SECTION 0B - LUB RICATION AND SERVICE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. LUBRICATION SPECIFICATIONS

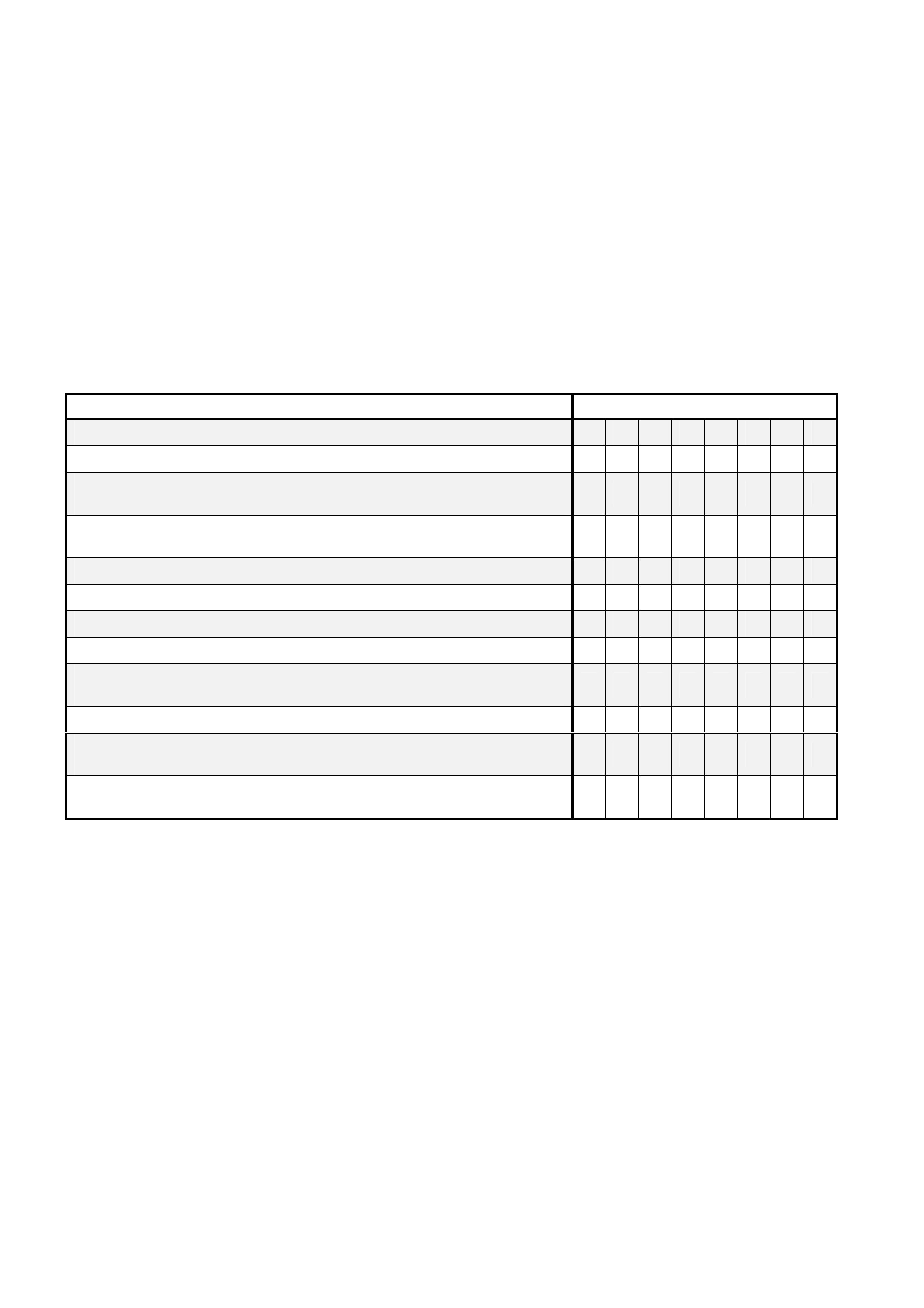

2.1 CAPACITIES CHART

2.2 RECOMMENDED LUBRICANTS

3. SERVICING

3.1 ABNORMAL OPERATING CONDITIONS

3.2 MAINTENANCE SCHEDULE – V6 AND

V6 SUPERCHARGED – DOMESTIC

ABNORMAL CONDITIONS

EXTRA SERVICES REQUIRED

MAINTENANCE SCHEDULE

UNDER HOOD

UNDER CAR

CAR INTERIOR

CAR EXTERIOR

ROAD TEST

3.3 MAINTENANCE SCHEDULE –

V6 – GULF STATES

ABNORMAL CONDITIONS

EXTRA SERVICES REQUIRED

MAINTENANCE SCHEDULE

UNDER HOOD

UNDER CAR

CAR INTERIOR

CAR EXTERIOR

ROAD TEST

3.4 MAINTENANCE SCHEDULE –

V6 WITH LPG

ABNORMAL CONDITIONS

EXTRA SERVICES REQUIRED

MAINTENANCE SCHEDULE

UNDER HOOD

UNDER CAR

LPG SYSTEM

CAR INTERIOR

CAR EXTERIOR

ROAD TEST

3.5 MAINTENANCE SCHEDULE –

GEN III V8 – DOMESTIC

ABNORMAL CONDITIONS

EXTRA SERVICES REQUIRED

MAINTENANCE SCHEDULE

UNDER HOOD

UNDER CAR

CAR INTERIOR

CAR EXTERIOR

ROAD TEST

3.6 MAINTENANCE SCHEDULE –

GEN III V8 – GULF STATES

ABNORMAL CONDITIONS

EXTRA SERVICES REQUIRED

MAINTENANCE SCHEDULE

UNDER HOOD

UNDER CAR

CAR INTERIOR

CAR EXTERIOR

ROAD TEST

Techline

1. GENERAL INFORMAT ION

This Section provides details of the lubricants and the servicing schedules for all models. The capacities of main

fluid levels as well as the International or General Motors specification are included in the tables. The Servicing

Section contains tables that are to be utilised by the technician to perform the services at the intervals stipulated.

2. LUBRIC ATION SPECIFICATIONS

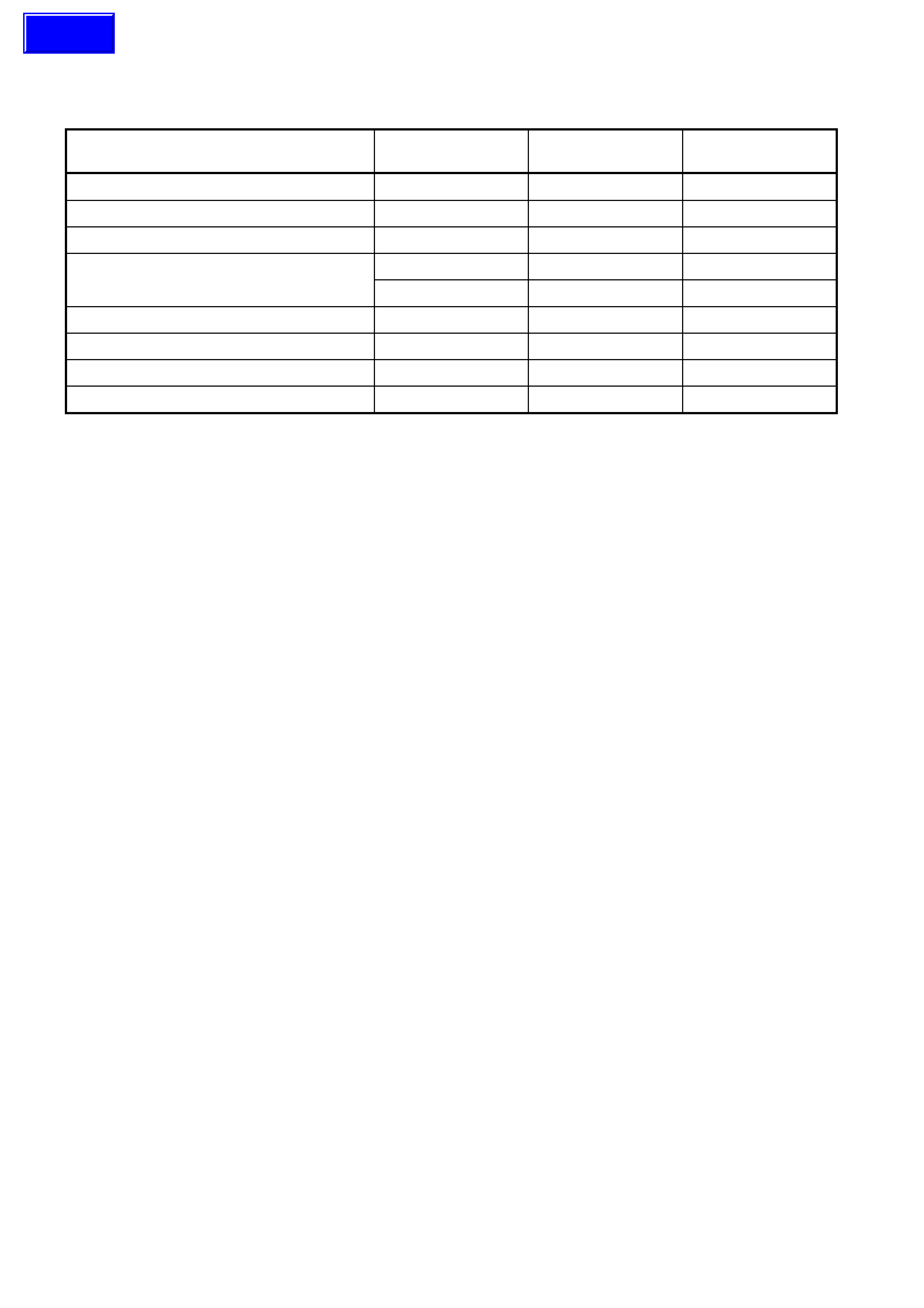

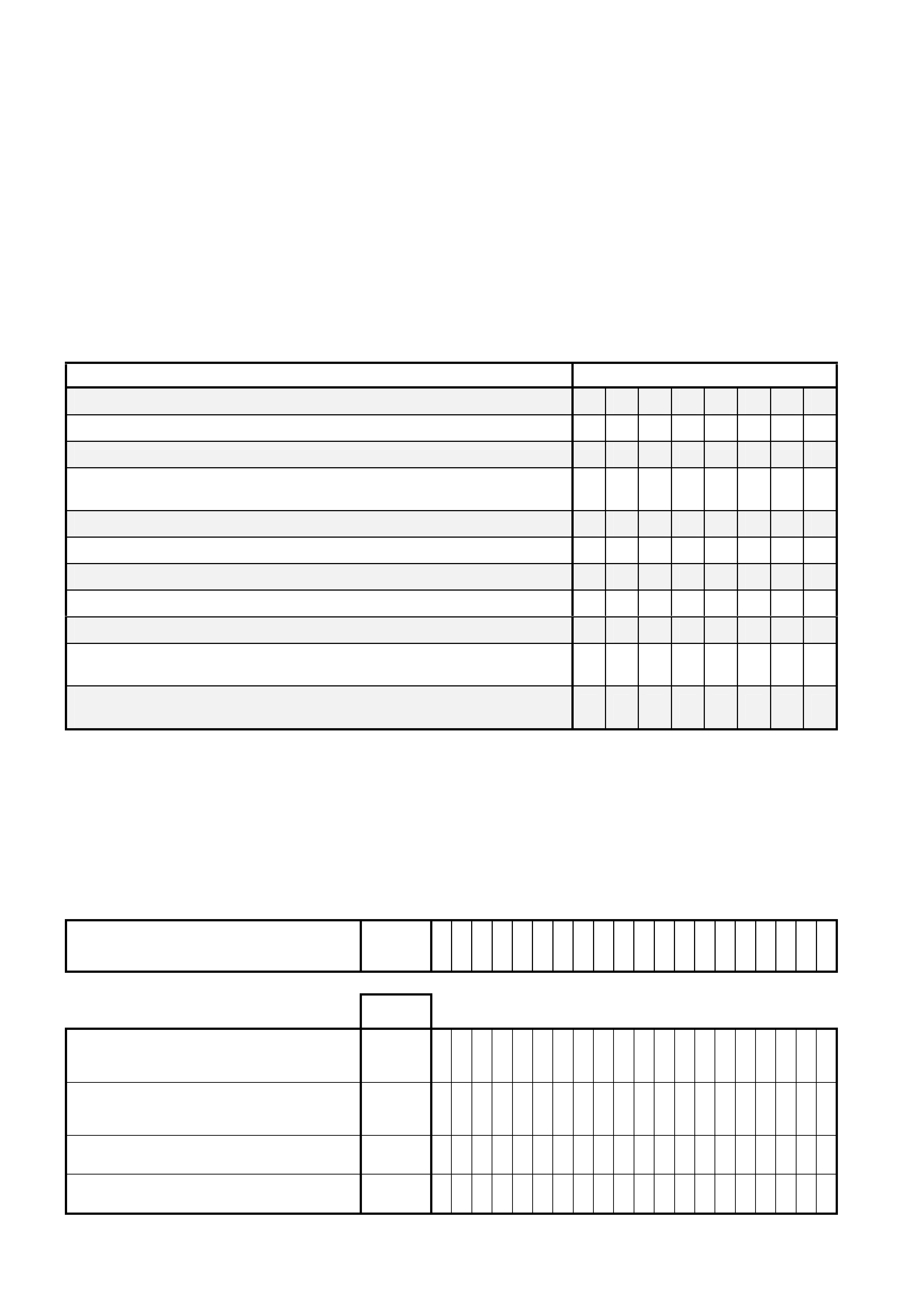

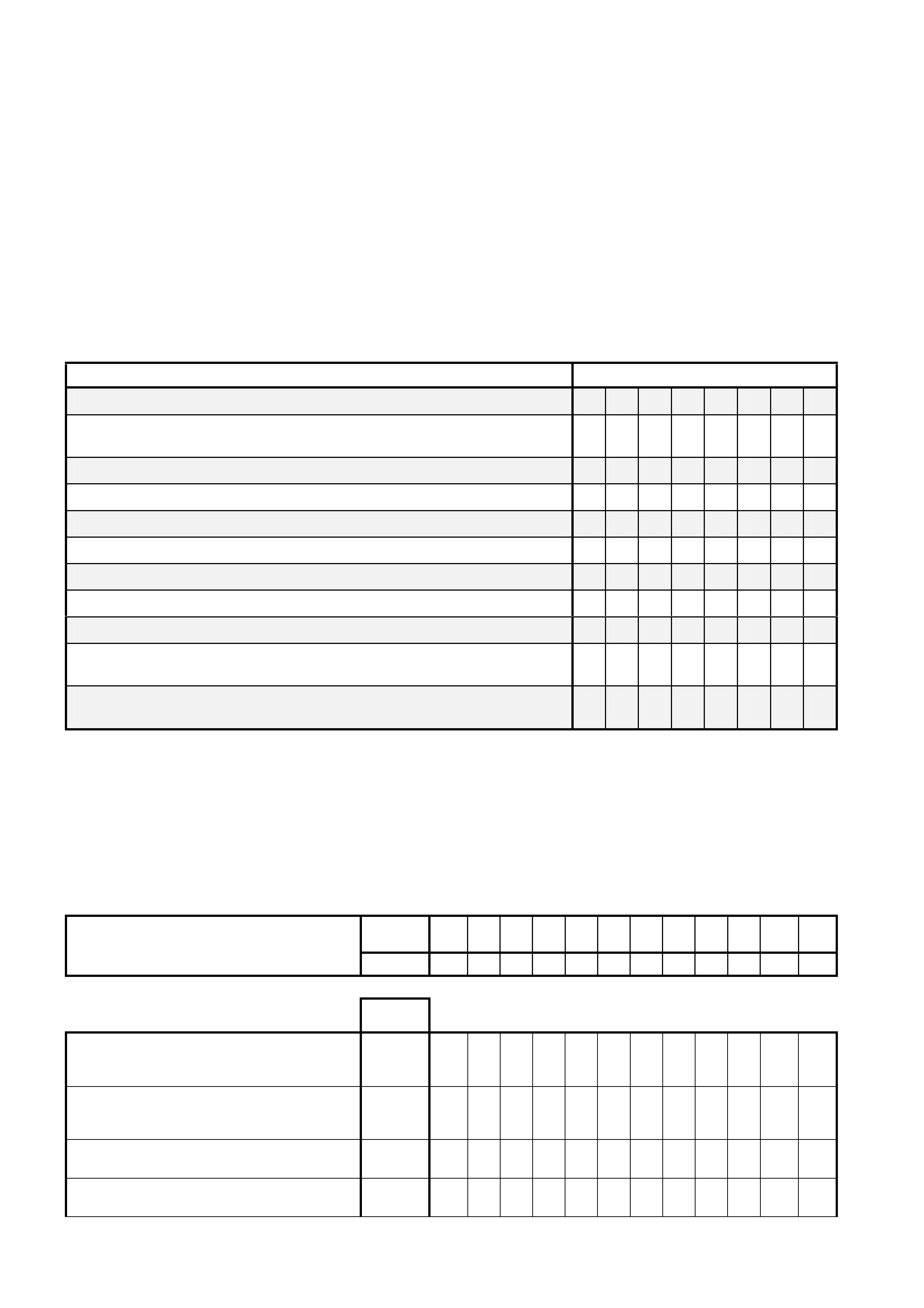

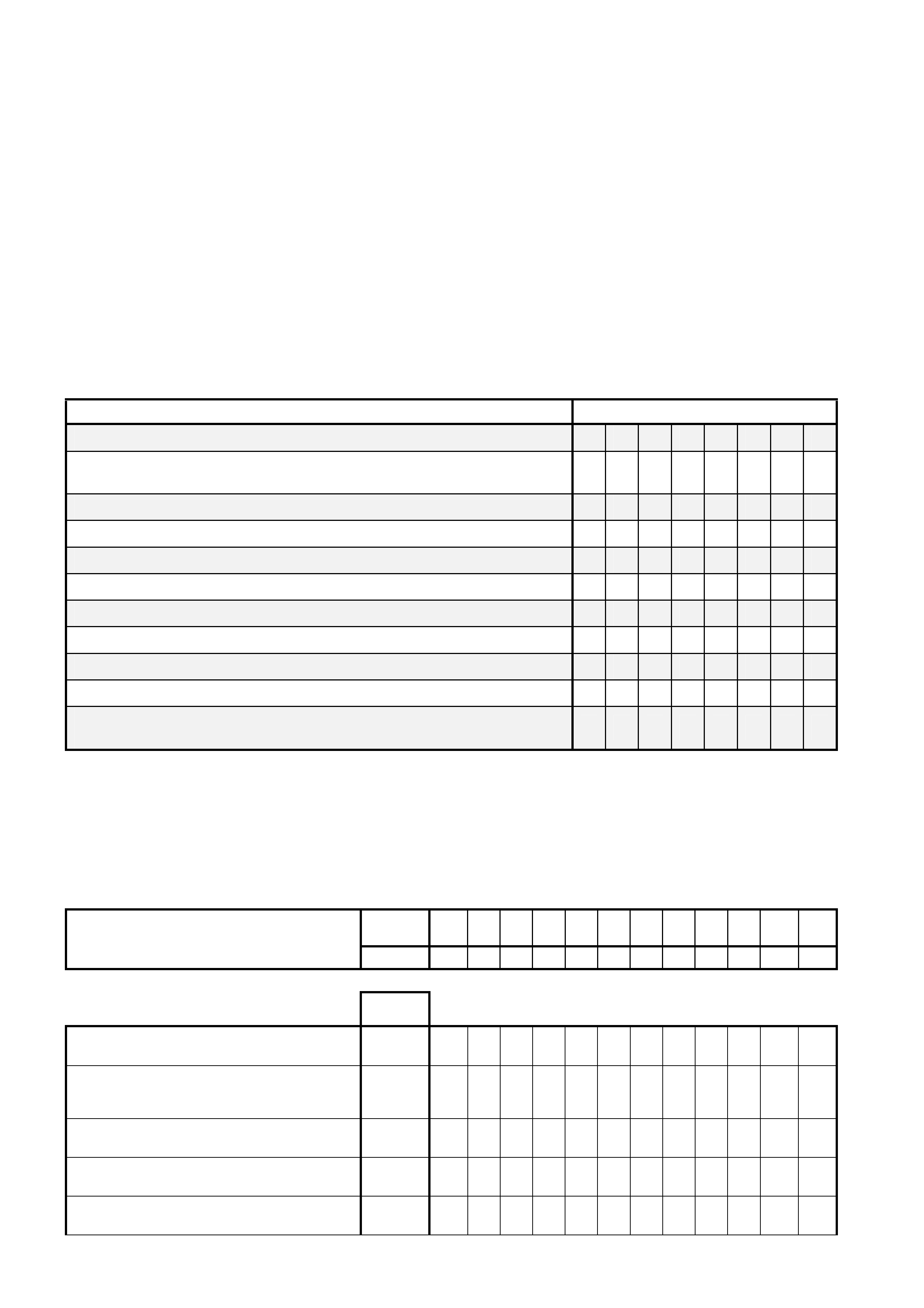

2.1 CAPACITIES CH ART

CAPACITIES – (LITRES – Approximate) 3.8 Litre V6

Non-Supercharged 3.8 Litre V6

Supercharged 5.7 Litre GEN III V8

Refill engine oil capa city (inclu ding filt er) 5.6 5.6 5.70

Supercharger - 0.12 -

Manual Transmission 2.00 2.00 4.40

Automatic Transmission - dry total 8.80 8.80 10.60

- service refill 4.80 4.80 5.00

Cooling System 12.0 12.0 14.3

Brake Hydraulic System 0.62 0.62 0.62

Final Drive 1.70 1.70 1.70

Power Steering 0.70 0.70 0.65

Techline

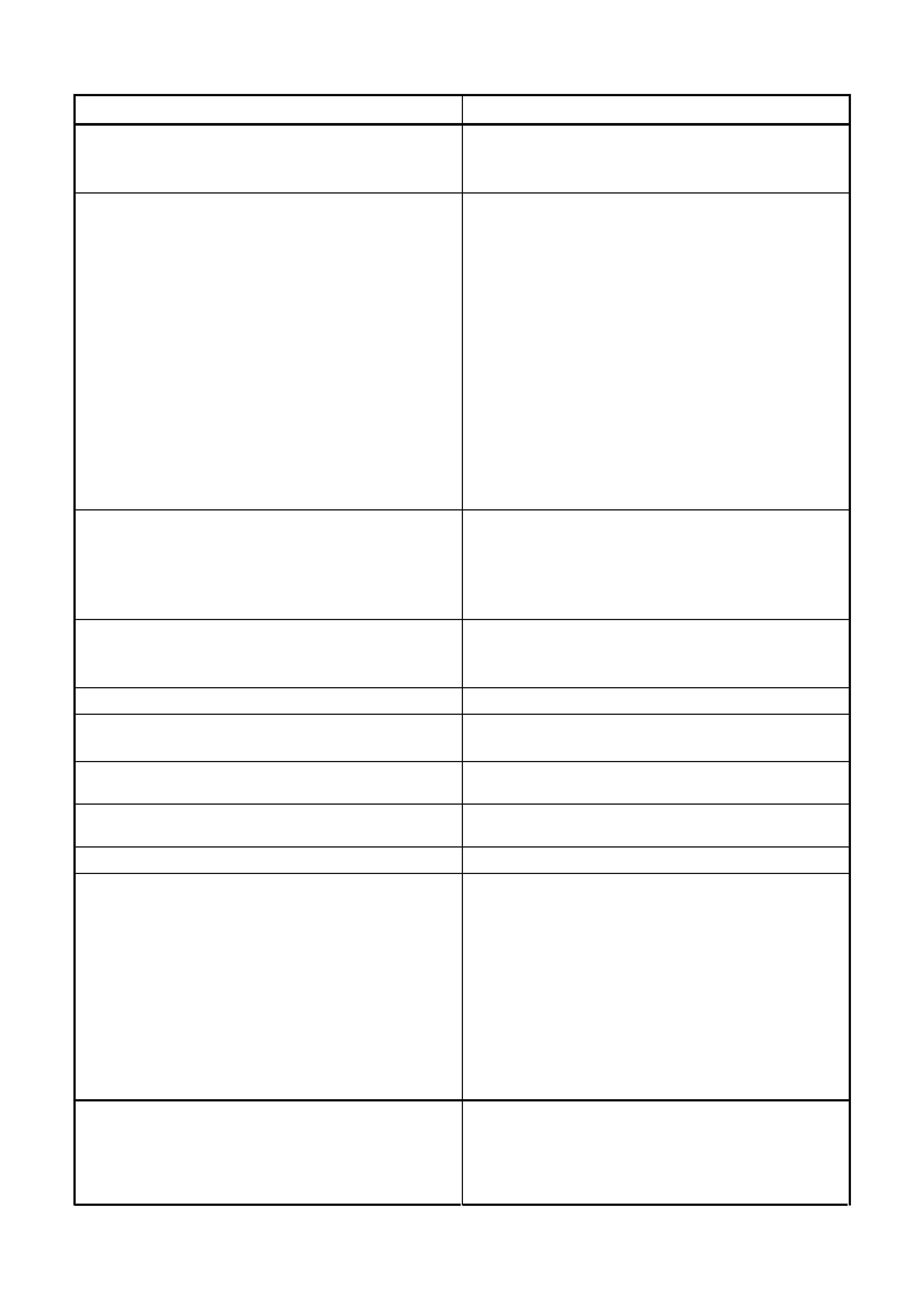

2.2 RECOMMENDED LUBRICANTS

APPLICATION LUBRICANT

Door lock striker

Door lock assembly fork

Instrument comp artm ent lid lock tongue Drilube

Hood pilot pin assembly

Hood lock assembly

Hood hinge pins

Door check assembly

Door hinge and hold opens

Rear compartment lid hinge

Rear compartment lid lock latch

Liftgate and endgate hinges

Liftgate and endgate lock latch

Liftgate, endgate and r ear co m partm ent loc k mechan is m

Door window regulators

Door window guides and runners

Door lock mechanism

Front seat adjuster

Front seat track and rail asse mbl ies

NLGI No. 1 Lithium Grease (with 9% Zinc Oxide)

Front door lock cylinder

Ignition and ste erin g lock cyli n der

Rear compartment lid lock cylinder

Instrument panel compartment lock cylinder

Liftgate lock cylinder

Powdered Graphite (applied through key aperture - do not

oil)

Starter motor drive mechan is m

Windshield wiper pivot points

Propeller shaft centre constant velocity joint

NLGI No. 2 Lithium Grease (with 10% Molybdenum

Disulphide)

Starter motor bearings Engine Oil at overhaul

Park brake shoe assemblies

Brake adjusting screw and nut NLGI No. 2 Clay Thickened Grease for High Temperature

Park brake shoe actuator pivots NLGI No. 2 Clay Thickened Grease with 5% minimum

Molybdenum Disulphide

Brake & clutch hydraulic system (domestic) Heavy duty brake fluid, conforming to Holden Specification

Number HN 1796 (Super DOT 4).

Brake & clutch hydraulic system (export) Heavy duty brake fluid, DOT 4 Plus, SAE J1704.

Final Drive:

All V6 equipped vehicles excluding:

• All V6 equipped Wagon/Utility with a manual

transmission.

• All V6 supercharged equipped vehicles.

Mineral Hypoid Gear Oil SAE 90 API GL5 with LSD additive

Final Drive:

All V8 equipped vehicles not fitted with a LSD.

All V6 equipped Wagon/Utility with manual transmission not

fitted with a LSD.

All V6 supercharged equipped vehicles not fitted with a

LSD.

Synthetic Hypoid Gear Oil SAE 80W-140 API GL5

(Mobilube SHC 1D, Castrol SAF-XA or equivalent)

Final Drive:

All V8 equipped vehicles fitted with LSD.

All V6 equipped Wagon/Utility fitted with a manual

transmissi on and LSD .

All V6 supercharged equipped vehicles fitted with a LSD.

Synthetic Hypoid Gear Oil SAE 80W-140 API GL5 and

Sturaco 7098 Oil Additive

(Mobilube SHC 1D, Castrol SAF-XA or equivalent)

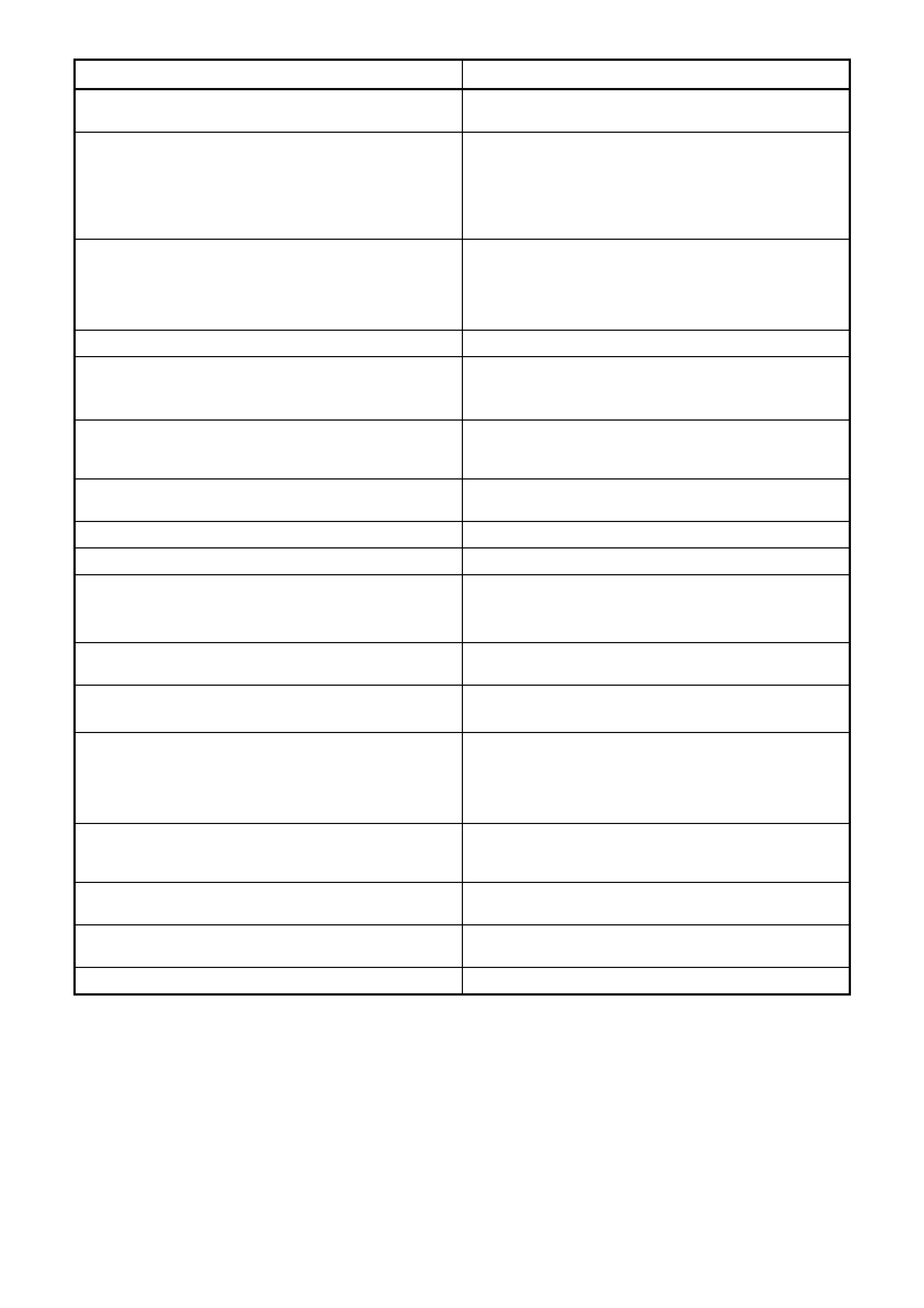

APPLICATION LUBRICANT

Engine oil: (all domestic engines excluding V6 with LPG) 10W/30 SJ ILSAC GF2 engine oil. If this oil is unavailable,

use SJ engine oil with a viscosity of 20W/50 or 15W/40

Engine oil: (all export engines)

10W/30 SJ ILSAC GF2 engine oil. If this oil is unavailable,

use SG, SH or SJ engine oil with a viscosity of 20W/50 or

15W/40. If driving for more than 10 minute s at a time in

extreme conditions (higher than 180 km/h and/or r.p.m.

over 4,000), use SJ (or better) synthetic engine oil, viscosity

grade 20W/50 or 15W/50.

Engine oil: (domestic V6 Engine with LPG)

SAE 20W/50 API SH/CG4 or 15W /40 API SH CG4 (Holden

Specification no HN2314). Products currently approved to

this specification are: BP Vanellus C3 15W/40 SH CG4,

Mobil Super LPG Oil 15W/40 SH CG4 and Mobil Delvac

MX 15W/40 SH CG4.

Engine supercharger oil Holden Part No. 12345982

Clutch throw-out bearing – Getrag five speed manual

transmission (V6)

Universal joints NLGI No. 2 Multipurpose Grease (Lithium Soap)

Bearing face of clutch throw-out bearing, input shaft splines

and spigot – Tremec six speed manual transmission (GEN

III V8) Molybdenum Disulphide Grease

Clutch and brake pedal pivots and bushes NLGI No. 2 Lithium Grease with 10% Molybdenum

Disulphide

Accelerator pedal pivots NLGI No. 1 Lithium Grease (with 9% Zinc Oxide)

Manual transmission – five speed (V6 Engine) Castrol VMX 80W Oil

Manual transmission – six speed (GEN III V8 Engine)

Automatic transmission

Power steering Dexron® III Automatic Transmission Fluid

Automatic transmission control pivot points NLGI No. 2 Lithium Grease (with 3% Molybdenum

Disulphide)

ABS wheel speed sensor NLGI No. 2 Clay Thickened High Temperature EP Grease

(Molykote FB180 or equivalent)

Coolant specification (V6 domestic only)

50% clean fresh water and 50% coolant, conforming to

Holden Specification Number HN2043, Part Number

92140054 (1 litre) or 92140057 (5 litres). In addition, 3

pellets, Part Number 92140053 must be added when the

coolant is repl ace d.

Coolant specification (GEN III V8 domestic only) 50% clean fresh water and 50% Extended life anti-freeze

coolant conforming to Specification Number GM 6277M,

Part Number 92145527 (5 litre).

Coolant specification (export only) 50% clean fresh water and 50% Dex-Cool conforming to

GM 6277M specification.

Check link housing (rear doors only) NLGI No. 2 Polyurea Grease (Mineral Oil Base) – 1.2g

applied to housing

Check link arm (rear doors only) NLGI No. 2 Lithium Complex Grease - 1.2g Applied to arm

3. SERVICING

3.1 ABNORMAL OPERATING CONDITIONS

If the veh icle is dri ven under an y of the abnor mal c onditions lis ted, it is rec omm ended that som e item s be serviced

more frequently than in the maintenance schedule.

The extra services are only required if the vehicle is driven under abnormal conditions. If the abnormal conditions

are encountered on a once-off basis, then any additional servicing should be for that time only. As a guide, if the

vehicle is operated continuall y over a per iod of one m onth or 1000 km under any of the abnorm al conditions, the n

additional servicing is recommended.

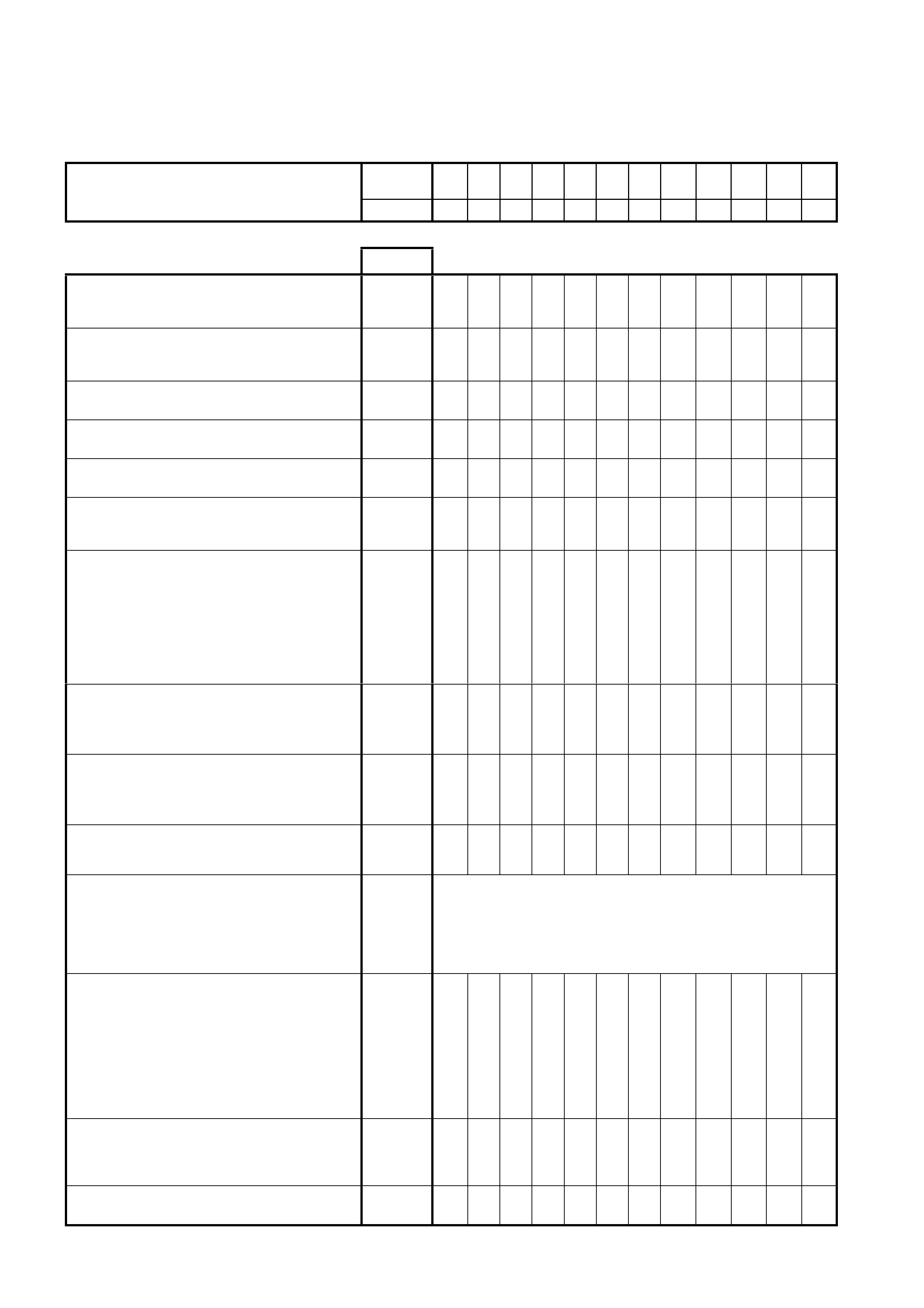

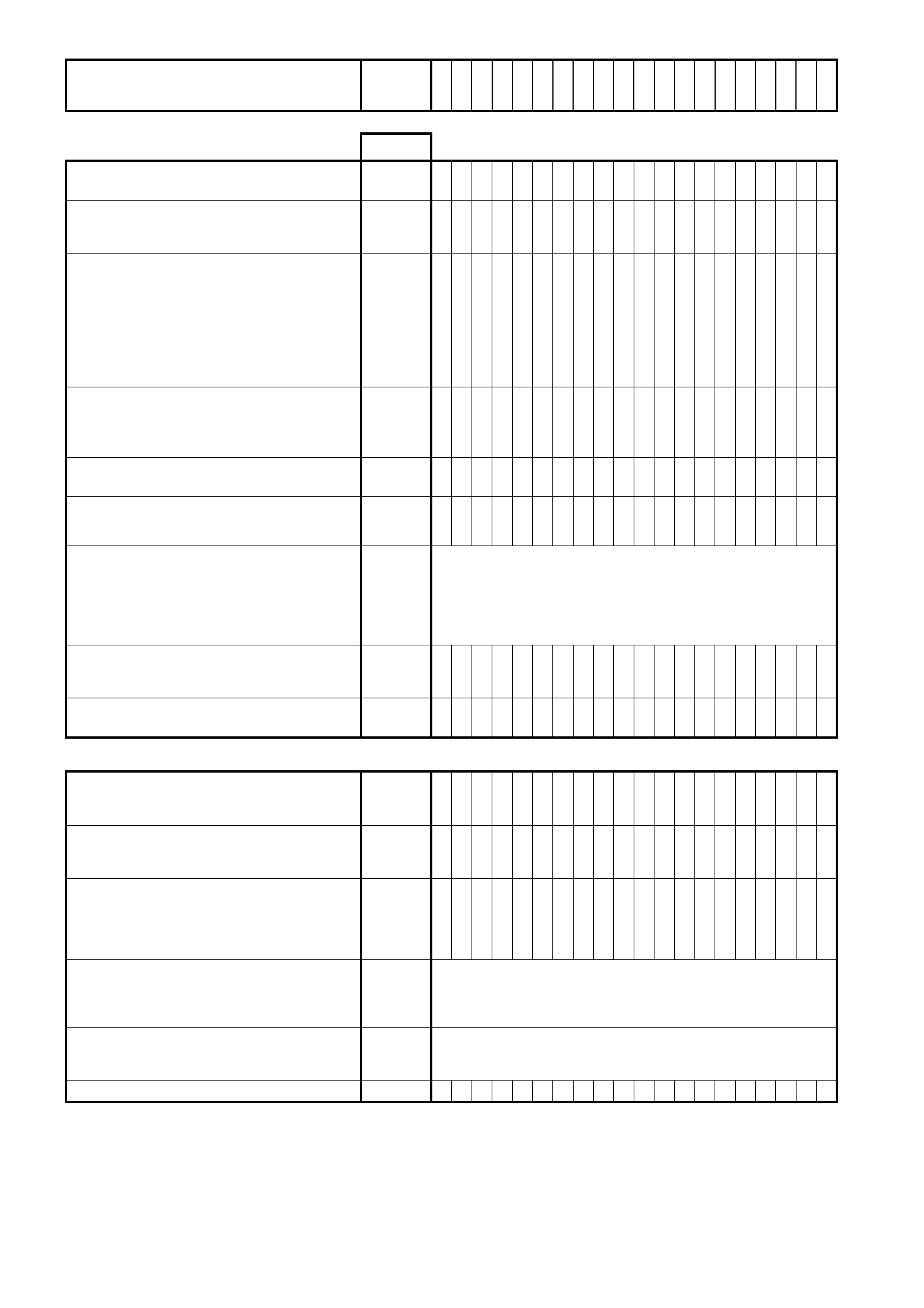

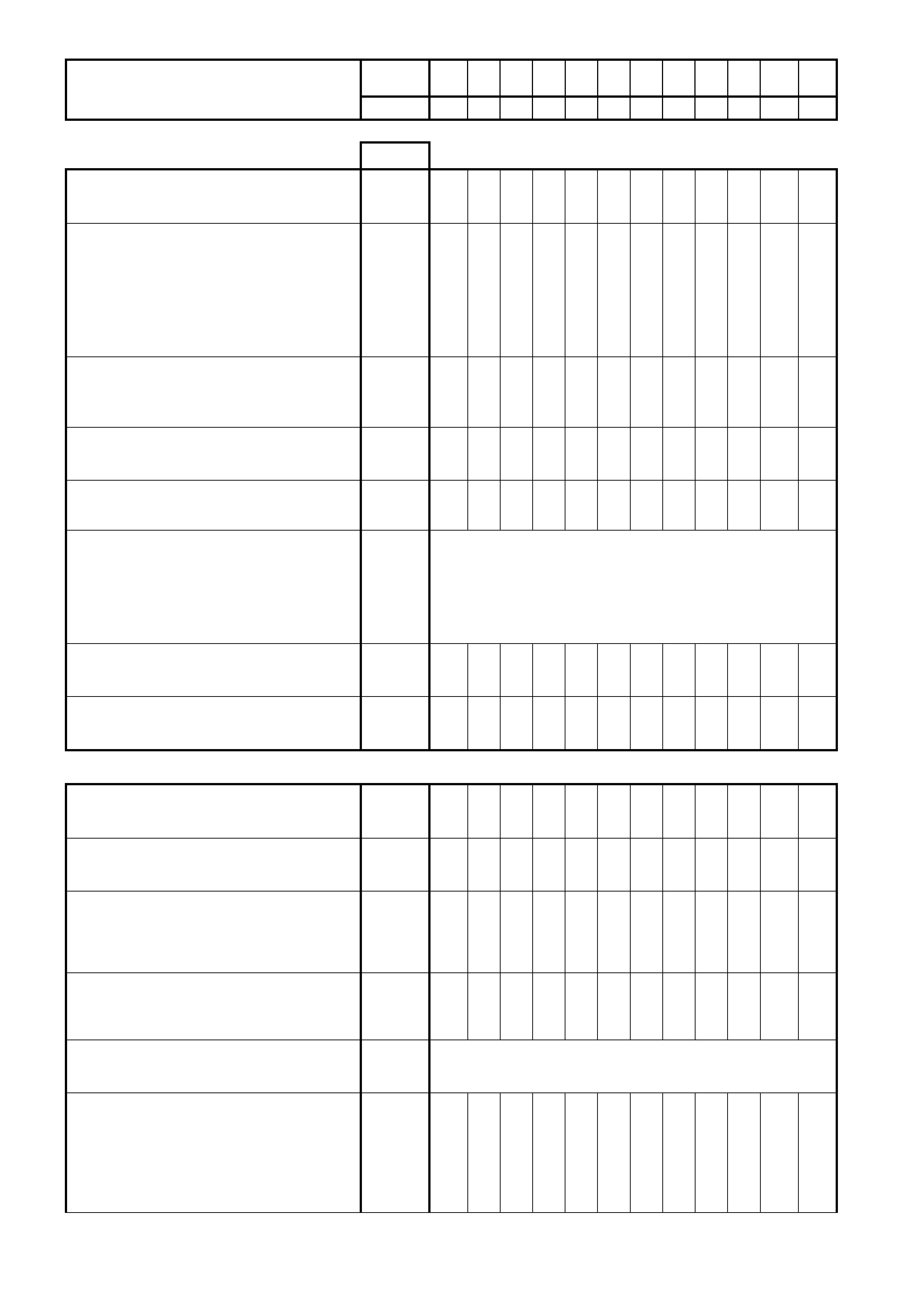

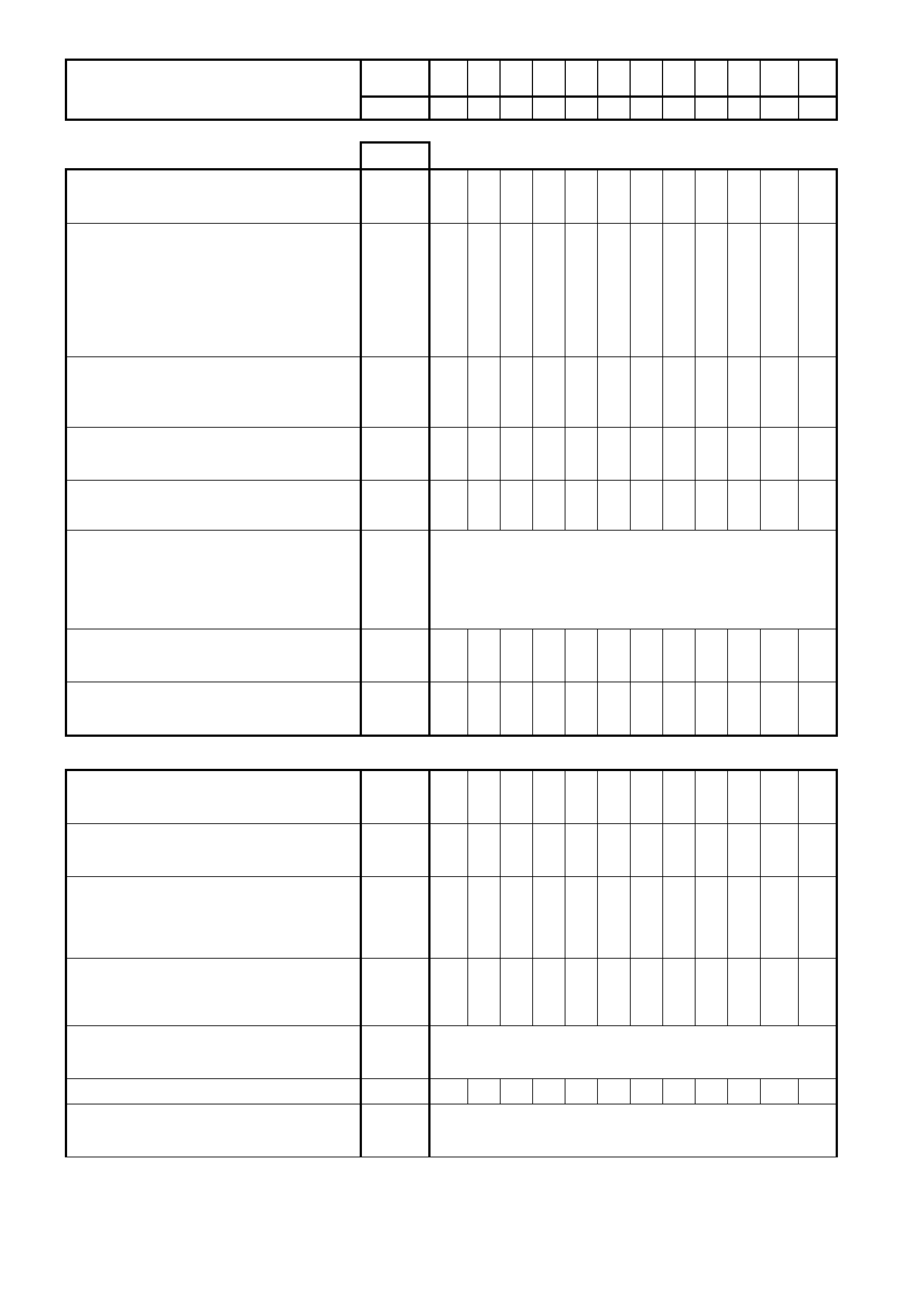

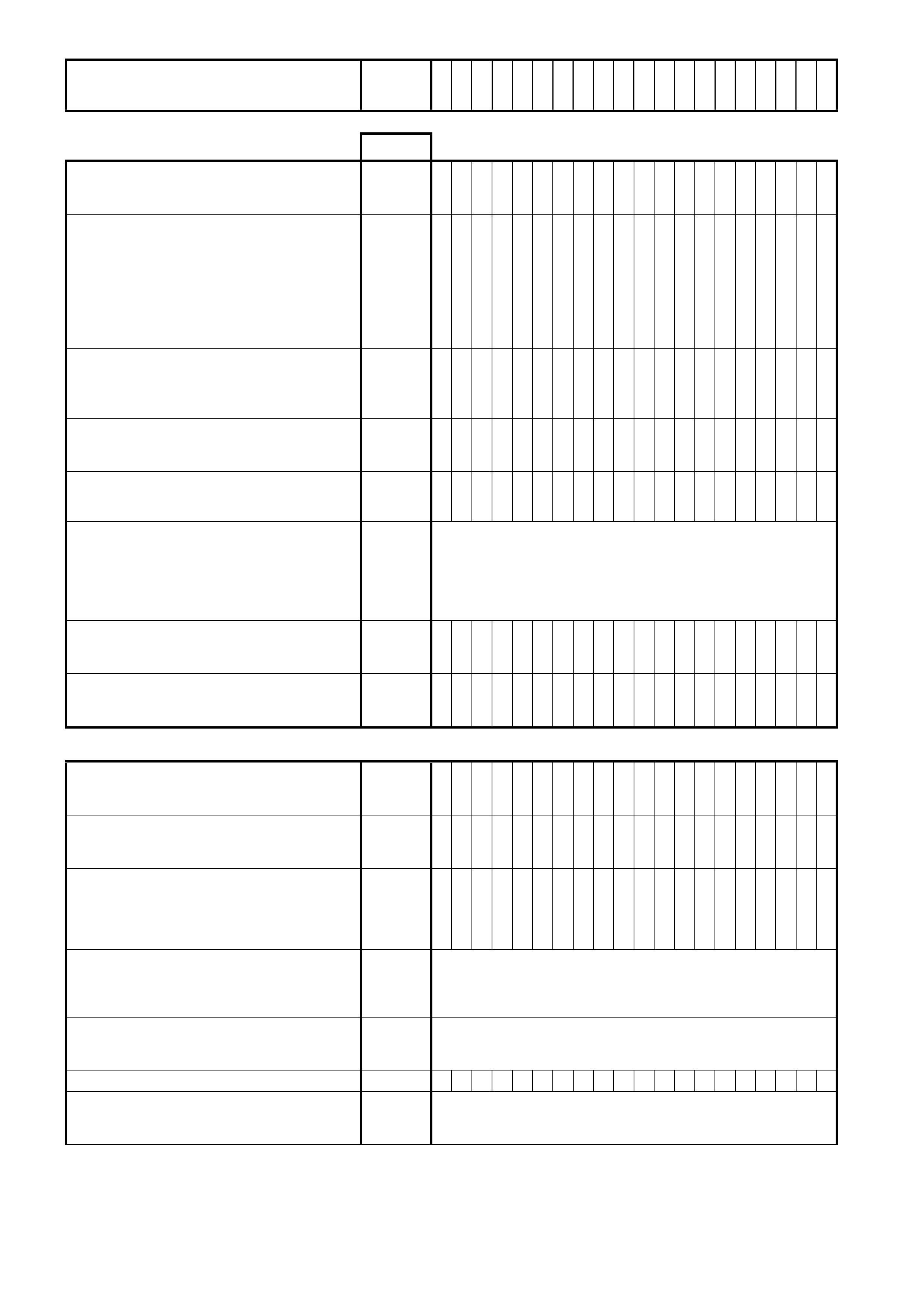

3.2 M AINTENANCE SCHEDULE – V6 AND V6 SUPERCHARGED – DOMESTIC

ABNORMAL CONDITIONS

A Frequent short trips (less than 10 km) where the engine does not generally reach operating temperature.

B Dust, dirt, loose road material.

C Muddy and wet areas.

D Cold weather (below 5 °C) and when most trips are less than 5 km.

E Stop-start driving, excessive idling or low speed operation as experienced in inner city driving

i.e. taxi, door to door delivery, police.

F Caravan or trailer towing.

G Extended heavy load high speed operation in temperatures above 35°C.

EXTRA SERVICES REQUIRED

SERVICE REQUIRED ABNORMAL CONDITION

Change the engine oil every 6 months A

Change the automatic transmission fluid and the strainer every 30,000 km E F G

Inspect the front suspension and the steering for leaks, wear or damage every

5,000 km B C

Replace the engine oil filter every 5,000 km or 3 months (whichever comes

first) B

Change the engine oil every 5, 000 km or 3 months (whic hev e r comes first) B D E F G

Replace the air cleaner element every 20,000 km B

Inspect and clean the park brake linings every 20,000 km B C

Change the final drive oil every 20,000 km F G

Change the brake fluid every 12 months if a 1600 kg (or higher) tow bar is

fitted * F

Change the power steering fluid every 50,000 km F G

Inspect the evaporative emissions control canister every 20,000 km and

change every 80,000 km B C

Inspect the rubber propeller shaft coupling every 10,000 km after 160,000 km

of abnormal operating conditions. F G

*: Brake f luid det erior a tes wit h time and should nor mally be re p laced ev ery 27 m onths . Ho wever , h ea vy duty to wing

requires fresher fluid due to the higher demand on the brake system. Therefore, brake fluid should be replaced

ever y 12 m onths if a 1,600 kg ( or higher) tow bar is fitt ed, so th at the brak e s ystem can c ope with th e next year’s

towing requirements.

MAINTENANCE SCHEDULE

The following chart provides the maintenance schedule, with the reference to the necessary procedure contained in

the Service Information Package, for all domestic V6 and V6 S/C engine equipped vehicles except those fitted with

an LPG system. If the vehicle is fitted with LPG (option code KL7), refer to 3.4 MAINTENANCE SCHEDULE – V6

WITH LPG.

x 1000

km 1.5 15 30 45 60 75 90 105 120 135 150 165

Use odometer reading or months, whichever

occurs first.

Months 1 +8 +9 +9 +9 +9 +9 +9 +9 +9 +9 +9

UNDER HOOD Extra

Change the engine oil and filter.

Refer to Section 6A1-1, 2.2 ENGINE OIL

CHANGE.

* X X X X X X X X X X X

Check the brake fluid l evel.

Refer to Section 5A, 2.3 BRAKE FLUID LEVEL

CHECK.

X X X X X X X X X X X X

Check the clutc h fl ui d level.

Refe r to Se ctio n 7A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X X X

Check the power steeri ng fl ui d level.

Refe r to Se ctio n 9A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X X X

Check the automati c t r ansm issi on fl ui d l evel.

Refer to Secti on 7C4, 2. 1 FLUID LEVEL CHECK. X X X X X X X X X X X X

Check the washer fluid l evel .

Refer to Section 12N, 2.10 FILLING THE

WASHER RESERVOIR.

X X X X X X X X X X X X

Check the coolant c oncent ration.

Refer to Section 6B1, 2.2 GLYCOL COOLANT

MAINTENANCE.

Check the coolant level. If the level is low,

pressure test the coolant system.

Refer to Section 6B1, 2.2 GLYCOL COOLANT

MAINTENANCE.

Refer to Secti on 6B1, 2.7 PRESSURE TESTING.

X X X X X X X X X X X X

Check batt ery el ectrolyte and fluid level.

Refer to Section 12A, 2.1 BATTERY

INSPECTION.

Refer to Section 12A, 2.2 HYDROMETER TEST.

X X X X X X X X X X X X

Check engine drive and acc essory bel ts .

Refer to Secti on 6A1-1, 2.6 DRIVE BELT.

Refer to Section 6A1-2, 2.9 SUPERCHARGER

DRIVE BELT.

X X X X X X X X X

Check for signs of deterioration and/or leaks from

engine, fluid reservoirs, air ducts, all hoses and

clamps.

X X X X X X X X X X X

Clean and refill the engine cooling sys tem.

Refer to Section 6B1–1, 2.4 CLEANING

COOLING SYSTEM.

Clean the outside of the radiator and air

conditioning condenser of debris that may hinder

airflow through the fins.

Change every 27 months (regardless of km)

Replace engine air cleaner element.

Refer to Section 6C1–3, 3.11 FUEL CONTROL

SYSTEM - AIR CLEANER ASSEMBLY for V6

equipped vehicles.

Refer to Section 8A2, 3.23 AIR CLEANER

ASSEMBLY for LPG equipped vehicles.

Refer to Section 6C1–3, 3.11 FUEL CONTROL

SYSTEM - AIR CLEANER ASSEMBLY for V6

supercharged equipped vehi cles.

* X X X

Check the supercharger oil level on V6

supercharged equipped vehi cles.

Refer to Section 6A1-2, 2.1 SUPERCHARGER

OIL LEVEL CHECK.

X X X

Replace the spark plugs (non supercharged).

Refer to Secti on 6D1-3, 2. 3 SPARK PLUGS. X X X

x 1000

km 1.5 15 30 45 60 75 90 105 120 135 150 165

Use odometer reading or months, whichever

occurs first.

Months 1 +8 +9 +9 +9 +9 +9 +9 +9 +9 +9 +9

Extra

Replace the spark plugs (superc harged only).

Refer to Secti on 6D1-3, 2. 3 SPARK PLUGS. X X X X X

UNDER CAR

Replace the fuel filter and retai ner.

Refer to Section 6C1-3, 3.10 FUEL CONTROL

SYSTEM - FUEL FILTER for V6 equipped

vehicles.

Refer to Section 6C1-3, 3.11 FUEL CONTROL

SYSTEM - FUEL FILTER for V6 supercharged

equipped vehicles.

X X X

Check the final drive oil l evel.

Refer to Section 4B, 2.1 CHECKING

DIFFERENTIAL CARRIER LUBRICANT.

X X X

Check the final drive and the automatic

transmission for leaks.

Refer to Section 7C3, 2.7 FLUID LEAK

DIAGNOSIS AND REPAIR to check for leaks from

the transmissi on.

X X X X X X X X X X X X

Change the automatic transmission fluid and

strainer.

Refer to Section 7C4, 3.1 FLUID REPLACEMENT

AND FILTER REPLACEMENT.

* X

Check the manual transmission oil level.

Refer to Section 7B1, 2.2 CHECKING

TRANSMISSION LUBRICANT LEVEL.

Oil level check not required

Check manual transmission for leaks. X X X X X X X X X X X X

Change the differenti al oil .

Refer to Se ction 4B, 2.2 CHANGING / FLUSHING

REAR AXLE LUBRICANT.

* Change not required under normal driving condit i ons

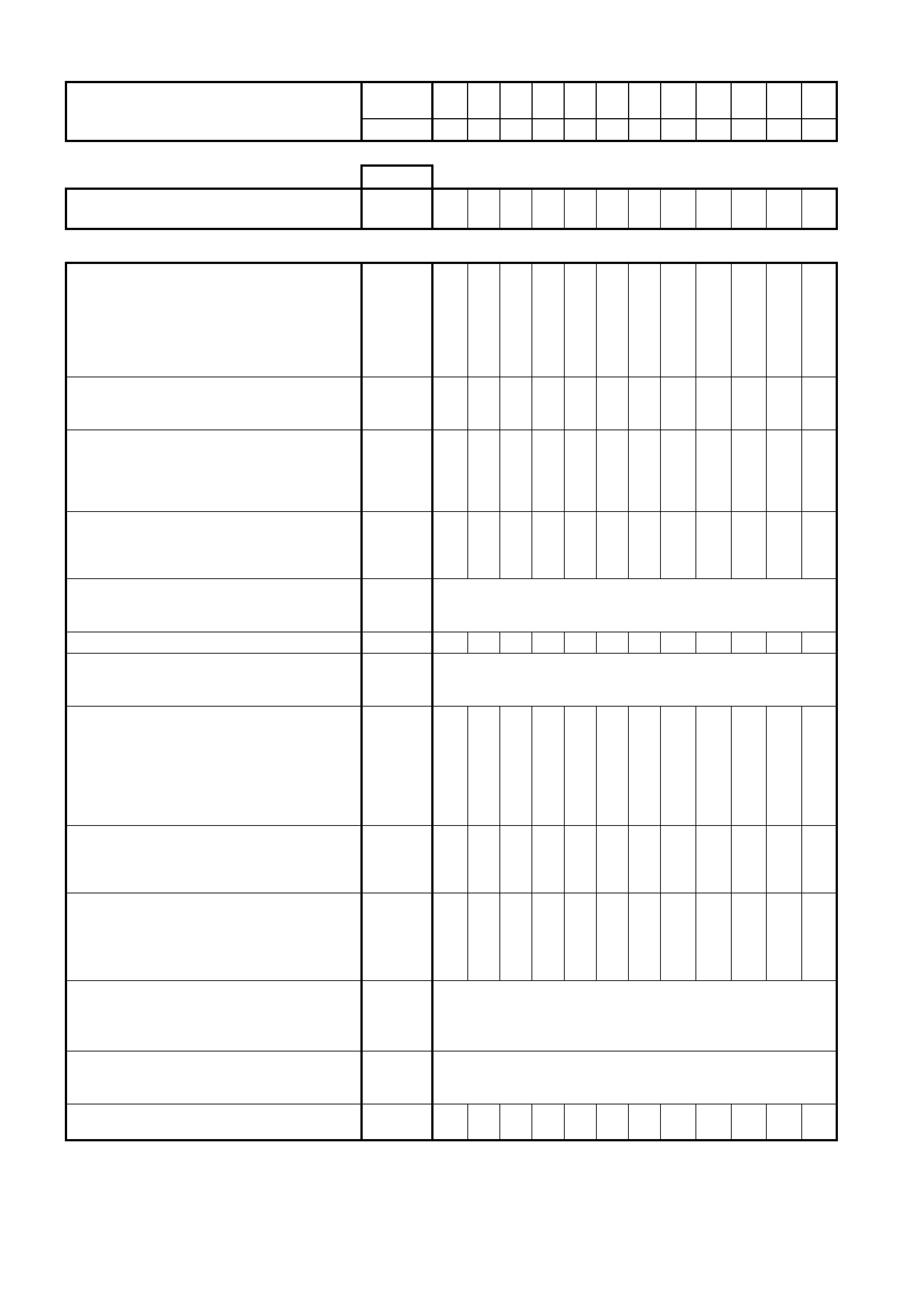

Inspect the front and the rear disc pads for wear

and the disc surfac e condition.

Refer to Section 5A, 2.6 BRAKE PAD WEAR

CHECK.

Rotate the wheels.

Refer to Secti on 10, 2.4 TYRE ROTATION.

Balance if required.

X X X X X X X X X X X

Check the park brake linings and the drums for

wear.

Refer to Section 5A, 3.6 PARKING BRAKE

LINING WEAR , CHECK.

* X X X

Inspect the tyres for irregul ar wear or dam age.

Check the wheels for damage.

Check the tyre air press ures.

Refer to Section 10, 2.1 TYRE INFLATION AND

INSPECTION.

X X X X X X X X X X X X

Drain, refi l l and bleed the brake system.

Refer to Section 5A, 2.4 BRAKE FLUID,

CHANGE.

Check the brake performance during the road test.

* Change every 27 months (regardless of km) under normal driving

conditions

Drain, refi l l and bleed the clutch system.

Refer to Section 7A1, 3.3 CLUTCH BLEEDING

PROCEDURE.

Change every 27 months (regardless of km)

Check all the brake and fuel lines / hoses for

conditi on, attachm ent and rout i ng, leaks etc . X X X X X X X X X X X X

x 1000

km 1.5 15 30 45 60 75 90 105 120 135 150 165

Use odometer reading or months, whichever

occurs first.

Months 1 +8 +9 +9 +9 +9 +9 +9 +9 +9 +9 +9

Extra

Inspect the front and rear suspension and the

steering system for damaged, loose or missing

parts, signs of wear or lack of lubrication. Inspect

the power steering lines / hoses for condition,

attachment and routing, leaks, etc. Check the

conditi on of all the rubber boots and the covers.

* X X X X X X X X X X X X

Inspect the exhaust and adj acent underbody. Look

for damaged, missing or out-of-position parts,

open seams, holes, or loose connect i ons.

Run car and check for exhaust l eaks.

X X X X X X X X X X X X

Inspect the constant velocit y joint for damage or a

torn boot and propeller shaft rubber couplings for

tears or splits.

X X X X X X X X X X X

Clean and lubricate the automatic transmission

shift linkage.

Refer to Secti on 7C4, 3. 2 SELECTOR LINKAGE.

X X X X

Check the evaporative emission control canister

for leaks or rest ri ctions.

Refer to Section 6E1, 2.2 EVAPORATIVE

EMISSION CONTROL CANISTER.

* X X X X

Inspect air conditi oni ng drain t ubes for blockage. X X X

Inspect sunro of dr ain hole s for bl o ckage. X X X X X X X X X X X

CAR INTERIOR

Check the park brake operati on.

Refer to Section 5A, 2.2 PARK BRAKE CABLE,

ADJUST.

X X X X X X X X X X X

Inspect the seat belt assemblies. Check the

webbing condition, the buckle operation and the

retractor mechanism.

X X X X X X X X X X X

Reset the ‘Service Reminder’ display. Refer to

Section 12C, 1.7 MULTI-FUNCTION DISPLAY –

ALL MODELS.

X X X X X X X X X X X X

CAR EXTERIOR

Check operation of all exterior li ghts. X X X X X X X X X X X X

Lubricate hood c atch, door hinges, rear door link s

only and lock cylinders.

Refer to Section 1A4, 2.3 HOOD PRIMARY

LATCH STRIKE R ASSEMBLY .

X X X X X X X X X X X

Check the transmitter range of the security

system.

Refer to Section 12J, 1.9 REMOTE

RECEIVER / KEY.

X X X X X X X X X X X

ROAD TEST

Check the braki ng, steering, engine respons e and

transmission operation. Check the operation of

cruise control if fitted. Check the park pawl

operation. Check the air conditioner performance.

Check the Neutral Start S witch operation.

X X X X X X X X X X X X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 3.1 ABNORM AL OP ER ATING CO NDITIONS in this Section.

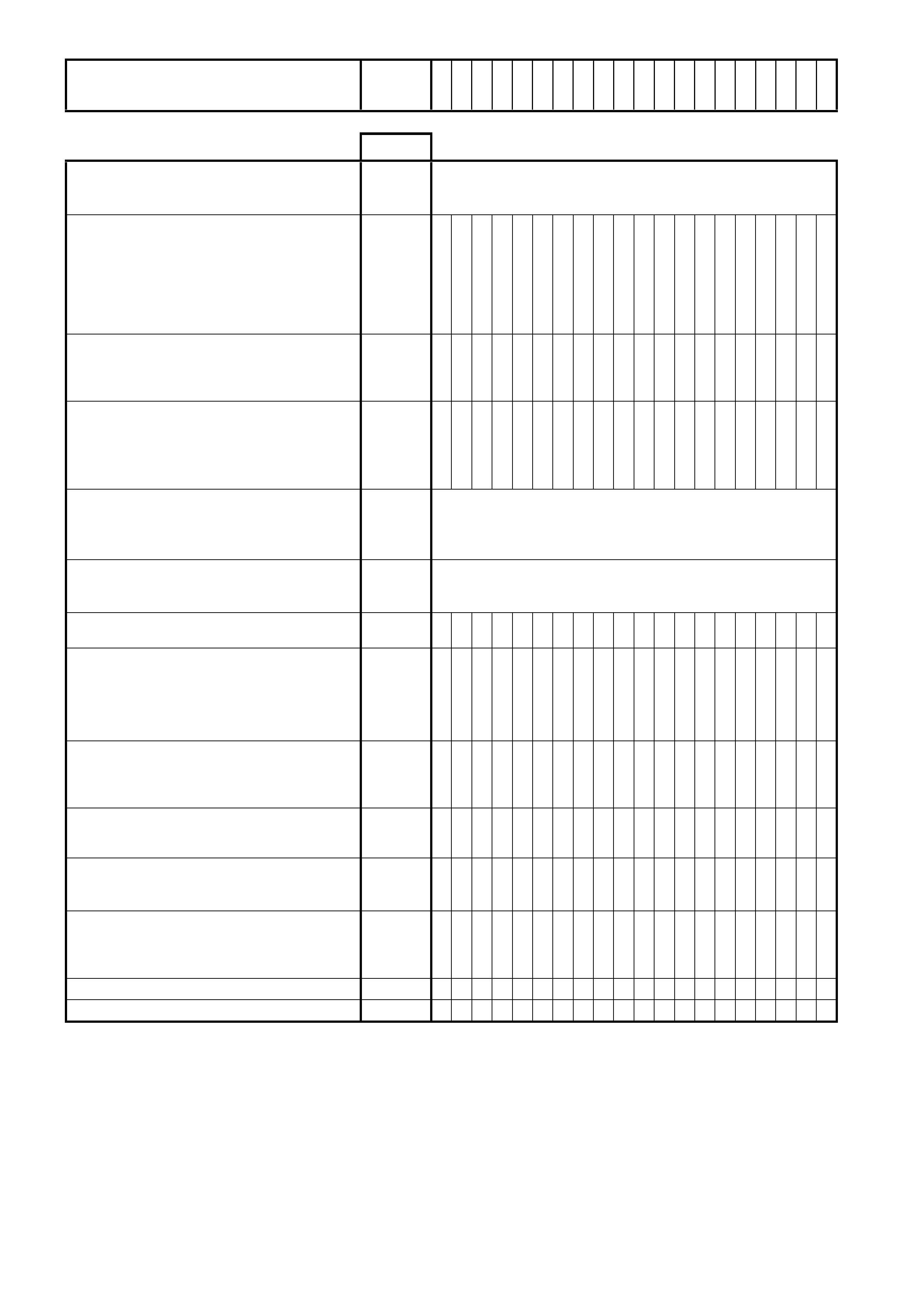

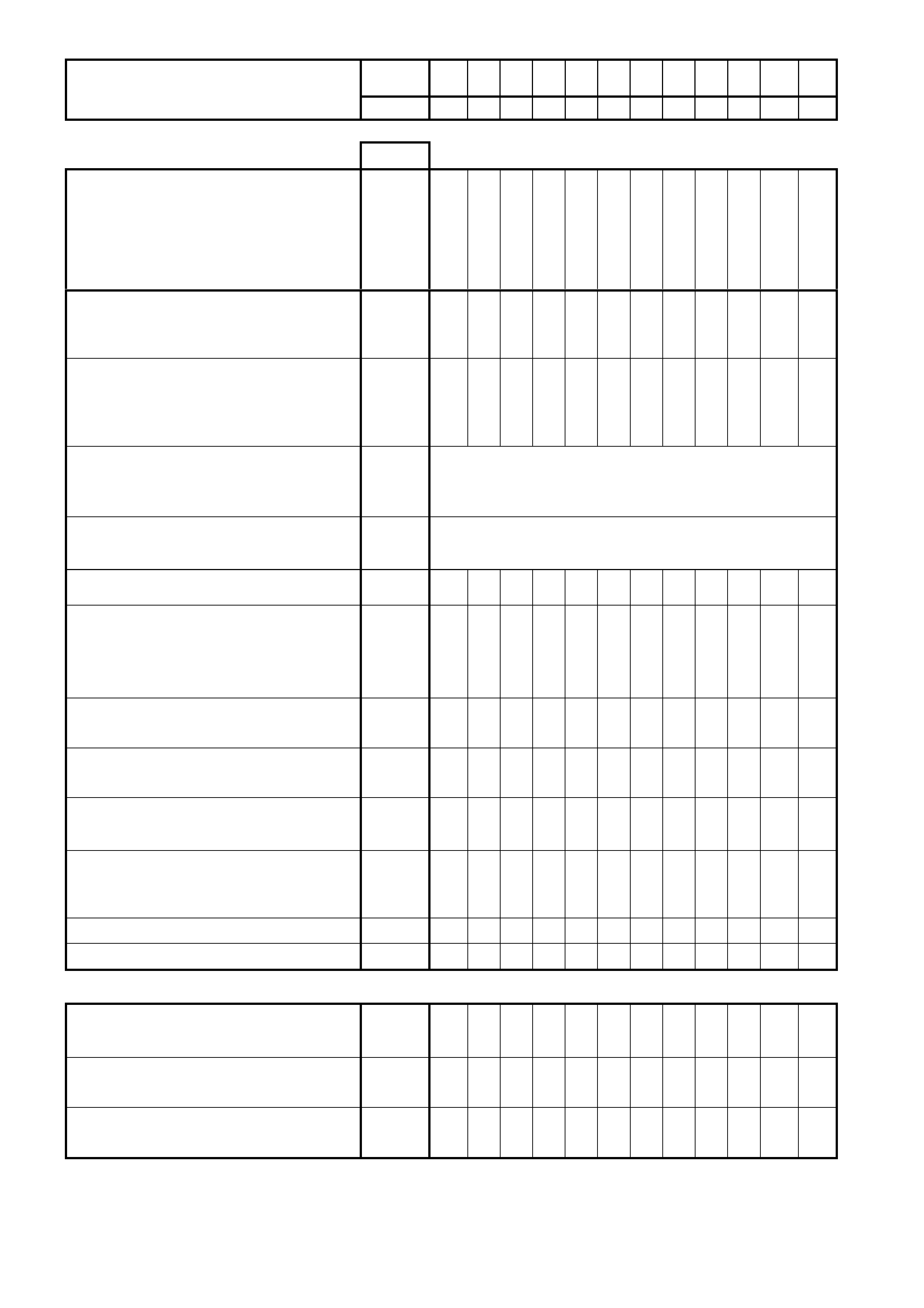

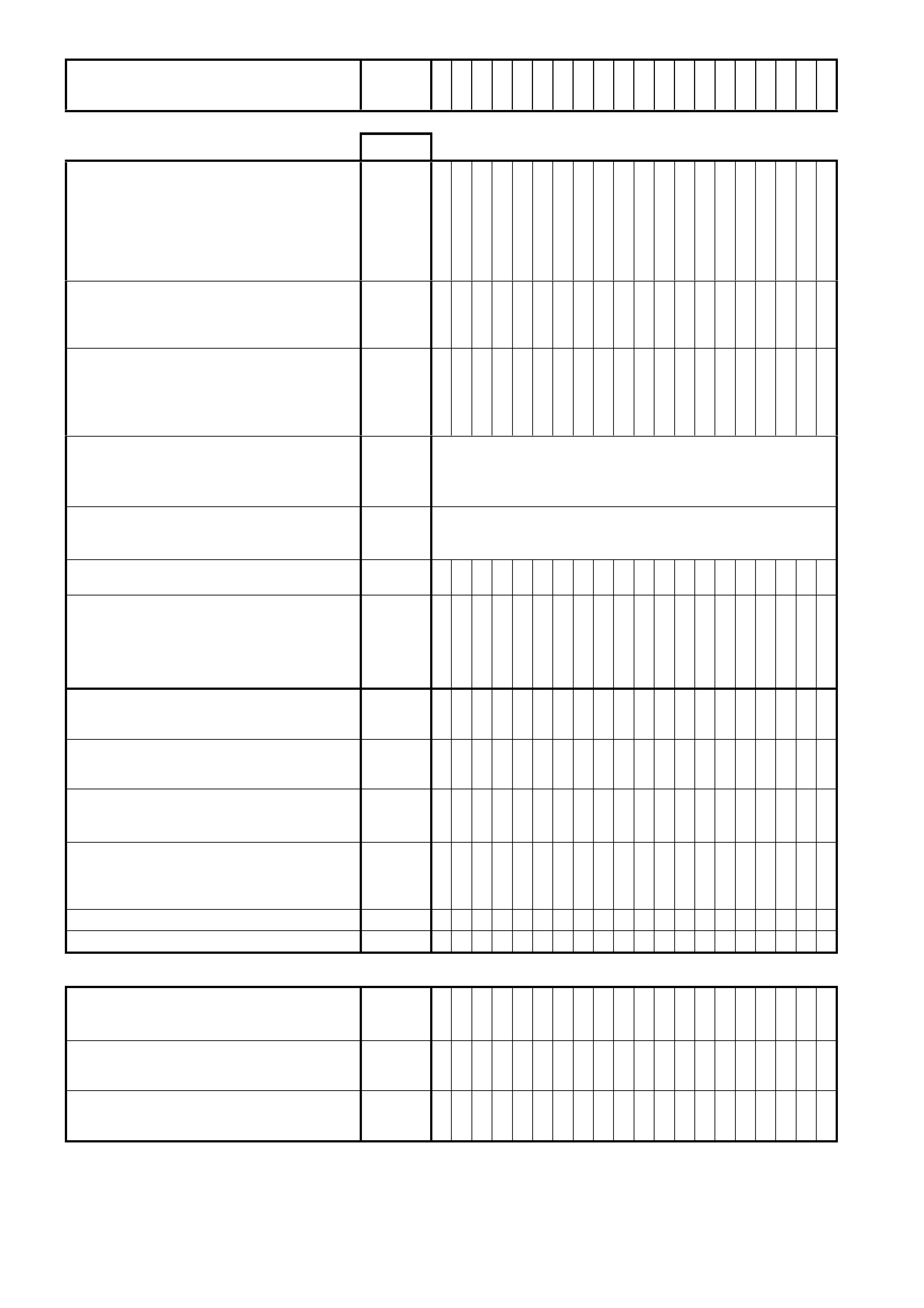

3.3 MAINTENANCE SCHEDULE – V6 – GULF STATES

ABNORMAL CONDITIONS

A When driving less than 5,000 km in 3 months.

B Dust, dirt, loose road material.

C Muddy and wet areas.

D Stop-start driving, excessive idling or low speed operation as experienced in inner city driving

i.e. taxi, door to door delivery.

E Extended heavy load high speed operation in temperatures above 35°C.

F When driving more than 250,000 km per 5 year.

EXTRA SERVICES REQUIRED

SERVICE REQUIRED ABNORMAL CONDITION

Change the engine oil at 3 months A

Change the automat ic tran sm i ssi on and strai ner at 4 years A

Change the automatic transmission fluid and the strainer at 20,000 km D E

Inspect the front suspension and the steering for leaks, wear or damage at

5,000 km B C

Replace the air cleaner element at 20,000 km B

Inspect and clean the park brake linings at 20,000 km B C

Change the final driv e oil at 20,000 km E

Change the power steering fluid at 50,000 km E

Change the engine coo lan t F

Inspect the evaporative emissions control canister at 20,000 km and change at

80,000 km B C

Inspect the rubber propeller shaft coupling at 10,000 km after 160,000 km of

abnormal operating conditions. E

*: Brake f luid deterior ates wit h time and s hould nor mall y be replaced every two years. Howev er, heav y dut y towing

requires fresher fluid due to the higher demand on the brake system. In countries where it is allowable to tow

mor e than 1600 kg, the brak e fluid shoul d be rep laced eac h year if a 1,600 kg (or higher ) tow bar is fitted, so that

the brake system can cope with the next year’s towing requirements.

MAINTENANCE SCHEDULE

The following chart provides the maintenance schedule, with the reference to the necessary procedure contained in

the Service Information Package, for all Gulf States V6 engine equipped vehicles.

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

UNDER HOOD Extra

Change the engine oil and filter.

Refer to Section 6A1-1, 2.2 ENGINE OIL

CHANGE.

* XXXXXXXXXXXX X X X X XXXX

Check the brake fluid l evel.

Refer to Section 5A, 2.3 BRAKE FLUID LEVEL

CHECK.

X X X X X X X X X X

Check the clutc h fl ui d level.

Refe r to Se ctio n 7A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X

Check the power steeri ng fl ui d level.

Refe r to Se ctio n 9A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

Extra

Check the automati c t r ansm issi on fl ui d l evel.

Refer to Secti on 7C4, 2. 1 FLUID LEVEL CHECK. X X X X X X X X X X

Check the washer fluid l evel .

Refer to Section 12N, 2.10 FILLING THE

WASHER RESERVOIR.

X X X X X X X X X X

Check the coolant c oncent ration.

Refer to Section 6B1, 2.2 GLYCOL COOLANT

MAINTENANCE.

Check the coolant level. If the level is low,

pressure test the coolant system.

Refer to Section 6B1, 2.2 GLYCOL COOLANT

MAINTENANCE.

Refer to Secti on 6B1, 2.7 PRESSURE TESTING.

X X X X X X X X X X

Check batt ery el ectrolyte and fluid level.

Refer to Section 12A, 2.1 BATTERY

INSPECTION.

Refer to Section 12A, 2.2 HYDROMETER TEST.

XXXXXXXXXXXX X X X X XXXX

Check engine drive and acc essory bel ts .

Refer to Secti on 6A1-1, 2.6 DRIVE BELT. X X X

Check for signs of deterioration and/or leaks from

engine, fluid reservoirs, air ducts, all hoses and

clamps.

X X X X X X X X X X

Clean and refill the engine cooling sys tem.

Refer to Section 6B1–1, 2.4 CLEANING

COOLING SYSTEM.

Clean the outside of the radiator and air

conditioning condenser of debris that may hinder

airflow through the fins.

Change every 5 years (regardles s of km)

Replace engine air cleaner element.

Refer to Section 6C1–3, 3.11 FUEL CONTROL

SYST EM - AIR CLEANE R ASSEMBLY.

* X X

Replace the spark plugs.

Refer to Secti on 6D1-3, 2. 3 SPARK PLUGS. X X

UNDER CAR

Replace the fuel filter and retai ner.

Refer to Section 6C1-3, 3.10 FUEL CONTROL

SYSTEM - FUEL FILTER.

X X

Check the final drive oil l evel.

Refer to Section 4B, 2.1 CHECKING

DIFFERENTIAL CARRIER LUBRICANT.

X X

Check the final drive and the automatic

transmission for leaks.

Refer to Section 7C3, 2.7 FLUID LEAK

DIAGNOSIS AND REPAIR to check for leaks from

the transmissi on.

X X X X X X X X X X

Change the automatic transmission fluid and

strainer.

Refer to Sect ion 7C4, 3.1 FLUID REPLACEMENT

AND FILTER REPLACEMENT.

* Change every 110,000 km

Check the manual transmission oil level.

Refer to Section 7B1, 2.2 CHECKING

TRANSMISSION LUBRICANT LEVEL.

Oil level check not required

Check manual transmission for leaks. X X X X X X X X X X

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

Extra

Change the differenti al oil .

Refer to S ection 4B, 2. 2 CHANGING / F LUSHING

REAR AXLE LUBRICANT.

* Change not required under norm al driving conditions

Inspect the front and the rear disc pads for wear

and the disc surfac e condition.

Refer to Section 5A, 2.6 BRAKE PAD WEAR

CHECK.

Rotate the wheels.

Refer to Secti on 10, 2.4 TYRE ROTATION.

Balance if required.

X X X X X X X X X

Check the park brake linings and the drums for

wear.

Refer to Section 5A, 3.6 PARKING BRAKE

LINING WEAR , CHECK.

* X X

Inspect the tyres for irregul ar wear or dam age.

Check the wheels for damage.

Check the tyre air press ures.

Refer to Section 10, 2.1 TYRE INFLATION AND

INSPECTION.

X X X X X X X X X X

Drain, refi l l and bleed the brake system.

Refer to Section 5A, 2.4 BRAKE FLUID,

CHANGE.

Check the brake performance during the road test.

* Change every 2 years (regardless of km) under normal driving

conditions

Drain, refi l l and bleed the clutch system.

Refer to Section 7A1, 3.3 CLUTCH BLEEDING

PROCEDURE.

Change every 2 years (regardles s of km)

Check all the brake and fuel lines / hoses for

conditi on, attachm ent and rout i ng, leaks etc . X X X X X X X X X X

Inspect the front and rear suspension and the

steering system for damaged, loose or missing

parts, signs of wear or lack of lubrication. Inspect

the power steering lines / hoses for condition,

attachment and routing, leaks, etc. Check the

conditi on of all the rubber boots and the covers.

* X X X X X X X X X X

Inspect the exhaust and adjacent underbody.

Look for damaged, missing or out-of-position

parts, open seams, holes, or l oose connecti ons.

Run car and check for exhaust l eaks.

X X X X X X X X X X

Inspect the const ant velocity joint for damage or a

torn boot and propeller shaft rubber couplings for

tears or splits.

X X X X X X X X X

Clean and lubricate the automatic transmission

shift linkage.

Refer to Secti on 7C4, 3. 2 SELECTOR LINKAGE.

X X

Check the evaporative emission control canister

for leaks or rest ri ctions.

Refer to Section 6E1, 2.2 EVAPORATIVE

EMISSION CONTROL CANISTER.

* X X X

Inspect air conditioning drain tubes for blockage. X X

Inspect sunroof drain holes for blockage. X X X X X X X X X X

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

CAR INTERIOR Extra

Check the park brake operati on.

Refer to Section 5A, 2.2 PARK BRAKE CABLE,

ADJUST.

X X X X X X X X X X

Inspect the seat belt assemblies. Check the

webbing condition, the buckle operation and the

retractor mechanism.

X X X X X

Reset the ‘Service Reminder’ display. Refer to

Section 12C, 1.7 MULTI-FUNCTION DISPLAY –

ALL MODELS.

XXXXXXXXXXXX X X X X XXXX

CAR EXTERIOR

Check operation of all exterior lights. X X X X X X X X X X

Lubricate hood catch, door hinges, rear door links

only and lock cylinders.

Refer to Section 1A4, 2.3 HOOD PRIMARY

LATCH STRIKE R ASSEMBLY .

X X X X X

Check the transmitter range of the security

system.

Refer to Section 12J, 1.9 REMOTE

RECEIVER / KEY.

X X X X X X X X X X

ROAD TEST

Check t he braking, steering, engine response and

transmission operation. Check the operation of

cruise control if fitted. Check the park pawl

operation. Check the air conditioner performance.

Check the Neutral Start S witch operation.

X X X X X X X X X X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 3.1 ABNORM AL OP ER ATING CO NDITIONS in this Section.

3.4 MAINTENANCE SCHEDULE – V6 WITH LPG

ABNORMAL CONDITIONS

A Dust, dirt, loose road material.

B Muddy and wet areas.

C Cold weather (below 5 °C) and when most trips are less than 5 km.

D Stop-start driving, excessive idling or low speed operation as experienced in inner city driving

i.e. taxi, door to door delivery, police.

E Caravan or trailer towing.

F Extended heavy load high speed operation in temperatures above 35°C.

EXTRA SERVICES REQUIRED

SERVICE REQUIRED ABNORMAL CONDITION

Change the automatic transmission fluid and the strainer at 30,000 km D E F

Inspect the front suspension and the steering for leaks, wear or damage at

5,000 km A B

Replace the engine oil filter at 5,000 km or 3 months (whichever comes first) A

Change the engine oil at 5,000 km or 3 months (whichev er co mes firs t) A C D E F

Replace the air cleaner element at 20,000 km A

Inspect and clean the park brake linings at 20,000 km A B

Change the final driv e oil at 20,000 km E F

Change the brake fluid at 1 year if a 1600 kg (or higher) tow bar is fitted * E

Change the power steering fluid at 50,000 km E F

Inspect the evaporative emissions control canister at 20,000 km and change at

80,000 km A B

Inspect the rubber propeller shaft coupling at 10,000 km after 160,000 km of

abnormal operating conditions. E F

*: Brake f luid deterior ates wit h time and s hould nor mall y be replaced every two years. Howev er, heav y dut y towing

requires fresher fluid due to the higher demand on the brake system. Therefore, brake fluid should be replaced

each year if a 1,600 k g (or hig her ) to w b ar is f itt ed, so that the br ak e system c an c ope with th e n ex t year’s to wing

requirements.

MAINTENANCE SCHEDULE

The following chart provides the maintenance schedule, with the reference to the necessary procedure contained in

the Ser vice Inf ormation Pack age, for a ll dom estic V6 engine eq uipped vehicl es that are fitt ed with a n LPG system .

LPG is only fitted to domestic V6 engine equipped vehicles with an automatic transmission.

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

UNDER HOOD Extra

Change the engine oil and filter.

Refer to Section 6A1-1, 2.2 ENGINE OIL

CHANGE.

* X X X X X X X X X X X

Check the brake fluid l evel.

Refer to Section 5A, 2.3 BRAKE FLUID LEVEL

CHECK.

X X X X X X X X X X X

Check the power steeri ng fl ui d level.

Refe r to Se ctio n 9A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X X

Check the automati c t r ansm issi on fl ui d l evel.

Refer to Secti on 7C4, 2. 1 FLUID LEVEL CHECK. X X X X X X X X X X X

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Extra

Check the washer fluid l evel .

Refer to Section 12N, 2.10 FILLING THE

WASHER RESERVOIR.

X X X X X X X X X X X

Check the coolant c oncent ration.

Refer to Section 6B1, 2.2 COOLANT

MAINTENANCE.

Check the coolant level. If the level is low,

pressure test the coolant system.

Refer to Section 6B1, 2.2 GLYCOL COOLANT

MAINTENANCE.

Refer to Secti on 6B1, 2.7 PRESSURE TESTING.

X X X X X X X X X X X

Check batt ery el ectrolyte and fluid level.

Refer to Section 12A, 2.1 BATTERY

INSPECTION.

Refer to Section 12A, 2.2 HYDROMETER TEST.

X X X X X X X X X X X X

Check engine drive and acc essory bel ts .

Refer to Section 6A1-1, 2.6 ENGINE DRIVE

BELTS.

X X X X

Check for signs of deterioration and/or leaks from

engine, fluid reservoirs, air ducts, all hoses and

clamps.

X X X X X X X X X X X

Clean and refill the engine cooling system with

recommended inhibitor and clean fresh water.

Refer to Section 6B1-1, 2.4 CLEANING COOLING

SYSTEM.

Clean the outside of the radiator and air

conditioning condenser of debris that may hinder

airflow through the fins.

Change every 2.5 years (regardless of km)

Replace engine air cleaner element.

Refer to Section 8A2, 3.23 AIR CLEANER

ASSEMBLY.

* X X

Replace the spark plugs.

Refer to Section 6D1-3, 2.3 SPARK PLUGS

AND / OR LEADS.

X X X X X

UNDER CAR

Replace the fuel filter and retai ner.

Refer to Section 6C3-3, 3.10 FUEL CONTROL

SYSTEM - FUEL FILTER.

X X

Check the final drive oil l evel.

Refer to Section 4B, 2.1 CHECKING

DIFFERENTIAL CARRIER LUBRICANT.

X X

Check the final drive and the automatic

transmission for leaks.

Refer to Section 7C3, 2.7 FLUID LEAK

DIAGNOSIS AND REPAIR to check for leaks from

the transmissi on.

X X X X X X X X X X X X

Change the automatic transmission fluid and

strainer.

Refer to Sect ion 7C4, 3.1 FLUID REPLACEMENT

AND FILTER REPLACEMENT.

* X

Change the differenti al oil .

Refer to S ection 4B, 2.2 CHANGING / F LUSHING

REAR AXLE LUBRICANT.

* Change not required under norm al driving conditions

Inspect the front and the rear disc pads for wear

and the disc surfac e condition.

Refer to Section 5A, 2.6 BRAKE PAD WEAR,

CHECK.

Rotate the wheels.

Refer to Secti on 10, 2.4 TYRE ROTATION.

Balance if required.

X X X X X X X X X X

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Extra

Check the park brake linings and the drums for

wear.

Refer to Section 5A, 3.6 PARKING BRAKE

LINING WEAR , CHECK.

* X X

Drain, refi l l and bleed the brake system.

Refer to Section 5A, 2.4 BRAKE FLUID,

CHANGE.

Check the brake performance during the road test.

* Change every 2 years (regardl ess of km) under normal driving

conditions

Inspect the tyres for irregul ar wear or dam age.

Check for damaged wheels.

Check the tyre air press ures.

Refer to Section 10, 2.1 TYRE INFLATION AND

INSPECTION.

X X X X X X X X X X X X

Drain, refill and bleed the brake system. Check

brake performance when road testing. * Change every 2 years (regardl ess of km) under normal driving

conditions.

Check all the brake and fuel lines / hoses for

conditi on, attachm ent and rout i ng, leaks etc . X X X X X X X X X X X

Inspect the front and rear suspension and the

steering system for damaged, loose or missing

parts, signs of wear or lack of lubrication. Inspect

the power steering lines / hoses for condition,

attachment and routing, leaks, etc. Check the

conditi on of all the rubber boots and the covers.

* X X X X X X X X X X X

Inspect the exhaust and adjacent underbody.

Look for damaged, missing or out-of-position

parts, open seams, holes, or l oose connecti ons.

X X X X X X X X X X X

Inspect the const ant velocity joint for damage or a

torn boot and propeller shaft rubber couplings for

tears or splits.

X X X X X X X X X X

Clean and lubricate the automatic transmission

shift linkage.

Refer to Secti on 7C4, 3. 2 SELECTOR LINKAGE.

X X X

Check the evaporative emissions control canister

for leaks or rest ri ctions.

Refer to Section 6E2, 2.2 EVAPORATIVE

EMISSION CONTROL CANISTER.

* X X X

Clean out the air conditioning drain tubes. X X

Inspect sunroof drain holes for blockage. X X X X X X X X X X X

LPG SYSTEM

Check the LPG install ation.

Refer to Section 8A2, 5. AFTER INSTALLATION

CHECK.

X

Check the LPG system f or leaks .

Refer to Secti on 8A2, 3.3 LEAK TESTING. X X X X X

Check the LPG tank mounting nuts for correct

torque specific ation.

Refer to Section 8A2, 3.6 LPG TANK.

X X X X X

Check the operation of the autom atic fill limiter.

Refer to Section 8A2, 3.10 AUTOMATIC FILL

LIMITER (AFL).

X X X X X

Perform the resistance check on the fuel control

valve.

Refer to Section 8A2, 3.19 FUEL CONTROL

VALVE.

X X

Replace the lock-off filter.

Refer to Section 8A2, 3.16 LPG LOCK-OFF. X

Overhaul the converter

Refer to Section 8A2, 3.17 CONVERTER. X

LPG tank pressure t est by a licensed LPG cylinder

testing station. Required every 10 years.

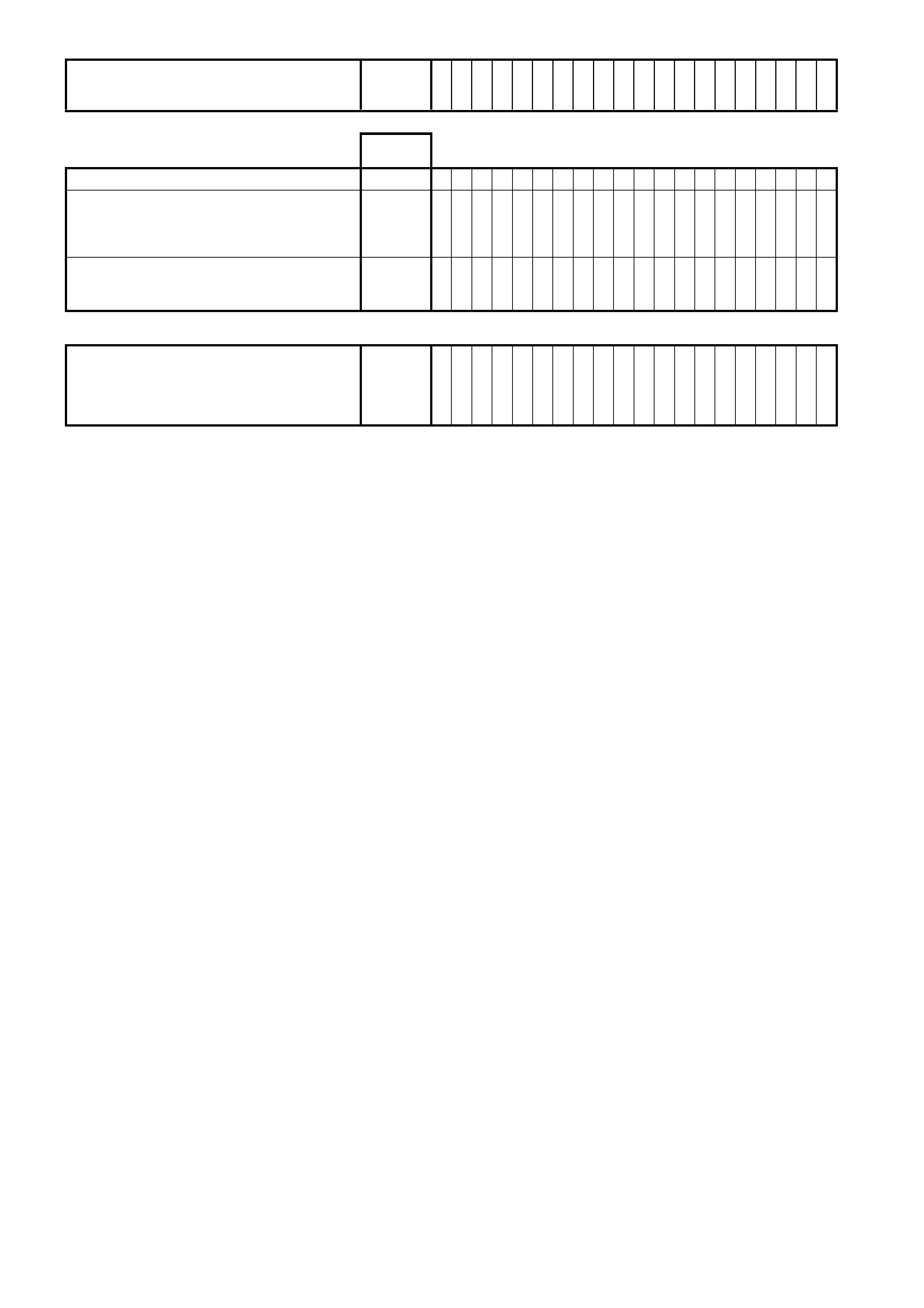

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

CAR INTERIOR Extra

Check the park brake operati on.

Refer to Section 5A, 2.2 PARK BRAKE CABLE,

ADJUST.

X X X X X X X X X X X

Inspect the seat belt assemblies. Check the

webbing condition, the buckle operation and the

retractor mechanism.

X X X X X

Reset the ‘Service Reminder’ display. Refer to

Section 12C, 1.7 MULTI-FUNCTION DISPLAY –

ALL MODELS.

X X X X X X X X X X X X

CAR EXTERIOR

Check operation of all exterior lights. X X X X X X X X X X X X

Lubricate hood catch, door hinges, rear door links

only and lock cylinders.

Refer to Section 1A4, 2.3 HOOD PRIMARY

LATCH STRIKE R ASSEMBLY .

X X X X X

Check transm i tt er range of sec urity system.

Refer to Section 12J, 1.9 REMOTE

RECEIVER / KEY.

X X X X X X X X X X X

ROAD TEST

Check braking, steering, engine response and

transmission operation. Check the operation of

cruise control if fitted. Check the park pawl

operation. Check the air conditioner performance.

Check the Neutral Start S witch operation.

X X X X X X X X X X X X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 3.1 ABNORM AL OP ER ATING CO NDITIONS in this Section.

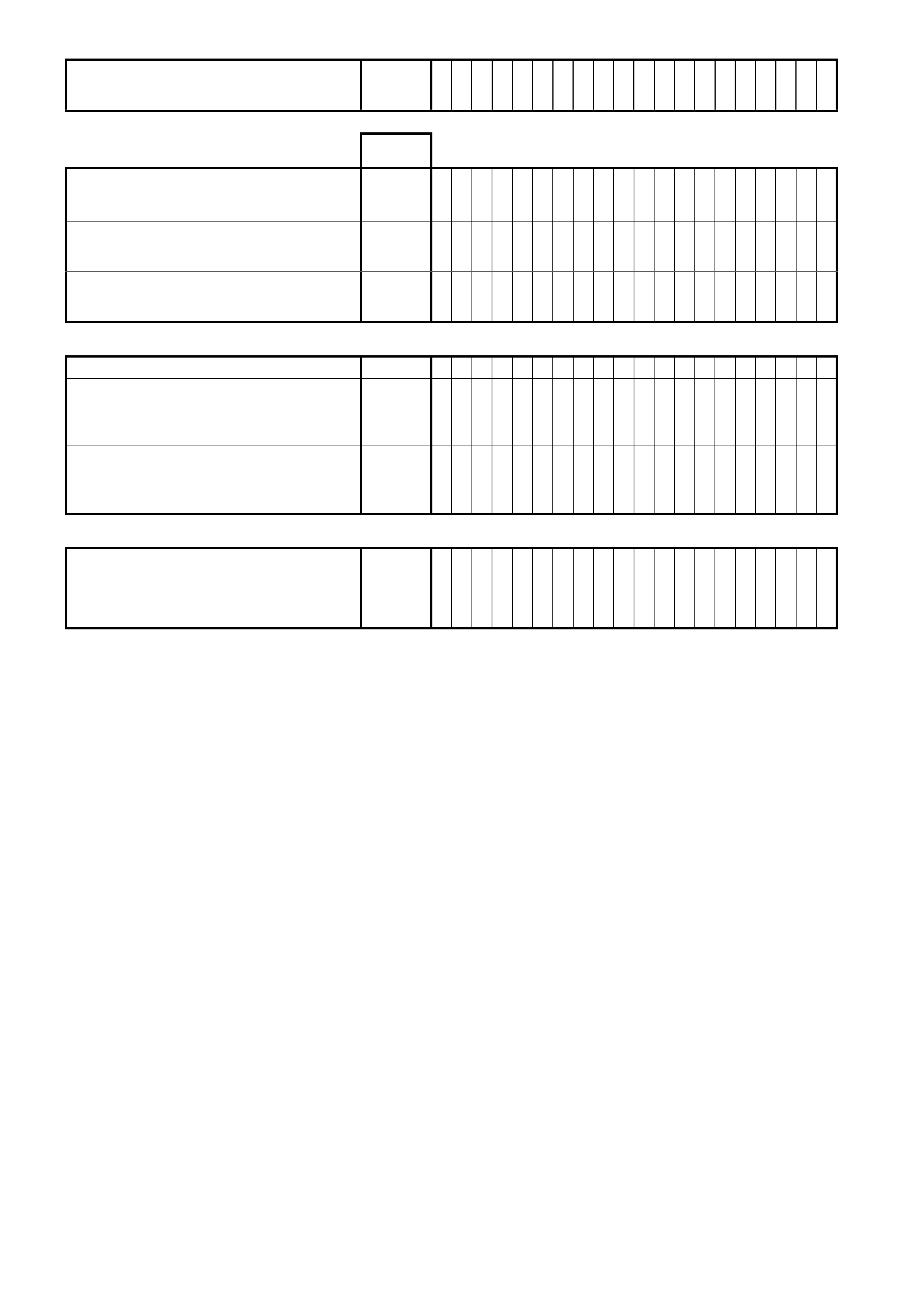

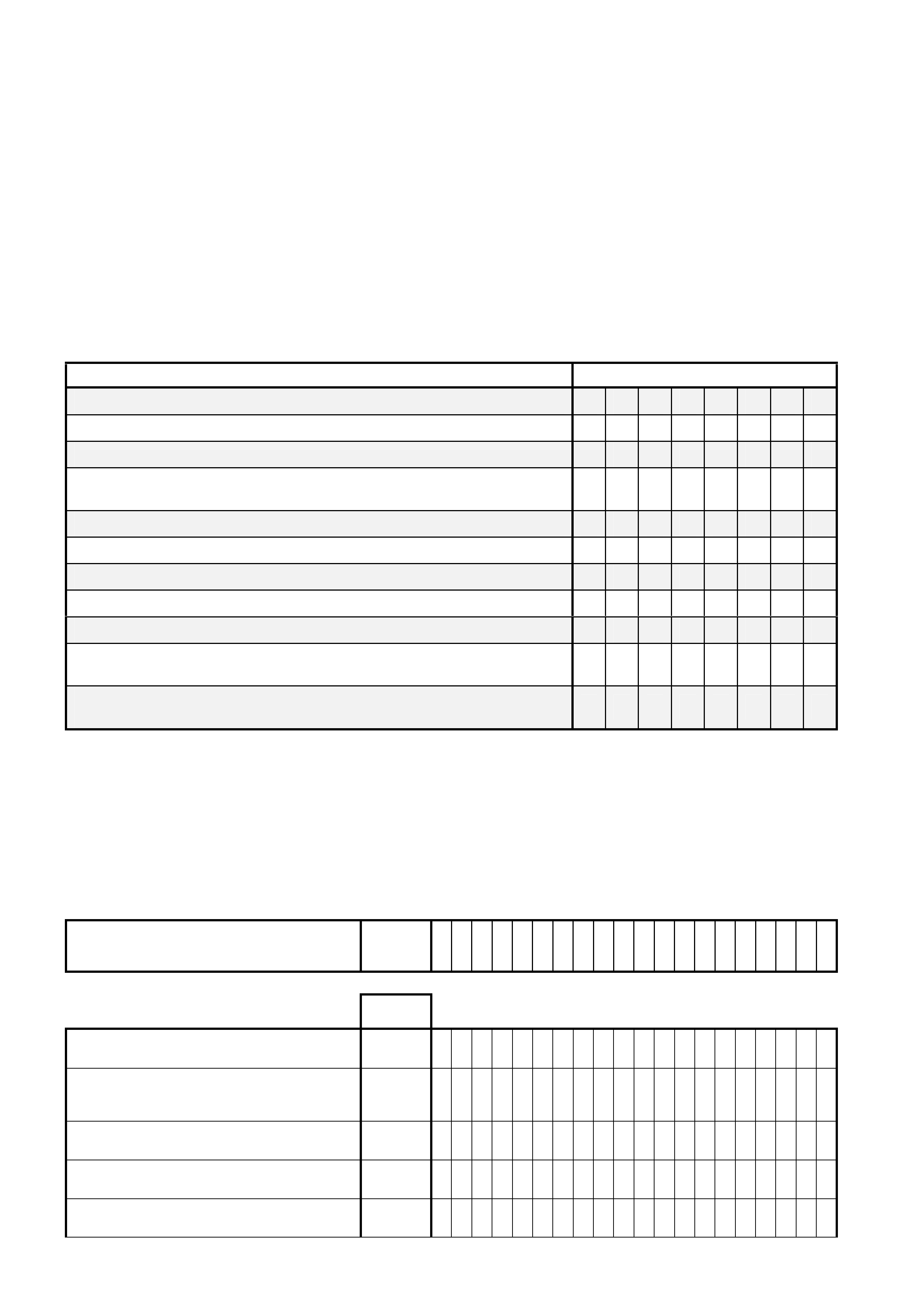

3.5 MAINTENANCE SCHEDULE – GEN III V8 – DOMESTIC

ABNORMAL CONDITIONS

A Dust, dirt, loose road material.

B Muddy and wet areas.

C Cold weather (below 5 °C) and when most trips are less than 5 km.

D Stop-start driving, excessive idling or low speed operation as experienced in inner city driving

i.e. taxi, door to door delivery, police.

E Caravan or trailer towing.

F Extended heavy load high speed operation in temperatures above 35°C.

G Driving more than 250,000 km per 5 years.

EXTRA SERVICES REQUIRED

SERVICE REQUIRED ABNORMAL CONDITION

Change the automatic transmission fluid and the strainer at 30,000 km D E F

Inspect the front suspension and the steering for leaks, wear or damage at

5,000 km A B

Replace the engine oil filter at 5,000 km or 3 months (whichever comes first) A

Change the engine oil at 5,000 km or 3 months (whichev er co mes firs t) A C D E F

Replace the air cleaner element at 20,000 km A

Inspect and clean the park brake linings at 20,000 km A B

Change the final driv e oil at 20,000 km E F

Change the brake fluid at 1 year if a 1600 kg (or higher) tow bar is fitted * E

Change the power steering fluid at 50,000 km E F

Change the engine coolant at 5 years or 250,000 km, whichever comes first. G

Inspect the evaporative emissions control canister at 20,000 km and change at

80,000 km A B

*: Brake f luid deterior ates wit h time and s hould nor mall y be replaced every two years. Howev er, heav y dut y towing

requires fresher fluid due to the higher demand on the brake system. Therefore, brake fluid should be replaced

each year if a 1,600 k g (or hig her ) to w b ar is f itt ed, so that the br ak e system c an c ope with th e n ex t year’s to wing

requirements.

MAINTENANCE SCHEDULE

The following chart provides the maintenance schedule, with the reference to the necessary procedure contained in

the Service Information Package, for all domestic GEN III V8 engine equipped vehicles.

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

UNDER HOOD Extra

Change the engine oil and filter.

Refer to Secti on 6A3, 2.2 ENGINE OIL CHANGE. * X X X X X X X X X X X

Check the brake fluid l evel.

Refer to Section 5A, 2.3 BRAKE FLUID LEVEL

CHECK.

X X X X X X X X X X X

Check the clutc h fl ui d level.

Refer to Secti on 7A1. 3.1 FLUID LEVEL CHE CK. X X X X X X X X X X X

Check the power steeri ng fl ui d level.

Refe r to Se ctio n 9A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X X

Check the automati c t r ansm issi on fl ui d l evel.

Refer to Secti on 7C4, 2. 1 FLUID LEVEL CHECK. X X X X X X X X X X X

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Extra

Check the washer fluid l evel .

Refer to Section 12N, 2.10 FILLING THE

WASHER RESERVOIR.

X X X X X X X X X X X

Check the coolant c oncent ration.

Refer to Section 6B3, 2.2 COOLANT

MAINTENANCE.

Check the coolant level. If the level is low,

pressure test the coolant system.

Refer to Section 6B3, 2.2 COOLANT

MAINTENANCE.

Refer to Secti on 6B3, 2.8 PRESSURE TESTING.

X X X X X X X X X X X

Check batt ery el ectrolyte and fluid level.

Refer to Section 12A, 2.1 BATTERY

INSPECTION.

Refer to Section 12A, 2.2 HYDROMETER TEST.

X X X X X X X X X X X X

Check engine drive and acc essory bel ts .

Refer to Section 6A3, 2.6 ENGINE DRIVE

BELTS – REPLACE.

X X X X

Check for signs of deterioration and/or leaks from

engine, fluid reservoirs, air ducts, all hoses and

clamps.

X X X X X X X X X X X

Clean and refill the engine cooling sys tem.

Refer to Section 6B3, 2.5 CLEANING COOLING

SYSTEM.

Clean the outside of the radiator and air

conditioning condenser of debris that may hinder

airflow through the fins.

* Change every 5 years

Replace engine air cleaner element.

Refer to Section 6C3–3, 3.23 AIR CLEANER

ASSEMBLY.

* X X

Replace the spark plugs.

Refer to Section 6D3-3, 2.1 SPARK PLUGS

AND / OR LEADS.

X

UNDER CAR

Replace the fuel filter and retai ner.

Refer to Section 6C3-3, 3.15 FUEL CONTROL

SYSTEM - FUEL FILTER.

X X

Check the final drive oil l evel.

Refer to Section 4B, 2.1 CHECKING

DIFFERENTIAL CARRIER LUBRICANT.

X X

Check the final drive and the automatic

transmission for leaks.

Refer to Section 7C3, 2.7 FLUID LEAK

DIAGNOSIS AND REPAIR to check for leaks from

the transmissi on.

X X X X X X X X X X X X

Change the automatic transmission fluid and

strainer.

Refer to Section 7C4, 3.1 FLUID REPLACEMENT

AND FILTER REPLACEMENT.

* X

Check the manual transmi ssion oil level

Refer to Section 7B3, 2.2 CHECKING

TRANSMISSION LUBRICANT LEVEL

Oil l evel check not requi red

Check manual transmission for leaks. X X X X X X X X X X X

Change the differenti al oil .

Refer to S ection 4B, 2.2 CHANGING / F LUSHING

REAR AXLE LUBRICANT.

* Change not required under norm al driving conditions

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

Extra

Inspect the front and the rear disc pads for wear

and the disc surfac e condition.

Refer to Section 5A, 2.6 BRAKE PAD WEAR,

CHECK.

Rotate the wheels.

Refer to Secti on 10, 2.4 TYRE ROTATION.

Balance if required.

X X X X X X X X X X

Check the park brake linings and the drums for

wear.

Refer to Section 5A, 3.6 PARKING BRAKE

LINING WEAR , CHECK.

* X X

Inspect the tyres for irregul ar wear or dam age.

Check for damaged wheels.

Check the tyre air press ures.

Refer to Section 10, 2.1 TYRE INFLATION AND

INSPECTION.

X X X X X X X X X X X X

Drain, refi l l and bleed the brake system.

Refer to Section 5A, 2.4 BRAKE FLUID,

CHANGE.

Check the brake performance during the road test.

* Change every 2 years (regardl ess of km) under normal driving

conditions

Drain, refi l l and bleed the clutch system.

Refer to Section 7A2, 2.3 CLUTCH BLEEDING

PROCEDURE.

Change every 2 years (regardl ess of km)

Check all the brake and fuel lines / hoses for

conditi on, attachm ent and rout i ng, leaks etc . X X X X X X X X X X X

Inspect the front and rear suspension and the

steering system for damaged, loose or missing

parts, signs of wear or lack of lubrication. Inspect

the power steering lines / hoses for condition,

attachment and routing, leaks, etc. Check the

conditi on of all the rubber boots and the covers.

* X X X X X X X X X X X

Inspect the exhaust and adjacent underbody.

Look for damaged, missing or out-of-position

parts, open seams, holes, or l oose connecti ons.

X X X X X X X X X X X

Inspect the const ant velocity joint for damage or a

torn boot and propeller shaft rubber couplings for

tears or splits.

X X X X X X X X X X

Clean and lubricate the automatic transmission

shift linkage.

Refer to Secti on 7C4, 3. 2 SELECTOR LINKAGE.

X X X

Check the evaporative emissions control canister

for leaks or rest ri ctions.

Refer to Section 6E2, 2.2 EVAPORATIVE

EMISSION CONTROL CANISTER.

* X X X

Clean out the air conditioning drain tubes. X X

Inspect sunroof drain holes for blockage. X X X X X X X X X X X

CAR INTERIOR

Check the park brake operati on.

Refer to Section 5A, 2.2 PARK BRAKE CABLE,

ADJUST.

X X X X X X X X X X X

Inspect the seat belt assemblies. Check the

webbing condition, the buckle operation and the

retractor mechanism.

X X X X X

Reset the ‘Service Reminder’ display. Refer to

Section 12C, 1.7 MULTI-FUNCTION DISPLAY –

ALL MODELS.

X X X X X X X X X X X X

x 1000

km 1.5 10 20 30 40 50 60 70 80 90 100 110

Use odomete r reading or years, whichever oc curs

first.

Years 1/12 0.5 1 1.5 2 2.5 3 3.5 4 4.5 5 5.5

CAR EXTERIOR Extra

Check operation of all exterior lights. X X X X X X X X X X X X

Lubricate hood catch, door hinges, rear door links

only and lock cylinders.

Refer to Section 1A4, 2.3 HOOD PRIMARY

LATCH STRIKE R ASSEMBLY .

X X X X X

Check transm i tt er range of sec urity system.

Refer to Section 12J, 1.9 REMOTE

RECEIVER/KEY.

X X X X X X X X X X X

ROAD TEST

Check braking, steering, engine response and

transmission operation. Check the operation of

cruise control if fitted. Check the park pawl

operation. Check the air conditioner performance.

Check the Neutral Start S witch operation.

X X X X X X X X X X X X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 3.1 ABNORM AL OP ER ATING CO NDITIONS in this Section.

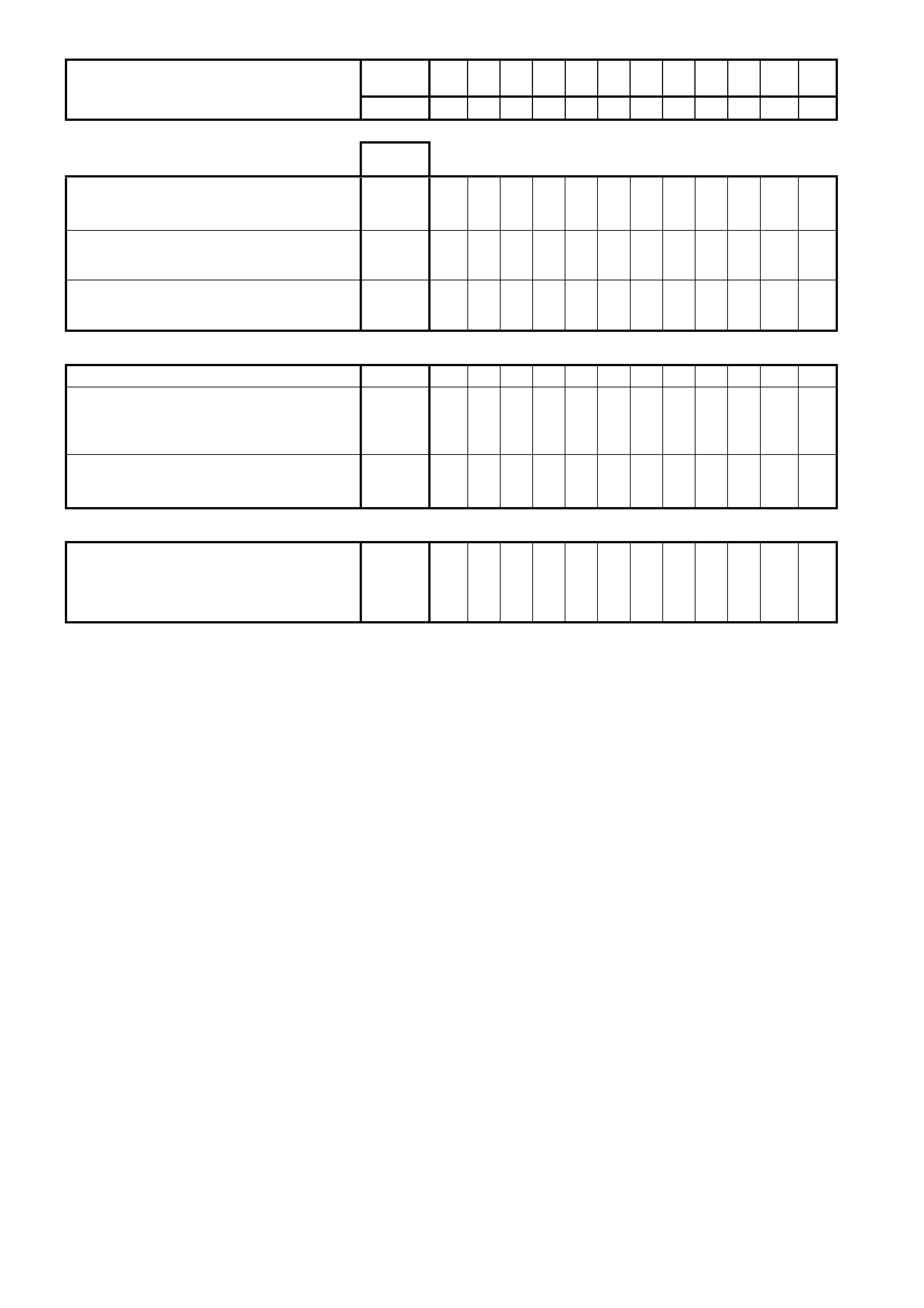

3.6 MAINTENANCE SCHEDULE – GEN III V8 – GULF STATES

ABNORMAL CONDITIONS

A When driving less than 5,000 km in 3 months.

B Dust, dirt, loose road material.

C Muddy and wet areas.

D Stop-start driving, excessive idling or low speed operation as experienced in inner city driving

i.e. taxi, door to door delivery.

E Extended heavy load high speed operation in temperatures above 35°C.

F When driving more than 250,000 km per 5 year.

EXTRA SERVICES REQUIRED

SERVICE REQUIRED ABNORMAL CONDITION

Change the engine oil at 3 months A

Change the automat ic tran sm i ssi on and strai ner at 4 years A

Change the automatic transmission fluid and the strainer at 20,000 km D E

Inspect the front suspension and the steering for leaks, wear or damage at

5,000 km B C

Replace the air cleaner element at 20,000 km B

Inspect and clean the park brake linings at 20,000 km B C

Change the final driv e oil at 20,000 km E

Change the power steering fluid at 50,000 km E

Change the engine coo lan t F

Inspect the evaporative emissions control canister at 20,000 km and change at

80,000 km B C

Inspect the rubber propeller shaft coupling at 10,000 km after 160,000 km of

abnormal operating conditions. E

*: Brake f luid deterior ates wit h time and s hould nor mall y be replaced every two years. Howev er, heav y dut y towing

requires fresher fluid due to the higher demand on the brake system. In countries where it is allowable to tow

mor e than 1600 kg, the brak e fluid shoul d be rep laced eac h year if a 1,600 kg (or higher ) tow bar is fitted, so that

the brake system can cope with the next year’s towing requirements.

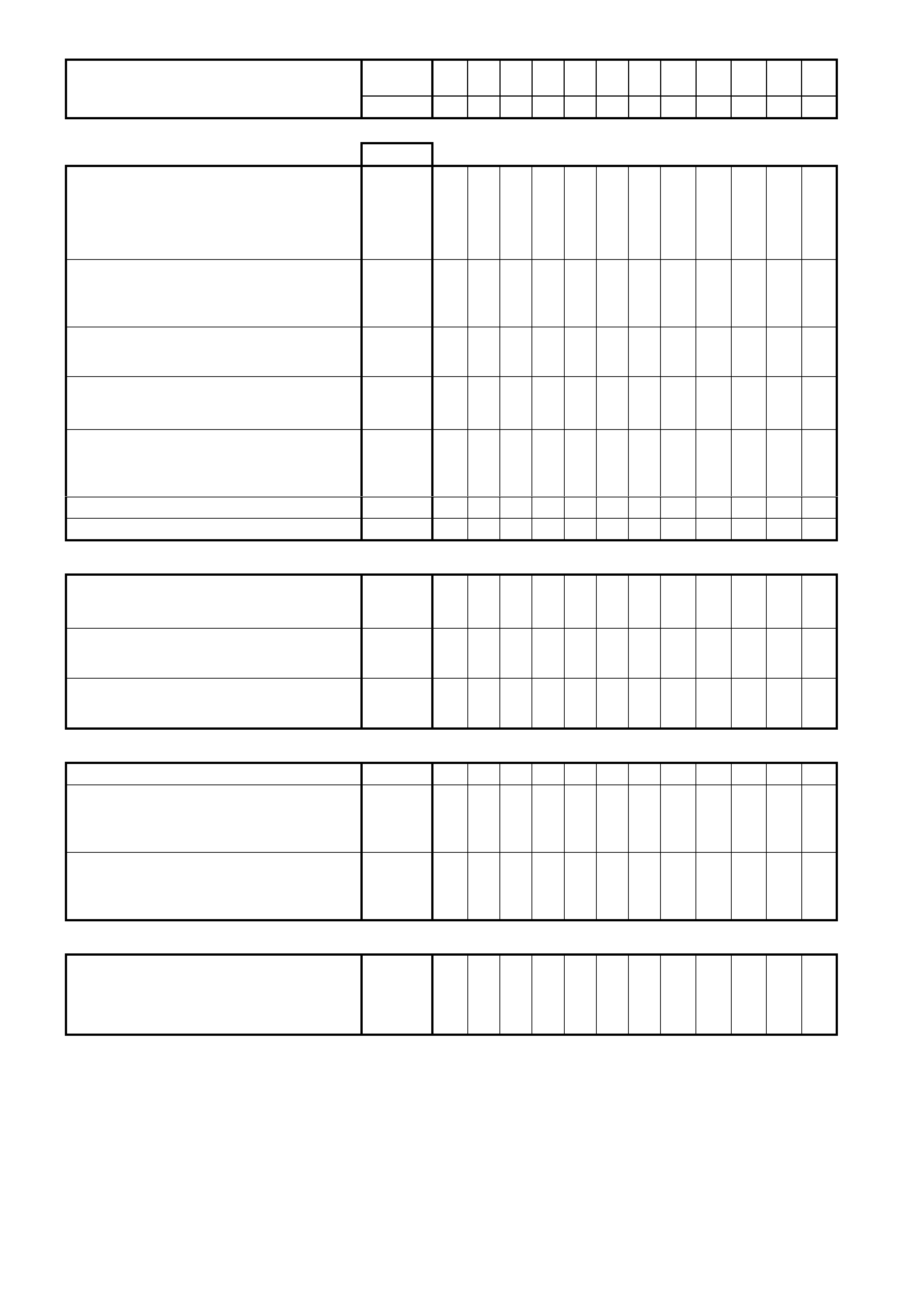

MAINTENANCE SCHEDULE

The following chart provides the maintenance schedule, with the reference to the necessary procedure contained in

the Service Information Package, for all Gulf States V8 GEN III engine equipped vehicles.

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

UNDER HOOD Extra

Change the engine oil and filter.

Refer to Secti on 6A3, 2.2 ENGINE OIL CHANGE. * XXXXXXXXXXXX X X X X XXXX

Check the brake fluid l evel.

Refer to Section 5A, 2.3 BRAKE FLUID LEVEL

CHECK.

X X X X X X X X X X

Check the clutc h fl ui d level.

Refer to Secti on 7A1. 3.1 FLUID LEVEL CHE CK. X X X X X X X X X X

Check the power steeri ng fl ui d level.

Refe r to Se ctio n 9A, 3.1 FLUID LE VEL C HECK . X X X X X X X X X X

Check the automati c t r ansm issi on fl ui d l evel.

Refer to Secti on 7C4, 2. 1 FLUID LEVEL CHECK. X X X X X X X X X X

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

Extra

Check the washer fluid l evel .

Refer to Section 12N, 2.10 FILLING THE

WASHER RESERVOIR.

X X X X X X X X X X

Check the coolant c oncent ration.

Refer to Section 6B3, 2.2 COOLANT

MAINTENANCE.

Check the coolant level. If the level is low,

pressure test the coolant system.

Refer to Section 6B3, 2.2 COOLANT

MAINTENANCE.

Refer to Secti on 6B3, 2.8 PRESSURE TESTING.

X X X X X X X X X X

Check batt ery el ectrolyte and fluid level.

Refer to Section 12A, 2.1 BATTERY

INSPECTION.

Refer to Section 12A, 2.2 HYDROMETER TEST.

XXXXXXXXXXXX X X X X XXXX

Check engine drive and acc essory bel ts .

Refer to Section 6A3, 2.6 ENGINE DRIVE

BELTS – REPLACE.

X X X

Check for signs of deterioration and/or leaks from

engine, fluid reservoirs, air ducts, all hoses and

clamps.

X X X X X X X X X X

Clean and refill the engine cooling sys tem.

Refer to Section 6B3, 2.5 CLEANING COOLING

SYSTEM.

Clean the outside of the radiator and air

conditioning condenser of debris that may hinder

airflow through the fins.

* Change every 5 years

Replace engine air cleaner element.

Refer to Section 6C3–3, 3.23 AIR CLEANER

ASSEMBLY.

* X X

Replace the spark plugs.

Refer to Section 6D3-3, 2.1 SPARK PLUGS

AND / OR LEADS.

X X

UNDER CAR

Replace the fuel filter and retai ner.

Refer to Section 6C3-3, 3.15 FUEL CONTROL

SYSTEM - FUEL FILTER.

X X

Check the final drive oil l evel.

Refer to Section 4B, 2.1 CHECKING

DIFFERENTIAL CARRIER LUBRICANT.

X X

Check the final drive and the automatic

transmission for leaks.

Refer to Section 7C3, 2.7 FLUID LEAK

DIAGNOSIS AND REPAIR to check for leaks from

the transmissi on.

X X X X X X X X X X

Change the automatic transmission fluid and

strainer.

Refer to Sect ion 7C4, 3.1 FLUID REPLACEMENT

AND FILTER REPLACEMENT.

* Change every 110,000 km

Check the manual transmi ssion oil level

Refer to Section 7B3, 2.2 CHECKING

TRANSMISSION LUBRICANT LEVEL

Oil level check not required

Check manual transmission for leaks. X X X X X X X X X X

Change the differenti al oil .

Refer to S ection 4B, 2.2 CHANGING / F LUSHING

REAR AXLE LUBRICANT.

* Change not required under norm al driving conditions

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

Extra

Inspect the front and the rear disc pads for wear

and the disc surfac e condition.

Refer to Section 5A, 2.6 BRAKE PAD WEAR,

CHECK.

Rotate the wheels.

Refer to Secti on 10, 2.4 TYRE ROTATION.

Balance if required.

X X X X X X X X X

Check the park brake linings and the drums for

wear.

Refer to Section 5A, 3.6 PARKING BRAKE

LINING WEAR , CHECK.

* X X

Inspect the tyres for irregul ar wear or dam age.

Check for damaged wheels.

Check the tyre air press ures.

Refer to Section 10, 2.1 TYRE INFLATION AND

INSPECTION.

X X X X X X X X X X

Drain, refi l l and bleed the brake system.

Refer to Section 5A, 2.4 BRAKE FLUID,

CHANGE.

Check the brake performance during the road test.

* Change every 2 years (regardless of km) under normal driving

conditions

Drain, refi l l and bleed the clutch system.

Refer to Section 7A2, 2.3 CLUTCH BLEEDING

PROCEDURE.

Change every 2 years (regardles s of km)

Check all the brake and fuel lines / hoses for

conditi on, attachm ent and rout i ng, leaks etc . X X X X X X X X X X

Inspect the front and rear suspension and the

steering system for damaged, loose or missing

parts, signs of wear or lack of lubrication. Inspect

the power steering lines / hoses for condition,

attachment and routing, leaks, etc. Check the

conditi on of all the rubber boots and the covers.

* X X X X X X X X X X

Inspect the exhaust and adjacent underbody.

Look for damaged, missing or out-of-position

parts, open seams, holes, or l oose connecti ons.

X X X X X X X X X X

Inspect the const ant velocity joint for damage or a

torn boot and propeller shaft rubber couplings for

tears or splits.

X X X X X X X X X

Clean and lubricate the automatic transmission

shift linkage.

Refer to Secti on 7C4, 3. 2 SELECTOR LINKAGE.

X X

Check the evaporative emissions control canister

for leaks or rest ri ctions.

Refer to Section 6E2, 2.2 EVAPORATIVE

EMISSION CONTROL CANISTER.

* X X X

Clean out the air conditioning drain tubes. X X

Inspect sunroof drain holes for blockage. X X X X X X X X X X

CAR INTERIOR

Check the park brake operati on.

Refer to Section 5A, 2.2 PARK BRAKE CABLE,

ADJUST.

X X X X X X X X X X

Inspect the seat belt assemblies. Check the

webbing condition, the buckle operation and the

retractor mechanism.

X X X X X

Reset the ‘Service Reminder’ display. Refer to

Section 12C, 1.7 MULTI-FUNCTION DISPLAY –

ALL MODELS.

XXXXXXXXXXXX X X X X XXXX

Use odometer reading. x 1000

km 51

01

52

02

53

03

54

04

55

05

56

0 6

5 7

0 7

5 8

0 8

59

09

51

0

0

CAR EXTERIOR Extra

Check operation of all exterior lights. X X X X X X X X X X

Lubricate hood catch, door hinges, rear door links

only and lock cylinders.

Refer to Section 1A4, 2.3 HOOD PRIMARY

LATCH STRIKE R ASSEMBLY .

X X X X X

Check transm i tt er range of sec urity system.

Refer to Section 12J, 1.9 REMOTE

RECEIVER/KEY.

X X X X X X X X X X

ROAD TEST

Check braking, steering, engine response and

transmission operation. Check the operation of

cruise control if fitted. Check the park pawl

operation. Check the air conditioner performance.

Check the Neutral Start S witch operation.

X X X X X X X X X X

NOTE: All items marked with an asterisk in the ‘Extra’ column, require additional servicing under some driving

conditions. Refer to 3.1 ABNORM AL OP ER ATING CO NDITIONS in this Section.