SECTION 1A1 - BODY

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to

Section 00 CAUT IONS AND NOT ES for correct workshop practices w ith regard to safety and/or property

damage.

CONTENTS

1. GENERAL DESCRIPTION

2. GENERAL SERVICE OPERATIONS

2.1 WATER & DUST LEAK DIAGNOSIS

2.2 BODY LUBRICATION

2.3 LOCK CYLINDERS & KEYS

2.4 PLASTIC COMPONENTS

3. WHEELHOUSE LINERS

3.1 FRONT WHEELHOUSE LINER

REMOVE

REINSTALL

3.2 REAR WHEELHOUSE LINER, SEDAN &

WAGON

REMOVE

REINSTALL

3.3 REAR WHEELHOUSE LINER, COUPE &

ULTILITY

REMOVE

REINSTALL

4. FUEL FILLER DOORS

4.1 FUEL FILLER DOOR ASSEMBLY,

SEDAN & COUPE

REMOVE

DISASSEMBLE

REINSTALL

4.2 FUEL FILLER DOOR ASSEMBLY, WAGON

REMOVE

DISASSEMBLE

REINSTALL

4.3 FUEL FILLER DOOR ASSEMBLY, UTILITY

REMOVE

REINSTALL

4.4 FUEL FILLER DOOR CABLE ASSEMBLY, RHD

SEDAN & WAGON

COUPE

4.5 FUEL FILLER DOOR LOCK ACTUATOR

ASSEMBLY, LHD

SEDAN & WAGON

COUPE

DIAGNOSIS

WIRING SCHEMATIC

CONNECTOR VIEWS

5. DRAIN TUBES, UTILITY

5.1 REAR FLOOR PANEL DRAIN TUBE, UTILITY

REMOVE

REINSTALL

5.2 REAR WINDOW PANEL DRAIN TUBE

ASSEMBLY, UTILITY

REMOVE

REINSTALL

6. TORQUE WRENCH SPECIFICATIONS

Techline

Techline

Techline

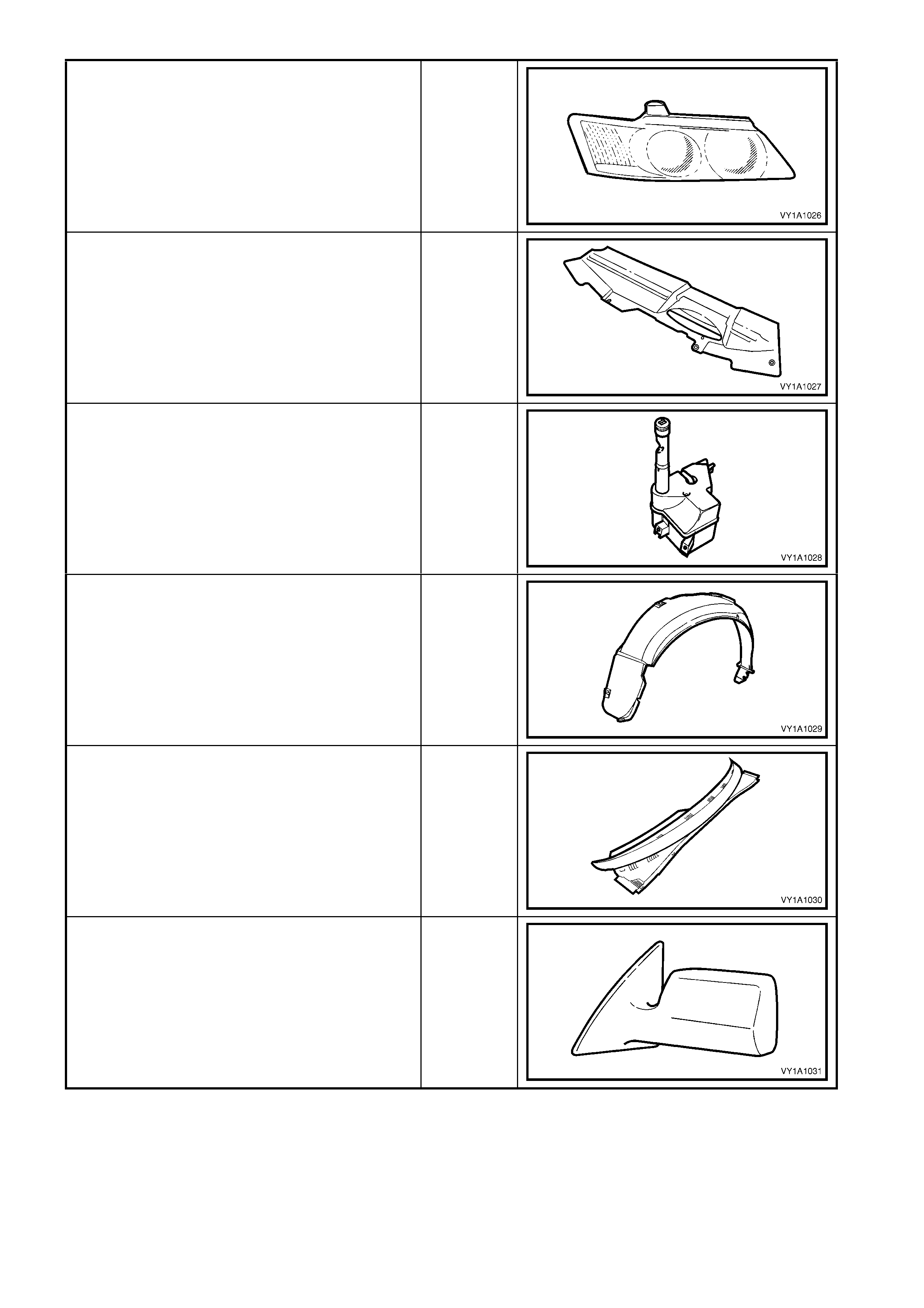

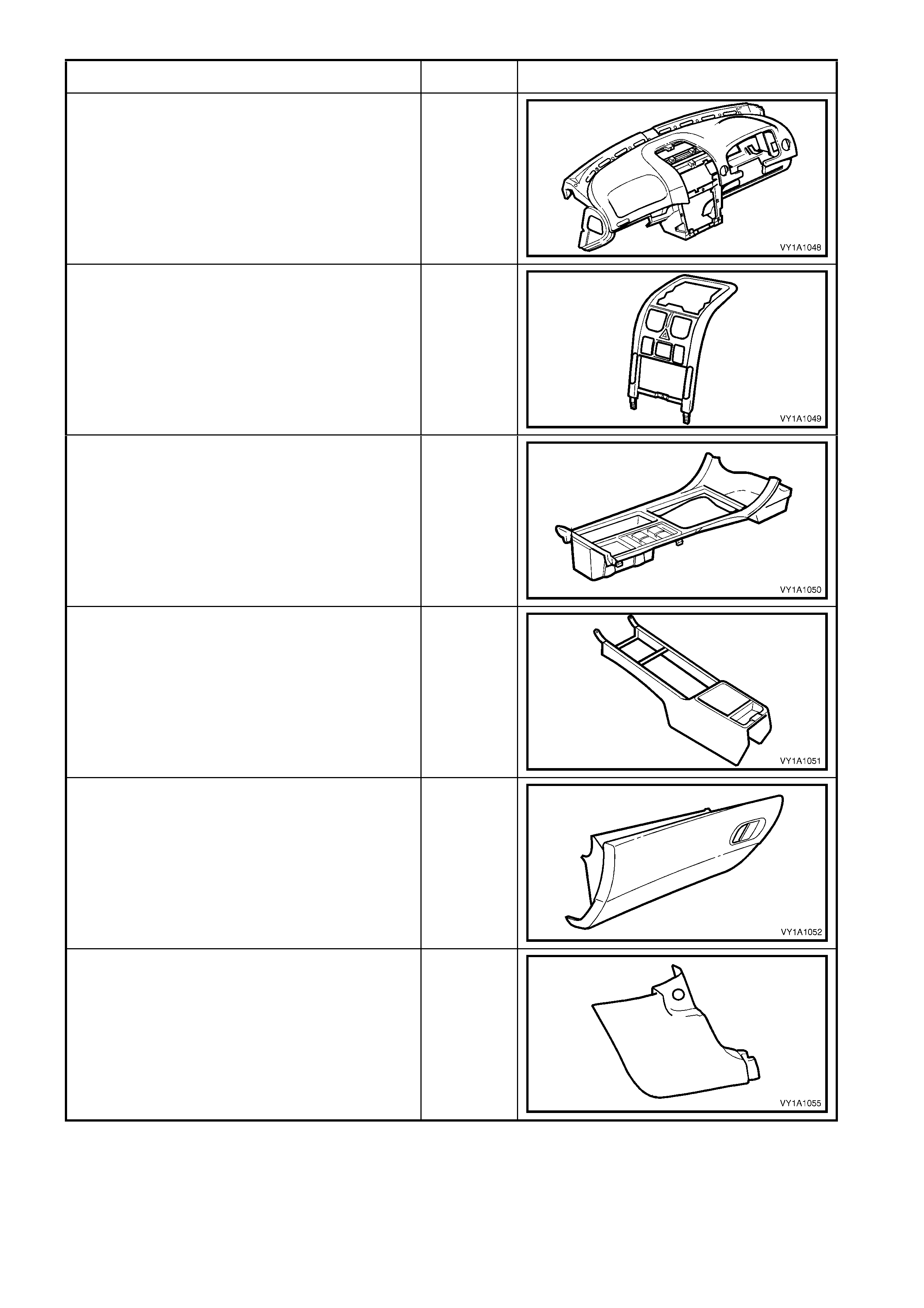

1. GENERAL DESCRIPTION

The MY 2003 VY Series is a major upgrade of the MY 2002 VX Series and marks the integration of the MY 2002

VU Series Utility into the one model designation.

The major body changes at the front include new bumper fascias, radiator grilles, headlamps, fenders and hood.

At the rear, m ajor changes are lim ited to the bumper fascias on W agon and Utility SS models. For the Sedan, the

rear changes are more substantial with a new rear compartment lid and license plate applique, rear quarter and

other rear panels, tail lamps and bumper fascias.

Exterior ornamentation changes are made across the board.

On the inside, all models gain a completely new instrument panel and console along with minor trim upgrades.

Also included in this publication is the MY 2003 V2 Series Coupe. This vehicle only receives m inor revisions when

compared to its predecessor externally, however it gains the new instrument panel and console from the MY 2003

VY Series.

For this public ation, the c ontents of the Body Sections have been rearranged. This Section contains non-s heetmetal

components, not related to components in other Sections.

Section 1A4 now includes the hood and all of its related components, including the release mechanism. The rear

compartment lid for both Sedan and Coupe along with the Wagon liftgate and Utility endgate and their related

components are also included in Section 1A4.

The body structure components can now be found in Section 1B Sheetmetal, along with the fender, Utility rear

compartment bolt-on sheetmetal components and other minor sheetmetal body components.

2. GENERAL SERVICE OPERATIONS

2.1 WATER AND DUST LEAK DIAG NOSIS

Diagnosis of body leaks is com plicated by the fac t that the appearanc e of dus t or water at one point can be c aused

by seepage through any one, or more, of many possible locations.

As an example of this indirect entry, the cause of wet front floor coverings may be due to water entering past the

door weatherstr ip, through the door inner panel, between the windshield and its adhes ive com pound or through any

one of the joins in the body structure. Therefore, the point or points of water or dust entry must be established

before effective resealing can be carried out.

W ater leak diagnosis is usually performed by having an assistant spray a gentle fan of water from a hose around

the suspected area until the leak can be generated. Removal of various trim components from the inside may be

required to determ ine point of entry. Narrowing down the water spray to the point of greatest water flow will assist in

determining the point of entry.

Dust entry quite often requires the following of signs of dust entry around seals or vent inlets or outlets, etc.

Once detected, repair the area by replacing faulty components or applying the correct sealer or adhesive as

specified in the MY 2003 VY & V2 Series BODY STRUCTURE REPAIR MANUAL.

Techline

2.2 BODY LUBRICATION

The moving mechanical parts of the body which have metal to metal contact are lubricated at assembly.

Operating conditions, whether normal or otherwise, determine the effective life of the lubricant and for this reason

lubrication in service is important. Equally important is the type of lubricant to be used.

IMPORTANT: Careless or excessive application of body lubricants can result in staining of the paint finish

and interior trim, can damage clothing, and can become a trap for dirt. Use lubricants sparingly and remove

excess material immediately.

Listed below are the body lubrication points. For the recommended lubricants and maintenance schedule refer to

Section 0B LUBRICATION & SERVICING.

PARTS READILY ACCESSIBLE:

• Hood Pilot Pin Assembly

• Hood Lock Assembly

• Hood Hinges

• Door Hinge Pins

• Door Check Assemblies

• Door Lock Cylinder

• Door Lock Striker

• Door Lock Assembly Fork

• Rear Compartment Lid Hinge

• Rear Compartment Lid Latch

• Liftgate or Endgate Hinge

• Liftgate Lock Cylinder

• Liftgate or Endgate Latch

• Ignition Lock Cylinder

• Instrument Panel Compartment Lock Cylinder

PARTS CONCEALED NECESSITATING

DISASSEMBLY:

• Door Window Regulator

• Door Window Guides & Runners

• Door Lock Mechanism

• Rear Compartment Lid Lock Mechanism

• Liftgate or Endgate Lock Mechanism

• Front Seat Adjuster

• Driver’s Seat Height Adjuster

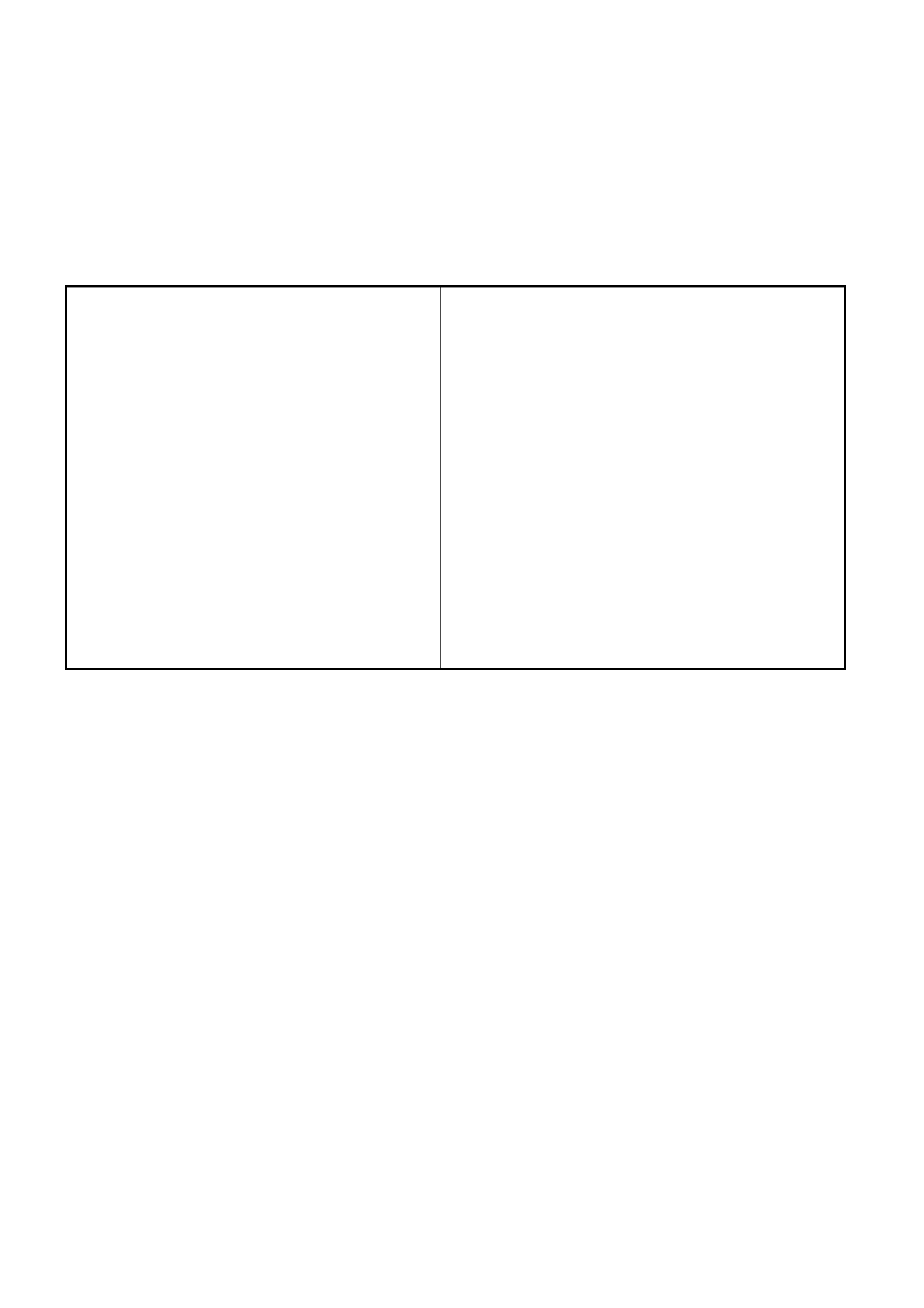

2.3 LOCK CYLINDE RS & KEYS

A com mon-key locking system is used which operates

the door and ignition locks. A unique key is provided

for the instrument panel compartment.

The door and ignition key features a remote function

that activates the central locking system and anti-theft

system from a distance of several metres.

Inserting the key into the lock cylinder incorporated in

the driver’s door handle also performs the same

function.

A separate button on the remote key for Sedan and

Coupe models opens the rear compartment lid. The

liftgate lock for Wagon models is operated as part of

the central locking system.

The k ey identif ication number is located on the vehicle

security card, stored with the owner’s manual. It is

essential that this key number be available should a

replacement key be required.

In the event of replacement, the BCM will require

reprogramming to accept the new key, refer

Section 12J, BODY CONTROL MODULE for

reprogramming and further information regarding the

anti-theft system.

For service procedures for the driver’s door lock

cylinder refer to Section 1A5, 2.8 – FRONT DOOR

OUTSIDE HANDLE ASSEMBLY.

For service procedures for the ignition lock cylinder

refer to Section 9A, STEERING.

Figure 1A1-1

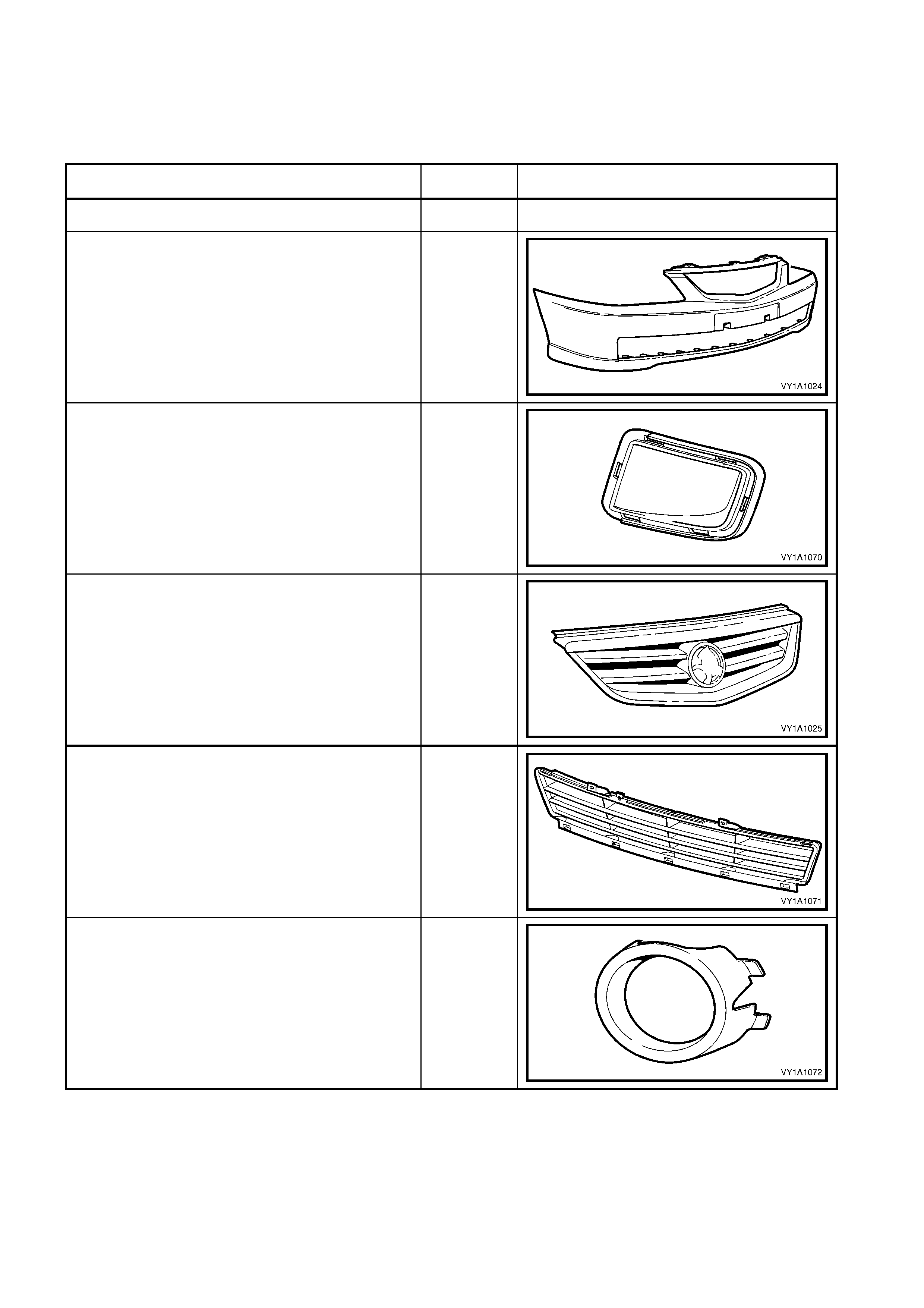

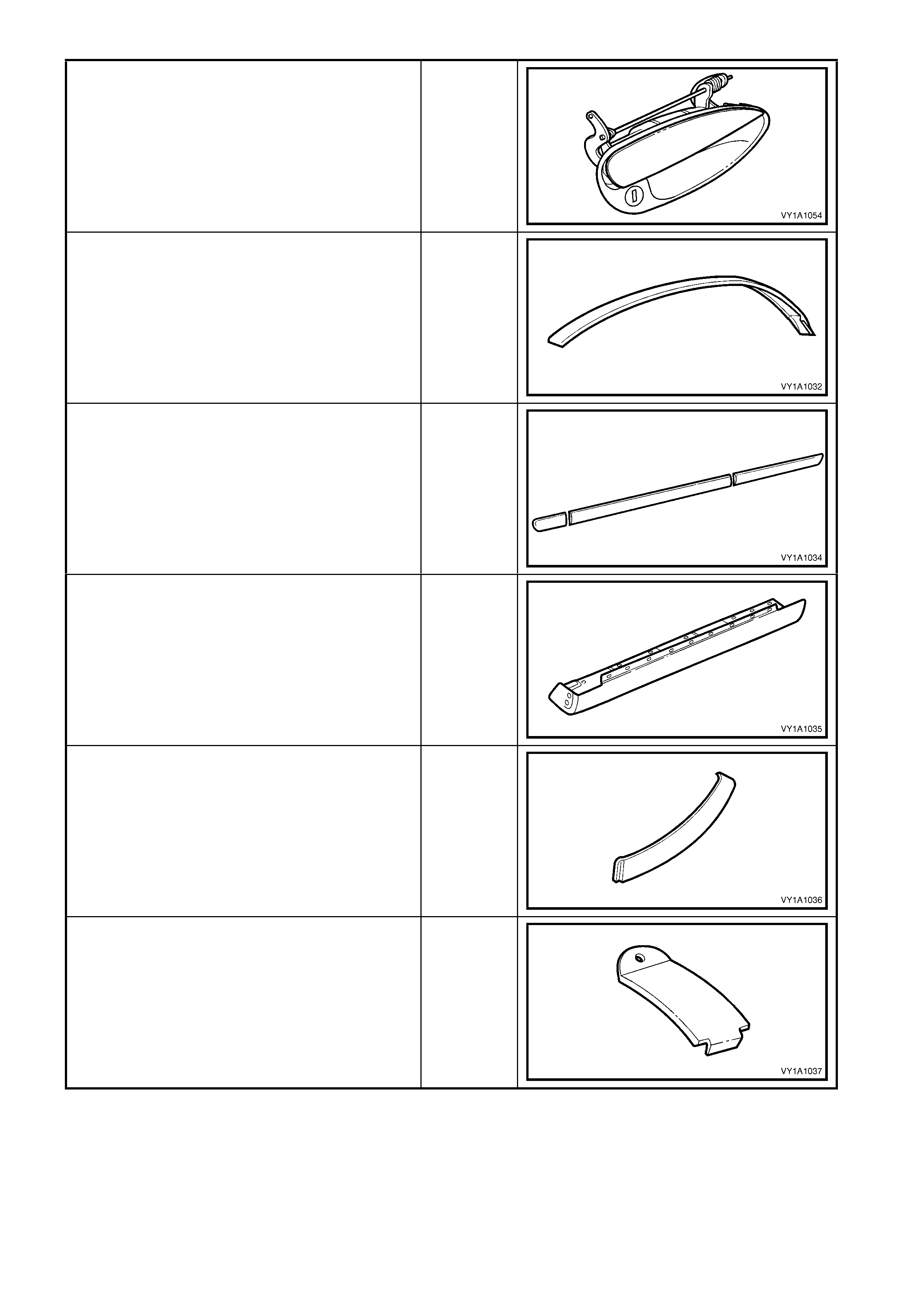

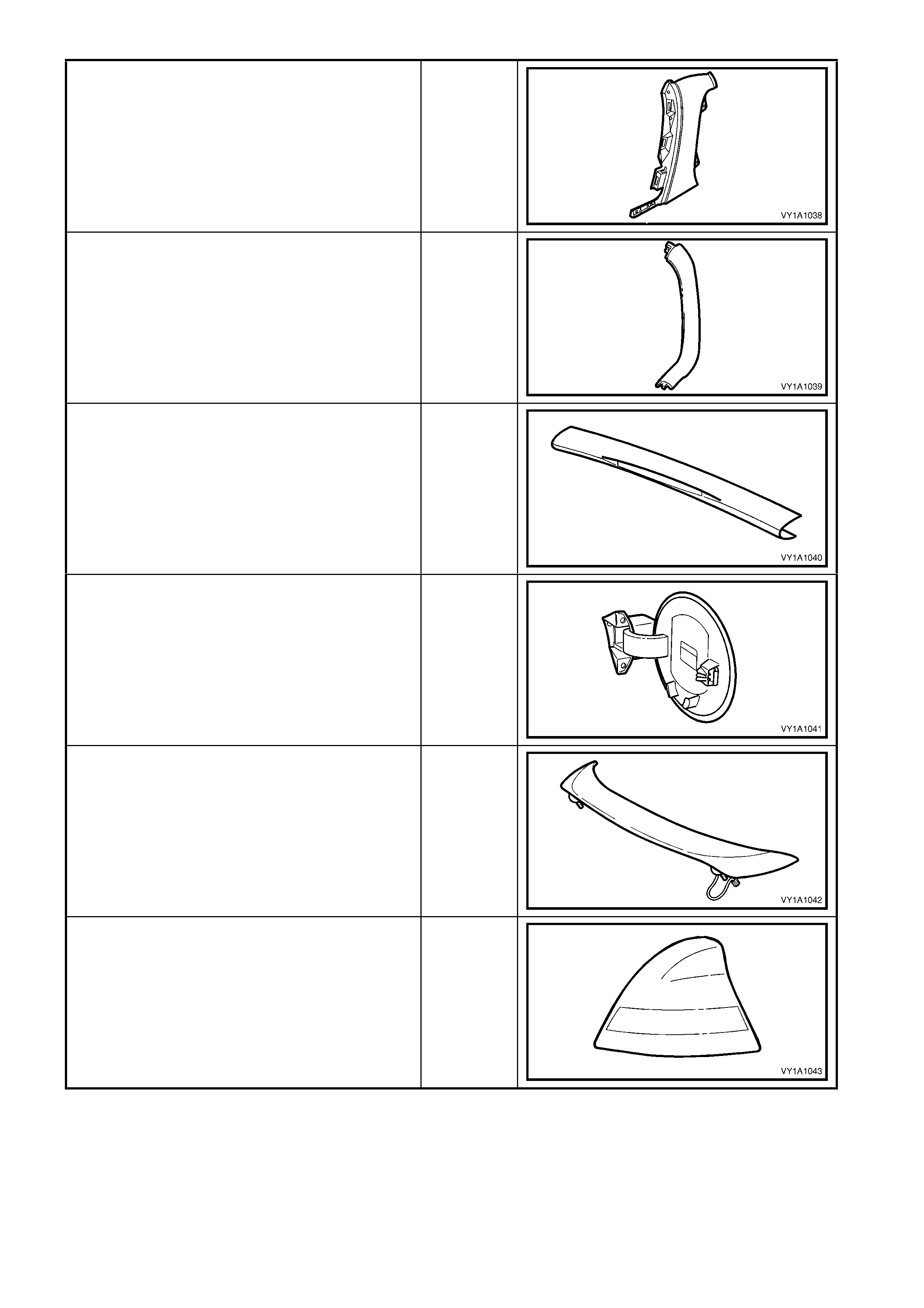

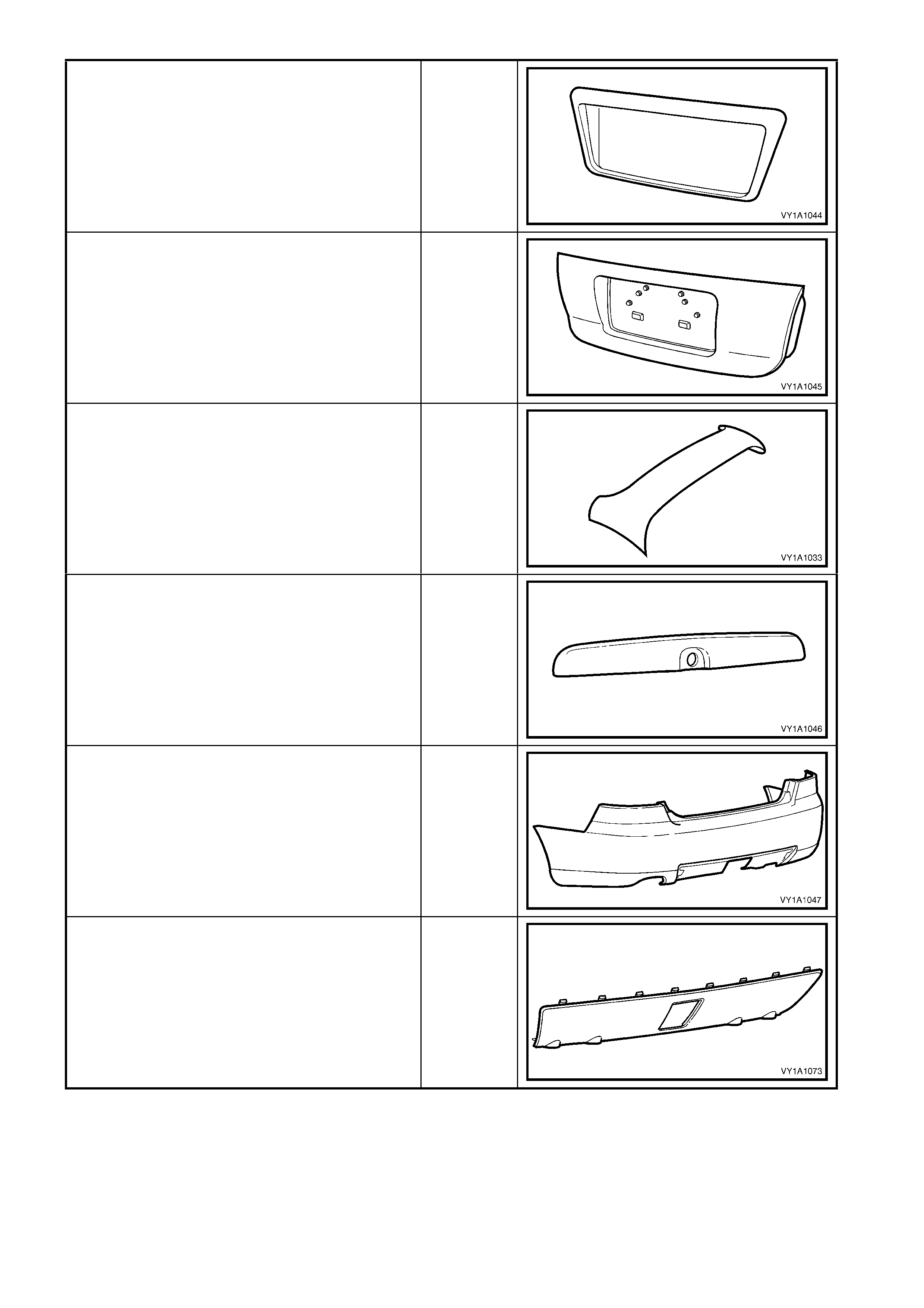

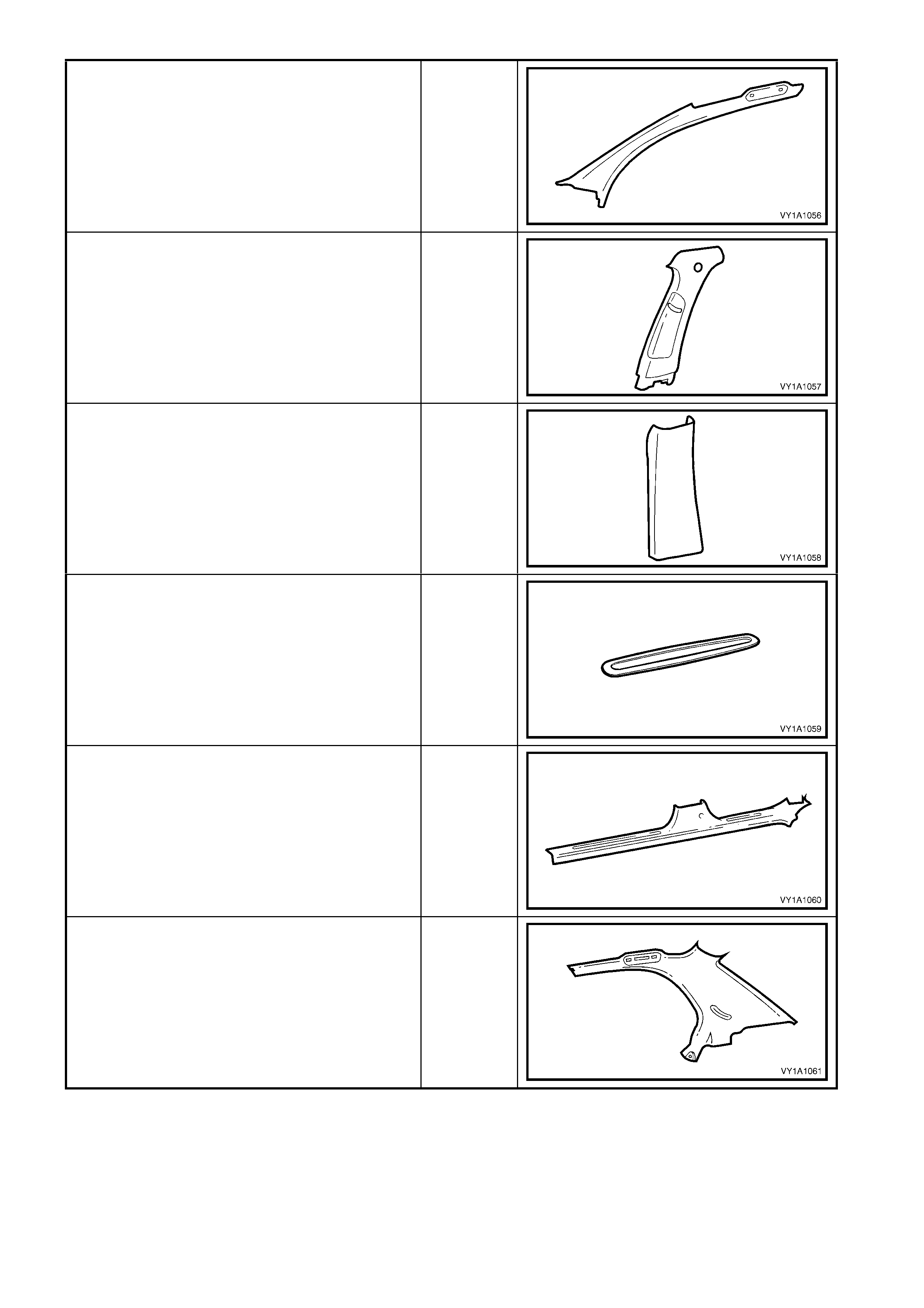

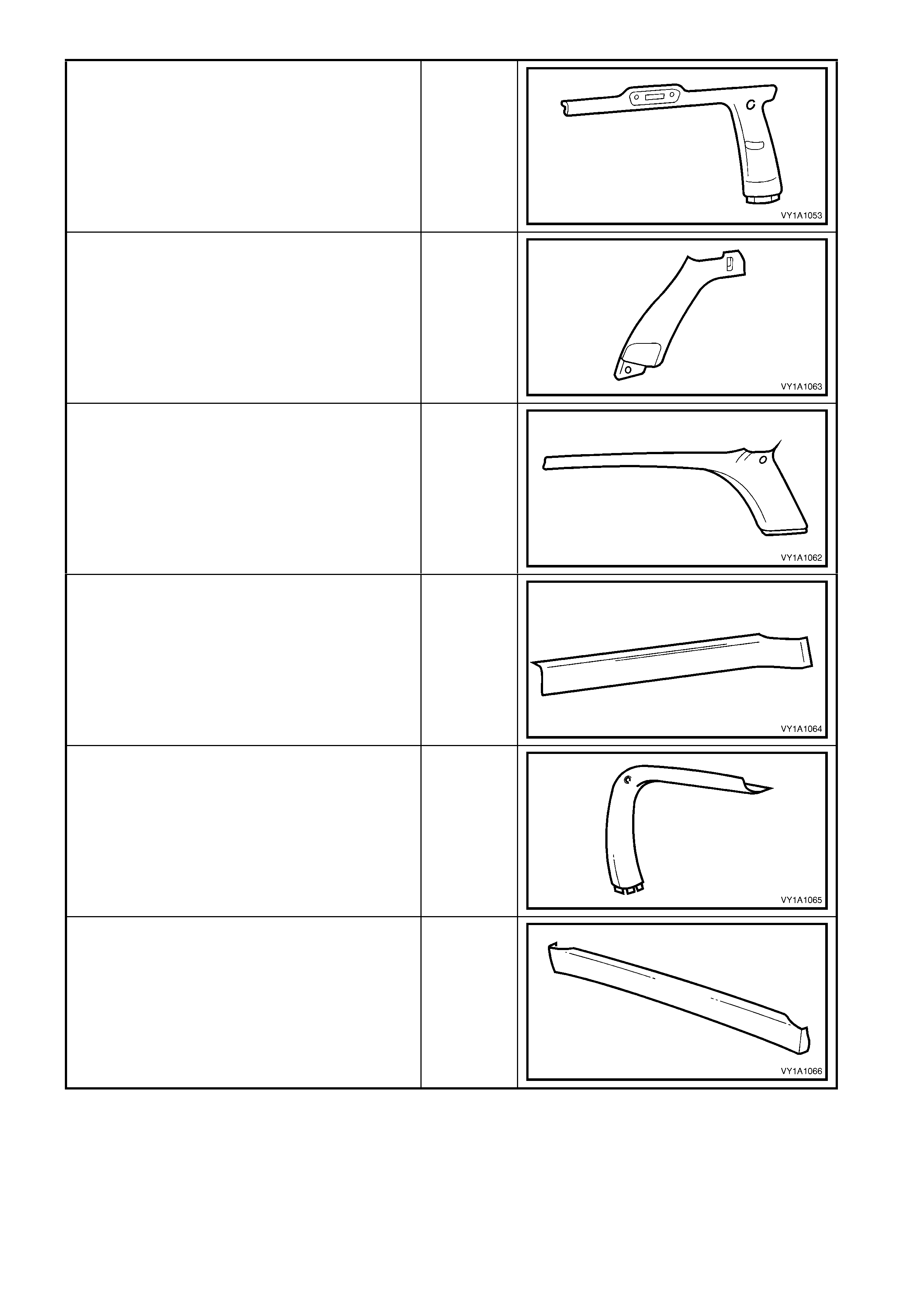

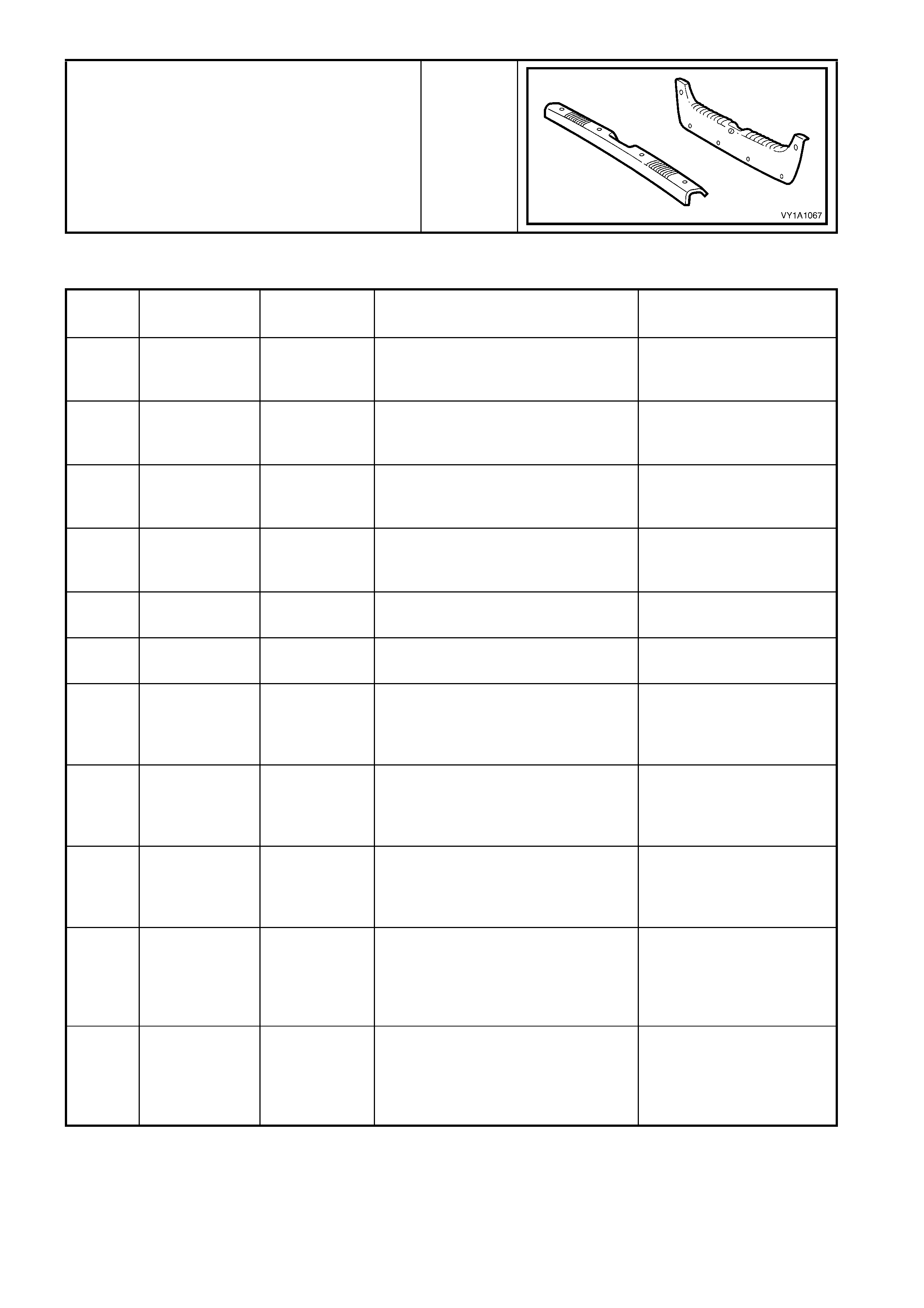

2.4 PLASTIC COMPONENTS

Plastic components are used throughout the vehicle. The following chart is included to assist with the

identification and composition of common components.

NOTE: Most components are also identified with the material code in an inconspicuous place.

COMPONENT CODE EXAMPLE

Exteri or / Engine Compartment:

Front Bumper Fascia PP

Front Bumper Access Hole Cover, Level 1 PP

Radiator Grille Assembly:

– Painted

– Unpainted

ABS

ASA

Lower Radiator Grille PP

Front Foglamp Bezel Assembly:

– Inner

– Outer

ASA

ABS

Headlamp Assembly:

– Lens

– Housing

PC

PP/T30

Upper Radiator Air Baffle PP

Radiator Surge Tank Assembly:

– V6

– V8

PP

PE

Wheelhouse Liner:

– Front

– Rear

PP

Plenum Cover Assembly PP

Outside Rear View Mirror Housing:

– Painted

– Unpainted

ABS

ASA / PC

Door Handle Assembly PA 66

Roof Panel Joint Moulding Assembly:

– Sedan & Coupe

– Front, Wagon

– Utility

PVC

PVC

PP

Body Side Moulding:

– Fender

– Front Door

– Rear Door

– Quarter Panel

ASA

Rocker Panel Moulding Assembly PP

Quarter Panel Belt Moulding, Sedan PPE/PA-

M20

Roof Panel Joint Finish Moulding, Wagon PP M20

Rear Quarter Window Moulding, Utility ABS / PC-

M6

Rear Window Side Moulding Assembly, Utility ABS / PC-

M6

Rear Window Upper Moulding Assembly,

Utility ABS / PC-

M6

Fuel Filler Door PPE / PA

Rear Spoiler Assembly ABS

Tail lamp Assembly:

– Lens

– Housing

PMMA

ABS

Rear Compartment Lid Applique Assembly,

Sedan ABS

Rear Compartment Lid Applique Assembly,

Coupe ABS

Liftgate Air Deflector Assembly , Wagon PC/ABS

Liftgate Handle Assembly, Wagon ABS

Rear Bumper Fascia PP

Rear Bumper Fascia Insert, Sedan PP

Interior:

Instrument Panel Pad Assembly:

– Carrier

– Pad Substrate

– Foam

– Skin

ABS

ABS

PP

PVC/ABS

Instrument Panel Centre Trim Assembly PC/ABS

Floor Console Cover Assembly PC/ABS

Front Floor Console PP

Instrument Panel Compartment PP

Hinge Pillar Trim PP

Windscreen Side Garnish PP

Centre Pillar Upper Trim PP

Centre Pillar Lower Trim PP

Side Sill Trim Plate PP

Side Sill Trim PP

Body Lock Pillar Garnish, Sedan PP

Body Lock Pillar Garnish, Wagon PP

Body Lock Pillar Lower Trim, Wagon PP

Body Rear Corner Garnish, Wagon PP

Quarter Inner Trim Upper, Wagon PP

Liftgate Window Upper Garnish, Wagon PP

Liftgate Window Lower Garnish, Wagon PP

Rear End Trim Panel PP

The repair procedure for plastic body parts must conform with the type of plastic material.

Precautions to be taken with plastic parts are detailed in the following chart.

Code Material

Name Heat Resisting

Temp* °C Resistance to

Alcohol or Gasoline Notes

ABS Acrylonitrile

Butadiene

Styrene Resin

80 Alcohol is harmless if applied only

for short time in small amounts (i.e.

quick wiping to remove grease)

Avoid gasoline and

organic or aromatic

solvents.

ASA Acrylate

Styrene

Acrylonitrile

80 Alcohol is harmless if applied only

for short time in small amounts (i.e.

quick wiping to remove grease)

Avoid gasoline and

organic or aromatic

solvents.

PC Polycarbonate 120 Alcohol is harmless. Avoid gasoline, brake

fluid, wax, wax removers

and organic solvents.

PMMA Polymethyl

Methacrylate 80 Alcohol is harmless if applied only

for short time in small amounts. Avoid dipping or

immersing in alcohol,

gasoline, solvents, etc.

PE Polyethylene 80 Alcohol and gasoline are harmless. Most solvents are

harmless.

PP /

PP67 Polypropylene 80 Alcohol and gasoline are harmless. Most solvents are

harmless.

PPE Polyphenylene

Ether 100 Alcohol and gasoline are harmless

if applied only for a short time in

small amounts (i.e. quick wiping to

remove grease)

Avoid dipping or

immersing in alcohol,

gasoline, solvents, etc.

PU Polyurethane

Foam 100 Alcohol and gasoline are harmless

if applied only for a short time in

small amounts (i.e. quick wiping to

remove grease)

Avoid dipping or

immersing in alcohol,

gasoline, solvents, etc.

PVC Polyvinyl

Chloride 80 Alcohol and gasoline are harmless

if applied only for short time in small

amounts. (i.e. quick wiping to

remove grease)

Avoid dipping or

immersing in alcohol,

gasoline, solvents, etc.

TPO Thermoplastic

Olefin 80 Alcohol is harmless.

Gasoline is harmless if applied only

for short time in small amounts.

Most solvents are

harmless but avoid

dipping or immersing in

alcohol, gasoline,

solvents, etc.

PPE/

PA-M20 Modified

Poly propylene

Ether &

Poly amide

Alloy

190 Alcohol and gasoline are harmless

if applied only for a short time in

small amounts (i.e. quick wiping to

remove grease)

Avoid dipping or

immersing in alcohol,

gasoline, solvents, etc.

∗ Temperatures higher than those listed here may result in material deformation.

3. WHEELHOUSE LINERS

3.1 FRONT WHE ELHOUSE LINER

LT Section No. – 12-425

For the left-hand side, two types of front wheelhouse liner are available depending on engine type. The coolant

reservoir for V6 engines is located next to the wheelhouse liner and effectively acts as part of the liner. As the

GEN III V8 engine has its c oolant r eser voir loc ated in the engine c ompartment, the wheelhouse liner is ex tended

to fill the void.

REMOVE

1. Remove the front road wheel, refer Section 10,

WHEELS & TYRES.

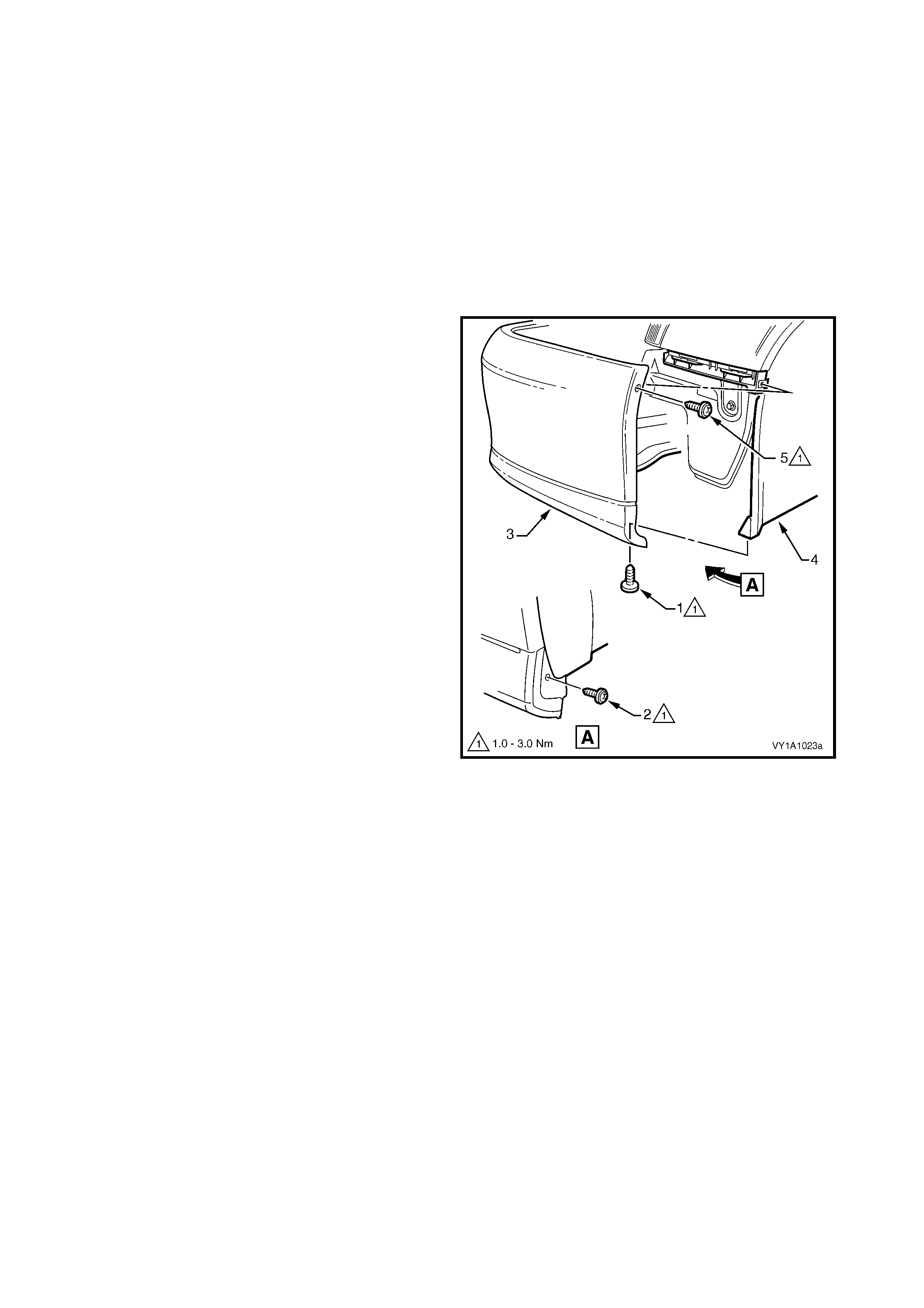

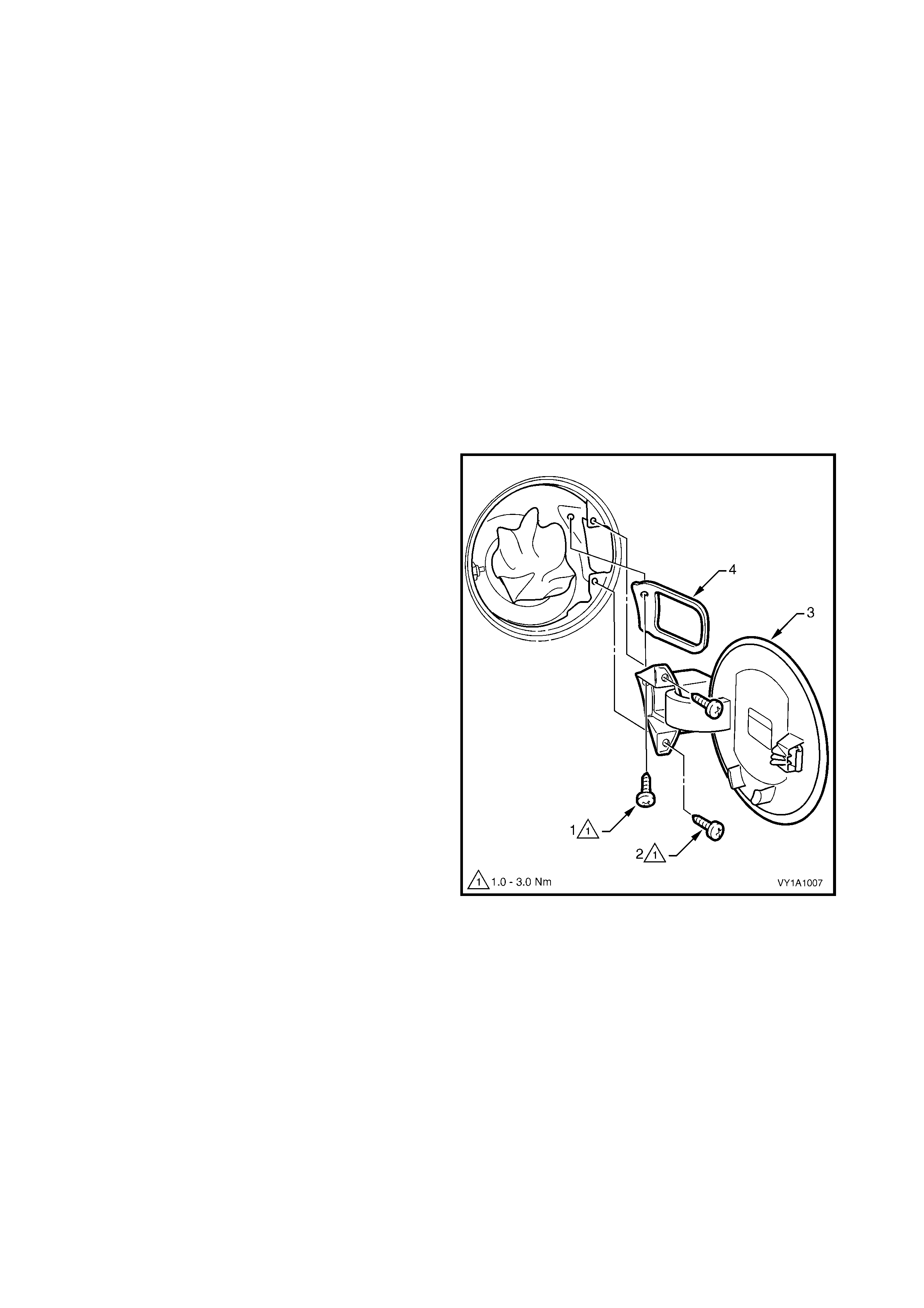

2. Remove the screw (1) or for S and SS vehicles

(2), attaching the f ront bum per fas cia assem bly (3)

to the front wheelhouse liner (4).

3. If required, also remove the screw (5) attaching

the fascia assembly to the vehicle to aid in removal

of the liner.

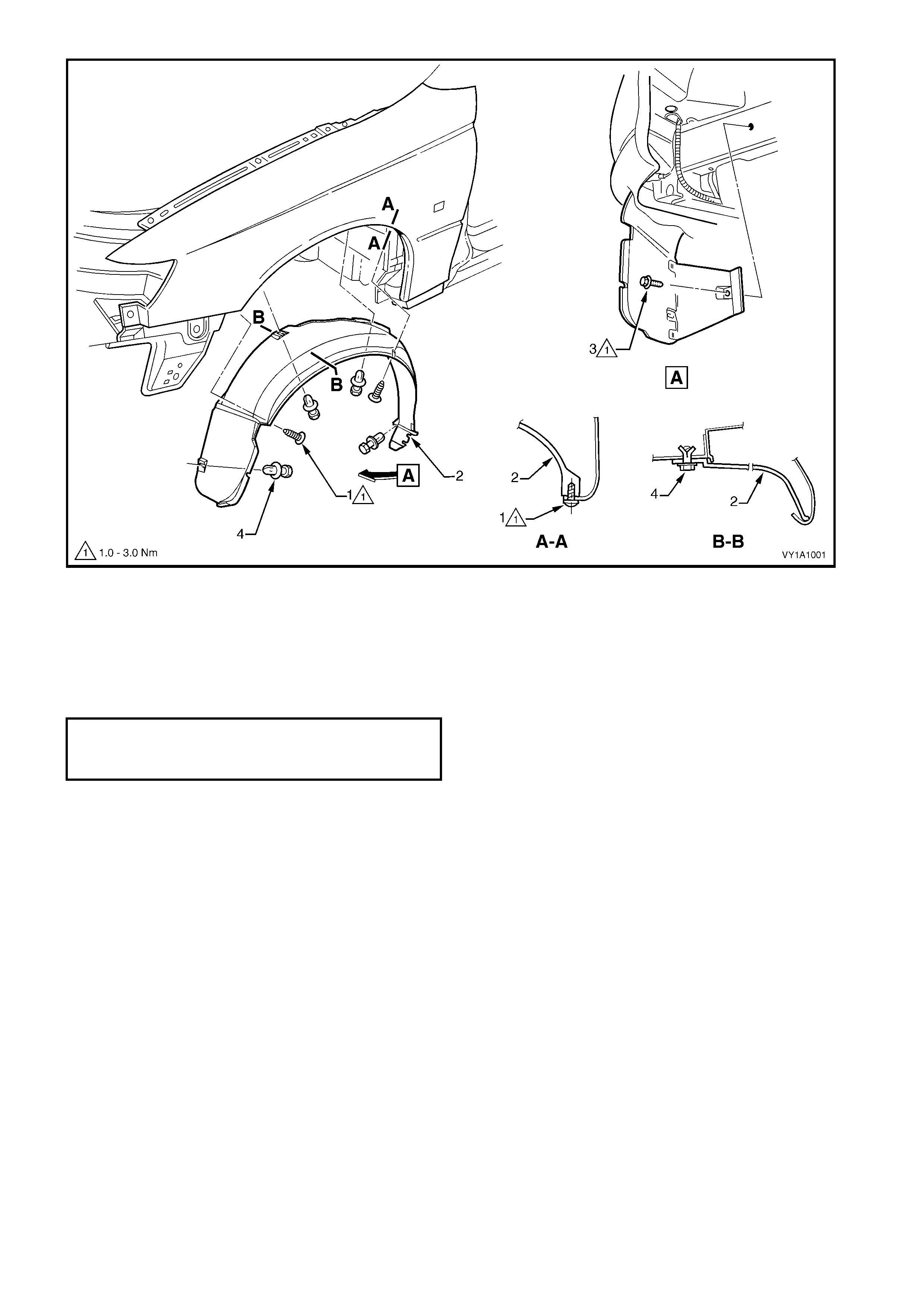

4. Remove the screws (1) attaching the liner (2) to

the fender, two places, refer Figure 1A1-3.

5. For vehicles with GEN III V8, remove the sc rew (3)

attaching the liner shown View A.

6. Remove the retainers (4) attaching the liner to the

vehicle:

• four places right-hand side,

• four places left-hand side V6, or

• three places left-hand side GEN III V8.

7. Remove the liner.

Figure 1A1-2

Figure 1A1-3

REINSTALL

1. Install the wheelhouse liner ensuring it is correctly

positioned as shown in Figure 1A1-3.

2. Install the screws attaching the liner and tighten to

the specified torque.

3. Install the retainers attaching the liner to the

vehicle.

4. Install the road wheel, refer Section 10, WHEELS

& TYRES.

FRONT WHEELHOUSE

LINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.2 REAR WHEELHOUSE LINER, SEDAN & W AGON

LT Section No. –

Newly designed rear wheelhouse liners are fitted on Sedan and Wagon models . The liners now cover the entire

wheelhouse and provide an additional reduction in noise transmittance into the passenger compartment.

REMOVE

1. Remove the rear road wheel, refer Section 10,

WHEELS & TYRES.

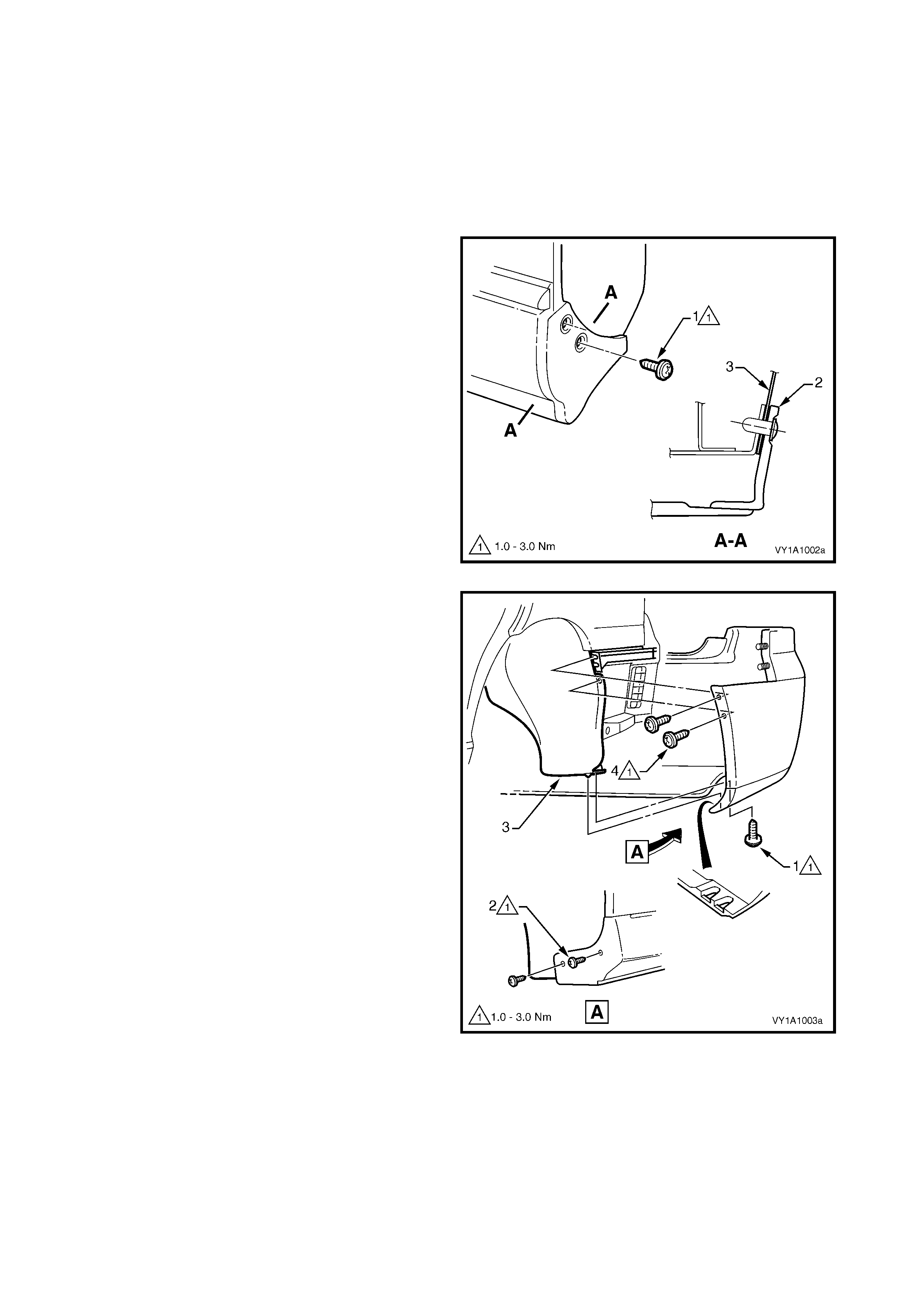

2. Remove the screw (1) two places, attaching the

rocker panel moulding assembly (2) and rear

wheelhouse liner (3).

Figure 1A1-4

3. Remove the screw (1), or for S and SS vehicles

(2) two places, attaching the rear bumper fascia

assembly to the wheelhouse liner (3).

4. Remove the two screws (4) attaching the fascia

assembly to the liner and rear bumper fascia

guide.

5. Carefully partially unclip the bumper fascia from

the fasc ia guide, and disengage the locating lug at

the base of the liner for all vehicles except S and

SS.

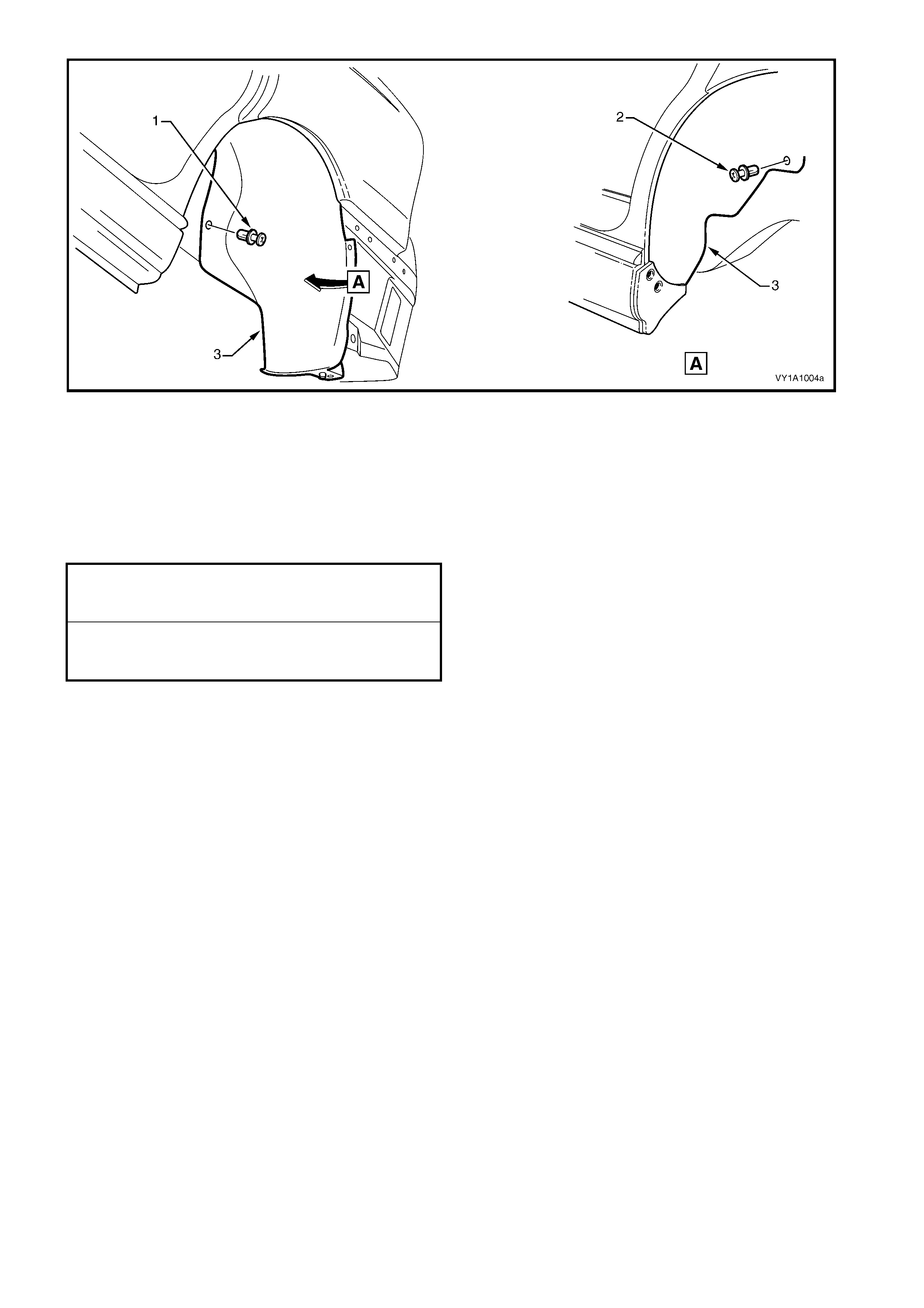

6. Remove the r etainer s ( 1 & 2) attaching the liner (3)

to the wheelhouse panel, refer Figure 1A1-6.

7. Manipulate the liner from behind the rocker panel

moulding assembly and bumper fascia and

remove.

Figure 1A1-5

Figure 1A1-6

REINSTALL

1. Install the liner, ensuring it is c orrectly located behind the rock er panel m oulding assem bly and rear bumper

fascia assembly.

2. Install the retainers attaching the liner to the body.

3. Install the screws attaching the rocker panel moulding assembly and bumper fascia and tighten to the

specified torque.

4. Install the rear road wheel, refer Section 10, WHEELS & TYRES.

ROCKER PANEL MOULDING

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.3 REAR WHEELHOUSE LINER, COUPE & UTILITY

LT Section No. –

REMOVE

1. Remove the rear road wheel, refer Section 10,

WHEELS & TYRES.

2. Remove the two screws (1) attaching the rear

bumper fascia (2) at the wheel-arch opening.

3. Remove the two screws (3) attaching the rear

bumper fascia to the wheelhouse liner and rear

bumper fascia guide.

4. Carefully partially unclip the fascia from the fascia

guide.

Figure 1A1-7

5. Remove the screw (1) and retainer (2) attaching

the rear wheelhouse liner (3) to the vehicle.

NOTE: Some vehicles may have a screw in place of

the retainer.

6. Manipulate the liner from within the wheelhouse

and remove.

Figure 1A1-8

REINSTALL

1. Install the rear wheelhouse liner ensuring it is correctly located behind the rear bumper fascia.

2. Install the screw and retainer attaching the liner to the vehicle and tighten the screw to the specified torque.

3. Install the screws attaching the rear bumper fascia and tighten to the specified torque.

4. Install the rear road wheel, refer Section 10, WHEELS & TYRES.

REAR WHEELHOUSE

LINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Techline

4. FUEL FILLER DOORS

4.1 FUEL FILLER DOOR ASSEMBLY, SEDAN & COUPE

LT Section No. – 03-028

The fuel filler door is painted the vehicle’s body colour. The door assembly is serviced with the moulding and

lock spring unattached, which allows the door to be painted, then the moulding and lock spring fitted as

described in this procedure.

The moulding is attached to the door with adhesive. Therefore if repairing paintwork on the filler door, the

moulding will require masking or removal and replacing with a new part, which is available individually.

Paint the door using the correct materials and techniques for PPE/PA resin (Polyphenylene/Polyamide). As the

mater ials and techniques required dif fer between paint brands, ref er to the technical data supplied by your paint

manufacturer.

NOTE: If the fuel filler door is being replaced, the warning labels affixed to the inside of the door must also be

replaced.

REMOVE

1. Open the fuel filler door by operating the release

lever (RHD vehicles) or by operating the release

button on the instrument panel (LHD vehicles).

2. Remove the fuel filler cap and cover the opening

with a rag as required.

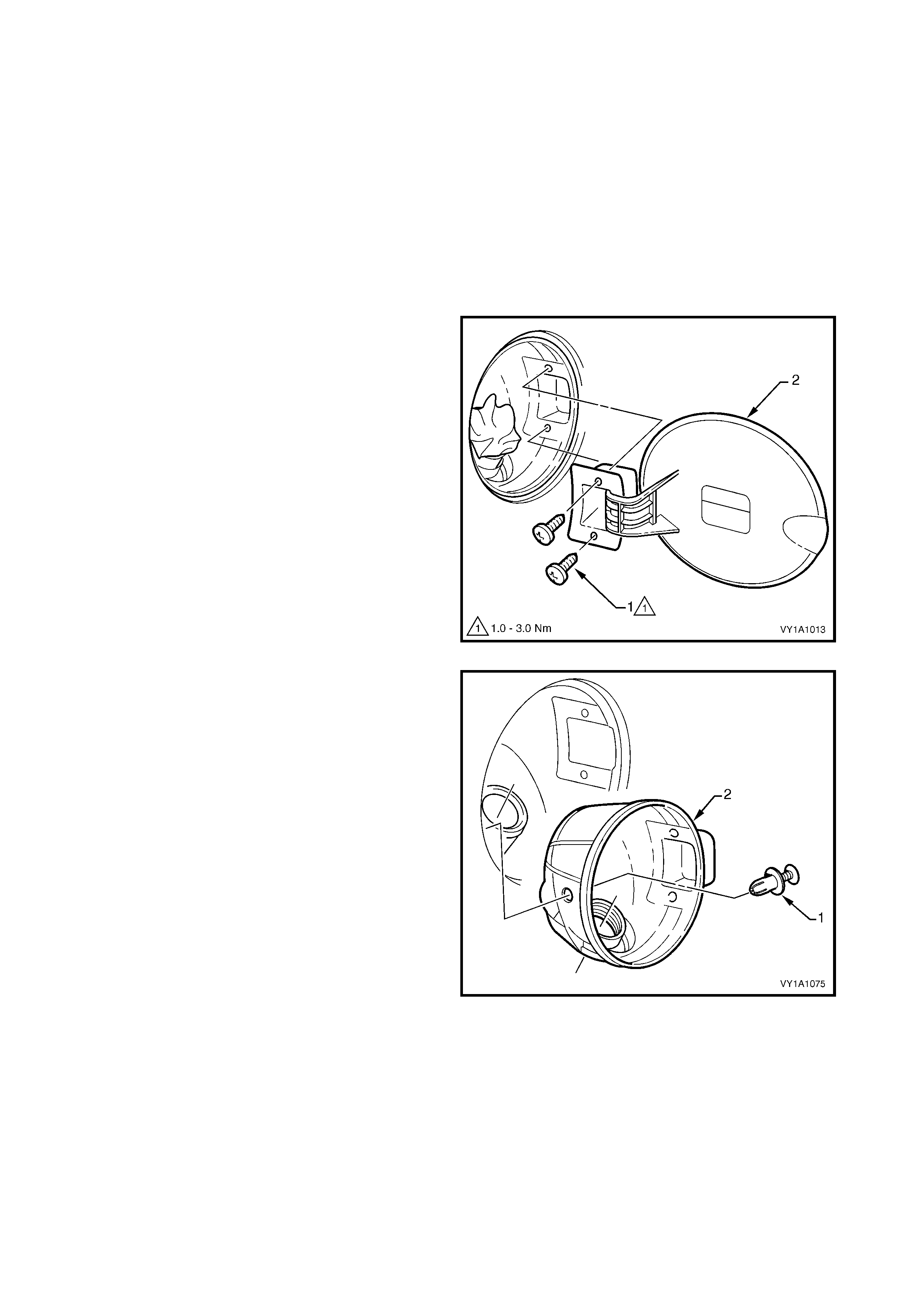

3. Remove the inner screw (1) and the two screws

(2), attaching the fuel filler door assembly (3).

4. Remove the door assembly by withdrawing it

rearward, ensuring the gasket (4) is also removed.

NOTE: When withdrawing the fuel filler door from the

fuel f iller pocket, a slight inter ference between the rear

edge of the plastic hinge s ec tion and the fuel filler neck

may occur. In this instance it will be necessary to flex

the rear edge of the fuel filler door hinge slightly.

Figure 1A1-9

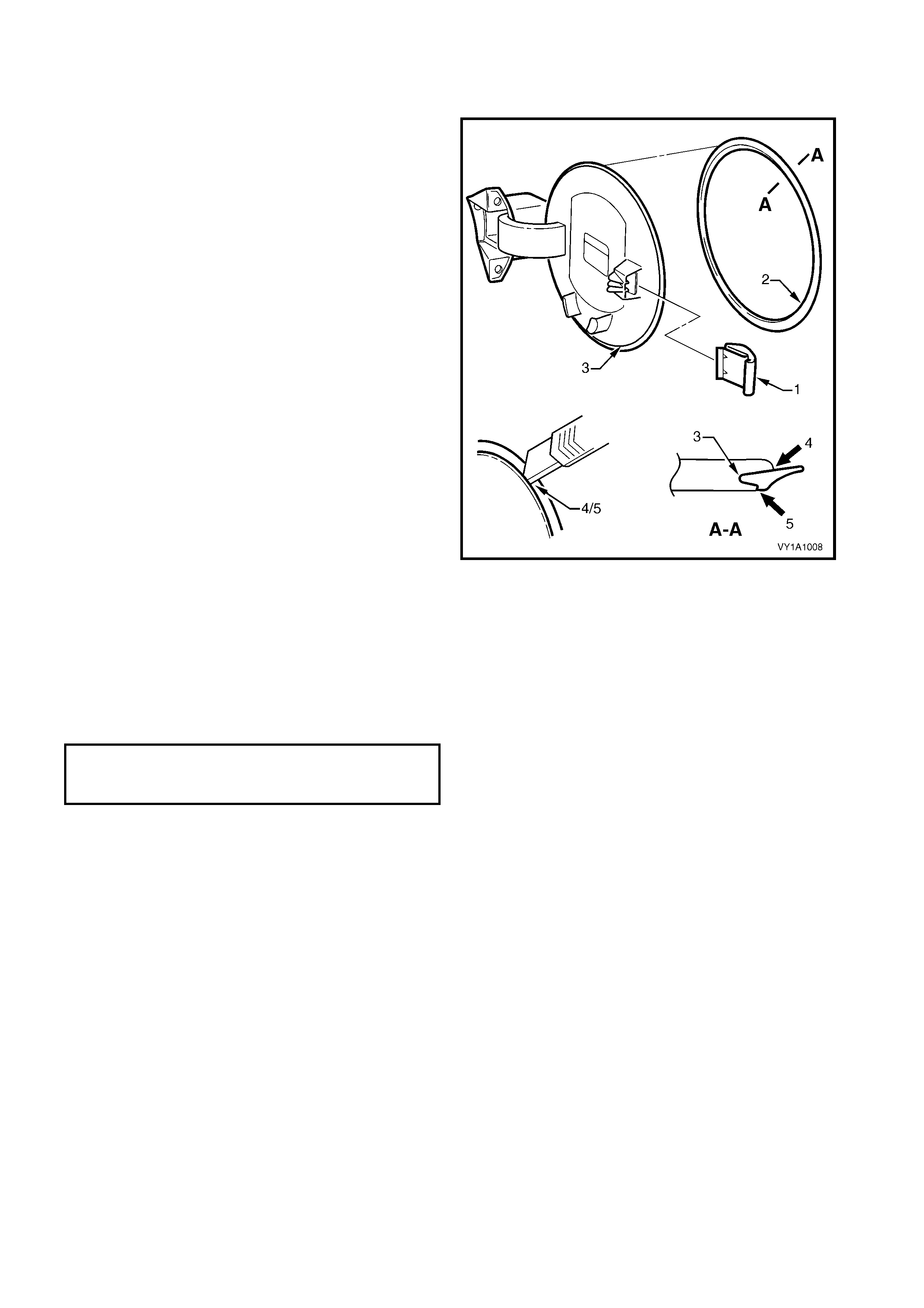

DISASSEMBLE

LOCK SPRING

NOTE: T he lock spring is not designed to be removed

it has several barbs that will cut into its mounting

surface.

1. Remove the lock spring (1) by inserting a small

screwdriver and levering the spring outwards.

2. To install, push the spring onto the mounting tab

fully.

MOULDING

1. The moulding (2) is seated in the recess (3)

around the circumference of the door and is

affixed with superglue gel. Removal may be

difficult, but by carefully peeling the moulding from

the door, it is possible to remove the moulding. It

will not be able to be reused.

NOTE: To aid removal, the moulding can be cut

around the inner (4) and outer sides (5) using a sharp

knife.

2. To install the moulding, carefully apply Loctite 454

(Superglue Gel) or equivalent into the fuel filler

door recess around the complete circumference.

IMPORTANT: Use of superglue can be harmful and

can damage paintwork. Carefully read and follow all

directions and cautions with the product prior to its use.

3. Ensuring it is correctly orientated, immediately fit

the moulding into the recess and leave for the

adhesive to cure.

Figure 1A1-10

REINSTALL

Installation of the fuel filler door assembly is the

reverse of removal, noting the following.

1. Ensure the screws are tightened to the specified

torque.

2. If a new door ass em bly is being installed, following

painting of the door flap, install the moulding and

lock spring onto the flap as described in

DISASSEMBLE in this procedure.

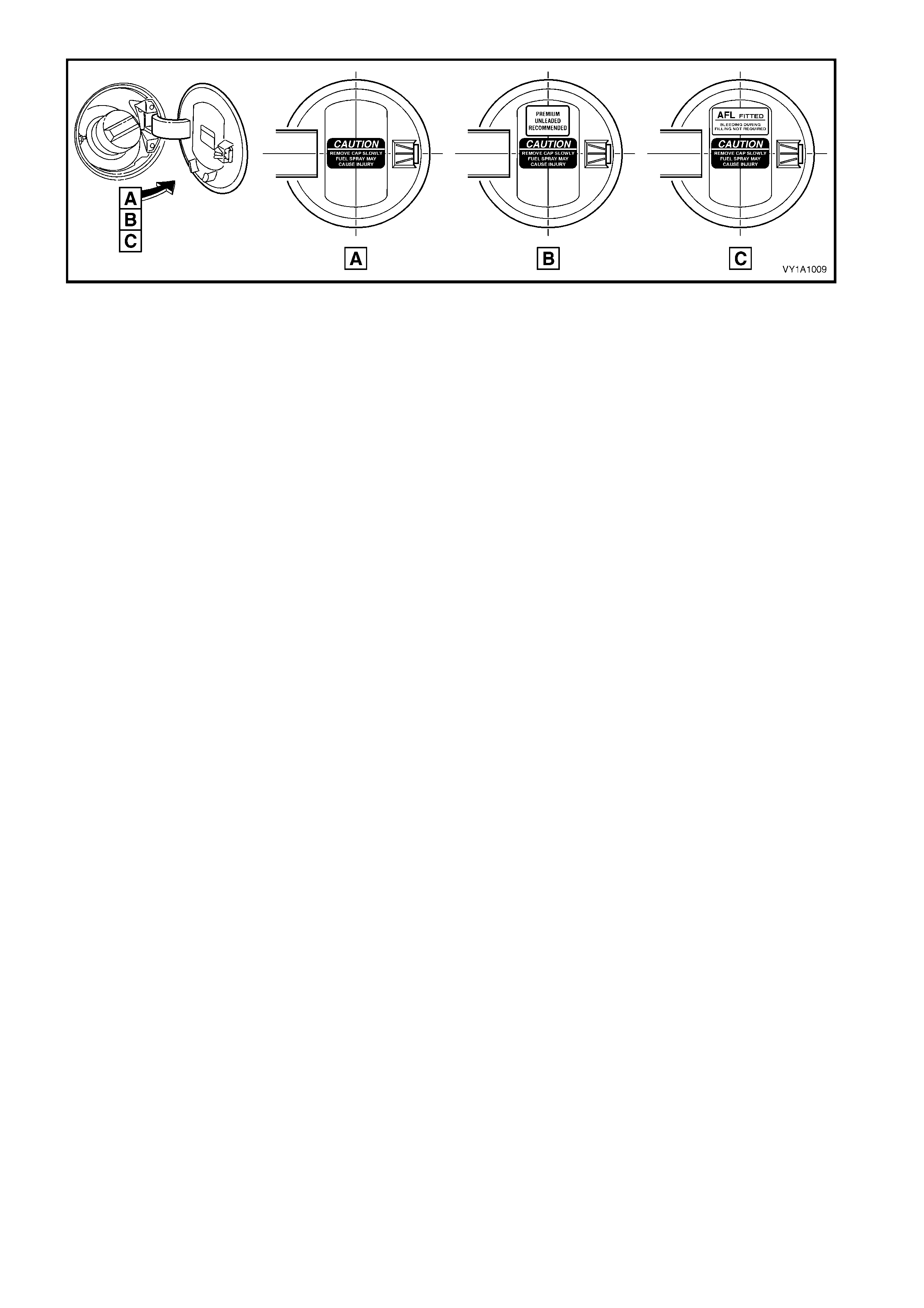

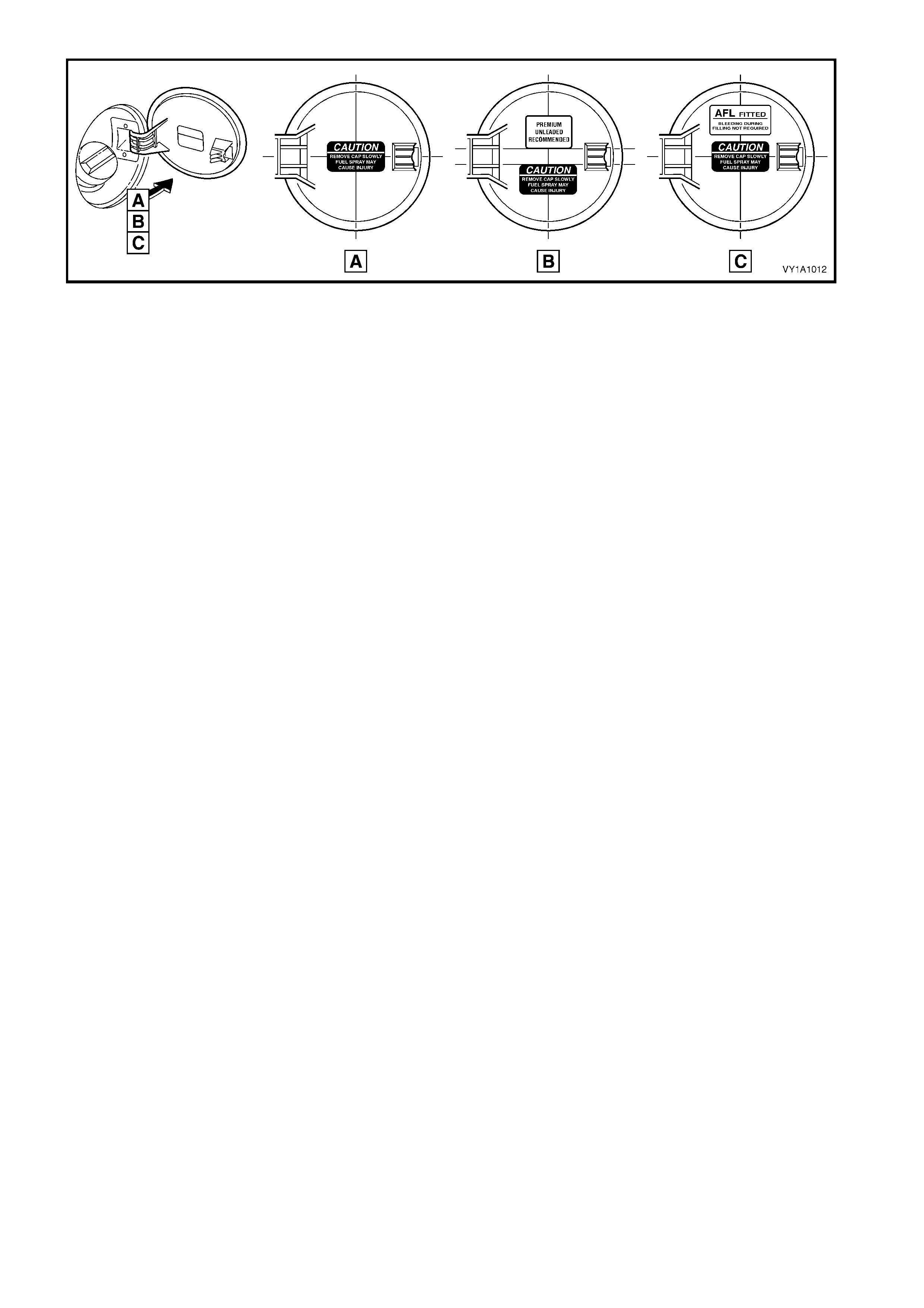

3. If the door has been replaced, apply the labels in

the positions shown, A – all vehicles except

supercharged V6 and LPG, B – vehicles with

supercharged V6, C – vehicles with LPG, refer

Figure 1A1-11.

NOTE: Prior to affixing the label(s) ensure the surface

is clean and dry. Avoid touching the back of the label.

4. Ensure the fuel filler door closes without the need

of excess force and is flush with the surrounding

panel.

FUEL TANK FILLER

DOOR ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 1A1-11

4.2 FUEL FILLER DOOR ASSEMBLY, WAGON

LT Section No. – 03-028

The fuel filler door is painted the vehicle’s body colour. The door assembly is serviced with the moulding

unattached, which allows the door to be painted, then the moulding fitted as described in this procedure.

The moulding is attached to the door flap with adhesive. Therefore if repairing paintwork on the filler door, the

moulding will require masking or removal and replacing with a new part, which is available individually.

Paint the door using the correct materials and techniques for PPE/PA resin (Polyphenylene/Polyamide). As the

mater ials and techniques required dif fer between paint brands, ref er to the technical data supplied by your paint

manufacturer.

NOTE: If the fuel filler door is being replaced, the warning labels affixed to the inside of the door must also be

replaced.

REMOVE

1. Open the fuel filler door, by operating the release

lever (RHD vehicles) or by operating the release

button on the instrument panel (LHD vehicles).

2. Remove the fuel filler cap and cover the opening

with a rag as required.

3. Rem ove the two screws (1) attaching the fuel filler

door assembly.

4. Remove the door assembly by withdrawing it

rearward, ensuring the gasket (2) is also removed.

Figure 1A1-12

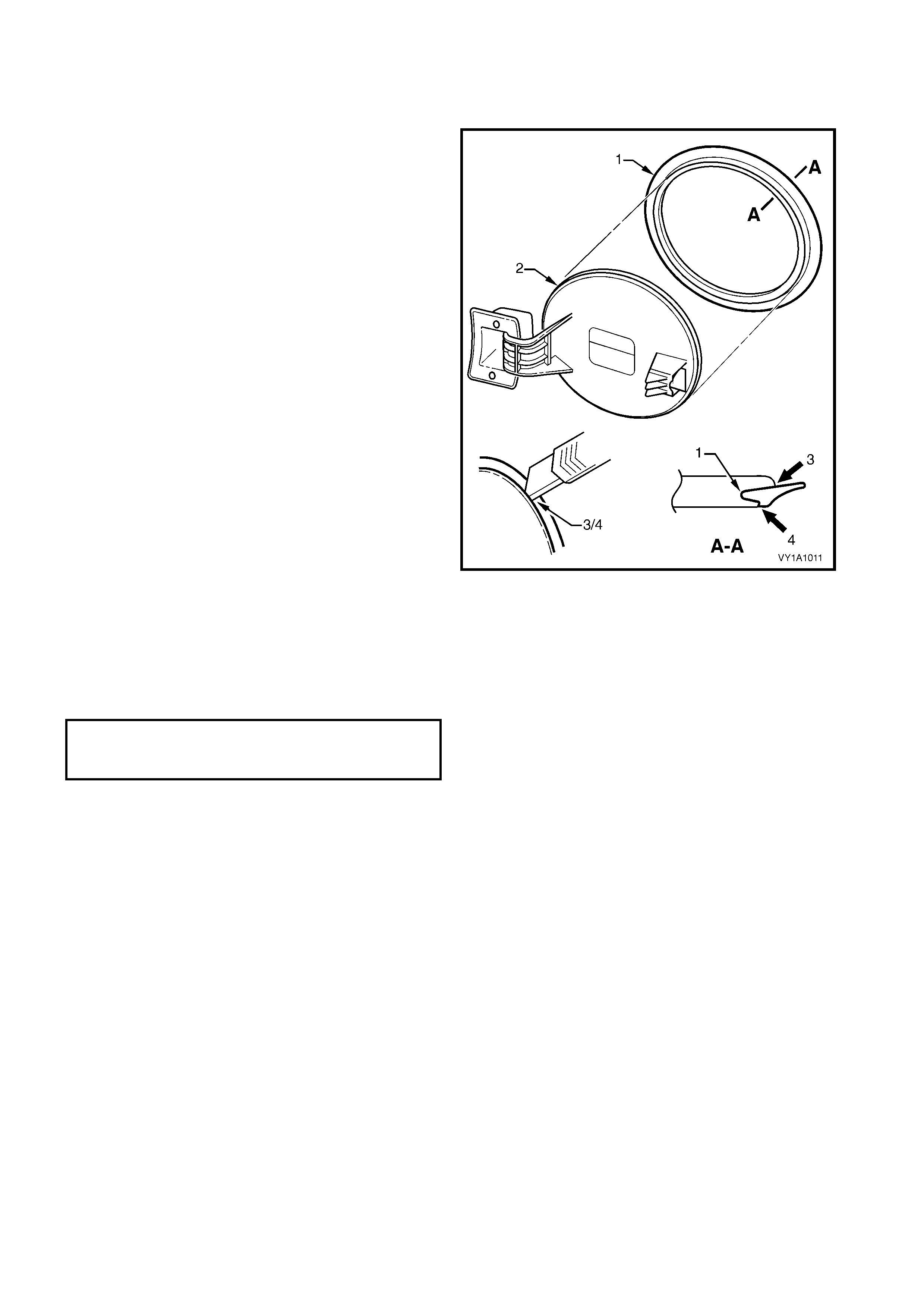

DISASSEMBLE

MOULDING

1. The moulding (1) is seated in the recess (2)

around the circumference of the door and is

affixed with superglue gel. Removal may be

difficult, but by carefully cutting around the inner

(3) and outer sides (4) of the moulding using a

sharp knife, it is possible to remove the moulding.

It will not be able to be reused.

2. To install the moulding, carefully apply Loctite 454

(Superglue Gel) or equivalent into the fuel filler

door recess around the complete circumference.

IMPORTANT: Use of superglue can be harmful and

can damage paintwork. Carefully read and follow all

directions and cautions with the product prior to its use.

3. Ensuring it is correctly orientated, fit the moulding

into the recess and leave for the adhesive to cure.

Figure 1A1-13

REINSTALL

Installation of the fuel filler door assembly is the

reverse of removal, noting the following.

1. Ensure the screws are tightened to the specified

torque.

2. If a new door ass em bly is being installed, following

painting of the door, install the moulding onto the

flap as described in DISASSEMBLE in this

procedure.

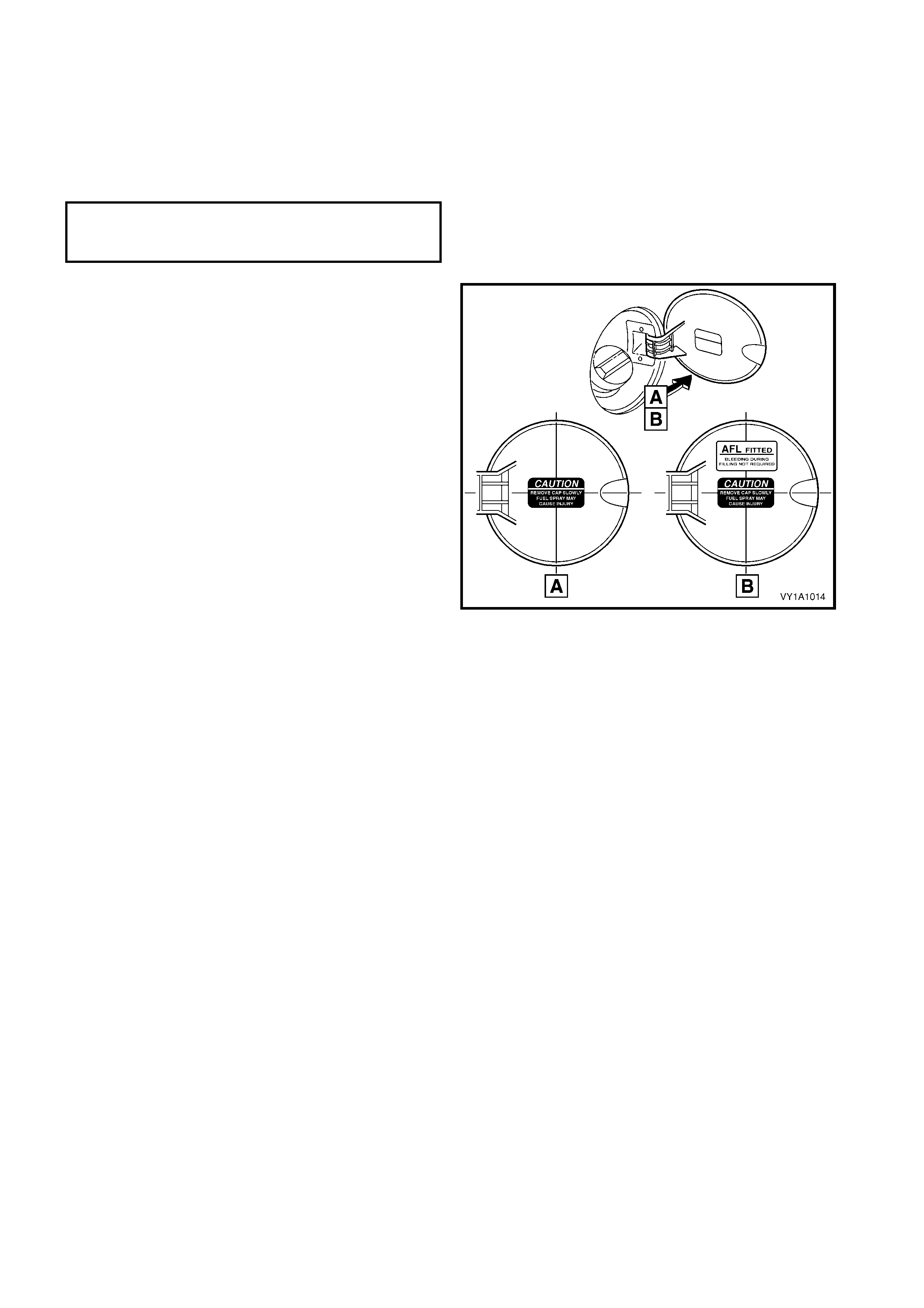

3. If the door has been replaced, apply the labels in

the positions shown, A – all vehicles except

supercharged V6 and LPG, B – vehicles with

supercharged V6, C – vehicles with LPG, refer

Figure 1A1-14.

NOTE: Prior to affixing the label(s) ensure the surface

is clean and dry. Avoid touching the back of the label.

4. Ensure the fuel filler door closes without the need

of excess force and is flush with the surrounding

panel.

FUEL TANK FILLER

DOOR ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 1A1-14

4.3 FUEL FILLER DOOR ASSEMBLY, UTILITY

LT Section No. – 03-028

The f uel filler door is painted the vehic le’s body colour . Paint the door assem bly using the c orrect m aterials and

techniques for PPE/PA resin (Polyphenylene/Polyamide). As the materials and techniques required differ

between paint brands, refer to the technical data supplied by your paint manufacturer.

NOTE: If the fuel filler door is being replaced, the warning labels affixed to the inside of the door must also be

replaced.

REMOVE

1. Open the fuel filler door by hand.

2. Remove the fuel filler cap and cover the opening

with a rag as required.

3. Rem ove the two screws (1) attaching the fuel filler

door assembly.

4. Remove the door assembly by withdrawing it

rearward.

5. If required, remove the fuel filler pipe seal (2) by

sliding the seal over the filler neck.

Figure 1A1-15

6. If required, remove the retainer (1) from the inner

opening of the fuel filler pipe seal (2).

7. Remove the seal by sliding it over the filler neck.

Figure 1A1-16

REINSTALL

Installation is the reverse of removal, noting the

following.

1. Ensure the retainer is seated correctly in the fuel

filler pipe seal.

2. Tighten the screws to the specified torque.

3. If the door has been replaced, apply the labels in

the positions shown, A – all vehicles except with

LPG, B – vehicles with LPG.

NOTE: Prior to affixing the label(s) ensure the surface

is clean and dry. Avoid touching the back of the label.

4. Ensure that when the fuel filler door is closed it

aligns with the surrounding panel.

Figure 1A1-17

FUEL TANK FILLER

DOOR ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

4.4 FUEL FILLER DOOR CABLE ASSEMBLY, RHD

SEDAN & WAGON

LT Section No. – 03-028

If required, first remove the following components:

1. Right-hand side sill trim and seat adjuster outer front cover, refer Section 1A8, 2.4 SIDE SILL TRIM &

PLATE for Sedan or 3.4 SIDE SILL TRIM & PLATE for Wagon.

2. Rear seat cushion assemblies, refer Section 1A7, SEAT ASSEMBLIES.

NOTE: For W agon m odels, rem ove the right-hand r ear seat bolster as sem bly and f old the rear seat bac kres t to

the horizontal position.

3. For Sedan models , the right-hand quarter inner rear side carpet, refer Section 1A8, 2.17 QUART ER INNER

REAR SIDE CARPET.

4. For Wagon models:

• body lock pillar lower trim, refer Section 1A8, 3.6 BODY LOCK PILLAR LOWER TRIM, and

• right-hand quarter inner trim upper, refer Section 1A8, 3.8 RIGHT-HAND QUARTER INNER TRIM

UPPER,

• quarter inner trim panel assembly, refer Section 1A8, 3.11 QUARTER INNER TRIM PANEL

ASSEMBLY.

REMOVE

1. Open the fuel filler door by operating the release

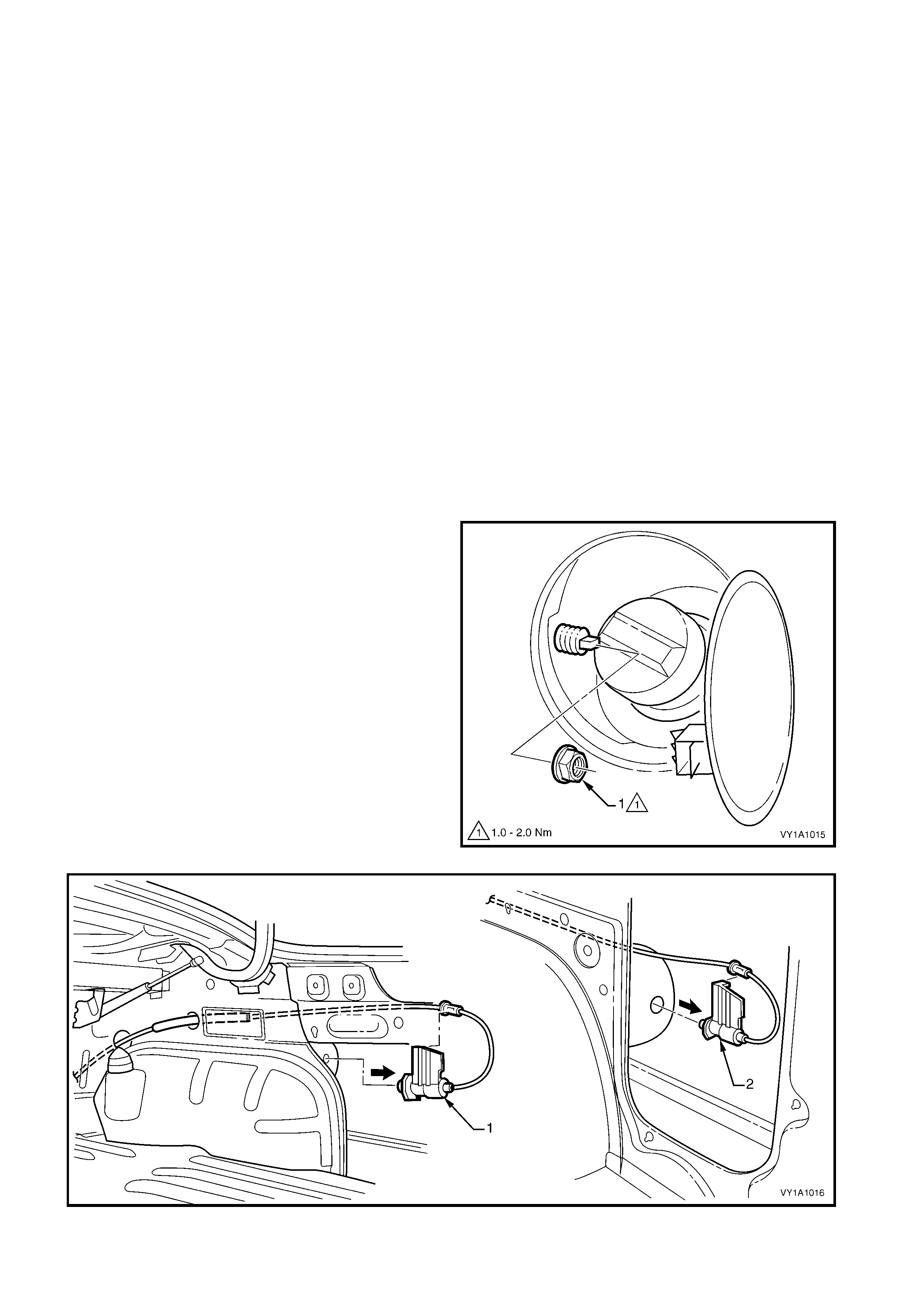

lever.

2. From within the fuel filler housing, remove the nut

(1) attaching the fuel filler door cable assembly.

3. From within the rear compartment, withdraw the

cable assembly (1 Sedan, 2 W agon) from the fuel

filler housing, refer Figure 1A1-19.

Figure 1A1-18

Figure 1A1-19

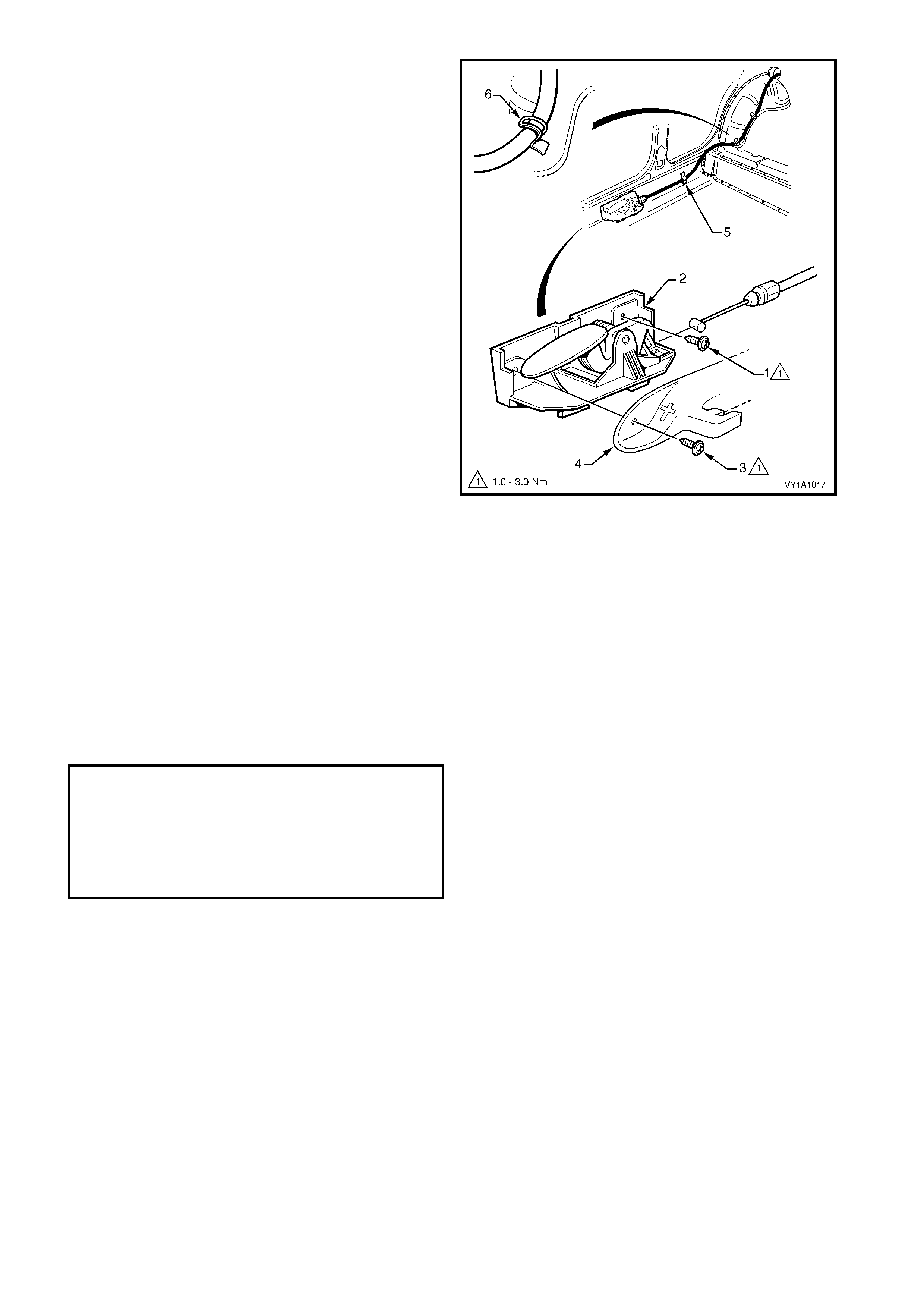

4. From inside the vehicle, remove the screw (1)

attaching the cable assembly lever (2) to the

rocker panel.

NOTE: T he previous ly removed sc rew (3) attaches the

seat adjuster outer front cover (4) and the cable

assembly lever.

5. Remove the tape (5) and bend the retaining tabs

(6) to release the cable assembly.

6. Remove the cable assembly from the vehicle,

feeding it through the back panel upper for Sedan

models.

7. If required, unclip the cable from the release lever.

Figure 1A1-20

REINSTALL

1. Installation is the reverse of removal. Ensure the

components are tightened to the specified torque.

NOTE 1: Ensure the cable assembly is routed

correctly and is fitted with the tab up as shown in

Figure 1A1-19.

NOTE 2: Ensure the cable assembly operates

correctly and the plunger completely retracts prior to

closing the fuel filler door. If satisfactory, close the door

ensuring it does not require excess force. The door

should spring ajar when the release is operated.

FUEL TANK FILLER DOOR

CABLE ASSEMBLY LATCH NUT

TORQUE SPECIFICATION 1.0 – 2.0 Nm

FUEL TANK FILLER DOOR

CABLE ASSEMBLY RELEASE

LEVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

COUPE

If required, first remove the following components:

1. Right-hand side sill trim and seat adjuster outer front cover, refer Section 1A8, 4.1 SIDE SILL TRIM &

PLATE.

2. Rear seat cushion assemblies, refer Section 1A7, SEAT ASSEMBLIES.

3. Right-hand quarter inner rear side carpet, refer Section 1A8, 4.14 QUARTER INNER REAR SIDE

CARPET.

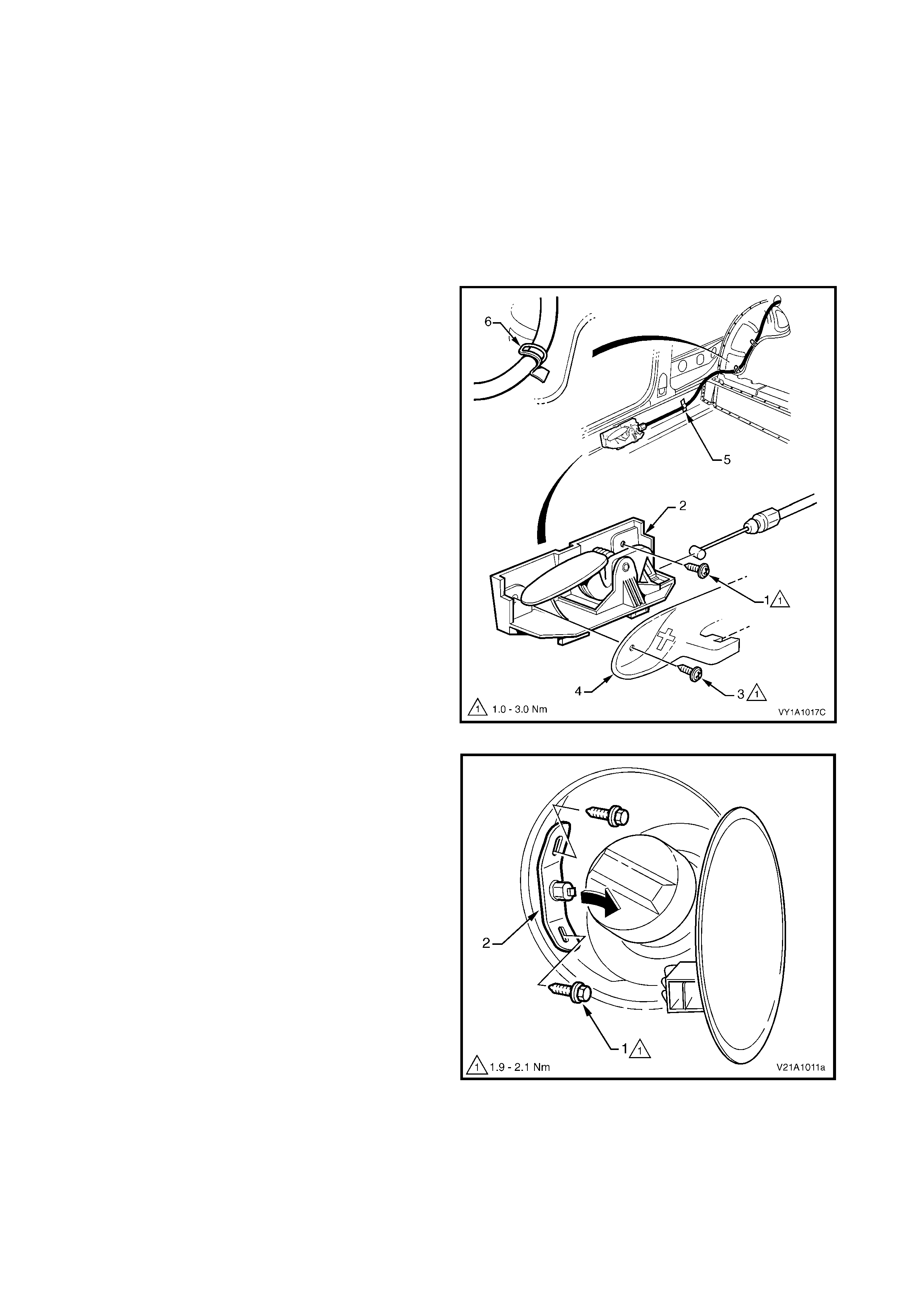

REMOVE

1. Open the fuel filler door by operating the release

lever.

2. From inside the vehicle, remove the screw (1)

attaching the cable assembly lever (2) to the

rocker panel.

NOTE: T he previous ly removed sc rew (3) attaches the

seat adjuster outer front cover (4) and the cable

assembly lever.

3. Remove the tape (5) and bend the retaining tabs

(6) to release the cable assembly.

4. Unclip the cable from the release lever.

5. Pull the cable through the back panel upper into

the rear compartment.

Figure 1A1-21

6. From within the fuel filler housing, remove the two

screws (1) attaching the cable assembly (2).

7. Withdraw the cable assembly from the fuel filler

housing.

Figure 1A1-22

REINSTALL

1. Installation is the reverse of removal. Tighten the

screws to the specified torque.

NOTE 1: Ensure the cable assembly is routed

correctly.

NOTE 2: Ensure the cable assembly operates

correctly and the plunger completely retracts prior to

closing the fuel filler door. If satisfactory, close the door

ensuring it does not require excess force. The door

should spring ajar when the release is operated.

FUEL TANK FILLER DOOR

CABLE ASSEMBLY LATCH SCREW

TORQUE SPECIFICATION 1.9 – 2.1 Nm

FUEL TANK FILLER DOOR

CABLE ASSEMBLY RELEASE

LEVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

4.5 FUEL FILLER DOOR LOCK ACTUATOR ASSEMBLY, LHD

SEDAN & WAGON

LT Section No. – 03-028

NOTE: For removal of the fuel filler door switch assembly, refer to the disassembly procedure in

Section 1A3, 3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY.

If required, first remove the following components:

1. F or Sedan, the right-hand quarter inner rear side carpet, refer Sect ion 1A8, 2.17 QUARTER INNER REAR

SIDE CARPET.

2. For Wagon models:

• body lock pillar lower trim , refer Section 1A8, 3.6 BODY LOCK PILLAR LOWER TRIM, and

• right-hand quarter inner trim upper, refer Section 1A8, 3.8 RIGHT-HAND QUARTER INNER TRIM

UPPER,

• quarter inner trim panel assembly, refer Section 1A8, 3.11 QUARTER INNER TRIM PANEL

ASSEMBLY.

REMOVE

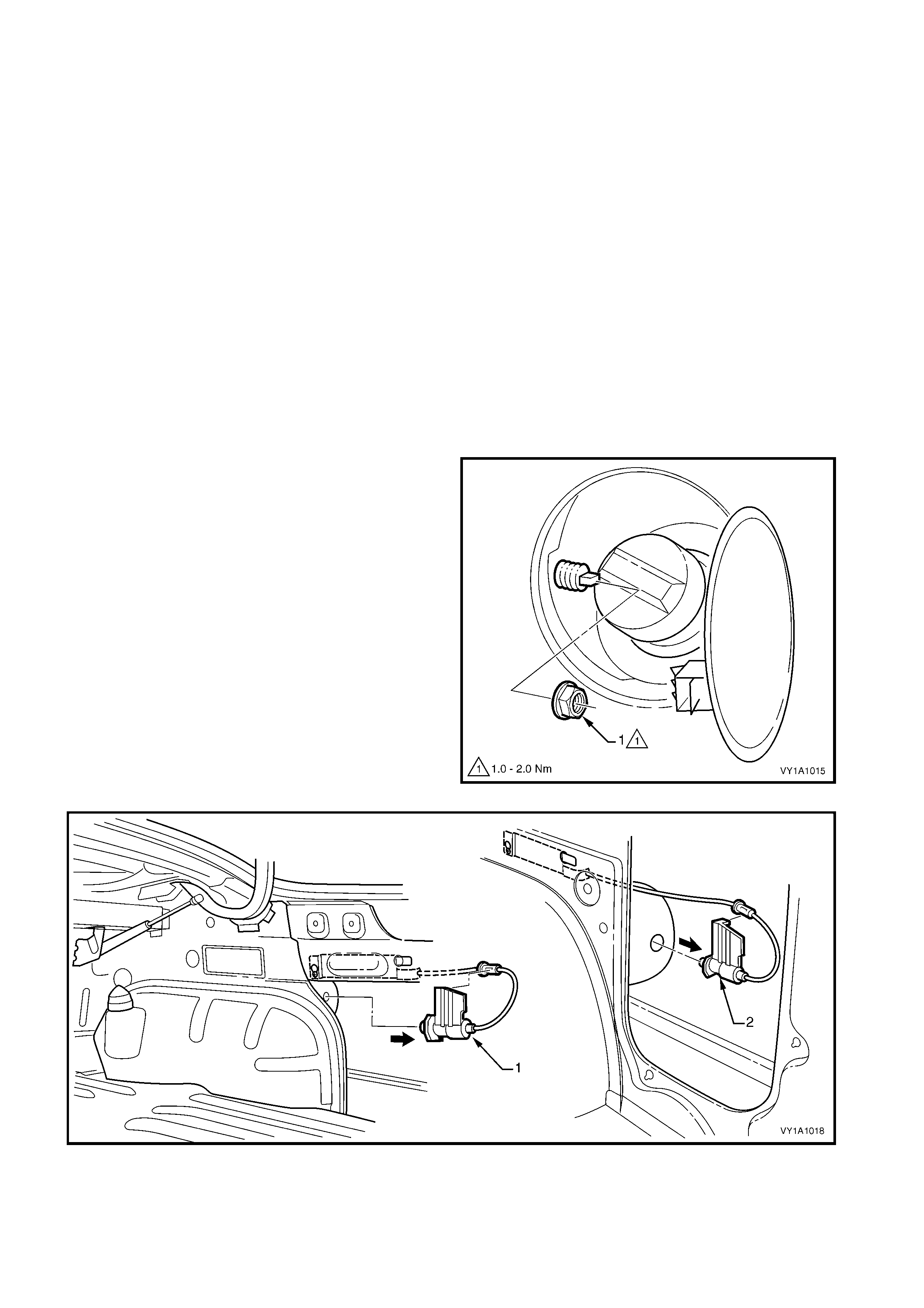

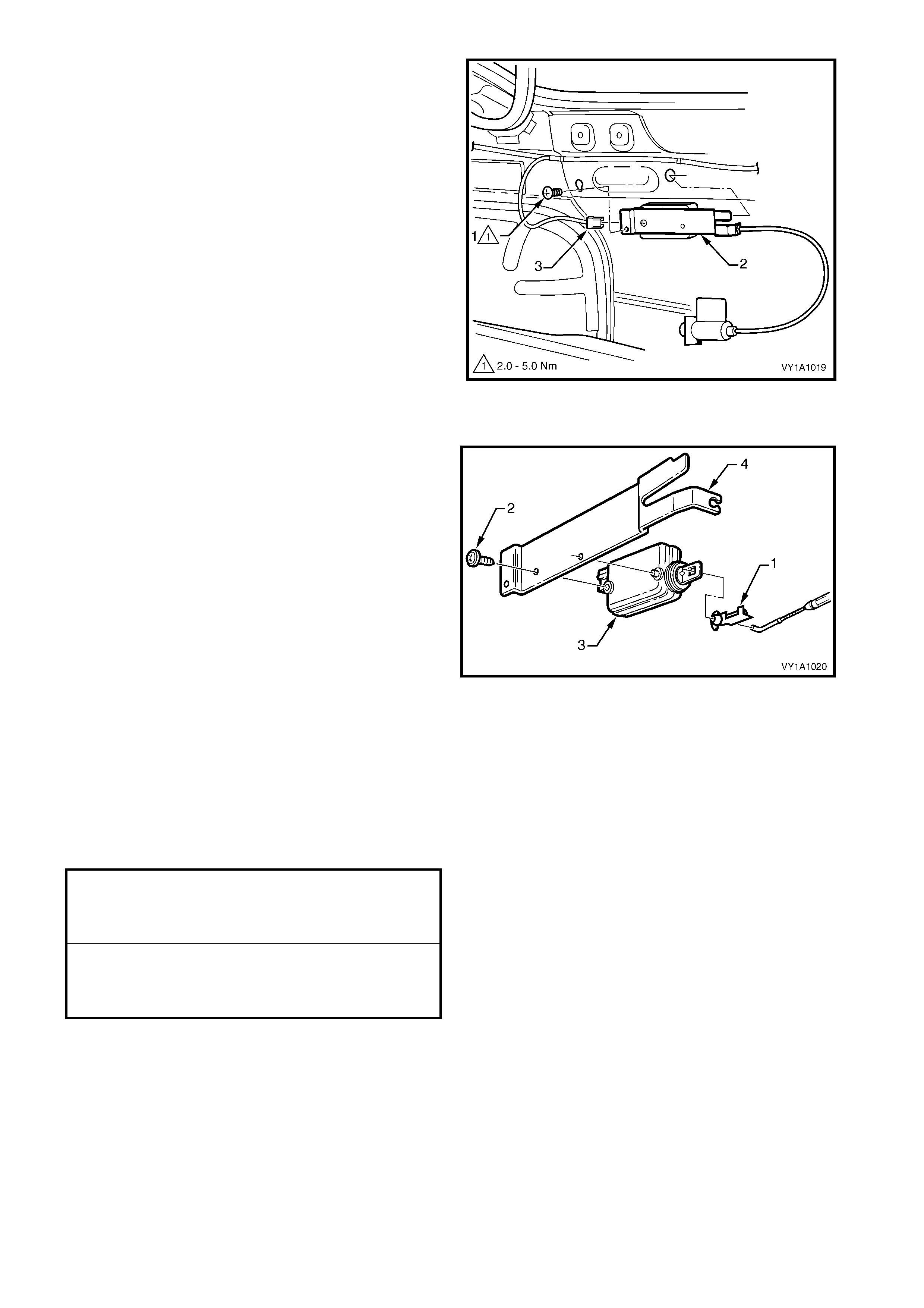

1. Open the fuel filler door by operating the fuel filler

door switch on the instrument panel.

2. From within the fuel filler housing, remove the nut

(1) attaching the fuel filler door lock actuator

assembly.

3. From within the rear compartment, withdraw the

actuator assembly (1 Sedan, 2 Wagon) from the

fuel filler housing, refer Figure 1A1-24.

Figure 1A1-23

Figure 1A1-24

4. Loosen or remove the screw (1) attaching the

actuator assembly (2) to the side panel inner.

NOTE: Sedan shown, other models similar.

5. Slide the front of the assembly up and remove

from the keyhole.

6. Withdraw the rear tab from its locating hole.

7. Disconnect the wiring connector (3) and remove

the assembly.

Figure 1A1-25

DISASSEMBLE

1. Unclip the retainer (1) from the cable end by

raising the locking tab. Withdraw the cable from

the actuator.

2. Remove the screw (2) attac hing the actuator (3) to

the mounting plate (4).

Figure 1A1-26

REINSTALL

1. Installation is the reverse of removal. Ensure the

components are tightened to the specified torque.

NOTE: Ensure the actuator assembly operates

correctly and the plunger completely retracts prior to

closing the fuel filler door. If satisfactory, close the door

ensuring it does not require excess force. The door

should spring ajar when the release is operated.

FUEL TANK FILLER

DOOR LOCK ACTUATOR

ASSEMBLY LATCH NUT

TORQUE SPECIFICATION 1.0 – 2.0 Nm

FUEL TANK FILLER DOOR

LOCK ACTUATOR ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

COUPE

LT Section No. –

NOTE: For removal of the fuel filler door switch assembly, refer to the disassembly procedure in

Section 1A3, 3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY.

If required, first remove the following components:

1. Right-hand quarter inner rear side carpet, refer Section 1A8, 4.14 QUARTER INNER REAR SIDE

CARPET.

2. Right-hand quarter inner trim panel assembly, refer Section 1A8, 4.2 QUARTER INNER TRIM PANEL

ASSEMBLY.

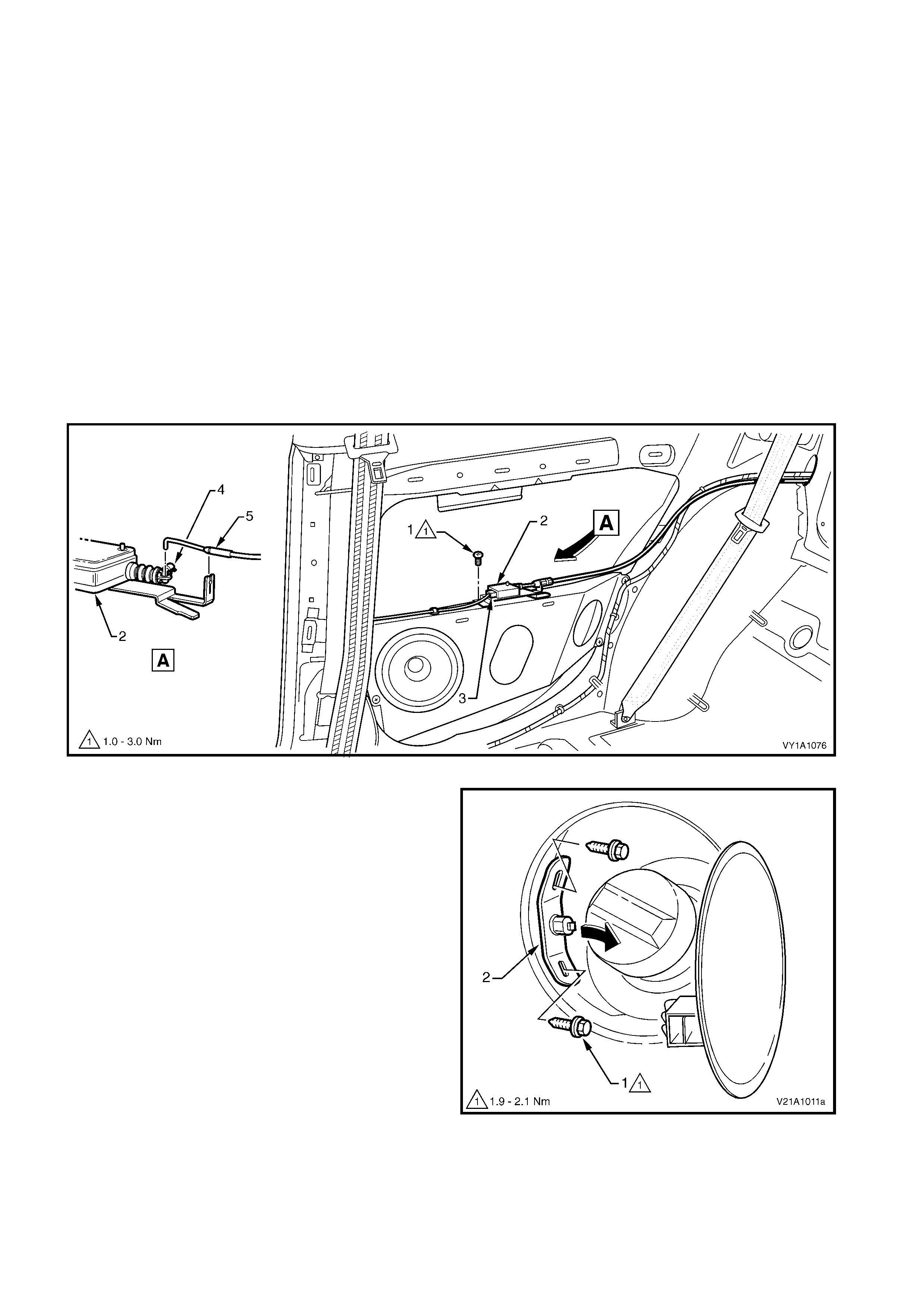

REMOVE

1. Open the fuel filler door by operating the fuel filler door switch on the instrument panel.

2. Rem ove the screw (1) attaching the actuator assembly (2) to the speaker mounting bracket, refer to Figure

1A1-27.

3. Disconnect the wiring connector (3) from the actuator assembly.

4. Open the retainer (4) and remove the cable (5) from the actuator assembly.

5. Remove the actuator assembly and if required, feed the cable into the rear compartment.

Figure 1A1-27

6. From within the fuel filler housing, remove the two

screws (1) attaching the cable assembly (2).

7. Withdraw the cable assembly from the fuel filler

housing.

Figure 1A1-28

DISASSEMBLE

1. Remove the screw (1) attac hing the actuator (2) to

the mounting plate (3).

2. Unclip the retainer (4) from the actuator.

REASSEMBLE

Assem bly is the revers e of the disass em bly procedure.

Tighten the screw securely.

Figure 1A1-29

REINSTALL

1. Installation is the reverse of removal. Ensure the

components are tightened to the specified torque.

NOTE: Ensure the actuator assembly operates

correctly and the plunger completely retracts prior to

closing the fuel filler door. If satisfactory, close the door

ensuring it does not require excess force. The door

should spring ajar when the release is operated.

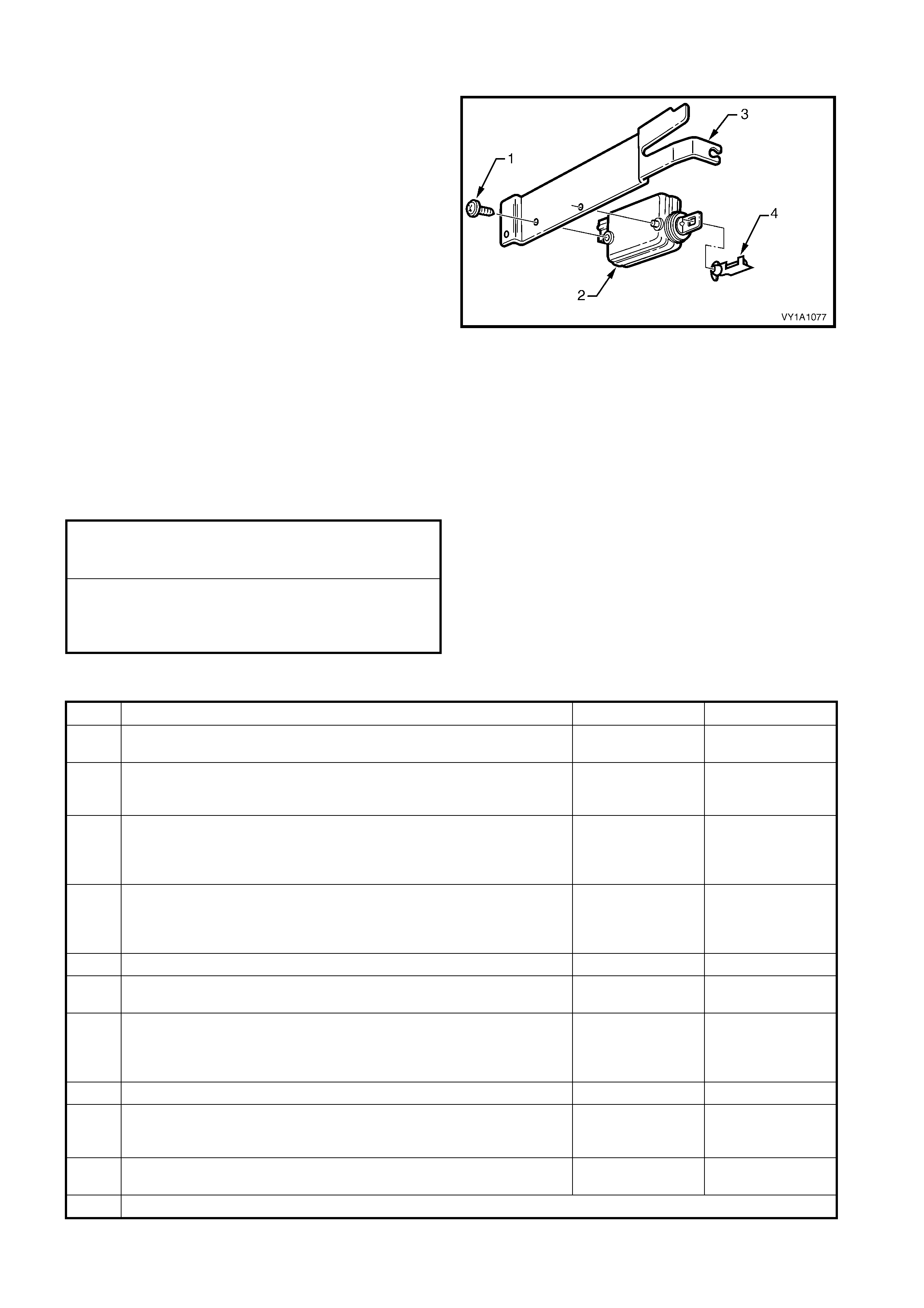

DIAGNOSIS

STEP ACTION YES NO

1 Press the fuel filler door release switch. Does the fuel filler door

open? OK. End Go to 2

2 Press the fuel filler door release switch. Does the actuator emit a

clicking sound? Door jammed or

cable broken.

Repair or replace

Go to 3

3 Check Fuse 105 in the engine compartment fuse and relay panel

assembly. Is it OK? Go to 4 Replace fuse.

If the fuse blows

again test for a

short to ground.

4 Check Fuse 20 in the passenger compartment fuse and relay panel

assembly. Is it OK? Go to 5 Replace fuse.

If the fuse blows

again test for a

short to ground.

5 Ground the switch connector S191 pin 3. Does the actuator operate? Go to 6 Go to 7

6 Ground the switch connector S191 pin 5 and press the switch.

Does the actuator operate? Repair circuit 151. Replace switch. *

7 Ground connector Y10 pin 3. Does actuator operate? Repair circuit

1447 between the

actuator and

switch.

Go to 8

8 Check for B+ at the actuator connector Y10 pin 1 Replace actuator. Go to 9

9 Check for B+ at connector X42 pin 22 in the passenger compartment

fuse and relay panel assembly Repair circuit 440

between fuse 20

and the actuator

Go to 10

10 Check for B+ at connector X18 pin 104 in the engine compartment

fuse and relay panel assembly. Repair circuit 342 Repair circuit 1

* Also check the suppression diode for continuity between pins A to B but not B to A.

FUEL TANK FILLER DOOR

CABLE ASSEMBLY LATCH SCREW

TORQUE SPECIFICATION 1.9 – 2.1 Nm

FUEL TANK FILLER DOOR

LOCK ACTUATOR ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

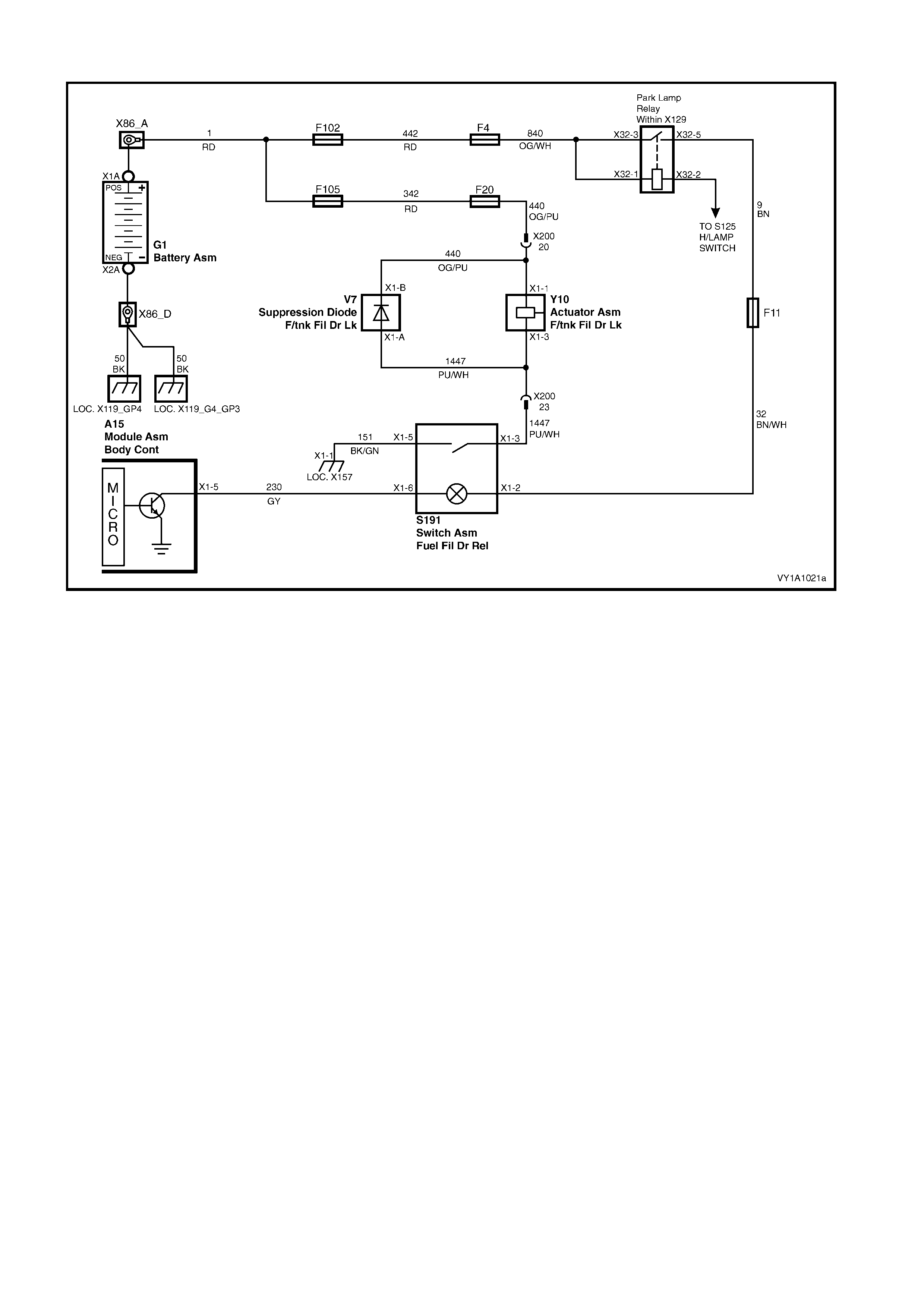

WIRING SCHEMATIC

Figure 1A1-30

CONNECTOR VIEWS

Figure 1A1-31

5. DRAIN TUBES, UTILITY

5.1 REAR FLOOR PANEL DRAIN TUBE, UTILITY

NOTE: If the tube becomes blocked or restricted, clear the obstruction with a length of wire.

LT Section No. –

1. If required, first remove the front load floor panel, refer Section 1B, 2.7 FRONT LOAD FLOOR PANEL.

NOTE: Although not shown, the drain tube can be removed with the fuel tank in place.

REMOVE

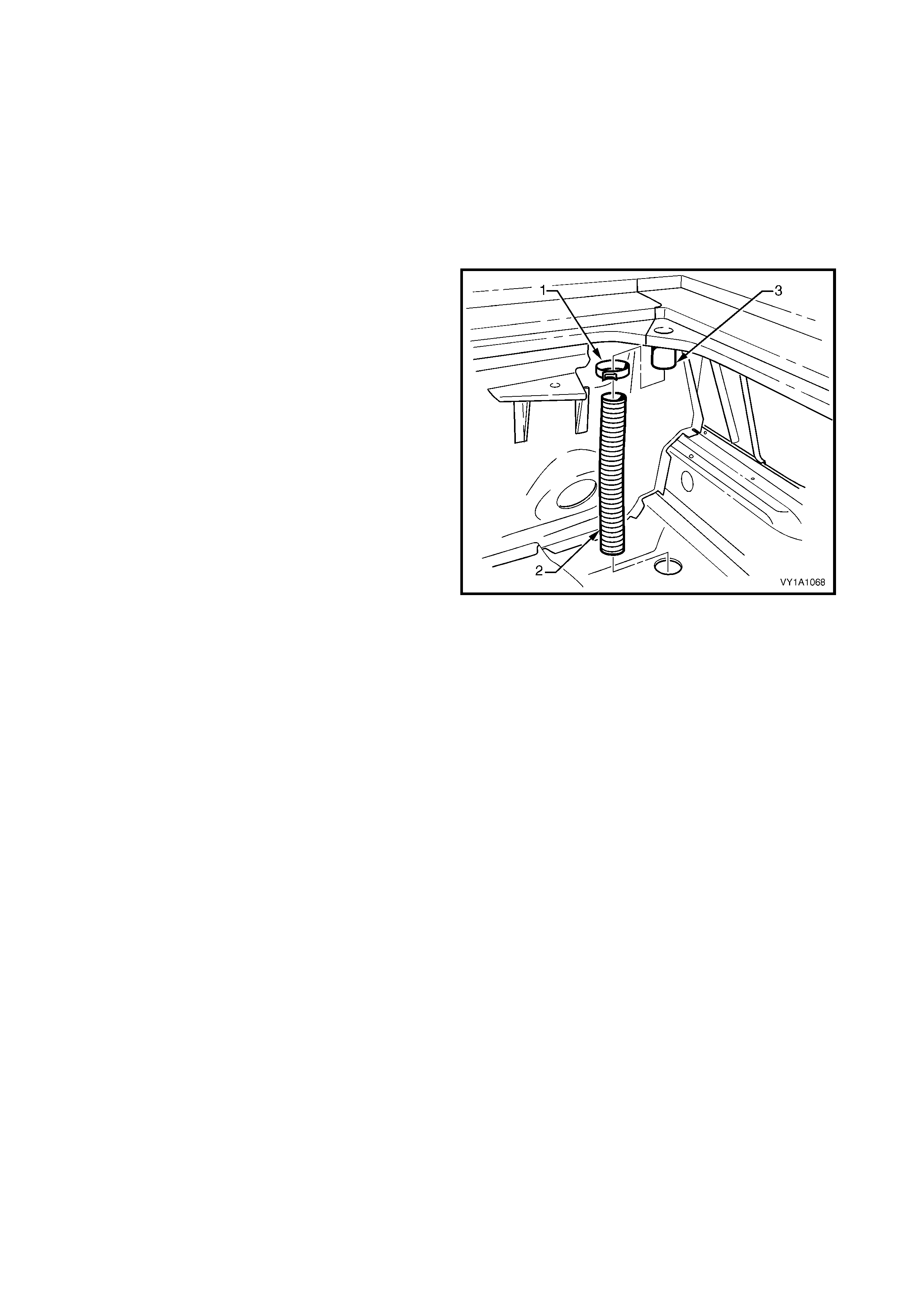

1. Using a pair of pliers, loosen the clamp (1) and

slide it down the rear floor panel drain tube (2).

2. Prise the tube from the floor panel outlet (3).

3. W ithdraw the tube from the hole in the floor panel

and remove.

Figure 1A1-32

REINSTALL

Installation is the reverse of removal. Ensure the tube

and clamp are correctly seated.

5.2 REAR WINDOW PANEL DRAIN TUBE ASSEMBLY, UTILITY

NOTE: If the tube becomes blocked or restricted clear the obstruction with a long length of wire.

LT Section No. –

If required, first remove the following components:

1. Rear window side moulding assembly, refer Section 1A9, 4.10 REAR WINDOW SIDE MOULDING

ASSEMBLY.

2. Rear quarter window moulding, refer Section 1A9, 4.11 REAR QUARTER WINDOW MOULDING.

3. Front load floor panel, refer Section 1B, 2.7 FRONT LOAD FLOOR PANEL.

NOTE: Although not shown, the drain tube can be removed with the fuel in place.

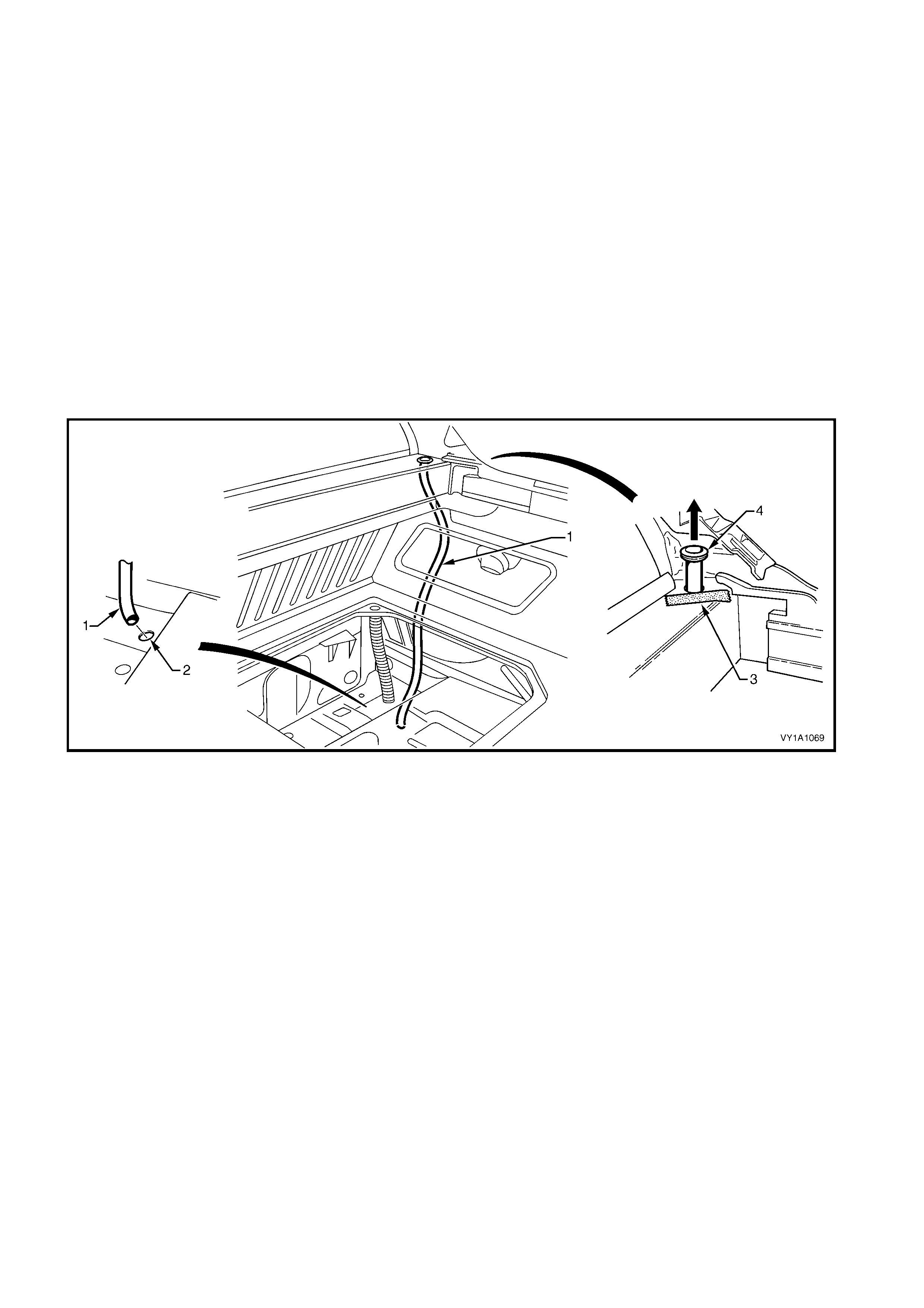

REMOVE

1. Withdraw the rear window panel drain tube assembly (1) from the hole in the floor panel (2), refer Figure

1A1-33.

2. Protect the paintwork on the panel adjacent to the tube assembly with a piece of tape (3).

3. Using a fine flat blade screwdriver, prise the tube assembly grommet (4) from the panel.

4. Withdraw the tube assembly through the hole in the panel and remove.

Figure 1A1-33

REINSTALL

Installation is the reverse of removal. Ensure the tube is correctly seated.

6. TORQUE WRENCH SPECIFICATIONS

Front wheelhouse liner attaching screw .........................................................1.0 – 3.0 Nm

Rear wheelhouse liner attaching screw..........................................................1.0 – 3.0 Nm

Rocker panel moulding assembly attaching screw.........................................1.0 – 3.0 Nm

Rear bumper fascia assembly attaching screw..............................................1.0 – 3.0 Nm

Fuel filler door attaching screw.......................................................................1.0 – 3.0 Nm

Fuel filler door cable assembly latch nut.........................................................1.0 – 2.0 Nm

Fuel filler door cable assembly release lever attaching screw .......................1.0 – 3.0 Nm

Fuel filler door cable assembly latch screw, Coupe........................................1.9 – 2.1 Nm

Fuel filler door lock actuator assembly attaching nut......................................1.0 – 2.0 Nm

Fuel filler door lock actuator assembly attaching screw .................................2.0 – 5.0 Nm