SECTION 1A4 - HOOD, REAR COMPARTMENT LID,

LIFTGATE & ENDGATE

IMPORTANT

Before perfo rming any Service O peration or oth er procedu re described in t his Sectio n, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

2. SERVICE OPERATIONS – HOOD

2.1 HOOD FRONT MOULDING ASSEMBLY

REMOVE

REINSTALL

2.2 HOOD SECONDARY LATCH

ASSEMBLY

REMOVE

REINSTALL

2.3 HOOD PRIMARY LATCH STRIKER

ASSEMBLY

REMOVE

REINSTALL

2.4 HOOD INSULATOR

REMOVE

REINSTALL

2.5 UNDER-HOOD LAMP ASSEMBLY

REMOVE

REINSTALL

2.6 HOOD STRUT ASSEMBLY

REMOVE

REINSTALL

2.7 HOOD & HINGE ASSEMBLIES

REMOVE

REINSTALL

ADJUST

2.8 HOOD PRIMARY LATCH ASSEMBLY

HOOD PRIMARY LATCH SPRING

HOOD PRIMARY LATCH RELEASE CABLE

ASSEMBLY, RHD

HOOD PRIMARY LATCH RELEASE CABLE

ASSEMBLY, LHD

3. SERVICE OPERATIONS – REAR

COMPARTMENT

3.1 REAR COMPARTMENT LID CARPET

REMOVE

REINSTALL

3.2 REAR COMPARTMENT LID APPLIQUE

ASSEMBLY, SEDAN

REMOVE

DISASSEMBLE

REINSTALL

3.3 REAR COMPARTMENT LID APPLIQUE

ASSEMBLY, COUPE

REMOVE

DISASSEMBLE

REINSTALL

3.4 REAR SPOILER ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

3.5 REAR COMPARTMENT LID LATCH

ASSEMBLY

REMOVE

REINSTALL

3.6 REAR COMPARTMENT LID ACTUATOR

ASSEMBLY

REMOVE

REINSTALL

3.7 REAR COMPARTMENT LID RELEASE

CABLE ASSEMBLY

REMOVE

REINSTALL

3.8 REAR COMPARTMENT LID STRUT

ASSEMBLY

REMOVE

REINSTALL

3.9 REAR COMPARTMENT LID ASSEMBLY

REMOVE

REINSTALL

ADJUST

3.10 REAR COMPARTMENT LID HINGE

ASSEMBLY

REMOVE

REINSTALL

3.11 REAR COMPARTMENT LID STRIKER

ASSEMBLY

REMOVE

REINSTALL

3.12 REAR COMPARTMENT LID WEATHERSTRIP

REMOVE

REINSTALL

4. SERVICE OPERATIONS – LIFTGATE, WAGON

4.1 LIFTGATE WINDOW LOWER GARNISH

REMOVE

REINSTALL

4.2 LIFTGATE LOWER TRIM PANEL

REMOVE

REINSTALL

4.3 LIFTGATE INSIDE HANDLE

REMOVE

REINSTALL

4.4 LIFTGATE WINDOW UPPER GARNISH

REMOVE

REINSTALL

4.5 LIFTGATE HANDLE ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

4.6 LIFTGATE HANDLE PUSH BUTTON

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

4.7 LIFTGATE LATCH ASSEMBLY

REMOVE

REINSTALL

Techline

Techline

4.8 LIFTGATE ACTUATOR ASSEMBLY

REMOVE

REINSTALL

4.9 LIFTGATE AIR DEFLECTOR ASSEMBLY

REMOVE

REINSTALL

4.10 REAR WINDOW WIPER ASSEMBLY

REMOVE

REINSTALL

4.11 REAR WINDOW WASHER NOZZLE &

HOSE ASSEMBLIES

REMOVE

REINSTALL

4.12 HIGH MOUNT STOP LAMP ASSEMBLY

REMOVE

REINSTALL

4.13 LIFTGATE STRUT ASSEMBLY

REMOVE

REINSTALL

4.14 LIFTGATE ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

ADJUST

4.15 LIFTGATE STRIKER ASSEMBLY

ADJUST

REMOVE

REINSTALL

4.16 LIFTGATE WEATHERSTRIP

REMOVE

REINSTALL

5. SERVICE OPERATIONS – ENDGATE, UTILITY

5.1 ENDGATE INNER PANEL ACCESS

HOLE COVER

REMOVE

REINSTALL

5.2 ENDGATE LOCK ANCHOR PLATE ASSEMBLY

REMOVE

REINSTALL

5.3 ENDGATE LATCH ASSEMBLY &

ENDGATE LATCH BRACKET ASSEMBLY

REMOVE

REINSTALL

5.4 ENDGATE STRIKER & ENDGATE

CABLE ASSEMBLY

REMOVE

REINSTALL

5.5 ENDGATE UPPER MOULDING ASSEMBLY

REMOVE

REINSTALL

5.6 ENDGATE ASSEMBLY

REMOVE

REINSTALL

ADJUST

5.7 ENDGATE HINGE ASSEMBLY

REMOVE

REINSTALL

5.8 ENDGATE WEATHERSTRIP

REMOVE

REINSTALL

6. TORQUE WRENCH SPECIFICATIONS

1. GENERAL DESCRIPTION

This Section describes the service procedures for the hood assembly, rear compartment lid assembly fitted to

Sedan & Coupe, the liftgate ass embly fitted to W agon and the endgate assem bly f itted to Utility. T o aid the user of

this m anual, associated c omponents previously located in other Sections, suc h as the rear spoiler s, etc. have been

integrated into this Section.

Sedan, Wagon and Utility models share a common hood that features new styling. Domestic Model Level 3 vehicles

feature a hood front moulding that integrates with the radiator grille when the hood is closed. Minor changes have

been made to the hinges to accommodate the new plenum cover.

For Coupe, the hood carries-over from V2 Series 1 and other than minor styling changes, from a servicing

perspective, is the same as Sedan, Wagon and Utility vehicles.

The hood release mechanism is common to all models and utilises a cable and lever arrangement. The release

lever is located below the driver’s side end of the instrument panel. For left-hand drive vehicles, the routing of the

cable extends from the right-hand to left-hand side of the engine compartment, across the dash panel assembly.

As with the hood, the rear compartment lid and attaching parts for Coupe are carry-over. A completely new rear

compartment lid is fitted to Sedan, which features new styling and a new applique assembly. Hinges carry-over.

Depending on model level, one of two styles of spoiler assemblies may be fitted. Both incorporate a high-mount

stop lamp.

The rear com partment lid latc h assem bly is operated by an actuator, which is controlled by a release switch located

in the instrument panel compartment, or by a button on the ignition key. A rear compartment lid release cable is

fitted to provide entry to the rear compartment in the event of power failure. A handle that operates the release is

accessible from behind the rear seat centre for Sedan or under the RH rear seat headrest for Coupe.

The lif tgate f or Wagon and endgate for utility are carry-over, with a few minor changes. T he liftgate latch is operated

via the pus h-button, which is part of the handle assem bly. Loc king is provided through the vehic le’s central lock ing

system or manually with the key.

2. SERVICE OPERATIONS – HOOD

2.1 HOOD FRONT MOULDING ASSEMBLY

LT Section No. -

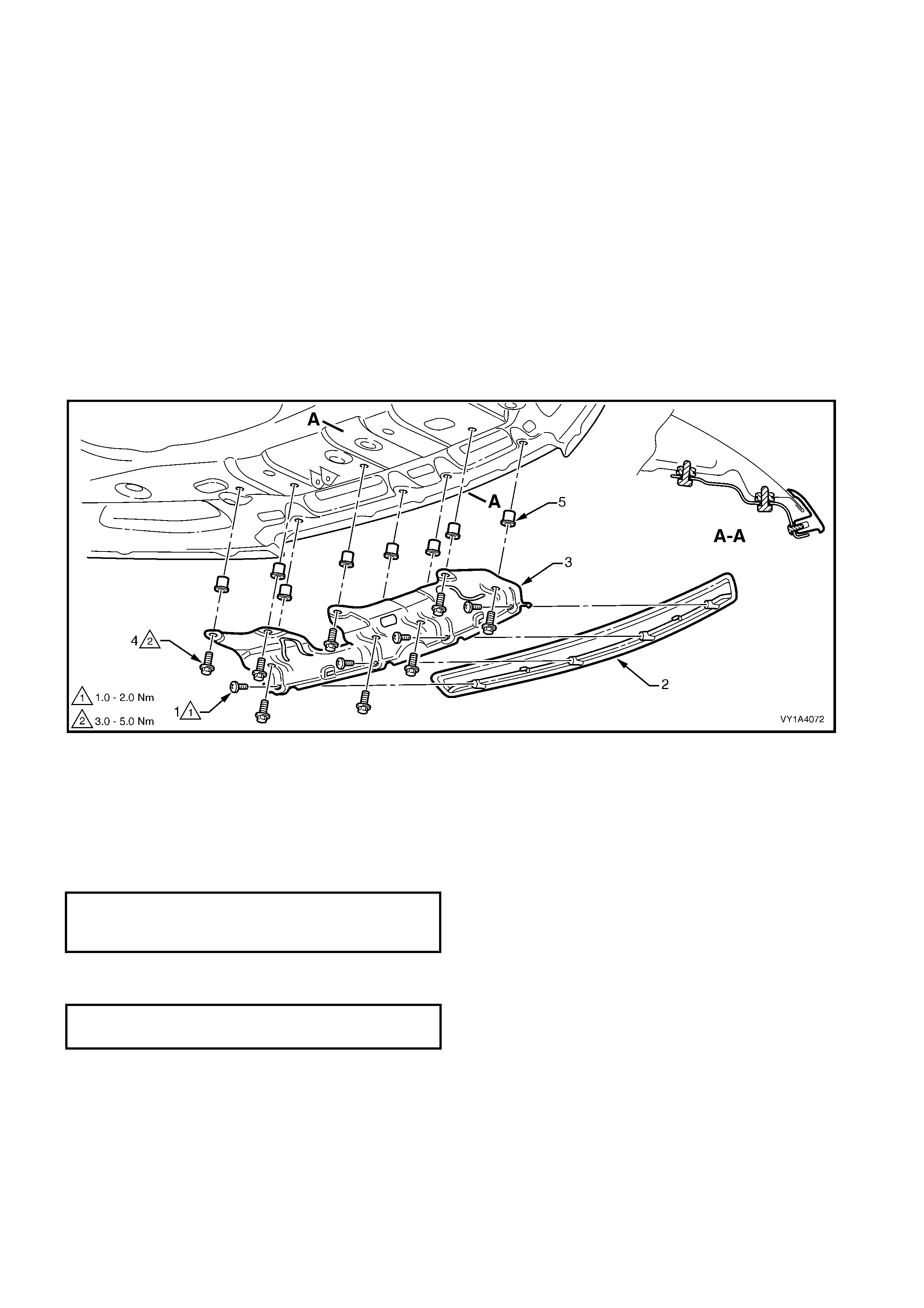

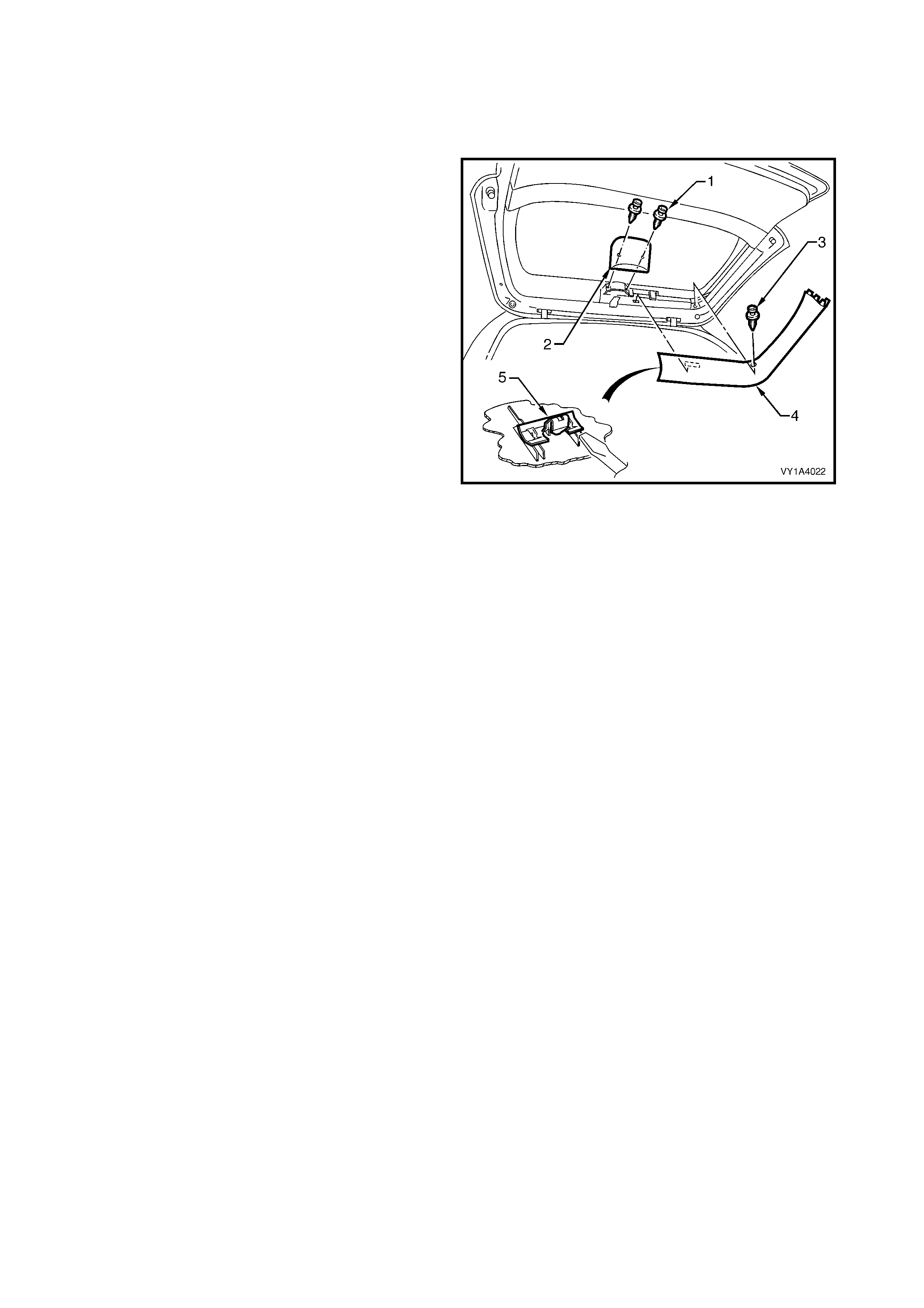

The hood front moulding assembly is fitted to domestic Model Level 3 vehicles and consists of the hood

moulding (1) and mounting bracket (2), refer to Figure 1A4-1. The following procedure describes removing the

parts sequentially, however if required the assembly can be removed from the hood with the moulding still

attached.

REMOVE

1. Raise the hood.

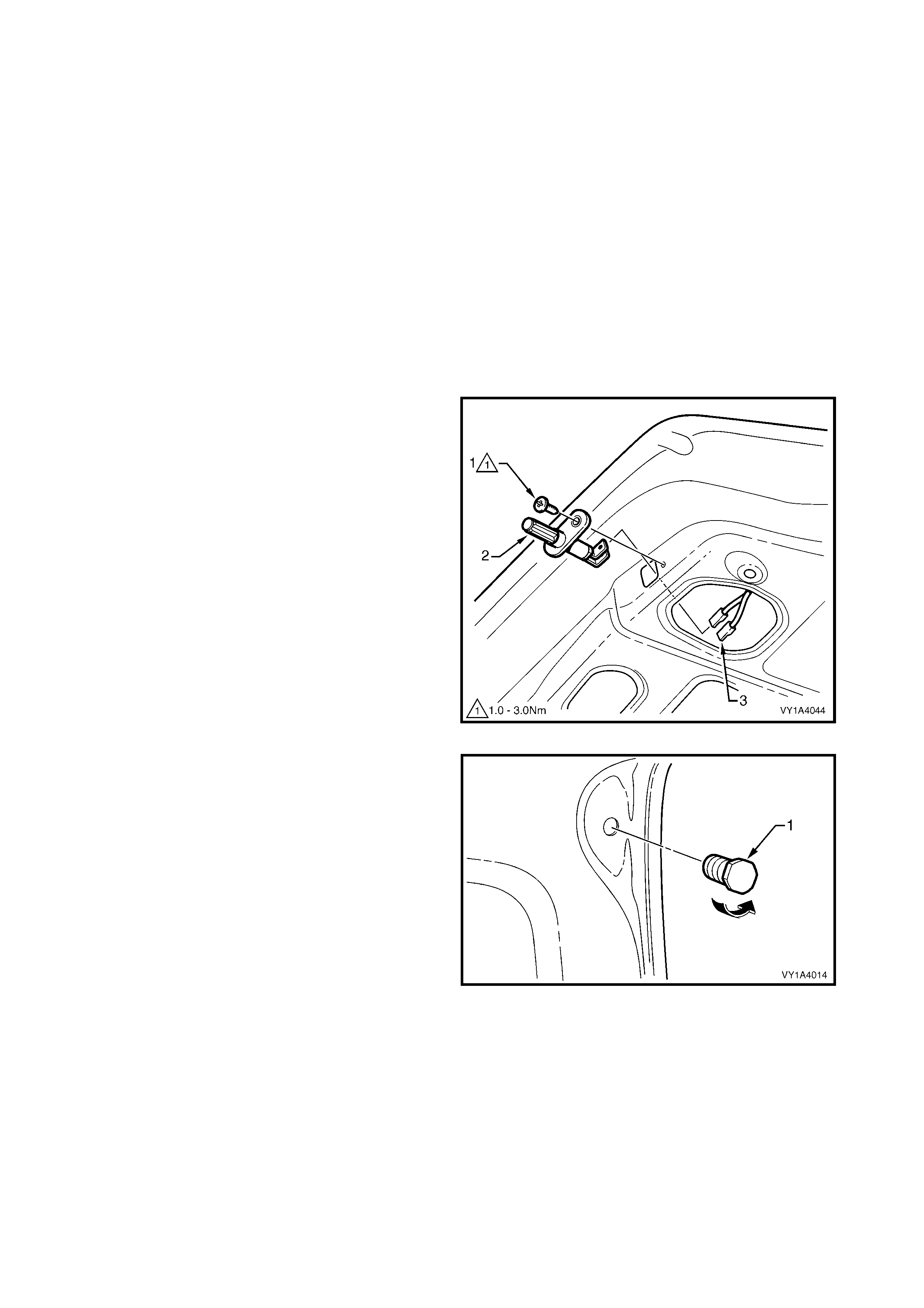

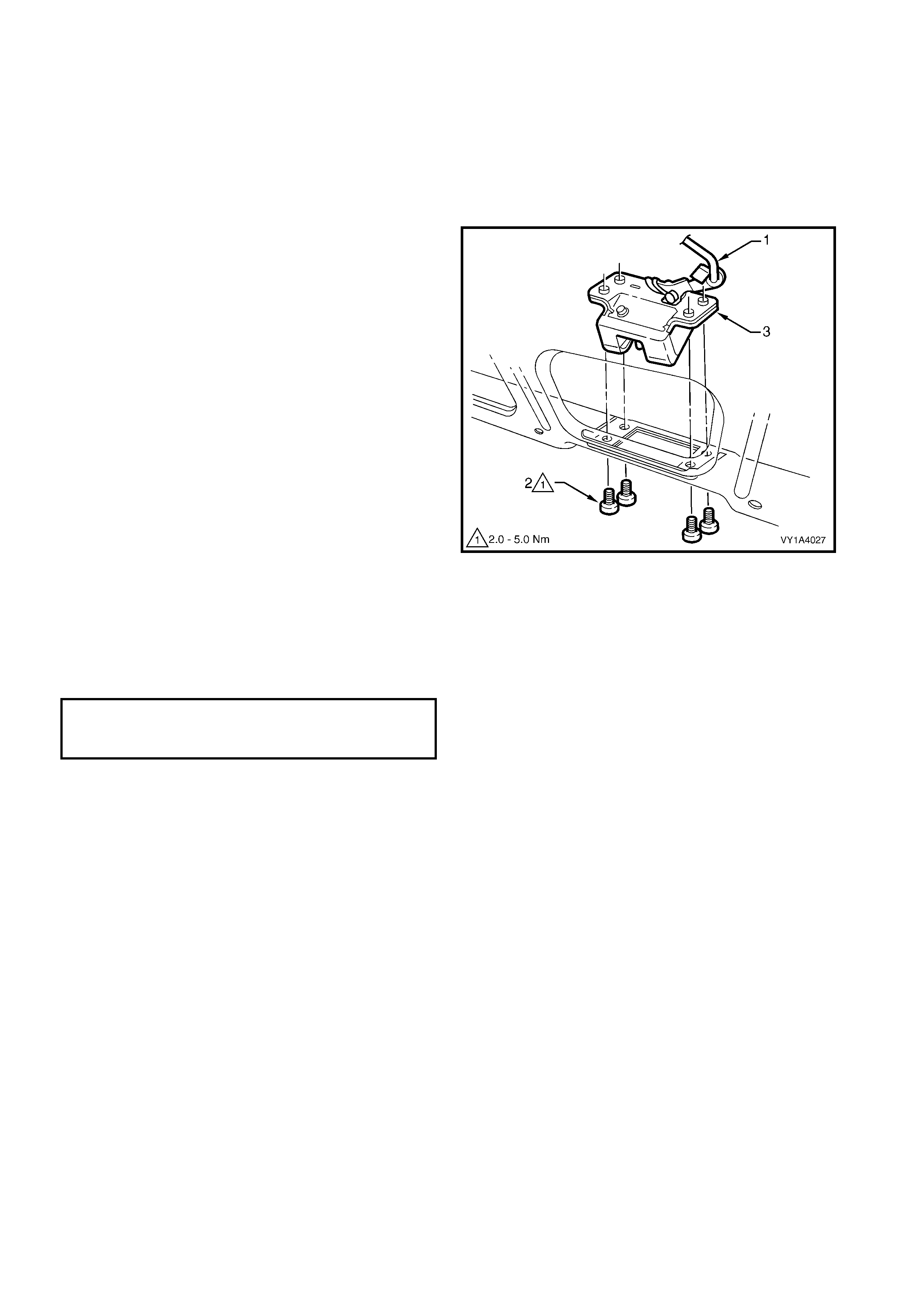

2. Remove the three screws (1) attaching the front moulding (2) to the mounting bracket (3), refer to Figure

1A4-1.

3. Unclip the moulding from the mounting bracket and remove.

4. Remove the eight screws (4) attaching the mounting bracket to the hood inner panel and remove the

bracket.

Figure 1A4-1

REINSTALL

1. If a new hood has been fitted, install eight M5 Nutserts (5) into the holes in the hood inner panel, using a

commercially available Nutsert gun, refer to Figure 1A4-1.

IMPORTANT: Use the correct Nutserts for this application. Some generic Nutserts may not be suitable.

2. Fit the mounting bracket and start the eight screws. Tighten to the specified torque.

3. Clip the moulding onto the mounting bracket, fit the three screws and tighten to the specified torque.

HOOD MOULDING MOUNTING

BRACKET SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

HOOD MOULDING ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 2.0 Nm

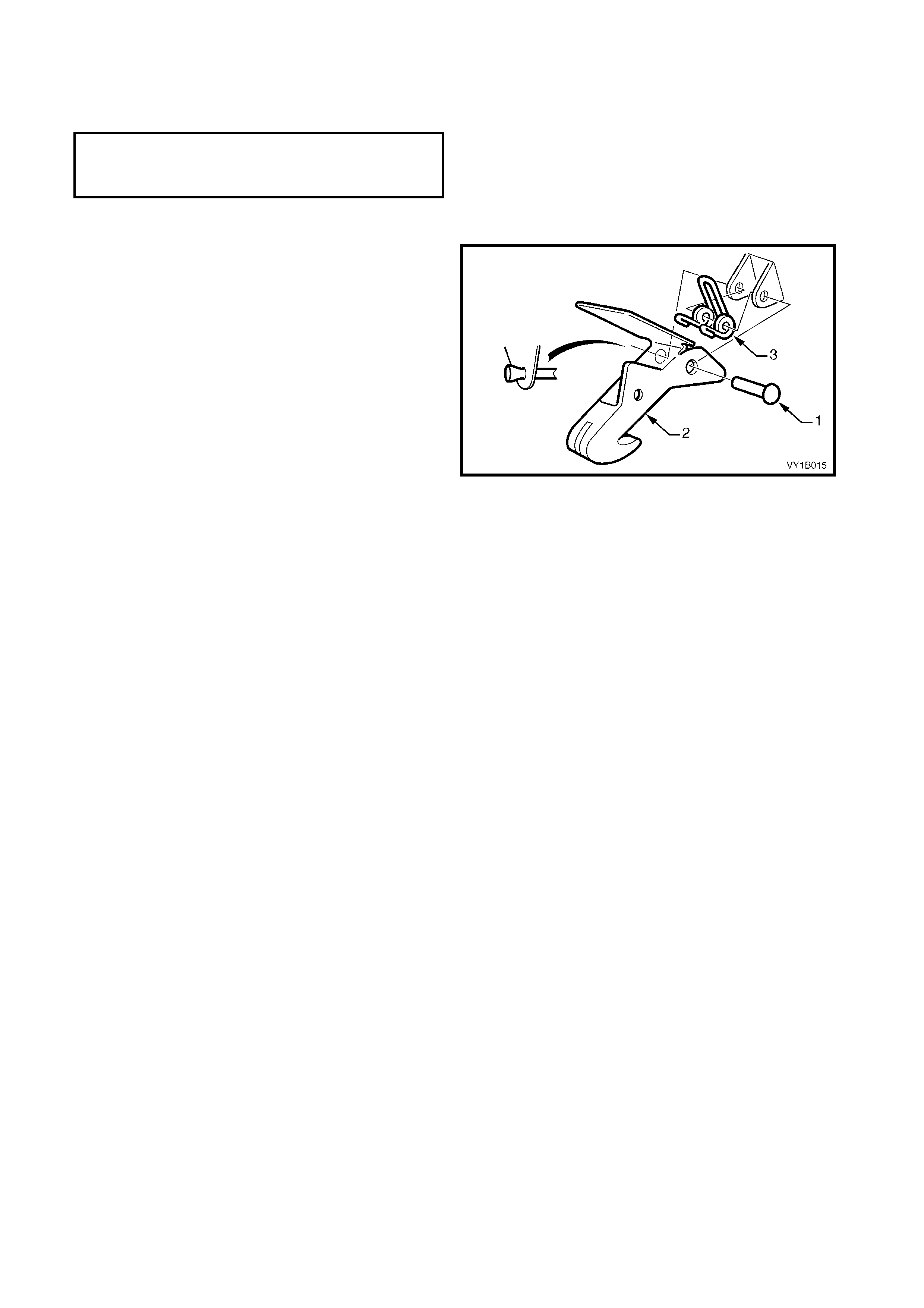

2.2 HOOD SECONDARY LATCH ASSEMBLY

LT Section No. – 12-050

REMOVE

1. Raise the hood.

2. Carefully cut the end of the secondary latch rivet

(1) securing the hood secondary latch (2) and

hood secondary latch spring (3) to the hood

assembly.

NOTE: Take care not to damage the paintwork.

3. Using a pin punc h, extract the rivet, also rem oving

the latch and spring.

Figure 1A4-2

REINSTALL

1. Assemble the spring in the latch ensuring it is

correctly orientated, refer to Figure 1A4-2.

2. While holding the latch and spring in position on

the hood, insert a new rivet.

NOTE: Lubricate the rivet prior to assembly with NLGI

No. 1 lithium grease or equivalent.

3. Crimp the rivet end to secure it in place.

4. Test the secondary latch operation.

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

§ Secondary latch rivet.

2.3 HOOD PRIMARY LATCH STRIKER ASSEMBLY

LT Section No. – 12-050

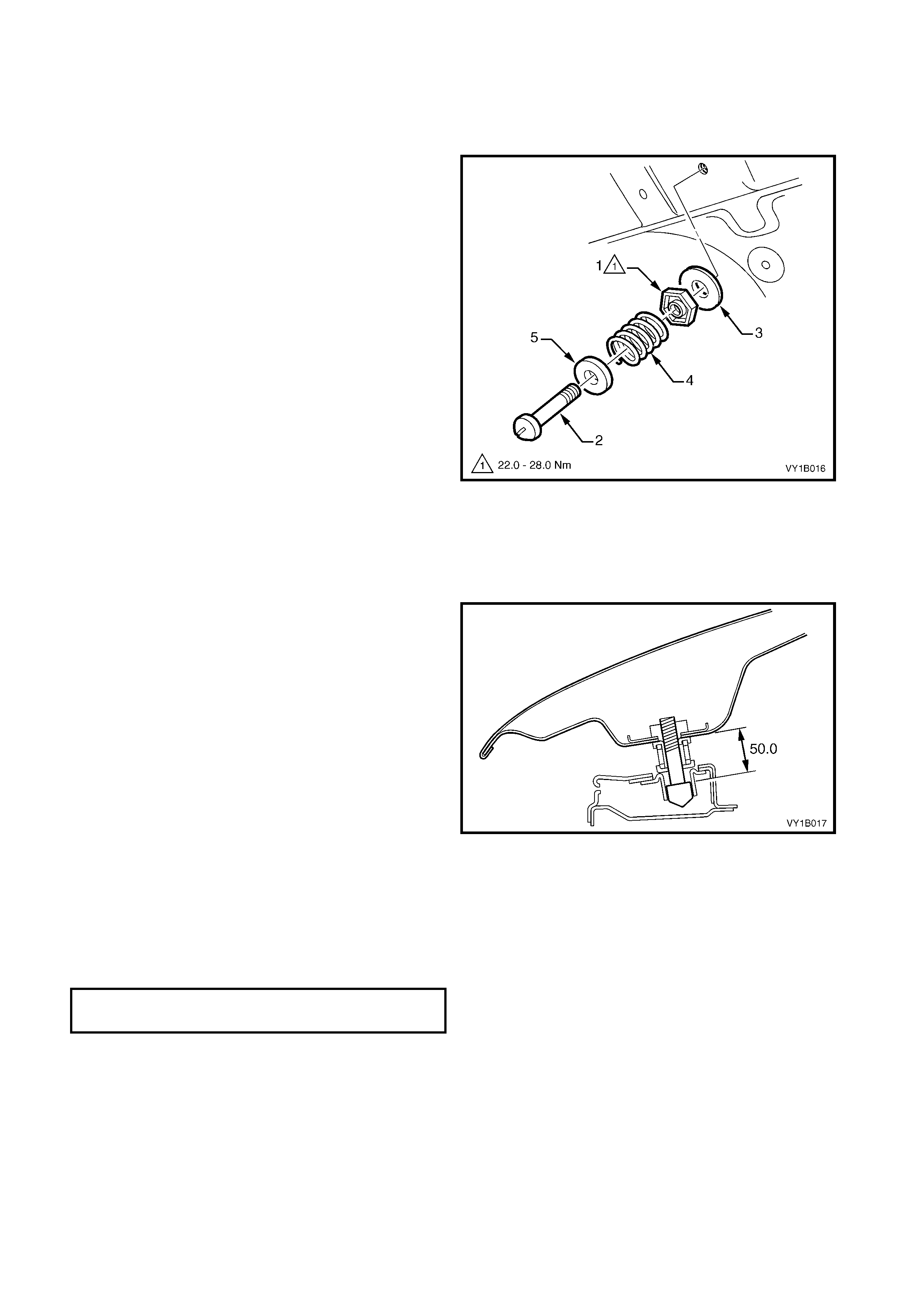

REMOVE

1. Raise the hood.

2. Loosen the hood primary latch striker nut (1).

3. Using a flat-blade screwdriver, unscrew the hood

primary latch striker bolt (2) ensuring the washer

(3) hood pop-up spring ( 4) and hood pop- up spr ing

retainer (5) remain on the bolt.

4. If required, secure the nut in a vice and

disassemble the components.

Figure 1A4-3

REINSTALL

1. Secure the hood primary latch striker nut in a vice

and assemble the components in their correct

order, refer to Figure 1A4-3.

2. Install the latch striker assembly on the hood and

tighten the bolt to achieve a nominal length of 50

mm.

3. Apply lubricant to the end of the bolt such as NLGI

No. 1 lithium grease or equivalent.

4. Close the hood by dropping from a height of

approximately 300 mm.

IMPORTANT: Do not push the hood closed as

damage to the panel surface may occur. If it doesn’t

close on the first attempt, try again from a slightly

greater height.

5. Check the height difference between the front of

the hood and fenders.

6. Open the hood and adjust the latch striker

assembly length by loosening and holding the nut

while rotating the bolt with a flat-blade screwdriver.

NOTE: As requir ed also set the hood adj ust bum per to

align the hood height.

7. Tighten the nut to the specified torque.

Figure 1A4-4

HOOD PRIMARY LATCH STRIKER NUT

TORQUE SPECIFICATION 22.0 – 28.0 Nm

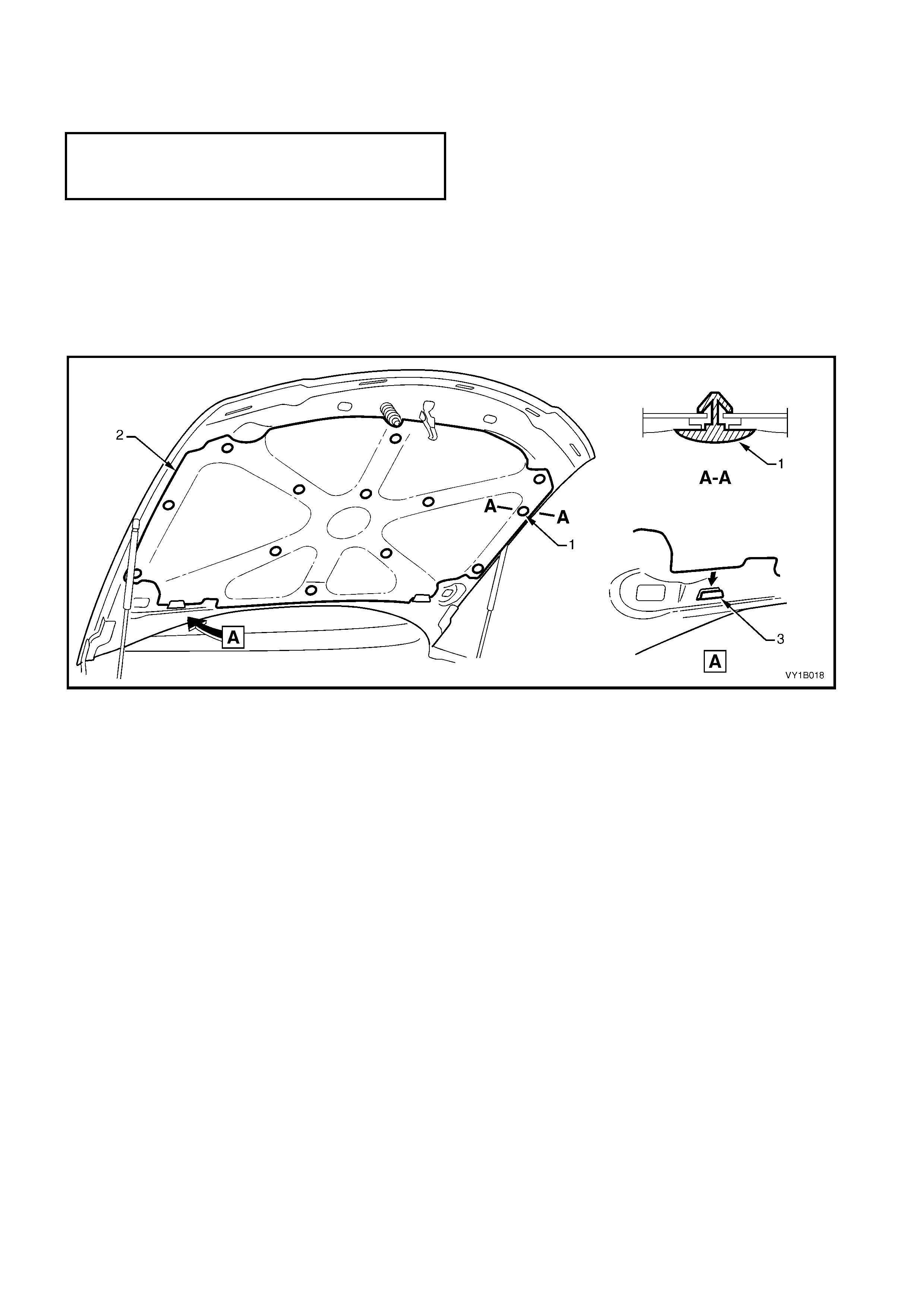

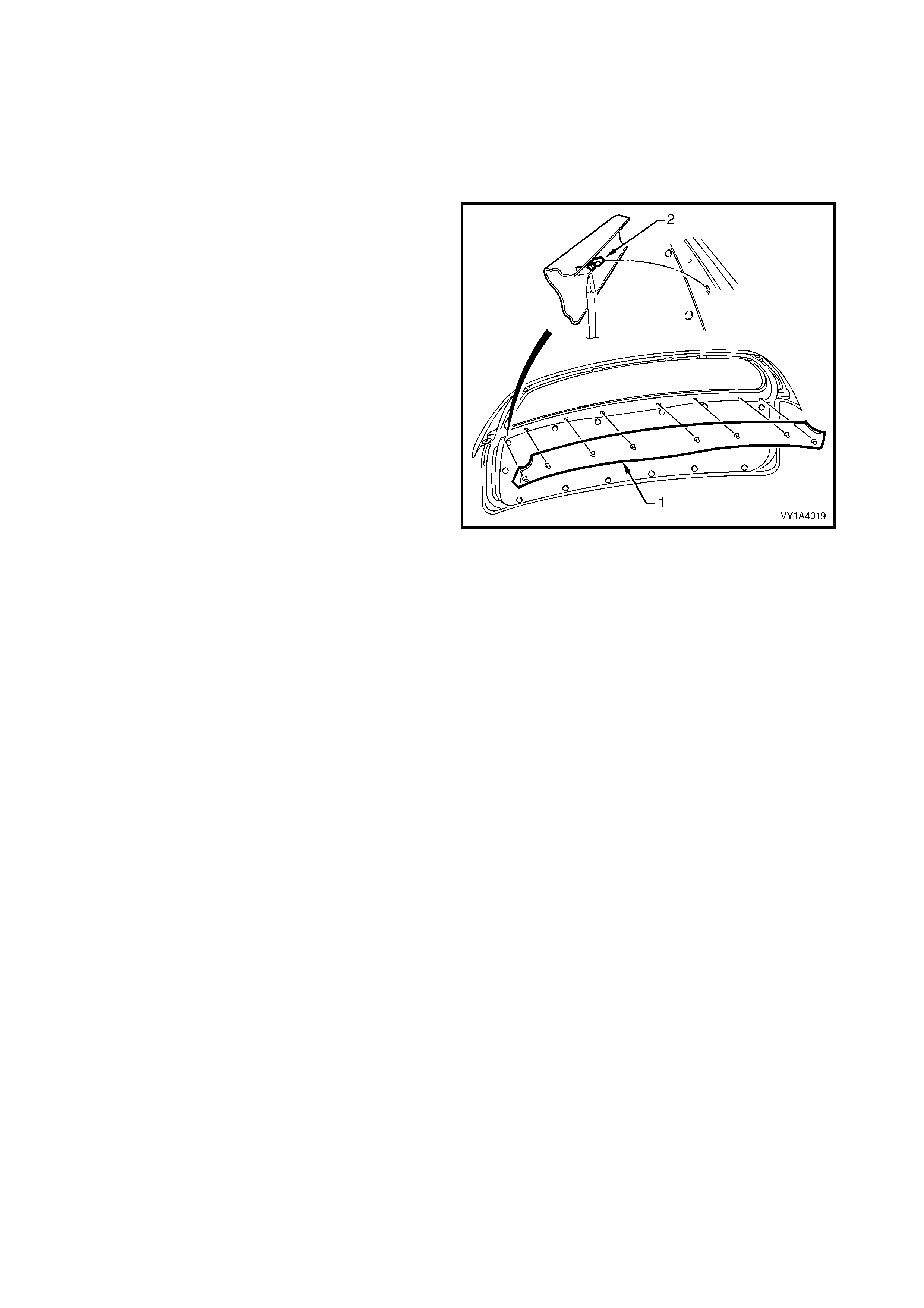

2.4 HOOD INSULATOR

LT Section – 12-050

REMOVE

1. Raise the hood.

2. Beginning at the rear of the hood and working toward the front, remove the hood insulator retainer (1), 13

places, attaching the hood insulator (2) to the hood assembly, refer to Figure 1A4-5.

NOTE: Take care not to crush or damage the insulator.

3. Slide the insulator from the slots (3) in the hood inner panel and remove.

Figure 1A4-5

REINSTALL

Reinstallation is the reverse of removal.

N

O

TE: The

f

ollowing components MAY RE

Q

UIRE

REPLACEMENT when performing this operation.

§ Hood insulator retainer.

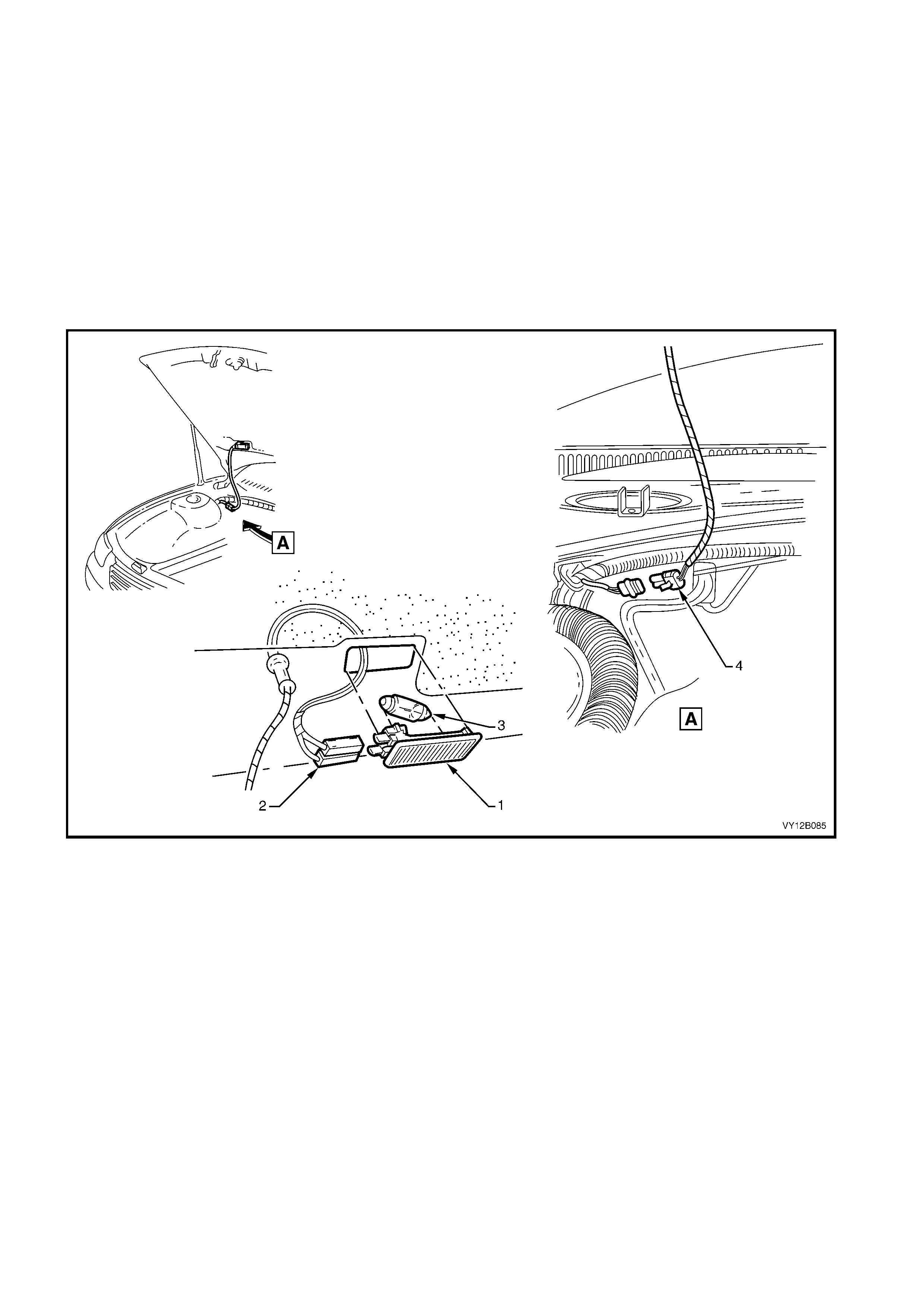

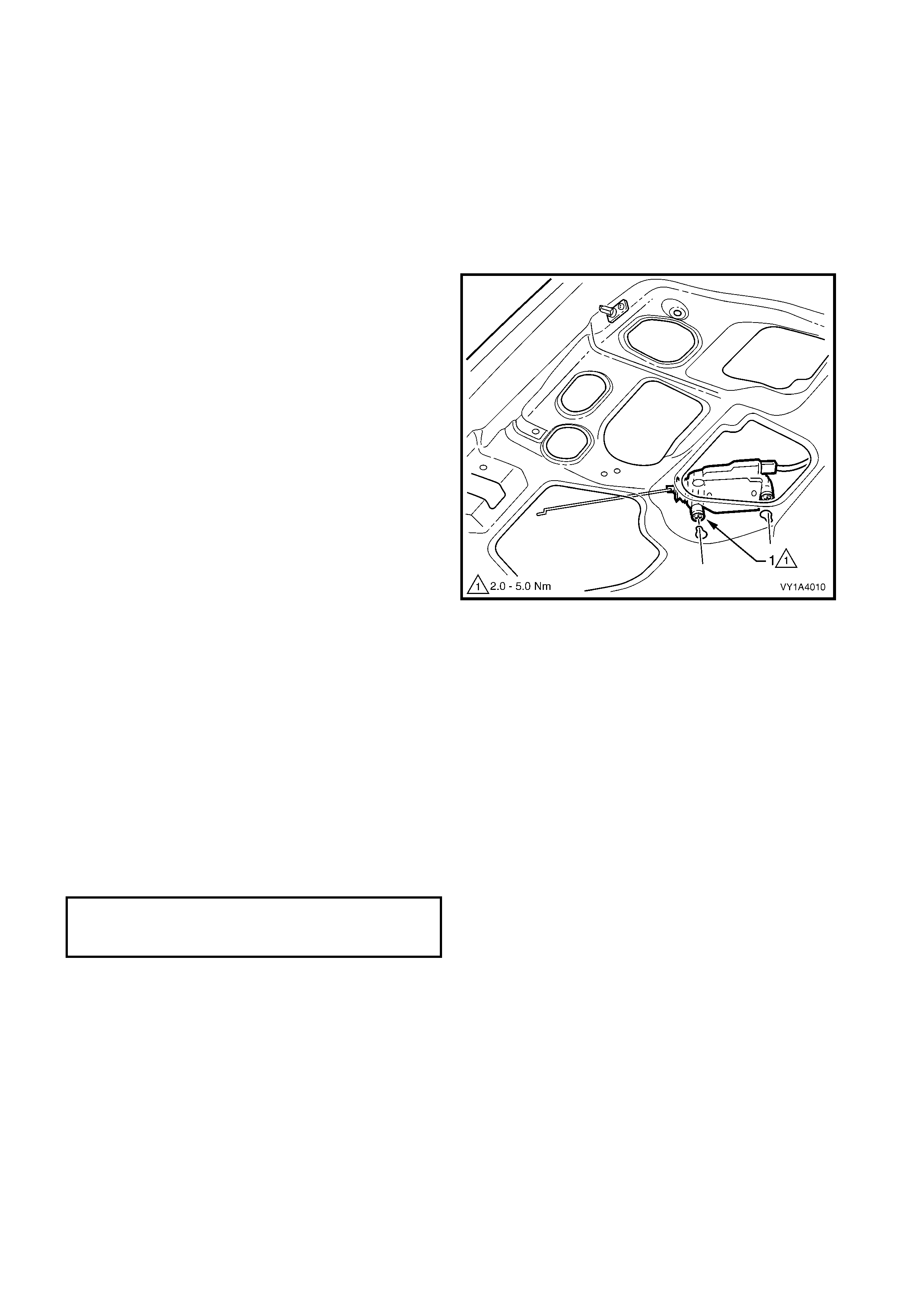

2.5 UNDER-HOOD LAMP ASSEMBLY

LT Section –

The under-hood lamp assembly is only fitted to select vehicles and is operated with the park lamps.

REMOVE

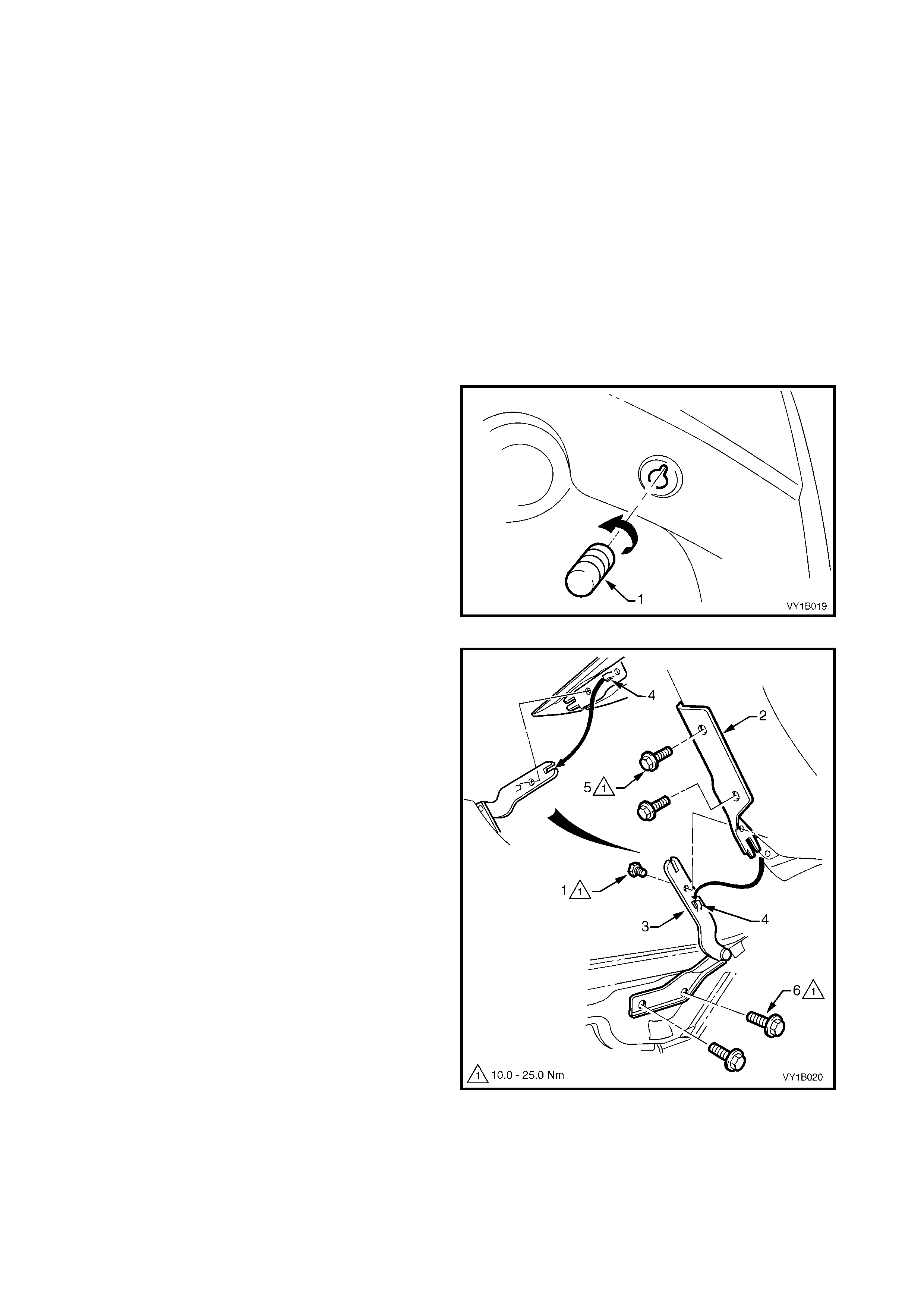

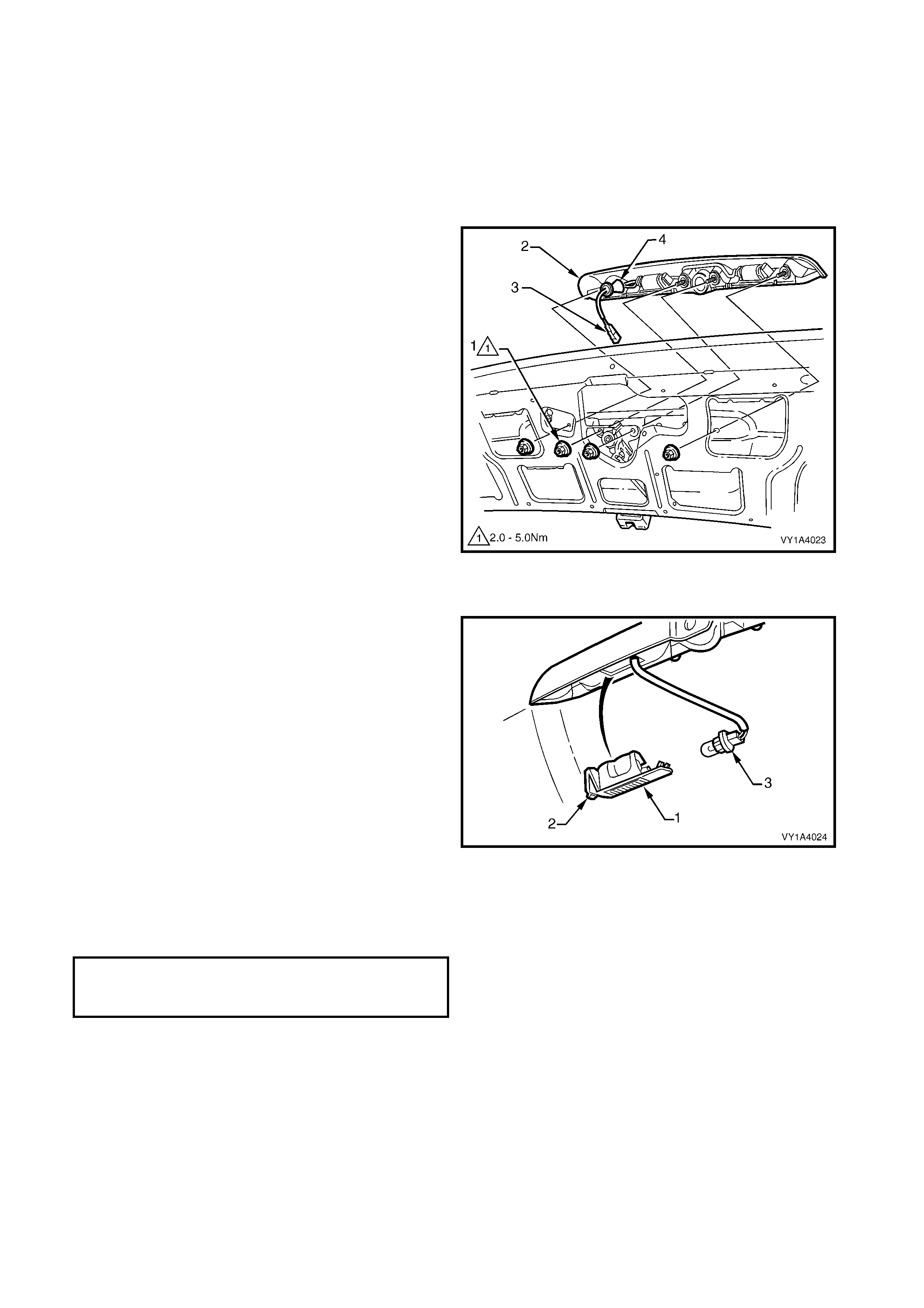

1. Remove the fusible link F102 from within the engine compartment fuse & relay panel.

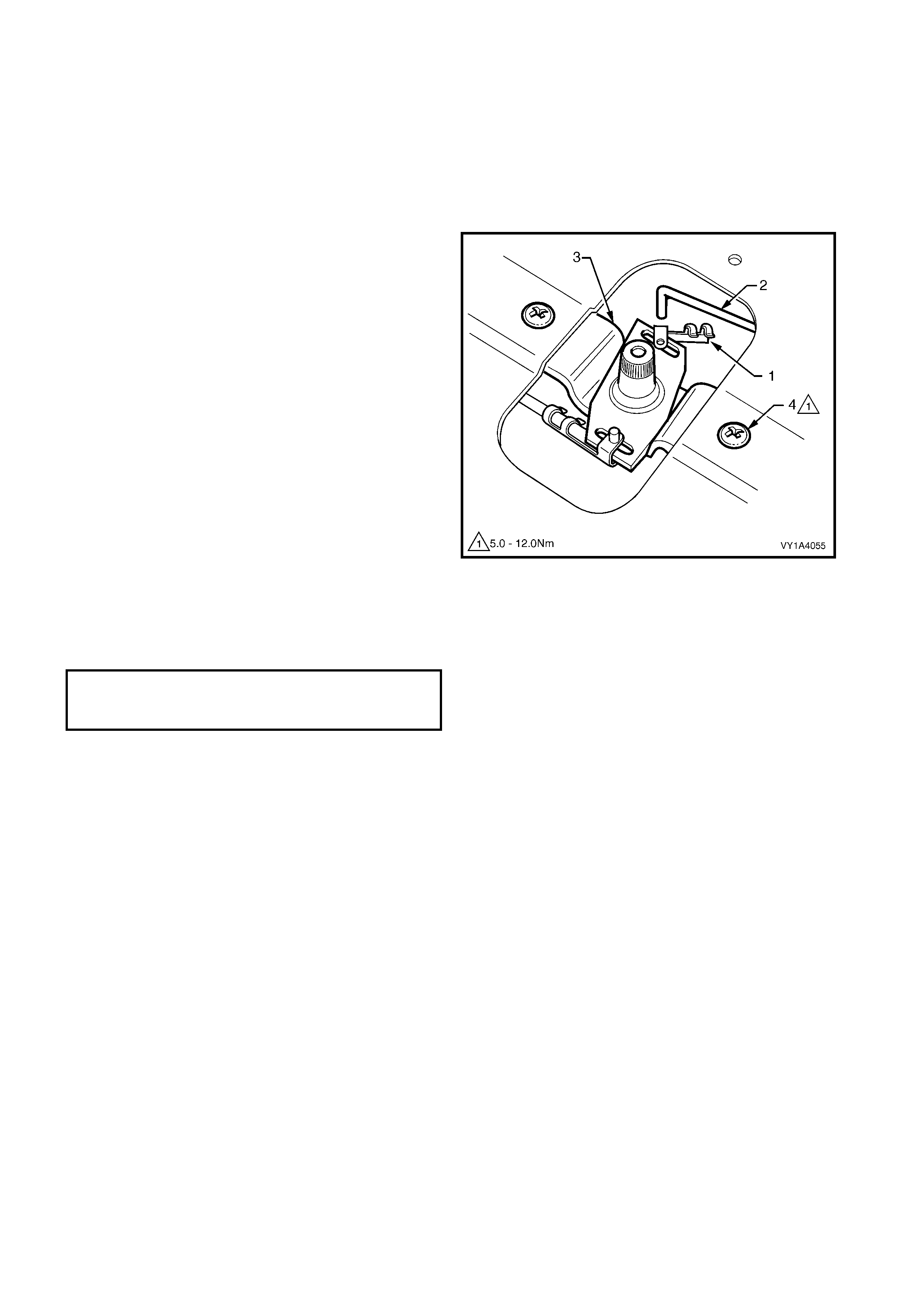

2. Pris e the under-hood lam p as sem bly (1) f rom the under side of the hood us ing a fine blade s crewdriver r efer

to Figure 1A4-6.

3. Disconnect the wiring harness connectors (2) from the lamp assembly.

4. If required, remove the bulb (3) from the assembly by depressing the metal contact.

5. Disconnect the under-hood wiring harness connector from the body harness (4).

6. Remove the grommet from the hood and withdraw the wiring.

Figure 1A4-6

REINSTALL

Reinstallation is the reverse of the removal procedure.

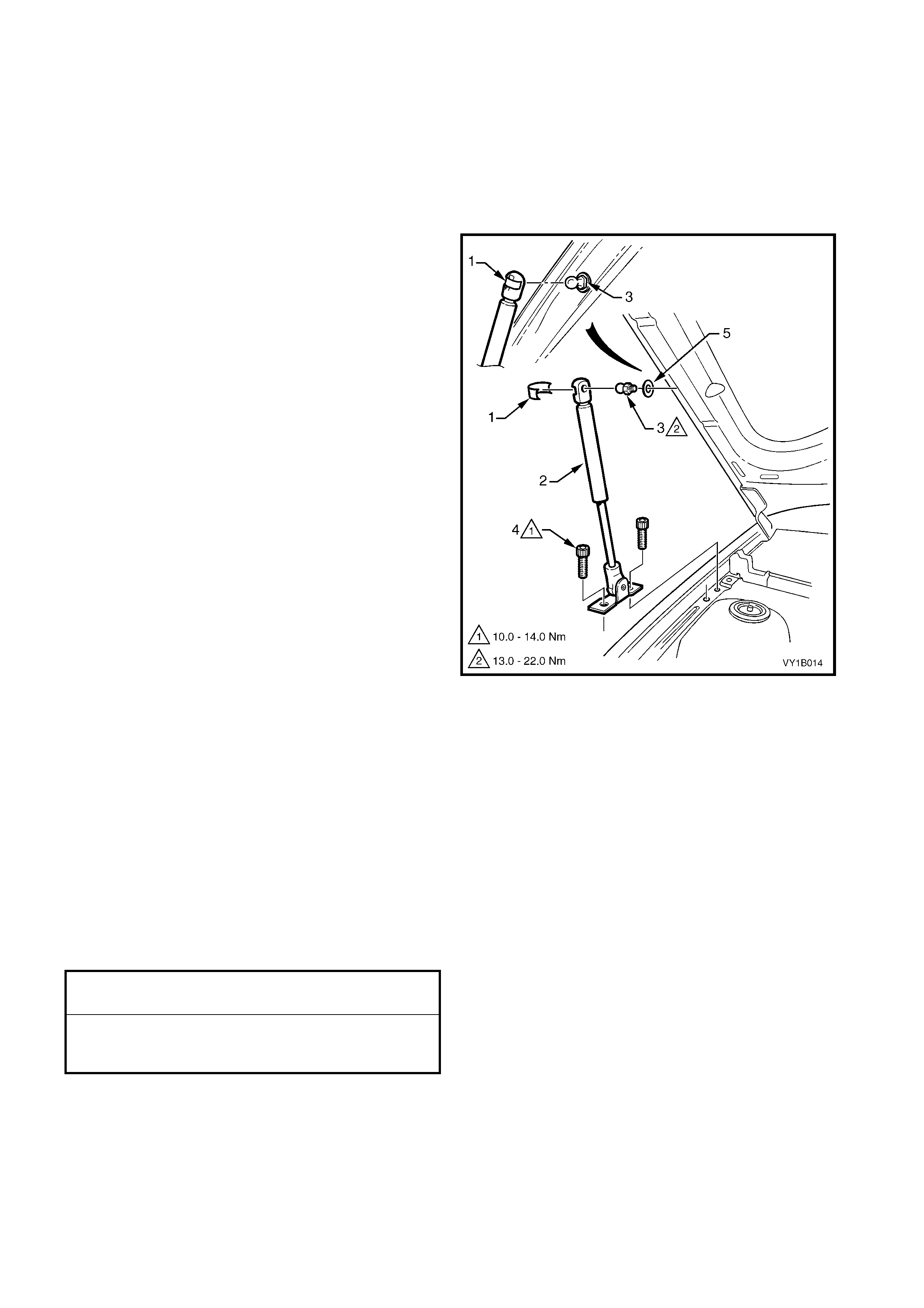

2.6 HOOD STRUT ASSEMBLY

LT Section No. – 12-050

CAUTION: The hood struts contain pressurised

gas and should not be subjected to extreme heat,

pressure or physical damage as personal injury

can result.

REMOVE

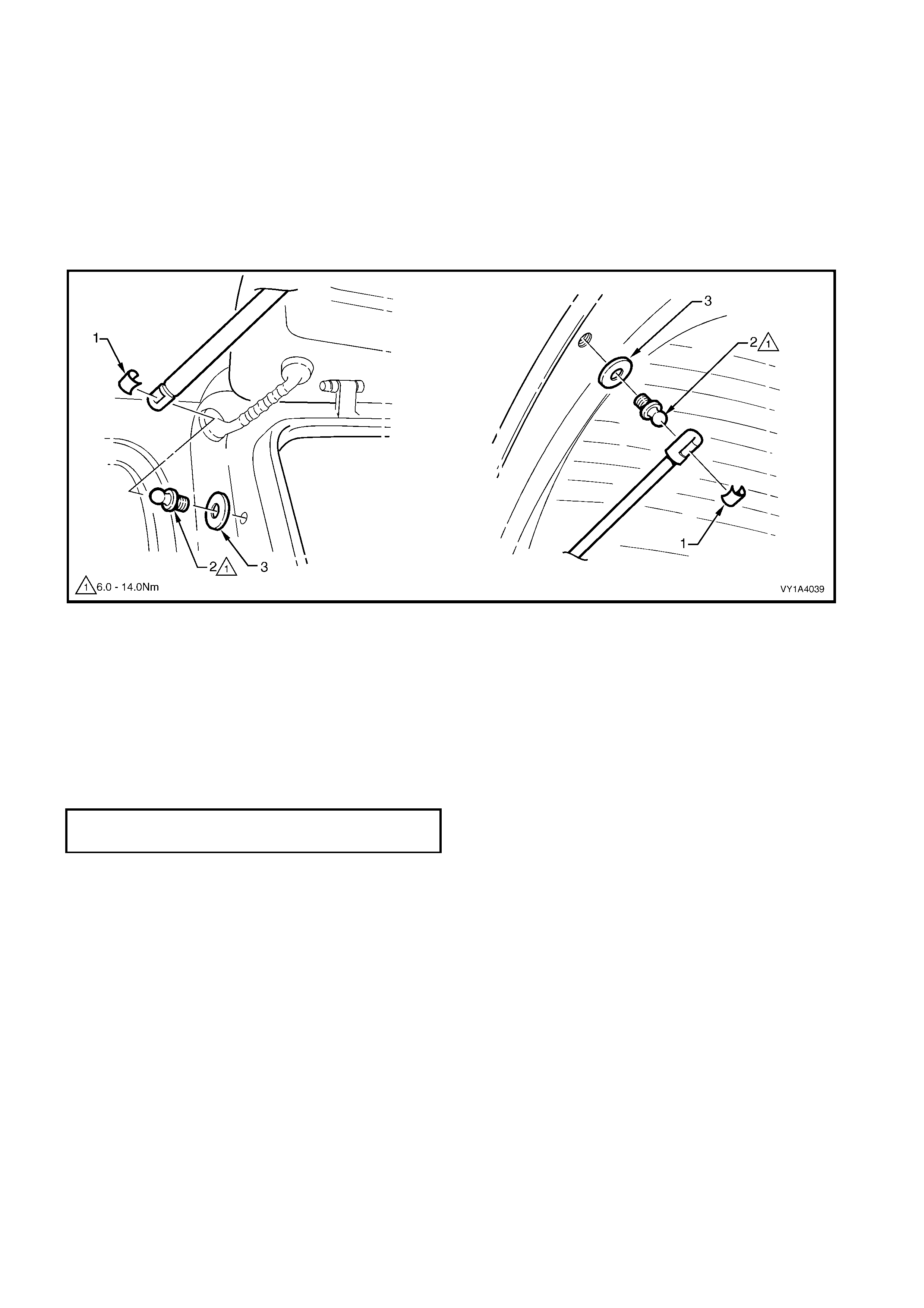

1. Adequately support the hood.

2. Using a fine flat-blade screwdriver, remove the

retainer ( 1) sec ur ing the hood str ut as sembly (2) to

the hood strut pin (3).

NOTE: Tak e car e as the retainer c an spr ing of f and be

easily lost.

3. Remove the two Torx head screws (4) attaching

the strut assembly to the fender.

4. Disconnect the strut assembly from the hood and

remove.

5. If required, unscrew the pin and washer (5) from

the hood.

Figure 1A4-7

REINSTALL

1. Install the hood strut pin and washer onto the

hood, if removed, and tighten to the specified

torque.

2. Apply a small amount of lithium based grease to

the inside of the strut ball cup.

3. Install the retainer into the strut assembly.

4. Align the strut end to the pin and push into place.

5. Install the screws attaching the strut assembly to

the fender and tighten to the specified torque.

6. Remove the support and check for correct

operation.

HOOD STRUT PIN

TORQUE SPECIFICATION 13.0 – 22.0 Nm

HOOD STRUT ASSEMBLY TO

FENDER ATTACHING SCREW

TORQUE SPECIFICATION 10.0 – 14.0 Nm

2.7 HOOD & HINGE ASSEMBLIES

LT Section – 12-425

As required, first remove the following components:

1. Hood front moulding assembly, where fitted, refer

to 2.1 HOOD FRONT MOULDING ASSEMBLY.

2. Hood secondary latch assembly, refer to

2.2 HOOD SECONDARY LATCH ASSEMBLY.

3. Hood primary latch striker assembly, refer to

2.3 HOOD PRIMARY LATCH STRIKER

ASSEMBLY.

4. Hood insulator, refer to 2.4 HOOD INSULATOR.

5. Under-hood lamp assembly, refer to

2.5 UNDER-HOOD LAMP ASSEMBLY.

REMOVE

1. Raise and support the hood.

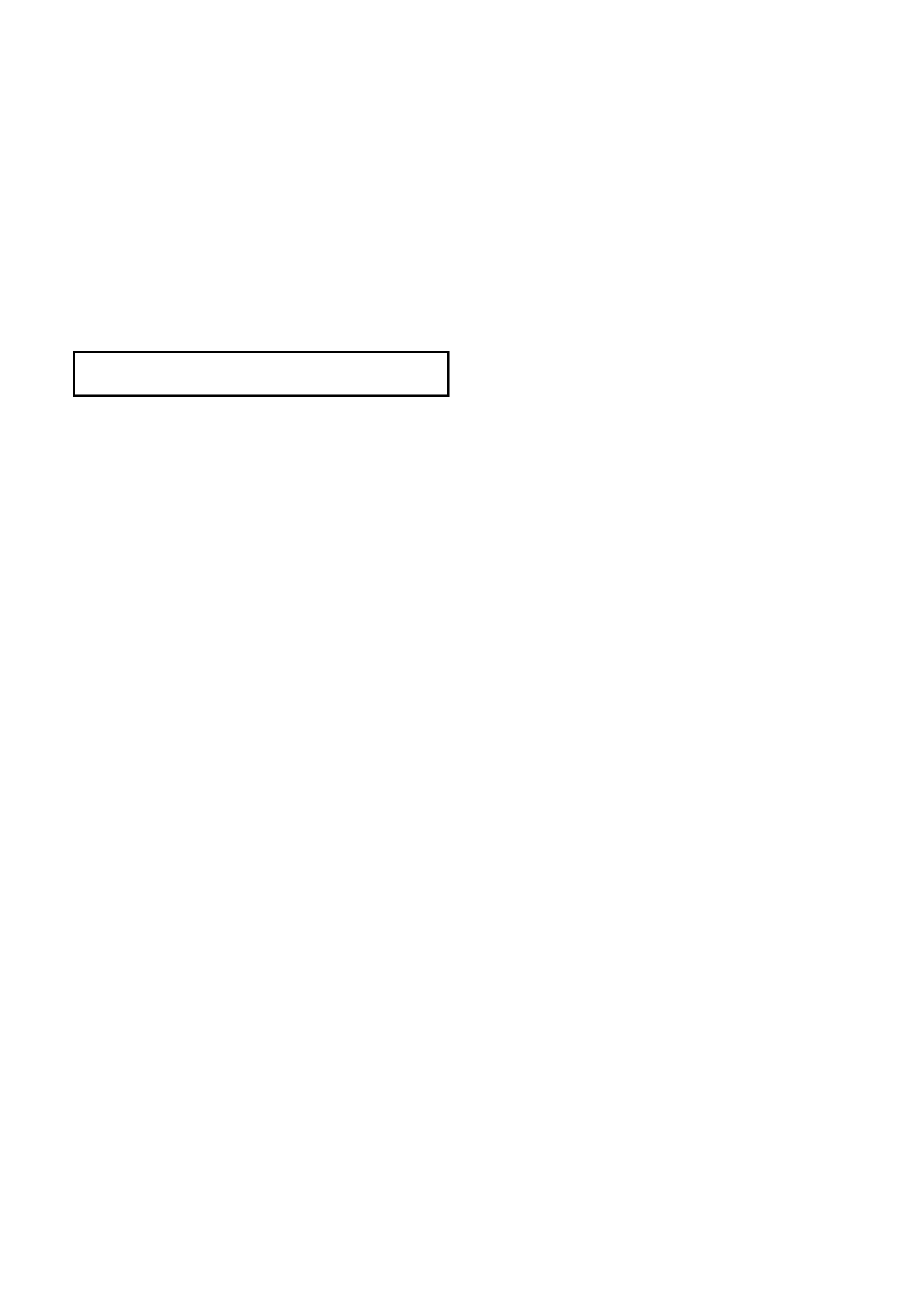

2. If required, from each side of the hood unscrew

and remove the hood adjust bumper (1).

3. Disconnect the hood strut assemblies from only,

refer to 2.6 HOOD STRUT ASSEMBLY.

Figure 1A4-8

4. Remove the hood from the vehicle with the aid of

an assistant by one of the following methods:

• Remove the single s crew (1) each side joining

the upper (2) and lower (3) hinge sections.

This method is best if the same hood

assembly is to be reinstalled as alignment is

not altered.

When removing the hood, slide it out of the

locating tabs (4).

• Remove the two screws (5) each side

attaching the hinges to the hood.

This m ethod is best if a new hood assem bly is

to be fitted.

• Remove the plenum cover assembly, refer

to Section 12N, 2.5 PLENUM COVER

ASSEMBLY – EXCEPT COUPE, or

2.6 PLENUM COVER ASSEM BLY – COUPE,

and then r emove the two screws (6) eac h side

attaching the hinges to the body.

Figure 1A4-9

REINSTALL

1. Install the hinges, if removed, by aligning them with any existing mark s, if possible. Otherwise, install with the

screws centrally in their holes, refer to Figure 1A4-9.

2. With the aid of an assistant slide the hood onto the hinges.

3. Install the screws as required.

4. If the single screw attaching the upper and lower hinge sections was removed, ensure the hinge sections are

correctly seated together and temporarily tighten the screws, refer to Figure 1A4-9.

5. If the hood was removed from the hinges, temporarily tighten the screws in alignment with the old marks or,

align the bolts centrally in their holes.

6. Install the hood adjust bumpers to their original position or half way along the thread, refer to Figure 1A4-8.

7. Install or reconnect the strut assemblies, refer to 2.8 HOOD STRUT ASSEMBLY.

8. Adjust the hood to the vehicle as described in the following procedure.

9. Tighten all screws to the specified torque.

10. Install the remaining hood components as required.

ADJUST

Correct alignment of the hood is critical to its operation and to the aesthetics of the vehicle. However, if the fenders

are not correctly positioned, the hood cannot be aligned.

Depending on the repairs performed, it may be advantageous to perform a measurement check between the

fenders prior to adjusting the hood.

Fender Alignment

1. Chec k that the m argins between the fr ont door s and fender s are c orrect. If not rec tify before proceeding, r efer

to Section 1B, 2.4 FENDER.

NOTE: Paint damage may occur. Use care and touch-up any paint damage as required.

2. Measure the distance between the rear of the fenders (1). This should be the width of the rear of the engine

hood plus 8.0 mm. If not adjust the fenders as required, refer to Section 1B, 2.4 FENDER.

3. Measure the distance between the fr ont of the fenders ( 2). This should be the width of the f ront of the engine

hood plus 8.0 mm. If not, adjust the fenders as required, refer to Section 1B, 2.4 FENDER.

4. Measure the distance between a suitable point at the rear of the LH fender and front of the RH fender (3). Note

the length.

5. Measure the distance between the opposite fender points (4). This measurement is to be within 1.5 mm of

result (3).

6. If the measurements are correct, align the hood as follows. If not adjust the fenders as required, refer to

Section 1B, 2.4 FENDER.

Engine Hood Alignment

1. If fitted, remove the hood primary latch striker assembly, refer to 2.3 HOOD PRIMARY LATCH STRIKER

ASSEMBLY.

2. Carefully close the hood, ensuring each side does not contact the fenders.

3. Check the alignment of the hood for:

• Length. Compare to the front edge of the fenders. They should be equal at point A.

• W idth of gap. Compar e the gap between the hood and fender each side. The gap s pecification is 4.0 m m

+0.5 mm / -1.0 mm.

• Consistency of gap. Com pare the width of gap between the hood and fender at the f ront, middle and rear

each side. It should be even.

• Height. Compare the hood to the fenders at each corner. The hood height specifications is -1 mm ±1.0

mm.

HOOD ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 10.0 – 25.0 Nm

4. Open the hood and as required:

• Loosen the screws attaching hood to the hinge for fore and aft adjustment, refer to Figure 1A4-9.

• Loosen the screws attaching the hinges to the body for rear height adjustment. If required, this also

provides fore and aft adjustment, refer to Figure 1A4-9.

• Turn the hood adjust bum per clockwise to lower the fr ont of the hood, or anti-c lockwise to rais e the hood,

refer to Figure 1A4-8.

NOTE: Do not m ake all adjus tments at once. Perfor m one adj ustment, c arefully close the hood, check its position

and make further adjustments until correct alignment is achieved.

5. Install the latch striker assembly, refer to 2.3 HOOD PRIMARY LATCH STRIKER ASSEMBLY.

6. Lower the hood while watching that the latch striker assembly aligns in the lock aperture.

7. Have an as sistant hold the hood r elease lever open, c heck the latch s trik er bolt does not foul the lock and that

the hood alignment does not alter. Adjust the latch striker bolt position as required.

8. Close the hood by dropping from a height of approximately 300 mm.

IMPORTANT: Do not push the hood closed as damage to the panel surface may occur. If it doesn’t close on the

first attempt, try again from a slightly greater height.

9. Check the height difference between the front of the hood and fenders.

10. As required, open the hood and adjust the latch strik er bolt length by loosening the hood primary latch strik er

nut slightly and rotating the bolt with a flat-blade sc rewdriver, refer to F igure 1A4-3, and/or adjusting the hood

adjust bumpers, refer to Figure 1A4-8.

11. Tighten the hood primary latch striker nut and recheck.

12. Check that all screws and nuts are tightened to their specified torque.

HOOD ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 10.0 – 25.0 Nm

HOOD PRIMARY LATCH STRIKER NUT

TORQUE SPECIFICATION 22.0 – 28.0 Nm

2.8 HOOD PRIMARY LATCH ASSEMBLY

LT Section – 12-050

HOOD PRIMARY LATCH SPRING

Remove

1. Raise the hood assembly.

2. Remove the radiator upper shroud, refer to

Section 6B1, 3.14 RADIATOR for V6 and V6 S/C

engines or Section 6B3, 2.15 COOLING FANS &

SHROUD ASSEMBLY for GEN III V8 engines.

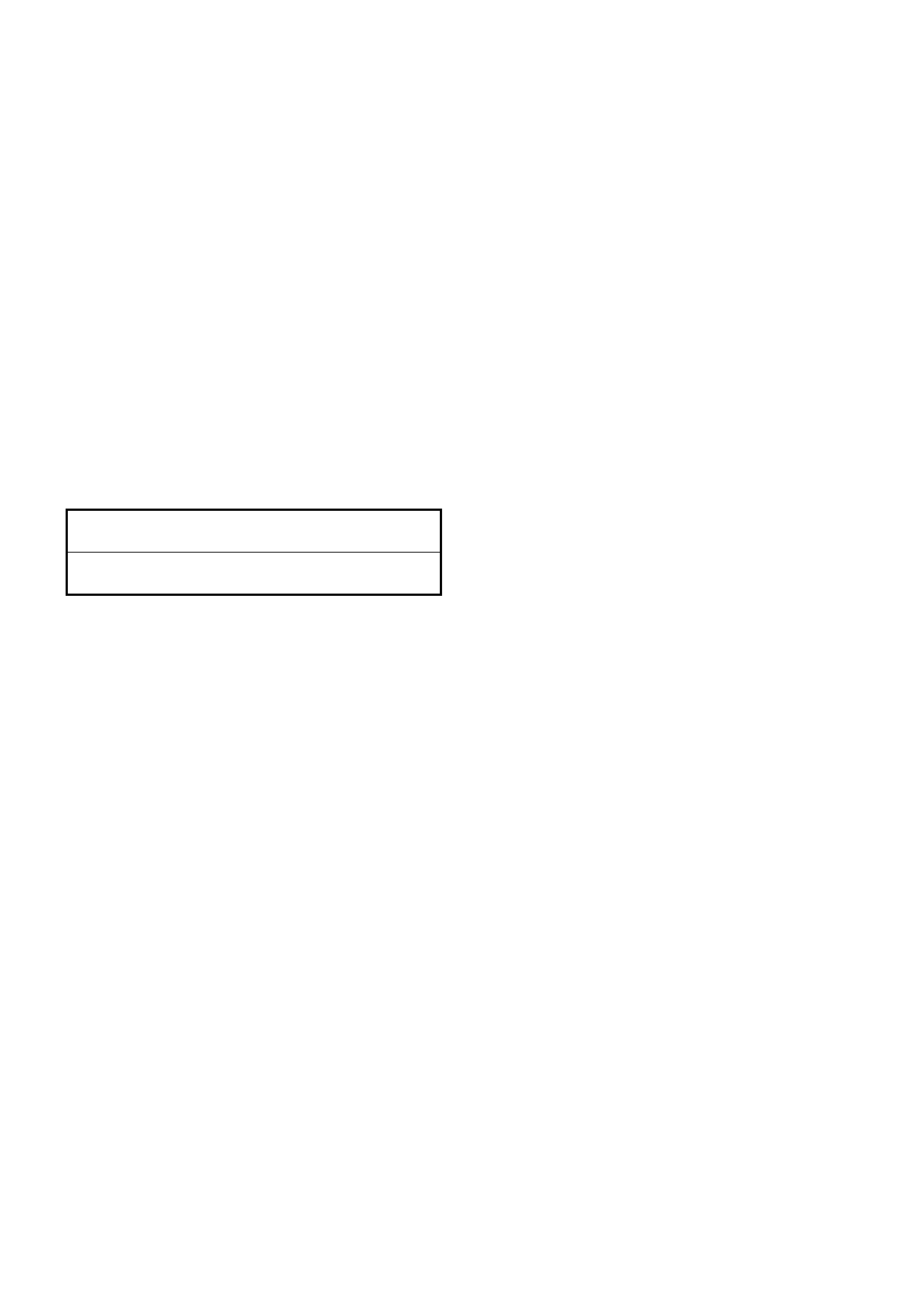

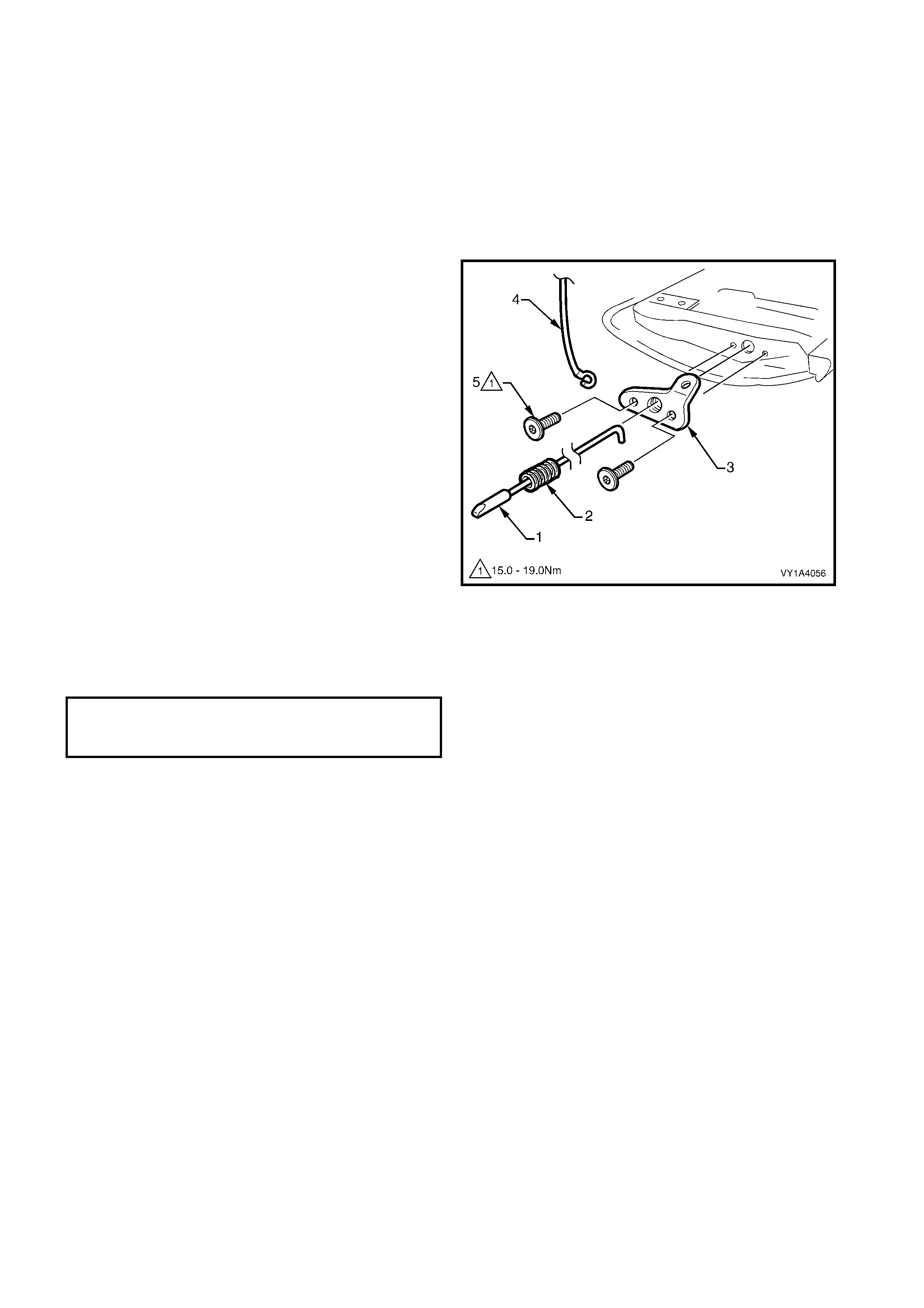

3. Us ing a pair of pliers, gr asp the hood prim ar y latch

spring at point (1) and carefully disengage from the

front panel in the direction shown.

4. Slide the cable end of the spring (2) to the open

position in the direction shown to clear the latch

hole.

5. Unhook the hood primary latch release cable

assembly (3) from the spring.

6. Grasp the end of the spring at point (1), rotate to

vertical and manipulate the section of the spring

within the front panel out through the spring coil

hole.

Figure 1A4-10

Reinstall

Reinstallation is the reverse of removal noting the

following:

1. Check the cable adjustment by inserting a 16 mm

pin (1) between the spring and latch hole and

check there is no clearance between the inner

cable ferrule and spring (2).

2. If required, loosen the cable retainer screw (4,

Figure 1A4-10) and adjust the cable as required.

NOTE: Ensure the outer cable ferrule (5, Figure 1A4-

10) is positioned before the retainer.

3. Tighten the retainer screw to the specified torque,

remove the 16 mm pin and check for correct

operation.

4. Apply NLGI Lithium based grease or equivalent to

the spring slot, the latch assembly hole to a depth

of the spring slot, and to the spring coils, refer to

points (3).

Figure 1A4-11

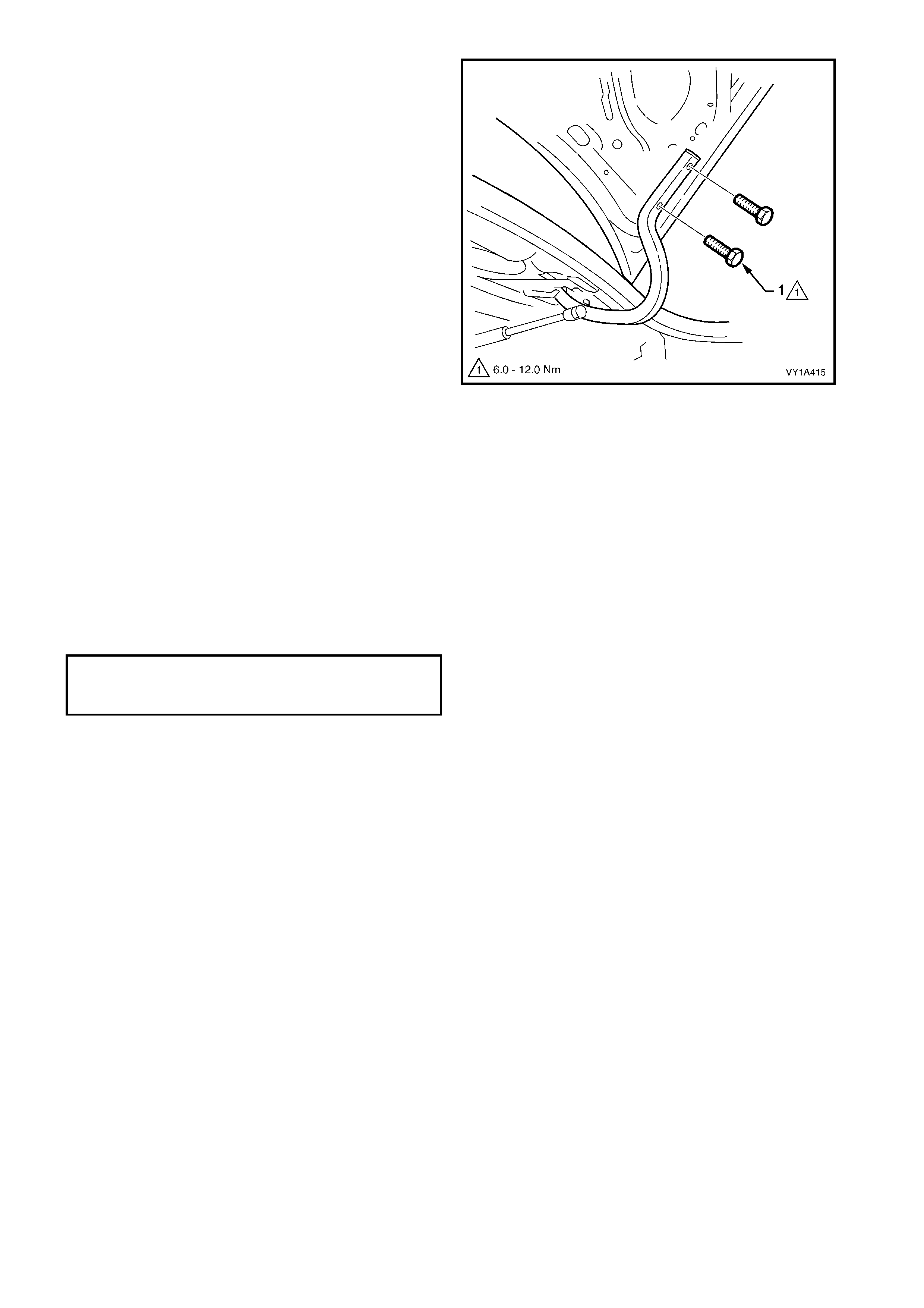

HOOD PRIMARY LATCH RELEASE

CABLE RETAINER SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

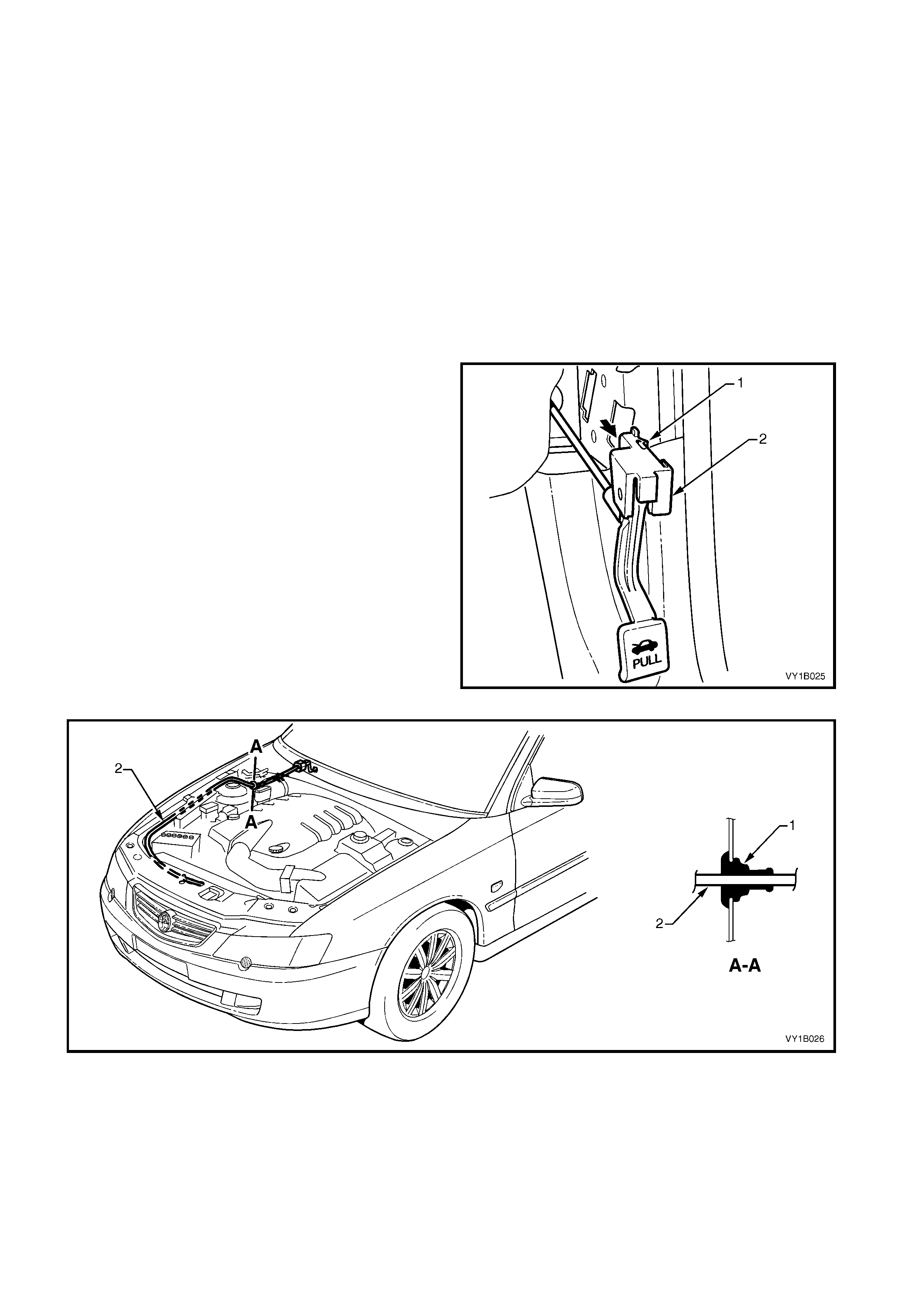

HOOD PRIMARY LATCH RELEASE CABLE ASSEMBLY, RHD

As required, first remove the following components:

1. Remove the radiator upper shroud, refer to Section 6B1, 3.14 RADIATOR for V6 and V6 S/C engines or

Section 6B3, 2.15 COOLING FANS & SHROUD ASSEMBLY for GEN III V8 engines.

2. Right-hand instrument panel outer cover, refer to Section 1A3, 3.17 INSTRUMENT PANEL OUTER

COVER.

3. Unattach the wiring harness conduit from the RH strut tower, refer to Section 12O, FUSES AND WIRING

HARNESSES.

Remove

1. Raise the hood.

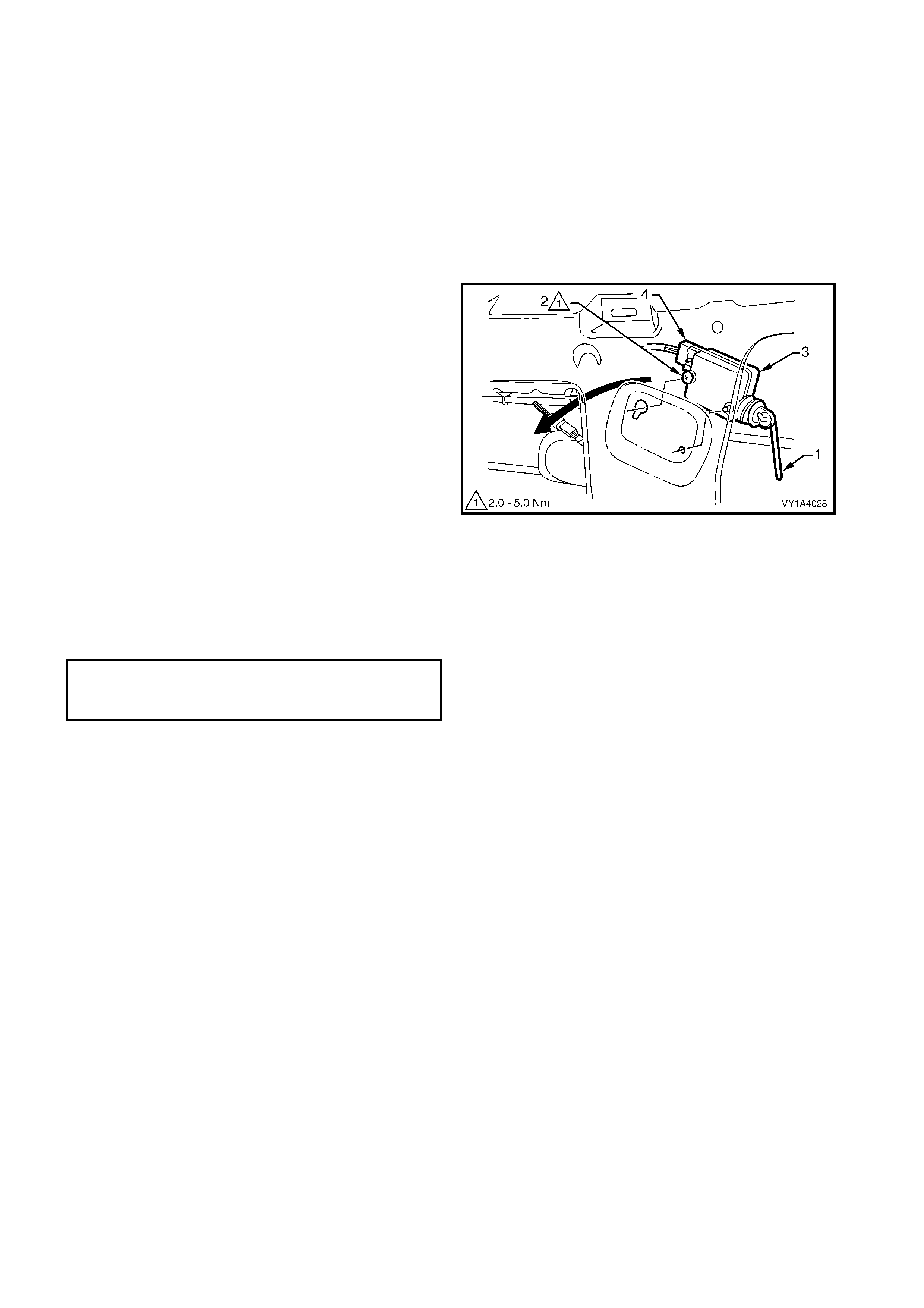

2. Remove the hood primary latch release cable

retainer screw, refer to (4, Figure 1A4-10) and

unhook the release cable assembly from the hood

primary latch spring.

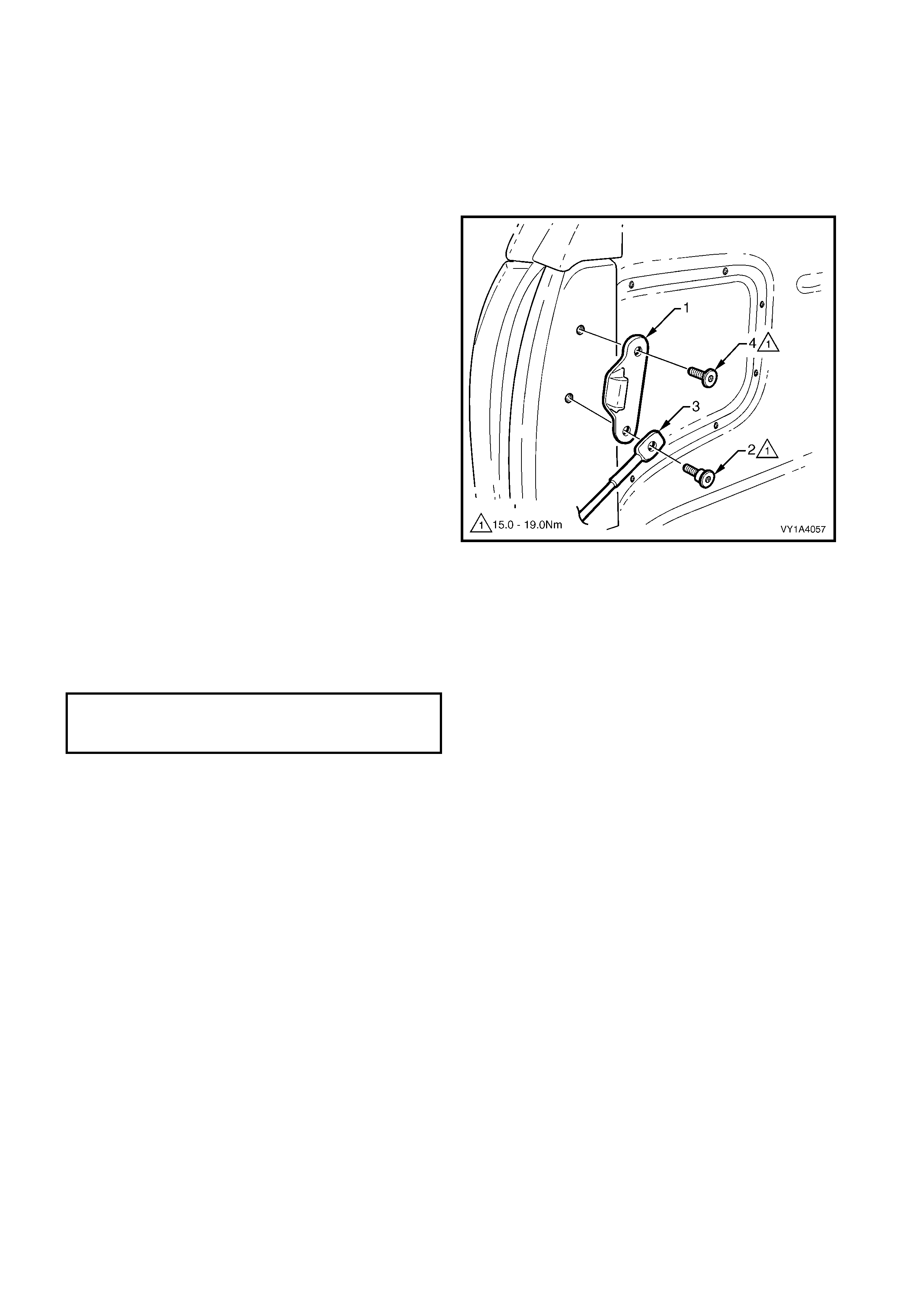

3. Using a fine flat-blade screwdriver, lever the

retaining tabs (1) top and bottom on the hood

release lever assembly (2) and slide the lever

assembly rearward.

4. From within the engine compartment, push the

grommet (1) through the dash panel, refer to

Figure 1A4-13.

5. Withdraw the cable assembly (2) from behind the

fuse and relay box and into the passenger

compartment.

Figure 1A4-12

Figure 1A4-13

Reinstall

Reinstallation is the reverse of removal noting the following:

1. Ensure the cable assembly is correctly routed and there are no sharp bends in the cable, refer to Figure

1A4-13.

2. Attach a spring scale to the lower edge of the release lever. The effort required to release the hood should

not exceed 40N.

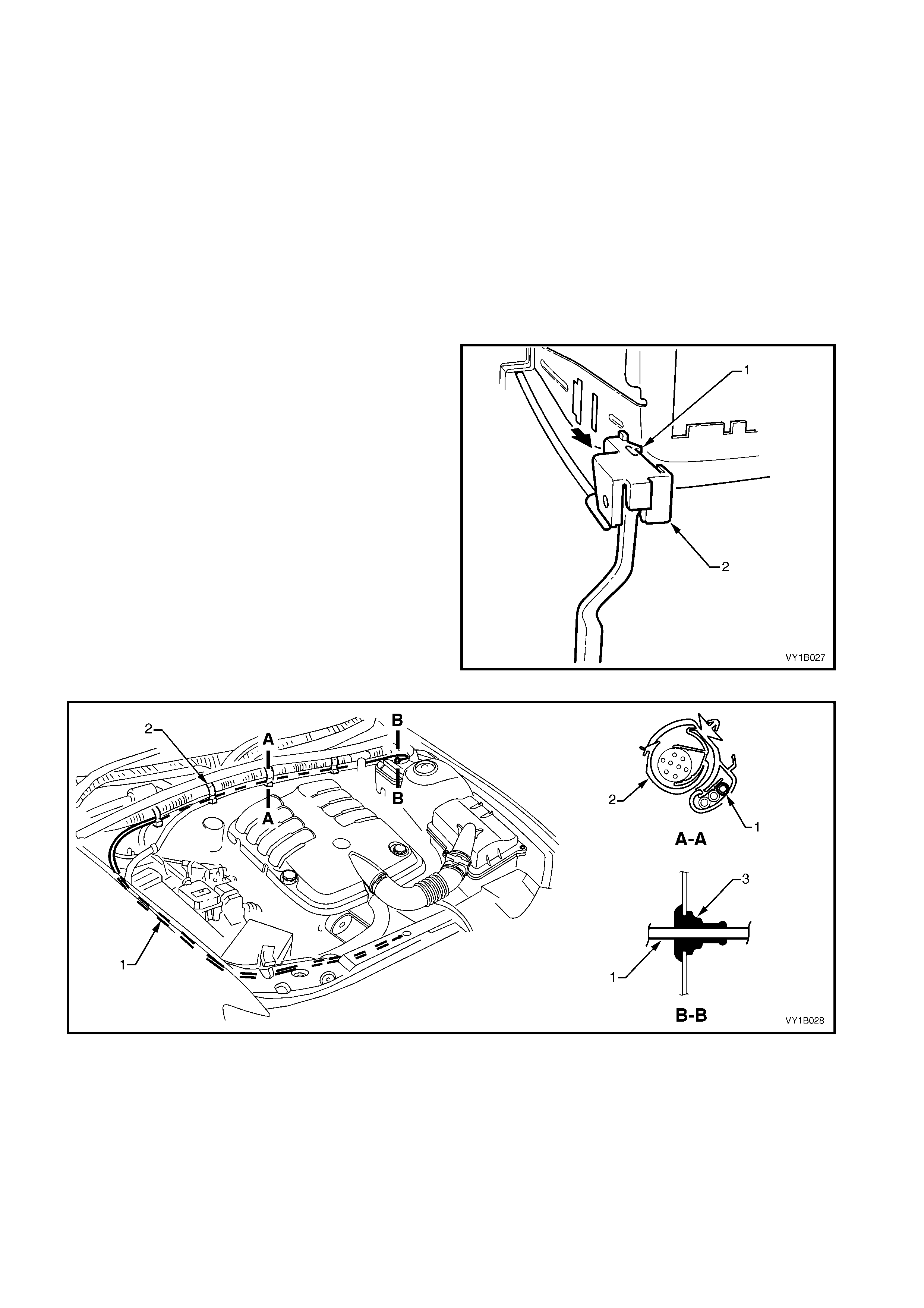

HOOD PRIMARY LATCH RELEASE CABLE ASSEMBLY, LHD

As required, first remove the following components:

1. Remove the radiator upper shroud, refer to Section 6B1, 3.14 RADIATOR for V6 and V6 S/C engines or

Section 6B3, 2.15 COOLING FANS & SHROUD ASSEMBLY for GEN III V8 engines.

2. Left-hand Instrument panel outer cover, refer to Section 1A3, 3.17 INSTRUMENT PANEL OUTER COVER.

3. Unattach the wiring harness from the right-hand strut tower, refer to Section 12O, FUSES AND WIRING

HARNESSES.

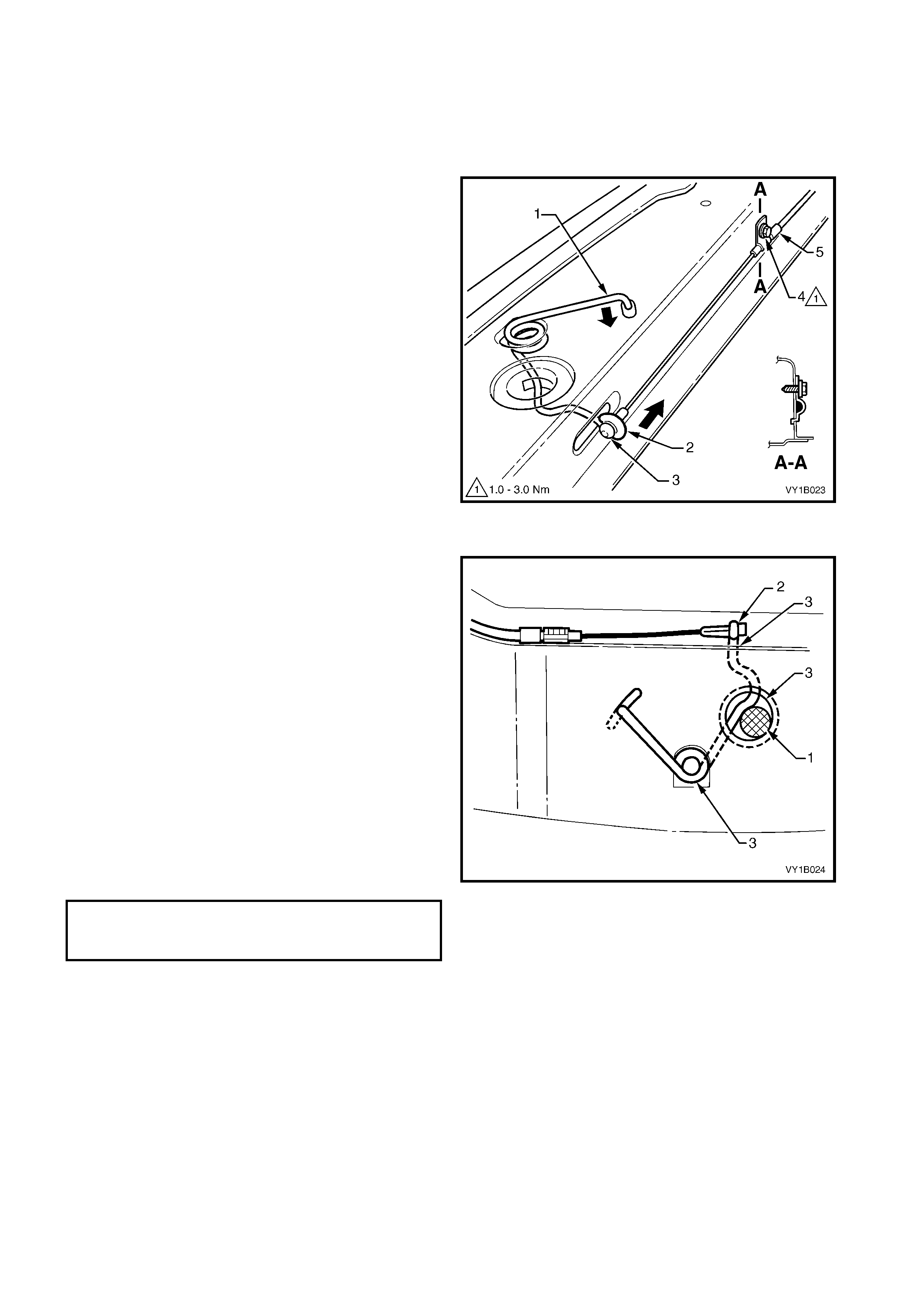

Remove

1. Raise the hood.

2. Remove the hood primary latch release cable

retainer screw , refer to (4, Figure 1A4-10) and

unhook the release cable assembly from the hood

primary latch spring.

3. Using a fine flat-blade screwdriver, lever the

retaining tabs (1) top and bottom on the release

lever bracket (2) and slide the lever assembly

rearward.

4. From within the engine compartment, remove the

cable assembly (1) from the wiring harness

retainers (2), four places, refer to Figure 1A4-15.

5. Push the grommet (3) through the dash panel.

6. Withdraw the c able as sembly from behind the f us e

& relay box, across the dash panel and into the

passenger compartment.

Figure 1A4-14

Figure 1A4-15

Reinstall

Reinstallation is the reverse of removal noting the following:

1. Ensure the cable assembly is correctly routed and there are no sharp bends in the cable.

2. Attach a spring scale to the lower edge of the release lever. The effort required to release the hood should

not exceed 40N.

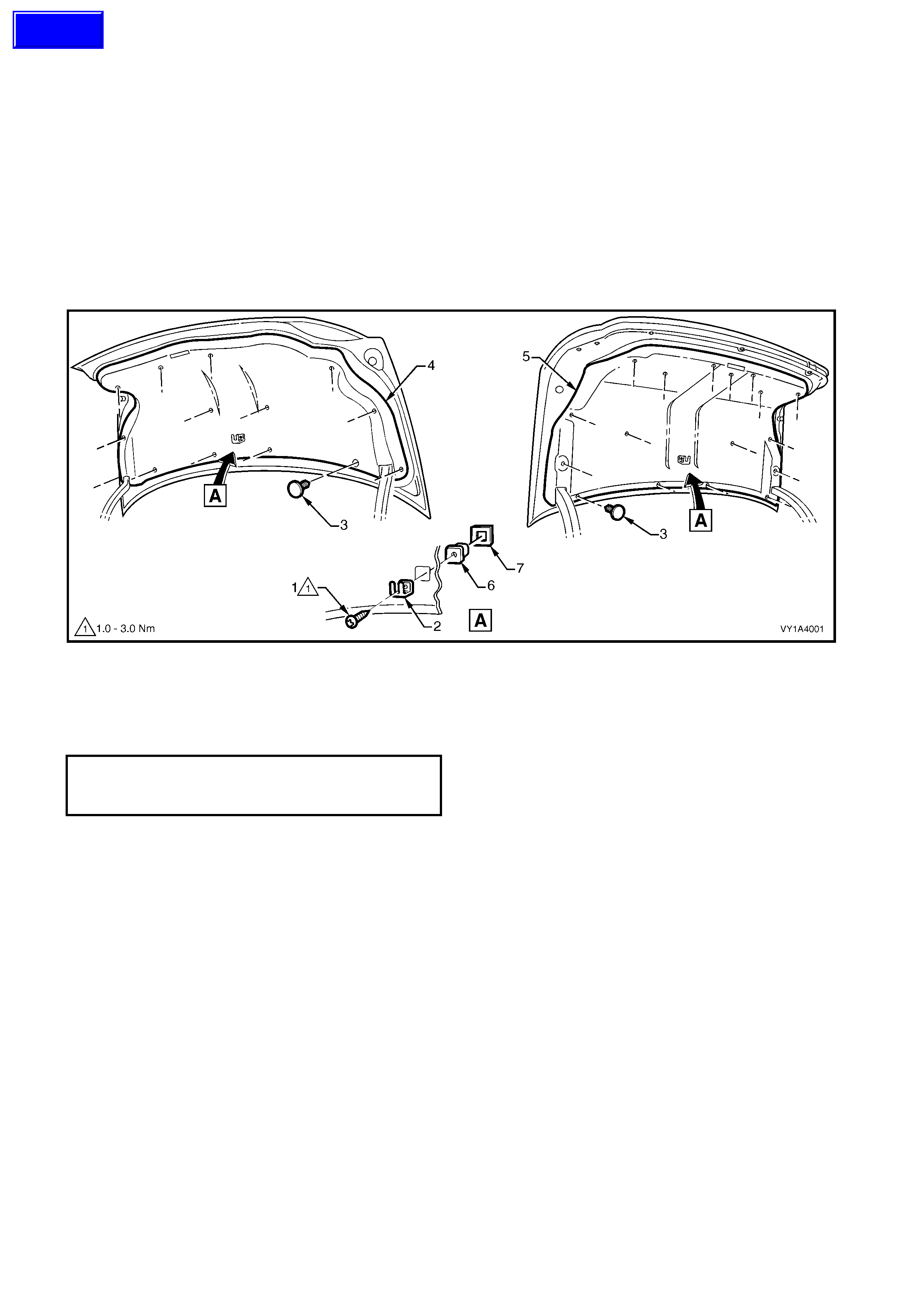

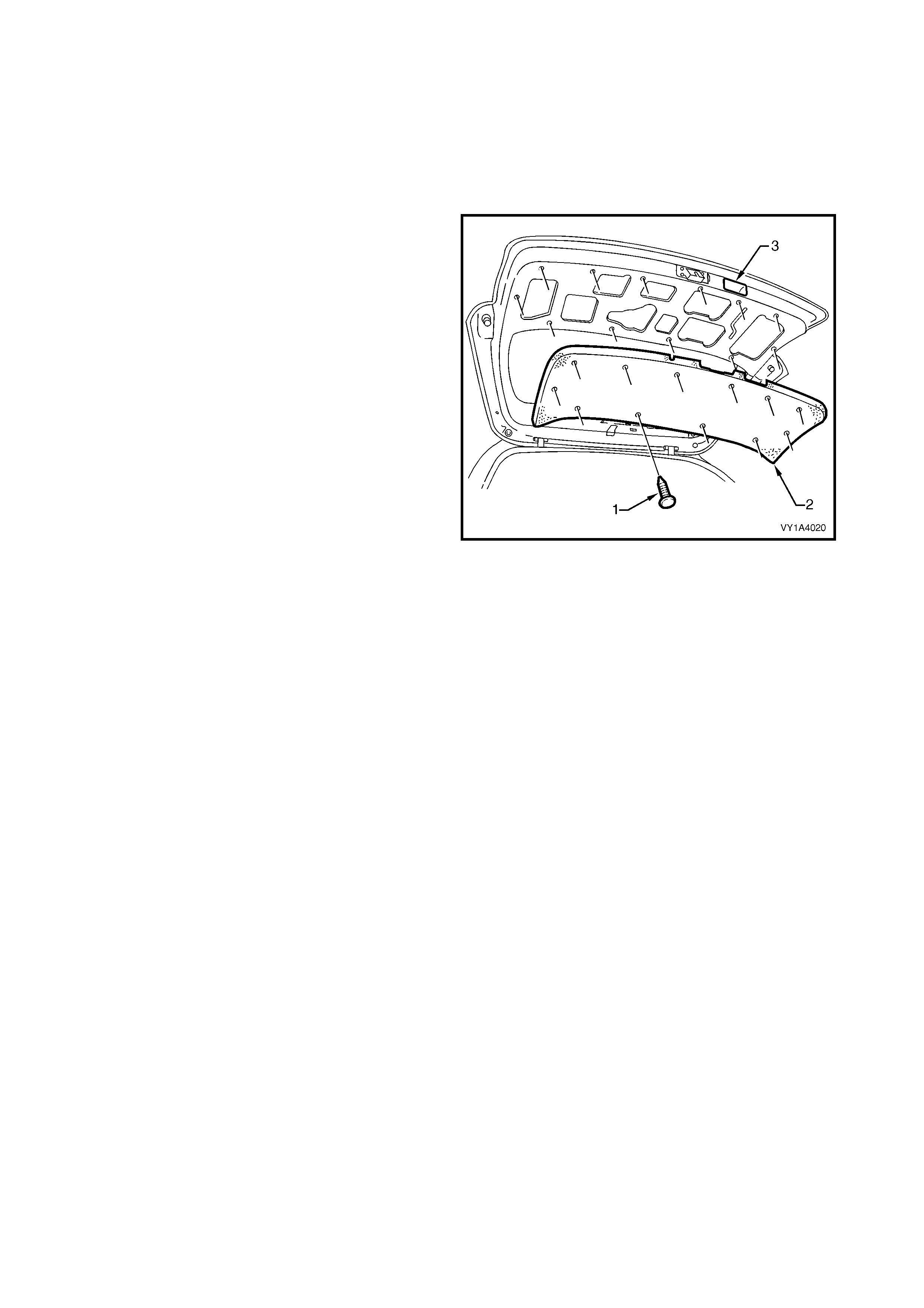

3. SERVICE OPERATIONS – REAR COMPARTM ENT LID

3.1 REAR COMPARTMENT LID CARPET

LT Section No. – 14-480

REMOVE

1. Remove the screw (1) attaching the spare wheel stowage cover hook (2), refer to Figure 1A4-16.

2. Using a suitable trim c lip r emoval tool, remove the retainers ( 3) attac hing the r ear c ompartment lid carpet (4)

Sedan 14 places, or (5) Coupe 17 places.

3. Remove the carpet from the rear compartment lid.

4. If required, prise the nut (6) and washer (7) from the rear compartment lid with a fine flat-blade screwdriver.

Figure 1A4-16

REINSTALL

1. Reinstallation is the reverse of rem oval. Tighten the spare wheel stowage cover hook screw to the s pecified

torque.

SPARE WHEEL STOWAGE COVER

HOOK ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Techline

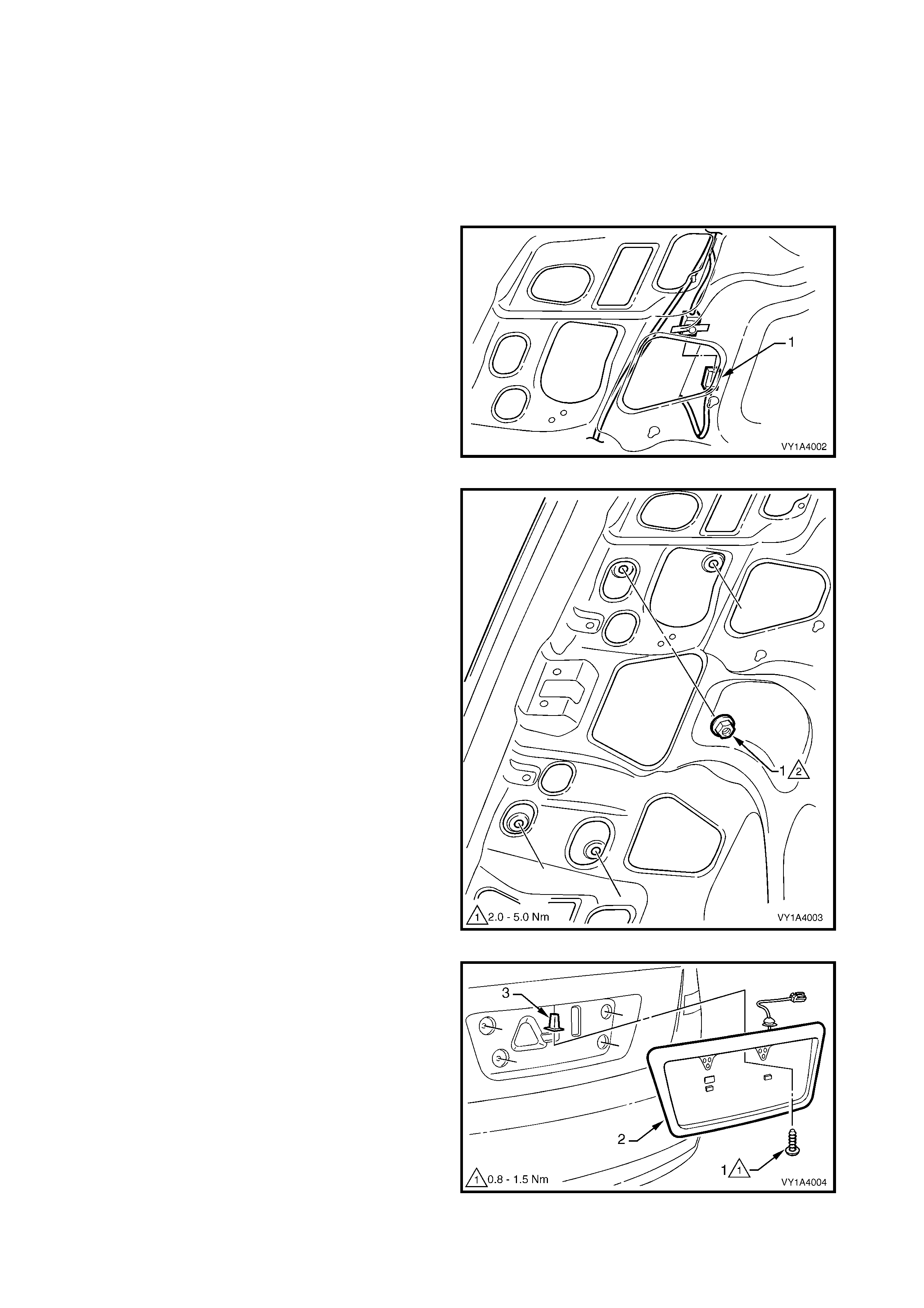

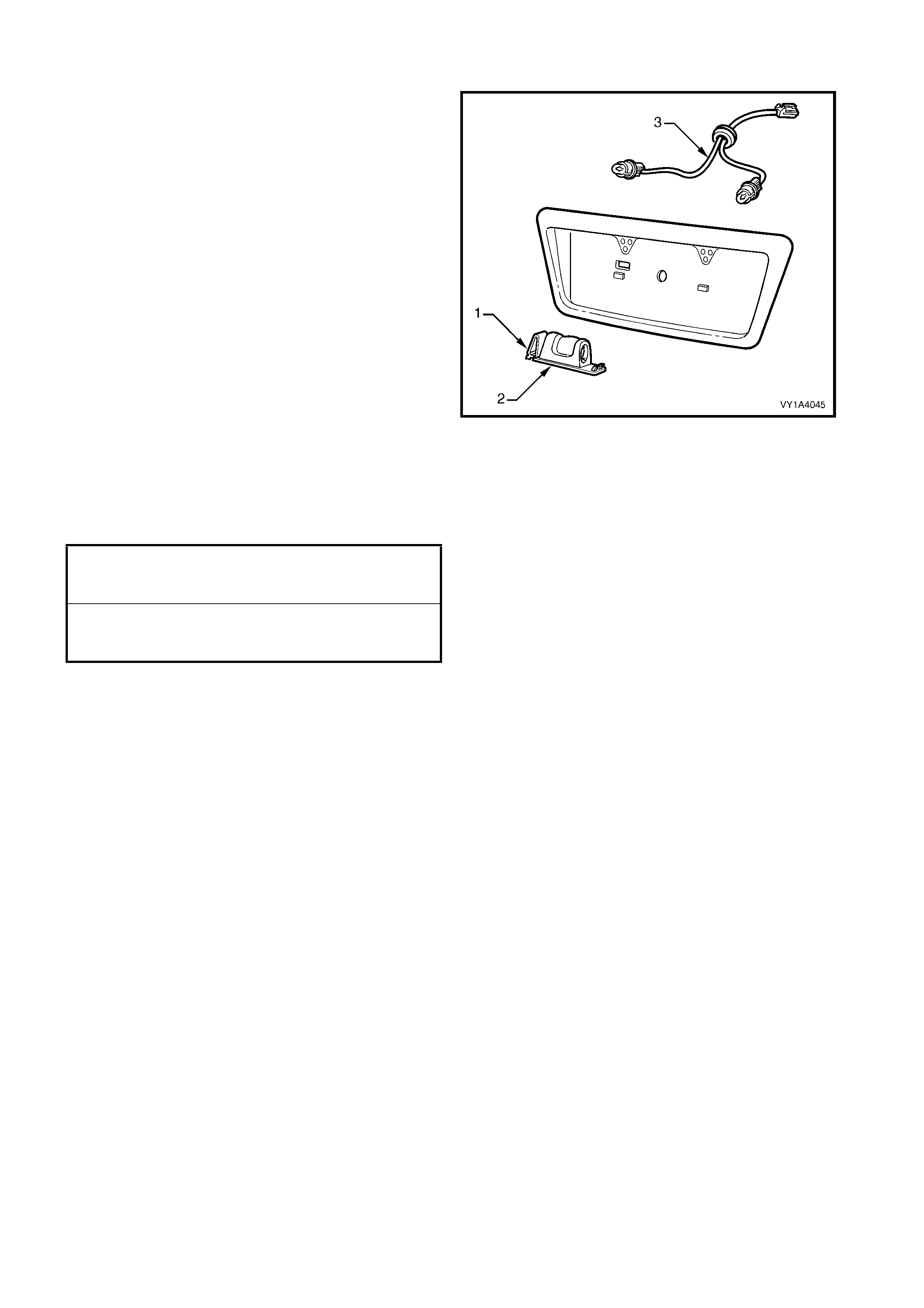

3.2 REAR COMPARTMENT LID APPLIQUE ASSEMBLY, SEDAN

LT Section No. 02-375

As required, first remove the following components:

1. Rear compartment lid carpet, refer to 3.1 REAR COMPARTMENT LID CARPET.

2. Licence plate.

REMOVE

1. From within the rear compartment lid cavity,

disconnect the lic ence plate lamp wiring connec tor

(1).

Figure 1A4-17

2. From within the rear compartment lid cavity,

remove the nut (1), four places, attaching the

applique assembly to the rear compartment lid.

Figure 1A4-18

3. Remove the screw (1) attaching the applique

assembly (2) to the rear compartment lid.

4. Withdraw the applique assembly from the rear

compartment lid, remove the wiring harness

grommet and withdraw the wiring harness.

5. Remove the applique assembly.

6. If required, remove the retainer (3) from the rear

compartment lid.

Figure 1A4-19

DISASSEMBLE

1. Depress the tab (1) and lower the rear licence

plate lamp housing ass em bly (2) from the applique

assembly.

2. Rotate the bulb socket and remove from the

housing assembly.

3. Remove the housing assembly and repeat for the

opposite side.

4. Remove the licence plate lamp harness assembly

(3) from the rear of the applique assembly.

Figure 1A4-20

REINSTALL

1. Reinstallation is the reverse of removal. Ensure

the seals are c or rec tly fitted and tighten the screws

and nuts to the specified torque.

REAR COMPARTMENT LID APPLIQUE

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 0.8 – 1.5 Nm

REAR COMPARTMENT LID APPLIQUE

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 5.0 Nm

3.3 REAR COMPARTMENT LID APPLIQUE ASSEMBLY, CO UPE

LT Section No. 02-375

As required, first remove the following components:

1. Rear compartment lid carpet, refer to 3.1 REAR COMPARTMENT LID CARPET.

2. Licence plate.

REMOVE

1. From within the rear compartment lid cavity,

disconnect the lic ence plate lamp wiring connec tor

(1).

Figure 1A4-21

2. Remove the Torx Head screw (1) and seal, three

places along the lower edge of the rear

compartment lid.

3. Remove the nut (2) and seal from within the rear

compartment lid cavity, one place each side.

4. Remove the screw (3) and seal, two places, each

side of the rear compartment lid.

Figure 1A4-22

5. Either:

• Remove the screw (1) from the retainer within

the rear compartment lid cavity, four places, or

• Depress the tab (2) each side to disengage

the retainer from the rear compartment lid

panel, four places.

Figure 1A4-23

6. Remove the applique assembly (1) away from the

rear compartment lid.

7. Remove the wiring harness grommet (2) and

withdraw the wiring harness.

8. Remove the applique assembly.

Figure 1A4-24

9. If not removed with the applique assembly, as

required carefully prise the four retainers (1) and

seals (2) from the rear compartment lid using a

fine, flat-blade screwdriver.

Figure 1A4-25

DISASSEMBLE

Referring to Figure 1A4-26:

1. Depress the tab (1) and lower the rear licence plate lamp housing assembly (2) from the applique assembly.

2. Rotate the bulb socket and remove.

3. Remove the housing assembly and repeat for the opposite side.

4. Remove the licence plate lamp harness assembly (3) from the rear of the applique assembly.

5. Carefully remove the rear compartment lid applique upper seal (4).

NOTE: The seal is attached with adhesive.

6. Remove rear compartment lid applique gasket (5) from each side of the applique assembly.

7. If not already done so, remove the screw (6) attaching the retainer (7) and seal to the applique assembly,

four places.

Figure 1A4-26

REINSTALL

1. Attach the removed components as required.

NOTE: Ensure the upper seal is affixed correctly to the applique assembly.

2. Fit the four retainers and seals (7, Figure 1A4-26) to the applique assem bly with the screws (6) and tighten

to the specified torque.

3. Feed the licence plate lam p wiring harness through its hole in the rear compar tment lid and fit the grom met

in position.

4. Install the applique assembly onto the rear compartment lid, ensuring the four retainers snap into position.

5. Install the nuts and screws, ensuring the seals are correctly fitted and tighten to the specified torque.

REAR COMPARTMENT LID APPLIQUE

ASSEMBLY RETAINER ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR COMPARTMENT LID APPLIQUE

ASSEMBLY LOWER ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR COMPARTMENT LID APPLIQUE

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 5.0 Nm

REAR COMPARTMENT LID APPLIQUE

ASSEMBLY OUTER ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

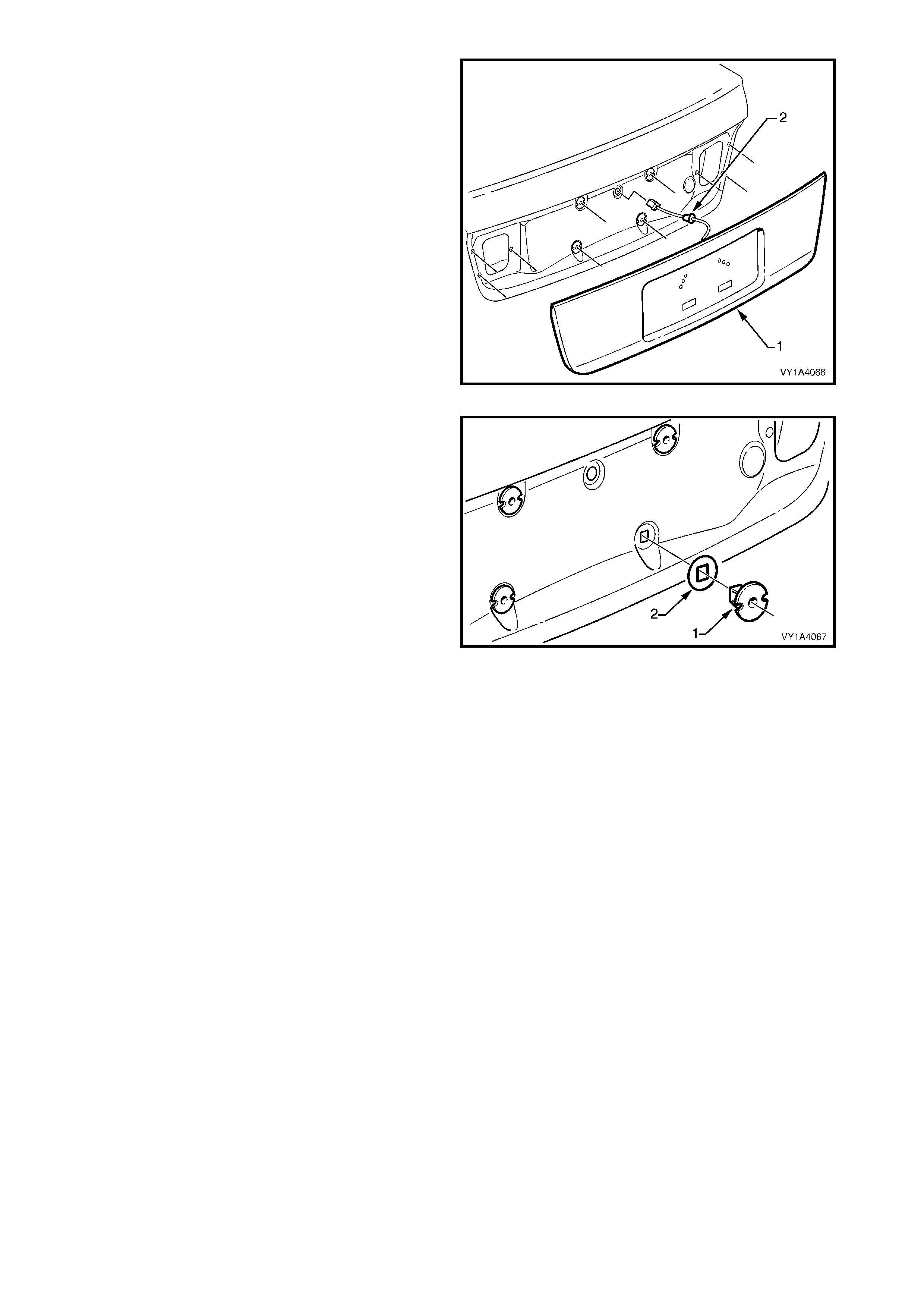

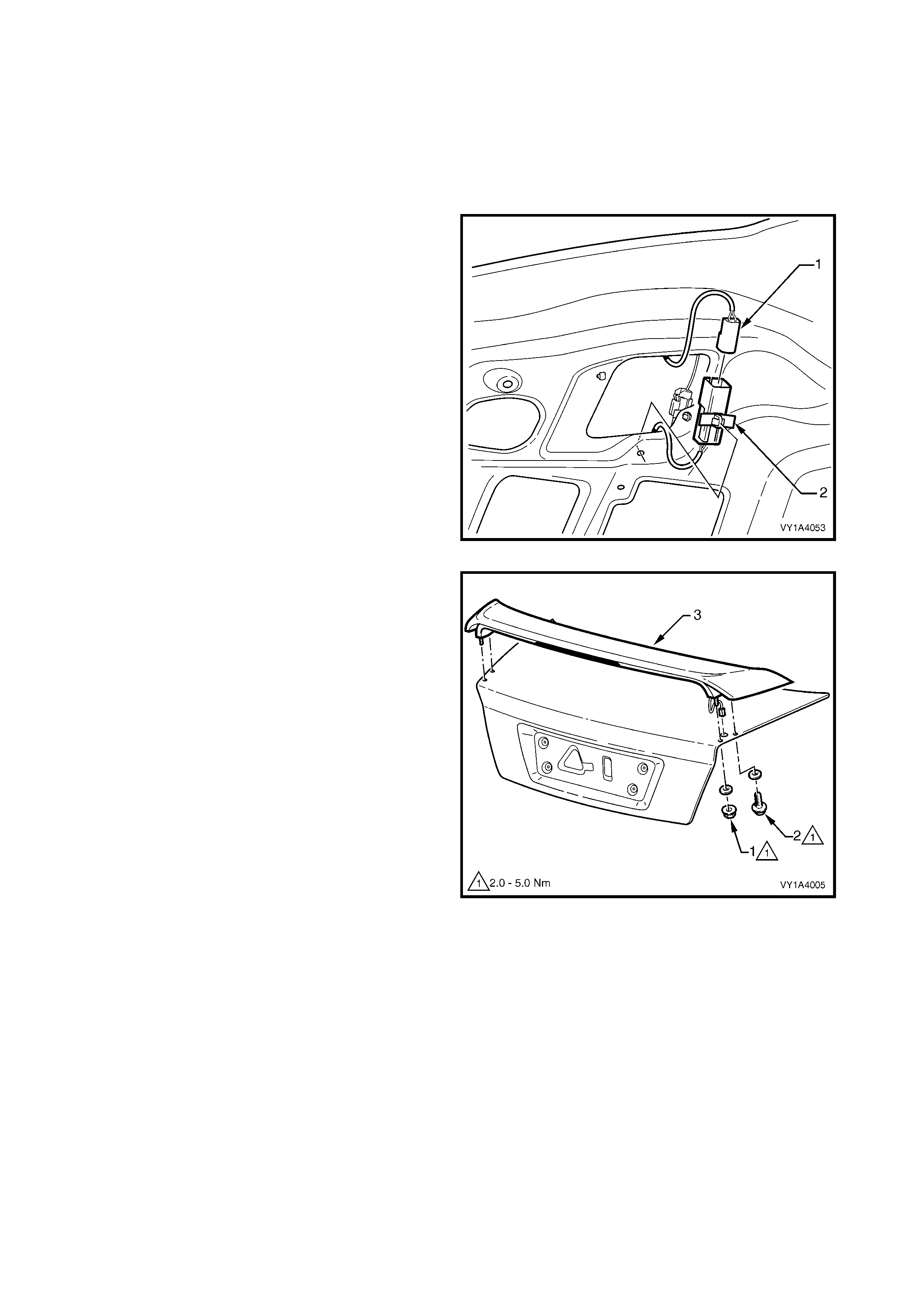

3.4 REAR SPOILER ASSEMBLY

LT Section No. 10-350

As required, first remove the rear compartment lid

carpet, refer to 3.1 REAR COMPARTMENT LID

CARPET.

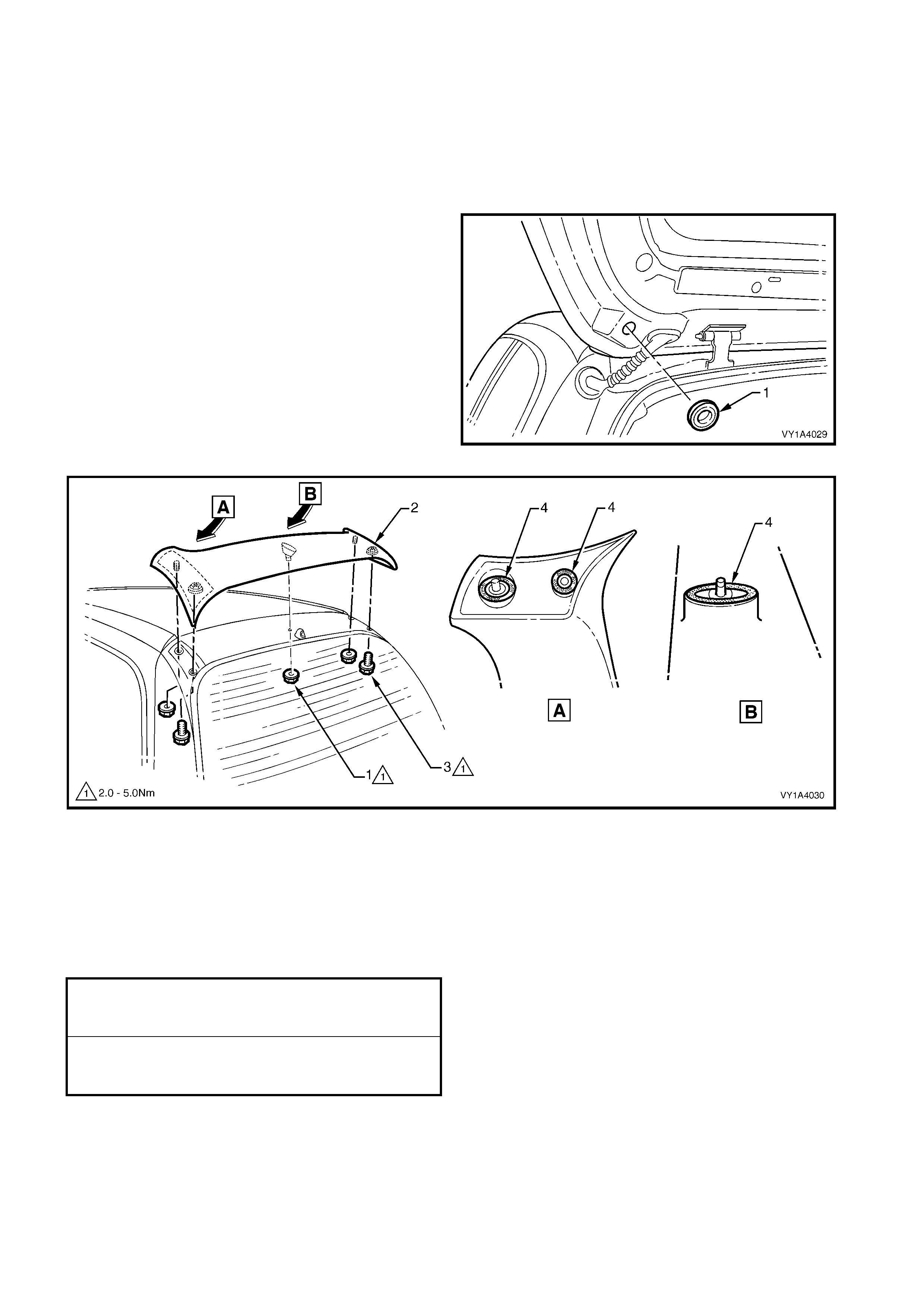

REMOVE

1. From within the rear compartment lid cavity,

disconnect the s poiler wiring harness connector (1).

The body wiring harness side of the connector is

attached to the rear compartment lid with a clip (2).

Figure 1A4-27

2. Remove the nut (1), screw (2) and seals attaching

the spoiler (3) to the rear compartment lid.

3. Remove the spoiler while withdrawing the high

mount stop lamp connector from the rear

compartment lid cavity.

Figure 1A4-28

DISASSEMBLE

Remove – High Mount Stop Lamp Assembly

1. Prise the screw caps (1) from the underside of the

spoiler and remove the two scr ews (2) attaching the

high mount stop lamp assembly (3) to the spoiler.

2. To aid reinstallation, tie a length of string to the

wiring connector.

3. Withdraw the wiring harness through the spoiler,

untie the string and remove the lamp assembly.

Leave the string in the cavity.

Reinstall – High Mount Stop Lamp Assembly

1. Tie the string to the wiring connector and pull

through the s poiler cavity or , manipulate the wiring

harness through the cavity. If required, make a

hook from a length of wire to aid pulling the

connector through.

2. Install the screws and tighten to the specified

torque. Fit the caps.

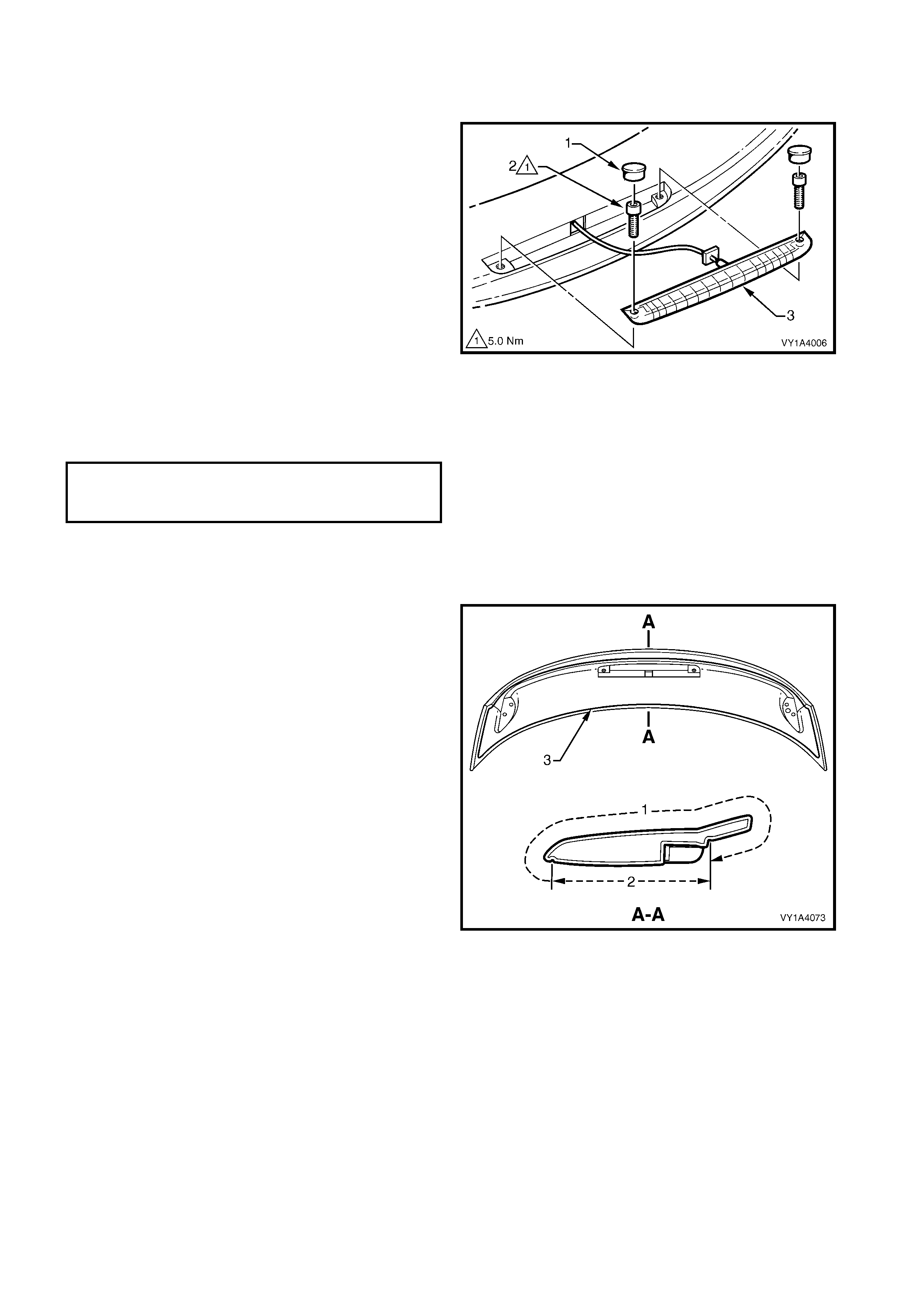

Figure 1A4-29

REINSTALL

The rear spoiler fitted to S vehicles is fully painted in

the vehicle’s body colour.

For SS vehicles the area (1) is painted in the vehicle’s

body colour, while the underside area (2) is painted

sk irt black. A gr oove (3) in the underside of the spoiler

is used as the colour separation point.

A new spoiler is to be painted prior to installation,

and while the painting procedures for the rear spoiler

are relatively straight-forward, the correct steps must

be followed for refinishing ABS plastic. Refer to

Section 1D BUMPER BARS for further information on

plastic painting or refer to your paint manufacturer.

NOTE: If the rear compartment lid has not been

replaced, proceed to Step 11.

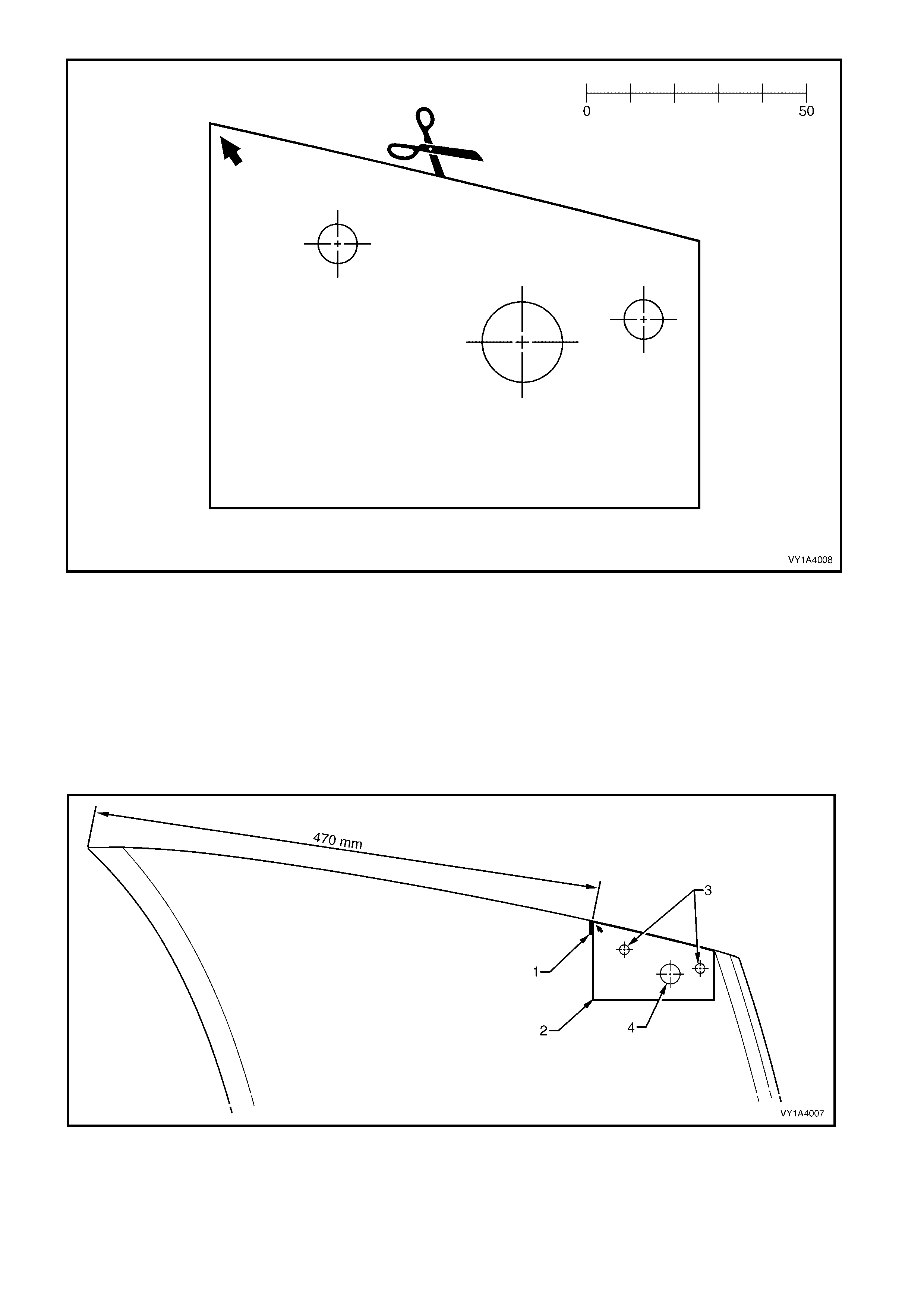

1. Construct a drilling template by printing Figure

1A4-31.

NOTE: Ensure it prints the correct size, compare the

scale.

Figure 1A4-30

HIGH MOUNT STOP LAMP

ASSEMBLY ATTACHING

SCREW TORQUE SPECIFICATION 5.0 Nm

Figure 1A4-31

2. Referring to Figure 1A4-32, place a mark (1) on the right-hand outer edge of the rear compartment lid,

measuring 470 mm from the front corner in a straight line.

NOTE: If the r ear com partment lid is painted, protect the paintwork in the area of the m ounting and wiring holes

with masking tape.

3. Place the template (2) on the rear compartment lid, aligning the corner with the arrow to the mark (1) and the

edge of the template with the edge of the rear compartment lid.

4. Mark the centre of the two mounting holes (3) and for the right-hand side only, the wiring harness hole (4).

5. Turn the template over and repeat steps 2 – 5 for the LH side.

IMPORTANT: Mark the mounting holes only, the wiring harness hole is for the right-hand side only.

Figure 1A4-32

6. Sit the spoiler in position on the rear com partm ent lid and check the m ounting studs align with the mounting

hole marks. Adjust as required.

7. Open the rear compartment lid slightly and place a block of wood under the drilling locations.

8. Car efully drill the m ounting holes. Initially drill 3.0 mm pilot holes , followed by 9.0 m m holes. Drill through the

inner and outer rear compartment lid panels

9. Carefully drill the wiring harness hole on the RH side only. Initially drill a 3.0 mm hole, then drill out to

18.0 mm. Drill through the outer panel only.

10. Debur the drill holes and remove all swarf. Apply primer to the bare metal as required.

11. Fit the spoiler to the rear compartment lid, feeding the high mount stop lamp harness through its hole.

12. Install the seals, screws and nuts onto the studs and hand tighten.

13. Check alignment of spoiler on rear compartment lid and tighten the screws and nuts to the specified torque.

14. Connect the wiring connector within the rear compartment lid cavity and clip onto the inner panel as shown in

Figure 1A4-27.

15. Check high mount stop lamp operation.

16. Refit the rear compartment lid carpet refer to 3.1 REAR COMPARTMENT LID CARPET.

REAR SPOILER ASSEMBLY

ATTACHING NUT & SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

3.5 REAR COMPARTMENT LID LATCH ASSEMBLY

LT Section No. 12-680

As required, first remove the rear compartment lid

carpet, refer to 3.1 REAR COMPARTMENT LID

CARPET.

REMOVE

1. Remove the two screws (1) attaching the latch

assembly (2) to the rear compartment lid.

2. Withdraw the latch assembly from the panel far

enough to enable disconnection of the actuator rod

(3) and rear compartment lid release cable (4).

3. Remove the latch assembly.

Figure 1A4-33

REINSTALL

Reinstallation is the reverse of removal noting the following:

1. Tighten the screws to the specified torque.

2. Lubricate the latch assembly with NLGI No.1 Lithium Grease.

3. Prior to closing the rear compartment lid, manually close the latch and check operation of the latch assembly

via the rear compartment lid release switch and the rear compartment lid release cable assembly. If

operation is satisfactory, close the rear compartment lid and recheck operation. If required adjust the rear

compartment lid striker, refer to 3.11 REAR COMPARTMENT LID STRIKER ASSEMBLY.

REAR COMPARTMENT LID LATCH

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 5.0 Nm

3.6 REAR COMPARTMENT LID ACTUATOR ASSEMBLY

LT Section No. 12-680

NOTE: T he rear com partm ent lid actuator assem bly is

controlled by the BCM. For diagnosis refer to

Section 12J, BODY CONTROL MODULE.

As required, first remove the rear compartment lid

carpet, refer to 3.1 REAR COMPARTMENT LID

CARPET.

REMOVE

1. Loosen the two screws (1) attaching the actuator

assembly (2) to the rear compartment lid.

2. If required, disconnect the connecting rod from the

rear compartment lid latch assembly.

3. Withdraw the actuator assembly from the keyhole

slots in the panel.

4. Remove the actuator assembly from the panel

cavity far enough to enable the wiring harness

connector (3) to be disconnected.

5. Remove the actuator assembly.

Figure 1A4-34

REINSTALL

Reinstallation is the reverse of removal noting the

following:

1. Tighten the screws to the specified torque.

2. Prior to clos ing the rear c ompartm ent lid, m anually

close the latch and check operation of the latch

assembly via the rear compartment lid release

switch and the rear compartment lid cable

assem bly latc h release. If operation is satisfac tory,

close the rear compartment lid and recheck

operation If required adjust the rear compartment

lid latch striker, refer to 3.11 REAR

COMPARTMENT LID STRIKER ASSEMBLY.

REAR COMPARTMENT LID ACTUATOR

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

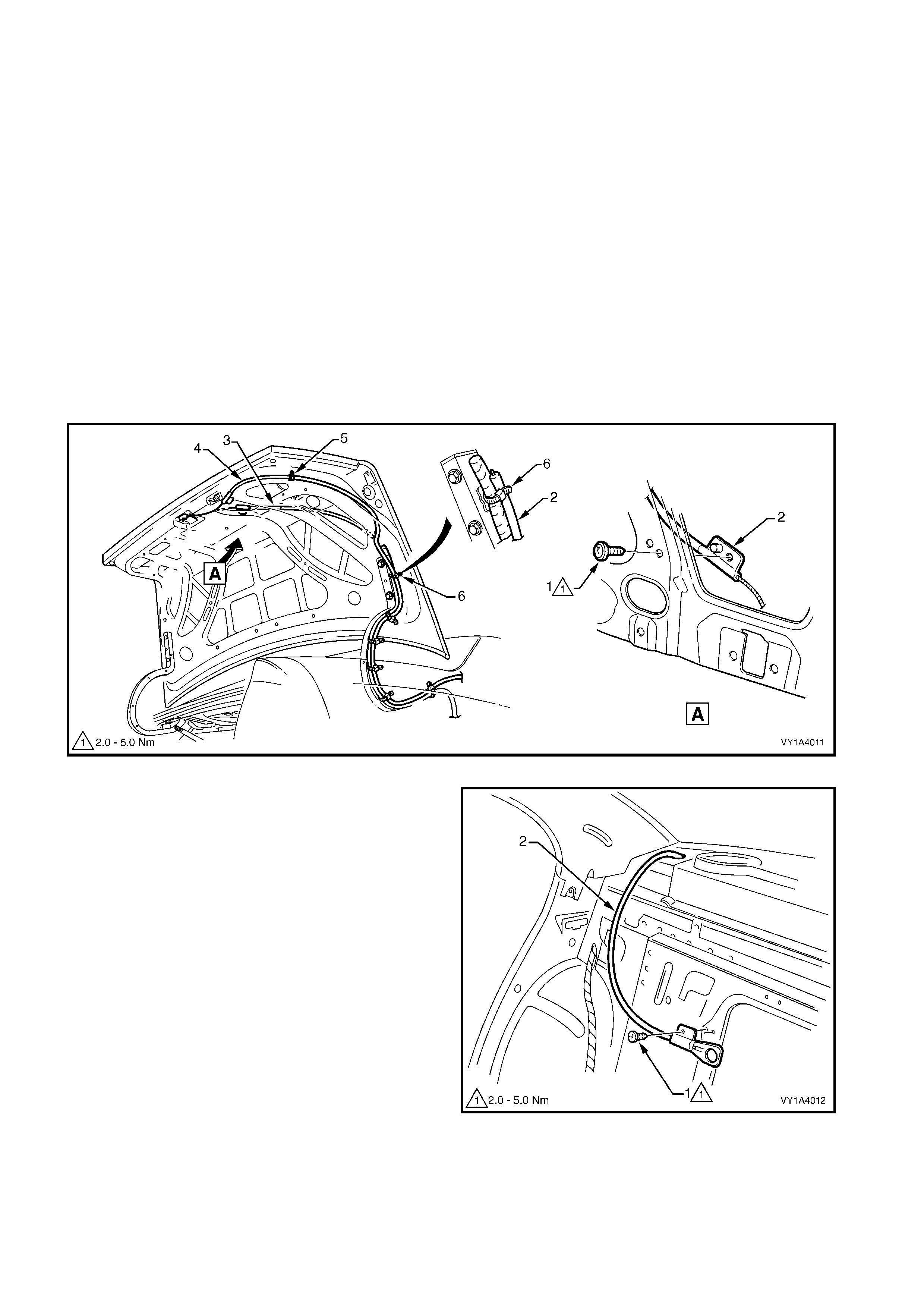

3.7 REAR COMPARTMENT LID RELEASE CABLE ASSEMBLY

LT Section No. 12-680

As required, first remove the following components:

1. Rear compartment lid carpet, refer to 3.1 REAR COMPARTMENT LID CARPET.

2. Rear compartment lid latch assembly, refer to 3.5 REAR COMPARTMENT LID LATCH ASSEMBLY.

3. Right-hand rear seat backrest, refer to Section 1A7, SEAT ASSEMBLIES.

4. Partial removal of the rear window trim panel assembly for Sedan only, refer to Section 1A8, 2.9 REAR

WINDOW TRIM PANEL ASSEMBLY.

REMOVE

1. Remove the screw (1) attaching the rear compartment lid release cable assembly (2) to the rear

compartment lid, refer to Figure 1A4-35 (Sedan shown, Coupe similar).

NOTE: Routing of the cable within the rear compartment lid cavity differs for Sedan (3) and Coupe (4).

2. For Coupe, remove the retainer (5) attaching the cable assembly to the rear compartment lid.

3. Remove the straps (6) attaching the cable assembly to the rear compartment lid wiring harness.

4. Withdraw the cable assembly from the rear compartment lid cavity and lay it on the rear compartment floor.

Figure 1A4-35

5. For Sedan:

• From within the RH rear passenger

compartment, remove the screw (1) attaching

the cable assembly to the back panel - upper.

• Carefully feed the cable assembly into the

passenger compartment and remove.

Figure 1A4-36

6. For Coupe:

• From within the RH rear passenger

compartment, remove the two screws (1)

attaching the cable assembly (2) to the back

panel - upper.

• Carefully feed the cable assembly into the

passenger compartment and remove.

Figure 1A4-37

REINSTALL

Reinstallation is the reverse of removal noting the

following:

1. Tighten the screws to the specified torque.

2. Prior to clos ing the rear c ompartm ent lid, m anually

close the latch and check operation of the latch

assembly via the rear compartment lid release

switch and the rear compartment lid release cable

assembly. If operation is satisfactory, close the

rear compartment lid and recheck operation If

required adjust the rear compartment lid latch

striker, refer to 3.11 REAR COMPARTMENT LID

STRIKER ASSEMBLY.

REAR COMPARTMENT LID RELEASE

CABLE ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

REAR COMPARTMENT LID RELEASE

CABLE ASSEMBLY TO BACK PANEL

UPPER ATTACHING SCREW

TORQUE SPECIFICATION, COUPE 1.9 – 2.1 Nm

3.8 REAR COMPARTMENT LID STRUT ASSEMBLY

LT Section No. 12-660

REMOVE

1. Support the rear compartment lid securely.

2. Using a fine, flat blade screwdriver, prise the

retainer (1) from the rear compartm ent lid strut end

(2).

3. Pull the strut assembly from the ball stud (3).

4. Repeat for the opposite end if required.

Figure 1A4-38

REINSTALL

NOTE: If a rear compartment lid strut assembly is

replaced, ensure the correct type is specified as

vehicles with a rear spoiler require stronger units.

1. Apply a small amount of lithium based grease to

the inside of the strut ball cup.

2. Install the retainer onto the strut end, if removed.

3. Align the strut with the ball stud and push into

place.

4. Repeat for the opposite end if required.

3.9 REAR COMPARTMENT LID ASSEMBLY

LT Section No. 12-660

As required, first remove the following components:

1. Rear compartment lid carpet, refer to 3.1 REAR COMPARTMENT LID CARPET.

2. Rear compartment lid applique assembly, refer to 3.2 REAR COMPARTMENT LID APPLIQUE

ASSEMBLY, SEDAN or 3.3 REAR COMPARTMENT LID APPLIQUE ASSEMBLY, COUPE.

3. Rear spoiler assembly if fitted, refer to 3.4 REAR SPOILER ASSEMBLY.

4. Rear compartment lid latch assembly, refer to 3.5 REAR COMPARTMENT LID LATCH ASSEMBLY.

5. Rear compartment lid actuator assembly, refer to 3.6 REAR COMPARTMENT LID ACTUATOR

ASSEMBLY.

6. Rear compartment lid release cable assembly from the rear compartment lid only, refer to

3.7 REAR COMPARTMENT LID RELEASE CABLE ASSEMBLY.

7. Badges and emblems, refer to Section 1A9, EXTERIOR ORNAMENTATION.

REMOVE

1. Remove the screw (1) attaching the rear

compartment courtesy lamp switch assembly (2) to

the rear compartment lid.

2. Withdraw the switch and disconnect the wiring

connectors (3).

3. Remove the body wiring harness assembly from

the rear compartment lid only. If required, refer to

Section 12O, FUSES AND WIRING

HARNESSES.

Figure 1A4-39

4. Unscrew the rear compartment lid bumper (1) from

each side of the rear compartment lid.

Figure 1A4-40

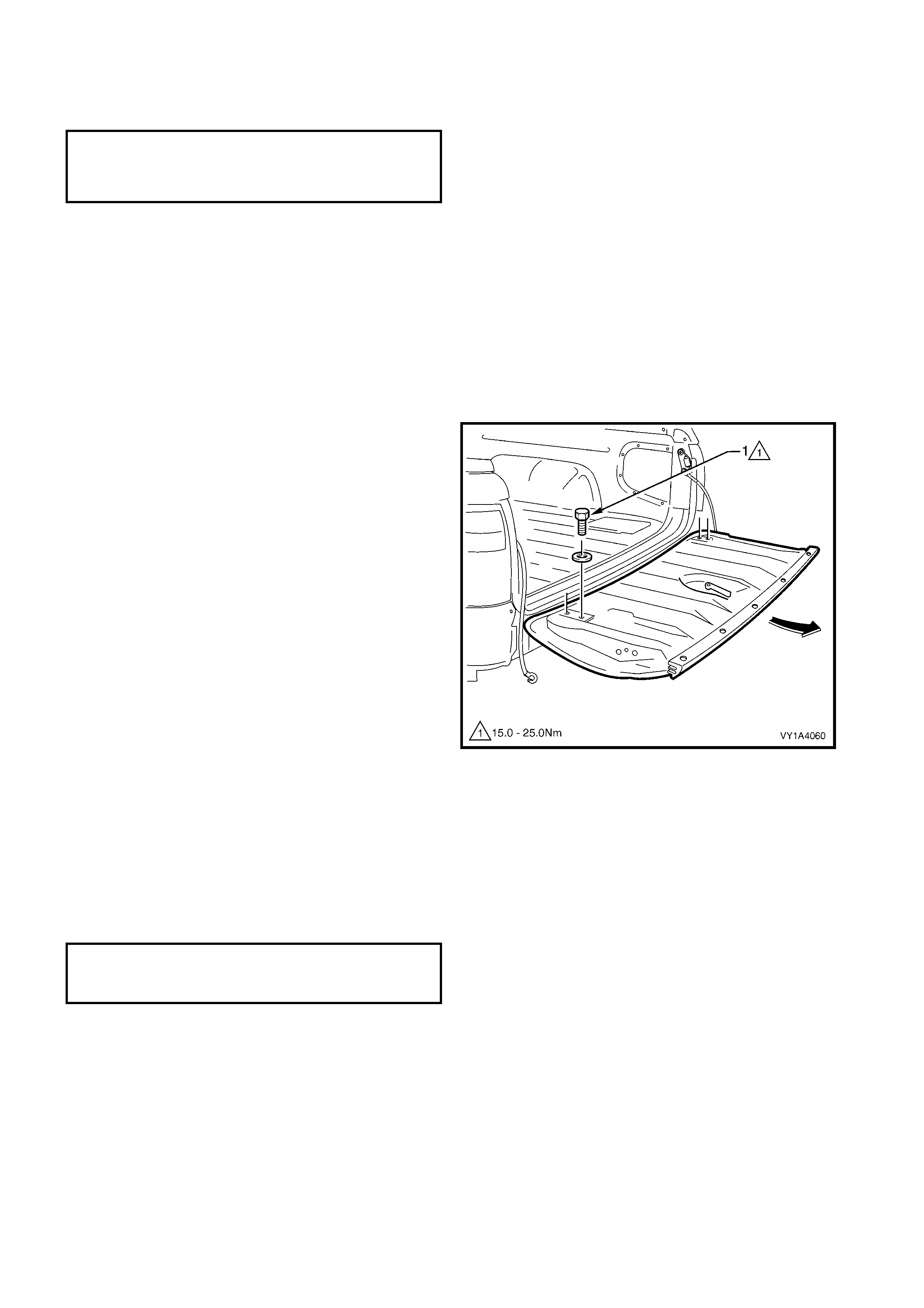

5. Mark the position of the rear compartment lid

screws (1) on the hinges to aid installation.

6. With the aid of an assistant to support the other

side of the rear compartment lid, remove the two

screws each side attaching the rear compartment

lid to the hinges.

7. Carefully lift the rear compartment lid from the

vehicle.

Figure 1A4-41

REINSTALL

1. With the aid of an assistant, lift the rear compartment lid into position.

2. Align the rear compartment lid with the screw holes in the hinges and install the four attaching screws, do not

tighten.

3. Align the s crew heads with the m ark s pr eviously made and tem porar ily tighten the scr ews. If no mark s exis t,

align the screws centrally in their holes.

4. Install the rear compartment lid bumper each side, setting them fully in.

5. Carefully close the rear compartment lid ensuring it does not contact the surrounding panels.

6. If required, adjust the position of the rear compartment lid, refer to the following procedure, ADJUST.

7. Tighten the rear compartment lid attaching screws to the specified torque.

8. Reinstallation of the remaining components is the reverse of removal.

NOTE: Ensure the body wiring harness assem bly is correctly routed and attached within the rear compartment

lid, refer to Section 12O, FUSES AND WIRING HARNESSES.

ADJUST

Correct alignment of the rear com partment lid is critical to its operation and to the aesthetics of the vehicle. T he

following components allow adjustment of the rear compartment lid:

• Rear compartment lid bumper: Provides vertical adjustment at the rear of the rear compartment lid.

• Rear compartment lid to hinge screws and rear compartment lid hinge to body screws: Provide forward,

rearward and skew adjustment of the rear compartment lid.

• Rear com partment lid s triker ass embly: Provides vertical and sideways adj ustment of the rear com partment

lid.

Whenever alignment is required, perform adjustment in the following order.

1. If fitted, remove the rear compartment lid striker assembly, refer to 3.11 REAR COMPARTMENT LID

STRIKER ASSEMBLY.

2. Ensure the rear compartment lid weatherstrip assembly is installed and the rear compartment lid bumpers

are fitted and set fully in.

3. Carefully close the rear compartment lid, watching each side does not contact the vehicle.

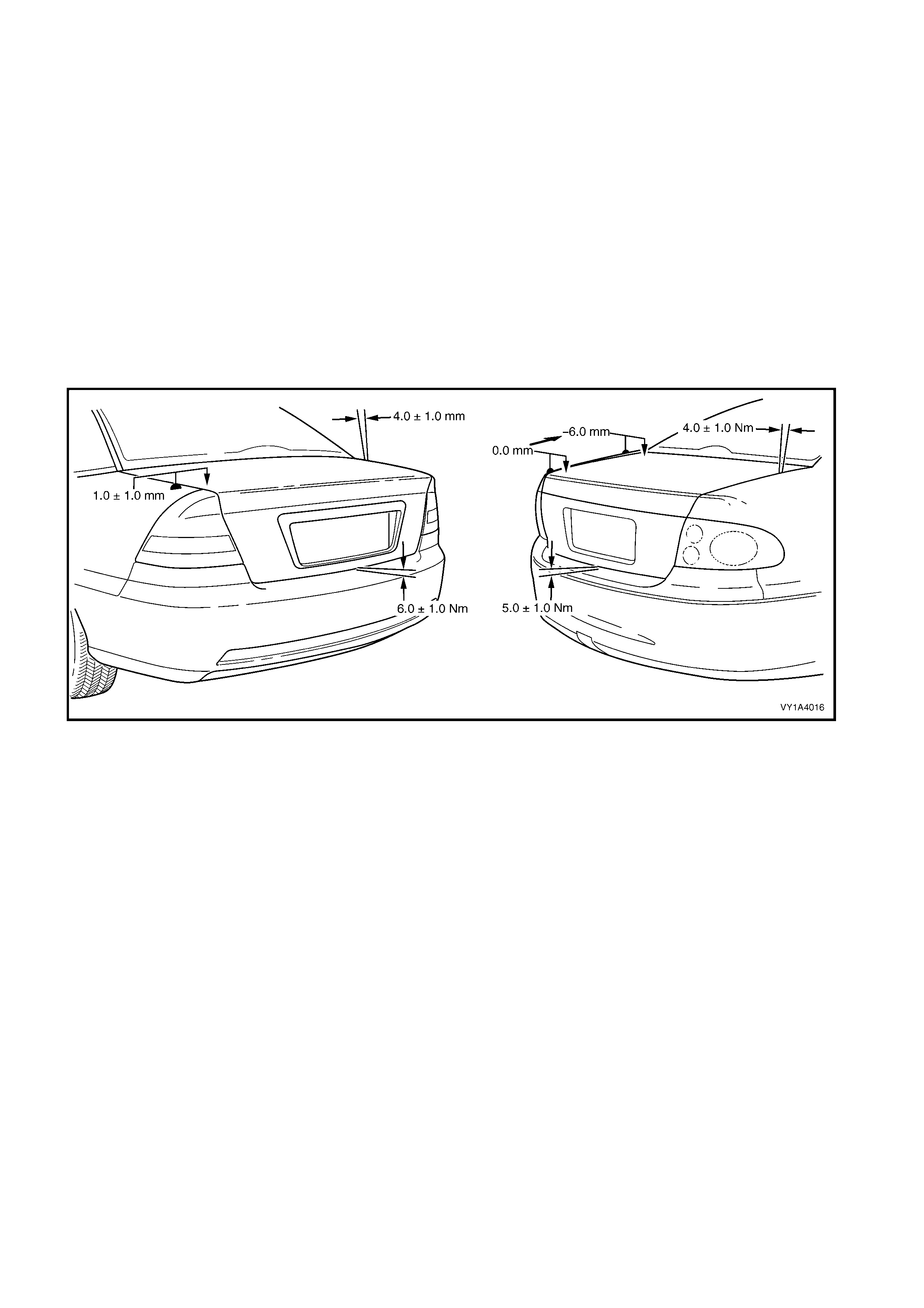

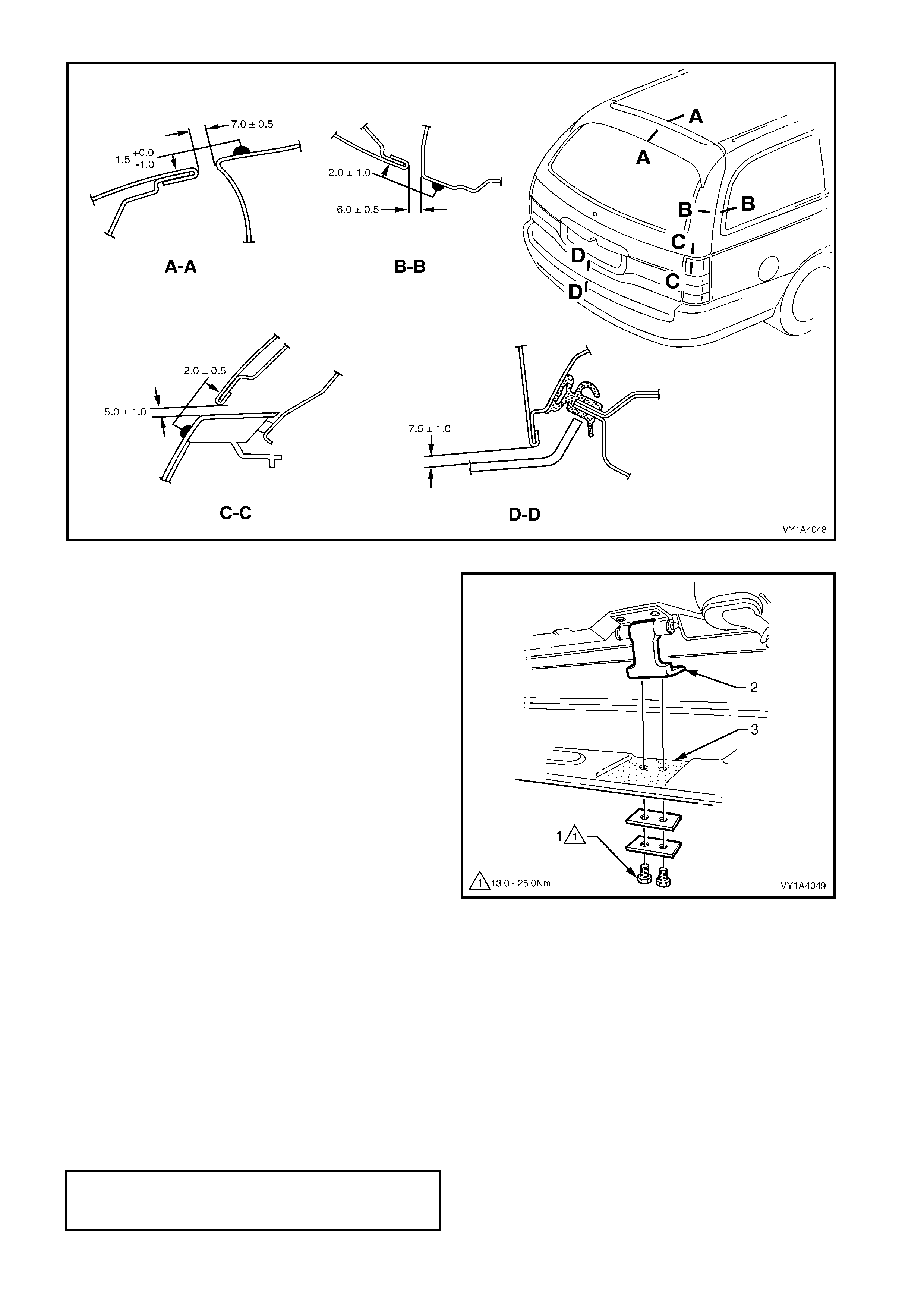

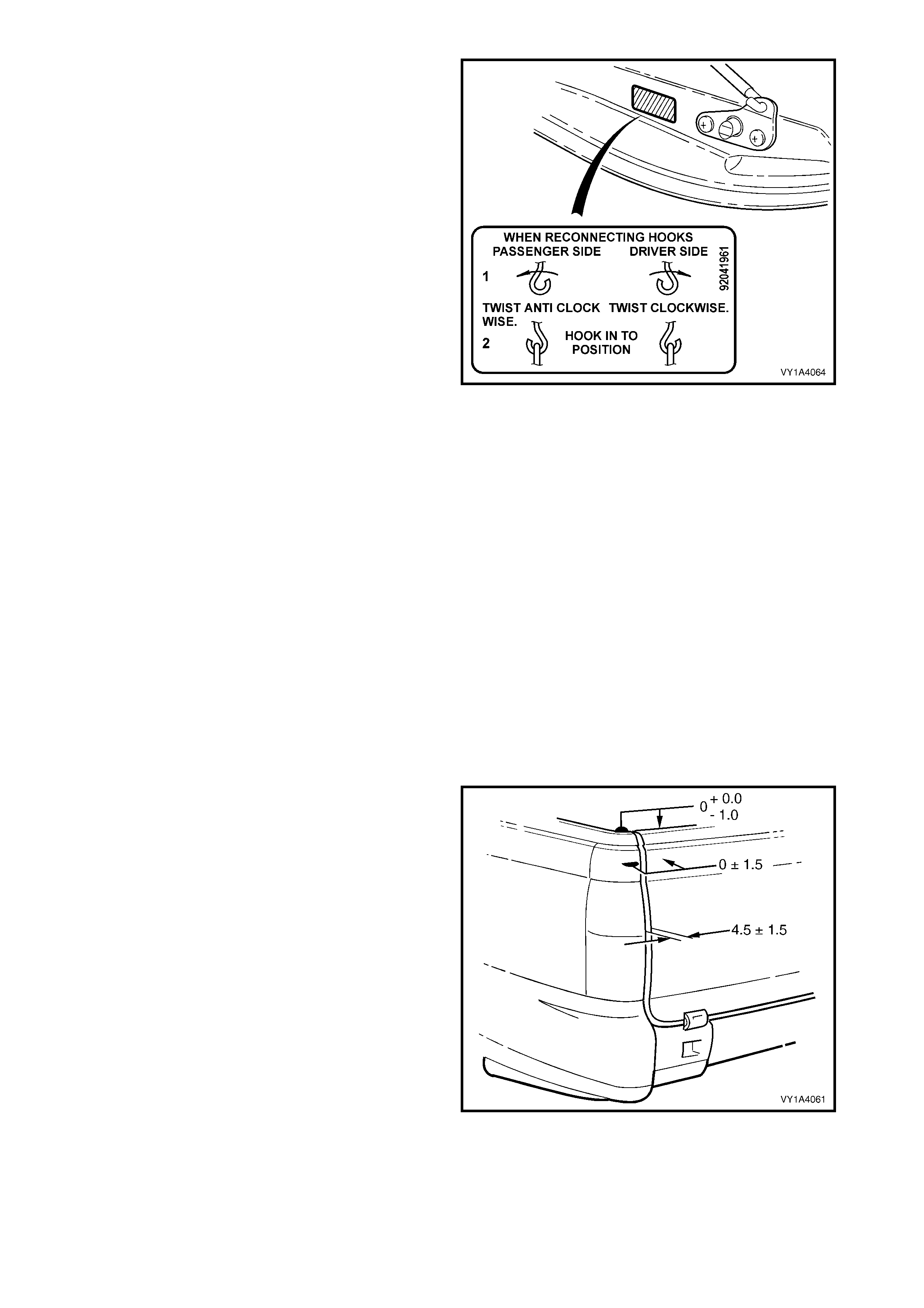

4. Referring to Figure 1A4-42, check the alignment of the rear compartment lid for:

• Length. Compare to the tail lamps. They should be equal.

• Width of gap. Compare the gap between the rear c ompartment lid and quarter panel eac h s ide. T he gap

specification is 4.0 mm ±1.0 mm.

• Consistency of gap. Compare the width of gap between the rear compartment lid and quarter panel at

the front, middle and rear each side. It should be even.

REAR COMPARTMENT LID

ATTACHING SCREW

TORQUE SPECIFICATION 6.0 – 12.0 Nm

5. Open the rear compartment lid and as required, loosen the screws attaching rear compartment lid to the

hinge assembly for fore, aft and skew adjustment, refer to Figure 1A4-41.

NOTE 1: Do not make all adjustments at once. Perform one adjustment, carefully close the hood, check its

position and make further adjustments until correct alignment is achieved.

NOTE 2: If further adjustment is required, loosen the screws attaching the rear compartment lid hinge to the

body and adjust the position of the hinge, refer to 3.10 REAR COMPARTMENT HINGE ASSEMBLY.

6. Install the rear compartment lid striker assembly, refer to 3.11 REAR COMPARTMENT LID STRIKER

ASSEMBLY.

7. Close the rear compartment lid watching that the striker does not pull the rear compartment lid to one side

changing the panel gaps. If it does, move the striker as required.

8. Check the height difference between the rear com partment lid and quarter panel each side. For Sedan the

specification is 1.0 mm ± 1.0 mm. For Coupe it is level at the rear of the rear compartment lid, tapering to

6.0 m m below the quarter panel at the f ront. The rear compartm ent lid to rear bum per fascia ass embly gap

specification is 6.0 mm ± 1.0 mm for Sedan or 5.0 mm ± 1.0 mm Coupe, refer to Figure 1A4-42.

9. As required, open the rear compartment lid, adjust the striker and/or bumper and recheck.

10. Check that all screws are tightened to their specified torque, refer to the appropriate procedures.

Figure 1A4-42

3.10 REAR COMPARTMENT LID HINGE ASSEMBLY

LT Section No. 12-660

As required, first remove the following components:

1. Partial removal of the rear window panel trim assembly, refer to Section 1A8, 2.9 REAR WINDOW TRIM

PANEL ASSEMBLY.

2. Rear compartment lid strut assembly from the hinge, refer to 3.8 REAR COMPARTMENT LID STRUT

ASSEMBLY.

3. Rear Compartment lid assembly, refer to 3.9 REAR COMPARTMENT LID ASSEMBLY.

REMOVE

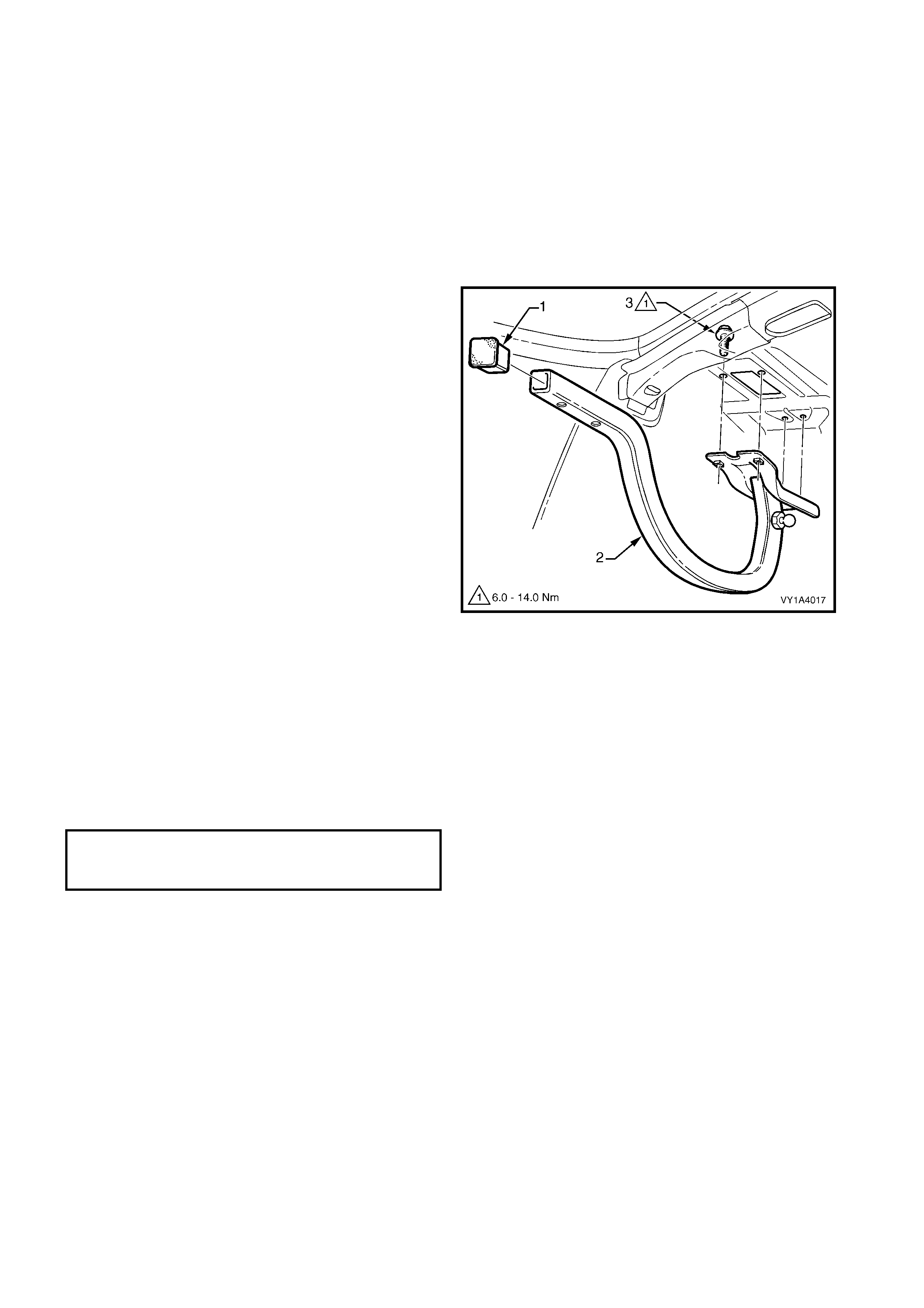

1. If required, prise the rear compartment lid hinge

cap (1) from the end of the hinge assembly (2).

2. If fitted, remove the sound deadener sheet from

above the hinge screws.

3. Have an assistant hold the hinge assembly.

4. From within the passenger compartment remove

the four screws (3) attaching the hinge assembly

to the vehicle.

5. Remove the hinge assembly.

Figure 1A4-43

REINSTALL

1. With the aid of an assistant, lift the rear

compartment lid hinge into position.

2. Install the screws, aligning them with the old marks

or centrally in their holes.

3. Install and align the rear compartment lid, refer to

3.9 REAR COMPARTMENT LID ASSEMBLY.

4. Tighten the screws to the specified torque.

REAR COMPARTMENT LID HINGE

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 6.0 – 14.0 Nm

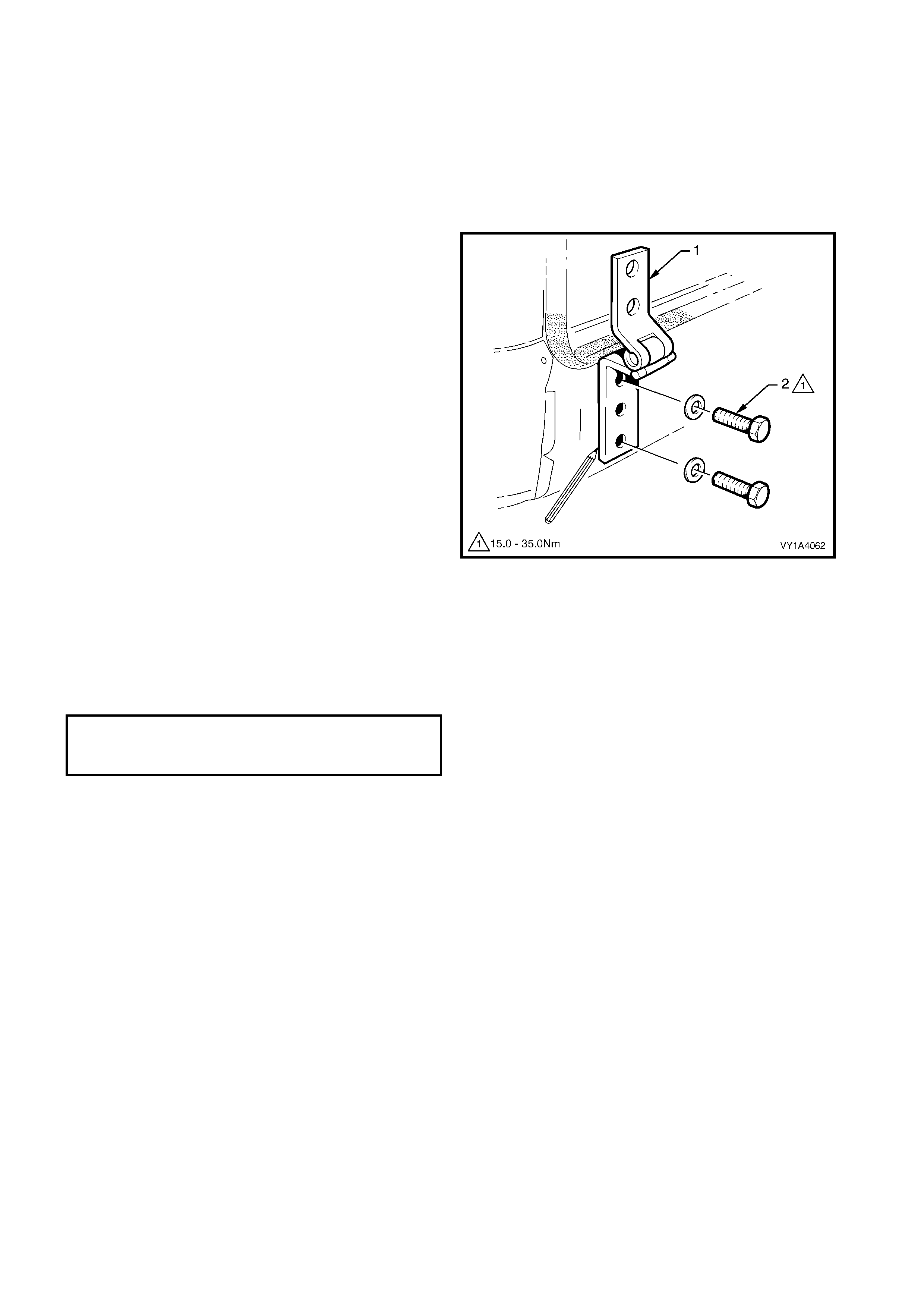

3.11 REAR COMPARTMENT LID STRIKER ASSEMBLY

LT Section No. 12-680

As required, first remove rear end trim panel, refer to

Section 1A8, 3.19 REAR END TRIM PANEL.

REMOVE

1. Mark the position of the striker with a pencil.

2. Remove the screw (1) attaching the striker

assembly (2) to the vehicle and remove the striker.

Figure 1A4-44

REINSTALL

1. Reinstallation is the reverse of removal.

NOTE: As required, adjust the pos ition of the strik er to

obtain correct rear compartment lid alignment, refer to

3.9 REAR COMPARTMENT LID ASSEMBLY –

ADJUST.

2. Tighten the screw to the specified torque.

REAR COMPARTMENT LID STRIKER

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 15.0 – 35.0 Nm

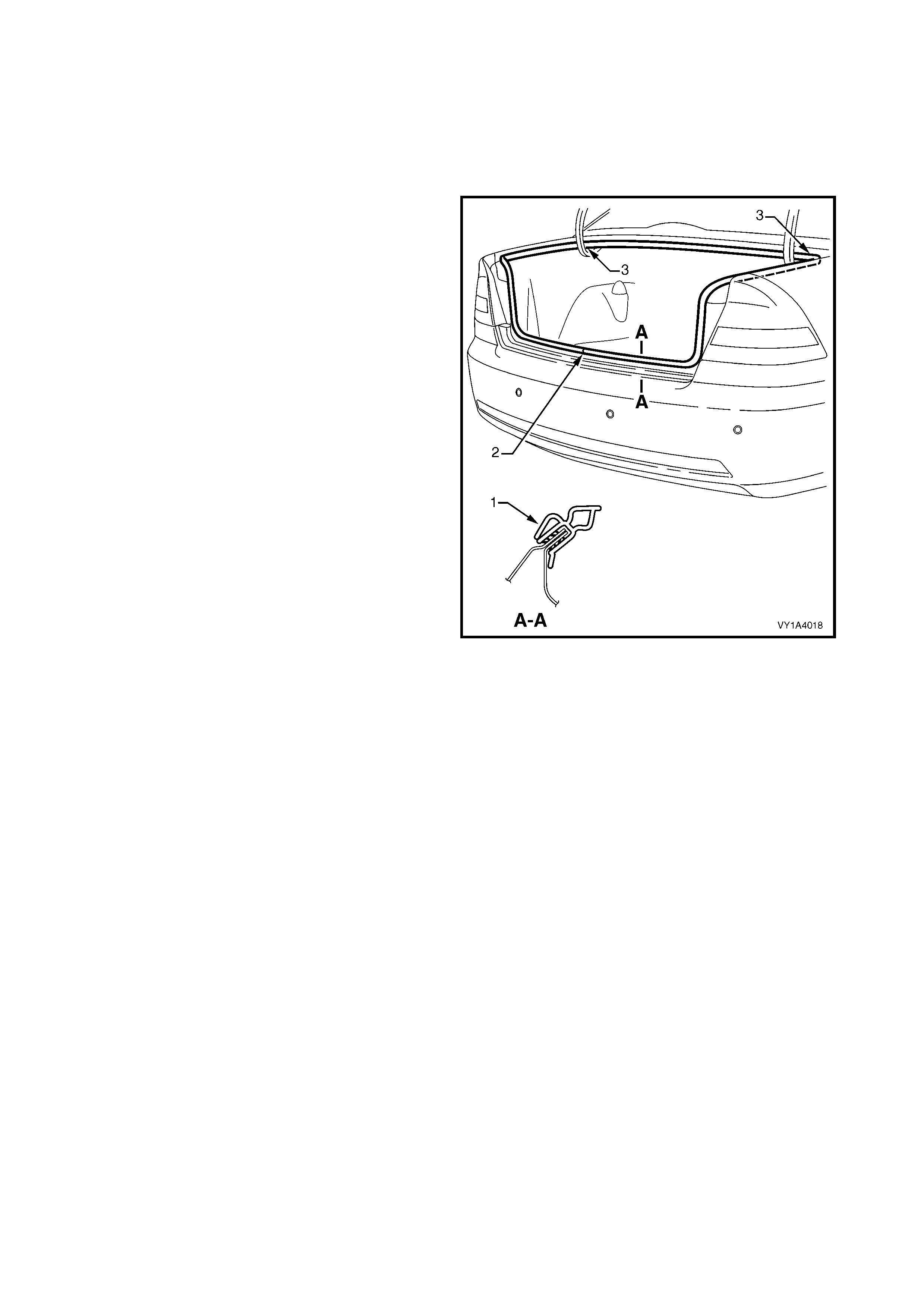

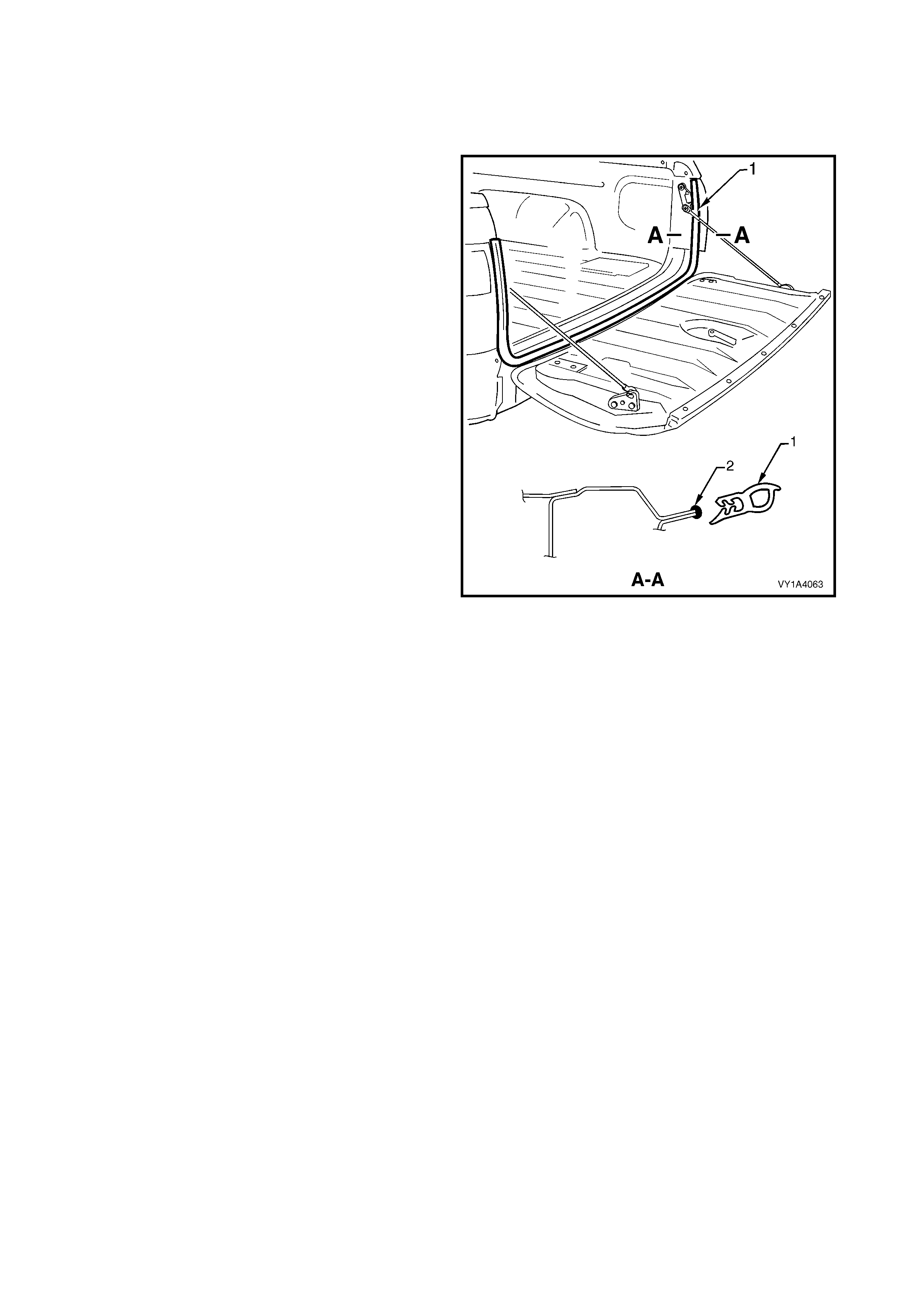

3.12 RE AR COMPARTMENT LID WEATHERSTRIP

LT Section No. 11-600

As required, f irst rem ove the rear end trim panel, refer

to Section 1A8, 3.19 REA R END TRIM PANEL.

REMOVE

1. Gr asp the weatherstr ip assem bly and c arefully pull

it from the body flange. Start at one point and

continue along its length.

2. Remove the weatherstrip from the vehicle, over

the rear compartment lid.

NOTE: Sedan shown, Coupe similar.

Figure 1A4-45

REINSTALL

1. Lay the weatherstrip on the f loor and ensure the L-

shaped lip (1) is to the inside, refer to Figure 1A4-

45.

2. Locate the weatherstrip join (2) which is to be

aligned with the striker assembly.

3. Fit the weatherstrip over the rear compartment lid

and push onto the body flange, beginning at the

join.

NOTE: Allow crowding of the weatherstrip in each

corner (3) to avoid short cutting of the corners.

4. SERVICE OPERATIONS – LIFTGATE, WAGON

4.1 LIFTGATE WINDOW LOWER GARNISH

LT Section No. – 14-500

REMOVE

1. Beginning at one end of the liftgate window lower

garnish (1), insert a flat blade screwdriver behind

the garnish at the retaining clip (2).

2. Repeat for the seven remaining clips, carefully

prising the garnish from the liftgate assembly.

3. If required, prise the clips from the garnish with a

flat blade screwdriver.

Figure 1A4-46

REINSTALL

1. If refitting the clips, ensure their correct orientation.

2. Align the clips with their holes in the liftgate panel

and clip the garnish onto the liftgate.

4.2 LIFTGATE LOWER TRIM PANEL

LT Section No. – 14-500

As required, first remove the liftgate window lower

garnish, refer to 4.1 LIFTGATE WINDOW LOWER

GARNISH.

REMOVE

1. Using a suitable trim clip removal tool, carefully

prise the retainer (1), 14 places, attaching the

liftgate lower trim panel (2) to the liftgate assembly.

2. Rem ove the panel, sliding it fr om under the liftgate

inside handle (3).

Figure 1A4-47

REINSTALL

1. Install the panel, sliding it under the liftgate inside

handle.

2. Fit the 14 retainers, pushing them in firmly.

4.3 LIFTGATE INSIDE HANDLE

LT Section No. –

REMOVE

1. Insert a flat blade screwdriver between the liftgate

assembly and the rear edge of the liftgate inside

handle (1).

NOTE: Place a rag between the sc rewdriver and panel

to protect the paintwork.

2. Carefully lever the screwdriver in the direction

shown to release the retaining tabs (2) from the

liftgate assembly.

3. Remove the handle.

Figure 1A4-48

REINSTALL

1. Install the handle ensuring the retaining tabs are

correctly seated.

4.4 LIFTGATE WINDOW UPPER GARNISH

LT Section No. – 14-500

REMOVE

1. Rem ove the two retainers (1) and remove the high

mount stop lamp cover (2).

2. Remove the retainer (3) from either the left-hand

or right-hand liftgate window upper garnish (4).

3. Insert a flat blade screwdriver behind the garnish

at the clip (5). Push on the clip tab and carefully

prise the clip and garnish from the liftgate

assembly.

4. Remove the garnish from the liftgate, also

detaching it fr om the lif tgate window lower garnish,

if not removed.

5. If required, prise the clip from the garnish.

Figure 1A4-49

REINSTALL

1. If refitting the clip, ensure its correct orientation.

2. Clip the garnis h onto the lif tgate, ins tall the retainer

and reinstall the high mount stop lamp cover.

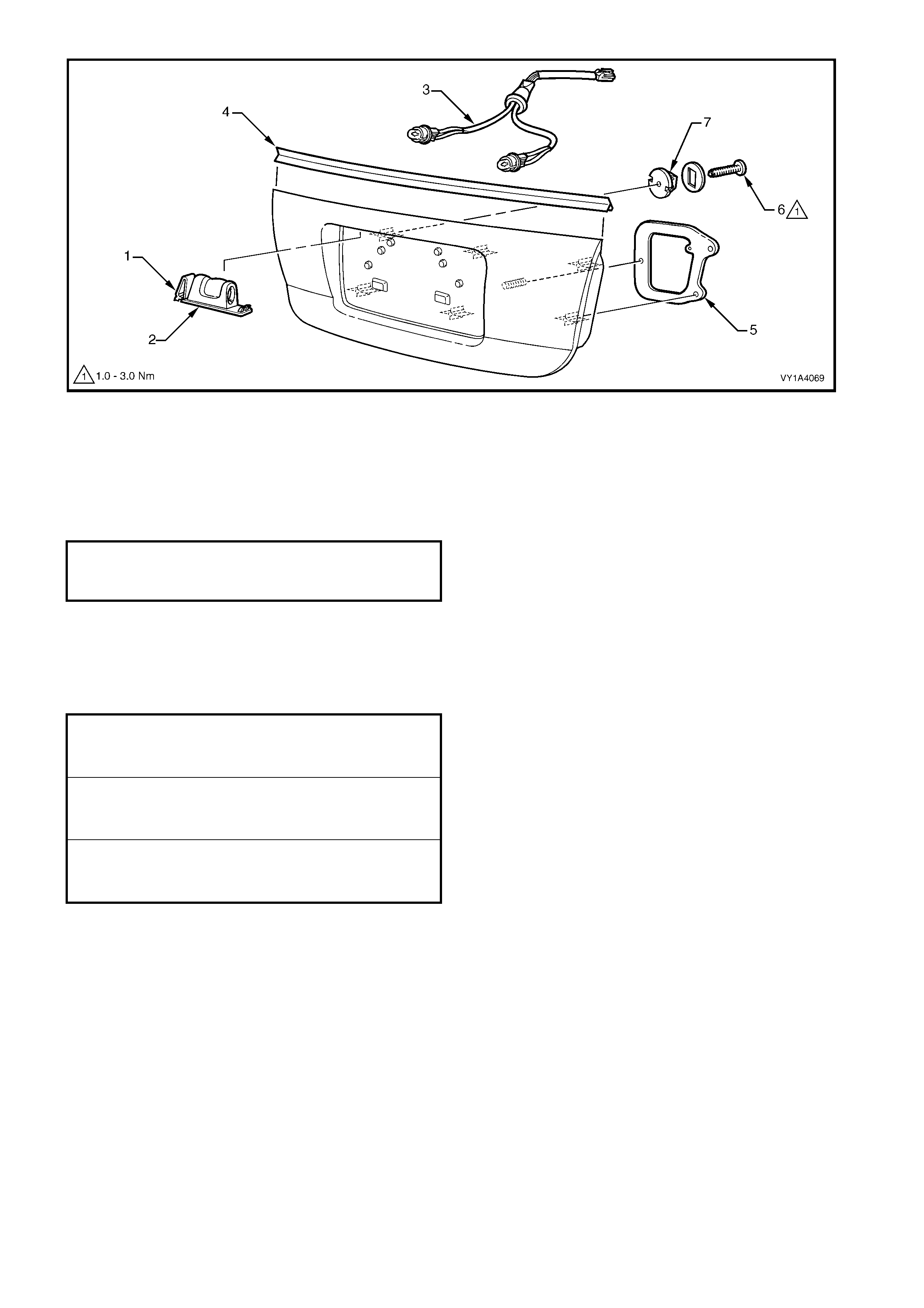

4.5 LIFTGATE HANDLE ASSEMBLY

LT Section No. – 02-385

As required, first remove the following components:

1. Liftgate window lower garnish, refer to 4.1 LIFTGATE WINDOW LOWER GARNISH.

2. Liftgate lower trim panel, refer to 4.2 LIFTGATE LOWER TRIM PANEL.

REMOVE

1. From within the liftgate cavity, remove the four

nuts (1) attaching the liftgate handle assembly (2)

to the liftgate assembly.

NOTE: The two inner nuts also attach the liftgate

handle push button assembly.

2. Dis connec t the licence plate lam p wiring connector

(3) from within the liftgate cavity .

3. Remove the handle assembly away from the

liftgate assembly and remove the licence plate

lamp wiring harness grommet (4).

4. Withdraw the licence plate lamp wiring harness

and remove the handle assembly.

Figure 1A4-50

DISASSEMBLE

1. Remove each r ear lic enc e plate lam p ass embly ( 1)

from the handle assembly by pushing on the tab

(2) and removing the housing assembly in the

direction shown.

2. Rotate the bulb socket (3) and remove from the

lamp housing.

3. Remove the wiring from the rear of the handle

assembly.

Figure 1A4-51

REINSTALL

1. Reinstallation is the reverse of removal. Tighten

the handle assembly nuts to the specified torque.

LIFTGATE HANDLE ASSEMBLY

ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 5.0 Nm

4.6 LIFTGATE HANDLE PUSH BUTTON ASSEMBLY

LT Section No. – 12-680

NOTE: A new liftgate handle push button assembly is supplied un-coded and will require disassembly and

sending to an authorised locksmith for coding to the vehicle’s keys.

As required, first remove the following components:

1. Liftgate window lower garnish, refer to 4.1 LIFTGATE WINDOW LOWER GARNISH.

2. Liftgate lower trim panel, refer to 4.2 LIFTGATE LOWER TRIM PANEL.

REMOVE

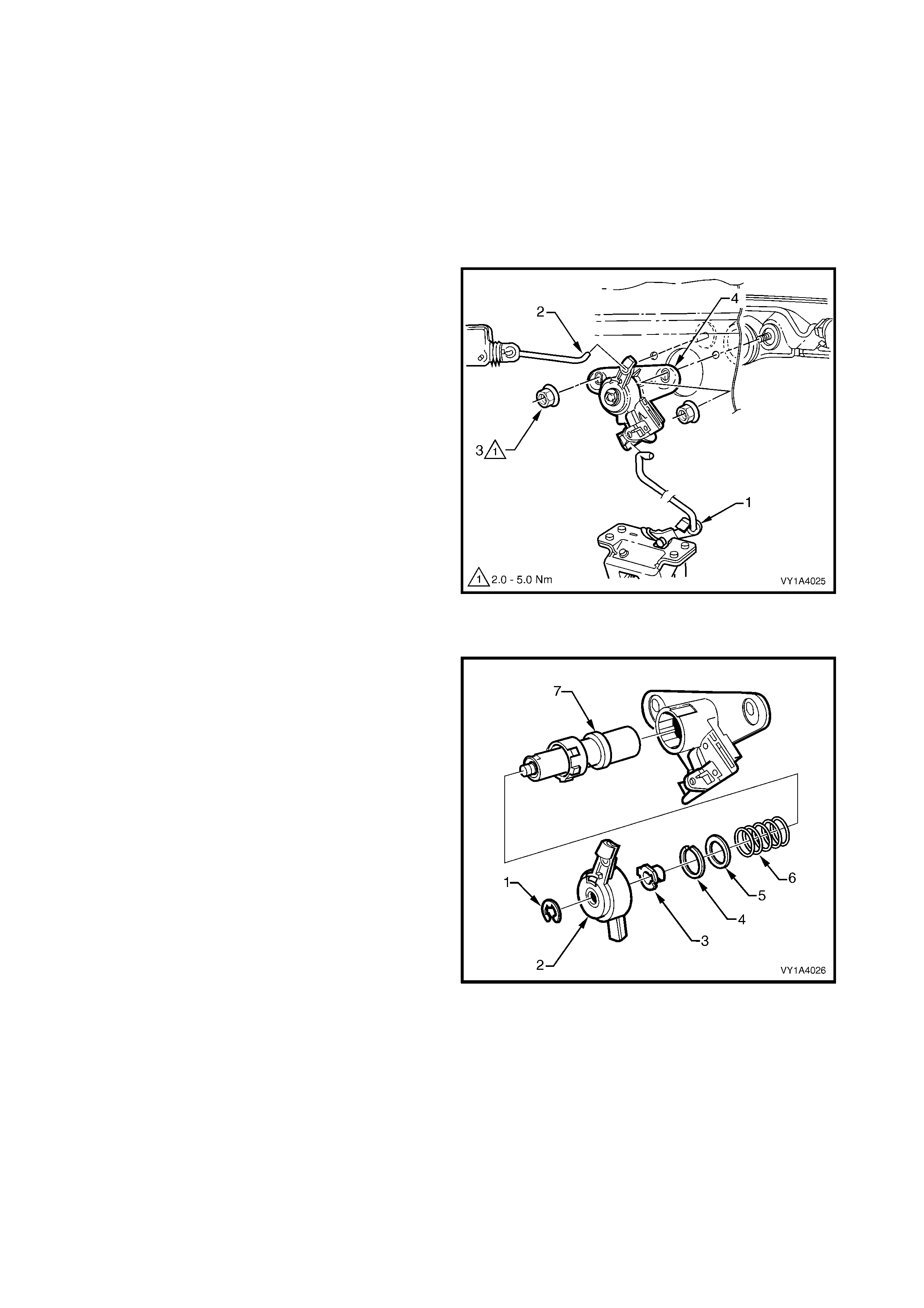

1. Disconnect the liftgate lock connecting rod (1) from

the latch assembly.

2. Disconnect the actuator connecting rod (2) from

the push button assembly.

3. F rom within the liftgate cavity, rem ove the two nuts

(3) attaching the push button assembly (4) to the

liftgate assembly.

NOTE: The two inner nuts also attach the liftgate

handle assembly.

4. Remove the push button assembly.

Figure 1A4-52

DISASSEMBLE

1. Remove the push button assembly components in

the following order:

• E-clip (1),

• Latch actuator cover (2),

• Drive cam (3),

• Spring clip (4),

• Washer (5),

• Spring, (6), and

• Lock cylinder assembly (7).

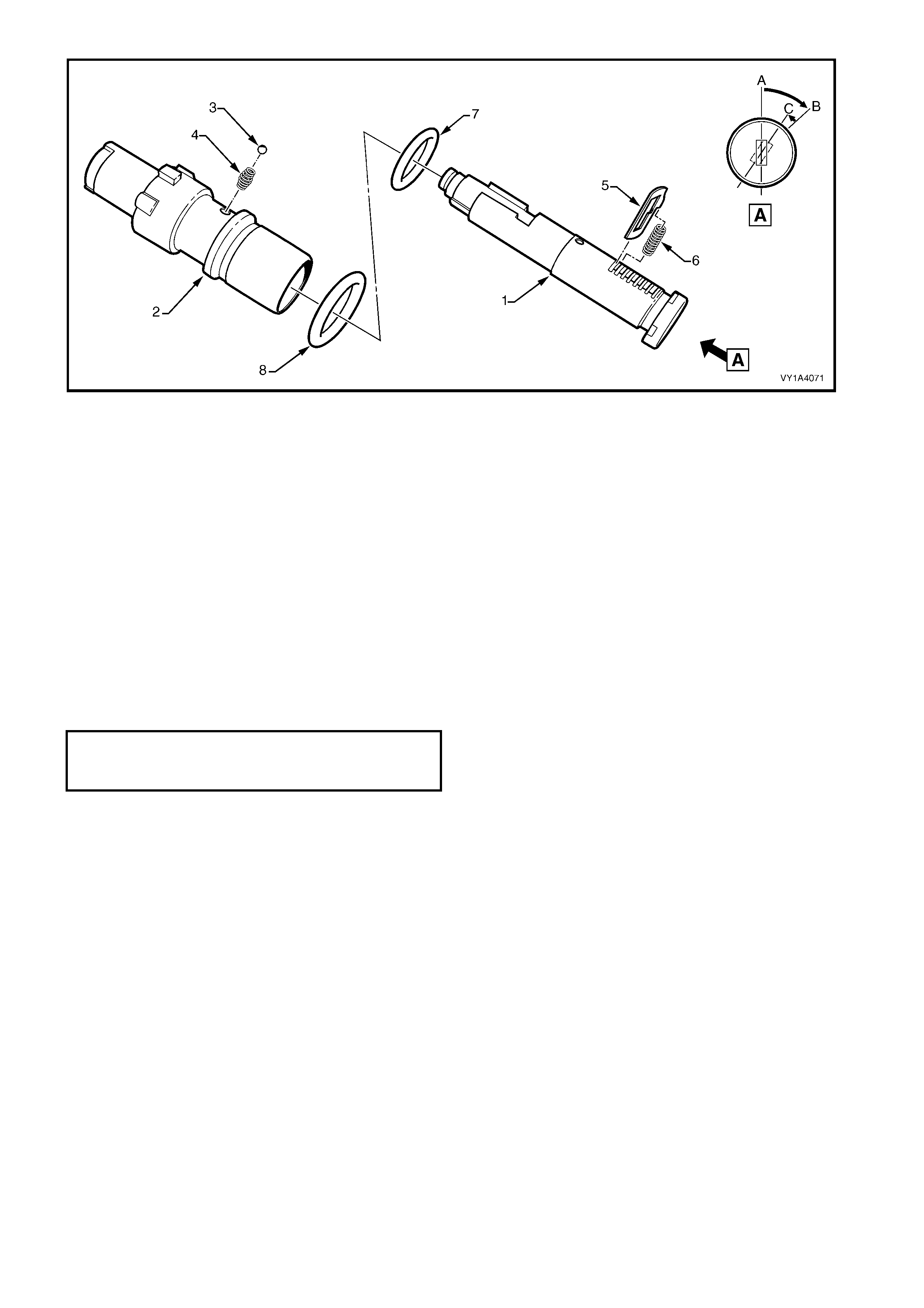

2. The lock cylinder assembly can be further

disassembled to enable coding as follows,

referring to Figure 1A4-54:

• Insert the key and turn from position A to B.

• Turn back slightly to position C and cover the

ball hole in the housing (1) with a finger. This

will stop the ball (2) from jumping out.

• Withdraw the lock barrel (3) from the housing

until the ball is released. Remove the ball and

spring (4) and completely remove the barrel.

• Remove each of the tumblers (5) and spring

(6) as required.

Figure 1A4-53

Figure 1A4-54

REASSEMBLE

If a new assembly is being fitted, a kit is supplied which

can be sent to an authorised locksmith for coding to

the vehicle’s keys.

Reassem ble the push button assembly components in

the reverse sequence to their disassembly.

REINSTALL

Reinstallation is the reverse of removal noting the

following.

1. The slotted holes in the push button assembly

provide adjustment of the latch connecting rod.

2. Tighten the nuts to the specified torque and test for

correct operation of the push button assembly prior

to installing the trim components.

LIFTGATE HANDLE ASSEMBLY

ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 5.0 Nm

4.7 LIFTGATE LATCH ASSEMBLY

LT Section No. – 12-680

As required, first remove the following components:

1. Liftgate window lower garnish, refer to 4.1 LIFTGATE WINDOW LOWER GARNISH.

2. Liftgate lower trim panel, refer to 4.2 LIFTGATE LOWER TRIM PANEL.

REMOVE

1. From within the liftgate cavity, disconnect the push

button assembly connecting rod (1).

2. Remove the four screws (2) attaching the liftgate

latch assembly (3) to the liftgate assembly.

3. Remove the latch assembly from the liftgate cavity.

Figure 1A4-55

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque and test for correct

operation of the lock assembly prior to installing the

trim components.

LIFTGATE LATCH ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

4.8 LIFTGATE ACTUATOR ASSEMBLY

LT Section No. – 12-680

NOTE: The liftgate actuator assembly is part of

the central locking system. For diagnosis refer to

Section 12J, BODY CONTROL MODULE.

As required, first remove the following components:

1. Liftgate window lower garnish, refer to 4.1 LIFTGATE WINDOW LOWER GARNISH.

2. Liftgate lower trim panel, refer to 4.2 LIFTGATE LOWER TRIM PANEL.

REMOVE

1. Disconnect the connecting rod (1) from the push

button assembly.

2. Loos en the scr ew (2) and slide the lif tgate actuator

assembly (3) from its keyhole slot.

3. Remove the actuator assembly from the liftgate

cavity as shown and disconnect the wiring

connector (4).

Figure 1A4-56

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screw to the specified torque and test for correct

operation of the lock assembly prior to installing the

trim components.

LIFTGATE ACTUATOR

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

4.9 LIFTGATE AIR DEFLECTOR ASSEMBLY

LT Section No. – 10-350

As required, first remove the high mount stop lamp

cover and liftgate window upper garnish, refer to

4.4 LIFTGATE WINDOW UPPER GARNISH.

REMOVE

1. Remove the plug (1) from each side of the liftgate

assembly.

2. Remove the thr ee nuts (1) attaching the liftgate air

deflector assembly (2) to the liftgate assembly,

refer to Figure 1A4-58.

3. Remove the two sc rews (3) attaching the deflec tor

assembly to the liftgate assembly and remove the

deflector assembly.

NOTE: Take care when removing the deflector

assembly not to damage the seals (4) as they are not

serviced.

Figure 1A4-57

Figure 1A4-58

REINSTALL

Reinstallation is the reverse of removal. Tighten the

nuts and screws to the specified torque.

NOTE: Prior to installation, ensure the seals are not

damaged, if in doubt apply a small amount of non-

hardening sealer.

LIFTGATE AIR DEFLECTOR

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 5.0 Nm

LIFTGATE AIR DEFLECTOR

ASSEMBLY - ATTACHING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

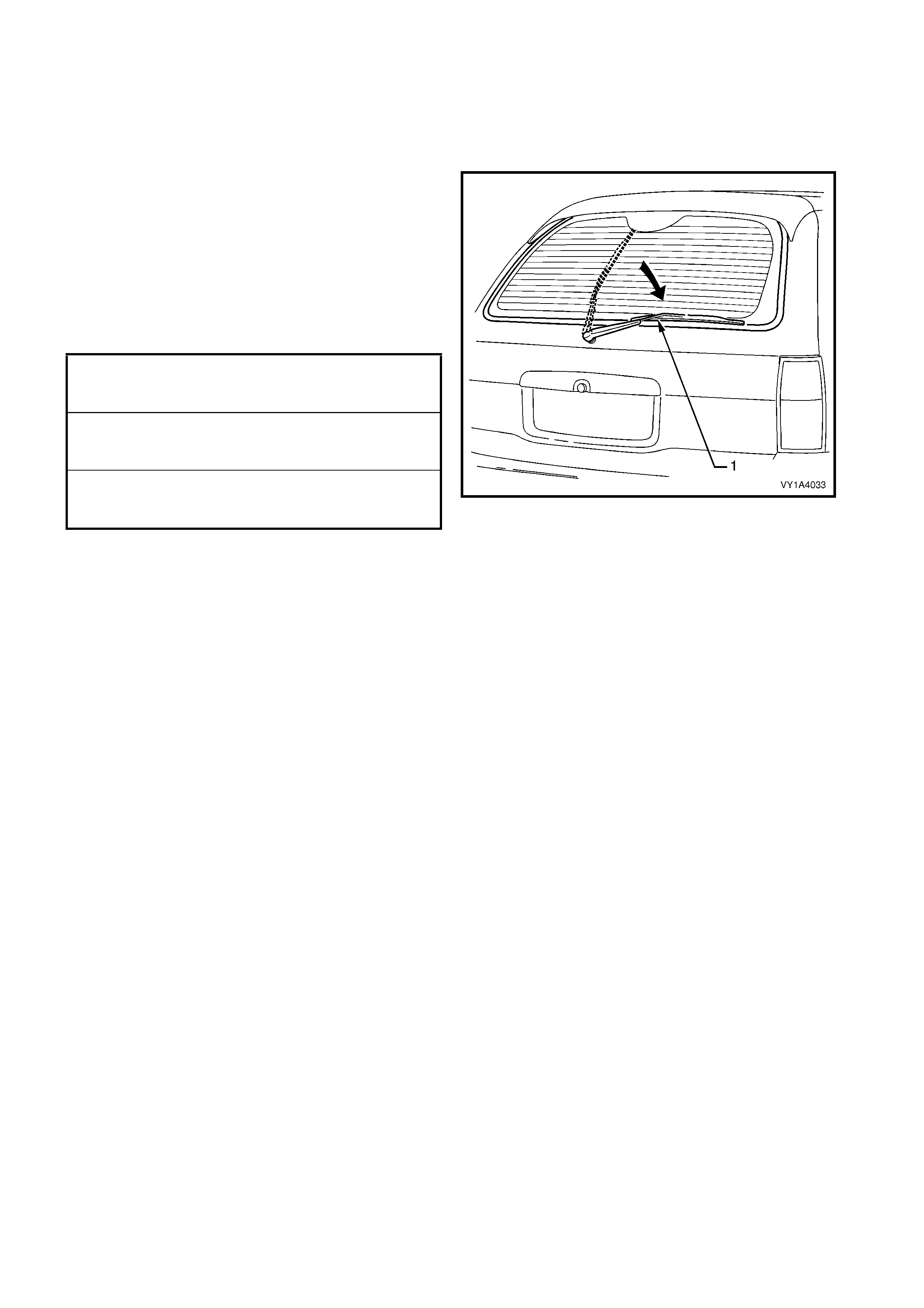

4.10 REAR WINDOW WIPER ASSEMBLY

LT Section No. – 10-525

NOTE: The following procedure describes the

replacement of the liftgate components of the wiper

assembly. For further information refer to Section

12N, WIPERS / WASHERS & HORN.

As access to the rear window wiper motor assembly is required, first remove the following components:

1. Liftgate window lower garnish, refer to 4.1 LIFTGATE WINDOW LOWER GARNISH.

2. Liftgate lower trim panel, refer to 4.2 LIFTGATE LOWER TRIM PANEL.

REMOVE

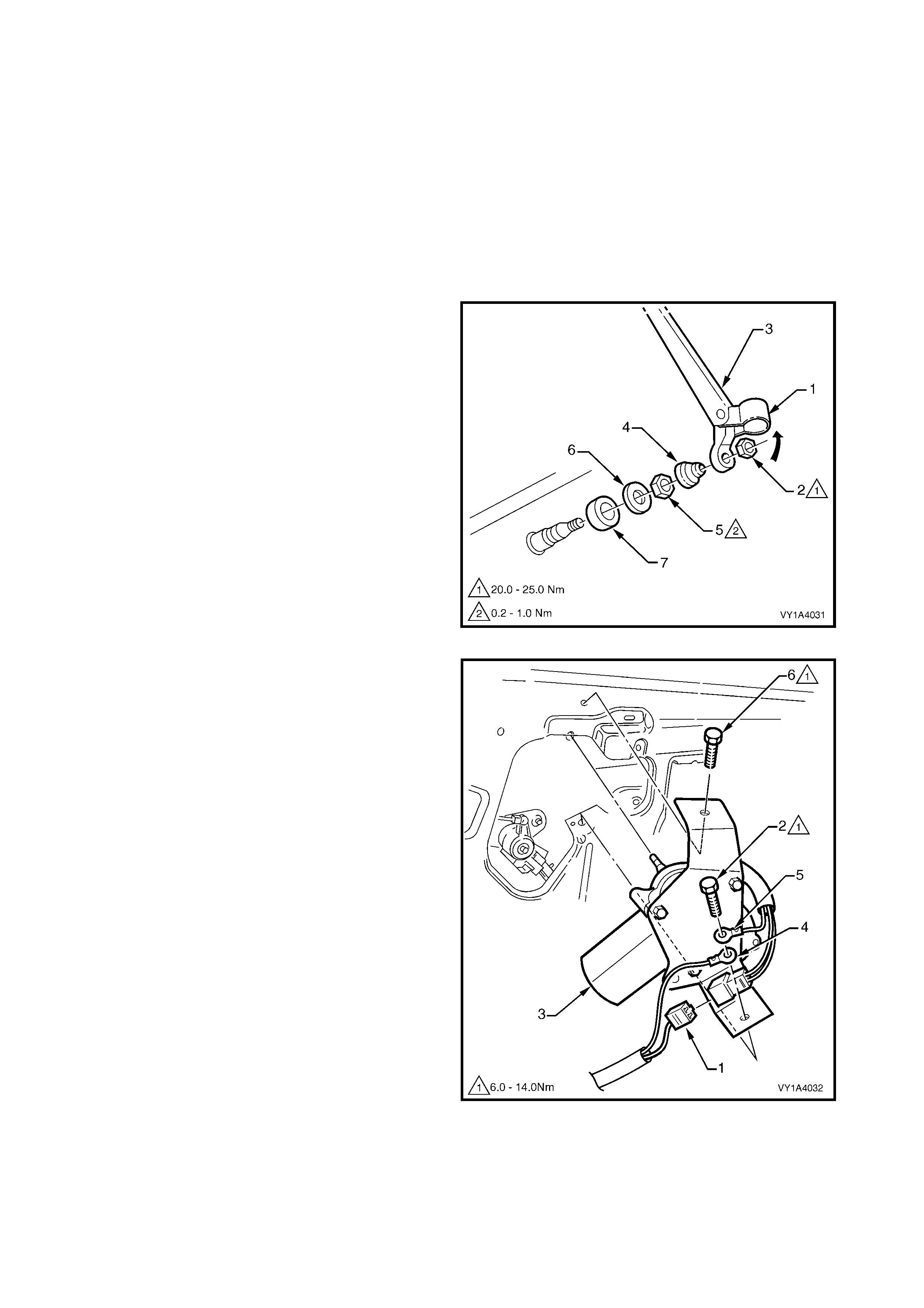

1. Lift the cap (1) and remove the nut (2) attaching

the rear window wiper arm assembly (3) to the

wiper pivot shaft.

2. Remove the cover (4), nut (5), cap (6) and spacer

(7) from the wiper pivot shaft.

Figure 1A4-59

3. Disconnect the wiring harness connector (1).

4. Remove the screw (2) attaching the rear window

wiper motor assembly (3), liftgate harness earth

connection (4) and motor assembly earth

connection (5) to the liftgate assembly.

5. Remove the screw (6) and remove the motor

assembly from the liftgate assembly.

Figure 1A4-60

REINSTALL

Reinstallation is the reverse of removal noting the

following.

1. Ens ure the com ponents and ear th connections are

assembled in the correct order.

2. When installing the rear window wiper arm

assem bly (1), fit the ar m onto the wiper pivot shaft

in the vertical position and with the blade set onto

the glass, rotate the arm clockwise until the blade

rests slightly above the liftgate window moulding.

3. Tighten the screws and nuts to the specified

torque.

4. Test for correct operation of the wiper assembly

prior to installing the trim components.

Figure 1A4-61

REAR WINDOW WI PER ARM

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 20.0 – 25.0 Nm

REAR WINDOW WIPER MOTOR

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 0.2 – 1.0 Nm

REAR WINDOW WIPER MOTOR

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 6.0 – 14.0 Nm

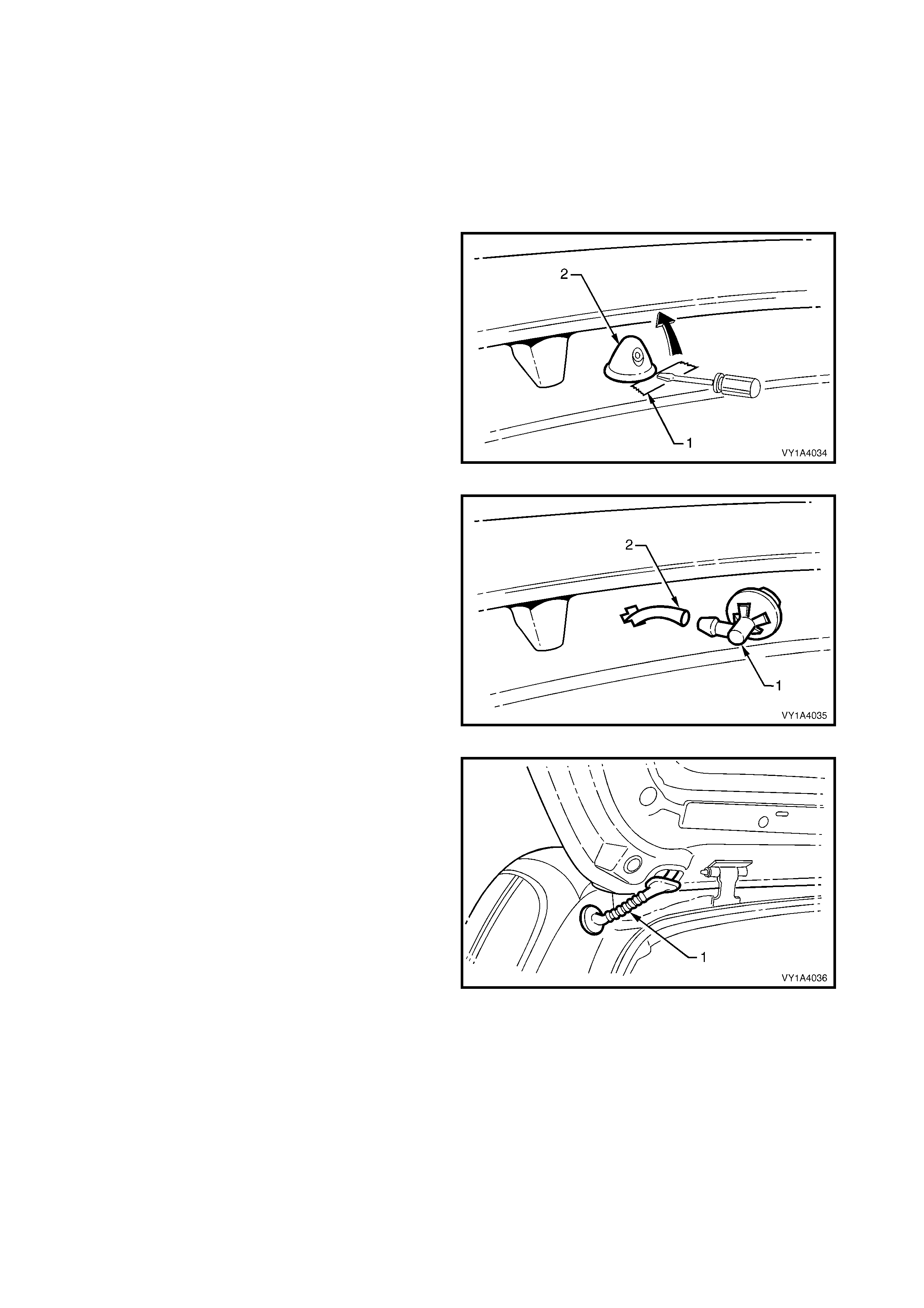

4.11 REAR WINDOW WASHER NOZZLE & HOSE ASSEMBLIES

LT Section No. – 10-500

NOTE: The following procedure describes the

replacement of the liftgate components of the rear

window washer system. F or fur ther inf orm ation ref er to

Section 12N, WIPERS /WASHERS & HORN.

REMOVE

1. Place a piece of tape (1) or similar on the

paintwork adjacent to the rear window washer

nozzle assembly (2) and using a fine flat blade

screwdriver prise the nozzle from the liftgate

assembly.

Figure 1A4-62

2. Disconnect the nozzle assembly (1) from the rear

window washer hose assembly (2).

Figure 1A4-63

3. Remove the grommet (1) from the liftgate

assembly and withdraw the washer hose from the

liftgate.

NOTE: If further disassembly of the rear

window washer system is required, refer to

Section 12N, WIPERS /WASHERS & HORN.

Figure 1A4-64

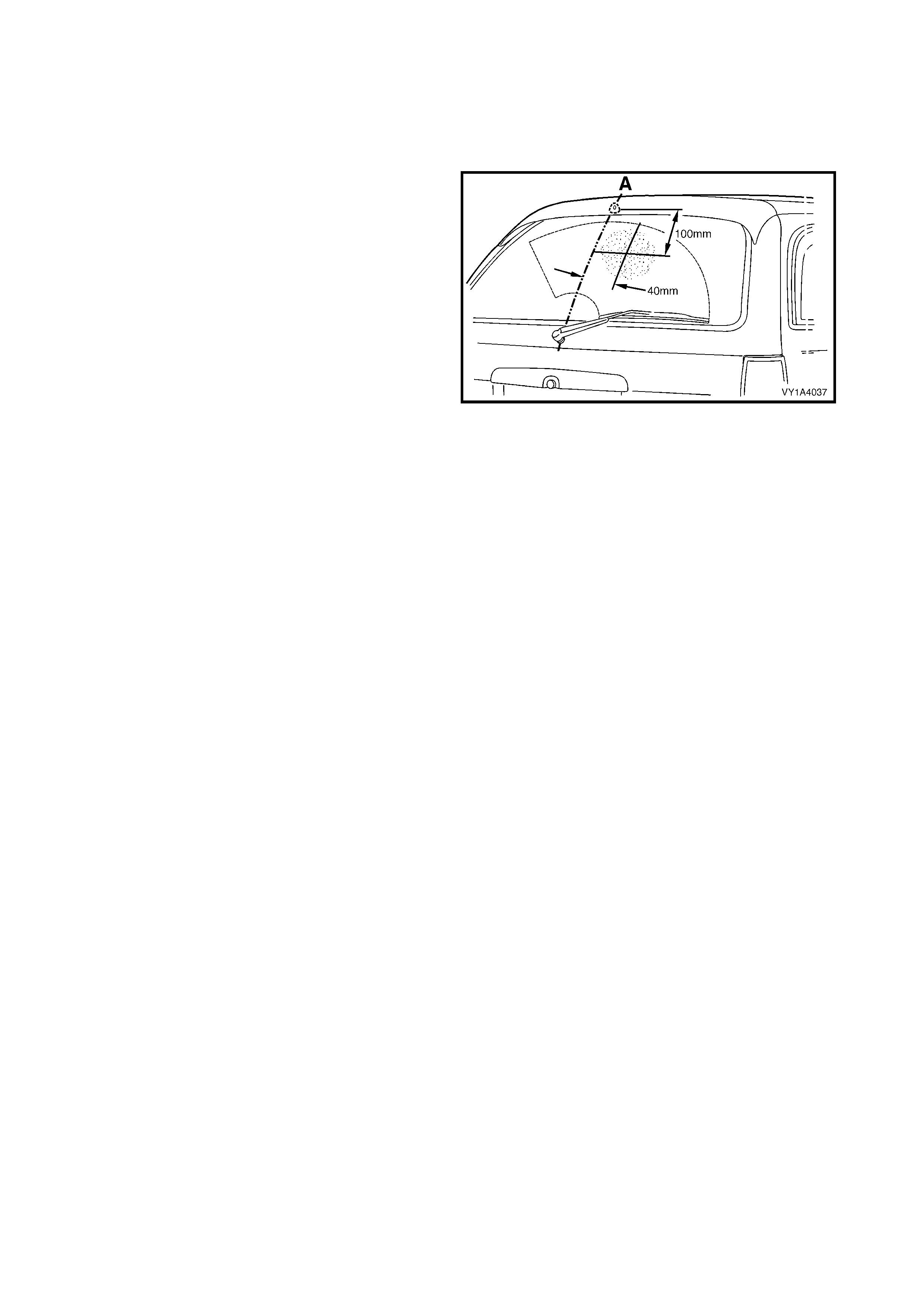

REINSTALL

Reinstallation is the reverse of removal noting the

following.

1. Ensure the nozzle assembly is correctly seated to

avoid water leaking into the liftgate cavity.

2. Test the operation of the washer. The spray from

the nozzle should strike the window within the 100

mm diameter area shown shaded.

3. If adjustment is required, insert a pin or fine piece

of wire into the nozzle jet and adjust as required.

Figure 1A4-65

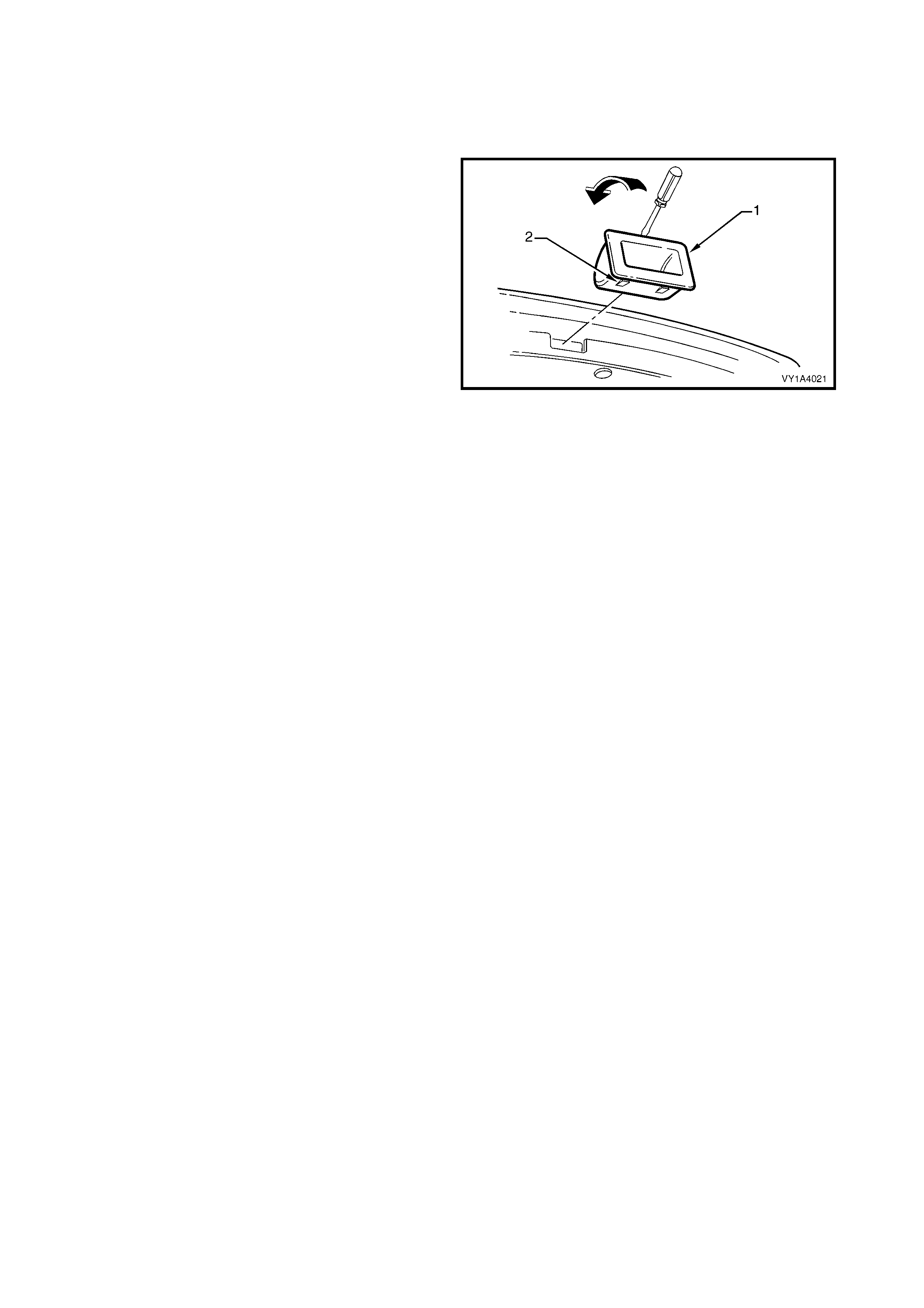

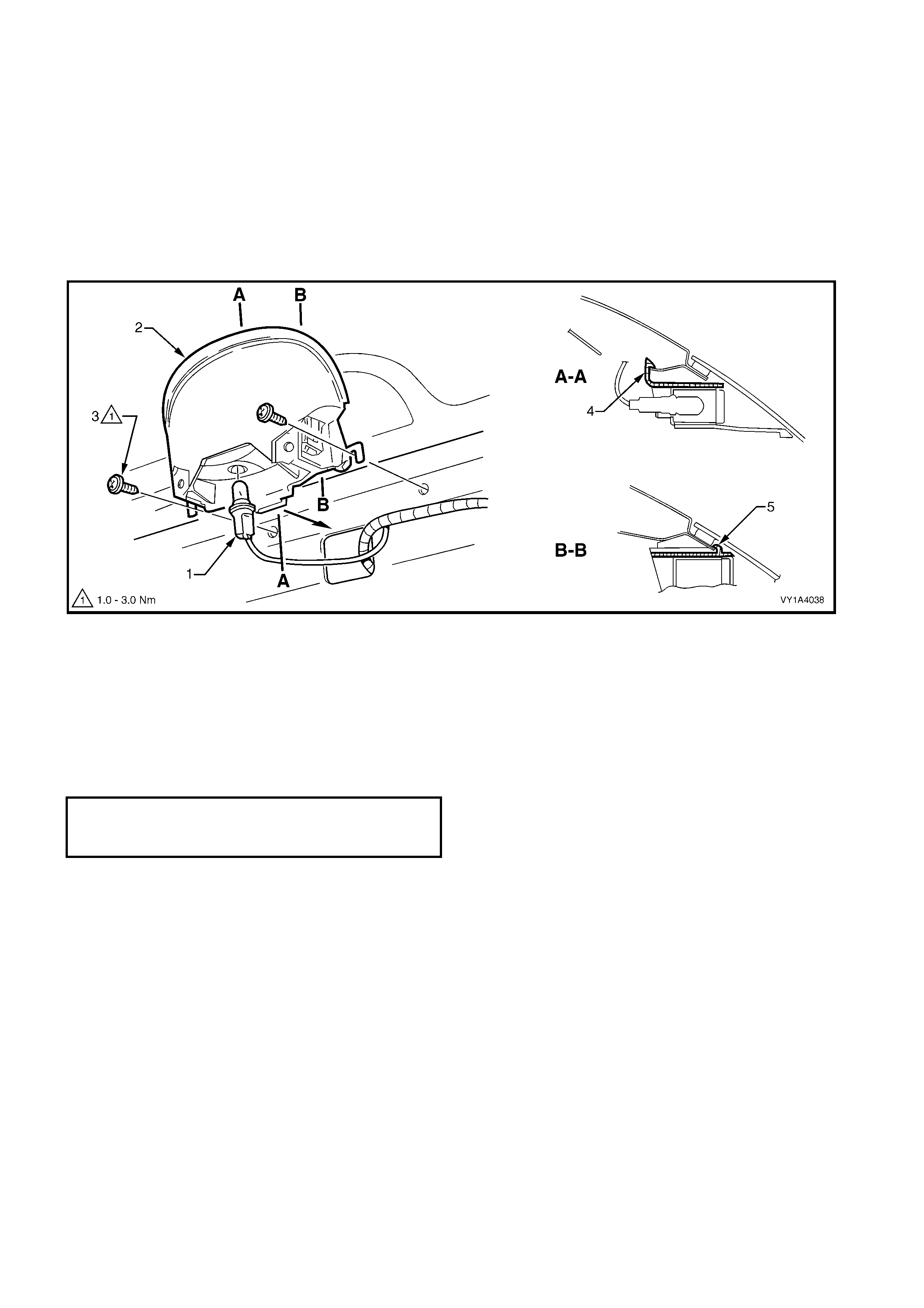

4.12 HIGH MOUNT STOP LAMP ASSEMBLY

LT Section No. – 02-350

As required, first remove the high mount stop lamp cover and liftgate window upper garnish, refer to

4.4 LIFTGATE WINDOW UPPER GARNISH.

REMOVE

1. Twist and remove the lamp socket (1) from the high mount stop lamp assembly (2), refer to Figure 1A4-66.

2. Remove the two screws (3) attaching the lamp assembly to the liftgate assembly.

3. Pr ise the lock ing tab ( 4) back s lightly, release the locking tabs (5) eac h side and rem ove the lam p as sem bly

from the liftgate assembly.

Figure 1A4-66

REINSTALL

Reinstallation is the reverse of removal noting the following.

1. Ensure the lamp assembly is correctly located by inserting locking tab (4) and pushing the lamp assembly

toward the window to engage the locking tabs (5), refer to Figure 1A4-66.

2. Tighten the screws to the specified torque.

3. Test for correct operation of the lamp assembly prior to installing the cover and garnishes.

HIGH MOUNT STOP LAMP

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

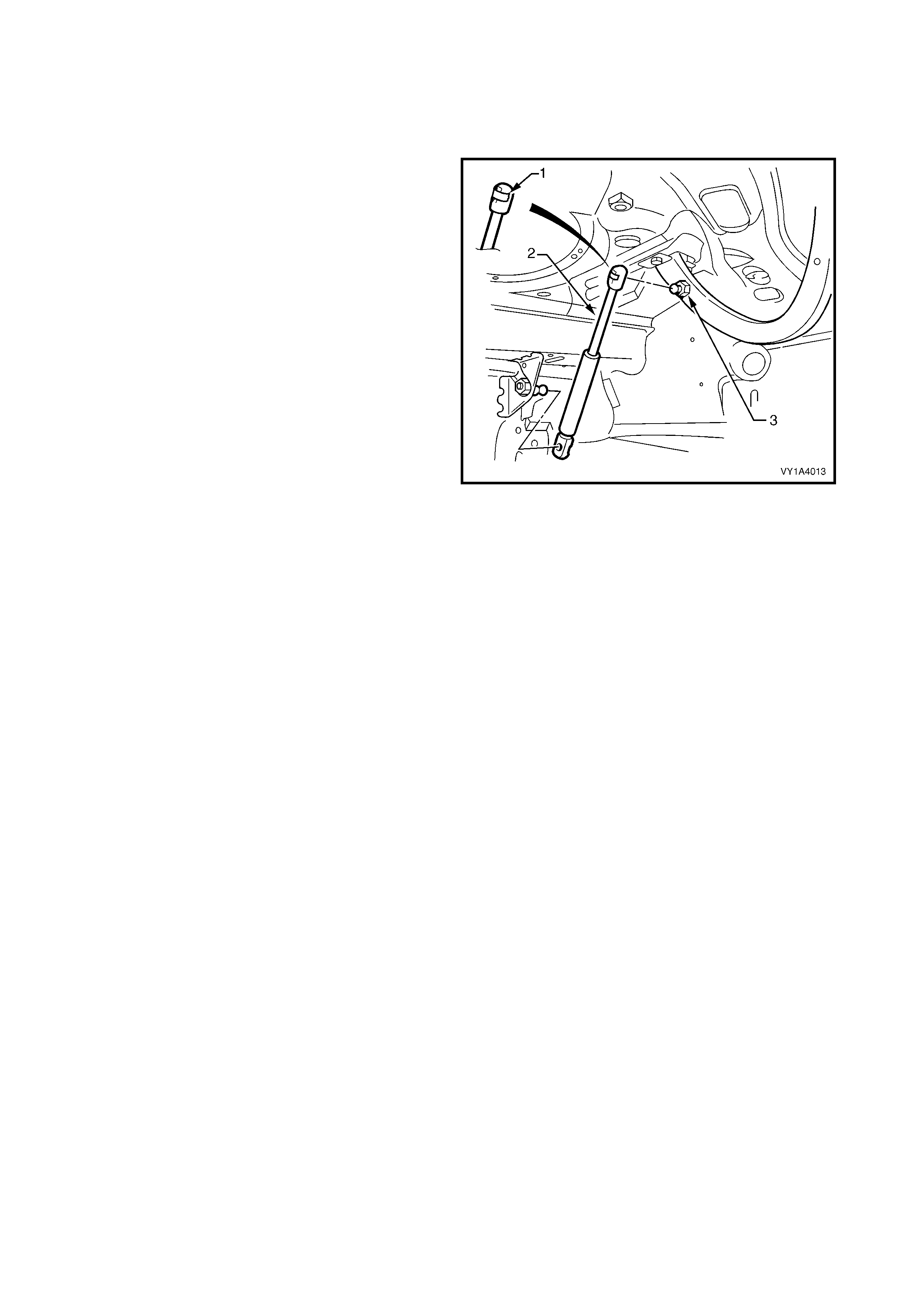

4.13 LIFTGATE STRUT ASSEMBLY

LT Section No. – 12-500

REMOVE

1. Support the liftgate assembly securely.

2. Using a fine, flat blade screwdriver, prise the retainer (1) from the strut end.

3. Pull the strut assembly from the ball stud (2).

4. Repeat for the opposite end as required.

5. If required, remove the ball stud and washer (3) from the liftgate assembly or vehicle.

Figure 1A4-67

REINSTALL

1. If removed, install the ball stud and washer. Tighten to the specified torque.

2. Apply a small amount of lithium based grease to the inside of the strut ball cup.

3. Install the retaining clip onto the strut end.

4. Align the strut with the ball stud and push into place.

NOTE: The strut assembly must be installed with the cylinder end attached to the vehicle.

5. Repeat for the opposite end if required.

LIFTGATE BALL STUD

TORQUE SPECIFICATION 6.0 – 14.0 Nm

4.14 LIFTGATE ASSEMBLY

LT Section No. – 12-500

As required, first remove the following components:

1. Liftgate window lower garnish, refer to 4.1 LIFTGATE WINDOW LOWER GARNISH.

2. Liftgate lower trim panel, refer to 4.2 LIFTGATE LOWER TRIM PANEL.

3. Liftgate inside handle, refer to 4.3 LIFTGATE INSIDE HANDLE.

4. High mount stop lamp cover and liftgate window upper garnish, refer to 4.4 LIFTGATE WINDOW UPPER

GARNISH.

5. Liftgate handle assembly, refer to 4.5 LIFTGATE HANDLE ASSEMBLY.

6. Liftgate handle push button assembly, refer to 4.6 LIFTGATE HANDLE PUSH BUTTON ASSEMBLY.

7. Liftgate latch assembly, refer to 4.7 LIFTGATE LATCH A SSEMBLY.

8. Liftgate actuator assembly , refer to 4.8 LIFTGATE ACTUATOR ASSEMBLY.

9. Liftgate air deflector assembly, refer to 4.9 LIFTGATE AIR DEFLECTOR ASSEMBLY.

10. Rear window wiper assembly, refer to 4.10 REAR WINDOW WIPER ASSEMBLY.

11. Rear window washer nozzle and hose assemblies, refer to 4.11 REAR WINDOW WASHER NOZZLE &

HOSE ASSEMBLIES.

12. High mount stop lamp assembly, refer to 4.12 HIGH MOUNT STOP LAMP ASSEMBLY.

13. Liftgate strut assembly from the liftgate, refer to 4.13 LIFTGATE STRUT ASSEMBLY.

14. Liftgate window assembly, refer to Section 1A6, 5.2 LIFTGATE WINDOW ASSEMBLY, WAGON.

15. Badges and emblems, refer to Section 1A9, EXTERIOR ORNAMENTATION.

REMOVE

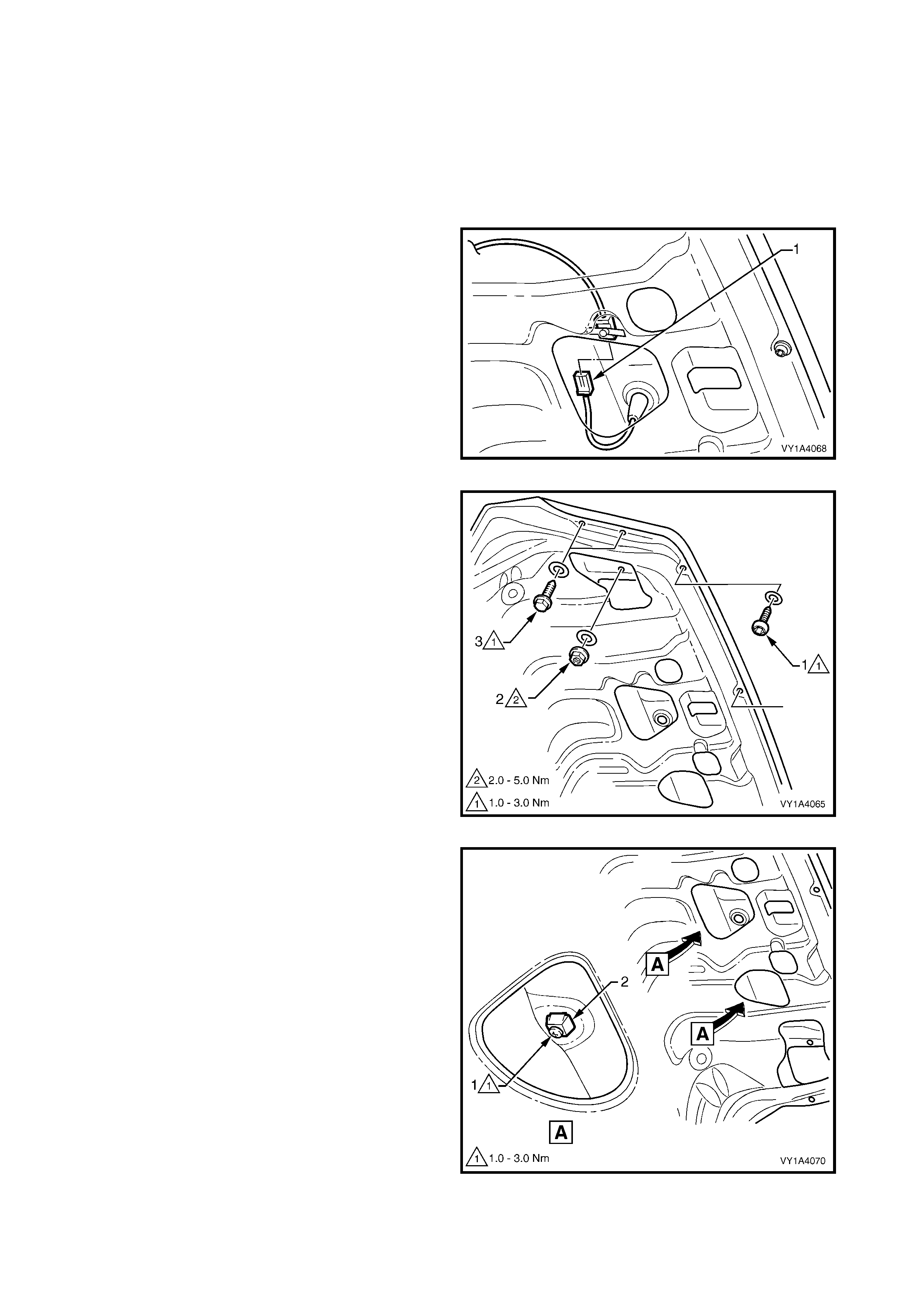

1. Partially remove the right-hand quarter inner trim

upper refer to Section 1A8, 3.8 QUARTER INNER

TRIM UPPER.

2. Partially remove the right-hand body rear corner

garnish, refer to Section 1A8, 3.9 BODY REAR

CORNER GARNISH.

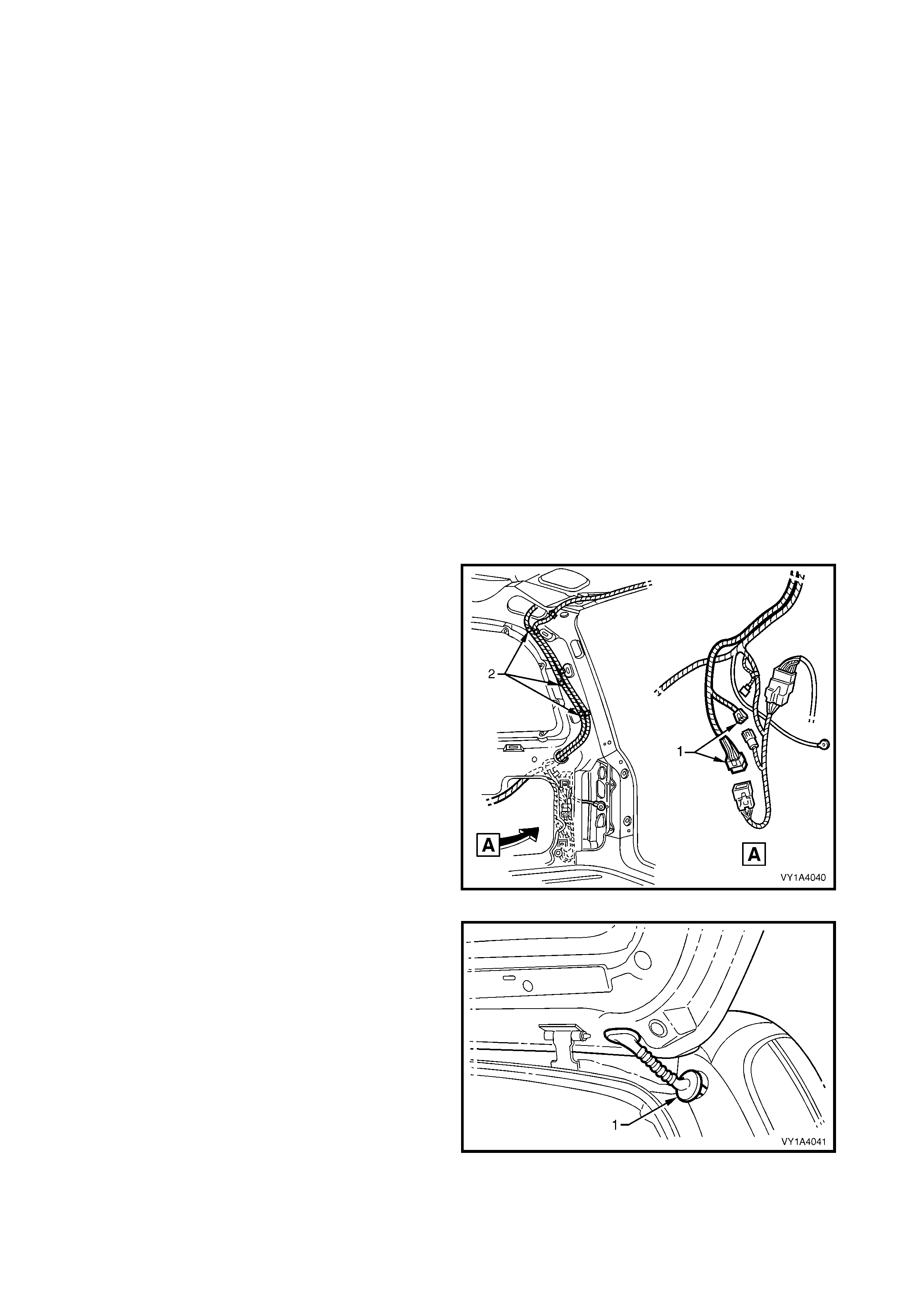

3. Disconnect the two liftgate assembly wiring

harness connectors (1).

4. Unclip the liftgate harness, three places (2).

Figure 1A4-68

5. Remove the right-hand grommet (1) from the

vehicle and withdraw the harness from the pillar

cavity.

Figure 1A4-69

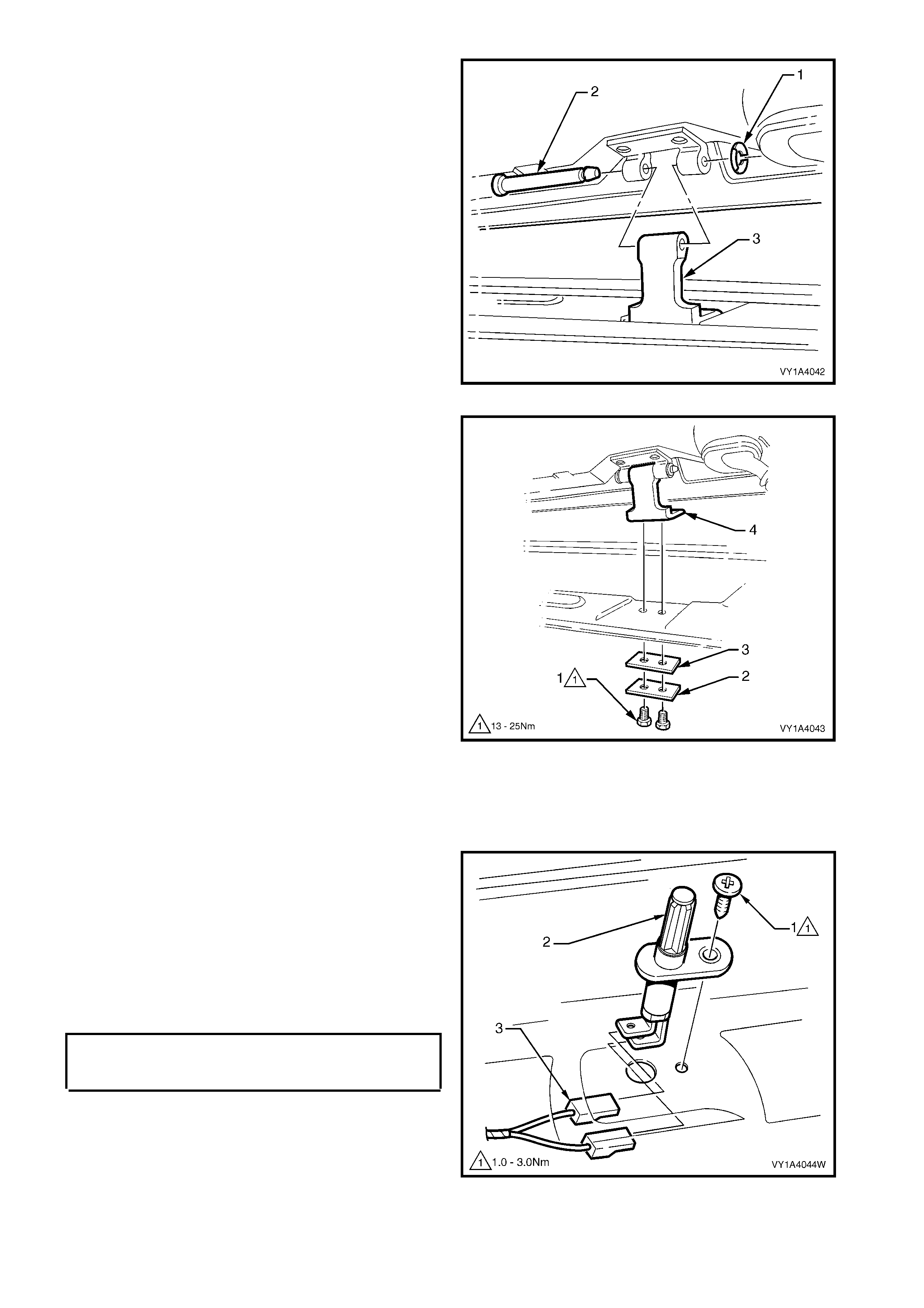

6. Remove the liftgate hinge pin retainer (1) from

each side of the vehicle.

7. Have an ass istant hold the other s ide of the lif tgate

and withdraw each liftgate hinge pin (2).

8. Remove the liftgate assembly leaving the liftgate

hinge (body side) (3) in position.

Figure 1A4-70

NOTE: As an alternative:

1. Remove the rear window upper garnish, refer to

Section 1A8, HEADLING & TRIM.

2. Remove the two screws (1), plate (2) and seal (3).

3. Remove the liftgate assembly with the liftgate

hinge (body side) (4).

Figure 1A4-71

DISASSEMBLE

Remove – Rear Compartment Courtesy Lamp

Switch Assembly

1. Remove the screw (1) attaching the switch

assembly (2) to the liftgate assembly.

2. W ithdraw the switch assembly and disconnect the

liftgate harness wiring connectors (3).

Reinstall – Rear Compartment Courtesy Lamp

Switch Assembly

1. Reinstallation is the reverse of removal. Tighten

the screw to the specified torque.

LIFTGATE HARNESS ASSEMBLY

For wiring harness assembly attachment and routing

information refer to Section 12O, FUSES AND

WIRING HARNESSES.

Figure 1A4-72

REAR COMPARTMENT COURTESY LAMP

SWITCH ASSEMBLY ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

Remove – Liftgate Bumper

1. Remove the liftgate bumper (1) each side by

unscrewing in the direction shown.

Reinstall –Liftgate Bumper

1. Install the bumper, screwing it all the way in. To set

the bumper to its correct position, refer to the

following liftgate adjustment procedure.

Figure 1A4-73

REINSTALL

Reinstallation is the reverse of removal noting the

following.

1. If the liftgate was removed from the liftgate hinge

pin, lubricate the pin with lithium based grease

prior to installation.

2. If the liftgate was removed with the liftgate hinge

(body side), apply sealer suc h as Lord Fusor #800

or #801 or equivalent to the area shown (1).

3. Set the two bumpers to the full-in position then

adjust to achieve the required alignment of the

liftgate, refer to the following adjustment

procedure.

4. Test the operation of the wiper, washer, high

mount stop lam p, r ear com par tm ent courtesy lamp

switch and lock mechanism before installing the

trim panels.

5. Tighten all screws to the specified torque.

Figure 1A4-74

ADJUST

Correct alignment of the liftgate is critical to its operation and to the aesthetics of the vehicle. The following

components allow adjustment of the liftgate:

• Liftgate bumper: Provides adjustment at the outer area of the liftgate assembly.

• Liftgate hinge (body side) screws: Provide forward, rearward and skew adjustment of the liftgate assembly.

• Liftgate striker assembly: Provides vertical and sideways adjustment of the liftgate assembly.

Whenever alignment is required, perform adjustment in the following order.

1. If fitted, remove the liftgate striker assembly, refer to 4.15 LIFTGATE STRIKER ASSEMBLY.

2. Ensure the liftgate weatherstrip assembly is installed and the liftgate bumpers are fitted and set fully in.

3. Carefully close the liftgate, watching the top and each side does not contact the vehicle.

4. Referring to Figure 1A4-75, check the alignm ent of the liftgate for width and consistency of gap to the roof

panel, quarter panel each side, tail lamps and rear bumper fascia.

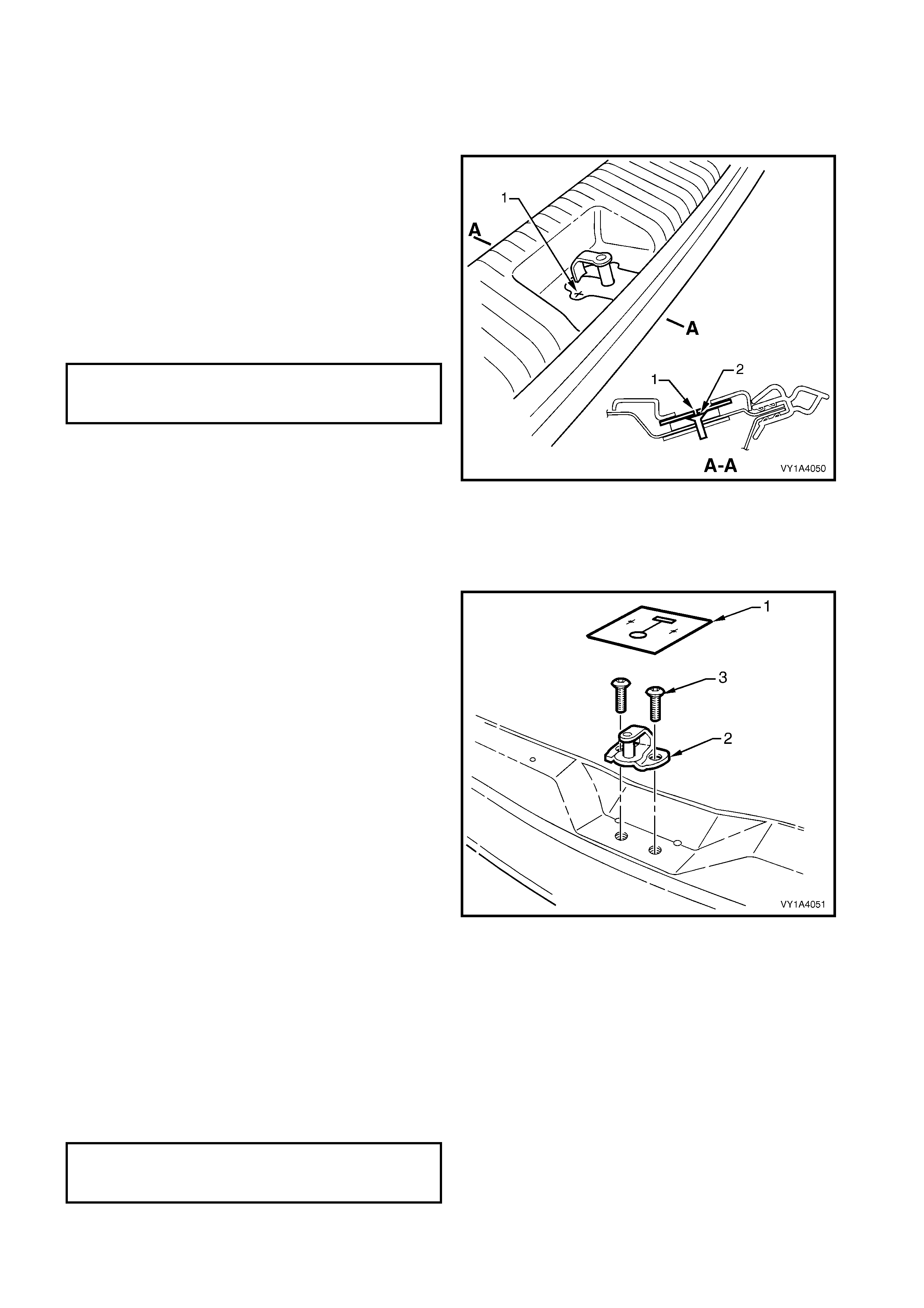

LIFTGATE HINGE (BODY SIDE)

ATTACHING SCREW

TORQUE SPECIFICATION 13.0 – 25.0 Nm

Figure 1A4-75

5. If the gap between the liftgate and r oof panel is not

within specification and/or is not parallel to the

quarter panel each side, open the liftgate and

adjust the position of the liftgate hinge(s)

• Remove the rear window upper garnish, refer

to Section 1A8, 3.10 REAR WINDOW UPPER

GARNISH.

• Loosen the two screws (1) attaching the

liftgate hinge (2).

• Lift the hinge away from the body and apply

sealer such as Lord Fusor #800 or #801 or

equivalent to the area shown (3).

• Adjust the position of the hinge, tighten the

screws and recheck the liftgate alignment.

NOTE: Do not make all adjustments at once. Perform

one adjustment, carefully close the liftgate, check its

position and make further adjustments until correct

alignment is achieved.

6. If the gap between the liftgate and roof panel is

within specific ation and the liftgate is parallel to the

quarter panel each side, open the liftgate and

adjust the liftgate bumpers to provide a slightly

greater gap at the lower edge of the liftgate above

each tail lamp. T his allows for the str iker to pull the

liftgate in slightly when closed.

Figure 1A4-76

7. Install the liftgate striker assembly, refer to

4.15 LIFTGATE STRIKER ASSEMBLY.

8. Close the liftgate, watching that the striker does

not pull the lif tgate to one side, changing the panel

gaps. If it does, move the striker as required.

9. Tighten all screws to their specified torque.

LIFTGATE HINGE (BODY SIDE)

ATTACHING SCREW

TORQUE SPECIFICATION 13.0 – 25.0 Nm

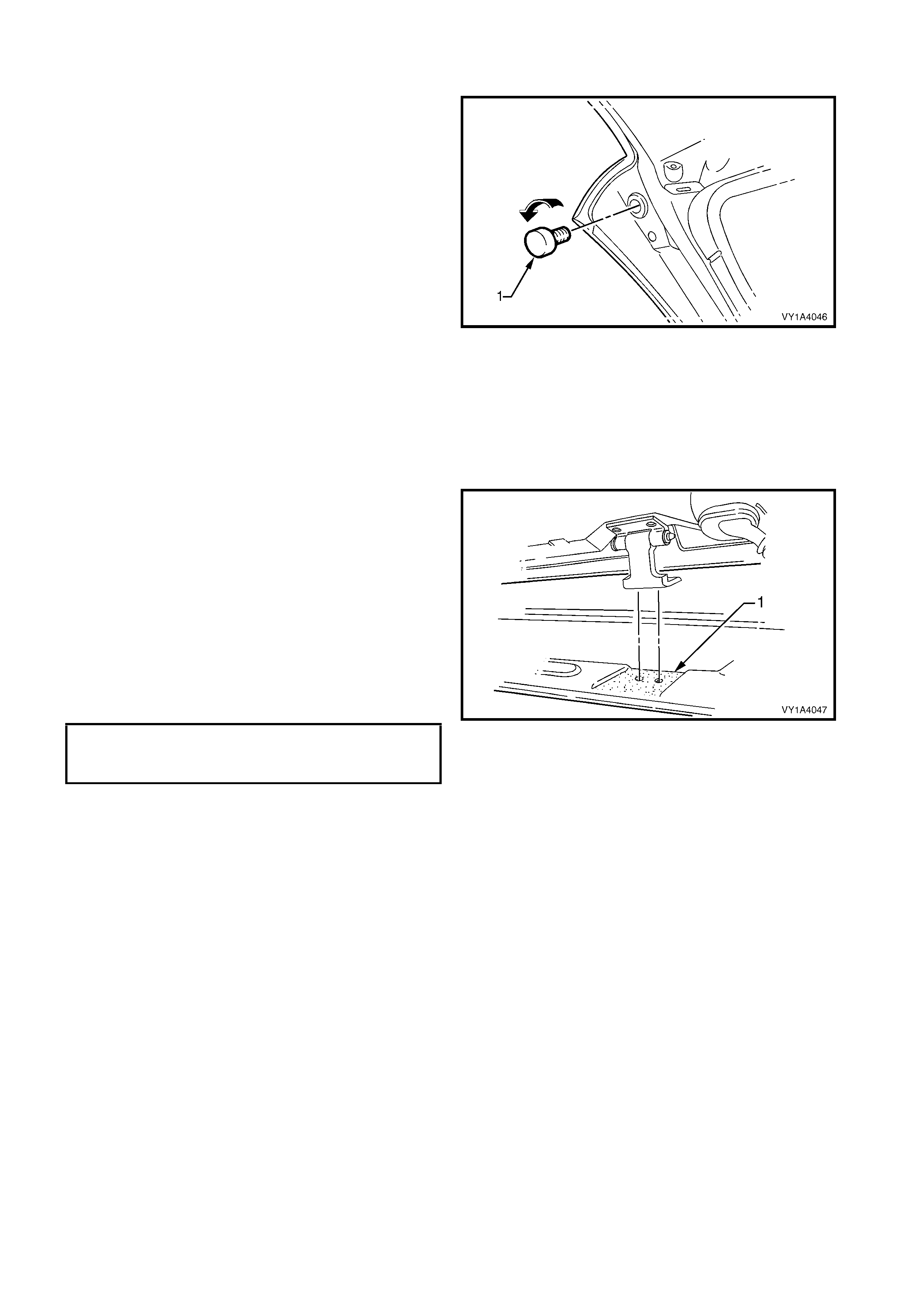

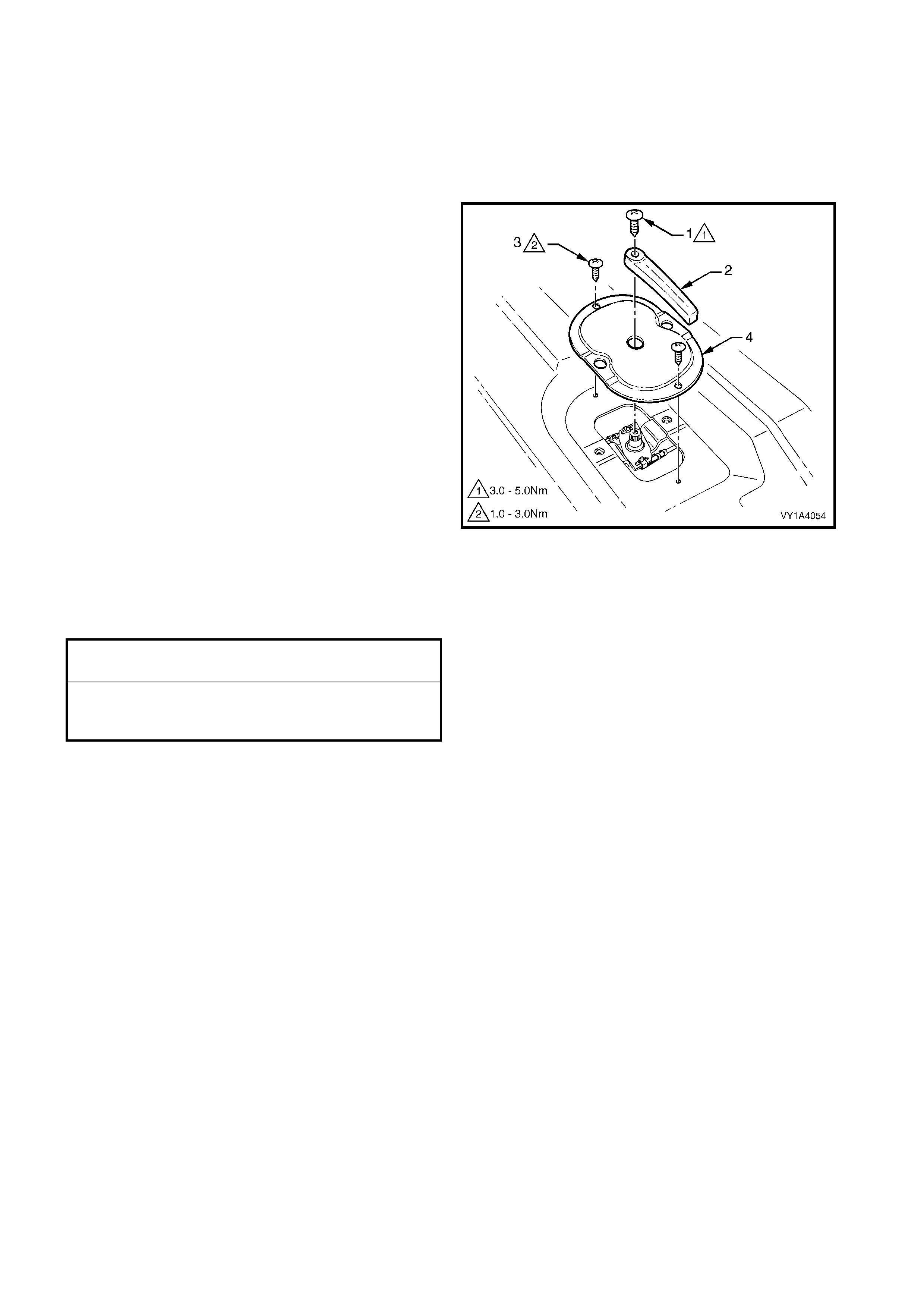

4.15 LIFTGATE STRIKER ASSEMBLY

ADJUST

LT Section No. – 12-500

1. Insert a Torx bit driver through the opening in the

rear end panel seal into the striker assembly

screw.

2. Loosen the screws and reposition the striker

assembly as required.

3. Tighten the screws and check alignment of the

liftgate assembly, refer to 4.14 LIFTGATE

ASSEMBLY.

4. When correct, tighten the striker assembly screws

to the specified torque.

Figure 1A4-77

REMOVE

LT Section No. – 12-680

1. As required, remove the rear end trim panel, refer to Section 1A8, 3.19 REAR END TRIM PANEL.

2. Remove the rear end panel seal (1) from the

striker assembly (2).

3. Mark the position of the striker assembly on the

surrounding panel with a marker pen.

4. Using a Torx bit driver remove the screws (3)

attaching the striker assembly.

5. Remove the striker assembly.

Figure 1A4-78

REINSTALL

Reinstallation is the reverse of removal noting the

following.

1. Align the striker assembly to the pen mark and if

required, adjust the position of the striker prior to

installing the trim components, refer to the

previous adjustment procedure.

2. Tighten the striker assembly screws to the

specified torque.

LIFTGATE STRIKER ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 13.0 – 25.0 Nm

LIFTGATE STRIKER ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 13.0 – 25.0 Nm

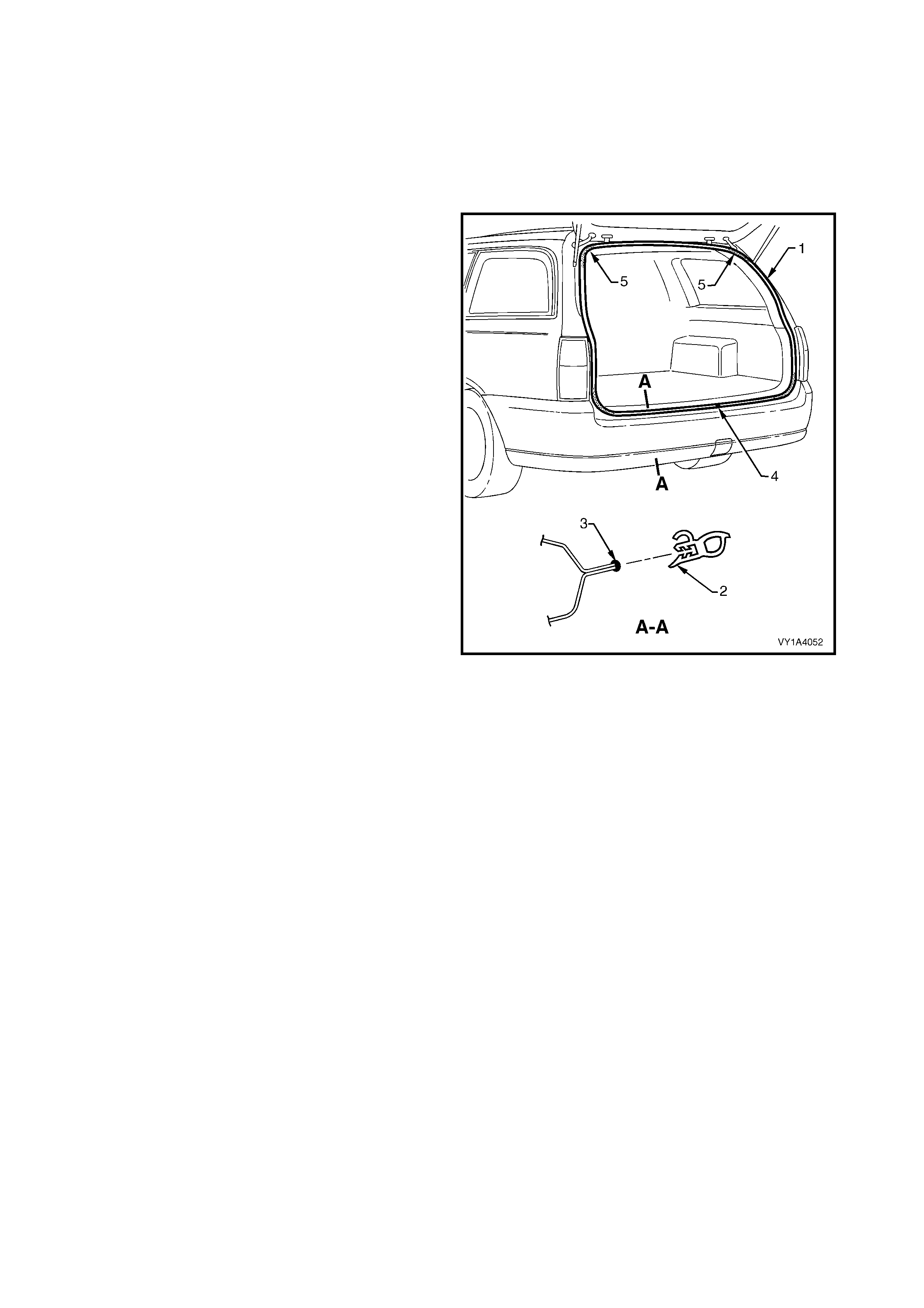

4.16 LIFTGATE WEATHERSTRIP

REMOVE

LT Section No. – 11-600

1. W hile not necessary, removal of the adjacent trim

panels will make installation of the weatherstrip

assembly easier.

2. Grasping the weatherstrip assembly (1) carefully

pull it from the body flange. Start at one point and

continue along its length.

3. Remove the weatherstrip assembly from the

vehicle.

Figure 1A4-79

REINSTALL

1. Lay the weatherstrip assembly on the floor and

ensure the longer side of the weatherstrip (2) is to

the outside, refer to Figure 1A4-79.

2. Apply a small bead of non-hardening windscreen

sealer suc h as butyl-m astic or equivalent (3) to the

weatherstrip flange.

3. Locate the weatherstrip join (4) which is to be

aligned with the striker assembly.

4. Fit the weatherstrip onto the body flange and

beginning at the join, push it into position.

NOTE: Allow crowding of the weatherstrip in each

corner (5) to avoid short cutting of the corners. If

required crimp the weatherstrip to ensure a tight fit

onto the flange.

5. SERVICE OPERATIONS – ENDGATE, UTILITY

5.1 ENDGATE INNER PANEL ACCESS HOLE COVER

LT Section No. – 12-685

REMOVE

1. Remove the screw (1) attaching the endgate

handle (2).

2. Remove the screw (3), two places, attaching the

endgate inner panel access hole cover (4).

Figure 1A4-80

REINSTALL

Reinstallation is the reverse of removal. Ensure the

screws are tightened to the specified torque.

ENDGATE HANDLE ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

ENDGATE INNER PANEL ACCESS HOLE

COVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

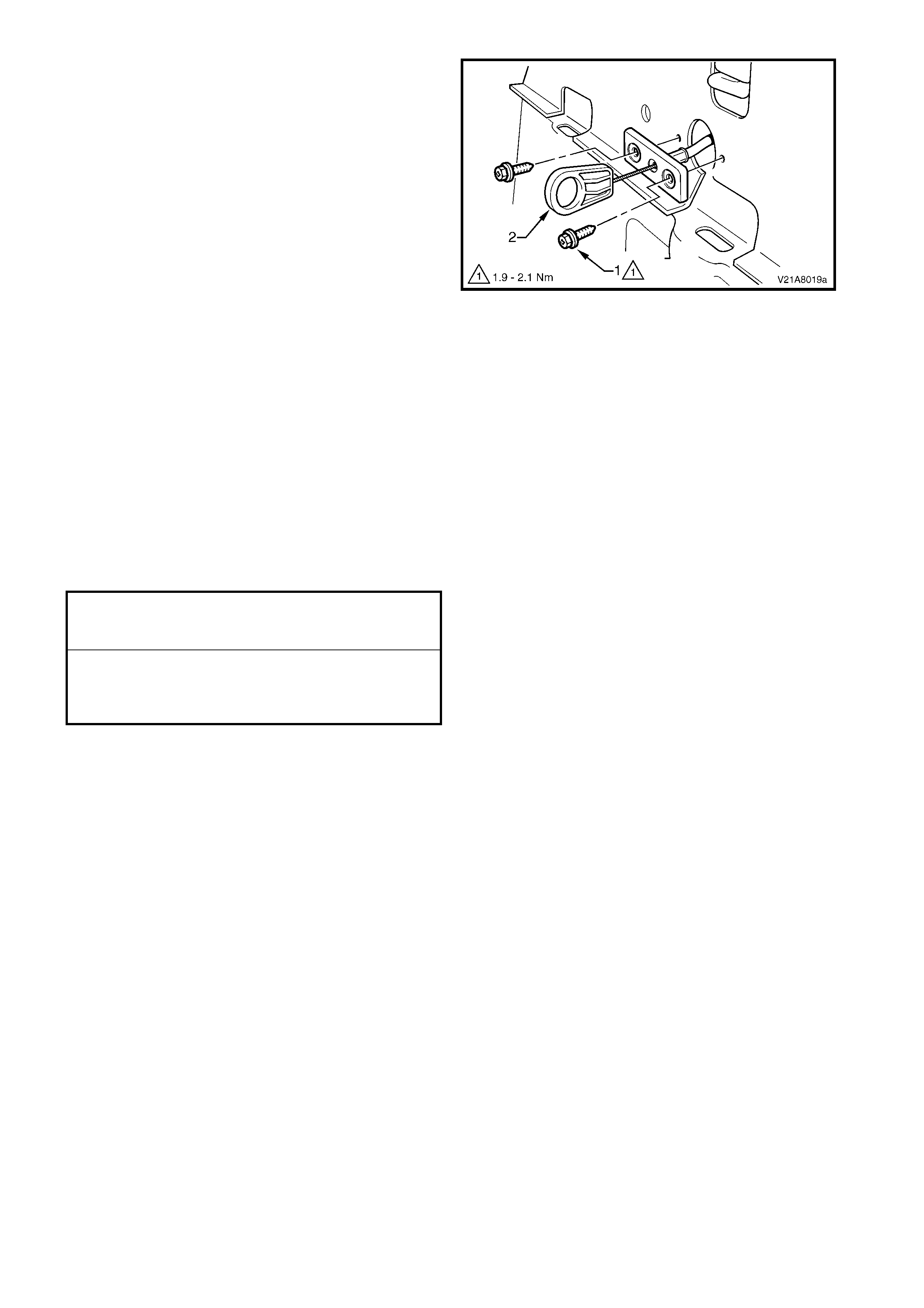

5.2 ENDGATE LOCK ANCHOR PLATE ASSEMBLY

LT Section No. – 12-685

1. As required, first remove the endgate handle and

endgate inner panel access hole cover, refer to

5.1 ENDGATE INNER PANEL ACCESS HOLE

COVER.

REMOVE

1. Unclip the retainer (1) from the endgate latch

assembly (2). Repeat for the other side.