SECTION 1A3 - INSTRUMENT PANEL

& CONSOLE

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

FLOOR CONSOLE COMPONENTS

INSTRUMENT PANEL COMPONENTS

2. SERVICE OPERATIONS – FLOOR CONSOLE

2.1 FLOOR CONSOLE COVER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

2.2 INSTRUMENT PANEL LOWER

EXTENSION SIDE TRIM

REMOVE

REINSTALL

2.3 FLOOR CONSOLE ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3. SERVICE OPERATIONS – INSTRUMENT PANEL

3.1 INSTRUMENT PANEL LOWER TRIM

PLATE ASSEMBLY

REMOVE

REINSTALL

3.2 INSTRUMENT PANEL COMPARTMENT

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3.3 INSTRUMENT PANEL COMPARTMENT

LAMP AND SWITCH

REMOVE

REINSTALL

3.4 INSTRUMENT PANEL LOWER TRIM PANEL

REMOVE

REINSTALL

3.5 INSTRUMENT PANEL LOWER TRIM

PANEL RETAINER

REMOVE

REINSTALL

3.6 RADIO ASSEMBLY

REMOVE

REINSTALL

3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

3.8 INSTRUMENT PANEL LOWER COMPARTMENT

OR ASHTRAY ASSEMBLY

REMOVE

REINSTALL

3.9 INSTRUMENT PANEL LOWER EXTENSION

REMOVE

REINSTALL

3.10 MANUAL HVAC CONTROLLER

REMOVE

REINSTALL

3.11 RADIO HOUSING AND RADIO BRACKET

ASSEMBLY

REMOVE

REINSTALL

3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

3.13 IN-CAR AIR TEMPERATURE SENSOR

REMOVE

REINSTALL

3.14 INSTRUMENT CLUSTER

REMOVE

REINSTALL

3.15 HEADLAMP SWITCH

REMOVE

REINSTALL

3.16 TRIP COMPUTER SWITCH

REMOVE

REINSTALL

3.17 INSTRUMENT PANEL OUTER COVER

REMOVE

REINSTALL

3.18 WINDSHIELD DEFROSTER GRILLE

REMOVE

REINSTALL

3.19 REMOTE KEY RECEIVER & HEADLAMP

AUTO CONTROL / SUNLOAD SENSOR

REMOVE

REINSTALL

3.20 INSTRUMENT PANEL SPEAKER

REMOVE

REINSTALL

3.21 INSTRUMENT PANEL PAD ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3.22 INSTRUMENT PANEL BRACKETS & BRACES

INSTRUMENT PANEL COMPARTMENT

BRACKET

INSTRUMENT PANEL LOWER BRACKET

INSTRUMENT PANEL OUTER UPPER

BRACKET

LOWER RADIO BRACKET

STEERING COLUMN BRACKET INNER

BRACE

STEERING COLUMN BRACKET OUTER

BRACE

4. TORQUE WRENCH SPECIFICATIONS

5. SPECIAL TOOLS

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL DESCRIPTION

Completely new instrument panel and floor consoles are fitted to MY 2003 VY and V2 series vehicles. The

Instrument panel houses the instr ument clus ter within a hood, while the centre f asc ia, which integrates with the floor

console, houses components such as the new double DIN sized audio system, controls for manual or electronic

climate control, centre vent outlets and new cup-holders for Level 2 and 3 vehicles.

The soft-touch instrument panel pad is attached to a dash panel carrier. Several brackets and braces form the

back bone of the instrum ent panel pad and carrier ass embly and support other com ponents such as the ins trument

panel inflatable restraint (if fitted) and fuse panel.

All models now include an instrument panel lower trim plate assembly, fitted between the instrument and dash

panels on each side of the vehicle. Sound-deadening foam is applied to the plate which provides an effective

reduction in noise transmittance. Where fitted, the stepwell lamps are mounted to the plate assembly.

The large instrument panel compartment is illuminated and can be locked with a unique key. As with previous

models , a large lower tr im panel is fitted on the driver’s side which c an be opened to provide ac c es s to the f us e and

relay panel.

For right-hand drive vehicles two storage compartments are provided, one on the instrument panel at the front of

the console and the other at the rear of the console (except utility). As an option for right-hand drive and as standard

for left-hand drive vehicles, an ashtray and cigar lighter assembly replaces the storage compartments.

A large storage com par tm ent with trim m ed arm r est is inc orporated in the f loor cons ole. An acces sory power sock et

is provided within the storage compartment providing a 12-volt power supply when the ignition switch is in accessory

or run positions.

Depending on model level or options f itted, the console m ay also include power side window switches, a c up-holder

for Level 1 vehicles, mobile phone holder for Level 2 and 3 vehicles and auxiliary switches for functions such as

LPG, traction control for manual transmission vehicles and a lights-out function for vehicles with police option pack.

The floor consoles for right and left-hand drive are virtually common as the hand-brake rem ains on the right-hand

side of the transmission tunnel. An air duct is fitted to the underside of the console on all models except utility, which

provides ventilation to the rear seat passengers through the rear air outlet housing at the end of the console. For

utility vehicles, a storage bin is provided at the rear of the console in place of the rear air outlet housing.

The instrument panel for left-hand drive vehicles is a mirror of the right-hand drive instrument panel, with a few

exceptions. The body control m odule remains on the r ight-hand s ide of the vehic le, mounted vertic ally for right-hand

drive or horizontally for left-hand drive. A fuel filler door release switch is m ounted in the left-hand drive instrum ent

cluster trim.

NOTE: The information that is provided in this Section is to be used for both left and right-hand drive vehicles.

Although the information shown is primarily right-hand drive, it is to be mirrored for left-hand drive vehicles unless

otherwise specified.

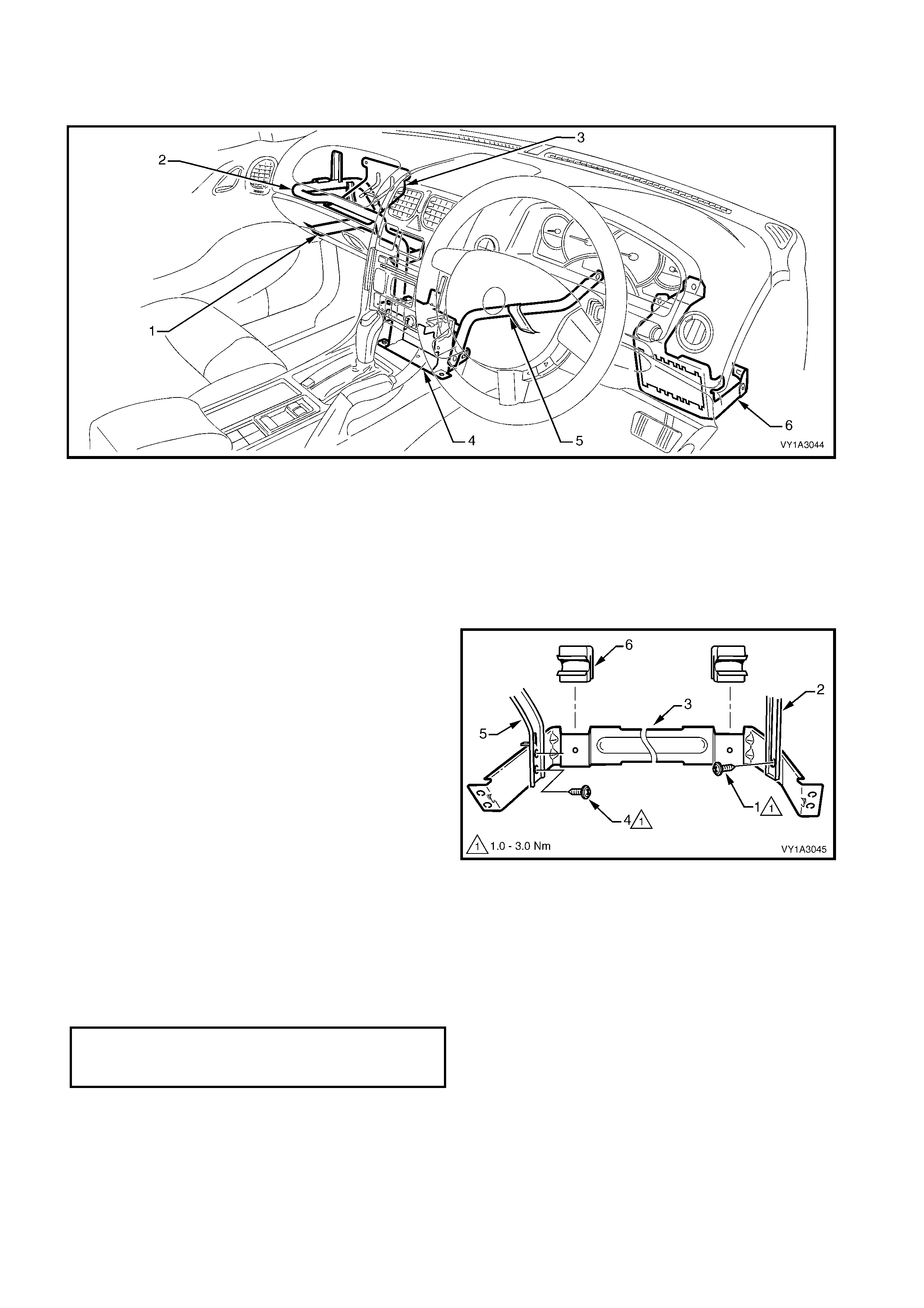

Refer to Figure 1A3-1 for an illustration of the console components and Figure 1A3-2 for the instrument panel

components fitted to MY 2003 VY and V2 Series II vehicles. Note that these diagrams do not show switches or

electrical components.

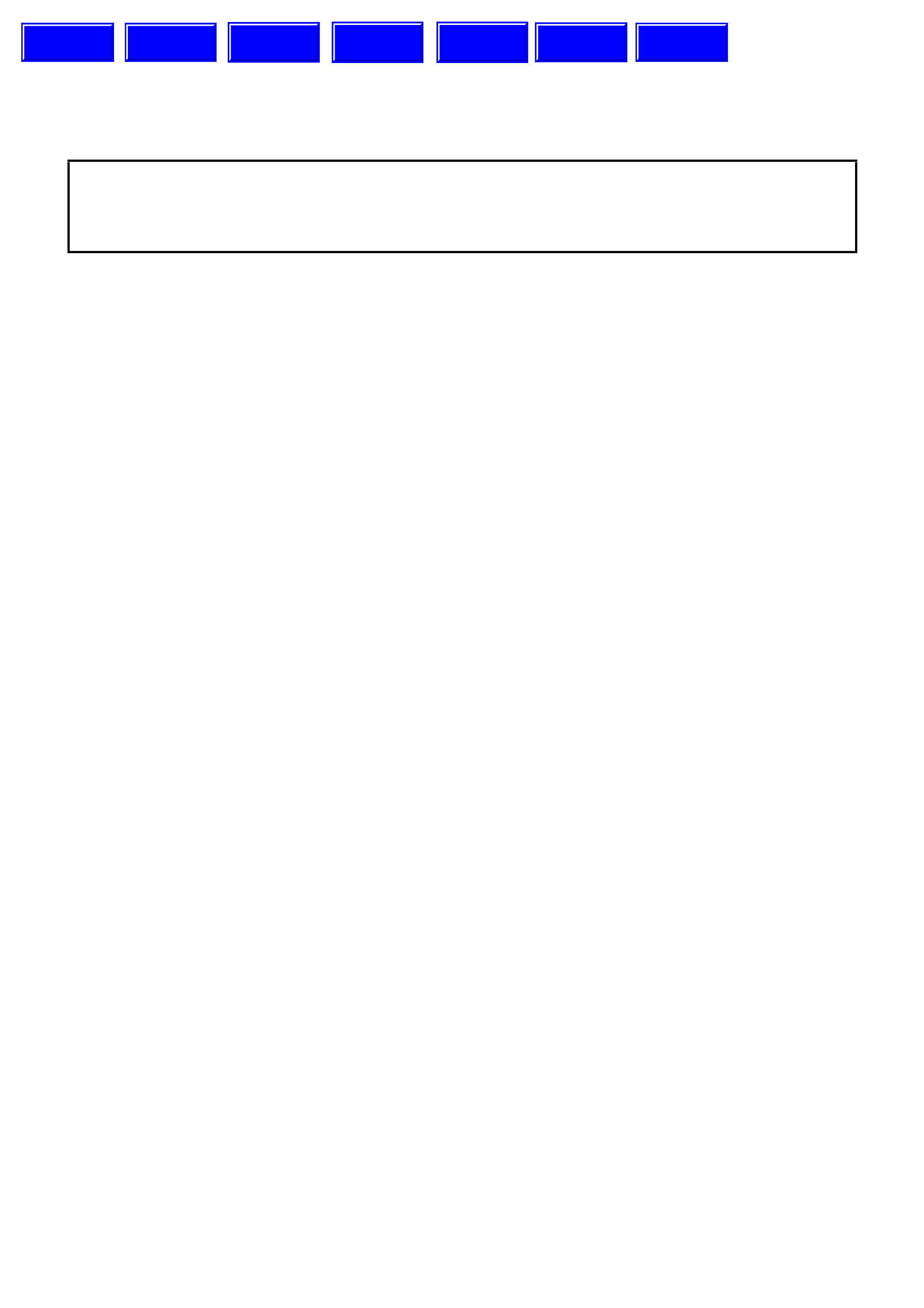

FLOOR CONSOLE COMPONENTS

Figure 1A3-1

Legend

1. Floor Console Front Compartment Liner 10. Instrument Panel Lower Extension Side Trim, RH

2. Floor Console Liner 11. Armrest Assembly

3. Auxiliary Switch Liner or Bezel 12. Floor Console Compartment Armrest Hinge

4. Floor Console Cover 13. Floor Console Compartment Liner

5. Mobile Phone Compartment, Level 2 & 3 14. Floor Console Rear Air Duct

6. Floor Console Storage Tray, Where Fitted 15. Floor Console Rear Air Outlet Housing Assembly, Except

Utility

7. Cup Holder, Level 1 16. Floor Console Rear Upper Compartment Assembly

8. Instrument Panel Lower Extension Side Trim, LH 17. Floor Console Rear Compartment or Ashtray Assembly

9. Floor Console 18. Floor Console Rear Compartment Liner

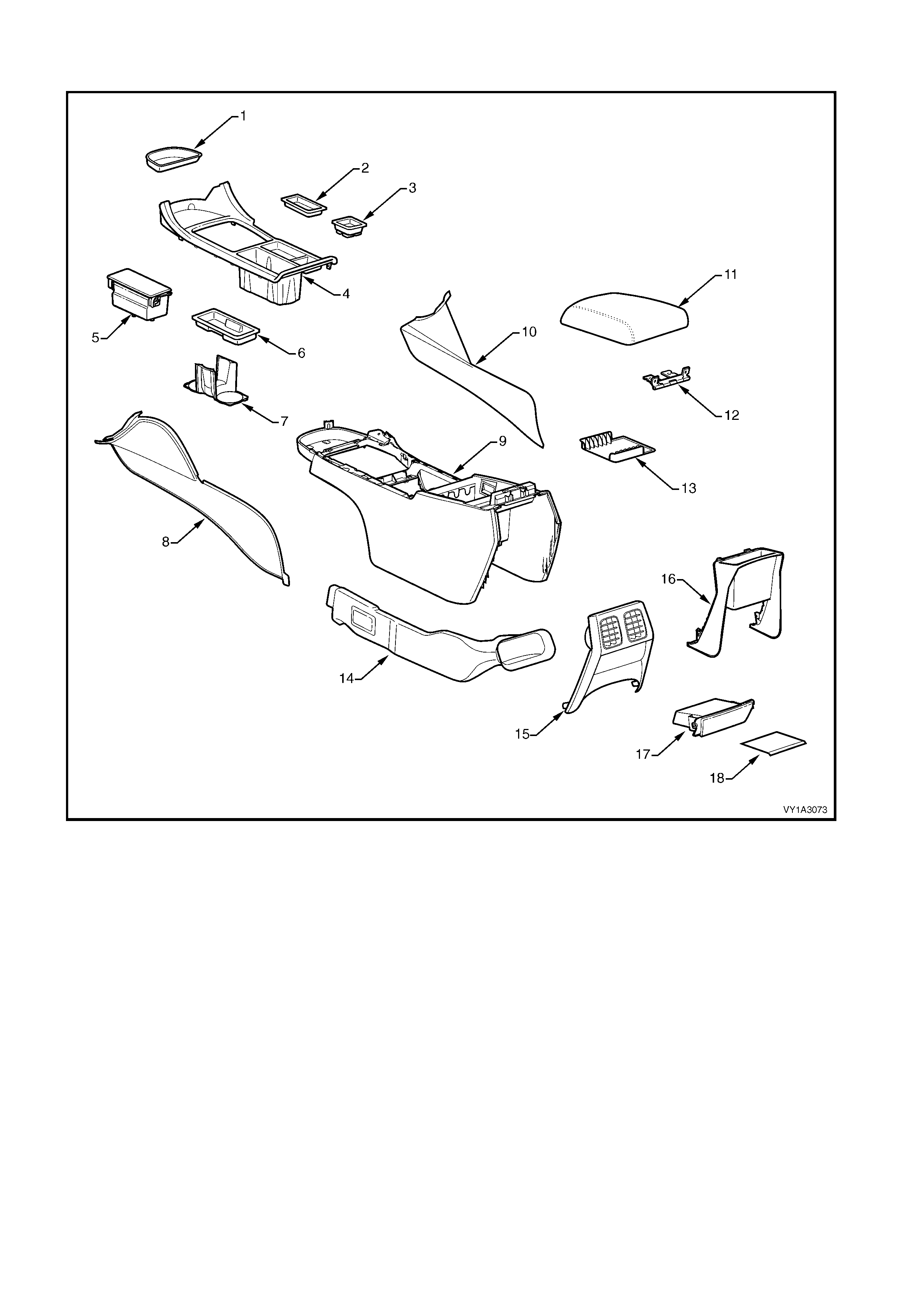

INSTRUMENT PANEL COMPONENTS

Figure 1A3-2

Legend

1. Windshield Defroster Grille, RH 20. Instrument Panel Lower Trim Panel Retainer

2. Windshield Defroster Grille, LH 21. Instrument Panel Lower Trim Panel Assembly

3. Instrument Panel Outer Upper Bracket * 22. Instrument Panel Lower Extension, RH

4. Instrument Panel Inflatable Restraint Bracket 23. Instrument Panel Centre Trim Assembly, Level 1

5. Steering Column Bracket Inner Brace 24. Instrument Panel Centre Trim Assembly, Level 2 & 3

6. Steering Column Bracket Outer Brace 25. Instrument Panel Lower Extension, LH

7. Instrument Panel Outer Cover, RH 26. Instrument Panel Upper Centre Trim Panel

8. Instrument Cluster Trim Assembly 27. Lower Radio Bracket

9. Instrument Panel Inflatable Restraint Opening Trim

Cover 28. Instrument Panel Compartment

10. Instrument Panel Lower Bracket 29. Instrument Panel Compartment Bumper Stop

11. Instrument Panel Compartment Hinge 30. Instrument Panel Compartment Liner

12. Instrument Panel Compartment Bracket 31. Instrument Panel Compartment Latch Assembly

13. Instrument Panel Outer Cover, LH 32. Instrument Panel Compartment Latch Rod

14. Instrument Panel Lower Trim Plate Assembly, LH 33. Instrument Panel Compartment Latch Retainer

15. Radio Bracket Assembly 34. Instrument Panel Compartment Door

16. Instrument Panel Compartment Lock Striker 35. Instrument Panel Compartment Latch Actuator

17. Radio Housing 36. Instrument Panel Lower Compartment or Ashtray Assembly

18. Instrument Panel Lower Trim Plate Assembly, RH 37. Instrument Panel Lower Compartment Liner

19. Instrument Panel Pad Assembly

* Vehicles without an instrument panel inflatable restraint

module

2. SERVICE OPERATIONS – FLOOR CONSOLE

2.1 FLOOR CONSOLE COVER ASSEMBLY

LT Section –

As required, first remove the following components:

1. Navigation remote control assembly, refer to Section 12L, 3.2 NAVIGATION REMOTE CONTROL

ASSEMBLY.

2. Navigation escutcheon, refer to Section 12L, 3.3 NAVIGATION DISPLAY ASSEMBLY.

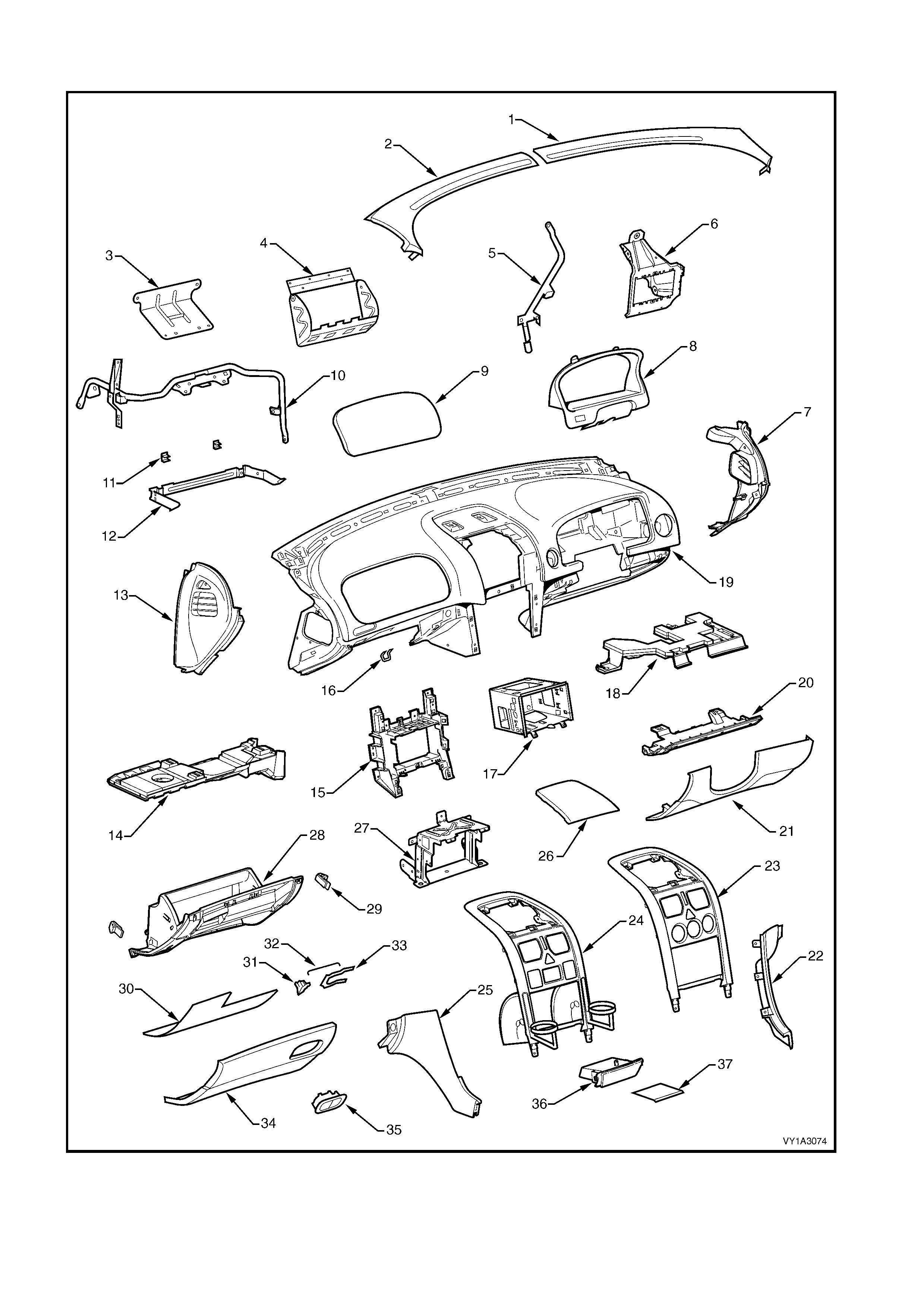

REMOVE

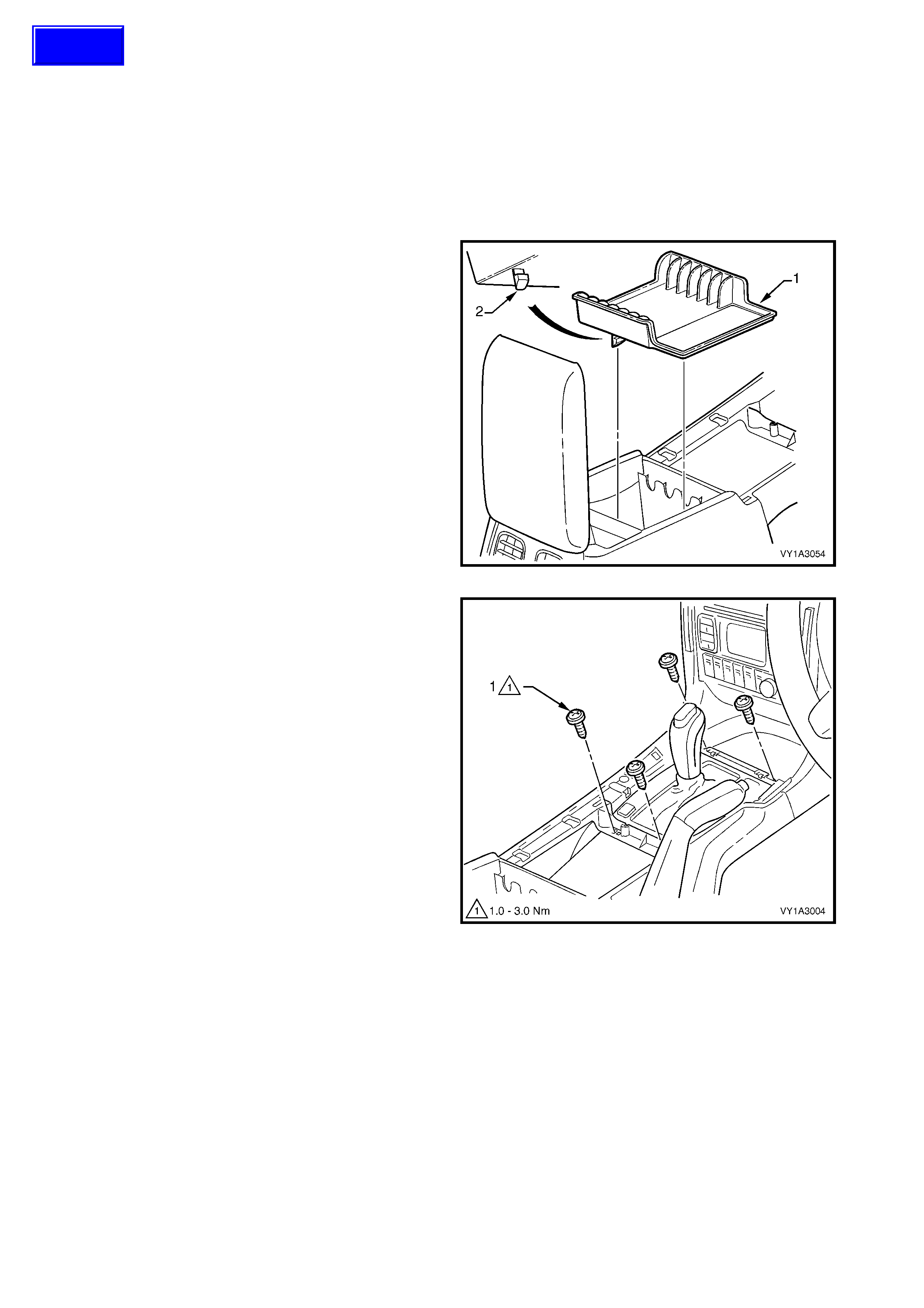

1. Remove the floor console front compartment liner

(1) by lifting upwards to disengage it from the

console cover.

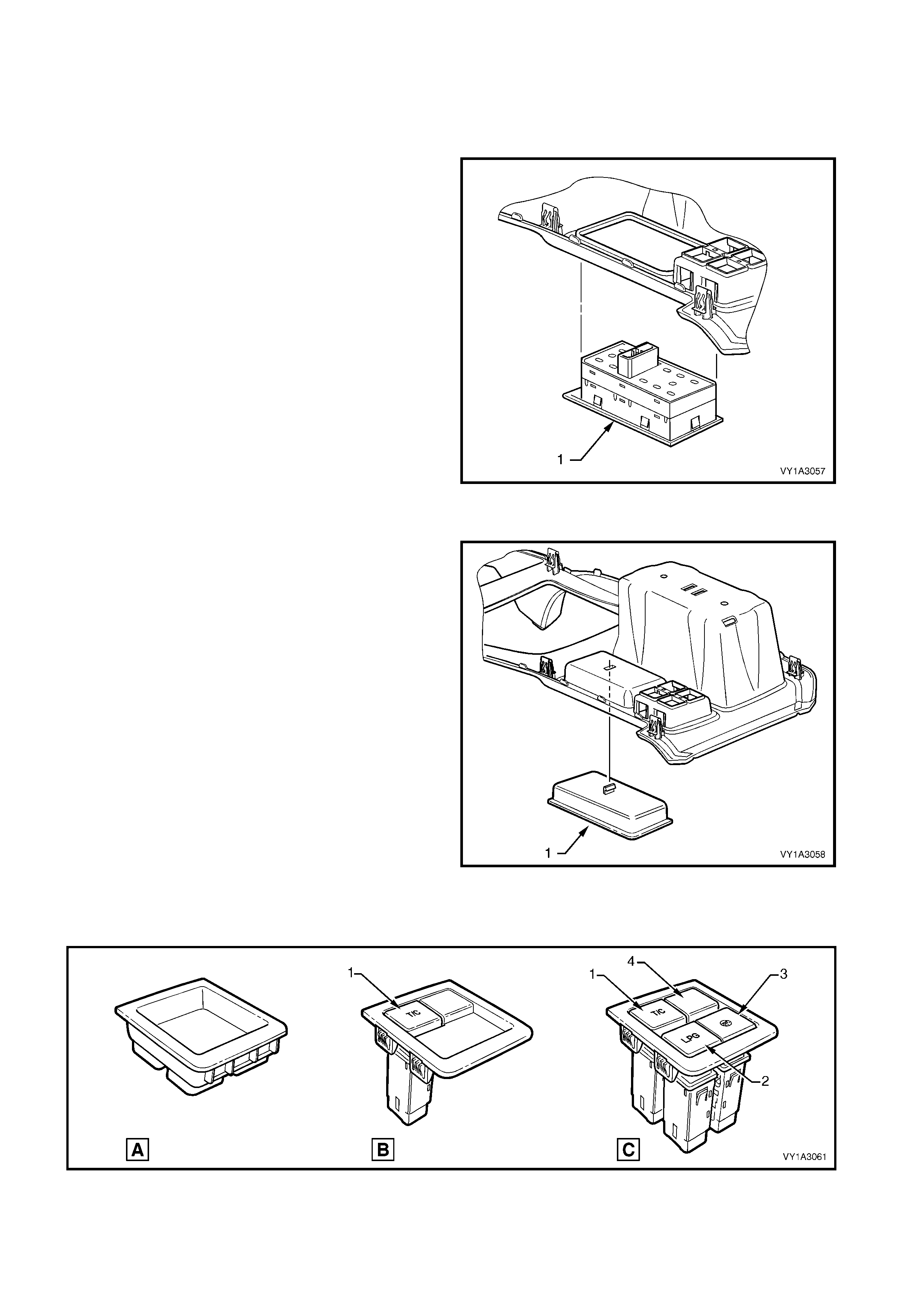

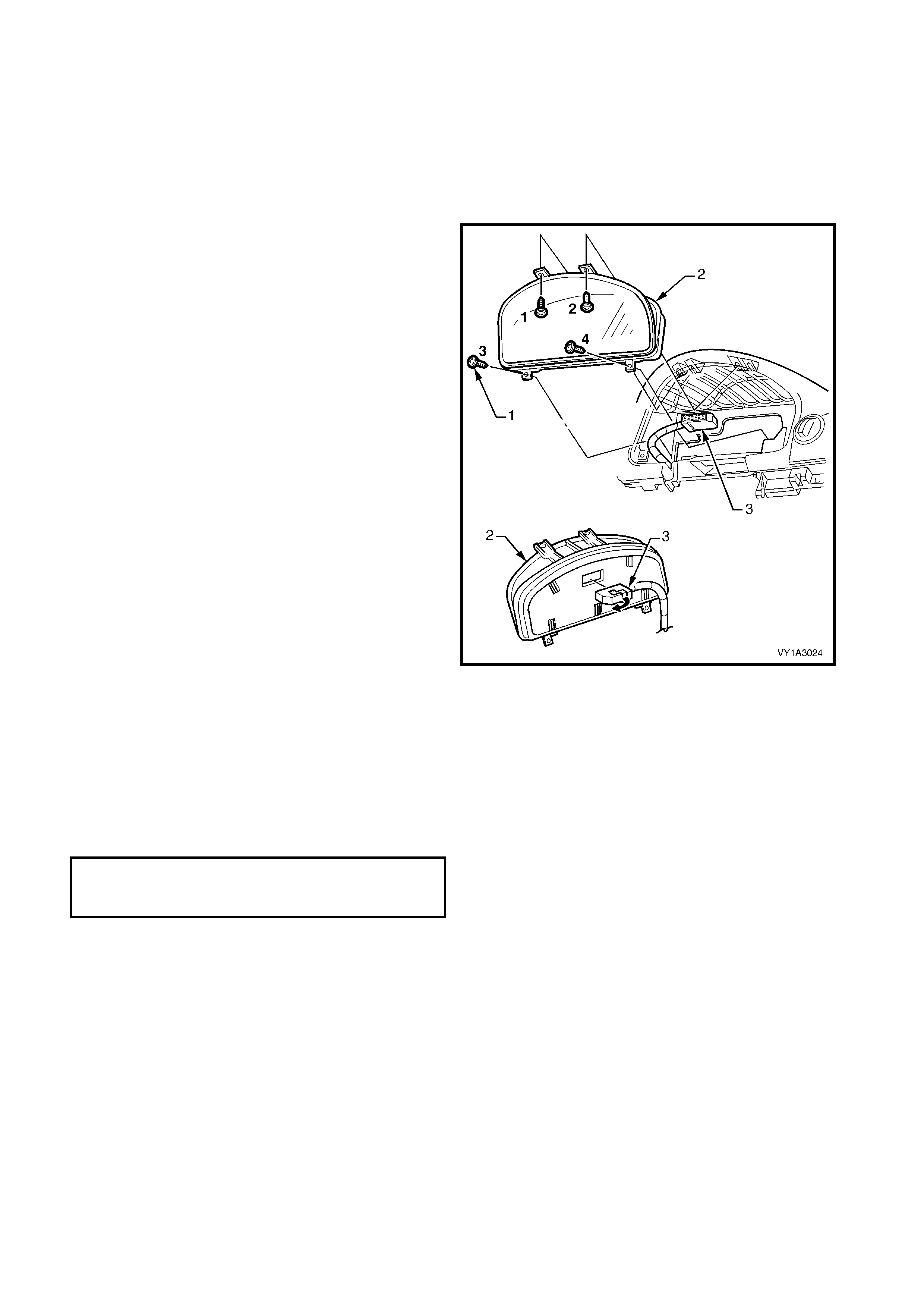

Figure 1A3-3

2. Remove the screw (1) slightly to the right of centre,

attaching the floor console cover assembly (2).

NOTE: Vehicles fitted with Navigation System do not

have this screw.

3. Prise the cover assembly from the floor console,

six places (3).

4. Lift the cover assembly up from the rear,

disconnect the wiring connector (4) from the side

window switch assembly and any auxiliary

switches if fitted, and remove the cover assembly.

Figure 1A3-4

DISASSEMBLE

Disassemble the components from the underside of

the console cover, where fitted.

SIDE WINDOW SWITCH ASSEMBLY

1. Depress the six retaining tabs securing the side

widow switch assembly (1), where fitted.

2. Remove the switch assembly from the console

cover.

Figure 1A3-5

FLOOR CONSOLE LINER

1. Remove the f loor console liner (1), where fitted, by

disengaging the retaining lug securing the liner to

the cover assembly.

AUXILIARY SWITCH LINER OR AUXILIARY

SWITCH AND BEZEL

1. Depending on options fitted, the location shown in

Figure 1A3-7 will be fitted with either:

a. An auxiliary switch liner (A) where no auxiliary

switches are fitted,

b. A one cavity auxiliary switch bezel (B) when

fitted with a manual transmission traction

control switch (1) only, or

c. A four cavity auxiliary switch bezel (C) when

fitted with:

- an LPG switch (2), or

- a police lights-out switch (3), or

- a manual transmission traction control

switch and LPG and/or police lights-out

switch(s).

In this configuration, empty cavities are fitted

with switch blank(s) (4).

Figure 1A3-6

Figure 1A3-7

2. Auxiliary switch liner (1):

a. Remove the liner by disengaging the retaining

lug securing the liner to the cover assembly.

3. Auxiliary switch bezel (2, one or four cavity type):

a. Depress the four tabs securing the auxiliary

switch bezel to the cover assembly and

remove.

b. Depress the two tabs s ecuring the switch(s) or

blanks to the cover assembly and remove the

switch or blank.

NOTE: T he switches can only fit in the one location as

shown in Figure 1A3-7.

Figure 1A3-8

FLOOR CONSOLE STORAGE TRAY AND CUP

HOLDER

1. Lift out the floor console storage tray (1), if fitted

and remove.

2. Remove the cup holder (2), fitted to Level 1

vehicles, by disengaging the retaining lug s ecuring

the liner to the cover assembly.

Figure 1A3-9

MOBILE PHONE COMPARTMENT

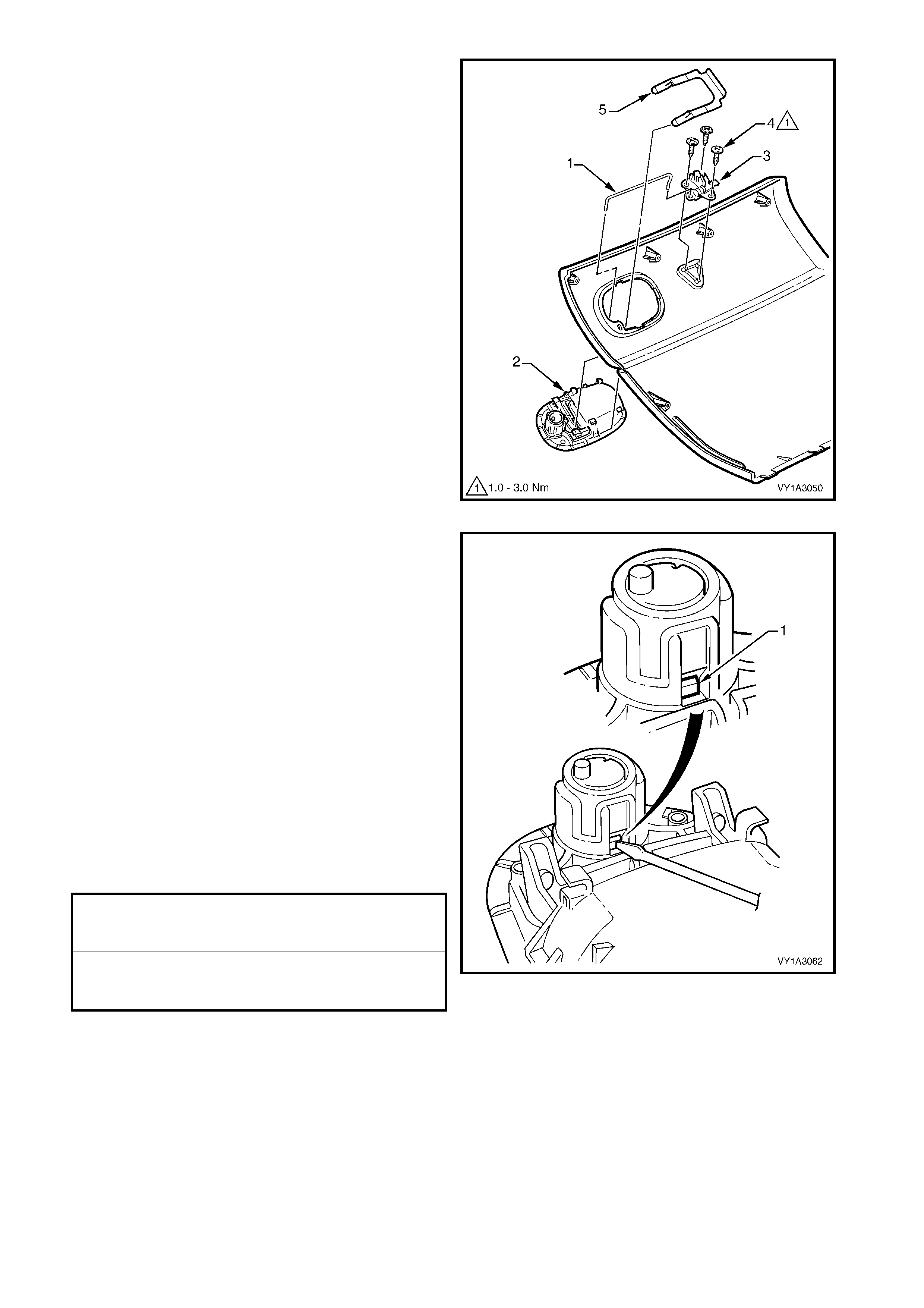

1. Remove the two screws (1) attaching the mobile

phone com partment ass embly (2), fitted to Level 2

and 3 vehicles.

2. Remove the compartment assembly from the

console cover.

Figure 1A3-10

REASSEMBLE

Reassembly is the reverse of removal noting the following:

1. Ensure correct orientation of the console components.

2. Tighten the screws, if fitted, to the specified torque

REINSTALL

Reinstallation of the floor console cover assembly is the reverse of removal noting the following:

1. If the vehicle is fitted with Navigation System, modify the front section of the floor console cover assembly,

refer to Section 12L, 3.8 FITTING A NEW FLOOR CONSOLE COVER ASSEMBLY.

2. Tighten the screw to the specified torque.

FLOOR CONSOLE COVER

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

MOBILE PHONE COMPARTMENT

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.2 INSTRUMENT PANEL LOWER EXTENSION SIDE TRIM

LT Section –

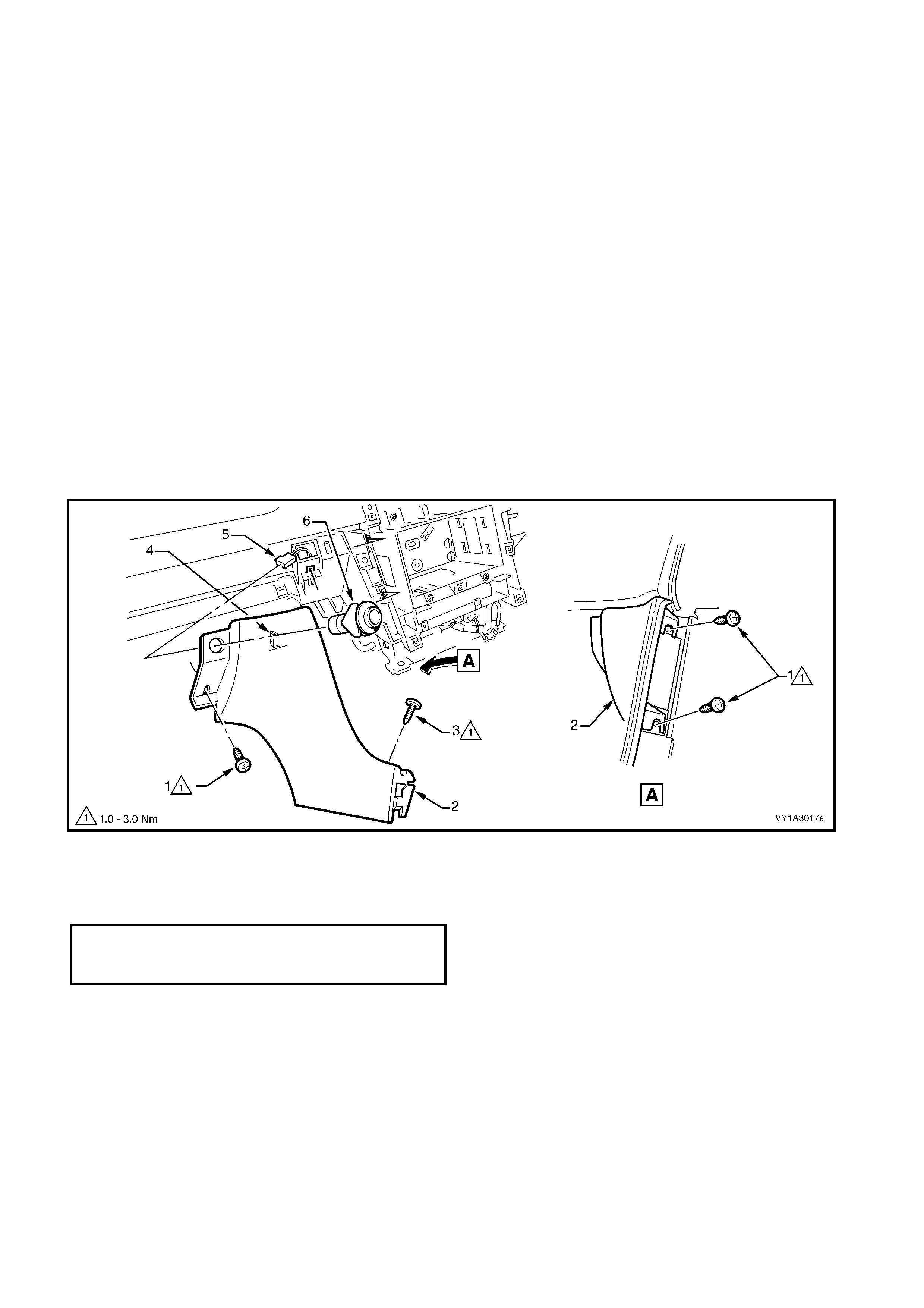

REMOVE

1. Move the front seats to their rearmost position. For the left-hand side, move the front to the uppermost

position.

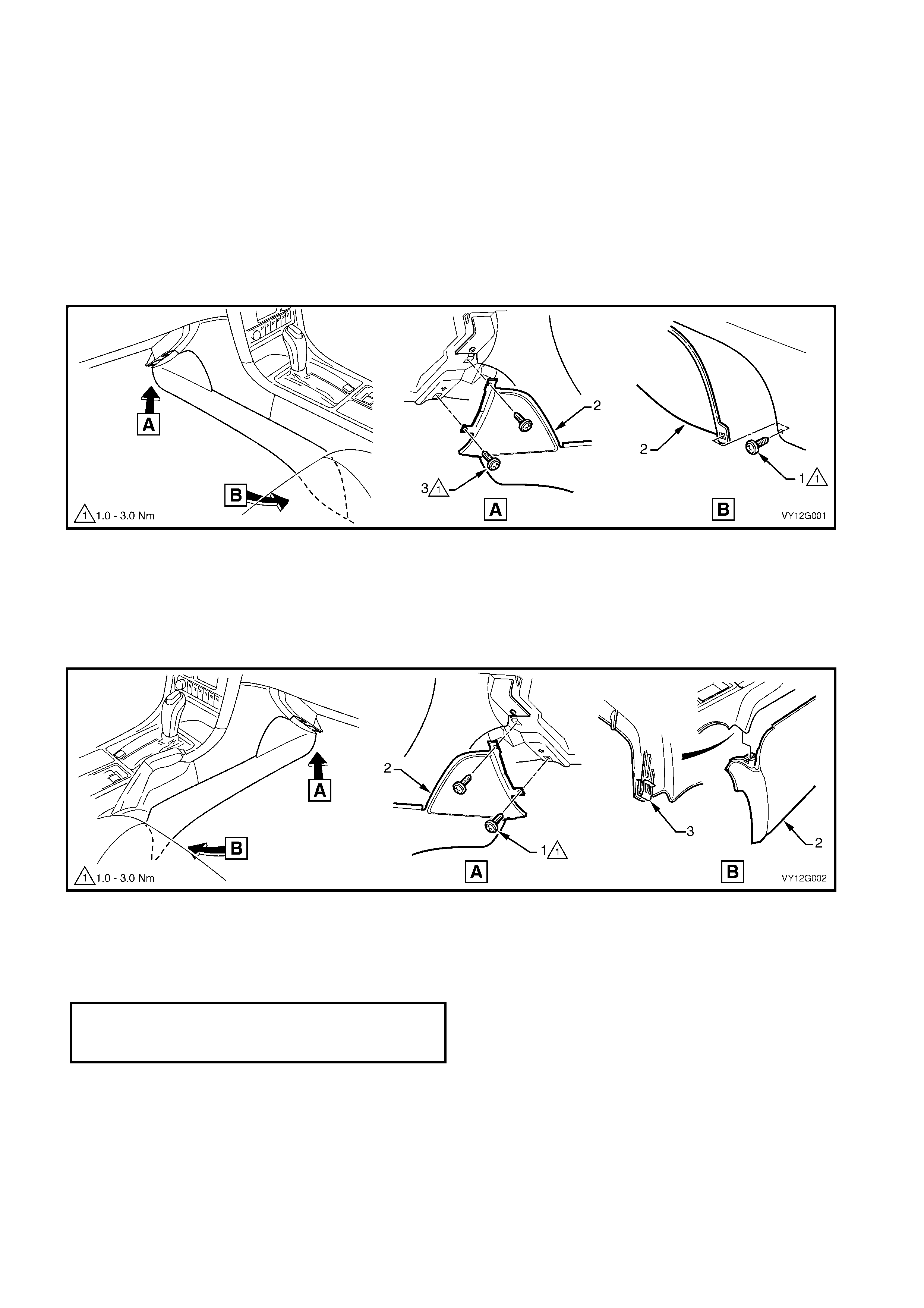

2. Referring to Figure 1A3-11, for the left-hand side:

a. Remove the screw (1) attaching the instrument panel lower extension side trim (2) to the floor console.

b. Open the instrument panel c ompartm ent (RHD) or instrum ent panel lower trim panel (LHD) and remove

the two screws (3) attaching the side trim to the instrument panel.

c. Remove the side trim.

Figure 1A3-11

3. Referring to Figure 1A3-12, for the right-hand side:

a. Open the instrument panel lower trim panel (RHD) or instrum ent panel com partment (LHD) and remove

the two screws (1) attaching the instrument panel lower extension side trim (2) to the instrument panel.

b. Prise the rear of the trim panel downward to disengage it from the floor console retaining clip (3).

c. Remove the side trim.

Figure 1A3-12

REINSTALL

Reinstallation is the reverse of removal. Ensure the trim panel is correctly seated and tighten the screws to the

specified torque.

INSTRUMENT PANEL LOWER EXTENSION

SIDE TRIM PANEL ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.3 FLOOR CONSOLE ASSEMBLY

LT Section –

As required, first remove the following components:

1. Floor console cover assembly, refer to 2.1 FLOOR CONSOLE COVER ASSEMBLY.

2. Left-hand and right-hand instrument panel lower extension side trims, refer to 2.2 INSTRUMENT PANEL

LOWER EXTENSION SIDE TRIM.

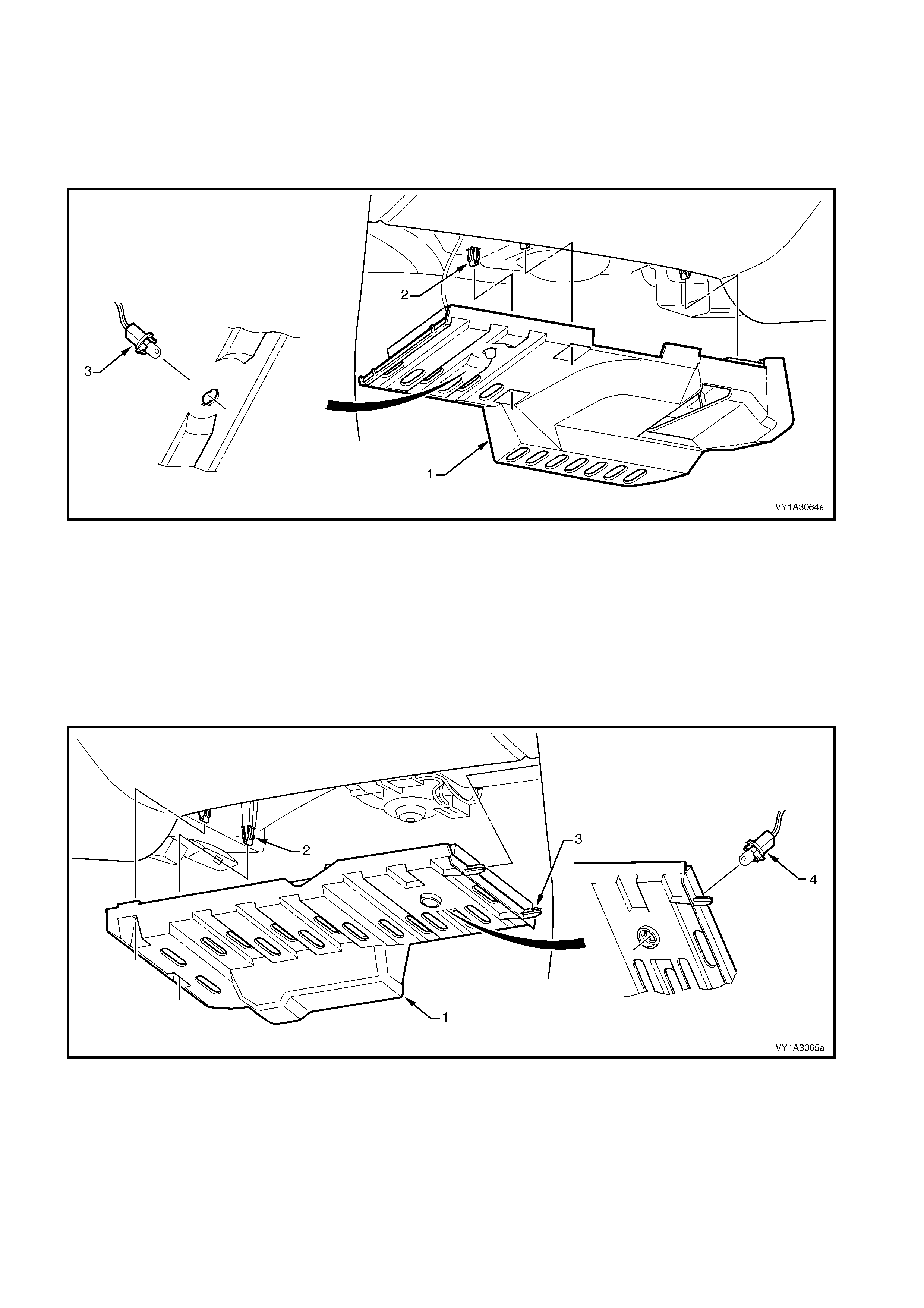

REMOVE

1. Remove the f loor c ons ole c ompartment liner (1) by

carefully grasping the liner and disengaging the

two lugs (2).

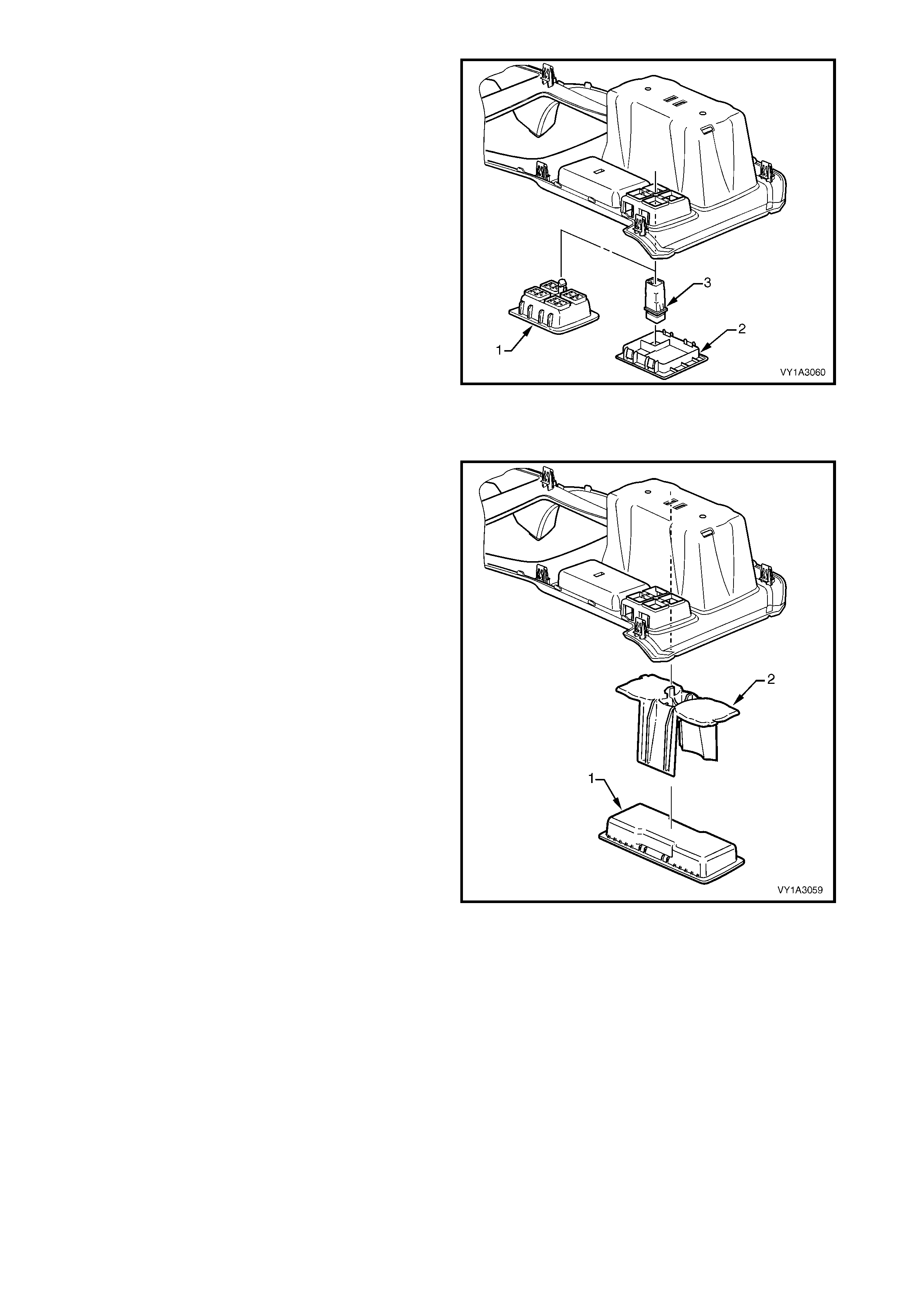

Figure 1A3-13

2. For automatic transmission vehicles, remove the

screw ( 1), four plac es, attaching the c onsole to the

automatic transmission selector assembly.

Figure 1A3-14

Techline

3. For manual transmission vehicles, use a fine flat-

blade screwdriver to disengage the lug (1),

attaching the manual transmission gear lever boot

assembly (2) to the console, two places front and

rear.

4. Remove the boot assembly from the console and

raise it over the gear knob. Remove the console

over the boot assembly when the remaining

fasteners are removed.

IMPORTANT: Do not attem pt to r emove the gear knob

from the gear lever shaft as it is glued in place. The

gear knob, boot assembly and lever shaft can be

removed from the transmission if required, refer to

Section 7B MANUAL TRANSMISSION.

Figure 1A3-15

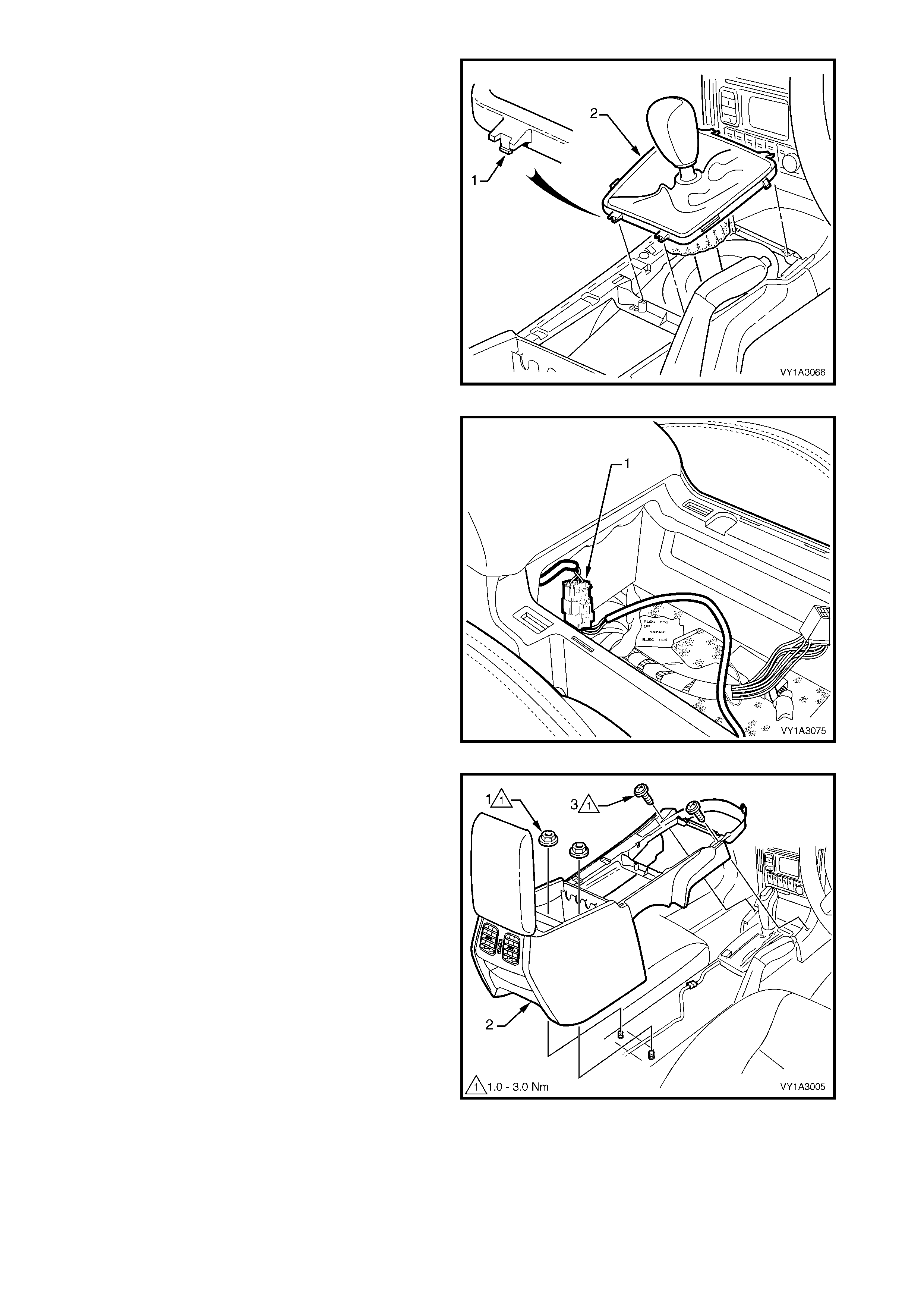

5. Disconnect the console wiring connector (1) from

the front of the console storage bin.

Figure 1A3-16

6. Remove the two nuts (1) attaching the floor

console (2) to the vehicle floor.

7. Remove the two screws (3) attaching the front of

the console to the instrument panel assembly.

8. Lift the rear of the console upward and remove.

NOTE: The console rear air duct will disconnect from

the console front air duct during removal. The rear air

duct will remain with the console.

Figure 1A3-17

DISASSEMBLE

For details of the floor console wiring harness routing

and attachment, refer to Section 120, FUSES,

RELAYS & WIRING HARNESSES .

ARMREST ASSEMBLY

1. Remove the screw (1), two places, attaching the

floor console compartment armrest hinge (2) and

armrest assembly to the floor console.

2. Slide the armrest assembly rearward to remove

the hinge from the floor console.

3. Remove the screw (3), four places, attaching the

armrest inner (4) to the armrest outer (5).

4. Unclip the inner at three places along each side

and remove from the outer.

5. Remove the screw (6), two places attaching the

hinge to the outer and remove.

REAR AIR OUTLET HOUSING ASSEMBLY OR

REAR UPPER COMPARTMENT ASSEMBLY

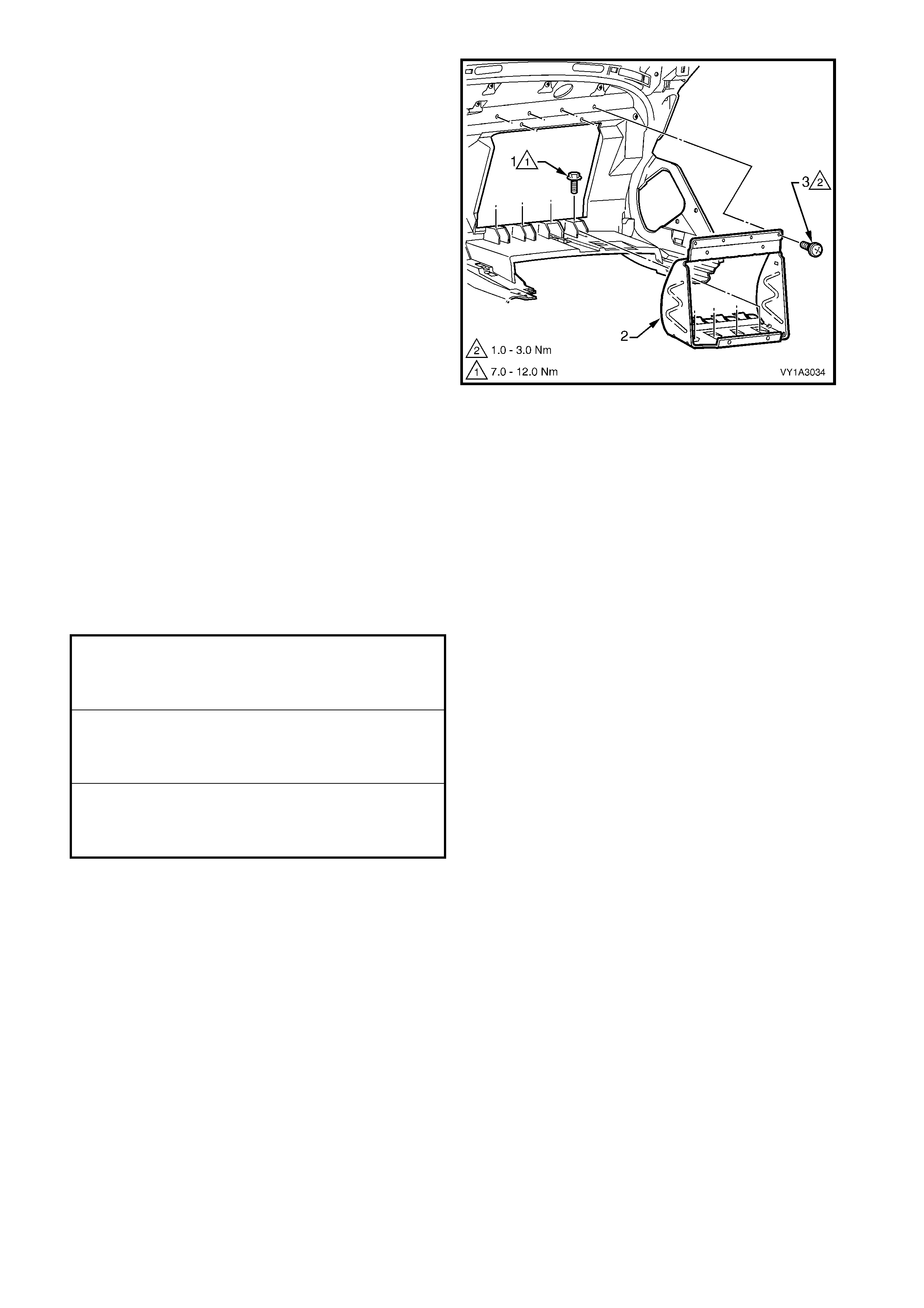

1. Referring to Figure 1A3-19:

a. Remove the screw (1), one place each side,

attaching the floor console rear upper

com partm ent assem bly for utility models (2) or

the floor console rear air outlet housing

assembly (3) to the floor console.

b. Remove the compartment or housing by

swinging the lower edge rearward and

detaching the upper tangs.

c. Remove the screw (4) attaching the floor

console rear air duct (5) to the floor console

and remove the duct.

Figure 1A3-18

Figure 1A3-19

FLOOR CONSOLE REAR COMPARTMENT

1. Remove the floor console rear compartment liner

(1) from within the floor console rear compartment

(2).

2. Remove the screw (3), two places attaching the

compartment to the rear air outlet housing

assembly (4).

3. Tilt the compartment downwards slightly and

disengage the two lugs (5) from beneath the

compartment and remove.

Figure 1A3-20

FLOOR CONSOLE LINER AND COMPARTMENT

LAMP ASSEMBLY OR LAMP OPENING COVER

1. Lift out the floor console liner (1), if fitted.

2. Prise the rear edge of either the floor console

compartment lamp opening cover (2) or floor

console compartment lamp assembly (3).

3. If f itted, disc onnec t the lamp wiring connectors and

remove the lamp assembly.

4. If fitted, prise the floor console compartment lamp

switch (4) from the console, disconnect the wiring

connectors and remove the switch.

Figure 1A3-21

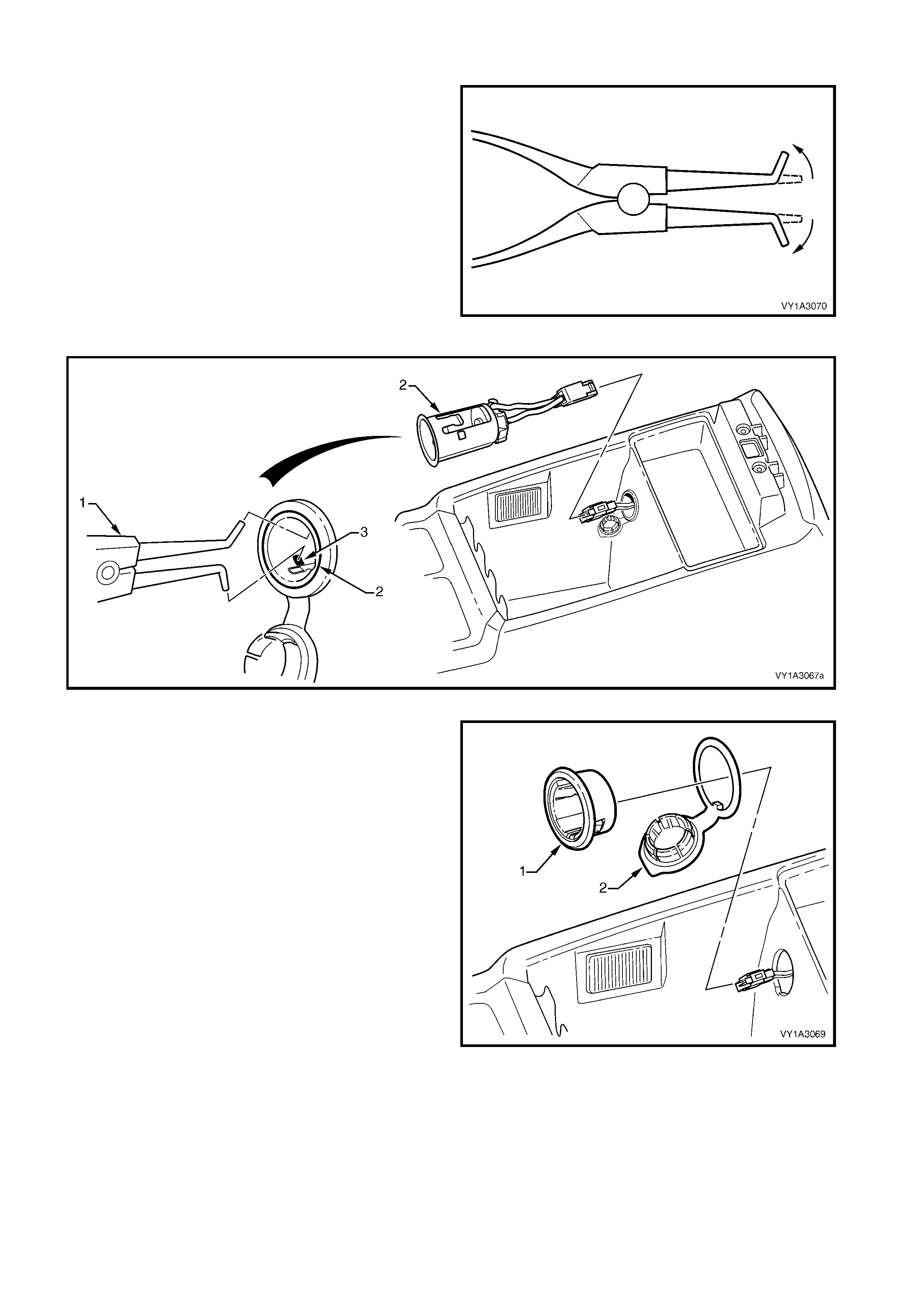

ACCESSORY POWER SOCKET

1. To remove the accessory power socket, a pair of

external circlip pliers will need to be modified.

Bend the tips of the pliers outward to between 60°

and 90°.

2. Referring to Figure 1A3-23:

a. From within the console compartment, insert

the circlip pliers (1) into the socket (2) and

locate the tips of the pliers onto the retaining

tab (3), two places.

b. Open the plier tips to depress the tabs, and

prise the soc ket f r om the bezel with a fine, flat-

blade screwdriver.

c. Withdraw the socket, disconnect the wiring

connector and remove the socket.

Figure 1A3-22

Figure 1A3-23

3. From within the console compartment, carefully

withdraw the bezel and cover.

NOTE: The socket must be removed before

performing this step as its removal releases the bezel

retaining tabs.

IMPORTANT: Take care as the tabs can break.

4. If required, slide the cover from the bezel.

Figure 1A3-24

REASSEMBLE

Reassembly of the floor console is the reverse of

disassembly noting the following:

1. The accessory power socket can only be installed

in the one orientation.

2. Tighten all fasteners to the specified torque.

REINSTALL

Reinstallation of the floor console assembly is the

reverse of removal noting the following:

1. If the vehicle is fitted with Navigation System

and a new floor console is being installed,

ensure the navigation remote control

presenter wedge Nutserts are fitted, refer to

Section 12L, 3.9 FITTING A NEW FLOOR

CONSOLE ASSEMBLY.

2. Tighten all fasteners to the correct torque

specifications.

3. Ensure the floor console assembly is correctly

seated against the instrument panel lower

extensions before tightening screws; tighten the

front screws first.

FLOOR CONSOLE ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE ATTACHING

NUT TORQUE SPECIFICATION 1.0 – 3.0 Nm

FL OOR CO NSOLE TO A UTOMATIC

TRANSMISSION SELECTOR ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE REAR COMPARTMENT

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE REAR AIR DUCT

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE REAR AIR OUTLET

HOUSING ASSEMBLY ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE REAR UPPER

COMPARTMENT ASSEMBLY ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE COMPARTMENT

ARMREST HINGE ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE COMPARTMENT

ARMREST INNER ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

3. SERVICE OPERATIONS – INSTRUM ENT PANEL

3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY

LT Section –

REMOVE

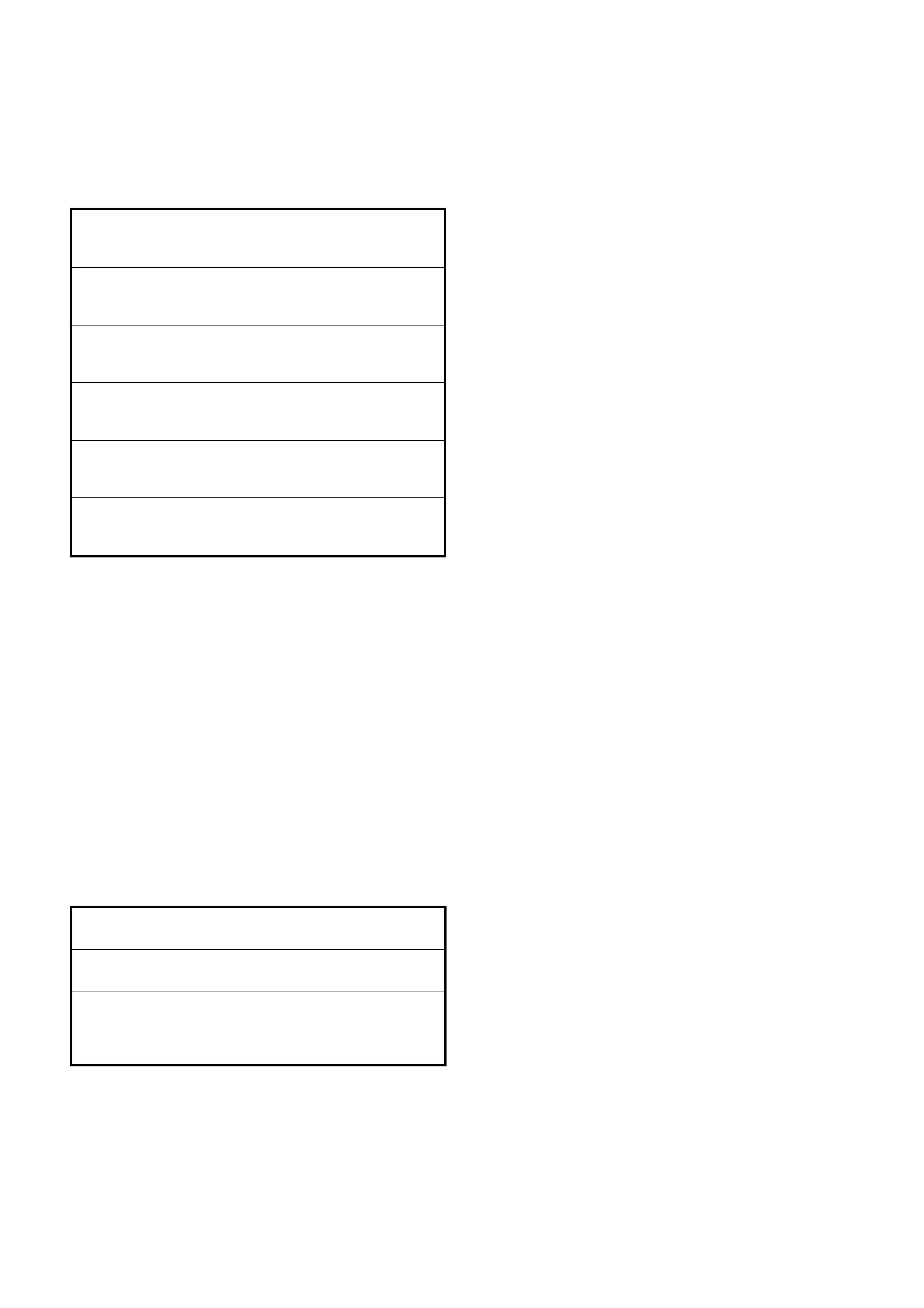

DRIVER SIDE, ALL VEHICLES

1. For autom atic transm ission vehicles, rem ove the retainer (1) attaching the ins trument panel lower trim plate

assembly (2) to the HVAC unit, refer Figure 1A3-25.

NOTE: The area shown A is removed for manual transmission vehicles.

2. Prise the insert and remove the retainer (3), two places, attaching the plate assembly to the instrument

panel.

3. Lower the plate assembly slightly and withdraw the lug (4) from the pedal bracket.

4. If fitted, remove the stepwell lamp (5) by rotating the socket and removing from the plate assembly.

5. Remove the plate assembly.

Figure 1A3-25

PASSENGER SIDE, RIGHT-HAND DRIVE VEHICLES

1. Grasp the instrument panel lower trim plate assembly (1) and carefully pull downward to disengage the

retaining clip (2), three places, refer Figure 1A3-26.

2. Lower the plate assembly slightly and if fitted remove the stepwell lamp (3), by rotating the socket and

removing from the plate assembly.

3. Remove the plate assembly.

Figure 1A3-26

PASSENGER SIDE, LEFT-HAND DRIVE VEHICLES

1. Grasp the inner end of the instrument panel lower trim plate assembly (1) and carefully pull downwards to

disengage the retaining clip (2), two places, refer Figure 1A3-27.

2. Withdraw the plate assembly from the hinge pillar trim panel, disengaging the lug (3), two places.

NOTE: The rear lug has a hook that engages the hinge pillar trim panel.

3. Lower the plate assembly slightly and if fitted remove the stepwell lamp (4), by rotating the socket and

removing from the plate assembly.

4. Remove the plate assembly.

Figure 1A3-27

REINSTALL

Reinstallation of the instrument panel lower trim plate assembly is the reverse of removal.

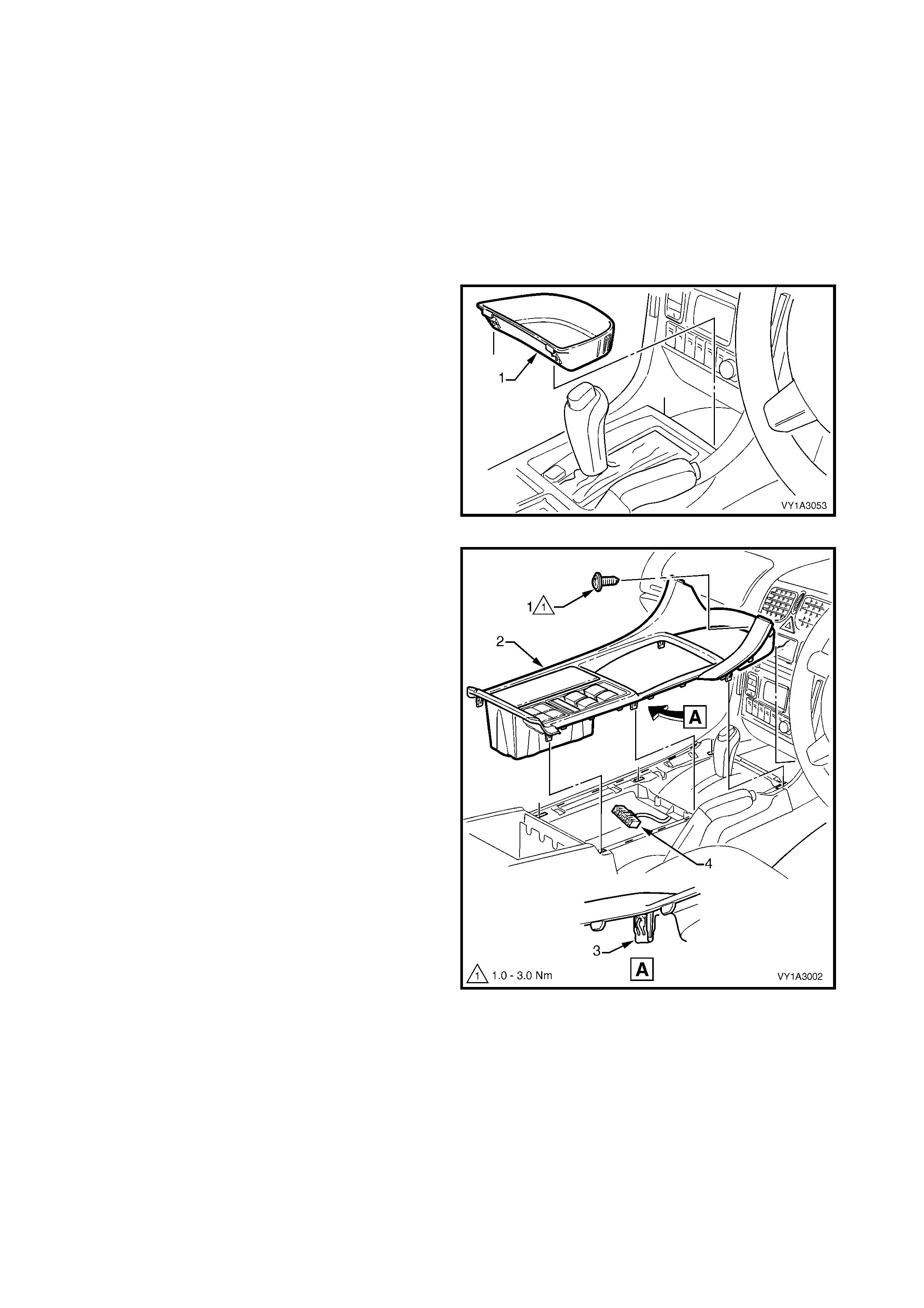

3.2 INSTRUMENT PANEL COMPARTMENT ASSEMBLY

LT Section – 09-140

REMOVE

1. Open the ins trum ent panel com par tm ent assem bly

(1).

2. Using a fine flat-blade screwdriver, flatten the

instrument panel compartment bumper stop (2)

each side, and carefully open the compartment

assembly fully.

3. From the inside of the compartment assembly,

push outwards on the bumper stop (2), and slide

the bumper from the lug (3). Repeat for the

opposite side.

4. Close the compartment assembly a third of the

way and grasping each side pull rearward to

disengage the compartment assembly from each

instrument panel compartment hinge (4).

IMPORTANT: T ake c are when disengaging the hinges

as removing the compartment assembly on the wrong

angle may cause damage.

NOTE: For removal of the instrument panel

compartment hinges refer to 3.22 INSTRUMENT

PANEL BRACKETS & BRACES.

5. As required, remove the two screws (5) attaching

the instrument panel compartment lock striker (6)

and remove the striker.

Figure 1A3-28

DISASSEMBLE

1. From the rear side of the compartment assembly,

remove the screw (1), six places, attaching the

instrument panel compartment (2) to the

instrument panel compartment door (3).

2. Lower the upper edge of the door and withdraw the

retaining tabs along the lower edge from the

compartment.

3. Remove the door and instrument panel

compartment liner (4).

Figure 1A3-29

Techline

Techline

4. Unclip the instrum ent panel com partm ent latch rod

(1) from the instrument panel compartment latch

actuator assembly (2) and instrument panel

compartment latch assembly (3).

5. Remove the three screws (4) attaching the latch

assembly to the door.

6. Depr es s the two tangs on the retainer (5) and s lide

the retainer from the actuator assembly.

7. Remove the actuator assembly.

Figure 1A3-30

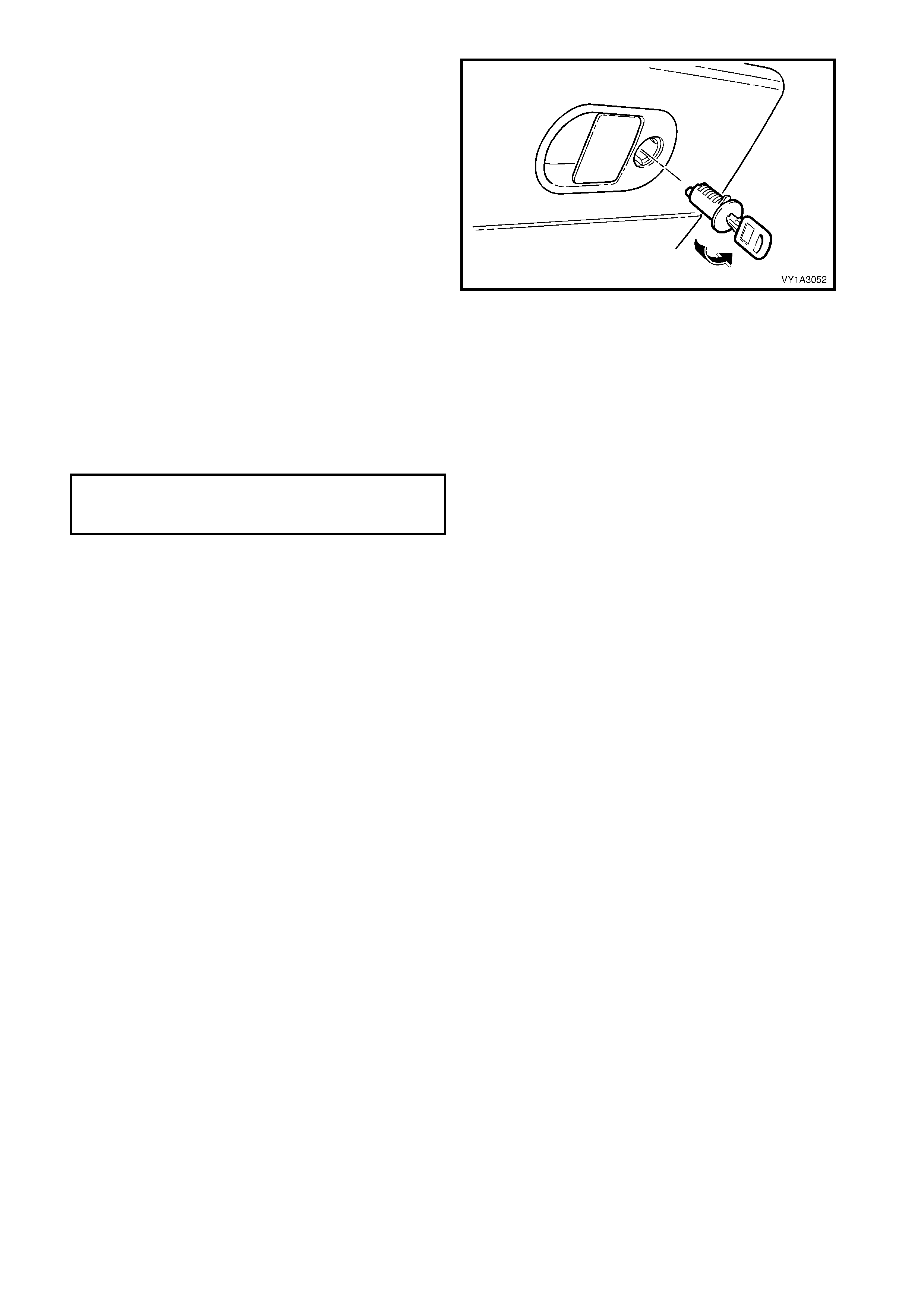

8. If required, remove the lock cylinder from the

actuator assembly by ins erting the key and turning

to the locked position (clockwise).

9. Insert a fine flat-blade screwdriver into the cavity

on the back of the actuator and depress the pin

(1).

10. While holding the pin depressed, turn the key

clockwise quarter of a turn.

11. Withdraw the cylinder.

NOTE: Replacement lock cylinders are supplied

complete with key.

REASSEMBLE

Reassembly is the reverse of disassembly noting the

following:

1. Tighten the screws to the specified torque.

Figure 1A3-31

INSTRUMENT PANEL COMPARTMENT

LATCH ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL COMPARTMENT

DOOR ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2. If installing the lock cylinder, insert the key and fit

the lock cylinder into its cavity in the vertical

position and rotate anti-clockwise half a turn.

3. Check the operation of the lock and actuator.

Figure 1A3-32

REINSTALL

Reinstallation of the instrument panel compartment

assembly is the reverse of removal. As required, adjust

the instrument panel compartment lock striker to

provide secure closing of the instrument panel

compartment and tighten the screws to the specified

torque.

INSTRUMENT PANEL COMPARTMENT

LOCK STRIKER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

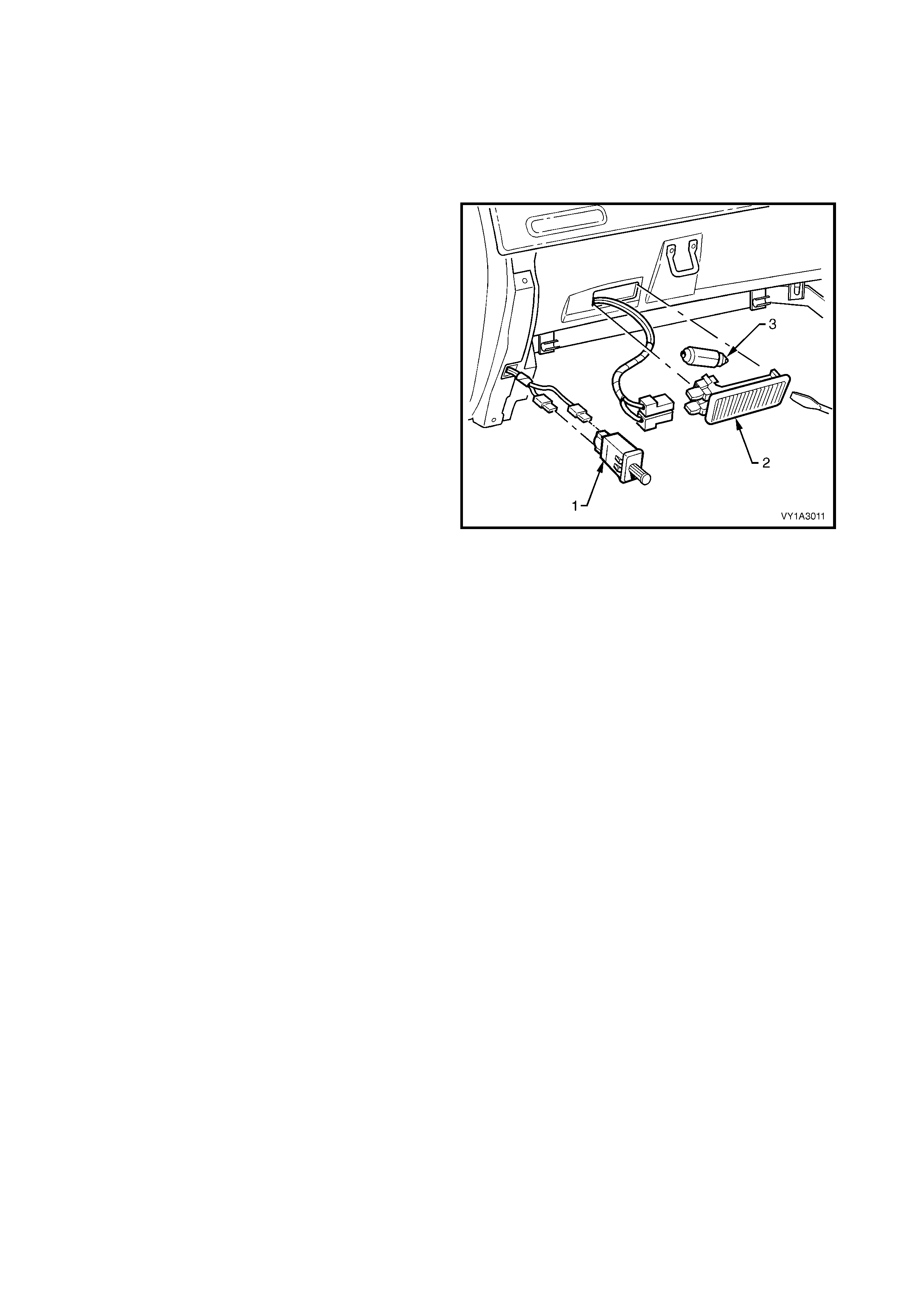

3.3 INSTRUME NT PANEL COMP ARTMENT LAMP & SWITCH

LT Section – 02-780

REMOVE

INSTRUMENT PANEL COMPARTMENT LAMP

SWITCH

1. From either side of the instrument panel

compartment lamp switch (1), carefully insert a

fine flat blade screwdriver and prise the switch

from the instrument panel.

2. Disconnect the wiring harness connectors and

remove the switch.

INSTRUMENT PANEL COMPARTMENT LAMP

1. From the right-hand side of the instrument panel

compartment lamp (2), carefully insert a fine flat

blade screwdriver.

2. Prise the lam p fr om the instrum ent panel and slide

it out of its cavity.

3. Disconnect the wiring harness connectors and

remove the lamp.

4. If required, remove the globe (3).

Figure 1A3-33

REINSTALL

Reinstallation is the reverse of removal.

3.4 INSTRUMENT PANEL LOWER TRIM PANEL ASSEMBLY

LT Section – 09-200

REMOVE

1. Grasp the upper edge of the instrument panel

lower trim panel as sem bly ( 1) and pull outwards to

disengage the three retaining clips (2).

2. Swing the panel assembly open.

3. Holding each side of the panel assembly, pull

rearwards to disengage it from the instrument

panel lower trim panel retainer (3), two places.

Figure 1A3-34

REINSTALL

Reinstallation is the reverse of removal.

NOTE: Ensure each retaining clip is aligned correctly

prior to pushing the panel assembly into place.

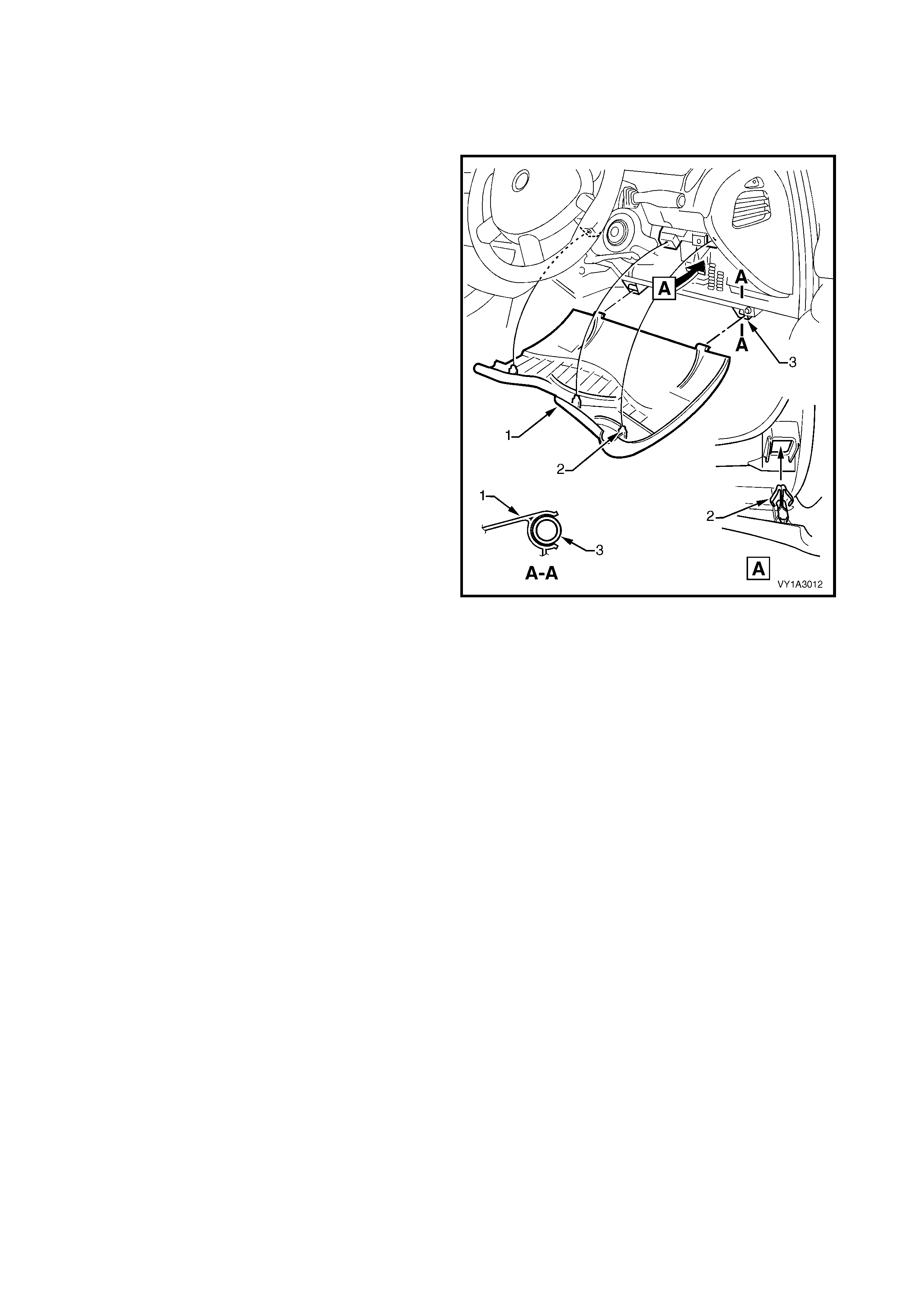

3.5 INSTRUMENT PANEL LOWER TRIM PANEL RETAINER

LT Section – 09-200

As required, first remove the following components:

1. Driver side instrument panel lower trim plate assembly, refer to 3.1 INSTRUMENT PANEL LOWER TRIM

PLA TE ASSEMBLY.

2. Instrument panel lower trim panel assembly, refer to 3.4 INSTRUMENT PANEL LOWER TRIM PANEL.

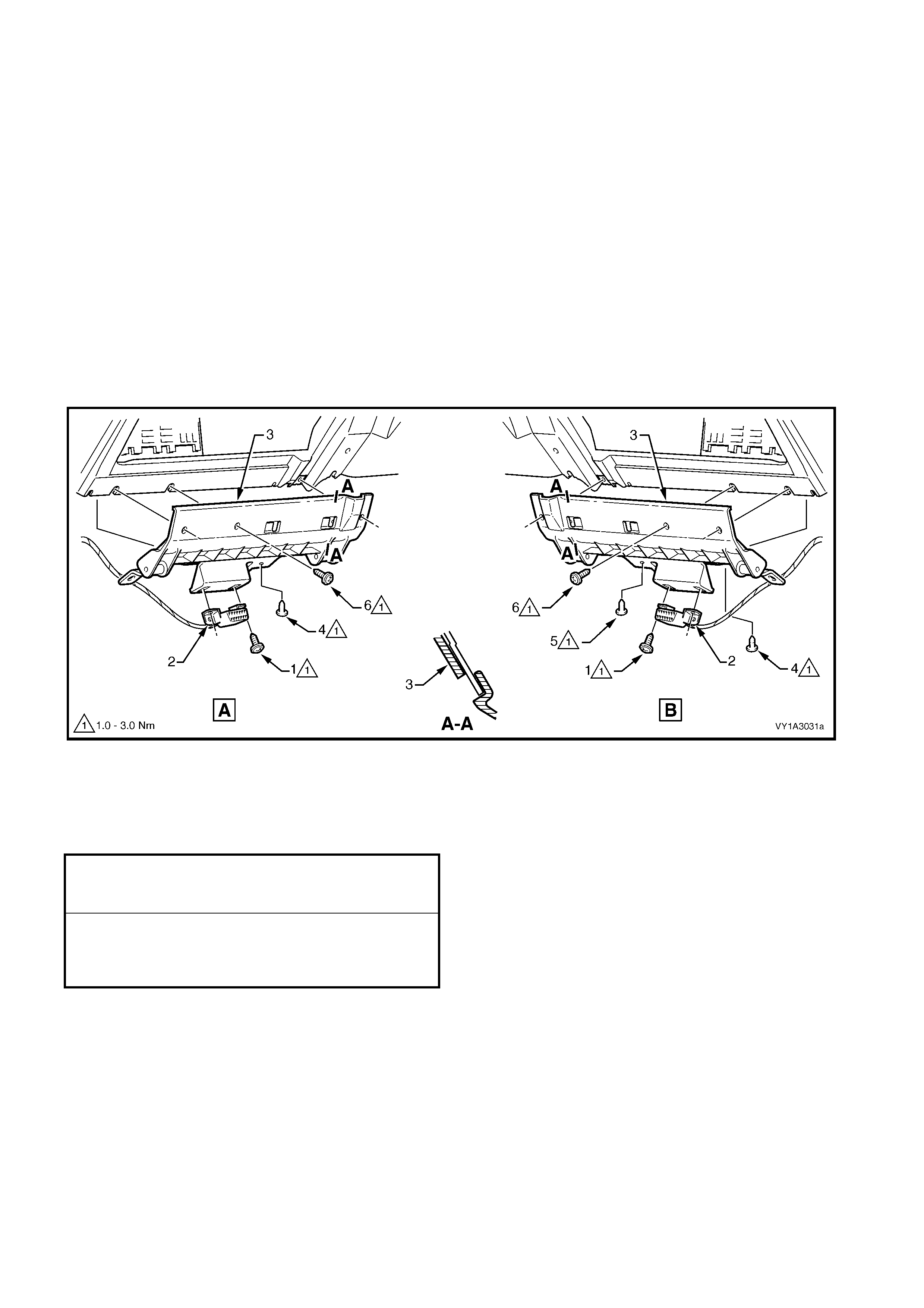

REMOVE

1. Remove the screw (1), two places, attaching the data link connector (2) to the instrument panel lower trim

panel retainer (3), refer to Figure 1A3-35, A – left-hand drive or B – right-hand drive.

2. For right-hand drive vehicles, remove the two screws (4 & 5) attaching the retainer to the air duct.

3. For left-hand drive vehicles, remove the screw (4) attaching the retainer to the air duct.

4. Rem ove the sc rew (6) , three places , attac hing the retainer to the inst rum ent panel ass em bly and instrument

panel.

5. Slide the retainer downward to disengage the two lugs from the instrument panel assembly as shown at

Section A-A and remove the retainer.

Figure 1A3-35

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

DATA LINK CONNECTOR

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL LOWER

TRIM PANEL RETAINER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.6 RADIO ASSEMBLY

LT Section – 09-440

REMOVE

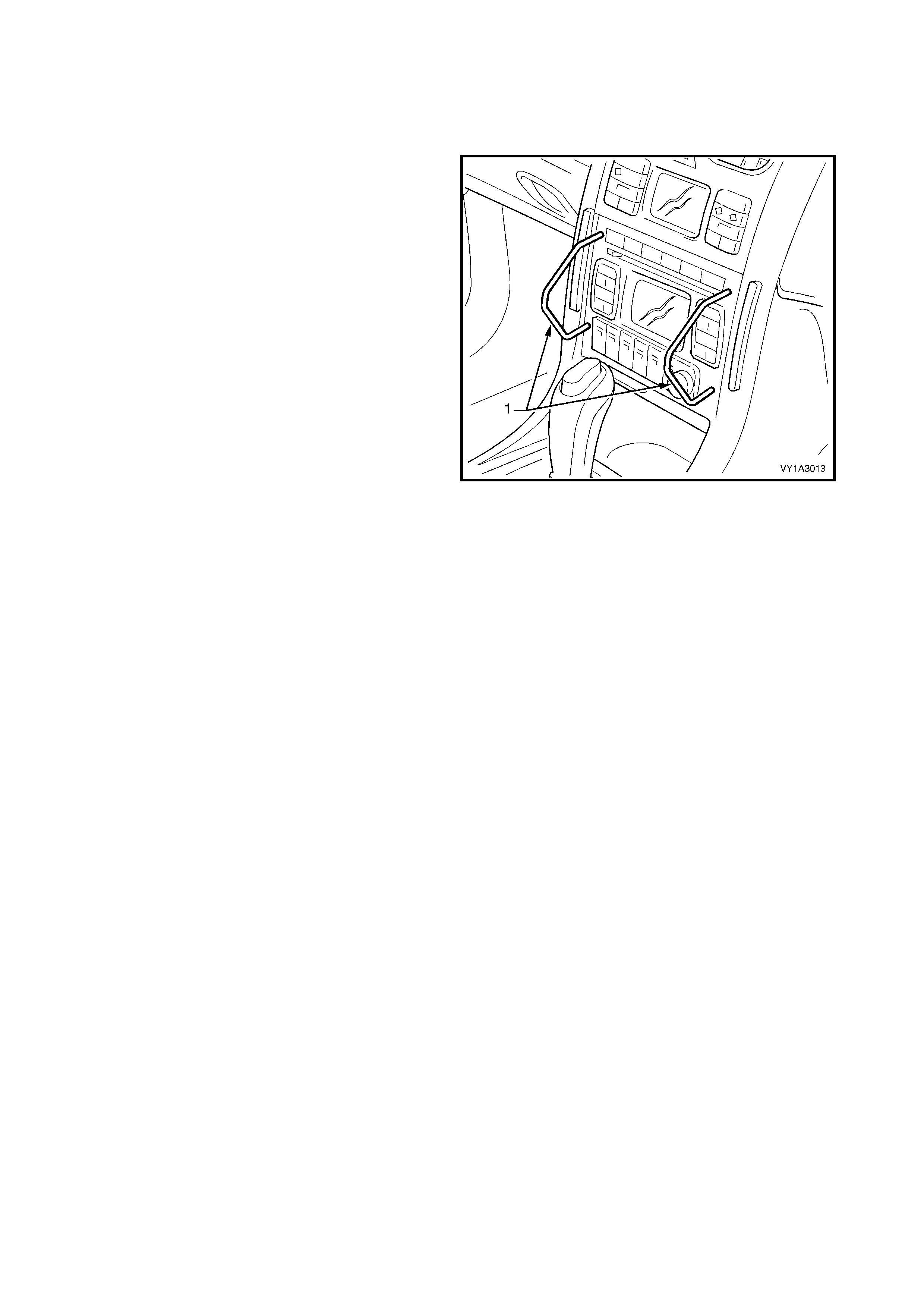

1. Ins er t Spec ial T ool KM6067 ( 1) into the holes eac h

side of the radio assembly.

2. While holding outward pressure on the tools

(toward each outer side of the vehicle), pull the

radio assembly from the radio housing.

NOTE: The wiring connectors remain attached to the

radio housing and will disconnect on removal of the

radio.

3. For service and diagnosis of the radio

assembly refer to Section 12D ENTERTAINMENT

SYSTEM.

Figure 1A3-36

REINSTALL

1. Insert the radio assembly into the housing.

2. Push the unit home to engage the retaining clips

and wiring connectors.

NOTE: The Special Tool is not required.

3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY

LT Section – 09-300

As required, first remove the following components:

1. Floor console cover assembly, refer to 2.1 FLOOR CONSOLE COVER ASSEMBLY.

2. Radio assembly, refer to 3.6 RADIO ASSEMBLY.

REMOVE

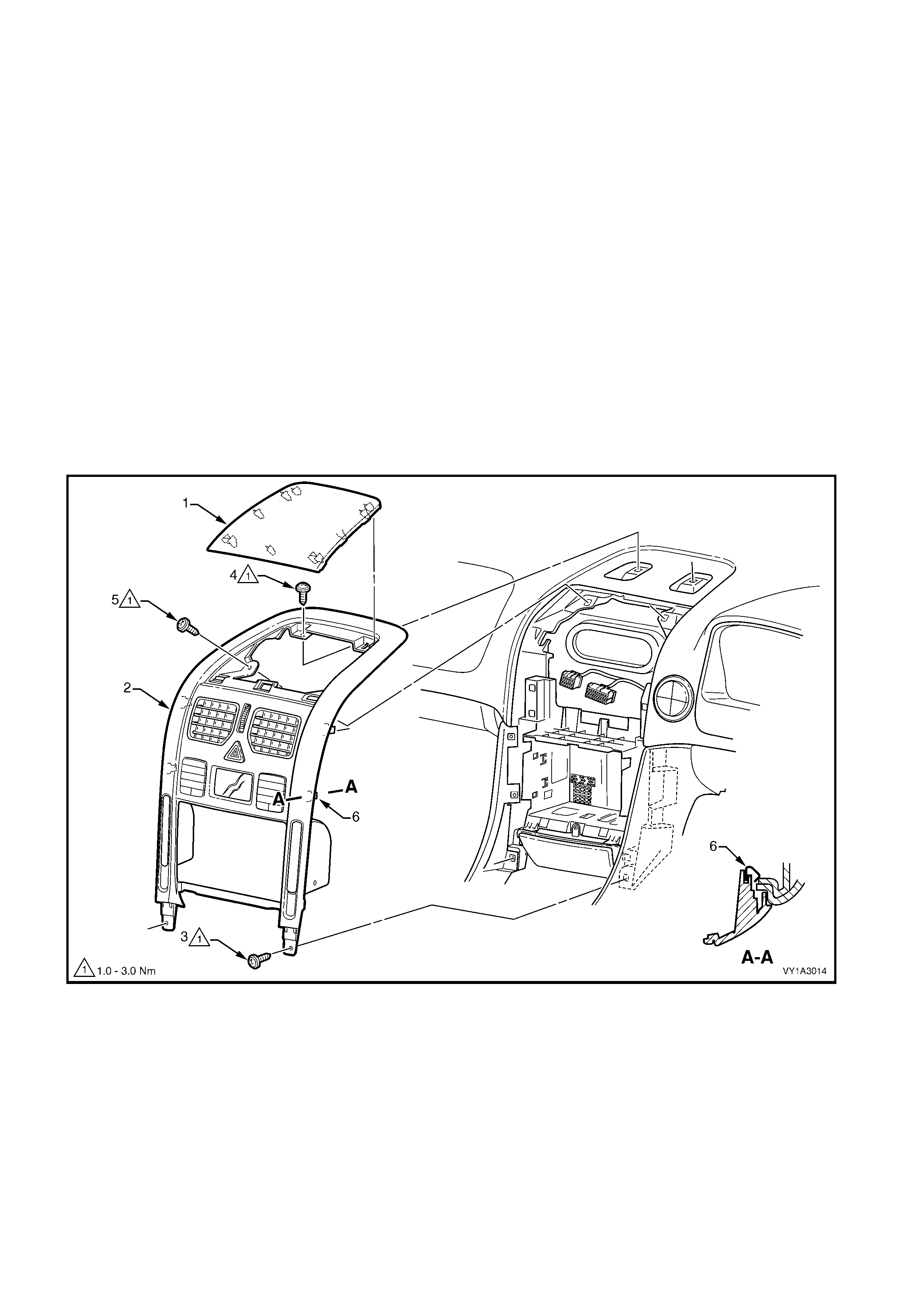

Referring to Figure 1A3-37:

1. Carefully prise the front edge of the instrument panel upper centre trim panel (1), and pull upward to

disengage the retaining clips at each corner from the centre trim assembly (2).

NOTE: A fine flat blade screwdriver may be used; however take steps to ensure the trims are not marked or

damaged.

2. Remove the lower screw (3), two places, attaching the centre trim assembly to the instrument panel.

3. Remove the upper screws (4 & 5), two places each, attaching the centre trim assembly to the instrument

panel.

4. Remove the centre trim assembly, disengaging the four clips (6), far enough to disconnect the wiring

connectors from the rear of the hazard warning switch and where fitted, the OCC control module.

NOTE: If manual HVAC is fitted, the manual HVAC controller remains attached to the instrument panel.

5. Remove the centre trim assembly.

Figure 1A3-37

DISASSEMBLE

NOTE: Depending on model not all of the following components will be fitted.

Referring to Figure 1A3-38:

1. Remove the s c rew ( 1) , one place each side, attac hing the OCC c ontr ol module (2) and c up holder ass embly

(3) to the cen tre trim (4).

2. Remove the screw (5), one place each side, attaching the OCC control module to the centre trim and

remove the control assembly.

3. Remove the screw (6) attaching the cup holder assembly to the centre trim and remove the cup holder.

4. Remove the four screws (7) attaching the instrument panel centre air outlet housing assembly (8) to the

centre trim and remove the housing assembly and hazard warning switch (9).

5. Unclip the hazard warning switch from the instrument panel centre air outlet housing assembly.

NOTE 1: For service and diagnosis of the OCC control module refer to Section 2E HVAC OCCUPANT

CLIMATE CONTROL (A UTO A/C).

NOTE 2: For service and diagnosis of the hazard warning switch refer to Section 12B, 3.25 HAZARD

WARNING SWITCH ASSEMBLY.

Figure 1A3-38

REINSTALL

Reinstallation is the reverse of removal. Tighten all screws to the specified torque.

INSTRUMENT PANEL CUP HOLDER

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

OCC CONTROL MODULE ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL CENTRE AIR OUTLET

HOUSING ASSEMBLY ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL CENTRE TRIM

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.8 INSTRUMENT PANEL LOWER COMPARTMENT OR ASHTRAY ASSEMBLY

LT Section – 09-300

NOTE: W here fitted, an instrument panel ashtray assembly replaces the instrument panel lower compartment.

Removal of both components is the same, however each has its own disassembly procedure, which is described

in this Section.

As required, remove the following components:

1. Floor console cover assembly, refer to 2.1 FLOOR CONSOLE COVER ASSEMBLY.

2. Radio assembly, refer to 3.6 RADIO ASSEMBLY.

3. Instrument panel centre trim assembly, refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY.

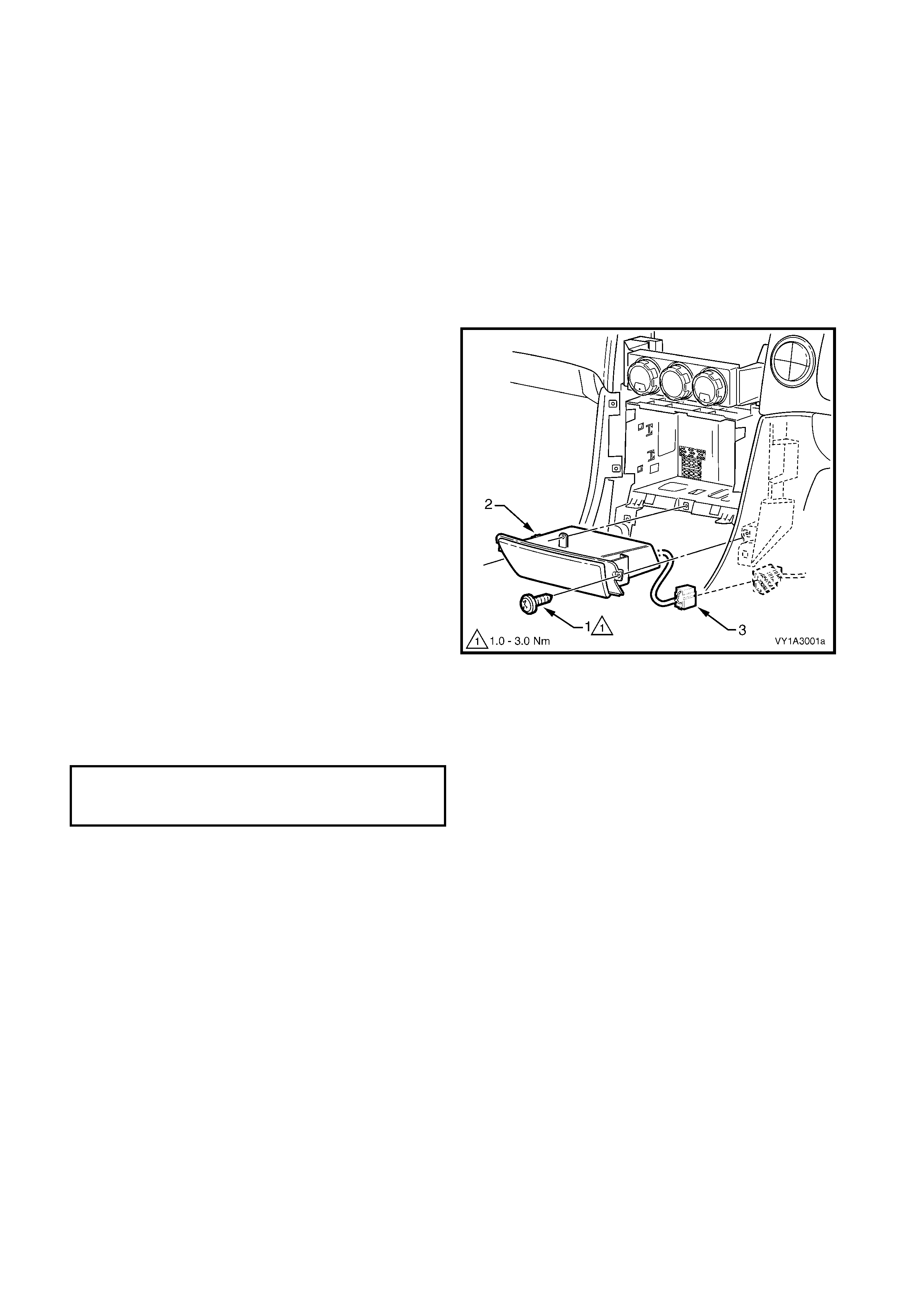

REMOVE

1. Rem ove the screw (1), three places, attaching the

instrument panel lower compartment assembly or

ashtray assembly (2) to the instrument panel.

2. Slide the compartment or ashtray assembly

outward to remove.

NOTE: If an ashtray assembly is fitted, disconnect the

wiring connector (3).

Figure 1A3-39

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

INSTRUMENT PANEL LOWER

COMPARTMENT OR ASHTRAY ASSEMBLY

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.9 INSTRUMENT PANEL LOWER EXTENSION

LT Section – 09-300

As required, first remove the following components:

1. Floor console cover assembly, refer to 2.1 FLOOR CONSOLE COVER ASSEMBLY.

2. Radio assembly, refer to 3.6 RADIO ASSEMBLY.

3. Instrument panel centre trim assembly, refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY.

4. Instrument panel lower compartment assembly or instrument panel ashtray assembly, refer to

3.8 INSTRUMENT PANEL LOWER COMPARTMENT OR ASHTRAY ASSEMBLY.

REMOVE

Referring to Figure 1A3-40:

1. Remove the three screws (1) attaching the instrument panel lower extension (2) to the instrument panel.

2. For the left-hand side, remove the screw (3) attaching the floor console front duct.

3. Grasp the top of the extension and pull rearwards to release the clip (4).

4. If fitted, dis connec t the wiring connector ( 5) f r om the rear c ompartment lid releas e switch (6) and remove the

panel.

5. If r equired, r emove the r ear c ompartment lid releas e s witch by depressing the tabs on the back of the switch

and pushing it out of the extension.

NOTE: For service and diagnosis of the rear compartment lid release switch refer to Section 12J BODY

CONTROL MODULE.

Figure 1A3-40

REINSTALL

Reinstallation is the reverse of removal. Tighten the screws to the specified torque.

INSTRUMENT PANEL LOWER

EXTENSION SIDE TRIM ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.10 MANUAL HVAC CONTROLLE R

LT Section – 08-155A

NOTE: For removal of OCC control module refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY -

DISASSEMBLE.

As required, first remove the following components:

1. Floor console cover assembly, refer to 2.1 FLOOR CONSOLE COVER ASSEMBLY.

2. Radio assembly, refer to 3.6 RADIO ASSEMBLY.

3. Instrument panel centre trim assembly, refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY.

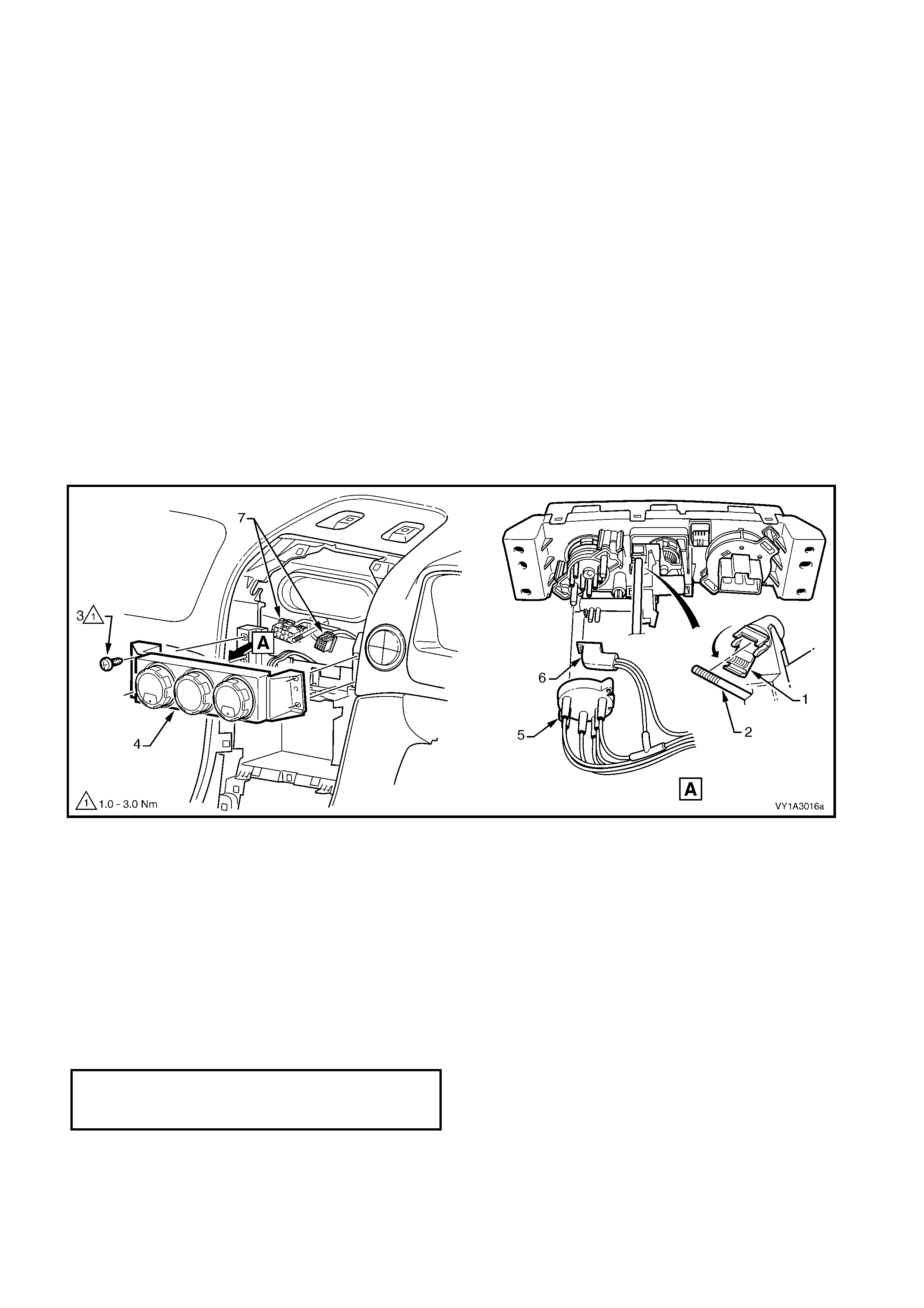

REMOVE

Referring to Figure 1A3-41:

1. From the rear of the controller, open the push-rod locking tab (1) and disconnect the control rod (2).

2. Remove the screw (3), two places each side, attaching the manual HVAC controller (4) to the instrument

panel.

3. Pull the control assembly outwards slightly to access the rear.

4. Disconnect the two vacuum hose connections (5 & 6) and two wiring connectors (7).

5. Remove the control assembly.

NOTE: For service and diagnosis of the manual HVAC controller, refer to Section 2C HVAC CLIMATE

CONTROL (MANUAL A/C) – SERVICING & DIAGNOSIS.

Figure 1A3-41

REINSTALL

1. Install the two wiring connectors and the lower then upper vacuum hose connections.

2. Push the control rod toward the HVAC unit (front of vehicle) fully.

3. Seat the control assembly in position.

4. Install the four screws and tighten to the specified torque.

5. Rotate the heat control knob to the full cold position.

6. Position the locking tab so that it will close upward.

7. Connect the control rod to the controller lever and close the locking-tab.

8. Check for correct operation.

MANUAL HVAC CONTROLLER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.11 RADIO HOUSING & RADIO BRACKET ASSEMBLY

LT Section –

For the radio housing, as required first remove the following components:

1. Floor console cover assembly, refer to 2.1 FLOOR CONSOLE COVER ASSEMBLY.

2. Radio assembly, refer to 3.6 RADIO ASSEMBLY.

3. Instrument panel centre trim assembly, refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY.

For the radio bracket, as required first remove the above components, the radio housing and the following

components:

1. Instrument panel lower compartment assembly or instrument panel ashtray assembly, refer to

3.8 INSTRUMENT PANEL LOWER COMPARTMENT OR ASHTRAY ASSEMBLY.

2. Left-hand and Right-hand instrument panel lower extension, refer to 3.9 INSTRUMENT PANEL LOWER

EXTENSION.

3. Manual HVAC controller if fitted, refer to 3.10 MANUAL HVAC CONTROLLER.

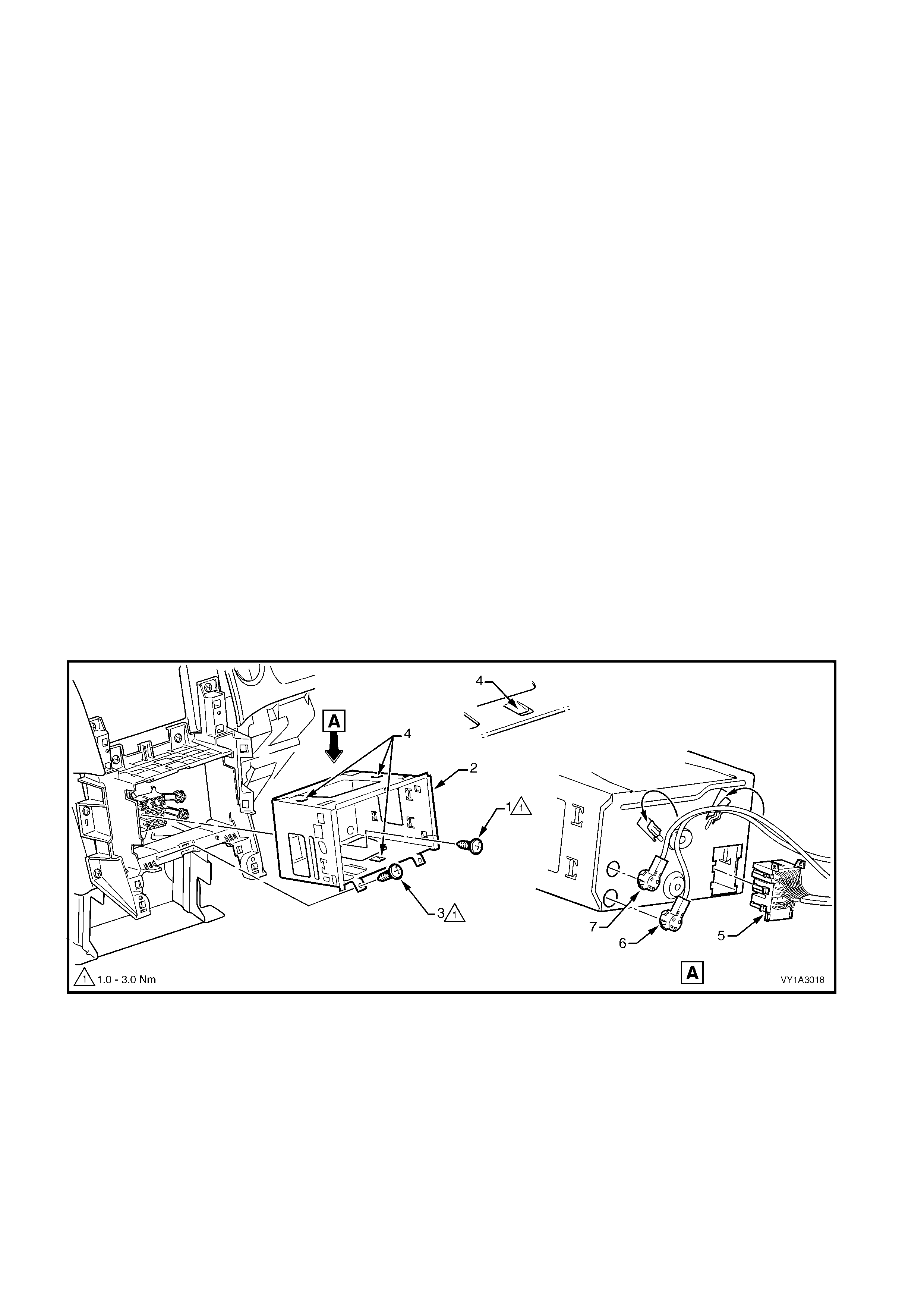

REMOVE

Referring to Figure 1A3-42:

1. Remove the screw (1) from the rear face of the radio housing (2) attaching the housing to the instrument

panel.

2. Remove the screw (3), two places, attaching the front edge of the radio housing.

3. Lift the retaining tab (4), two places in the top of the housing and one place at the bottom.

4. Withdraw the hous ing f r om the brac ket assembly far enough to allow access to the r adio and antenna wiring

connectors.

NOTE: If ther e is not suf fic ient length in the radio harness , either unclip the connector fr om within the housing or

remove the passenger side instrument panel lower extension side trim and unclip the harness from the vehicle

floor.

5. From the rear of the housing, unclip the radio wiring connector (5), if not previously done, the antenna

connector (6) and if fitted, the diversity antenna connector (7) from the housing.

6. Unattach the antenna lead(s) and remove the housing.

Figure 1A3-42

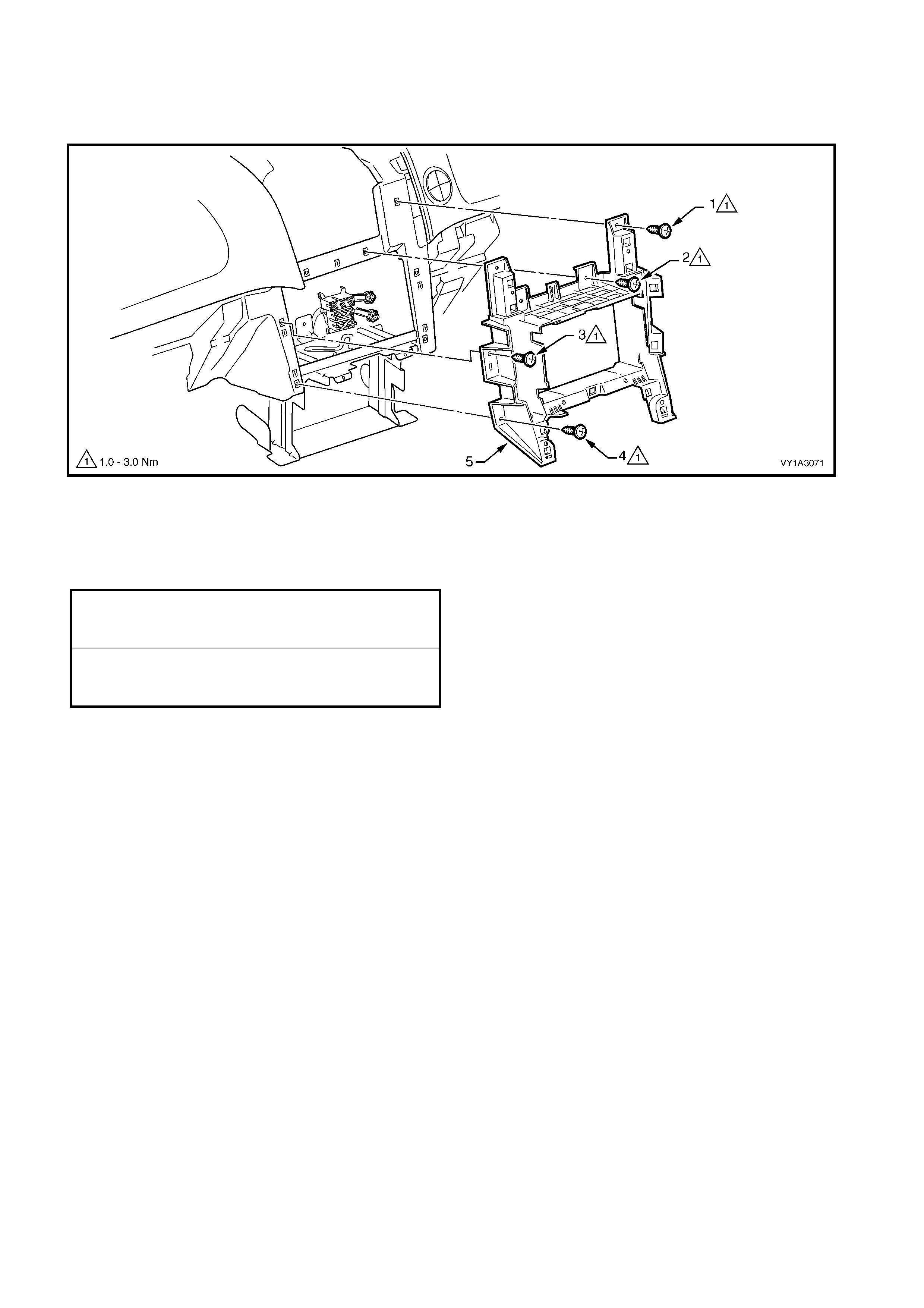

Referring to Figure 1A3-43:

7. Remove the screws (1, 2, 3 & 4), two places each side, attaching the radio bracket assembly (5) to the

instrument panel.

8. Remove the bracket assembly from its locating tabs.

Figure 1A3-43

REINSTALL

Reinstallation is the reverse of removal. Tighten the screws to the specified torque.

NOTE: To avoid operational problems, ensure the radio wiring and antenna connectors are installed correctly.

RADIO BRACKET ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

RADIO HOUSING

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY

LT Section – 09-100

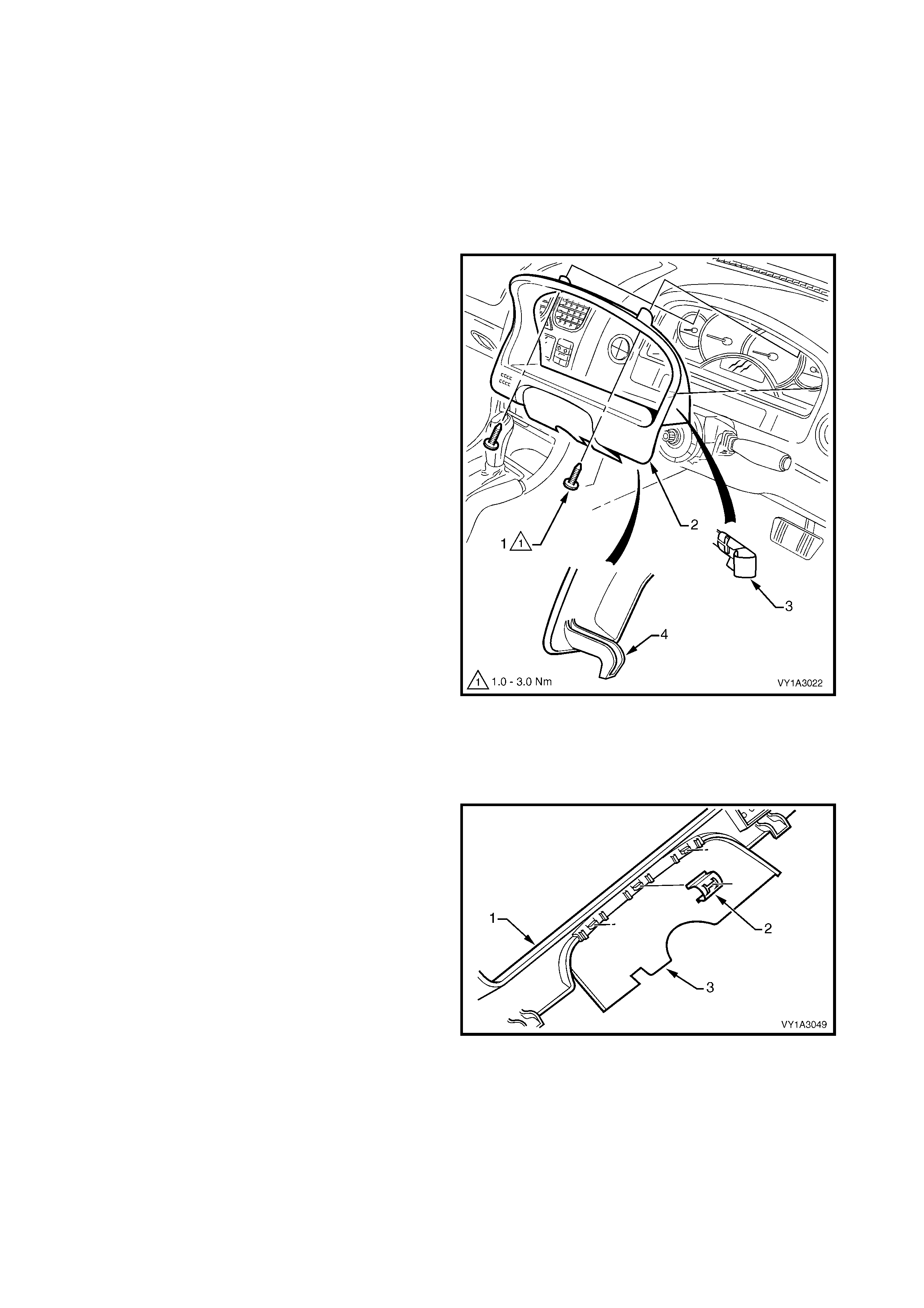

REMOVE

NOTE: The steering wheel has been removed for

clarity; the cluster trim can be removed with steering

column, covers and steering wheel installed.

1. Release the s teering column adj ustment lever and

move the column to its lowest position.

2. Remove the two screws (1) attaching the

instrument cluster trim assembly (2) to the

instrument panel.

3. Depress the top of the trim assembly slightly and

tilt the top of the trim assembly out of the

instrument panel pad, disengaging the retaining

clips (3) each side.

4. Unhooking each lug (4) from the instrument panel

pad.

5. For left-hand drive vehicles, disconnect the fuel

tank filler door lock release switch wiring

connector.

6. Remove the trim assembly.

Figure 1A3-44

DISASSEMBLE

REMOVE – INSTRUMENT PANEL STEERING

COLUMN OPENING FILLER

1. From the rear of the instrument cluster trim

assembly (1), prise the retainers (2), three places,

attaching the instrument panel steering column

opening filler (3).

2. Remove the filler from the trim assembly.

REINSTALL – INSTRUMENT PANEL STEERING

COLUMN OPENING FILLER

1. Fit the filler to the trim assembly, ensuring it is

correctly seated on each lug.

2. Attach the three retainers securely.

Figure 1A3-45

REMOVE – FUEL FILLER DOOR RELEASE SWITCH

ASSEMBLY, LHD

1. From the rear of the instrument cluster trim

assembly (1), depr ess the tab eac h s ide of the f uel

filler door release switch (2) to unclip the switch

assembly.

2. Rem ove the switch ass em bly from the f ace s ide of

the trim assembly.

NOTE: F or diagnosis of the f uel filler door switch, r efer

to Section 1A1, 4.5 FUEL TANK FILLER DOOR

LOCK ACTUATOR ASSEMBLY, LHD.

REINSTALL – FUEL FILLER DOOR RELEASE

SWITCH ASSEMBLY, LHD

1. Install the switch assembly from the face side of

the trim assembly, ensuring it clicks into place

securely.

Figure 1A3-46

REINSTALL

Reinstallation of the instrument cluster trim assembly

is the reverse of removal. Ensure the cluster trim and

filler are seated correctly Tighten the screws to the

specified torque.

INSTRUMENT CLUSTER TRIM

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.13 IN-CAR AIR TEMPERATURE SENSOR

LT Section –

As required, first remove the instrument cluster trim assembly, refer to 3.12 INSTRUMENT CLUSTER TRIM

ASSEMBLY.

REMOVE

1. Remove the screw (1) attaching the in-car air

temperature sensor (2) to the instrument panel.

2. Extract the sensor assembly from the cavity and

disconnect the air tube and wiring connector.

3. Remove the sensor assembly.

NOTE: For service and diagnosis of the sensor

assembly refer to Section 2F HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) - DIAGNOSTICS.

Figure 1A3-47

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

IN-CAR AIR TEMPERATURE

SENSOR ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.14 INSTRUMENT CLUSTER

LT Section – 09-100

As required, first remove the following components:

1. Instrument cluster trim assembly, refer to 3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY.

2. In-car air temperature sensor, if fitted, refer to 3.13 IN-CAR AIR TEMPERATURE SENSOR.

REMOVE

1. Remove the four screws (1) attaching the

instrument cluster (2) to the instrument panel.

2. Roll the top of the cluster from its cavity.

3. Using a fine f lat blade screwdriver, open the wiring

connector locking tab (3) on the back of the

cluster.

4. Remove the cluster assembly.

NOTE: For service and diagnosis of the instrument

cluster refer to Section 12C INSTRUMENTS.

Figure 1A3-48

REINSTALL

Reinstallation is the reverse of removal.

NOTE: Ensure the locking tab on the wiring connector

is fully closed.

IMPORTANT: Tighten the screws in the correct

sequence, refer to Figure 1A3-48, to the specified

torque.

INSTRUMENT CLUSTER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.15 HEADLAMP SWITCH

LT Section – 02-800

As required, first remove following components:

1. Instrument cluster trim assembly, refer to 3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY.

2. Right-hand instrument panel outer cover, refer to 3.17 INSTRUMENT PANEL OUTER COVER.

3. The driver’s side outer duct, refer to Section 2B, 18.2 HVAC SYSTEM DUCTS.

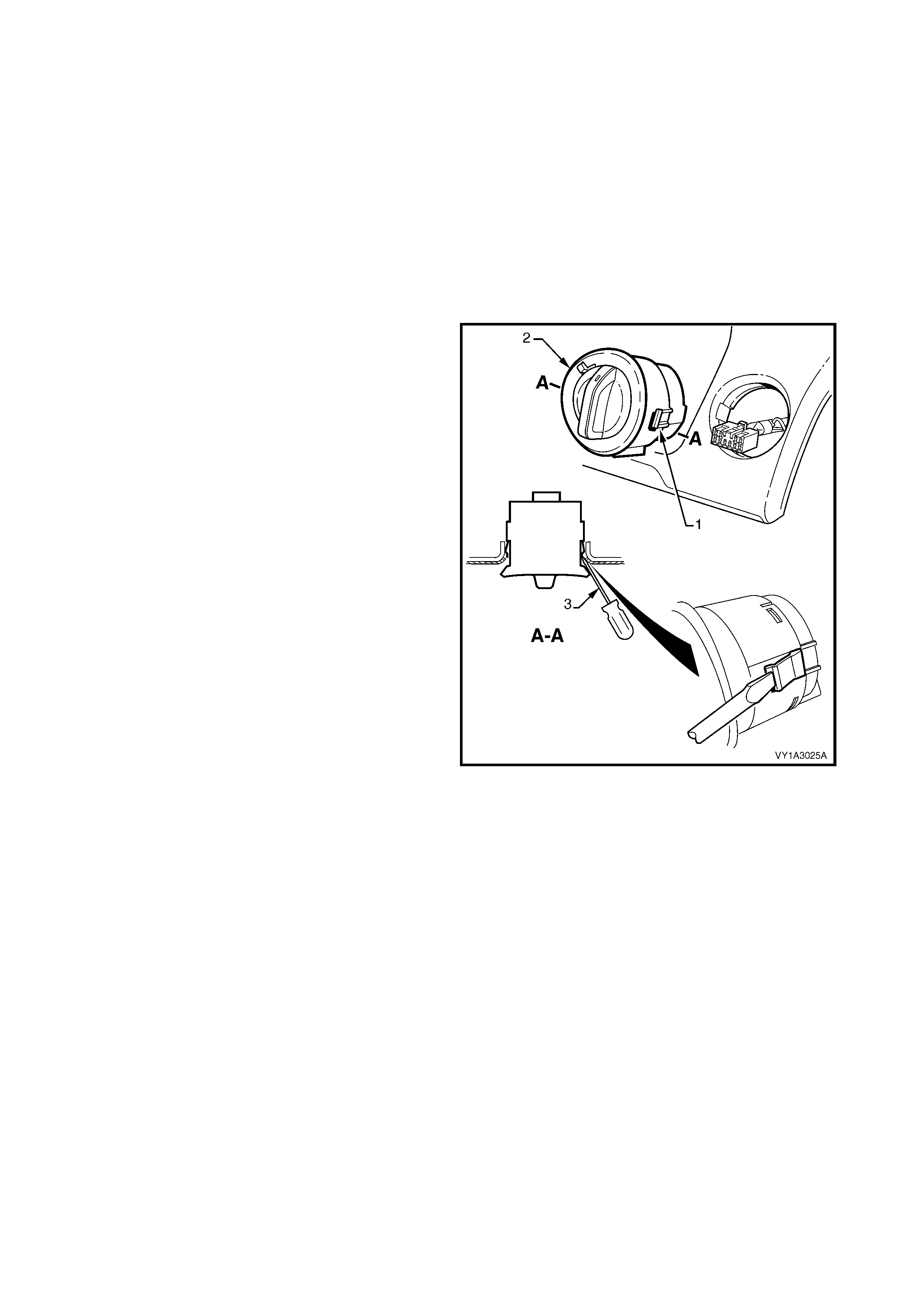

REMOVE

IMPORTANT: Care m ust be exercis ed when rem oving

the headlamp switch as the retaining clip and locating

guide will catch and damage the instrument panel

outer material.

1. Squeeze the retaining clips (1) on either side of the

headlamp switch assembly (2) and carefully push

the assembly part way from the cavity.

2. Insert a fine blade screwdriver (3) as shown and

hold the retaining clip depressed while slowly

manipulating the switch from its cavity. Repeat for

the opposite side and for the locating guide

underneath as required.

3. Disconnect the wiring connector and remove the

switch assembly.

NOTE: For service and diagnosis of the headlamp

switch assembly refer to Section 12B LIGHTING

SYSTEM.

Figure 1A3-49

REINSTALL

Reinstallation is the reverse of removal. Ensure the

retaining clips are correctly seated.

3.16 TRIP COMP UTER SWITCH

LT Section – 02-800

As required, first remove the following components:

1. Instrument cluster trim assembly, refer to 3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY.

2. Instrument panel centre trim assembly, refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY.

3. Manual HVAC controller, refer to 3.10 MANUAL HVAC CONTROLLER.

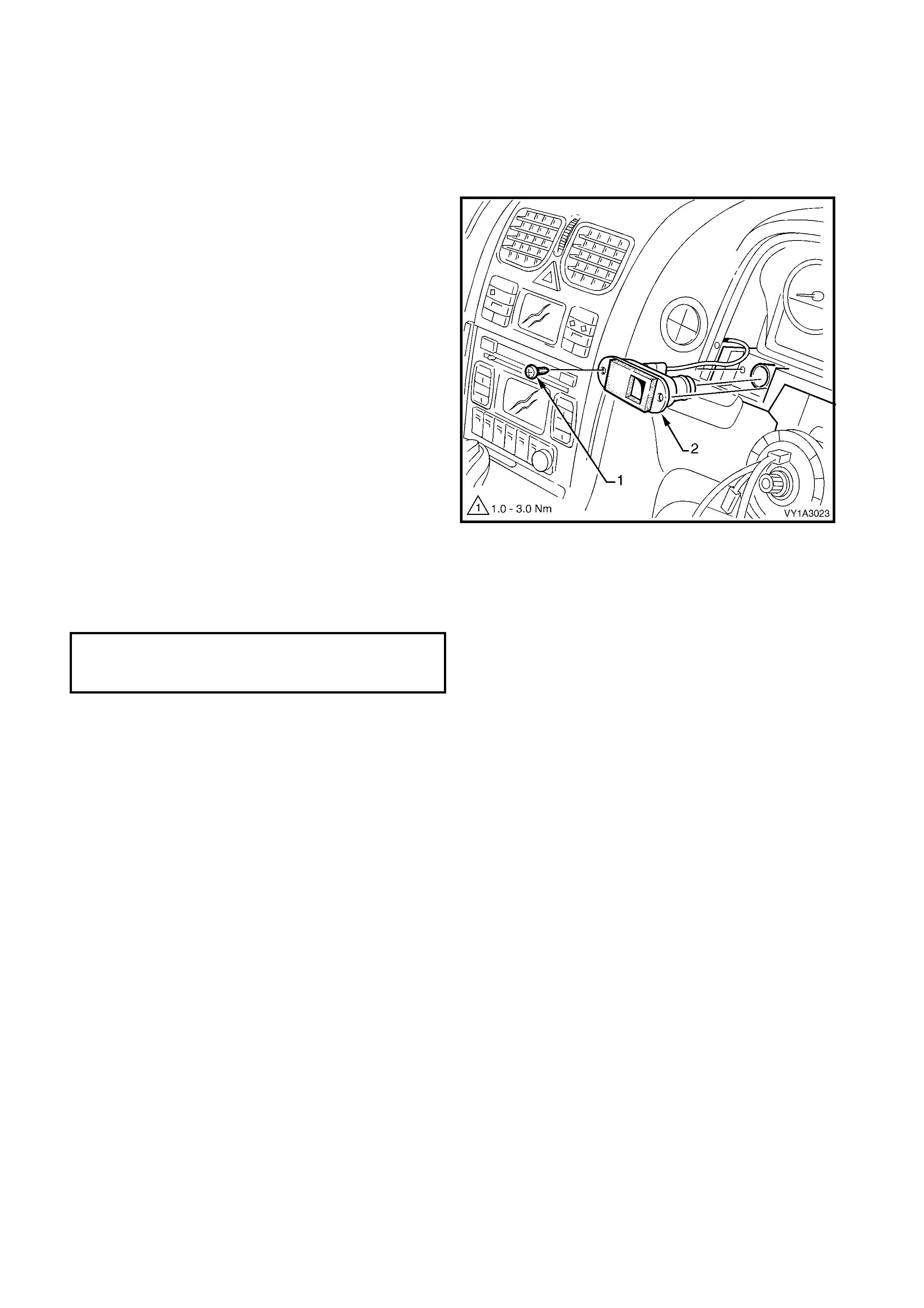

REMOVE

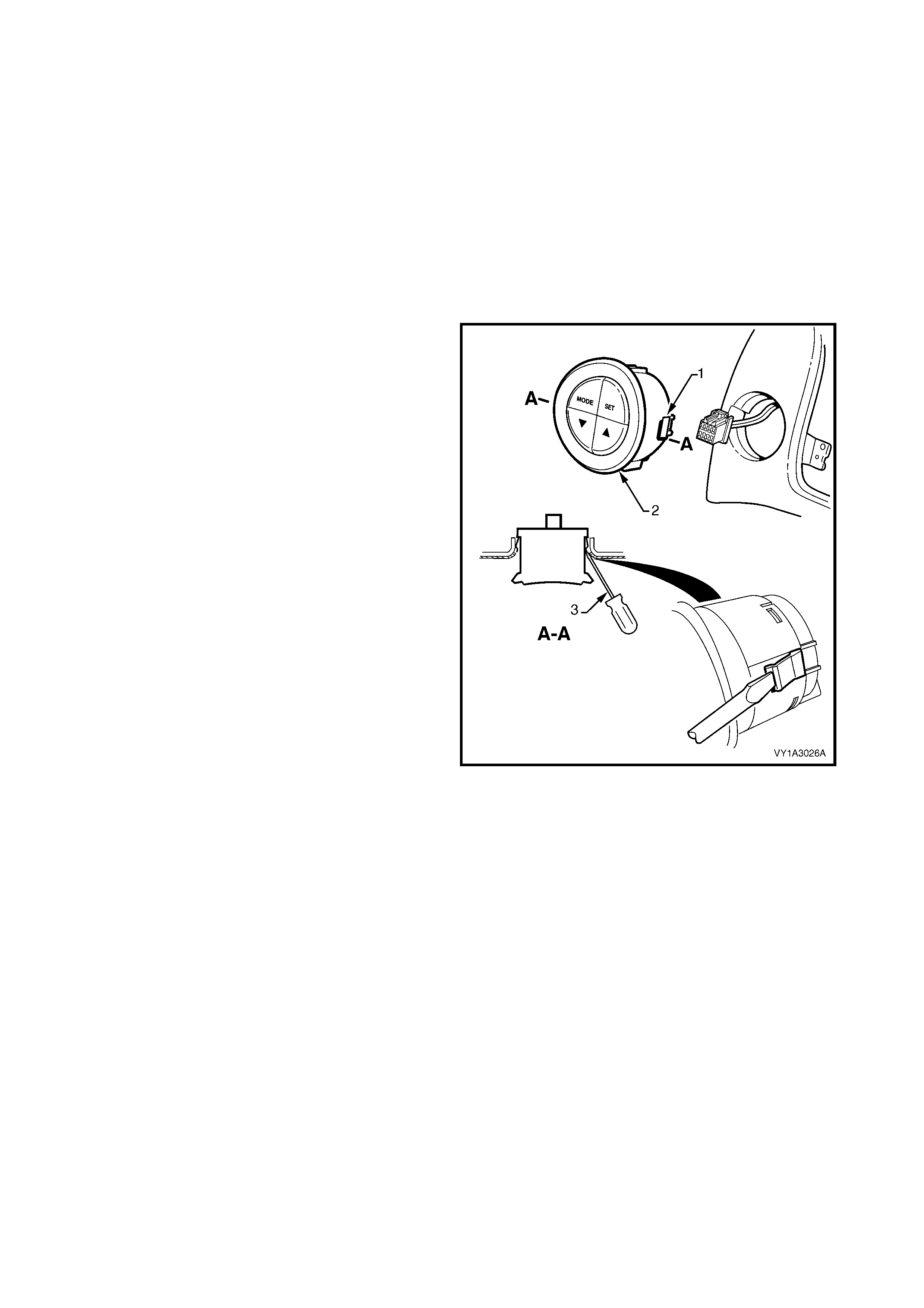

IMPORTANT: Care m ust be exercis ed when rem oving

the trip computer switch as the retaining clip and

locating guide will catch and damage the instrument

panel outer material.

1. Squeeze the retaining clips ( 1) on either side of the

trip computer switch assembly (2) and carefully

push the assembly part way out.

2. Insert a fine flat blade screwdriver (3) as shown

and hold the r etaining clips depres sed while slowly

manipulating the switch from its cavity. Repeat for

the opposite side and for the locating guide

underneath as required.

3. Disconnect the wiring connector and remove the

switch assembly.

NOTE: For service and diagnosis of the trip computer

switch refer to Section 12C INSTRUMENTS.

Figure 1A3-50

REINSTALL

Reinstallation of the trip switch is the reverse of

removal. Ensure the retaining clips are correctly

seated.

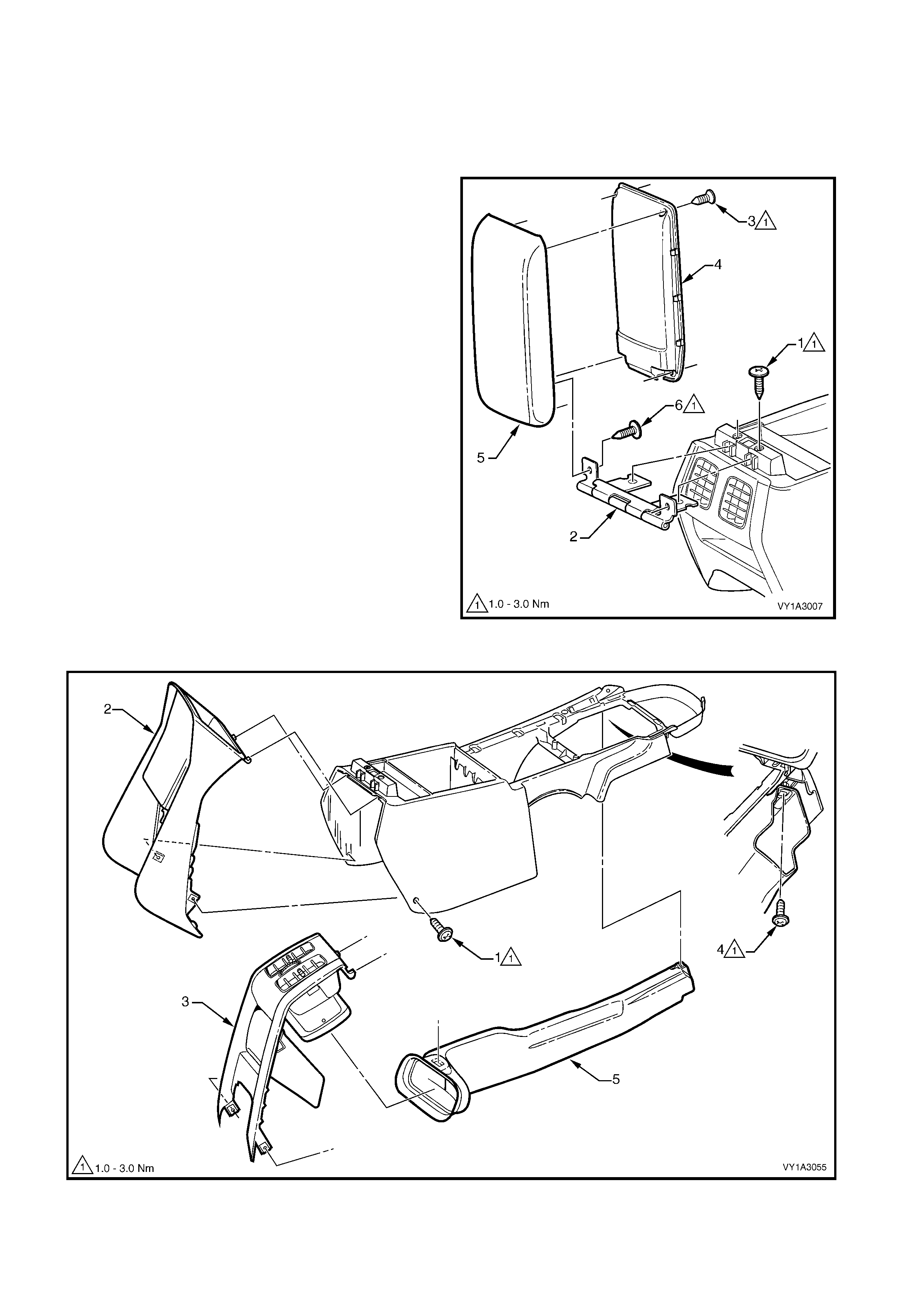

3.17 INS TRUMENT PANEL OUTER COVER

LT Section – 09-135

REMOVE

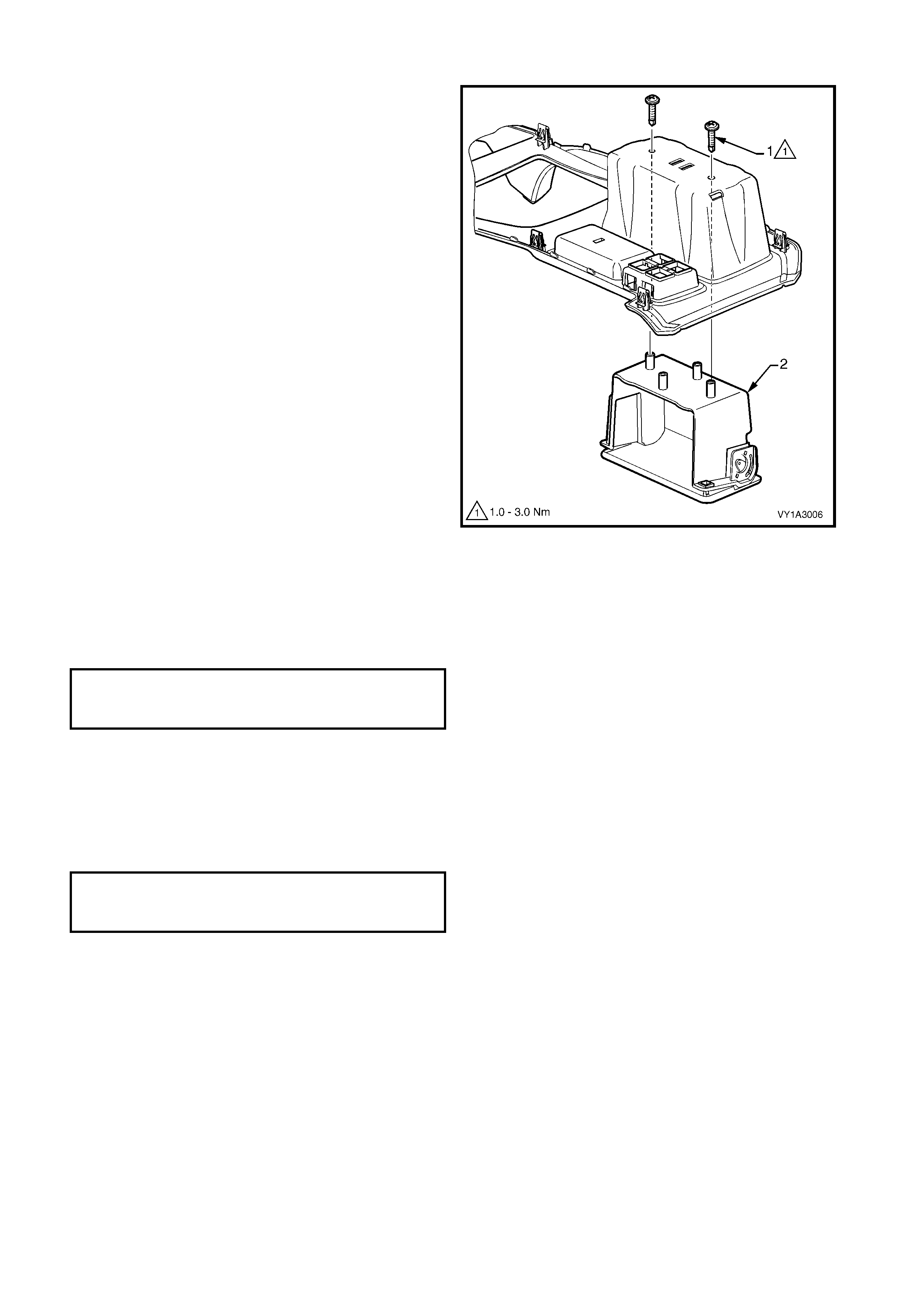

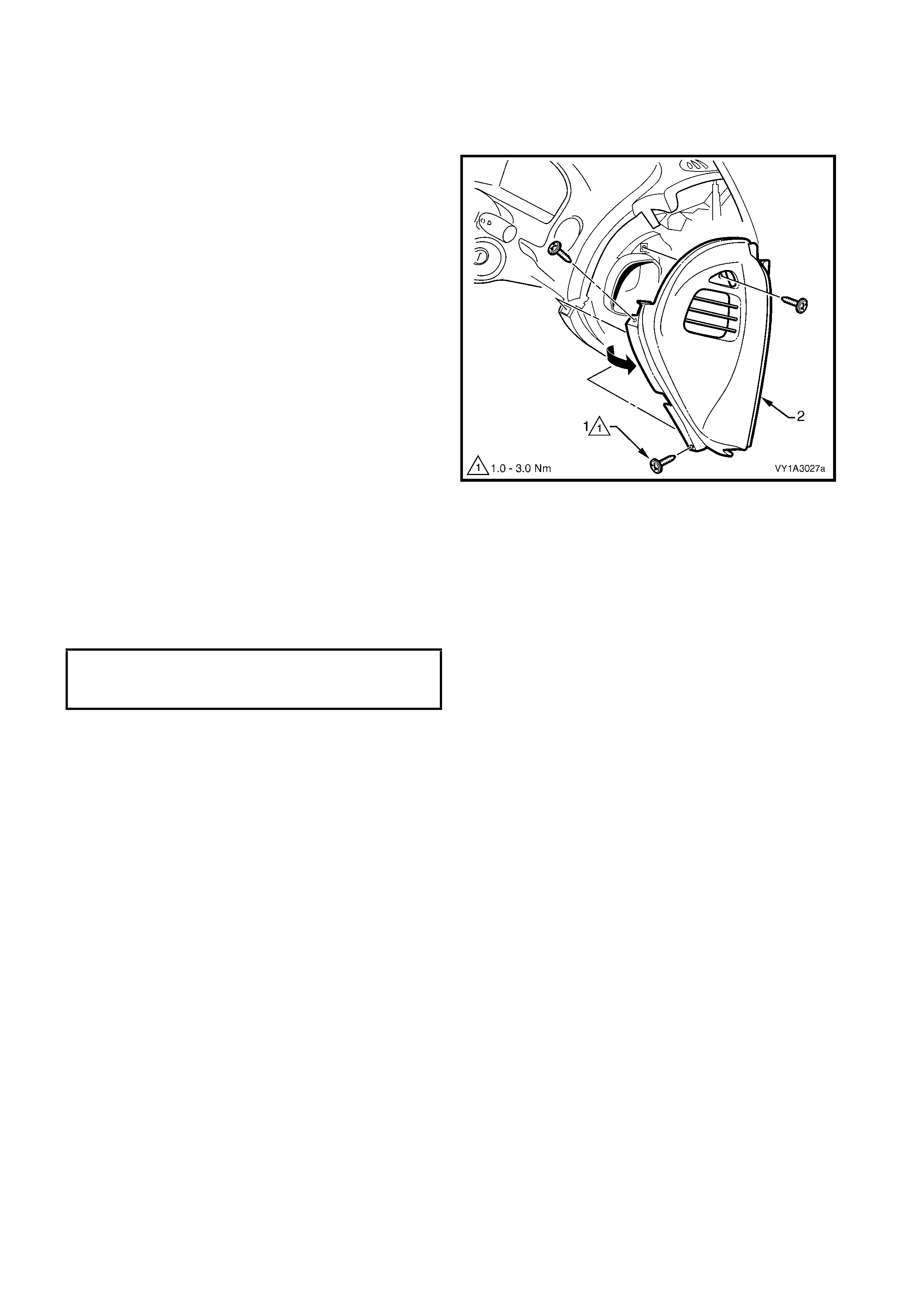

1. Remove the three screws (1) attaching the either

the right-hand (shown) or left-hand instrument

panel outer cover (2) to the instrument panel.

2. Remove the cover by rotating outward to

disengage the ventilation ducts.

Figure 1A3-51

REINSTALL

Reinstallation of the instrument panel outer cover is

the reverse of removal. Tighten the screws to the

specified torque.

NOTE: Ensure the ventilation ducts are correctly

seated and any seals are in place.

INSTRUMENT PANEL OUTER COVER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

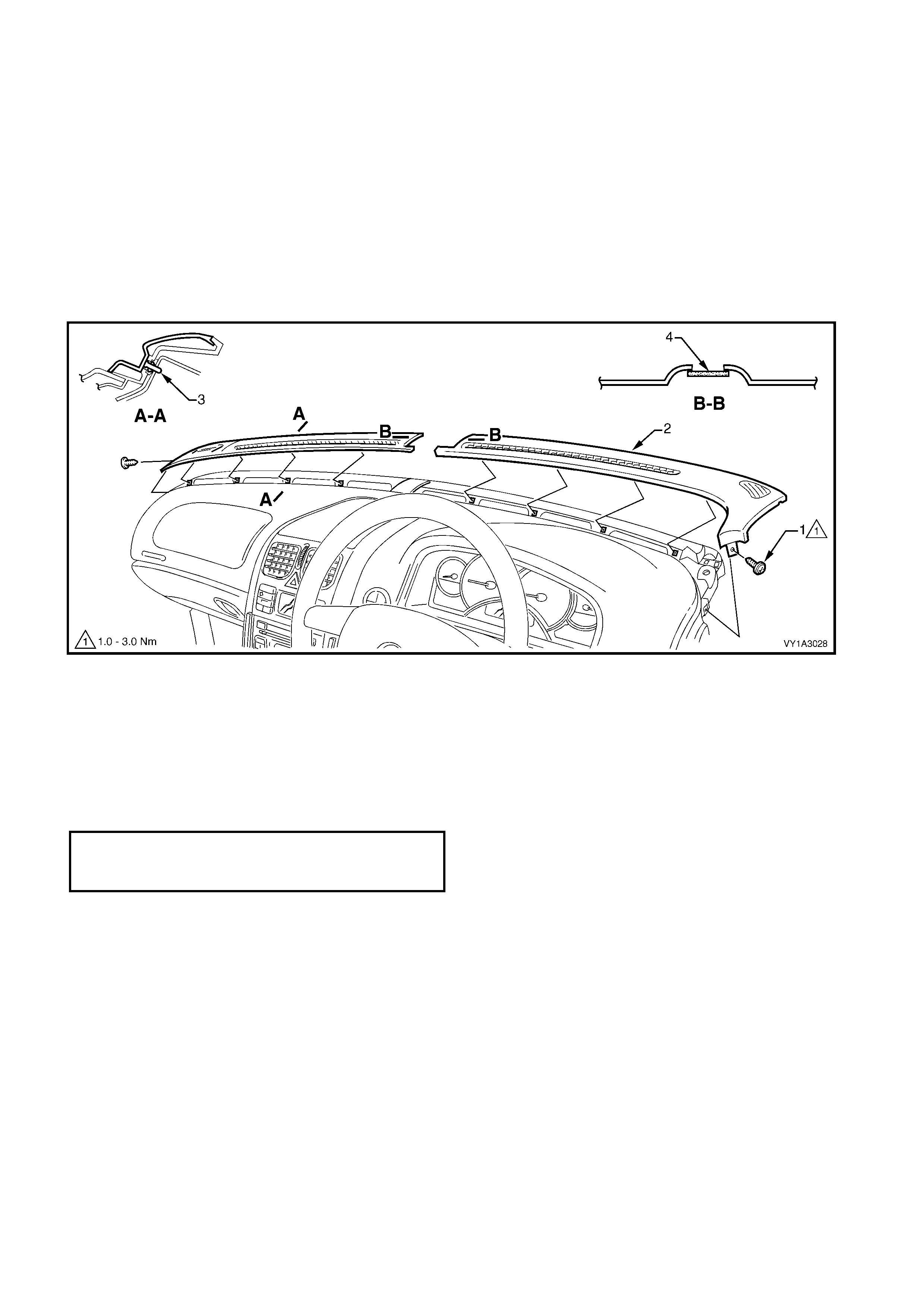

3.18 WINDSHIELD DEFROSTE R GRILLE

LT Section – 09-125

1. As required, first remove the instrument panel outer cover from the appropriate side(s), refer to

3.17 INSTRUMENT PANEL OUTER COVER.

REMOVE

Referring to Figure 1A3-52:

1. Remove the screw (1) attaching each windshield defroster grille (2) to the instrument panel.

2. Carefully remove the grille by unclipping (3), four places, at an angle equal to the windshield.

NOTE: As the grille is retained securely, removal may prove difficult. If required, a hook (such as an Allen key

held with vice-grips) can be used to assist removal. Insert the hook at the inner then outer end of the vent

opening. Ensure it is hooked under the grille and not the sheetmetal below.

Figure 1A3-52

REINSTALL

Reinstallation is the reverse of removal, noting the following:

1. Ensure the remote key receiver & headlamp auto control / sunload sensor (4) is correctly seated prior to

installing the grille assembly.

2. Ensure the four clips are correctly seated prior to installing the screw.

3. Tighten the screws to the specified torque.

WI NDSHIELD DEFROSTER

GRILLE ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

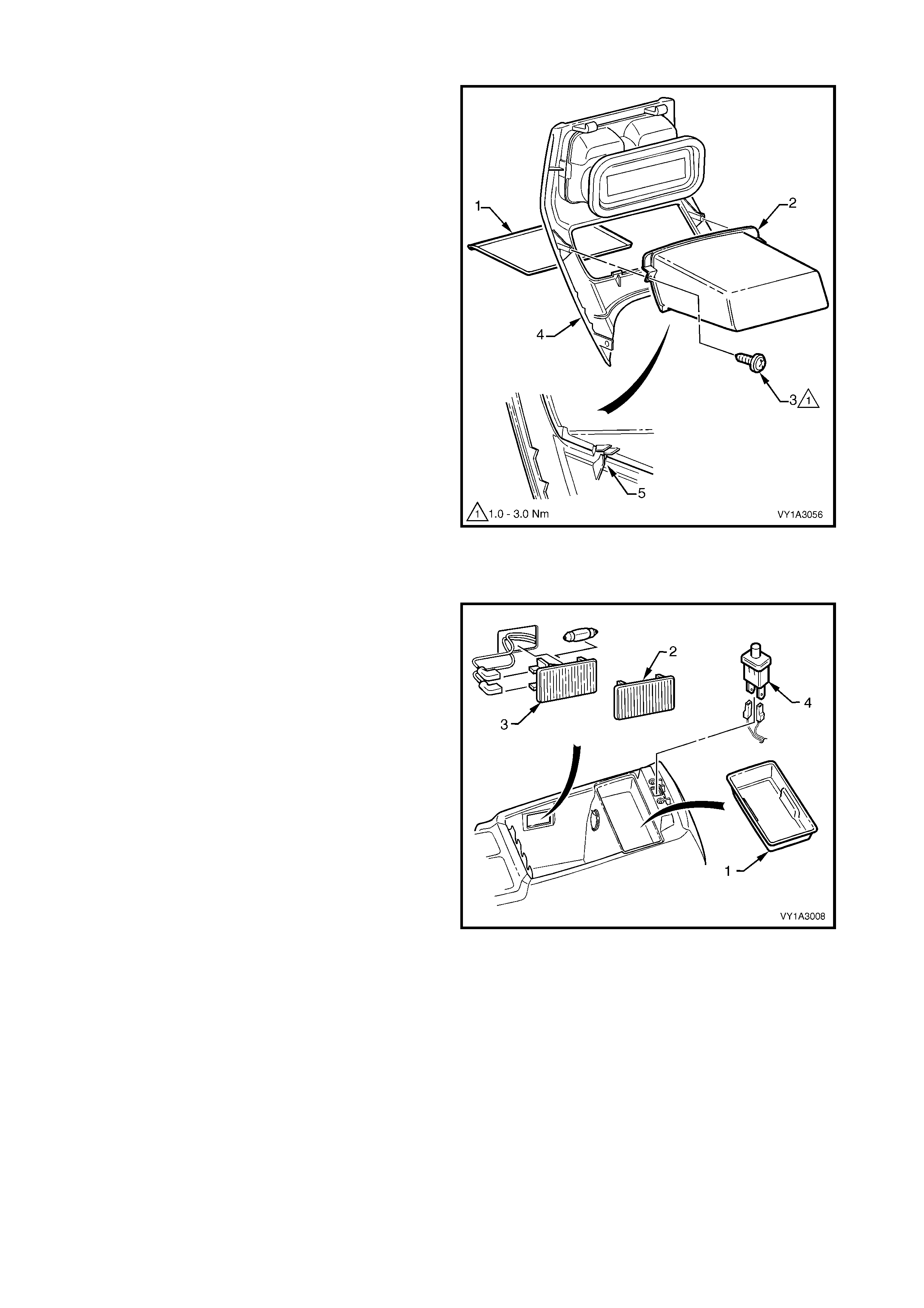

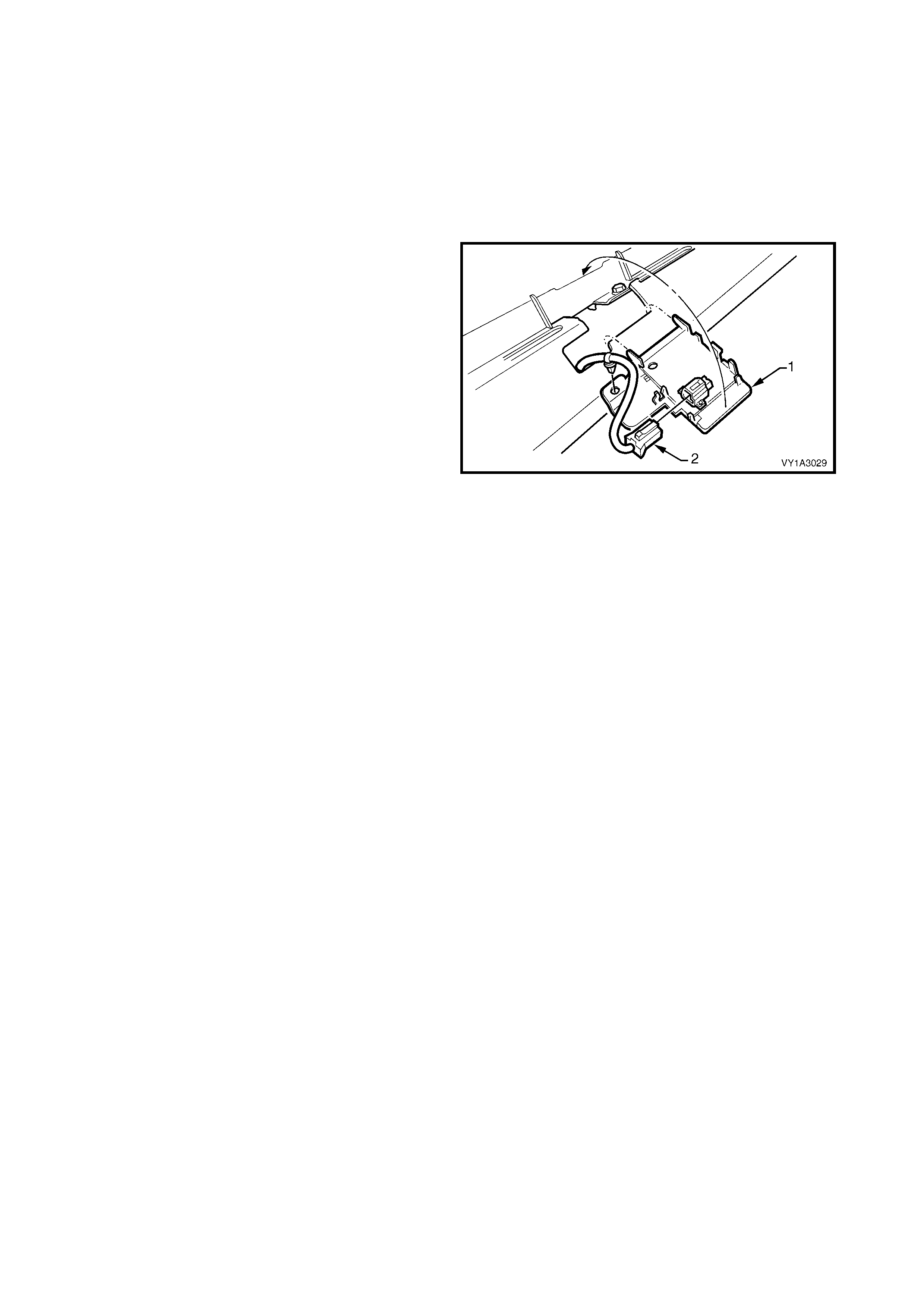

3.19 RE MOTE KEY RECEIVER & HE ADLAMP AUTO CONTROL / SUNLOAD SENSOR

LT Section – 08-155A

As required, first remove the following components:

1. Instrument panel outer cover from both sides, refer to 3.17 INSTRUMENT PA NEL OUTER COVER.

2. Windshield defroster grille assembly from both sides, refer to 3.18 WINDSHIELD DEFROSTER GRILLE

ASSEMBLY.

REMOVE

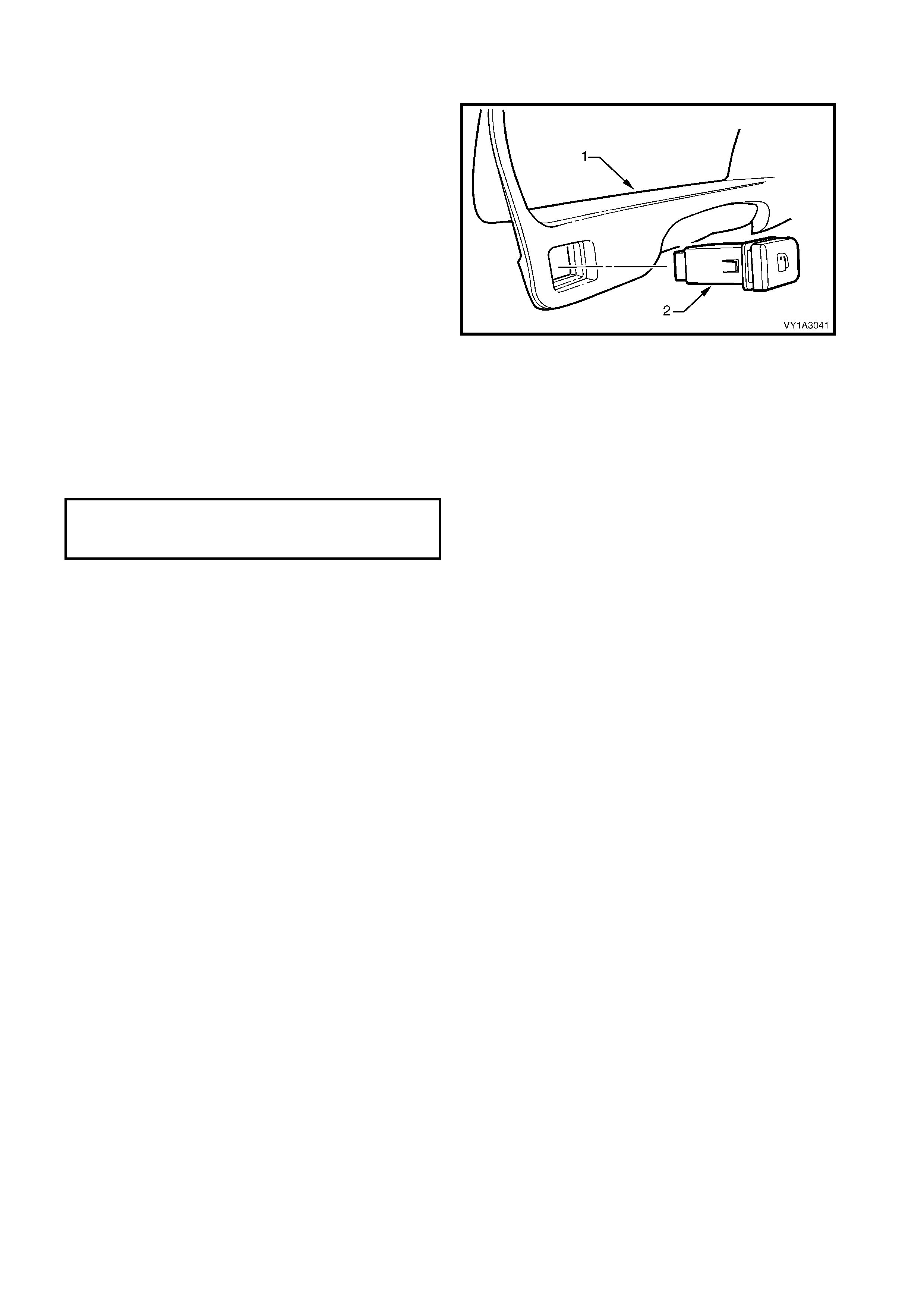

1. Carefully unclip the receiver and sensor (1) from

the instrument panel.

2. Disconnect the wiring connector (2), unclip the

wiring harness from the sensor assembly and

remove.

NOTE 1: For service and diagnosis of the remote key

receiver & headlamp auto control sensor refer to

Section 12J BODY CONTROL MODULE.

NOTE 2: For service and diagnosis of the sunload

sensor, refer to Section 2D HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C).

Figure 1A3-53

REINSTALL

Reinstallation of the sens or assem bly is the r everse of

removal.

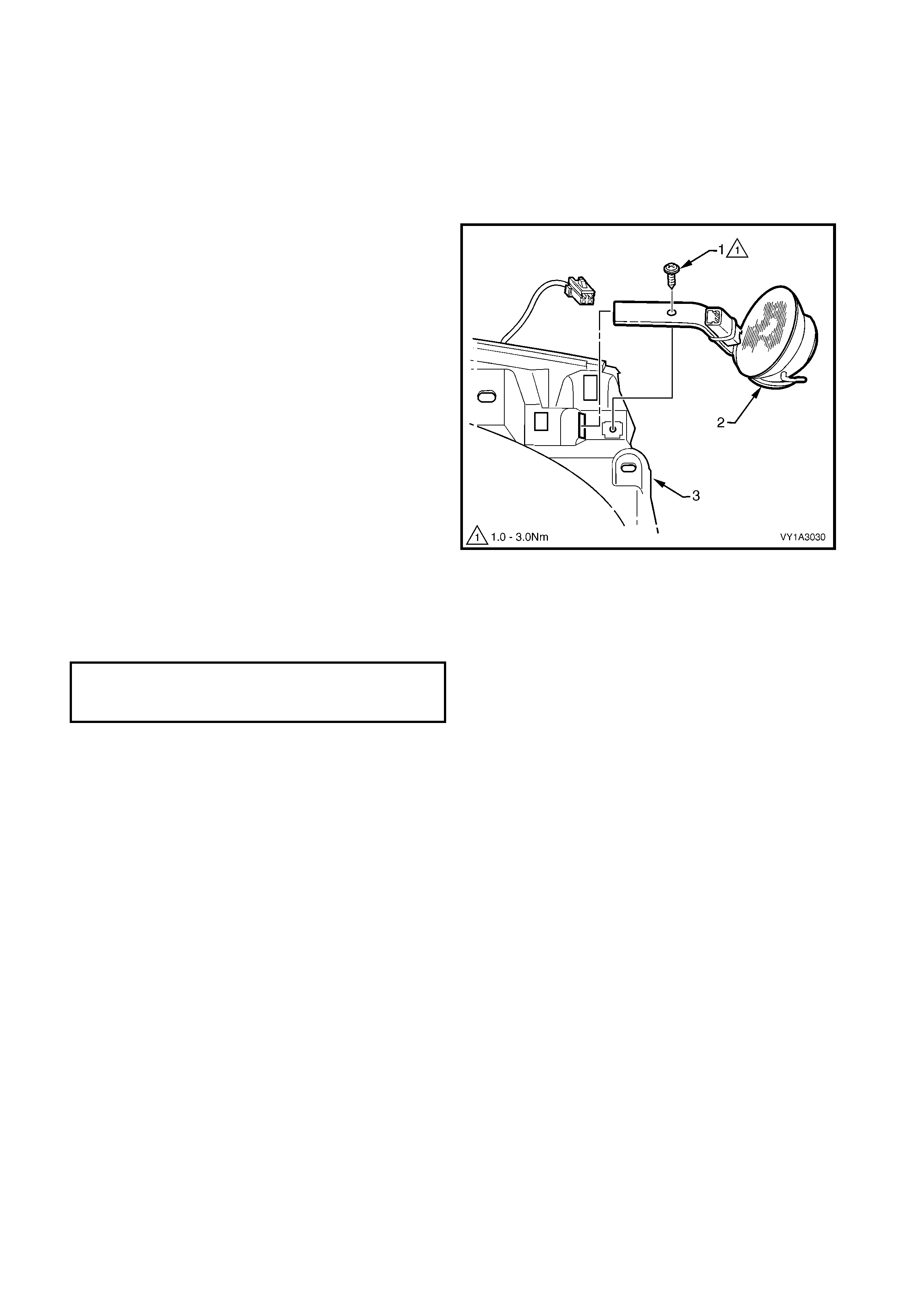

3.20 INSTRUMENT PANEL SPEAKER

LT Section – 09-500

As required, first remove the following components on the applicable side:

1. Instrument panel outer cover, refer to 3.17 INSTRUMENT PANEL OUTER COVER.

2. Windshield defroster grille assembly, refer to 3.18 WINDSHIELD DEFROSTER GRILLE ASSEMBLY.

REMOVE

1. Remove the screw (1) attaching the instrument

panel speaker (2) to the instrument panel (3).

2. Disconnect the wiring connector and remove the

speaker by withdrawing it from the slot in the

instrument panel.

NOTE: For service and diagnosis of the instrument

panel speaker refer to Section 12D

ENTERTAINMENT SYSTEM.

Figure 1A3-54

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screw to the specified torque.

INSTRUMENT PANEL SPEAKER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.21 INSTRUMENT PANEL PAD ASSEMBLY

LT Section – 09-125

As required, first remove the following components:

1. Floor console assembly, refer to 2.3 FLOOR CONSOLE ASSEMBLY.

2. Driver and passenger side instrum ent panel lower trim plate assembly, refer to 3.1, INSTRUMENT PANEL

LOWER TRIM PLATE ASSEMBLY.

3. Instrument panel compartment assembly, refer to 3.2 INSTRUMENT PANEL COMPARTMENT

ASSEMBLY.

4. Instrument panel compartment lamp and instrument panel compartment lamp switch, refer to

3.3 INSTRUMENT PANEL COMPARTMENT LAMP & SWITCH.

5. Instrument panel lower trim panel, refer to 3.4 INSTRUMENT PANEL LOWER TRIM PANEL.

6. Instrument panel lower trim panel retainer, refer to 3.5 INSTRUMENT PANEL LOWER TRIM PANEL

RETAINER.

7. Radio assembly, refer to 3.6 RADIO ASSEMBLY.

8. Instrument panel centre trim assembly, refer to 3.7 INSTRUMENT PANEL CENTRE TRIM ASSEMBLY.

9. Instrument panel lower compartment or ashtray assembly, refer to 3.8 INSTRUMENT PANEL LOWER

COMPARTMENT or ASHTRAY ASSEMBLY.

10. Instrument panel lower extension, refer to 3.9 INSTRUMENT PANEL LOWER EXTENSION.

11. Manual HVAC controller, where fitted, refer to 3.10 MANUAL HVAC CONTROLLER.

12. Radio housing and radio bracket assembly, refer to 3.11 RADIO HOUSING AND RADIO BRACKET

ASSEMBLY.

13. Instrument cluster trim assembly, refer to 3.12 INSTRUMENT CLUSTER TRIM ASSEMBLY.

14. In-car air temperature sensor, if fitted, refer to 3.13 IN-CAR AIR TEMPERATURE SENSOR.

15. Instrument cluster, refer to 3.14 INSTRUMENT CLUSTER.

16. Headlamp switch, refer to 3.15 HEADLAMP SWITCH.

17. Trip Switch, refer to 3.16 TRIP SWITCH.

18. Left-hand and right-hand instrument panel outer covers, refer to 3.17 INSTRUMENT PANEL OUTER

COVER.

19. Left-hand and right-hand windshield defroster grille assemblies, refer to 3.18 WINDSHIELD DEFROSTER

GRILLE.

20. Rem ote key receiver & headlamp auto control / sunload sensor, refer to 3.19 REMOT E KEY RECIEVER &

HEADLAMP AUTO CONTROL / SUNLOAD sensor.

21. Instrument panel speaker, refer to 3.20 INSTRUMENT PANEL SPEAKER.

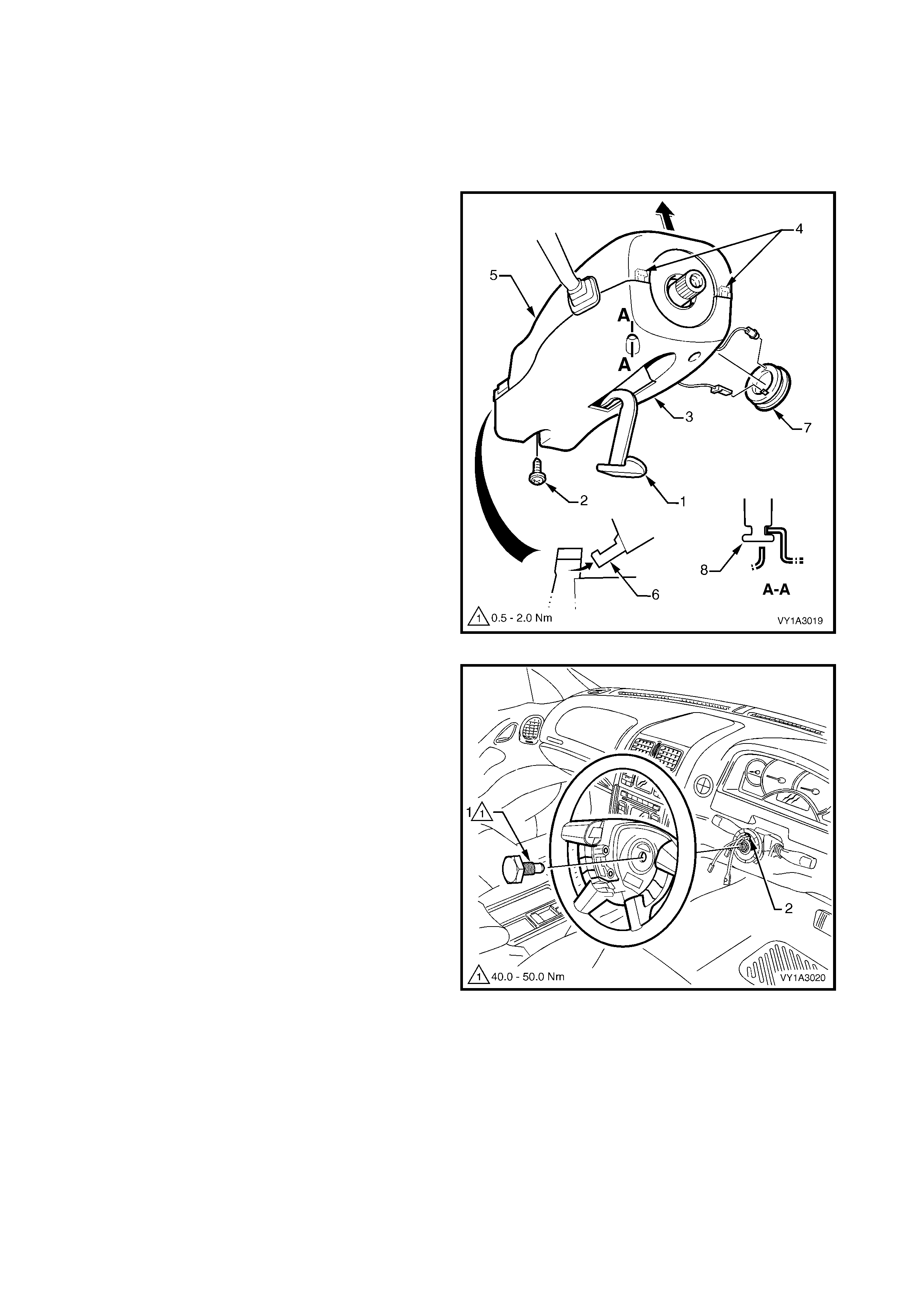

REMOVE

IMPORTANT: Disconnection of the battery

affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION

PROCEDURES before disconnecting the battery.

1. Disconnect the battery.

2. Release the steering column adjustment lever (1)

and move the column to its lowest position.

3. From below the steering column, remove the

screw (2 ) attaching the lower cover (3).

NOTE: The covers can be removed with the steering

wheel installed, however it is not shown for clarity.

4. Depress the face of the lower cover inwards to

disengage the tabs (4) and lift the steering colum n

upper cover (5).

5. Raise the upper cover as high as possible to

disengage the lugs (6) and remove the cover.

6. Push the outer ring of the theft deterrent receiver

assembly (7) into the steering column lower cover.

7. Slide the lower cover rearward to disengage it from

the lugs (8) and remove the cover.

8. Remove the steering wheel inflatable restraint

module, refer to Section 12M OCCUPANT

PROTECTION SYSTEM.

NOTE: Special Tool required.

Figure 1A3-55

9. Place the road wheels in the straight-ahead

position and lock the steering column.

10. Remove the screw (1).

11. Remove the steering wheel, disconnecting and

feeding the wires through the aperture as required.

NOTE: A puller should not be required, however if the

wheel assembly cannot be removed fairly easily, use

puller J1859-A and legs E1408.

12. Check that the green indicator (2) on the inflatable

restraint module coil assembly has engaged the

inner clock spring to lock it in the central position.

Figure 1A3-56

13. Disconnect the wiring connectors from the rear of

the turn signal switch assem bly (1) and windshield

wiper & washer switch assembly.

14. Depress the two tabs (2) securing the switch and

slide from the steering column assembly. Repeat

for the other switch.

NOTE 1: For service and diagnosis of the turn signal

switch assembly refer to Section 12B LIGHTING

SYSTEM.

NOTE 2: For service and diagnosis of the windshield

wiper & washer switch assembly refer to Section 12N

WIPERS / WASHERS & HORN.

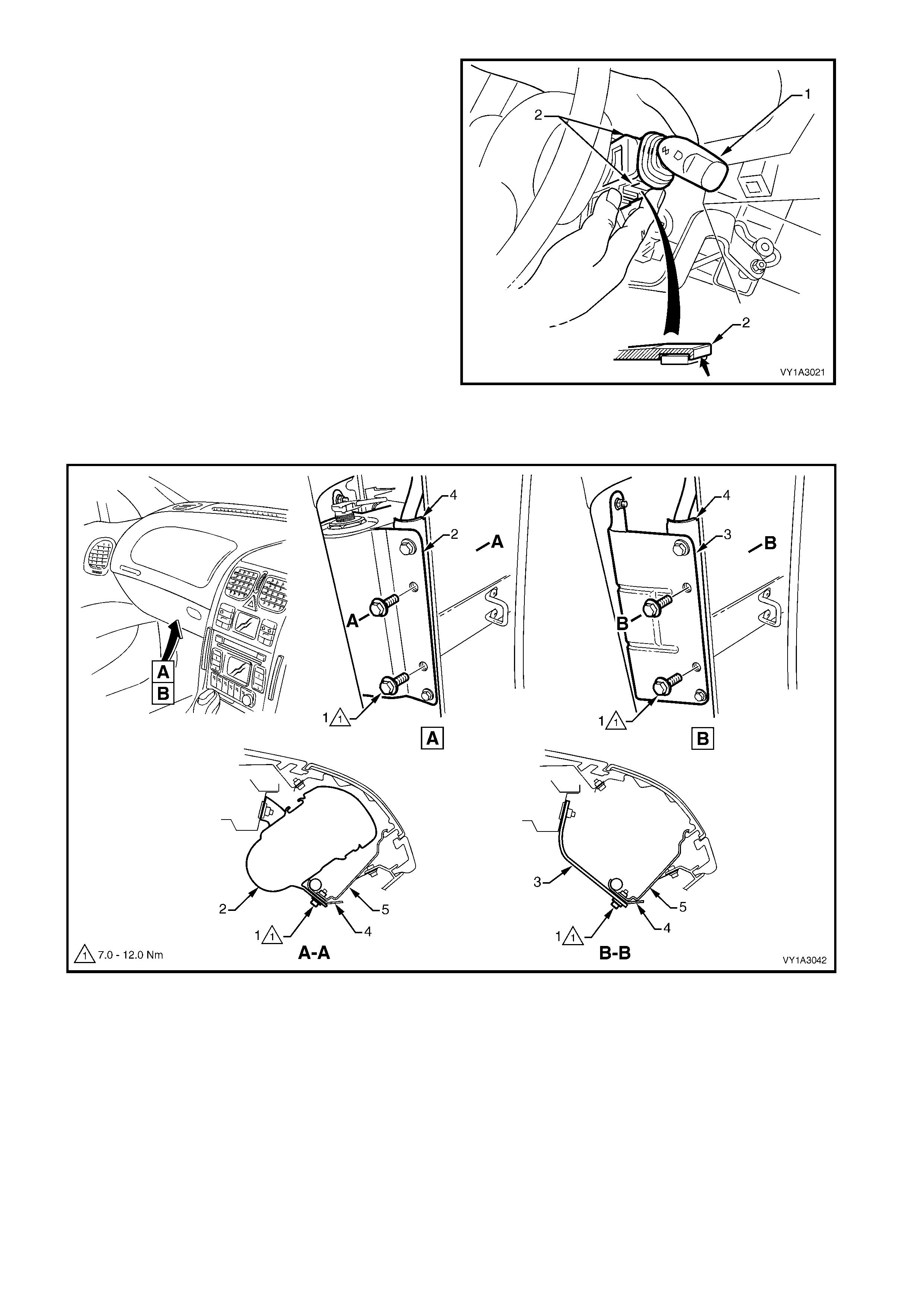

15. Remove the two inner screws (1) attaching the

instrument panel inflatable restraint (2) or

instrument panel outer upper bracket (3) and

instrument panel lower bracket (4) to the

instrument panel inflatable restraint bracket (5),

refer to Figure 1A3-58.

NOTE: View A is for vehicles with an instrum ent panel

inflatable restraint. View B is for vehicles without an

instrument panel inflatable restraint.

Figure 1A3-57

Figure 1A3-58

16. Referring Figure 1A3-59, remove the following screws attaching the instrument pad assembly:

a. left-hand end (1) one place,

b. to the left-hand air duct (2) one place,

c. passenger side lower (3 & 4) two places each,

d. left of centre (5) one place,

e. driver side lower (6) one place,

f. within the instrument cluster hood (7), one place,

g. to the right-hand air duct (8) one place,

h. right-hand end (9) one place,

i. along the upper edge (10), five places.

17. With the aid of an assistant, carefully lift the pad assembly out of the vehicle and place on a soft surface.

Figure 1A3-59

DISASSEMBLE

NOTE: The instrument panel pad is attached to the

carrier with screws and adhesive and is not serviced.

1. From the rear side of the instrument panel pad

assembly, remove the four screws (1) attaching

the instrument panel inflatable restraint opening

trim cover (2) to the instrument panel inflatable

restraint bracket (3).

2. While pushing on the trim cover, detach the four

tabs (4) and remove the trim cover.

Figure 1A3-60

3. From the rear side of the instrument panel pad

assembly, remove the screw (1), four places,

attaching the instrument panel inflatable restraint

bracket (2) to the pad assembly.

4. Remove the screw (3) , six places, and r emove the

bracket from the pad assembly.

Figure 1A3-61

REASSEMBLE

1. Fit the bracket in position, ensuring the lower

screw hole tabs ar e correctly positioned in the pad

assembly.

2. Install the upper and lower screws and tighten to

the specified torque.

3. Locate the trim cover in the pad assem bly opening

and align the trim cover with the four tabs.

4. Push the trim cover into position, install the four

screws and tighten to the specified torque.

INSTRUMENT PANEL INFLATABLE

RESTRAINT BRACKET LOWER

ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

INSTRUMENT PANEL INFLATABLE

RESTRAINT BRACKET UPPER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL INFLATABLE

RESTRAINT OPENING TRIM COVER

ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

REINSTALL

Reinstallation of the instrument panel pad assembly is

the reverse of removal noting the following:

1. Ensure the wiring connectors are located through

their correct cavity, refer to Section 12O FUSES &

WIRING HARNESS.

2. Tighten the screws to the specified torque.

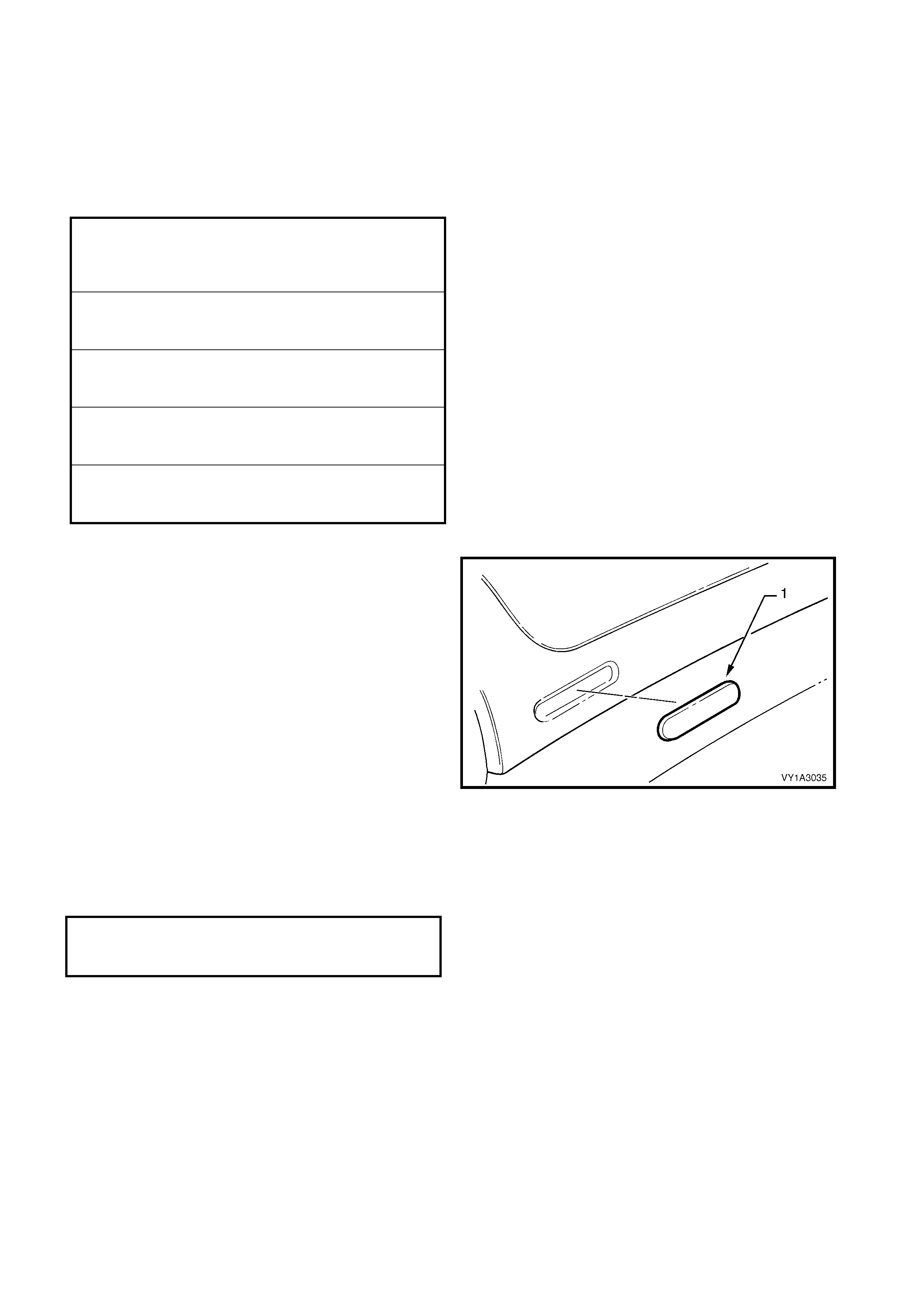

3. If a new instrument panel pad assembly is being

installed, fit a new nameplate (1). Clean the

surface with wax and grease remover such as

Prepsol or equivalent and affix the emblem

centrally in its recess.

NOTE: Press the emblem firmly for at least 10

seconds.

4. Install the windshield wiper switch assembly and

turn signal switch assembly, ensure they are

correctly seated.

5. Connect the wiring connectors to the back of the

switches and ensure the wiring is correctly routed,

refer to Section 12O FUSES & WIRING

HARNESS.

6. Install the steer ing colum n covers in the revers e of

removal. Tighten the screw to the specified torque.

NOTE: Ensure the turn signal / wiper switch boots are

seated correctly.

Figure 1A3-62

INSTRUMENT PANEL INFLATABLE

RESTRAINT TO INSTRUMENT PANEL

LOWER BRACKET SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

INSTRUMENT PANEL PAD ASSEMBLY

SIDE ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL PAD ASSEMBLY

TO AIR DUCT ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL PAD ASSEMBLY

LOWER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL PAD ASSEMBLY

UPPER ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

STEERING COLUMN LOWER

COVER ATTACHING SCREW

TORQUE SPECIFICATION 0.5 – 2.0 Nm

7. Ensure the road wheels are in the straight-ahead

position and that the green indictor on the s teering

wheel inflatable restraint coil assembly is visible.

8. Install the steering wheel assembly in its correct

orientation, feeding the wires through the aperture.

9. Apply Loctite 242 or equivalent to the thread of the

steering wheel screw thread.

10. Tighten the screw to the specified torque.

11. Connect the wiring connectors as required.

12. Install the steering wheel inflatable restraint

module, refer to Section 12M OCCUPANT

PROTECTION SYSTEM.

STEERING WHEEL ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 40.0 – 50.0 Nm

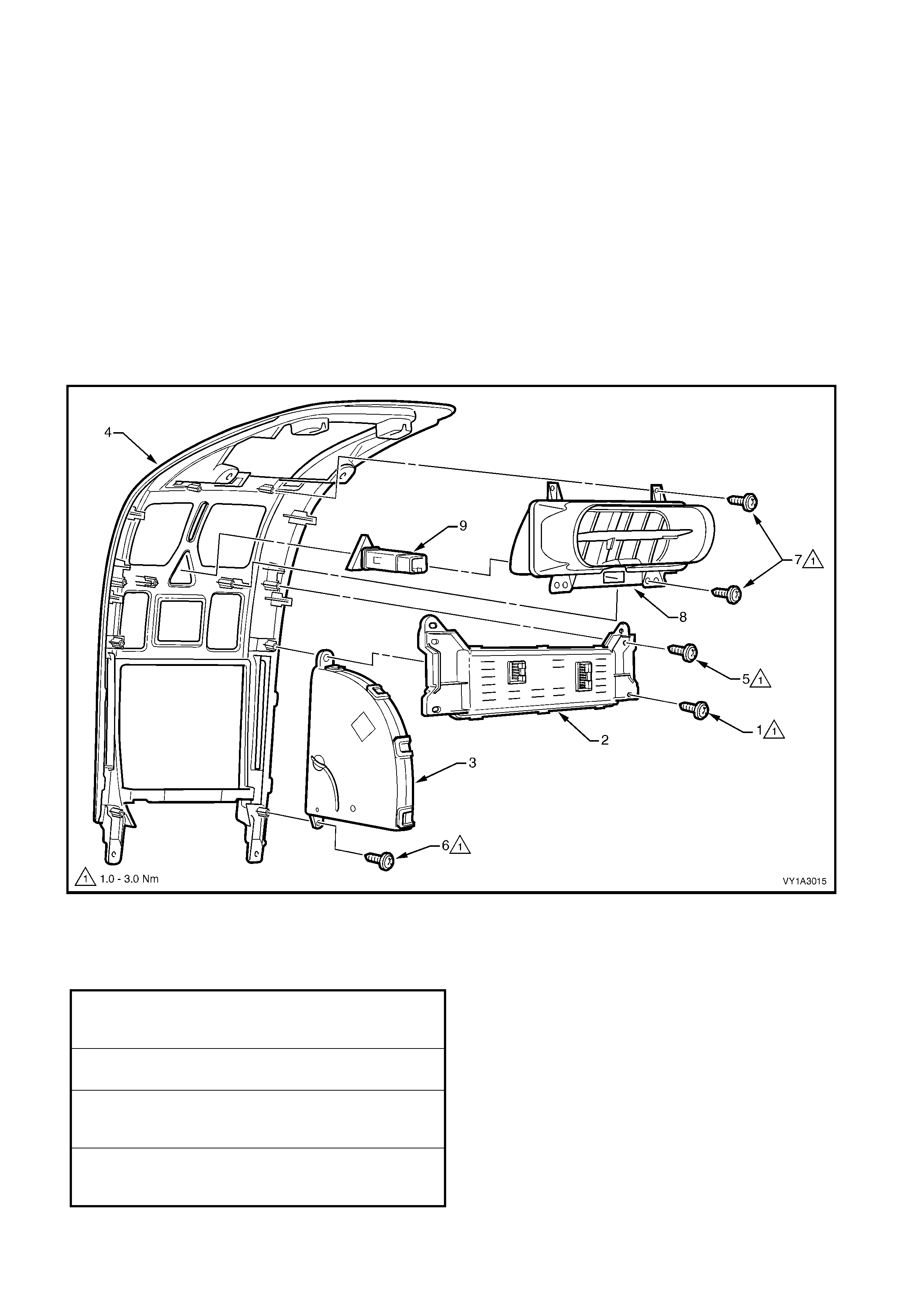

3.22 INSTRUMENT PANEL BRACKE TS & BRACES

LT Section –

Figure 1A3-63

Legend

1. Instrument Panel Compartment Bracket

2. Instrument Panel Lower Bracket

3. Instrument Panel Outer Upper Bracket

4. Lower Radio Bracket

5. Steering Column Bracket Inner Brace

6. Steering Column Bracket Outer Brace

INSTRUMENT PANEL COMPARTMENT BRACKET

REMOVE

1. Remove the instrument panel compartment, refer

to 3.2 INSTRUMENT PANEL COMPARTMENT

ASSEMBLY.

2. Remove the sc rew (1) attaching the HVAC unit (2)

to the instrument panel compartment bracket (3).

3. Remove the screw (4), two places, attaching the

bracket to the instrument panel lower bracket (5)

and remove the bracket.

4. As required, prise each instrument panel

compartment hinge (6) from the bracket.

Figure 1A3-64

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

NOTE: Take care not to over-tighten the screw

attaching the HVAC unit as the bracket can be easily

damaged.

INSTRUMENT PANEL COMPARTMENT

BRACKET ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL LOWER BRACKET

As required, first remove the following components:

1. Instrument panel pad assembly, refer to 3.21 INSTRUMENT PANEL PAD ASSEMBLY.

2. Instrument panel compartment bracket as previously described.

3. Telematics module, if fitted, refer to Section 12K TELEMATICS.

4. Navigation speaker assembly, if fitted, refer to Section 12L, 3.4 NAVIGATION SPEAKER ASSEMBLY.

REMOVE

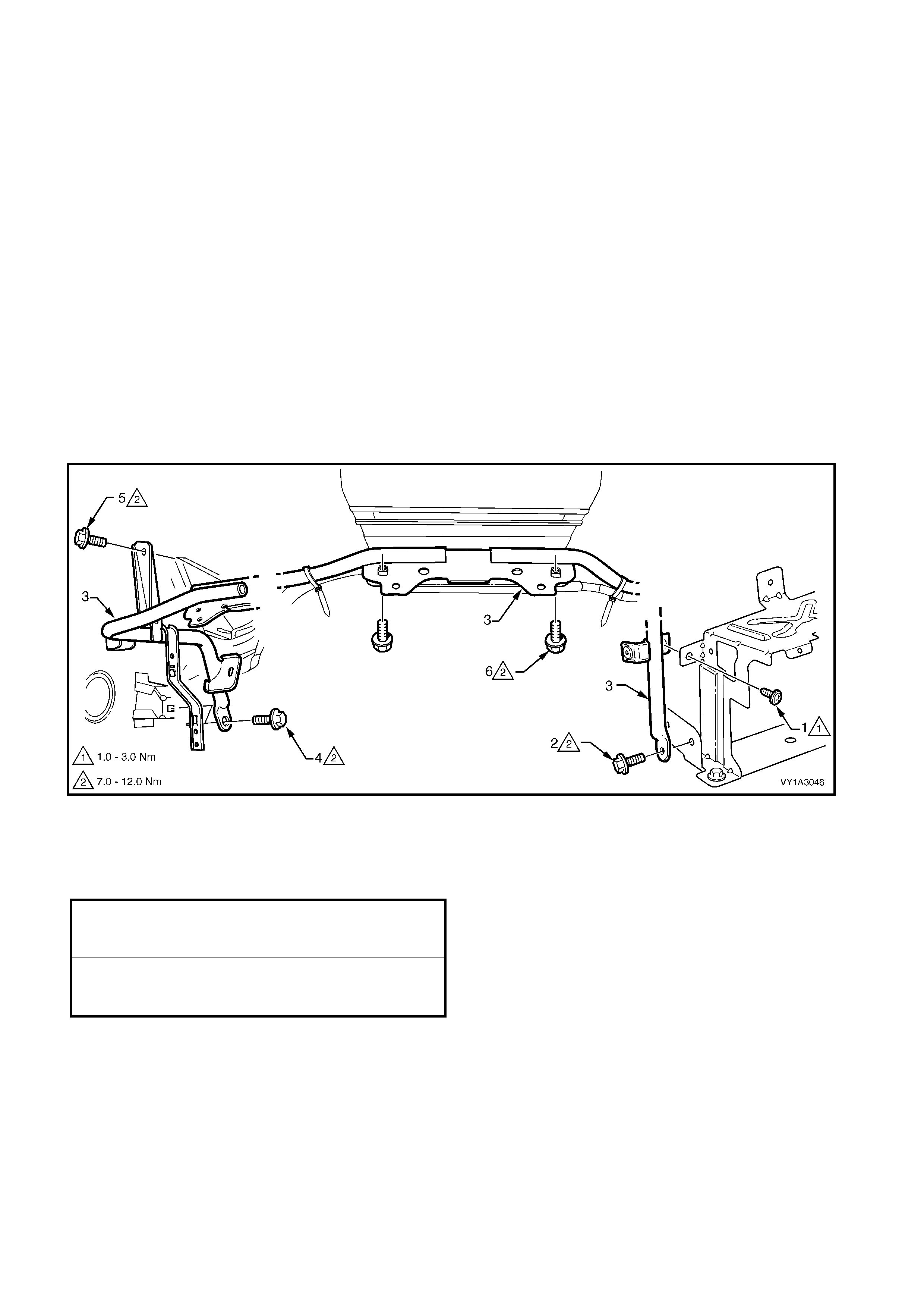

Referring to Figure 1A3-65:

1. Remove the screws (1 & 2) attaching the

instrument panel lower bracket (3) to the lower

radio bracket.

2. Remove the screws (4 & 5) attaching the bracket

to the vehicle.

3. Remove the two screws (6) attaching the bracket

to the instrument panel inflatable restraint or

instrument panel outer upper bracket (vehicles

without instrument panel inflatable restraint),

unattach the wiring harness(s) as required and

remove the bracket.

Figure 1A3-65

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

INSTRUMENT PANEL LOWER BRACKET

ATTACHING SELF-TAPPING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL LOWER

BRACKET ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

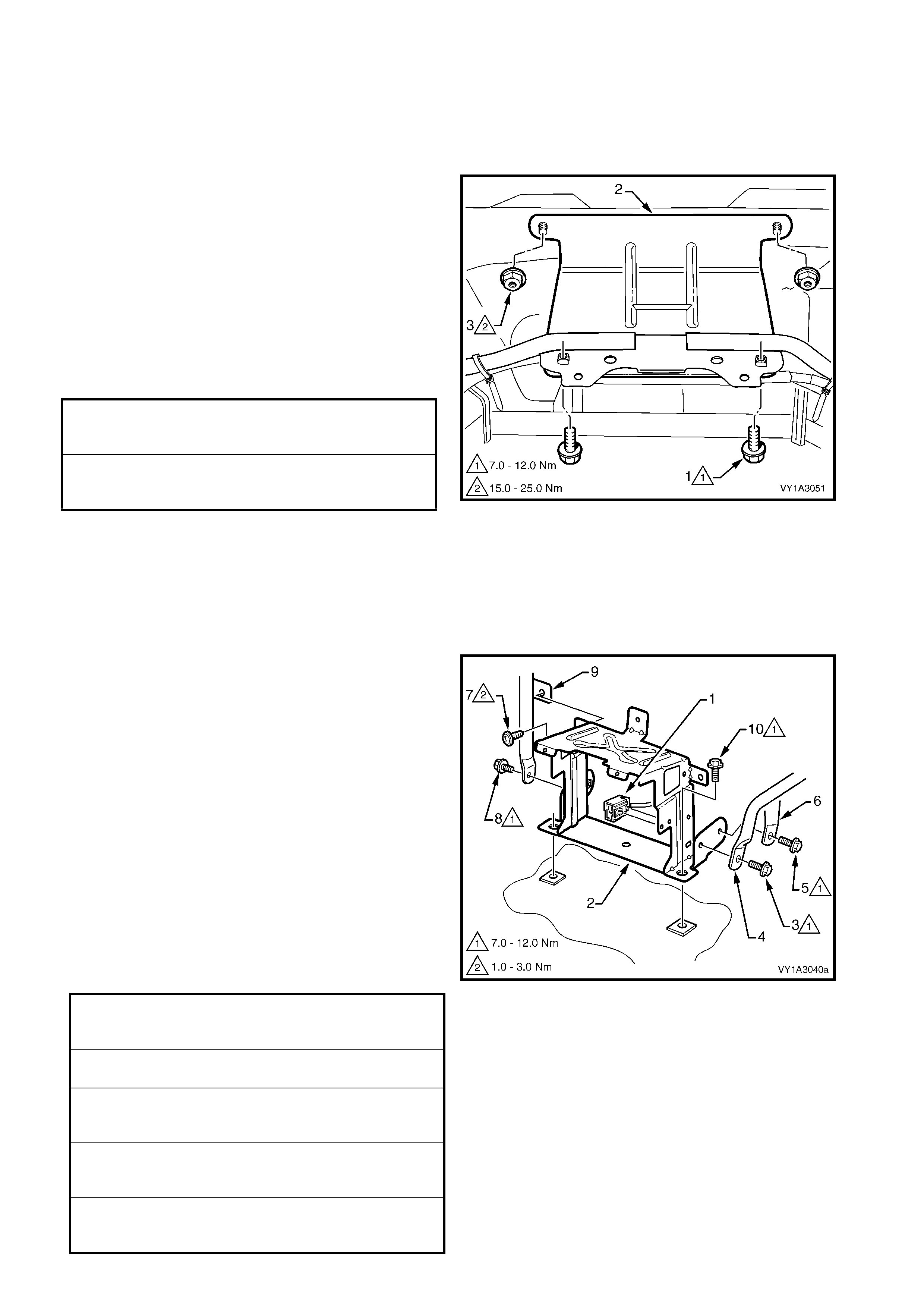

INSTRUMENT PANEL OUTER UPPER BRACKET

NOTE: The instrument panel outer upper bracket is

only fitted to vehicles without an instrument panel

inflatable restraint module.

REMOVE

1. Remove instrument panel pad assembly, refer to

3.21 INSTRUMENT PANEL PAD ASSEMBLY.

2. Remove the screw (1), two places, attaching the

instrument panel outer upper bracket (2) to the

instrument panel lower bracket.

3. Remove the nut (3), two places, attaching the

bracket to the dash panel assembly and remove

the bracket.

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

Figure 1A3-66

LOWER RADIO BRACKET

As required, first remove the following components:

1. Instrument panel pad assembly, refer to 3.21 INSTRUMENT PANEL PAD ASSEMBLY.

2. Navigation display assembly, if fitted, refer to Section 12L, 3.3 NAVIGATION DISPLAY ASSEMBLY.

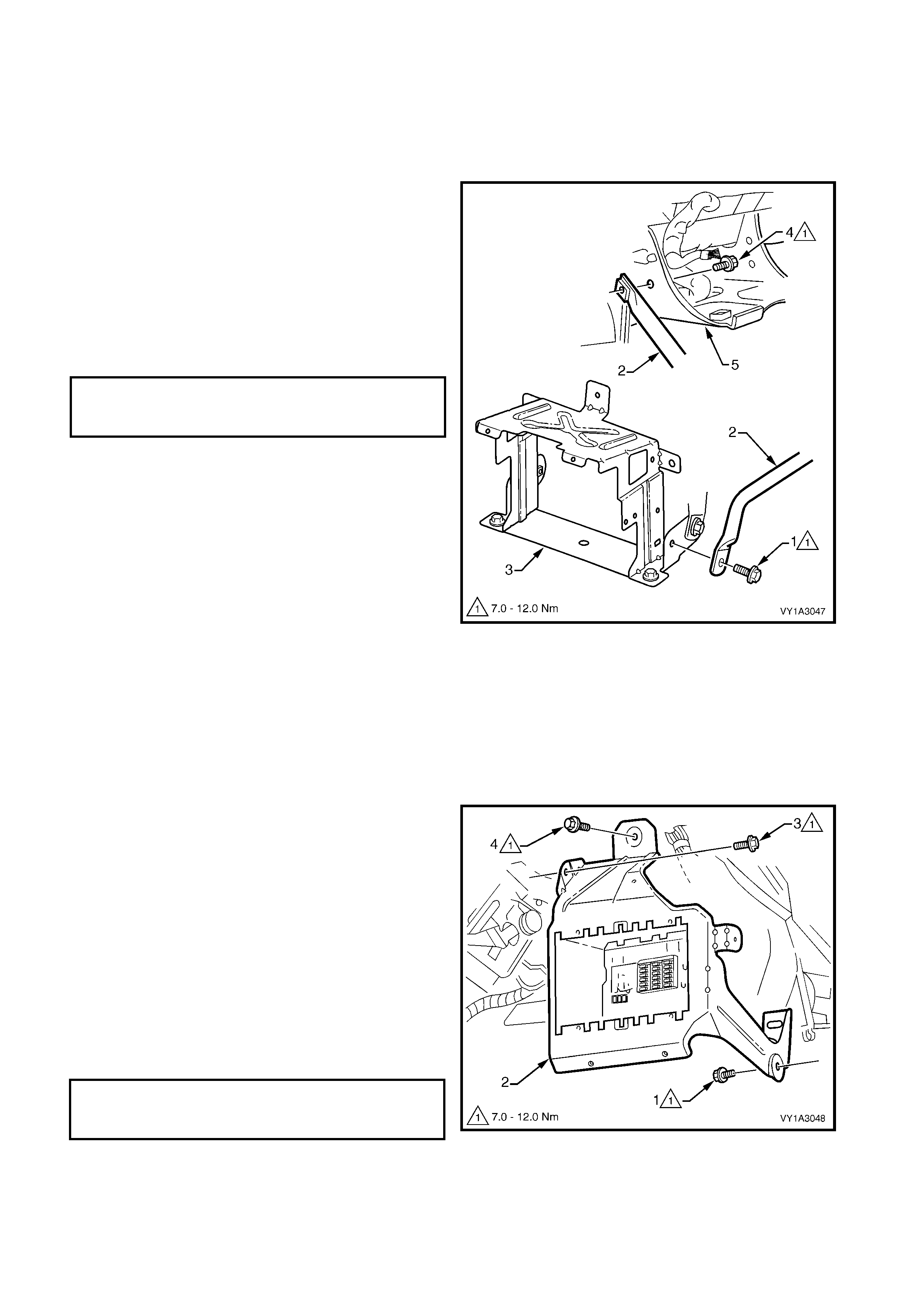

REMOVE

1. Withdraw the floor console front duct from the

HVAC unit.

2. Unclip the wiring connector (1) from the lower

radio bracket (2).

3. From the driver’s side, remove the screw (3),

attaching the steering column bracket inner brace

(4) to the lower bracket.

4. Remove the s cr ew (5), attac hing the HVAC unit (6)

to the bracket.

5. From the passenger side, rem ove the screws ( 7 &

8) attac hing the instrum ent panel lower brack et (9)

to the bracket.

6. Remove the screw (10), two places, attaching the

bracket to the vehicle and remove the bracket.

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

Figure 1A3-67

STEERING COLUMN BRACKET INNER

BRACE ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

HVAC UNIT ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

INSTRUMENT PANEL LOWER BRACKET

ATTACHING SELF-TAPPING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL LOWER

BRACKET ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

LOWER RADIO BRACKET

ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

INSTRUMENT PANEL UPPER OUTER

BRACKET ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

INSTRUMENT PANEL UPPER OUTER

BRACKET ATTACHING NUT

TORQUE SPECIFICATION 15.0 – 25.0 Nm

STEERING COLUMN BRACKET INNER BRACE

As required, first remove the instrument panel pad assembly, refer to 3.21 INSTRUMENT PANEL PAD

ASSEMBLY.

REMOVE

1. Remove the screw (1) attaching the steering

column bracket inner brace (2) to the lower radio

bracket (3).

2. Remove the screw (4) attaching the brace to the

steering column bracket (5).

3. Remove the brace.

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

Figure 1A3-68

STEERING COLUMN BRACKET OUTER BRACE

As required remove the following components:

1. Instrument panel pad assembly, refer to 3.21 INSTRUMENT PANEL PAD ASSEMBLY.

2. Body control module, refer to Section 12J BODY CONTROL MODULE.

3. Fuse & relay block, refer to Section 12O FUSES & WIRING HARNESS.

REMOVE

1. For left-hand drive vehicles, remove the hood

primary latch release lever, refer to Section 1A4,

2.8 HOOD PRIMARY LATCH ASSEMBLY and

also remove the wiring harness connector.

2. Remove the screw (1) attaching the steering

column bracket outer brace (2) to the vehicle.

3. Remove the screw (3) attaching the brace to the

steering column bracket.

4. Remove the screw (4) attaching the brace to the

dash panel and remove the brace.

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

Figure 1A3-69

STEERING COLUMN BRACKET

INNER BRACE ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

STEERING COLUMN BRACKET

OUTER BRACE ATTACHING SCREW

TORQUE SPECIFICATION 7.0 – 12.0 Nm

4. TORQUE WRENCH SPECIFICATIONS

Mobile phone compartment assembly screw.............................................................. 1.0 – 3.0 Nm

Floor console cover assembly screw.......................................................................... 1.0 – 3.0 Nm

Instrument panel lower extension side trim screw...................................................... 1.0 – 3.0 Nm

Floor console rear compartment screw ...................................................................... 1.0 – 3.0 Nm

Floor console rear air duct screw................................................................................ 1.0 – 3.0 Nm

Floor console rear air outlet housing assembly screw................................................ 1.0 – 3.0 Nm

Floor console rear upper compartment assembly screw............................................ 1.0 – 3.0 Nm

Floor console compartment armrest hinge screw....................................................... 1.0 – 3.0 Nm

Floor console compartment armrest inner screw........................................................ 1.0 – 3.0 Nm

Floor Console screw ................................................................................................... 1.0 – 3.0 Nm

Floor console nut......................................................................................................... 1.0 – 3.0 Nm

Floor console to automatic transmission selector assembly screw............................ 1.0 – 3.0 Nm

Instrument panel compartment latch assembly screw................................................ 1.0 – 3.0 Nm

Instrument panel compartment door screw ................................................................ 1.0 – 3.0 Nm

Instrument panel compartment lock striker screw ...................................................... 1.0 – 3.0 Nm

Data link connector screw........................................................................................... 1.0 – 3.0 Nm

Instrument panel lower trim panel retainer screw....................................................... 1.0 – 3.0 Nm

Instrument panel cup holder assembly screw............................................................. 1.0 – 3.0 Nm

OCC control module screw......................................................................................... 1.0 – 3.0 Nm

Instrument panel centre air outlet housing assembly screw....................................... 1.0 – 3.0 Nm

Instrument panel centre trim assembly screw............................................................. 1.0 – 3.0 Nm

Instrument panel lower compartment or ashtray assembly screw.............................. 1.0 – 3.0 Nm

Instrument panel lower extension side trim screw...................................................... 1.0 – 3.0 Nm

Manual HVAC controller screw................................................................................... 1.0 – 3.0 Nm

Radio bracket assembly screw................................................................................... 1.0 – 3.0 Nm

Radio housing screw................................................................................................... 1.0 – 3.0 Nm

Instrument cluster trim assembly screw...................................................................... 1.0 – 3.0 Nm

In-car air temperature sensor screw........................................................................... 1.0 – 3.0 Nm

Instrument cluster screw............................................................................................. 1.0 – 3.0 Nm

Instrument panel outer cover screw............................................................................ 1.0 – 3.0 Nm

Windshield defroster grille screw................................................................................ 1.0 – 3.0 Nm

Instrument panel speaker screw................................................................................. 1.0 – 3.0 Nm

Instrument panel inflatable restraint bracket lower screw........................................... 7.0 – 12.0 Nm

Instrument panel inflatable restraint bracket upper screw.......................................... 1.0 – 3.0 Nm

Instrument panel inflatable restraint opening trim cover screw................................... 7.0 – 12.0 Nm

Instrument panel inflatable restraint to instrument panel lower bracket screw........... 7.0 – 12.0 Nm

Instrument panel pad assembly side screw................................................................ 1.0 – 3.0 Nm

Instrument panel pad assembly to air duct screw....................................................... 1.0 – 3.0 Nm

Instrument panel pad assembly lower screw.............................................................. 1.0 – 3.0 Nm

Instrument panel pad assembly upper screw ............................................................. 7.0 – 12.0 Nm

Steering column lower cover screw............................................................................ 0.5 – 2.0 Nm

Steering wheel assembly screw.................................................................................. 40.0 – 50.0 Nm

Instrument panel compartment bracket screw............................................................ 1.0 – 3.0 Nm

Instrument panel lower bracket self-tapping screw..................................................... 1.0 – 3.0 Nm

Instrument panel lower bracket screw ........................................................................ 7.0 – 12.0 Nm

Instrument panel upper outer bracket screw............................................................... 7.0 – 12.0 Nm

Instrument panel upper outer bracket nut................................................................... 15.0 – 25.0 Nm

Steering column bracket inner brace screw................................................................ 7.0 – 12.0 Nm

HVAC unit to lower radio bracket screw...................................................................... 7.0 – 12.0 Nm

Instrument panel lower bracket self-tapping screw..................................................... 1.0 – 3.0 Nm

Instrument panel lower bracket screw ........................................................................ 7.0 – 12.0 Nm

Lower radio bracket screw.......................................................................................... 7.0 – 12.0 Nm

Steering column bracket inner brace screw................................................................ 7.0 – 12.0 Nm

Steering column bracket outer brace screw................................................................ 7.0 – 12.0 Nm

5. SPECIAL TOOLS

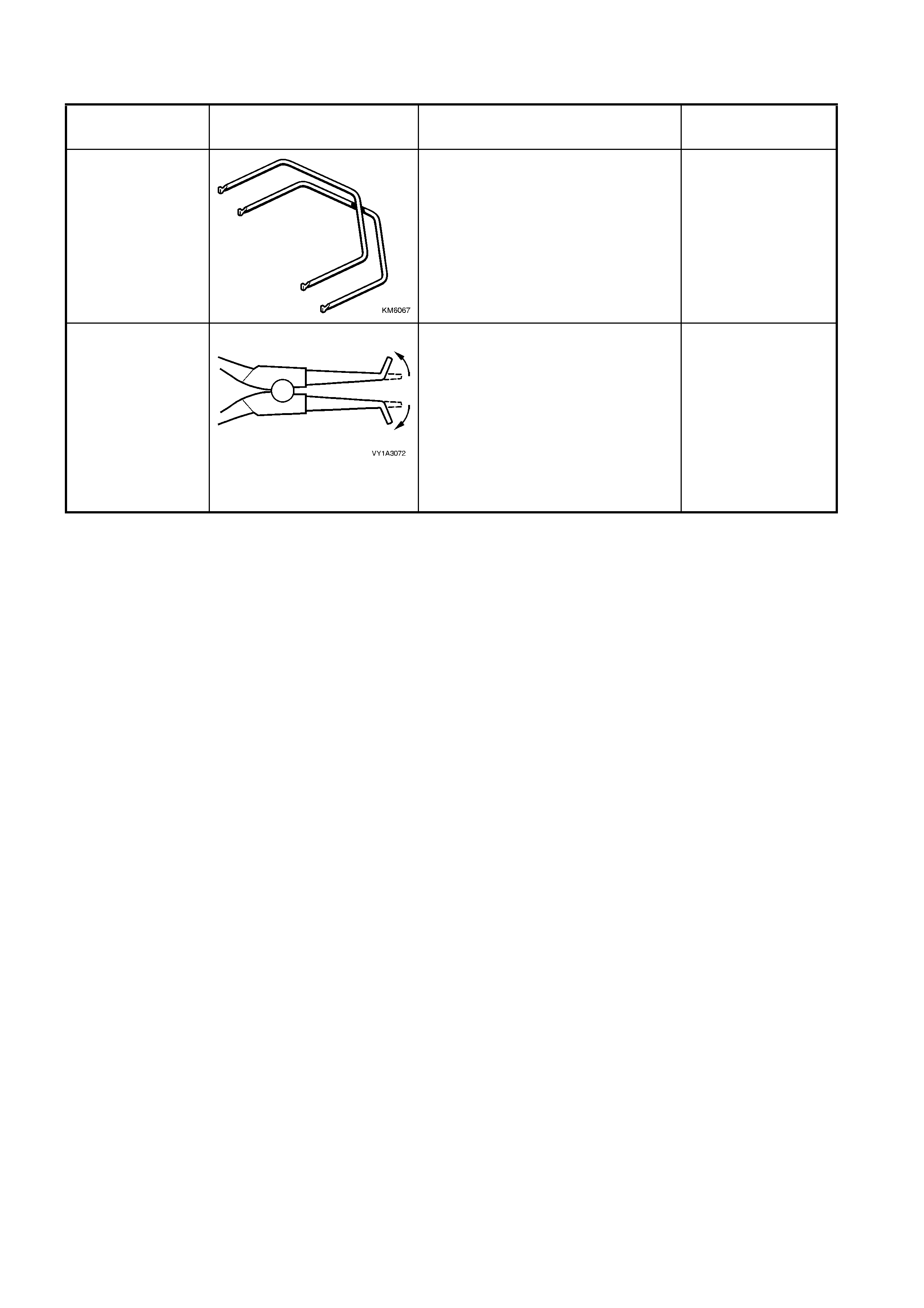

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASIFICATION

KM6067 RADIO REMOVAL TOOL

Used for removing VY audio unit

from its mounting location.

New tool for VY.

Mandatory

– ACCESSORY SOCKET REMOVAL

TOOL

Modified commercially available

external circlip pliers. Used for

removing the floor console

accessory power socket from its

retaining bezel.

Refer to 2.3 FLOOR CONSOLE

ASSEMBLY

Dealer Fabricated