SECTION 1A5 - FRONT & REAR DOOR ASSEMBLIES

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1 GENERAL DESCRIPTION

2 FRONT DOOR SERVICE OPERATIONS

2.1 FRONT DOOR HINGE LUBRICATION

2.2 FRONT DOOR LOCK STRIKER

REMOVE

REINSTALL

2.3 ADJUST FRONT DOOR ASSEMBLY

2.4 FRONT DOOR WINDOW REGULATOR

HANDLE ASSEMBLY

REMOVE

REINSTALL

2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE)

REMOVE

REINSTALL

2.6 FRONT DOOR TRIM PANEL ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

2.7 FRONT DOOR LOCK ASSEMBLY

REMOVE

DISASSEMBLE

ADJUST

REINSTALL

2.8 FRONT DOOR OUTSIDE HANDLE

ASSEMBLY

REMOVE

DISASSEMBLE - DRIVER’S DOOR

ASSEMBLE

REINSTALL

RESET

2.9 FRONT DOOR WINDOW REGULATOR

ASSEMBLY

REMOVE

REINSTALL

2.10 FRONT WINDOW INNER FILLER

ASSEMBLY

REMOVE

REINSTALL

2.11 FRONT DOOR BELT OUTER REVEAL

MOULDING ASSEMBLY

REMOVE

REINSTALL

2.12 FRONT WINDOW GUIDE ASSEMBLY

REMOVE

REINSTALL

2.13 FRONT DOOR GUIDE CHANNEL

ASSEMBLY

REMOVE

REINSTALL

2.14 FRONT DOOR WINDOW ASSEMBLY

REMOVE

REINSTALL

ADJUST

2.15 FRONT DOOR WEATHERSTRIP

ASSEMBLIES

REMOVE

REINSTALL

2.16 FRONT DOOR WINDOW FRAME

UPPER SCALP MOULDING

REMOVE

REINSTALL

2.17 FRONT DOOR WIRING HARNESS ASSEMBLY

2.18 FRONT DOOR ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

ADJUST

2.19 FRONT DOOR OPENING WEATHERSTRIP

ASSEMBLY, EXCEPT COUPE

REMOVE

REINSTALL

2.20 FRONT DOOR OPENING WEATHERSTRIP

ASSEMBLY, COUPE

REMOVE

REINSTALL

3 REAR DOOR SERVICE OPERATIONS

3.1 REAR DOOR HINGE LUBRICATION

3.2 REAR DOOR LOCK STRIKER

REMOVE

REINSTALL

3.3 ADJUST REAR DOOR ASSEMBLY

3.4 REAR WINDOW REGULATOR HANDLE

ASSEMBLY

REMOVE

REINSTALL

3.5 REAR DOOR INSIDE HANDLE

ASSEMBLY (REMOTE)

REMOVE

REINSTALL

3.6 REAR DOOR TRIM PANEL ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

3.7 REAR DOOR LOCK ASSEMBLY

REMOVE

DISASSEMBLE

ADJUST

REINSTALL

3.8 REAR DOOR OUTSIDE HANDLE ASSEMBLY

REMOVE

REINSTALL

3.9 REAR WINDOW INNER FILLER ASSEMBLY

REMOVE

REINSTALL

3.10 REAR DOOR BELT OUTER REVEAL

MOULDING ASSEMBLY

REMOVE

REINSTALL

3.11 REAR DOOR CHANNEL ASSEMBLY

REMOVE

REINSTALL

3.12 REAR DOOR WINDOW ASSEMBLY

REMOVE

REINSTALL

ADJUST

Techline

Techline

Techline

Techline

Techline

Techline

Techline

3.13 REAR DOOR WINDOW REGULATOR

ASSEMBLY

REMOVE

REINSTALL

3.14 REAR DOOR STATIONARY WINDOW

ASSEMBLY

REMOVE

REINSTALL

3.15 REAR DOOR WEATHERSTRIP

ASSEMBLIES

REMOVE

REINSTALL

3.16 REAR DOOR WINDOW FRAME UPPER

SCALP MOULDING

REMOVE

REINSTALL

3.17 REAR DOOR WIRING HARNESS ASSEMBLY

3.18 REAR DOOR ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

ADJUST

3.19 REAR DOOR OPENING

WEATHERSTRIP ASSEMBLY

REMOVE

REINSTALL

4 TORQUE WRENCH SPECIFICATIONS

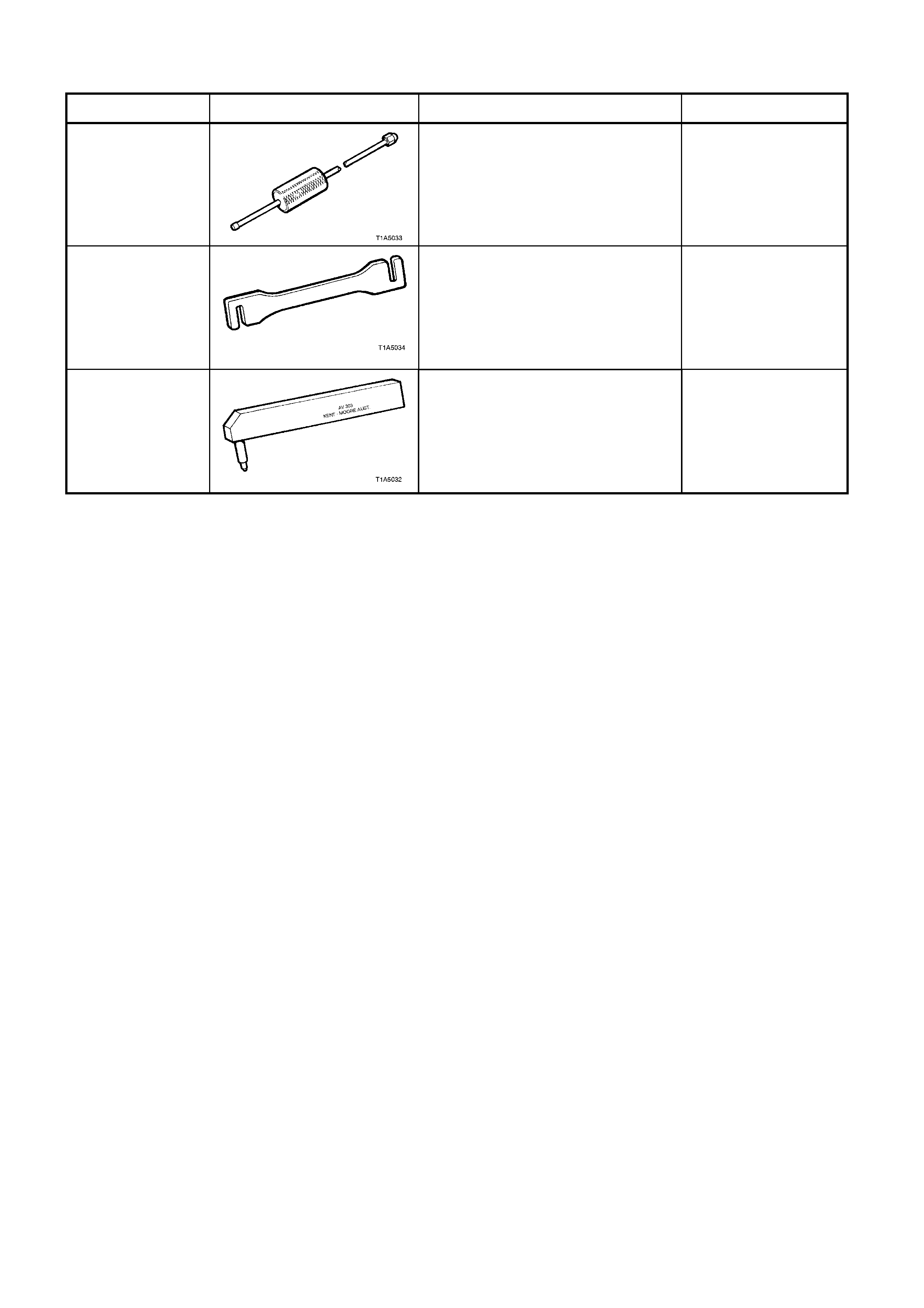

5 SPECIAL TOOLS

1. GENERAL DESCRIPTION

The front and rear door assemblies consist of an outer panel which are hemmed over the inner panel at their outer

edges. Structural adhesive is applied within the hemmed joint and joint sealer, hand putty and cavity wax are used

for the pr evention of corr osion. A rolled up per door fram e retains the sliding gl ass run channe ls. Door hinge m ale

sections are welde d to the door inner panel f acings and the f em ale sections to th e body pillar s. A door c heck and

hold open link is located between the door assemblies and the body pillars.

For the front doors sliding windows are operated by double arm scissor type window regulators, attached to the

glass lifter channels and door inner panel. Cable type mechanisms attached to the door inner panel and glass

lifter channels operate the rear door sliding windows.

Electrically operated front sliding windows are available on all models and, for Sedan and Wagon, electrically

operated rear sliding windows are also available.

Lift-bar exterior door handles operate the fork type door locks in conjunction with door lock striker bolts.

A two key locking system uses a master key (with inbuilt remote security features) to operate all locks on the

vehicle. A secondary key, operates the glove compartment only. A snib locking button operates the door locks

internally.

The f ront door lock c ylinder , fitted onl y to th e dri ver’s door , is of the ‘free turn ing’ desig n which pre vents unlo ck ing

of the door by objec ts ot her than t he c or rec t key. If a n y obj ect, exc ept the cor r ect k e y, is ins er ted into th e lock , the

cylinder will rotate without unlocking the door.

Electric door lock actuators and electric external rear vision mirrors are standard features.

The front door trims feature a map pocket, air vents with side window defog, radio speaker grille, courtesy lamp

(where fitted) and a cloth or leather insert. On Sedan and Wagon, rear door trims feature a radio speaker grille,

courtesy lamp (where fitted) and a cloth or leather insert.

Door weatherstrips incorporate plastic clips which reta in the weatherstrip in holes located around the outer lo wer

edge of the door inner panel. The upper section of the weatherstrip is retained in a channel which is an integral

part of the rolled section upper door frame.

2. FRONT DOOR SERVICE OPERATIONS

2.1 FRONT DOOR HINGE LUBRICATION

LT Section No. –

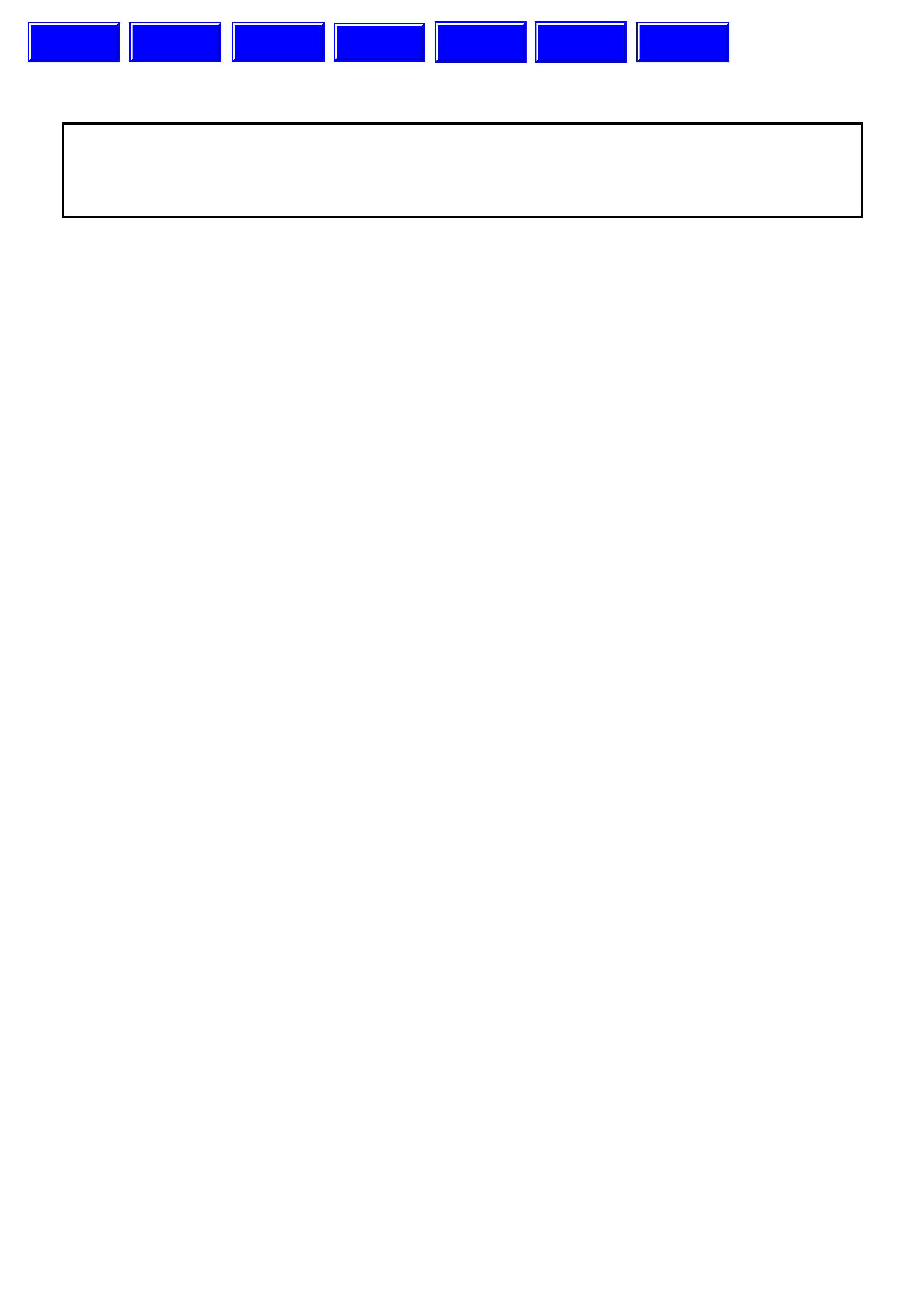

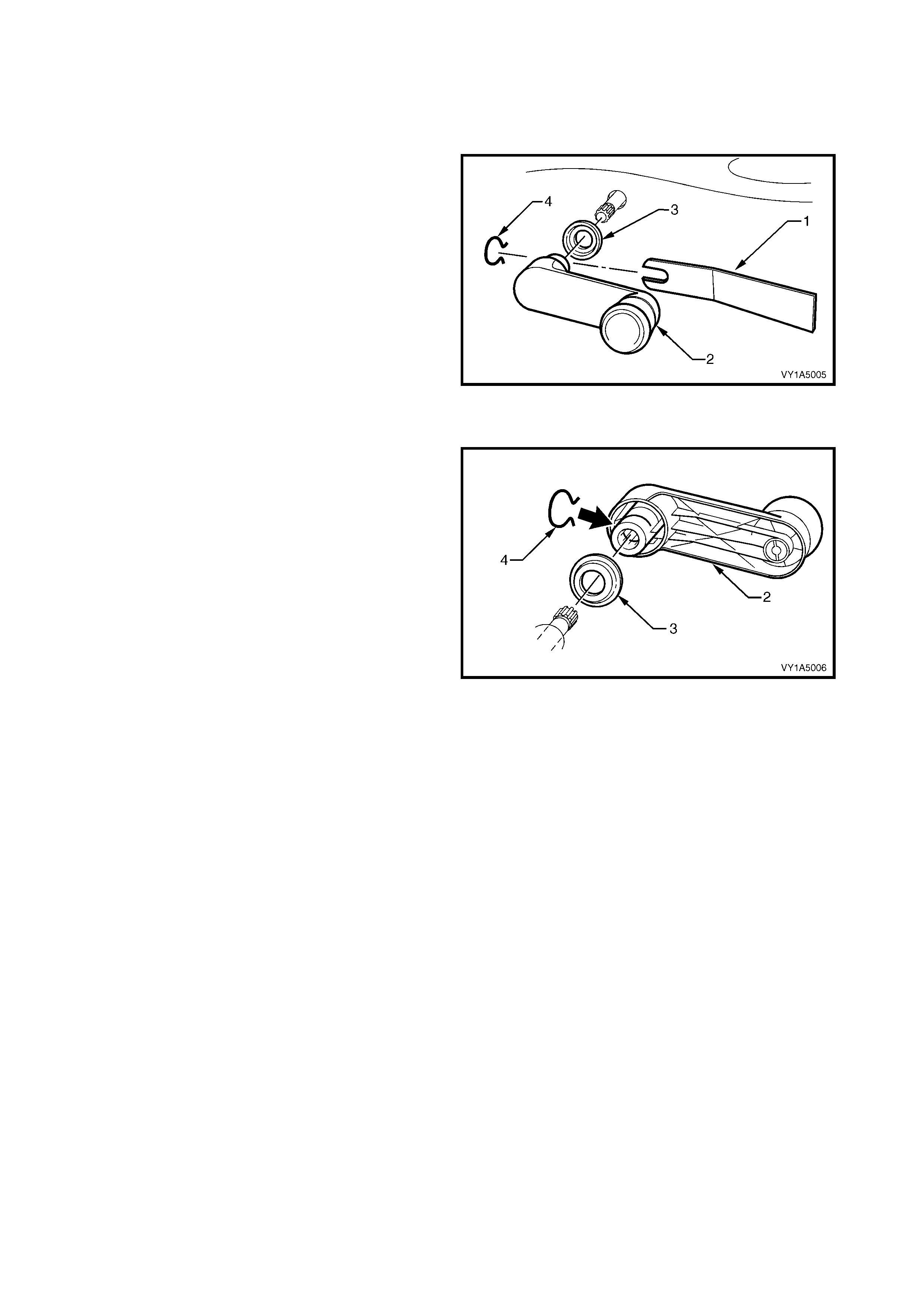

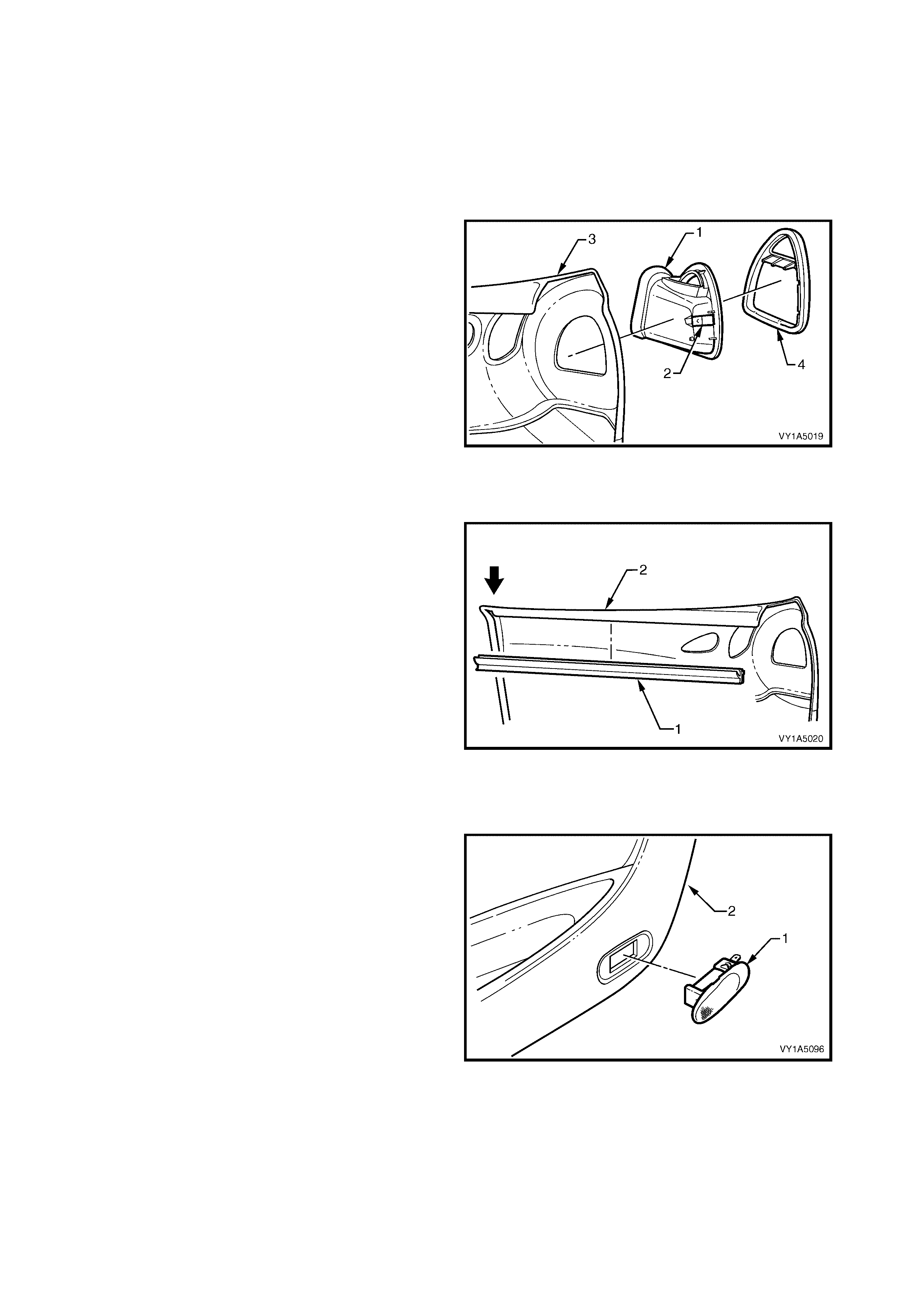

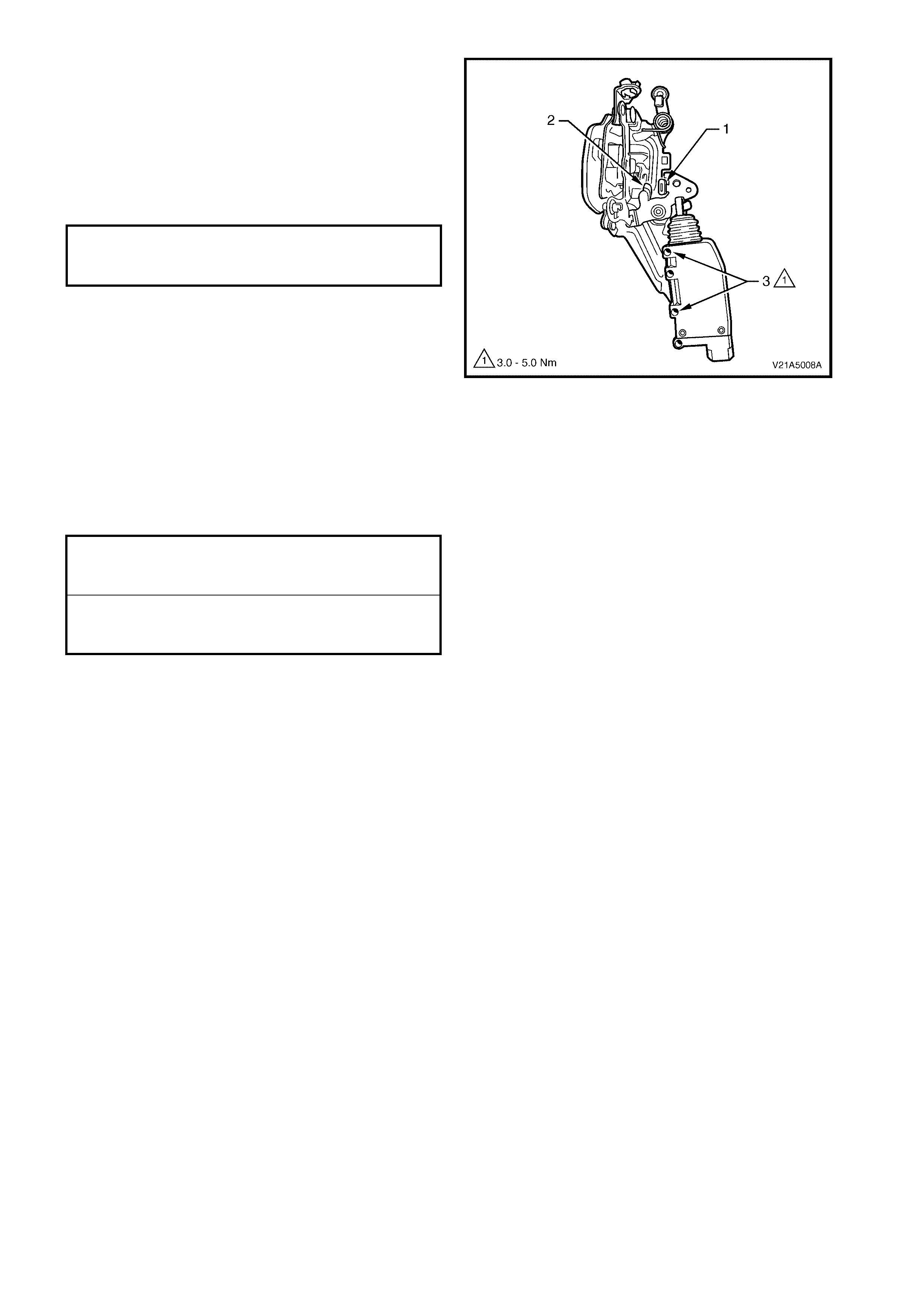

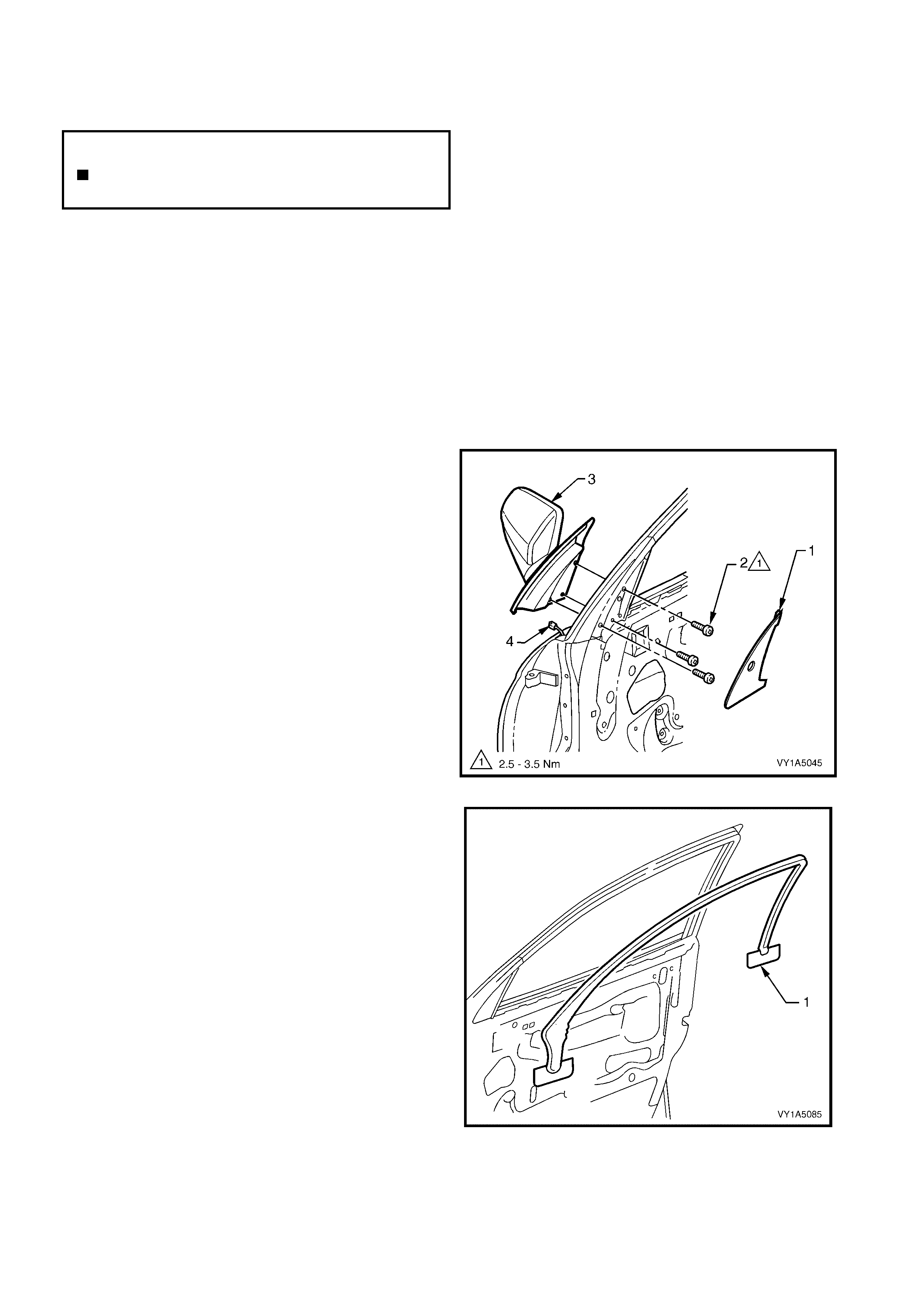

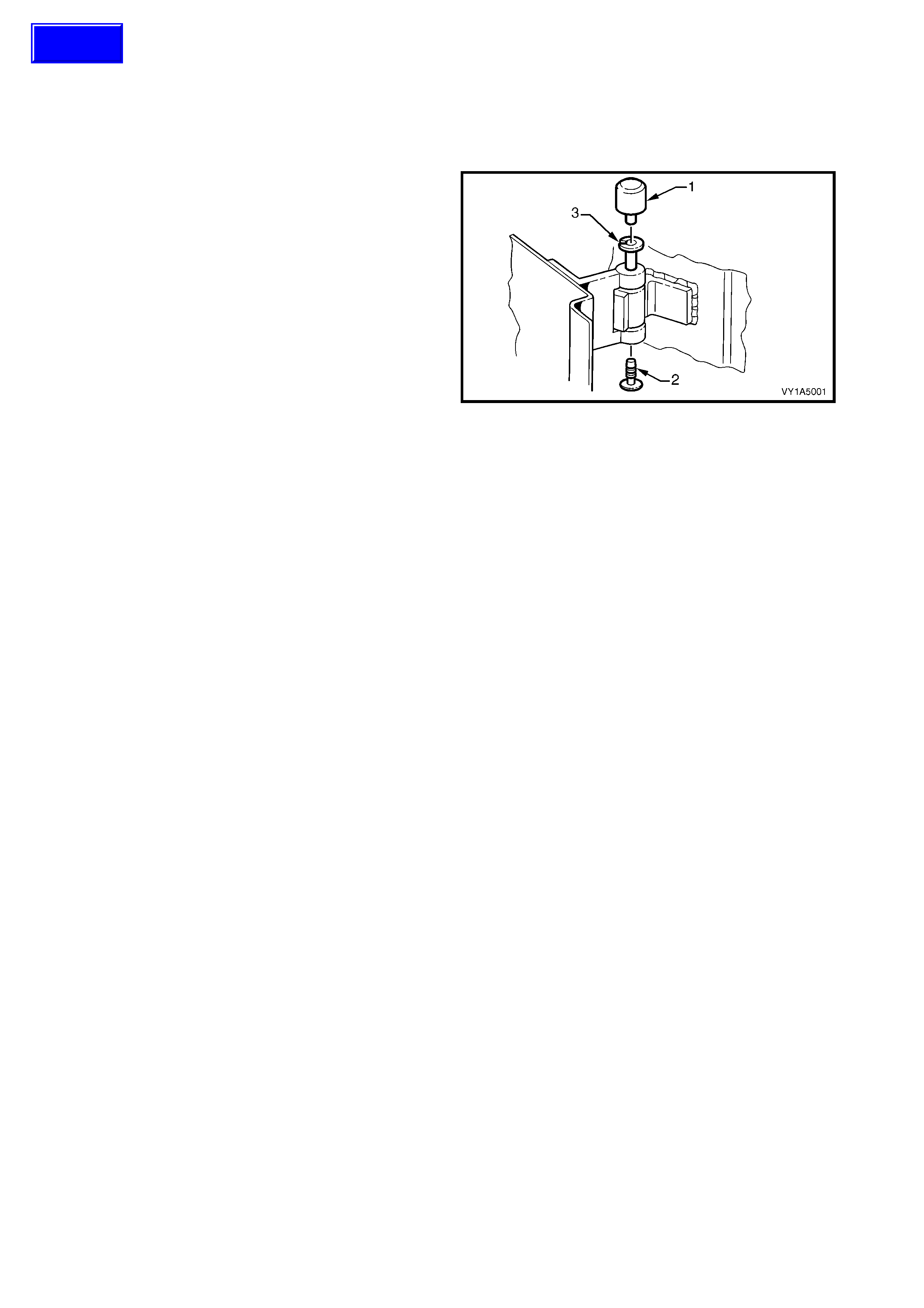

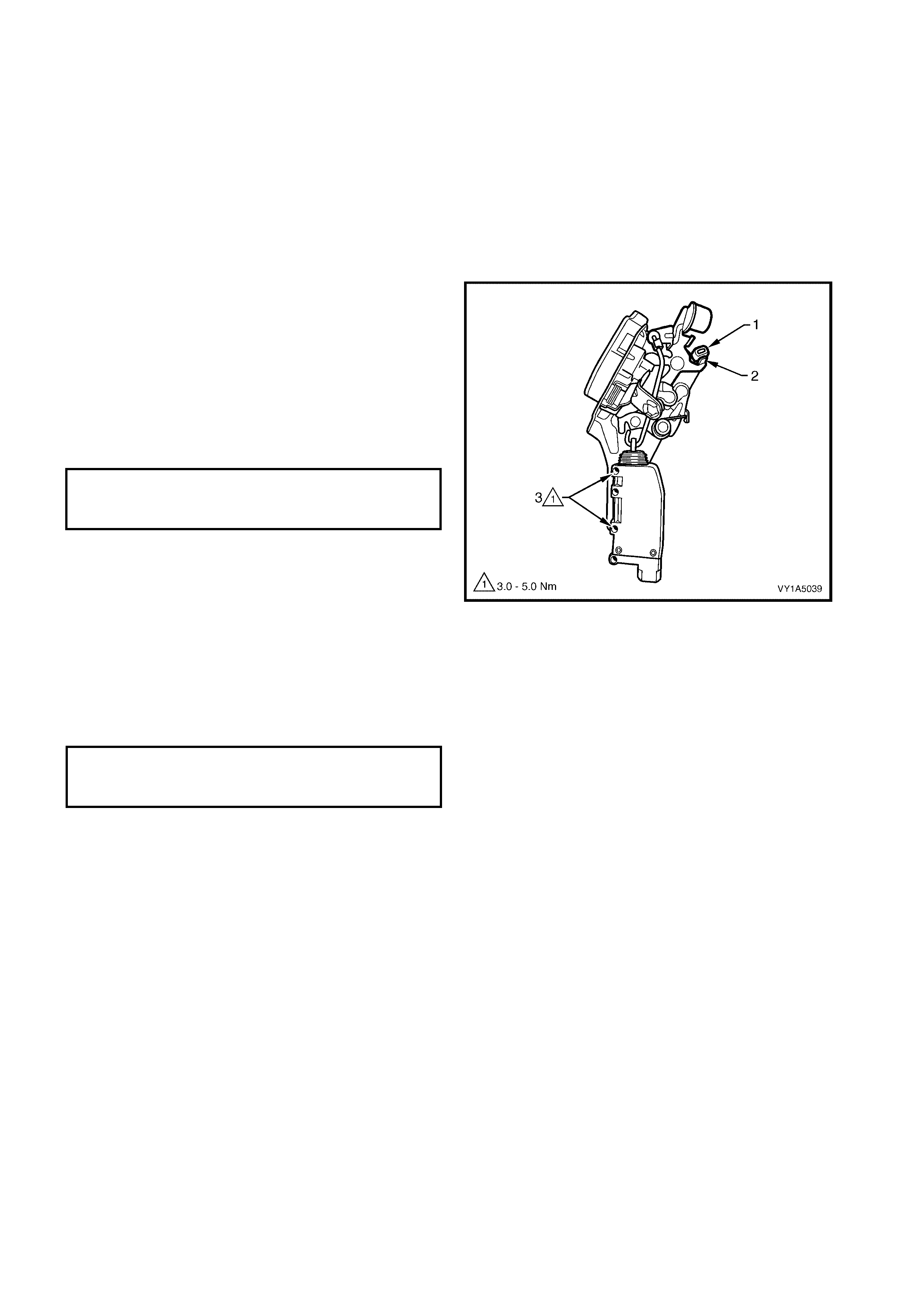

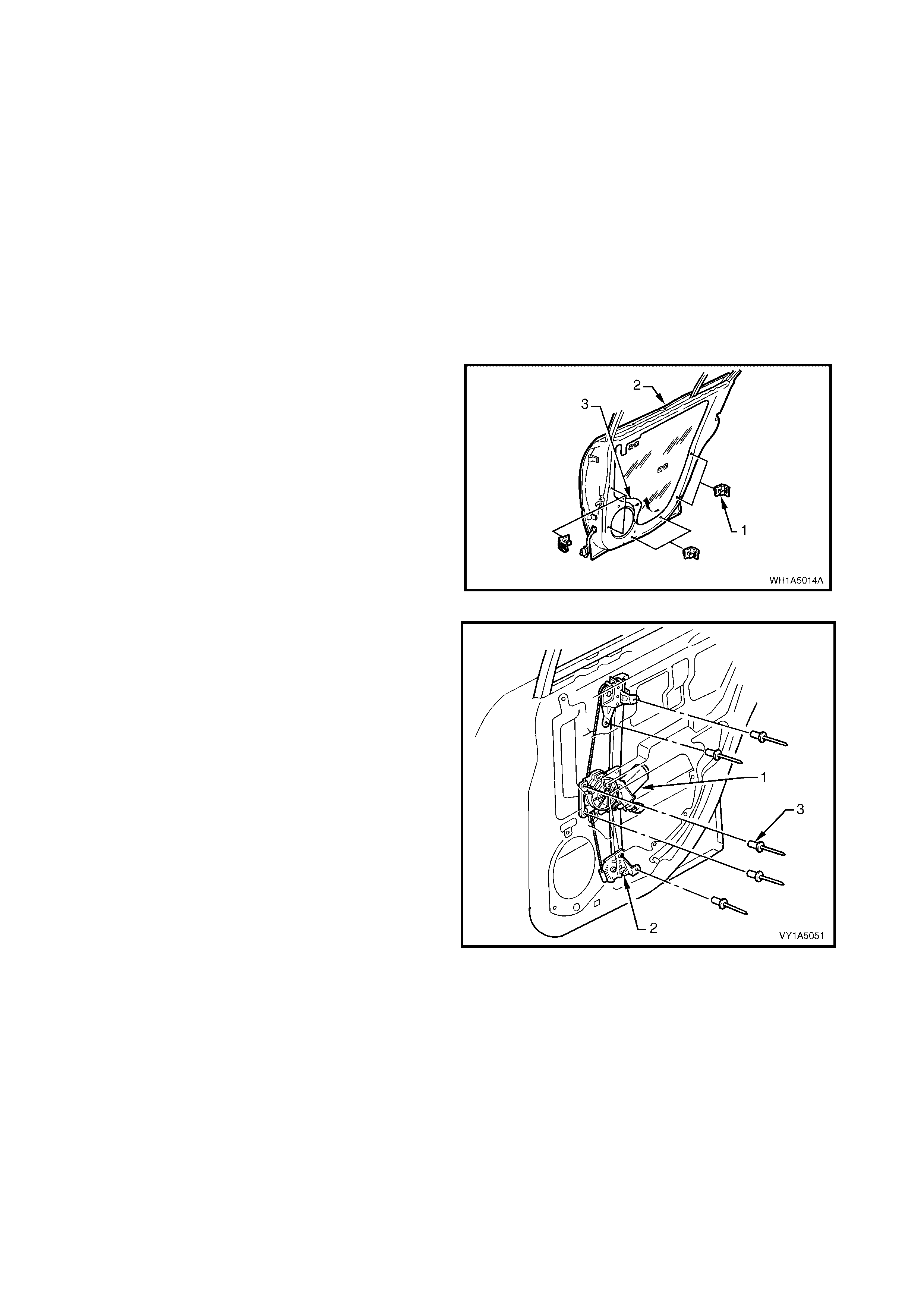

1. Remove the front hinge pin cap (1) and the front

hinge plug (2) from the front hinge pin (3) on the

upper and lower hinges.

2. Using a grease gun, inject into the front hinge pin

Lithium base grease NLGI No. 1 (with 9 % zinc

oxide) or equivalent.

3. Reinstall the cap and plug.

4. Wipe off any excess grease.

Figure 1A5-1

2.2 FRONT DOOR LOCK STRIKER

LT Section No. – 11-725

REMOVE

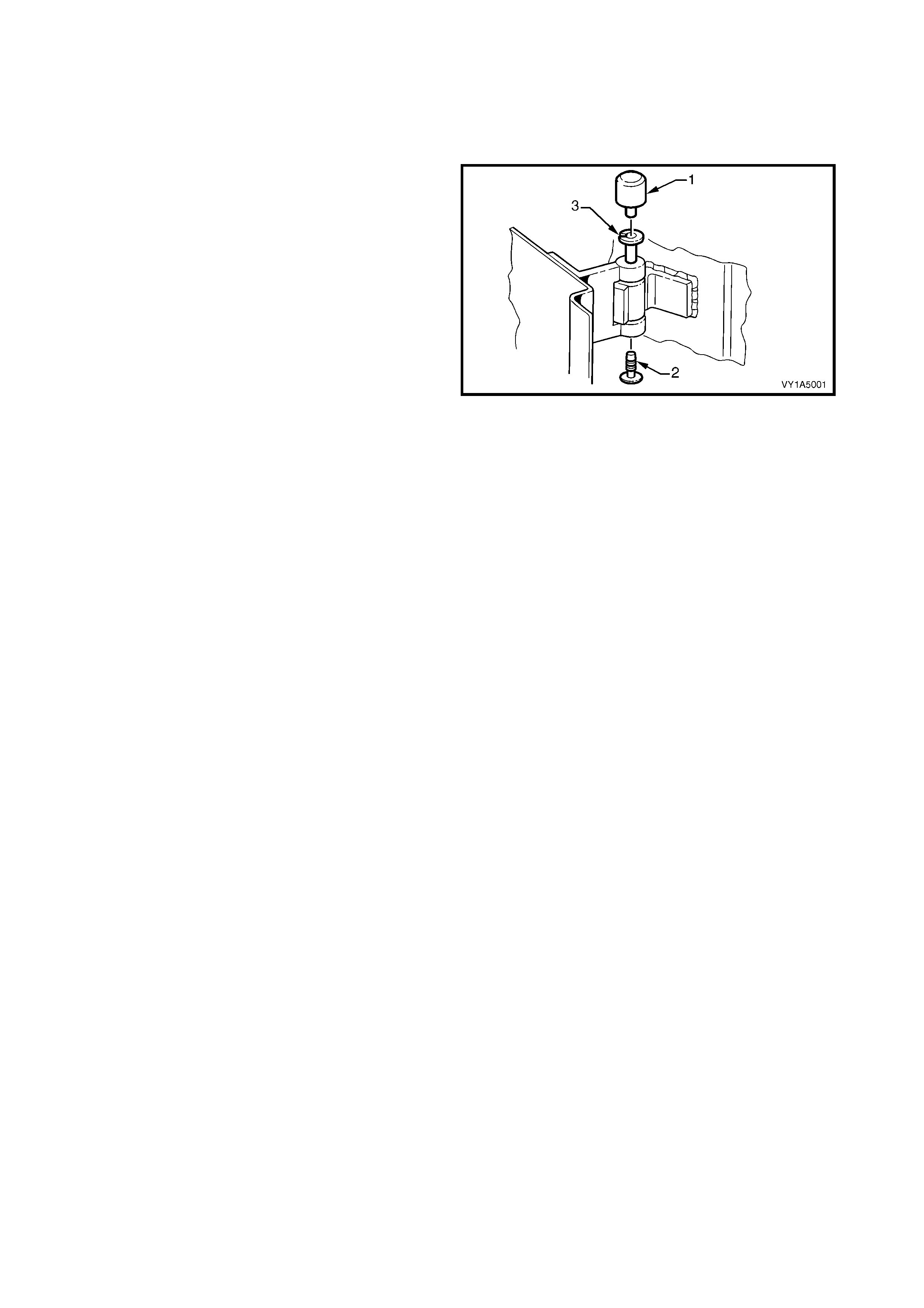

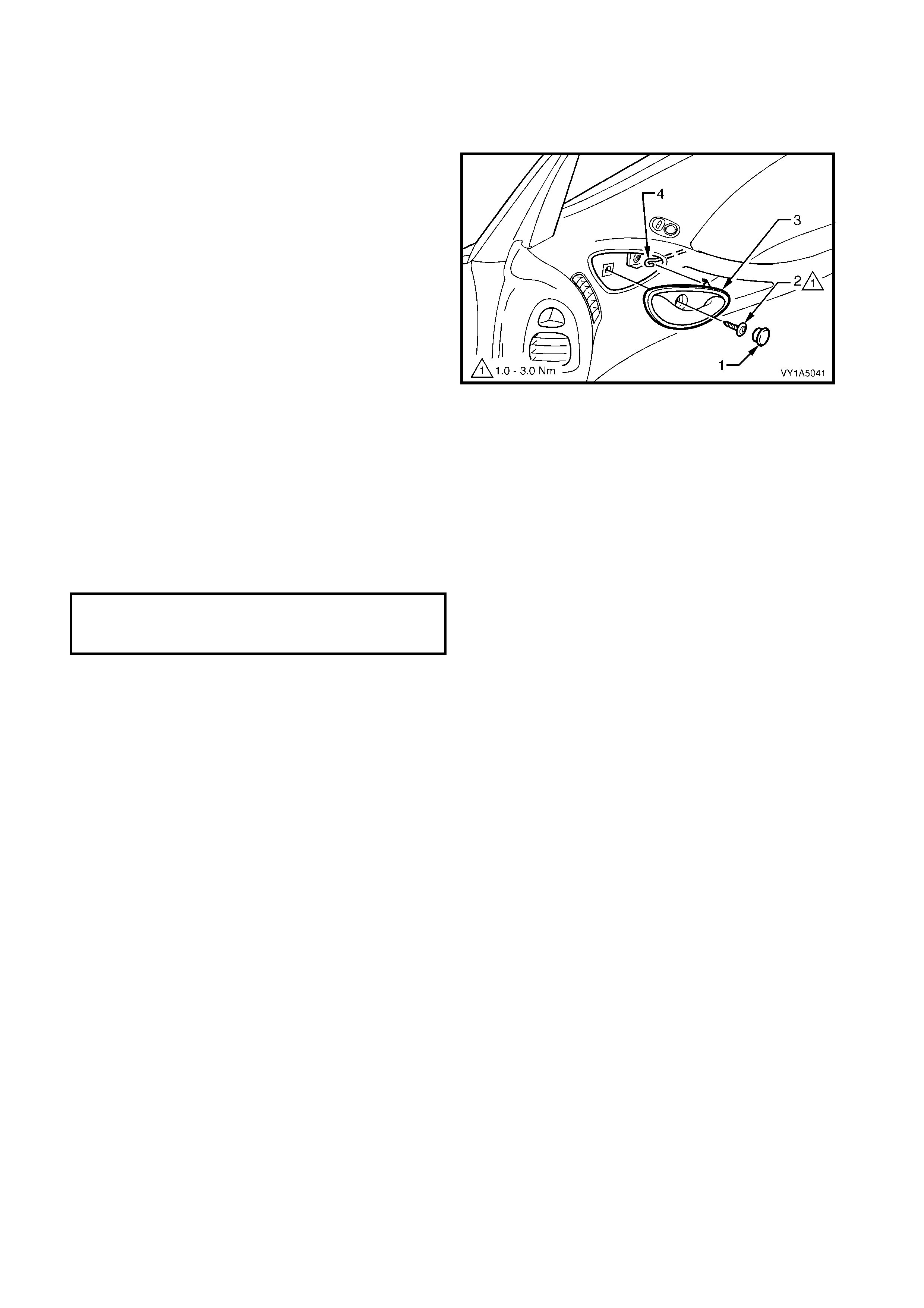

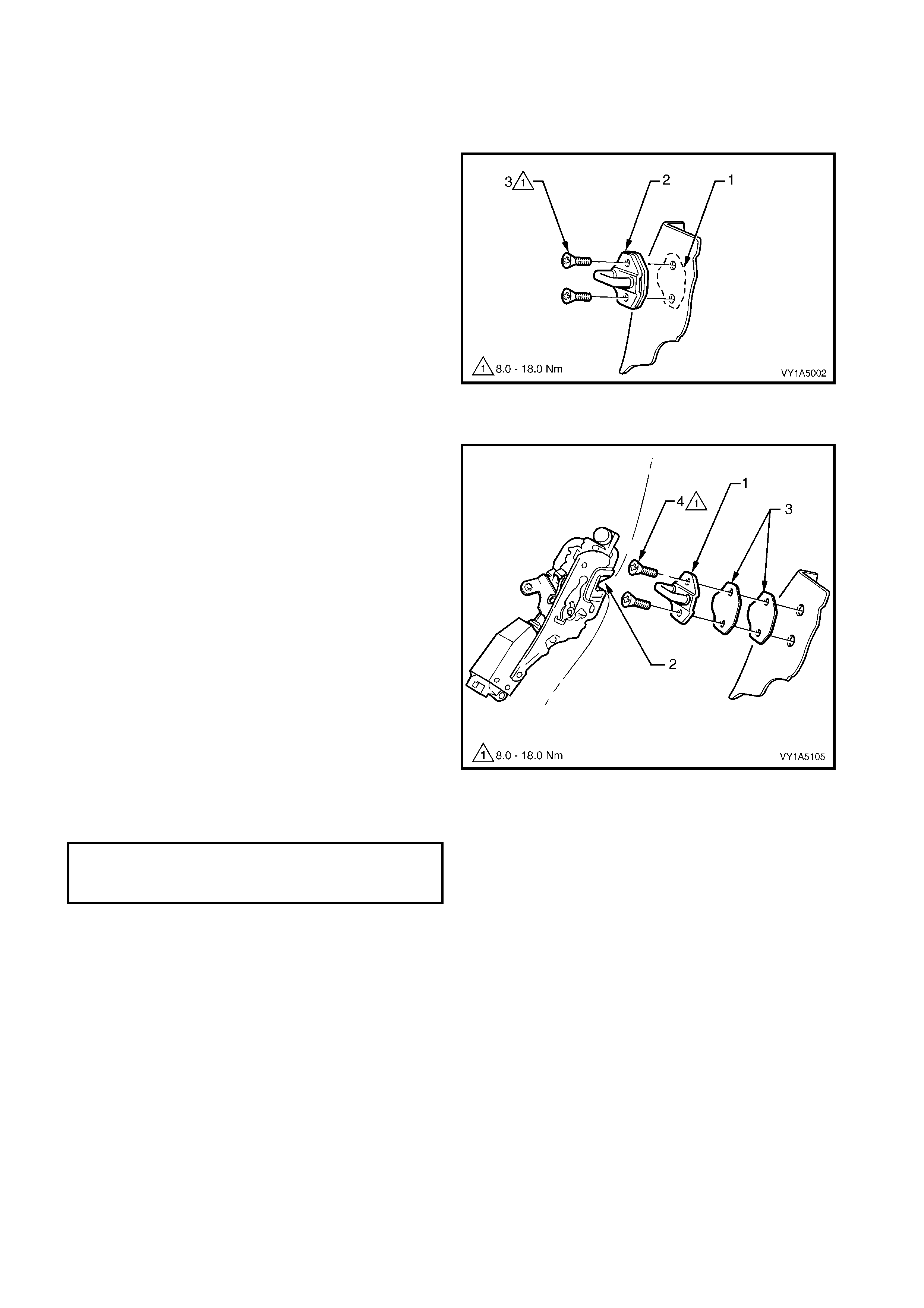

1. Pencil scribe (1) the location of the door lock

striker assembly (2) on to the body pillar before

removal, to facilitate installation.

2. Using a Torx bit (30 T), remove two retaining

screws. (3)

3. Remove the striker and spacer plates, if fitted.

Figure 1A5-2

REINST ALL

1. Align the door lock striker assembly (1), so that the

bridge of the striker locates centrally in the door

fork lock ass embly (2) as t he door is being clos ed.

Firmly tighten the striker assembly.

2. Correct engagement can be achieved by vertical

or horizontal adjustment of the door lock

striker assembly. The door must not ‘Ride’ on

the striker. Add or delete the door lock striker

washer (3) between the striker assembly and

body pillar to achieve correct engagement of the

striker assembly to the lock. Also refer to

2.3 ADJUST FRONT DOOR ASSEMBLY.

TIP: It is sound practice to remove the door lock striker

assembly and allow the door to hang free on the

hinges. Set th e hin ges as neces s ar y to achieve c orr ect

alignment and uniform margins, then reinstall the

striker and adjust.

3. When correct alignment of the striker assembly is

achieved, tighten the striker assembly retaining

screw (4) to the correct torque specification.

Figure 1A5-3

STRIKER ASSEMBLY

RETAINING SCREW

TORQUE SPECIFICATION 8.0 – 18.0 Nm

2.3 ADJUST FRONT DOOR ASSEMBLY

LT Section No. – 12-460

Attention should be given to uniform margins and alignment between the door and surrounding parts when

adjustments are being performed.

Uniform margins and alignment of the doors in relation to the body opening can be achieved by

setting the appropriate door hinge. Refer to MY2003 VY & V2 Series Service Manual Supplement,

Body Structure Repair Manual for specifications.

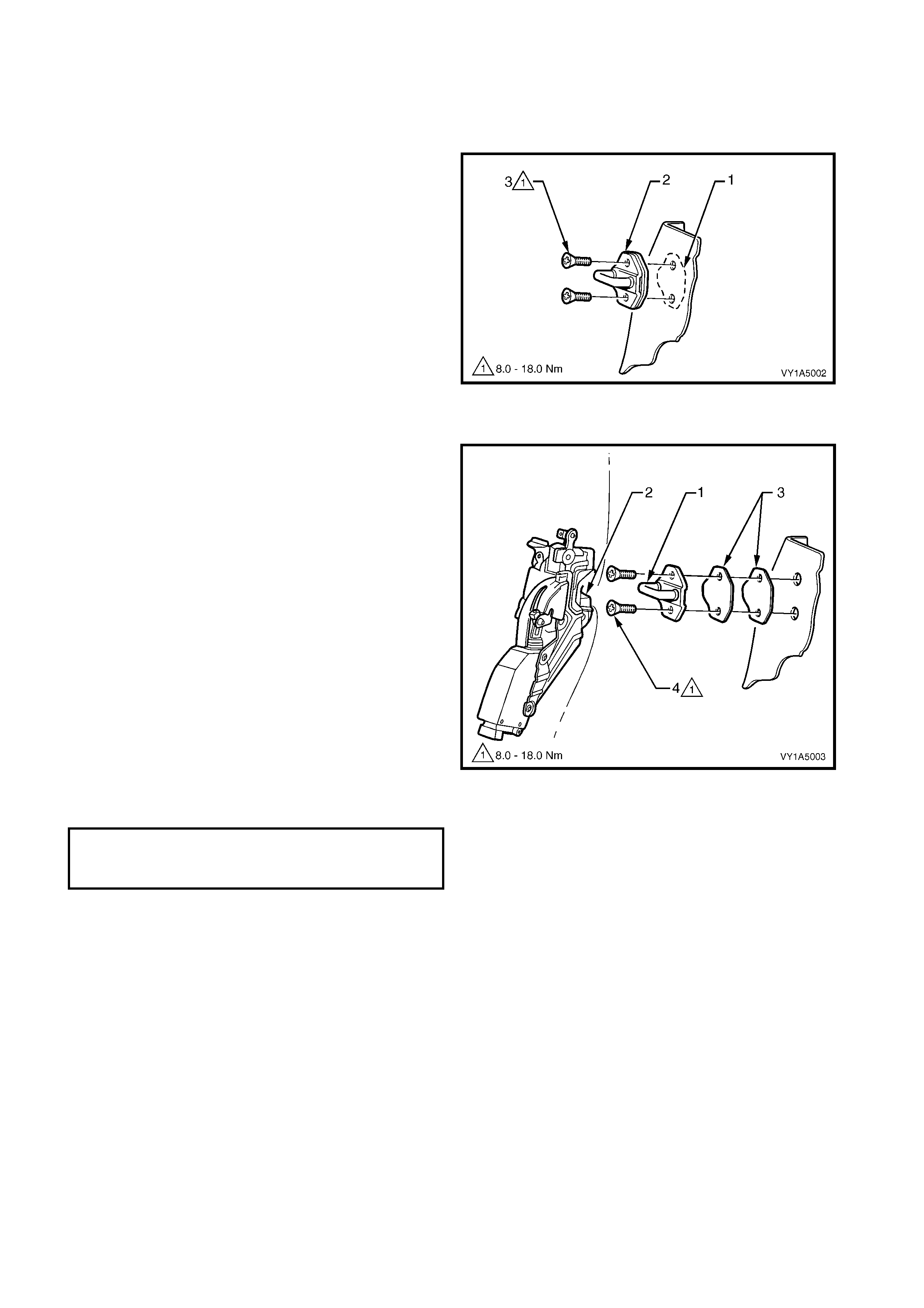

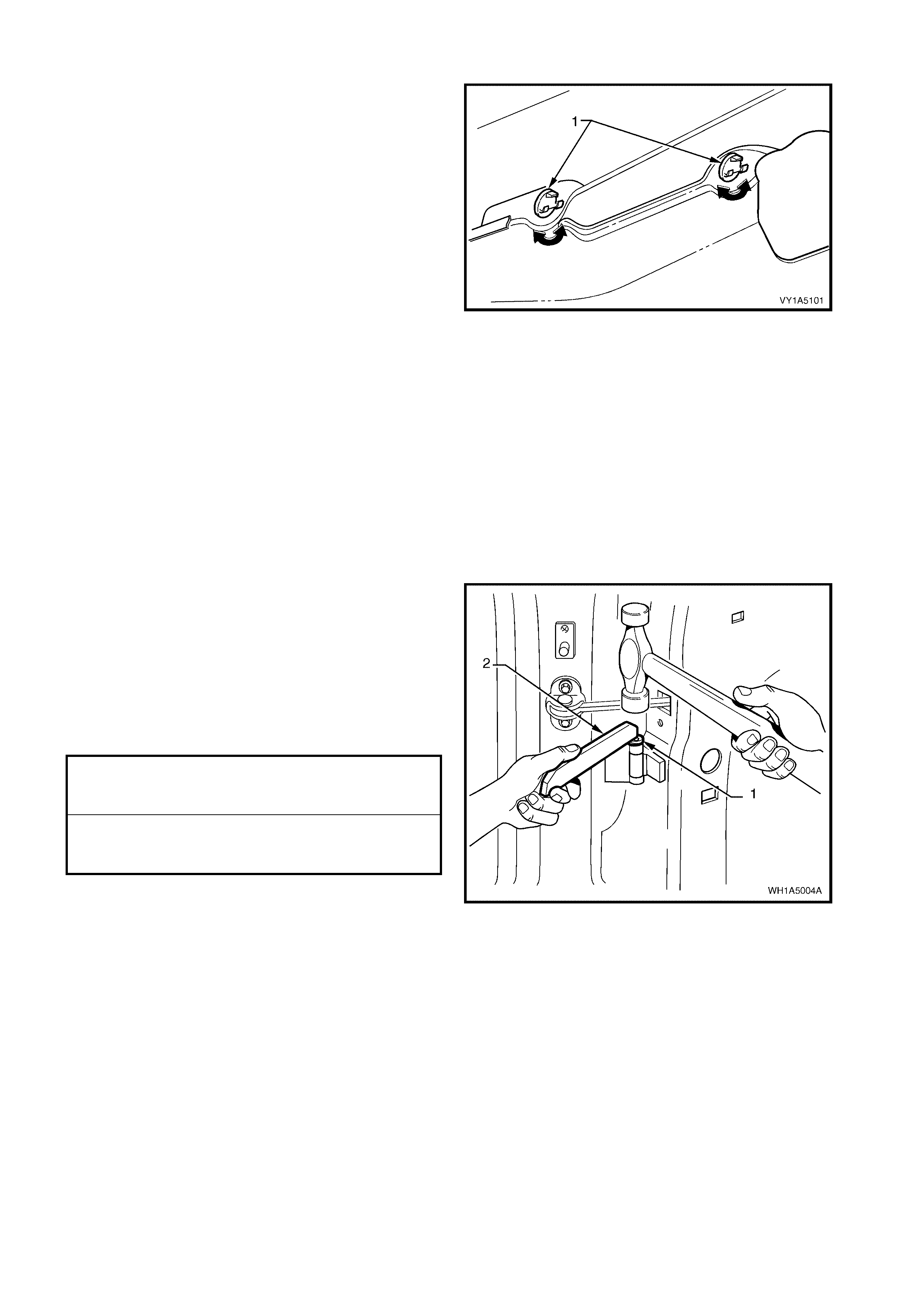

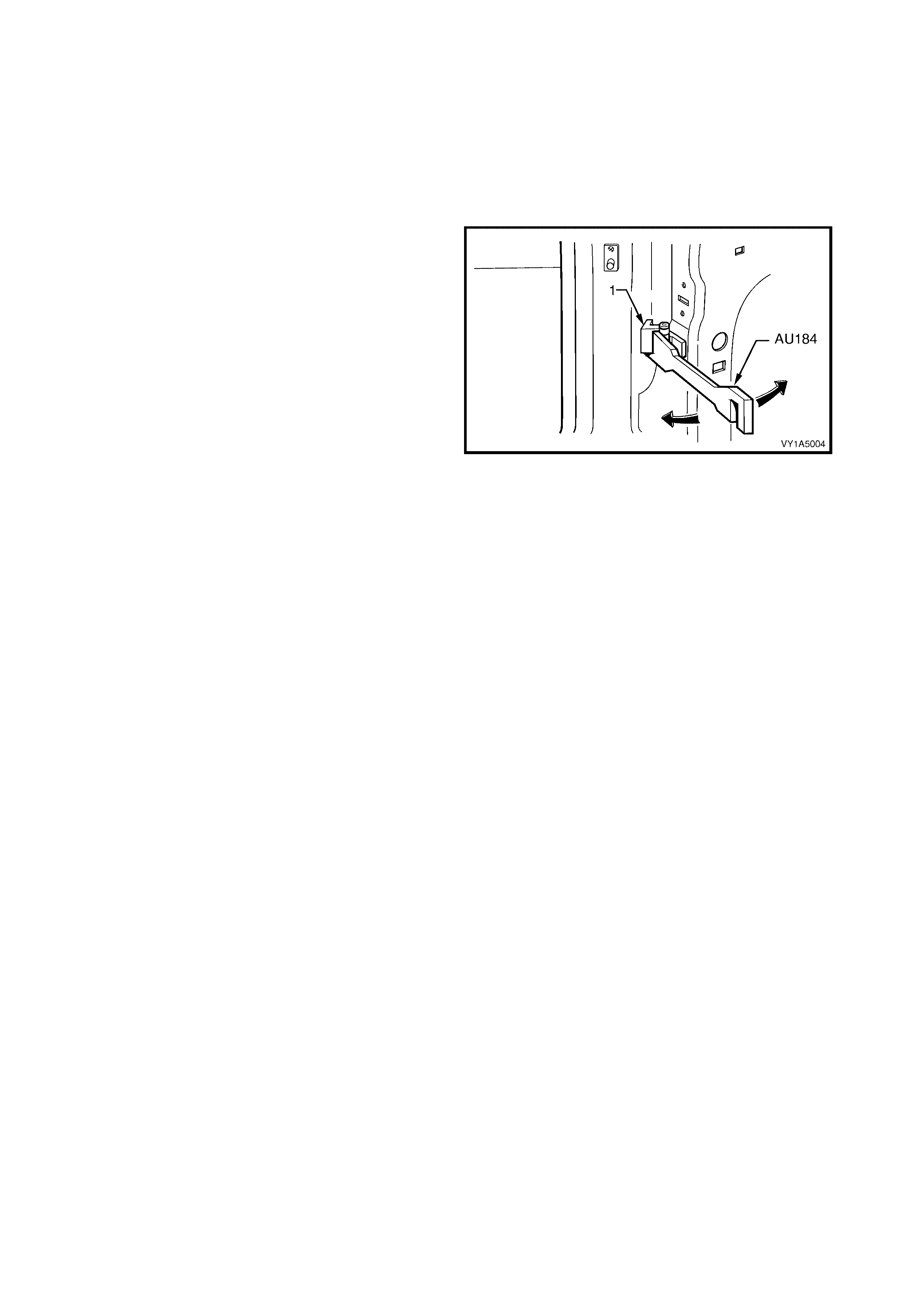

Use Tool No AU184 to set door hinges by slightly

bending the front door hinge (1) noting the following:

1. Take care when adjusting the doors not to

misalign the hinge pins. Any significant

misalignment will cause the pins to shear when

the door is opened or closed.

2. Excessive bending or levering of the window

frame will cause damage.

3. Final adjustment must take place when all the

door components and seals are installed.

IMPORTANT: Adjust the doors with the striker

assembly removed. The striker assembly should only

be fitted o nce satisf actor y alignment is achieve d. The y

must NOT be used to pull the door into the correct

position.

Figure 1A5-4

2.4 FRONT WINDOW REGU LATOR HA ND LE A SSEM B LY

LT Section No. – 11-675

REMOVE

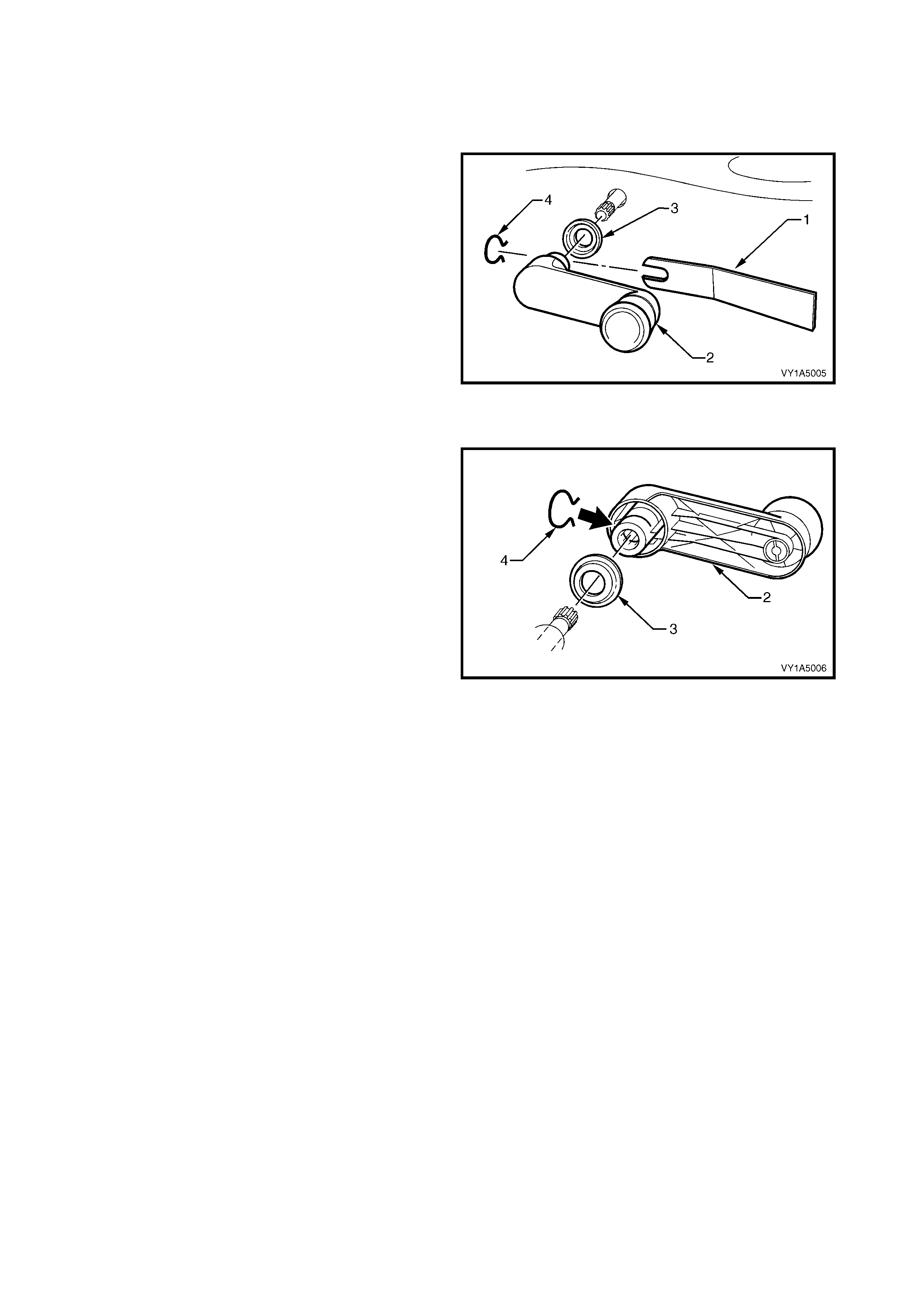

1. Insert a commercially available window regulator

handle removal tool (1), between the base of the

front door window regulator handle (2), and the

window regulator handle washer (3), in line with

the arm of the handle.

2. Disengage the front window regulator handle clip

(4), then remove the handle.

NOTE: Take care when disengaging the front window

regulator handle clip that it does not spring off.

Figure 1A5-5

REINST ALL

1. Locate the front window regulator handle clip (4),

in the window regulator handle (2), with the open

ends of the clip facing the handle arm.

NOTE : Make sure both the front door win dows are at

the same height before fitting the handle assemble.

2. Fit the window regulator handle washer (3).

3. Ensure that the handle is positi oned symm etric ally

with the handle on the opposite door, then press

the handle ont o the window regula tor splines, unt il

the clip engages the groove at the base of the

splines.

Figure 1A5-6

2.5 FRONT DOOR INSIDE HANDLE ASSEMBLY (REMOTE)

LT Section No. – 11-360

REMOVE

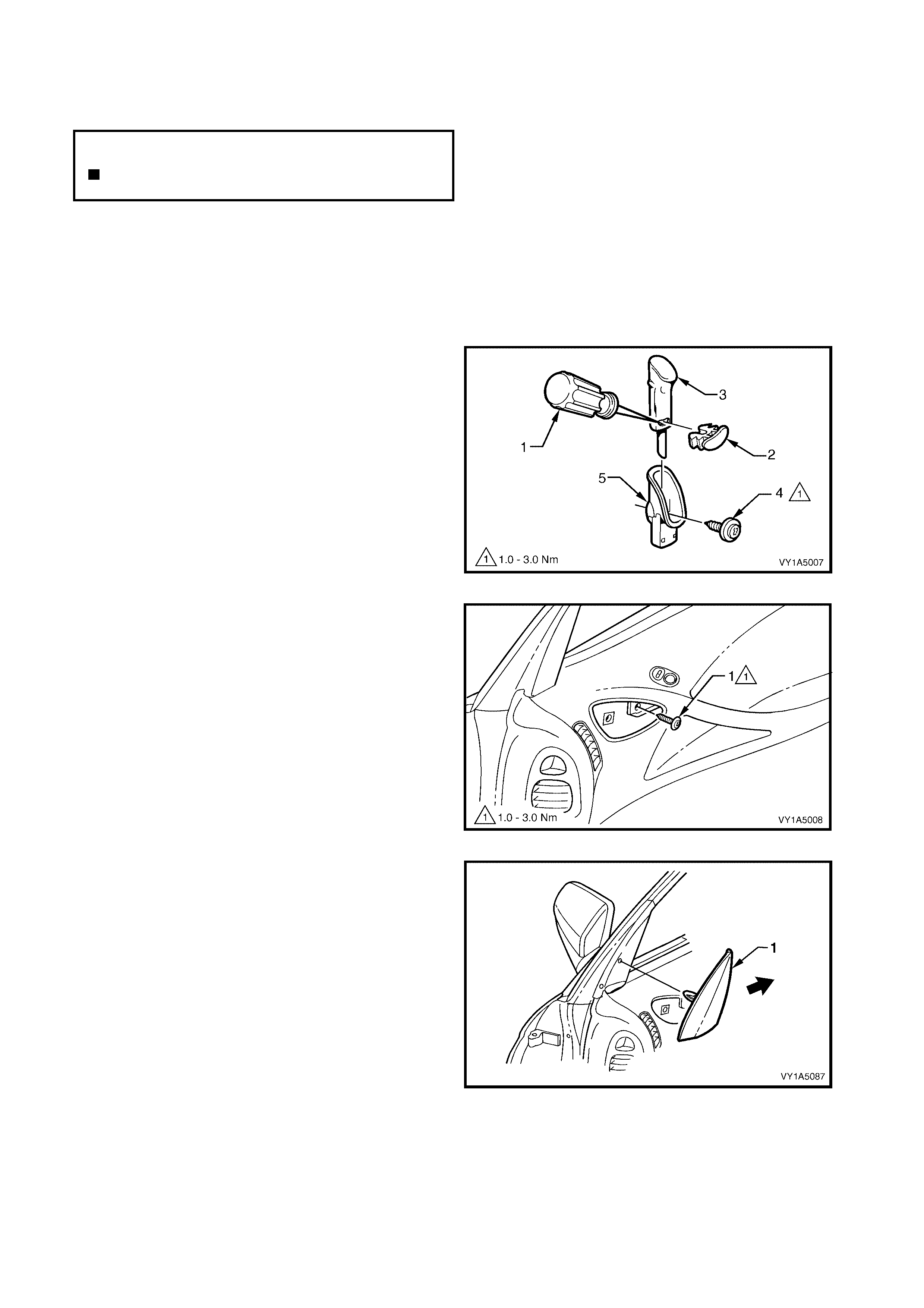

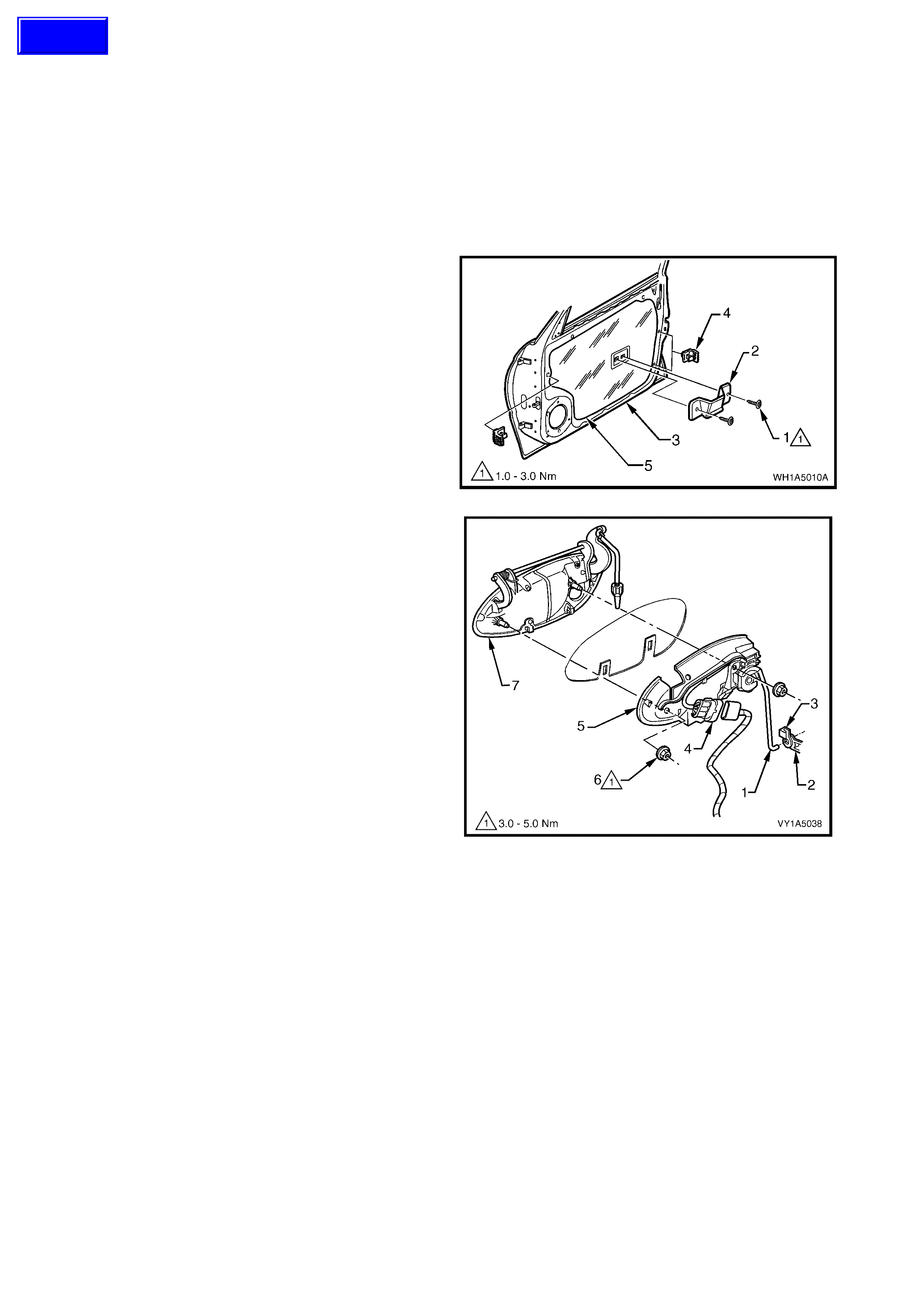

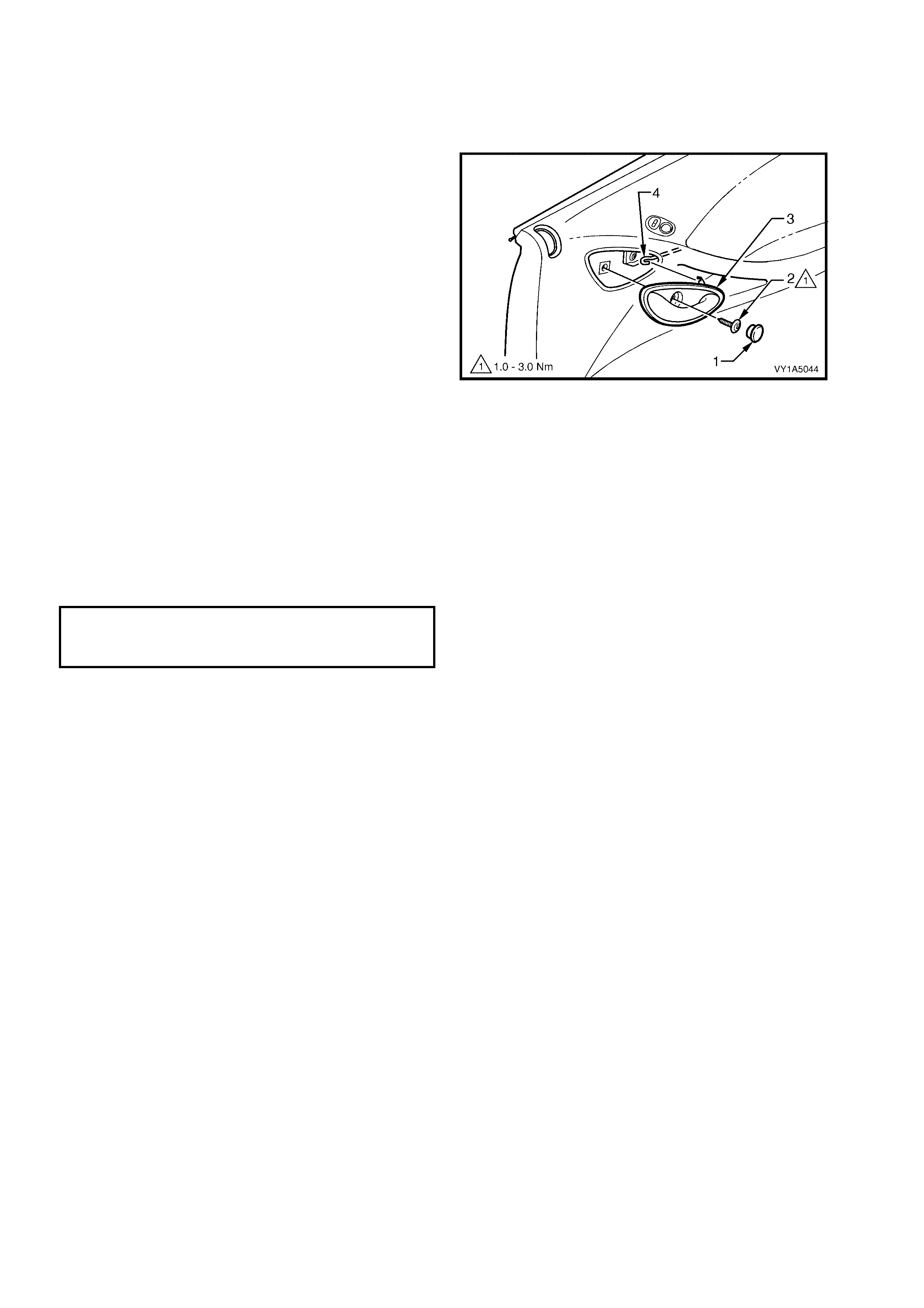

1. Prise off the front door inside handle bolt finisher

cap (1).

2. Remove the screw (2) securing the front door

inside handle assembly (remote) (3) to the front

door trim.

3. Remove the handle assembly in a forward

direction and unhook the front inside handle rod

(4) from the handle assembly.

Figure 1A5-7

REINST ALL

Reinstal lation of the front door ins ide hand le assem bly

(remote) is the reverse of the removal, refer Figure

1A5-7, noting the following:

1. Ensure the handle assembly and remote rod are

engaged before final fitment.

2. Tighten the retaining screw to the correct torque

specification.

FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE) SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.6 FRONT DOOR TRIM PANEL ASSEMBLY

LT Section No. – 14-220

If required, first remove the following components,

1. Front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR WINDOW

REGULATOR HANDLE ASSEMBLY.

2. Front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE ASSEMBLY

(REMOTE).

REMOVE

1. Using a s mall f lat bladed screwdr iver or sc ribe (1) ,

gently pris e the or ange f ron t door loc k ing rod k nob

retainer (2) from the front door locking rod knob

assembly (3), taking care not to damage the knob

assembly. Remove the knob assembly.

NOTE: The orange front door locking rod knob

retainer, will be damaged during this operation and

must be replaced.

2. Lift the knob assembly up, removing it from the

door locking rod.

3. Remove the screw (4) securing the front door

locking rod ferrule (5) to the door trim panel

assem bl y and remove the f er rule.

Figure 1A5-8

4. Remove the front door trim retaining screw (1)

from the handle assembly aperture.

Figure 1A5-9

5. Gently prise the front edge of the side window

outlet defogger (1) and remove to the rear.

Figure 1A5-10

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

Front door locking rod knob retainer .

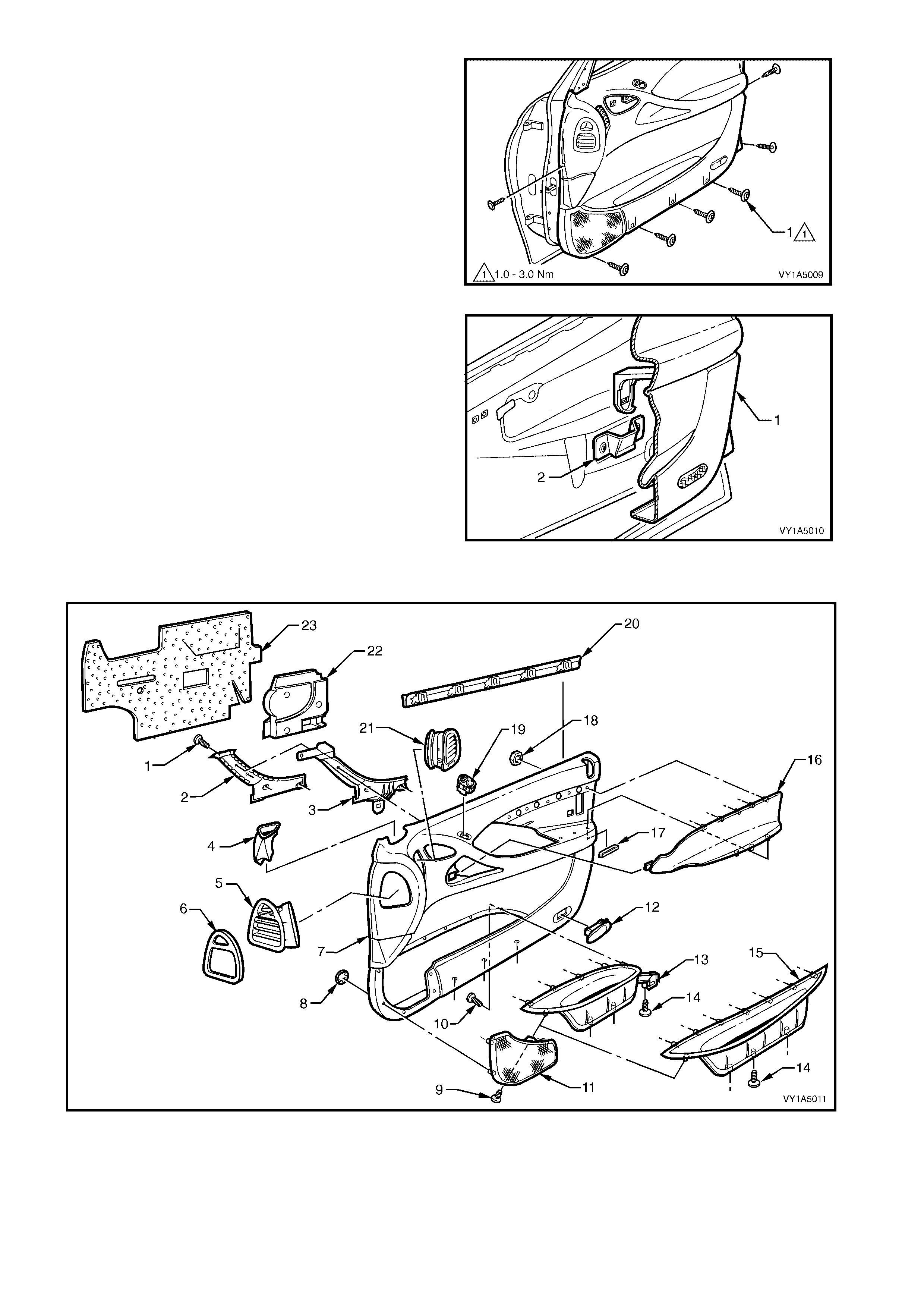

6. Remove the seven screws (1), securing the front

door trim panel assembly to the door inner panel.

7. Lift the top of the panel assembly, up and out of

the door inner channel.

Figure 1A5-11

8. Unclip the panel assembly (1) from the front pull

handle bracket (2) except Coupe, by pushing in

and lifting the centre of the panel assembly at

armrest height.

NOTE: Wiring harness connectors are still connected.

9. While supporting the panel assembly, disconnect

all the wiring harn ess conn ec tors .

10. Remove the panel assembly.

Figure 1A5-12

DISASSEMBLE

Figure 1A5-13

Legend

1. Front Door Inside Handle Screw (4 places)

2. Front Door Inside Handle Cover

3. Front Door Inside Handle Bracket

4. Side Window Defogger Air Duct

5. Front Door Air Duct Assembly

6. Front Door Air Duct Seal

7. Front Door Trim Foundation Assembly

8. Radio Front Door Speaker Grille Retainer (6 Places)

9. Radio Front Door Speaker Grille Screw

10. Pocket Assembly Screw (7 Places With Side Impact

Airbags, 5 Places Without Side Impact Airbags)

11. Radio Front Door Speaker Grille

12. Front Door Courtesy Lamp

13. Front Door Map Pocket Assembly (Vehicles Without

Side Impact Airbags)

14. Pocket Assembly Screw (3 Places)

15. Front Door Map Pocket Assembly (Vehicles With Side

Impact Airbags)

16. Front Door Armrest Insert Assembly

17. Insert Assembly Door Armrest Clip (3 Places), (Coupe,

5 Places)

18. Insert Assembly Door Armrest Clip (5 Places) (Coupe,

7 Places)

19. Rear View Mirror Switch (Driver’s Side Only)

20. Front Window Inner Sealing Strip Assembly

21. Front Door Air Outlet Assembly

22. Lower Side Impact Insert (Coupe and Vehicles Without

Side Impact Airbags)

23. Front Door Insulator Assembly

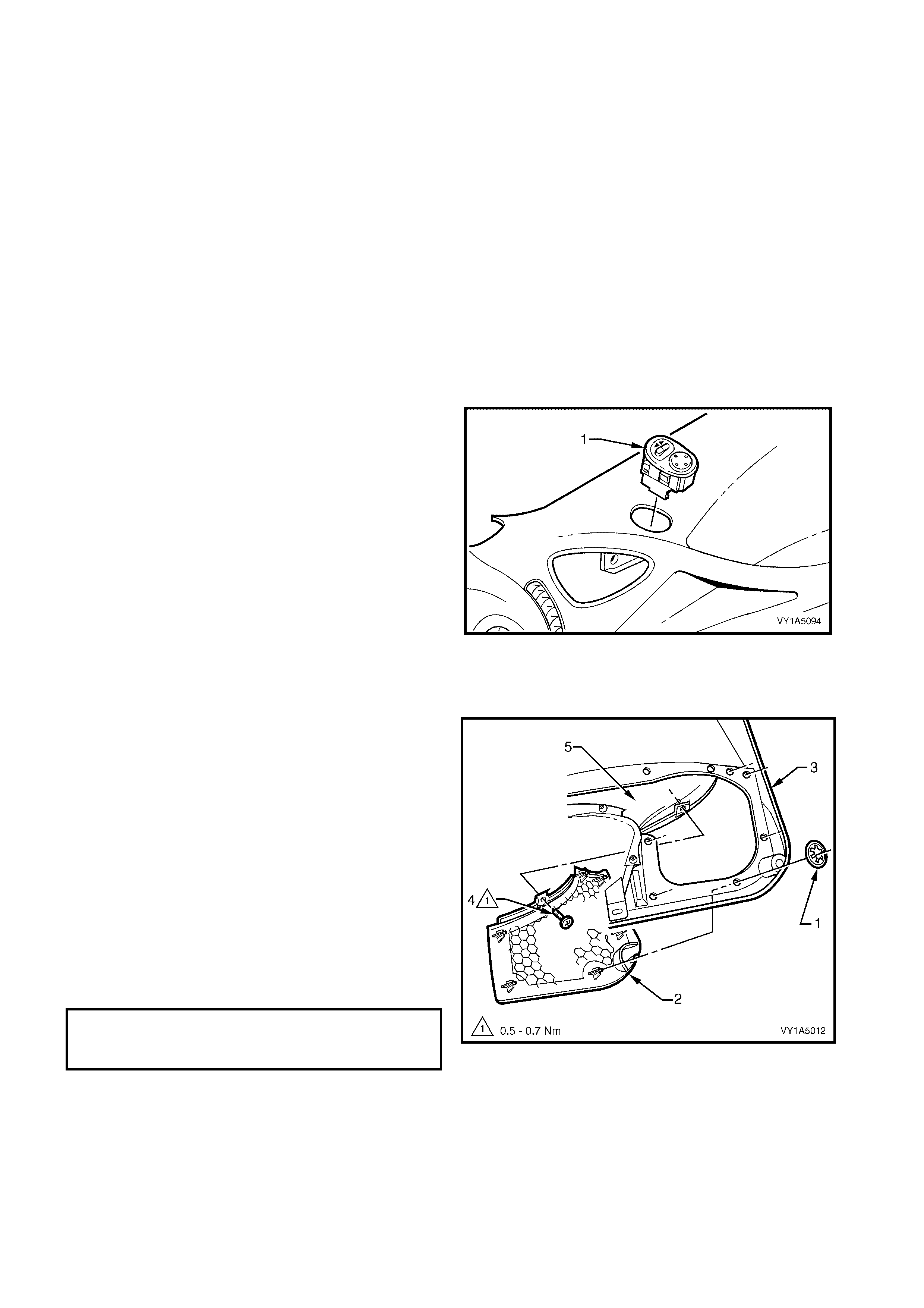

Remove – Rear View Mirror Switch

1. From behind the door trim assembly, push the rear

view mirror switch (1), free by depressing the

tangs.

2. Remove the switch.

NOTE: For further information regarding Service and

Diagnosis of the ex ternal r ear v ision m irr or and s witch,

refer to Section 12H REAR VIEW MIRRORS.

Reinstall – Rear View Mirror Switch

Reinstallation of the rear view mirror switch is the

reverse of removal, noting the following.

1. Press the s witch assem bly firm ly into the door trim

assem bly.

Figure 1A5-14

Remove – Radio Front Door Speaker Grille

1. Remove six clips (1) securing the radio front door

speaker grille (2) to the front door trim (3).

NOTE: Take care when removing clips, not to break

the speaker grille shafts on which the clips are

attached.

2. Remove the s crew (4) atta ching the r adio speak er

grille to the front door map pocket assembly (5).

3. Remove the radio speaker grille.

Reinstall – Radio Front Door Speaker Grille

Reinstallation of the radio speaker grille is the re verse

of the removal, noting the following:

1. Tighten retaining screw to the correct torque

specification.

Figure 1A5-15

RADIO FRONT DOOR SPEAKER

GRILLE RETAINING SCREW

TORQUE SPECIFICATION 0.5 – 0.7 Nm

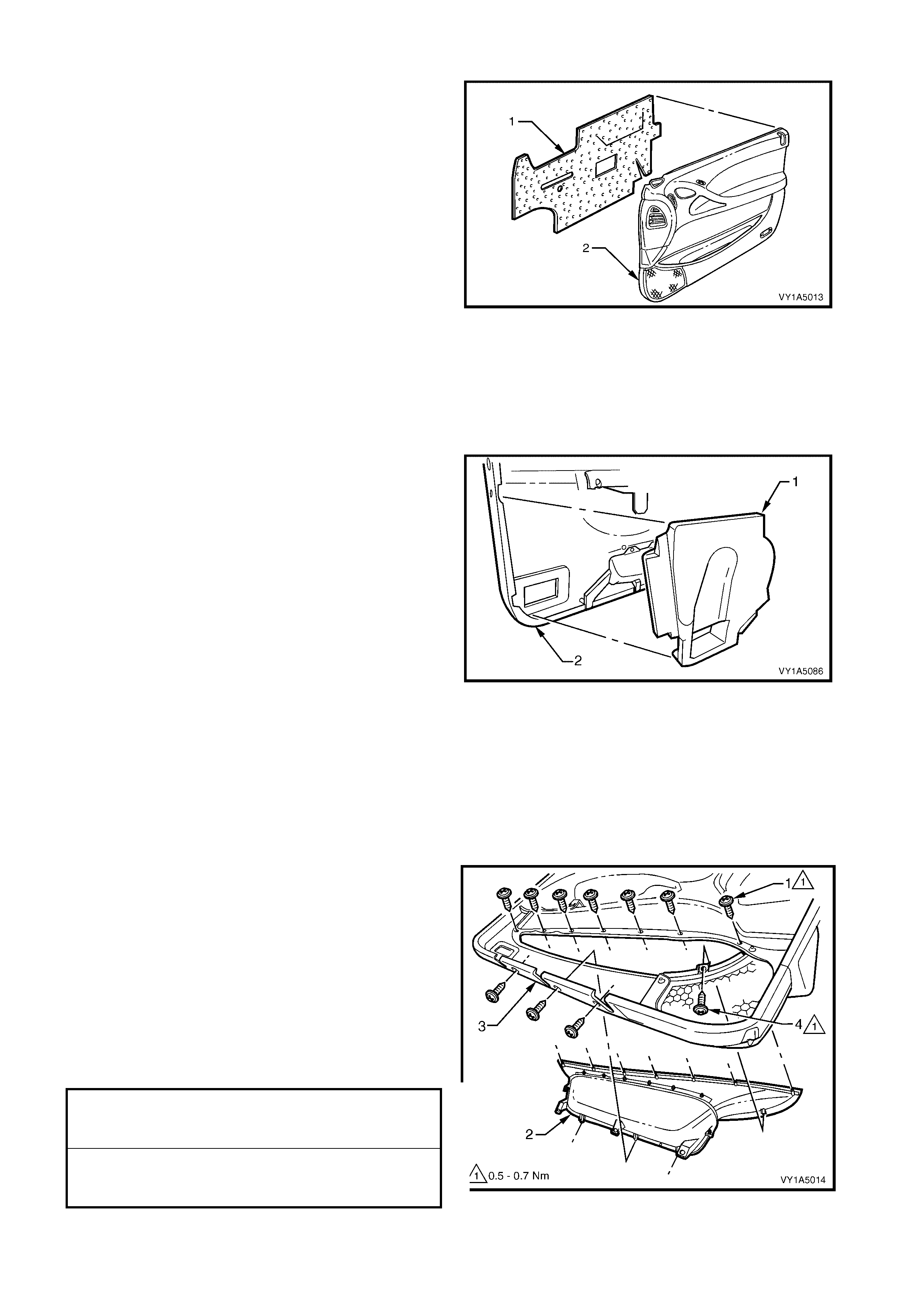

Remove – Front Door Insulator Assembly

1. Remove the front door insulator assembly (1),

from the back of the front door trim panel

assembly (2), by peeling the insulator slowly

across the panel.

NOTE: Take care not to tear the insulator. Retain as

much adhesive as possible on the insulator. Do not

fold the insulator and store in a flat location with the

adhesive facing away from objects.

Reinstall – Front Door Insulator Assembly

1. Locate the insulator assembly centrally within the

front door trim panel assembly, and press firmly

into position.

NOTE: If required, apply additional hot melt adhesive

with a high softening point (eg. 90°c).

Figure 1A5-16

Remove – Lower Side Impact Insert

NOTE: Only for Coupe and vehicles without side impact airbags.

1. Peel back the insulator assembly from the lower rear portion of the door trim assembly, allowing access to

the lower side impact insert, refer this Section.

2. Remove the lower side impact insert (1) from the

back of the front door trim panel assembly (2), by

pulling the insert slowly away from the panel

assembly, allowing the adhesive to stay on the

insert.

Reinstall – Lower Side Impact Insert

Reinstallation of the lower side impact insert, is the

reverse of the removal, noting the following:

1. Press the lower side impact insert, firmly into

position.

NOTE: If required apply additional hot melt adhesive

with a high softening point (eg. 90°c).

Figure 1A5-17

Remove – Front Door Map Pocket Assembly

1. Peel back the insulator assembly from the lower

portion of the door trim ass embly, allo wing access

to the door map pocket assembly attaching

screws, refer this Section.

2. If required, remove the lower side impact insert,

refer this Section.

3. Remove ten screws (1) for vehicles with side

impact airbags, or remove eight screws (1) for

vehicles without side im pact airbags, attac hing the

pocket assembly (2) to the panel assembly (3).

4. Remove the s crew (4) atta ching the r adio speak er

grille, to the pocket assembly.

5. Remove the pocket assembly.

Reinstall – Front Door Map Pocket Assembly

Reinstal lation of the poc ket assem bly is the revers e of

the removal procedure, noting the following:

1. Tighten all retaining screws to the correct torque

specification.

Figure 1A5-18

FRONT DOOR MAP POCKET

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 0.5 – 0.7 Nm

RADIO FRONT DOOR SPEAKER

GRILLE RETAINING SCREW

TORQUE SPECIFICATION 0.5 – 0.7Nm

Remove – Front Door Armrest Insert Assembly

IMPORTANT: Take care when removing the clips, as

the rotating action will cut-off the front door armrest

insert assembly shaft, to which the clips are attached,

requiring a replacement insert assembly to be fitted.

1. Peel back the insulator assembly from the lower

portion of the door tr im assem bly, allowi ng access

to the insert assembly attaching parts, refer this

Section.

2. Remove the lower side impact insert, refer this

Section.

3. Rem ove the clips (1), three places (five places for

Coupe), by sliding them away from panel

assembly (2).

4. Remove the nuts (3), f ive places (s even places f or

Coupe), attaching the armrest to the door trim

panel assembly.

5. Before removal, pry the armrest insert assembly

(4) a way from the panel as sembl y. Slide the i nsert

assembly to the rear of the panel assembly and

remove.

Reinstall – Armrest Insert Assembly

Reinstallation of the insert assembly is the reverse of

the removal procedure, noting the following.

1. The insert assembly, must be sitting flush against

the panel assembly, along the entire top

contacting surface.

2. Tighten all retaining nuts to the correct torque

specification.

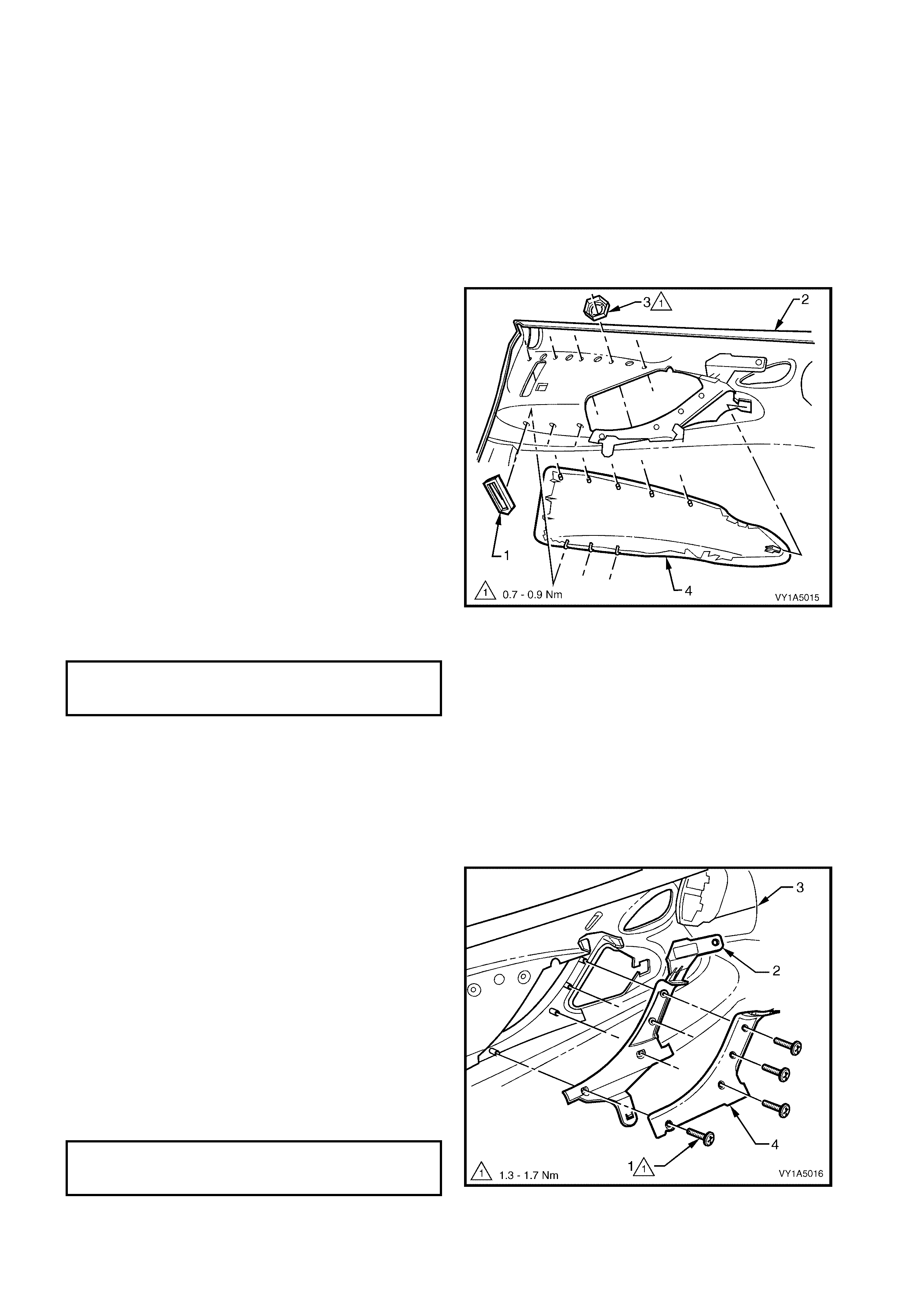

Figure 1A5-19

Remove – Front Door Inside Handle Assembly

(Pull)

1. Remove the armrest insert assembly, refer this

Section.

2. Remove the lower side impact insert, refer this

Section.

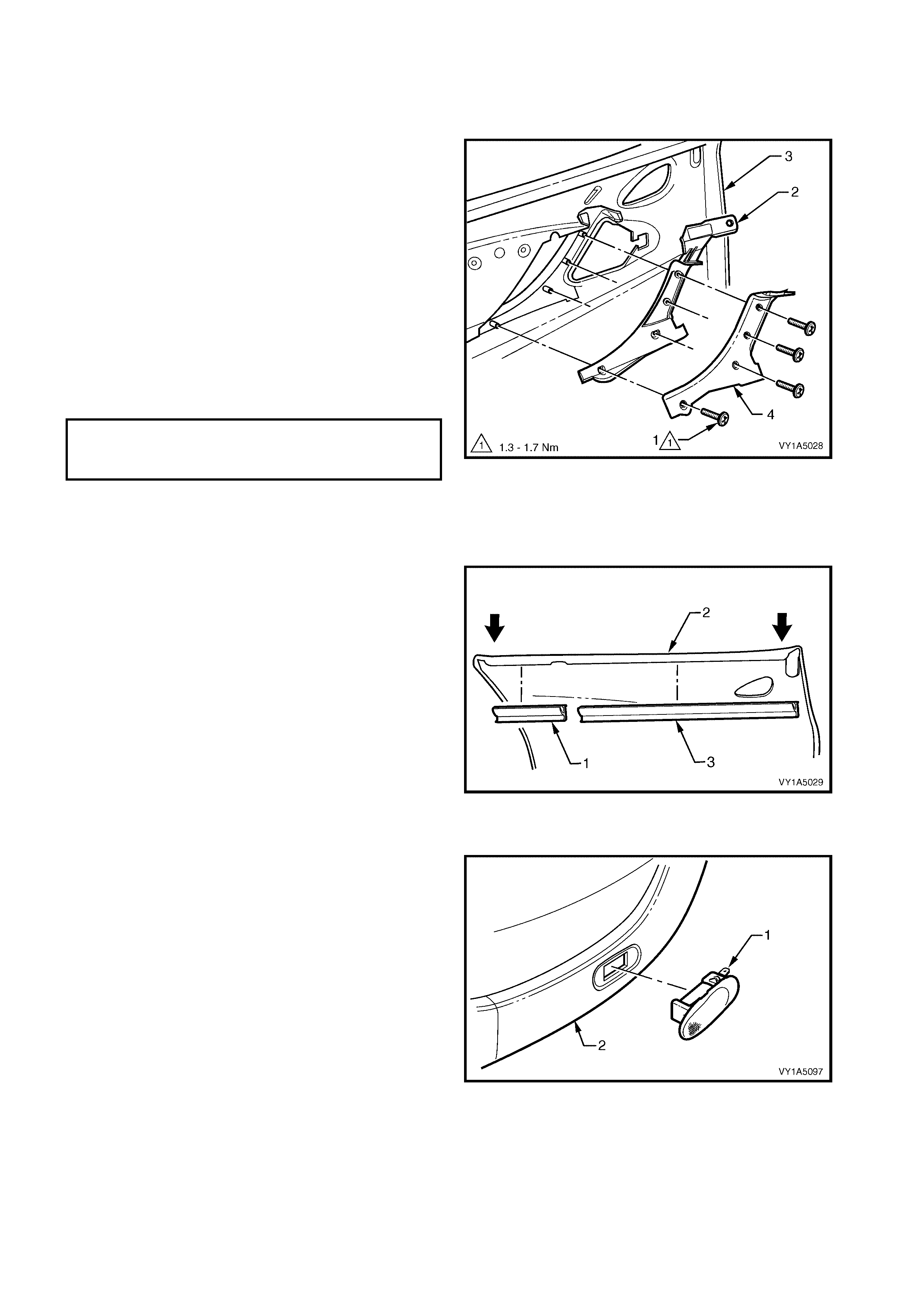

3. Remove four screws (1) attaching the front door

inside handle bracket (2) to the panel assembly

(3).

4. Remove the front door inside handle assembly.

5. Peel off the cover (4), from the front door inside

handle brac k et.

Reinstall – Front Door Inside Handle Assembly

(Pull)

Reinstal lation of the hand le ass embl y is the rev erse of

the removal procedure, noting the following:

1. Tighten all retaining screws to the correct torque

specification.

Figure 1A5-20

ARMREST INSERT ASSEMBLY

RETAINING NUT

TORQUE SPECIFICATION 0.7 – 0.9 Nm

FRONT DOOR INSIDE HANDLE

ASSEMBLY (PULL) SCREW

TORQUE SPECIFICATION 1.3 – 1.7 Nm

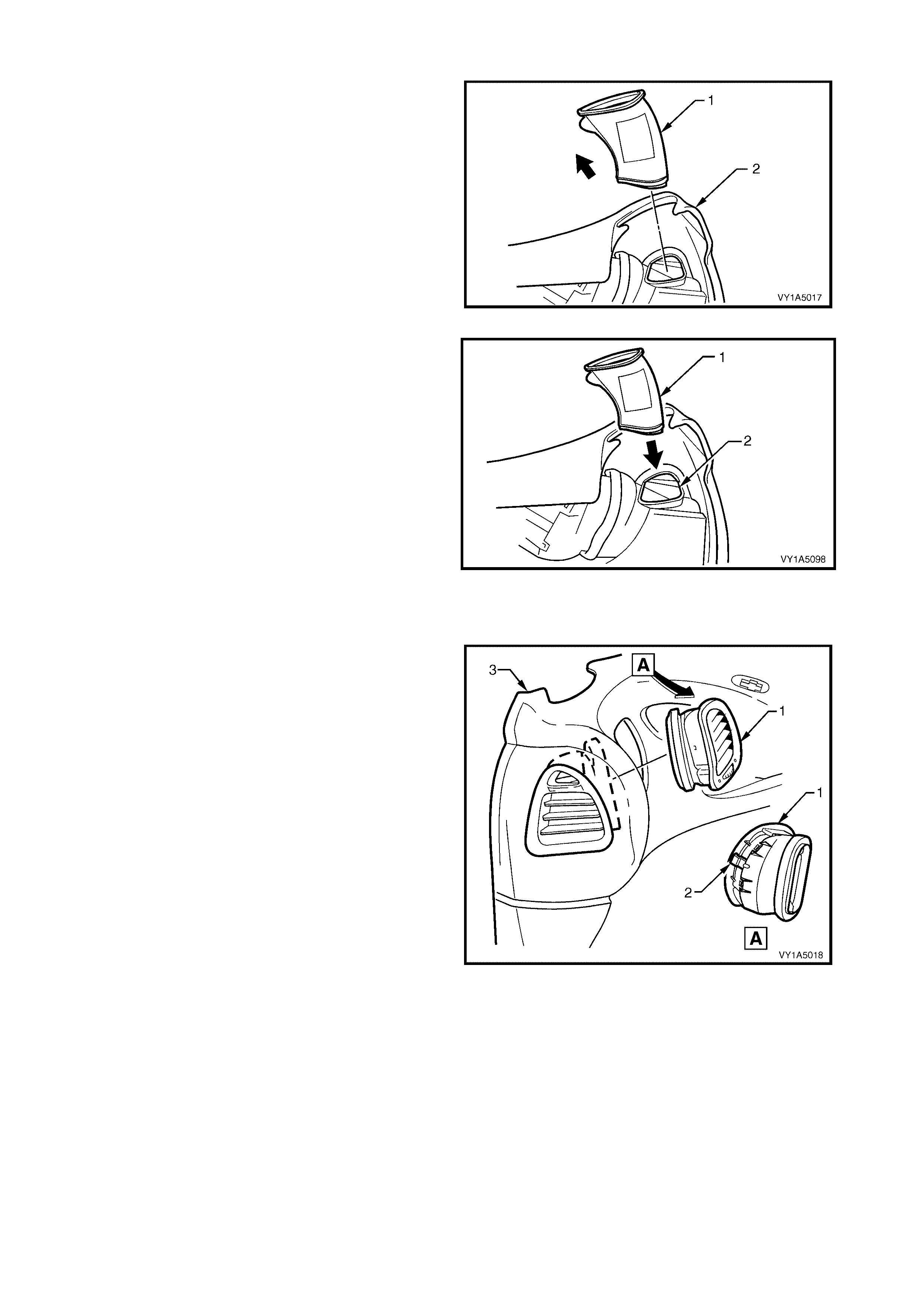

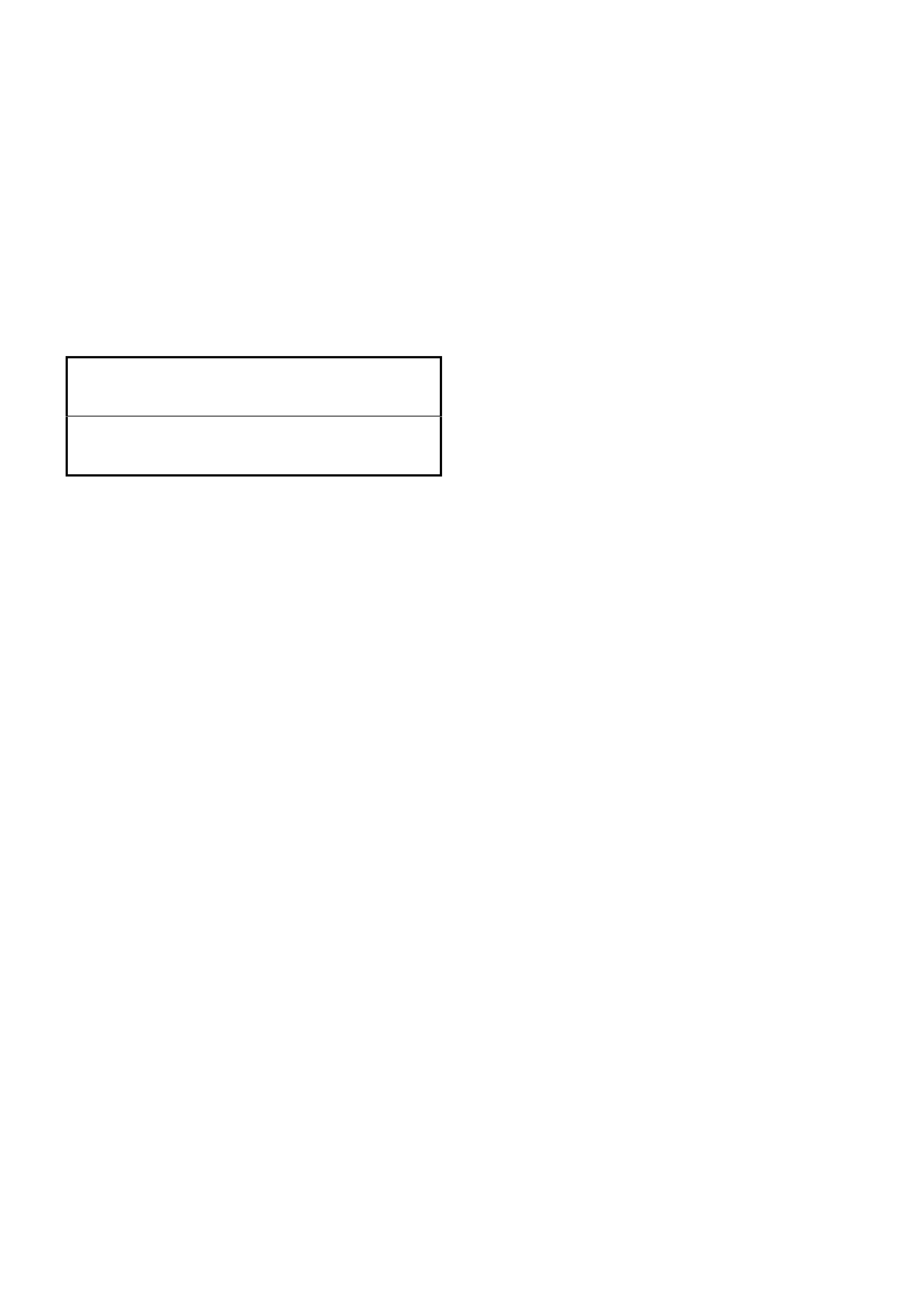

Remove – Side Window Defogger Air Duct

1. Remove the side window defogger air duct (1) by

pulling upwards, out of the panel assembly (2).

Figure 1A5-21

Reinstall – Side Window Defogger Air Duct

Reinstal lation of the defogg er air duc t is the r everse of

the removal, noting the following:

1. Align the defogger air duct (1) with the opening

aperture in the duct assembly (2), making sure

they form a tight seal.

Figure 1A5-22

Remove – Front Door Air Outlet Assembly

1. Remove the front door air outlet assembly (1) by

pushing on the spring clip retainer (2) to release

the housing from the panel assembly (3).

2. Remove the air out let hous i ng.

Reinstall – Front Door A ir Outlet Assembly

1. Align the outlet assembly with the opening in the

panel assembly and push in firm ly.

Figure 1A5-23

Remove – Front Door Air Duct Assembly

1. Remove the side window defogger air duct, refer

this Section.

2. Remove the front door air outlet assembly, refer

this Section.

3. Peel back the insulator assembly from the front

upper portion of the panel assembly, allowing

access to the duct a ssembly, refer this Section.

4. Release the front door air duct assembly (1) from

the panel assembly (3), by pushing on the spring

clip retainer (2).

5. Remove the duct ass embly.

6. Remove the seal from the door vent duct (4).

Reinstall – Front Door Air Duct Assembly

1. Refit the seal to the duct assembly.

2. Align the outlet assembly with the opening in the

panel assembly and push in firmly.

Figure 1A5-24

Remove – Front Door Sealing Strip Assembly

1. Remove the front door inner sealing strip

assembly (1) from the panel assembly (2), by

pushing down on one end and progressively

moving along the sealing strip.

Reinstall – Front Door Sealing Strip Assembly

Reinstallation of the sealing strip assembly is the

reverse of the removal, noting the following:

1. Align sealing strip assembly with the edge of the

panel assembly.

Figure 1A5-25

Remove – Front Door Courtesy Lamp (where

fitted)

1. From the back of the door trim (1), depress the

retaining tangs securing the door courtesy lamp

(2) to the trim.

2. Push the lamp out of its aperture and remove.

NOTE: For s ervice and dia gnosis of the door courtes y

lamp refer Section 12B LIGHTING SYSTEMS.

Reinstall – Front Door Courtesy Lamp

1. Push the door courtesy lamp into its aperture in

the door trim f irm ly and ensure the r etaining ta ngs

are secured to the trim.

Figure 1A5-26

REINST ALL

Reinstallation of panel assembly is the reverse of the

removal procedure, noting the following:

1. Connect the front door wiring harness connectors

to the rear view mirror switch and the front door

courtesy lamp, (where fitted).

2. Ensure the - front door inside handle assembly

(remote) and the front inside handle rod, are

engaged before final fitment, refer

2.5 FRONT DOOR INSIDE H ANDLE ASSEMBLY

(REMOTE).

3. Tighten all retaining screws to the correct torque

specification.

NOTE: Screws along the bottom of the front door trim

are wax-tip sealing screws, refer Figure 1A5-11.

4. Use a new front door locking rod knob retainer,

refer Figure 1A5-8.

5. Fit the rear edge of the side window outlet

defogger, before pushing retaining clip into the

upper frame, refer Figure 1A5-10.

FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE) SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT DOOR TRIM PANEL

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT DOOR LOCKING ROD

FERRULE RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.7 FRONT DOOR LOCK ASSEMBLY

LT Section No. – 11-360

1. Remove the front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR

WINDOW REGULATOR HANDLE ASSEMBLY.

2. Remove the front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE).

3. Remove the front door trim panel assembly refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

REMOVE

NOTE: The front door water shield ne ed only be partl y

removed to allow access to complete this procedure,

however as required remove the following

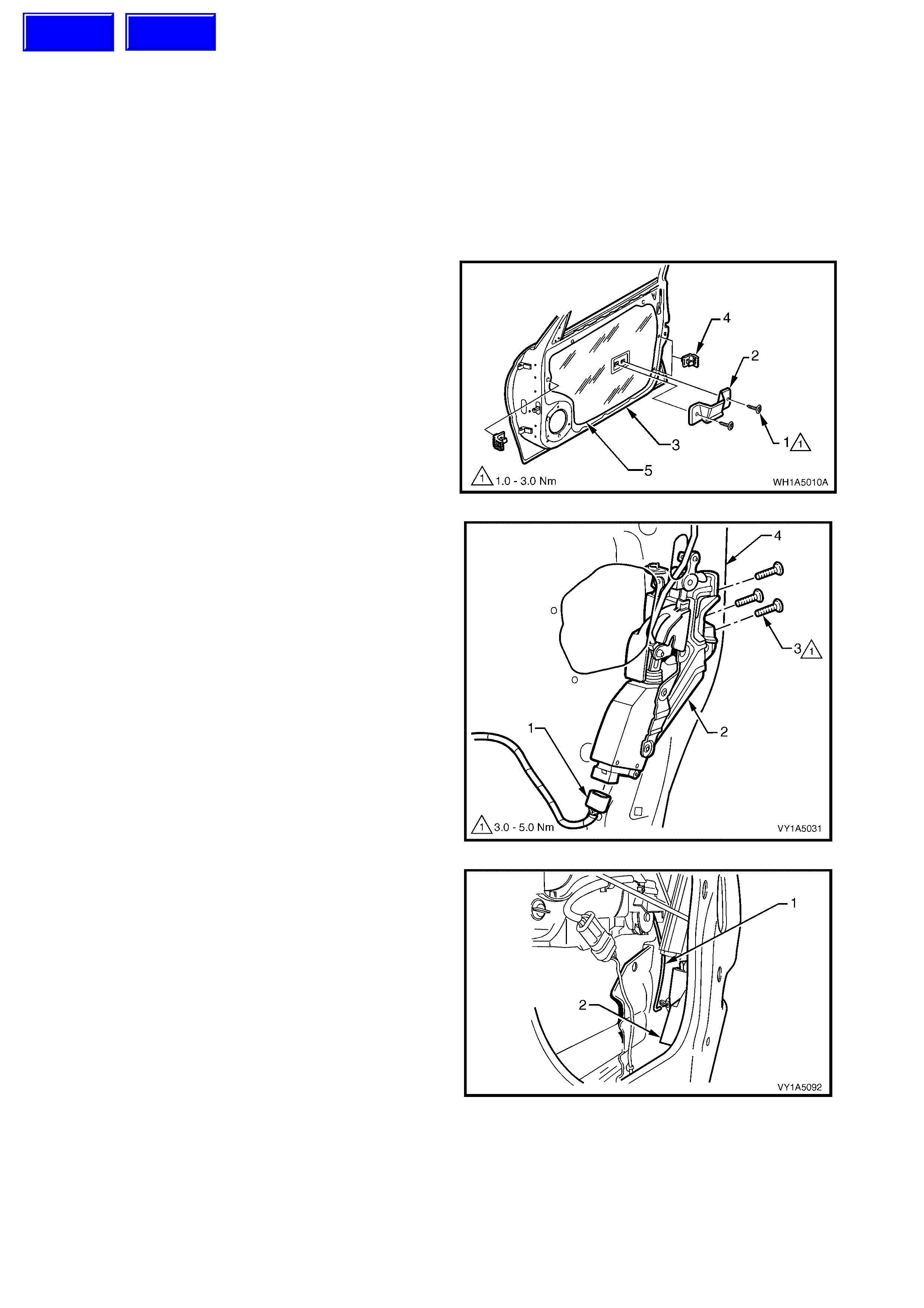

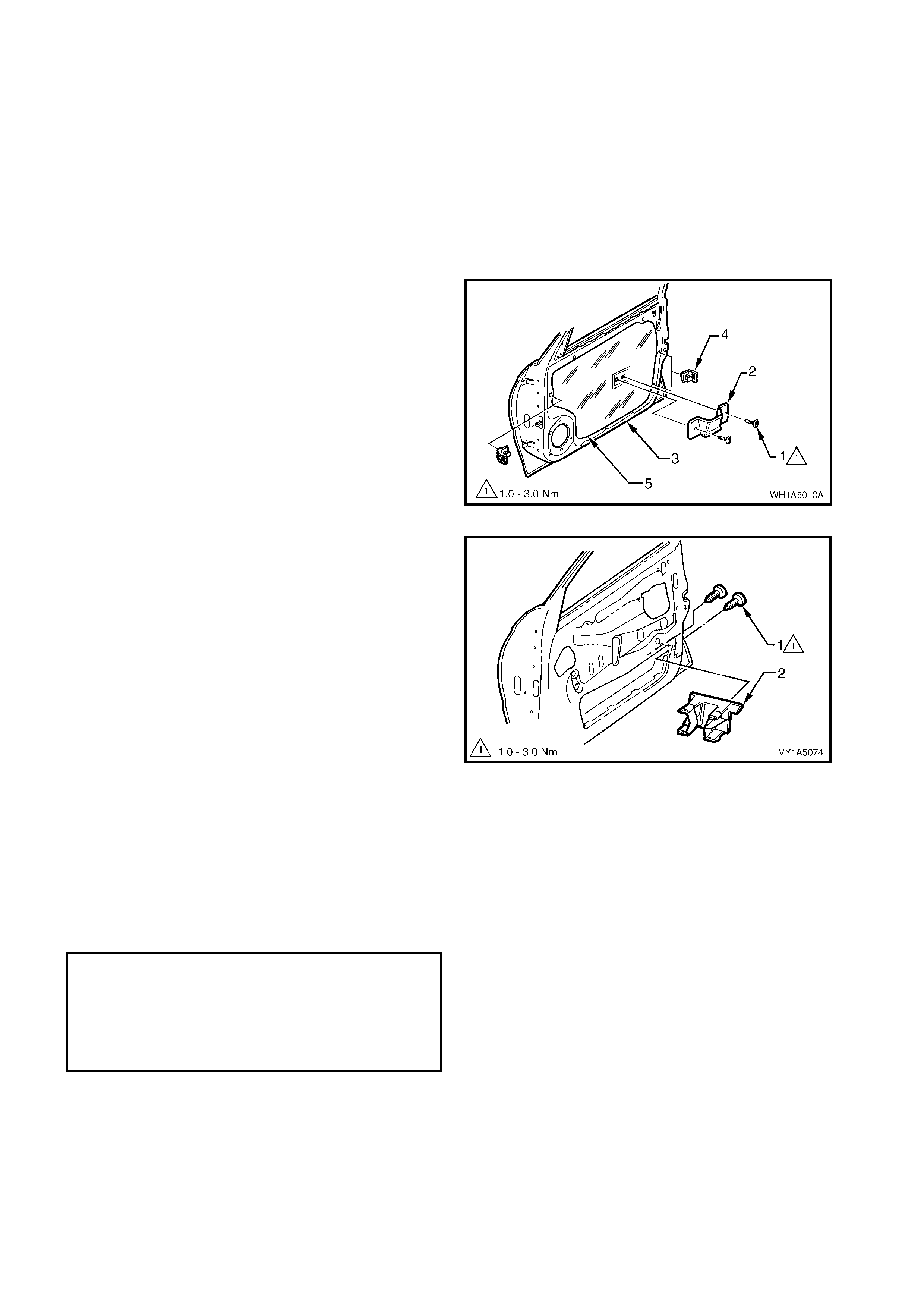

components:

1. Remove the t wo screws (1) securing the f ront side

pull bracket (2) except Coupe, to the front door

inner panel (3) and remove the bracket.

2. Remove the three front door brackets (4) from the

door inner panel by levering out the centre pin of

the bracket.

3. Carefully peel off the front door water shield (5)

from the front door inner panel.

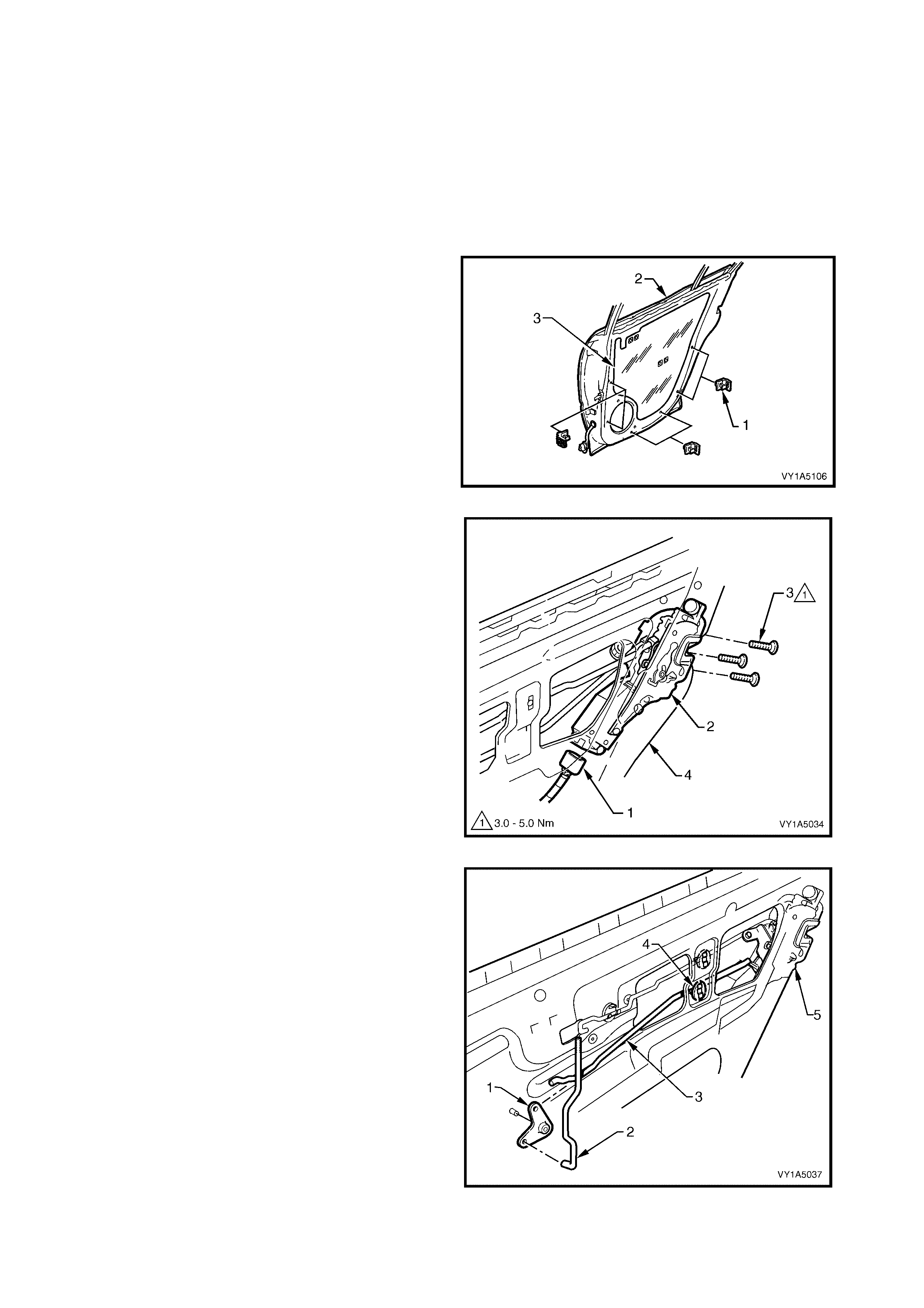

Figure 1A5-27

4. Disconnect the door harness electrical connector

(1) from the front door lock assembly (2).

5. Remove the three screws (3) securing the front

door lock assembly to the door inner panel (4).

Figure 1A5-28

6. For the driver’s door only, disconnect the front

door lock cylinder rod (1) from the front door lock

assembly (2) by releasing the rod retainer.

Figure 1A5-29

Techline

Techline

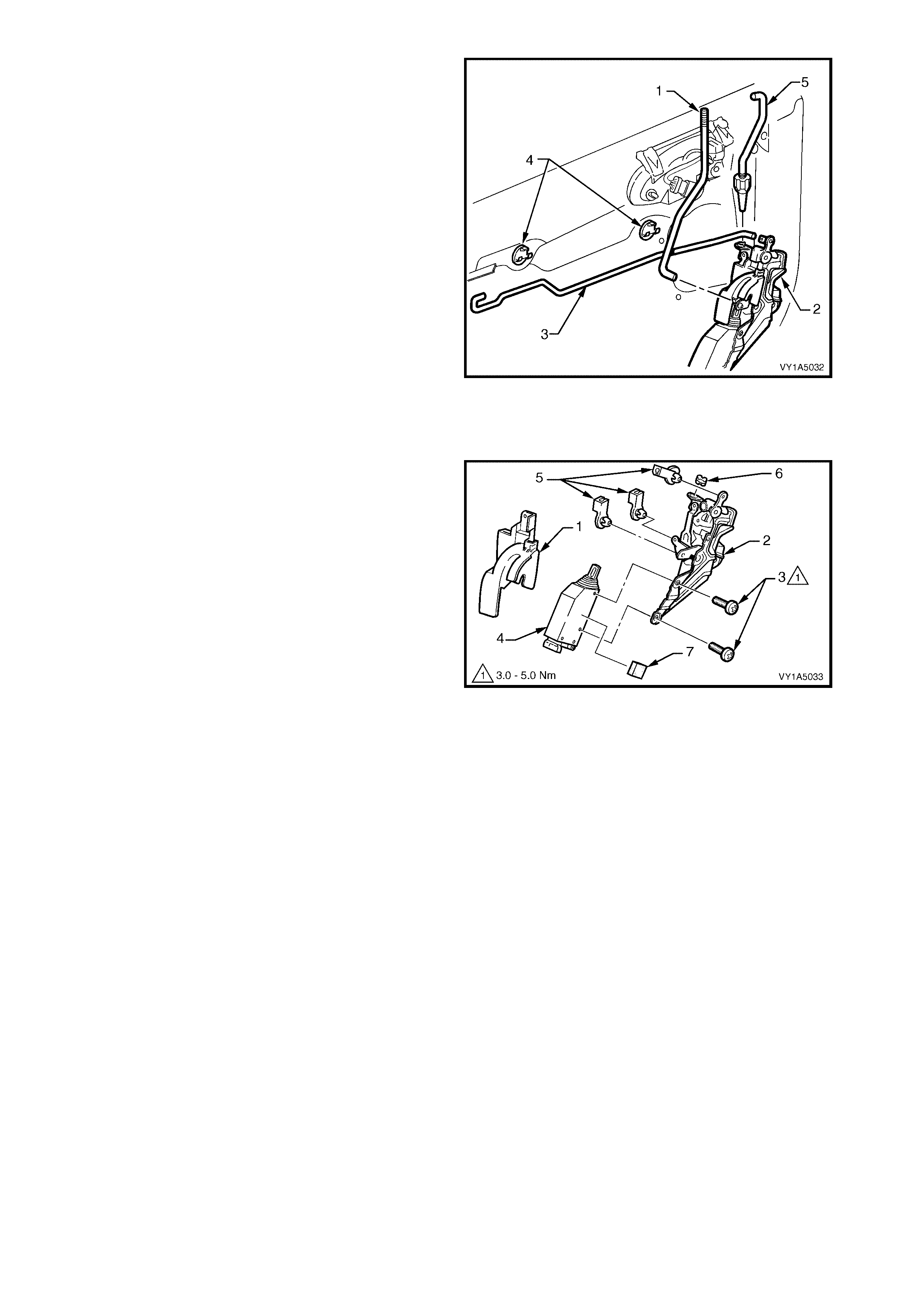

7. Disconnect the front door locking rod (1) from the

front door lock assembly (2) by releasing the rod

retainer, and then remove the rod.

8. Disconnect th e front ins ide handle rod ( 3) from the

lock assembly by releasing the rod retainer. If

required, remove the rod by disengaging it from

the two front door inside handle rod clips (4).

9. The front door outside handle rod assembly (5) will

disengage from the lock assembly, when the lock

assembly is being removed.

10. Remove the assembly through the aperture in the

door inner panel.

Figure 1A5-30

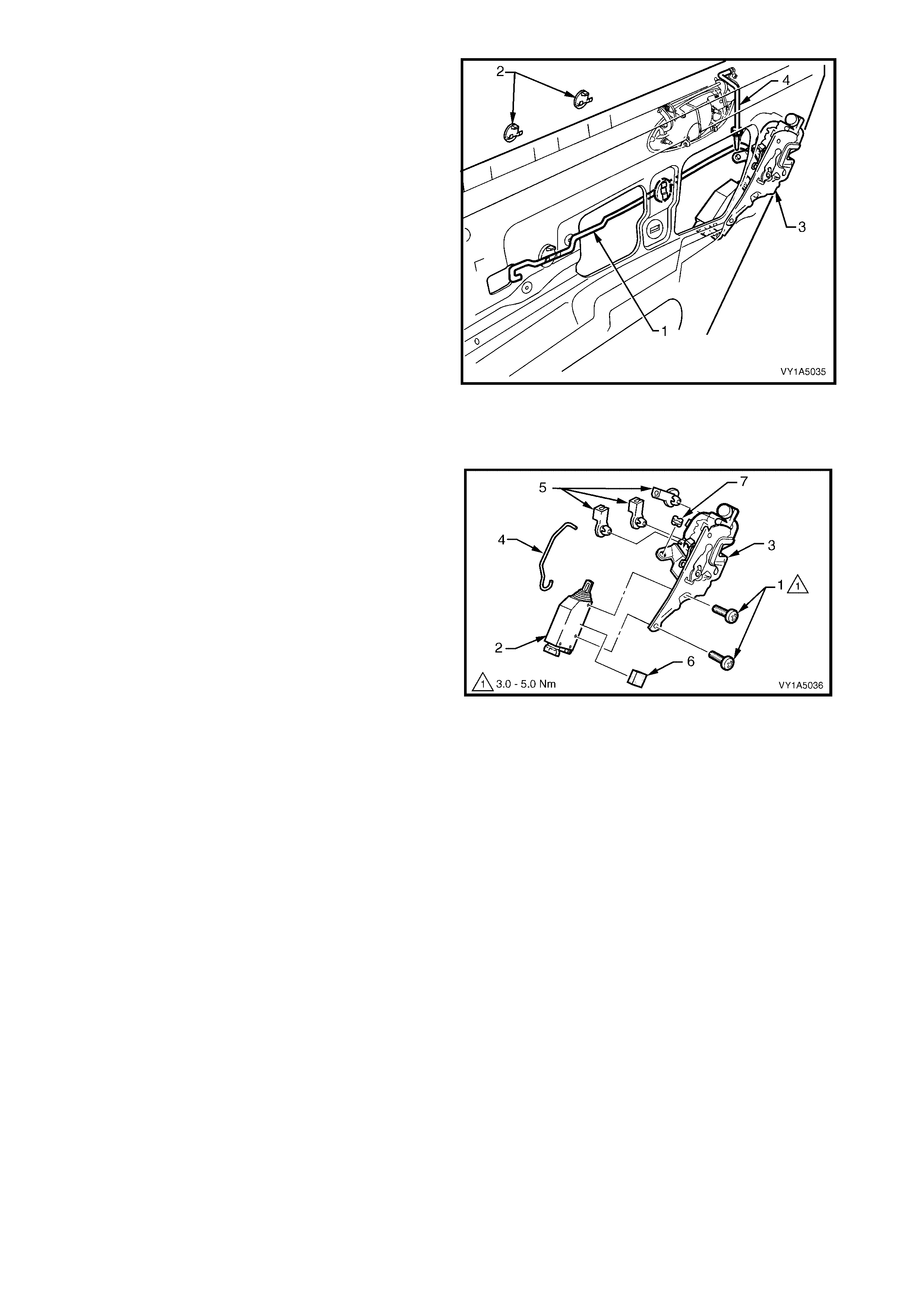

DISASSEMBLE

Remove – Front Door Lock Actuator Assembly

1. Rem ove the ant i-thef t cov er ( 1) fr om the fr ont door

lock assembly (2).

2. Remove the t wo s c rews ( 3) s ec uring th e f ront door

lock actuator assembly (4) to the lock assembly.

3. Remove the three retaining clips (5), and the door

lock bush (6) from the lock assembly.

4. If required remove the front door lock actuator

insulator (7), from the actuator assembly.

Reinstall – Front Door Lock Actuator Assembly

Reinstal lation of the f ront door lock actuator ass embly,

is the reverse of the removal procedure, noting the

following:

1. Adjust the position of the actuator assembly as

described below.

Figure 1A5-31

ADJUST

Adjustment of the door lock and actuator is critical to ensure correct operation of the electric door lock system.

The following adjustment procedure is to be performed if a diagnostic test in Section 12J Body Control

Module suggests that the door lock and actuator assembly may be incorrectly adjusted, or if any of the following

symptoms occur:

• Ineffective deadlock operation.

• Failure to lock and unlock.

• Door lock actuator motors oscillate, ie. machine gunning.

If not already done so, remove the front door lock assembly, refer to 2.7 FRONT DOOR LOCK ASSEMBLY.

1. Us ing the d oor loc king butt on r o d le ver , LOCK an d

UNLOCK the actuator mechanism, checking that

the actuator lever (1) rests on the rubber pad (2).

2. If required, loosen the screws (3) and reposition

the actuator assem bly until the r equire d position is

achieved.

3. Tighten the actuator screws securely, without

moving its position.

Figure 1A5-32

REINST ALL

Reinstallation of the front door lock assembly is the

reverse of the removal procedure, noting the following:

1. Tighten all retaining screws to the correct torque

specification.

2. Ensure the front door outside handle rod

assembly, is engaged correctly with the front door

lock assembly, refer Figure 1A5-30.

3. Ensure the front door seal is correctly fitted to the

door panel.

FRONT DOOR LOCK AC TUATOR

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

FRONT DOOR LOCK ASSEMBLY

RETAINING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

FRONT SIDE PULL BRACKET

RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.8 FRONT DOOR OUTSIDE HANDLE ASSEMBLY

LT Section No. – 11-360

1. Remove the door window regulator handle assembly, (where fitted), refer to 2.4 FRONT DOOR WINDOW

REGULATOR HANDLE ASSEMBLY.

2. Remove the front door inside handle assembly, refer to 2.5 FRONT DOOR INSIDE HANDLE ASSEMBLY

(REMOTE).

3. Remove the front door trim panel assembly, refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

REMOVE

NOTE: The front door water shield, need only be

partly removed to allow access to complete this

procedure, however as required remove the following

components:

1. Remove the t wo screws (1) securing the f ront side

pull bracket (2) except Coupe, to the front door

inner panel (3) and remove the bracket.

2. Remove the three front door brackets (4) from the

door inner panel by levering out the centre pin of

the bracket.

3. Carefully peel off the front door water shield (5)

from the front door inner panel.

Figure 1A5-33

4. For the driver’s door only; disconnect the front

door lock cylinder rod (1) from the door lock

assembly (2) by releasing the lock cylinder

retainer (3).

5. On the driver’s door only, disconnect the door

wiring harness from the door lock micro-switch

wiring harness connector (4).

6. Remove the two handle retaining nuts (6), and

remove the front door outside handle assembly

(7), and the front door outside handle bracket

assembly (5).

NOTE 1: The front door outside handle bracket

assembly on the driver’s door is an assembly, and

consists of a micro-switch, door lock cylinder and

bracket.

NOTE 2: To test the door micro-switch, refer to

Section 12J BODY CONTROL MO DULE.

Figure 1A5-34

Techline

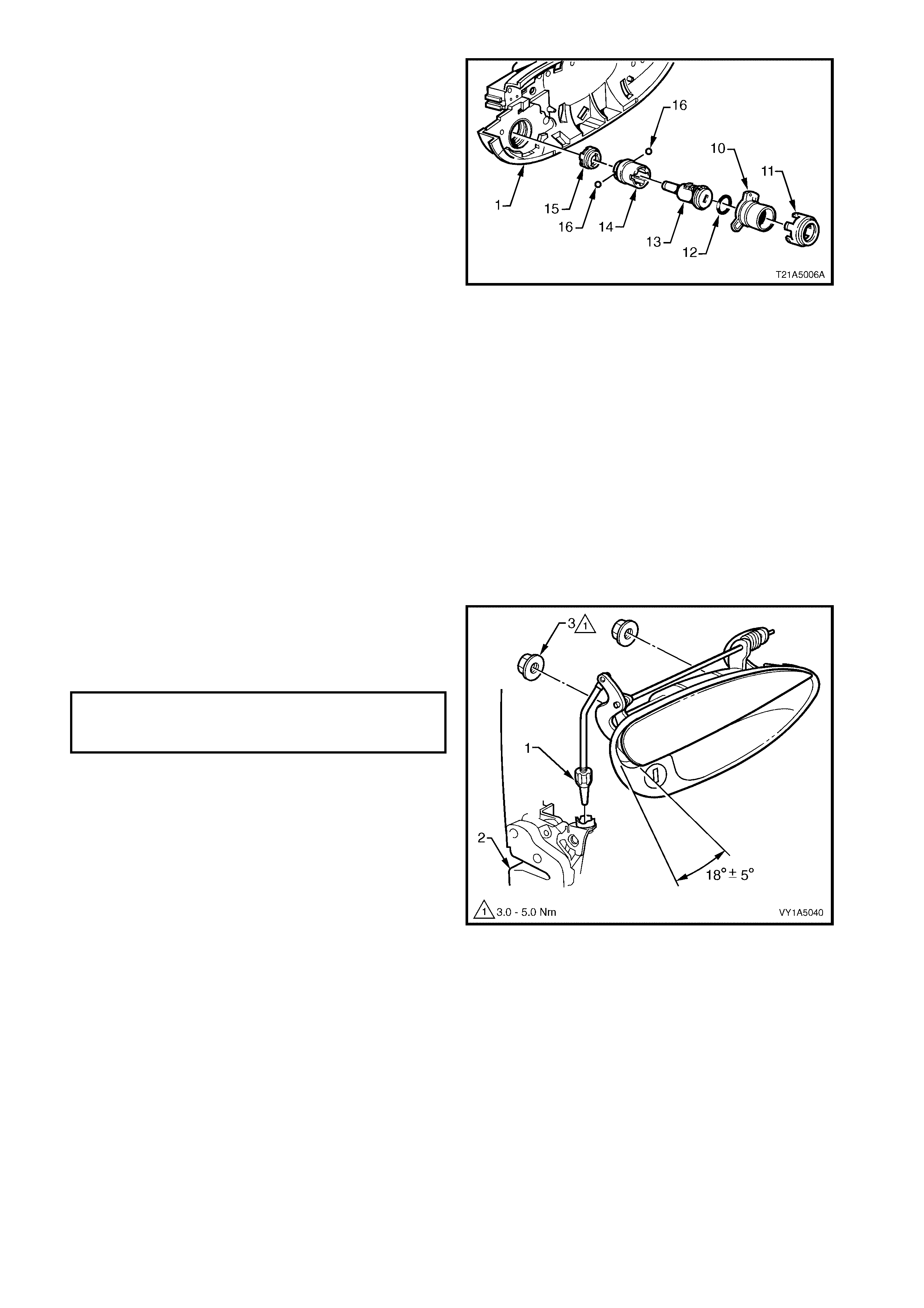

DISASSEMBLE – DRIVER’S SIDE

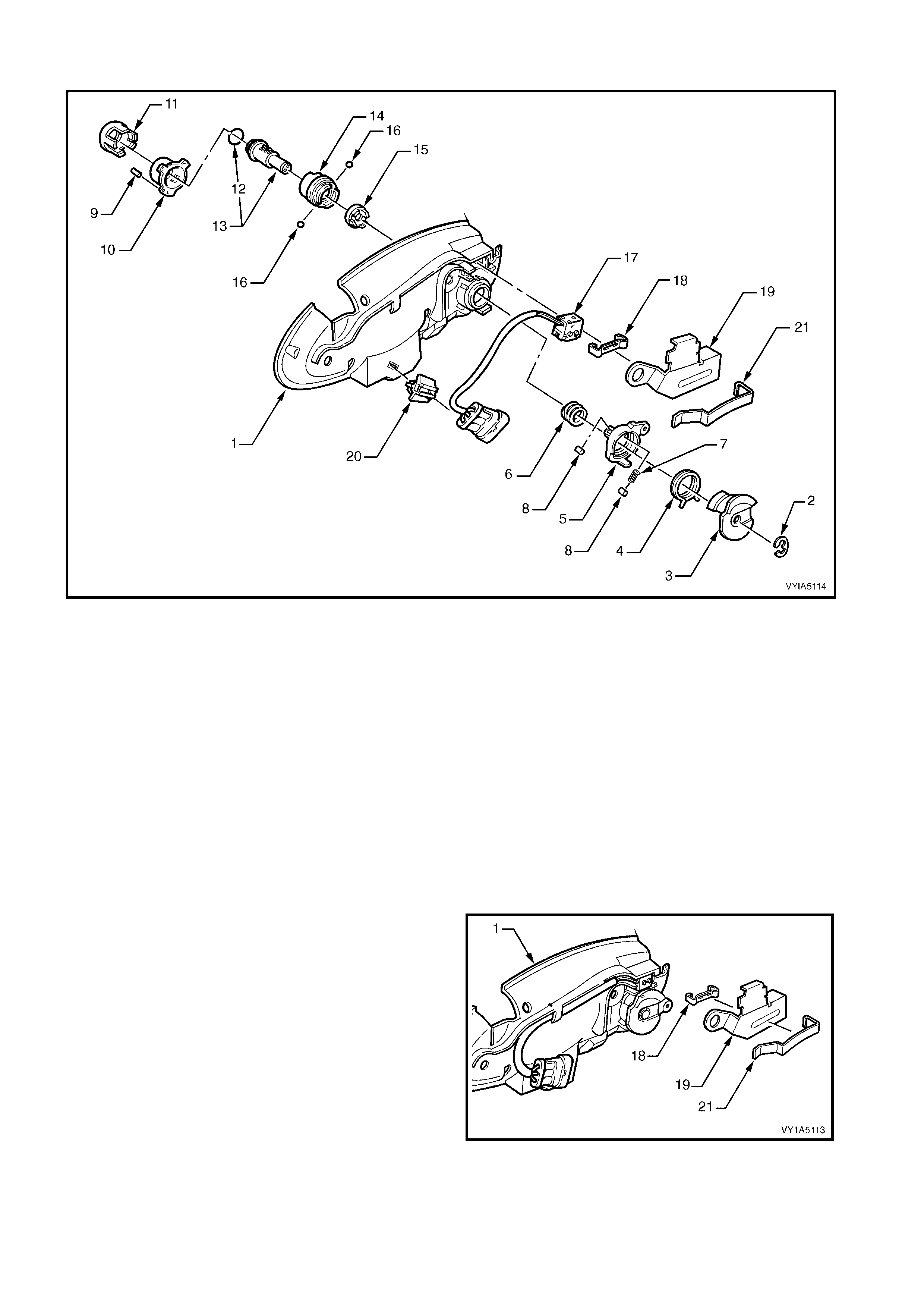

Figure 1A5-35

Legend

1. Front Door Outside Handle Bracket

2. Lock Barrel Clip

3. Door Lock Micro Switch Control Cam

4. Torsion Door Lock Spring

5. Door Lock Lever

6. Thrust Door Lock Clutc h Spring

7. Roller Spring

8. Door Lock Lever Roller

9. Door Lock Barrel Housing Pin

10. Door Lock Barrel Housing

11. Door Lock Housing Cover

NOTE: For specific procedure refer below.

12. O-Ring

13. Front Door Lock Cylinder Assembly

14. Cylinder Lock Sleeve

15. Door Lock Barrel Sleeve

16. Door Lock Clutch Balls

17. Electric Door Lock Switch Micro

18. Door Lock Micro Switch Clip

19. Door Lock Barrel Shield

20. Micro Switch Cable Retaining Clip

21. Lock Shield To Bracket Clip

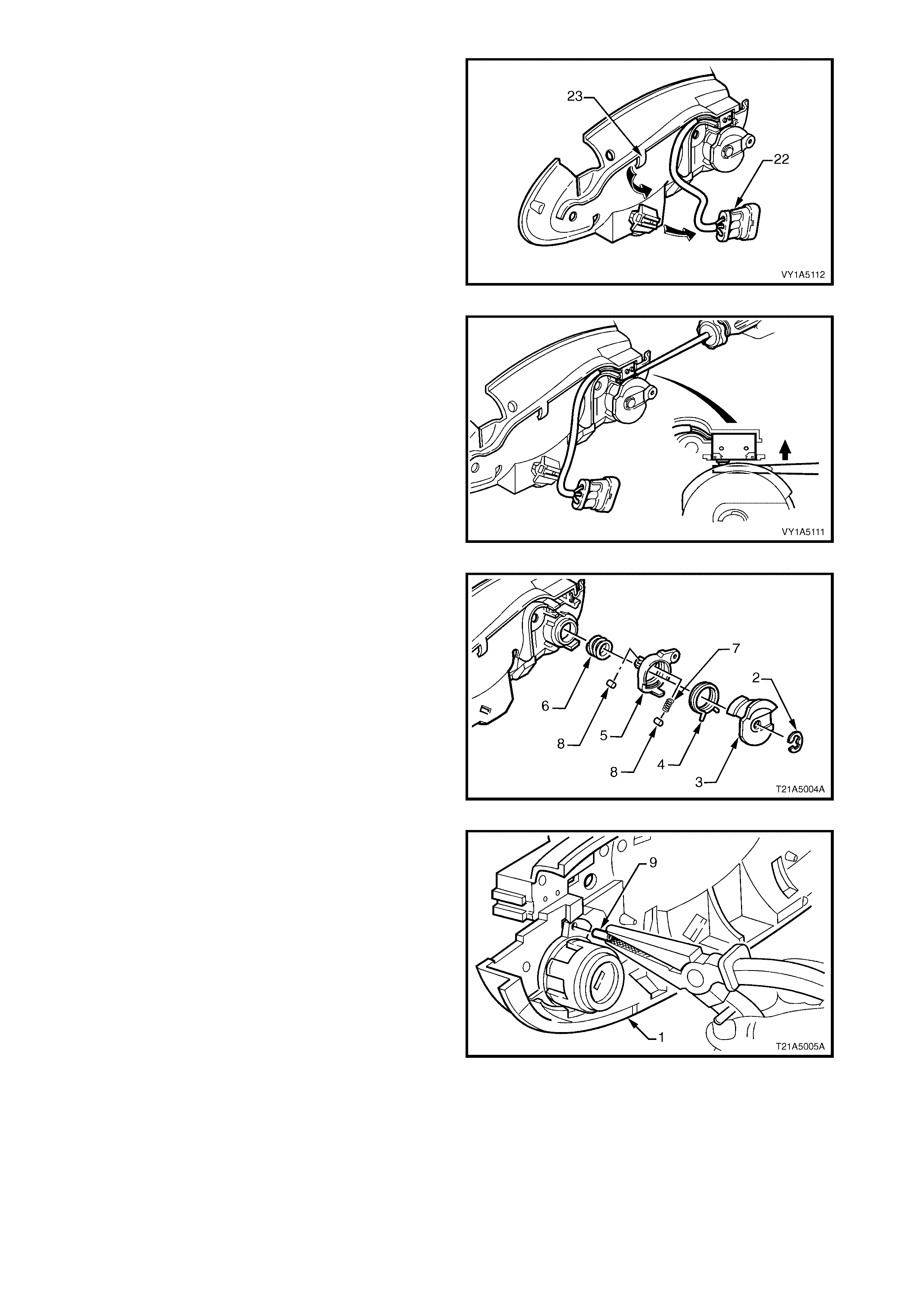

1. Using a small screwdriver, gently remove the clip

lock shield (21) away from the front door outside

handle bracket assembly (1) and r emove the door

lock barrel shield (19).

2. Using a small s crewdriver, gent ly remove the do or

lock micro switch clip (18) away from the front

door outside handle bracket assembly.

Figure 1A5-36

3. Slide the micro switch wiring harness connector

(22) off the connector retaining bracket and feed

the wiring harness out from under the bracket

assembly retainer (23).

Figure 1A5-37

4. Using a small flat bladed screwdriver, push the

two mic ro switch cont acts in and r em ove the m icro

switch assembly .

Figure 1A5-38

5. Remove the clip (2) and slide the cam (3), spring

(4), and lever (5) away from the lock assembly.

NOTE: Be careful not to lose the spring (7) and

rollers (8).

6. Remove the spring (6) from the lock assembly.

Figure 1A5-39

7. Using a suitable pair of pliers, pull the door lock

barrel housing pin (9) out of the front door outside

handle brac k et (1).

Figure 1A5-40

8. Rotate the cover (11), housing (10), O-ring (12),

cylinder assembly (13), sleeve (14), and coupling

(15) in an anti-clockwise direction, being careful

not to lose the two balls (16) while removing from

the door outside handle bracket (1).

Figure 1A5-41

ASSEM BLE

Assem bly of the front door outside handle assem bly is

the reverse of the removal procedure, noting the

following:

1. Lock cylinder service replacement kits are

supplied un-coded, which facilitates re-coding of

the lock cylinder to match the original key. It is

recommended that the overhaul and re-coding of

the lock cylinder is sublet and performed by an

authoris ed locksmith.

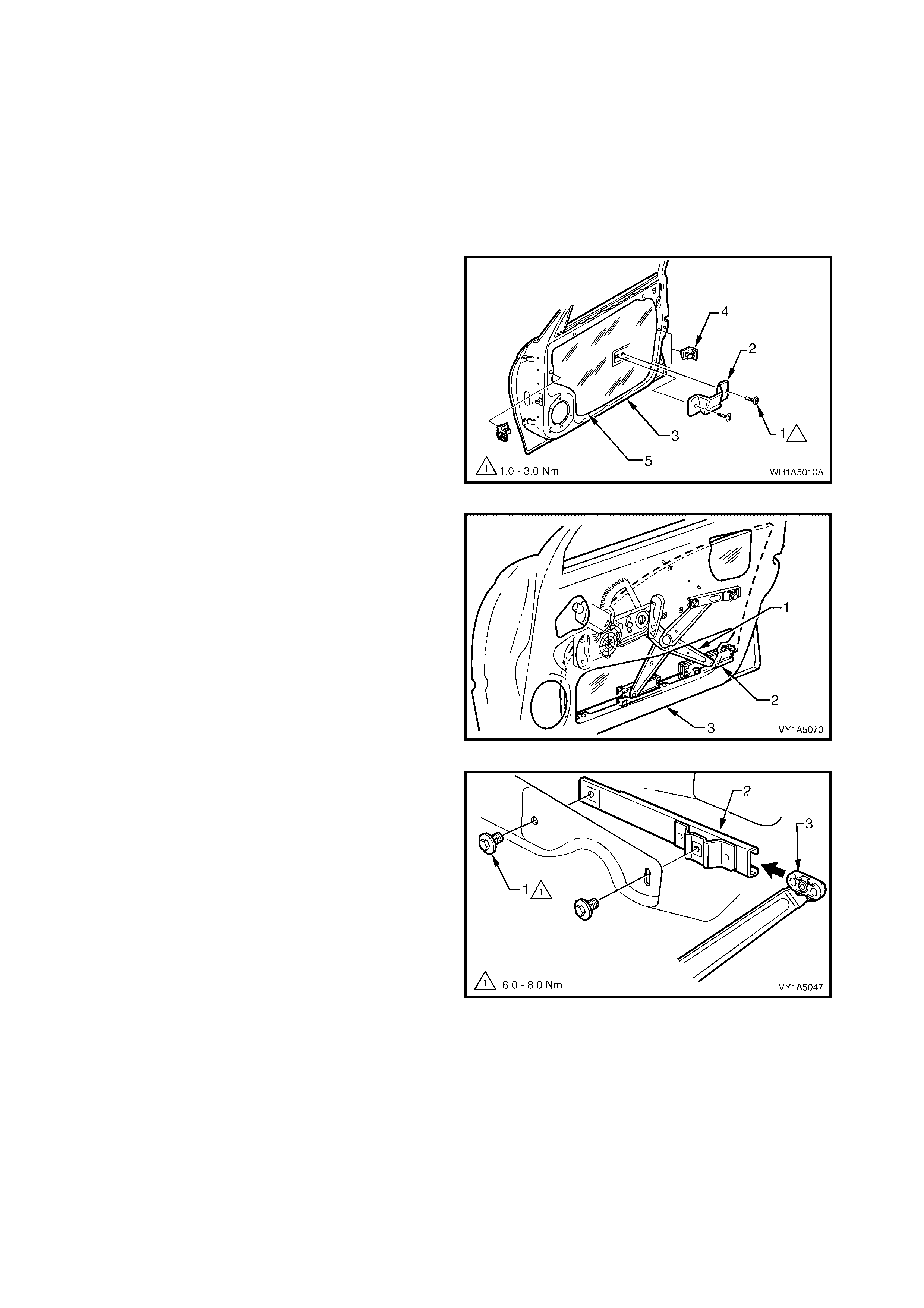

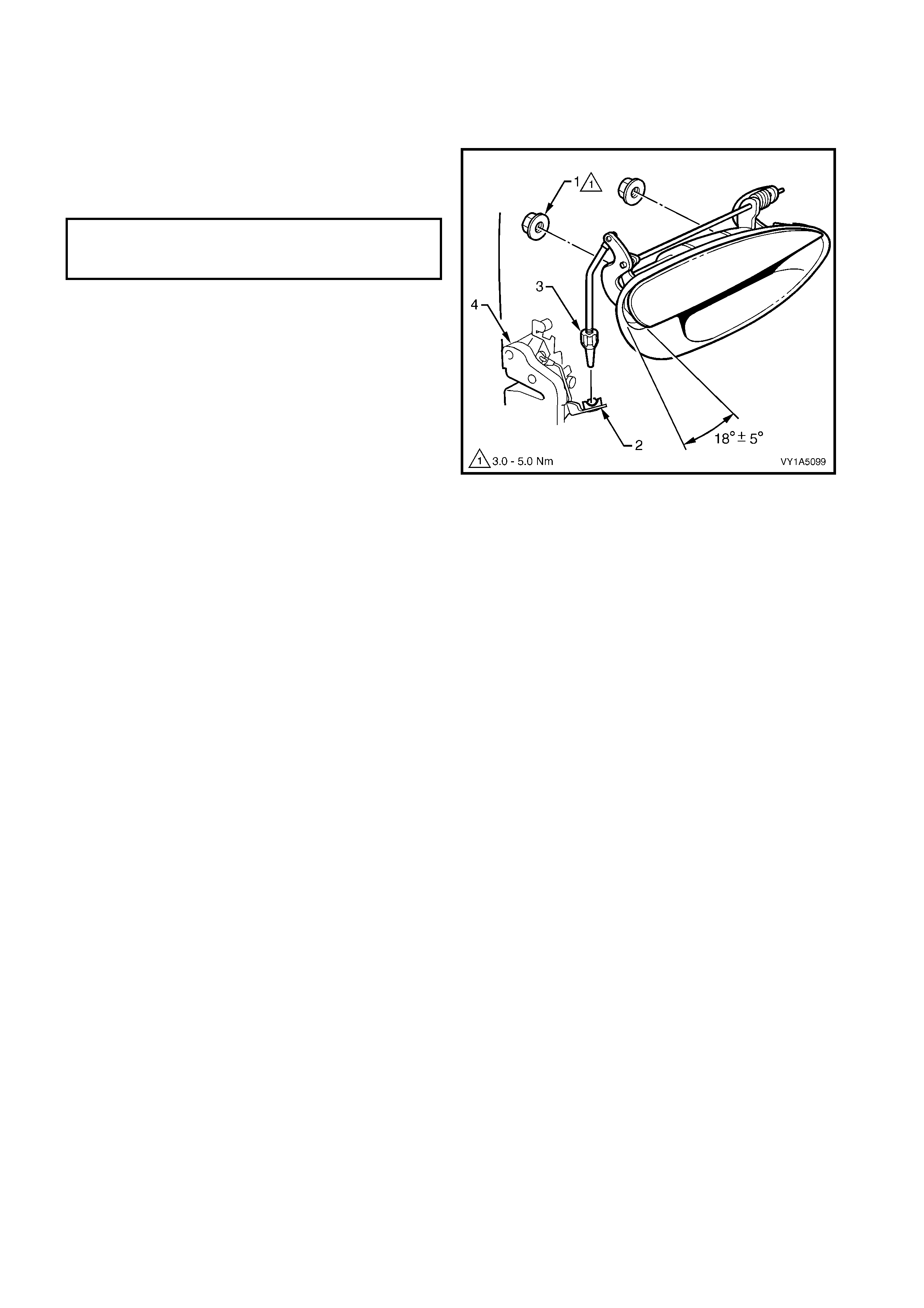

REINST ALL

Reinstallation of the front door outside handle

assembly is the reverse of the removal procedure,

noting the following:

1. Ensure that the adjusting nut (1) is seated in the

lock and actuator assembly (2) before installing

the front door outside handle assembly retaining

nuts (3).

2. Check and if necessary, adjust the handle

assembly adjusting nut to allow latch

disengagement with striker when the exterior d oor

handle openi ng is 18° ± 5° from the rest position.

3. Ensure the front door water shield is correctly

fitted to the door panel.

Figure 1A5-42

RESET (‘FREE TURN’ LOCK CYLINDER)

NOTE: If the ‘free turn’ lock cylinder becomes misaligned due to the insertion of the incorrect key, a foreign

object or if the correct key is not inserted fully when turned, the following procedure will need to be carried out.

1. Inser t the k ey full y into the l ock , preferabl y in the vert ical pos iti on and turn the k ey slo wly anti-c lock wise unti l

a click is felt.

2. Then slowly turn the key clockwise until a click is felt.

3. Return the key to the vertical position (if not already there) and withdraw the key.

4. Reinsert the key at the vertical position and check if the key will lock and unlock the vehicle.

NOTE: If the key does not work properly, keep the key in the lock and turn the key 180° anti-clockwise, then

repeat the proced ur e.

FRONT DOOR HANDLE ASSEMBLY

OUTSIDE RETAINING NUT

TORQUE SPECIFICATION 3.0 – 5.0 Nm

2.9 FRONT DOOR WINDOW REGULATOR ASSEMBLY

LT Section No. – 11-675

1. Remove the front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR

WINDOW REGULATOR HANDLE ASSEMBLY.

2. Remove the front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE).

3. Remove the front door trim panel assembly refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

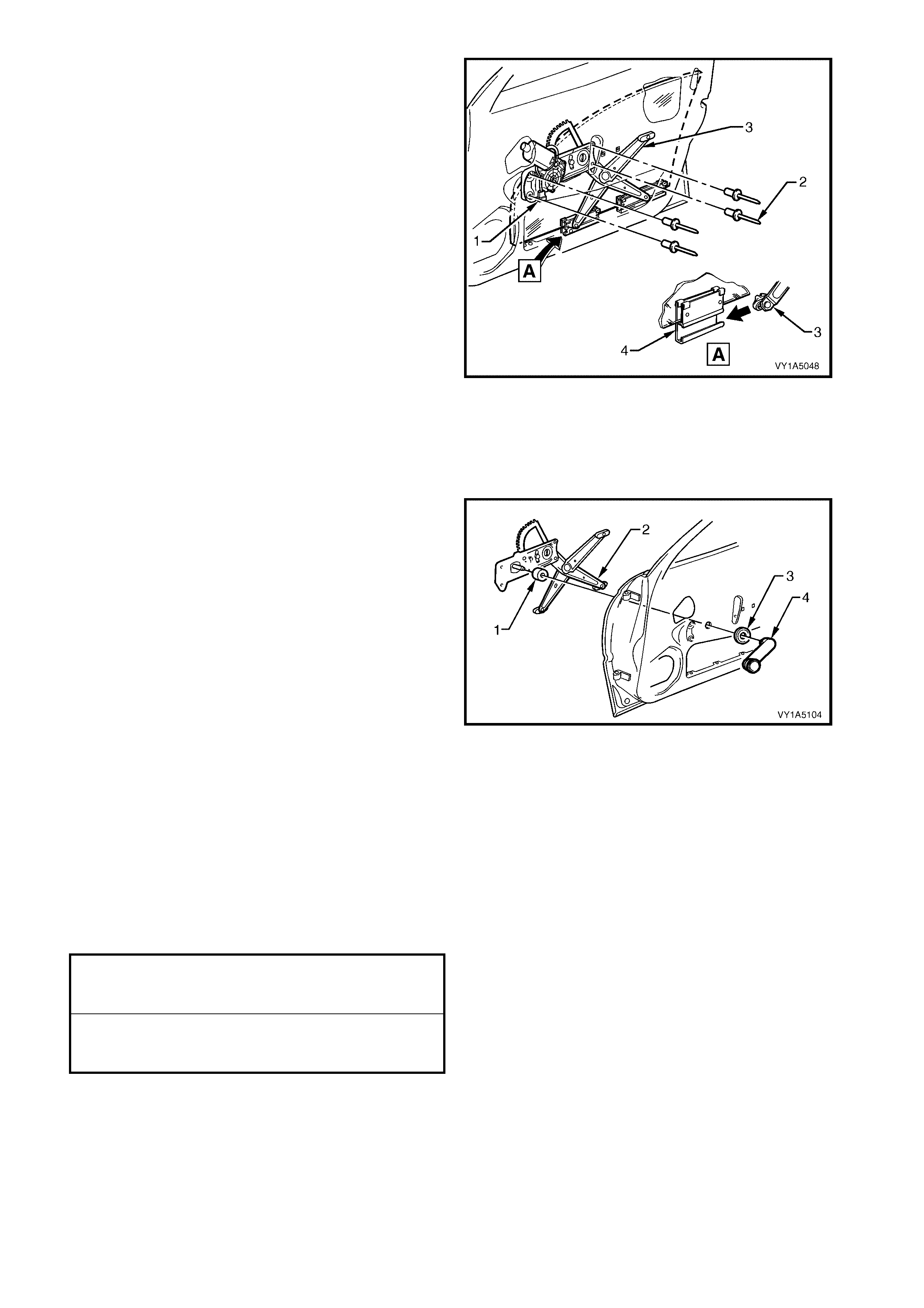

REMOVE

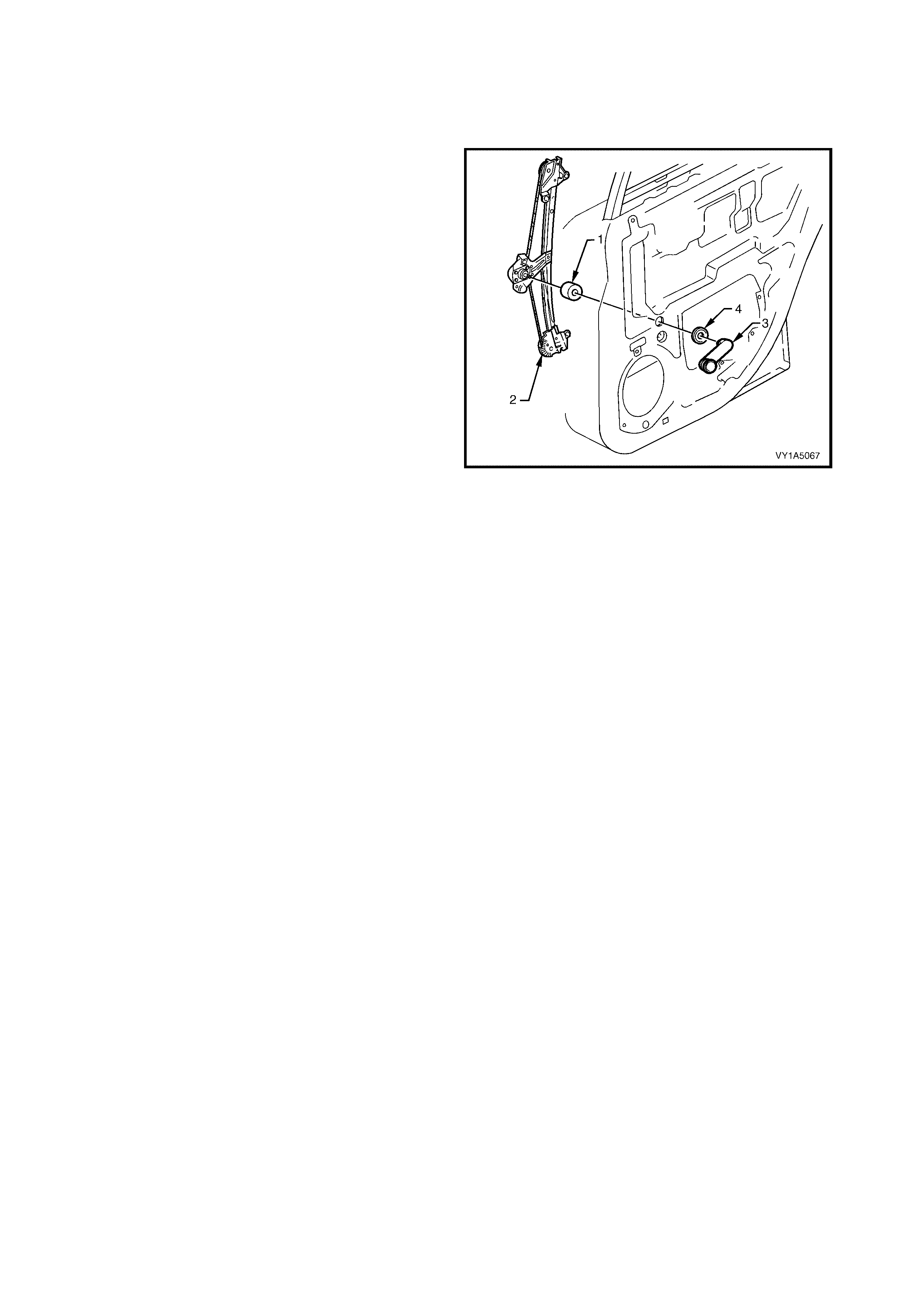

1. Remove the t wo screws (1) securing the f ront side

pull bracket (2) except Coupe, to the front door

inner panel (3) and remove the bracket.

2. Remove the three front door brackets (4) from the

door inner panel by levering out the centre pin of

the bracket.

3. Carefully peel off the front door water shield (5)

from the front door inner panel.

Figure 1A5-43

4. Prior to commencing the following procedures,

lower the window assembly, to a position where

the regulator guide runners (1) and the window

guide rails (2) are visible through the aperture in

the door inner panel (3).

Figure 1A5-44

5. Remove the two att aching scr ews ( 1) securing the

front windo w r egu lat or c ha nne l as s embly (2) to th e

door inner panel.

6. Slide the channel out of the regulator assembly

(3).

7. Remove the channel assembly from the door

assem bly upper opening.

Figure 1A5-45

8. Disconnect the regulator assembly wiring harness

connector (1) from the door harness (where fitted).

9. While having an assistant support the window

glass, drill out the four rivets (2) securing the

regulator assembly (3) to the door panel, (using a

5mm drill bit).

10. Slide the runners out of window assembly (4).

11. Raise the window glas s by hand.

12. Remove the window regulator assembly through

the door inner panel aperture.

13. Place a wooden chock inside the door panel to

hold the window assembly up, while replacing the

window regulator assembly.

Figure 1A5-46

REINST ALL

Reinstallation of the front door regulator assembly is

the reverse of the removal procedure, noting the

following:

1. Ins tal l th e f r ont door window re gul ator h and le s h af t

seal (1) (where fitted), to the regulator assembly

(2), before installing into the door panel.

NOTE: The fr ont door wind o w washer ( 3) a nd the fr ont

door window regulator handle assembly (4) are to be

installed after the trim panel assembly, (where fitted).

2. Locate the regulator assembly inside the door.

Insert the regulator arms into the glass channels.

Align the attaching holes in the regulator with the

corresponding holes in the door inner panel, refer

Figure 1A5-46.

3. Attach the regulator assembly to the door inner

panel using 5mm rivets.

NOTE: The attaching holes in the door panel may

have been enlarged, when the rivets were drilled out.

Washers may be inserted when refitting the regulator

assem bly.

4. Install the front window regulator channel

assembly. Adjust the front door window and

regulator as per the adjustment procedure, refer

2.14 FRONT DOOR WINDOW A SSEMBLY.

5. Tighten all retaining screws to the correct torque

specification.

6. Ensure all frictional surfaces of the window

regulator assembly and associated parts are

adequately lubricated with Lithium base grease

NLGI No. 1 (with 9 % zinc oxide) or equivalent.

7. Ensure the front door water shield is correctly

fitted to the door panel, refer Figure1A5-43.

Figure 1A5-47

FRONT SIDE PULL BRACKET

RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT WINDOW REGULATOR

CHANNEL ASSEMBLY RETAINING

SCREW TORQUE SPECIFICATION 6.0 – 8.0 Nm

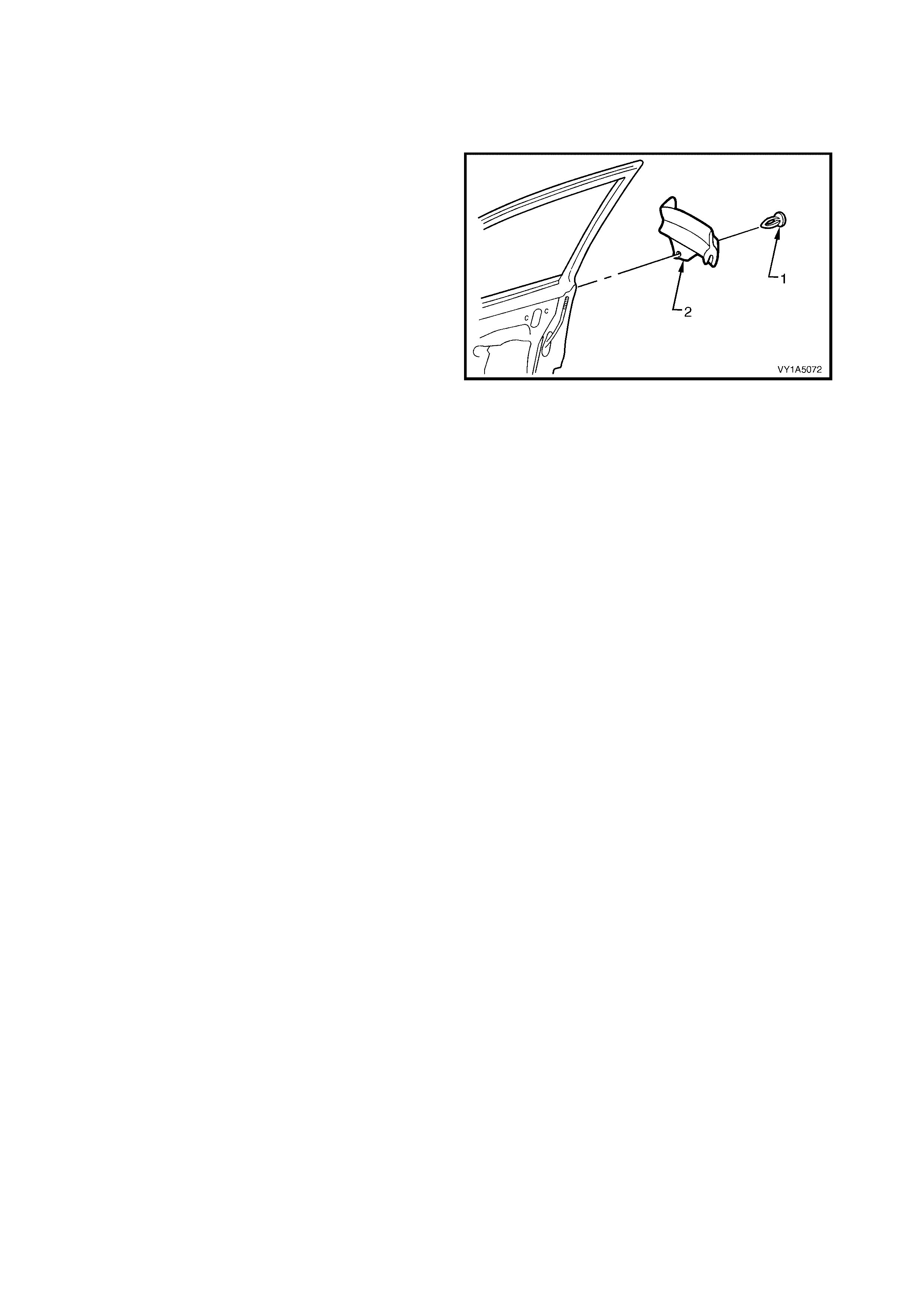

2.10 FRONT WI NDOW INNER FILLER ASSEMBLY

LT Section No. –

REMOVE

1. Gently prise out the filler assembly retainer (1),

from the rear inner sealing strip front filler

assembly (2).

2. Remove filler assembly from the rear of the front

door.

Figure 1A5-48

REINST ALL

Reinstallation of the filler assembly retainer, is the

reverse of the removal.

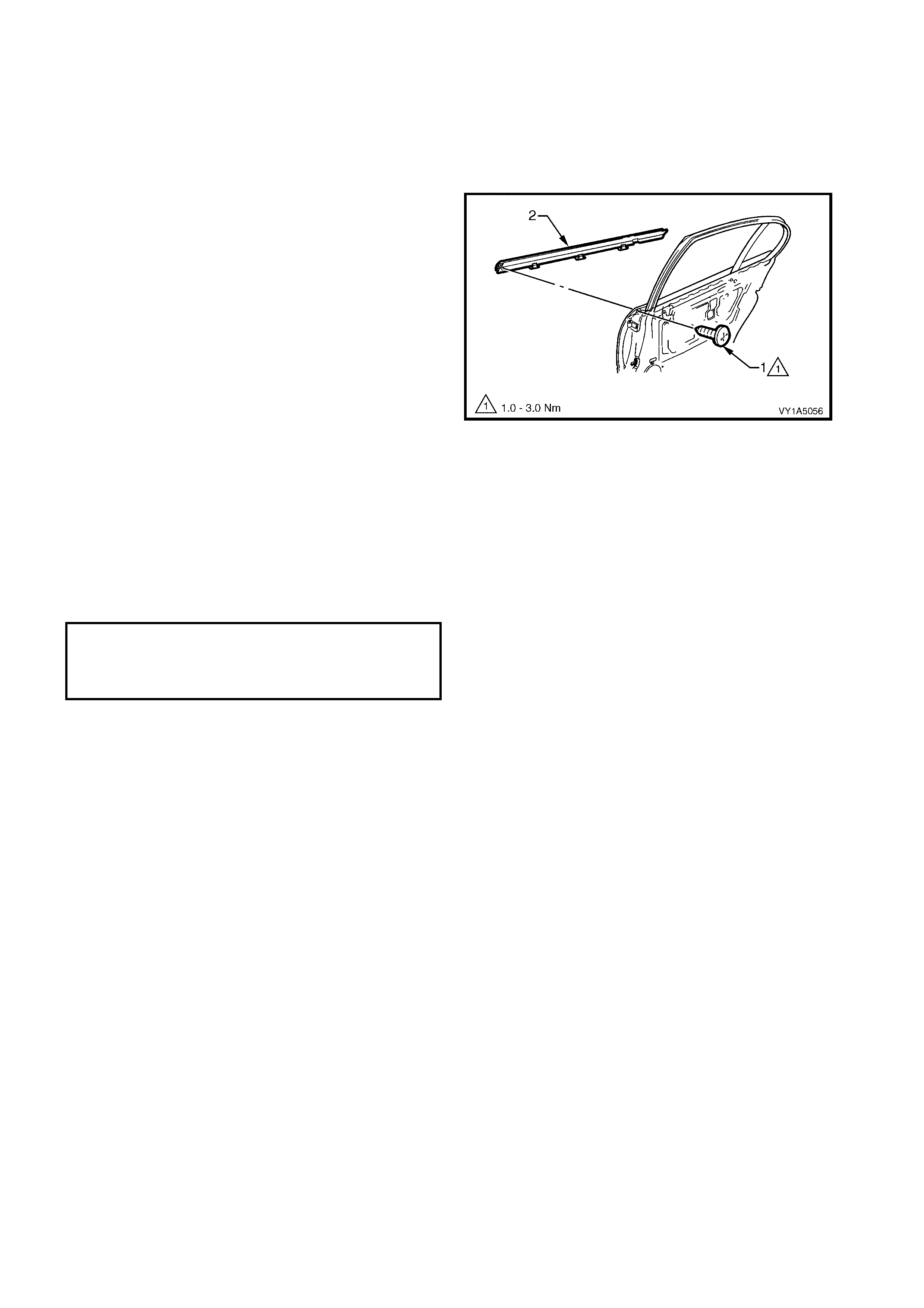

2.11 FRONT DOOR BELT OUTER REVEAL MOULDING ASSEMBLY

LT Section No. – 11-650

REMOVE

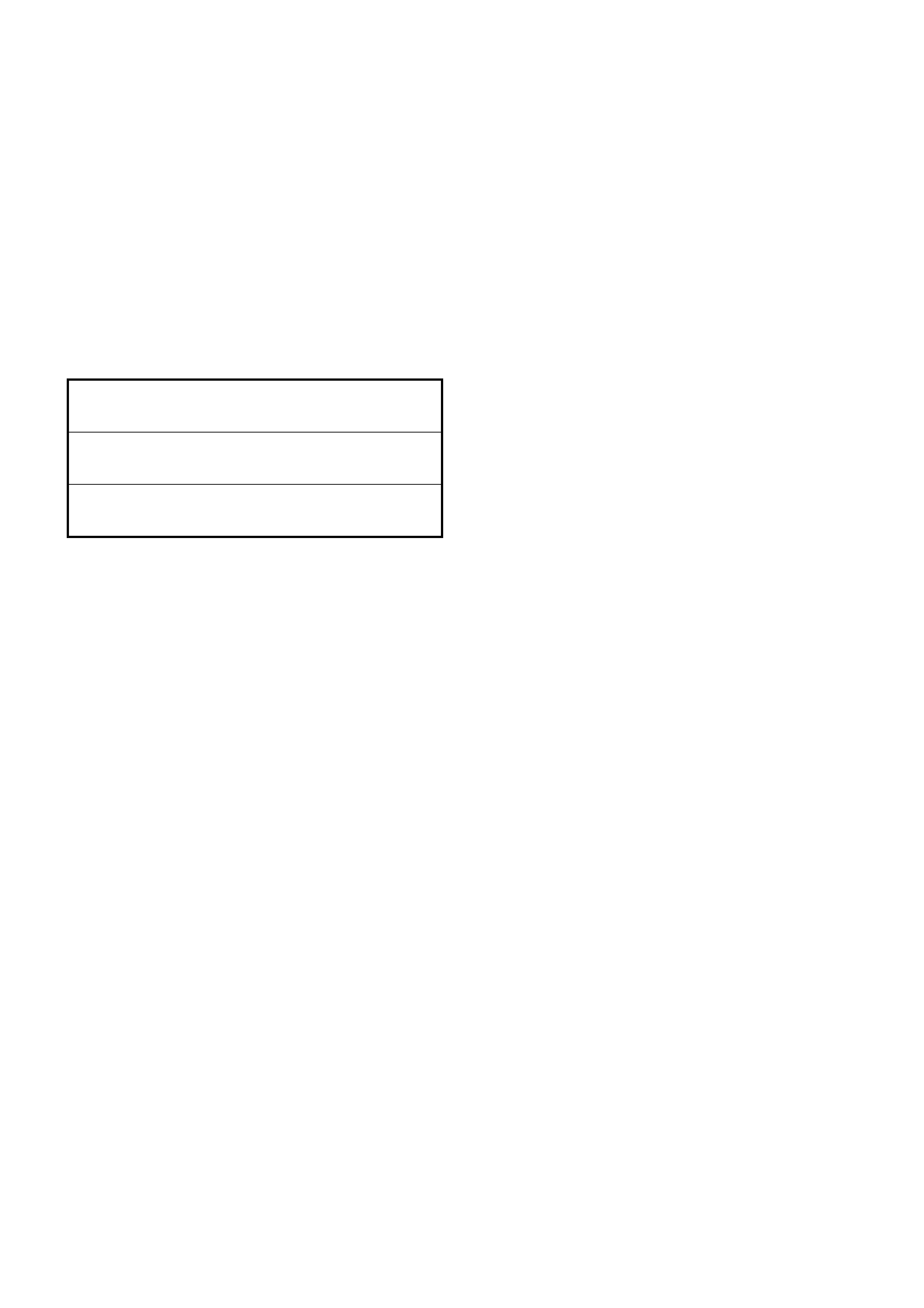

1. Lower the windo w ass embly.

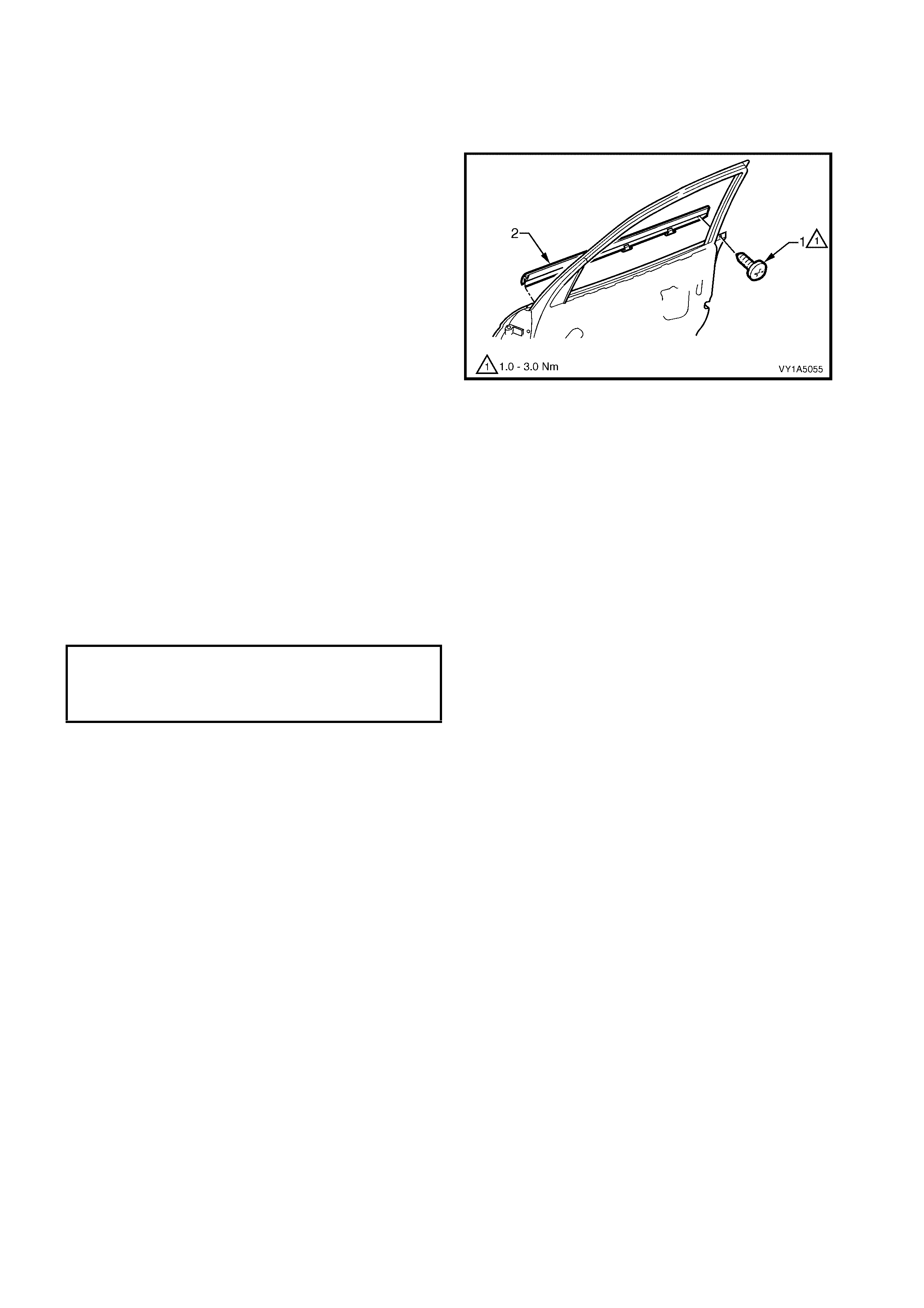

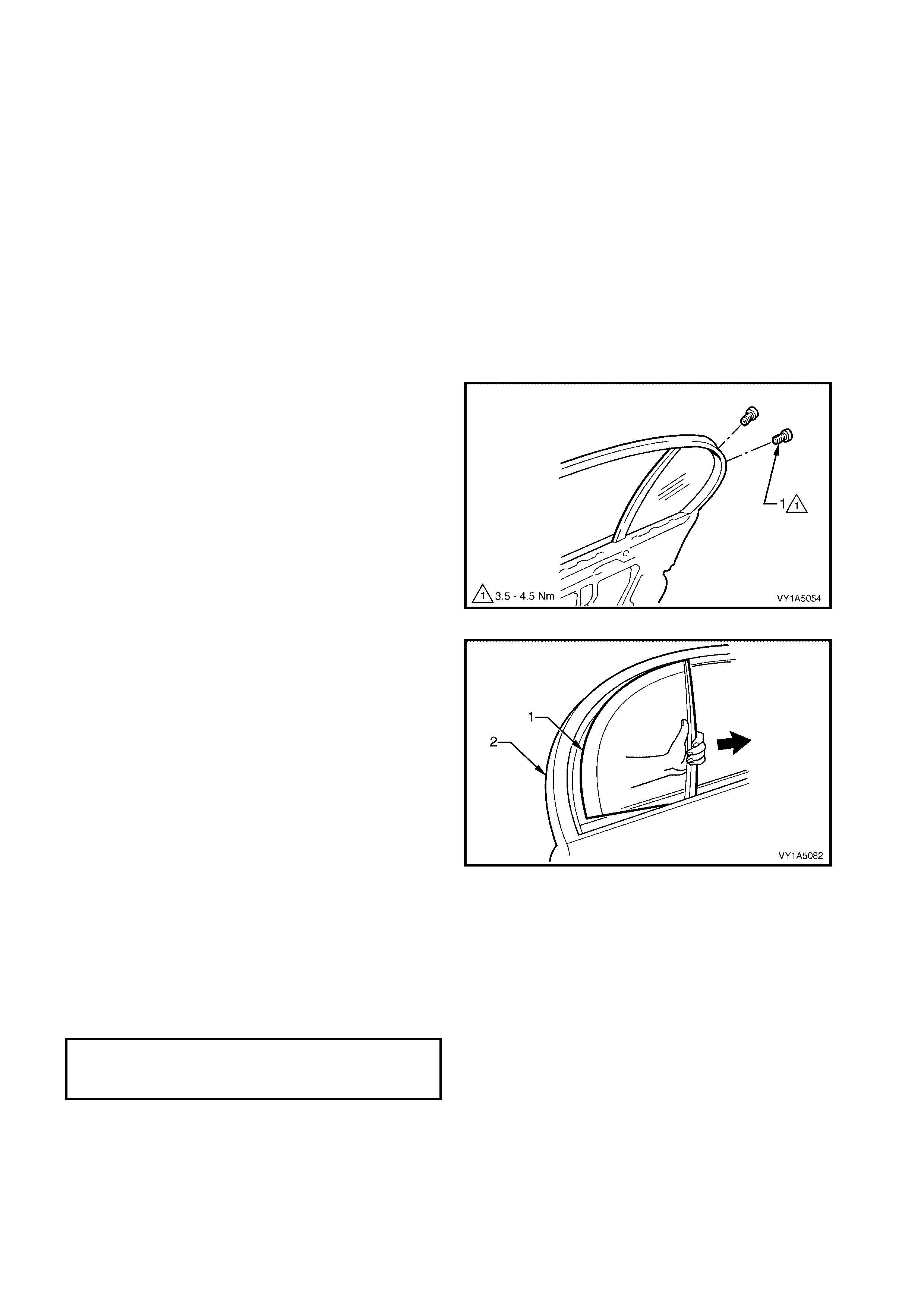

2. Remove the moulding assembly retaining screw

(1).

3. Start ing at the rear of the door , prise the f ront door

belt outer reveal moulding assembly (2), in an

upward dir ection f rom the door. Slid e the m oulding

assembly out from underneath the rear vision

mirror assembly.

NOTE: Take care not to damage the moulding or the

plastic retaining clips.

Figure 1A5-49

REINST ALL

Reinstallation of the front door belt outer reveal

moulding assembly, is the reverse of removal, refer

Figure 1A5-49, noting the foll o wing:

1. Slide the front door belt outer reveal moulding

assembly, under the rear vision mirror assembly.

2. Align the rear of the moulding with the rear of the

door. Using the palm of the hand, firmly tap the

assembly down, over the door outer upper flange.

3. Tighten the retaining screw to the correct torque

specification.

FRONT SIDE WINDOW BELT OUTER

REVEAL MOULDING ASSEMBLY

RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.12 FRONT WINDOW GUIDE ASSEMBLY

LT Section No. –

1. Have the window in the up position.

2. Remove the front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR

WINDOW REGULATOR HANDLE ASSEMBLY.

3. Remove the front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE).

4. Remove the front door trim panel assembly refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

REMOVE

NOTE: The front door water shield ne ed only be partl y

removed to allow access to complete this procedure.

1. Remove the t wo screws (1) securing the f ront side

pull bracket (2) except Coupe, to the front door

inner panel (3) and remove the bracket.

2. If required remove the three front door brackets (4)

from the door inner panel by levering out the

centre pin of the bracket.

3. Carefully peel off the front door water shield (5)

from the front door inner panel.

Figure 1A5-50

4. Remove the two screws (1) securing the front

window guide assembly (2).

5. Remove the guide assembly through the opening

in the door inner panel.

Figure 1A5-51

REINST ALL

Reinstallation of the front window guide assembly is

the reverse of the removal noting the following:

1. Ensure the front door water shield is correctly

fitted to the door panel.

2. Tighten all retaining screws to the correct torque

specification.

FRONT PULL BRACKET

RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT DOOR GLASS GUIDE

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.13 FRONT DOOR GUIDE CHANNEL ASSE MBLY

LT Section No. – 11-625

1. Remove the front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR

WINDOW REGULATOR HANDLE ASSEMBLY.

2. Remove the front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE).

3. Remove the front door trim panel assembly refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

REMOVE

1. Remove the t wo screws (1) securing the f ront side

pull bracket (2) except Coupe, to the front door

inner panel (3) and remove the bracket.

2. Remove the three front door brackets (4) from the

door inner panel by levering out the centre pin of

the bracket.

3. Carefully peel off the front door water shield (5)

from the front door inner panel. (2).

Figure 1A5-52

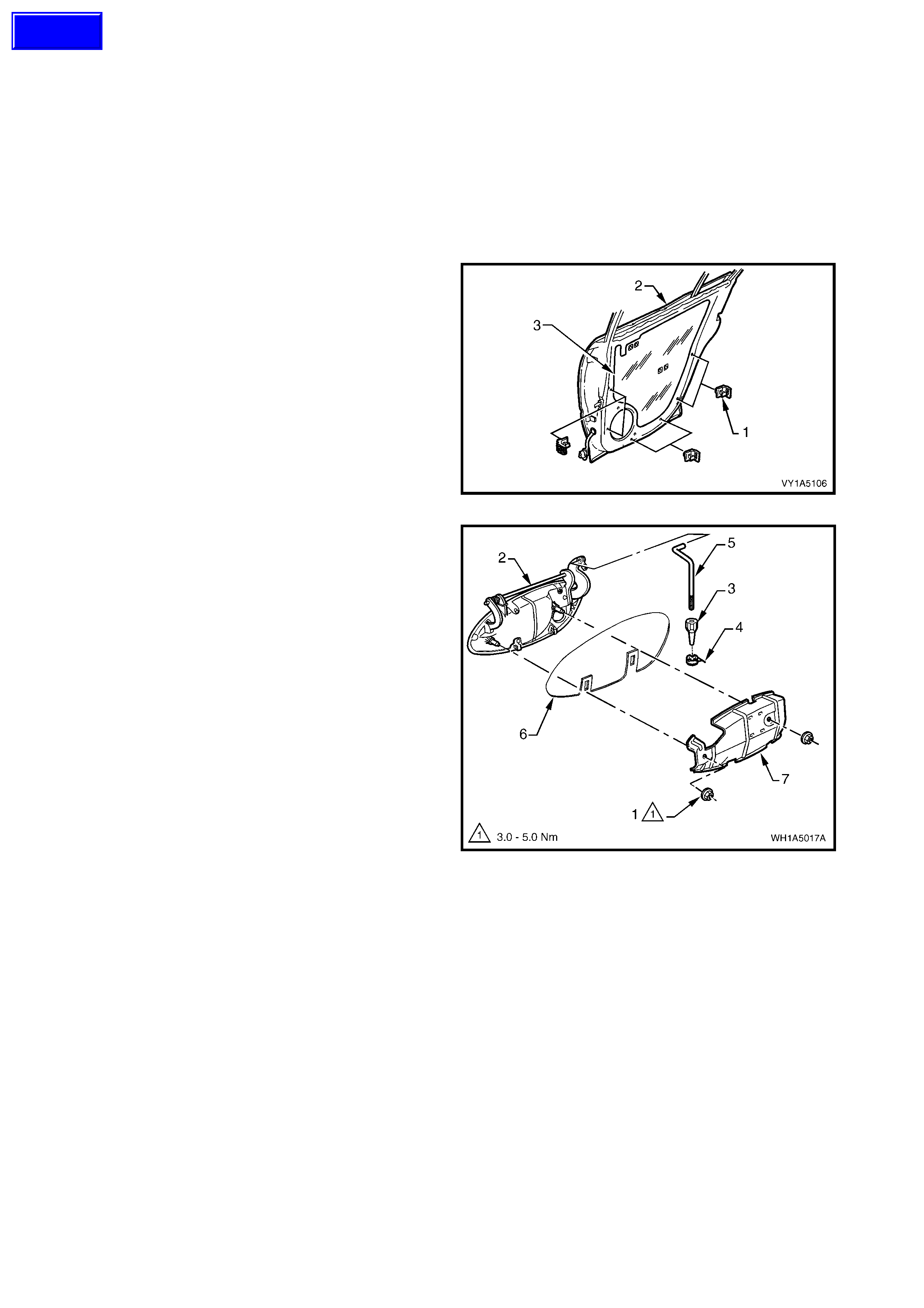

4. Peel back the outside rear view mirror seal (1) to

gain excess to screws.

5. Remove the three screws (2) securing the outside

rear view mirror assembly (3) to the door panel.

While supporting the mirror, disconnect the wiring

harness connector (4) and remove the mirror.

NOTE: For service and diagnosis of the rear view

mirror, refer to Section 12H REAR VIEW MIRRORS.

Figure 1A5-53

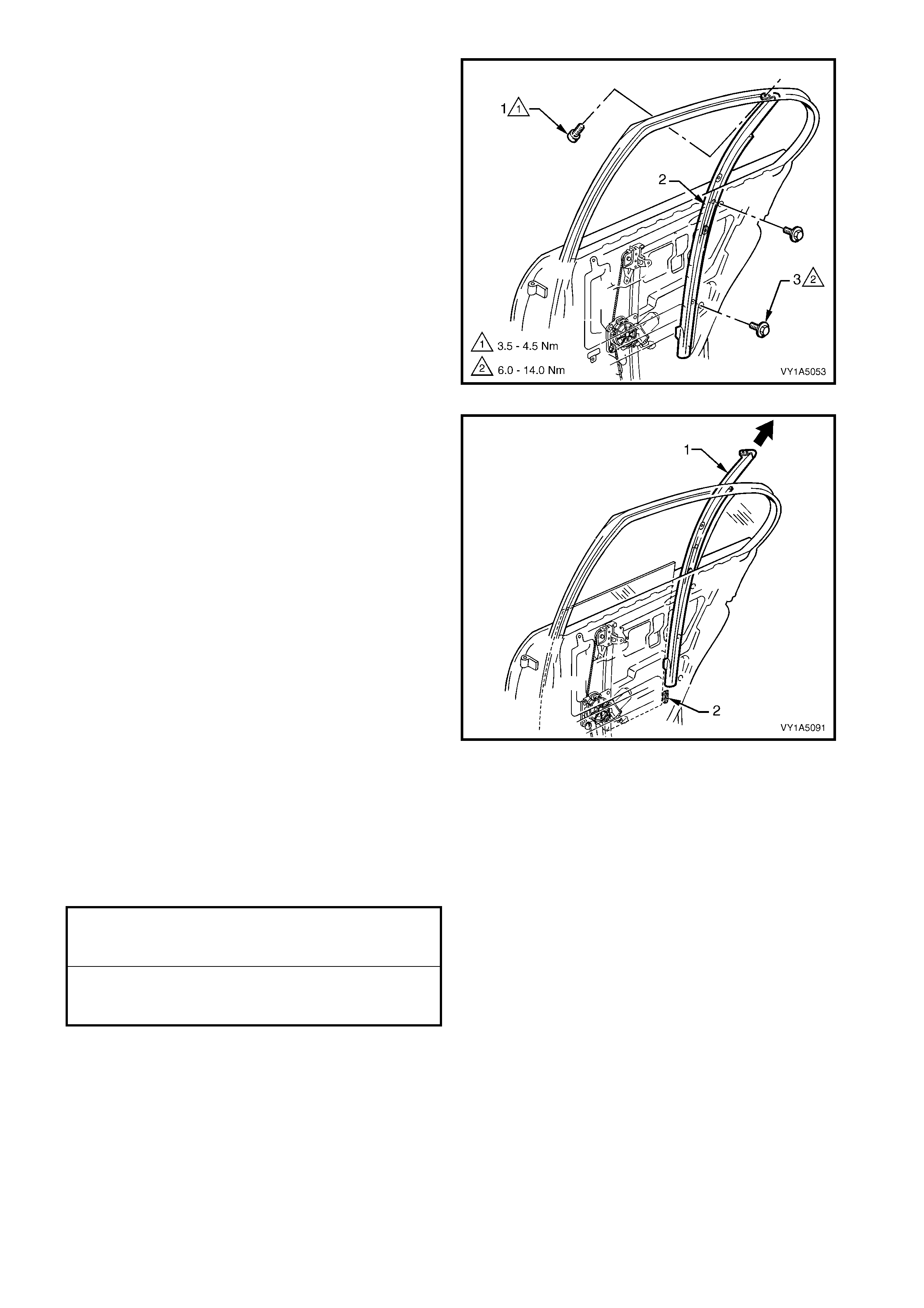

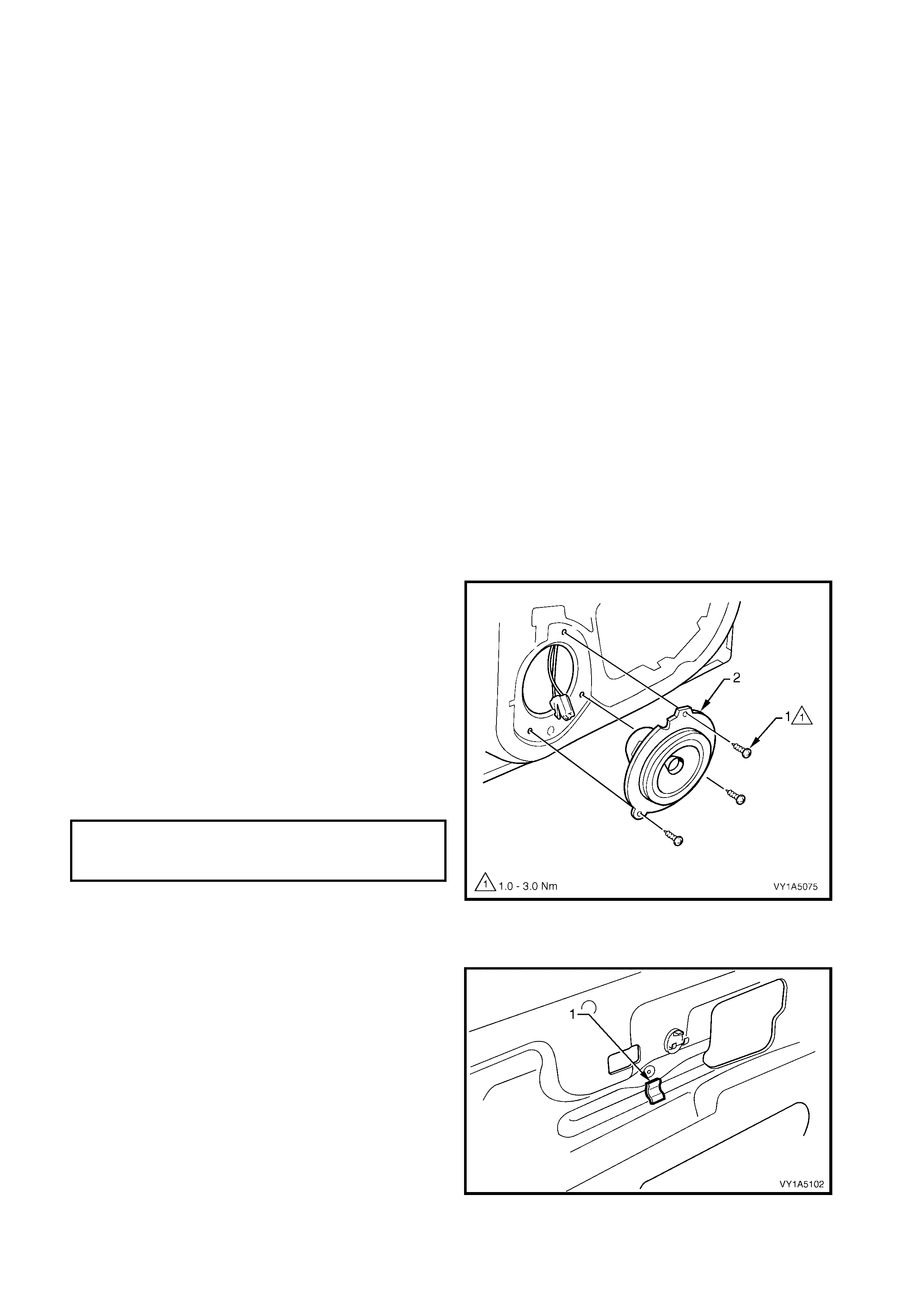

6. Remove the three screws (1) securing the front

door speaker assembly (2) to the door inner panel.

7. Remove the speak er assembly far enough to gain

access to the wiring harness connector (3).

8. Disconnect wiring harness connector and remove

speaker assembly.

NOTE: For service and diagnosis of the door speaker

assembly, refer to Section 12D ENTERTAINMENT

SYSTEM.

Figure 1A5-54

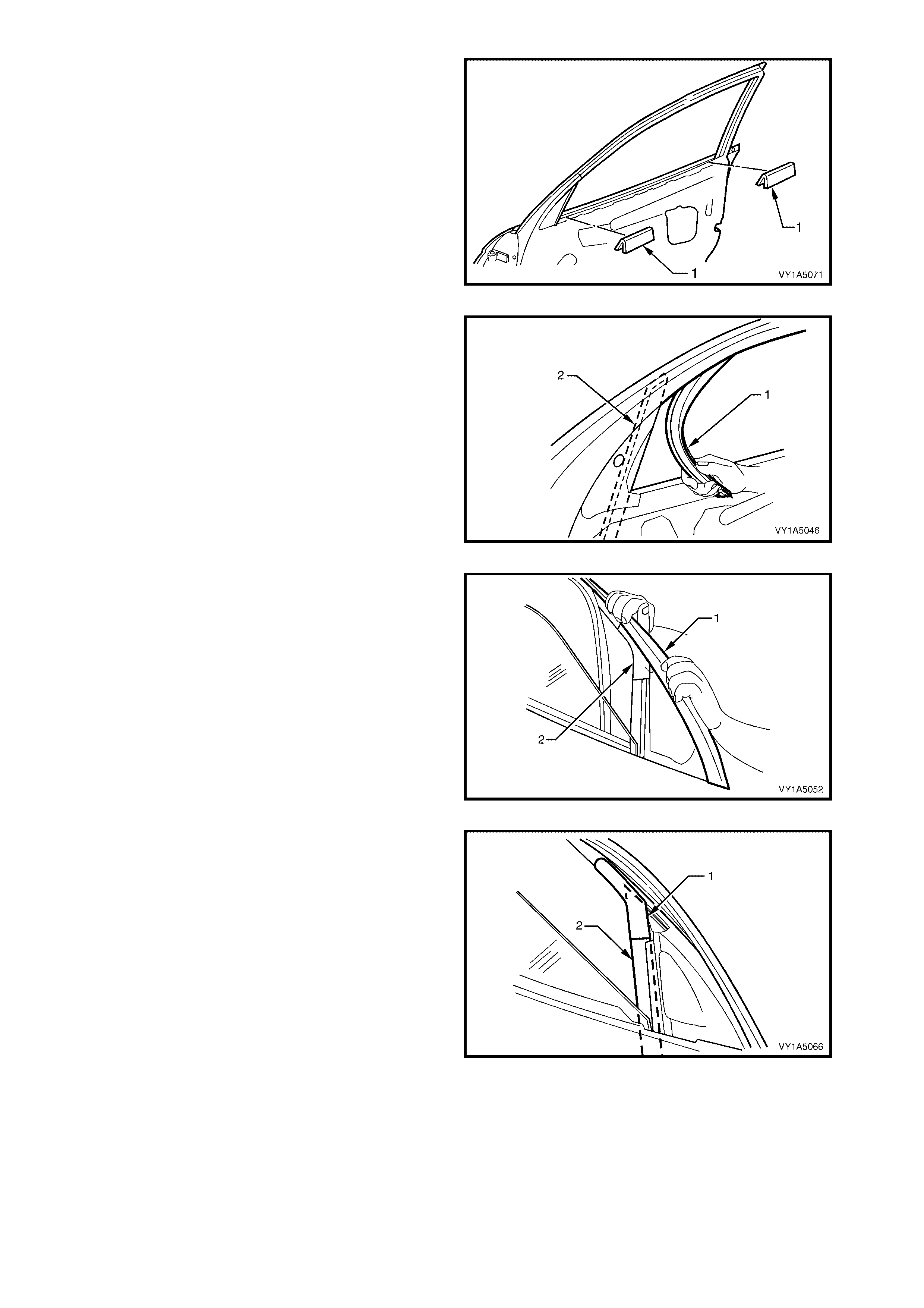

9. Remove the two front door inner panel belt

seals (1).

Figure 1A5-55

10. Carefully remove the front window upper

weatherstrip assembly (1) from the front window

channel guide assembly (2).

NOTE: It is not necessary to remove the weatherstrip

assembly completely, only from the front window

channel guide assembly.

Figure 1A5-56

11. Partially remove the front door upper weatherstrip

assem bly (1) f rom the lip o n the d oor u pper f ram e,

to allow excess to the sealing front window

channel guide cap (2).

NOTE: It is not necessary to remove the weatherstrip

assembly completely.

Figure 1A5-57

12. Carefully peel back the sealing front window

channel guide cap (1) away from the guide

channel assembly (2).

Figure 1A5-58

13. Remove the three bolts (1) securing the front

window channel guide assembly (2) to the door

panel (3).

NOTE: The front window down stop nut (4) is not

welded to the door and when the guide assembly

retaining bolt is removed, this nut may become lost.

Figure 1A5-59

14. Rem ove the front wind ow channel g uide ass embl y

(1) from the door assembly (2) in an upward

directi on, disenga ging the windo w assembl y slid es

(3) from the guide assembly.

Figure 1A5-60

REINST ALL

Reinstallation of the front door guide channel assembly is the reverse of the removal procedure noting the

following:

1. Tighten all retaining screws to the correct torque specification.

2.

3.

4.

2. If required before installing the door inner trim panel, adjust the front door window and regulator, refer

2.14 FRONT DOOR WINDOW A SSEMBLY.

3. Ensure the front door water shield is correctly fitted to the door panel.

FRONT DOOR GUIDE CHANNEL ASSEMBLY

GLASS CHANNEL RETAINING

SCREW TORQUE SPECIFICATION 6.0 – 8.0 Nm

FRONT SIDE PULL RETAINING

BRACKET SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

OUTSIDE REAR VIEW MIRROR

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 2.5 – 3.5 Nm

FRONT DOOR RADIO SPEAKER

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 1.5 – 3.0 Nm

2.14 FRONT DOOR WINDOW ASSEMBLY

LT Section No. – 11-020

1. Remove the front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR

WINDOW REGULATOR HANDLE ASSEMBLY.

2. Remove the front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE).

3. Remove the front door trim panel assembly refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

4. Remove the window regulator assembly, refer to 2.9 FRONT DOOR WINDOW REGULATOR ASSEMBLY.

5. Remove the front door belt outer reveal moulding assembly, refer to 2.11 FRONT DOOR BELT OUTER

REVEAL MOULDING ASSEMBLY.

6. Remove the front door guide channel assembly, refer to 2.13 FRONT DOOR GUIDE CHANNEL

ASSEMBLY.

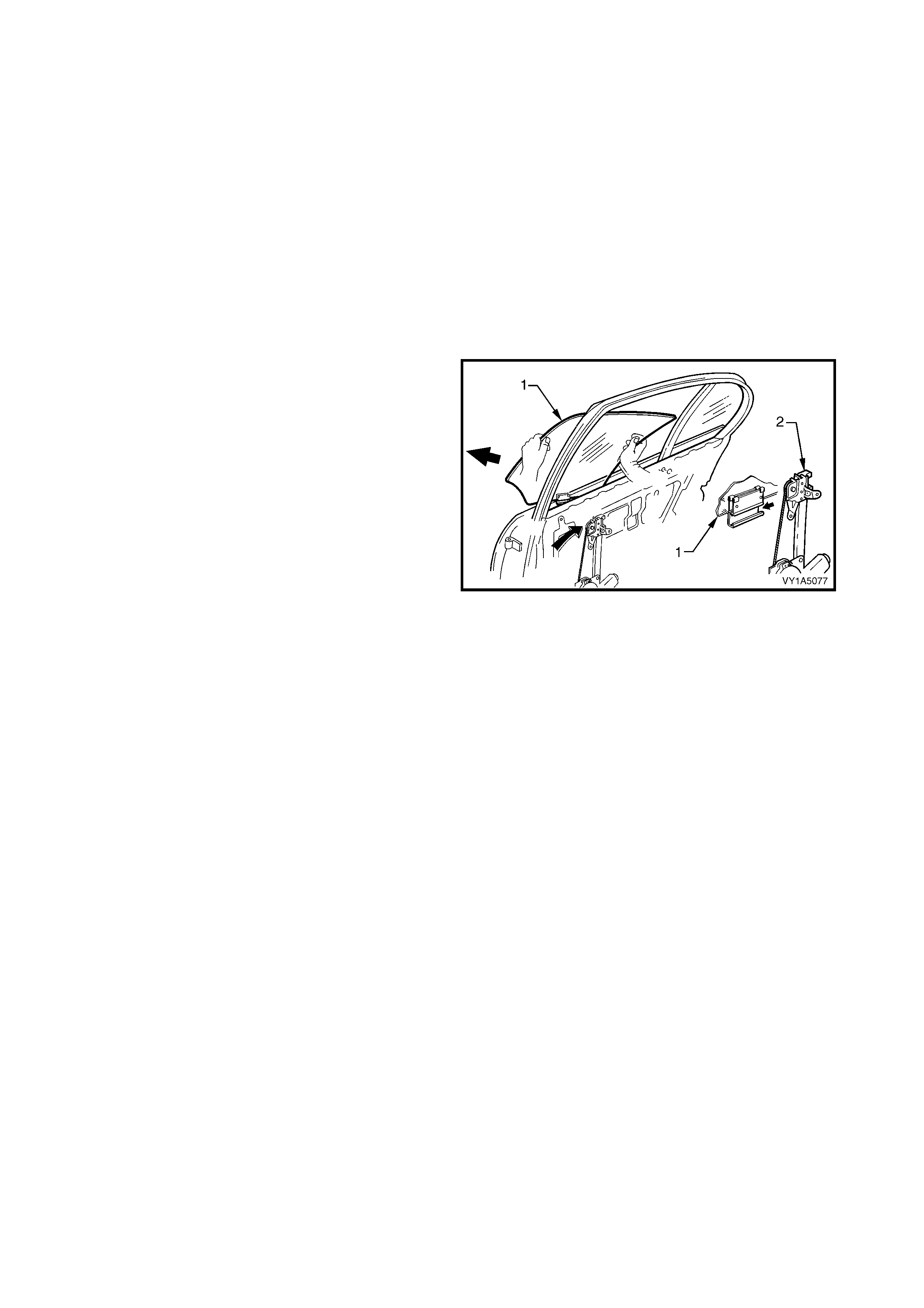

REMOVE

1. Lift the f ront door windo w assembl y (1) up t hrough

the door belt opening and slide to the rear.

Figure 1A5-61

REINST ALL

Reinstal lation of the fr ont door win dow ass em bly is the

reverse of the removal procedure noting the following:

1. Ensure all frictional surfaces of the window

regulator assembly and associated parts are

adequately lubricated with Lithium base grease

NLGI No. 1 (with 9 % zinc oxide) or equivalent.

2. Install the front window regulator channel

assembly (1).

NOTE: The initial attachment is to be loose. Tighten

the screw (2) to the specified tor que when the glass is

installed and in the down position, refer to ADJUST in

this Section.

Figure 1A5-62

FRONT SIDE WINDOW CHANNEL

ASSEMBLY RETAINING

SCREW PRELIMINARY

TORQUE SPECIFICATION 6.0 – 8.0 Nm

3. Ins tal l th e f r ont door window re gul ator h and le s h af t

seal (1) (where fitted), to the regulator assembly

(2), before installing into the door panel.

NOTE: The fr ont door wind o w washer ( 3) a nd the door

window regulator handle assembly (4) are to be

installed after the trim panel assembly, (where fitted).

4. Before installing the front door inner trim panel,

adjust the front door window and regulator as per

the following adjustment procedure, refer Figure

1A5-64.

5. Ensure the front door seal is correctly fitted to the

door panel, refer Figure1A5-52.

Figure 1A5-63

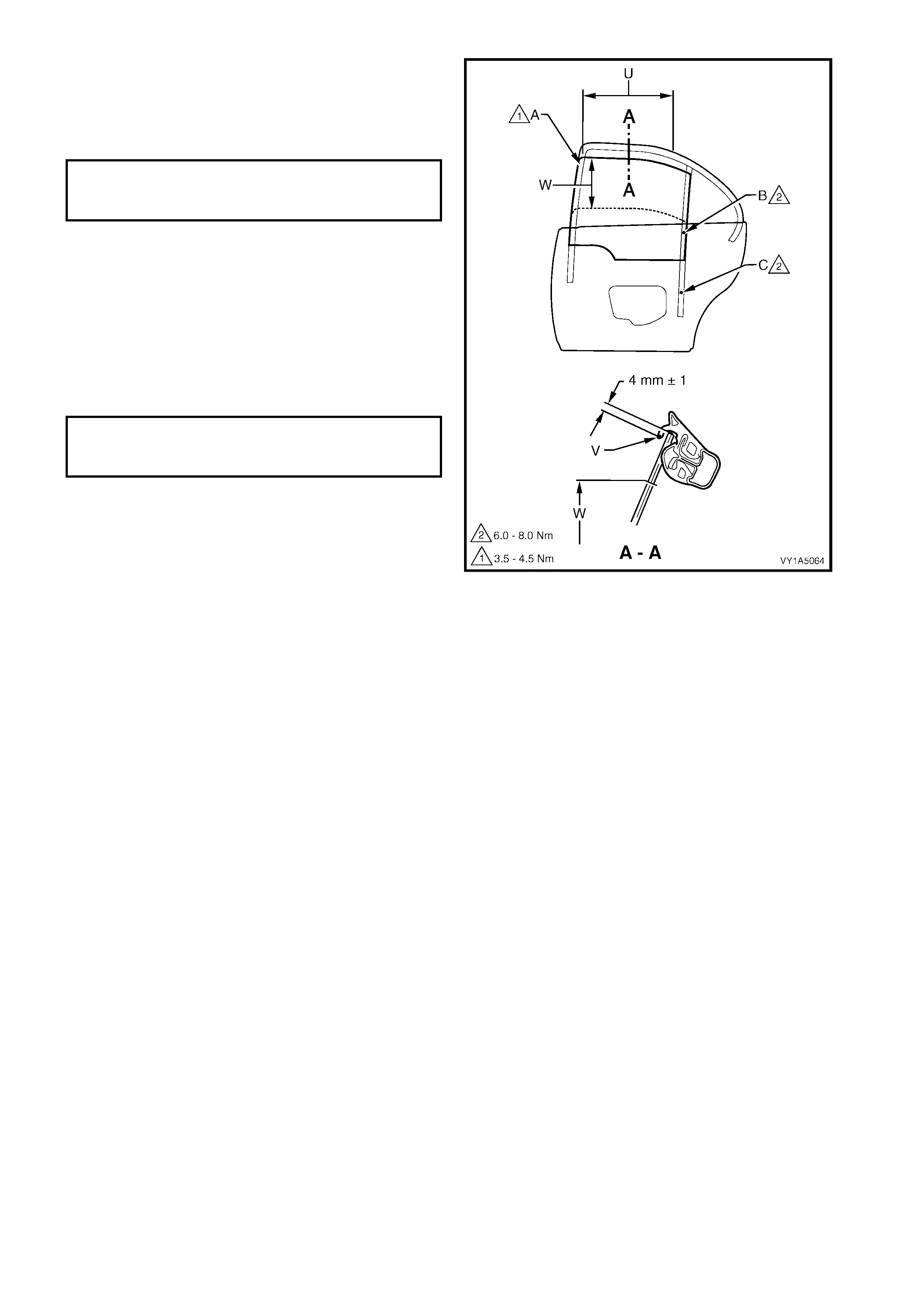

ADJUST

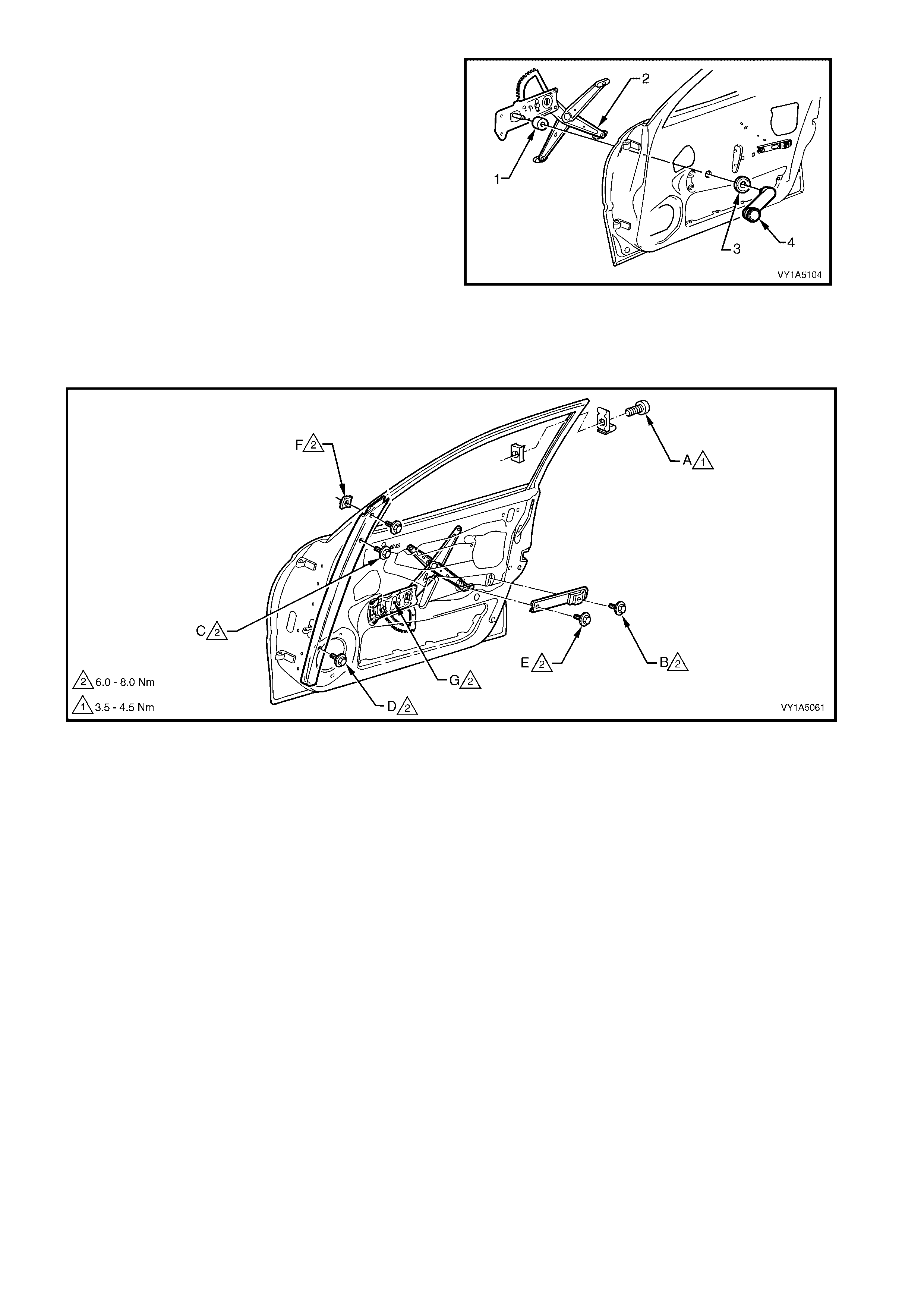

NOTE: Figure 1A5-64 shows the screw locations for

the following window assembly adjustment procedure.

Figure 1A5-64

Legend

A. Front Window Stop Assembly Attaching Screw

B. Front Window Regulator Rear Channel Assembly

Attaching Screw

C. Front Window Channel Centre Guide Assembly

Attaching Screw

D. Front Window Channel Lower Guide Assembly

Attaching Screw

E. Front Window Regulator Front Channel Assembly

Attaching Screw

F. Front Window Stop Screw

G. Regulator Assembly Front Window Stop

1. Adjust the front window stop assembly, point (A),

at the rear of the door s o that th ere is a 1 m m gap

below the highest possible end stop position.

Tighten the attaching screw to the specified

torque.

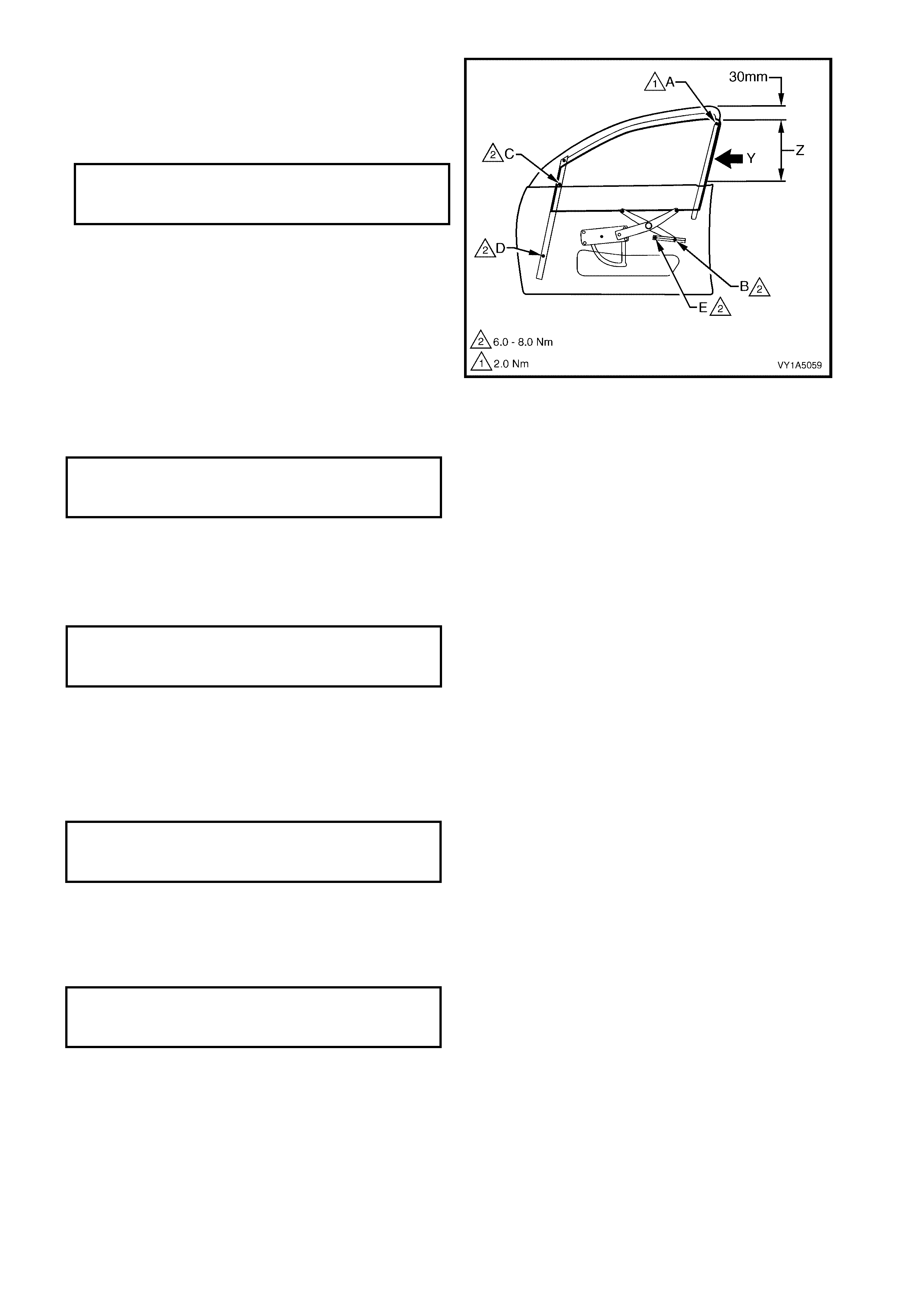

2. W ind the front door window assembly, up through

area (Z) ‘, while at the s ame tim e, pressing the ra il,

which is bonded to the rear edge of the window

assembly, in the direction of arrow (Y). Continue

winding the window assembly up until it the

window assembly is approximately 30 mm before

the closed position.

3. Secure the front window regulator channel

assembly, in position, without imposing any

stresses, by tightening the rear attaching screw,

point (B), to the specified torque.

4. Tighten the window channel guide assembly

centre attaching screw, point (C), to the specified

torque. Ensure that the window assembly is held

approximately 30 mm before the closed position.

Figure 1A5-65

5. Wind the window assembly to approximately 30

mm above the do or belt moul ding assem bly, while

at the same time, pressing the rear edge of the

window assembly, in the direction of arrow (Y).

Tighten the lower attaching screw, point (D), on

the guide assembly to the specified torque.

6. Secure the front window regulator channel

assembly in position without imposing any stress,

by tightening the front attaching screw, point (E),

to the specified torque.

FRONT WINDOW STOP ASSEMBLY

ADJUSTING SCREW PRELIMINARY

TORQUE SPECIFICATION 2.0 Nm

FRONT WINDOW CHANNEL ASSEMBLY

RETAINING REAR SCREW

TORQUE SPECIFICATION 6.0 – 8.0 Nm

FRONT CHANNEL GUIDE

ASSEMBLY RETAINING CENTRE

SCREW TORQUE SPECIFICATION 6.0 – 8.0 Nm

FRONT CHANNEL GUIDE

ASSEMBLY RETAINING LOWER

SCREW TORQUE SPECIFICATION 6.0 – 8.0 Nm

FRONT WINDOW CHANNEL ASSEMBLY

RETAINING FRONT SCREW

TORQUE SPECIFICATION 6.0 – 8.0 Nm

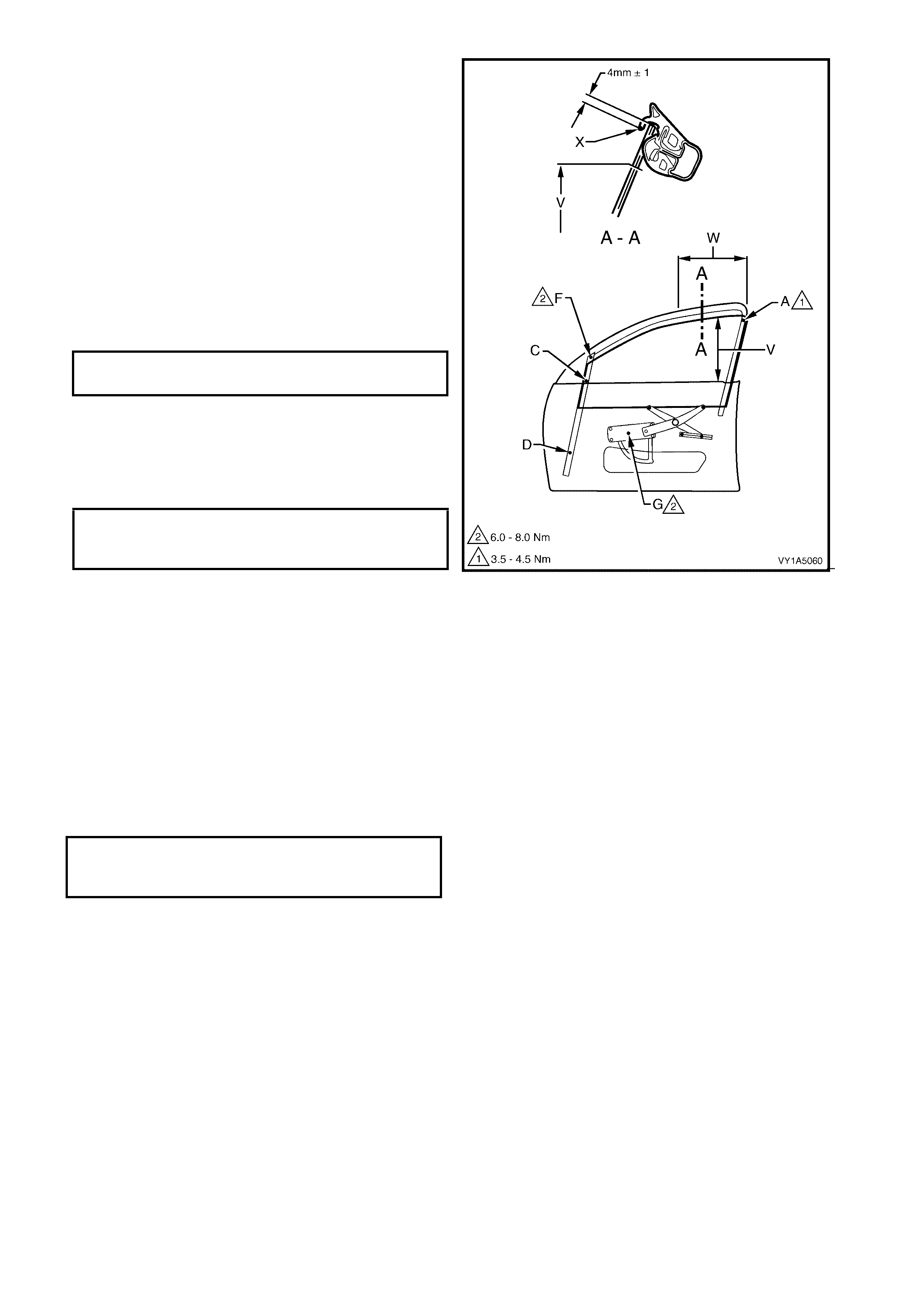

7. Wind the windo w ass embly up to a pos ition where

the upper edge of the window assembly is flush

with the up per edg e of the door m irror housing, as

seen from the outside. In this position, the upper

edge of the window assembly must be parallel

with point (X) on the front window upper

weatherstrip assembly, over area (W).

8. Check the cranking load of the window assembly

in area (V). If the window assembly binds, or the

motor load sounds excessive, re-adjust the

window assembly by correcting the guide

assembly attaching, points (C) and (D).

9. Adjust the front window stop screw, point (F), so

that the stop contacts with the window assembly.

Tighten attaching screw to the specified torque.

10. With the window in the closed position, adjust the

front window regulator assembly stop, point (G),

so that it contacts the toothed sector of the

regulator assembly and then tighten the screw to

the specified torque.

11. Check the upper edge of the window to ensure

that the lip of the glass run channel, point (X), is

parallel over the area (W).

The upper edge of the window must be 4 mm

above the lip of the glass run channel, point (X),

over the area (W).

If either th e dev iation in par allel ism or the ins ertion

depth exceeds 1 mm from specification, the stop

assemblies at points (A), and (F), must be

readjusted.

13. Tighten the window stop screw, point (A), to the

specified torque.

Figure 1A5-66

FRONT WINDOW ST OP

ASSEMBLY ADJUSTING SCREW

TORQUE SPECIFICATION 3.5 - 4.5Nm

REGULATOR ASSEMBLY FRONT

WINDOW DOWN STOP ADJUSTING

NUT TORQUE SPECIFICATION 6.0 – 8.0 Nm

FRONT WINDOW STOP ADJUSTING

SCREW TORQUE SPECIFICATION 6.0 – 8.0 Nm

2.15 FRONT DOOR WEATHERSTRIP ASSEMBLIES

LT Section No. – 11-650

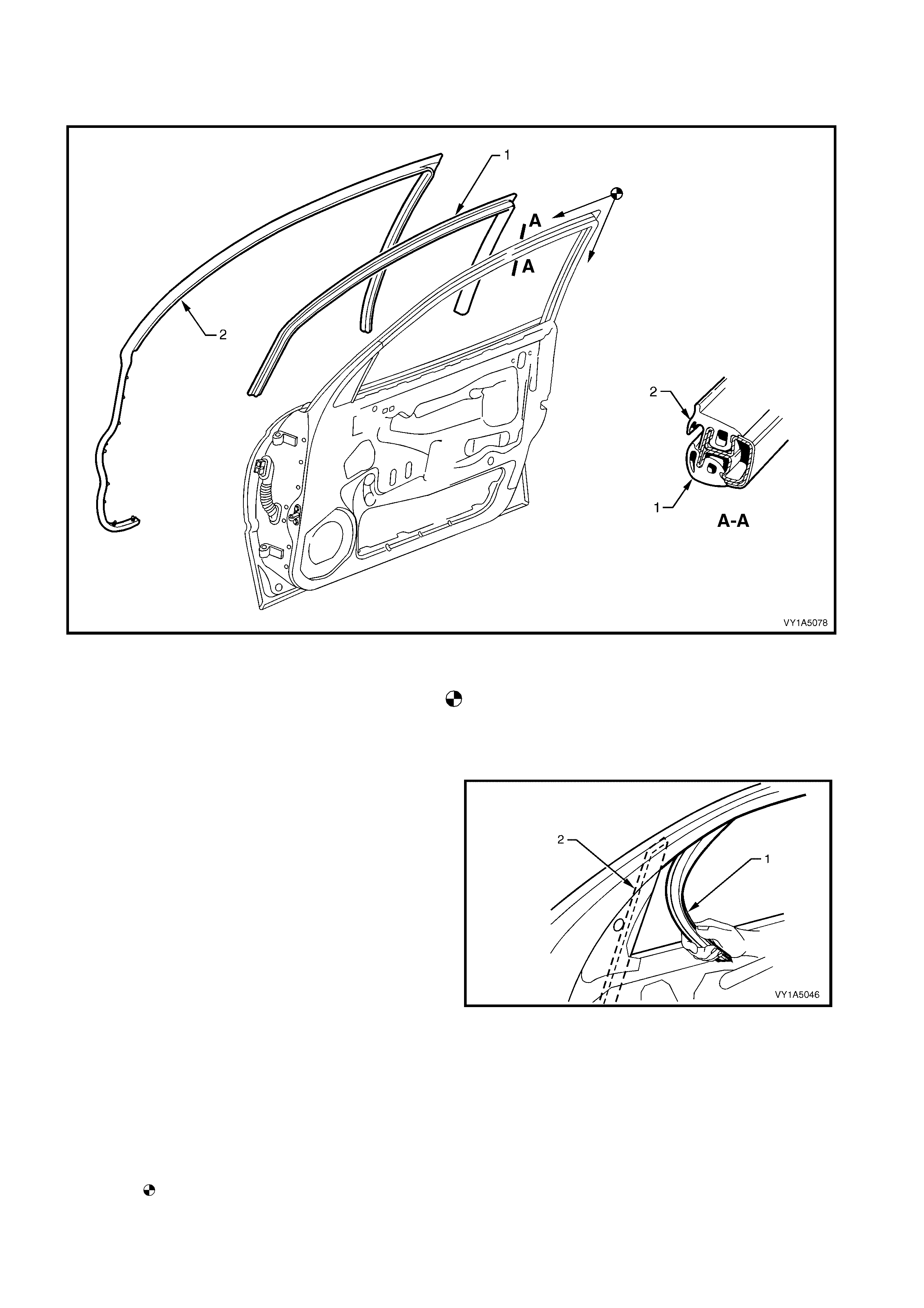

Figure 1A5-67

Legend

1. Front Door Window Upper Weatherstrip Assembly.

2. Front Door Upper Weatherstrip Assembly. Install Weatherstrip Corner Aligning Locating Marks On

Door Frame, Then Proceed In Direction Of Arrows.

REMOVE

1 With the window glass lowered, starting at the

guide ra ils (2), progressi vely peel the door window

upper weatherstrip assembly (1) away from the

door windo w frame.

2 Pull the weatherstrip u p and out, at the rear of the

door.

3 Progressively remove the front door upper

weatherstrip assembly, from the lip on the door

upper frame, refer Figure 1A5-67.

4 Carefully remove the weatherstrip from the belt

line, allowing the retainer clips to pull out of the

weatherstrip and remain in the door panel.

5 Remove th e r et ai ner cl ips f rom the door panel with

a clip removal tool and refit them back into the

weatherstrip ready for reinstallation.

Figure 1A5-68

REINST ALL

Reinstal lation is the re verse of the removal proc edure,

refer Figure 1A5-67, noting the following:

1. When installing t he weatherstrips, start installation

process from the top corner of the door frame as

shown .

2.16 FRONT DOOR WINDOW FRAME UPPER SCALP MOULDING

LT Section No. – 11-650

IMPORTANT: Prior to commencing any of the following procedures, lower the window assembly, to its down

position.

1. Remove the front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR

WINDOW REGULATOR HANDLE ASSEMBLY.

2. Remove the front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE

ASSEMBLY (REMOTE).

3. Remove the front door trim panel assembly refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

4. Partially remove the front door weatherstrip assembly and remove the front door upper weatherstrip

assembly, refer to 2.15 FRONT DOOR WEATHERSTRIP ASSEMBLY.

REMOVE

1. Peel back the outside rear view mirror seal (1) to

gain excess to the screws.

2. Remove the three screws (2) securing the outside

rear view mirror assembly (3) to the door panel.

While supporting the mirror, disconnect the wiring

harness connector (4) and remove the mirror.

Figure 1A5-69

3. W ith the aid of a k nife, progress ively peel th e front

door window frame upper scalp moulding (1),

away from around the door window frame,

separating the adhesive from the frame.

4. Clean the surface of the door frame with Prepsol

or equivalent as required.

NOTE: The front door window frame upper scalp

moulding will be damaged during this operation and

must be replaced.

Figure 1A5-70

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

Front door window frame upper scalp moulding

assembly.

REINST ALL

Reinstallation of the front door window frame upper

scalp moulding will require a new self adhesive

moulding assembly, refer Figure 1A5-70.

1. Tighten all retaining screws to the correct torque

specification.

OUTSIDE REAR VIEW MIRROR

ASSEMBLY RETAINING SCREW

TORQUE SPECIFICATION 2.5 – 3.5 Nm

2.18 FRONT DOOR ASSEMBLY

LT Section No. – 12-460

REMOVE

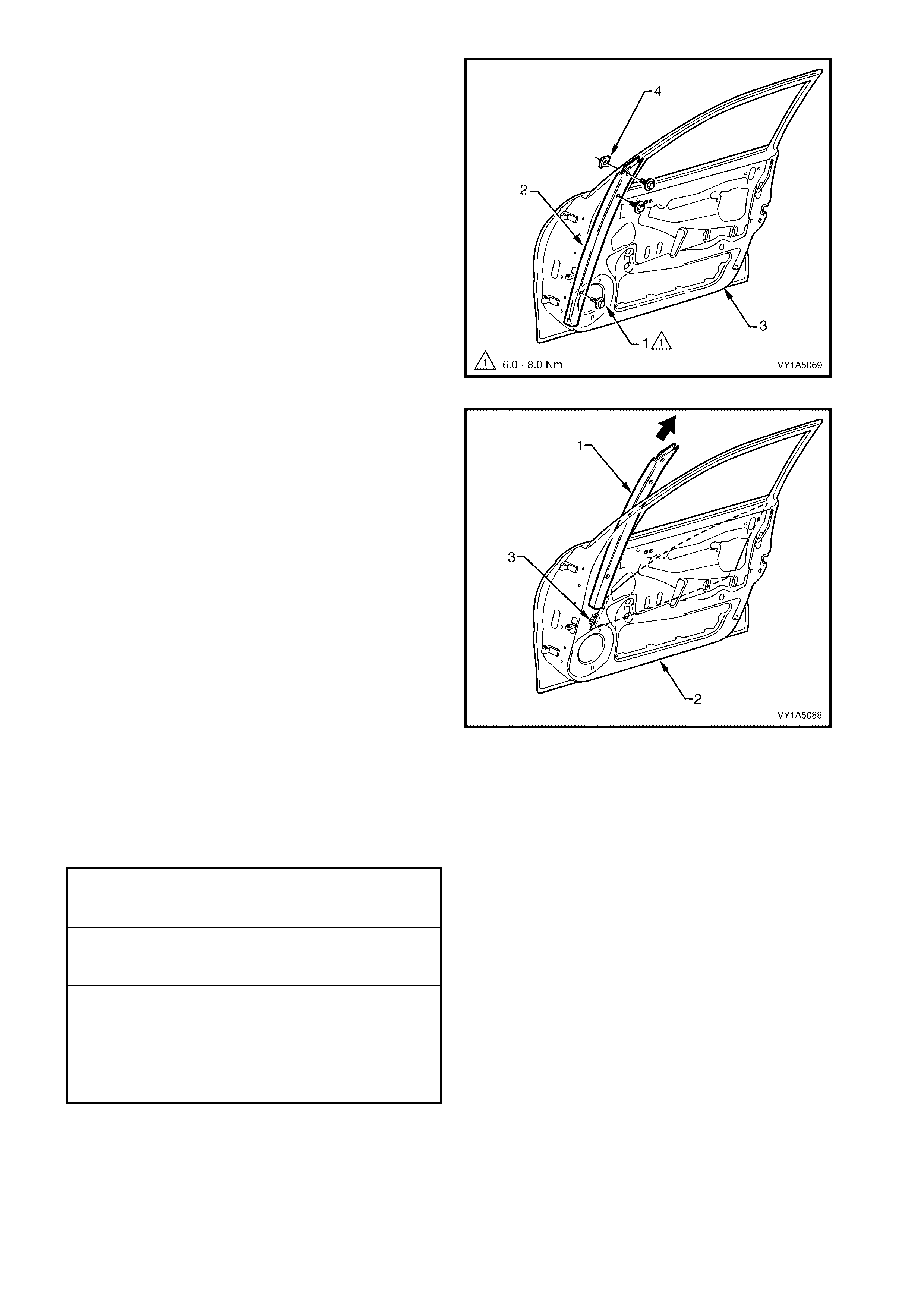

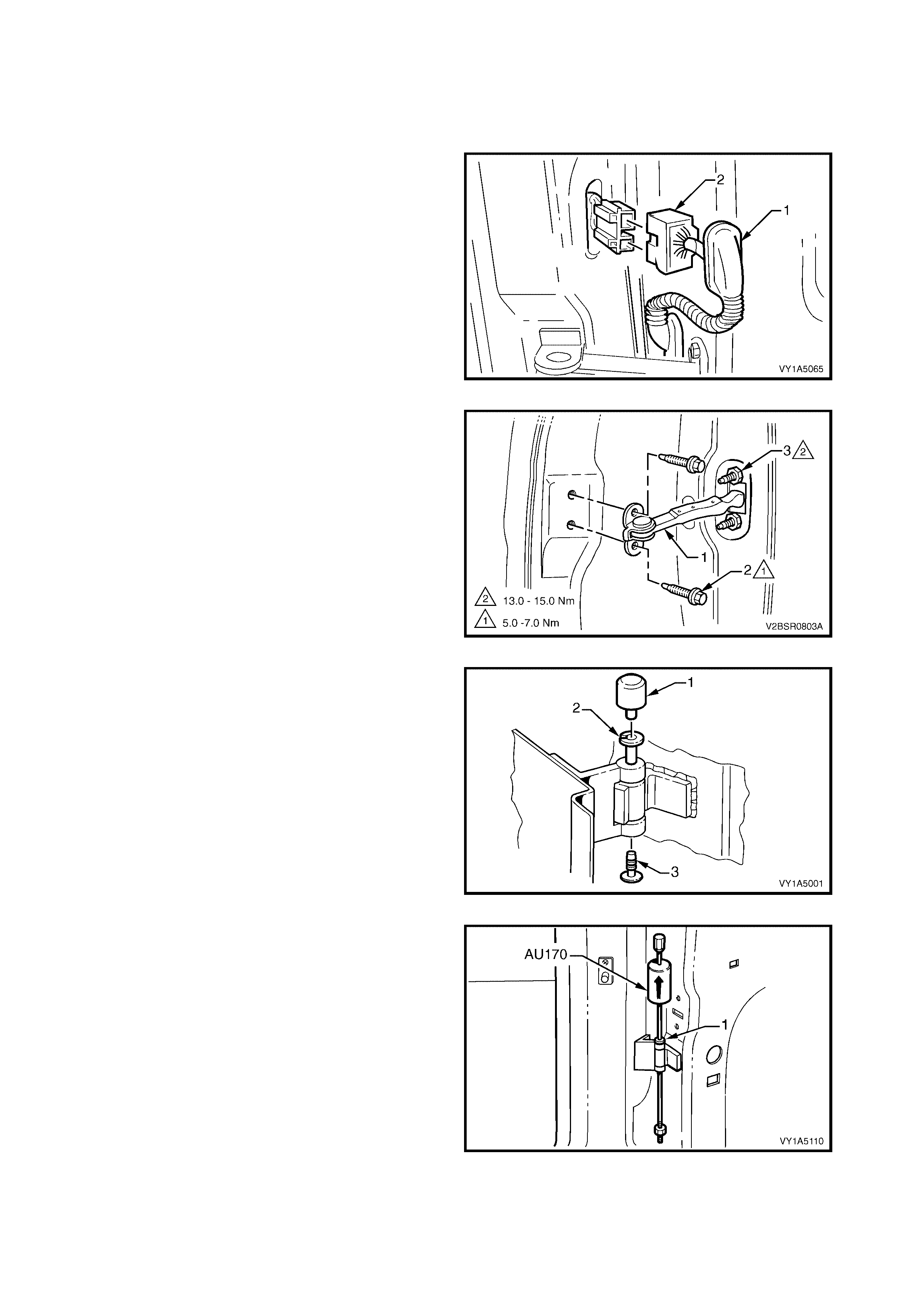

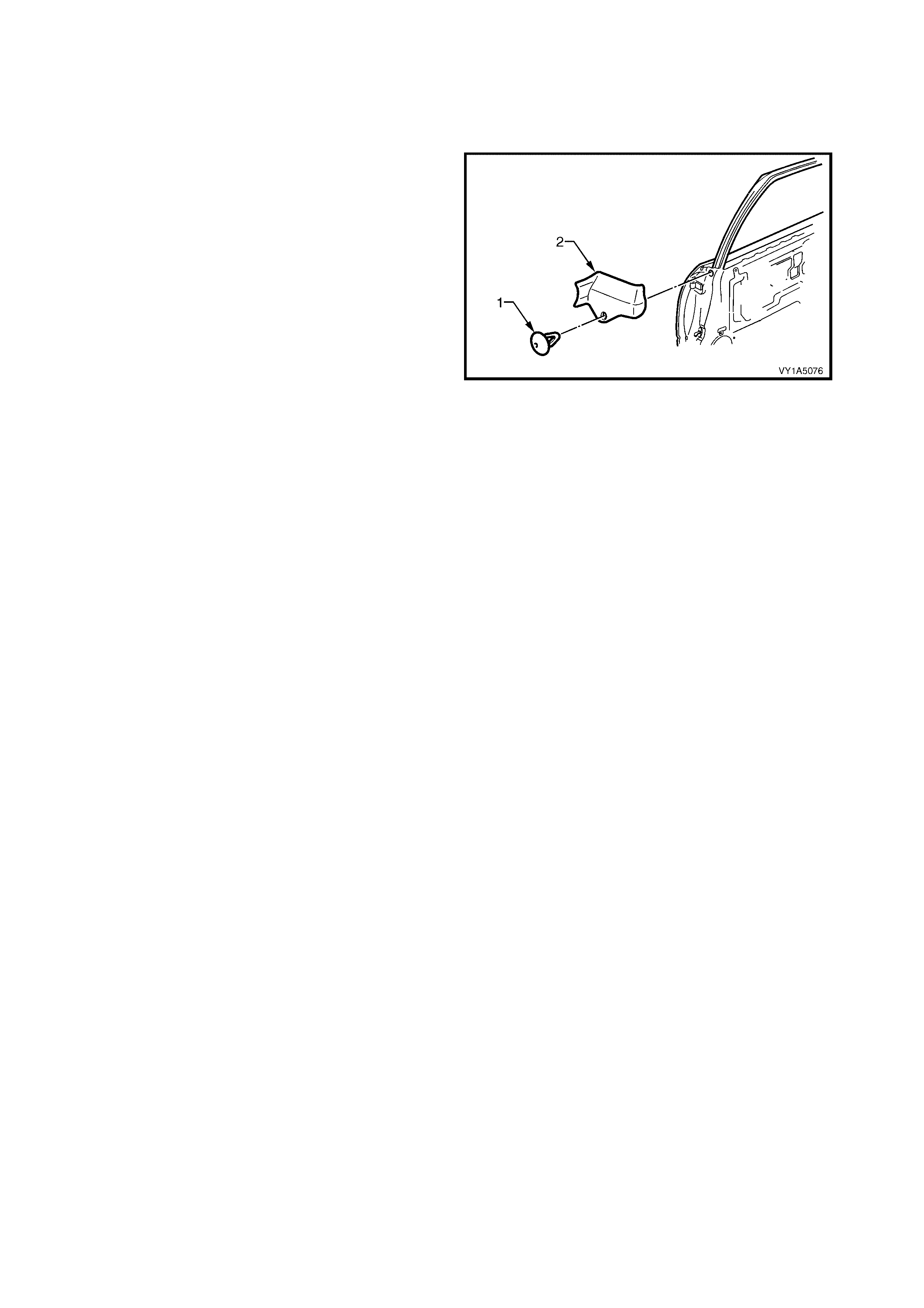

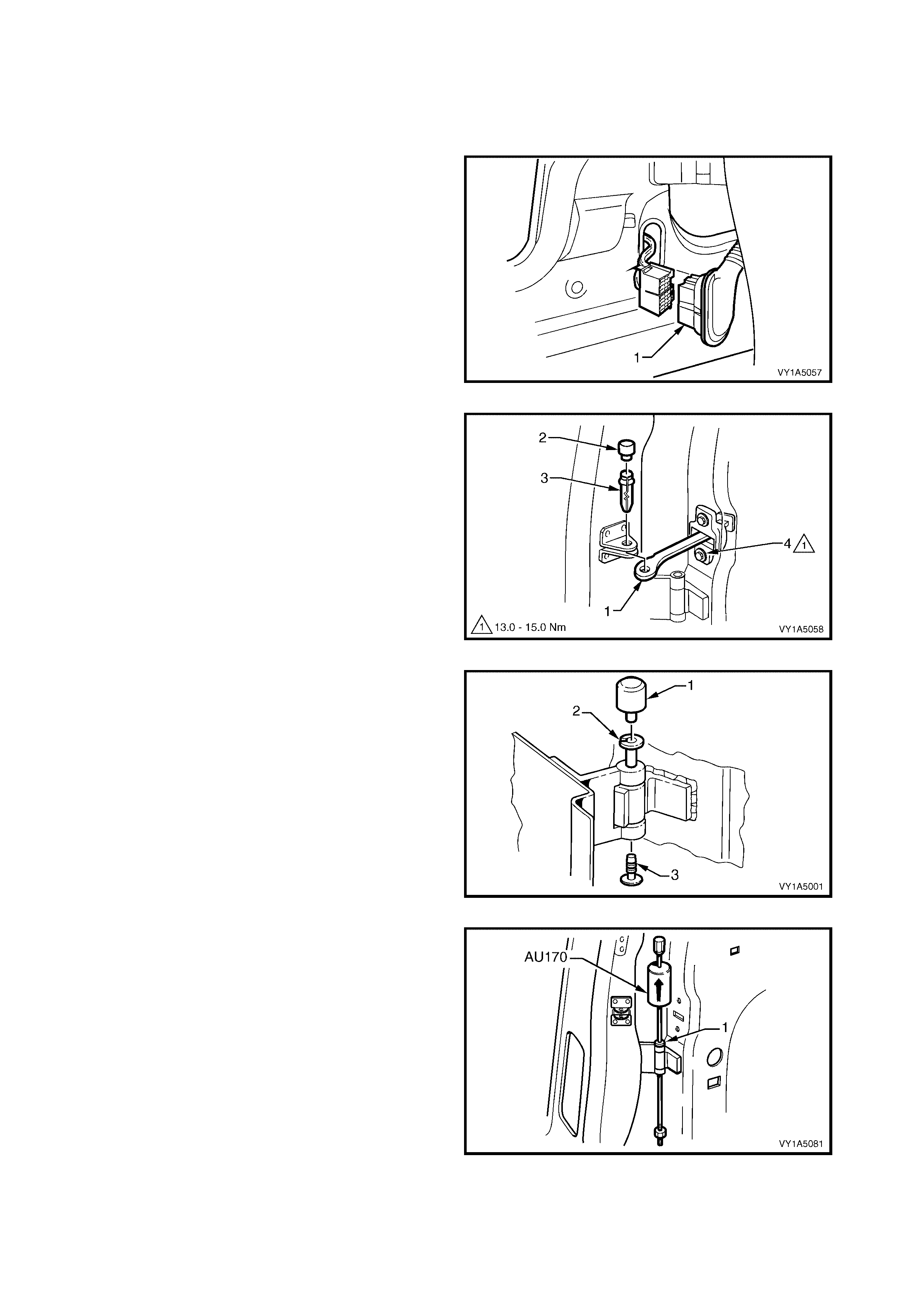

1. Remove the grommet (1) from the door wiring

harness connector plug (2).

2. Depress the tabs and gently pull on the wiring

harness to withdraw the connector from the body.

3. Disconnect the connector.

Figure 1A5-71

4. Remove the front door check assembly (1) from

the vehicle by removing the two screws (2).

NOTE 1: If required, remove the two nuts (3),

attaching the check assembly to the door, allowing

access to the hinge pins.

NOTE 2: Ensure the door cannot swing freely causing

damage.

Figure 1A5-72

5. Remove the front hinge pin cap (1) and the front

hinge plug (3) from the front hinge pin (2) on the

upper and lower hinges.

6. Have an assistant support the door or support the

base of the door on a wooden block and a trolley

jack.

Figure 1A5-73

7. Using the Tool No. AU170, drive the lower and

then the upper hinge pivot sleeves (1) from the

hinges.

8. Remove the door assembly.

Figure 1A5-74

DISASSEMBLE

As required remove the following components, refer to the appropriate Sections:

1. Front door window regulator handle assembly (where fitted), refer to 2.4 FRONT DOOR WINDOW

REGULATOR HANDLE ASSEMBLY.

2. Front door inside handle assembly (remote), refer to 2.5 FRONT DOOR INSIDE HANDLE ASSEMBLY

(REMOTE).

3. Front door trim panel assembly, refer to 2.6 FRONT DOOR TRIM PANEL ASSEMBLY.

4. Front door lock assembly, refer to 2.7 FRONT DOOR LOCK ASSEMBLY.

5. Front door outside handle assembly, refer to 2.8 FRONT DOOR OUTSIDE HA NDLE A SSEMBLY.

6. Window regulator assembly, refer to 2.9 FRONT DOOR WINDOW REGULATOR ASSEMBLY.

7. Front window inner filler assembly, refer to 2.10 FRONT WINDOW INNER FILLER ASSEMBLY.

8. Front door belt outer reveal moulding assembly, refer to 2.11 FRONT DOOR BELT OUTER REVEAL

MOULDING ASSEMBLY.

9. Front door guide assembly, refer to 2.12 FRONT DOOR GUIDE ASSEMBLY.

10. Front door guide channel assembly, refer to 2.13 FRONT DOOR GUIDE CHANNEL ASSEMBLY.

11. Front door window assembly, refer to 2.14 FRONT DOOR WINDOW ASSEMBLY.

12. Front door weatherstrip assembly, refer to 2.15 FRONT DOOR WEATHERSTRIP ASSEMBLY.

13. Front door window frame upper scalp moulding, refer to 2.16 FRONT DOOR WINDOW FRAME UPPER

SCALP MOULDING.

14. Front door wiring harness assembly, refer to 2.17 FRONT DOOR WIRING HARNESS ASSEMBLY.

15. Front door opening weatherstrip assembly, refer to 2.19 FRONT DOOR OPENING WEATHERSTRIP

ASSEMBLY, EXCEPT COUPE and 2.20 FRONT DOOR OPENING WEATHERSTRIP ASSEMBLY,

COUPE.

16. Front door body side moulding, for Sedan refer to Section 1A9, 2.11 BODY SIDE MOULDINGS, and for

Wagon refer to Section 1A9, 3.12 BODY SIDE MOULDINGS.

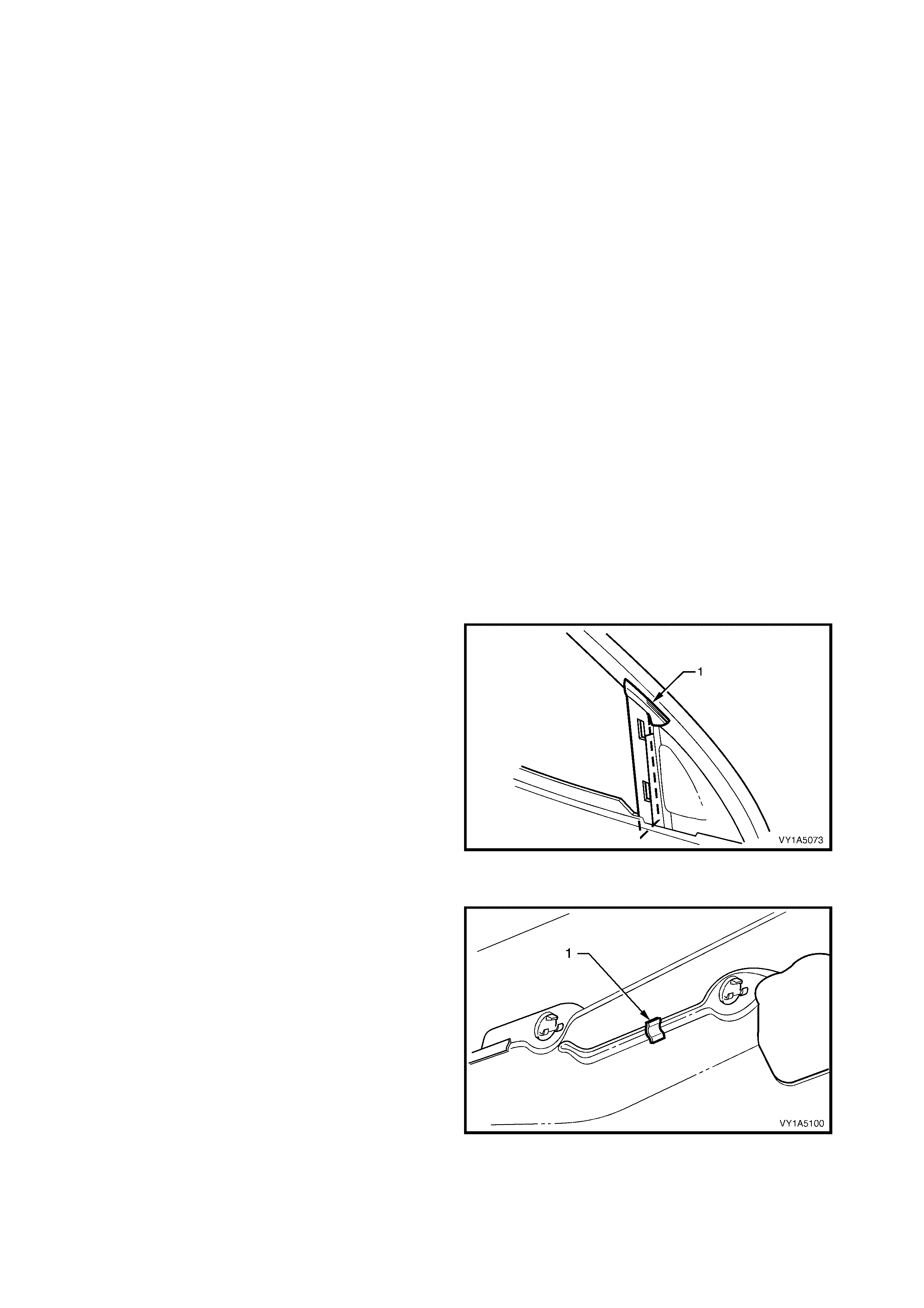

Remove – Front Door Window Channel Seal

1. Carefully remove the front door window channel

seal (1) from the front door panel upper frame.

Reinstall – Front Door Window Channel Seal

Reinstal lation of the fr ont door windo w channe l seal, is

the reverse of the removal.

Figure 1A5-75

Remove – Front Door Deadener

1. Prise the front door deadener (1), from the front

door panel inner.

Reinstall – Front Door Deadener

Reinstallation of the - front door deadener, is the

reverse of the removal.

NOTE: If reusing the s ame part, appl y a sm all amount

of contact adhesive.

Figure 1A5-76

Remove – Front Door Inside Handle Rod Clip

1. Remove the two front door inside handle rod clips

(1), by turning 90°and then removing from the front

door panel inner.

Reinstall – Front Door Inside Handle Rod Clip

Reinstallation of the front door inside handle rod clip,

is the reverse of the removal.

Figure 1A5-77

REINST ALL

IMPORTANT: If using a new door panel assembly it

must be prepared to maintain original manufacturers

specifications. This includes the application of joint

sealer, hand putty and cavity wax. Refer to the

MY2003 V Y & V 2 Series Ser vice Manual Su pplement,

Body Structure Repair Manual for specifications.

Reinstal lation of the fr ont door as sem bl y is the revers e

of the removal procedure, noting the following:

1. Apply Lithium base grease NLGI No. 1 (with 9 %

zinc oxide) or equivalent, to the hinge pivot

sleeves prior to installation.

2. Using Tool No. AU303 (2), and a hammer, install

the hinge pivot sleeves (1).

3. Check the fit of the door and adjust as required,

refer to ADJUST in this Section.

NOTE: Make allowances in the adjustment if the trim

and hardwar e are not insta l led.

4. Tighten all retaining screws to the correct torque

specification.

5. Reinstall the trim and hardware as required.

6. Connect and install the door wiring harness

connector to the body wiring harness and refit the

grommet.

7. Refit the hinge pivot sleeve dust caps, refer

Figure 1A5-73.

Figure 1A5-78

CHECK ASSEMBLY TO PILLAR

RETAINING SCREW

TORQUE SPECIFICATION 5.0 – 7.0 Nm

CHECK ASSEMBLY TO

DOOR RETAINING NUT

TORQUE SPECIFICATION 13.0 – 15.0

ADJUST

Attention s hould b e give n to unif orm m argins and alig nm ent between t he door an d surr ounding p arts when door

adjustments are being carried out.

Uniform margins and alignment of the front and rear doors in relation to the body opening can be achieved by

setting the appropriate door hinge. Refer to MY2003 VY & V2 Series Service Manual Supplement,

Body Structure Repair Manual for specifications.

Adjust hi nges in conjunc tion with a djustm ent to the lock striker to ac hieve an acce ptable door closing ef fort with

correct door lock to striker engagement, refer to 2.2 FRONT DOOR LOCK STRIKER.

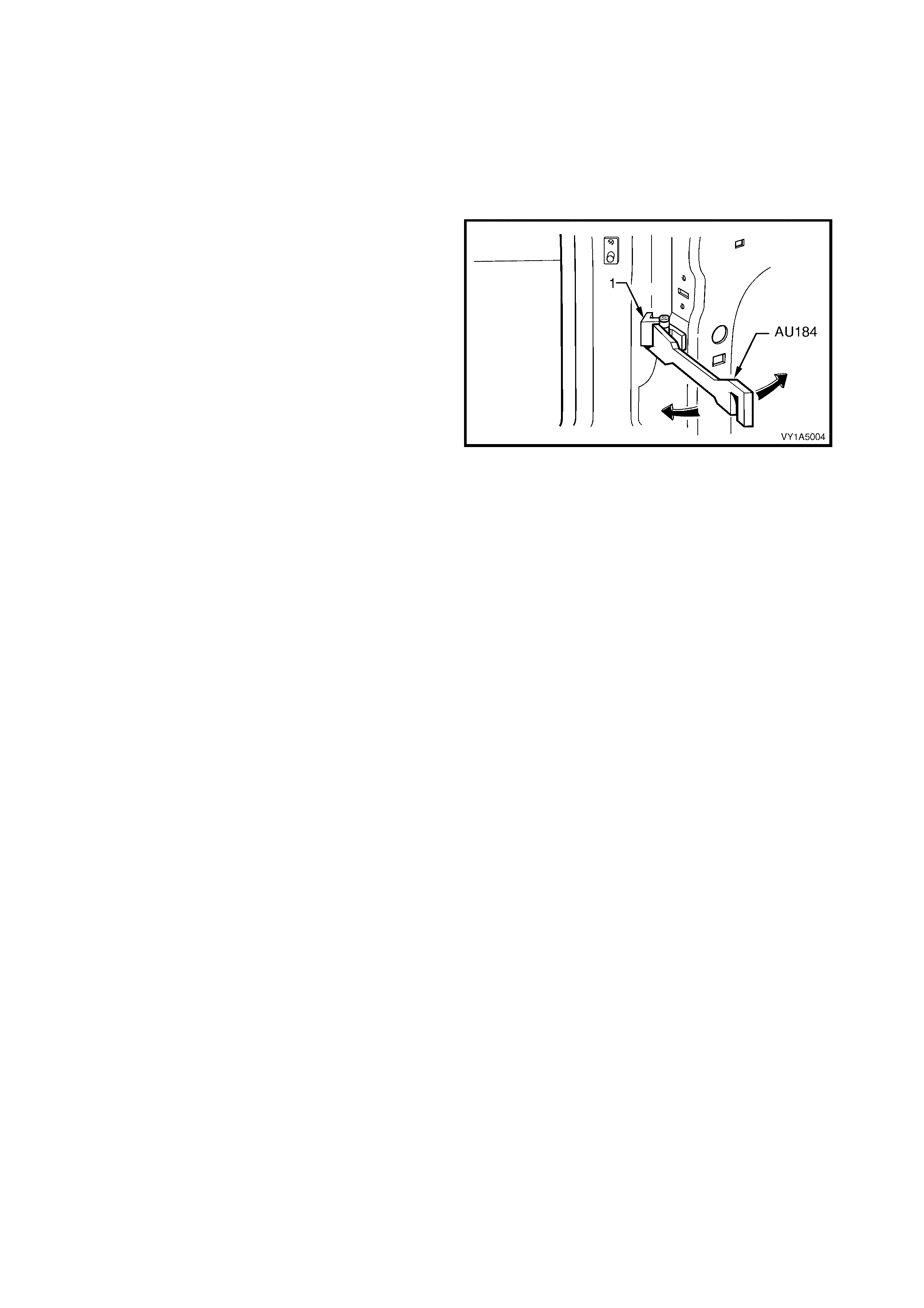

Use Tool No AU184 to set door hinges by slightly

bending the front door hinge (1) noting the following:

1. Take care when adjusting the doors not to

misalign the hinge pins. Any significant

misalignment will cause the pins to shear when

the door is opened or closed.

2. Excessive bending or levering of the window

frame will cause damage.

3. Final adjustment must take place when all the

door components and seals are installed.

IMPORTANT: Adjust doors with striker assembly

removed. Striker assembly should only be fitted once

satisf actory alignm ent is achieve d. They mu st NOT be

used to pull the door into the correct position.

Figure 1A5-79

2.19 FRONT DOOR OPENING WEATHERSTRIP ASSEMBLY, EXCEPT COUPE

LT Section No. – 11-600

As required, remove the following components :

1. Side sill trim and plate, quarter trim panel assembly, centre pillar upper trim, windshield side garnish and

hinge pillar trim, refer to Section 1A8 HEADLINING & INTERIOR TRIM.

2. Instrument panel outer cover, refer to Section 1A3 INSTRUMENT PA NEL & CONSOLE.

REMOVE

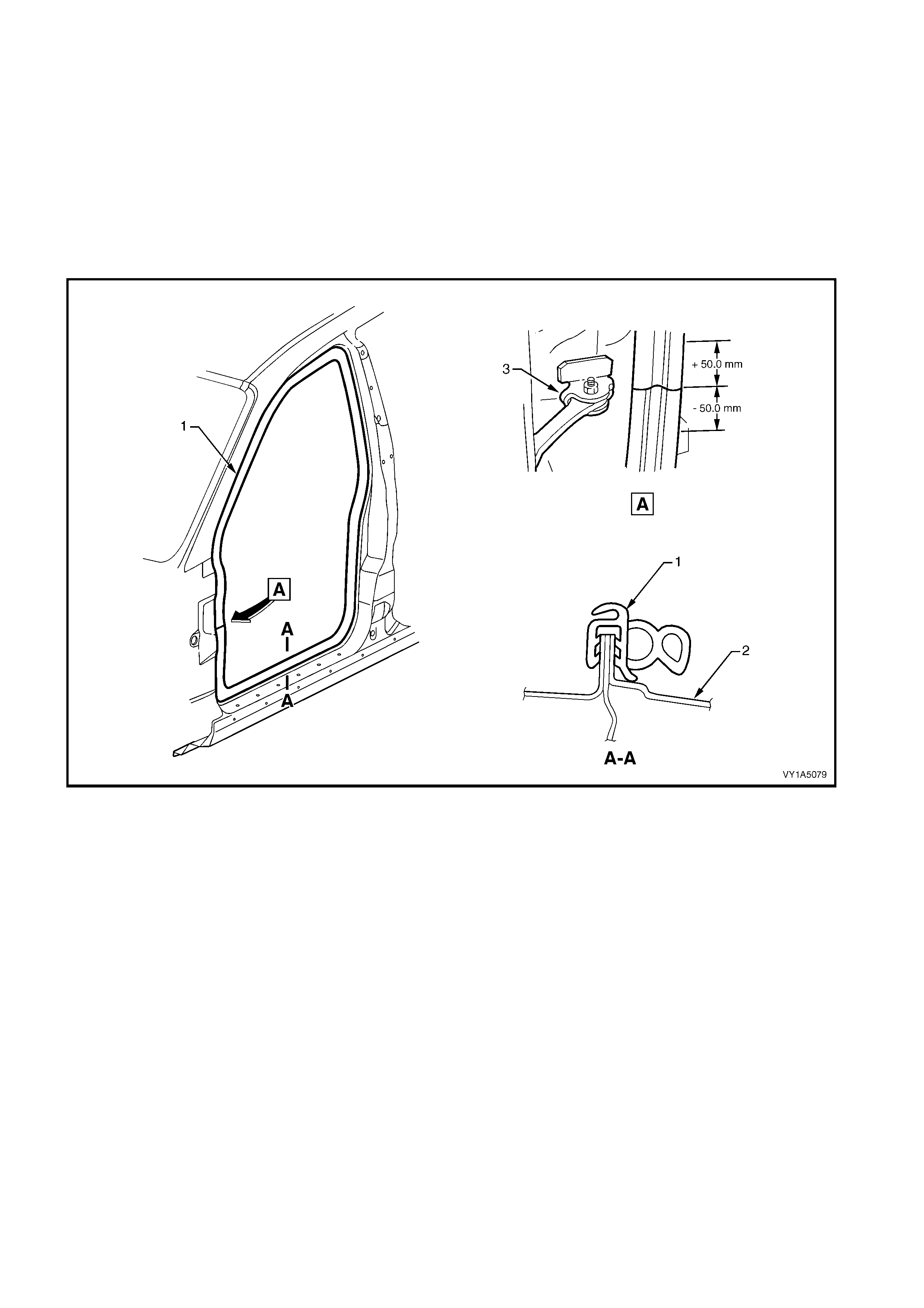

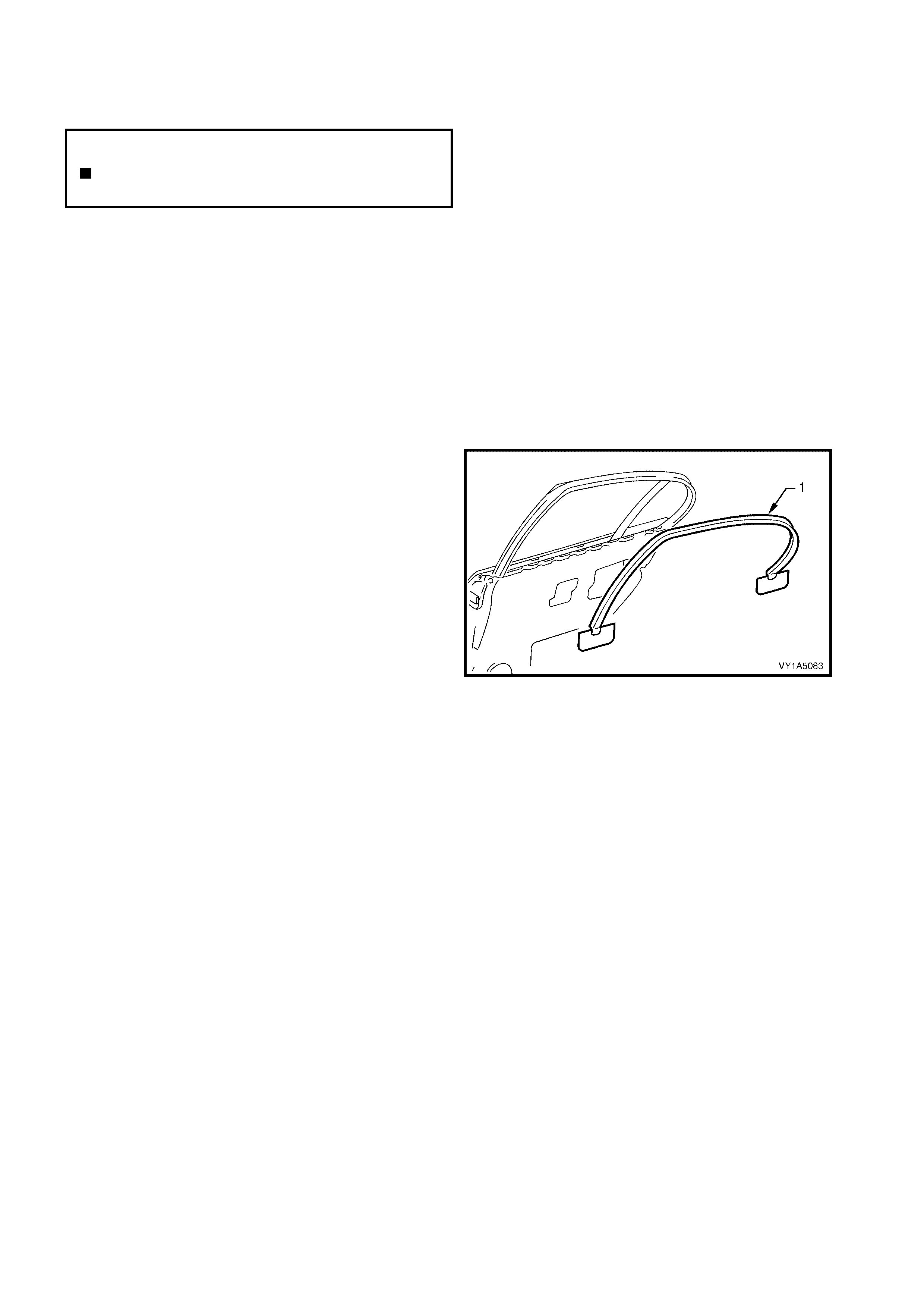

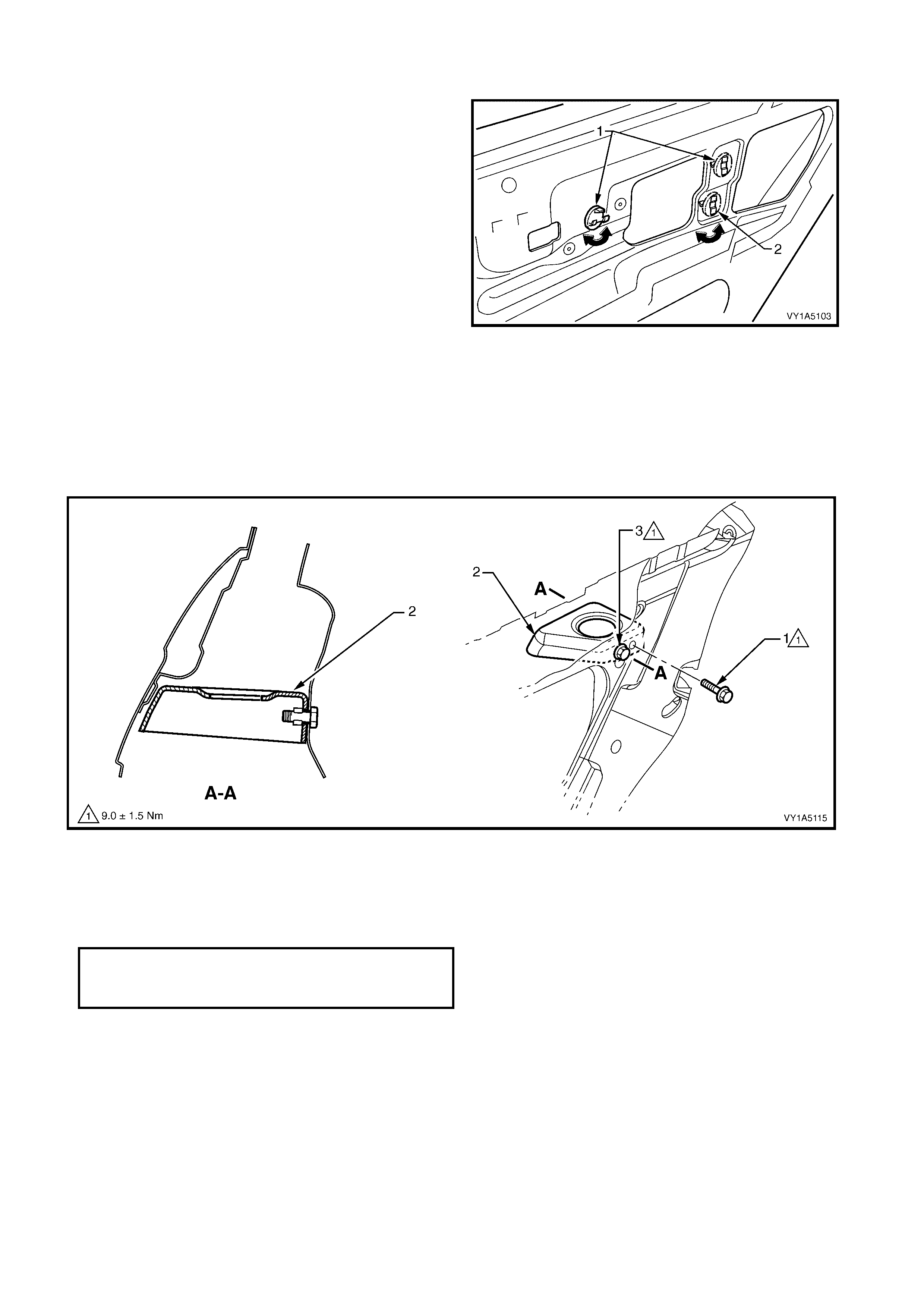

1. Gently prise the weatherstrip (1) from the door

opening.

Figure 1A5-80

Legend

1. Front Door Weatherstrip Assembly 2. Door Opening Frame 3. Front Hinge Check Assembly

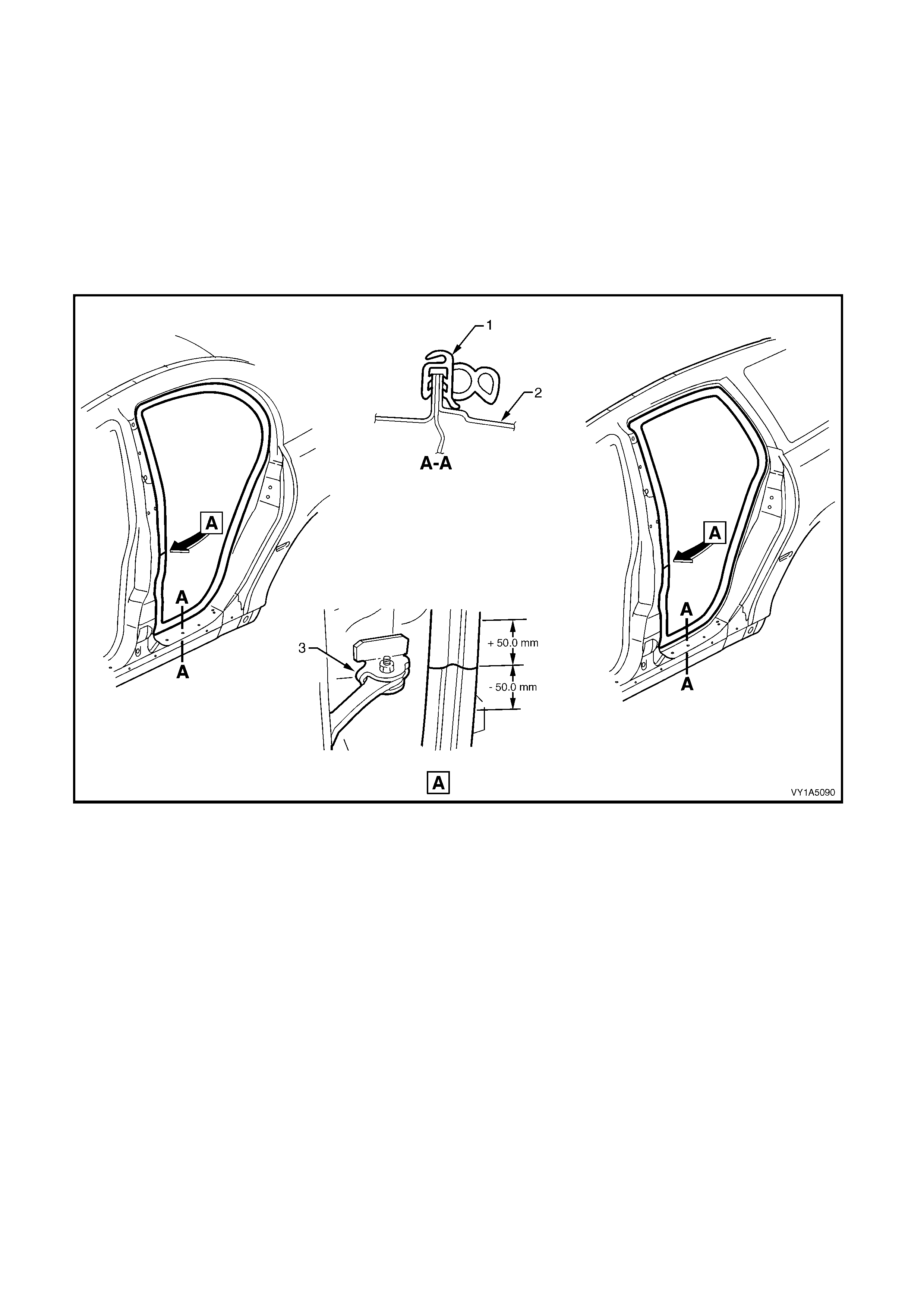

REINST ALL

Reinstallation of the front door weatherstrip assembly,

is the reverse of the removal procedure, noting the

following:

1. Align identification mark on weatherstrip with the

front hinge check assembly (3) in the door frame

opening (2) ± 50 mm as shown, refer Figure

1A5-80.

NOTE: Allow crowding of the weatherstrip in all

corners of the door opening frame (2). Ensure

weatherstrip does not short cut corners and foul the

door trim.

2. Ensure the weatherstrip lip sits over trim panels.

3. Tighten all trim attaching screws to the correct

torque specification, refer to Section 1A8,

HEADLINING AND INTERI OR TRIM.

2.20 FRONT DOOR OPENING WEATHERSTRIP ASSEMBLY, COUPE

LT Section No. – 11-600

As required, remove the following components:

1. Moulding - Windshield Si de G ar nis h, Pan el - Body Hinge Pi ll ar Trim , Panel - Cent re Pillar Upp er T r im , Panel

Assembly - Quarter Trim, Retainer Assembly - Front & Rear Door Opening Floor Carpet, refer to

Section 1A8 HEADLINING & INTERIOR TRIM.

2. Cover - Instrument Outer Trim, refer to Section 1A3 INSTRUMENT PANEL & CONSOLE.

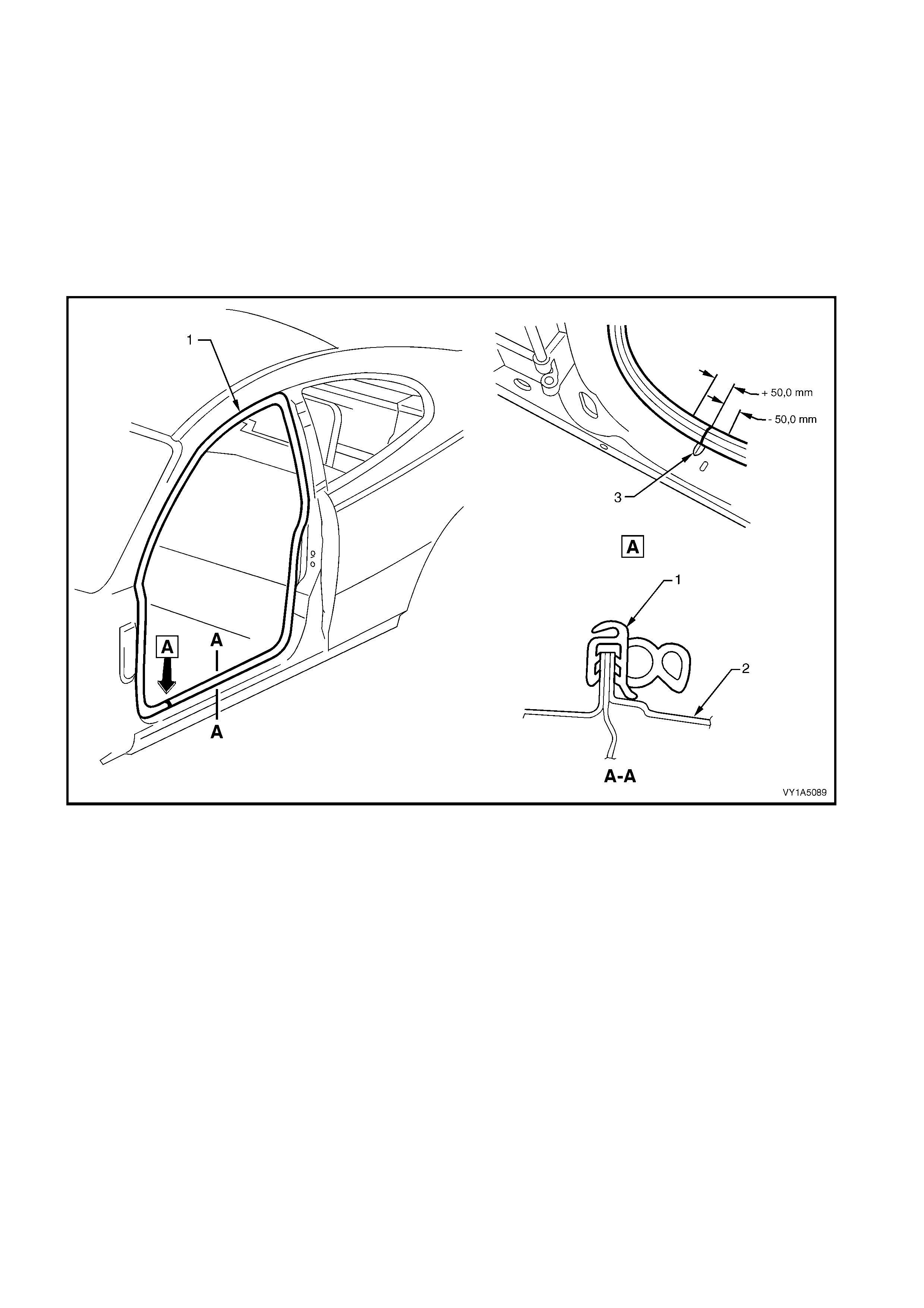

REMOVE

1. Gently prise the weatherstrip (1) from the door

opening.

Figure 1A5-81

Legend

1. Front Door Weatherstrip Assembly 2. Door Opening Frame 3. Door Frame Dart

REINST ALL

Reinstallation of the front door weatherstrip assembly,

is the reverse of the removal procedure, noting the

following:

1. Align the identification mark on the weatherstrip

with the centre line of the dart (3) in the door frame

opening (2) ± 50 mm, refer to Figure 1A5-81.

NOTE: Allow crowding of the weatherstrip in all

corners of the door opening frame (2). Ensure

weatherstrip does not short cut corners and foul the

door trim.

2. Ensure the weatherstrip lip sits over trim panels.

3. Tighten all trim attaching screws, to the correct

torque specification, refer to Section 1A8

HEADLINING & INTERIOR TRIM.

3. REAR DOOR SERVICE OPERATIONS

3.1 REAR DOOR HINGE LUBRICATION

LT Section No. –

1. Remove the rear hinge pin cap (1) and the rear

hinge plug (2) from the rear hinge pin (3) on the

upper and lower hinges.

2. Using a grease gun, inject into the rear hinge pin

Lithium base grease NLGI No. 1 (with 9 % zinc

oxide) or equivalent.

3. Reinstall the cap and plug.

4. Wipe off any excess grease.

Figure 1A5-82

Techline

3.2 REAR DOOR LOCK STRIKER

LT Section No. – 11-725

REMOVE

1. Pencil scribe (1) the location of the rear door lock

striker assembly (2) on to the body pillar before

removal, to facilitate installation.

2. Using a Torx bit (30 T), remove two retaining

screws (3).

3. Remove the striker and spacer plates, if fitted.

Figure 1A5-83

REINST ALL

1. Align the rear door lock striker assembly (1), so

that the brid ge of the strik er locat es c entra lly in the

door fork lock assembly (2) as the door is being

closed. Firmly tighten the striker assembly.

2. Correct engagement can be achieved by vertical

or horizontal adjustment of the door lock striker

assembly. The door must not ‘Ride’ on the striker.

Add or delete the door lock striker washer (3)

between the striker assembly and body pillar to

achieve correct engagement of the striker

assembly to the lock. Also refer to

3.3 ADJUST REAR DOOR ASSEMBLY.

TIP: It is sound practice to remove the door lock striker

assembly and allow the door to hang free on the

hinges. Set th e hin ges as neces s ar y to achieve c orr ect

alignment and uniform margins, then reinstall the

striker and adjust.

3. When the correct alignment of the striker

assem bly is ach ieved, tig hten the s trik er assem bly

retaining screw (4) to the correct torque

specification.

Figure 1A5-84

STRIKER ASSEMBLY

RETAINING SCREW

TORQUE SPECIFICATION 8.0 – 18.0 Nm

3.3 ADJUST REAR DOOR ASSEMBLY

LT Section No. – 12-460

Attention should be given to uniform margins and alignment between the door and surrounding parts when

adjustments are being performed.

Uniform margins and alignment of the doors in relation to the body opening can be achieved by

setting the appropriate door hinge. Refer to MY2003 VY & V2 Series Service Manual Supplement,

Body Structure Repair Manual for specifications.

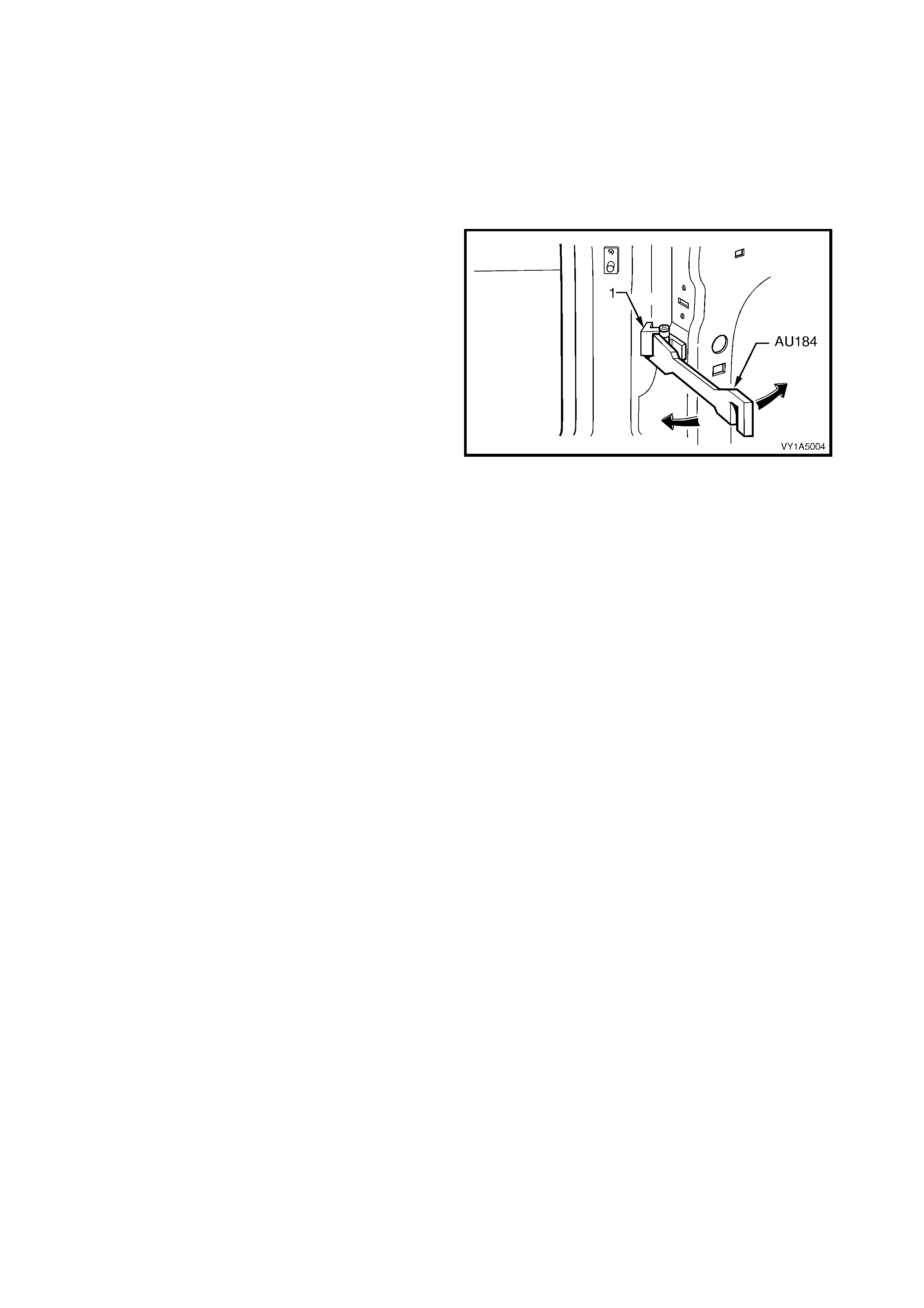

Use Tool No AU184 to the set door hinges by slightly

bending the rear door hinge (1) noting the following:

1. Take care when adjusting the doors not to

misalign the hinge pins. Any significant

misalignment will cause the pins to shear when

the door is opened or closed.

2. Excessive bending or levering of the window

frame will cause damage.

3. Final adjustment must take place when all the

door components and seals are installed.

IMPORTANT: Adjust doors with the striker assembly

removed. Striker assembly should only be fitted once

satisf actory alignm ent is achieve d. They mu st NOT be

used to pull the door into the correct position.

Figure 1A5-85

3.4 REAR WINDOW REGULATOR HANDLE ASSEMBLY

LT Section No. – 11-675

REMOVE

1. Insert a commercially available window regulator

handle removal tool (1) between the base of rear

door window regulator the handle assembly (2),

and the rear door window washer (3), in line with

the arm of the handle.

2. Disengage the rear door window regulator handle

clip (4), then remove the handle.

NOTE: Take care when disengaging the rear door

window regulator handle clip that it does not spring off.

Figure 1A5-86

REINST ALL

1. Locate the rear door window regulator handle clip

(4), in the rear door inside handle assembly (2),

with the open ends of the clip facing the handle

arm.

NOTE : Make sure both rear door windows are at the

same height before fitting handle assemble.

2. Fit the rear door window washer (3).

3. Ensure that the handle is positi oned symm etric ally

with the handle on the opposite door, then press

the handle ont o the window regula tor splines, unt il

the clip engages the groove at the base of the

splines.

Figure 1A5-87

3.5 REAR DOOR INSIDE HANDLE ASSEMBLY (REMOTE)

LT Section No. – 11-725

REMOVE

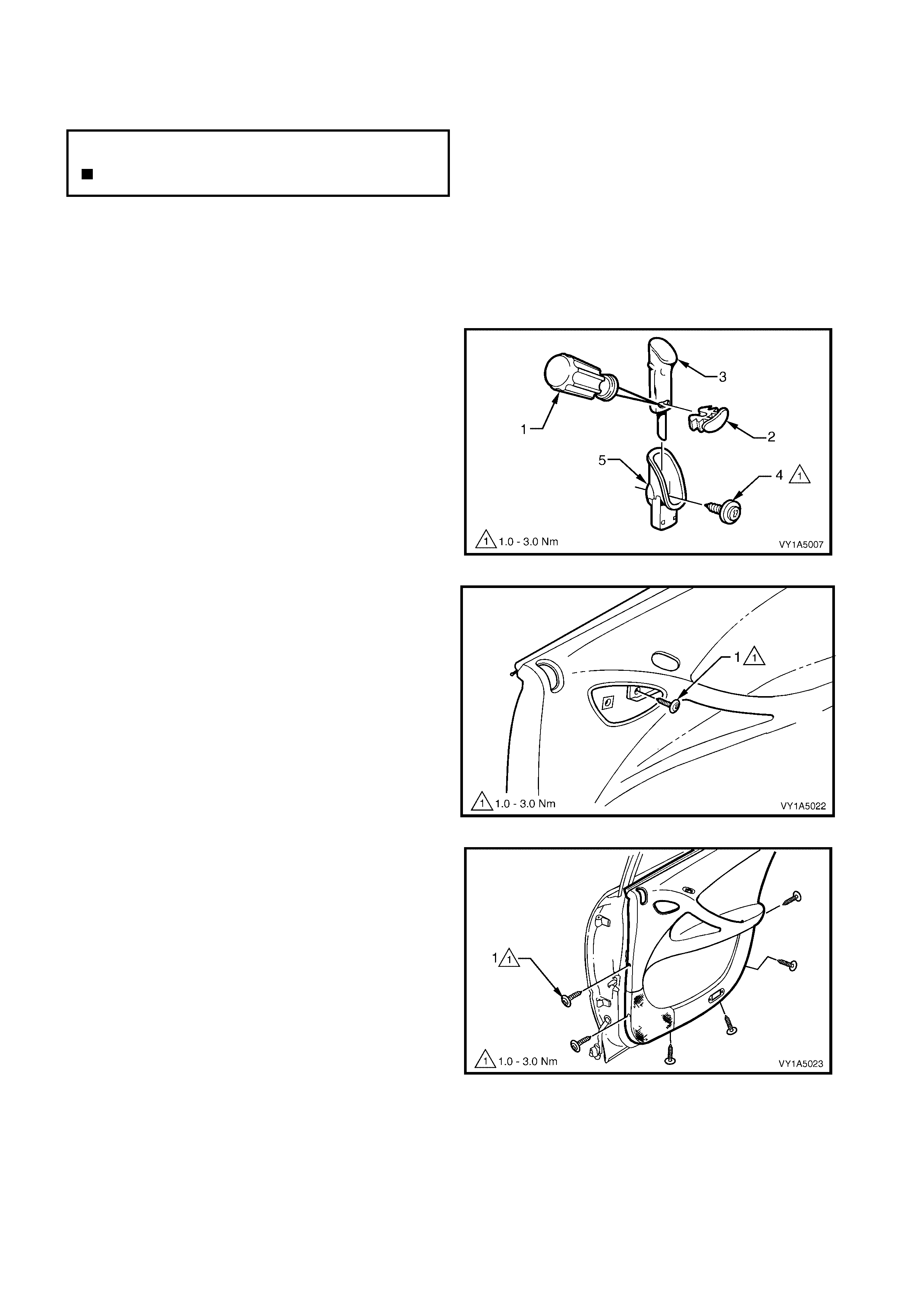

1. Prise off the rear door inside handle bolt finisher

cap (1).

2. Remove the screw (2) securing the rear door

inside handle assembly (remote) (3) to the rear

door trim.

3. Remove the handle assembly in a forward

direction and unho ok the rear insid e ha ndl e rod ( 4)

from the handle assembly.

Figure 1A5-88

REINST ALL

Reinstallation of the rear door inside handle assembly

(remote) handle is the reverse of the removal, refer

Figure 1A5-88, noting the foll o wing:

1. Ensure the rear door inside handle assembly

(remote) and rem ote rod are engaged before final

fitment.

2. Tighten the all retaining screw to the correct

torque specification.

REAR DOOR INSIDE HANDLE

ASSEMBLY (REMOTE) RETAINING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.6 REAR DOOR TRIM PANEL ASSEMBLY

LT Section No. – 14-270

Remove the following components,

1. Rear window regulator handle assembly, refer to 3.4 REAR WINDOW REGULATOR HANDLE

ASSEMBLY.

2. Rear door inside handle assembly, refer to 3.5 REAR DOOR INSIDE HANDLE ASSEMBLY (REMOTE).

REMOVE

1. Using a s mall f lat bladed screwdr iver or sc ribe (1) ,

gently pr ise the ora nge rear door locking r od knob

retainer (2) from the rear door locking rod knob

assembly (3), taking care not to damage the knob

assembly. Remove the knob assembly.

NOTE: The orange - rear door locking rod knob

retainer, will be damaged during this operation and

must be replaced.

2. Lift the knob assembly up, removing it from the

door locking rod.

3. Remove the screw (4) securing the rear door

locking rod ferrule (5) to the door trim panel

assem bl y and remove the f er rule.

Figure 1A5-89

4. Remove the rear door trim retaining screw (1) from

the rear door inside aper t ur e handle ass embly.

Figure 1A5-90

5. Remove six screws (1) securing the panel

assembly to the door panel.

6. Lift the top of the panel assembly up and out of the

door inner channel.

NOTE: Wiring harness connectors are still connected.

7. While supporting the panel assembly, disconnect

all the wiring harn ess conn ec tors .

8. Remove the panel assembly.

Figure 1A5-91

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

Rear door locking rod knob retainer.

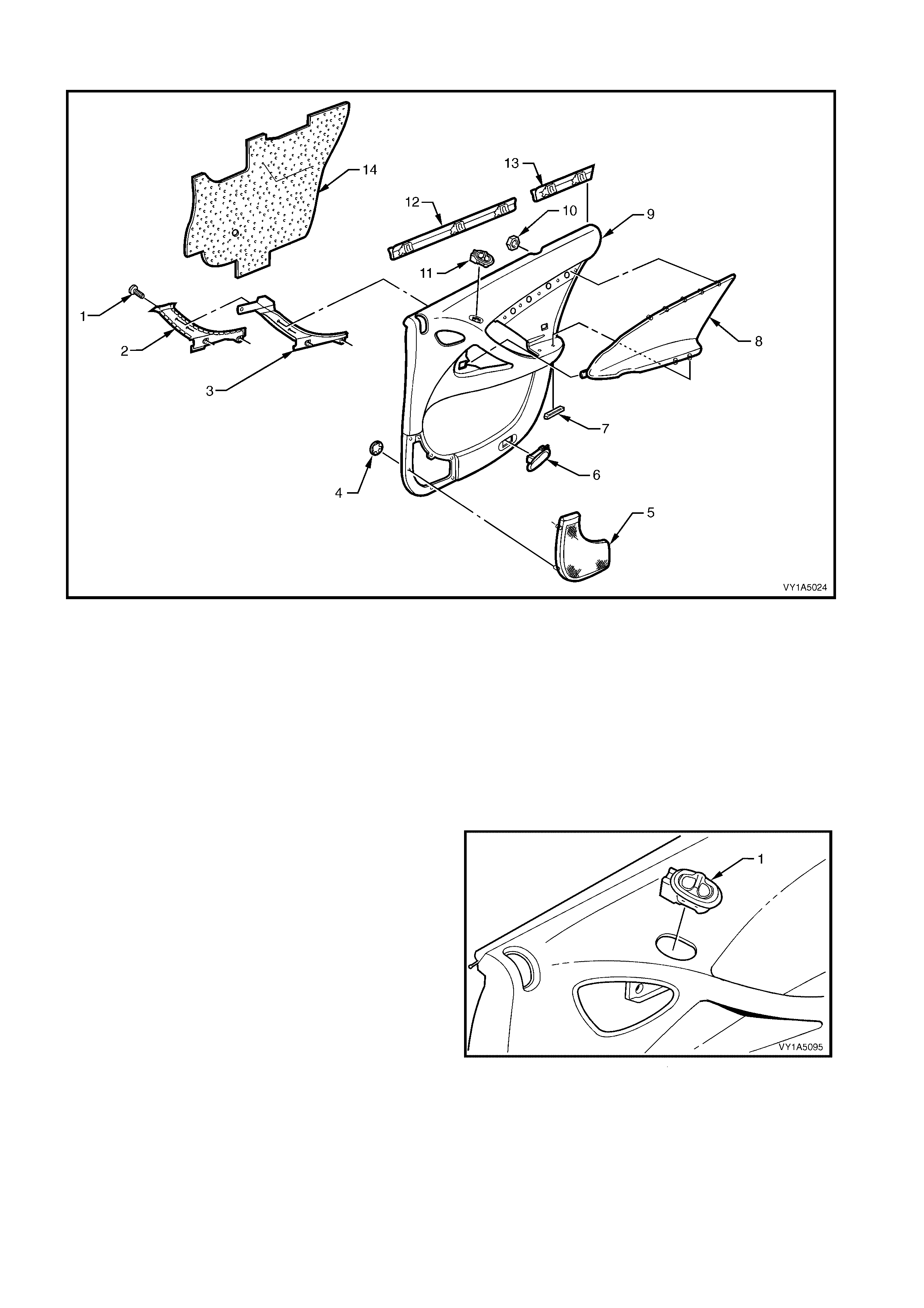

DISASSEMBLE

Figure 1A5-92

Legend

1. Rear Door Inside Handle Screw (4 Places)

2. Rear Door Inside Handle Cover

3. Rear Door Inside Handle Bracket

4. Radio Rear Door Speaker Grille Retainer (7 Places)

5. Rear Door Radio Grille Speaker

6. Rear Door Courtesy Lamp

7. Door Armrest Insert Assembly Clip. (2 Places)

8. Rear Door Inside Armrest Insert Assembly

9. Rear Door Trim Panel Foundation Assembly

10. Insert Assembly Door Armrest Clip (5 Places)

11. Rear Door Window Switch

12. Rear Window Inner Front Sealing Strip

13. Rear Window Inner Rear Sealing Strip

14. Rear Door Insulator Assembly

Remove – Rear Door Window Switch

1. From behind the door trim assembly, push the rear

door window switch (1), free by depressing tangs.

2. Remove the switch.

NOTE: For further information regarding Service and

Diagnosis of the rear door power window switch, refer

to Section 12J BODY CONTROL MODULE.

Reinstall – Rear Door Window Switch

Reinstallation of the rear door window switch is the

reverse of removal, noting the following.

1. Press the s witch assem bly firm ly into the door trim

assem bly.

Figure 1A5-93

Remove – Radio Speaker Grille

1. Remove the seven c lips (1) securing the rear d oor

radio grille speaker (2) to the door trim (3).

NOTE: Take care when removing clips, not to break

the speaker grille shafts on which the clips are

attached.

2. Remove the radio speaker grille.

Reinstall – Radio Speaker Grille

Reinstal lation of the s peak er gril le is the r evers e of th e

removal.

Figure 1A5-94

Remove – Rear Door Insulator Assembly

1. Remove the rear door insu lator assembly (1) from

the back of the rear door trim panel assembly, (2)

by peeling the insulator slowly across the panel.

NOTE: Take care not to tear the insulator. Retain as

much adhesive as possible on the insulator. Do not

fold the insulator and store in a flat location with the

adhesive facing away from objects.

Reinstall – Rear Door Insulator Assembly

Locate the insulator assembly centrally within the rear

door trim panel assembly, and press firmly into

position.

NOTE: If required apply additional hot melt adhesive

with a high softening point (eg.90°c).

Figure 1A5-95

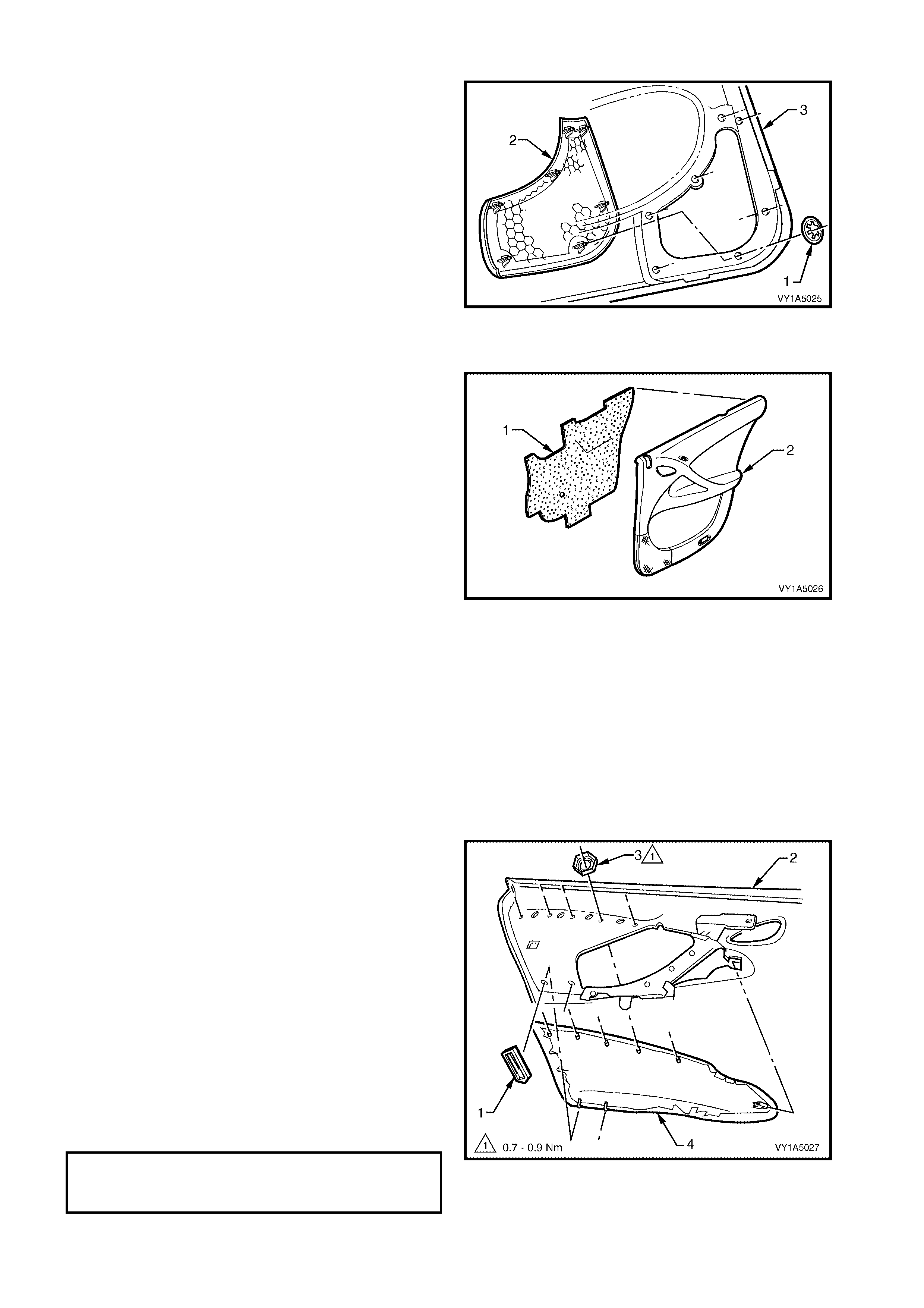

Remove – Rear Door Armrest Insert Assembly

IMPORTANT: Take care when removing the clips, as

the rotating action will cut-off the rear door armrest

insert assembly shaft, to which the clips are attached,

requiring a replacement insert assembly be fitted.

1. Peel back the insulator assembly, from the upper

portion of the rear door trim assembly, allowing

access to the insert assembly attaching parts,

refer this Section.

2. Remove two clips (1) by sliding them away from

the panel assembly (2).

3. Remove the nuts (3), five places, attaching the

armrest insert (4) to the panel assembly.

4. Before removal, prise the armrest insert away from

the panel ass embl y. Sli de the arm rest insert to the

rear of panel assembly and remove.

Reinstall – Rear Door Armrest Insert Assembly

Reinstallation of the insert assembly is the reverse of

the removal, noting the following.

1. The insert assembly must be sitting flush against

the panel assembly, along the entire top

contacting surface.

2. Tighten all retaining nuts to the correct torque

specification.

Figure 1A5-96

ARMREST INSERT ASSEMBLY

RETAINING NUT

TORQUE SPECIFICATION 0.7 – 0.9 Nm

Remove – Rear Door Inside Handle Assembly

(Pull)

1. Remove the insert ass embly arm r est. ref er this

Section.

2. Remove four screws (1) attaching the handle

reinforcement bracket (2) to the panel assembly

(3).

3. Remove the rear door inside handle assembly.

4. Peel off the cover (4), from the handle

reinforcement bracket.

Reinstall – Rear Door Inside Handle Assembly

(Pull)

Reinstal lation of the hand le ass embl y is the rev erse of