SECTION 0A - GENERAL INFORMATION

IMPORTANT

Before perfo rming any Service Operat ion or oth er procedure described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 HOIST PAD LOCATIONS

2. MODEL AVAILABILITY AND EQUIPMENT

2.1 DOMESTIC

2.2 BRAZIL

2.3 GULF STATES

2.4 SOUTH AFRICA

3. MAJOR OPTION CODES

4. POWERTRAIN COMBINATIONS

5. TRANSMISSION RATIOS

6. ENGINE DATA

7. EXTERIOR DIMENSIONS

8. VEHICLE WEIGHTS

9. SERIAL NUMBERS – DOMESTIC

9.1 LOCATION OF IDENTIFICATION PLATES

9.2 SAFETY COMPLIANCE PLATE

9.3 BODY AND OPTION

IDENTIFICATION PLATE

9.4 VEHICLE IDENTIFICATION NUMBER

VIN PLATE

VIN BODY STAMPING

9.5 VEHICLE IDENTIFICATION

NUMBERING SYSTEM

9.6 FUEL CONSUMPTION LABEL

10. SERIAL NUMBERS – BRAZIL

10.1 LOCATION OF IDENTIFICATION PLATES

10.2 BODY AND OPTION

IDENTIFICATION PLATE

10.3 MAUNUFACTURER LABEL

10.4 PAINT LABEL

10.5 VIS LABEL

10.6 VEHICLE IDENTIFICATION NUMBER

VIN PLATE

VIN BODY STAMPING

10.7 VEHICLE IDENTIFICATION

NUMBERING SYSTEM

11. SERIAL NUMBERS – GULF STATES

11.1 LOCATION OF IDENTIFICATION PLATES

11.2 SAFETY COMPLIANCE LABEL

11.3 BODY AND OPTION

IDENTIFICATION PLATE

11.4 VEHICLE IDENTIFICATION NUMBER

VIN PLATE

VIN BODY STAMPING

11.5 VEHICLE IDENTIFICATION

NUMBERING SYSTEM

12. SERIAL NUMBERS – SOUTH AFRICA

12.1 LOCATION OF IDENTIFICATION PLATES

12.2 SAFETY COMPLIANCE PLATE

12.3 BODY AND OPTION

IDENTIFICATION PLATE

12.4 VEHICLE IDENTIFICATION NUMBER

VIN PLATE

VIN BODY STAMPING

12.5 VEHICLE IDENTIFICATION

NUMBERING SYSTEM

13. ENGINE SERIAL NUMBERS

13.1 V6 ENGINE

13.2 GEN III V8 ENGINE

14. TRANSM ISSION SERIAL NUMBER

14.1 AUTOMATIC TRANSMISSION

14.2 MANUAL TRANSMISSION – 5 SPEED

14.3 MANUAL TRANSMISSION – 6 SPEED

15. FINAL DRIVE ASSEMBLY SERIAL

NUMBER

16. CONSOLIDATED TOOL LIST

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL I NFORMATION

The MY2003 VY Ser ies and V2 Ser ies II vehicles ar e a major m odel upgrade. T he main changes ar e summ arised

in the following list. Additional and more detailed information is provided in the relevant Section in this Service

Information package.

• New hood, fenders, quarter panels and rear compartment lid.

• New front and rear lamp units.

• New bumper fascias.

• Low wind-noise exterior mirrors.

• New grille inserts, badges and side mouldings.

• New alloy wheels or wheel trims.

• Revised interior trim colours and materials.

• New instrument panel and console with 2.25 DIN specification audio sy stem.

• Reverse Parking Aid (RPA) system availability for sedans and coupe.

• New multi-function display instruments.

• Modular condenser-radiator-fan assembly.

• New steering wheel and airbag.

• Stand-alone navigation system (option).

• Wider interior mirror.

• Twilight sentinel for Level 1 models.

• New spoilers for S and SS models.

• Sunglass holder with reading lamps for Level 2 and 3 models.

• New fog lamps for Level 3 models.

• Mobile phone stowage provision for Level 3 models.

This Sect ion contains inf or mation about vehic le hoisting, model availability, model options, powertrain com binations ,

transmission ratios, engine data and exterior dimensions and vehicle numbering.

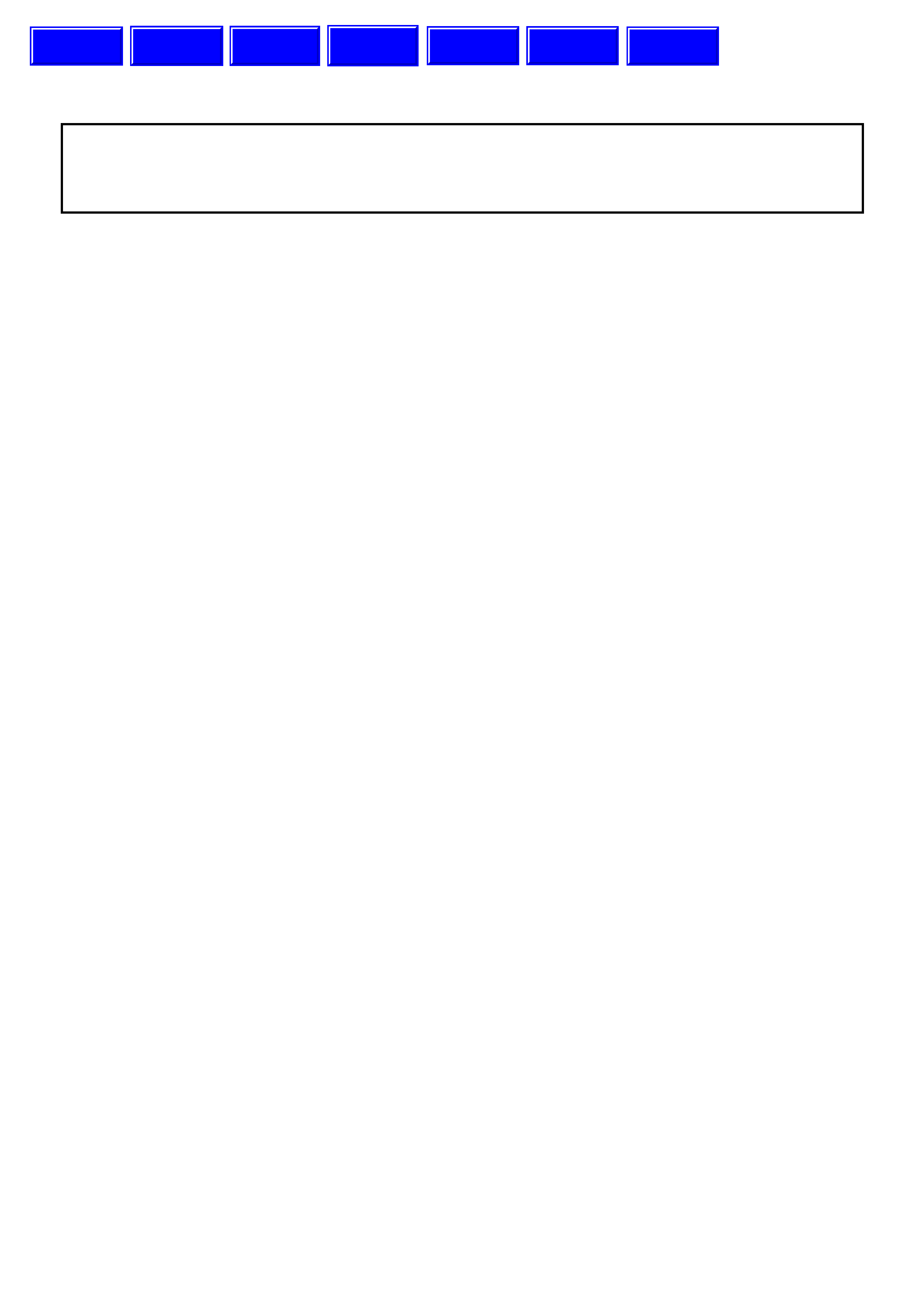

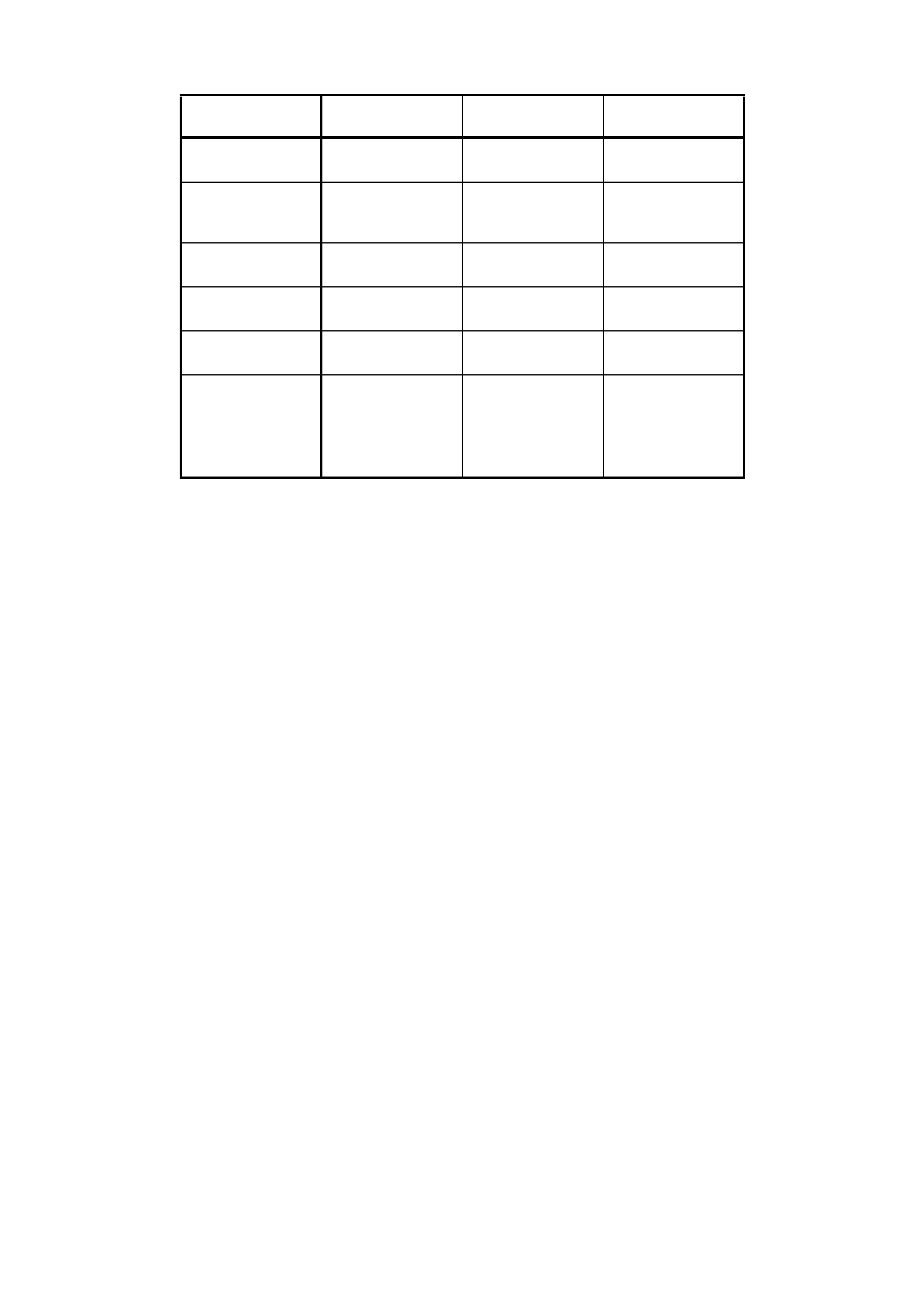

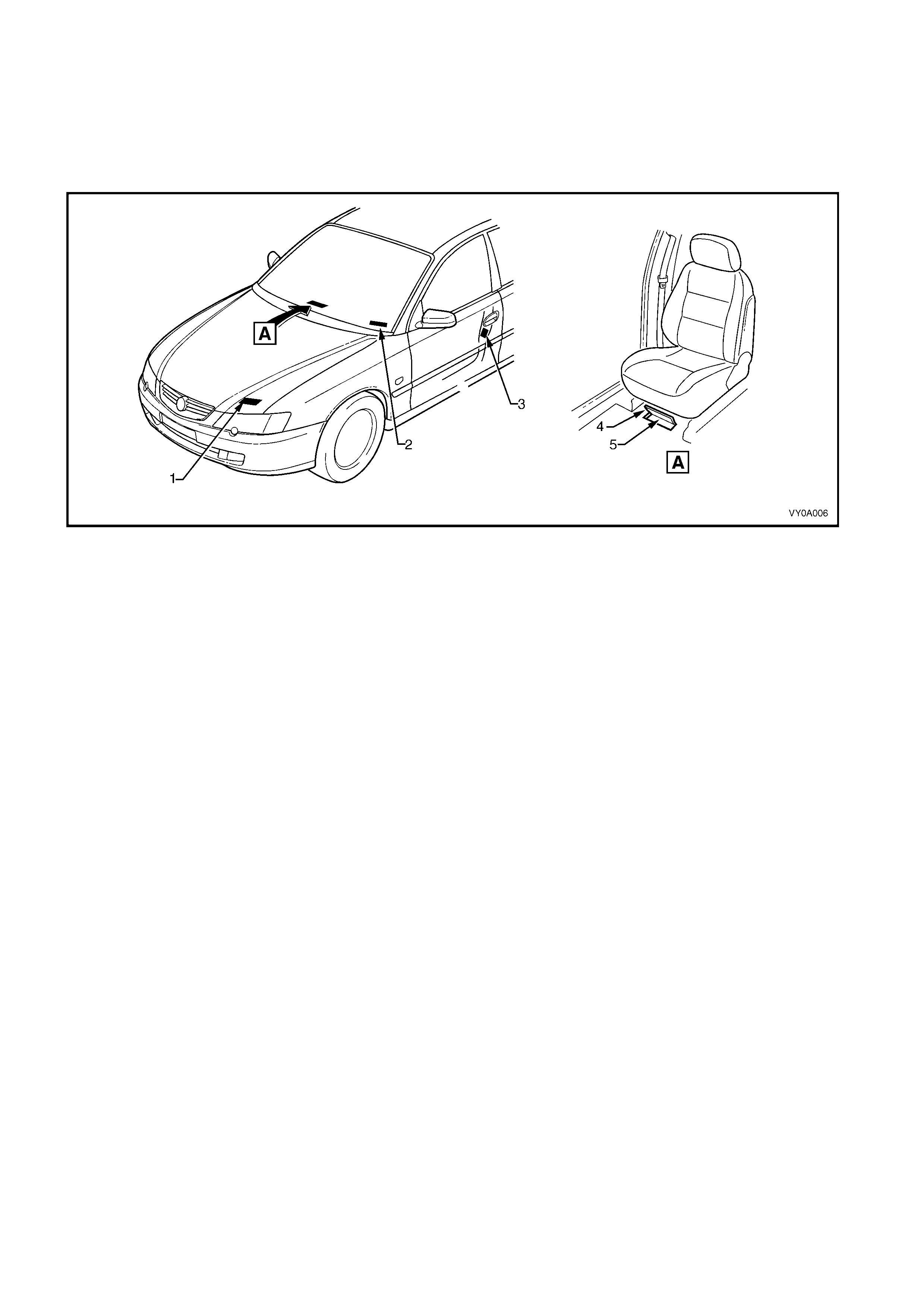

1.1 HOIST PAD LOCATIONS

When using a trolley jack to raise the vehic le, it is im portant that the jac k be positioned under the su spension c ross

member or hoist pad (1) locations. Do not jack under the suspension control arm. The vehicle should always be

supported by jack stands at the hoist pad locations when raised.

Figure 0A-1

2. MODEL AVAILABILITY AND EQUIPMENT

NOTE: For tyre and wheel information, refer to Section 10 WHEELS AND TYRES.

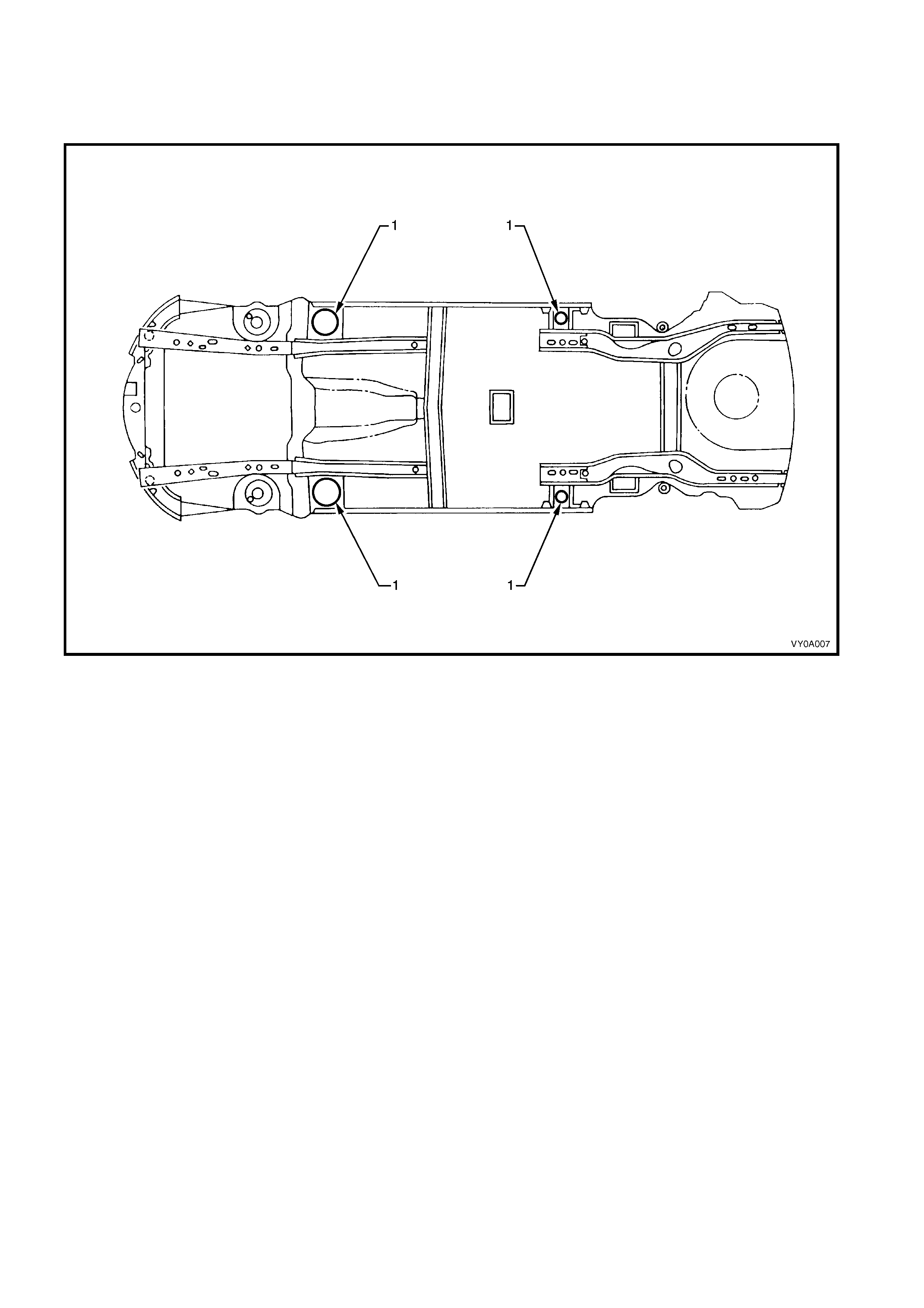

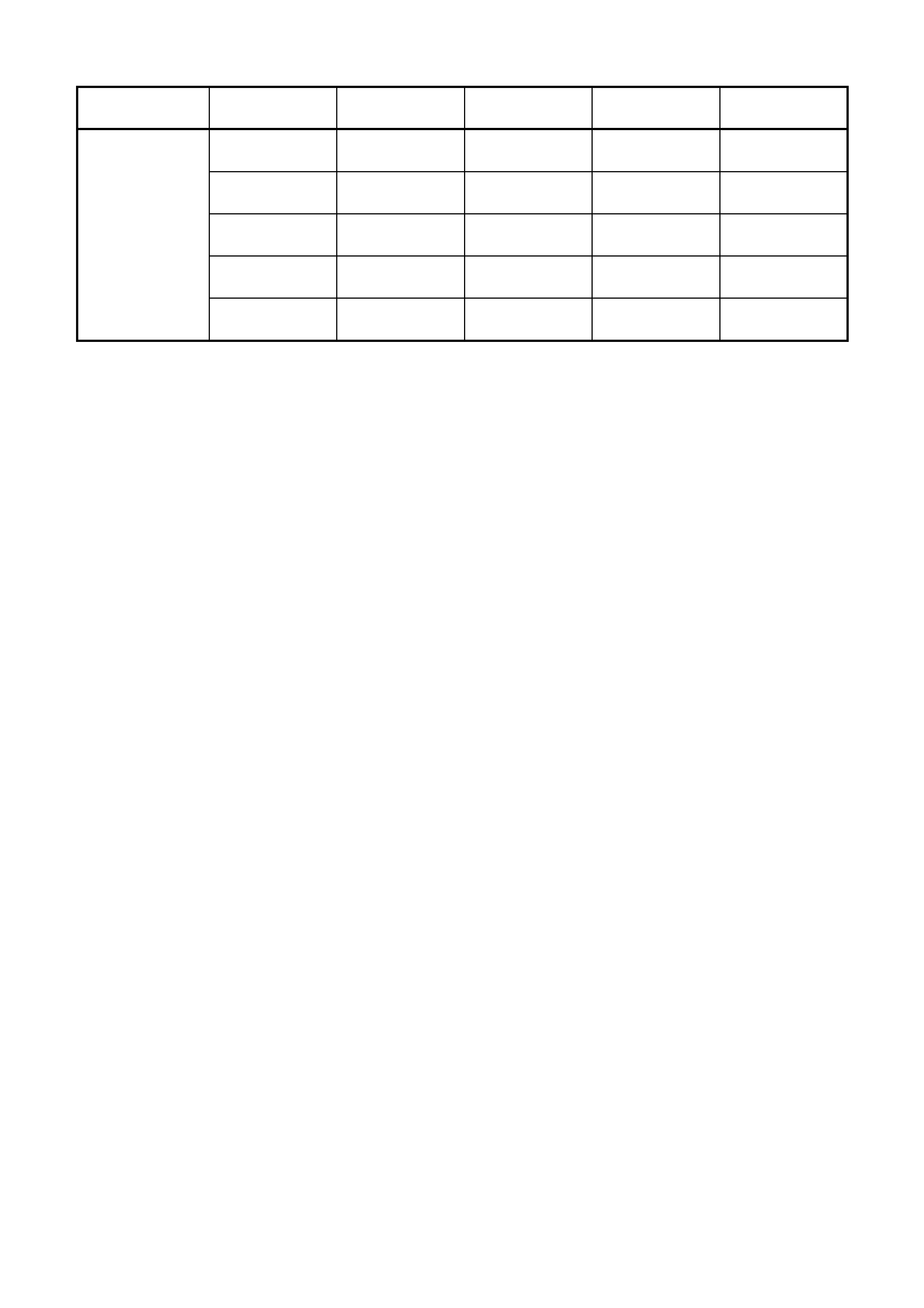

2.1 DOMESTIC

BRAND NAME MODEL NAME LUXURY LEVEL

(DESCRIPTION) MODEL NO. BODY STYLE

(DOORS) ENGINE

(OPTION)

8VK69 Sedan (4)

V6, (V6 S/C),

(V8)

Executive Level 1

(Base) 8VK35 Wagon (5) V6, (V8)

8VK69 Sedan (4) V6

Acclaim Level 1

(Safety / family) 8VK35 Wagon (5) V6, (V8)

S Level 1

(Base sport) 8VK69 Sedan (4) V6, (V6 S/C)

SV8 Level1

(Base sport) 8VK69 Sedan (4) V8

Holden

Commodore

SS Level 1

(Sport) 8VK69 Sedan (4) V8

— Level 1

(Base) 8VK80 Utility (2) V6

S Level 1

(Base sport) 8VK80 Utility (2) V6, (V8)

Holden Utility

SS Level 1

(Sport) 8VK80 Utility (2) V8

8VL69 Sedan (4)

V6, (V6 S/C),

(V8)

Holden Berlina — Level 2

(Upmarket) 8VL35 Wagon (5)

(V6), V6 S/C,

(V8)

Holden Calais — Level 3

(Luxury sport) 8VX69 Sedan (4)

V6, (V6 S/C),

(V8)

CV6 Level 1

(Sport) 8VK37 Coupe (2) V6 S/C

Holden Monaro CV8 Level 3

(Luxury sport) 8VX37 Coupe (2) V8

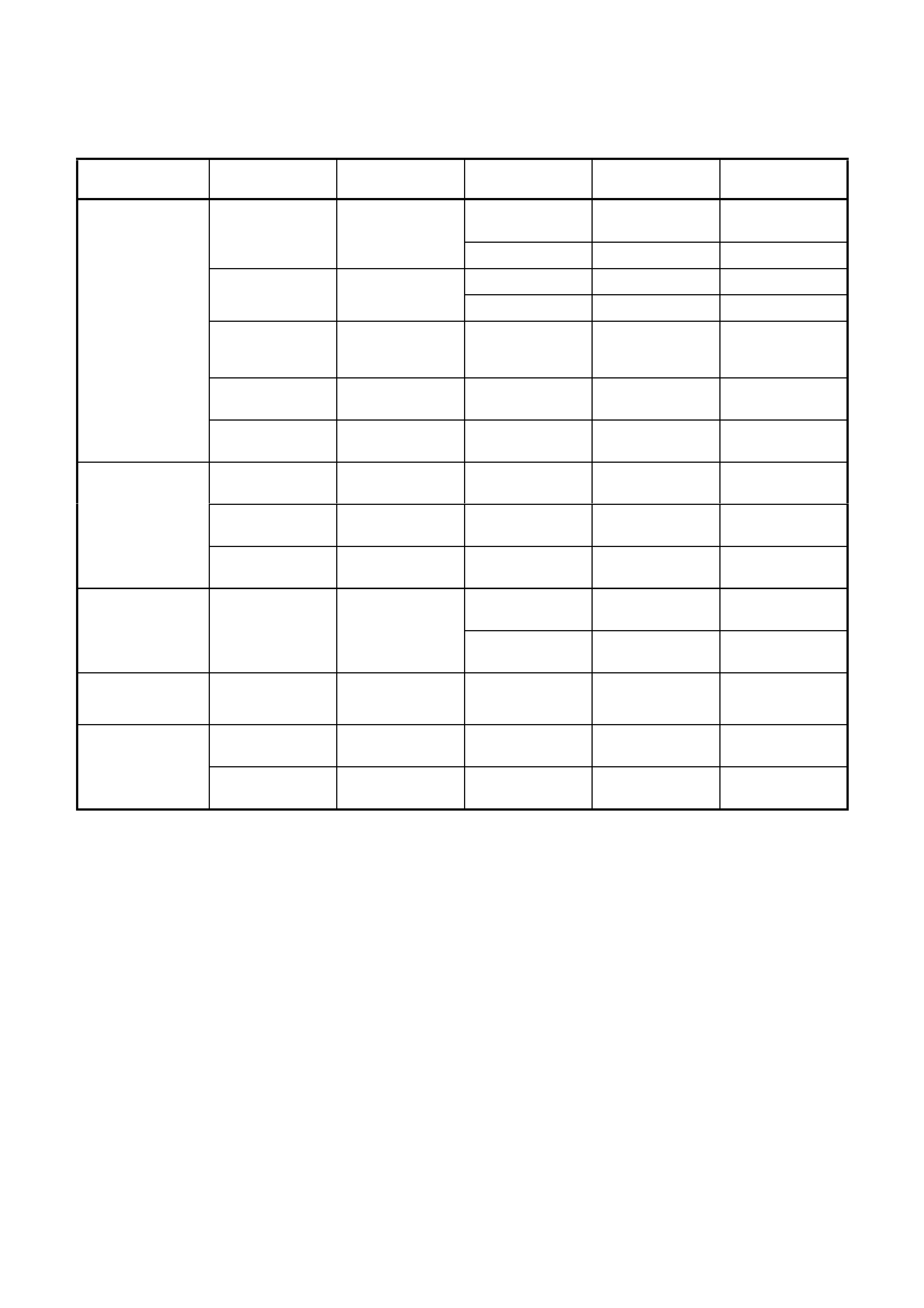

2.2 BRAZIL

BRAND NAME MODEL NAME LUXURY LEVEL

(DESCRIPTION) MODEL NO. BODY STYLE

(DOORS) ENGINE

(OPTION)

Chevrolet Omega CD Level 3

(Luxury) 1VX69 Sedan (4) V6

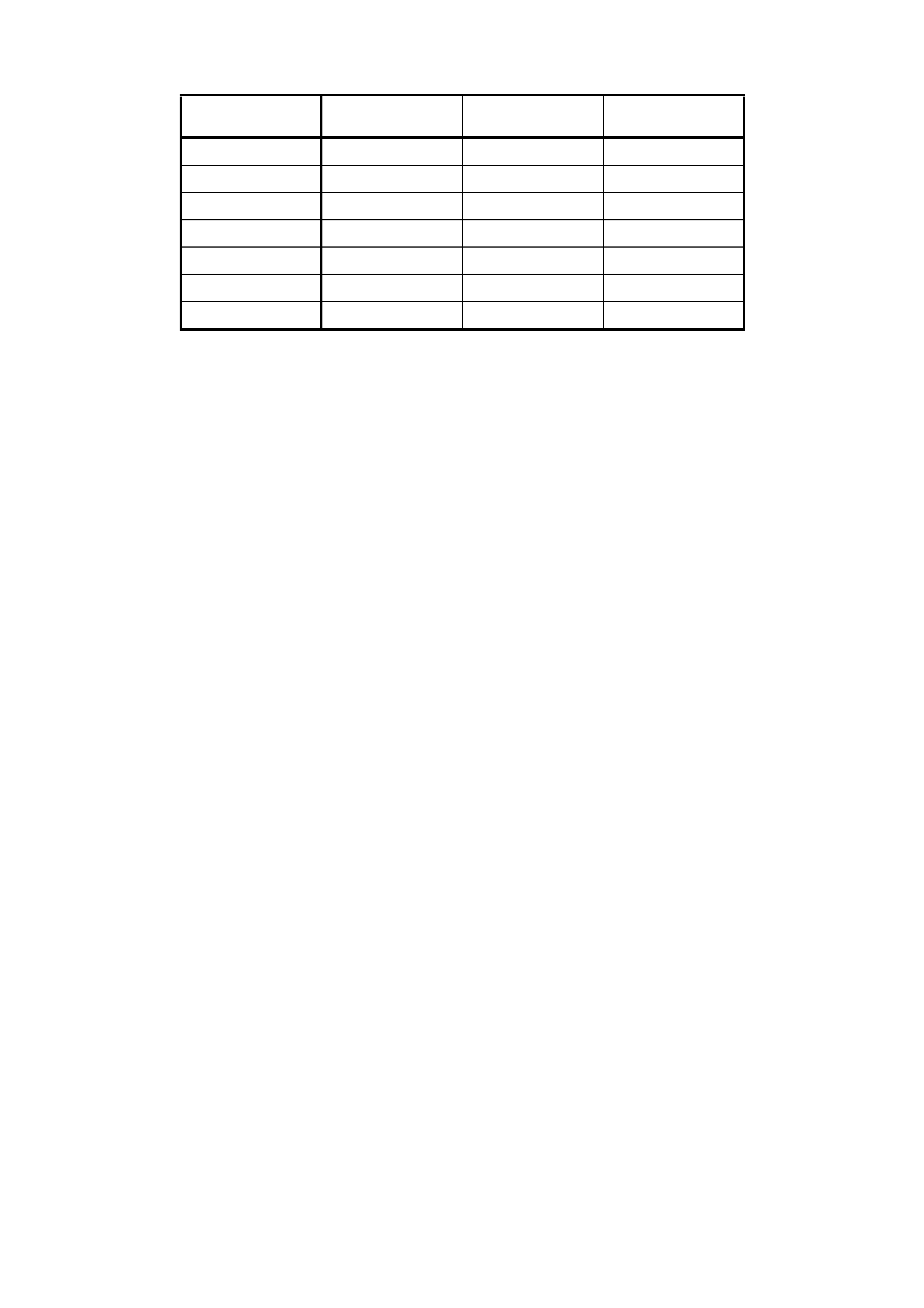

2.3 GULF STATES

BRAND NAME MODEL NAME LUXURY LEVEL

(DESCRIPTION) MODEL NO. BODY STYLE

(DOORS) ENGINE

(OPTION)

1VK69 Sedan (4) V6

LS Level 1

(Base) 1VK35 Wagon (5) V6

LTZ Level 2

(Upmarket) 1VL69 Sedan (4) V6

S Level 1

(Base sport) 1VK69 Sedan (4) V6

SS Level 1

(Sport) 1VK69 Sedan (4) V8

S Level 1

(Sport) 1VK37 Coupe (2) V6

Chevrolet Lumina

SS Level 3

(Luxury sport) 1VX37 Coupe (2) V8

2.4 SO UTH AFRICA

BRAND NAME MODEL NAME LUXURY LEVEL

(DESCRIPTION) MODEL NO. BODY STYLE

(DOORS) ENGINE

(OPTION)

LS Level 1

(Base) 1VK69 Sedan (4) V6

S Level 1

(Base sport) 1VK69 Sedan (4) V6

SS Level 1

(Sport) 1VK69 Sedan (4) V8

LTZ Level 2

(Upmarket) 1VL69 Sedan (4) V6

Chevrolet Lumina

SS Level 1

(Sport) 1VK80 Utility (2) V8

3. M AJOR OPTION CODES

OPTION CODE DESCRIPTION OPTION CODE DESCRIPTION

9C1 Police options pack KL7 LPG

9C3 Police options pack, LHD L67 Engine, 3.8 V6 supercharged

A8V Police options Pack, SS LN3 Engine, 3.8 V6

A9D S vehicles LS1 Engine, 5.7 GEN III V8

A9E SV8 vehicles M30 Transmission, 4 speed automatic

A9F SS vehicles M35 Transmission, 5 speed manual

C60 HVAC manual control MM6 Transmission, 6 speed manual

C61 HVAC automatic control (ECC) NC6 Performance exhaust, V8

CJ2 HVAC dual zone NW9 Traction control (with ABS)

FE1 Suspension, soft ride UY4 Navigation system

FE2 Suspension, sports CF5 Sunroof, Holden By Design

FR1 Suspension, country pack CC5 Sunroof

G80 Differential (LSD) T82 Headlamps-on

JL9 Anti-lock brake system (ABS) UE1 Telematics

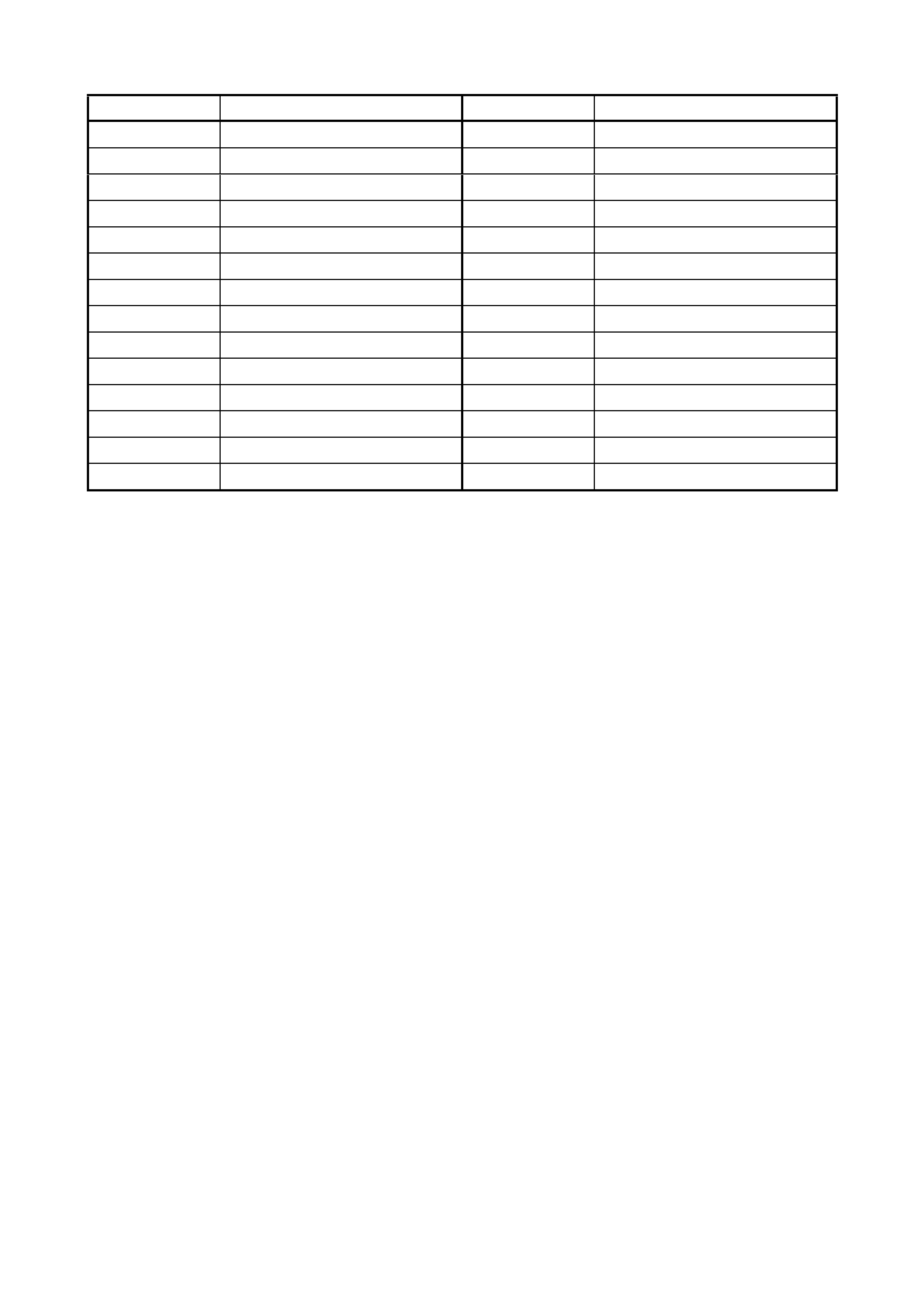

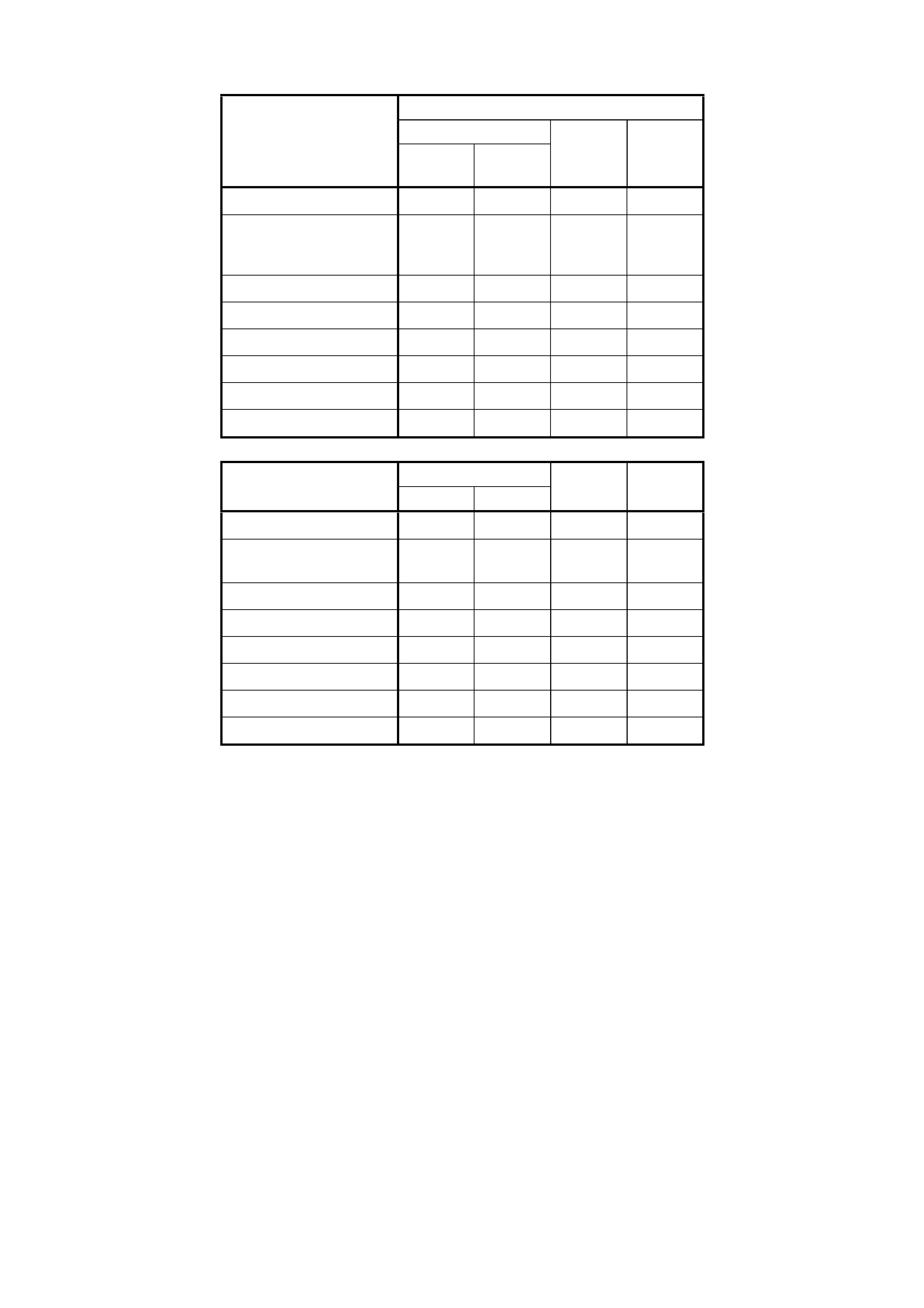

4. POWERTRAIN COMBINATIONS

ENGINE TRANSMISSION

TYPE FIRST GEAR

RATIO RE AR AXLE RATIO

5 Speed Manual 3.83:1 3.08:1

V6

3.8 LITRE PFI 4 Speed Automatic 3.06:1 3.08:1

V6

3.8 LITRE PFI

SUPERCHARGED 4 Speed Automatic 3.06:1 3.08:1

4 Speed Automatic 3.06:1 3.08:1 V8

5.7 LITRE PFI

(GEN III) 6 Speed Manual 2.66:1 3.46:1

5. TRANSMISSION RATIOS

4 SPEED

AUTOMATIC 5 SPEED MANUAL 6 SPEED MANUAL

1ST 3.06:1 3.83:1 2.66:1

2ND 1.63:1 2.20:1 1.78:1

3RD 1.00:1 1.40:1 1.30:1

4TH 0.70:1 1.00:1 1.00:1

5TH - 0.81:1 0.74:1

6TH - - 0.50:1

REV 2.29:1 3.46:1 2.90:1

6. ENGINE DATA

ENGINE

DESIGNATION V6 – 3.8 LITRE PFI V6 – 3.8 LITRE

SUPERCHARGED V8 – 5.7 LITRE PFI

(GEN III)

Number of

Cylinders 6 6 8

Piston

Displacement

Nom. - cm3 3791 3791 5667

Compression

Ratio 9.4:1 8.5:1 10.1:1

Bore x Stroke -

mm 96.5 x 86.3 96.5 x 86.3 99 x 92

Taxable H.P.

RAC OR SAE 34 34 48.6

Power kW /

Torque Nm

(ECE) 152 / 305 171 / 375

225 / 460 (*1)

235 / 465 (*2)

220 / 446 (*3)

242 / 468 (*4)

*1 Excluding Gulf States

*2 Performance exhaust (excluding Gulf States)

*3 Low output (Gulf States)

*4 High output (Gulf States)

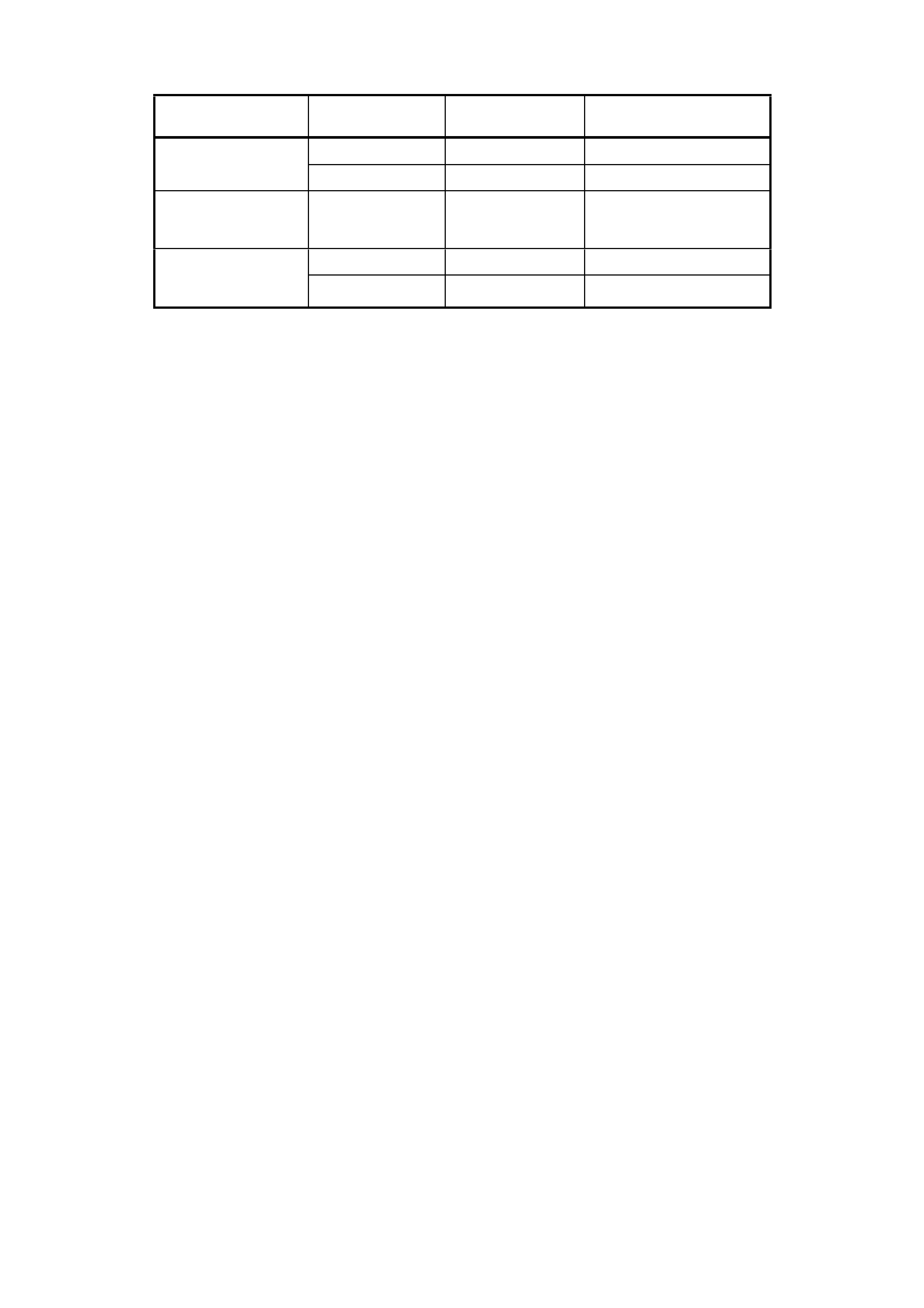

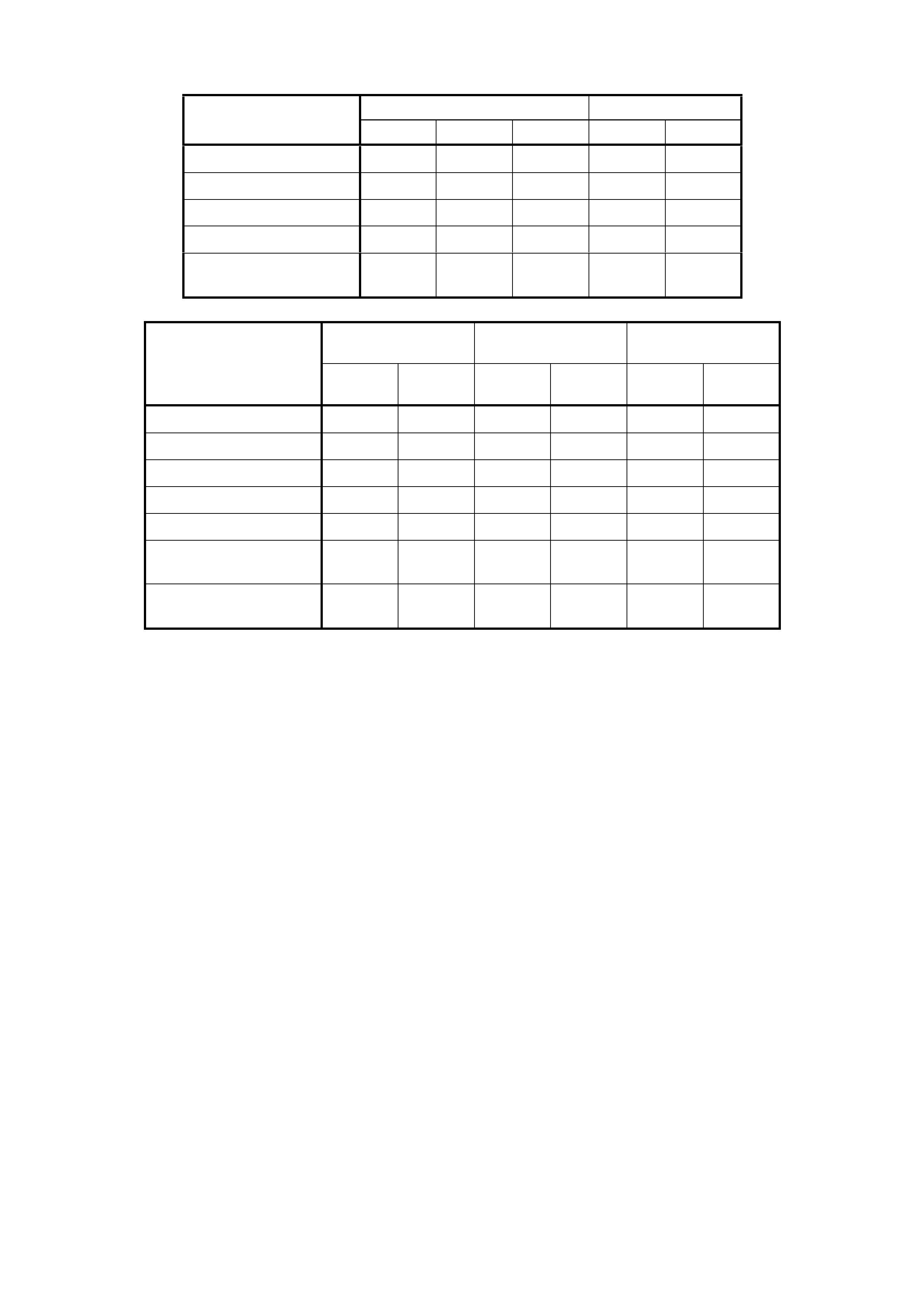

7. EXTERIOR DIM ENSIONS

SEDAN

LEVEL 1

BODY DIMENSIONS Except S

& SS S & SS LEVEL 2 LEVEL 3

VEHICLE LENGTH 4891 4903 4964 4964

VEHICLE WIDTH

(EXCLUDING

MOULDING) 1824 1824 1824 1824

VEHICLE HEIGHT 1425 1425 1425 1425

WHEELBASE 2788 2788 2788 2788

OVERHANG – FRONT 933 943 972 972

OVERHANG REAR 1169 1171 1203 1203

TRACK – FRONT 1569 1569 1569 1569

TRACK - REAR 1587 1587 1587 1587

WAGON BODY

DIMENSIONS LEVEL 1 LEVEL 2 UTILITY COUPE

VEHICLE LENGTH 5046 5084 5049 4802

VEHICLE WIDTH

(EXCL. MOULDING) 1824 1824 1845 1824

VEHICLE HEIGHT 1521 1521 1484 1400

WHEELBASE 2938 2938 2939 2788

OVERHANG – FRONT 933 972 933 943

OVERHANG – REAR 1174 1174 1178 1071

TRACK – FRONT 1569 1569 1569 1569

TRACK – REAR 1587 1587 1587 1587

8. VEHICLE WEIGHTS

SEDAN WAGON

VEHICLE WEIGHTS LEVEL1 LEVEL 2 LEVEL 3 LEVEL 1 LEVEL 2

KERB MASS – V6 1543 1584 1642 1606 1655

KERB MASS – V8 1628 1639 1667 1685 1711

RE AR AXLE LOAD V6 1167 1167 1167 1315 1315

RE AR AXLE LOAD V8 1167 1167 1167 1315 1315

PAYLOA D

(5 Pass. + Cargo) 408 408 408 480 480

UTILITY COUPE

(DOMESTIC) COUPE

(GULF STATES)

VEHICLE WEIGHTS LEVEL 1

(Auto) LEVEL 1

(Manual) LEVEL 1

(Auto) LEVEL 3

(Auto) LEVEL 1

(Manual) LEVEL 1

(Auto)

KERB MASS – V6 1519 1497 — — 1549 1572

KERB MASS – V6 S/C — — 1603 — — —

KERB MASS – V8 1590 1583 — 1652 — 1640

RE AR AXLE LOAD V6 1390 1390 1004 — 1004 —

RE AR AXLE LOAD V8 1390 1390 — 1016 — 1016

PAYLOAD

(4 Pass. + Cargo) — — 326 326 326 326

PAYLOAD

(2 Pass. + Cargo) 790 790 — — — —

NOTE 1: Figures are estimates only for base models and are measured in kilograms.

NOTE 2: Payload figures include luggage, goods, pass engers, roof r ack load and a full tank of fuel.

When towing, the weight on the tow bar ball must also be included.

NOTE 3: Maximum rear axle load is the maximum for all conditions.

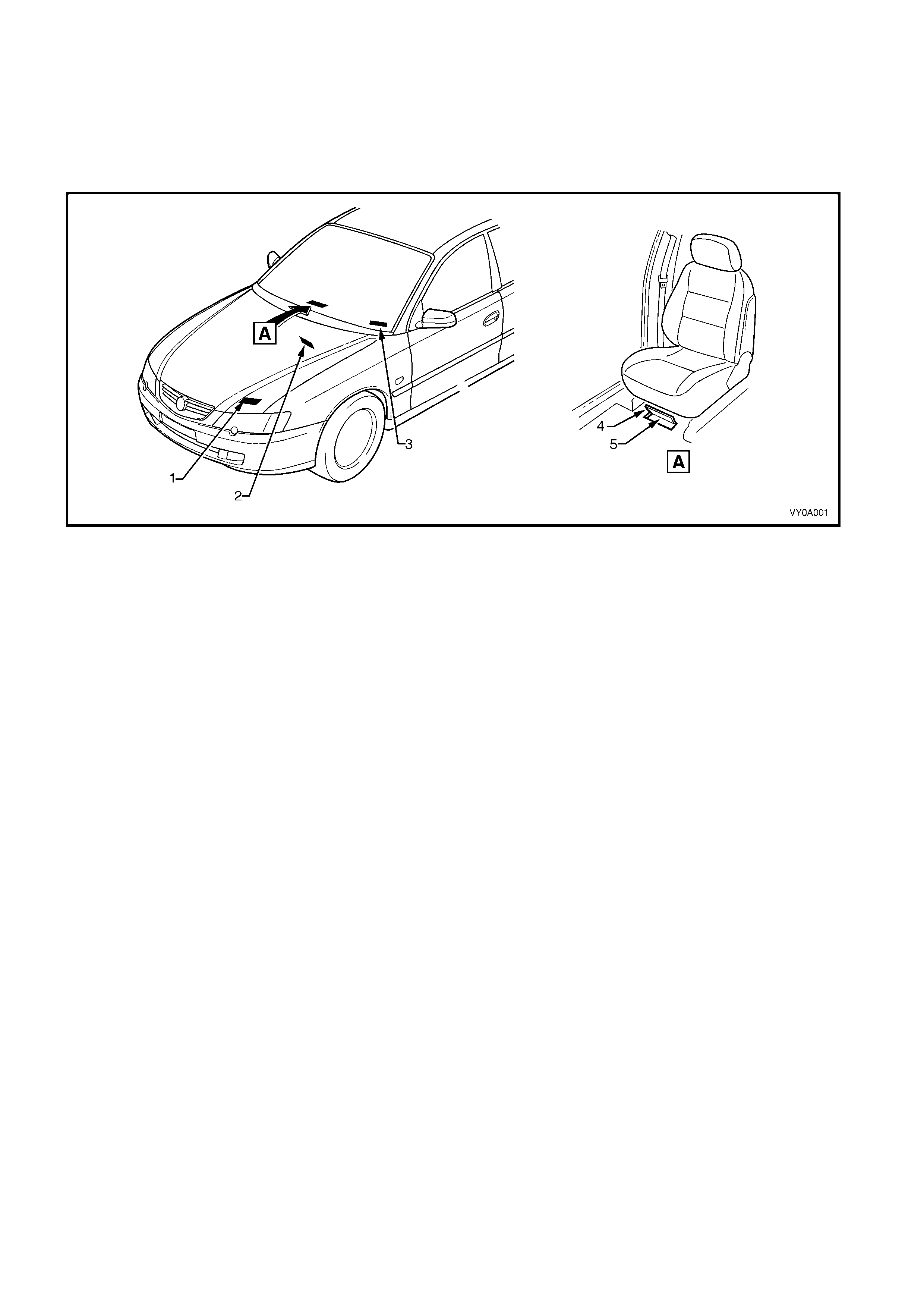

9. SERIAL NUMBERS – DOMESTIC

The com plete vehicle and various components of the vehicle are identified by num ber plates or numbers stamped

into the body. It is essential that when compiling warranty claims or product and field reports, that the Vehicle

Identification Number (VIN) is quoted in conjunction with the identification number of the component affected.

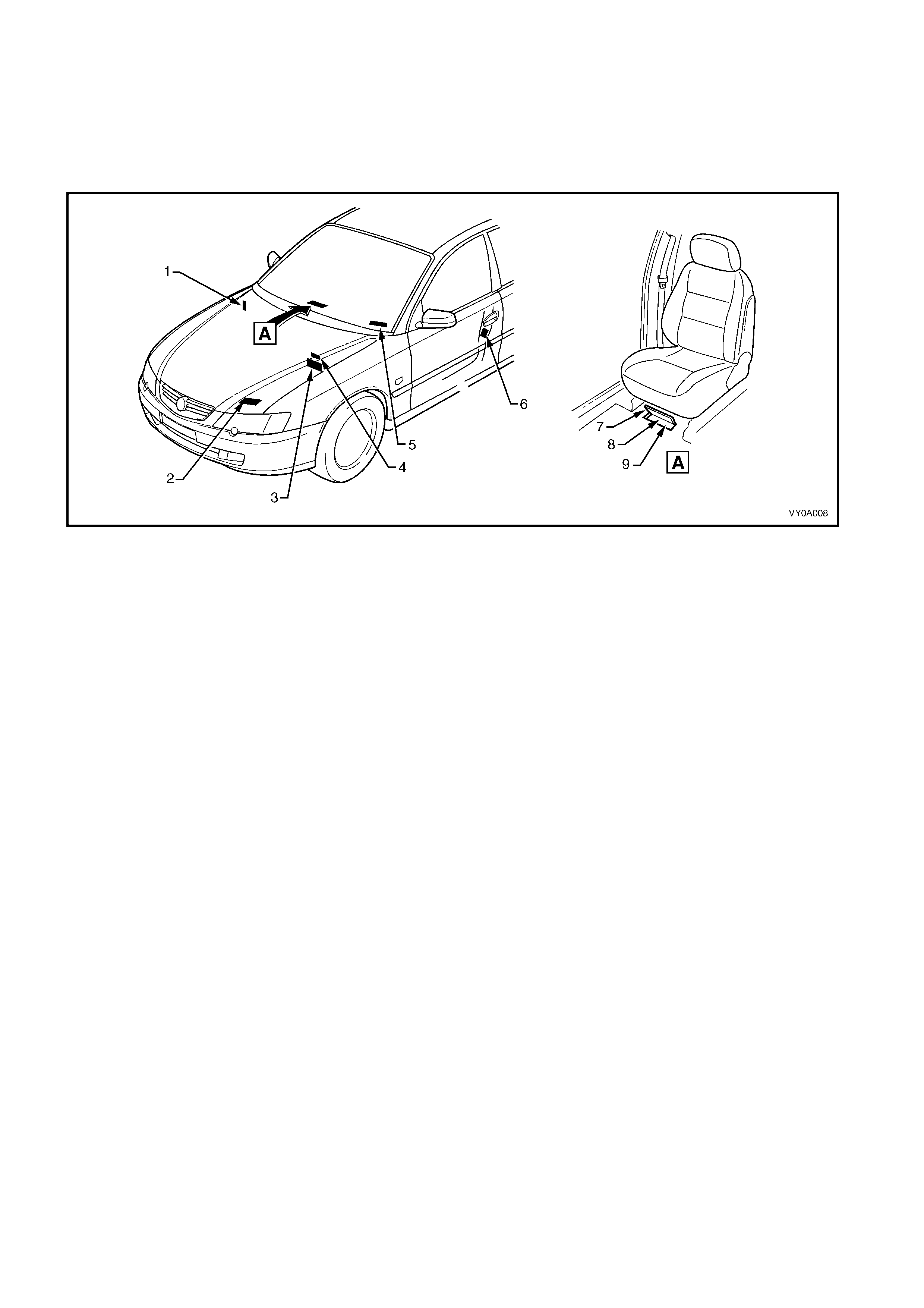

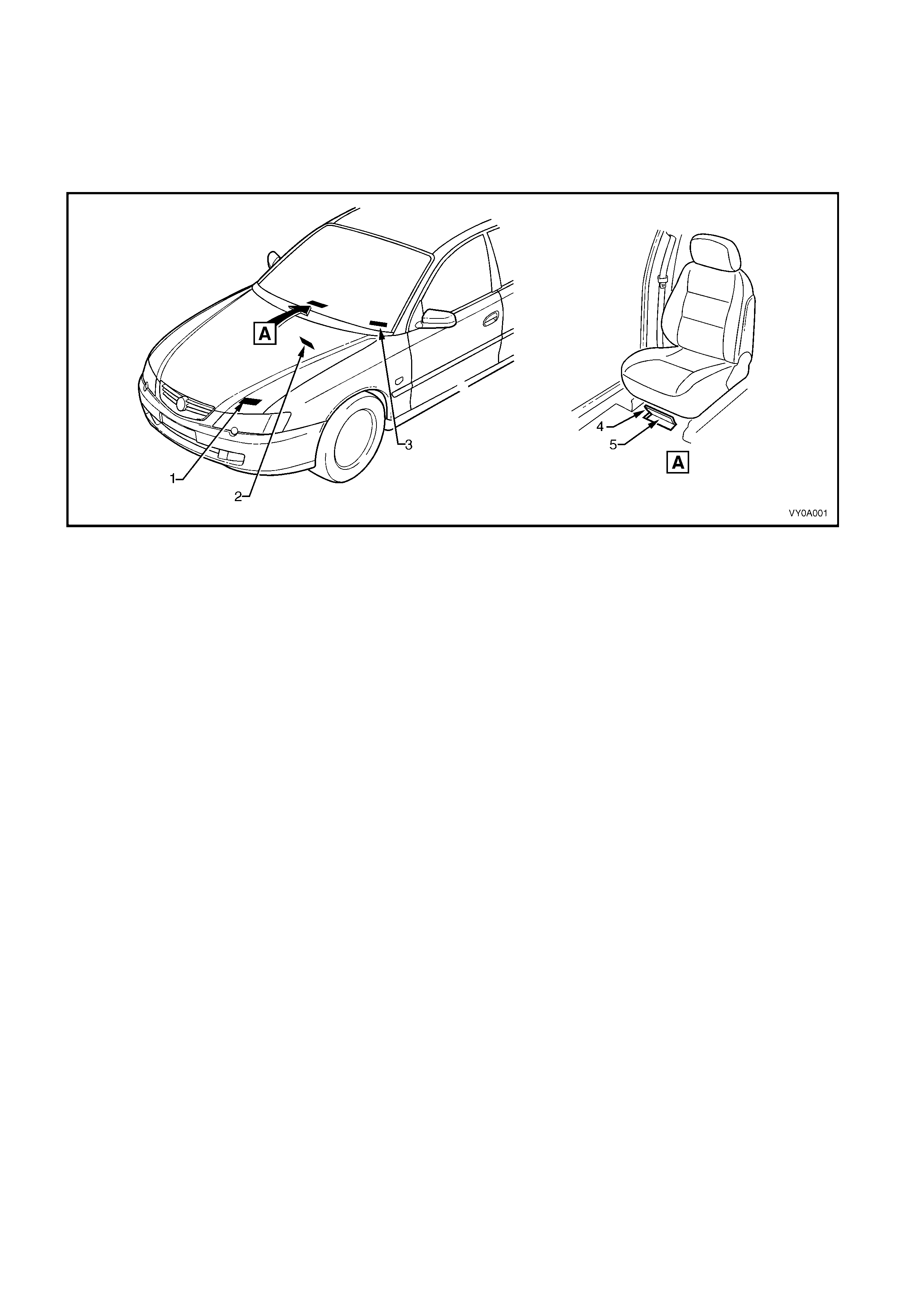

9.1 LOCATION OF IDENTIFICATION PLATES

Figure 0A-2

Legend

1. Body And Option Identification Plate – Left-Hand Side

of the Front Panel Upper

2. Safety Compliance Plate – Dash Panel Assembly

3. Vehicle Identification Number Plate – Under

Windscreen Carpet Flap

4. Vehicle Identification Number – Under Front Seat

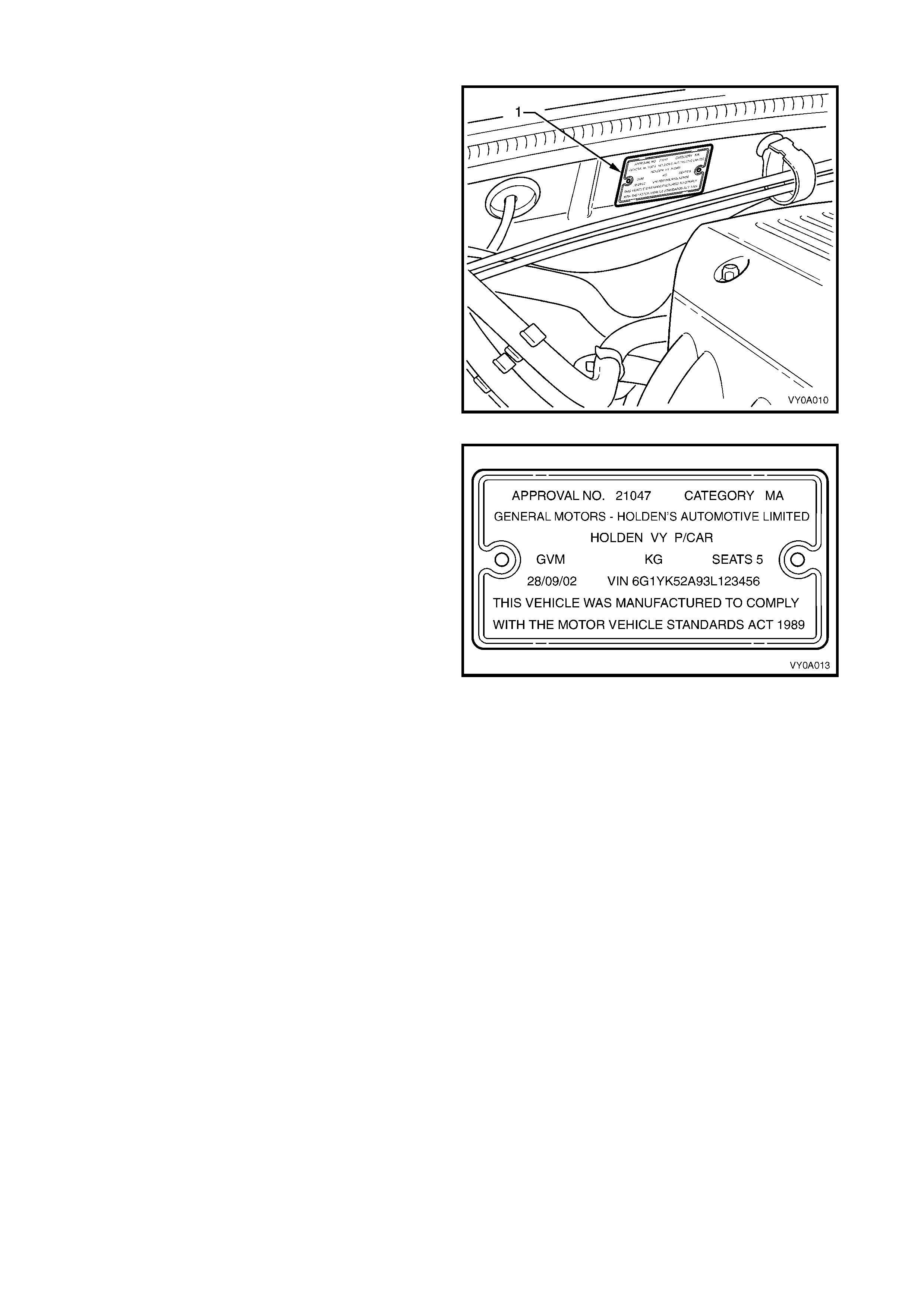

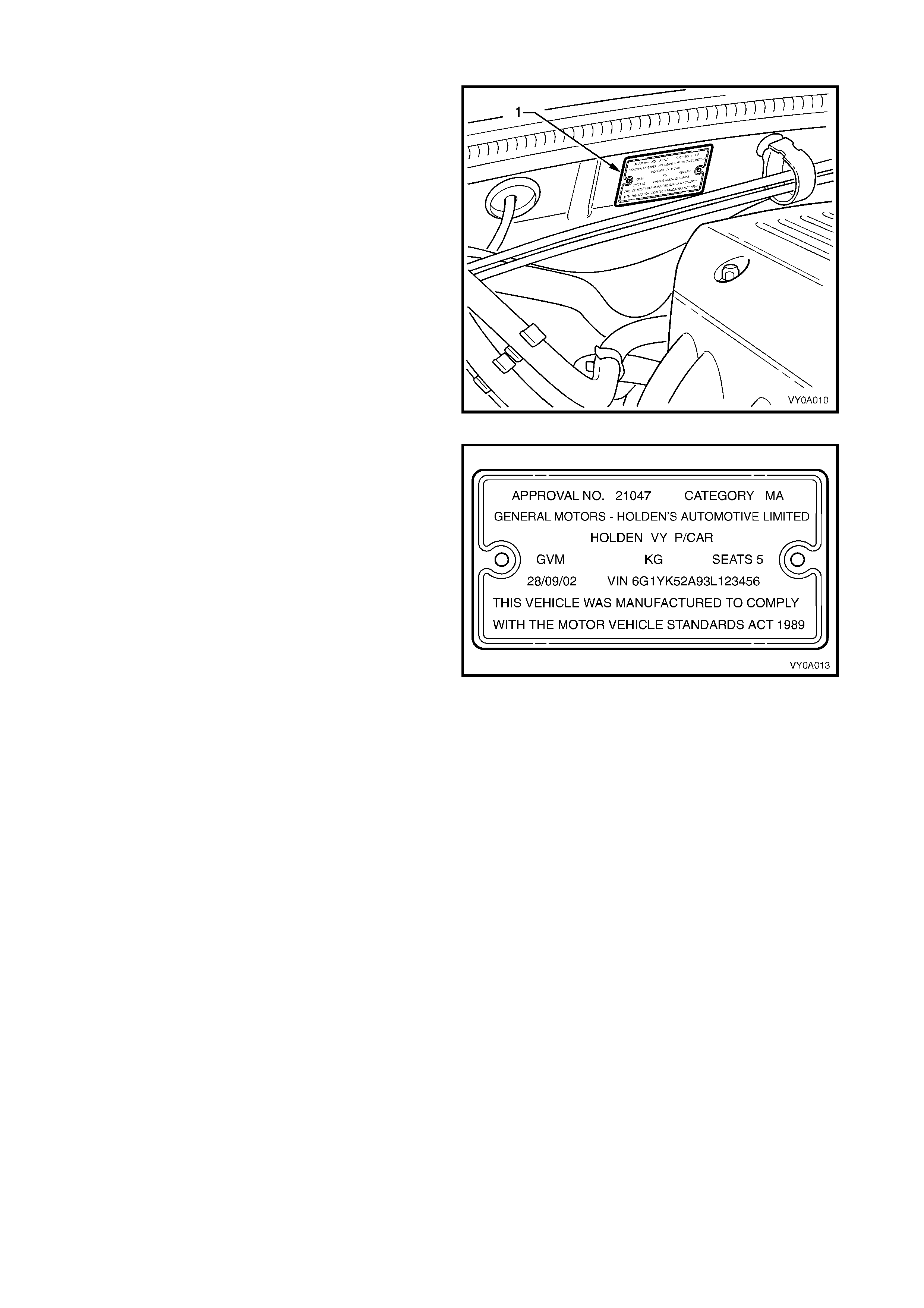

9.2 SAFETY COMPLIANCE PLATE

The safety compliance plate is located on the dash

panel assembly within the engine compartment.

Figure 0A-3

The safety compliance plate is stamped with the

following information:

• Compliance plate approval number.

• Vehicle category code.

• Name appearing on compliance plate approval.

• Make / Model.

• Gross vehicle mass. This is the maximum loaded

mass at which the vehicle complies with the

approved design rules. Not required for passenger

vehicles. (Required for utility.)

• Seating capacity.

• Number of adult positions for which seat belts are

provided.

• Date of manufacture.

• The day, month and year that the vehicle is

manufactured.

• Vehicle Identification Number (VIN).

Figure 0A-4

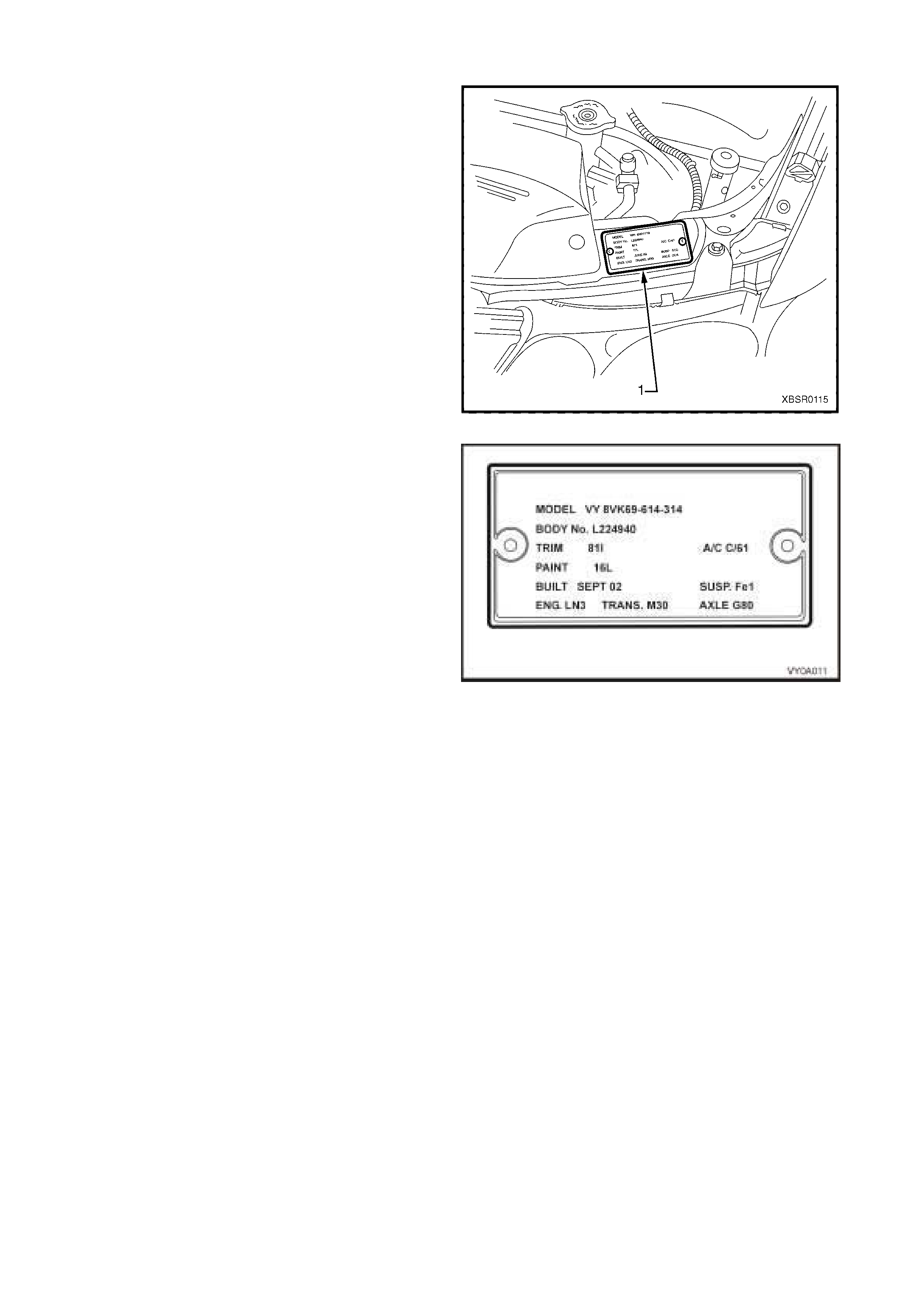

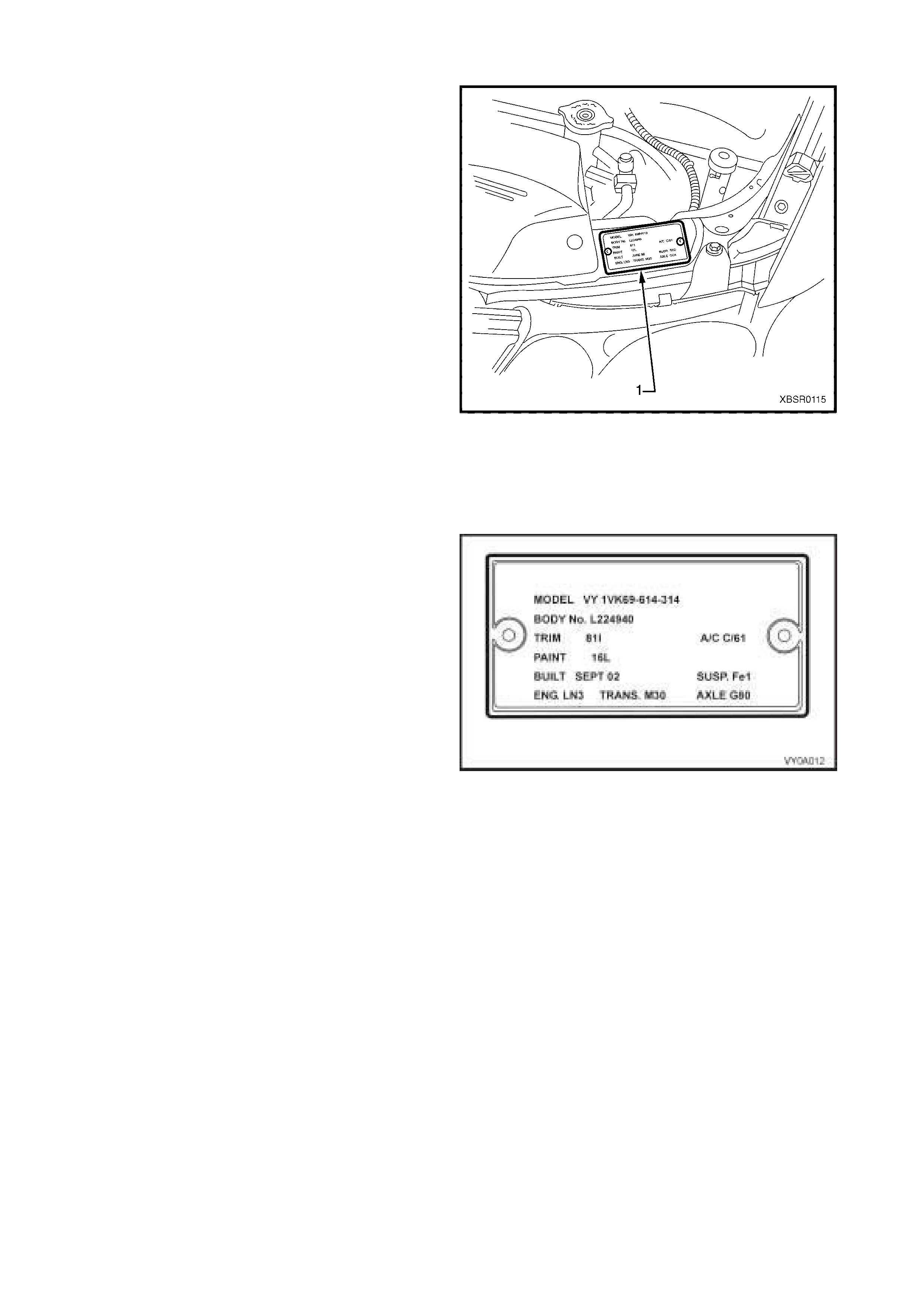

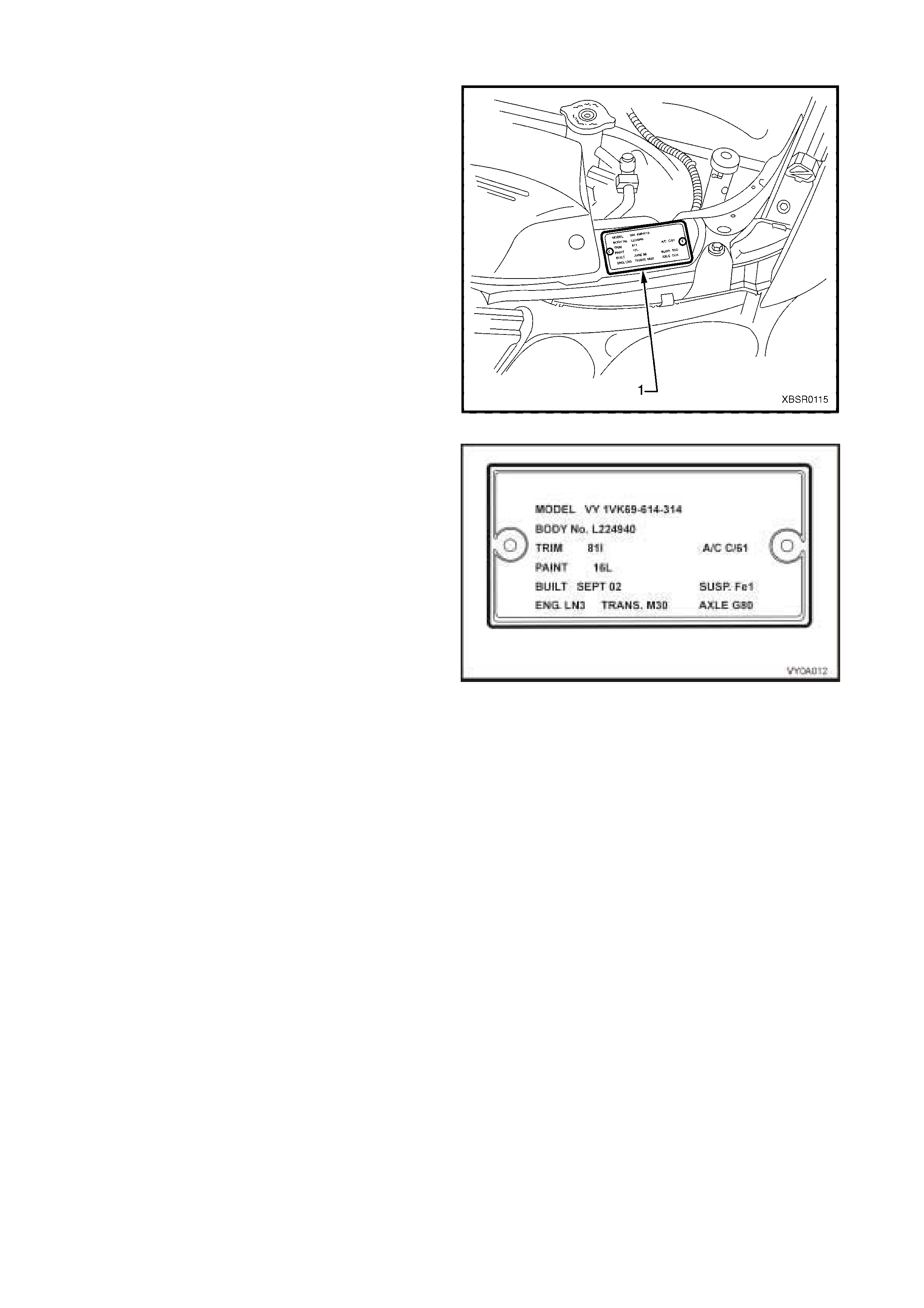

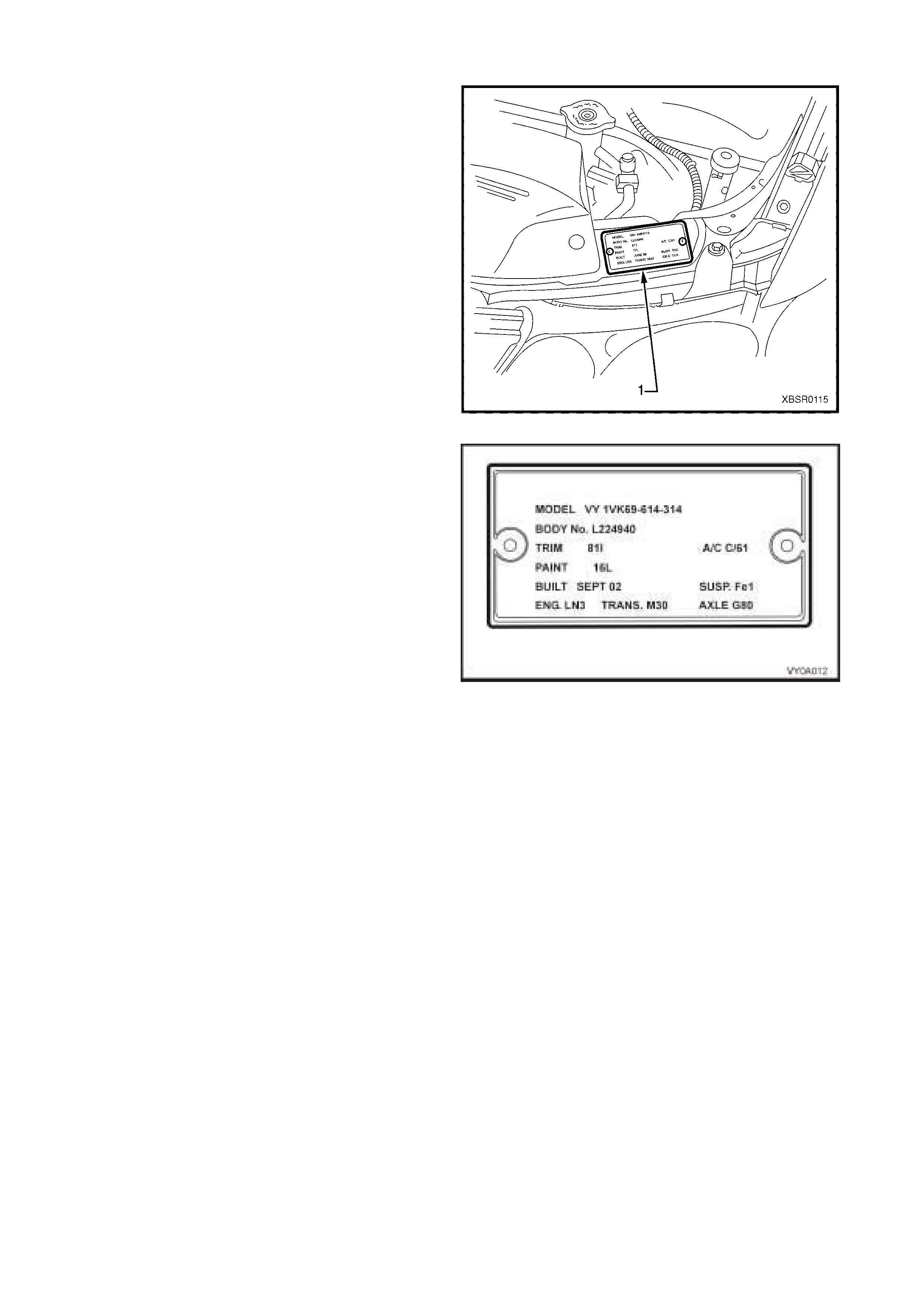

9.3 BODY AND OPTION IDENTIFICATION PLATE

The Body and Option Identification Plate (1) is located

on the front panel assembly and is stamped with the

following information.

Model

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

A listing of production and smart pack option numbers

can be found by referring to the latest spare parts

information for the applicable model.

Body

Production build number; run in continuous sequence

regardless of model, body type and series.

Trim

Trim combination.

Paint

Exterior paint material and colour identification.

Built

The date of manufacture by calendar month and year

in which the body shell and power train are conjoined

and the vehicle is driven or moved from the produc tion

line.

Susp

Suspension option code identification.

FE1 identifies vehicles with standard suspension.

FE2 identifies vehicles with sport suspension.

Engine, Transmission and Axle.

Identification option codes for specific engine,

transmission and rear axle.

A/C

C60 identifies vehicles fitted with air conditioning.

C61 Identifies vehicles fitted with automatic climate

control air conditioning.

Figure 0A-5

Figure 0A-6

9.4 VEHICLE IDENTIFICATION NUMBER

The Vehicle Identif ication Num bering (VIN) system is based on the unif orm Car Model Des ignation Sys tem . T his

identifies the vehicle in one coded series of characters.

The Vehicle Identification Number is positioned in the following locations.

1. VIN plate under the windscreen – viewed through the windscreen aperture.

2. Body and option identification plate – left-hand side of the front panel upper.

3. Safety compliance plate – dash panel.

4. Stamping in the front floor panel under the front right-hand seat.

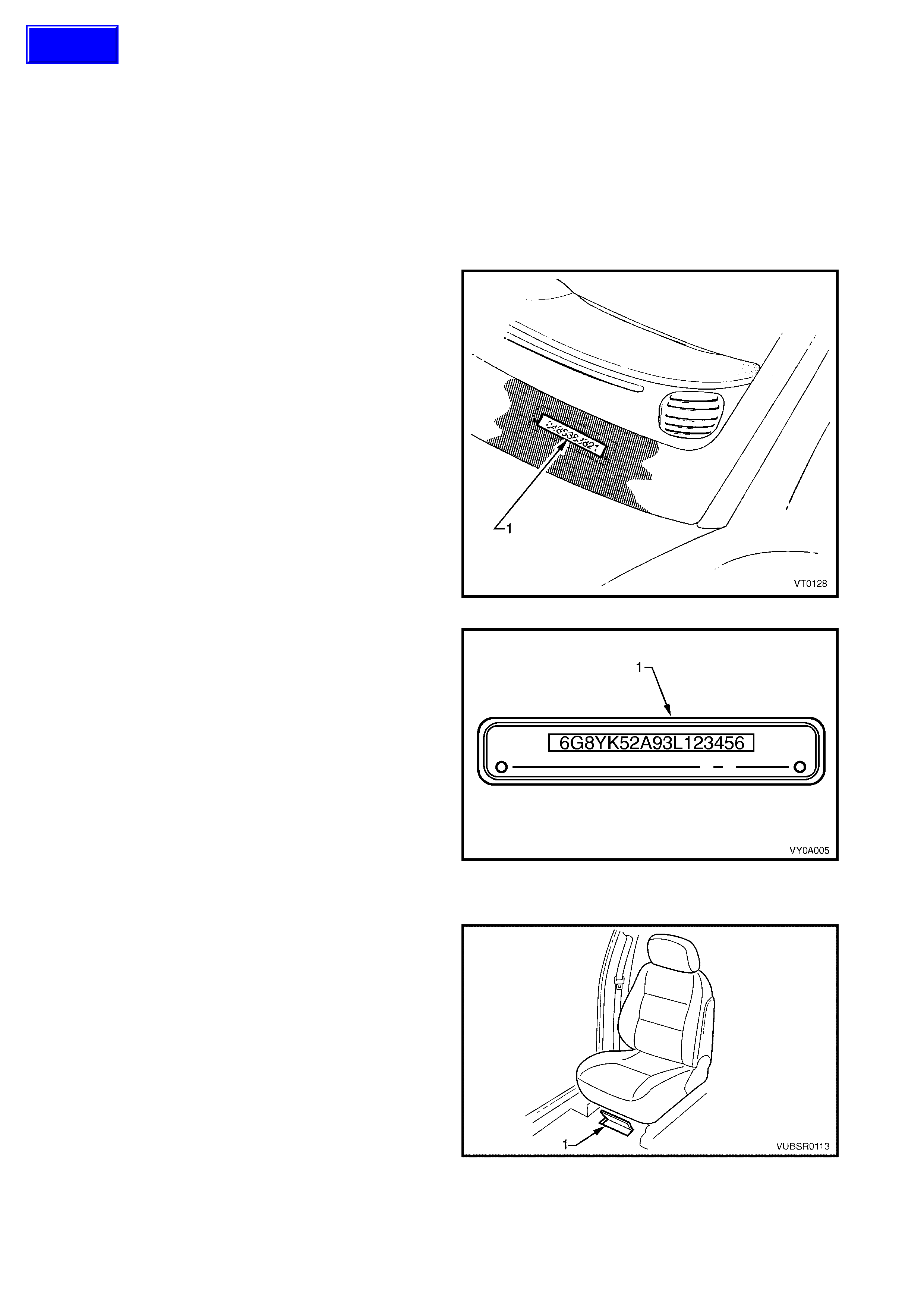

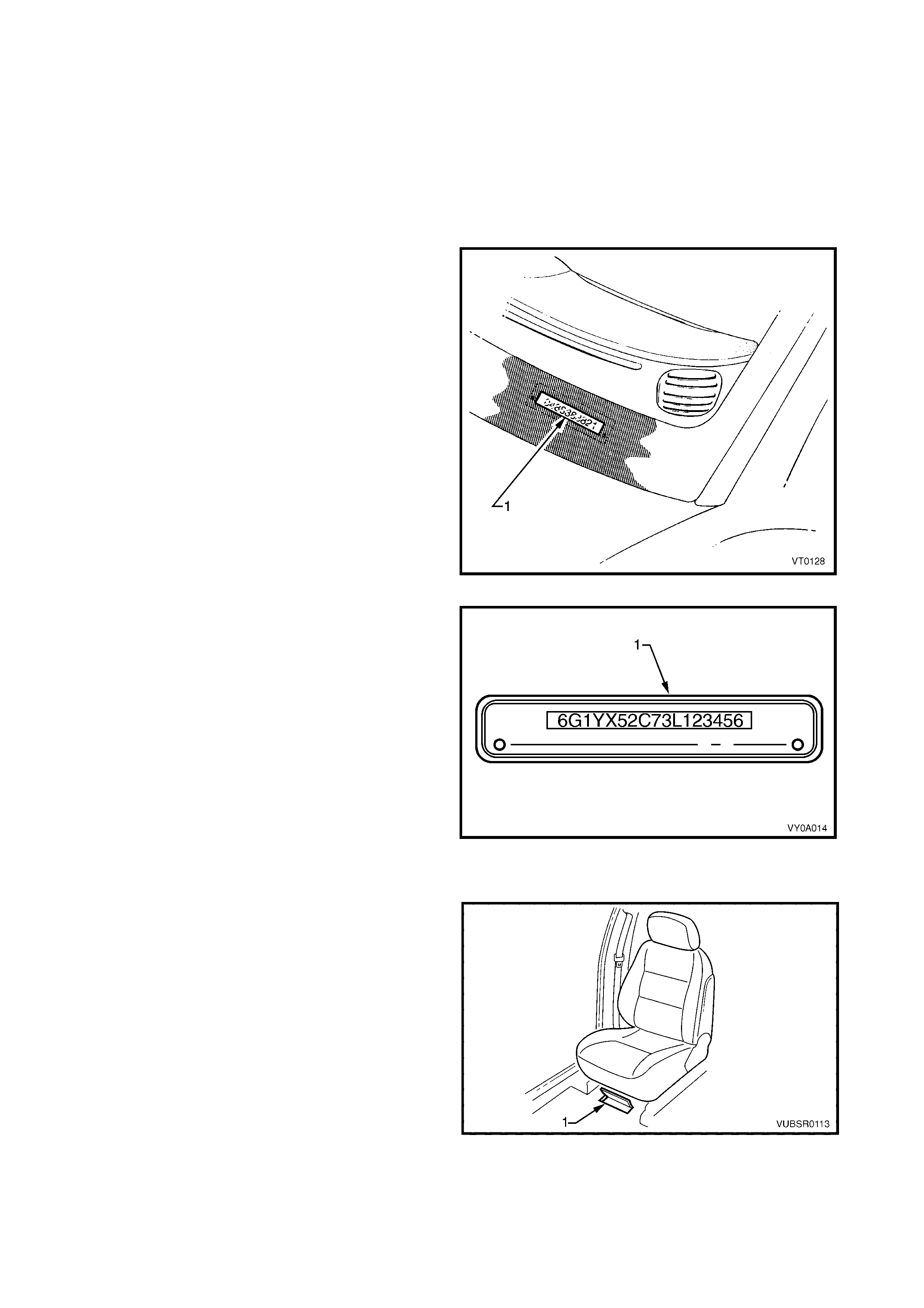

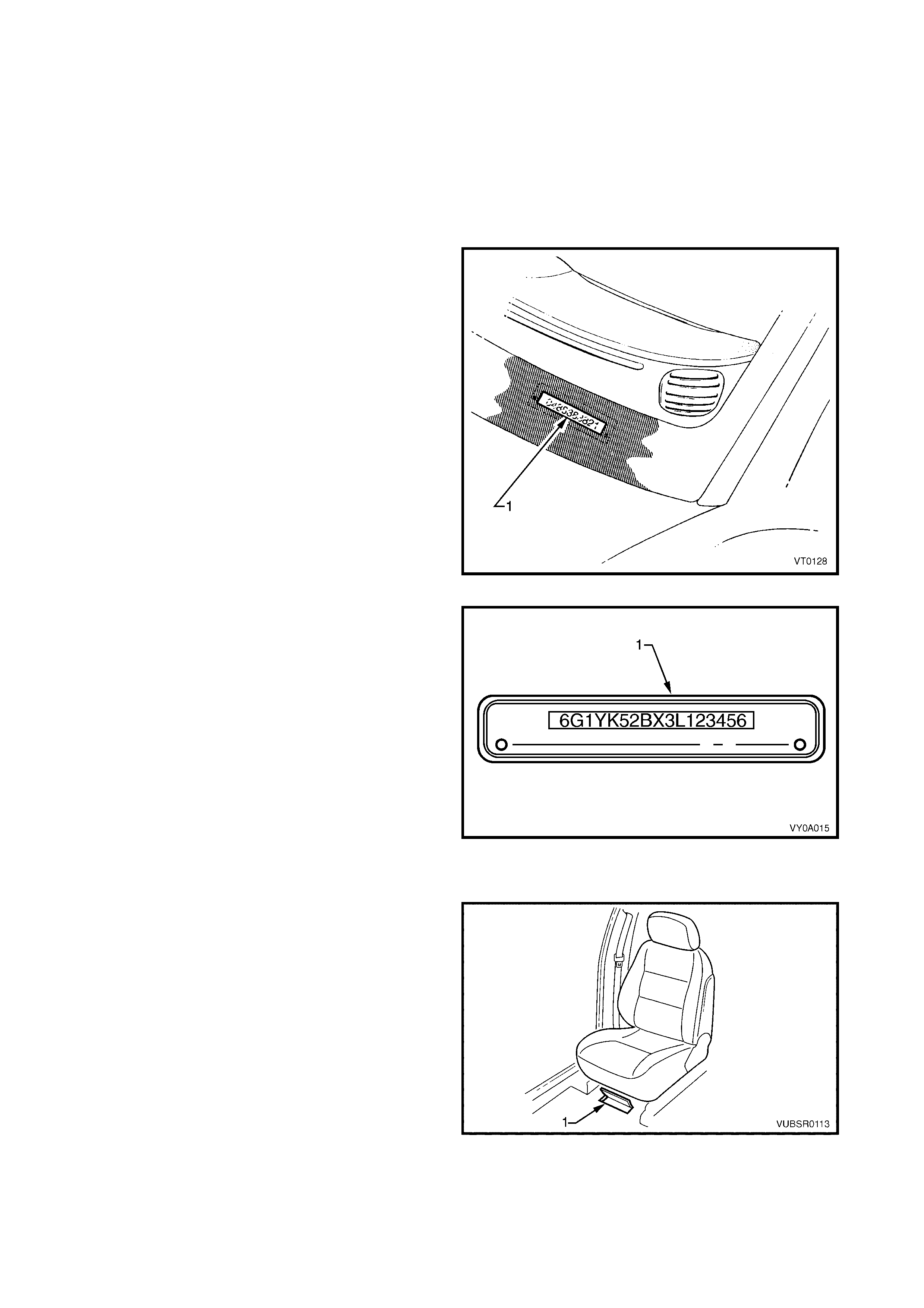

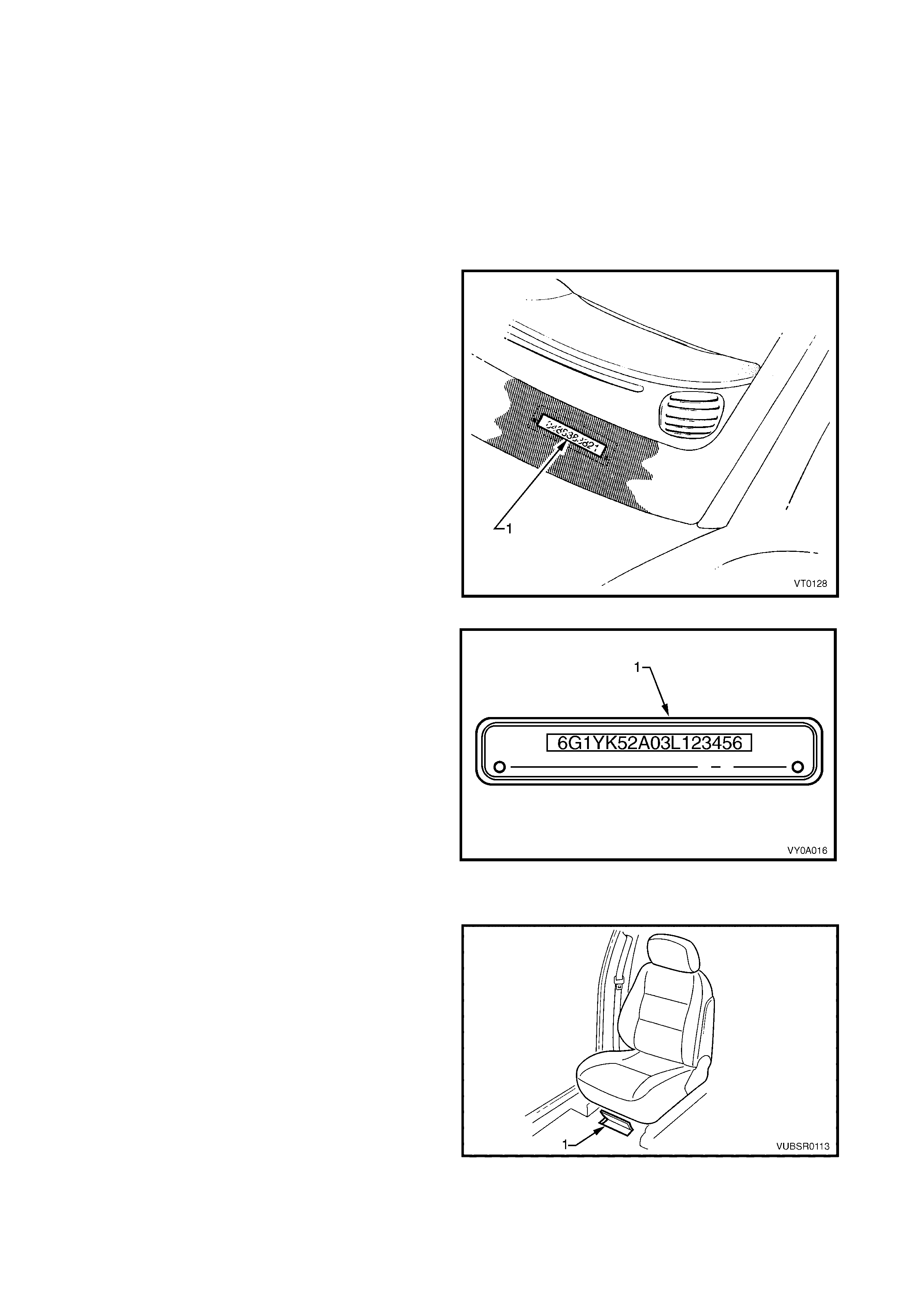

VIN PLATE

The VIN Plate (1) is located under the windscreen and

is viewed through the windscreen aperture.

Figure 0A-7

Figure 0A-8 shows the VIN plate (1) that is located

under the windscreen aperture and is attached to the

dash panel assembly with unique rosette headed

rivets.

Figure 0A-8

VIN BODY STAMPING

The VIN is stam ped into the f ront floor panel under the

right-hand f r ont s eat. The VIN ( 1) is vis ible by lifting the

carpet flap.

NOTE 1: If the front floor panel assembly is to be

replaced, the VIN will be lost. Contact your local Road

Traffic Authority prior to replacing the panel to obtain

the correct procedure for renumbering the vehicle.

NOTE 2: A replacement body shell assembly is

stamped during manufacture with a unique VIN that

identifies it as a replacement part.

NOTE 3: If an error is made to the VIN stamping

during manufacture, it is lined out so that it remains

legible and the correct number is stamped underneath.

Figure 0A-9

Techline

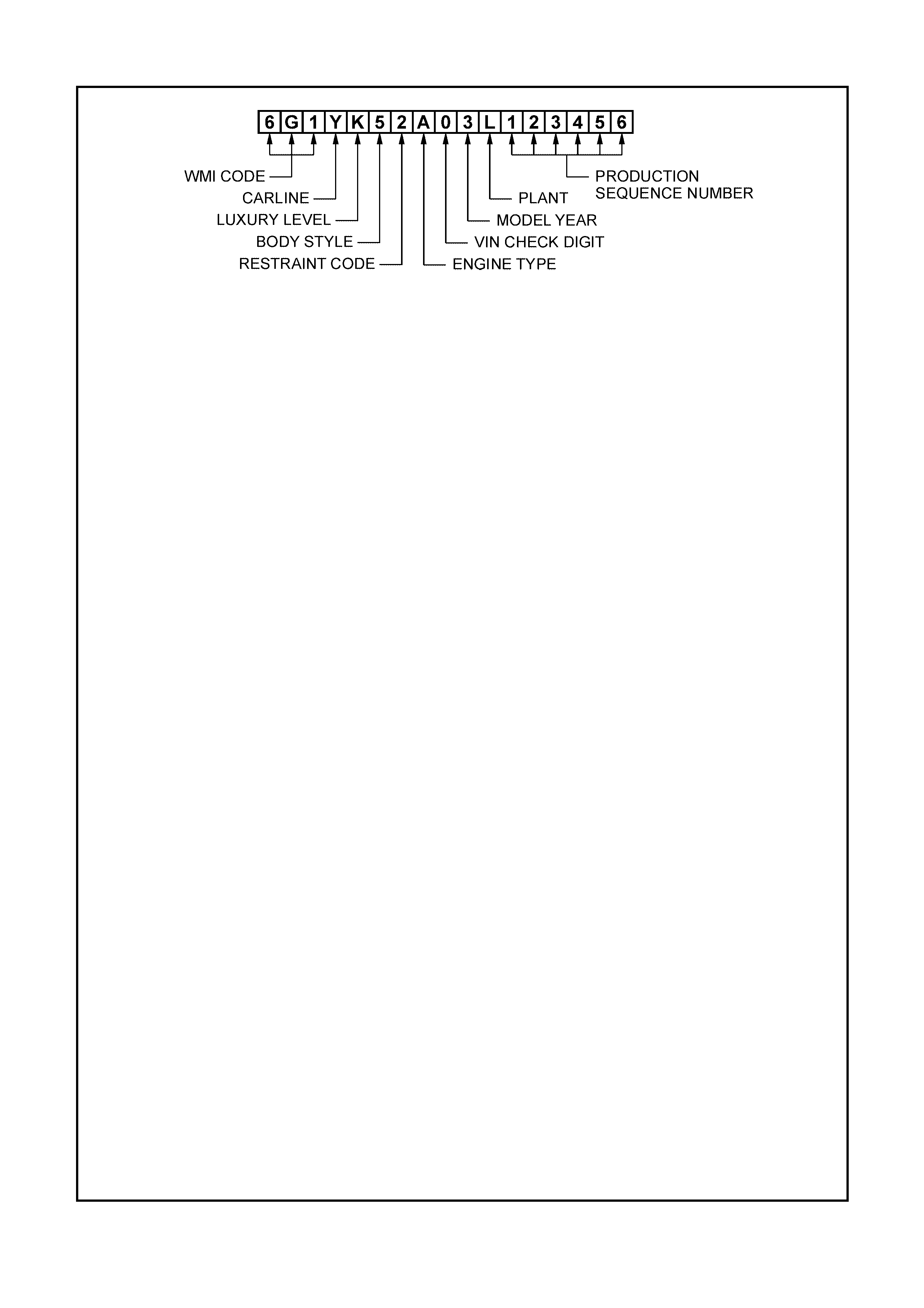

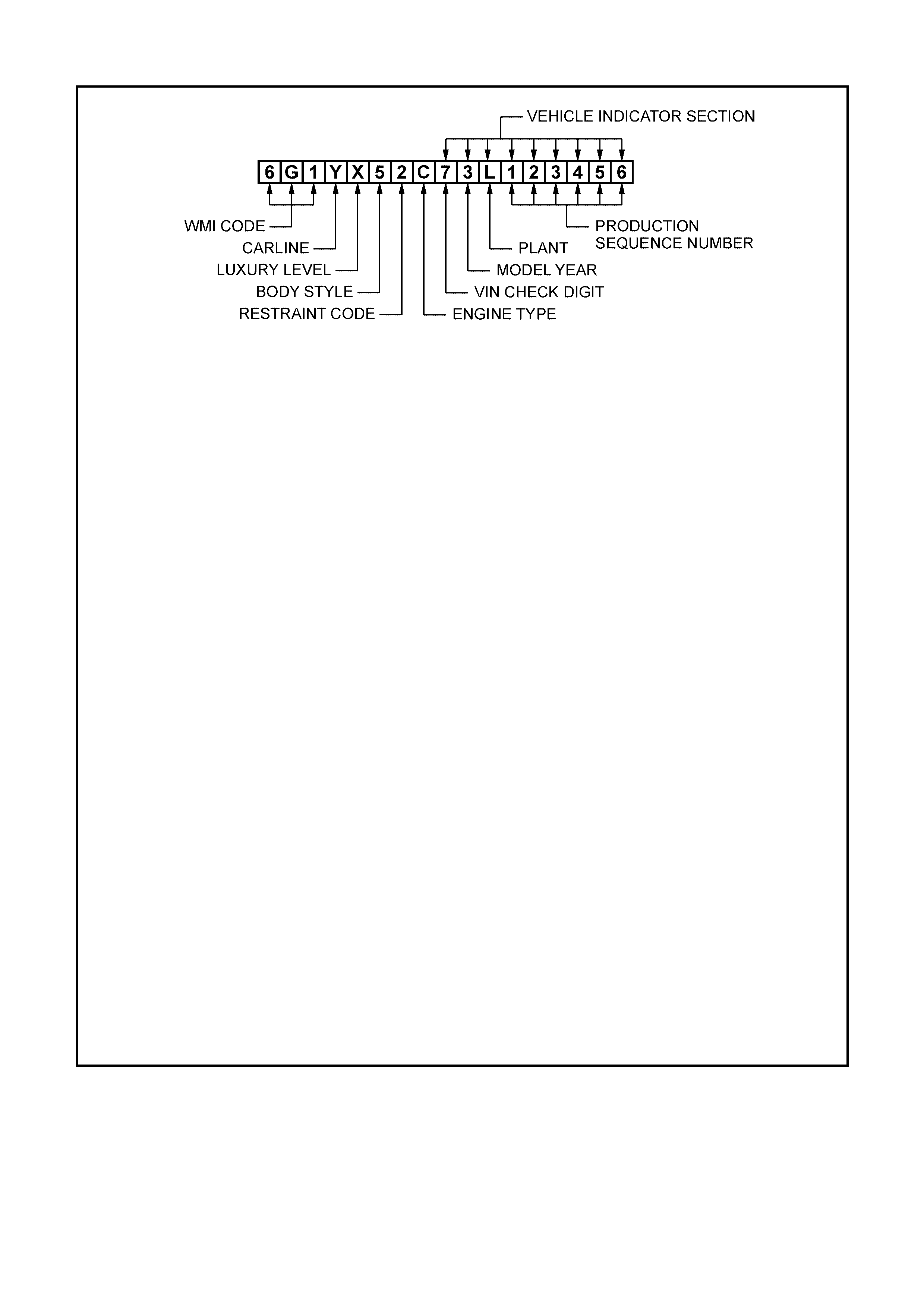

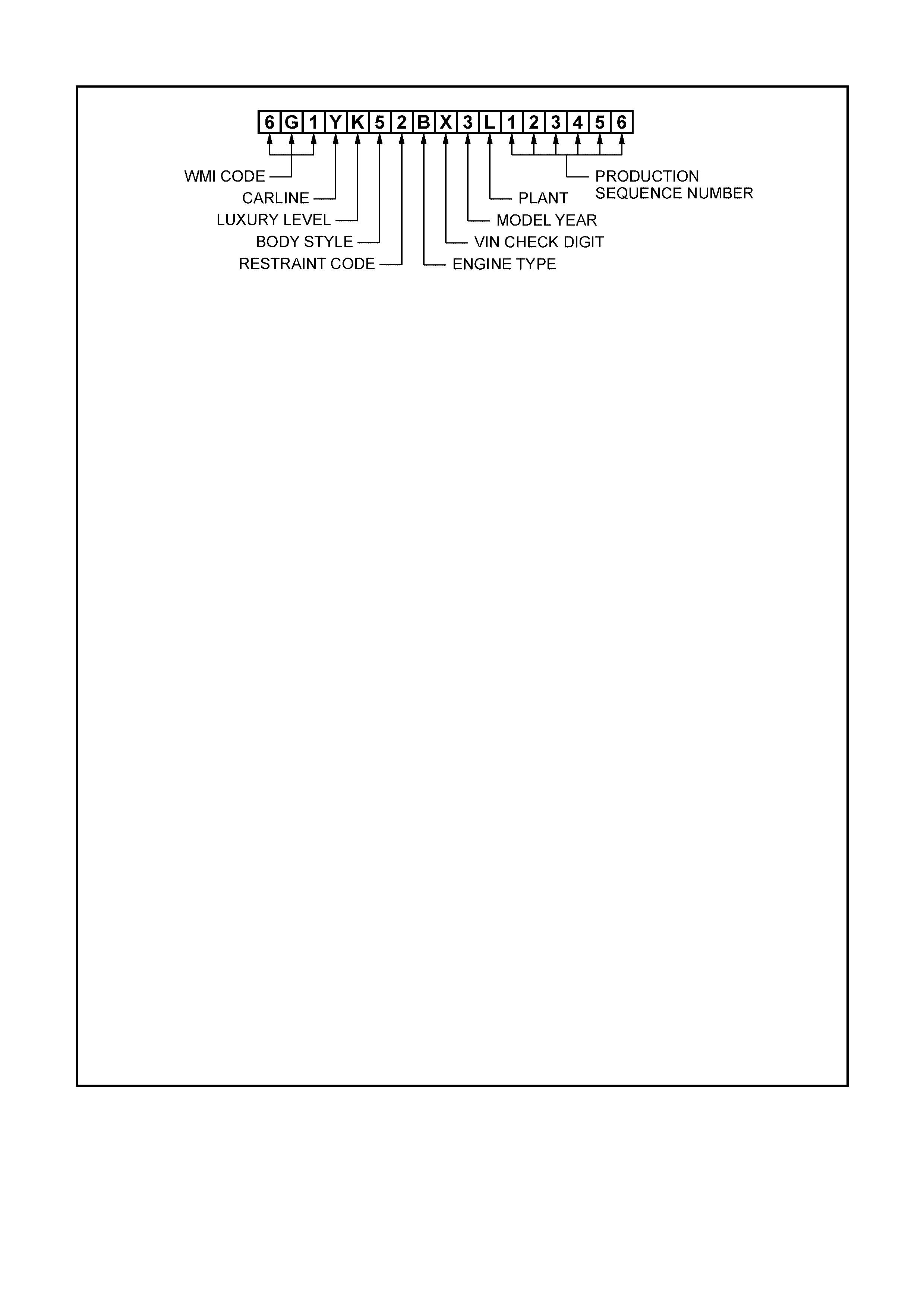

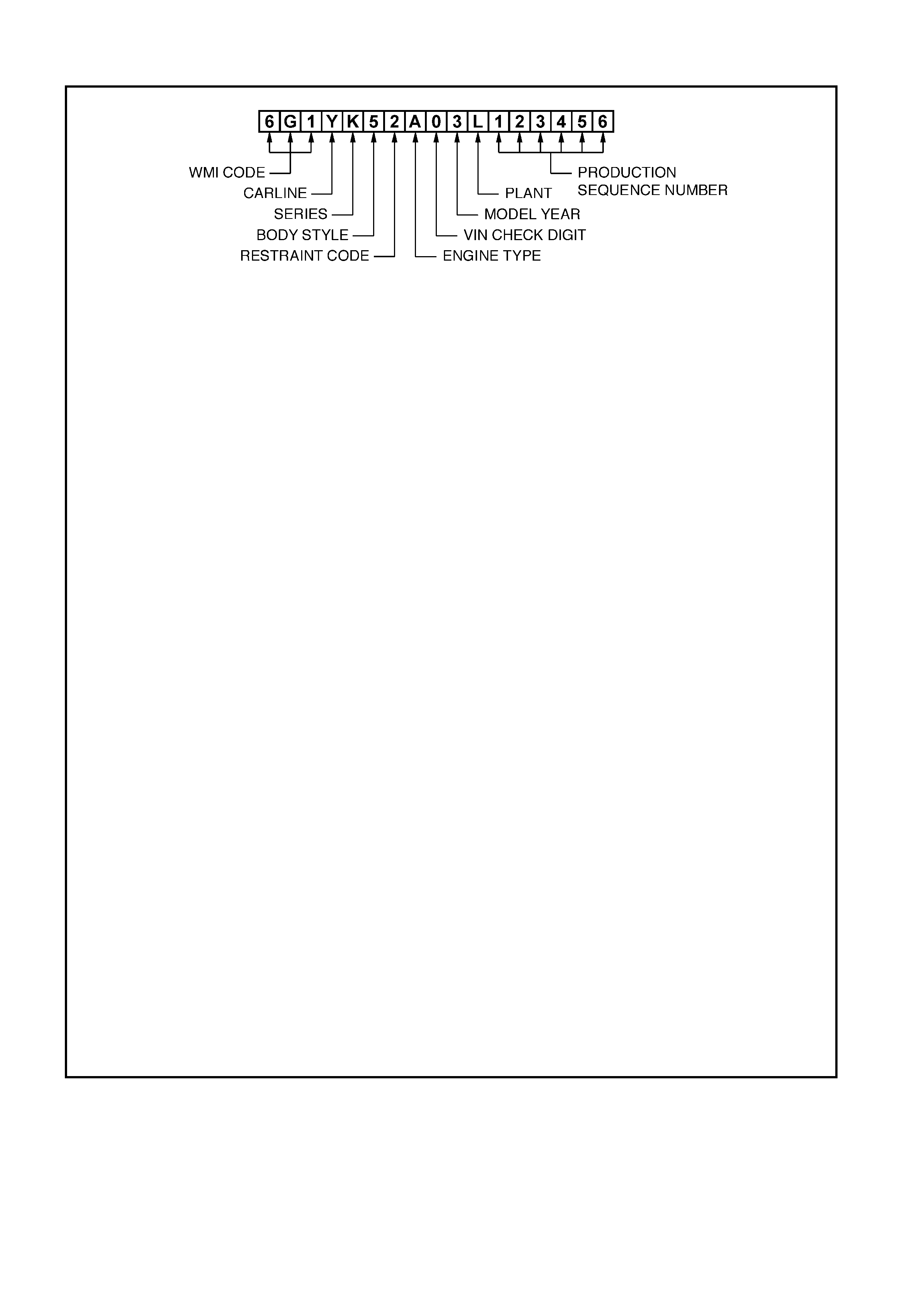

9.5 VEHICLE IDE NTIFICATION NUMBERING SYSTEM

WMI CODE: 6 – Oceania

G – Australia

1 – Holden

CARLINE: Y – VY series

2 – V2

LUXURY LEVEL: K – Level 1

L – Level 2

X – Level 3

BODY STYLE: 1 – 2 door coupe (37)

4 – 2 door utility (80)

5 – 4 door sedan (69)

8 – 5 door station wagon (35)

RESTRAINT CODE: 1 – Active (manual) seat belts

2 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal

3 – Active (manual) seat belts with driver inflatable restraint system – frontal

4 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal and side

ENGINE TYPE: A – 3.8 litre V6 engine (domestic variant)

R – 3.8 litre V6 engine supercharged

F – 5.7 litre GEN III V8 engine

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 3 – 2003

4 – 2004

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUMBER:

123456 – Sequential Production Serial Number

NOTE: The pr oduc tion s equence number is sequentially allocated to each vehicle,

regardless of vehicle type.

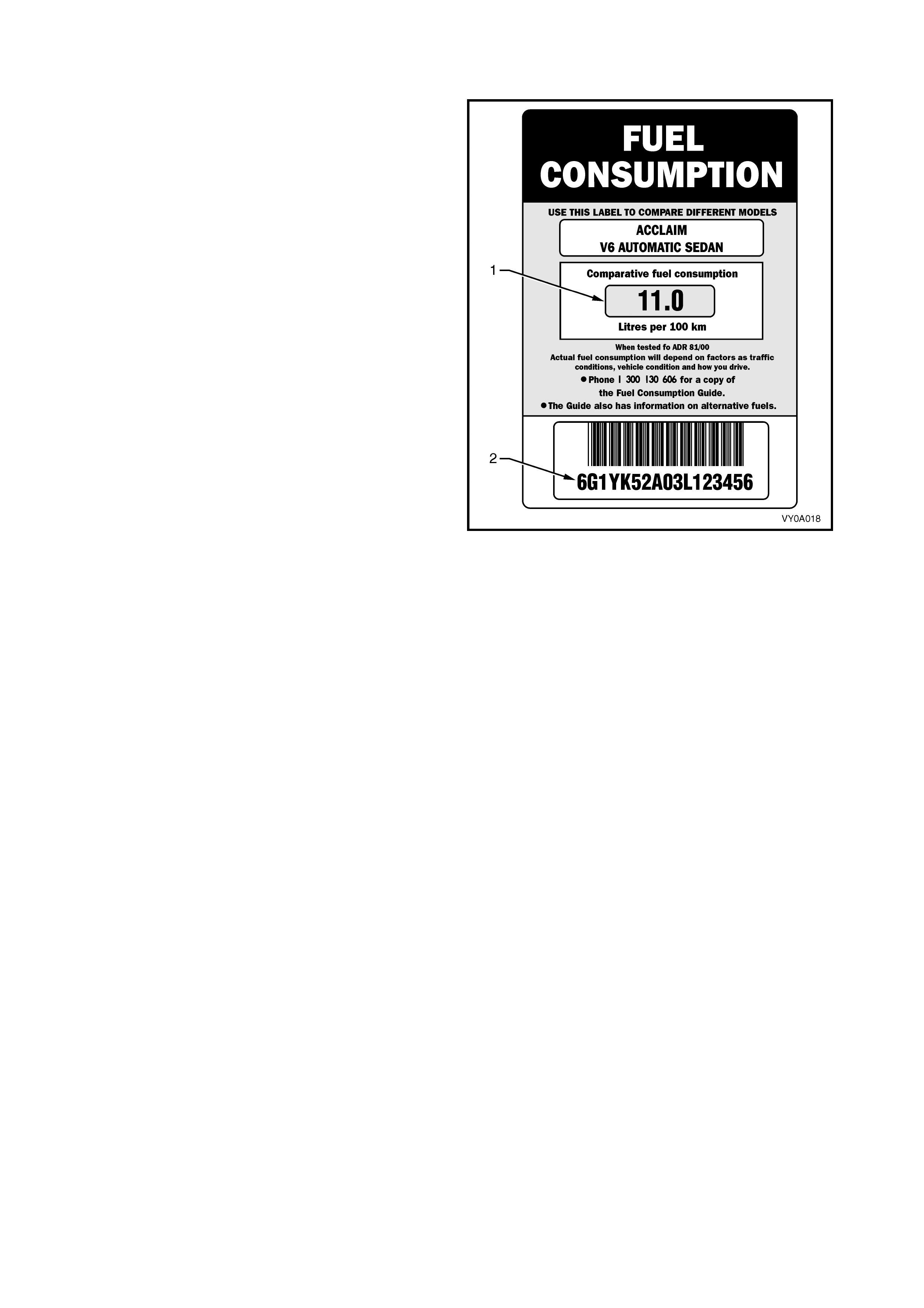

9.6 FUEL CONSUMPTION LABEL

ADR 81/00 requires that from 1 January 2001, a label

sim ilar to that shown in Figure 0A- 10 is attached to the

windscreen of any new vehicle which is displayed for

sale.

The fuel consumption label figures (1) quoted are the

results of tests carried out in accordance with the City

Cycle test procedure of AS2877 – 1986, an Australian

standard for fuel consumption testing. Each vehicle is

tested under identical conditions. The tests therefore

enable a comparison to be made between vehicles.

The label should be removed from the windscreen

immediately prior to the vehicle being delivered to the

owner.

The number on the lower por tion of the label (2) s hould

match the Vehicle Identification Number.

Figure 0A-10

10. SERIAL NUMBERS – BRAZIL

The com plete vehicle and various components of the vehicle are identified by num ber plates or numbers stamped

into the body. It is essential that when compiling warranty claims or product and field reports, that the Vehicle

Identification Number (VIN) is quoted in conjunction with the identification number of the component affected.

10.1 LOCATION OF IDENTIFICATION PLATES

Figure 0A-11

Legend

1. VIS Label – Right-Hand A-pillar

2. Body and Option Identification Plate – Left-Hand Side

of the Front Panel Upper

3. Manufacturer Label

4. Vehicle Indicator Section Label – Left-Hand

Suspension Tower

5. Vehicle Identification Number Plate – Under

Windscreen

6. Paint Label – Left-Hand B-pillar

7. Carpet Flap

8. Vehicle Identification Number – Under Front Seat

9. VIS Label – Under Front Seat

10.2 BODY AND OPTION IDENTIFICATION PLATE

The Body and Option Identification Plate (1) is located

on the front panel assembly and is stamped with the

following information.

Model

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

A listing of production and smart pack option numbers

can be found by referring to the latest spare parts

information for the applicable model.

Body

Production build number; run in continuous sequence

regardless of model, body type and series.

Trim

Trim combination.

Paint

Exterior paint material and colour identification.

Built

The date of manufacture by calendar month and year

in which the body shell and power train are conjoined

and the vehicle is driven or moved f rom the production

line.

Figure 0A-12

Susp.

Suspension option code identification.

FE1 identifies vehicles with standard suspension.

FE2 identifies vehicles with sport suspension.

Engine, Transmission and Axle

Identification option codes for specific engine,

transmission and rear axle.

A/C

C60 identifies vehicles fitted with air conditioning.

C61 Identifies vehicles fitted with automatic climate

control air conditioning.

Figure 0A-13

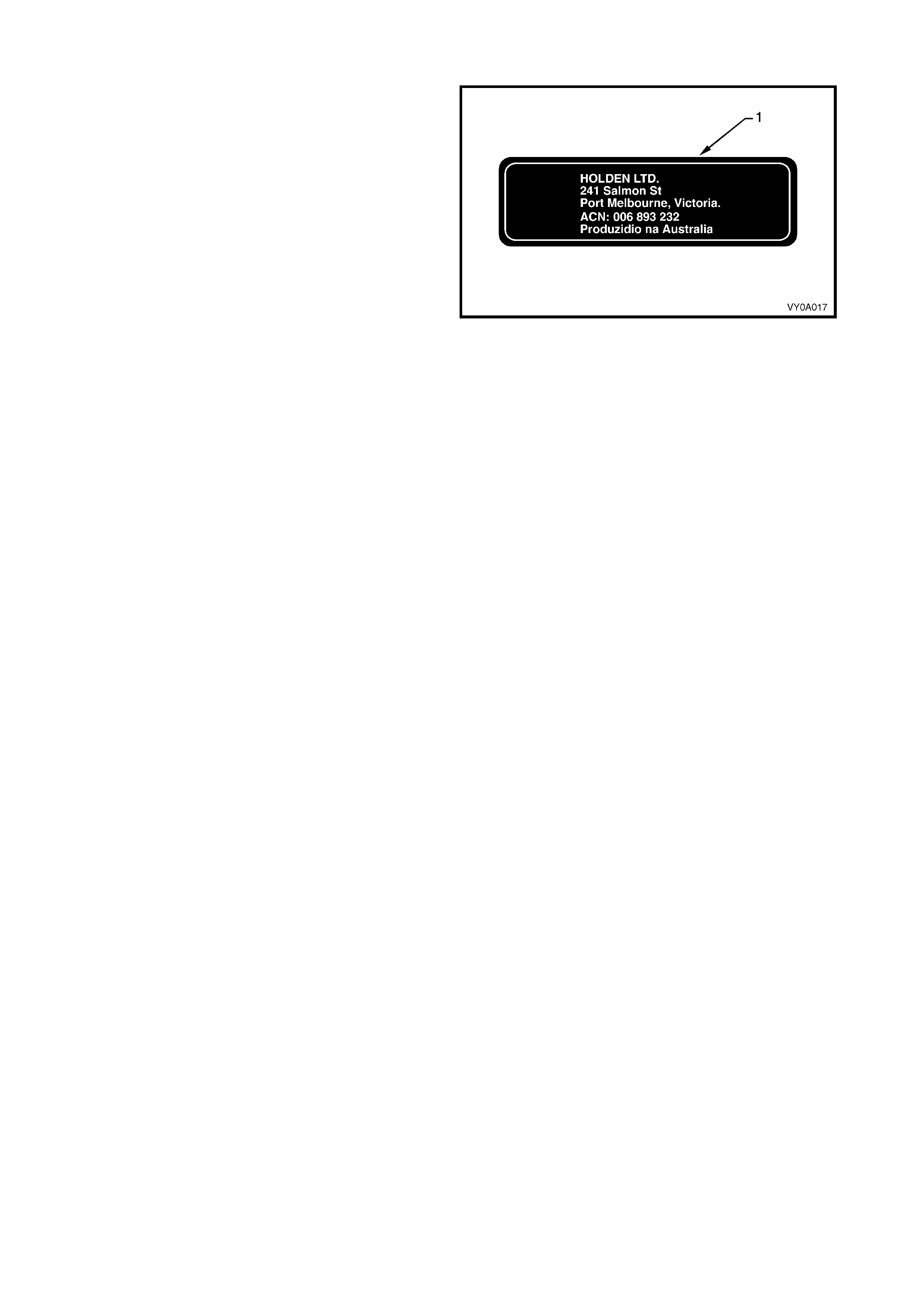

10.3 MANUFACTURER LABEL

The manufacturer label (1) is located on the left-hand

front suspension tower and contains information about

the vehicle manufacturer.

Figure 0A-14

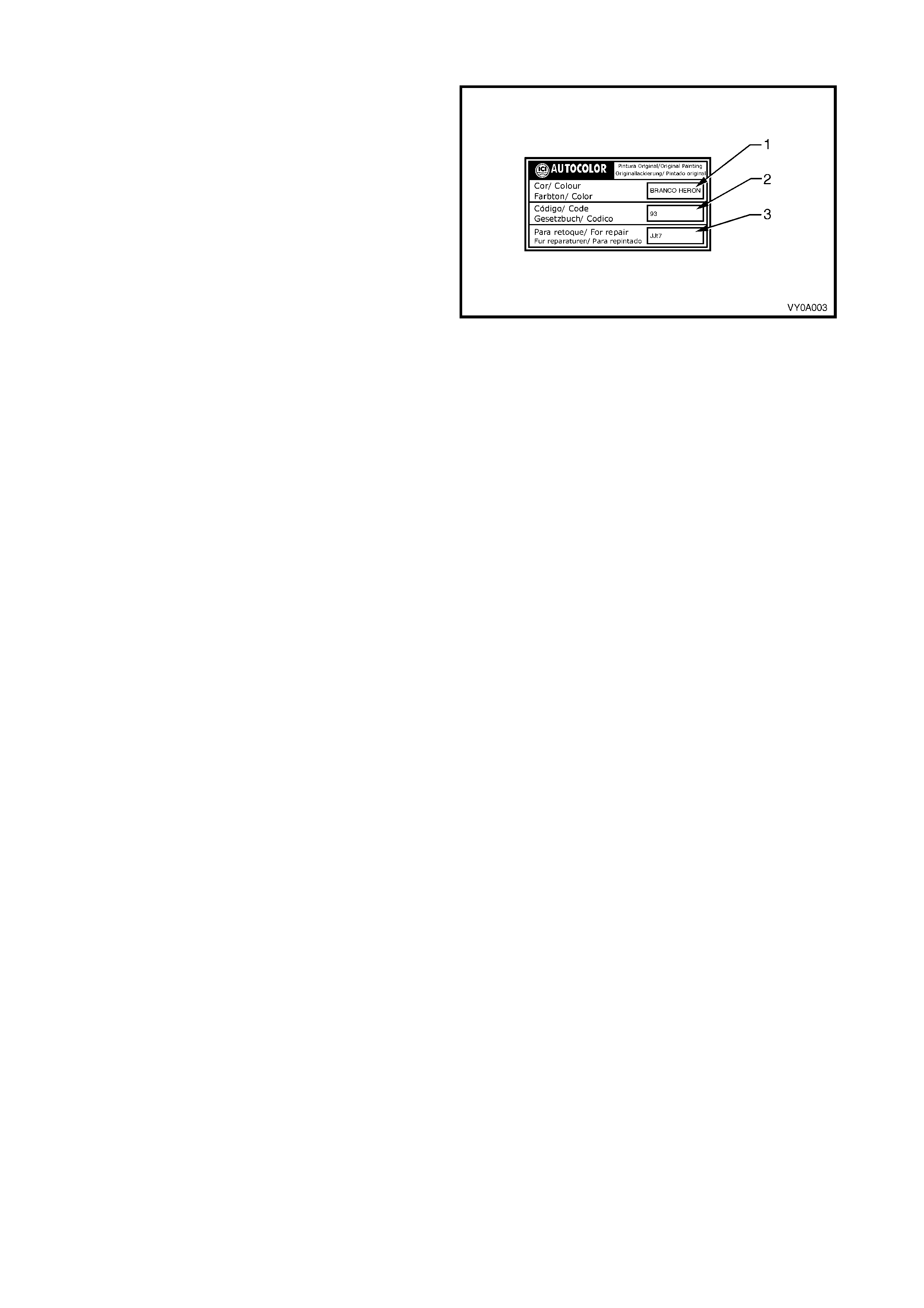

10.4 PAINT LABEL

The paint label is located on the left-hand B-pillar and

contains the paint colour (1), paint code (2) and repair

paint (3) for the vehicle.

The paint code enables the original paint colour to be

matched with refinish paint.

NOTE: T he paint on the vehicle m ay not exactly match

the original colour due to fade, in which case paint

colour m atching will be required. As this is an acquired

skill, it is a task that must be performed by qualified

individuals.

Figure 0A-15

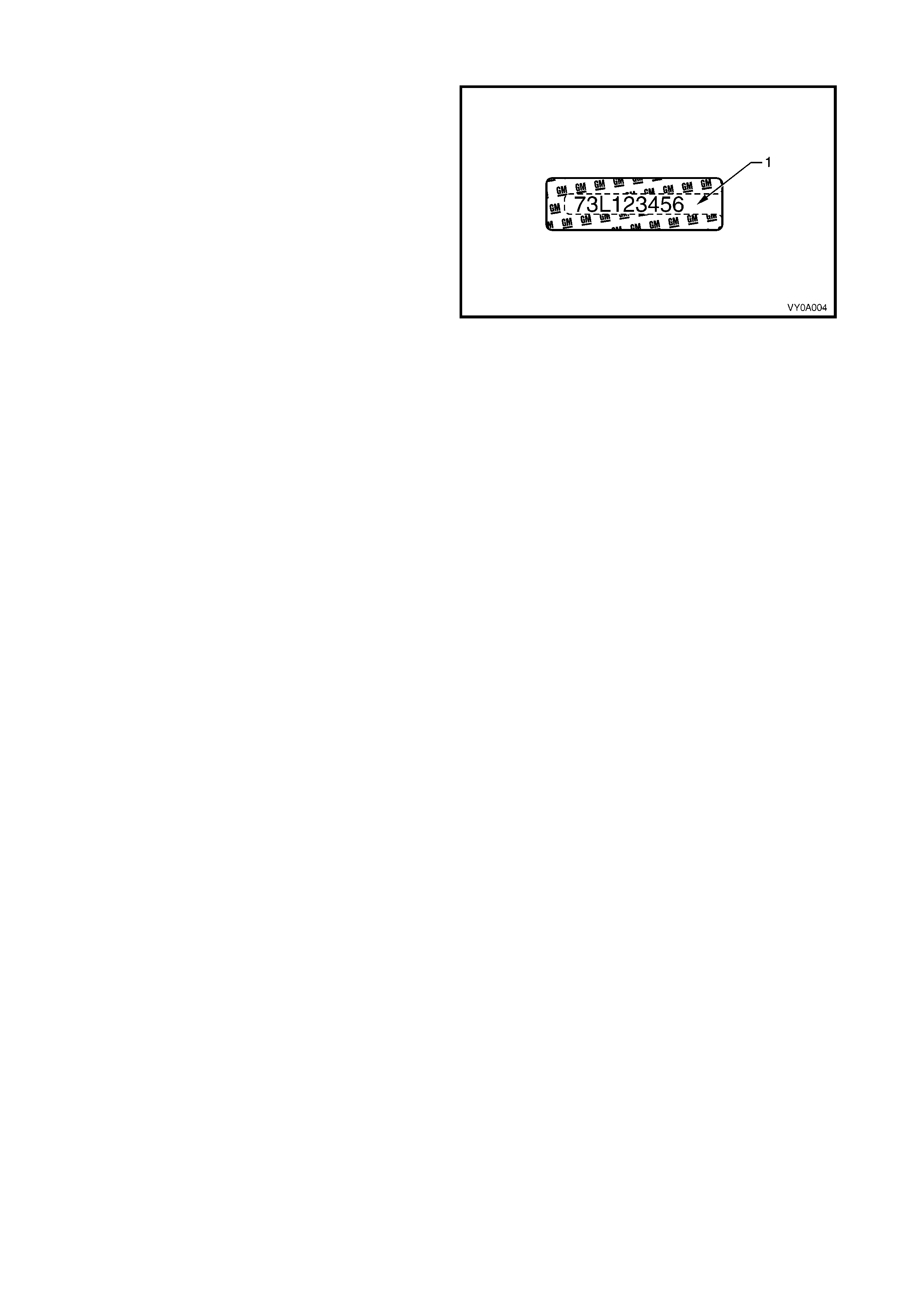

10.5 VIS LABEL

Vehicle Indicator Section (VIS) labels are located

under the right front seat, on the front left strut tower

and on the right-hand A-pillar.

The VIS label contains the last nine characters of the

VIN (1).

Figure 0A-16

10.6 VEHICLE IDENTIFICATION NUMBER

The Vehic le Identification Number ing (VIN) s ystem is bas ed on the unif or m Car Model Des ignation System. This

identifies the vehicle in one coded series of characters.

The Vehicle Identification Number is positioned in the following locations.

1. VIN plate under the windscreen – viewed through the windscreen aperture.

2. Body and option identification plate – left-hand side of the front panel upper.

3. Stamping in the front floor panel under the front right-hand seat.

VIN PLATE

The VIN Plate (1) is located under the windsc reen and

is viewed through the windscreen aperture.

Figure 0A-17

Figure 0A-18 shows the VIN plate (1) that is located

under the windscreen aperture and is attached to the

dash panel assembly with unique rosette headed

rivets.

Figure 0A-18

VIN BODY STAMPING

The VIN is stam ped into the f ront floor panel under the

right-hand f r ont s eat. The VIN ( 1) is vis ible by lifting the

carpet flap.

NOTE 1: If the front floor panel assembly is to be

replaced, the VIN will be lost. Contact your local Road

Traffic Authority prior to replacing the panel to obtain

the correct procedure for renumbering the vehicle.

NOTE 2: A replacement body shell assembly is

stamped during manufacture with a unique VIN that

identifies it as a replacement part.

NOTE 3: If an error is made to the VIN stamping

during manufacture, it is lined out so that it remains

legible and the correct number is stamped underneath.

Figure 0A-19

10.7 VE HICLE IDE NTIFICATION NUMBERING SYSTEM

WMI CODE: 6 – Oceania

G – Australia

1 – Chevrolet

CARLINE: Y – VY series

LUXURY LEVEL: X – Level 3

BODY STYLE: 5 – 4 door sedan (69)

RESTRAINT CODE: 1 – Active (manual) seat belts

2 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal

3 – Active (manual) seat belts with driver inflatable restraint system – frontal

4 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal and side

ENGINE TYPE: C – 3.8 litre V6 engine (Brazil variant)

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 3 – 2003

4 – 2004

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUMBER:

123456 – Sequential Production Serial Number

NOTE: The pr oduc tion s equence number is sequentially allocated to each vehicle,

regardless of vehicle type.

11. SERIAL NUMBERS – GULF STATES

The com plete vehicle and various components of the vehicle are identified by num ber plates or numbers stamped

into the body. It is essential that when compiling warranty claims or product and field reports, that the Vehicle

Identification Number (VIN) is quoted in conjunction with the identification number of the component affected.

11.1 LOCATION OF IDENTIFICATION PLATES

Figure 0A-20

Legend

1. Body And Option Identification Plate – Left-Hand Side

of the Front Panel Upper

2. Vehicle Identification Number Plate – Under

Windscreen

3. Safety Compliance Label – Left-Hand B-pillar

4. Carpet Flap

5. Vehicle Identification Number – Under Front Seat

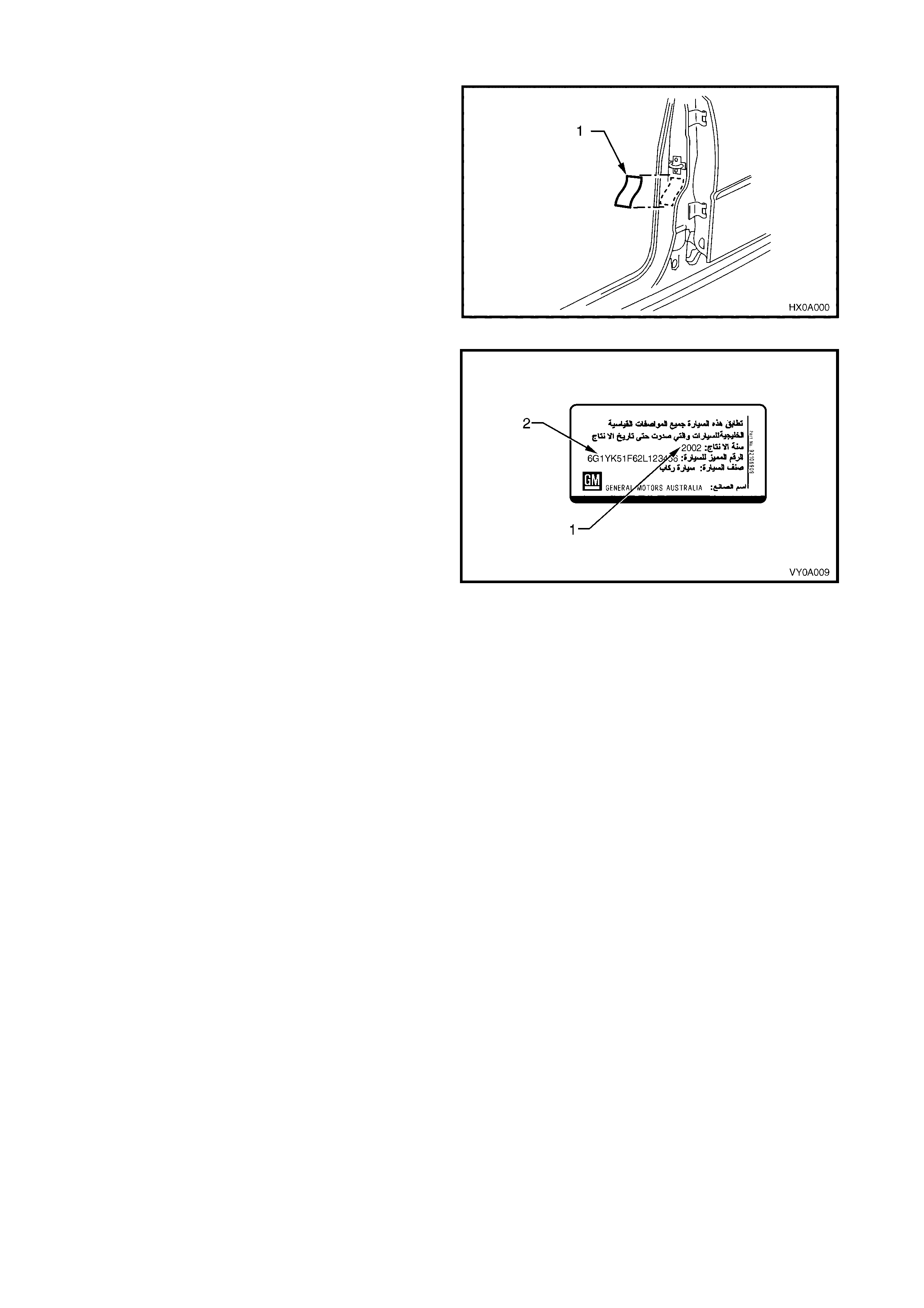

11.2 S AFETY COMPLIANCE LABE L

The safety compliance label (1) is attached to the B-

pillar.

Figure 0A-21

The safety compliance label contains the following

information:

• Vehicle conformity statement

• Date of Manufacture (1)

• Vehicle Identification Number (2)

• Category of vehicle: passenger car

• Manufactured by: General Motors Corporation

Figure 0A-22

11.3 BODY AND OPTION IDENTIFICATION PLATE

The Body and Option Identification Plate (1) is located

on the front panel assembly and is stamped with the

following information.

Model

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

A listing of production and smart pack option numbers

can be found by referring to the latest spare parts

information for the applicable model.

Body

Production build number; run in continuous sequence

regardless of model, body type and series.

Trim

Trim combination.

Paint

Exterior paint material and colour identification.

Built

The date of manufacture by calendar month and year

in which the body shell and power train are conjoined

and the vehicle is driven or moved from the produc tion

line.

Susp.

Suspension option code identification.

FE1 identifies vehicles with standard suspension.

FE2 identifies vehicles with sport suspension.

Engine, Transmission and Axle

Identification option codes for specific engine,

transmission and rear axle.

A/C

C60 identifies vehicles fitted with air conditioning.

C61 Identifies vehicles fitted with automatic climate

control air conditioning.

Figure 0A-23

Figure 0A-24

11.4 VEHICLE IDENTIFICATION NUMBER

The Vehicle Identif ication Num bering (VIN) system is bas ed on the uniform Car Model Designation System. T his

identifies the vehicle in one coded series of characters.

The Vehicle Identification Number is positioned in the following locations.

1. VIN plate under the windscreen – viewed through the windscreen aperture.

2. Body and option identification plate – left-hand side of the front panel upper.

3. Stamping in the front floor panel under the front right-hand seat.

VIN PLATE

The VIN Plate (1) is located under the windscreen and

is viewed through the windscreen aperture.

Figure 0A-25

Figure 0A-26 shows the VIN plate (1) that is located

under the windscreen aperture and is attached to the

dash panel assembly with unique rosette headed

rivets.

Figure 0A-26

VIN BODY STAMPING

The VIN is stam ped into the f ront floor panel under the

right-hand f r ont s eat. The VIN ( 1) is vis ible by lifting the

carpet flap.

NOTE 1: If the front floor panel assembly is to be

replaced, the VIN will be lost. Contact your local Road

Traffic Authority prior to replacing the panel to obtain

the correct procedure for renumbering the vehicle.

NOTE 2: A replacement body shell assembly is

stamped during manufacture with a unique VIN that

identifies it as a replacement part.

NOTE 3: If an error is made to the VIN stamping

during manufacture, it is lined out so that it remains

legible and the correct number is stamped underneath.

Figure 0A-27

11.5 VE HICLE IDE NTIFICATION NUMBERING SYSTEM

WMI CODE: 6 – Oceania

G – Australia

1 – Chevrolet

CARLINE: Y – VY series

2 – V2 series

LUXURY LEVEL: K – Level 1

L – Level 2

BODY STYLE: 5 – 4 door sedan (69)

8 – 5 door station wagon (35)

RESTRAINT CODE: 1 – Active (manual) seat belts

2 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal

3 – Active (manual) seat belts with driver inflatable restraint system – frontal

4 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal and side

ENGINE TYPE: B – 3.8 litre V6 engine (Gulf States variant)

F – 5.7 litre GEN III V8 engine

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 3 – 2003

4 – 2004

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUMBER:

123456 – Sequential Production Serial Number

NOTE: The pr oduc tion s equence number is sequentially allocated to each vehicle,

regardless of vehicle type.

12. SERIAL NUMBERS – SOUTH AFRICA

The com plete vehicle and various components of the vehicle are identified by num ber plates or numbers stamped

into the body. It is essential that when compiling warranty claims or product and field reports, that the Vehicle

Identification Number (VIN) is quoted in conjunction with the identification number of the component affected.

12.1 LOCATION OF IDENTIFICATION PLATES

Figure 0A-28

Legend

1. Body And Option Identification Plate – Left-Hand Side

of the Front Panel Upper

2. Safety Compliance Plate – Dash Panel Assembly

3. Vehicle Identification Number Plate – Under

Windscreen

4. Carpet Flap

5. Vehicle Identification Number – Under Front Seat

12.2 SAFETY COMPLIANCE PLATE

The safety compliance plate is located on the dash

panel assembly within the engine compartment.

Figure 0A-29

The safety compliance plate is stamped with the

following information:

• Compliance Plate Approval Number.

• Vehicle Category Code.

• Name Appearing On Compliance Plate Approval.

• Make/Model.

• Gross Ve hicle Mass.

• This is the maximum loaded mass at which the

vehicle complies with the approved design rules.

Not required for passenger vehicles. (Required for

utility .)

• Seating Capacity.

• Number of adult positions for which seat belts are

provided.

• Date Of Manufacture.

• The day, month and year that the vehicle is

manufactured.

• Vehicle Identification Number.

Figure 0A-30

12.3 BODY AND OPTION IDENTIFICATION PLATE

The Body and Option Identification Plate (1) is located

on the front panel assembly and is stamped with the

following information.

Model

Combination of letters and numbers identifying the

body style, the mechanical pack and smart pack

options.

A listing of production and smart pack option numbers

can be found by referring to the latest spare parts

information for the applicable model.

Body

Production build number; run in continuous sequence

regardless of model, body type and series.

Trim

Trim combination.

Paint

Exterior paint material and colour identification.

Built

The date of manufacture by calendar month and year

in which the body shell and power train are conjoined

and the vehicle is driven or moved from the produc tion

line.

Susp.

Suspension option code identification.

FE1 identifies vehicles with standard suspension.

FE2 identifies vehicles with sport suspension.

Engine, Transmission and Axle

Identification option codes for specific engine,

transmission and rear axle.

A/C

C60 identifies vehicles fitted with air conditioning.

C61 Identifies vehicles fitted with automatic climate

control air conditioning.

Figure 0A-31

Figure 0A-32

12.4 VEHICLE IDENTIFICATION NUMBER

The Vehicle Identif ication Num bering (VIN) system is bas ed on the uniform Car Model Designation System. T his

identifies the vehicle in one coded series of characters.

The Vehicle Identification Number is positioned in the following locations.

1. VIN plate under the windscreen – viewed through the windscreen aperture.

2. Body and option identification plate – left-hand side of the front panel upper.

3. Safety compliance plate – dash panel.

4. Stamping in the front floor panel under the front right-hand seat.

VIN PLATE

The VIN Plate (1) is located under the windscreen and

is viewed through the windscreen aperture.

Figure 0A-33

Figure 0A-34 shows the VIN plate (1) that is located

under the windscreen aperture and is attached to the

dash panel assembly with unique rosette headed

rivets.

Figure 0A-34

VIN BODY STAMPING

The VIN is stam ped into the f ront floor panel under the

right-hand f r ont s eat. The VIN ( 1) is vis ible by lifting the

carpet flap.

NOTE 1: If the front floor panel assembly is to be

replaced, the VIN will be lost. Contact your local Road

Traffic Authority prior to replacing the panel to obtain

the correct procedure for renumbering the vehicle.

NOTE 2: A replacement body shell assembly is

stamped during manufacture with a unique VIN that

identifies it as a replacement part.

NOTE 3: If an error is made to the VIN stamping

during manufacture, it is lined out so that it remains

legible and the correct number is stamped underneath.

Figure 0A-35

12.5 VE HICLE IDE NTIFICATION NUMBERING SYSTEM

WMI CODE: 6 – Oceania

G – Australia

1 – Chevrolet

CARLINE: Y – VY series

LUXURY LEVEL: K – Level 1

L – Level 2

BODY STYLE: 5 – 4 door sedan (69)

8 – 5 door wagon (35)

8 – 2 door utility (80)

RESTRAINT CODE: 1 – Active (manual) seat belts

2 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal

3 – Active (manual) seat belts with driver inflatable restraint system – frontal

4 – Active (manual) seat belts with driver & passenger inflatable restraint

system – frontal and side

ENGINE TYPE: A – 3.8 litre V6 engine (domestic variant)

F – 5.7 litre GEN III V8 engine

VIN CHECK DIGIT: Calculated check digit

MODEL YEAR: 3 – 2003

4 – 2004

PLANT: L – Adelaide (Elizabeth) South Australia

PRODUCTION SEQUENCE NUMBER:

123456 – Sequential Production Serial Number

NOTE: The pr oduc tion s equence number is sequentially allocated to each vehicle,

regardless of vehicle type.

13. ENGINE SERIAL NUMBERS

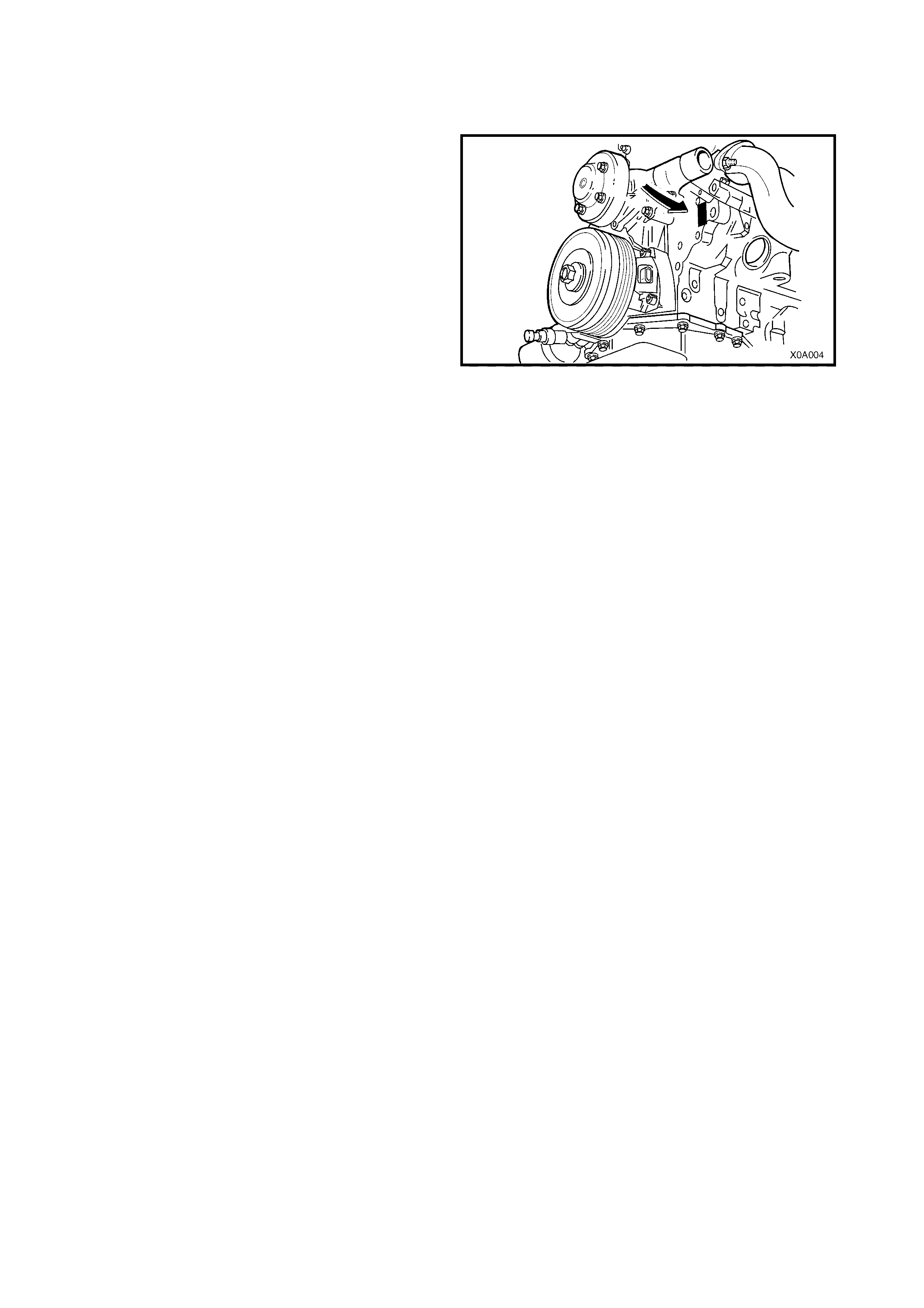

13.1 V6 ENGINE

The engine serial number for the 3.8 litre V6 and V6

supercharged engines is stamped on a pad that is

located adjacent to the engine coolant outlet pipe and

below the ignition coil.

Figure 0A-36

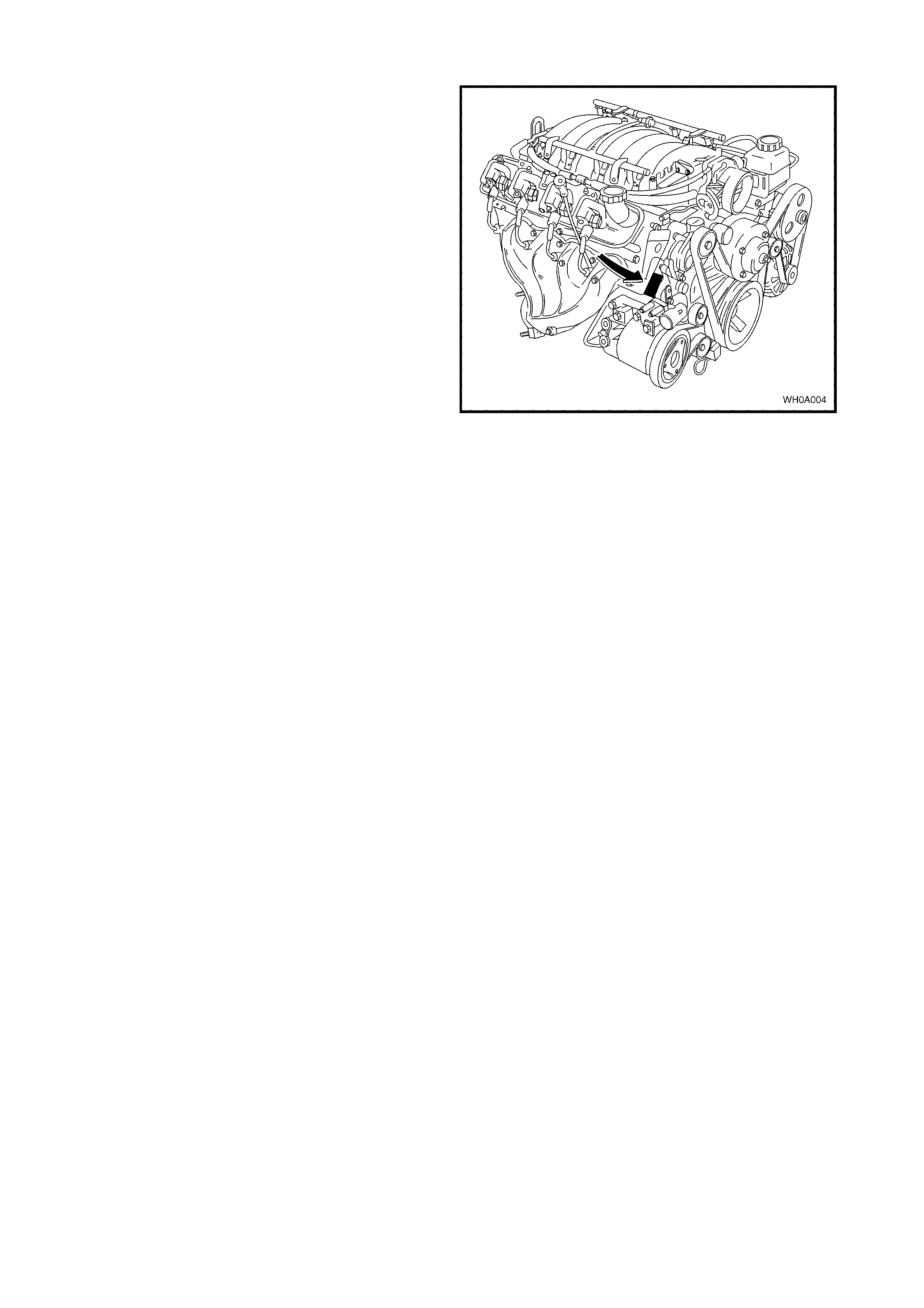

13.2 GEN III V8 ENGINE

The 5.7 litre Gen III V8 engine serial number is

stamped on a pad that is located adjacent to the

engine coolant outlet pipe and below number 2 cylinder

spark plug.

Figure 0A-37

14. TRANSMISSION SERIAL NUMBER

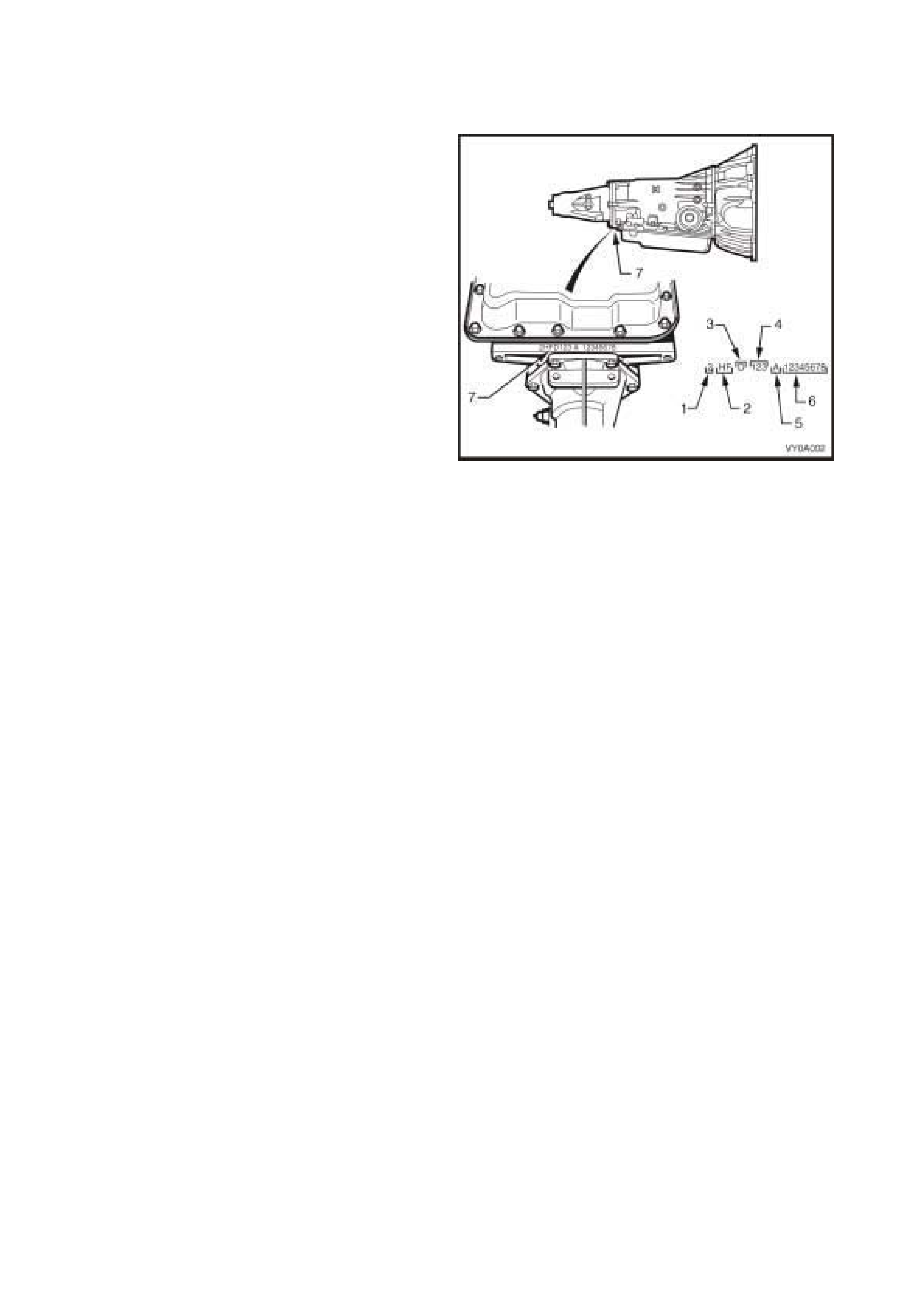

14.1 AUTOMATIC TRANSMISSION

The automatic transmission serial number is stamped

into a machined surface at the rear underside of the

transmission centre case.

1. Model Year (‘2’ = 2002, ‘3’ = 2003, ‘4’ = 2004)

2. Model: V8 – 5.7 litre......................... HA

V6 – 3.8 litre ........................ HF

V6 Supercharged – 3.8 litre. HN

3. Transmission Model Identifier (D = 4L60-E).

4. Julian Date (or day of year).

5. Shift Built (A, B, J = first shift;

C, H, W = second shift).

6. Individual Transmission Serial Number.

7. Transmission Identification Number Location.

Figure 0A-38

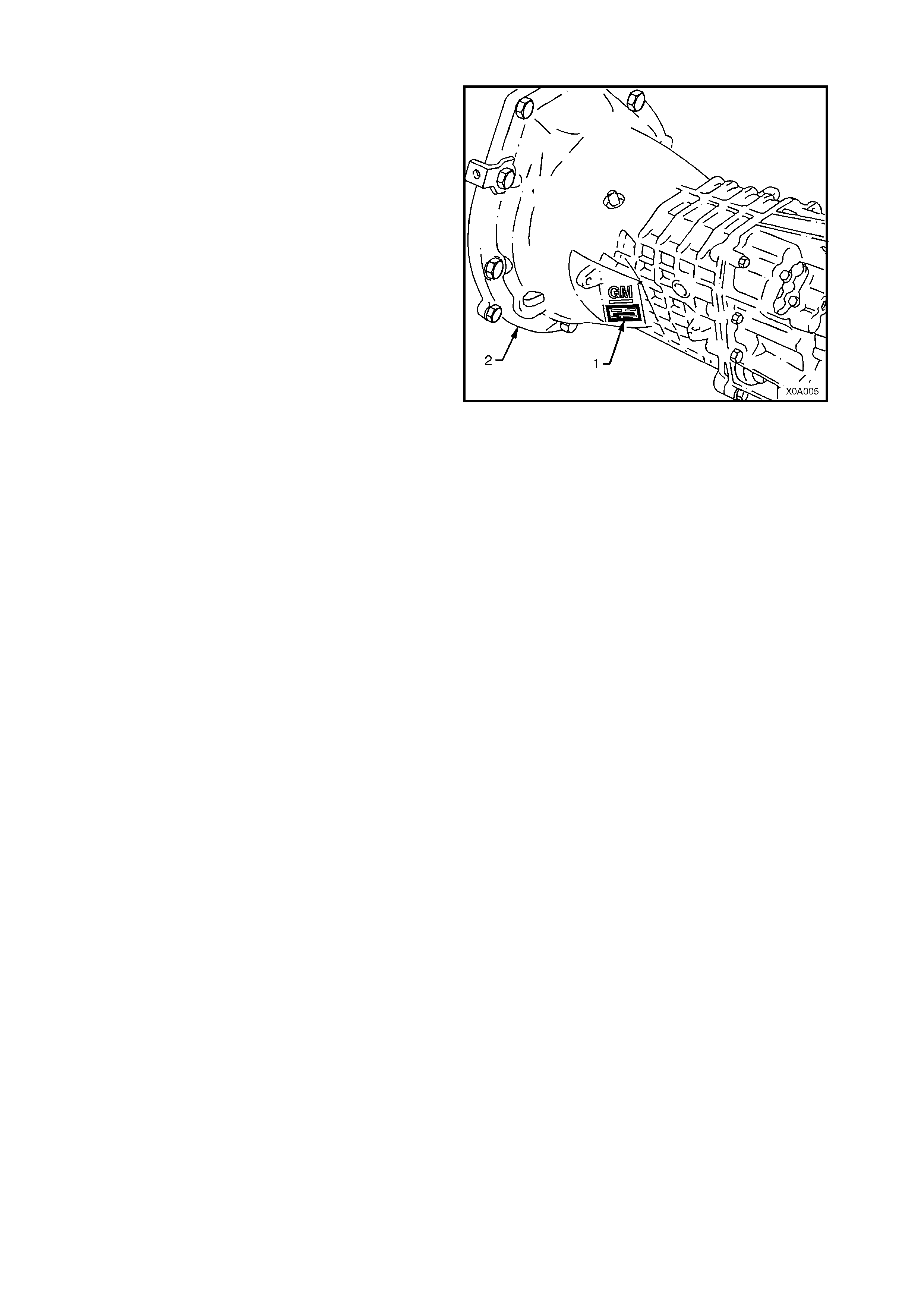

14.2 MANUAL TRANSMISSION – 5 SPEED

The Getrag five speed manual transmission serial

number is located on a self-adhesive label (1)

attached to the left side of the transmission front

cover.

This number provides coded information that could be

significant to parts interpretation and should be

referred to when ordering replacement parts.

NOTE: if this label is removed or becomes

unreadable, the serial number is also stamped onto

the lower left-hand side of the transmission front

cover (2).

Figure 0A-39

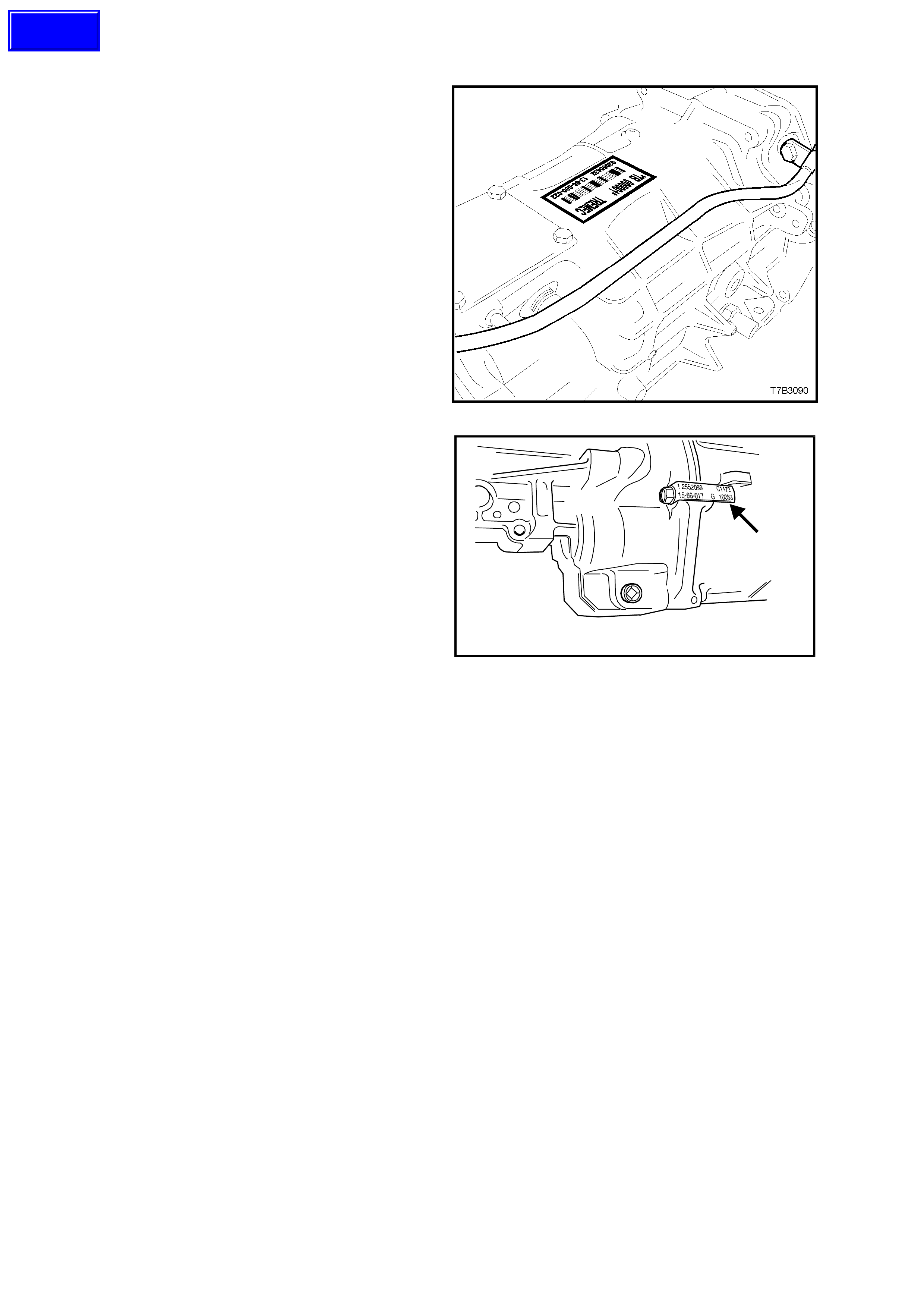

14.3 MANUAL TRANSMISSION – 6 SPEED

The Borg-W arner (Tremec) T56 six speed manual

transmission serial number is located on a self-

adhesive decal attached to the top of the

transmission case.

This num ber provides coded information that could

be significant to parts interpretation and should be

referred to when ordering replacement parts.

In addition, an identification tag is attached to the

transmission under an extension housing bolt, on

the right-hand side.

Figure 0A-40

T20A002

Figure 0A-41

Techline

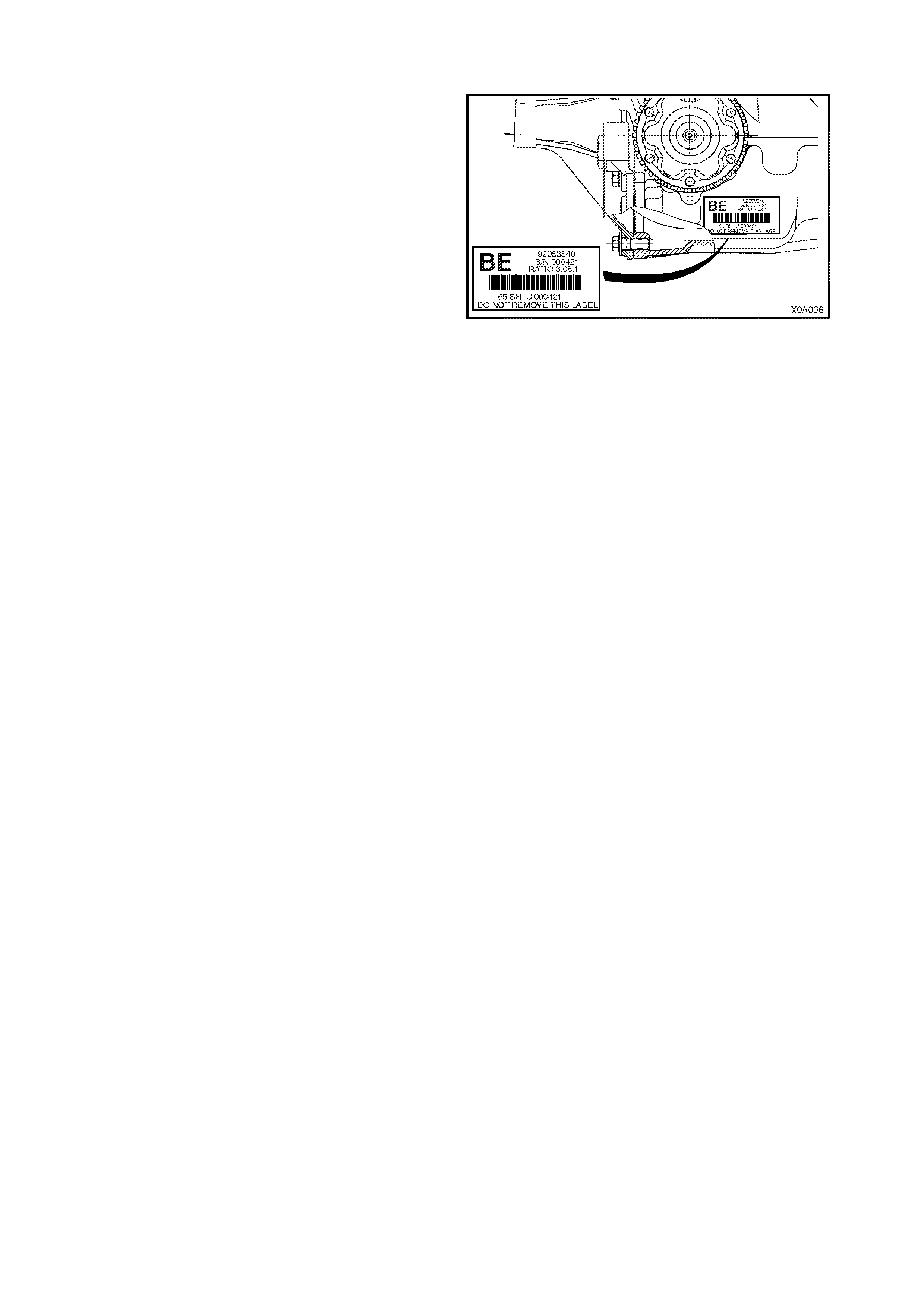

15. FINAL DRIVE ASSEMBLY SERI AL NUMBER

An identification tag is adhered to the final drive

assembly to the right-hand side of the carrier housing.

The tag carries the Holden part number for the

assem bly, the final drive ratio and the s erial number of

the assembly.

Figure 0A-42

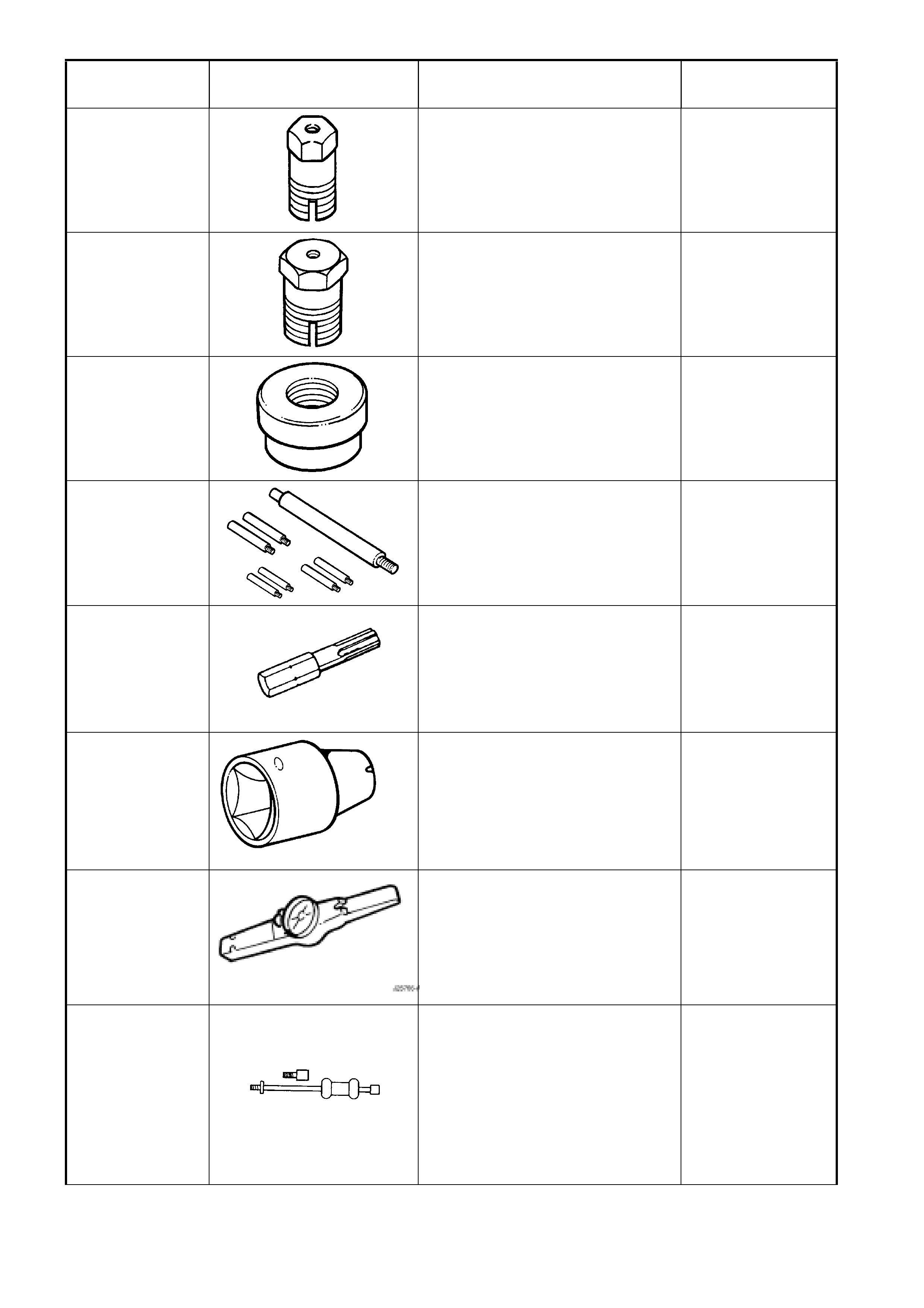

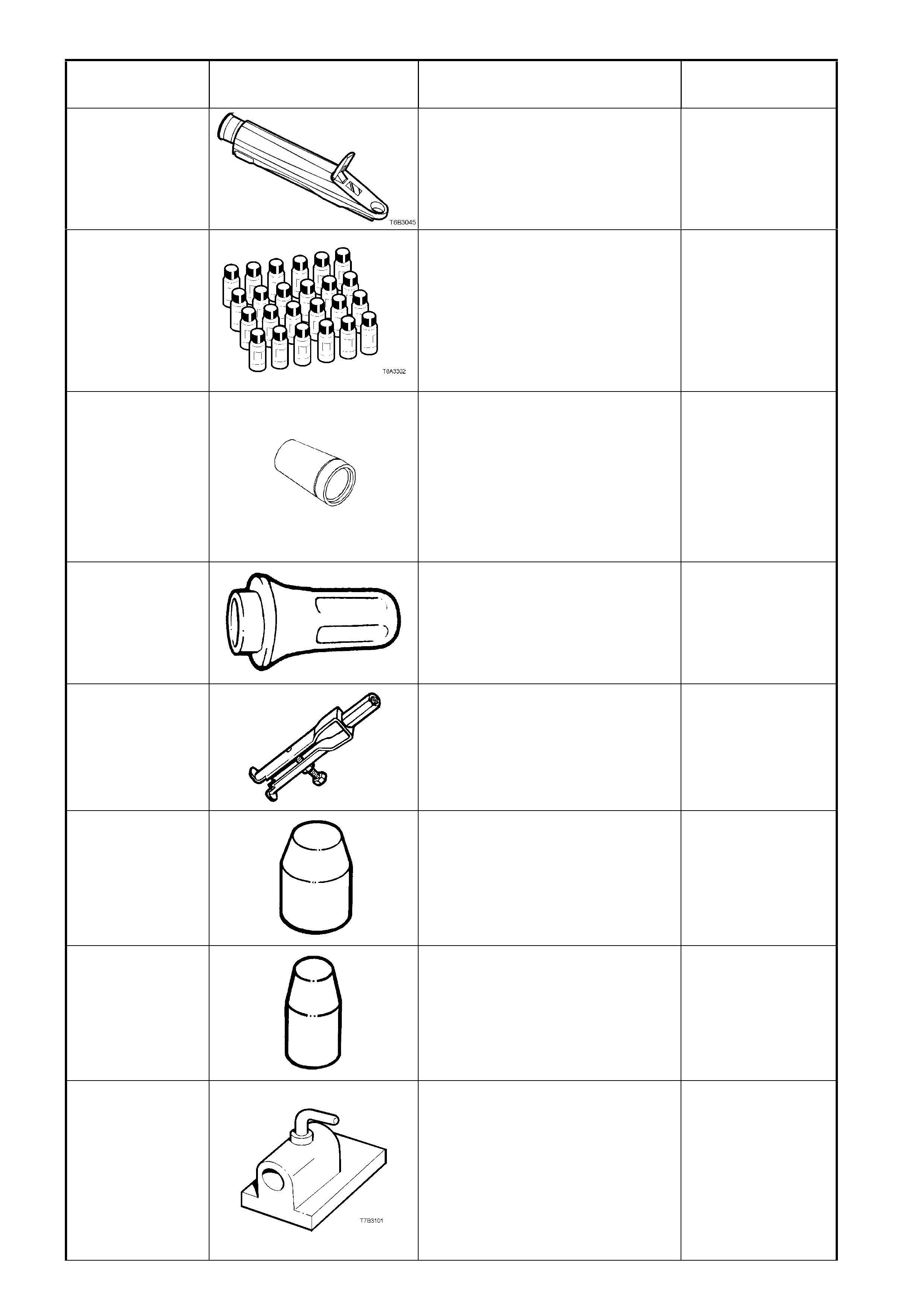

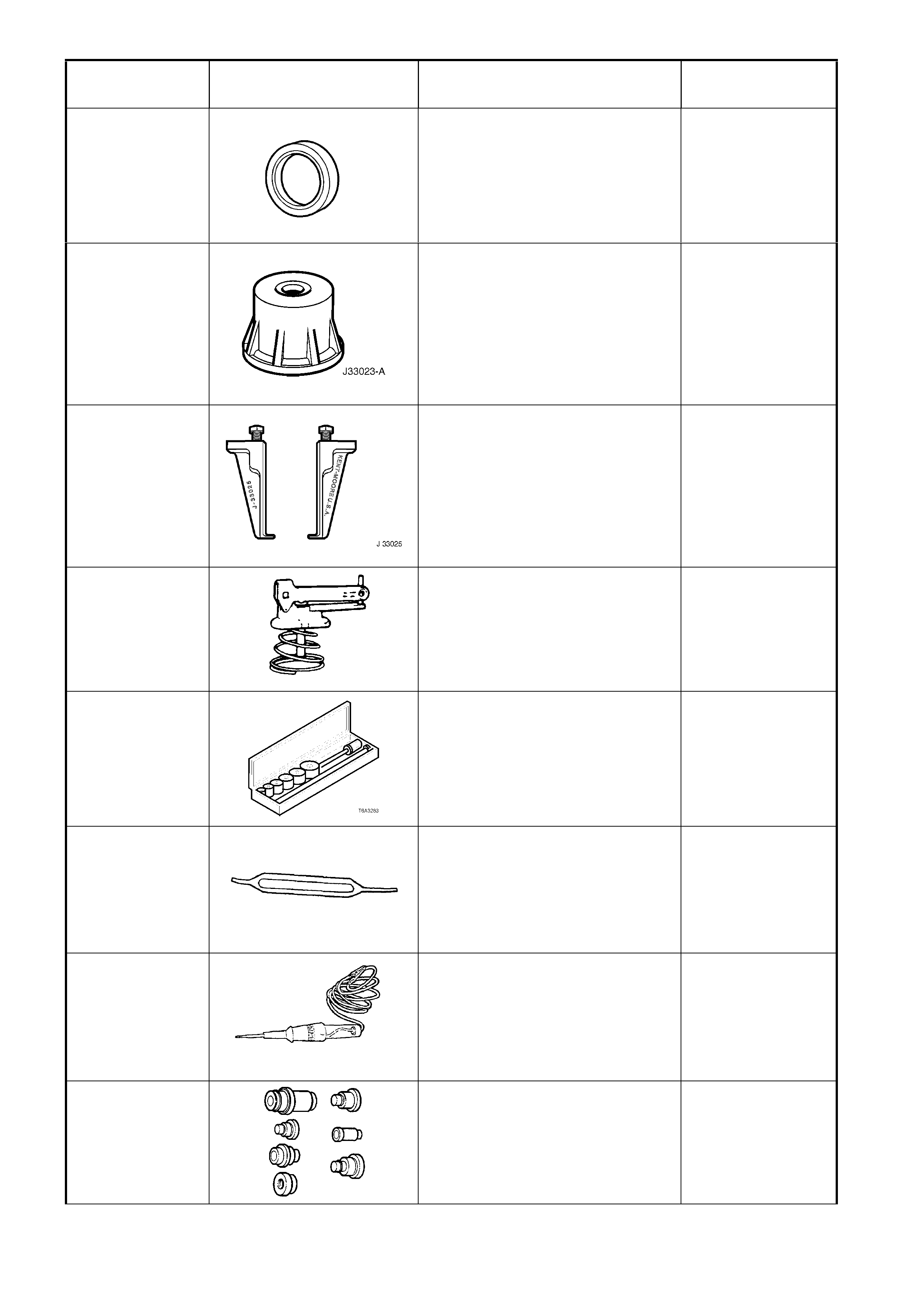

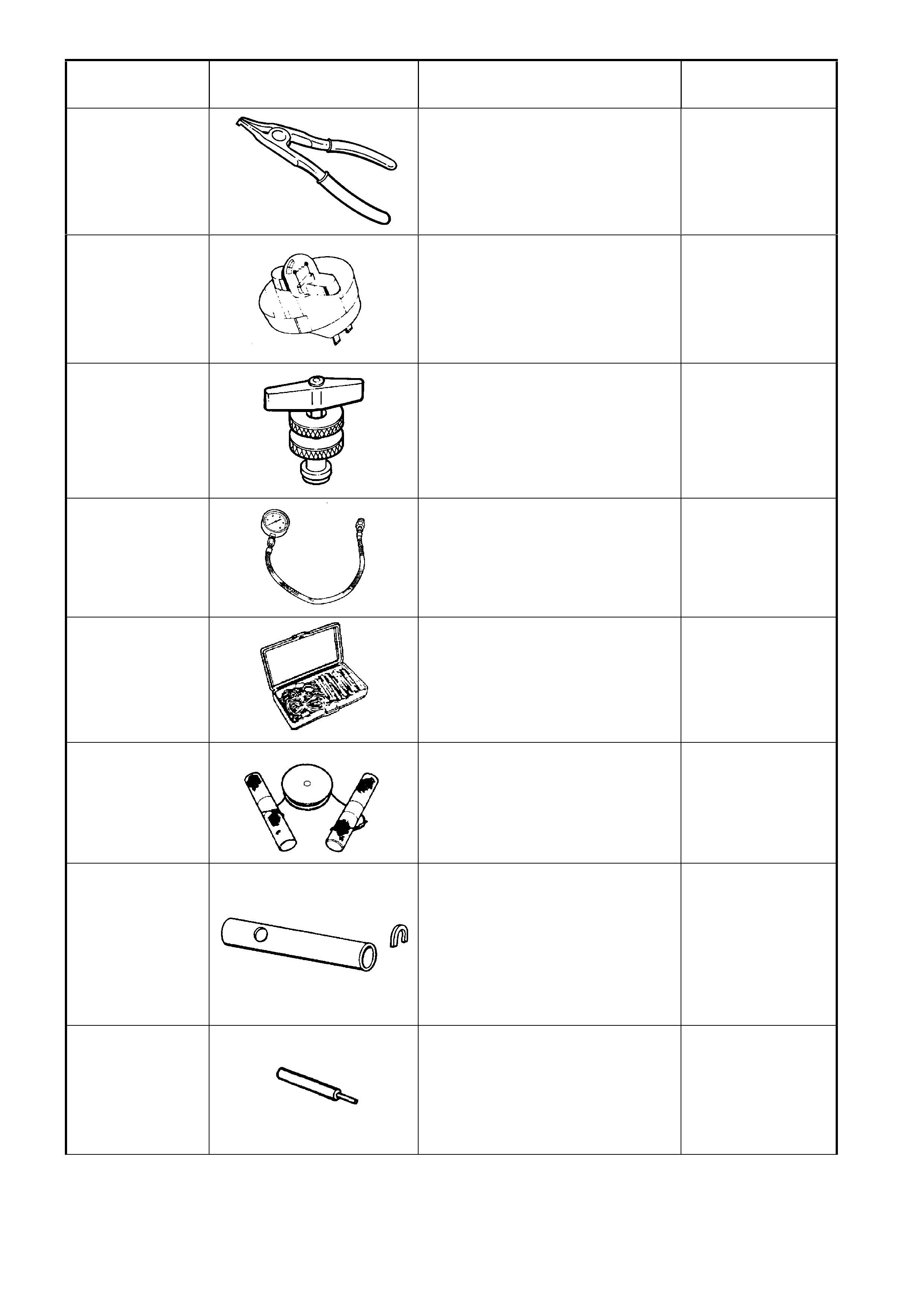

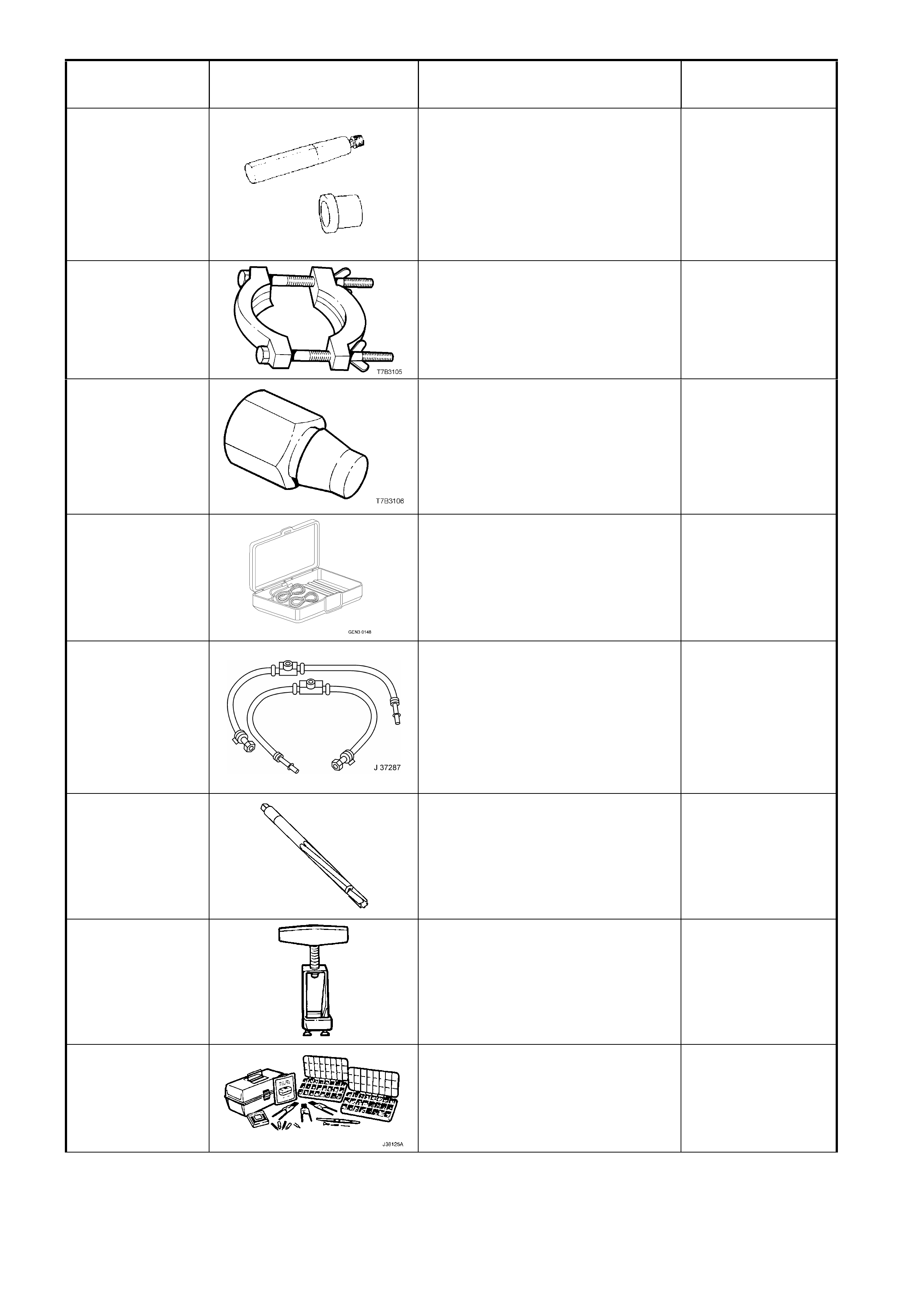

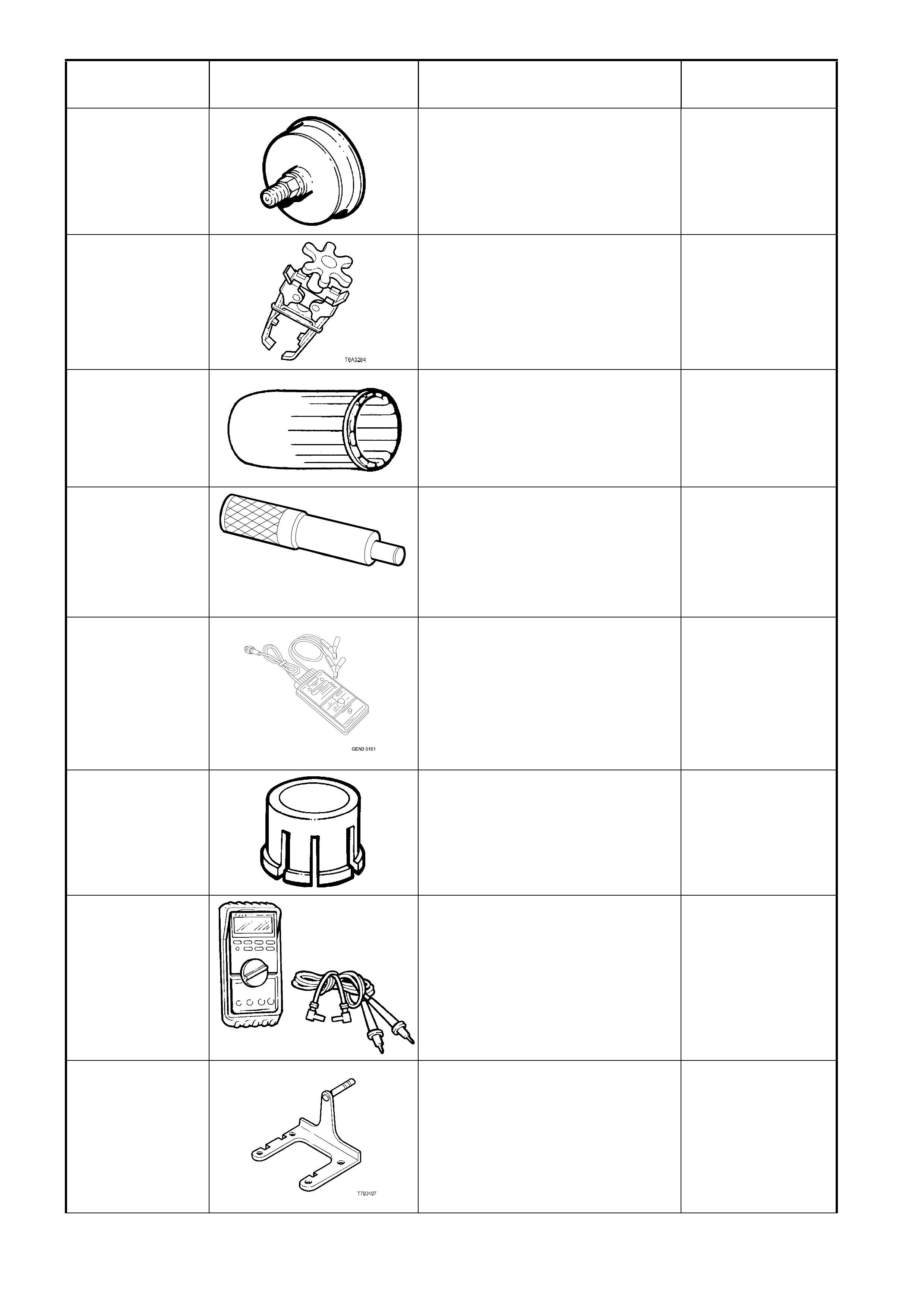

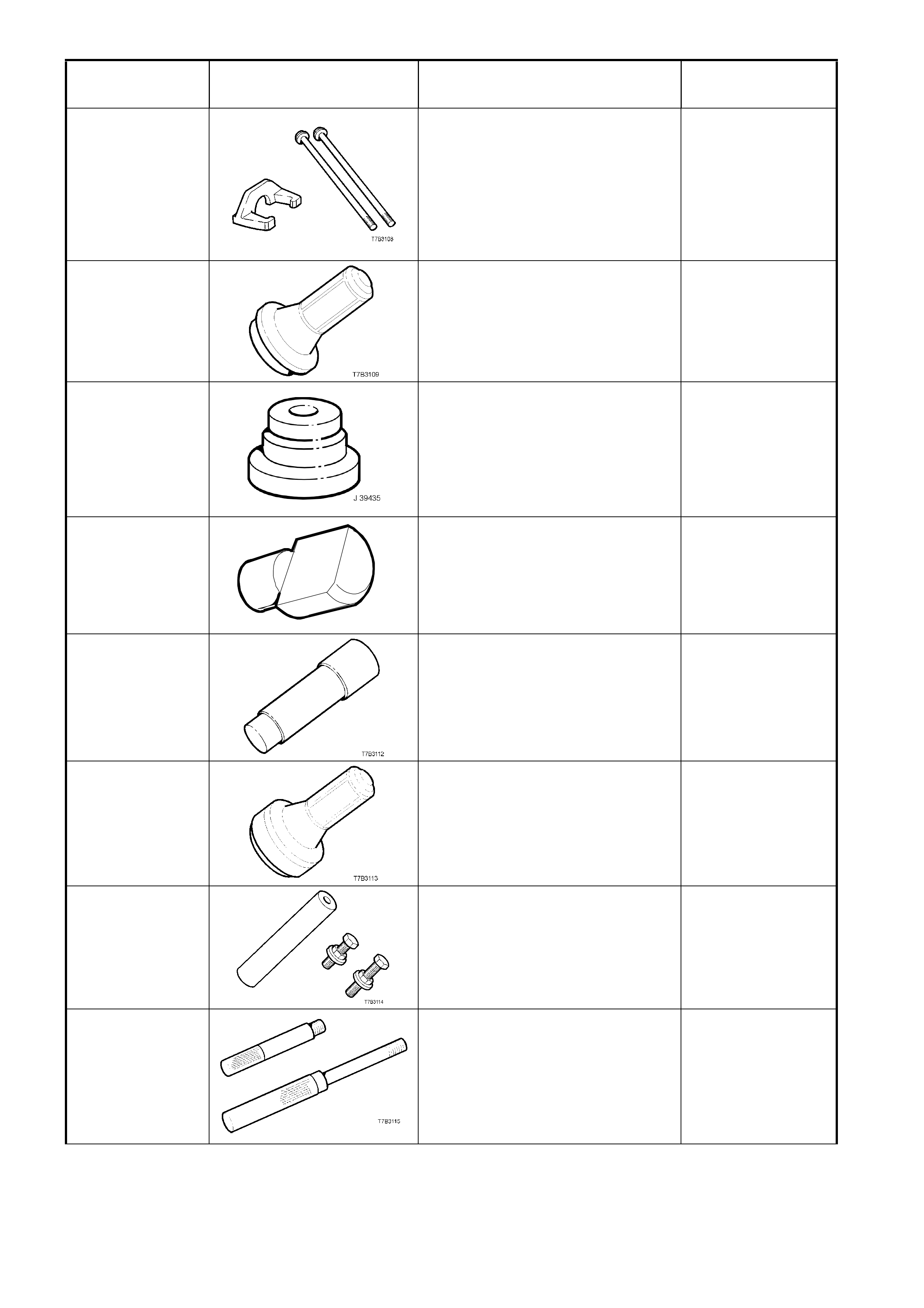

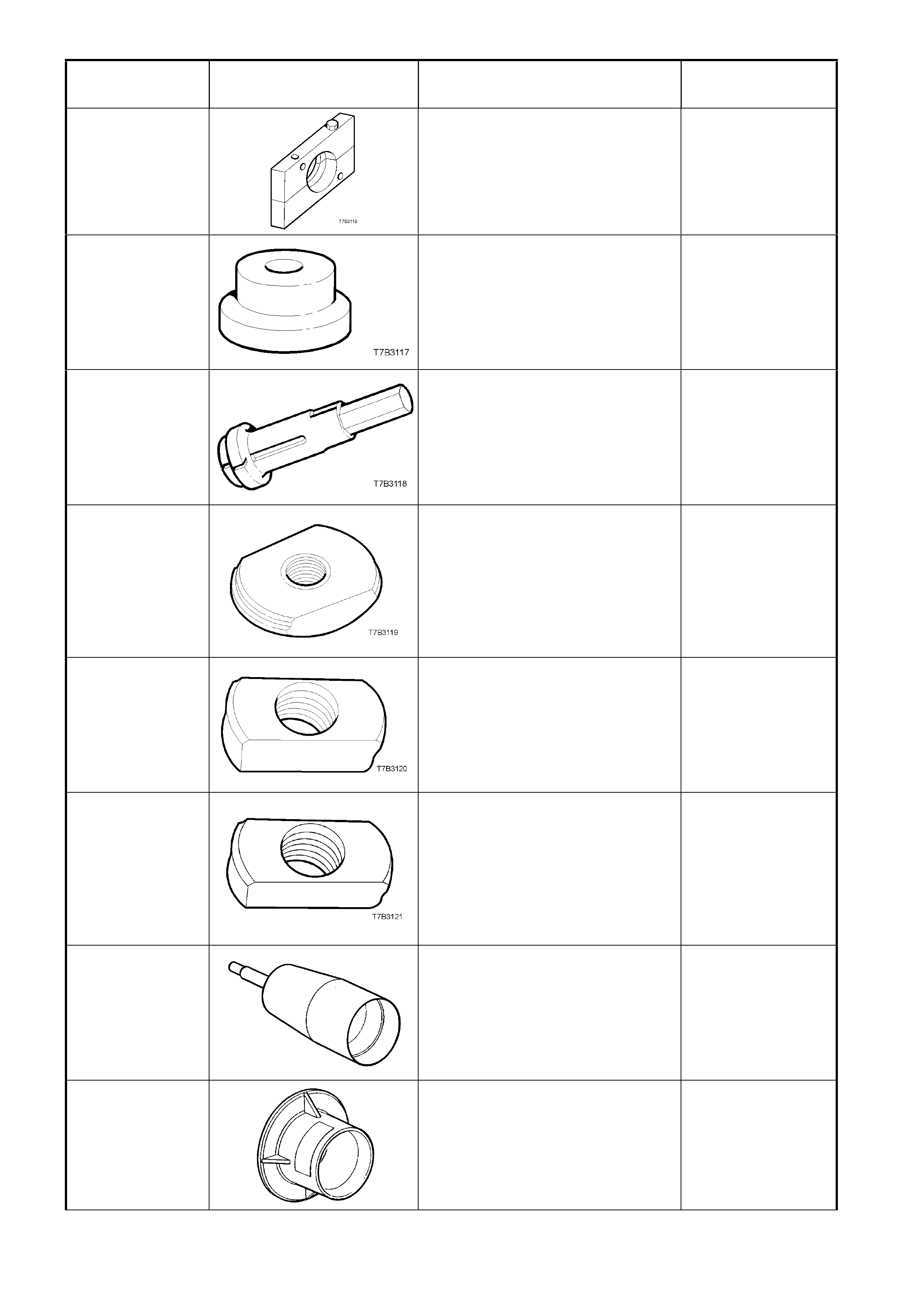

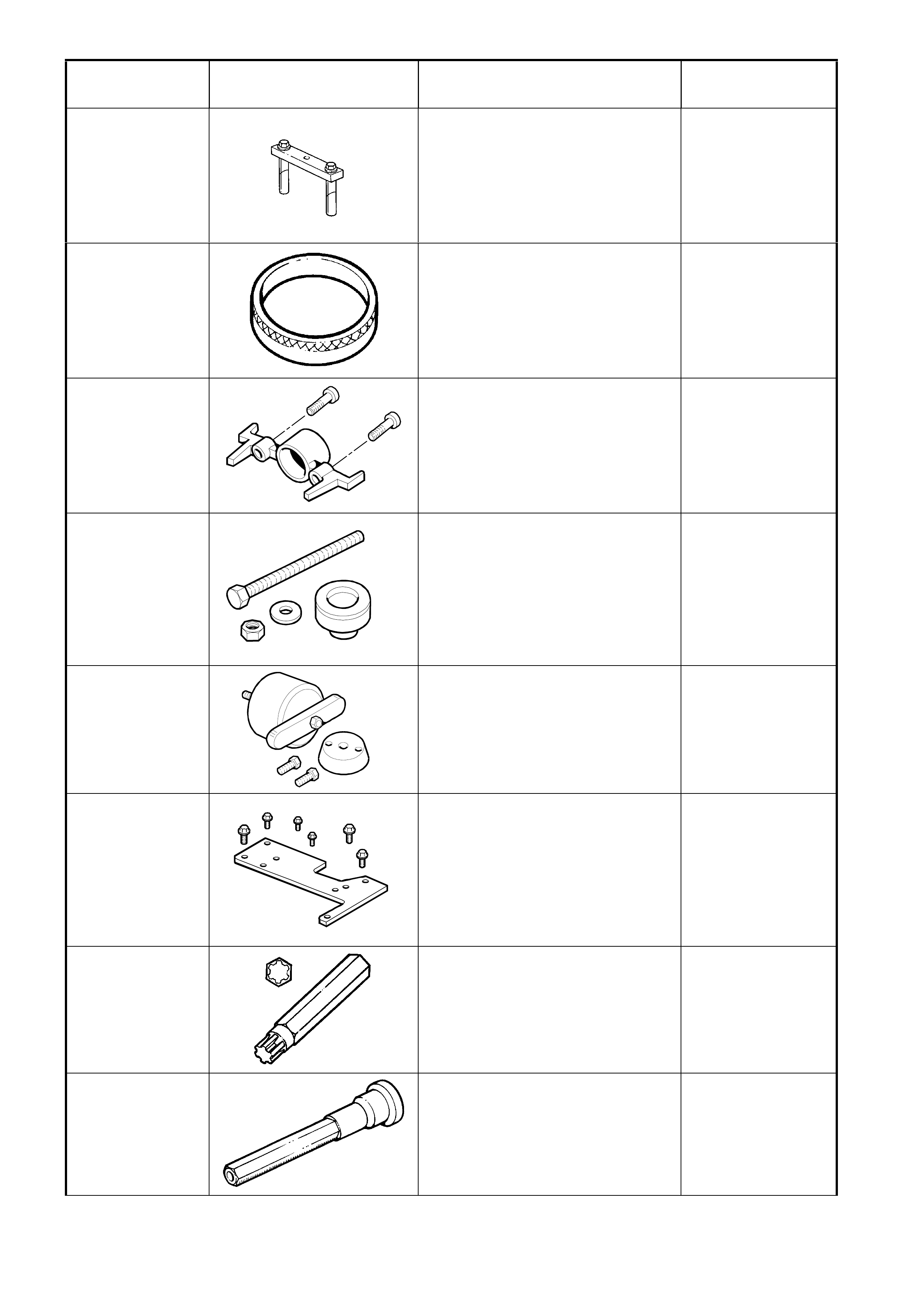

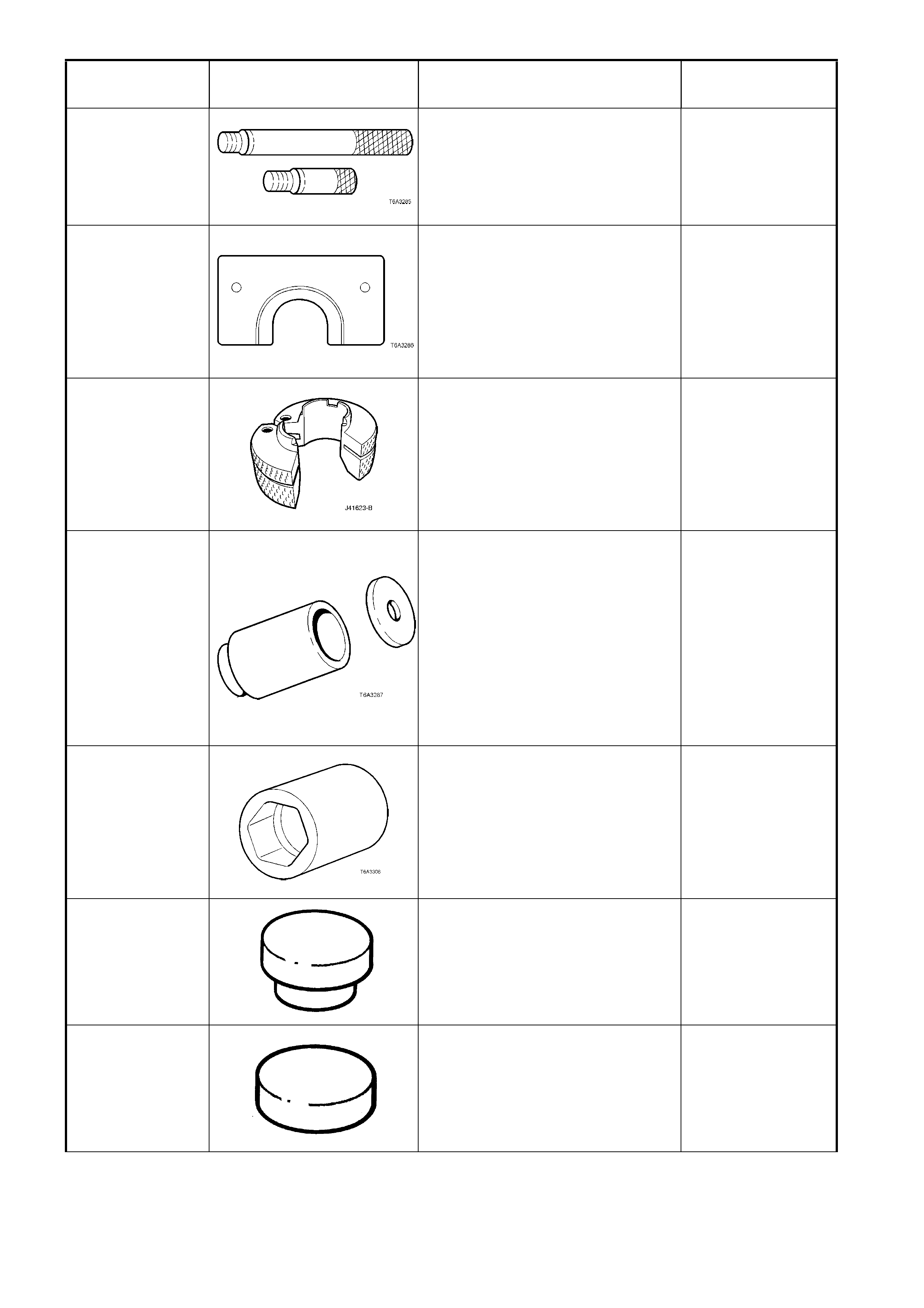

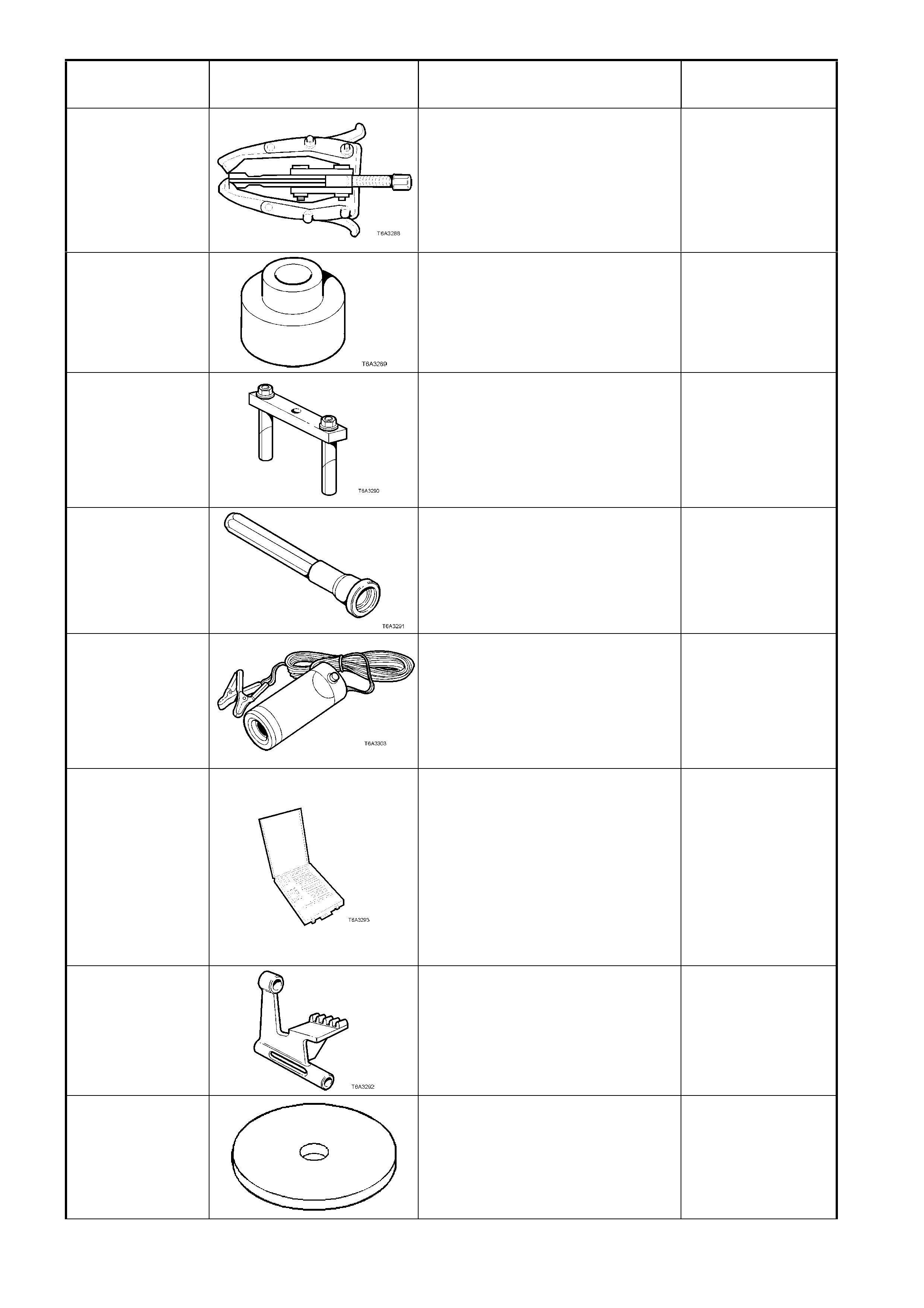

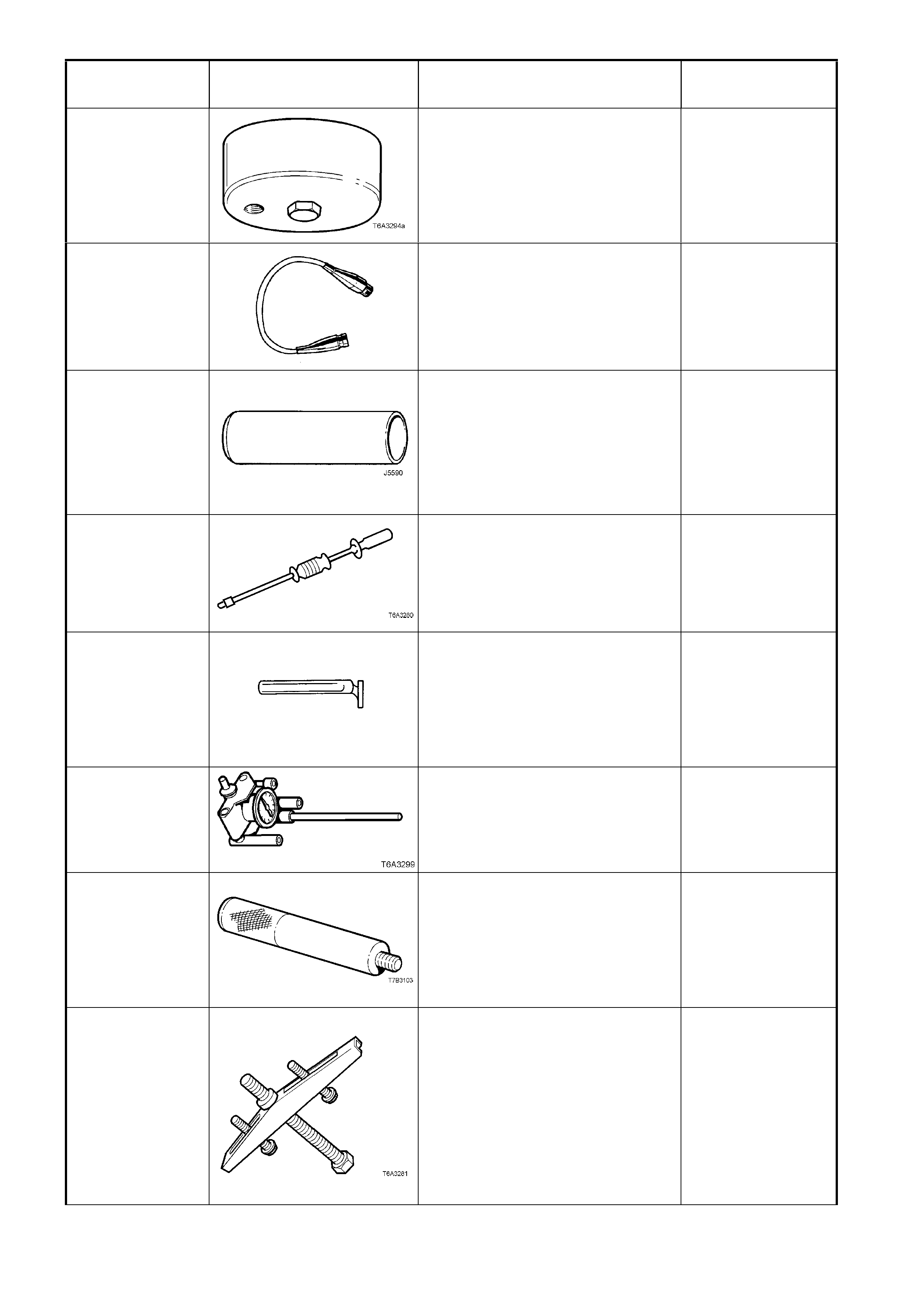

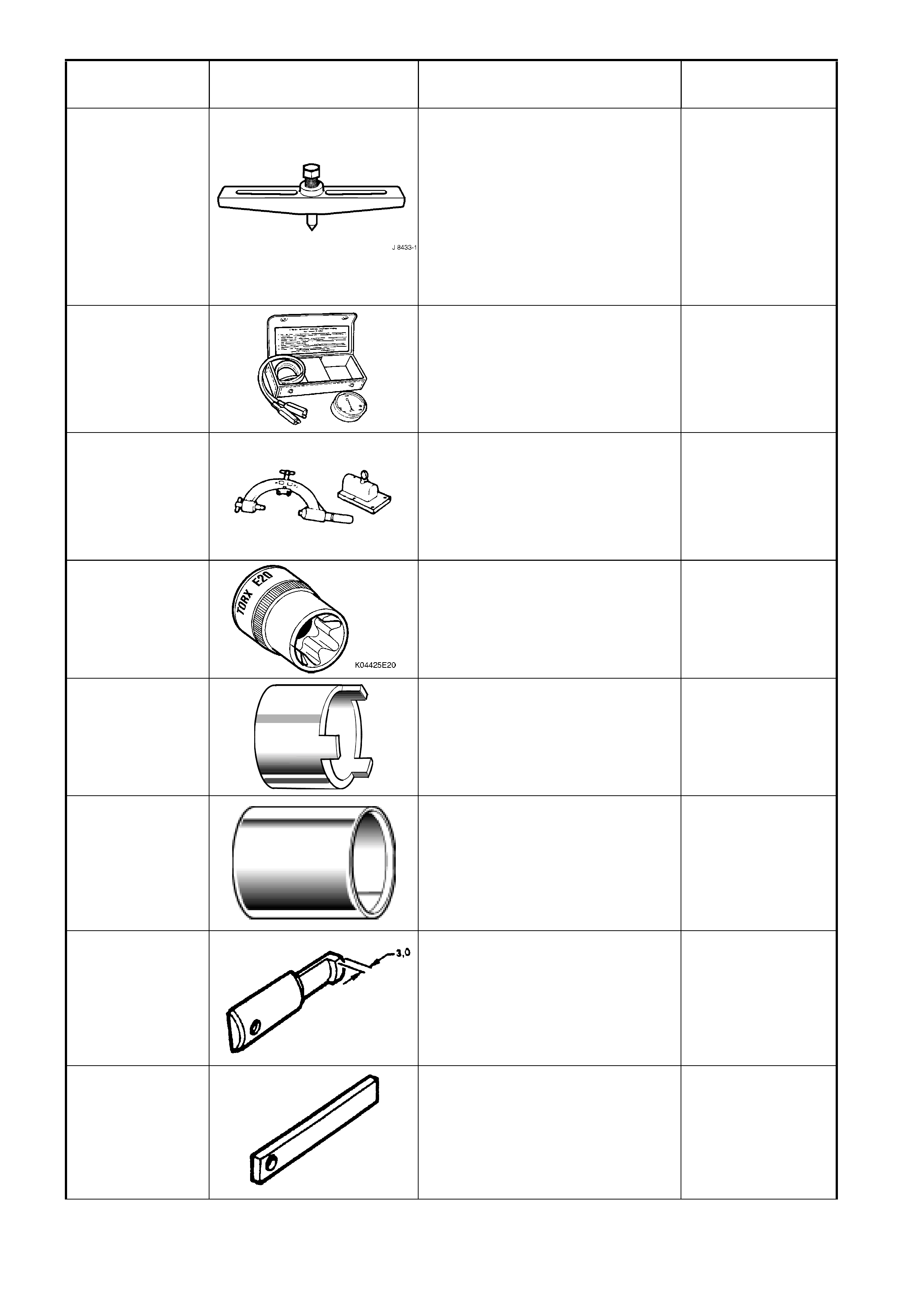

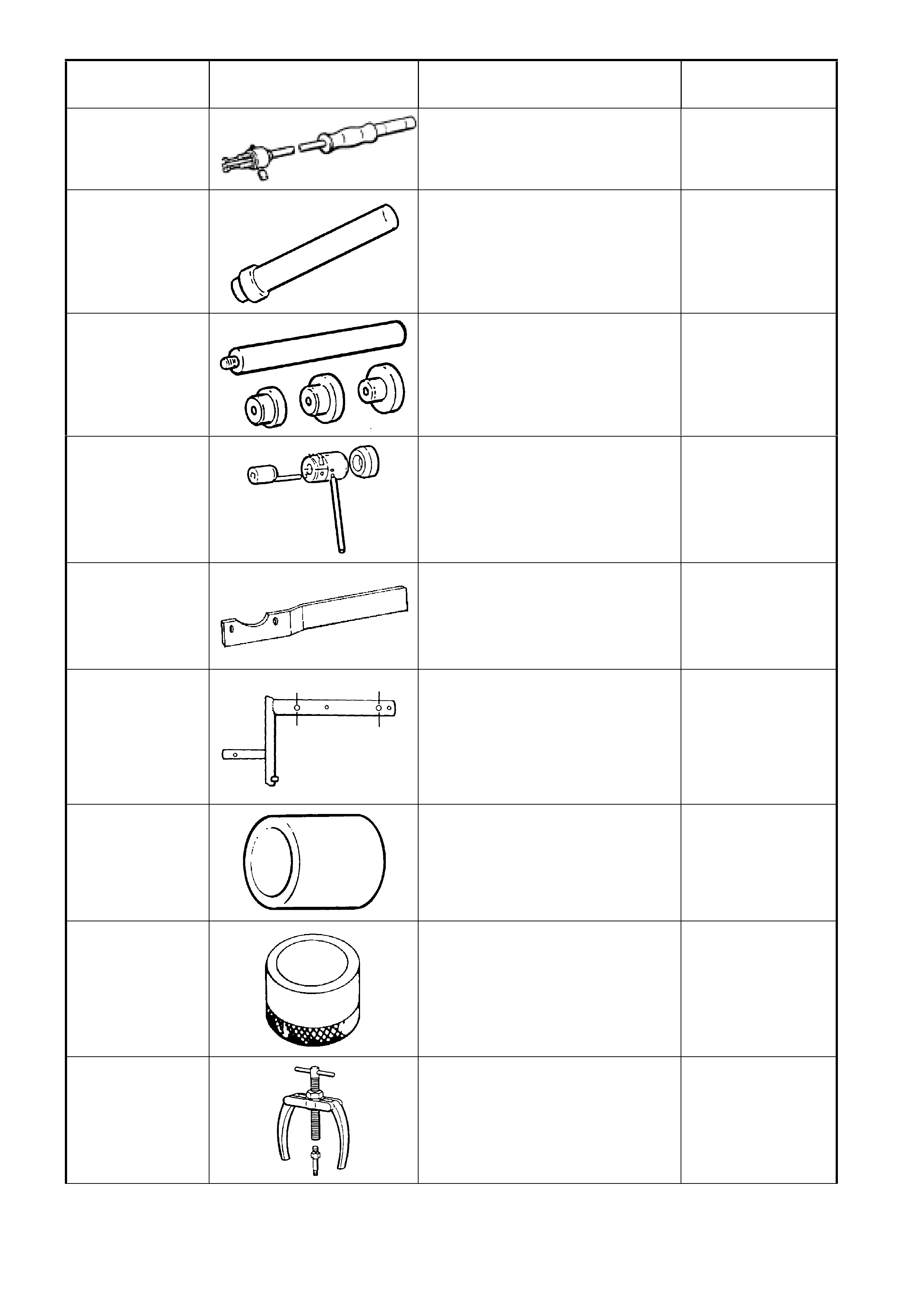

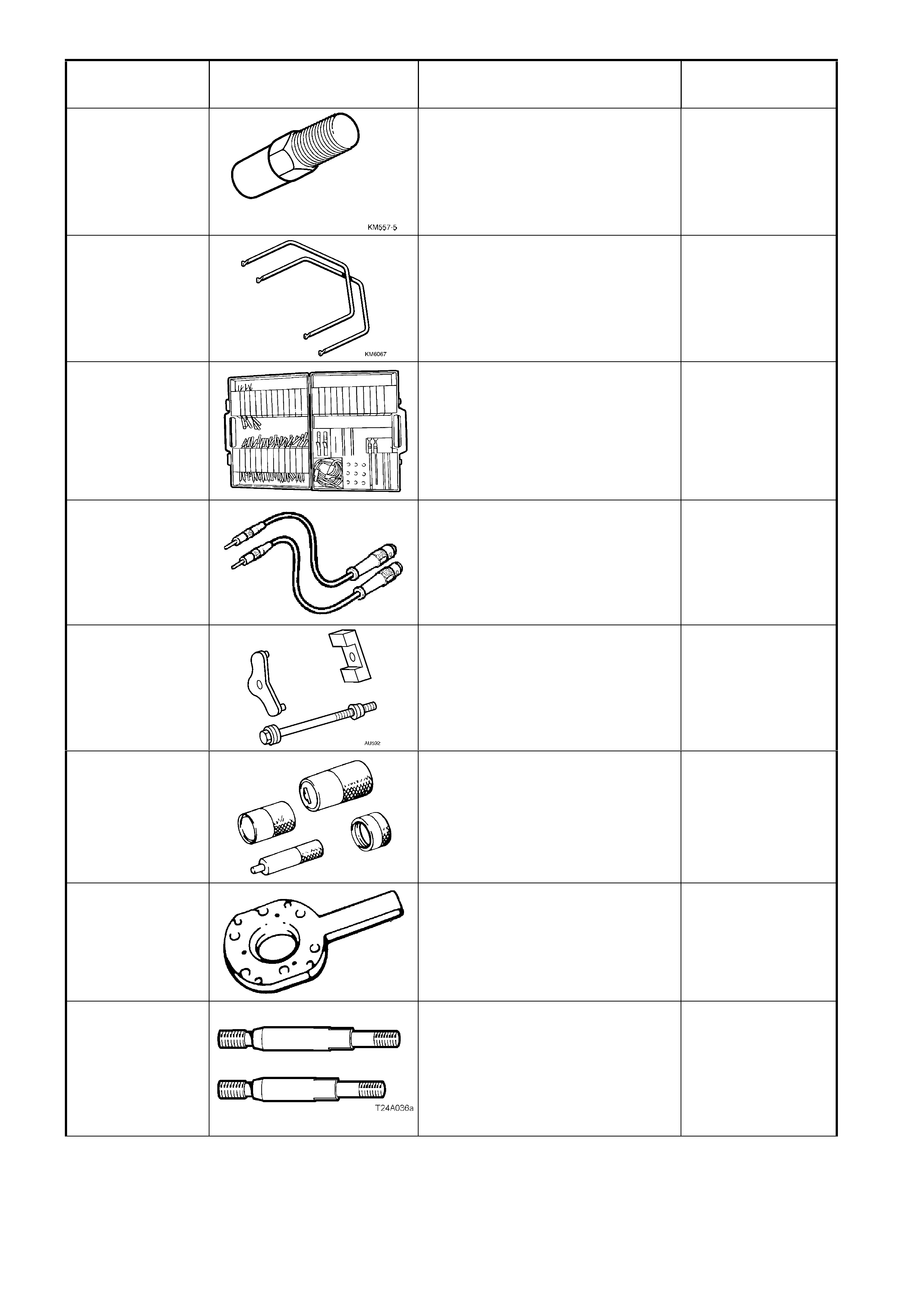

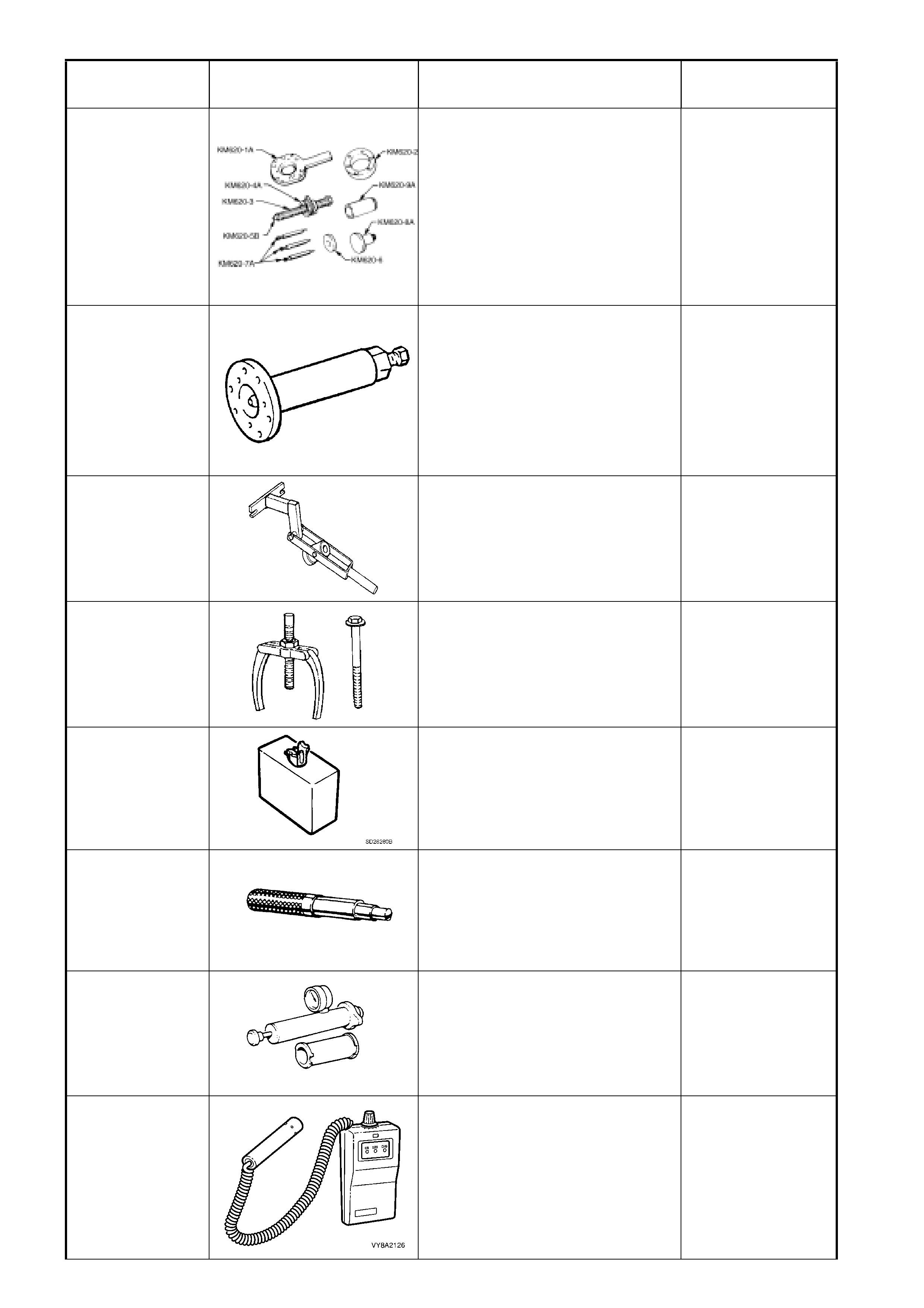

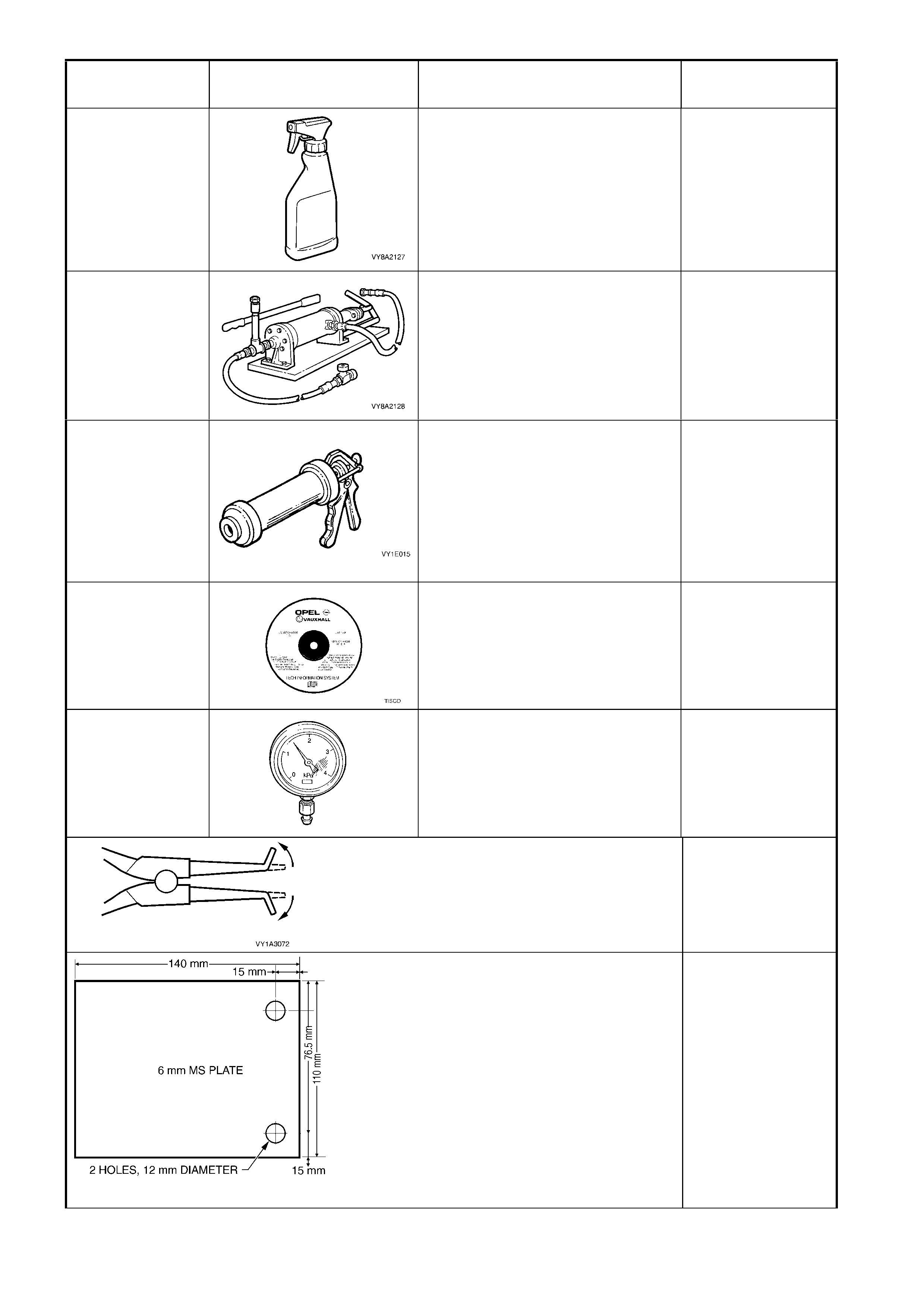

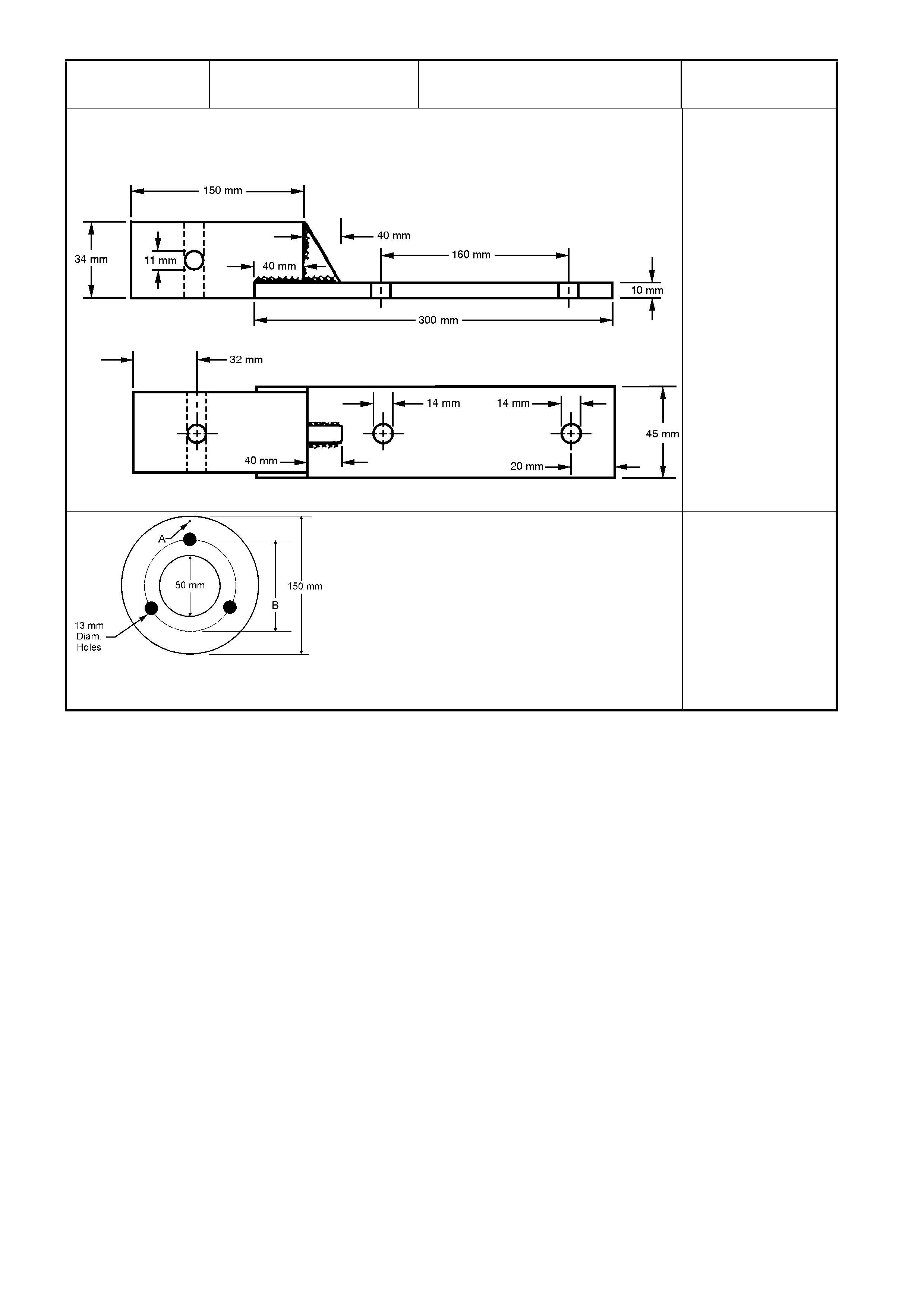

16. CONSOLIDATED TOOL LIST

The f ollowing pages lis t and illus tr ate the spec ial s er vice tools r equired f or us e on MY2003 VY Series & MY2003 V2

Series II vehicles. The tools are listed in numerical then alphabetical order and are classified into the following

categories:

Mandatory: When required to perform routine maintenance operations and adjustments, or are required to carry

out fault diagnosis procedures.

Desirable: These tools should be considered for purchase since their use will greatly facilitate performing

designated tasks and permit achievement of standard times.

Unique: These tools are those that must be employed when overhauling major assemblies or performing

relatively large tasks.

Available: Are those tools that are of a general natur e for which comm ercially available equivalents exis t, or tools

which have had previous application.

Unless otherwise specified, all tools are available from:

SPX Australia PTY. LTD.

Service Solutions

28 Clayton Road

Notting Hill, Victoria, 3168

Telephone: (03) 9544 6222

Facsimile: (03) 9544 5222

Email: [email protected]

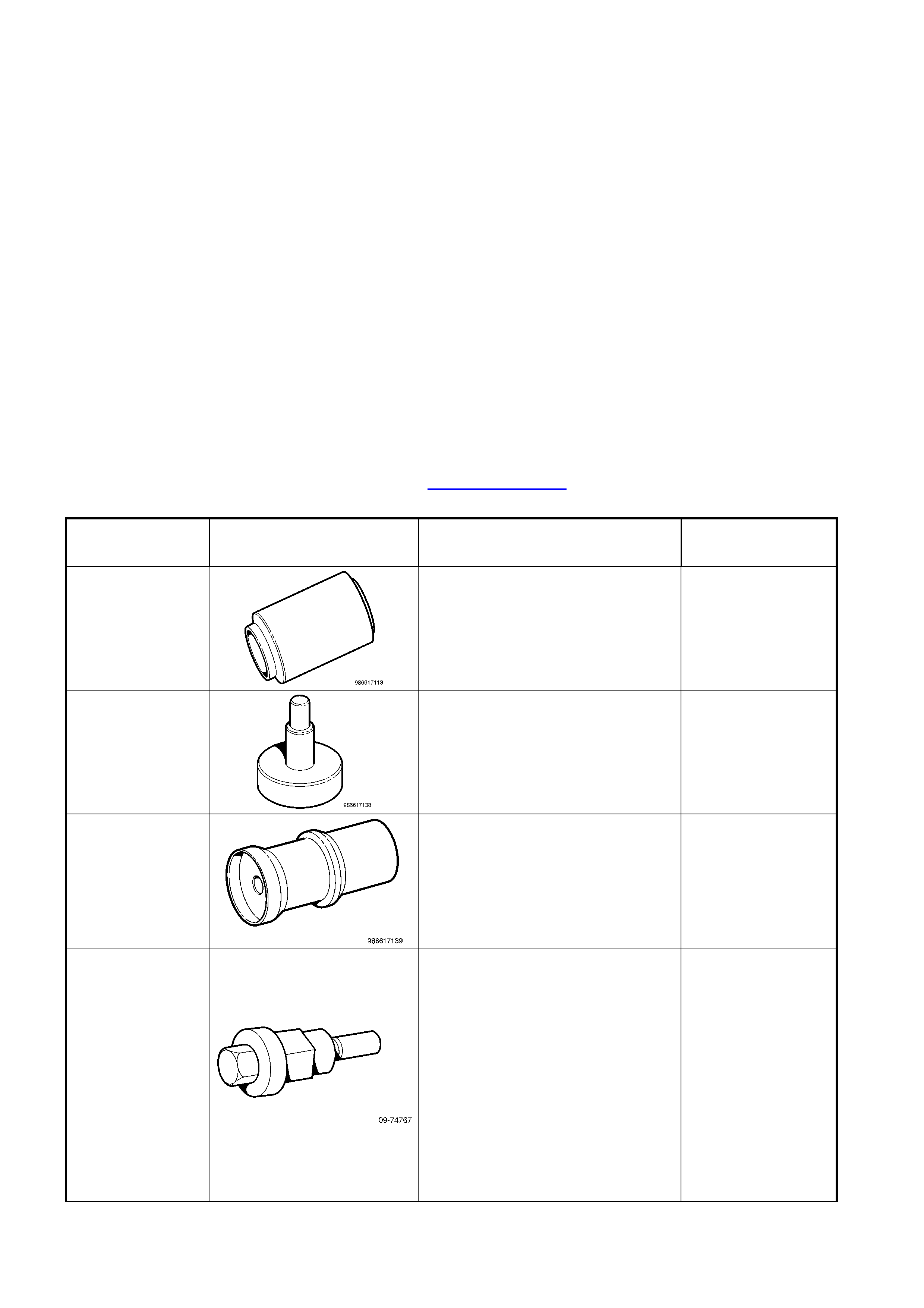

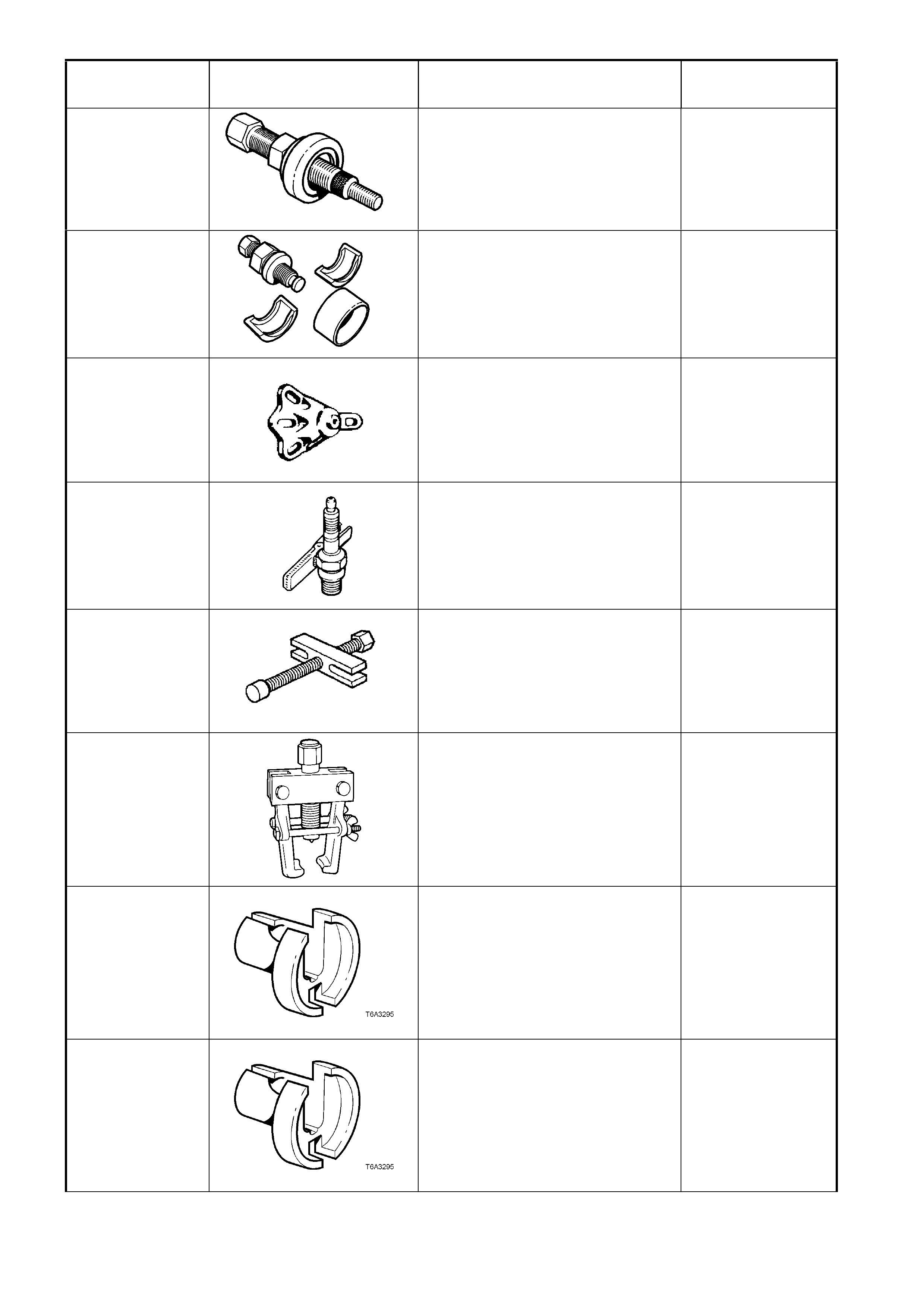

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

0 986 617 113

REMOVER

Used in conjunction with tool no.

0 986 617 138 for the removal of

the starter motor drive-end stop-

ring and retainer.

Unique

0 986 617 138

REMOVER

Used in conjunction with tool no.

0 986 617 113 for the removal of

the starter motor drive-end stop-

ring and retainer.

Unique

0 986 617 139

ASSEMBLY TOOL

Used to assist in brush plate

assembly on starter motors.

Unique

09-74767 A/C CLUTCH HUB AND DRIVE

PLATE INSTALLER

Used for installing A/C clutch drive

plate and hub assembly.

Available from:

The Aftermarket Department

Air International P/L

80 Turner Street

Port Melbourne

Victoria, 3207

Mandatory

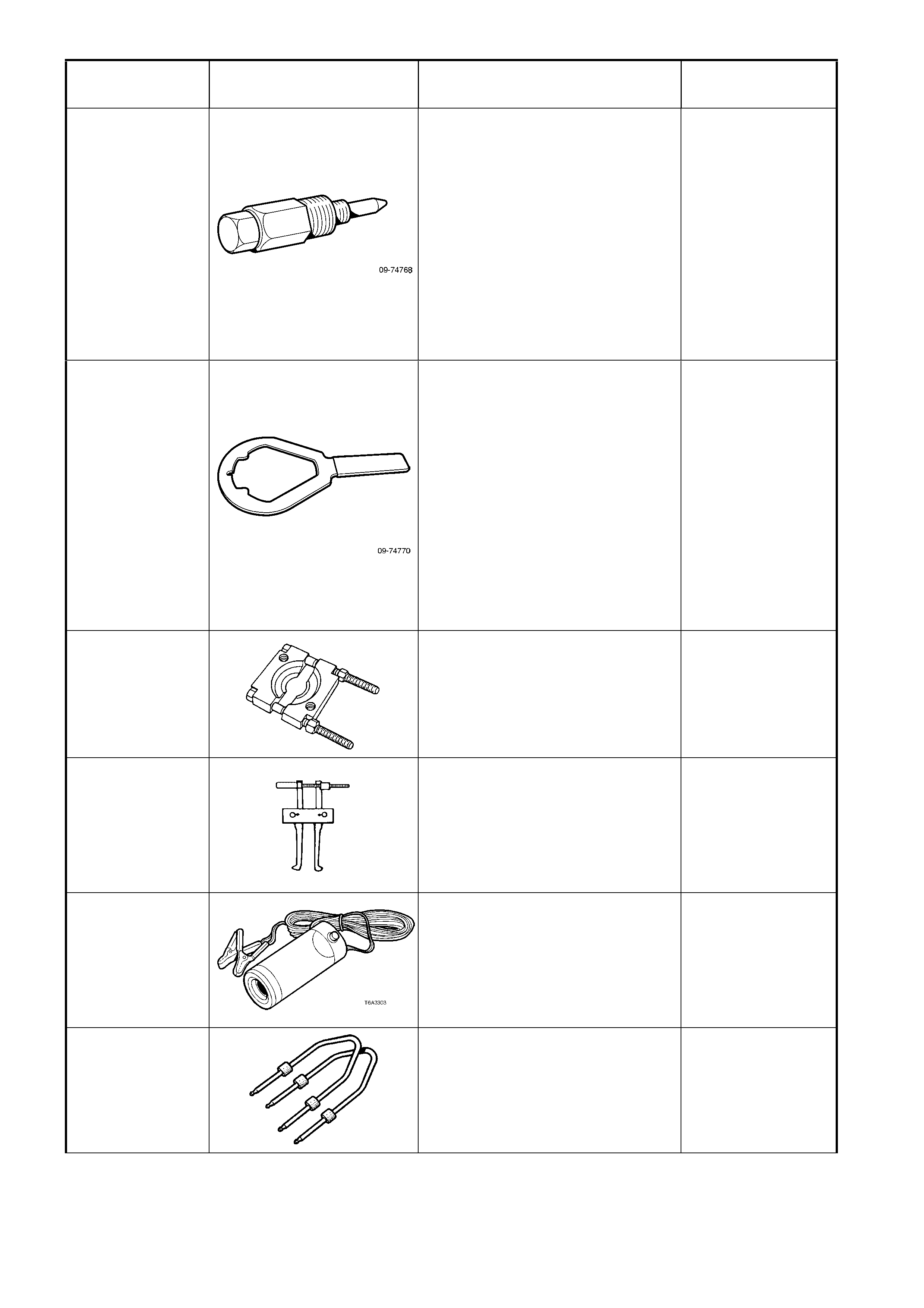

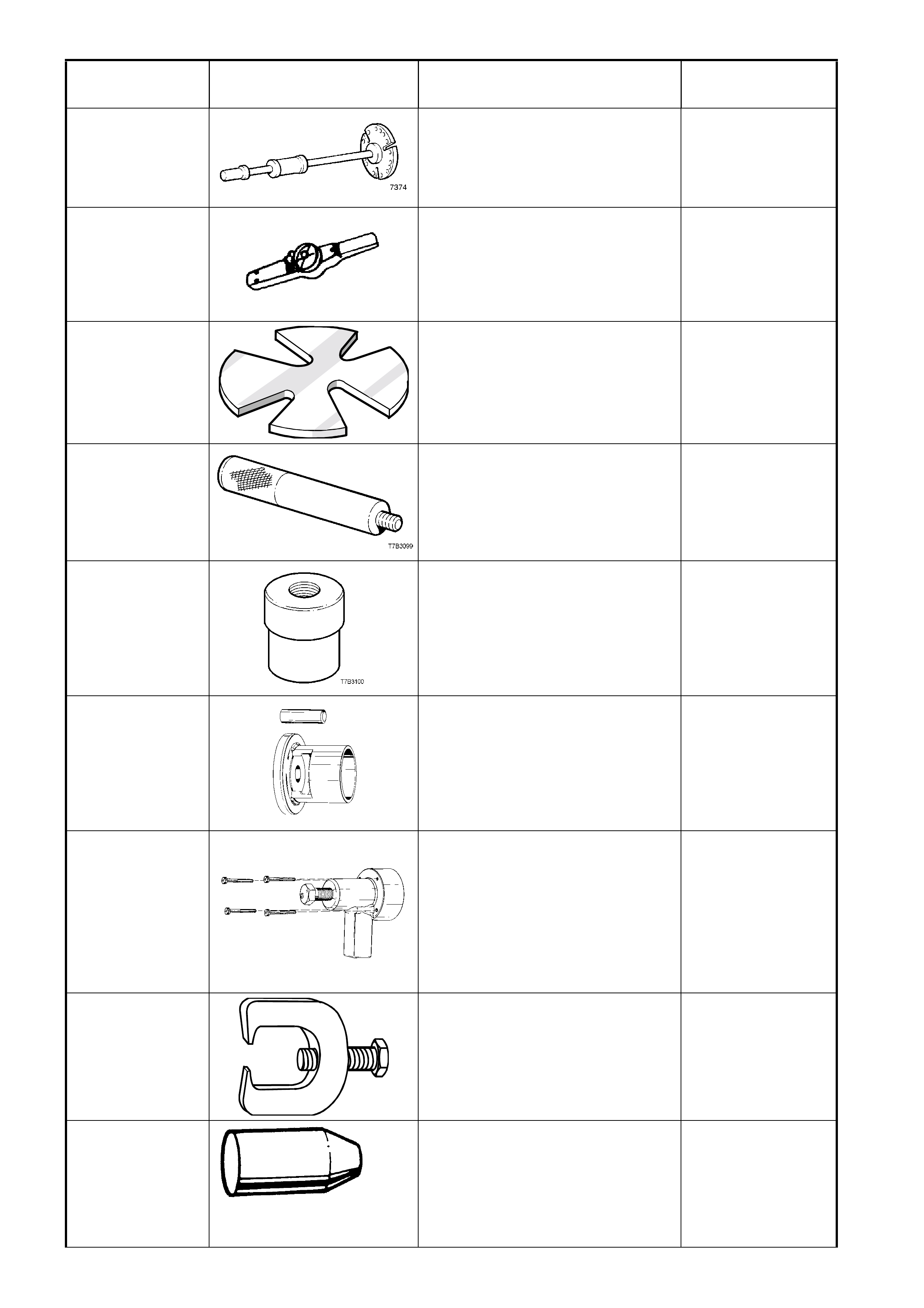

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

09-74768 A/C CLUTCH HUB AND DRIVE

PLATE REMOVER

Used for removing A/C clutch drive

plate and hub assembly.

Available from:

The Aftermarket Department

Air International P/L

80 Turner Street

Port Melbourne

Victoria, 3207

Desirable

09-74770 A/C CLUTCH HUB HOLDER

Used for holding A/C clutch

hub/drive plate during A/C clutch

drive plate and hub assembly

removal and installation.

Available from:

The Aftermarket Department

Air International P/L

80 Turner Street

Port Melbourne

Victoria, 3207

Desirable

1123

(J22912-01)

(E6673)

PRESS PLATES

Used for many applications for

pressing on and off components.

Previously released.

Desirable

1150

PULLER

Used in conjunction with forcing

screw E6661S and adaptor AU412

to remove side bearing cups from

the screw adjusters.

Previously released.

Unique

16296

(J42220)

BLACK LIGHT, LEAK DETECTION

LAMP

Used in conjunction with dye, Tool J

28431-B to locate the source of

various vehicle fluid leaks.

Previously released.

Desirable

179 1308 0000

RADIO REMOVAL TOOL

On VY, used for removing

navigation system processor from

its mounting location.

Previously released.

Mandatory

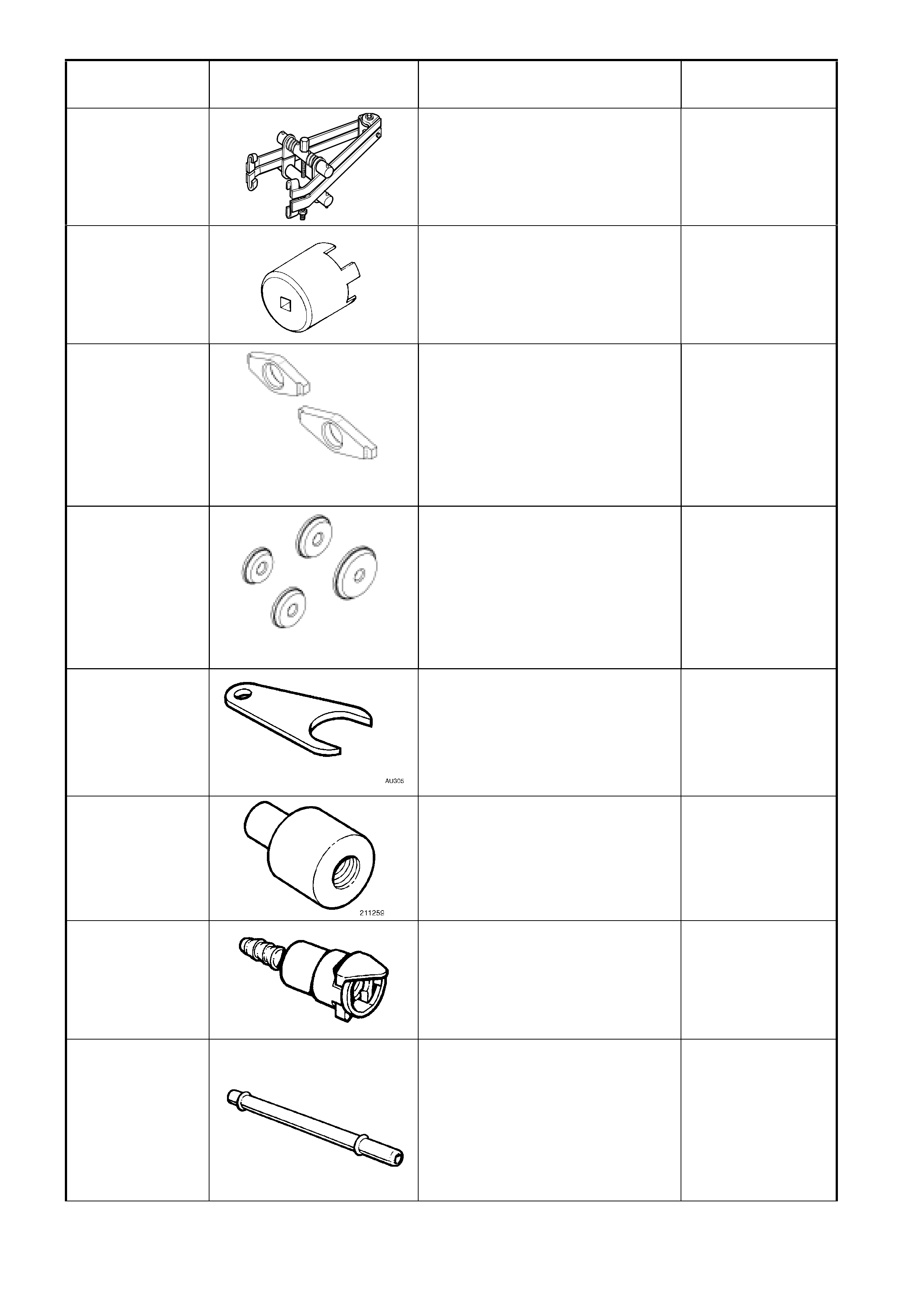

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

180

(6072)

SPRING COMPRESSOR

Used for front spring removal and

reinstallation off vehicle.

Previously released.

Desirable

205-463

(AU407)

SCREW ADJUSTER SOCKET

Used for checking and adjusting

final drive side bearings.

Previously released.

Unique

205-551

ADAPTORS

Used to remove the pinion bearing

cups, in conjunction with

Remover/Installer E9293.

205-551-1 is required for 3.07:1

and 3.46:1 assemblies.

New release.

Unique

205-552

ADAPTORS

Used to install the pinion bearing

cups, in conjunction with

Remover/Installer E9271.

205-552-2 is required for 3.07:1

and 3.46:1 assemblies.

New release.

Unique

211-258

TIE ROD WRENCH

Used to tighten tie rod assembly

from steering rack.

New release.

Unique

211-259

LOWER PINION BEARING

REMOVER

Used in conjunction with Driver

Handle AU355-A.

Previously released.

Unique

212157

COUPLER

Used in conjunction with hose

AU470 and gauge AU338 for

checking fuel pressure.

Previously released.

Mandatory

216812 TUBE

Used in conjunction with hose

SD28057 and coupler 212157 and

gauge SD28018 (or AU338) for

checking fuel system pressure.

Part of AU470

Previously released.

Mandatory

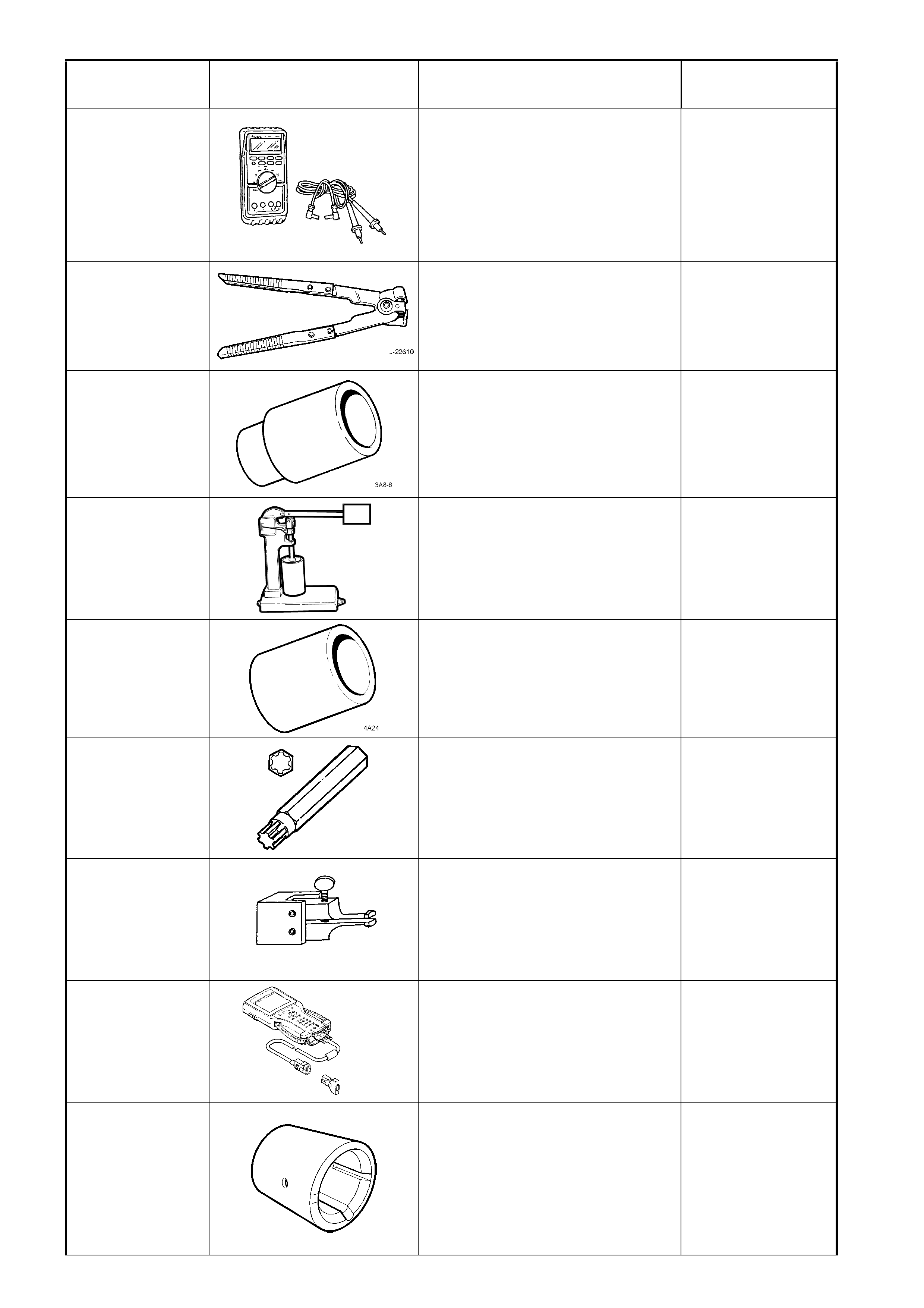

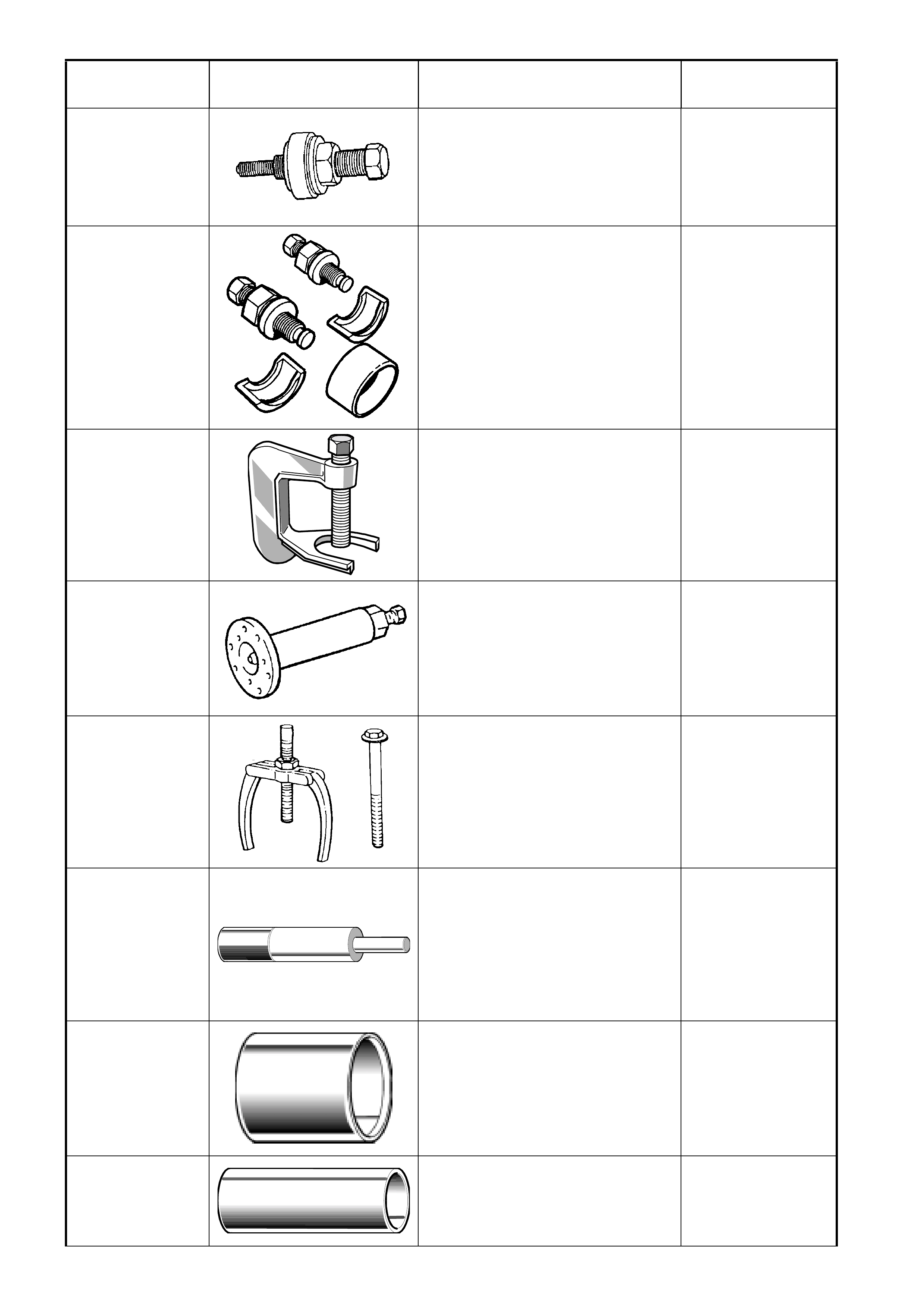

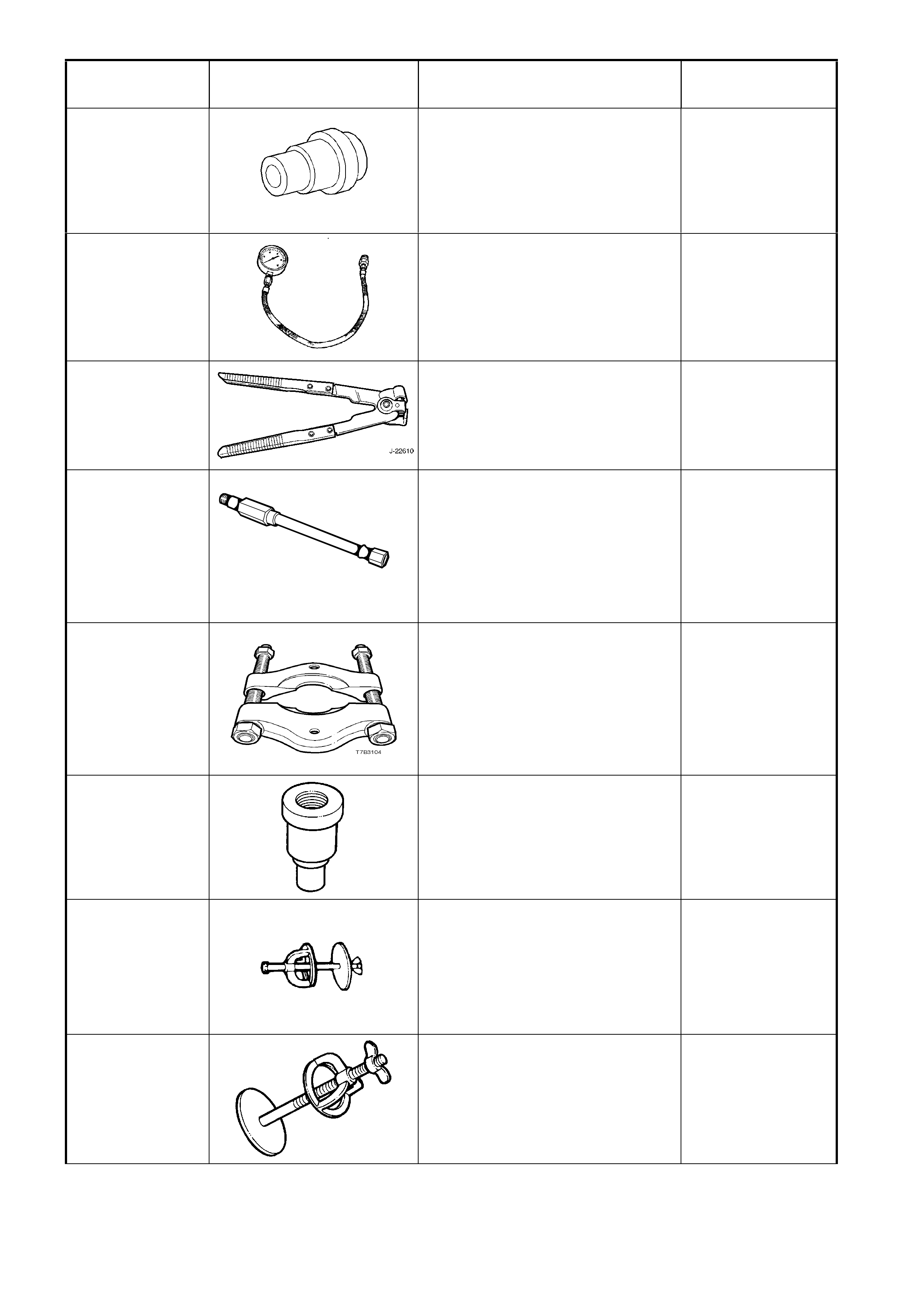

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

3588

(J39200)

DIGITAL MULTIMETER

Used for various measurement

functions. Must have at least

10 MΩ input impedance and be

capable of reading frequencies.

Previously released (or use

commercial equivalent).

Available

3A13

(E1896)

(J22610)

KEYSTONE CLAMP PLIERS

Used to tighten the sliding joint boot

clamp.

Previously released.

Available

3A8-6

(E1891-6)

SLEEVE

Used to install the 1st/2nd gear

synchromesh hub to the mainshaft.

Previously released.

Unique

49 U012 005

(6A23)

T6A3114b

VALVE LIFTER TESTER

Used in conjunction with testing

fluid Kent Moore No. E1151.

Previously released.

Unique

4A24

(E1662)

SLEEVE

Used to install the bearing cup into

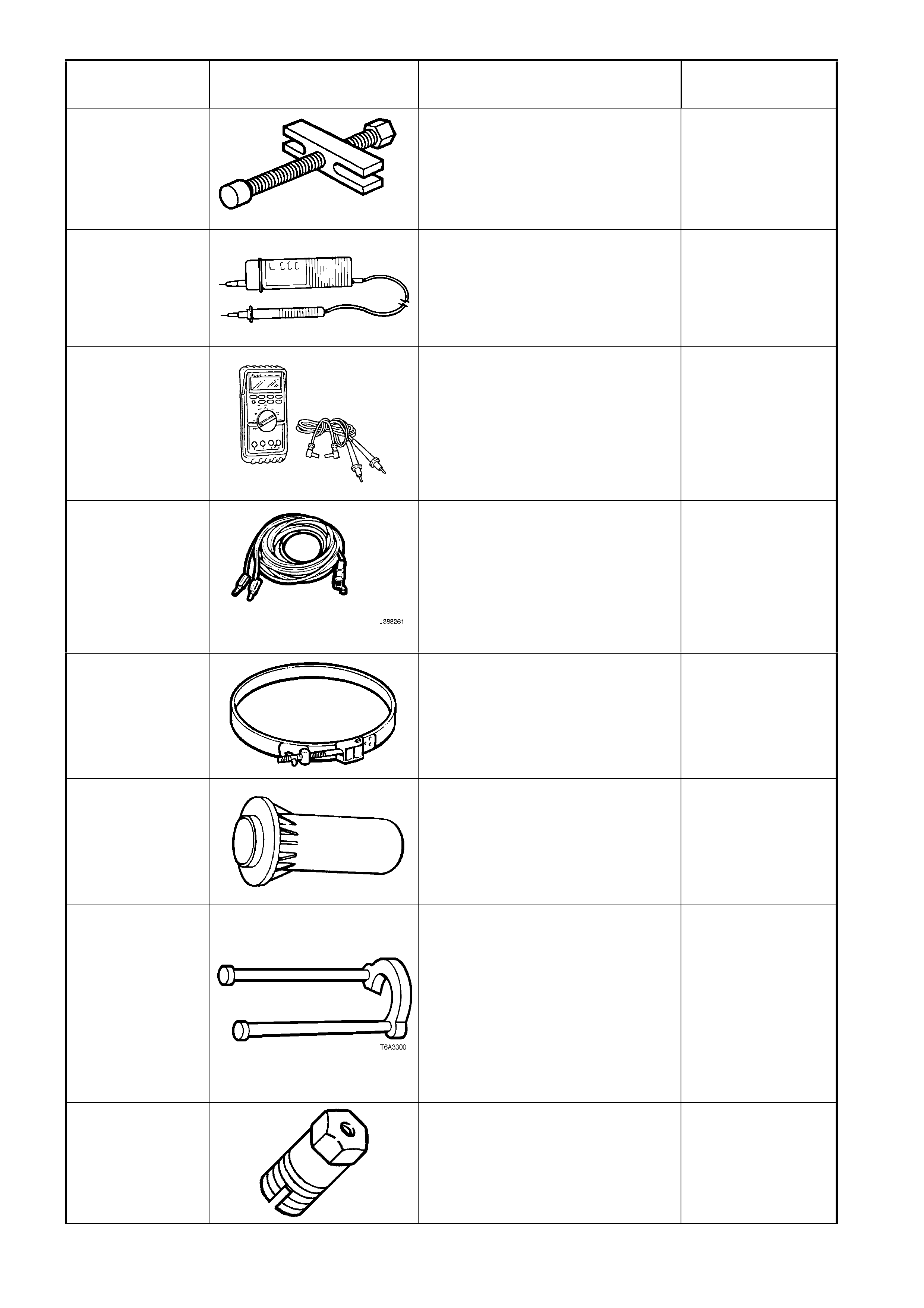

the input shaft gear.

Previously released.

Unique

6194

(J41510)

#50 TORX PLUS BIT

Used for tightening torque

converter housing to transmission

main case attaching bolts.

Previously released.

Unique

6A22-2

SPIGOT BEARING REMOVER

Alternatively, use J23907 or E6668

which includes its own slide

hammer.

Previously released.

Desirable

7000086I

TECH 2 DIAGNOSTIC SCAN

TOOL

Used for diagnosis of vehicle

electrical system.

Previously released.

Mandatory

700-4208

PASS-THRU CONNECTOR

RELEASE TOOL

Used to release the four locking

tangs on the Pass-Thru electrical

connector from the automatic

transmission case.

New release

Available

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

7005

POWER STEERING PUMP

PULLEY INSTALLER

Previously released.

Desirable

7185

POWER STEERING PUMP

PULLEY REMOVER

Previously released.

Desirable

7208 REAR AXLE REMOVAL ADAPTOR

Used in conjunction with E6662B

for L.S.D. torque check.

Previously released.

Unique

7230

(ST-125)

HEI TESTER (TEST PLUG)

Used in diagnostic checks with

engine management system.

Previously released.

Mandatory

7245

(J1859-A)

STEERING WHEEL PULLER

Used in conjunction with E1408 to

remove steering wheel (or use

commercially available equivalent).

Previously released.

Mandatory

7311

(9A10)

(E1465)

TIE ROD BALL JOINT REMOVER

Used to disconnect steering tie rod

ball joints from steering knuckle.

Previously released.

Desirable

7370

QUICK CONNECT RELEASE

TOOL – 5/16”

Used for releasing fuel hose quick

connects at the dash panel and fuel

rail connections, once the fuel

system has been depressurised.

Previously released.

Mandatory

7371

QUICK CONNECT RELEASE

TOOL – 3/8”

Used for releasing fuel hose quick

connects at the dash panel and fuel

rail connections, once the fuel

system has been depressurised.

Previously released.

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

7374 SLIDE HAMMER & PLATE

Used to remove inner axle shafts

from the rear axle assembly .

Previously released.

Desirable

7380

(J25765-A)

PRE-LOAD GAUGE (3/8” DRIVE)

Used for many applications.

Previously released.

(0-150 in lbs)

Mandatory

7A42

PRESS PLATES

Previously released.

Desirable

7AT2

(E1502)

DRIVER HANDLE

Used in conjunction with 7AT5 to

remove/install the slip yoke bushing

in the extension housing.

Previously released.

Unique

7AT5

(E1505)

(J23062-14)

SLIP YOKE BUSH REMOVER/

INSTALLER

Used in conjunction with 7AT2 to

remove/install the slip yoke bushing

in the extension housing.

Previously released.

Unique

9981 066 600

BEARING ASSEMBLY FIXTURE

Used for pressing generator

bearings on at the same time. Tool

available from Robert Bosch

Australia.

Previously released.

Unique

9981 066 601 ROTOR BEARING REMOVAL

TOOL

Used for removing rotor from drive

end housing.

Tool available from Robert Bosch

Australia.

Previously released.

Unique

9A10

(7311)

(E1465)

STEERING LINKAGE BALL STUD

REMOVER

Previously released.

Desirable

9A23

(E1483)

EXPANDER - SLEEVE SEALS

Used for expanding steering gear

rotary valve and sleeve assembly

seals before installation.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

A7005

(J25033-B)

(E9239A)

POWER STEERING PUMP

PULLEY

RE-INSTALLER

Previously released.

Desirable

A7185 POWER STEERING PUMP

PULLEY

REMOVER – GEN III

Previously released.

Mandatory

AJ24292-C

PRESS TOOL

Used to remove wheel studs from

front wheel hub assembly.

Previously released.

Unique

AKM-628-A EXTRACTOR TOOL

Used to remove the mainshaft

flange and to separate the two

transmission housings on

disassem bly.

Previously released.

Unique

AMKM-557

PULLER

Previously released.

Used for removing bushing from

crossmember front mounting.

Previously released.

Desirable

AU158 FRONT LOWER CONTROL ARM

ROD BUSHING REMOVER AND

INSTALLER MANDREL

Used in conjunction with KM158-2

for removing bush and AU159 and

KM157-2 for installing.

Previously released.

Desirable

AU158-2

FRONT LOWER CONTROL ARM

ROD BUSHING INSTALLING

SUPPORT SLEEVE

Used in conjunction with AU158

and AU159.

Previously released.

Desirable

AU159 FRONT LOWER CONTROL ARM

ROD BUSHING REPLACER

SLEEVE

Previously released.

Desirable

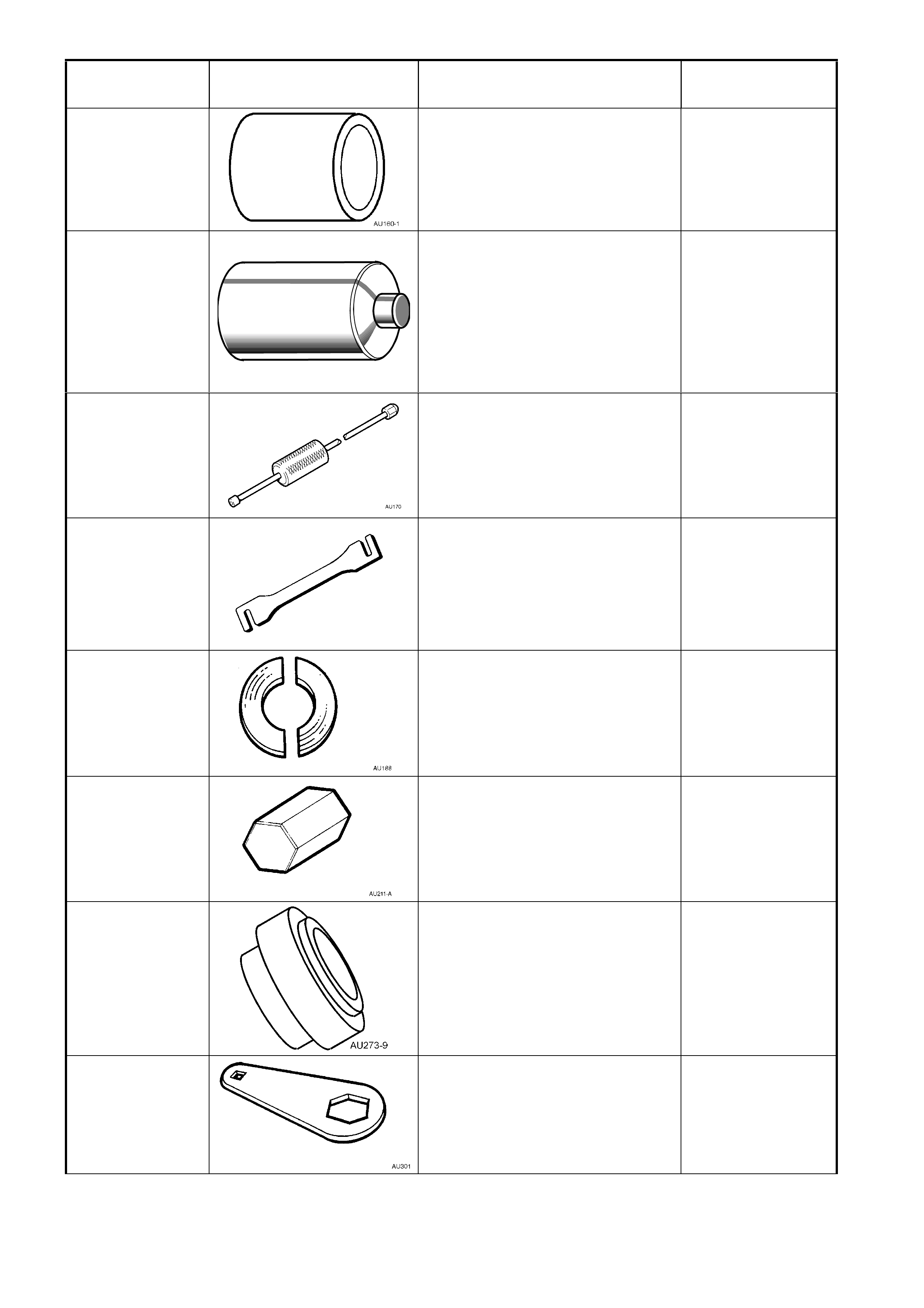

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU160-1

SUPPORT

Used to support front lower control

arm when installing a new inner

insulator.

Previously released.

Desirable

AU162 FRONT LOWER CONTROL ARM

PIVOT BUSHING

REMOVAL MANDREL

Used in conjunction with AU160-1

and KM157-2.

Previously released.

Desirable

AU170

DOOR HINGE SLEEVE

REMOVER

Used for removing door hinge pivot

sleeves.

Previously released.

Available

AU184 DOOR HINGE SETTING TOOL

Used to adjust door alignment.

Previously released.

Desirable

AU188

PRESS PLATES

Previously released.

Unique

AU211-A

(E9326-8)

RACK PAD ADJUSTING SCREW

WRENCH

Previously released.

Desirable

AU273-9

ADAPTOR

Used in replacement of propeller

shaft centre bearing

Previously released.

Unique

AU301

(E9326-7)

RACK PAD ADJUSTING SCREW

LOCK NUT WRENCH

Previously released.

Desirable

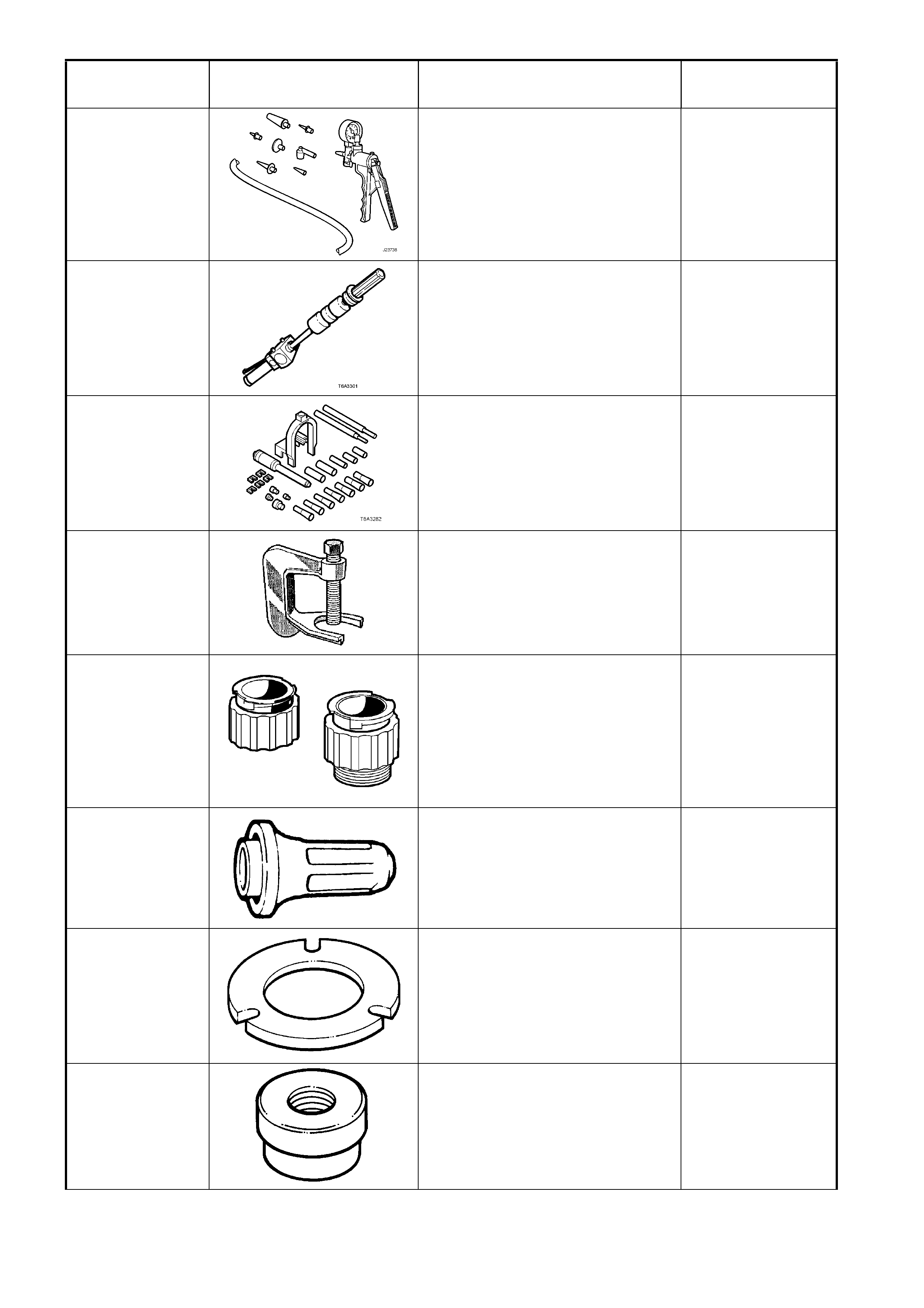

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

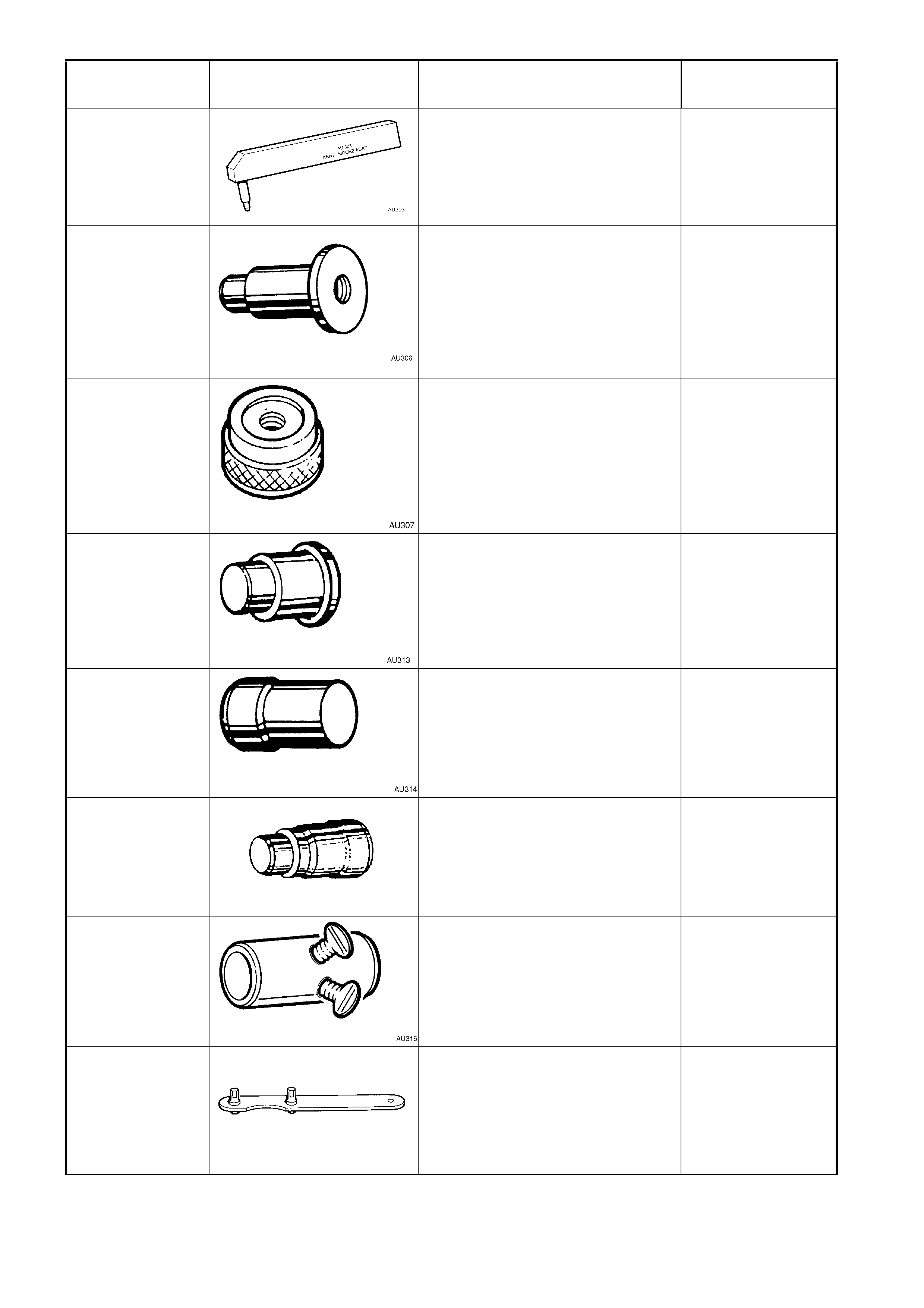

AU303

DOOR HINGE SLEEVE

INSTALLER

Used to install door hinge pivot

sleeves.

Previously released.

Available

AU306 LOWER PINION BEARING

REMOVER

Used in conjunction with driver

handle AU355-A (or M523-1) to

remove steering gear pinion lower

bearing.

Previously released.

Unique

AU307 LOWER PINION BEARING

INSTALLER

Used to install steering gear pinion

lower bearing.

Previously released.

Unique

AU313 UPPER PINION POWER

STEERING FLUID SEAL

INSTALLER

Previously released.

Used to install valve housing

bearing.

Unique

AU314 VALVE HOUSING SEAL AND

BEARING REMOVER

Previously released.

Unique

AU315-A

STEERING GEAR VALVE

HOUSING SEAL AND BEARING

INSTALLER

Previously released.

Unique

AU316 PRE-LOAD ADAPTOR

Previously released.

Unique

AU320

(AU448)

CRANKSHAFT BALANCER

HOLDING TOOL

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

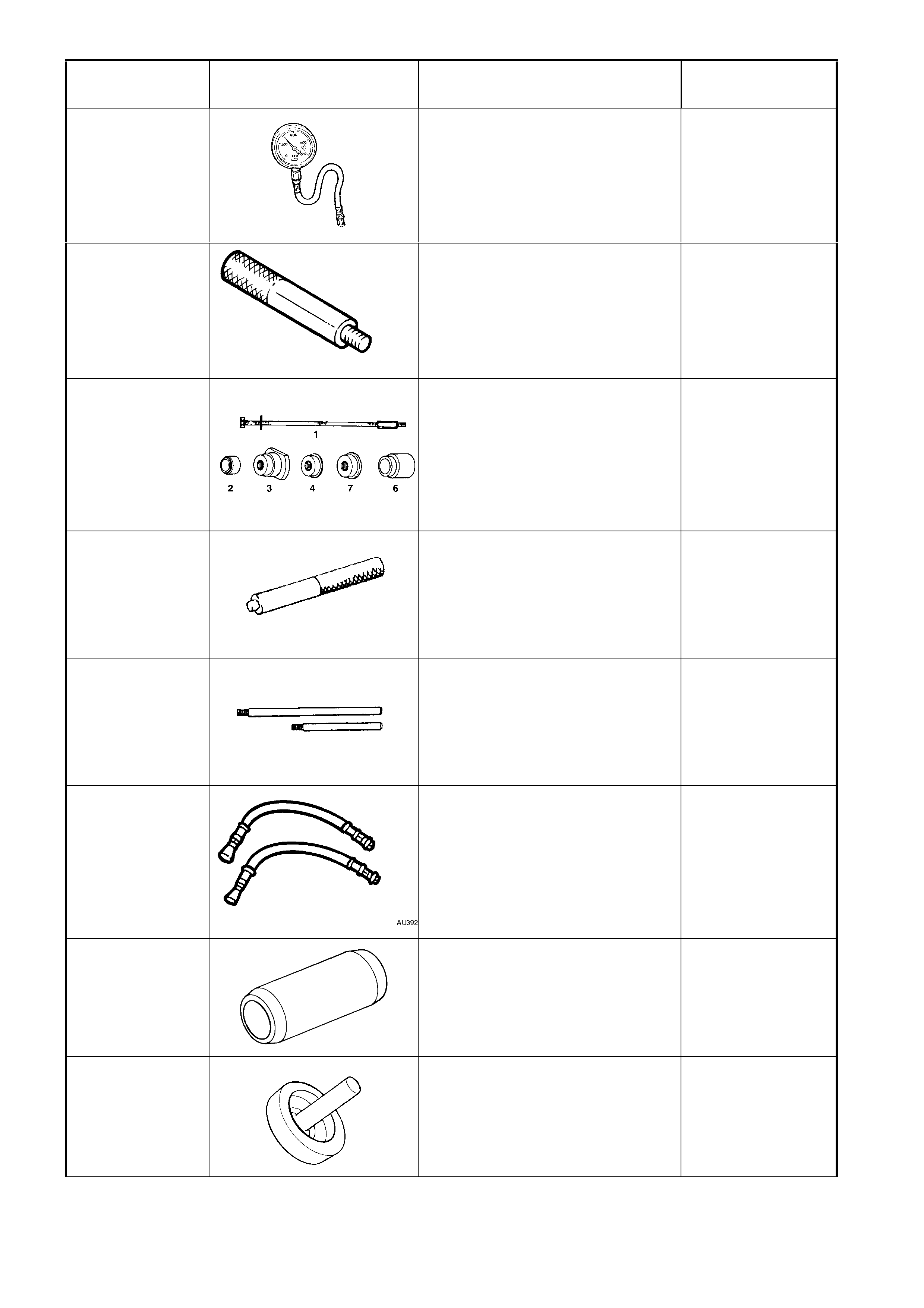

AU338

(SD28018)

FUEL PRESSURE GAUGE - HIGH

PRESSURE

Used for checking fuel system

pressure in conjunction with

AU453.

Previously released.

Mandatory

AU355-A DRIVER HANDLE

Previously released as KM523-1.

Used in conjunction with AU306

and AU315.

Previously released.

Unique

AU384-B PULLER SCREW

Used in conjunction with AU384-2,

AU384-3, AU384-4, AU384-7 and

AU384-6A to remove / install

camshaft and balance shaft

bearings.

Previously released.

Desirable

AU385-4

REMOVER / INSTALLER

Used to remove and install bushes

into rear suspension stabiliser bar.

Previously released.

Desirable

AU388 CONNECTING ROD GUIDE

TOOLS

Used in conjunction with AU388-1

and AU388-2.

Previously released.

Unique

AU392 PRESSURE HOSE SET

Comprises:

AU392-1, hose with male end

fitting.

AU392-2, hose with female end

fitting.

Previously released.

Mandatory

AU408

DUMMY ARBOUR

Used in conjunction with dummy

pinion from E9300A.

Previously released.

Unique

AU409

PRESS FIXTURE

Used to install needle bearings into

screw adjusters. Used in

conjunction with AU411.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

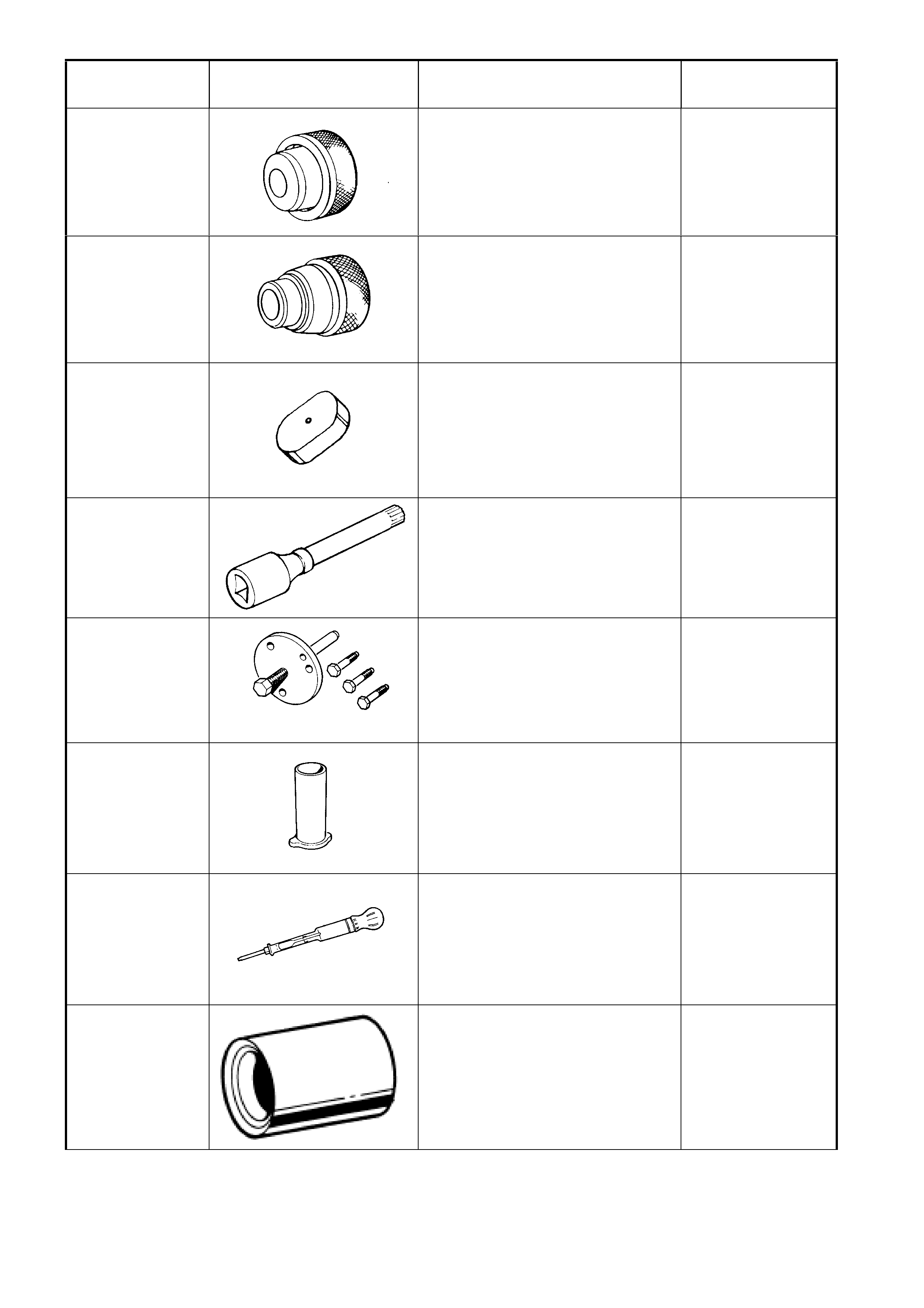

AU410

SEAL INSTALLER

Used to install inner axle seals to

screw adjusters.

Previously released.

Unique

AU411

BEARING AND CUP REMOVER

Used in conjunction with AU409.

Previously released.

Unique

AU412

ADAPTOR

Used in conjunction with forcing

screw E6661S and puller 1150 to

remove side bearing cups from

screw adjusters.

Previously released.

Unique

AU416

TOR X BIT

Used to remove and reinstall upper

rear brake backing plate to trailing

arm bolts.

Previously released.

Unique

AU424

CRANKSHAFT BALANCER

PULLER

Puller bolts must be 70 mm x 1/4”

NF.

Previously released.

Mandatory

AU425 COOLING SYSTEM FILLER TUBE

Used to ensure coolant level is

correct.

Previously released.

Mandatory

AU435 COOLANT TESTER

Used to check condensation.

Previously released.

Mandatory

AU440 CONTRACTOR - SLEEVE SEALS

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

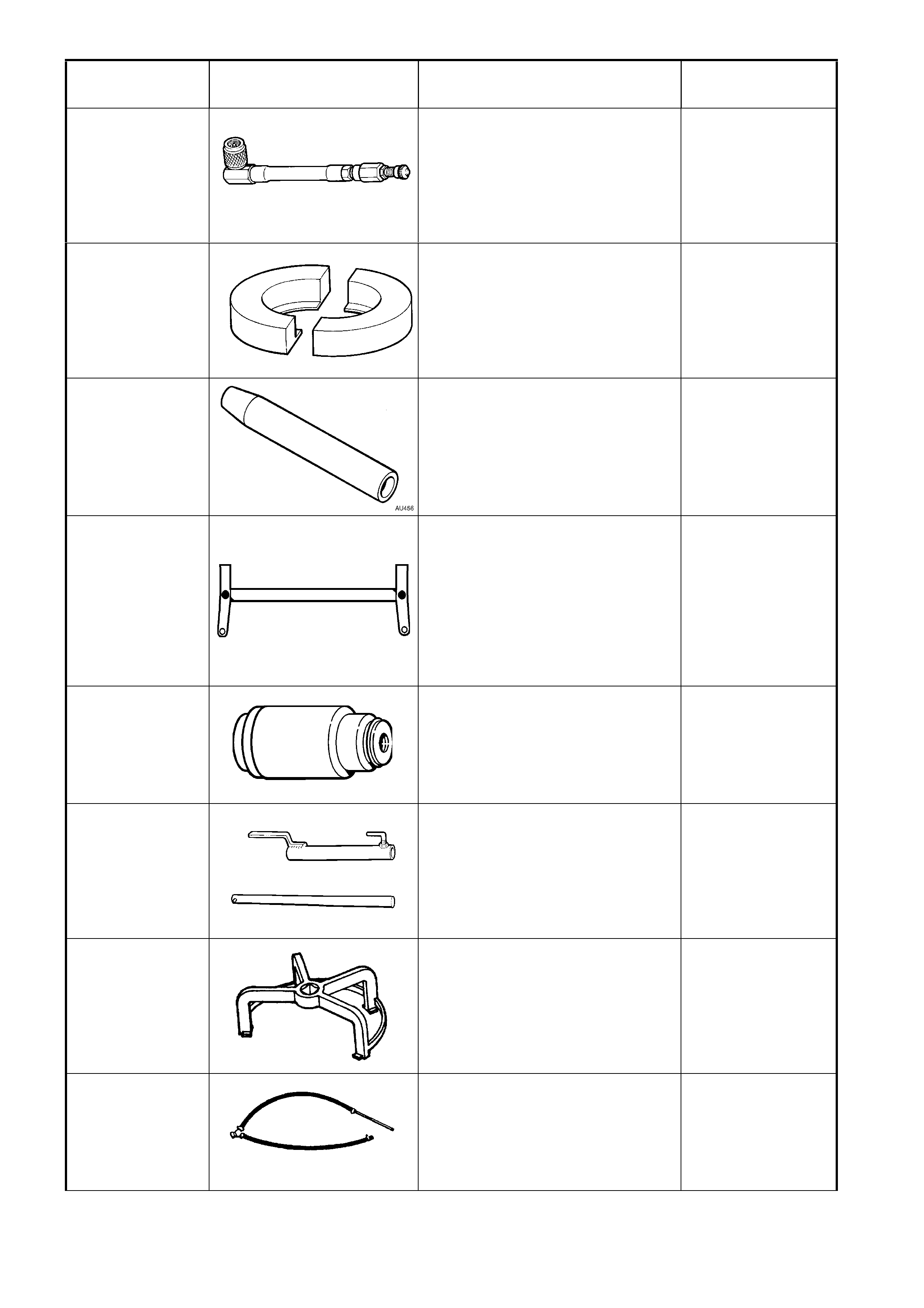

AU453 FUEL GAUGE SCHRADER

ADAPTOR

Used for checking system fuel

pressure in conjunction with

AU338.

Previously released.

Mandatory

AU454 GEAR REMOVER PLATES

Used to remove 3rd/4th

synchromesh assembly, 3rd speed

gear, 2nd speed gear and related

components from the mainshaft.

Previously released.

Unique

AU456 RACK SEAL PROTECTOR - LONG

Used when overhauling steering

gear.

Previously released.

Unique

AU458 REAR CROSSMEMBER

CENTERING TOOL

Used when any service operation

requires removal / reinstallation of

frame assembly - rear suspension,

or when checking rear end

alignment.

Previously released.

Desirable

AU460 INSTALLER - INNER RACK SEAL

AND SPACER

Used in conjunction with driver

handle AU355-A.

Previously released.

Unique

AU462

SELECT LEVER SPRING AND

BUSH INSTALLER

Used to load the select lever spring

and components for reassembly

into transmission rear housing.

Previously released.

Unique

AU469

(J39765)

FUEL SENDER LOCKNUT

WRENCH

This tool is used for removal of the

modular fuel sender assembly

retaining ring.

Previously released.

Mandatory

AU470

(SD28057)

FUEL PRESSURE GAUGE HOSE

Used in conjunction with gauge

AU338 (or SD28018) to check fuel

pressure.

Previously released.

Mandatory

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

AU471

(SD28280B)

DRIVER’S SIDE AIRBAG DUMMY

LOAD

Used when carrying out airbag

electronic diagnostic checks.

Previously released.

Mandatory

AU485

AU485

DUMMY LOAD

Used for side-impact inflatable

restraint (side-impact airbag) and

seat belt pretensioner.

Previously released.

Mandatory

AU505

(AU435)

COOLING SYSTEM

HYDROMETER

Used for testing coolant

concentration level.

Previously released.

Mandatory

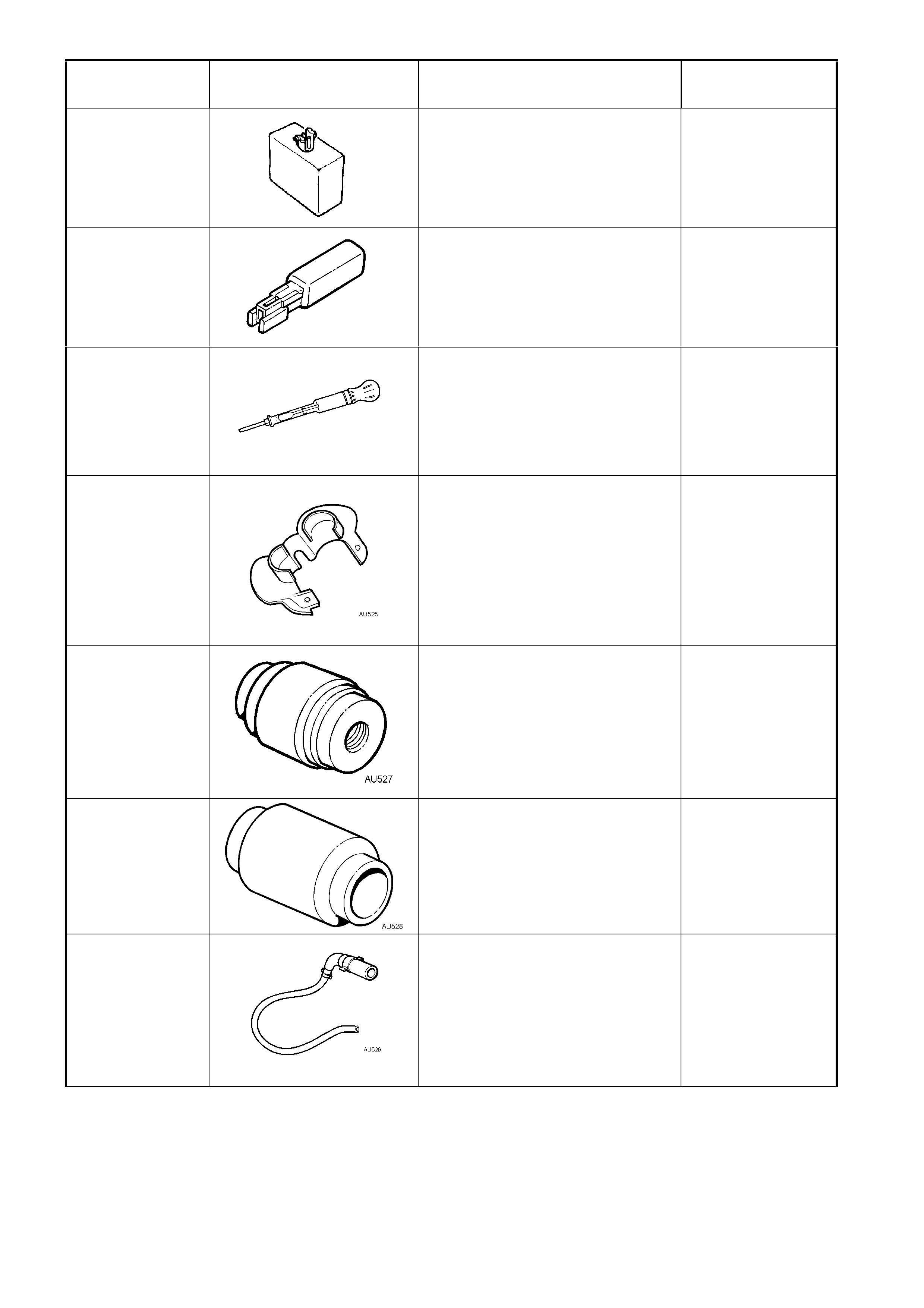

AU525

QUICK CONNECT RELEASE

TOOL

Use to release the quick connect

fittings on the automatic

transmission fluid cooler lines at the

radiator end, when the vehicle is so

equipped.

Previously released.

Mandatory

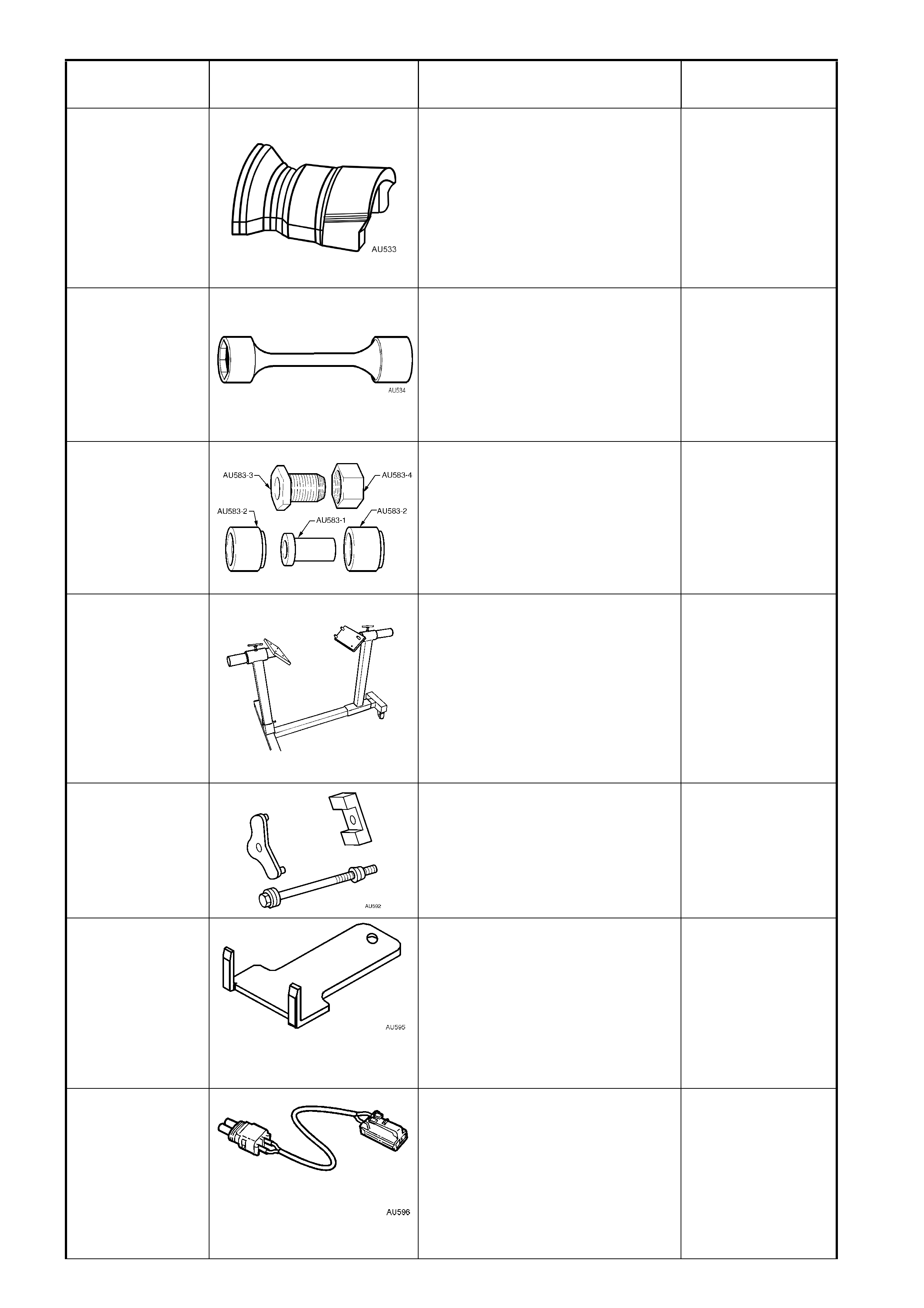

AU527

INTERMEDIATE PINION

BEARING AND POWER

STEERING FLUID SEAL

INSTALLER

Used in conjunction with driver

handle AU355-A.

Previously released.

Unique

AU528

UPPER PINION BEARING AND

POWER STEERING FLUID SEAL

INSTALLER

Previously released.

Unique

AU529

CLUTCH SLAVE CYLINDER

BLEED TOOL

Used to bleed air from the Central

Slave Cylinder fitted to the T56, 6

speed manual transmission

available for the GEN III V8 engine.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

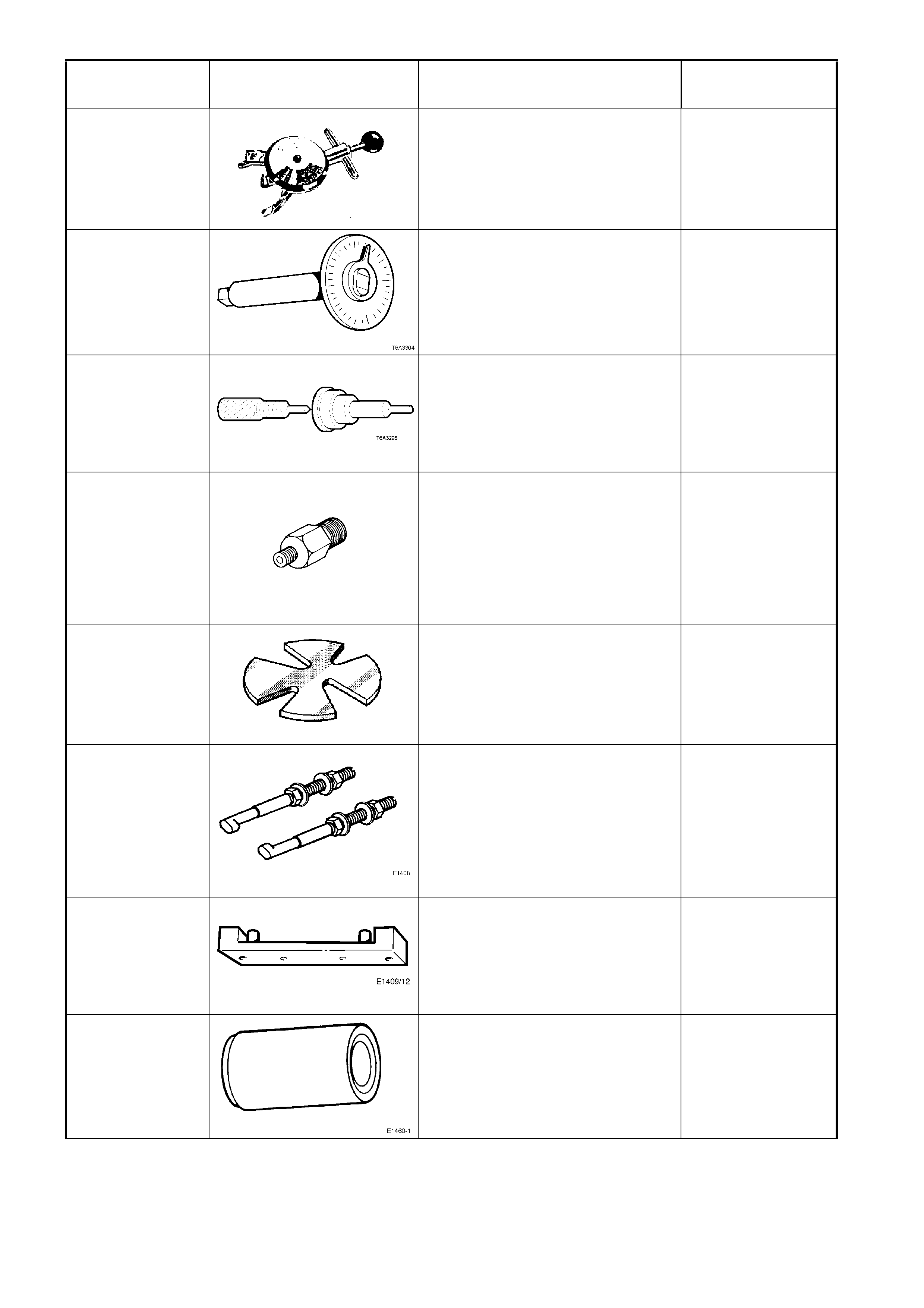

AU533

QUICK CONNECT FITTING

RELEASE TOOL

Released in two sizes:

Red for 5/16” fittings and

Blue for 3/8” fittings.

Also available commercially under

P/N AUSP45.

Previously released.

Mandatory

AU534 TORQUE LIMITING SOCKET

Used in conjunction with an impact

gun to tighten wheel nuts.

Previously released.

Mandatory

AU583 SELECTOR SHAFT SEAL

REMOVER/ INSTALLER

Use to remove and install the

manual shaft oil seal, with the

transmission installed in the

vehicle.

Previously released.

Unique

AU591

GEN III ENGINE STAND

Engine stand specifically designed

to accommodate the GEN III

engine.

Comes complete with mounting

heads and detachable stand.

Commercially available.

Previously released.

Available

AU592

INSTALLER

Used for installing new & existing

bushes into rear suspension

crossmember front mounting for on

vehicle operation.

Previously released.

Desirable

AU595

STEERING WHEEL INFLATABLE

RESTRAINT (DRIVER’S AIRBAG)

MODULE REMOVAL TOOL

Used for removing the steering

wheel inflatable restraint (driver’s

airbag) module from the steering

wheel hub.

New release.

Mandatory

AU596 DEPLOYMENT HARNESS

ADAPTOR FOR SEAT BELT

PRETENSIONER

Used in conjunction with

deployment harness J213526-1 for

deploying seat belt pretensioner

when removed from the vehicle.

New release.

Available

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

BT3373-F

BELT TENSION GAUGE

Used when checking drive and

accessory belt tension and

adjustment.

Previously released.

Desirable

BT8653-A

(E7115)

ANGLE WRENCH

Used to tighten component

fasteners when angle torque is

required.

Previously released.

Mandatory

E1152

(6A24)

VALVE LIFTER ASSEMBLY

TOOLS

Used to assist assembly of valve

lifters.

Previously released.

Unique

E1178B

AIR LINE ADAPTOR - 14MM

(TAPERED SEAT)

Used to apply air pressure to

engine cylinder during various

service operations or diagnostic

checks.

Previously released.

Desirable

E1312

(7A42)

PRESS PLATES

Used in many applications for

pressing on and off components.

Previously released.

Desirable

E1408 STEERING WHEEL PULLER

LEGS

Used in conjunction with a suitable

steering wheel puller such as

J1858-A or 7245 for removing

steering wheel.

Previously released.

Desirable

E1409A

(9A6-1)

REAR MAIN SEAL HOUSING

ALIGNING TOOL

Used for aligning rear main seal

housing on V6 engine.

Previously released.

Desirable

E1460-1 POWER STEERING PUMP

SHAFT SEAL INSTALLER

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

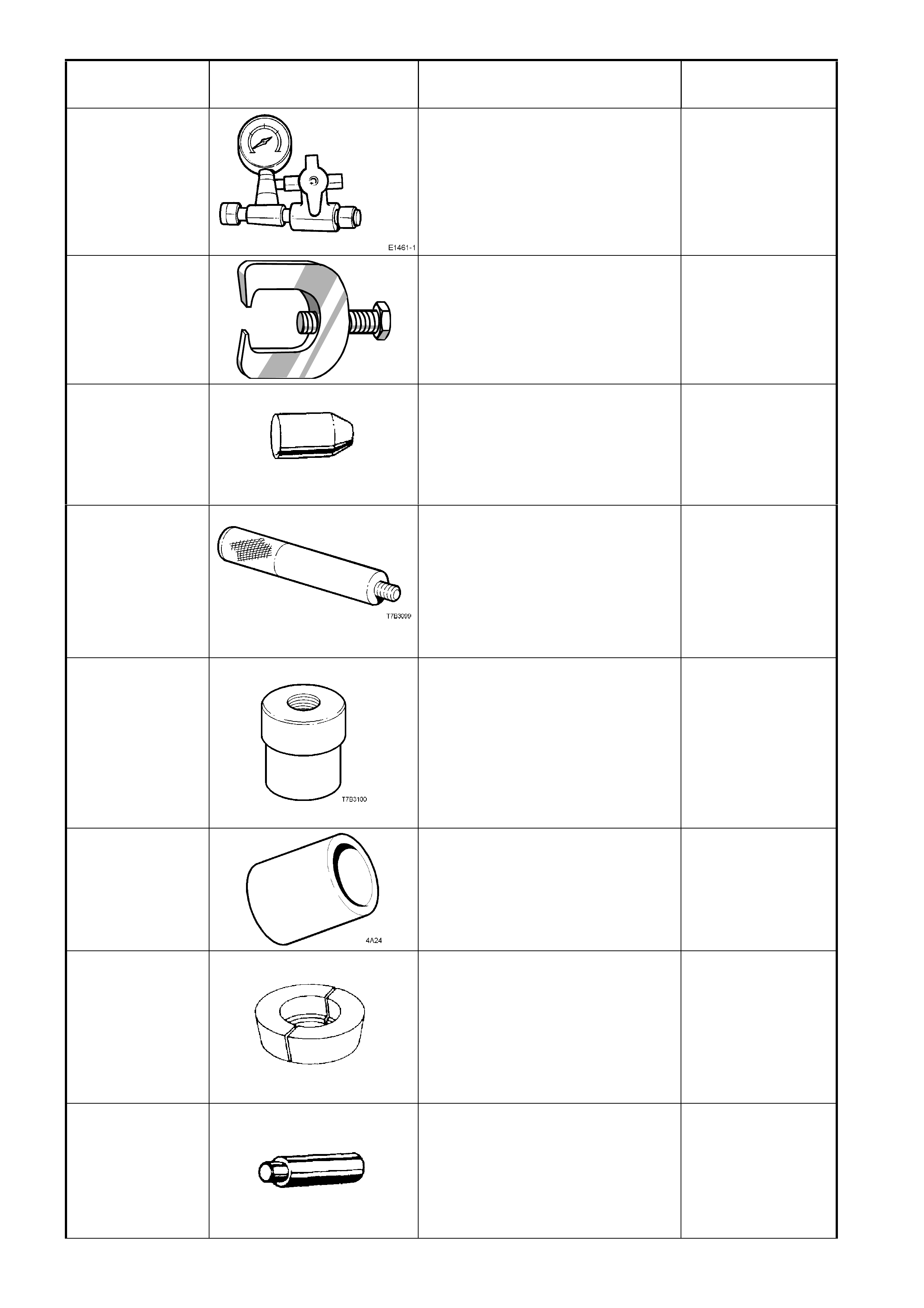

E1461-1 PRESSURE GAUGE ASSEMBLY

Previously released.

Mandatory

E1465

(9A10)

(7311)

STEERING LINKAGE BALL STUD

REMOVER

Previously released.

Desirable

E1483

(9A23)

EXPANDER – SLEEVE SEALS

Used for expanding steering gear

rotary valve and sleeve assembly

seals before installation.

Previously released.

Unique

E1502

(7AT2)

DRIVER HANDLE

Used in conjunction with 7AT5 to

remove/install the slip yoke bushing

in the extension housing on the

Tremec 6 speed manual

transmission.

Previously released.

Unique

E1505

(7AT5)

SLIP YOKE BUSH

REMOVER/INSTALLER

Used in conjunction with 7AT2 to

remove/install the slip yoke bushing

in the extension housing on the

Tremec 6 speed manual

transmission.

Previously released.

Unique

E1662

(4A24)

SLEEVE

Used to install the bearing cup into

the input shaft gear on the Tremec

6 speed manual transmission.

Previously released.

Unique

E1673A15

ADAPTOR

Used in conjunction with puller

E1673MT and stepped plug

E1673B16 to remove the rear

pinion bearing on

3.08:1 assemblies.

Previously released.

Unique

E1673B16

STEPPED PLUG

Used in conjunction with puller

E1673MT and adaptors E1673A15

/ E1673N15 to remove bearings

from the final drive assembly.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E1673MT

BASIC PULLER

Used in conjunction with adaptors

to remove bearings from the final

drive assembly .

Previously released.

Unique

E1673N15

ADAPTOR

Used in conjunction with puller

E1673MT and stepped plug

E1673B16 to remove the side

bearings from differential case.

Previously released.

Unique

E1673S15 ADAPTOR

Used with puller E1673MT to

remove the rear pinion bearing on

3.07:1 and 3.46:1 assemblies.

Previously released.

Unique

E1891-6

(3A8-6)

SLEEVE

Used to install the 1st/2nd gear

synchromesh hub to the mainshaft

on the Tremec 6 speed manual

transmission. Part of E1891A Kit.

Previously released.

Unique

E1896

(3A13)

(J22610)

KEYSTONE CLAMP PLIERS

Used to tighten the sliding joint boot

clamp.

Previously released.

Available

E1992 DEPLOYMENT HARNESS

ADAPTOR

Used in conjunction with

deployment harness J213526-1 for

deploying OPS / SRS components

when removed from the vehicle

Previously released.

Available

E19M25

(AU316)

PRE-LOAD ADAPTOR

Used to measure steering gear

input shaft / steering mechanism

turning torque in conjunction with a

suitable torque wrench.

Previously released.

Unique

E308

(56750)

(49V012001)

SEAL REMOVER

Used as a universal seal remover.

Previously released.

Available

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E3C10AER PINION REAR BEARING

REPLACER

Used to install the pinion bearing

during final drive overhaul.

Previously released.

Unique

E6661S

FORCING SCREW

Used in conjunction with puller

1150 and adaptor AU412.

Previously released.

Unique

E6662B

TORQUE WRENCH ADAPTOR

Used in conjunction with 7208 to

check breakaway torque of L.S.D.

differential.

Previously released.

Desirable

E6673

(J22912-1)

PRESS PLATES

Previously released.

Desirable

E7110 PRESS PLATE

Previously released.

Used for supporting stabilizer shaft

link while pressing out or installing

bushing.

Available

E7115

(BT8653-A)

ANGLE WRENCH

Used to tighten component

fasteners when angle torque is

required.

Previously released.

Mandatory

E8803-10

RACK SEAL TEST ADAPTOR

Used in conjunction with hand

vacuum pump J-23738-A to assess

rack seal serviceability.

Previously released.

Mandatory

E8803-11 RACK END SEAL/BUSH

INSTALLER

Used to install rack end seal and

bush.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E8803-6 RACK SEAL PROTECTOR -

SHORT

Previously released.

Unique

E8803-7

RACK PISTON TOOL

Used to rotate the end bushing to

remove/install retaining wire clip.

Previously released.

Unique

E8803-9 RACK PISTON SEAL EXPANDER

Used to expand the rack piston seal

prior to installation.

Previously released.

Unique

E9055

(17-010A)

PINION OIL SEAL INSTALLER

Used to install the pinion oil seal.

Previously released.

Unique

E9239

(J25033-B)

POWER STEERING PUMP

PULLEY INSTALLER

Previously released.

Desirable

E9254GMH

(E1461-1)

PRESSURE HOSE & GAUGE SET

Used for checking power steering

system pressures.

Previously released.

Mandatory

E9271 PINION BEARING CUP

INSTALLER

Previously released.

Unique

E9277 SIDE BEARING INSTALLER

Used to install the bearings to the

differential case.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

E9293 PINION BEARING CUP

REMOVER

Previously released.

Unique

E9300A PINION HEIGHT SETTING

GAUGE

Used in conjunction with Dummy

Arbor AU408 to check pinion height

on final drive assembly.

Previously released as E9300, this

set now has an additional spacer to

be used on the 3.07:1 and 3.46:1

ratio, final drive assemblies.

Previously released.

Unique

E9326-7

(AU301)

RACK PAD ADJUSTING SCREW

LOCK NUT WRENCH

Previously released.

Desirable

E9326-8

(AU211-A)

RACK PAD ADJUSTING SCREW

WRENCH

Previously released.

Desirable

E9332-A

SOCKET ASSEMBLY RELEASE

TOOL

Previously released.

Used to release the front lower

control arm socket from the

steering knuckle or the rear

suspension control arm.

Desirable

ETX30H

T30H TORX BIT

Used in conjunction with Torx bit

holder J25359-8 (or ETX55HLD)

Also commercially available as a

T30H Torx bit.

Previously released.

Mandatory

GM24505373

BY-PASS VALVE ACTUATOR

SETTING TOOL

Used for checking and setting

adjustment of by-pass valve

actuator used with V6

supercharged engine.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

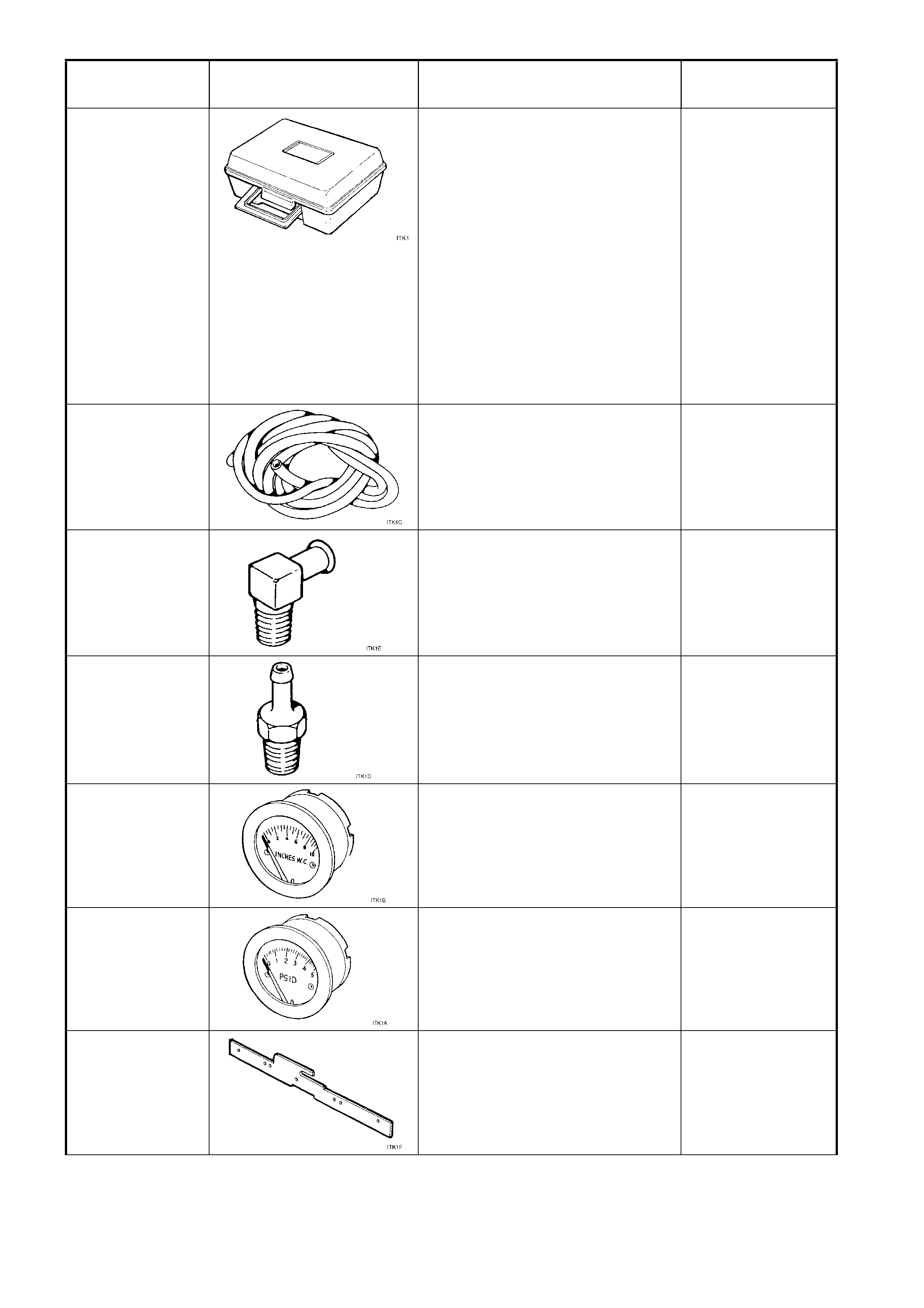

ITK-1

LPG TEST KIT

AVAILABLE FROM:

IMPCO TECHNOLOGIES

1 - 3 TAUNTON DRIVE

CHELTENHAM VIC. 3192

ALL CORRESPONDENCE TO:

P.O.BOX 45, CHELTENHAM VIC.

3192

TELEPHONE: (03) 9584 5644

FAX: (03) 9583 0696

The LPG test kit contains the

following tools.

Previously released.

Available

ITK-1

(c)

PRESSURE GAUGE HOSE

Part of LPG test kit ITK-1.

Available

ITK-1

(e)

PRESSURE GAUGE HOSE

CONNECTOR FOR INCHES W.C.

PRESSURE GAUGE

Part of LPG test kit ITK-1.

Available

ITK-1

(d)

PRESSURE GAUGE HOSE

CONNECTOR FOR PSID

PRESSURE GAUGE

Part of LPG test kit ITK-1.

Available

ITK-1

(b)

PRESSURE GAUGE INCHES

W.C.

Part of LPG test kit ITK-1.

Available

ITK-1

(a)

PSID PRESSURE GAUGE

Part of LPG test kit ITK-1.

Available

ITK-1

(f)

SECONDARY DIAPHRAGM

LEVER ADJUSTMENT GAUGE

Part of LPG test kit ITK-1.

Available

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J1859-A

(7245)

STEERING WHEEL PULLER

Previously released.

Mandatory

J21008-A SELF POWERED TEST LIGHT

Used during electrical circuit

diagnostic checks (or use

commercially available equivalent).

Previously released.

Mandatory

J213200

DIGITAL MULTIMETER

Used for various measurement

functions. Must have at least

10 MΩ input impedance and be

capable of reading capacitance.

Previously released (or use

commercial equivalent).

Available

J213526-1

DEPLOYMENT HARNESS

Used in conjunction with

deployment harness adaptors

E1992 and AU596 for deploying

OPS / SRS components when

removed from the vehicle

Previously released

Available

J21368

OIL PUMP ALIGNMENT BAND

Used to align the oil pump cover to

oil pump body before tightening the

bolts.

Previously released.

Unique

J21426

(7AT-6)

SEAL INSTALLER

Used to install the rear extension

housing oil seal.

Previously released.

Unique

J21427-01 PULLER ADAPTOR

Used in conjunction with J8433-1,

J41558 and J41816-2 to remove

the crankshaft timing gear sprocket

on GEN III V8 engine.

Used in conjunction with J8433 to

remove the output speed sensor

ring from the mainshaft.

Previously released.

Unique

J21465-15

REMOVER

Used in conjunction with slide

hammer J6125-1B to remove the

stator shaft front bushing.

Previously released

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J21465-2

INSTALLER

Used in conjunction with driver

J8092 to install the front stator shaft

bush

Previously released

Unique

J21867

PRESSURE GAUGE AND HOSE

ASSEMBLY

Used for checking automatic

transmission oil pressure.

Previously released.

Mandatory

J22610

(3A13)

(E1896)

KEYSTONE CLAMP PLIERS

Used to tighten the sliding joint boot

clamp.

Previously released.

Available

J22794

T6A3256a

ADAPTOR

Used to facilitate the application of

air pressure to a cylinder when

replacing a valve spring or valve

stem oil seal with the cylinder head

installed.

Previously released.

Desirable

J22912-01

(E6673)

PRESS PLATES

Used in a number of different

applications in removing bearings

and other transmission components

when pressing operations are

required.

Previously released.

Desirable

J23062-14

BUSH REMOVER

Used in conjunction with driver

handle J8092 to remove and install

extension housing rear bush.

Previously released.

Unique

J23327

CLUTCH SPRING COMPRESSOR

Used to compress automatic

transmission clut ch assembly

springs during transmission

overhaul.

Previously released.

Unique

J23327-1

CLUTCH SPRING COMPRESSOR

Needed to compress the clutch,

before dismantling.

Plate J42628 is also required.

Previously released

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J23738-A

HAND VACUUM PUMP (20 IN. HG

MINIMUM)

Used for applications where a

controlled vacuum is required to be

applied.

Previously released and also

commercially available.

Mandatory

J23907

(6A22-2)

(7A28)

SLIDE HAMMER

Used in conjunction with a number

of different pullers to remove

bushes and bearing cups in the

transmission.

Previously released.

Unique

J24086-C

PISTON PIN

REMOVER/INSTALLER

Universal tool containing selective

components to suit multiple engine

applications.

Previously released.

Unique

J24292-C

(C4150-A)

(AJ24292-C)

PRESS TOOL

Used to remove rear wheel studs

from the trunnion flange.

Previously released.

Unique

J24460-92

COOLING SYSTEM TEST

ADAPTORS

Used to pressure test the screw-on

cooling system pressure cap and

the cooling system on GEN III V8

engines.

Previously released.

Mandatory

J25016

OIL PUMP SEAL INSTALLER

Used to install automatic

transmission oil pump seal.

Previously released.

Unique

J25018-A

CLUTCH SPRING COMPRESSOR

ADAPTOR

Used in conjunction with J23327 to

compress clutch springs during

automatic transmission overhaul.

Previously released.

Unique

J25019-12

BUSH INSTALLER

Used in conjunction with driver

handle J8092.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J25019-14

BUSH REMOVER

Used in conjunction with slide

hammer J6125-1B.

Previously released.

Unique

J25019-16

BUSH REMOVER

Used in conjunction with slide

hammer J6125-1B.

Previously released.

Unique

J25019-9

BUSH INSTALLER

Used in conjunction with driver

handle J8092.

Previously released.

Unique

J25025-B

DIAL INDICATOR STAND AND

GUIDE PIN SET

Used in many applications.

Previously released.

Unique

J25359-19 NO. 15 TORX BIT

Used to remove Powertrain Control

Module access cover screws.

Previously released.

Mandatory

J25359-8 TOR X BIT HOLDER

Commercially available.

Previously released.

Mandatory

J25765-A DIAL TYPE TORQUE WRENCH

Previously released or use

commercially available equivalent,

capable of measuring from

0.4 - 6.0 Nm.

Previously released.

Mandatory

J26125-B

(AU354)

SLIDE HAMMER

Used in conjunction with 6A22-2 to

remove spigot bearing from rear of

crankshaft.

To remove rear bearing cap on V6

engines, two J26125-B must be

used.

Previously released.

Desirable

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J26568

(AU435)

REFRACTOMETER

Used for testing coolant

concentrate.

Previously released.

Mandatory

J28431-B

FLUID DYE

Used in conjunction with black light,

leak detection lamp 16296 to locate

various types of vehicle fluid leaks.

Supplied in packs of 24, 1 ounce

bottles.

Previously released.

Desirable

J28458

SEAL PROTECTOR AND

DIAPHRAM RETAINER

INSTALLER

Used to protect the power piston

seal and install the diaphragm

retainer on the 4L60-E automatic

transmission.

Previously released.

Unique

J28540-A

SEAL INSTALLER

Used for installing front cover oil

seal on V6 engines.

Previously released.

Unique

J29369-2

UNIVERSAL BUSH REMOVER

Used in conjunction with slide

hammer J23907.

Previously released.

Unique

J29882

INNER OVERRUN CLUTCH SEAL

PROTECTOR

Used to protect the inner, forward

clutch piston seal from damage

during installation.

Previously released.

Unique

J29883

INNER FORWARD CLUTCH SEAL

PROTECTOR

Used to protect the inner, forward

clutch piston seal from damage

during installation.

Previously released.

Unique

J3289-20

HOLDING FIXTURE BASE

Used in conjunction with either

MK480 or dealer fabricated bracket

to hold the final drive assembly.

Used in conjunction with

transmission holding fixture

J39430.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J33017

PULLEY & BEARING ASSEMBLY

TOOL

Used in conjunction with J33013-C

to reinstall A/C compressor clutch

pulley and bearing assembly.

Previously released.

Desirable

J33023-A

PULLER PILOT

Used in conjunction with J8433-1

for removing clutch rotor and

bearing assembly from A/C

compressor shaft.

Previously released.

Desirable

J33025

CLUTCH COIL PULLER LEGS

Used in conjunction with J8433-1

for removing clutch rotor and

bearing assembly from A/C

compressor shaft.

Previously released.

Desirable

J33037

2 - 4 BAND APPLY PIN TOOL

Used to check the selective apply

pin length.

Previously released.

Unique

J33049

CAMSHAFT BEARING

REMOVER/INSTALLER

Universal tool containing selective

components to suit multiple engine

applications.

Previously released.

Unique

J33095 MICRO PACK TERMINAL

REMOVER

Used for the safe removal of Micro-

Pack connector terminals.

Previously released.

Unique

J34142-B

(CT-40-C)

UNPOWERED TEST LIGHT

Must have current draw of less than

0.3 Amp.

Commercially available.

Previously released.

Mandatory

J34196-B

BUSH REMOVER / INSTALLER

SET

Used to remove / install various

bushings in automatic transmission.

Previously released.

Unique

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J34627

SNAP RING PLIERS

Specific purpose is to assist in the

removal/replacement of the output