SECTION 1A6 - STATIONARY WINDOWS

IMPORTANT

Before perfo rming any Service O perat ion or o th er pro cedu re describ ed in th is Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property

damage.

CONTENTS

1. GENERAL DESCRIPTION

2. SERVICE NOTES

2.1 MINOR WATER LEAK CORRECTION -

BONDED WINDOWS

3. SERVICE OPERATIONS - FRONT

3.1 WINDSHIELD ASSEMBLY

REMOVE

REINSTALL - SHORT METHOD

REINSTALL - LONG METHOD

4. SERVICE OPERATIONS - SIDE

4.1 QUARTER WINDOW ASSEMBLY, WAGON

REMOVE

REINSTALL

4.2 QUARTER WINDOW ASSEMBLY, UTILITY

REMOVE

REINSTALL

4.3 QUARTER WINDOW ASSEMBLY, COUPE

REMOVE

REINSTALL

5. SERVICE OPERATIONS - REAR

5.1 REAR WINDOW ASSEMBLY,

SEDAN AND COUPE

REMOVE

REINSTALL - SHORT METHOD

REINSTALL - LONG METHOD

5.2 LIFTGATE WINDOW ASSEMBLY, WAGON

REMOVE

REINSTALL - SHORT METHOD

REINSTALL - LONG METHOD

5.3 REAR WINDOW ASSEMBLY, UTILITY

REMOVE

REINSTALL - SHORT METHOD

REINSTALL - LONG METHOD

6. TORQUE WRENCH SPECIFICATIONS

7. SPECIAL TOOLS

Techline

Techline

1. GENERAL DESCRIPTION

The windshield ass em bly, which is lam inated and f eatures a tinted upper band, is bonded to the vehicle body in the

window opening with urethane.

The rear window assembly for Sedan, Coupe, Utility and the liftgate window assembly for the Wagon, all have an

electrically heated demist facility, and are also bonded in the window openings with urethane.

The quarter window assembly for Coupe, Utility and Wagon utilise a self-adhesive foam weatherstrip to seal the

window to the window opening. Plastic nuts are used to secured the window to the vehicle.

Toughened safety glass is used for all the windows except the windshield assembly.

For replacement of urethane bonded windows, urethane service kits have been developed and must be used to

maintain original installation requirements. Windows installed with urethane require either partial or complete

removal of the urethane when replacing the window.

Two diff e rent ins tallation methods ar e us ed when replacing the windshield assembly, rear window assembly and the

liftgate window assem bly: a ‘short m ethod’ and a ‘long m ethod’. Partial r em oval of the ur ethane is ref erred to as the

‘short method’. Complete removal of the urethane is known as the ‘long method’.

The short method is to be used when after the window removal, the original urethane remaining on the window

opening flanges, c an serve as a bas e for the new window. This m ethod would be used in cases where replacem ent

of cracked windshields or removal of windows that are intact. The amount of urethane left in the window opening

can be controlled during window removal, leaving the maximum amount of original urethane intact on the body

opening flange.

The long method is to be used when after the window removal, the original urethane remaining on the window

opening f langes, c annot s erve as a base f or the r eplacement window. This method would be used in c ases needing

metal work and / or paint refinishing in the window opening, or in cases where the window has been previously

replaced using the short method. In such instances, the build up of urethane could position the window too high in

the body opening. In these cases, the original urethane must be completely removed and replaced with new

urethane following the long method window installation.

For service procedures related to the rear door fixed window, refer to Section 1A5, 3.14 REAR DOOR

STATIONARY WINDOW ASSEMBLY.

The windshield and Sedan and Coupe rear window become structural members of the vehicle once the urethane

adhesive cures, and aid in vehicle rigidity. The windshield also plays an important role in occupant protection by

supporting the pass enger airbag dur ing deployment. It is im perative that the procedures in this Section for replacing

bonded windows are followed, as incorrect installation may lead to injury or death.

2. SERVICE NOTES

CAUTION: Safety glasses and work gloves must be worn at all times when operating with glass.

IMPORTANT: Only use urethane adhesive such as Betaseal 15685 or equivalent for water leak correction on

bonded windows.

Skinning ( partial c uring) of the ur ethane commences af ter expos ur e to the atmospher e. At 23 degrees Cels ius and

50 percent relative humidity, skinning commences after 30 minutes. Complete curing of the urethane at this

temperature and humidity takes 72 hours.

Urethane service kits are available from most windshield agents. Manufacturer’s instructions should always be

followed.

Window assemblies should be installed in the window opening within 5 minutes of the application of urethane.

2.1 MINOR WATER LEAK CORRECTION -BONDED W INDOWS

LT Section No. – 11-020

1. Secure protective covering with masking tape

adjacent to the leak suspect area.

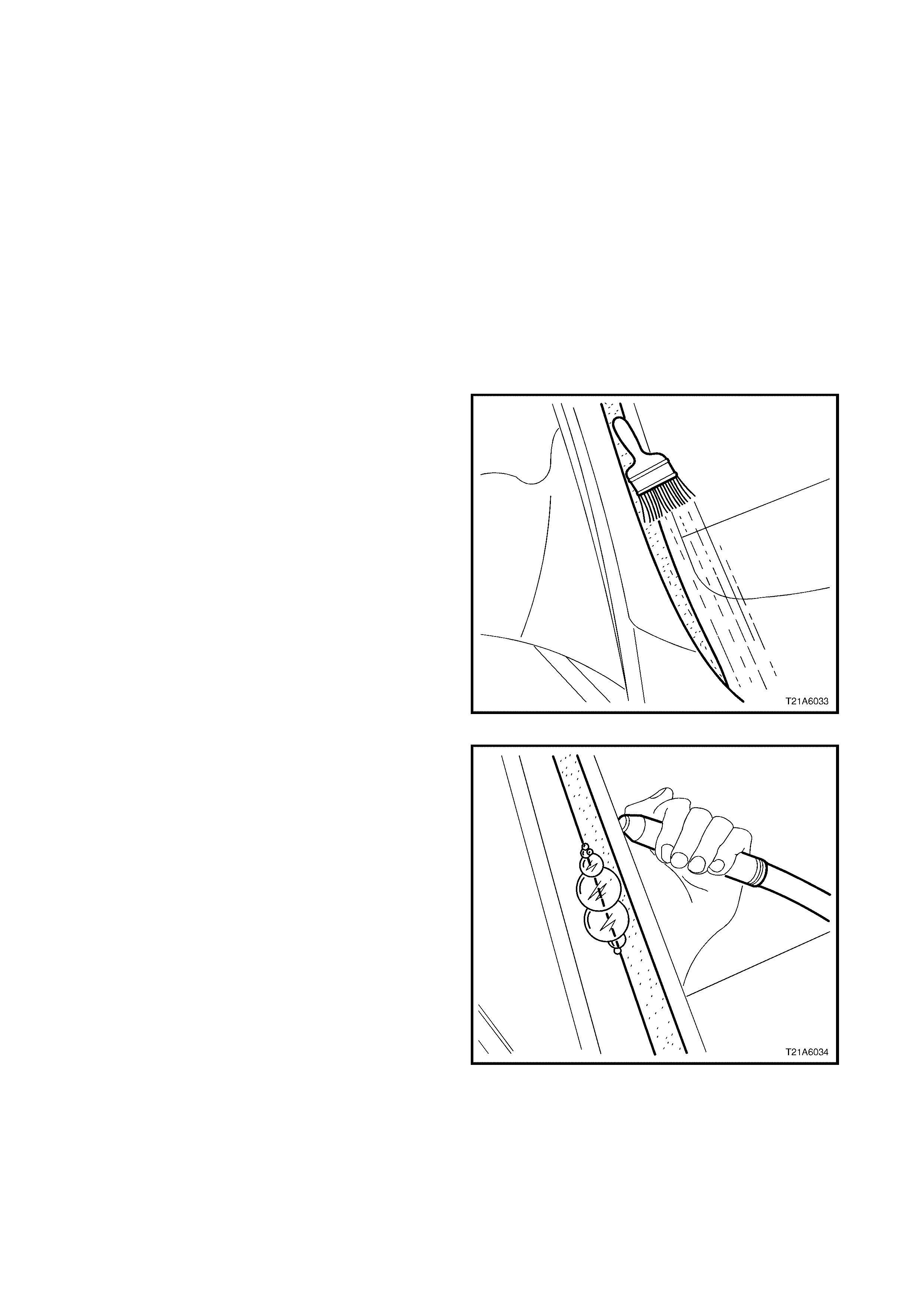

2. To determine the precise location of the water

leak, use the air and soap bubble leak test. The

soap and water solution can be applied with either

a spray applicator or brush.

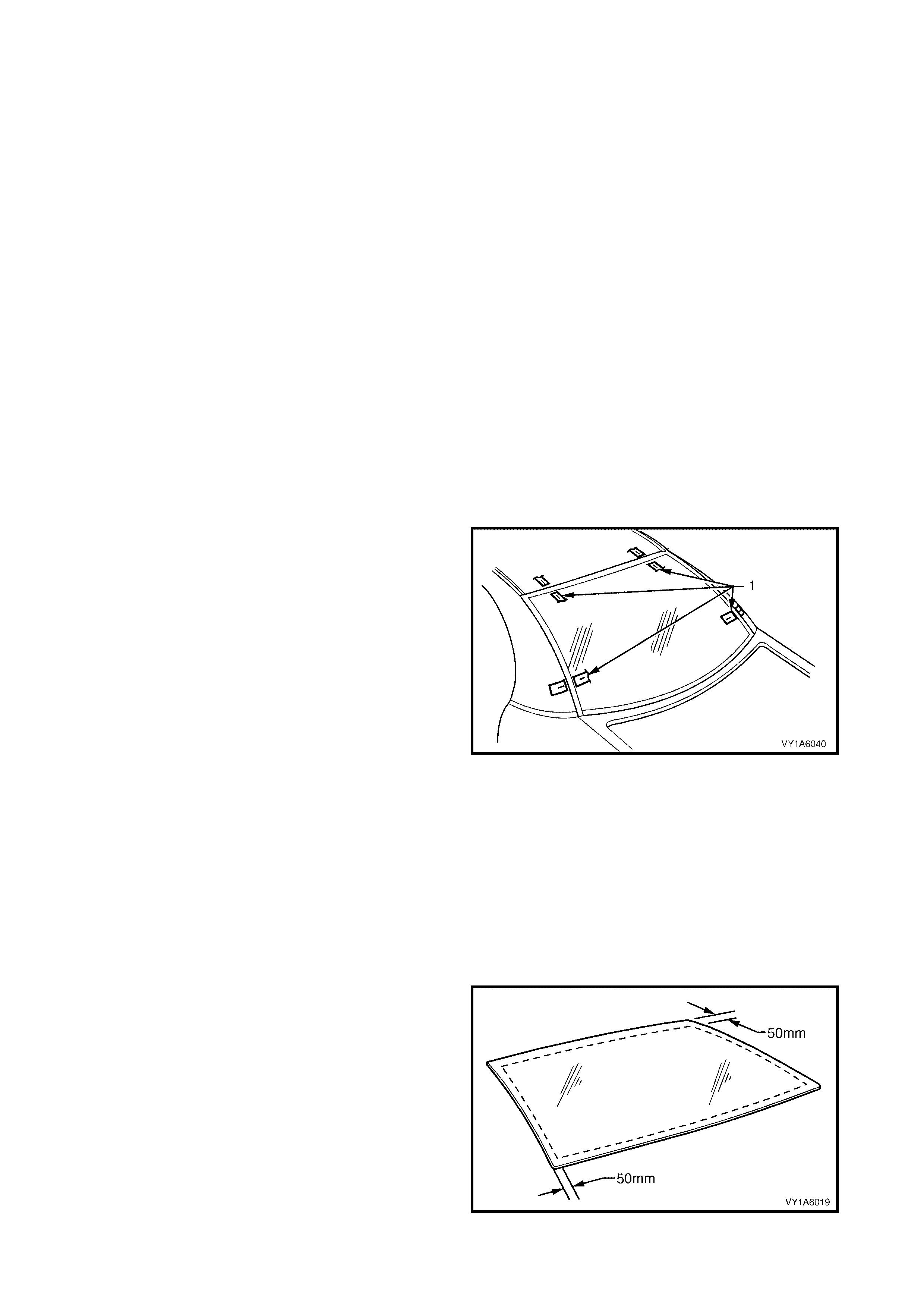

Figure 1A6-1

3. Locate an air-hose nozzle on the inside of the

windshield or rear window assembly. Have an

assistant outside the vehicle and apply a soapy

water solution opposite the air s ource. As a low air

pressure (60 kPa) is applied, soap bubbles will

form on the outside of the window, indicating the

location of the leak.

4. If the suspec t leak ar ea is not obvious, com m ence

the testing acros s the top and down the sides until

the leak location has been determined.

5. Using a spatula, work fresh urethane such as

Betaseal 15685 or equivalent, in and around the

leak area.

NOTE: It is only necessary to remove dus t and foreign

matter, as water activates the curing process of

urethane.

6. Leak test the repair , using the air/ soap bubble leak

test or a non-pressurised water leak test.

Remove the mask ing tape and protective covers, then

clean the window assembly and adjacent paint and

trim surfaces.

Figure 1A6-2

3. SERVICE OPERATIONS - FRONT

CAUTION 1: Safety glasses and work gloves must be worn at all times when operating with glass.

CAUTION 2: Care must be taken during any operation involving the windshield assembly removal or

installation, not to exert any load on the windshield. Failure to observe this may result in damage to the

window.

IMPORTANT: Only use urethane adhesive such as Betaseal 15685 or equivalent for windshield installation. The

windshield plays an important r ole in occ upant pr otection by supporting the pass enger air bag during deployment. It

is imperative that the procedures in this Section for replacing bonded windows are followed, as incorrect

installation may lead to injury or death.

3.1 WINDSHIELD ASSEMBLY

LT Section No. – 11-020

The windshield ass embly removal pr ocedur e is the s ame for both the s hort and long ins tallation methods , with one

exception. If the short method installation is to be used, care must be taken during the windshield removal to

ensure that an even sur f ac e of the or iginal remaining urethane ex is ts in the body opening. This is required to serve

as a base for the new urethane bead and the replacement windshield.

To prevent damage and to m inim ise clean up of the paint f inish and the trim , m ask -up and place protective covers

over parts adjacent to the windshield.

If required, remove the following components:

1. Windshield wiper arm assembly, refer to Section 12N, 2.3 WIPER WASHERS AND HORN.

2. Plenum cover assembly, refer to Section 12N, 2.5 WIPER WASHERS AND HORN.

3. Instrument panel end cap covers, and the windshield defroster grille assembly, refer to

Section 1A3 INSTRUMENT PANEL AND CONSOLE.

4. W indshield side garnish, f or Sedan refer to Section 1A8, 2.5 WINDSHIELD SIDE GARNISH, for W agon refer

to Section 1A8, 3.5 WINDSHIELD SIDE GARNISH, for Coupe refer to Section 1A8, 4.4 WINDSHIELD SIDE

GARNISH and for Utility refer to Section 1A8, 5.5 WINDSHIELD SIDE GARNISH.

5. Internal rear-view mirror, refer to Section 12H, 2.4 INTERNEL REAR-VIEW MIRROR.

REMOVE

IMPORTANT: Note that on all vehicles a keyless entry control m odule is installed between the left and right-hand

windshield defroster grille assembly, located on the instrument panel. While it is not necessary to remove the

module, care must be taken to avoid damage during windshield removal.

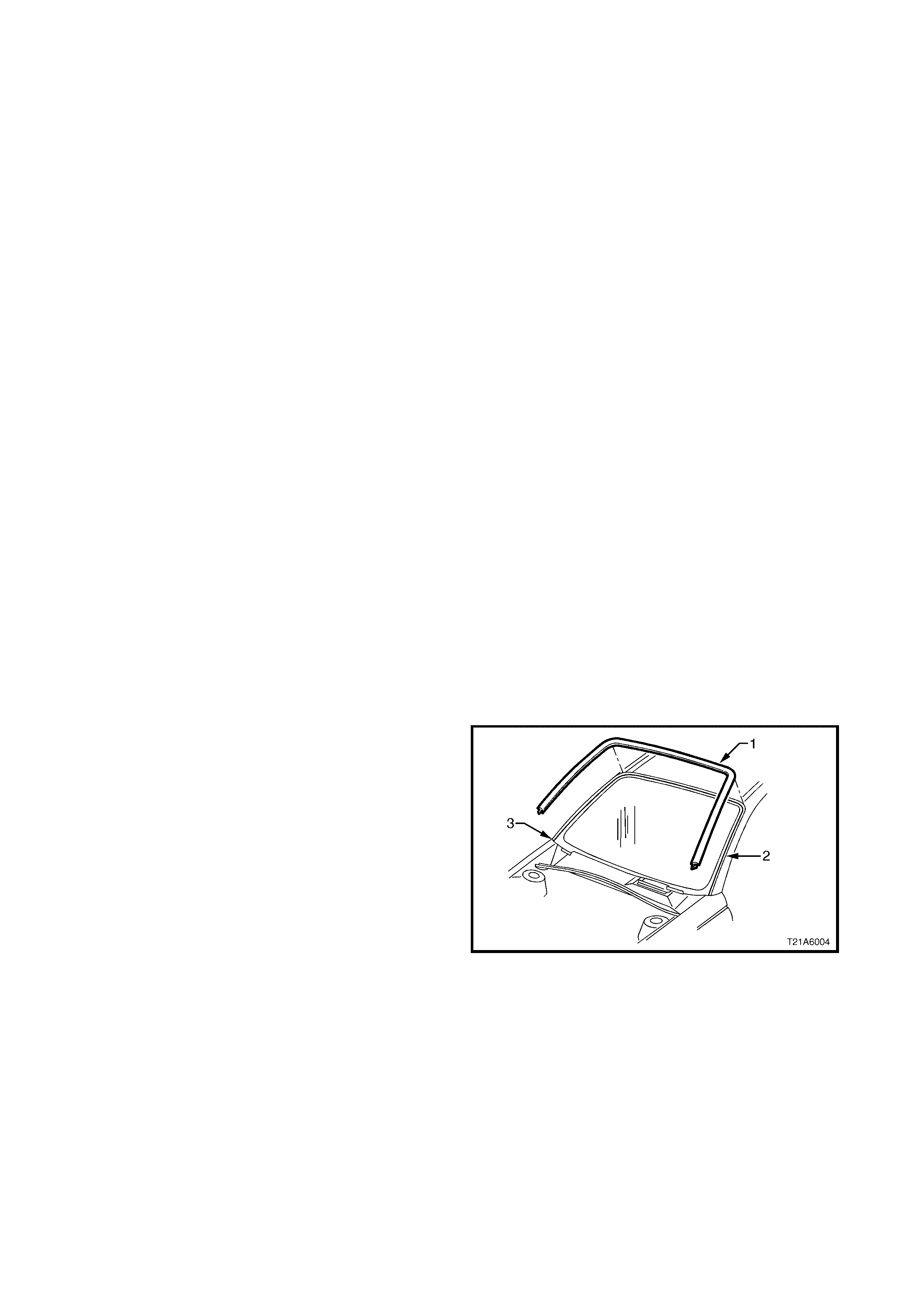

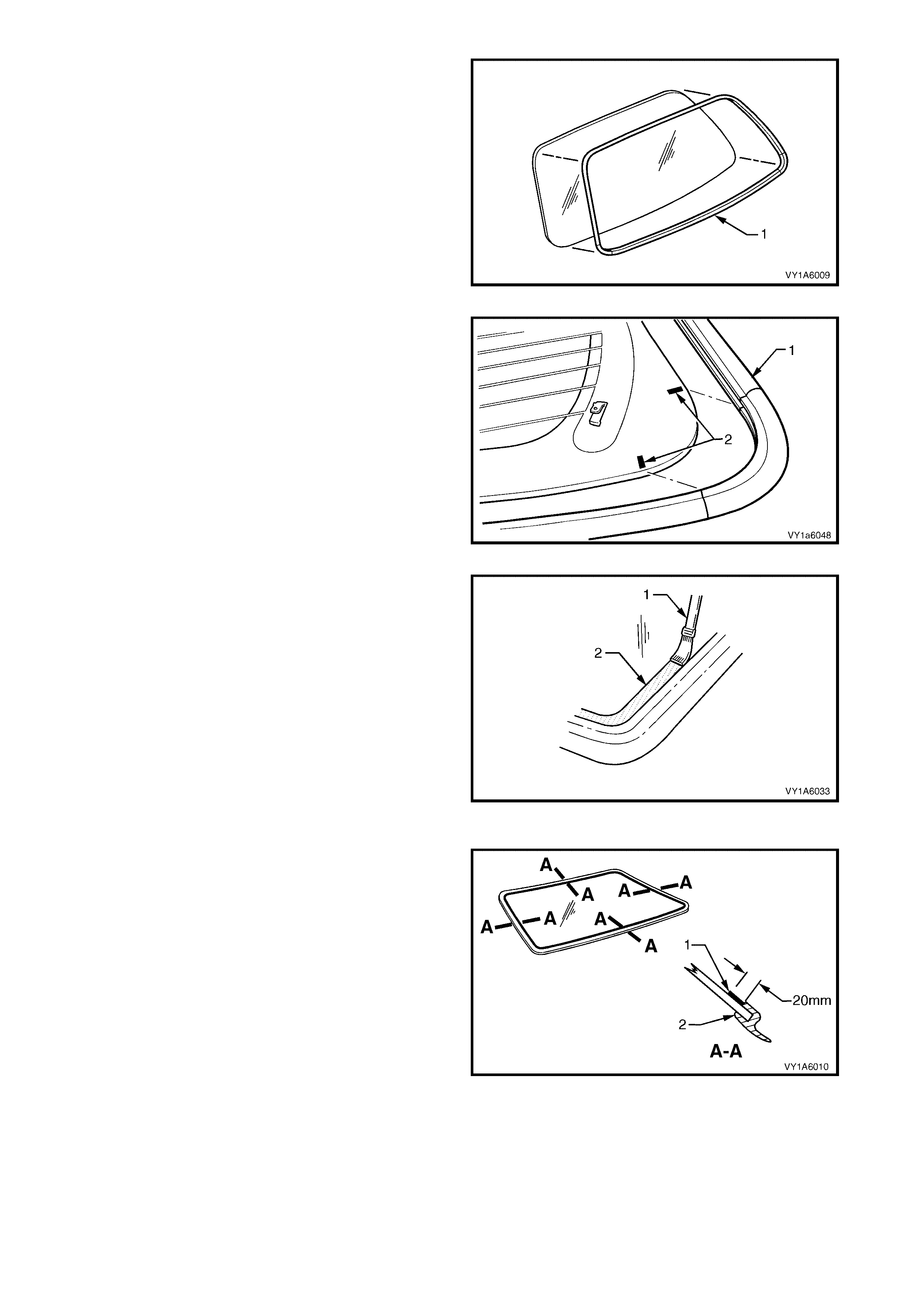

1. Remove the windshield reveal moulding assembly

(1) by pulling the moulding from the windshield to

the body join (2), starting at the lower corner (3)

and working around the windshield.

2. Should the windshield be broken, caref ully rem ove

all fragments of glass from the windshield opening.

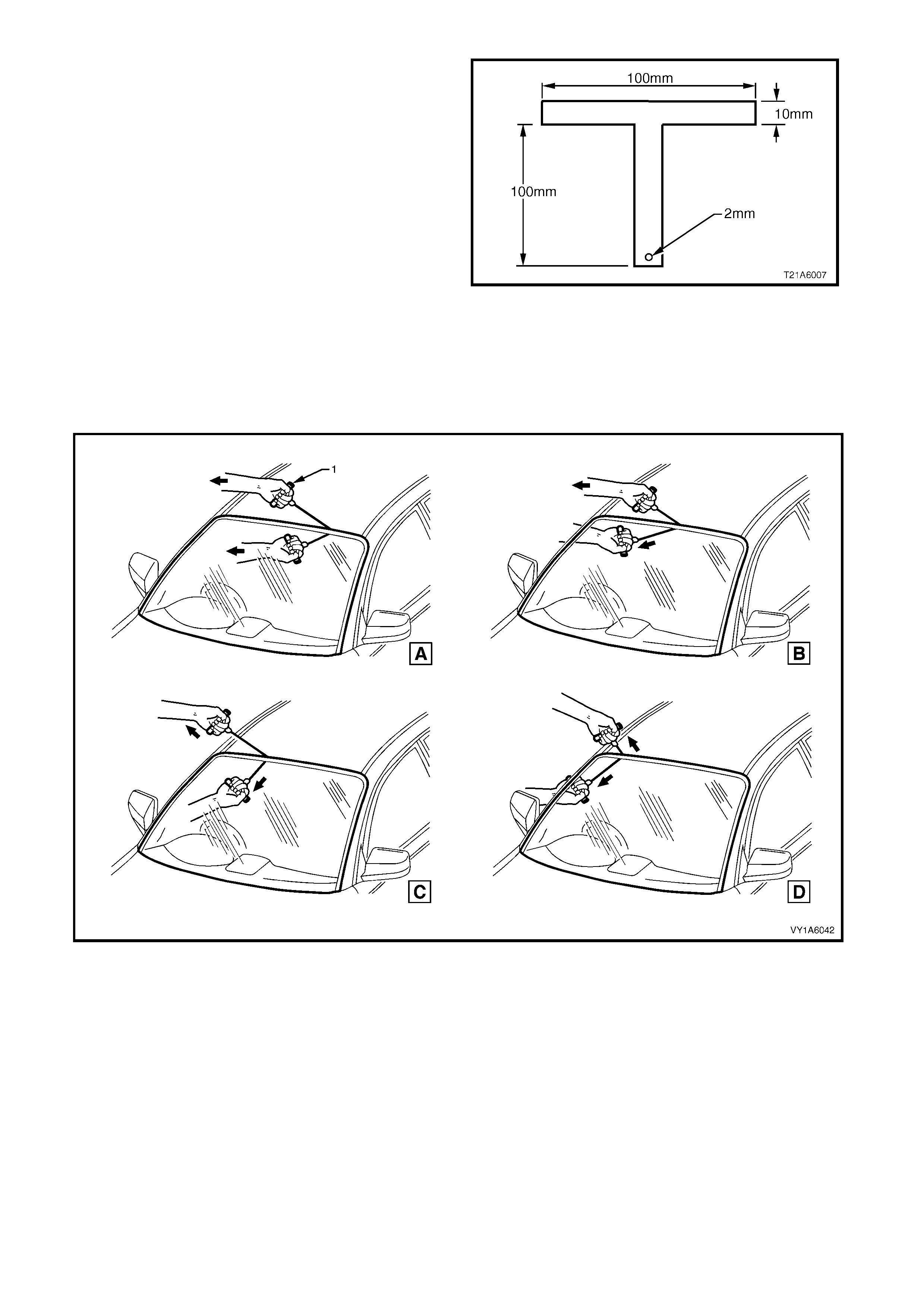

3. Using special tool J36020 thread one end of the

piano wire through the urethane, starting at the

windshield upper corner, pulling the end of the wire

through with pliers

Figure 1A6-3

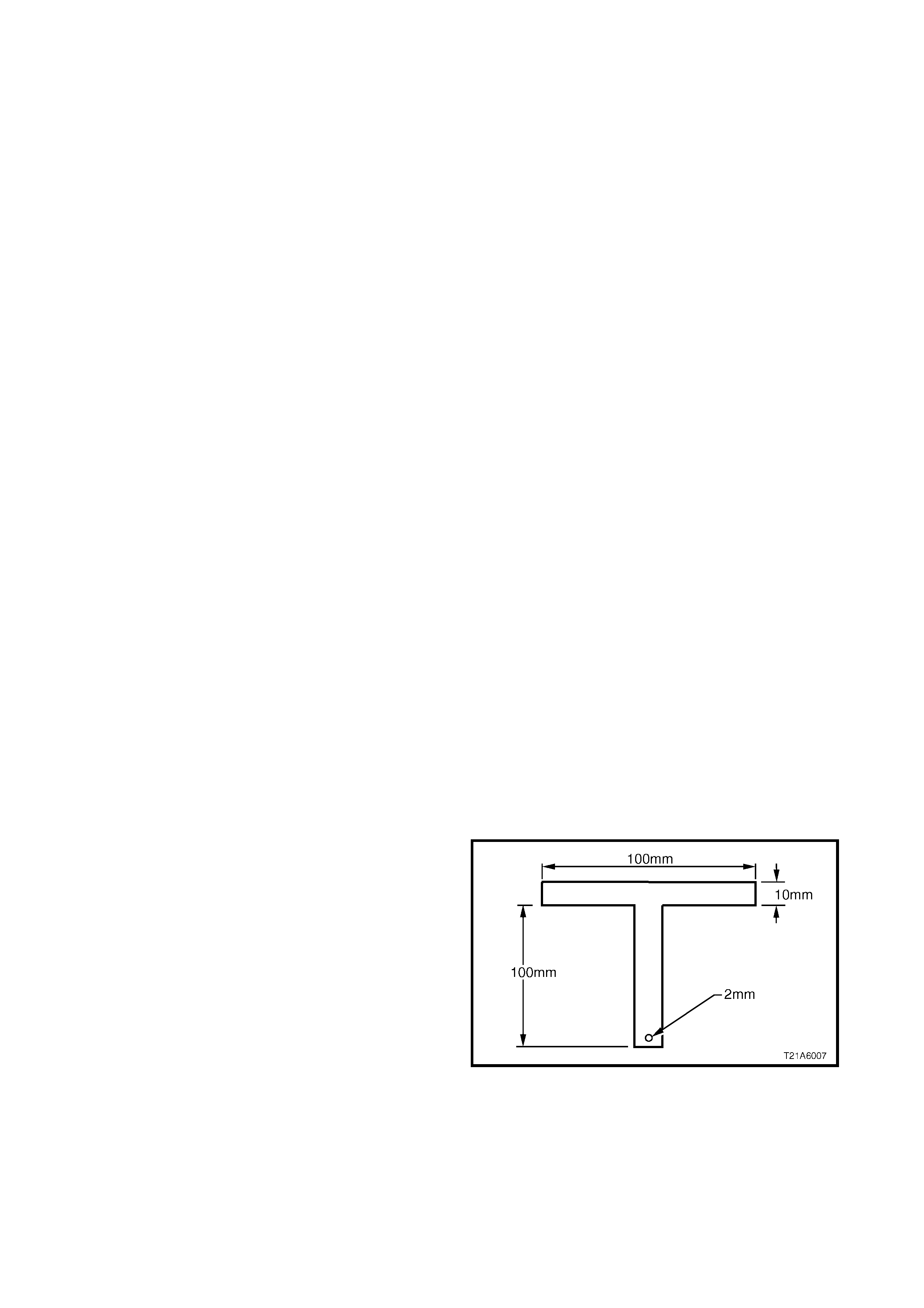

4. Alternately, manufacture two T-handles to the

dimensions shown. Secure at least 700mm of

piano wire to one handle, thread the other end of

the wire through the urethane as previously

described.

NOTE: Ens ure that the headlining and other trim item s

are not damaged.

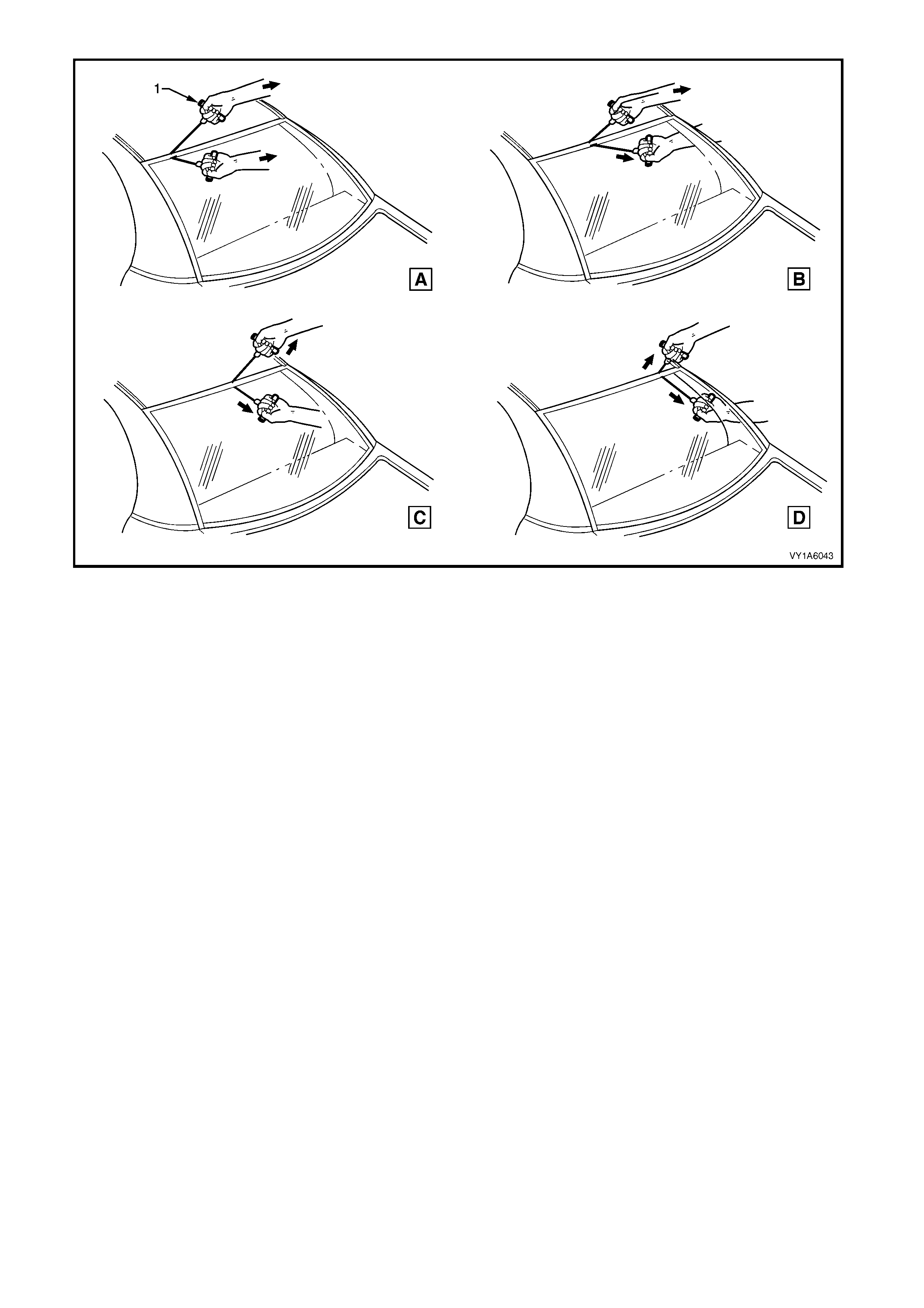

5. Connect the wire to the remaining T-handle and

with the aid of an assistant, com menc e cutting the

urethane bead, keeping the outside T-handle (1)

parallel to the edge of the windshield using the full

length of the wire to prevent heat build up in the

wire.

NOTE: To minimise the damage to the interior of the

vehicle, the operator inside the vehicle should act as

an anchor point. Holding the T-handle as close as

possible to the windshield at all times, (especially along

the lower edge of the windshield), while the outside

operator pulls the wire up to the interior T-handle in a

‘walking’ motion, refer to Figure 1A6-5.

Figure 1A6-4

Figure 1A6-5

6. Carefully lift the windshield out of the body

opening. If there is evidence of the windshield

adhering to the urethane, cut the area again with

the piano wire.

7. With the exception of Coupe, remove the two

windshield locators f rom the windshield reinforcing

flange, refer Figure 1A6-6. Retain for reinstallation

of the windshield.

8. If the original windshield is to be installed again,

place the windshield on a clean protected surface

or a holding fixture.

NOTE 1: The use of suction cups will greatly assist any handling of the windshield.

NOTE 2: All traces of urethane must be removed from the windshield. It is not necessary to remove all traces of

the original urethane f rom the body opening, unless the ‘long m ethod’ of reinstallation is being used. However , any

original urethane remaining must be smooth and firm.

REINSTALL - SHORT METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours providing it is driv en only on a smooth road at speeds not exceeding 80 km/h with the

door windows partially lowered.

Description

The short method installation involves the maximum amount of the original urethane being left intact on the body

opening to form a sound base for the replacement urethane and windshield.

This method is recommended when replacing a cracked or broken windshield, or a leak condition that cannot be

overcome by using minor water leak repair procedures, refer to 2.1 MINOR WATER LEA K CORRECTION.

If m aterial other than ur ethane has been used f or pr evious ser vicing of the windshield, the long m ethod installation

procedure (complete removal of adhesive) is mandatory to achieve an effective window to metal bond.

CAUTION 1: Care should be taken to ensure that the windshield does not strike the windshield opening.

Chipped edges can lead to subsequent breakage of the windshield.

CAUTION 2: Do not use petroleum based solvents to clean the window assembly - rear or the rear opening

flange, as the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Using a sharp scraper, carefully remove any

original urethane from around the windshield.

Clean the windshield to be installed with a suitable

oil free cleaning agent.

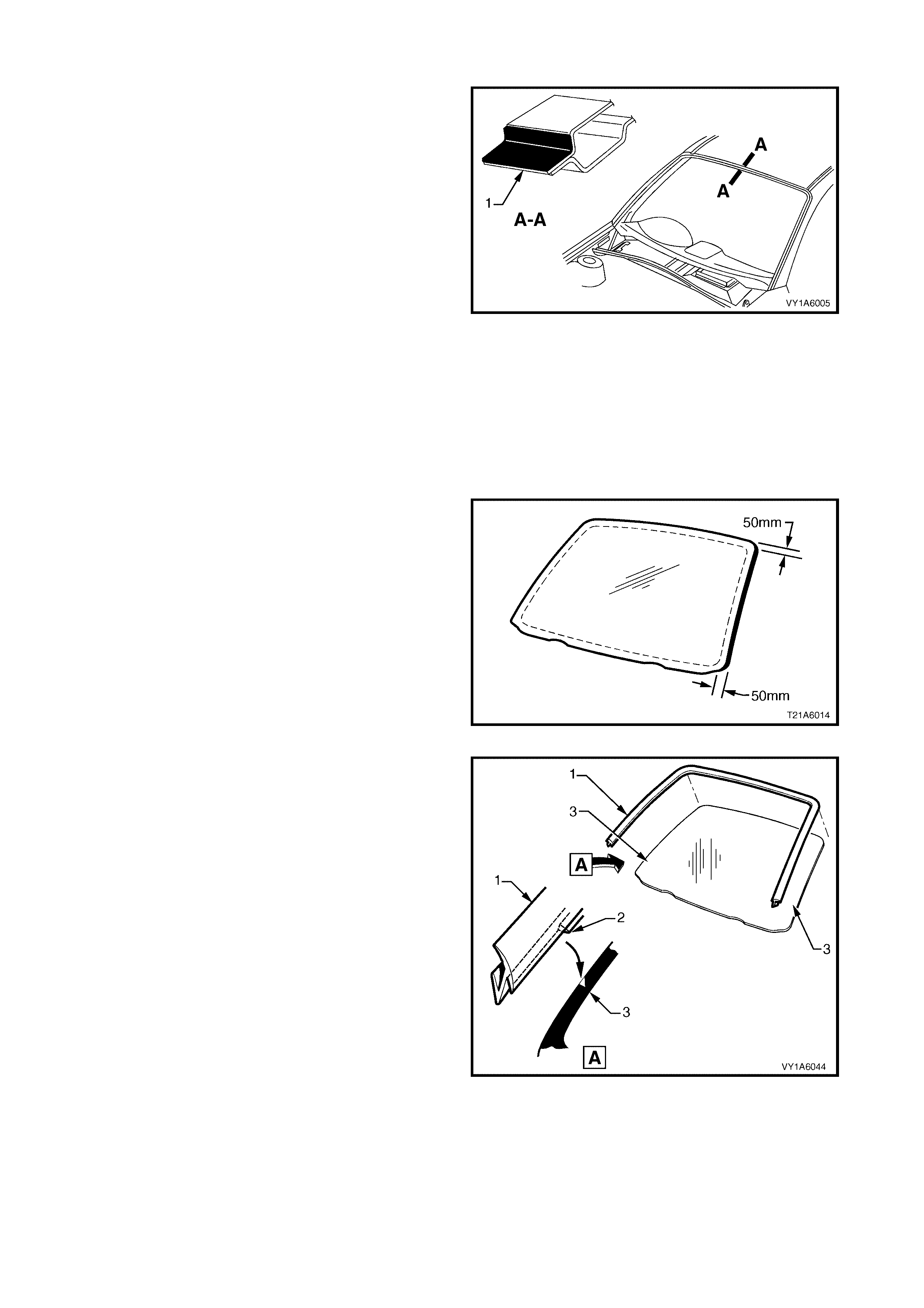

• Sedan, Wagon and Utility: Check for correct

alignment buy temporarily placing the

windshield in the body opening. Place the

windshield locator (1) between the lower

windshield edge (2) and the reinforcing flange

(3), to correctly locate the windshield.

• Coupe: Check for correct alignment buy

temporarily placing the windshield, on to the

extrusion ( 4) fitted to the reinf orcing flange (3) .

If required place windshield locator (1)

between the lower windshield edge (2) and the

extrusion to correctly locate the windshield in

the body opening.

2. Ensure the windshield is centralised in the body

opening left to right, by checking that the gaps

between the windshield and body opening are

even on both sides of the vehicle.

3. With masking tape (5), mark the outer top and side

of the windshield pillar and the roof.

NOTE: This procedure will assist in the alignment of

the windshield in the correct horizontal and vertical

plane during final windshield installation.

4. Remove and place the windshield face down on a

clean protected surface or fixture.

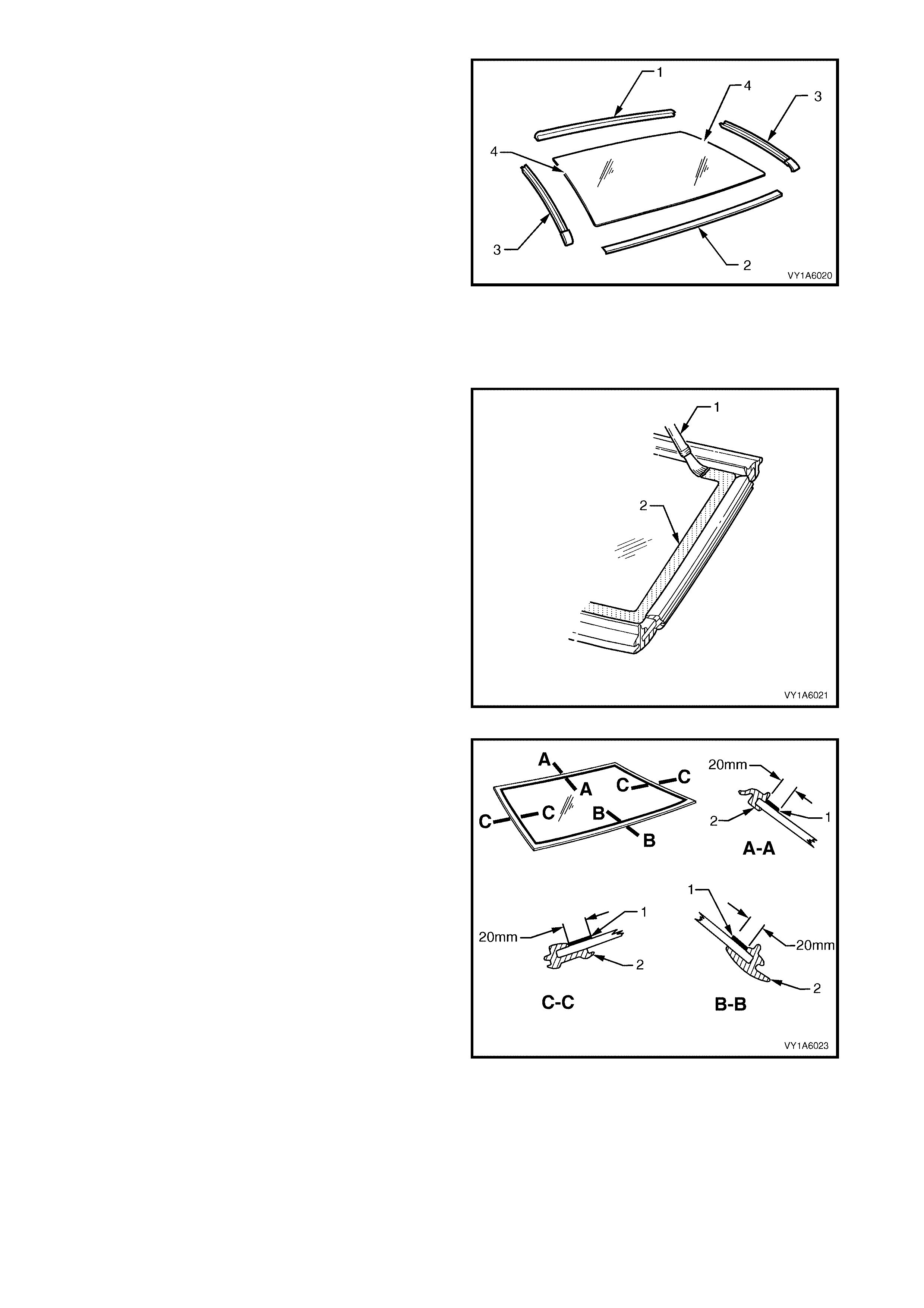

Figure 1A6-6

Reinstall

1. Thoroughly clean the inner surface and edges of

the windshield to which the urethane is to be

applied, using clean lint-free cloths and a suitable

oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the windshield, or the body opening flange

as the presence of the oil in the solvent will

prevent the adhesion of the new urethane.

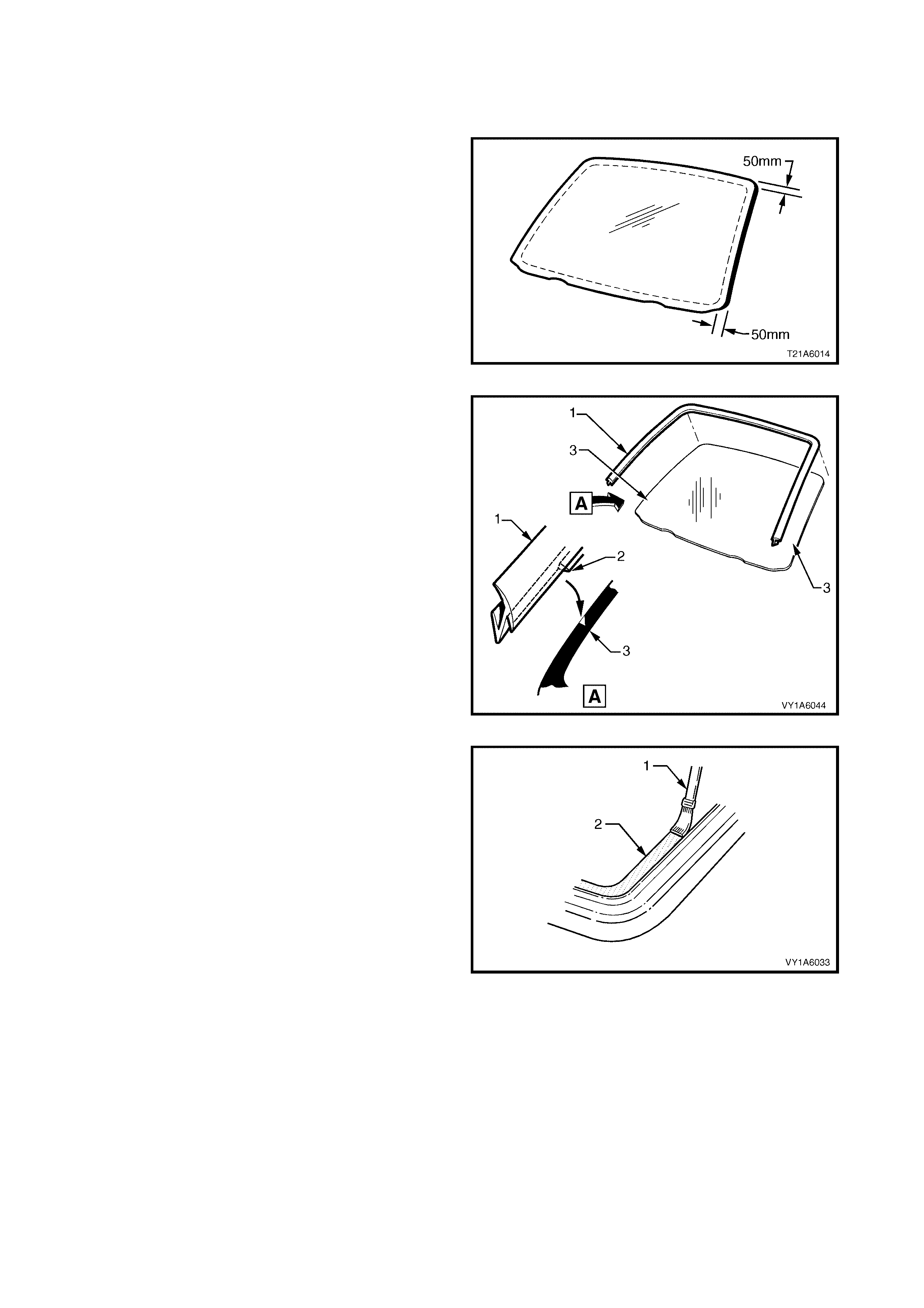

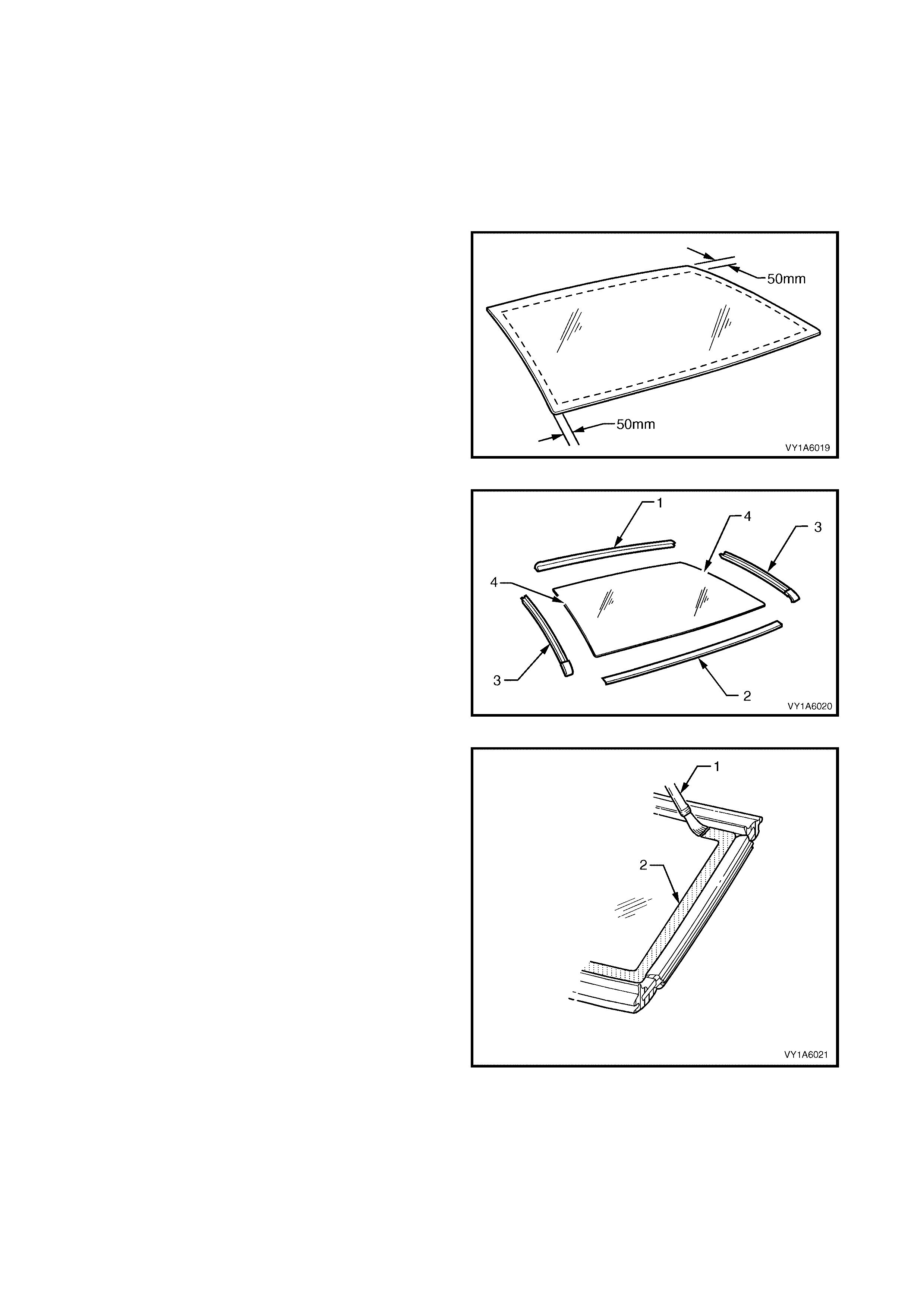

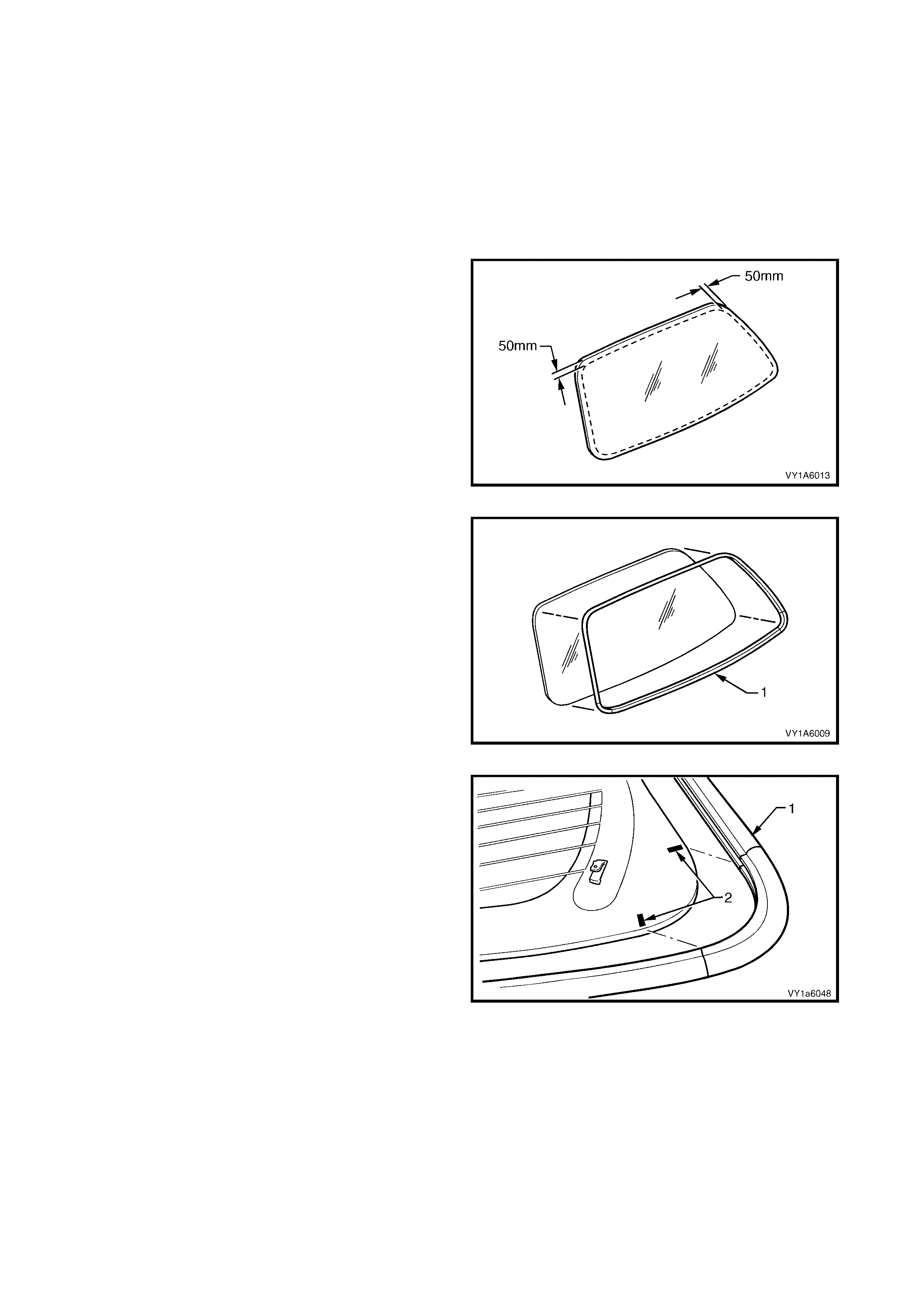

2. Apply clear windshield adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perimeter of the windshield. Immediately wipe off

with a lint-free cloth.

Figure 1A6-7

3. Check the condition of the windshield reveal

moulding ass em bly (1). Discard and r eplace with a

new moulding if damaged.

4. Fit the moulding assembly to the sides and upper

section of the windshield. Ensure that the notch of

the moulding (2) is aligned with the ‘V’ locating

mar k (3) on the lower portion of the right-hand and

the left-hand side of the windshield.

5. Check the condition of the original urethane

around the windshield opening flange for voids or

looseness.

6. Cut away any loose pieces of urethane.

7. Using a suitable spatula, spread fresh urethane

smoothly into any voids or uneven sections.

Figure 1A6-8

8. Use the applic ator (1) inc luded in the service kit, to

apply black windshield adhesive primer (2) to the

windshield as described in the following step.

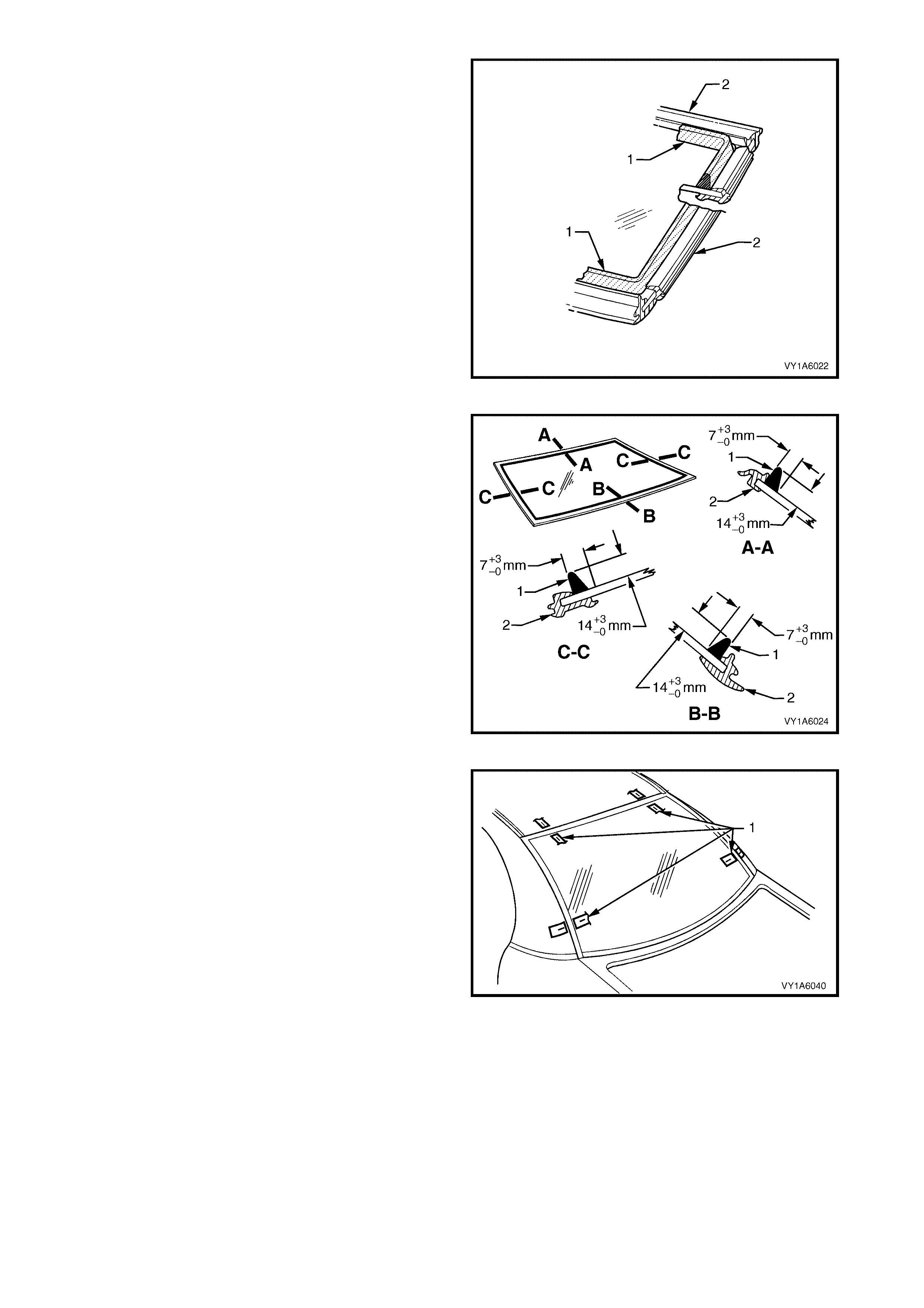

Figure 1A6-9

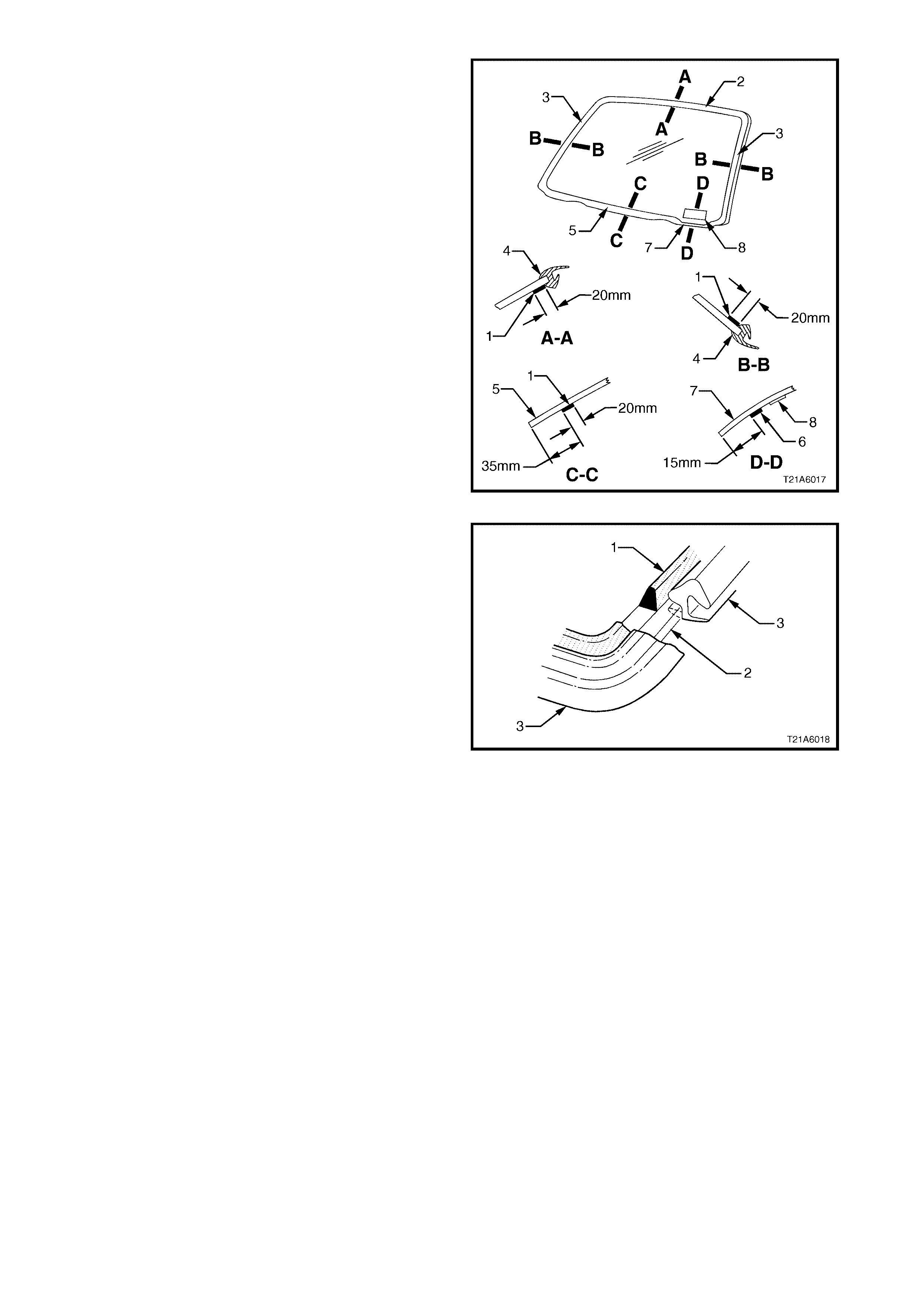

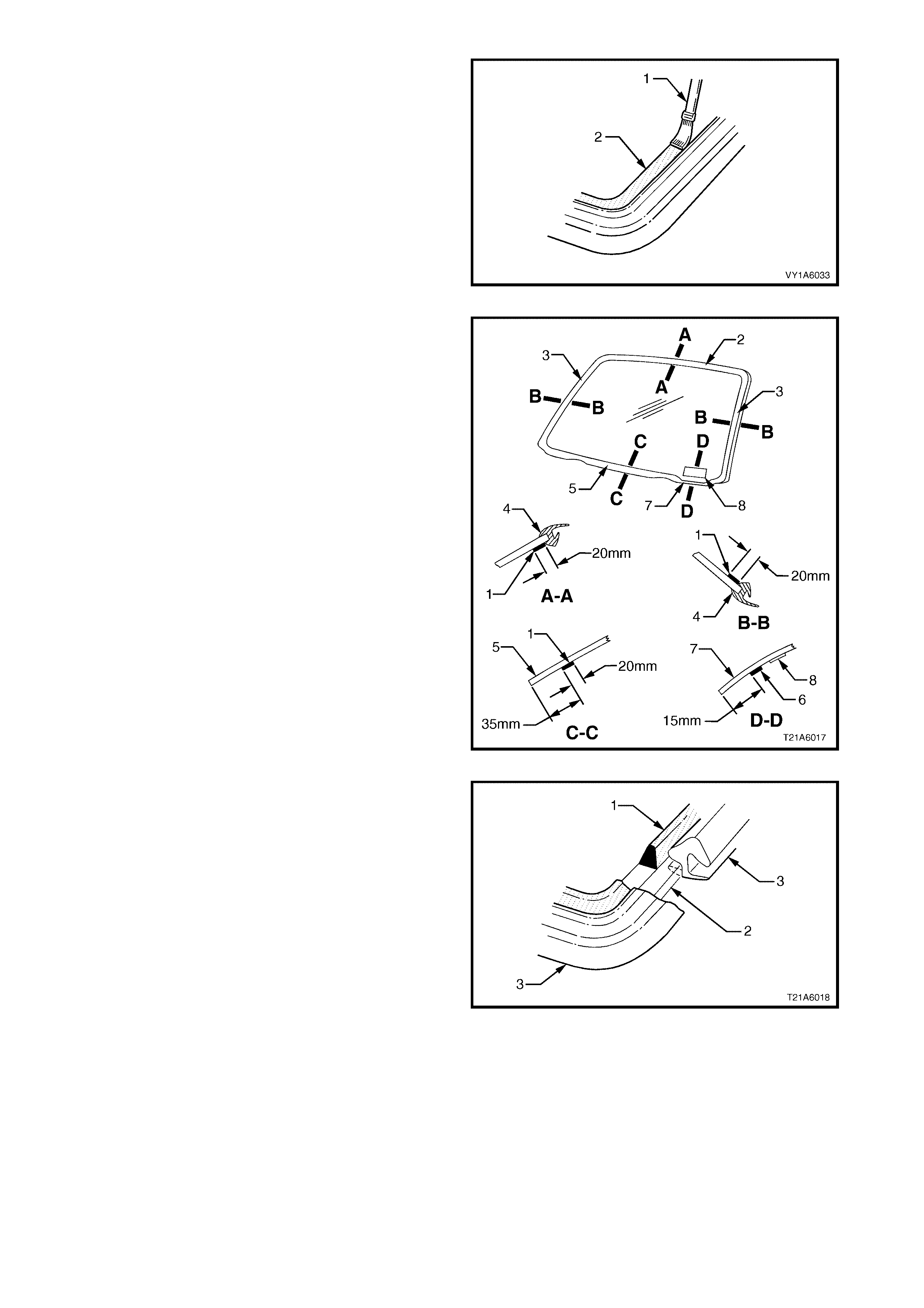

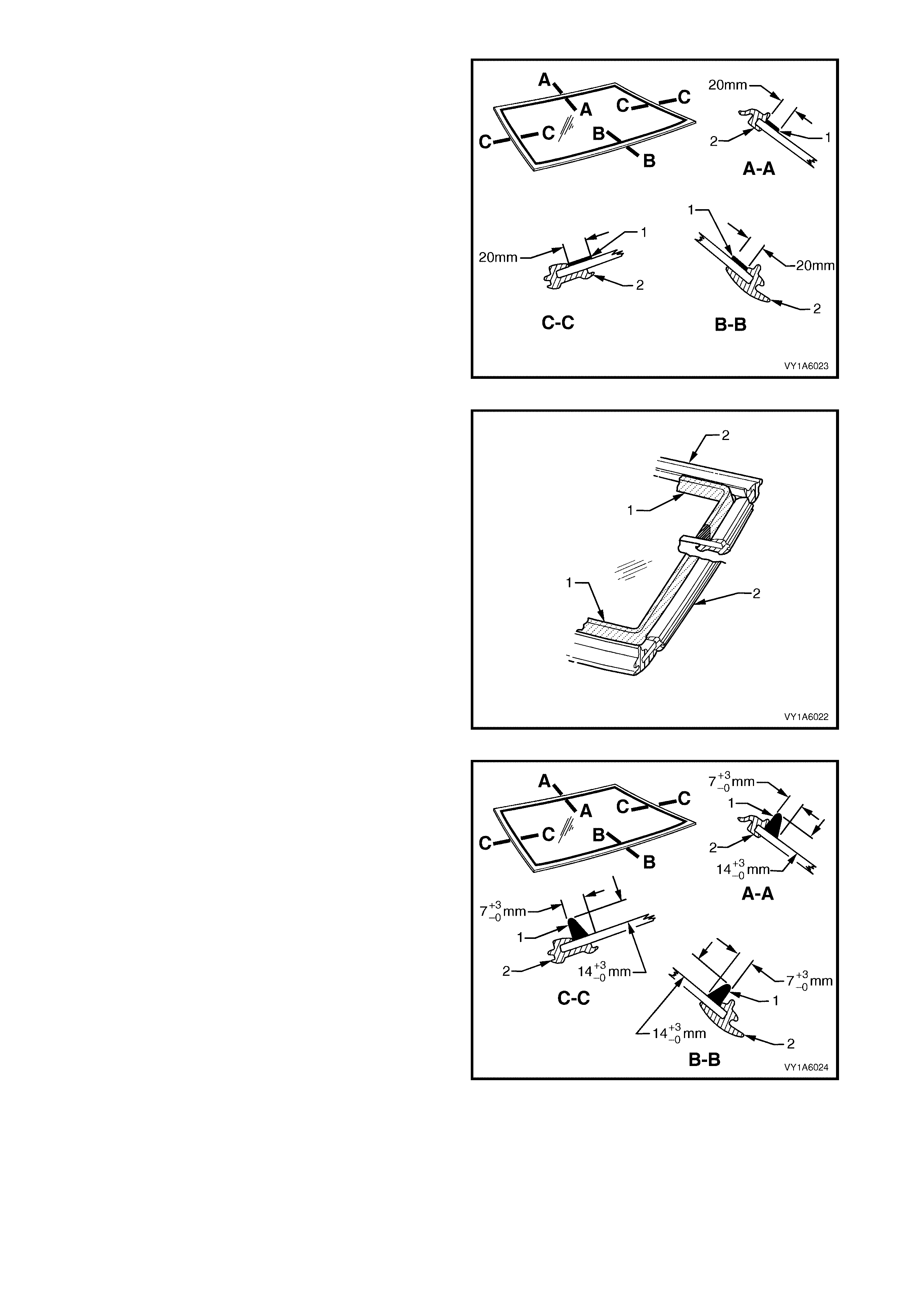

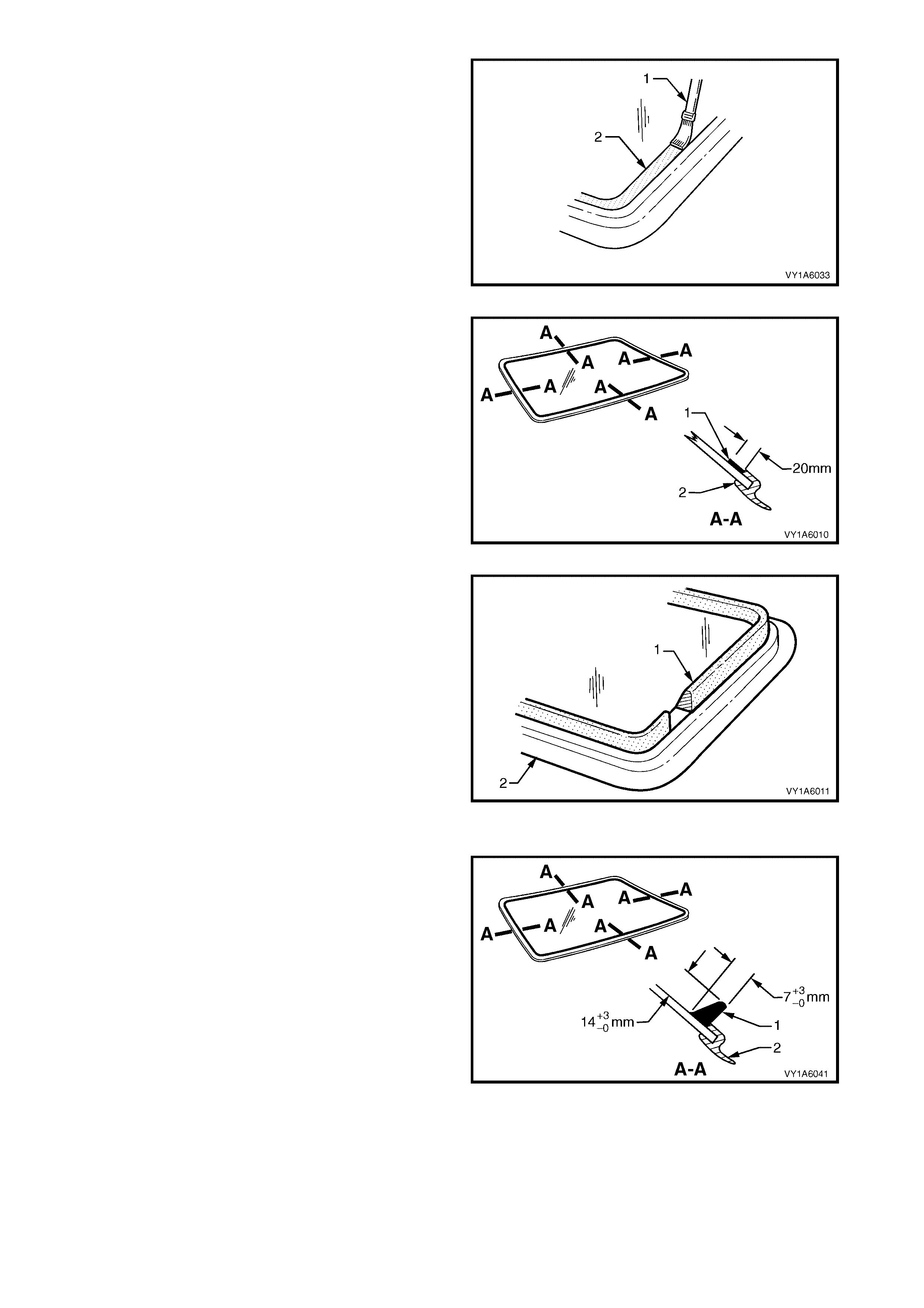

9. Apply black windshield adhesive primer (1) to the

inner s urf ac e of the upper s ect ion (2) and sides (3)

of the windshield over a width of 20 mm inboard

from the moulding (4). Repeat this proces s 35 m m

from the bottom edge (5) of the windshield. Ensure

that a suitably reduced application of primer (6) is

applied 15 mm from the lower edge of the

windshield (7) adjacent to the VIN plate (8).

Figure 1A6-10

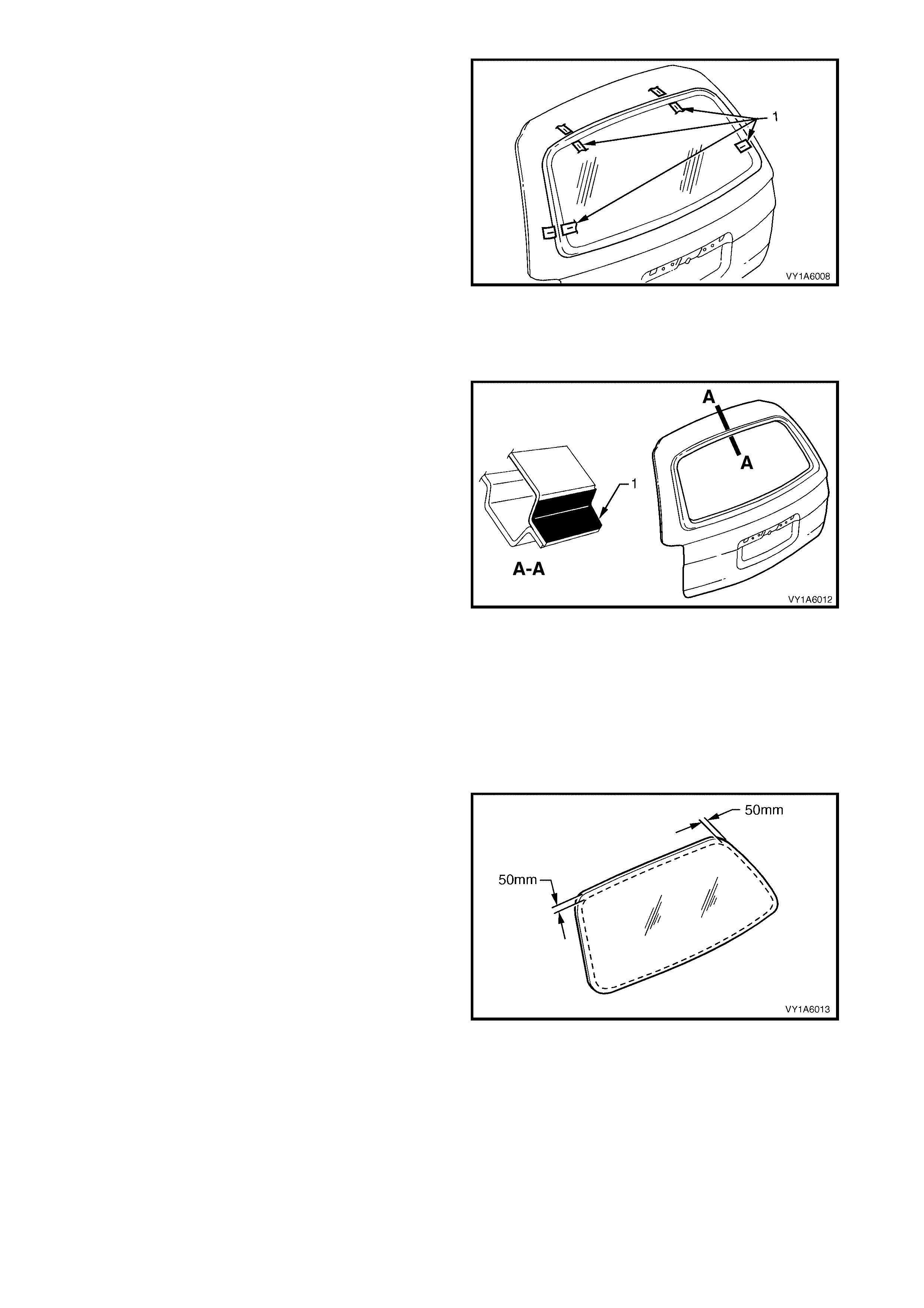

10. Using a hand or automatic applicator, apply a

smooth continuous bead of windshield adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, to the windshield (2) along the inside

edge of the moulding (3). The bead dimensions

are shown in Figure 1A6-12.

NOTE: 1 Depending on the amount of urethane

remaining on the windshield opening flange, the

amount of the new urethane should be reduced

accordingly, while maintaining adequate strength and

sealing properties. The dimensions shown are the

maximum allowable and are only for reference.

NOTE: 2 In cold weather, the placement of cartridges

adjacent to a sourc e of warm th will ass ist in the flow of

urethane when using a hand applicator.

Figure 1A6-11

IMPORTANT: On the lower section of the body

opening, care must be taken to ensure the urethane

bead diameter is such that when compressed by the

windshield installation, the Vehicle Identification

Number plate is not obscured.

11. Apply urethane (1) adjacent to the moulding (2)

and 35 mm inboard (3) from the lower edge of the

windshield (4). A suitably reduced amount of

urethane (5) s hould be applied adjacent to the VIN

plate (6) to ensure that the VIN is not obscured

when the windshield is installed.

12. For ease of installation and to avoid unnecessary

stress on related components, it is recommended

that the interior mirror assembly be fitted

to the windshield prior to installation of the

windshield to the vehicle, refer to Section 12H,

2.4 INTERNEL REAR-VIEW MIRROR.

Figure 1A6-12

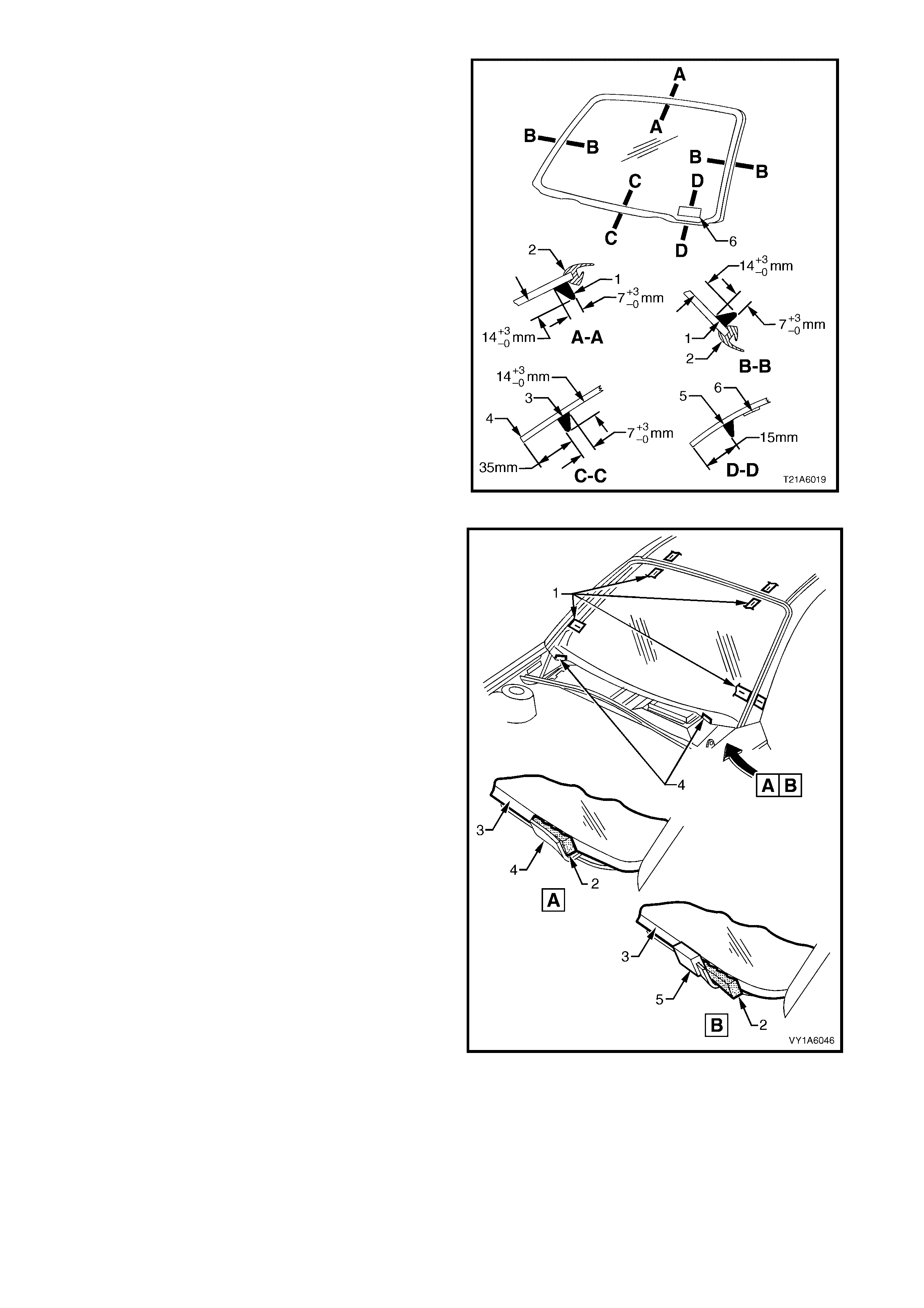

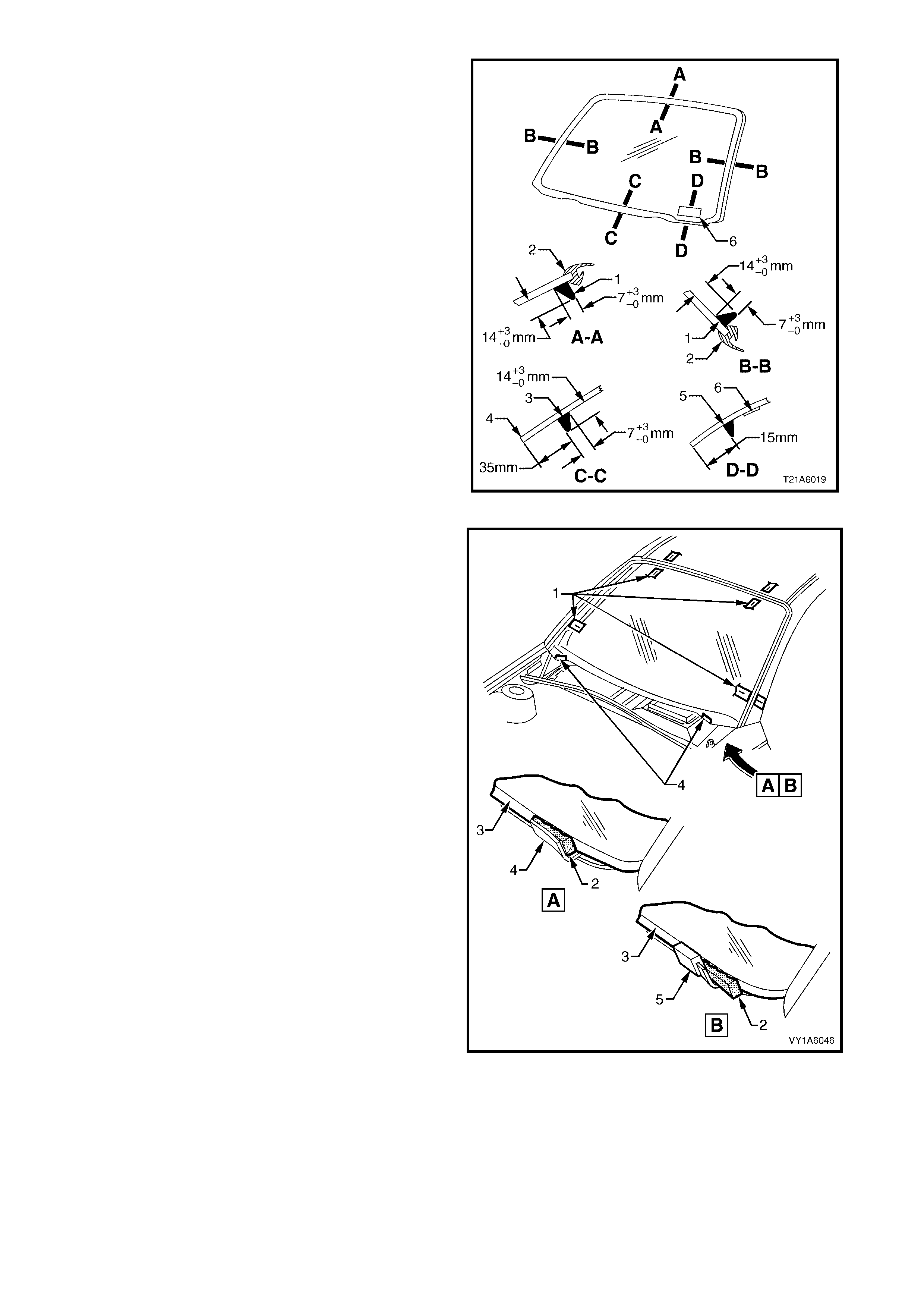

13. With the aid of an assistant, install the windshield

using the previously attached masking tape (1) on

the roof and windshield pillar to ensure accurate

installation.

• Sedan, Wagon and Utility: Use a windshield

locator (2) , between the lower windshield edge

(3) and the reinf orcing f lange (4) in two places,

to locate the windshield vertically in the

windshield opening.

• Coupe: If requir ed, use a windshield locator (2)

between the lower windshield edge (3) and the

extrusion (5) to correctly locate the windshield

in the body opening.

14. Press windshield firmly into position.

15. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing ex is t, apply

additional urethane to fill these gaps.

16. Wait two hours then water test the windshield,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

17. Clean off any excess urethane using Prepsol or

white spirit. Clean the windshield, then rem ove the

masking tape previously installed.

18. Reinstall the trim and hardware as required.

Figure 1A6-13

REINSTALL – LONG METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The long method for the windshield replacement is used when the original urethane adhesive material cannot

serve as a base for the replacement windshield.

This method should be used on vehicles requiring metal or paint repair to the windshield opening, when the

original adhesive is completely removed and replaced with new urethane for the windshield installation.

This method is also used when the windshield has been previously replaced using the short method. In such

instances, the build-up of urethane could position the windshield too high in the opening.

CAUTION 1: Do not use petroleum based solvents to clean the windshield or the opening flange, as the

presence of the oil in the solvent will prevent the adhesion of the new urethane.

CAUTION 2: Care should be taken to ensure that the windshield does not strike the windshield opening.

Chipped edges can lead to subsequent breakage of the windshield.

Preparation

1. Using a sharp scraper, carefully remove any original urethane from around the windshield. Clean the

windshield to be installed with a suitable oil free cleaning agent.

2. Using a knife or sharp scraper, remove the original urethane from around the entire perimeter of the

windshield opening flange. Avoid the removal of paint when removing urethane from opening flange.

Body Opening Check

1. Thoroughly check the windshield opening flange for any irregularities before installing the windshield.

2. To check for correct alignment, temporarily place the windshield in the windshield opening. If necessary,

reform the windshield opening flange to produce a uniform flange to the windshield contour.

• Sedan, Wagon and Utility: Check for correct

alignment buy temporarily placing the

windshield in the body opening. Place the

windshield locator (1) between the lower

windshield edge (2) and the reinforcing flange

(3), to correctly locate the windshield.

• Coupe: Check for correct alignment buy

temporarily placing the windshield, on to the

extrusion ( 4) fitted to the reinf orcing flange (3) .

If required place windshield locators (1)

between the lower windshield edge and the

extrusion to correctly locate the windshield in

the body opening.

3. Ensure the windshield is centralised in the body

opening left to right, by checking that the gaps

between the windshield and body opening are

even on both sides of the vehicle.

4. With masking tape (5), mark the outer top and side

of the windshield pillar and the roof.

5. NOTE: This procedure will assist in the alignment

of the windshield in the correct horizontal and

vertical plane during final windshield installation.

6. Remove and place the windshield face down on a

clean protected surface or fixture.

Figure 1A6-14

Reinstall

IMPORTANT: Flange primer is NOT required if using

the recommended urethane adhesive Betaseal 15685.

If not using Betaseal 15685, and are using an

equivalent system, refer to technical data supplied by

the manufacturer.

If requir ed by the m anufactur er, apply f lange primer (1)

as directed.

Figure 1A6-15

1. Thoroughly clean the inner surface and edges of

the windshield to which the urethane is to be

applied, using clean lint-free cloths and a suitable

oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the windshield, or the body opening flange

as the presence of the oil in the solvent will

prevent the adhesion of the new uretha ne.

2. Apply clear windshield adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perimeter of the windshield. Immediately wipe off

with a lint-free cloth.

Figure 1A6-16

3. Check the condition of the windshield reveal

moulding ass em bly (1). Discard and r eplace with a

new moulding if damaged.

4. Fit the moulding assembly to the sides and upper

section of the windshield. Ensure that the notch of

the moulding (2) is aligned with the ‘V’ locating

mar k (3) on the lower portion of the right-hand and

the left-hand side of the windshield.

Figure 1A6-17

5. Use the applic ator (1) inc luded in the service kit, to

apply black windshield adhesive primer (2) to the

windshield as described in the following step.

Figure 1A6-18

6. Apply black windshield adhesive primer (1) to the

inner s urf ac e of the upper s ect ion (2) and sides (3)

of the windshield over a width of 20 mm inboard

from the moulding (4). Repeat this proces s 35 m m

from the lower edge (5) of the windshield. Ensure

that a suitably reduced application of primer (6) is

applied 15 mm from the lower edge of the

windshield (7) adjacent to the VIN plate (8).

Figure 1A6-19

7. Using a hand or automatic applicator, apply a

smooth continuous bead of windshield adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, to the windshield (2) along the inside

edge of the moulding (3). The bead dimensions

are shown in Figure 1A6-21.

Figure 1A6-20

IMPORTANT: On the lower section of the body

opening, care must be taken to ensure the urethane

bead diameter is such that when compressed by the

windshield installation, the Vehicle Identification

Number plate is not obscured.

8. Apply urethane (1) adjacent to the moulding (2)

and 35 mm inboard (3) from the lower edge of the

windshield (4). A suitably reduced amount of

urethane (5) s hould be applied adjacent to the VIN

plate (6) to ensure that the VIN is not obscured

when the windshield is installed.

NOTE: In cold weather, the placement of cartridges

adjacent to a sourc e of warm th will ass ist in the flow of

urethane when using a hand applicator.

9. For ease of installation and to avoid unnecessary

stress on related components, it is recommended

that the interior mirror assembly be fitted to the

windshield prior to installation of the windshield to

the vehicle, refer to Section 12H, 2.4 INTERNEL

REAR-VIEW MIRROR.

Figure 1A6-21

10. With the aid of an assistant, install the windshield

using the previously attached masking tape (1) on

the roof and windshield pillar to ensure accurate

installation.

• Sedan, Wagon & Utility: Use a windshield

locator (2) , between the lower windshield edge

(3) and the reinf orcing f lange (4) in two places,

to locate the windshield vertically in the

windshield opening.

• Coupe: If requir ed, use a windshield locator (2)

between the lower windshield edge (3) and the

extrusion (5) to correctly locate the windshield

in the body opening.

11. Press windshield firmly into position.

12. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps.

13. Wait two hours then water test the windshield,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

14. Clean off any excess urethane using Prepsol or

white spirit. Clean the windshield, then rem ove the

masking tape previously installed.

15. Reinstall the trim and hardware as required.

Figure 1A6-22

4. SERVICE OPERATIONS - SIDE

CAUTION 1: Safety glasses and work gloves must be worn at all times when operating with glass.

CAUTION 2: Care must be taken during any operation involv ing the w indow assembly - quarter removal or

installation, not to exert any load on the window. Failure to observe this may result in damage to the

window.

4.1 QUARTER WINDOW ASSEMBLY, WAGON

LT Section No. – 11-030

If required, first remove the following components:

1. Rear door opening weatherstrip assembly, refer to Section 1A5, 3.19 REAR DOOR OPENING

WEATHERSTRIP ASSEMBLY.

2. Body lock pillar garnish, refer to Section 1A8, 3.7 BODY LOCK PILLAR GARNISH.

3. Body rear corner garnish, refer to Section 1A8, 3.9 BODY REAR CORNER GARNISH.

4. Quarter inner trim panel assembly, refer to Section 1A8, 3.11 QUARTER INNER TRIM PANEL ASSEMBLY.

REMOVE

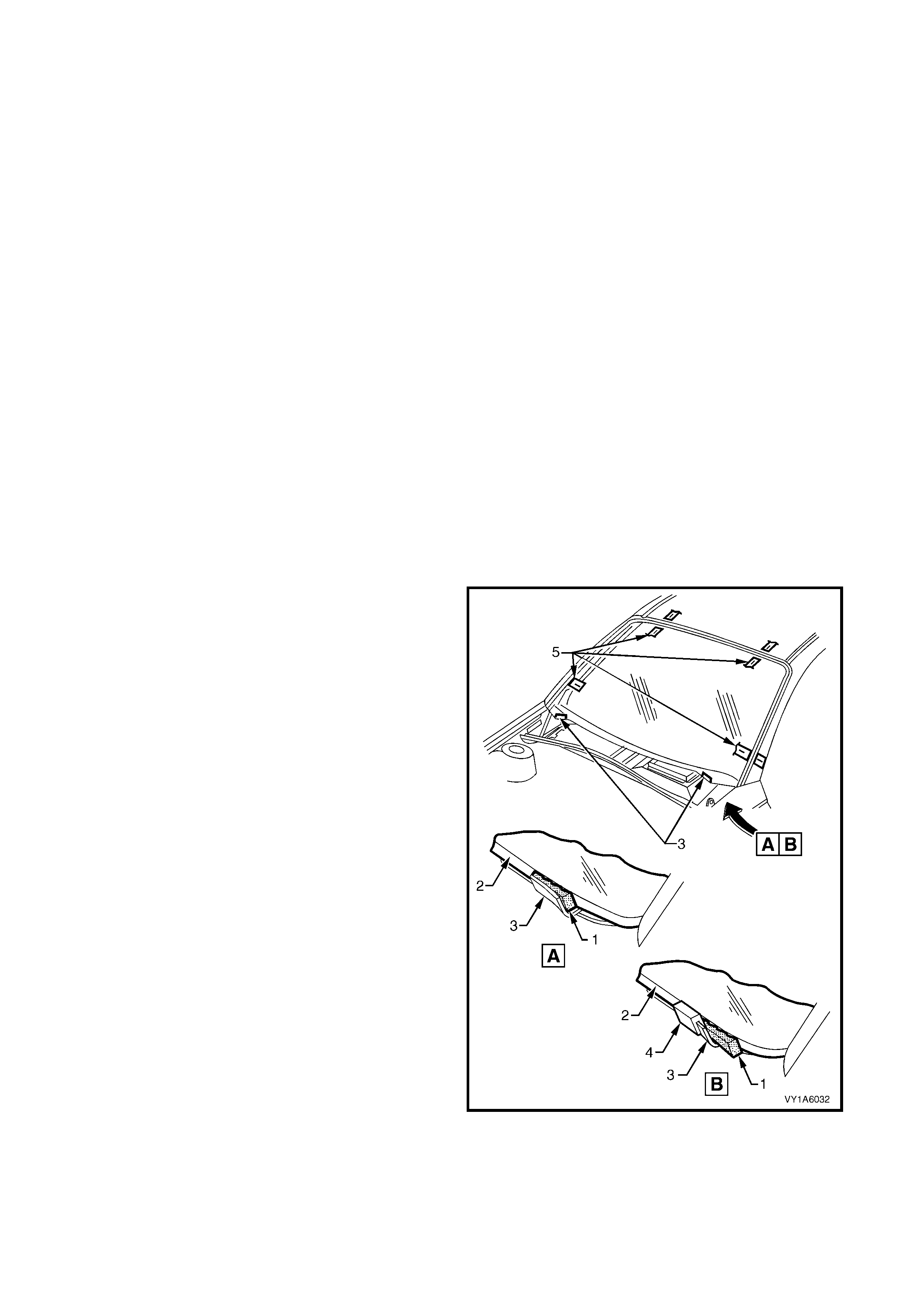

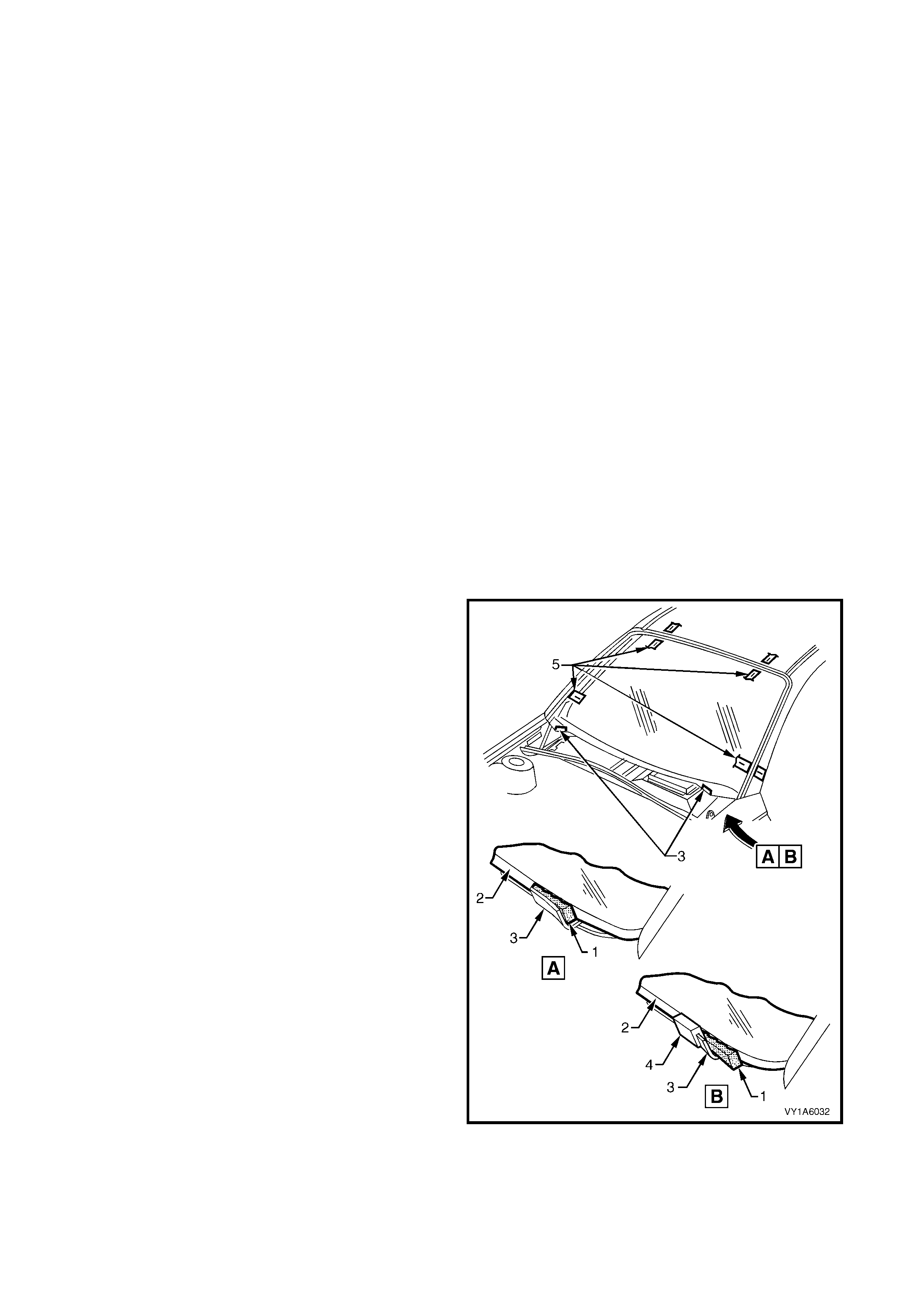

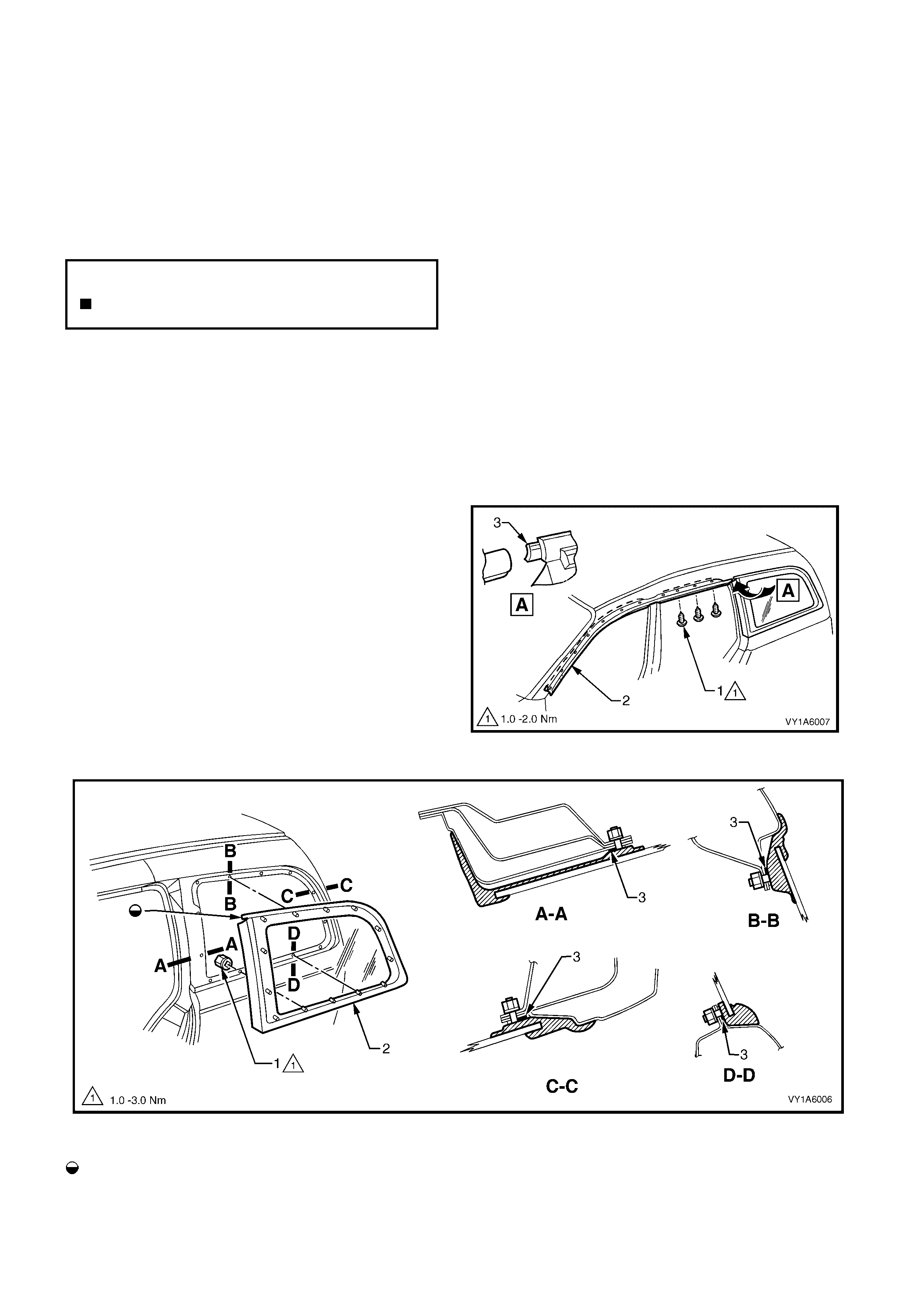

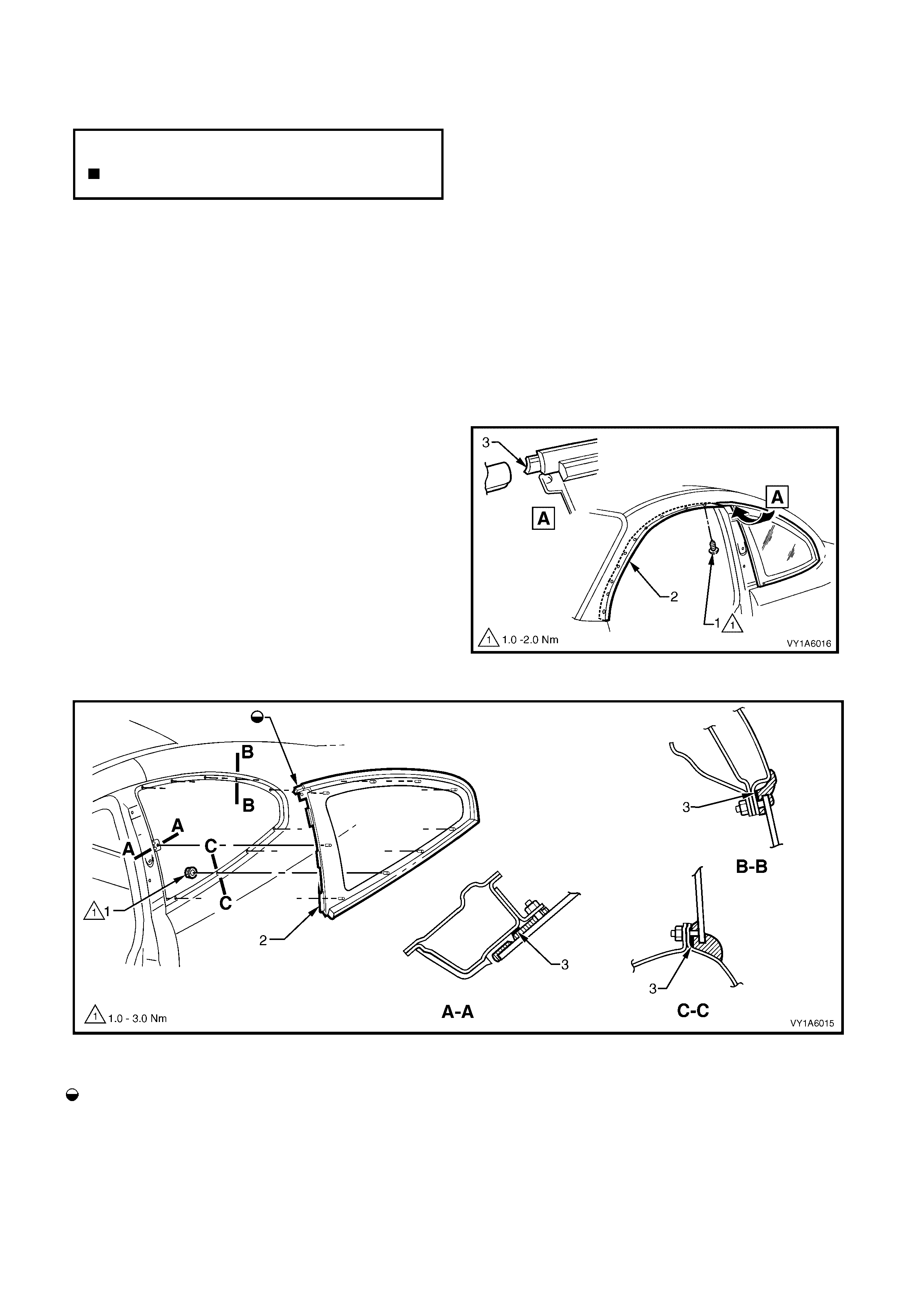

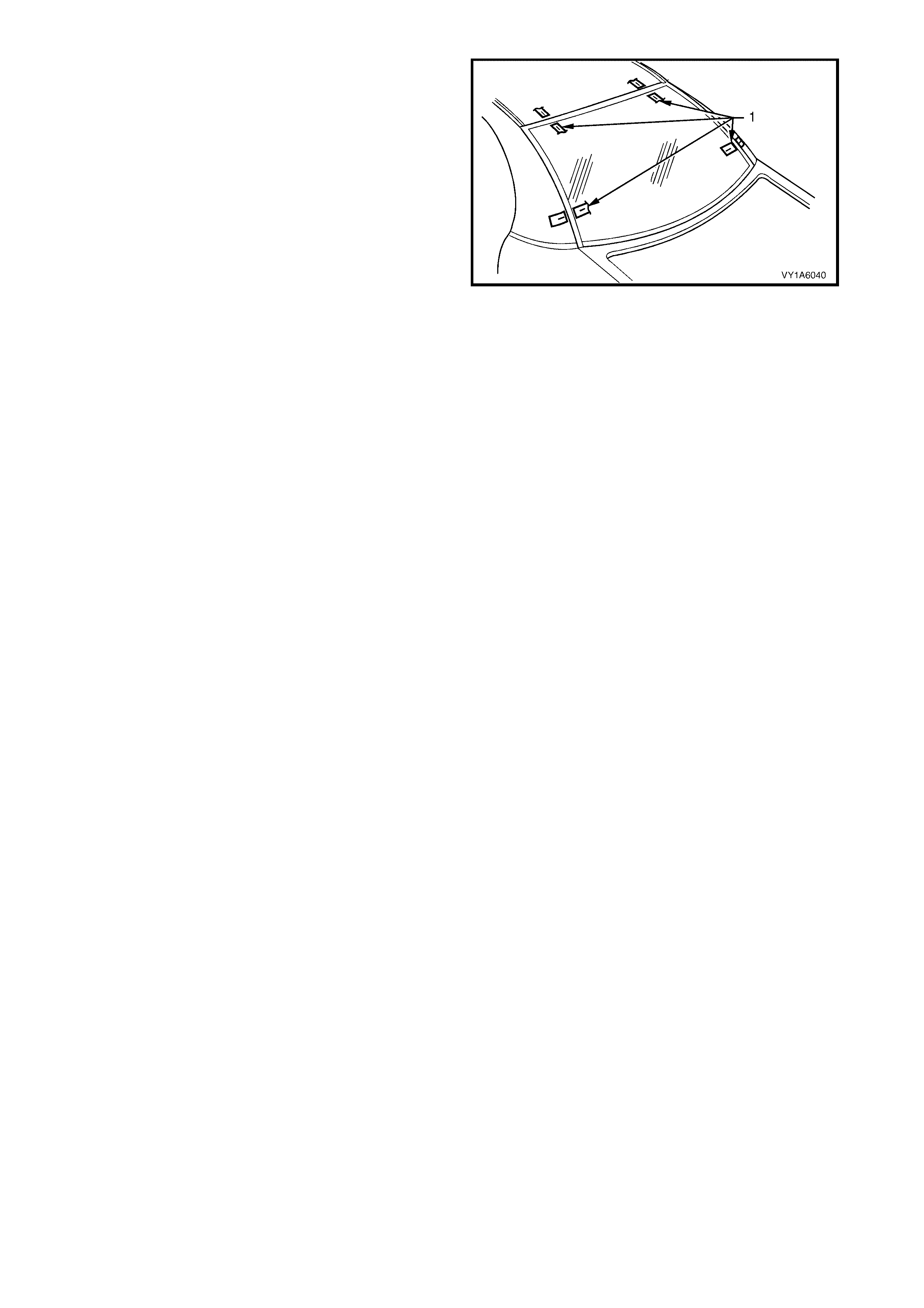

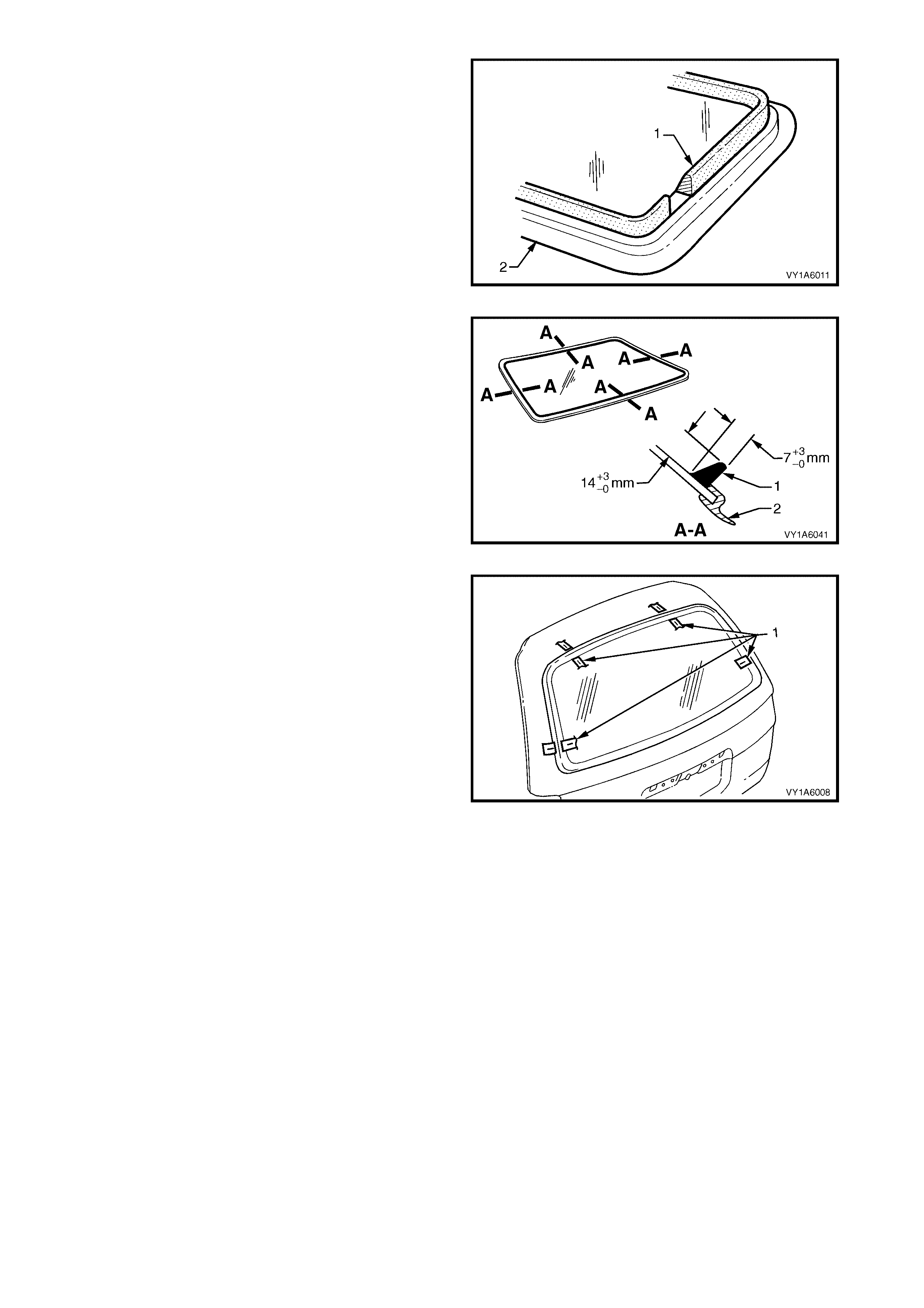

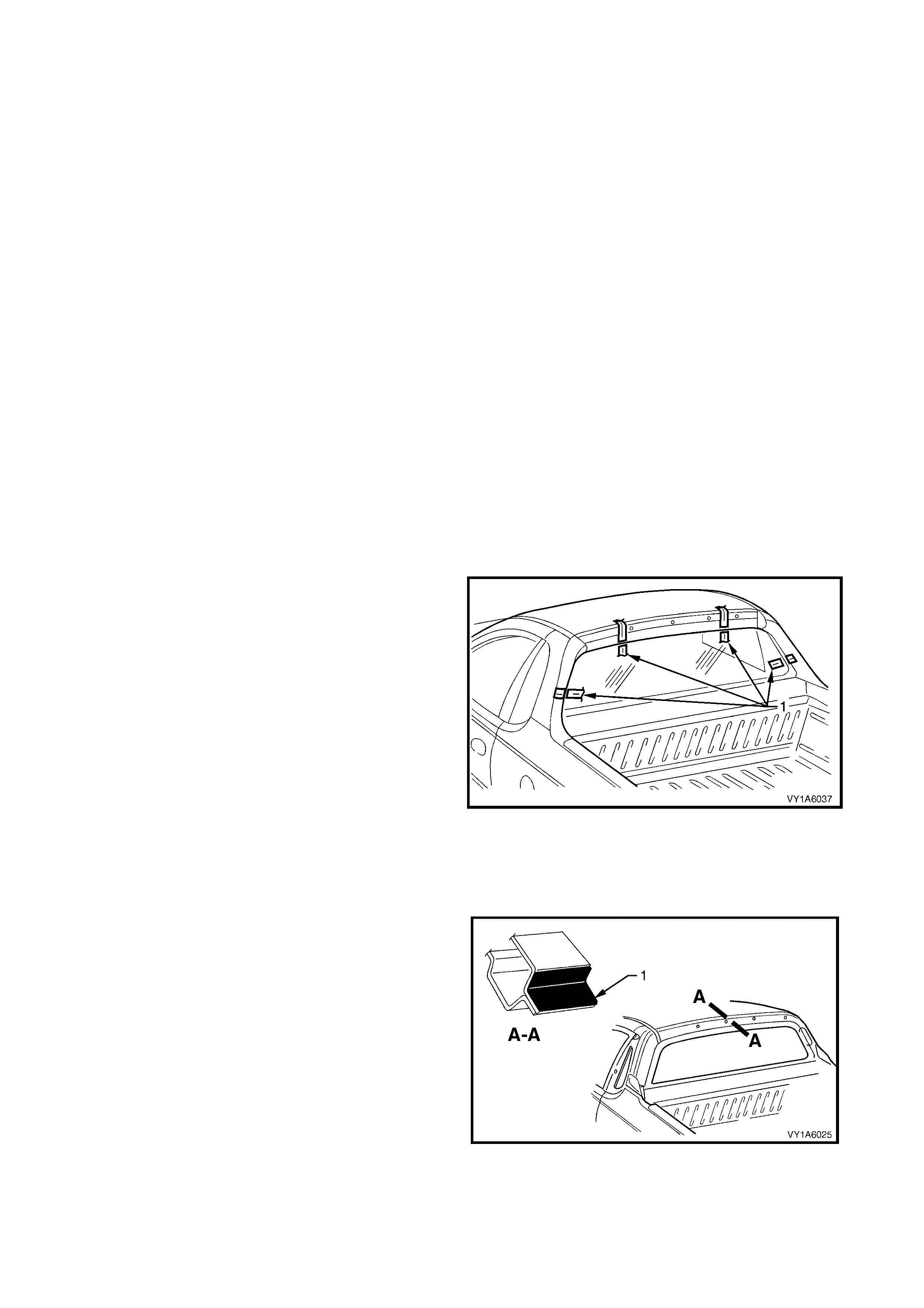

1. Remove the screws (1) and partially remove the

rear section of the door frame opening moulding

(2) wher e it joins the quarter window assem bly tab

(3).

2. Remove the quarter window nut (1) thirteen

places, securing the quarter window assembly (2)

to the body opening, refer Figure 1A6-24.

NOTE: The quarter window nut will be damaged during

this operation and must be replaced, to retain a

watertight seal.

3. Carefully lift the window from the vehicle.

CAUTION: Take care when removing the quarter

window from the body opening, that the attaching

pins are clear of the outer body.

Figure 1A6-23

Figure 1A6-24

legend

Tab To Engage With Moulding

Assembly Front And Rear Side Door

Opening Frame Reveal

1. Nut - Quarter Wi ndow (13 Places)

2. Window Assembly - Quarter 3. Foam Seal

NOTE: Sectional views show installed condition.

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

Quarter window nut.

REINSTALL

Reinstallation of the quarter window assembly is the

reverse of the removal noting the following:

1. Use new quarter window nuts (thirteen places).

2. Leave the nuts loose, until the door fram e opening

moulding is fastened into position.

3. Position the quarter window assembly and tighten

the nuts to the correct torque specification.

4. Reinstall the trim and hardware as required.

QUARTER WINDOW ASSEMBLY

RETAINING NUT

TORQUE SPECIFICATION 1.0 – 3.0 Nm

DOOR FRAME OPENING MOULDING

RETAINING SCREWS

TORQUE SPECIFICATION 1.0 – 2.0Nm

4.2 QUARTER WINDOW ASSEMBLY, UTILITY

LT Section No. – 11-025

If required, first remove the following components:

1. Front door opening weatherstrip assembly, refer to Section 1A5, 2.19 FRONT DOOR OPENING

WEATHERSTRIP ASSEMBLY.

2. Centre pillar lower trim, refer to Section 1A8, 5.2 CENTRE PILLAR LOWER TRIM.

3. Body lock pillar upper trim refer to Section 1A8, 5.3 BODY LOCK PILLAR UPPER TRIM.

4. Centre pillar upper finisher, refer to Section 1A9, 4.8 CENTRE PILLAR UPPER FINISHER.

REMOVE

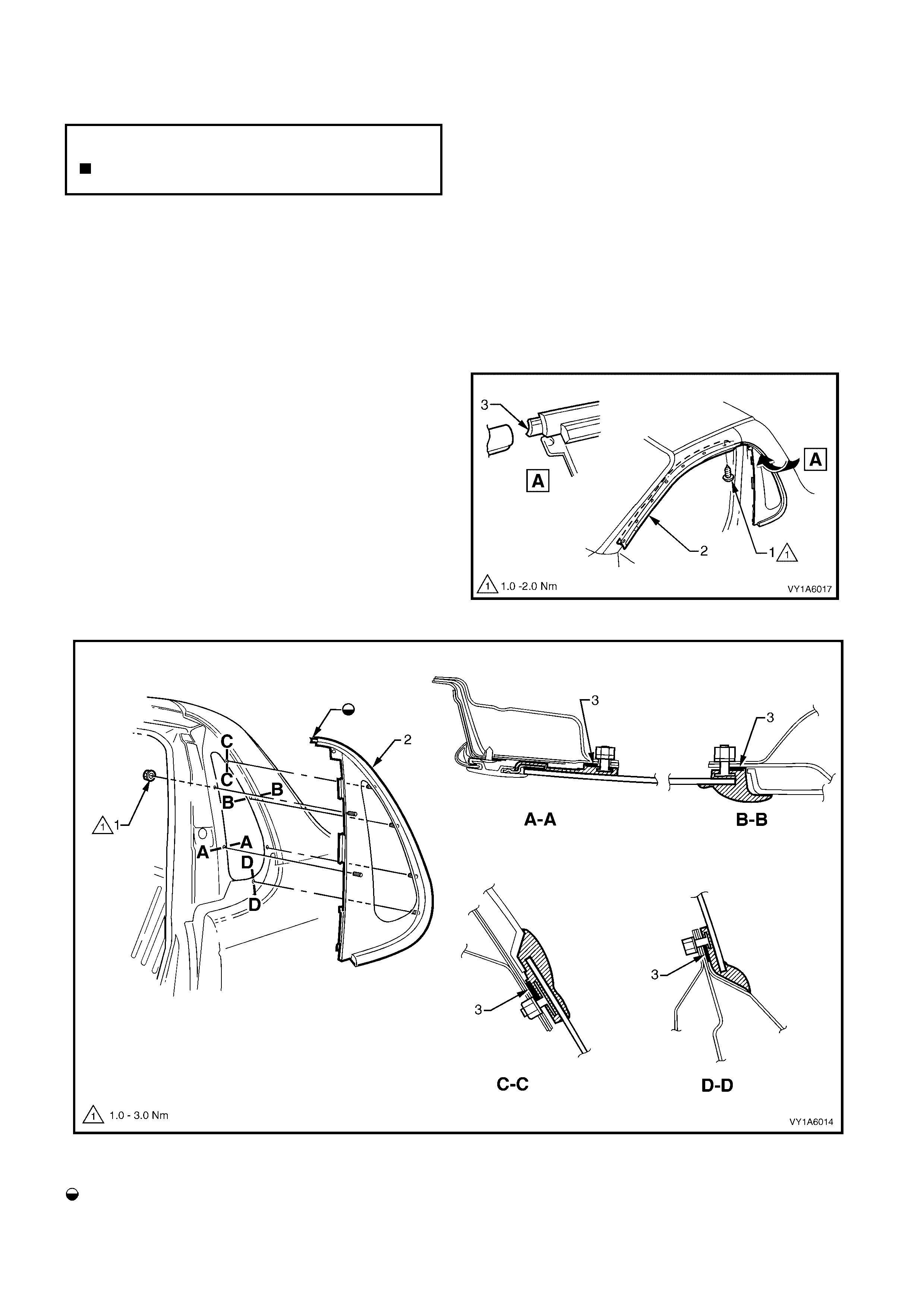

1. Remove the screws (1) and partially remove the

rear section of the door frame opening moulding

(2) where it joins the quarter window assem bly tab

(3).

2. Remove the quarter window nut (1) six places,

securing the quarter window assembly (2) to the

body opening, refer Figure 1A6-26.

NOTE: The quarter window nut will be damaged during

this operation and must be replaced, to retain a

watertight seal.

3. Carefully lift the window from the vehicle.

CAUTION: Take care when removing the quarter

window from the body opening, that the attaching

pins are clear of the outer body.

Figure 1A6-25

Figure 1A6-26

Legend

Tab To Engage Wit h Moulding - Door

Frame Opening 1. Nut - Quarter Window (6 Places)

2. Wi ndow As sembly - Quarter 3. Foam Seal

NOTE: Sectional views show installed condition.

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

Quarter window nut.

REINSTALL

Reinstallation of the quarter window assembly is the reverse of the removal noting the following:

1. Use new quarter window nuts (six places).

2. Leave the nuts loose, until the door frame opening moulding is fastened into position.

3. Position the quarter window assembly and tighten the nuts to the correct torque specification.

4. Reinstall the trim and hardware as required.

QUARTER WINDOW ASSEMBLY

RETAINING NUT

TORQUE SPECIFICATION 1.0 – 3.0 Nm

DOOR FRAME OPENING MOULDING

RETAINING SCREWS

TORQUE SPECIFICATION 1.0 – 2.0 Nm

4.3 QUARTER WINDOW ASSEMBLY, COUPE

LT Section No. –

If required, first remove the following components:

1. Front door opening weatherstrip assembly, refer to Section 1A5, 2.20 FRONT DOOR OPENING

WEATHERSTRIP ASSEMBLY.

2. Partially remove the side sill trim and plate, refer to Section 1A8, 4.1 SIDE SILL TRIM AND PLATE.

3. Quarter trim panel assembly, refer to Section 1A8, 4.2 QUARTER TRIM PANEL ASSEMBLY.

4. Centre pillar upper trim assembly, refer to Section 1A8, 4.3 CENTRE PILLAR UPPER TRIM ASSEMBLY.

5. Body rear corner garnish, refer to Section 1A8, 4.5 BODY REAR CORNER GARNISH.

6. Centre pillar upper finisher, refer to Section 1A9, 5.8 CENTRE PILLAR UPPER FINISHER.

REMOVE

1. Remove the screws (1) and partially remove the

rear section of the door frame opening moulding

(2) wher e it joins the quarter window assem bly tab

(3).

2. Remove the quarter window nut (1) nine places,

securing the quarter window assembly (2) to the

body opening, refer Figure 1A6-28.

NOTE: The quarter window - nut will be damaged

during this operation and m ust be replaced, to r etain a

watertight seal.

3. Carefully lift the window from the vehicle.

CAUTION: Take care when removing the quarter

window from the body opening, that the attaching

pins are clear of the outer body.

Figure 1A6-27

Figure 1A6-28

Legend

Tab To Engage Wit h Moulding - Door

Frame Opening 1. Nut - Quarter Window (9 Places)

2. Wi ndow As sembly - Quarter 3. Foam Seal

NOTE: Sectional views show installed condition.

N

O

TE: The

f

ollowing component WILL RE

Q

UIRE

REPLACEMENT when performing this operation.

Quarter window nut.

REINSTALL

Reinstallation of the quarter window assembly is the reverse of the removal noting the following:

1. Use new quarter window nuts (thirteen places).

2. Leave the nuts loose, until the door frame opening moulding is fastened into position.

3. Position the quarter window assembly and tighten the nuts to the correct torque specification.

1.

4. Reinstall the trim and hardware as required.

QUARTER WINDOW ASSEMBLY

RETAINING NUT

TORQUE SPECIFICATION 2.0 – 2.5 Nm

DOOR FRAME OPENING MOULDING

RETAINING SCREWS

TORQUE SPECIFICATION 1.0 – 2.0 Nm

5. SERVICE OPERATIONS - REAR

CAUTION 1: Safety glasses and work gloves must be worn at all times when operating with glass.

CAUTION 2: Care must be taken during any operation involving the window assembly - rear removal or

installation, not to exert any load on the window. Failure to observe this may result in damage to the

window.

IMPORTANT: Only use ur ethane adhesive suc h as Betaseal 15685 or equivalent f or rear window installation. It is

imperative that the procedure in this Section for replacing bonded windows are followed, as incorrect installation

may lead to injury or death.

5.1 REAR WINDOW ASSEMBLY, SEDAN AND COUPE

LT Section No. – 11-020

The rear window assembly removal procedure is the same for both the short and long installation methods, with

one exception. If the short method installation is to be used, care must be taken during the rear window removal to

ensure that an even surface of the original remaining urethane exists in the body opening, to serve as a base for

the new urethane bead and the replacement rear window.

To prevent damage and to m inim ise clean up of the paint f inish and the trim , m ask -up and place protective covers

over parts adjacent to the rear window.

If required, remove the following components:

1. Roof panel joint finish moulding, refer to Section 1A9, 2.7 ROOF JOINT MOULDING Sedan and 5.6 ROOF

JOINT MOULDING Coupe.

2. Body lock pillar garnish, for Sedan refer to Section 1A8, 2.6 BODY LOCK PILLAR GARNISH.

3. Rear window upper garnish, for Sedan refer to Section 1A8, 2.7 REAR WINDOW UPPER GARNISH.

4. Body rear corner garnish, for Coupe refer to Section 1A8, 4.5 BODY REAR CORNER GARNISH.

REMOVE

IMPORTANT: Note that on all vehicles a high mount s top lam p ass em bly is installed in the rear window trim panel

assem bly. Car e must be tak en to avoid damage to the lamp as sembly during window removal procedur e. It is not

necessary to remove the lamp assembly, but to ensure that it is clear of any debris before window installation.

1. Carefully disconnect the rear window electrical

demister connectors and cellular telephone

antenna if fitted.

2. Should the rear window be broken, carefully

remove all fragments of glass from the window

opening.

3. Using special tool J36020 thread one end of the

piano wire through the urethane, starting at the

windshield upper corner, pulling the end of the wire

through with pliers

4. Alternately, manufacture two T-handles to the

dimensions shown. Secure at least 700mm of

piano wire to one handle, thread the other end of

the wire through the urethane as previously

described.

NOTE: Ens ure that the headlining and other trim item s

are not damaged.

5. Connect the wire to the remaining T-handle and

with the aid of an assistant, com menc e cutting the

urethane bead, keeping the outside T-handle (1)

parallel to the edge of the window using the full

length of the wire to prevent heat build up in the

wire.

NOTE: To minimise the damage to the interior of the

vehicle, the operator inside the vehicle should act as

an anchor point. Holding the T-handle as close as

possible to the window at all times, while the outside

operator pulls the wire up to the interior T-handle in a

‘walking’ motion, refer to Figs.1A6-30.

Figure 1A6-29

Figure 1A6-30

6. Carefully lift the rear window out of the rear

opening. If there is evidence of the window

adhering to the urethane, cut the area again with

the piano wire.

7. If the original rear window is to be installed again,

place the window on a clean protected surface or a

holding fixture.

NOTE 1: The use of suction cups will greatly assist

any handling of the rear window.

NOTE 2: All traces of ur ethane must be removed f rom

the rear window. It is not necessary to remove all

traces of the original urethane from the body opening,

unless the ‘long m ethod’ of reins tallation is being used.

However, any original urethane remaining must be

smooth and firm.

REINSTALL - SHORT METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The short method installation involves the maximum amount of the original urethane being left intact on the rear

window opening to form a sound base for the replacement urethane and rear window assembly.

This method is recommended when replacing a cracked or broken window, or a leak condition that cannot be

overcome by using minor water leak repair procedures, refer to 2.1 MINOR WATER LEA K CORRECTION.

If material other than urethane has been used for previous servicing of the rear window, the long method

installation procedure (complete removal of adhesive) is mandatory to achieve an effective window to metal bond.

CAUTION 1: Care should be taken to ensure that the rear window does not strike the rear window

opening. Chipped edges can lead to subsequent breakage of the window.

CAUTION 2: Do not use petroleum based solvents to clean the rear window assembly or the rear opening

flange, as the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Using a sharp scraper, carefully remove any

original urethane from around the rear window.

Clean the rear window to be installed with a

suitable oil free cleaning agent.

2. To check for correct alignment, temporarily place

the rear window in the body opening.

3. Ensure the rear window is centralised in the body

opening left to right, by checking that the gaps

between the rear window and body opening are

even on both sides of the vehicle.

4. With masking tape (1), mark the outer top of the

roof and the rear quarter panel.

NOTE: This procedure will assist in the alignment of

the window in the correct horizontal and vertical plane

during final window installation.

5. Remove and plac e the rear window assem bly fac e

down on a clean protected surface or fixture.

Figure 1A6-31

Reinstall

1. Thoroughly clean the inner surface and edges of

the rear window assem bly to which the urethane is

to be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the rear window assembly, or the rear

opening flange as the presence of the oil in the

solvent will prevent the adhesion of the new

urethane.

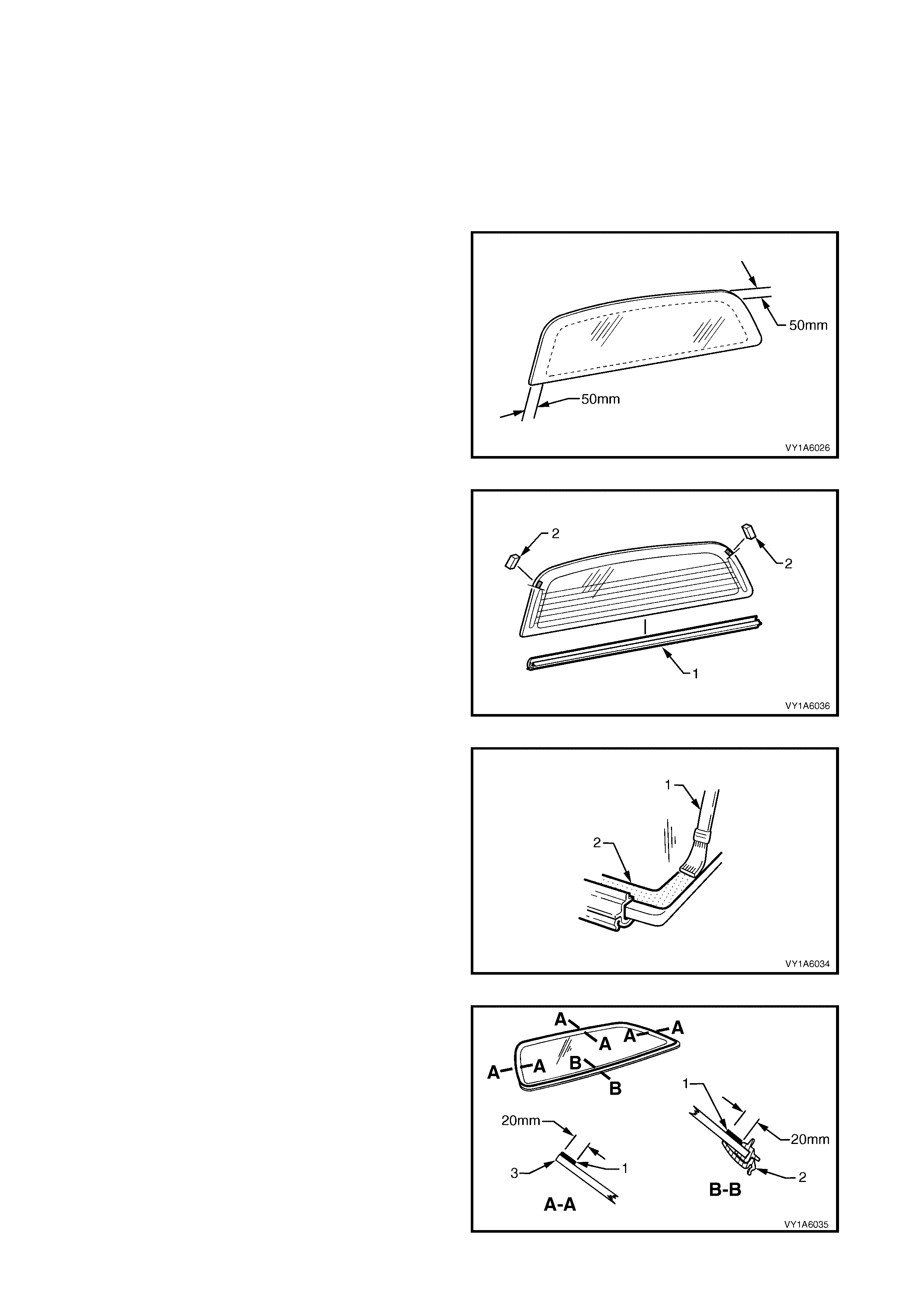

2. Apply clear window adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perim eter of the rear window. Im m ediately wipe of f

with a lint-free cloth.

Figure 1A6-32

3. Check the condition of the rear window mouldings .

Discard and replace with new mouldings if

damaged.

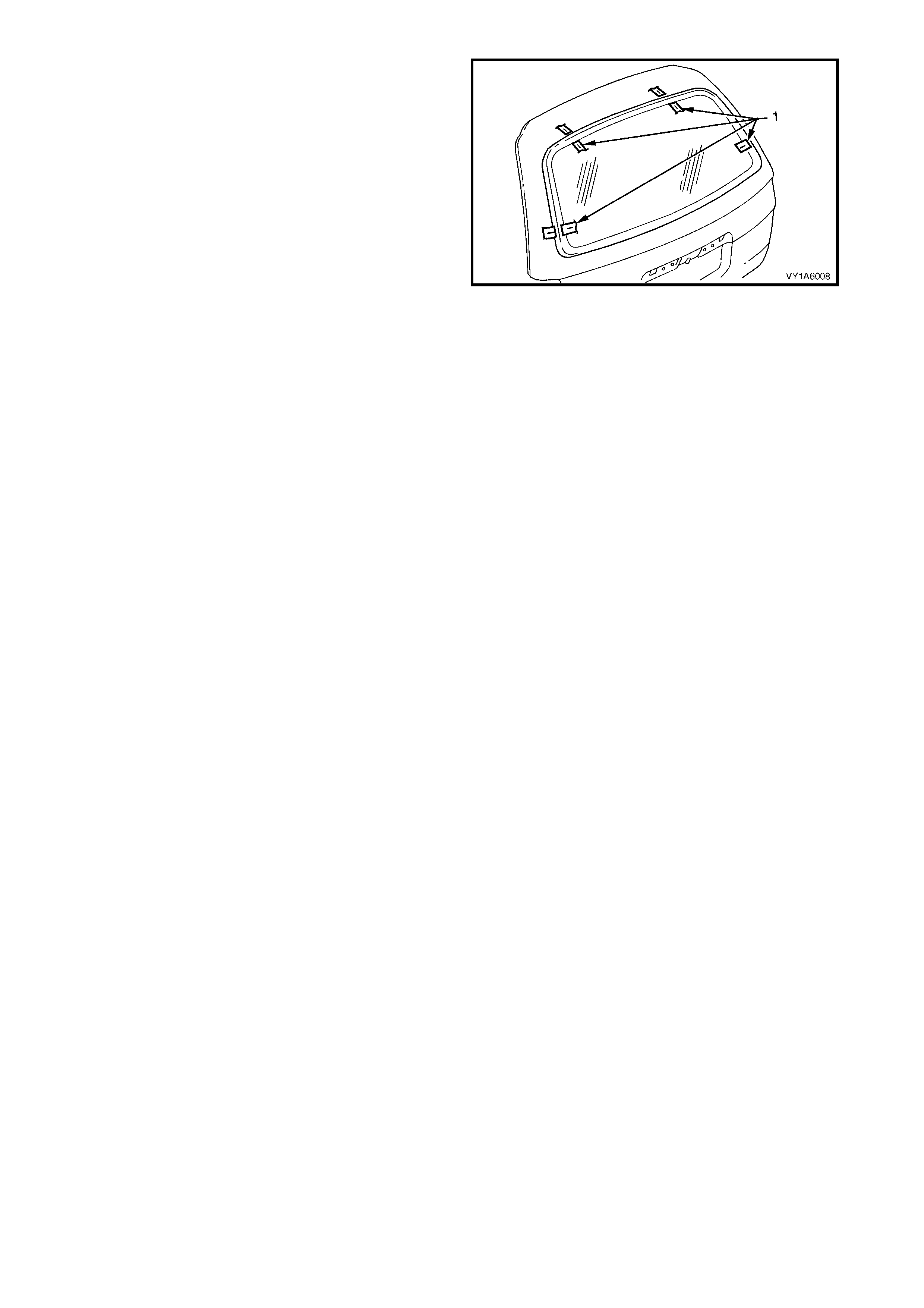

4. Install the rear window upper reveal moulding (1)

and the rear window lower reveal moulding (2)

over the edge of the window. Ensure the

mouldings are fitted correctly to the window.

5. Install the rear window side moulding retainer (3)

two places. Ensure the retainers are positioned to

alignment marks (4), and are fitted correctly to

edge of the window.

6. Check the condition of the original urethane

around the window opening flange for voids or

looseness.

7. Cut away any loose pieces of urethane.

8. Using a suitable spatula, spread fresh urethane

smoothly into any voids or uneven sections.

Figure 1A6-33

1. Use the applic ator (1) inc luded in the service kit, to

apply black window adhesive prim er (2) to the rear

window as described in the following step.

Figure 1A6-34

2. Apply black window adhesive primer (1) to the

inner surface, around the perimeter of the rear

window over a width of 20 mm, along the inside

edge of the window moulding (2).

Figure 1A6-35

3. Using a hand or automatic applicator, apply a

smooth continuous bead of window adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, around the perimeter of the window,

along the inside edge of the mouldings (2). The

bead dimensions are shown in Figure 1A6-37.

NOTE: 1 Depending on the amount of urethane

remaining on the body opening flange, the amount of

the new urethane should be reduced accor dingly, while

maintaining adequate strength and sealing properties.

The dimensions shown are the maximum allowable

and are only for reference.

NOTE: 2 In cold weather, the placement of cartridges

adjacent to a sourc e of warm th will ass ist in the flow of

urethane when using a hand applicator.

Figure 1A6-36

Figure 1A6-37

4. With the aid of an ass istant, ins tall the r ear window

assembly, using the previously attached masking

tape (1) on the roof and the rear quarter panel to

ensure accurate installation.

NOTE: Ensure the rear window is centralised in the

body opening left to right by checking that the gaps

between the window moulding and body opening are

even on both sides of the vehicle.

5. Press the rear window firmly into position.

6. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps.

7. Wait two hours then water test the rear window,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

8. Clean off any excess urethane using Prepsol or

white spirit. Clean the rear window, then remove

the masking tape previously installed.

9. Connect the electrical demist connectors and

cellular telephone antenna if fitted.

10. Reinstall the trim and hardware as required.

Figure 1A6-38

REINSTALL - LONG METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The long m ethod for the rear window assem bly replac ement is used when the original urethane adhesive m aterial

cannot serve as a base for the replacement rear window.

This method should be used on vehicles requiring metal or paint repair to the rear window opening, when the

original adhesive is completely removed and replaced with new urethane for the window installation.

This method is also used when the rear window has been previously replaced using the short method. In such

instances, the build-up of urethane could position the window assembly too high in the opening.

CAUTION: Do not use petroleum based solvents to clean the rear window or the rear opening flange, as

the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Us ing a s har p sc r aper, c ar ef ully rem ove any original urethane fr om around the rear window. Clean the window

to be installed with a suitable oil free cleaning agent.

2. Using a knife or sharp scraper, remove the original urethane from around the entire perimeter of the window

opening flange. Avoid the removal of paint when removing urethane from opening flange.

Rear Window Opening Check

1. Thoroughly check the rear window opening flange for any irregularities before installing the rear window

assembly.

CAUTION: Care should be taken to ensure that the rear window does not strike the rear window opening.

Chipped edges can lead to subsequent breakage of the window assembly.

2. To check for correct alignment, temporarily place

the rear window in the body opening.

3. If necessary, reform the rear window opening

flange to produce a uniform flange to the window

contour.

4. Ensure the rear window is centralised in the body

opening left to right, by checking that the gaps

between the rear window and body opening are

even on both sides of the vehicle.

5. With masking tape (1), mark the outer top of the

roof and the rear quarter panel.

NOTE: This procedure will assist in the alignment of

the window in the correct horizontal and vertical plane

during final window installation.

6. Remove and plac e the rear window assem bly fac e

down on a clean protected surface or fixture.

Figure 1A6-39

Reinstall

IMPORTANT: Flange primer is NOT required if using

the recommended urethane adhesive Betaseal 15685.

If not using Betaseal 15685, and are using an

equivalent system, refer to technical data supplied by

the manufacturer.

If requir ed by the m anufactur er, apply f lange primer (1)

as directed.

Figure 1A6-40

1. Thoroughly clean the inner surface and edges of

the rear window assembly to which the urethane is

to be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the rear window assembly, or the rear

opening flange as the presence of the oil in the

solvent will prevent the adhesion of the new

urethane.

2. Apply clear window adhesive primer, over the width

of the solid black ceramic pattern (or a width of

50 mm), to the inner surface around the perimeter

of the rear window. Im mediately wipe off with a lint-

free cloth.

Figure 1A6-41

3. Check the condition of the rear window mouldings.

Discard and replace with new mouldings if

damaged.

4. Install the rear window upper reveal moulding (1)

and the rear window lower reveal moulding ( 2) over

the edge of the window. Ensure the mouldings are

fitted correctly to the window.

5. Install the rear window side moulding retainer (3)

two places. Ensure the retainers are positioned to

alignment marks (4), and are fitted correctly to edge

of the window.

Figure 1A6-42

6. Use the applicator (1) included in the service kit, to

apply black window adhesive primer (2) to the rear

window as described in the following step.

Figure 1A6-43

7. Apply black window adhesive prim er ( 1) to the inner

surf ace, around the perim eter of the window over a

width of 20 mm, along the inside edge of the

window moulding (2).

Figure 1A6-44

8. Using a hand or automatic applicator, apply a

smooth continuous bead of window adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, around the perimeter of the window,

along the inside edge of the mouldings (2). The

bead dimensions are shown in Figure 1A6-46.

NOTE: In cold weather, the placement of cartridges

adjacent to a source of warmth will assist the flow of

urethane when using a hand applicator.

Figure 1A6-45

Figure 1A6-46

9. W ith the aid of an assistant, install the rear window

assembly, using the previously attached masking

tape (1) on the roof and the rear quarter panel to

ensure accurate installation.

NOTE: Ensure the rear window is centralised in the

body opening left to right by checking that the gaps

between the window moulding and the body opening

are even on both sides of the vehicle.

10. Press the rear window firmly into position.

11. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps.

12. Wait two hours then water test the rear window,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

13. Clean off any excess urethane using Prepsol or

white spirit. Clean the rear window, then remove the

masking tape previously installed.

14. Connect the electrical demist connectors and

cellular telephone antenna if fitted.

15. Reinstall the trim and hardware as required.

Figure 1A6-47

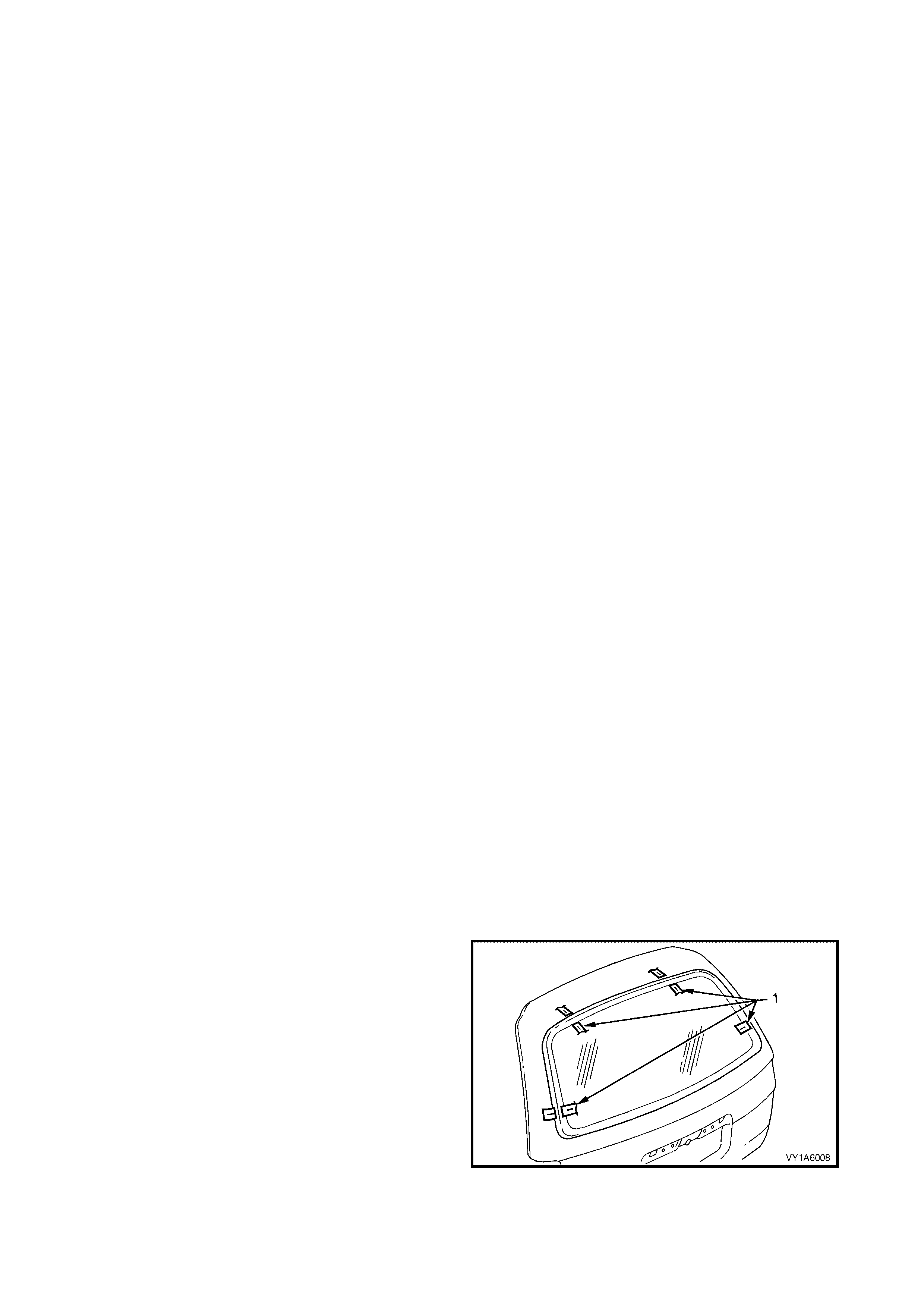

5.2 LIFTGATE WINDOW ASSEMBLY, WAGON

LT Section No. – 11-030

The liftgate window ass embly removal pr ocedure is the s ame f or both the short and the long inst allation methods,

with one exception. If the short method installation is to be used, more care must be taken during the liftgate

window removal to ensur e that an even surfac e of the original rem aining urethane exis ts in the liftgate opening, to

serve as a base for the new urethane bead and the replacement liftgate window.

To prevent damage and to m inim ise clean up of the paint f inish and the trim , m ask -up and place protective covers

over parts adjacent to the liftgate.

If required, remove the following components:

1. Rear window w iper arm assembly, refer to Section 1A4, 4.10 REAR WINDOW WIPERS ASSEMBLY.

2. High mount stop lamp, refer to Section 1A4, 4.12 HIGH MOUNT STOP LAMP ASSEMBLY.

3. Liftgate window lower garnish, refer to Section 1A4, 4.1 LIFTGATE WINDOW LOWER GARNISH.

4. Liftgate window upper garnish, refer to Section 1A4, 4.4 LIFTGATE WINDOW UPPER GARNISH.

5. Liftgate Air Deflector Assembly, refer to Section 1A4, 4.9 LIFTGATE AIR DEFLECTOR ASSEMBLY.

REMOVE

1. Carefully disconnect the liftgate window assembly electrical demister connectors.

2. Should the liftgate window be broken, carefully remove all fragments of glass from the window opening.

3. If the window is intact, carefully cut out the liftgate window by following the procedure set out in Steps 3 to 6,

refer to 5.1 REAR WINDOW ASSEMBLY, SEDAN AND COUPE.

REINSTALL - SHORT METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The s hort method ins tallation involves the maximum amount of the or iginal ur ethane being lef t intac t on the lif tgate

opening to form a sound base for the replacement urethane and liftgate window assembly.

This method is recommended when replacing a cracked or broken window, or a leak condition that cannot be

overcome by using minor water leak repair procedures, refer to 2.1 MINOR WATER LEA K CORRECTION.

If material other than urethane has been used for previous servicing of the liftgate window, the long method

installation procedure (complete removal of adhesive) is mandatory to achieve an effective window to metal bond.

CAUTION 1: Care should be taken to ensure that the liftgate window does not strike the liftgate window

opening. Chipped edges can lead to subsequent breakage of the window.

CAUTION 2: Do not use petroleum based solvents to clean the liftgate window assembly or the liftgate

opening flange, as the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Using a sharp scraper, carefully remove any

original urethane from around the liftgate window.

Clean the liftgate window to be installed with a

suitable oil free cleaning agent.

2. To check for correct alignment, temporarily place

the liftgate window in the liftgate opening.

3. Ensure the liftgate window is centralised in the

liftgate opening left to right, by checking that the

gaps between the liftgate window and liftgate

opening are even on both sides of the vehicle.

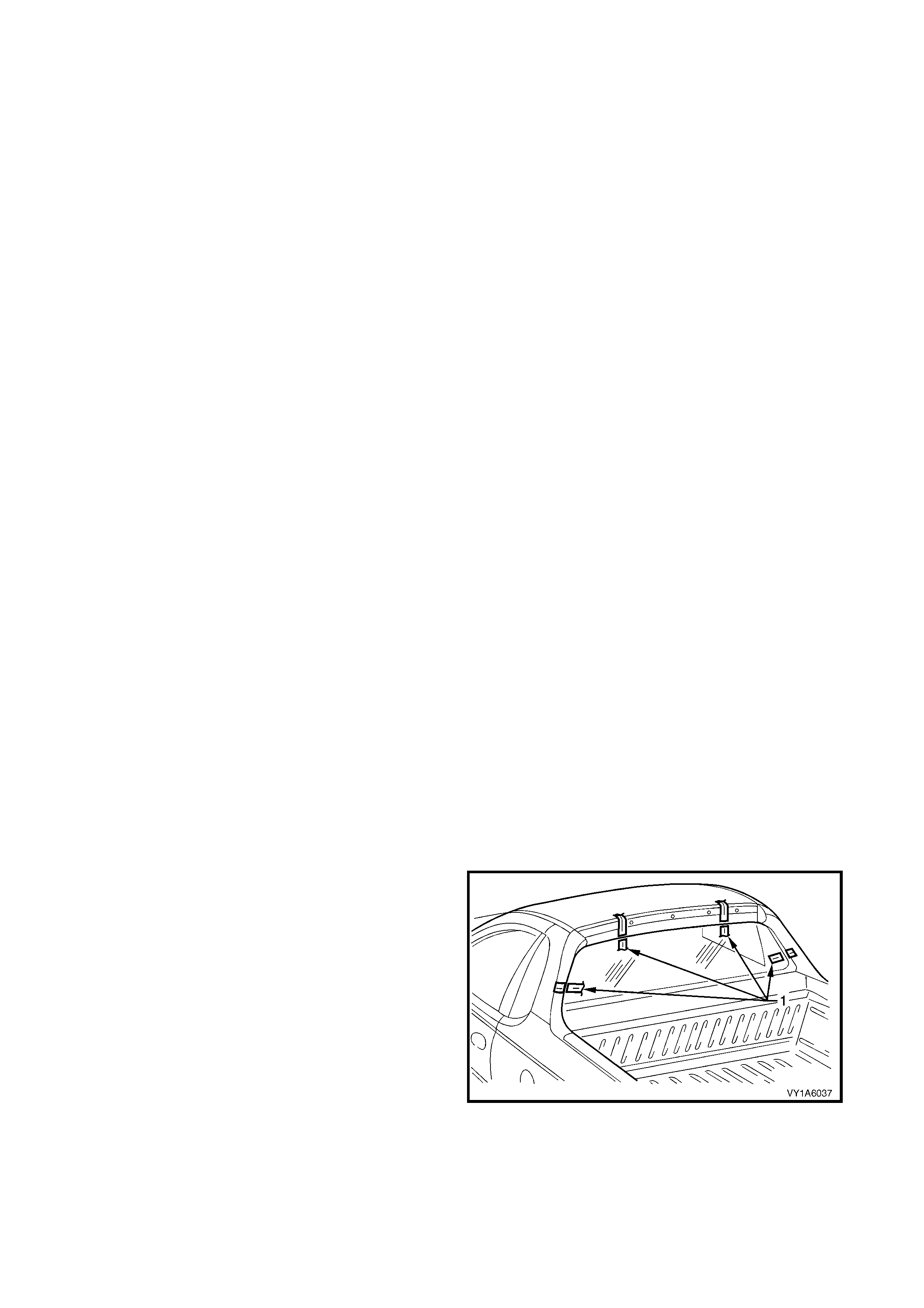

4. With masking tape (1), mark the outer top and side

of the liftgate.

NOTE: This procedure will assist in the alignment of

the window in the correct horizontal and vertical plane

during final window installation.

5. Remove and place the liftgate window assembly

face down on a clean protected surface or fixture.

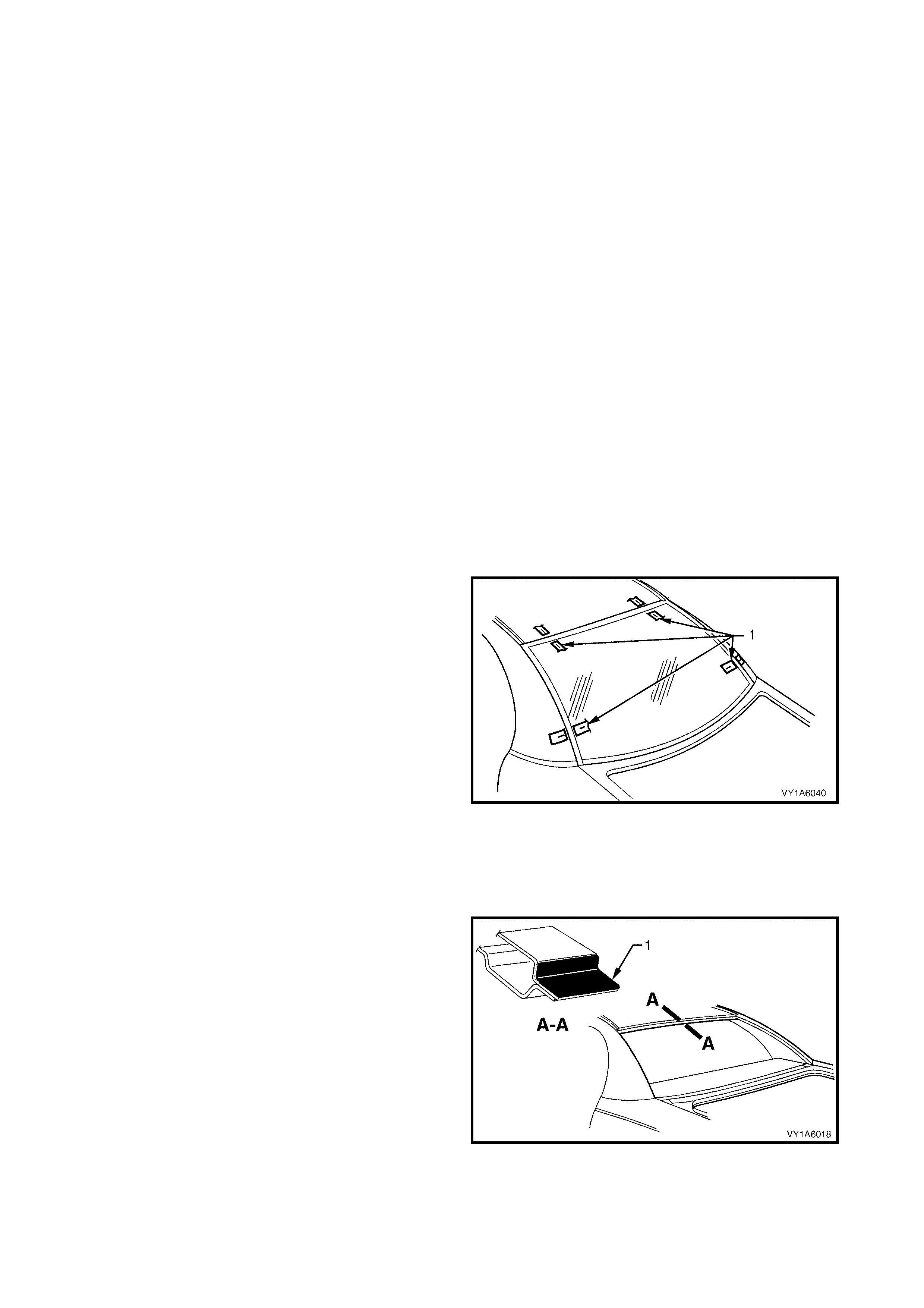

Figure 1A6-48

Reinstall

6. Thoroughly clean the inner surface and edges of

the liftgate window assem bly to which the urethane

is to be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the liftgate window assembly, or the rear

opening flange as the presence of the oil in the

solvent will prevent the adhesion of the new

urethane.

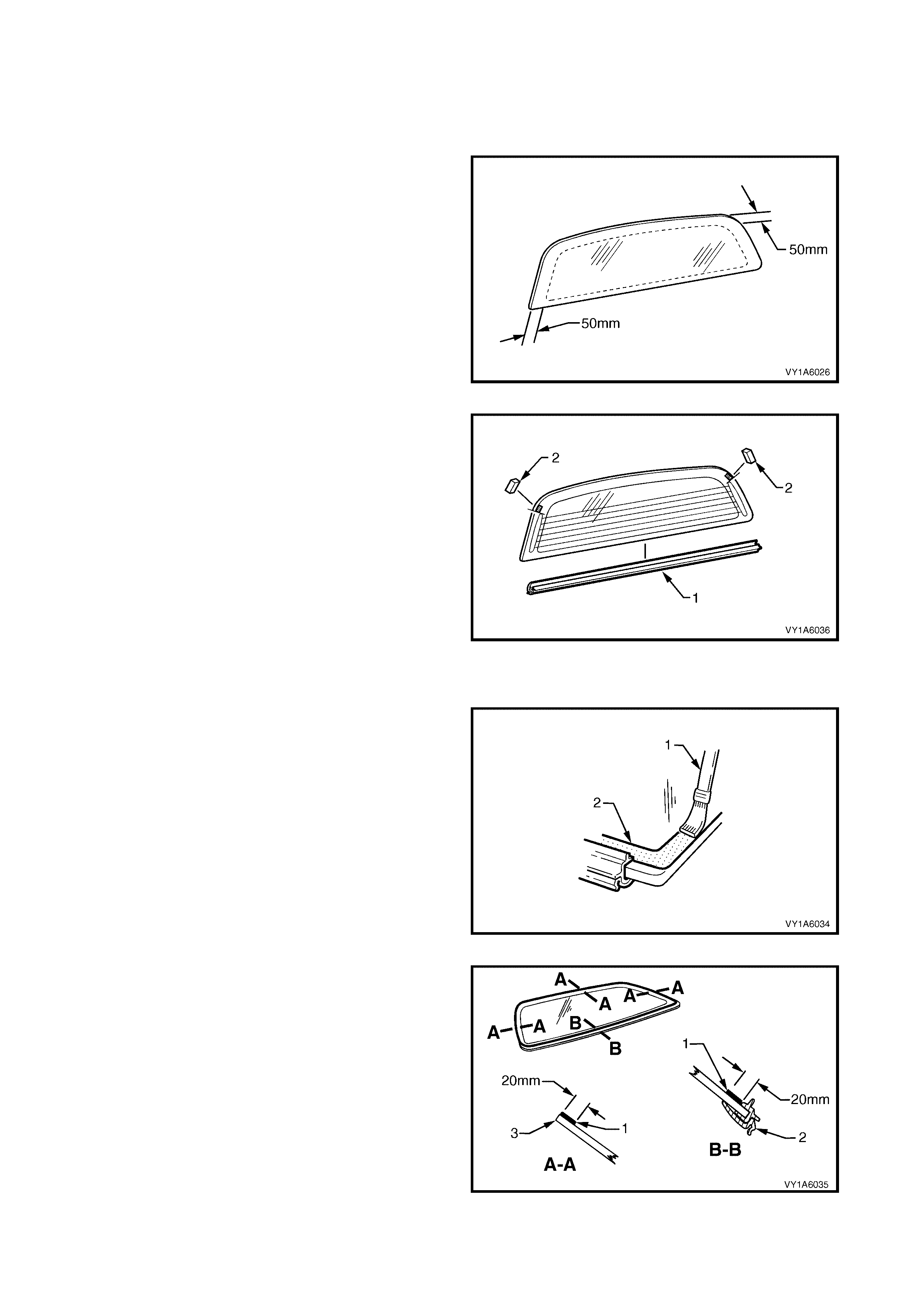

7. Apply clear window adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perimeter of the liftgate window. Immediately wipe

off with a lint-free cloth.

Figure 1A6-49

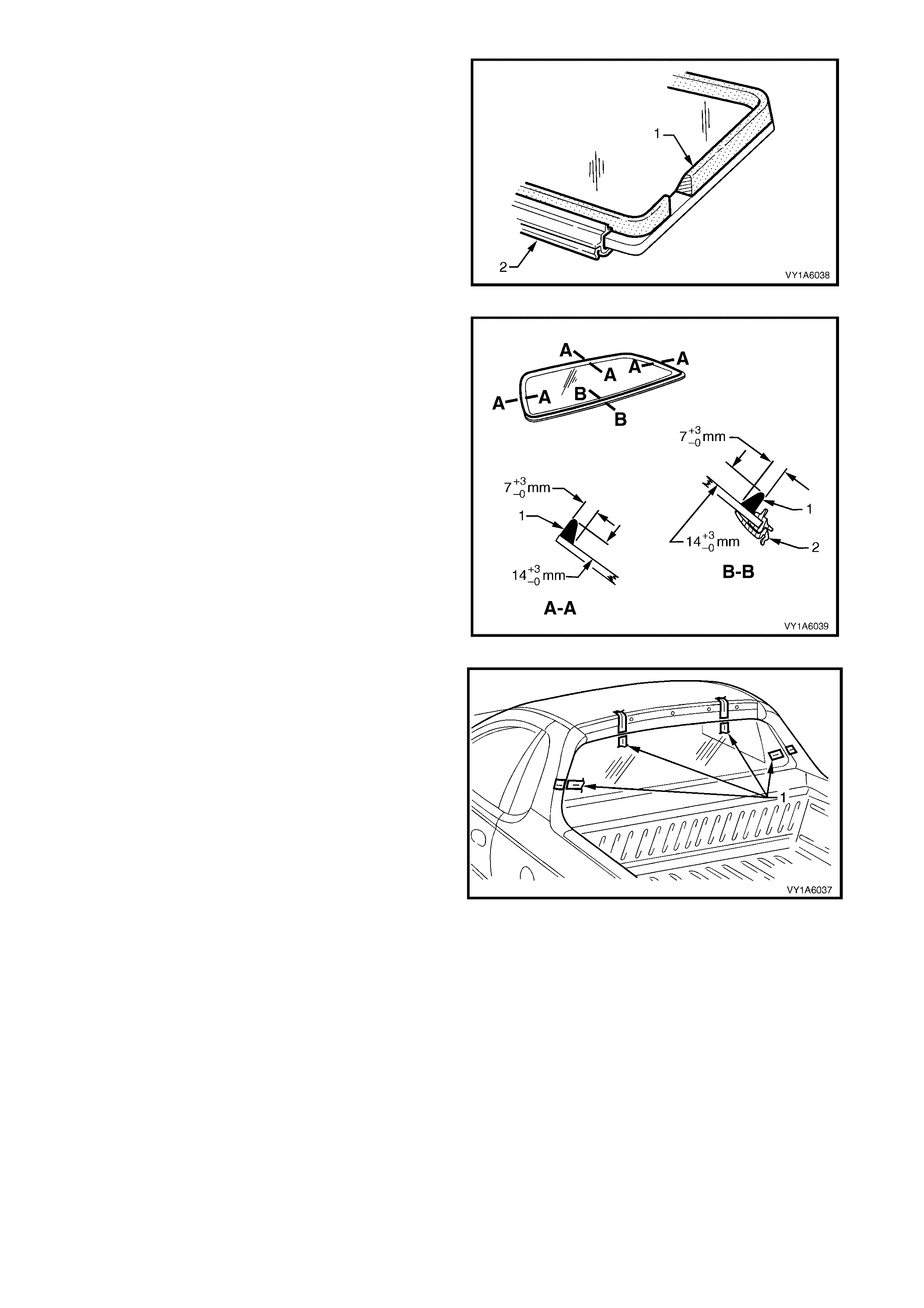

8. Check the condition of the liftgate window reveal

moulding (1) and replace if damaged.

Figure 1A6-50

9. Align the window moulding corner (1) with the

alignment marks (2) on the underside of the

window in both the left hand and right hand lower

corners.

10. Ensure the moulding is fitted correctly to the

window.

11. Check the condition of the original urethane

around the liftgate opening flange for voids or

looseness.

12. Cut away any loose pieces of urethane.

13. Using a suitable spatula, spread fresh urethane

smoothly into any voids or uneven sections.

Figure 1A6-51

14. Use the applicator ( 1) included in the servic e kit, to

apply black window adhesive primer (2) to the

liftgate window as described in the following step.

Figure 1A6-52

15. Apply black window adhesive primer (1) to the

inner surface, around the perimeter of the liftgate

window over a width of 20 mm, along the inside

edge of the window moulding (2).

Figure 1A6-53

16. Using a hand or automatic applicator, apply a

smooth continuous bead of window adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, around the perimeter of the window,

along the inside edge of the moulding (2). The

bead dimensions are shown in Figure 1A6-37.

NOTE: 1 Depending on the amount of urethane

rem aining on the liftgate opening f lange, the am ount of

the new urethane should be reduced accor dingly, while

maintaining adequate strength and sealing properties.

The dimensions shown are the maximum allowable

and are only for reference.

NOTE: 2 In cold weather, the placement of cartridges

adjacent to a sourc e of warm th will ass ist in the flow of

urethane when using a hand applicator.

Figure 1A6-54

Figure 1A6-55

17. With the aid of an assistant, install the liftgate

window assembly, using the previously attached

masking tape (1) on the outer top and side of the

liftgate to ensure accurate installation.

NOTE: Ensure the liftgate window is centralised in the

liftgate opening left to right by checking that the gaps

between the window m oulding and the liftgate opening

are even on both sides of the vehicle

18. Press the liftgate window firmly into position.

19. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps.

20. W ait two hours then water test the liftgate window,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

21. Clean off any excess urethane using Prepsol or

white spirit. Clean the lif tgate window, then rem ove

the masking tape previously installed.

22. Connect the electrical demist.

23. Reinstall the trim and hardware as required.

Figure 1A6-56

REINSTALL - LONG METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The long method for the liftgate window assembly replacement is used when the original urethane adhesive

material cannot serve as a base for the replacement liftgate window.

This method should be used on vehicles requiring metal or paint repair to the liftgate window opening, when

original adhesive is completely removed and replaced with new urethane for the window installation.

This method is also used when the liftgate window has been previously replaced using the short method. In such

instances, the build-up of urethane could position the window assembly too high in the opening.

CAUTION: Do not use petroleum based solvents to clean the liftgate window or the liftgate opening flange,

as the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Using a sharp scraper, carefully remove any original urethane from around the liftgate window. Clean the

window to be installed with a suitable oil free cleaning agent.

2. Using a knife or sharp scraper, remove the original urethane from around the entire perimeter of the liftgate

opening flange. Avoid the removal of paint when removing urethane from opening flange.

Liftgate Window Opening Check

1. Thoroughly check the liftgate window opening flange for any irregularities before installing the liftgate window

assembly.

CAUTION: Care should be taken to ensure that the liftgate window does not strike the liftgate window

opening. Chipped edges can lead to subsequent breakage of the window assembly.

2. To check for correct alignment, temporarily place

the liftgate window in the liftgate opening.

3. If necessary, reform the liftgate opening flange to

produce a uniform flange to the window contour.

4. Ensure the liftgate window is centralised in the

liftgate opening left to right, by checking that the

gaps between the liftgate window and liftgate

opening are even on both sides of the vehicle.

5. With masking tape (1), mark the outer top and side

of the liftgate.

NOTE: This procedure will assist in the alignment of

the window in the correct horizontal and vertical plane

during final window installation.

6. Remove and place the liftgate window assembly

face down on a clean protected surface or fixture.

Figure 1A6-57

Reinstall

IMPORTANT: Flange primer is NOT required if using

the recommended urethane adhesive Betaseal 15685.

If not using Betaseal 15685, and are using an

equivalent system, refer to technical data supplied by

the manufacturer.

If requir ed by the m anufactur er, apply f lange primer (1)

as directed.

Figure 1A6-58

24. Thoroughly clean the inner surface and edges of

the liftgate window assem bly to which the urethane

is to be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the liftgate window, or the liftgate opening

flange as the presence of th e oil in the solvent will

prevent the adhesion of the new uretha ne.

25. Apply clear window adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perimeter of the liftgate window. Immediately wipe

off with a lint-free cloth.

Figure 1A6-59

26. Check the condition of the liftgate window reveal

moulding (1) and replace if damaged.

Figure 1A6-60

27. Align the window moulding corner (1) with the

alignment marks (2) on the underside of the

window in both the left hand and right hand lower

corners.

28. Ensure the moulding is fitted correctly to the

window.

Figure 1A6-61

29. Use the applicator ( 1) included in the servic e kit, to

apply black window adhesive primer (2) to the

liftgate window as described in the following step

Figure 1A6-62

30. Apply black window adhesive primer (1) to the

inner surface, around the perimeter of the liftgate

window over a width of 20 mm, along the inside

edge of the window moulding (2).

Figure 1A6-63

31. Using a hand or automatic applicator, apply a

smooth continuous bead of window adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, around the perimeter of the window,

along the inside edge of the moulding (2). The

bead dimensions are shown in Figure 1A6-65.

NOTE: In cold weather, the placement of cartridges

adjacent to a source of warmth will assist the flow of

urethane when using a hand applicator.

Figure 1A6-64

Figure 1A6-65

32. With the aid of an assistant, install the liftgate

window assembly, using the previously attached

masking tape (1) on the outer top and side of the

liftgate to ensure accurate installation.

NOTE: Ensure the liftgate window is centralised in the

liftgate opening left to right by checking that the gaps

between the window m oulding and the liftgate opening

are even on both sides of the vehicle.

33. Press liftgate window firmly into position.

34. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing ex is t, apply

additional urethane to fill these gaps.

35. W ait two hours then water test the liftgate window,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

36. Clean off any excess urethane using Prepsol or

white spirit. Clean the liftgate window, then rem o ve

the masking tape previously installed.

37. Connect the electrical demist connectors.

38. Reinstall the trim and hardware as required.

Figure 1A6-66

5.3 REAR WINDOW ASSEMBLY, UTILITY

LT Section No. – 11-030

The rear window assembly removal procedure is the same for both the short and the long installation methods,

with one exception. If the short method installation is to be used, care must be taken during the rear window

rem oval to ens ure that an even s ur f ac e of the original r emaining urethane exis ts in the body opening, to serve as a

base for the new urethane bead and the replacement rear window.

To prevent damage and to m inim ise clean up of the paint f inish and the trim , m ask -up and place protective covers

over parts adjacent to the rear window.

If required, remove the following components:

1. Rear window upper moulding assembly, refer to Section 1A9, 4.10 REAR WINDOW UPPER MOULDING.

2. Body lock pillar upper trim, refer to Section 1A8, 5.3 BODY LOCK PILLAR UPPER TRIM.

REMOVE

1. Carefully disconnect the rear window electrical demister connectors and cellular telephone antenna if fitted.

2. Should the rear window be broken, carefully remove all fragments of glass from the window opening.

3. If the window is intact, caref ully cut out the rear window by f ollowing the procedure set out in Steps 3 to 6, refer

to 5.1 REAR WINDOW ASSEMBLY, SEDAN AND COUPE.

REINSTALL - SHORT METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The short method installation involves the maximum amount of the original urethane being left intact on the rear

window opening to form a sound base for the replacement urethane and rear window assembly.

This method is recommended when replacing a cracked or broken window, or a leak condition that cannot be

overcome by using minor water leak repair procedures, refer to 2.1 MINOR WATER LEA K CORRECTION.

If material other than urethane has been used for previous servicing of the rear window, the long method

installation procedure (complete removal of adhesive) is mandatory to achieve an effective window to metal bond.

CAUTION 1: Care should be taken to ensure that the rear window does not strike the rear window

opening. Chipped edges can lead to subsequent breakage of the window.

CAUTION 2: Do not use petroleum based solvents to clean the rear window assembly or the rear opening

flange, as the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Using a sharp scraper, carefully remove any

original urethane from around the rear window.

Clean the rear window to be installed with a

suitable oil free cleaning agent.

2. To check for correct alignment, temporarily place

the rear window in the body opening.

3. Ensure the rear window is centralised in the body

opening left to right, by checking that the gaps

between the rear window and body opening are

even on both sides of the vehicle.

4. With masking tape (1), mark the outer top of the

roof and the rear quarter panel.

NOTE: This procedure will assist in the alignment of

the window in the correct horizontal and vertical plane

during final window installation.

5. Remove and plac e the rear window assem bly fac e

down on a clean protected surface or fixture.

Figure 1A6-67

Reinstall

6. Thoroughly clean the inner surface and edges of

the rear window assem bly to which the urethane is

to be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the rear window assembly, or the rear

opening flange as the presence of the oil in the

solvent will prevent the adhesion of the new

urethane.

7. Apply clear window adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perim eter of the rear window. Im m ediately wipe of f

with a lint-free cloth.

Figure 1A6-68

8. Check the condition of the rear window reveal

moulding (1) and replace if damaged.

9. Install the moulding over the edge of the window.

Ensure the moulding is fitted correctly to the

window.

10. Fit the two self adhesive rear window spacers (2),

ensuring they are positioned on edge of the

window adjacent to the end of the bus bar on the

right and left-hand side.

11. Check the condition of the original urethane

around the window opening flange for voids or

looseness.

12. Cut away any loose pieces of urethane.

13. Using a suitable spatula, spread fresh urethane

smoothly into any voids or uneven sections.

Figure 1A6-69

14. Use the applicator ( 1) included in the servic e kit, to

apply black window adhesive prim er (2) to the rear

window as described in the following step.

Figure 1A6-70

15. Apply - black window adhesive primer (1), to the

inner surface of the rear window over a width of

20 mm, along the inside edge of the rear window

reveal moulding (2). Continue around the

remaining perimeter of the rear window (3) and

inboard of the rear window spacers.

Figure 1A6-71

16. Using a hand or automatic applicator, apply a

smooth continuous bead of window adhesive

(urethane) (1), such as Betaseal 15685 or

equivalent, around the perimeter of the window

along the inside edge of the rear window reveal

moulding (2). Continue around the remaining

perimeter of the rear window (3) inboard of the

rear window spacers. The bead dimensions are

shown in Figure1A6-73.

NOTE: 1 Depending on the amount of urethane

remaining on the body opening flange, the amount of

the new urethane should be reduced accor dingly, while

maintaining adequate strength and sealing properties.

The dimensions shown are the maximum allowable

and are only for reference.

NOTE: 2 In cold weather, the placement of cartridges

adjacent to a sourc e of warm th will ass ist in the flow of

urethane when using a hand applicator.

Figure 1A6-72

Figure 1A6-73

17. With the aid of an ass ist ant, install the r ear window

assembly, using the previously attached masking

tape (1) on the roof and the rear quarter panel to

ensure accurate installation.

NOTE: Ensure the rear window is centralised in the

body opening left to right by checking that the gaps

between the window moulding and body opening are

even on both sides of the vehicle.

18. Press the rear window firmly into position.

19. Check effectiveness of sealing from inside the

vehicle. Should any gaps in the sealing exist, apply

additional urethane to fill these gaps.

20. Wait two hours then water test the rear window,

using a moderate spray of water.

NOTE: Do not direct a heavy stream of water onto

freshly applied urethane. If a water leak is evident,

apply additional urethane to the leak area, using a

spatula to work the urethane into the source of the

leak.

21. Clean off any excess urethane using Prepsol or

white spirit. Clean the rear window, then remove

the masking tape previously installed.

22. Connect the electrical demist connectors and

cellular telephone antenna if fitted.

23. Reinstall the trim and hardware as required.

Figure 1A6-74

REINSTALL - LONG METHOD

CAUTION: Ensure that door windows are partially lowered to eliminate pressure build up which can be

caused by slamming doors. A curing time of 24 hours is recommended, although the vehicle may be

driven after 5 hours, providing it is driven only on a smooth road at speeds not exceeding 80 km/h with

the door windows partially lowered.

Description

The long m ethod for the rear window assem bly replac ement is used when the original urethane adhesive m aterial

cannot serve as a base for the replacement rear window.

This method should be used on vehicles requiring metal or paint repair to the rear window opening, when the

original adhesive is completely removed and replaced with new urethane for the window installation.

This method is also used when the rear window has been previously replaced using the short method. In such

instances, the build-up of urethane could position the window assembly too high in the opening.

CAUTION: Do not use petroleum based solvents to clean the rear window or the rear opening flange, as

the presence of the oil in the solvent will prevent the adhesion of the new urethane.

Preparation

1. Us ing a s har p sc r aper, c ar ef ully rem ove any original urethane fr om around the rear window. Clean the window

to be installed with a suitable oil free cleaning agent.

2. Using a knife or sharp scraper, remove the original urethane from around the entire perimeter of the window

opening flange. Avoid the removal of paint when removing urethane from opening flange.

Rear Window Opening Check

1. Thoroughly check the rear window opening flange for any irregularities before installing the rear window

assembly.

CAUTION: Care should be taken to ensure that the rear window does not strike the rear window opening.

Chipped edges can lead to subsequent breakage of the window assembly.

2. To check for correct alignment, temporarily place

the rear window in the body opening.

3. If necessary, reform the rear window opening

flange to produce a uniform flange to the window

contour.

4. Ensure the rear window is centralised in the body

opening left to right, by checking that the gaps

between the rear window and body opening are

even on both sides of the vehicle.

5. With masking tape (1), mark the outer top and side

of the roof and the rear quarter panel.

NOTE: This procedure will assist in the alignment of

the window in the correct horizontal and vertical plane

during final window installation.

6. Remove and place the rear window assembly face

down on a clean protected surface or fixture.

Figure 1A6-75

Reinstall

IMPORTANT: Flange primer is NOT required if using

the recommended urethane adhesive Betaseal 15685.

If not using Betaseal 15685, and are using an

equivalent system, refer to technical data supplied by

the manufacturer.

If requir ed by the m anufactur er, apply f lange primer (1)

as directed.

Figure 1A6-76

7. Thoroughly clean the inner surface and edges of

the rear window assem bly to which the urethane is

to be applied, using clean lint-free cloths and a

suitable oil free cleaning solvent.

CAUTION: Do not use petroleum b ased solven ts to

clean the rear window assembly, or the rear

opening flange as the presence of the oil in the

solvent will prevent the adhesion of the new

urethane.

8. Apply clear window adhesive primer, over the

width of the solid black ceram ic pattern (or a width

of 50 mm), to the inner surface around the

perim eter of the rear window. Im m ediately wipe of f

with a lint-free cloth.

Figure 1A6-77

9. Check the condition of the rear window reveal

moulding (1) and replace if damaged.

10. Install the moulding over the edge of the window.

Ensure the moulding is fitted correctly to the

window.

11. Fit the two self adhesive rear window spacers (2),