SECTION 6C3-2B - SYMPTOMS - GEN III V8 ENGINE

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES in this VX Service Information for correct workshop practices with regards to

safety and/or property damage.

GENERAL DES CRIPTION

When no diagnostic trouble codes have been set and the Tech 2 scan tool data values are within typical ranges,

you should diagnose the condition based on the symptoms of the complaint.

This Symptom Section starts with preliminary checks that must be performed in order to diagnose by symptom.

Then, intermittent conditions are discussed. These preliminary pages provide important information to assist you

with symptom diagnosis. Next, the contents of this Section presents the various symptoms and lists a series of

checks for each.

Many of the s ymptom diagnostic s s tar t with a very important proc edur e, a visual/physical inspection. Always look for

the obvious first. Some situations may warrant observing the driver. Is the driver using the correct shift lever position

or riding the brake pedal? Visually check the engine, transmission , PCM, and PIM connectors. Are there any

disconnected wires or incorrectly installed components?

Finally, are there obvious signs that someone may have perform ed incorrect r epairs? These c hecks tak e very little

time; they can eliminate the time spent on a broad-base systematic diagnosis by directing you to the problem. If they

do not reveal the problem, proceed to check the other suspect systems, as referred to in the VX Series Service

Information.

PCM / PIM

Since the PCM and PIM can have a failure which may affect only one circuit, following the Diagnostic Procedures, in

the VX Series Service Information, will determine which circuit has a problem and where it is.

If a diagnostic T able indicates that the PCM , PIM and/ or connection is the cause of a problem and the PCM

or PIM has been replaced, but does not correct the problem, one of the following may be the reason:

• There is a problem with the PCM or PIM terminal connections. The diagnostic Table will say "PCM or PIM

connections or PCM/PIM." The terminals may have to be removed from the connector in order to check them

properly.

• The PCM or PIM is not c or rec t f or the applic ation. T he inc or rec t PCM or PIM may cause a malfunction and may

or may not set a code.

• The problem is intermittent. This means that the problem is not present at the time the system is being

checked. In this case, refer to the SYMPTOMS Tables and make a careful physical inspection of all

components of the system involved.

• Shorted solenoid, relay coil, or harness. Solenoids and relays are turned ON and OFF by the PCM, using

internal electronic switches called "Drivers." Each "driver" is part of a group of four (called "Quad drivers").

Failure of one driver may cause other driver s in the set to m alfunction. Solenoid and relay coil resistance m ust

measure more than 20 ohms, in most cases. Less resistance may cause early failure of the PCM "driver."

Before replacing a PCM or PIM, be sure to check the coil resistance of all solenoids and relays controlled by the

PCM or PIM. See PCM and PIM wiring diagram for the solenoid(s) and relay(s) and the coil terminal

identification.

• The replacement PCM or PIM may be faulty. After the PCM or PIM is replaced, the system should be

rechecked for proper operation. If the diagnostic Table again indicates the PCM or PIM is the problem,

substitute a known good PCM or PIM. Although this is an extremely rare condition, it could occur.

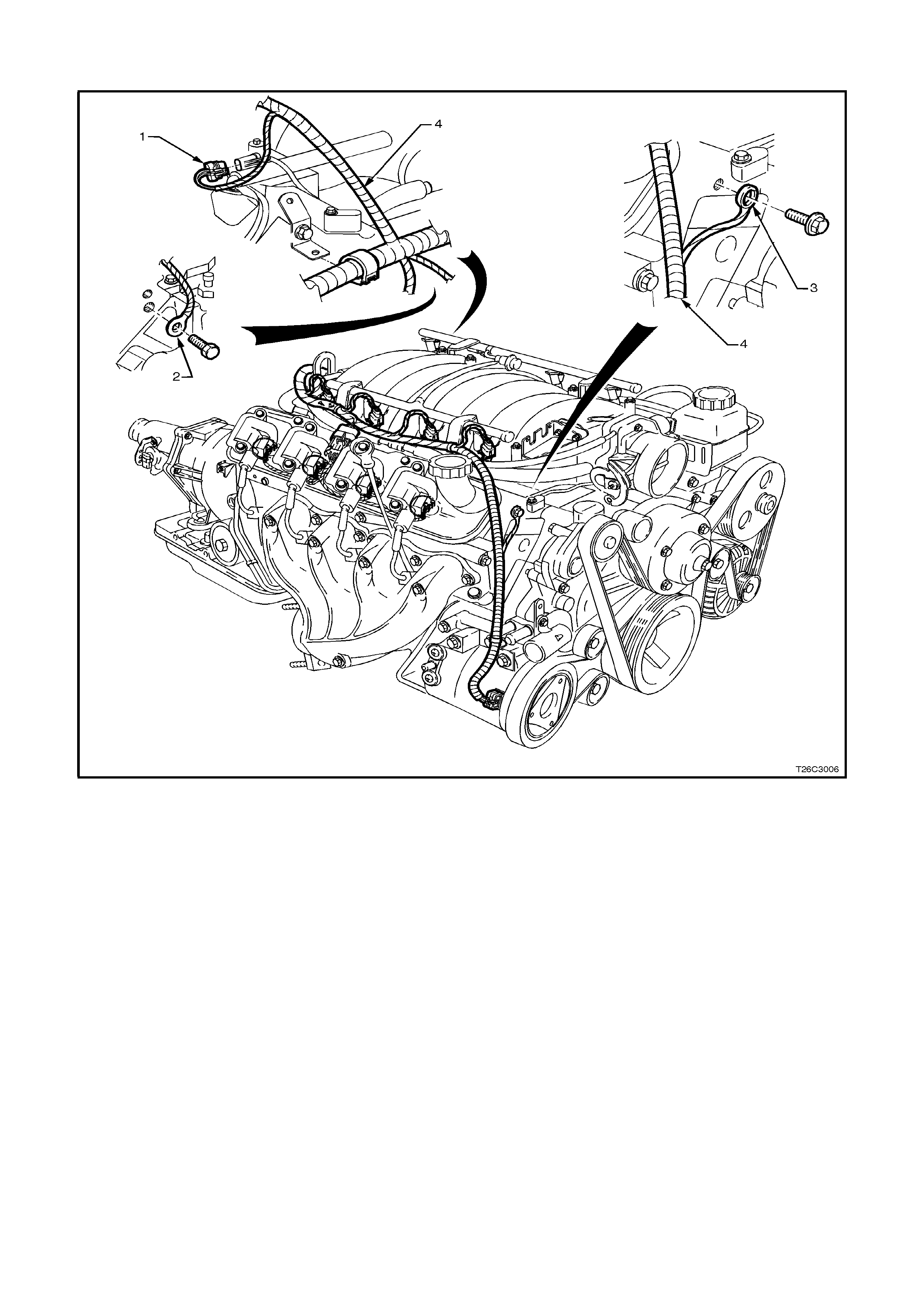

ENGINE EARTH LOCATIONS

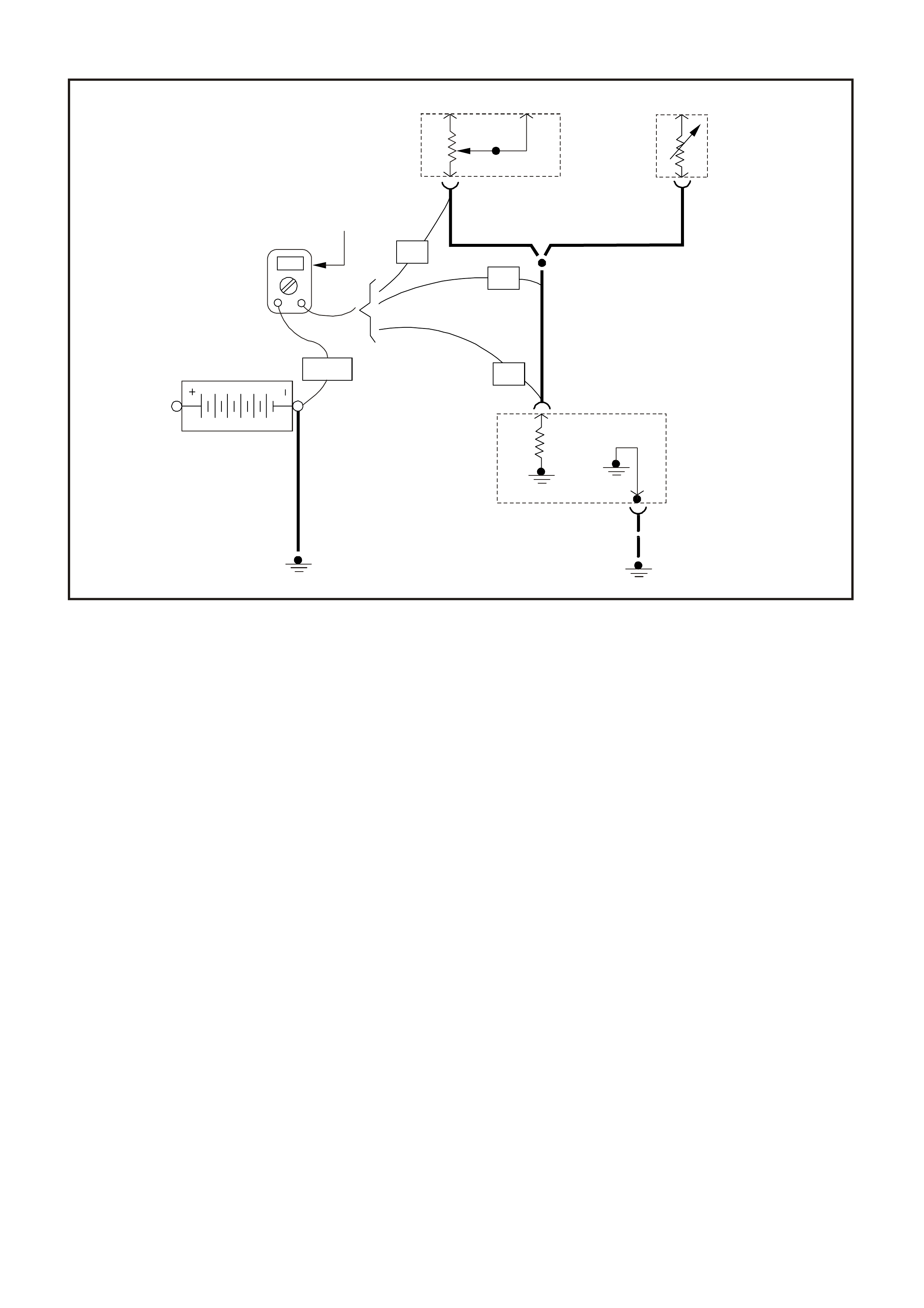

Figure 6C3-2B-1 Engine Powertrain Wiring Harness to Engine Assembly Earth Location.

1. Knock Sensors Jumper Harness Connector

2. PCM Earth Location Left Rear Head

3. PCM Earth Location Right Front Head

4. PCM Wiring Harness to A/C Compressor

SYMPTOMS

IMPORTANT PRELIMINARY CHECKS BEFORE STA RTING

Perform the Powertrain OBD Sy stem Check before using the System Tables, and verify all of the following are true:

• The PCM/PIM and CPL (Check Powertrain Lamp) are operating correctly.

• There are no PCM or PIM DTC(s) stored.

• Ensure that the engine coolant temperature is not above 130°C (266°F). This condition causes the PCM to

operate in Engine Coolant O ver T e mperature- Fuel Dis abled Mode. While in Engine Coolant O ver T e mperature-

Fuel Disabled Mode, the PCM turns the f uel O FF to f our c ylinders at a tim e in order to keep engine temperature

from reaching damaging levels. The system perceives Engine coolant Over Temperature as a lack of power,

mis s , or r ough idle. If the vehic le is oper ating in Engine Coolant Over Temper ature- F uel Disabled Mode, refer to

Section 6B3 ENGINE COOLING – GEN III V8 ENGINE, in VX Service Information for diagnosis.

• The Tech 2 scan tool data is within the normal operating range, refer to

Section 6C3-2 DIAGNOSIS – GEN III V8 ENGINE, in this VX Series Service Information.

• Verify the driver com plaint, and locate the correct symptom in the table of contents. Check the item s indicated

under that symptom.

INSPECTION

Several of the symptom procedures require a careful visual and physical inspection. This step is extremely

important-it can lead to correcting a problem without further checks and can save valuable time.

This check includes:

• The PCM/PIM earths for being clean, tight, and in their proper location.

• Vacuum hos es for splits , k ink s, and pr oper connections , as s hown on the Vehicle Emis sion Control Inf orm ation

label. Check thoroughly for any type of leak or restriction.

• The Mas s Air Flow (MAF) s ensor installation. T he arrows on the plastic portion of the sensor must point toward

the engine.

• The air intake ducts for being collapsed, split or for having damaged areas.

• Air leaks at throttle body mounting area, Mass Air Flow (MAF) sensor, and the intake manifold sealing surfaces.

• The ignition wires for cracking, hardness, proper routing and carbon tracking.

• The engine harness wiring and terminals for proper connections, pinches or cuts.

INTERMITTENTS

IMPORTANT:

Check for improper installation of electrical components if an intermittent condition exists. Inspect for aftermarket

theft deterr ent devices, lights and cellular phones . Ensure that no afterm arket equipm ent is connected to the Class

II circuit. If you c an not locate an interm ittent condition, a cellular phone signal c omm unication m ay be the caus e of

the condition.

IMPORTANT:

The problem may or may not turn ON the Check Powertrain Lamp (CPL) or store a DTC. DO NOT use the

Diagnostic Trouble Code (DTC) tables for intermittent problems. The fault must be present in order to locate the

problem.

Faulty electrical connections or wiring cause most intermittent problems. Perform a careful inspection for the

following conditions:

• Poor mating of the connector halves or a terminal not fully seated in the connector body (backed out).

• An improperly formed or damaged terminal.

• Reform or replace connector terminals in the problem circuit in order to insure proper contact tension.

• Poor terminal to wire connection requires removing the terminal from the connector body in order to check.

• Road test the vehic le with a Digital Multim eter ( DMM) J 39200 c onnected to the s uspected c ircuit. An abnorm al

voltage when the malfunction occurs is a good indication that there is a malfunction in the circuit being

monitored.

Use a scan tool in order to help detect inter mittent conditions. T he scan tool has sever al features that you can use

to locate an intermittent condition. Use the following features to find intermittent faults:

• You can trigger the Snaps hot f eatur e in order to captur e and s tore engine par ameters within the scan tool when

the malfunction occurs. You can then review this stored information in order to see what caused the

malfunction.

• Using the Scan Tool’s Freeze Frame/Fa ilure Records can als o aid in locating an intermittent c ondition. Review

and capture the information in the Freeze Frame/Failure Records associated with the intermittent DTC being

diagnosed. Drive the vehicle in the conditions that were present when the DTC was originally set.

IMPORTANT:

If the interm ittent condition exists as a start and then stall condition, check f or DTC(s) relating to the theft deterrent

system. Check for improper installation of electrical options such as lights, cellular phones etc.

Any of the following may cause an intermittent Check Powertrain Lamp (CPL) with no stored DTC:

• The ignition coils shorted to a earth, arcing at the ignition wires or the spark plugs.

• The PCM/PIM earths, refer to Section 12P WIRING DIAGRAMS, in VX Service Information.

• The Ignition Control ( IC) wires f or being routed too c lose to the sec ondary ignition wires , coils , or the generator.

Ensure that all of the circuits from the PCM to the ignition coils have good connections.

• An open diode across the A/C compressor clutch and the other open diodes, refer to

Section 12P WIRING DIAGRAMS, in VX Service Information.

Use the following tables when diagnosing a symptom complaint:

• Hard Start

• Surges/Chuggles

• Lack of Power, Sluggishness, or Sponginess

• Detonation/Spark Knock

• Hesitation, Sag, Stumble

• Cuts Out, Misses

• Poor Fuel Economy

• Rough, Unstable, or Incorrect Idle, Stalling

• Dieseling, Run-On

• Backfire

HARD START

Checks Actions

Definition: Engine cranks OK, but does not start for a long time. Does eventually run, may start but stalls immediately.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information.

• Refer to Service Bulletins for relevant information.

Sensor/System • Check the Engine Coolant Temperature (ECT) Sensor for an incorrect value.

Compare the Engine Coolant Temperature against the Intake Air Temperature

(IAT) on a cold engine. The ECT and IAT Sensor values should be within ± 3°C

(5°F) of each other. If the ECT Sensor is out of range with the IAT sensor,

check the resistance of the ECT sensor. Refer to Temperature vs Resistance

for resistance specifications. Replace the ECT Sensor if the resistance is not

within the specification. If the sensor is within the specification, repair ECT

signal circuit for high resistance.

• Check the Mass Air Flow sensor installation. A MAF sensor that is incorrectly

installed may cause hard starting. The embossed arrows on the MAF sensor

indicate the direction of the intake air flow. The arrow must point toward the

engine. Install the MAF in the proper direction. Refer to MAF Sensor

Replacement in Section 6C3-3 SERVICE OPERATIONS – in VX Service

Information.

Fuel System • Check the fuel pump relay operation. The fuel pump should turn ON for 2

seconds when you turn on the ignition. Refer to Fuel Pump Relay Circuit

Diagnosis in Section 6C3-2A DIAGNOSTIC TABLES – in VX Service

Information .

• A faulty in-take fuel pump check valve slows the fuel in the lines to drain back

to the tank after the engine stops. To check for this condition, refer to Fuel

System Diagnosis in Section 6C3-2A DIAGNOSTIC TABLES – in VX Service

Information .

• Check both injector fuses for being open. An open injector fuse causes four

injectors and four ignition coils not to operate. Replace the fuse. Inspect the

injector circuit and the ignition coil circuits for an intermittent short to earth.

• Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

Checks Actions

Ignition System • Check both injector fuses for being open. An open injector fuse causes four

injectors and four ignition coils not to operate. Replace the fuse. Inspect the

injector circuit and the ignition coil circuits for an intermittent short to earth.

• Check for proper ignition voltage output with spark tester J 26792. Refer to

Section 6D3-3 IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service

Information .

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• Determine the causes of the fouling before replacing the spark plugs, if the

spark plugs are fuel or oil fouled.

• Check for bare or shorted ignition wires.

• Check for loose ignition coil earths.

• Check the spark plugs for proper heat range.

Refer to Section 6D3-3 IGNITION SYSTEM – GEN III V8 ENGINE in VX Service

Information.

Engine Mechanical • Excessive oil in combustion chamber - leaking valve seals. Refer to Section

6A3 ENGINE MECHANICAL– GEN III V8 ENGINE, in VX Service Information .

• Low cylinder compression. Refer to Section 6A3 ENGINE MECHANICAL–

GEN III V8 ENGINE, in VX Service Information.

• Inspect combustion chambers for excessive carbon build-up. Clean the

chambers using a de-carboning agent. Follow the instructions of the product.

• Check for incorrect basic engine parts. Inspect the following: Cylinders,

camshaft, pistons, etc.

Refer to Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE in VX Service

Information.

SURGES/CHUGGLES

Checks Actions

Definition: Engine power variation under steady throttle or cruise. Vehicle speeds up and slows down with no change in the

accelerator pedal position.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information .

• Be sure the driver understands the operation of the transmission torque

converter clutch and A/C compressor operation as explained in the Owner’s

Handbook. Inform the driver on how the TCC and the A/C clutch operates.

Sensor/System • Check the Heated Oxygen Sensor (HO2S). The Heated Oxygen Sensors

(HO2S) should respond quickly to different throttle positions. If they do not,

check the HO2S for silicon or other contaminates from fuel or the use of

improper RTV sealant. The sensors may have a white powdery coating and

result in a high but false signal voltage (rich exhaust indication). The PCM will

then reduce the amount of fuel delivery to the engine causing a severe

driveability problem.

• Check the MAF sensor connections.

Fuel System • Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

• Check that each injector harness is connected to the correct injector/cylinder

according to the firing order (1-8-7-2-6-5-4-3). Relocate injector harnesses as

necessary.

• Check the items that cause an engine to run rich (long term fuel trim near

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor .

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Checks Actions

Ignition System • Wet down the secondary ignition system with water from a spray bottle.

Wetting down the secondary ignition system may help locate damaged or

deteriorated components. Look/listen for arcing or misfiring as you apply the

water.

• Check for proper ignition voltage output with spark tester J 26792.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An incorrect spark plug gap will cause a driveability problem. Set the spark

plug gaps using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information, for diagnosis of the rich condition

• For oil fouling refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE, in VX Service Information, for diagnosis of the oil fouling condition.

• Check for loose ignition coil earths.

• Check the spark plugs for proper heat range. Refer to Section 6D3-3 IGNITION

SYSTEM – GEN III V8 ENGINE, in VX Service Information.

Engine Mechanical Ensure that the engine coolant temperature is not above 130°C (266°F). This

condition causes the PCM to operate in Engine Coolant Over Temperature-Fuel

Disabled Mode. While in Engine Coolant Over Temperature-Fuel Disabled Mode,

the PCM turns fuel OFF to four cylinders at a time to keep engine temperatures

from reaching damaging levels. The system perceives Engine Coolant Over

Temperature-Fuel Disabled Mode as a lack of power, miss, or rough idle. If the

vehicle operates in Engine Coolant Over Temperature-Fuel Disabled Mode, refer to

Section 6B3 ENGINE COOLING – GEN III V8 ENGINE, in VX Service Information.

Additional Checks • Inspect vacuum hoses for splits, kinks, proper connections and routing.

• Check the Torque Converter Clutch (TCC) operation. A TCC applying too soon

can cause the engine to detonate. Refer to Section 7C2 AUTOMATIC

TRANSMISSION – ELECTRICAL DIAGNOSIS, in VX Service Information.

LACK OF POWER, SLUGGISHNESS, OR SPONGINESS

Checks Actions

Definition: Engine delivers less than normal power. Little or no increase in speed when the accelerator pedal is partially

depressed.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

• Remove the air filter element and check for dirt or for being restricted. Refer to

Air Cleaner Element Replacement in Section 6C3-3 SERVICE OPERATIONS

– in VX Service Information, and replace as necessary.

Fuel System • Check both injector fuses for being open. An open injector fuse causes four

injectors and four ignition coils not to operate. Replace the fuse. Inspect the

ignition coil circuits and the injector circuits for an intermittent short to earth.

• Check for a low fuel pressure condition. Refer to Section 6C3-2A

DIAGNOSTIC TABLES – GEN III V8 ENGINE, in the VX Series Service

Information.

• Check for a restricted fuel filter. Refer to Section 6C3-2A DIAGNOSTIC

TABLES – GEN III V8 ENGINE, in the VX Series Service Information.

• Check for a contaminated fuel condition.

• Check the items that cause an engine to run rich (long term fuel trim near -

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Sensor/System • Use the Tech 2 scan tool in order to monitor the knock sensor system for

excessive spark retard activity. Refer to Section 6C3-2A DIAGNOSTIC

TABLES in the VX Series Service Information.

Ignition System • Check both injector fuses for being open. An open injector fuses causes four

injectors and four ignition coils not to operate. Replace the fuse. Inspect the

ignition coil circuits and the injector circuits for an intermittent short to earth.

• Wet down the secondary ignition system with water from a spray bottle.

Wetting down the secondary ignition system may help locate damaged or

deteriorated components. Look/listen for arcing or misfiring as you apply the

water.

• Check for correct ignition voltage output with spark tester J 26792. Refer to

Electronic Ignition System Diagnosis Section 6C3-2C FUNCTIONAL CHECKS

– GEN III V8 ENGINE in the VX Series Service Information.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An incorrect spark plug gap will cause a driveability problem. Set the spark

plug gaps using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information, in the VX Series Service Information, for

diagnosis of the rich condition

• For oil fouling refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE, in VX Service Information, for diagnosis of the oil fouling condition.

• Check for loose ignition coil earths.

• Check the spark plugs for proper heat range. Refer to Section 6D3-3 IGNITION

SYSTEM – GEN III V8 ENGINE, in VX Service Information.

Checks Actions

Engine Mechanical • Ensure that the engine coolant temperature is not above 130°C (266°F). This

condition causes the PCM to operate in Engine Coolant Over Temperature-

Fuel Disabled Mode. While in Engine Coolant Over Temperature-Fuel

Disabled Mode, the PCM turns fuel OFF to four cylinders at a time to keep

engine temperatures from reaching damaging levels. The system perceives

Engine Coolant Over Temperature-Fuel Disabled Mode as a lack of power,

miss, or rough idle. If the vehicle operates in Engine Coolant Over

Temperature - Fuel Disabled Mode, refer to Section 6B3 ENGINE COOLING –

GEN III V8 ENGINE, in VX Service Information for diagnosis.

• Excessive oil in combustion chamber - leaking valve seals. Refer to Section

6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service Information .

• Low cylinder compression. Refer to Section 6A3 ENGINE MECHANICAL –

GEN III V8 ENGINE, in VX Service Information for diagnosis.

• For incorrect basic engine parts. Inspect the following:

- Camshaft

- Cylinder heads

- Pistons, etc.

Refer to Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX

Service Information for diagnosis.

Additional Checks • Check the exhaust system for possible restrictions. Check for the following:

- Inspect the exhaust system for damaged or collapsed pipes.

- Inspect the exhaust manifold for a collapsed inner wall.

- Inspect the muffler for heat distress or possible internal failure.

- Inspect for possible restricted catalytic converters by comparing exhaust

system back pressure on each side of the engine.

• Check Torque Converter Clutch (TCC) for proper operation. Refer to Section

7C2 AUTOMATIC TRANSMISSION – ELECTRICAL DIAGNOSIS, in VX

Service Information for diagnosis.

DETONATION/SPARK KNOCK

Checks Actions

Definition: A mild to severe ping, usually worse under acceleration. The engine makes sharp metallic knocks that change

with throttle opening.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information .

• If the Tech 2 scan tool readings are normal (refer to the supporting text of the

Powertrain On-Board Diagnostic (OBD) System Check) and there are no

engine mechanical faults, fill the fuel tank with a premium petrol that has a

minimum octane reading of 92 and re-evaluate the vehicle’s performance.

Fuel System • Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis.

• Check for a contaminated fuel condition.

• Check the items that cause an engine to run rich (long term fuel trim near -

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor.

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Ignition System Check the spark plugs for proper heat range. Refer to Section 6D3-3 IGNITION

SYSTEM – GEN III V8 ENGINE, in VX Service Information.

Engine Mechanical Check for the following engine mechanical problems:

• Excessive oil in combustion chamber-leaking valve seals. Refer to Section 6A3

ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service Information .

• Low cylinder compression. Refer to Section 6A3 ENGINE MECHANICAL –

GEN III V8 ENGINE, in VX Service Information.

• Inspect combustion chambers for excessive carbon build-up. Clean the

chambers using a de-carboning agent. Follow the instructions of the product.

• For incorrect basic engine parts. Inspect the following:

- Cylinders

- Camshaft

- Pistons, etc.

• Refer to Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX

Service Information.

Additional Checks • Check the Park/Neutral Position (PNP) switch operation. Refer to Section 7C2

AUTOMATIC TRANSMISSION – ELECTRICAL DIAGNOSIS, in VX Service

Information for diagnosis.

• Check the TCC operation. The TCC applying too soon can cause the engine to

spark knock. Refer to Section 7C2 AUTOMATIC TRANSMISSION –

ELECTRICAL DIAGNOSIS, in VX Service Information for diagnosis.

HESITATION, SAG, STUMBLE

Checks Actions

Definition: Momentary lack of response as the accelerator is depressed. Can occur at any vehicle speed. Usually more

pronounced when first trying to make the vehicle move from a standing start. May cause the engine to stall if severe enough.

Preliminary • Refer to Symptoms, IMPORTANT Preliminary Checks Before Starting.

• Search for Service Bulletins.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information.

Sensor/System Check the MAP sensor operation. Refer to Section 63-2A DIAGNOSTIC TABLES,

in the VX Series Service Information.

Fuel System • Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES in VX Service Information, in the VX

Series Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

• Check both injector fuses for being open. An open injector fuse causes four

injectors and four ignition coils not to operate. Replace the fuse. Inspect the

ignition coil circuits and the injector circuits for an intermittent short to earth.

• Perform the injector balance test. Refer to Fuel Injector Balance Test in

Section 6C3-2C FUNCTIONAL CHECKS – in VX Service Information for

procedure.

• Check the items that cause an engine to run rich (long term fuel trim near -

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor.

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Checks Actions

Ignition System • Wet down the secondary ignition system with water from a spray bottle.

Wetting down the secondary ignition system may help locate damaged or

deteriorated components. Look/listen for arcing or misfiring as you apply the

water.

• Check both injector fuses for being open. An open injector fuse causes four

injectors and four ignition coils not to operate. Replace the fuse. Inspect the

ignition coil circuits and the injector circuits for an intermittent short to earth

• Check for proper ignition voltage output with spark tester J 26792. Refer to

Electronic Ignition System Diagnosis in Section 6C3-2C FUNCTIONAL

CHECKS – in VX Service Information, for procedure.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An Incorrect spark plug gap will cause a driveablitiy problem. Set the spark

plug gap using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information, for diagnosis of the rich condition

• For oil fouling refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE , in VX Service Information for diagnosis of the oil fouling condition.

• Check for loose ignition coil earths.

• Check the spark plugs for proper heat range. Refer to Section 6D3-3 IGNITION

SYSTEM – GEN III V8 ENGINE, in VX Service Information.

Engine Cooling System Check the engine thermostat for proper operation and for proper heat range. Refer

to in Section 6B3 ENGINE COOLING – in VX Service Information.

Additional Checks Check the generator output voltage. Refer to in Section 6D3-1 CHARGING

SYSTEM – in VX Service Information. Repair the charging system if the generator

output voltage is less than 9 volts or more than 16 volts.

CUTS OUT, MISSES

Checks Actions

Definition: Steady pulsation or jerking that follows engine speed, usually more pronounced as an engine load increases. This

condition is not normally felt above 1500 RPM or 48 km/h. The exhaust has a steady spitting sound at idle or low speed.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information .

• Remove the air filter element and check for dirt or for being restricted. Refer to

Air Cleaner Element Replacement in Section 6C3-3 SERVICE OPERATIONS

– in VX Service Information, and replace as necessary.

Fuel System • Perform the injector balance test. Refer to Fuel Injector Balance Test for

procedure.

• Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

• Check the items that cause an engine to run rich (long term fuel trim near -

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor.

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Sensor/System • Use a Tech 2 scan tool in order to monitor the knock sensor system for

excessive spark retard activity. Refer to Section 6C3-2A DIAGNOSTIC

TABLES, in the VX Series Service Information.

Ignition System • Wet down the secondary ignition system with water from a spray bottle.

Wetting down the secondary ignition system may help locate damaged or

deteriorated components. Look/listen for arcing or misfiring as you apply the

water.

• Check for proper ignition voltage output with spark tester J 26792. Refer to

Electronic Ignition System Diagnosis in Section 6C3-2C FUNCTIONAL

CHECKS – in VX Service Information.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An Incorrect spark plug gap will cause a driveablitiy problem. Set the spark

plug gap using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information, for diagnosis of the rich condition

• For oil fouling refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE, in VX Service Information, for diagnosis of the oil fouling condition.

• Refer to Electronic Ignition System Diagnosis in Section 6C3-2C

FUNCTIONAL CHECKS – in VX Service Inform ation.

• Inspect the Secondary ignition for the following:

- Ignition wires for cross firing

- Ignition wires arcing to earth

- Ignition wires for proper routing

• - Ignition coils for crack or carbon tracking

Checks Actions

Engine Mechanical • Check engine mechanical for the following:

- Check compression

- Sticking or leaking valves

- Worn camshaft lobes

- Valve timing

- Bent push rods

- Worn roc ker arms

- Broken valve springs

- Excessive oil in combustion chamber - leaking valve seals

- Low cylinder compression

• For incorrect basic engine parts. Inspect the following:

- Camshaft

- Cylinder heads

- Pistons, etc.

Refer to in Section 6A3 ENGINE MECHANICAL – in VX Service Information.

Additional Checks • Check the exhaust system for possible restrictions. Check for the following:

- Inspect the exhaust system for damaged or collapsed pipes.

- Inspect the exhaust manifold for a collapsed inner wall.

- Inspect the muffler for heat distress or possible internal failure.

- Inspect for possible restricted catalytic converters by comparing exhaust

system back pressure on each side of the engine. Check back pressure by

removing the Heated Oxygen Sensors.

• Electromagnetic Interference (EMI) on the reference circuit can cause an

engine miss condition. A sudden increase in engine RPM with no change of

throttle position indicates EMI may be present. Check routing of secondary

ignition wires, high voltage components (near ignition control circuits) if a

problem exists.

• Check the intake manifold and the exhaust manifold passages for casting

flash. Refer to in Section 6A3 ENGINE MECHANICAL – in VX Service

Information.

POOR FUEL ECONOMY

Checks Actions

Definition: Fuel economy, as measured by an actual road test, is noticeably lower than normal.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information .

• Check the driver’s driving habits.

• Is the A/C ON or the demister mode ON all the time?

• Are the tyres at the correct pressure?

• Are excessively heavy loads being carried?

Fuel System • Remove the air filter element and check for dirt or for being restricted.

• Perform the injector balance test. Refer to Fuel Injector Balance Test in

Section 6C3-2 FUNCTIONAL CHECKS – in VX Service Information .

• Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

• Check that each injector harness is connected to the correct injector/cylinder

according to the firing order (1-8-7-2-6-5-4-3). Relocate injector harness as

necessary.

• Check for injectors that are shorted internally. Compare the injector

resistances. Injector resistance should be within one ohm of each other. Refer

to Fuel Injector Coil Test - ECT Between 10-35° C in Section 6C3-2

FUNCTIONAL CHECKS – in VX Service Information for procedure.

• Check for foreign material accumulation in the throttle bore, carbon build-up on

the throttle valve, or on the throttle shaft. Also, inspect for throttle body

tampering.

• Check the items that cause an engine to run rich (long term fuel trim near -

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor.

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Sensor/System • Check the air intake system and crankcase for air leaks.

• Check the PCV System for correct operation. Place a finger over the inlet hole

in the valve end several times. The valve should snap back. If not, replace the

valve.

• Check for proper calibration of speedometer. Using the Tech 2 scan tool,

command vehicle speed output. Speedometer should read same as Tech 2

output. If not, refer to Section 12C INSTRUMENTS, WIPERS/WASHERS &

HORN, in VX Service Information.

• Use the Tech 2 scan tool in order to monitor the knock sensor system for

excessive spark retard activity. Refer to Section 6C3-2A DIAGNOSTIC

TABLES, in the VX Series Service Information.

Checks Actions

Ignition System • Check for proper ignition voltage output with spark tester J 26792. Refer to

Electronic Ignition System Diagnosis in Section 6C3-2C FUNCTIONAL

CHECKS – in VX Service Information.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An incorrect spark plug gap will cause a driveablitiy problem. Set the spark

plug gap using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information for diagnosis of the rich condition

• For oil fouling, refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE, in VX Service Information, for diagnosis of the oil fouling condition.

• Inspect the Secondary ignition for the following:

- Ignition wires arcing to earth

- Ignition wires for proper routing

• Wetting down the secondary ignition system with water from a spray bottle

may help locate damaged or deteriorated components. Look and listen for

arcing or misfiring as you apply water.

• Check for loose ignition coil earths.

Engine Cooling System • Check the engine coolant level for being low. Refer to Section 6B3 ENGINE

COOLING – GEN III V8 ENGINE, in VX Service Information.

• Check the engine thermostat for proper operation and for the correct heat

range. Refer to Section 6B3 ENGINE COOLING – GEN III V8 ENGINE, in VX

Service Information.

Checks Actions

Engine Mechanical • Check engine mechanical for the following:

- Check compression

- Sticking or leaking valves

- Worn camshaft lobes

- Valve timing

- Bent push rods

- Worn roc ker arms

- Broken valve springs

- Excessive oil in combustion chamber - leaking valve seals

- Low cylinder compression

• For incorrect basic engine parts. Inspect the following:

- Cylinders

- Camshaft

- Pistons, etc.

Refer to Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service

Information.

Additional Checks • Check the vacuum hoses for splits, kinks, and proper connections.

• Check the TCC operation. The Tech 2 scan tool should indicate an RPM drop,

when the system commands the TCC ON. Refer to Section 7C2 AUTOMATIC

TRANSMISSION – ELECTRICAL DIAGNOSIS, in VX Service Information. .

Check the exhaust system for possible restrictions. Check for the following:

- Inspect the exhaust system for damaged or collapsed pipes.

- Inspect the exhaust manifold for a collapsed inner wall.

- Inspect the muffler for heat distress or possible internal failure.

- Inspect for possible restricted catalytic converters by comparing exhaust

system back pressure on each side of the engine. Check back pressure by

removing the heated oxygen sensors.

• Electromagnetic Interference (EMI) on the reference circuit can cause an

engine miss condition. A sudden increase in engine RPM with no change of

throttle position indicates EMI may be present. Check routing of secondary

ignition wires, high voltage components (near ignition control circuits) if a

problem exists.

• Check PNP s witch circ uit. Refer to Section 7C2 AUTOMATIC TRANSMISSION

– ELECTRICAL DIAGNOSIS, in VX Service Information.

• Check for faulty engine mounts. Refer to Section 6A3 ENGINE MECHANICAL

– GEN III V8 ENGINE, in VX Service Information for inspection of mounts.

• Check the intake and the exhaust manifold passages for casting flash. Refer to

Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service

Information.

ROUGH, UNSTABLE, OR INCORRECT IDLE , STALLING

Checks Actions

Definition: Engine runs unevenly at idle. If severe, the engine or vehicle may shake. Engine idle speed may vary in RPM.

Either condition may be severe enough to stall the engine.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information.

• Remove and check the air filter element for dirt, or for being restricted. Refer to

Air Cleaner Element Replacement in Section 6C3-3 SERVICE OPERATIONS

– in VX Service Information. Replace as necessary.

Fuel System • Perform the injector balance test. Refer to Fuel Injector Balance Test in

Section 6C3-2C FUNCTIONAL CHECKS in VX Service Information for this

procedure.

• Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

• Check that each injector harness is connected to the correct injector/cylinder

according to the firing order (1-8-7-2-6-5-4-3). Relocate injector harness as

necessary.

• Check the items that cause an engine to run rich (long term fuel trim near -

13%). For a rich condition, refer to DTC P0132 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0152 HO2S Circuit High Voltage Bank 2 Right

Sensor.

• Check the items that can cause an engine to run lean (long term fuel trim near

23%). For a lean condition, refer to DTC P0131 HO2S Circuit High Voltage

Bank 1 Left Sensor and DTC P0151 HO2S Circuit High Voltage Bank 2 Right

Sensor.

Sensor/System • Check the PCV System for correct operation. Place a finger over inlet hole of

the valve end several times. valve should snap back. If not, replace the valve.

• Use the Tech 2 scan tool in order to monitor knock sensor system for

excessive spark retard activity. Refer to Section 6C3-2A DIAGNOSTIC

TABLES, in the VX Series Service Information.

Ignition System • Check for proper ignition voltage output with spark tester J 26792. Refer to

Electronic Ignition System Diagnosis in Section 6C3-2C FUNCTIONAL

CHECKS – in VX Service Information.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An Incorrect spark plug gap will cause a driveablitiy problem. Set the spark

plug gap using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information, for diagnosis of the rich condition

• For oil fouling, refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE, in VX Service Information, for diagnosis of the oil fouling condition.

• Inspect the Secondary ignition for the following:

- Ignition wires arcing to earth

- Ignition wires for proper routing

• Wetting down the secondary ignition system with water from a spray bottle

may help locate damaged or deteriorated components. Look and listen for

arcing or misfiring as you apply water.

• Check for loose ignition coil earths.

Techline

Checks Actions

Engine Mechanical • Check engine mechanical for the following:

- Check compression

- Sticking or leaking valves

- Worn camshaft lobes

- Valve timing

- Bent push rods

- Worn roc ker arms

- Broken valve springs

- Excessive oil in combustion chamber - leaking valve seals

- Low cylinder compression

• For incorrect basic engine parts. Inspect the following:

- Cylinder

- Camshaft

- Pistons, etc.

Refer to Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service

Information.

Additional Checks • Check the exhaust system for possible restrictions. Check for the following:

- Inspect the exhaust system for damaged or collapsed pipes.

- Inspect the exhaust manifold for a collapsed inner wall.

- Inspect the muffler for heat distress or possible internal failure.

- Inspect for possible restricted catalytic converters by comparing exhaust

system back pressure on each side of the engine. Check back pressure by

removing the heated oxygen sensors.

• Electromagnetic Interference (EMI) on the reference circuit can cause an

engine miss condition. A sudden increase in engine RPM with no change of

throttle position indicates EMI may be present. Check routing of secondary

ignition wires, high voltage components (near ignition control circuits) if a

problem exists.

• Check PNP switch circuit.

• Check for faulty engine mounts. Refer to Section 6A3 ENGINE MECHANICAL

– GEN III V8 ENGINE, in VX Service Information for inspection of the mounts.

• Check the intake and the exhaust manifold passages for casting flash. Refer to

Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service

Information.

DIESELING, RUN-ON

Checks Actions

Definition: Engine continues to run after key is turned OFF, but runs very rough. If the engine runs normally, check the

ignition switch and the ignition switch adjustment.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information .

• Pre-ignition due to build up of carbon in the combustion chamber.

Fuel System Inspect the injectors for leaking condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information, for this

procedure.

BACKFIRE

Checks Actions

Definition: Fuel ignites in the intake manifold or in the exhaust system, making a loud popping noise.

Preliminary • Refer to SYMPTOMS, IMPORTANT PRELIMINARY CHECKS BEFORE

STARTING, in the VX Series Service Information.

• Refer to Service Bulletins for relevant information.

• Check the PCM/PIM earths for being clean, tight and in their proper locations.

Refer to Section 12P WIRING DIAGRAMS, in VX Service Information.

Fuel System • Check for a low fuel pressure condition. Refer to Fuel System Diagnosis in

Section 6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a restricted fuel filter. Refer to Fuel System Diagnosis in Section

6C3-2A DIAGNOSTIC TABLES – in VX Service Information.

• Check for a contaminated fuel condition.

• Check that each injector harness is connected to the correct injector/cylinder

according to the firing order (1-8-7-2-6-5-4-3). Relocate injector harness as

necessary.

Sensor/System • Check the air intake system and crankcase for air leaks.

• Check the PCV System for correct operation. Place a finger over the inlet hole

in the valve end several times. The valve should snap back. If not, replace the

valve.

• Check for proper calibration of speedometer. Using Tech 2 scan tool,

command vehicle speed output, speedometer should read same as Tech 2

output. If not, refer to Section 12C INSTRUMENTS, WIPERS/WASHERS &

HORN, in VX Service Information.

• Use the Tech 2 scan tool in order to monitor the knock sensor system for

excessive spark retard activity. Refer to Section 6C3-2A DIAGNOSTIC

TABLES, in the VX Series Service Information.

Ignition System • Check for proper ignition voltage output with spark tester J 26792. Refer to

Electronic Ignition System Diagnosis in Section 6C3-2C FUNCTIONAL

CHECKS – in VX Service Information.

• Check for an intermittent ignition system malfunction in the following circuits:

- Intermittent ignition control circuit.

- Use the scan tool’s Snapshot feature in order to help locate an intermittent

ignition failure.

• Remove the spark plugs and check for the following:

- Wet plugs

- Cracks

- Wear

- Incorrect gap

- Burned electrodes

- Heavy deposits

• An Incorrect spark plug gap will cause a driveablitiy problem. Set the spark

plug gap using a wire gauge gap tool (J 41319). Refer to Section 6D3-3

IGNITION SYSTEM – GEN III V8 ENGINE, in VX Service Information .

• If spark plugs are fouled, determine the cause of the fouling before replacing

them.

• For fuel fouling, refer to DTC P0172 Fuel Trim System Rich Bank 1 and DTC

P0175 Fuel Trim System Rich Bank 2 in Section 6C3-2A DIAGNOSTIC

TABLES – in VX Service Information, for diagnosis of the rich condition

• For oil fouling refer to Section 6A3 ENGINE MECHANICAL – GEN III V8

ENGINE, in VX Service Information, for diagnosis of the oil fouling condition.

• Inspect the Secondary ignition for the following:

- Ignition wires for cross firing

- Ignition wires arcing to earth

- Ignition coils arcing routing

• Wetting down the secondary ignition system with water from a spray bottle

may help locate damaged or deteriorated components. Look and listen for

arcing or misfiring as you apply water.

• Check for loose ignition coil earths.

Checks Actions

Engine Cooling System • Check the engine coolant level for being low. Refer to Section 6B3 ENGINE

COOLING – GEN III V8 ENGINE, in VX Service Information.

• Check the engine thermostat for proper operation and for the correct heat

range. Refer to Section 6B3 ENGINE COOLING – GEN III V8 ENGINE, in VX

Service Information.

Engine Mechanical • Check engine mechanical for the following:

- Check compression

- Sticking or leaking valves

- Worn camshaft lobes

- Valve timing

- Bent push rods

- Worn roc ker arms

- Broken valve springs

- Excessive oil in combustion chamber - leaking valve seals

- Low cylinder compression

• Check for incorrect basic engine parts. Inspect the following:

- Cylinder

- Camshaft

- Pistons, etc.

• Refer to Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX

Service Information.

Additional Checks • Check the vacuum hoses for splits, kinks, proper connections and routing.

• Check the TCC operation. The scan tool should indicate an RPM drop, when

the system commands the TCC ON. Refer to Section 7C2 AUTOMATIC

TRANSMISSION – ELECTRICAL DIAGNOSIS, in VX Service Information.

• Check the exhaust system for possible restrictions. Check for the following:

- Inspect the exhaust system for damaged or collapsed pipes.

- Inspect the exhaust manifold for a collapsed inner wall.

- Inspect the muffler for heat distress or possible internal failure.

- Inspect for possible restricted catalytic converters by comparing exhaust

system back pressure on each side of the engine. Check back pressure by

removing the Heated Oxygen Sensors. Refer to Restricted Exhaust System

Checks and Engine Exhaust.

• Electromagnetic Interference (EMI) on the reference circuit can cause an

engine miss condition. A sudden increase in engine RPM with no change of

throttle position indicates EMI may be present. Check routing of secondary

ignition wires, high voltage components (near ignition control circuits) if a

problem exists.

• Check PNP s witch circ uit. Refer to Section 7C2 AUTOMATIC TRANSMISSION

– ELECTRICAL DIAGNOSIS, in VX Service Information for diagnosis.

• Check for faulty engine mounts. Refer to Section 6A3 ENGINE MECHANICAL

– GEN III V8 ENGINE, in VX Service Information for inspection of the mounts.

• Check the intake and the exhaust manifold passages for casting flash. Refer to

Section 6A3 ENGINE MECHANICAL – GEN III V8 ENGINE, in VX Service

Information.

RESTRICTED EXHAUST SYSTEM CHECK

Step Action Value(s) Yes No

1 Did you perform the Powertrain On-Board Diagnostic

(OBD) System Check? Go to Step 2 Go to Powertrain

OBD System

Check

2 1. Carefully remove the HO2S for Bank 1 Left Sensor.

2. Install the Exhaust Back Pressure tester BT-8515 in

place of the Heated Oxygen Sensor.

3. Idle the engine at normal operating temperature.

4. Observe the exhaust system back pressure reading

on the gauge.

Does the reading exceed the specified value?

8.6 kPa

(1.25 psi)

Go to Step 5 Go to Step 3

3 1. The Exhaust Back pressure Gauge still installed.

2. Increase engine speed to 2000 RPM.

3. Observe the exhaust system back pressure reading

on the gauge.

Does the reading exceed the specified value?

20.7 kPa

(3 psi)

Go to Step 6 Go to Step 4

4 1. Ignition OFF.

2. Reinstall Bank 1 HO2S.

3. Carefully remove the HO2S for Bank 2 Right Sensor.

4. Install the Exhaust Back Pressure tester BT-8515 in

place of the Heated Oxygen Sensor.

5. Idle the engine at normal operating temperature.

6. Observe the exhaust system back pressure reading

on the gauge.

Does the reading exceed the specified value?

8.6 kPa

(1.25 psi)

Go to Step 6 Go to Step 5

5 1. The Exhaust Back pressure Gauge still installed.

2. Increase engine speed to 2000 RPM.

3. Observe the exhaust system back pressure reading

on the gauge.

Does the reading exceed the specified value?

20.7 kPa

(3 psi)

Go to Step 6 No Exhaust

Restrictions

found. If a

driveability

symptom exists,

refer to

SYMPTOMS

6 Repair the restriction in the exhaust system. Check

exhaust system for the following:

• Restricted Exhaust Manifolds

• Collapsed pipes

• Heat distress

• Internal muffler failure

• Damaged Catalytic Converter

Is the action complete?

System OK

TESTING EARTHS

Unusual displays in the instrument cluster, lamps

that are dim or flash unexpectedly, unexpected

readings - gremlins? Probably not; these are

classic symptoms of earth problems.

This section discusses the importance of good

earth circuits. It starts by explaining some basic

theories. Then, you are shown how to diagnose a

solid-state circuit earth condition and how, if there

is a problem, to correct it.

BASICS

For a circuit to operate properly, you need three

things - a good power supply to components, good

components, and good earths. Circuits are

complete systems; current must flow from

beginning to end as designed, not hindered by

unexpected resistance anywhere in the circuit.

Some tec hnic ians r ealis e that the power supply to a

circuit must be free of unwanted resistance, but

have difficulty visualising why an earth circuit must

also be f r ee of unwanted res istanc e. Curr ent f low is

through a complete circuit; it passes through and

out of a component like water flowing through a

tub. With a properly draining tub (no clogs), the

water can flow out as freely as it flowed in. Current

mus t enter and leave c om ponents f reely, if they are

to perform as designed.

3

RI

4

4289

2

1

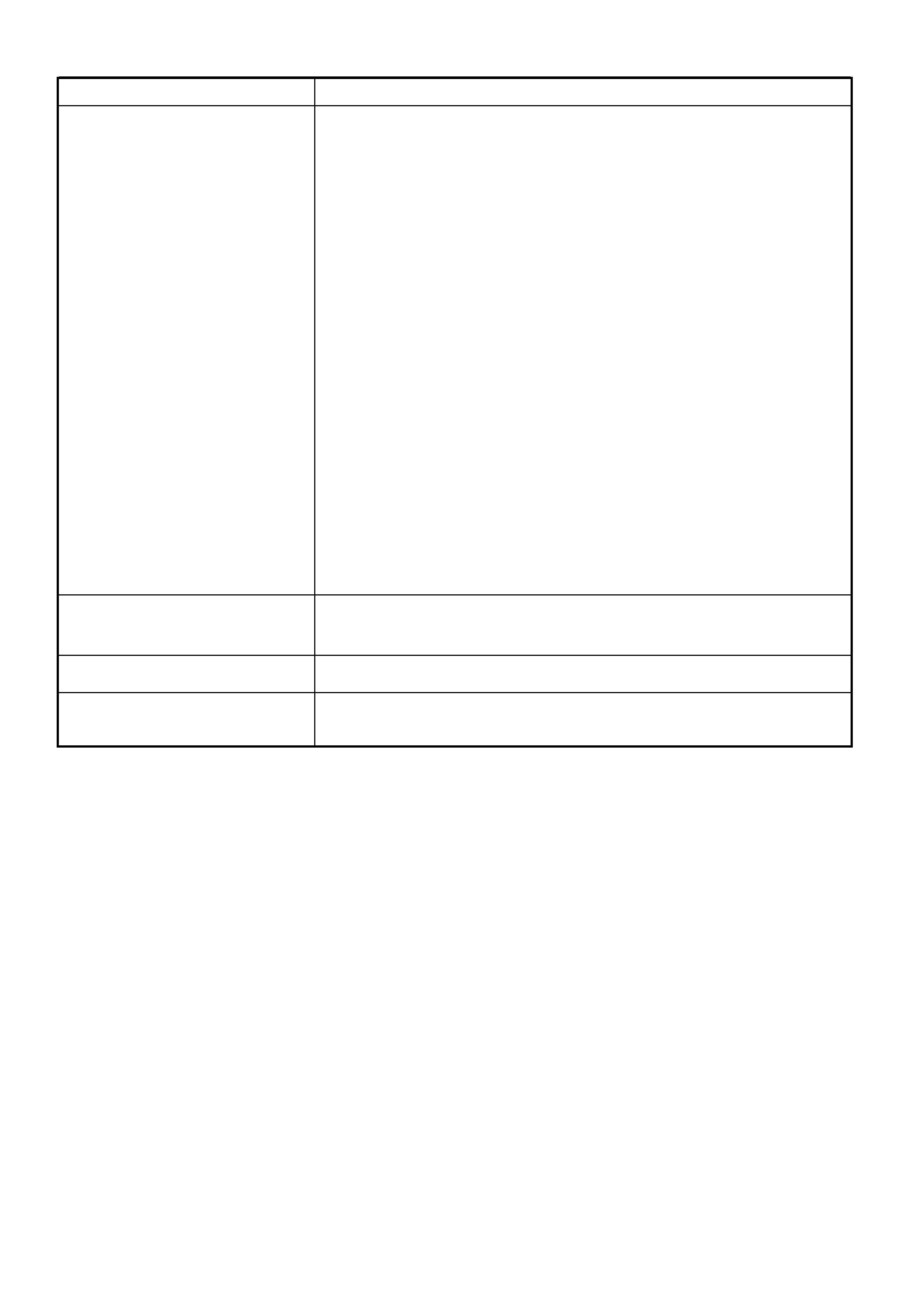

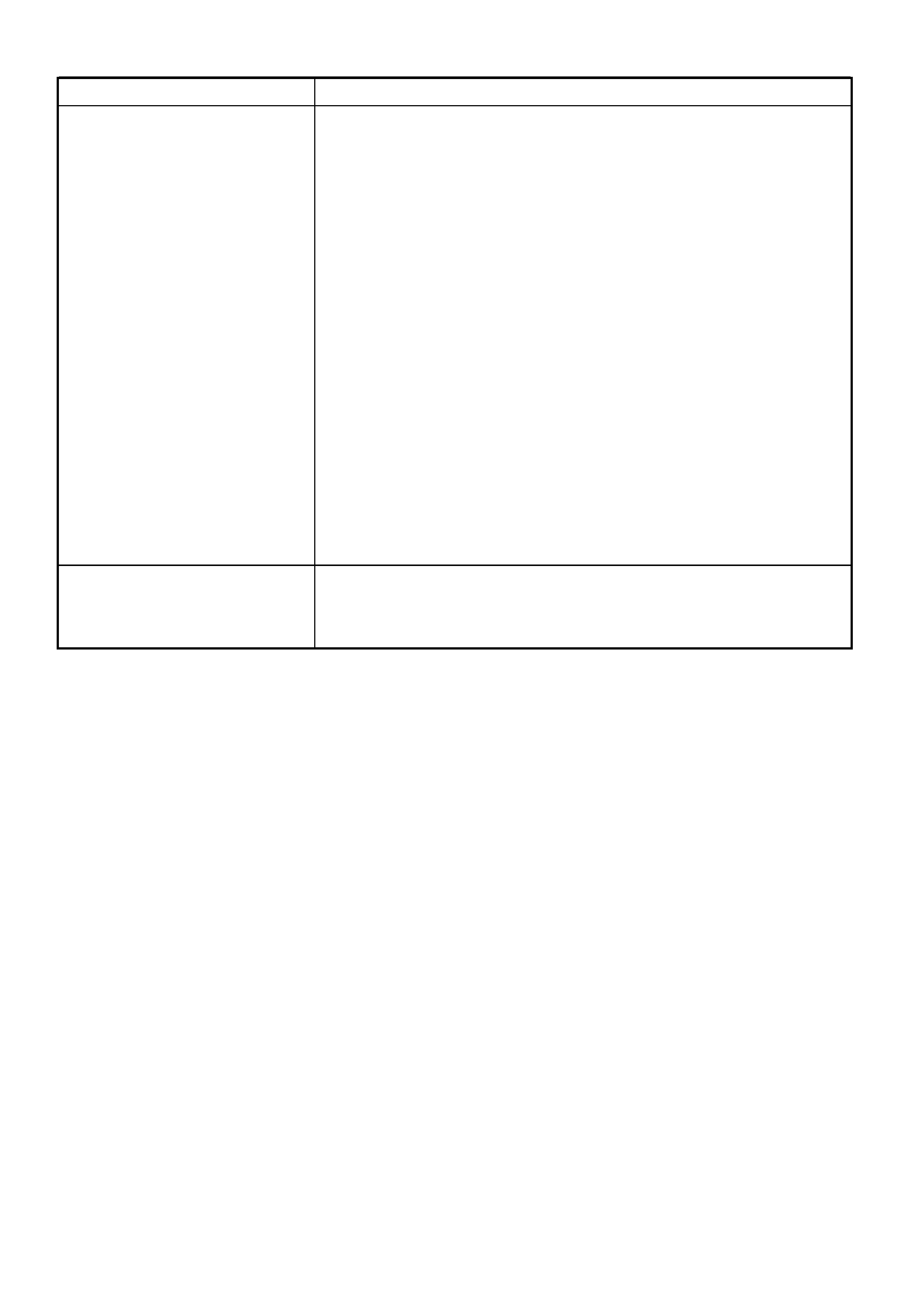

Figure 6C3-2B-2

1. Voltage = Resistance X Current V = R X I

2. Resistance = Current Relationship With Fixed Voltage

3. Large Resistance, Small Current

4. Small Resistance, Large Current

Sensitive solid-state systems have their own earths;

high cur rent devices (lik e motor s) do not earth at the

same location. High current devices can cause

voltage spikes (sudden changes in voltage) when

turned ON or OFF. To prevent these spikes from

affecting sensitive solid-state circuits, the two

different types of systems use different earth

locations. The use of a dedicated wire to connect an

isolated earth junction block to the battery negative

terminal. This wire reduces the effect of spikes on

sensitive circuits at the earth junction block.

Solid-state circuits are particularly sensitive to poor

circuit c ontinuity becaus e in mos t cases they use low

current flow. This section on testing earths concerns

one solid-state device, the PCM. However, the

information included here applies to all solid-state

earth circuits.

Severe restrictions in the earth circuit can cause

resets and intermittent codes in solid-state systems.

The PCM operates devices (fuel injectors, idle air

control, etc.) and receives inputs from low voltage

sensors, manifold absolute pressure sensor,

crankshaft speed/position. These input and output

devices need good circuitry for correct operation.

Remember, that when maladjusted or imperfect

sensors cause values to shift there are usually

driveability problems. If there is excessive resistance

in the earth circ uit, the res ult will be the same; shifted

sensor outputs with corresponding driveability

conditions. These conditions may not be severe

enough to set diagnostic trouble codes, but they will

reduce vehicle efficiency and performance and may

be noticed by the driver.

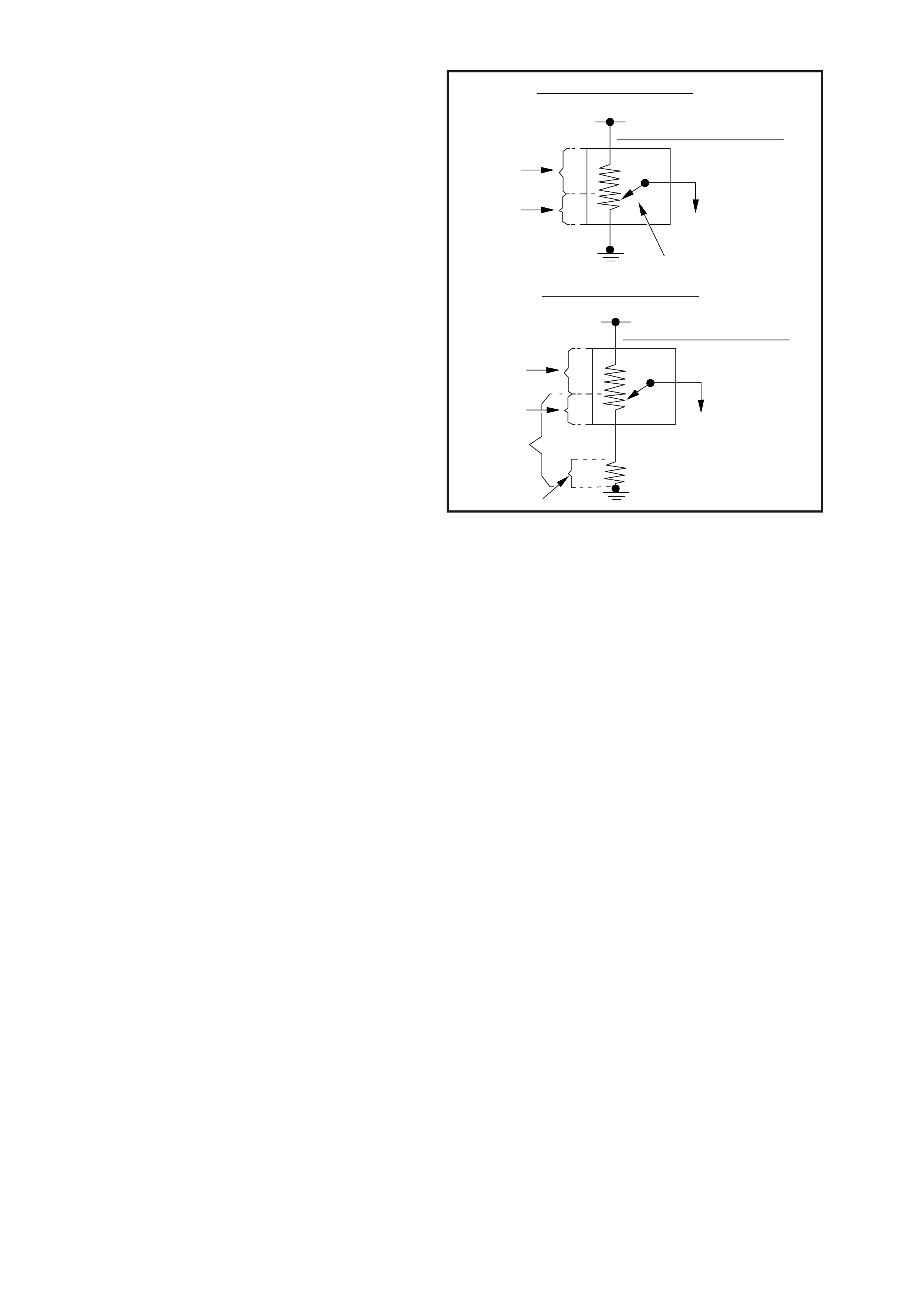

SENSOR CIRCUIT EARTH SENSITIVITY

- an example.

Looking at the Throttle Position (TP) Sensor circuit

will provide an example of how a little resistance in

the earth circuit can cause problems. The

accompanying figure shows a TP Sensor first with

a good earth circuit and then with a poor

connection in the earth circuit. Refer to this figure

as you proceed through the text that follows.

A Throttle Position Sensor consists of a resistor

and a wiper. One terminal of the resistor is

connected to a supply voltage and the other earth.

As the wiper moves along the resistor, the voltage

of the wiper terminal progressively changes. If the

wiper is near the supply voltage end of the resist or,

the wiper output will approach the supply voltage

(over 4.5 volts at wide open throttle).

As the wiper moves toward the earthed end of the

resistor, the voltage of the wiper output decreases

to near zero (about 0.5 volts for the closed throttle

in this exam ple). (The ac tual closed and wide open

throttle voltage specifications m ay vary for diff erent

engines.) The sensor output should never be

greater than reference supply voltage or less then

.20 volts. (The PCM would set a diagnostic trouble

code if this occurs.)

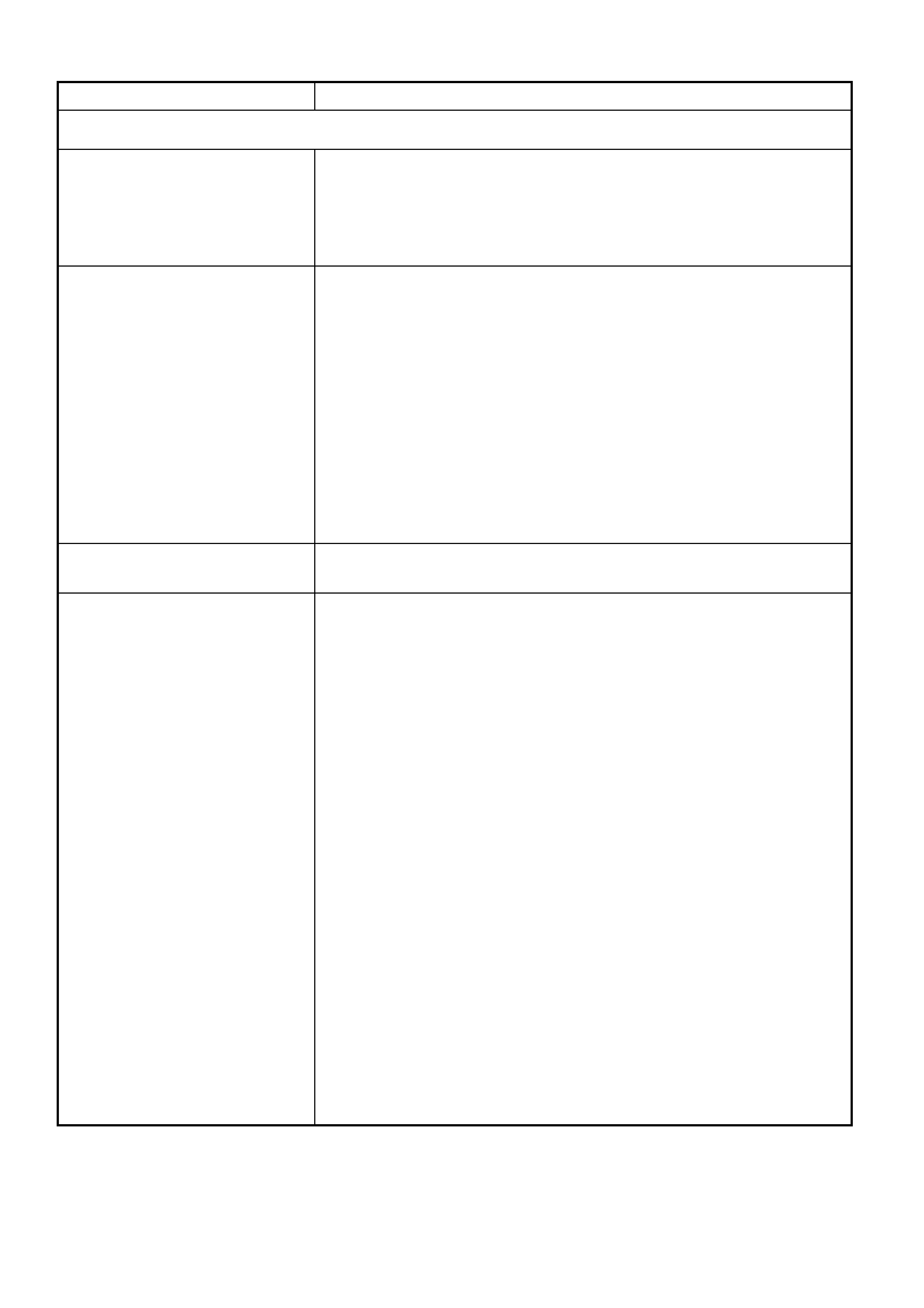

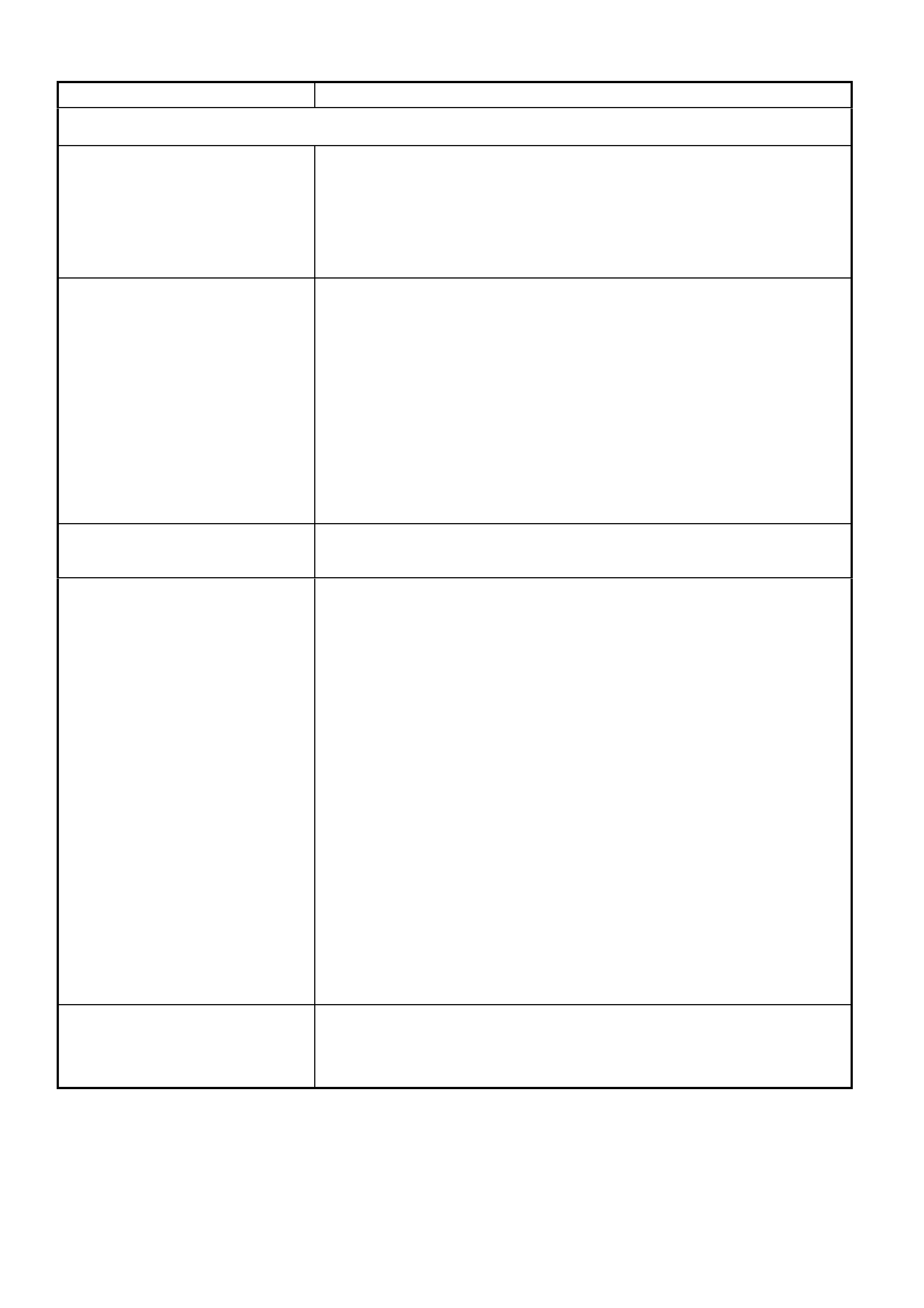

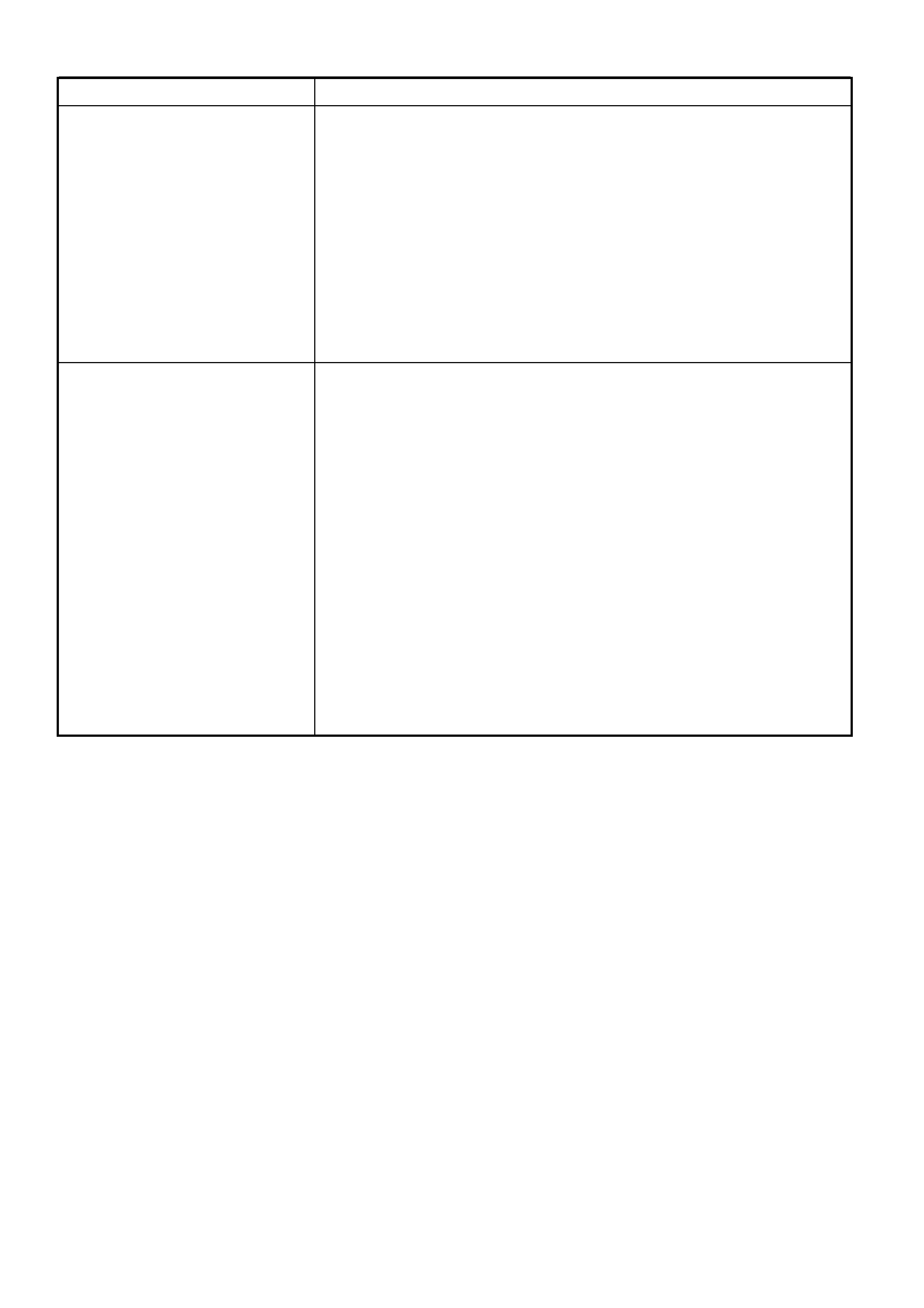

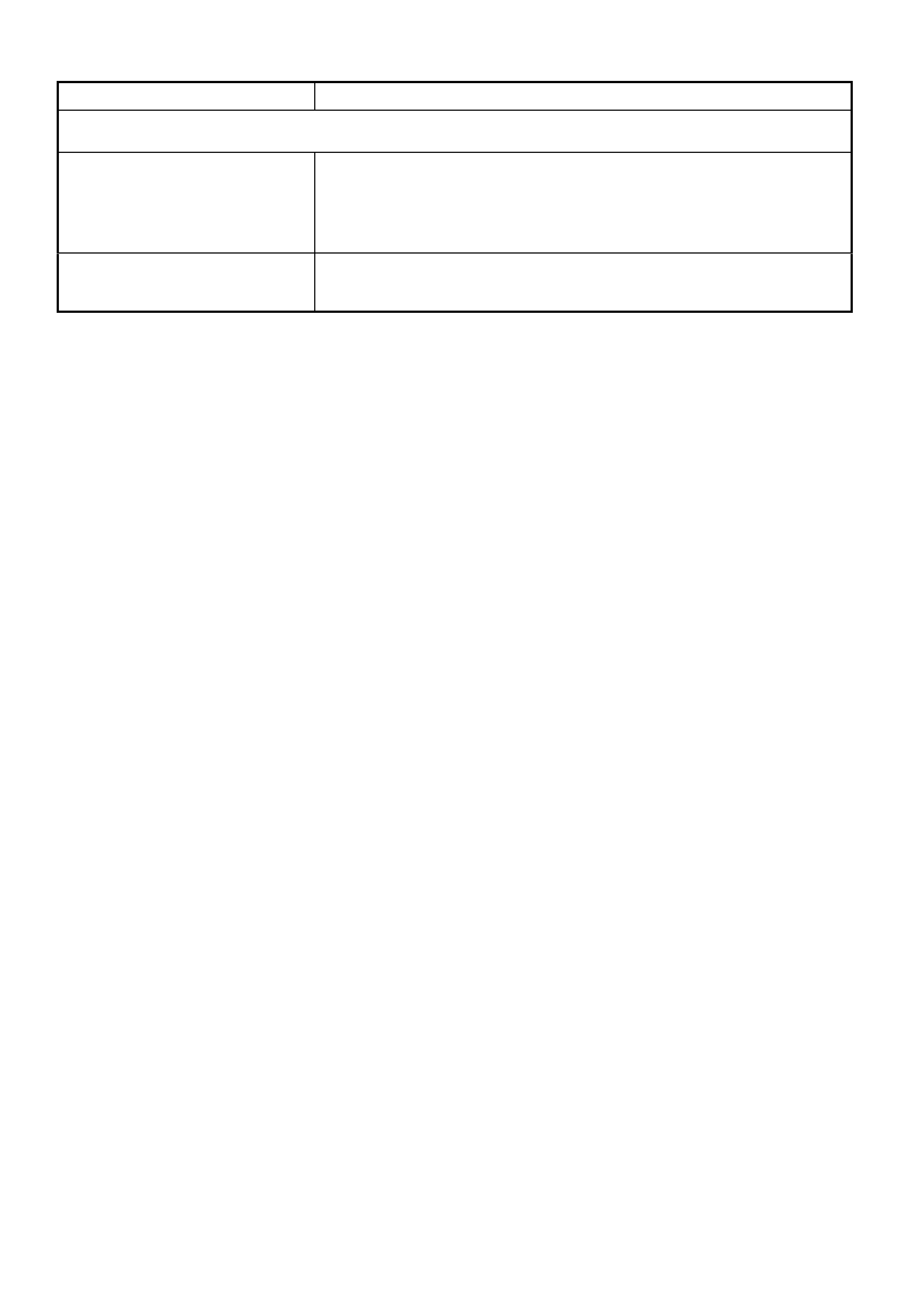

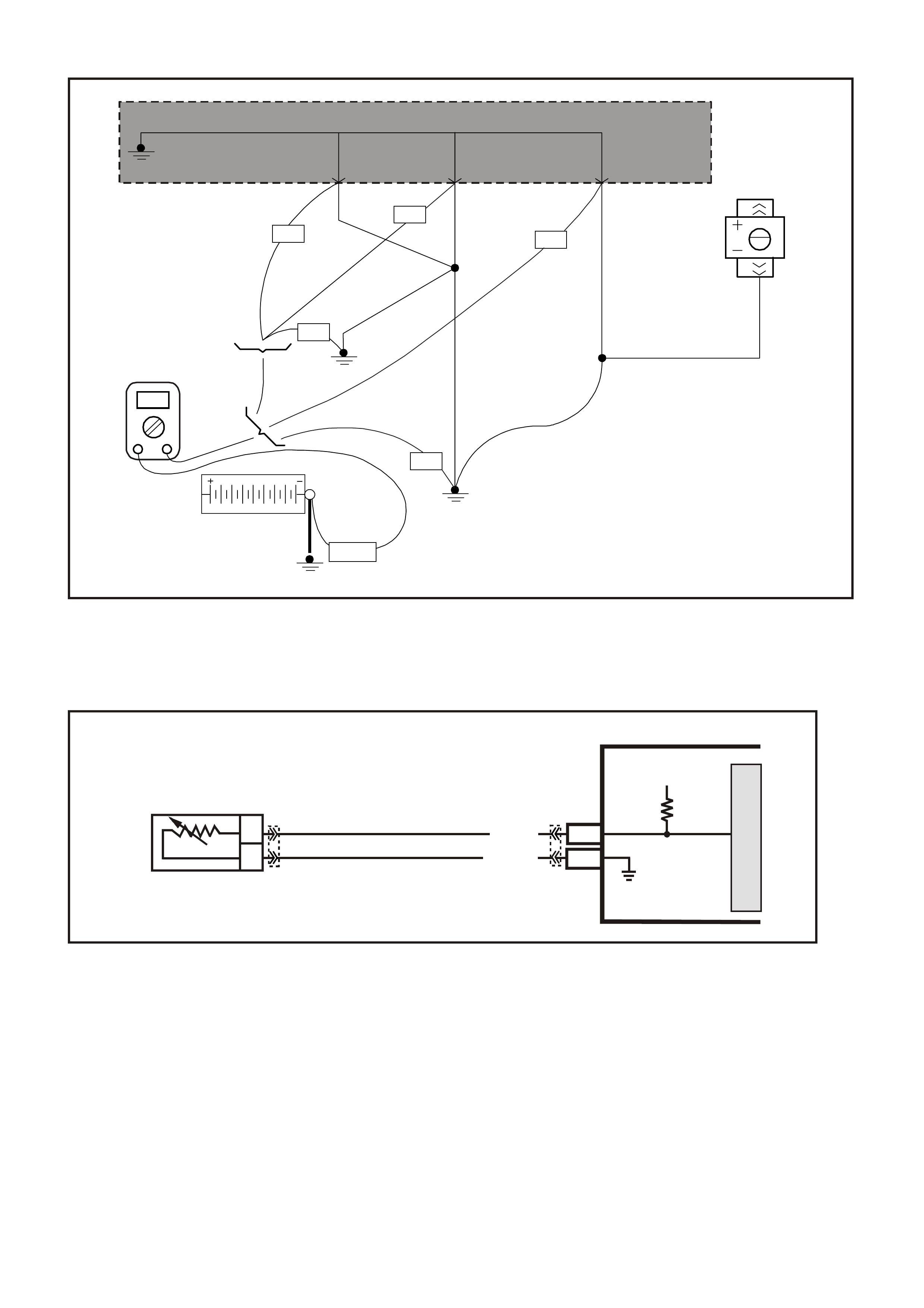

The diagram to the right shows voltage drops

across various points in the circuit. In the example

with good circuit earth, the TP Sensor is shown with

the wiper in the closed throttle position. The total

voltage across the resistor in the TP Sensor is 5

volts. The voltage drop from the resistor source

voltage terminal to the wiper is 4.5 volts. The

voltage drop from the wiper to the resistor earth

side is 0.5 volts. The wiper output is 0.5 volts - a

good value for this example of a closed throttle.

Now, look at the sens or with the bad signal caused

by resistance in the earth circuit. The throttle

positions stays the same but the sensor output

voltage changes. In this example the increased

resistanc e causes an additional voltage drop of 0.5

volts. The voltage drop from the wiper to found is

now 1.0 volt (0.5 + 0.5 = 1.0). Because the source

voltage is a constant 5 volts, the voltage drop from

the source voltage input to the wiper can now be

only 4 volts (5.0 - 1.0 = 4.0). The PCM now

receives 1.0 volt from the TP sensor. This is not a

good value (in this example) of a closed throttle

Now you can s ee why good earths are needed and

how sensitive some circuits can be.

EARTH CIRCUITS

How do you know which wires are earth wires,

which connectors they go through, and whether

they are connected to an earth junction or the

body?

Section 12P WIRING DIAGRAMS in Section in VX

Service Information should be used whenever you

are diagnosing any electrical condition, including

earths. The individual circuits show the power and

earth circuits for components in specific systems.

1

23

4

5

7

4290

11

10

9

8

6

23

10

12

Figure 6C3-2B-3

Voltage Drop Illustration

1. Sensor With Good Earth.

2. Fixed 5 Volts.

3. Throttle Position Sensor.

4. 0.5 Volts Sensor Output.

5. Wiper.

6. Sensor With Poor Earth.

7. 1.0 Volts Sensor Output.

8. Voltage Drop Caused By Resistance of Poor Earth is 0.5

Volts.

9. Total Voltage Drop Below Wiper is 1.0 Volts.

10. Voltage Drop of 0.5 Volts.

11. Voltage Drop of 4.0 Volts.

12. Voltage Drop of 4.5 Volts.

If you suspect sever al cir cuits ar e being af f ec ted by a

poor or a back-feed to earth, look at the circuits to

see how the systems m ight interact. If they have any

common earth wires, that is where you should start

your diagnosis.

Back-feeding is when current, seeking earth, feeds

back through inactive circuits (the reverse direction

of normal current flow) to find a path to earth. This

can only happen when the active circuit (needing an

earth) shares a disconnected or poor earth with an

inactive circuit and the voltage supply side of the

inactive circuit feeds other components with good

earths.

PARALLEL EARTHS

Some solid-state components use redundant earth

circuits; that is, they have more than one wire

connecting to earth. The PCM has more than one

earth circuit wire. There are several reasons for

redundant earths.

The PCM has many low-current circuits, but the

current from all these circuits (when they are

active) adds up to a larger current. Higher current

loads are managed more easily with several regular

size wires, rather than with one large diameter wire.

Basic circuit theory shows that the effective

resistance of parallel resistors is less than any of

the individual resistors. This is true for even the

small resistances in wires. Parallel wires provide

the lowest resistance. Because of them, in many

solid-state systems a pr oblem with one of the earth

wires would not affect the circuit; the redundant

wires could handle the c ur rent load. F or other s olid-

state systems the loss of even one redundant ear th

may affect operation, but the remaining earth

wire(s) may allow the vehicle to be driven.

Here is one exam ple which can pr ove to be dif ficult

to diagnose:

Symptom: A vehicle has driveability symptoms.

W henever a Tech 2 scan tool is connected and

the vehicle tested, none of the complaint

symptoms are displayed.

Cause: The PCM earths are not providing a good

earth, hence the resulting driveability condition.

When a scan tool is plugged in, a good earth

path is provided for the PCM through the Data

Link Connec tor ( DLC). T he DLC uses a diff erent

earth than the PCM.

Always test for driveability symptoms before

hooking up a scan tool. If they disappear when the

scan tool is hooked up, check the earth circuit for

continuity.

The severity of the symptom(s) is proportional to

the severity of the problem in the earth circuit. A

complete open in the circuit has the most severe

effect. Use the severity of the symptom(s) as an

indication of the extent of the resistance in the

earth circuit.

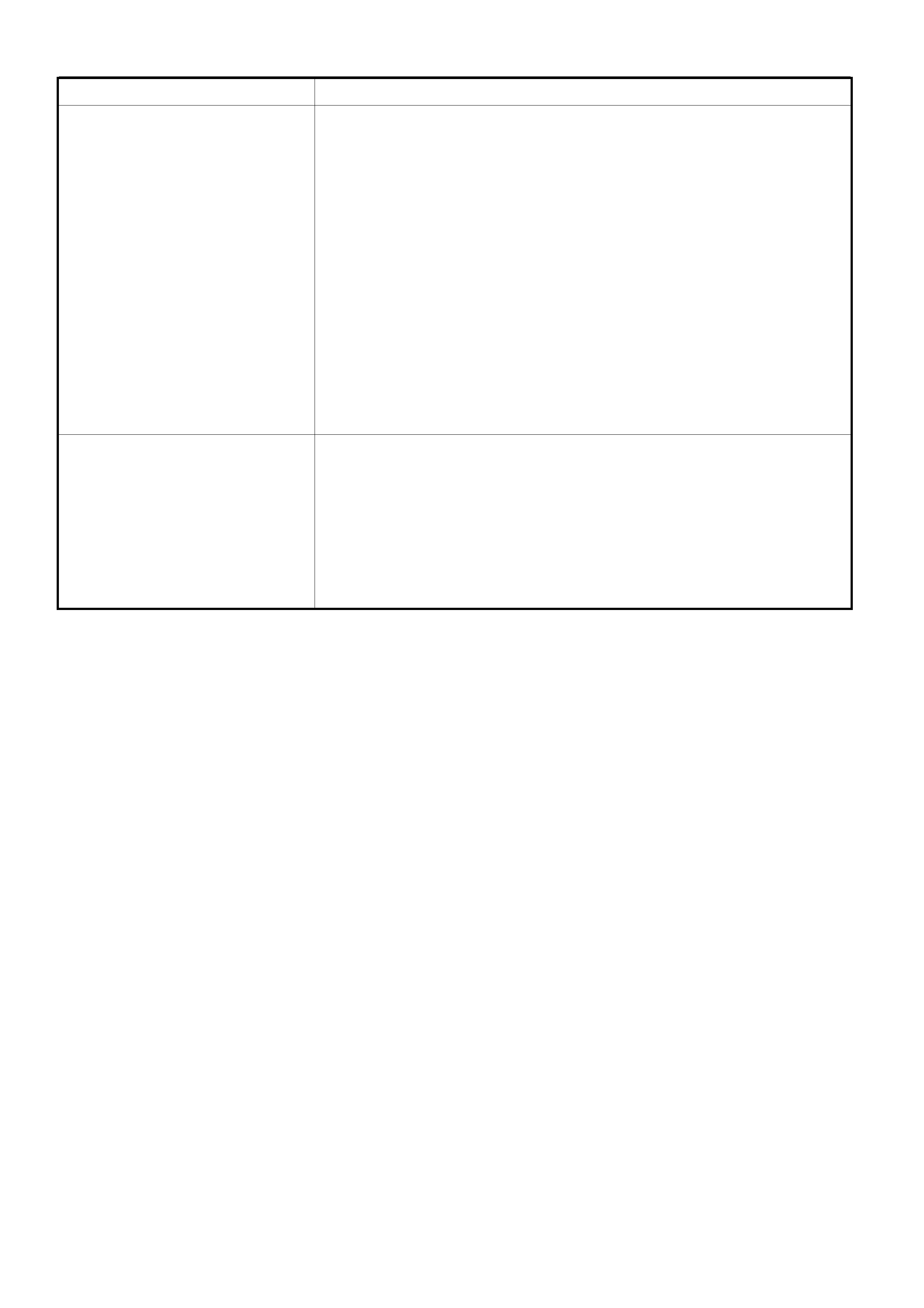

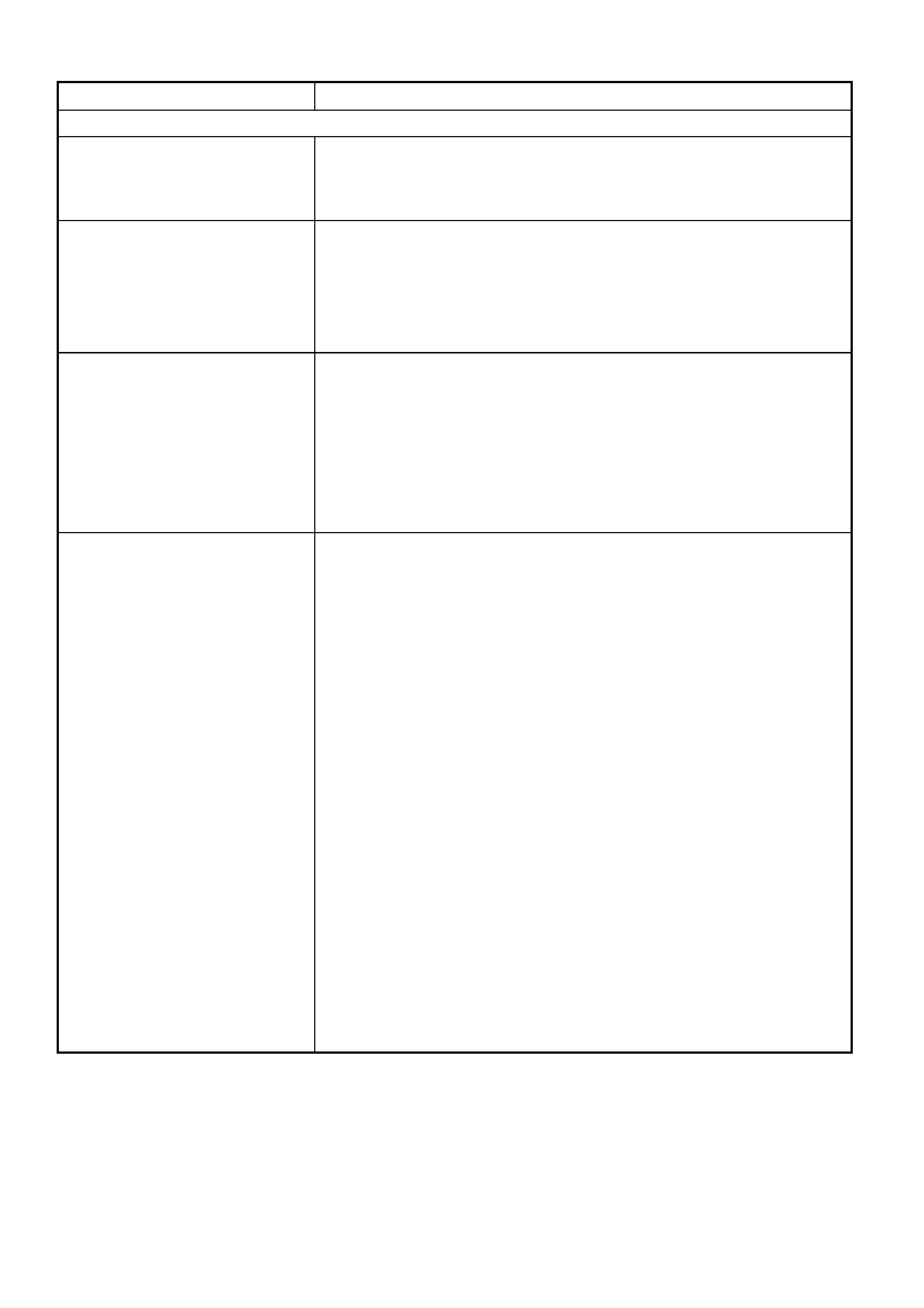

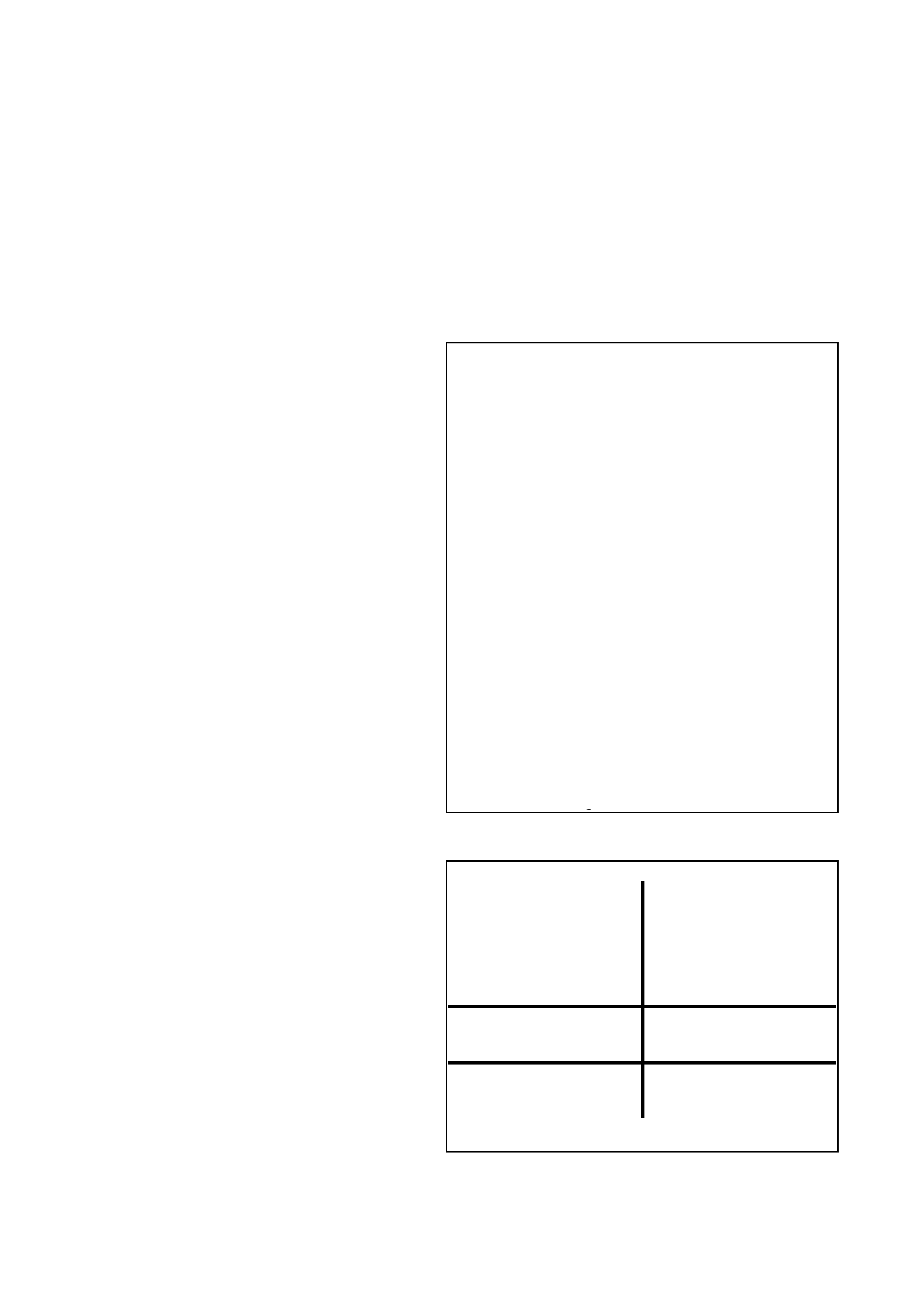

Figure 6C3-2B-4

Figure 6C3-2B-4

1 1 1 1

------ = -------- + ------ + ------- +

R TOTAL R 1 R 2 R 3

EXAMPLE: 2 PARALLEL CIRCUITS, ONE WITH

ONE OHM RESISTANCE AND

THE OTHER WITH TWO OHMS

RESISTANCE.

1 1 1

------ = -------- + ------

R TOTAL 11 2 2

1 2 1

------ = -------- + ------

R TOTAL 2 2

1 3

------ = --------

R TOTAL 2

2

R TOTAL = -------- Ω

3

WITH METER

NEGATIVE (BLACK)

PROBE AT THE

BATTERY NEGATIVE

TERMINAL, PLACE THE

METER POSITIVE (RED)

PROBE BETWEEN:

MAXIMUM ALLOWABLE

VOLTAGE

SENSOR AND PCM

0.060 (60 MILLIVOLTS)

PCM AND BATTERY

NEGATIVE TERMINAL

0.020 (20 MILLIVOLTS)

CHECKING EARTHS

Once you determine that the cause of the vehic le symptom (s) m ay be caused by a bad earth, it is tim e to check f or

poor earth with one more tool: a high-impedance voltmeter.

The best way to check for poor earth c onnections in low-curr ent solid-state c ircuits is to c heck the voltage dr op. To

do this you need a high-impedance voltmeter rated at a minimum of 10 megaohms (10,000,000 ohms) per volt.

Most quality digital multimeters meet or exceed this specification. Voltmeters with less impedance can affect the

circuit you are testing and also give an incorrect reading.

Start by checking the entire suspect earth circuit. With a voltmeter set on the 2 volt DC scale, connect the black

negative lead to the batter y negative term inal. ( If you are using an auto-ranging m eter, s et it to the DC volts setting.

Connect the red positive lead to the earth terminal of the component to be tes ted. W ith the circuit activated, c heck

the voltage drop in the circ uit. If the voltage reading is within specif ications, look f or a caus e other than a poor earth

at this component.

If the voltage reading is too high, proceed by isolating the cause of the high voltage dr op. Move the positive lead to

the next connection in the ear th c irc uit. (Keep the negative lead c onnected to the batter y negative terminal.) Be sure

to check both sides of each in-line connector and both the eyelet and the stud or screw at earth points. Repeat this

process through the earth path until the voltmeter reading is within specifications. The high resistance causing the

earth problem is located between where you obtained a good reading and the last high reading.

When a c ircuit us es redundant earths be sure to c heck

all the earth circuits for excessive voltage drop.

SOLID-STATE CIRCUIT VOLTAGE DROP SPECIFICATIONS

There ar e two ac c eptable maximum voltage dr ops for solid- state c irc uits . If you are meas ur ing the voltage drop of a

circuit that will pass through a solid-s tate com ponent bef ore going to earth (suc h as the ECT sensor circuit between

the ECT sensor and the PCM), measured voltage cannot be higher than 0.060 volts (60 millivolts).

If you are measuring the voltage drop of a solid-state earth circuit anywhere in the earth path at or after the solid-

state component (such as the PCM earth circuit from the PCM to the battery), the maximum allowable measured

voltage is 0.020 volts (20 millivolts). If you measure a voltage above specifications, repair the earth circuit.

Checking the voltage drop in a solid-state sensor circuit - an example. Look again at a throttle position sensor

circuit. W ith the voltmeter negative lead connected to the negative battery terminal and the ignition in RUN, check

the voltages at various points between the ECT sensor pin "B" and pin "E16" of the PCM. A voltage reading of 0.060

volts or less with the meter positive lead at the ECT sensor pin "B" terminal indicates that the entire earth circuit

from the ECT sensor to the battery is continuous and suf ficiently low in r esistance. A voltage reading of 0.060 volts

at "the splice" or the PCM connector "E16" pin would also be within specifications.

When voltage measurements are made in the earth circuit after the PCM, the specification changes. A voltage

reading of 0.020 volts (20 millivolts) or less is within specification. If voltage is not within specifications check the

diff erent connectors to find where the exces s voltage is. Be sure to c heck both s ides of in-line connector s and both

the eyelet and the stud at earth points.

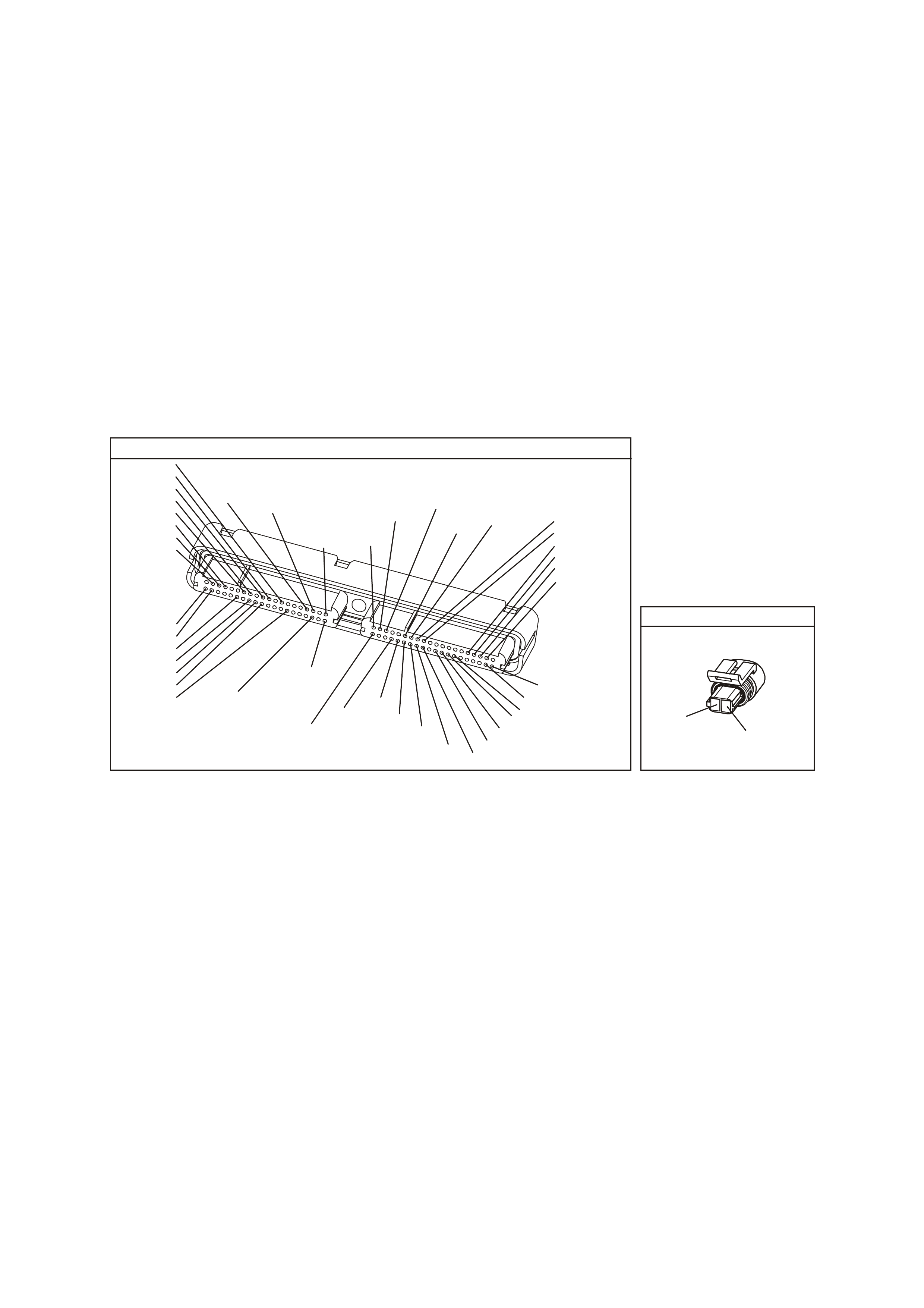

Figure 6C3-2-6 Testing Voltage Drop Before the PCM

1. Throttle Position Sensor. 5. Red Lead.

2. Engine Coolant Temperature Sensor. 6. Black Lead.

3. PCM 7. Battery.

4. Sensor Return. 8. 0.60 Volts Maximum.

8

5

6

7

5

12

4

3

4291

5

Figure 6C3-2B-7 Testing Voltage Drop After the PCM

1. Earth. 5. Black Lead.

2. PCM. 6. Battery3

3. Oxygen Sensor 7. 0.020 Volts Maximum.

4. Red Lead

4

4

4

4

4

3

2

111

5

6

7

4292

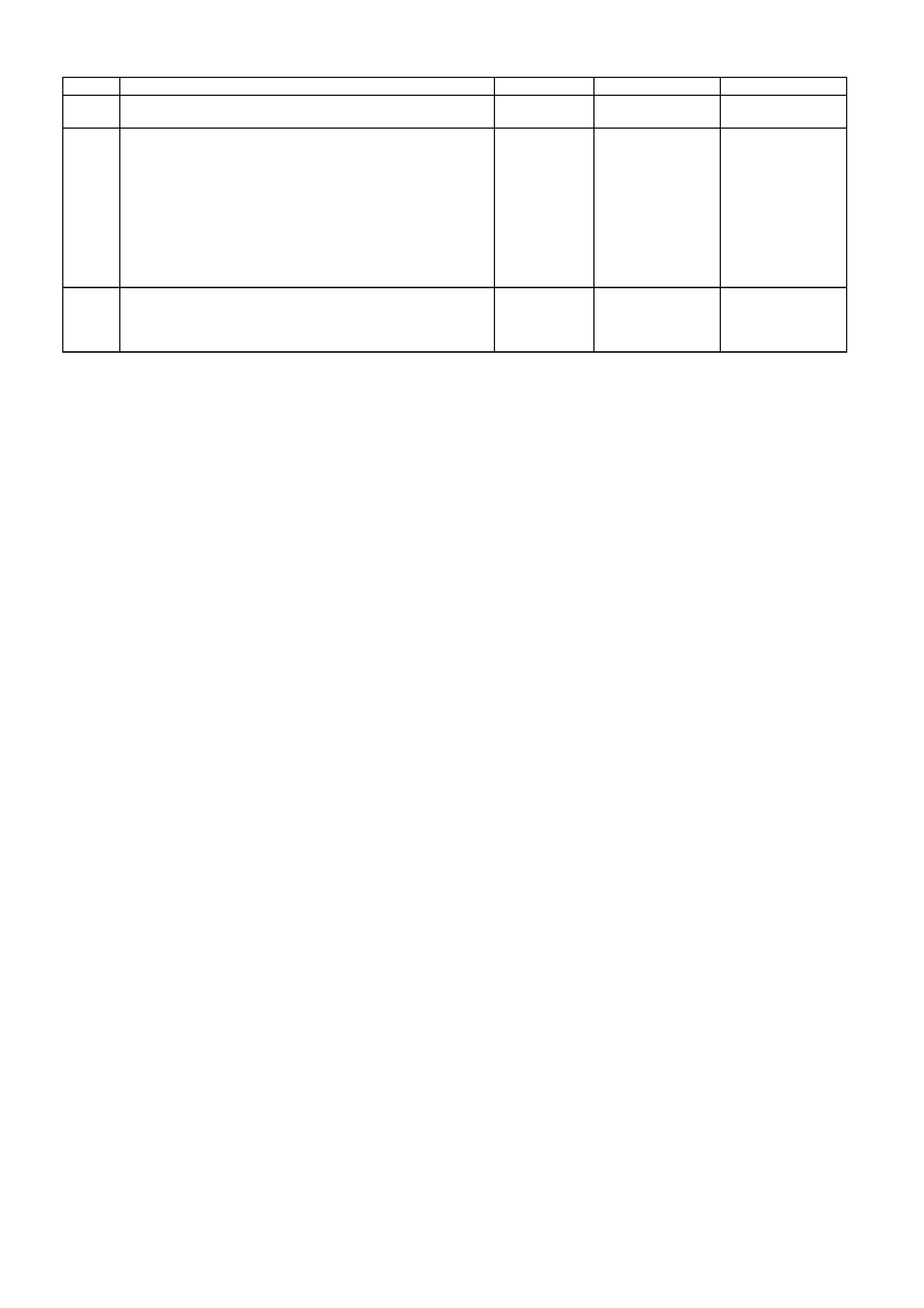

G3PCM002PT

J2-57

J2-25

A

B

INTAKE AIR

TEMPERATURE SENSOR

SENSOR EARTH

IAT SENSO R SIGN AL

PCM

5V

BR (472 )

G/O (469)

YE23 YE123

M

I

C

R

O

EARTH CREDIBILITY CHE CK

CIRCUIT DESCRIPTION:

The earth credibility check can be either used at the beginning of all diagnostic pr ocedures or it can be used when

no diagnostic trouble codes are set, but a sy mptom still exists.

Test Description: Number(s) below refer to step number(s) on the diagnostic Table.

1. To properly test the voltage drop of the powertrain control module system earth a load must be present on

the circuit.

Using the scan tool:, select CANISTER PURGE. By turning "ON" the Purge solenoid, this will cause a

sufficient draw on the system for testing.

2. Check connectors in earth circuit to find where the excessive voltage is. Make sure to check both sides of

in-line connectors.

Diagnostic Aids:

Because the powertrain control module operates on such small current even a minor corrosion problem will cause

problems with the system. Make sure the earths are clean and tight. Remember a good earth is about 25% of the

total systems circuit. Normally you will check the wiring for: power, continuity, the load, but rarely check the earth.

Powertrain control module system earths are very important to proper operation.

Y E 123

P.C.M CONNE CTOR 2

(750)

(1228)

(1229)

(465)

(121)

(259)

G/B

BR

G/W

GY/BLU

R

B/R

(418)

BR

(59)

(832)

G

T

(831)

(417)

(472)

(976) (974)

(432)

(428)

(631)

BLU BR G/Y

BLU/W

LG

BR/W

W/B

LG W

(977)

Y

(971)

BLU/W W

B/R

(750)

(304)

(792)

(1223)

(1222)

(123)

(1227)

(469)

(331)

Y/B

LG

V/W

B/Y

G/O BR/W

(1687)

GY/B

(366)

LG/B

GY/R

(422)

V

(442)

(444)

(443)

(975)

(972)

(978)

(1224)

(973)

(959)

LG/W

LG/B

LBLU/B

GY

(773)

BR/Y

BLU

G

Y/B

LBLU

(958)

BR

(441)

LBLU

1

41

40

80

J2

RED

Y

(838)

AIR TEMP SENS OR

YE 23

B/R

(472)

G/O

(469)

STEP ACTION VALUE YES NO

1. Was the "On-Board Diagnostic" (OBD) System Check

performed? Go to Step 2. Go to OBD

System Check.

2. 1. Ignition "OFF"

2. Disconnect IAT sensor connector.

3. Using digital volt ohm meter set to DC voltage scale,

connect negative lead to negative battery cable at

battery and connect positive lead to the black wire at

the IAT sensor connector.

4. Ignition "ON"

5. Using a scan tool, select CANISTER PURGE.

6. Turn "ON'" Canister Purge with up/down arrow keys.

Is voltage measured less than value shown.

0.060 volts

(60 Millivolts) No problem

found, continue

with symptom

diagnosis.

Go to Step 3

3. 1. Remove and thoroughly clean the PCM earth

terminals and connection.

2. Reassemble the PCM Earth terminals.

Is action complete?

Verify Repair

CORRECTING PROBLEMS IN EARTH CIRCUITS

Once a high resistance condition in a earth circuit has been located, you must determine the actual cause.

If the problem is at a connector, check for bent, corroded, or loose connector terminals. Terminals must have a

slight drag when disassembled/assembled. If they slide apart/together without resistance, they will not provide a

good connection.