SECTION 1A2 - BODY DIMENSIONS

IMPORTANT

Before perfo rming any Service O perat ion or o th er pro cedu re describ ed in th is Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

CONTENTS

1. GENERAL DESCRIPTION

2. SERVICE OPERATIONS

2.1 UNDERBODY DIMENSIONS – PROJECTED

SEDAN

WAGON

COUPE

UTILITY

2.2 UPPERBODY DIMENSIONS – ACTUAL

FRONT – ALL MODELS

SIDE & INTERIOR – SEDAN

SIDE & INTERIOR – WAGON

SIDE & INTERIOR – COUPE

SIDE & INTERIOR – UTILITY

RE AR – SEDAN

REAR – WAGON

REAR – UTILITY

REAR – COUPE

2.3 SUSPENSION FRAMES & TRANS-

MISSION SUPPORT ALIGNMENT

FRONT SUSPENSION FRAME ASSEMBLY

TRANSMISSION SUPPORT

REAR SUSPENSION FRAME ASSEMBLY

3. TORQUE WRENCH SPECIFICATIONS

4. SPECIAL TOOLS

1. GENERAL DESCRIPTION

Correct alignment of the body structure is essential to ensure the vehicle performs as intended. A body structure

that is outside design tolerances can suffer difficult operation and poor fitment of the doors, hood, rear compartment

lid, liftgate or endgate. Suspension performance and vehicle handling can also suffer and noise vibration and

harshness may become evident.

The body structure should therefore be aligned to within ± 1.5 mm of dimensions specified in this Section.

As a m inimum, these dimens ions s hould be ac c urately check ed with a trammel gauge cons isting of a parallel bar or

rod fitted with two adjustable trammels.

In preparation f or an underbody alignment chec k , the vehicle m ust be c orrec tly set-up on a level surfac e, preferably

using a measuring or jigging system specifically designed for the task of checking and correcting vehicle body

alignment.

Note that the dim ens ions provided for the underbody are projected: the meas uring points are tr ans posed onto a two

dimensional (flat) surface and the measurements are taken along the one plane.

All upperbody measurements are actual: the distance from point to point.

Incorrect alignment of the suspension frames and transmission support can also have an adverse affect on the

vehicle’s performance and introduce noise vibration and harshness.

Any time a suspension frame or the transmission support is removed, it must be aligned as described in this

Section.

2. SERVICE OPERATIONS

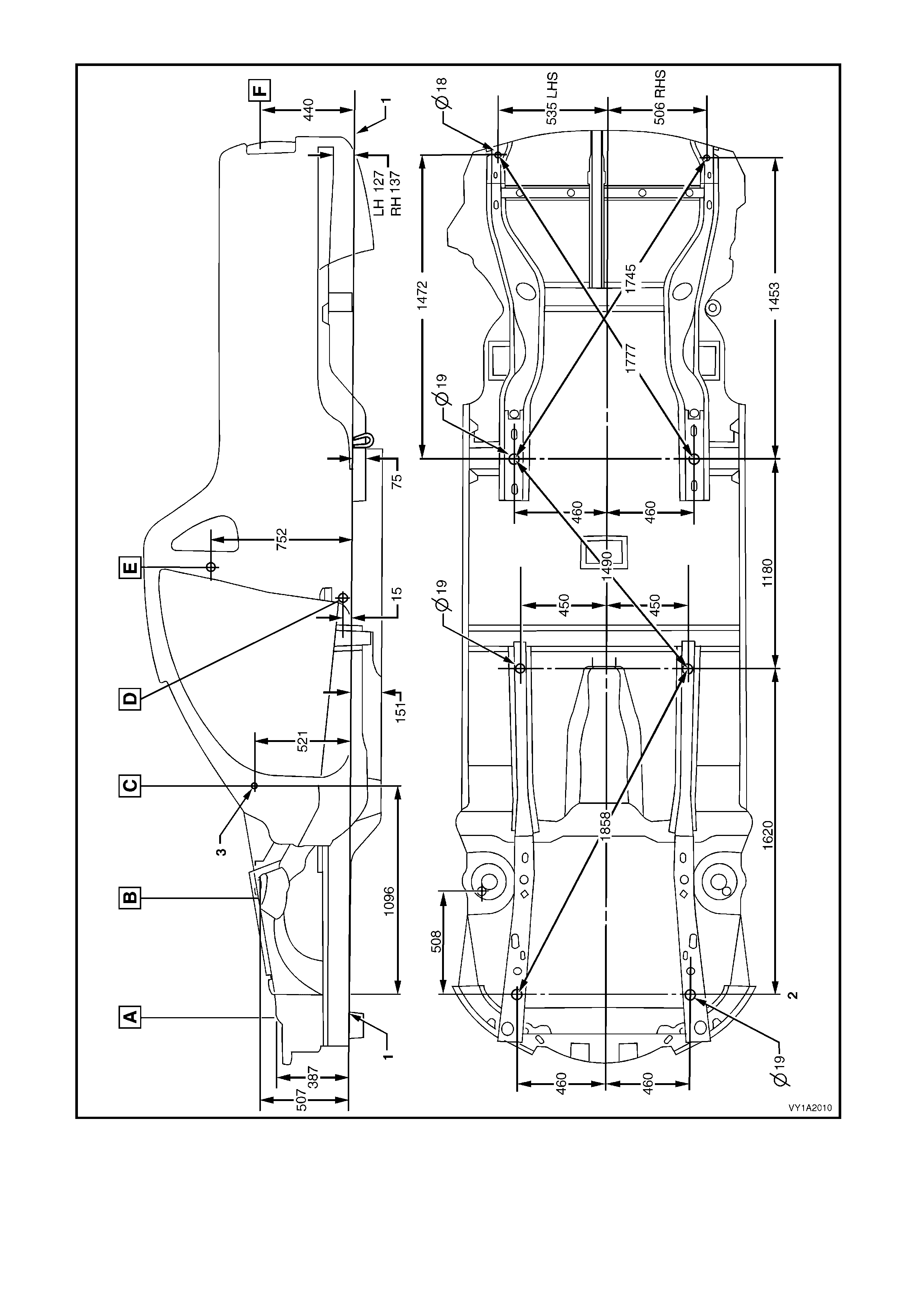

2.1 UNDERBODY DIME NSIONS – PROJECTED

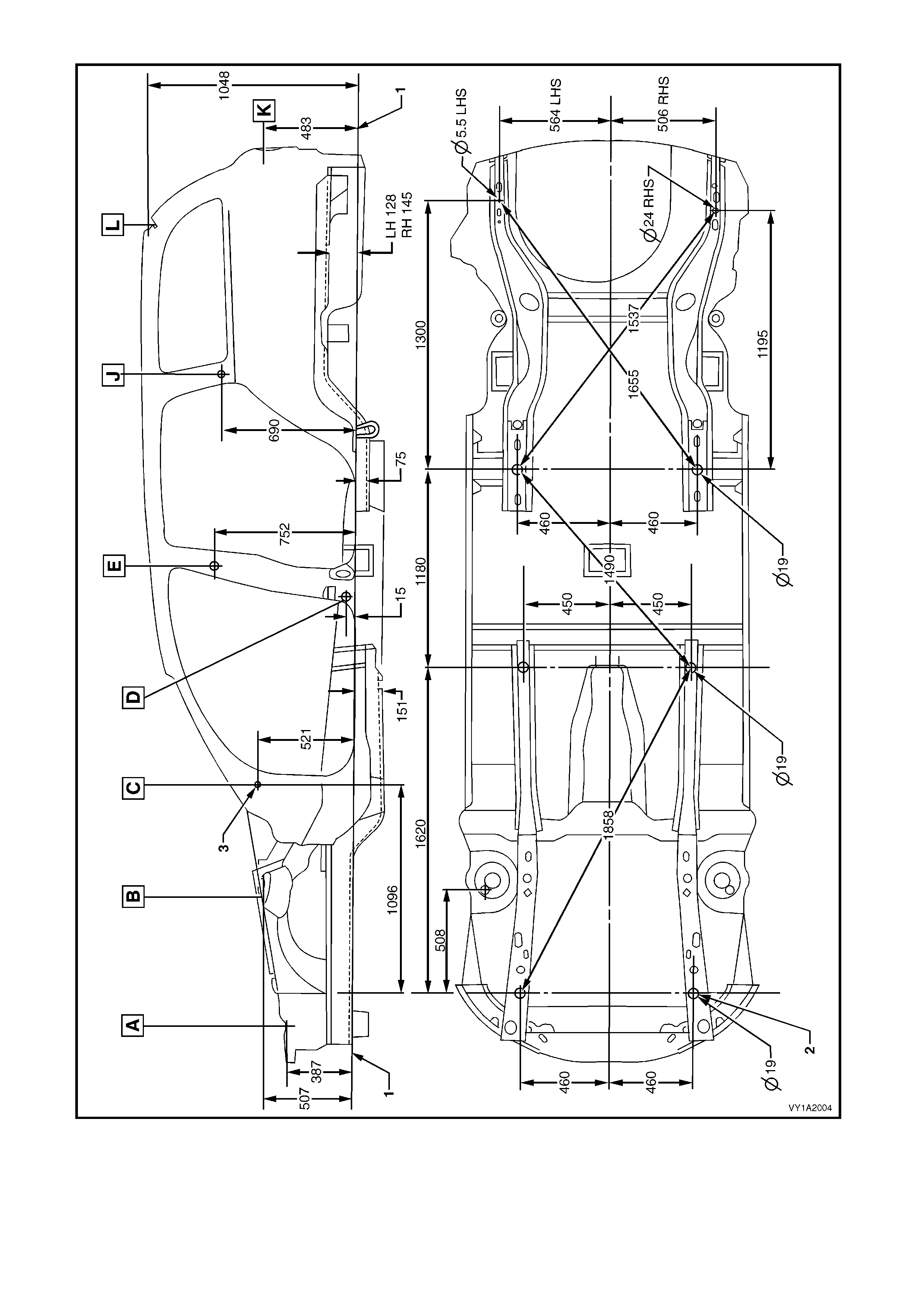

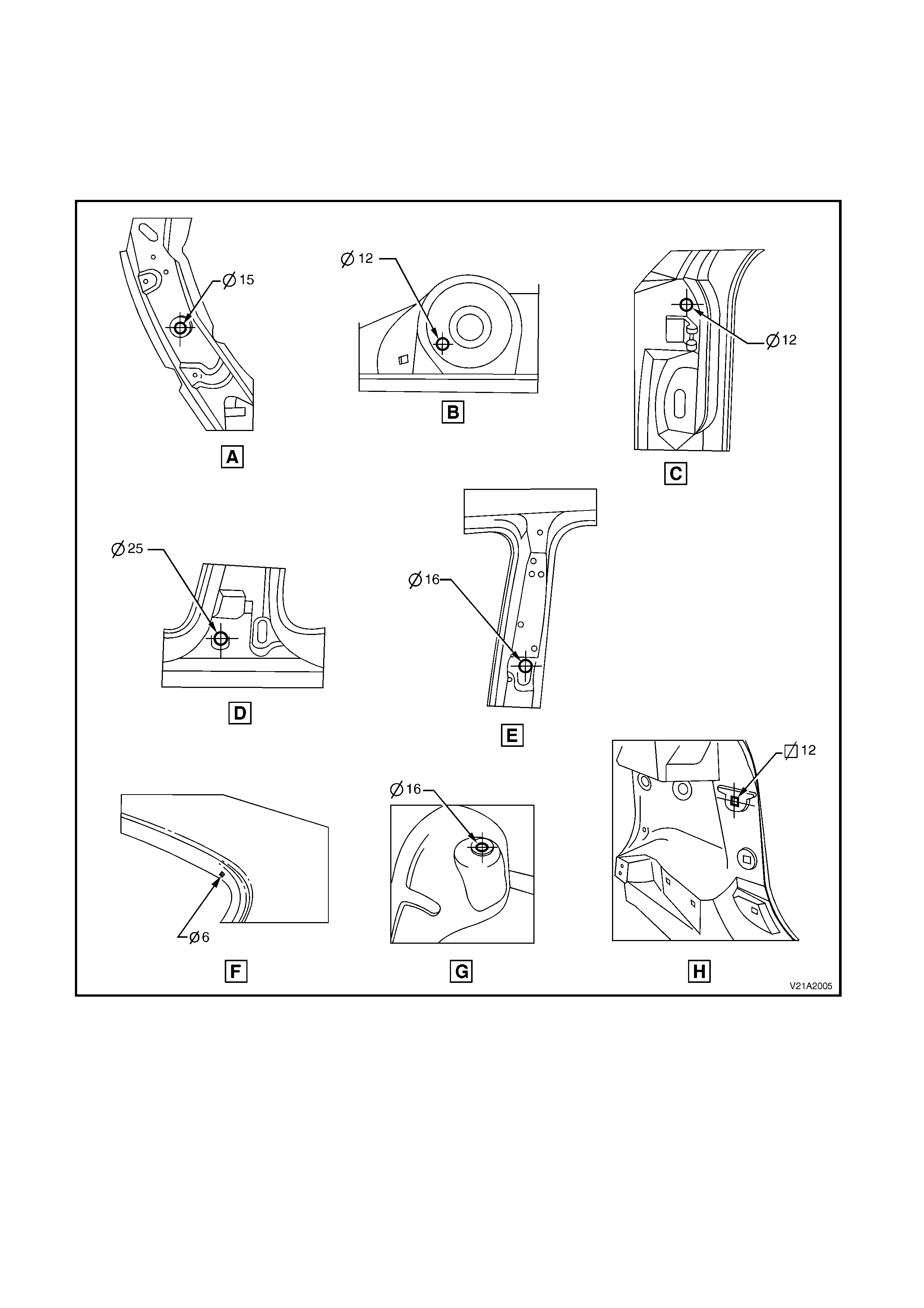

SEDAN

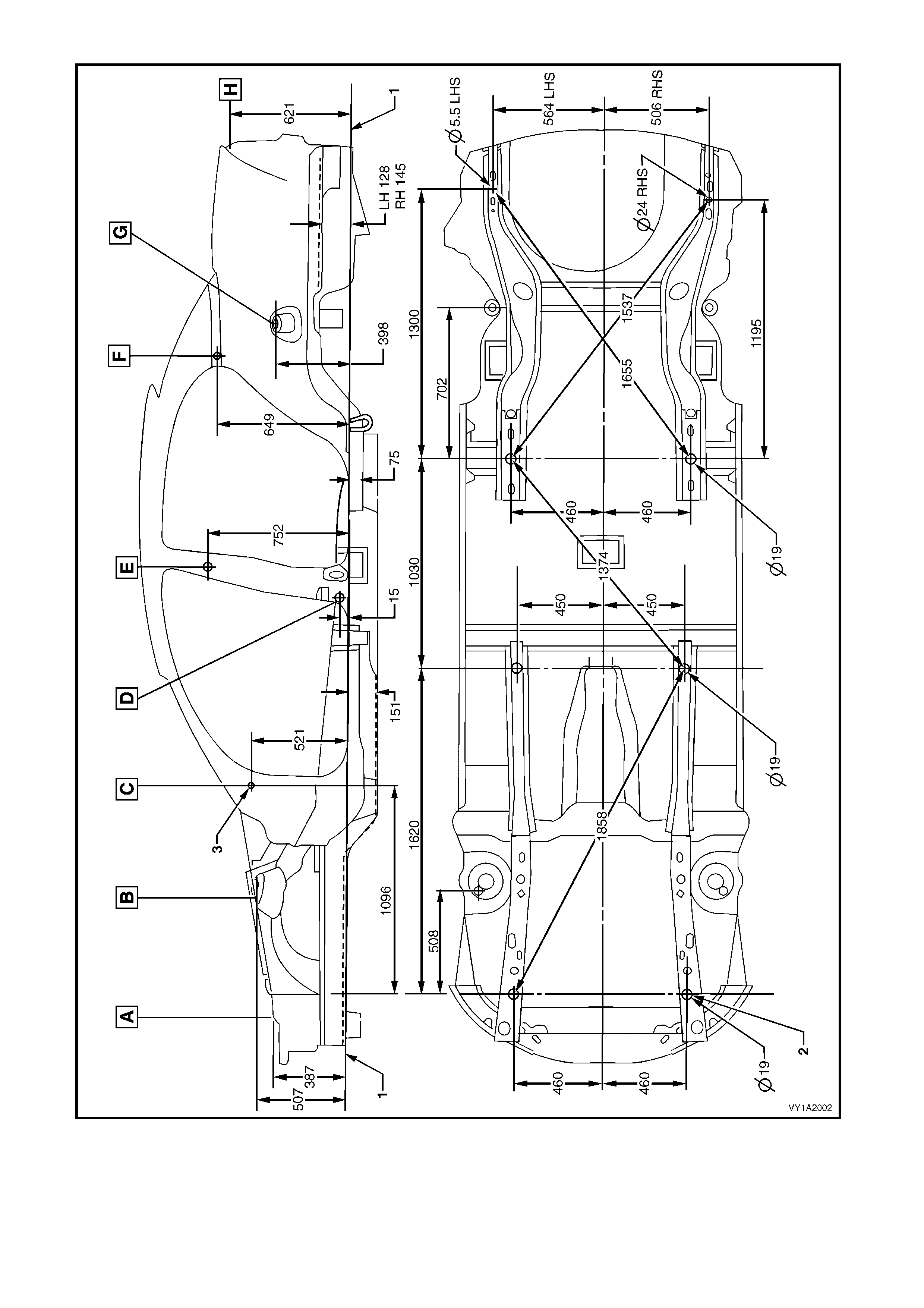

All dimensions are given in mm and are measured from the centre of holes, on the outer side of the metal surface.

The main datum surface (1) is the underside of the front side rail assembly, refer to Figure 1A2-2.

The main datum hole (2) is a 19 mm hole on the underside of the front side rail assembly, refer to Figure 1A2-2.

The dash panel assembly attaching hole (3) in Figure 1A2-2 is the datum hole also depicted at View C in

Figure 1A2-1.

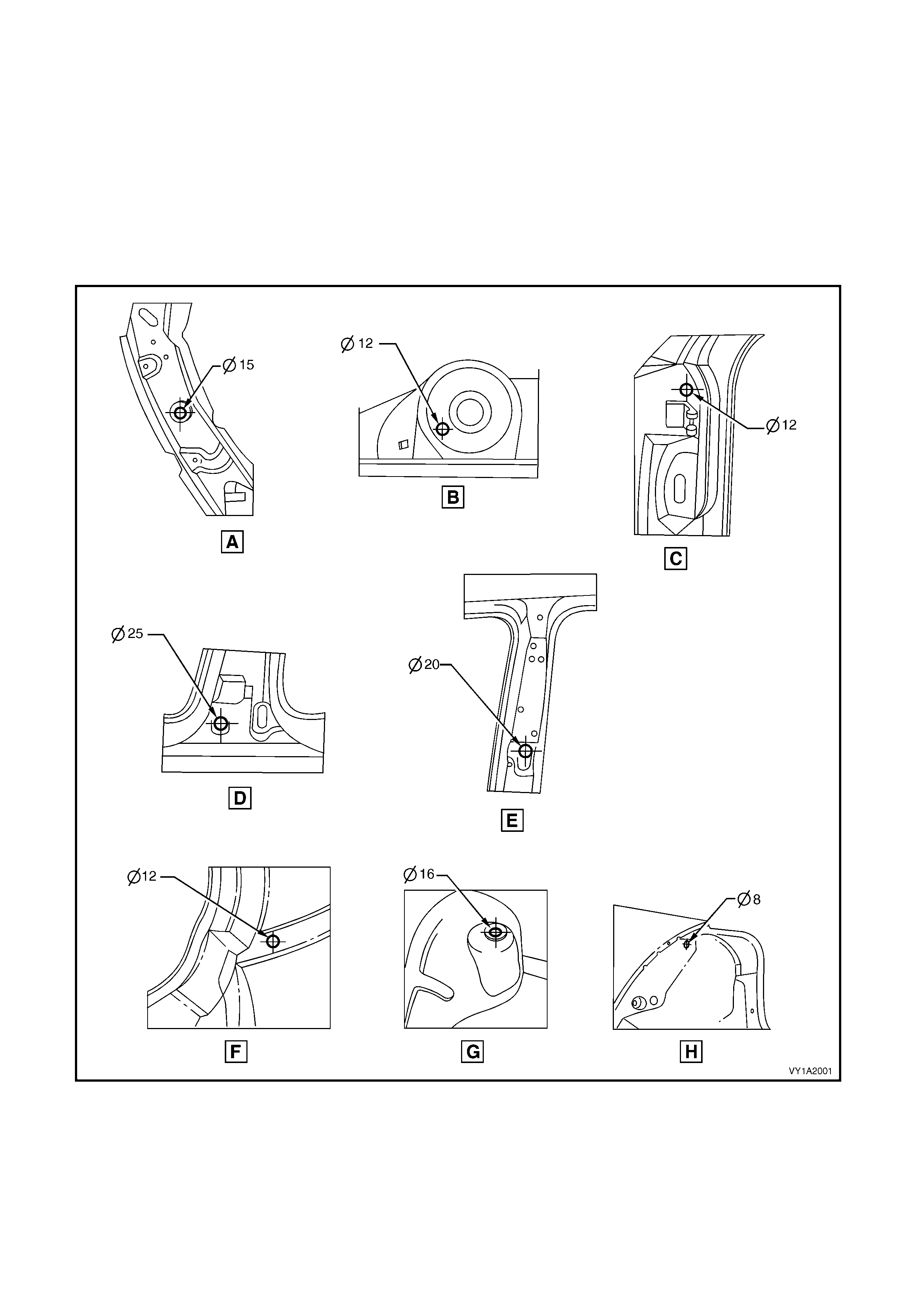

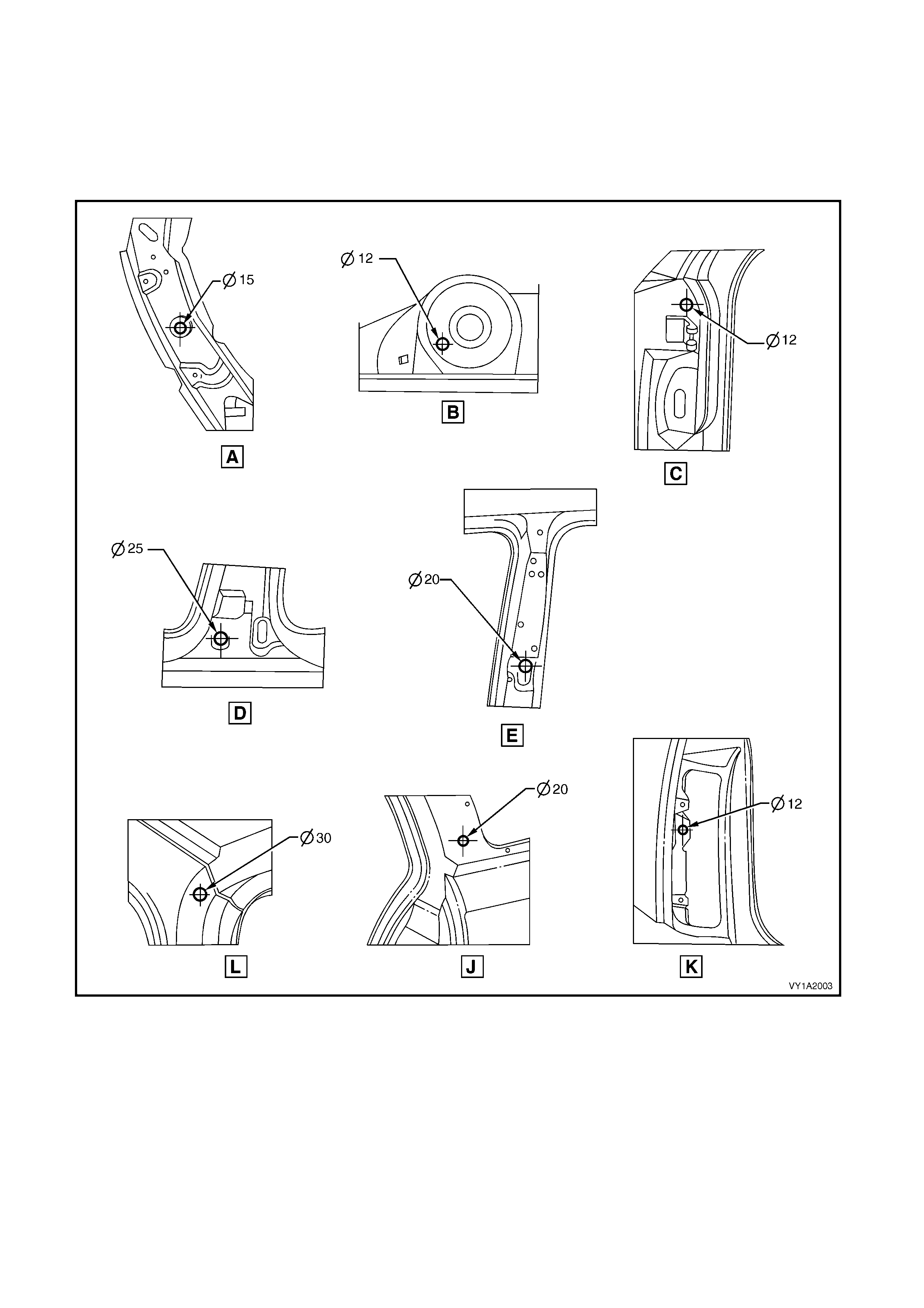

Figure 1A2-1

Figure 1A2-2

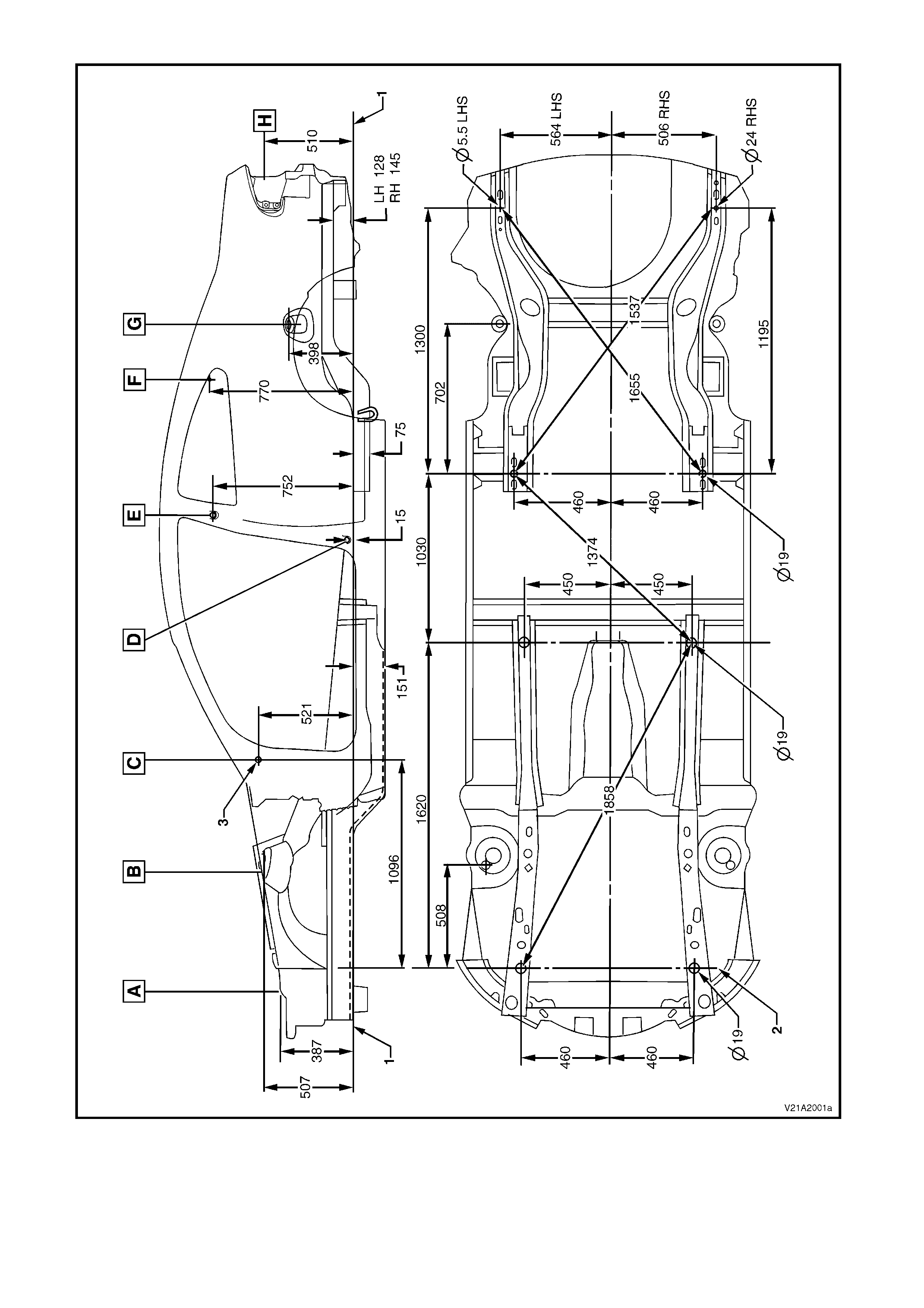

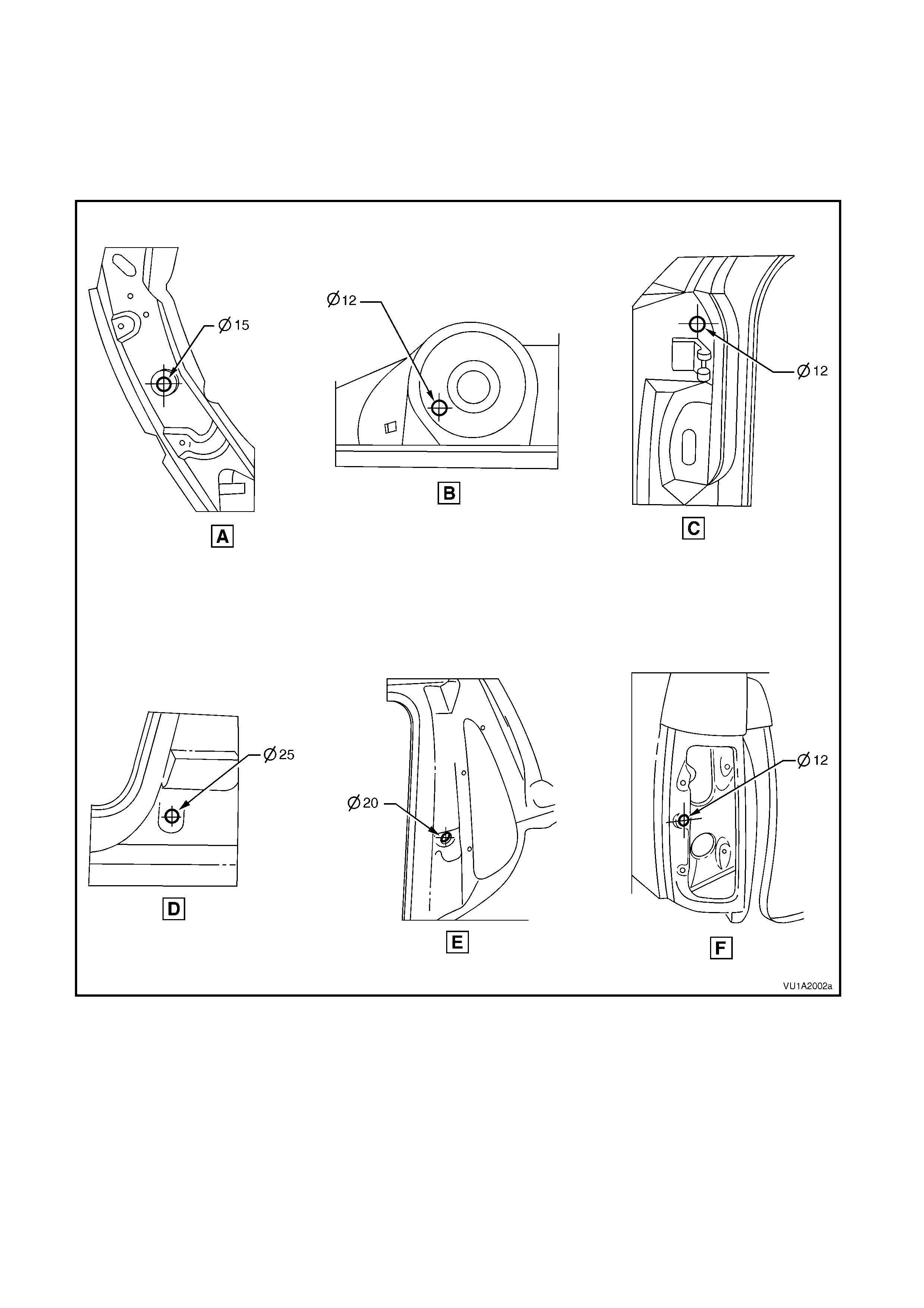

WAGON

All dimensions are given in mm and are measured from the centre of holes, on the outside of the metal surface.

The main datum surface (1) is the underside of the front side rail assembly, refer to Figure 1A2-4.

The main datum hole (2) is a 19 mm hole on the underside of the front side rail assembly, refer to Figure 1A2-4.

The dash panel assembly attaching hole (3) in Figure 1A2-4 is the datum hole also depicted at View C in

Figure 1A2-3.

Figure 1A2-3

Figure 1A2-4

COUPE

All dimensions are given in mm and are measured from the centre of holes, on the outside of the metal surface.

The main datum surface (1) is the underside of the front side rail assembly, refer to Figure 1A2-6.

The main datum hole (2) is a 19 mm hole on the front side rail assembly, refer to Figure 1A2-6.

The dash panel assembly attaching hole (3) in Figure 1A2-6 is the datum hole also depicted at View C in

Figure 1A2-5.

Figure 1A2-5

Figure 1A2-6

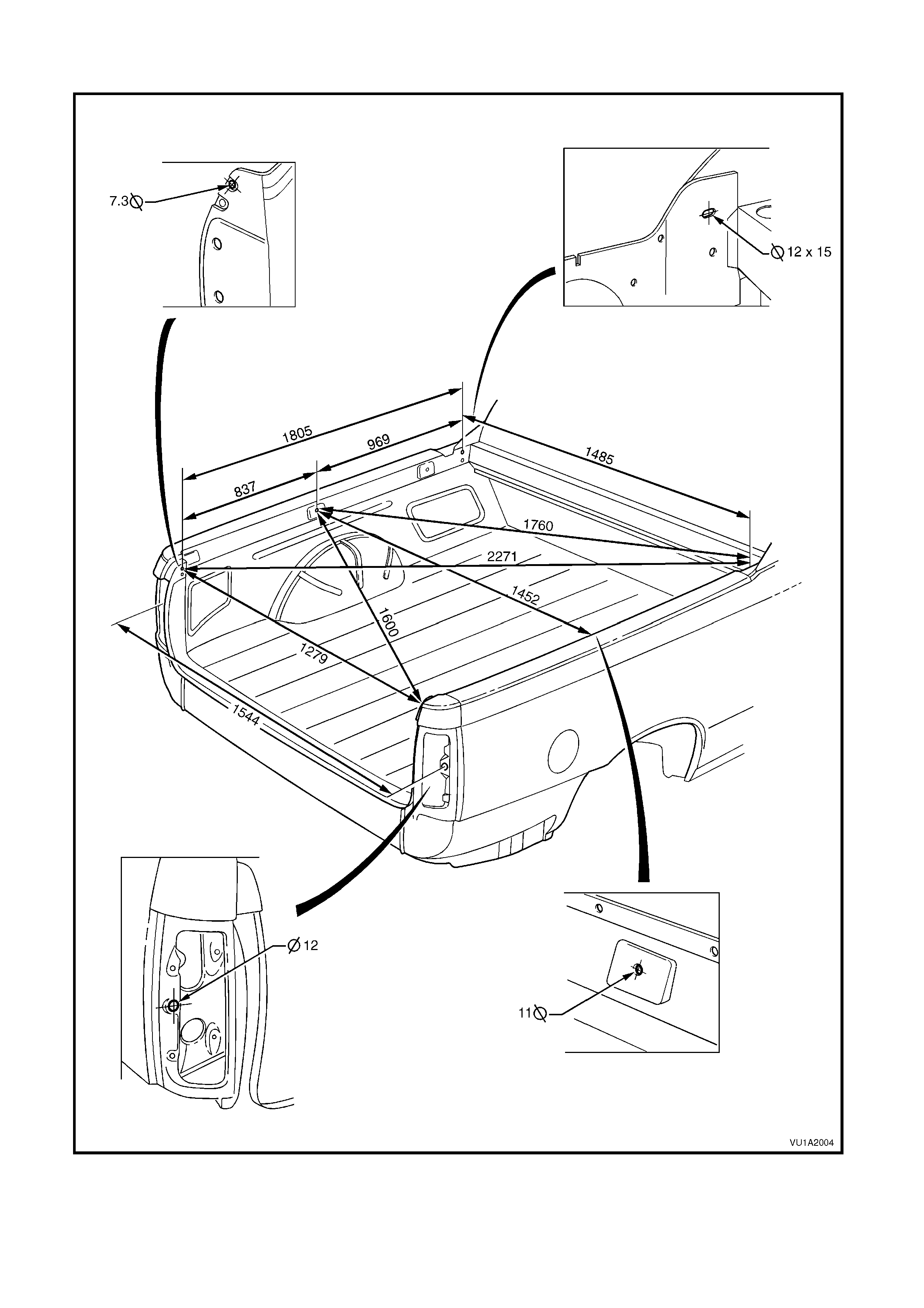

UTILITY

All dimensions are given in mm and are measured from the centre of holes, on the outside of the metal surface.

The main datum surface (1) is the underside of the front side rail assembly, refer to Figure 1A2-8.

The main datum hole (2) is a 19 mm hole on the underside of the front side rail assembly, refer to Figure 1A2-8.

The dash panel assembly attaching hole (3) in Figure 1A2-8 is the datum hole also depicted at View C in

Figure 1A2-7.

Figure 1A2-7

Figure 1A2-8

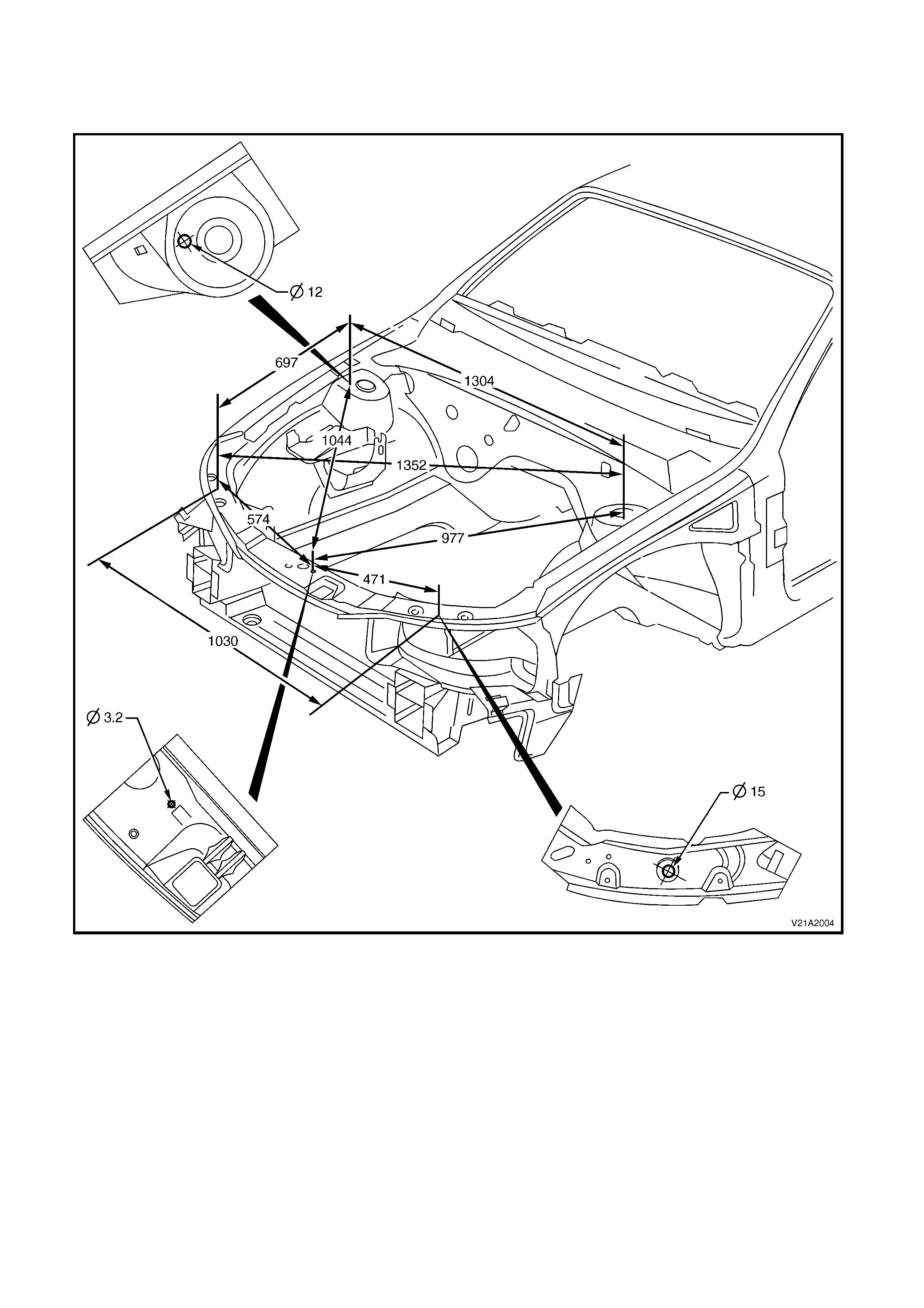

2.2 UPP ERBODY DIMENSIONS – ACTUAL

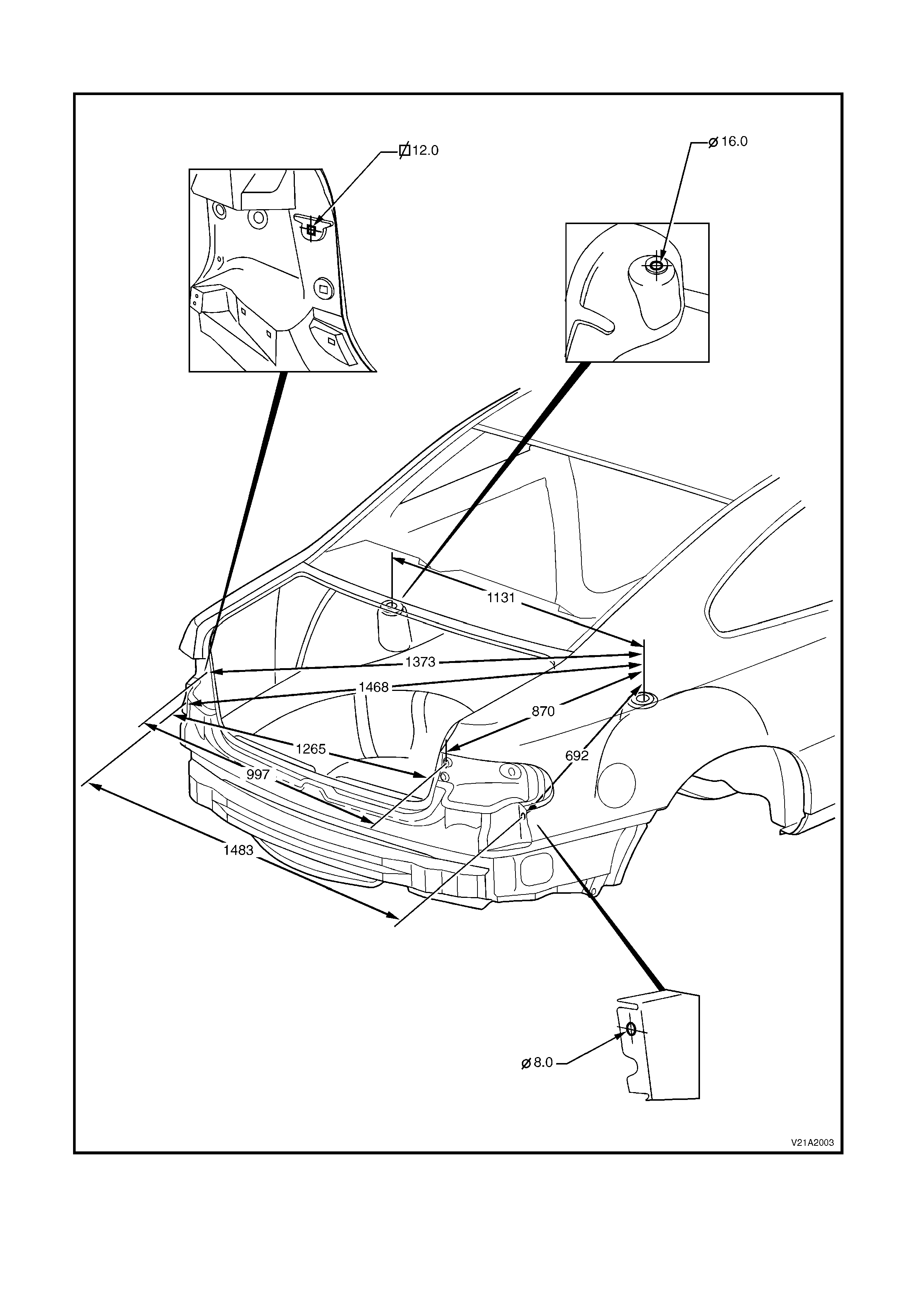

FRONT – ALL MODELS

Figure 1A2-9

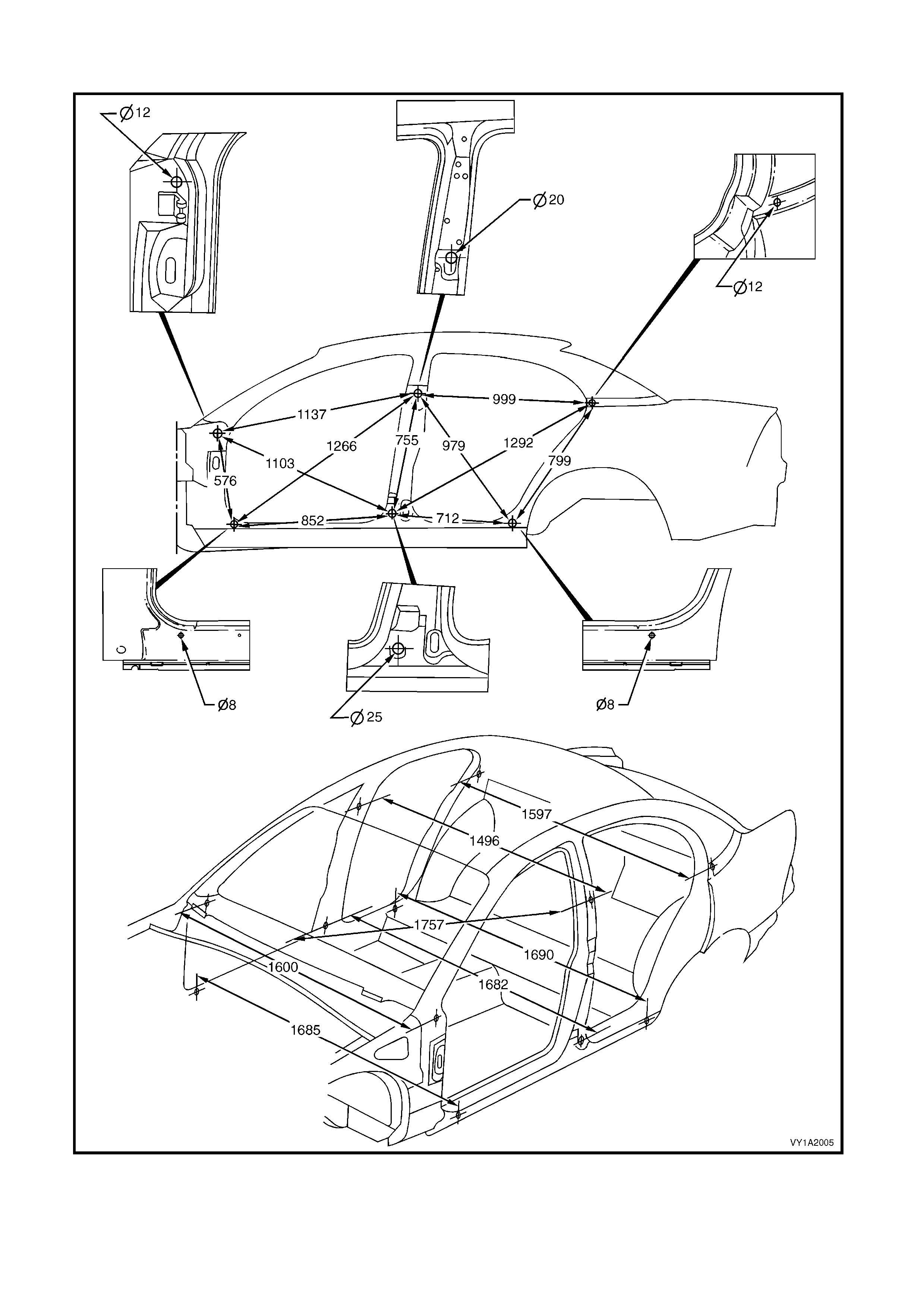

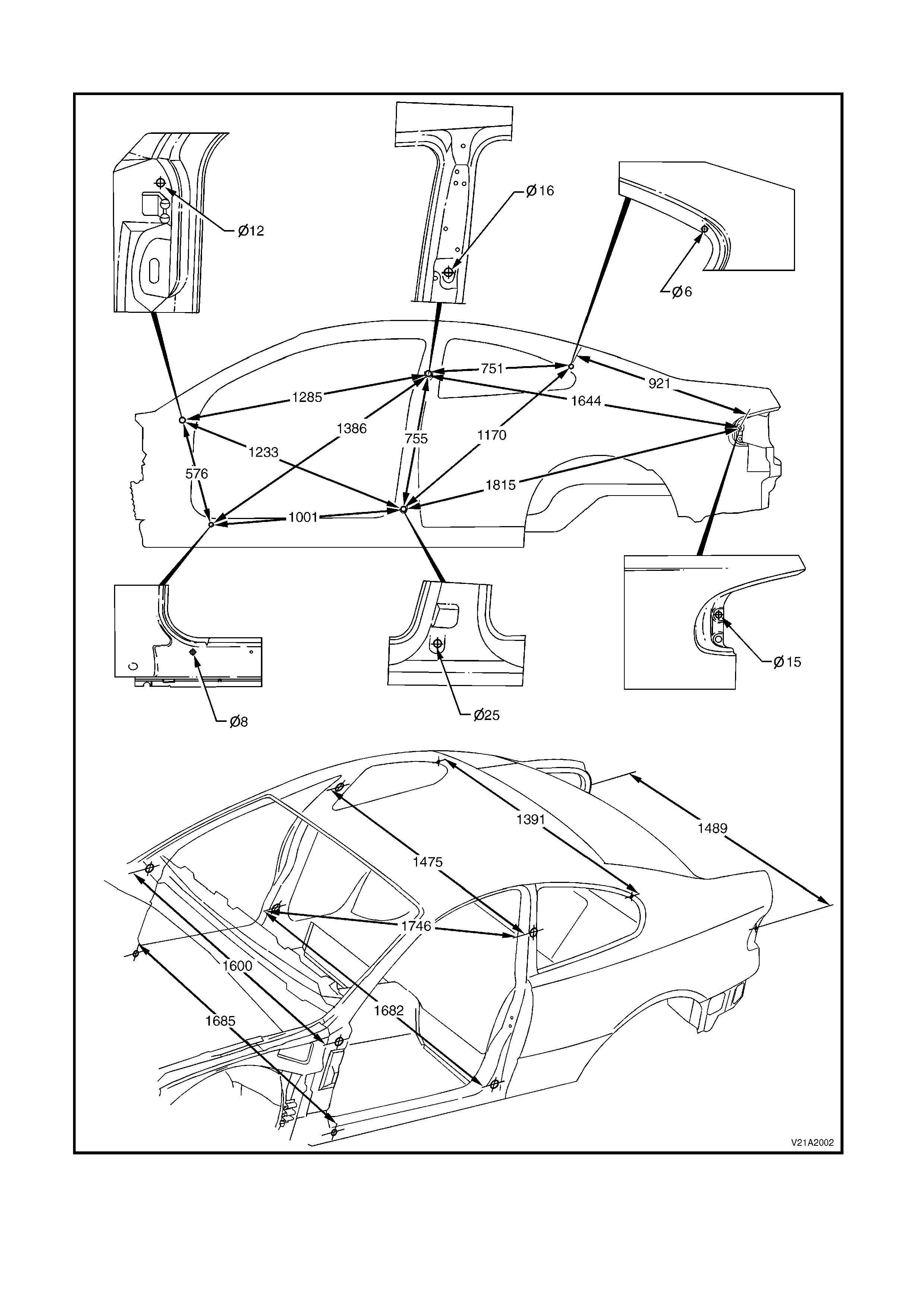

SIDE & INTERIOR – SEDAN

Figure 1A2-10

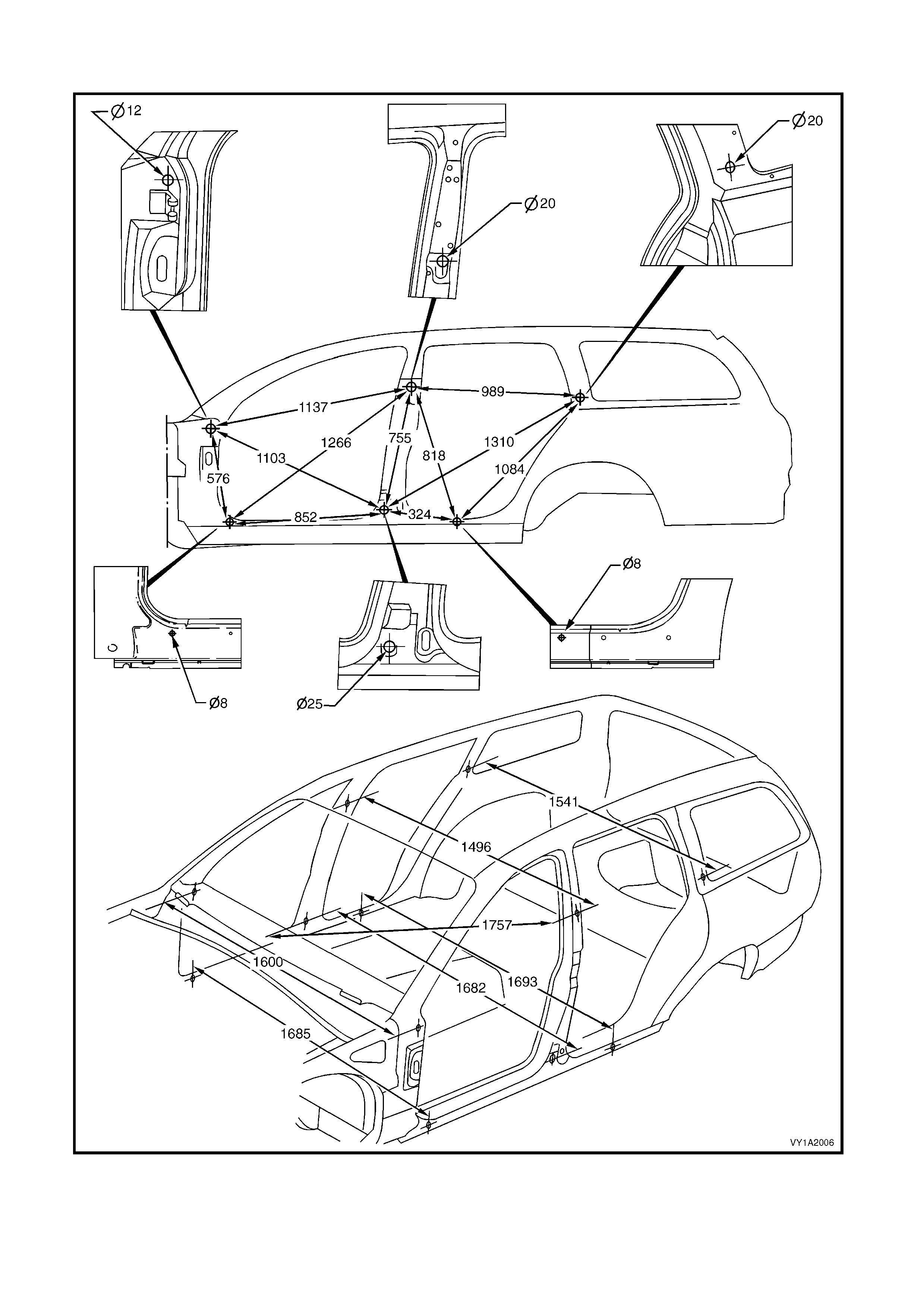

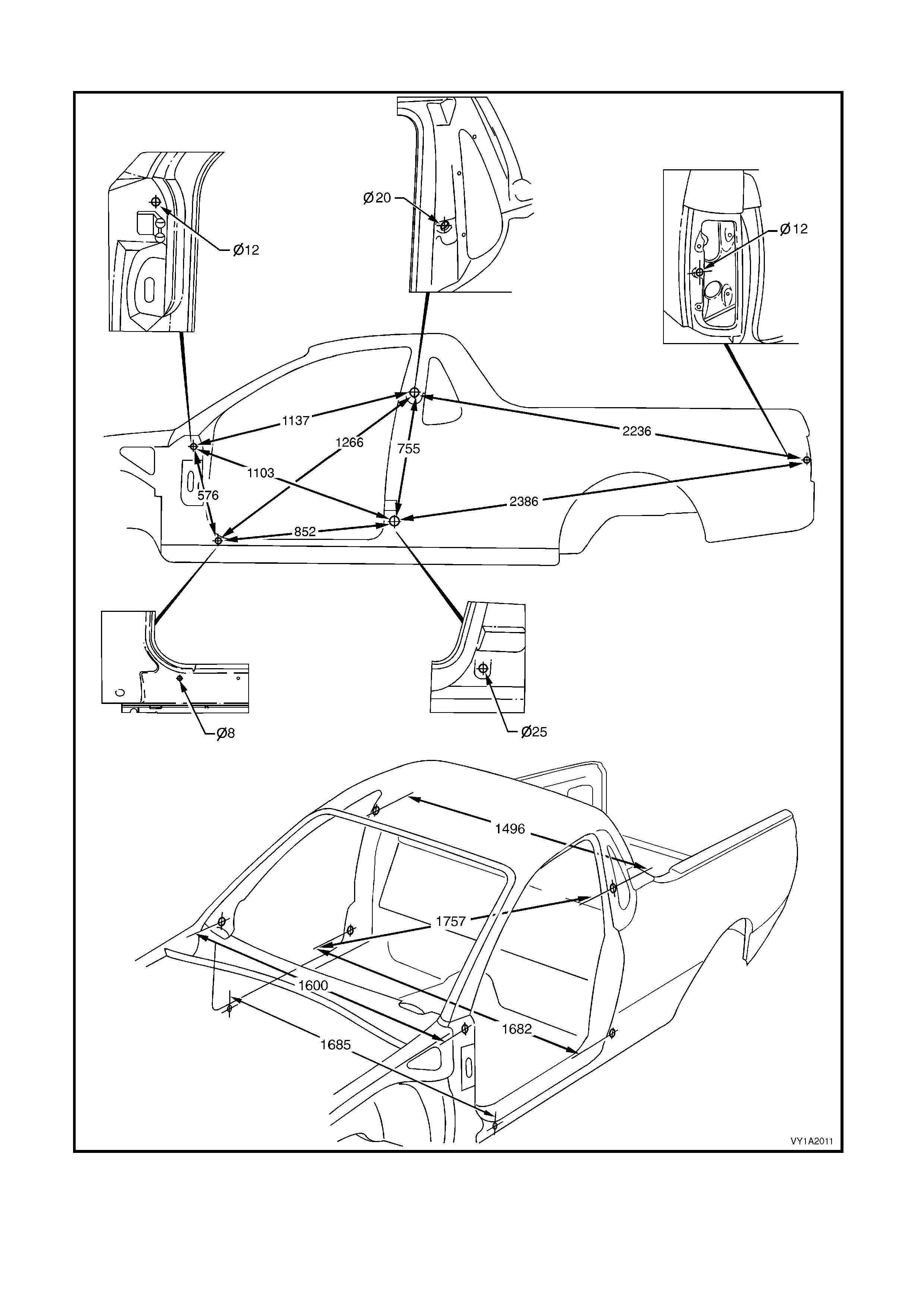

SIDE & INTERIOR – WAGON

Figure 1A2-11

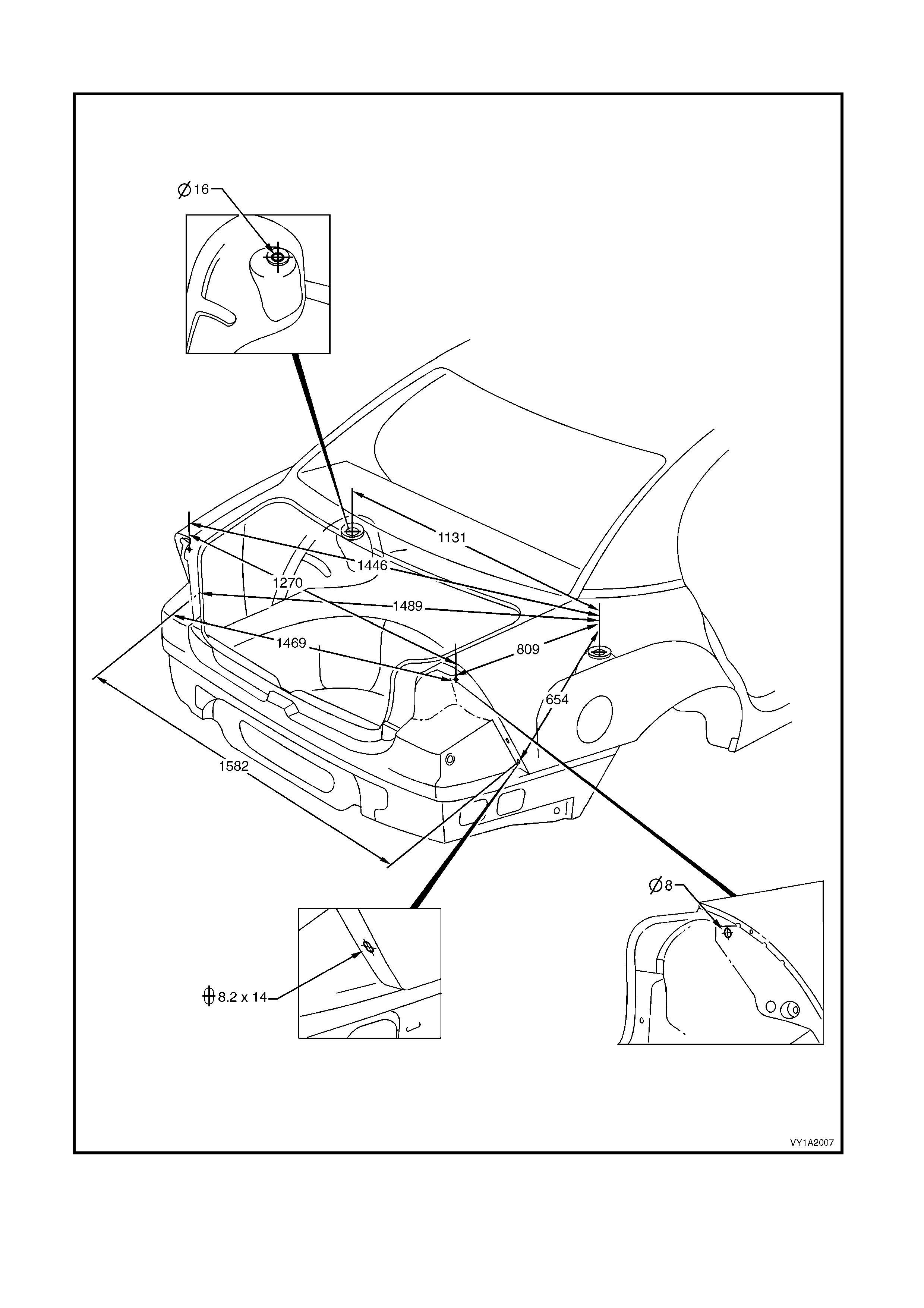

SIDE & INTERIOR – COUPE

Figure 1A2-12

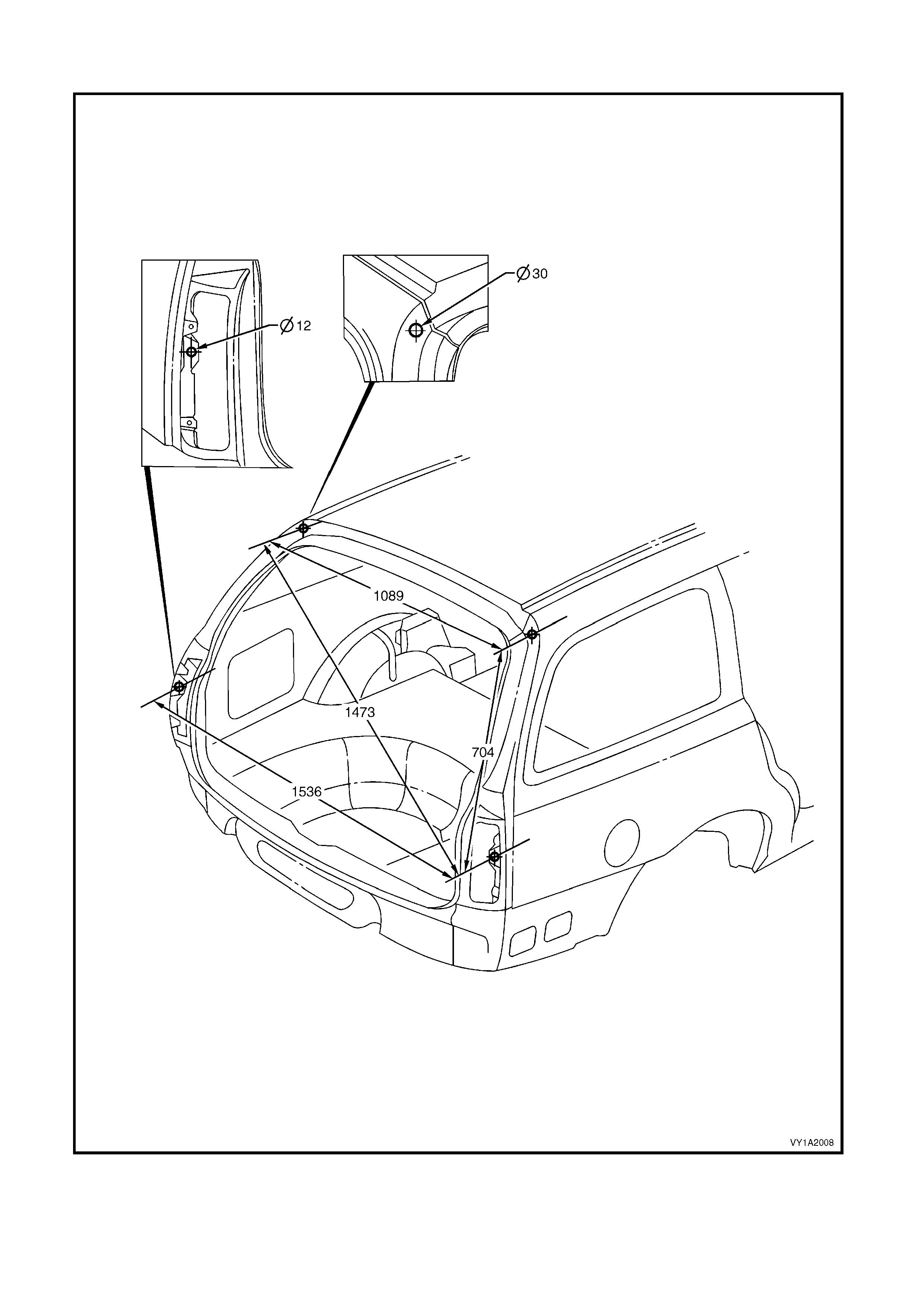

SIDE & INTERIOR – UTILITY

Figure 1A2-13

REAR – SEDAN

Figure 1A2-14

REAR – WAGON

Figure 1A2-15

REAR – UTILITY

Figure 1A2-16

REAR – COUPE

Figure 1A2-17

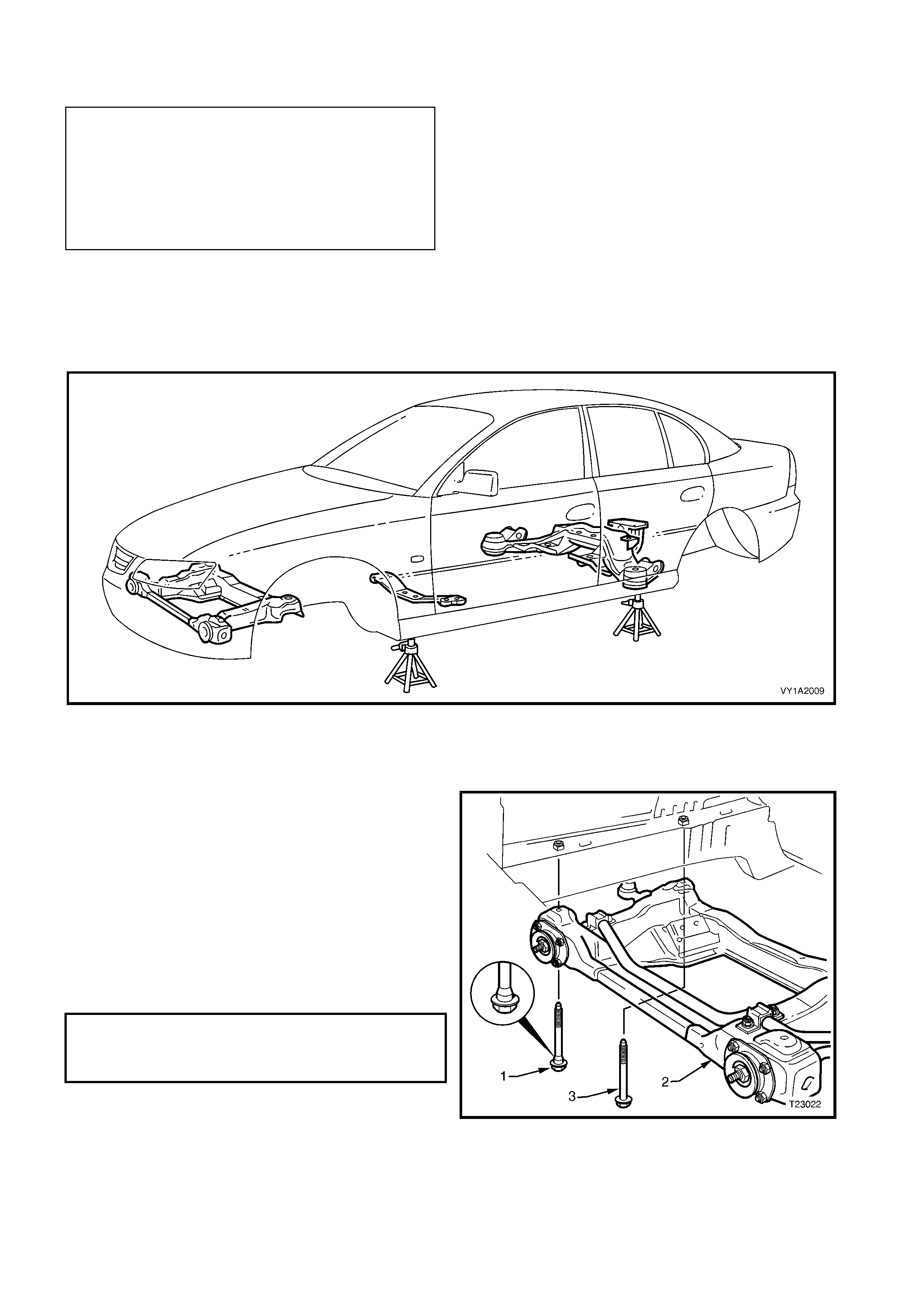

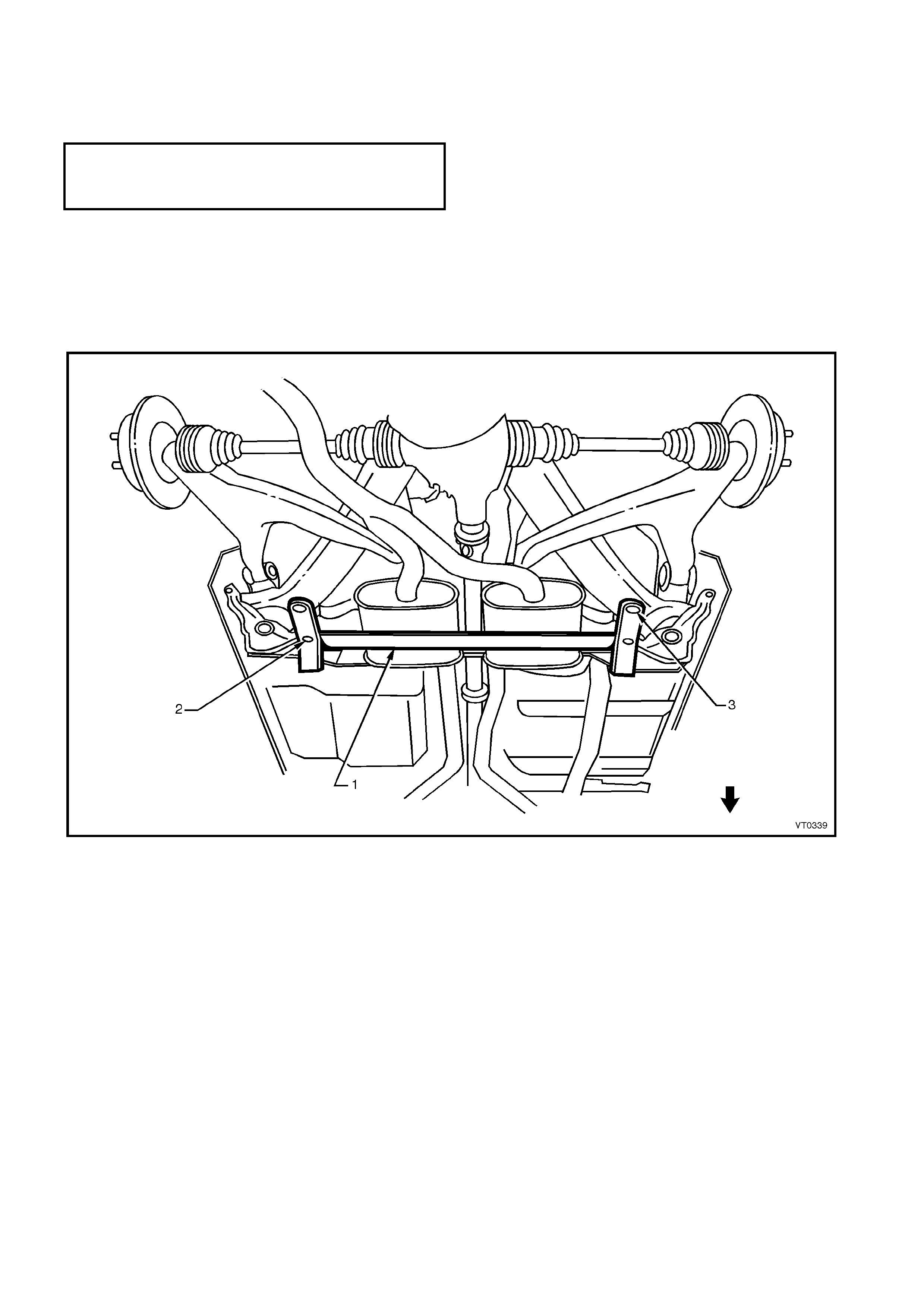

2.3 SUSPENSION FRAMES & TRANSMISSION SUPPORT ALIGNMENT

The front suspension frame assembly (1), transmission support (2) and rear suspension frame assembly (3) as

shown in F igure 1A2- 18 will require r e- alignment if they have been removed dur ing repair work, or if they have been

disturbed as a result of a vehicle collision.

Correct underbody alignment is essential as any mis-alignment can adversely affect suspension perform ance. The

underbody alignment should therefore be checked and aligned, if required, to the dimensions specified in this

Section prior to performing the following alignment procedures.

Figure 1A2-18

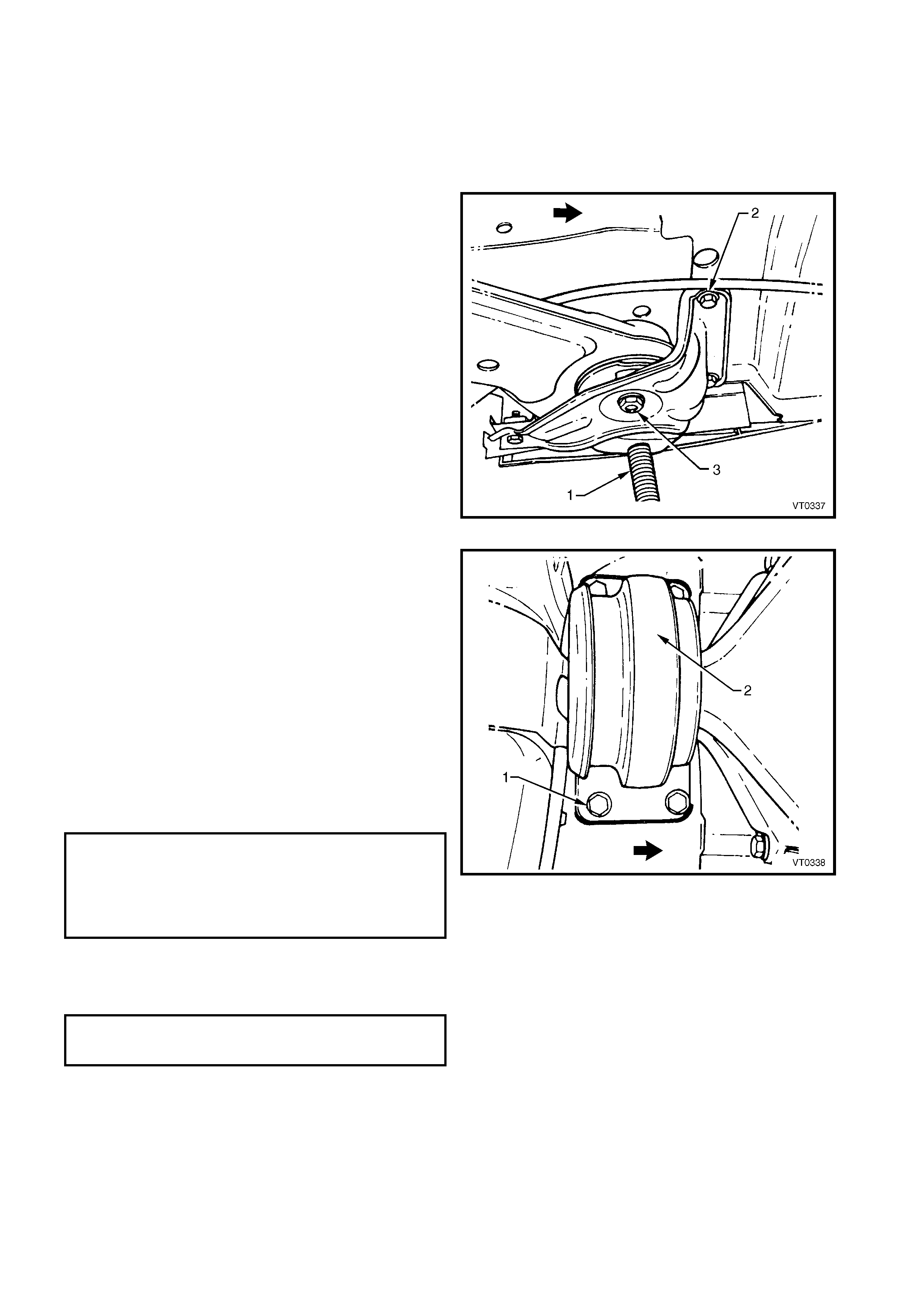

FRONT SUSPENSION FRAME ASSEMBLY

LT Section No. 06-200

When reinstalling the frame assembly, install the two

front, black coloured, stepped shank bolts (1) and

tighten to the correct torque specification. This will

correctly align the frame assem bly (2) to the front side

rail assemblies.

Install the two rear, silver coloured, straight shanked

bolts (3) to the two rear positions and tighten them to

the correct torque specification.

NOTE: Prior to installation of the frame assembly,

ensure the vehicle underbody alignment is within

specification.

Figure 1A2-19

NOTE: The following fasteners MUST be replaced

when performing this operation:

+

++

+

Front suspension frame assembly mounting

bolts.

+

++

+

Rear suspension frame assembly attaching

bolts.

+

++

+

Final drive rear mount attaching screws.

FRONT SUSPENSION FRAME

ASSEMBLY MOUNTING BOLT

TORQUE SPECIFICATION 120.0 – 125.0 Nm

TRANSMISSION SUPPORT

LT Section No. 04-020

1. Using chassis stands, support vehicle at hoist pad

locations.

2. From underneath the vehicle, support the

transmission with a trolley jack. Raise the jack

slightly to take some weight off the transmission

mount.

3. Remove the two nuts (1) securing the transmission

mount assembly (2) to the transmission support

(3).

4. Loosen the four bolts (4) attaching the

transmission support to the underbody.

5. Centralise the transmission support within the bolt

holes.

6. Tighten the four bolts.

7. With the help of an assistant, manoeuvre the

transmission to ensure that the studs (1) (from

which the M8 nuts have been removed) protruding

through the transmission support are centralised

within the stud holes.

8. Reinstall the M8 nuts securing the transmission

mount to the transmission support and tighten to

the specified torque.

9. Gently lower the trolley jack and remove from

under the vehicle.

10. Remove the vehicle from the chassis stands.

Figure 1A2-20

TRANSMISSION MOUNT NUT

TORQUE SPECIFICATION 20.0 – 30.0 Nm

TRANSMISSION SUPPORT

MOUNTING BOLT

TORQUE SPECIFICATION 50.0 – 65.0 Nm

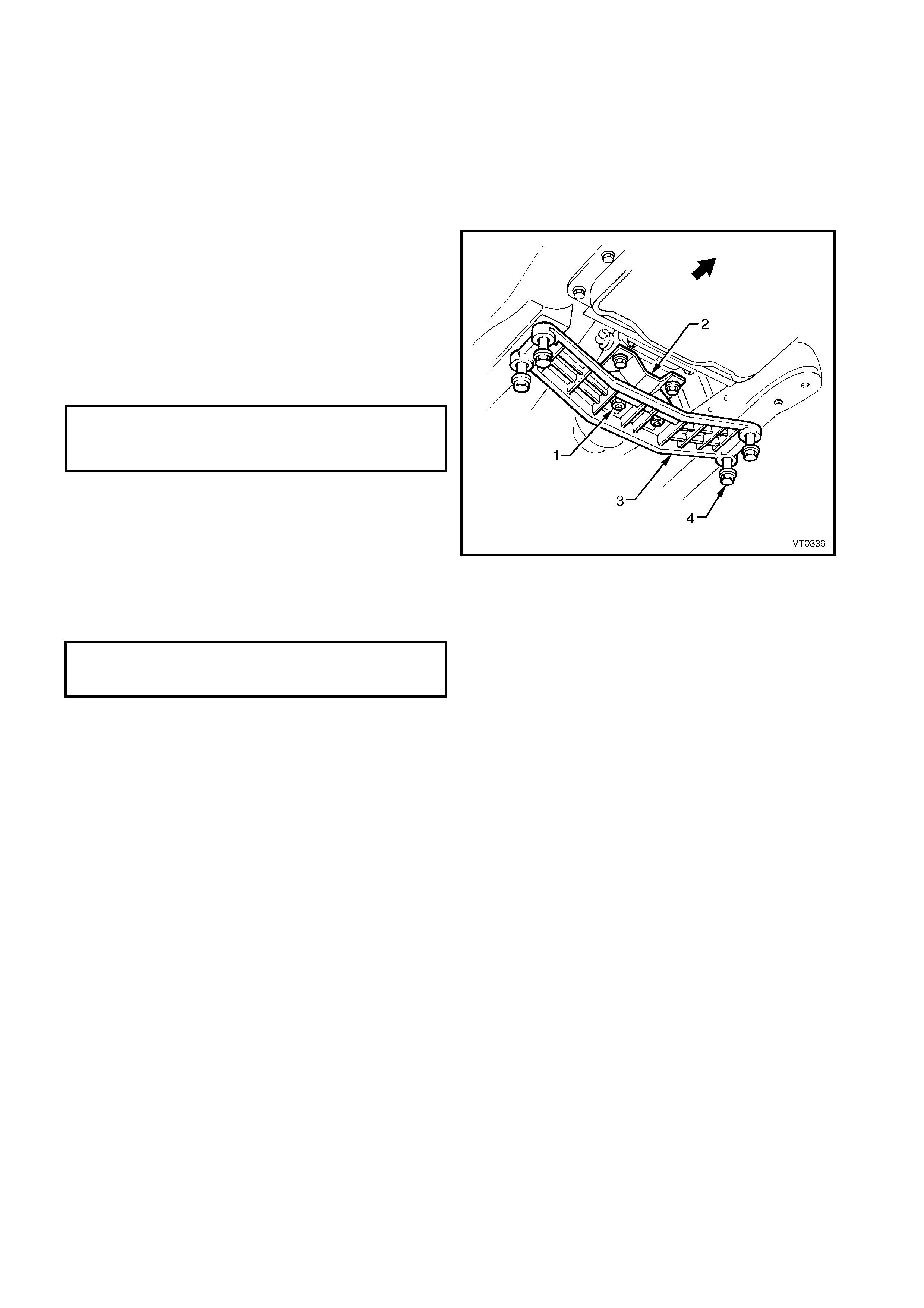

REAR SUSPENSION FRAME ASSEMBLY

LT Section No. 07-150A

NOTE. The rear suspension frame assembly centering

tool needs to be held in position during the alignment

procedure. Therefore, assistance will be required to

complete this operation.

1. Using chassis stands (1), support the vehicle at

hoist pad locations.

2. Remove the wheels, refer to Section 10,

WHEELS AND TYRES.

3. Remove intermediate muffler and pipe assembly

together with rear muffler and pipe assembly.

Refer to Section 8B, EXHAUST SYSTEM.

4. From underneath the vehicle, support the final

drive assembly with a trolley jack. Raise the jack

slightly to take some of the weight off the final

drive mount.

5. Loosen the three M10 screws (2) attaching the

rear suspension support insulator bracket to the

vehicle, LH and RH side.

6. Loosen the rear frame assembly M14 attaching

bolts (3) LH and RH side.

Figure 1A2-21

7. Loosen the four scr ews (1) attaching the final drive

rear mount (2).

8. Fit rear suspension centering tool No AU 458 (1),

refer to Figure 1A2-23.

NOTE: The rear crossmember centering tool locates

into 19 mm diameter body datum holes (2) positioned

forward of the rear suspension frame assembly.

9. With the help of an assistant, manoeuvre the rear

suspension assembly until the location pins (3) of

the rear crossmember centering tool engage the

alignment holes on the rear frame assembly.

10. Tighten the rear frame assembly M14 attaching

bolts LH and RH side to the specified torque, refer

to (3) Figure 1A2-21.

11. Tighten the f our s c rews (1) attac hing the f inal dr ive

rear mount (2), refer to Figure 1A2-22.

Figure 1A2-22

REAR SUSPENSION FRAME

ASSEMBLY ATTACHING BOLT

TORQUE SPECIFICATION Stage 1 125 Nm

Stage 2 Turn 30°- 45°

Min. total 135 Nm

FINAL DRIVE REAR MOUNT ATTACHING

SCREWS TORQUE SPECIFICATION 30.0 – 45.0 Nm

12. Tighten to the specified torque, the three M10

screws (2) attaching the rear suspension support

insulator bracket to the vehicle, LH and RH side,

refer to Figure 1A2-21.

13. Remove the rear crossmember centering tool.

14. Gently lower trolley jack and remove from under

vehicle.

15. Fit the wheels. Refer to Section 10, WHEELS

AND TYRES.

16. Remove vehicle from chassis stands.

Figure 1A2-23

REAR SUSPENSION SUPPORT INSULATOR

BRACKET ATTACHING SCREWS

TORQUE SPECIFICATION 60.0 – 85.0 Nm

3. TORQUE WRENCH SPECIFICATIONS

+

++

+

Front suspension frame assembly mounting bolt .................................................. 120 – 125 Nm

Transmission support mounting bolt...................................................................... 50 – 65 Nm

Transmission mount nuts....................................................................................... 20 – 30 Nm

+

++

+

Rear suspension frame assembly attaching bolt................................................... 125 Nm

30° – 45°

Min. total of 135 Nm

+

++

+

Final drive rear mount attaching screws................................................................ 30 – 45 Nm

Rear suspension support insulator bracket attaching screws................................ 60 – 85 Nm

+

++

+

Must be replaced

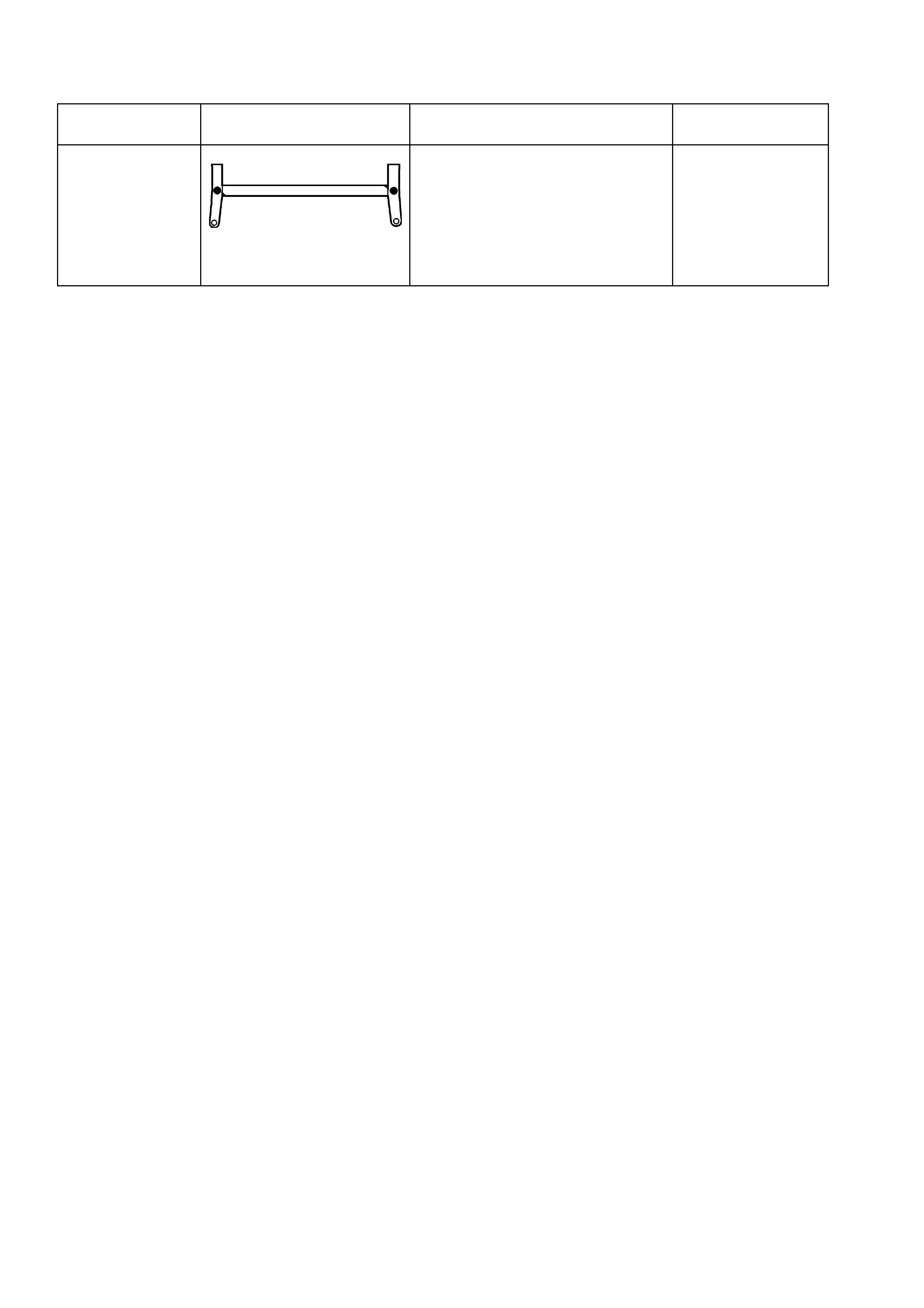

4. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASIFICATION

AU 458 REAR CROSSMEMBER

CENTERING TOOL

Used When Any Service Operation

Requires Removal / Reinstallation

Of The Frame Assembly - Rear

Suspension, Or When Checking

Rear End Alignment

Previously Released.

DESIRABLE