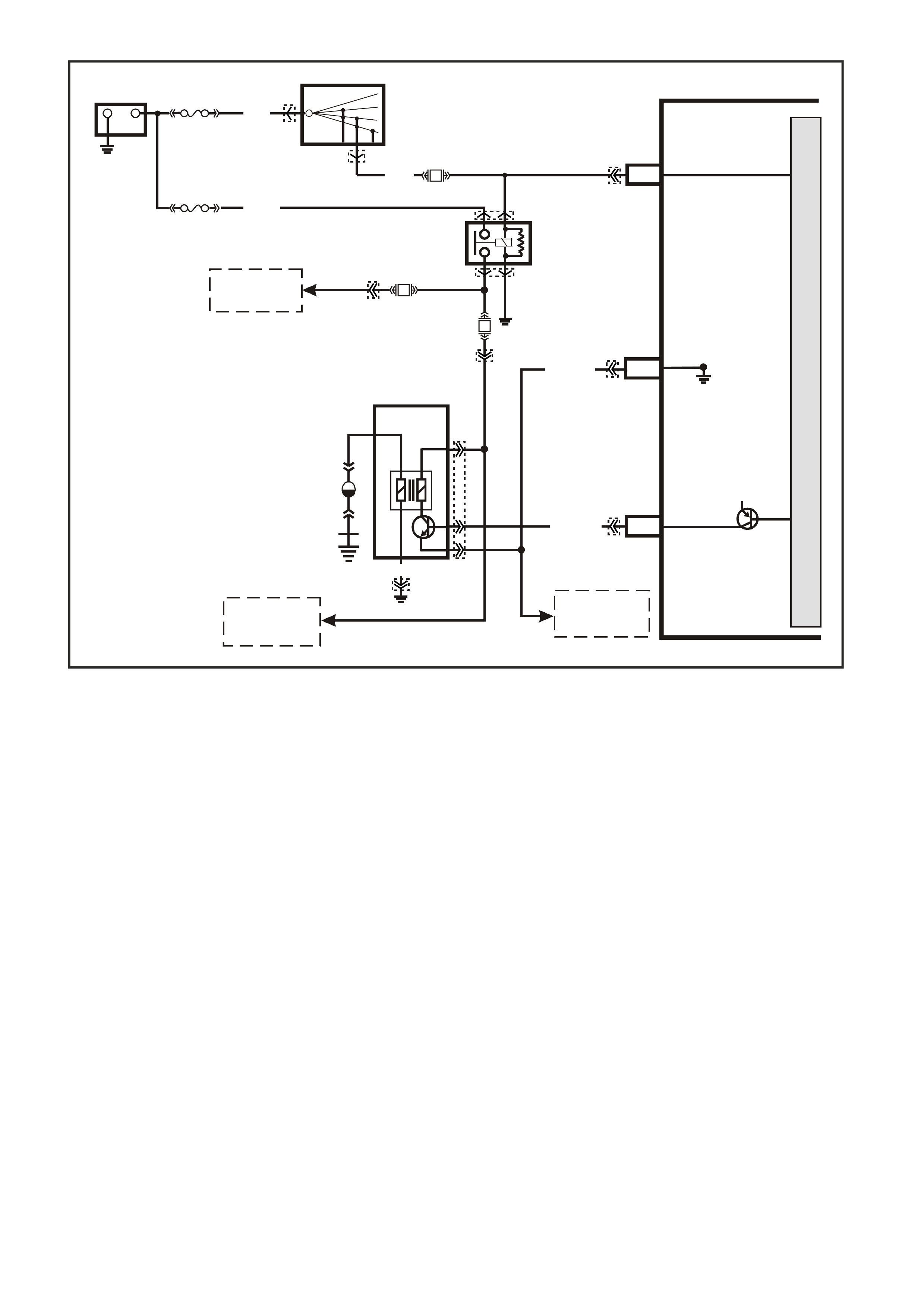

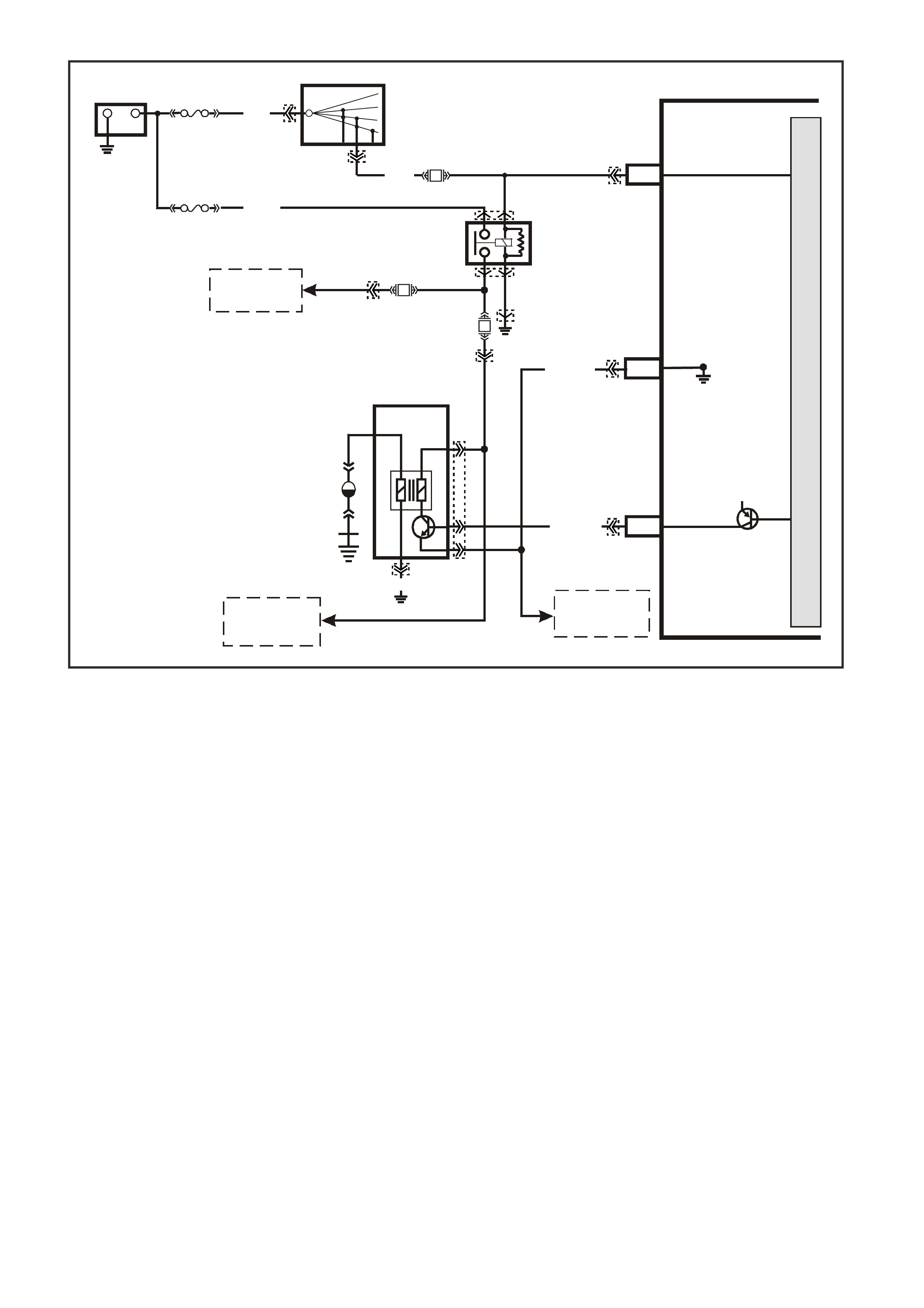

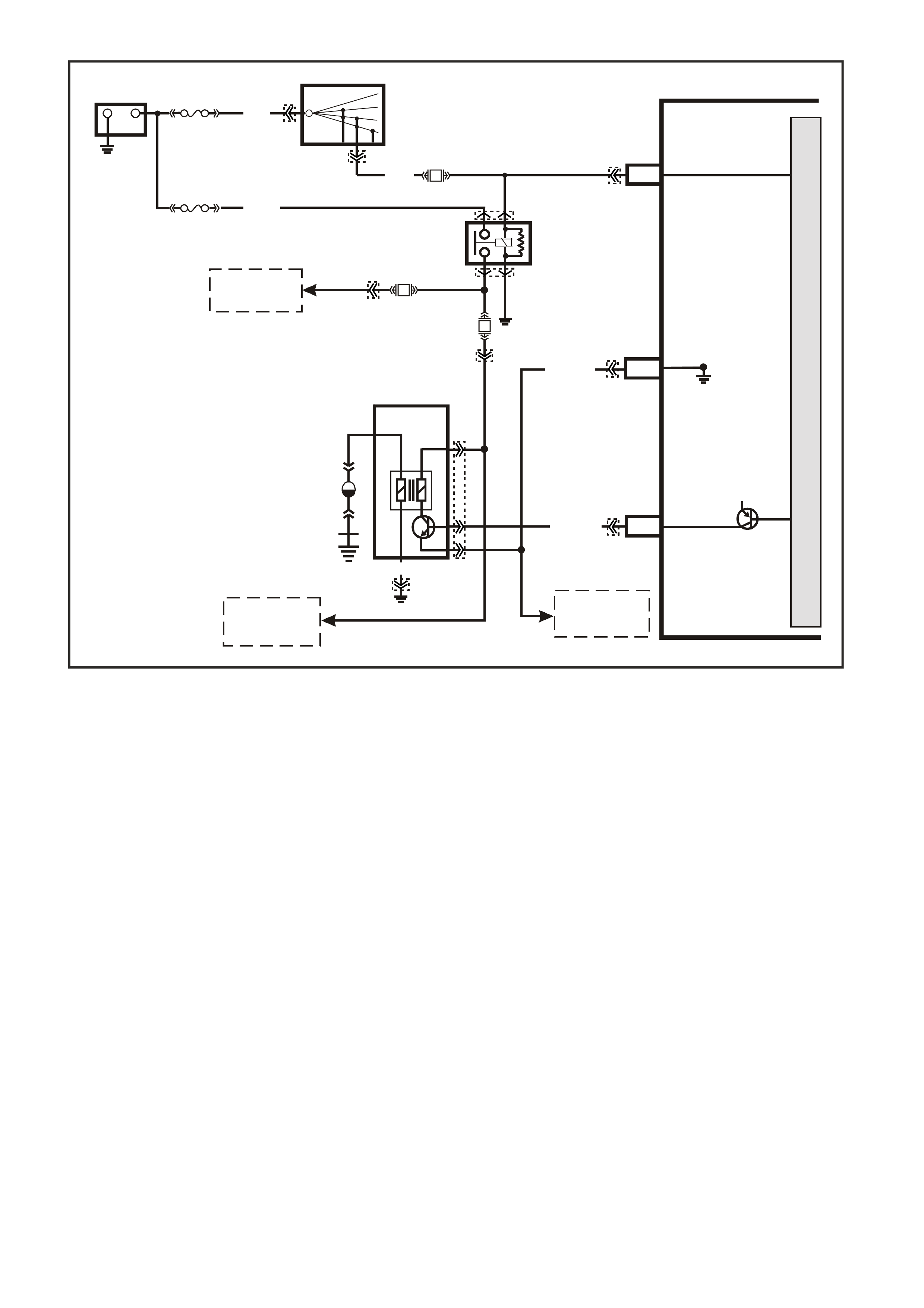

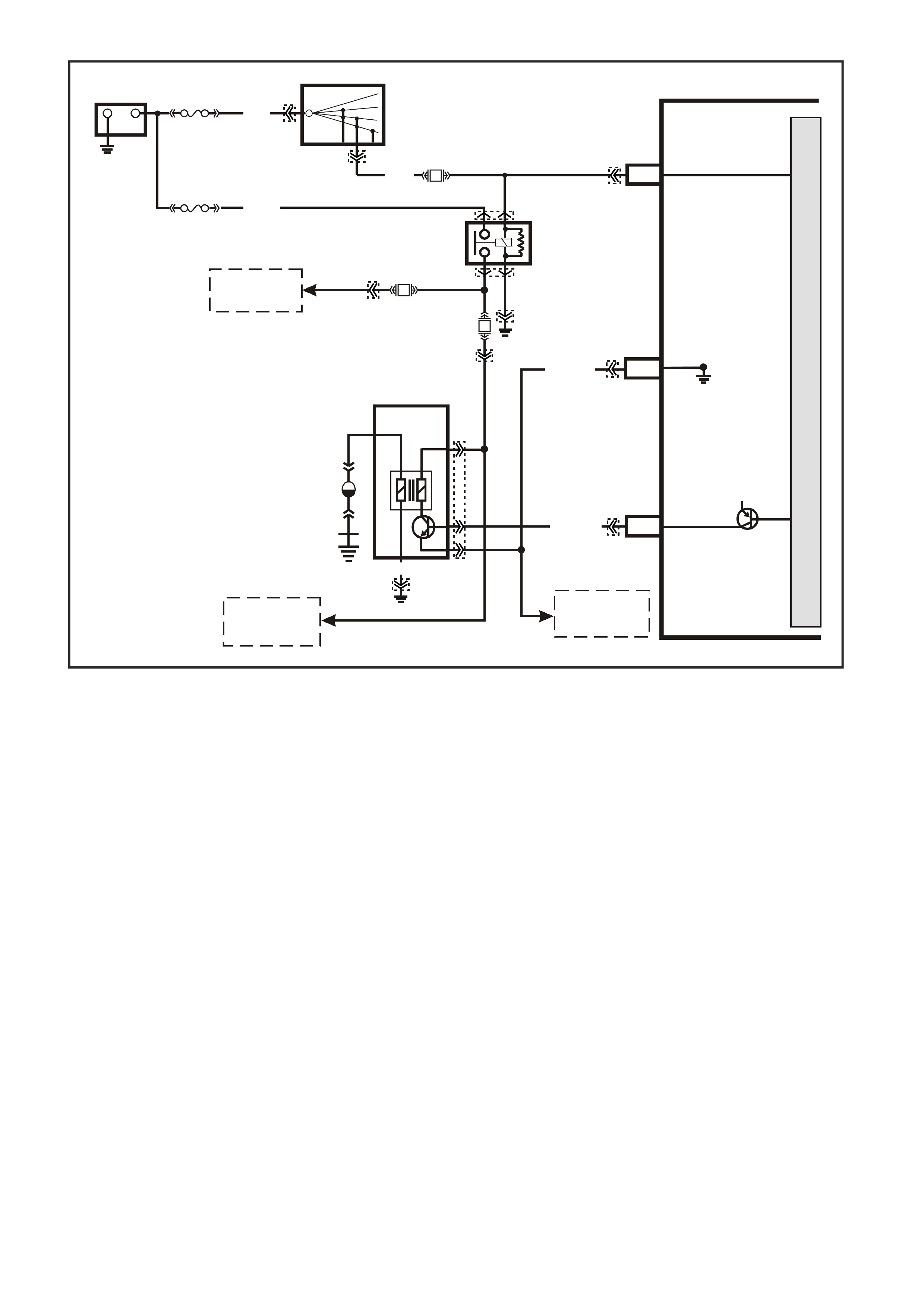

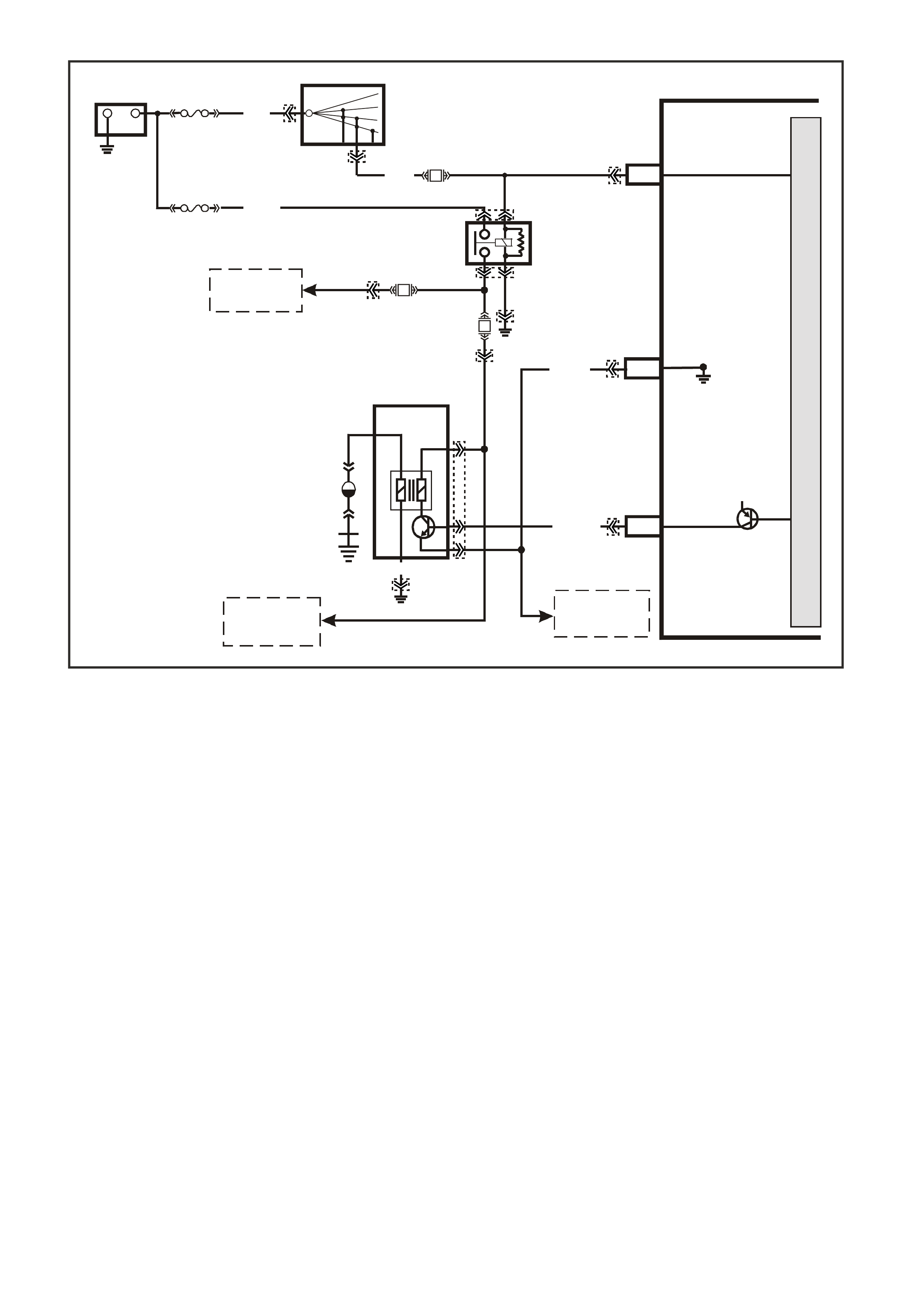

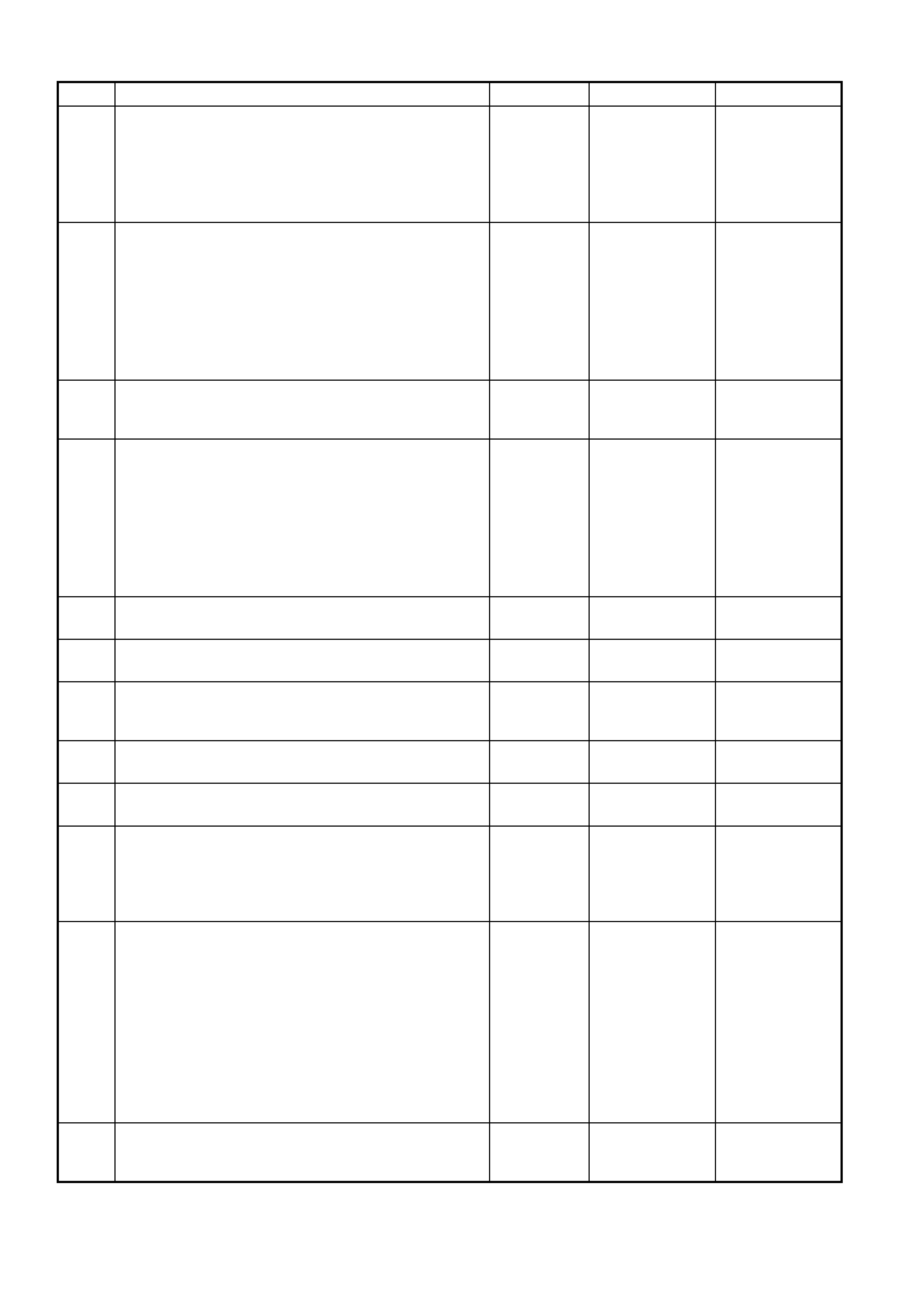

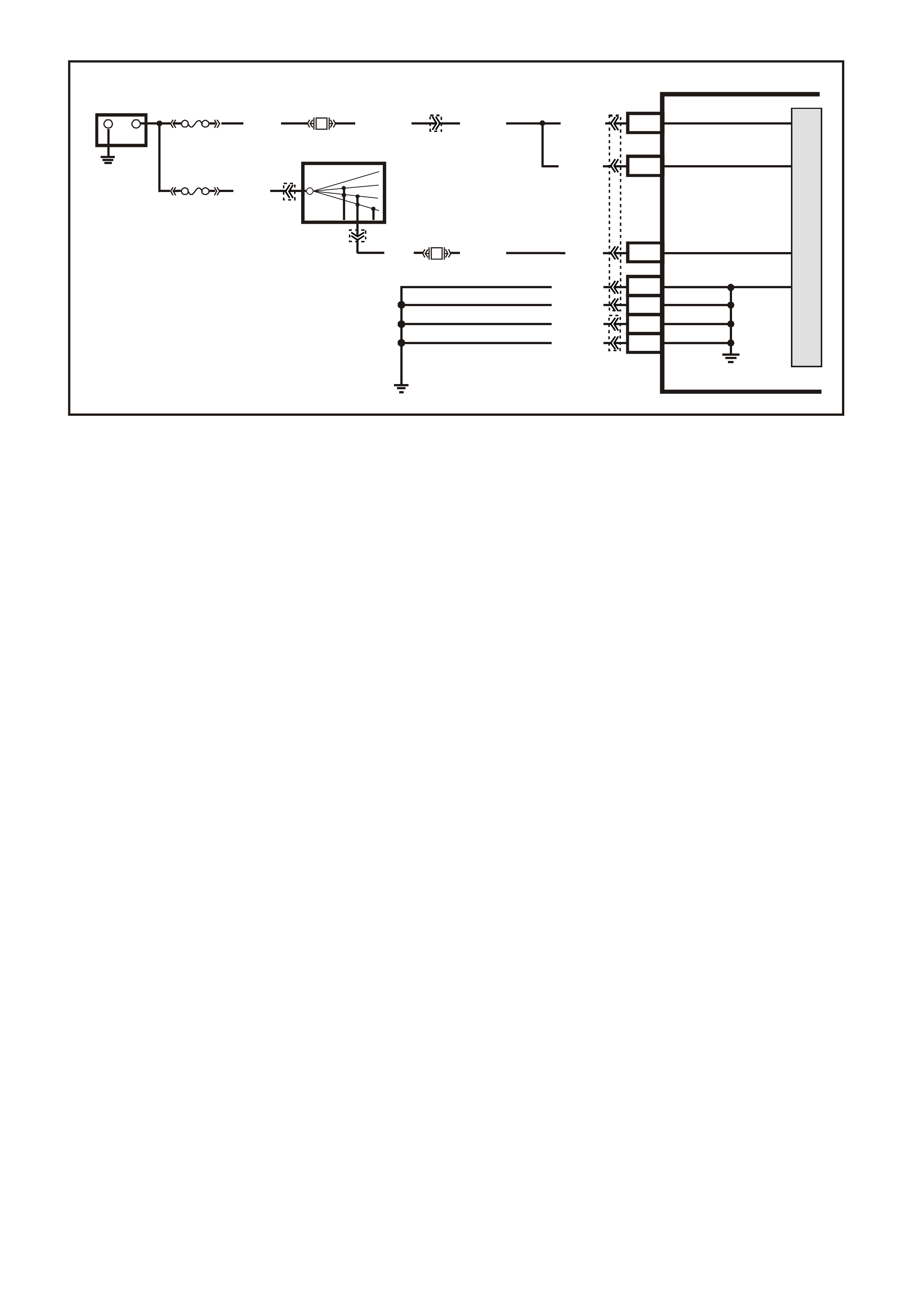

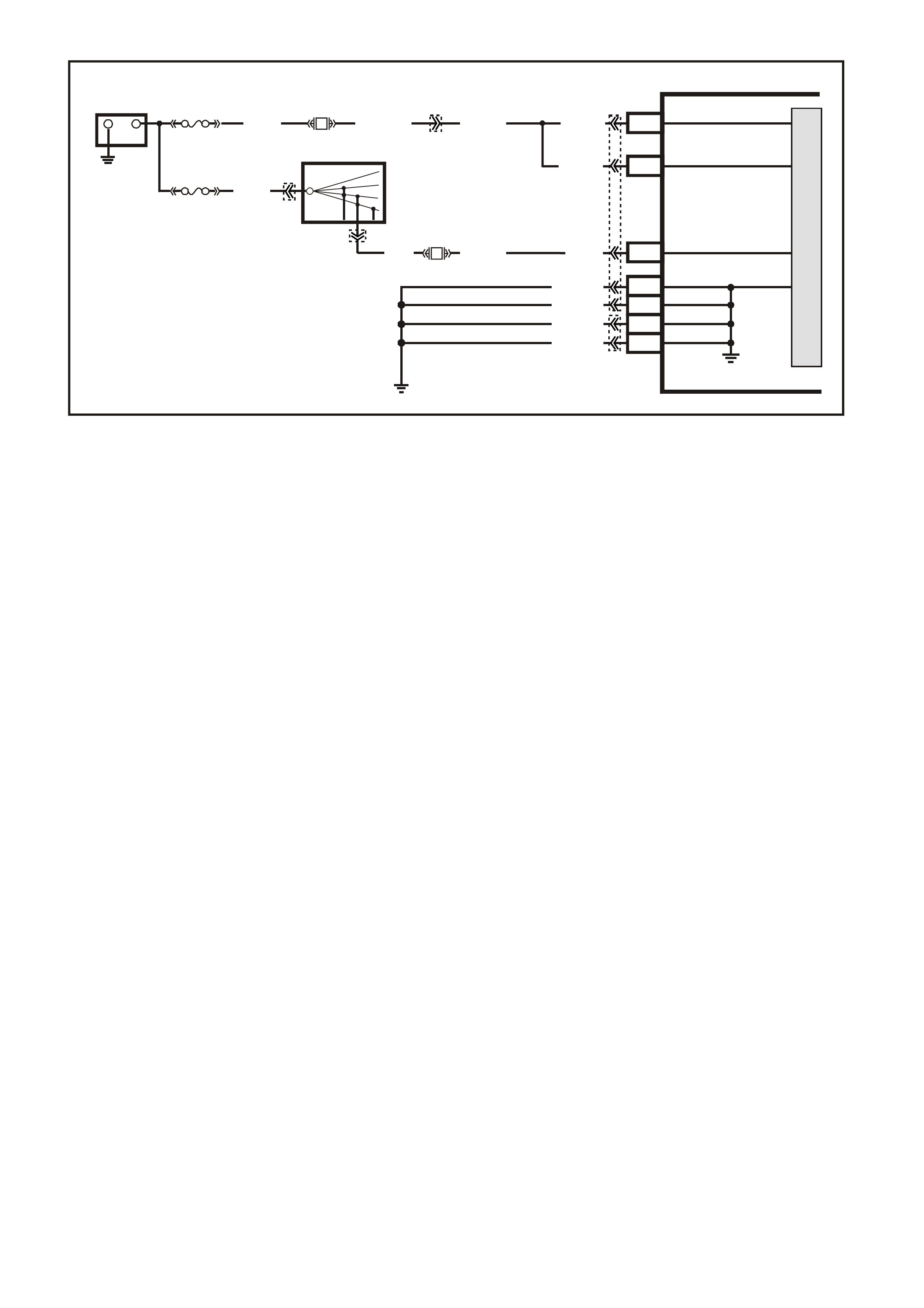

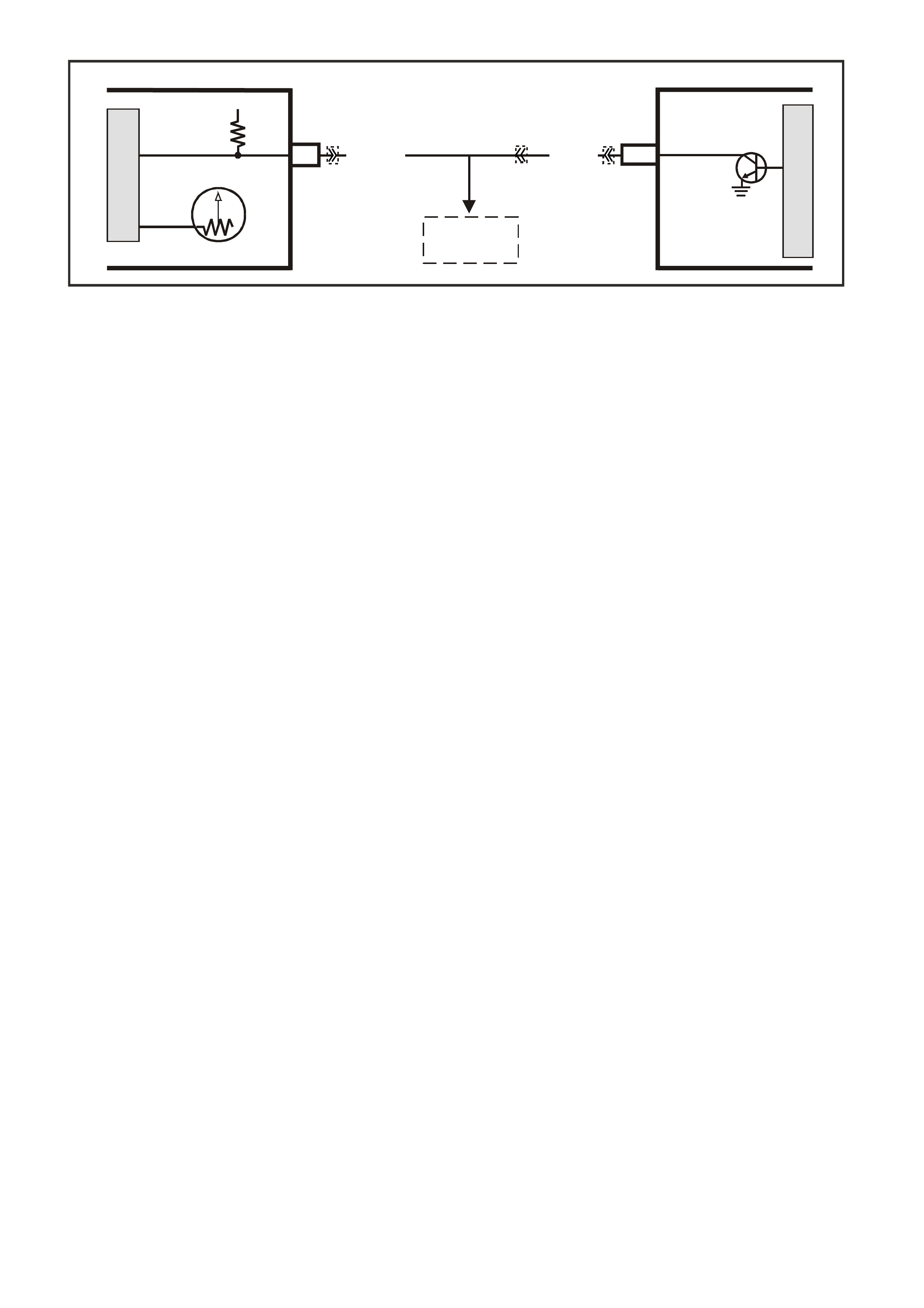

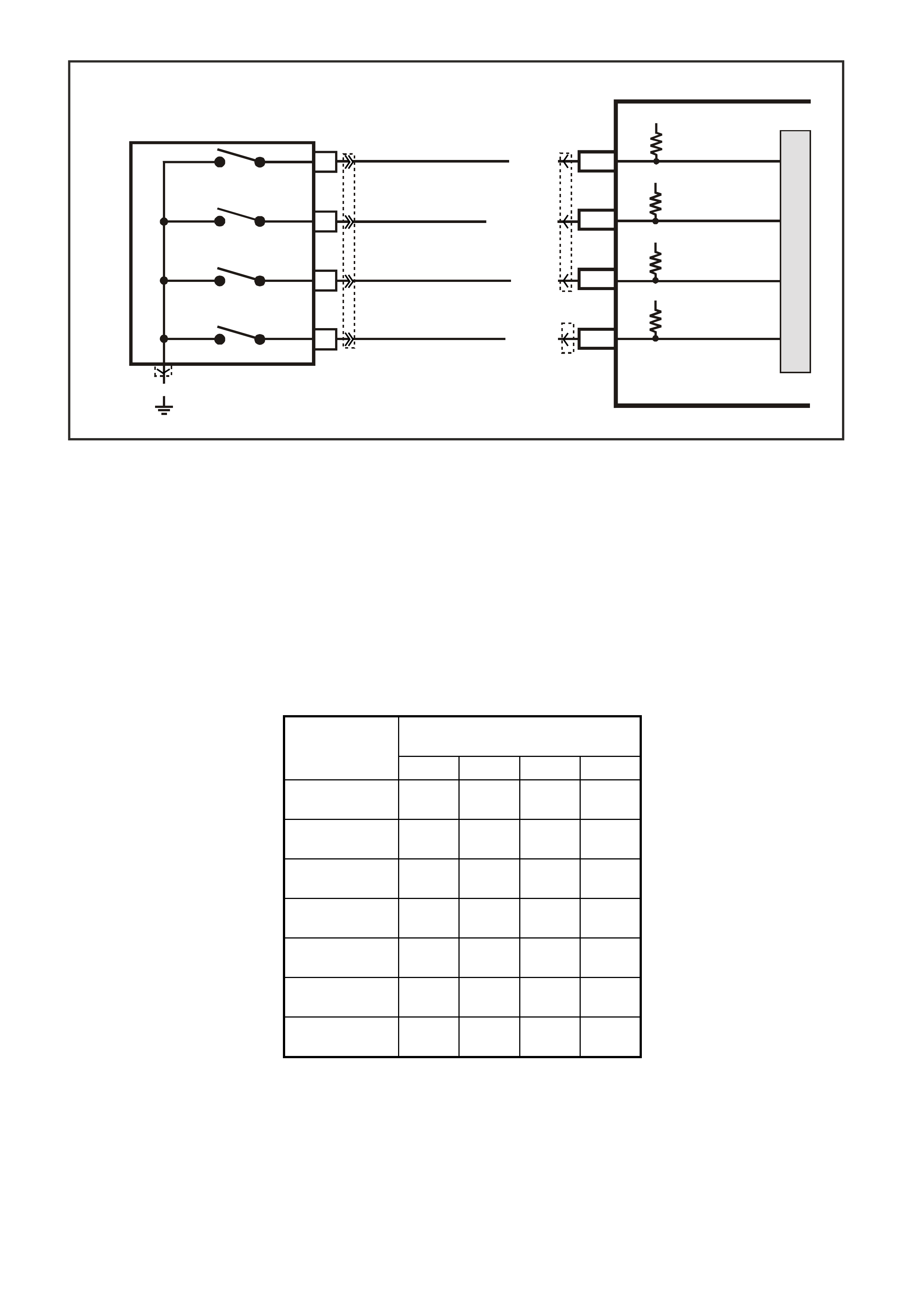

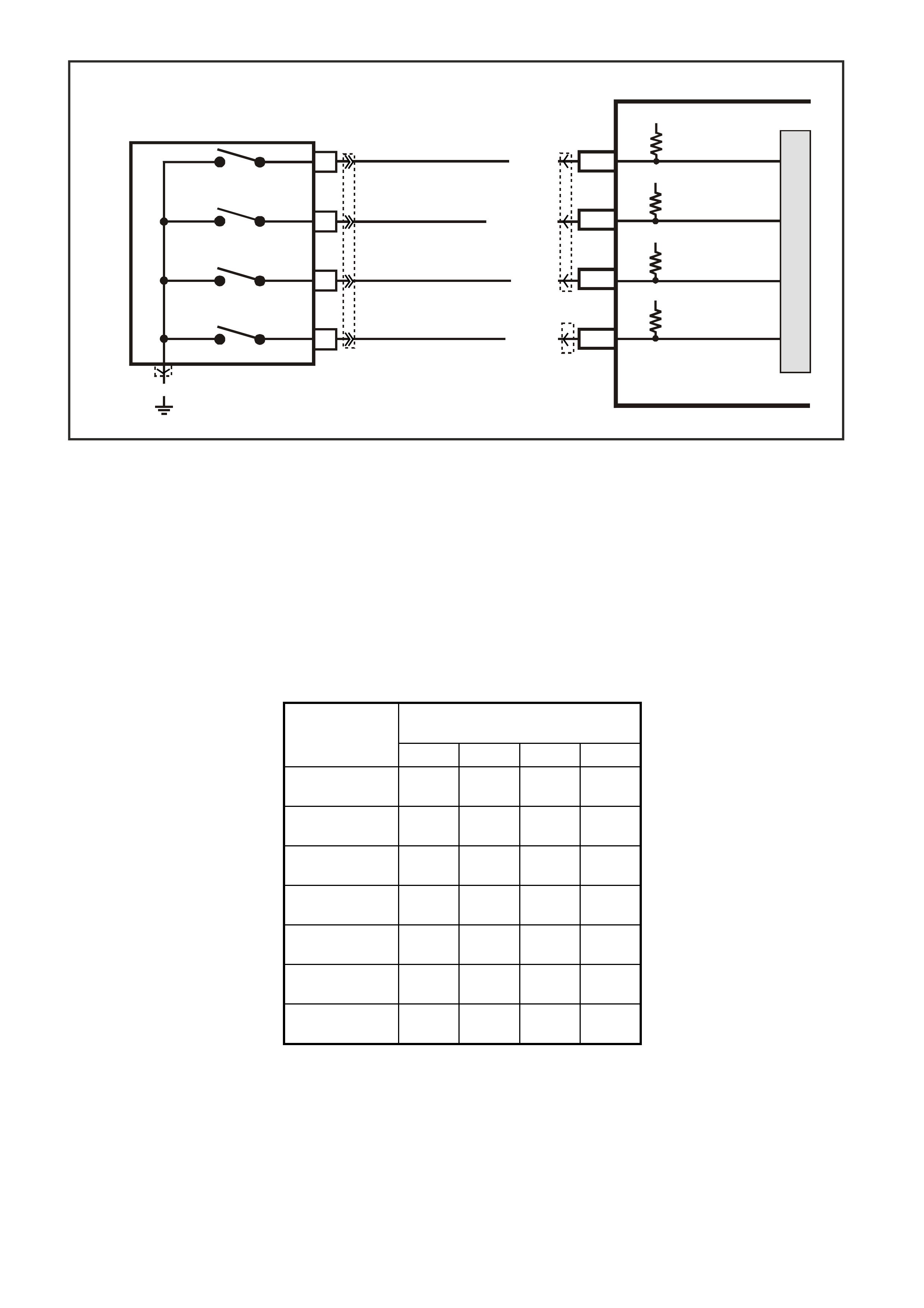

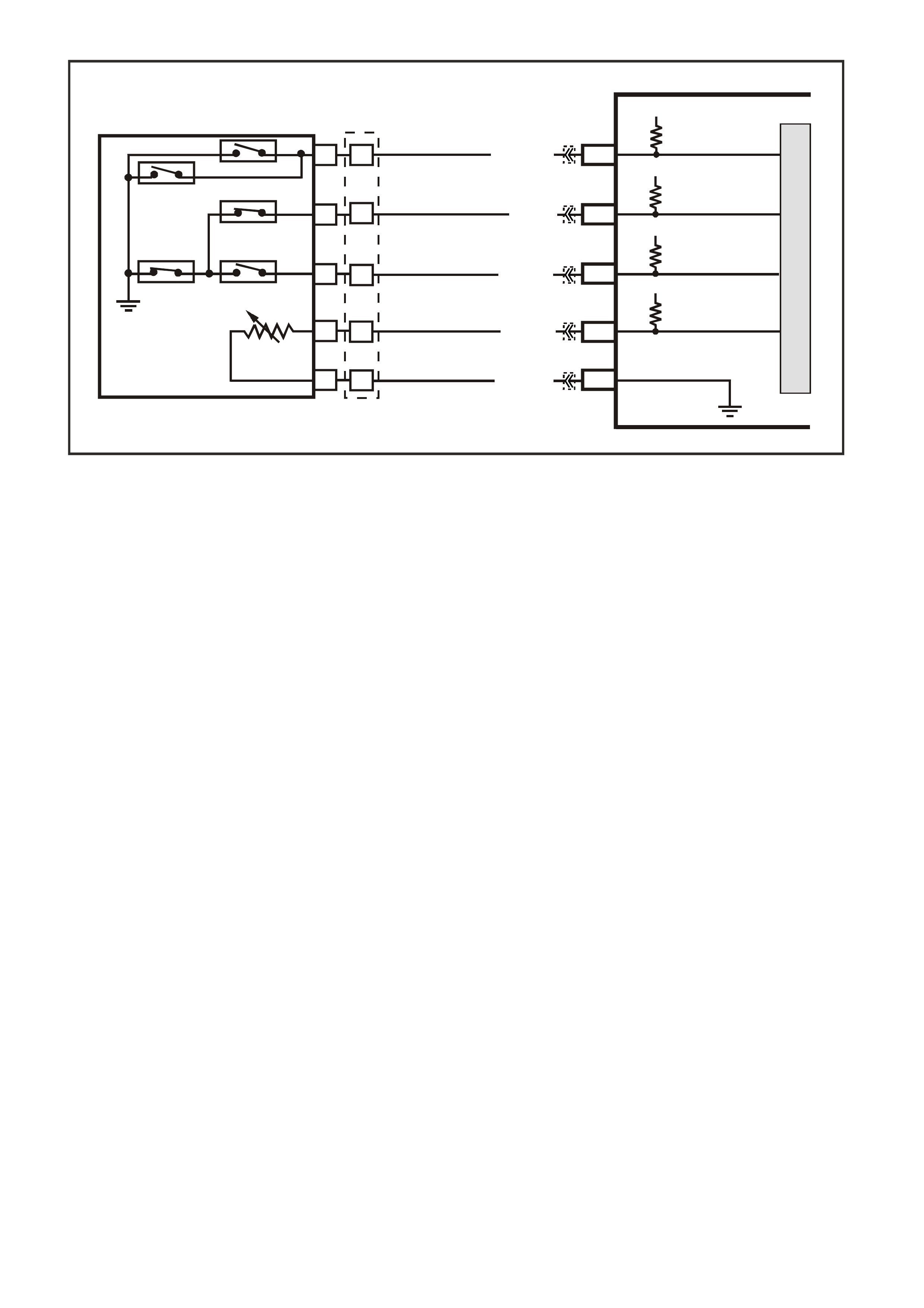

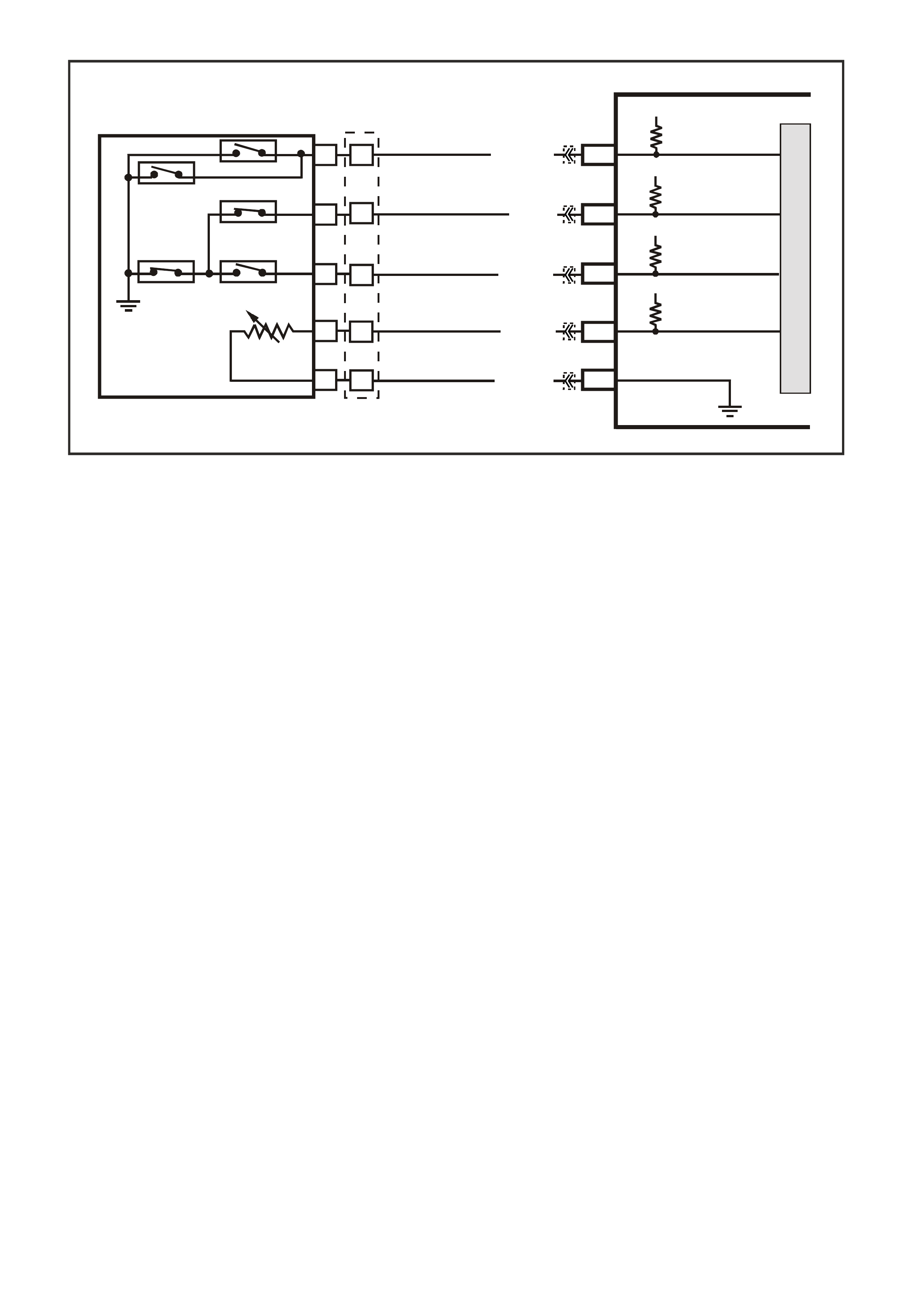

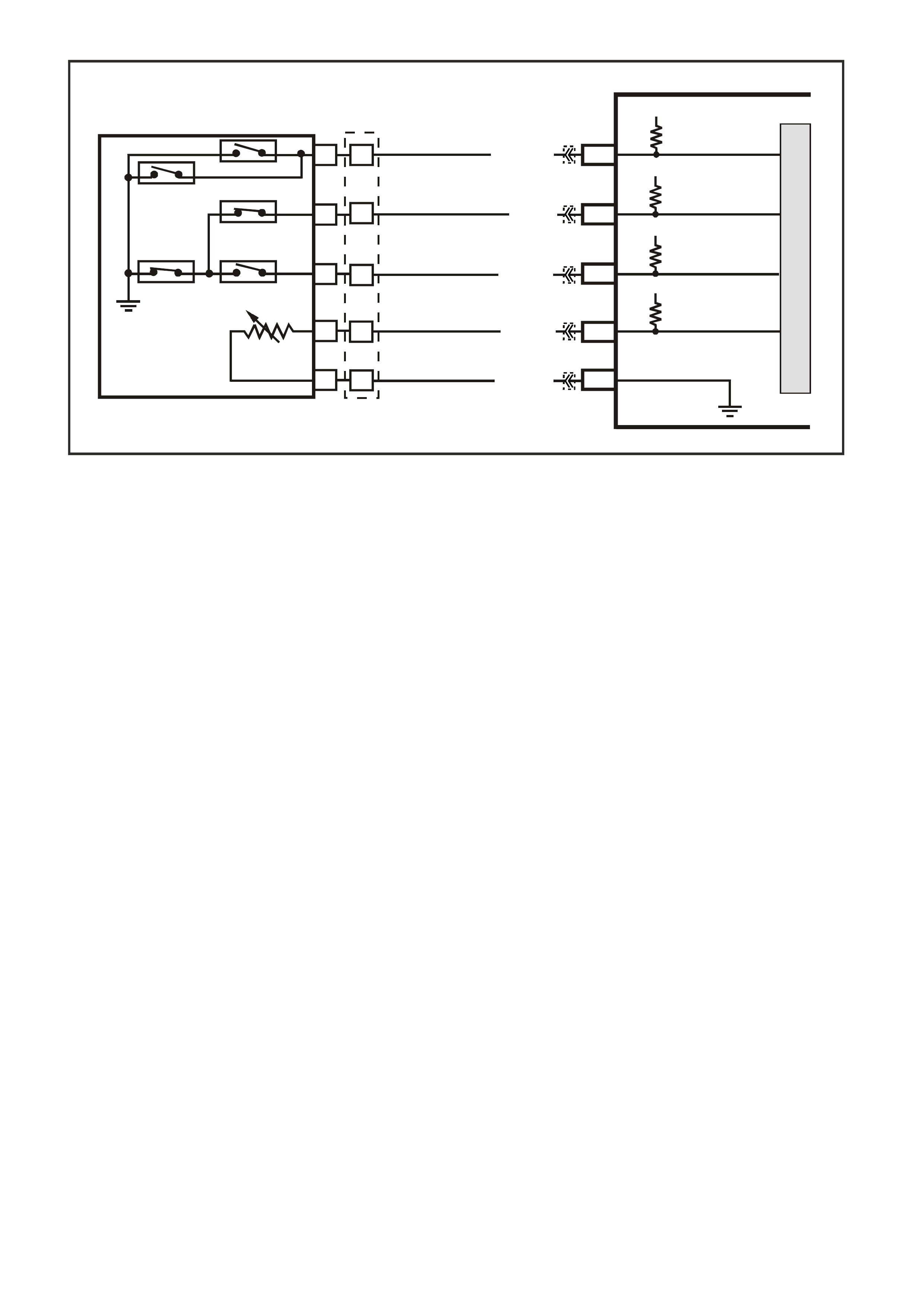

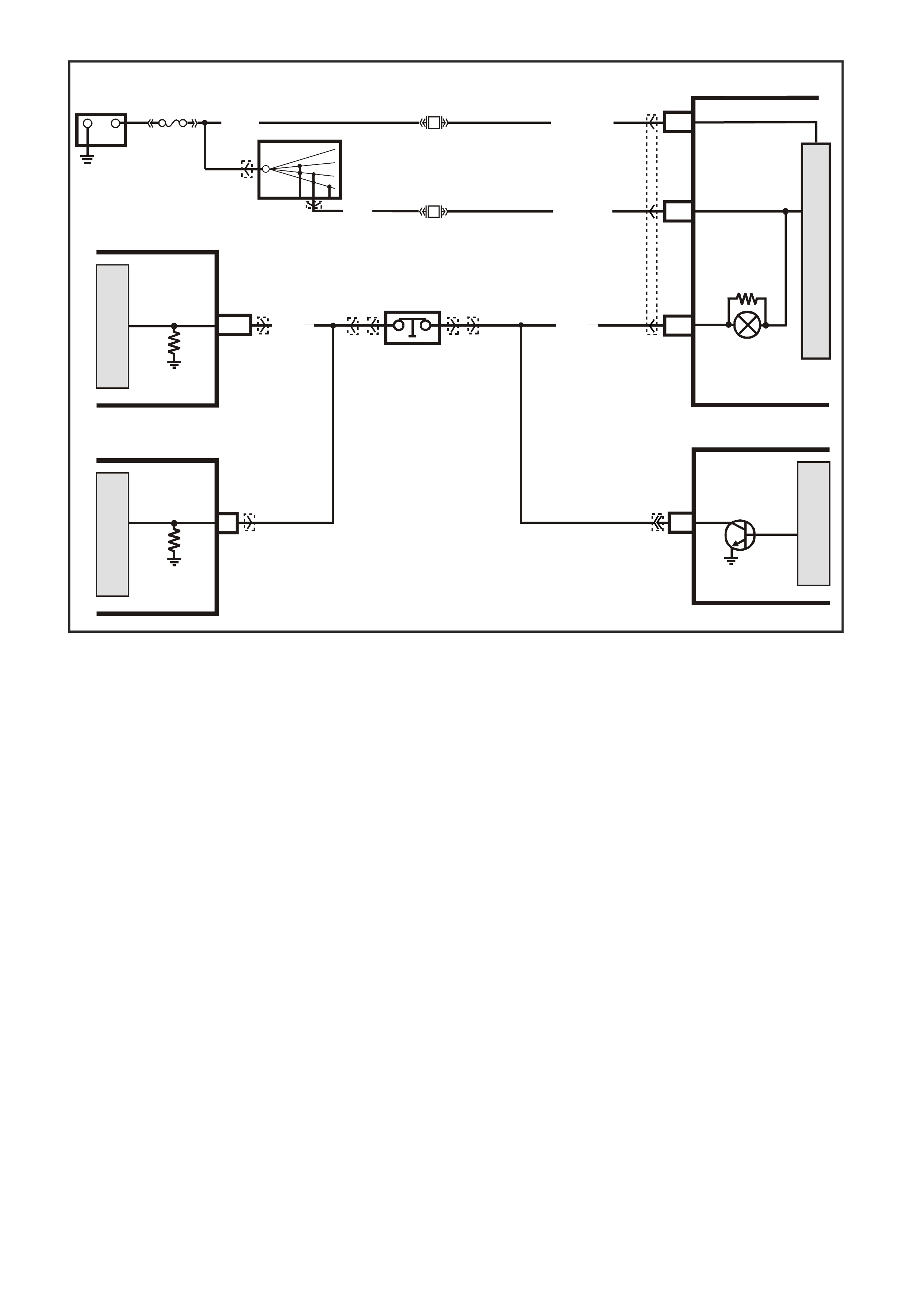

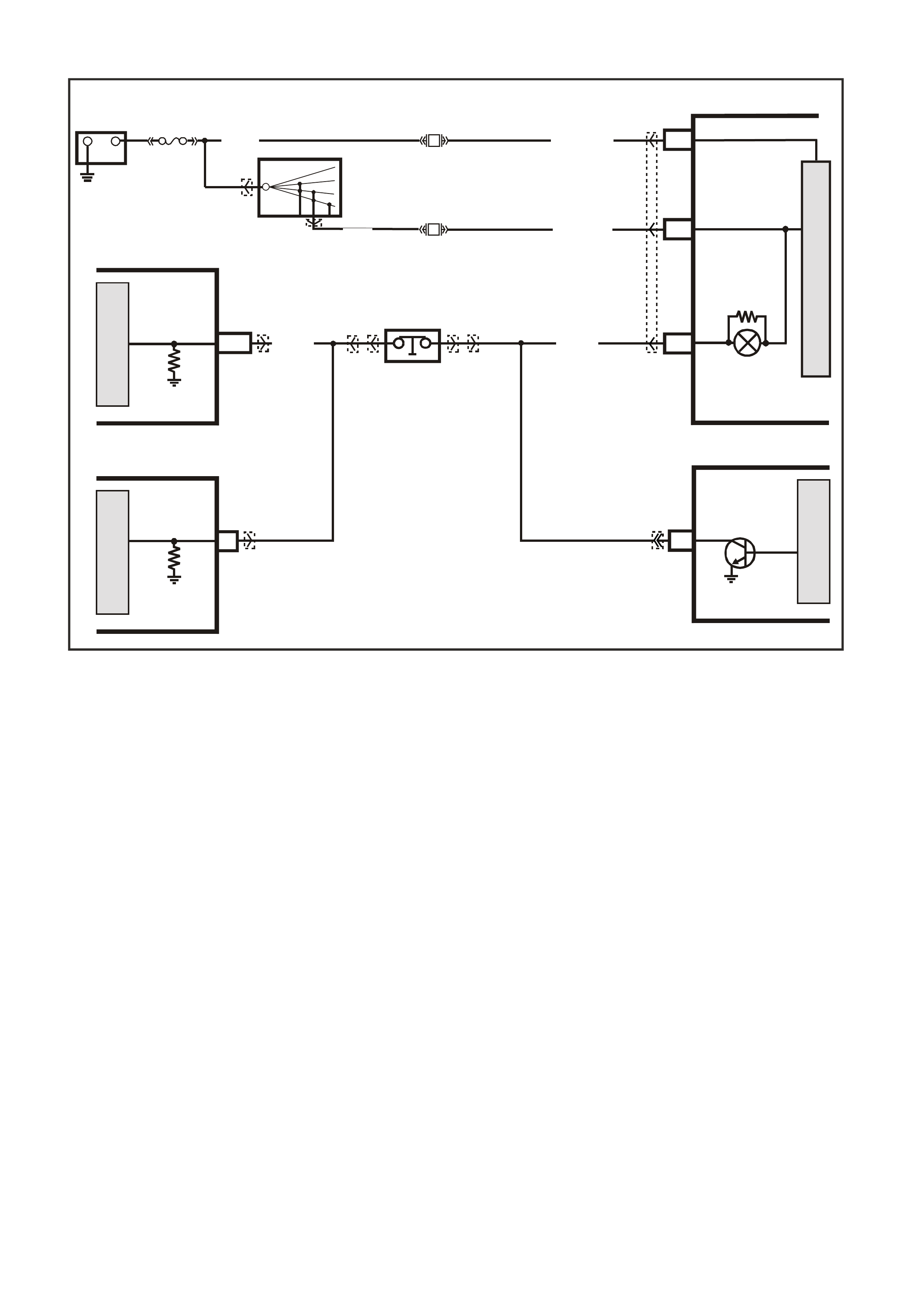

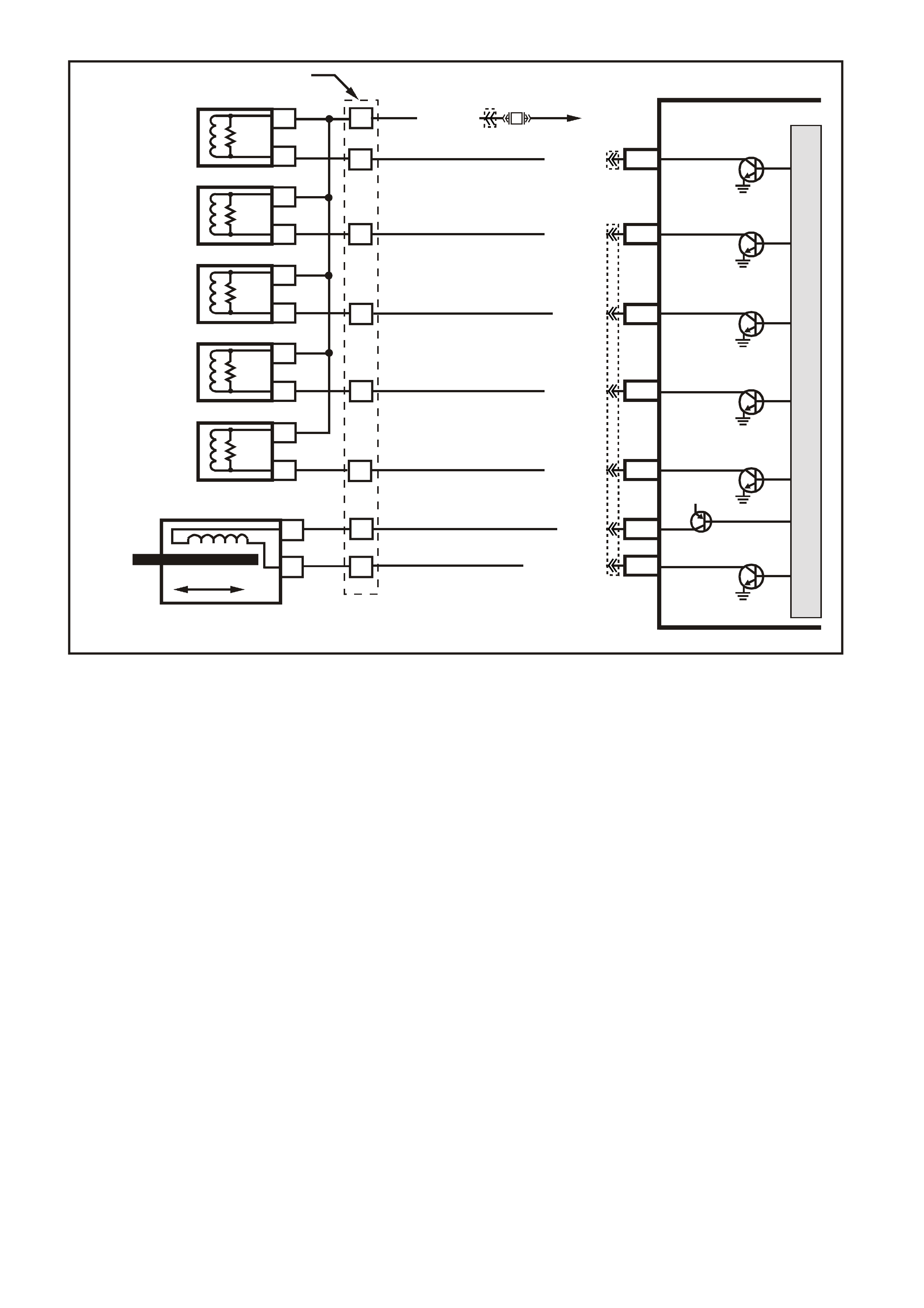

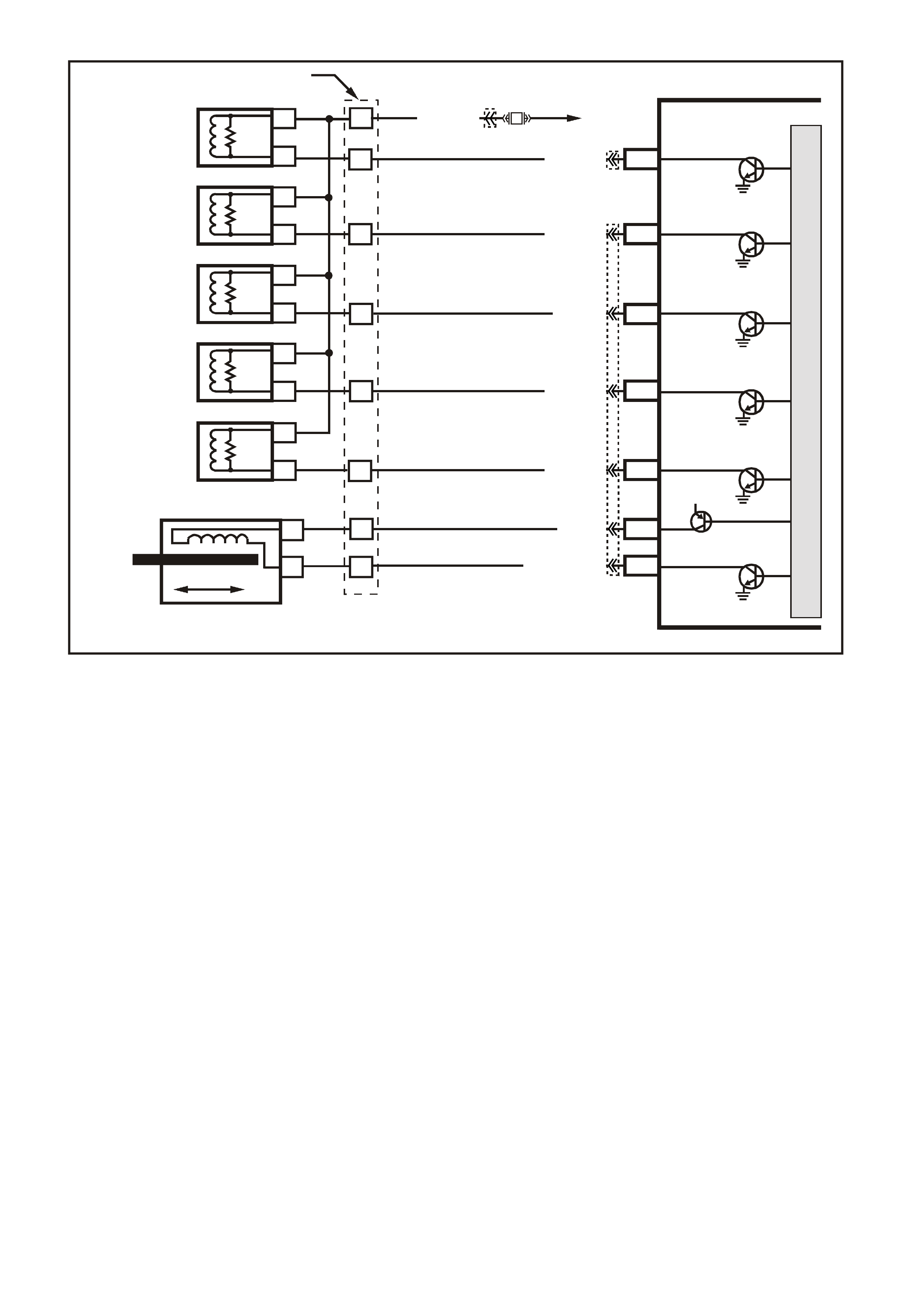

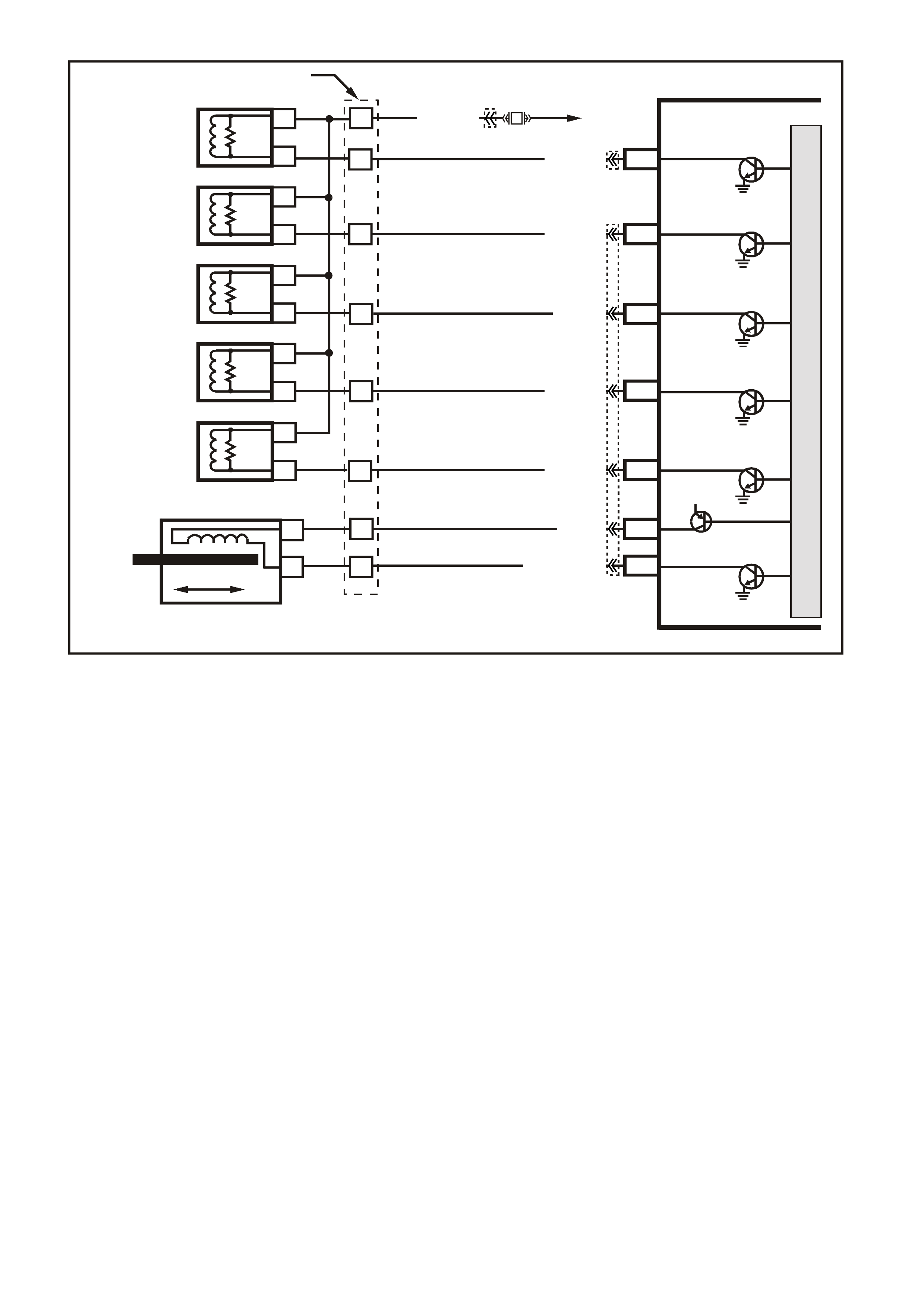

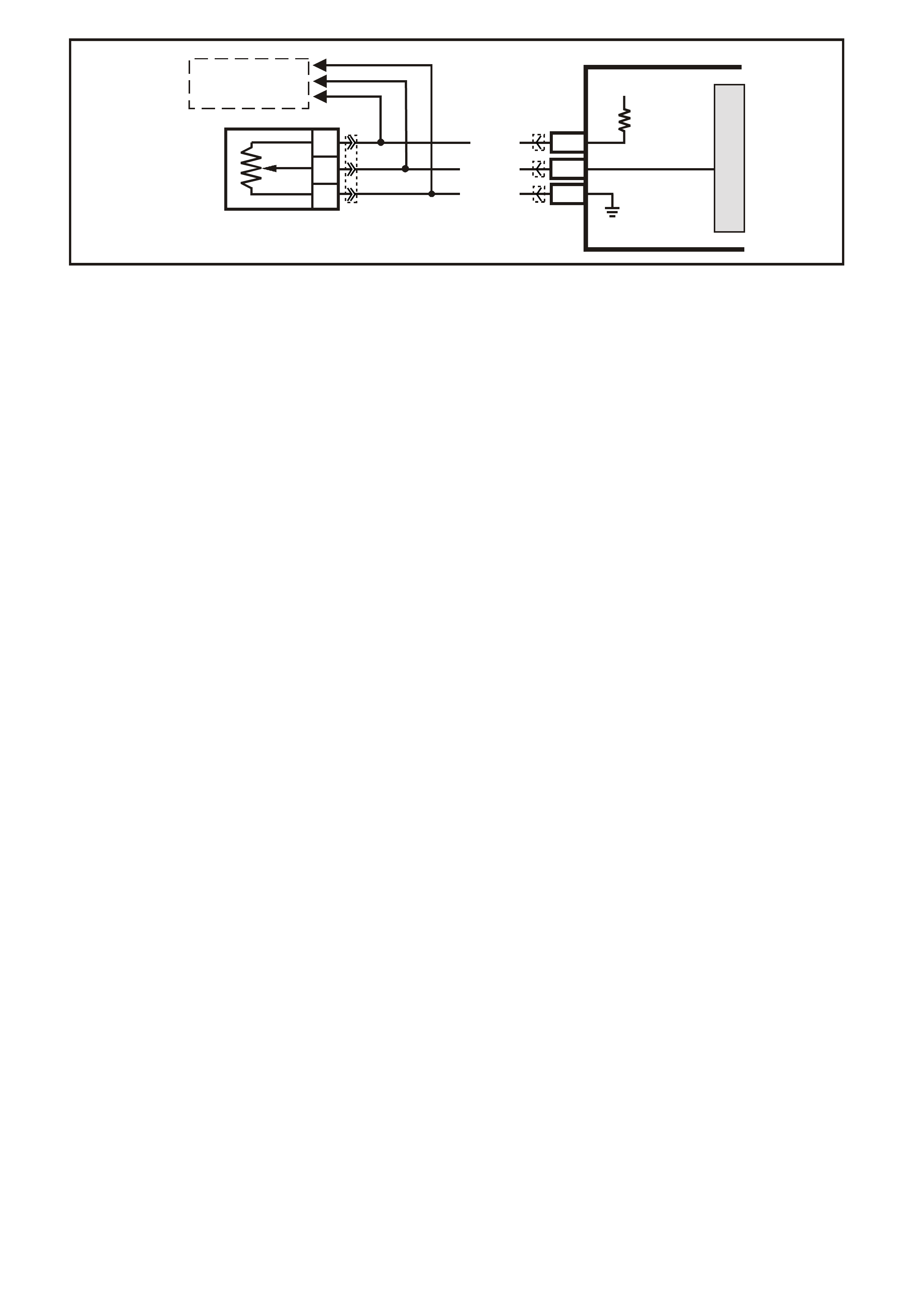

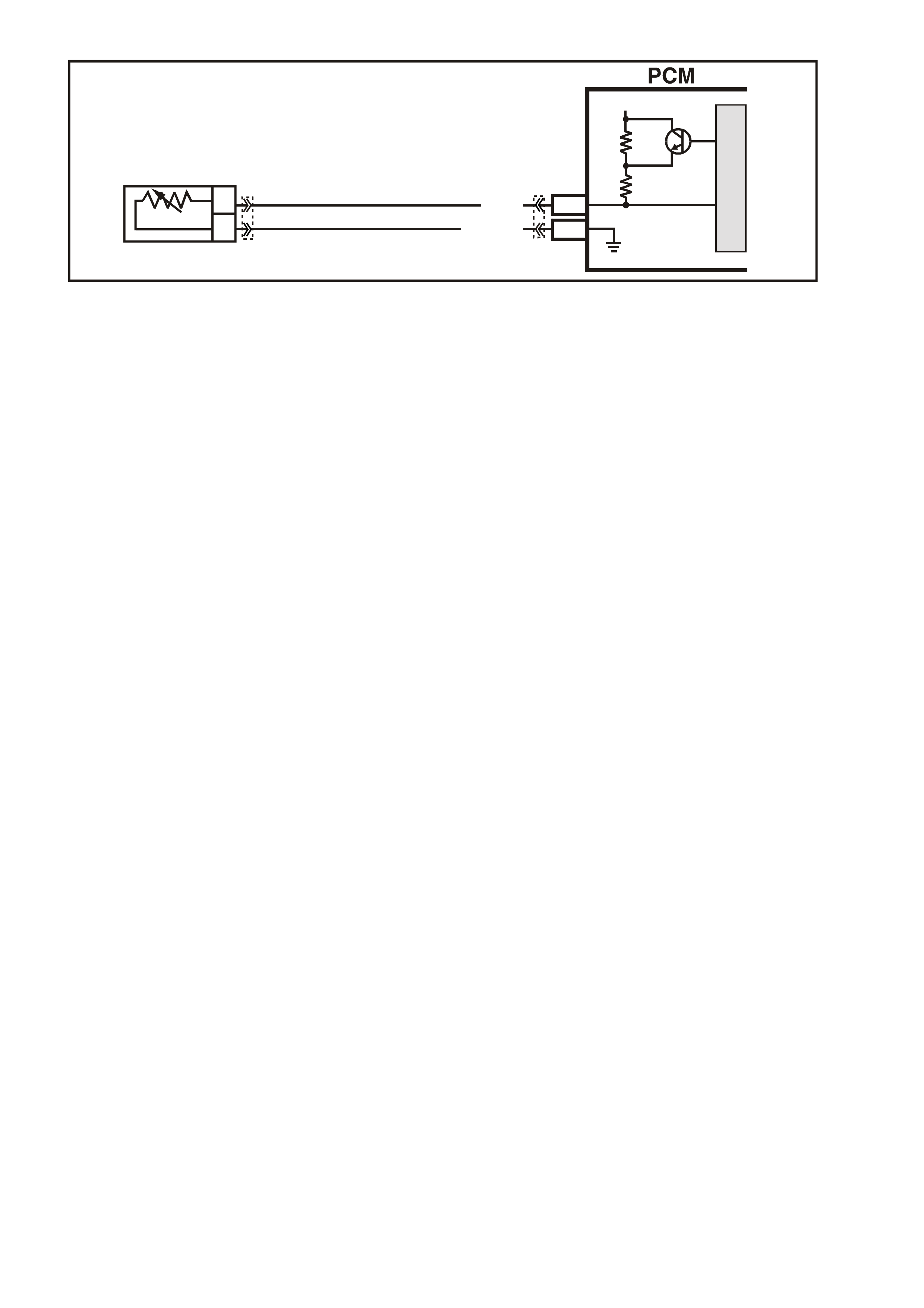

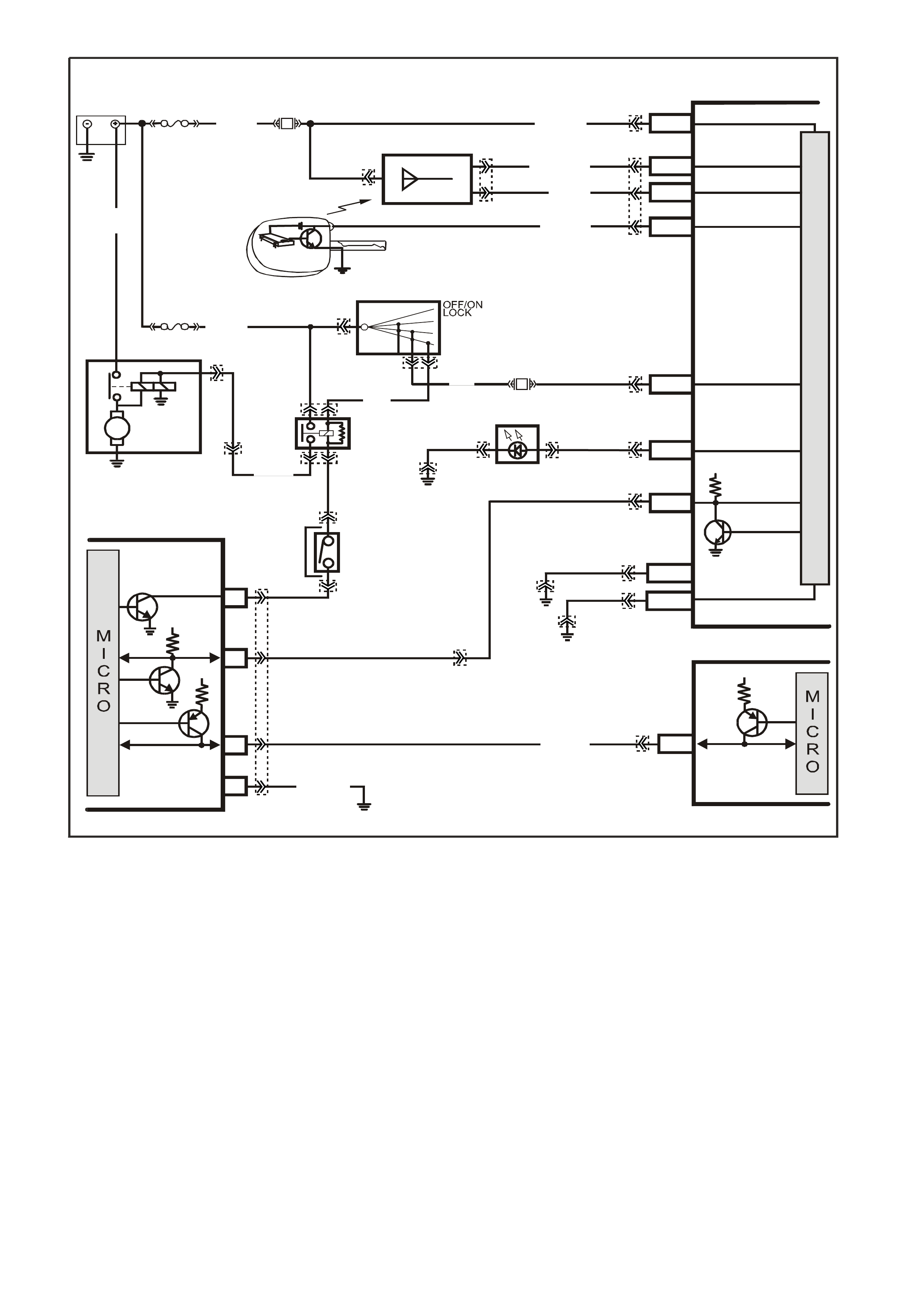

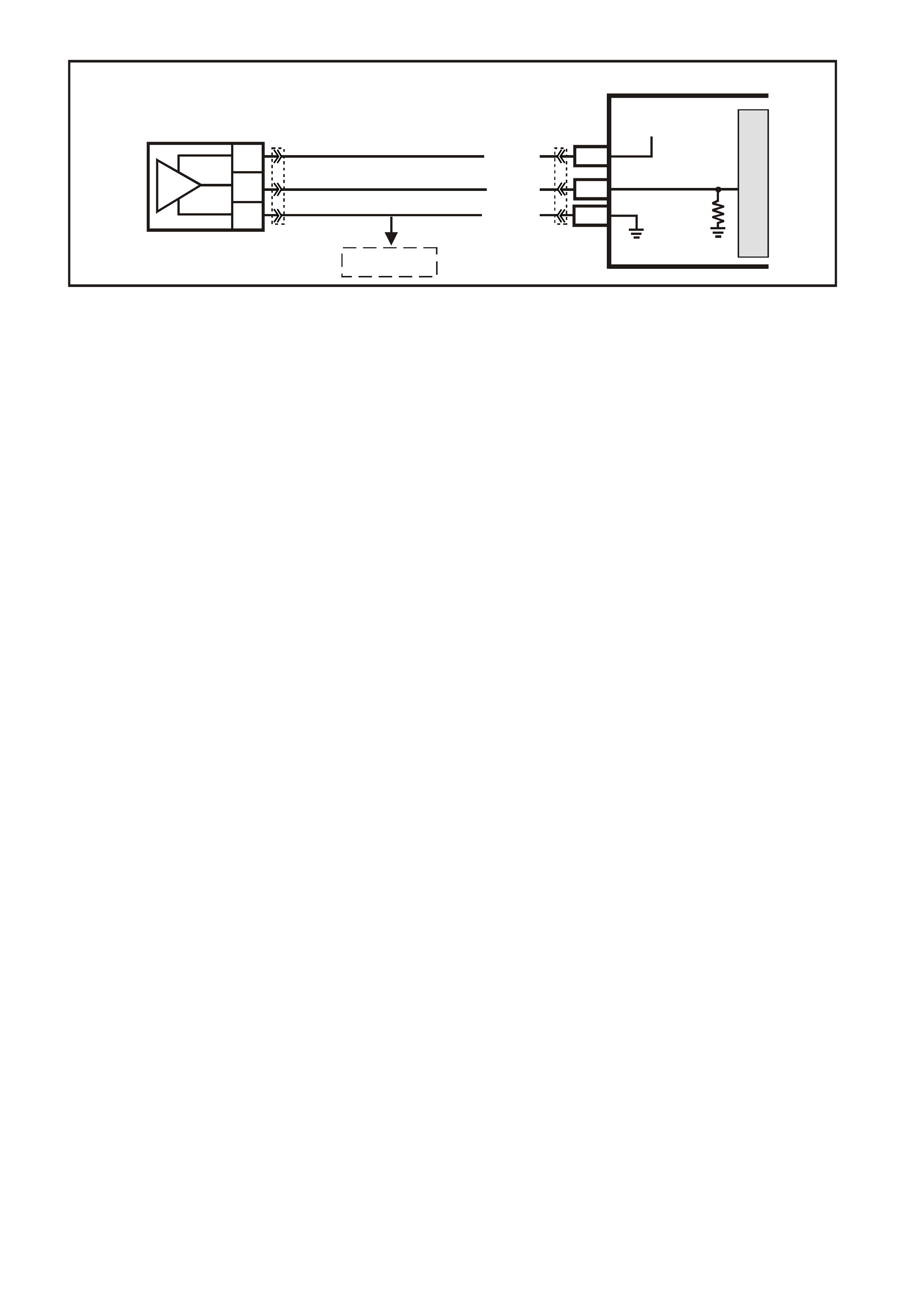

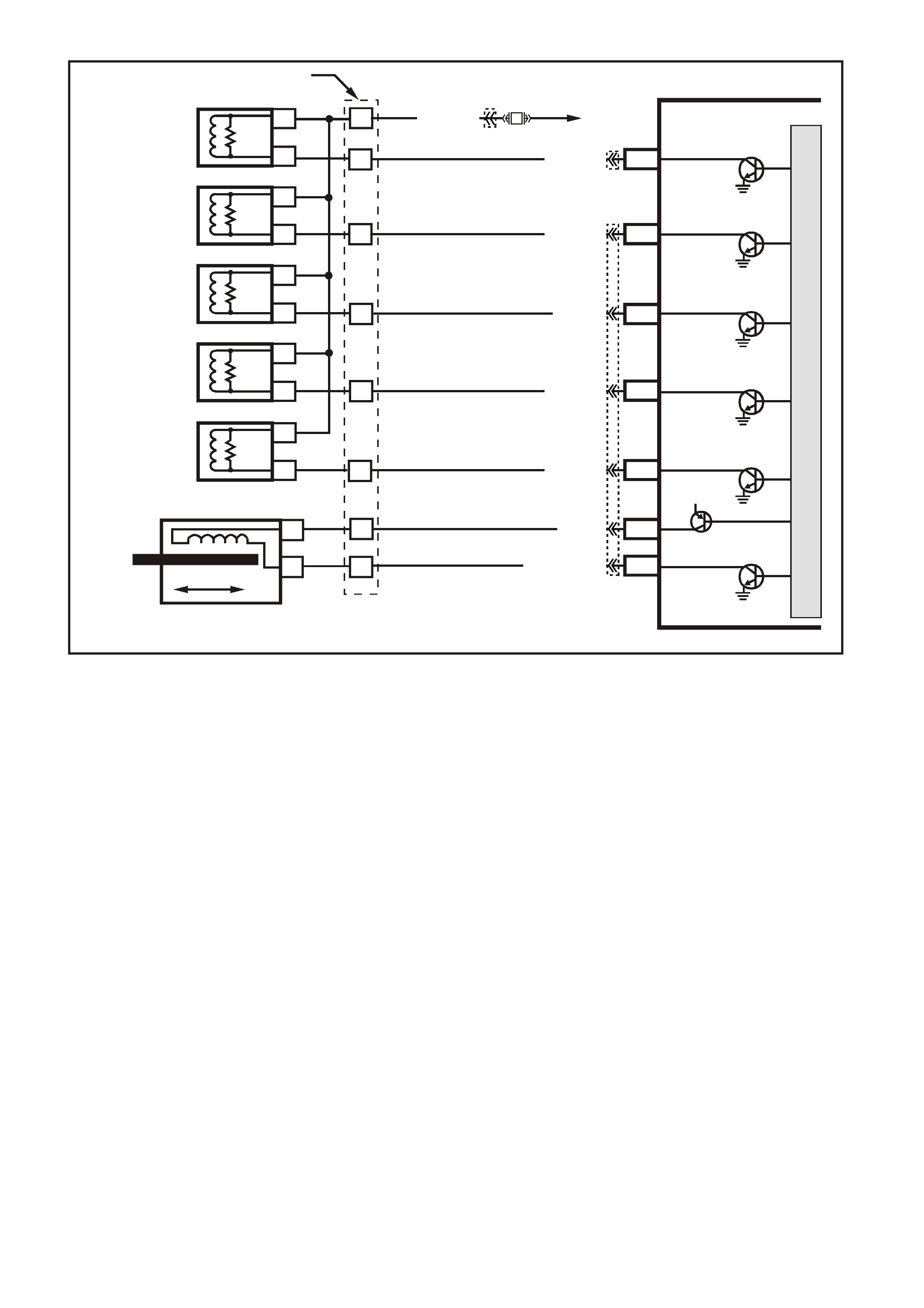

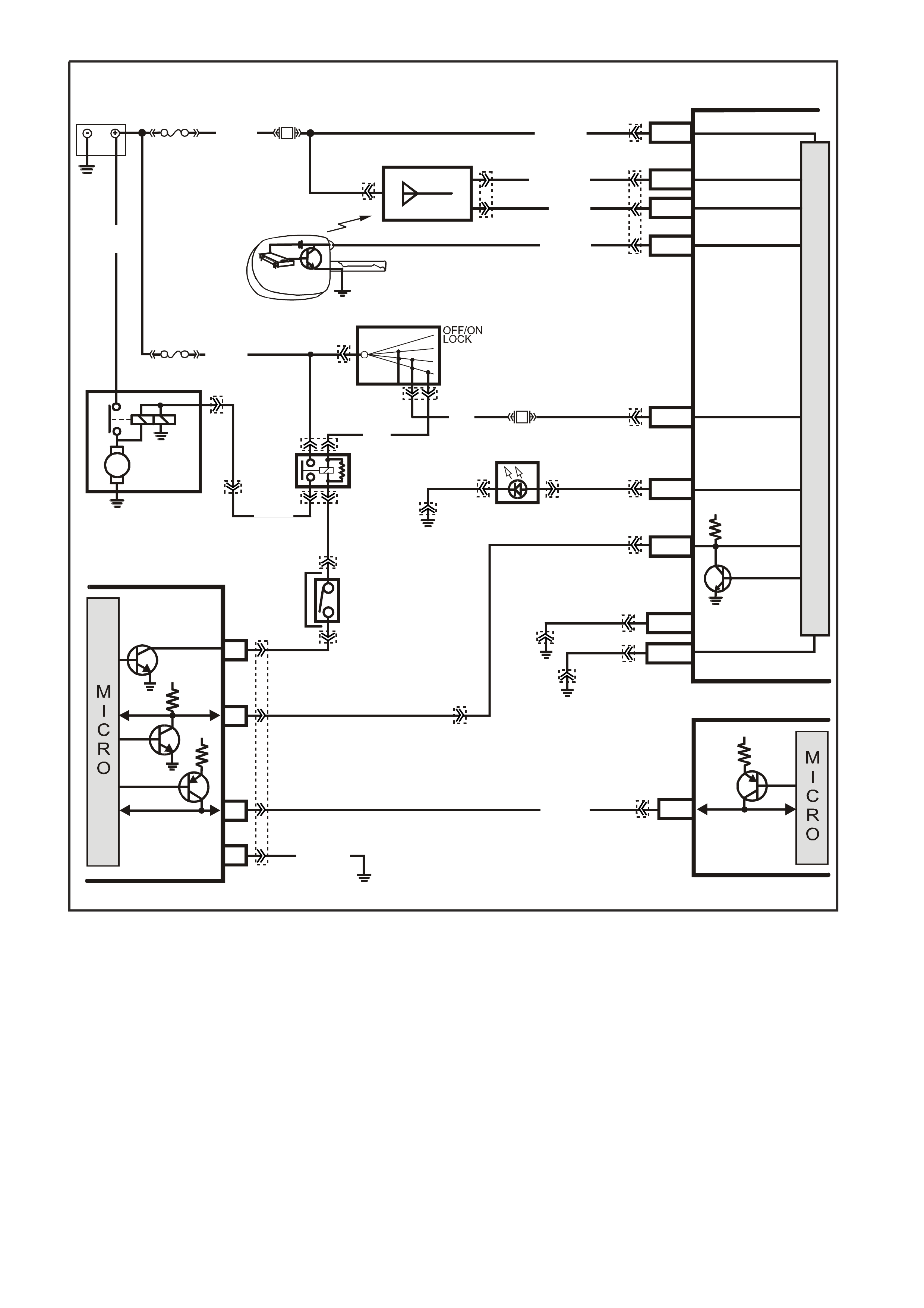

Figure 6C3-2A-7 Powertrain Controls Schematics (1 of 12) – Fused Power Circuits

G3PCM054PT

PCM

M

I

C

R

O

P

R

O

C

E

S

S

O

R

+-

BATTERY

LOC . E 1

FS

(1040)

O (740)O/B (740) J1-20

J1-57

BATTERY

BATTERY

F31

J1-19 IGNITION

FJ

BLUE

FUSIBLE

LINK

FU

FT

R

(2H)

15a 15 50

30 OFF/ON

LOCK

ACC

IGN

START

IGNITION SWITCH

P (3) F14

P (39)

P/B (39)

EFI RELAY

O/Y

(479)

LOC. E3

R

(481)

LG

(482)

P

(439)

P/BLU

(339)

O/BLU

(204)

R

(203)

O/B

(208)

B/W

(152)

F34

F35

F33

F32

TO R.H. BANK

INJECTORS

TO L.H. BANK

INJECTORS

TO R.H.

IGNITION

MODULES

TO L.H.

IGNITION

MODULES

TO R.H. HEATED

OXYGEN SENSOR

TO L.H. HEATED

OXYGEN SENSOR

TO A/C

RELAY

TO MAF

SENSOR

TO CANISTER

PURGE SOLENOID

TO 3-2

SOLENOID

TO 1-2 SHIFT

SOLENOID A

TO 2-3 SHIFT

SOLENOID B

TO TCC ENABLE

SOLENOID

TO TCC PWM

SOLENOID

F28

TO

FUEL PUMP

RELAY TO

DLC

TO REMOTE

RECEIVER

MODULE

TO BODY

CONTROL

MODULE

ENGINE

COOLING

FAN 2

ENGINE

COOLING

FAN 1

J1-01

J1-40

J2-01

J2-40

LOC. E5/E15

EARTH

EARTH

EARTH

EARTH

B/R (750)

B/R (750)

B/R (750)

B/R (750)

YE122

YE122

YE123

YE112

YB128

YB176

YB165

YB95

YB44

YE39

YE114

YE111

YE124

YE111

YE125

YE99

YE110

YE118 YE119

YE95

YE101

YE100

YE39

YE96

YB44

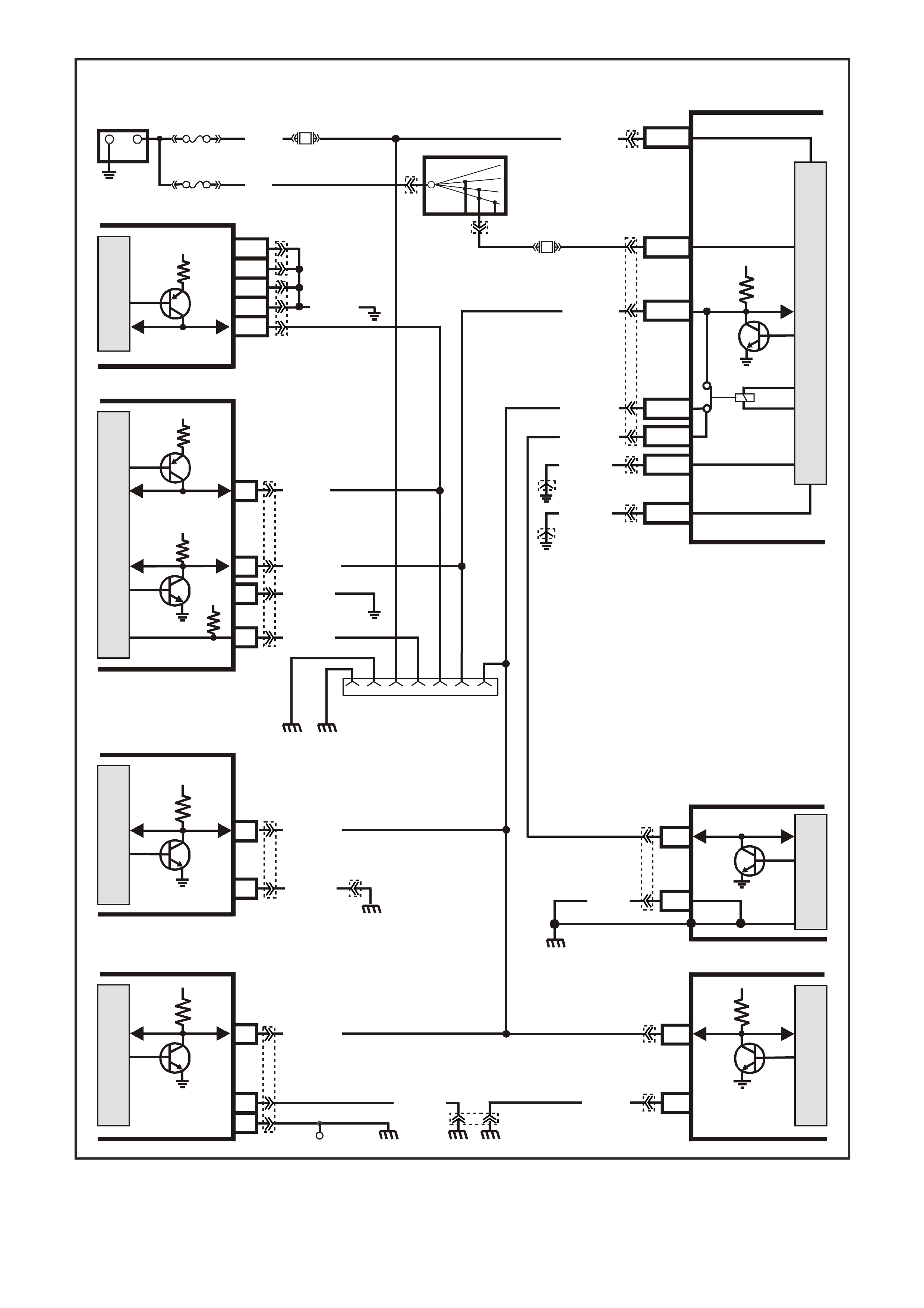

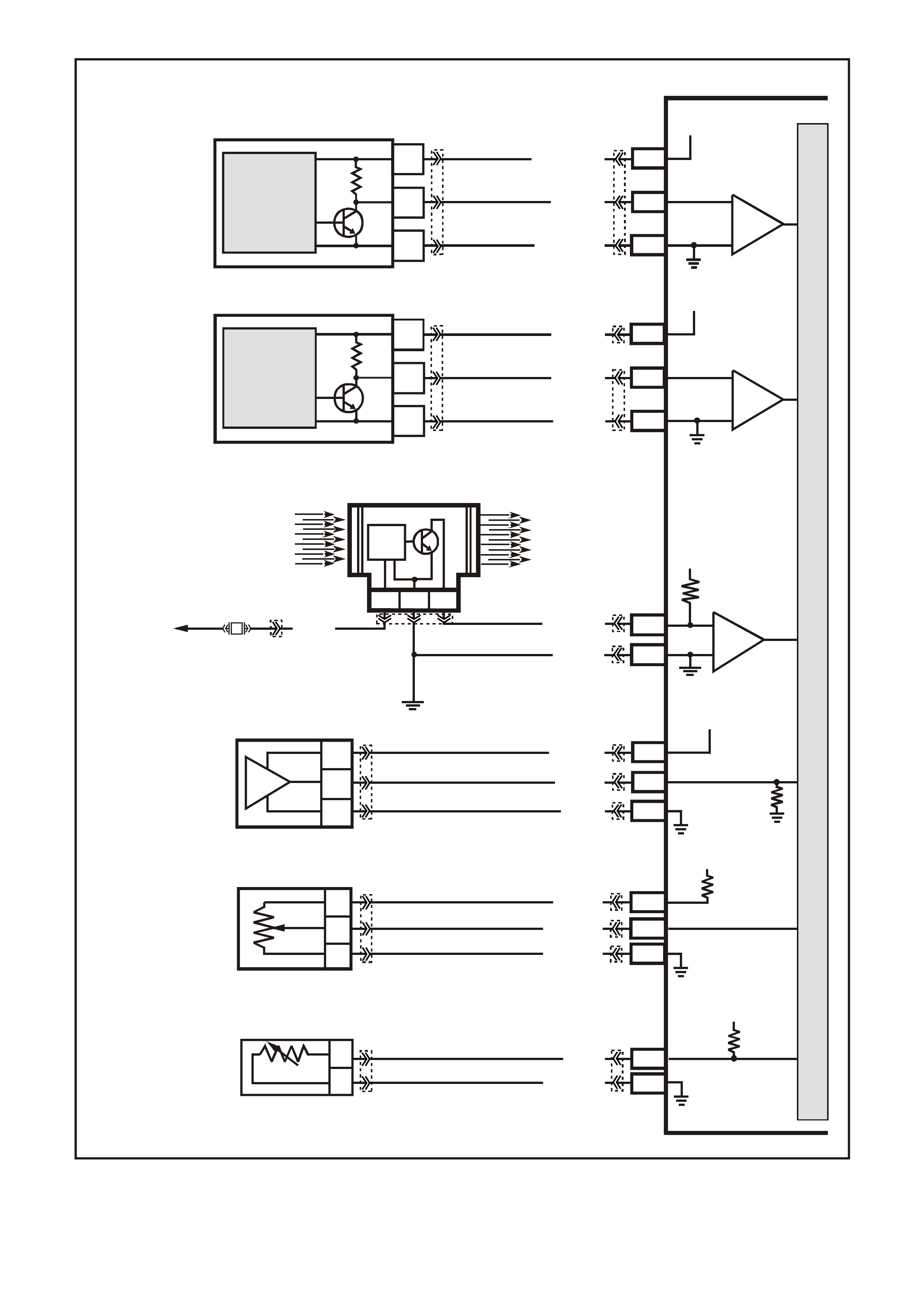

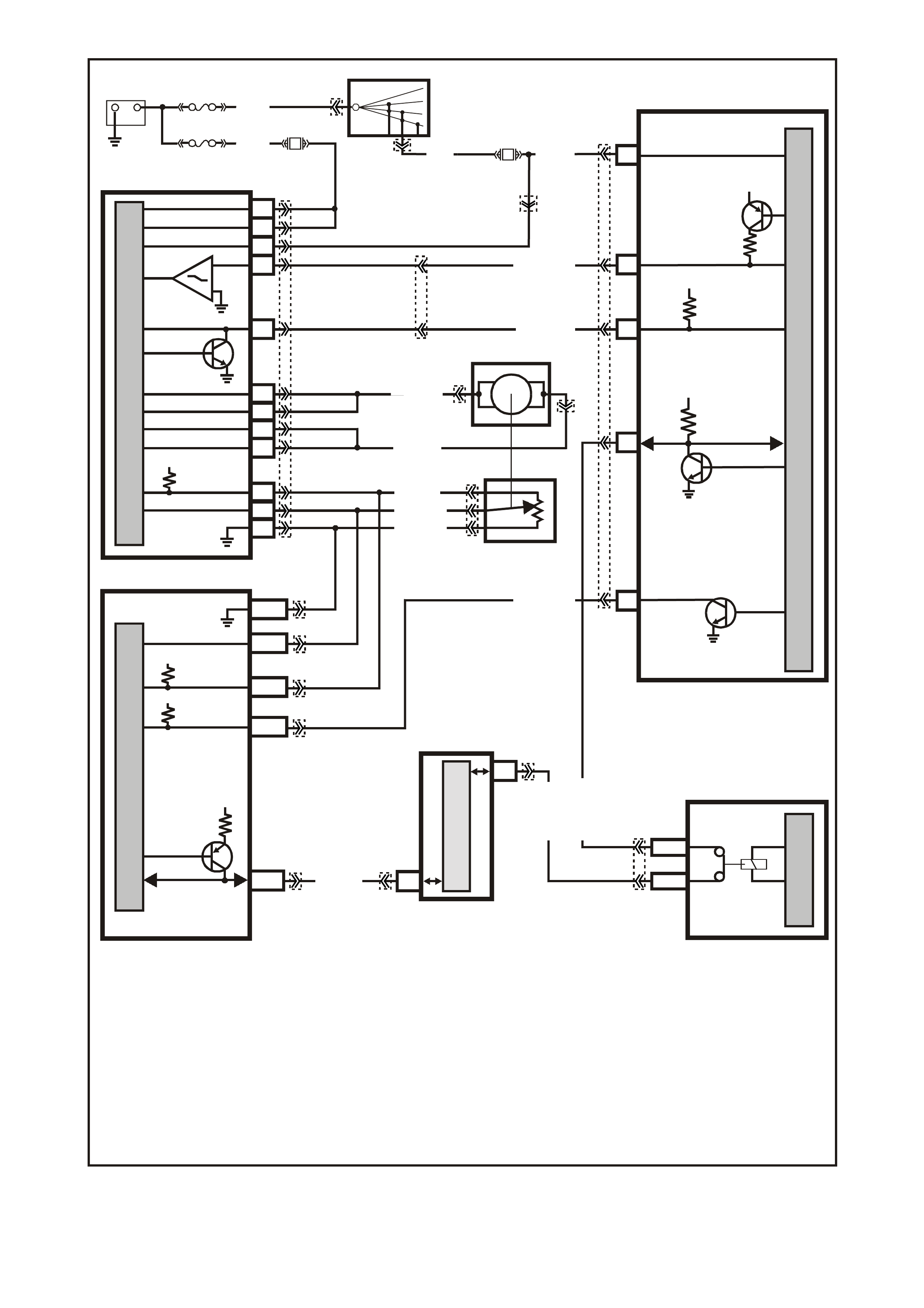

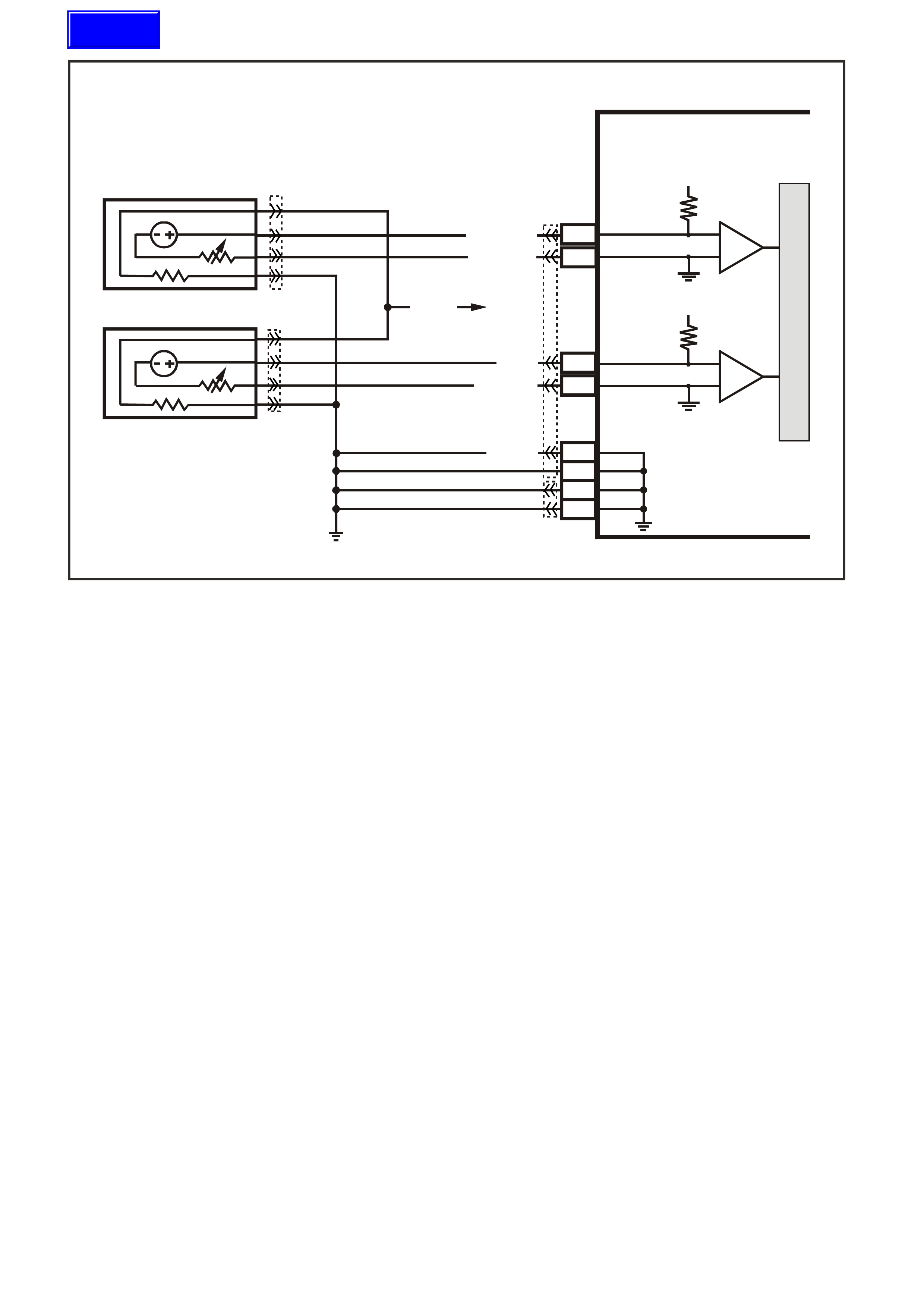

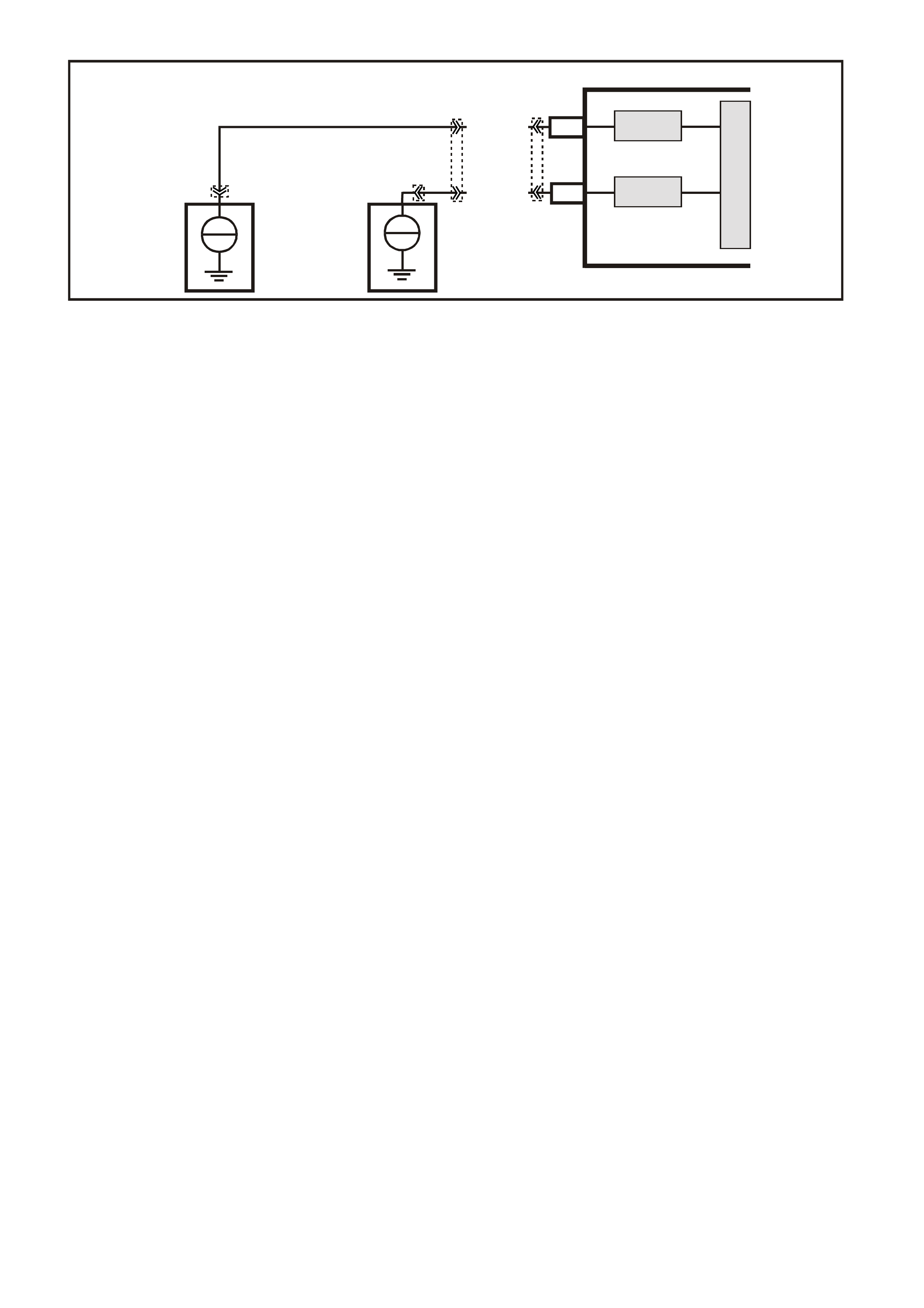

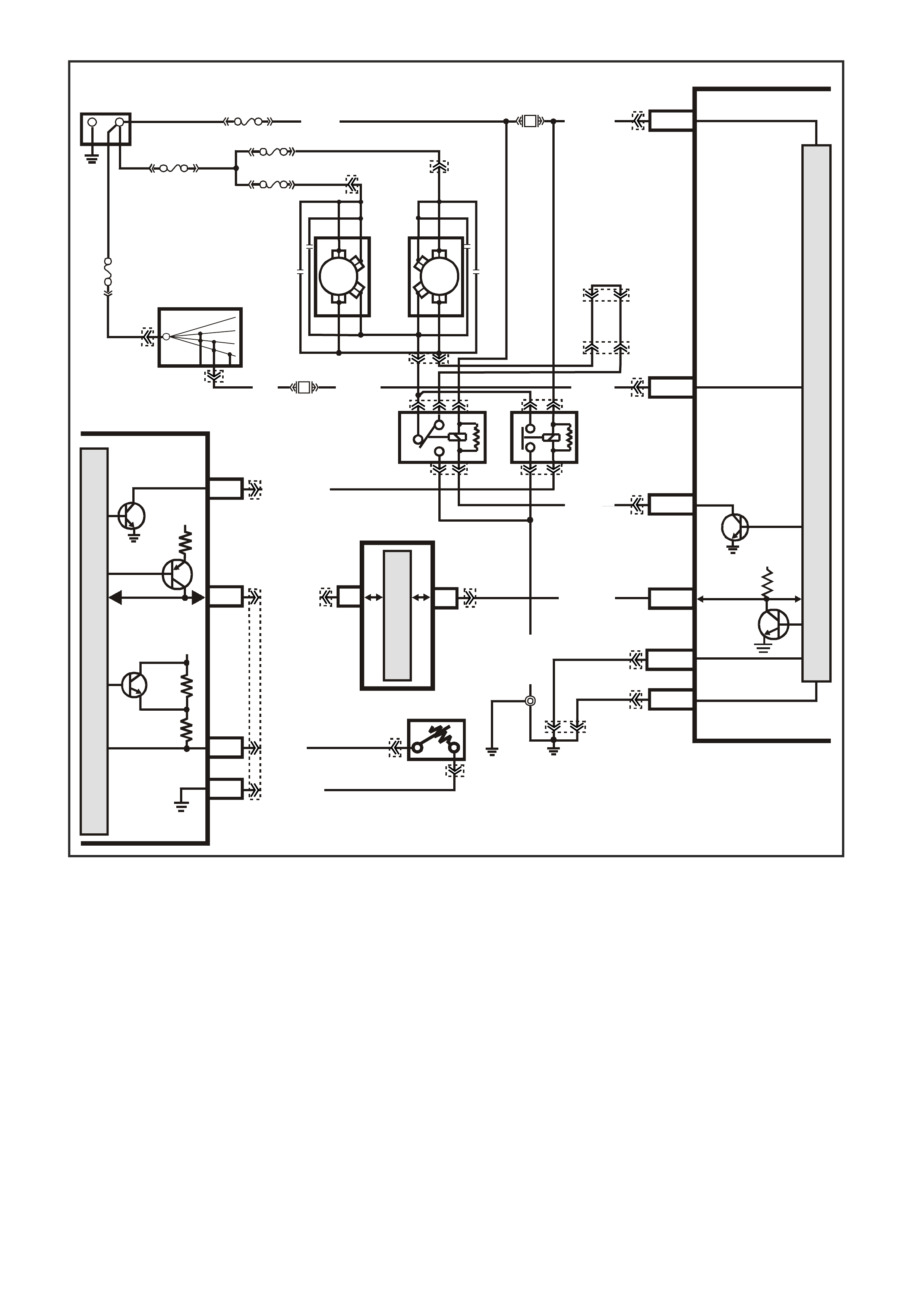

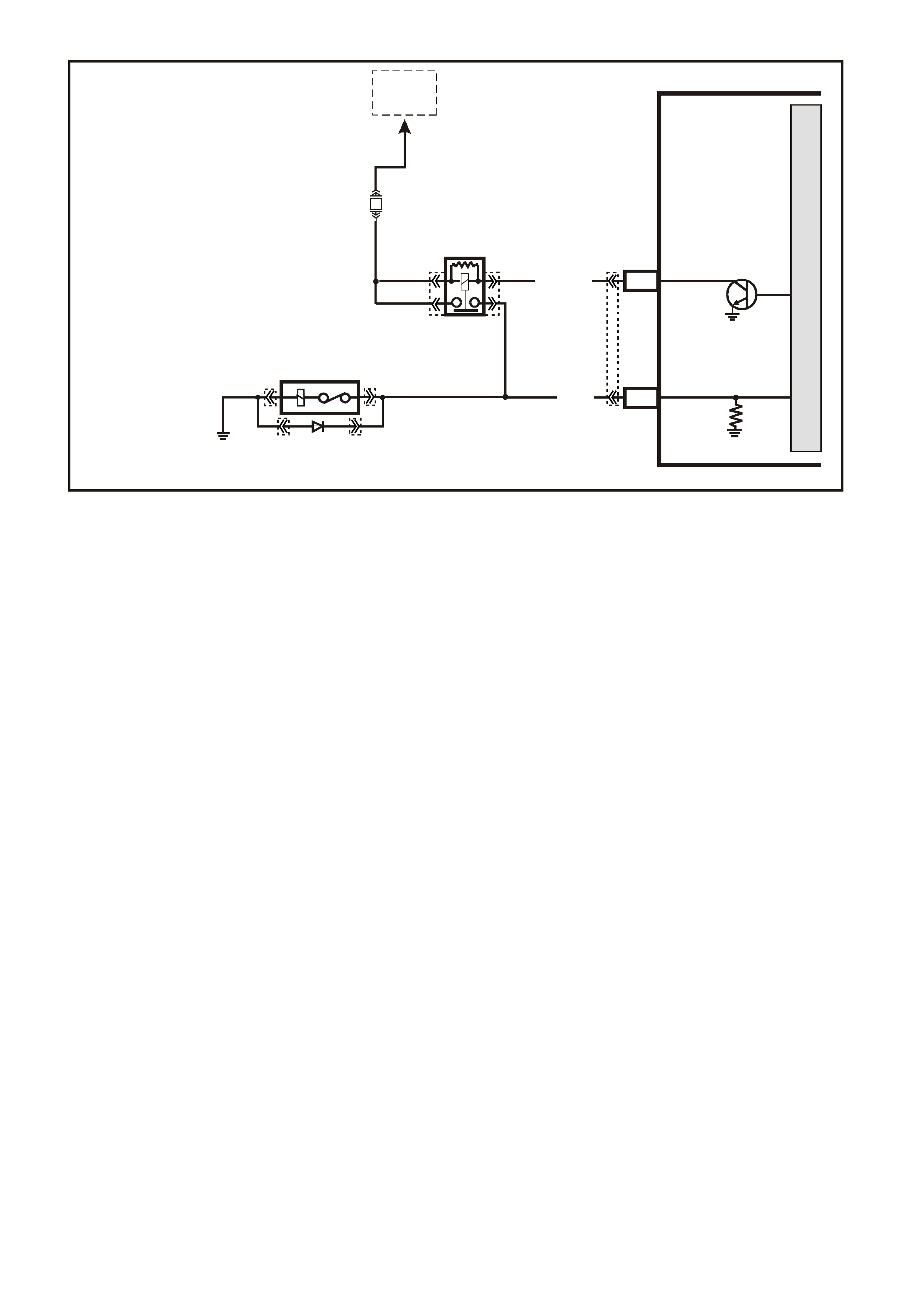

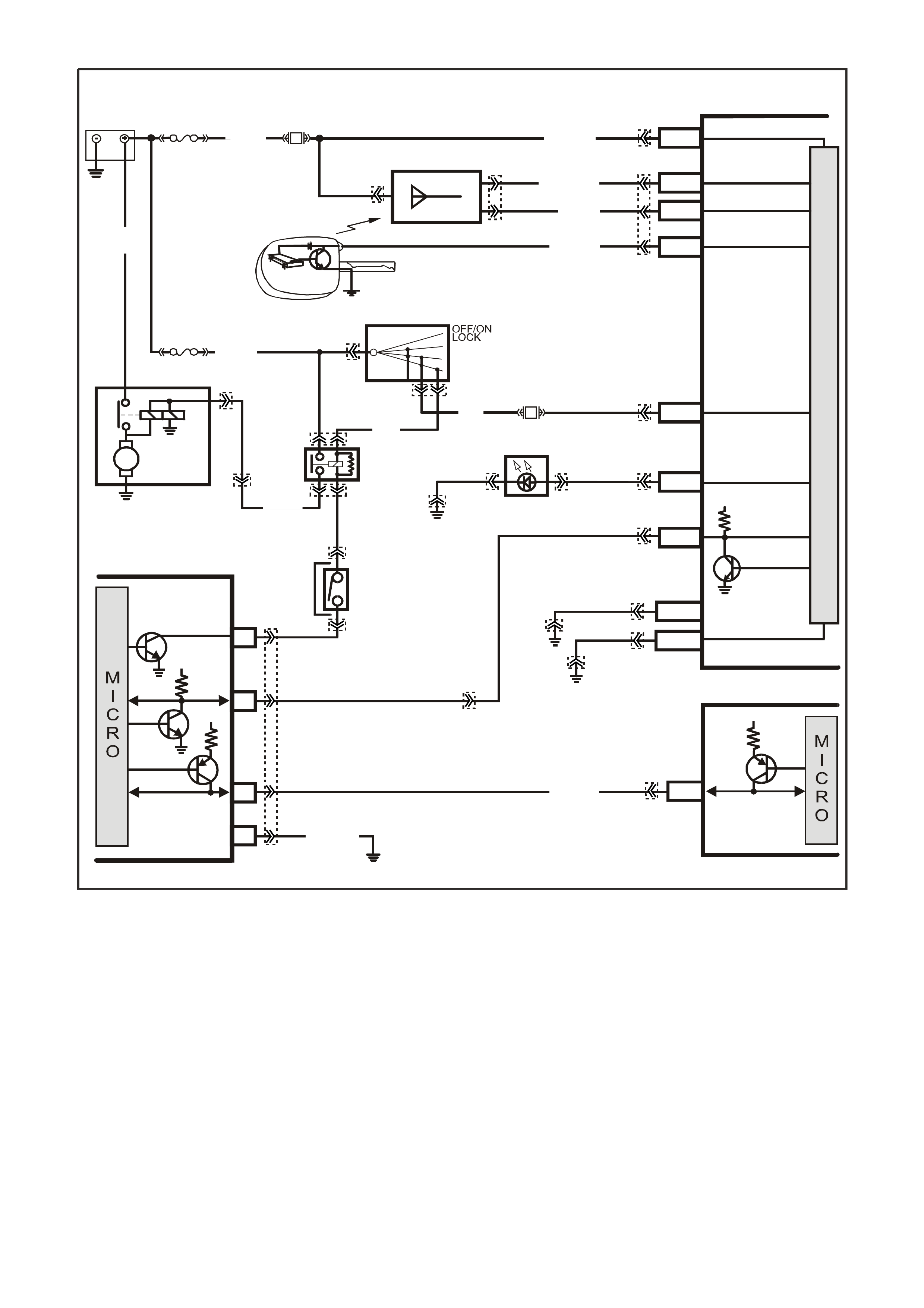

Figure 6C3-2A-8 Powertrain Control Schematics (2 of 12) – DLC and Instruments Lamps Circuits

G3PCM057APT

PCM

J1-58 CLASS 2

SERIAL

DATA

7V

BCM

E2/D2

E9/D3

E3/D13

M

I

C

R

O

SERIAL

DATA

MAIN

SERIAL

DATA AUX.

5V

W/G (1220)

Y/R (88)

G/W (1220)

HIGH SERIES

BCM TERMINALS

NOMINATED FIRST

DATA LINK

CONNECTOR

12345678

910111213141516

Y (1049)

LOC. E3

B/Y (155)

B (150)

INSTRUMENTS

ABS/ETC

11

SERIAL

DATA

5V

12 SERIAL

DATA

5V

M

I

C

R

O

CHECK

POWERTRAIN

OIL PRESSURE

POWER ECONOMY

LOW COOLANT

R

12V

P

N

D

3

1

2

SRS

ECC

9

6

M

I

C

R

O

M

I

C

R

O

SERIAL

DATA

SERIAL

DATA

5V

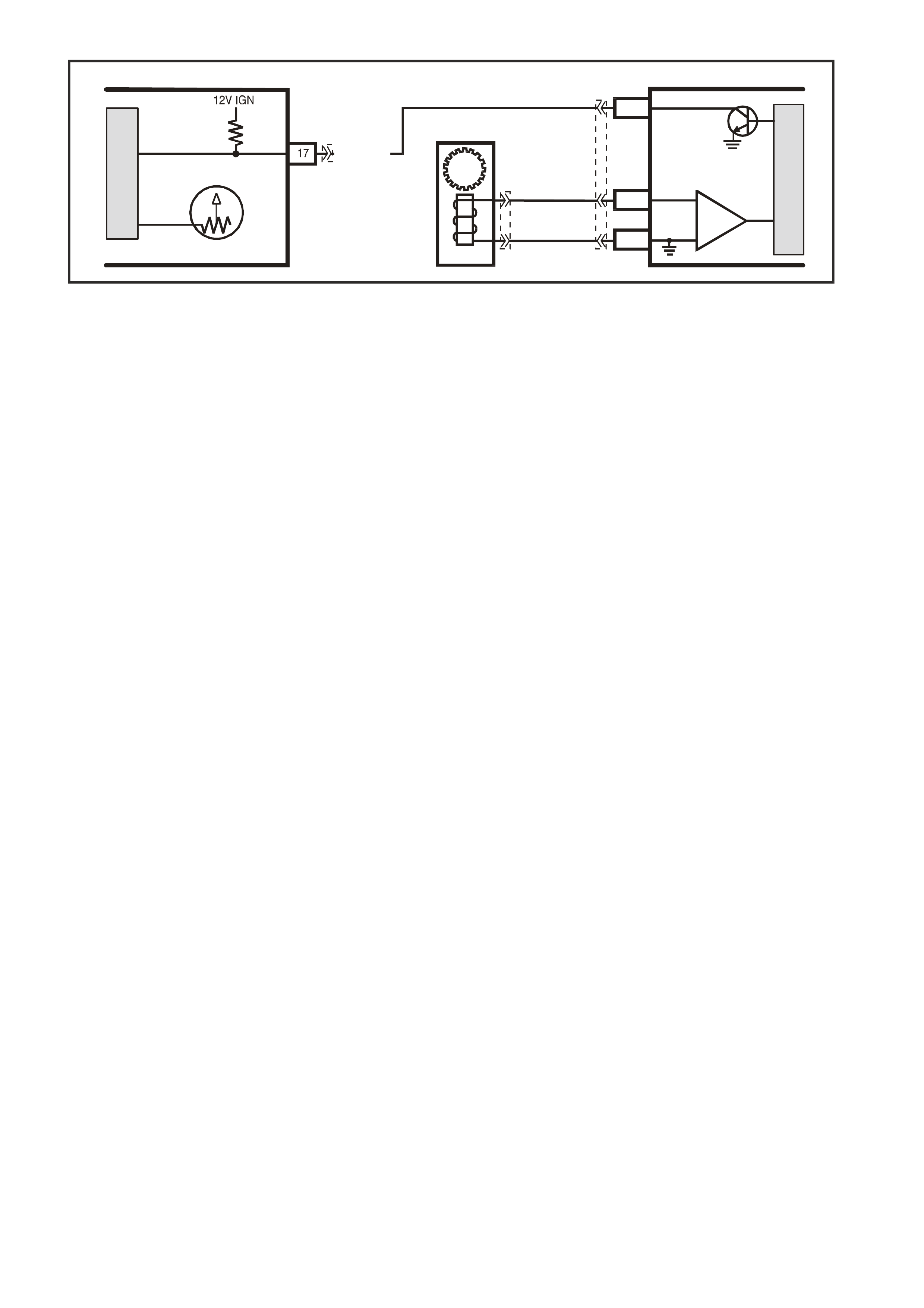

12V IGN

17

12V

VEHICLE

SPEED

18

12V

TACHO

SIGNAL

SPEEDOMETER

TACHO

TACHO

SIGNAL

VEHICLE

SPEED

J2-10

J2-50

V/W (123)

BR/R (121)BR (121)

M

I

C

R

O

P

R

O

C

E

S

S

O

R

LOW TR ACTION 20

BRAKE SWIT CH

J1-33

BR (86)

PIM

M

I

C

R

O

R/B (1221)

UART

SERIAL

DATA

5V

6

12V

11

DI AG. ENABL E

Y (1049)

7V

7

CLASS 2

SERIAL DA TA

W/B (451)

STOP LAMP

SWITCH B

(NC)

M

I

C

R

O

11 LOW

TRACTION

LAMP

YE122

YE123

YB12

YB12

YB66

YB191

YB190

YB189

YE98

YB87

YB175

YB164

YB215

Figure 6C3-2A-9 Powertrain Control Schematics (3 of 12) – Serial Data Circuits

B/Y

(155)

B

(150)

LOC. E3

642516 9 1

G3PCM039PT

INSTRUMENTS

ABS/ETC

SRS

ECC

BCM

DATA LINK

CONNECTOR

12

11

19

16

6

16

9

8

6

M

I

C

R

O

M

I

C

R

O

M

I

C

R

O

SERIAL

DATA

SERIAL

DATA SERIAL

DATA

5V

5V 5V

M

I

C

R

O

P

R

O

C

E

S

S

O

R

+

-

BATTERY

FS

F31

A5/A6

O/B (740)

(1040)

BATTERY M AIN P OWER

HIGH SERIES

BCM TERMINALS

NOMINATED FIRS T

FJ

LOC. E1

R (2)

F14

E20/D6

P/B

(39) IGNITION ON

15a 15 50

30 OFF/ON

LOCK

ACC

IGN

START

IGNITION SWITCH

P

(3)

B/Y (155 )

B/G (151)

LOC. E3

LOC. E3

R/B (1221)

G/W (1220)

G/W (1220)

G/W (1220)

G/W (1220)

LOC.G11

LOC.E3

LOC.E2

LOC.E3 EARTH

SERIAL

DATA

B (305)

B/Y (155 ) 2

B (150)

B/O

(154) B/R

(157)

B/Y(155)

B/R ( 750)

W/B (451)

R/B (1221)

Y (1049)

PIM

M

I

C

R

O

UART

SERIAL

DATA

5V

7V

7V

12V

ELECTRONIC EARTH

HIGH CURRENT

EARTH

A1/A5

B10/B11

E2/D2

E9/D3

E3/D13

SERIAL

DATA

MAIN

SERIAL

DATA AUX.

5V

6

11

7

DI AG. ENABL E

CLASS 2

SERIAL DA TA

LOC. E5/E15

LOC. E5/E15

GEN III V8 PCM

J1-58

J2-01

J2-40

J1-40

J1-01

M

I

C

R

O

CLASS 2

SERIAL DA TA

B/R ( 750)

M

I

C

R

O

YB176

YB165

YB175

YB164

YB174

YB163

YB176

YB165

YB190

YB189

YB89

YE114

YB98

YB66

YE114

YB215

YE122

YE123

YB87

YE114

YE114

YB44

YB44

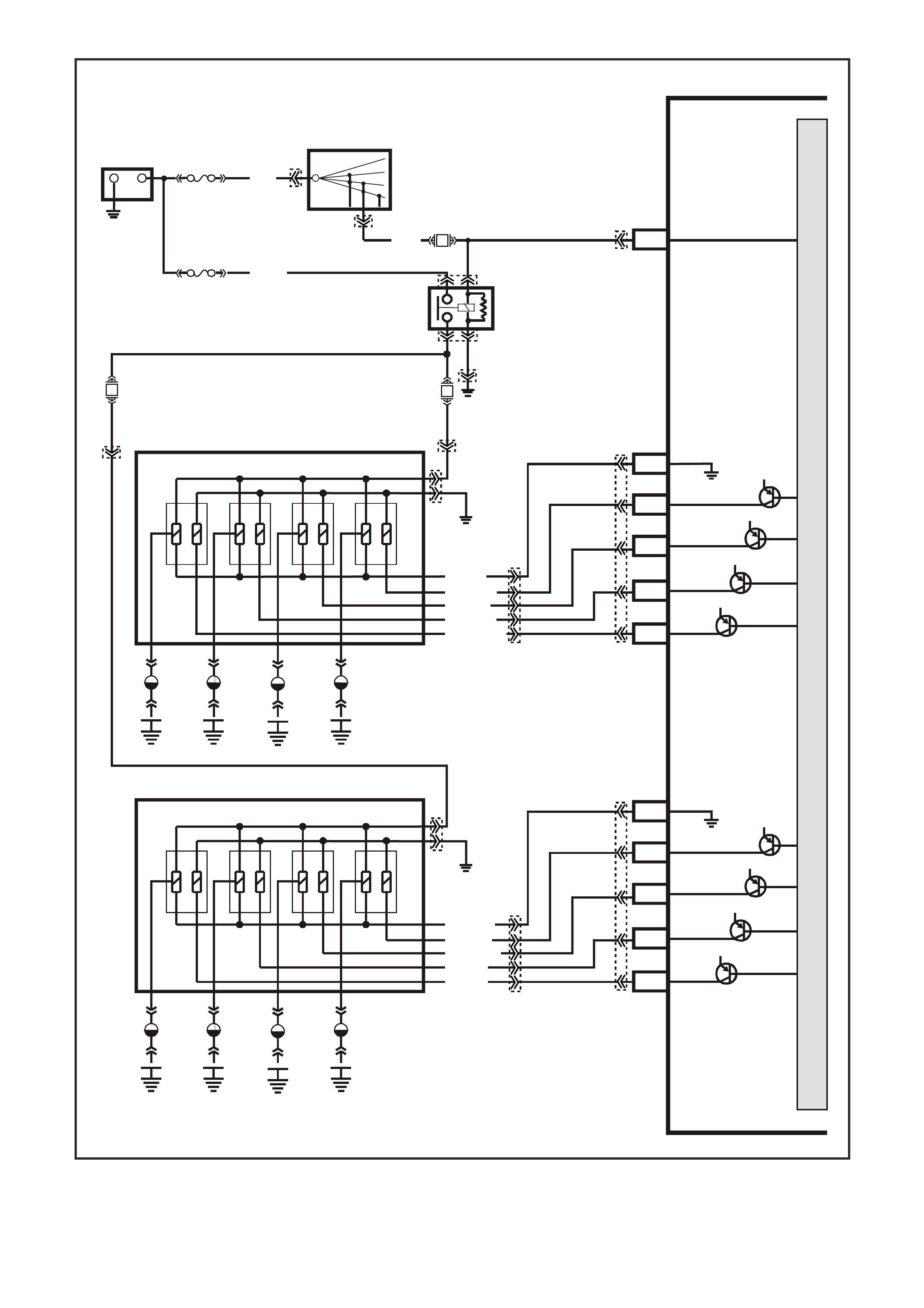

Figure 6C3-2A-10 Powertrain Control Schematics (4 of 12) – Ignition Modula Circuits

G3PCM037PT

PCM

J1-19

J2-67

J2-26

J2-61

J2-60

J2-29

J2-69

J2-28

J2-68

J2-66

J2-27

CYL. 2

IGNITION

REFERENCE LOW

IGNITION

REFERENCE LOW

CYL. 8

CYL. 6

CYL. 4

IGNITION

M

I

C

R

O

P

R

O

C

E

S

S

O

R

+-

BATTERY

FS

LOC. E3

(1040)

FJ

R (2)

15a 15 50

30 OFF/ON

LOCK

ACC

IGN

START

IGNITION SWITCH

P (3)

H

H

E

E

G

B

CYL 8

CYL 7

CYL 2

CYL 1

CYL 6

CYL 5

F

C

B

G

R.H IGNITION MODULE

L.H IGNITION MODULE

A

A

C

F

CYL 4

CYL 3

LOC.

E5/E15

LOC.

E5/E15

V (95 9)

BR (958)

Y/B (972)

W (971)

W (974)

BLU (973)

L/G (976)

G (975)

LBLU (978)

Y (97 7)

EFI

RELAY

F14

F35

F34

R

(481)B/W

(152)

L/G

(482)

SPARK PLUGS

SPARK PLUGS

12V

12V

12V

12V

CYL. 1

CYL. 7

CYL. 5

CYL. 3

12V

12V

12V

12V

YE122

YE39

YB44

YE39

YE114

YE111

YE124

YE124

YE125

YE125

YE111

YE123

YE123

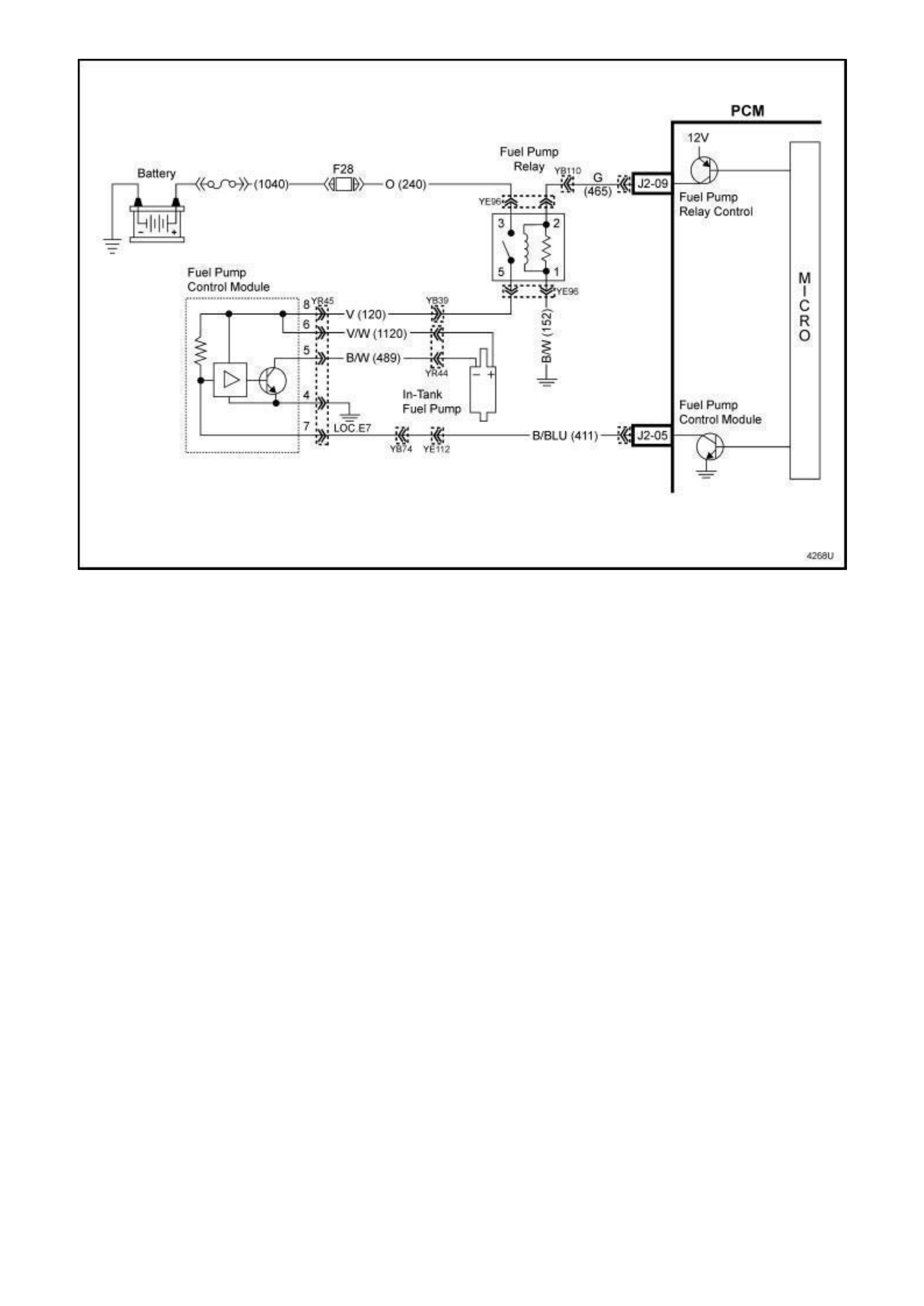

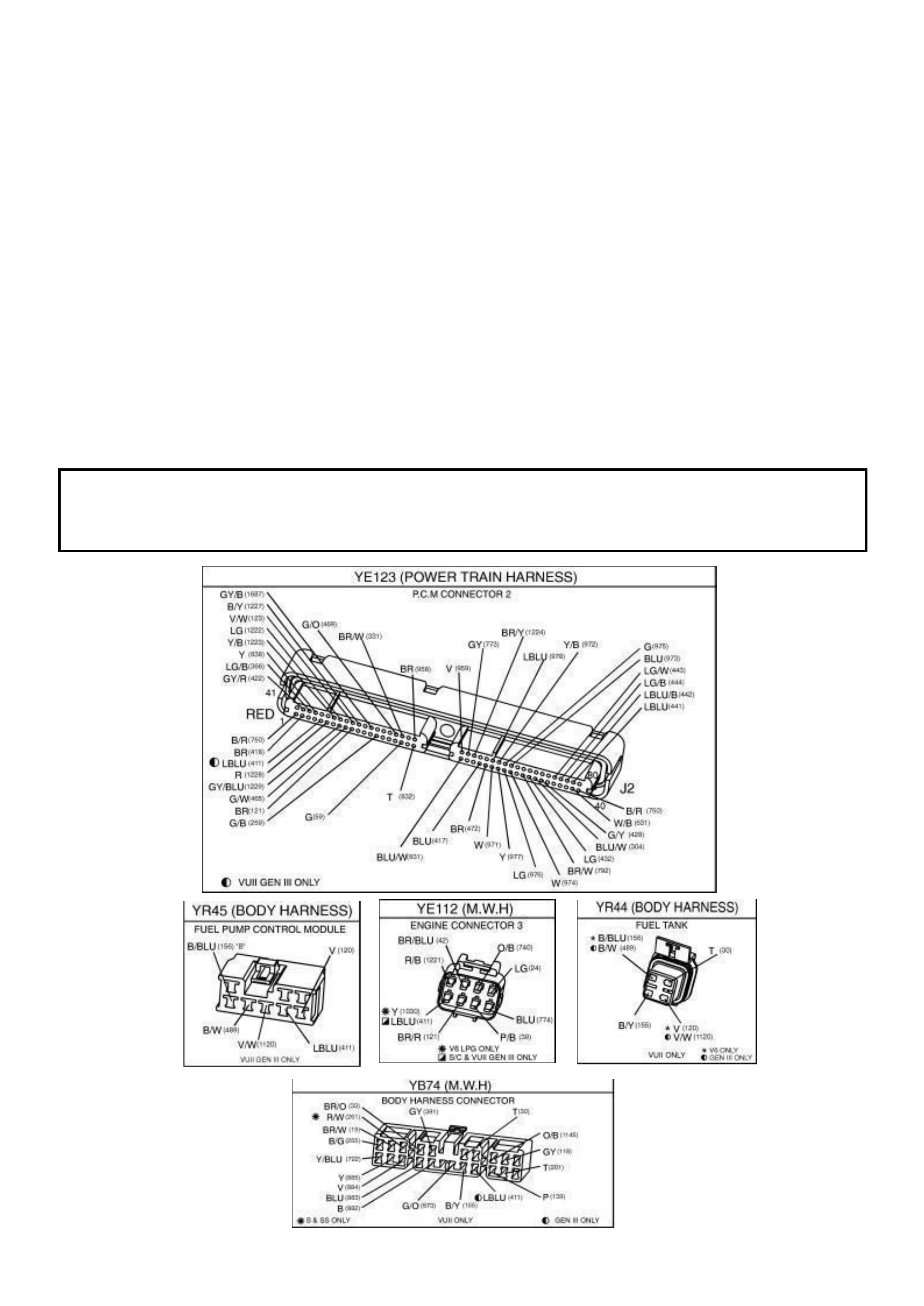

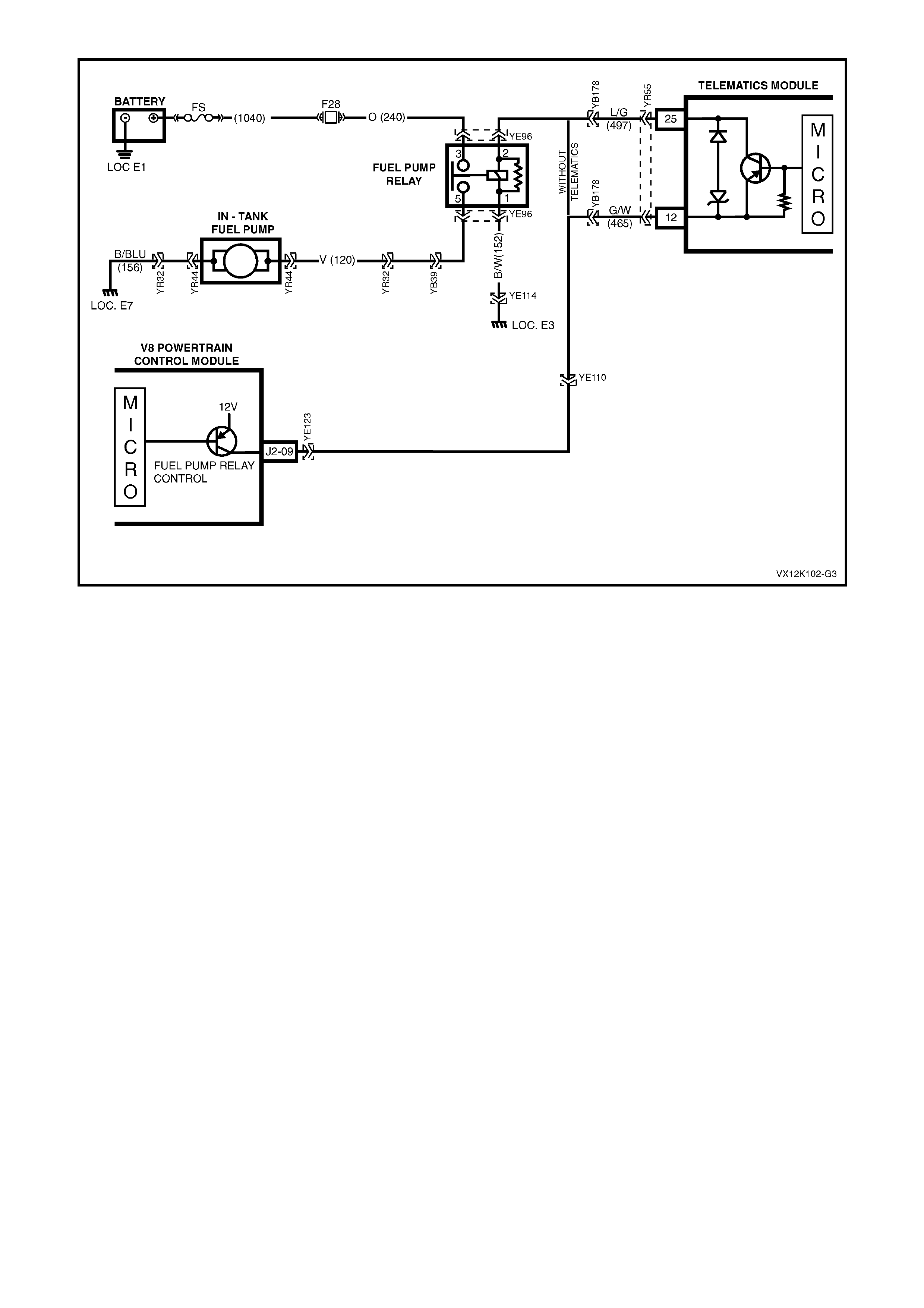

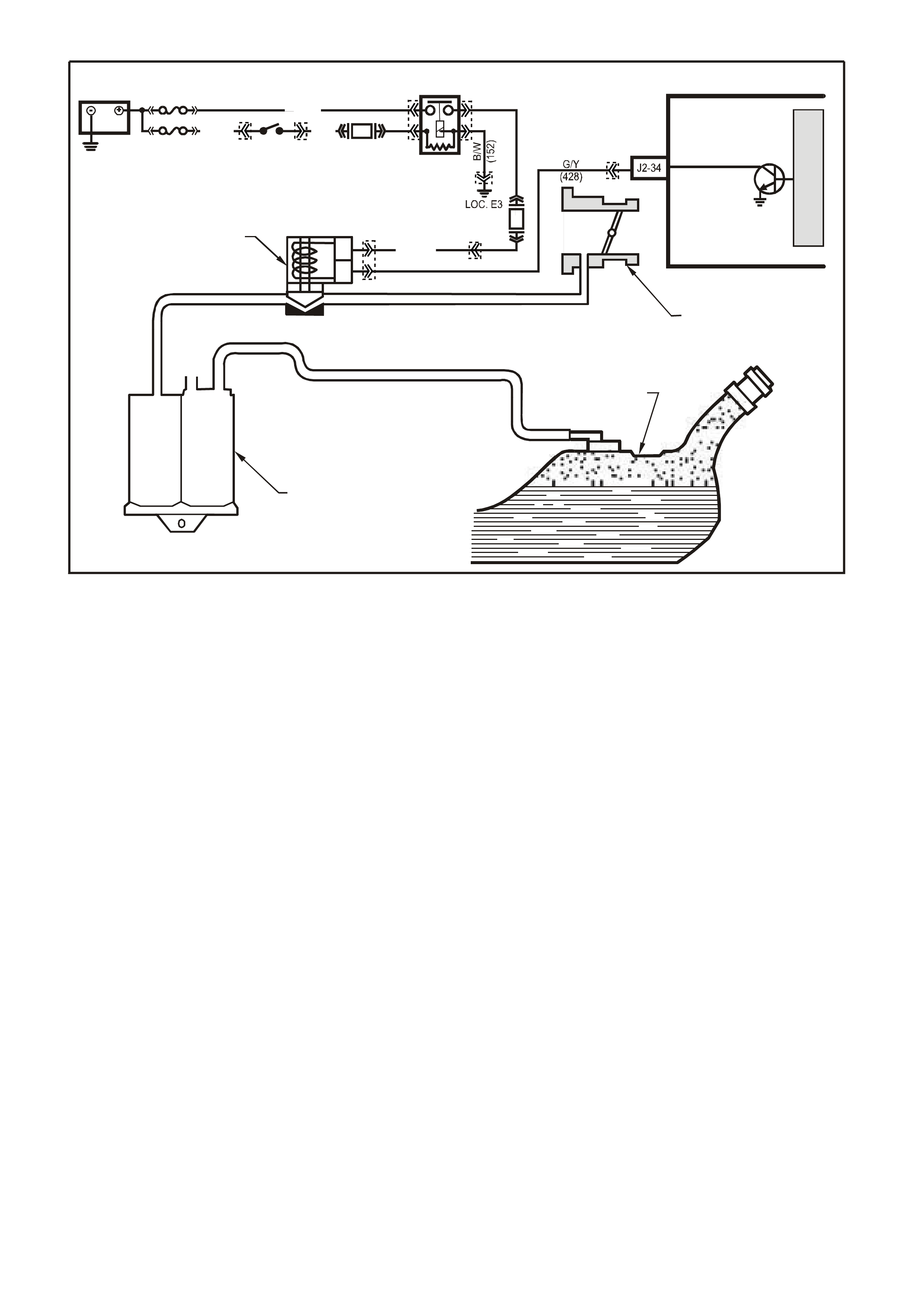

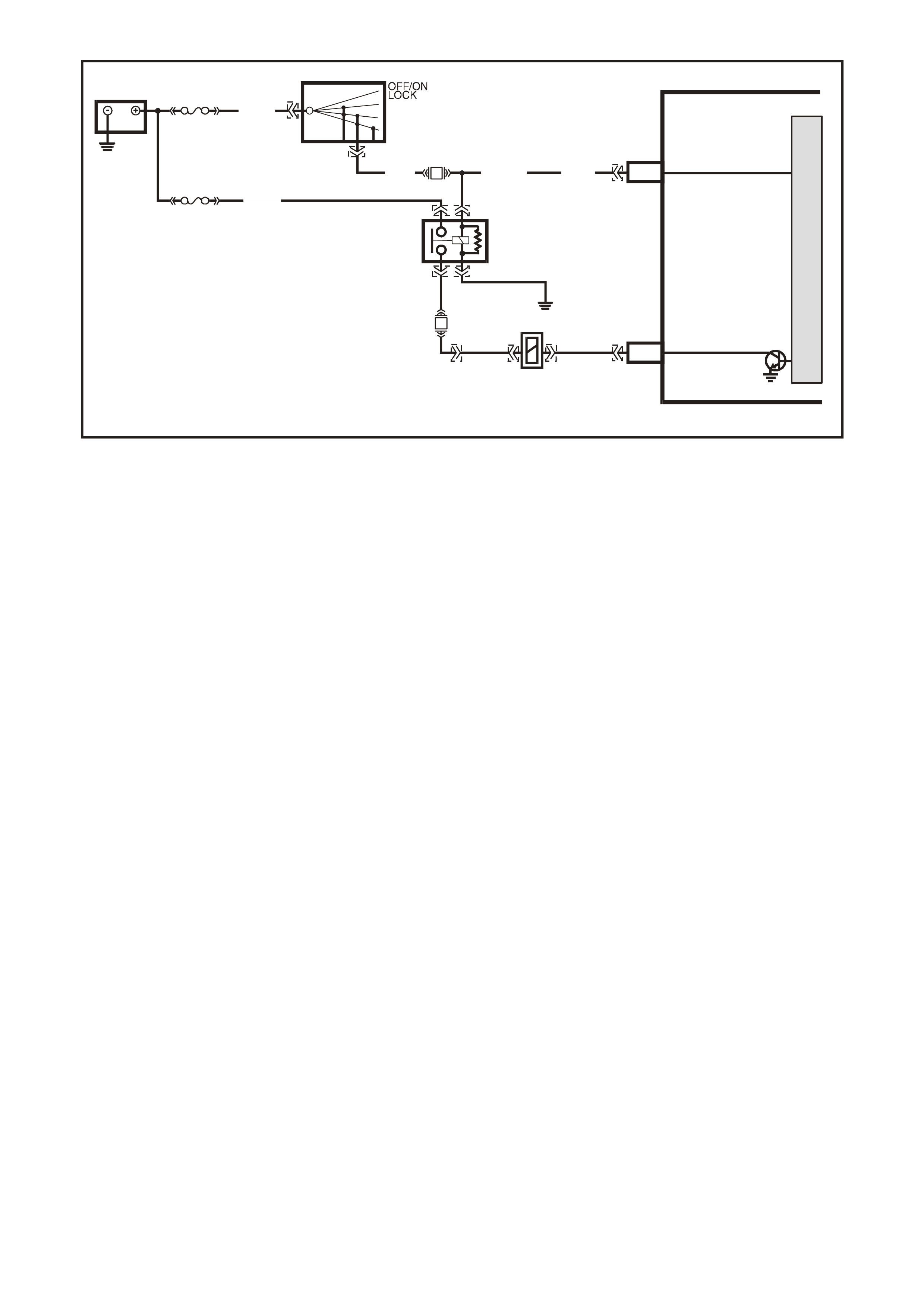

Figure 6C3-2A-11 Powertrain Control Schematics (5 of 12) – Fuel System,

Reverse Inhibit Canister Purge Solenoid, A/C Circuits

G3PCM055PT

PCM

IGNITION

J1-19

P (39 )

A/C RELAY

J2-43LG/B (366)

A/C CLUTCH

CONTROL

M

I

C

R

O

P

R

O

C

E

S

S

O

R

(1040)

R (2H)

F14

P/B

(39)

15a 15 50

30 OFF/ON

LOCK

ACC

IGN

START

IGNITION SWITCH

P

(3)

LOC. E3

F33

O/Y

(479)

B/W

(152)

EFI

RELAY

A

B

CANISTER PURGE

SOLENOID VALVE

CANISTER PURGE

J2-34

G/Y (428)

P (43 9)

B/R

(750)

LOC. E5/E15

A/C

COMPRESSOR

J2-18

G (59) A/C RELAY STA TUS

J2-44

REVERSE INHIBIT

SOLENOID

REVERSE INHIBIT

SOLENOID

F32

Y

(838)

P/BLU

(339)

J2-09 FUEL PUMP RELAY

CONTROL

B/BLU

(156)

LOC. E7 LOC. E3

IN - TANK

FUEL PUMP

FUEL PUMP

RELAY

G/W (465)

12V

+-

BATTERY

FS

LOC. E1

F28

(1040) O (240)

V (120 )

B/W(152)

32

51

FJ

YE105 YE105

YE101

YE99

Y123

YE101

YE110

YE114

YE122

YB44

YB44

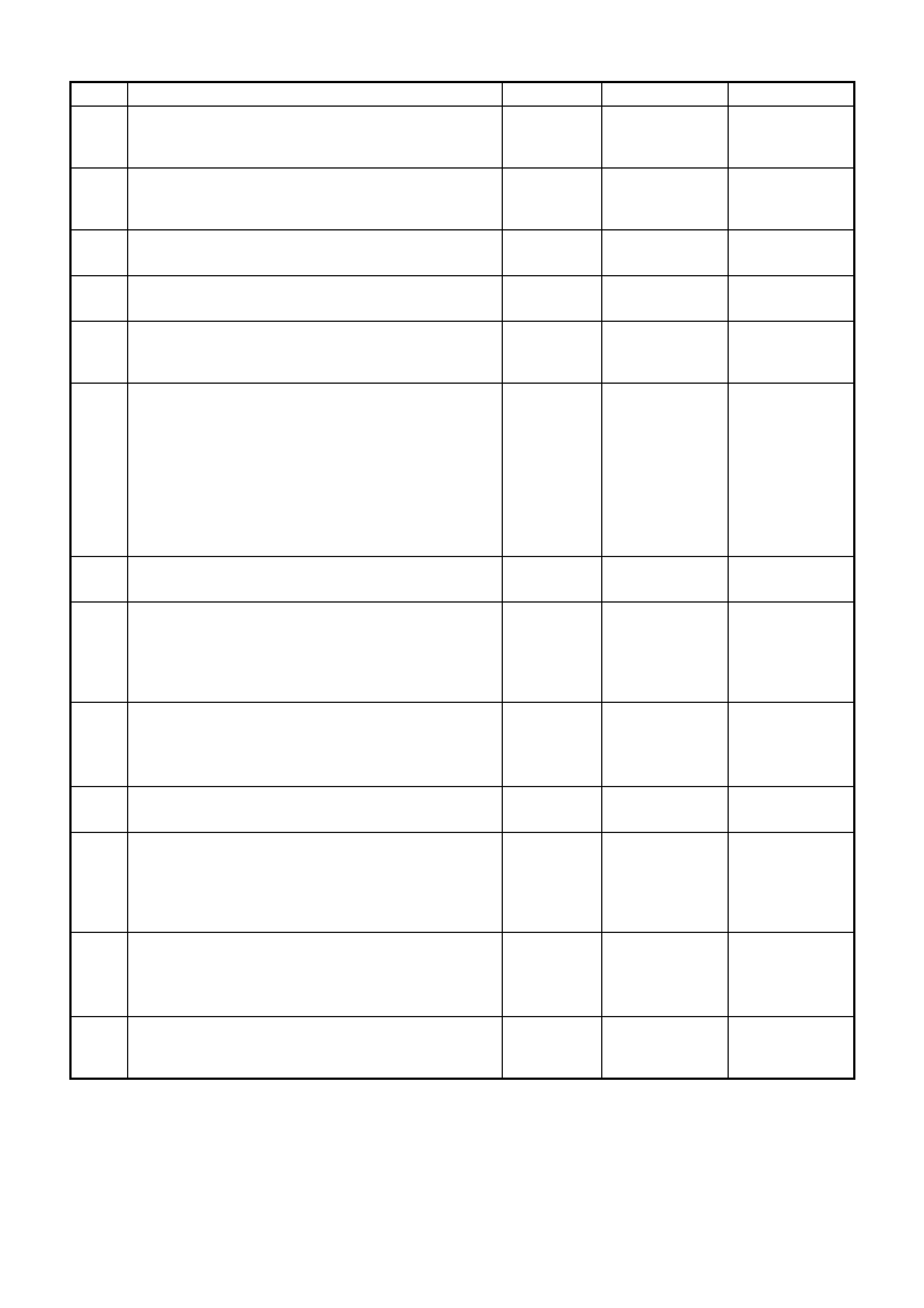

YR44

YR32

YR44

YR32 YB39

YE96

YE96

YE110

YE123

YE114

YE39

YE39

YB125YB125

YE120YE120

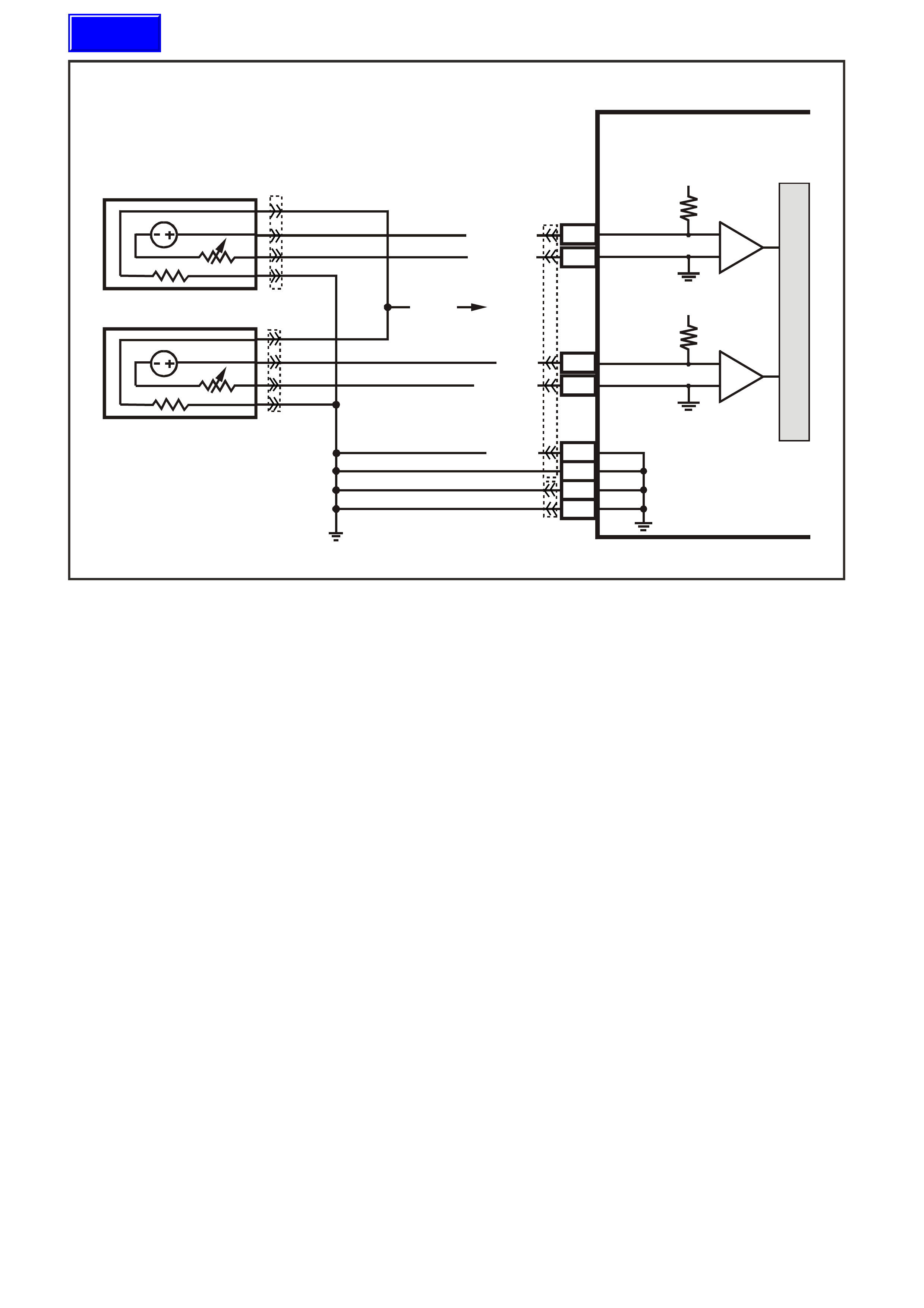

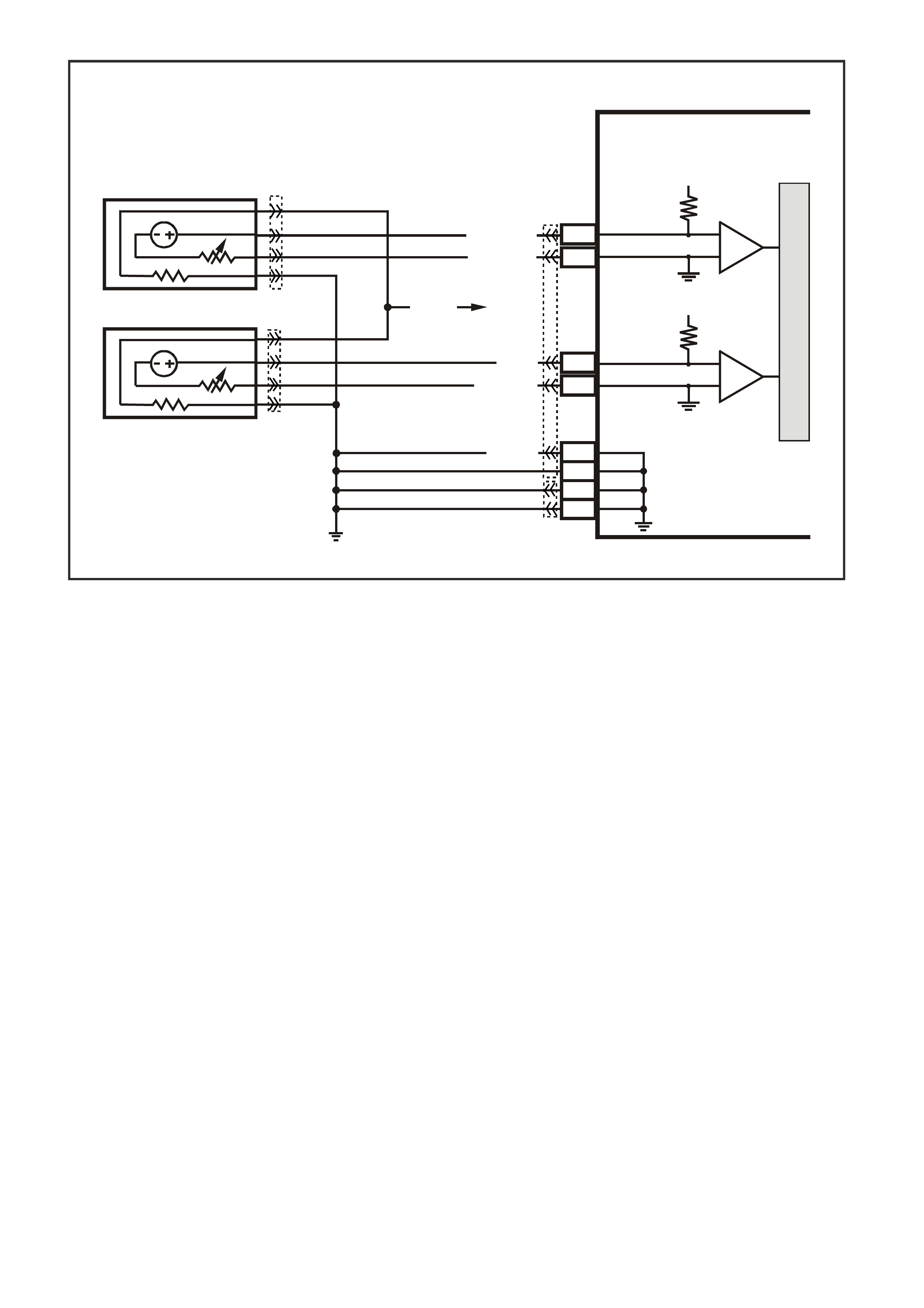

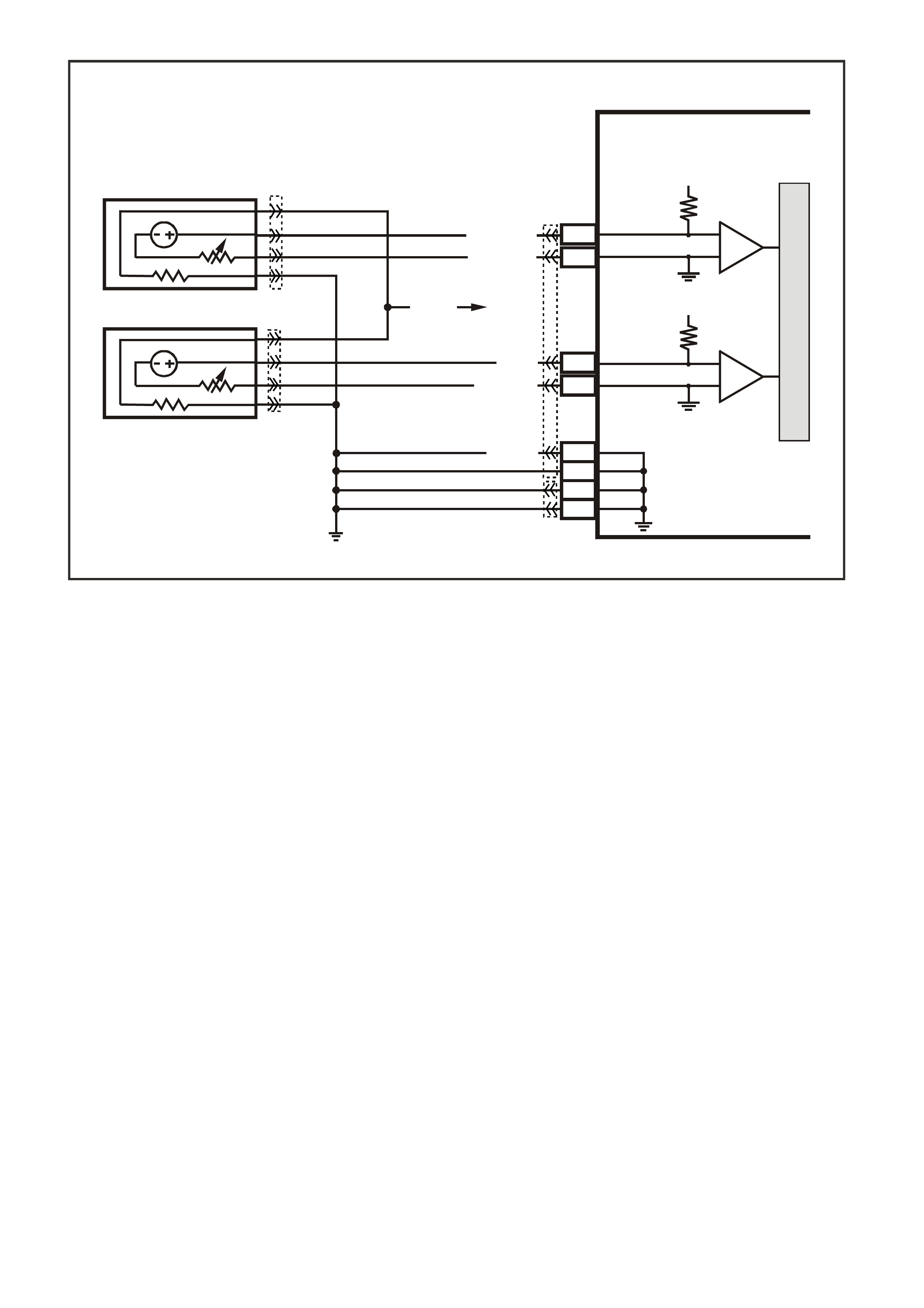

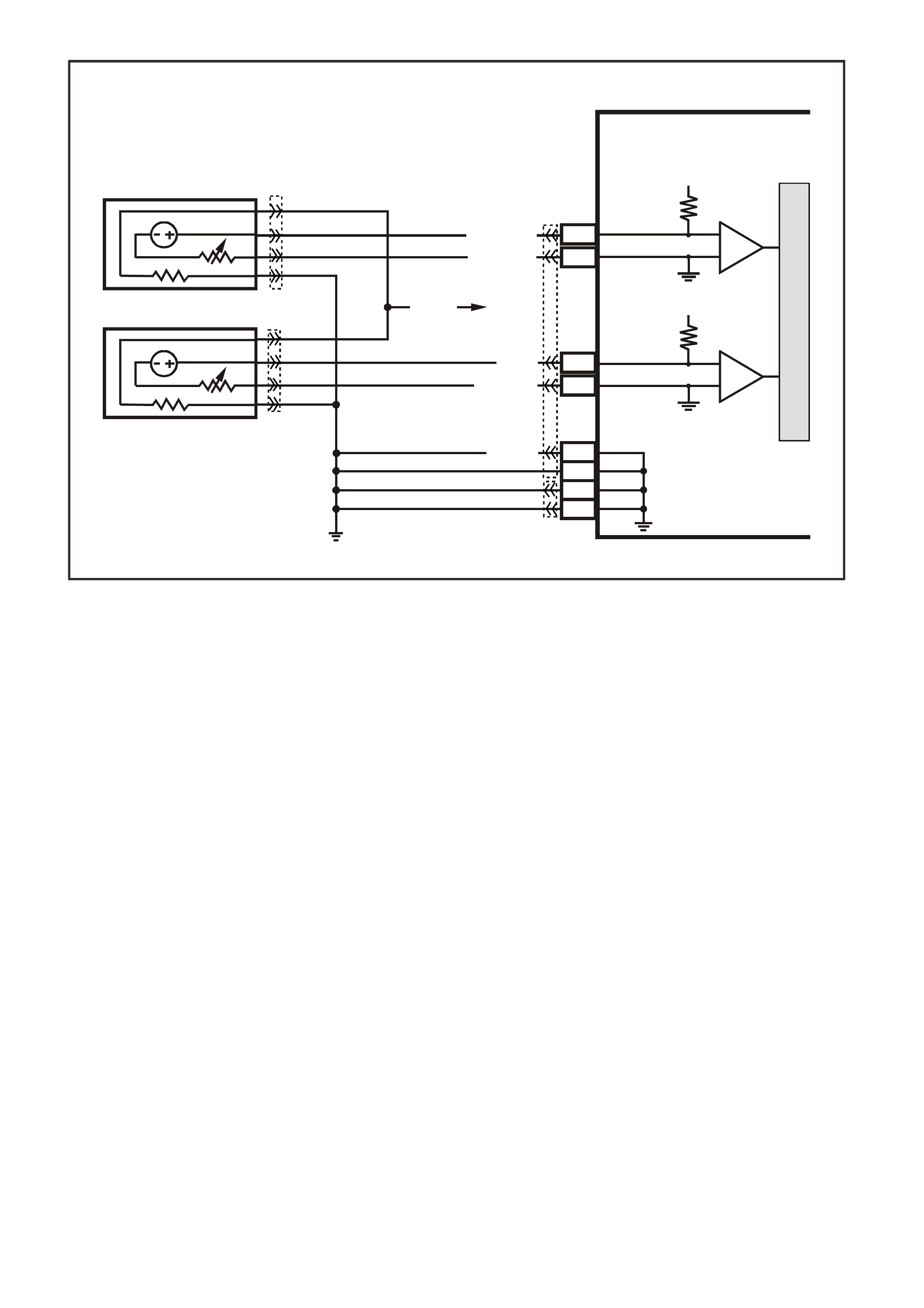

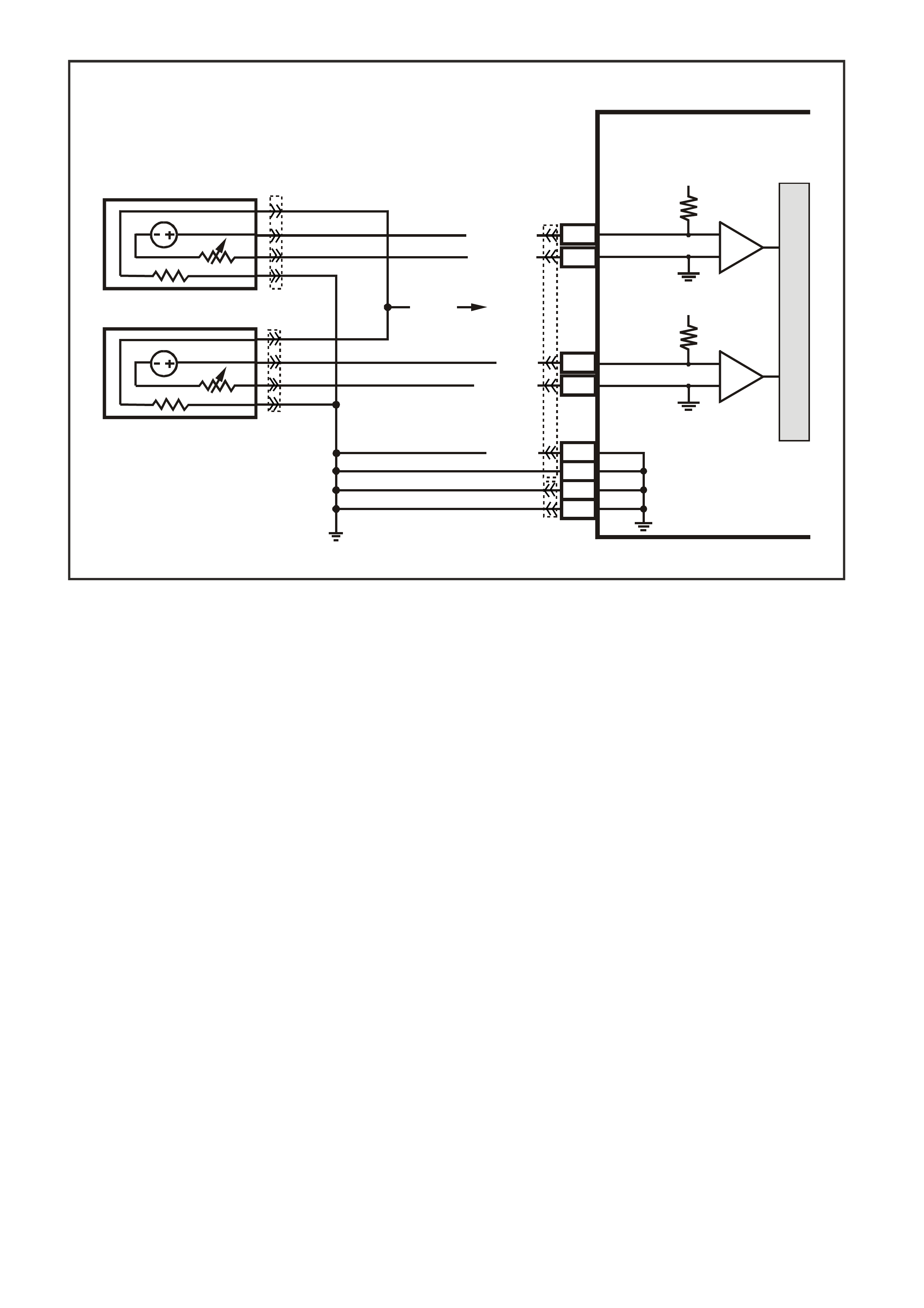

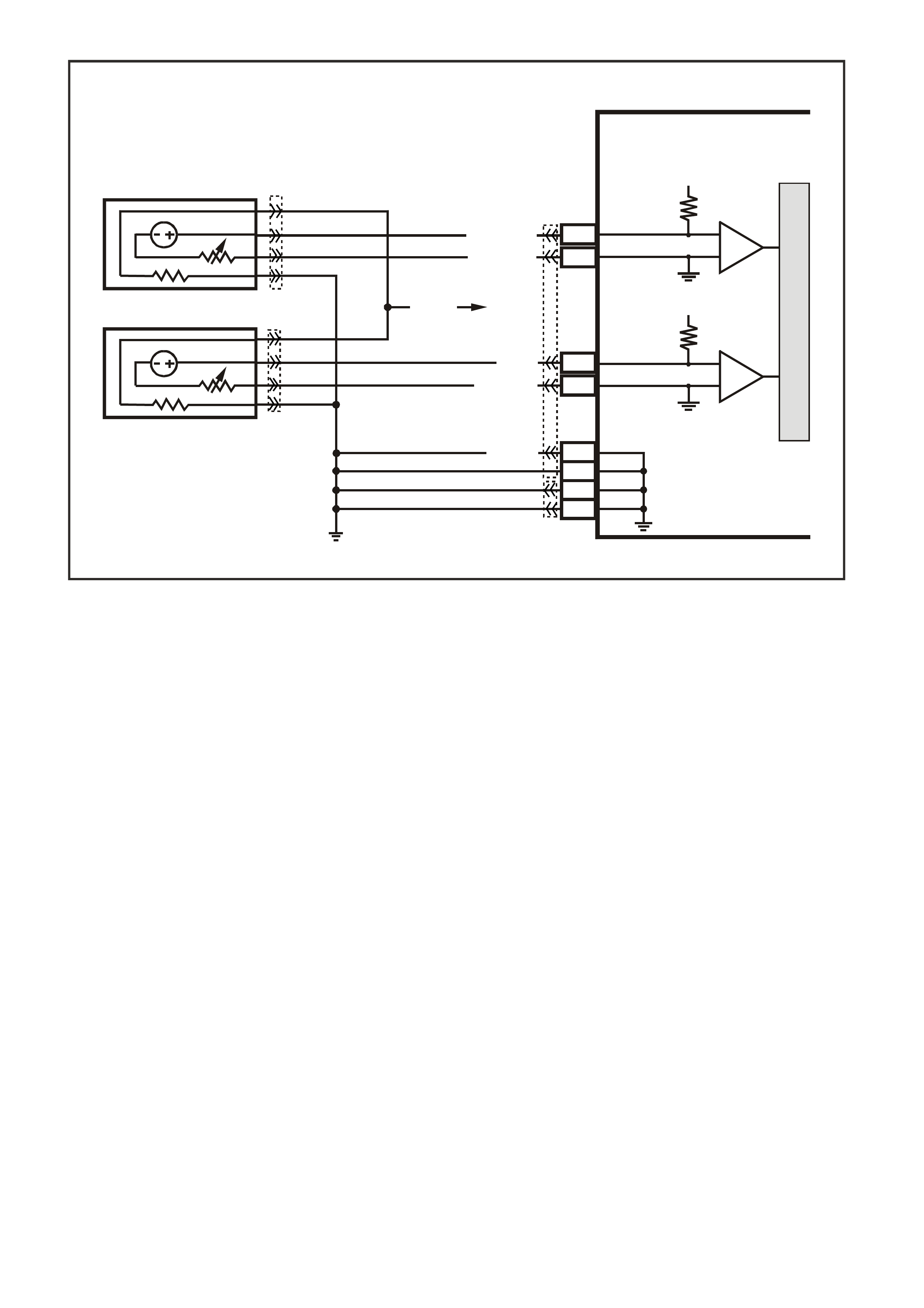

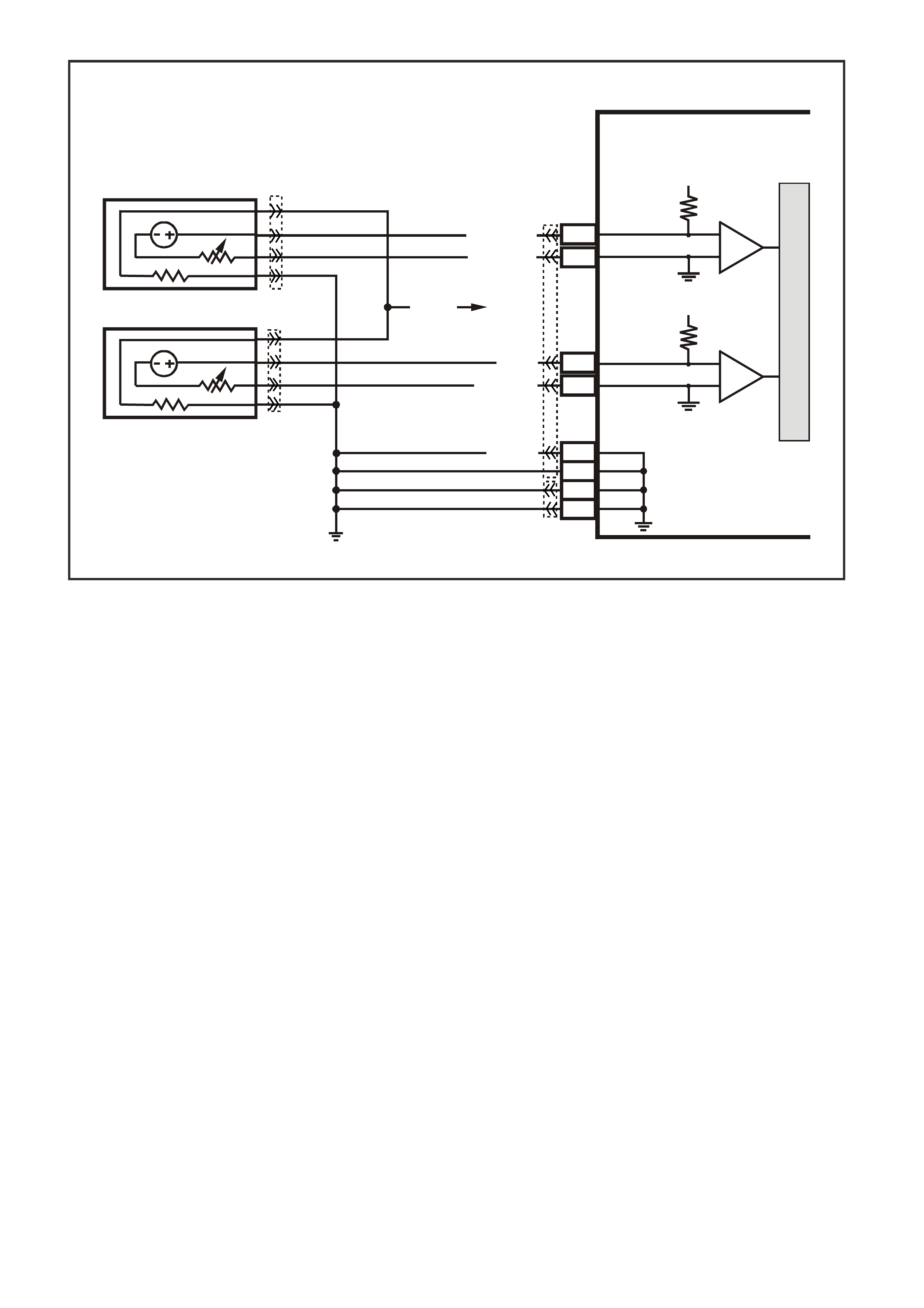

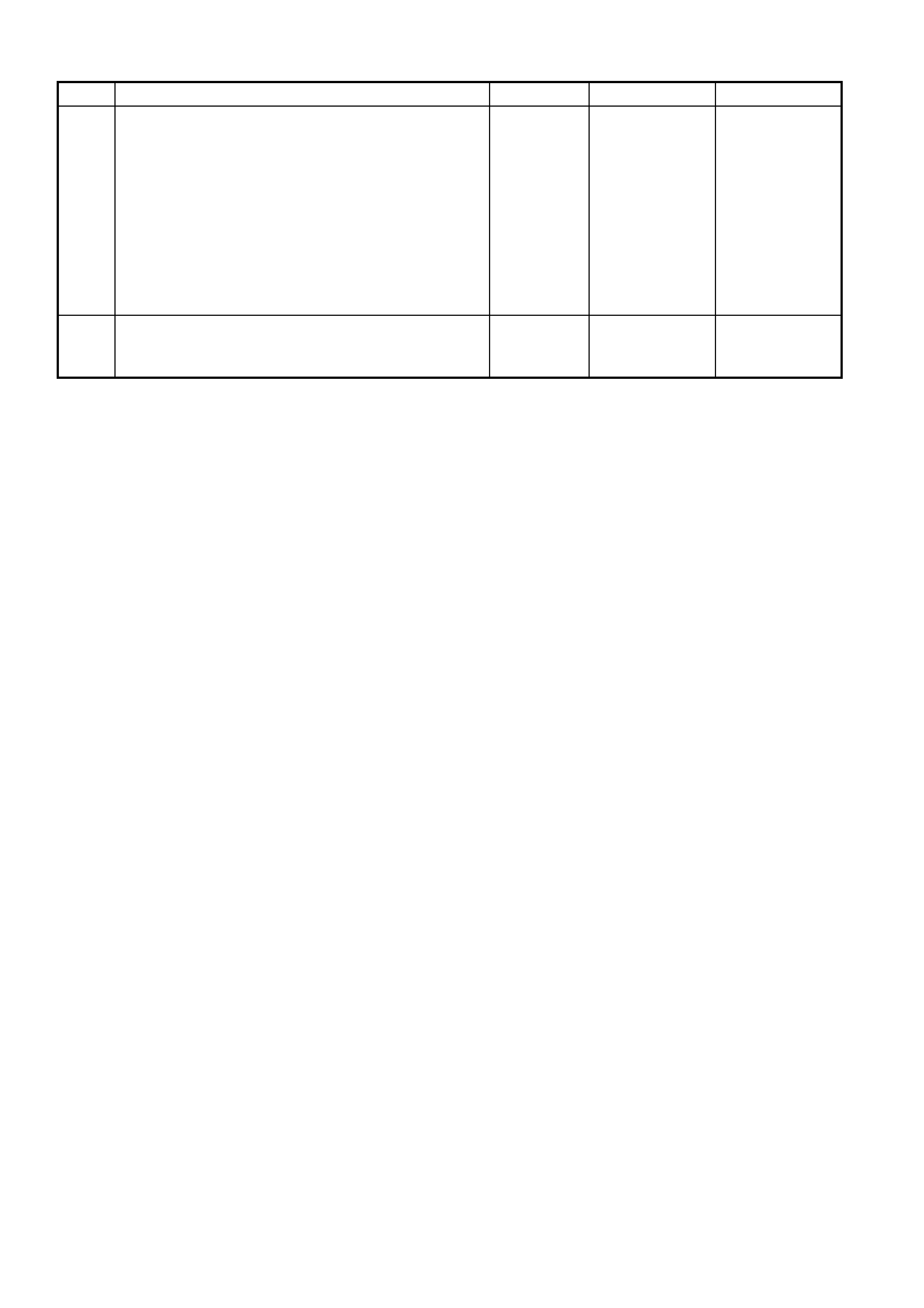

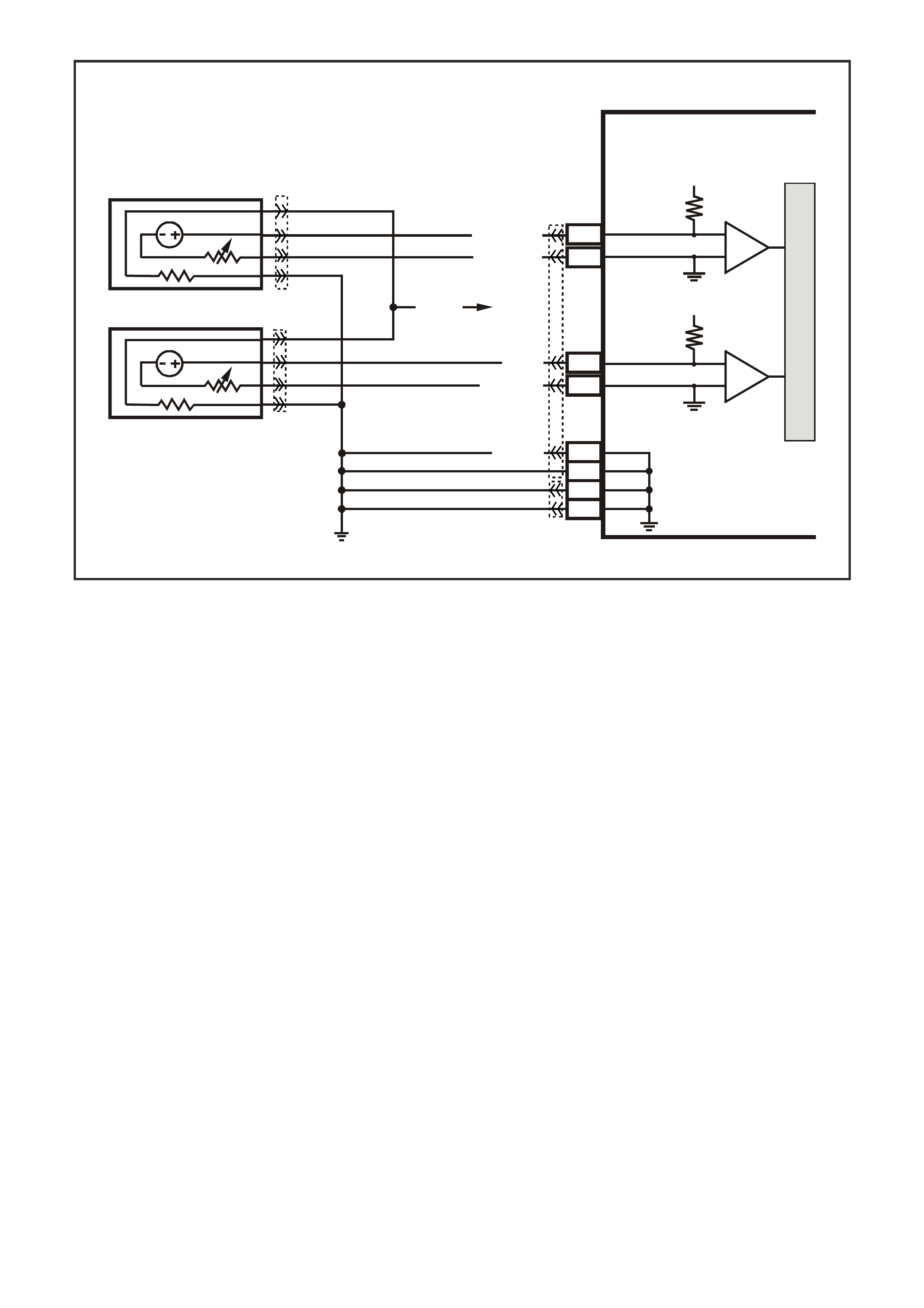

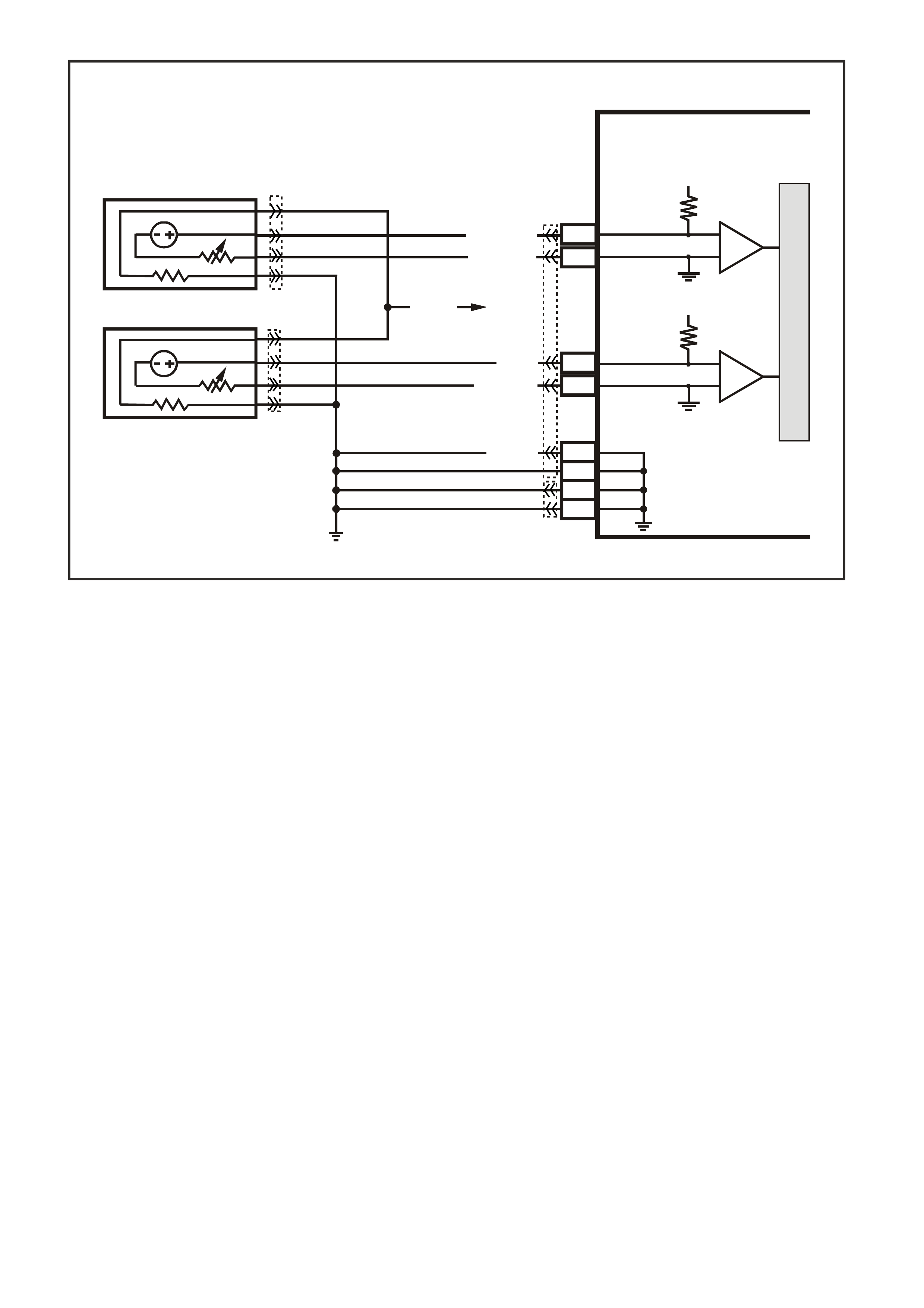

Figure 6C3-2A-12 Powertrain Control Schematics (6 of 12) – Injectors, Heated Oxygen Sensor Circuits

G3PCM053PT

PCM

M

I

C

R

O

P

R

O

C

E

S

S

O

R

J1-19

J1-36

J1-04

J1-03

J1-44

J1-76

J1-37

J1-20

J1-43

J1-77

J1-57

INJECTOR 1

INJECTOR 2

INJECTOR 7

INJECTOR 8

BATTERY

BATTERY

INJECTOR 5

INJECTOR 6

INJECTOR 3

INJECTOR 4

IGNITION

+-

BATTERY

FS

(1040)

O/Y

(479)

B/W

(152)

FJ

LOC. E1

LOC. E3

R (2H)

15a 15 50

30 OFF/ON

LOCK

ACC

IGN

START

IGNITION SWITCH

P (3) P/B (39) P (39)

EFI

RELAY

F14

F35

F34F31 BLU

(841)

V

(843)

GY

(845)

P/B

(847)

G

(842)

BR/Y

(844)

Y

(846)

LG

O (740)

O/B

(740)

R

(481)

L/G

(482)

J1-26

J1-66

D

D

B

B

A

A

C

C

J1-01

J1-40

J2-01

J2-40

GY/B (1413)

GY (1412)

RIGHT OXYGEN SENSOR

BANK TWO SENSOR ONE

LEFT OXYGEN SENS OR

BANK ONE SENSOR ONE

LOC. E5/E15

J1-69

J1-29

BLU/B (413)

V (41 2)

P (43 9)

TO FUSE

F33

RIGHT OXYGEN

SENSOR SIGNAL LO

LEFT OXYGEN

SENSOR SIGNAL LO

RIGHT OXYGEN

SENSOR SIGNAL HI

EARTH

EARTH

EARTH

EARTH

LEFT OXYGEN

SENSOR SIGNAL HI

B/R (750)

YE111

YE112

YE95

YE95

YE123

YE122

YB44

YB44

YB39

YB39

YE114

YE77 YE77

YE79 YE79

YE81 YE81

YE83 YE83

YE80 YE80

YE82 YE82

YE84 YE84

YE78 YE78

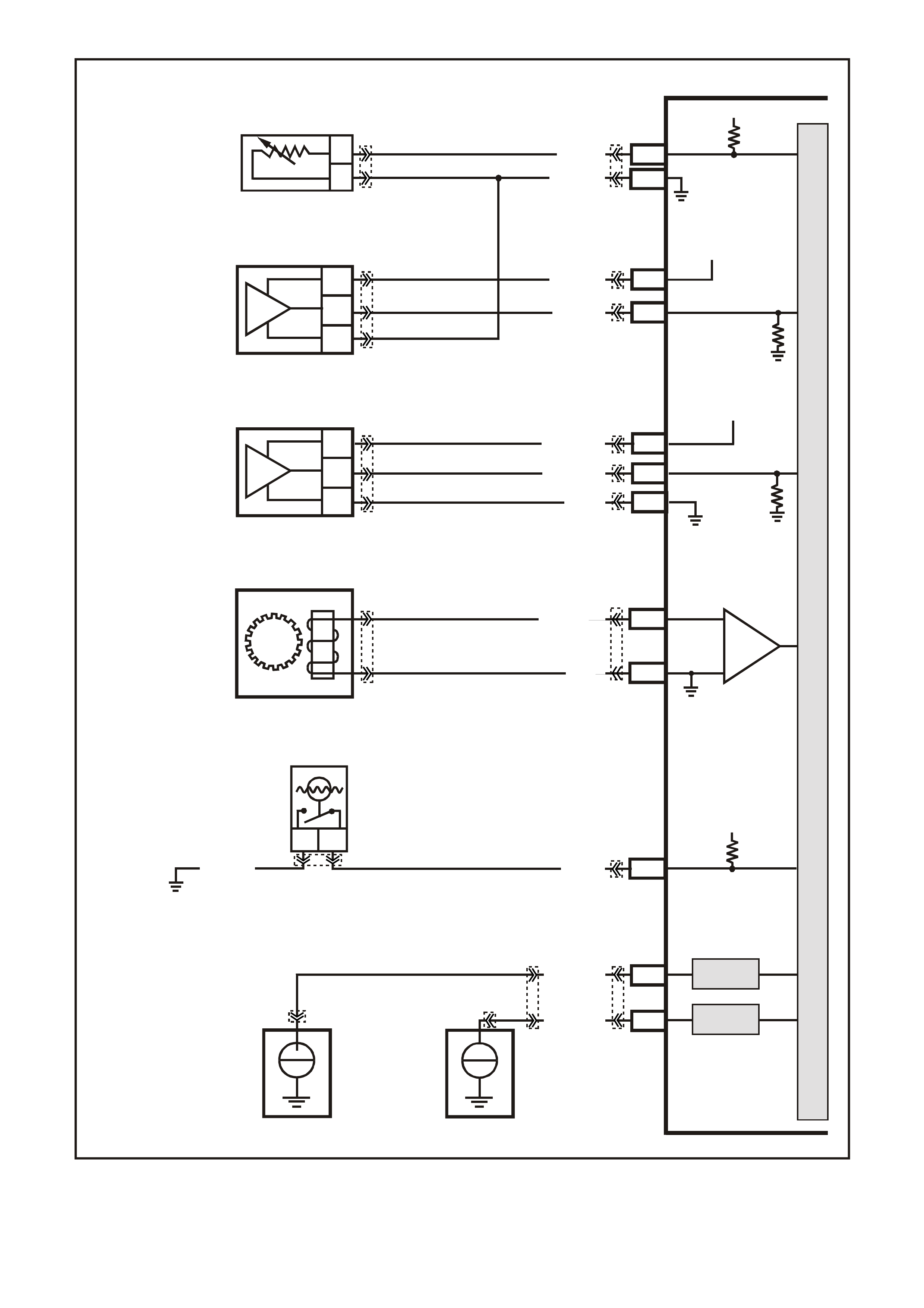

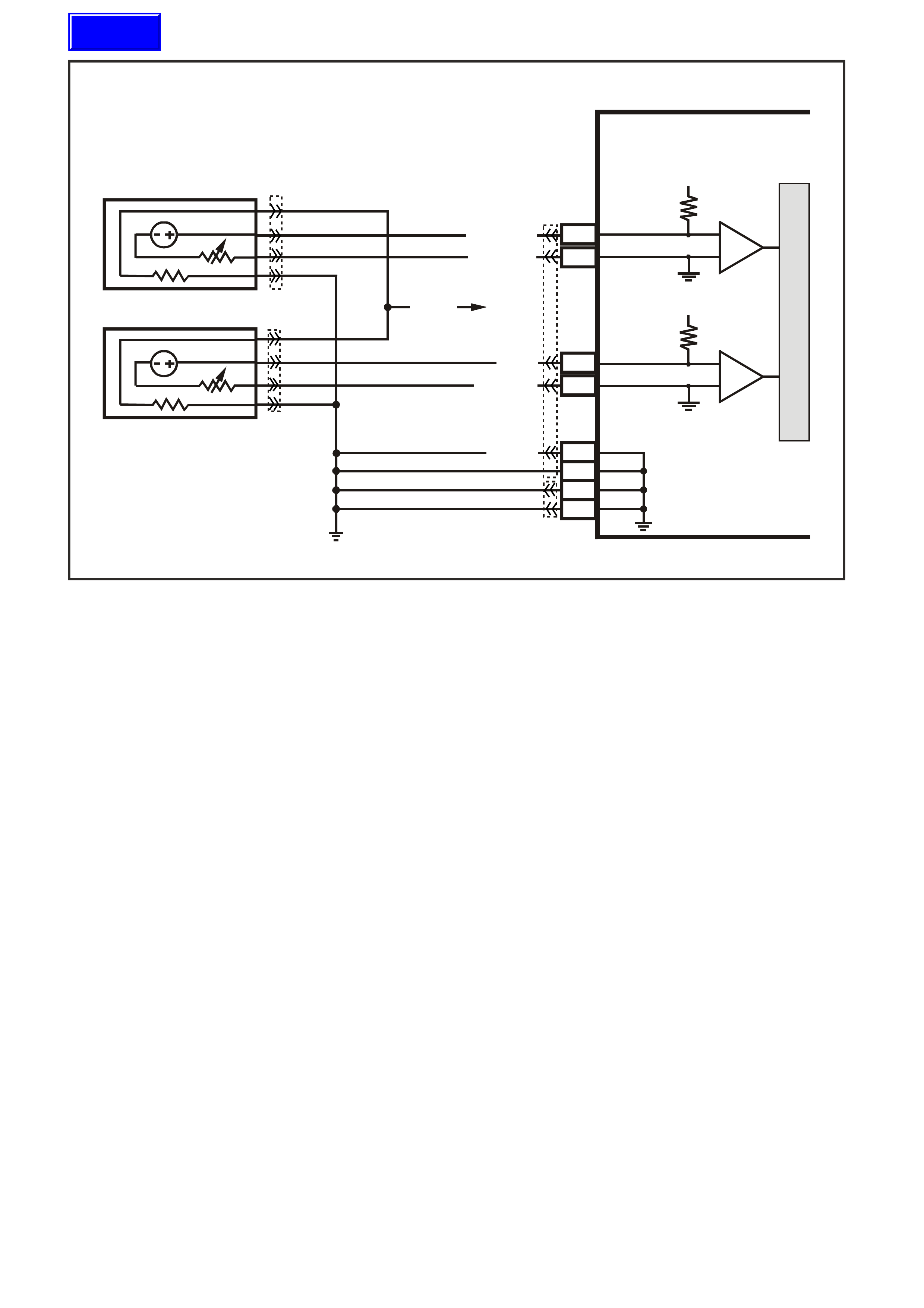

Figure 6C3-2A-13 Powertrain Control Schematics (7 of 12) – CKP, CMP, MAF, MAP, TP and ECT Circuits

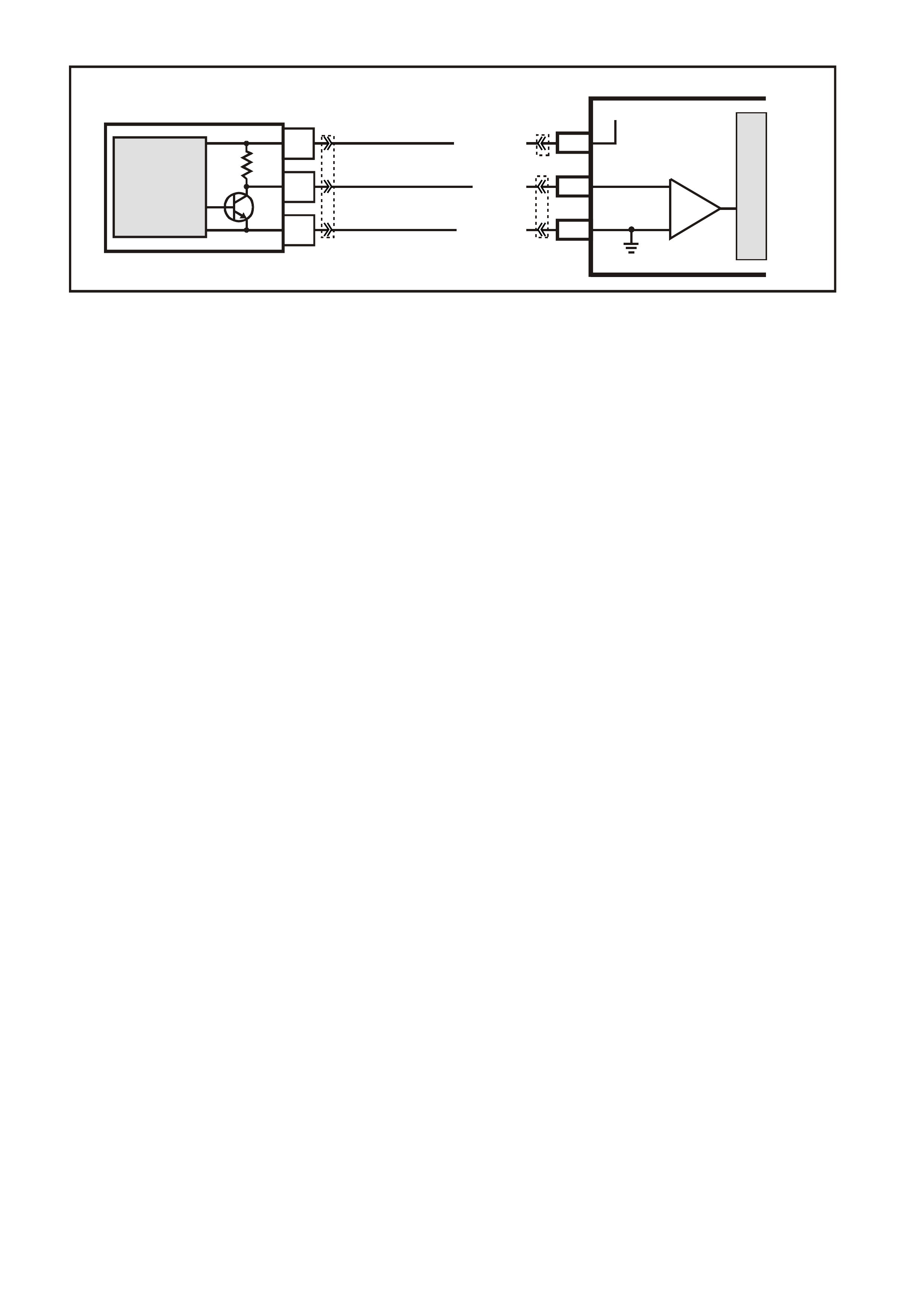

G3PCM051PT

PCM

A

C

B

CRANKSHAFT

POSITION

SENSOR

J1-02

LBLU/W (646)

J1-21

SENSOR EARTH

LBLU/B (64 7)

12V

J1-12

BLU (643)

CRANKSHAFT

POSITION

SENSOR

SIGNAL

MAGNETO

RESISTIVE

INTEGRATED

CIRCUIT

IC

CAMSHAFT

POSITION

SENSOR

J1-61

SENSOR EARTH

R/W (632)

J2-39

W/B (631)

12V

J1-73

BR (633)

CAMSHAFT POSITION

SENSOR

SIGNAL

A

C

B

HALL EFF ECT

INTEGRATED

CIRCUIT

IC

IC

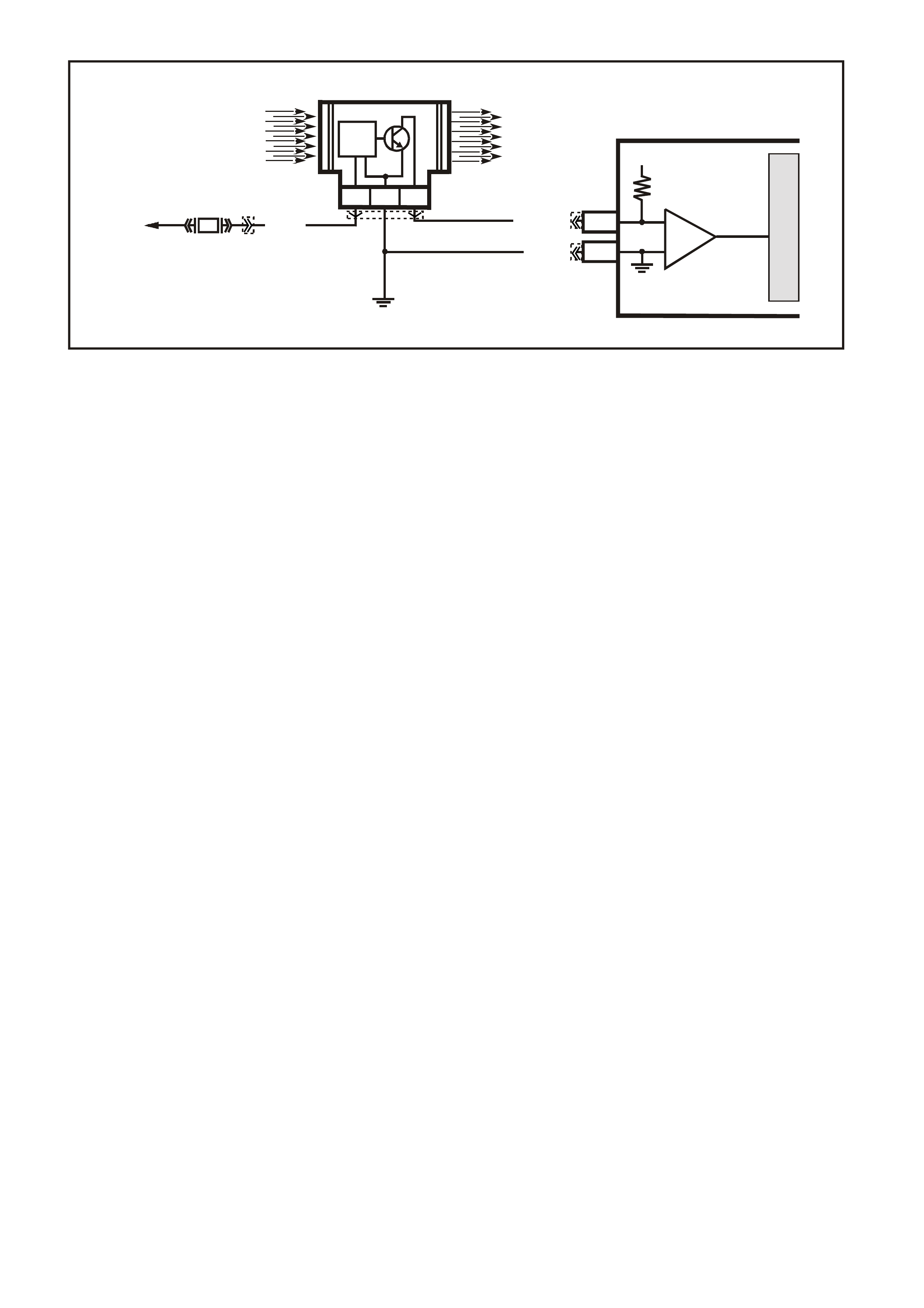

CIRCUIT

MASS A IR FLO W SE NSOR

J2-31

J1-01

CBA

AIR FLOW

FROM

AIR FILTER

AIR FLOW

TO

THROTTLE BODY

EFI

RELAY

P (43 9) BR/W (792)

MASS AIR

FLOW

INPUT

SIGNAL

EARTH

IC

B/R (750)

LOC. E5/E15

F33

J2-32

J1-54

C

B

A

MANIFOLD

ABSOLUTE

PRESSURE SENSOR

J1-48

SENSOR EARTH

MAP SENSOR

SIGNAL

5V

5V

V/W (414)

B (42 1)

LG (432)

SENSOR EARTH

TP SENSOR SIGNAL

TP SENSOR

REFERENCE

VOLTAGE

5V

J1-08

J2-24

J1-60

A

C

B

THROTTLE

POSITION SENSOR

GY (416)

BLU (417)

B/Y (452)

J1-80

J1-74

B

A

ENGINE COOLANT

TEMPERATURE

SENSOR

SENSOR EARTH

ETC SENSOR SIGNAL

Y (41 0)

GY/B (455)

5V

M

I

C

R

O

P

R

O

C

E

S

S

O

R

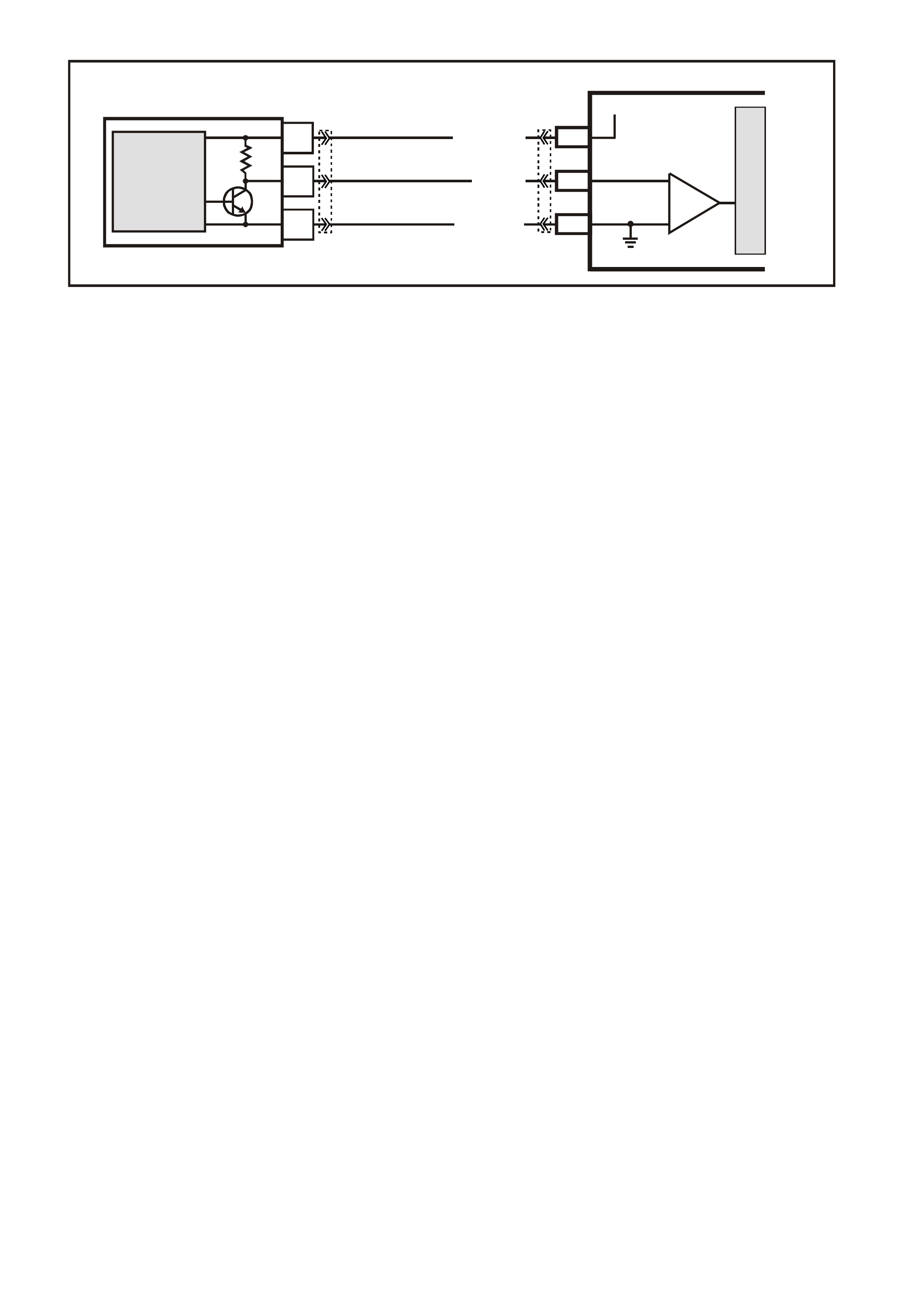

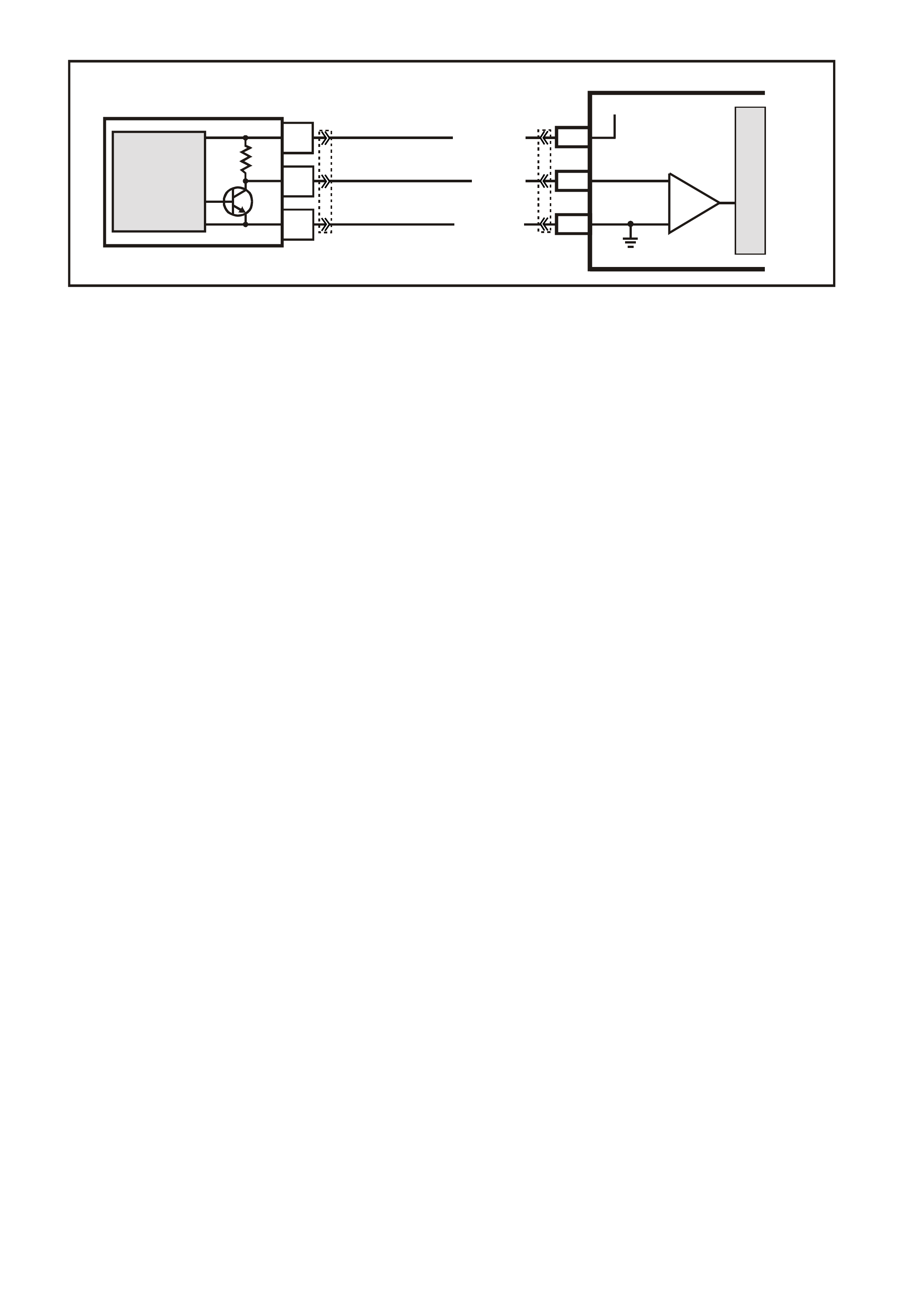

YE67

YE69 YE122

YE122

YE123

YE123

YE122

YE122

YE123

YE122

YE122

YE123

YE122

YE122

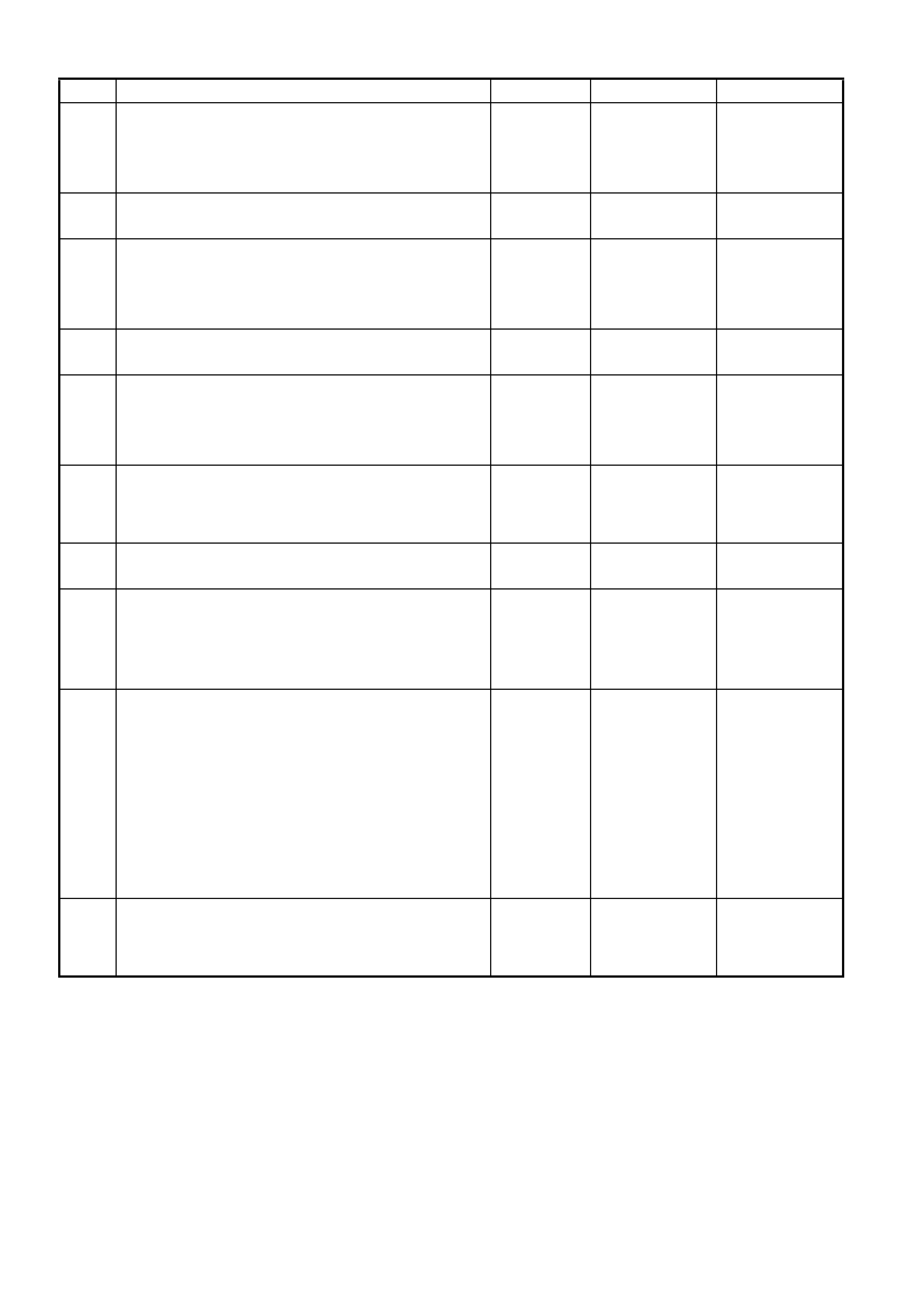

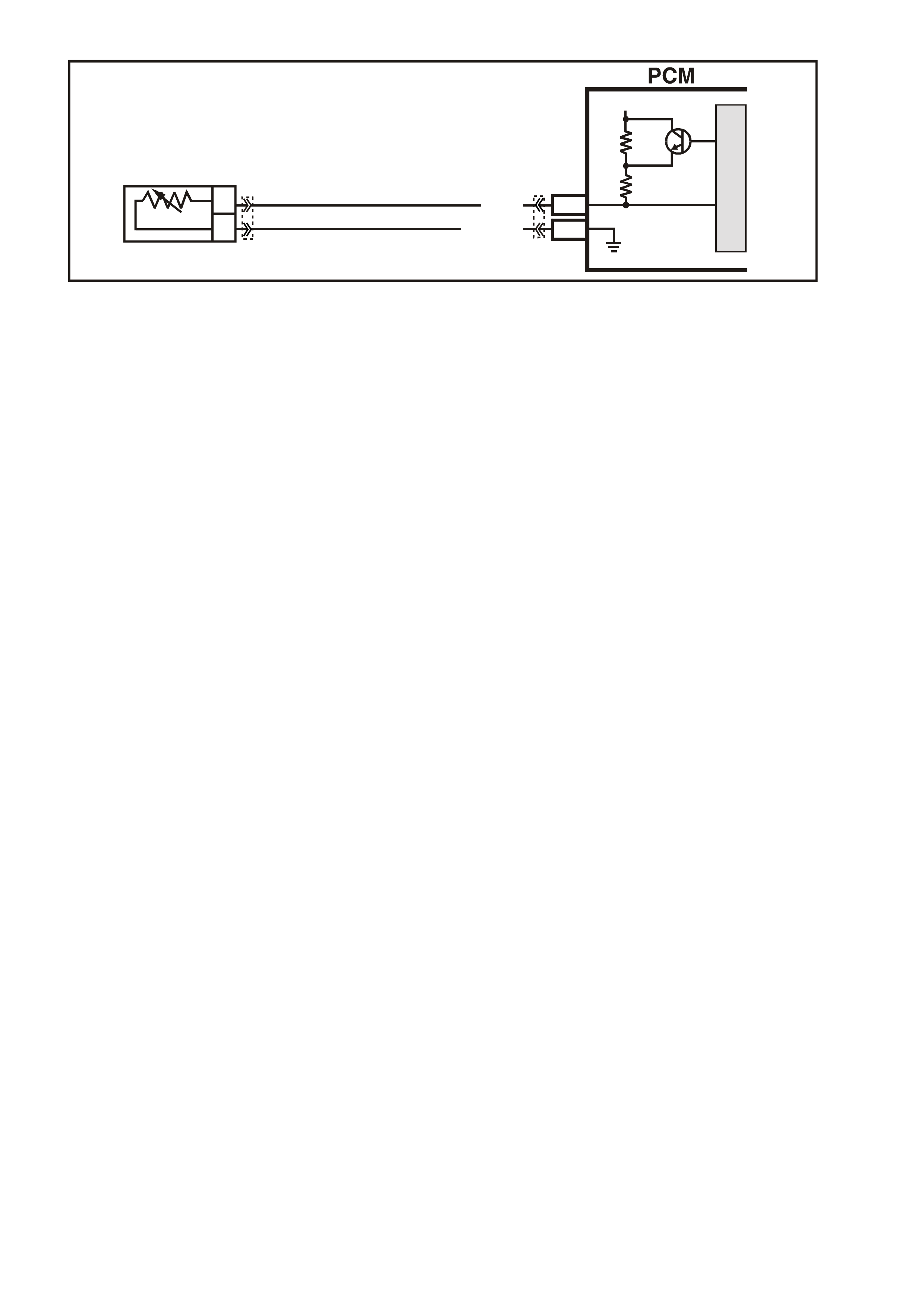

YE65

YE30

YE27

YE111

YE100

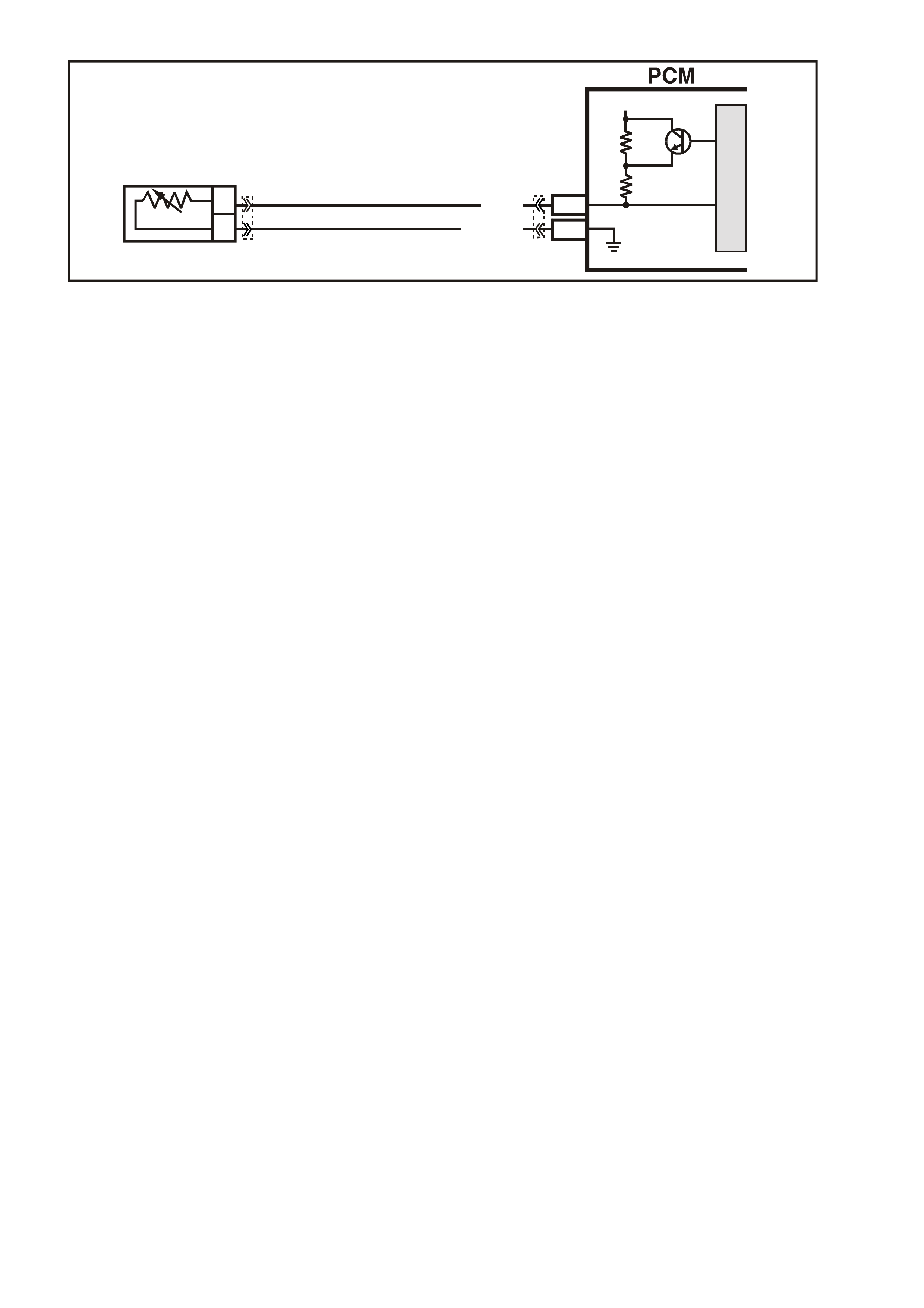

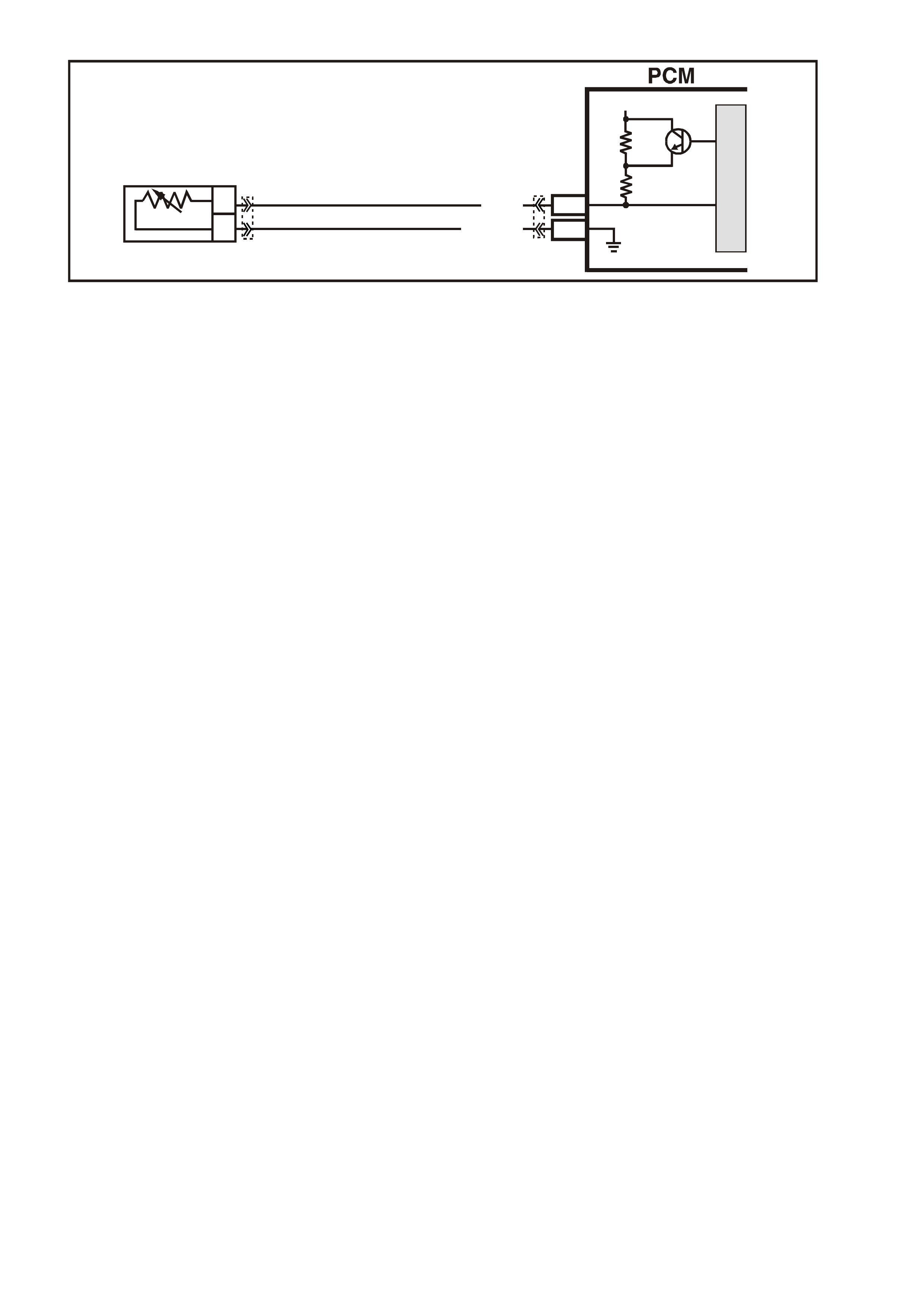

Figure 6C3-2A-14 Powertrain Control Schematics (8 of 12) – IAT, A/C Pressure Sensor, Oil Pressure,

VSS, Low Coolant and KS Circuits

G3PCM052PT

PCM

J2-57

J2-25

A

B

INTAKE AIR

TEMPERATURE

SENSOR

SENSOR EARTH

IAT SENSO R SIGN AL

5V

BR (472)

G/O (469)

J2-14

A/C

PRESSURE

SENSOR

J1-45 A/C PRESSURE

SENSOR SIGNAL

5V

V/W (415)

G/B (259)

C

B

A

OIL

PRESSURE

SENSOR

J2-58

J1-63

J1-07

SENSOR EARTH

OIL PRESSURE

SENSOR SIGNAL

5V

BLU/Y (334)

G (335)

BR/W (331)

C

B

A

J1-30

BA

LOW COOLANT

LEVEL SWITCH

LOW COOLANT LEVEL

SW ITCH SIG NAL

12V

G (69)

B/R (750)

LOC. E5/E15

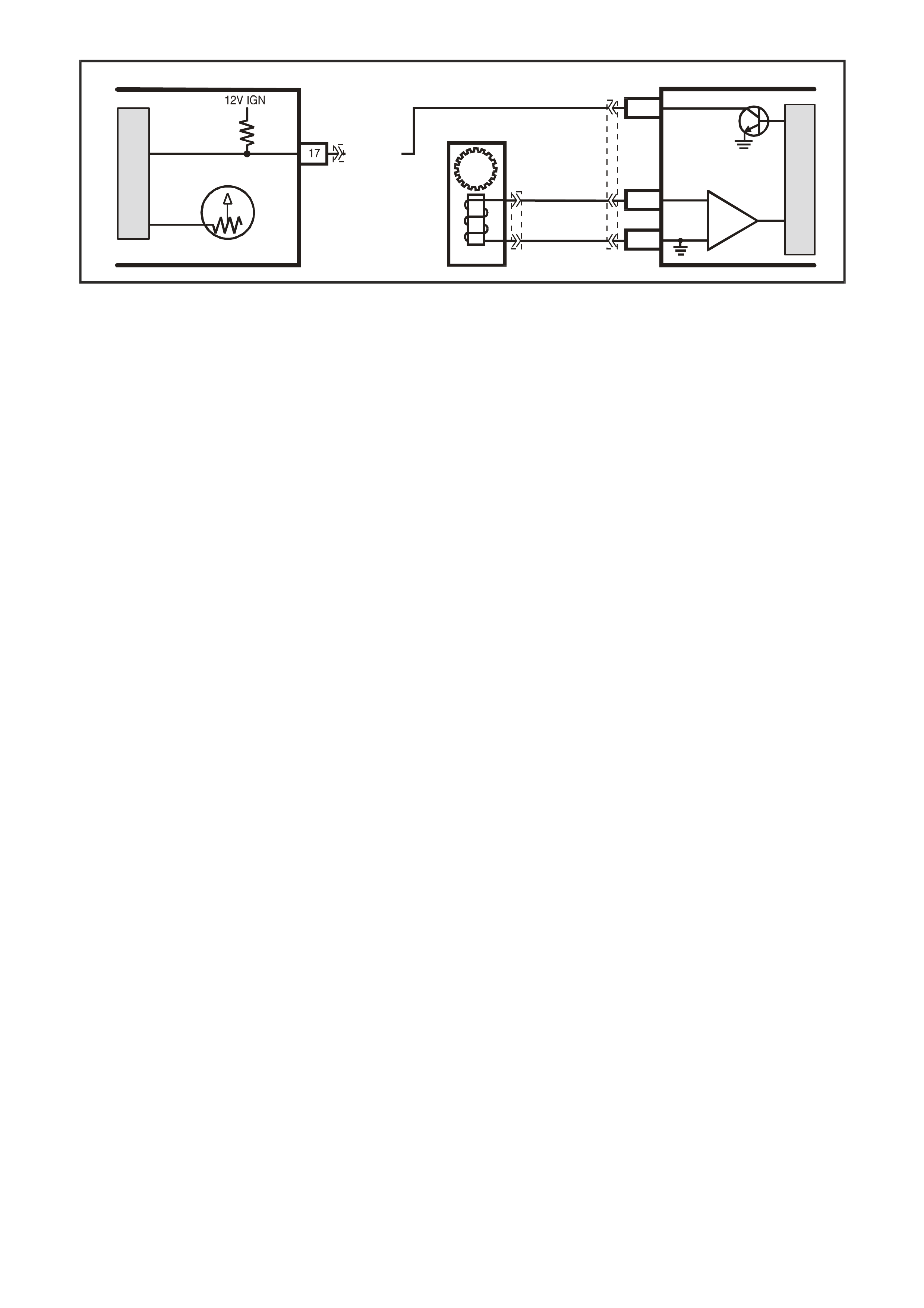

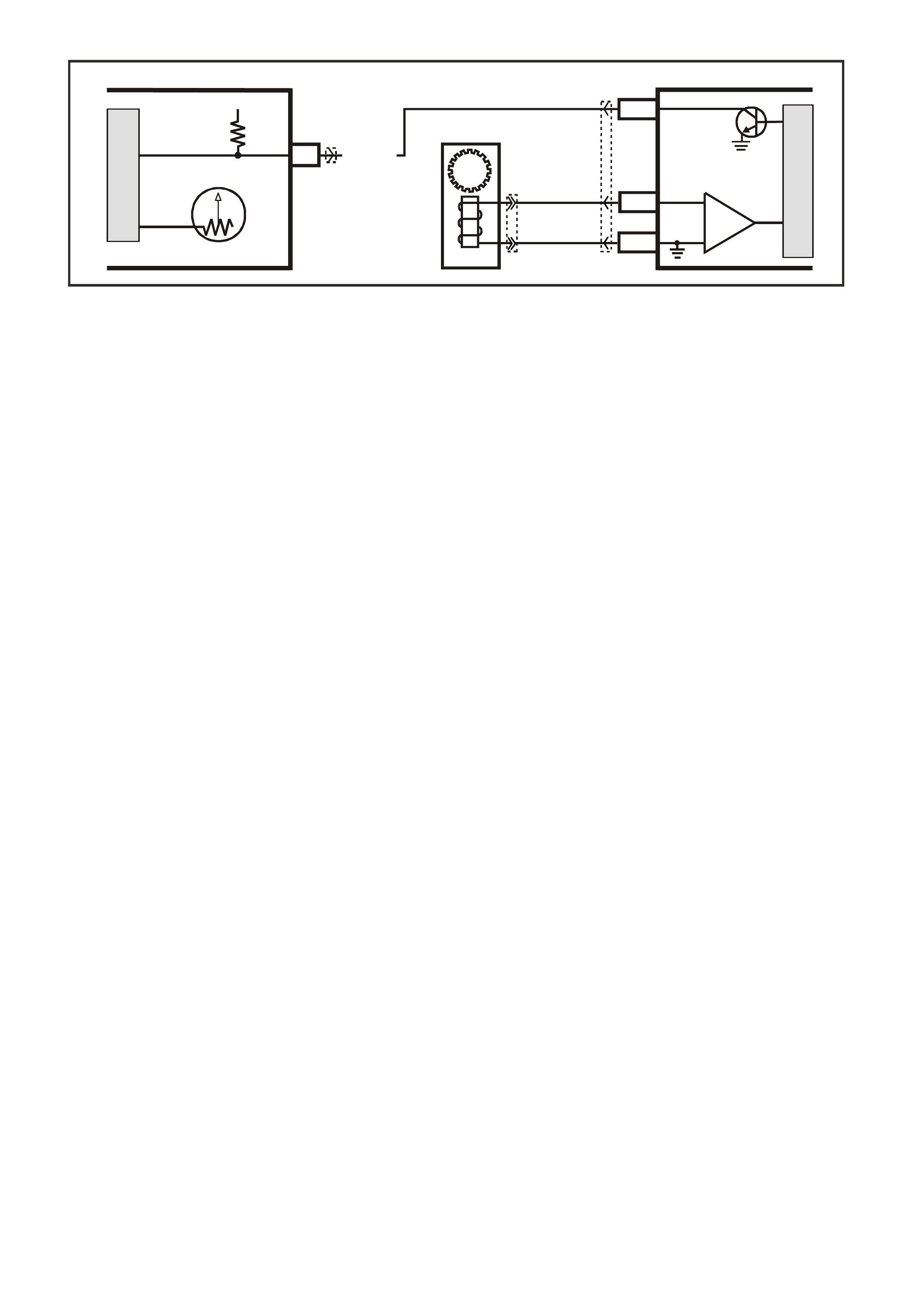

VEHICLE SPEED

SENSOR

IC

VSS HI

VSS LO

J2-21

J2-20

BLU/W (831)

T (832)

DSNEF

DSNEF

FRONT KNOCK

SENSOR SIGNAL INPUT

REAR KNOC K

SENSOR SIGNAL INPUT

J1-51

J1-11

REAR

KNOCK

SENSOR

FRONT

KNOCK

SENSOR

+

-

+

-

BLU (815)

LBLU (826)

M

I

C

R

O

P

R

O

C

E

S

S

O

R

YE123

YE122

YE123

YE122

YE122

YE123

YE122

YE122

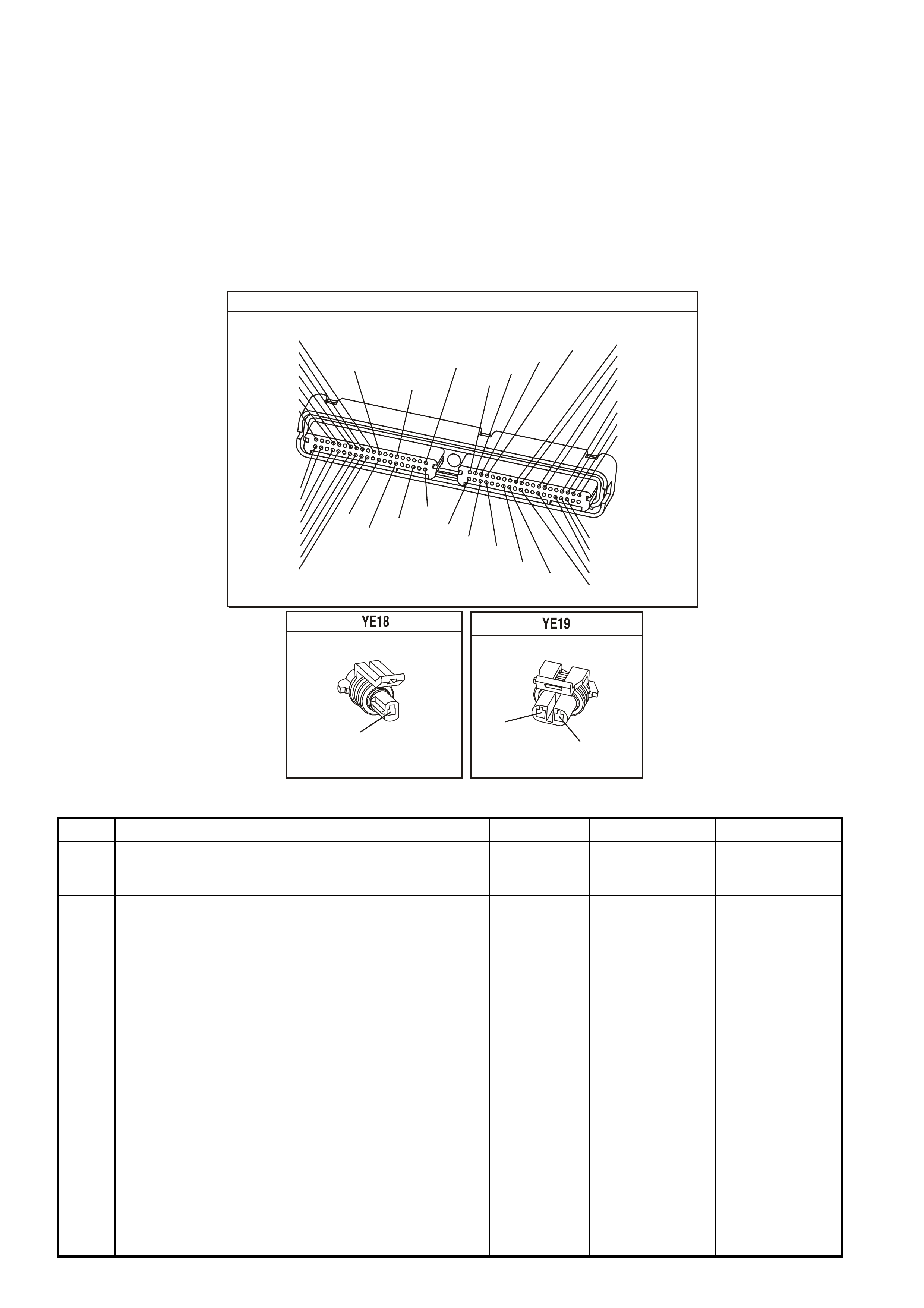

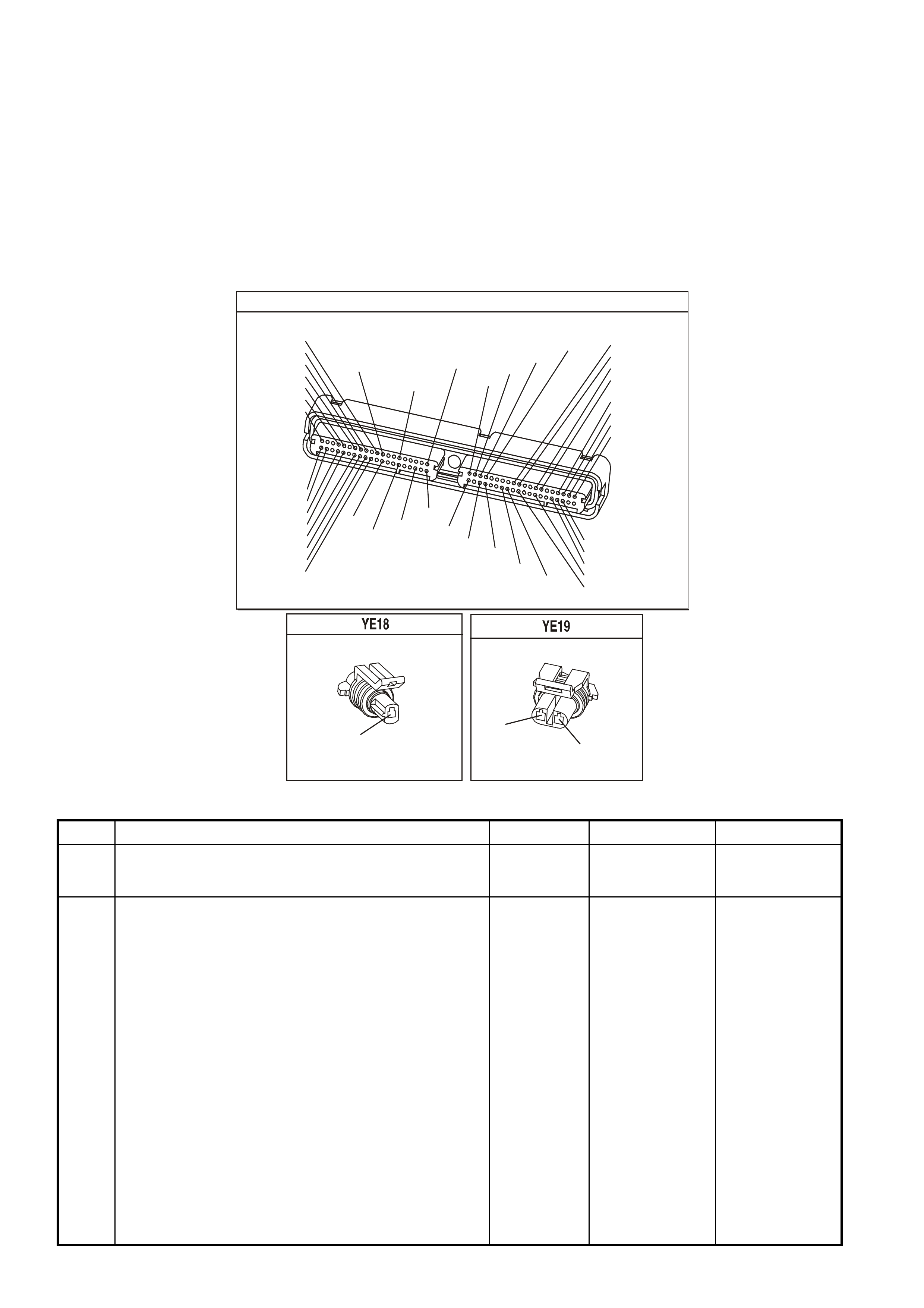

YE19

YE18

YE18

YE131

YB195

YE32

YE113

YE23

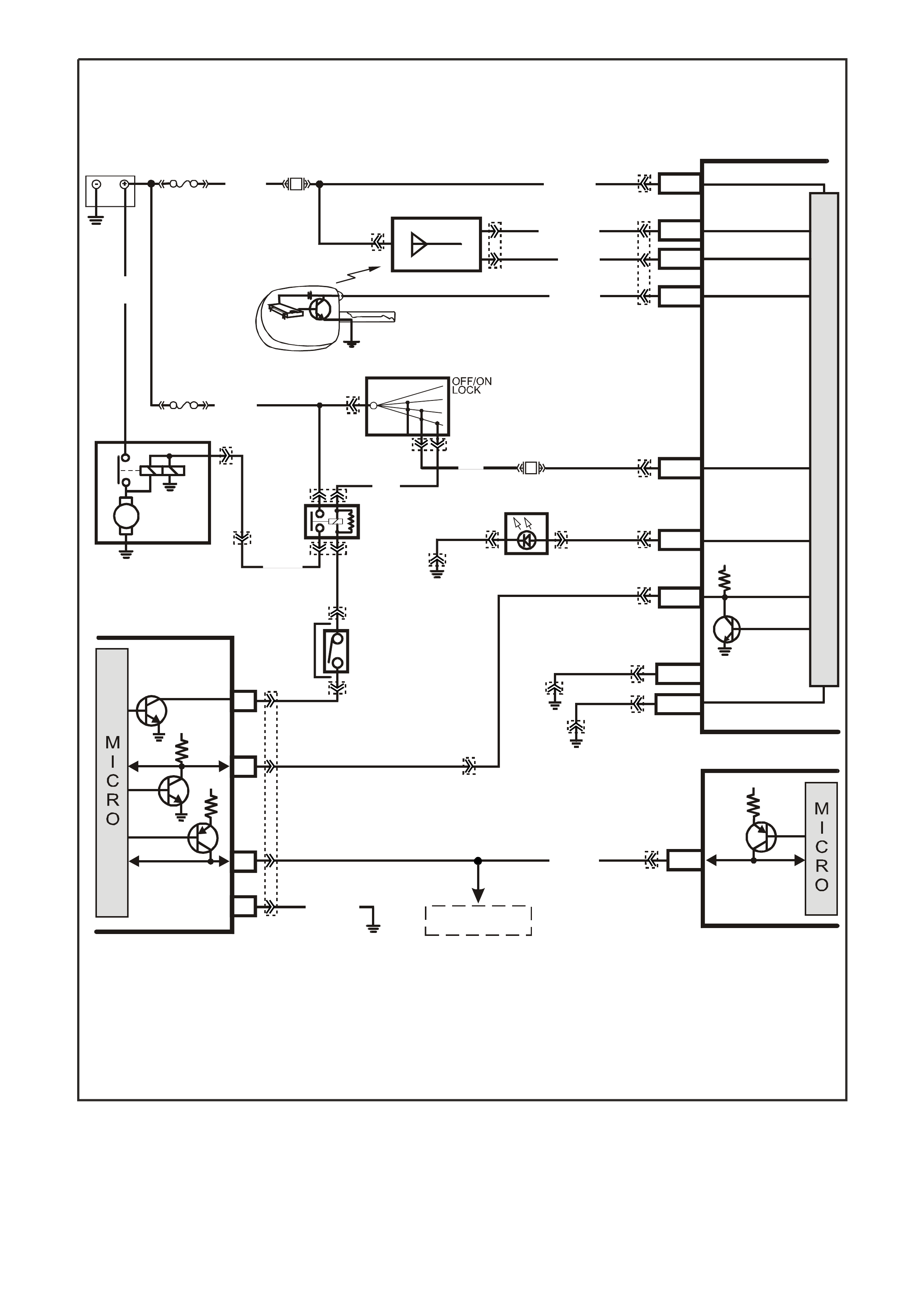

Figure 6C3-2A-15 Powertrain Control Schematics (9 of 12) – Start Relay Circuits

BAT TERY MAIN POWER

HIGH SERIES

BCM TERMINALS

NOMINA TED FIRST

BCM

REMOTE

CODED KEY

V/R (229) E1/D12 KEY R EADER

BATTERY

FS

LOC.

E1

LOC. G1

F31

A5/A6

O/B (740)

(1040)

REMOTE KEY

RECEIVER

Y (266) E8/D1 RECEIVER DATA

BR/G (271) E7/D11 RECE IVER EARTH

O/B

(740)

FJ

M

I

C

R

O

P

R

O

C

E

S

S

O

R

GY/BLU

(1434)

G3PCM045PT

THEFT DETERRENT

ALERT INDICA TOR

R/B

(1221)

E2/D2 SERIAL DATA

5V

R (2H)

E20/D6 IGNITION

NEUTRAL ST ART

BACK-UP SW.

(FOR AUTO TRANS)

(FOR MANUAL

TRANS)

GY

(434)

R (1)

V/W (6)

F14

START

RELAY

IGN ITIO N SWITC H

15a 15 50

30 ACC

IGN

START

V (5) P (3) P/B

(39)

A6/A8

LBLU

(263) THE FT LED

B/Y

(155)

LOC. E3

B/G

(151) B10/B11 HIGH CURRENT

EARTH

B/Y

(155) ELECTRONIC EARTH

A1/A5

LOC. E3

LOC. E3

PIM

UART

SERIAL

DATA

START

RELAY

5V

6

8

16

7V

7

CLASS 2

SERIAL DATA

B/R (750)

LOC. E5/E15

R/B

(1221)

7V

PCM

J1-58 CLASS 2

SERIAL DATA

Y (1049)

Y

(1049)

STARTER

MOTOR

M

YB215

YE112

YB35

YE104

YE8

YB35

YE114 YB56 YB56

YE49

YB44

YE49

YB44

YB95

YB175

YB164

YB176

YB165

YB175

YB164

YB175

YB164

YB174

YB163

YE114

YE114 YB176

YB165

YE122

YB176

YB165

YB95

TO

DLC TERMINAL 2

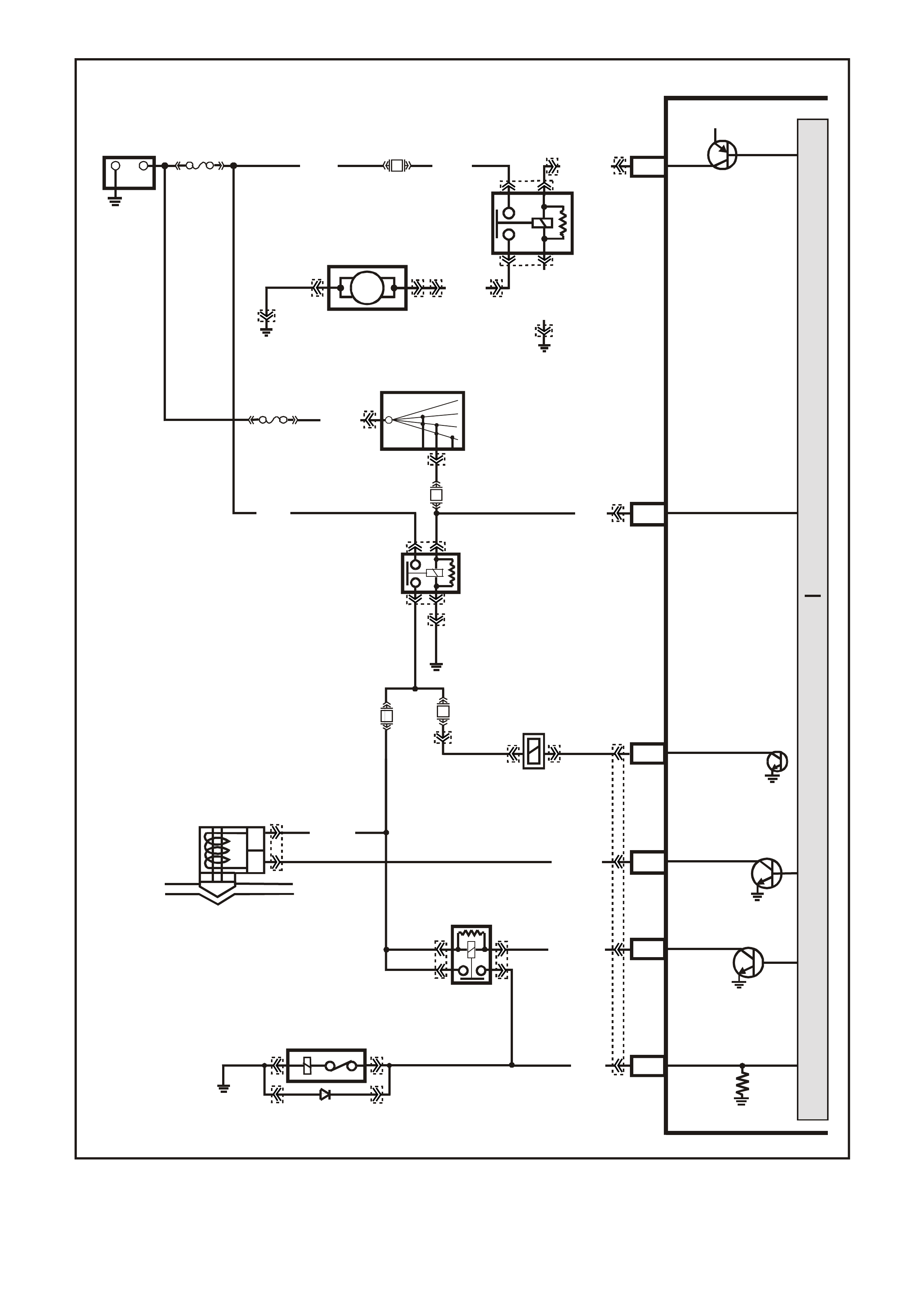

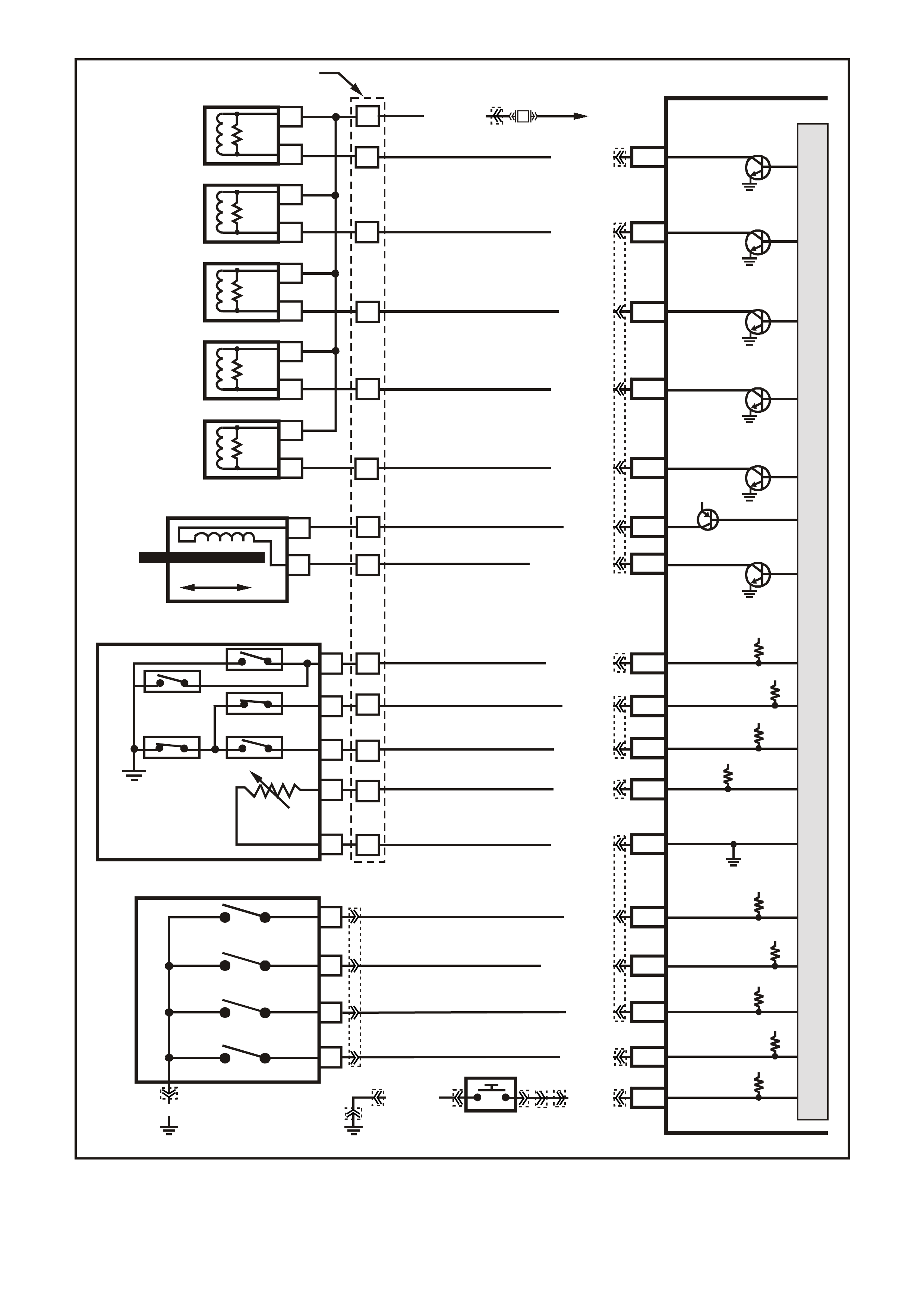

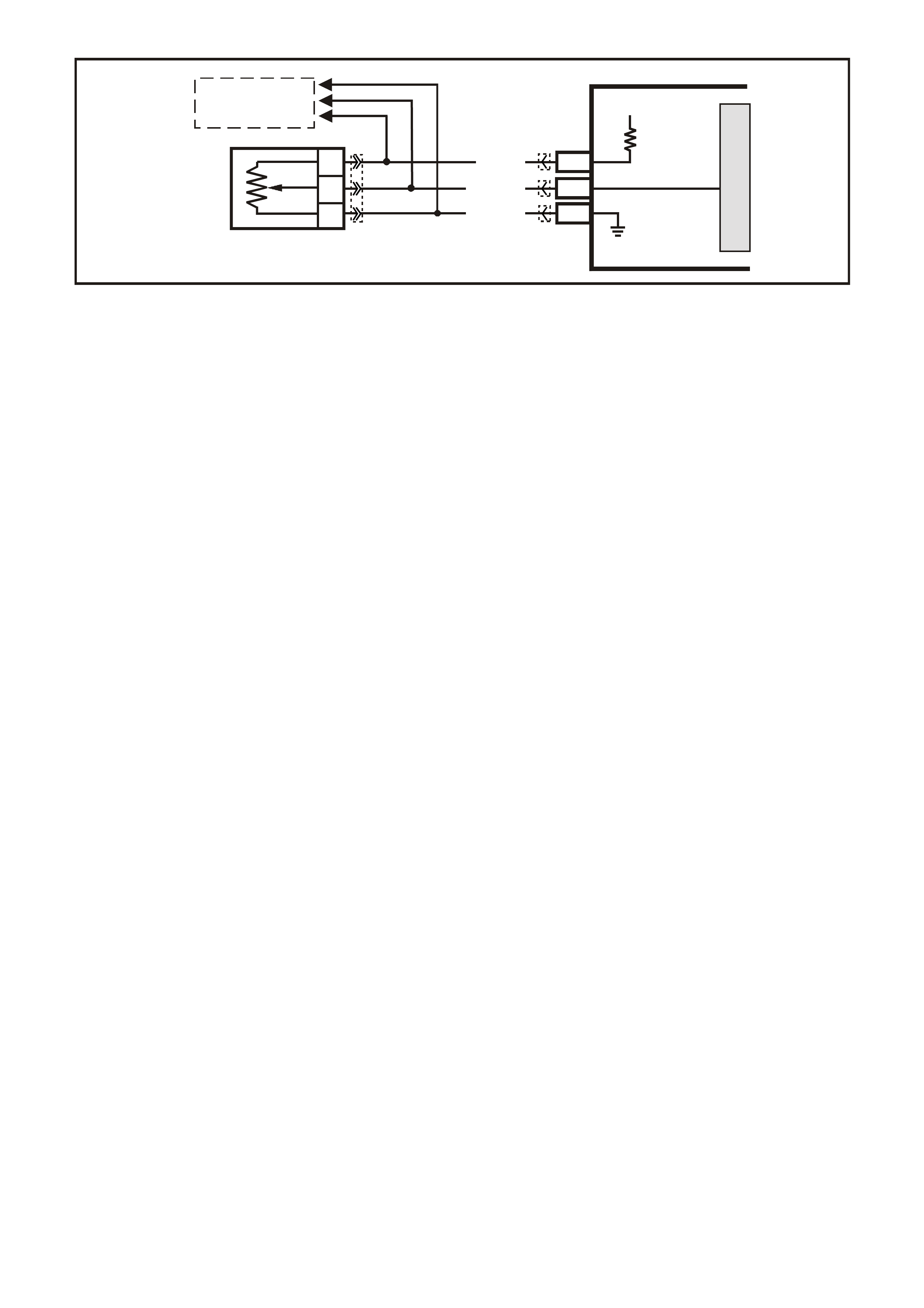

Figure 6C3-2A-16 Powertrain Control Schematics (10 of 12) – Engine Cooling Fans, IAC Valve Circuits

G3PCM056PT

PCM

M

I

C

R

O

P

R

O

C

E

S

S

O

R

87A

30

87

85

86

87

30

85

86

ENGINE

COOLING

FAN 1

ENGINE

COOLING

FAN RELAY

(LOW SPEED)

ENGINE

COOLING

FAN RELAY

(HIGH SPEED)

R

Y

B

G

O/B (473)

BLUE

FUSIBLE

LINK

LOC.

E1

F31

ENGINE

COOLING

FAN 2

+

-

BATTERY

FS

FT FAN 2

FU FAN 1

(1040)

R

(203)

(250)

O/Y

(533)

BLU/Y

Fan 1

340 Fan 2

300

R

(001)

R

(001)

O/B

(208)

O/BLU

(204)

BLU/W

(304) J2-33

HIGH

SPEED FAN

LOC.

E2

LOC.

E3

B/R

(157)

BCM

LOW SPEED FAN B7/B7

M

I

C

R

O

12V

J2-53 ETC DATA

CONTROL

( S PARK RETA R D)

GY/B (1687)

ABS/ETC

28

SPARK

RETARD

M

I

C

R

O

J2-77

J2-78

J2-79

J2-76

LG/B (444)

A

B

C

D

IAC VALVE

LG/W (443)

LBLU (441)

LBLU/B (44 2)

IAC COIL B LO

IAC COIL B HI

IAC COIL A LO

IAC COIL A HI

ØØ

YE140

YE139

YE119

YE103 YE43

YE43

YE110 YE123

YE103

YE104

YB163

YB174

YE114

YE36

YE98 YE129 YE123

YE123

YE118

YE119

Figure 6C3-2A-17 Powertrain Control Schematics (11 of 12) – Throttle Relaxer, Tachometer Signal Circuits

G3PCM035PT

HIGH SERIES

BCM TE RMIN ALS

NOMINATED FIRST

12V

12V

27

E2/D2

E9/D3

13

REQUESTED

THROTTL E (DKR)

ACTUAL

THROTTL E (DKI)

O/W (1426)

B/W (1427)

M

I

C

R

O

P

R

O

C

E

S

S

O

R

MAIN POWER

15

ABS/ETC

CONTROL MODULE

BCM

37

35

M

I

C

R

O

DKR

IGNITION

BATTERY

BATTERY

DKI

MOTOR +

MOTOR +

MOTOR -

MOTOR -

Y (1049)

M

I

C

R

O

5V

41

22

A

C

B

40

49

43

26

53

5 VOLT REF.

TPS SIGNAL

TPS GROUND

THROTTLE

POSITION SENSOR

THROTTLE

RELAXER

5V

12V

J1-08

J2-53

5 VOLT REF.

SPARK RETARD

TPS SIGNAL

TPS GROUND

J2-24

J1-60

J1-58

CLASS 2

SERIAL DA TA

7V

M

I

C

R

O

PIM

6

7

M

I

C

R

O

CLASS 2 SERIAL DATA

UART SERIAL DATA

11

SERIAL

DATA

5V

28

SPARK

RETARD

GY (416)

R/B (466)

R/W (456) AB

BLU (417)

B/Y (452)

R/B (1221)

+-

BATTERY

FJ

LOC.

E1 FS

IGNITION

SWITCH

15a 15 50

30

OFF/ON

LOCK

ACC

IGN

START

F27

F36

P (3)

R (8 55)

1

24

51

TH R OTTLE R ELAX ER

CONTROL MODULE

R (2 H)

(1040)

R/Y

(480)

GY/B (1687)

G/W (1220)

PCM

YB44

YB44

YE127

YE127

YE30

YE98

YB215

YB215YE122

YE123

YE122

YE122

YB170

YE123

YB175

YB164

YE110

YE129

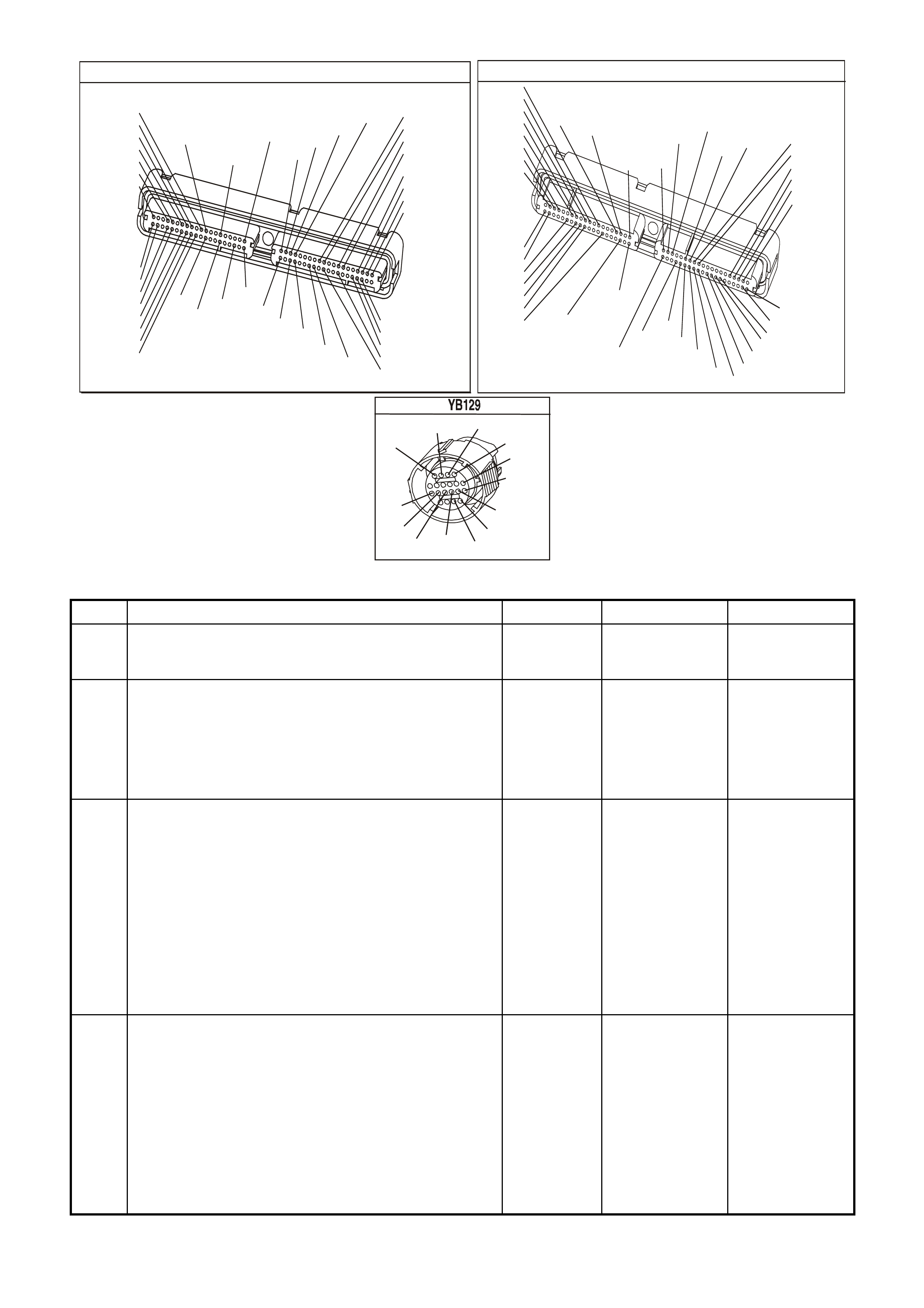

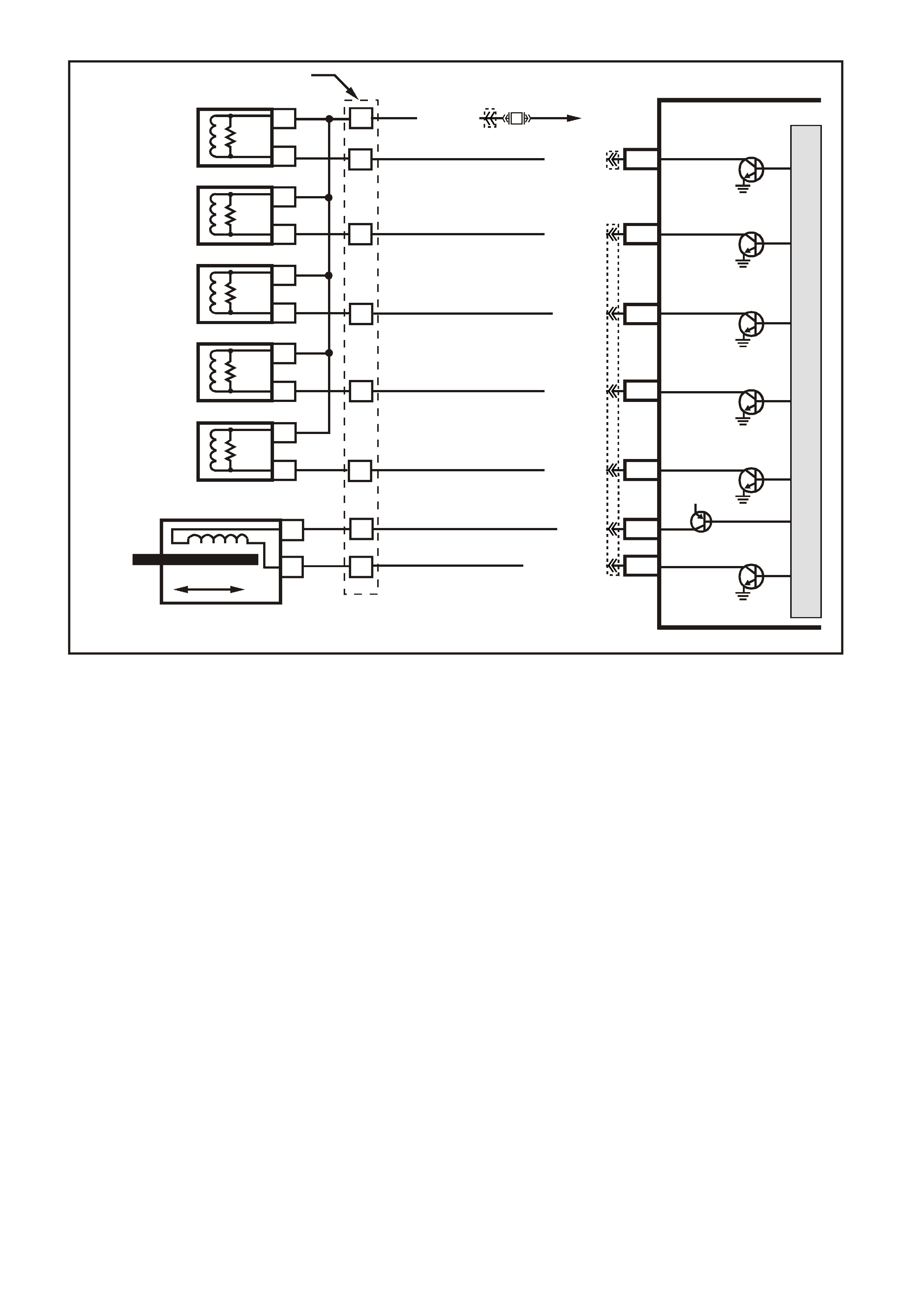

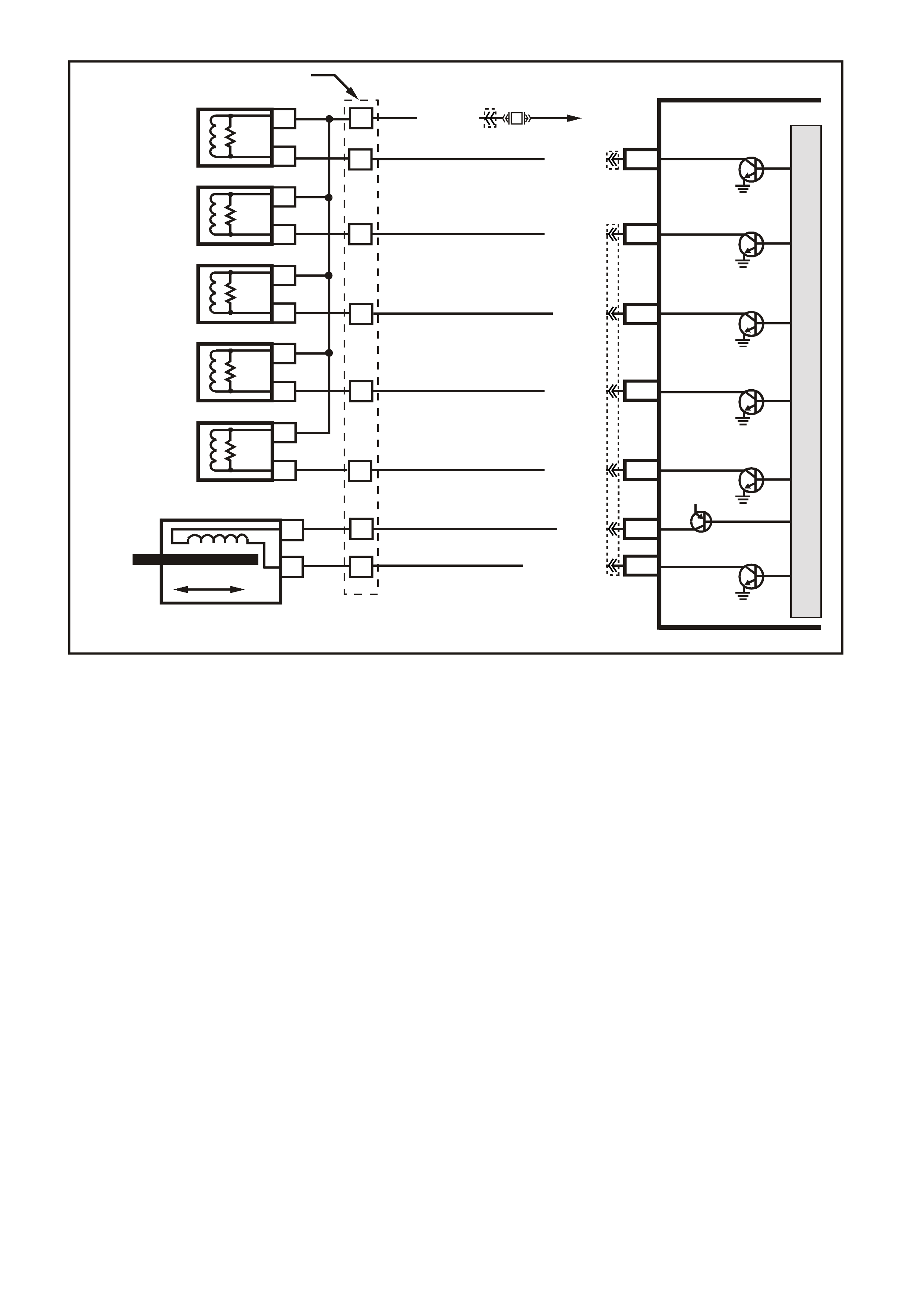

Figure 6C3-2A-18 Powertrain Control Schematics (12 of 12) – Transmission, Power/Economy Circuits

G3PCM050PT

PCM

J2-47

J2-48

J1-79

J2-42

J2-04

J2-08

J2-06

TCC PWM

SOLENOID

3-2 CONTROL

SOLENOID

1-2 SHIFT

SOLENOID A

2-3 SHIFT

SOLENOID B

PRESSURE

CONTROL

SOLENOID

LOW

PRESSURE CONTROL

SOLENOID HIGH

B

A

A

B

B

B

A

A

B

A

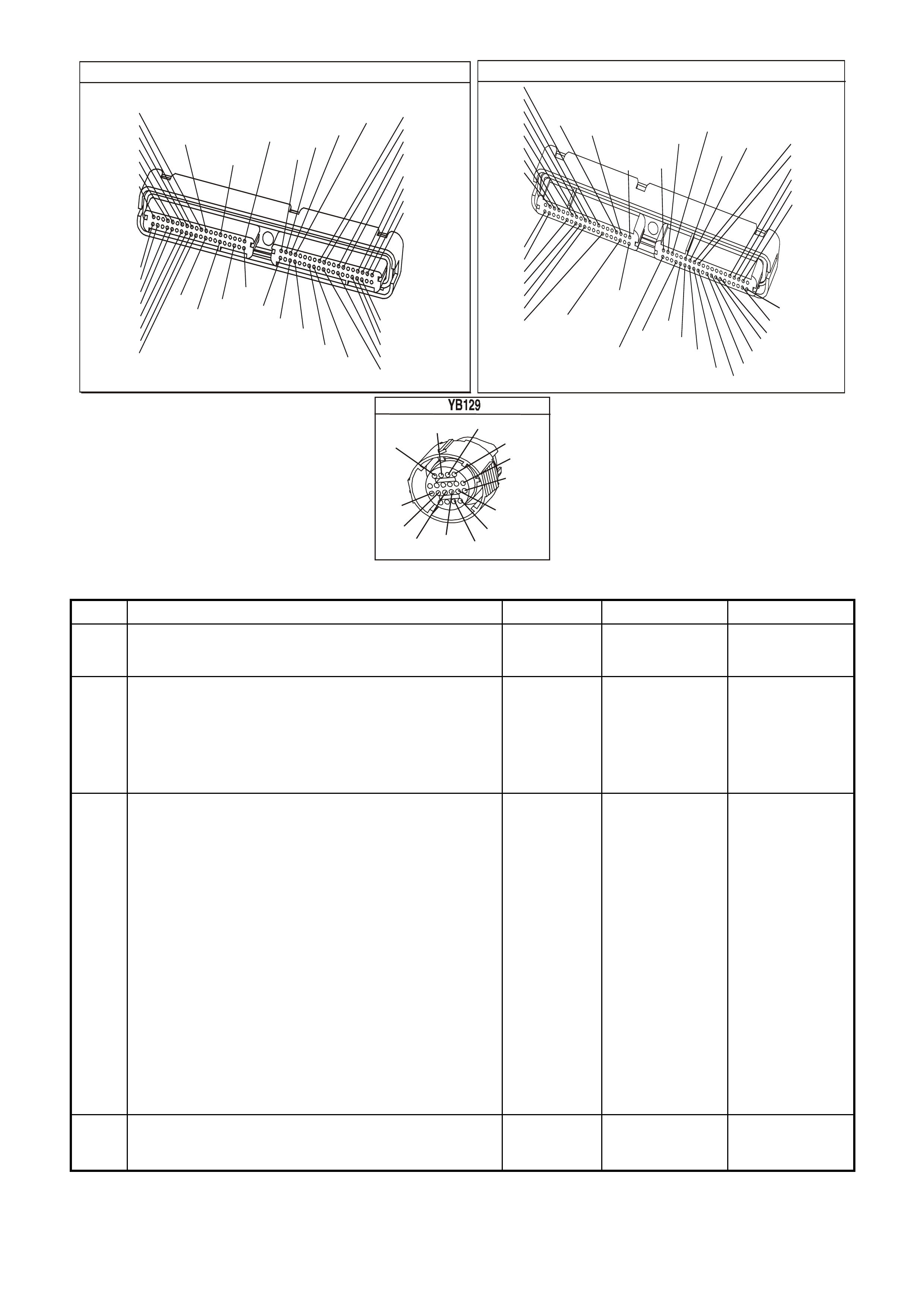

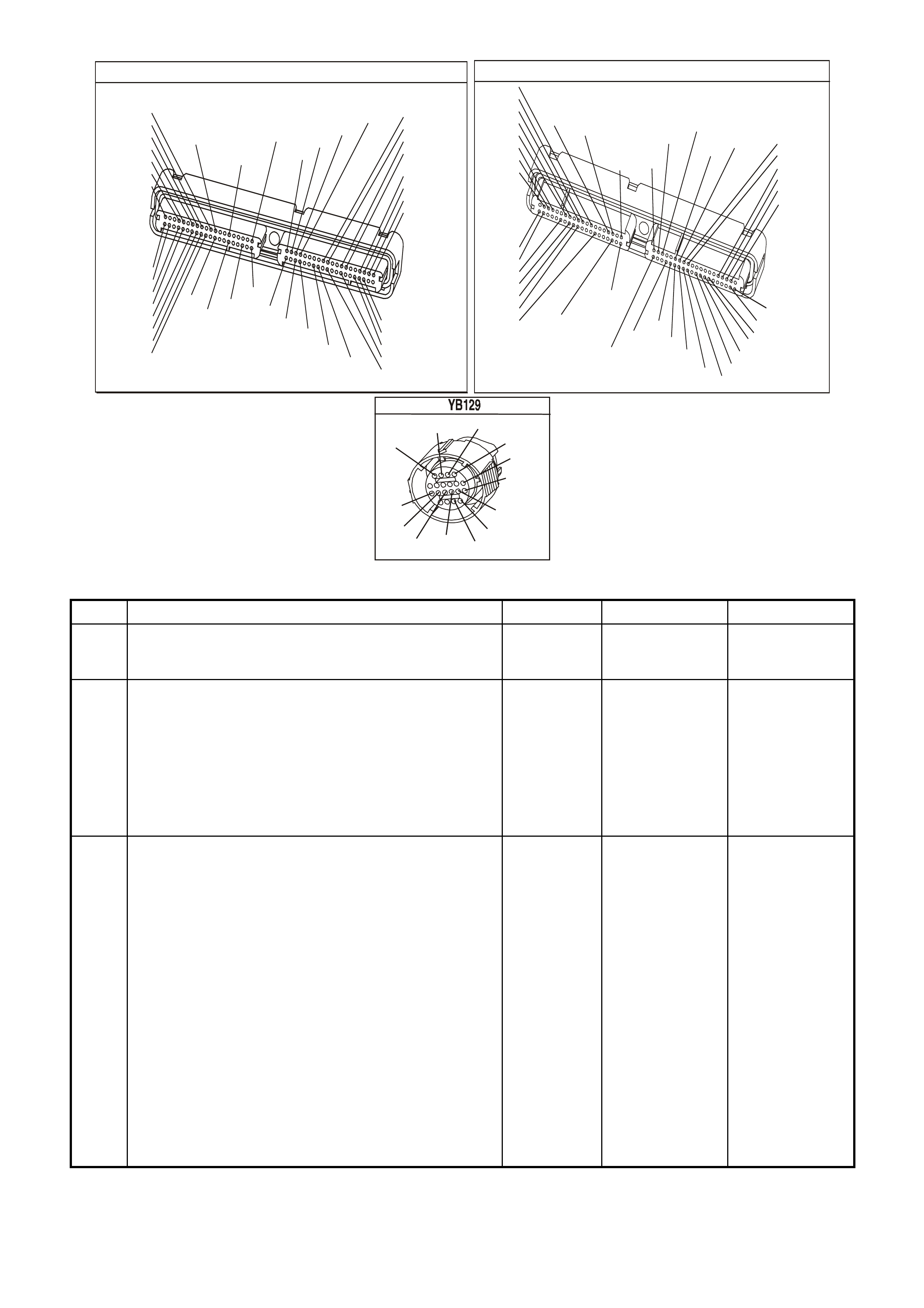

YB 129 TRANS MISSION

PASS-THRU CONNECTOR

TORQUE

CONVERTER

CLUTCH (TCC)

(PWM)

SOLENOID

TORQUE

CONVERTER

CLUTCH (TCC)

ENABLE

SOLENOID

3-2 DOWNSHIFT

CONTROL

SOLENOID

1-2 SHIFT

SOLENOID A

2-3 SHIFT

SOLENOID B

PRESSURE

CONTROL

SOLENOID

C

D

U

S

T

E

A

B

P/BLU (339)

J2-63

J1-17

J1-18

J1-53

TFP SIGNAL A

TFP SIGNAL B

TFP SIGNAL C

TRANSMISSION FLUID

TEMPERATURE (TFT)

SENSOR SIGNAL

SENSOR

EARTH

N

C

R

E

DP

TRANSMISSION FLUID

TEMPERATURE

(TF T ) SENSOR

AUTOMATIC TRANSMISSION FLUID PRESSURE

MANUAL VALVE POSITION SWITCH (TFP)

J1-71 POWER/ECONOMY

SWITCH

POWER/ECONOMY

SWITCH

TCC ENABLE

SOLENOID

B

A

EFI

RELAY

F32

G/W (897)

LG (1222)

Y/B (1223)

GY/BLU (1229)

R (1228)

BR/Y (1224)

Y (1225)

GY (1226)

J2-51

A

B

L

M

B/Y (1227)

B/W (1230)

12V

12V

12V

12V

12V

12V

12V

12V

12V

5V

M

I

C

R

O

P

R

O

C

E

S

S

O

R

J1-32

J1-72

A

SWITCH P

SWITCH A

SWITCH B

SWITCH C

LOC. E5/E15 LOC. E3

D

B

C

P R N D L SWITCH

J2-62

J1-34

BLU/W (771)

Y (77 2)

GY (773)

W (776)

B/R (750)

RANGE

SIGNAL P

RANGE

SIGNAL A

RANGE

SIGNAL B

RANGE

SIGNAL C

BLU (774)

B/G (151)

BR (418)

GY/R (422)

YB30

YB20

YE114

YB35 YB34

YB30

YE112

YE122

YE123

YE123

YE123

YE122

YE122

YE122

YE123

YB34

YE110

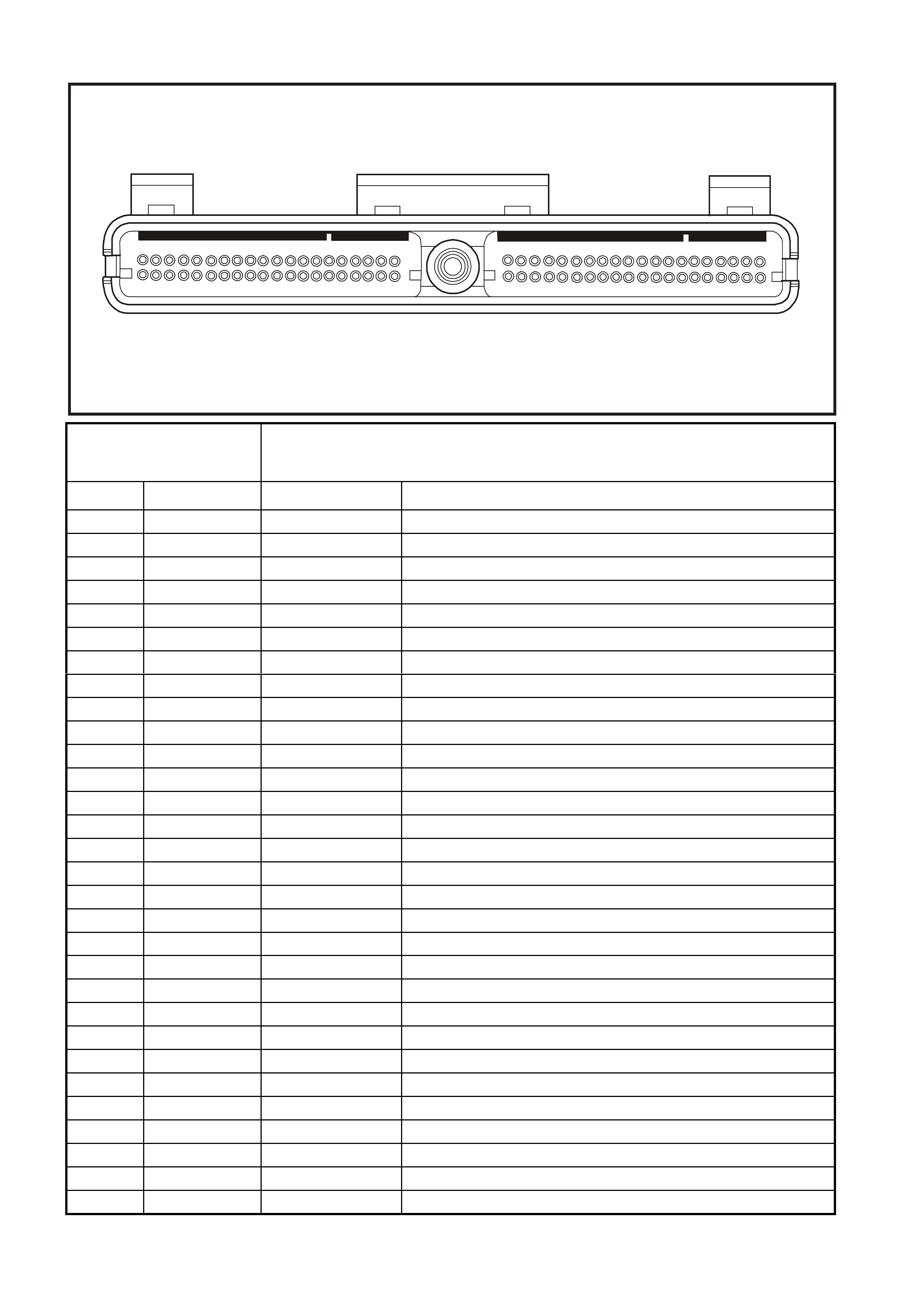

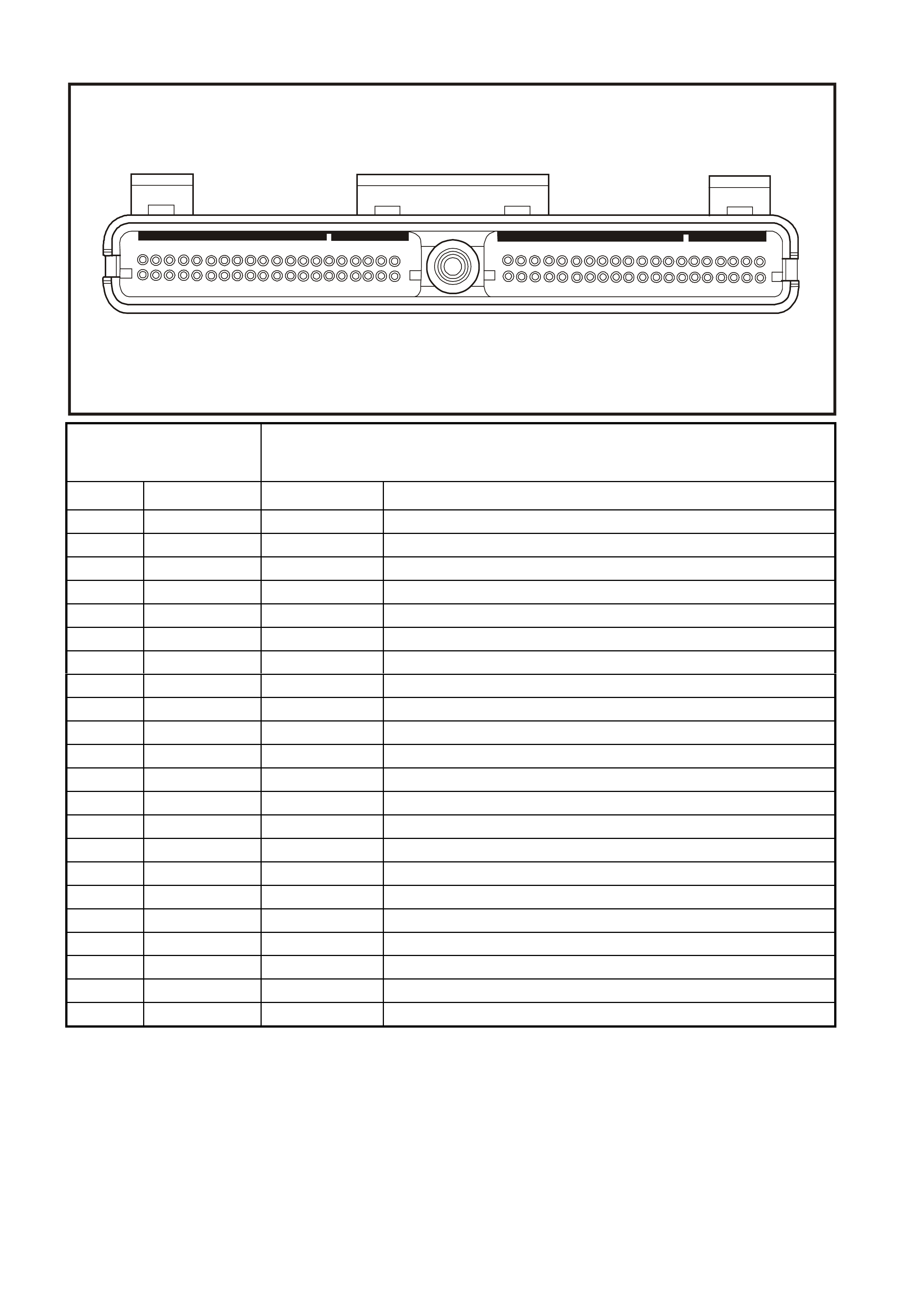

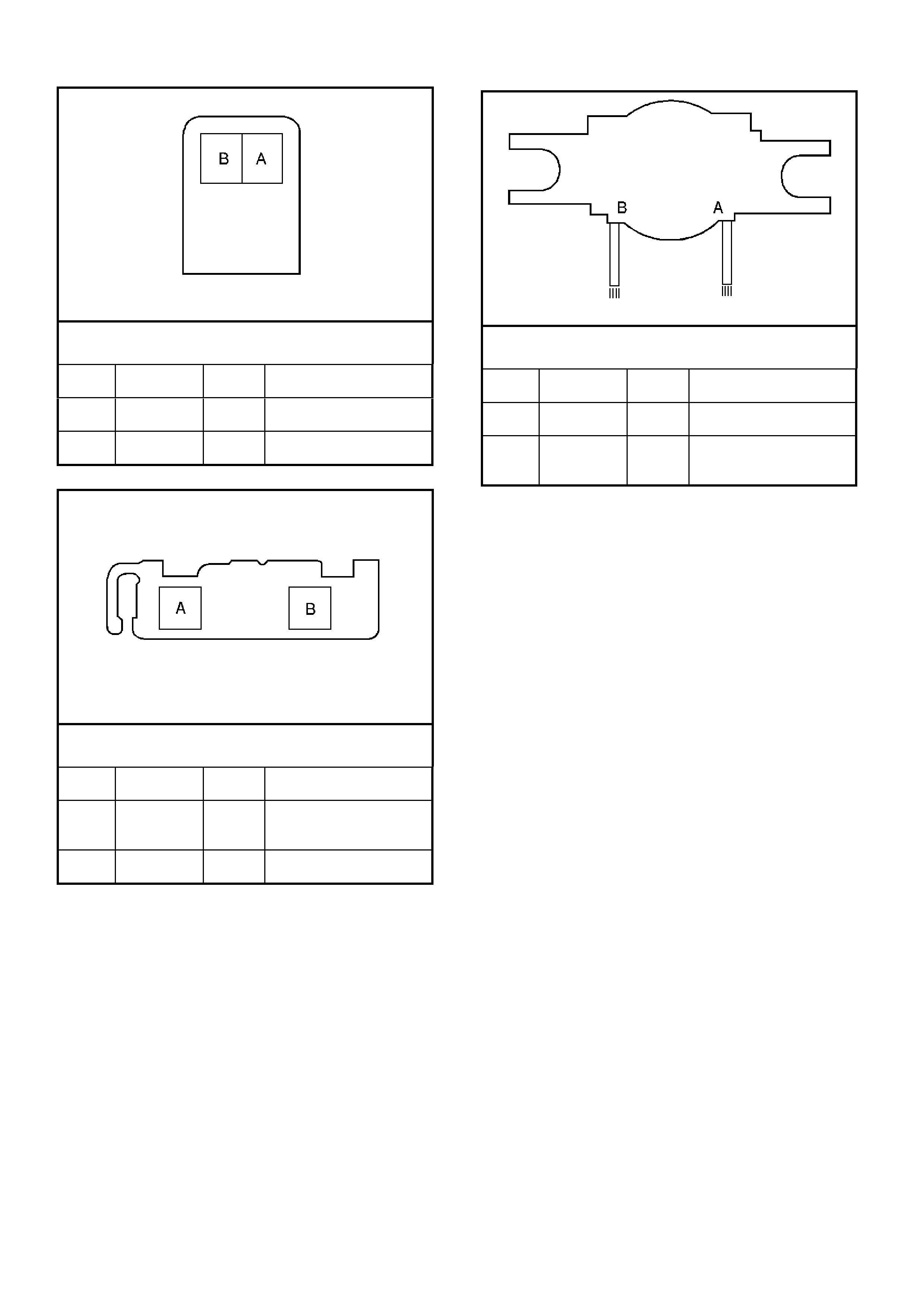

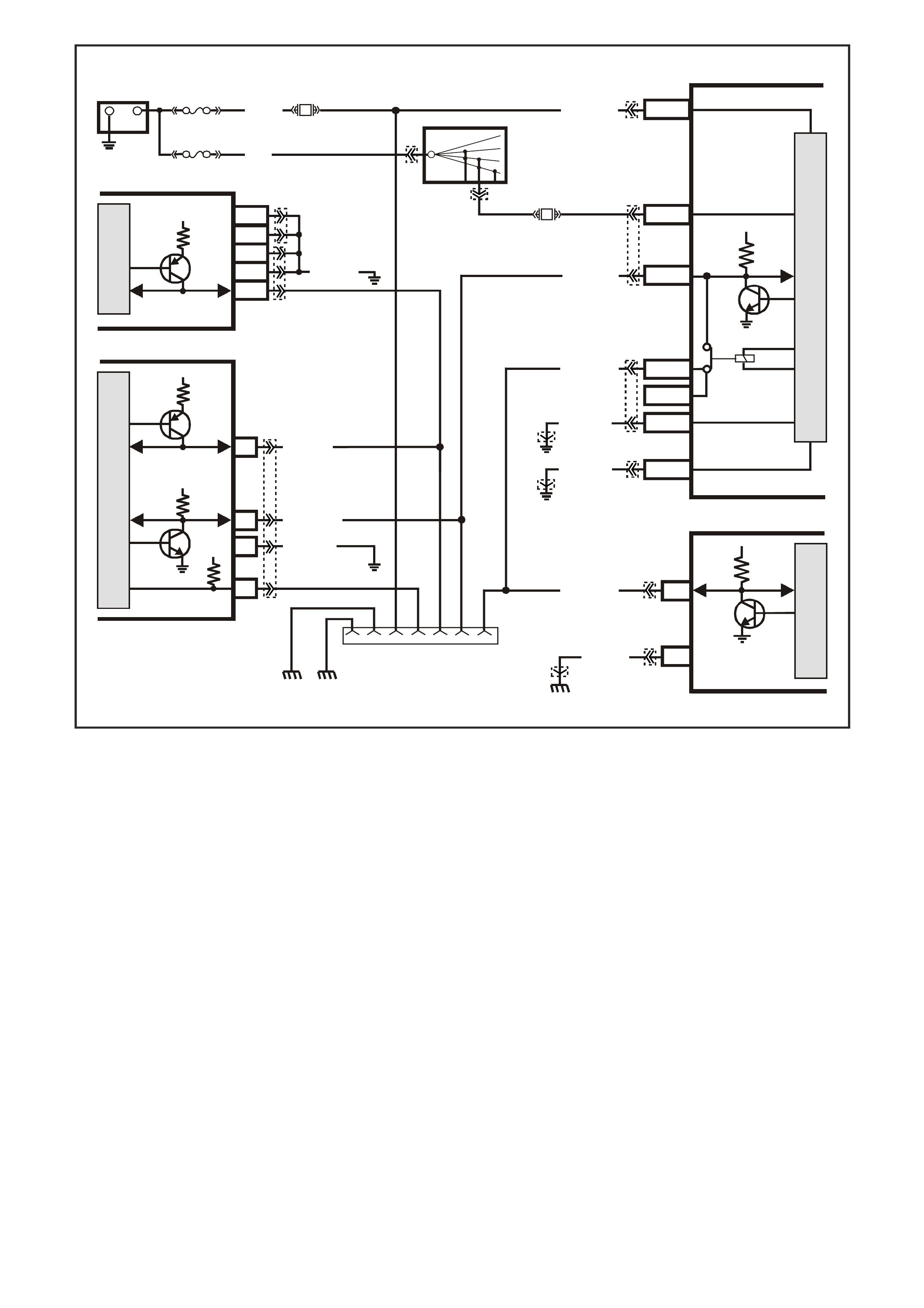

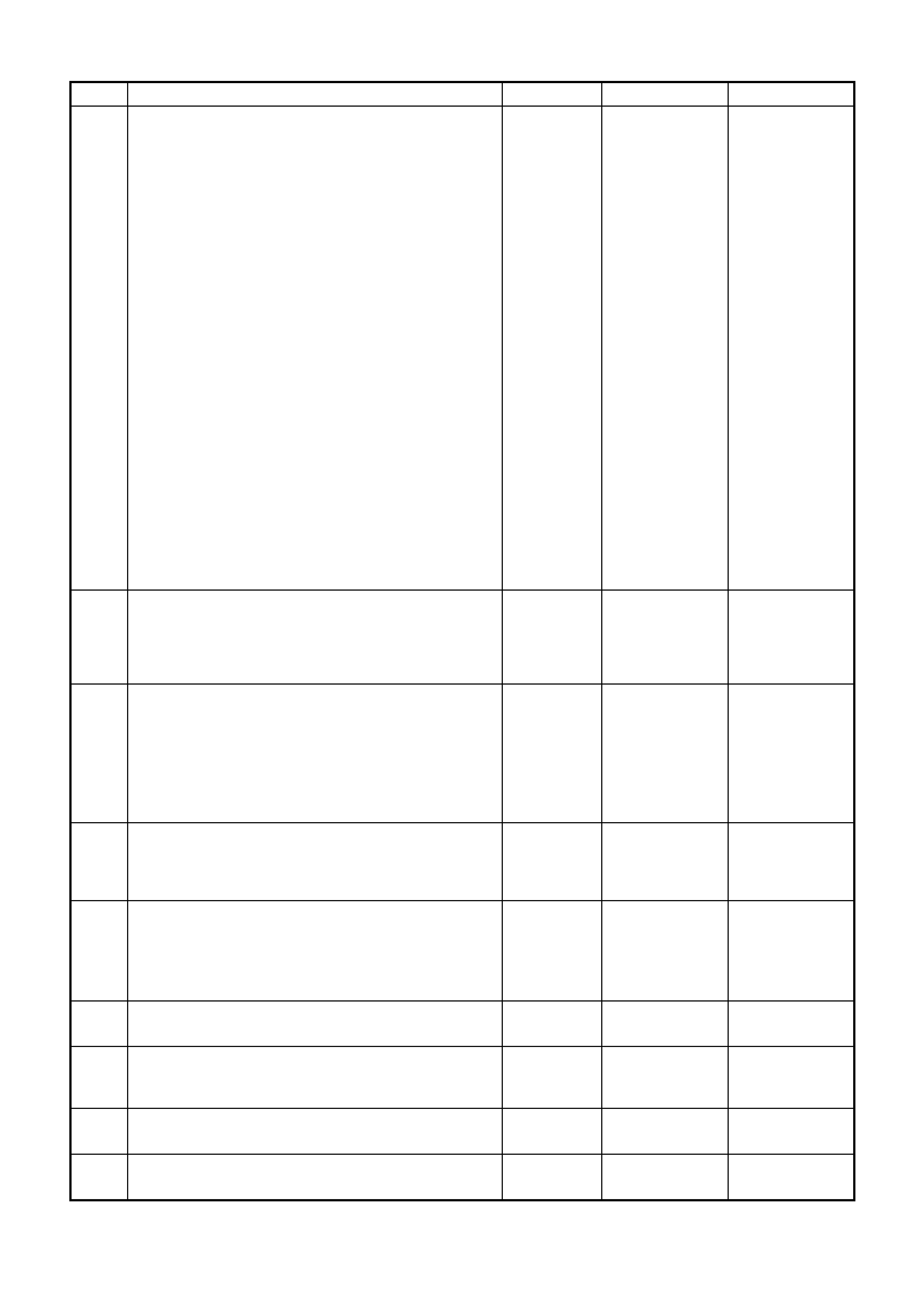

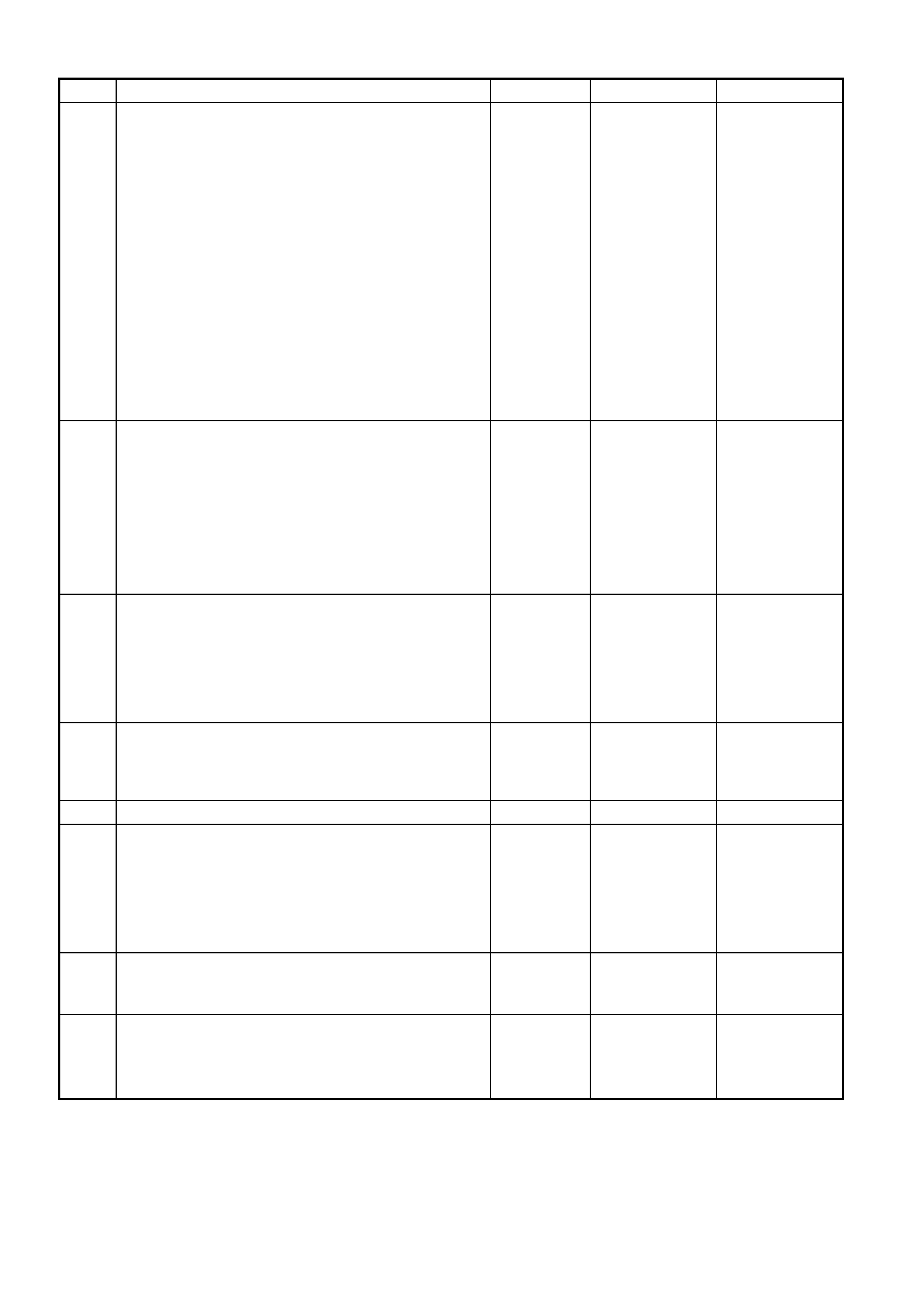

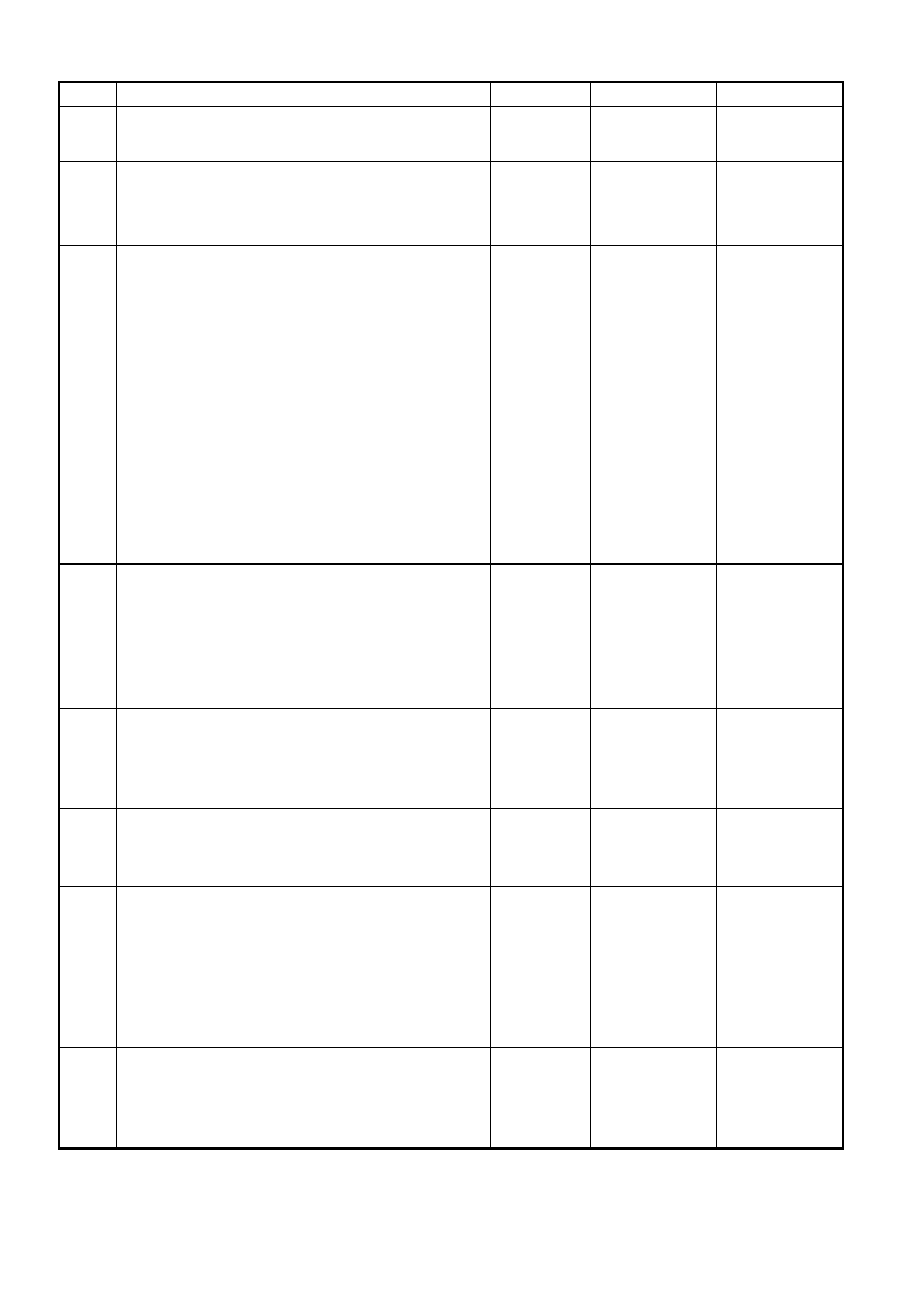

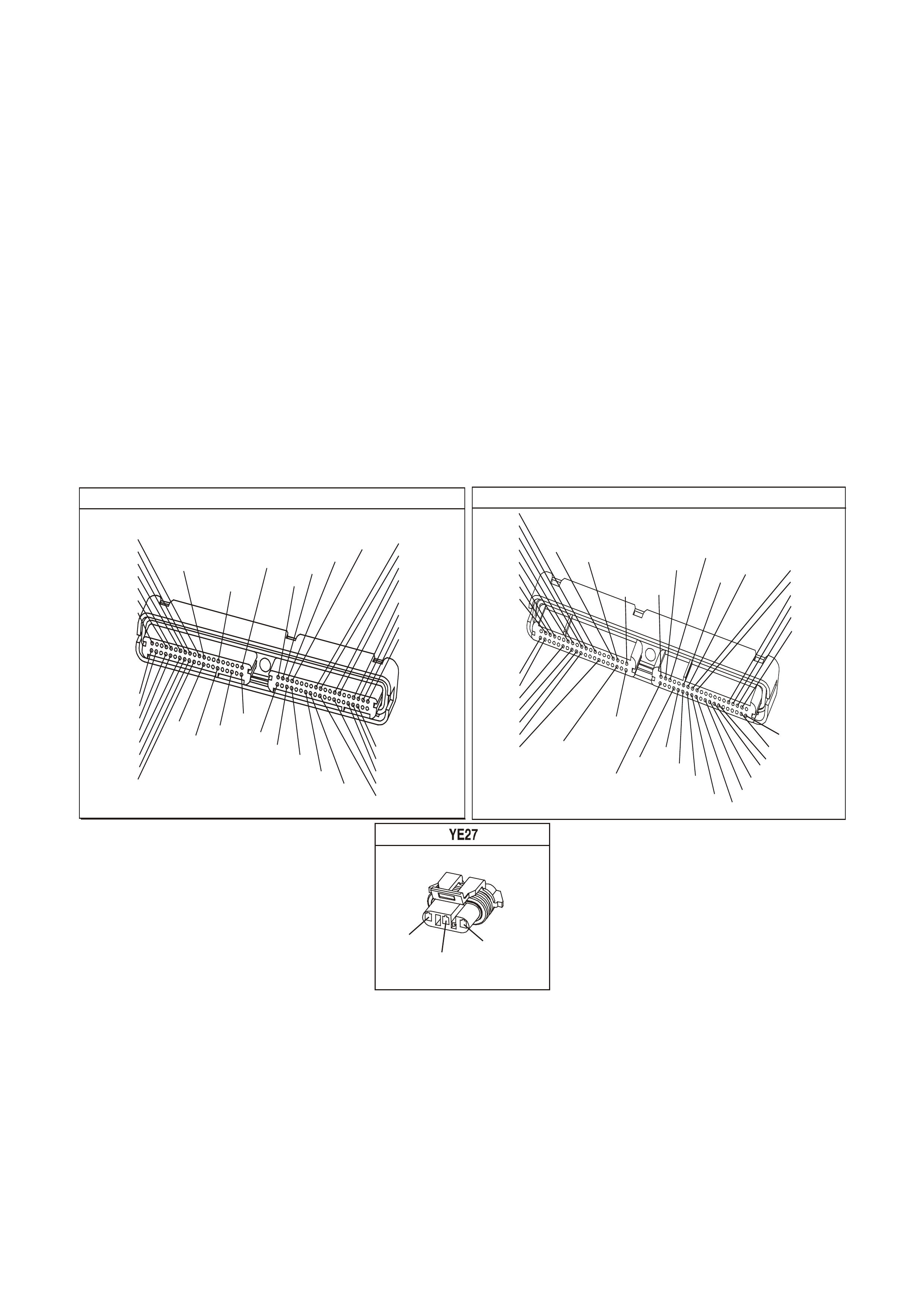

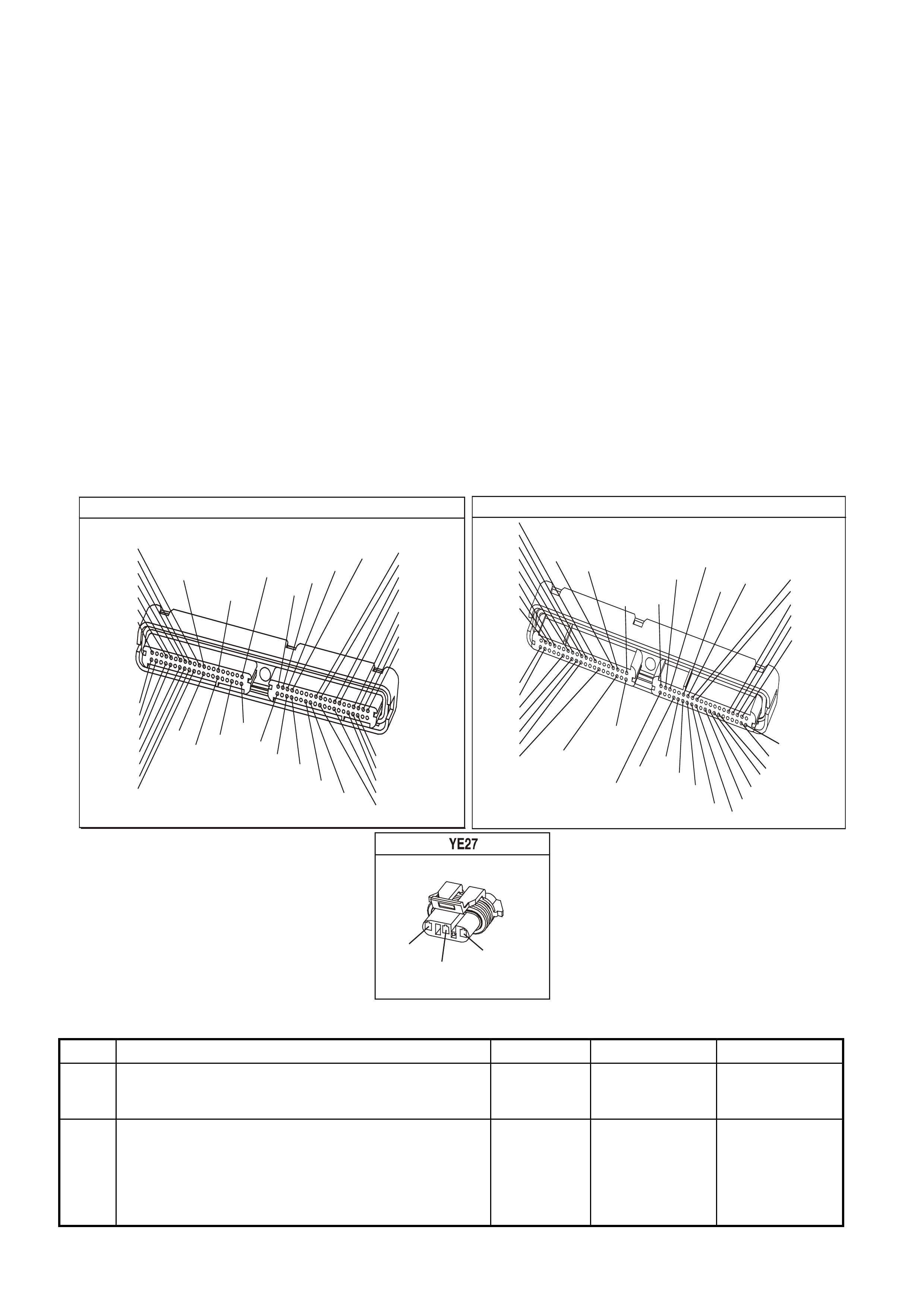

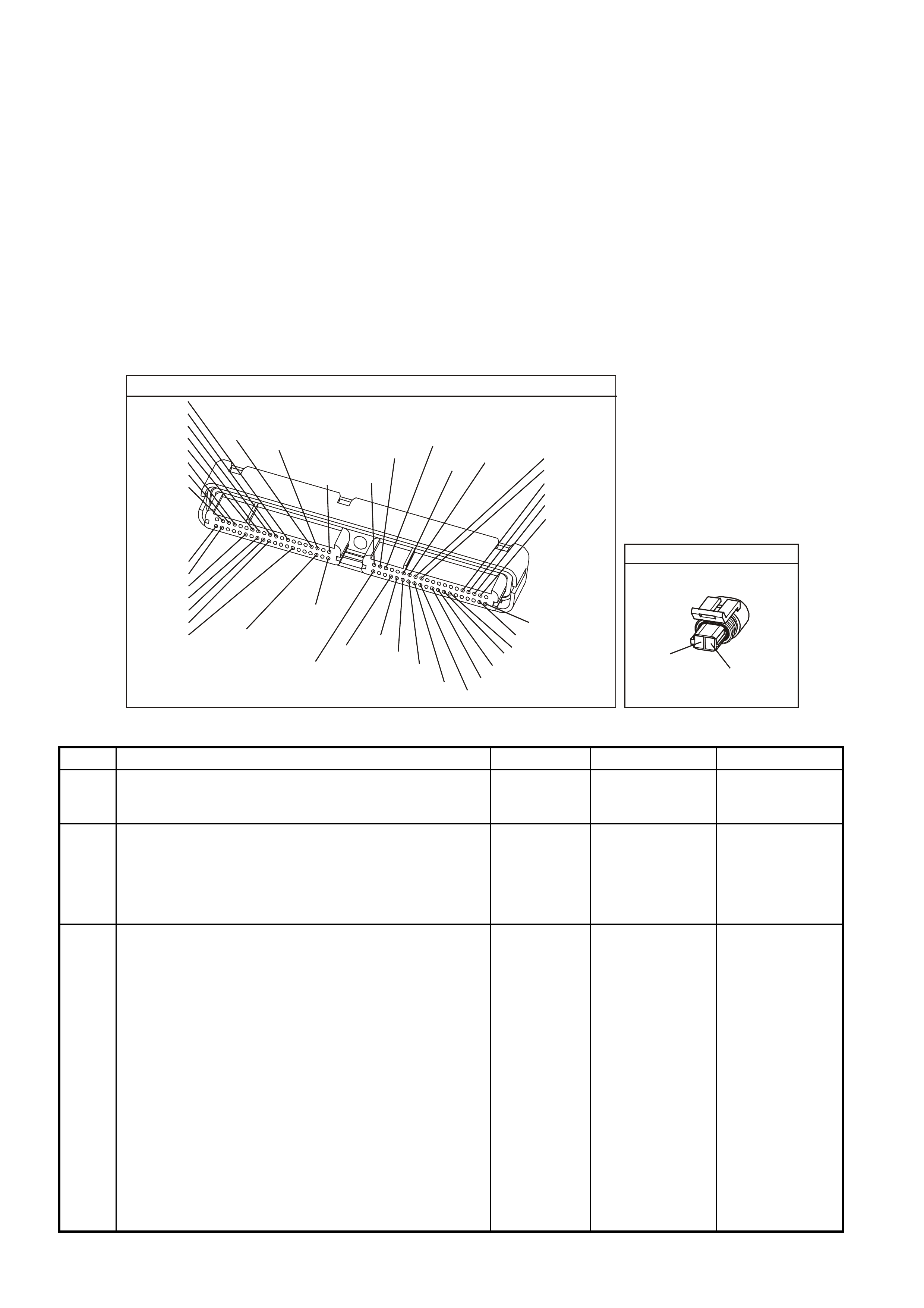

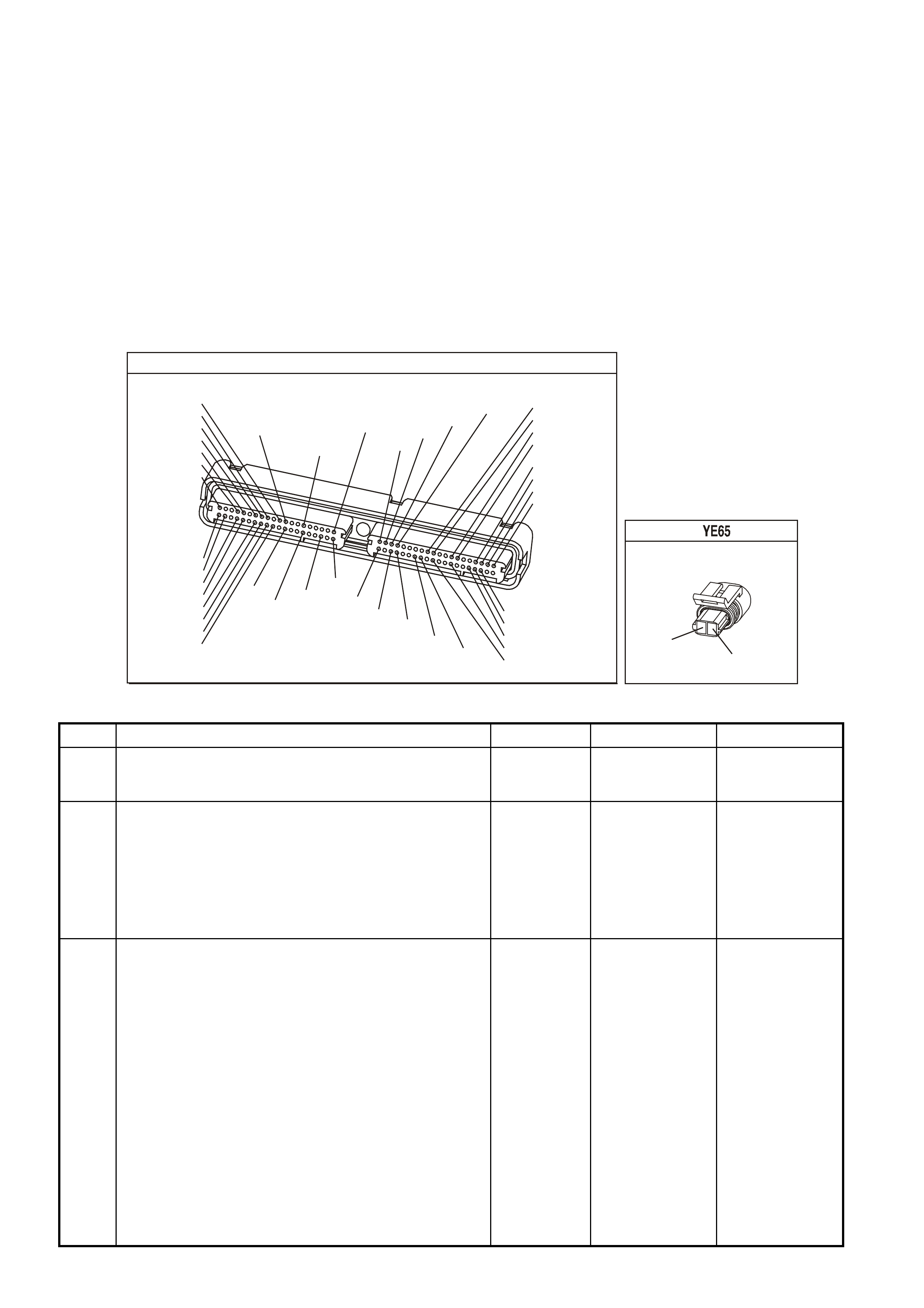

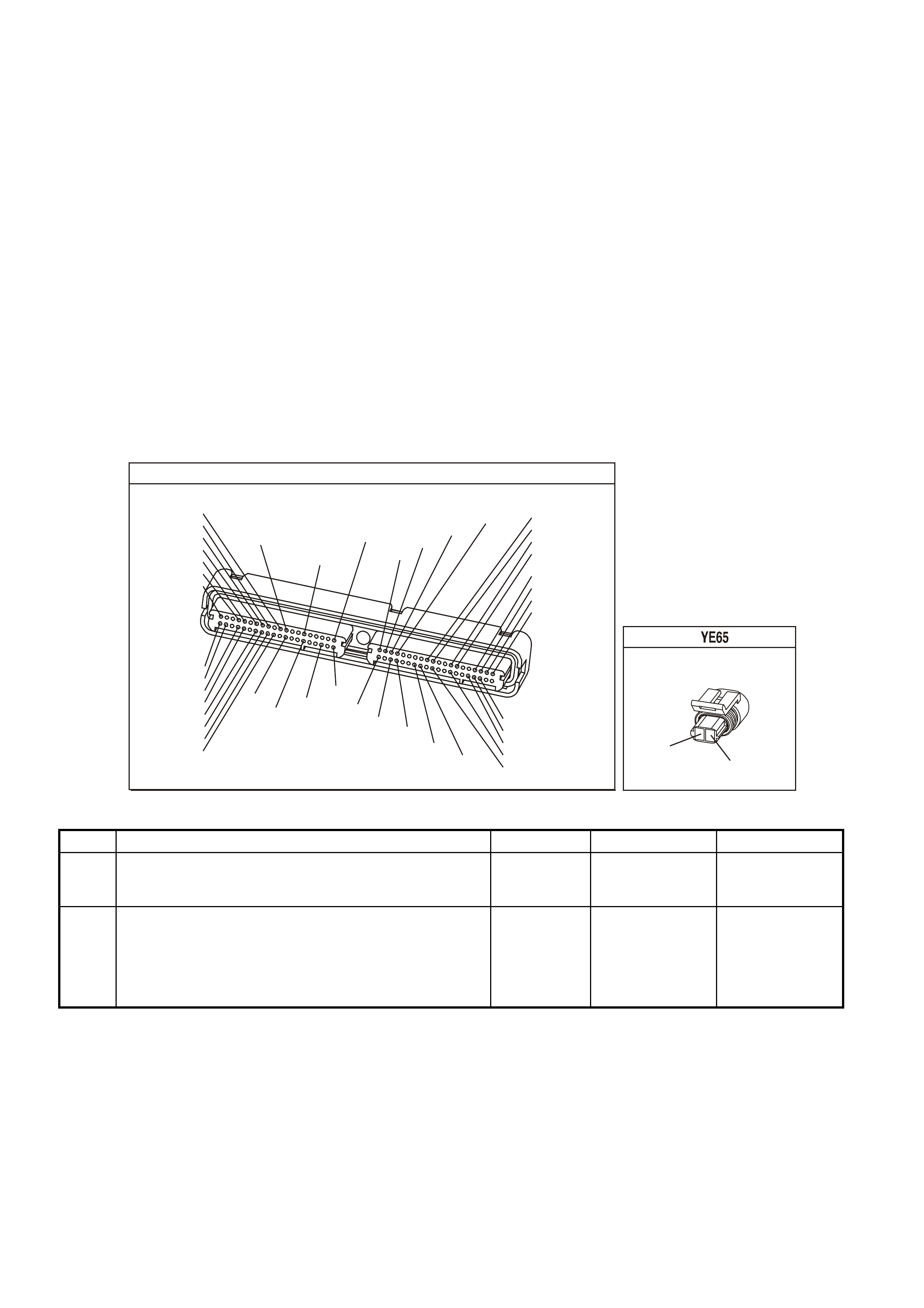

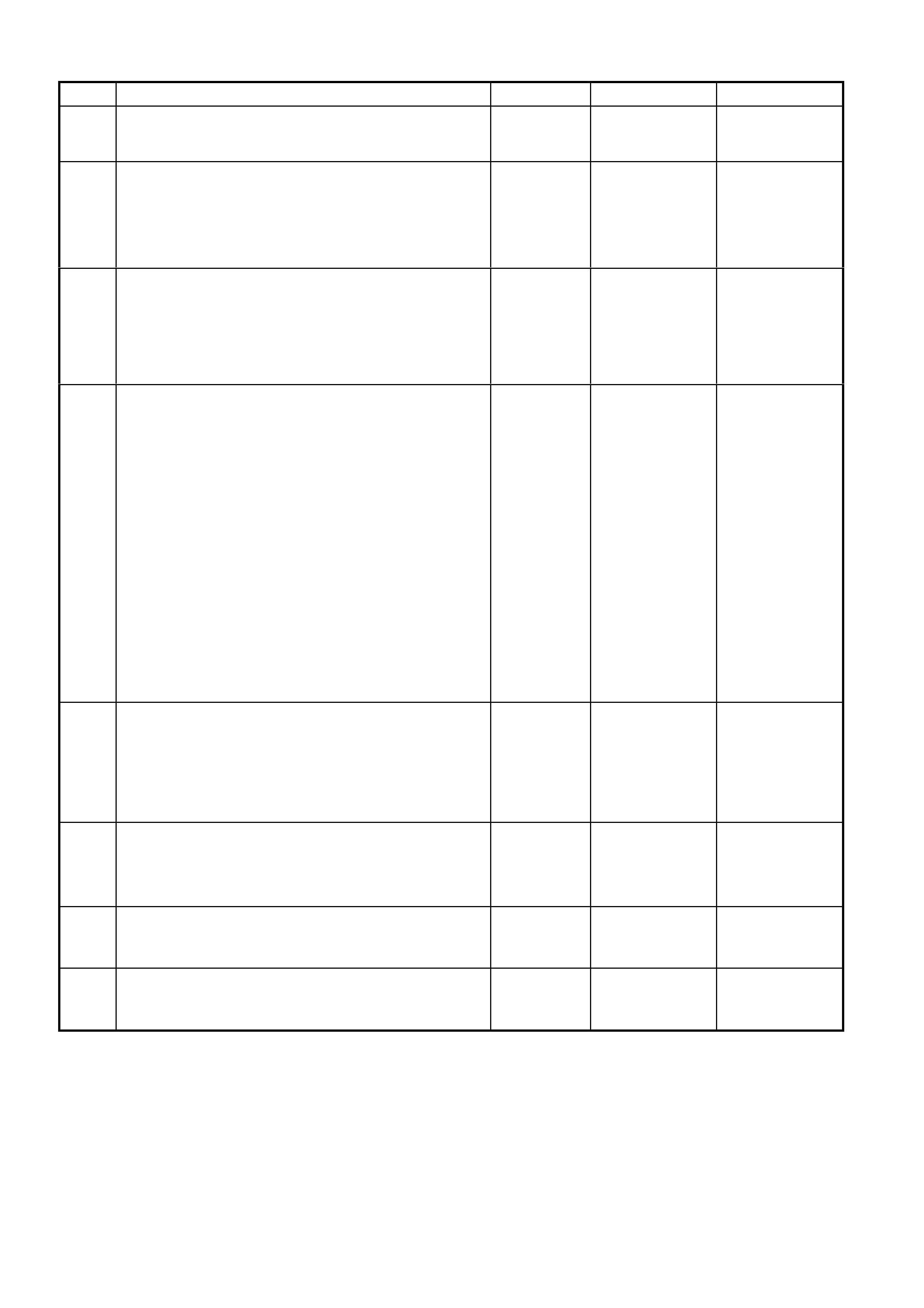

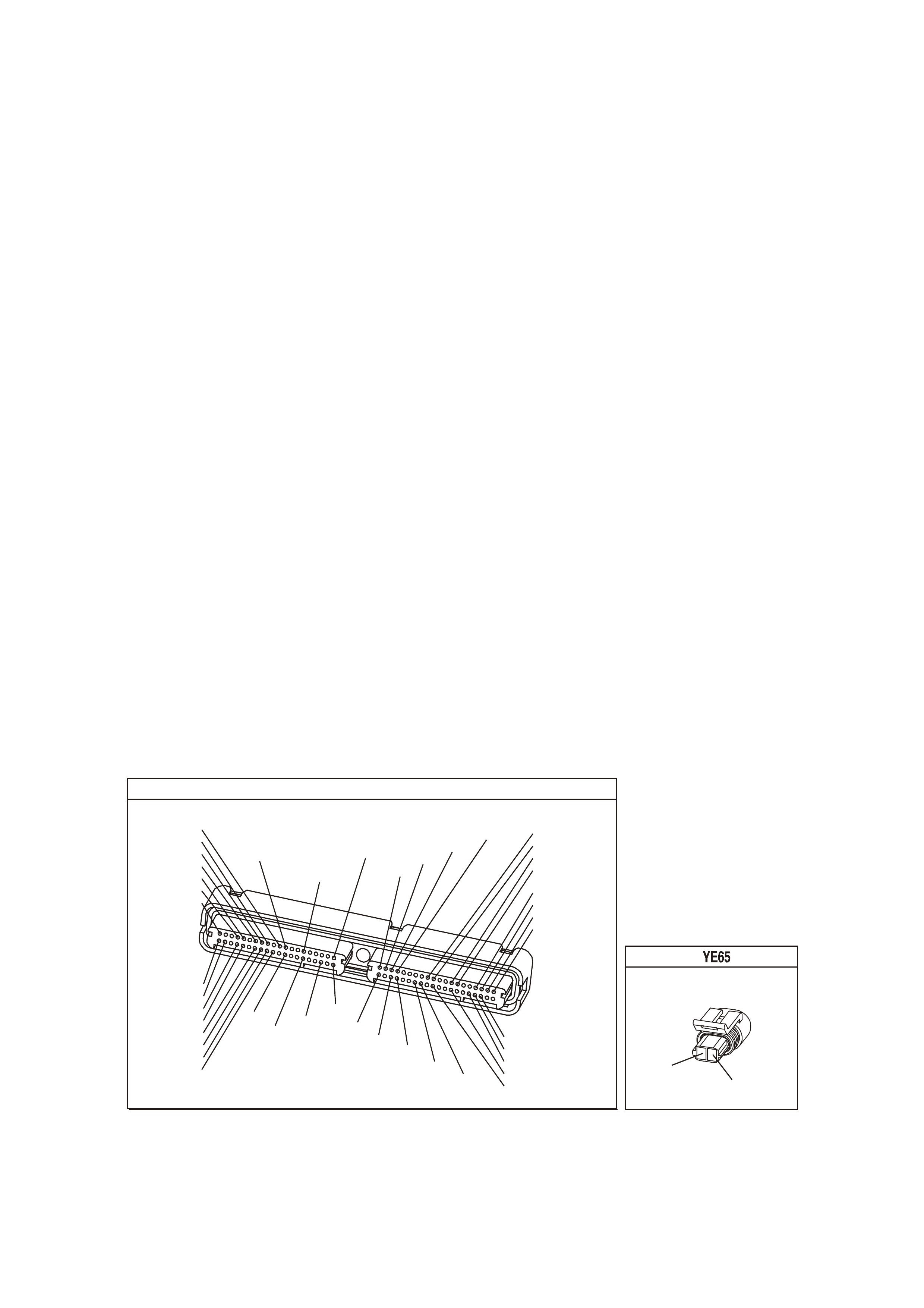

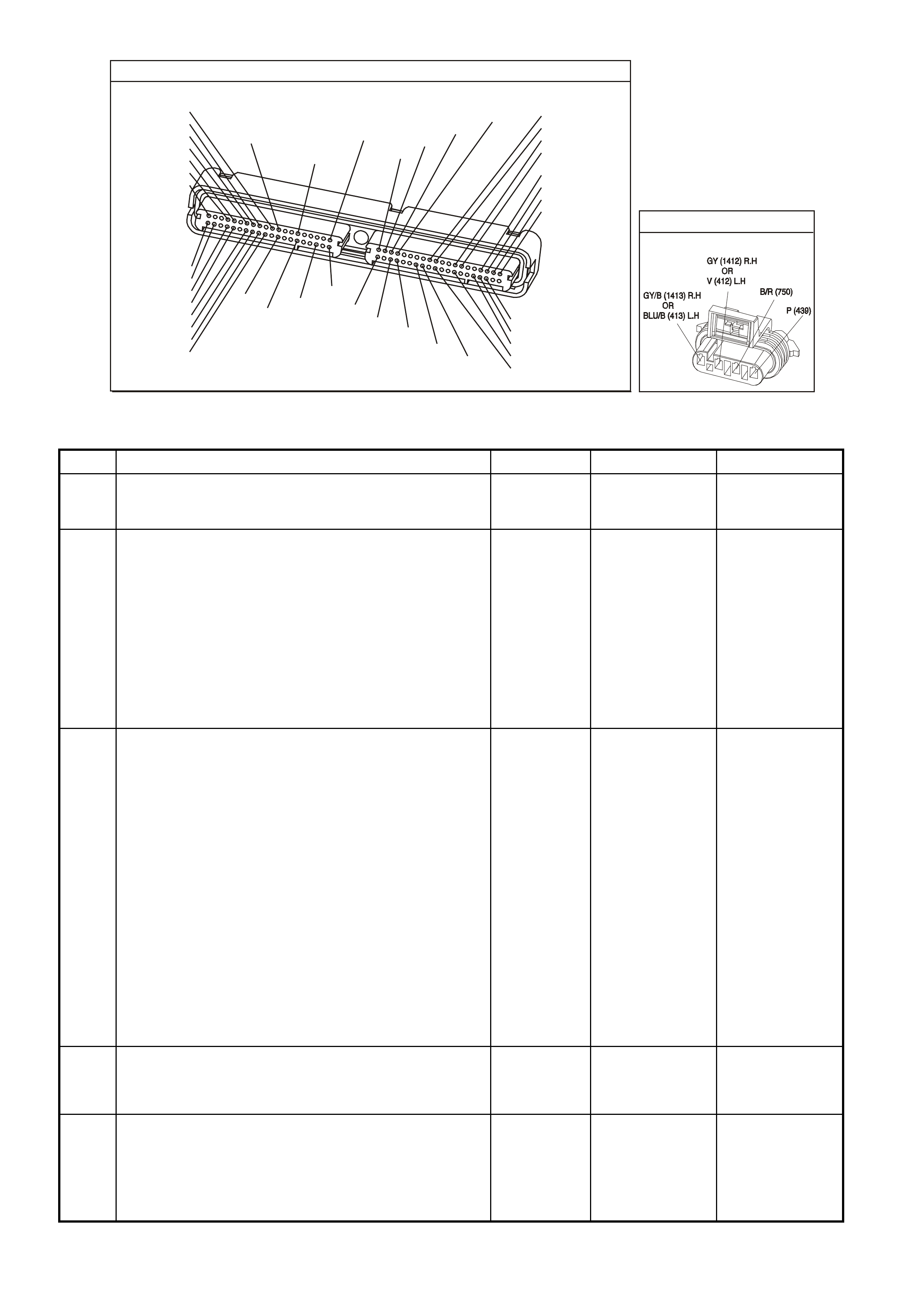

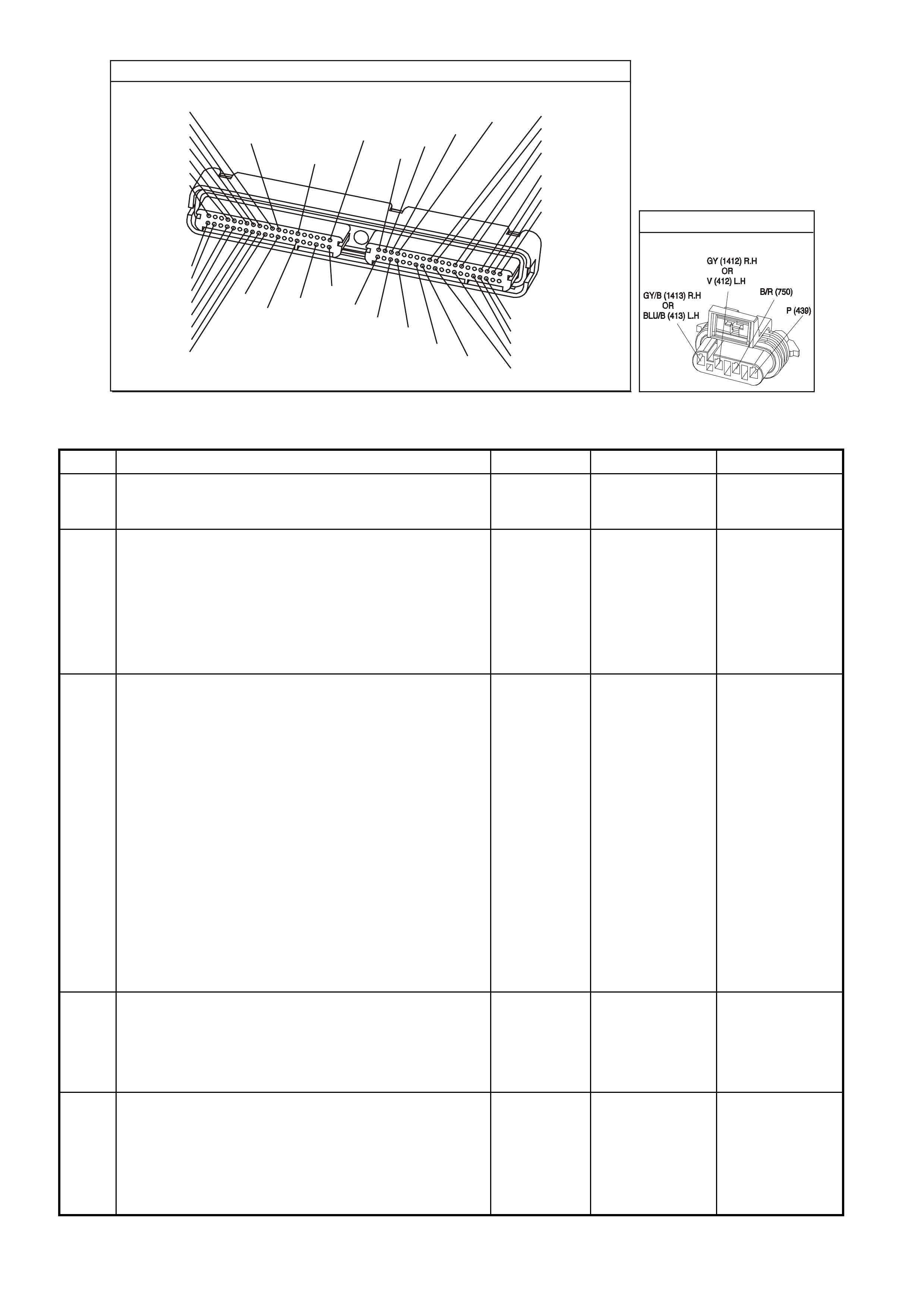

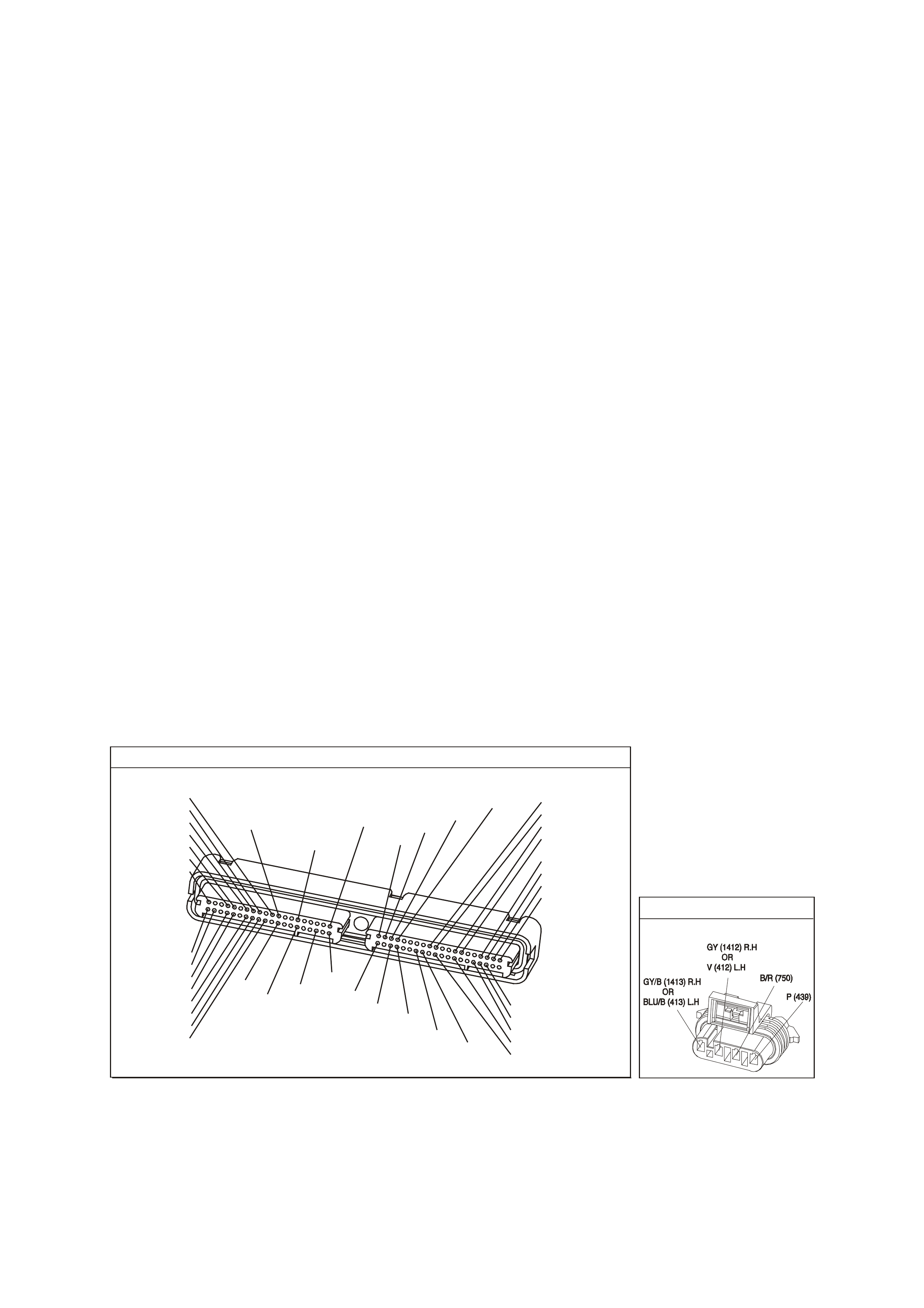

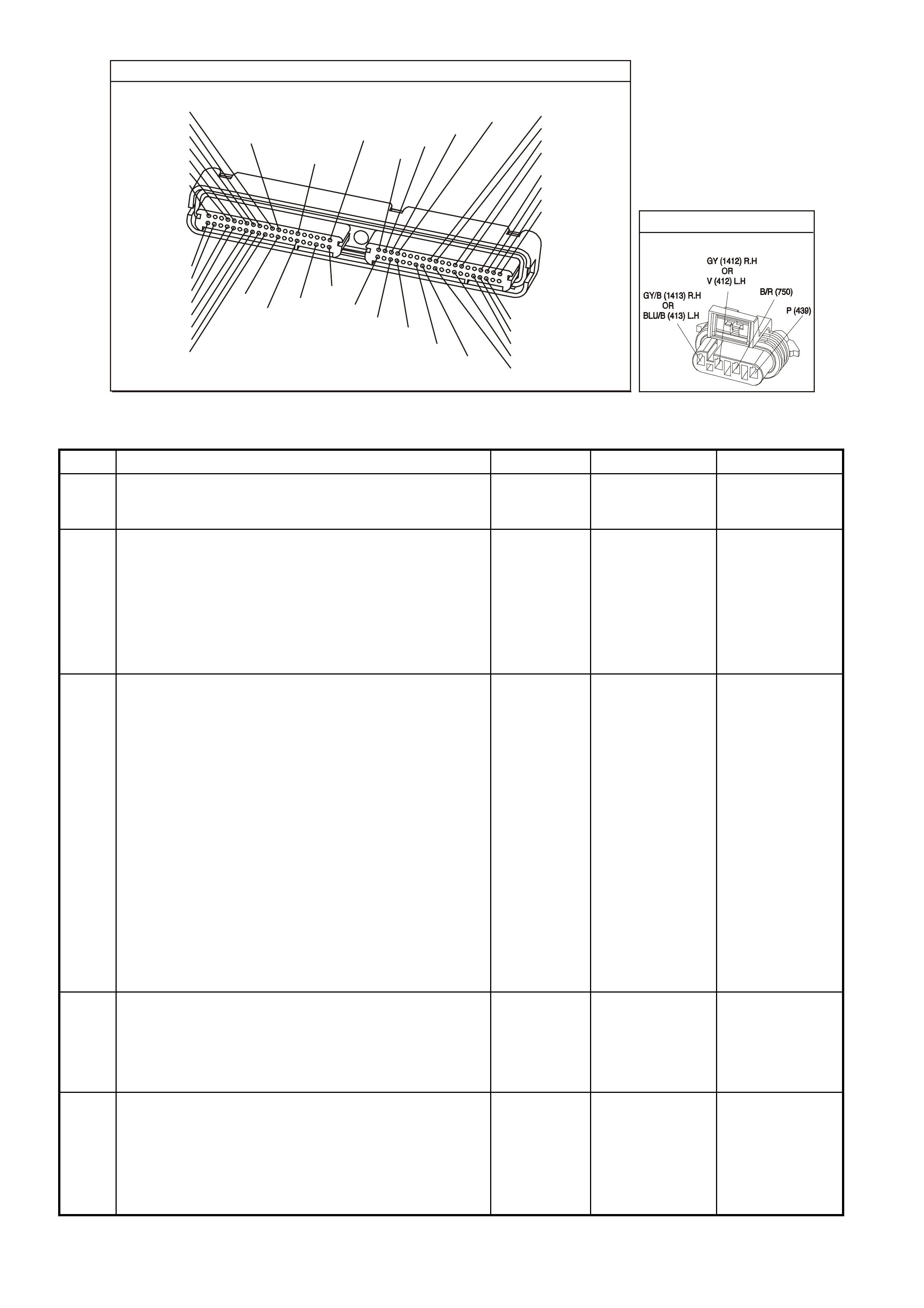

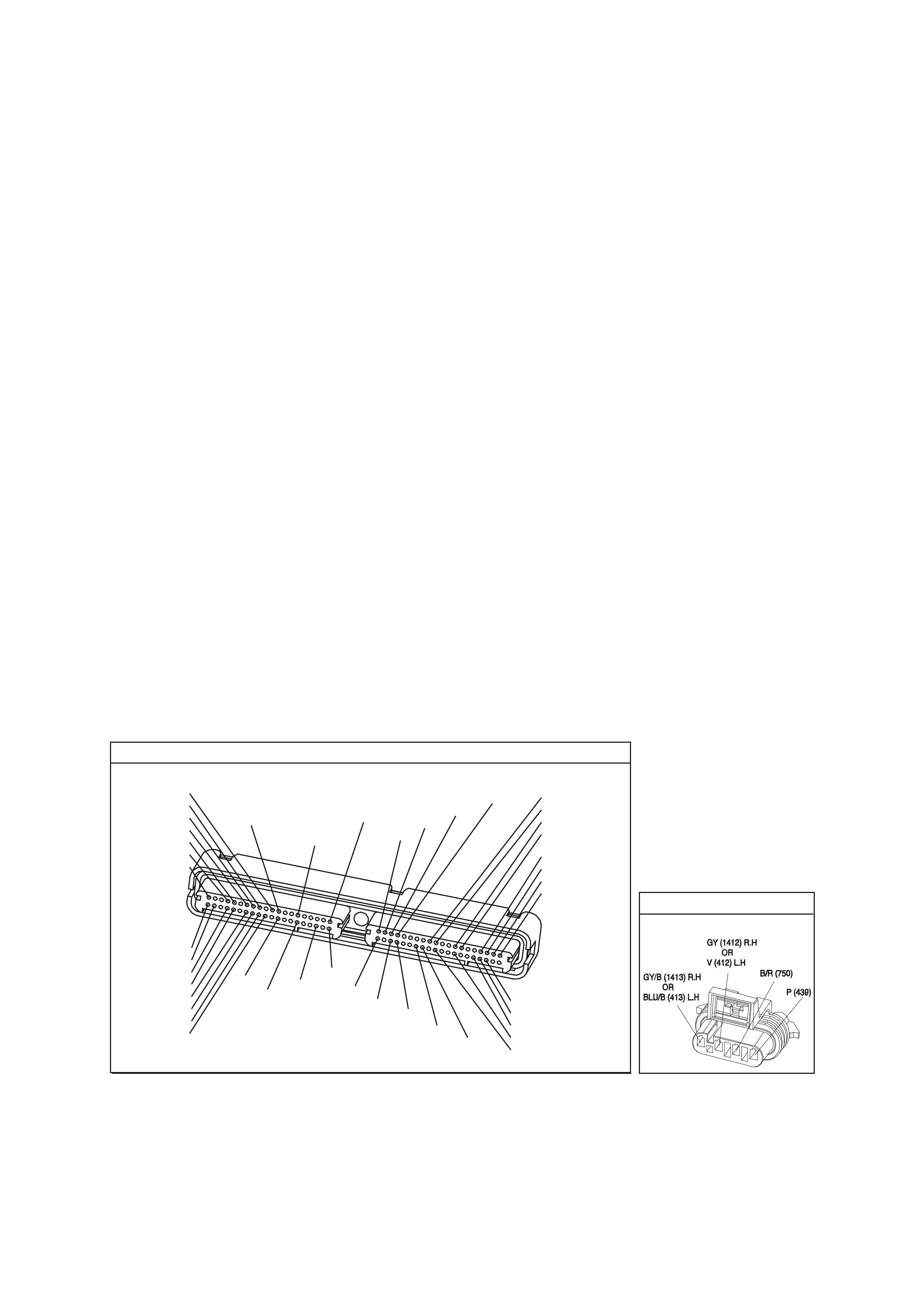

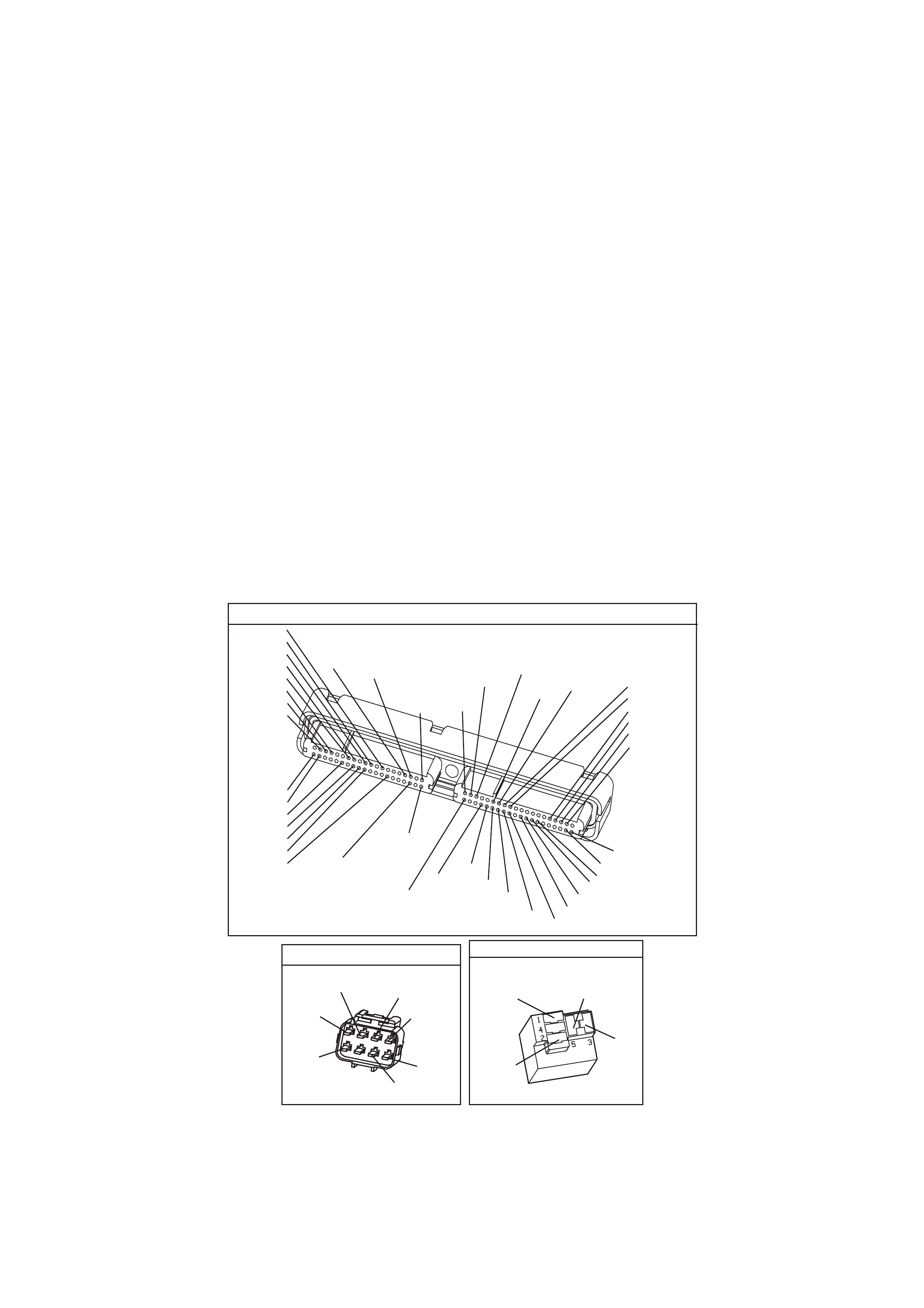

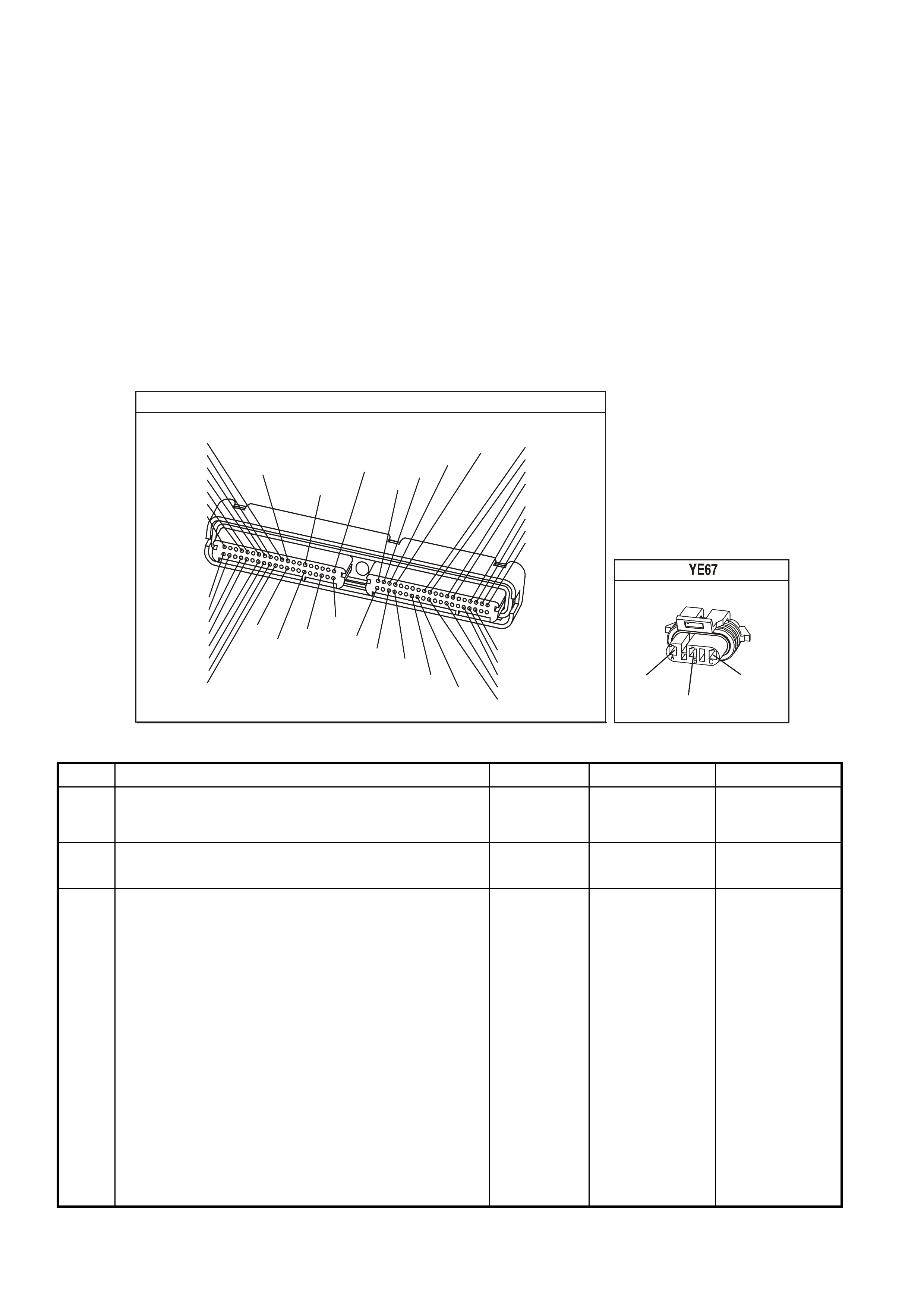

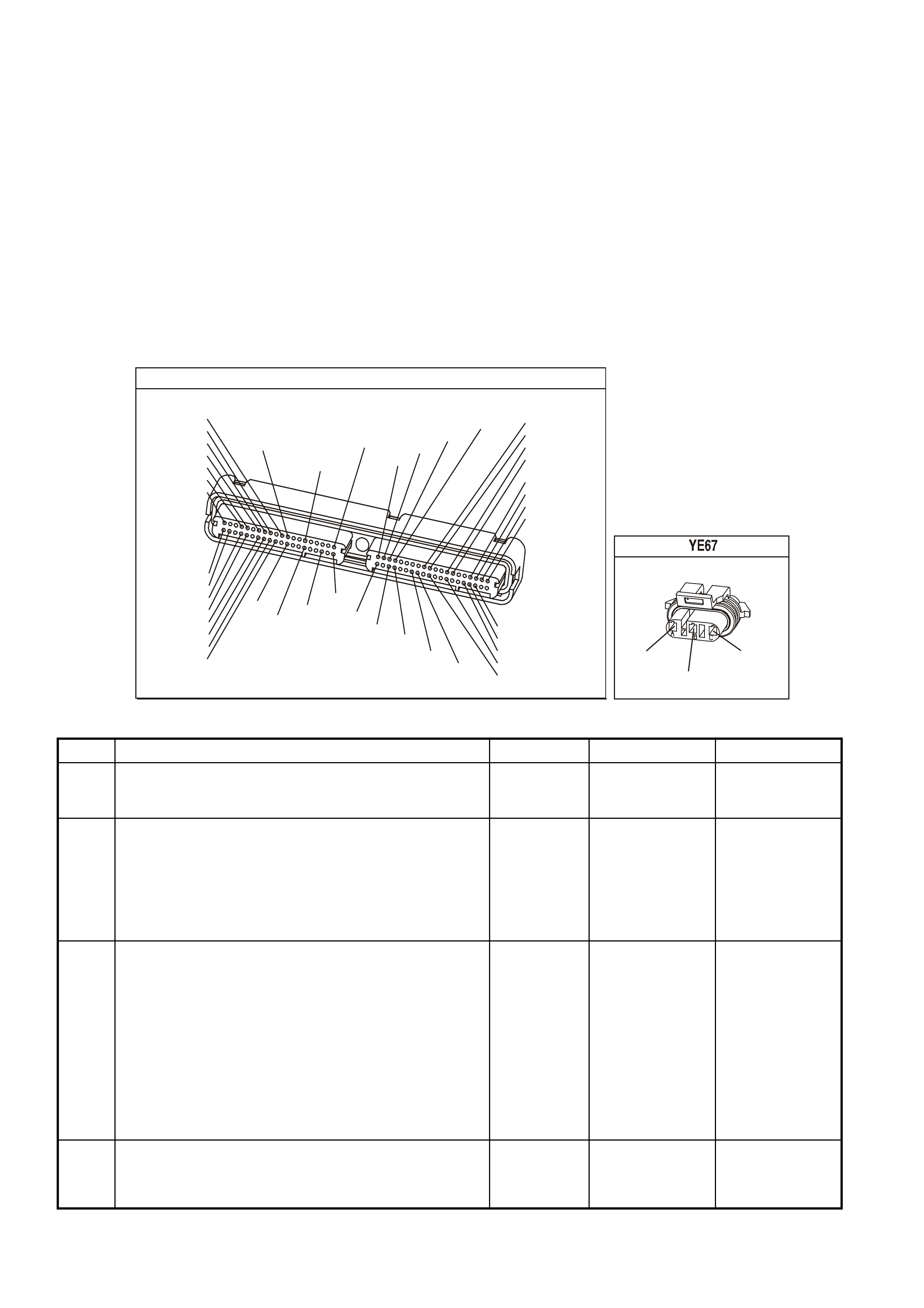

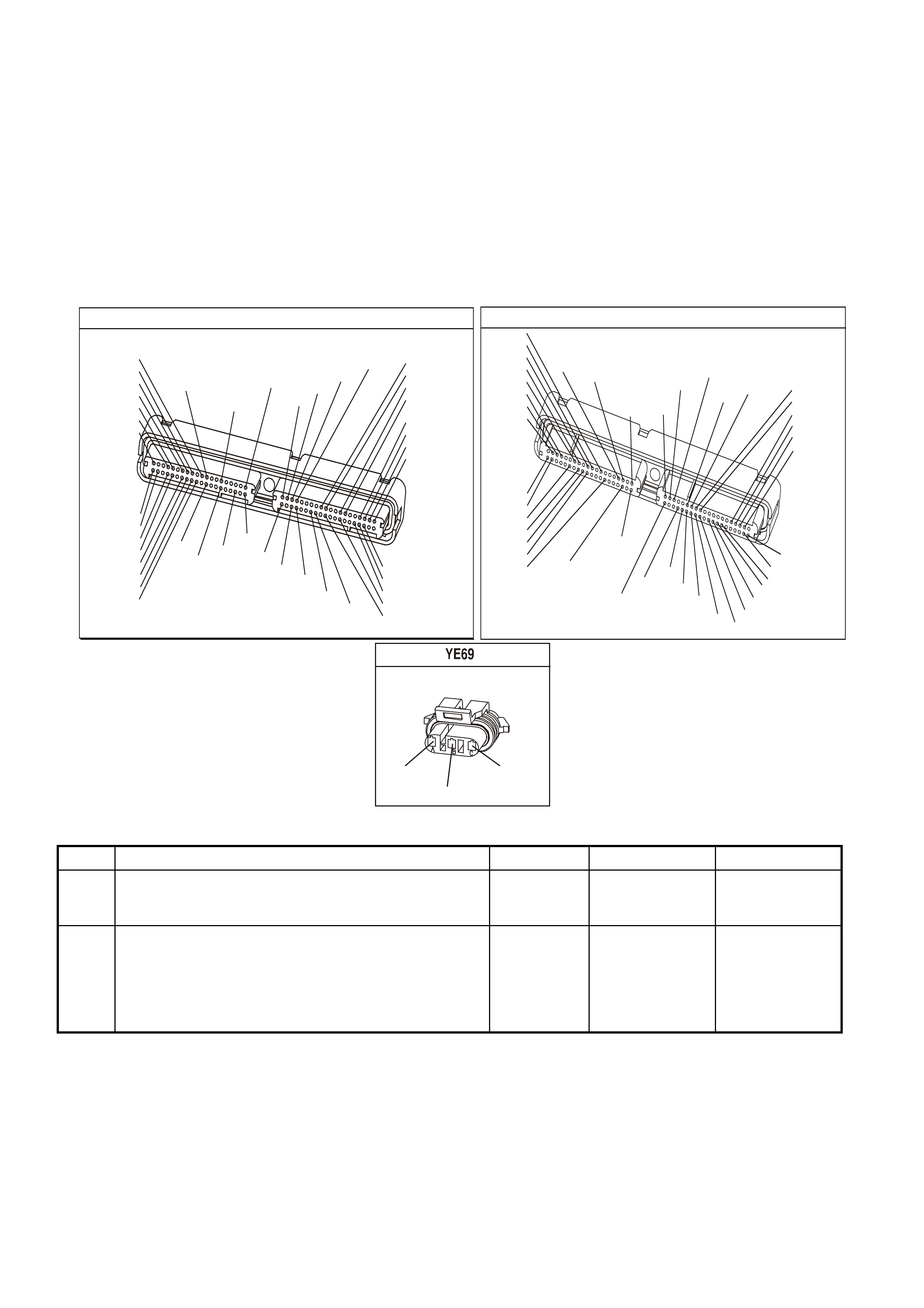

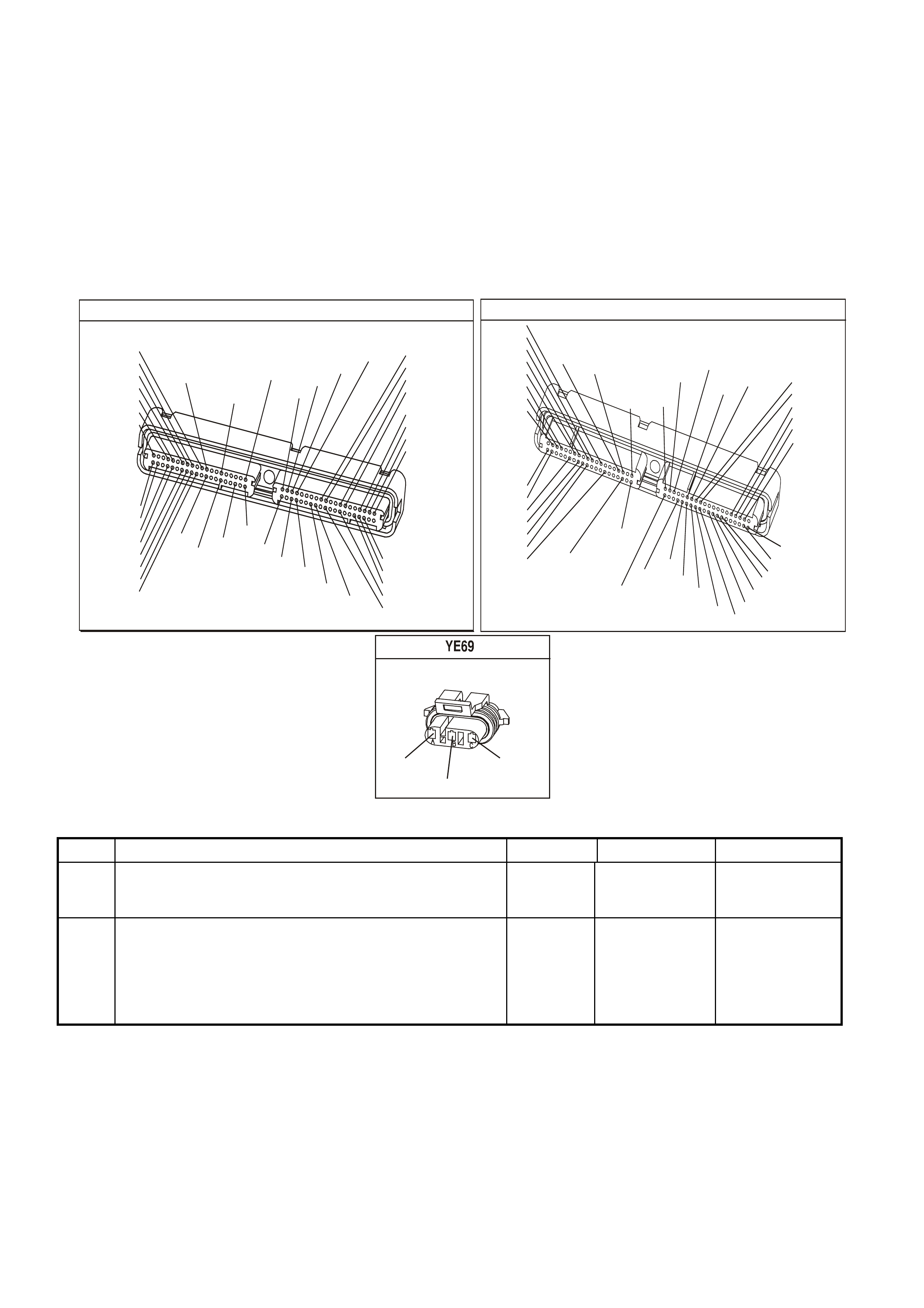

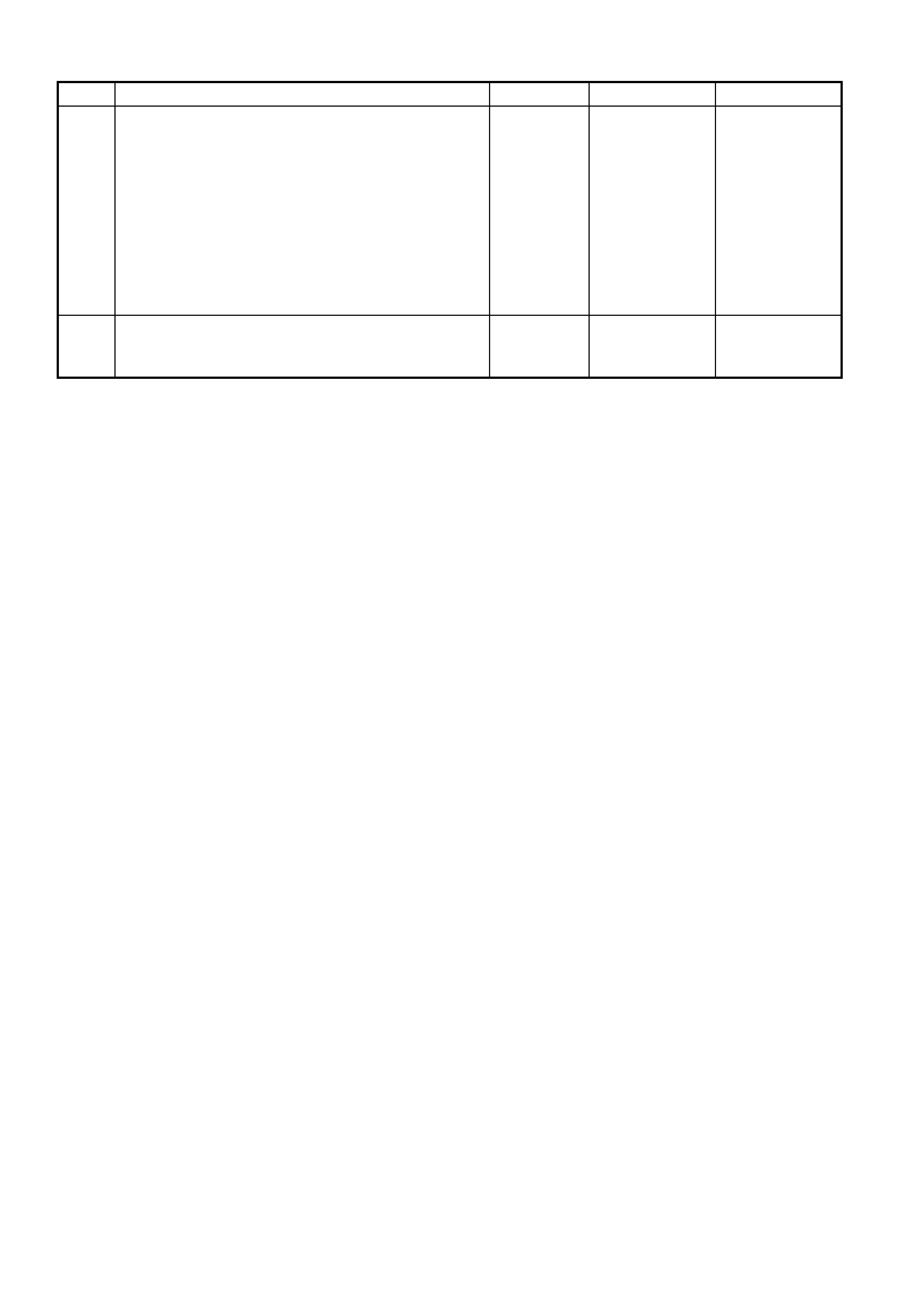

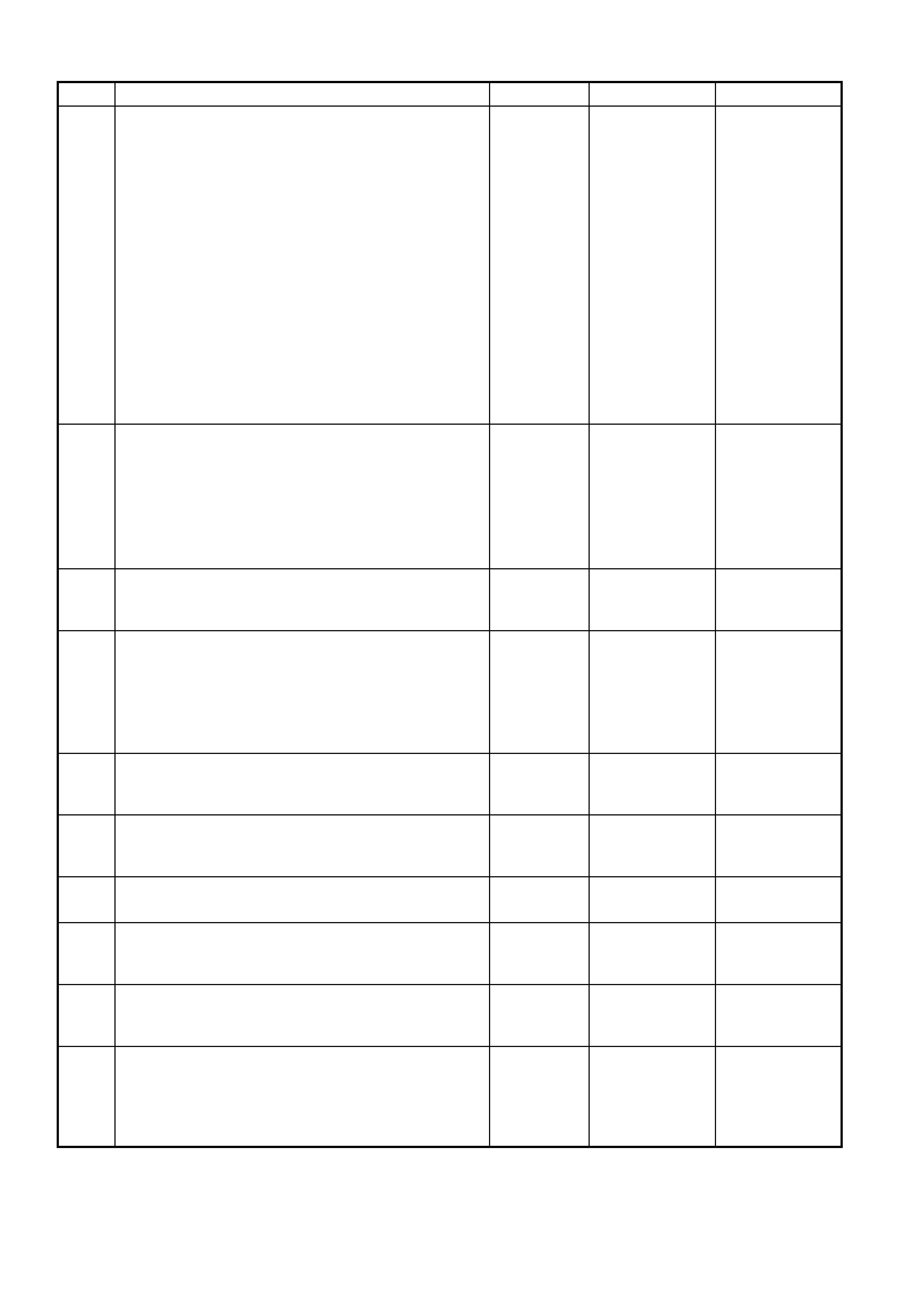

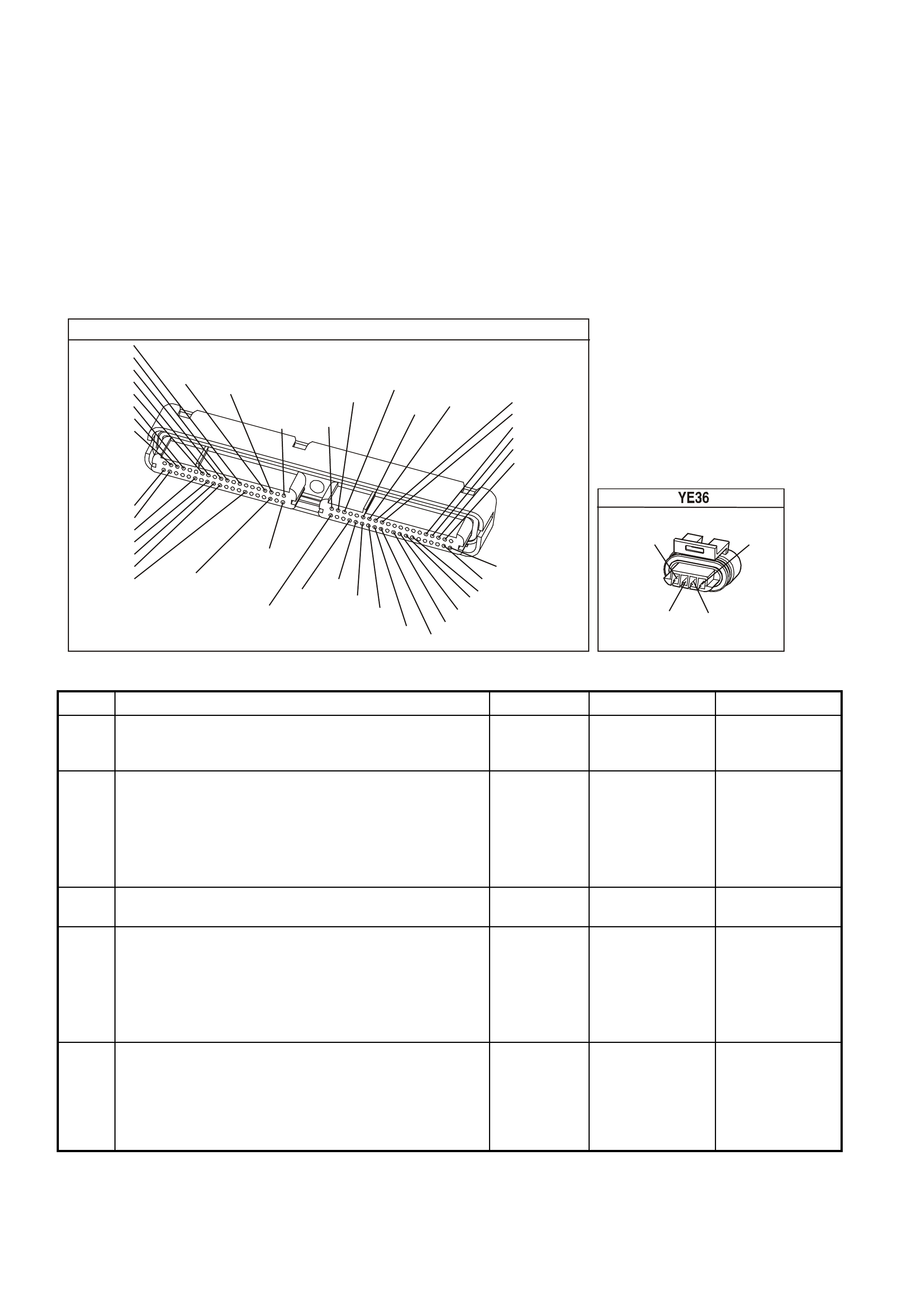

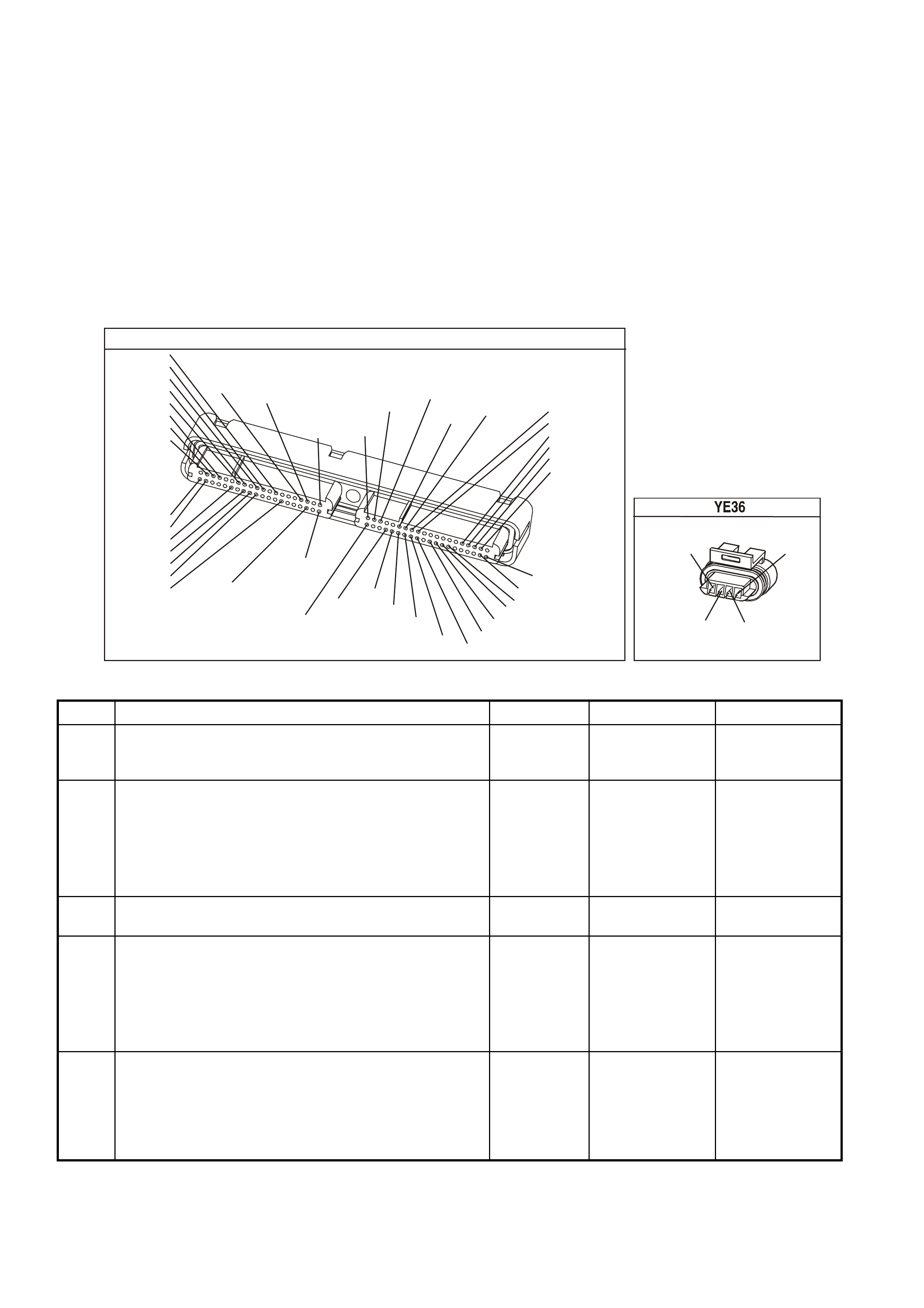

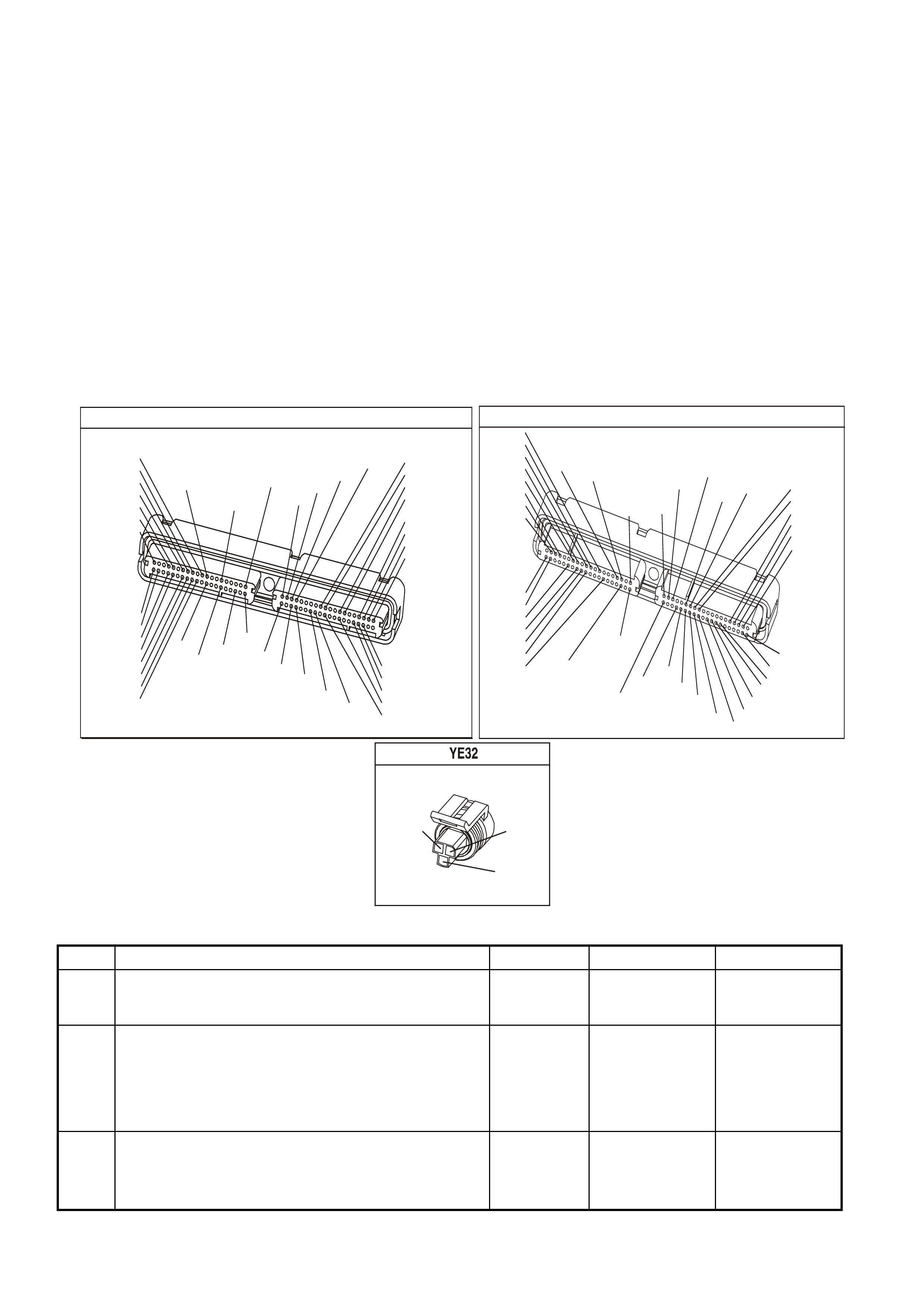

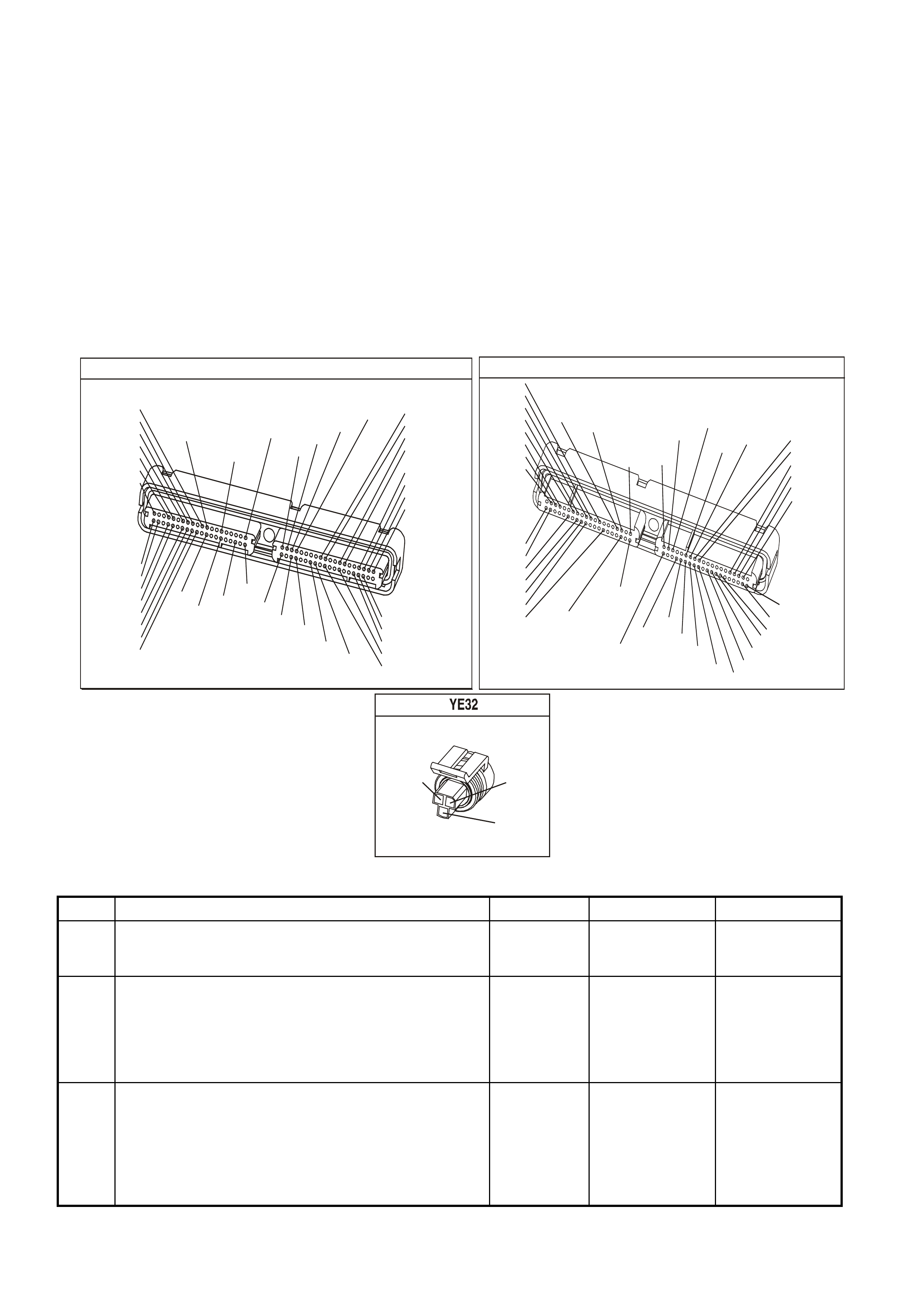

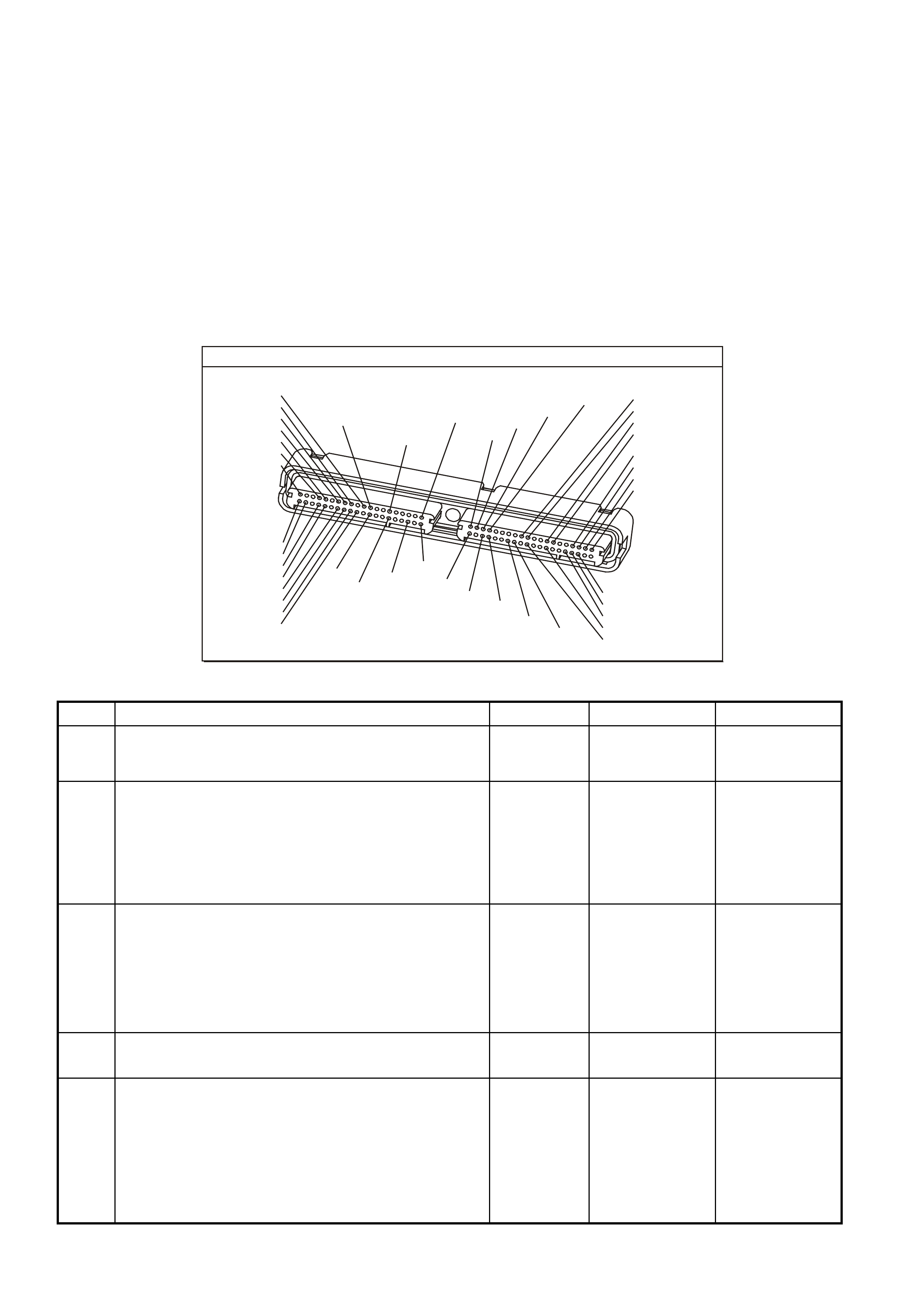

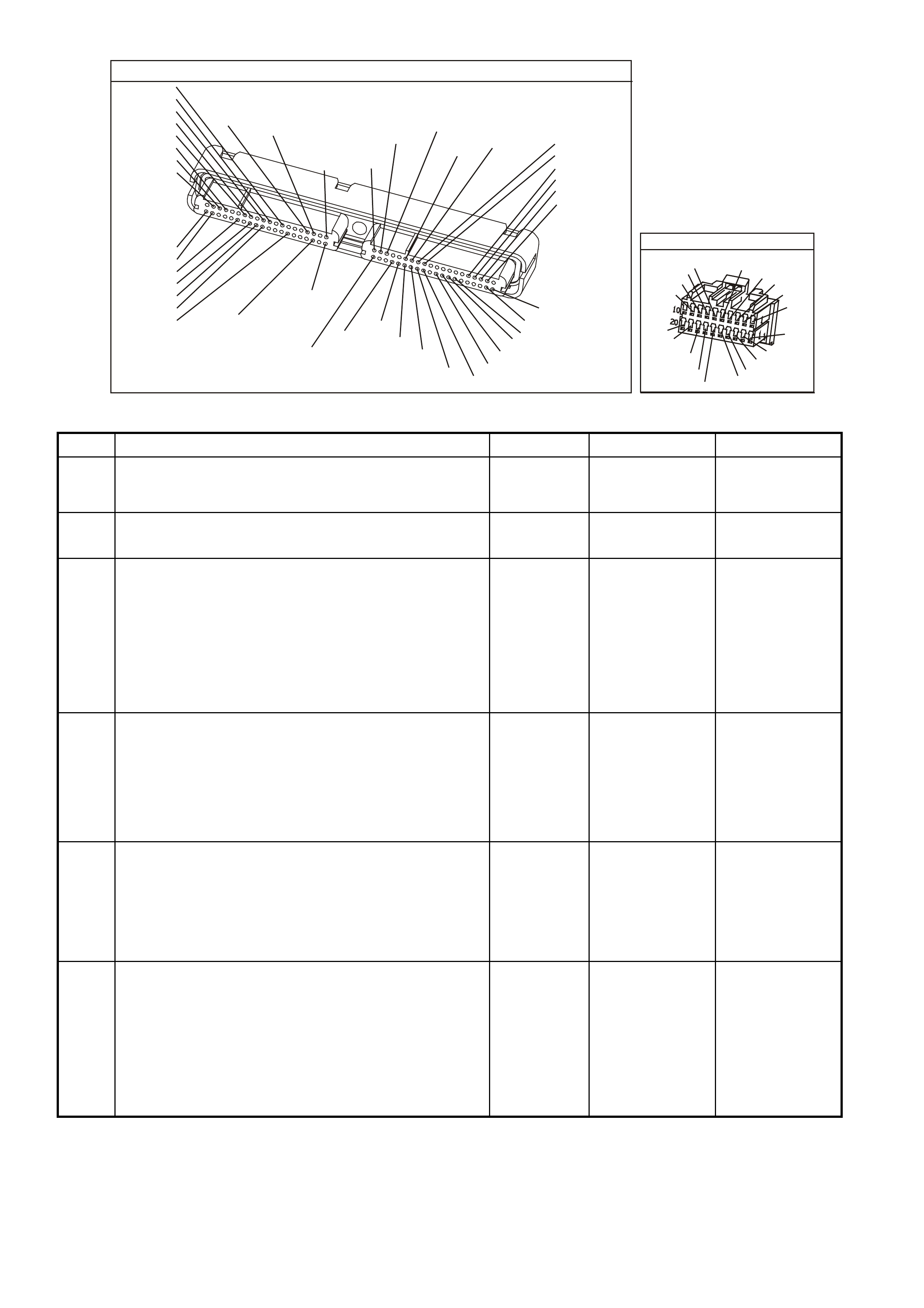

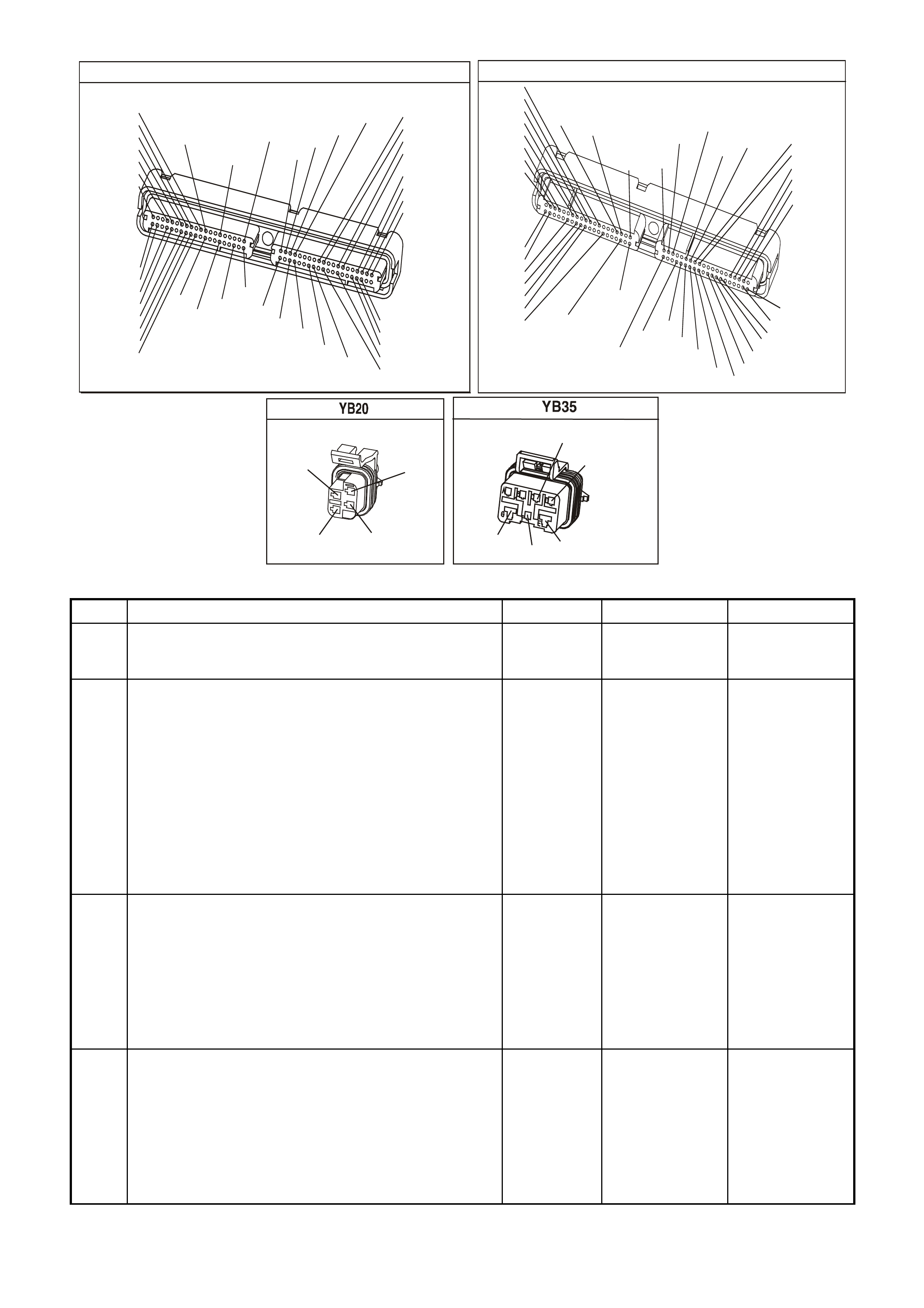

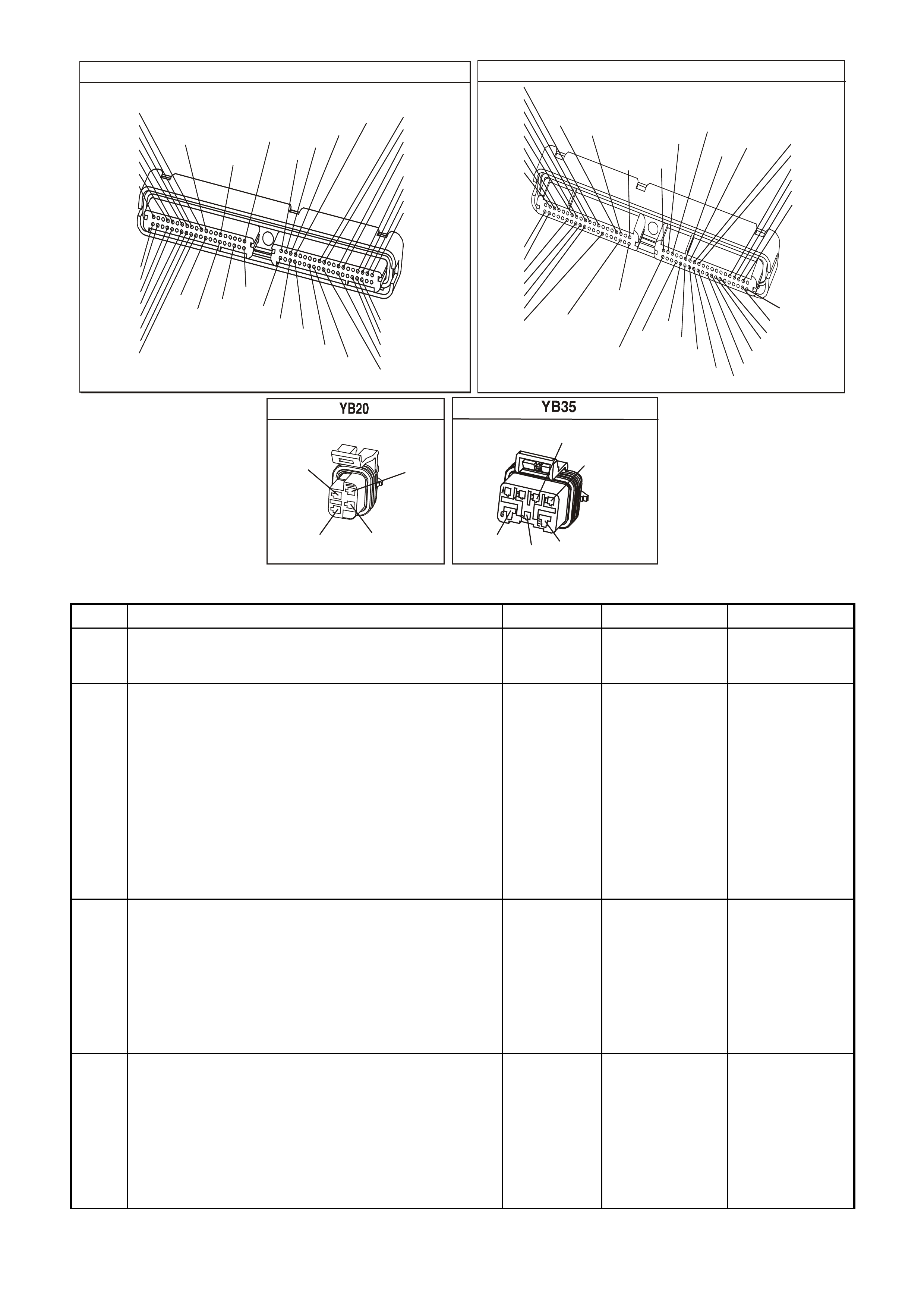

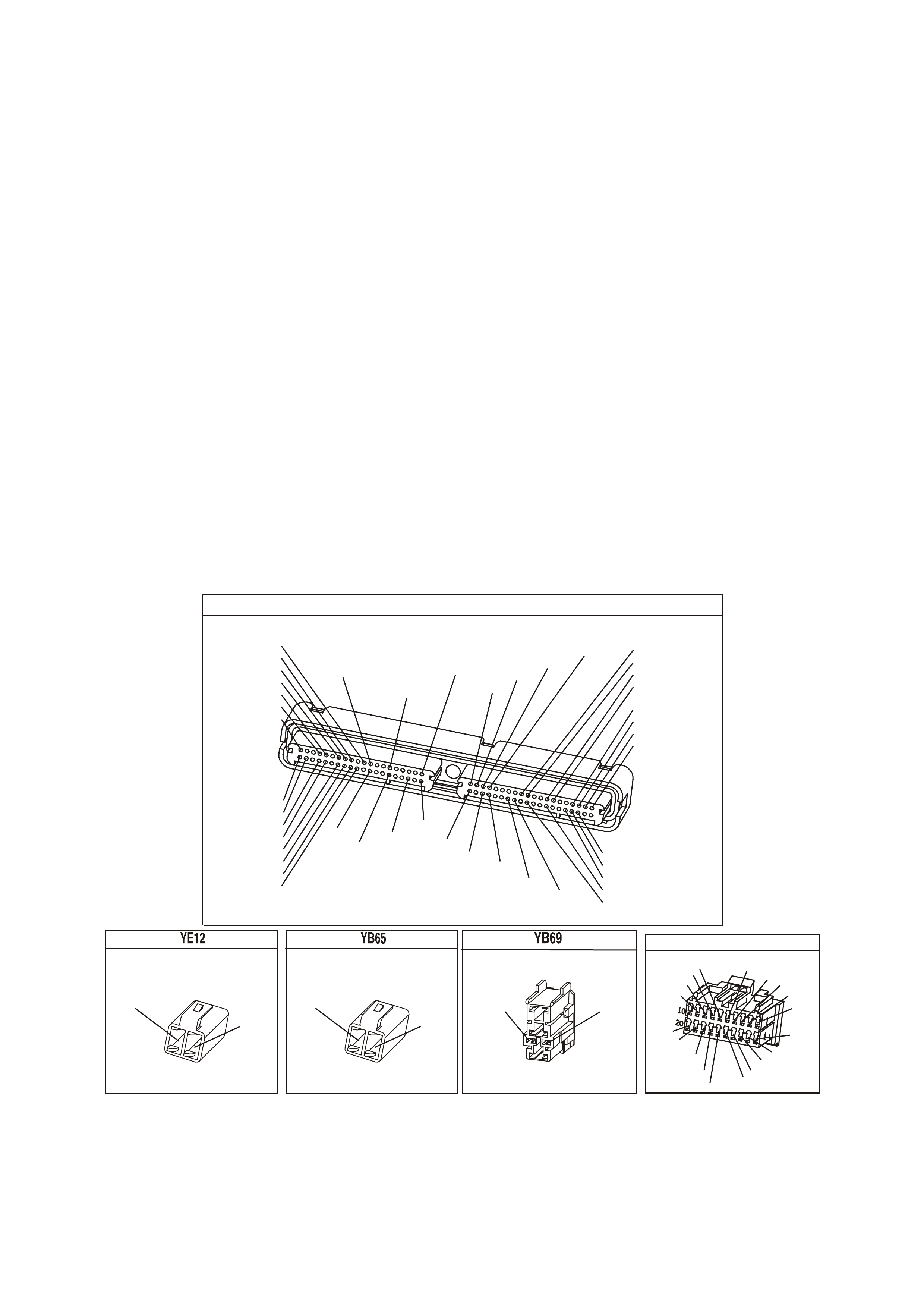

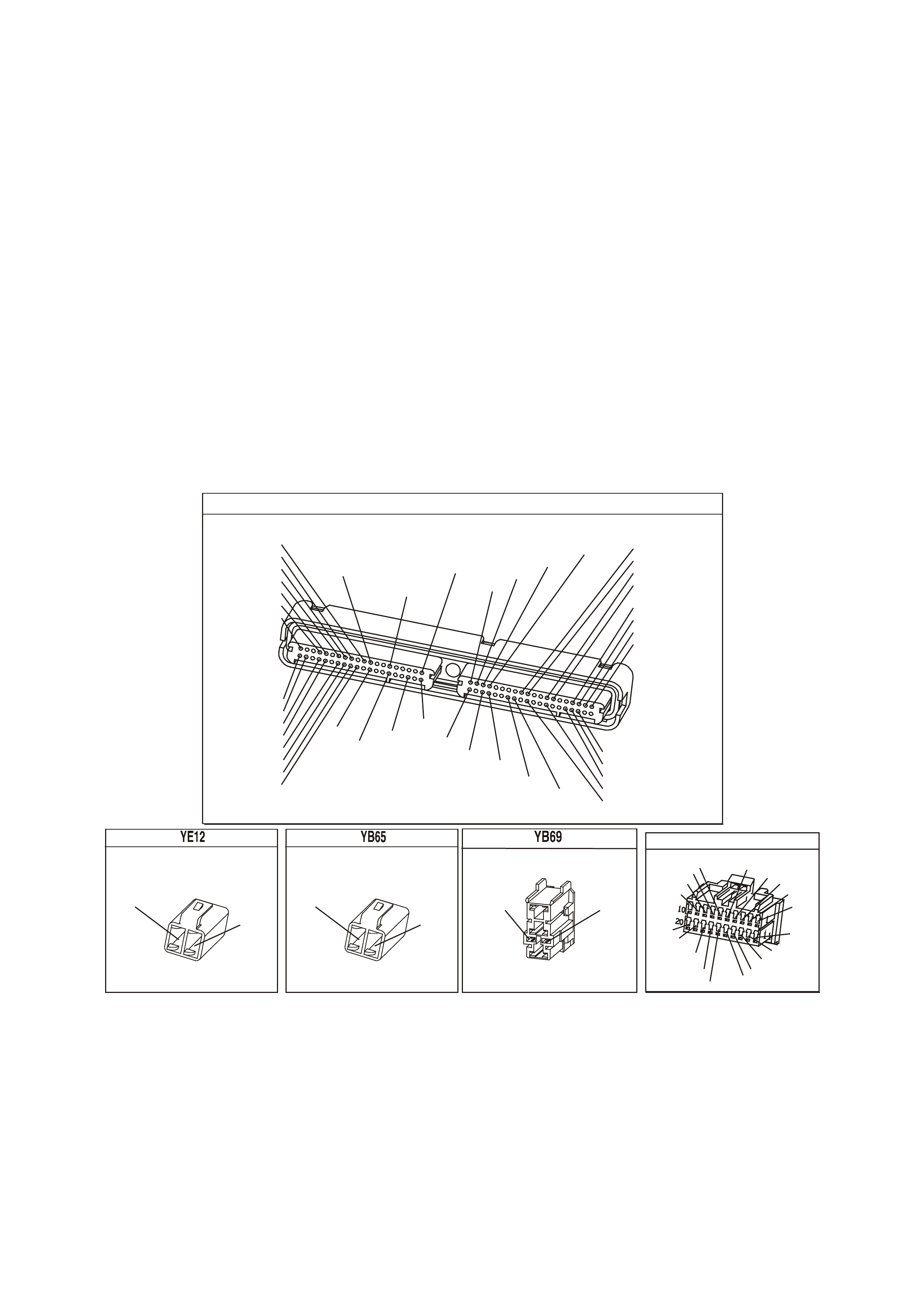

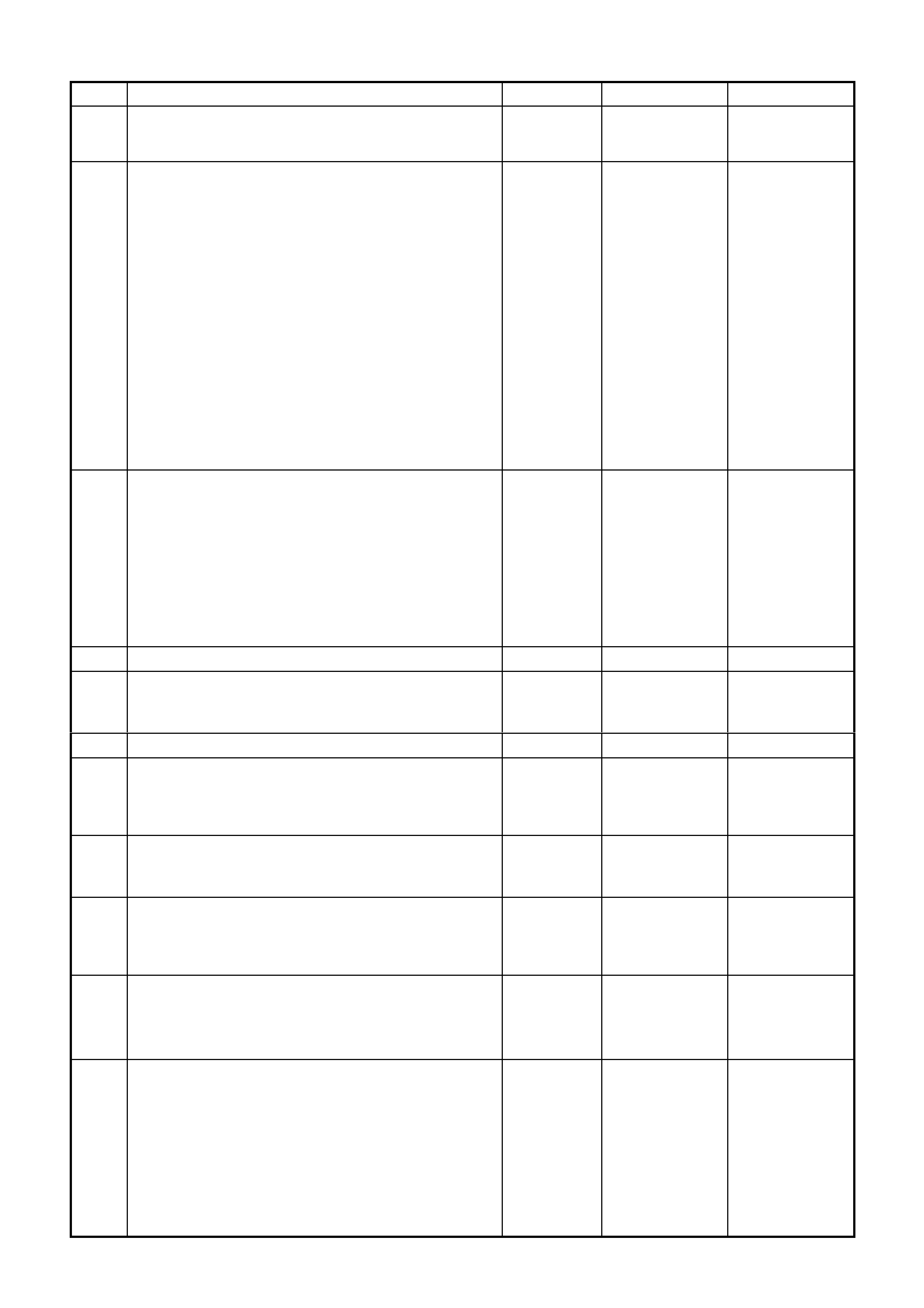

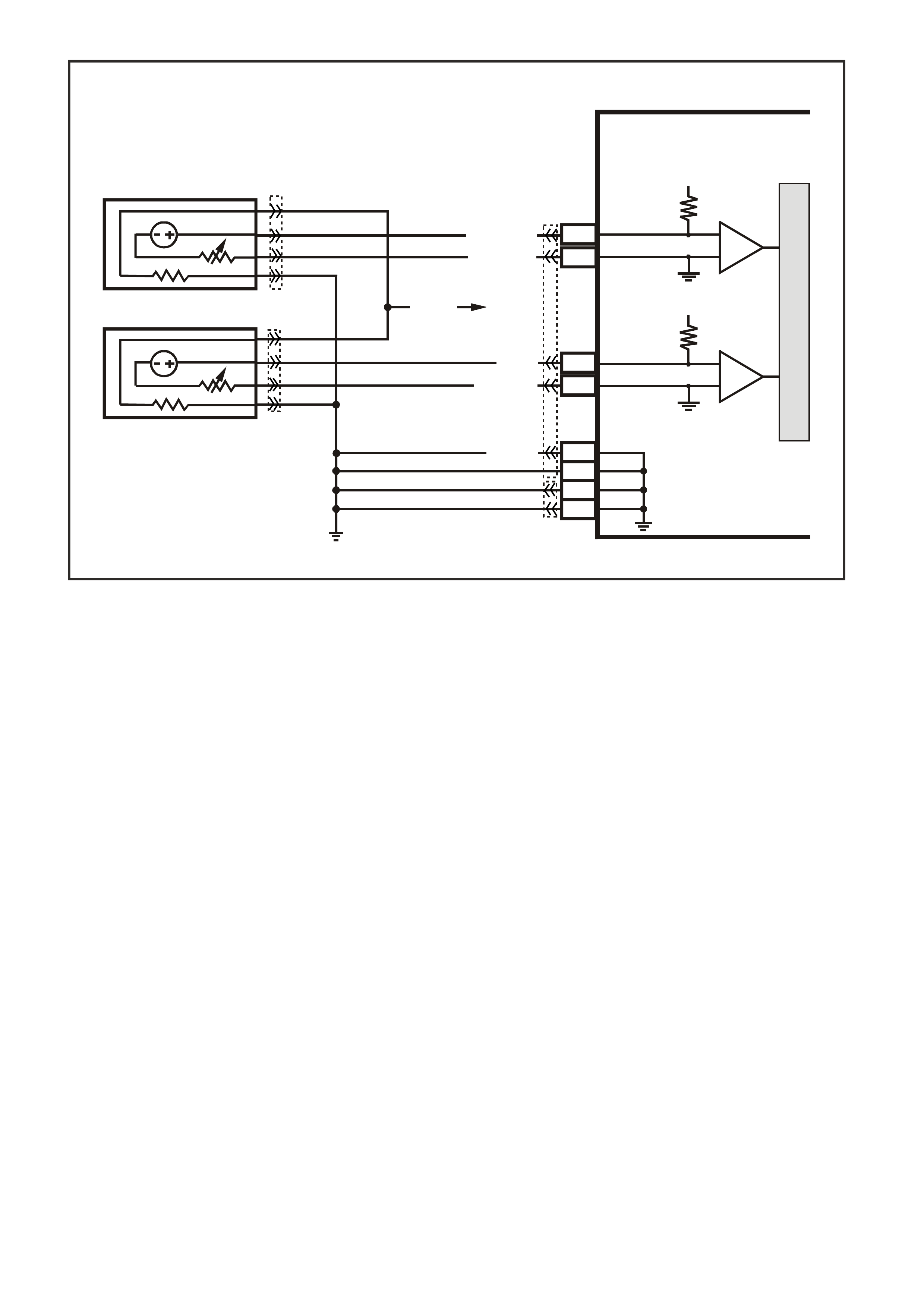

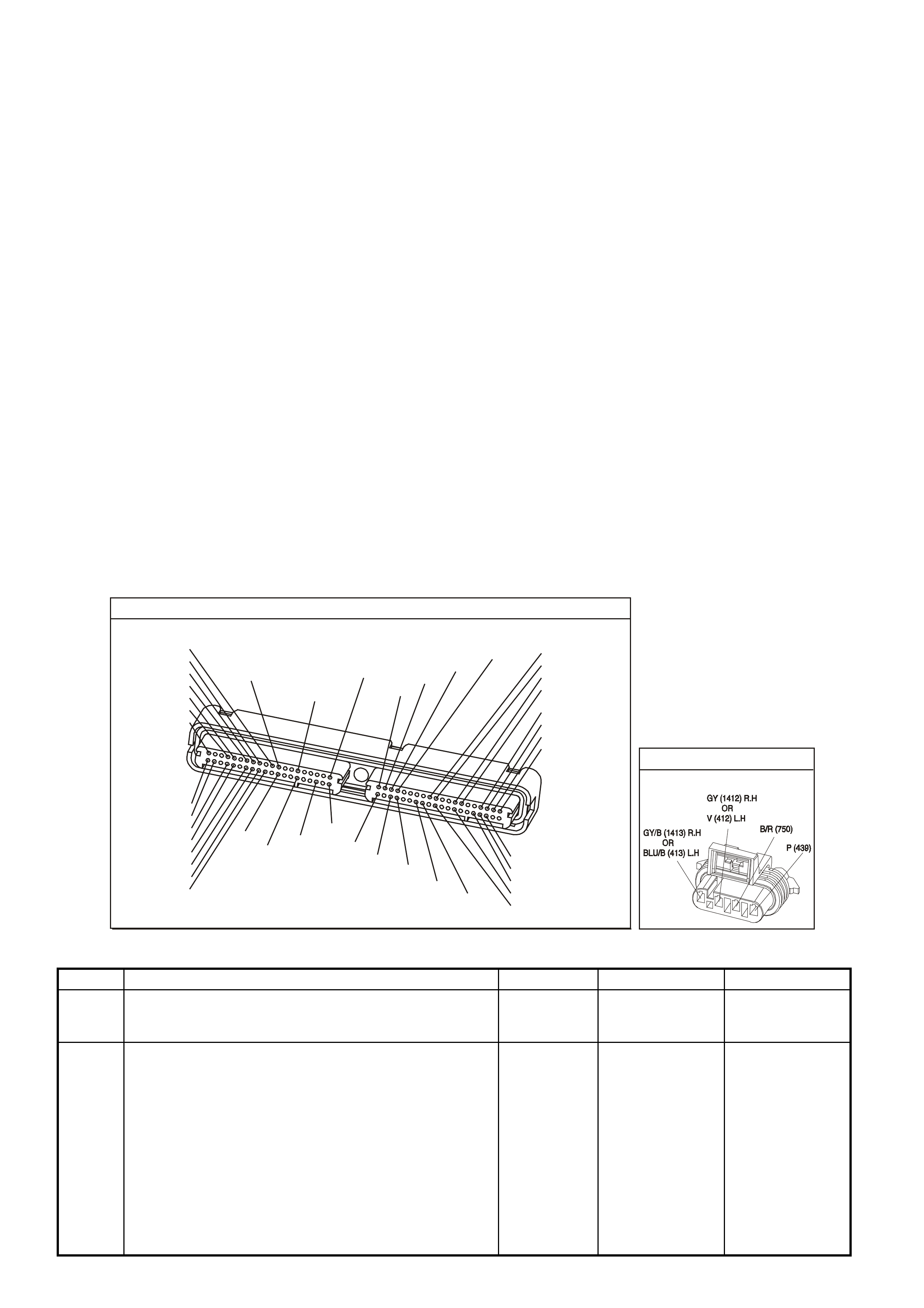

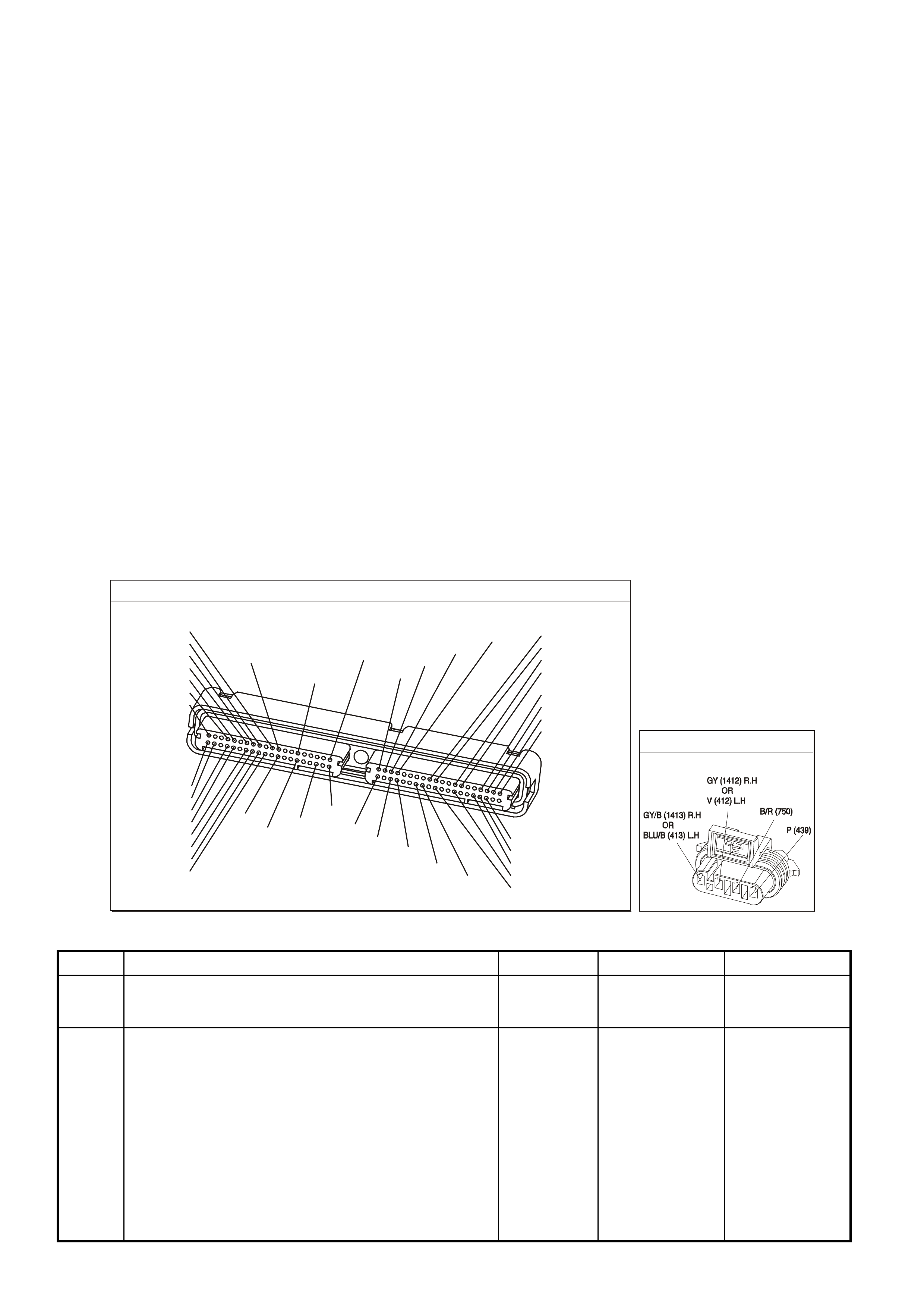

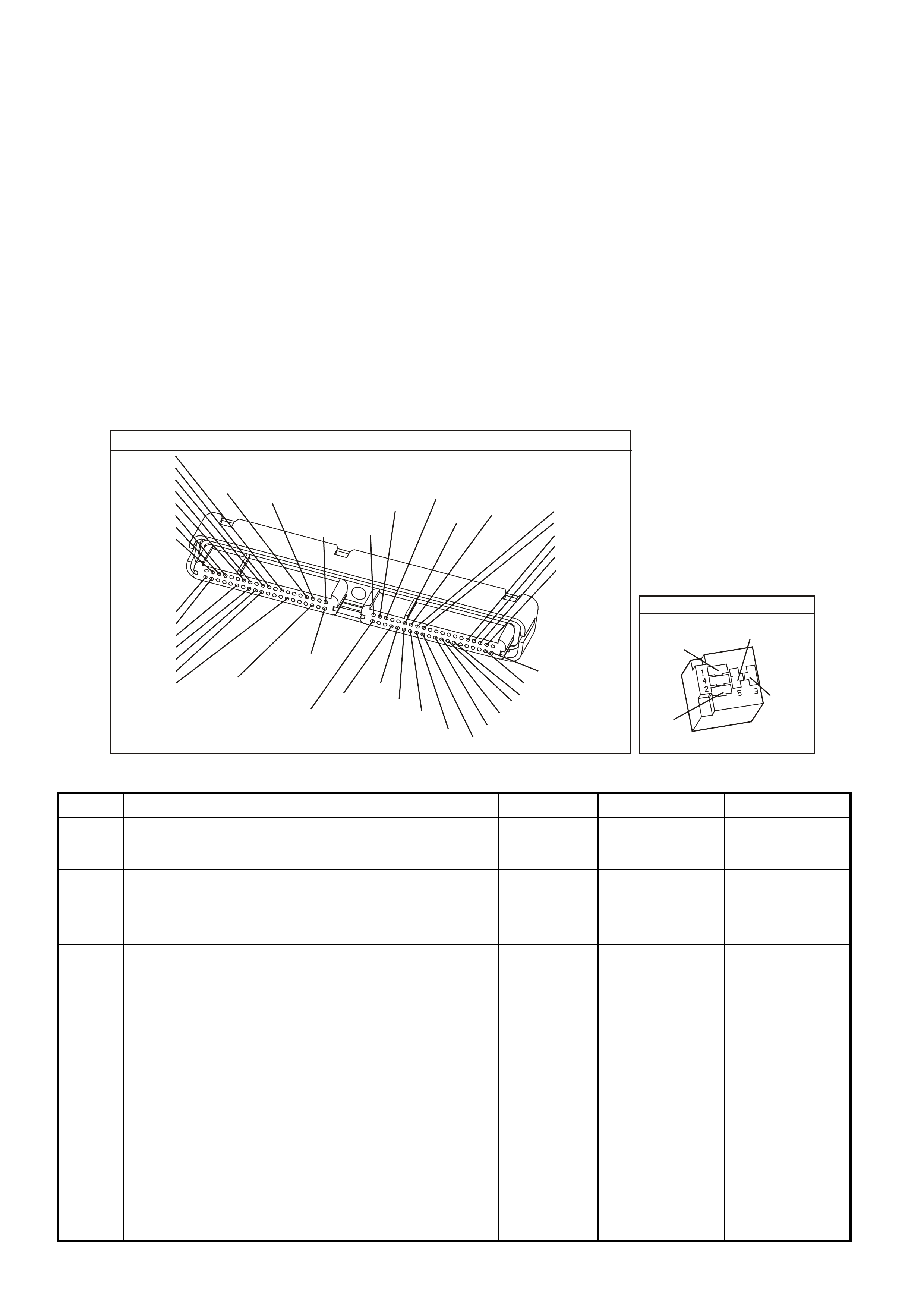

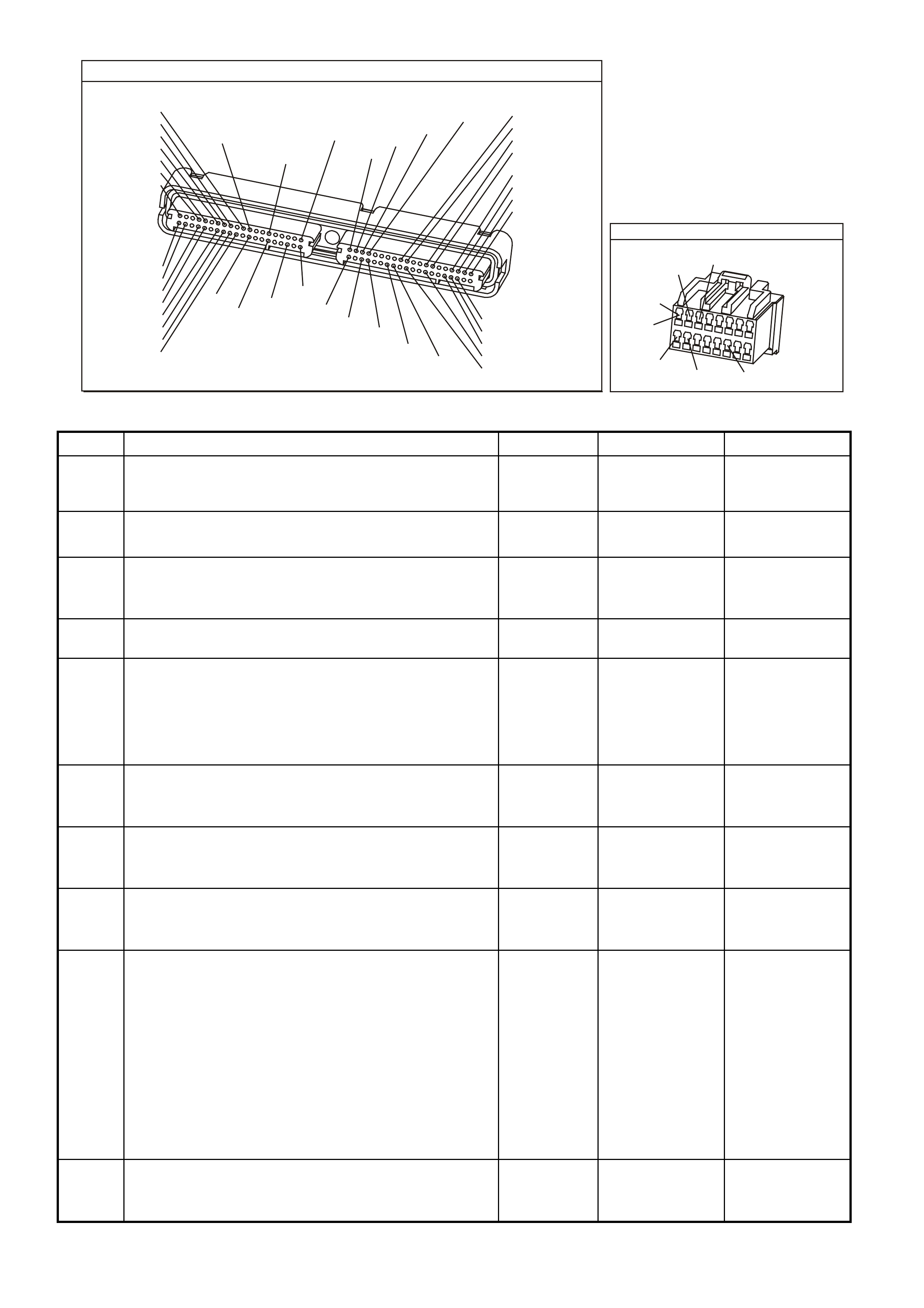

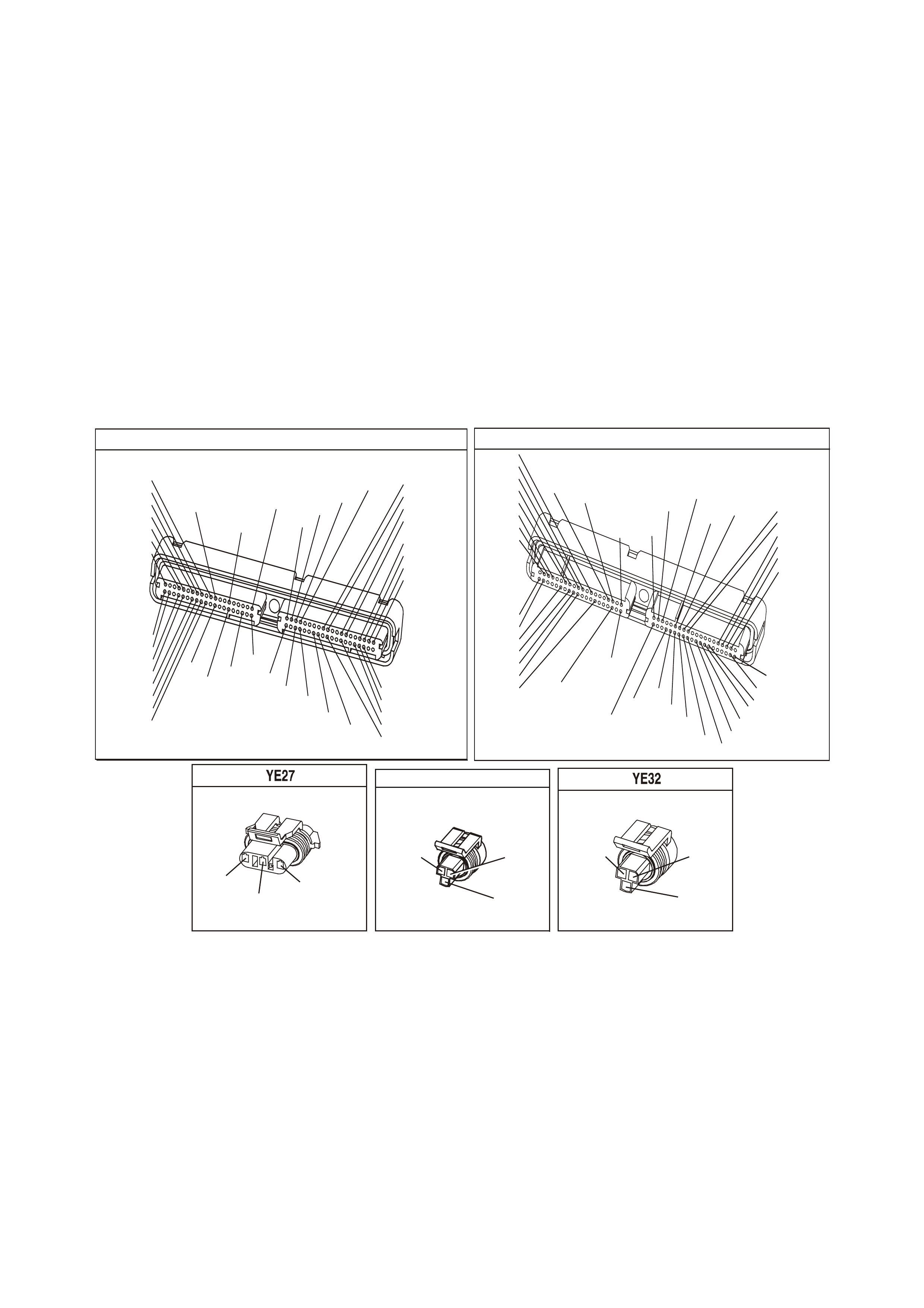

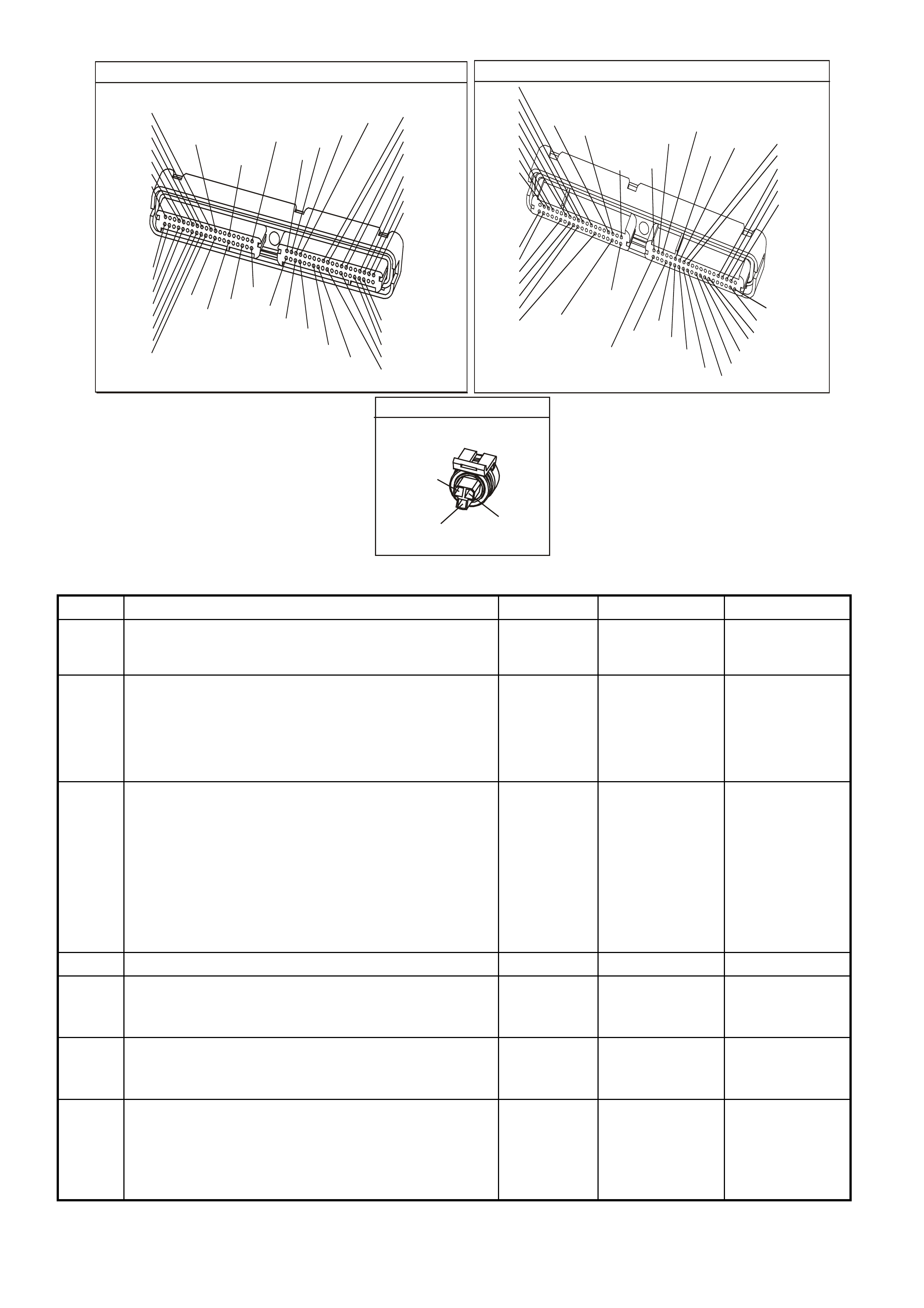

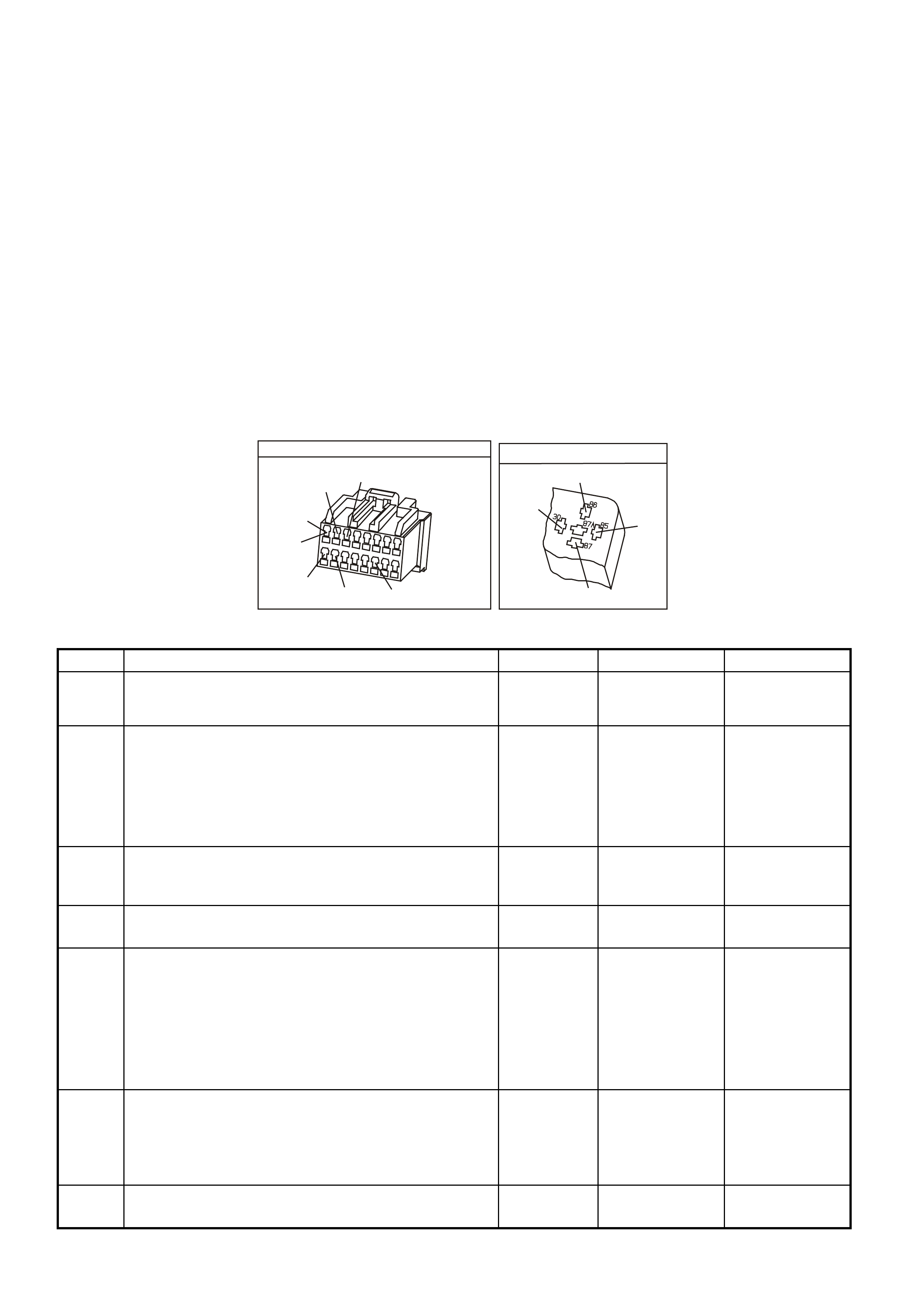

PCM CONNECTOR END VIEWS

PCM CONNECTOR J1 (BLUE)

60

20

61

21

80

401

41

4547

Connector Part

Information • PCM Connector YE122 J1 (Blue)

• 80 Pin Connector

Pin Wire Color Circuit No. Function

1 Brown/Red 750 System Earth

2 LT Blue/White 646 Crankshaft Position Sensor Ignition Voltage Feed

3 Violet 843 Fuel Injector #3 Driver

4 Green 842 Fuel Injector #2 Driver

5 Not Used - -

6 Not Used - -

7 Blue/Yellow 334 Oil Pressure Sensor 5 Volt Reference

8 Grey 416 Throttle Position Sensor 5 Volt Reference

9 Not Used - -

10 Not Used - -

11 LBLU 826 Rear Knock Sensor Input Signal

12 Blue 643 Crankshaft Position Sensor Input Signal

13 Not Used - -

14 Not Used - -

15 Not Used - -

16 Not Used - -

17 Yellow 1225 Transmission Range B Input

18 Grey 1226 Transmission Range C Input

19 Pink 39 Ignition Positive Voltage

20 Orange 740 Battery Feed

21 LT Blue/Black 647 Crankshaft Position Sensor Reference Low

22 Not Used - -

23 Not Used - -

24 Not Used - -

25 Not Used - -

26 Grey/Black 1413 Bank 2 Sensor 1Heated Oxygen Sensor Signal Low

27 Not Used - -

28 Not Used - -

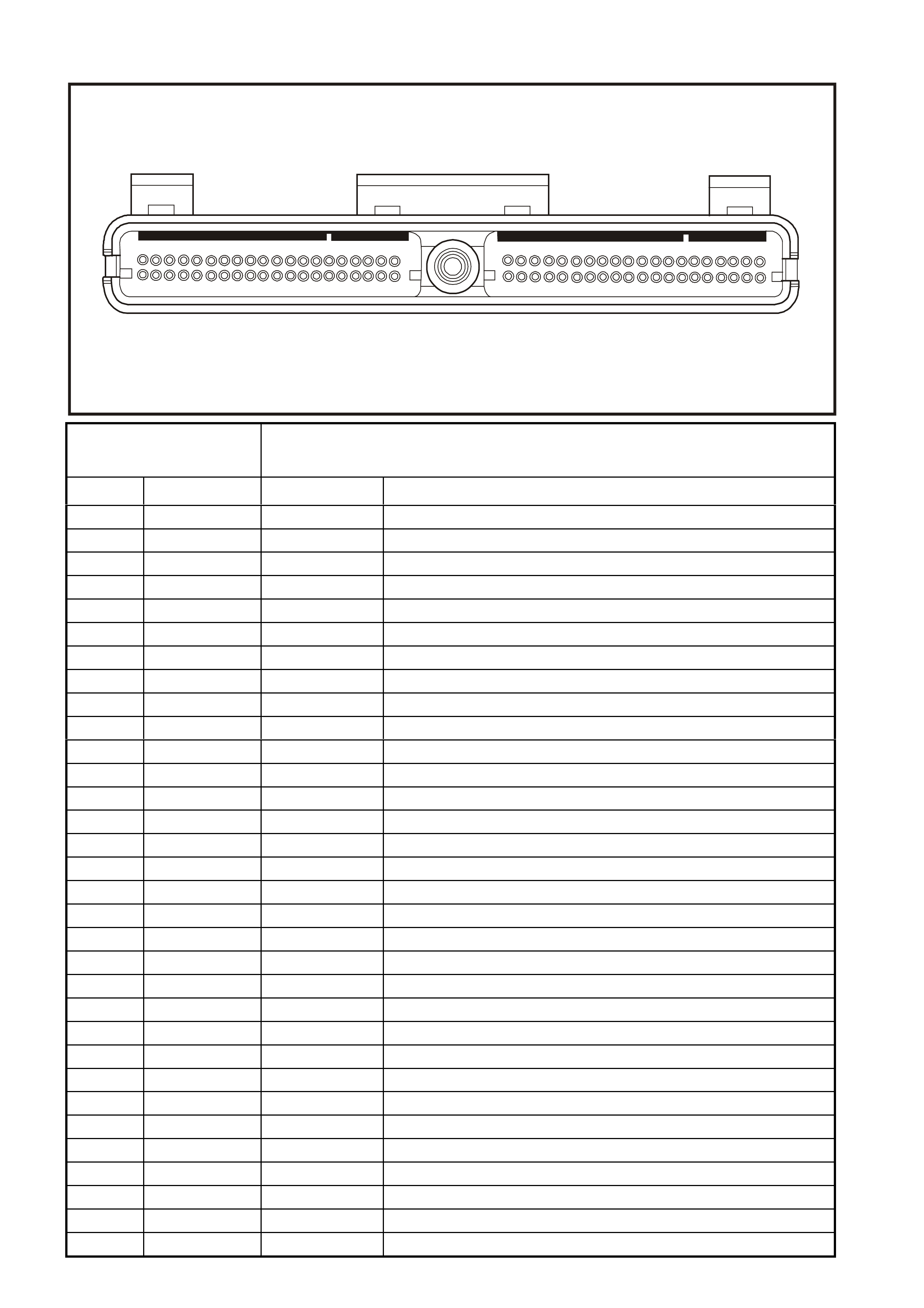

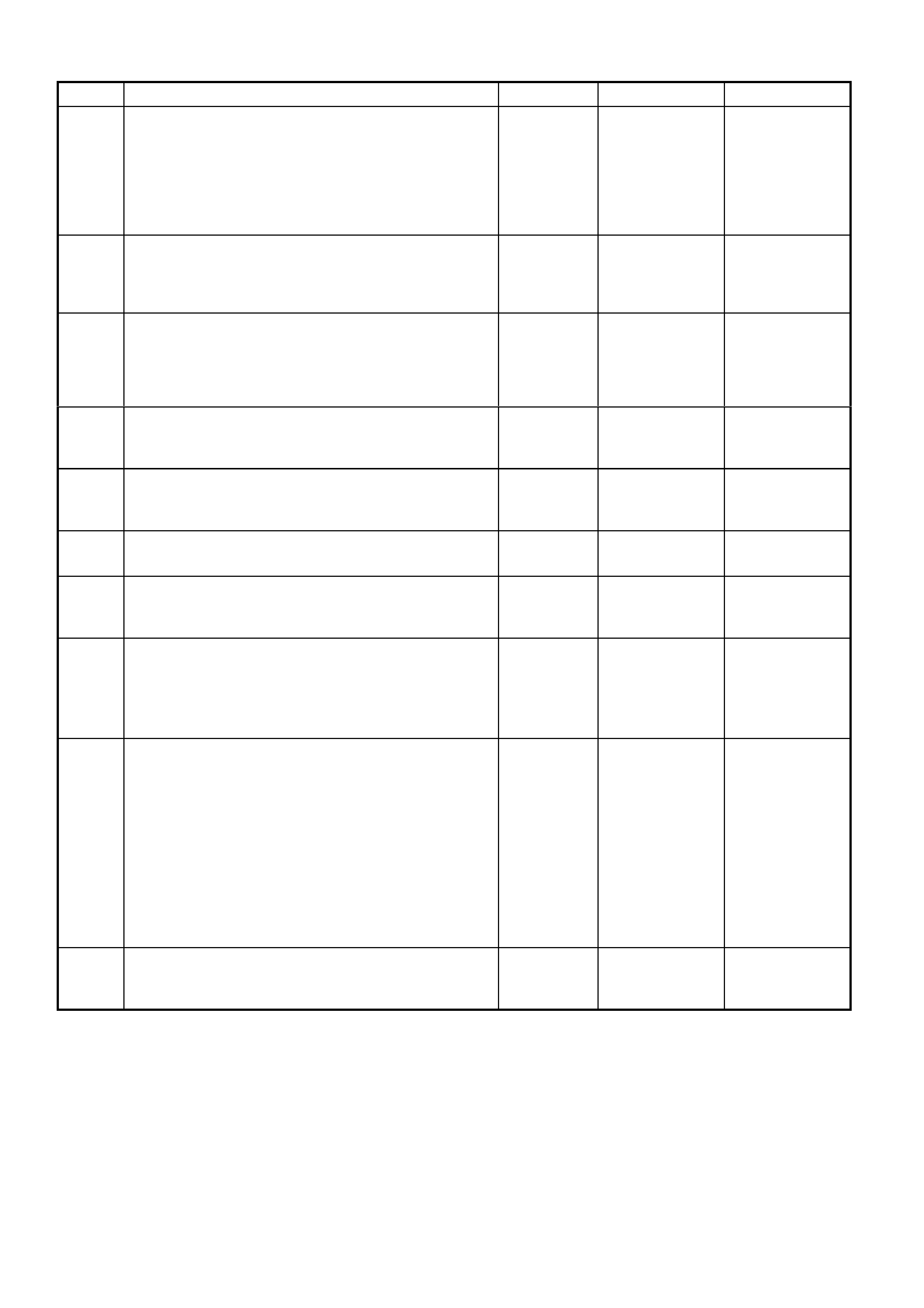

PCM CONNECTOR J1 (BLUE) CONTINUED

60

20

61

21

80

401

41

4547

Connector Part

Information • PCM Connector YE122 J1 (Blue)

• 80 Pin Connector

Pin Wire Color Circuit No. Function

29 Blue/Black 413 Bank 1 Sensor 1 Heated Oxygen Sensor Signal Low

30 Green 69 Engine Coolant Level switch Input Signal

31 Not Used - -

32 Blue/White 771 PRNDL A

33 Brown 86 Torque Converter Clutch/Cruise Brake Switch Input Signal

34 White 776 PRNDL P

35 Not Used - -

36 Blue 841 Fuel Injector #1 Driver

37 Yellow 846 Fuel Injector #6 Driver

38 Not Used - -

39 Not Used - -

40 Brown/Red 750 System Earth

41 Not Used - -

42 Not Used - -

43 Pink/Black 847 Fuel Injector #7 Driver

44 Brown/Yellow 844 Fuel Injector #4 Driver

45 Violet/White 415 A/C Refrigerant Pressure Sensor 5 Volt Reference

46 Not Used - -

47 Not Used - -

48 Violet/White 414 Manifold Absolute Pressure Sensor 5 Volt Reference

49 Not Used - -

50 Not Used - -

51 Blue 815 Front Knock Sensor Input Signal

52 Not Used - -

53 Black/White 1230 Transmission Fluid Temperature Sensor Earth

54 Black 421 Manifold Absolute Pressure Sensor Earth

55 Not Used - -

56 Not Used - -

57 Orange 740 Battery Feed

58 Yellow 1049 Serial Data (Class II)

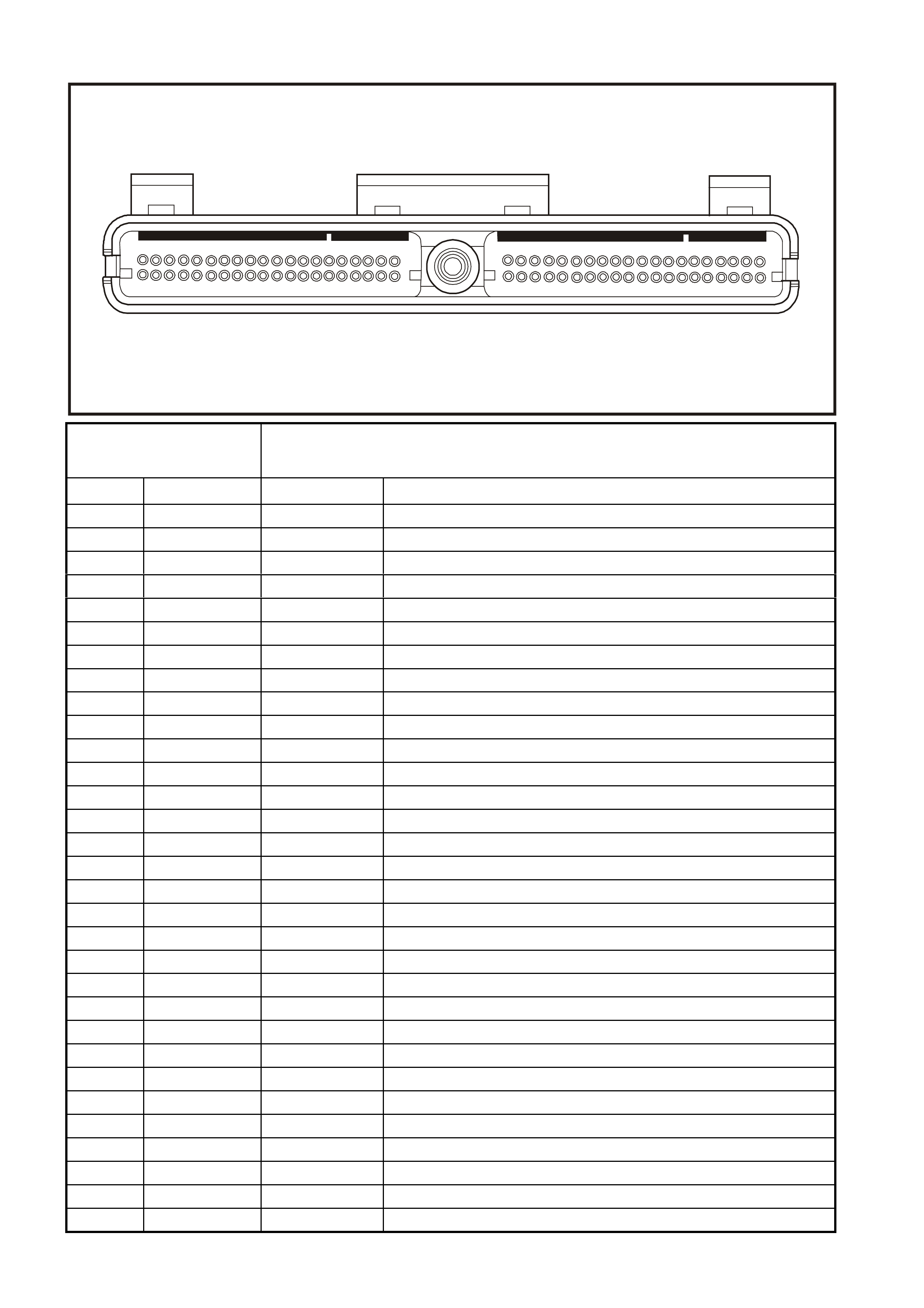

PCM CONNECTOR J1 (BLUE) CONTINUED

60

20

61

21

80

401

41

4547

Connector Part

Information • PCM Connector YE122 J1 (Blue)

• 80 Pin Connector

Pin Wire Color Circuit No. Function

59 Not Used - -

60 Black/Yellow 452 Throttle Position Sensor Earth

61 Red/White 632 Camshaft Position Sensor Reference Low

62 Not Used - -

63 Green 335 Oil Pressure Sensor Earth

64 Not Used - -

65 Not Used - -

66 Grey 1412 Bank 2 Sensor 1 Heated Oxygen Sensor Signal High

67 Not Used - -

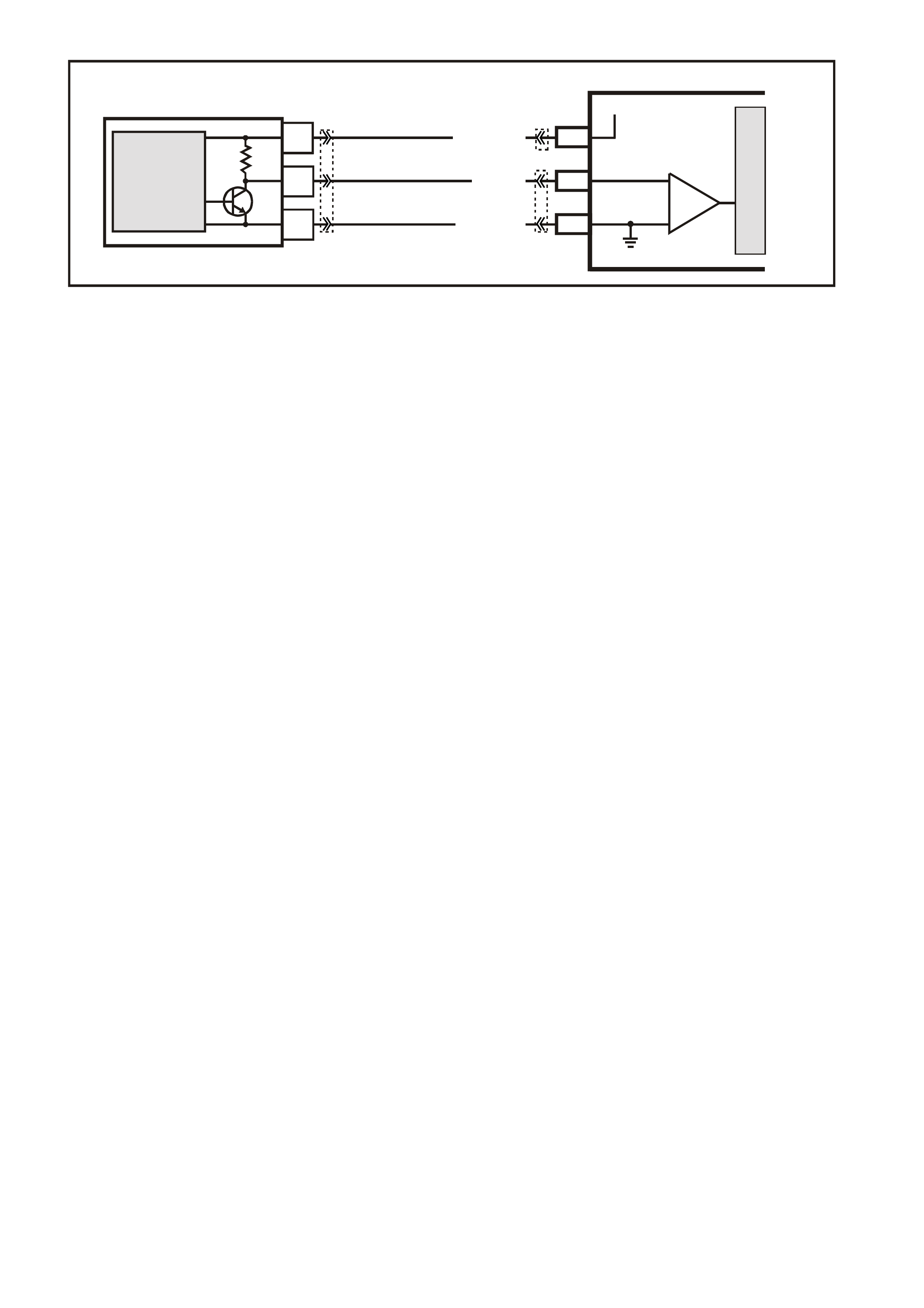

68 Not Used - -

69 Violet 412 Bank 1 Sensor 1 Heated Oxygen Sensor Signal High

70 Not Used - -

71 Blue 774 Power/Economy Switch Input

72 Yellow 772 PRNDL B

73 Brown 633 Camshaft Position Sensor Input Signal

74 Yellow 410 Engine Coolant Temperature Sensor Signal

75 Not Used - -

76 Grey 845 Fuel Injector #5 Driver

77 LT Green 848 Fuel Injector #8 Driver

78 Not Used - -

79 Green/White 897 3-2 Shift Solenoid Control

80 Grey/Black 455 Engine Coolant Temperature Sensor Earth

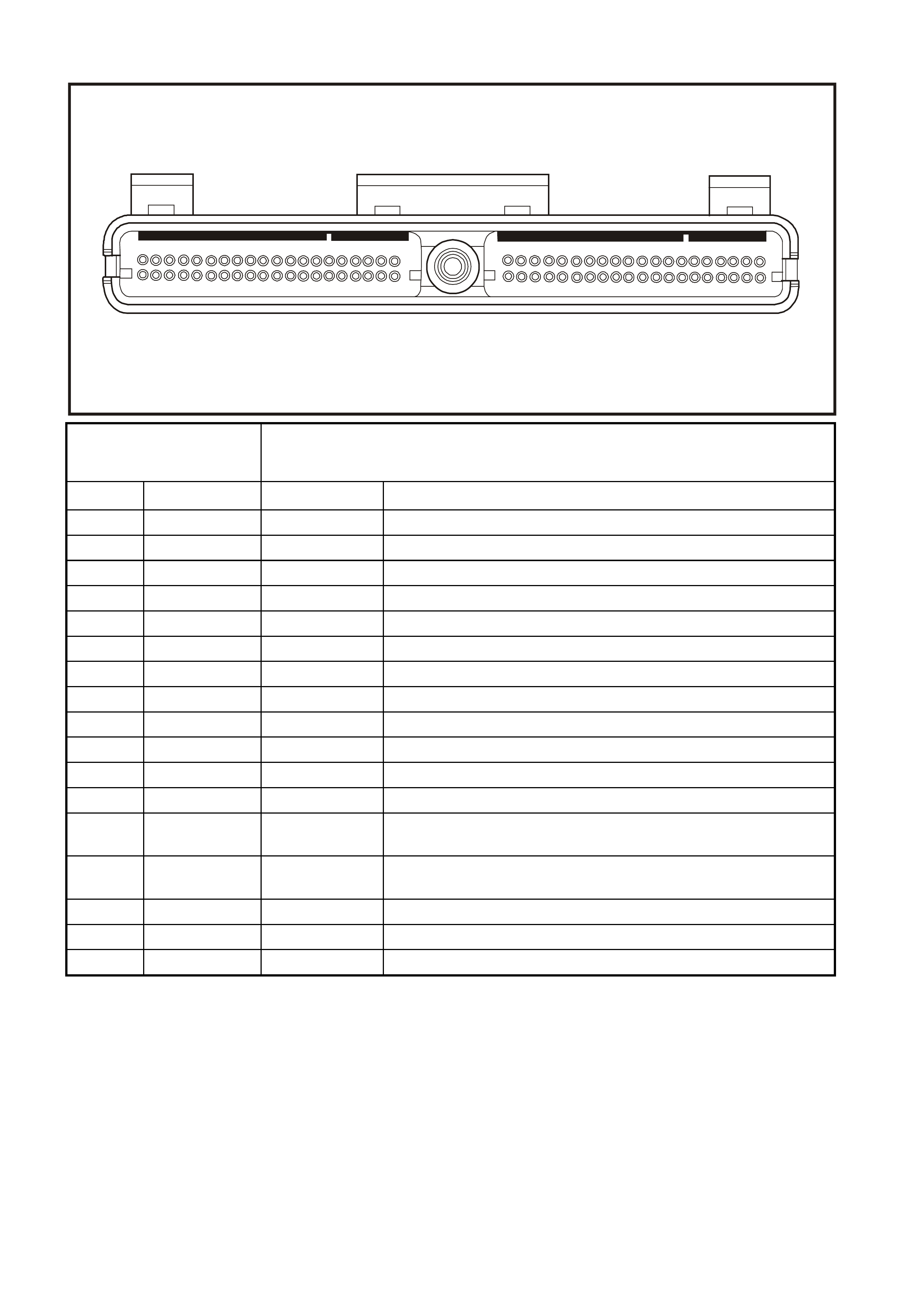

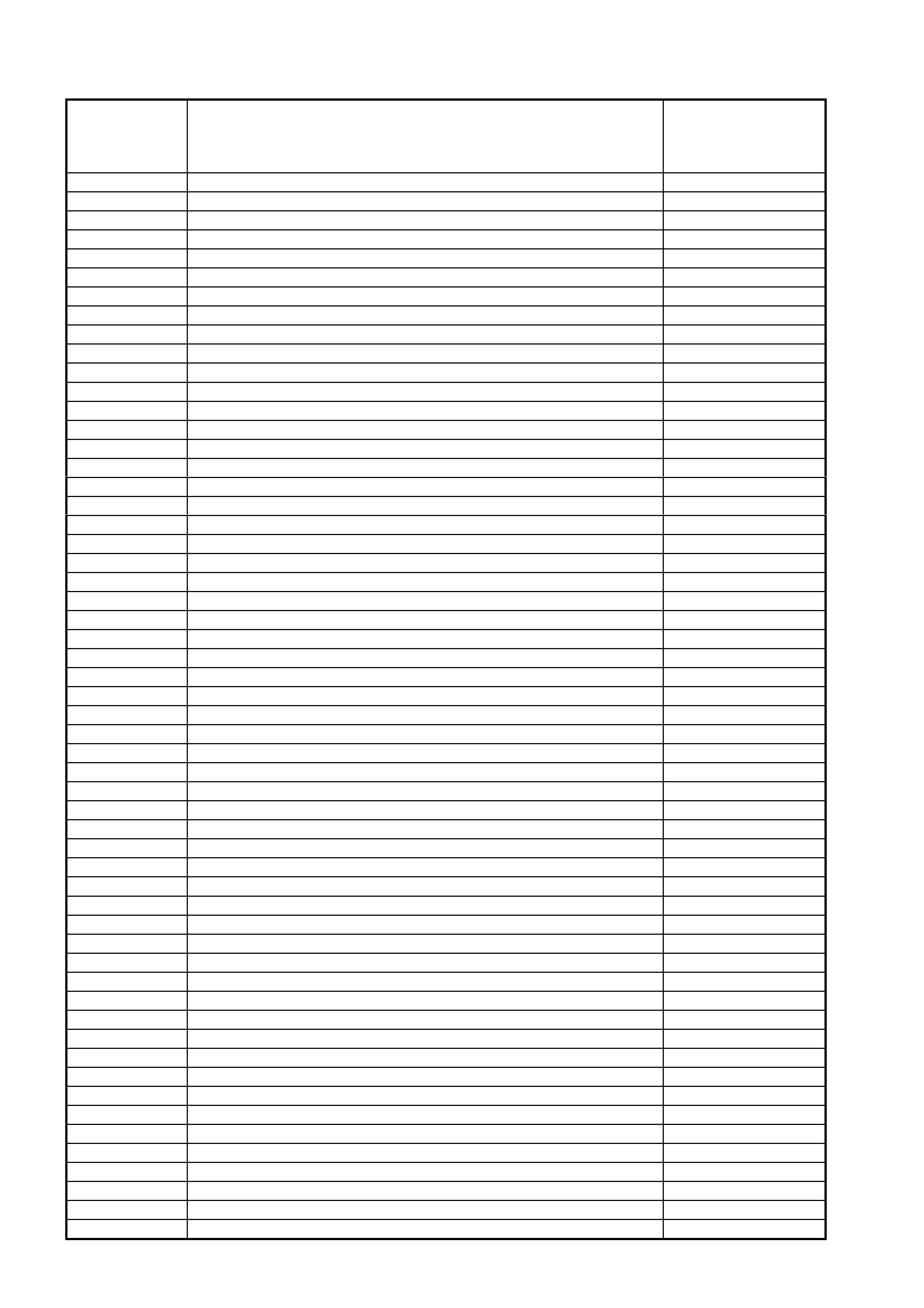

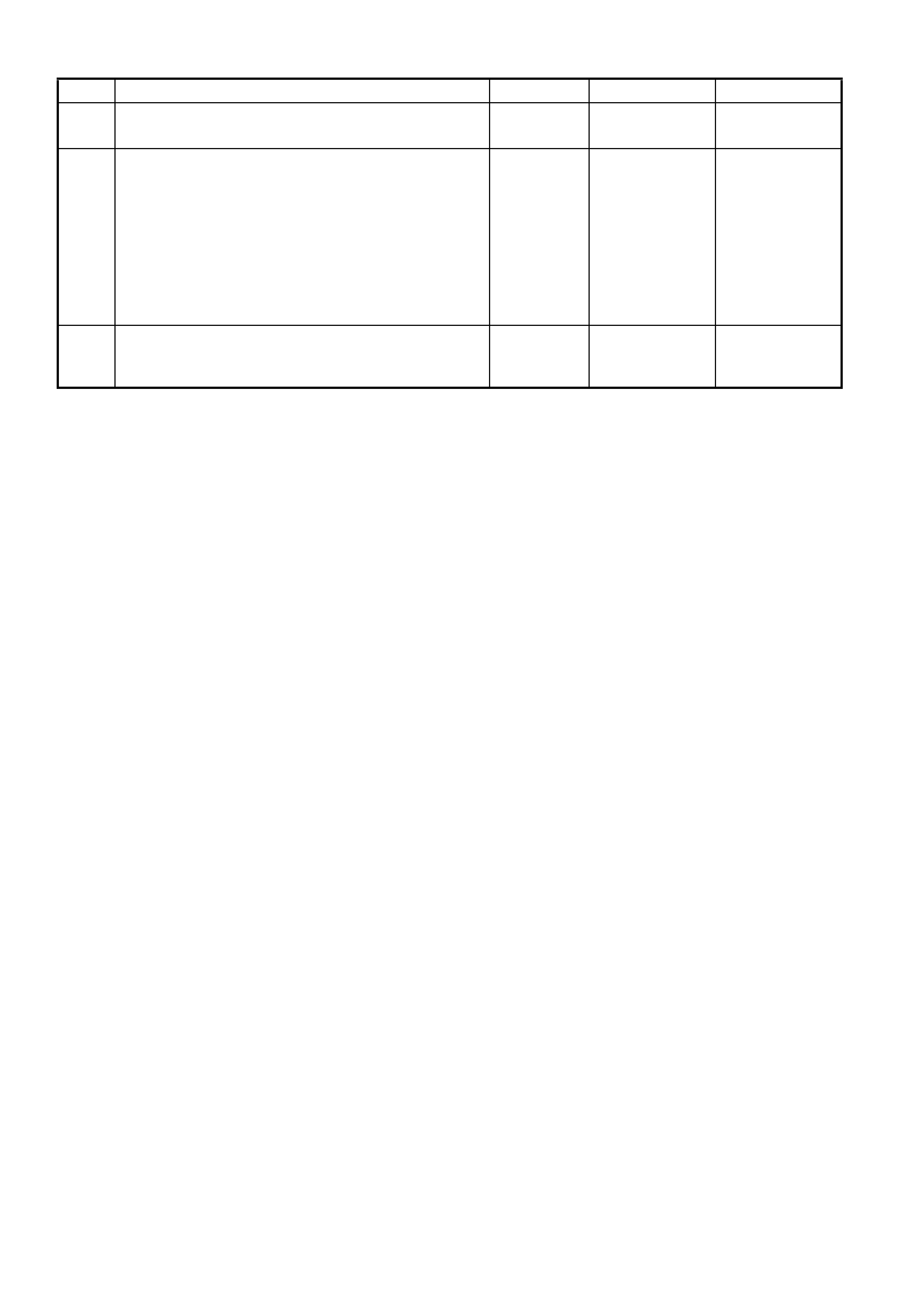

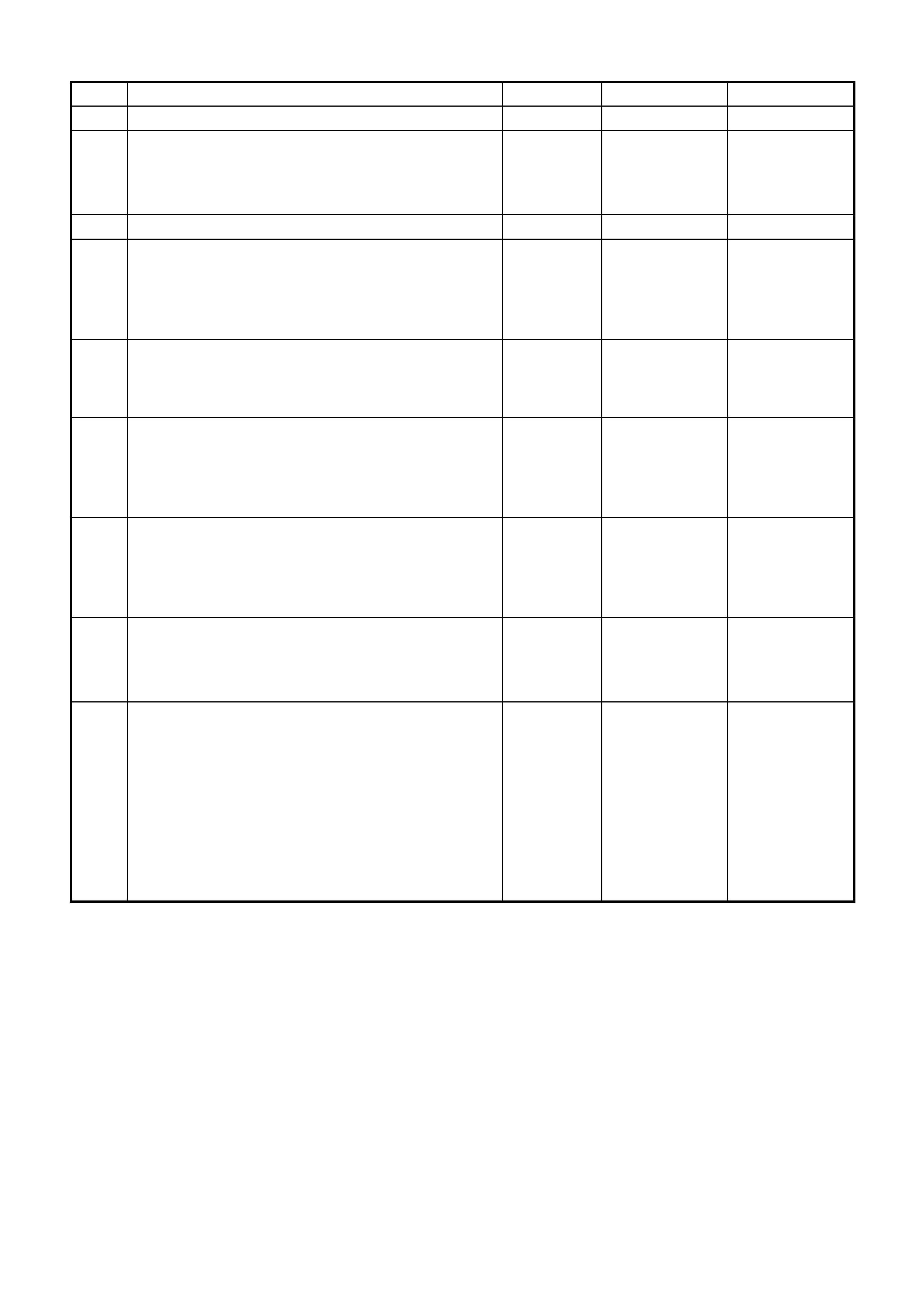

PCM CONNECTOR J2 (RED)

60

20

61

21

80

401

41

4547

Connector Part

Information • PCM Connector YE123 J2 (Red)

• 80 Pin Connector

Pin Wire Color Circuit No. Function

1 Brown/Red 750 System Earth

2 Not Used - -

3 Not Used - -

4 Brown 418 Torque Converter Clutch Pulse Width Modulation Solenoid Control

5 Not Used - -

6 Red 1228 Pressure Control Solenoid Signal High

7 Not Used - -

8 Grey/Blue 1229 Pressure Control Solenoid Signal Low

9 Green/W hite 465 Fuel Pump Relay Control

10 Brown 121 Tachometer Output Signal

11 Not Used - -

12 Not Used - -

13 Not Used - -

14 Green/Black 259 A/C Refrigerant Pressure Sensor Input Signal

15 Not Used - -

16 Not Used - -

17 Not Used - -

18 Green 59 A/C Clutch Status

19 Not Used - -

20 Tan 832 Vehicle Speed Sensor Signal Low

21 Blue/White 831 Vehicle Speed Sensor Signal High

22 Not Used - -

23 Not Used - -

24 Blue 417 Throttle Position Sensor Input Signal

25 Brown 472 Intake Air Temperature Sensor Signal

26 White 971 Ignition Coil/Module Control #1

27 Yellow 977 Ignition Coil/Module Control #7

28 LT Green 976 Ignition Coil/Module Control #6

29 White 974 Ignition Coil/Module Control #4

30 Not Used - -

31 Brown/White 792 Mass Air Flow Sensor Signal

32 LT Green 432 Manifold Absolute Pressure Sensor Input Signal

PCM CONNECTOR J2 (RED) CONTINUED

60

20

61

21

80

401

41

4547

Connector Part

Information

• PCM Connector YE123 J2 (Red)

• 80 Pin Connector

Pin Wire Color Circuit No. Function

33 Blue/White 304 Engine Cooling Fan Relay High Speed Control

34 Green/Yellow 428 Evaporative Emission Canister Purge Solenoid Control

35 Not Used - -

36 Not Used - -

37 Not Used - -

38 Not Used - -

39 White/Black 631 Camshaft Sensor Ignition Voltage Feed

40 Brown/Red 750 System Earth

41 Not Used - -

42 Grey/Red 422 Torque Converter Clutch Solenoid Control

43 LT Green/Black 366 A/C Clutch Relay Control

44 Yellow 838 Manual Transmission Reverse Lock-Out Control

45 Not Used - -

46 Not Used - -

47 Yellow/Black 1223 2-3 Shift Solenoid Control

48 LT Green 1222 1-2 Shift Solenoid Control

49 Not Used - -

50 Violet/White 123 Vehicle Speed Sensor Output Signal

51 Black/Yellow 1227 Transmission Fluid Temperature Sensor Input Signal

52 Not Used - -

53 Grey/Black 1687 Electronic Traction Control Retard Signal

54 Not Used - -

55 Not Used - -

56 Not Used - -

57 Green/Orange 469 Intake Air Temperature / A/C Refrigerant Pressure Sensor Earth

58 Brown/White 331 Oil Pressure Sensor Input Signal

59 Not Used - -

60 Brown 958 Ignition Reference Low

61 Violet 959 Ignition Reference Low

62 Grey 773 PRNDL C

63 Brown/Yellow 1224 Transmission Range A Input

PCM CONNECTOR J2 (RED) CONTINUED

60

20

61

21

80

401

41

4547

Connector Part

Information • PCM Connector YE123 J2 (Red)

• 80 Pin Connector

Pin Wire Color Circuit No. Function

64 Not Used - -

65 Not Used - -

66 LT Blue 978 Ignition Coil/Module Control #8

67 Yellow/Black 972 Ignition Coil/Module Control #2

68 Green 975 Ignition Coil/Module Control #5

69 Blue 973 Ignition Coil/Module Control #3

70 Not Used - -

71 Not Used - -

72 Not Used - -

73 Not Used - -

74 Not Used - -

75 Not Used - -

76 LT

Green/White 443 Idle Air Control Valve Coil B High

77 LT

Green/Black 444 Idle Air Control Valve Coil B Low

78 LT Blue/Black 442 Idle Air Control Valve Coil A Low

79 LT Blue 441 Idle Air Control Valve Coil A High

80 Not Used - -

PCM CONNECTOR TERMINAL DE FINITIONS

PCM CONNECTOR J1 (BLUE)

1 – SYSTEM EARTH – This terminal should have zero volts. This circuit is connected directly to the engine earth.

2 – CRANKSHAFT POSITION SENSOR IGNITION VOLTAGE FEED – This voltage should be always be B+

anytime the ignition is ON. It is a regulated voltage output from the PCM and supplies B+ to the CKP sensor.

3 – FUEL INJECTOR #3 DRIVER – W ith the engine OFF and the ignition ON, the voltage should be B+. W ith the

engine running at idle, the charging s ys tem inc reases the battery voltage slightly, s o this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

4 – FUEL INJECTOR #2 DRIVER – W ith the engine OFF and the ignition ON, the voltage should be B+. W ith the

engine running at idle, the charging s ys tem inc reases the battery voltage slightly, s o this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

5 – NOT USED

6 – NOT USED

7 – OIL PRESSURE SENSOR 5V REFERENCE – This voltage should always be 5 volts whenever the ignition is

ON. The reference voltage is a regulated voltage from the PCM, and supplies 5 volts to the oil pressure sensor.

8 – THROT TLE PO SITION SENSOR 5 VOL T REFERENCE – T his voltage should always be 5 volts whenever the

ignition is ON. The reference voltage is a regulated voltage from the PCM, and supplies 5 volts to the TP sensor.

9 – NOT USED

10 – NOT USED

11 – REAR KNOCK SENSOR INPUT SIGNAL – The knock sensor detects when detonation is occurring in the

combustion chambers. W hen detected, the PCM will reduce the amount of spark advance being delivered on the

EST output circuits to the ignition COIL/MODULES.

12 – CRANKSHAFT POSITION SENSOR INPUT SIGNAL – This terminal could be called the tech input. It

provides the PCM with RPM and crank shaft pos ition inform ation. T he PCM uses this signal to control fuel injection,

and spark timing.

13 – NOT USED

14 – NOT USED

15 – NOT USED

16 – NOT USED

17 – TRANSMISSION RANGE B INPUT – The PCM sends out a buffered B+ signal to the pressure switch

assembly., located in the automatic transmission valve body. The B+ signal must pass through either a normally

open or normally closed switch to reach earth. When the switches are closed, the signal should be near 0 volts.

The PCM monitors the status of these signals to determine which gear servo is actually receiving hydraulic apply

pressure.

18 – TRANSMISSION RANGE C INPUT – The PCM sends out a buffered B+ signal to the pressure switch

assembly located in the automatic transmission valve body. The B+ signal must pass through either a normally

open or normally closed switch to reach earth. When the switches are closed, the signal should be near 0 volts.

The PCM monitors the status of these signals to determine which gear servo is actually receiving hydraulic apply

pressure.

19 – IGNIT ION POSITIVE VO LTAG E – This is the wak e up s ignal to the PCM f rom the ignition s witch. It is not the

power supply to the PCM, it only tells the PCM that the ignition switch is ON. The voltage should equal the battery

voltage when the key is in either the RUN, or CRANK position.

20 – BATTERY FEED – T his supplies the PCM with full tim e B+ volts. This circuit stays hot even when the ignition

is turned OFF. The battery voltage feed circuit receives it’s voltage from fuse F31.

21 – CRANKSHAFT POSITION SENSOR REFERENCE LOW – This terminal should always be zero volts. It is

connected from the PCM to the CKP sensor and provides the earth signal needed for the sensor to operate.

22 – NOT USED

23 – NOT USED

24 – NOT USED

25 – NOT USED

26 – BANK 2 SENSOR 1 HEATED OXYGEN SENSO R SIGNAL LO W – This term inal should have zero volts. It is

connected f rom the PCM to the HO2S. T his term inal earth’s the PCM circuitry for the HO2S voltage monitor inside

the PCM.

27 – NOT USED

28 – NOT USED

29 – BANK 1 SENSOR 1 HEATED OXYGEN SENSO R SIGNAL LO W – This term inal should have zero volts. It is

connected f rom the PCM to the HO2S. T his term inal earth’s the PCM circuitry for the HO2S voltage monitor inside

the PCM.

30 – ENGINE COOLANT LEVEL SWITCH INPUT SIGNAL – This ter minal indicates to the PCM when the coolant

level is low. W hen the PCM receives this signal from the Engine Coolant Level switch, the PCM will turn ON a low

coolant warning lamp on the instrument panel.

31 – NOT USED

32 – PRNDL A – This circuit along with the circuits on PCM connec tor pins J1 34, 72 & J 2 62 indicate to the PCM

what transm ission gear the driver has selected. T he PCM will then send a com mand via the serial data line to the

instrument panel cluster (smart cluster) to indicate to the driver what gear has been selected.

33 – TORQUE CONVERTER CLUTCH/CRUISE BRAKE SWITCH INPUT SIGNAL – This signal indicates to the

PCM when the driver has depressed the brake pedal. The PCM will then disengage the TCC and or cruise if

activated. This circuit also indicates to the PCM and cruise control actuator when the ABS/ETC module is

requesting the Low Traction lamp ON.

34 – PRNDL P – T his circuit along with the circuits on PCM connector pins J1 32, 72 & J2 62 indicate to the PCM

what transmission gear the driver has selected. The PCM will then send a com mand via the serial data line to the

instrument panel cluster (smart cluster) to indicate to the driver what gear has been selected.

35 – NOT USED

36 – FUEL INJECTOR #1 DRIVER – With the engine OFF and the ignition ON, the voltage should be B+. With the

engine running at idle, the charging system increases battery voltage slightly, so this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

37 – FUEL INJECTOR #6 DRIVER – With the engine OFF and the ignition ON, the voltage should be B+. With the

engine running at idle, the charging system increases battery voltage slightly, so this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

38 – NOT USED

39 – NOT USED

40 – SYSTEM EARTH – This terminal should have zero volts. This circuit is connected directly to the engine earth.

41 – NOT USED

42 – NOT USED

43 – FUEL INJECTOR #7 DRIVER – With the engine OFF and the ignition O N, the voltage should be B+. With the

engine running at idle, the charging s ys tem inc reases the battery voltage slightly, s o this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

44 – FUEL INJECTOR #4 DRIVER – With the engine OFF and the ignition ON, the voltage should be B+. With the

engine running at idle, the charging s ys tem inc reases the battery voltage slightly, s o this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

45 – A/C REFRIGERANT PRESSURE SENSOR 5 VOLT REFERENCE – This voltage should always be 5 volts

anytim e the ignition is ON. It is a regulated voltage output from the PCM, and supplies 5 volts to the A/C Pressure

Sensor.

46 – NOT USED

47 – NOT USED

48 – MANIFOLD ABSOLUTE PRESSURE SENSOR 5 VOLT REFERENCE – This voltage should always be 5

volts anytime the ignition is ON. It is a regulated voltage output from the PCM and supplies 5 volts to the map

Sensor.

49 – NOT USED

50 – NOT USED

51 – FRONT KNOCK SENSOR – The Knock Sensor detects when detonation is occurring in the combustion

chambers. W hen detected, the PCM will reduce the amount of spark advance being delivered on the EST output

circuits to the ignition COIL/MODULES.

52 – NOT USED

53 – TRANSMISSION FLUID TEMPERATURE SENSOR EARTH – This terminal should be zero volts. It is

connected through the PCM circuitry to engine earth.

54 – MANIFOLD ABSOLUTE PRESSURE SENSOR EARTH – This terminal should have zero volts . T his circuit is

connected directly to the earth through the PCM.

55 – NOT USED

56 – NOT USED

57 – BATTERY FEED – T his supplies the PCM with full tim e B+ volts. This circuit stays hot even when the ignition

is turned off. The battery voltage feed circuit receives it’s voltage fuse F31.

58 – SERIAL DATA (CLASS II) –This is a dedicated line for the Tech 2 scan tool communication. The circuit

connects the PCM, PIM, ABS/ET C, and BCM. The Tec h 2 scan tool can talk to eac h of these m odules by sending

a message to a controller and asking only it to respond. The communication carried on Class II data streams are

prioritised. The normal voltage on this line is 0 volts, but when the Tech 2 scan tool is connected, the voltage will

about 7 volts indicating communication.

59 – NOT USED

60 – THROTTLE POSITION SENSOR EARTH – This terminal should have zero volts. This circuit is connected

directly to the earth through the PCM.

61 – CAMSHAFT POSITION SENSOR REFERENCE LOW – This terminal should always be zero volts. It is

connected from the PCM to the CMP sensor and provided the earth signal needed for the sensor to operate.

62 – NOT USED

63 – OIL PRESSURE SENSOR EARTH – This ter minal s hould always be zero volts. It is c onnected from the PCM

to the oil pressure sensor and provides the earth signal needed for the sensor to operate.

64 – NOT USED

65 – NOT USED

66 – BANK 2 SENSOR 1 OXYGEN SENSOR SIGNAL HIGH – With the ignition ON and the engine not running,

the voltage should be 350 – 450 millivolts (0.350 0.450 volts). This is the PCM supplied HO2S circuit bias voltage.

W hen the HO2S is hot and the engine is running, the voltage should be rapidly changing, somewhere between 10

– 1000 millivolts (0.010 – 1000 volts).

67 – NOT USED

68 – NOT USED

69 – BANK 1 SENSOR 1 HEATED OXYGEN SENSOR SIGNAL HIGH – W ith the ignition ON and the engine not

running, the voltage should be 350 – 450 millivolts (0.350 0.450 volts ). This is the PCM s upplied HO2S circuit bias

voltage. When the HO2S is hot and the engine is running, the voltage should be rapidly changing, somewhere

between 10 – 1000 millivolts (0.010 – 1000 volts).

70 – NOT USED

71 – POWER/ECONOM Y SWIT CH INPUT – T he PCM sends a signal of about 12 volts , and m onitors the status of

this circuit. In the ECONOMY position the switch is open, the PCM voltage status signal remains high – about 12

volts, and the PCM does not allow shift point changes. When the transmission switch is pressed to the POWER

position the switch is momentarily closed and the PCM voltage status signal is momentarily pulled low. The PCM

senses the momentary voltage signal drop and enables power mode shifting only if other criteria are met. These

criteria include throttle position and engine speed.

72 – PRNDL B – Th is circuit along with the circ uits on PCM connector pins J1 32, 34 & J2 62 indicate to the PCM

what transm ission gear the driver has selected. T he PCM will then send a com mand via the serial data line to the

instrument panel cluster (smart cluster) to indicate to the driver what gear has been selected.

73 – CAM SHAFT POSIT ION SENSOR INPUT SIGNAL – This s ignal indicates to the PCM when number 1 cylinder

is on the compression stroke.

74 – ENGINE COOLANT TEMPERATURE SENSOR SIGNAL – The PCM sends a 5 volt signal voltage to the

Engine Coolant Temperature sensor, which is a temperature variable resistor called thermistor. The sensor, being

also connected to earth, will alter the voltage according to engine coolant temperature. As the engine coolant

temper ature incr eases, the voltage s een on term inal C1 74 decr eases. At 0 degrees C engine coolant tem perature,

the voltage will be above 4 volts. At normal operating temperature, the voltage will be less than 2 volts. The PCM

uses this signal for fueling.

75 – NOT USED

76 – FUEL INJECTOR #5 DRIVER – With the engine OFF and the ignition O N, the voltage should be B+. With the

engine running at idle, the charging s ys tem inc reases the battery voltage slightly, s o this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

77 – FUEL INJECTOR #8 DRIVER – With the engine OFF and the ignition O N, the voltage should be B+. With the

engine running at idle, the charging s ys tem inc reases the battery voltage slightly, s o this voltage will increase. With

higher engine RPM or more engine load, the resulting increase in injector pulse frequency or injector pulse width

will cause this voltage to become slightly less.

78 – NOT USED

79 – 3-2 SHIFT SOLENOID CONTROL- The 3-2 shift solenoid is a normally closed, pulse width modulated

solenoid used to contr ol the 3-2 downshif t. The PCM oper ates the 3-2 s hift solenoid at a frequenc y of 50 Hz (cycles

per second). The solenoid is constantly fed B+ and the PCM controls the length of time the path to earth for the

electrical circuit is closed.

80 – ENGINE COOLANT TEM PERAT URE SENSOR EART H – This term inal should have zero volts. T his circuit is

connected directly to the earth through the PCM.

PCM CONNECTOR J2 (RED)

1 – SYSTEM EARTH – This terminal should have zero volts. This circuit is connected directly to the engine earth.

2 – TORQUE CONVERTER CLUTCH PULSE WIDTH MODULATION SOLENOID CONTROL – The PCM uses

the pulse width modulation (PWM) TCC apply solenoid to smoothly engage the torque converter clutch after the

TCC ENABLE s olenoid is energised. By varying the duty cycle puls e width m odulation, the PCM can slowly engage

the torque converter clutch, allowing very smooth TCC engagement.

3 – NOT USED

4 – NOT USED

5 – NOT USED

6 – PRESSURE CONTROL SOLENOID HIGH – The duty cycle, and amount of current flow to the TFP, is

controlled by the PCM. This circuit is the B+ supply line from the PCM to the TFP. The duty cycle and amperage

are controlled by the PCM.

7 – NOT USED

8 – PRESSURE CONT ROL SOLENOID LOW – The 4L60-E automatic transm ission uses an electric al solenoid to

control hydraulic pressure inside the transmission. This electrical solenoid allows the PCM to control line pressure,

similar to other automatic transmissions that use a throttle valve cable or vacuum modulator. The duty cycle, and

amount of cur rent f low to the PCS, are both controlled by the PCM. By m onitoring this line, the PCM can determ ine

if the commanded amperage has gone to the PCS and returned to the PCM.

9 – FUEL PUMP (FP) RELAY CONTROL – Turning the ignition ON causes the PCM to energise (+12V) the Fuel

Pump Relay. If no crankshaft reference input pulses are received, the PCM turns OFF the relay. As soon as the

PCM receives crankshaft reference input pulses, the PCM will turn the Fuel Pump Relay ON again.

10 – TACHOMETER OUTPUT SIGNAL – This signal is used to operate the tachometer located in the instrument

panel cluster. The PCM determines then signal based off of the CKP sensor.

11 – NOT USED

12 – NOT USED

13 – NOT USED

14 – A/C REFRIGERANT PRESSURE SENSOR INPUT SIGNAL – The signal that is sent from the pressure

sensor to the PCM indicates to the PCM what the A/C pressure is. Depending on the A/C pressure, this signal will

indicate to the PCM if A/C pressure is too LOW or too HIGH.

15 – NOT USED

16 – NOT USED

17 – NOT USED

18 – A/C CLUTCH STATUS – This circuit is a feed back signal to the PCM indicating that the A/C compressor

relay has supplied the s ignal to the c ompress or c lutch. The PCM uses this c irc uit to determine if there is a f ault with

the A/C compressor relay.

19 – NOT USED

20 – VEHICLE SPEED SENSOR SIGNAL LOW – T he transm ission has an output shaf t speed sensor used by the

PCM to calculate Vehicle Speed, and to help determine various transmission shifting functions. It is a magnetic

inductive sensor that generates an AC voltage signal sent to the PCM. If m easured with the digital AC multim eter,

no voltage will appear until the output shaft begins turning.

21 – VEHICLE SPEED SENSOR SIGNAL HIGH – The tr ansm ission has an output shaft s peed sensor used by the

PCM to calculate vehicle speed, and to help determine various automatic transmission shifting functions. It is a

magnetic inductive sensor that generates an AC voltage signal sent to the PCM. If measured with the digital AC

multimeter, no voltage will appear until the output shaft begins turning.

22 – NOT USED

23 – NOT USED

24 – THROTT LE POSIT ION SENSOR INPUT SIGNAL – The T P sensor input voltage, which f ollows actual throttle

changes, is variable from 0 to 5 volts. Typically the voltage is less than 1 volt at idle, and 4 to 5 volts at wide-open

throttle.

25 – INTAKE AIR TEM PERATURE SENSO R SIGNAL – T he PCM sends a 5 volt s ignal voltage to the IAT sensor ,

which is a tem perature – variable – resistor called a thermist or. T he sensor is also c onnected to earth, and will alter

the signal voltage ac cor ding to inc oming air temperatur e. As the air temperature inc r eas es, the voltage s een on this

term inal decreas es. At 0 degrees C, the voltage will be above 4 volts. At norm al operating temperature (10 degrees

C to 80 degrees C) the voltage will be less than 4 volts.

26 – IGNITION COIL/MODULE CONTROL #1 – This terminal is what triggers the ignition system coil/module for

cylinder #1. This terminal is connected from the PCM to the #1 ignition coil/module connector terminal G.

27 – IGNITION COIL/MODULE CONTROL #7 – This terminal is what triggers the ignition system coil/module for

cylinder #1. This terminal is connected from the PCM to the #7 ignition coil/module connector terminal B.

28 – IGNITION COIL/MODULE CONTROL #6 – This terminal is what triggers the ignition system coil/module for

cylinder #1. This terminal is connected from the PCM to the #6 ignition coil/module connector terminal F.

29 – IGNITION COIL/MODULE CONTROL #4 – This terminal is what triggers the ignition system coil/module for

cylinder #1. This terminal is connected from the PCM to the #4 ignition coil/module connector terminal C.

30 – NOT USED

31 – M ASS AIR FLOW SENSOR SIGNAL – The PCM supplies a 5-volt signal voltage to the mass air flow sensor

on this circuit. The mass air flow sensor pulses the 5-volt signal to earth. These earth pulses occur at a very fast

rate – f r om les s than 500 per s ec ond (500 Hz) with no airflow through the sens or , to upwards of many thousands of

pulses per s econd at high air f low rates such as dur ing acceleration. If meas ured, the voltage seen will be between

0.5 and 4.5 volts, depending on air flow through the sensor.

32 – MANIFOLD ABSOLUTE PRESSURE SENSOR INPUT SIGNAL – The voltage seen will vary with intake

manifold pressure. With the ignition ON but the engine not running (High manifold pressure), the voltage will be

above 4 volts . At this time the s ensor ac tually is meas ur ing the barometric pres s ur e, so this voltage will change with

both barometric pressure and altitude changes. W hen the engine is running at idle, the manifold pressure is quite

low because of engine vacuum, and the voltage will also be low, 1 to 2 volts. The voltage is variable, mostly from

engine vacuum changes, but can also change with barometric pressure or altitude changes. This input is typically

called the engine load input.

33 – ENGINE COOLING FAN RELAY HIGH SPEED CONTROL – This terminal will have battery voltage until the

PCM energises the high speed cooling fan relay by supplying the earth; then it will be close to zero. The input that

causes the PCM to ener gise the high speed fan relay is the engine coolant temper ature sensor. The PCM will also

energise the high speed fan relay in the Diagnostic Mode – i.e., ignition ON, engine stopped, and DLC diagnostic

test enable terminal earthed. (The Body Control Module operates the cooling fan low speed relay).

34 – EVAPORATIVE EMISSION CANISTER PURGE SOLENOID CONTROL – The PCM operates a normally

closed solenoid valve, which controls vacuum to purge the evaporative emissions storage canister of stored fuel

vapours. The PCM turns ON the pulse width modulated control of the purge solenoid to control purging of the

stored vapours . If the PCM is not energising the pur ge solenoid, the voltage m easur ed at this term inal s hould equal

battery voltage. If the PCM is controlling the solenoid, the measured voltage will be between battery voltage and

0.50 volts.

35 – NOT USED

36 – NOT USED

37 – NOT USED

38 – NOT USED

39 – CAMSHAFT SENSOR IGNITION VOLTAGE FEED – This voltage should be always be B+ anytime the

ignition is ON. It is a regulated voltage output from the PCM, and supplies B+ to the CMP sensor.

40 – SYSTEM EARTH – This terminal should have zero volts. This circuit is connected directly to the engine earth.

41 – NOT USED

42 – TORQUE CONVERTER CLUTCH SOLENOID CONTROL – The PCM is used to either open or provide a

path to earth for the torque converter solenoid. When the PCM provides a path to earth, the TCC solenoid is

considered ON and voltage should be near 0 volts. The PCM uses both the TCC enable solenoid and the TCC

PWM solenoid to control the torque converter clutch.

43 – A/C CLUTCH RELAY CONTROL – When the A/C is requested, the BCM will communicate to the PCM

through the PIM via the serial data line, requesting A/C. The PCM supplies the earth path on this terminal to

energise the A/C control relay. The voltage will be less than 1 volt when the PCM energises the relay. When the

PCM does energise the A/C control relay, the voltage will be more than 0.1, but less than 1 volt.

44 – MANUAL TRANSMISSION REVERSE LOCK-OUT CONTROL – If this vehicle is equipped with a manual

transmission, this solenoid will prevent the transmission from going into reverse gear when the vehicle speed is

above 8 Kmh. W hen the vehicle speed is below 8 Kmh the PCM will supply the earth signal to the solenoid which

will allow the transmission to be shifted into reverse gear. The PCM looks at the VSS input signal to determine

vehicle speed for reverse shifting. If there is a fault with this circuit, DTC P0801 will set.

45 – NOT USED

46 – NOT USED

47 – 2-3 SHIFT SOLENOID CONTROL – The PCM is used to either open or provide a path to earth for the 2-3

shift solenoid. When the PCM provides a path to earth, the 2-3 shift solenoid is considered ON and the voltage

should read 0 volts.

48 – 1-2 SHIFT SOLENOID CONTROL – The PCM is used to either open or provide a path to earth for the 1-2

shift solenoid. When the PCM provides a path to earth, the 1-2 shift solenoid is considered ON and the voltage

should read 0 volts.

49 – NOT USED

50 – VEHICLE SPEED SENSOR OUTPUT SIGNAL – The PCM alternately earth’s this signal, in pulses, when it

receives a vehicle speed signal from the vehicle speed sensor in the transm ission. This pulsing action takes place

about 6250 times per kilometre. The speedometer calculates vehicle speed based on the time between pulses.

51 – TRANSMISSION F LUID T EM PERAT URE SENSOR INPUT SIGN AL – The PCM s ends a 5 volt signal voltage

out to the transmission fluid temperature sensor, which is a temperature-variable-resistor called a thermistor. The

sensor, being als o connected to ear th, will alter the voltage accor ding to transm is sion fluid tem perature. As the fluid

temperature increases, the voltage seen on this terminal will decrease.

52 – NOT USED

53 – ELECTRONIC TRACTION CONTROL RETARD SIGNAL – The ABS/ETC module will send a N.m signal to

the PCM when torque reduction is r equested fr om the ABS/ET C m odule for traction contr ol. T his N.m signal s hould

match closely with Torque Achieved N.m signal, when traction control is being requested.

54 – NOT USED

55 – NOT USED

56 – NOT USED

57 – INTAKE AIR TEMPERATURE SENSOR & A/C REFRIGERANT PRESSURE SENSOR EARTH – This

terminal should be zero volts. It is connected through the PCM circuitry to engine earth.

58 – OIL PRESSURE SENSOR INPUT SIGNAL – T his s ignal indic ates to the PCM when the oil level is low. When

the PCM receives this predetermined voltage from the oil pressure sensor, the PCM will turn ON the oil warning

lamp.

59 – NOT USED

60 – IGNITION REFERENCE LOW – T his term inal should always be zero volts. It is the earth signal f or the ignition

coil/modules 1, 3, 5 & 7.

61 – IGNITION REFERENCE LOW – T his term inal should always be zero volts. It is the earth signal f or the ignition

coil/modules 2, 4, 6 & 8.

62 – PRNDL C – T his circ uit, along with the c ircuits on PCM connec tor pins J1 32, 34 & 72 , indicates to the PCM

what transm ission gear the driver has selected. T he PCM will then send a com mand via the serial data line to the

instrument panel cluster (smart cluster) to indicate to the driver what gear has been selected.

63 – TRANSMISSION RANGE A INPUT – The PCM sends out a buffered 12 volt signal to the pressure switch

assem bly, located in the autom atic tr ansm iss ion valve body. The 12 volt signal mus t pass through either a normally

open or normally closed switch to reach earth. When the switches are closed, the signal should be near 0 volts.

The PCM monitors the status of these signals to determine which gear servo is actually receiving hydraulic apply

pressure.

64 – NOT USED

65 – NOT USED

66 – IGNITION COIL/MODULE CONTROL #8 – This terminal is what triggers the ignition system coil/module for

cylinder #8. This terminal is connected from the PCM to the #8 ignition coil/module connector terminal G.

67 – IGNITION COIL/MODULE CONTROL #2 – This terminal is what triggers the ignition system coil/module for

cylinder #2. This terminal is connected from the PCM to the #2 ignition coil/module connector terminal B.

68 – IGNITION COIL/MODULE CONTROL #5 – This terminal is what triggers the ignition system coil/module for

cylinder #5. This terminal is connected from the PCM to the #5 ignition coil/module connector terminal C.

69 – IGNITION COIL/MODULE CONTROL #3 – This terminal is what triggers the ignition system coil/module for

cylinder #3. This terminal is connected from the PCM to the #3 ignition coil/module connector terminal F.

70 – NOT USED

71 – NOT USED

72 – NOT USED

73 – NOT USED

74 – NOT USED

75 – NOT USED

76 – IDLE AIR CONT ROL VALVE COIL B HIGH – T his term inal connec ts the Idle Air Contr ol valve, located on the

throttle body, to the PCM. It is diff icult to predict what the voltage will be, and the meas urement is unusable for any

service procedures.

77 – IDLE AIR CONTROL VALVE COIL B LOW – This ter m inal connec ts the Idle Air Control valve, loc ated on the

throttle body, to the PCM. It is diff icult to predict what the voltage will be, and the meas urement is unusable for any

service procedures.

78 – IDLE AIR CONTROL VALVE COIL A LOW – This term inal connec ts the Idle Air Control valve, located on the

throttle body, to the PCM. It is diff icult to predict what the voltage will be, and the meas urement is unusable for any

service procedures.

79 – IDLE AIR CONT ROL VALVE COIL A HIGH – This ter m inal connects the Idle Air Control valve, loc ated on the

throttle body, to the PCM. It is diff icult to predict what the voltage will be, and the meas urement is unusable for any

service procedures.

80 – NOT USED

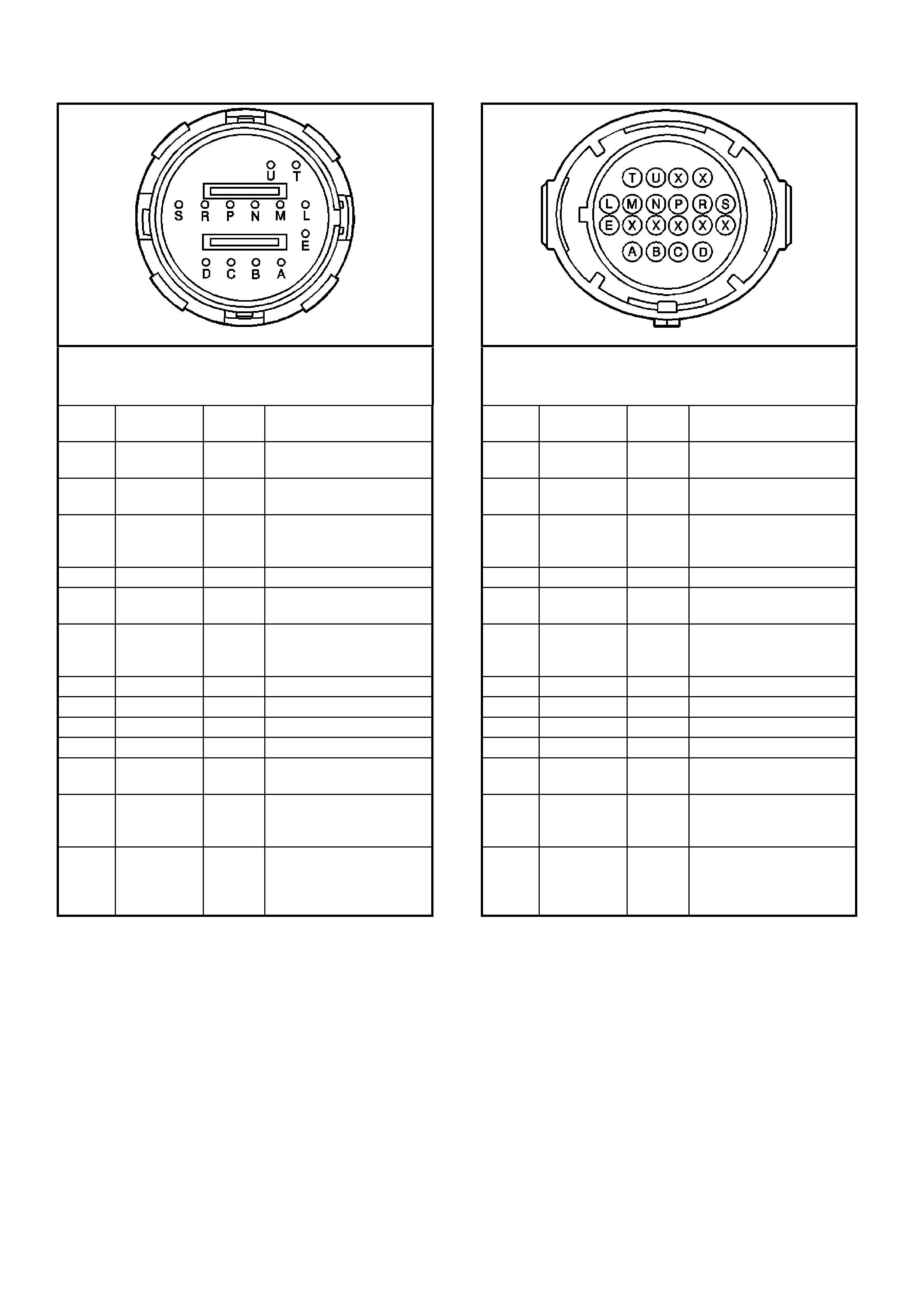

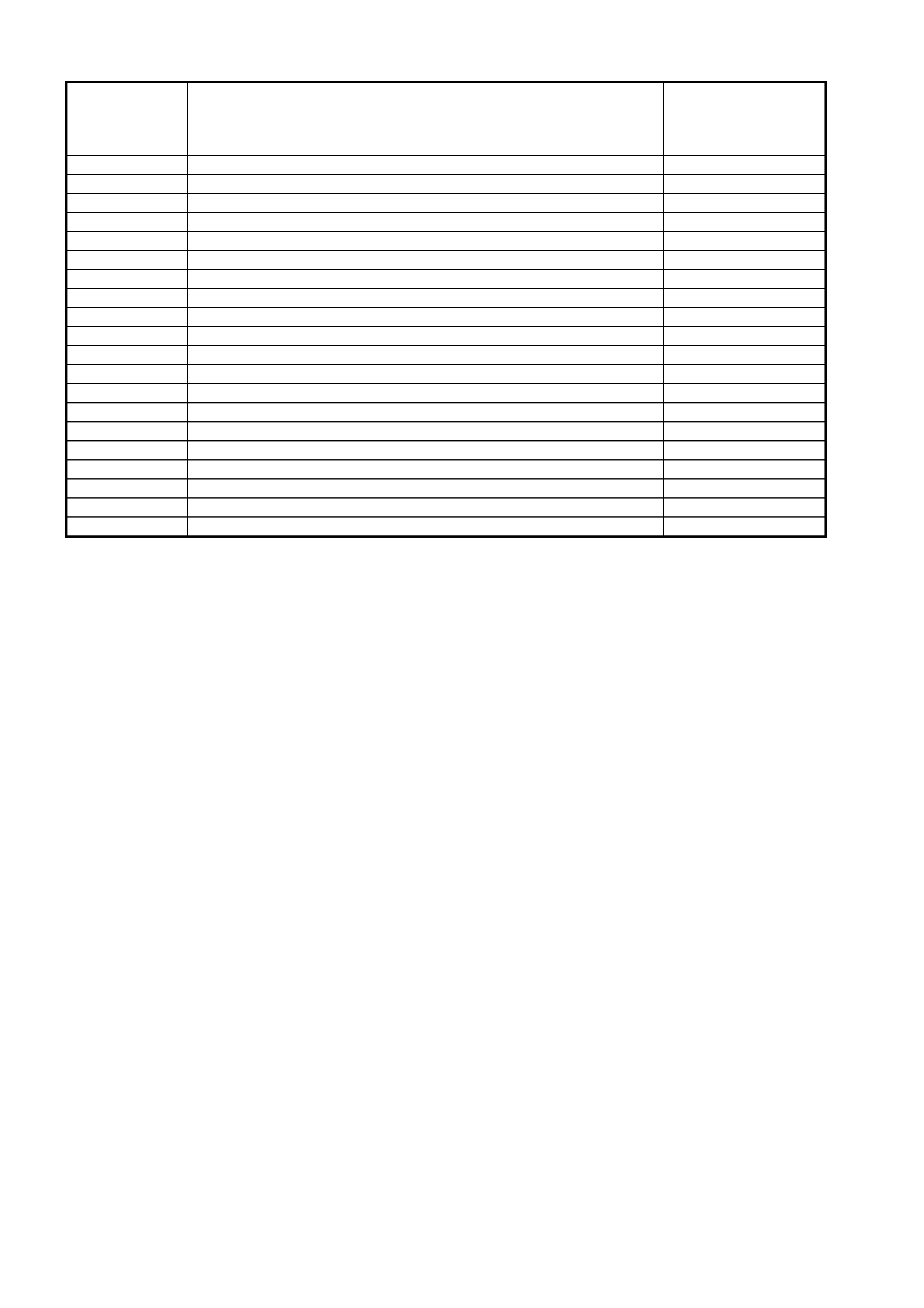

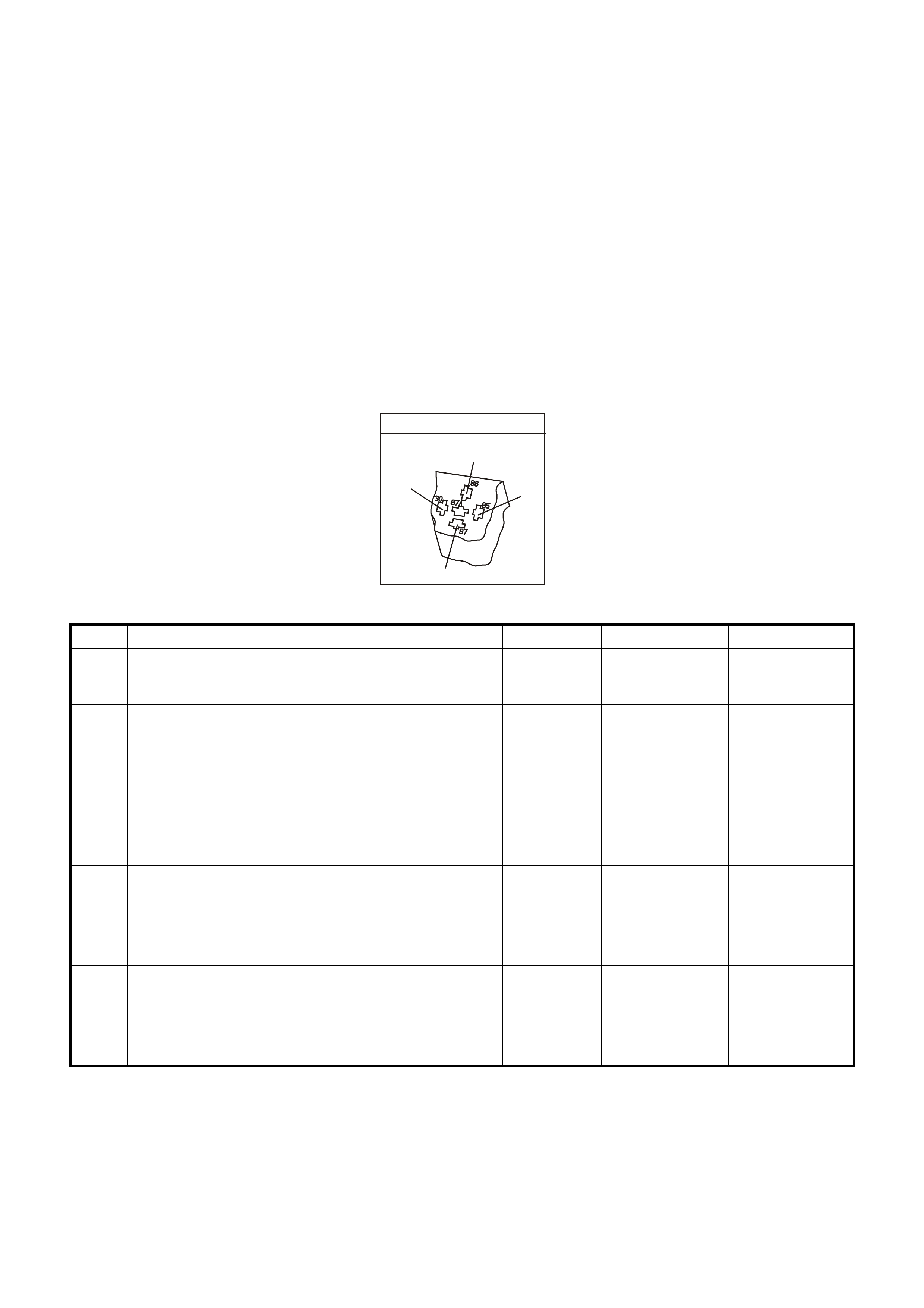

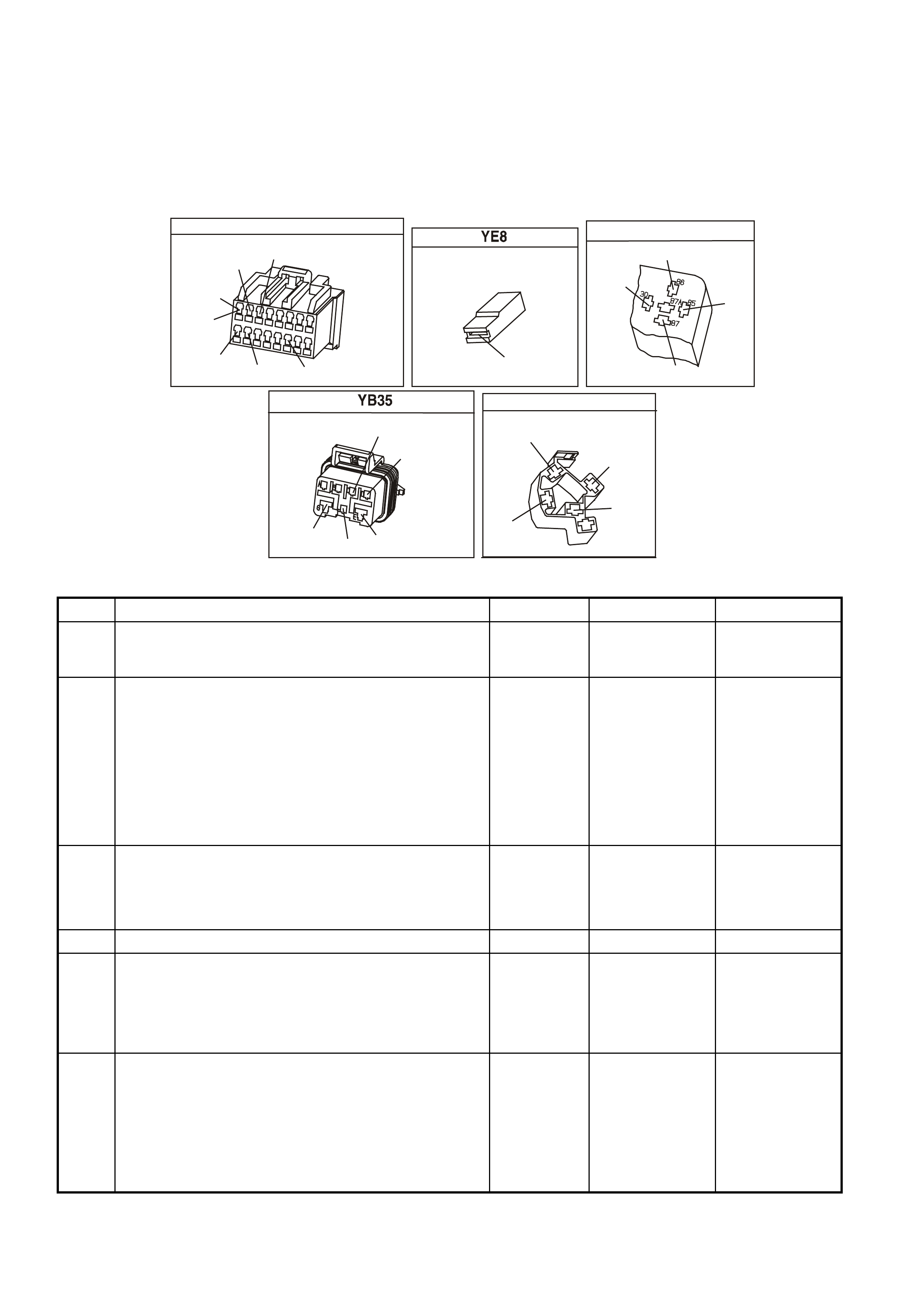

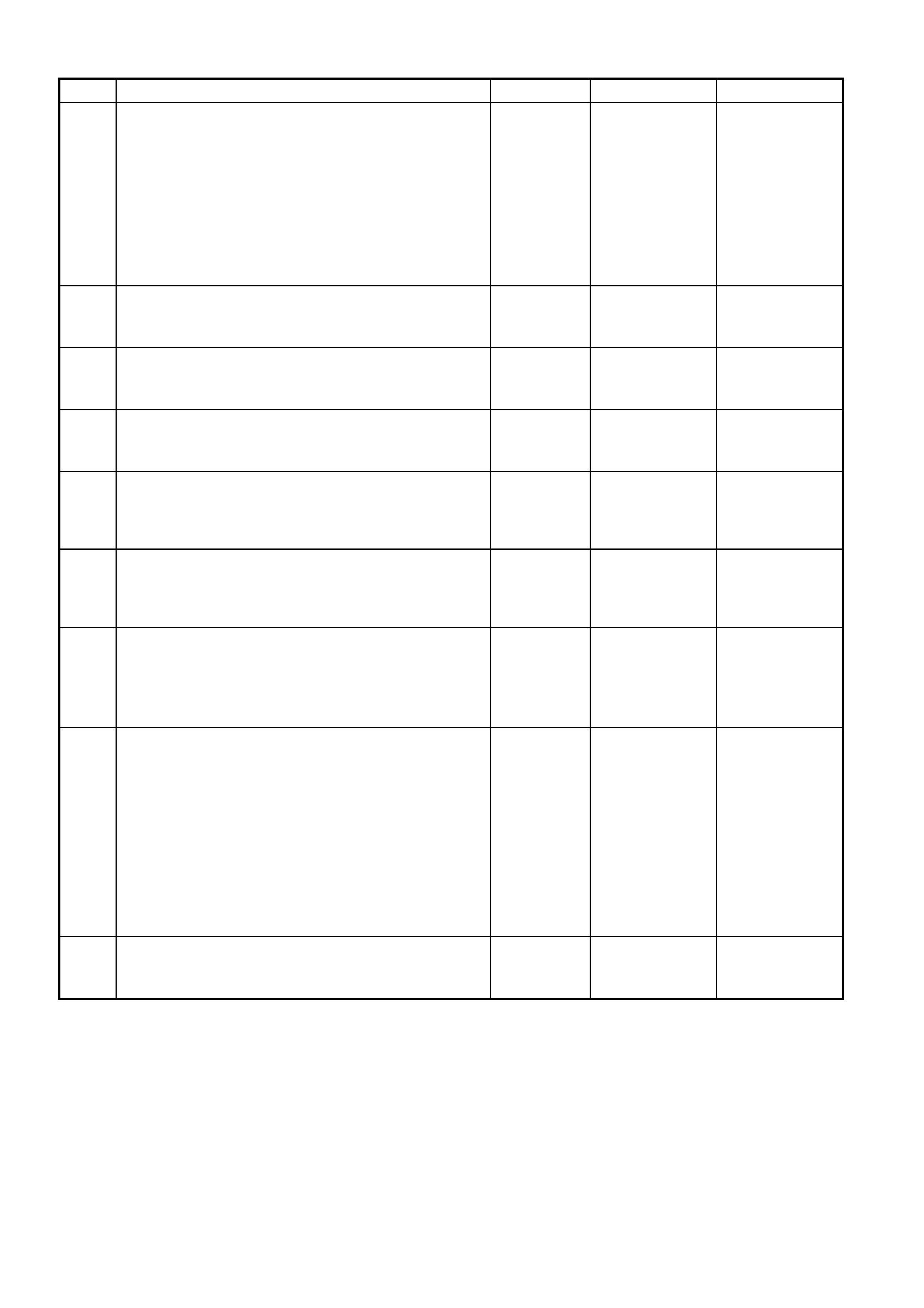

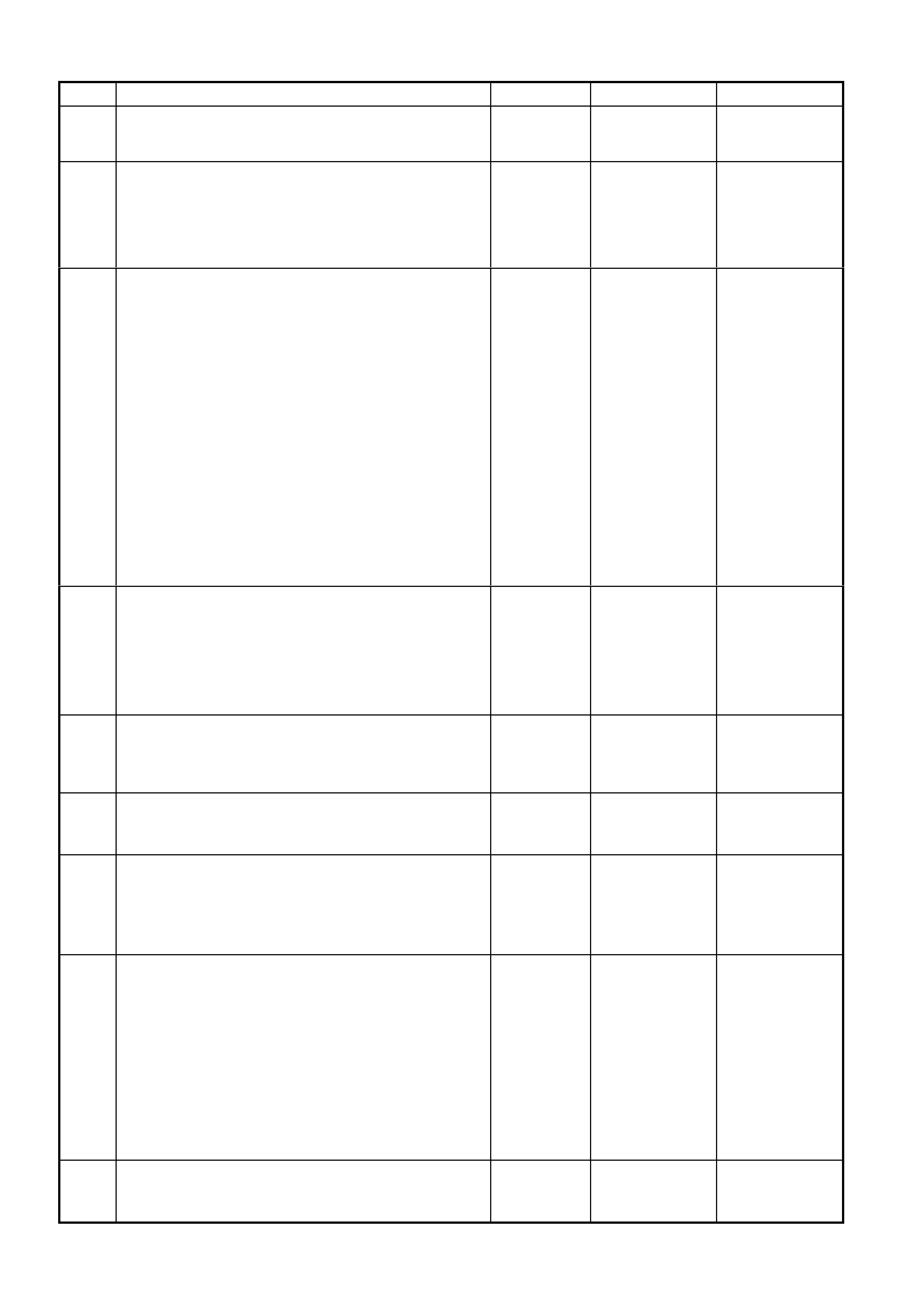

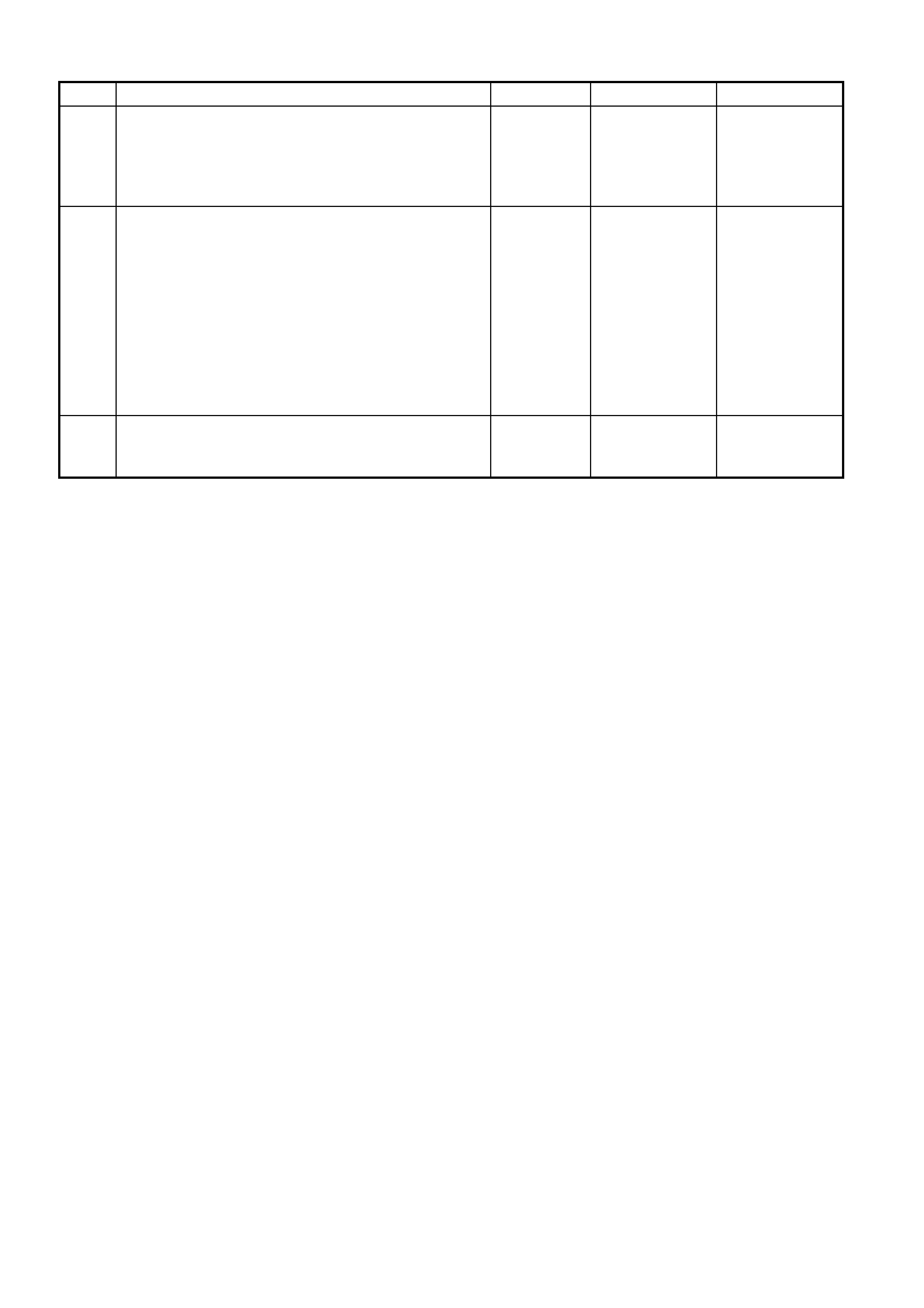

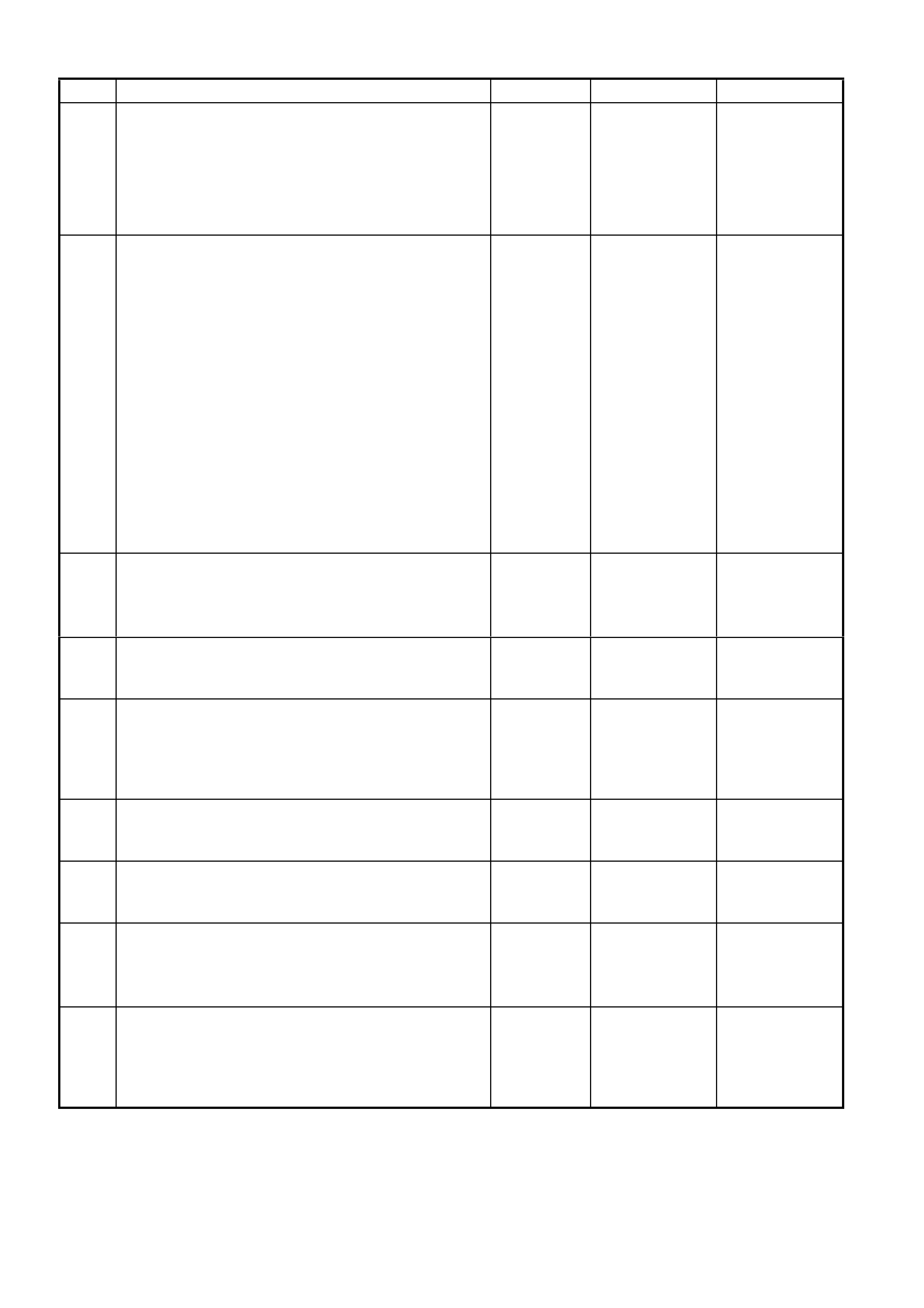

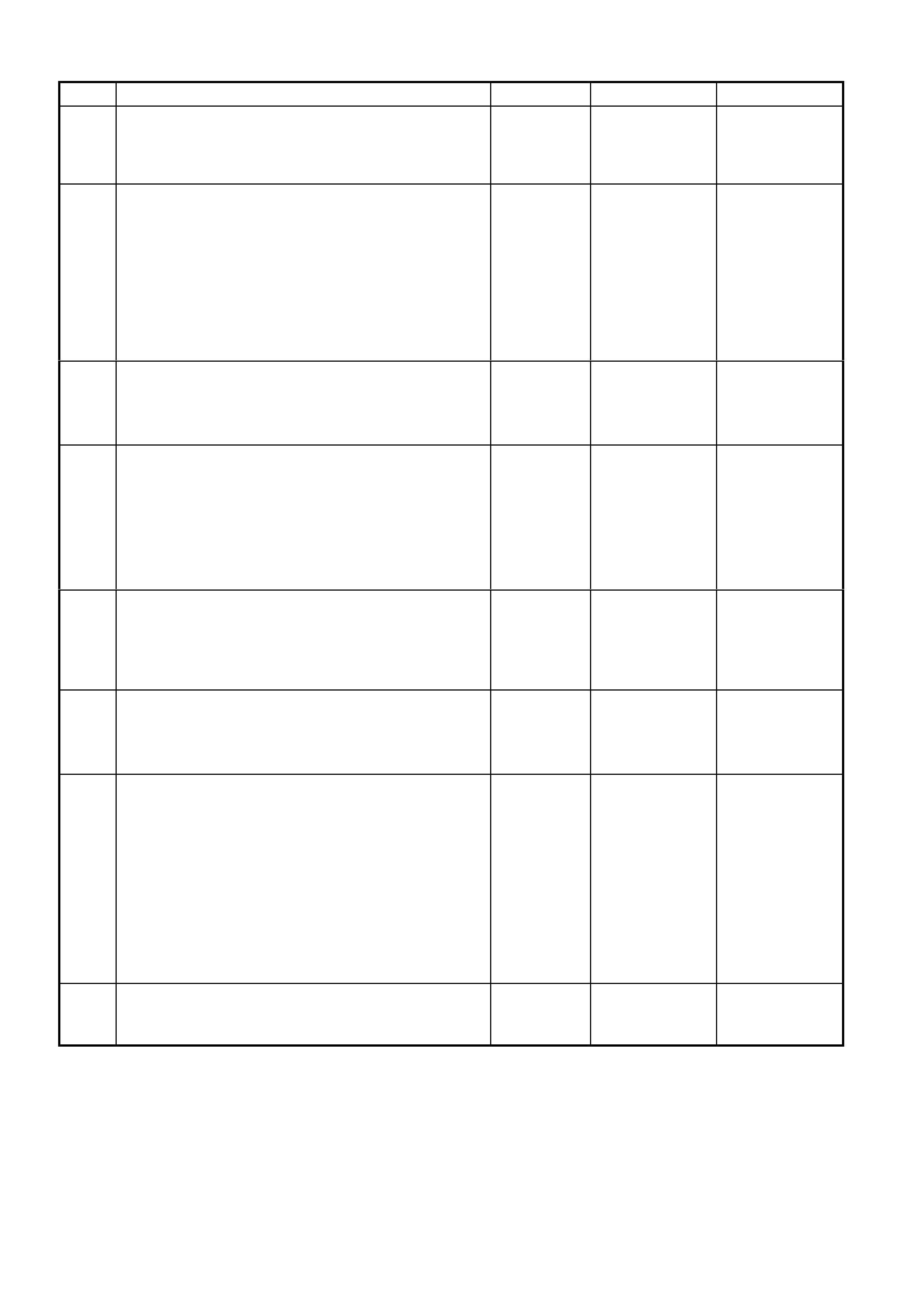

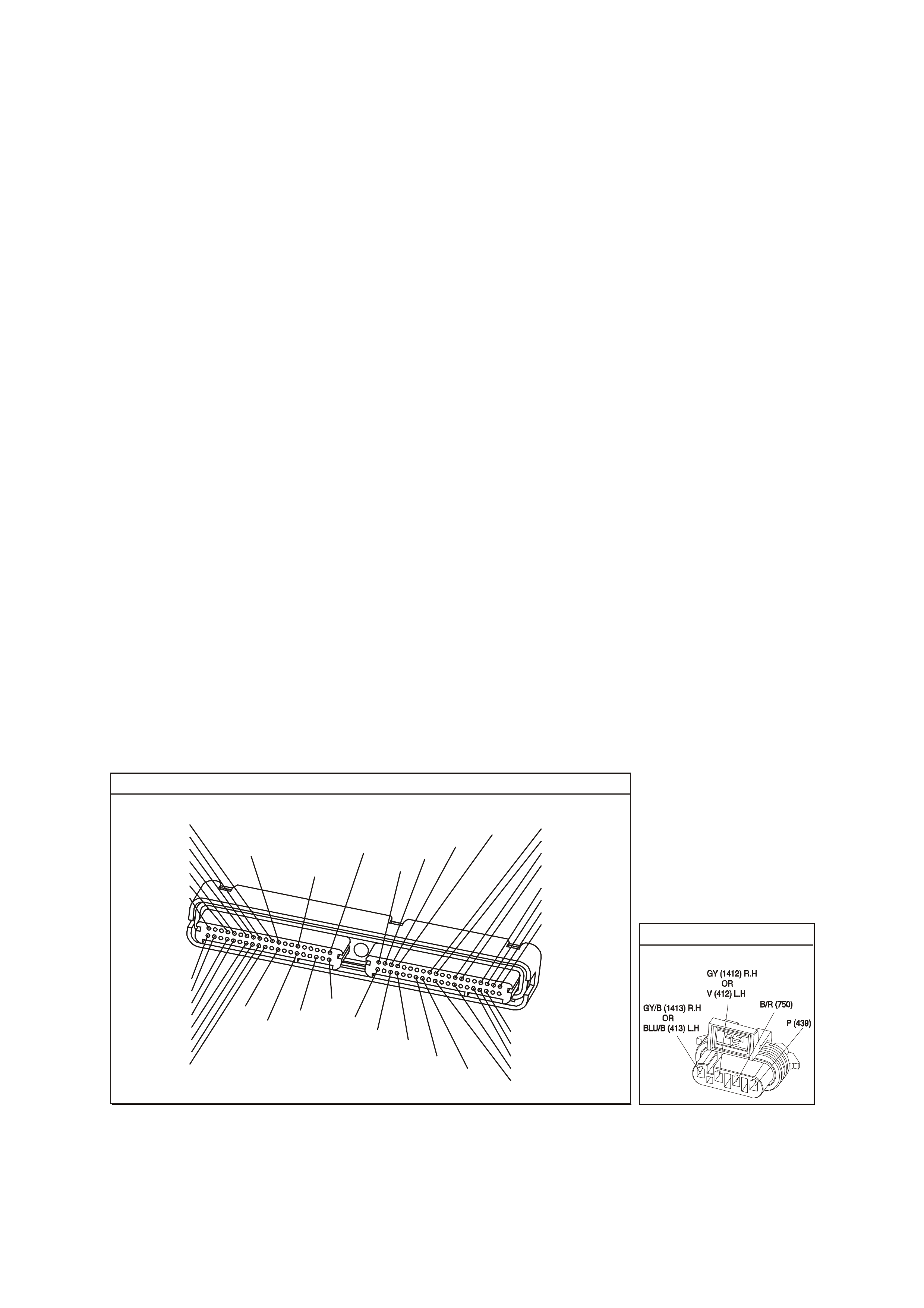

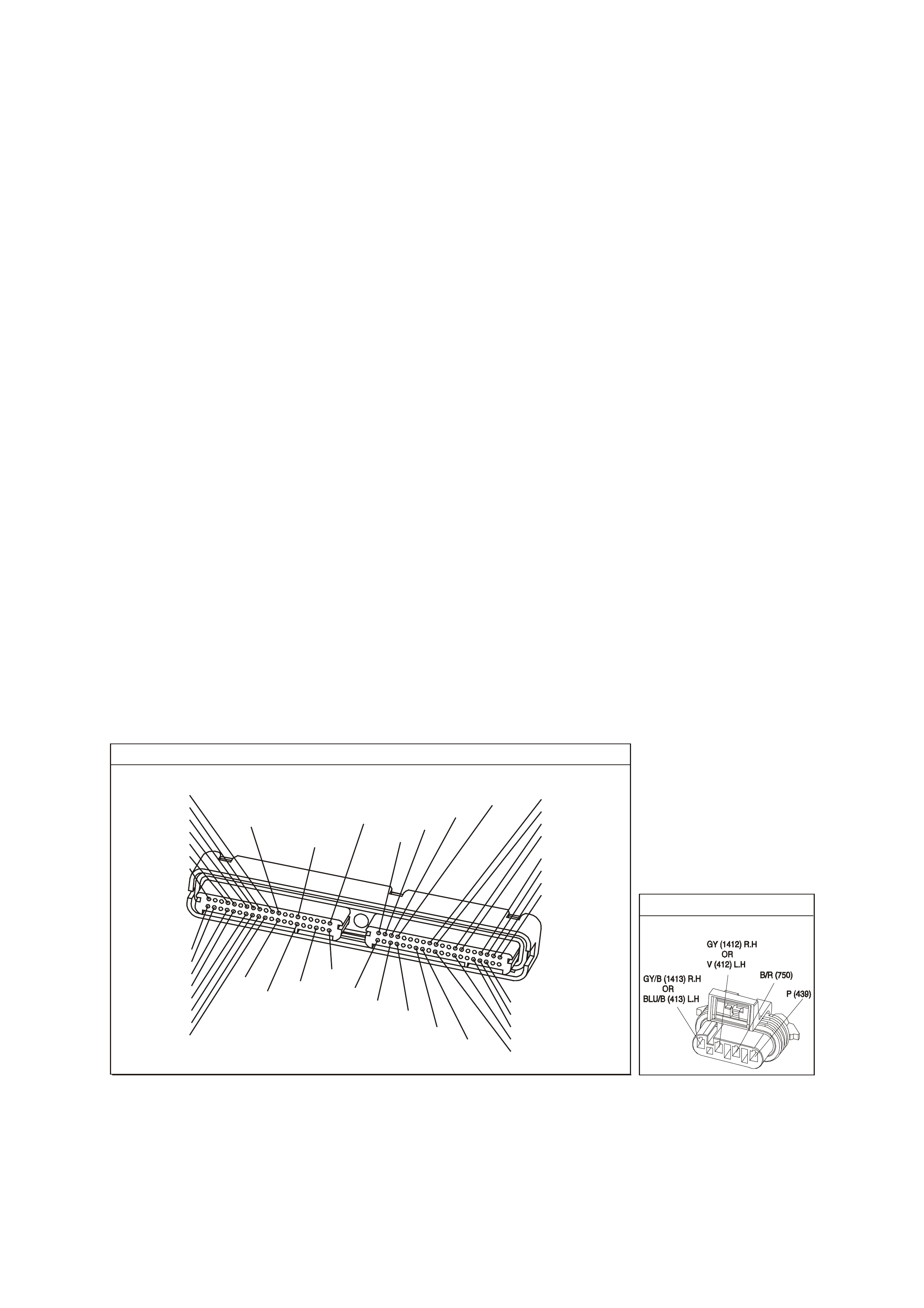

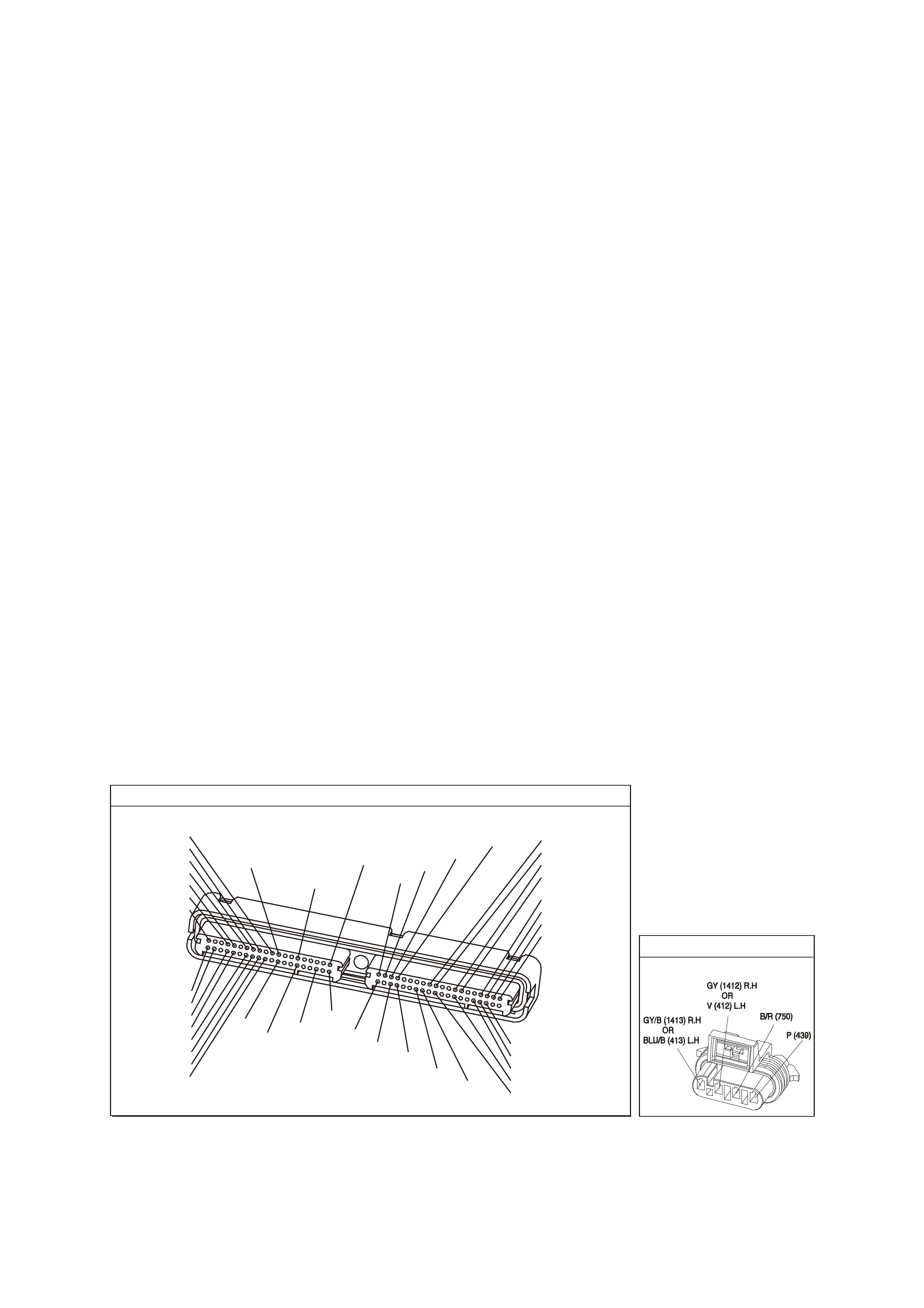

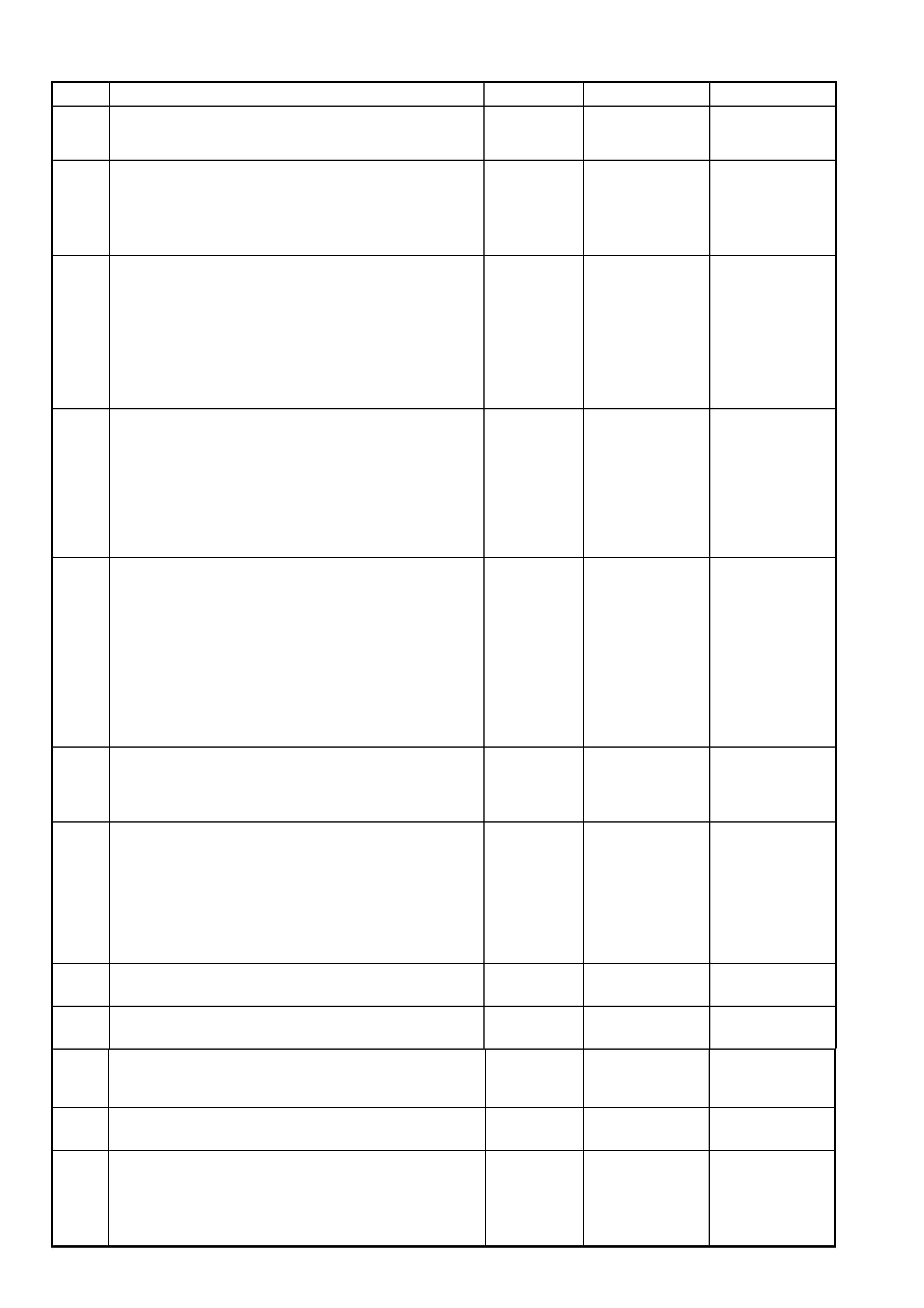

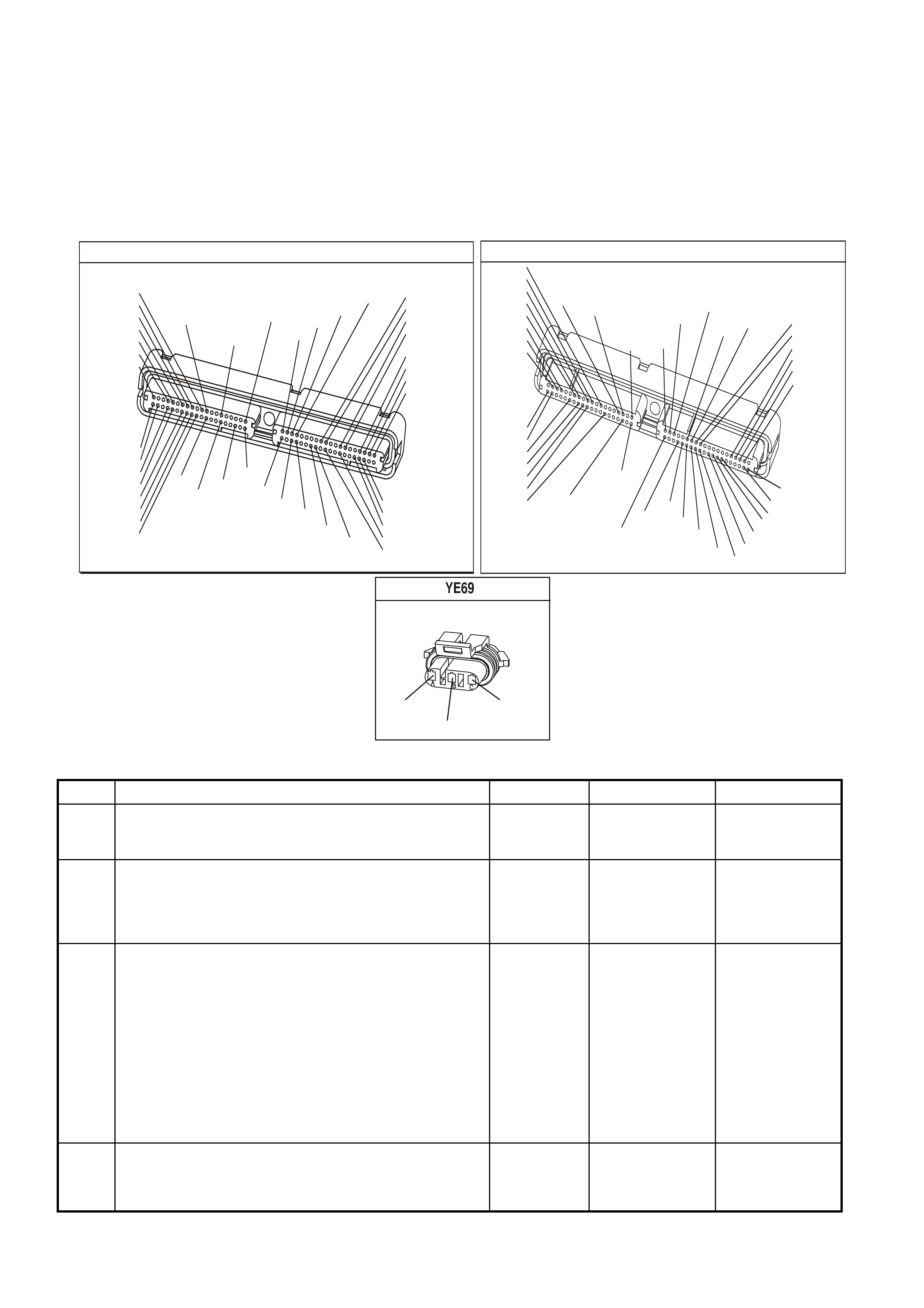

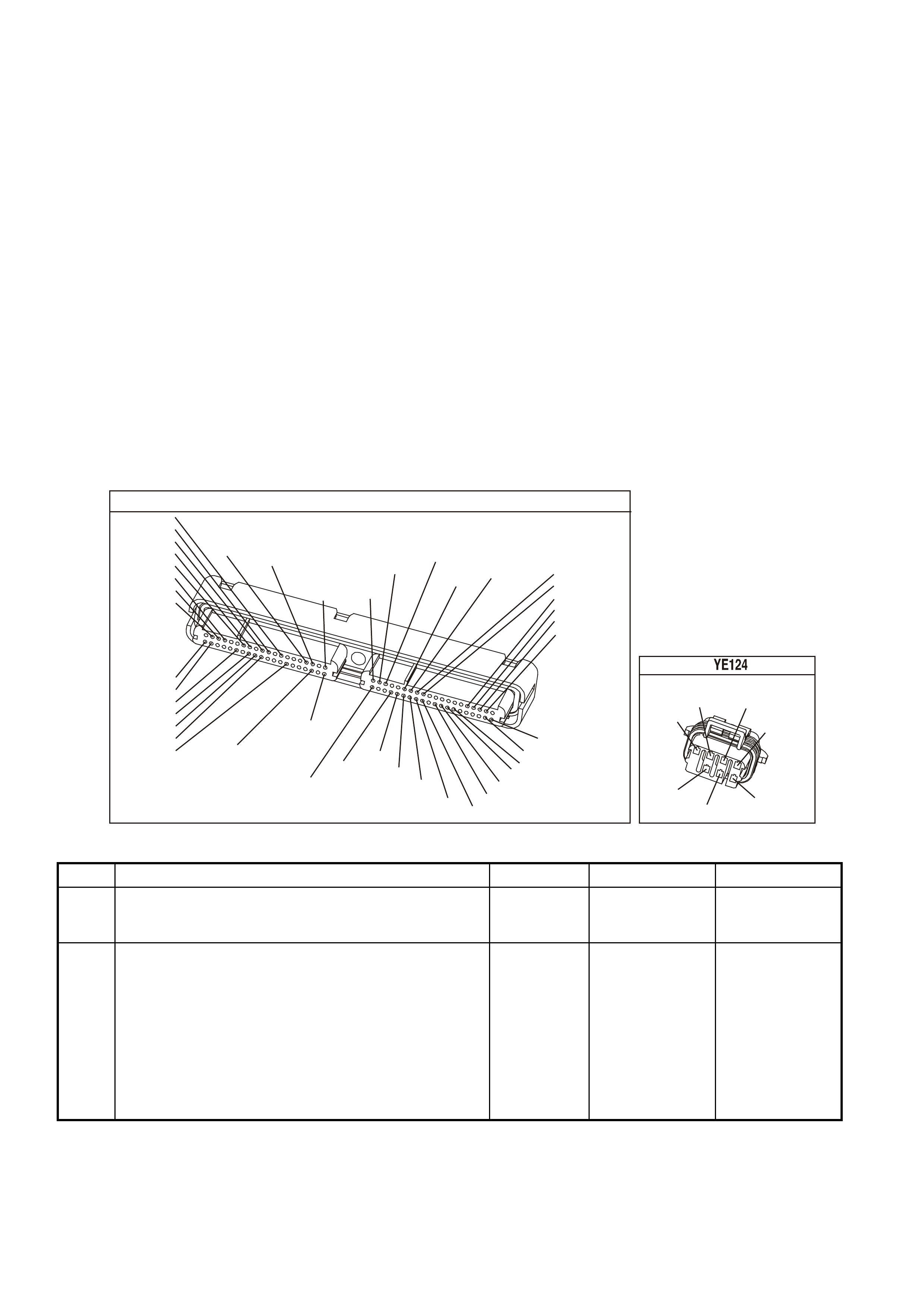

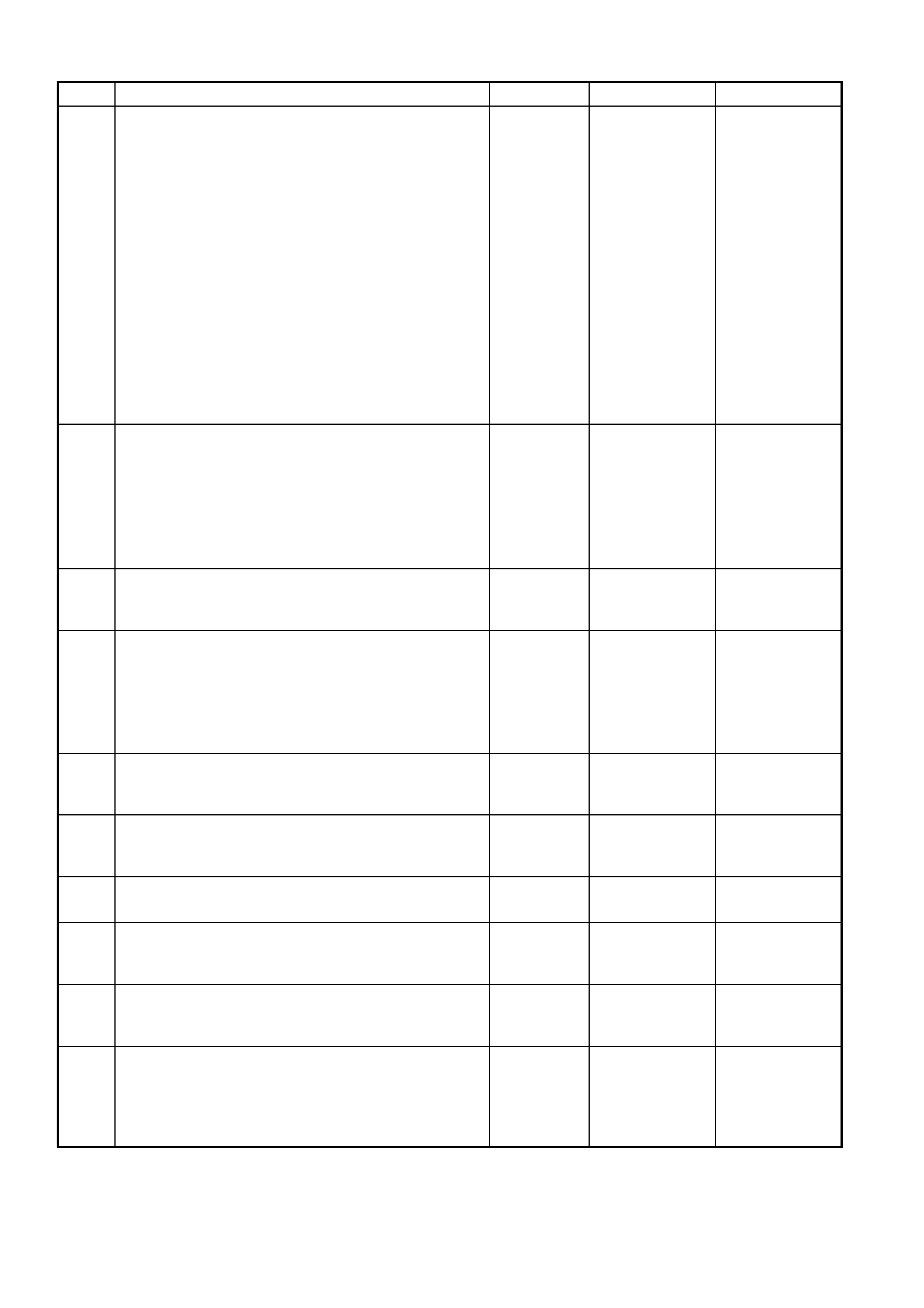

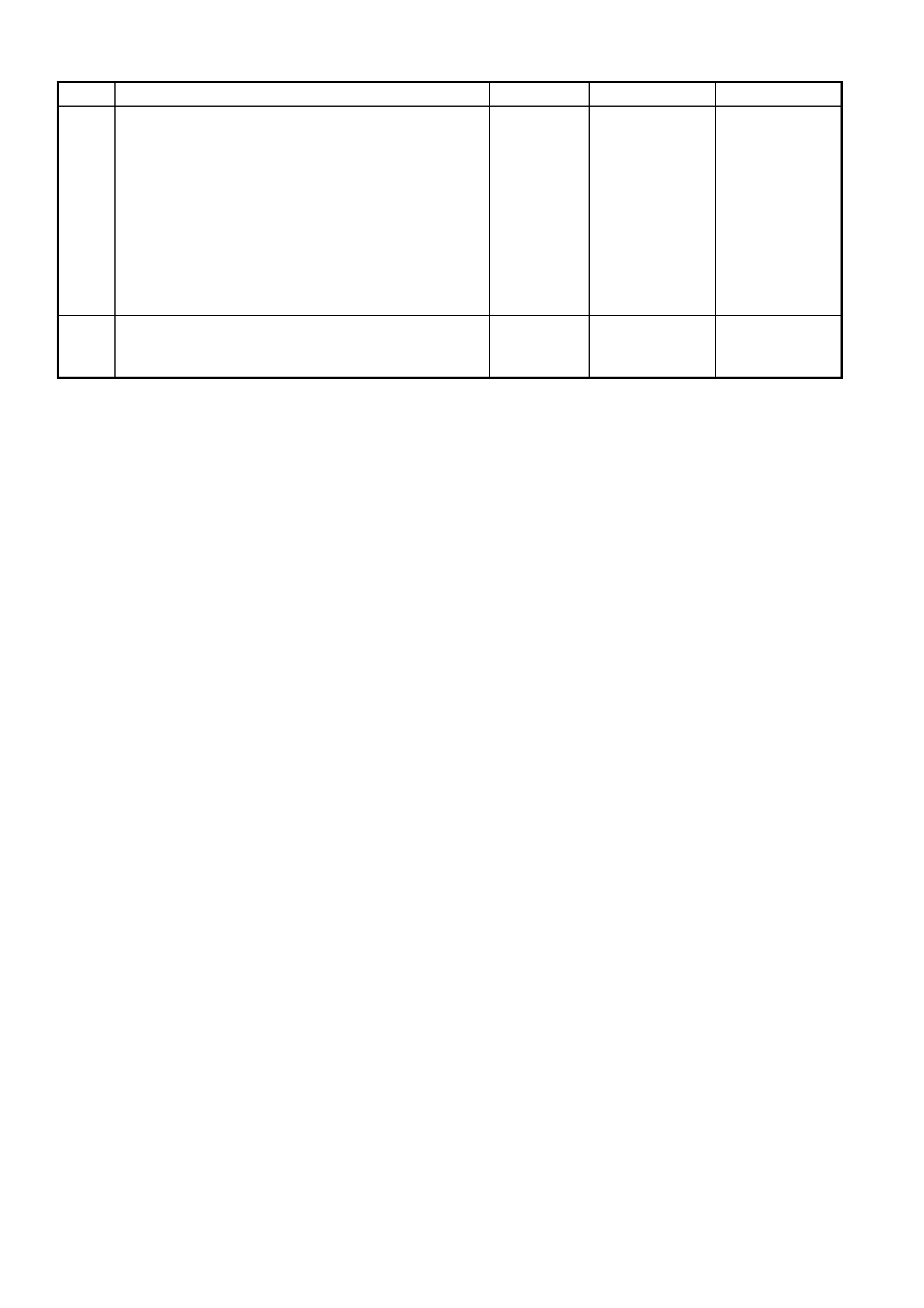

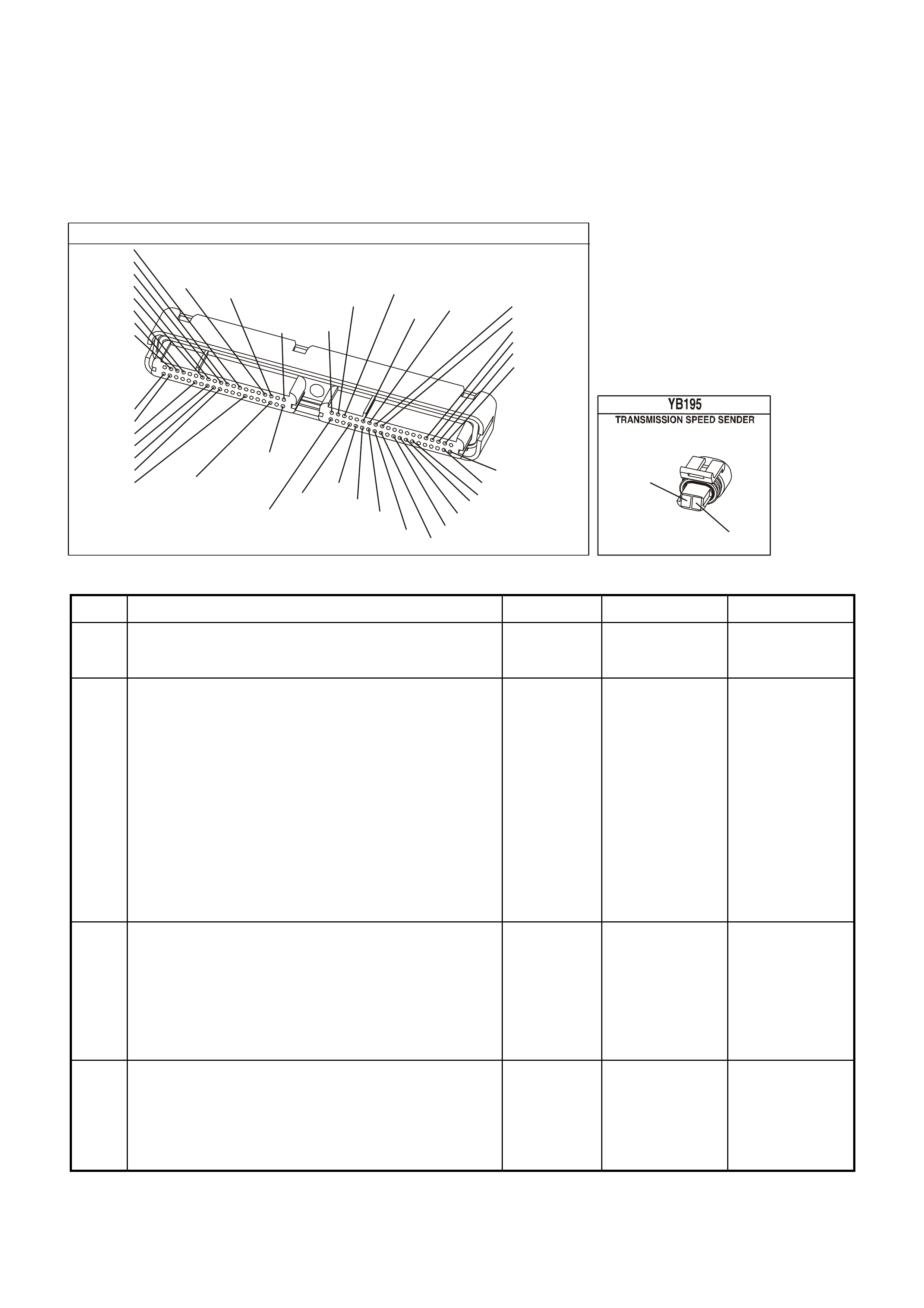

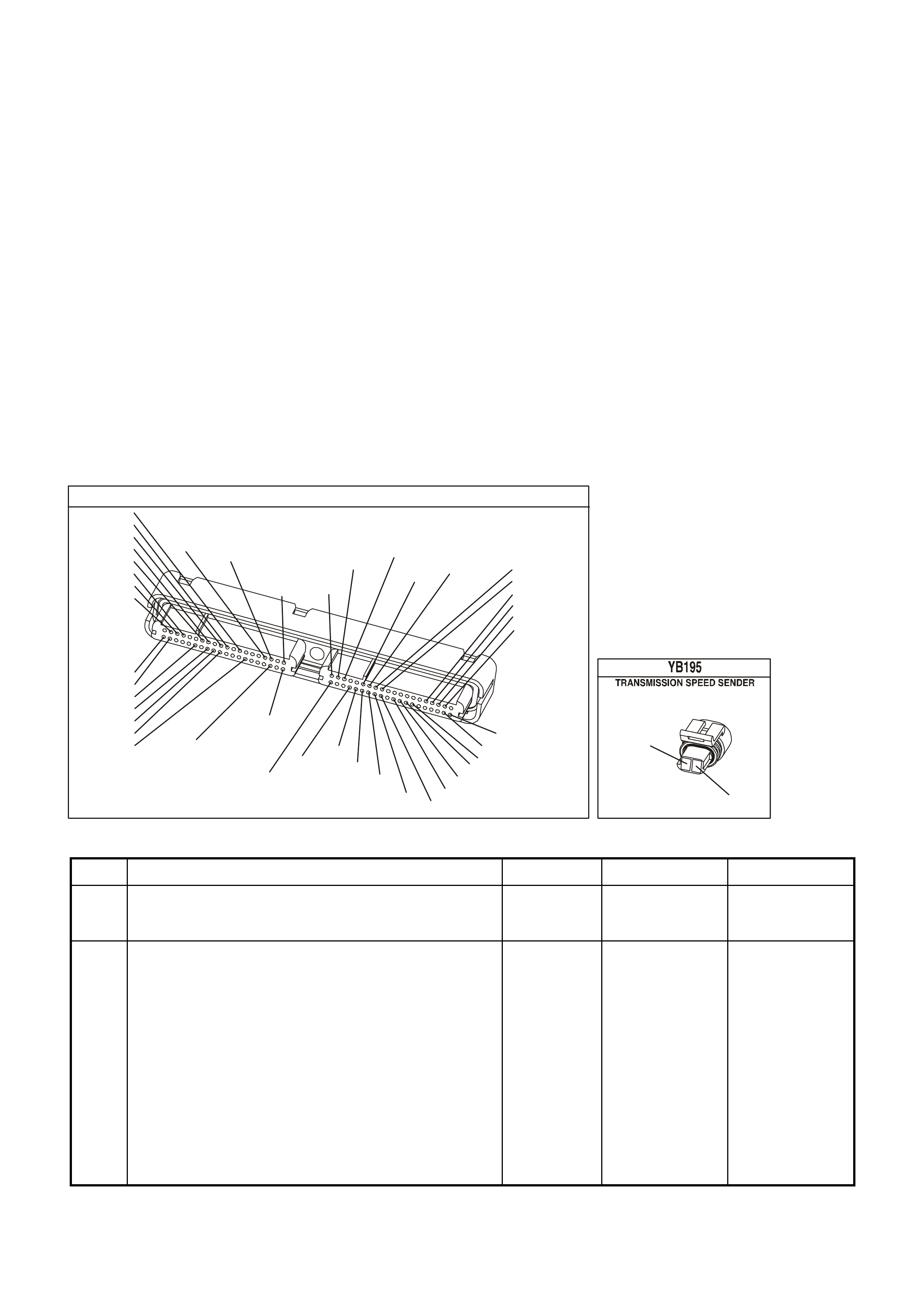

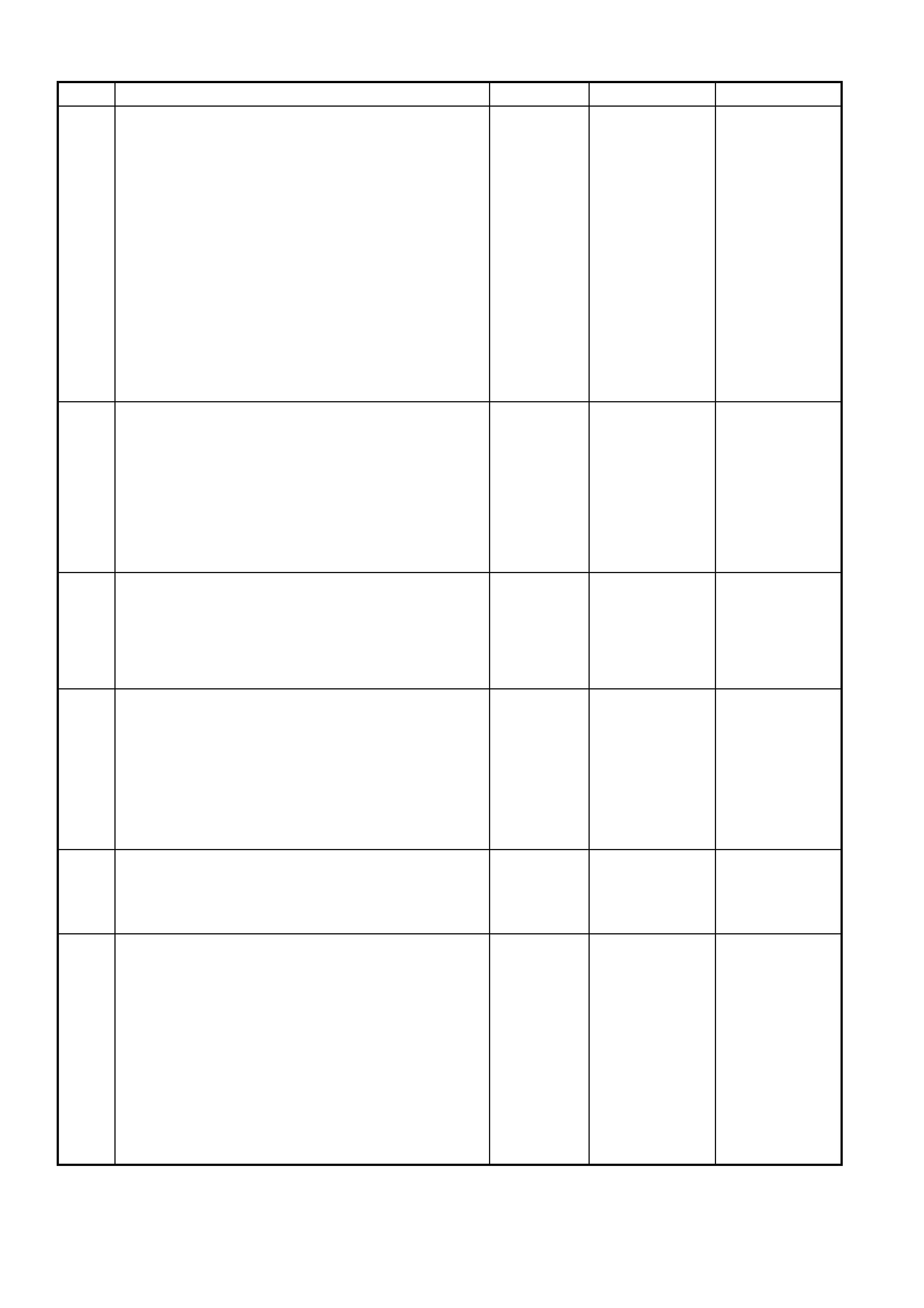

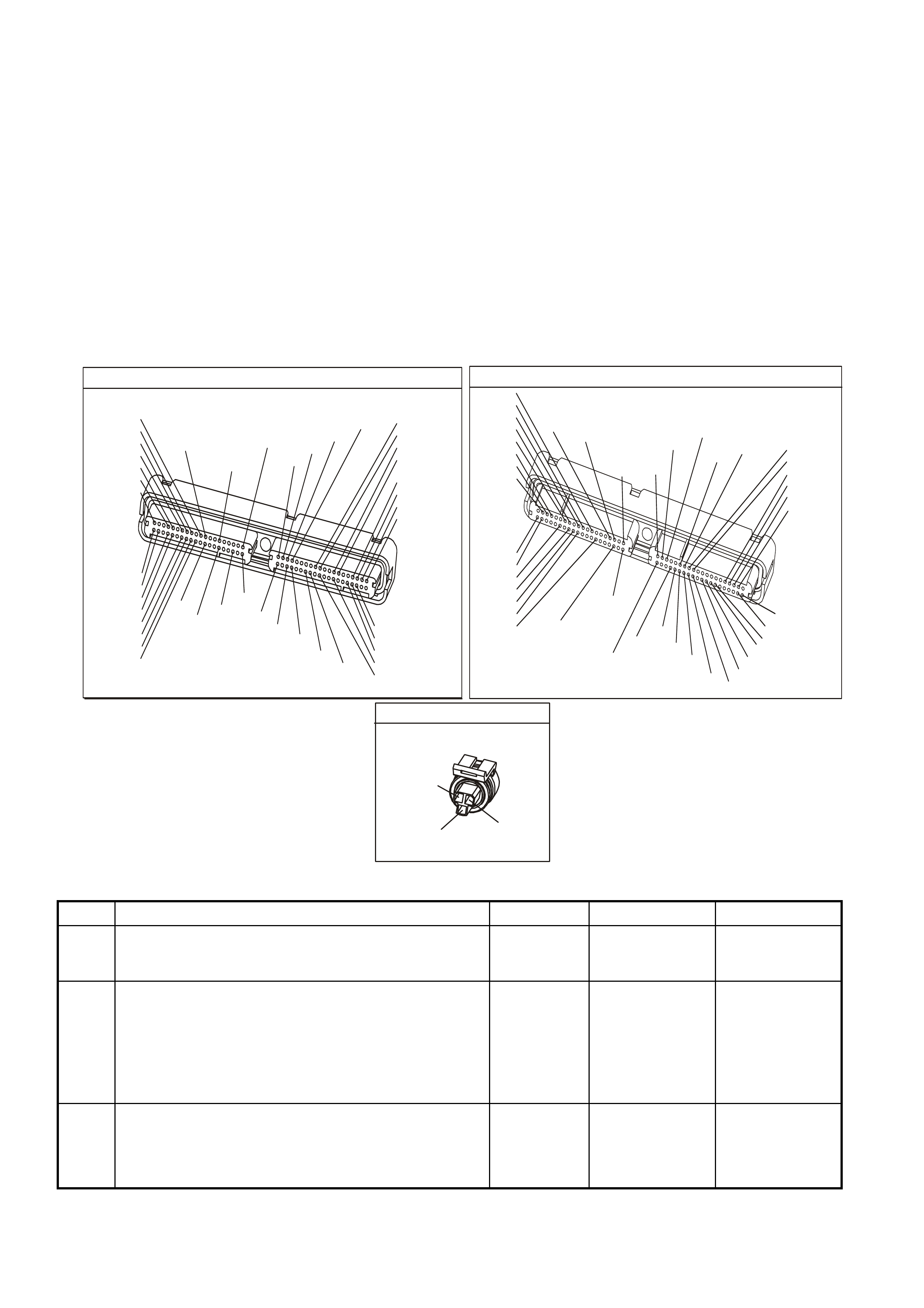

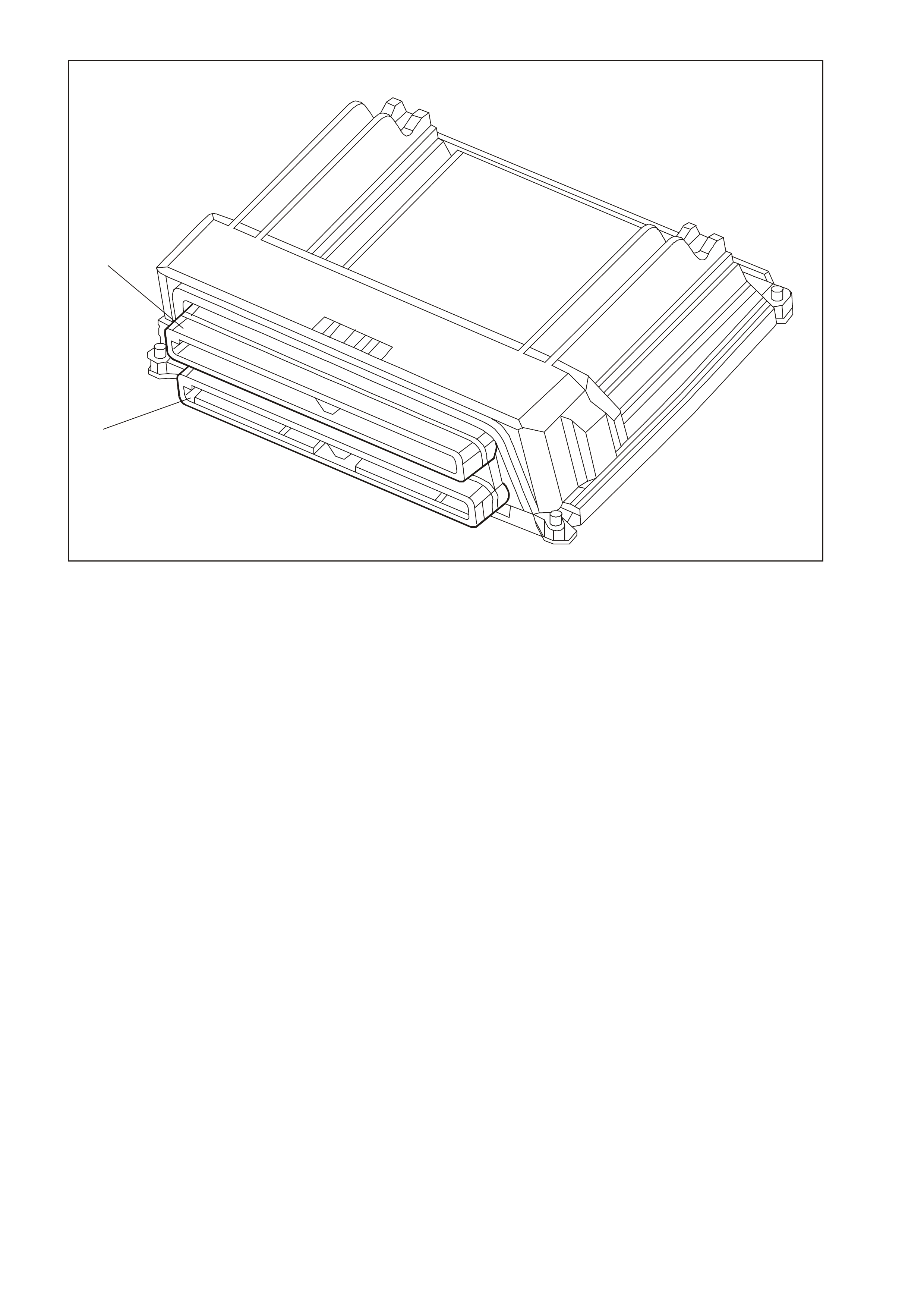

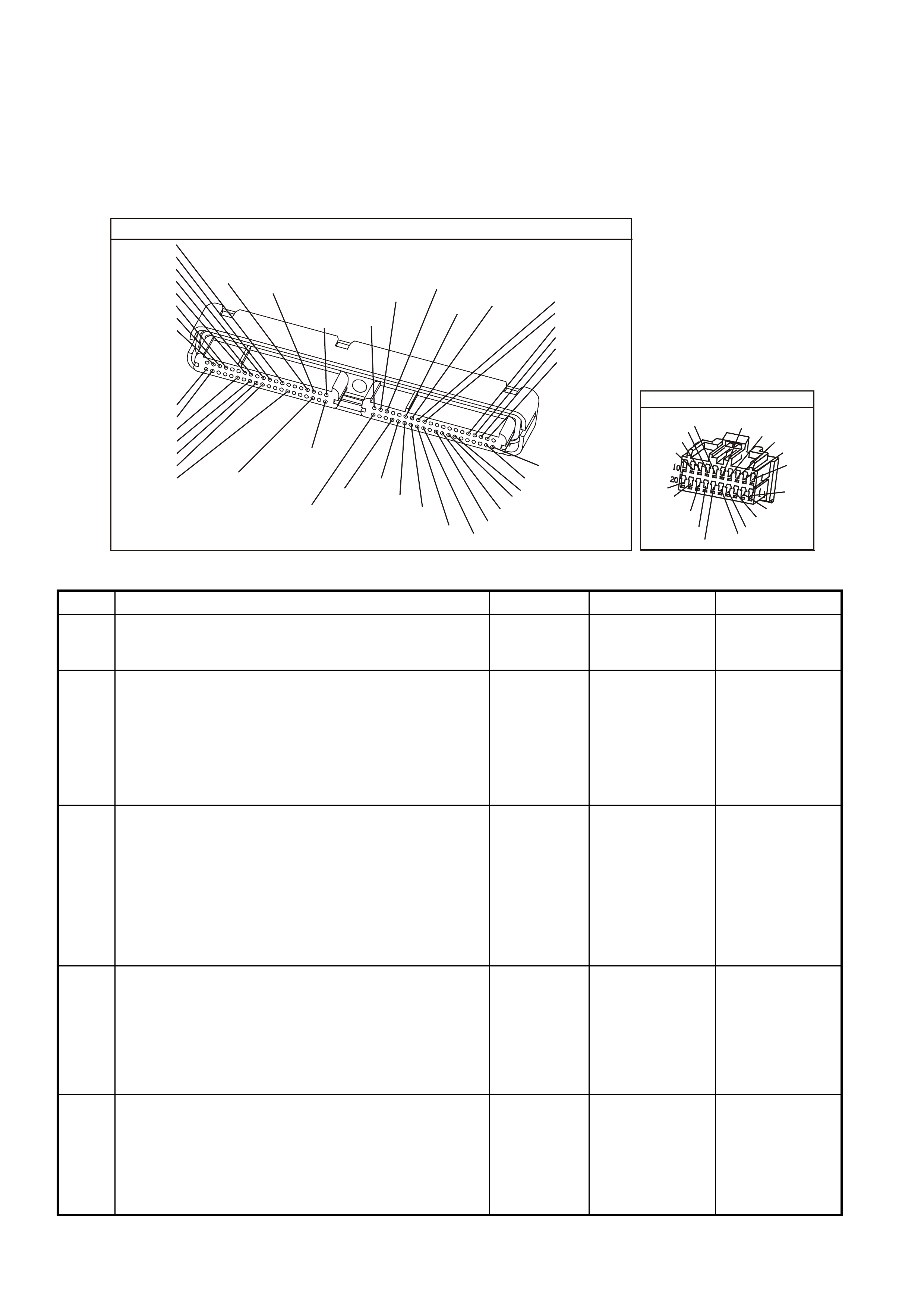

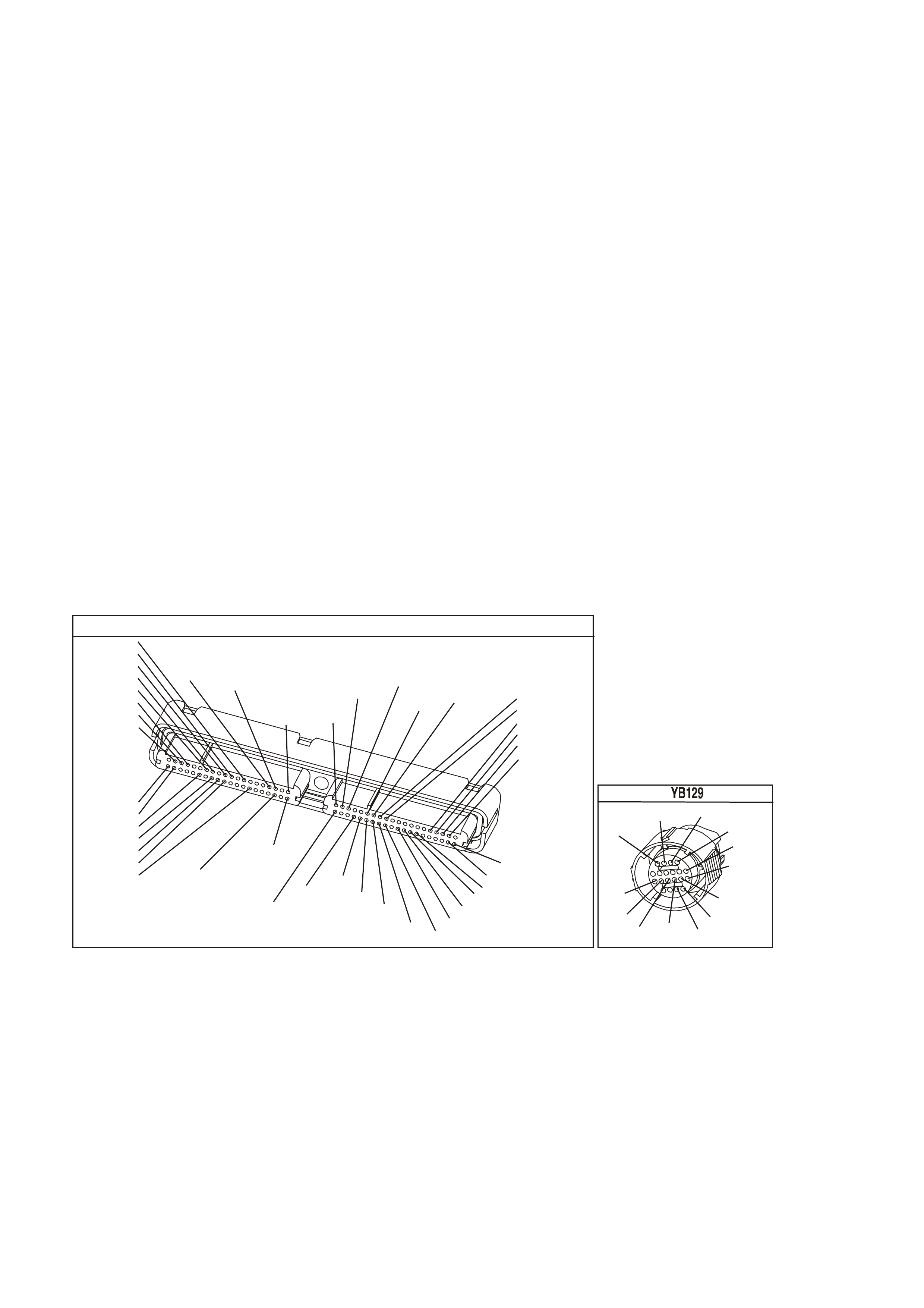

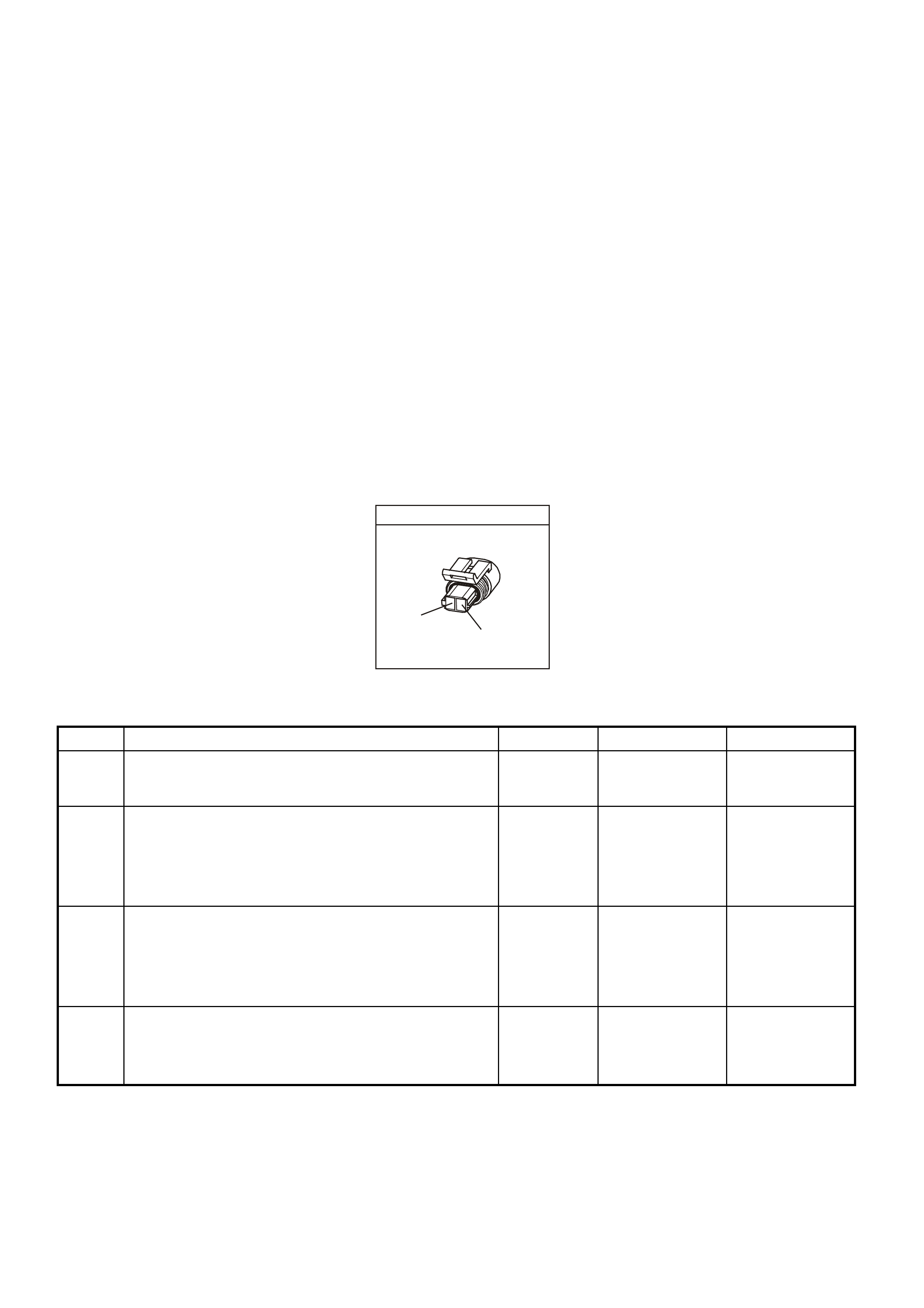

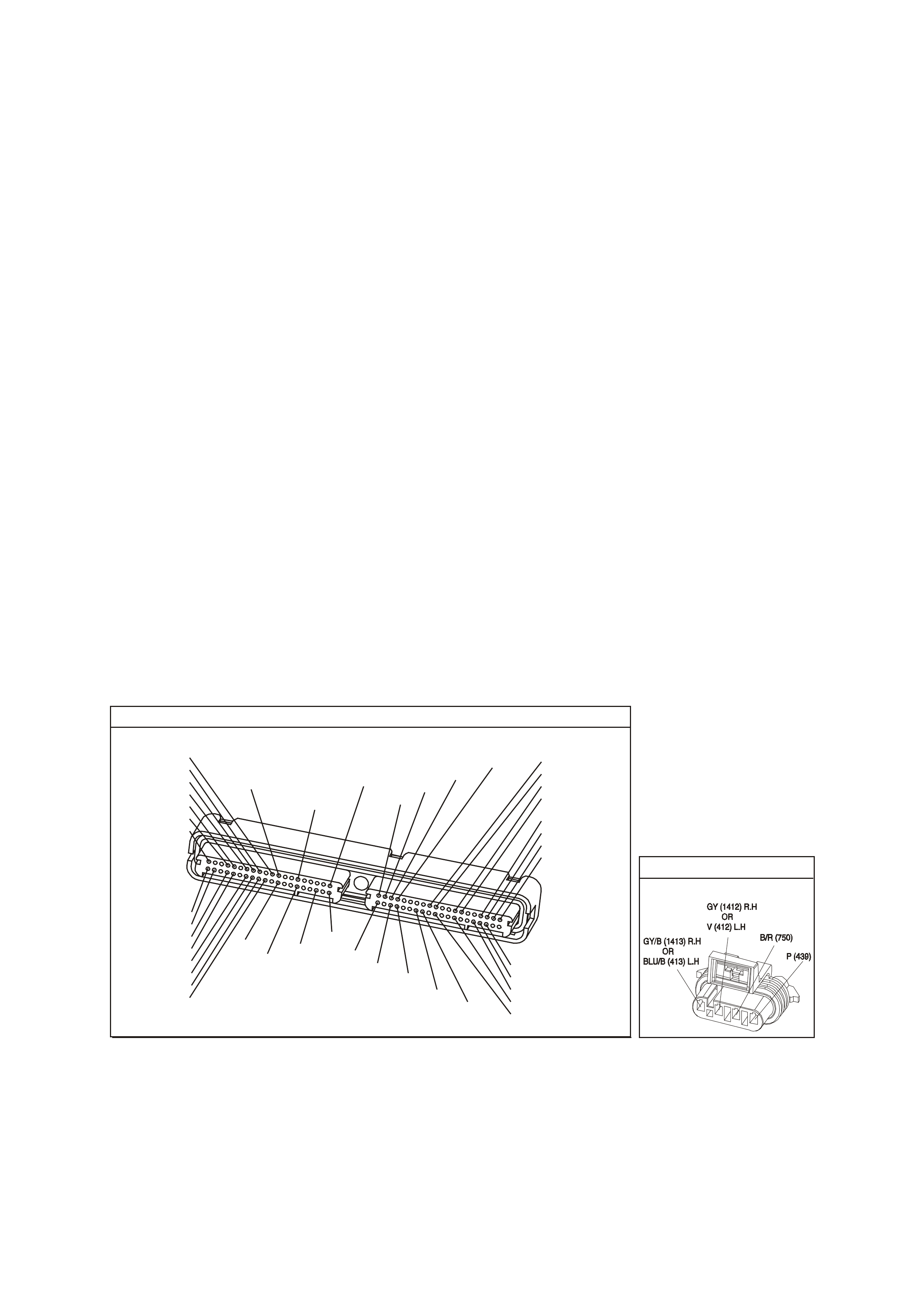

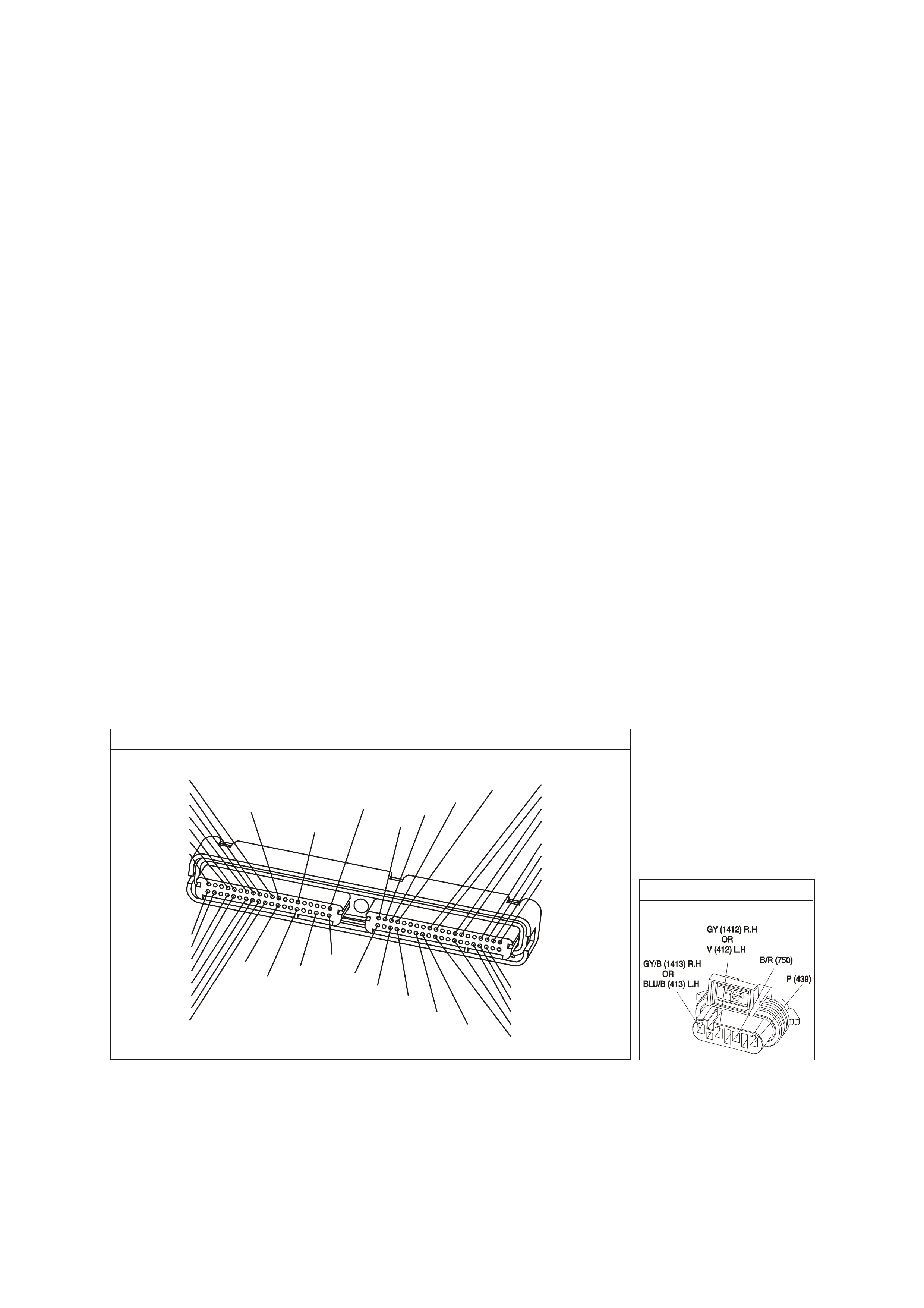

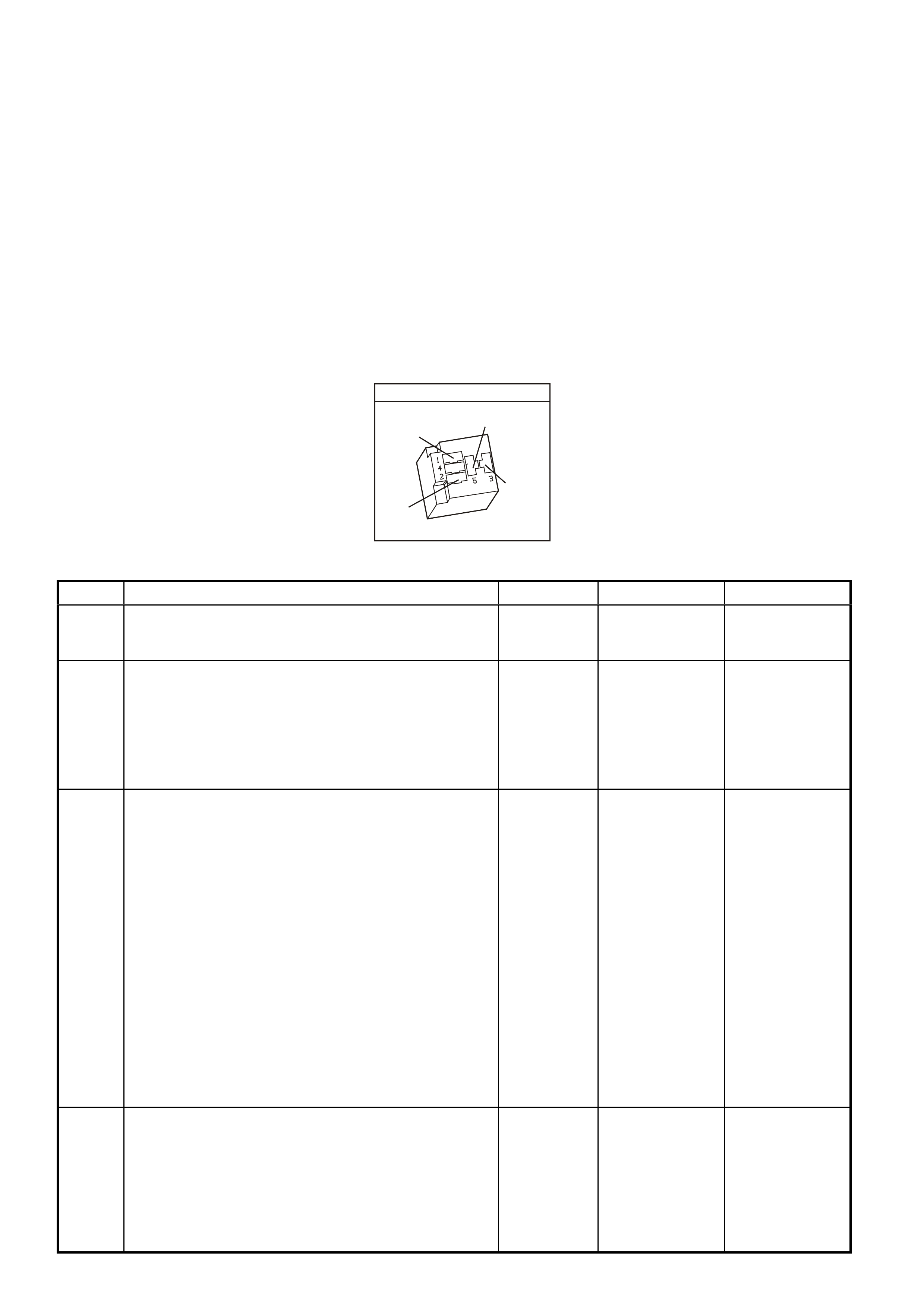

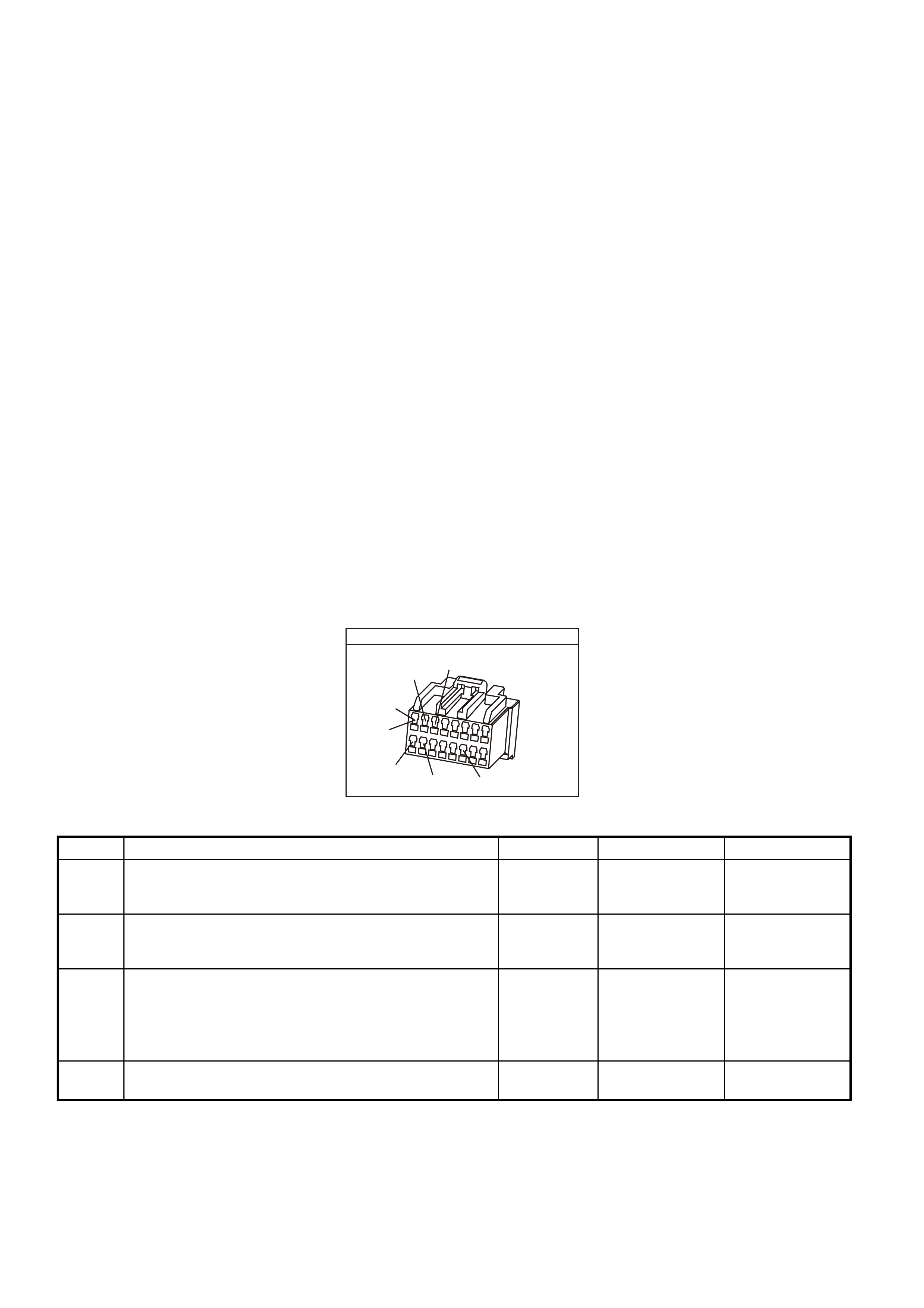

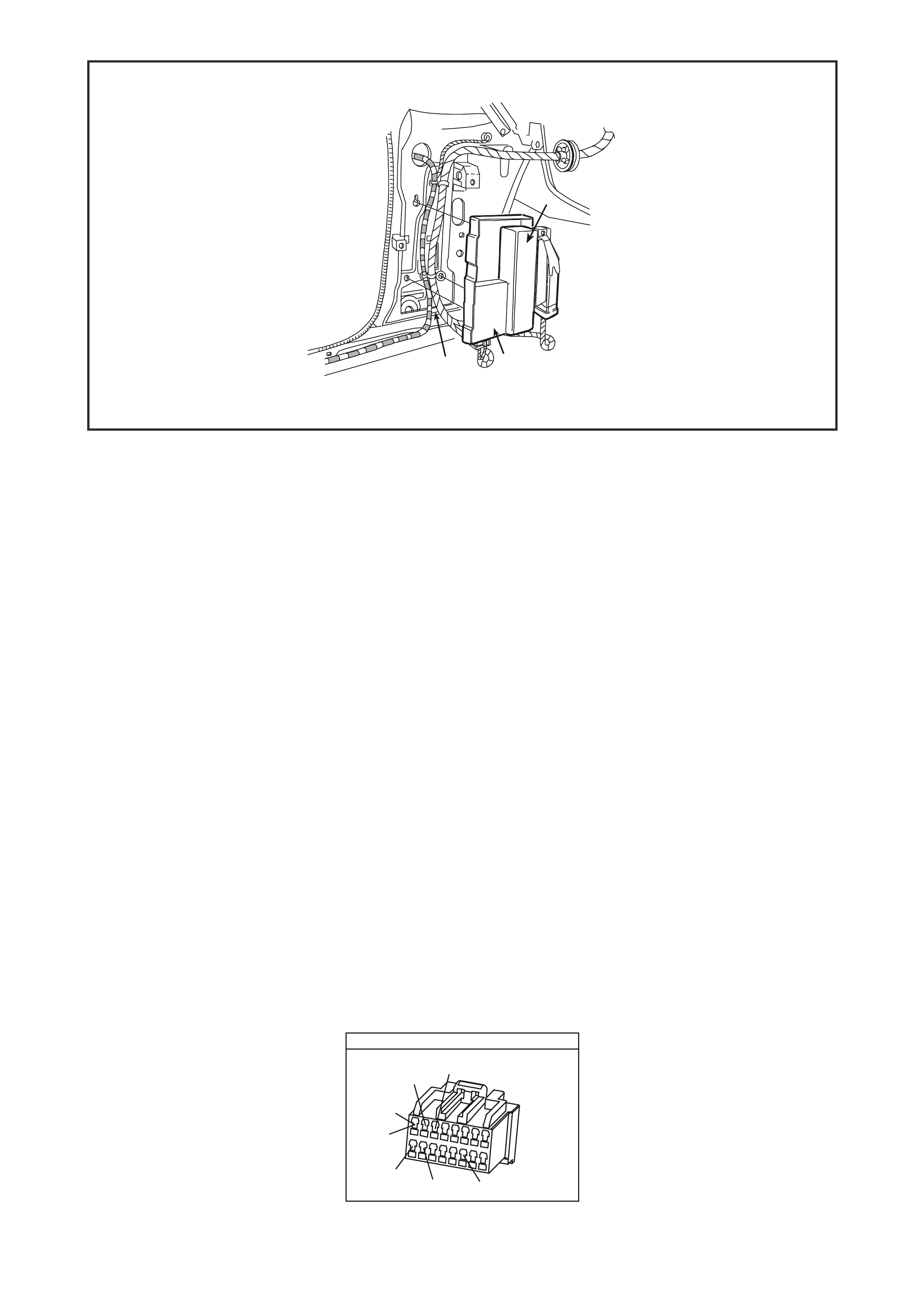

PIM CONNECTOR END VI EW

PIM CONNECTOR

Connector Part

Information • PIM Connector YB215

• 16 Pin Connector

Pin Wire Color Circuit No. Function

1 Not Used - -

2 Not Used - -

3 Not Used - -

4 Not Used - -

5 Not Used - -

6 Red/Black 1221 UART Serial Data

7 Yellow 1049 Class II Serial Data

8 Grey/Blue

(AUTO)

Grey

(MANUAL)

1434

(AUTO)

434

(MANUAL)

Starter Relay Control

9 Not Used - -

10 Not Used - -

11 White/Black 451 Diagnostic Test Enable

12 Not Used - -

13 Not Used - -

14 Not Used - -

15 Pink 39 Ignition Feed

16 Black/Red 750 System Earth

GEN3 0104

8

16

1

9

PIM CONNECTOR TERMINAL DEFINITIONS

PIM CONNECTOR

1 – NOT USED

2 – NOT USED

3 – NOT USED

4 – NOT USED

5 – NOT USED

6 – SERIAL DATA (UART) – This is a dedicated line for the Tech 2 scan tool communications. The circuit

connects the PIM, BCM, and ABS/ECT. The Tech 2 scan tool can talk to each of these modules by sending a

mes s age to a c ontro ller and as king only it to respond. T he c ommunication r ate is at 8192 baud. The normal voltage

on this circuit is about 5 volts, but when the Tech 2 scan tool is communicating with a controller, the voltage will

vary and if read with a DMM may read about 2.5 volts.

7 – SERIAL DATA (CLASS II) – This is a dedicated line for the Tech 2 scan tool communication. The circuit

connects the PCM, PIM, ABS/ET C, and BCM. The Tec h 2 scan tool can talk to eac h of these m odules by sending

a message to a controller and asking only it to respond. The communication carried on Class II data streams are

prioritised. The normal voltage on this line is 0 volts, but when the Tech 2 scan tool is connected, the voltage will

about 7 volts indicating communication.

8 – STARTER RELAY CONTROL – W hen the PIM receives the proper Theft Deterrent signal from the BCM, the

PIM will supply a earth signal to the Start Relay. This will allow the vehicle to crank.

If a improper Theft Deterrent signal is sensed by the PIM, then the PIM will not supply a earth signal to the Start

Relay, and the PIM will not send a message to the PCM to allow fuel injection.

9 – NOT USED

10 – NOT USED

11 – DIAGNOSTIC T EST ENABLE – T his terminal is connected to the DLC diagnostic test enable ter minal. W hen

the diagnostic tes t term inal is not ear thed, this term inal will have 5 volts on it. When the DLC diagnostic tes t enable

terminal is earthed, the resulting zero voltage at the PIM will instruct the PCM to operate in Diagnostic Mode.

12 – NOT USED

13 – NOT USED

14 – NOT USED

15 – IGNITION FEED – This is the power supply to the PIM from the ignition switch. The voltage should equal the

battery voltage when the key is in either the RUN, or CRANK position.

16 – SYSTEM EARTH – This terminal should have zero volts. This circuit is connected directly to the engine earth.

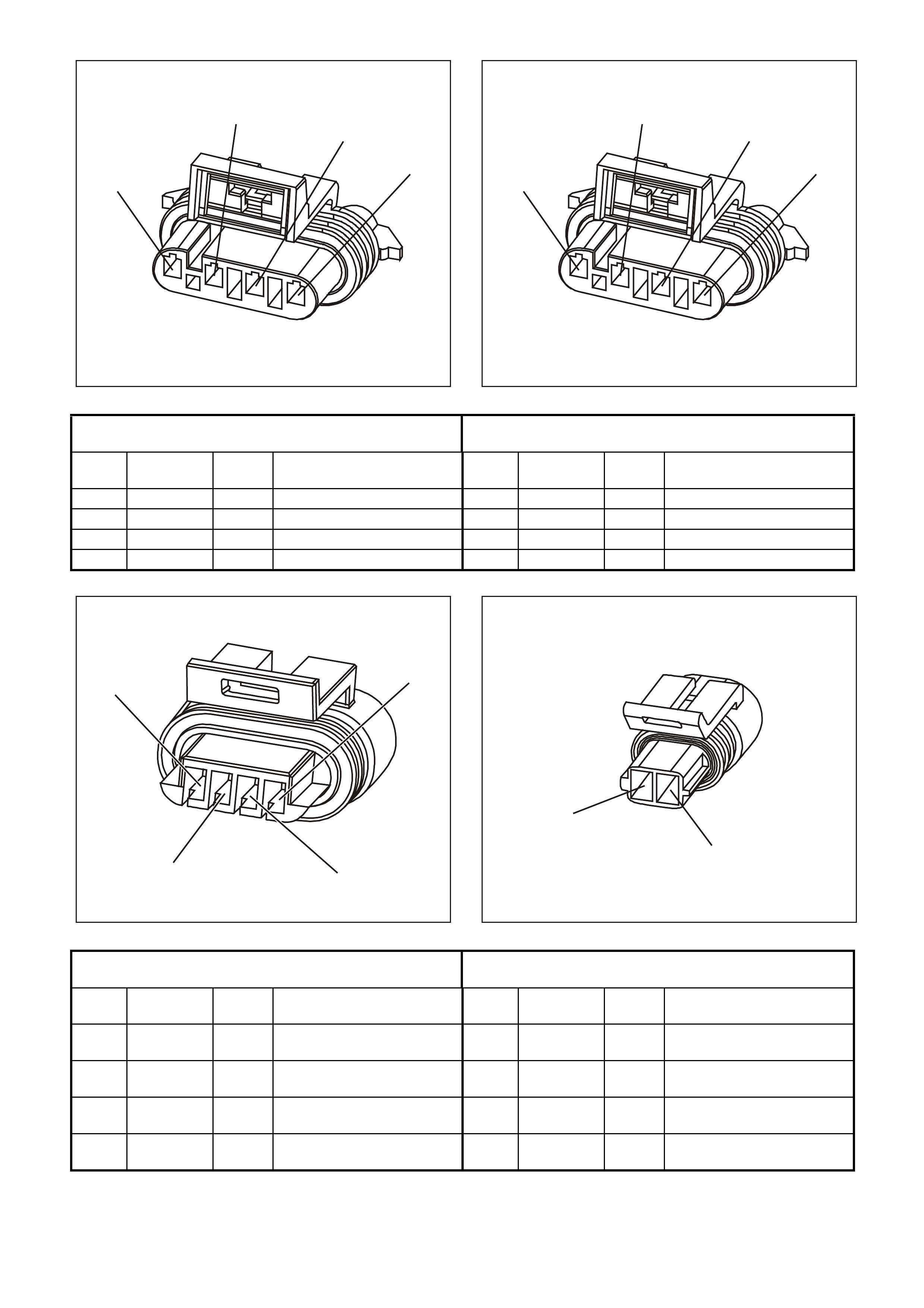

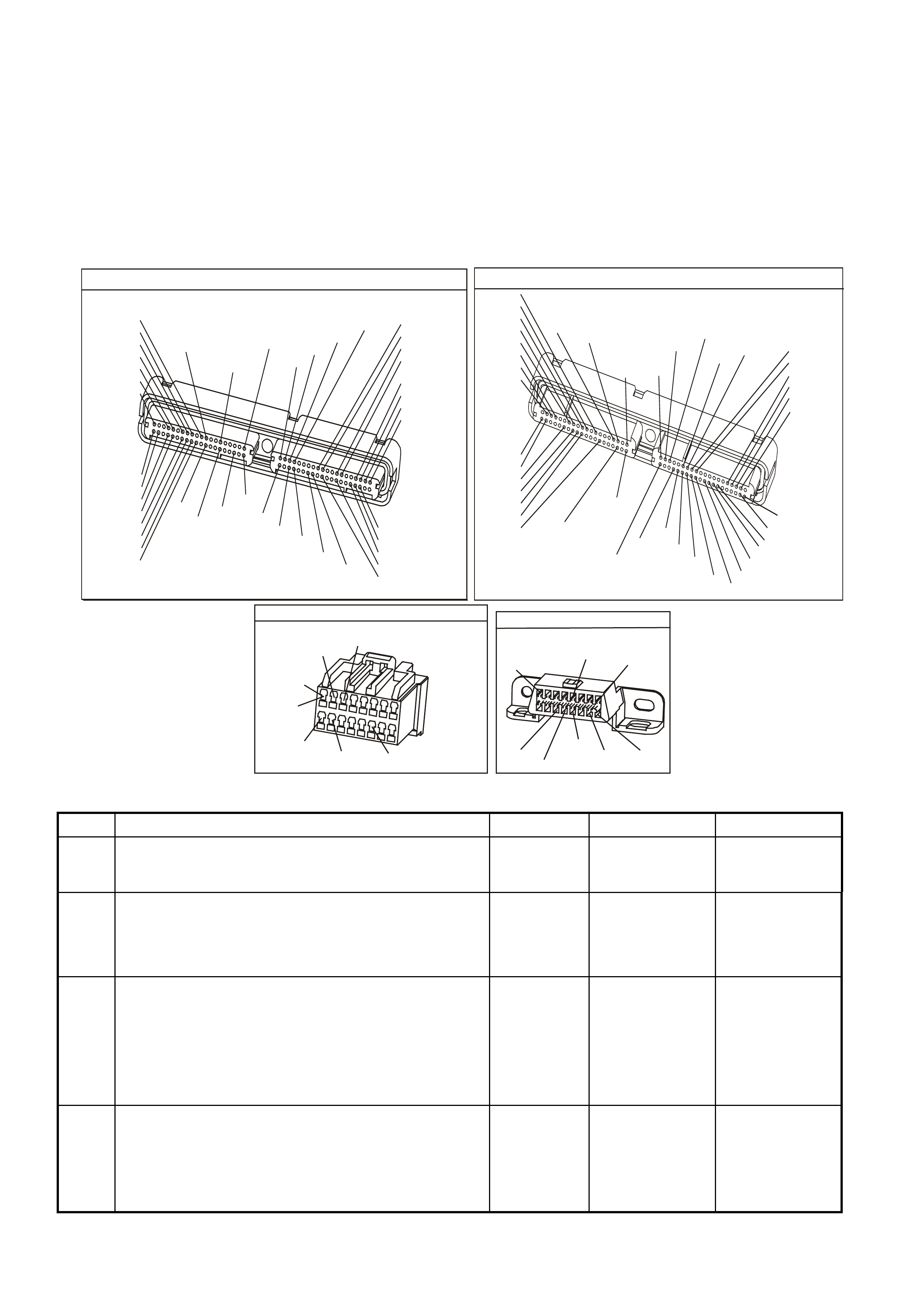

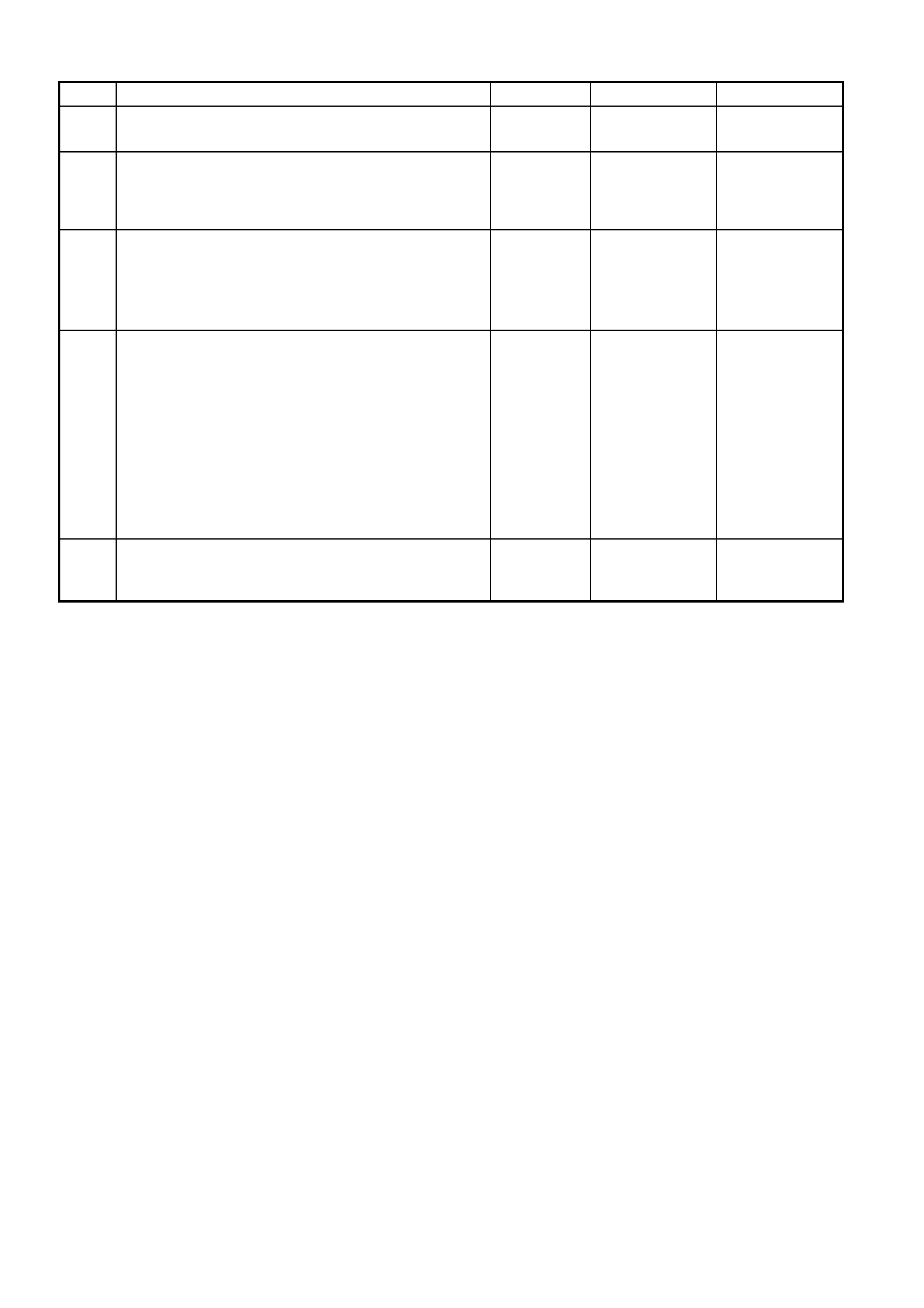

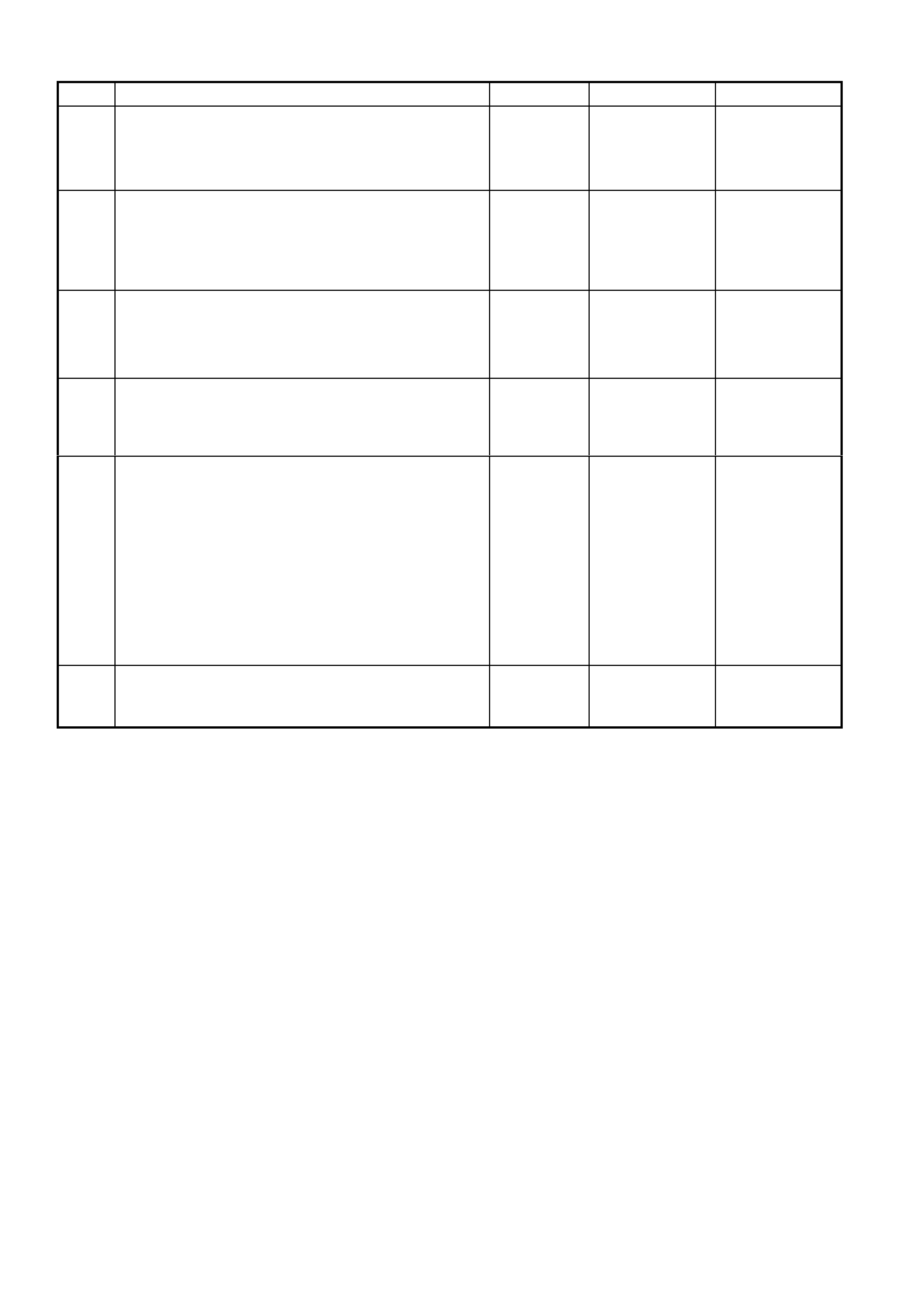

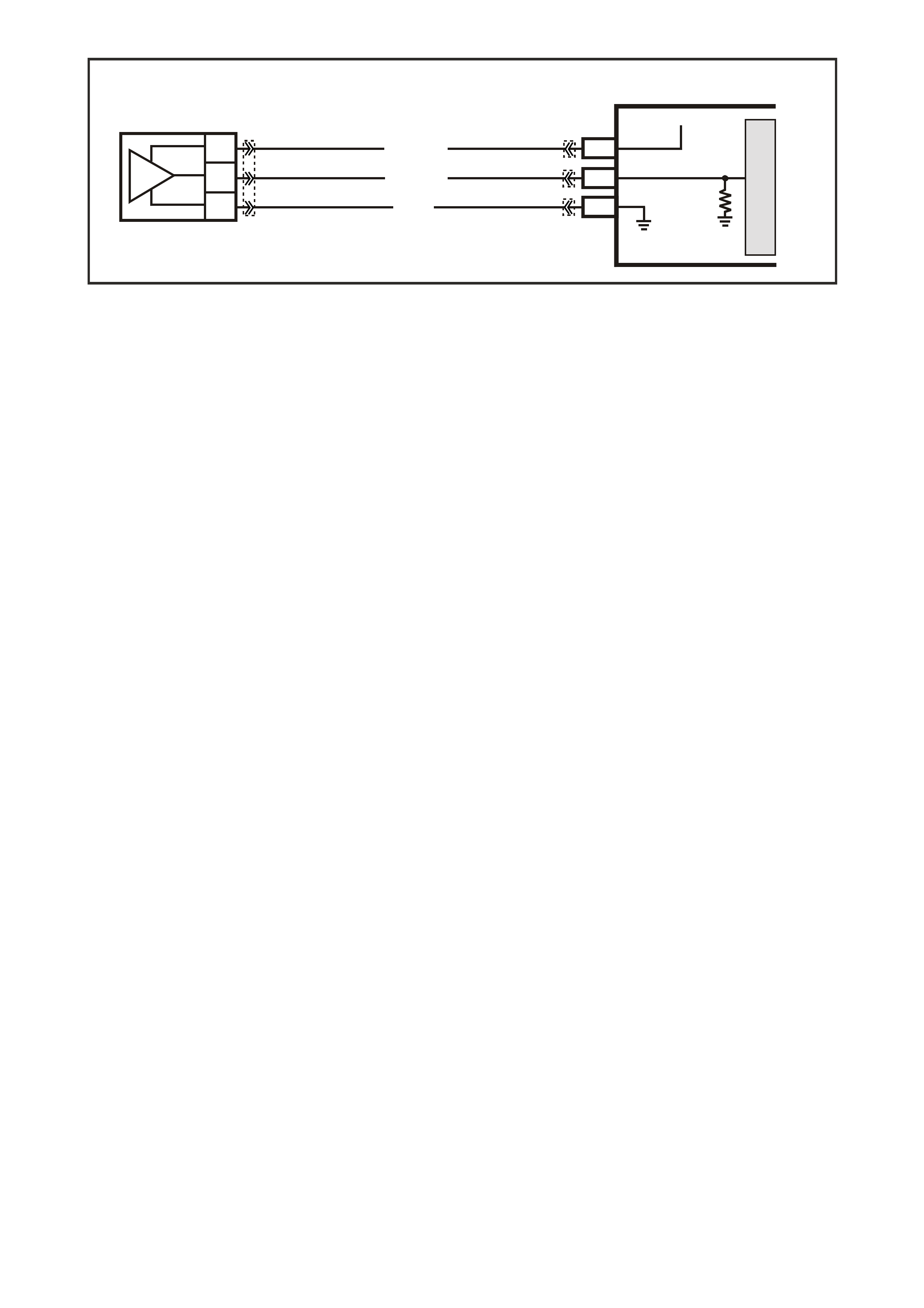

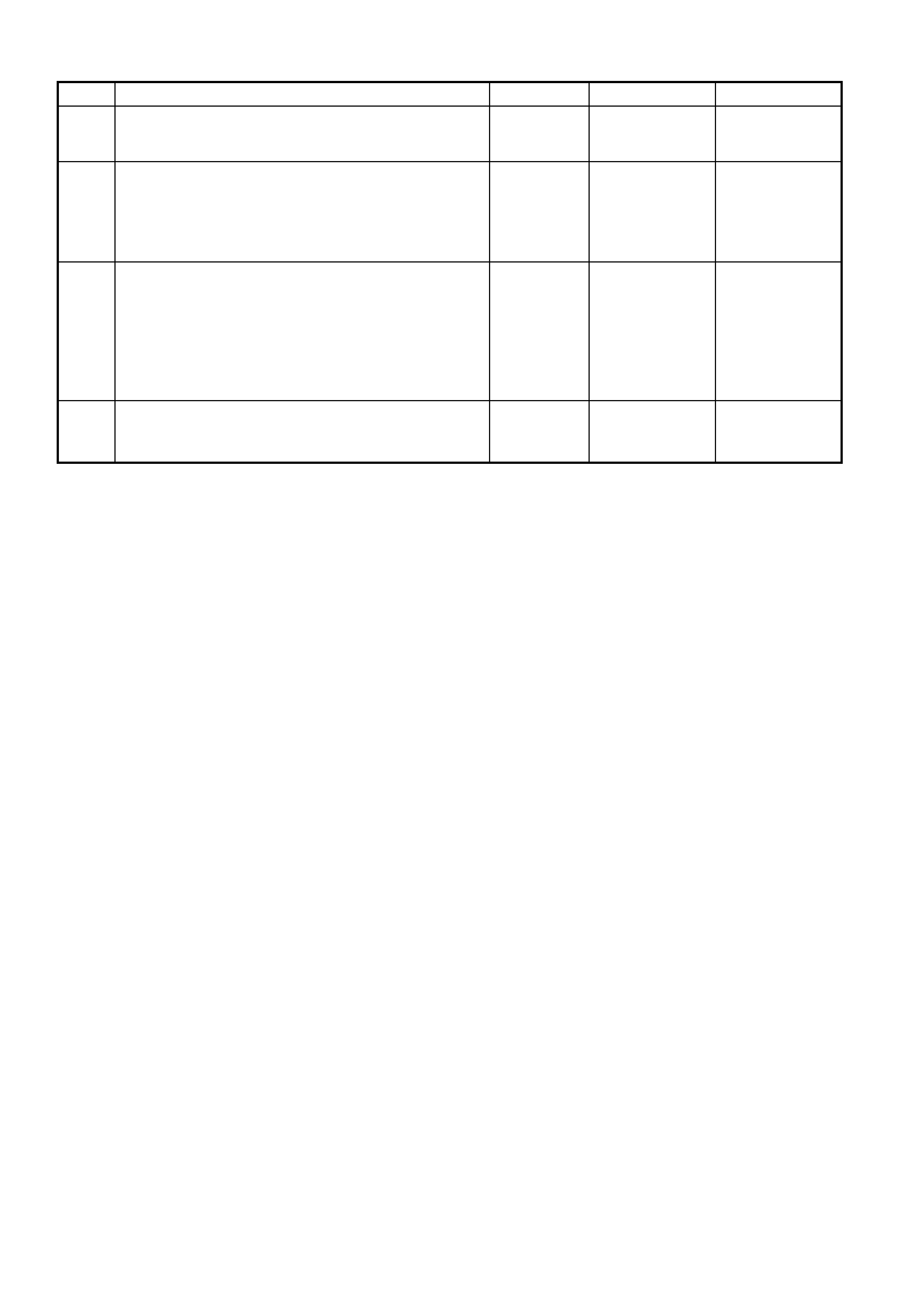

ENGINE CONTROL CONNECTOR END VIEWS

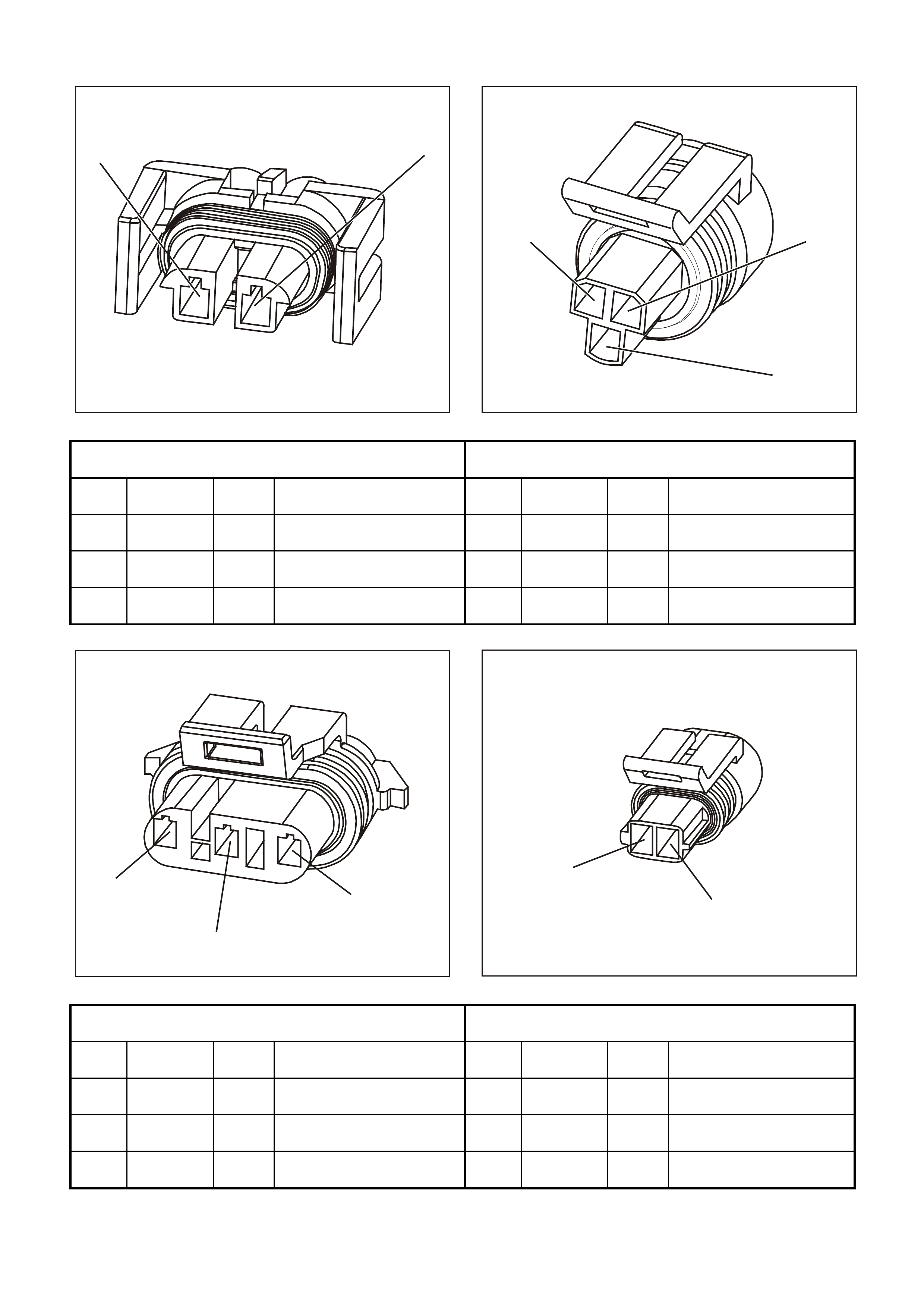

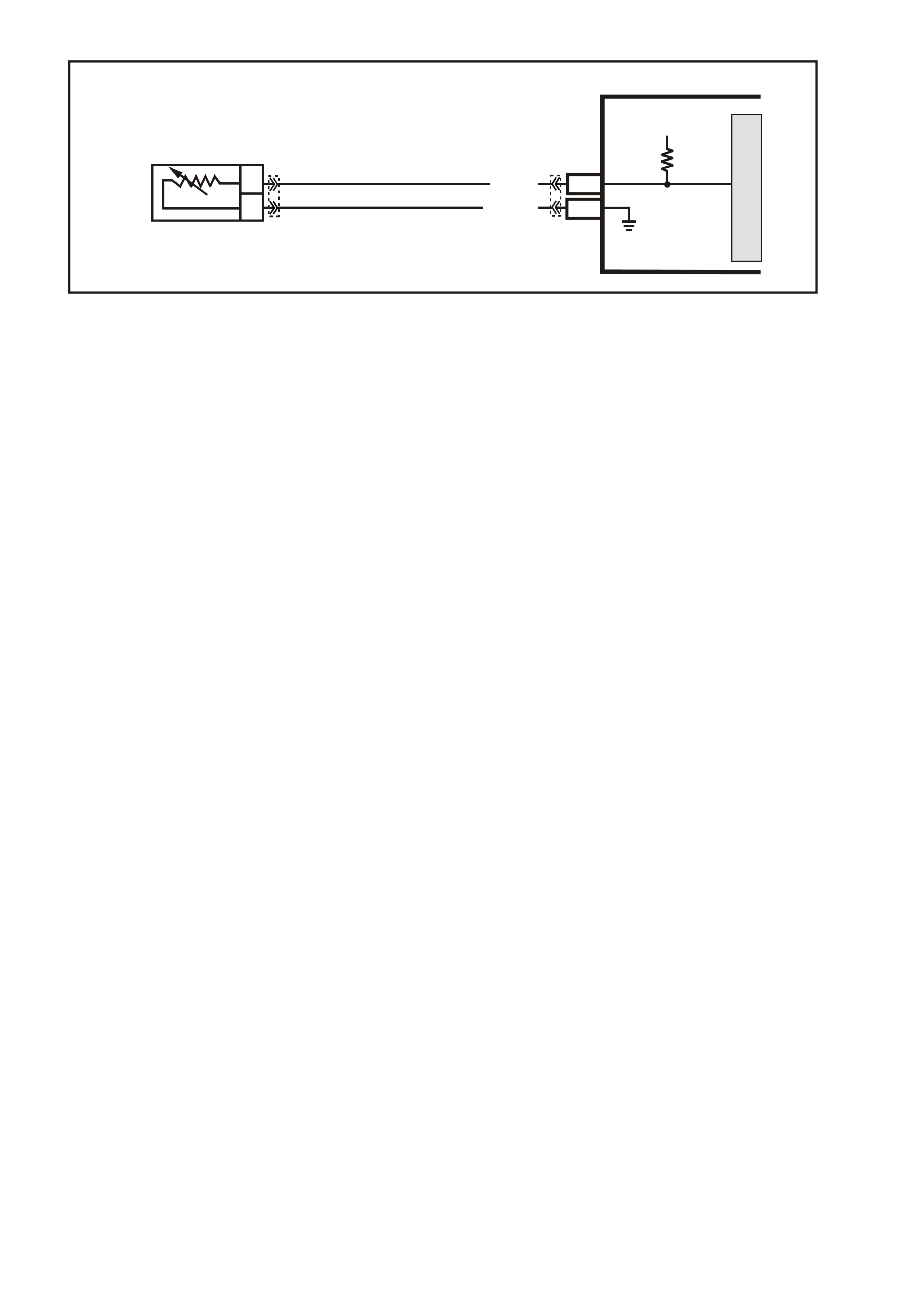

GE N 3 0073

21

2

3

1

A/C Compressor Clutch Connector

YE105 A /C Refrigerant Pressure Sensor Connector

YE113

Pin Wire Colour Circuit

No. Function Pin Wire Colour Circuit

No. Function

1 (B) B/R 750 A/C Compressor Clutch

Earth 1 (A) G/O 469 A/C Refrigerant Pressure

Sensor Earth

2 (A) G 59 A/C Compressor Clutc h

Control 2 (B) V/W 415 A/C Refrigerant Pressure

Sensor 5.0 V Reference

3 (C) G/B 259 A/C Refrigerant Pressure

Sensor Signal

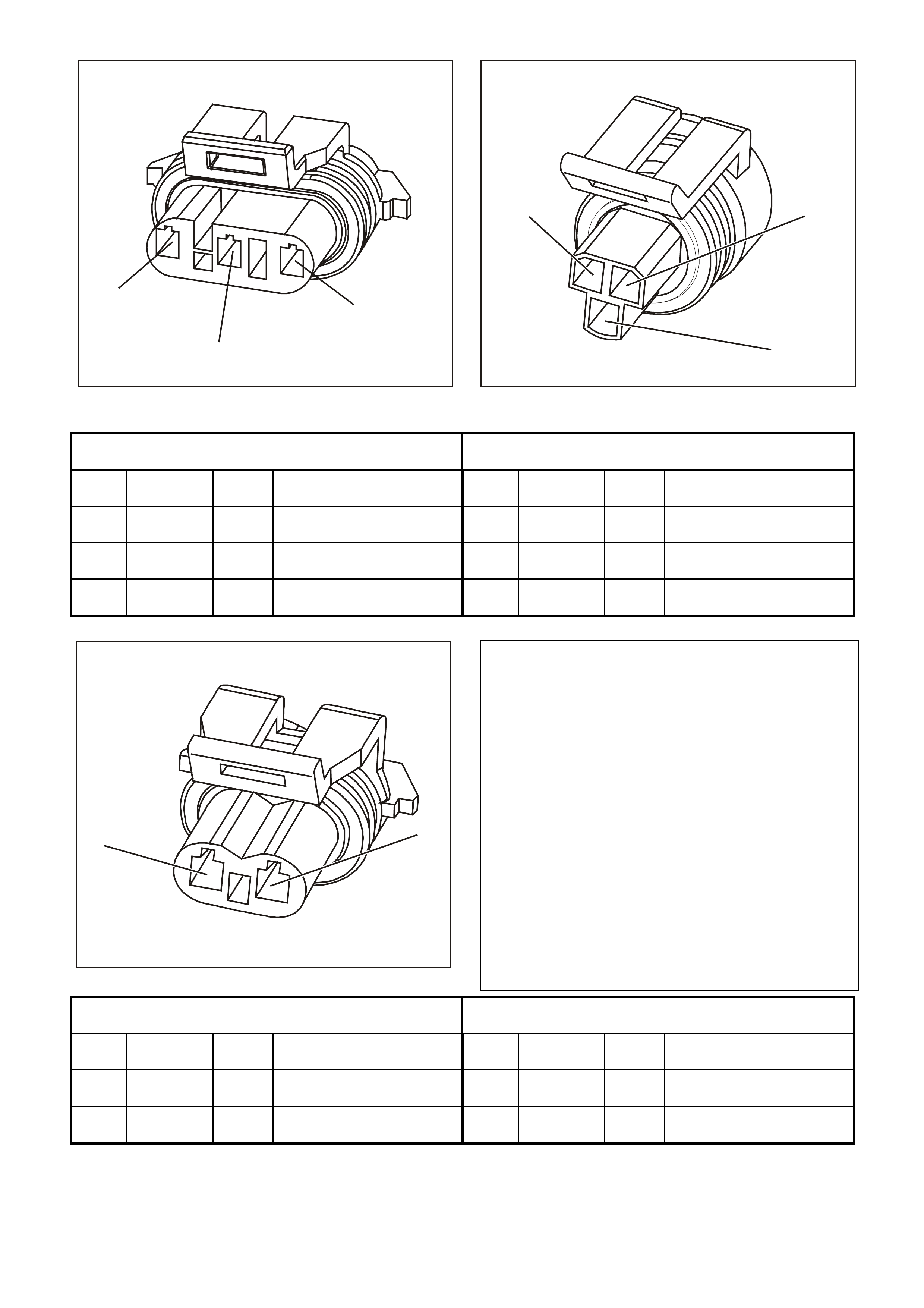

GE N 3 0075

1

2

3

GE N 3 0076

1

2

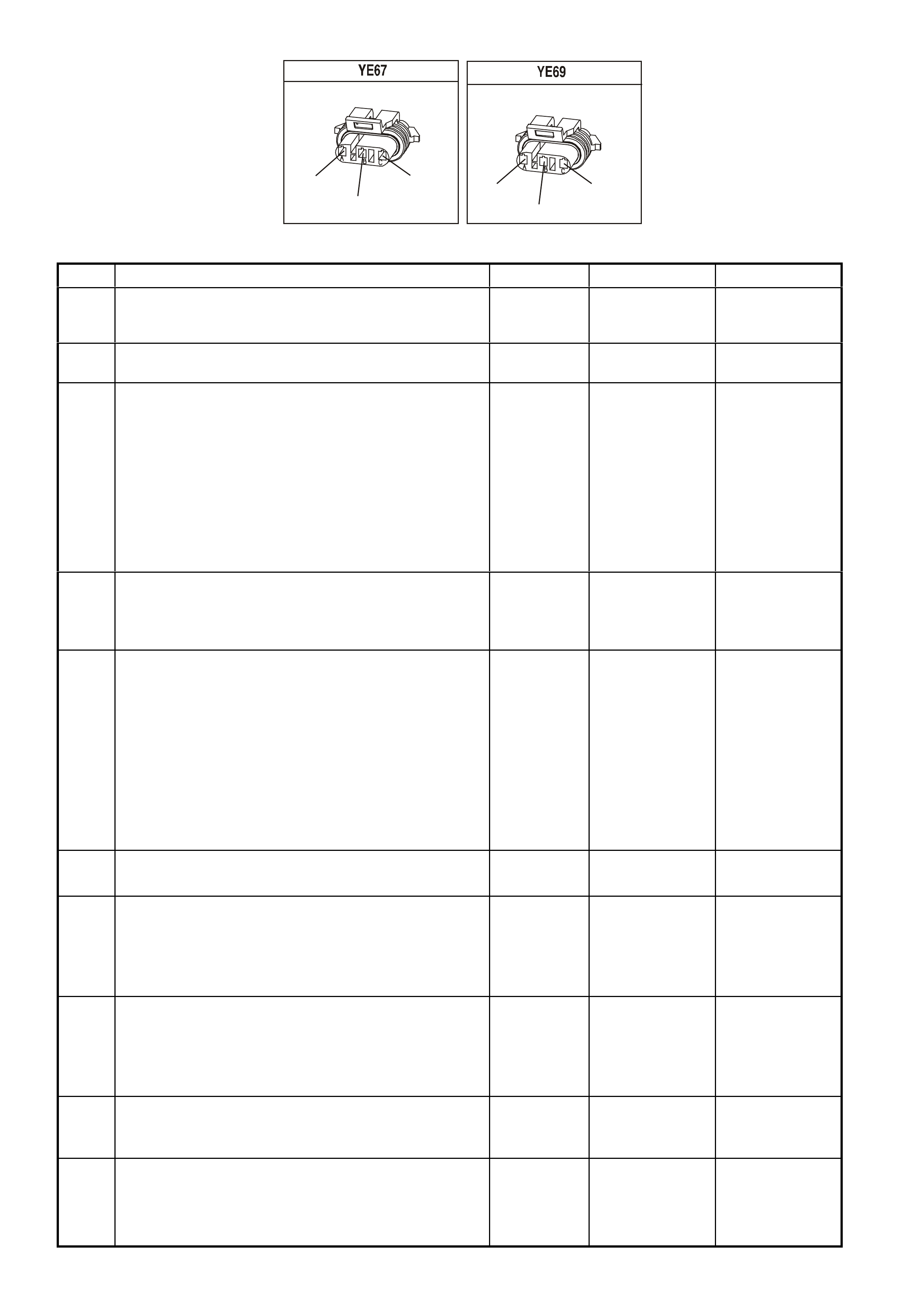

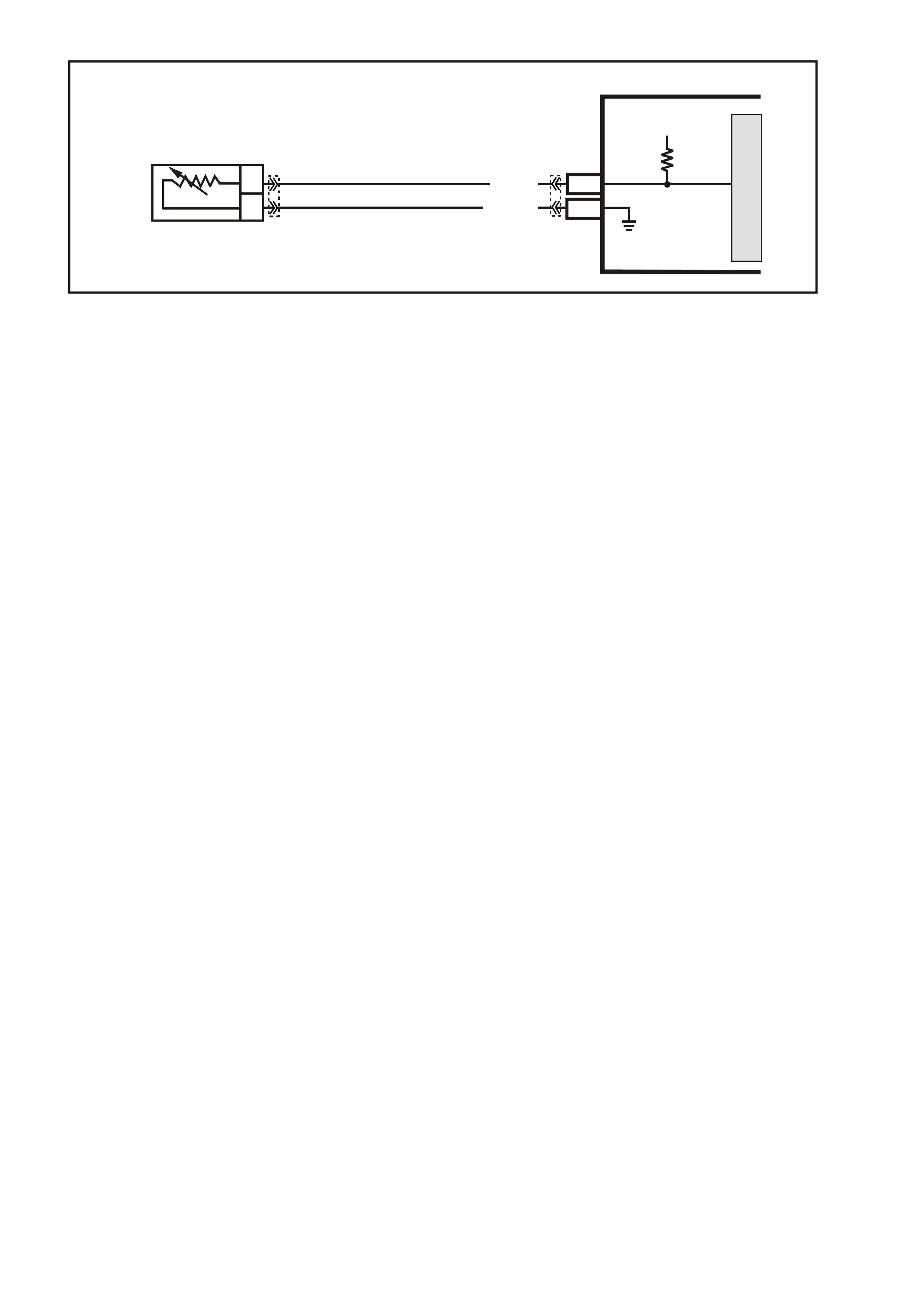

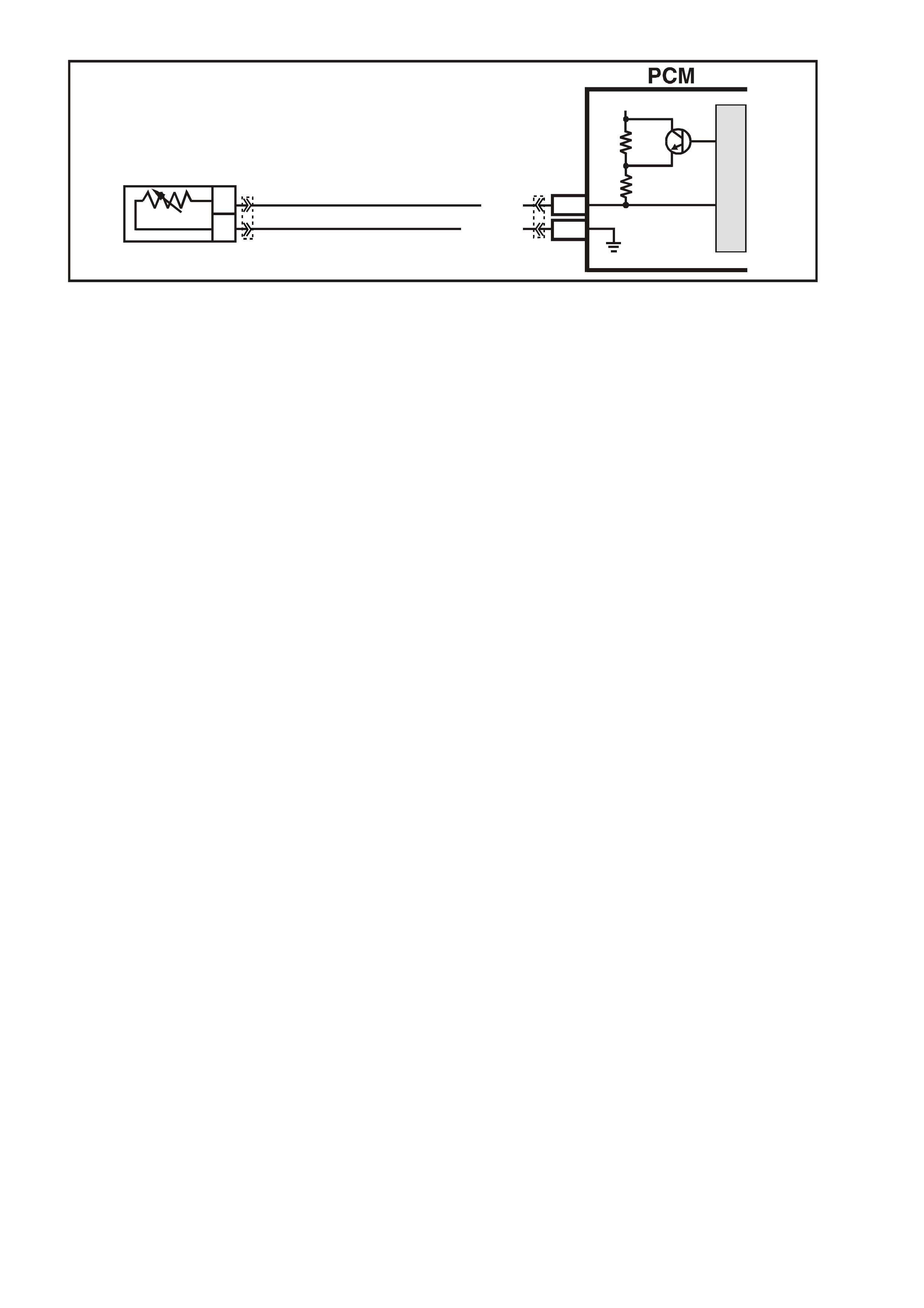

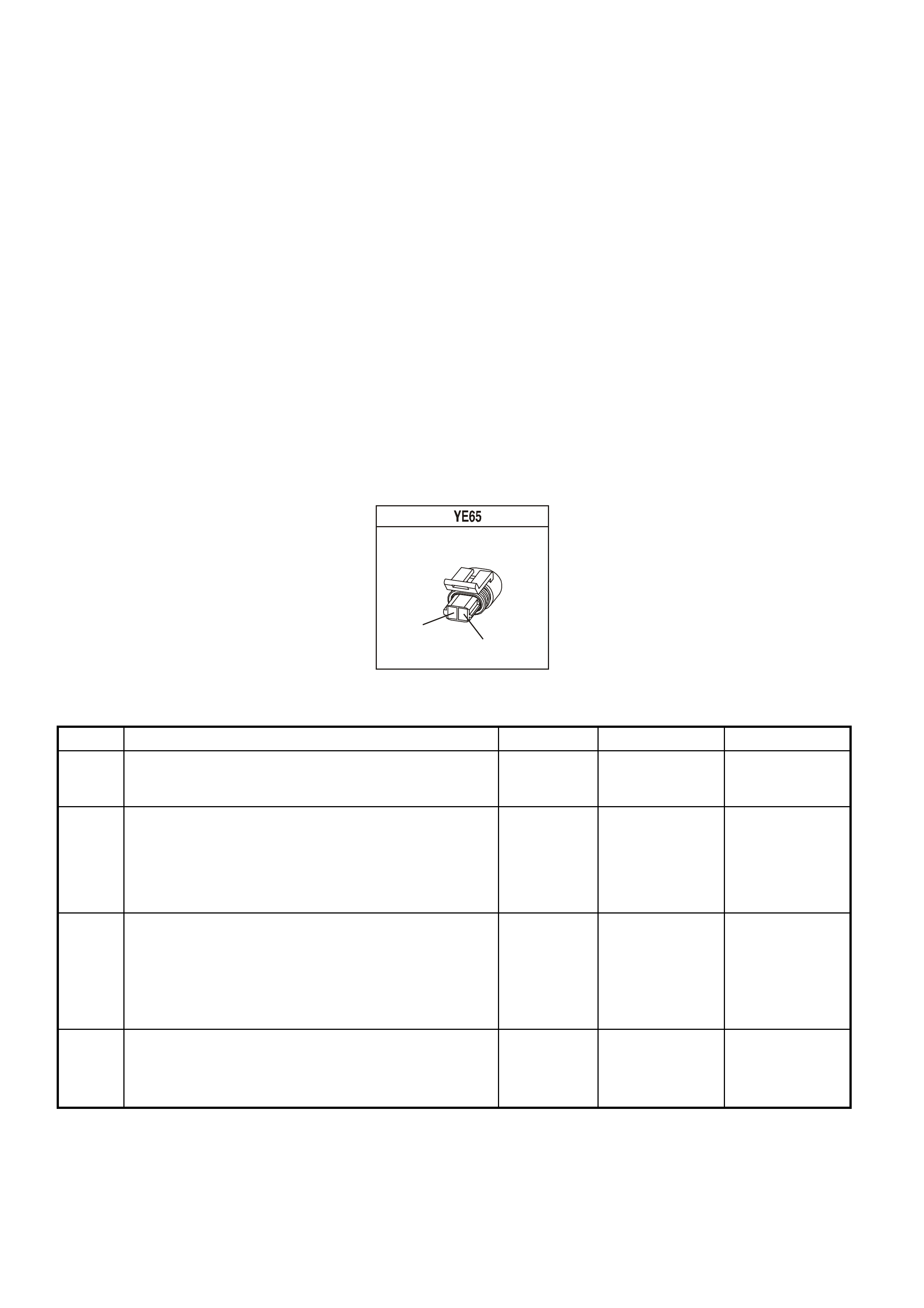

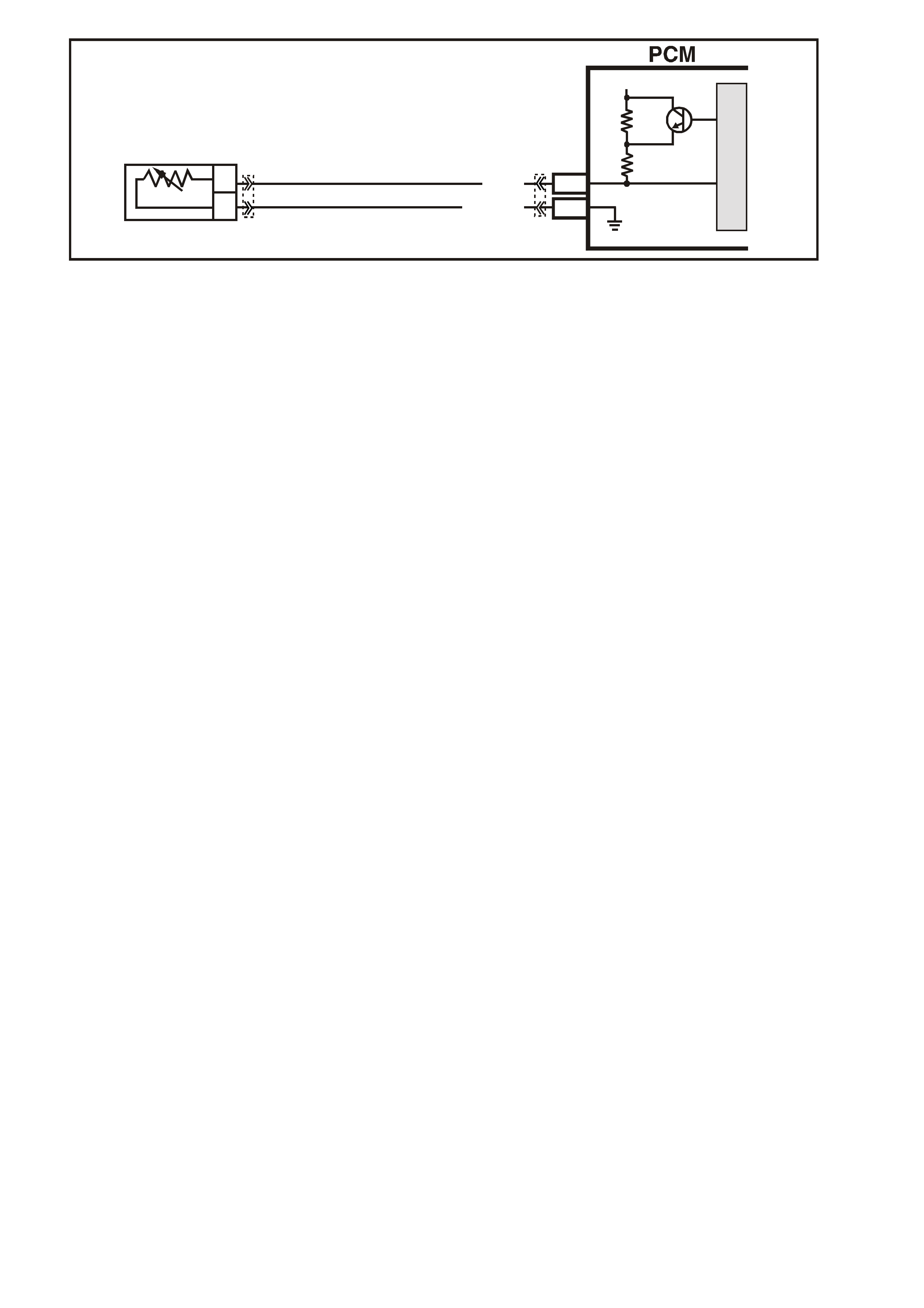

Camshaft Position (CMP) Sensor Connector

YE69 Engine Coolant Temperature (ECT) Sensor Connector

YE65

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) BR 633 Camshaft Position (CMP)

Sensor Signal – Input 1 (A) GY/B 455 Coolant Temperature

Sensor Earth

2 (B) R/W 632 Camshaft Position (CMP)

Sensor Reference Low 2 (B) Y 410 Coolant Temperature

Sensor Signal

3 (C) W/B 631 Camshaft Position (CMP)

Sensor Ignition Feed

GE N 3 0075

1

2

3

GE N 3 0077

12

3

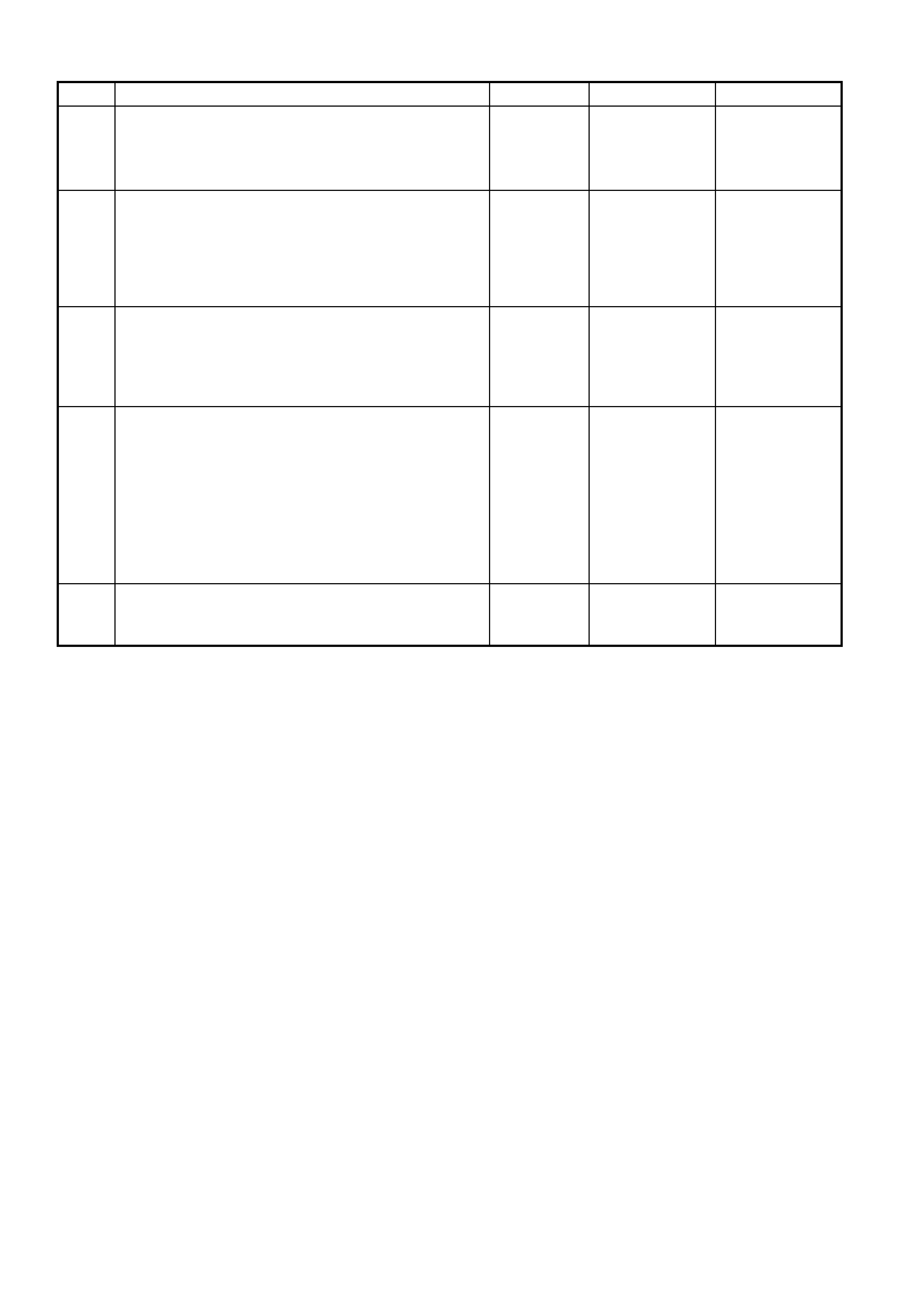

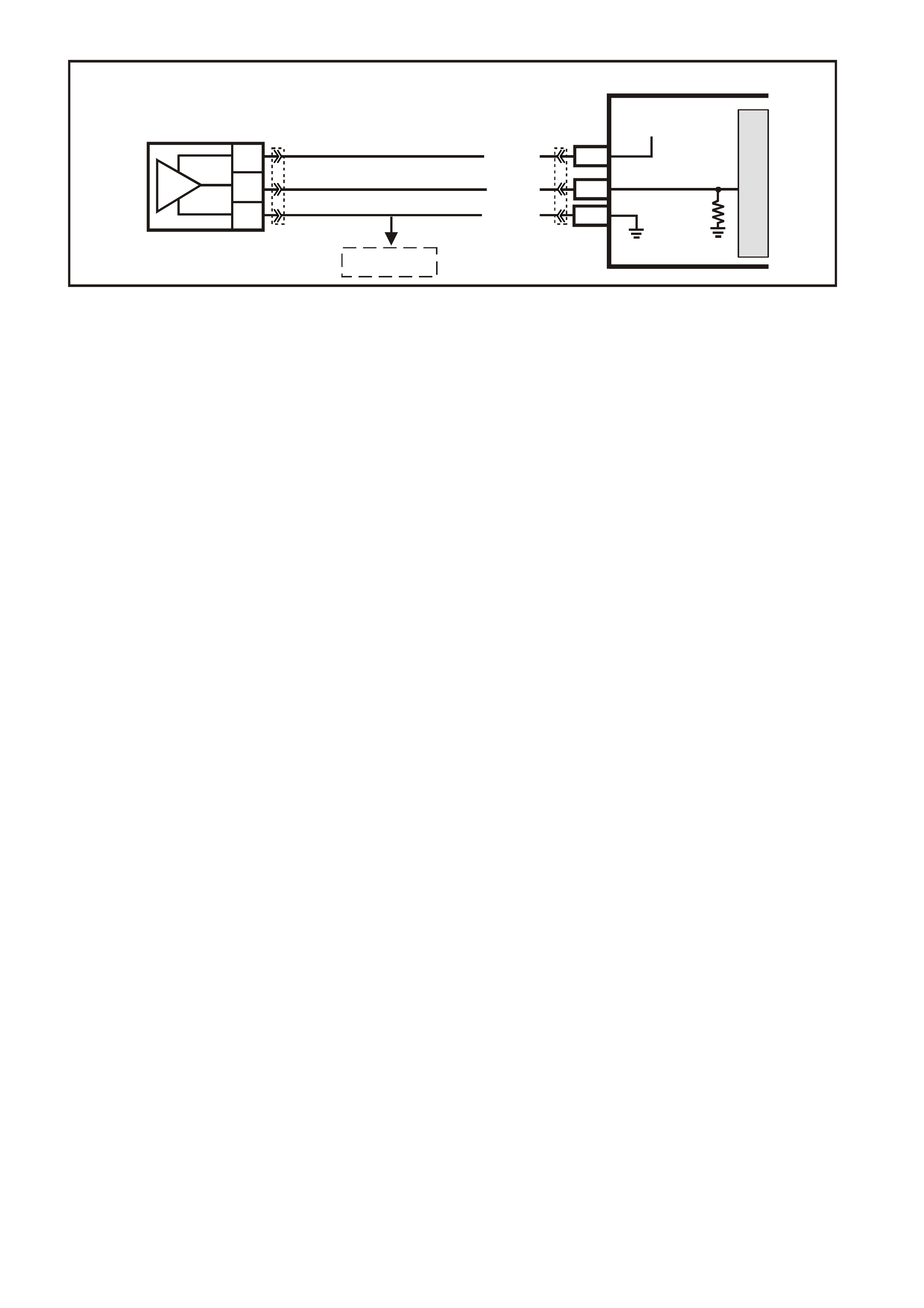

Crankshaft Position (CKP) Sensor Connector

YE67 Oil Pressure Sensor Connector

YE32

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) BLU 643 Crankshaft Position (CKP)

Sensor Signal – Input 1 (B) BLU/Y 334 Oil Pressure Sensor 5.0 V

Reference

2 (B) LBLU/B 647 Crankshaft Position (CKP)

Sensor Reference Low 2 (A) G 335 Oil Pressure Sensor

Reference Low

3 (C) LBLU/W 646 Crankshaft Position (CKP)

Sensor Ignition Feed 3 (C) BR/W 331 Oil Pressure Sensor –

Signal Input

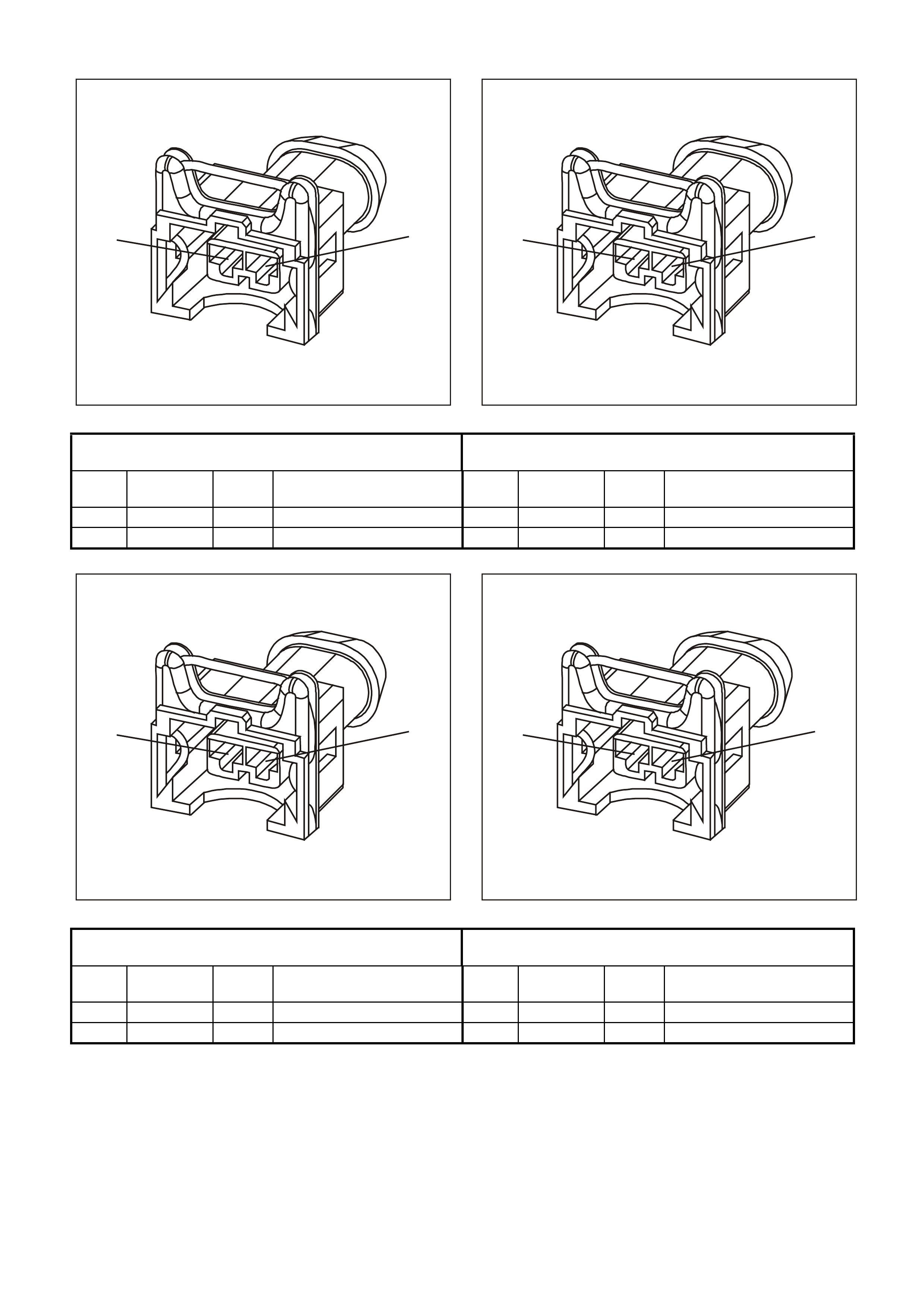

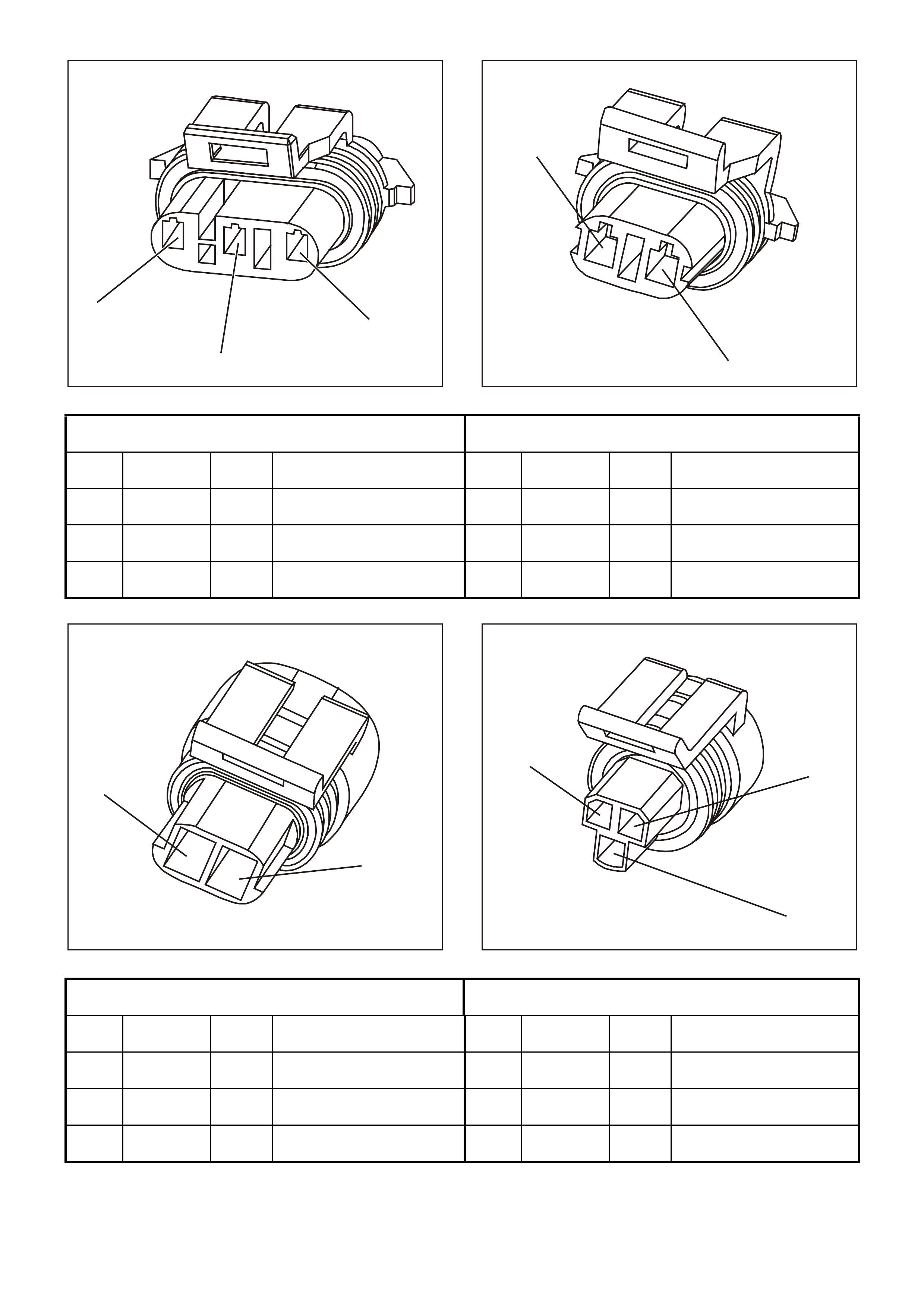

GE N 3 0078

12

Evaporative Emission (EVAP) Canister Purge Solenoid

Connector YE99 Engine Coolant Level Switch Connector

YE131

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) P 439 Canister Purge Solenoid

Ignition Feed 1 (A) B/R 750 Engine Coolant Level

Switch Earth

2 (B) G/Y 428 Canister Purge Solenoid

Control 2 (B) G 69 Engine Coolant Level

Switch Signal – Input

GE N 3 0080

12

GE N 3 0080

12

Fuel Injector #1 Connector

YE77 Fuel Injector #2 Connector

YE78

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) LG 482 Injector #1 Ignition Feed 1 (A) R 481 Injector #2 Ignition Feed

2 (B) BLU 841 Injector #1 Control 2 (B) G 842 Injector #2 Control

GE N 3 0080

12

GE N 3 0080

12

Fuel Injector #3 Connector

YE79 Fuel Injector #4 Connector

YE80

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) LG 482 Injector #3 Ignition Feed 1 (A) R 481 Injector #4 Ignition Feed

2 (B) V 843 Injector #3 Control 2 (B) BR/Y 844 Injector #4 Control

GE N 3 0080

12

GE N 3 0080

12

Fuel Injector #5 Connector

YE81 Fuel Injector #6 Connector

YE82

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) LG 482 Injector #5 Ignition Feed 1 (A) R 481 Injector #6 Ignition Feed

2 (B) GY 845 Injector #5 Control 2 (B) Y 846 Injector #6 Control

GE N 3 0080

12

GE N 3 0080

12

Fuel Injector #7 Connector

YE83 Fuel Injector #8 Connector

YE84

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) LG 482 Injector #7 Ignition Feed 1 (A) R 481 Injector #8 Ignition Feed

2 (B) P/B 847 Injector #7 Control 2 (B) LG 848 Injector #8 Control

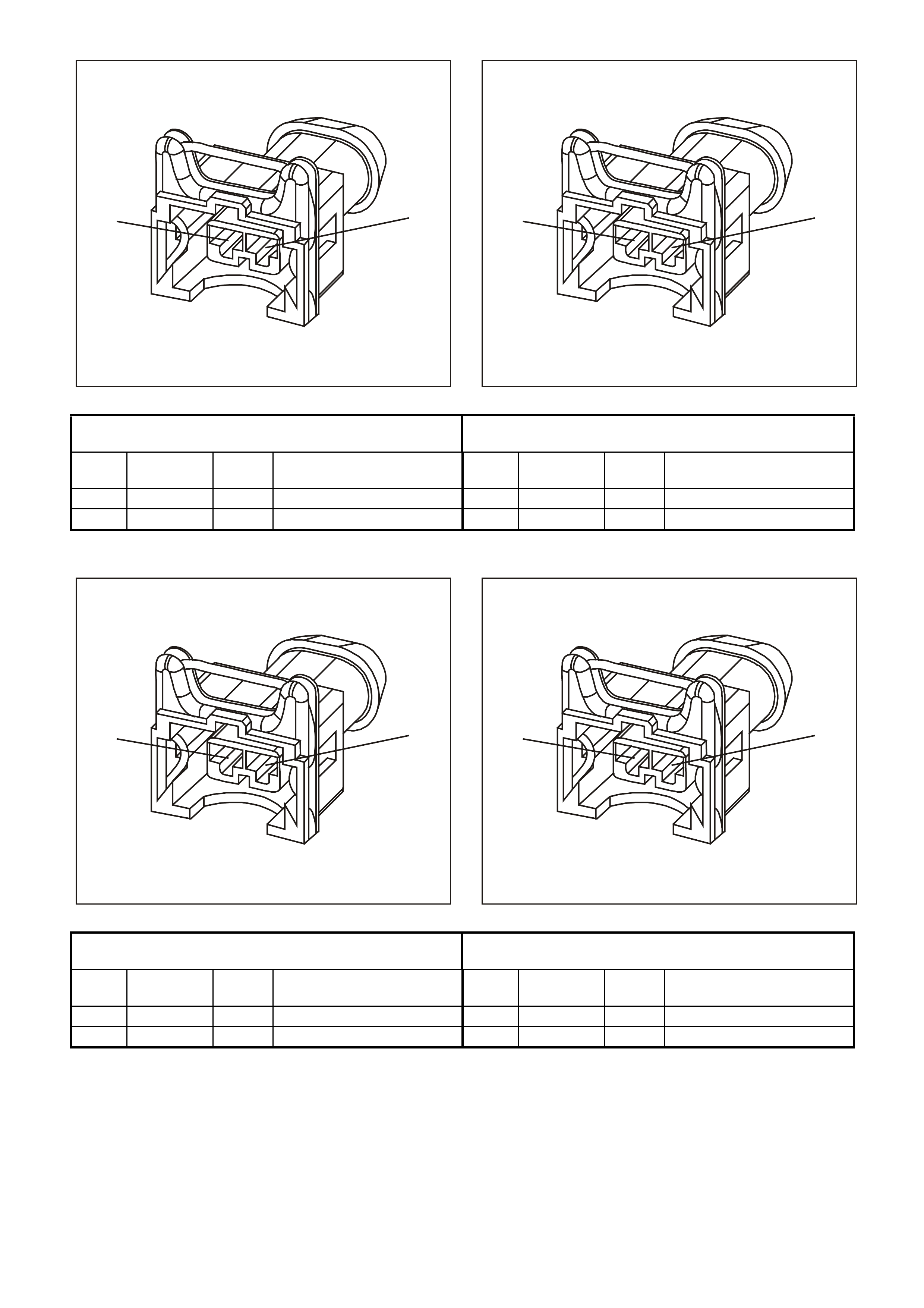

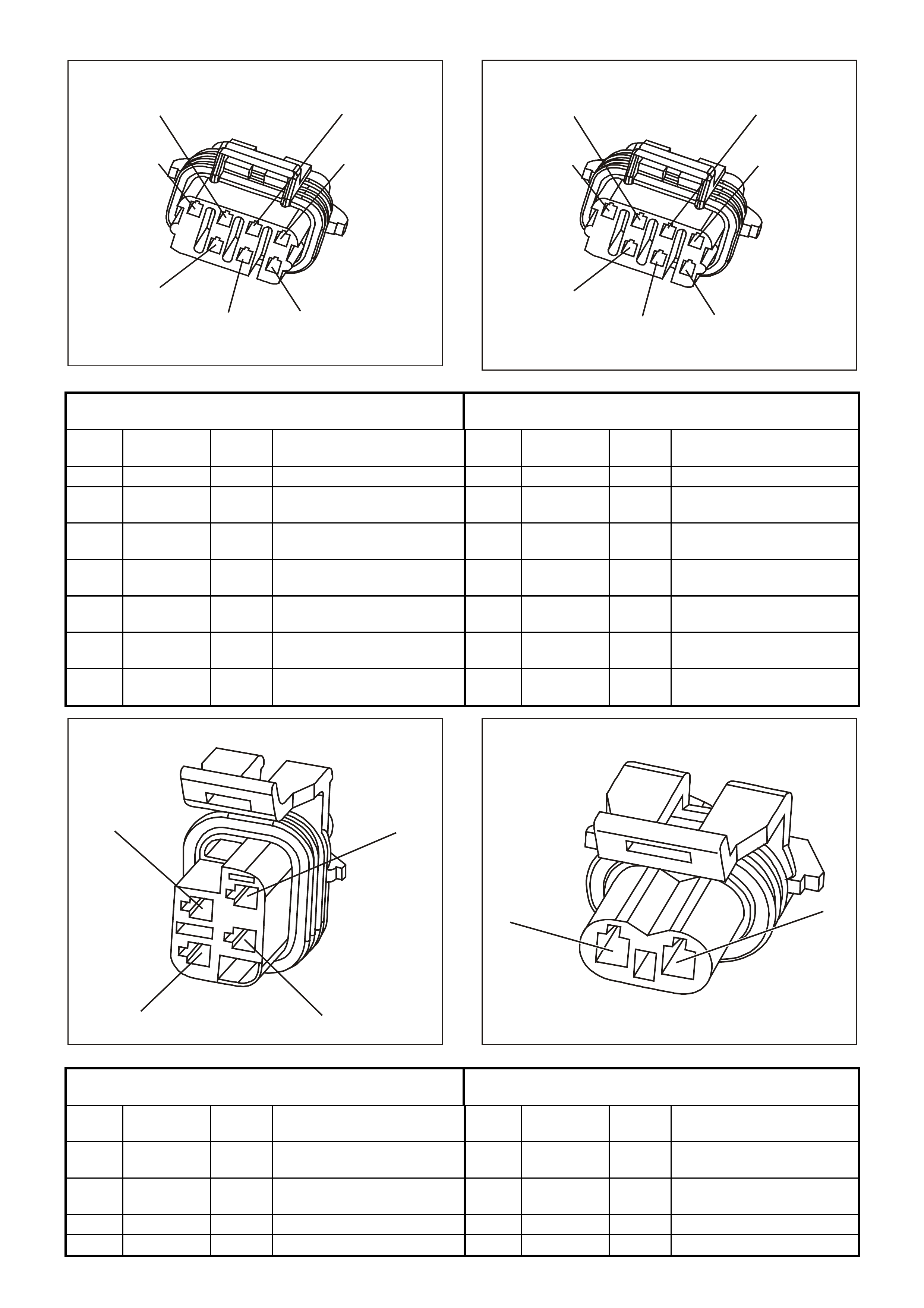

GE N 3 0081

2

1

3

4

GE N 3 0081

2

1

3

4

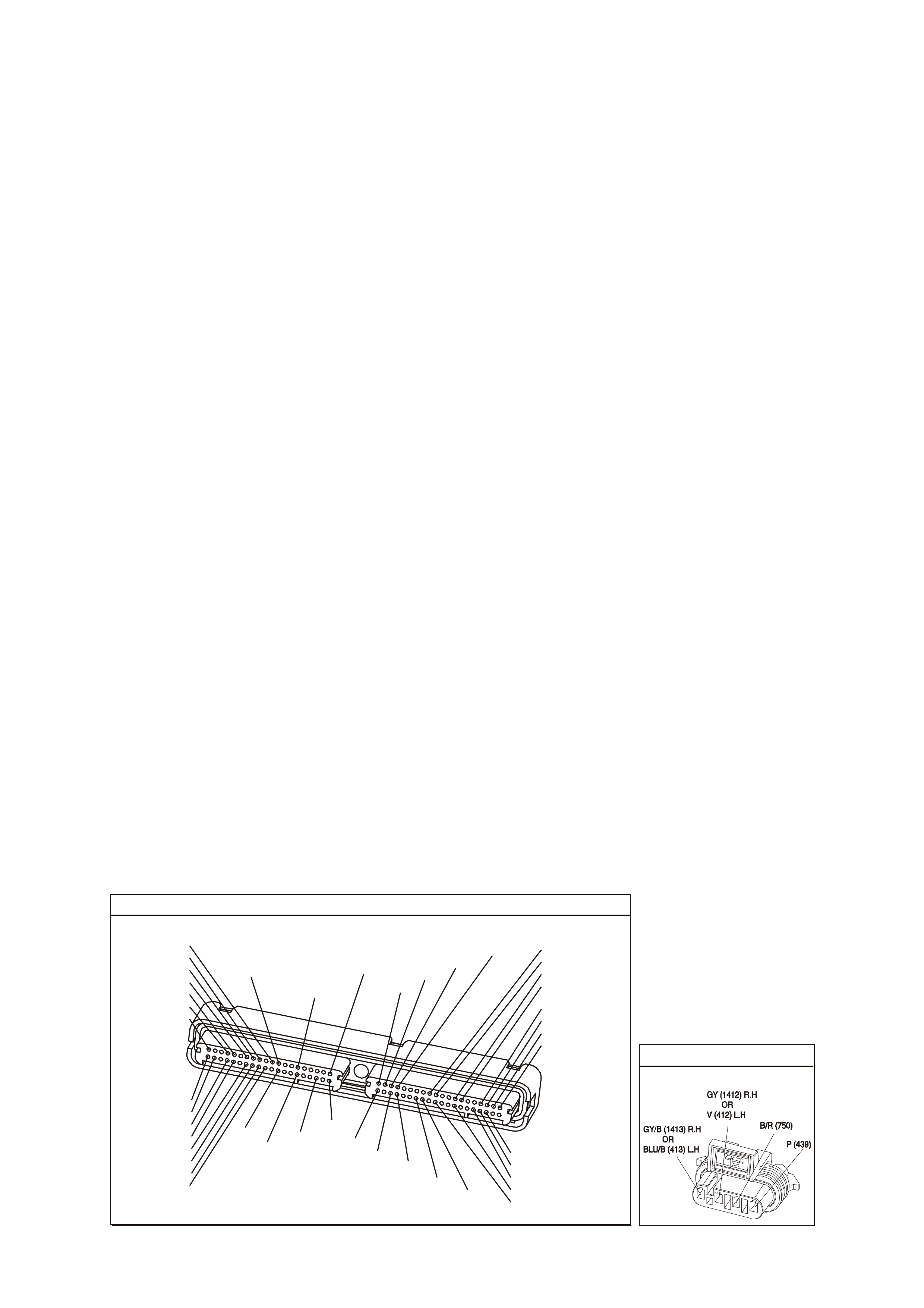

Bank 1 Left Heated Oxygen (HO2S) Sensor Connector

YE95 Bank 2 Right Heated Oxygen (HO2S) Sensor Connector

YE95

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) BLU/B 413 HO2S Low 1 (A) GY/B 1413 HO2S Low

2 (B) V 412 HO2S High 2 (B) GY 1412 HO2S High

3 (C) B/R 750 HO2S Earth 3 (C) B/R 750 HO2S Earth

4 (D) P 439 HO2S Ignition Feed 4 (D) P 439 HO2S Ignition Feed

GE N 3 0082

41

32

GE N 3 0076

1

2

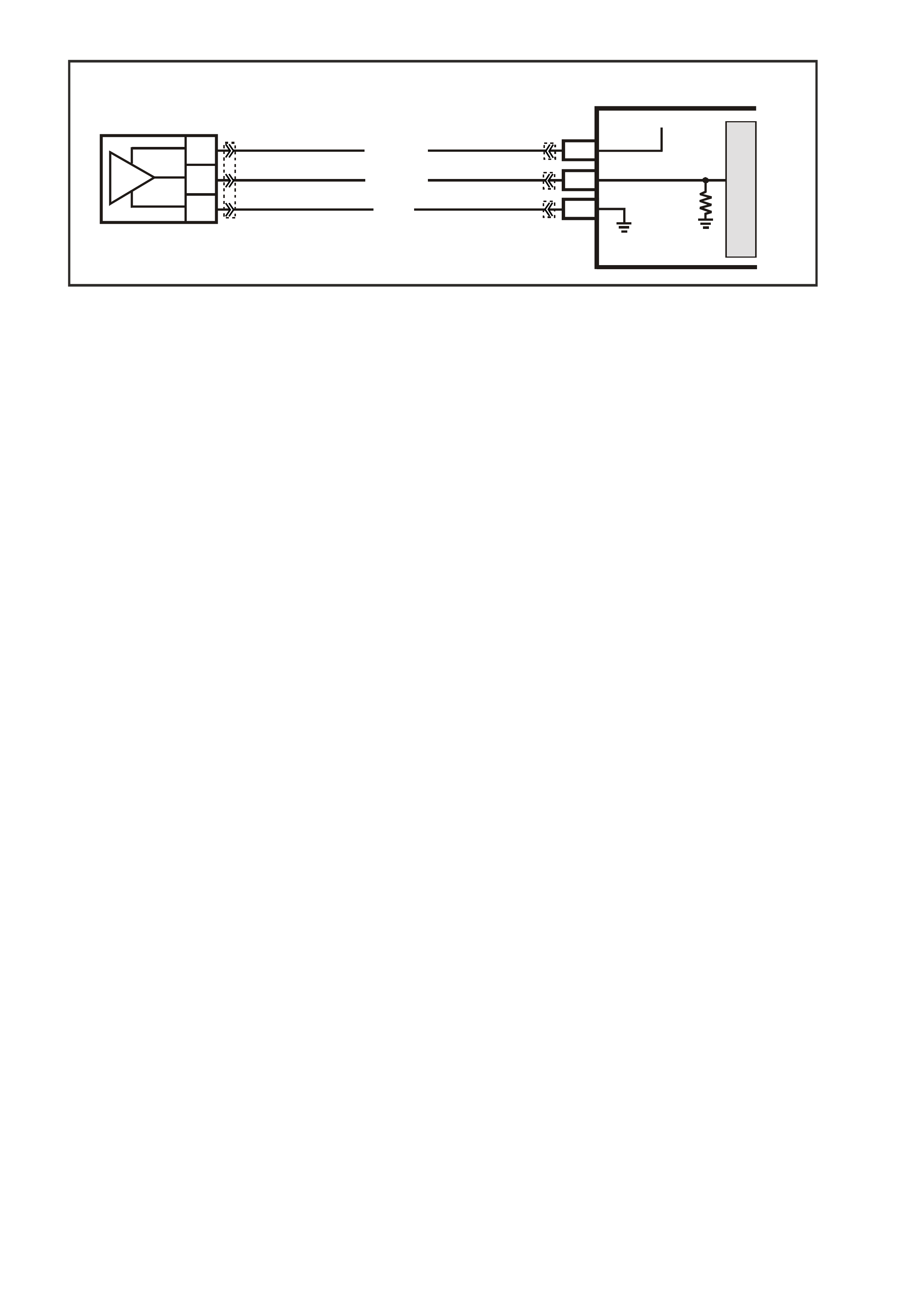

Idle Air Control (IAC) Valve Connector

YE36 Intake Air Temperature (IAT) Sensor Connector

YE23

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) LG/B 444 Idle Air Control (IAC) Valve

Coil B Signal – Low 1(A) G/O 469 Intake Air Temperature

(IAT) Sensor Earth

2 (B) LG/W 443 Idle Air Control (IAC) Valve

Coil B Signal – High 2 (B) BR 472 Intake Air Temperature

(IAT) Sensor Signal – Input

3 (C) LBLU/B 442 Idle Air Control (IAC) Valve

Coil A Signal – Low

4 (D) LBLU 441 Idle Air Control (IAC) Valve

Coil A Signal – High

GE N 3 0083

1

2

GE N 3 0084

1

Knock Sensor (KS) Two Way Harness Connector

YE19 Front Knock Sensor (KS) Connector

YE18

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) BLU 815 Front Knock Sensor Signal

Circuit 1 BLU 815 Front Knock Sensor (KS)

Signal Circuit

2 (B) LBLU 826 Rear Knock Sensor Signal

Circuit

GE N 3 0084

1

GE N 3 0085

1

2

3

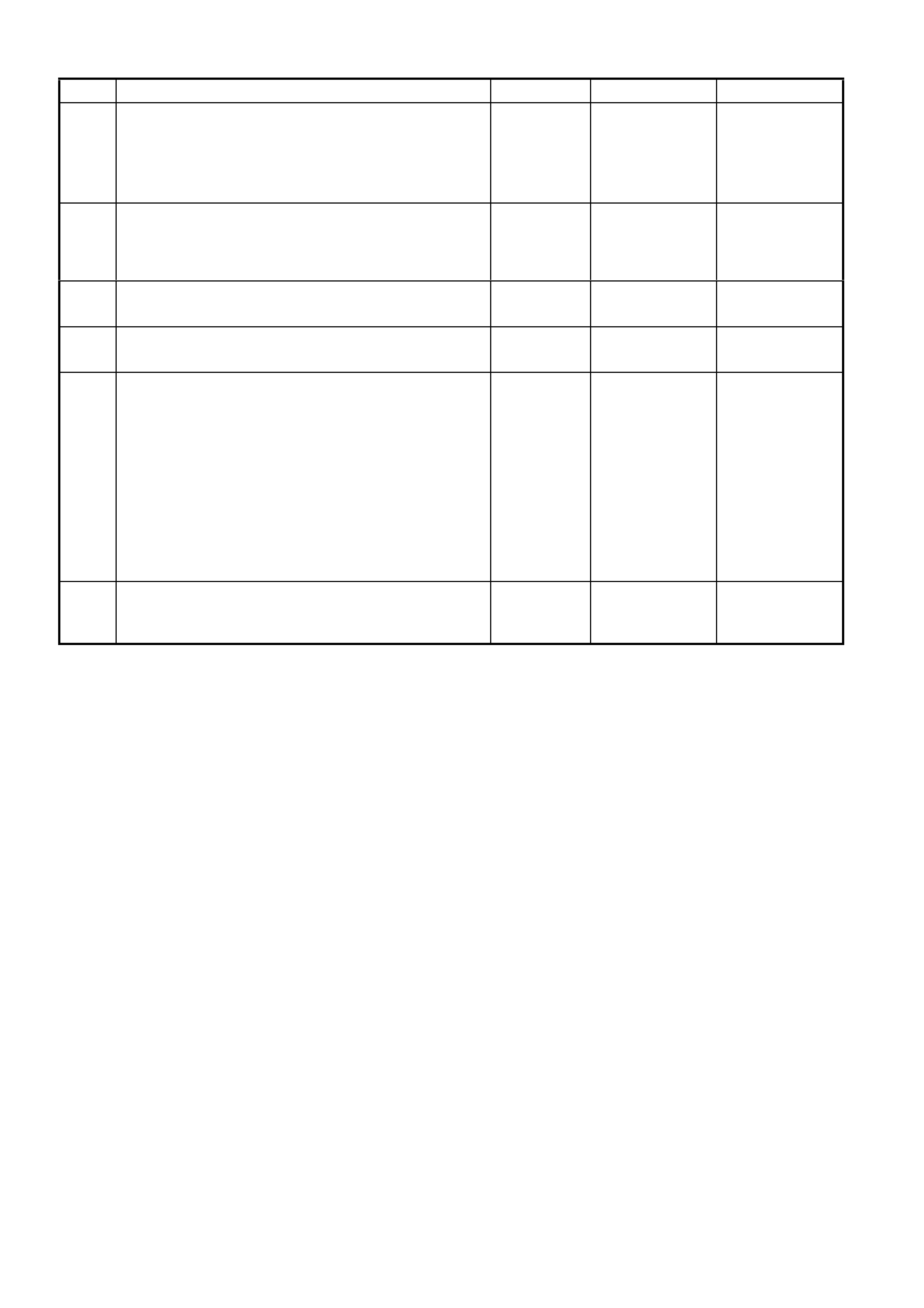

Rear Knock Sensor (KS) Connector

YE18 Manifold Absolute Pressure (MAP) Sensor Connector

YE27

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 LBLU 826 Rear Knock Sensor (KS)

Signal Circuit 1 (A) B 421 Manifold Absolute

Pressure (MAP) Sensor

Earth

2 (B) LG 432 Manifold Absolute

Pressure (MAP) Sensor

Signal

3 (C) V/W 414 Manifold Absolute

Pressure (MAP) Sensor

5.0 V Reference

GE N 3 0086

1

2

3

ABC

GE N 3 0087

1

2

Mass Air Flow (MAF) Sensor Connector

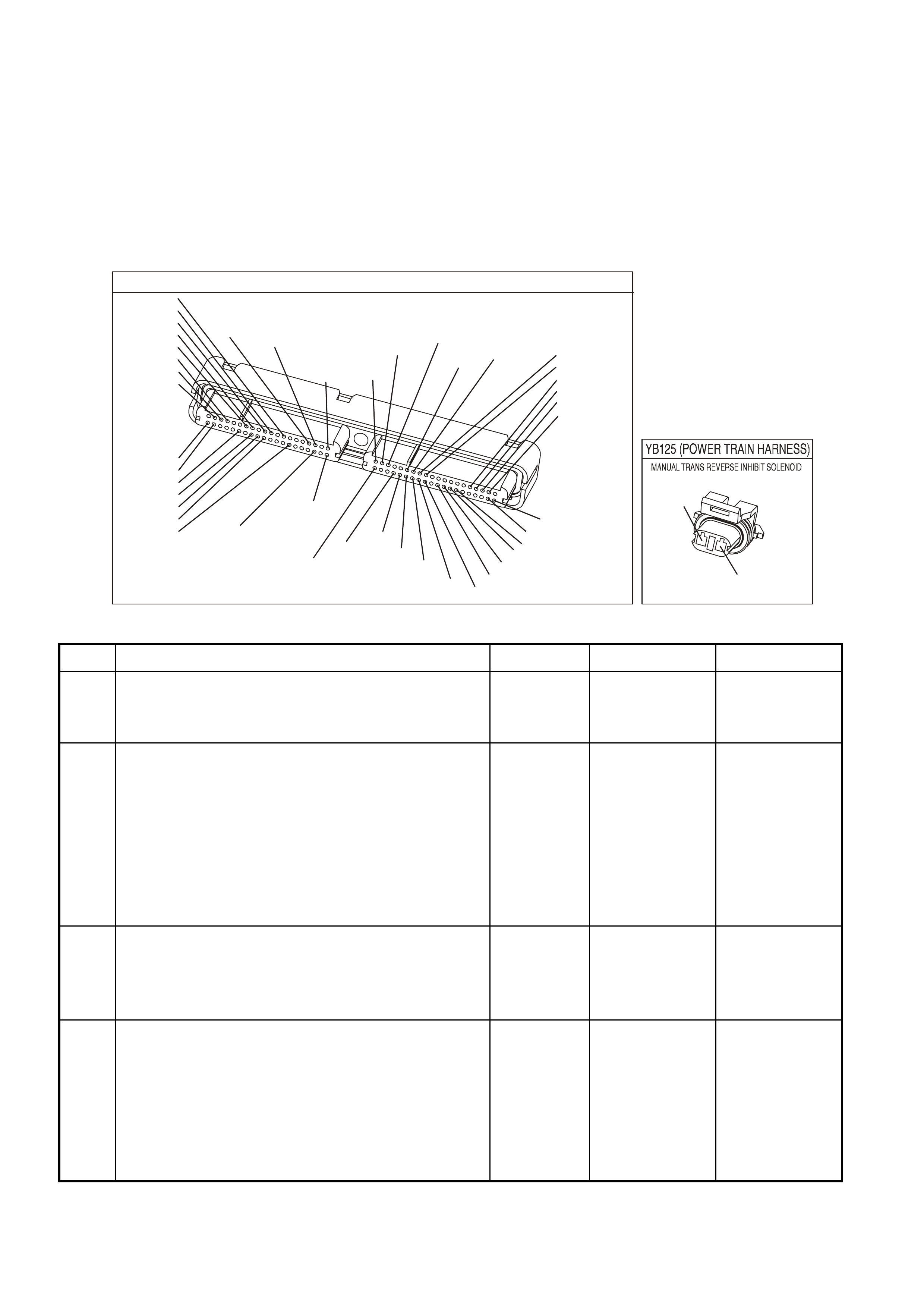

YE100 Manual Transmission Reverse Inhibit Connector YB125

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) BR/W 792 Mass Air Flow (MAF)

Sensor Signal 1 (B) P/BLU 339 Reverse Inhibit Ignition

Feed

2 (B) B/R 750 Mass Air Flow (MAF)

Sensor Earth 2 (A) Y 838 Reverse Inhibit Control

3 (C) P 439 Mass Air Flow (MAF)

Sensor Ignition Feed

GE N 3 0088

2

1

GE N 3 0103

1

2

3

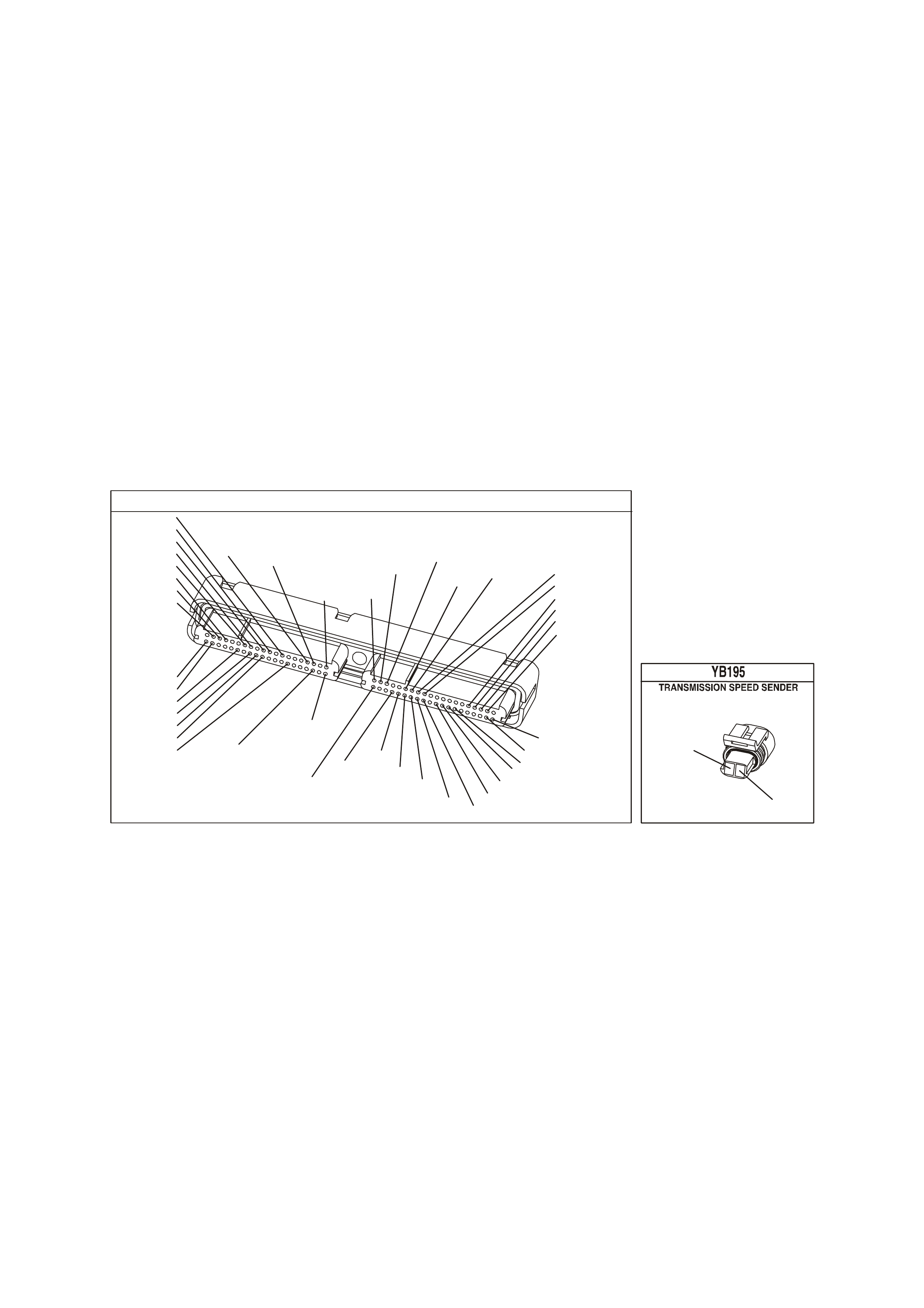

Vehicle Speed Sensor (VSS) Connector

YB195 Throttle Position (TP) Sensor Connector

YE30

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) T 832 Vehicle Speed Sensor

(VSS) Signal – Low 1 (A) GY 416 Throttle Position (TP)

Sensor 5.0 V Reference

2 (B) BLU/W 831 Vehicle Speed Sensor

(VSS) Signal – High 2 (B) B/Y 452 Throttle Position (TP)

Sensor Earth

3 (C) BLU 417 Throttle Position (TP)

Sensor Signal

GE N 3 0089

5

4

3

21

6

7

GE N 3 0089

5

4

3

21

6

7

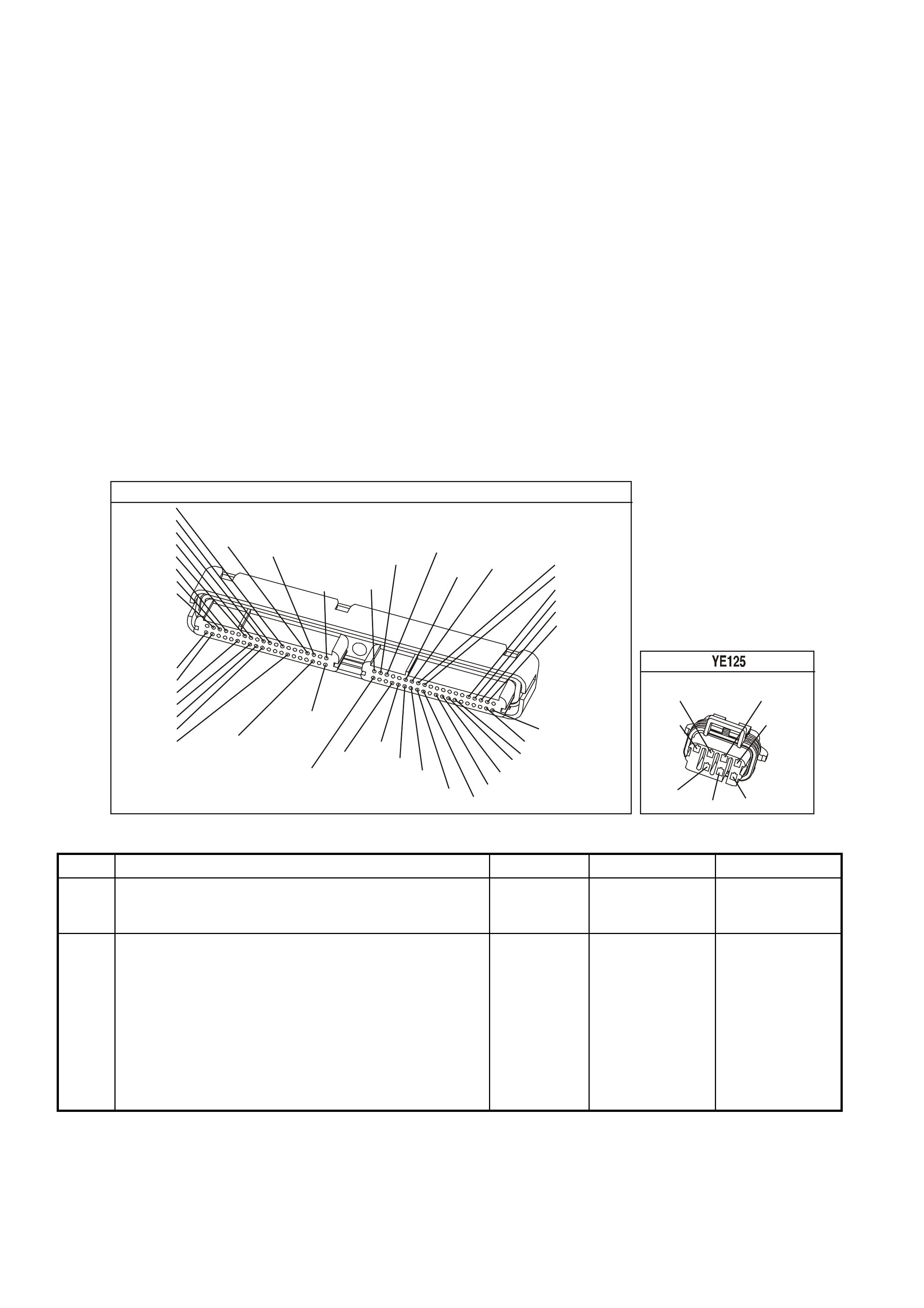

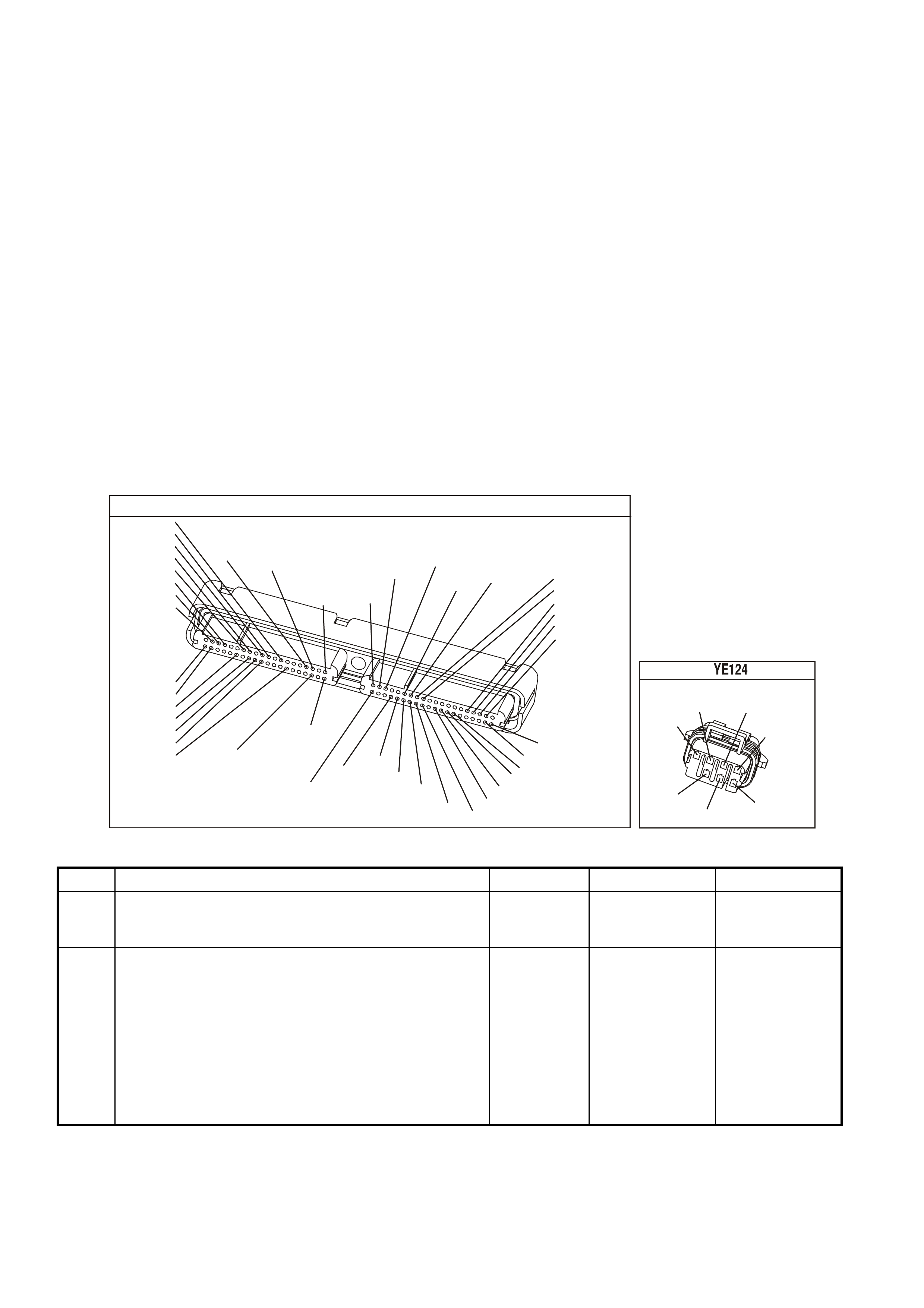

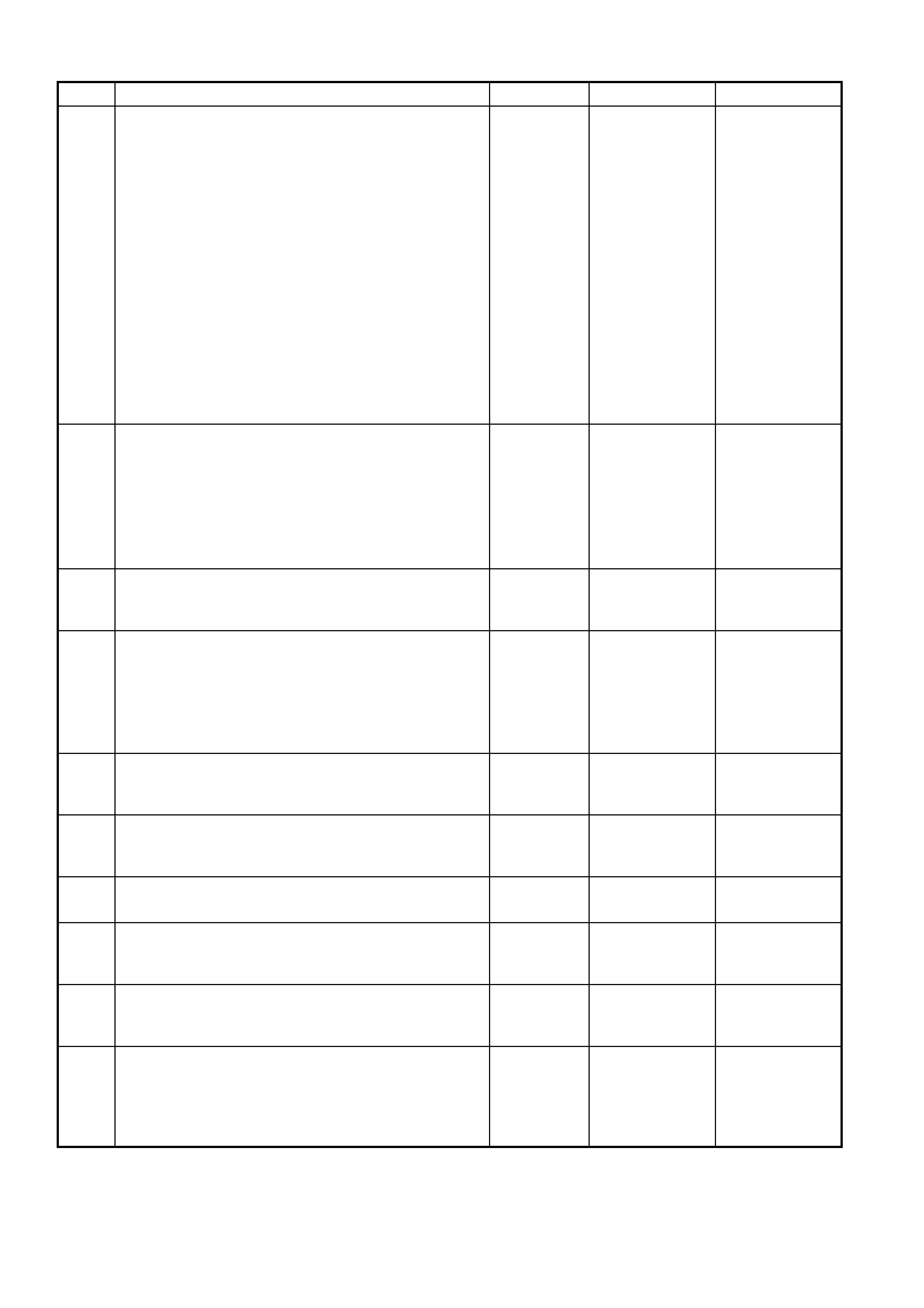

Right Bank Ignition Module Connector

YE124 Left Bank Ignition Module Connector

YE125

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) B/R 750 Ignition Module Earth 1 (A) B/R 750 Ignition Module Earth

2 (B) Y/B 972 Ignition Coil/Module #2

Control 2 (B) Y 977 Ignition Coil/Module #7

Control

3 (C) W 974 Ignition Coil/Module #4

Control 3 (C) G 975 Ignition Coil/Module #5

Control

4 (E) V 959 Ignition Coil/Module

Reference Low 4 (E) BR 958 Ignition Coil/Module

Reference Low

5 (F) LG 976 Ignition Coil/Module #6

Control 5 (F) BLU 973 Ignition Coil/Module #3

Control

6 (G) LBLU 978 Ignition Coil/Module #8

Control 6 (G) W 971 Ignition Coil/Module #1

Control

7 (H) R 481 Right Bank Coil/Module

Ignition Feed 7 (H) LG 482 Left Bank Coil/Module

Ignition Feed

GE N 3 0090

4

3

2

1

GE N 3 0078

12

PRNDL Switch Connector

YB20 Throttle Relaxer Connector

YE127

Pin Wire

Colour Circuit

No. Function Pin Wire

Colour Circuit

No. Function

1 (A) BLU/W 771 PRNDL Switch A Input 1 (B) R/B 466 Throttle Relaxer Power

Control

2 (B) GY 773 PRNDL Switch C Input 2 (A) R/W 456 Throttle Relaxer Earth

Control

3 (C) W 776 PRNDL Switch P Input

4 (D) Y 772 PRNDL Switch B Input

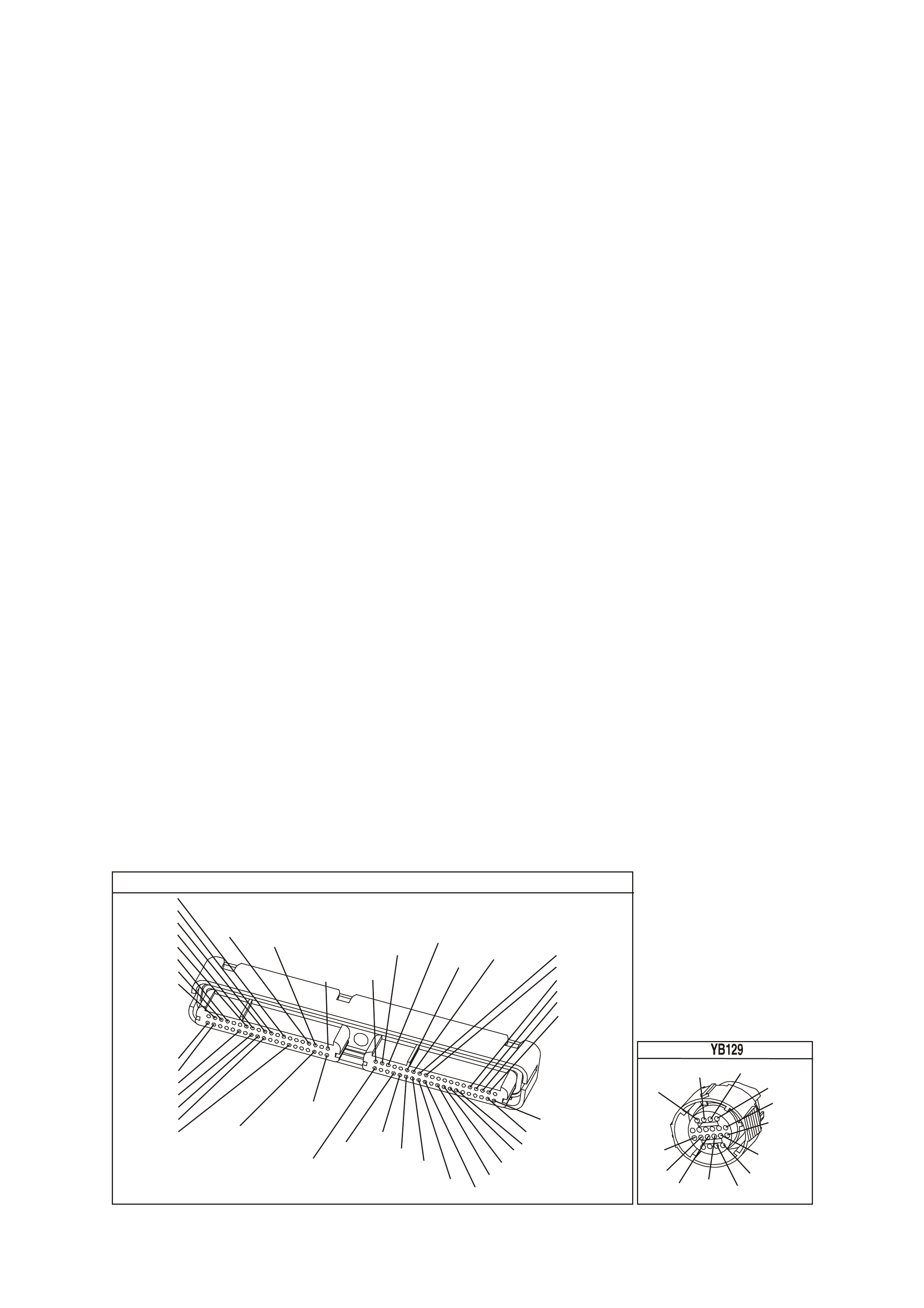

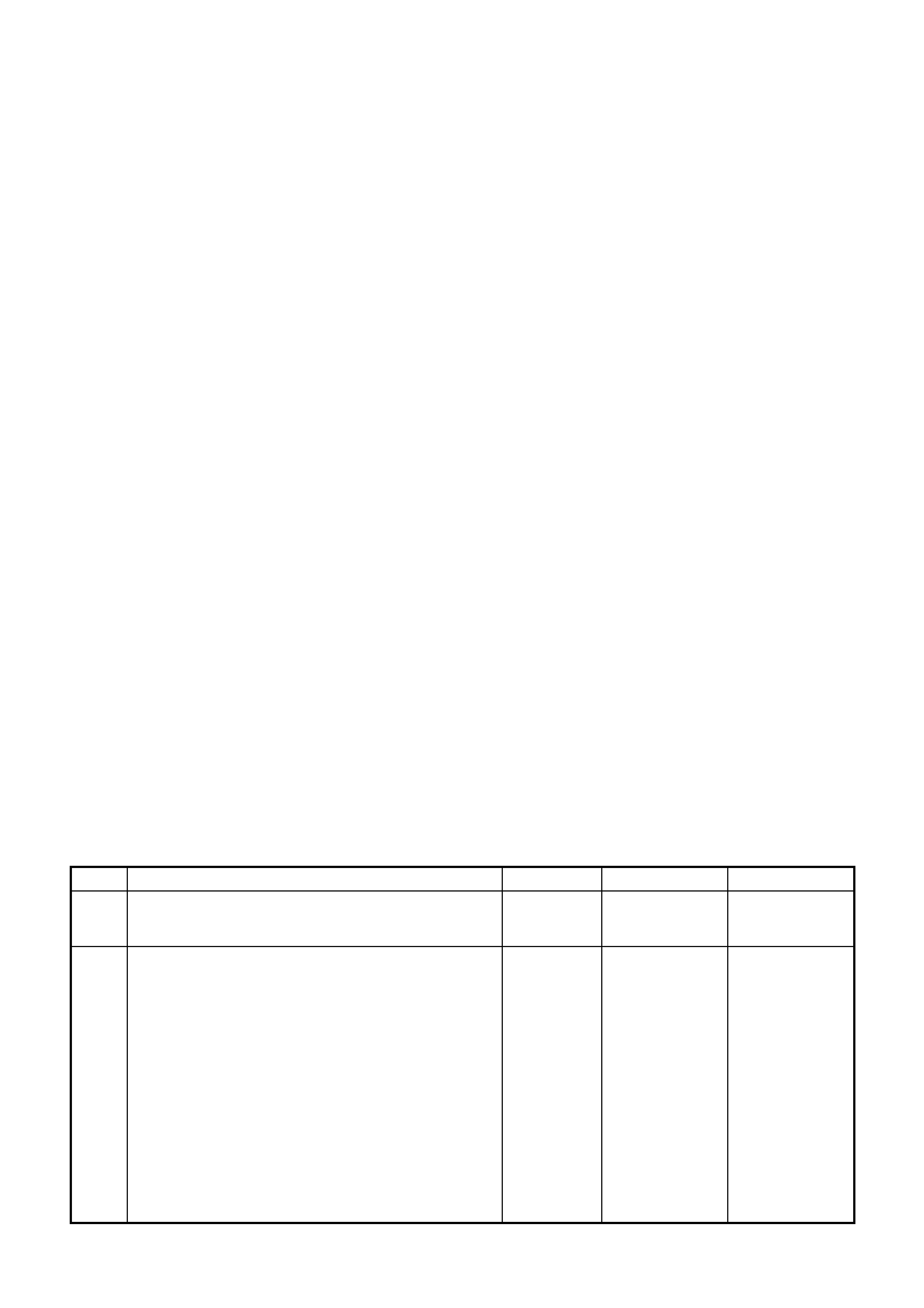

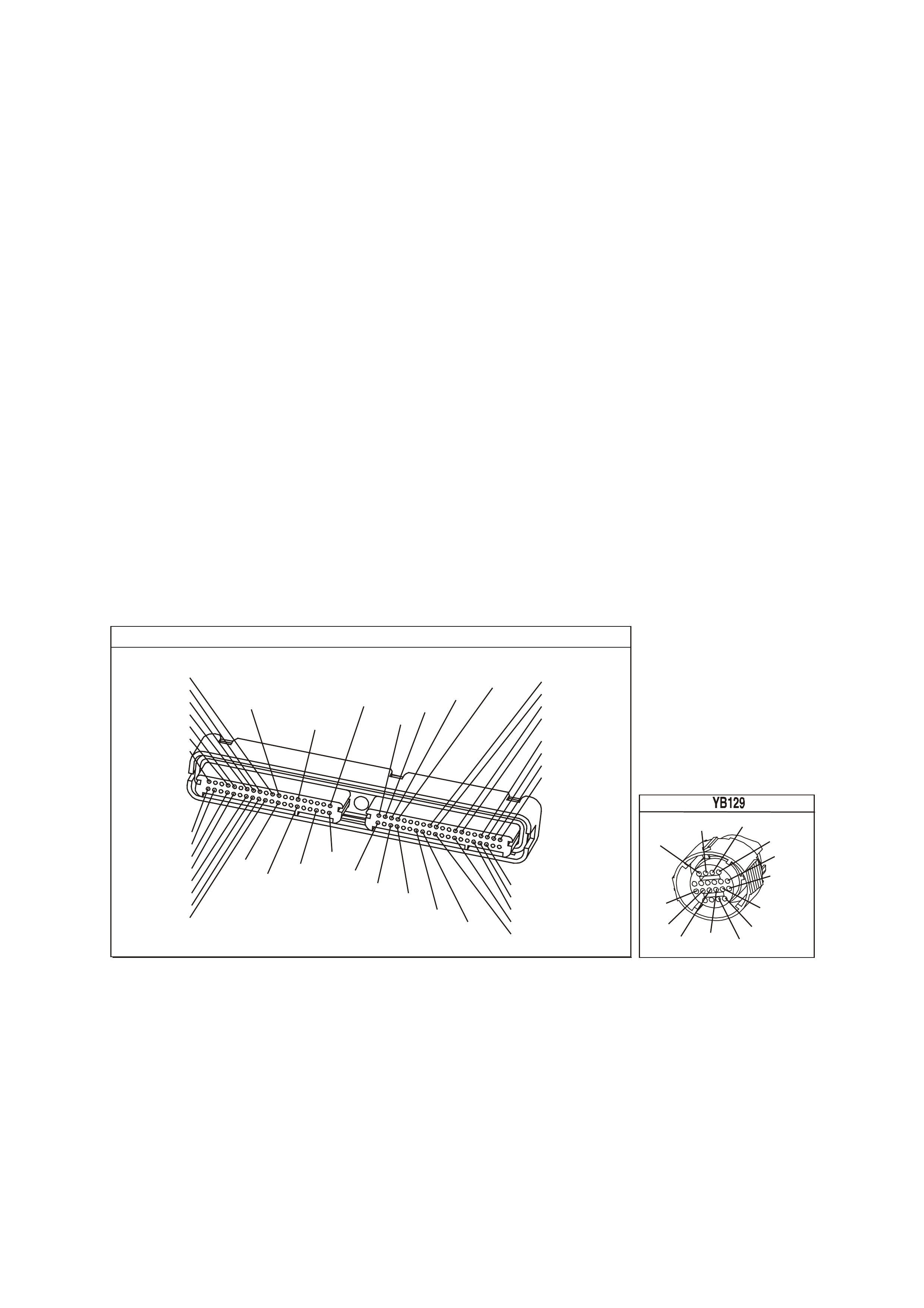

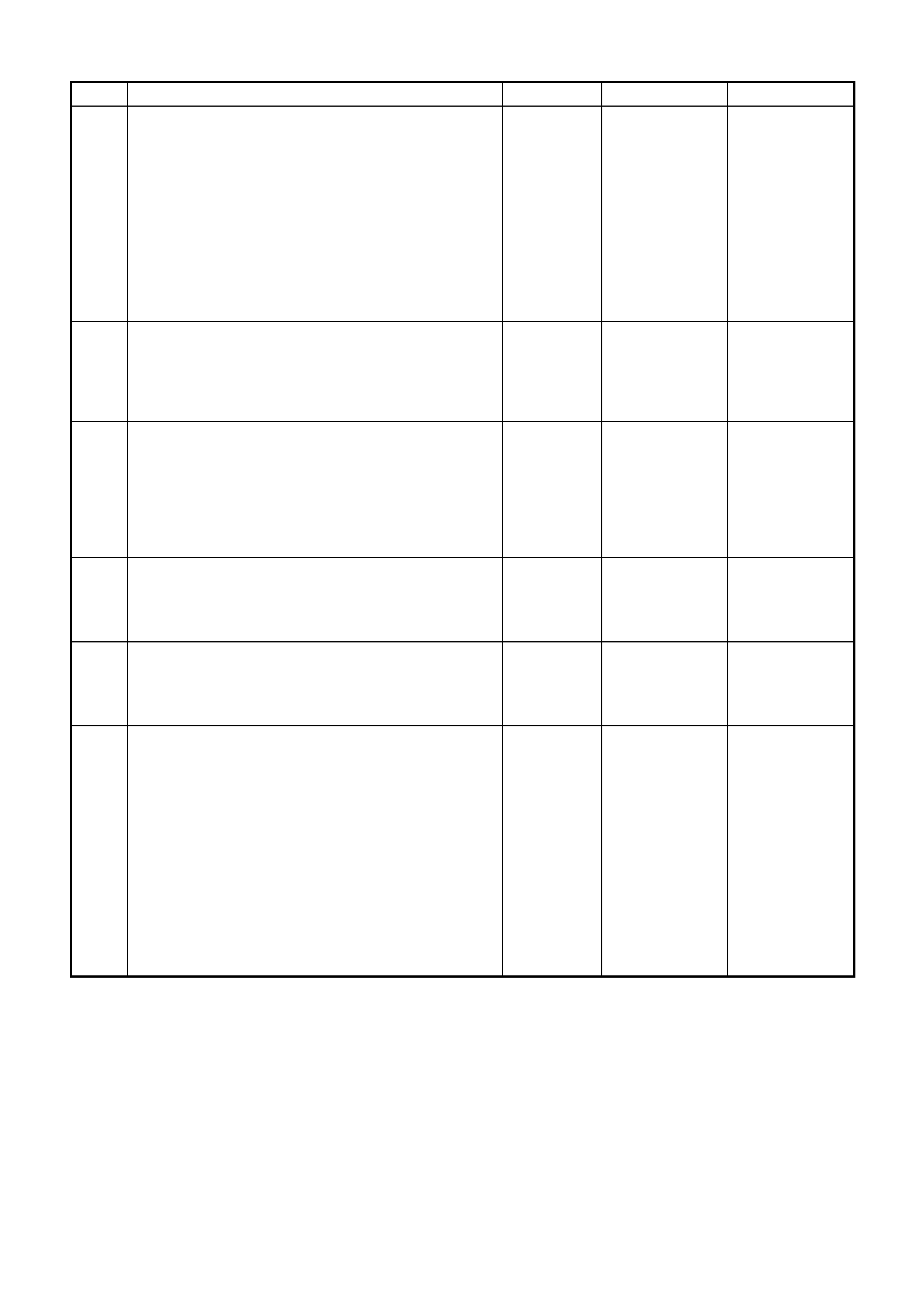

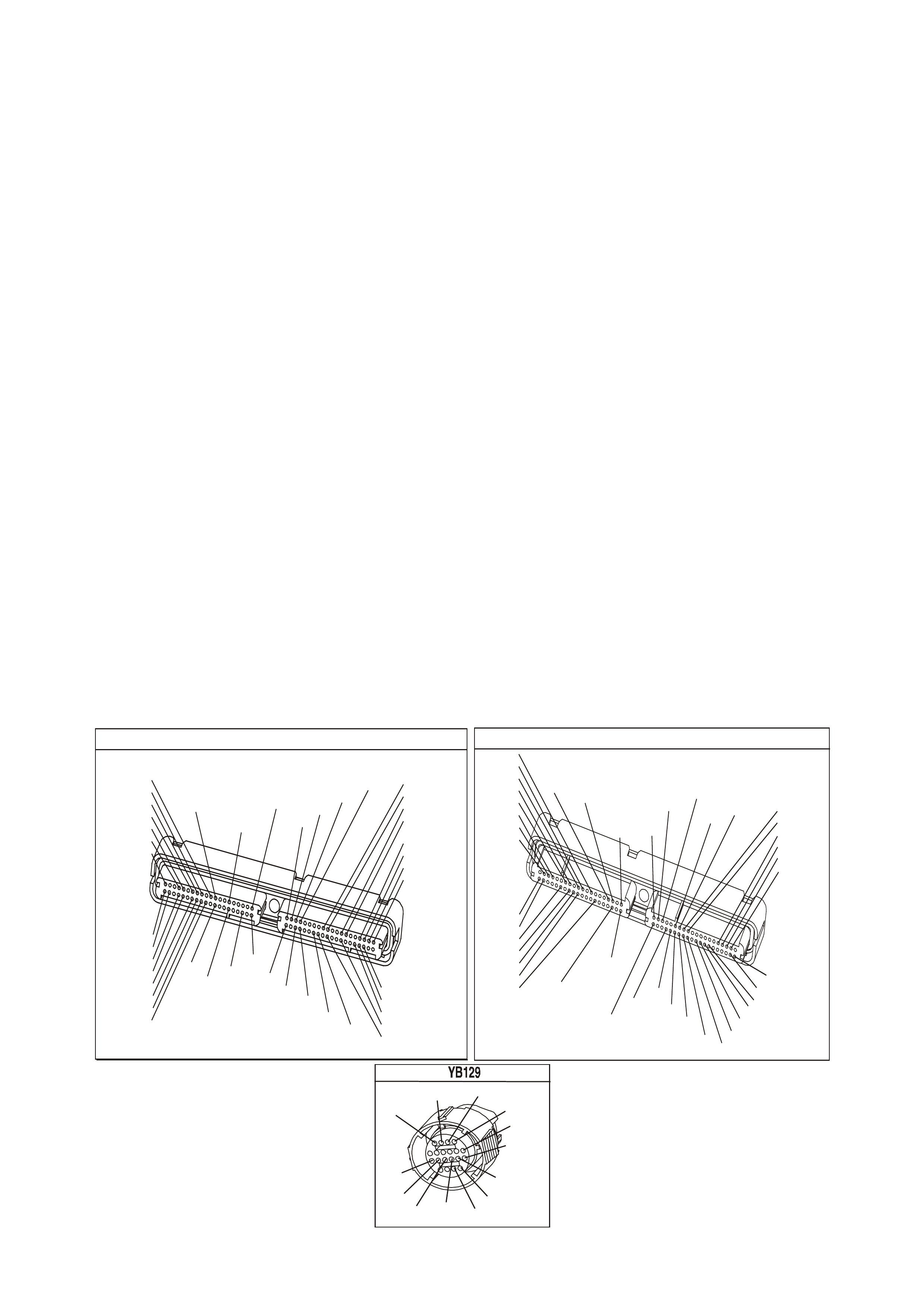

AUTOMATIC TRANSMISSION INLINE HARNESS CONNECTOR END VIEWS

Automatic Transmission Wiring Harness,

Transmission Side

YB 129

Pin Wire Color Circuit

No. Function

A LG 1222 1-2 Shift Solenoid (A)

Valve Control

B Y 1223 2-3 Shift Solenoid (B)

Valve Control

C V 1228 Pressure Control

Solenoid (PCS) Valve

HIGH

D LBLU 1229 PCS Valve LOW

E R 339 Transmission Solenoid

Power

L BR 1227 Transmission Fluid

Temperature (TFT)

Sensor HIGH

M GY 1230 TFT Sensor LOW

N P 1224 Range Signal A

P O 1226 Range Signal C

R DKBLU 1225 Range Signal B

S W 897 3-2 Shift Solenoid Valve