SECTION 7C - HYDRA-MATIC 4L60-E

AUTOMATIC TRANSMISSION

IMPORTANT

Before p erf orming any Service Operatio n o r oth er pro cedu re describ ed in th is Sectio n, refer t o Sect ion 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

1. GENERAL INFORMATION

SPACER PLATE AND GASKETS

1.1 MY2003 TRANSMISSION

TRANSMISSION IDENTIFICATION –

MY2003

PRESSURE CONTROL SOLENOID (PCS)

BOOST VALVE BUSHING

1.2 ‘HAD’ MODEL TRANSMISSION

3-4 CLUTCH

2. ELECTRICAL DIAGNOSIS

3. HYDRAULIC/MECHANICAL DIAGNOSIS

3.1 LINE PRESSURE CHECK

PRELIMINARY INFORMATION

PROCEDURE

4. ON-VEHICLE SERVICING

4.1 COOLER PIPE QUICK-CONNECT FITTING

REMOVE

REINSTALL

5. UNIT REPAIR

6. SPECIAL TOOLS

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL I NFORMATION

The Hydra-Matic 4L60-E automatic transmission fitted to VX, VU and WH Series II Models carries over from VX

Series I Models, noting the following:

• Eff ec tive f r om a Julian build date (r ef er to Figure 7C-2), of “1HXD002 A 0000001”, the Torque Converter Clutch

(TCC) Regulator Valve exhaust port was reduced in s ize. T his change has meant that, not only has the c ontrol

valve body changed but the spacer plate and both gaskets have also been modified. The early and later

gaskets and spacer plates can be physically identified as shown in Figure 7C-1.

• With the introduction of the MY2003 Hydra-Matic 4L60-E automatic transmission into WH Series II Models

during O ctober 2002, the press ure control solenoid and boos t valve bushing were revised. As the design of the

wiring harness connec tor for the pr essure contr ol solenoid is also new, the internal trans mis sion wiring harness

also changes.

• With the introduction of the MY2003 Hydra-Matic 4L60-E automatic transmission into WH Series II Models

during October 2002, new quick-connect fittings have replaced the flare nut fittings where the transmission

cooler pipes connect to the radiator and transmission.

• A new HAD (heavy duty) transmission was introduced into WH Series II Models fitted with the GEN III V8

engine during October 2002.

Apart from the information regarding the identification of the early and late type control valve body spacer plate

and gasket, the general information provided in this Section only applies to the MY2003 transmissions

introduced into WH Series II during October 2002. For the general information relating to the Hydra-Matic

4L60-E automatic transmission fitted to VX, VU and WH Series II Models not covered in this Section, refer to

Section 7C1 HYDRA-MATIC 4L60-E AUTOMATIC TRANSMISSION – GENERAL INFORMATION in the VX

Series I Service Information.

SPACER PLATE AND GASKETS

Control Valve Body Gaskets Control Valve Body Spacer Plate

A B

C D

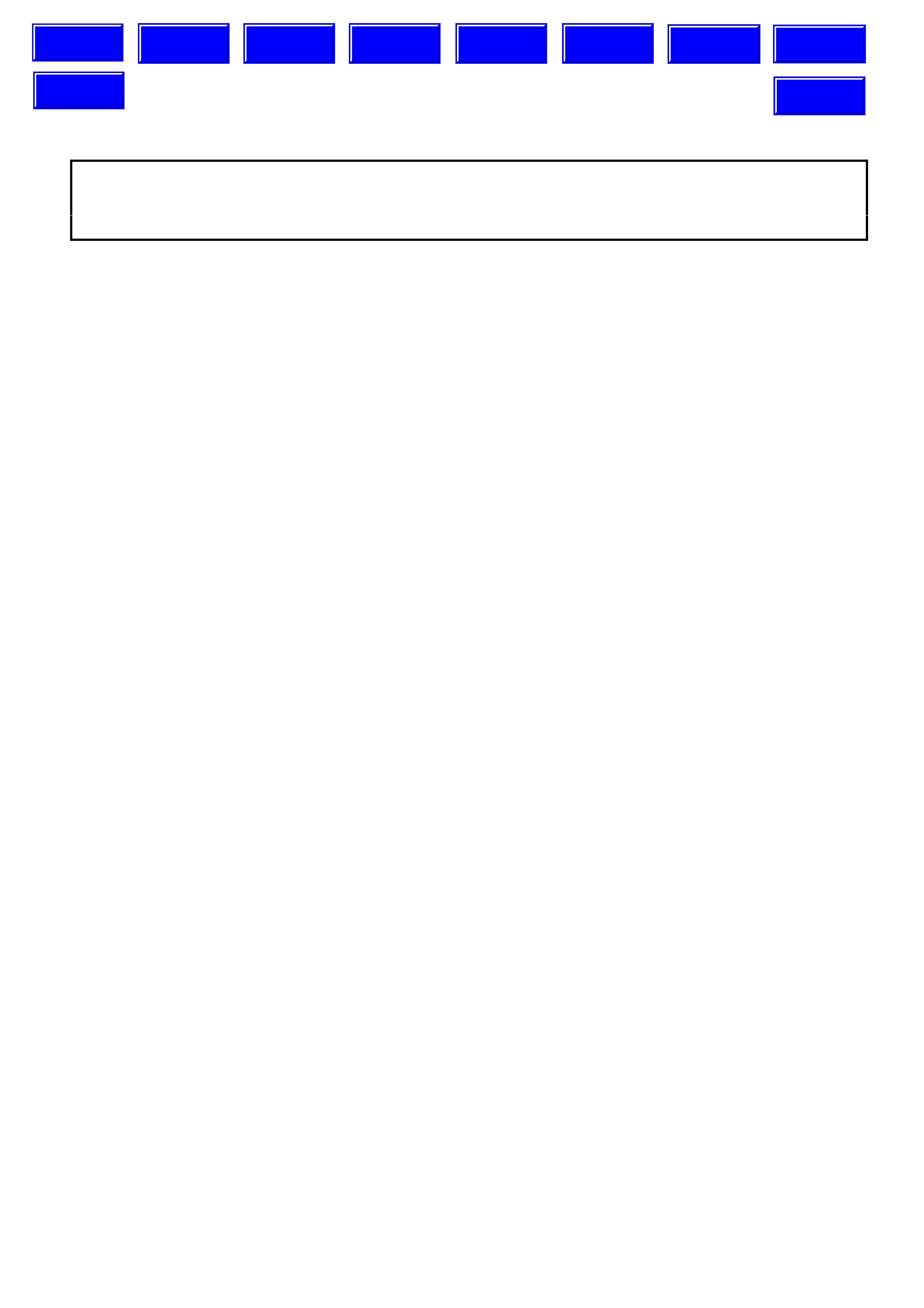

Figure 7C-1

Legend:

A. Pre-Change Gaskets – ‘V’ is the Valve body side, ‘C’ is the Case Gasket

B. Pre-Change Spacer Plate – Identification in an embossed ‘TJ’

C. Post-Change Gaskets – ‘VB’ is the Valve body side, ‘CA’ is the Case Gasket

D. Post-Change Spacer Plate – Identification in an embossed ‘1TJ’

Techline

1.1 MY2003 TRANSMISSION

With the introduction of the MY2003 release of the 4L60-Eautomatic transmission into WH Series II Models, the

following changes have been affected;

• The pressure control solenoid was revised.

• The boost valve bushing was revised.

• As the design of the wiring harness connector for the pressure control solenoid is also new, the internal

transmission wiring harness also changes.

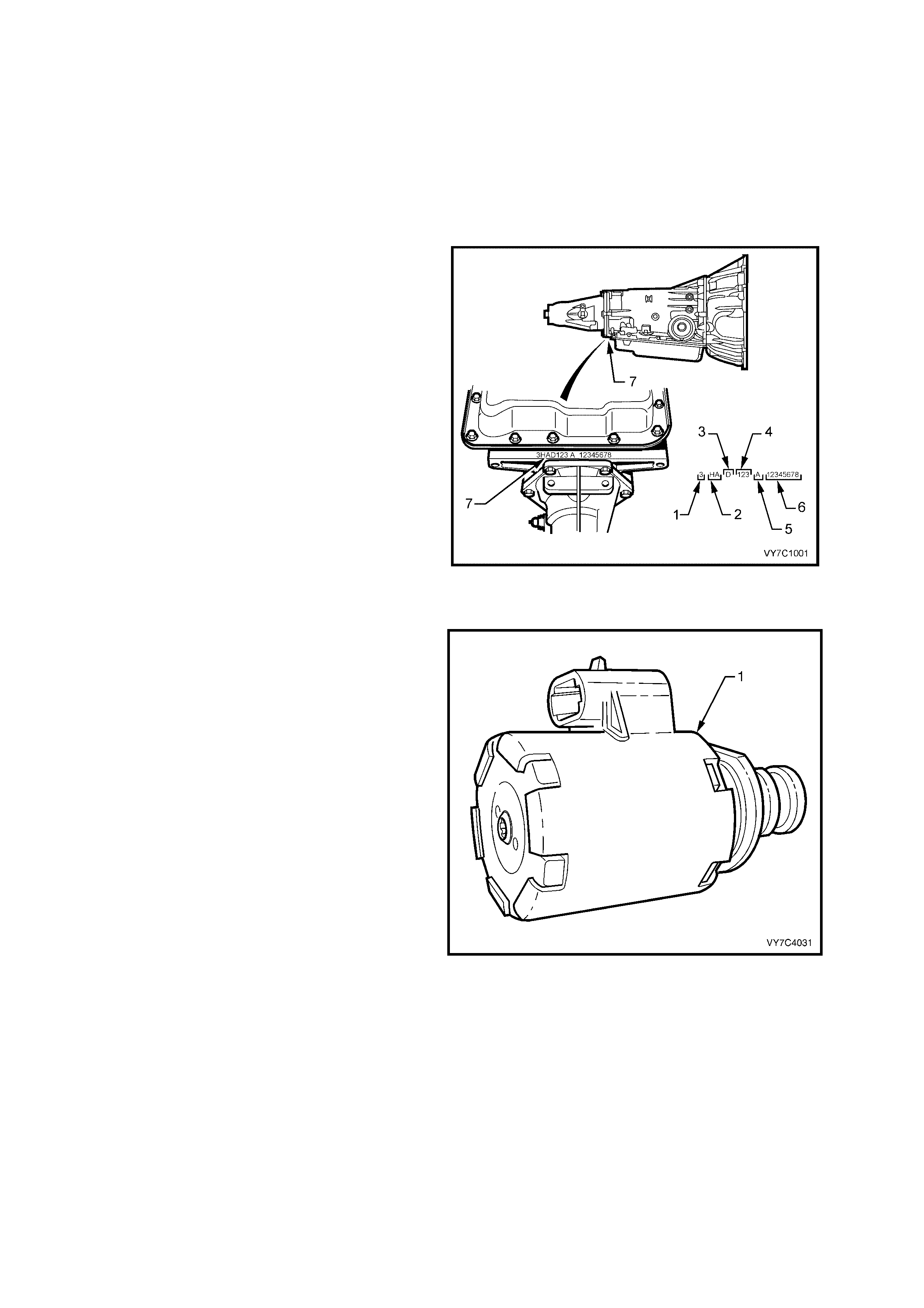

TRANSMISSION IDENTIFICATION – MY2003

The 4L60-E automatic tr ansm iss ion application and

identification can be determined from the stamping

in the rear of the transmission case, in the location

shown (7).

The coded number can be interpreted from the

following breakdown;

1. Model Year (‘3’ = 2003)

2. Model:

3.8 litre V6 (LN3)............. HF

3.8 litre V6 S/C (L67)....... HN

5.7 litre GEN III V8 (LS1) HA

3. Transmission Model Identifier (‘D’ = 4L60-E)

4. Julian Date (Day of the Year)

5. Shift Build ‘A’, ‘B’, ‘J’ = First Shift;

‘C’, ‘H’, ‘W’ = Second Shift

6. Individual Transmission Serial Number

Figure 7C-2

PRESSURE CONTROL SOLENOID (PCS)

The Pressure Control Solenoid (PCS) is a new

design.

As the design of the terminal connection is also

new, the internal transmission wiring harness also

changes.

With the change in the PCS, a change has been

effected in the line pressure, that means a change

in the pressure checking procedure and results.

Refer to 3.1 LINE PRESSURE CHECK in this

Section for specific details.

Figure 7C-3

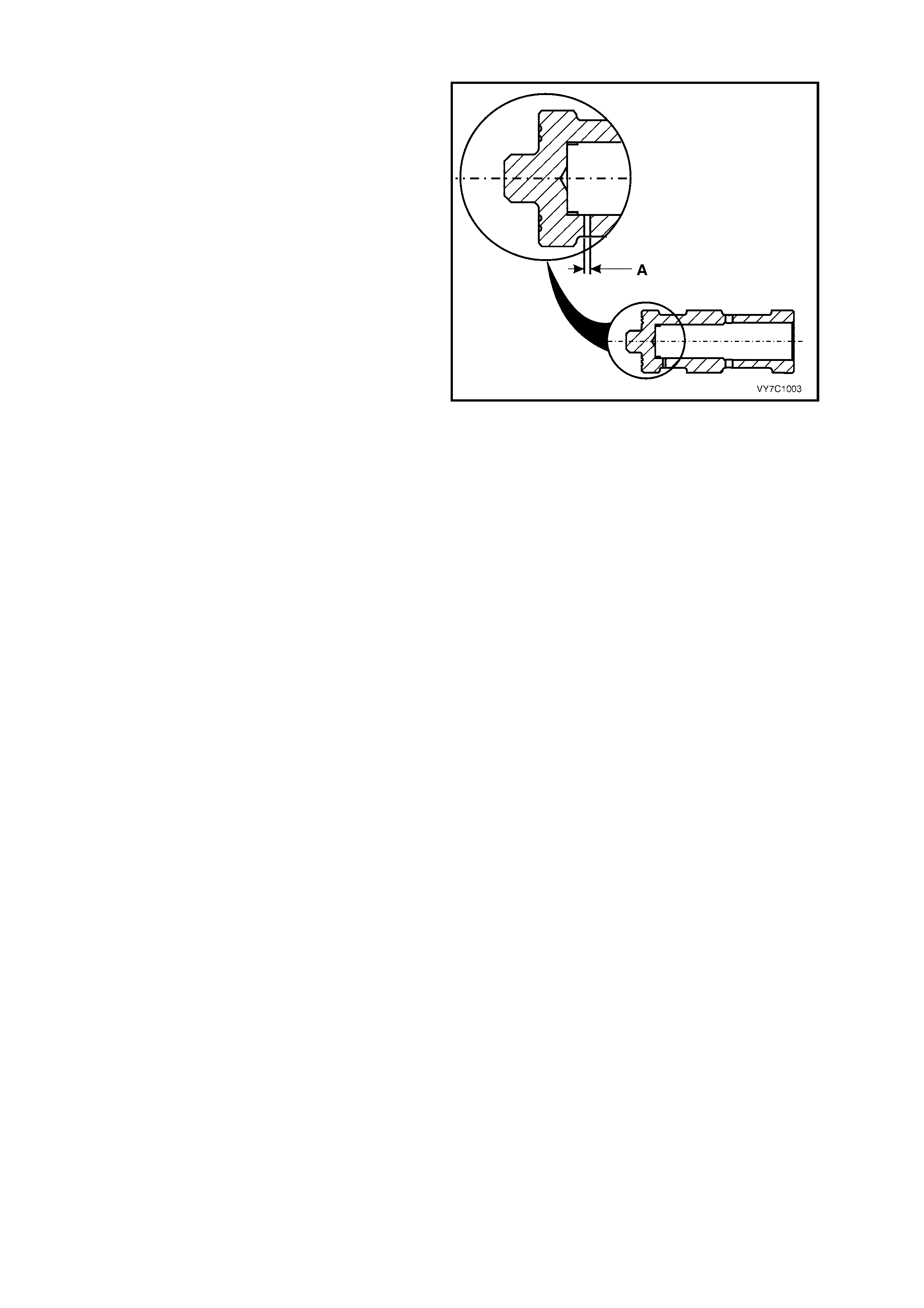

BOOST VALVE BUSHING

The orifice size (‘A’) in the boost valve sleeve,

(mounted in the oil pump housing) has been

reduced from a nominal 1.08 mm to 0.89 mm

(+0.07 mm/–0.06 mm), which affects the ATF

pressure boost characteristics of the valve.

Apart from this changed dimension, the bushing

has a new part number and has yellow dye applied

to it, for identification purposes.

Figure 7C-4

1.2 ‘HAD’ MODEL TRANSMISSION

To increase durability of the 4L60-E automatic transmission fitted to the GEN III V8 engine, a number of changes

have been eff ected for the MY2003 transm iss ion releas e. Res ulting f r om these changes the trans mission pref ix has

been changed from ‘HPD’ to ‘HAD’.

3-4 CLUTCH

The number of plates in the 3-4 clutch pack has been increased from six to seven plates. To achieve this result

without undergoing major internal component changes, the plates are thinner. This means that the same selective

plates can be used to achieve the same end float specification.

Apart from the change in part number, the HAD clutch plates can be physically identified by;

Composition plates – Thickness of new plates (1.62 ± 0.10 mm) and by one or more lightly coloured stripes

across the friction surfaces.

Steel plates – Thickness of new plates (2.42 +0.08 –0.07 mm).

2. ELECTRICAL DIAGNOSIS

The information regarding the electrical diagnosis of the Hydra-Matic 4L60-E automatic transmission as fitted to

VX, VU and WH Series II Models carries over from the information provided for VX Series I Models, noting the

following:

• Although there was a revised pressure control solenoid wiring harness connector introduced with the MY2003

automatic transmissions, the internal transmission harness layout remains unchanged.

For information relating to the Hydra-Matic 4L60-E automatic transmission fitted to VX, VU and WH Series II

Models, refer to Section 7C2 HYDRA-MATIC 4L60-E AUTOMATIC TRANSMISSION – ELECTRICAL

DIAGNOSIS in the VX Series I Service Information.

3. HYDRAULI C/ MECHANI CAL DIAGNOSIS

The inf orm ation regar ding the hydraulic/mec hanical diagnosis of the Hydra-Matic 4L60-E autom atic transm is sion as

fitted to VX, VU and WH Series II Models c arries over f rom the inform ation provided f or VX Series I Models , noting

the following:

• A revised pressure control solenoid was introduced with the MY2003 automatic transmissions, resulting in a

new pressure checking procedure and results.

For information relating to hydraulic/mechanical diagnosis of the Hydra-Matic 4L60-E automatic transmission fitted

to VX, VU and WH Series II Models not covered in this Section, refer to Section 7C3 HYDRA-MATIC 4L60-E

AUTOMATIC TRANSMISSION – HYDRAULIC/MECHANICAL DIAGNOSIS in the VX Series I Service Information.

3.1 LINE P RE SSURE CHECK

PRELIMINARY INFORMATION

Line pressures are calibrated for two sets of gear ranges – Drive/Park/Neutral and Reverse. This allows the

transmission line pressure to be appropriate for two different pressure needs in different gear ranges:

Gear Range Line Pressure Range

Drive, Park or Neutral...... 380 – 1,300 kPa

Reverse........................... 440 – 2,235 kPa

Before performing a line pressure check, verify that the pressure control (PC) solenoid is receiving the correct

electrical signal from the PCM, as follows:

1. Install Tech 2. Refer to 3.1 CONNECTING TECH 2 TO THE VEHICLE in Section 0C - TECH 2, in the VX

Series I Service Information for the necessary procedure.

2. Start the engine and firmly apply the park brake.

3. Check for stored diagnostic trouble code/s (DTC) and in particular, for a pressure control solenoid DTC.

4. Rectify as necessary.

NOTE: The transmission may experience harsh, soft or mushy shifts for up to two days after this procedure.

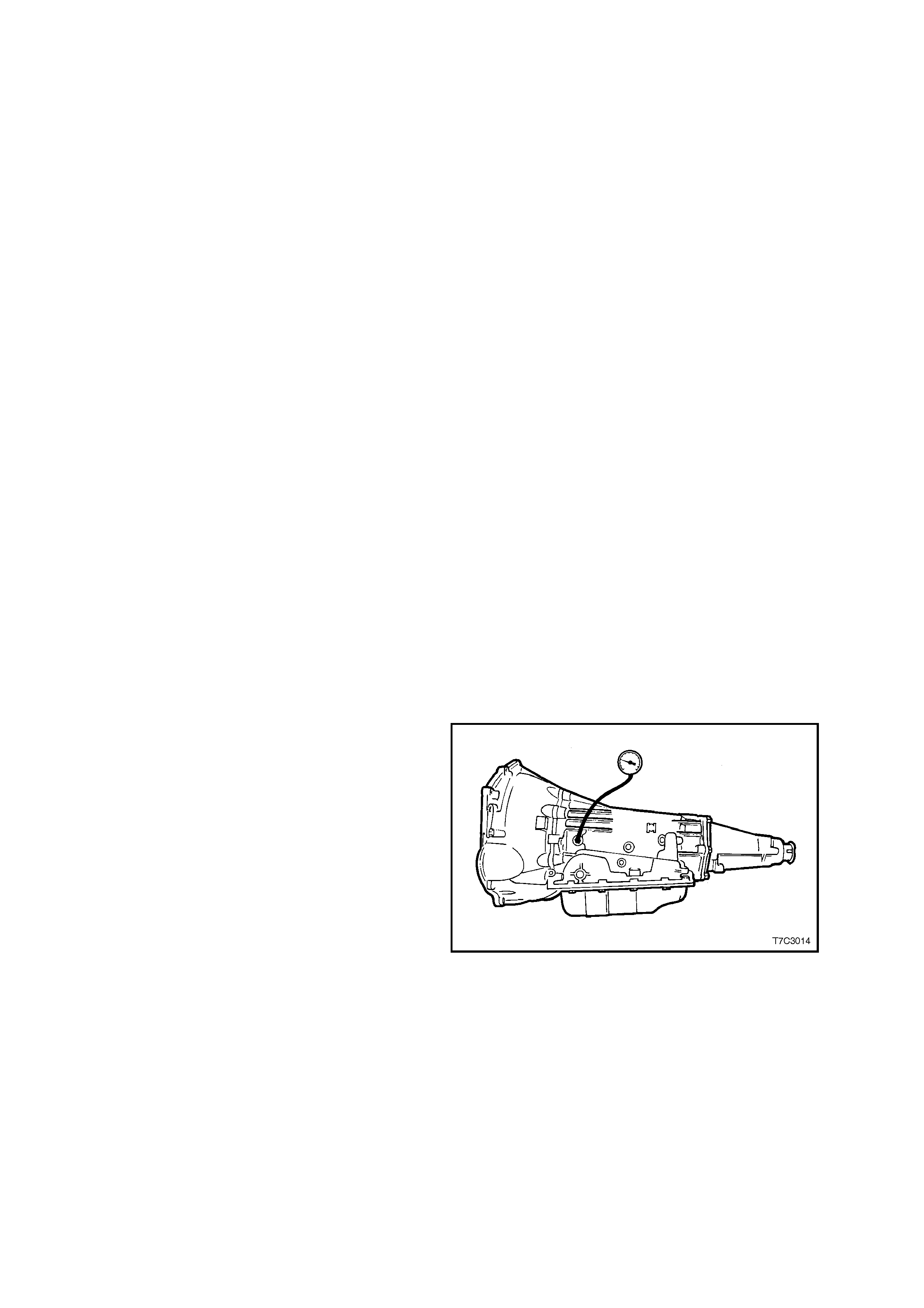

PROCEDURE

1. Check engine and transmission fluid levels.

2. Check manual linkage for correct adjustment and wear.

3. If not previously carried out, install Tech 2 to the vehicle. Refer to 3.1 CONNECTING TECH 2 TO THE

VEHICLE in Section 0C - TECH 2, in the VX Series I Service Information for the necessary procedure.

4. Install an oil pressure gauge such as Tool

J21867 or commercial equivalent, to the line

pressure tapping point on the transmission, as

shown.

5. Select ‘P’ (Park) range and firmly apply the

park brake.

6. Start the engine and allow to warm up, at idle.

7. Access ‘Miscellaneous Tests’ on Tech 2, then

the PCS CONTROL test.

8. Increase ACTUAL PCS in 0.1 Amp increments

on Tech 2 and read the corresponding line

pressure reading on the fluid pressure gauge.

(Allow the pressure to stabilise for 5 seconds

after each current change.

9. Compare the pressure readings against the

charts shown next.

IMPORTANT: Total test running time should not

exceed 2 minutes or transmission damage could

occur.

Figure 7C-5

NOTE 1: Pressures are to be taken at an engine speed of 1,500 rpm and a temperature of 66°C. Line pressure

drops as temperature increases.

NOTE 2: If pressure readings differ greatly from the line pressure chart, refer to the Diagnostic Section in:

Section 6C1 POWERTRAIN MANAGEMENT – V6 ENGINE,

Section 6C2 POWERTRAIN MANAGEMENT – V6 SUPERCHARGED ENGINE or

Section 6C3 POWERTRAIN MANAGEMENT – GEN III V8 ENGINE.

NOTE 3: T ech 2 is only able to control the PC solenoid in Park , and Neutral, with the vehicle stopped. This protects

the clutch packs from extremely high or low pressures in Drive or Reverse ranges.

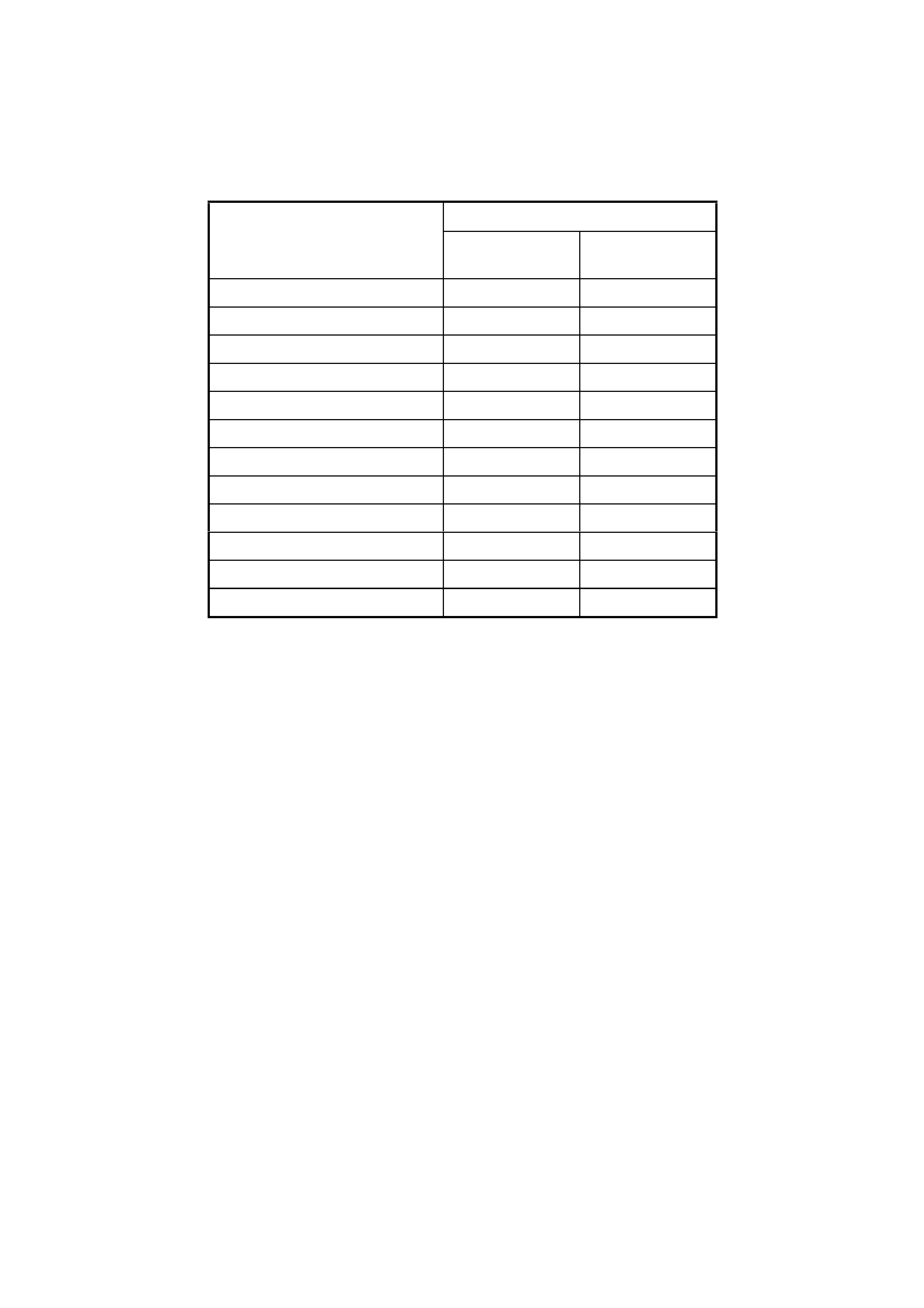

Pressure Control Solenoid Line Pressure (kPa)

Current (Amp) V6 Engine GEN III V8

Engine

0.00 1,261 – 1,399 1,369 – 1,507

0.10 1,257 – 1,395 1,356 – 1,494

0.20 1,233 – 1,371 1,334 – 1,472

0.30 1,201 – 1,339 1,299 – 1,437

0.40 1,139 – 1,277 1,229 – 1,367

0.50 1,055 – 1,193 1,143 – 1,281

0.60 921 – 1,059 1,016 – 1,154

0.70 818 – 956 868 – 1,006

0.80 649 – 787 693 – 831

0.90 439 – 577 481 – 619

1.00 379 – 517 333 – 471

1.10 339 – 477 —

Table 7C-6

4. ON-VEHICLE SERVICING

The information regarding the on-vehicle servicing of the Hydra-Matic 4L60-E automatic transmission as fitted to

VX, VU and WH Series II Models carries over from the information provided for VX Series I Models, noting the

following:

• With the introduction of the MY2003 Hydra-Matic 4L60-E automatic transmissions into WH Series II Models

during October 2002, new quick-connect fittings have replaced the flare nut fittings where the transmission

cooler pipes connect to the transmission.

For information relating to on-vehicle servicing of the Hydra-Matic 4L60-E automatic transmission fitted to VX, VU

and W H Series II Models not covered in this Section, refer to Section 7C4 HYDRA-MATIC 4L60-E AUTOMATIC

TRANSMISSION – ON-VEHICLE SERVICING in the VX Series I Service Information.

4.1 COOLER PIP E QUICK-CONNECT FITTING

REMOVE

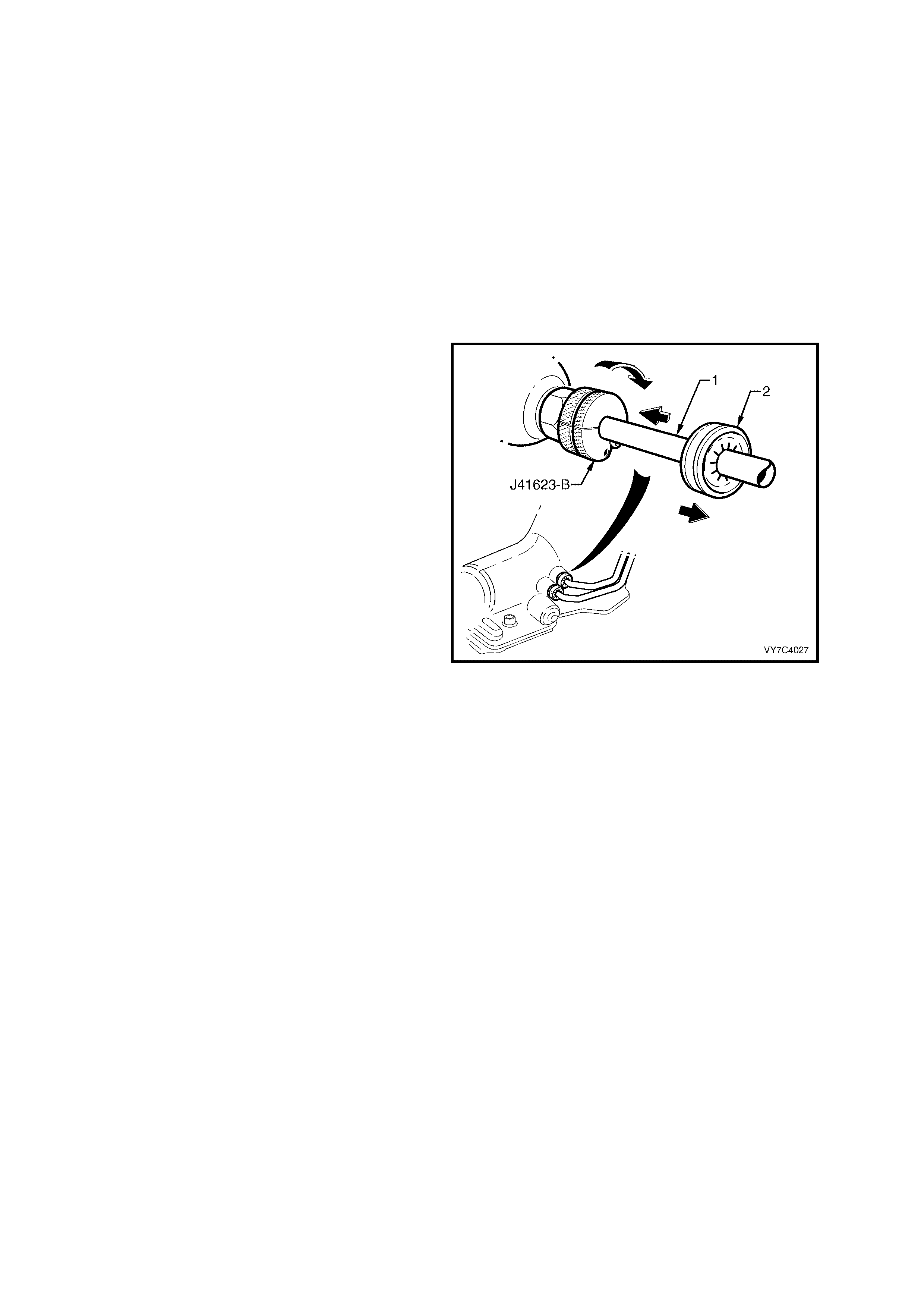

1. Release the verifier disc (2) by pulling back

with the fingertips, then slide back down the

cooler pipe (1).

2. Open the cooler line release Tool J41623-B

and slip over the cooler pipe to be

disconnected from the transmission, above the

verifier disc (2), as shown.

3. Slide the release tool along the pipe to engage

with the quick-connect fitting.

4. While pushing inwards, rotate the tool about

one sixth of a turn to release the spring clip

holding the pipe.

5. With the release tool held in this position, pull

back on the cooler pipe to release.

6. Repeat this process with the remaining pipe

and quick-connect fitting.

7. Plug all openings to prevent foreign matter

entry.

Figure 7C-7

REINSTALL

1. Remove the plugs from the cooler pipes and

quick connect fittings, wipe the pipes clean,

then smear with clean automatic transmission

fluid.

2. Push each pipe into its respective quick

connect fitting.

3. Attempt to pull the pipe free to ensure correct

engagement.

4. Slide each verif ier disc up to the quick connect

fitting. If it engages with the fitting, then the

pipe has been correctly installed.

5. UNIT REPAIR

The inf orm ation regar ding the hydraulic/mec hanical diagnosis of the autom atic transm is sion as f itted to VX, VU and

WH Series II Models carries over from the information provided for VX Series Models, noting the following:

• Eff ect ive f rom a Julian build date of ‘1HX D002 A 0000001’, the Torque Converter Clutc h (TCC) Regulator Valve

exhaust port was r educed in size. This change has m eant that, not only has the control valve body changed but

the spac er plate and both gask ets have also been m odified. T he early and later gaskets and s pacer plates c an

be physically identified as shown in Figure 7C-1.

• With the introduction of the MY2003 Hydra-Matic 4L60-E automatic transmission into WH Series II Models

during October 2002, the pressure control solenoid and boost valve bushing was revised. As the design of the

wiring harness connec tor for the pr essure contr ol solenoid is also new, the internal trans mis sion wiring harness

also changes.

• For the HAD trans m ission fitted to WH Ser ies II Models with the GEN III V8 engine, the num ber of plates in the

3-4 clutch pack has been increased from six to seven plates. To achieve this result without undergoing major

internal com ponent changes, the plates are thinner. T his means that the same selective plates can be used to

achieve the same end float specification.

For information relating to unit repair of the Hydra-Matic 4L60-E automatic transmission fitted to VX, VU and WH

Series II Models, refer to Section 7C5 HYDRA-M ATIC 4L60-E AUTOM ATIC TRANSMISSION – UNIT REPAIR in

the VX Series I Service Information.

6. SPECIAL TOOLS

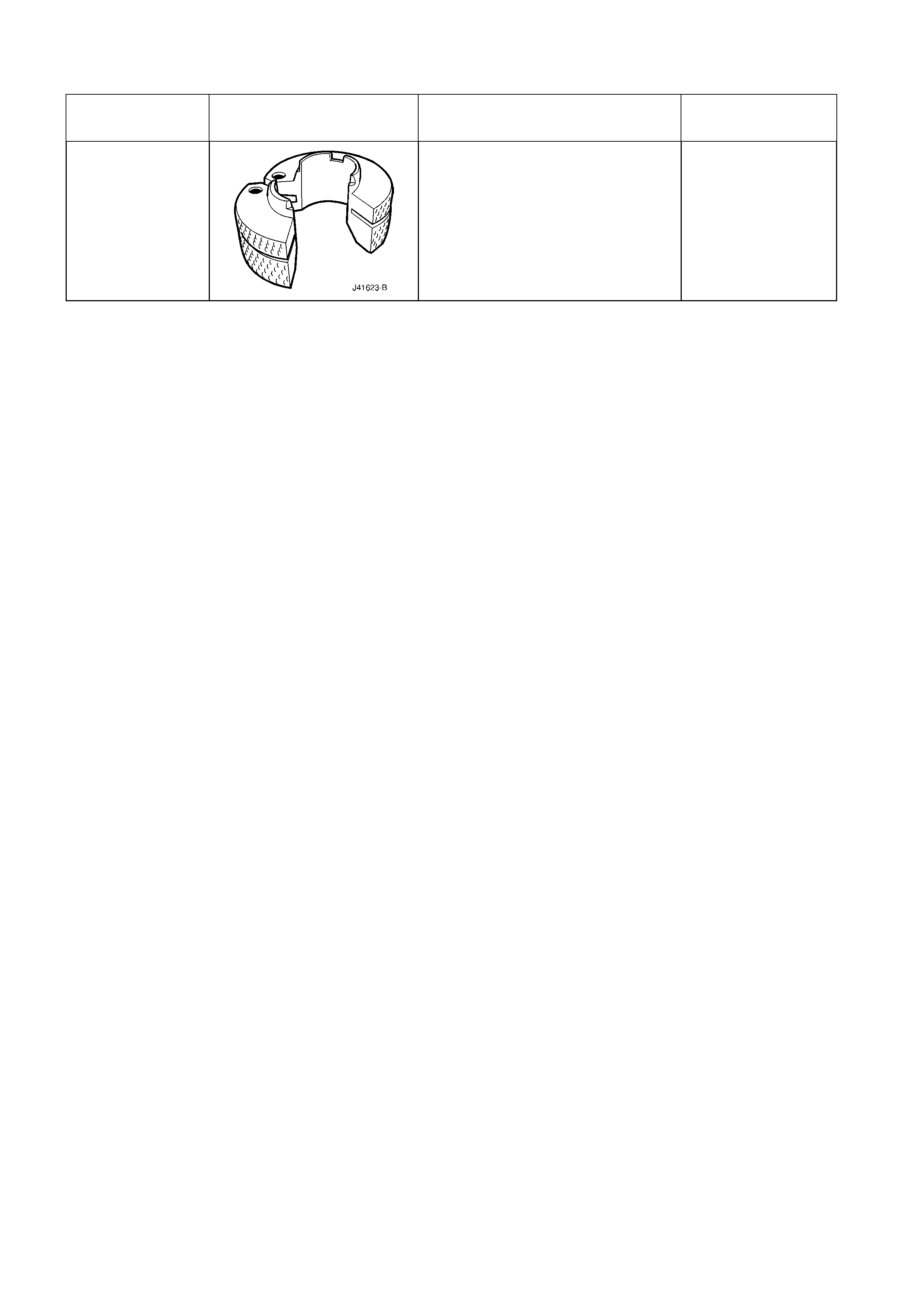

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J41623-B

COOLER PIPE QUICK-CONNECT

RELEASE TOOL

New release.

Mandatory