SECTION 1A7 - SEAT ASSEMBLIES

IMPORTANT

Before perfo rming any Service O perat ion or o th er pro cedu re describ ed in th is Sectio n, ref er to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 GENERAL DESCRIPTION

1.2 FRONT SEAT ASSEMBLY,

FOUR-WAY ELECTRIC

1.3 FRONT SEAT ASSEMBLY, EIGHT-WAY

EXCEPT COUPE

1.4 EZ-ENTRY SYSTEM, COUPE

OCCUPANT SENSING MAT

1.5 FRONT SEAT ASSEMBLY, EIGHT-WAY

COUPE – NON MEMORY

1.6 FRONT SEAT ASSEMBLY, EIGHT-WAY

COUPE – MEMORY

MEMORY SETS

MEMORY BUTTONS

PRIORITY RECALL FUNCTION

2. SERVICE OPERATIONS - FRONT

SEAT, EXCEPT COUPE

2.1 FRONT SEAT USAGE CHART -

EXCEPT COUPE

HOW TO USE THIS CHART

2.2 FRONT SEAT ASSEMBLY

REMOVE

REINSTALL

2.3 FRONT SEAT OUTER SIDE COVER

REMOVE

REINSTALL

2.4 FRONT SEAT ADJUSTM ENT SWITCH

REMOVE

REINSTALL

2.5 FRONT SEAT INNER SIDE COVER

REMOVE

REINSTALL

2.6 FRONT SEAT-BACK LOWER COVER

ASSEMBLY AND LUMBAR SUPPORT

ADJUSTER KNOB

REMOVE

DISASSEMBLE

REINSTALL

2.7 FRONT SEAT HEAD RESTRAINT

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

2.8 FRONT SEAT HEAD RESTRAINT GUIDE

REMOVE

REINSTALL

2.9 FRONT SEAT-BACK PAD AND

COVER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

2.10 FRONT SEAT-BACK FRAME ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

2.11 SIDE IMPACT AIRBAG ASSEMBLY

2.12 FRONT SEAT CUSHION PAD AND

COVER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

2.13 FRONT SEAT CUSHION FRAME ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

2.14 FRONT SEAT ADJUSTER ASSEMBLY

REMOVE

REINSTALL

2.15 FRONT SEAT LIFT MOTORS

2.16 FRONT SEAT FORE / AFT MOVEMENT

MOTOR

2.17 FRONT SEAT RECLINING MOTOR,

GEARBOX AND POTENTIOMETERS

ASSEMBLY

2.18 DRIVE MOTOR POTENTIOM ETERS

3. DIAGNOSTICS - FRONT SEAT,

EXCEPT COUPE

PREREQUISITES

3.1 MECHANICAL DIAGNOSIS –TWO-WAY/

FOUR-WAY SEAT

LUMBER SUPPORT INOPERATIVE

SEAT RECLINE FORWARD AND / OR

BACK FUNCTION IS INOPERATIVE

SEAT FORE / AFT FUNCTION IS

INOPERATIVE OR IS NOT SMOOTH

3.2 ELECTRICAL DIAGNOSIS – FOUR-WAY

SEAT, NON-MEMORY

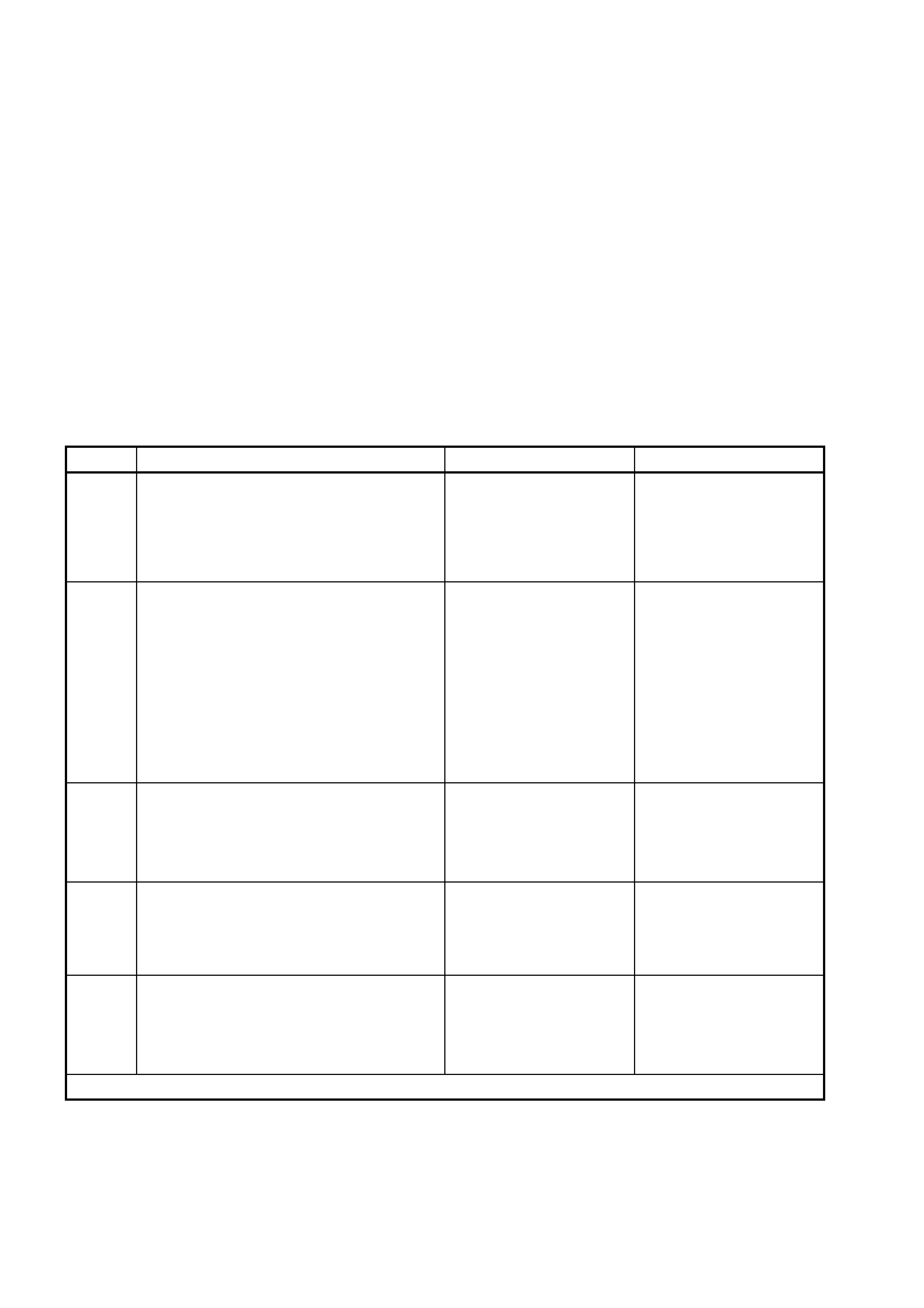

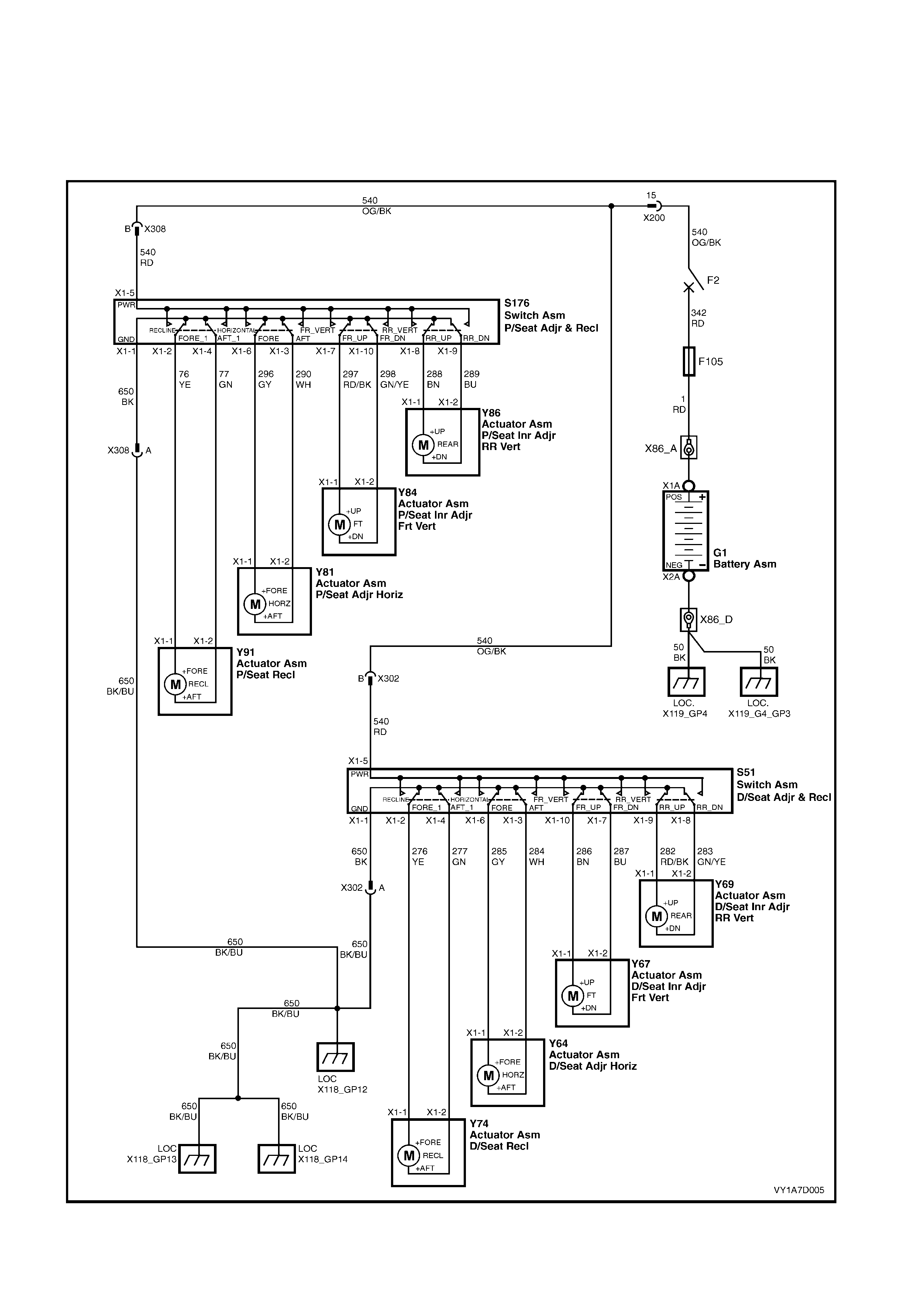

WIRING DIAGRAM – FOUR-WAY SEAT,

NON-MEMORY

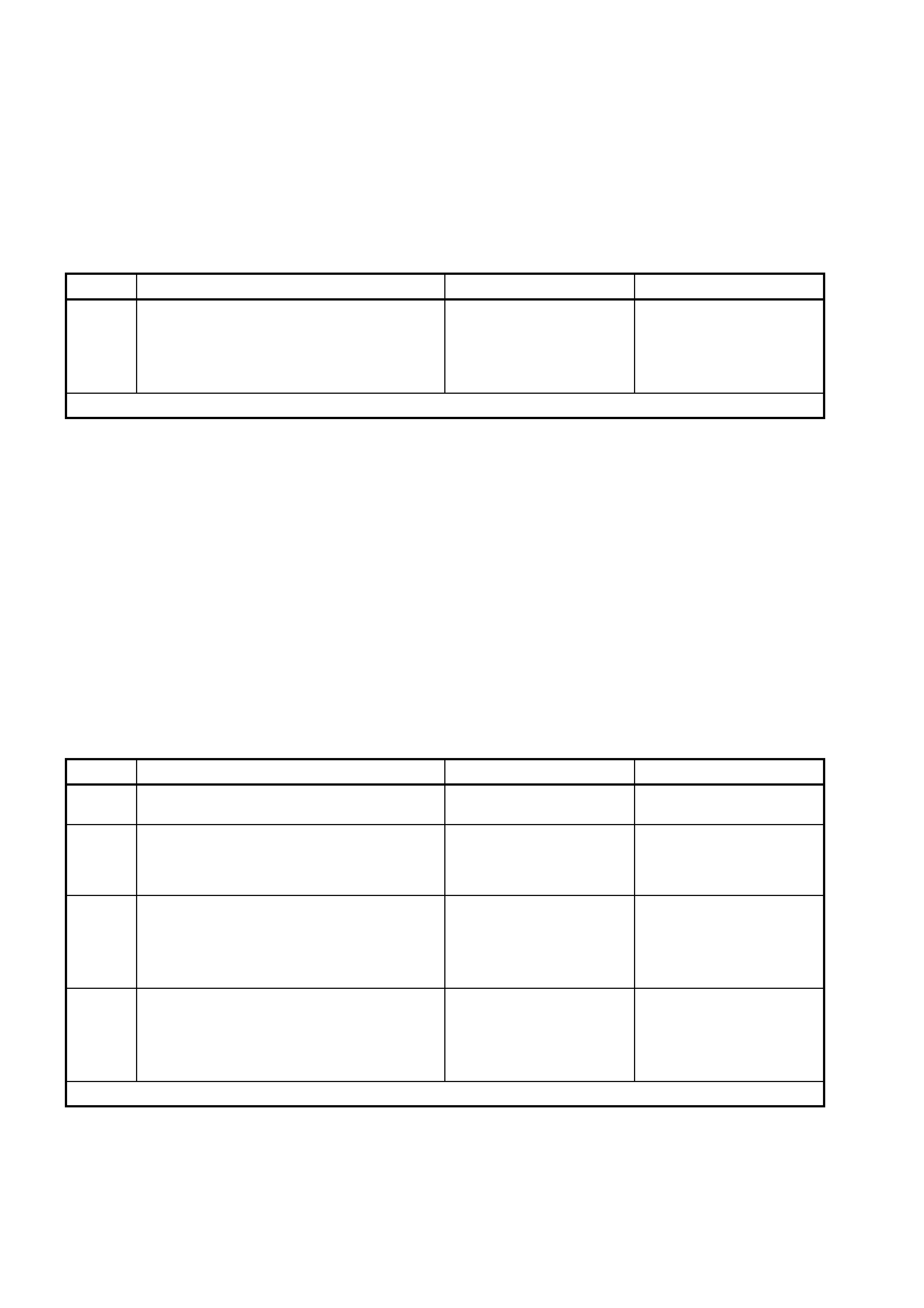

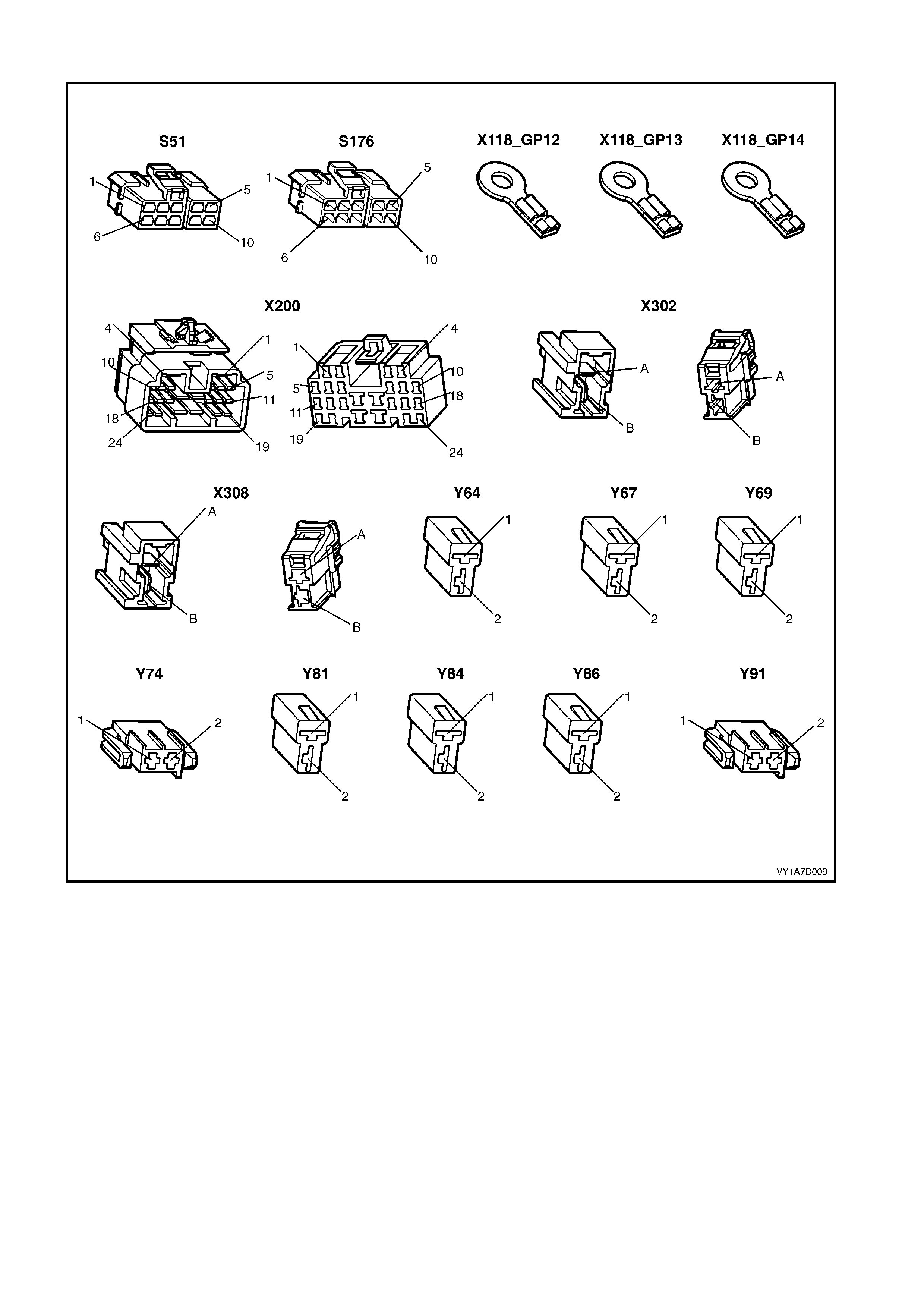

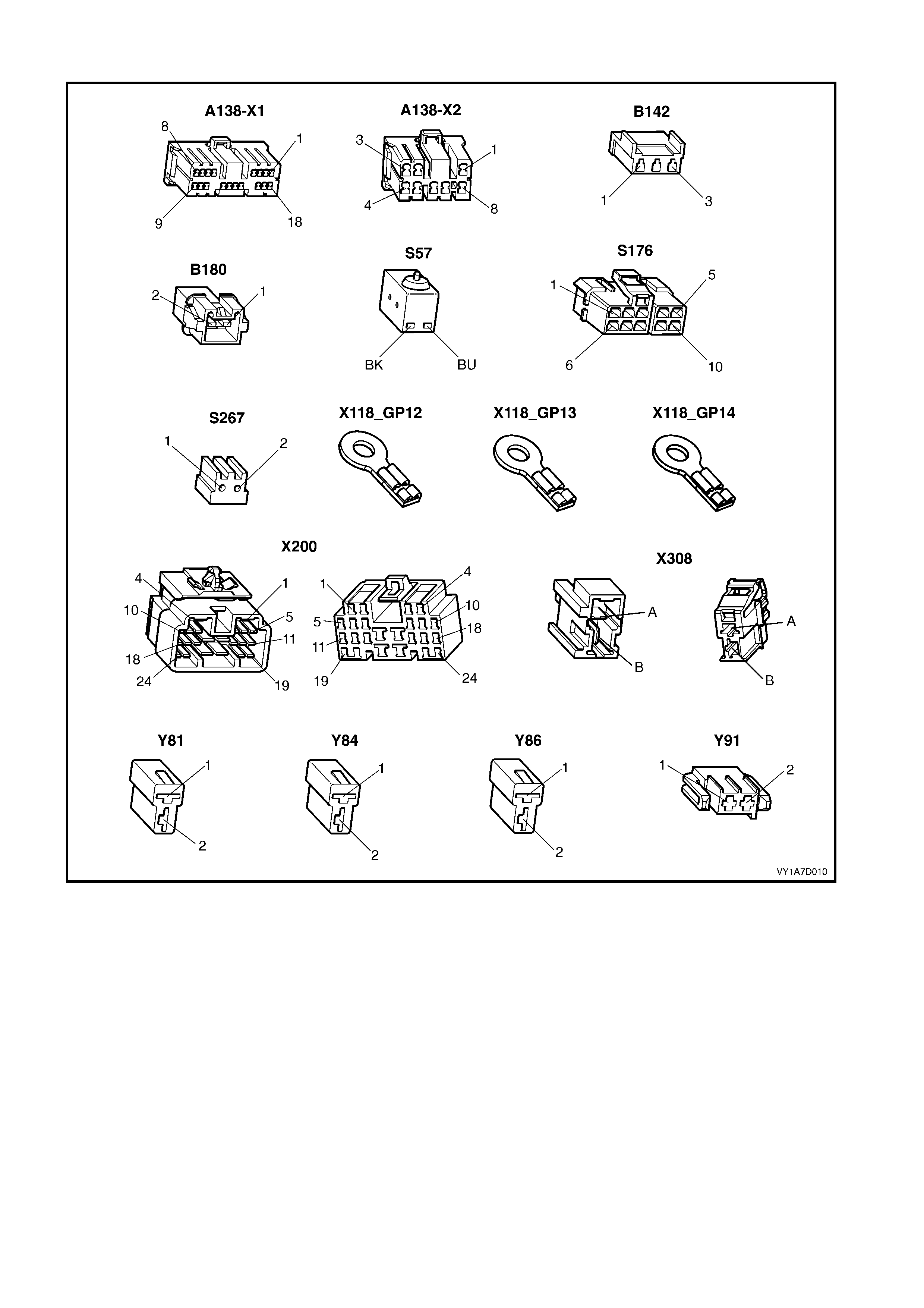

CONNECTOR CHART – FOUR-WAY SEAT,

NON-MEMORY

NEITHER SEAT ADJ USTMENT SWITCH

FUNCTIONS OPERATE

NONE OF THE DRIVER’S FOUR-WAY

SEAT ADJUSTMENT SWITCH

FUNCTIONS OPERATE

FRONT / REAR OF THE DRIVER’S SEAT

DOES NOT RAISE AND / OR LOWER

NONE OF THE PASSENGER’S FOUR-WAY

SEAT ADJUSTMENT SWITCH FUNCTIONS

OPERATE

FRONT / REAR OF THE PASSENGER’S

SEAT DOES NOT RAISE AND / OR LOWER

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

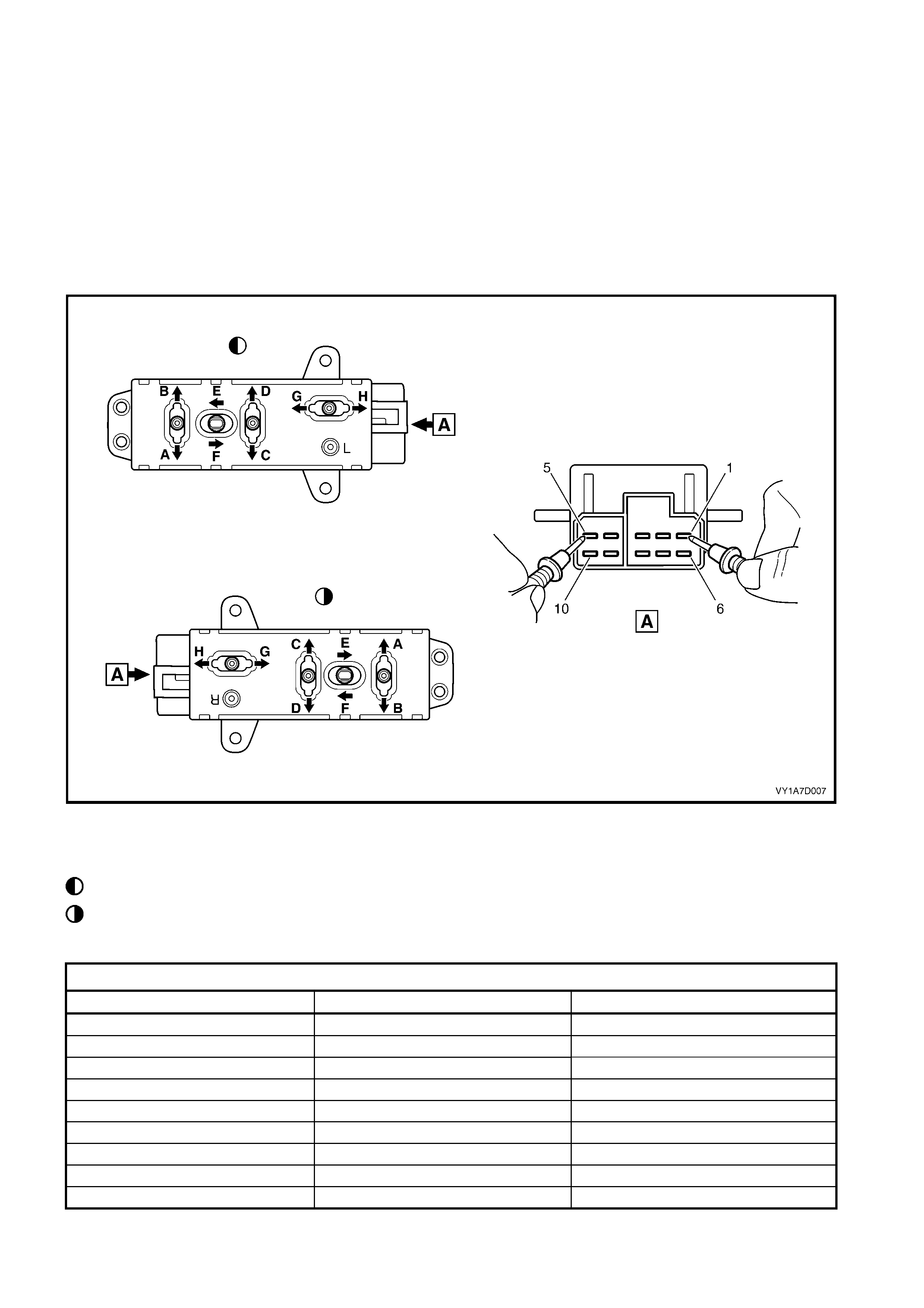

3.3 FOUR-WAY SEAT ADJUSTMENT

SWITCH TEST

TEST

3.4 MECHANICAL DIAGNOSIS – EIGHT-

WAY SEAT, NON-MEMORY

LUMBER SUPPORT INOPERATIVE

3.5 ELECTRICAL DIAGNOSIS –

EIGHT-WAY SEAT, NON-MEMORY

WIRING DIAGRAM – EIGHT-WAY

SEAT, NON-MEMORY

CONNECTOR CHART - EIGHT-WAY

SEAT, NON-MEMORY

NEITHER SEAT ADJ USTMENT SWITCH

FUNCTIONS OPERATE

NONE OF THE DRIVER’S EIGHT-WAY

SEAT ADJUSTMENT SWITCH

FUNCTIONS OPERATE

FRONT / REAR OF THE DRIVER’S SEAT

DOES NOT RAISE AND / OR LOWER

DRIVER’S SEAT FORE / AFT FUNCTION

IS INOPERATIVE OR NOT SMOOTH

DRIVER’S SEAT RECLINE FORWARD

AND / OR AFT FUNCTION IS

INOPERATIVE

NONE OF THE PASSENGER’S

EIGHT-WAY SEAT ADJUSTMENT

SWITCH FUNCTIONS OPERATE

FRONT / REAR OF THE PASSENGER’S

SEAT DOES NOT RAISE AND / OR

LOWER

PASSENGER’S SEAT FORE / AFT

FUNCTION IS INOPERATIVE OR NOT

SMOOTH

PASSENGER’S SEAT RECLINE

FORWARD AND / OR AFT FUNCTION IS

INOPERATIVE

3.6 EIGHT-WAY SEAT ADJUSTMENT

SWITCH TEST

TEST

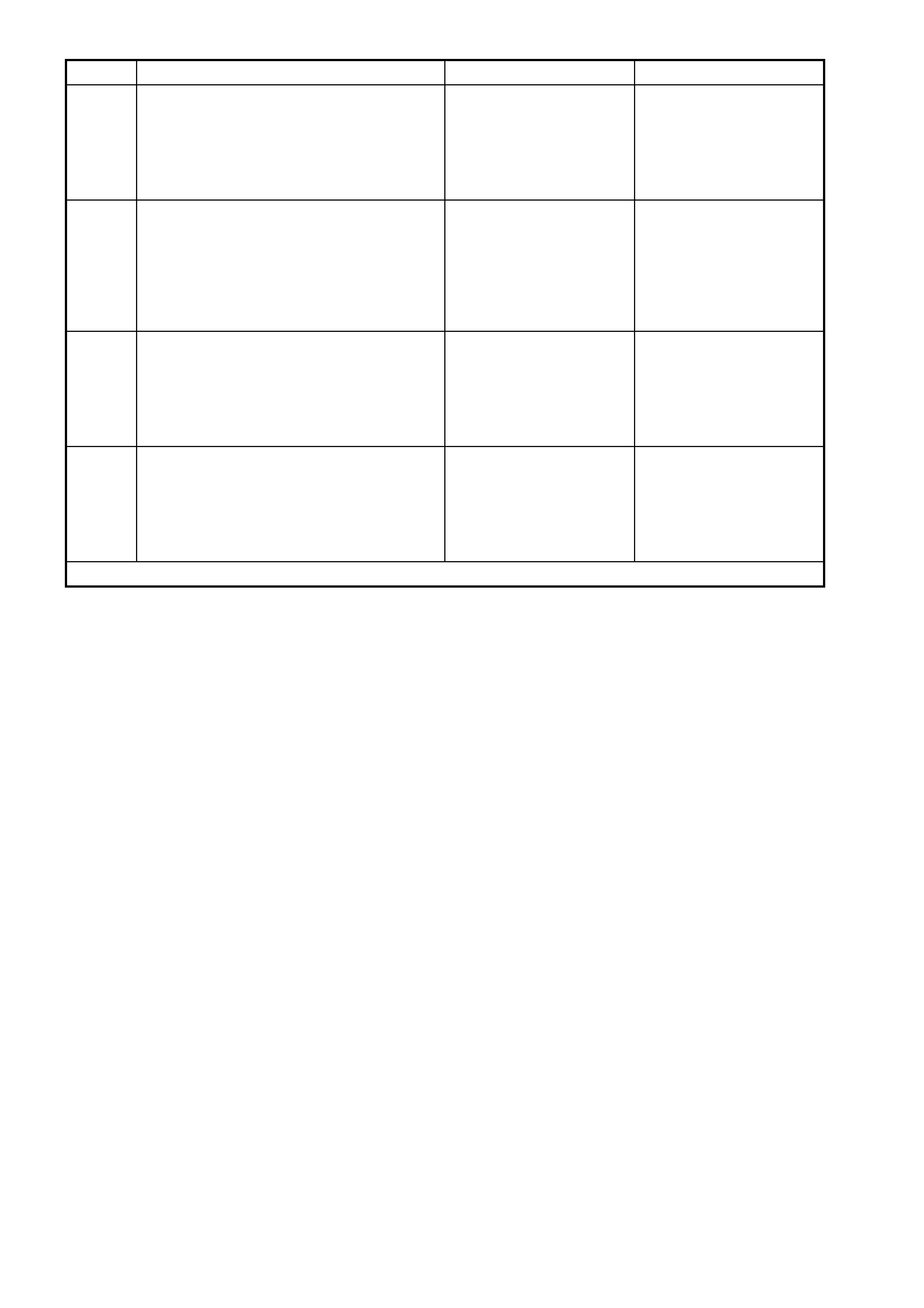

4. SERVICE OPERATIONS - FRONT

SEAT, COUPE

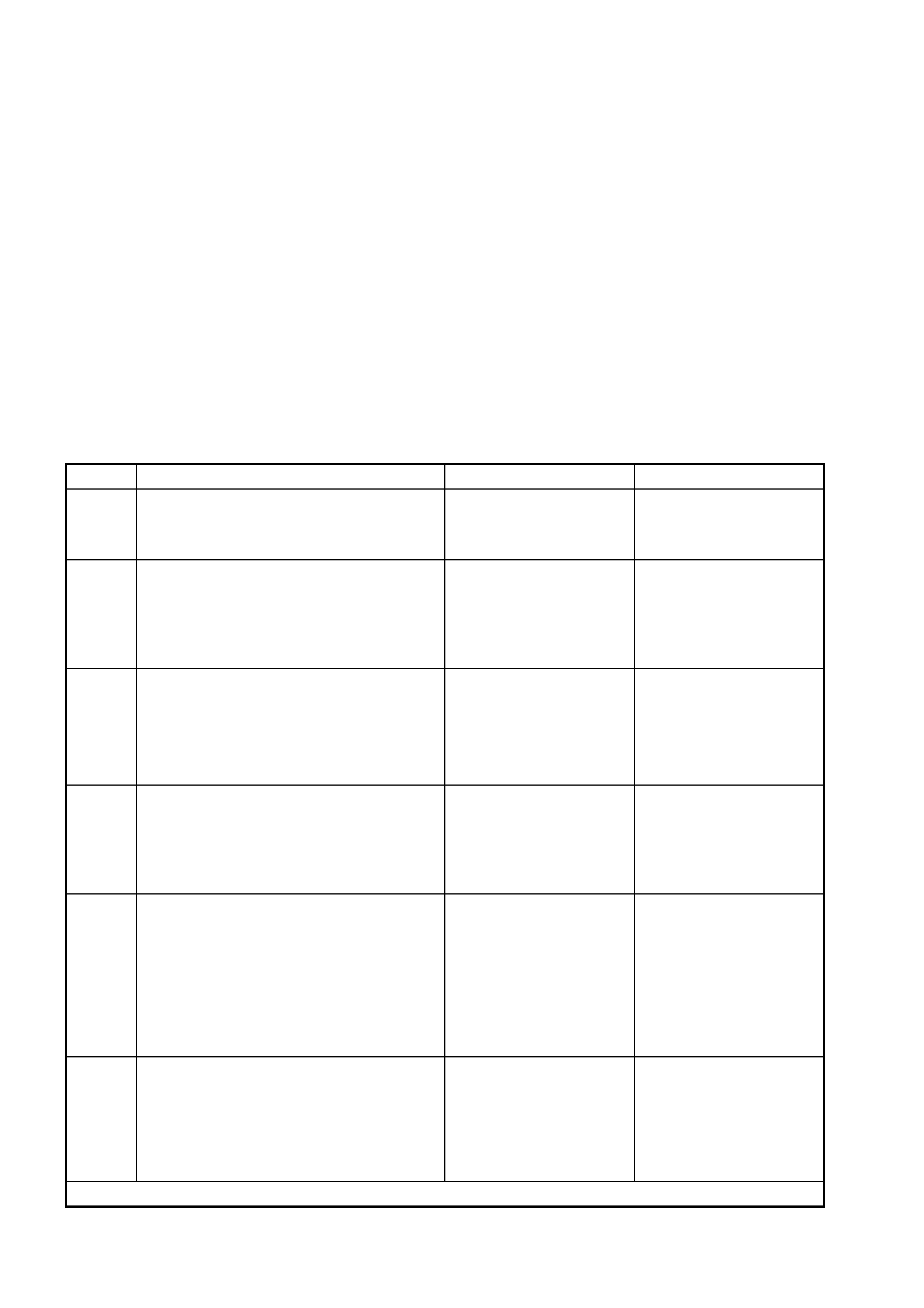

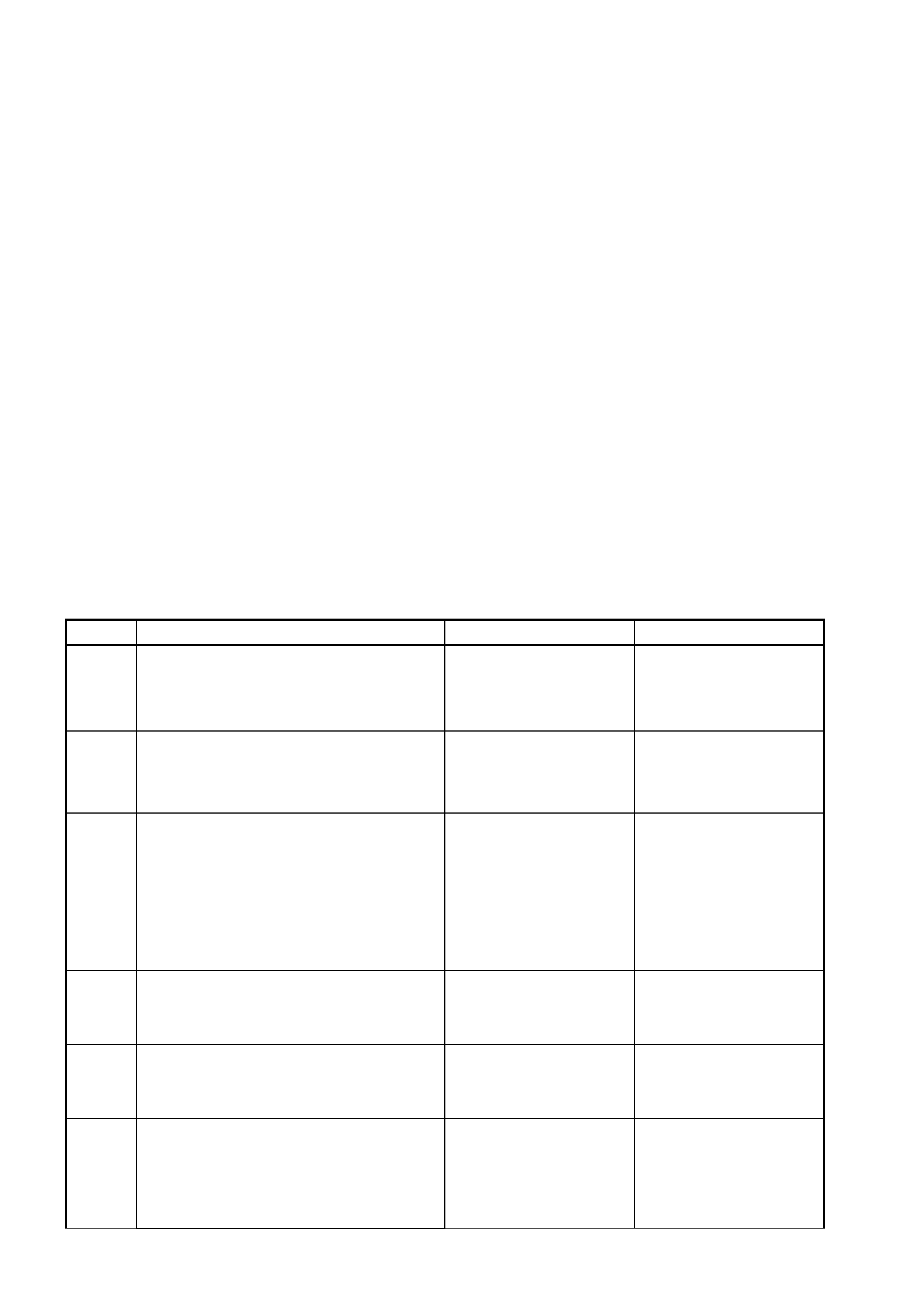

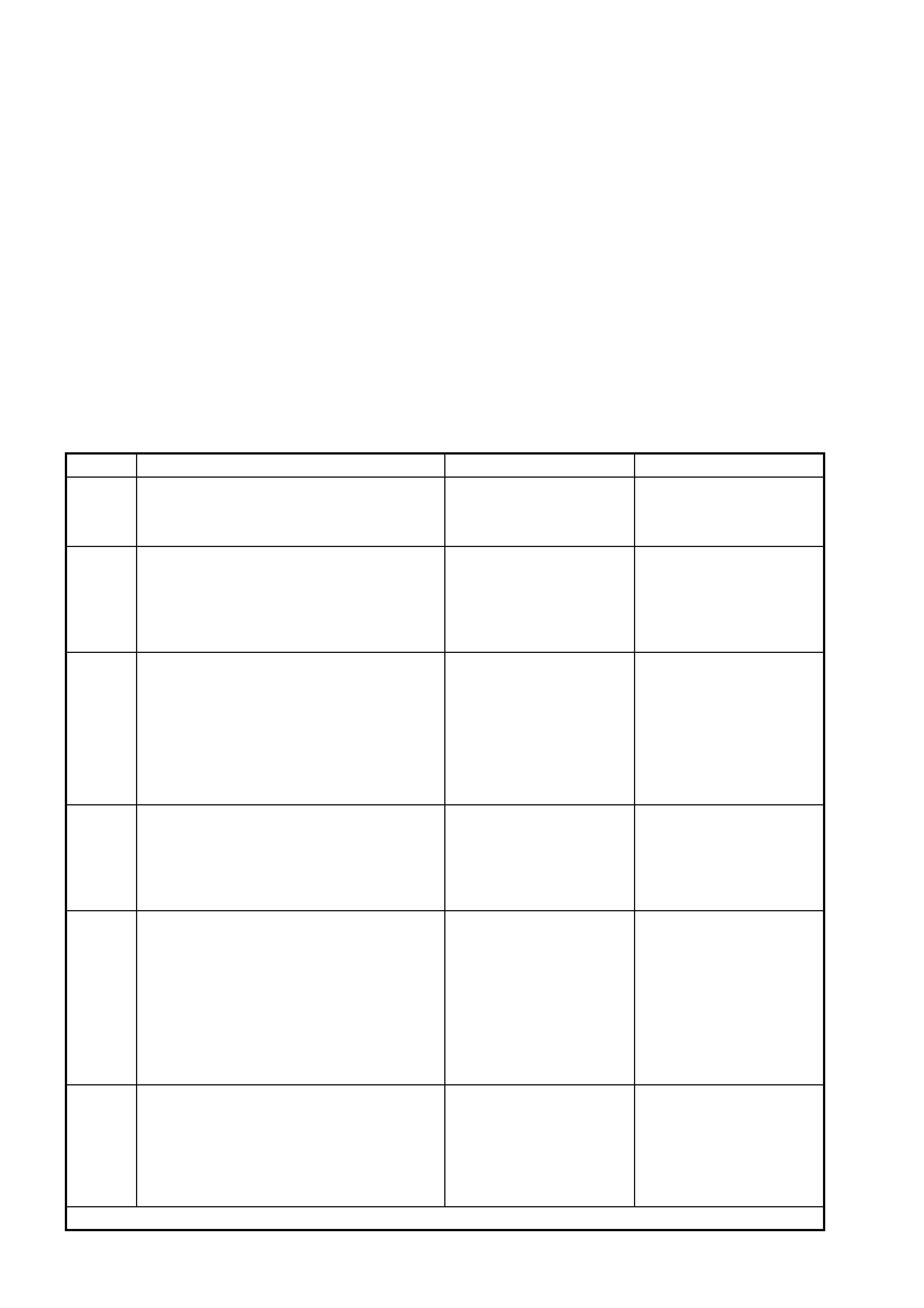

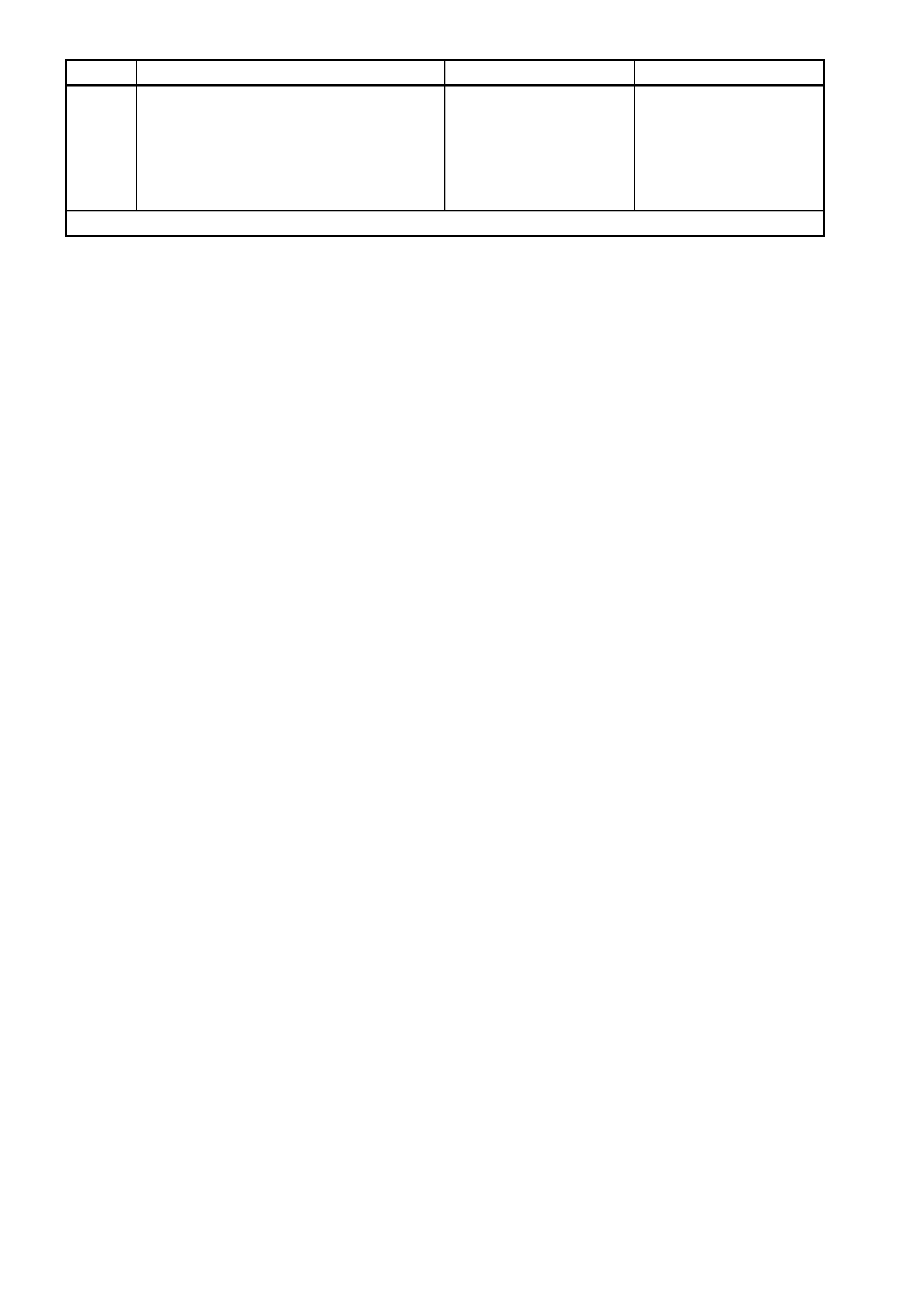

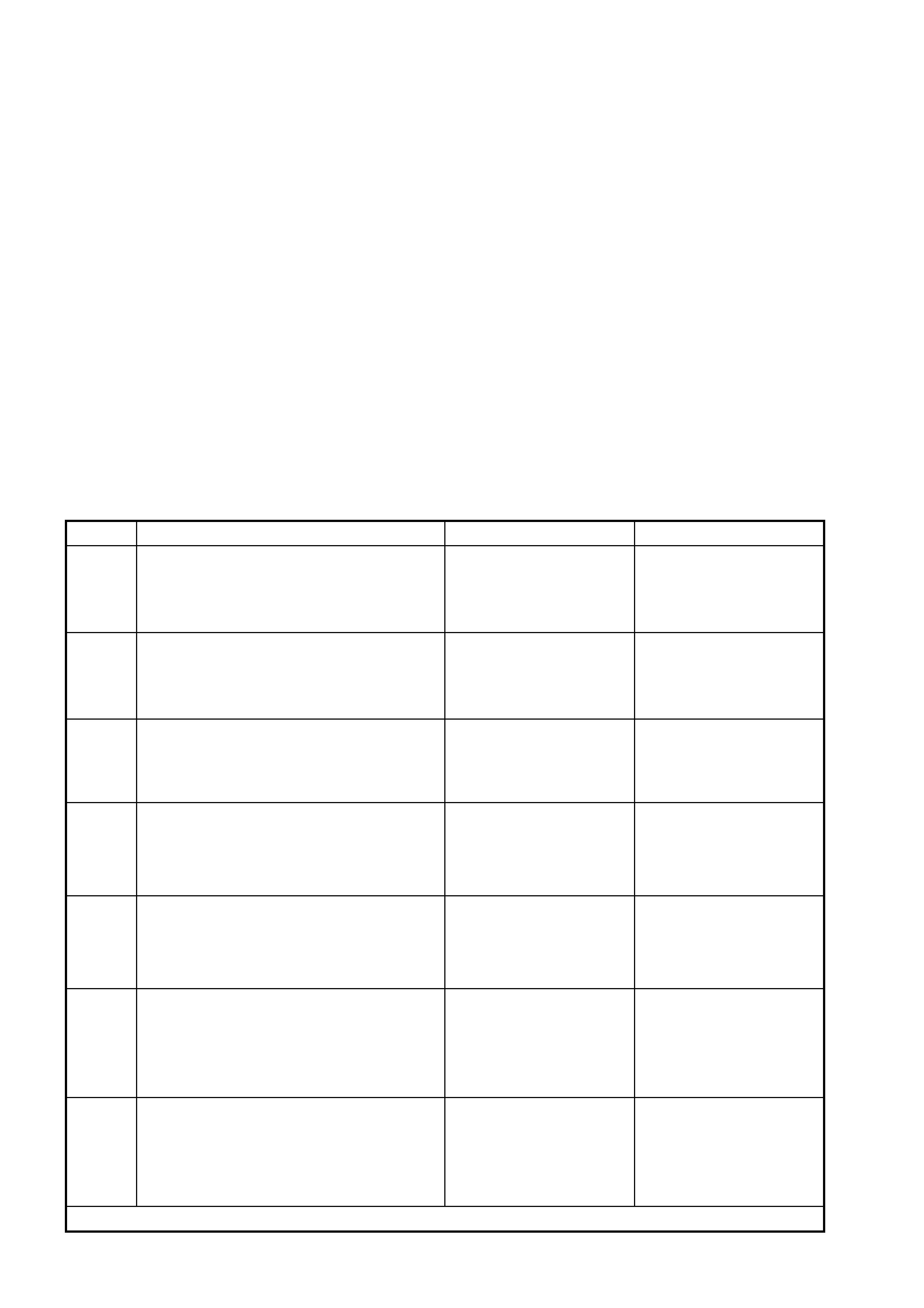

4.1 FRONT SEAT USAGE CHART - COUPE

HOW TO USE THIS CHART

4.2 FRONT SEAT ASSEMBLY

REMOVE

REINSTALL

4.3 FRONT SEAT OUTER SIDE COVER

REMOVE

REINSTALL

4.4 EIGHT-WAY SEAT ADJUSTMENT SWITCH

REMOVE

REINSTALL

4.5 MEMORY POSITION SWITCH

REMOVE

REINSTALL

4.6 FRONT SEAT CONTROL MODULE,

EIGHT-WAY MEMORY SEAT

REMOVE

REINSTALL

4.7 EZ-ENTRY MODULE, EIGHT-WAY

NON-MEMORY SEAT

REMOVE

REINSTALL

4.8 FRONT SEAT INNER SIDE COVER

REMOVE

REINSTALL

4.9 FRONT SEAT-BACK LOWER COVER

ASSEMBLY AND LUMBAR SUPPORT

ADJUSTER KNOB

REMOVE

DISASSEMBLE

REINSTALL

4.10 FRONT SEAT HEAD RESTRAINT ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

4.11 FRONT SEAT HEAD RESTRAINT GUIDE

REMOVE

REINSTALL

4.12 EZ-ENTRY LEVER ARM, ESCUTCHEON

AND SEAT RETURN SWITCH

ASSEMBLY

REMOVE

REINSTALL

4.13 EZ-ENTRY CABLE AND SWITCH ASSEMBLY

4.14 FRONT SEAT-BACK PAD AND

COVER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

4.15 FRONT SEAT-BACK FRAME ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

4.16 SIDE IMPACT AIRBAG ASSEMBLY

4.17 FRONT SEAT CUSHION PAD AND

COVER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

4.18 FRONT SEAT CUSHION FRAME ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

4.19 FRONT SEAT ADJUSTER ASSEMBLY

4.20 FRONT SEAT LIFT MOTORS

4.21 FRONT SEAT FORE / AFT

MOVEMENT MOTOR

4.22 FRONT SEAT RECLINING MOTOR,

GEARBOX AND POTENTIOMETER ASSEMBLY

4.23 DRIVE MOTOR POTENTIOM ETERS

5. DIAGNOSTICS - FRONT SEAT, COUPE

PREREQUISITES

5.1 MECHANICAL DIAGNOSIS -FRONT SEAT

LUMBER SUPPORT INOPERATIVE

EZ-ENTRY LEVER FUNCTION

INOPERATIVE

5.2 ELECTRICAL SELF TEST DIAGNOSIS -

EIGHT-WAY SEAT, NON-MEMORY

EZ-ENTRY DIAGNOSTICS

5.3 ELECTRICAL DIAGNOSIS – EIGHT-WAY

SEAT, NON-MEMORY

NEITHER SEAT ADJ USTMENT SWITCH

FUNCTIONS OPERATE

5.4 ELECTRICAL DIAGNOSIS – DRIVERS

EIGHT-WAY SEAT, NON-MEMORY

WIRING DIAGRAM - DRIVERS EIGHT-WAY

SEAT, NON-MEMORY

CONNECTOR CHART – DRIVER'S

EIGHT-WAY SEAT, NON-MEMORY

NONE OF THE DRIVER’S EIGHT-WAY

SEAT ADJUSTM ENT SWITCH

FUNCTIONS OPERATE

FRONT / REAR OF THE DRIVER’S SEAT

DOES NOT RAISE AND / OR LOWER

DRIVER’S SEAT FORE / AFT FUNCTION

IS INOPERATIVE OR NOT SMOOTH

DRIVER’S SEAT RECLINE FORWARD

AND / OR AFT FUNCTION IS

INOPERATIVE

DRIVER’S SEAT EZ-ENTRY SWITCH

FUNCTION IS INOPERATIVE

DRIVER’S SEAT RETURN SWITCH

FUNCTION IS INOPERATIVE

DRIVER’S SEAT TRACK MOTOR POSITION

SENSOR POTENTIOMETER TEST

DRIVER’S SEAT OCCUPANT SENSING

MAT TEST

5.5 ELECTRICAL DIAGNOSIS –

PASSENGER’S EIGHT-WAY SEAT,

NON-MEMORY

WIRING DIAGRAM - PASSENGER’S

EIGHT-WAY SEAT, NON-MEMORY

CONNECTOR CHART – PASSENGER’S

EIGHT-WAY SEAT, NON-MEMORY

NONE OF THE PASSENGER’S EIGHT-

WAY SEAT ADJUSTMENT SWITCH

FUNCTIONS OPERATE

FRONT / REAR OF THE PASSENGER’S

SEAT DOES NOT RAISE AND / OR

LOWER

PASSENGER’S SEAT FORE / AFT

FUNCTION IS INOPERATIVE OR

NOT SMOOTH

PASSENGER’S SEAT RECLINE

FORWARD AND / OR AFT FUNCTION

IS INOPERATIVE

PASSENGER’S SEAT EZ-ENTRY SWITCH

FUNCTION IS INOPERATIVE

PASSENGER’S SEAT RETURN SWITCH

FUNCTION IS INOPERATIVE

PASSENGER’S SEAT TRACK MOTOR

POSITION SENSOR POTENTIOMETER

TEST

PASSENGER’S SEAT OCCUPANT

SENSING MAT TEST

5.6 ELECTRICAL SELF TEST DIAGNOSIS -

EIGHT-WAY SEAT, MEMORY

EZ-ENTRY AND MEMORY DIAGNOSTICS

5.7 ELECTRICAL DIAGNOSIS – EIGHT-WAY

SEAT, MEMORY

NEITHER SEAT ADJUSTMENT

SWITCH FUNCTIONS OPERATE

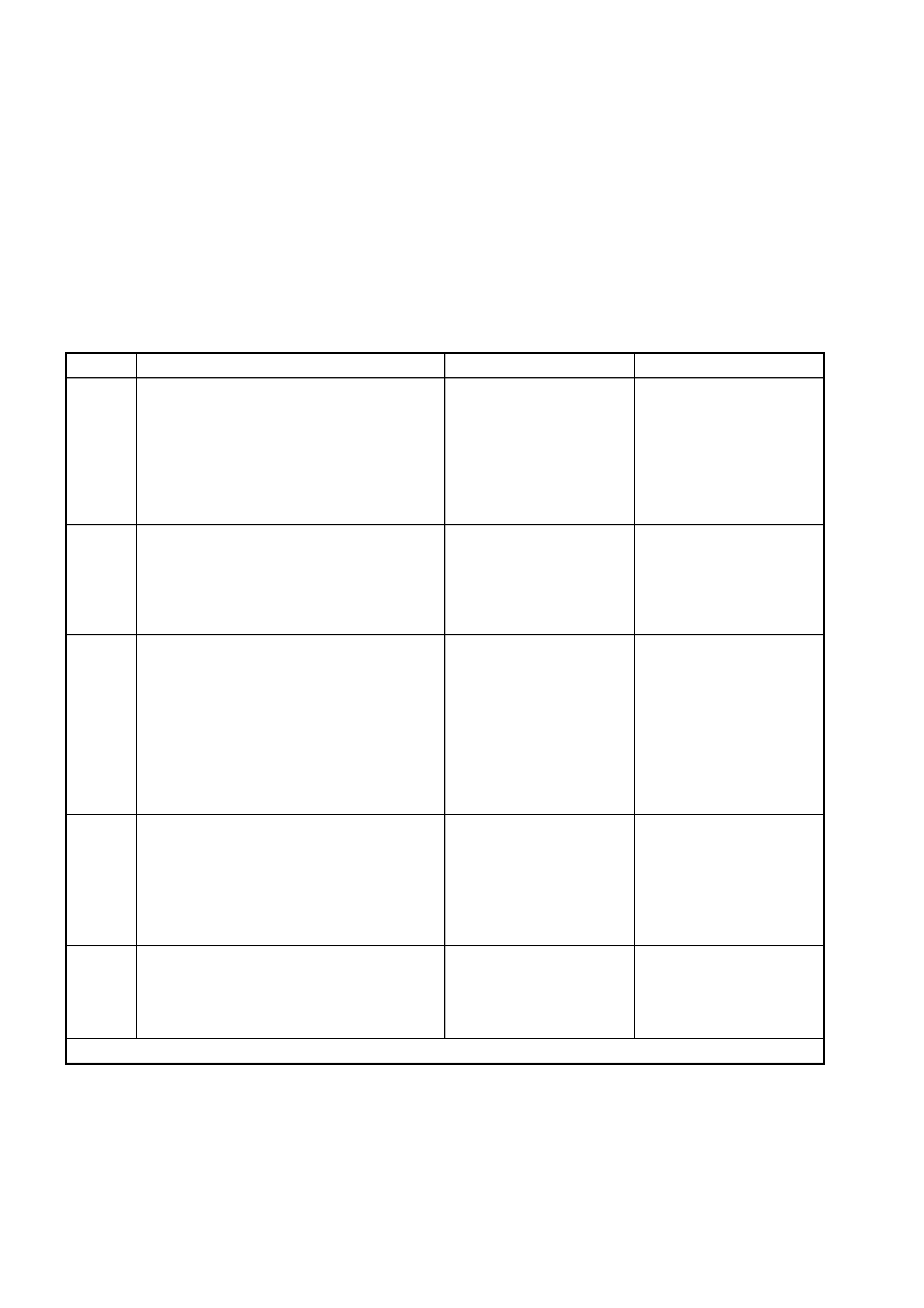

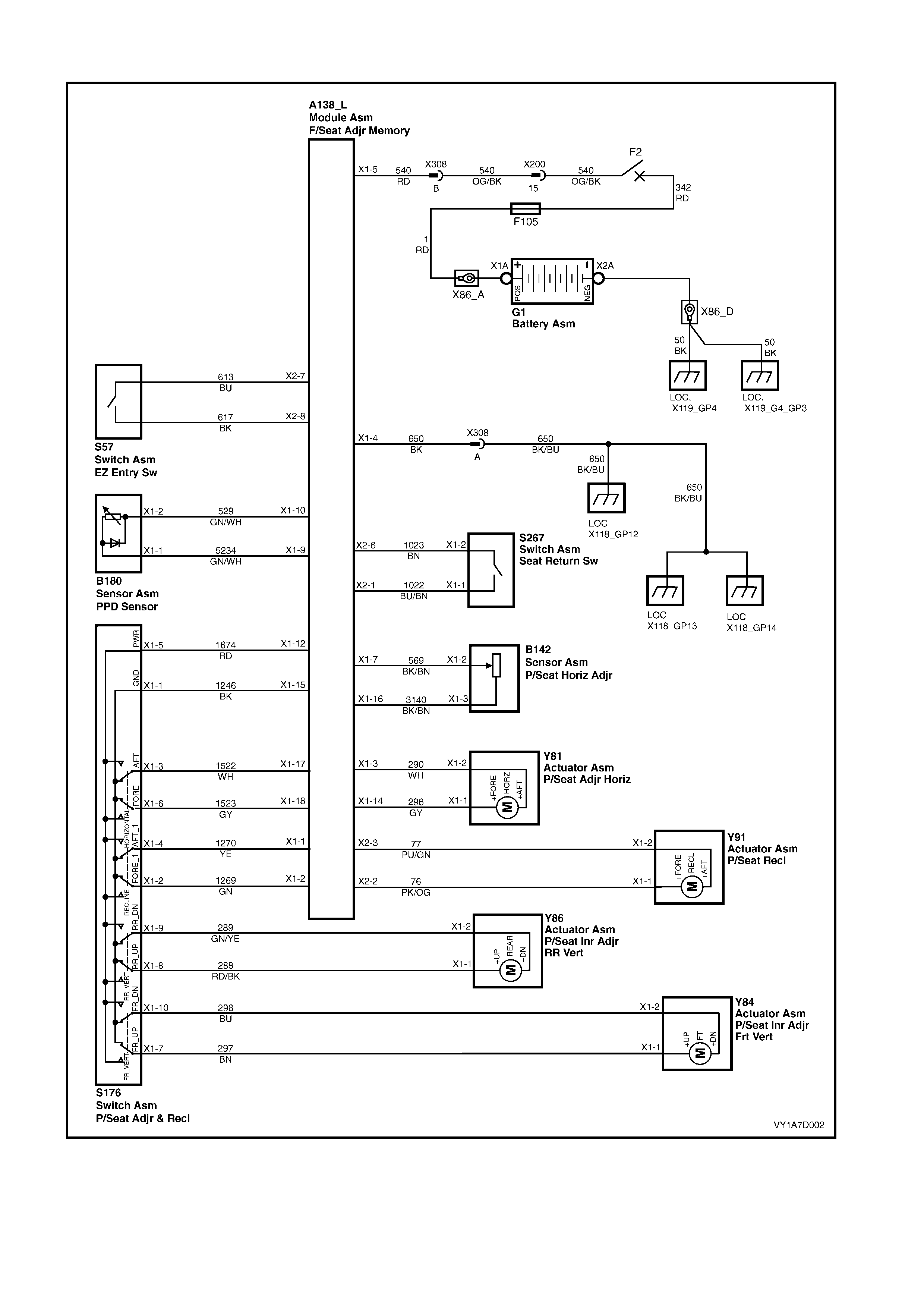

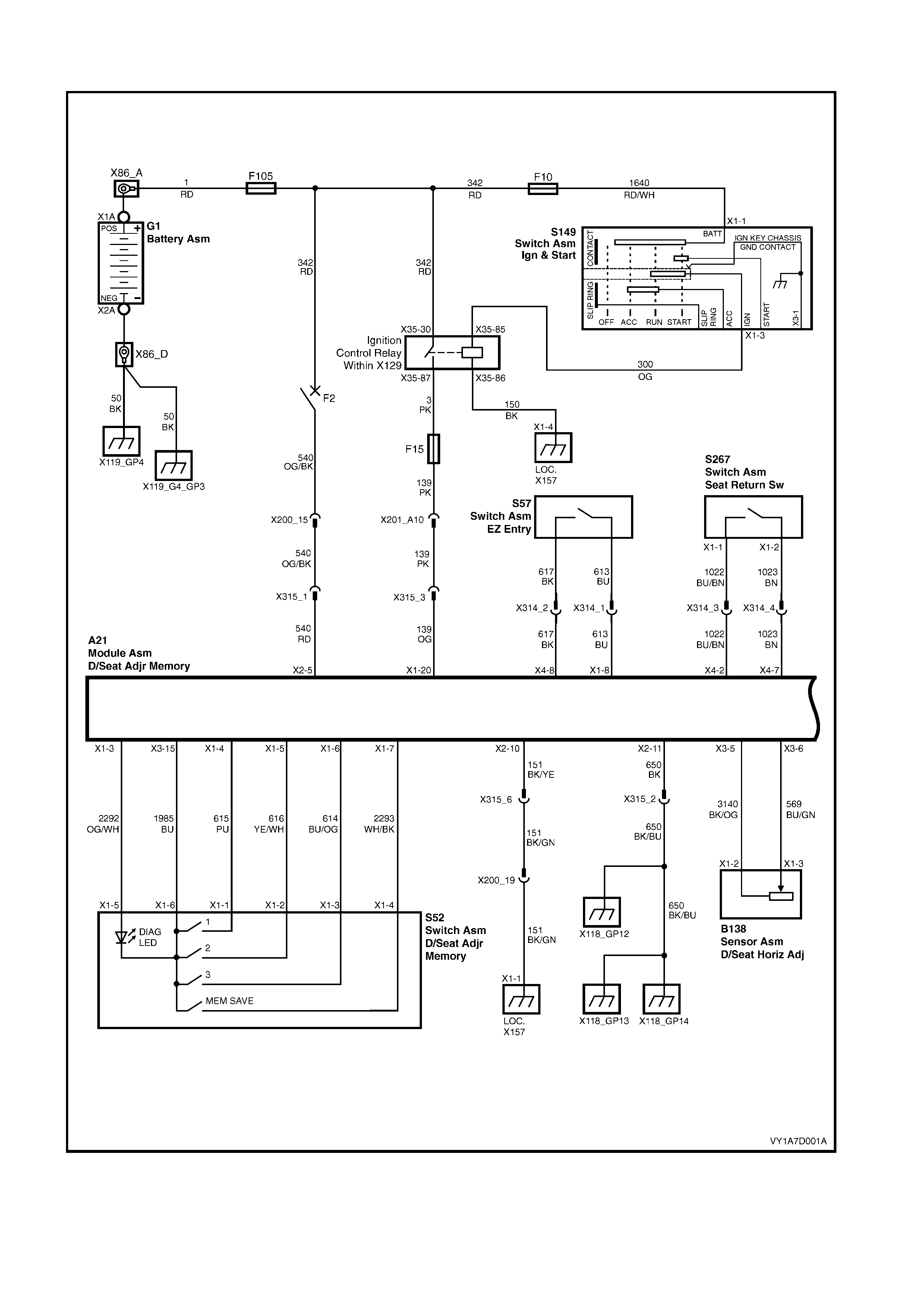

5.8 ELECTRICAL DIAGNOSIS – DRIVERS

EIGHT-WAY SEAT, MEMORY

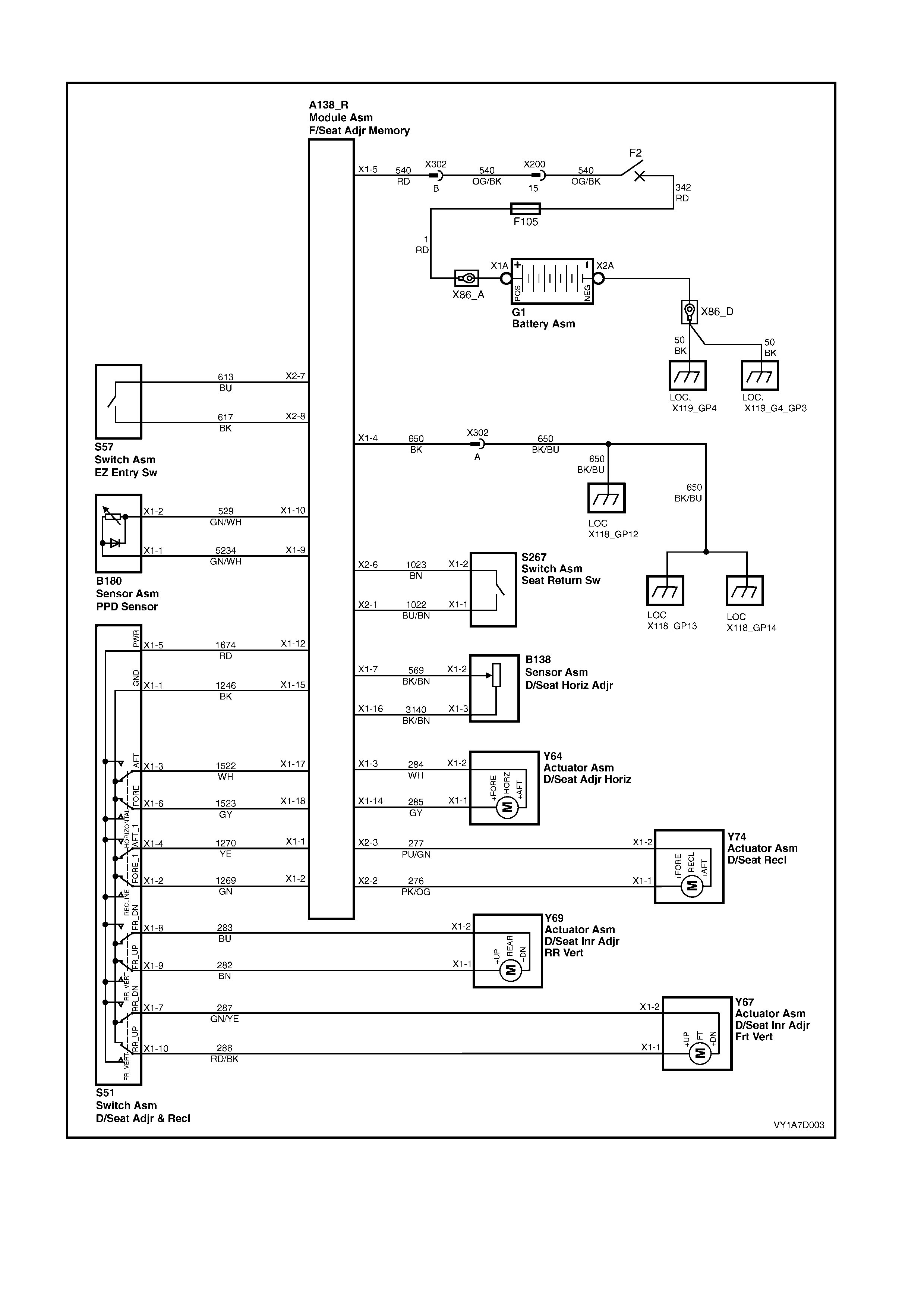

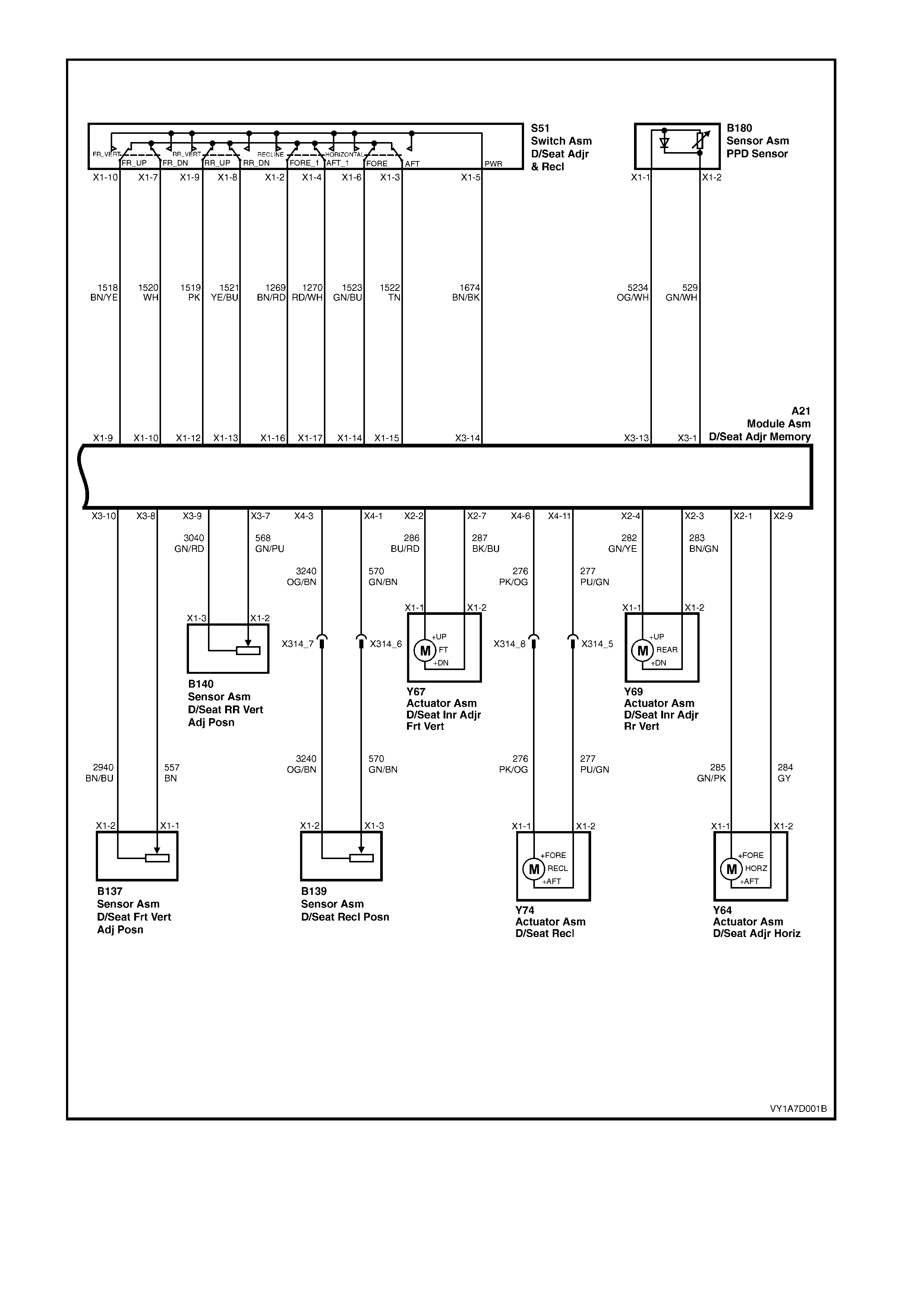

WIRING DIAGRAM - DRIVERS EIGHT-

WAY SEAT, MEMORY

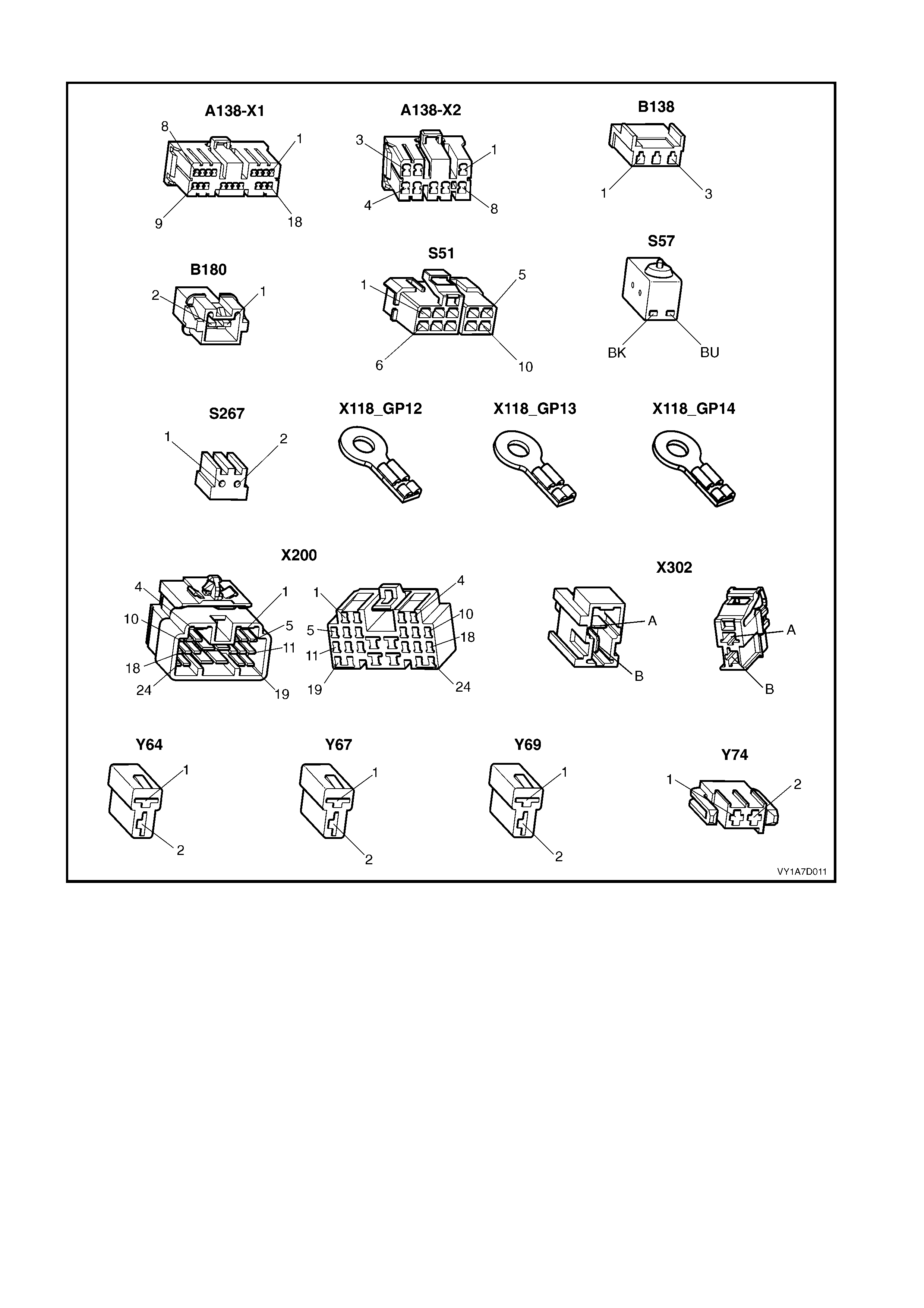

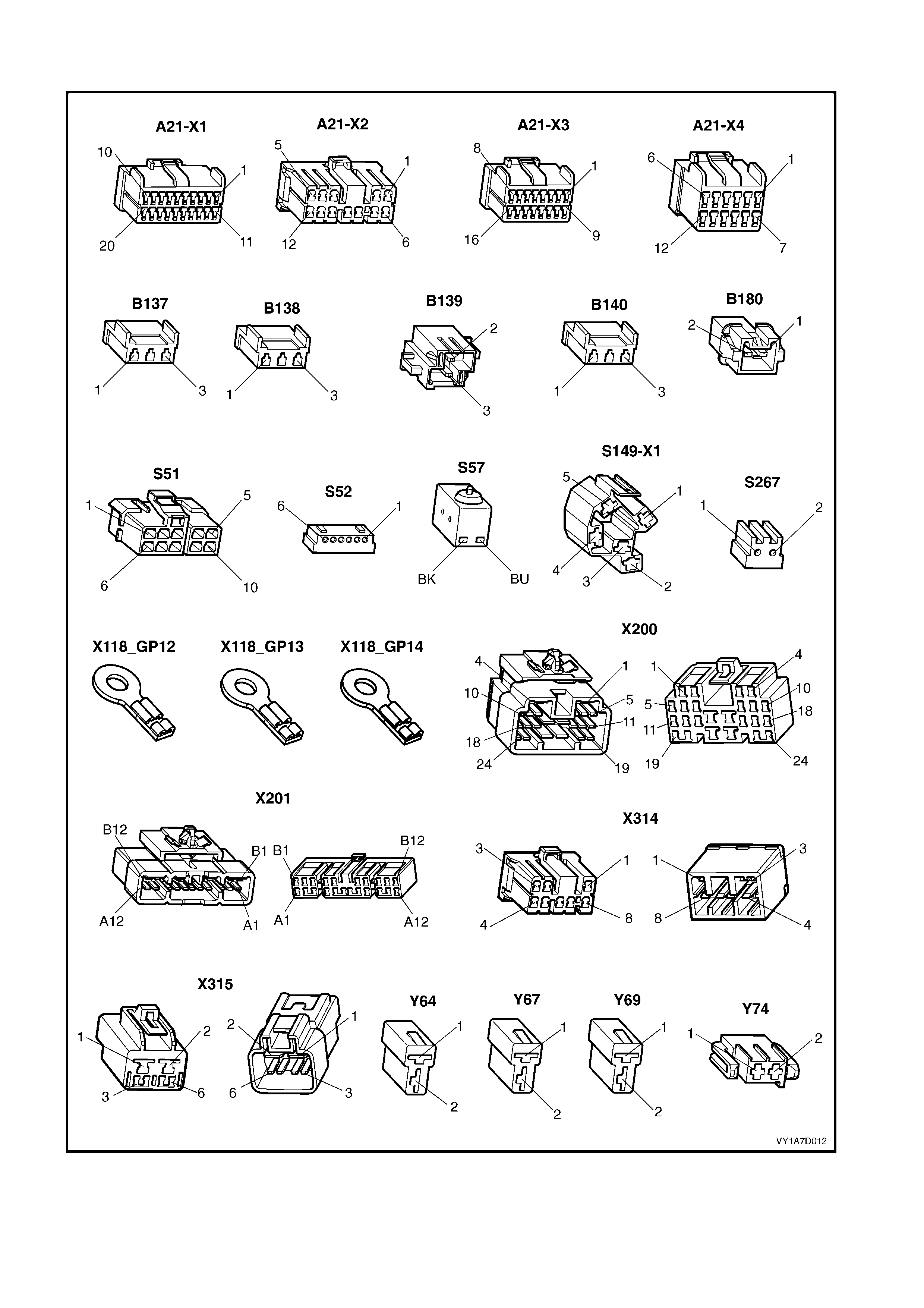

CONNECTOR CHART – DRIVER'S

EIGHT-WAY SEAT, MEMORY

NONE OF THE DRIVER’S EIGHT-WAY

SEAT ADJUSTM ENT SWITCH

FUNCTIONS OPERATE

FRONT / REAR OF THE DRIVER’S SEAT

DOES NOT RAISE AND / OR LOWER

DRIVER’S SEAT FORE / AFT FUNCTION IS

INOPERATIVE OR NOT SMOOTH

DRIVER’S SEAT RECLINE FORWARD

AND / OR AFT FUNCTION IS

INOPERATIVE

DRIVER’S SEAT EZ-ENTRY SWITCH

FUNCTION IS INOPERATIVE

DRIVER’S SEAT RETURN SWITCH

FUNCTION IS INOPERATIVE

DRIVER’S SEAT TRACK MOTOR POSITION

SENSOR POTENTIOMETER TEST

DRIVER’S SEAT RECLINE MOTOR POSITION

SENSOR POTENTIOMETER TEST

DRIVER’S SEAT FRONT LIFT MOTOR POSITION

SENSOR POTENTIOMETER TEST

DRIVER’S SEAT REAR LIFT MOTOR POSITION

SENSOR POTENTIOMETER TEST

DRIVER’S SEAT OCCUPANT SENSING

MAT TEST

DRIVER’S SEAT MEMORY POSITION

SWITCH TEST

5.9 MEMORY POSITION SWITCH TEST

TEST

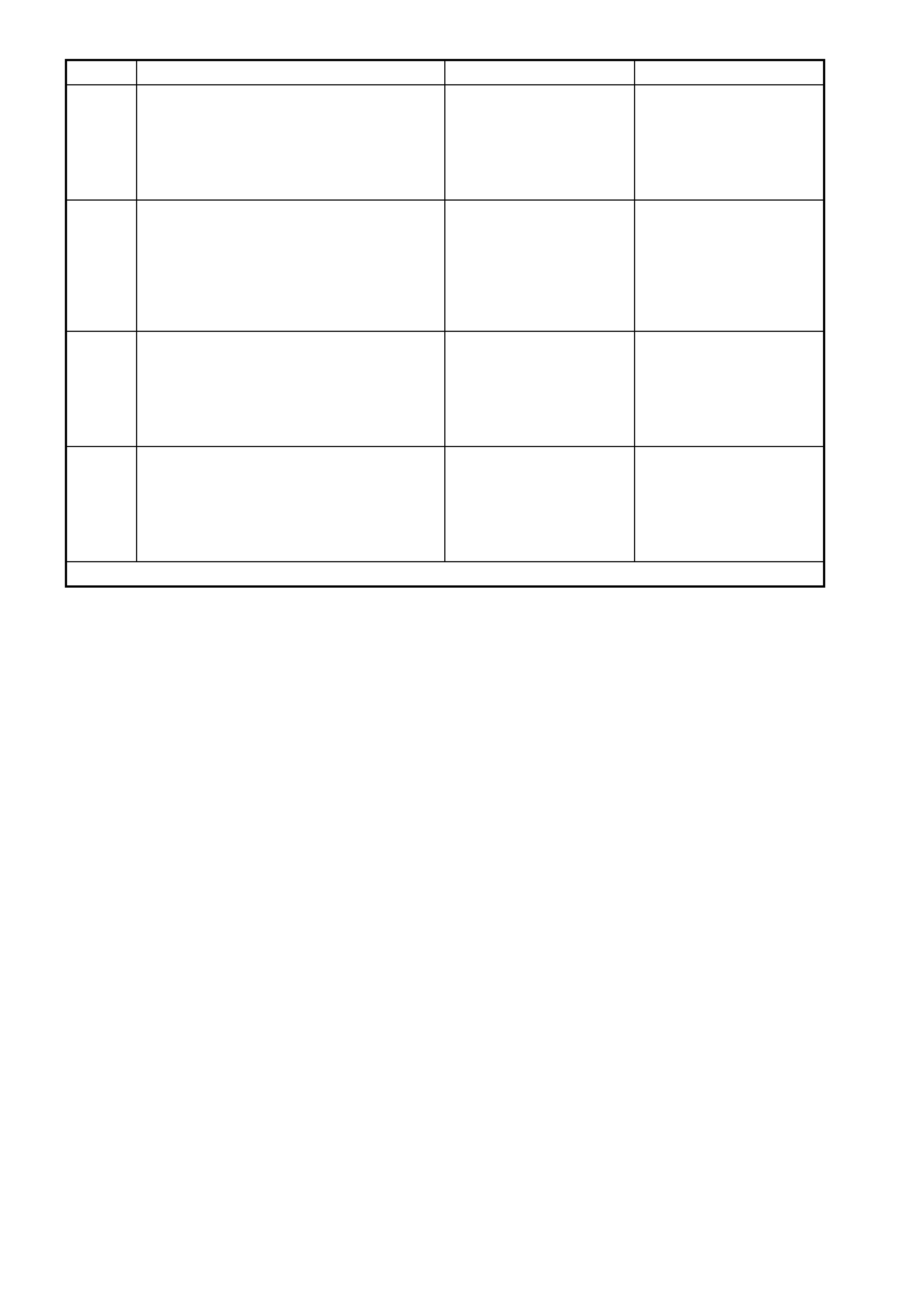

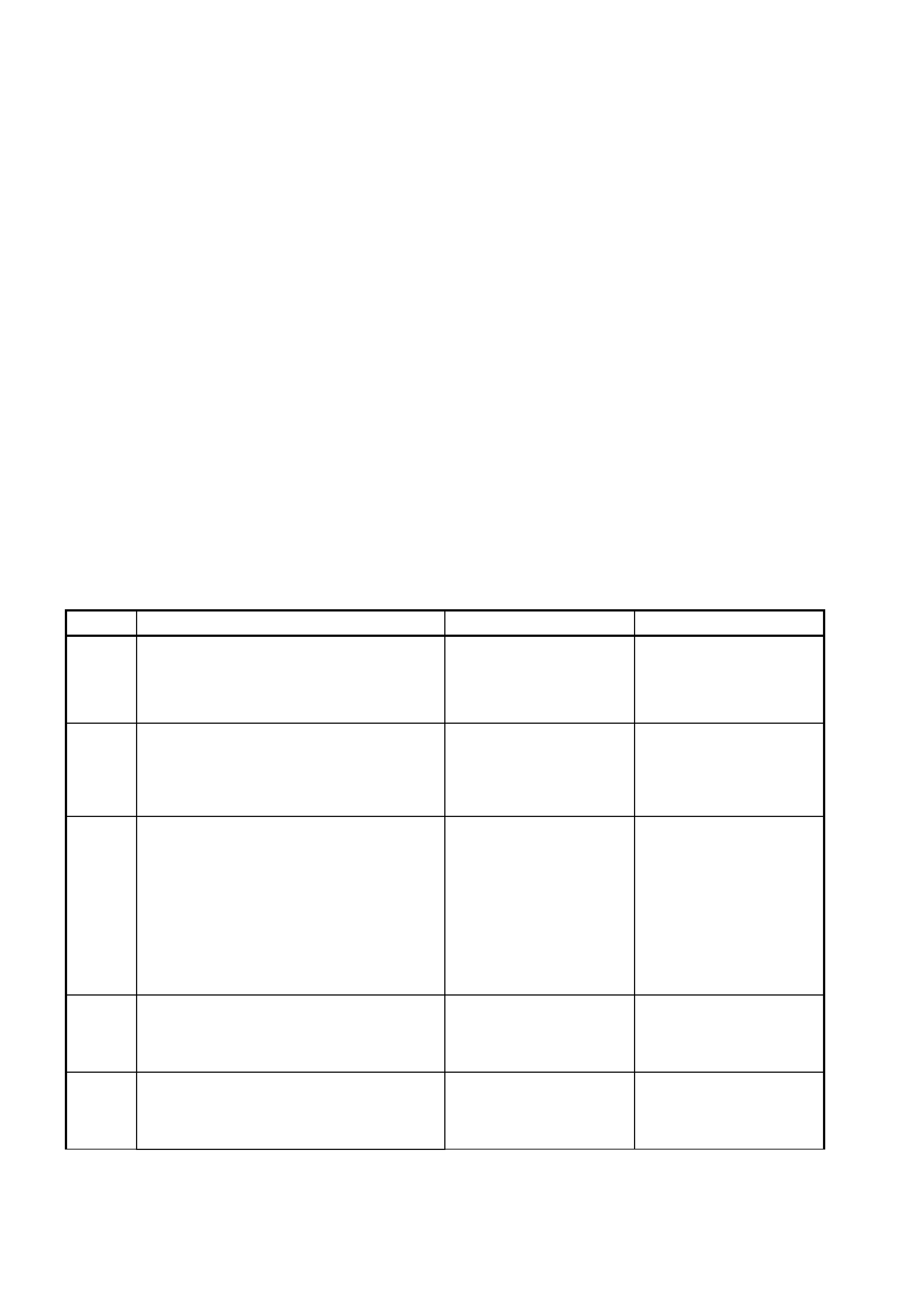

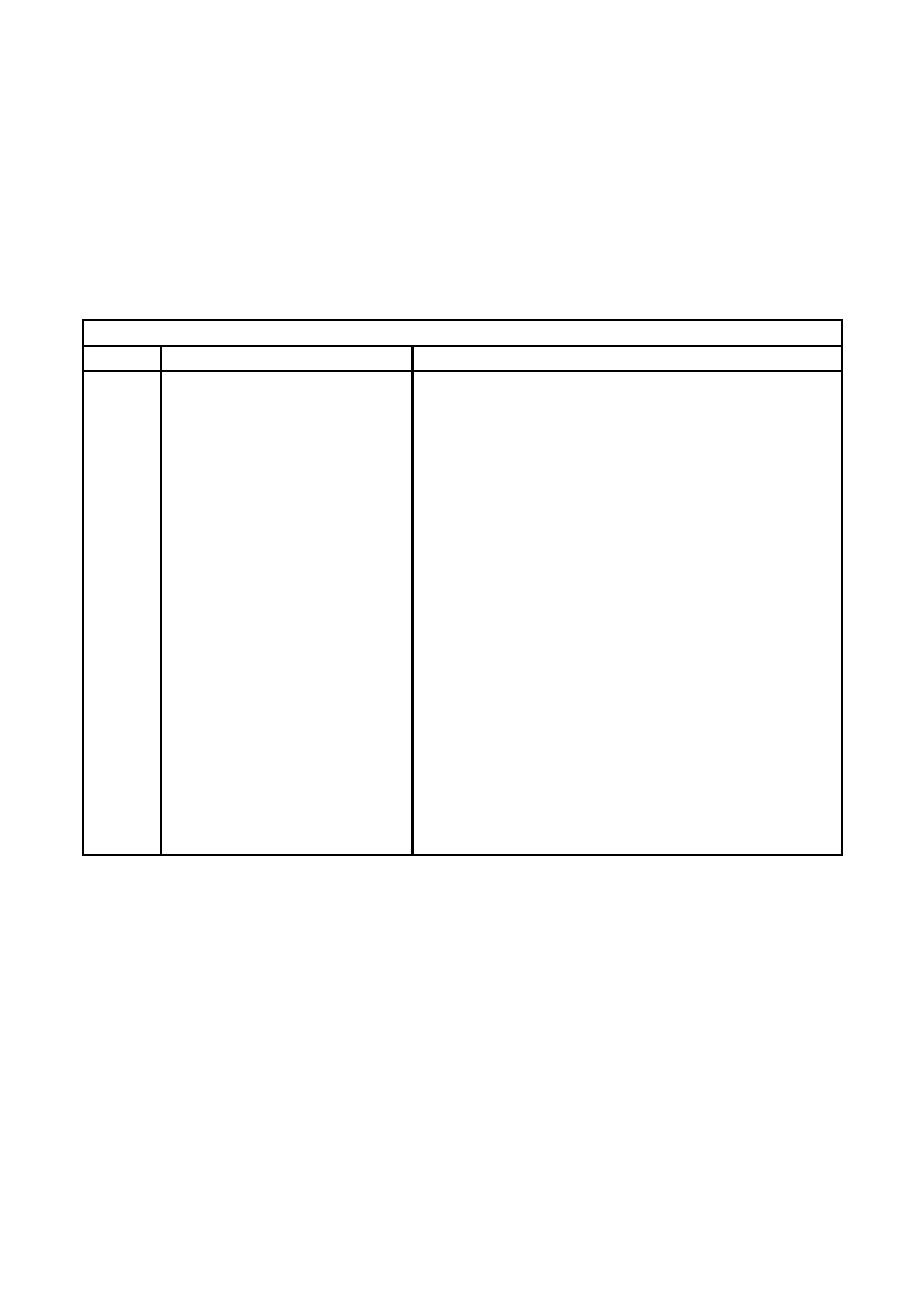

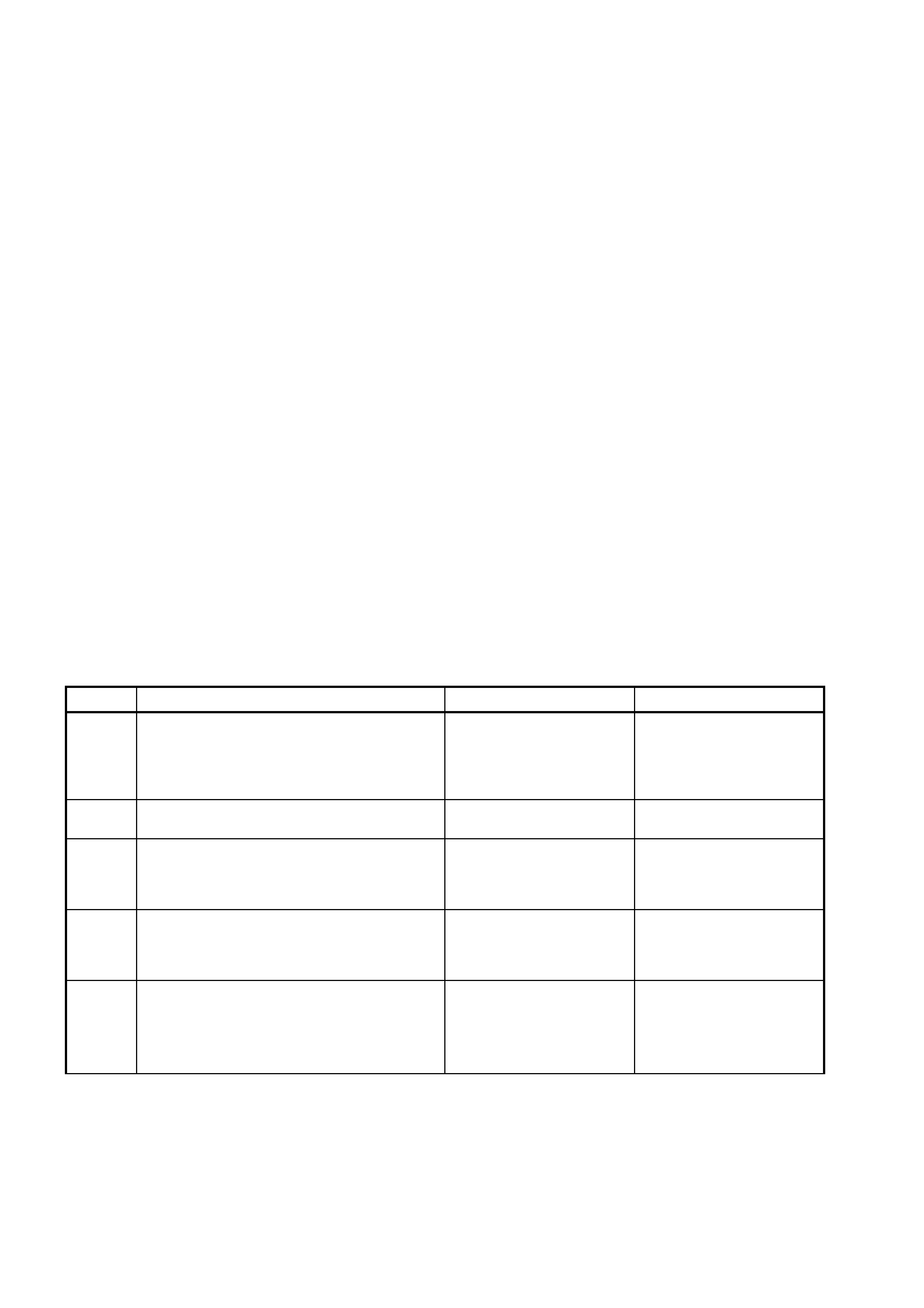

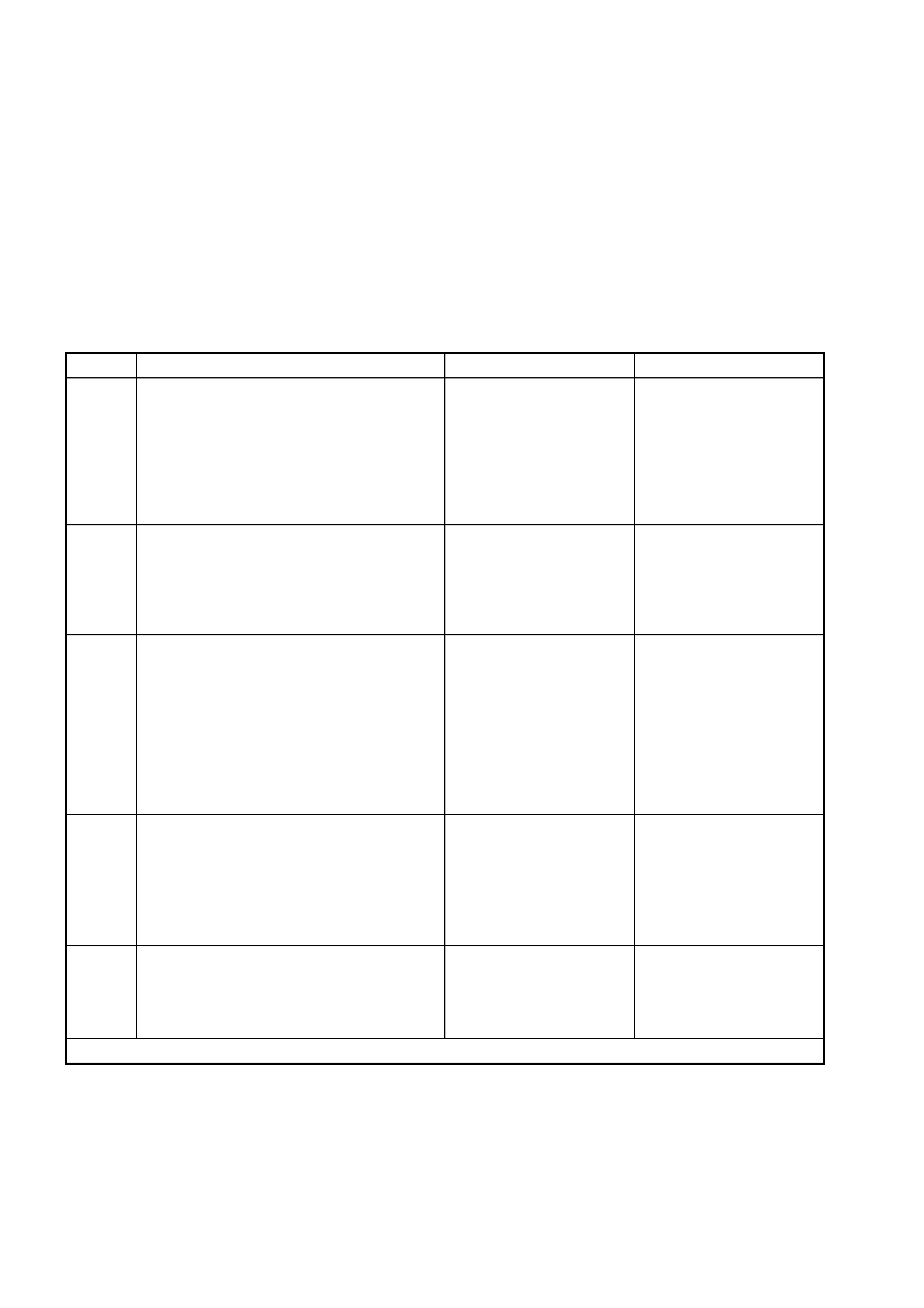

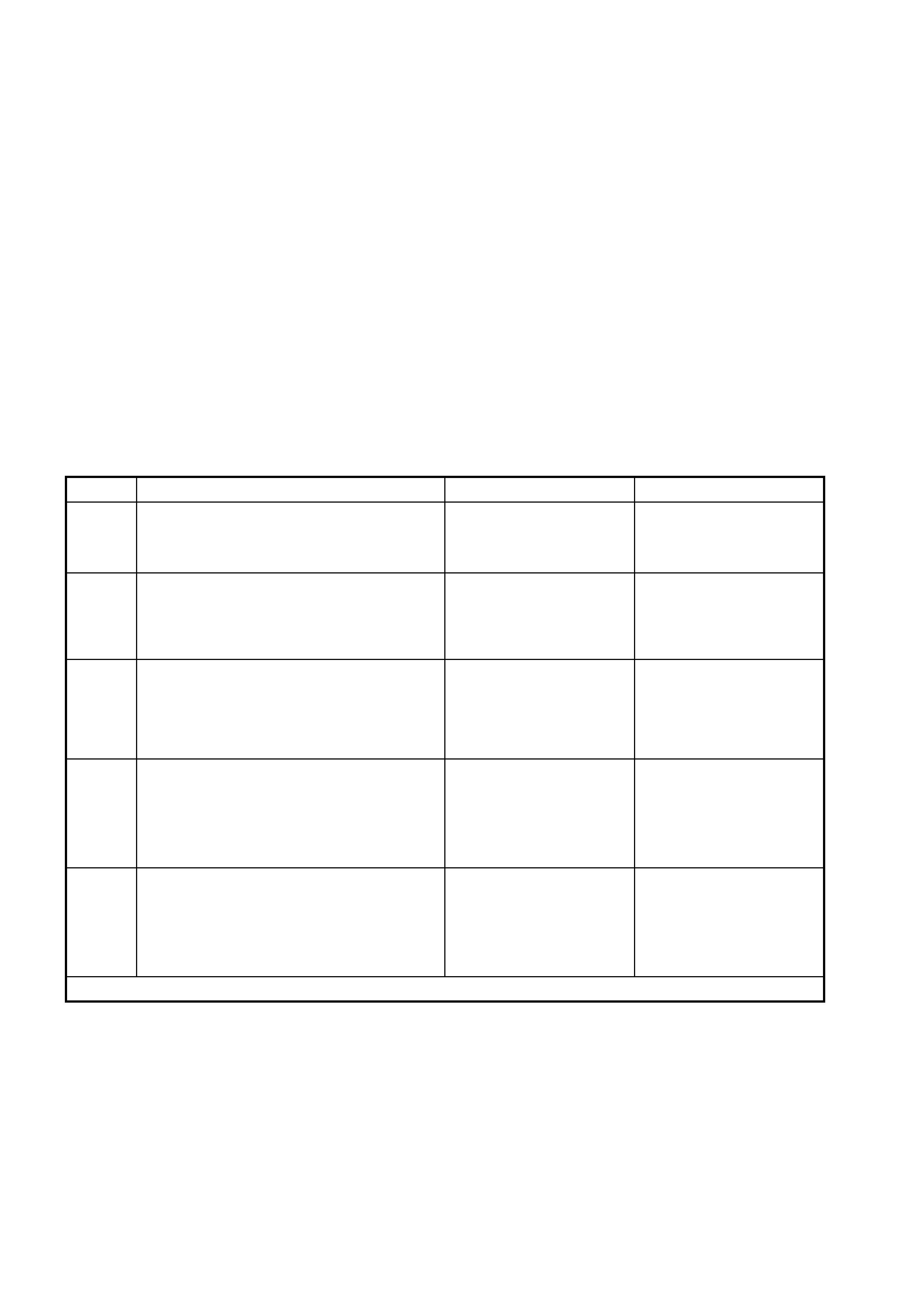

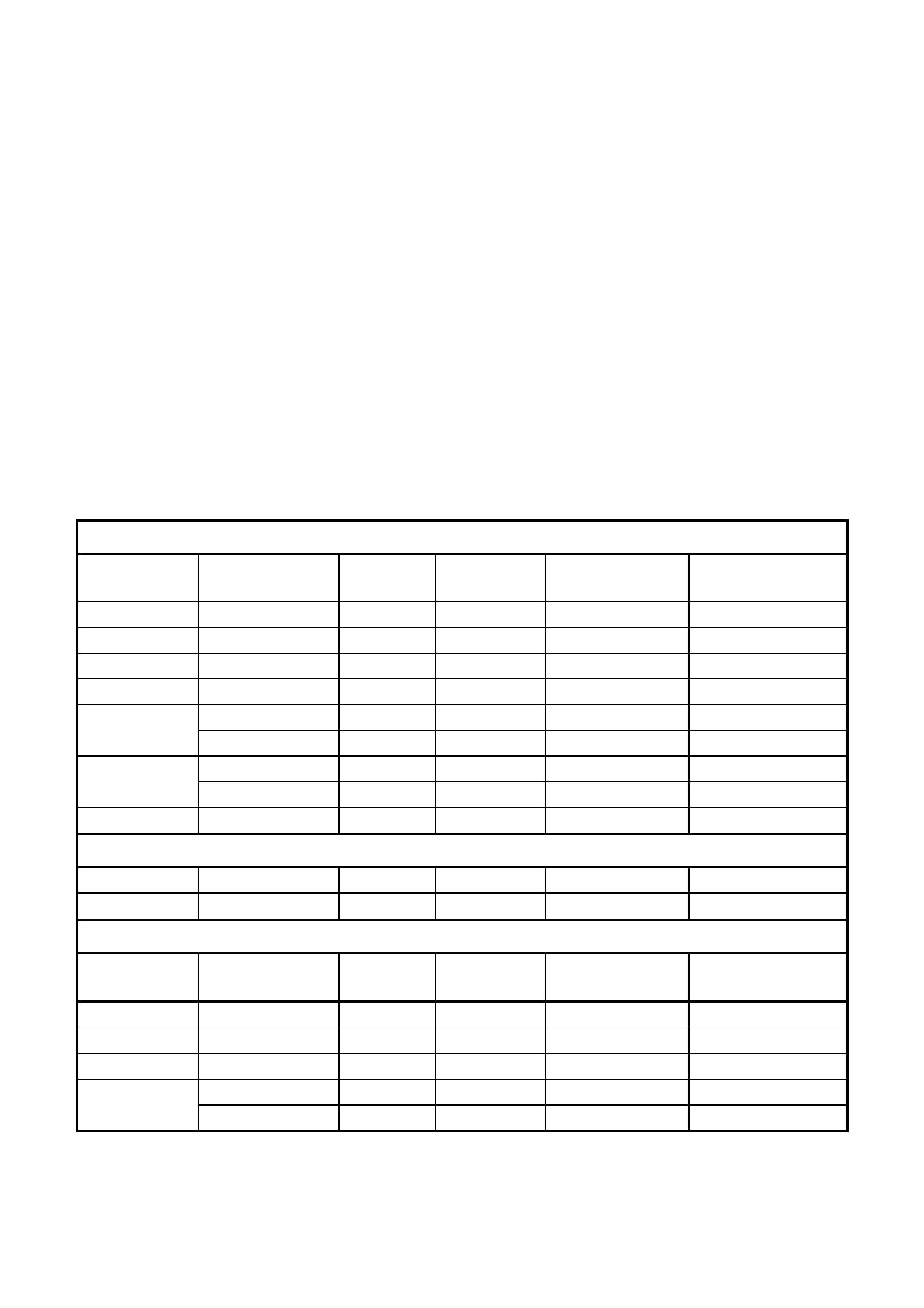

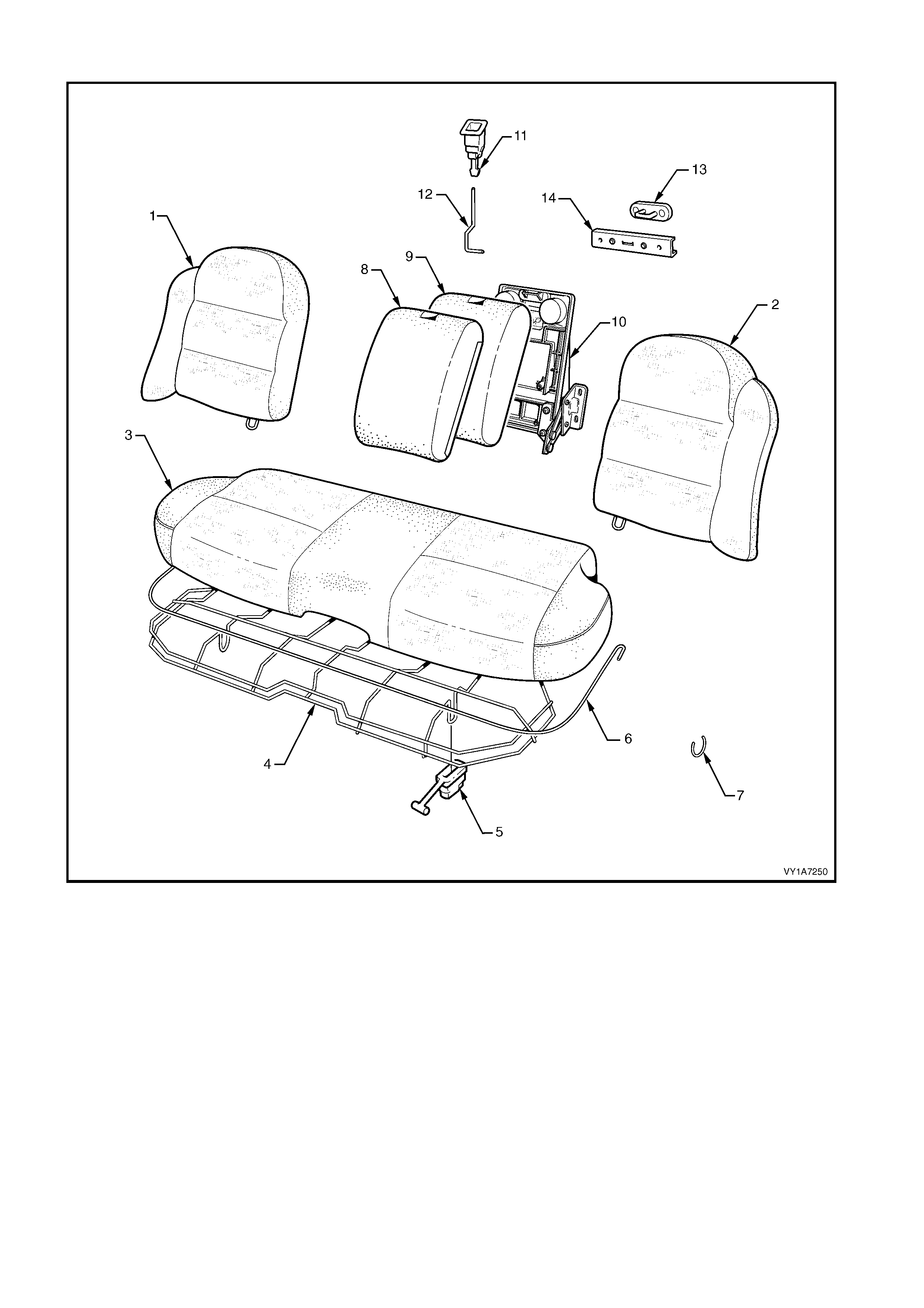

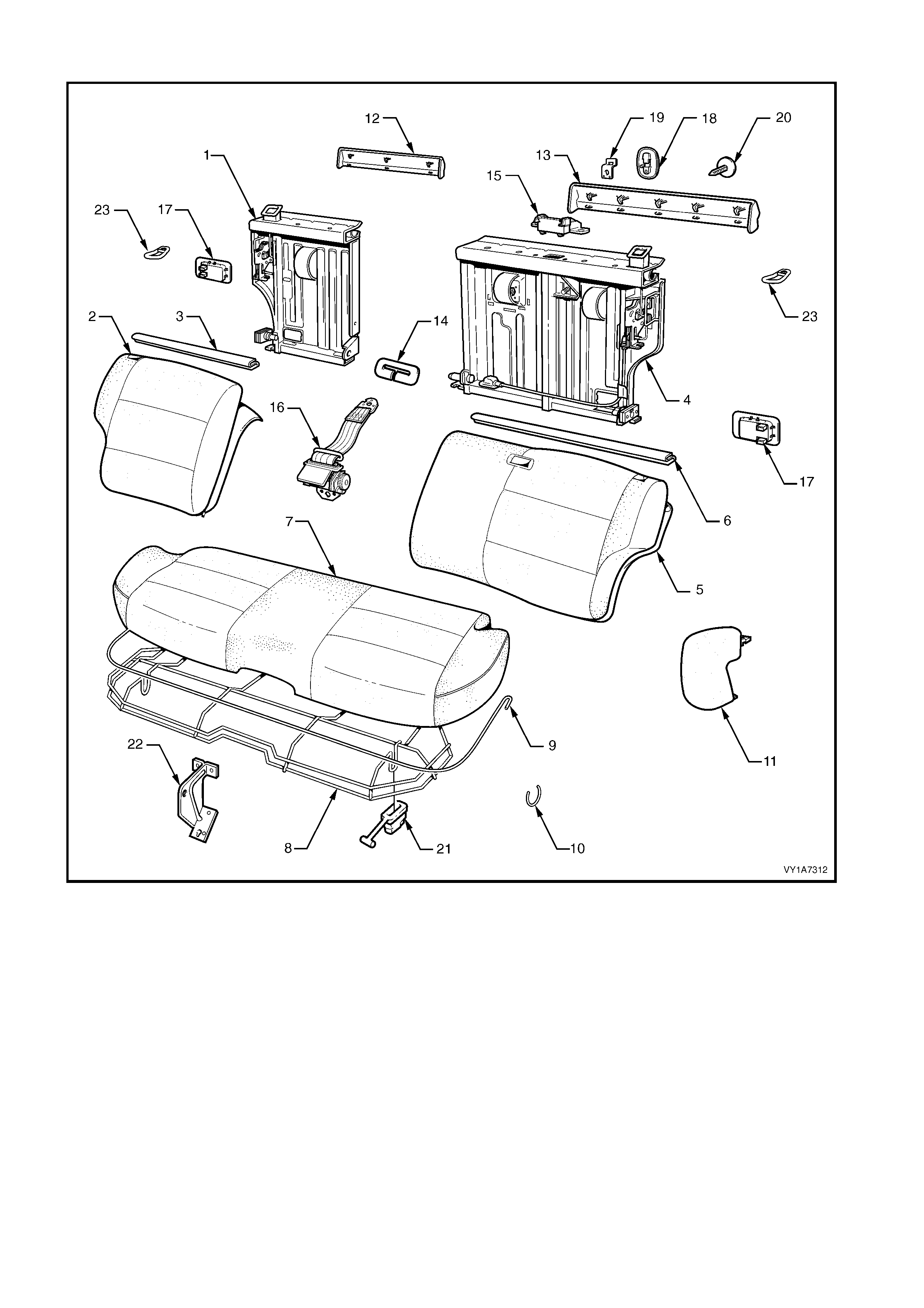

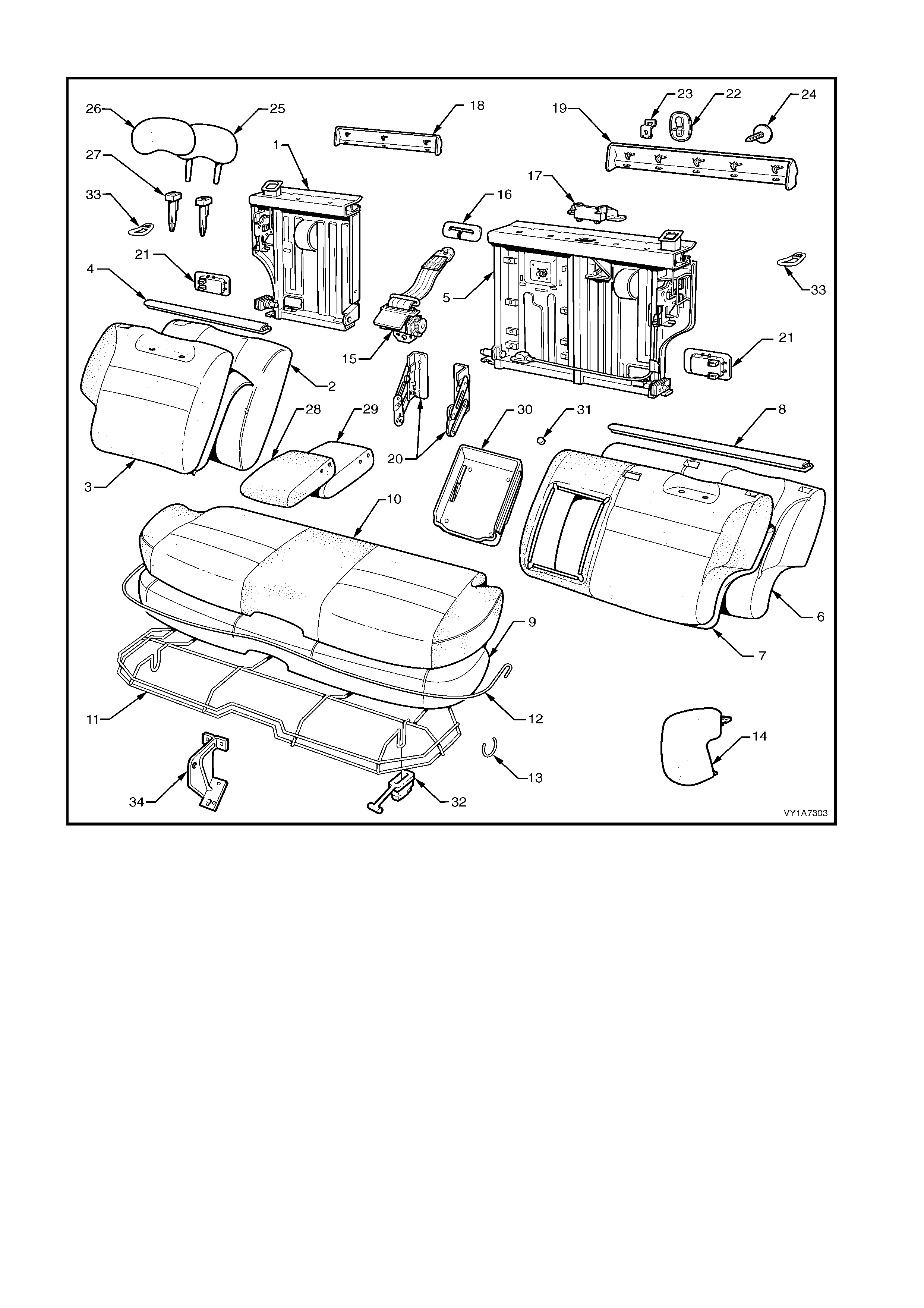

6. SERVICE OPERATIONS - REAR SEAT, SEDAN

6.1 REAR SEAT USAGE CHART - SEDAN

HOW TO USE THIS CHART

6.2 REAR SEAT CUSHION ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

6.3 REAR SEAT-BACK ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

6.4 REAR SEAT-BACK HEAD RESTRAINT

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

6.5 REAR SEAT-BACK HEAD RESTRAINT GUIDE

REMOVE

REINSTALL

6.6 REAR SEAT-BACK CENTRE, ARMREST

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

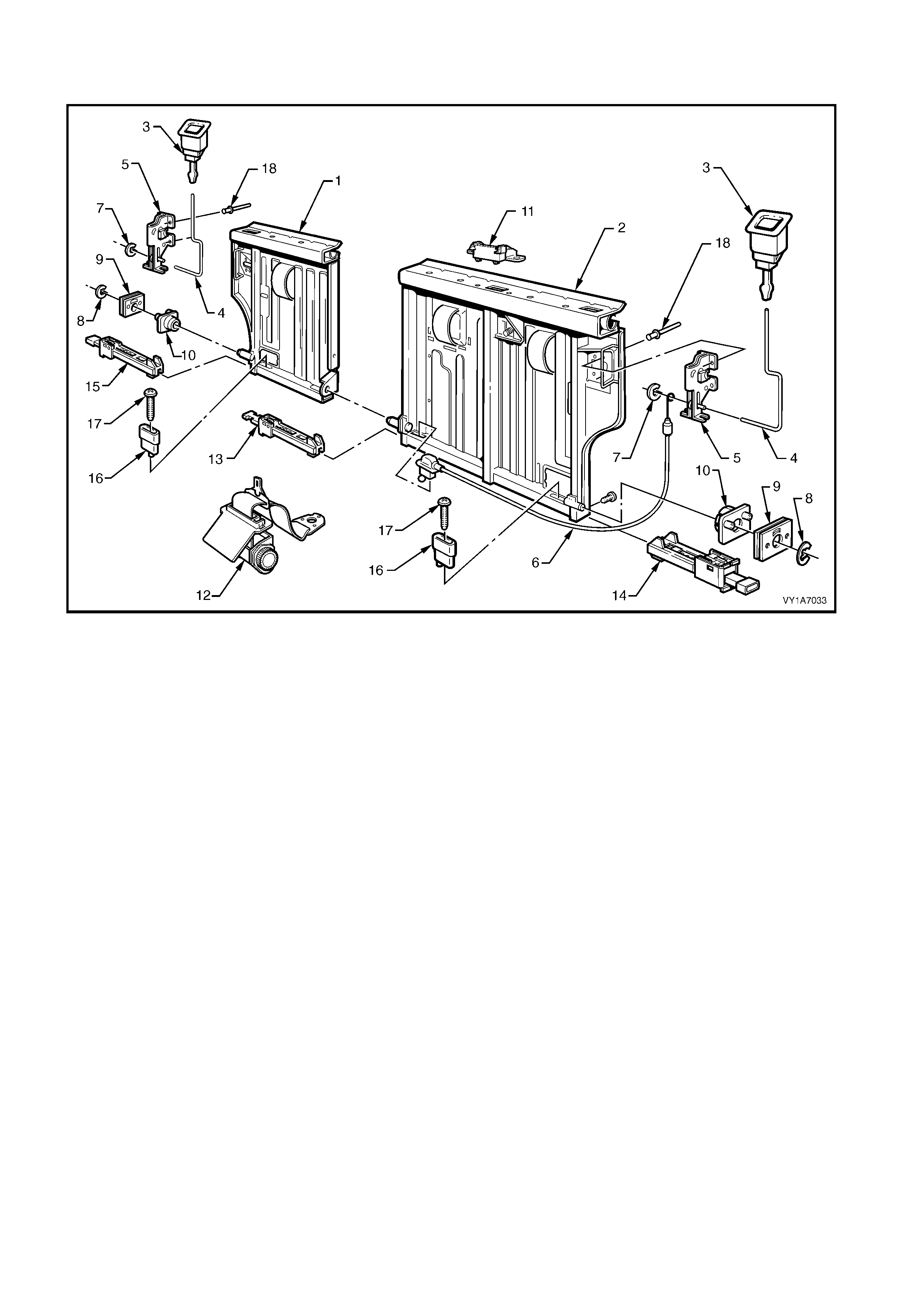

6.7 REAR SEAT CENTRE BACK ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

6.8 REAR SEAT CENTRE BACK, LOCK STRIKER

REMOVE

REINSTALL

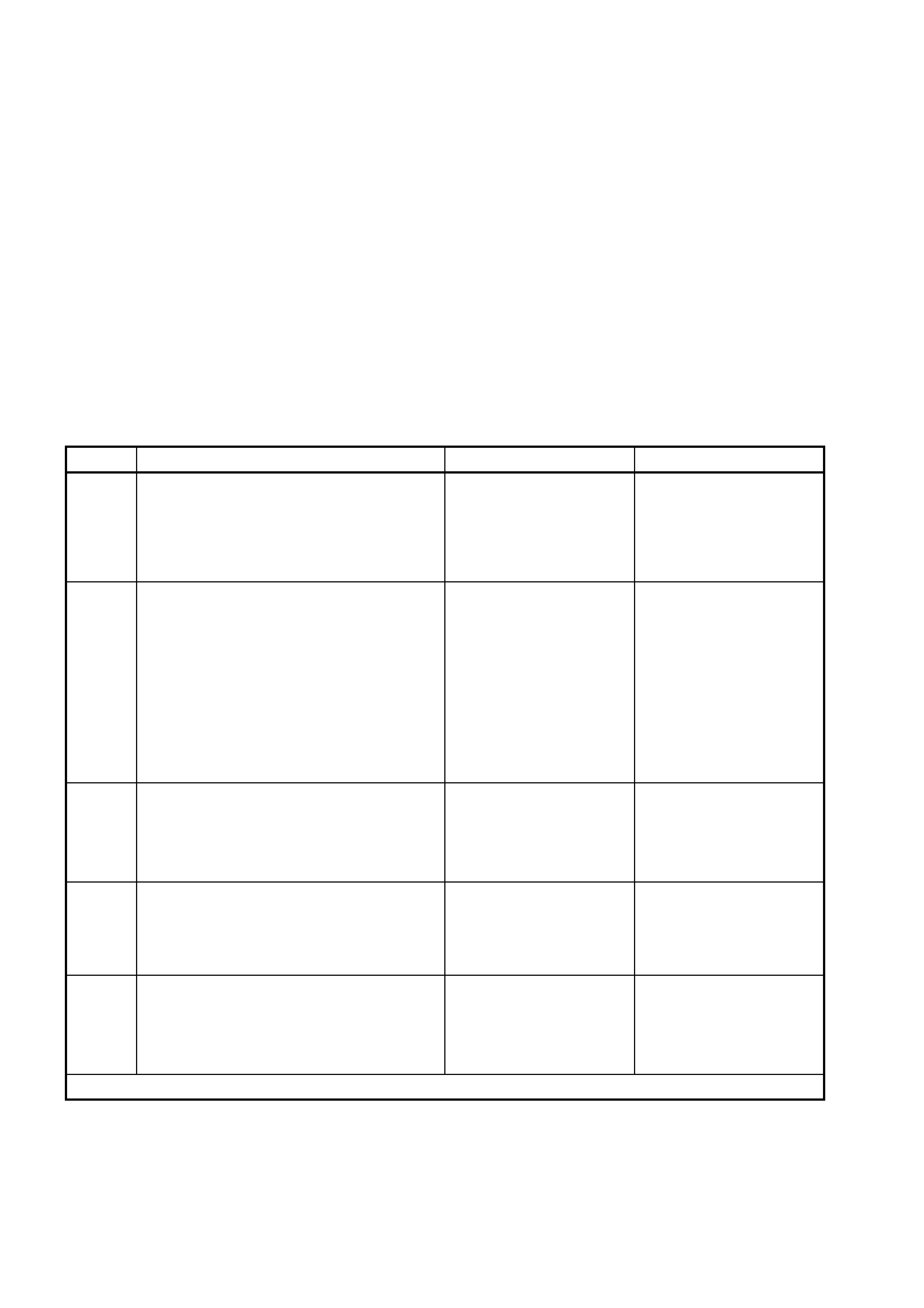

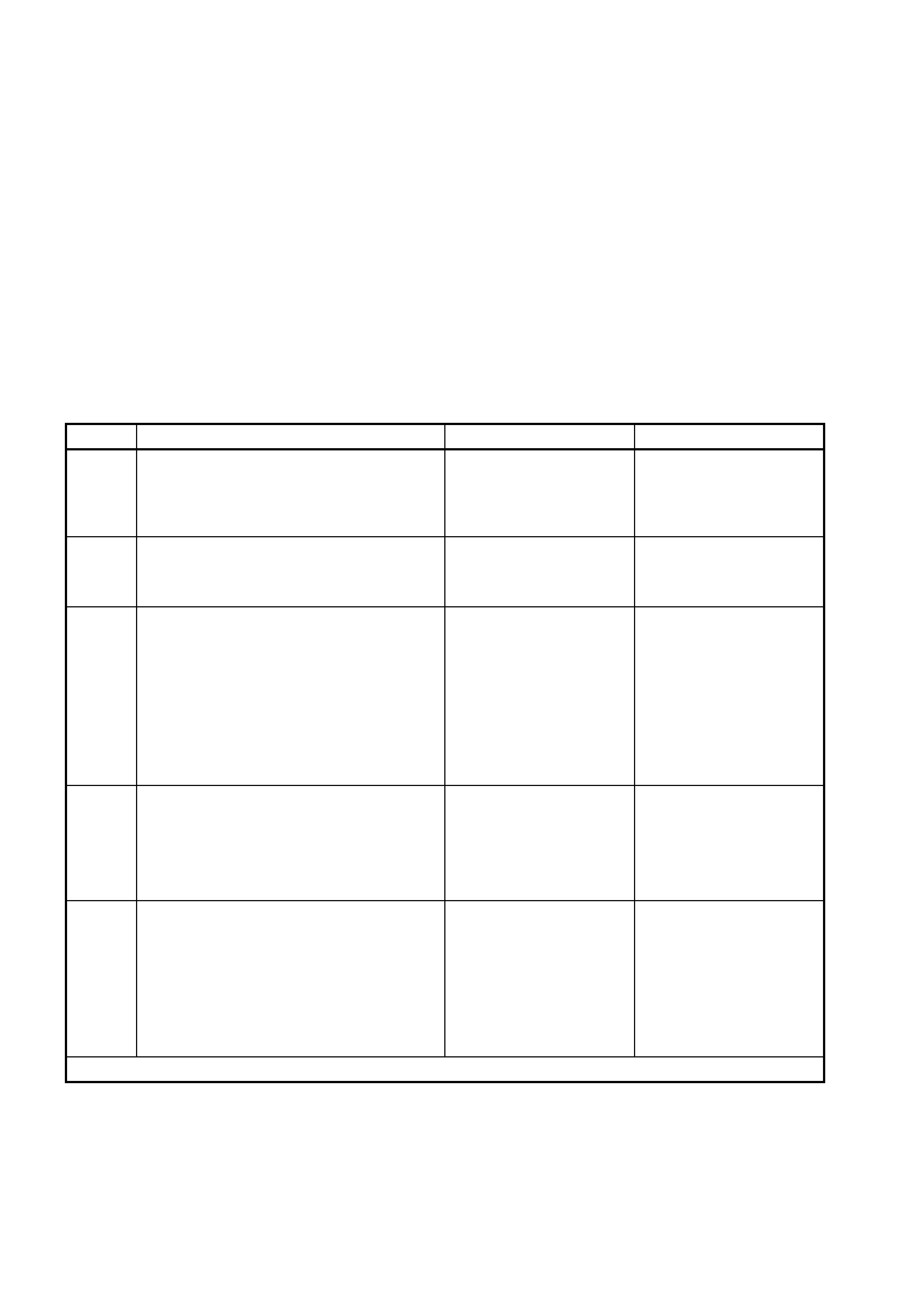

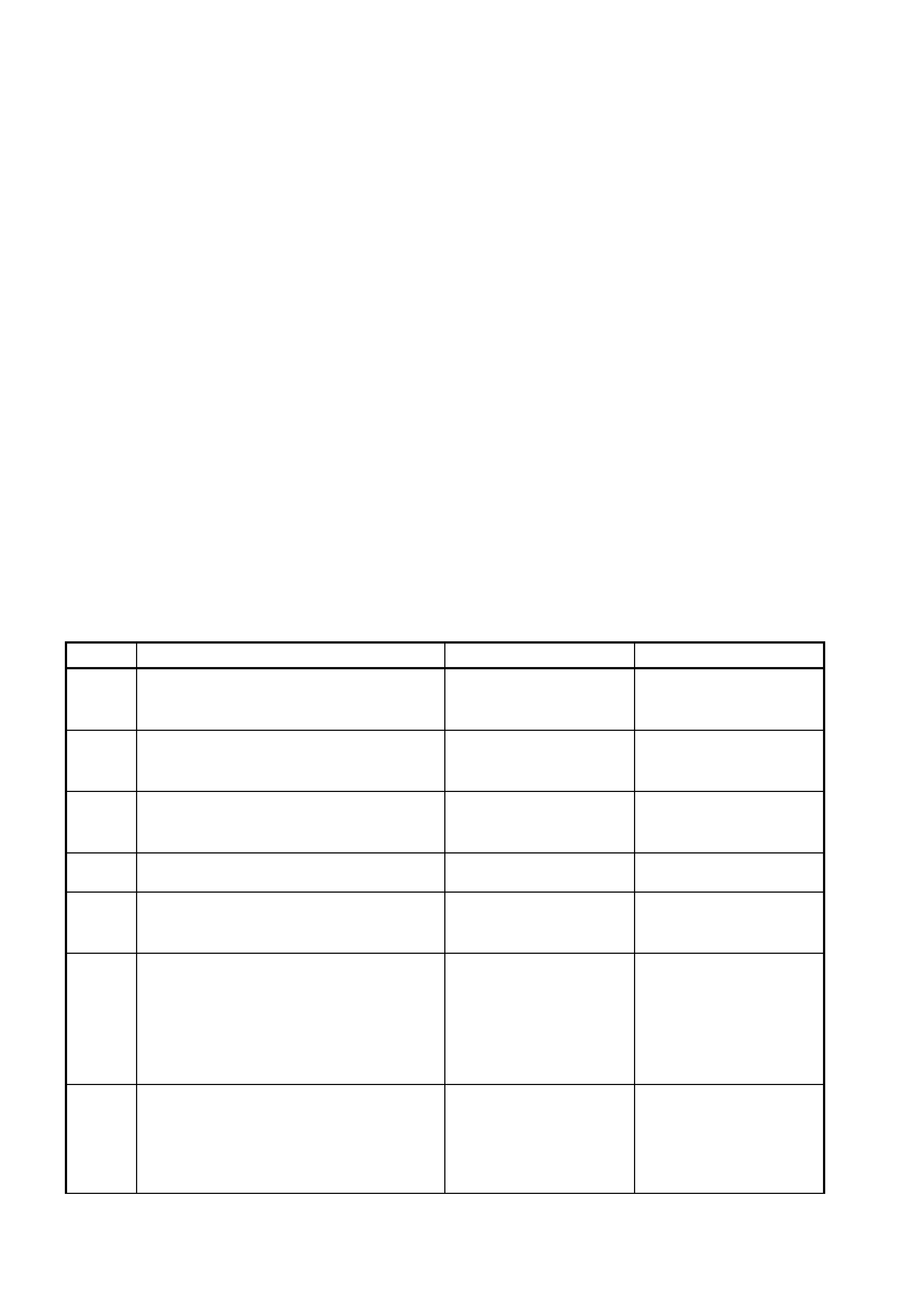

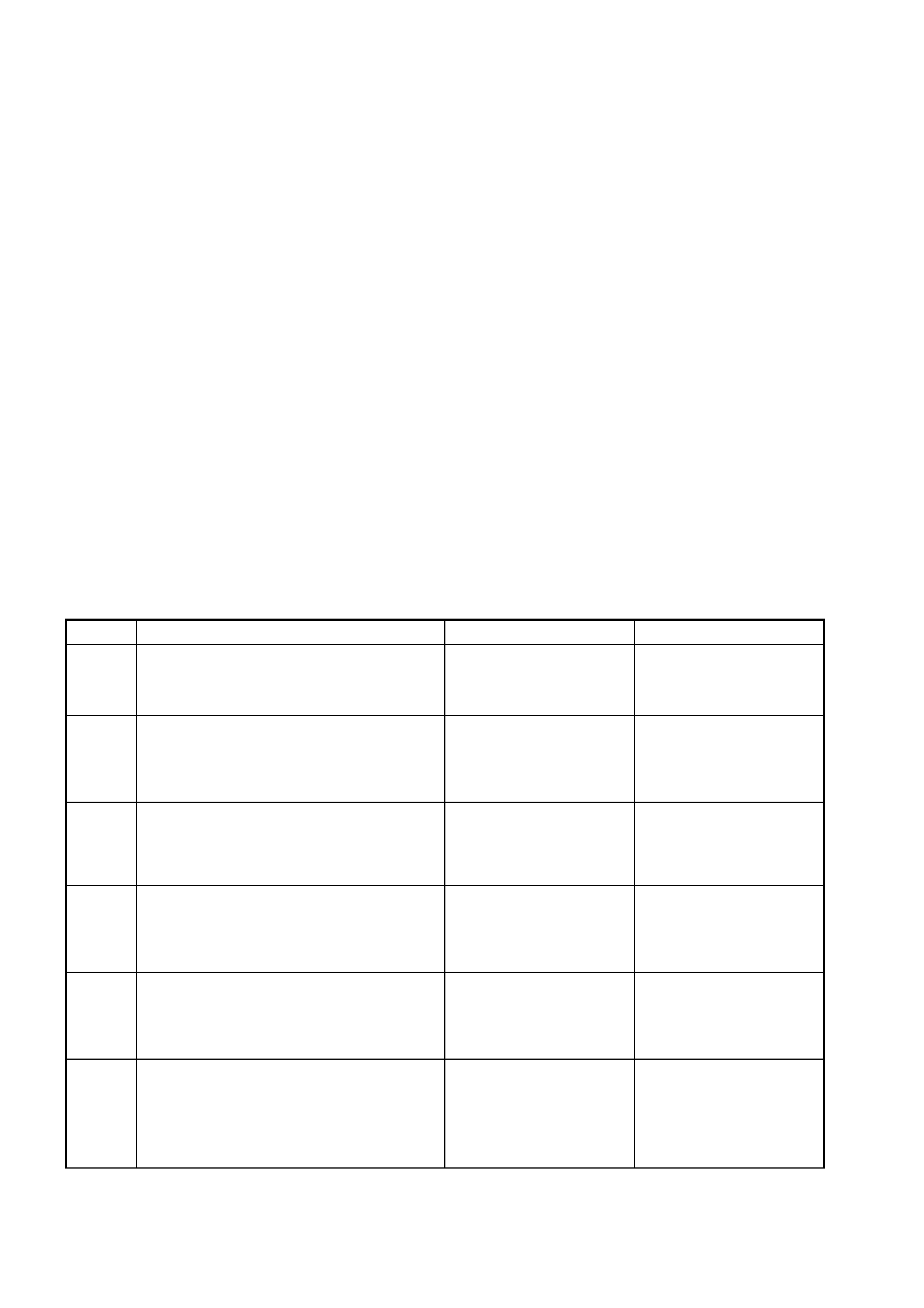

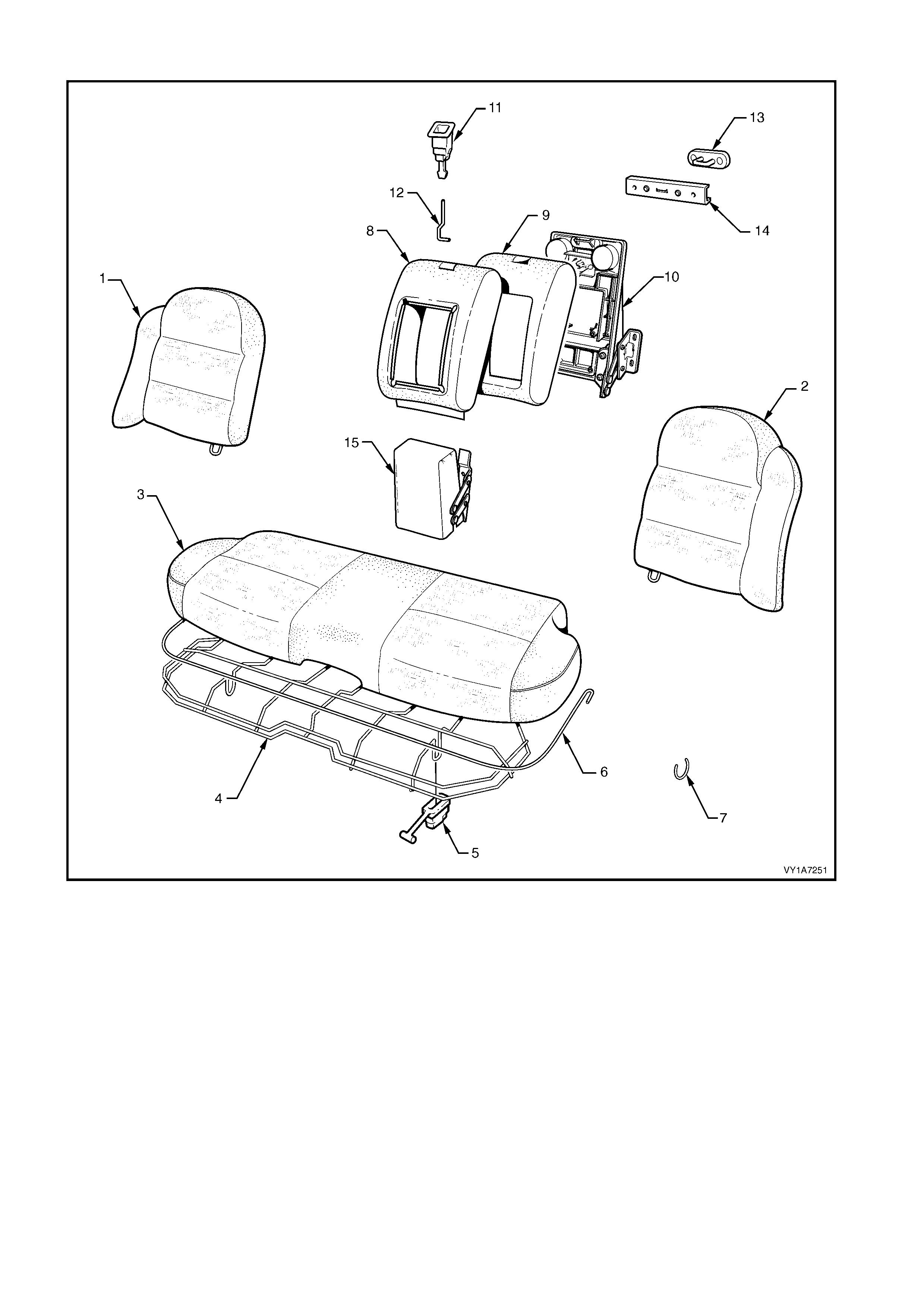

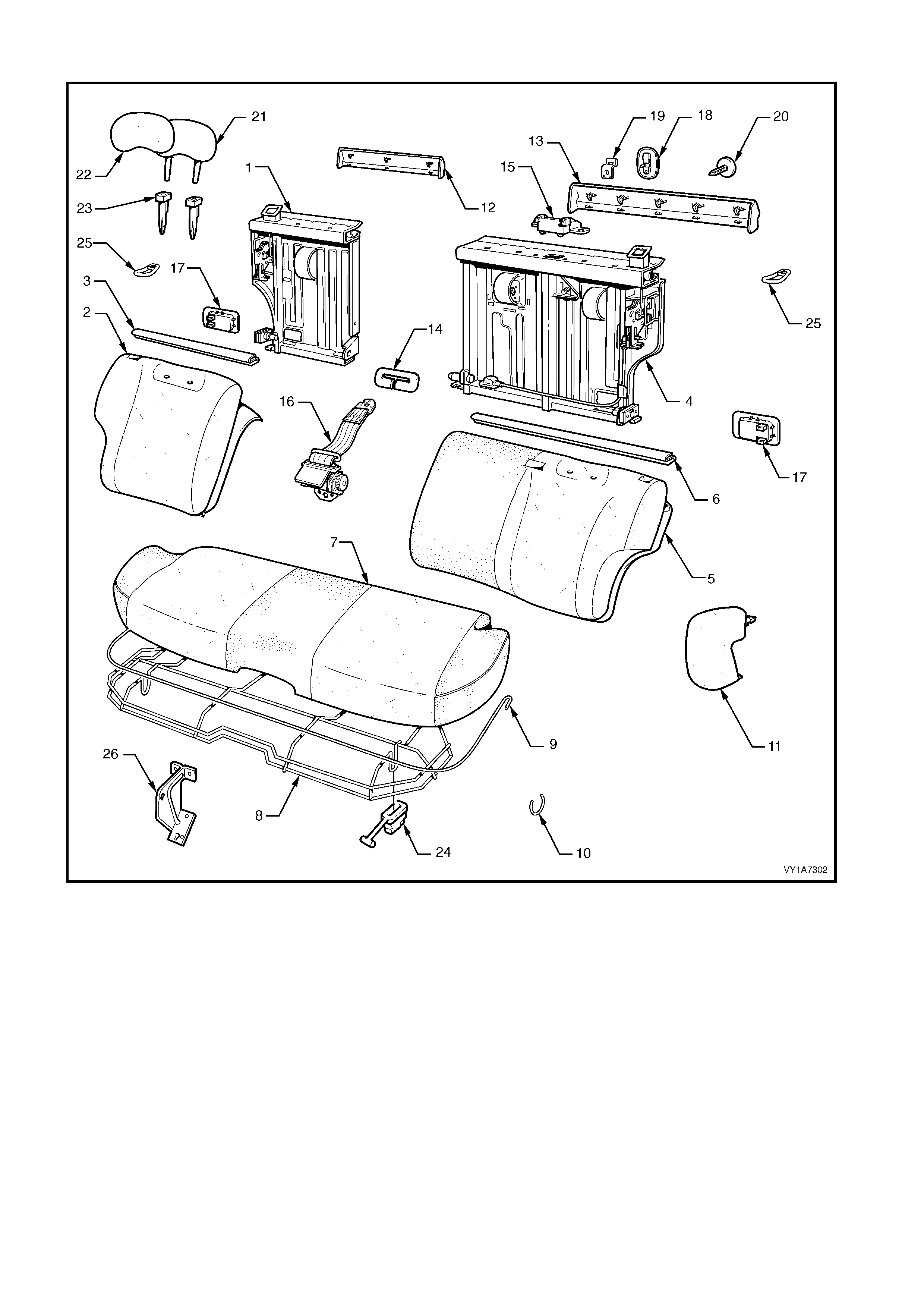

7. SERVICE OPERATIONS - REAR

SEAT, WAGON

7.1 REAR SEAT USAGE CHART - WAGON

HOW TO USE THIS CHART

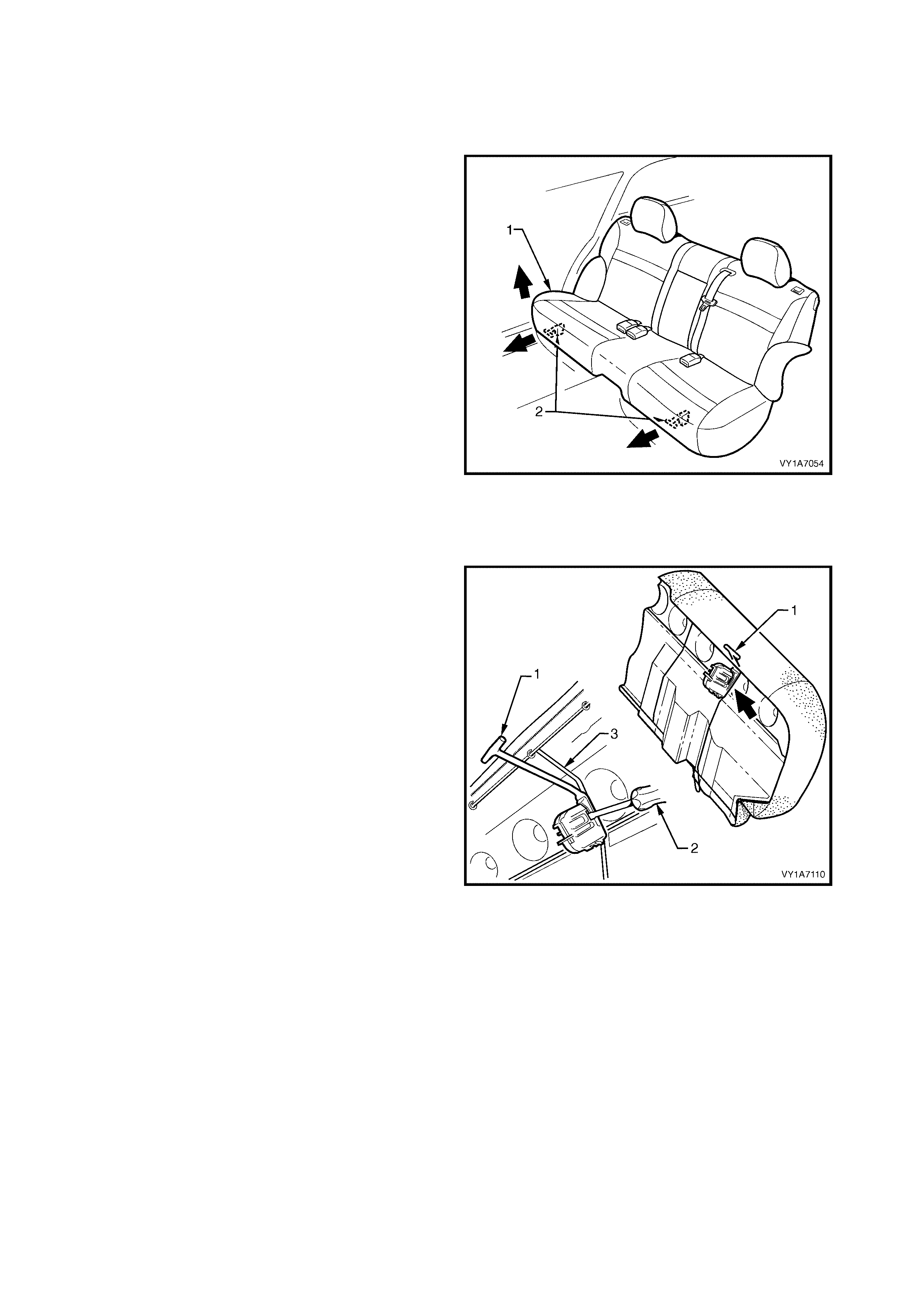

7.2 REAR SEAT CUSHION ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

7.3 REAR SEAT BOLSTER ASSEMBLY

REMOVE

REINSTALL

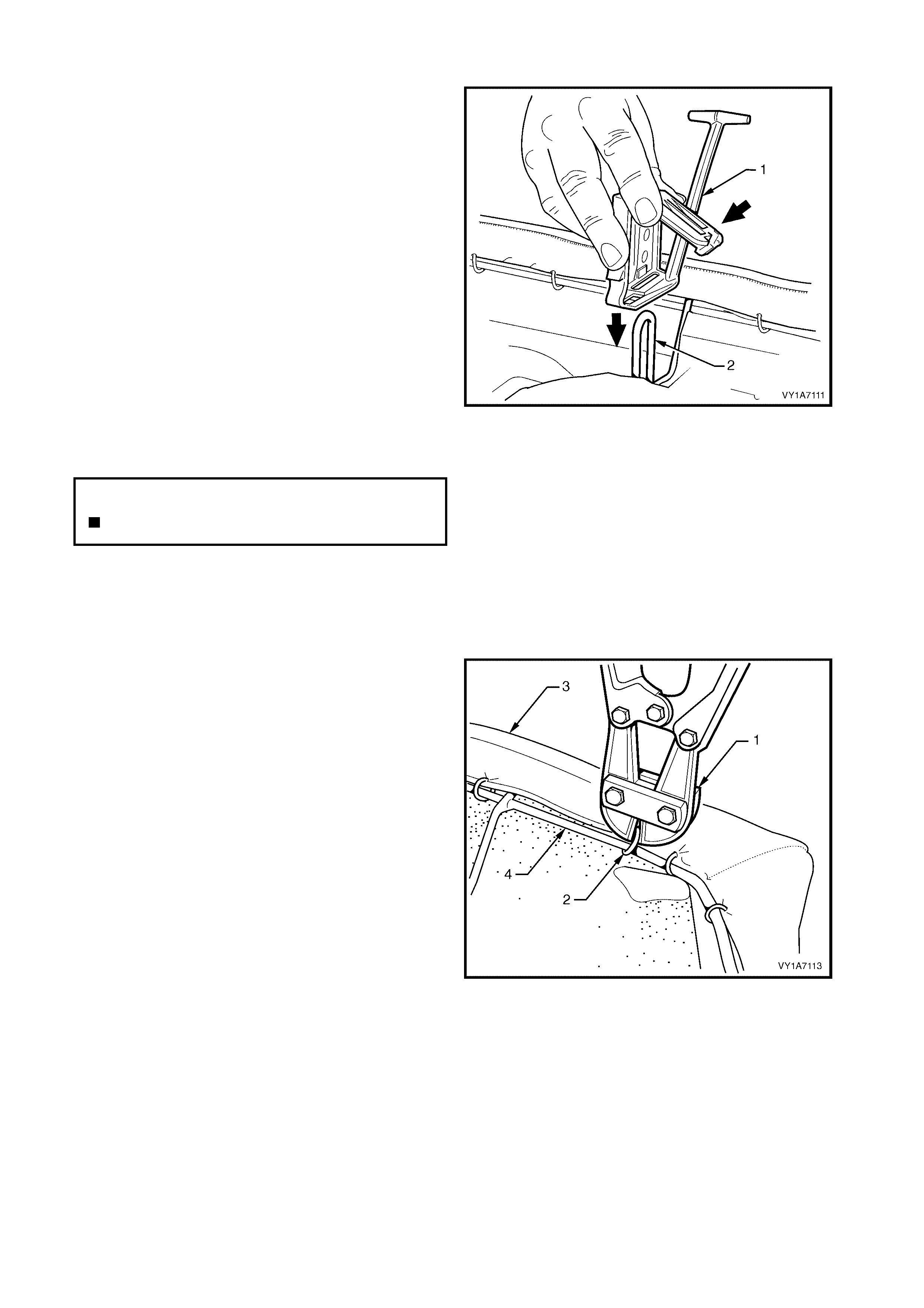

7.4 REAR SEAT-BACK ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

7.5 REAR SEAT-BACK HEAD RESTRAINT

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

7.6 REAR SEAT-BACK HEAD RESTRAINT

GUIDE

REMOVE

REINSTALL

7.7 REAR SEAT-BACK ARMREST

ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

7.8 REAR SEAT-BACK ARMREST HINGE

ASSEMBLY AND CENTRE COVER

REMOVE

REINSTALL

7.9 REAR SEAT CENTRE SUPPORT

REMOVE

REINSTALL

7.10 REAR SEAT-BACK LOCK STRIKER

REMOVE

REINSTALL

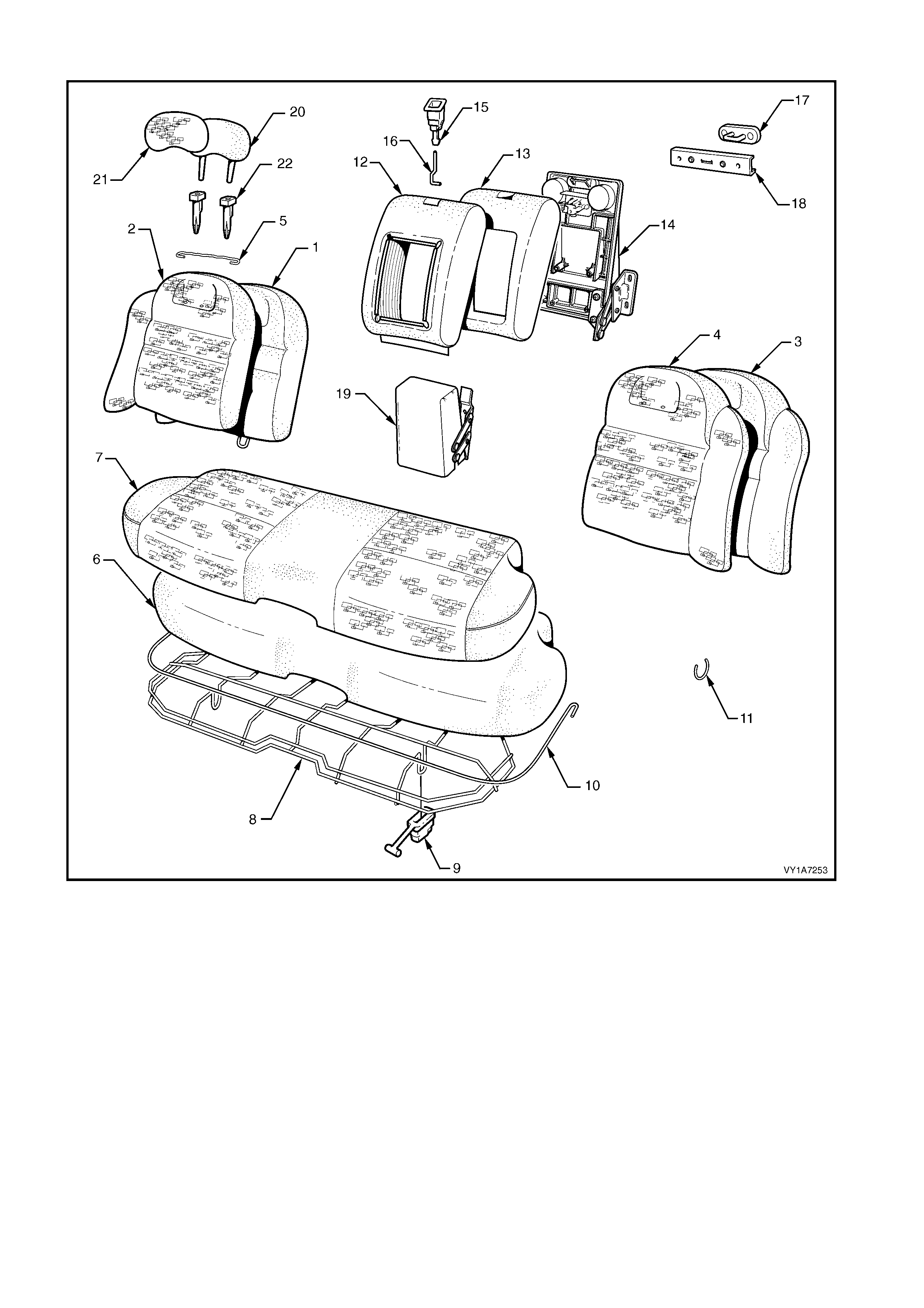

8. SERVICE OPERATIONS - REAR SEAT,

COUPE

8.1 REAR SEAT CUSHION ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

8.2 REAR SEAT-BACK ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

8.3 REAR SEAT HEAD RESTRAINT

ASSEMBLY

REMOVE

REINSTALL

8.4 REAR SEAT HEAD RESTRAINT GUIDE

REMOVE

REINSTALL

9. TORQUE WRENCH SPECIFICATIONS

1. GENERAL INFORMATION

This seat ass em bly Section for the MY2003 VY Series & MY2003 V2 Series II service inf orm ation has been divided

into seven s ections: Front Seat, ex cept Coupe; Diagnosis Fr ont Seat, except Coupe; Front Seat, Coupe; Diagnos is

Front Seat, Coupe; Rear Seat, Sedan; Rear Seat, Wagon and Rear Seat, Coupe.

At the start of each Section, usage charts are provided for domestic and export markets to aid the seat

identification. T he charts include the vehicle m odel, trim f abric, trac k ass embly, the addition of lumber support, side

airbag and the construction of the trim covers to the trim pads.

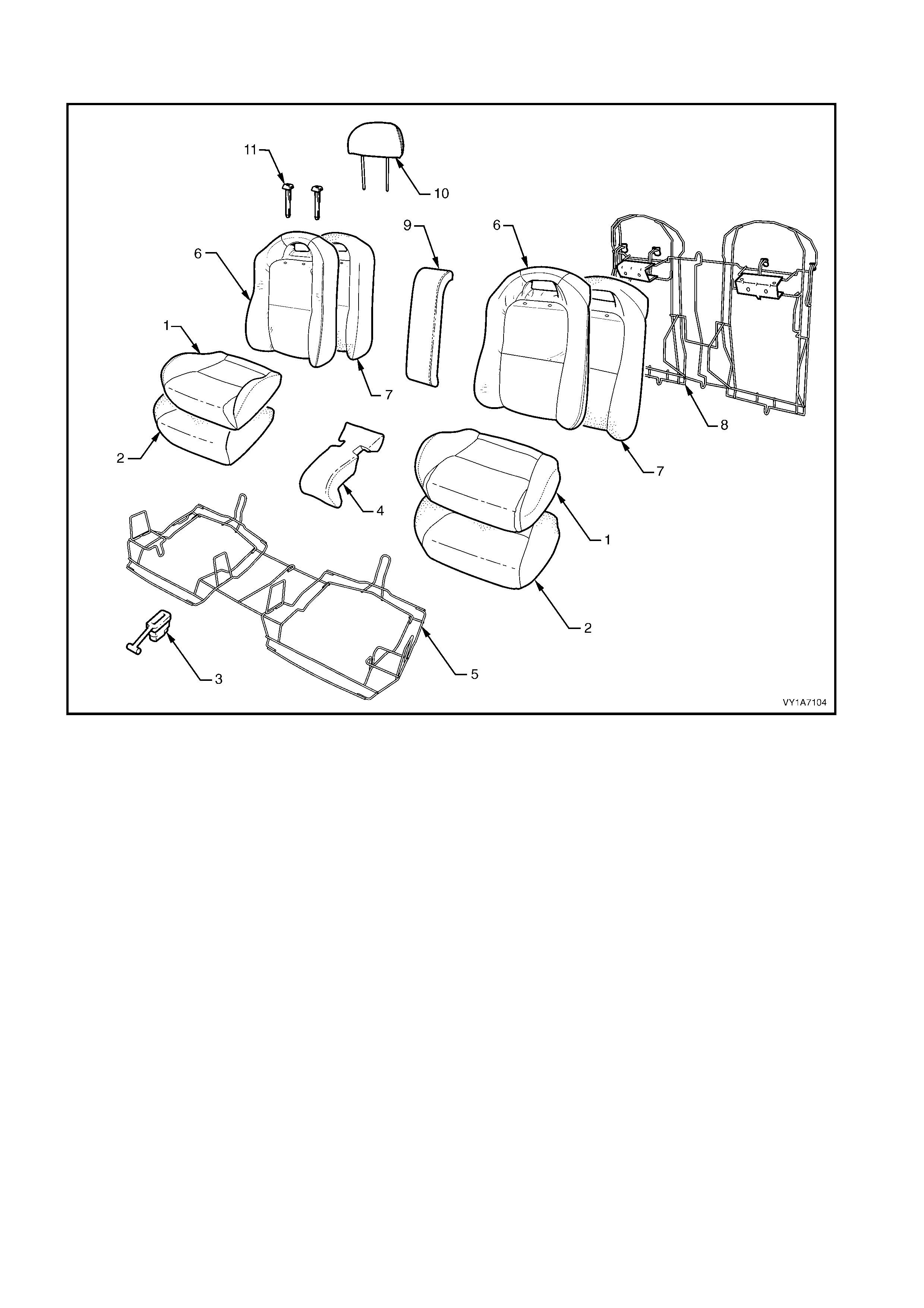

For the rear s eats these c harts inc lude the addition of headres ts and an armrest. T he charts are com plim ented with

illustrations of the complete breakdown of each of the individual seat combinations available.

A four- way electric adjustable driver s eat (f r ont up and down, and rear up and down) is fitted as standard equipm ent

to all models except Level 3 and Coupe.

An eight-way elec tric adjus table driver and passenger seat, fitted to Level 3 and optional on som e Level 2 left-hand

drive vehicles, has four extra movements over the four-way, (fore/aft movement and seat-back recliner).

Coupe models are fitted with eight-way electrically adjustable driver and passenger seats, which also include side

impac t airbags and an EZ -entry feature. In addition, the dr iver’s seat in the CV8 is fitted with an integrated mem ory

seat system. Leather trim is standard on all Coupe models.

All other front seats provide manual fore/aft adjustment only.

For f ront and rear s eats, there are two methods of cover as sem bly c onstruction, Surebond and Hook and Loop. All

vehicles with leather trim, plus all Level 2, 3 and coupe have Hook and loop construction.

Surebond cover assemblies are not serviced as they are glued to the seat-back pad. Hook and Loop cover

assemblies are fully serviced and attached in the groves of the seat pad and the corresponding cover.

The rear seat fitted to the Coupe m odel is a new two-passenger design, with a unique construction and adjustable

rear head restraints.

While the remove and replace of the front seatbelt pretensioner assembly is included in this section

for completeness, specific seatbelt and seatbelt pretensioner service procedures are combined in

Section 12M OCCUPANT PROTECTION SYSTEM.

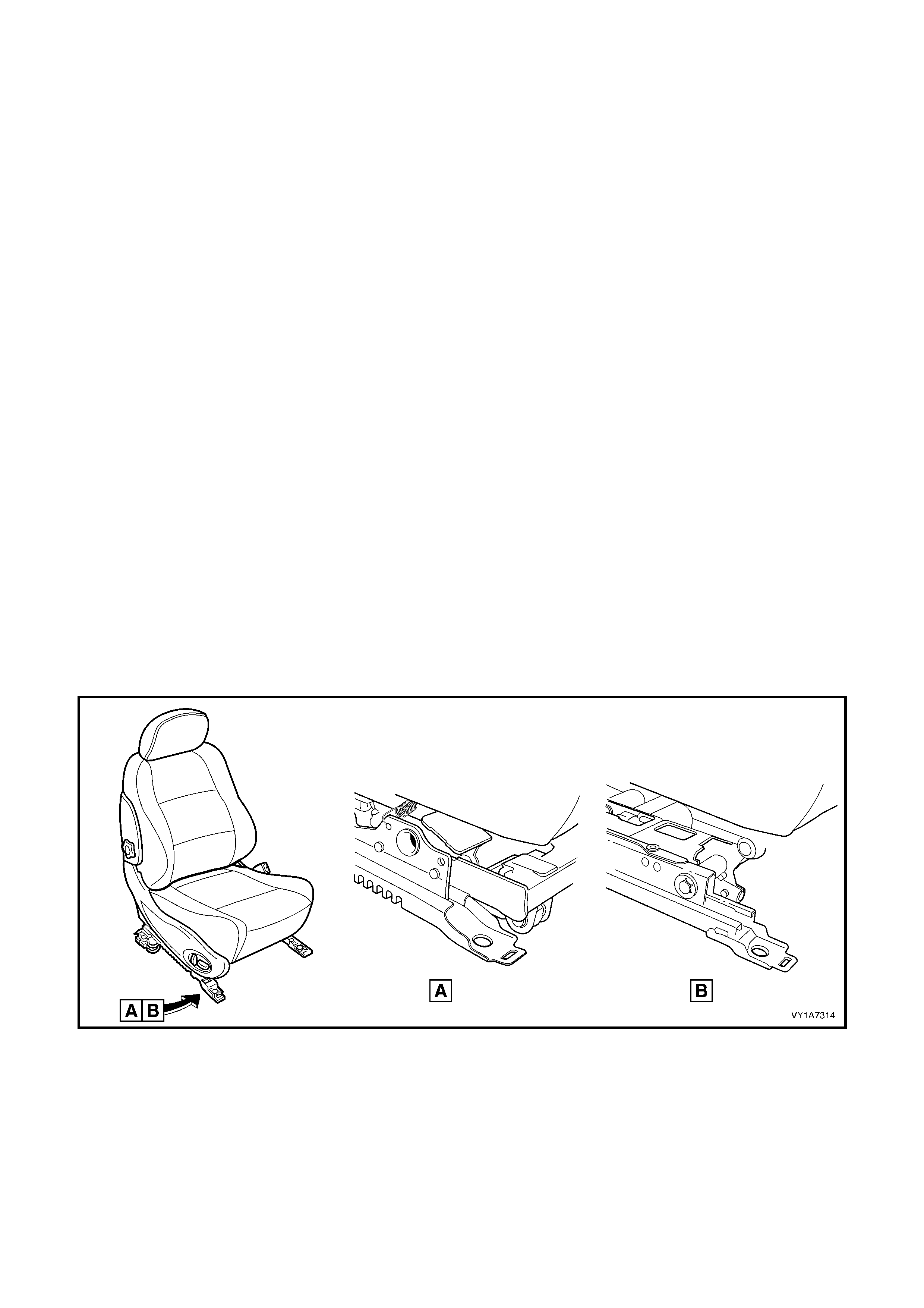

During production of the MY 2003 VY Series vehicles, the front s eat as semblies gained a revised front seat adjus ter

assembly, refer to Figure 1A7-1

This change to the f r ont s eat ass emblies af fected some ser vice oper ations . Where there are changes to the service

procedures, the seat assemblies prior to the running change are referred to as "early type" View A and additional

information has been added to cover the late type seat adjuster assembly, View B.

Figure 1A7-1

These following Cautions apply to service operations detailed in this Section.

CAUTION 1: Accessory and after m arket seat covers MUST NOT be fitted to any vehicle with side airbags unless

approved by the manufactur er. Non-approved seat c overs m ay inhibit the operation of the side airbag, reducing the

protection otherwise provided to the occupants during a side-impact collision.

CAUTION 2: Befor e perform ing any servic e operation on a front seat ass embly, ensure the SRS is disabled. Refer

to Section 12M OCCUPANT PROTECTION SYSTEM.

IMPORTANT: Some of the procedures relating to memory seat diagnosis detailed in 5. DIAGNOSTICS – FRONT

SEAT, COUPE, require the use of both the Priority 1 Key and the Priority 2 Key.

1.1 GENERAL DESCRIPTION

The four-way electric adjustable driver seat (front up and down, and rear up and down), is controlled by two lift

motor and gearbox assemblies. Each can be operated independently of the other, or operated together to raise or

lower the complete seat assembly.

The eight-way electric adjus table driver and pas senger seats have four extra m ovem ents over the four-way: f ore/af t

movement and seat-back recliner. In addition to the two motor and gearbox assemblies described previously, a

fore/af t m ovem ent m otor dr ives two gearboxes which control s eat forward or rearward positioning. The fourth mo tor

controls the seat-back recliner position.

Each lif t m otor and gear box ass em bly is bolted to the inboard side of the seat height adj ust ass em bly. W hen the lif t

motor is operating, it drives the gearbox which draws in or extends out the mating worm shaft which in turn operates

on a lever and cross-brace. The cross-brace is connected to another lever on the opposite side of the seat height

adjust assem bly and this allows the raising or lowering of that section of the seat. Reversing the polarity on the lift

motor terminals causes the motor to operate in the reverse direction and the seat moves in the opposite direction.

To control seat fore/aft movement, a worm shaft is attached to each seat rail with the movement motor and

gearboxes attached to the seat height adjust assembly. Components making up the adjuster and guide rail

assembly are not serviced due to safety regulations.

The s eat-bac k recliner angle is adj us ted by a recliner m otor attac hed to the inner f r ame. T he motor output shaf t has

a drive gear which is meshed with a driven gear attached to the seat-back frame. Motor operation causes rotation of

the drive gear which turns the driven gear and seat-back frame, thereby altering the seat-back recliner angle.

Reversing the polarity on the recliner motor terminals causes the motor to drive in the reverse direction and the

seat-back m oves in the oppos ite direc tion. Components mak ing up the s eat-bac k recliner mechanis m assembly are

not serviced due to safety regulations.

The Coupe eight-way electric front seat motor and gearboxes have the same function as the Level 3 vehicle. The

front s eat als o incor porates an EZ -entr y feature that provides a s imple one touch mechanis m to m ove the f r ont seat

and allow rear seat passengers to enter or exit the vehicle. A lever on the outer upper corner of the seat-back

disengages the seat-back locking mechanism. An internal micro switch senses when the lever is operated and

signals to the m odule that the EZ-entry f eature has been activated, which in turn drives the seat forward. The seat

fore and af t position is m onitored by a potentiometer (incor porated into the fore/aft drive m otor) and recorded in the

seat module. Once the seat-back is returned to the locked position, the operator must press and hold the seat

return switch to m ove the seat rearwards. When the seat reaches the last recorded location, the af t movem ent will

pause for approximately three seconds before continuing to the fully rearward position.

An internal occupant sensing mat is incorporated into the Coupe front seat cushions. The occupant sensing mat

signals to the seat c ontro l module whenever the seat is oc cupied with a weight in exces s of 15 kg. The module then

prevents the seat from driving forward should the EZ-entry lever be operated.

In addition, the driver’s seat in the CV8 is fitted with an integrated memory seat system. On key-less entry to the

vehicle, the m emory seat system in conj unction with the Body Control Module (BCM) recognises which ignition key

has been used (Priority 1 or Priority 2) and adjusts the seat accordingly .

The memory seat system allows the driver to adjust the seat position to any of the positions stored in memory by

pressing one of the three memory buttons.

Audio and visual feedback for the various functions of the memory seat system is provided. The system has a

green LED and an audio c hime located in the s eat ass embly which are used to indicate m emory saves, the rec all of

priority memory numbers and for seat diagnostic procedures.

All coupe f r ont s eats contain a seat c ontr ol module under the lower side c over. T he s eat c ontrol module f itted to the

memory type seat has a non-volatile memory, so that disconnecting the battery supply from the module does not

erase the seat memory settings.

W atchdog tim ers in the memory seat system lim it the time a seat drive motor can operate. The lift and m ovement

motors are limited to 25 seconds, while the recliner motor is limited to 50 seconds.

1.2 FRONT SEAT ASSEMBLY, FOUR-WAY ELECTRIC

CAUTION: For reasons of personal safety, the vehicle must only be driven when the seat is adjusted to

the co rrect d riv ing posit ion . Do n ot adju st t he d riv er’s seat when th e v ehicle is mo v ing as th e seat co uld

move away from the driving position, ca using loss of control.

A seat control adjustment switch (1) is fitted to the

outside of each seat frame. This switch assembly

provides independent control of front and/or rear seat

height (up and down movement).

During seat adjustment, the drive motors will stop

operating at end of travel via an internal thermal cut-

out switch, even if the seat adjustment switch is held

on.

Figure 1A7-2

1.3 FRONT SEAT ASSEMBLY, EIGHT-WAY EXCEPT COUPE

CAUTION: For reasons of personal safety, the vehicle must only be driven when the seat is adjusted to

the co rrect d riv ing posit ion . Do n ot adju st t he d riv er’s seat when th e v ehicle is mo v ing as th e seat co uld

move away from the driving position, ca using loss of control.

A seat control adj ustm ent switch is fitted to the outside

of each seat frame. This switch assembly provides

independent control of:

1. Vertical switch - seat-back recliner angle.

2. Horizontal switch - front and rear cushion height

(up and down movement) of the seat along with

fore/ aft movement.

During seat adjustment, the drive motors will stop

operating at end of travel via an internal thermal cut-

out switch, even if the seat adjustment switch is held

on.

Figure 1A7-3

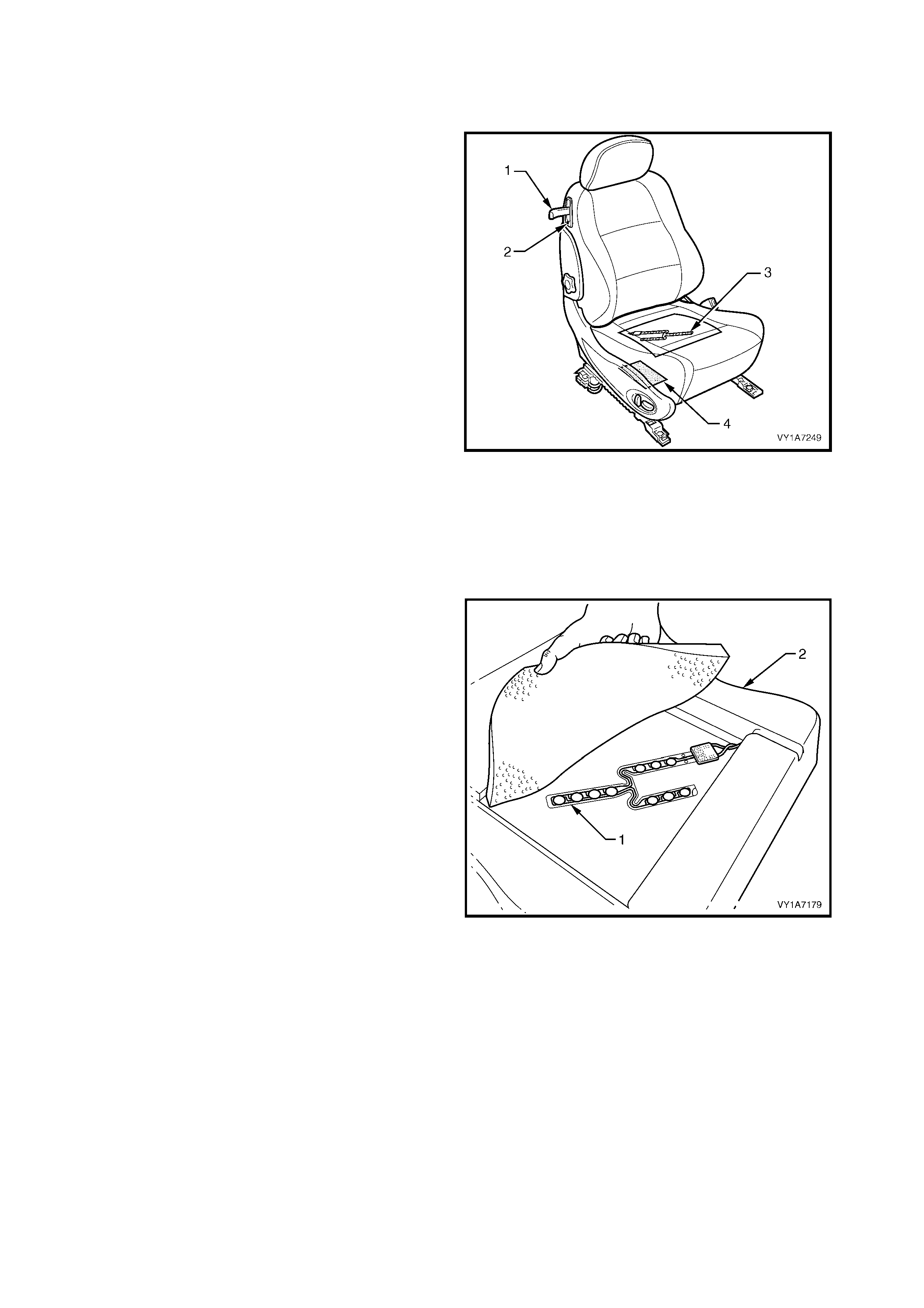

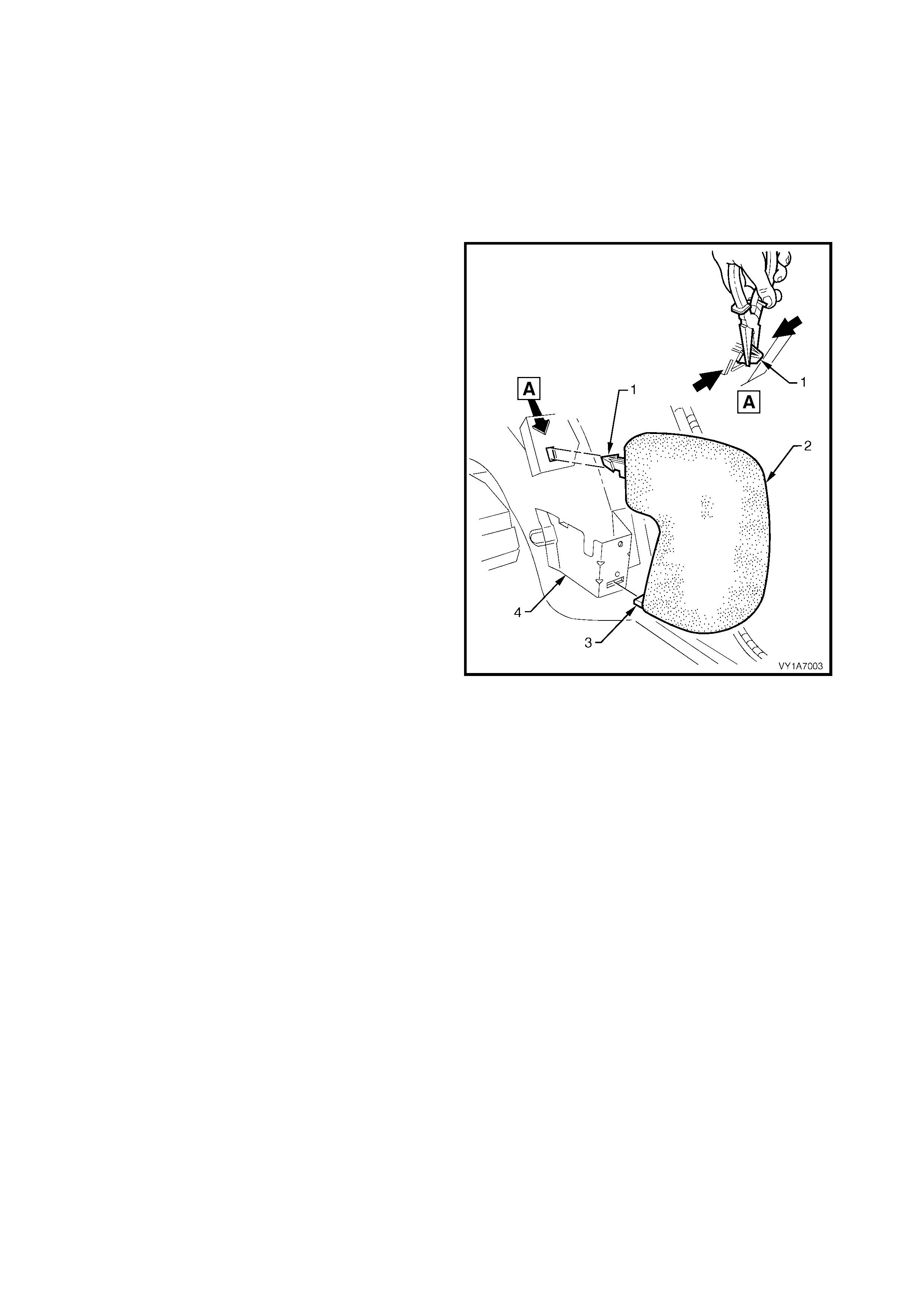

1.4 EZ-ENTRY SYSTEM, COUPE

OCCUPANT SENSING MAT

1. The EZ-entry system provides a one touch

mechanism to move the front seat and allow rear

seat passengers to enter or exit the vehicle. The

EZ-entry system comprises:

• An EZ-entry lever (1) on the upper outer side

of the front seat.

• A return button (2) in the EZ-entry lever

escutcheon.

• An internal occupant sensing mat (3).

• The front seat control module (4) located

under the seat.

2. When the EZ-entry lever is un-latched, the seat-

back collapses forward and the seat automatically

launches to the full forward position.

3. The seat will return to the pr e-launch pos ition once

the lever is latched (i.e. the seat-back is returned

to the upright position) and the seat return switch

is pressed and held.

4. If a passenger (or load in excess of 15 kg) is

present in the seat or enters the seat while it is

automatically moving, the movement will cease. If

weight detection causes the EZ-entry function to

cease, a period of one second must pass without

weight before a restart will commence.

Figure 1A7-4

5. The occupant sensing mat (1) is installed inside

the front seat cushions (2). The occupant sensing

mat is a pressure switch with a nominal high or

open circuit condition with no weight on the seat.

The resistance decreases as the weight is

increased. An integral diode is provided within the

occupant sensing mat and is used by the module

to verify connection of the occupant sensing mat

prior to the automatic forward movement of the

seat during the operation of the EZ-entry function.

The module will test whether for the following

conditions on the occupant sensing mat:

• Either line connected to ground or battery.

• Either line open circuited.

6. Detection of weight over the occupant s ensing m at

(seat cushion) will cause the seat m odule to either

cancel an autom atic forward m ovement or prevent

an automatic forward movement from

commencing. The module should detect a

minimum weight on the seat of 15 kg.

Figure 1A7-5

1.5 FRONT SEAT ASSEMBLY, EIGHT-WAY COUPE – NON MEMORY

A seat control adj ustm ent switch is fitted to the outside

of each seat frame. This switch assembly provides

independent control of:

1. Vertical switch - seat-back recliner angle.

2. Horizontal switch - front and rear cushion height

(up and down movement) of the seat along with

fore/ aft movement.

During seat adjustment, the drive motors will stop

operating at end of travel via an internal thermal cut-

out switch, even if the seat adjustment switch is held

on.

The eight-way position switch is disabled during

automatic movement requested by operation of the

EZ-entry function. The switch will be enabled once the

automatic movement is completed or cancelled. The

eight-way position switch is monitored by the module

during automatic movement, and if the switch is

operated, the automatic movement will be cancelled

and the seat will enter the manual mode.

Figure 1A7-6

1.6 FRONT SEAT ASSEMBLY, EIGHT-WAY COUPE – MEMORY

The memory seat system comprises:

• the seat control module located under the seat lower side cover (refer to Fig. 1A7-3);

• the m em ory pos ition switch, which includes m em ory buttons and associated LED, located on the side of the

driver’s seat (refer to Fig. 1A7-6);

• the ignition keys;

• the body control module (BCM).

The s eat control module has five mem ory sets which allows up to f ive individual seat settings to be s tored. Two

of these memory settings are associated with the priority keys and the remaining three settings correspond to

the memory buttons 1, 2 and 3 located on the side of the driver’s seat.

The memory seat system has two modes of operation; a low-current sleep mode and an awake mode. A

5 minute tim er cir cuit switches the system between m odes as required, and the cur rent m ode is indic ated by the

green LED on the side of the seat. When the LED is illuminated the system is in awake mode, and when the

LED is extinguished, the system is in sleep mode.

The sleep mode is entered when:

• the ignition key is in the OFF position, and

• there are no active priority signals, and

• there are no manual seat adjustments for 5 minutes.

The awake mode is entered when:

• the ignition key is in the IGN position, or

• the priority signals are active, or

• there is a manual seat adjustment, or

• a seat memory button is pressed.

Entering the awake mode resets the 5 minute timer.

MEMORY S ETS

There are five memory sets, as follows:

• Memory set P1 – Priority Key 1,

• Memory set P2 – Priority Key 2,

• Memory set 1 – Button 1 on seat,

• Memory set 2 – Button 2 on seat, and

• Memory set 3 – Button 3 on seat.

Each memory set comprises four co-ordinates for the seat position (in seat control module); seat cushion front

height, seat cushion rear height, seat stroke and backrest position.

A priority key setting can also be stored and recalled by use of one of the three memory buttons on the seat.

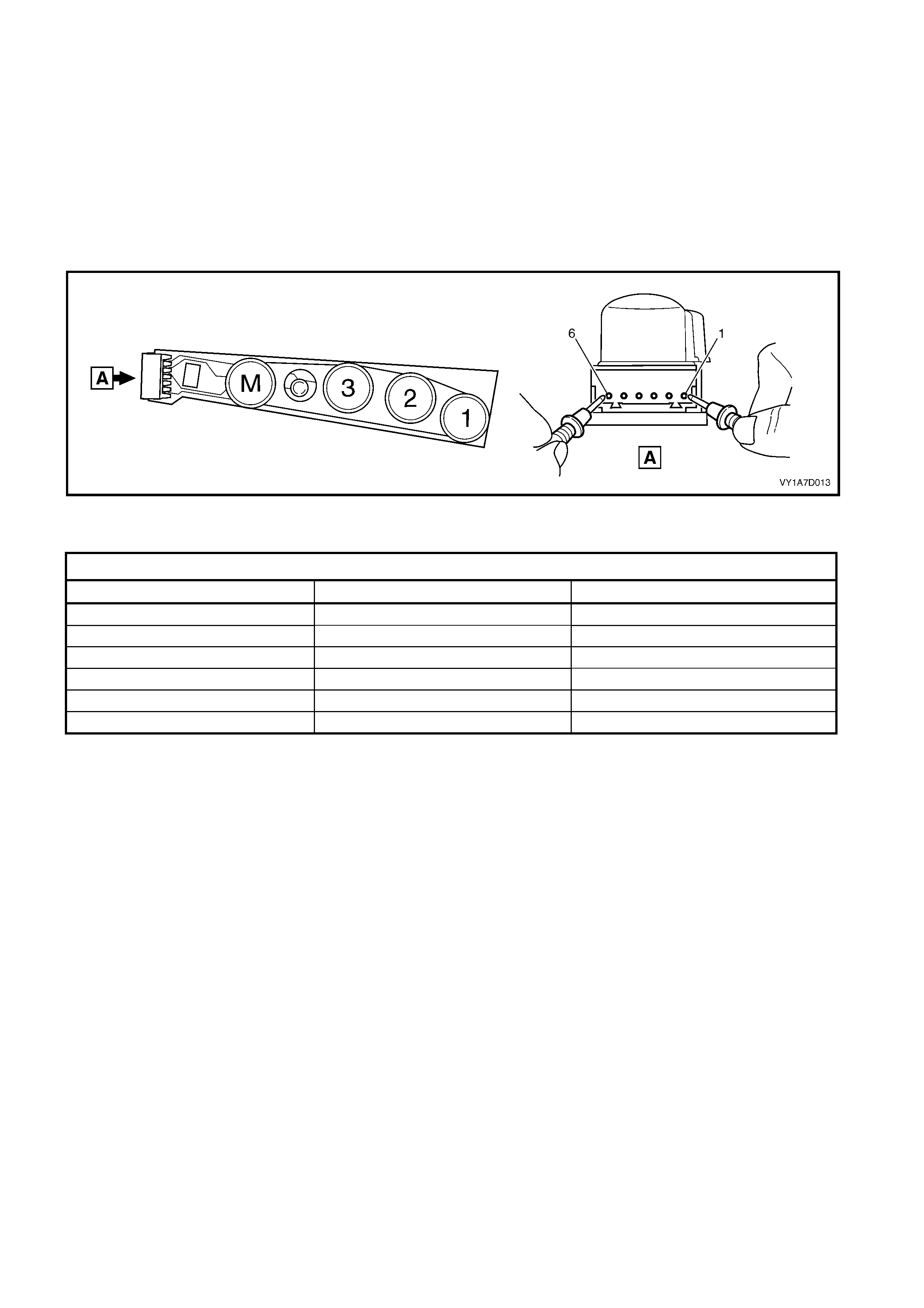

MEMORY BUTTONS

The three memory recall buttons, the memory store button and the associated LED are located on the seat lower

side cover close to the front edge of the seat. The memory recall buttons are labelled 1, 2 and 3.

Press and hold a s eat mem ory button to recall the m emory position. Once the s eat has reached the m em orised

position the button can be released. If the button is released before the seat reaches the memorised position,

the seat will simply stop moving. Even though the seat may then be adjusted to a new position, pressing a button

will return the seat to the memory position stored for that button.

To change a mem ory position, adjust the seat with the seat control switch, then press the memory store button

(M) (confir med by a single c hime) followed by the desired m emor y button ( 1, 2 or 3) within 5 seconds. A double

chime will be heard when a new memory is stored.

For safety reasons, no memory button recall is allowed when the ignition is on. However, if a recall is initiated

and the ignition is then set to on, the seat movement recalled from memory will continue until completed.

Pressing any other button after a memory recall is initiated will terminate the recall move.

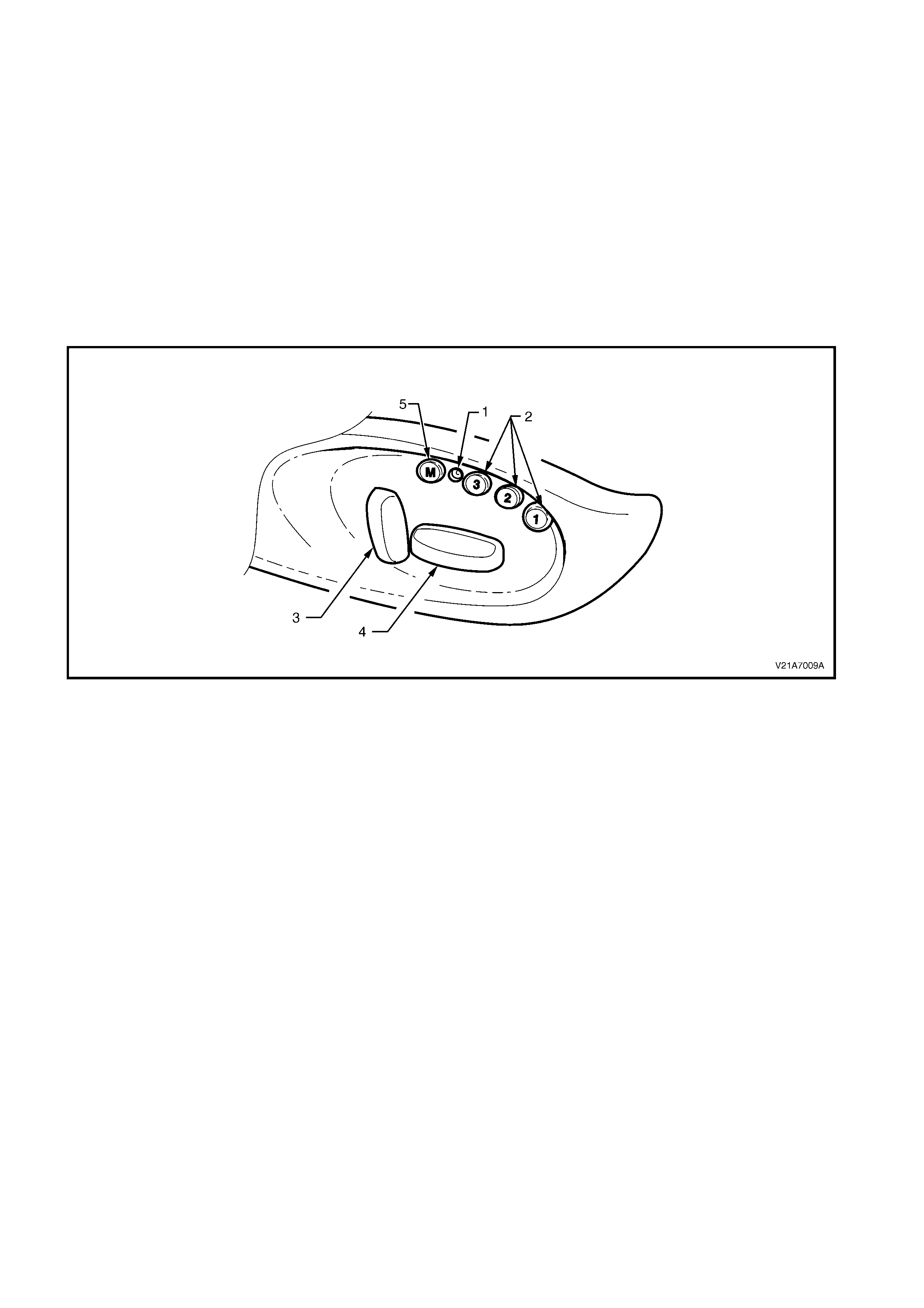

Figure 1A7-7

Legend

1. Diagnostic LED

2. Memory Recall Buttons

3. Seat-back Recliner Button

4. Fore/Aft/Up/Down/Tilt Adjust Button

5. Memory Store Button

PRIORITY RECALL FUNCTION

The priority recall signals generated by the BCM wake up the memory seat system to recall the last saved

priority seat positions associated with the ignition key in use (Priority 1 or Priority 2).

For safety reasons, the priority recall function is ac tivated only when the ignition switch is in the OFF position. No

automatic movement of the system occurs when the ignition switch is set to IGN. If a priority move has been

initiated before the ignition tr ansition from O F F to IG N, the system c ompletes the move befor e dis abling the one-

touch or priority recall function.

After the ignition switch is set to IGN, the system notes the active priority key number used. The system only

updates the current memory when the driver makes a manual adjustment to the seat. The update includes the

current seat position.

When the seat is adjusted by the driver using the manual buttons, the current priority memory is updated

immediately after the movement stops.

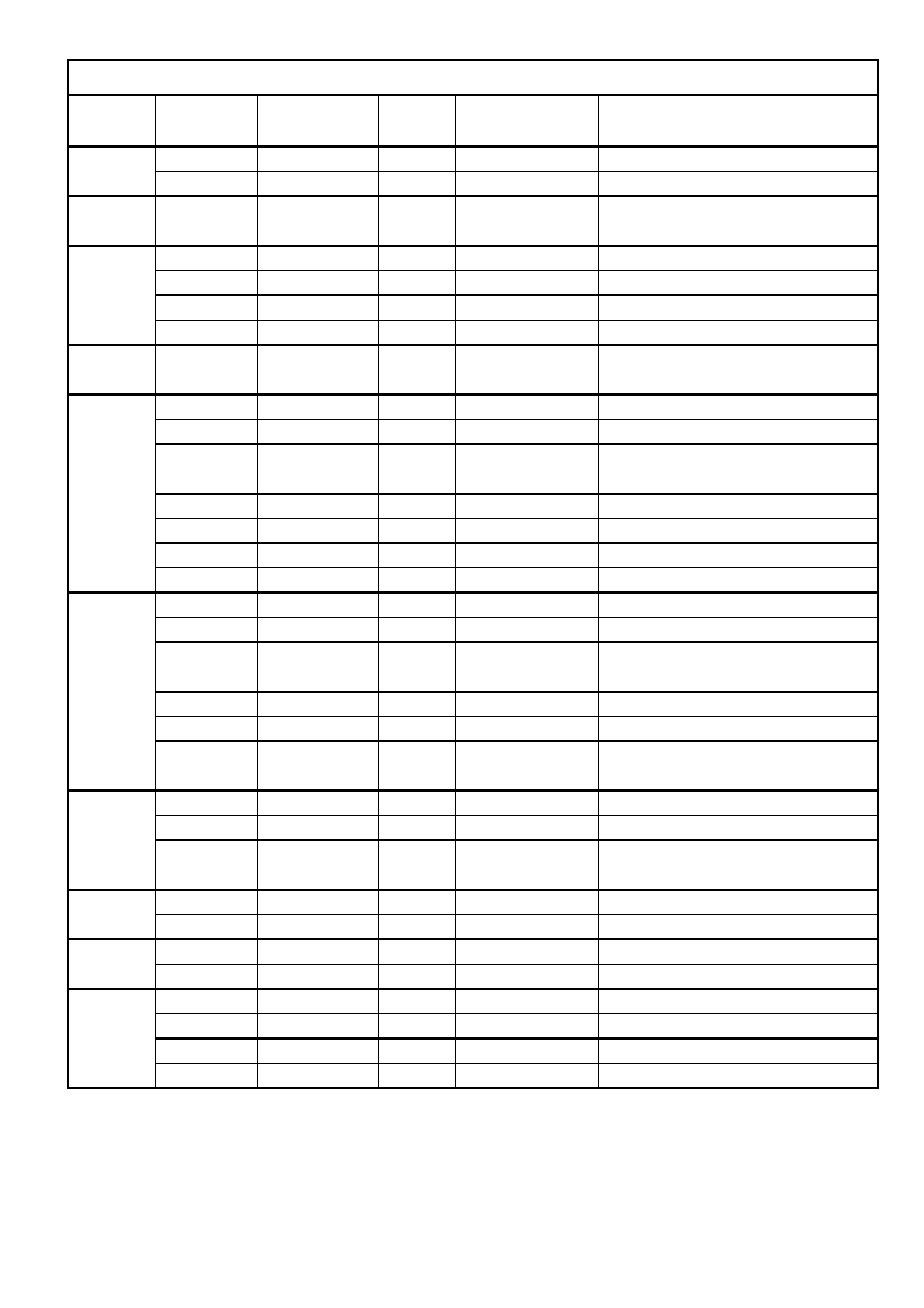

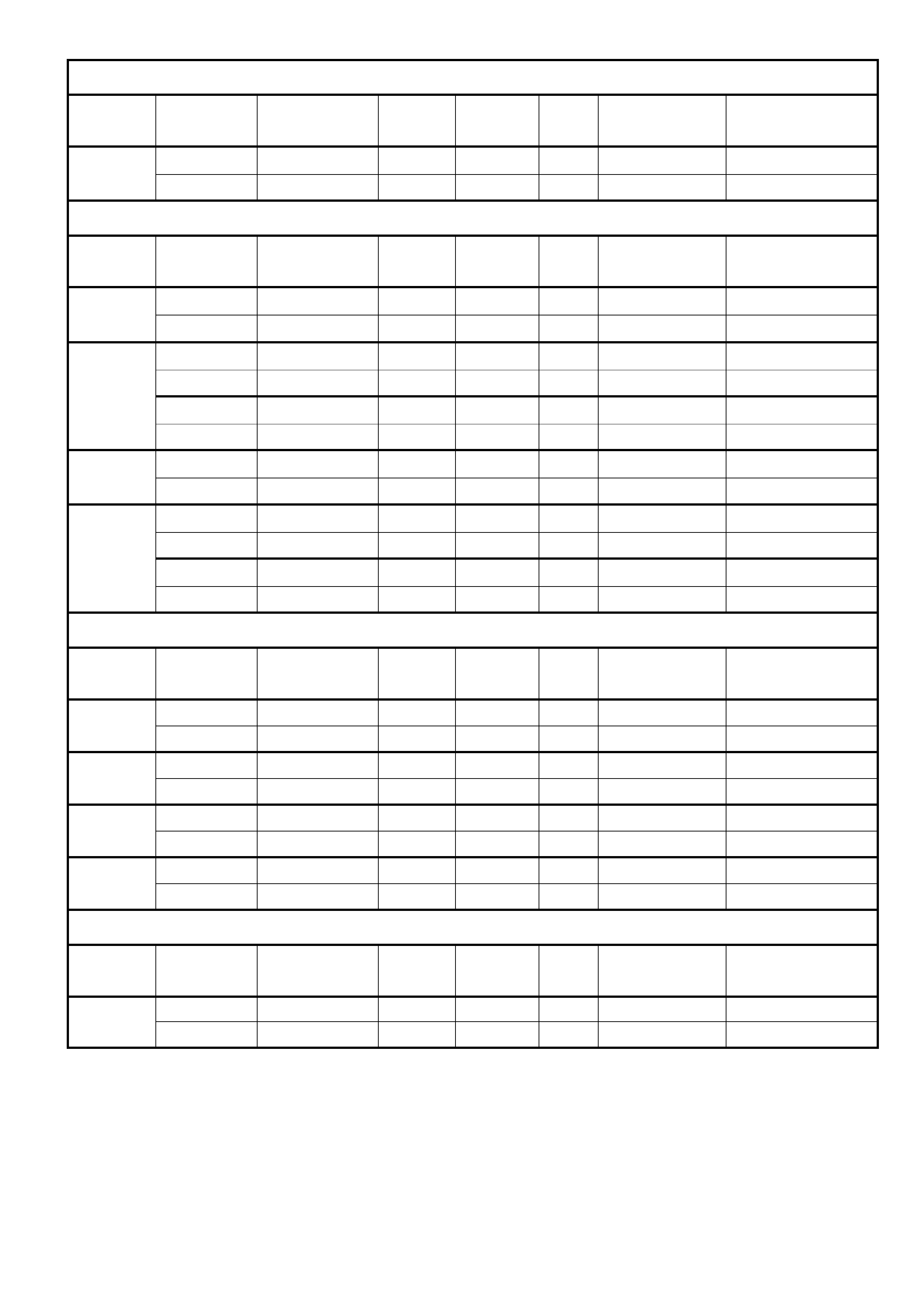

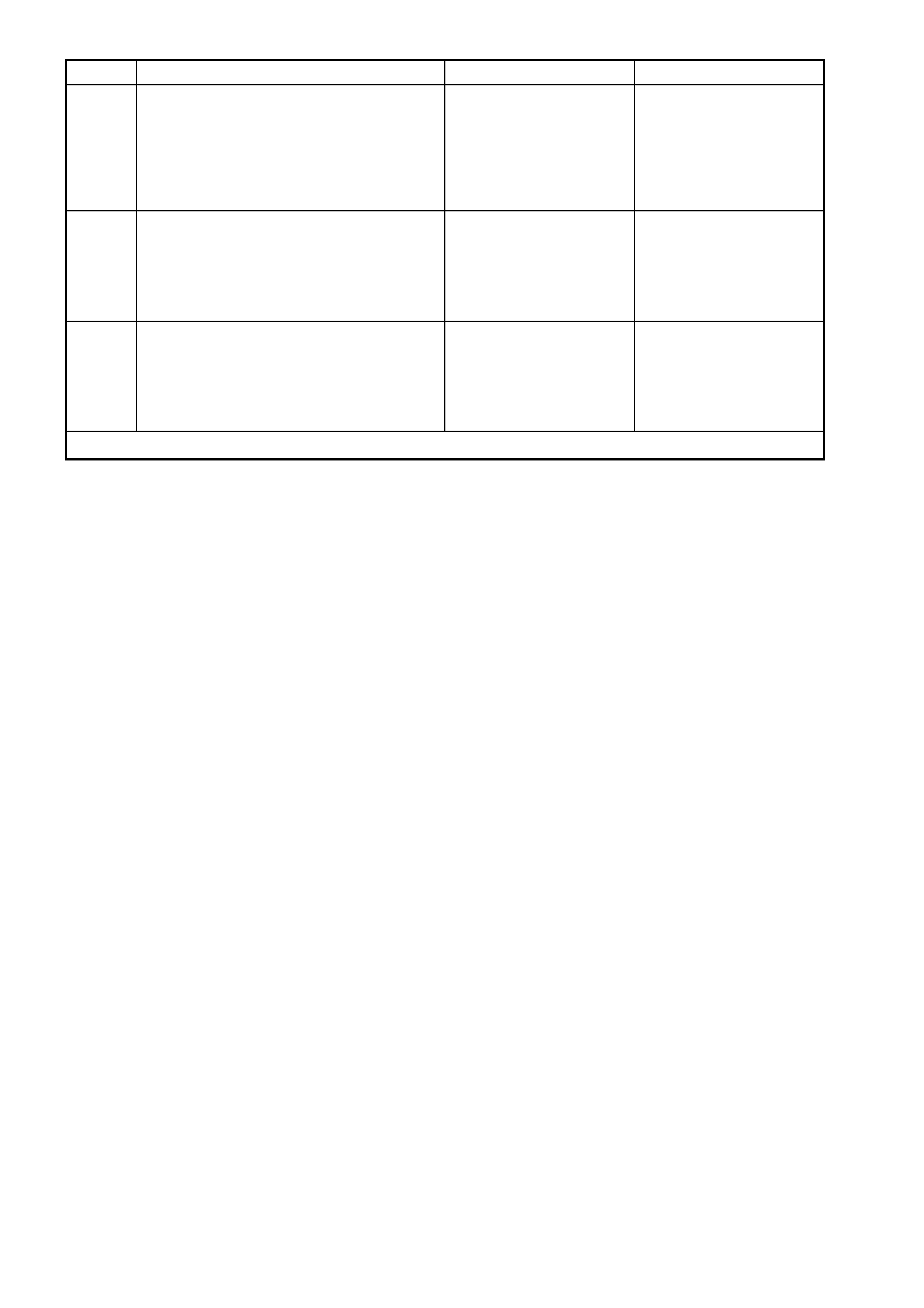

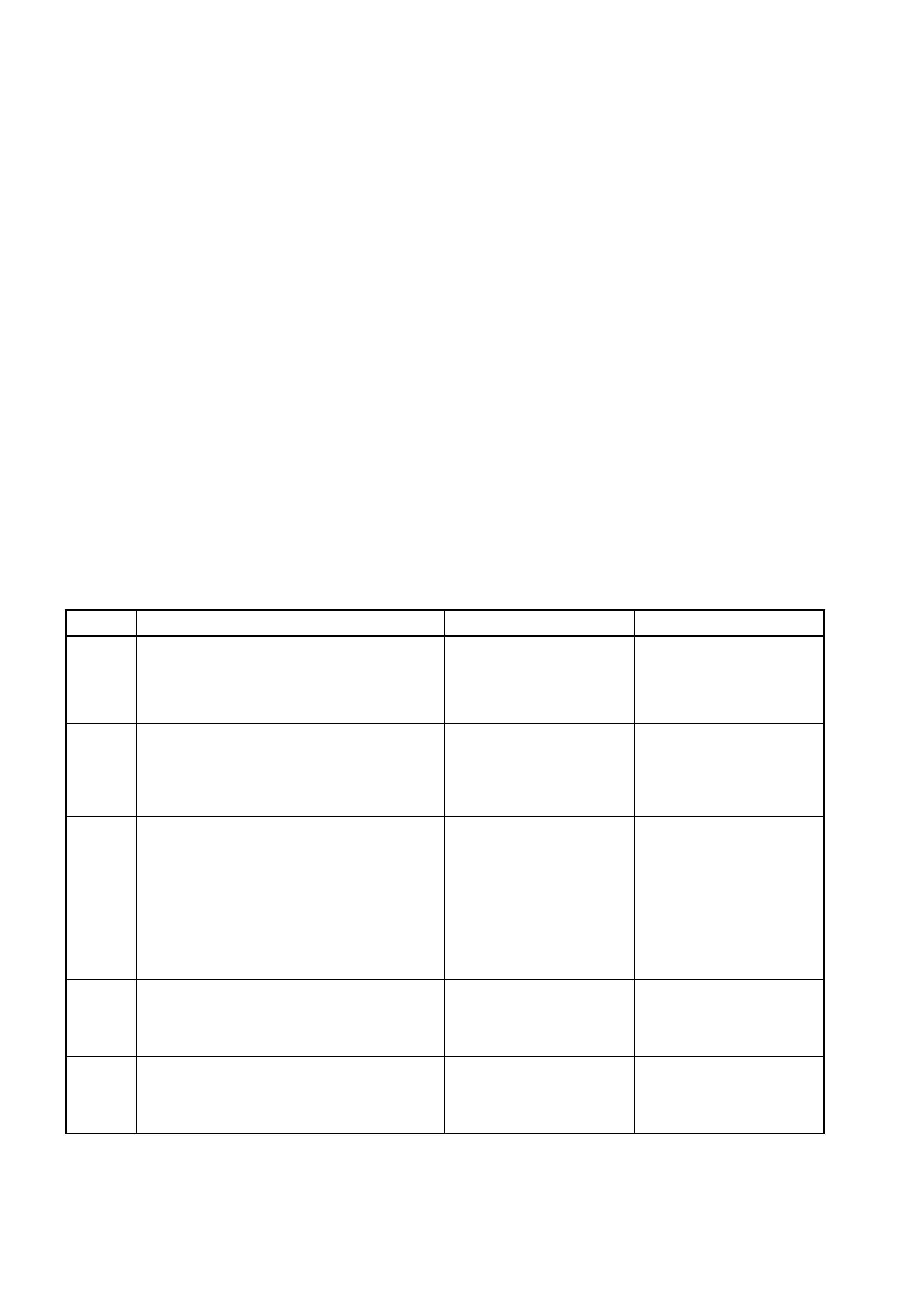

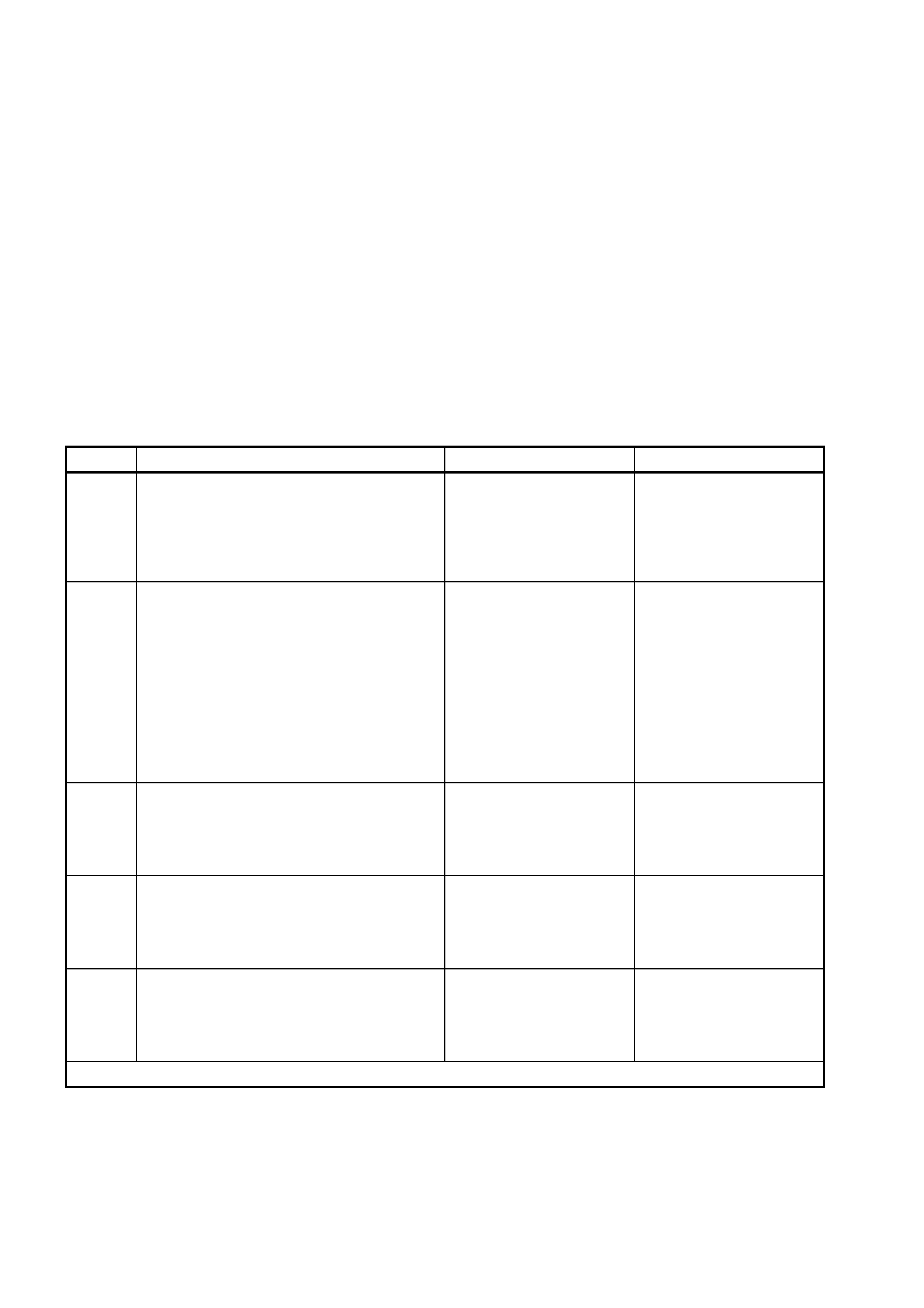

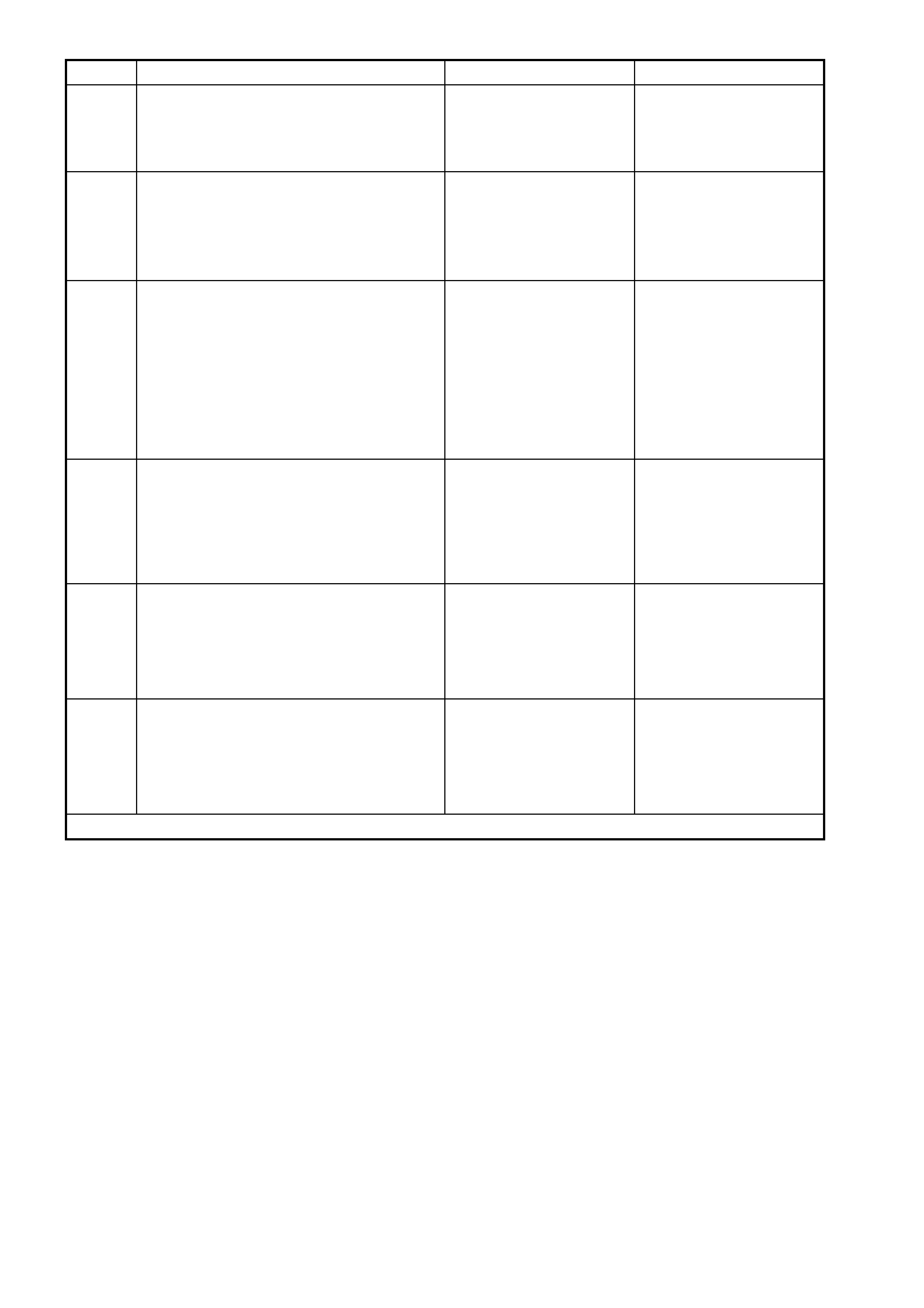

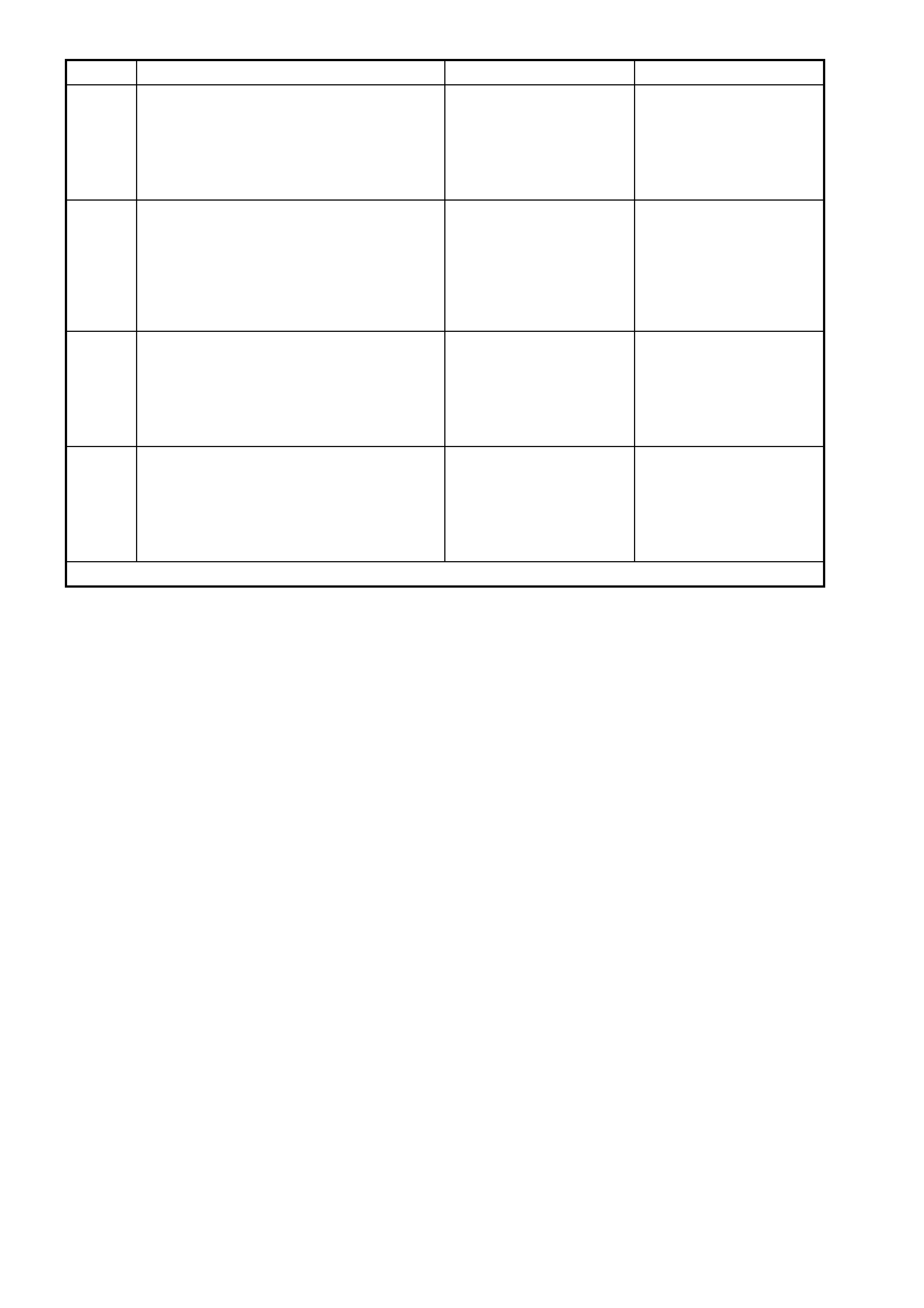

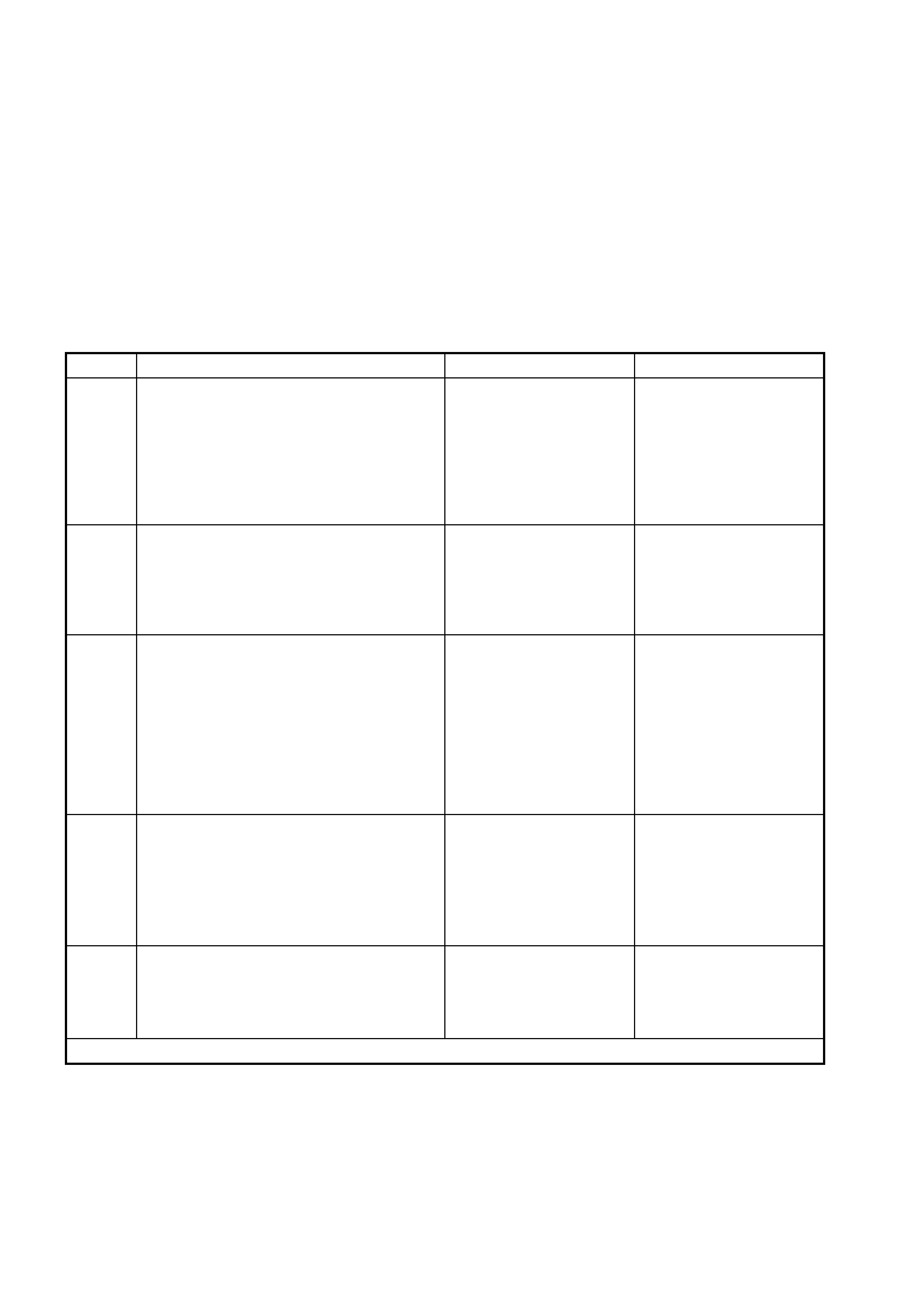

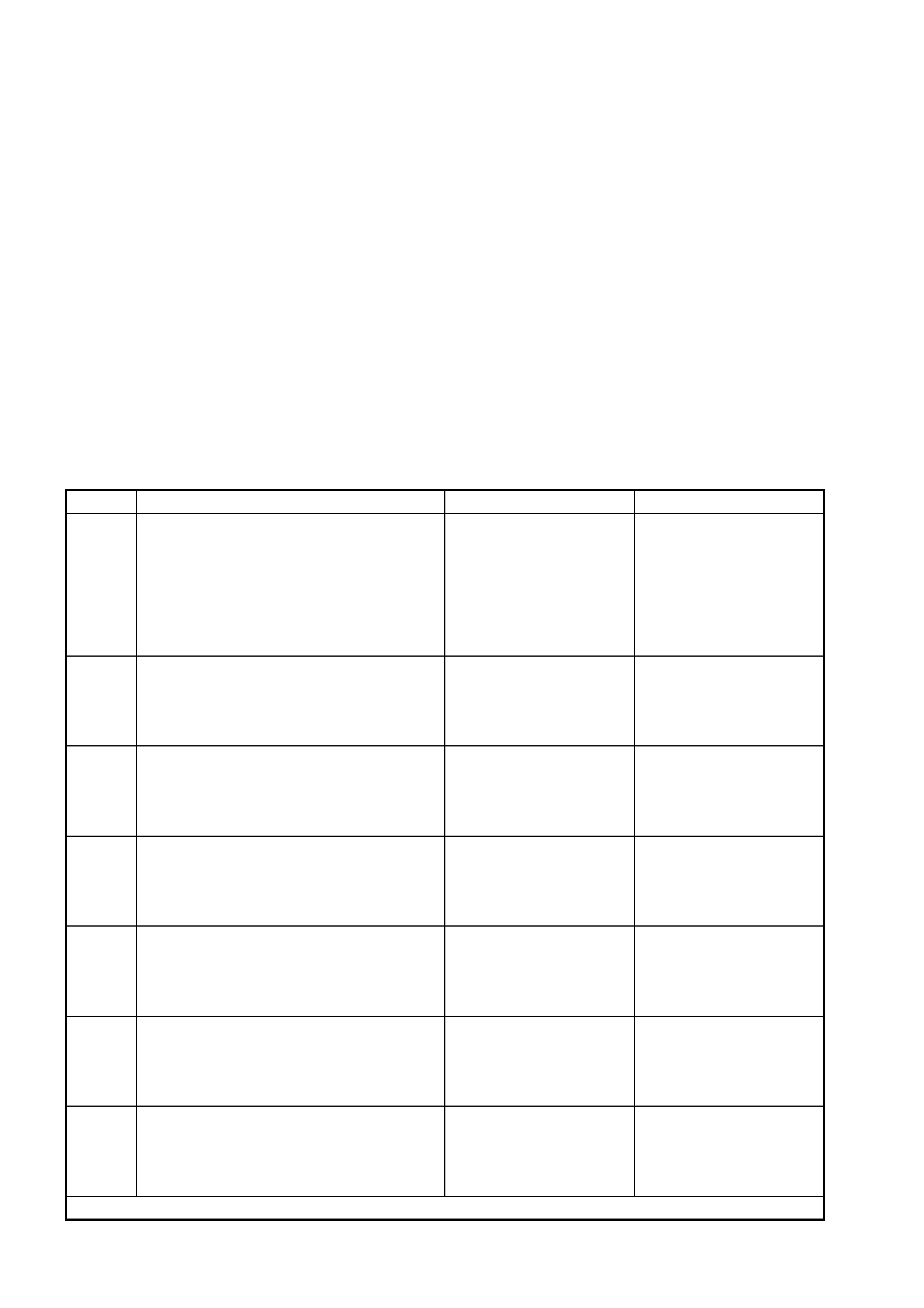

2. SERVICE OPERATIONS – FRONT SEAT, EXCEPT COUPE

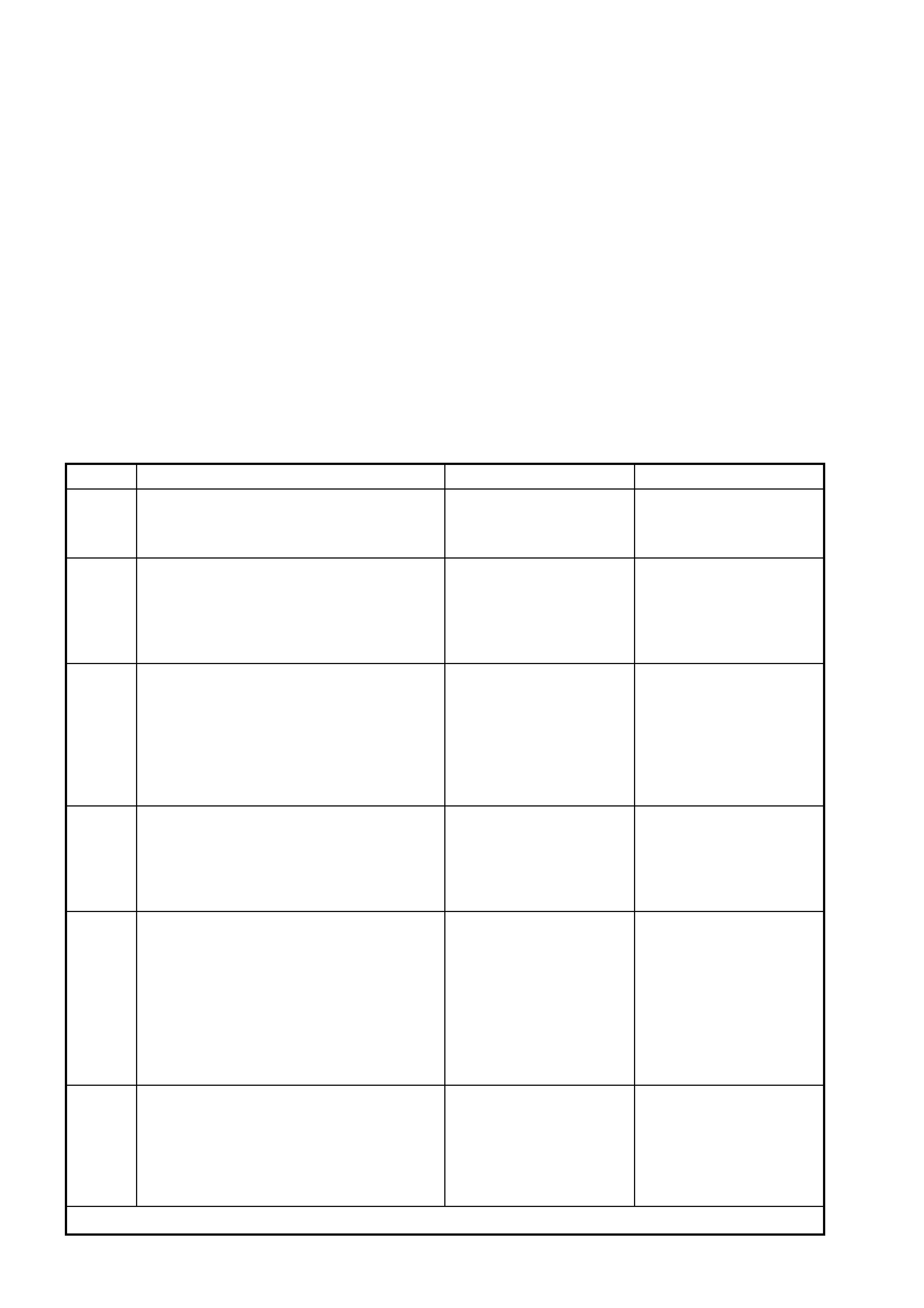

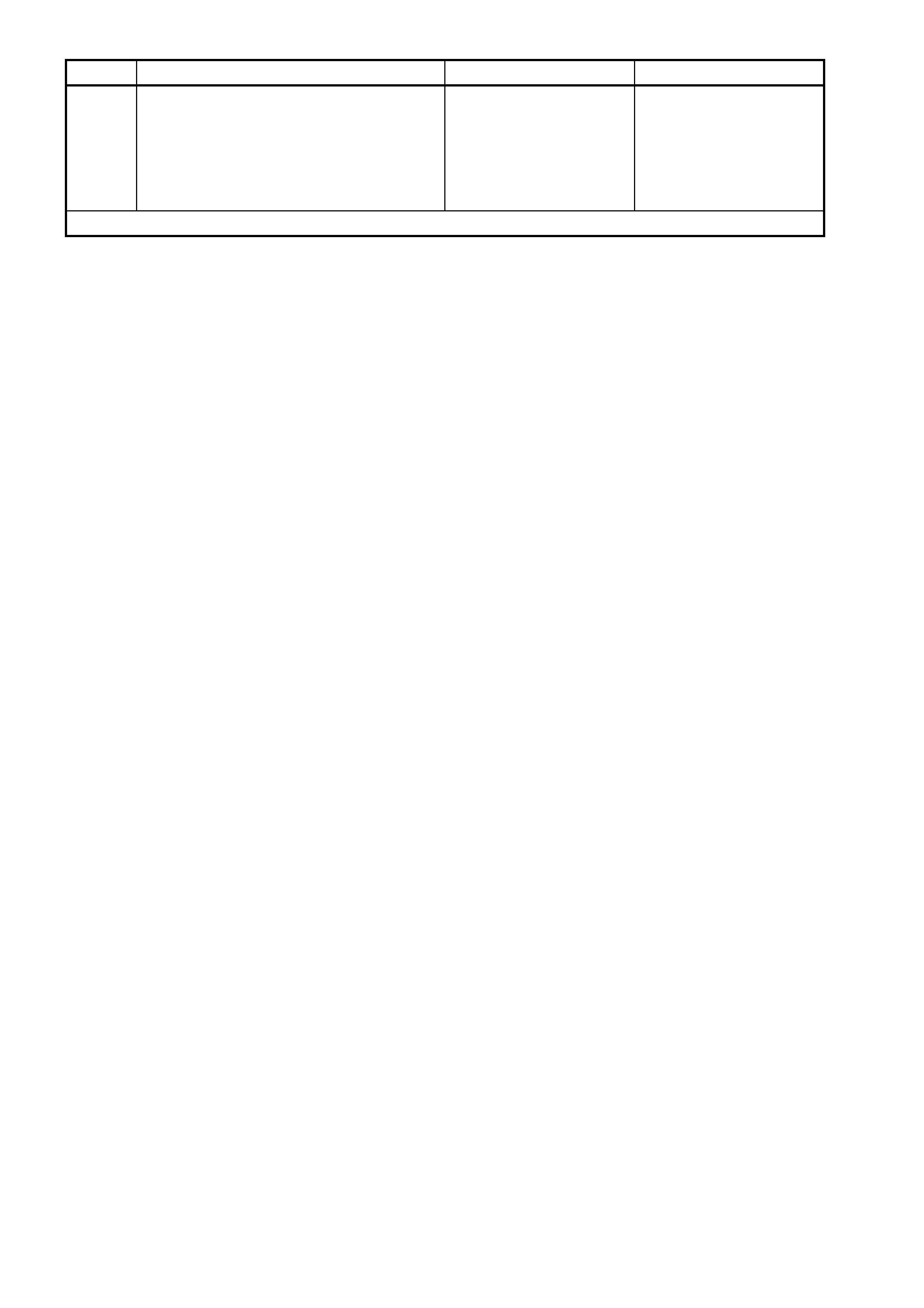

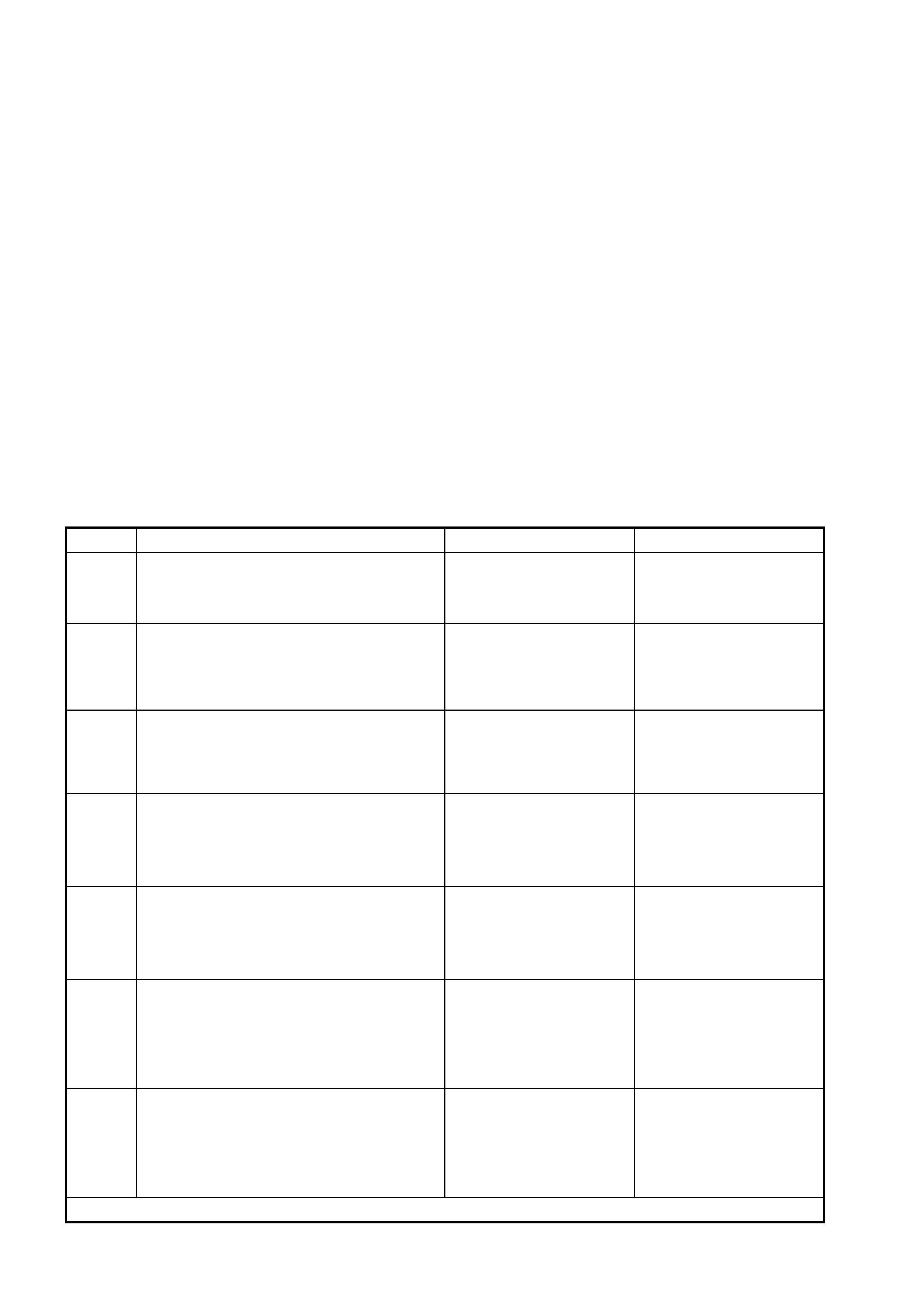

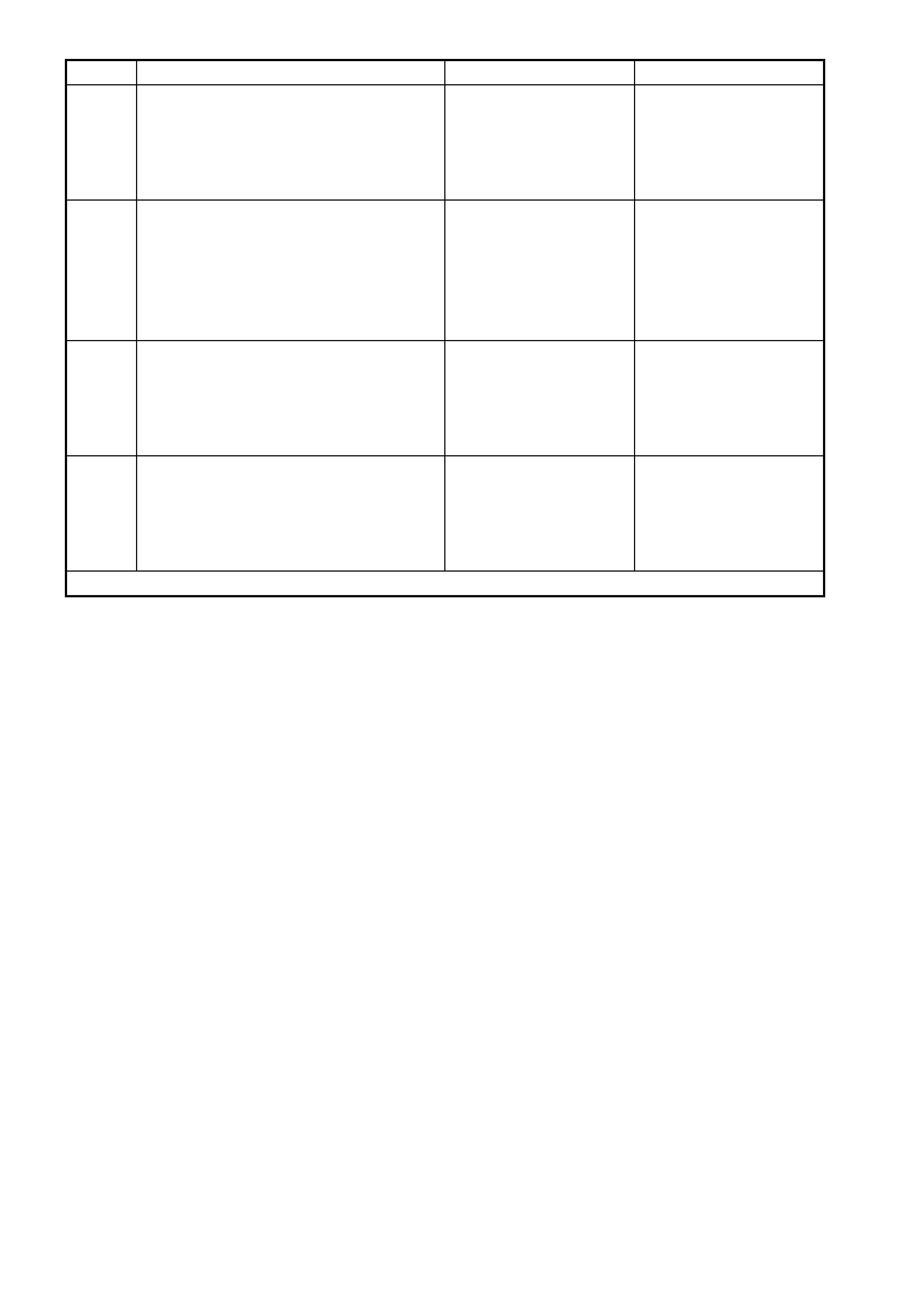

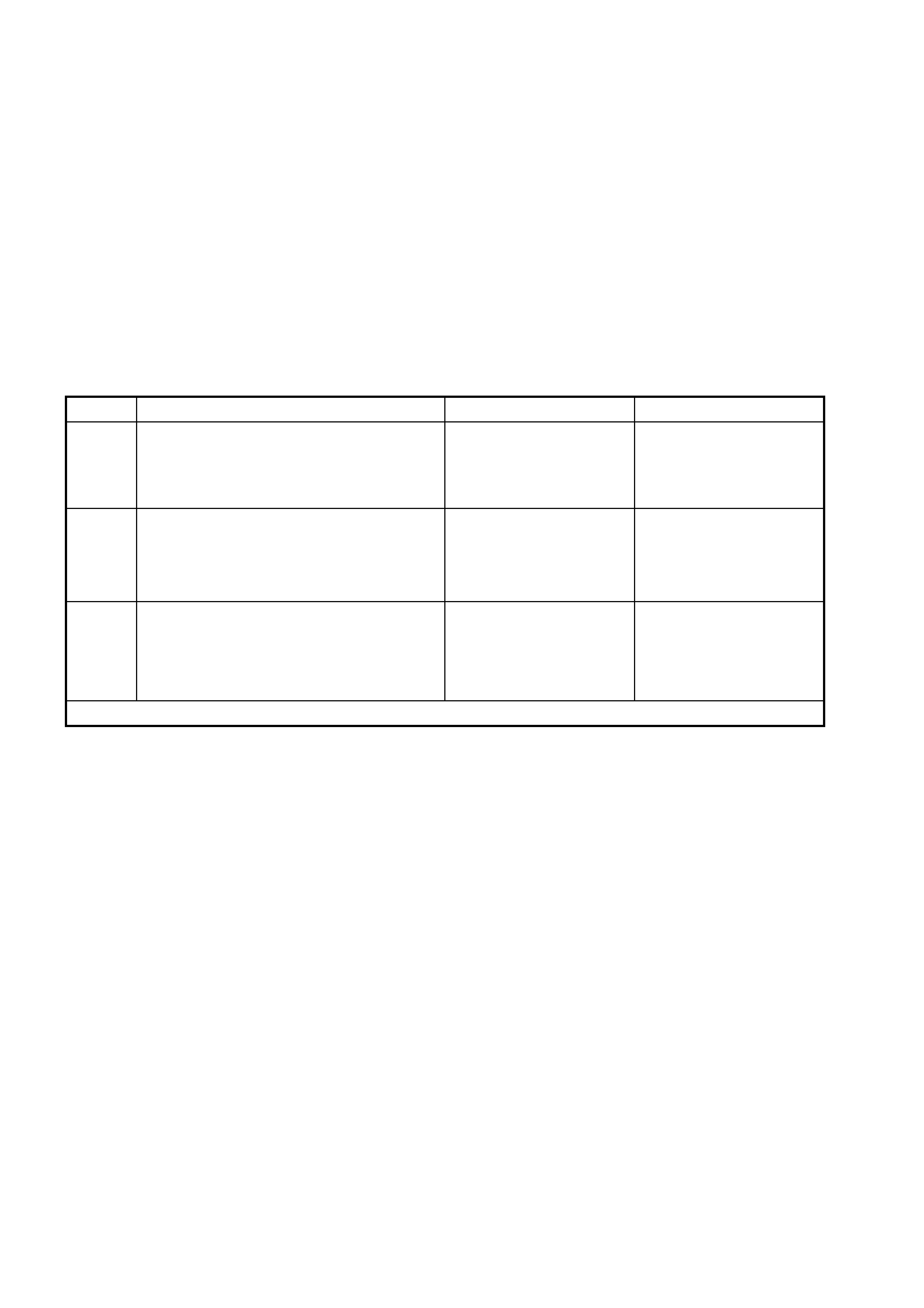

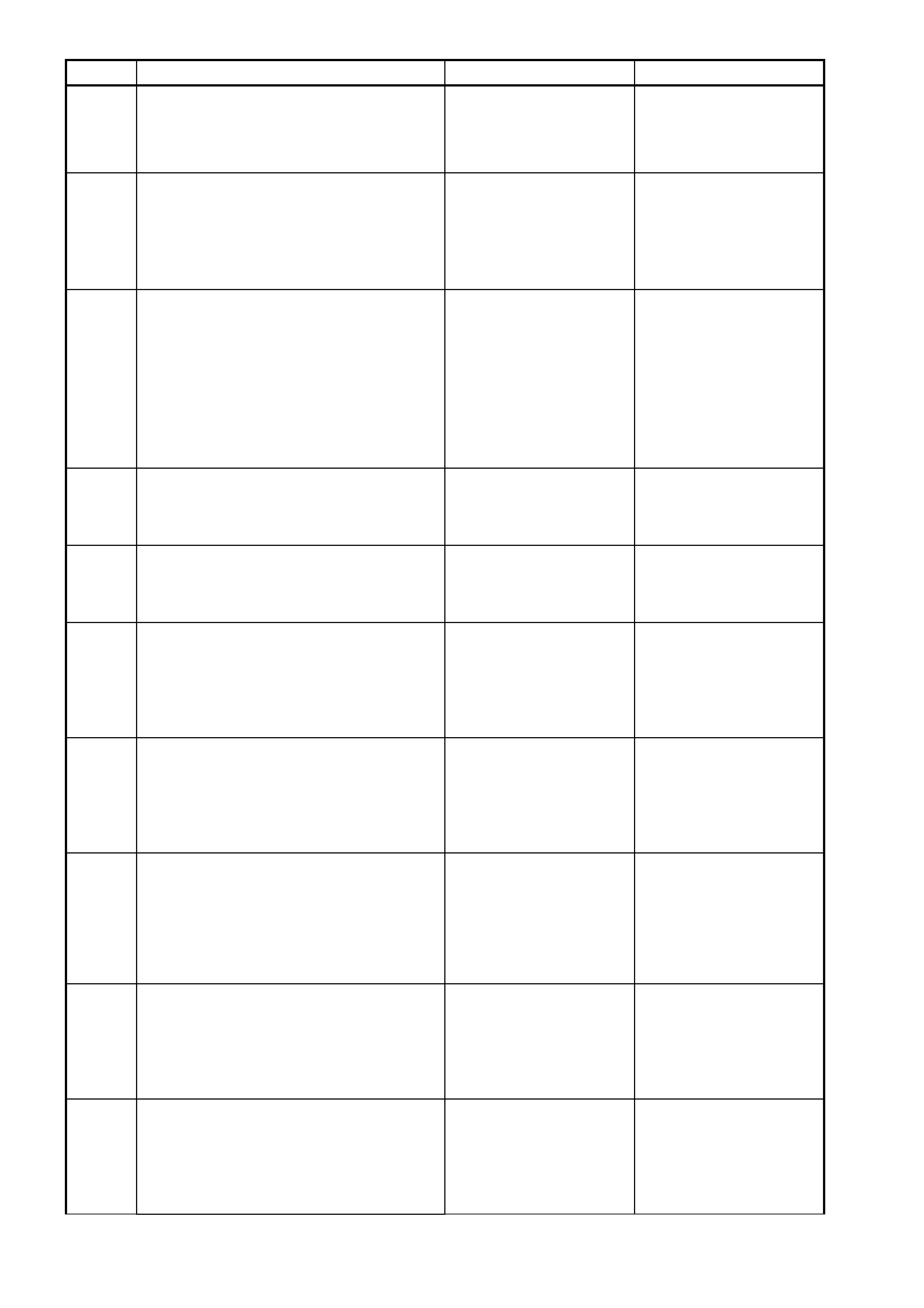

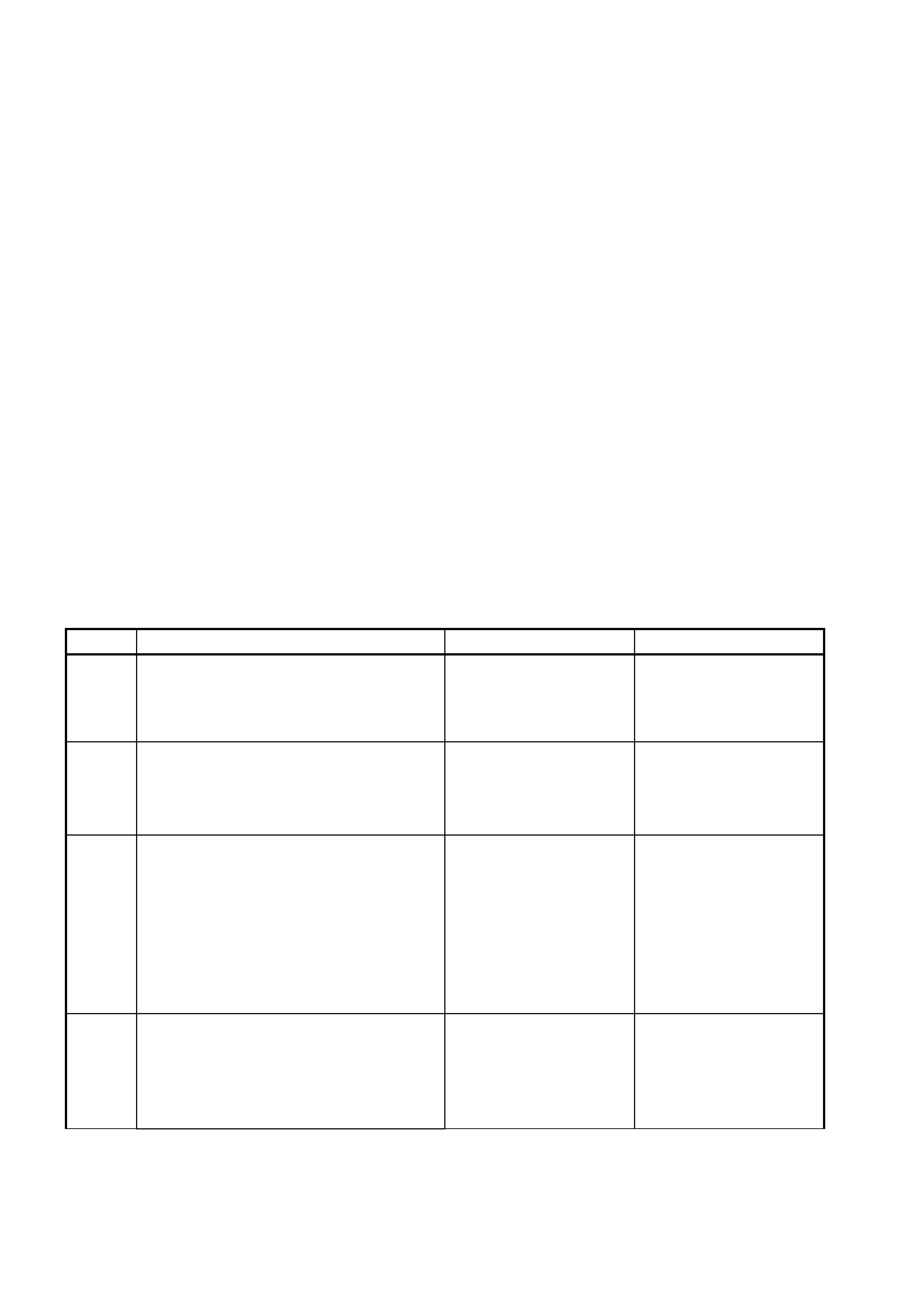

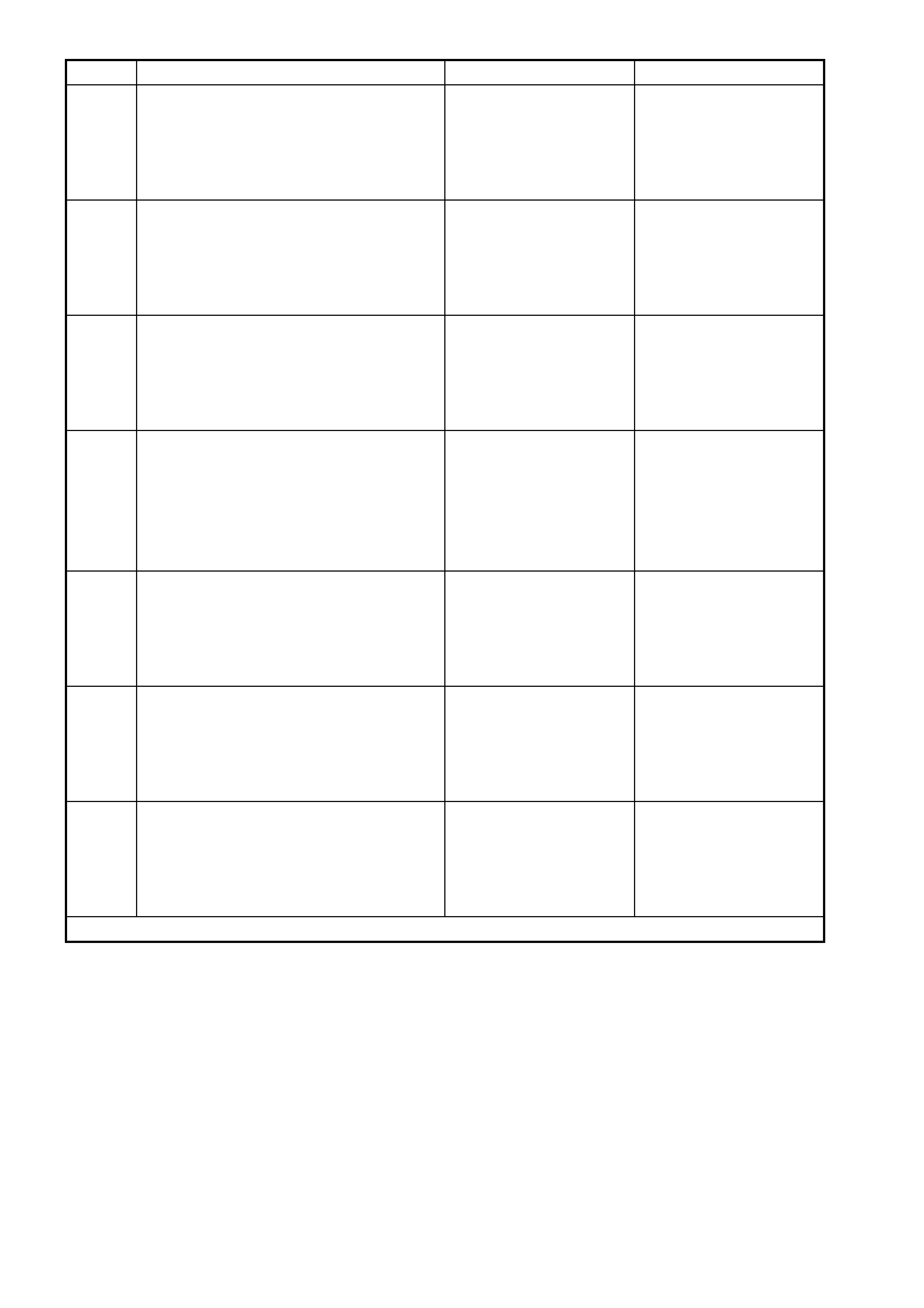

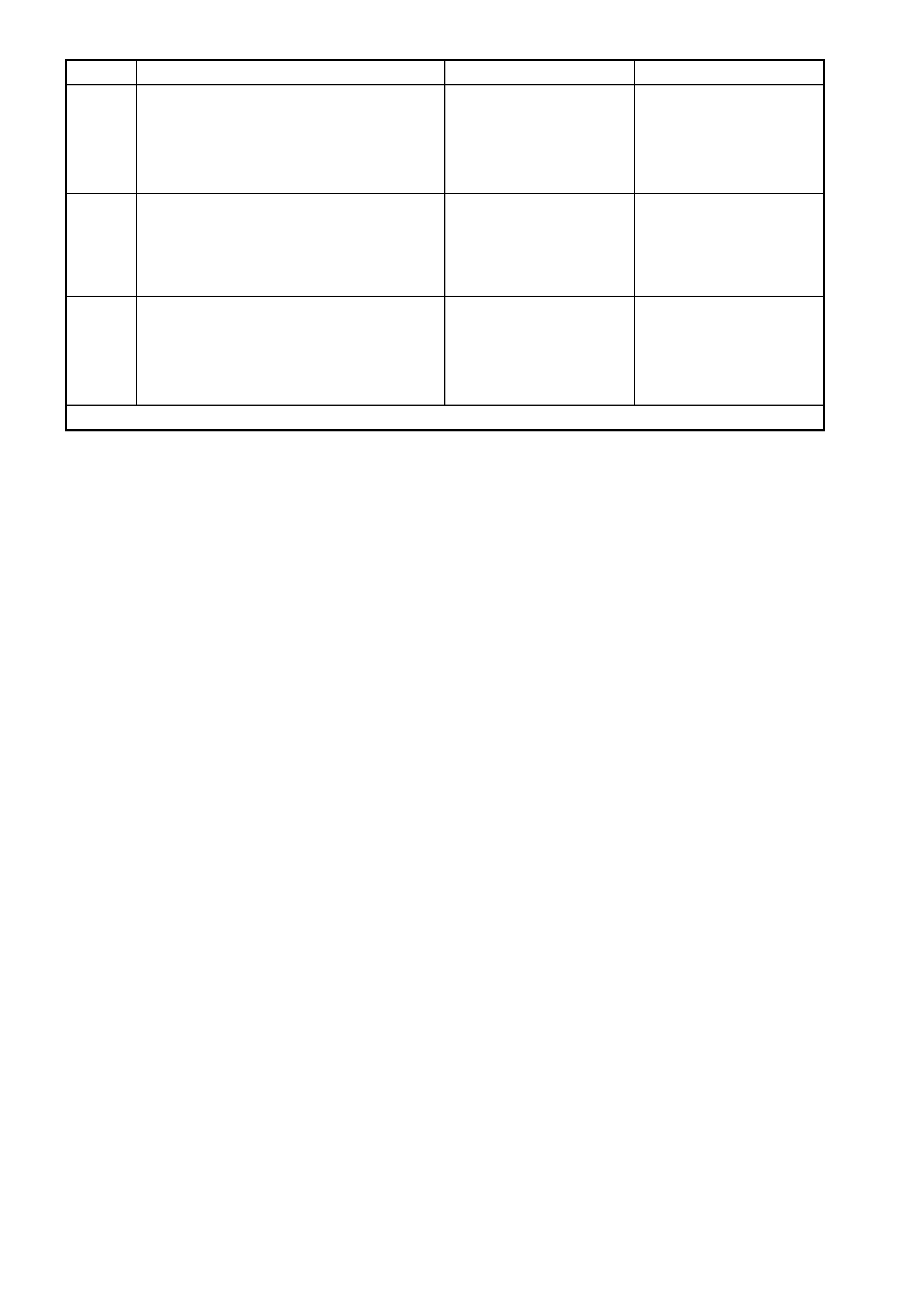

2.1 FRONT SEAT USAGE CHART - EXCEPT COUPE

HOW TO USE THIS CHART

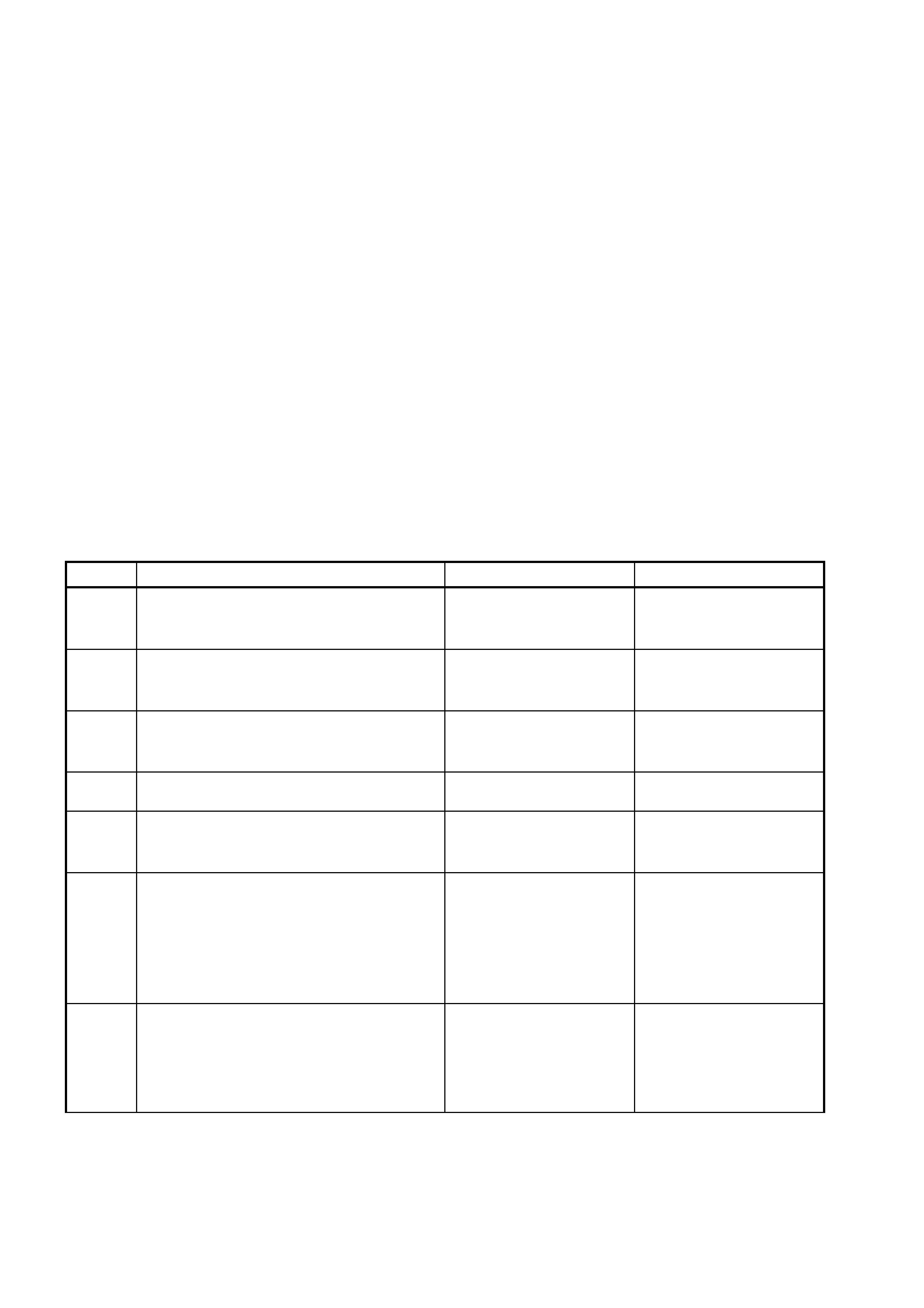

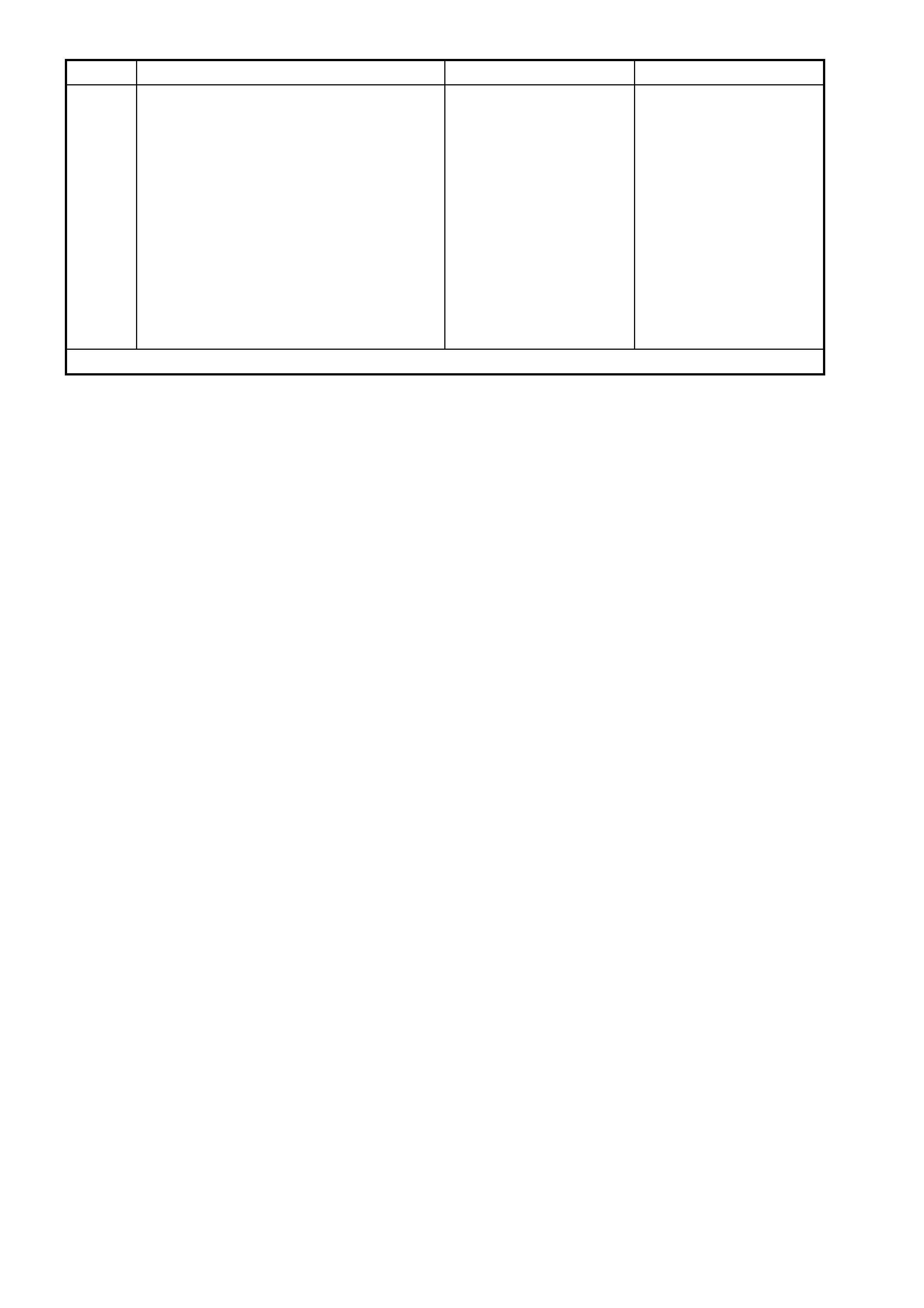

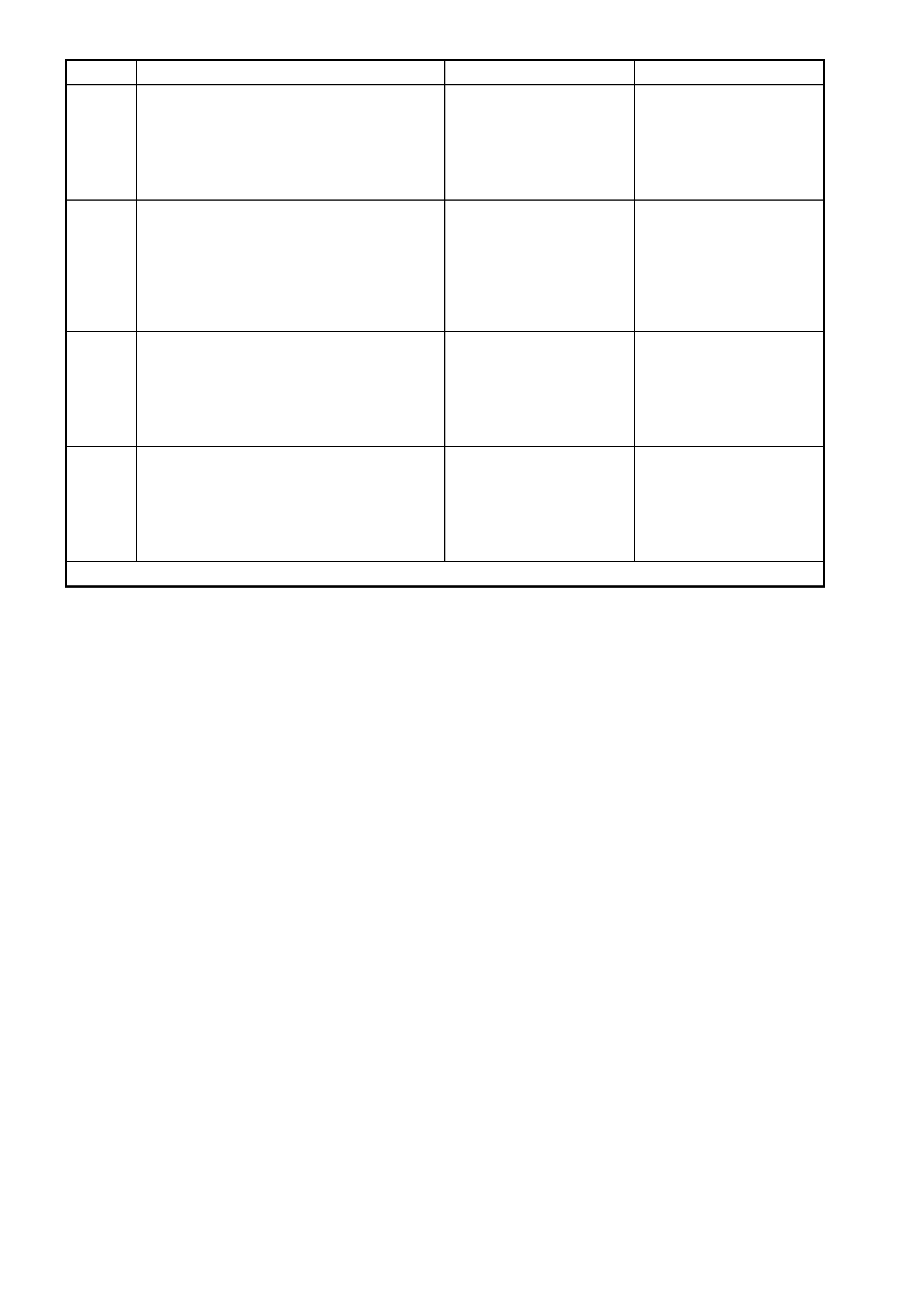

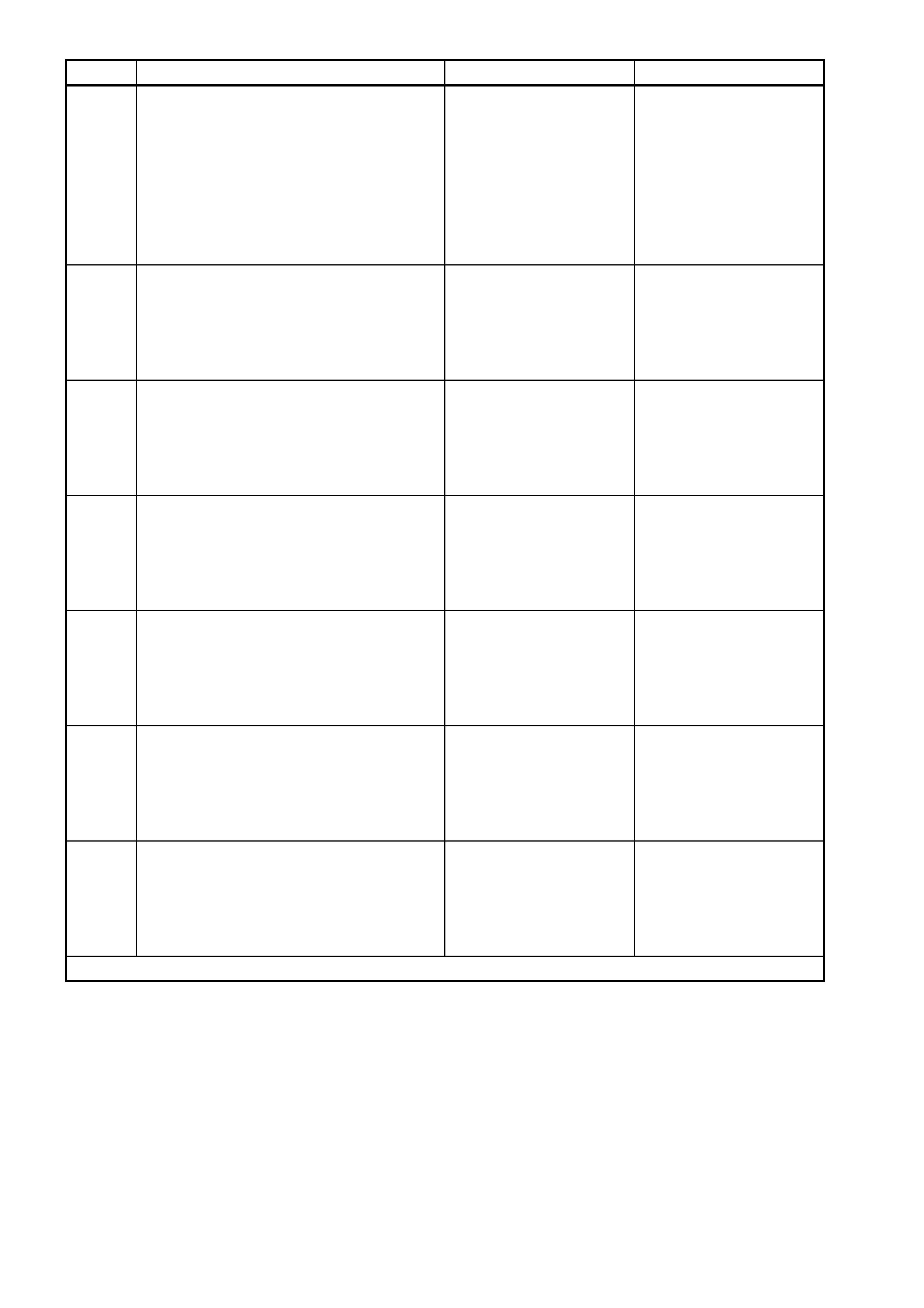

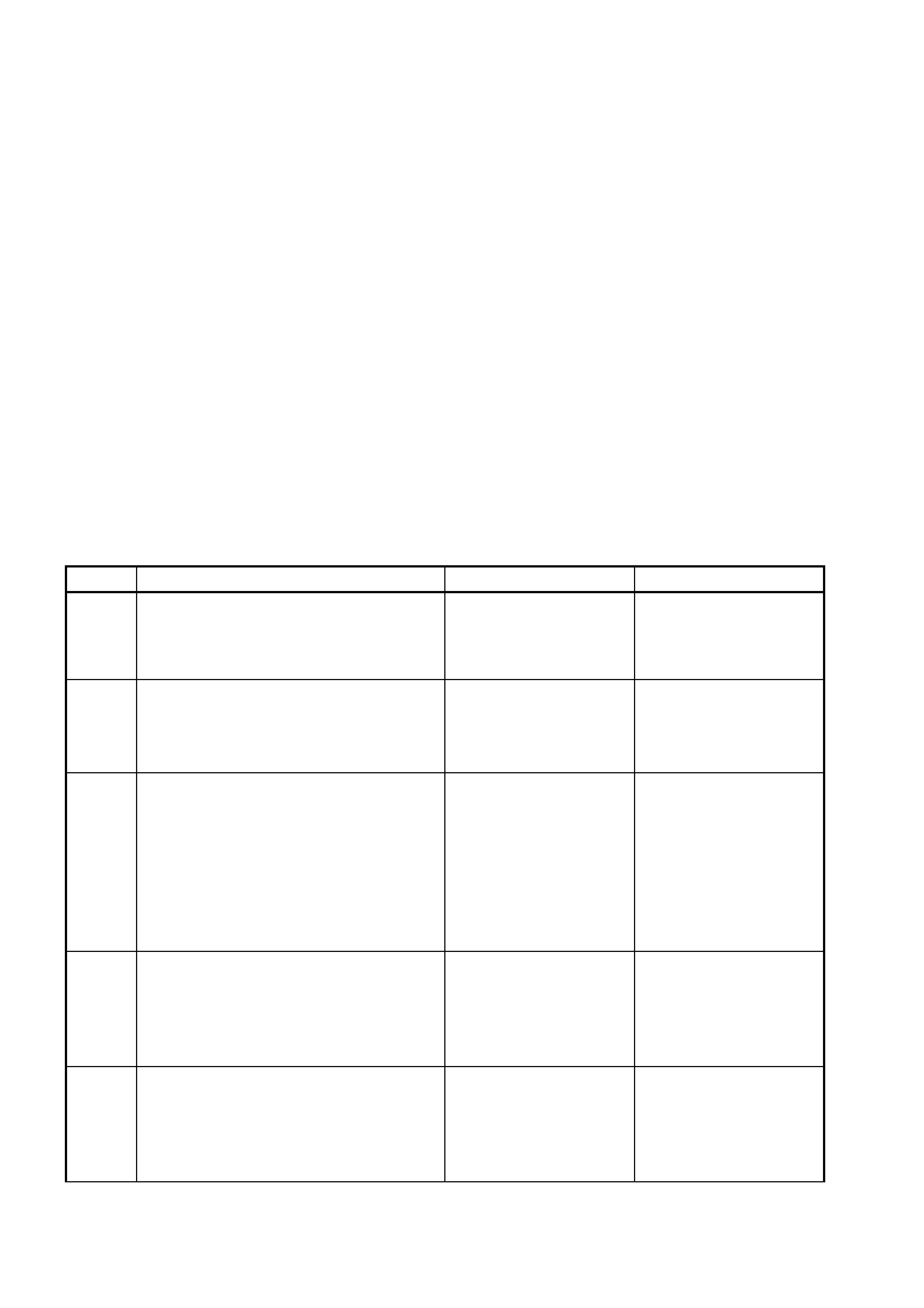

Thirteen front seat configurations are used in MY2003 VY Series Sedan Wagon and Utility vehicles. The

following usage chart is provided to help determine the seat type fitted to the vehicle. This is important prior to

repairs being performed as the failed / damaged part may not be serviceable.

To determine the seat fitted to the vehicle, obtain the vehicle model, which seat requires attention and the seat

cover fabric. Then establish if the vehicle has a side impact airbag and/or manually adjustable lumber support.

Using the chart will lead to the elimination of all other seat combinations, allowing the identification of the type

and the construction of the seat. Finally, refer to the Figure shown in TYPE for a component breakdown of the

front seat assembly.

1. VEHICLE – Vehicle model identification.

2. SEATING – Driver front seat or passenger front seat.

3. FABRIC – Cloth or leather seat covers.

4. TRACK – Indicates the number of directions the electric seat track can be moved, except for the two way

which is manually operated.

5. LUMBER – If the front seat-back is fitted with a manually adjust lumber support.

6. SIAB – If the front seat is fitted with a side impact airbag.

7. CONSTRUCTION – Surebond refers to the seat cover being glued to the seat pad and only serviced as a

cover and pad ass embly. Hook and Loop refer s to the seat c over being able to be attached or removed from

the seat pad and both being serviced as separate parts.

8. TYPE – Identif ies the seat type and provides ref er enc e to the f ollowing illustrations which s how a break down

of the serviced component for each rear seat assembly.

Techline

DOMESTIC

VEHICLE SEATING FABRIC TRACK LUMBER SIAB CONSTRUCTION TYPE

(Refer to)

Driver Leather / Cloth 8 Way Yes Yes Hook & Loop 1 (Figure 1A7-8)

Calais Passenger Leather / Cloth 8 Way Yes Yes Hook & Loop 1 (Figure 1A7-8)

Driver Leather / Cloth 4 Way Yes Yes Hook & Loop 2 (Figure 1A7-9)

Berlina Passenger Leather / Cloth 2 Way Yes Yes Hook & Loop 6 (Figure 1A7-13)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Passenger Cloth 2 Way No No Surebond 10 (Figure 1A7-17)

Driver Cloth 4 Way Yes Yes Surebond 4 (Figure 1A7-11)

Executive

Passenger Cloth 2 Way No Yes Surebond 11 (Figure 1A7-18)

Driver Cloth 4 Way Yes Yes Surebond 4 (Figure 1A7-11)

Acclaim Passenger Cloth 2 Way Yes Yes Surebond 9 (Figure 1A7-16)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Cloth 4 Way Yes Yes Surebond 4 (Figure 1A7-11)

Passenger Cloth 2 Way Yes Yes Surebond 9 (Figure 1A7-16)

Driver Leather 4 Way Yes No Hook & Loop 5 (Figure 1A7-12)

Passenger Leather 2 Way Yes No Hook & Loop 7 (Figure 1A7-14)

Driver Leather 4 Way Yes Yes Hook & Loop 2 (Figure 1A7-9)

S Sedan

Passenger Leather 2 Way Yes Yes Hook & Loop 6 (Figure 1A7-13)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Cloth 4 Way Yes Yes Surebond 4 (Figure 1A7-11)

Passenger Cloth 2 Way Yes Yes Surebond 9 (Figure 1A7-16)

Driver Leather 4 Way Yes No Hook & Loop 5 (Figure 1A7-12)

Passenger Leather 2 Way Yes No Hook & Loop 7 (Figure 1A7-14)

Driver Leather 4 Way Yes Yes Hook & Loop 2 (Figure 1A7-9)

SS

Sedan

Passenger Leather 2 Way Yes Yes Hook & Loop 6 (Figure 1A7-13)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Passenger Cloth 2 Way No No Surebond 10 (Figure 1A7-17)

Driver Cloth 4 Way Yes Yes Surebond 4 (Figure 1A7-11)

SV8

Passenger Cloth 2 Way No Yes Surebond 11 (Figure 1A7-18)

Driver Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Utility Passenger Cloth 2 Way No No Surebond 10 (Figure 1A7-17)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

S Utility Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Leather 4 Way Yes No Hook & Loop 5 (Figure 1A7-12)

SS Utility

Passenger Leather 2 Way Yes No Hook & Loop 7 (Figure 1A7-14)

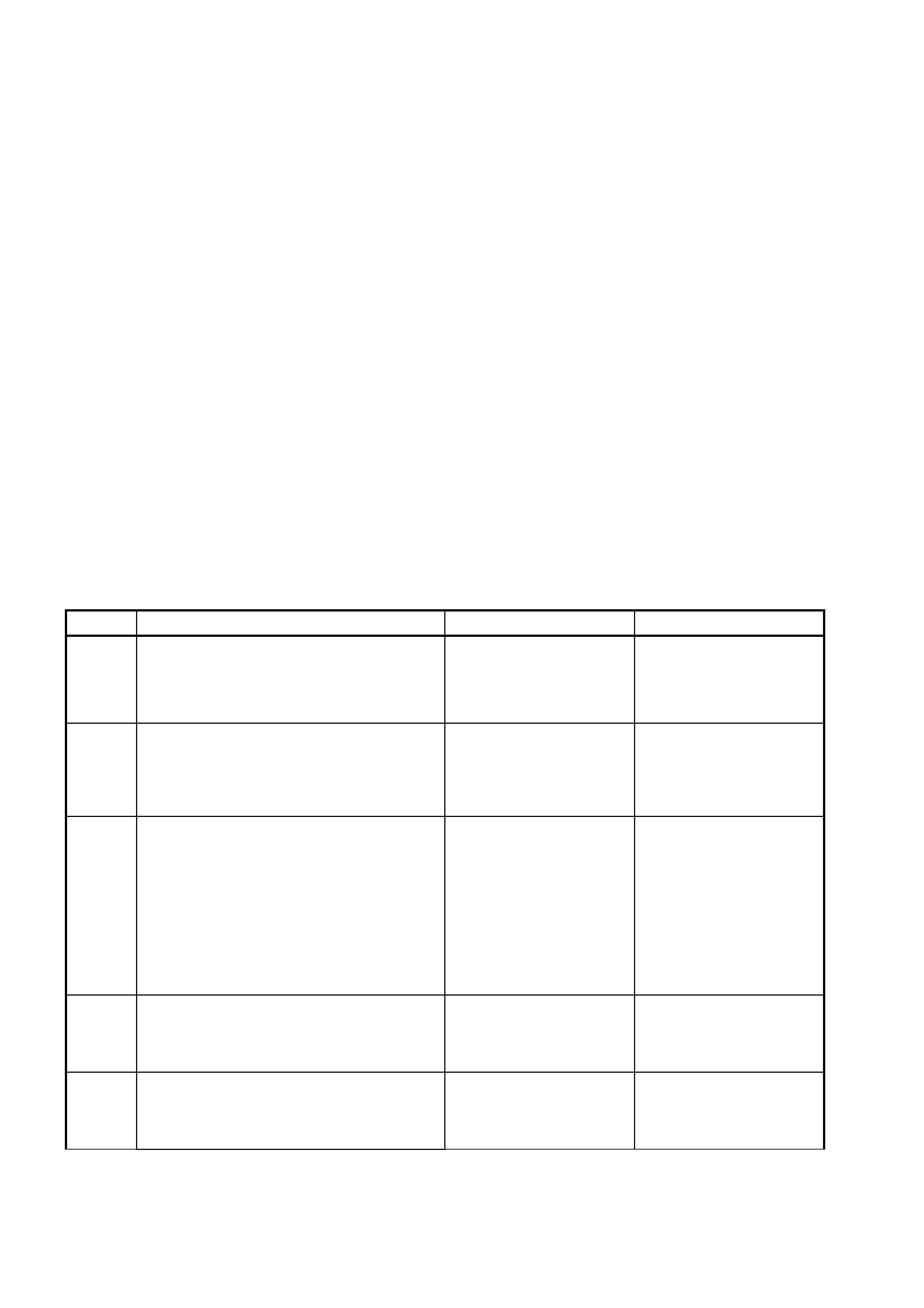

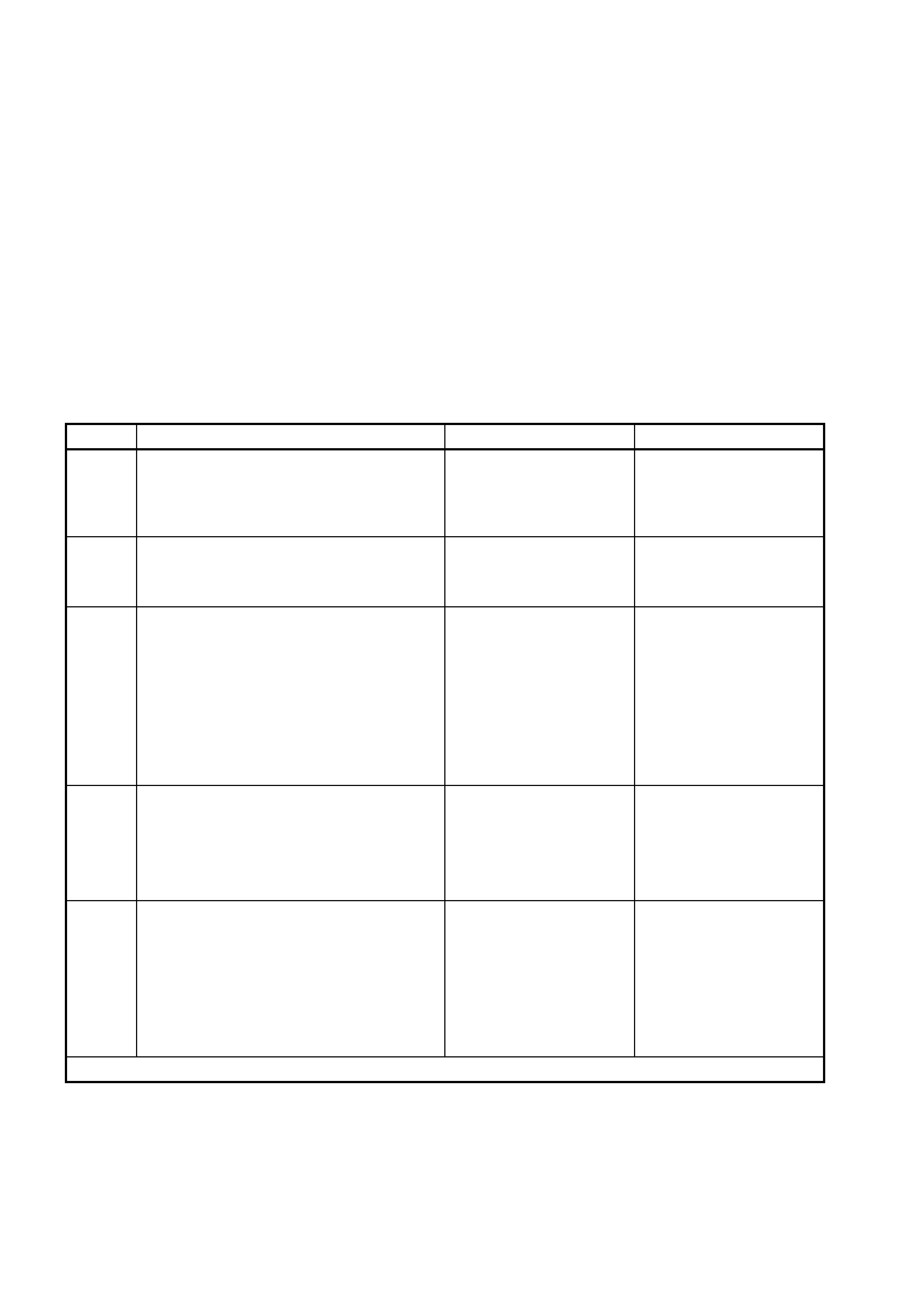

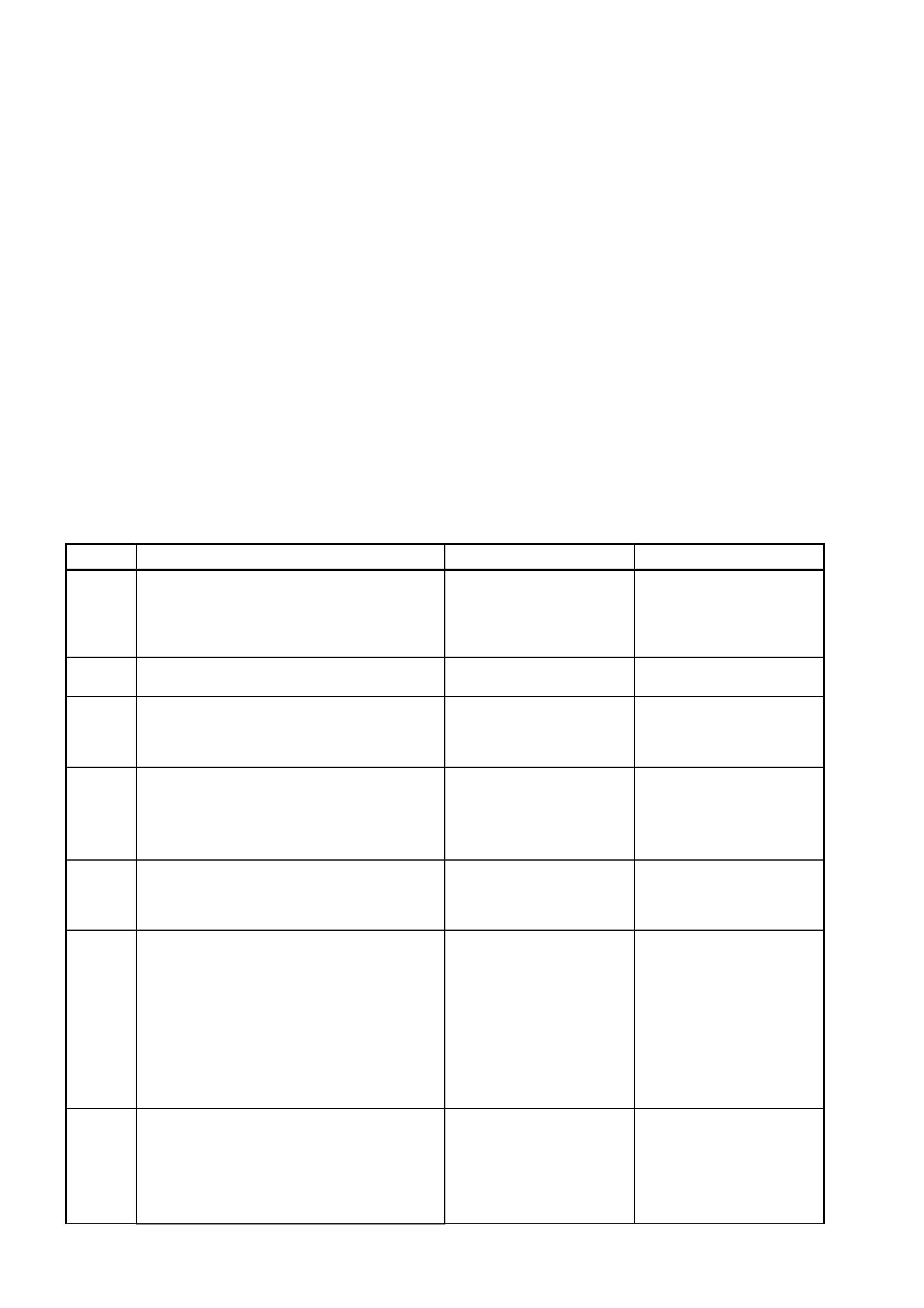

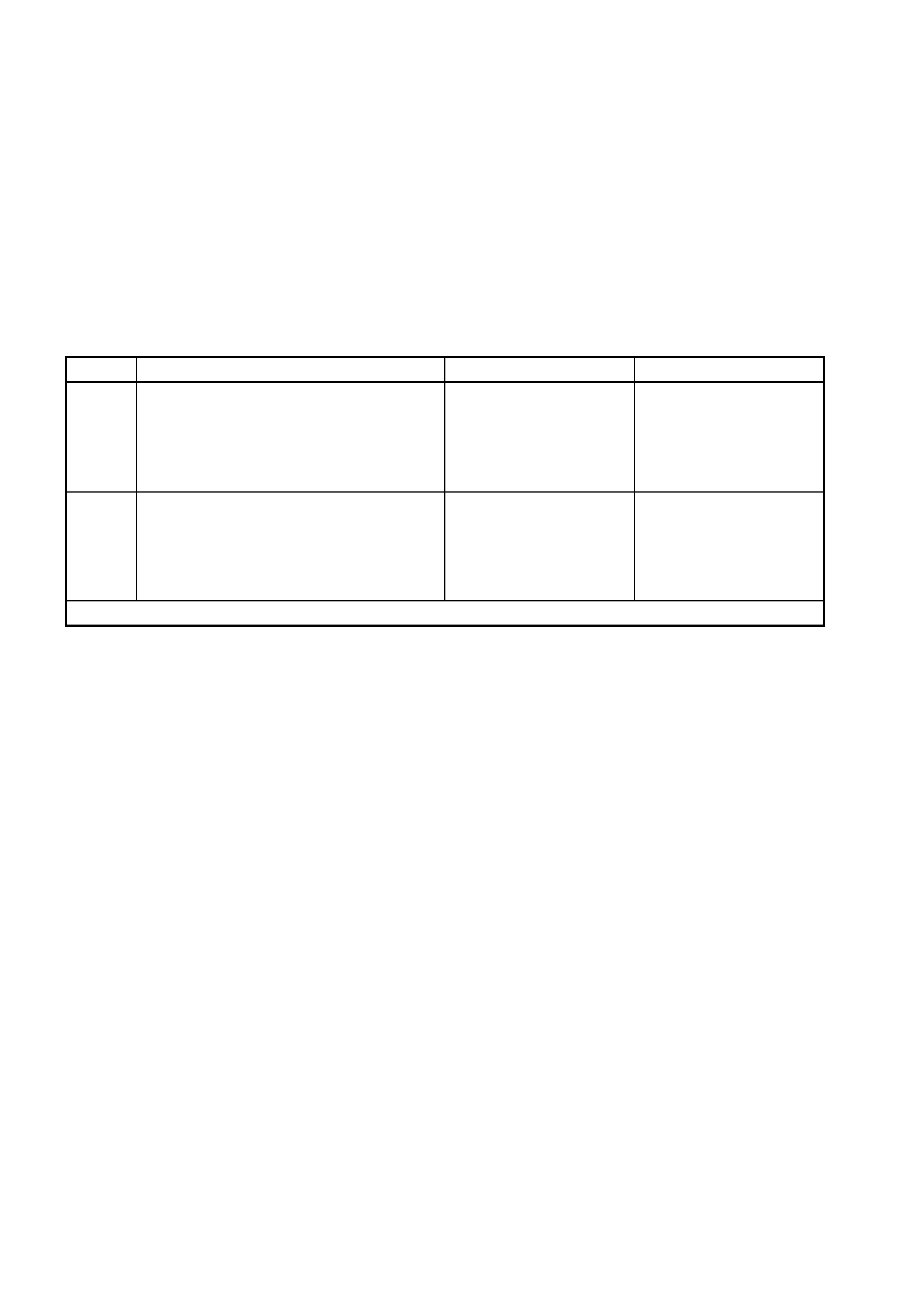

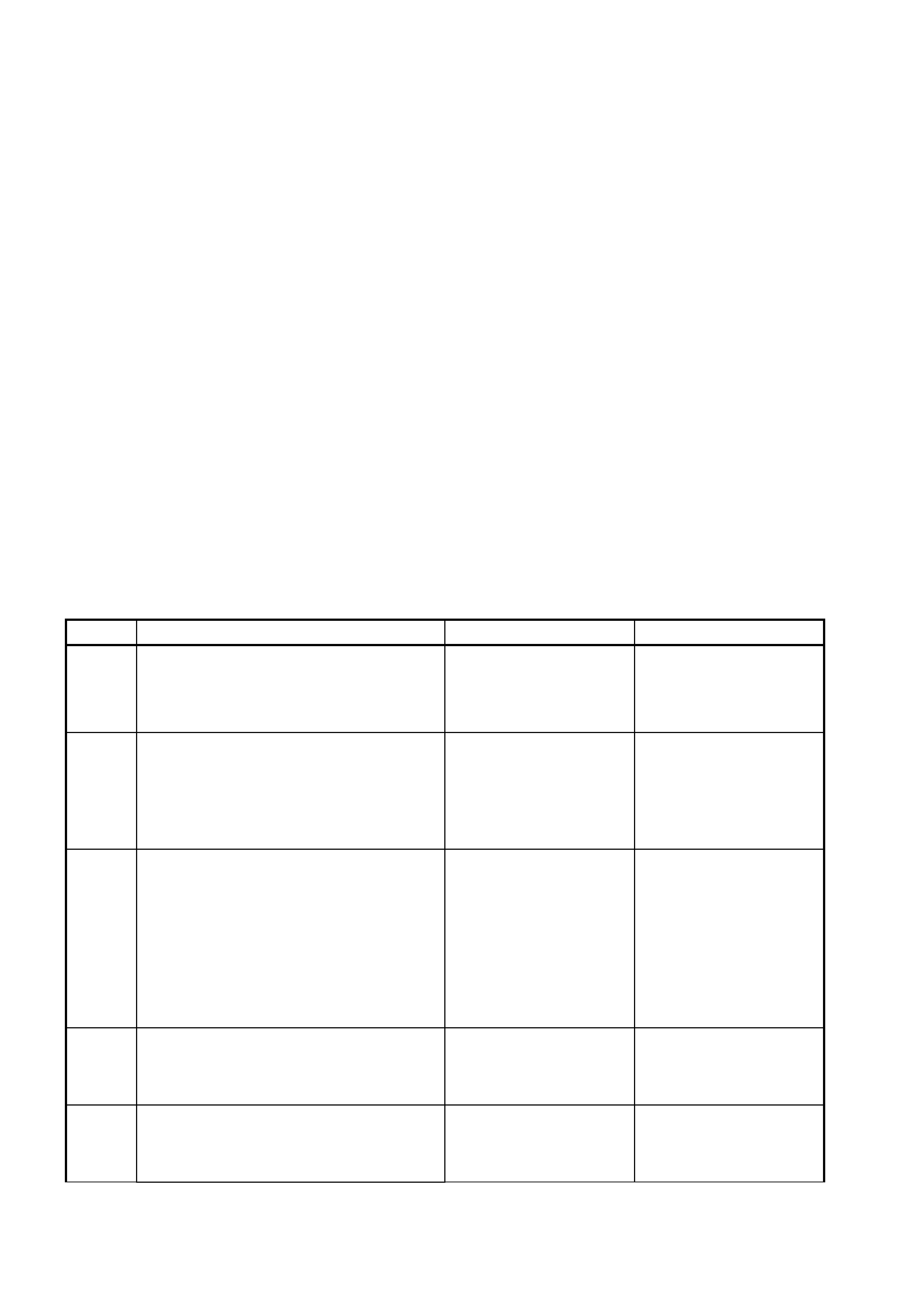

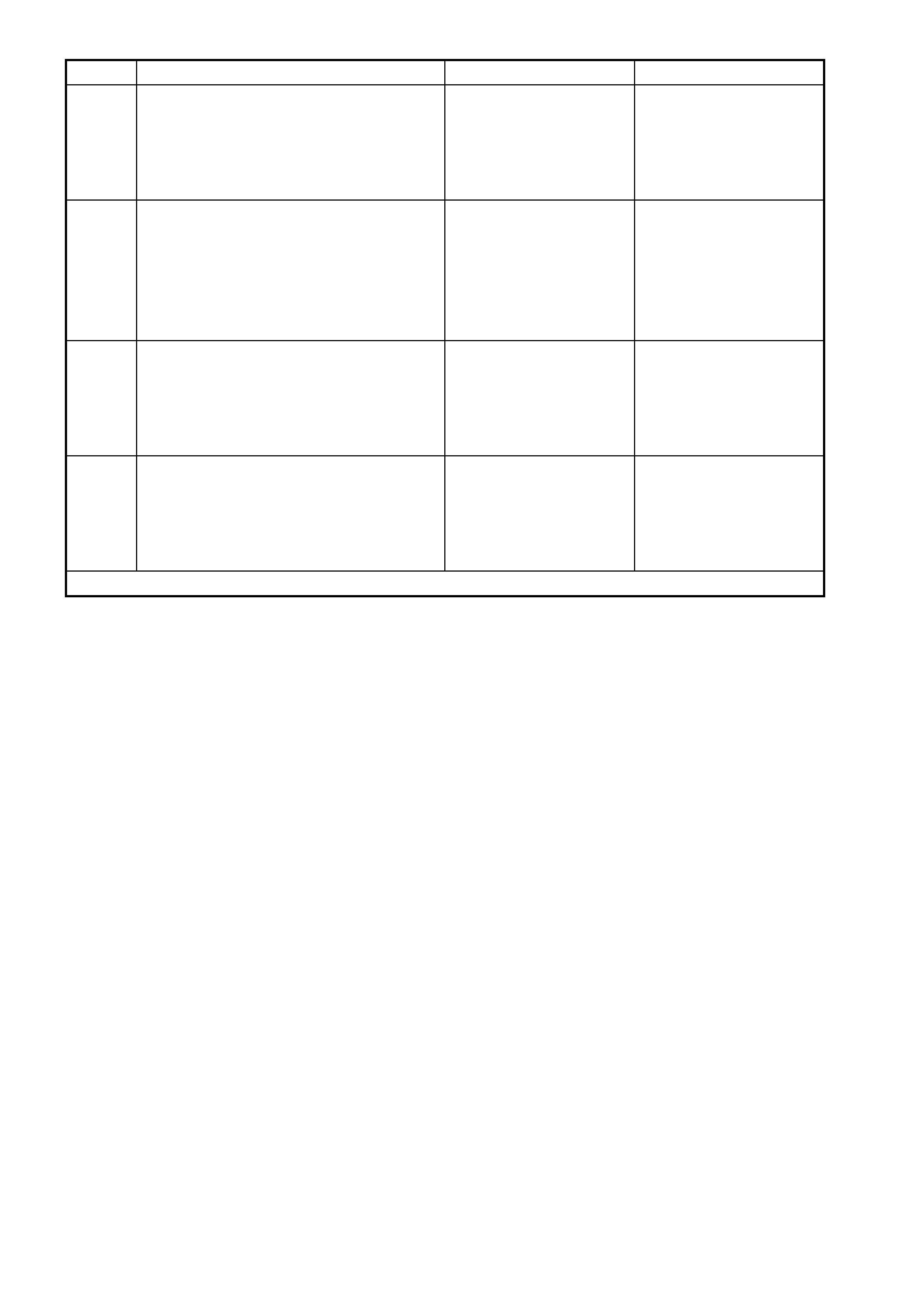

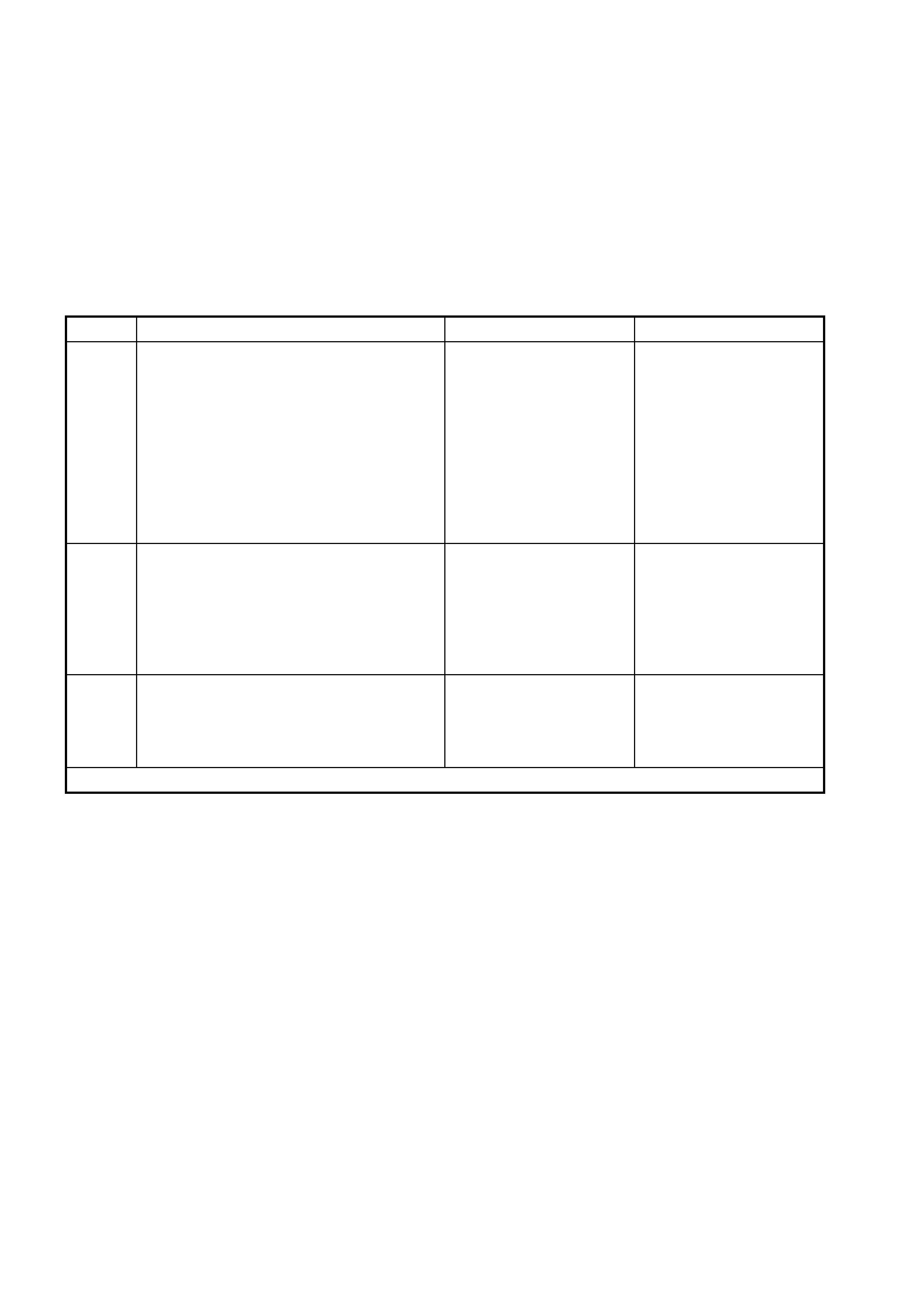

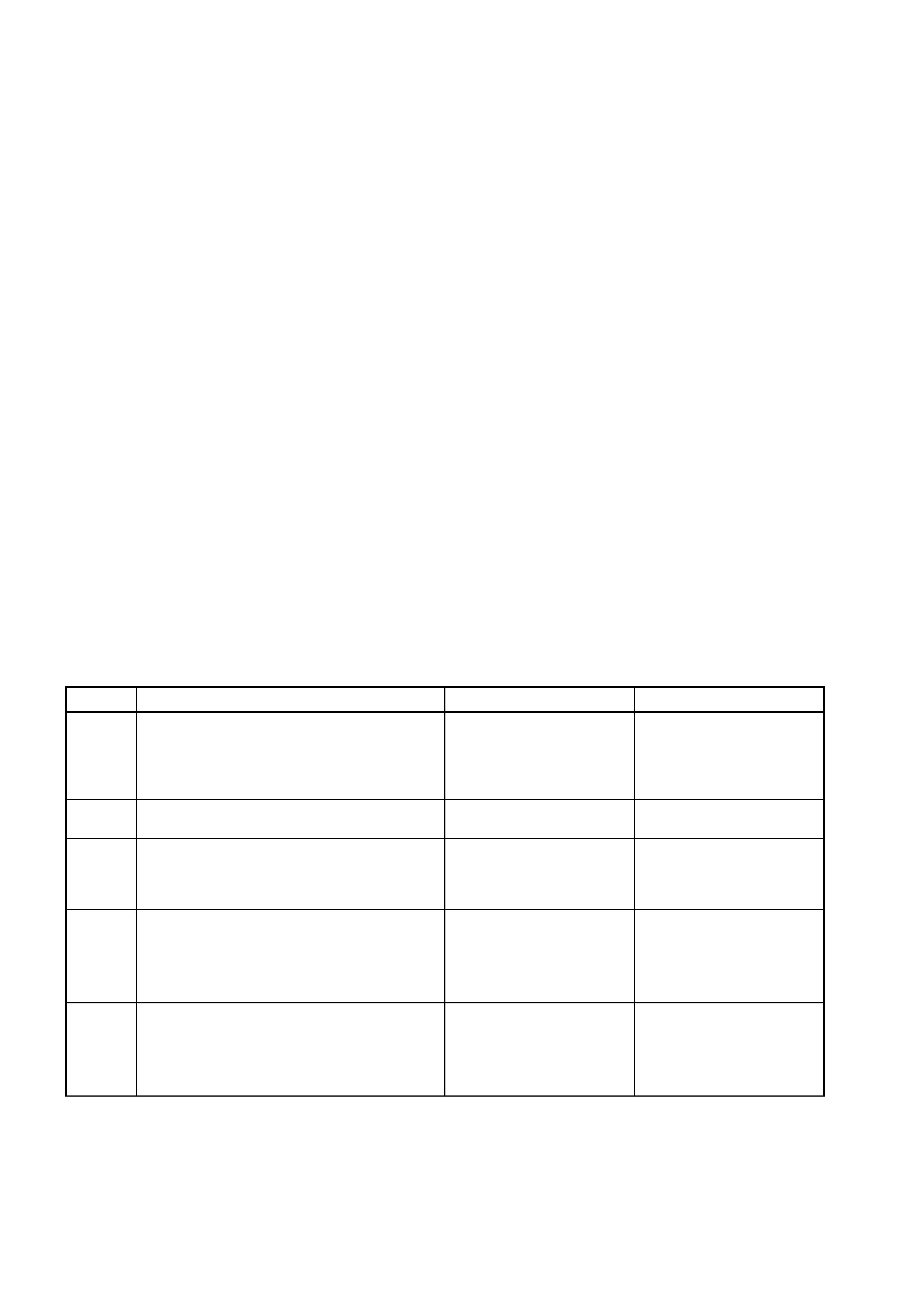

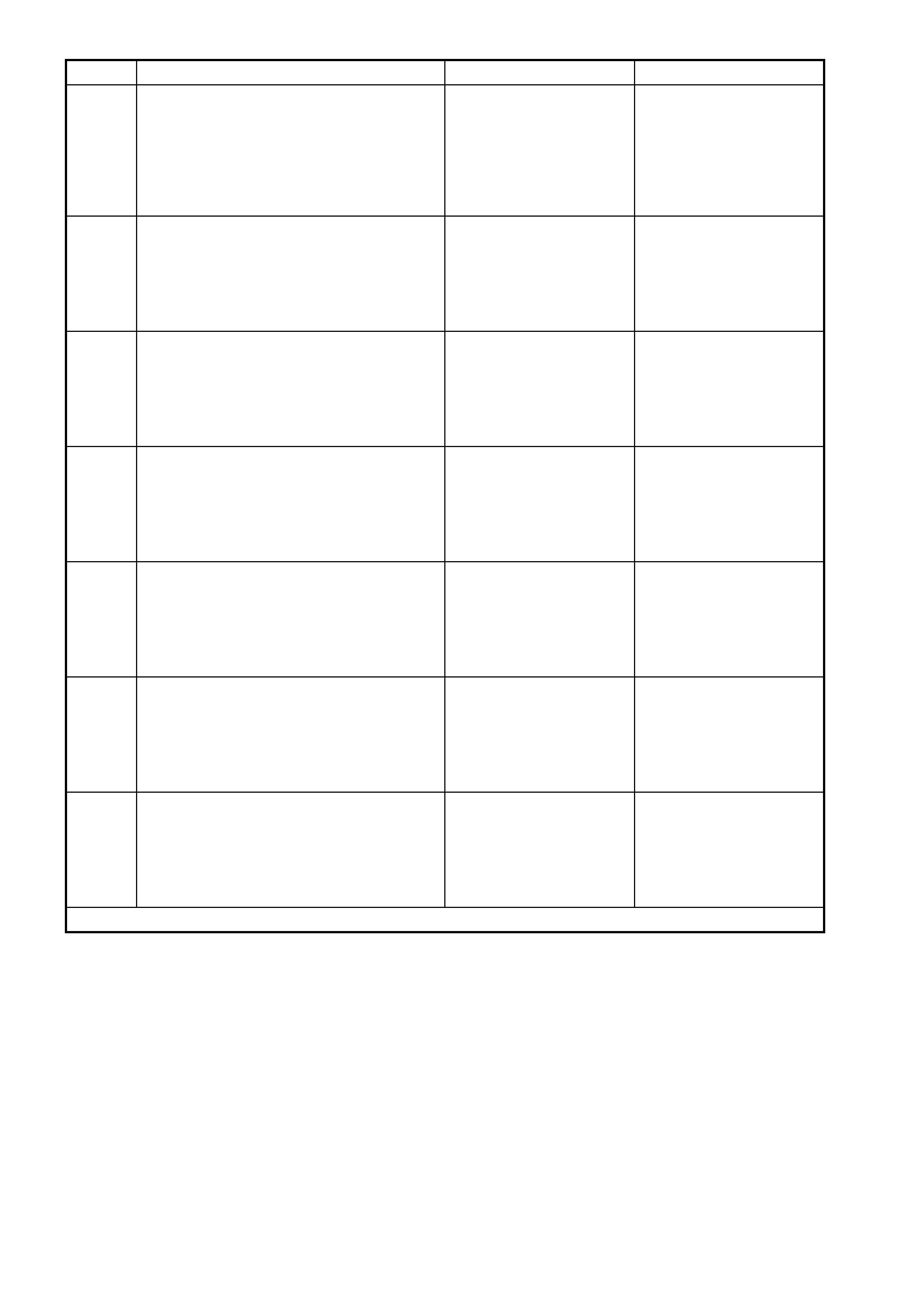

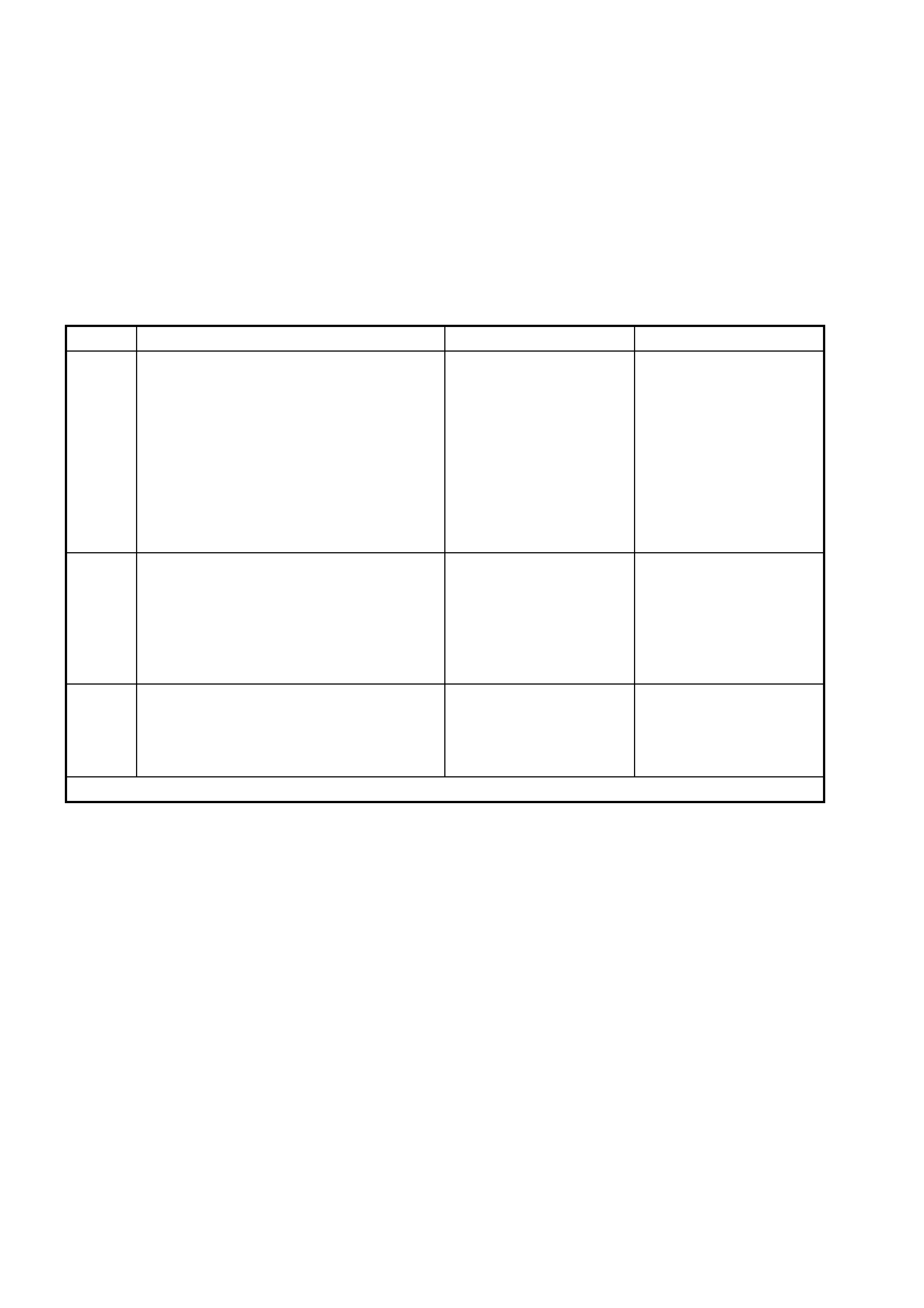

BRAZIL

VEHICLE SEATING FABRIC TRACK LUMBER SIAB CONSTRUCTION TYPE

(Refer to)

Driver Leather 8 Way Yes Yes Hook & loop 1 (Figure 1A7-8)

Omega

CD Passenger Leather 8 Way Yes Yes Hook & loop 1 (Figure 1A7-8)

GULF STATES

VEHICLE SEATING FABRIC TRACK LUMBER SIAB CONSTRUCTION TYPE

(Refer to)

Driver Leather / Cloth 8 Way Yes No Hook & Loop 12 (Figure 1A7-19)

Lumina

LTZ Passenger Leather / Cloth 8 Way Yes No Hook & Loop 12 (Figure 1A7-19)

Driver Cloth 8 Way Yes No Surebond 13 (Figure 1A7-20)

Passenger Cloth 8 Way Yes No Surebond 13 (Figure 1A7-20)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Lumina

LS

Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Lumina S Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Passenger Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Driver Leather 4 Way Yes No Hook & Loop 5 (Figure 1A7-12)

Lumina

SS

Passenger Leather 4 Way Yes No Hook & Loop 5 (Figure 1A7-12)

SOUTH AFRICA

VEHICLE SEATING FABRIC TRACK LUMBER SIAB CONSTRUCTION TYPE

(Refer to)

Driver Leather 4 Way Yes Yes Hook & Loop 2 (Figure 1A7-9)

Lumina

LTZ Passenger Leather 2 Way Yes Yes Hook & Loop 6 (Figure 1A7-13)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Lumina

LS Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Cloth 4 Way Yes No Surebond 3 (Figure 1A7-10)

Lumina S Passenger Cloth 2 Way Yes No Surebond 8 (Figure 1A7-15)

Driver Leather 4 Way Yes Yes Hook & Loop 2 (Figure 1A7-9)

Lumina

SS Passenger Leather 2 Way Yes Yes Hook & Loop 6 (Figure 1A7-13)

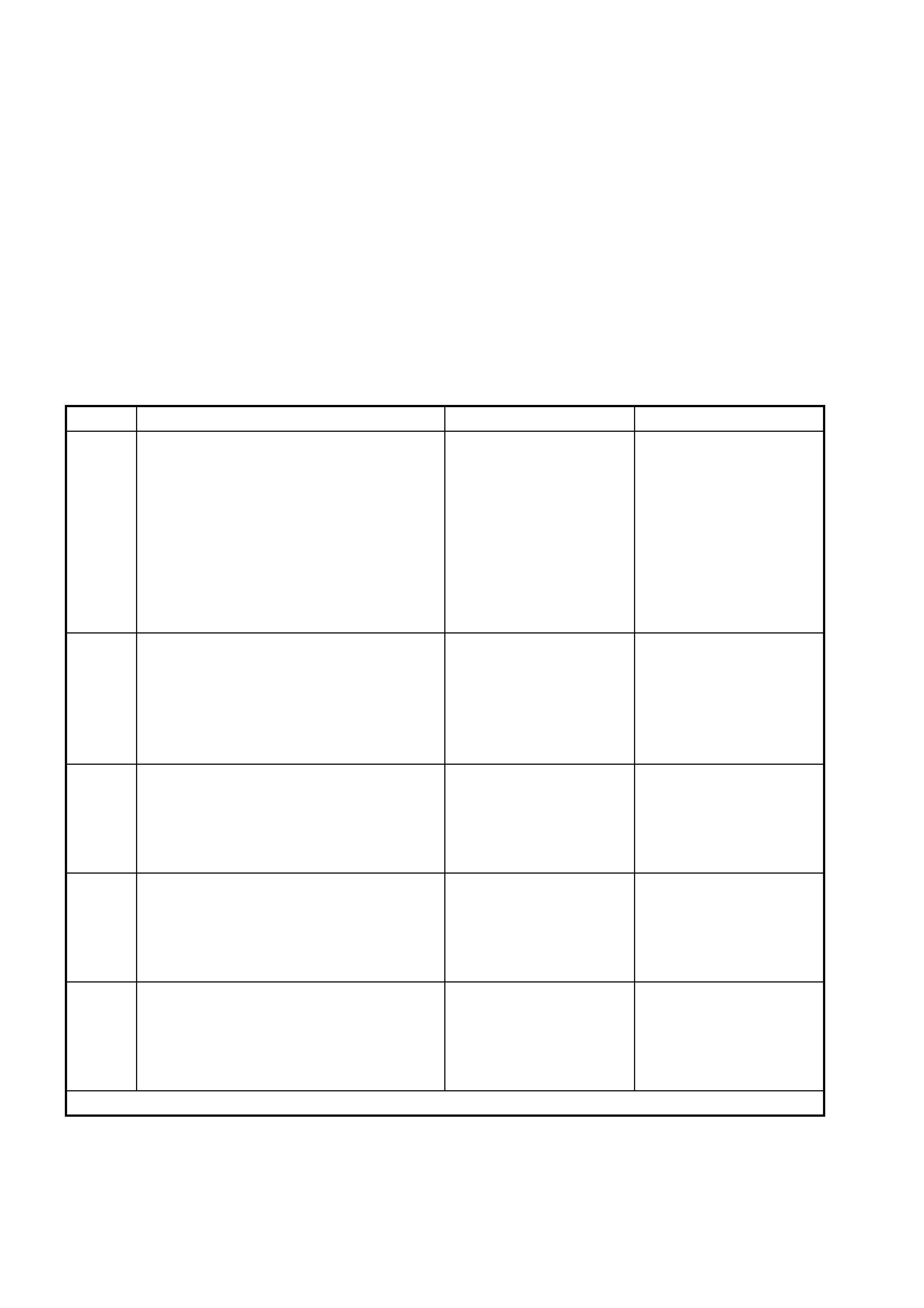

INDONESIA

VEHICLE SEATING FABRIC TRACK LUMBER SIAB CONSTRUCTION TYPE

(Refer to)

Driver Leather / Cloth 4 Way Yes Yes Hook & Loop 2 (Figure 1A7-9)

Lumina

LTZ Passenger Leather / Cloth 2 Way Yes Yes Hook & Loop 6 (Figure 1A7-13)

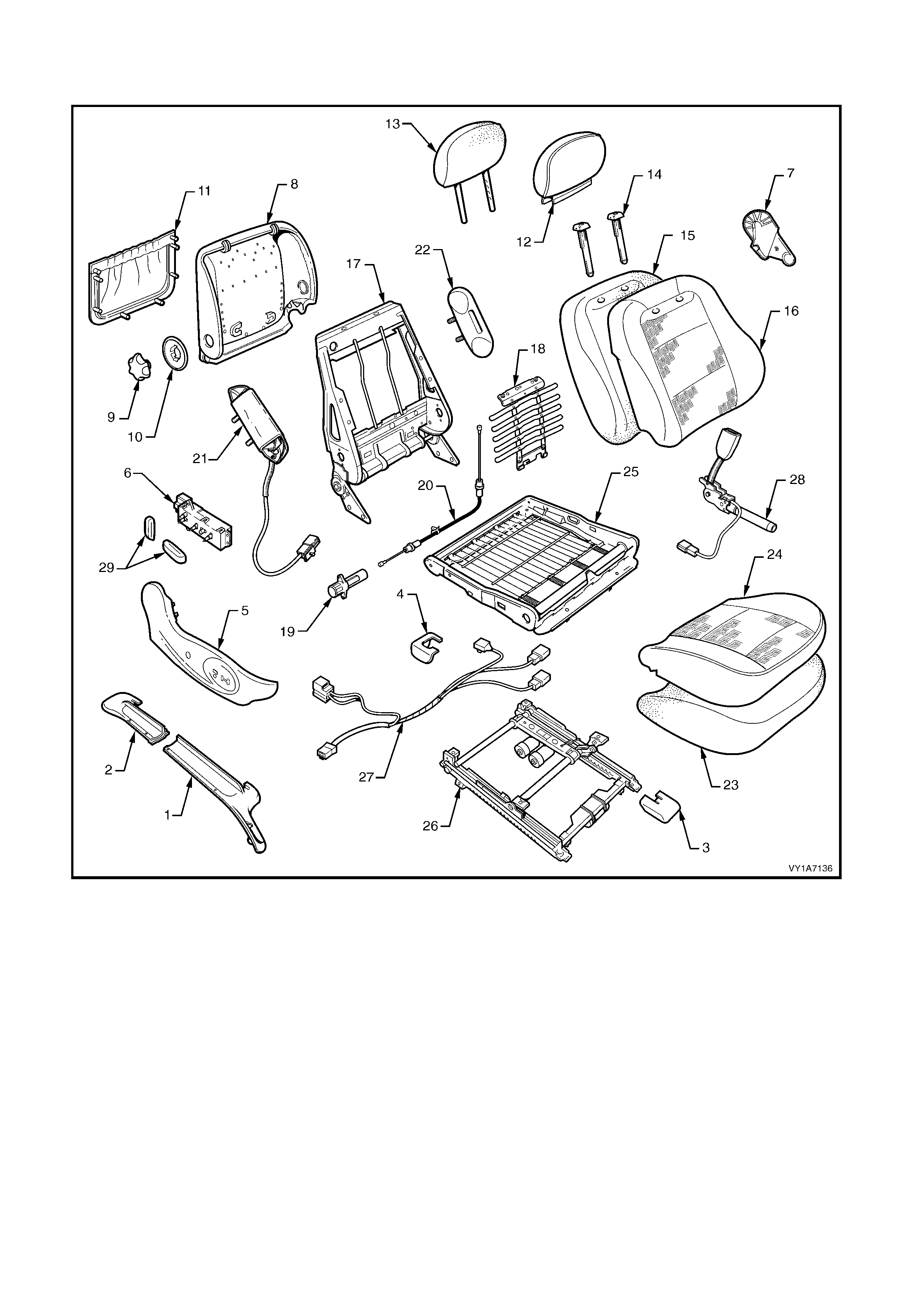

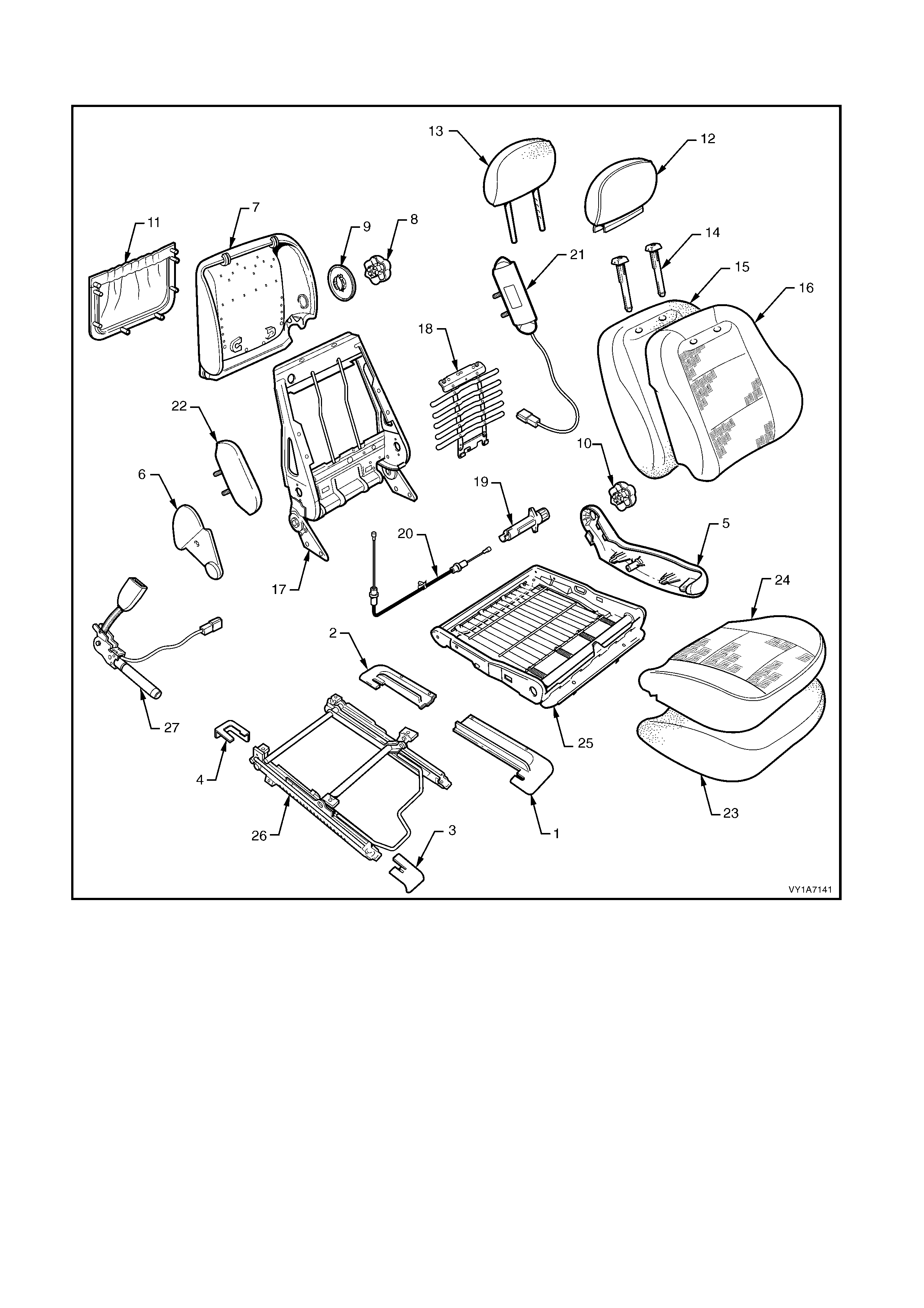

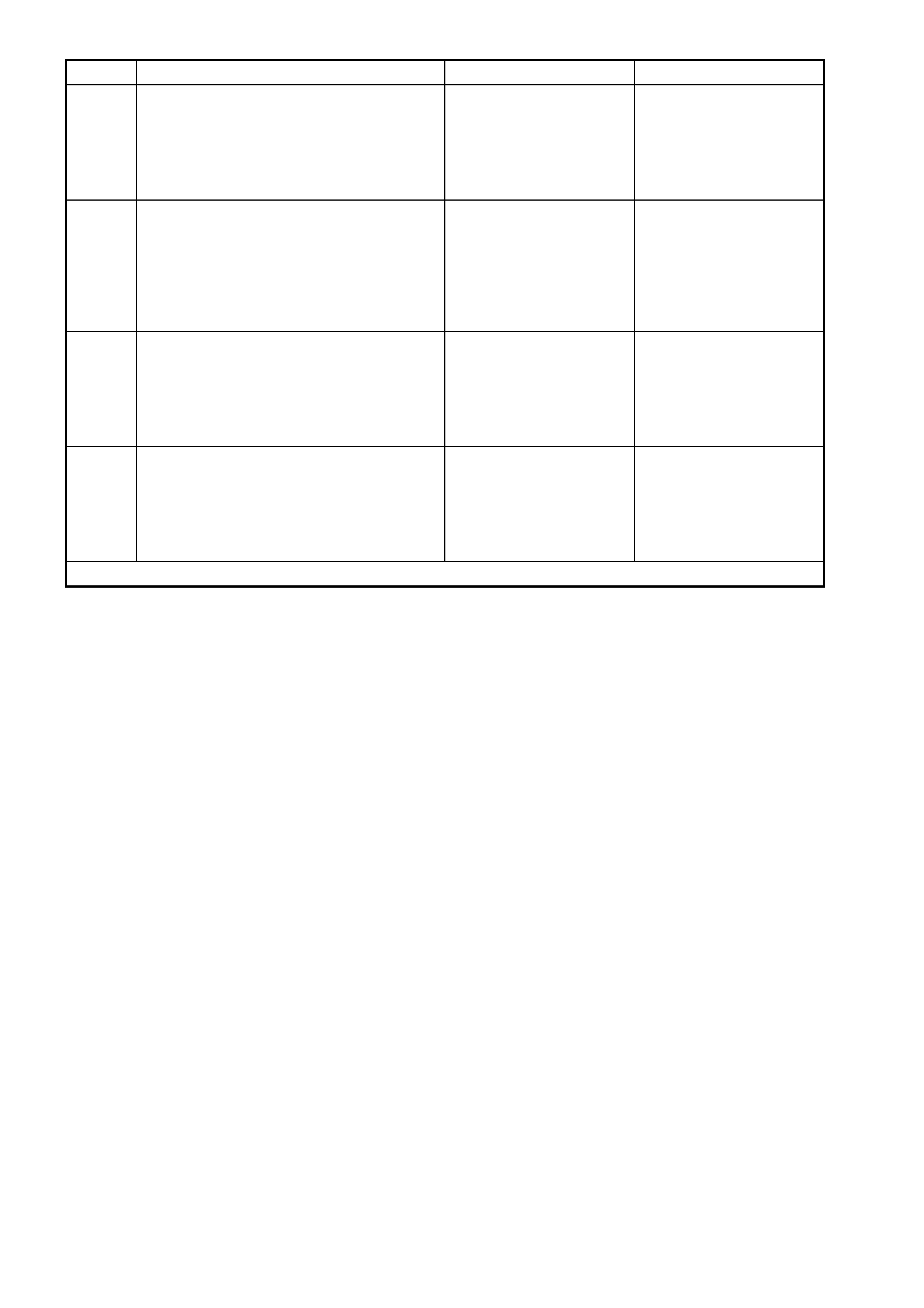

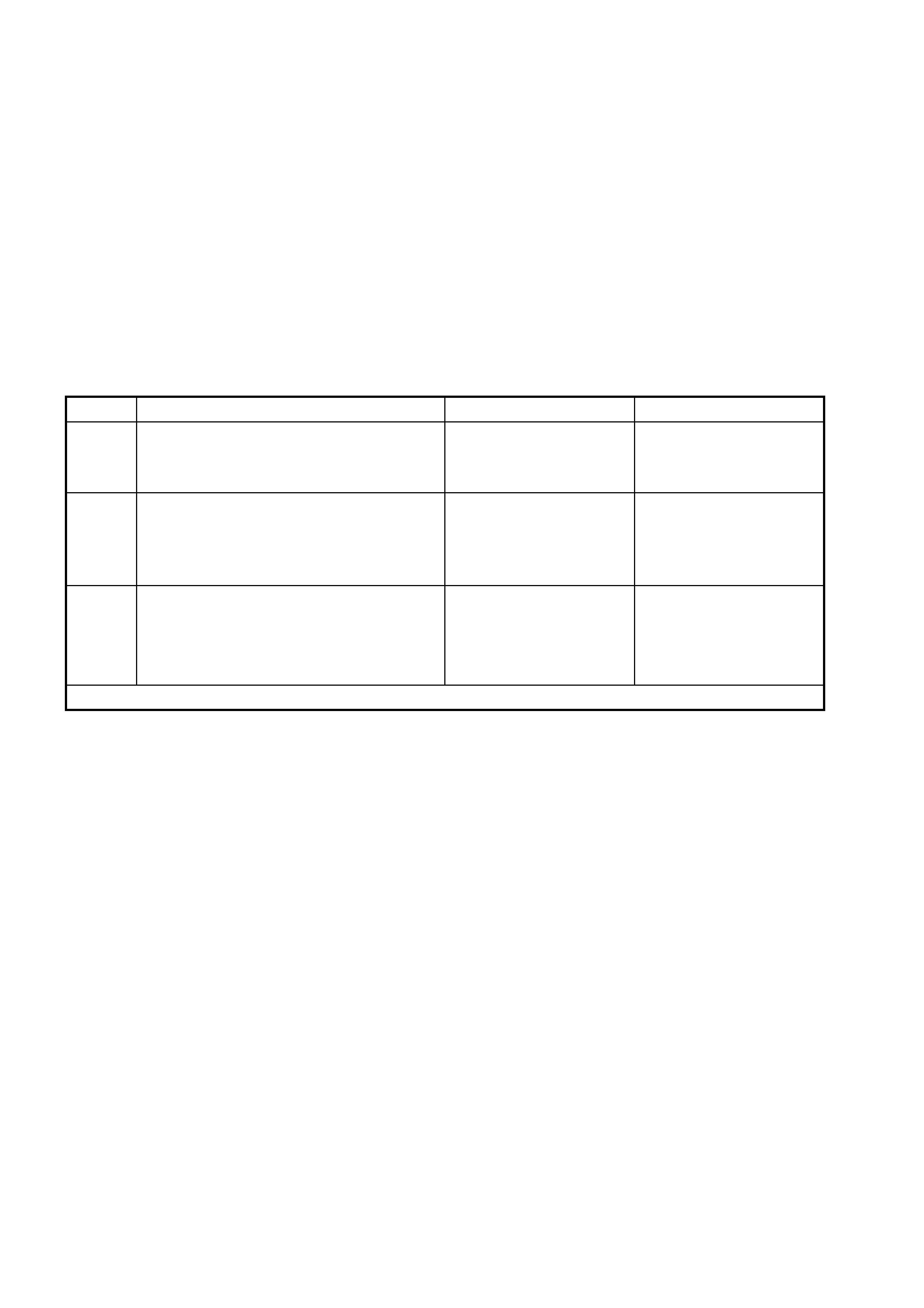

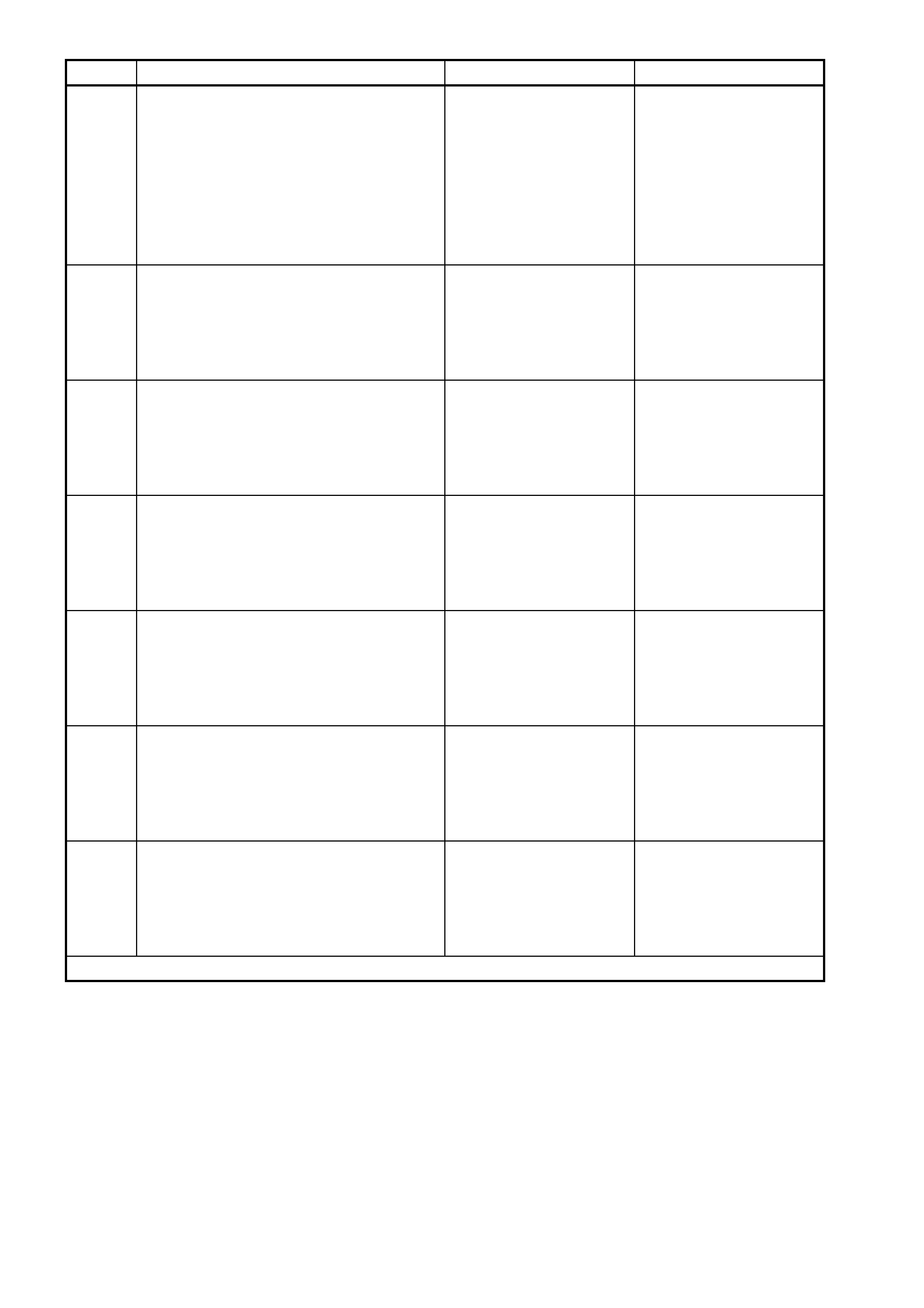

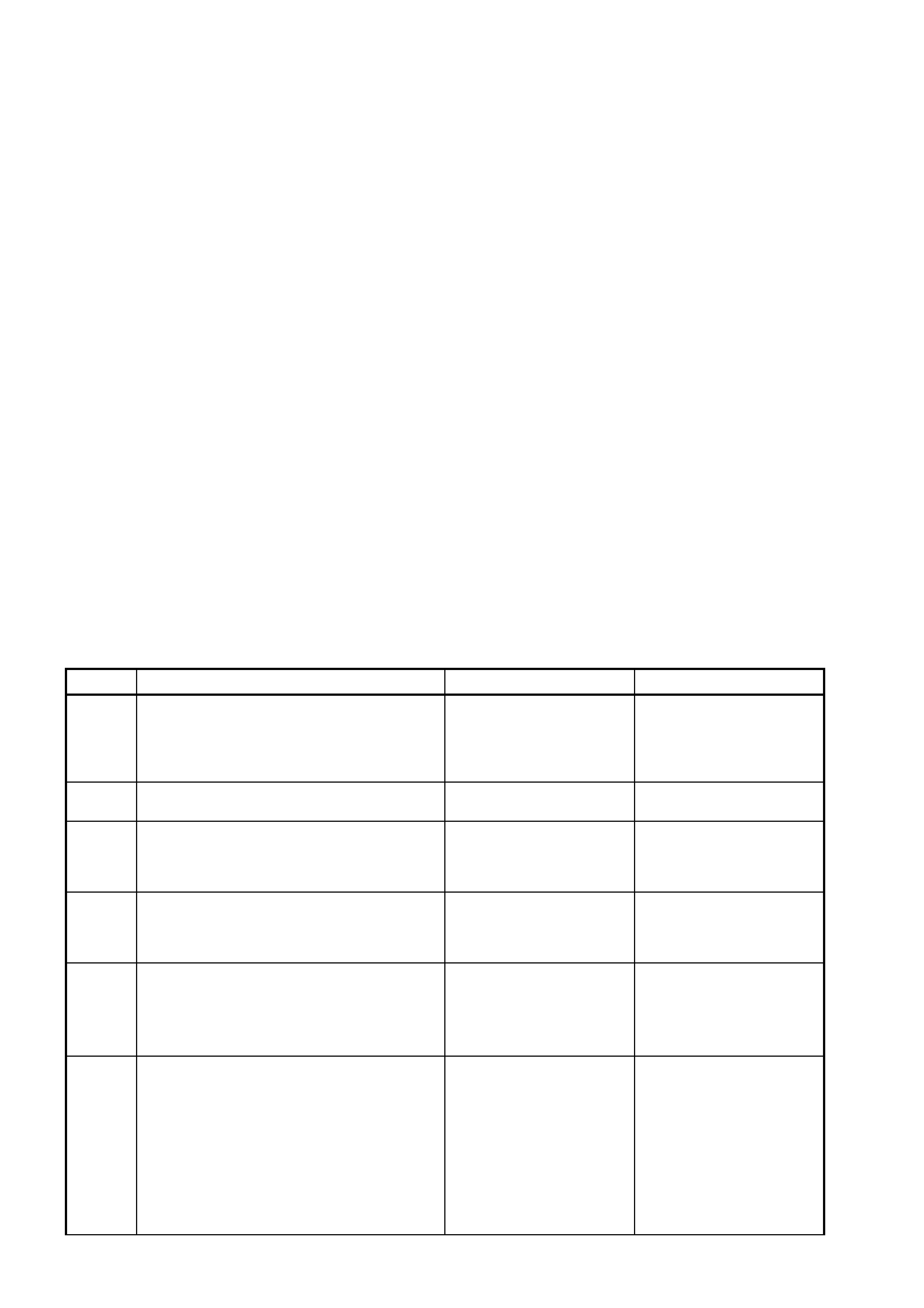

Type 1: Front Seat Assembly - 8 Way Adjust - with SIAB - with Lumber - Hook & Loop

Right-hand Shown

Figure 1A7-8

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Eight-way - Non Memory

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Pad

16. Front Seat-back Cover

17. Front Seat-back Frame Assembly

18. Lumbar Support Assembly

19. Lumbar Support Assembly Adjuster

20. Lumbar Support Adjuster Cable

21. Side Impact Airbag

22. Front Seat Foam Block Insert Assembly

23. Front Seat Cushion Pad

24. Front Seat Cushion Cover

25. Front Seat Cushion Frame Assembly

26. Adjuster & Guide Rail Assembly - Eight-way *

27. Guide Rail Assembly Wiring Harness

28. Seatbelt Buckle & Pretensioner Assembly

29. Adjustment Knobs

* Early type shown.

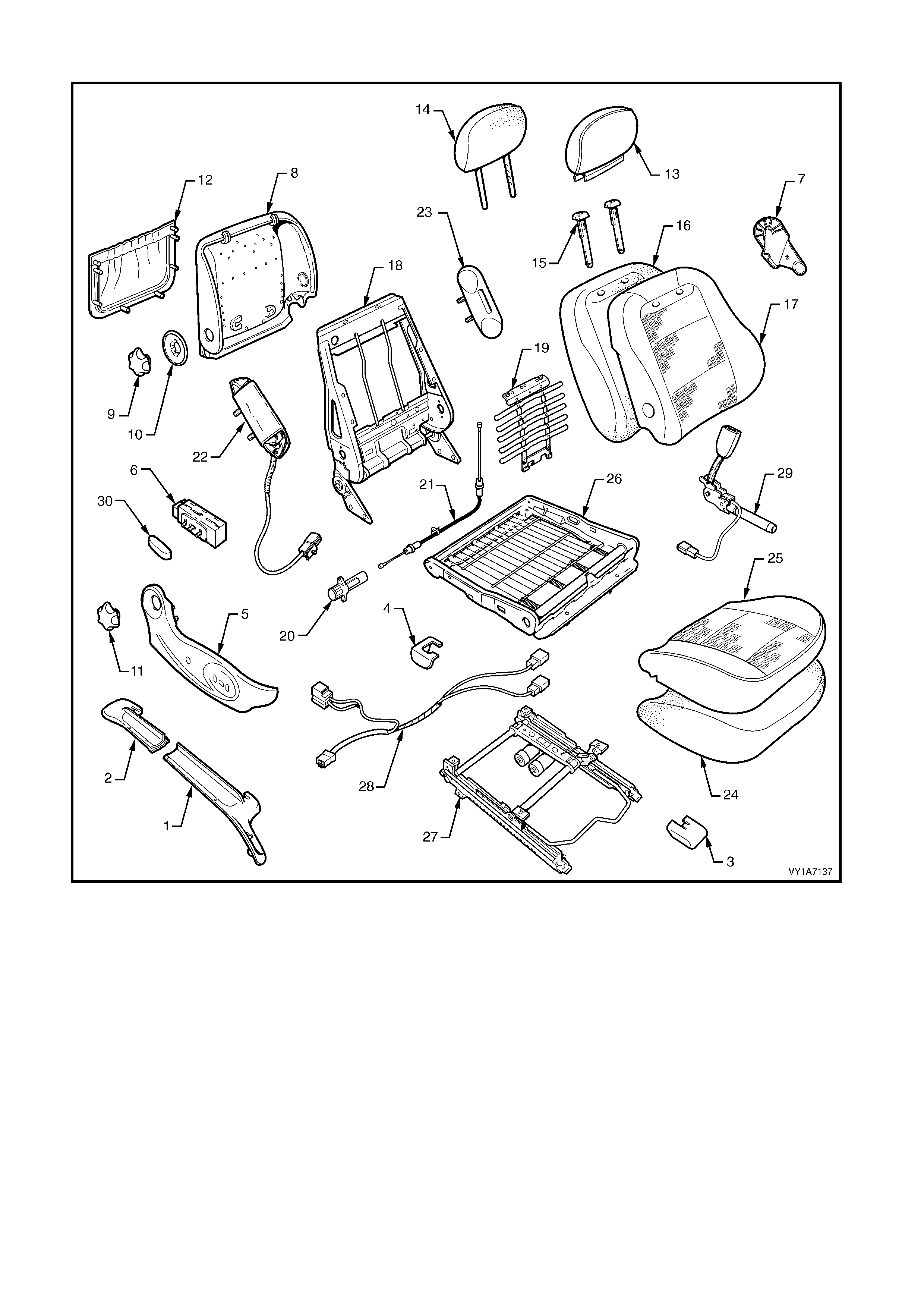

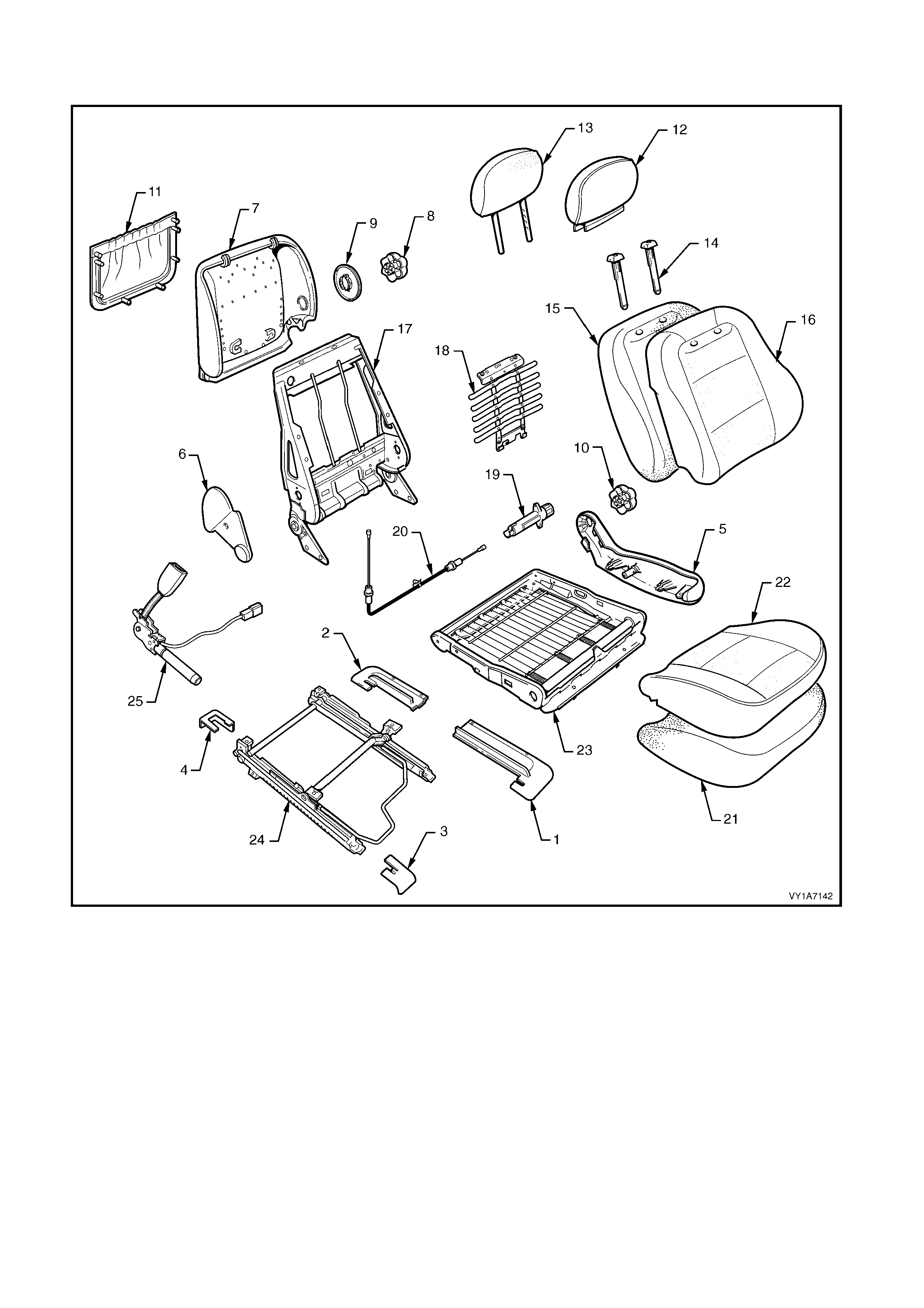

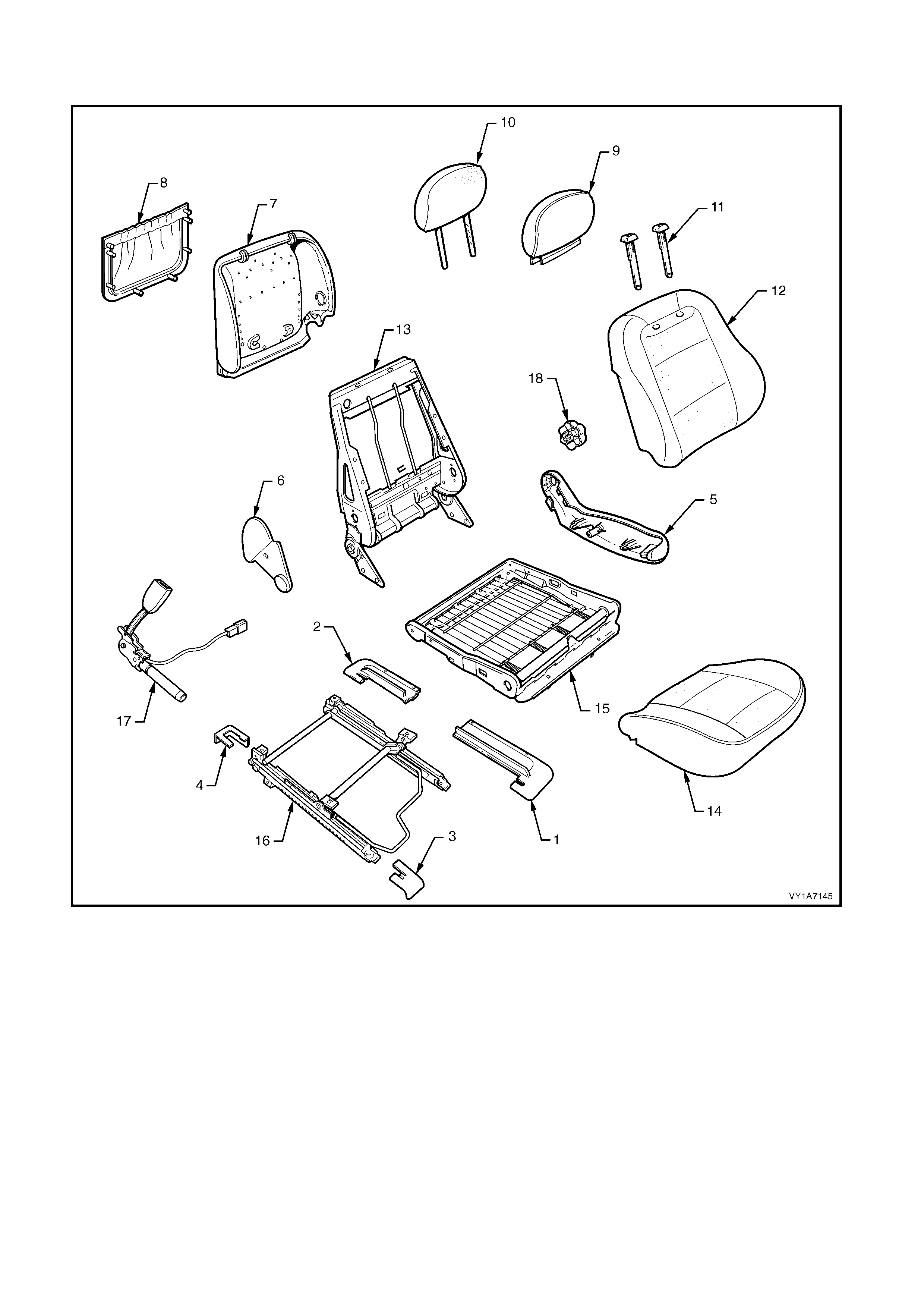

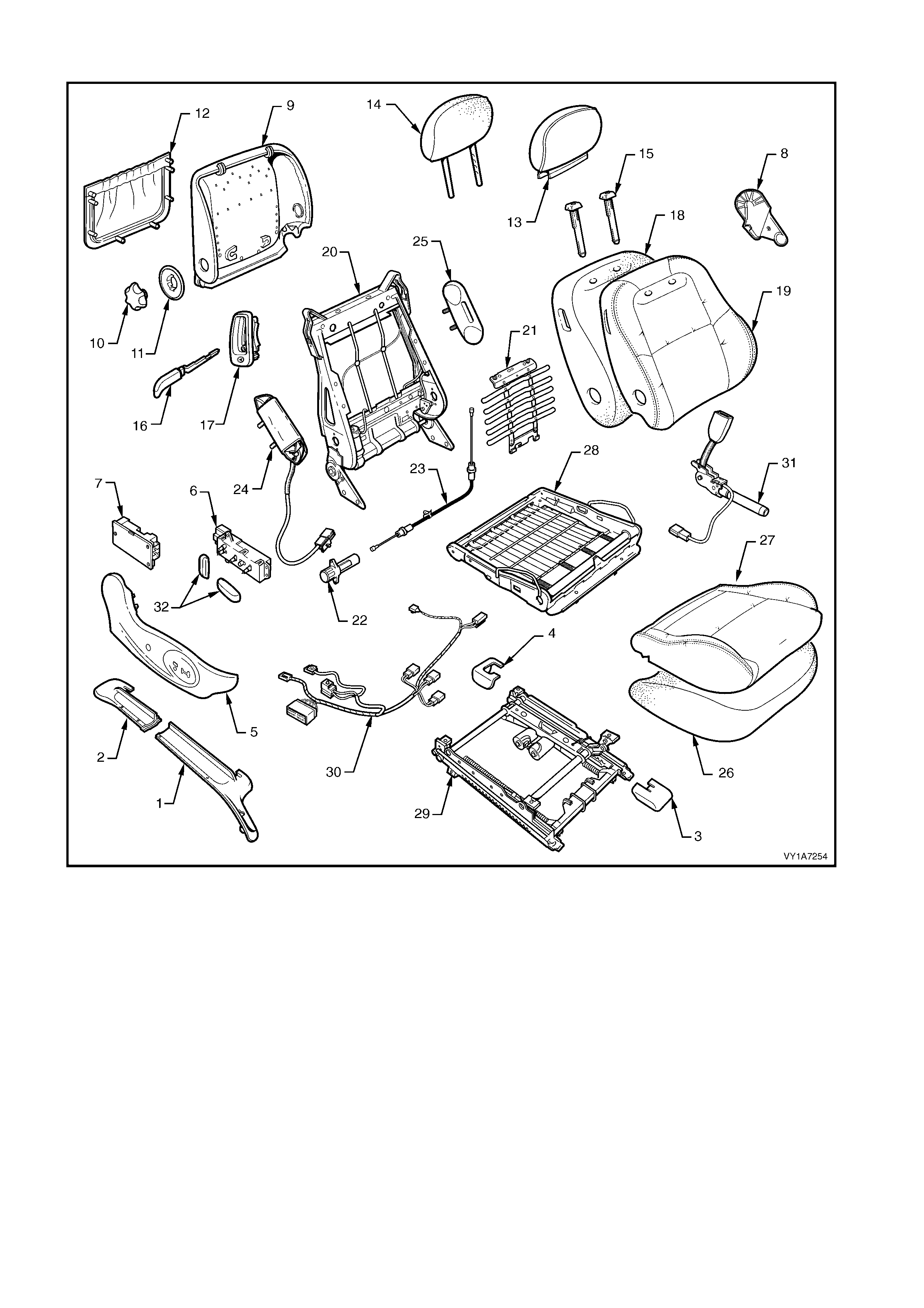

Type 2: Front Seat Assembly - 4 Way Adjust - with SIAB - with Lumber - Hook & Loop

Figure 1A7-9

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Four-way

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Recliner Adjuster Knob

12. Front Seat-back Lower Cover Pocket

13. Front Seat Head Restraint Cover

14. Front Seat Head Restraint Pad Assembly

15. Front Seat Head Restraint Guide (2 Places)

16. Front Seat-back Pad

17. Front Seat-back Cover

18. Front Seat-back Frame Assembly

19. Lumbar Support Assembly

20. Lumbar Support Assembly Adjuster

21. Lumbar Support Adjuster Cable

22. Side Impact Airbag

23. Front Seat Foam Block Insert Assembly

24. Front Seat Cushion Pad

25. Front Seat Cushion Cover

26. Front Seat Cushion Frame Assembly

27. Adjuster & Guide Rail Assembly- Four-way *

28. Guide Rail Assembly Wiring Harness

29. Seatbelt Buckle & Pretensioner Assembly

30. Adjustment Knob

* Early type shown.

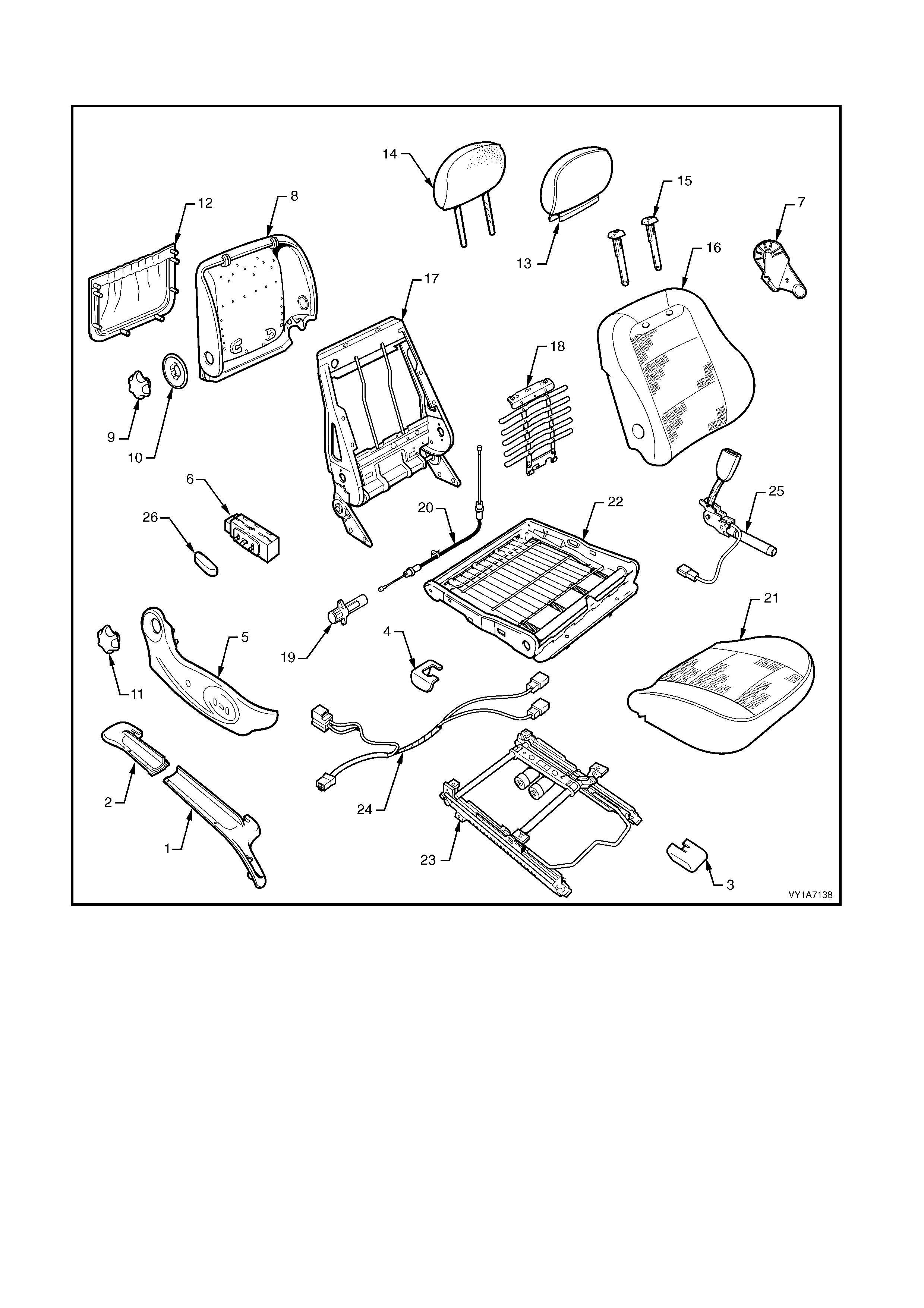

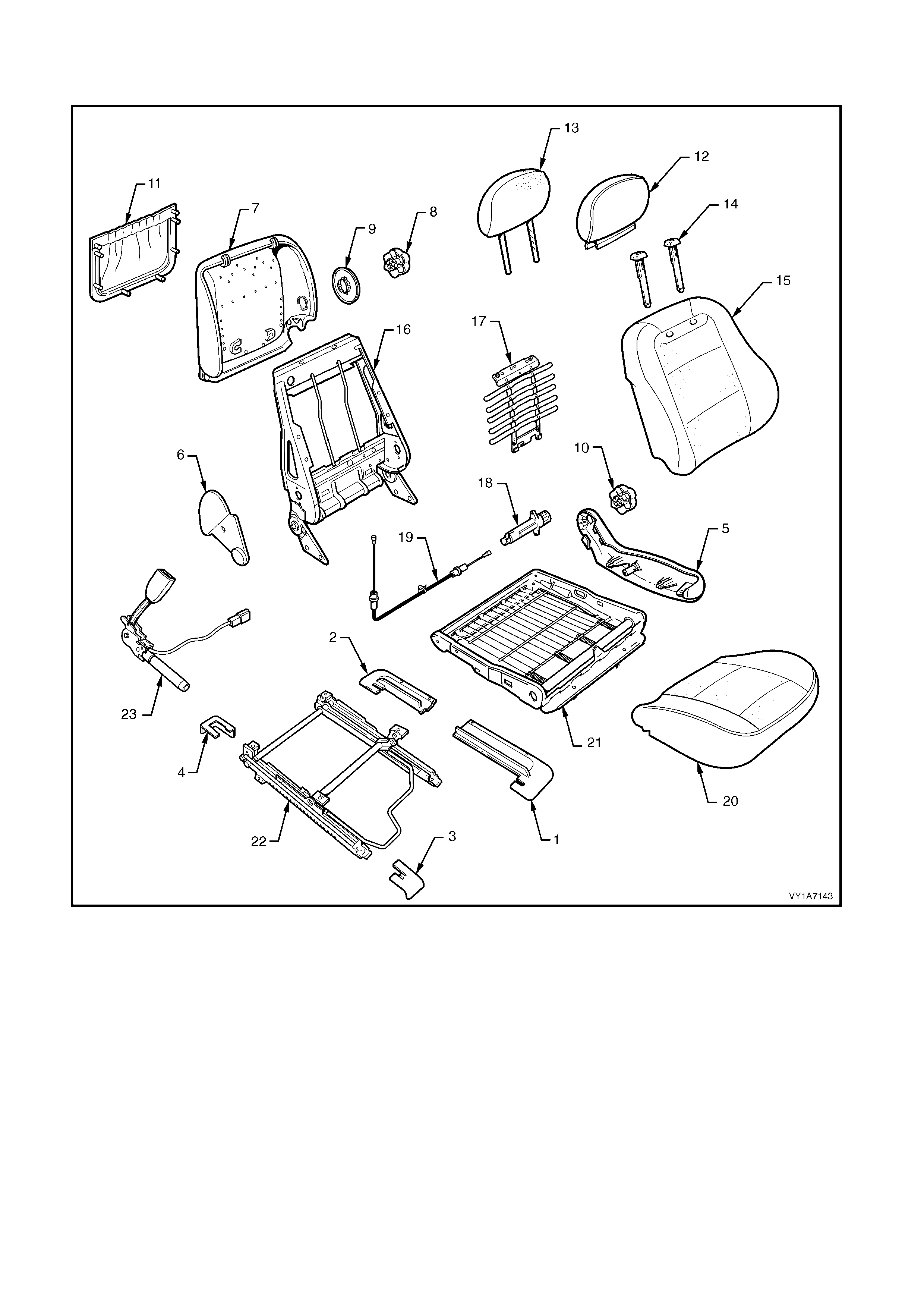

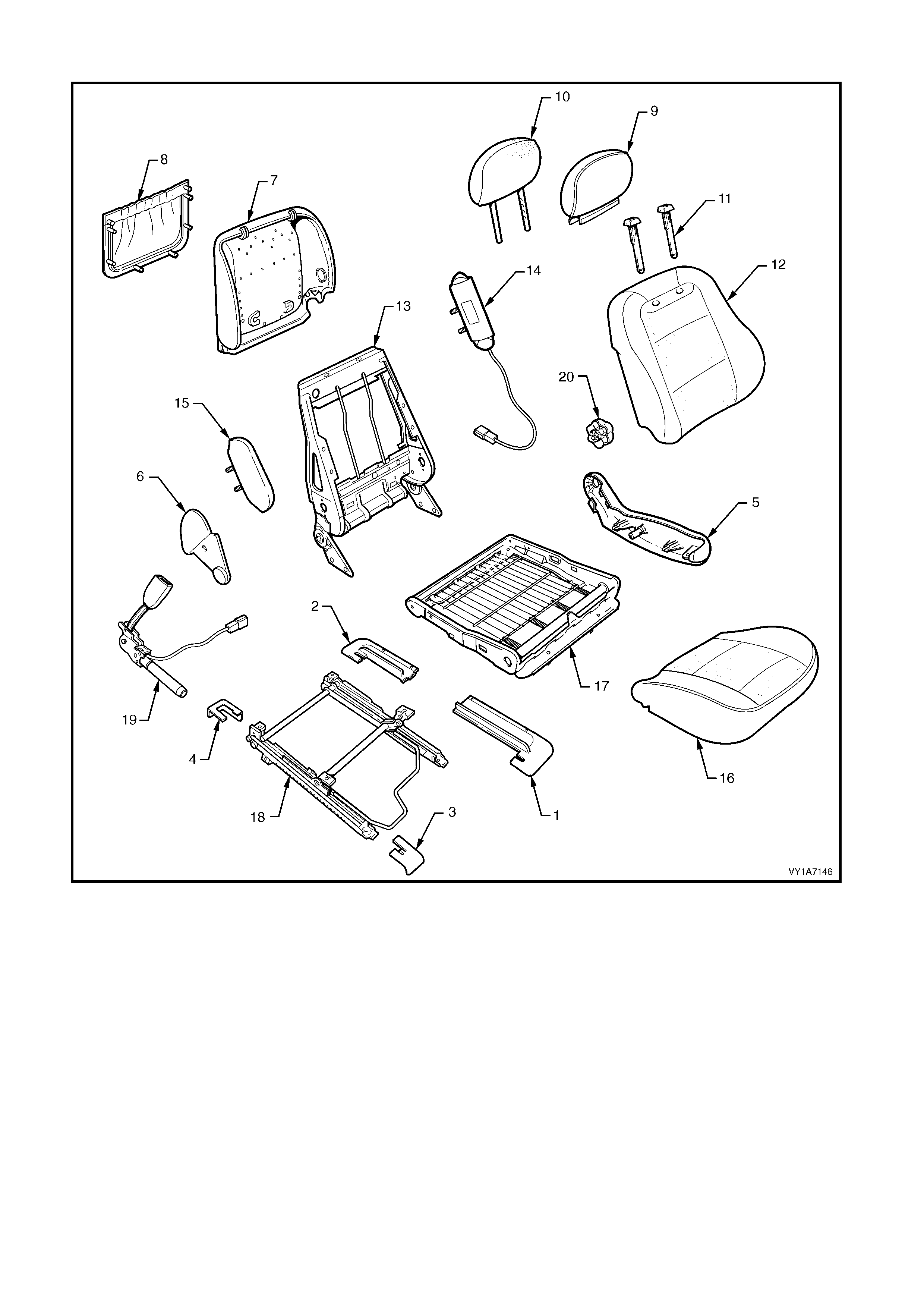

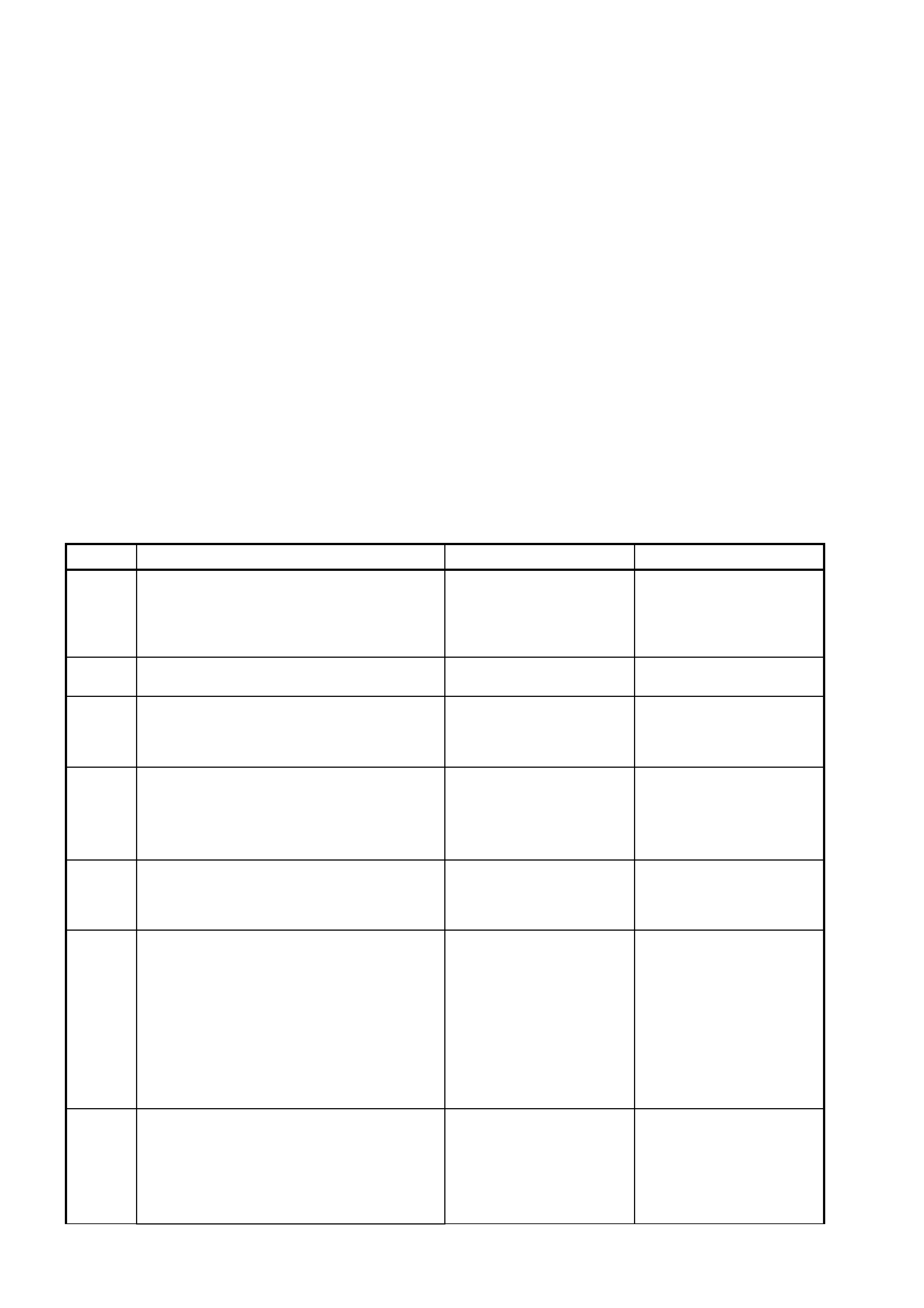

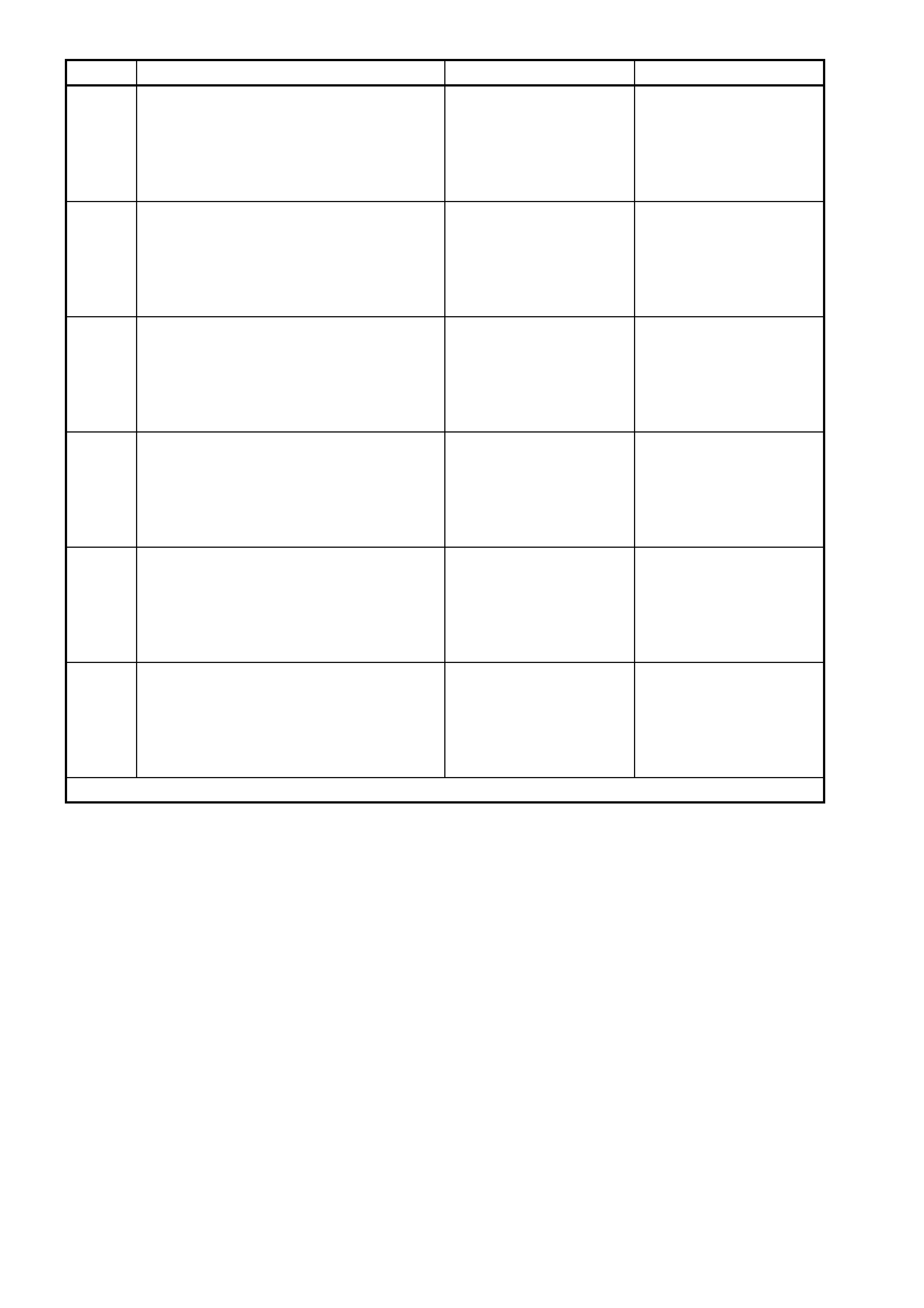

Type 3: Front Seat Assembly - 4 Way Adjust - No SIAB - with Lumber - Surebond

Right-hand Shown

Figure 1A7-10

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Four-way

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Recliner Adjuster Knob

12. Front Seat-back Lower Cover Pocket

13. Front Seat Head Restraint Cover

14. Front Seat Head Restraint Pad Assembly

15. Front Seat Head Restraint Guide - 2 Places

16. Front Seat-back Cover and Pad Assembly

17. Front Seat-back Frame Assembly

18. Lumbar Support Assembly

19. Lumbar Support Assembly Adjuster

20. Lumbar Support Adjuster Cable

21. Front Seat Cushion Cover and Pad

22. Front Seat Cushion Frame Assembly

23. Adjuster & Guide Rail Assembly - Four-way *

24. Guide Rail Assembly Wiring Harness

25. Seatbelt Buckle & Pretensioner Assembly

26. Adjustment Knob

* Early type shown.

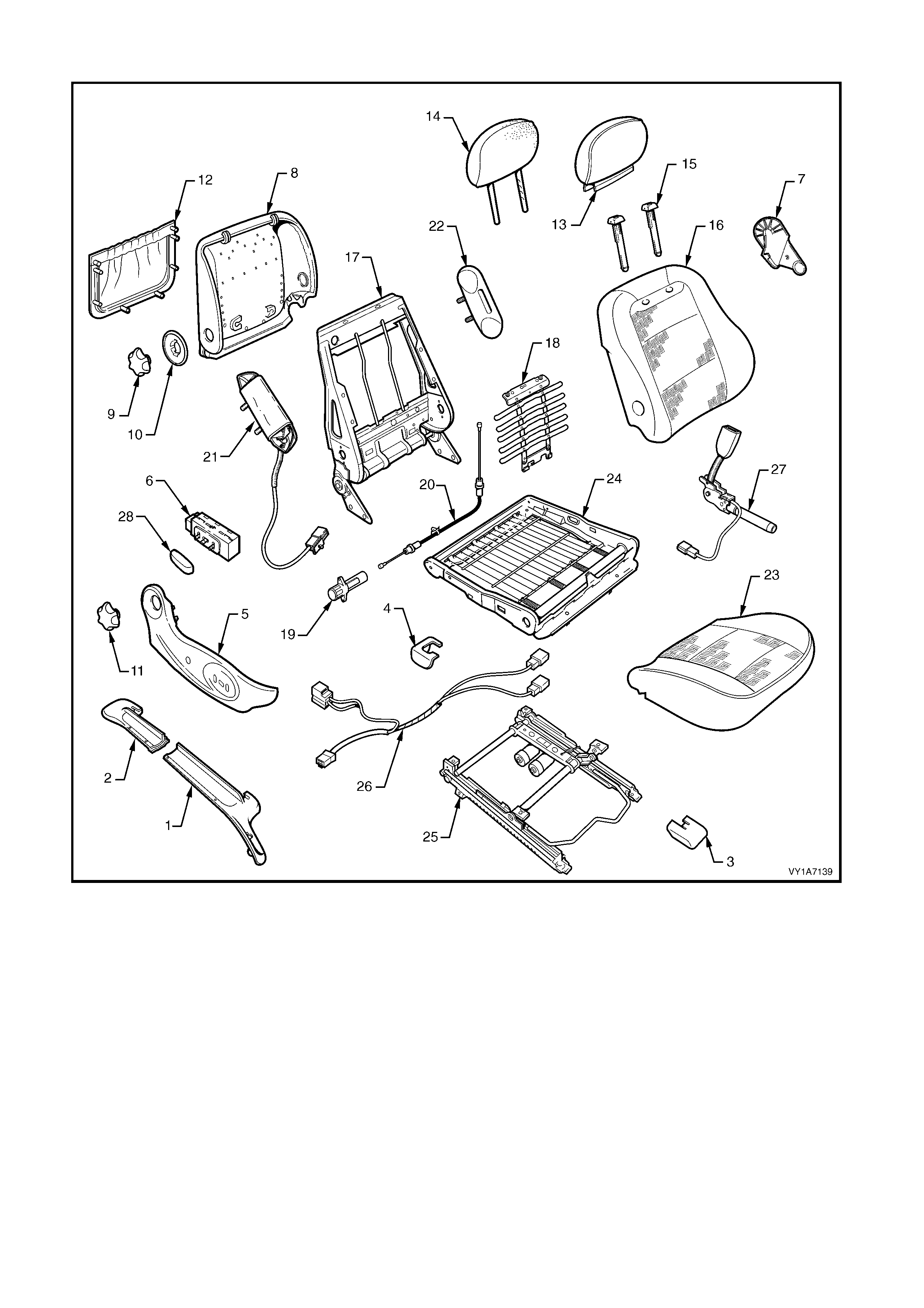

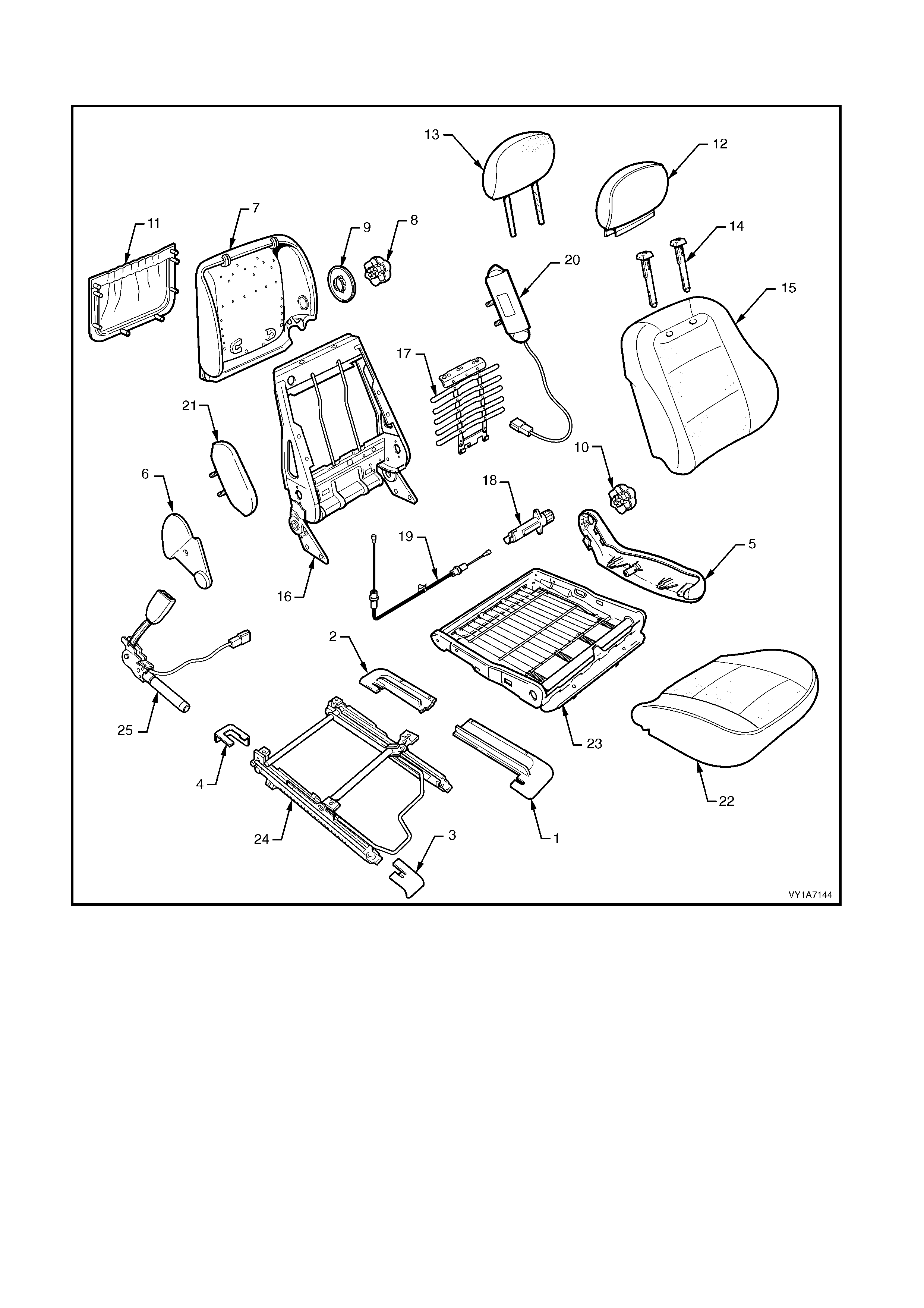

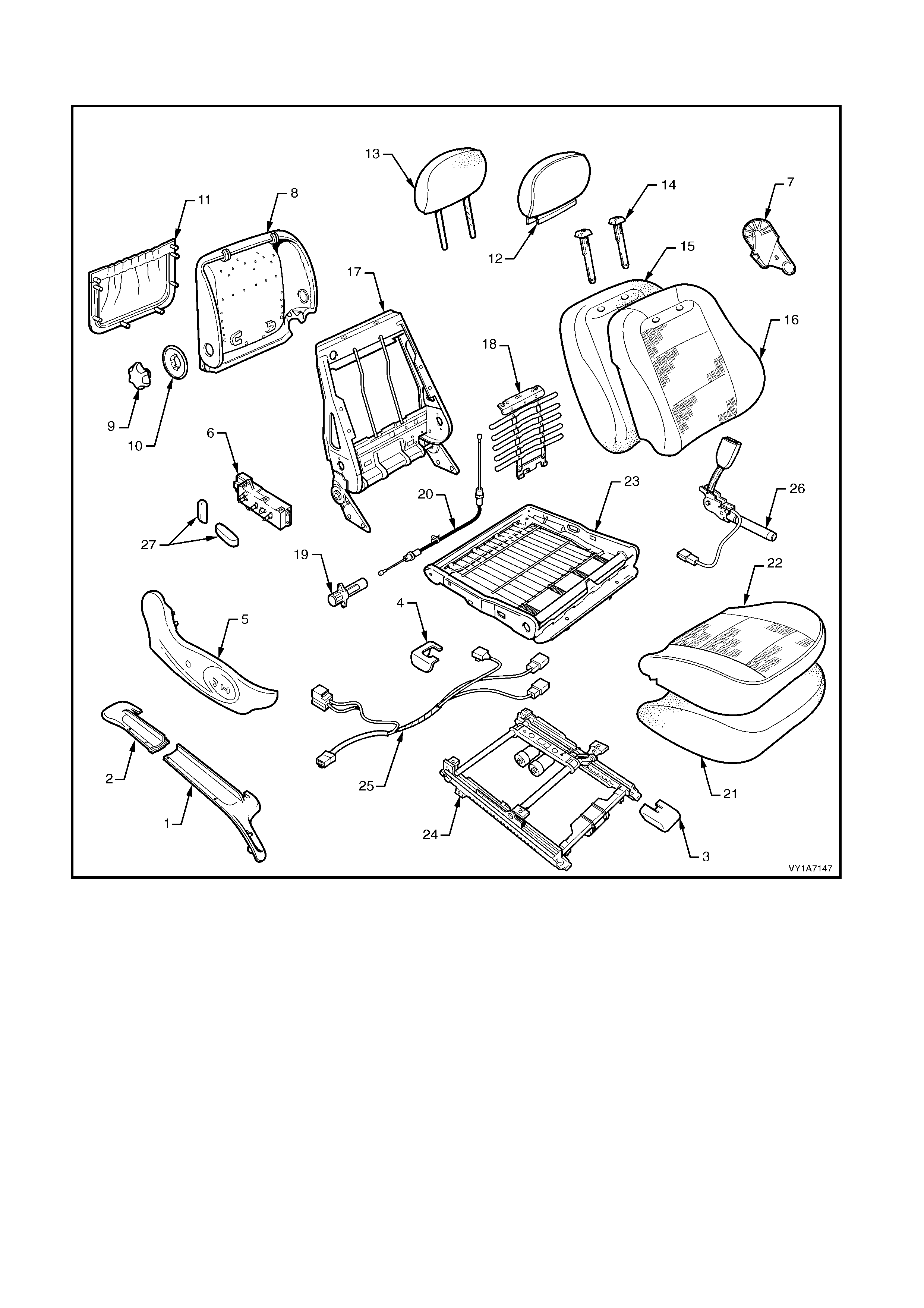

Type 4: Front Seat Assembly - 4 Way Adjust - with SIAB - with Lumber - Surebond

Figure 1A7-11

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Four-way

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Recliner Adjuster Knob

12. Front Seat-back Lower Cover Pocket

13. Front Seat Head Restraint Cover

14. Front Seat Head Restraint Pad Assembly

15. Front Seat Head Restraint Guide - 2 Places

16. Front Seat-back Cover and Pad Assembly

17. Front Seat-back Frame Assembly

18. Lumbar Support Assembly

19. Lumbar Support Assembly Adjuster

20. Lumbar Support Adjuster Cable

21. Side Impact Airbag

22. Front Seat Foam Block Insert Assembly

23. Front Seat Cushion Cover and Pad

24. Front Seat Cushion Frame Assembly

25. Adjuster & Guide Rail Assembly - Four-way *

26. Guide Rail Assembly Wiring Harness

27. Seatbelt Buckle & Pretensioner Assembly

28. Adjustment Knob

* Early type shown.

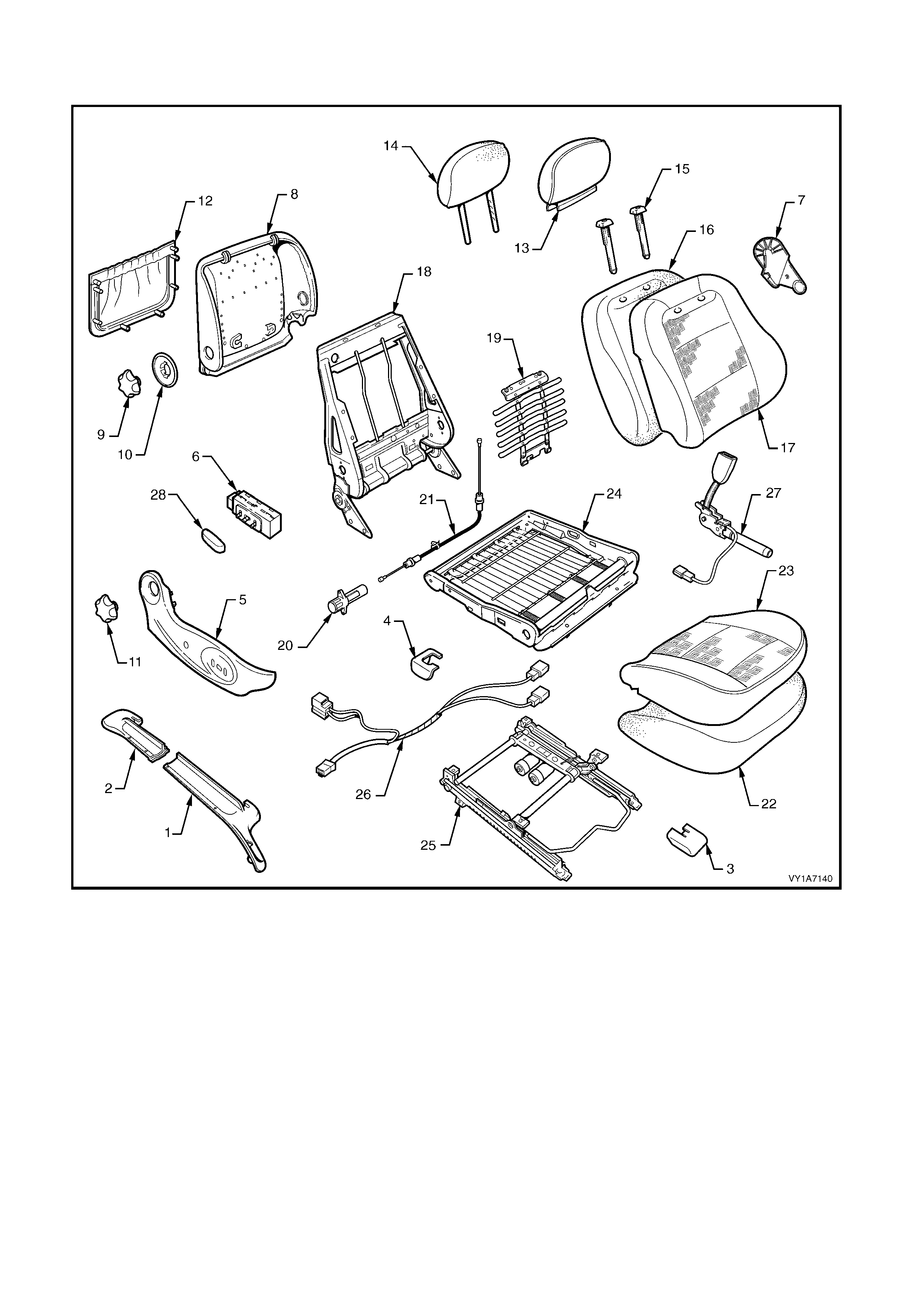

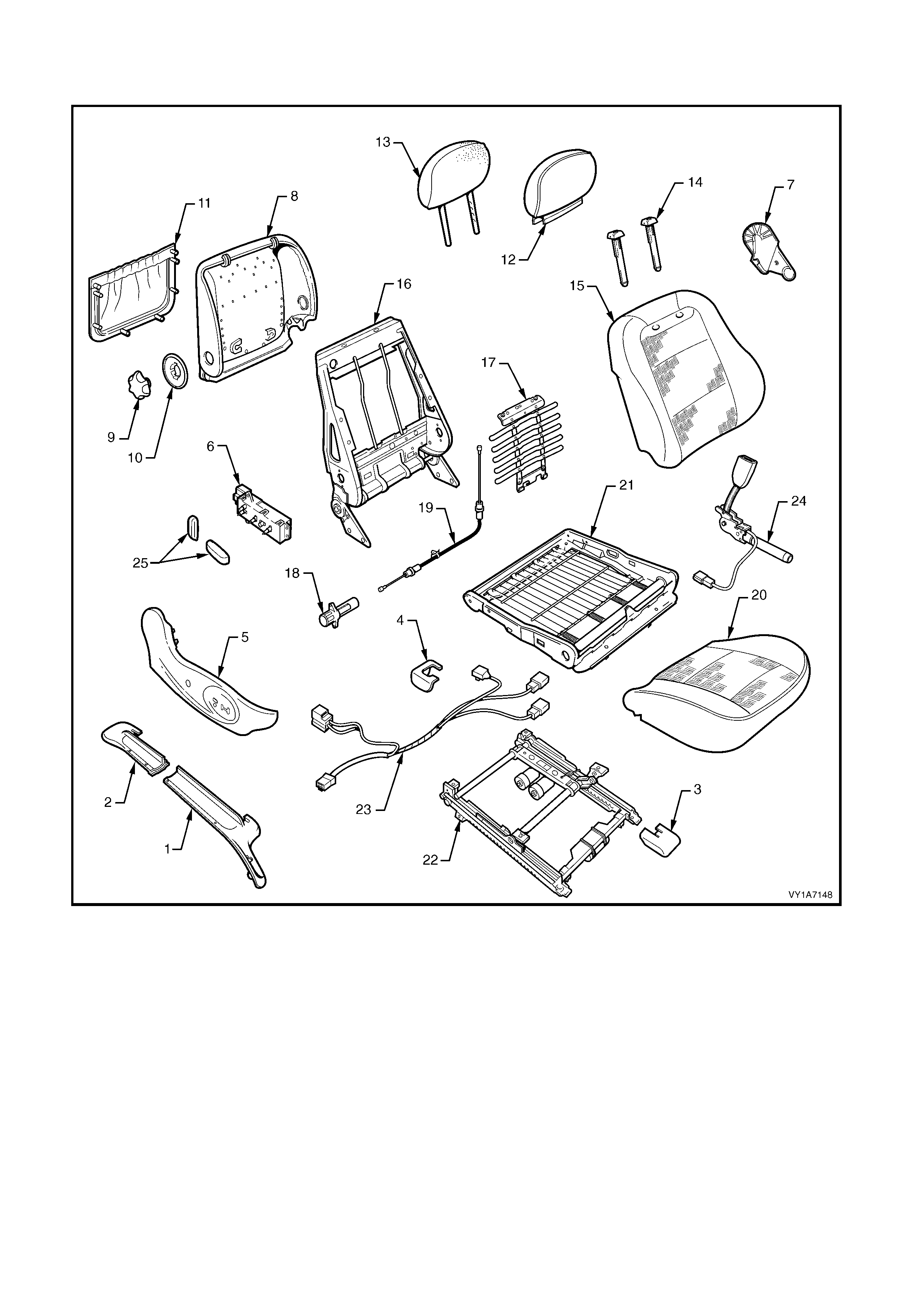

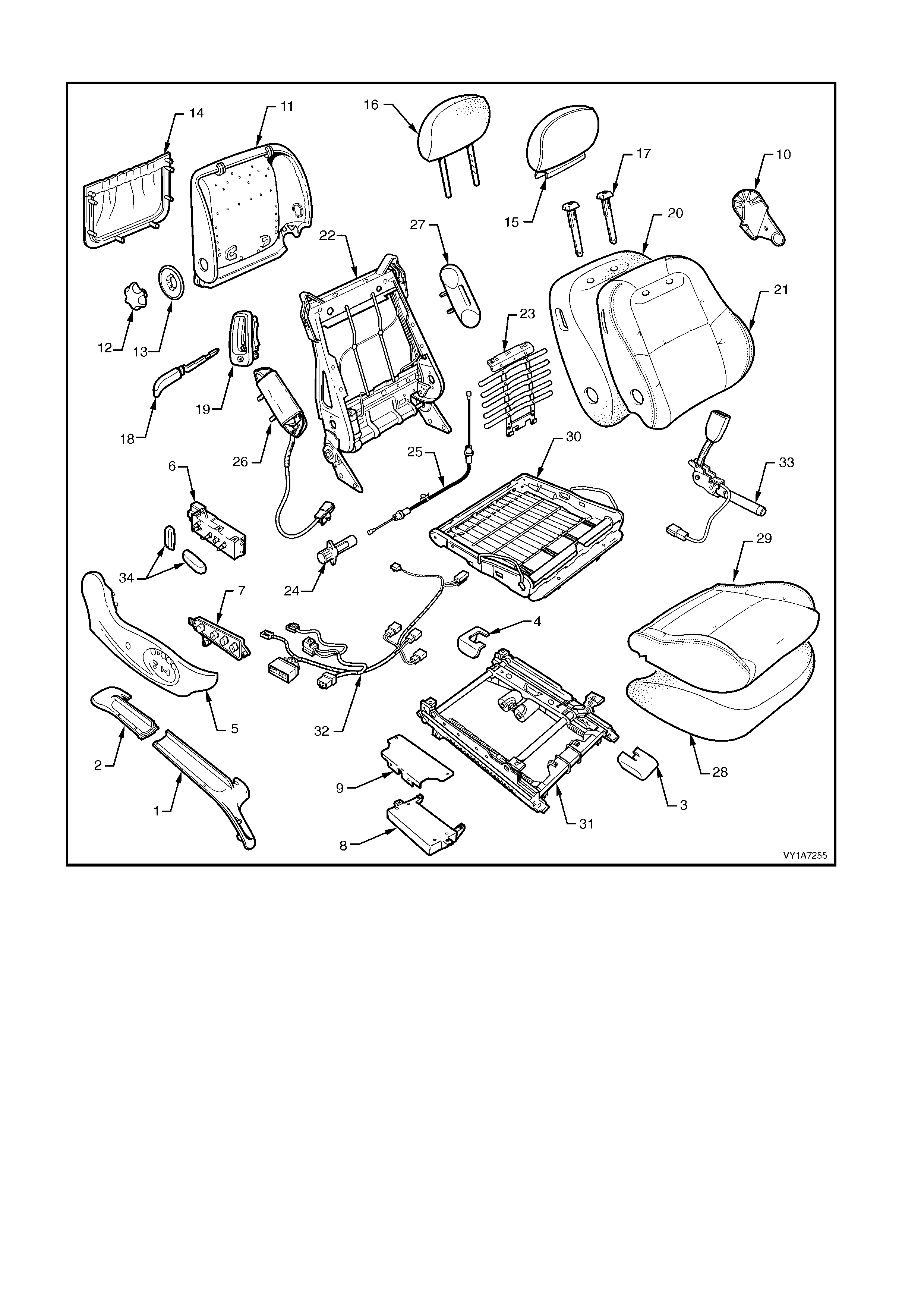

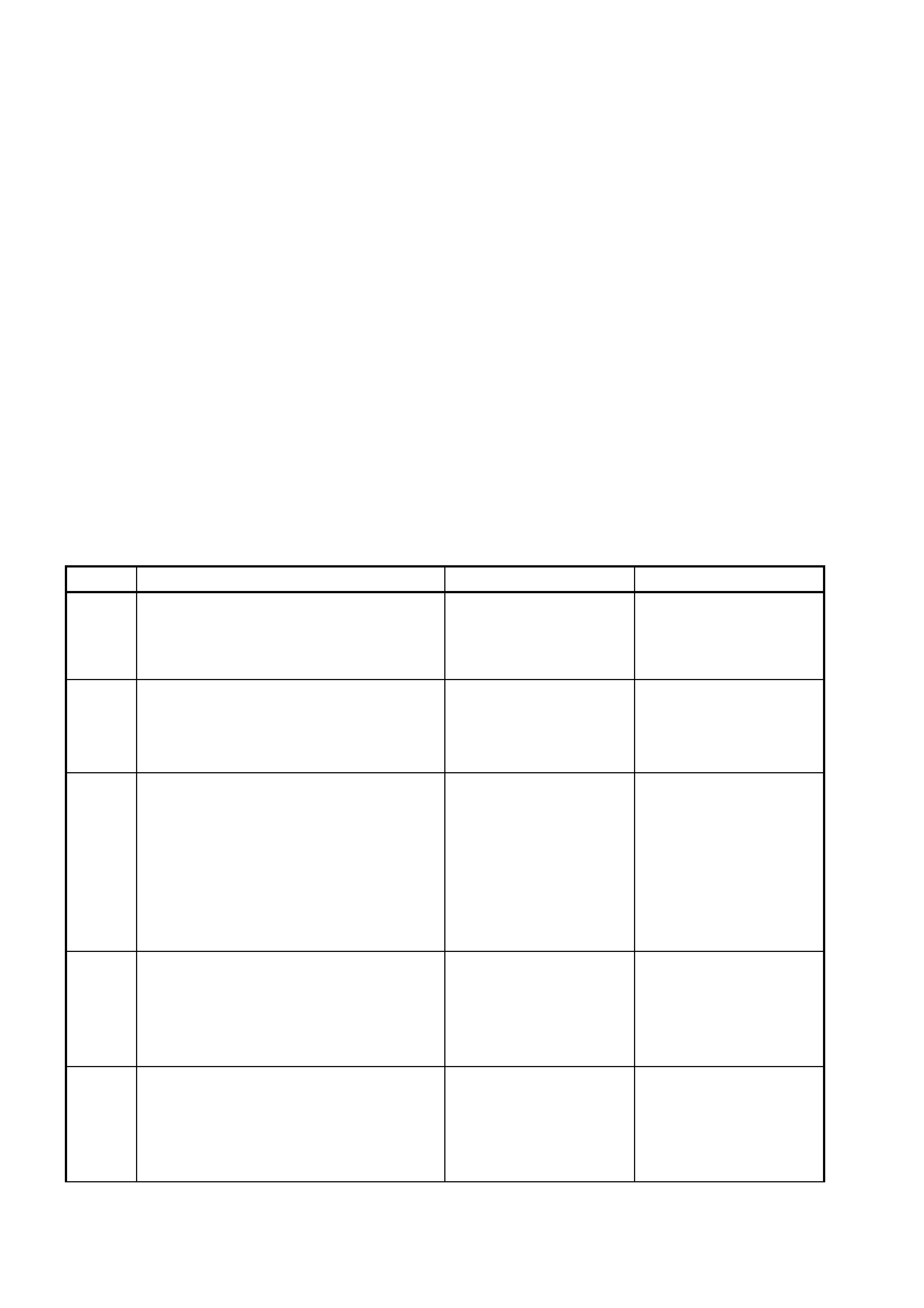

Type 5: Front Seat Assembly - 4 Way Adjust - No SIAB - with Lumber - Hook & Loop

Right-hand Shown

Figure 1A7-12

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Four-way

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Recliner Adjuster Knob

12. Front Seat-back Lower Cover Pocket

13. Front Seat Head Restraint Cover

14. Front Seat Head Restraint Pad Assembly

15. Front Seat Head Restraint Guide - 2 Places

16. Front Seat-back Pad

17. Front Seat-back Cover

18. Front Seat-back Frame Assembly

19. Lumbar Support Assembly

20. Lumbar Support Assembly Adjuster

21. Lumbar Support Adjuster Cable

22. Front Seat Cushion Pad

23. Front Seat Cushion Cover

24. Front Seat Cushion Frame Assembly

25. Adjuster & Guide Rail Assembly - Four-way *

26. Guide Rail Assembly Wiring Harness

27. Seatbelt Buckle & Pretensioner Assembly

28. Adjustment Knob

* Early type shown.

Type 6: Front Seat Assembly - 2 Way Adjust - with SIAB - with Lumber - Hook & Loop

Left-hand Shown

Figure 1A7-13

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Inner Side Cover

7. Front Seat-back Lower Cover

8. Lumbar Support Adjuster Knob

9. Lumber Support Adjuster Knob Adapter

10. Recliner Adjuster Knob

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Pad

16. Front Seat-back Cover

17. Front Seat-back Frame Assembly

18. Lumbar Support Assembly

19. Lumbar Support Assembly Adjuster

20. Lumbar Support Adjuster Cable

21. Side Impact Airbag

22. Front Seat Foam Block Insert Assembly

23. Front Seat Cushion Pad

24. Front Seat Cushion Cover

25. Front Seat Cushion Frame Assembly

26. Adjuster & Guide Rail Assembly - Two Way *

27. Seatbelt Buckle & Pretensioner Assembly

* Early type shown.

Type 7: Front Seat Assembly - 2 Way Adjust - No SIAB - with Lumber - Hook & Loop

Left-hand Shown

Figure 1A7-14

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Inner Side Cover

7. Front Seat-back Lower Cover

8. Lumbar Support Adjuster Knob

9. Lumber Support Adjuster Knob Adapter

10. Recliner Adjuster Knob

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Pad

16. Front Seat-back Cover

17. Front Seat-back Frame Assembly

18. Lumbar Support Assembly

19. Lumbar Support Assembly Adjuster

20. Lumbar Support Adjuster Cable

21. Front Seat Cushion Pad

22. Front Seat Cushion Cover

23. Front Seat Cushion Frame Assembly

24. Adjuster & Guide Rail Assembly - Two Way *

25. Seatbelt Buckle & Pretensioner Assembly

* Early type shown.

Type 8: Front Seat Assembly - 2 Way Adjust - No SIAB - with Lumber - Surebond

Left-hand Shown

Figure 1A7-15

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Inner Side Cover

7. Front Seat-back Lower Cover

8. Lumbar Support Adjuster Knob

9. Lumber Support Adjuster Knob Adapter

10. Recliner Adjuster Knob

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Cover and Pad Assembly

16. Front Seat-back Frame Assembly

17. Lumbar Support Assembly

18. Lumbar Support Assembly Adjuster

19. Lumbar Support Adjuster Cable

20. Front Seat Cushion Cover and Pad

21. Front Seat Cushion Frame Assembly

22. Adjuster & Guide Rail Assembly - Two Way *

23. Seatbelt Buckle & Pretensioner Assembly

* Early type shown.

Type 9: Front Seat Assembly - 2 Way Adjust - with SIAB - with Lumber - Surebond

Left-hand Shown

Figure 1A7-16

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Inner Side Cover

7. Front Seat-back Lower Cover

8. Lumbar Support Adjuster Knob

9. Lumber Support Adjuster Knob Adapter

10. Recliner Adjuster Knob

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Cover and Pad Assembly

16. Front Seat-back Frame Assembly

17. Lumbar Support Assembly

18. Lumbar Support Assembly Adjuster

19. Lumbar Support Adjuster Cable

20. Side Impact Airbag

21. Front Seat Foam Block Insert Assembly

22. Front Seat Cushion Cover and Pad Assembly

23. Front Seat Cushion Frame Assembly

24. Adjuster & Guide Rail Assembly - Two Way *

25. Seatbelt Buckle & Pretensioner Assembly

* Early type shown.

Type 10: Front Seat Assembly - 2 Way Adjust - No SIAB - No Lumber - Surebond

Left-hand Shown

Figure 1A7-17

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Inner Side Cover

7. Front Seat-back Lower Cover

8. Front Seat-back Lower Cover Pocket

9. Front Seat Head Restraint Cover

10. Front Seat Head Restraint Pad Assembly

11. Front Seat Head Restraint Guide - 2 Places

12. Front Seat-back Cover and Pad Assembly

13. Front Seat-back Frame Assembly

14. Front Seat Cushion Cover and Pad

15. Front Seat Cushion Frame Assembly

16. Adjuster & Guide Rail Assembly - Two Way *

17. Seatbelt Buckle & Pretensioner Assembly

18. Recliner Adjuster Knob

* Early type shown.

Type 11: Front Seat Assembly - 2 Way Adjust - with SIAB - No Lumber - Surebond

Figure 1A7-18

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Inner Side Cover

7. Front Seat-back Lower Cover

8. Front Seat-back Lower Cover Pocket

9. Front Seat Head Restraint Cover

10. Front Seat Head Restraint Pad Assembly

11. Front Seat Head Restraint Guide - 2 Places

12. Front Seat-back Cover and Pad Assembly

13. Front Seat-back Frame Assembly

14. Side Impact Airbag

15. Front Seat Foam Block Insert Assembly

16. Front Seat Cushion Cover and Pad

17. Front Seat Cushion Frame Assembly

18. Adjuster & Guide Rail Assembly - Two Way *

19. Seatbelt Buckle & Pretensioner Assembly

20. Lumbar Support Adjuster Knob

* Early type shown.

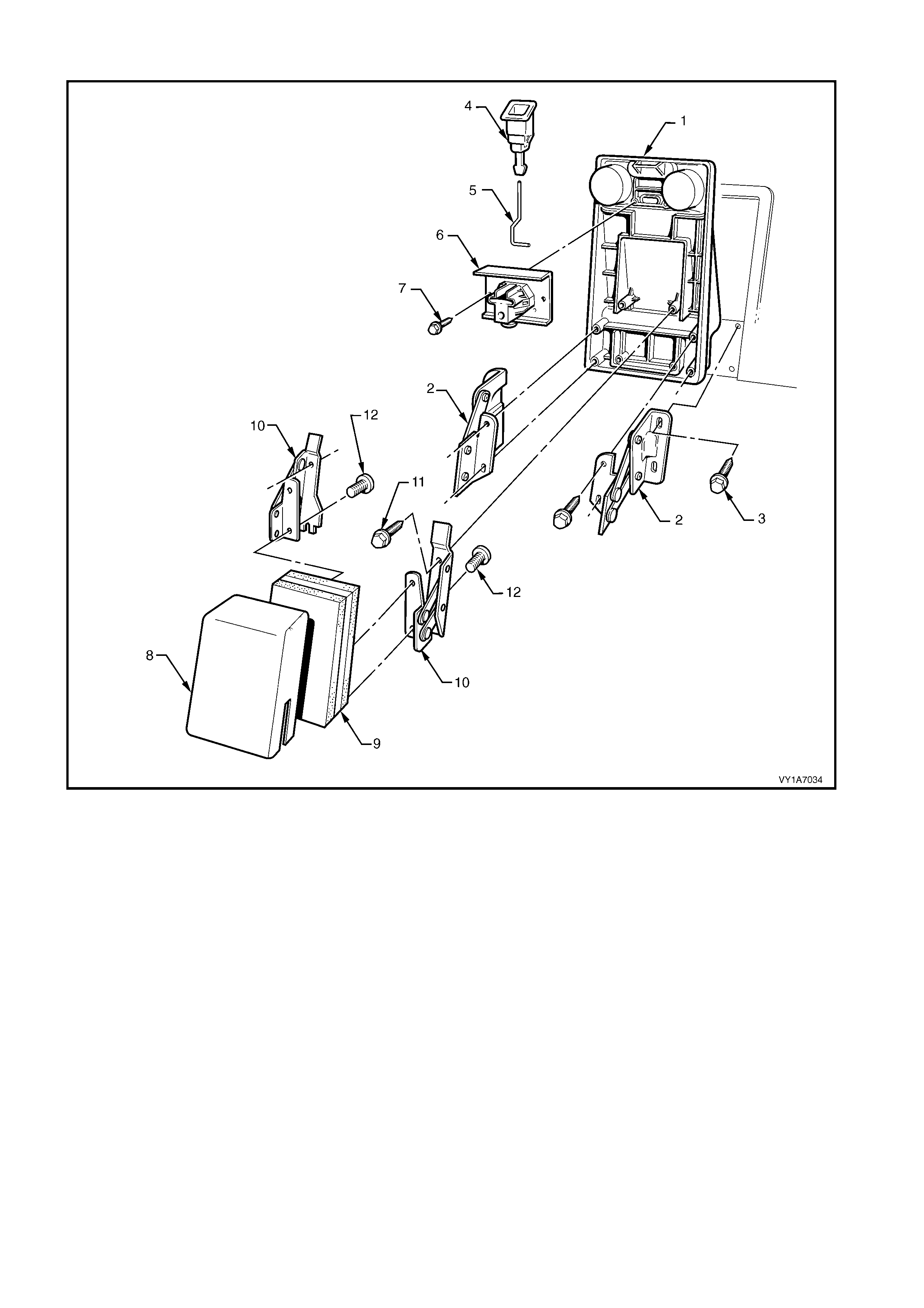

Type 12: Front Seat Assembly - 8 Way Adjust - No SIAB - with Lumber - Hook & Loop

Right-hand Shown

Figure 1A7-19

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Eight-way -

Non Memory

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Pad

16. Front Seat-back Cover

17. Frame Assembly - Front Seat-back

18. Lumbar Support Assembly

19. Lumbar Support Assembly Adjuster

20. Lumbar Support Adjuster Cable

21. Front Seat Cushion Pad

22. Front Seat Cushion Cover

23. Front Seat Cushion Frame Assembly

24. Adjuster & Guide Rail Assembly- Eight-way *

25. Guide Rail Assembly Wiring Harness

26. Seatbelt Buckle & Pretensioner Assembly

27. Adjustment Knobs

* Early type shown.

TYPE 13: Front Seat Assembly - 8 Way Adjust - No SIAB - with Lumber - Surebond

Right-hand Shown

Figure 1A7-20

Legend

1. Seat Adjuster Outer Front Cover

2. Front Seat Outer Lower Rear Cover

3. Front Inner Guide Rail Cover

4. Rear Inner Guide Rail Cover

5. Front Seat Outer Side Cover

6. Front Seat Adjustment Switch - Eight-way - Non Memory

7. Front Seat Inner Side Cover

8. Front Seat-back Lower Cover

9. Lumbar Support Adjuster Knob

10. Lumber Support Adjuster Knob Adapter

11. Front Seat-back Lower Cover Pocket

12. Front Seat Head Restraint Cover

13. Front Seat Head Restraint Pad Assembly

14. Front Seat Head Restraint Guide - 2 Places

15. Front Seat-back Cover and Pad Assembly

16. Front Seat-back Frame Assembly

17. Lumbar Support Assembly

18. Lumbar Support Assembly Adjuster

19. Lumbar Support Adjuster Cable

20. Front Seat Cushion Cover and Pad

21. Front Seat Cushion Frame Assembly

22. Adjuster & Guide Rail Assembly- Eight-way *

23. Guide Rail Assembly Wiring Harness

24. Seatbelt Buckle & Pretensioner Assembly

25. Adjustment Knobs

* Early type shown.

2.2 FRONT SEAT ASSEMBLY

LT Section No. – 14-295

CAUTION 1: Before performing any service operation on a front seat assembly fitted with side impact

airbags, ensure the occupant protection system is disabled, refer to Section 12M OCCUPANT

PROTECTION SYSTEM.

CAUTION 2: Accessory and after market seat covers MUST NOT be fitted to a vehicle with side impact

airbags, unless approved by the vehicle manufacturer. Seat covers that are not approved by the vehicle

manufacturer could greatly inhibit the performance of the side impact airbag and the occupant’s safety in

the event of side impact airbag deployment.

IMPORTANT 1: If the seat assembly is to be dissembled and it has an electric seat height adjuster, adjust the

seat assembly to its highest position before disconnecting the power to the seat.

IMPORTANT 2: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: Clean hands are essential when working on the interior trim.

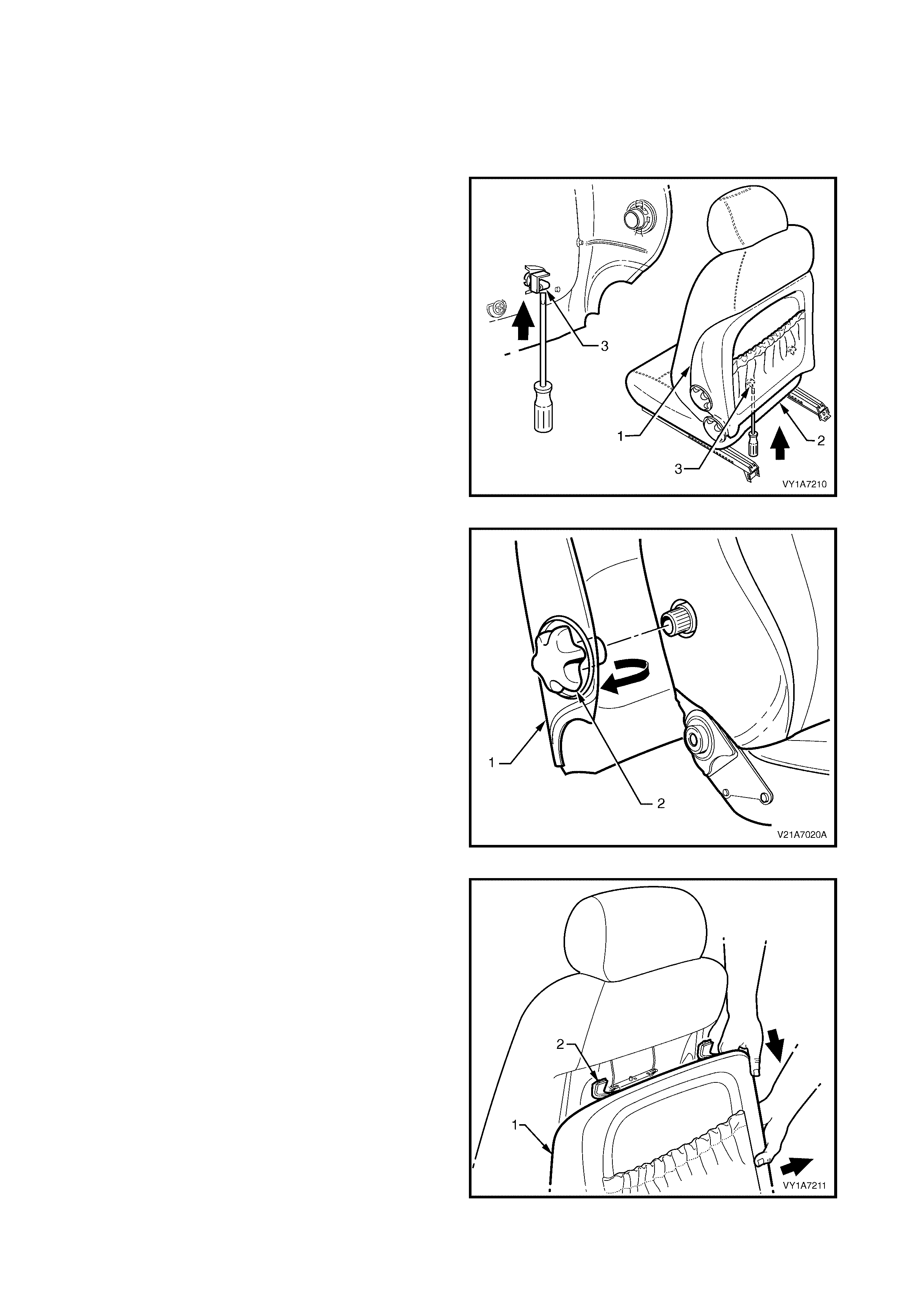

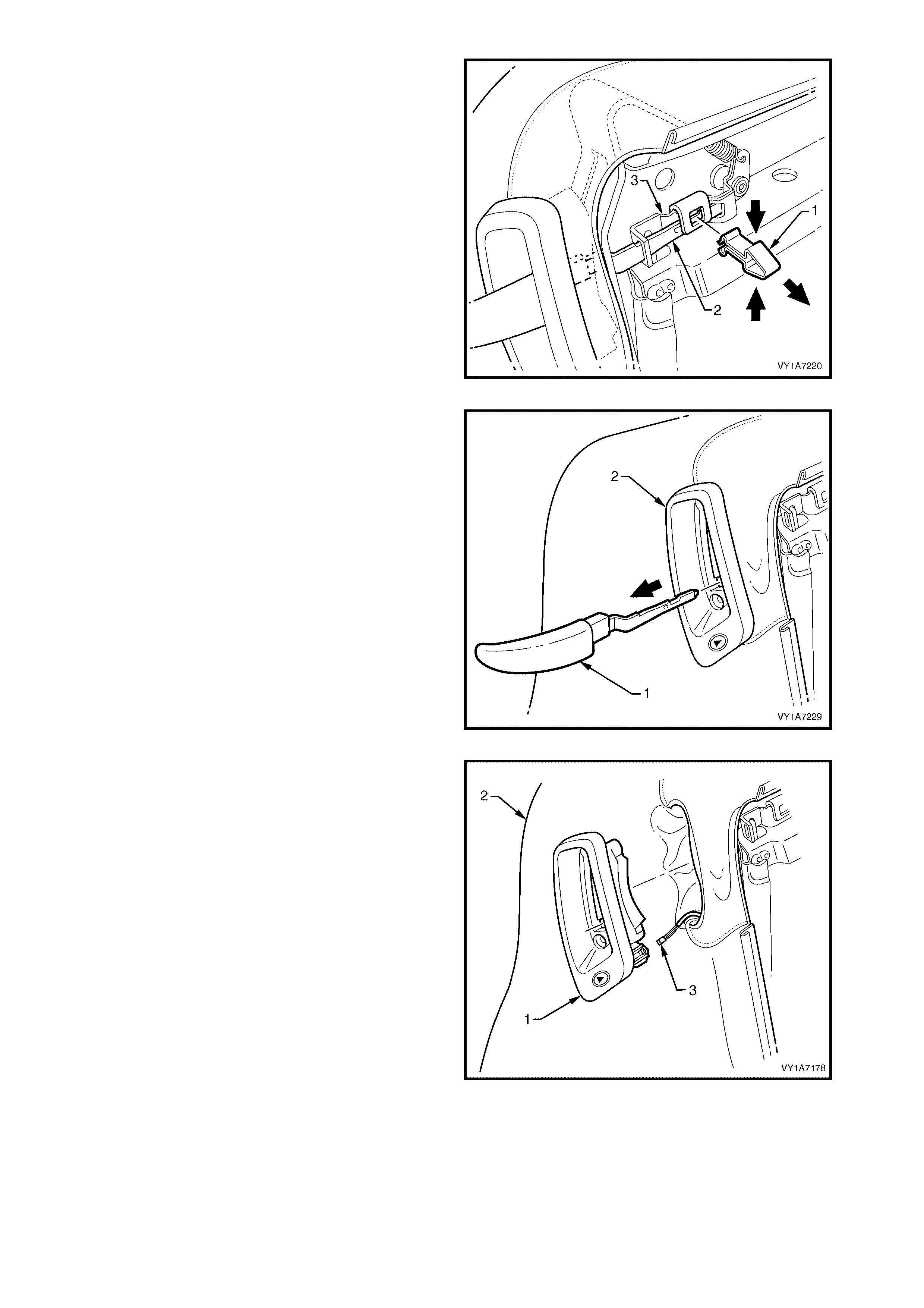

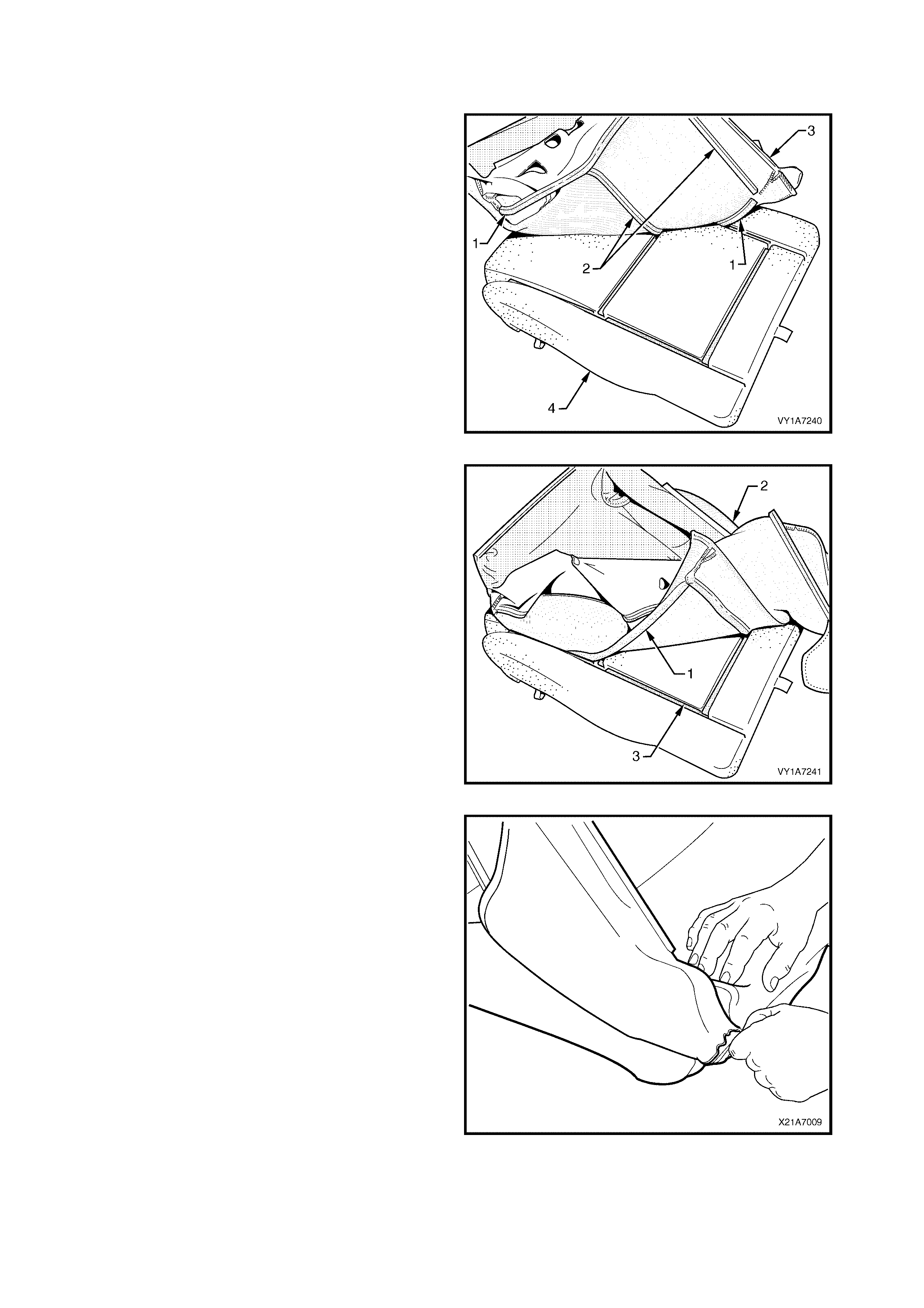

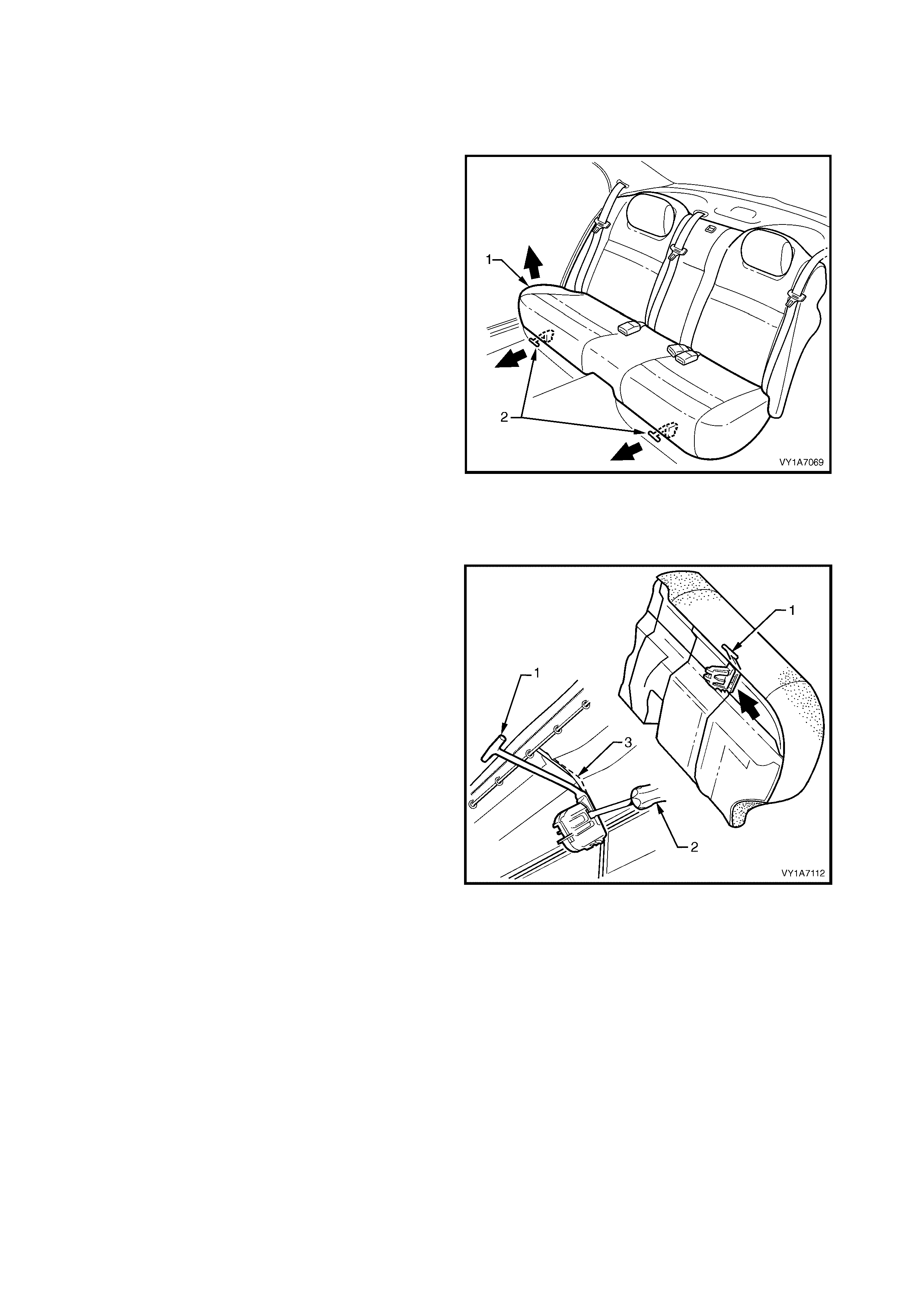

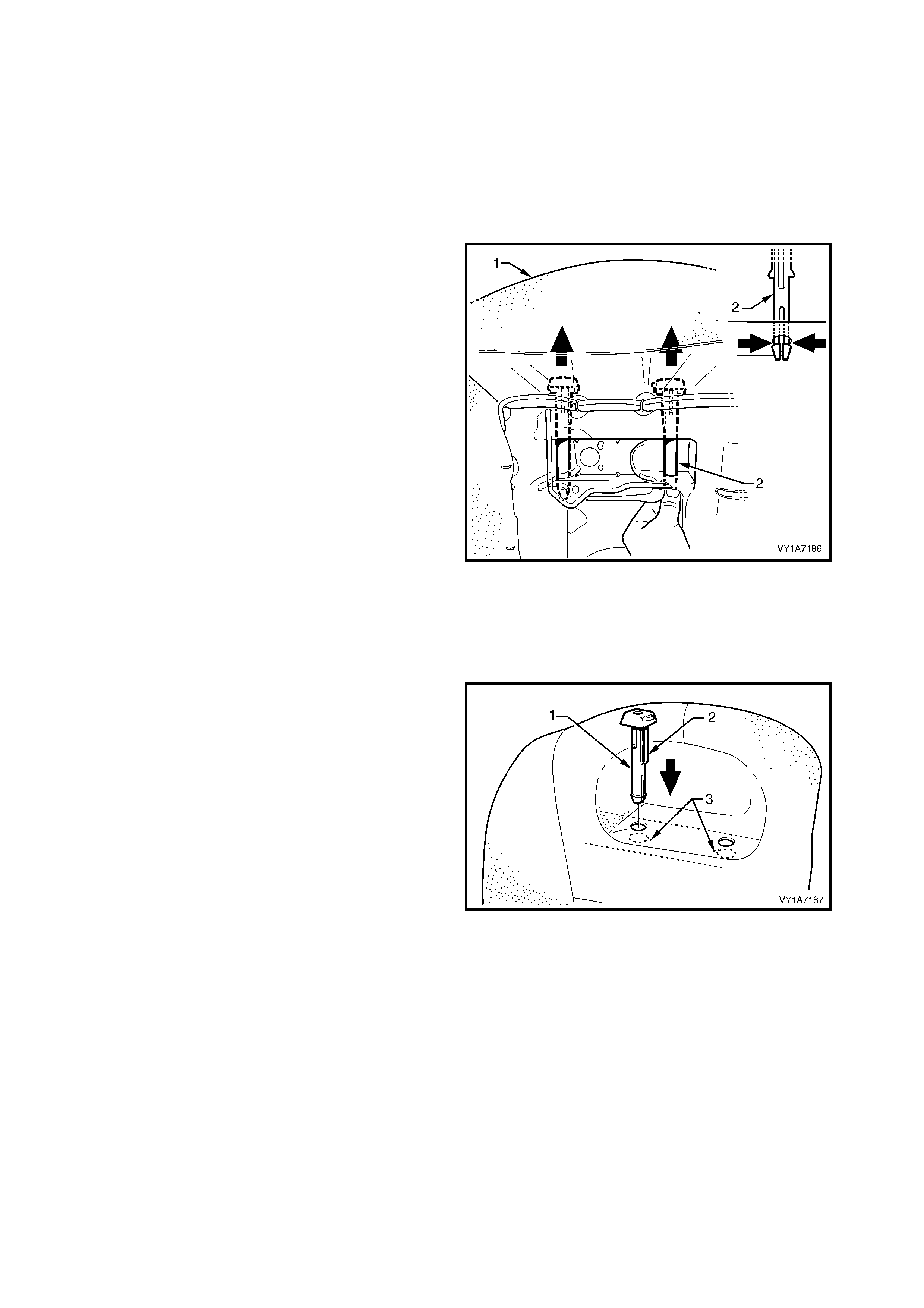

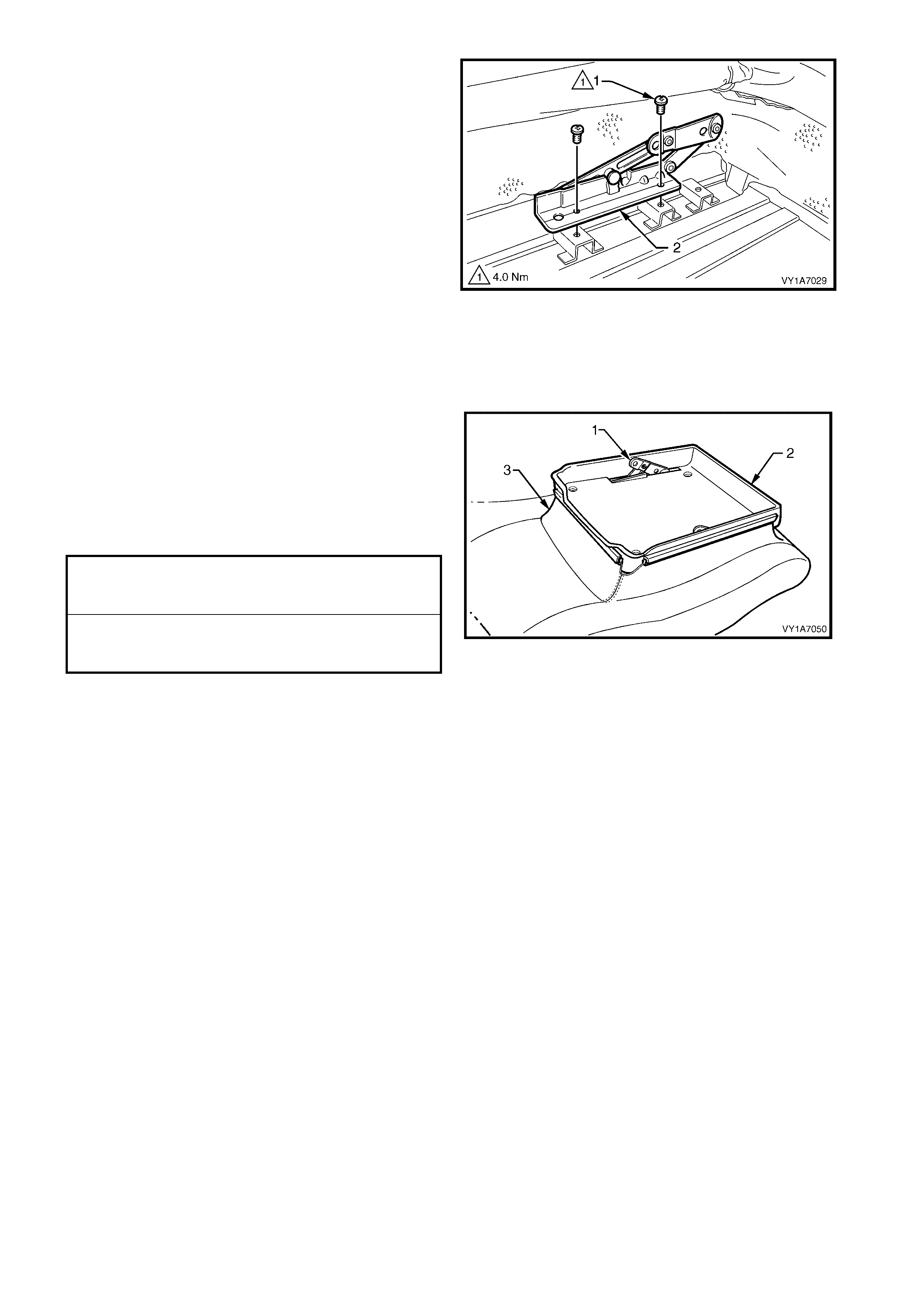

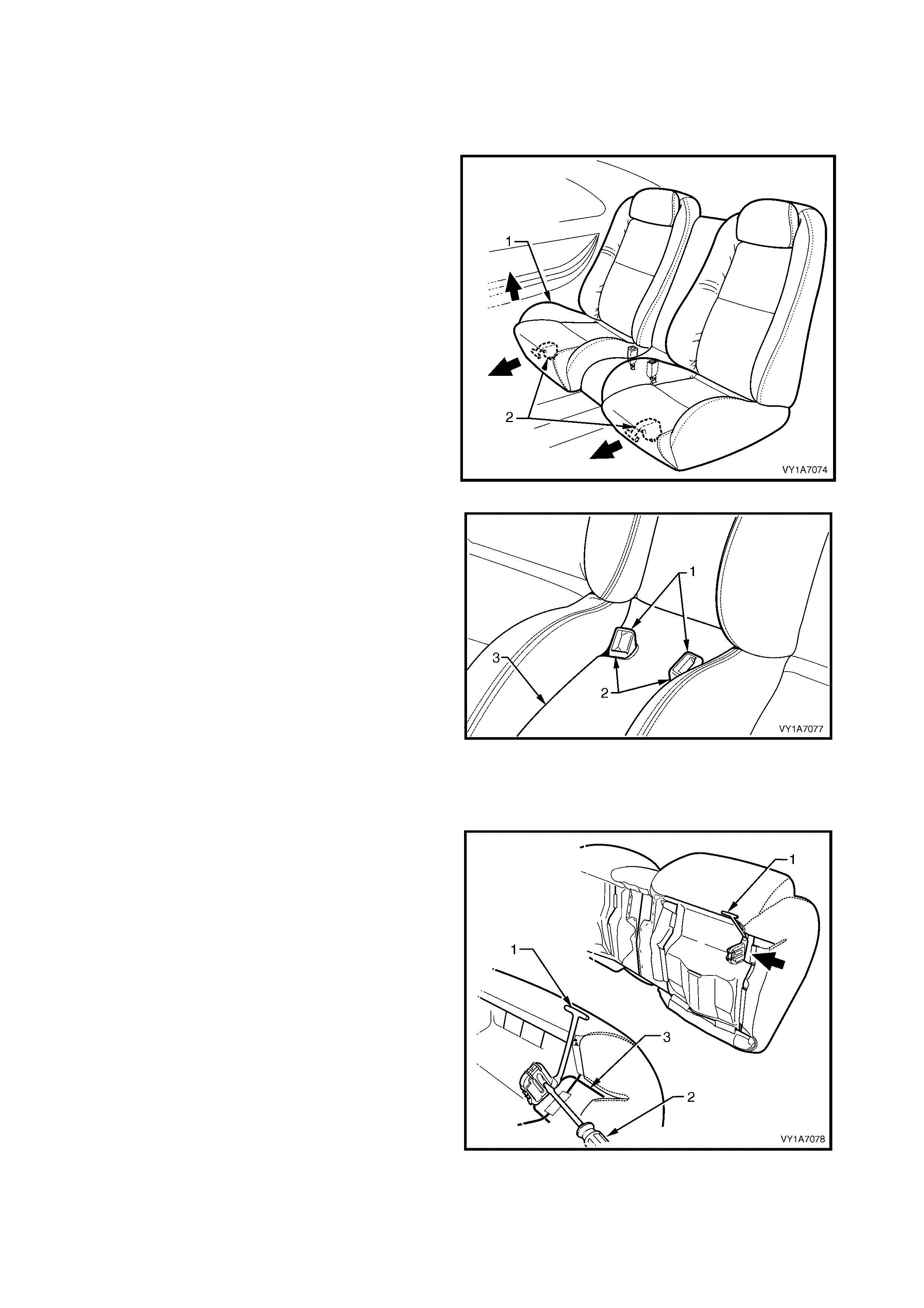

REMOVE

1. Disconnect the battery.

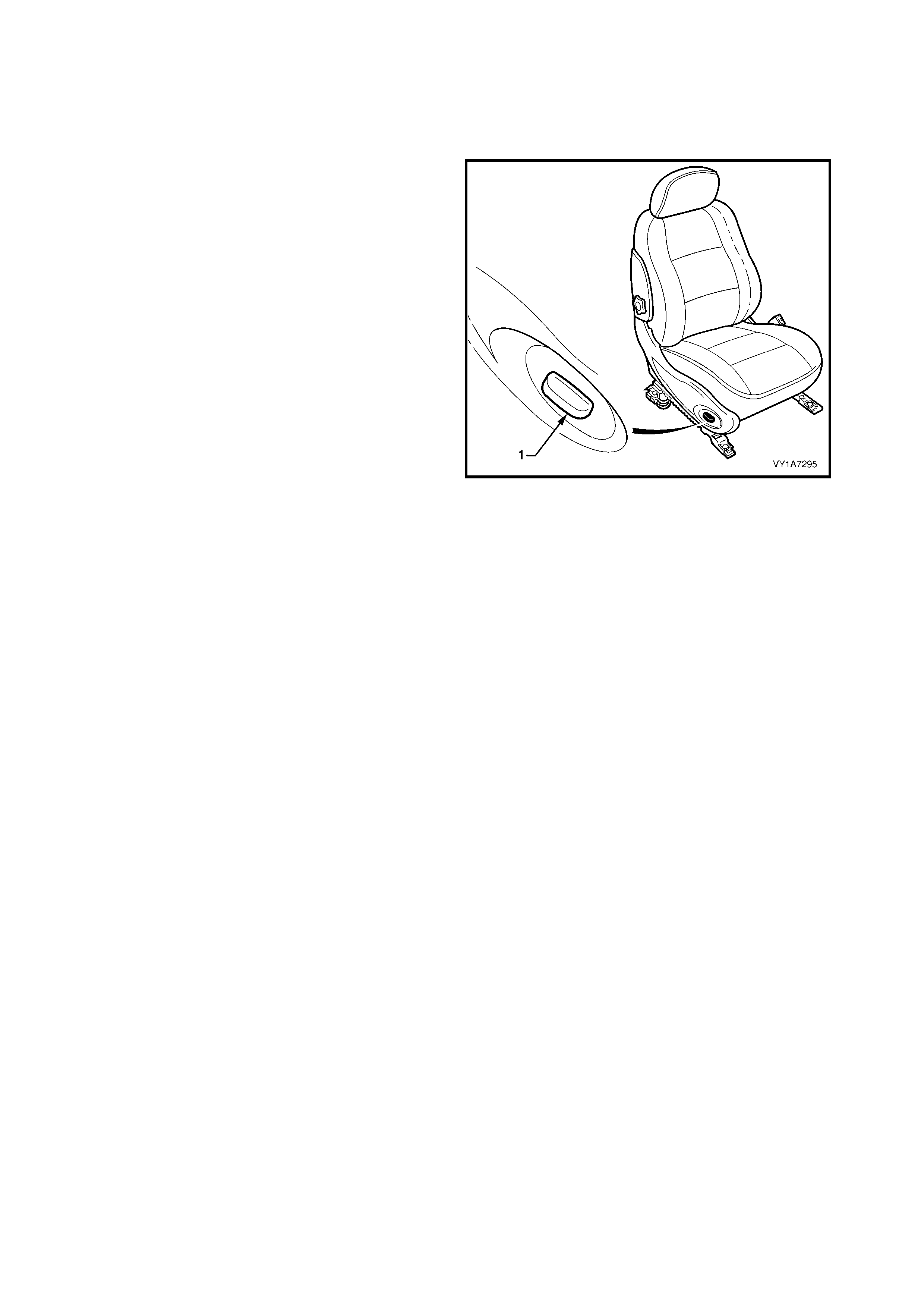

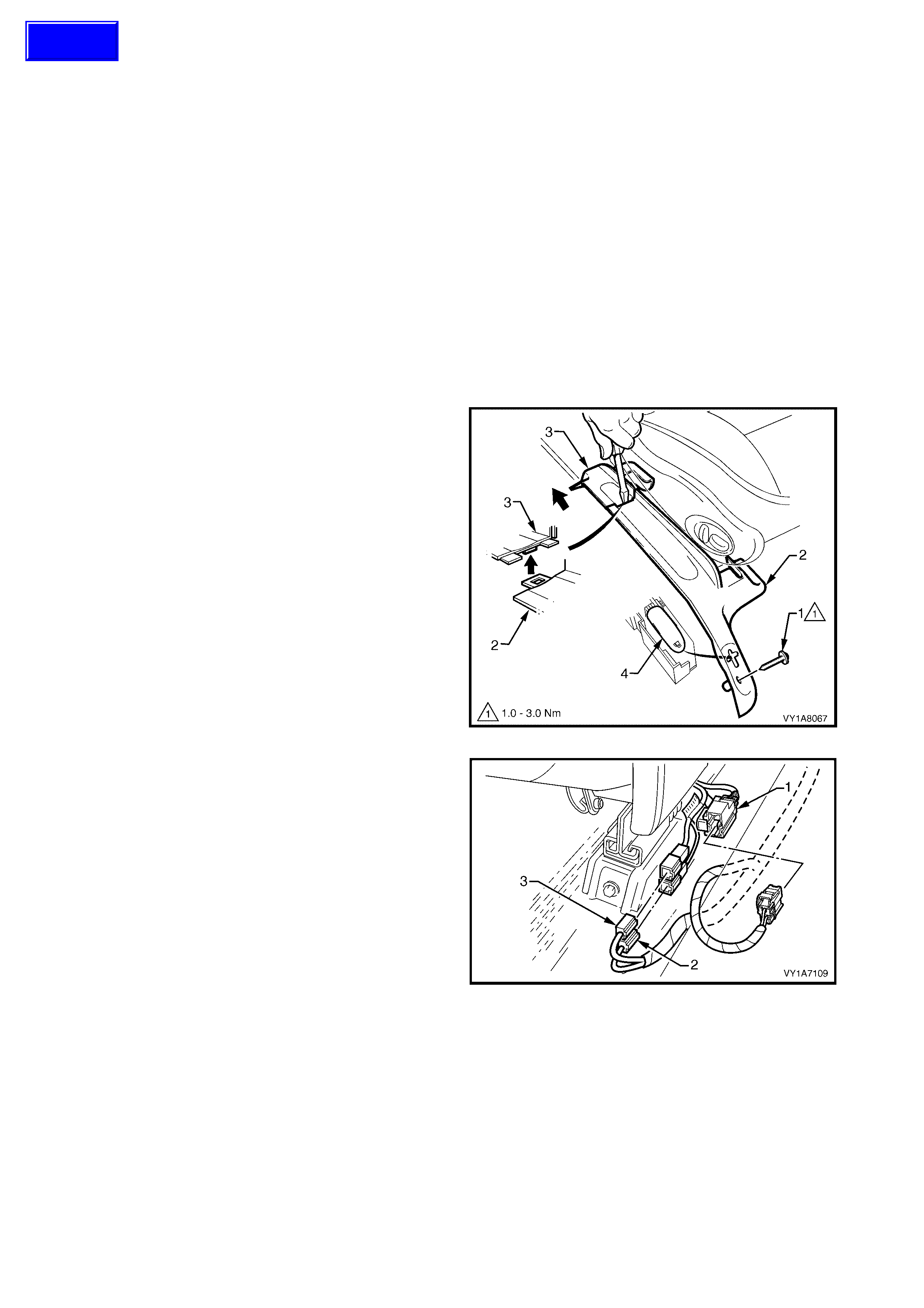

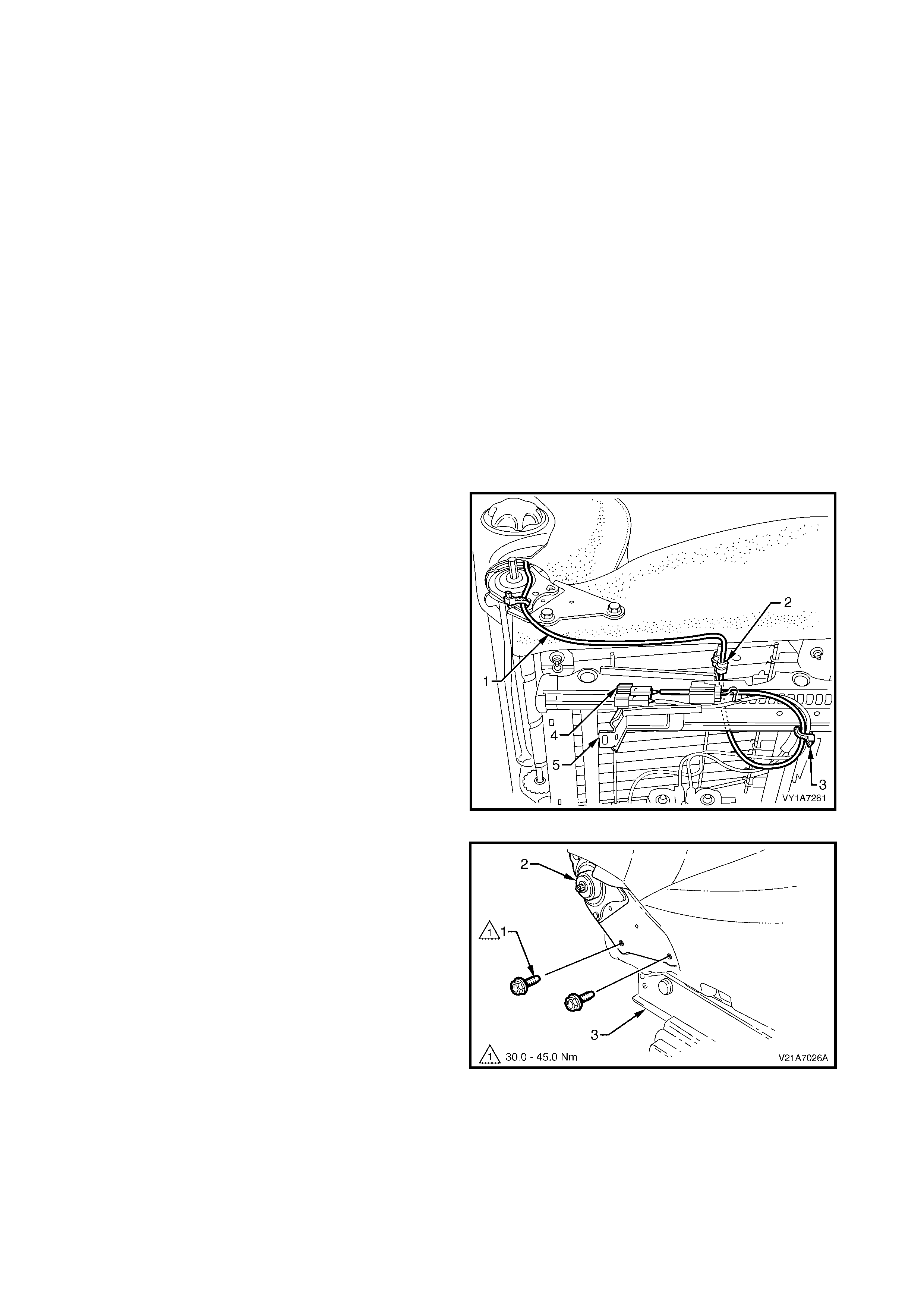

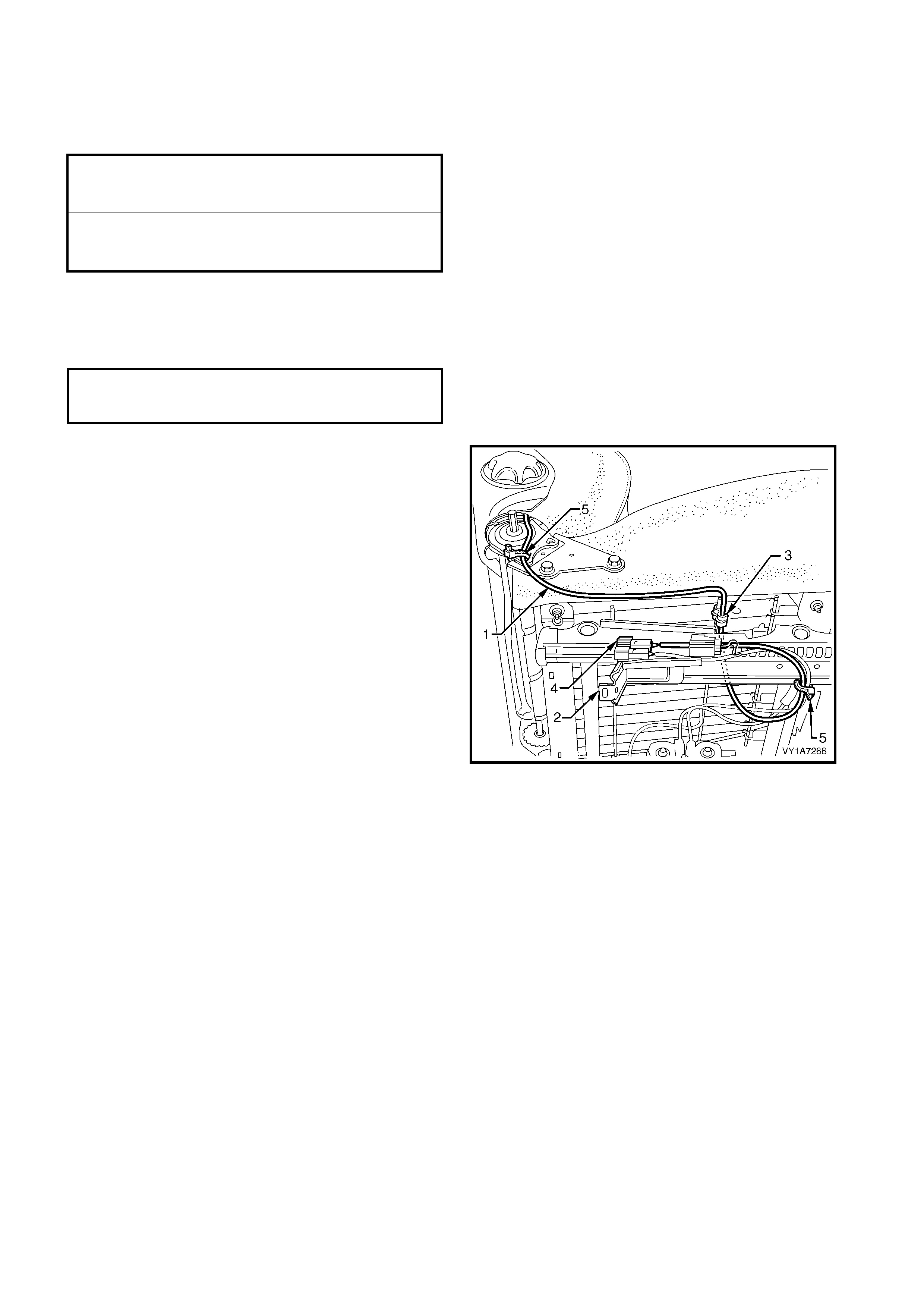

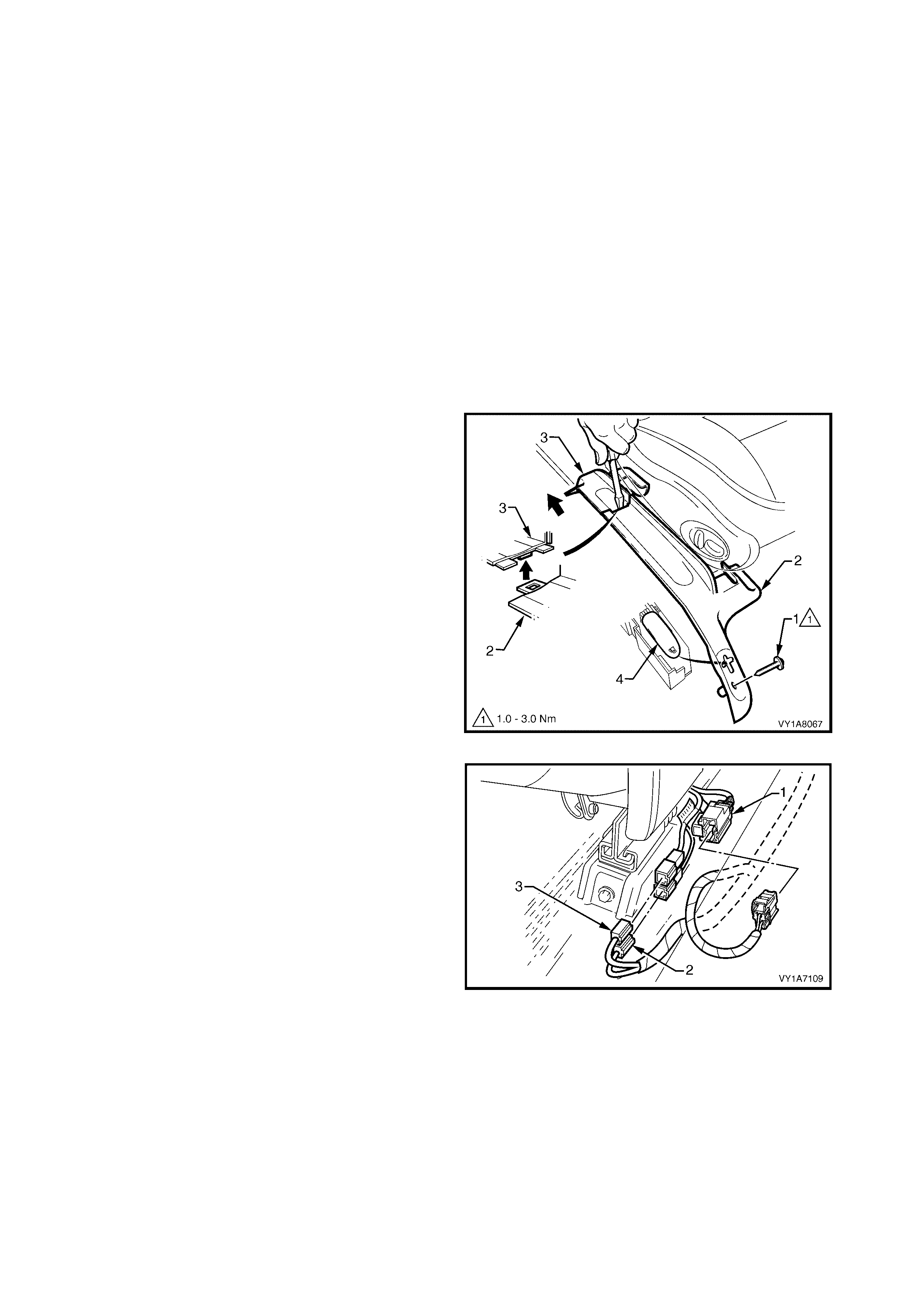

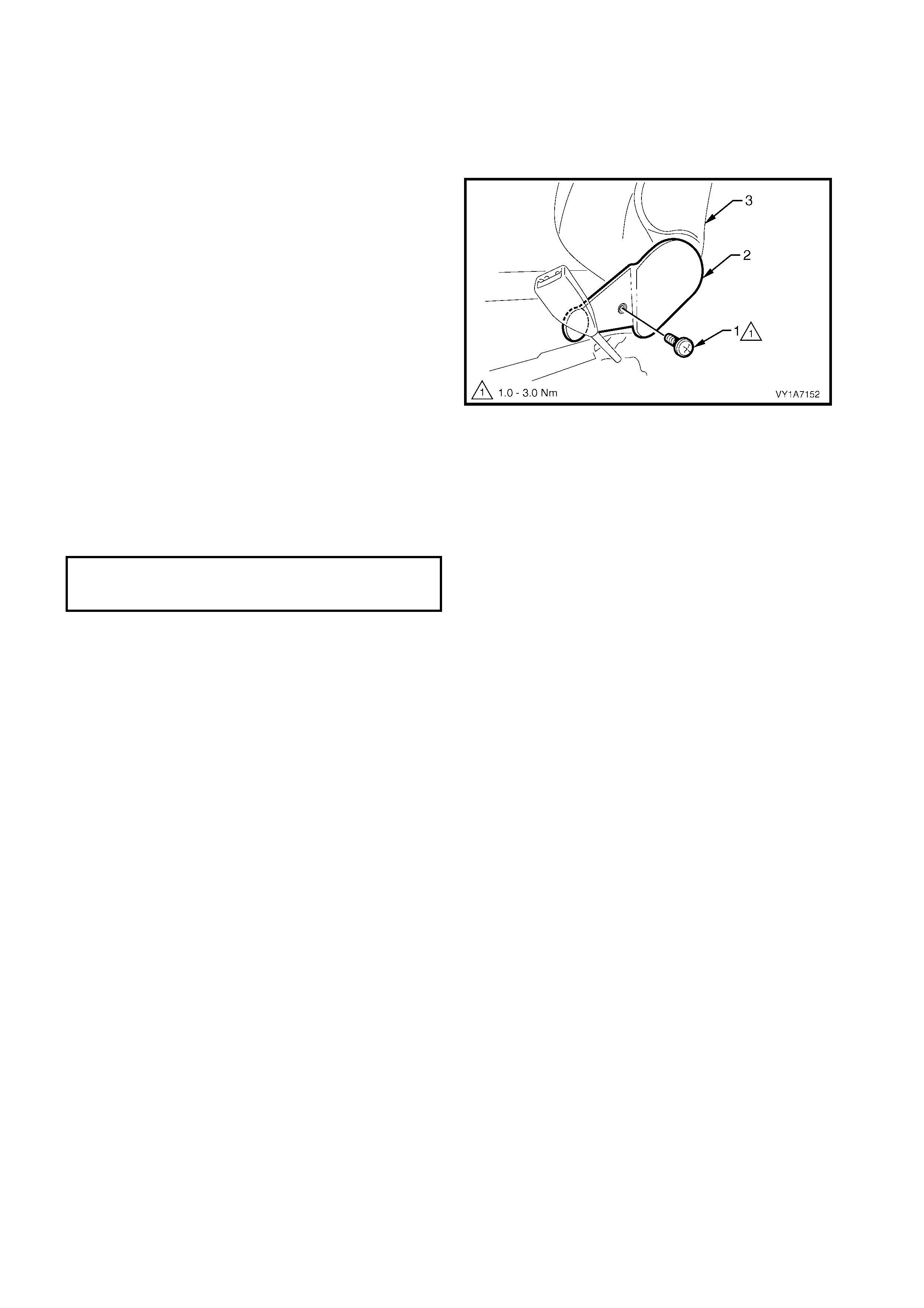

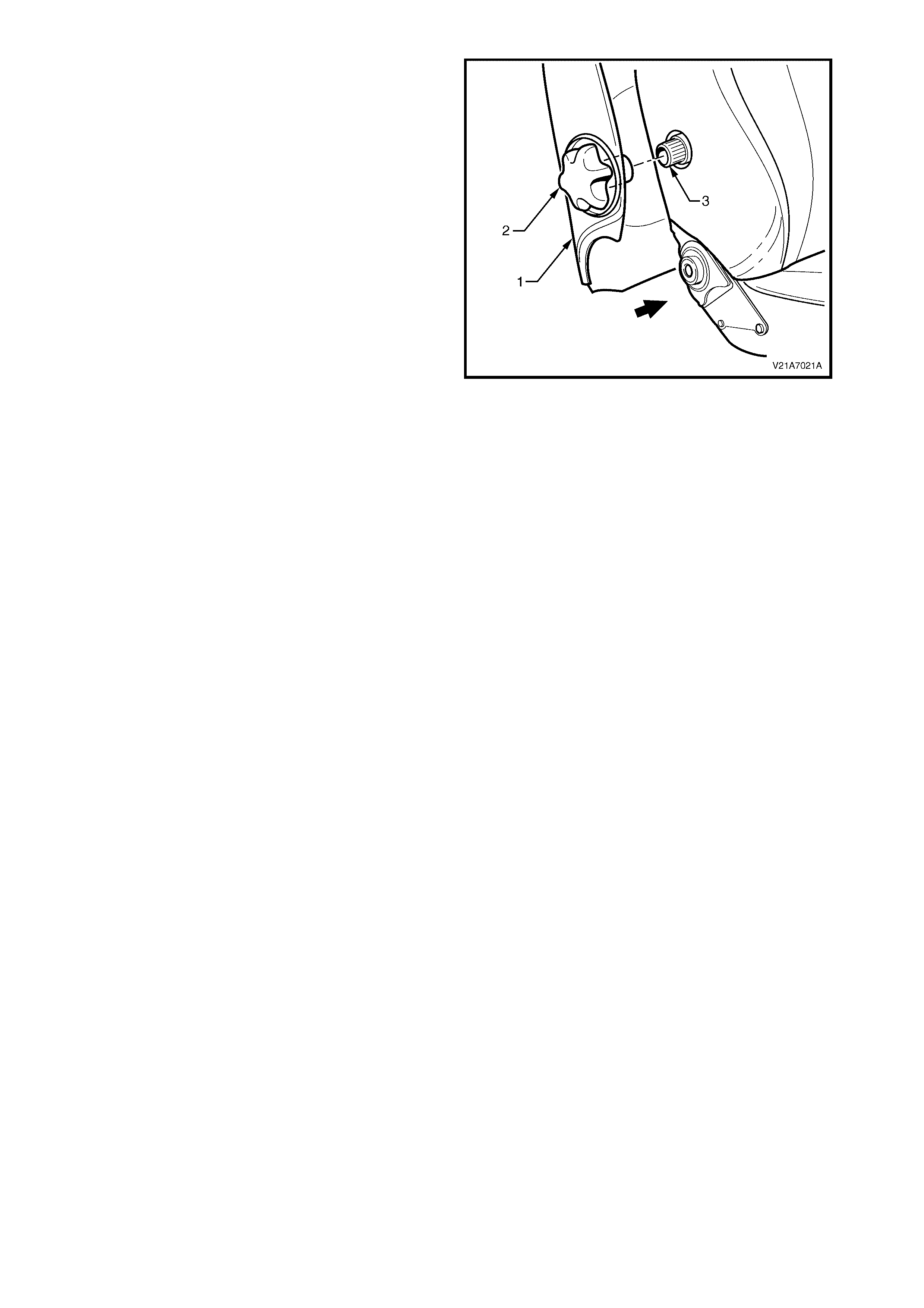

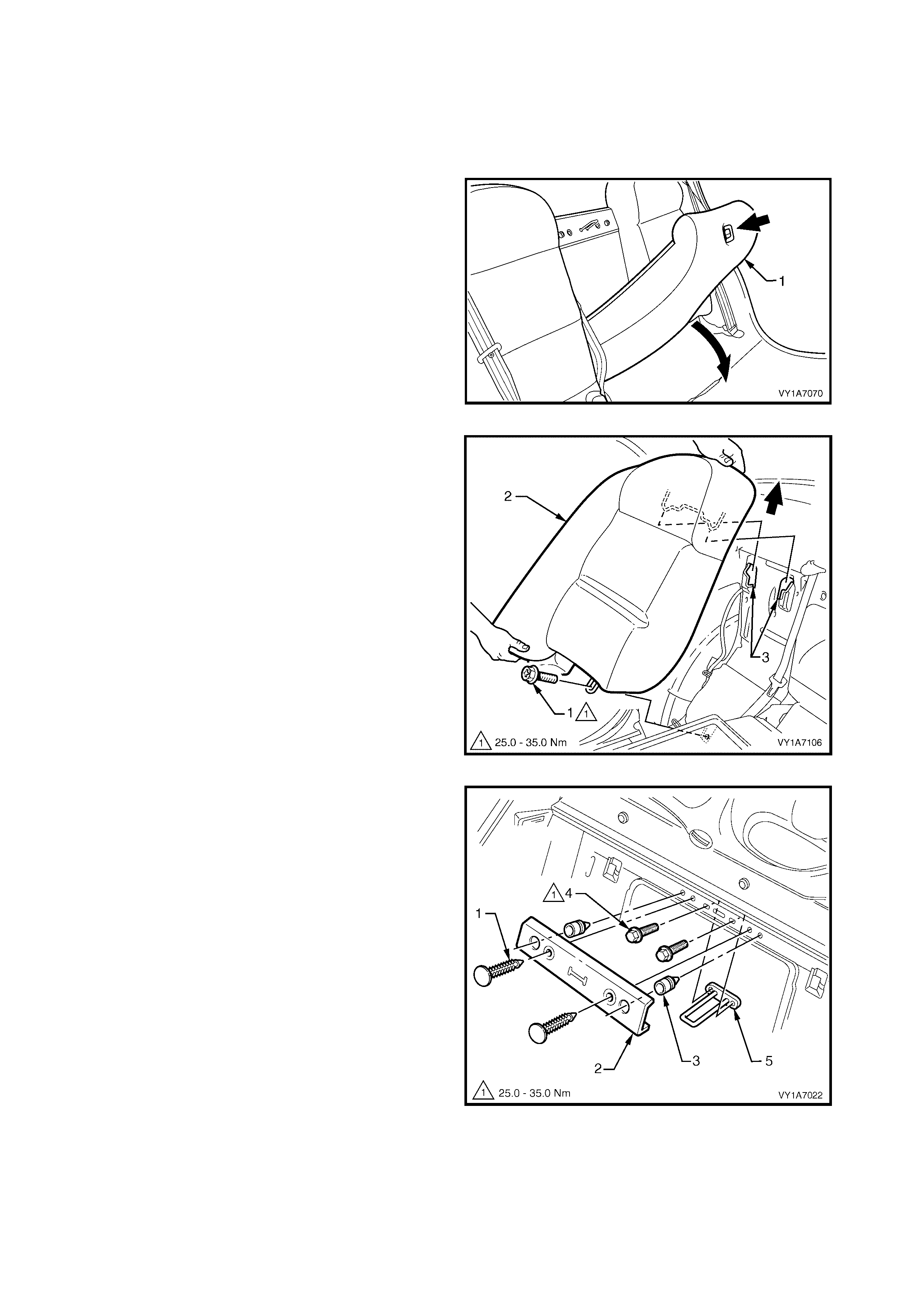

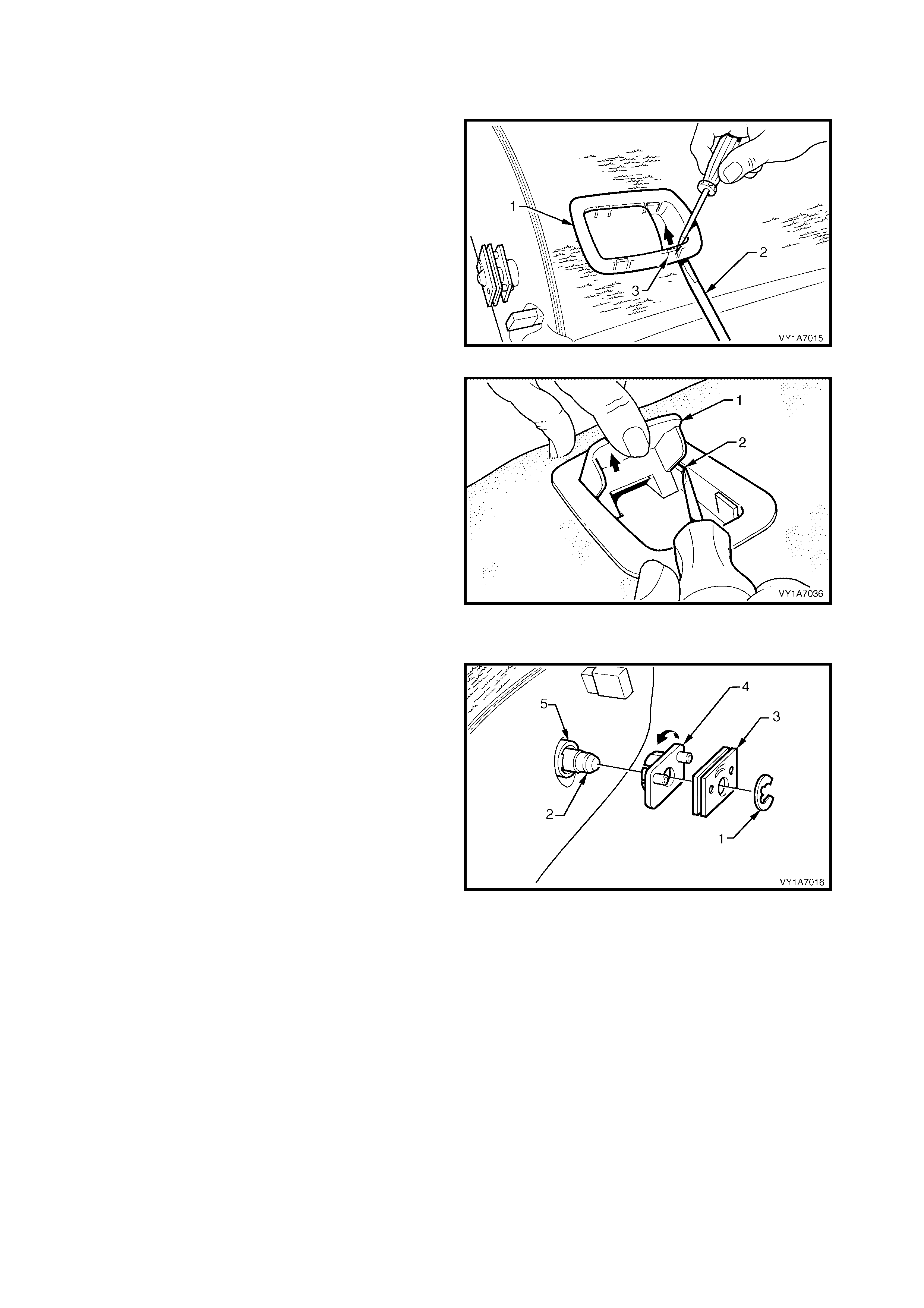

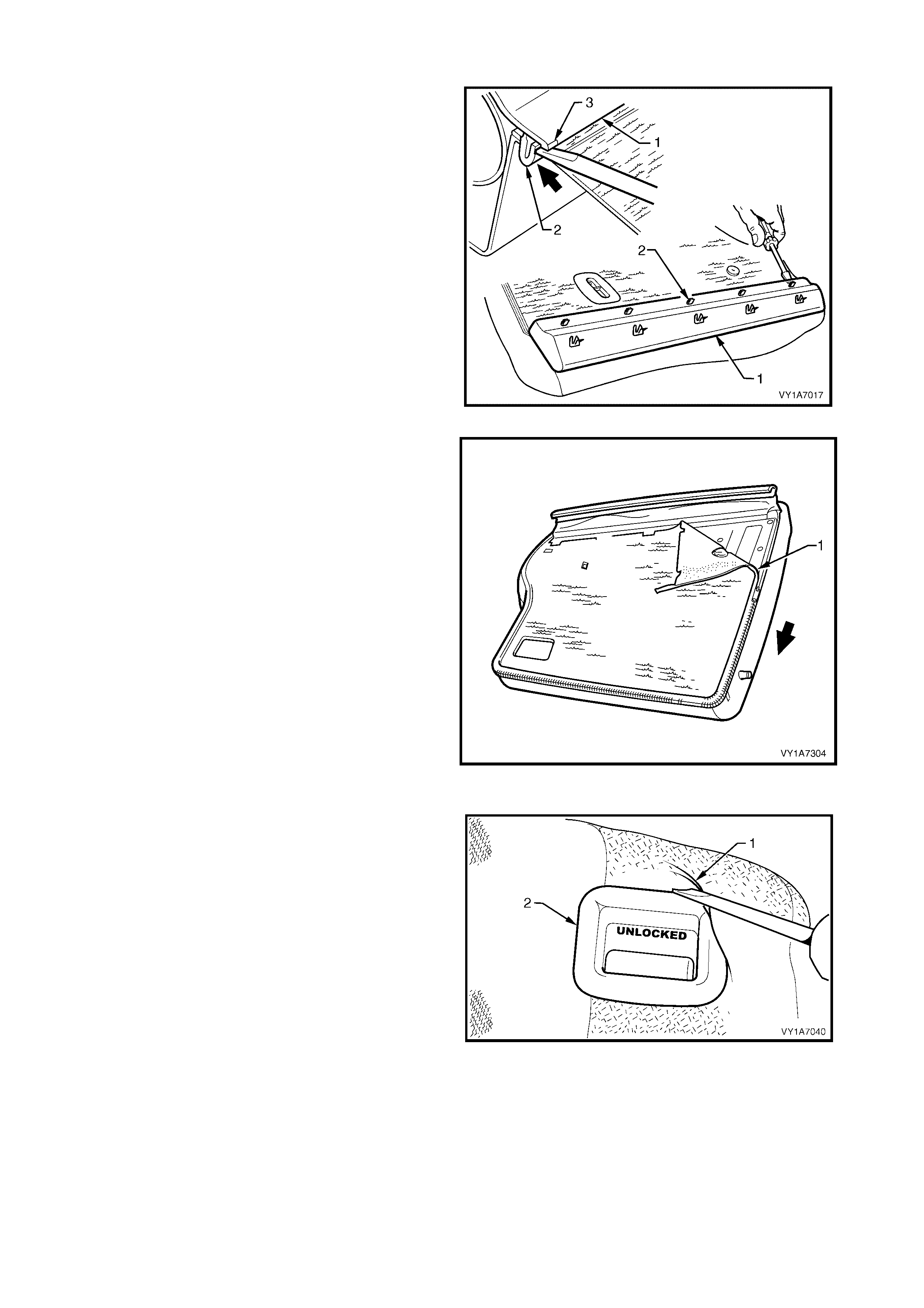

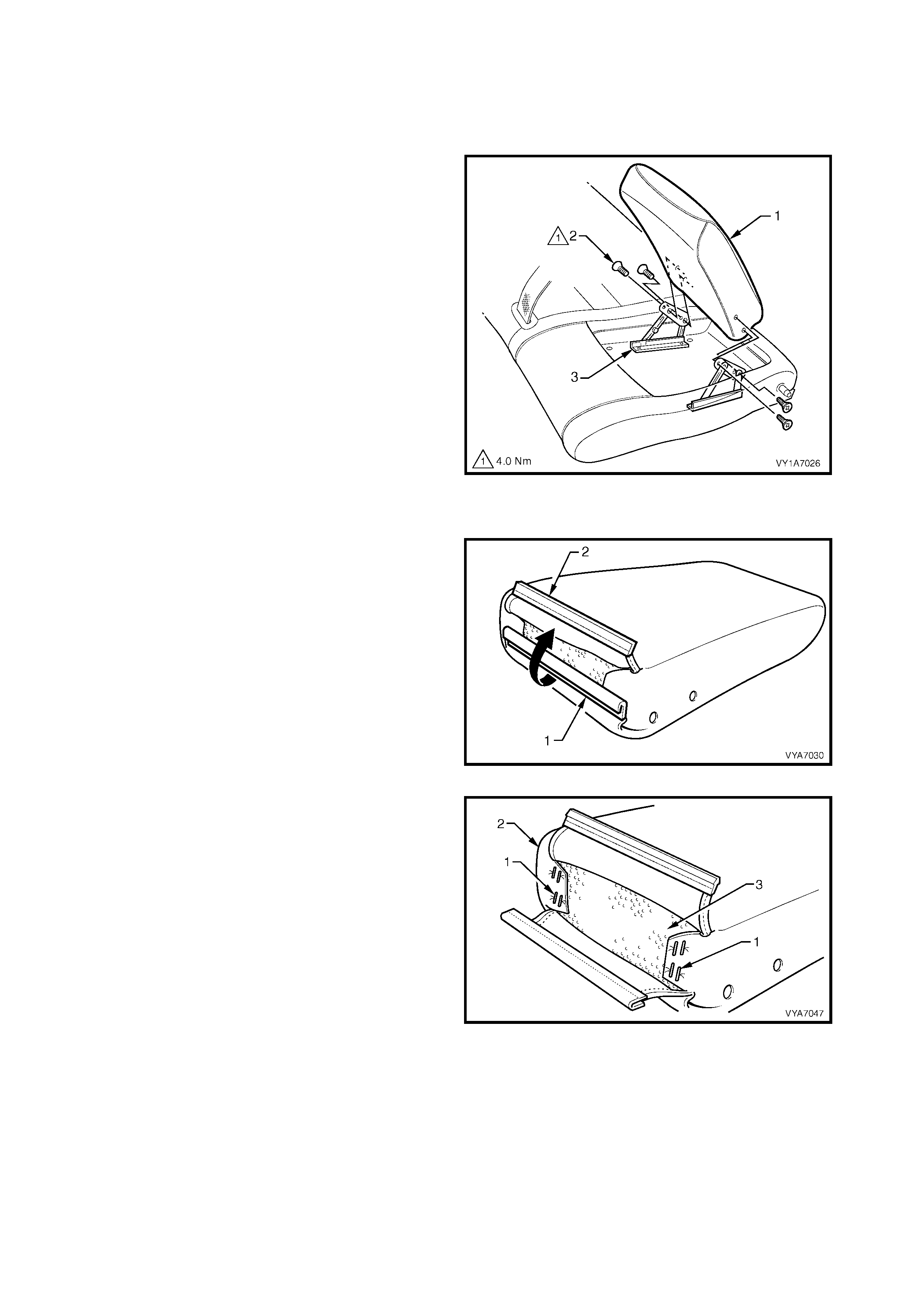

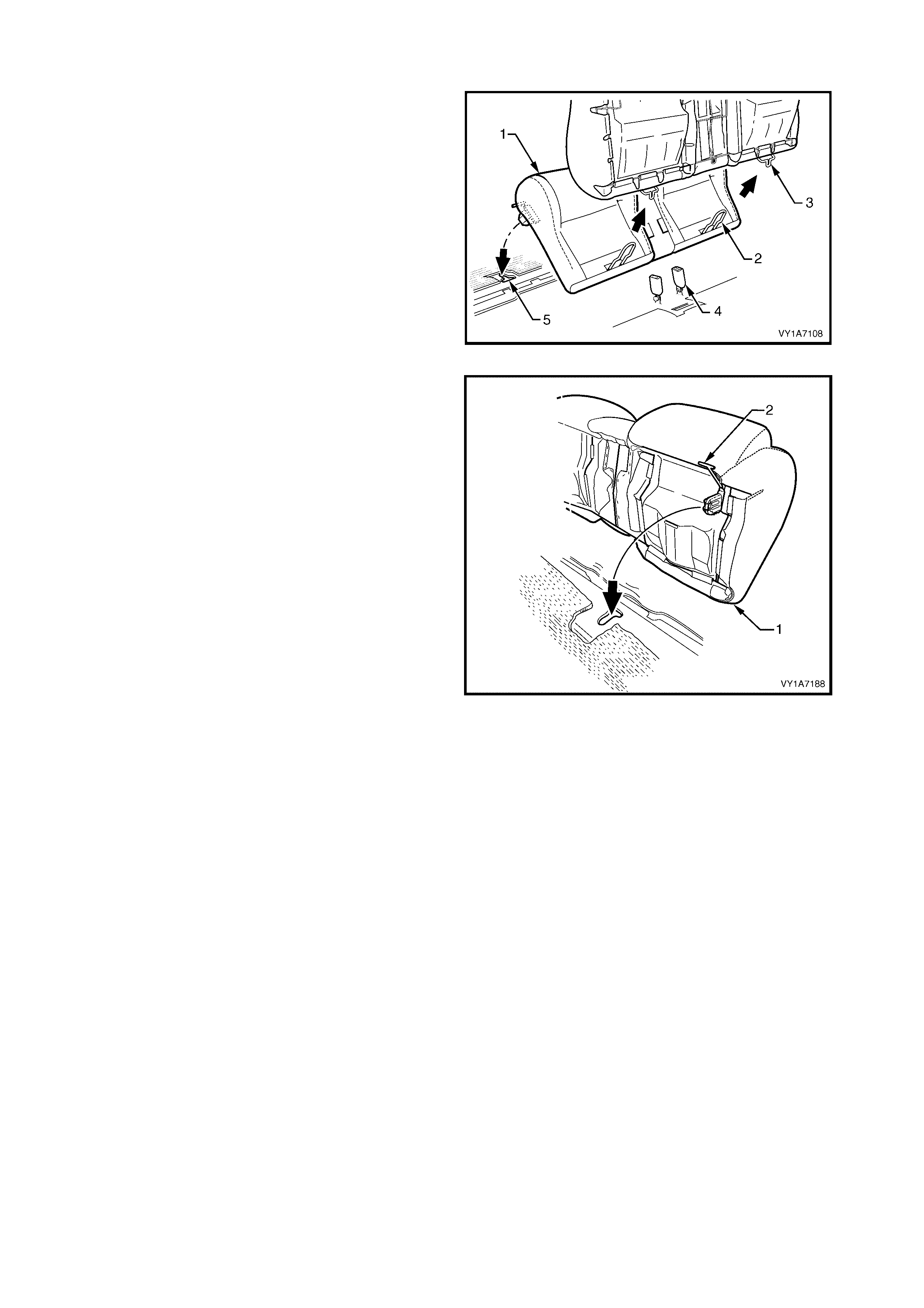

2. For the driver’s s eat on right-hand drive sedan and

wagon vehicles, remove the screw (1) attaching the

seat adjuster outer front cover (2).

3. Using a small scr ewdriver, pus h in the c entre of the

join to separate the front cover and the front seat

outer lower rear cover (3).

4. Unclip the covers from the seat track and

disengage from the side sill trim.

5. Pull the covers apart and remove the rear cover.

6. For the driver’s side on right-hand drive vehicles,

except utility, slide the front c over over the fuel filler

door release lever (4) and remove.

Figure 1A7-21

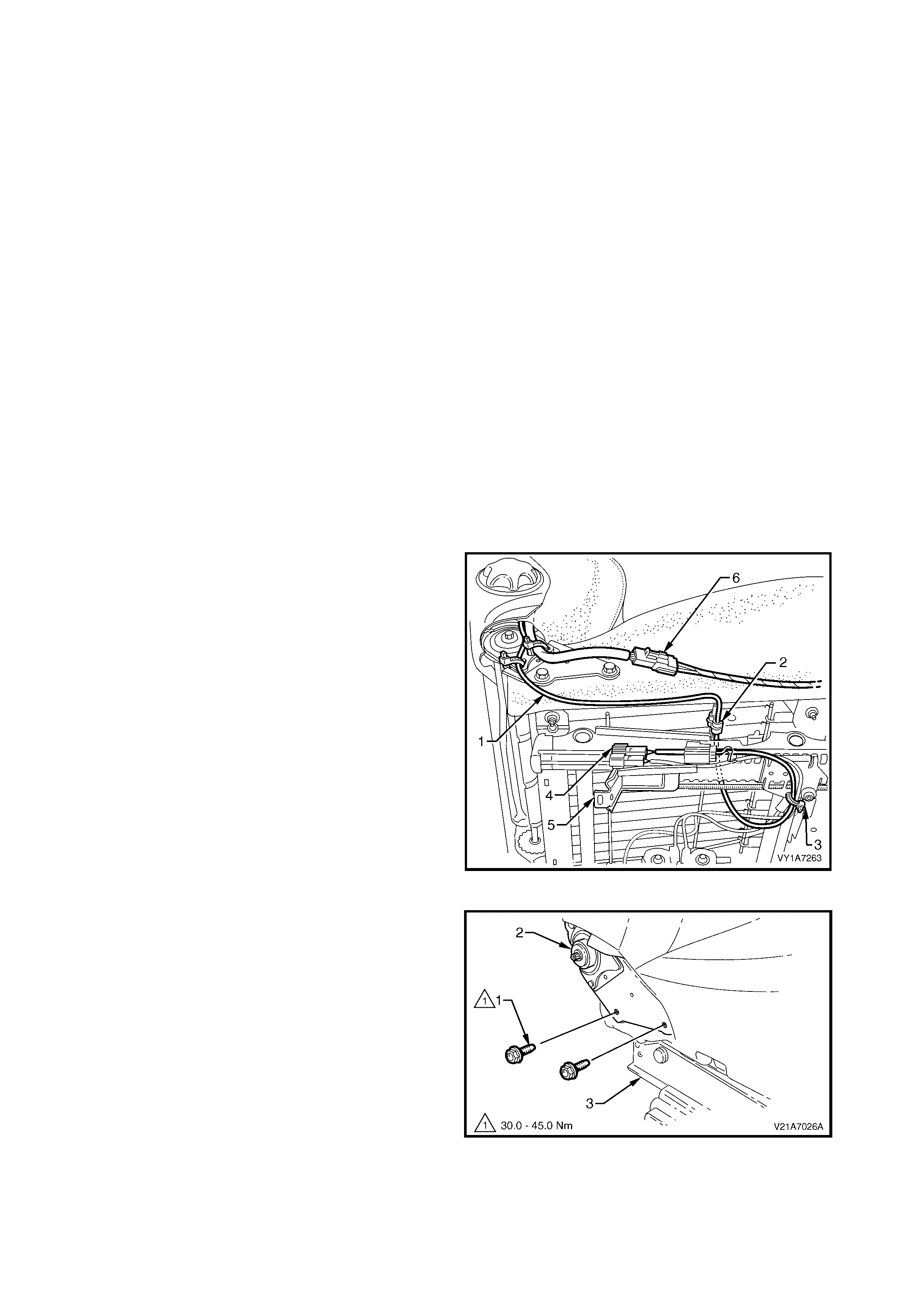

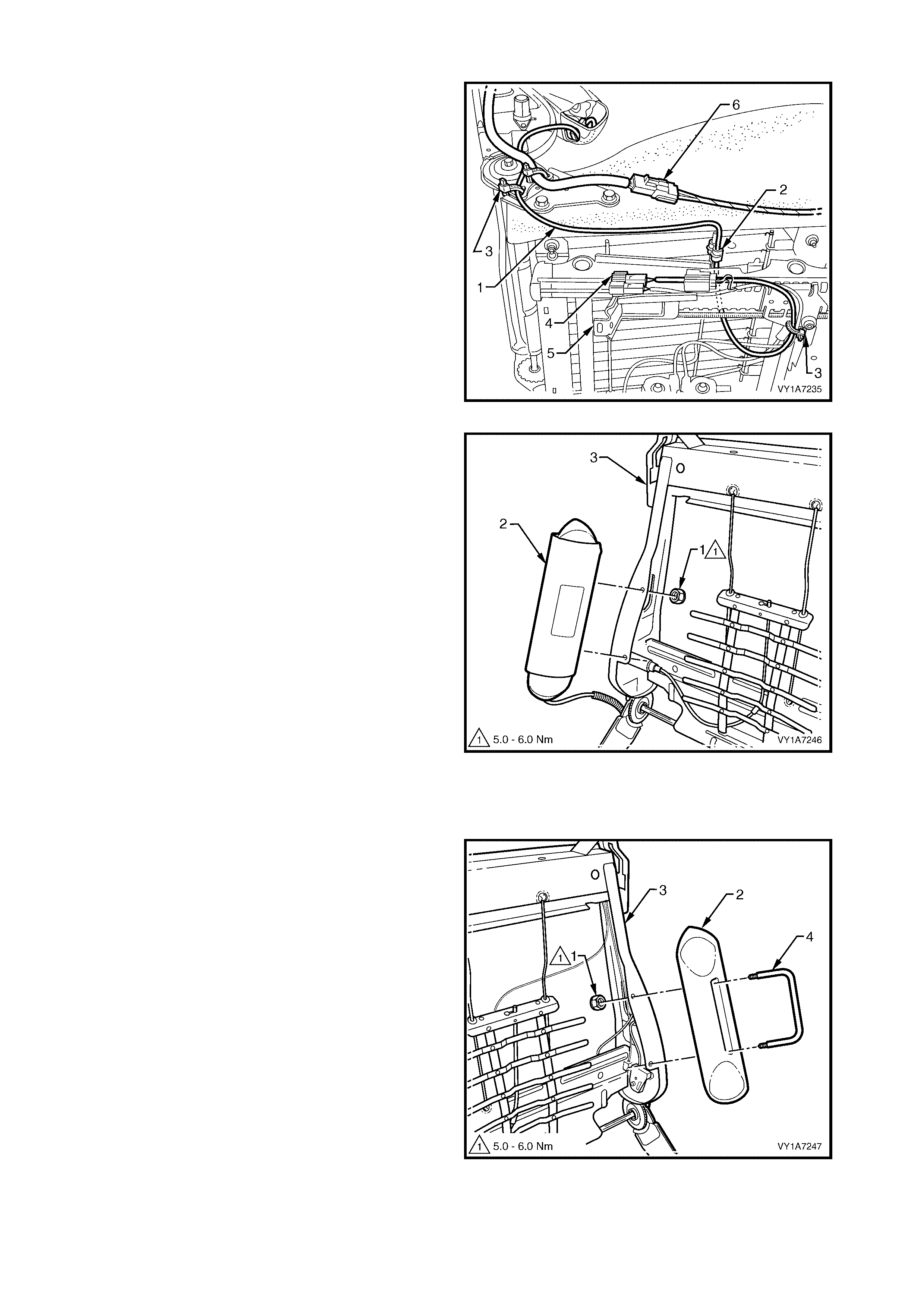

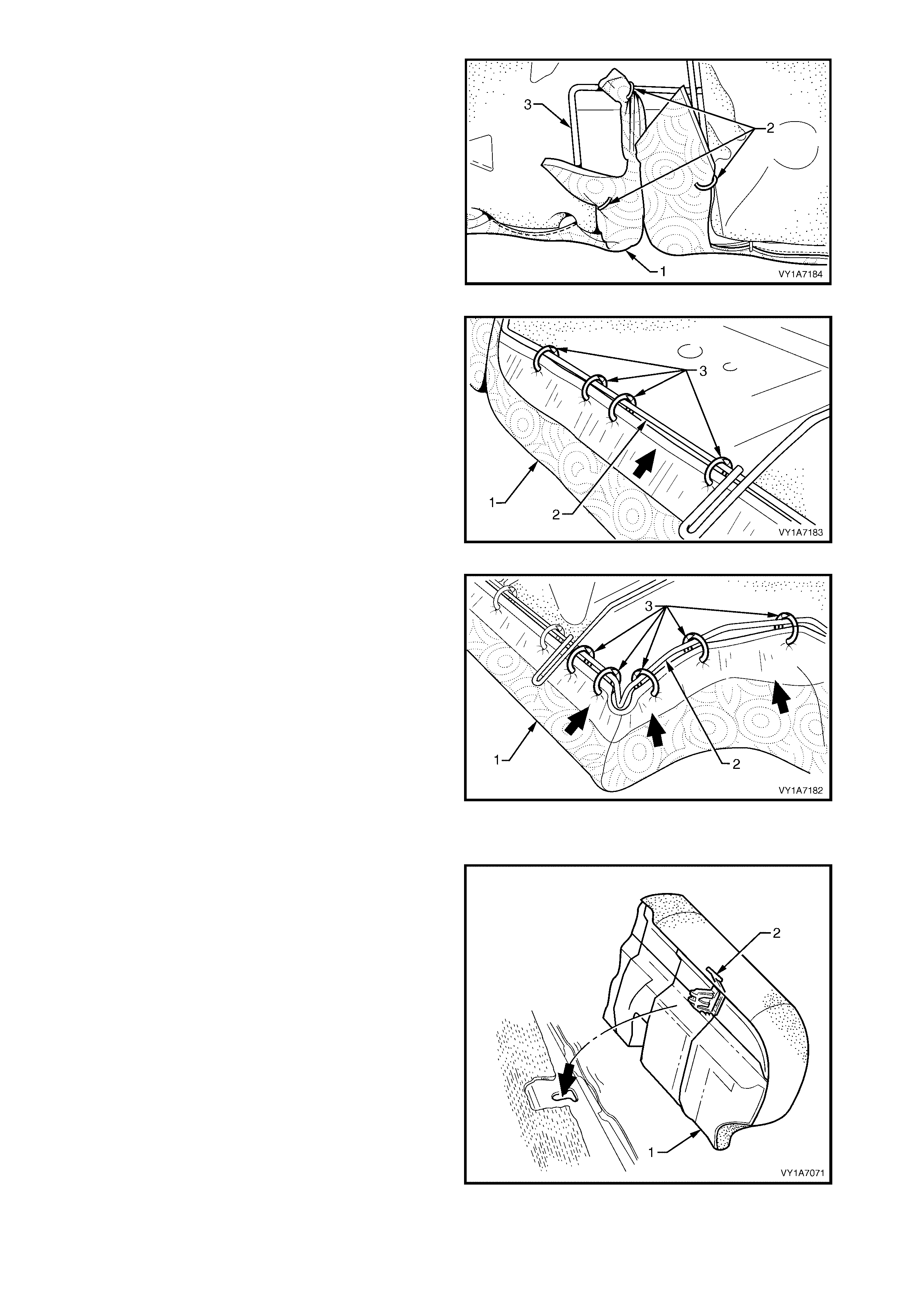

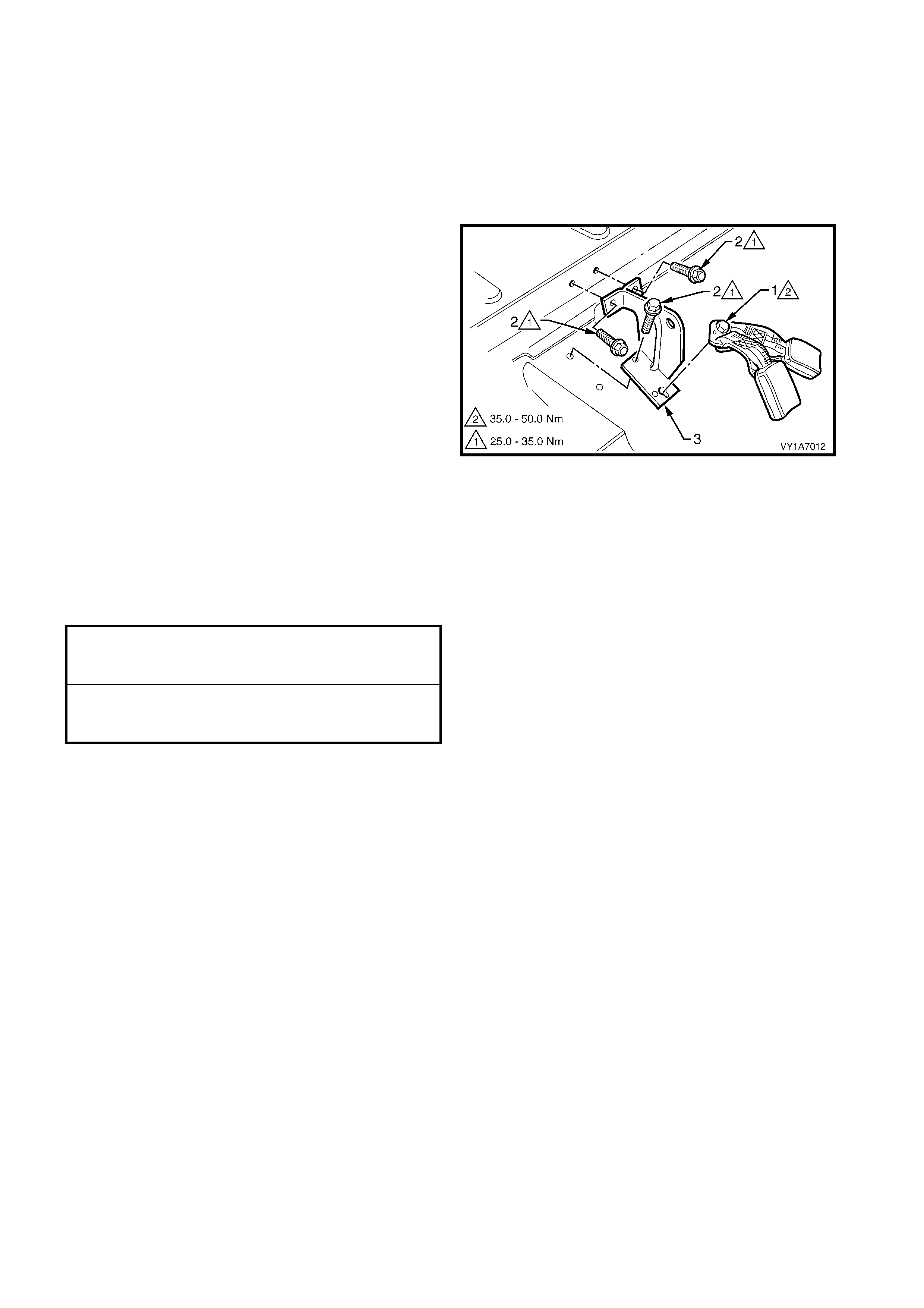

7. If fitted, disconnect the seat assembly wiring

harness (1), the seatbelt pretensioner harness (2)

and the side airbag module harness (3).

Figure 1A7-22

Techline

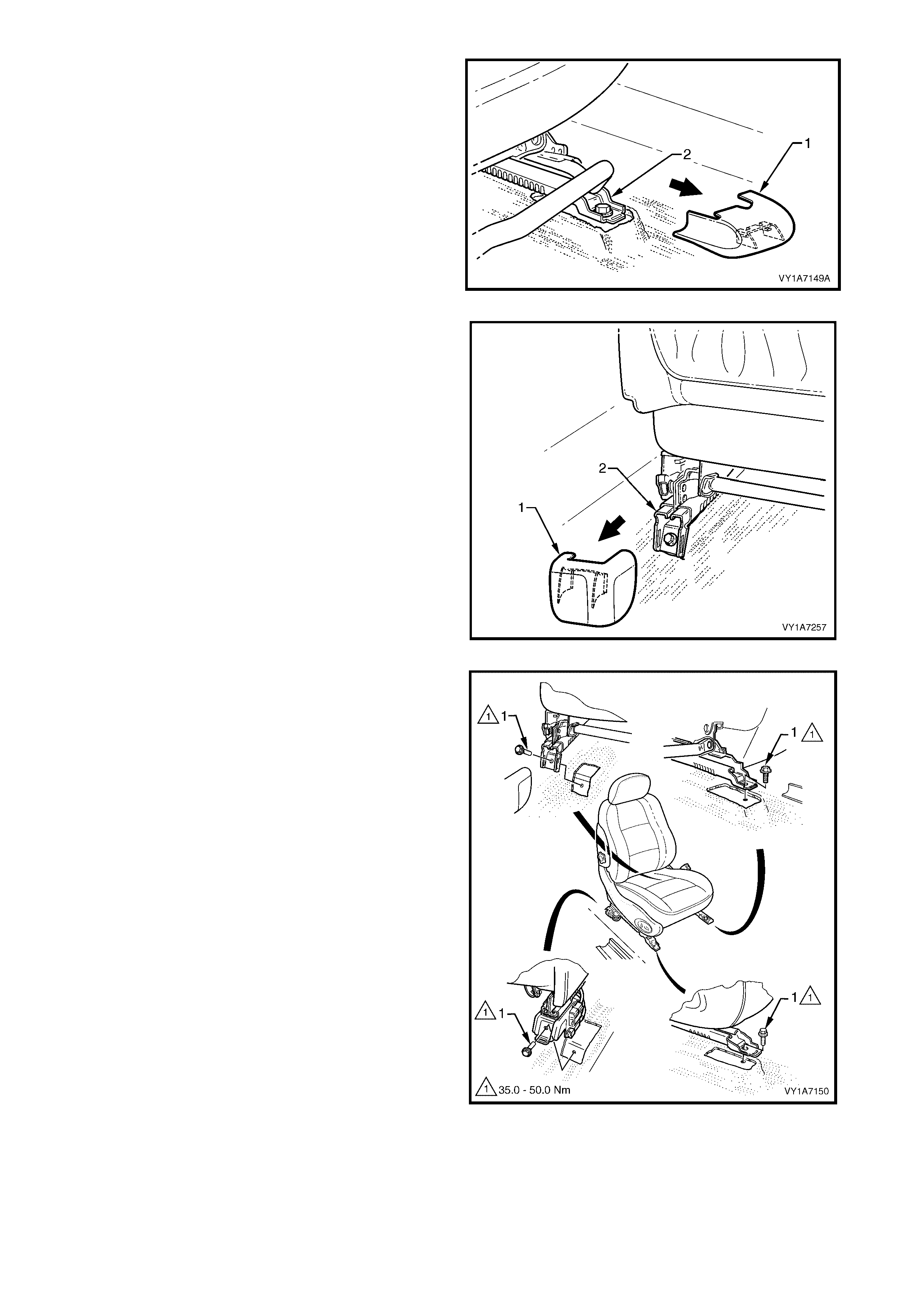

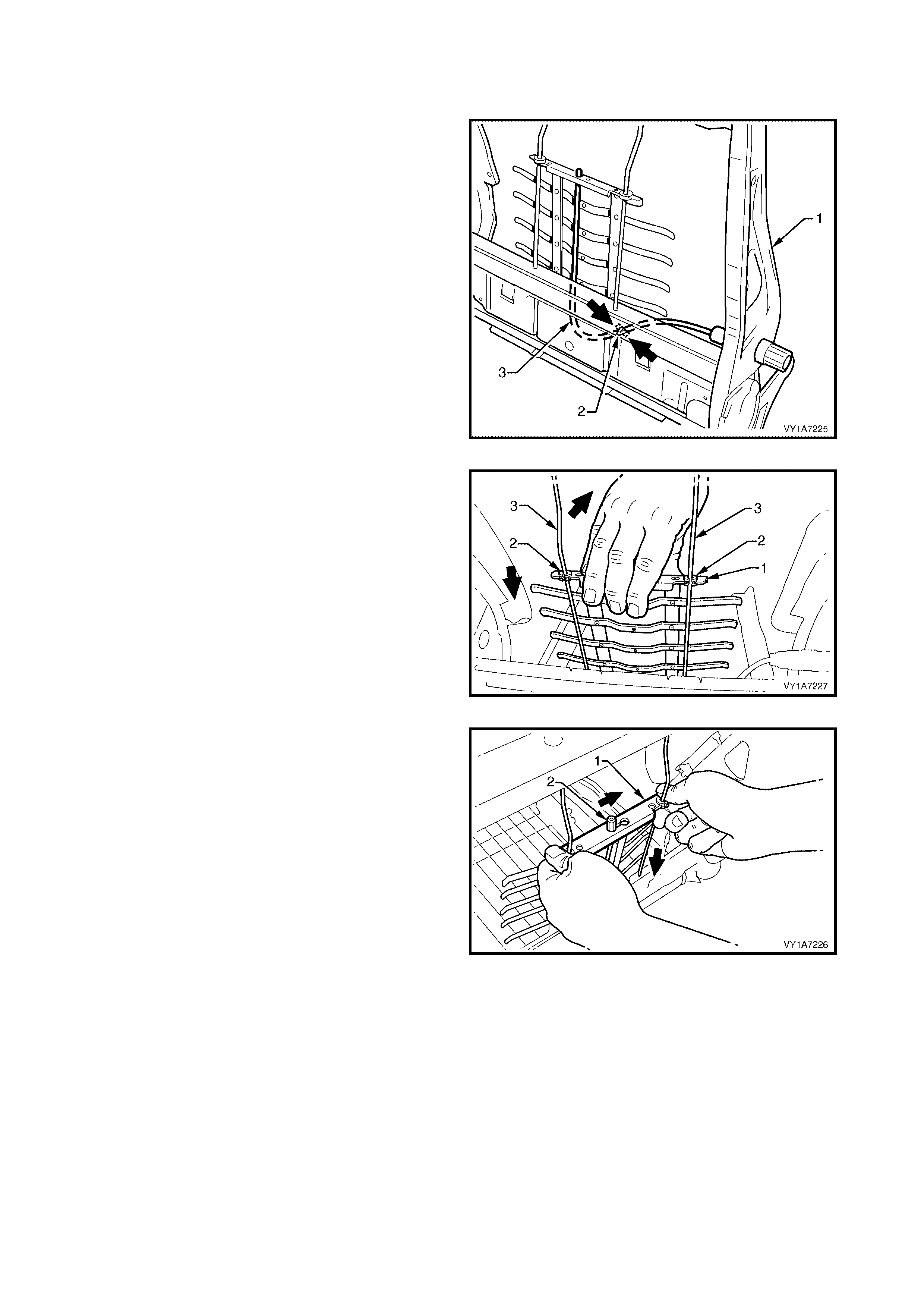

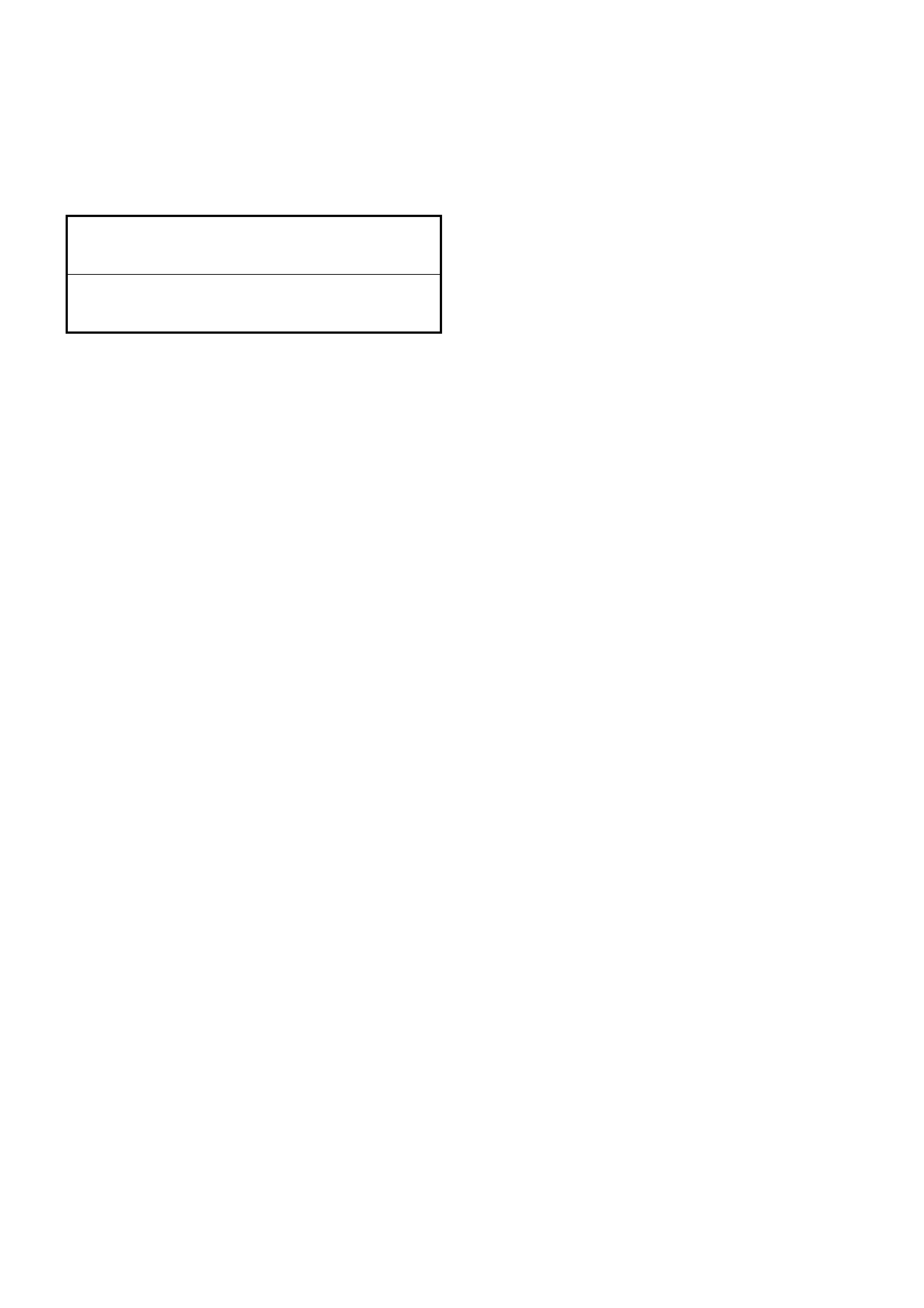

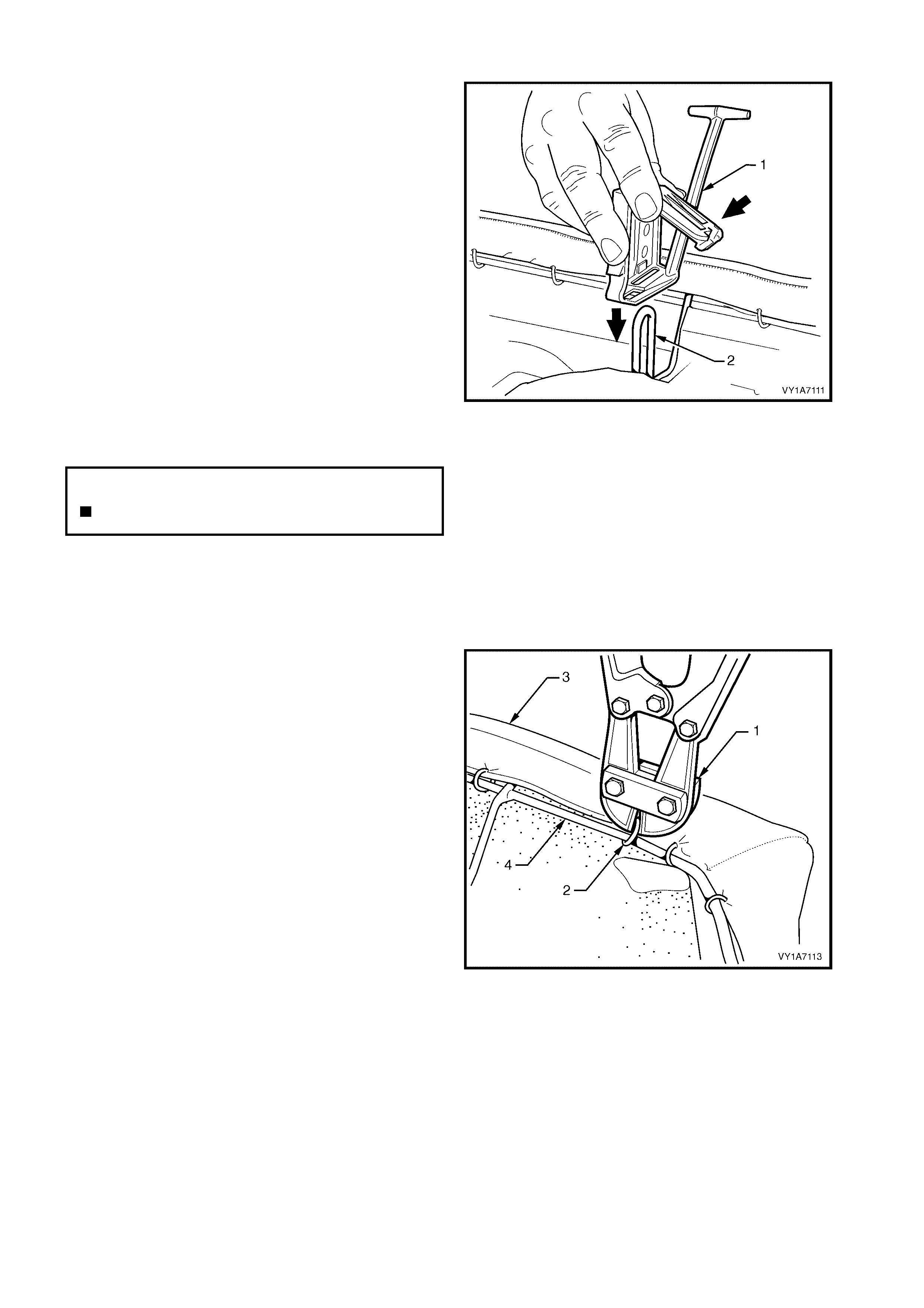

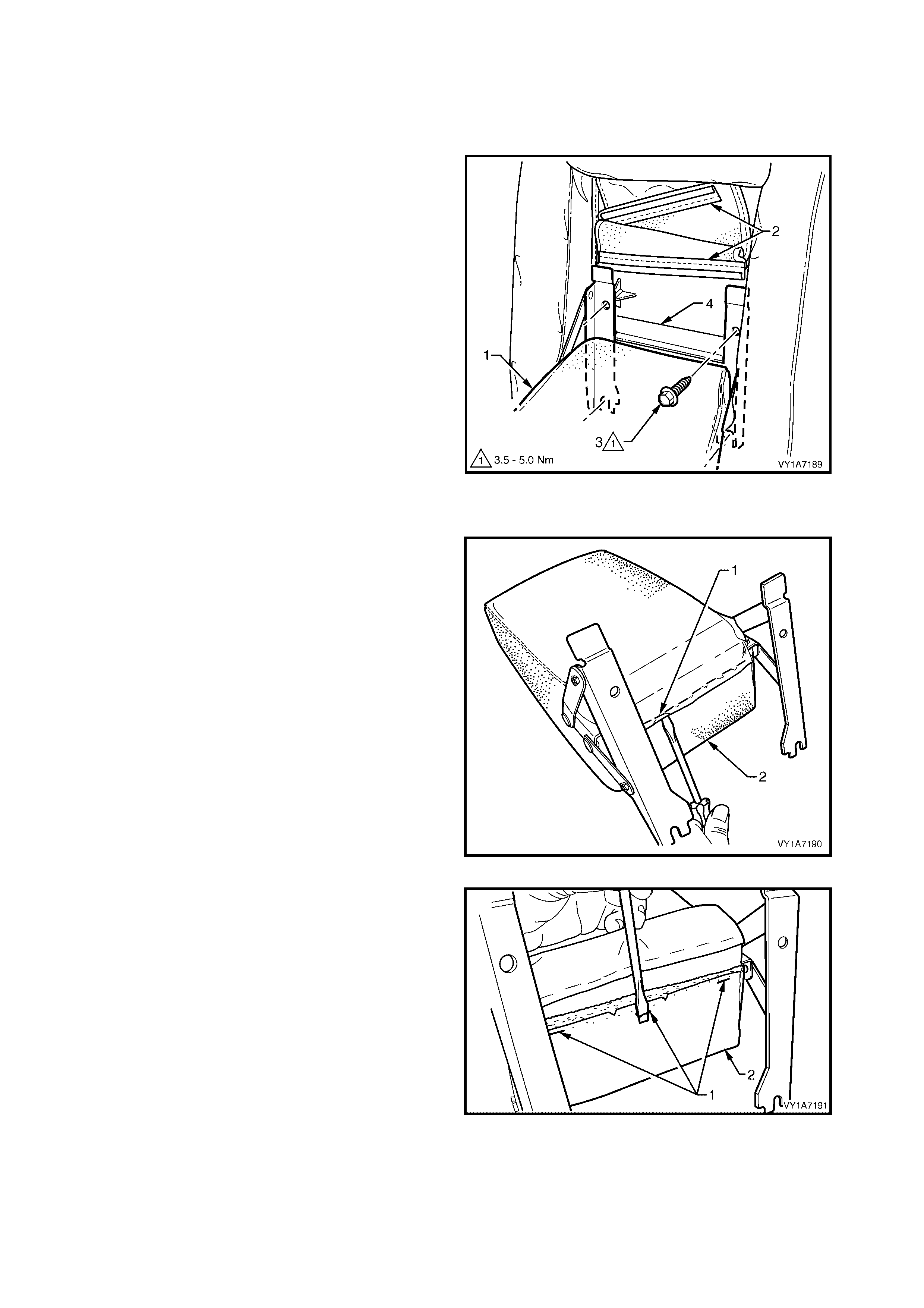

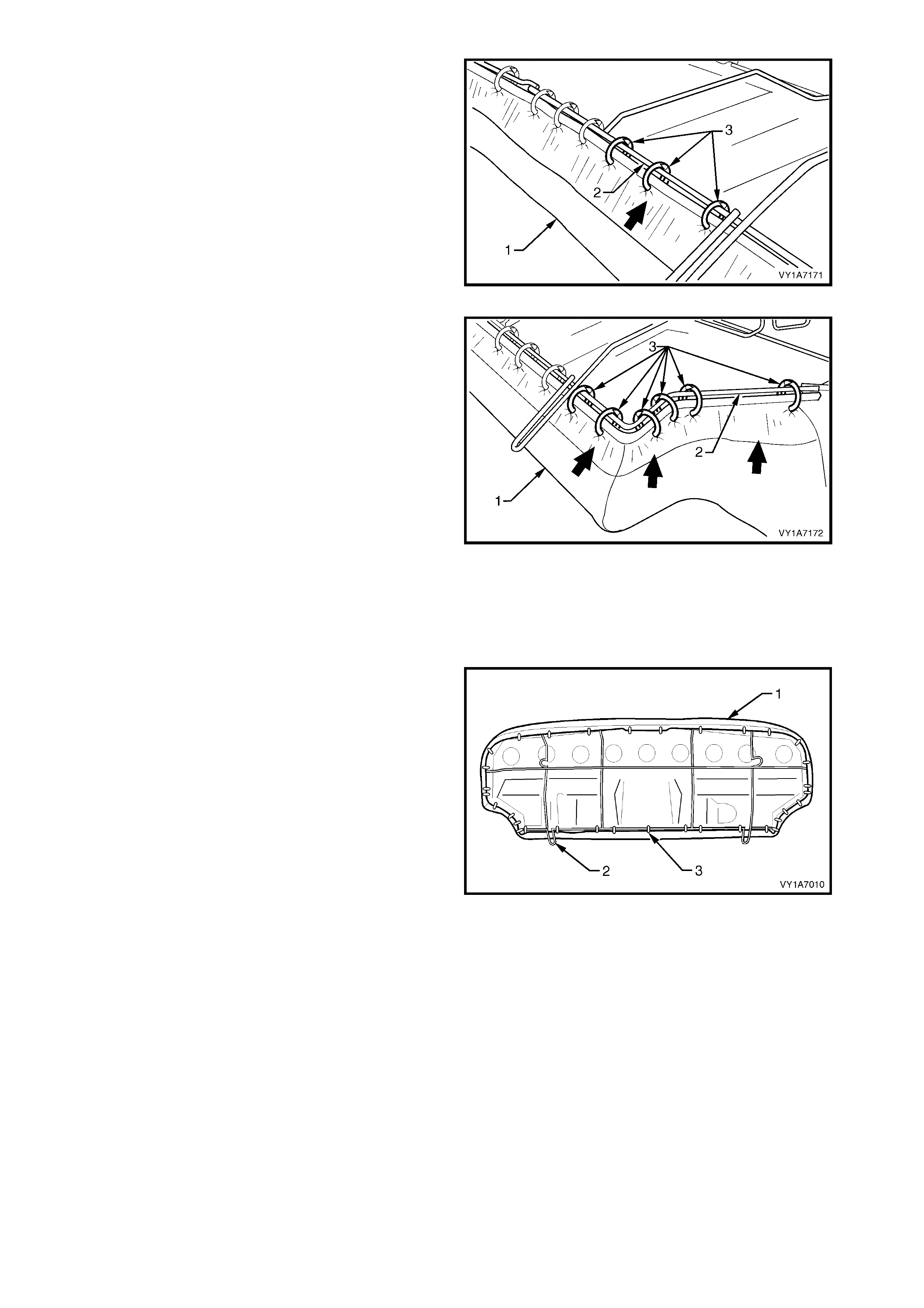

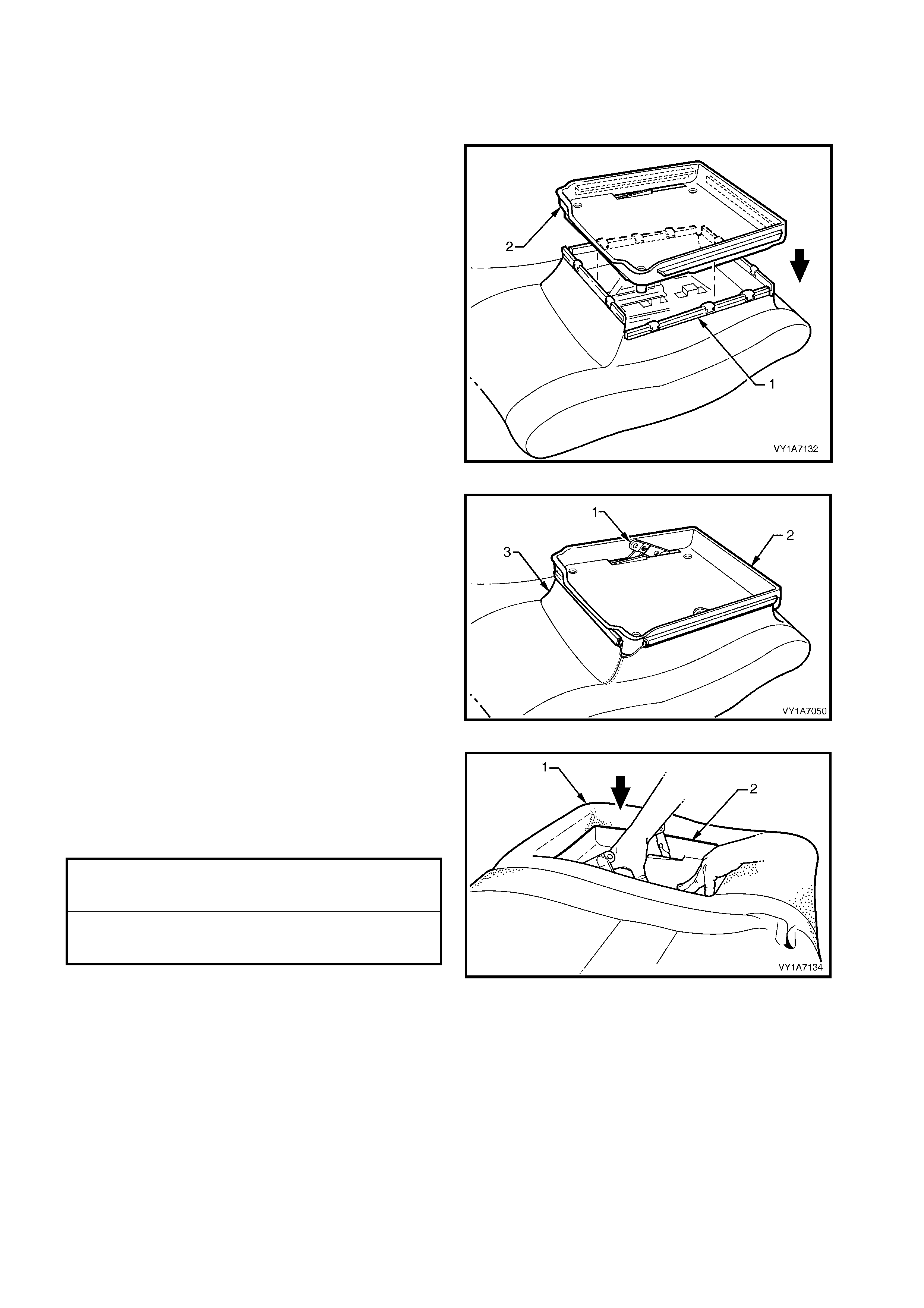

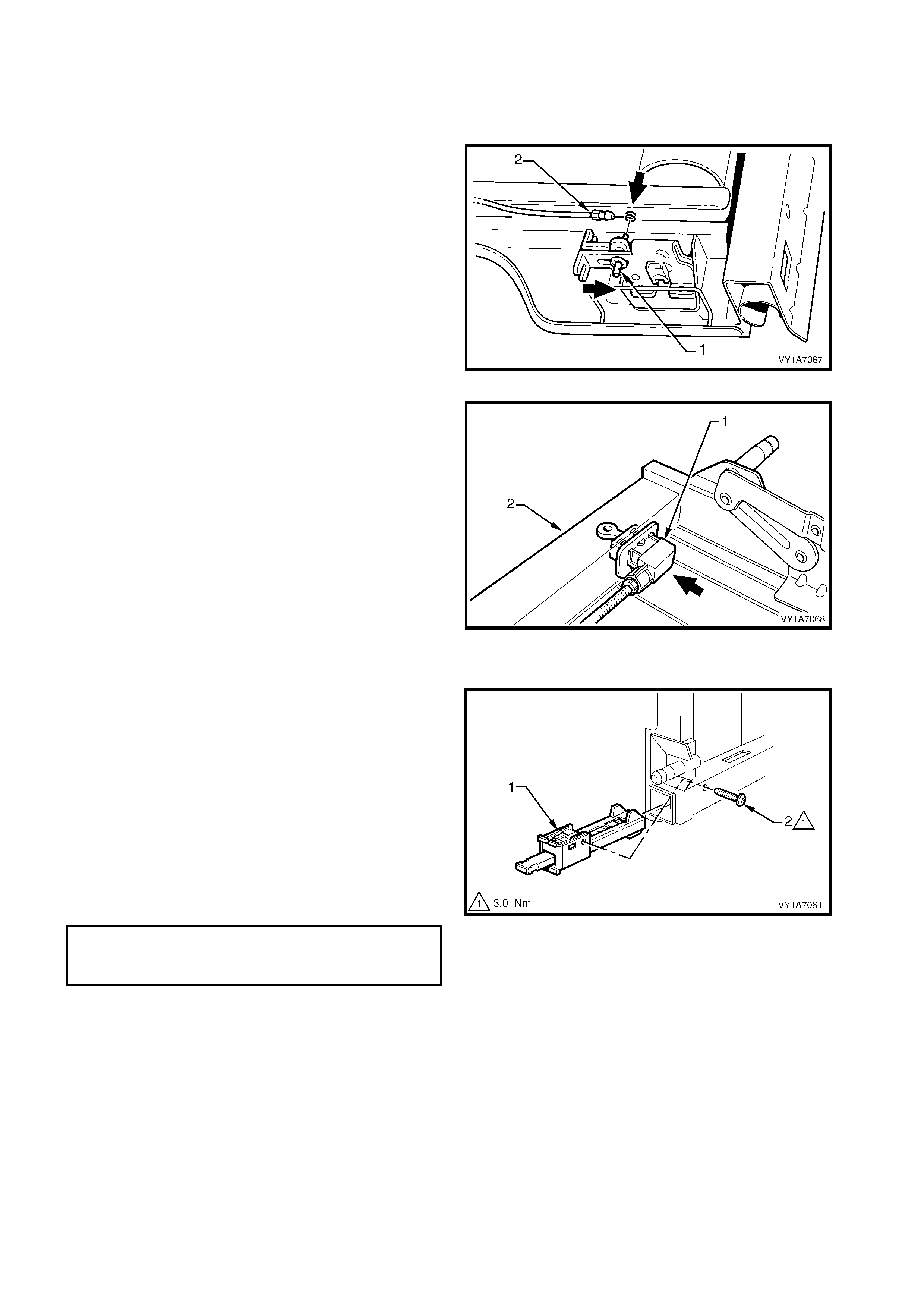

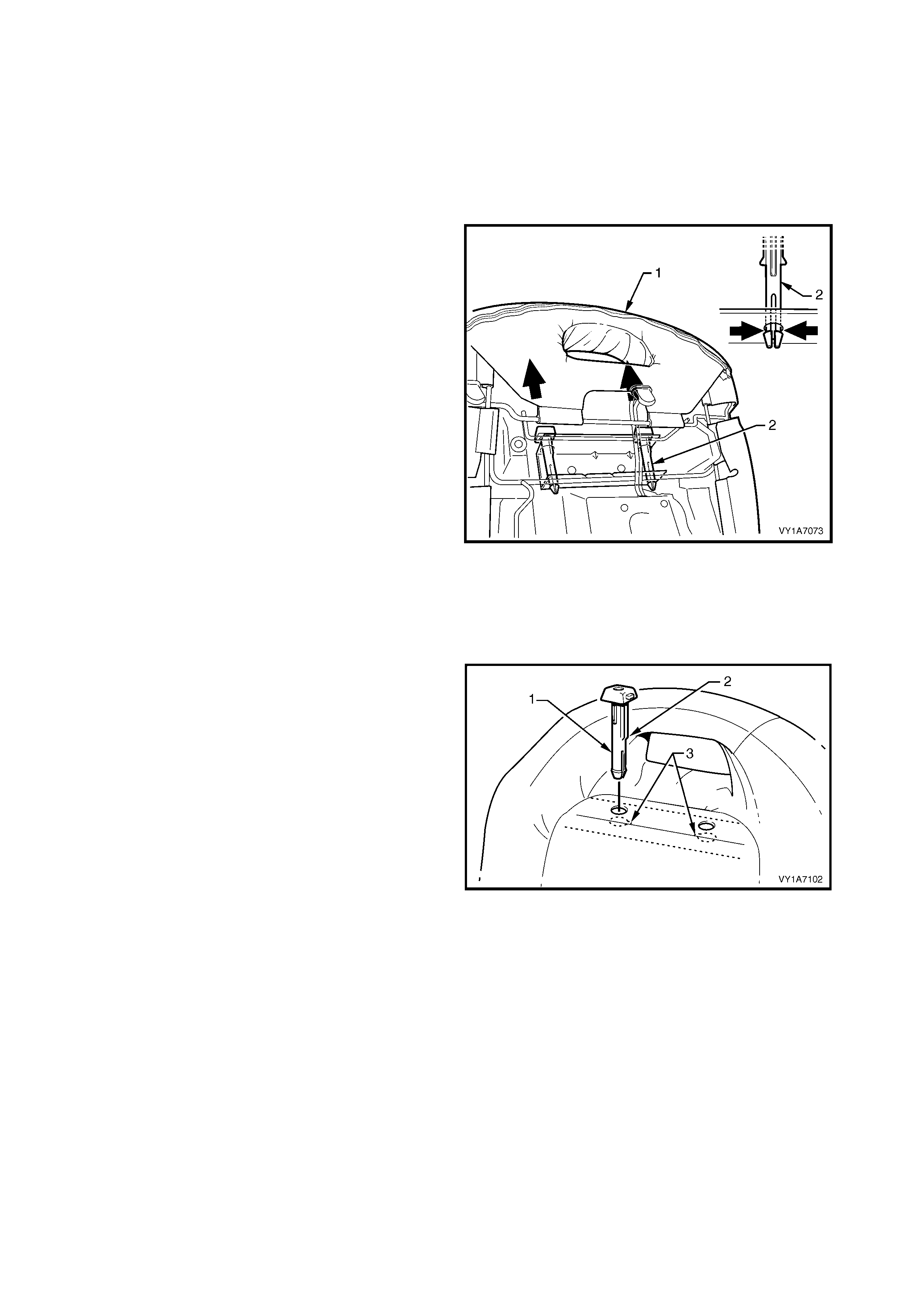

8. Unclip the front inner guide rail cover (1) from the

seat track (2).

Figure 1A7-23

9. Unclip the rear inner guide rail cover (1) from the

seat track (2).

Figure 1A7-24

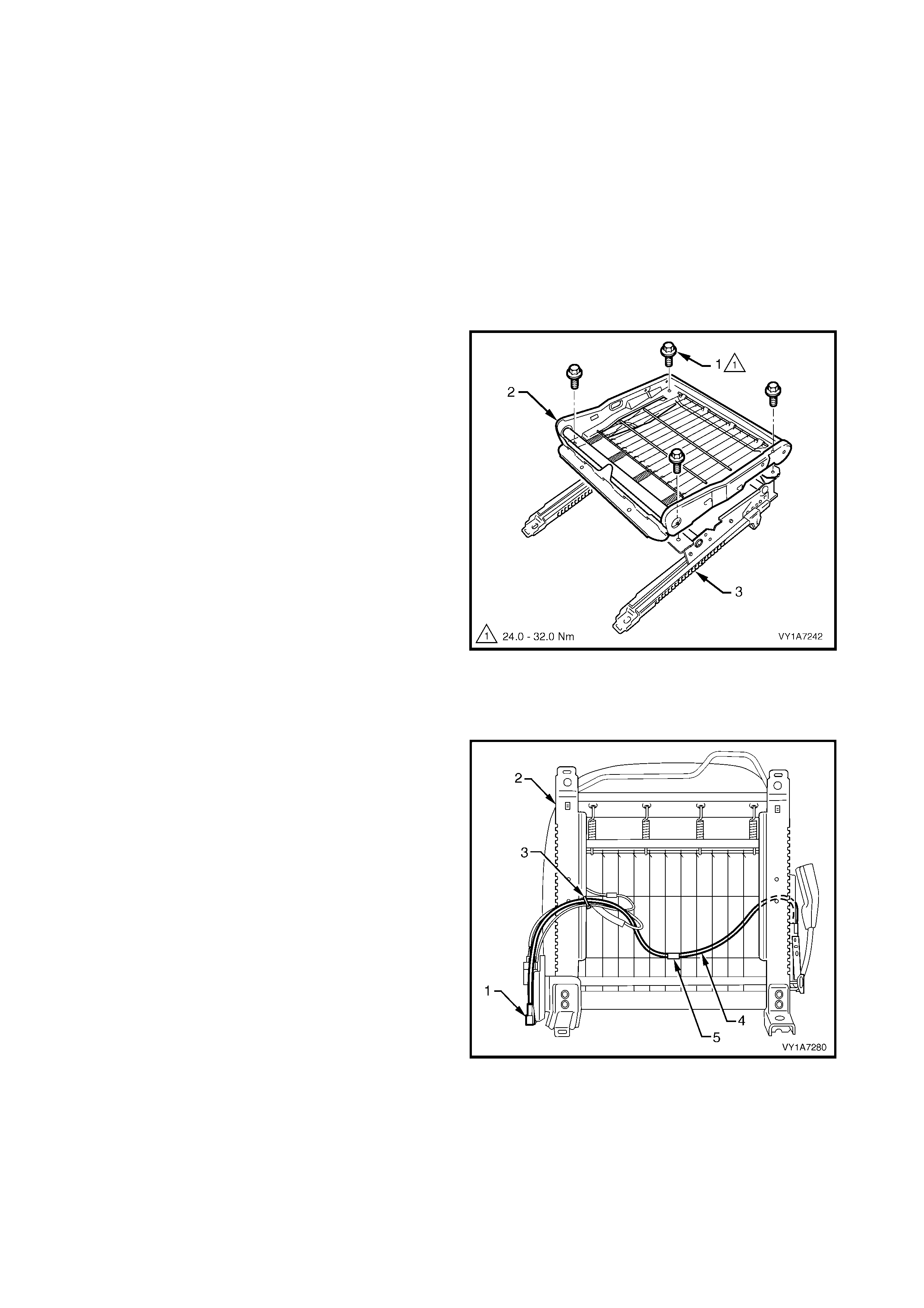

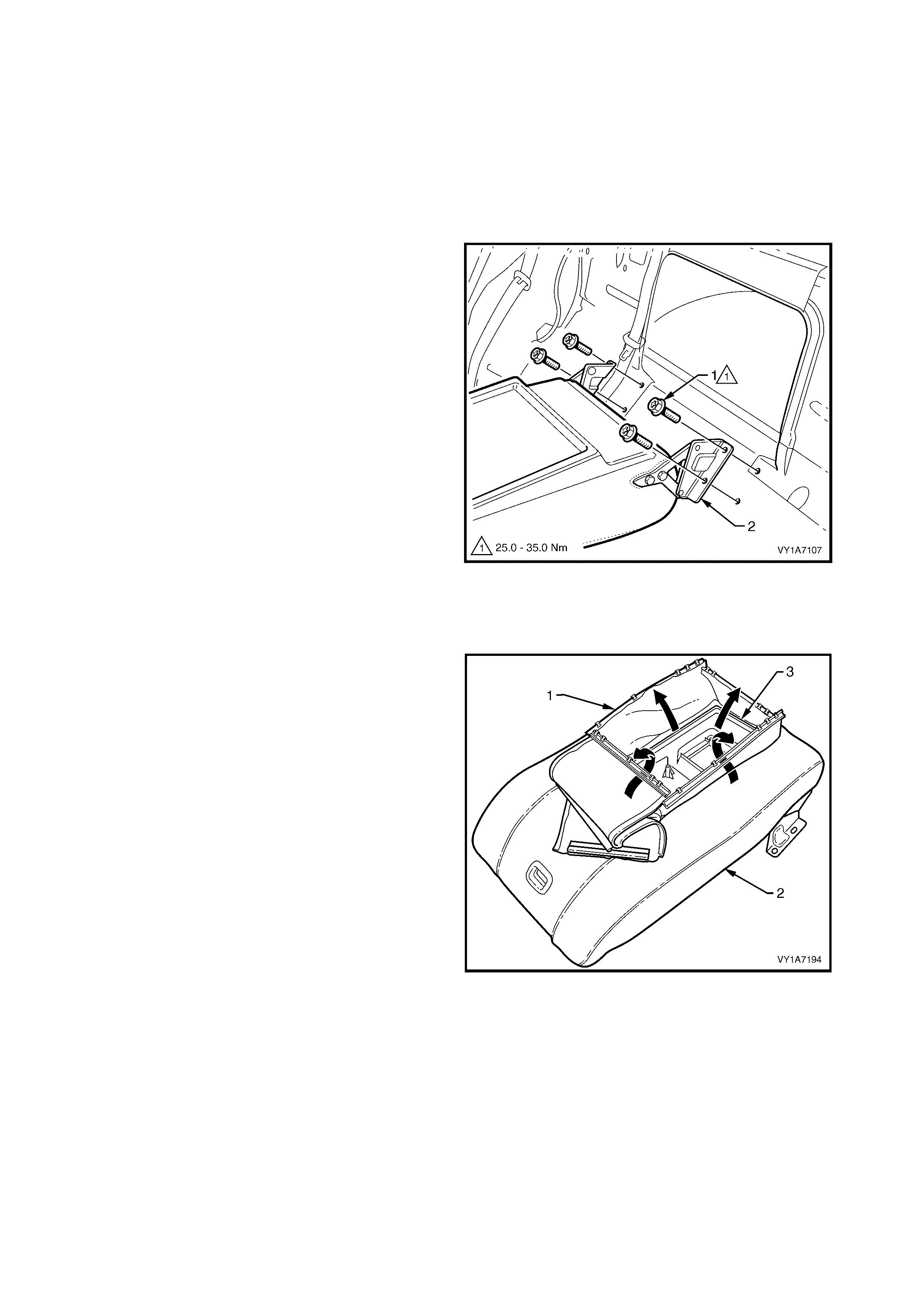

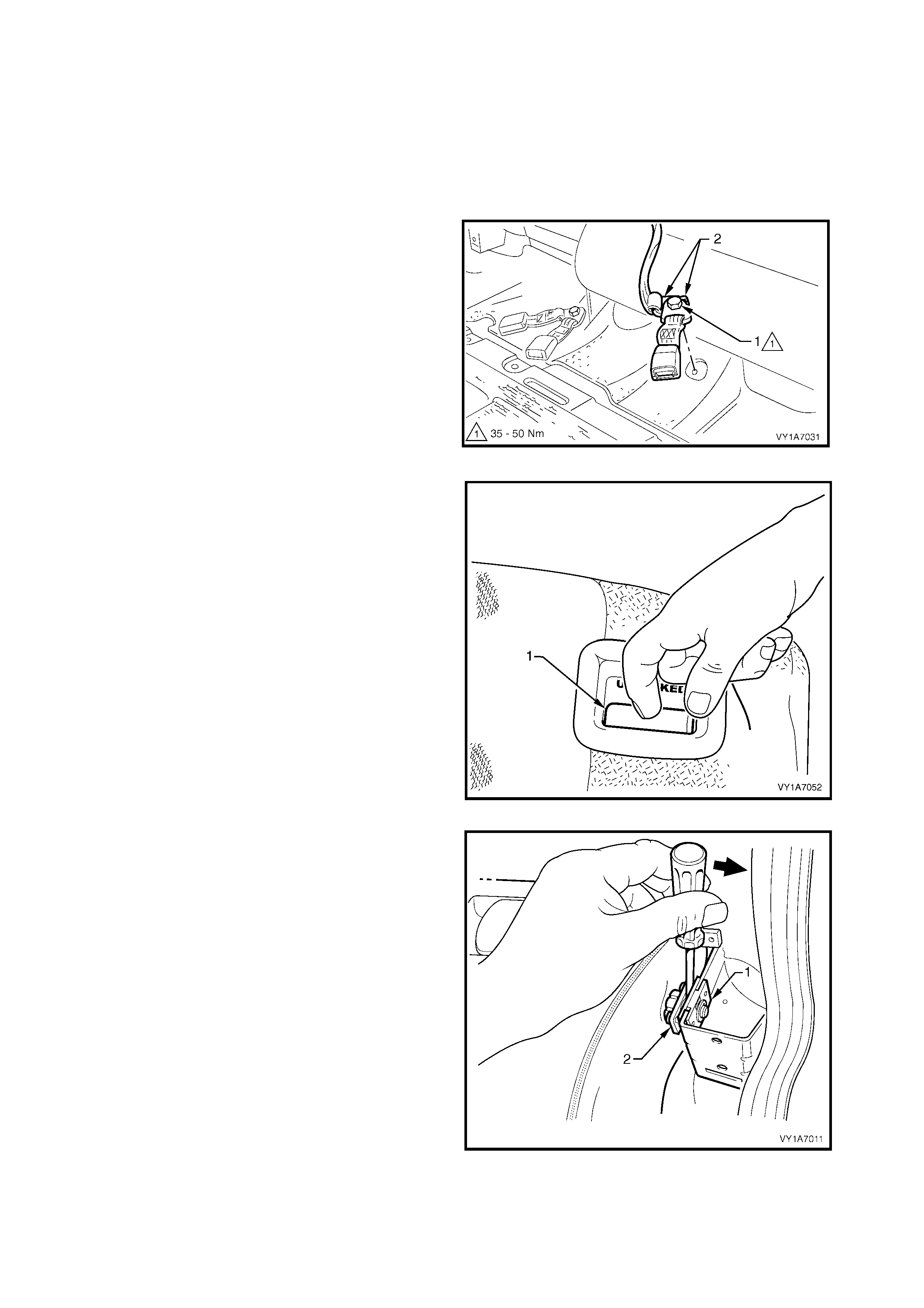

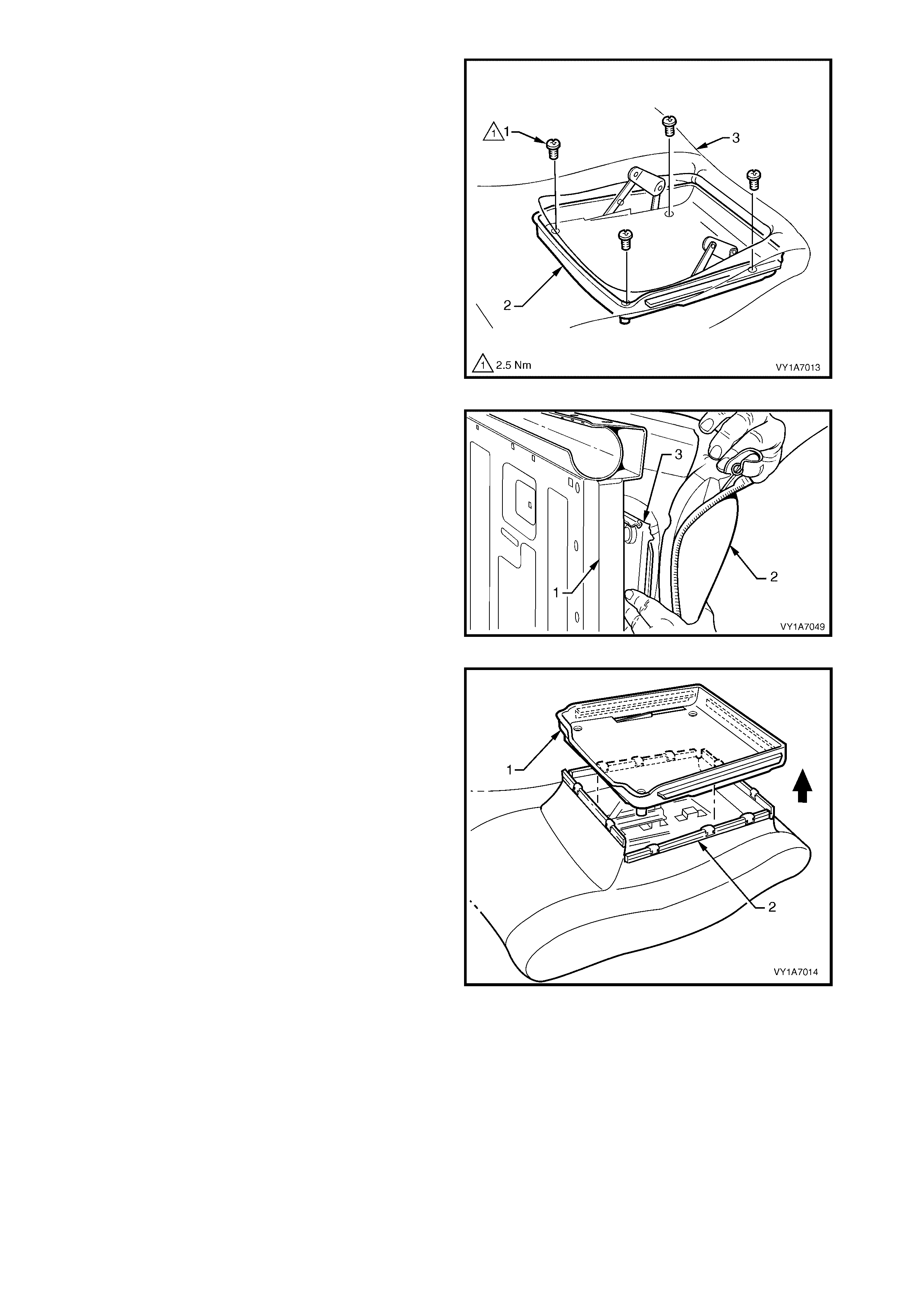

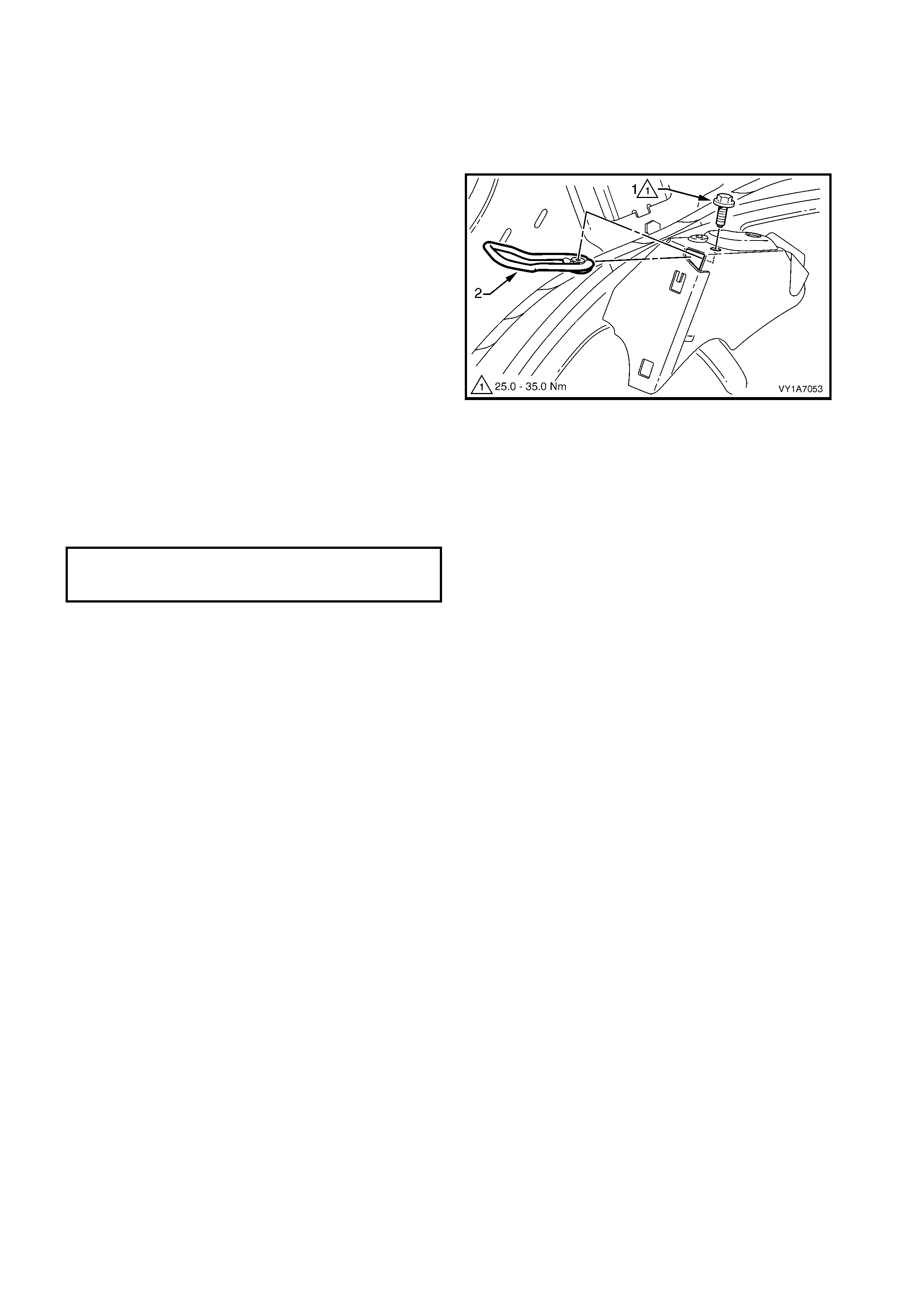

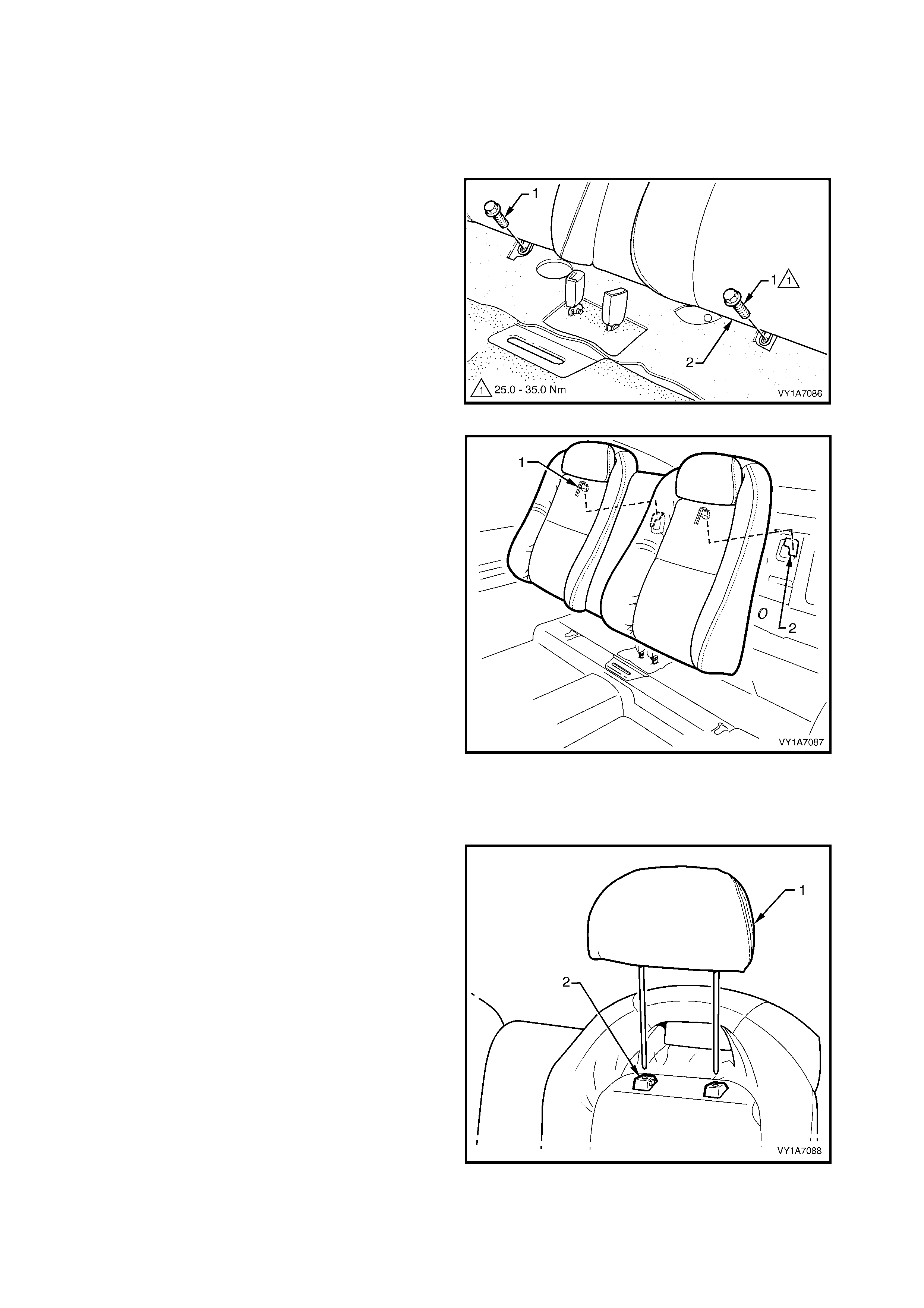

10. Remove the f our scr ews (1) securing the f ront seat

to the floor.

11. Remove the seat from the vehicle.

Figure 1A7-25

REINSTALL

Reinstallation of the front seat assembly is the reverse of the removal, noting the following:

1. Position the front seat assembly into the vehicle.

2. Install the four screws securing the front seat to the floor.

3. Connect the seat pretensioner harness and if fitted, the side airbag module and seat wiring harness

connectors.

4. Tighten all retaining screws to the correct torque specification.

5. Align the front outer seat guide rail cover’s two retaining clips and push firmly to engage.

6. Push the front of the outer seat guide rail cover down to engage the cover with the front of the seat rail.

If the seat is fitted with a side impact airbag, switch the ignition ON and observe the SRS warning indicator in the

instrument cluster.

• If no fault is detected, the SRS warning indicator should illuminate for approximately five seconds while the

system performs a self-test, and then go off.

• If a fault is present, the SRS warning indicator will remain illuminated and a warning chime may sound after

approximately three seconds. The warning message ‘SRS Airbag Fault’ is also displayed in the instrument

cluster multi-function display. To diagnose the fault, refer to Section 12M, 4. DIAGNOSTICS.

SEAT ADJUSTER OUTER FRONT

COVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT SEAT ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 35.0 – 50.0 Nm

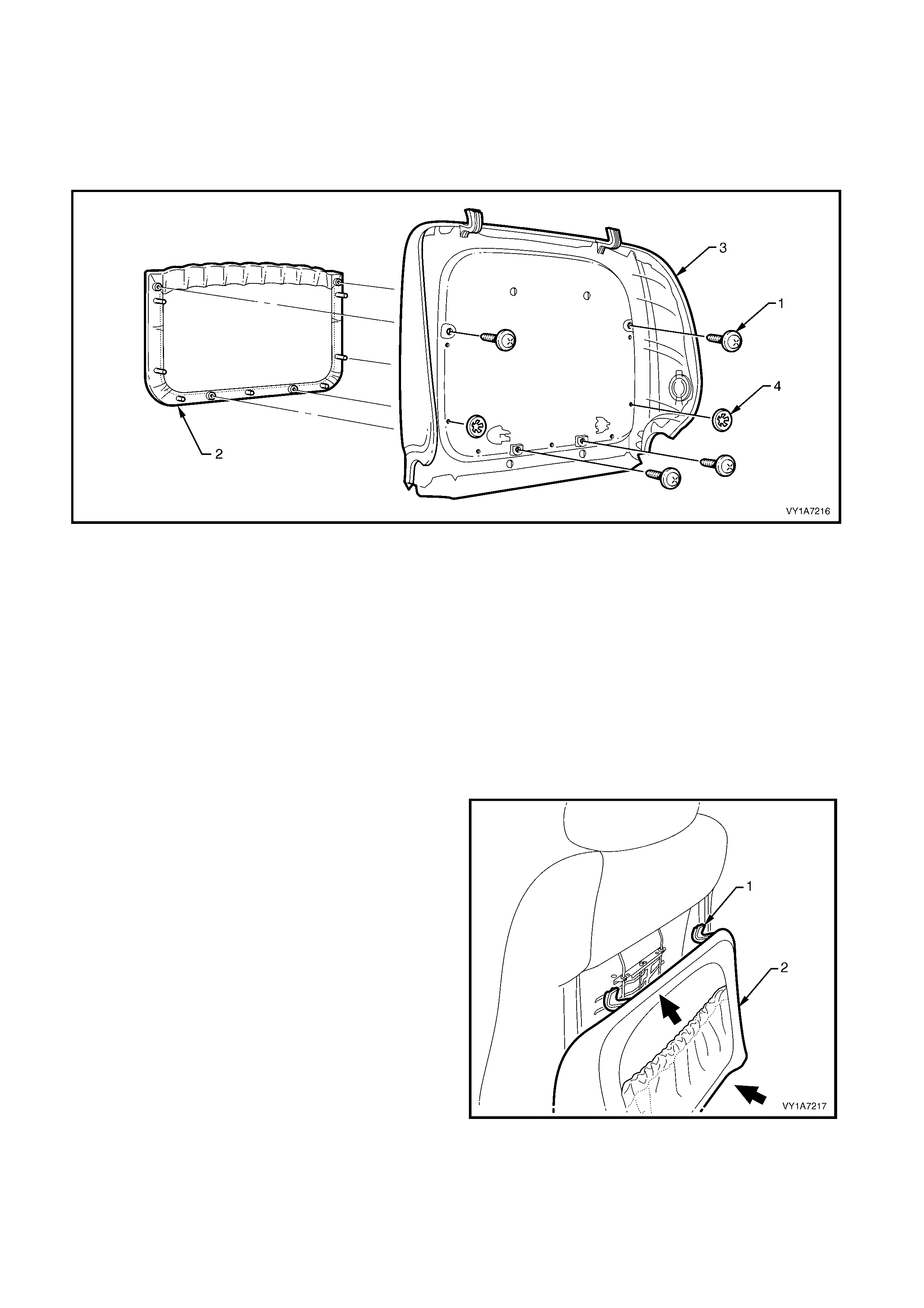

2.3 FRONT SEAT OUTER SIDE COVER

LT Section No. – 14-322

IMPORTANT: If the s eat assem bly is to be dissem bled and it has an electric seat height adjuster , adjust the seat

assembly to its highest position before disconnecting the power to the seat.

REMOVE

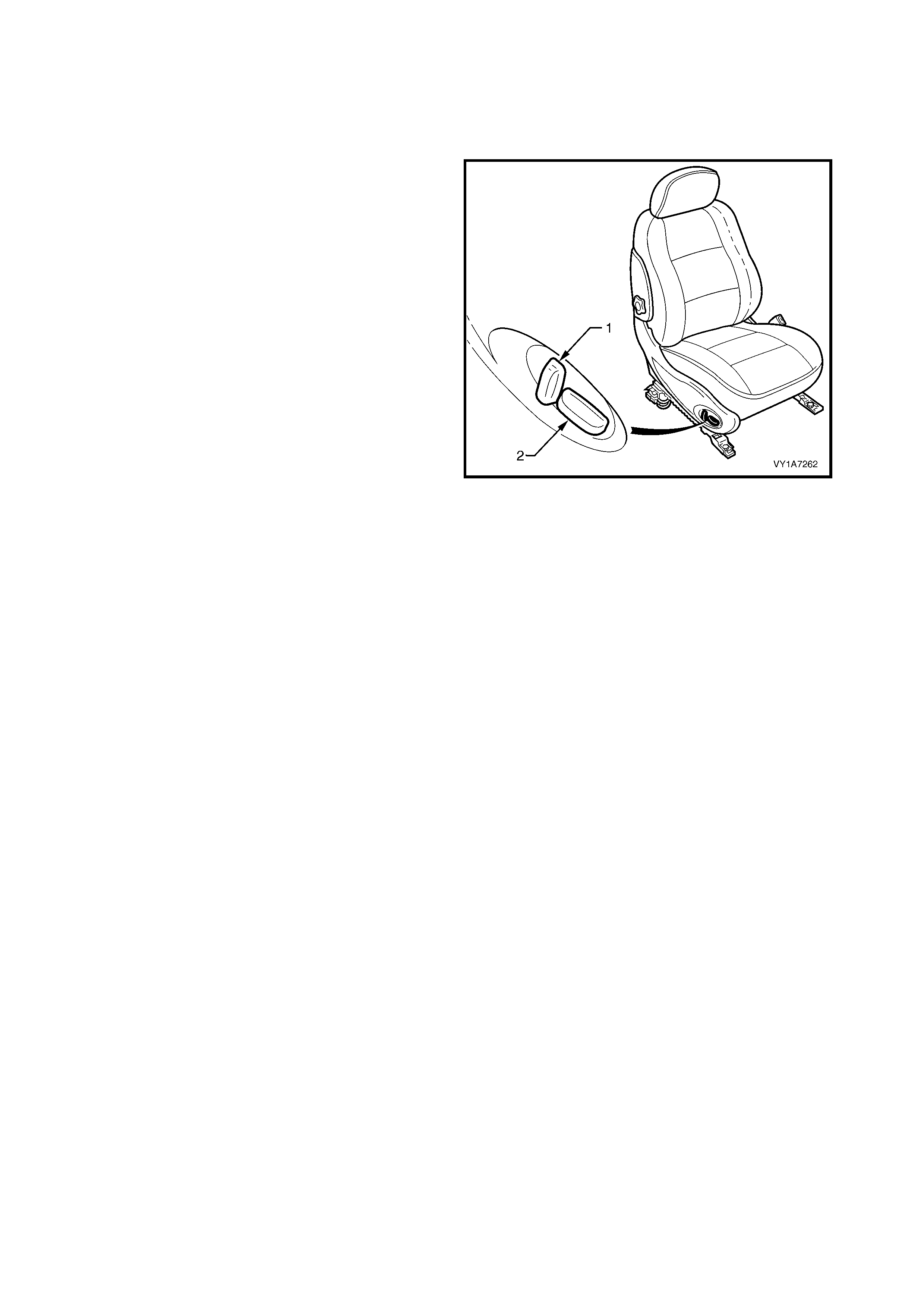

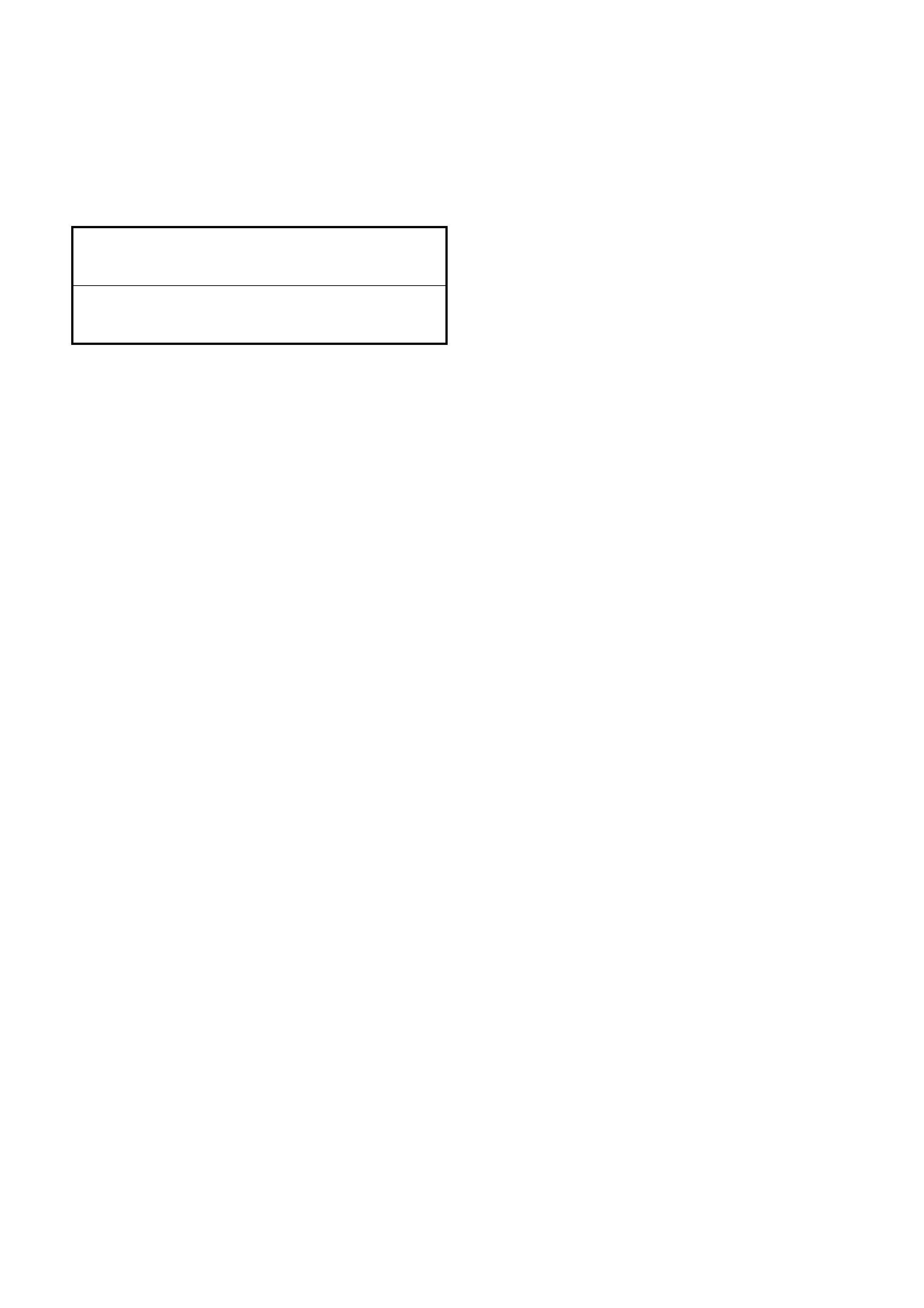

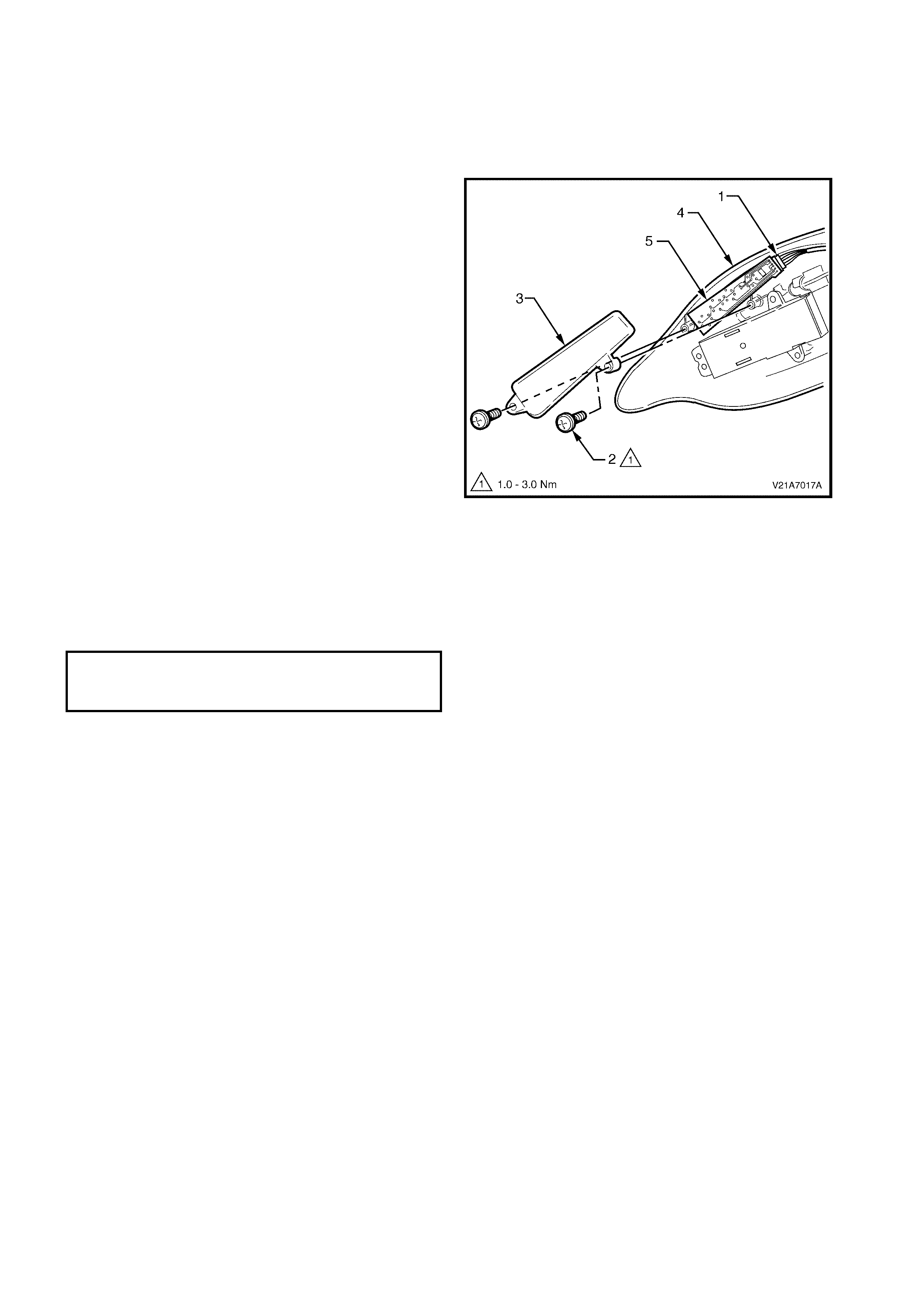

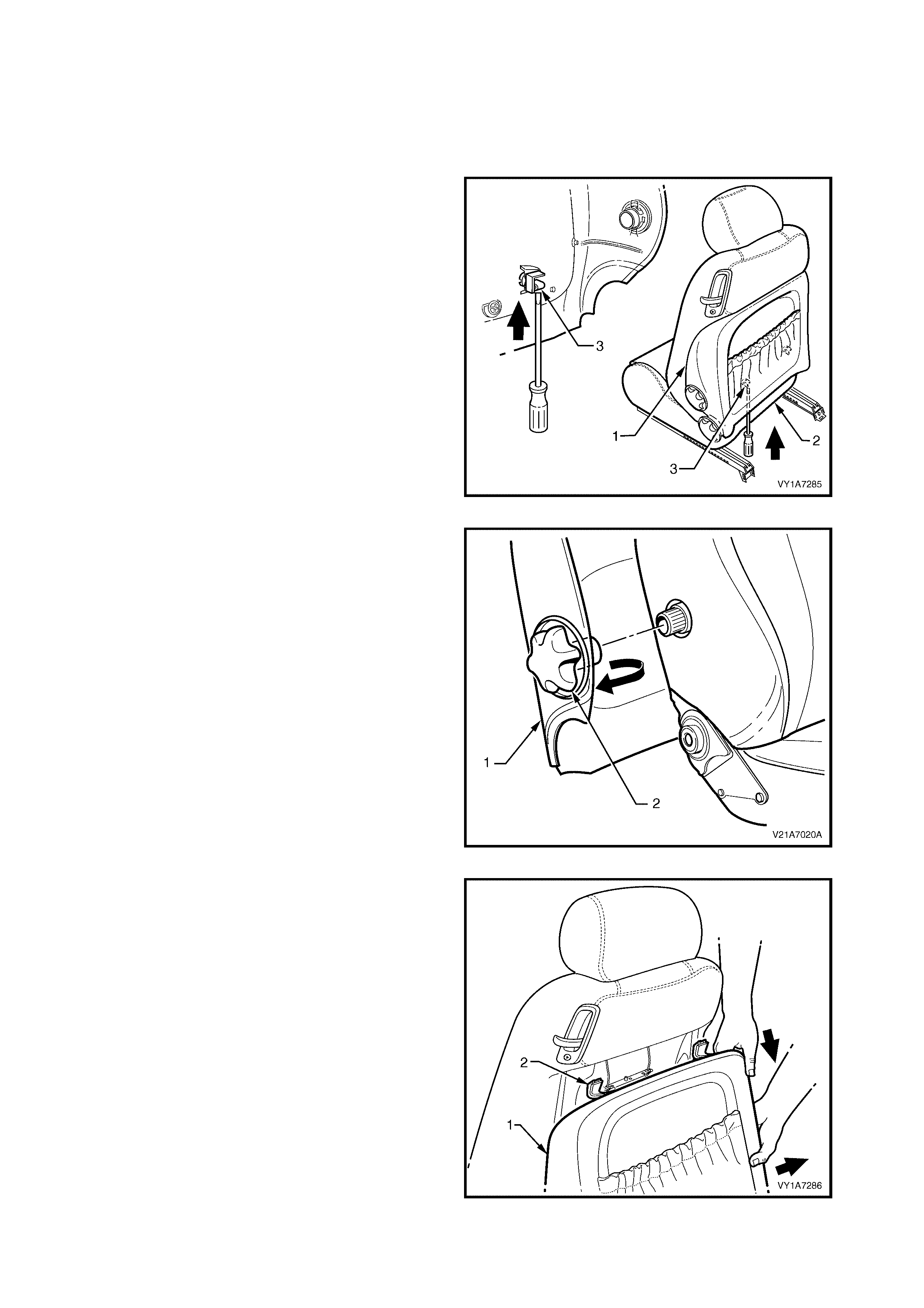

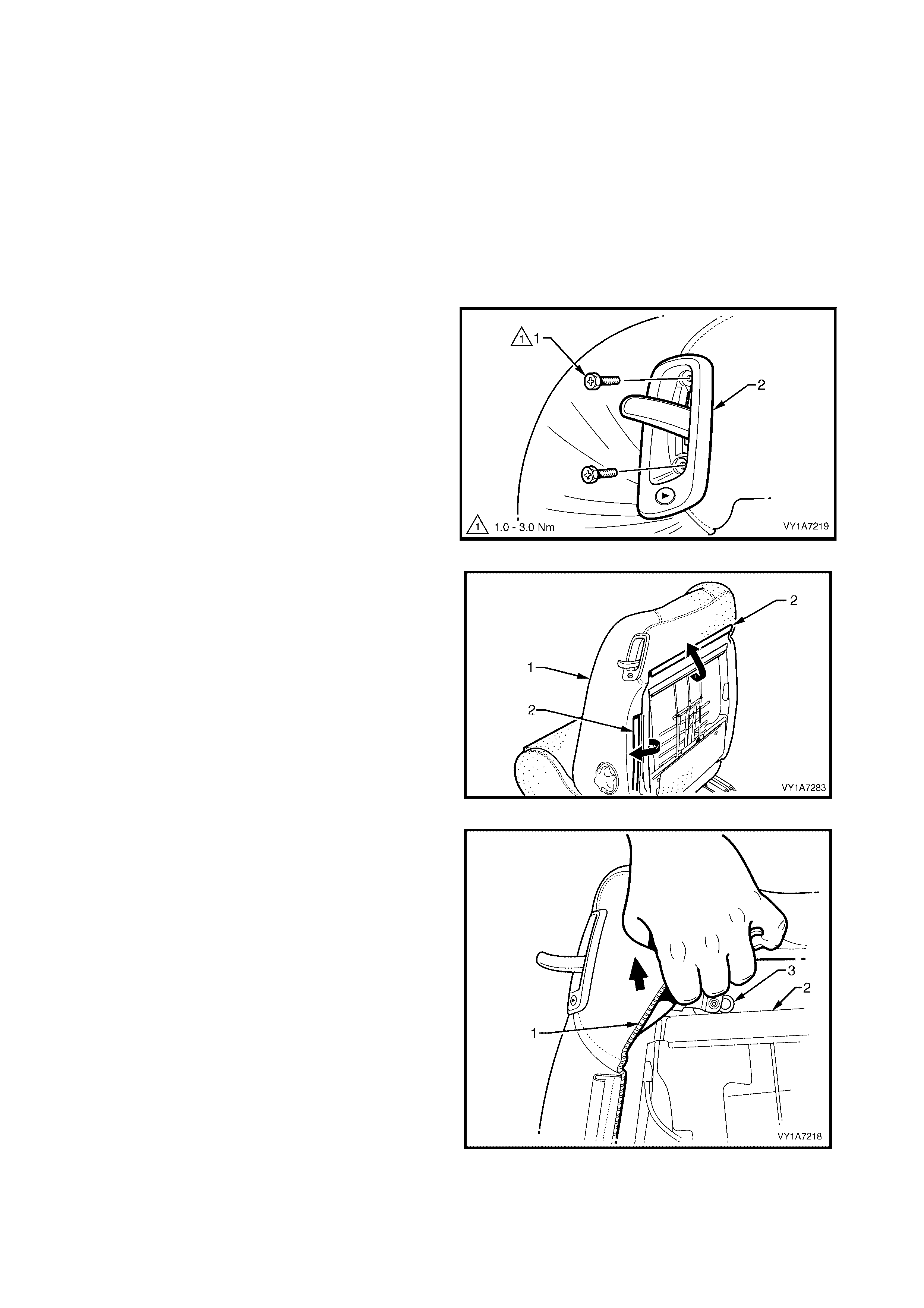

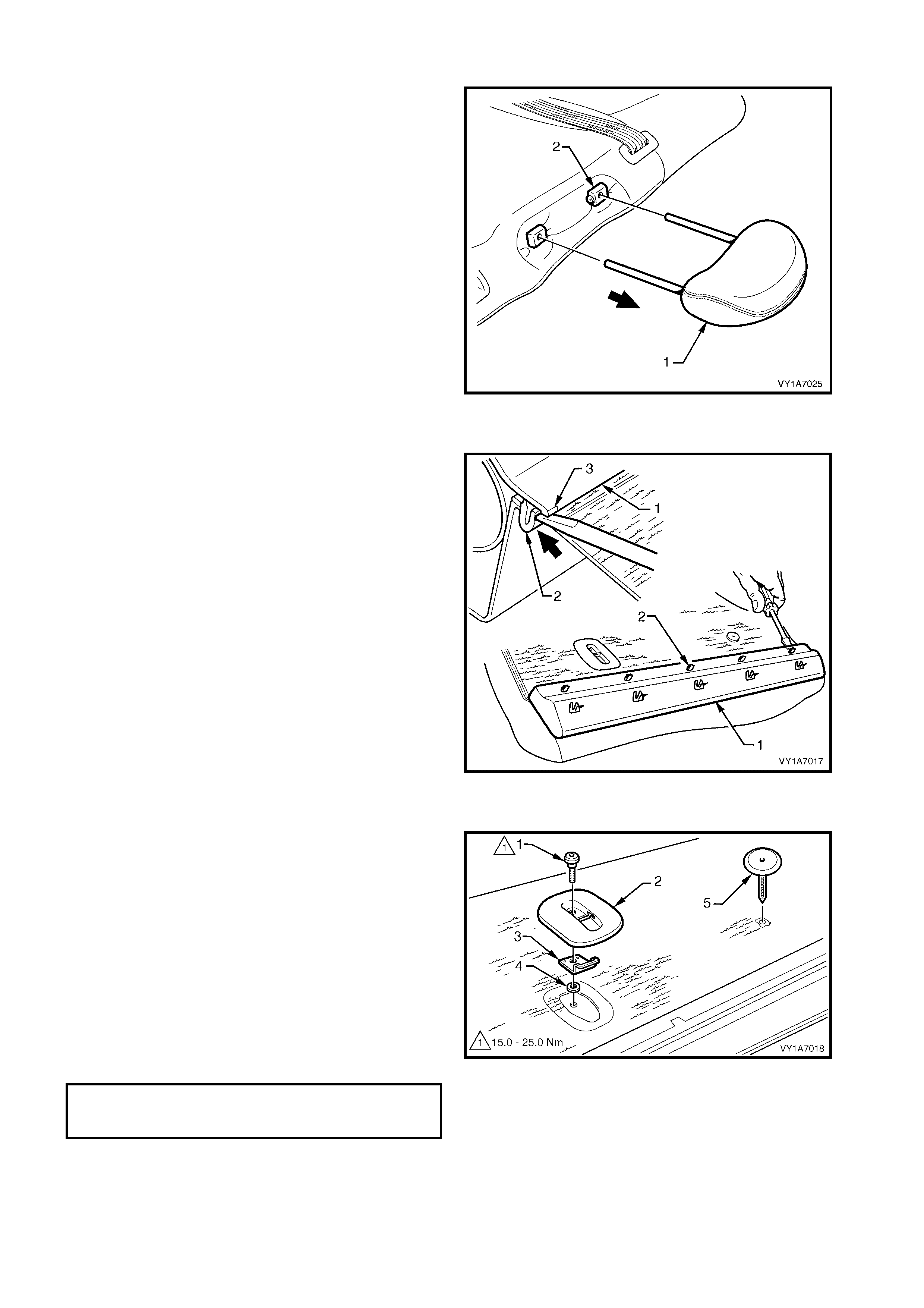

1. Remove the screw (1) from the front of the outer

side cover (2).

2. If fitted remove the recliner knob (3).

3. Remove the front seat outer side cover plug (4) by

rotating the plug anti-clockwise, one quarter of a

turn.

TIP: A fine screwdriver, would be useful to aid the

removal of the side cover plug without damage.

4. Remove the screw (5) located behind the plug.

5. Gently pull the outer cover away from the seat-

back recliner to disengage the two clips (6)

attached to the recliner frame.

6. Reach up under the seat assembly and squeeze

together the two retaining tangs (7), on the inner

side of the outer cover while gently pulling the outer

cover.

NOTE: Only remove the outer cover far enough away

from the seat cushion assembly to gain access to the

seat wiring harness connectors.

Figure 1A7-26

7. For vehic les fitted with the four-way seat as sem bly,

disconnect the four-way adjustment switch

connector (1) and remove the cover.

Figure 1A7-27

8. For vehicles fitted with the eight-way, non-memory

seat assembly:

• Disconnect the eight-way adjustment switch

connector (1).

• Disconnect the recliner motor connector (2).

• Remove the outer side cover.

Figure 1A7-28

REINSTALL

Reinstallation of the front seat outer side cover is the reverse of the removal operation, noting the following:

1. Ensure all screws are tightened to the correct torque specification.

FRONT OUTER SIDE COVER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.4 FRONT SEAT ADJUSTMENT SWITCH

LT Section No. – 14-275

1. Remove the front seat outer side cover, refer to 2.3 FRONT SEAT OUTER SIDE COVER.

REMOVE

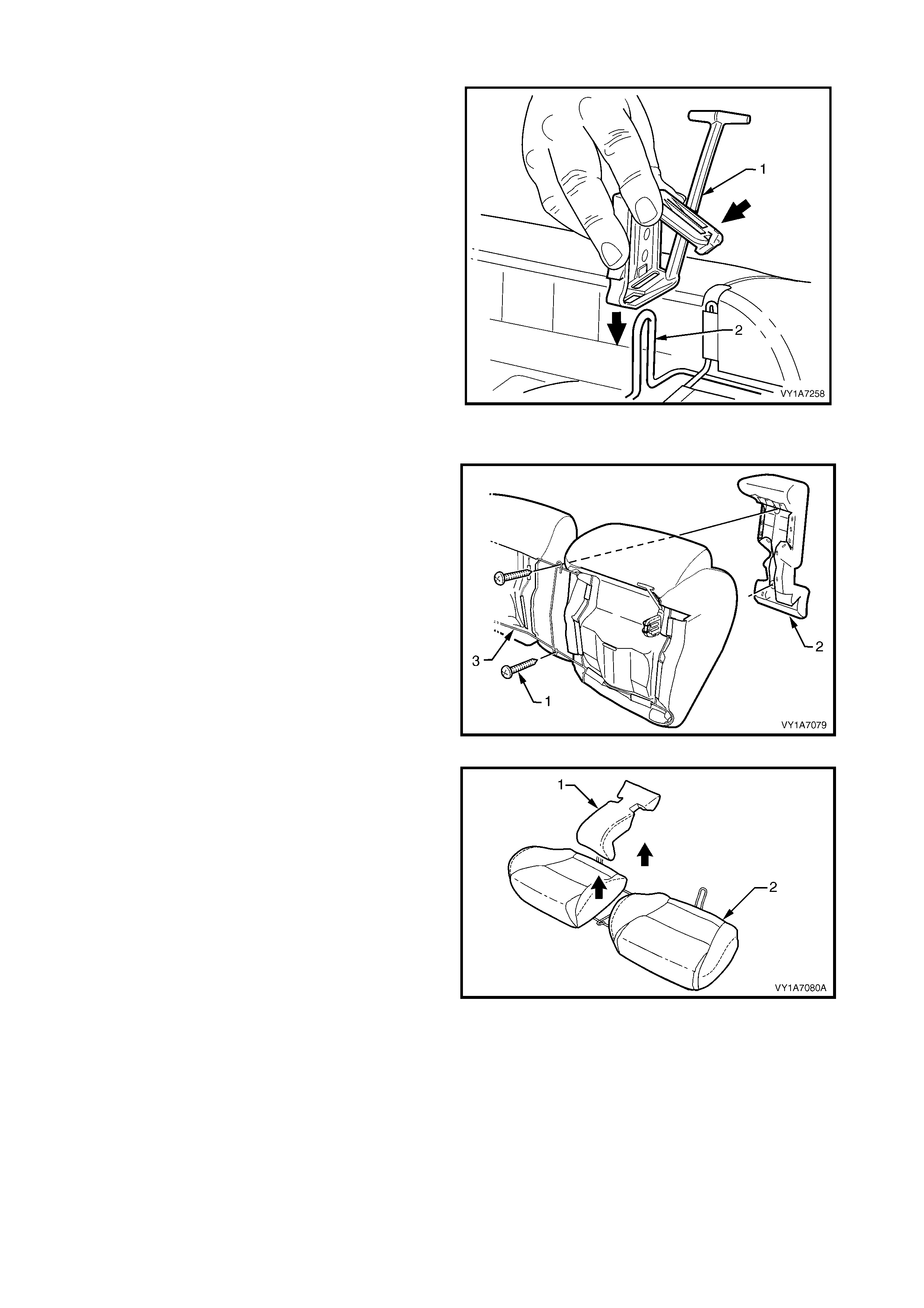

Four-way Adjustment Switch (up and down only)

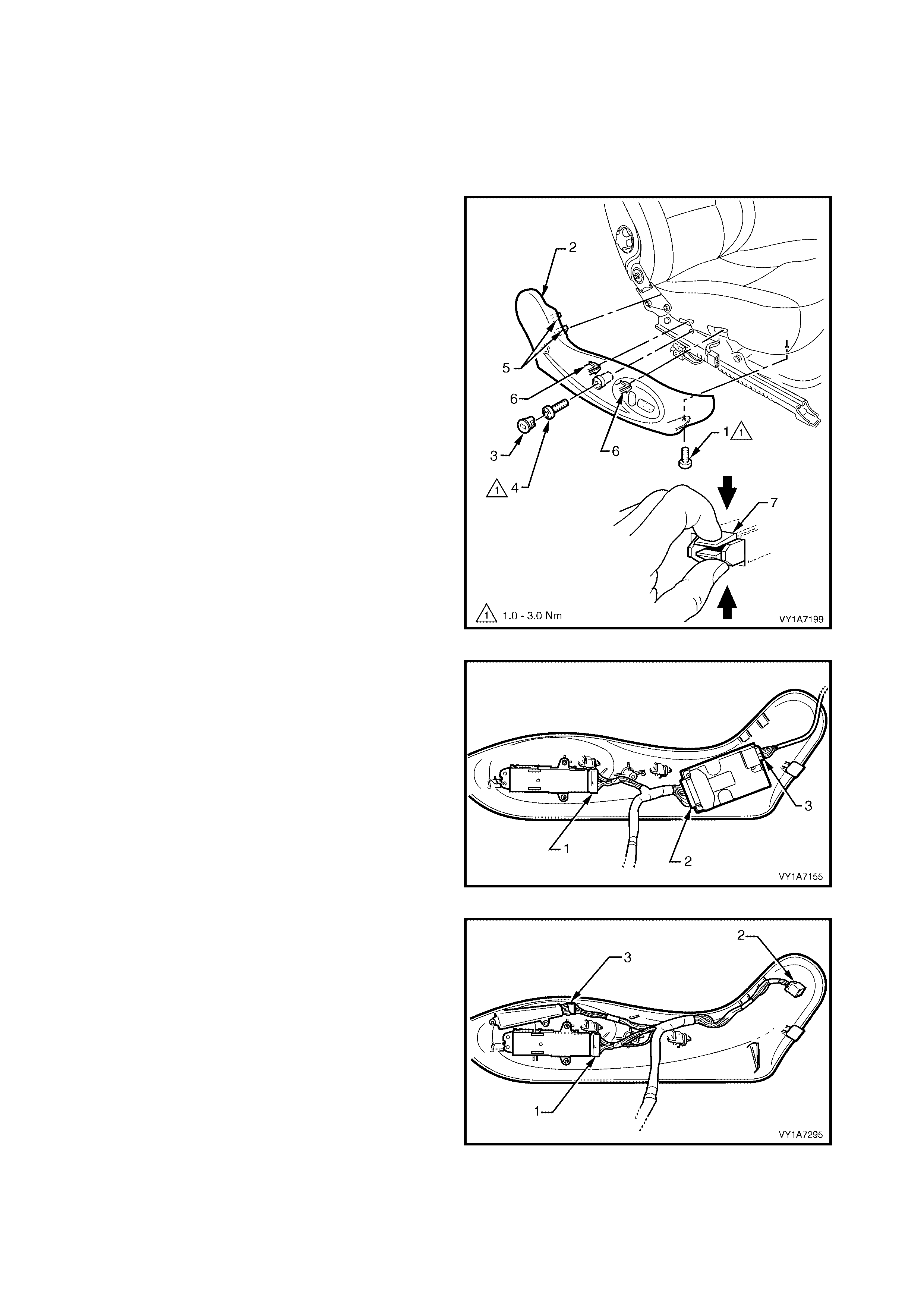

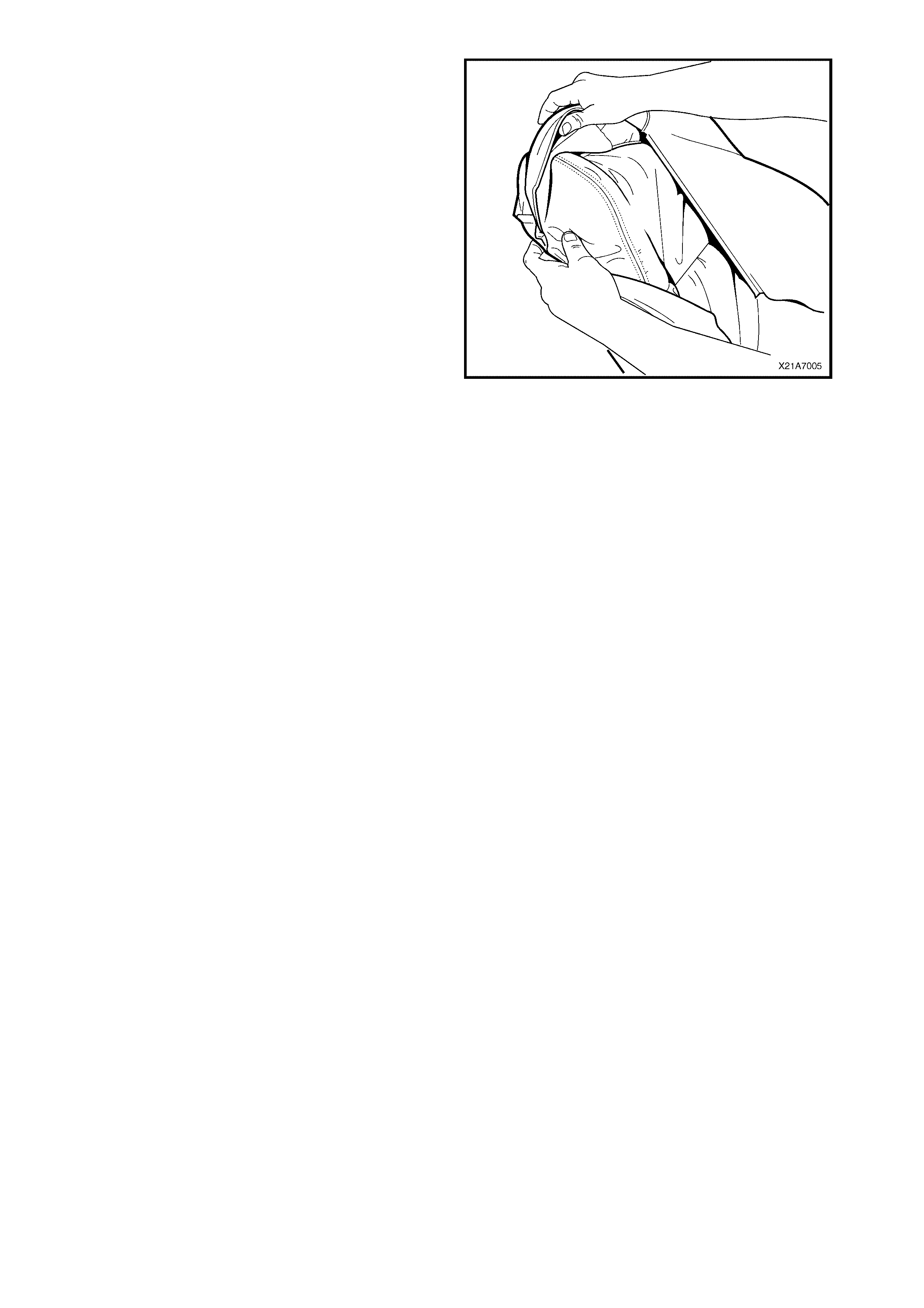

1. Remove the adjusting knob (1) from the seat

adjustment switch (2) by carefully prising it free with

a sm all flat tip s crewdriver wrapped in a clean shop

rag (3).

Figure 1A7-29

2. Gently prise the seat adjustment switch (1) from

the outer side cover (2) with the aid of a

screwdriver.

Figure 1A7-30

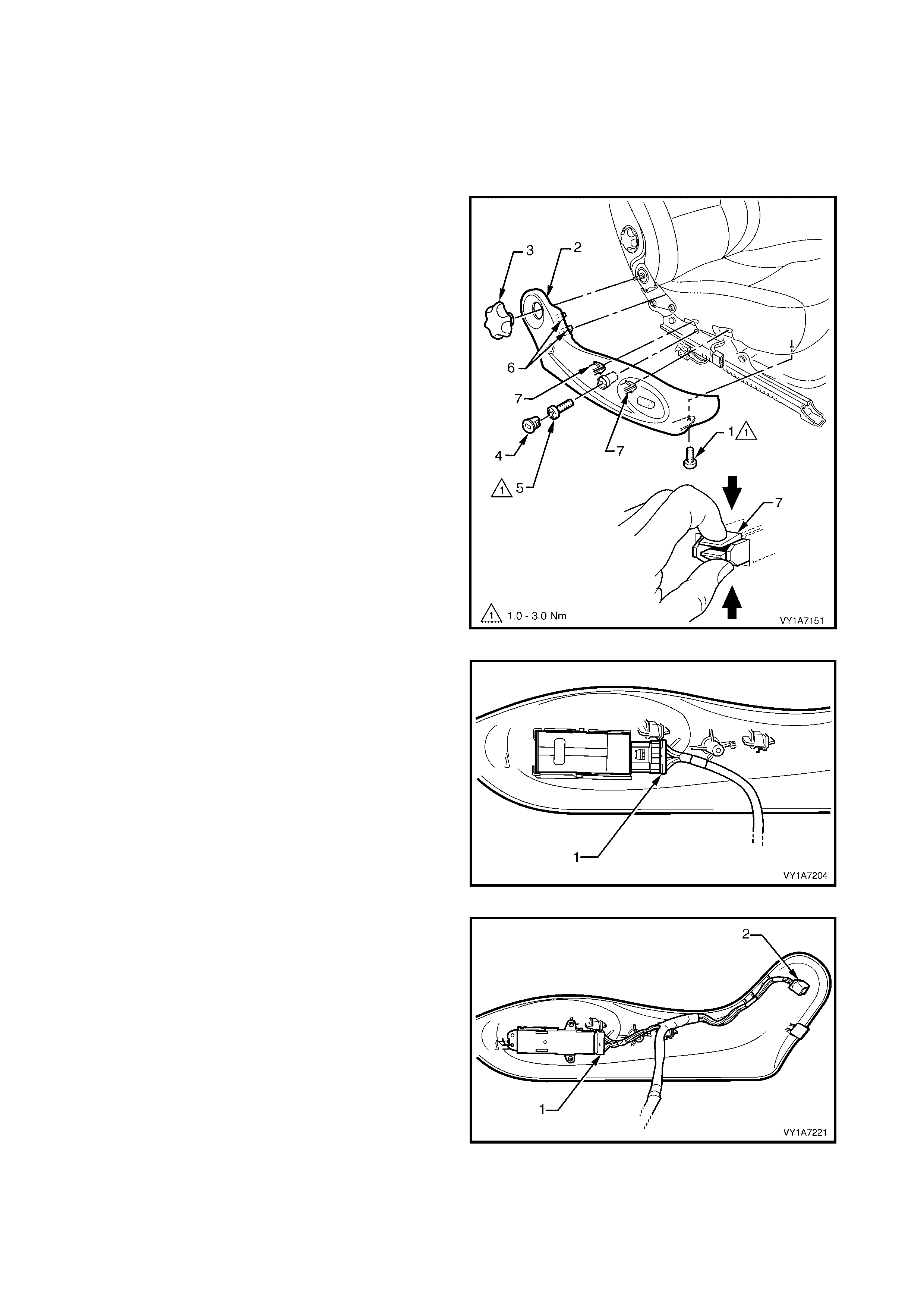

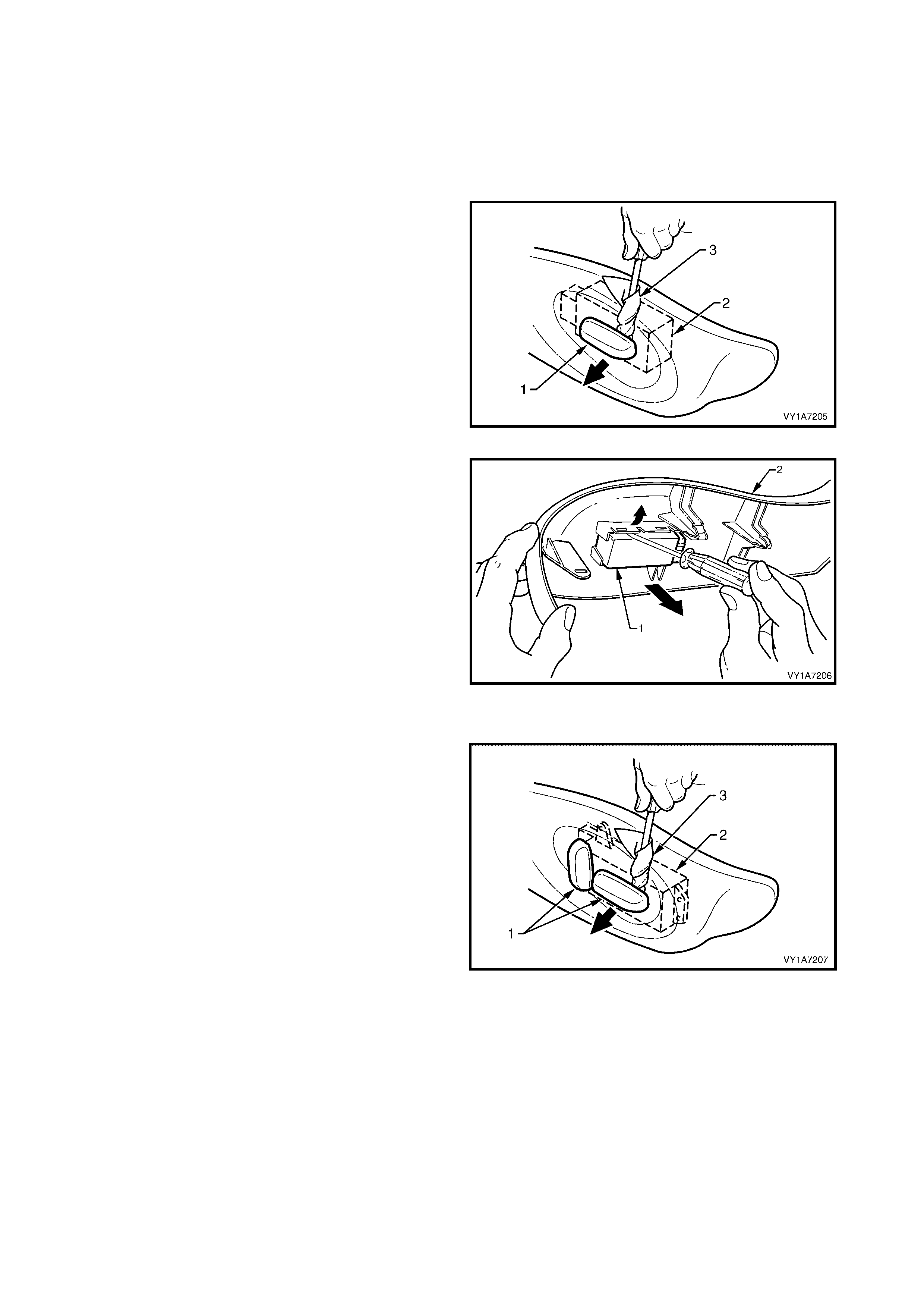

Eight-way Adjustment Switch - Non-memory (up, down, fore, aft and recline)

1. Remove the two adjustment knobs (1) from the

seat adjus tm ent switch (2) by ca refully prising them

free with a small flat tip screwdriver wrapped in a

clean shop rag (3).

Figure 1A7-31

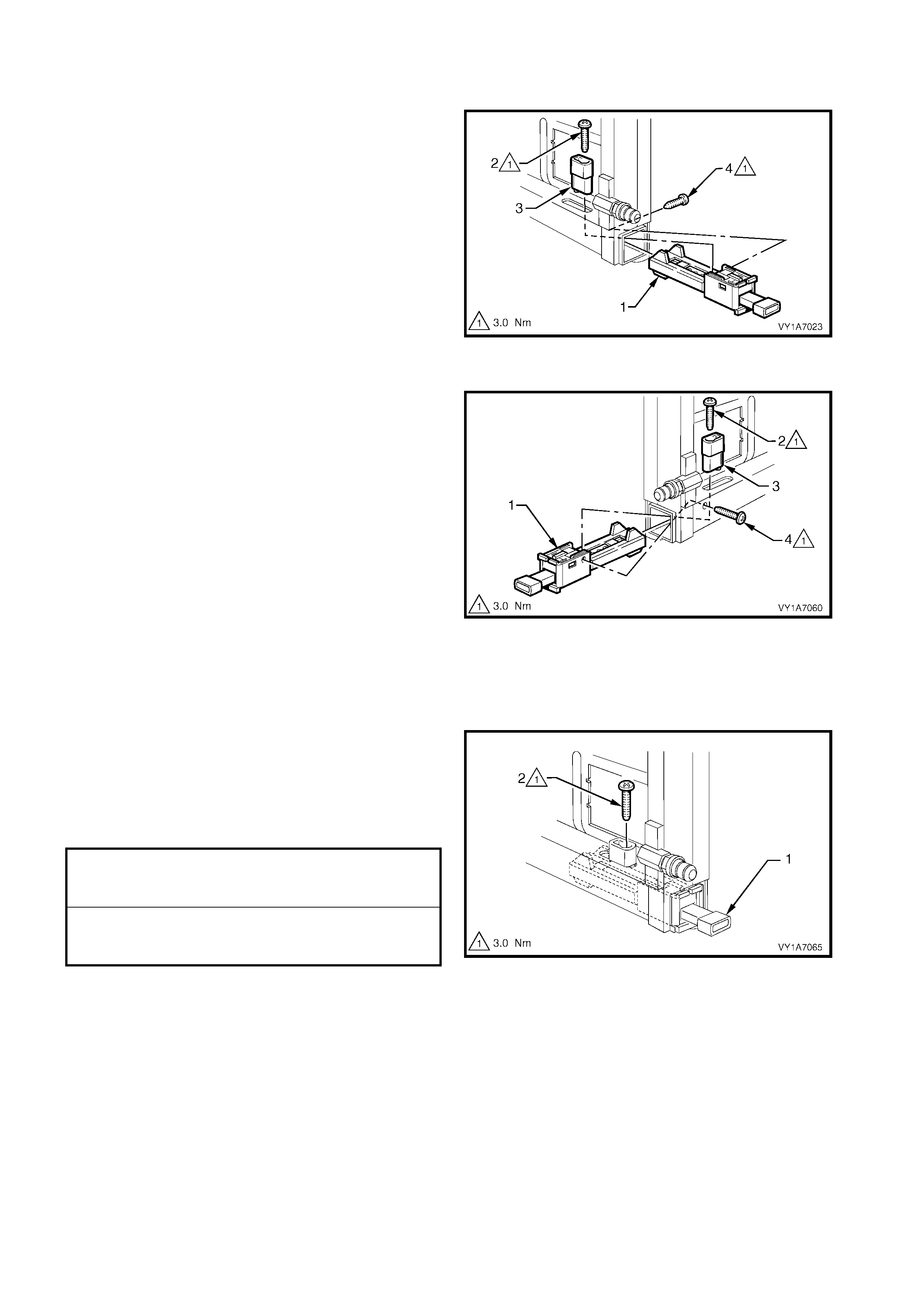

2. Remove the three screws (1) attaching the seat

adjustment switch (2) to the outer side cover (3).

3. Remove the seat adjustment switch.

Figure 1A7-32

REINSTALL

Reinstallation of the four-way and the eight-way seat

adjustment switch is the reverse of the removal

operation, noting the following:

1. Ensure all screws are tightened to the correct torque

specification.

EIGHT-WAY SEAT ADJUSTMENT

SWITCH ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.5 FRONT SEAT INNER SIDE COVER

LT Section No. – 14-322

1. Remove the front seat assembly, refer to 2.2 FRONT SEAT ASSEMBLY.

REMOVE

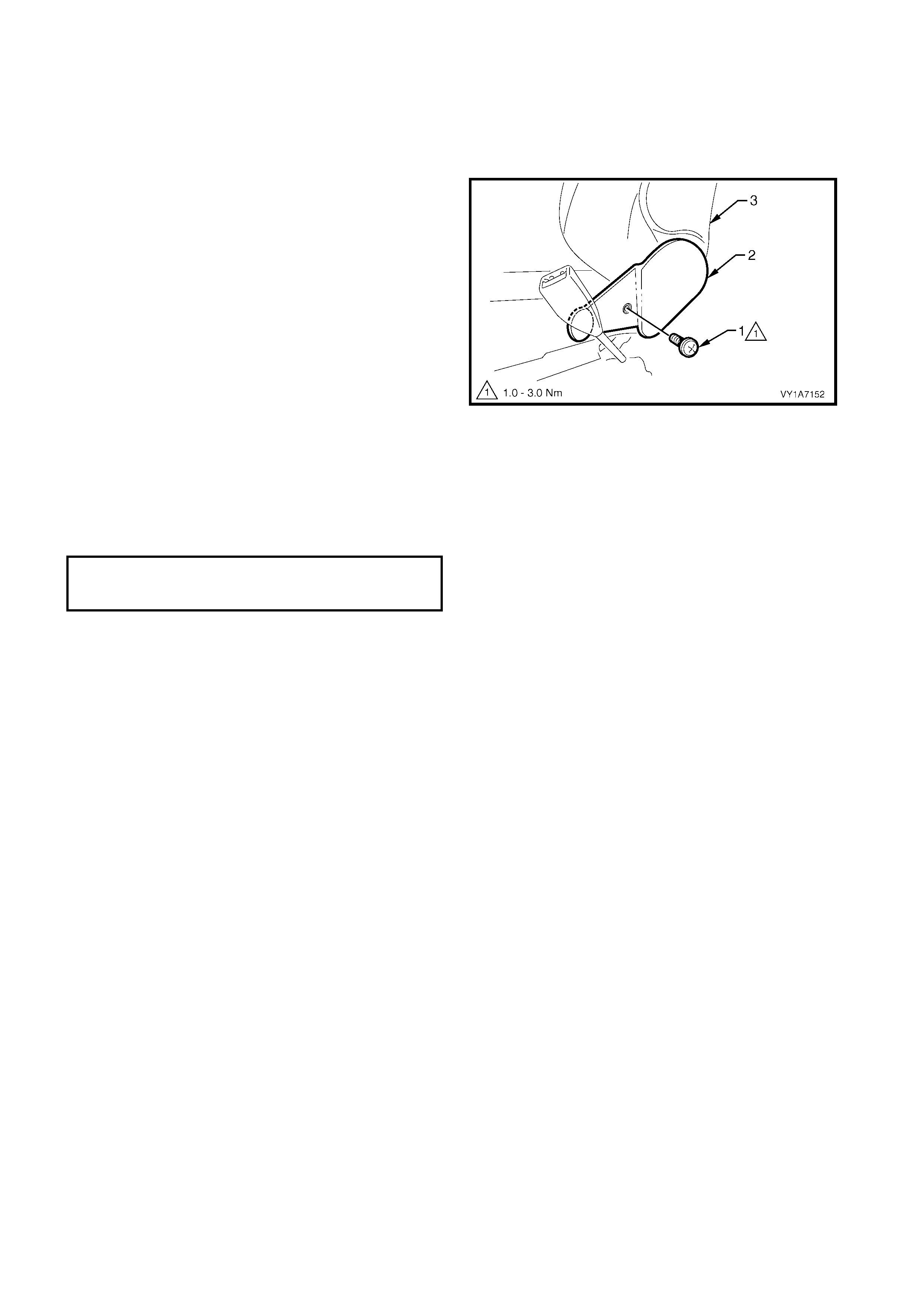

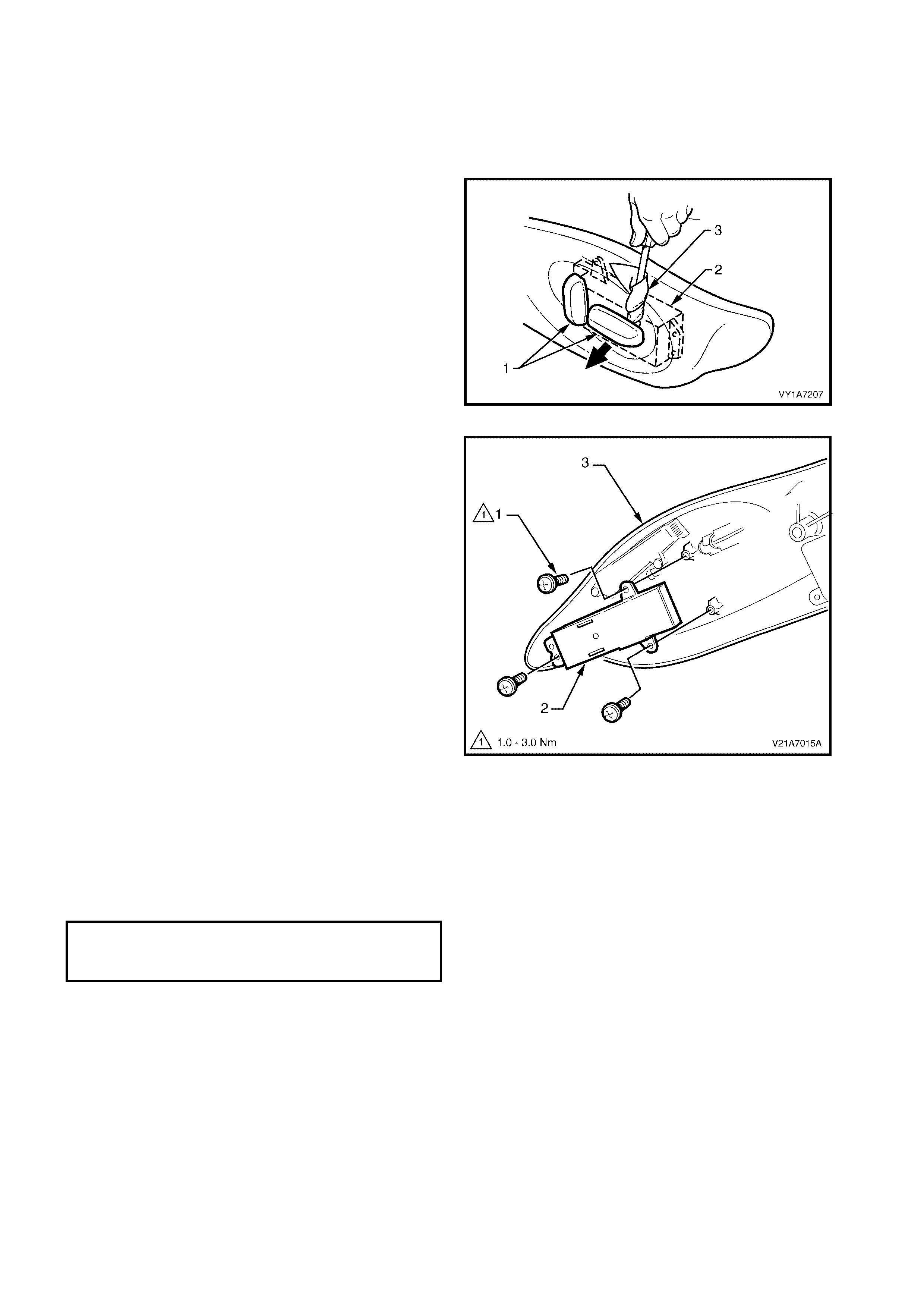

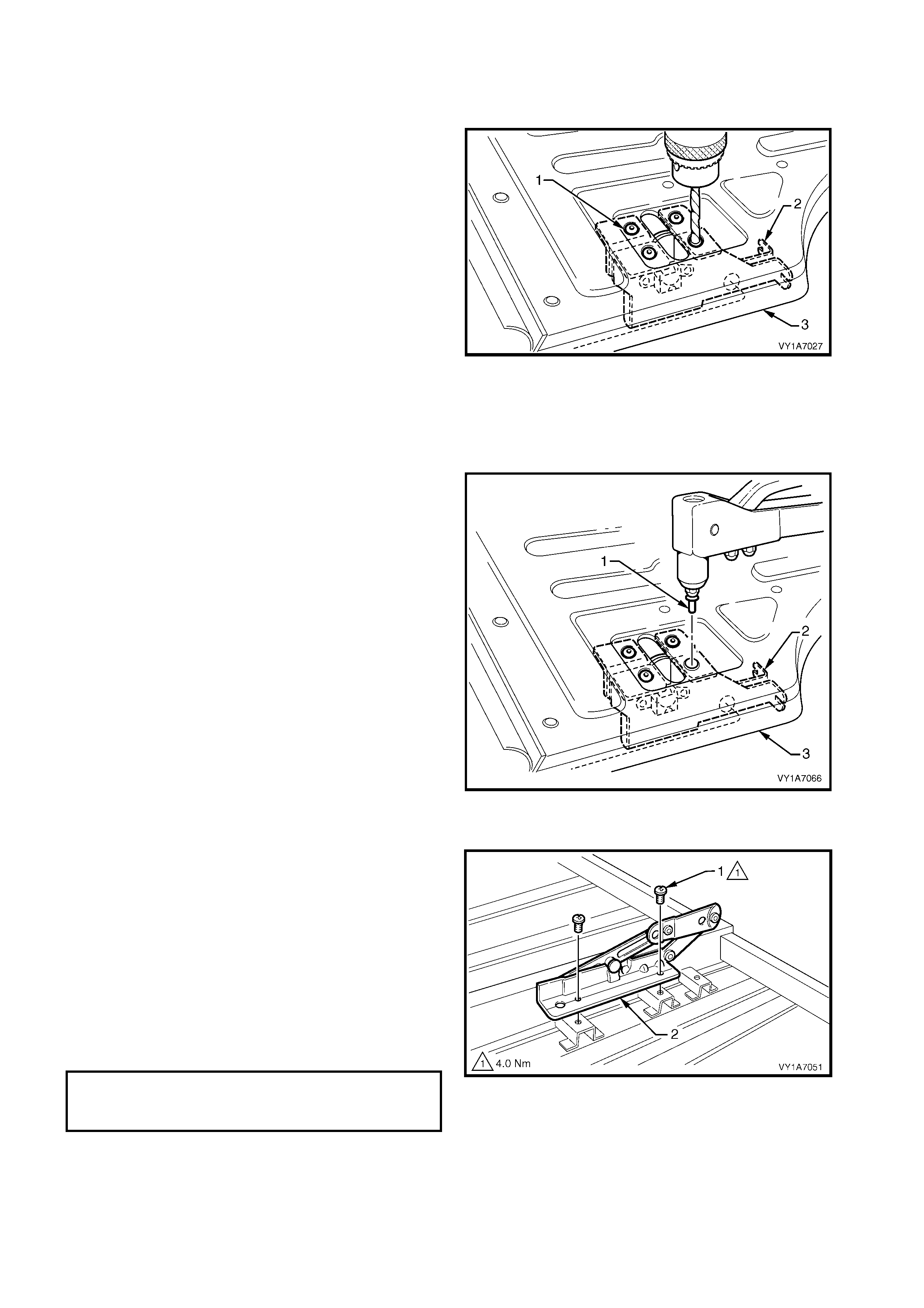

1. Remove the screw (1) securing the inner side

cover (2) to the seat assembly (3) and remove the

inner side cover.

Figure 1A7-33

REINSTALL

Reinstallation of the inner side cover is the reverse of

the removal operation, noting the following:

1. Ensure the screws are tightened to the correct

torque specification.

FRONT SEAT INNER SIDE

COVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.6 FRONT SEAT-BACK LOWER COVER ASSEMBLY AND LUMBAR

SUPPORT ADJUSTER KNOB

LT Section No. – 14-322

REMOVE

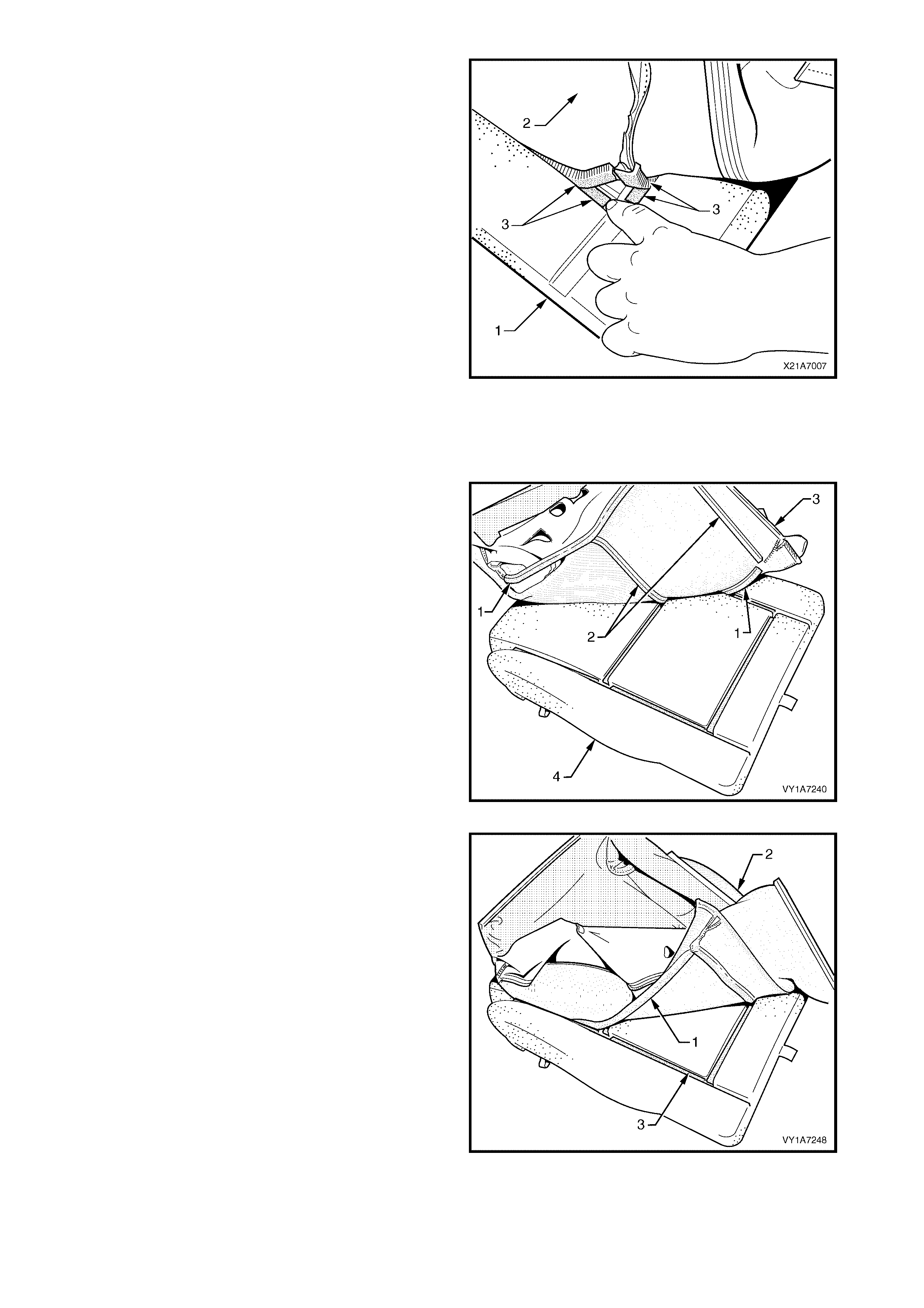

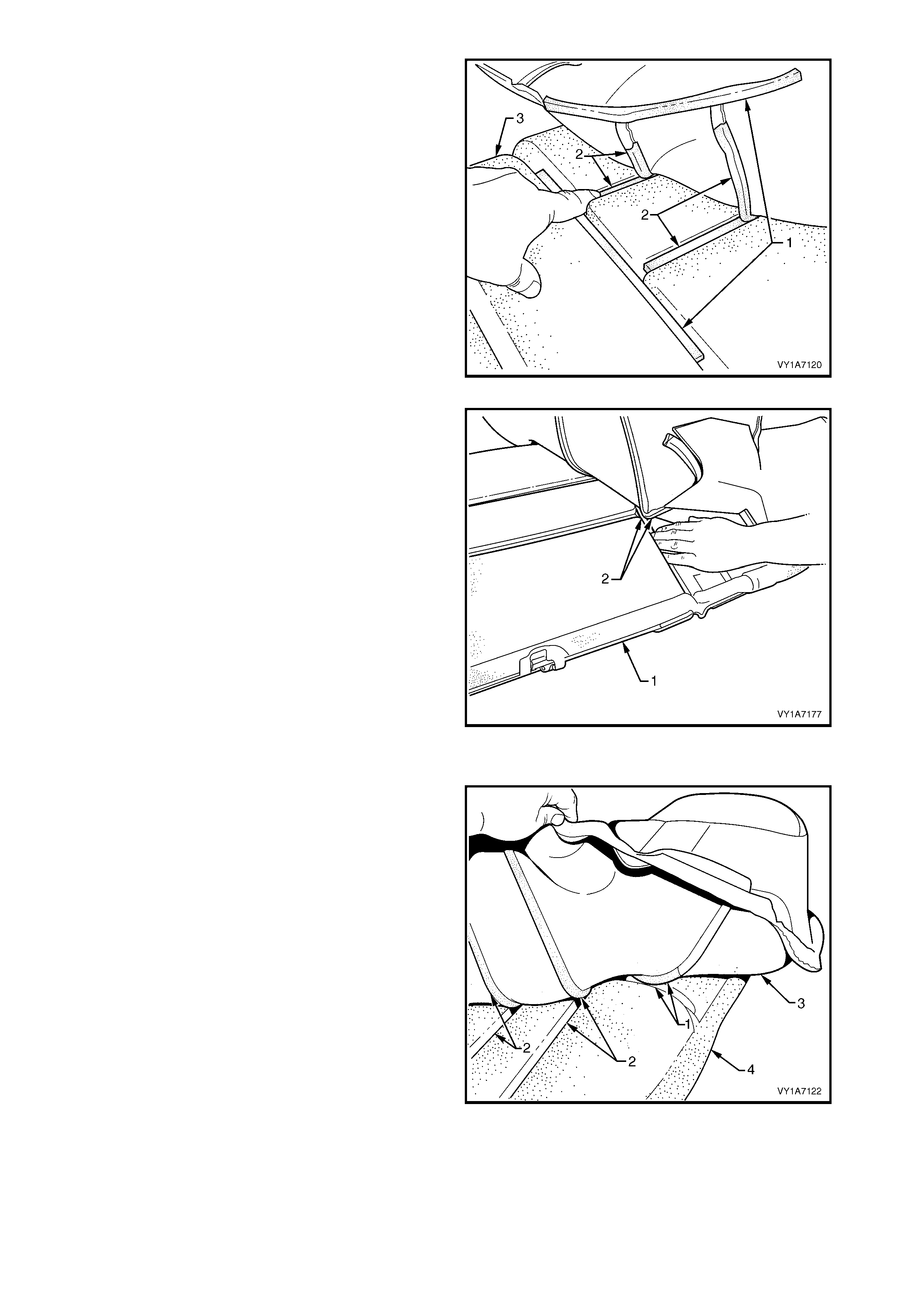

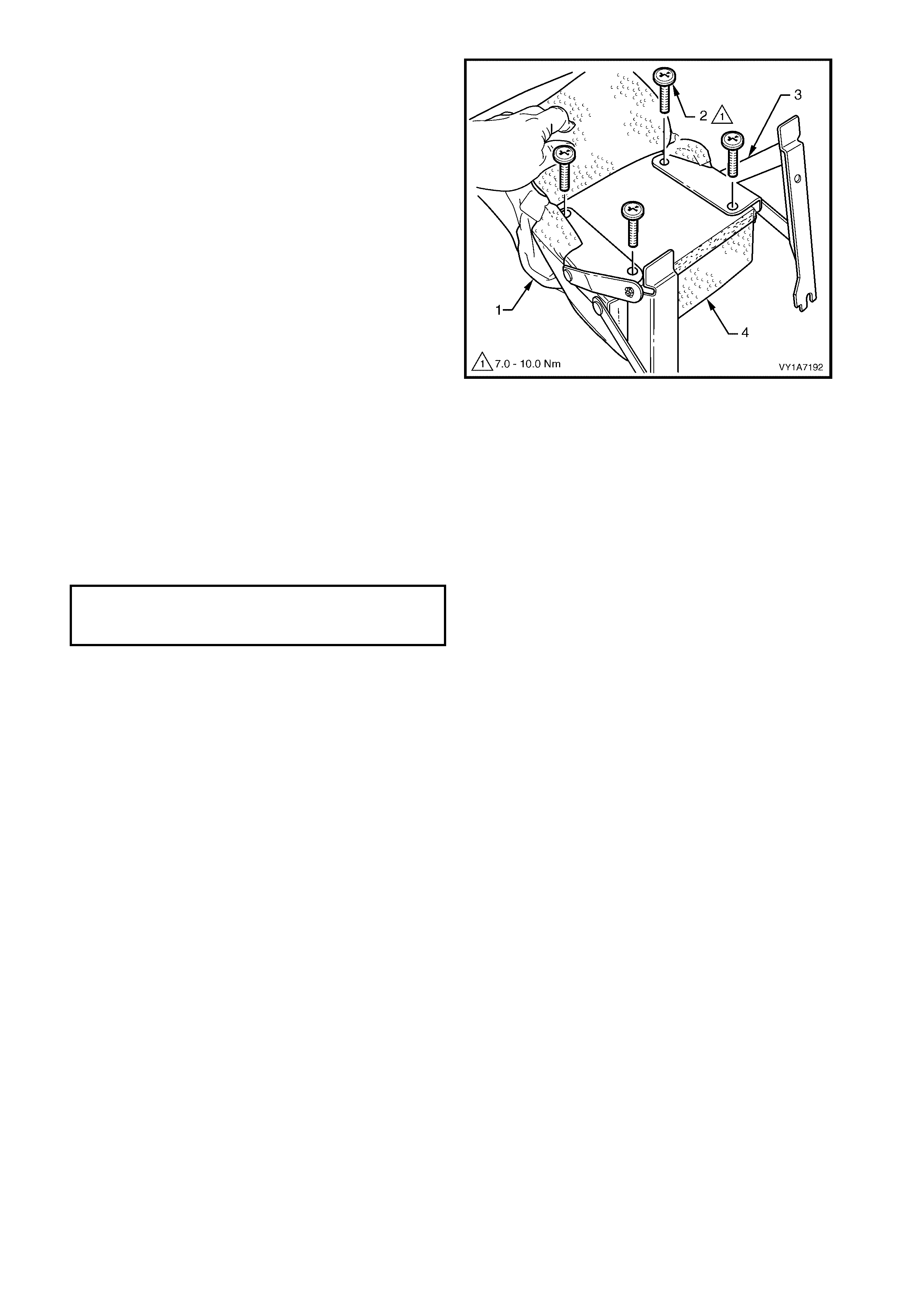

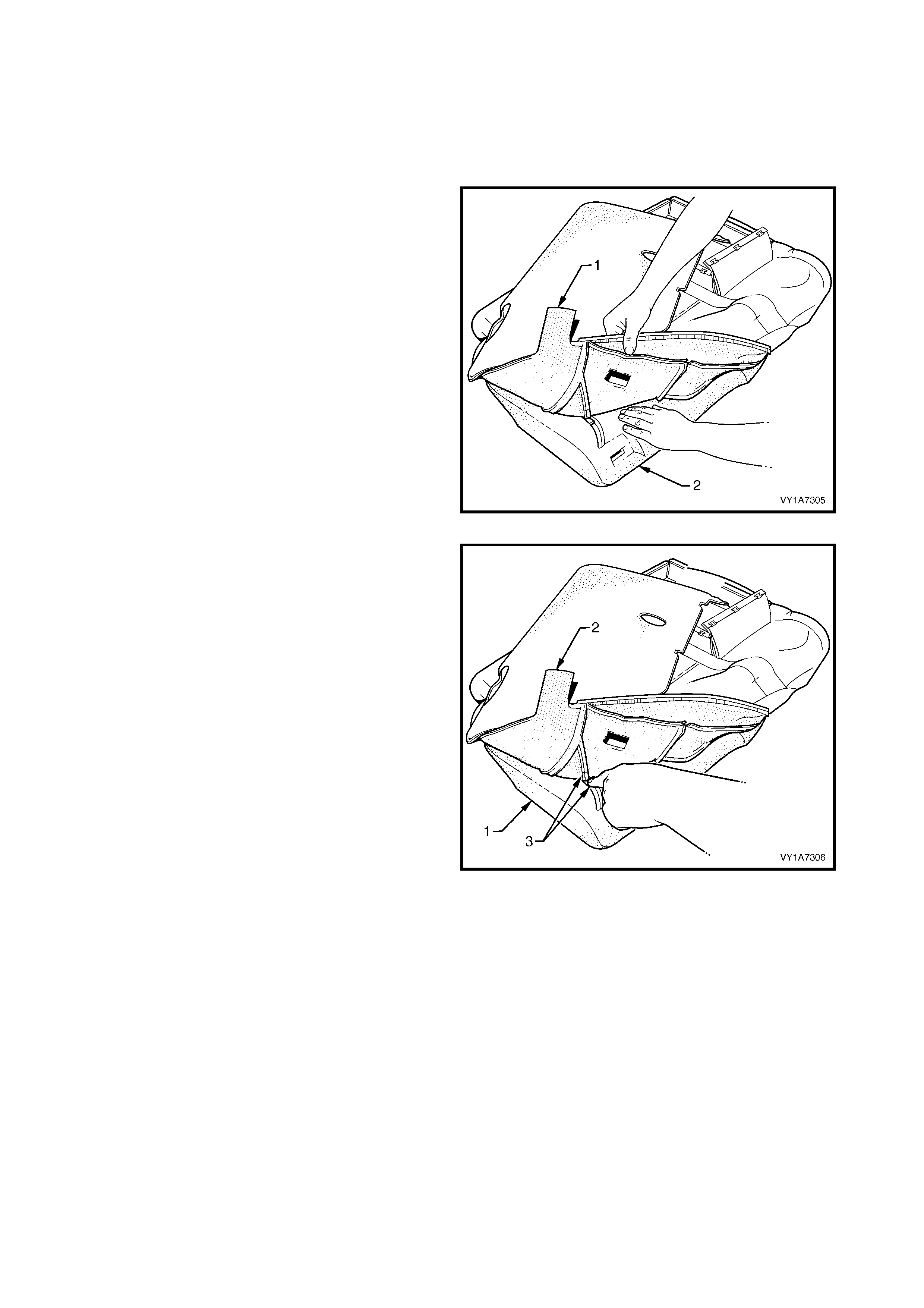

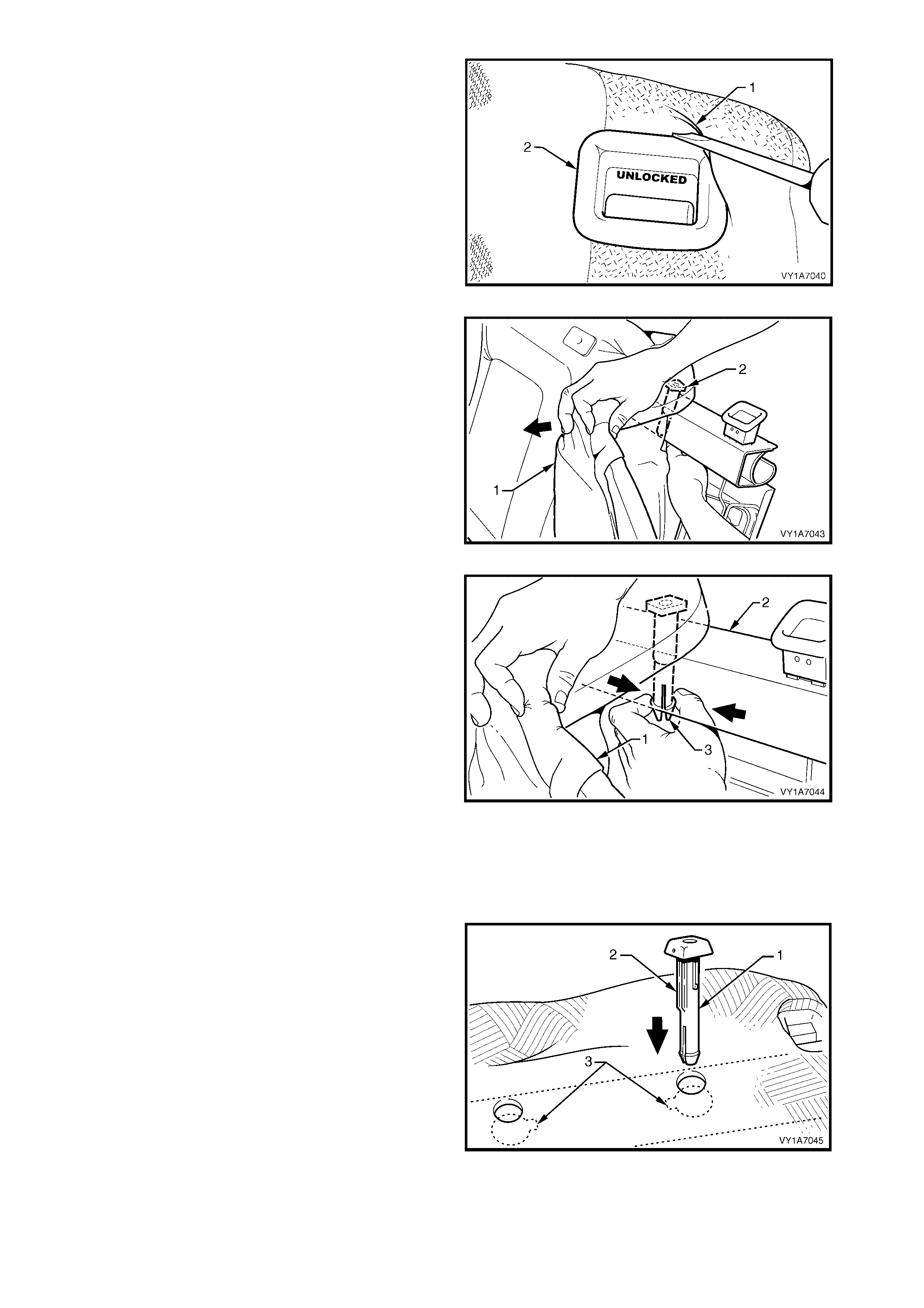

1. Insert a flat-tip screwdriver between the front seat-

back lower cover (1) and the seat-back (2).

2. Push up on each lower retaining clip (3) (two

places) while pulling the bottom of the back cover

out, away from seat, to release the lower retaining

clips.

Figure 1A7-34

3. Where fitted, pull the front edge of the front seat-

back lower cover ( 1), forward of the lumbar s upport

adjuster k nob ( 2), outward to disengage the lum ber

support adjuster knob.

Figure 1A7-35

4. W hile holding the side of the front seat-back lower

cover out (1), pull the cover down to release the

upper retainers (2), two places.

5. Remove the cover.

Figure 1A7-36

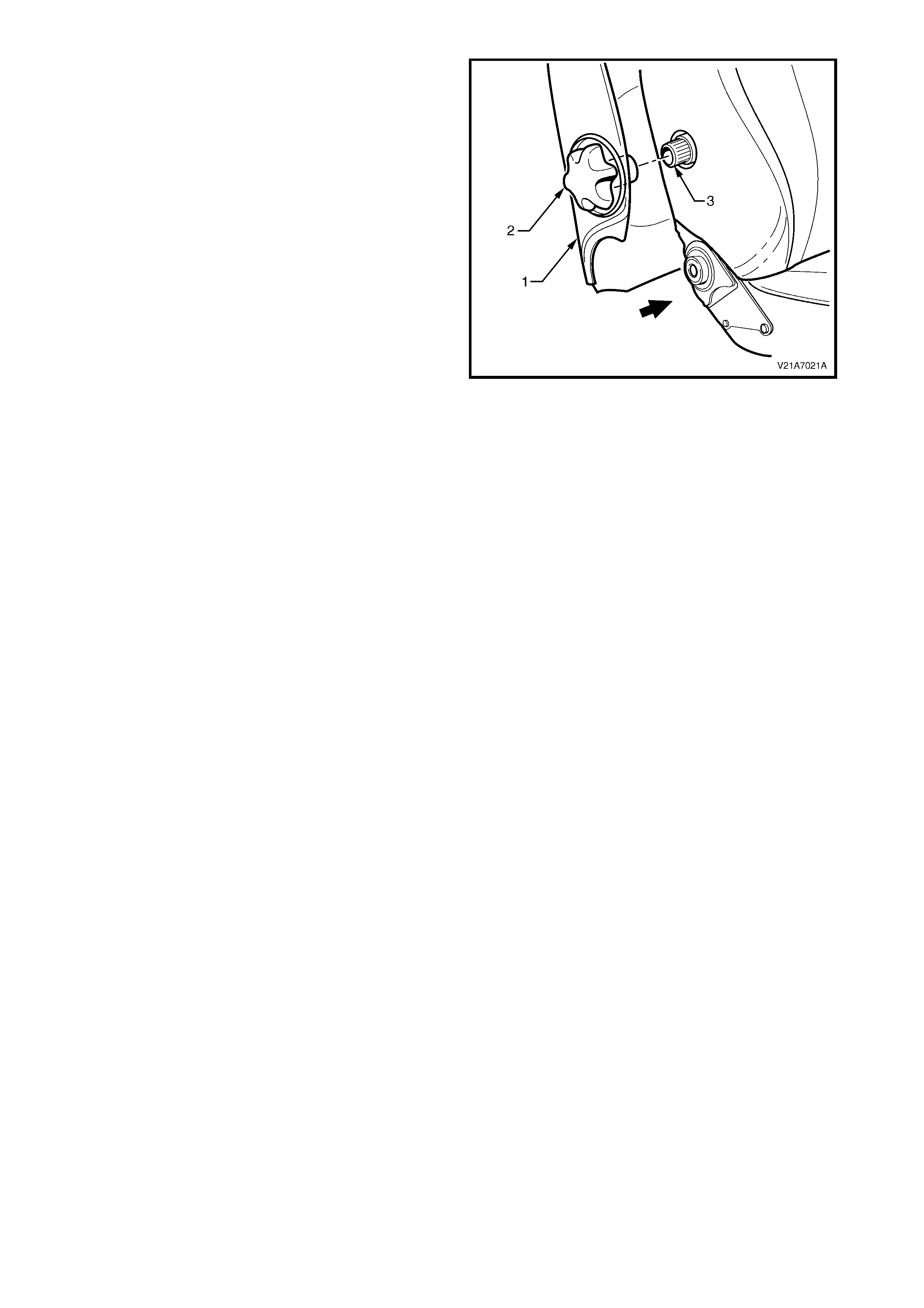

DISASSEMBLE

Remove - Lumbar Support Adjuster Knob and Adapter

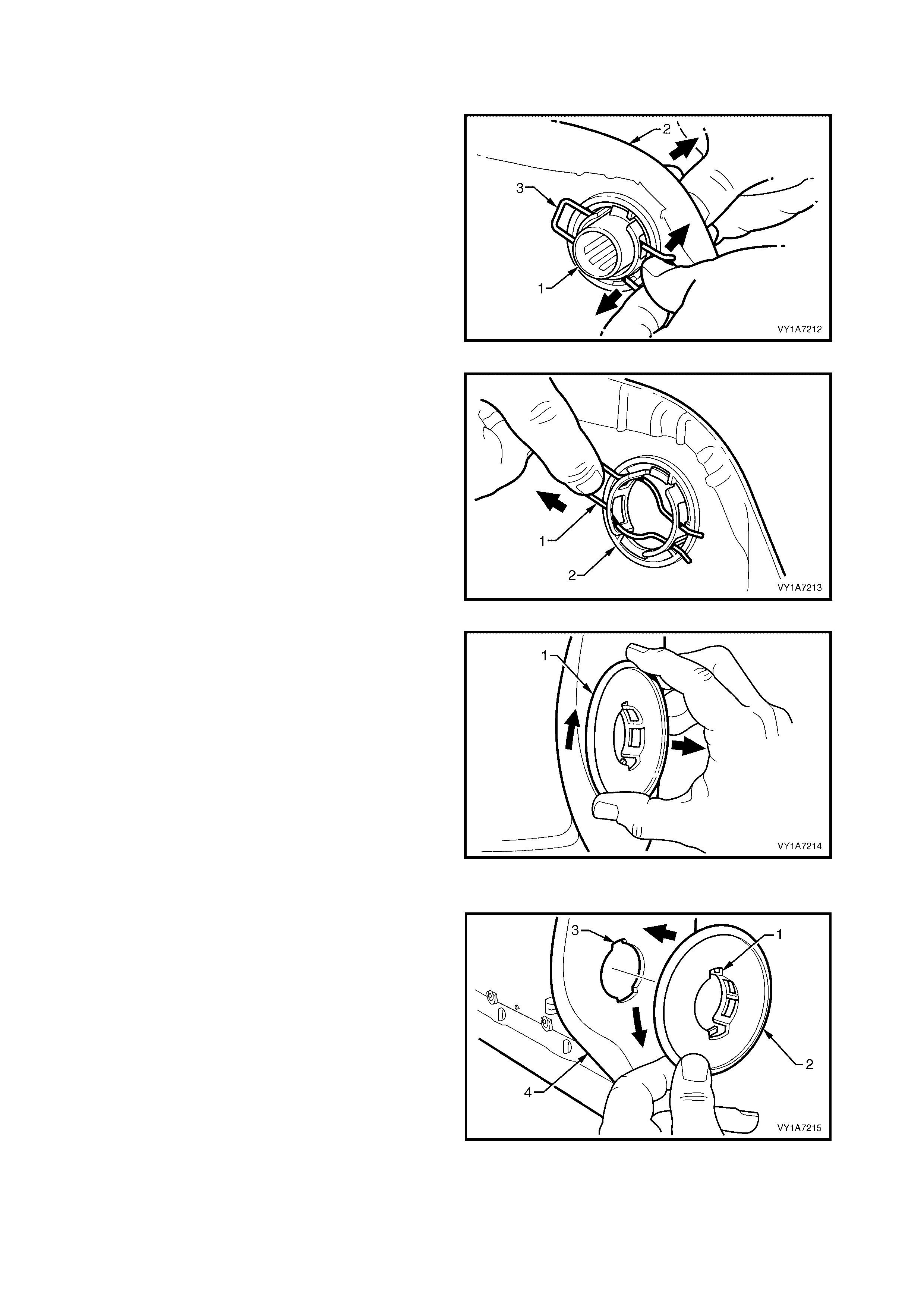

1. Remove the lum bar support adj uster knob (1) from

the front seat-back cover (2) by spreading the

retaining clip (3) and withdrawing the lumbar

support adjuster knob.

Figure 1A7-37

2. Remove the retaining clip (1) by pulling it from the

lumber support adjuster knob adapter (2).

Figure 1A7-38

3. Rotate the lumber support adjuster knob adapter

(1) approximately 90° clockwise.

4. Remove the lumber support adjuster knob adapter.

Figure 1A7-39

Reinstall - Lumbar Support Adjuster Knob and Adapter

Reinstallation of the lumbar support adjuster knob and

adapter is the rever se of the rem oval procedure, noting

the following:

1. Align the narrow tab (1) on the lumber support

adjuster knob adapter (2) with the narrow key-way

(3) in the front seat-back low er cover (4).

2. Insert the adapter into the cover and rotate

approximately 90° anti-clockwise until locked.

Figure 1A7-40

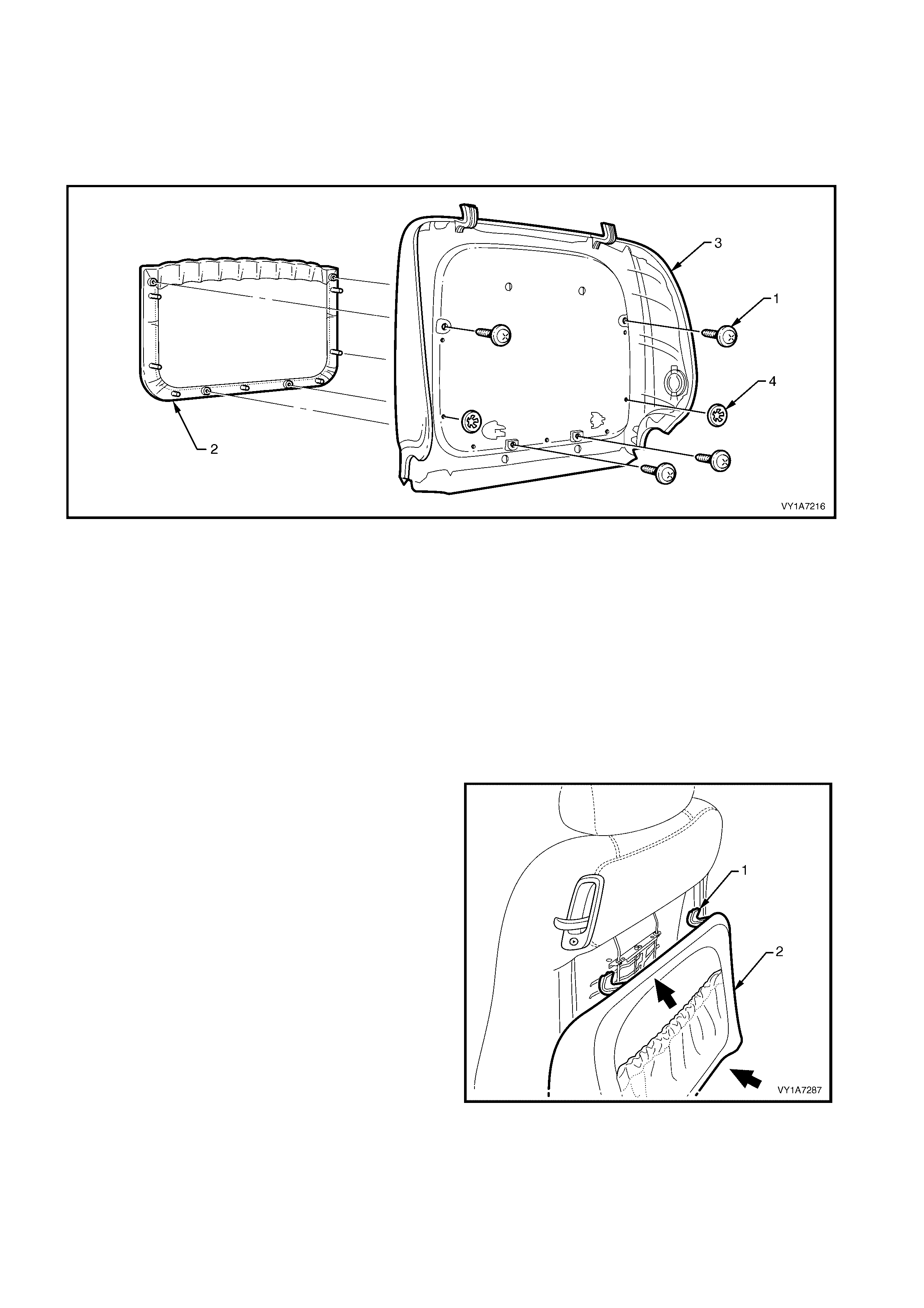

Remove - Front Seat-back Lower Cover Pocket

1. Remove the four screws (1) attaching the front seat-back lower cover pock et (2) to the front seat- back lower

cover (3), refer Figure 1A7-41.

2. Remove the two clips (4) securing the rear cover pocket to the front seat-back lower cover.

NOTE: Take care when removing the clips not to break the rear cover pocket shafts on which the clips are

attached.

Figure 1A7-41

Legend

1. Front Seat-back Pocket Screw - 4 Places

2. Front Seat-back Lower Cover Pocket 3. Front Seat-back Lower Cover

4. Front Seat-back Pocket Attach Clip - 2 Places

Reinstall - Front Seat-back Lower Cover Pocket

Reinstallation of the f ront seat-bac k lower cover pocket

is the reverse of the removal procedure, noting the

following:

1. Ensure all fasteners are tightened securely.

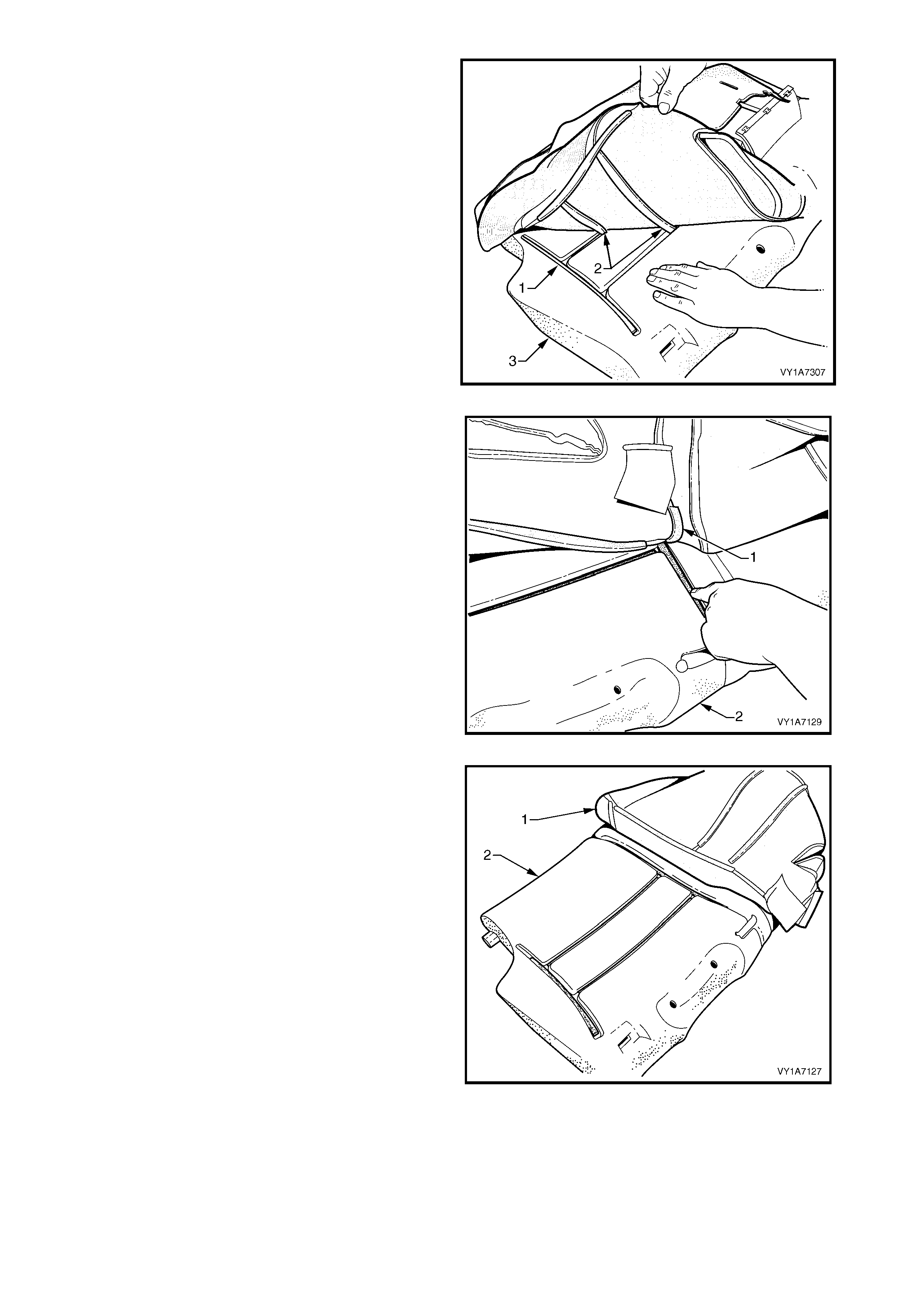

REINSTALL

1. Locate the two upper retaining clips (1) on the

seat-back cover (2) with the seat-back.

Figure 1A7-42

2. Where fitted, pull the side of the front seat-back

lower cover (1) out and align the splines on the

lumber support adjuster knob (2) with the splines

on the lumbar support adjuster (3).

3. Push the lumber support adjuster knob onto the

lumbar support shaft.

4. Push the seat-back cover into the seat-back to

engage the two lower retaining clips.

Figure 1A7-43

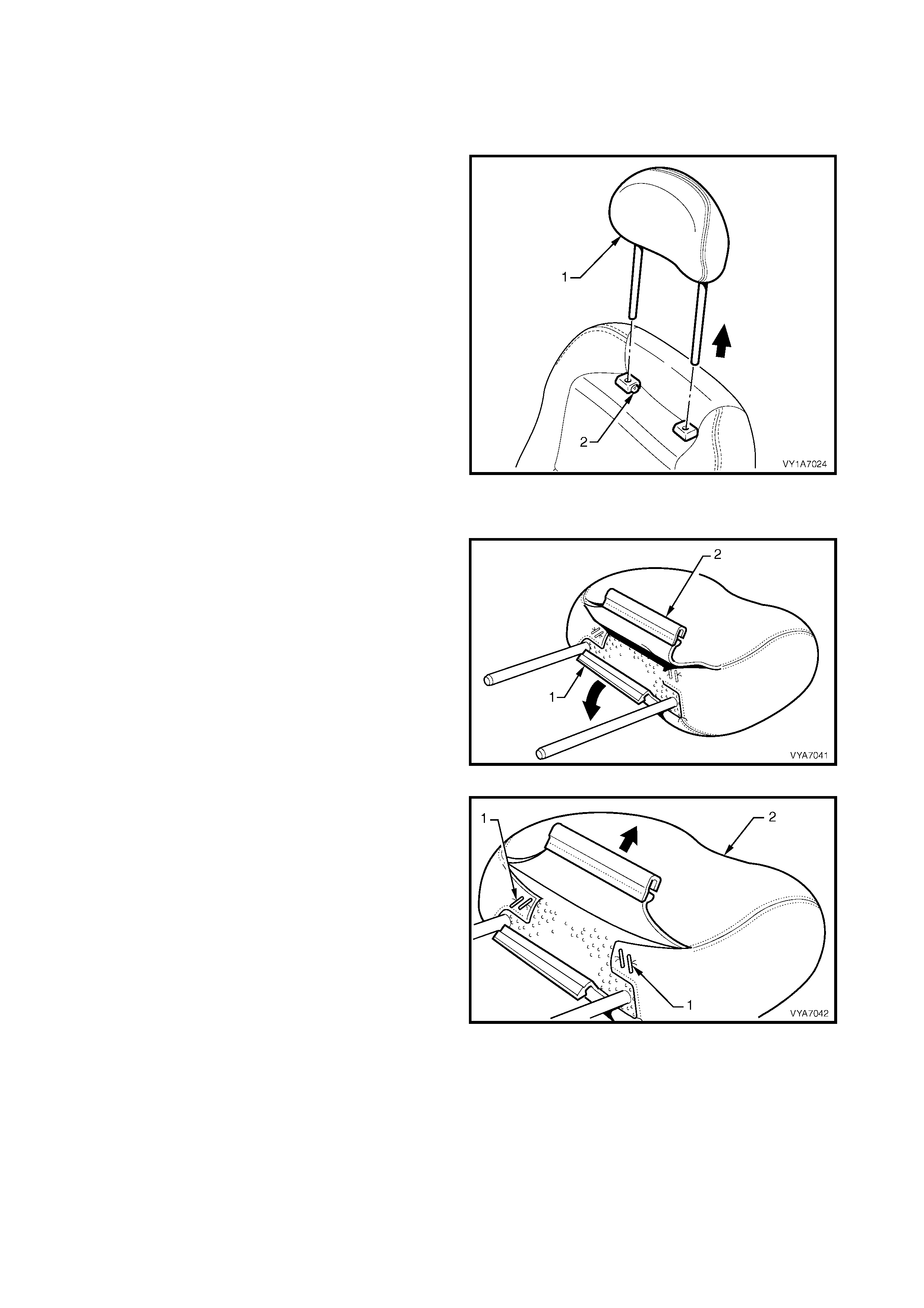

2.7 FRONT SEAT HEAD RESTRAINT ASSEMBLY

LT Section No. – 14-295

REMOVE

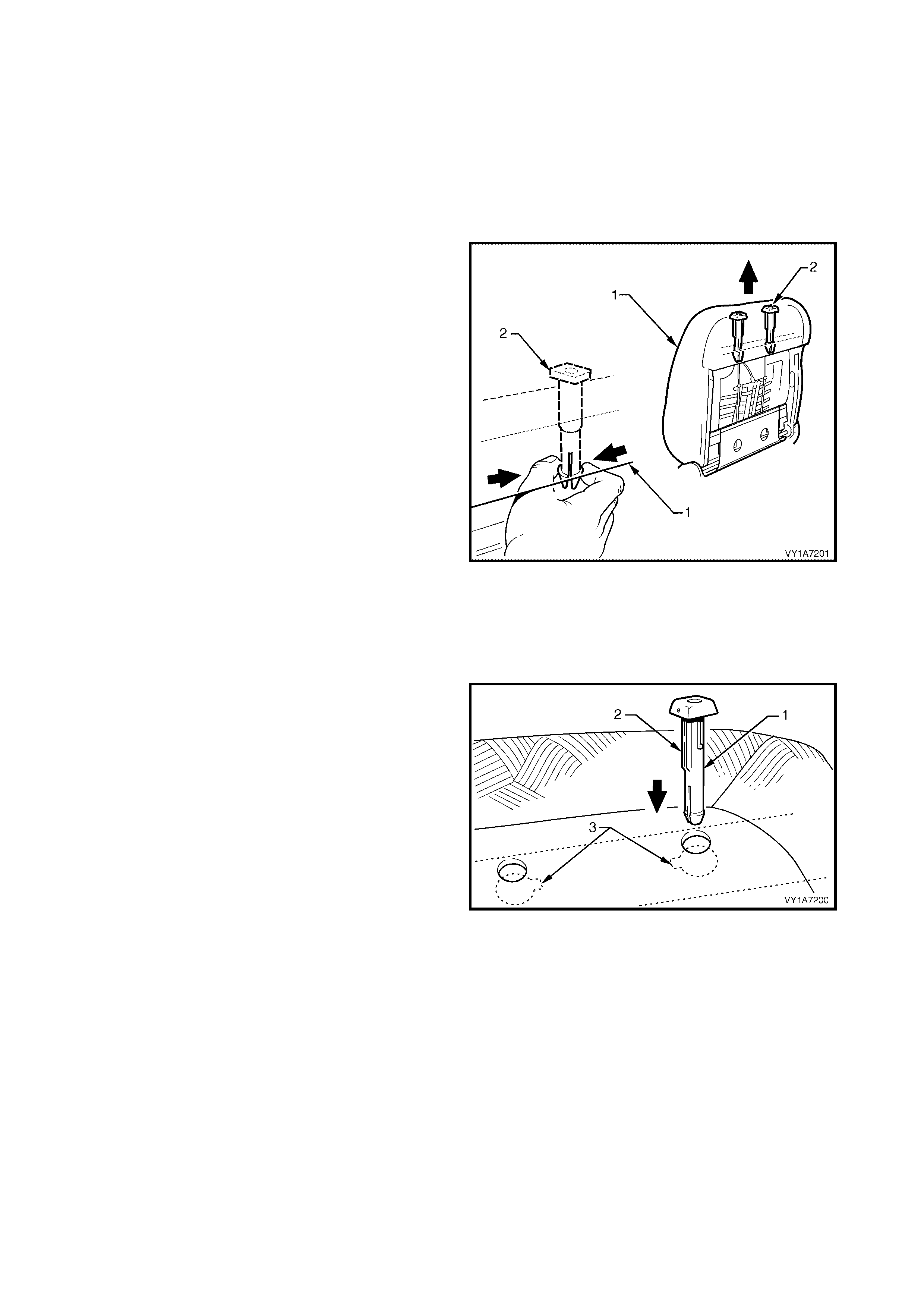

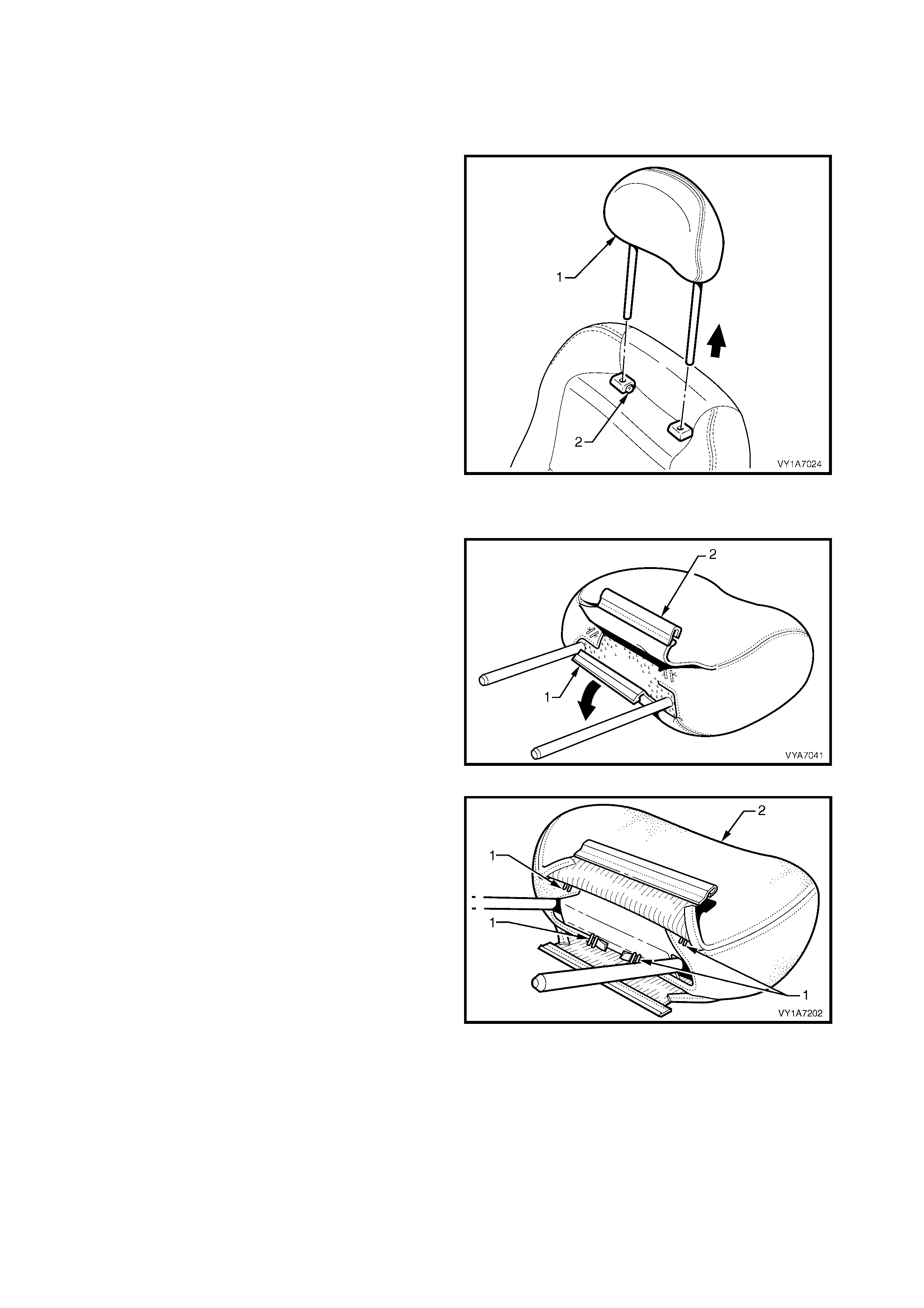

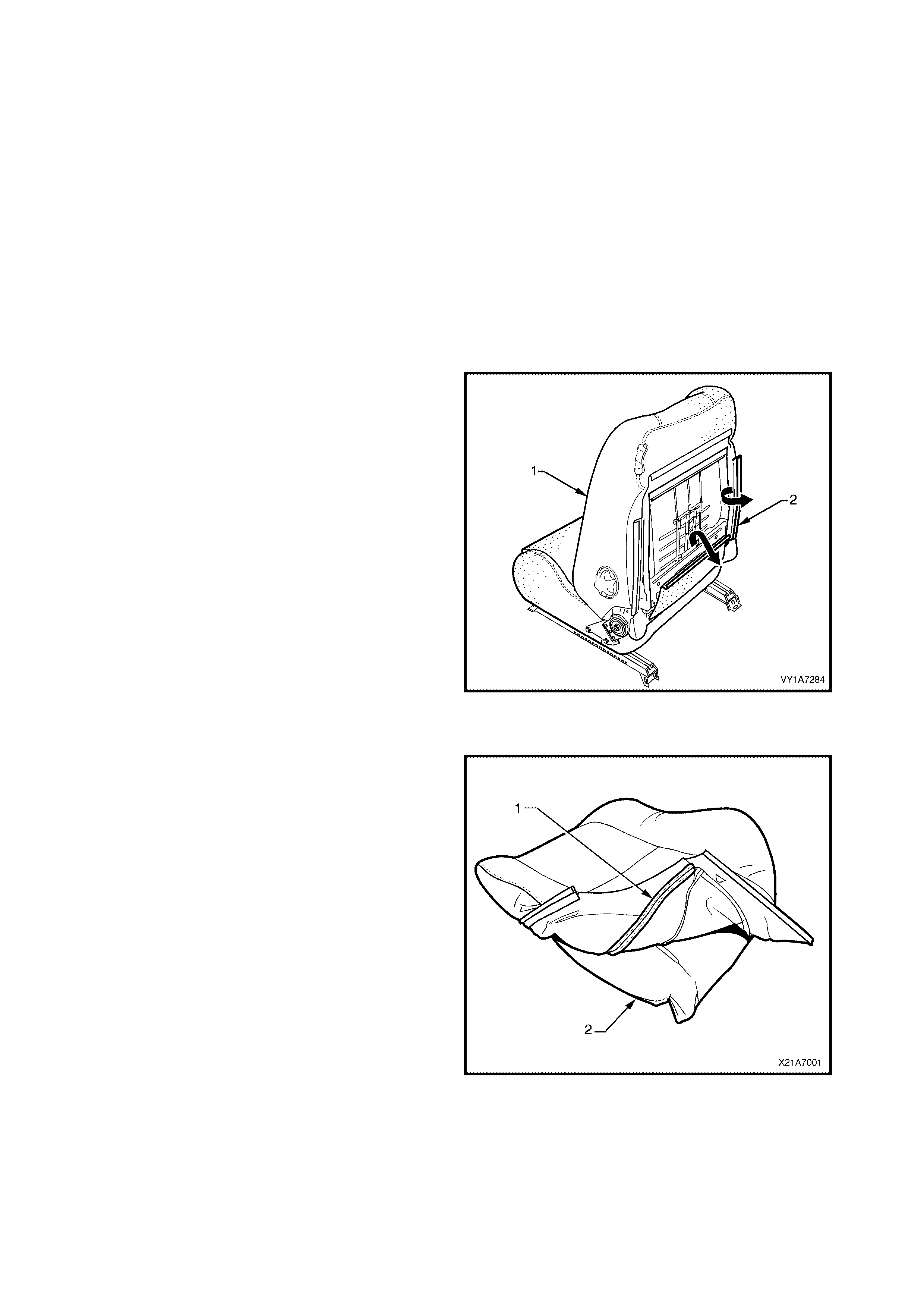

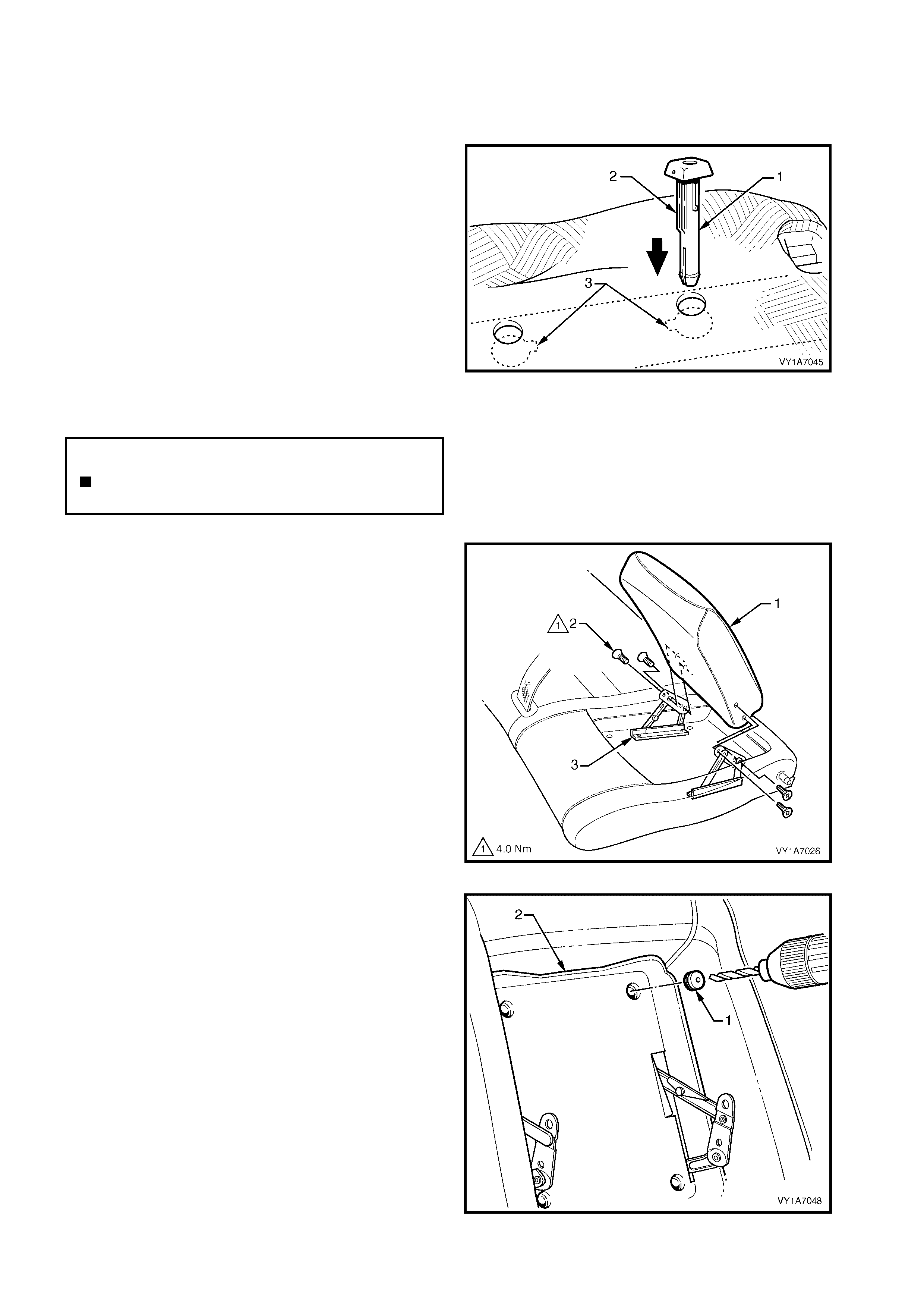

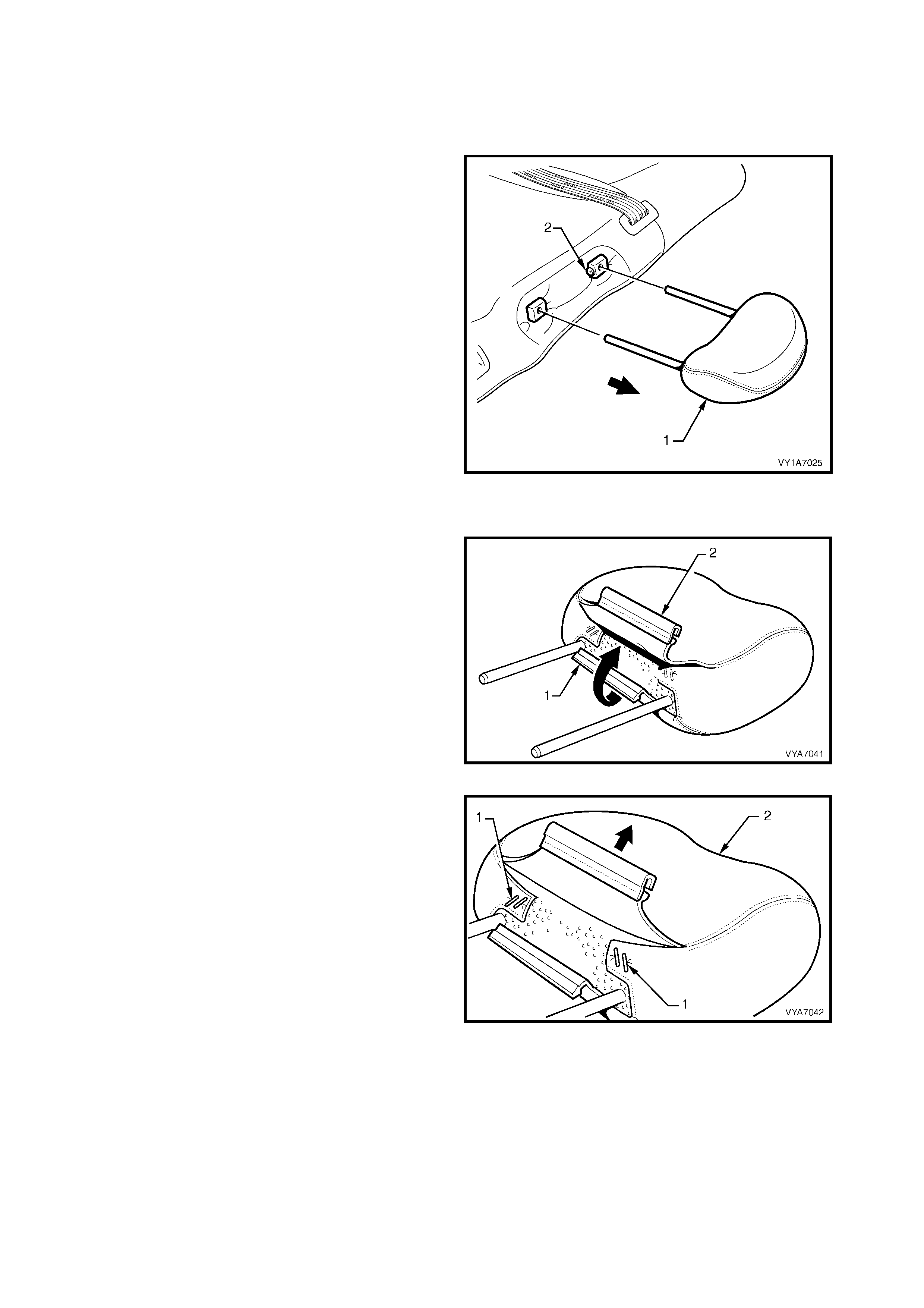

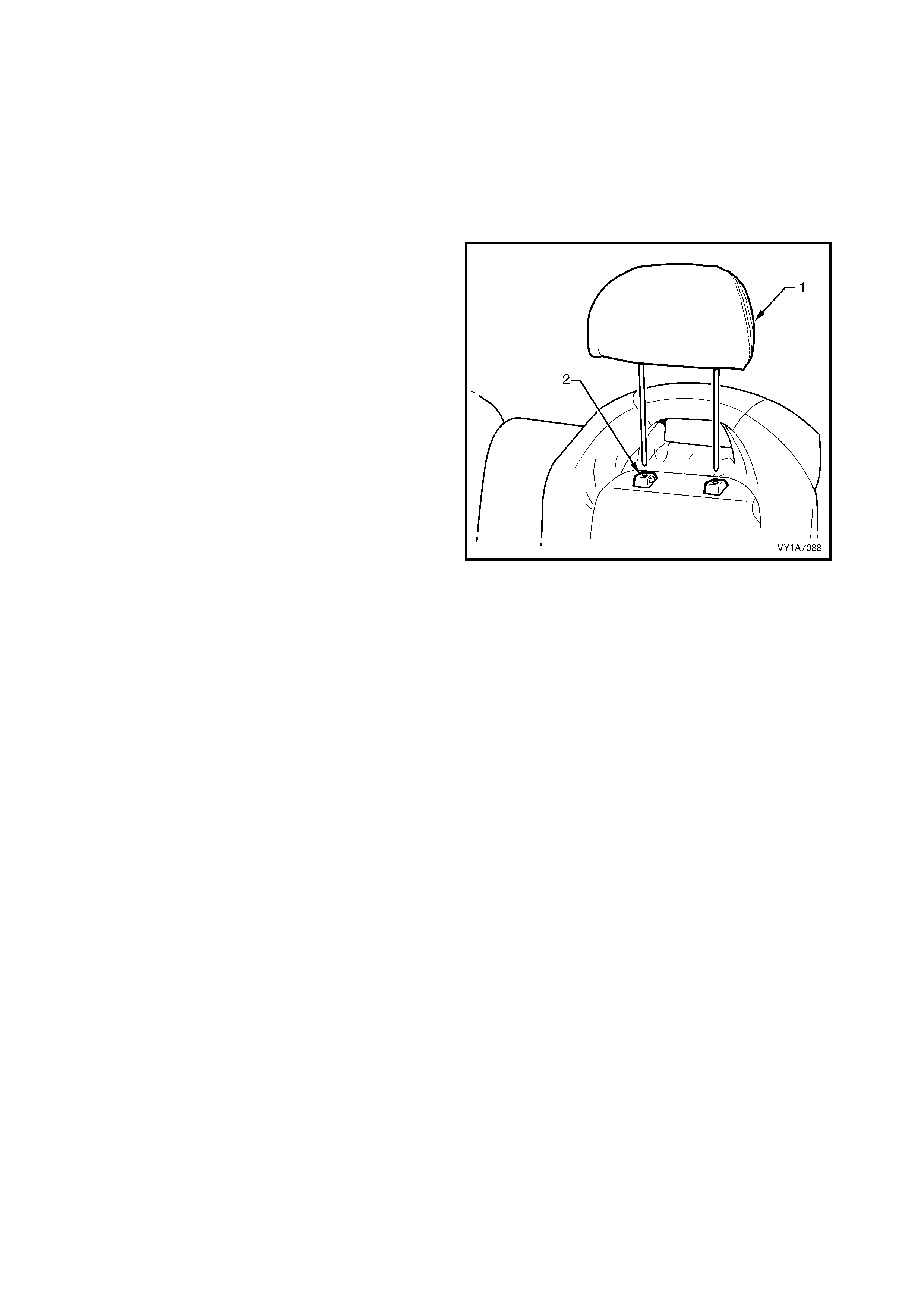

1. Rem ove the front seat head restraint assembly (1)

by depressing the head restraint guide height

adjuster lock button (2), and lifting the head

restraint completely out of the guide.

Figure 1A7-44

DISASSEMBLE

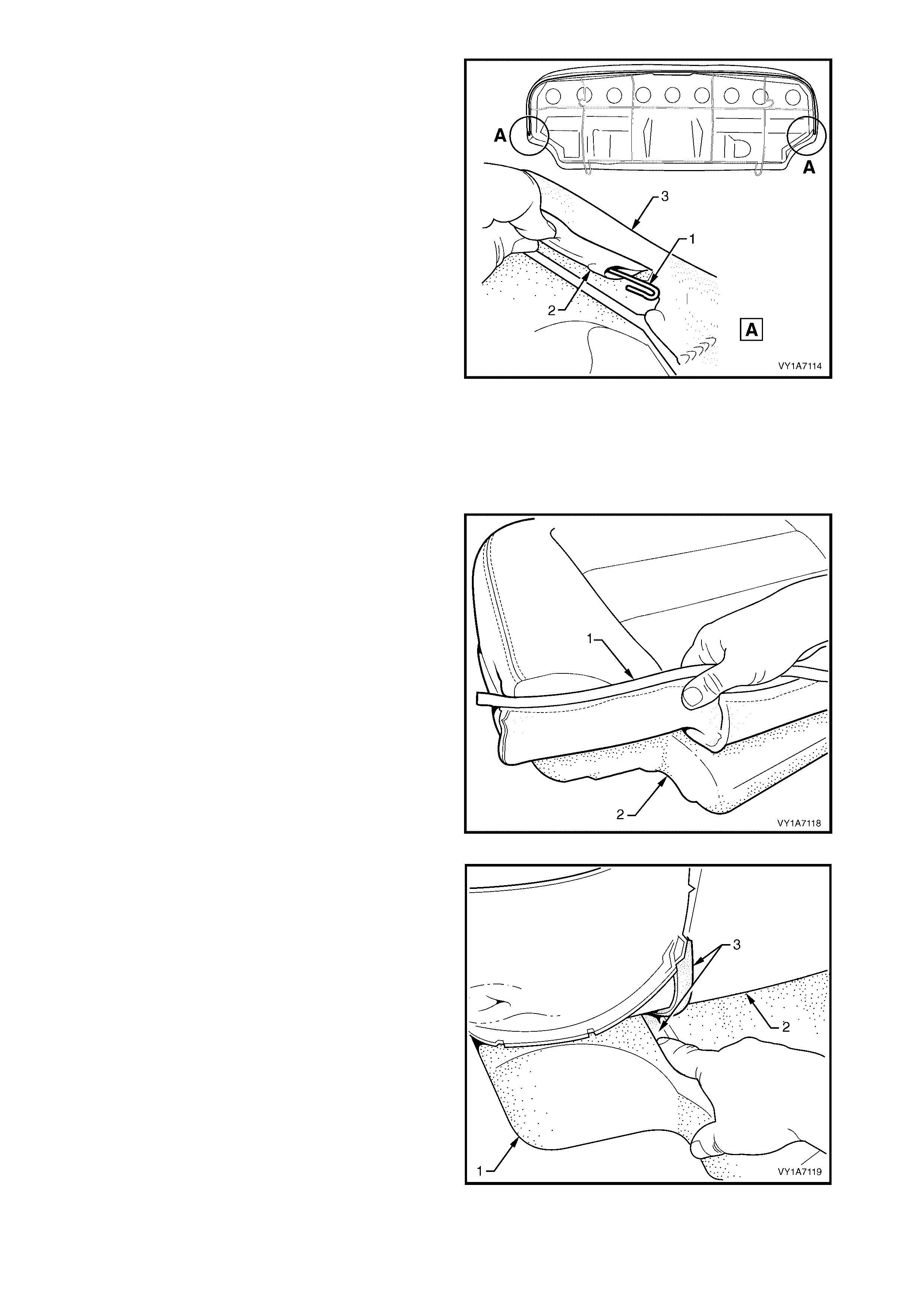

1. Disengage the front head restraint cover J-strip (1)

by pulling the flap (2) up.

Figure 1A7-45

2. Remove the four staples (1) retaining the cover (2)

to the head restraint pad assembly.

3. Remove the cover from the pad assembly.

Figure 1A7-46

REASSEMBLE

Reassembly of the front seat-back head restraint assembly is the reverse of the removal procedure, noting the

following:

1. Ensure the head restraint cover J-clip is fully engaged.

REINSTALL

Reinstallation of the front seat head restraint assembly is the reverse of the removal procedure.

2.8 FRONT SEAT HEAD RESTRAINT GUIDE

LT Section No. – 14-275

1. Remove the front seat outer side cover, refer to 2.3 FRONT SEAT OUTER SIDE COVER.

2. Remove the front seat-back lower cover assembly and lumber support adjuster knob, refer to

2.6 FRONT SEAT-BA CK LOWER COVER ASSEMBLY AND LUMBER SUPPORT ADJUSTER KNOB.

3. Remove the front seat head restraint assembly, refer to 2.7 FRONT SEAT HEAD RESTRAINT ASSEMBLY.

REMOVE

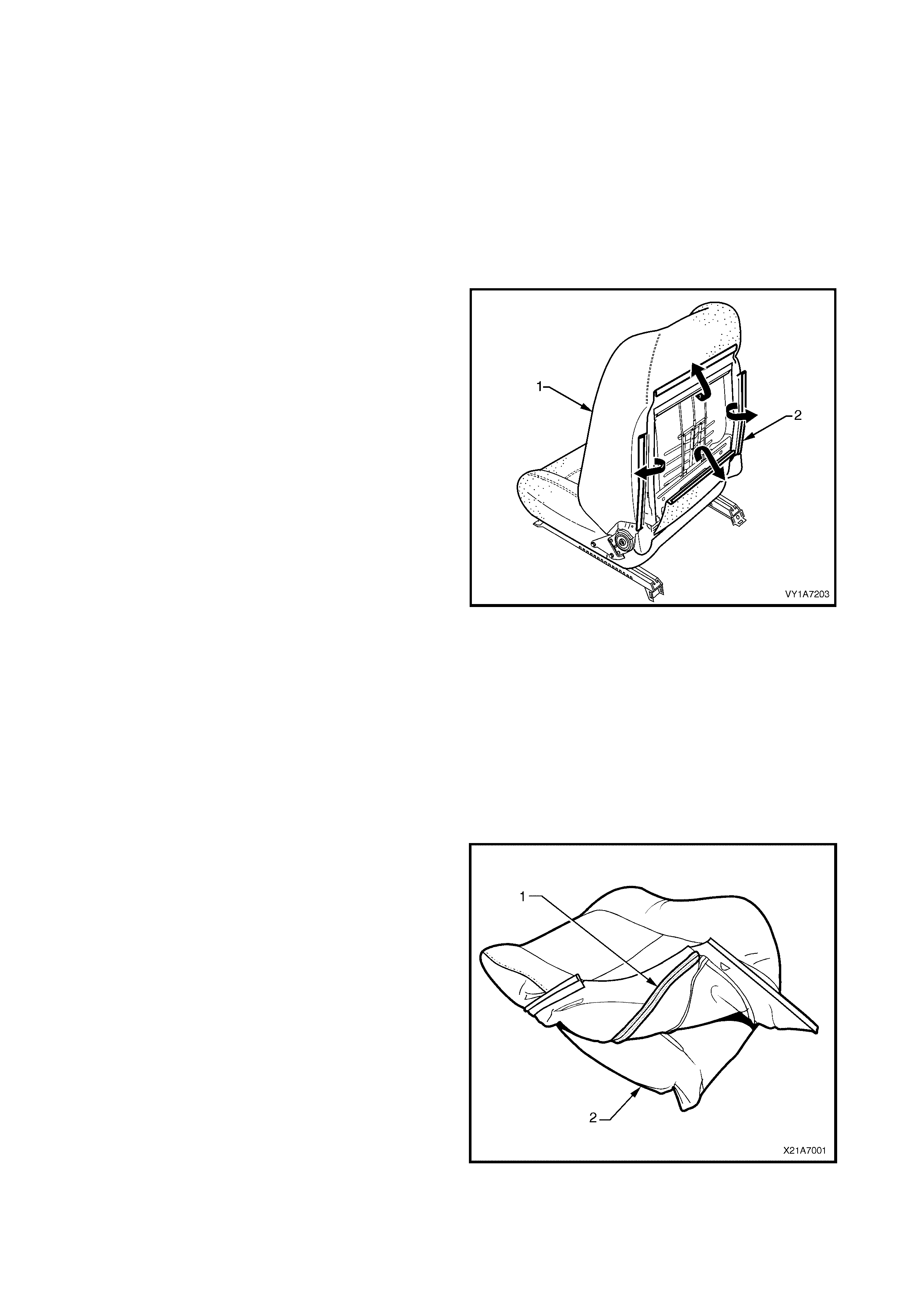

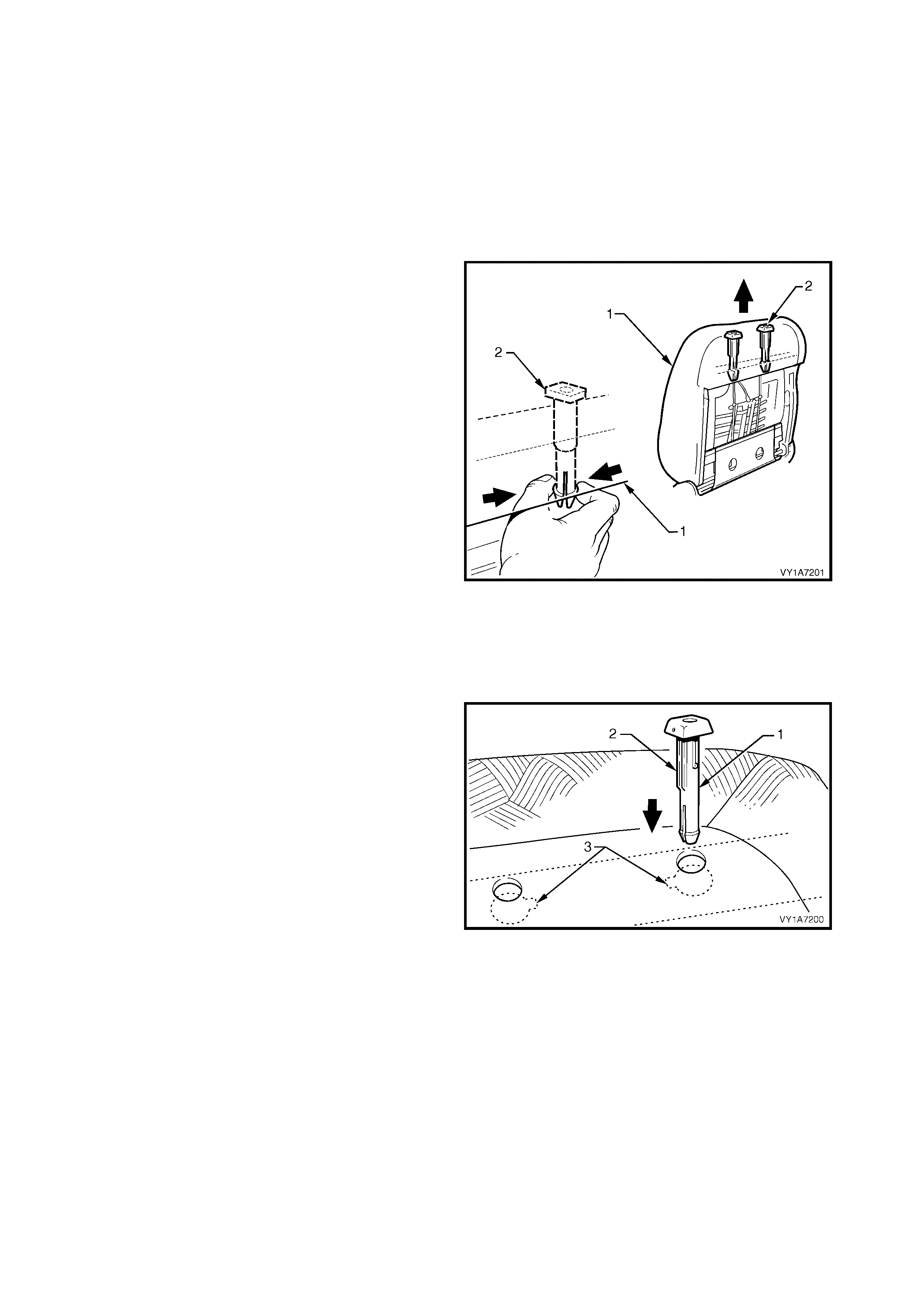

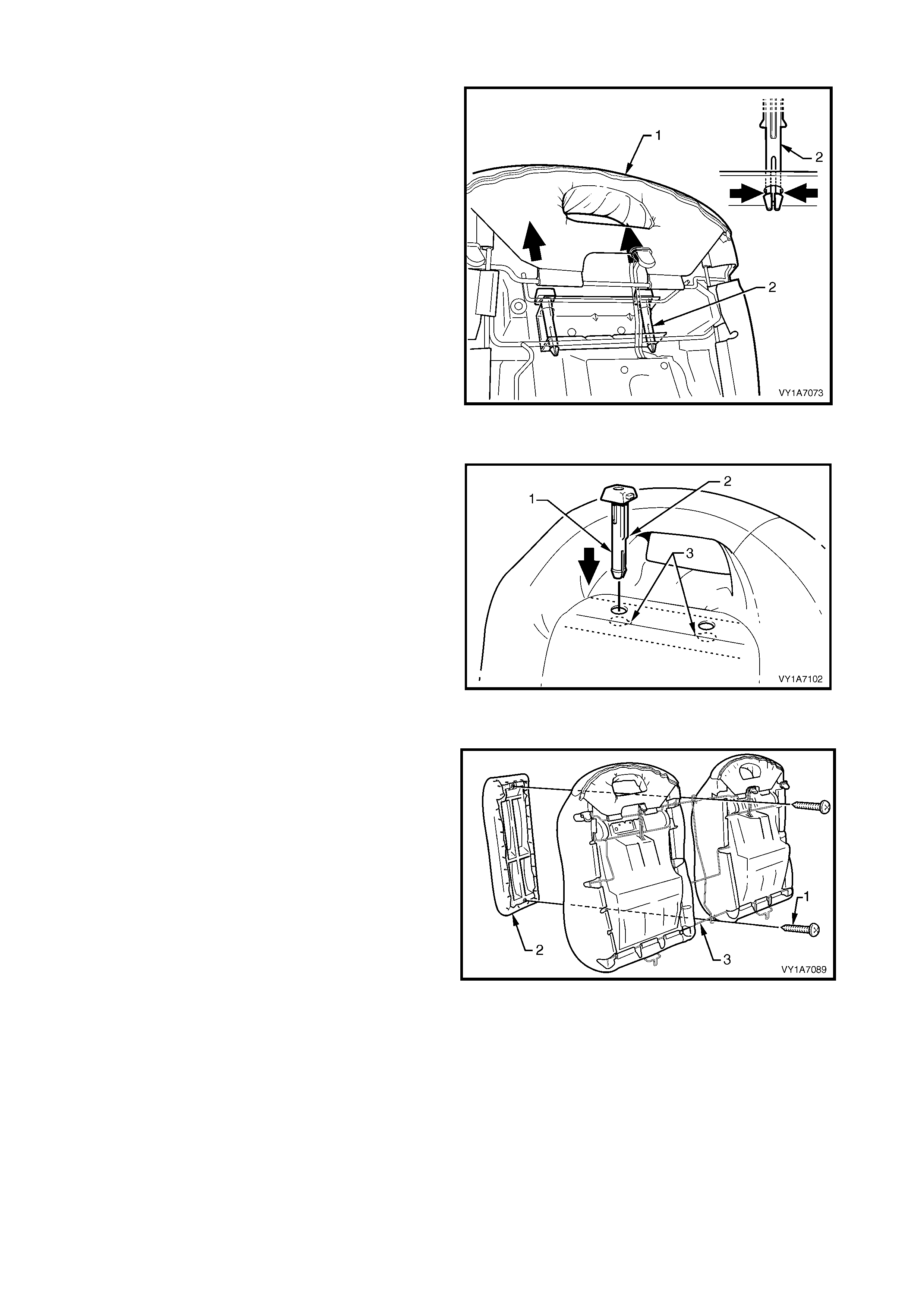

1. From the rear of the front seat-back (1), squeeze

the locking prongs of the head restraint guide (2)

together while pulling the top of the guide out of

seat-back assembly.

Figure 1A7-47

REINSTALL

Reinstallation of the front seat head restraint guide is

the reverse of the removal procedure, noting the

following:

1. When installing the head restraint guide (1), align

the locating ribs (2) with the key-way (3) in the

seat-back frame.

NOTE: Ensure the guide with the height adjuster lock is

installed on the s ide that corresponds to the notches in

the head restraint shaft.

Figure 1A7-48

2.9 FRONT SEAT-BACK PAD AND COVER ASSEMBLY

LT Section No. – 14-295

1. Remove the front seat assembly, refer to 2.2 FRONT SEAT ASSEMBLY.

2. Remove the front seat outer side cover, refer to 2.3 FRONT SEAT OUTER SIDE COVER.

3. Remove the front seat-back lower cover assembly and lumber support adjuster knob, refer to

2.6 FRONT SEAT-BA CK LOWER COVER ASSEMBLY AND LUMBER SUPPORT ADJUSTER KNOB.

4. Remove the front seat head restraint assembly, refer to 2.7 FRONT SEAT HEAD RESTRAINT ASSEMBLY.

5. Remove the front seat head restraint guide, refer to 2.8 FRONT SEAT HEAD RESTRAINT GUIDE.

REMOVE

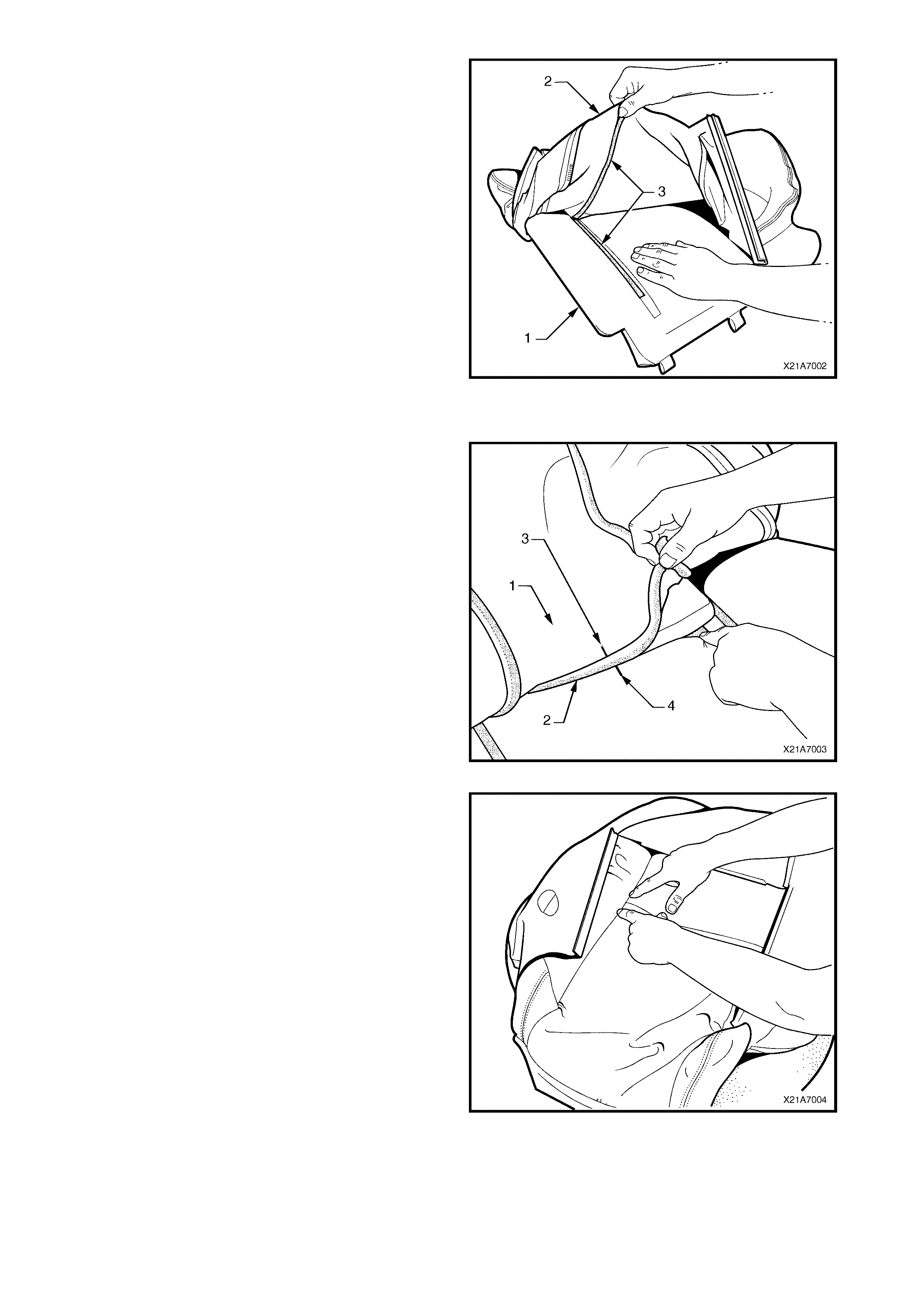

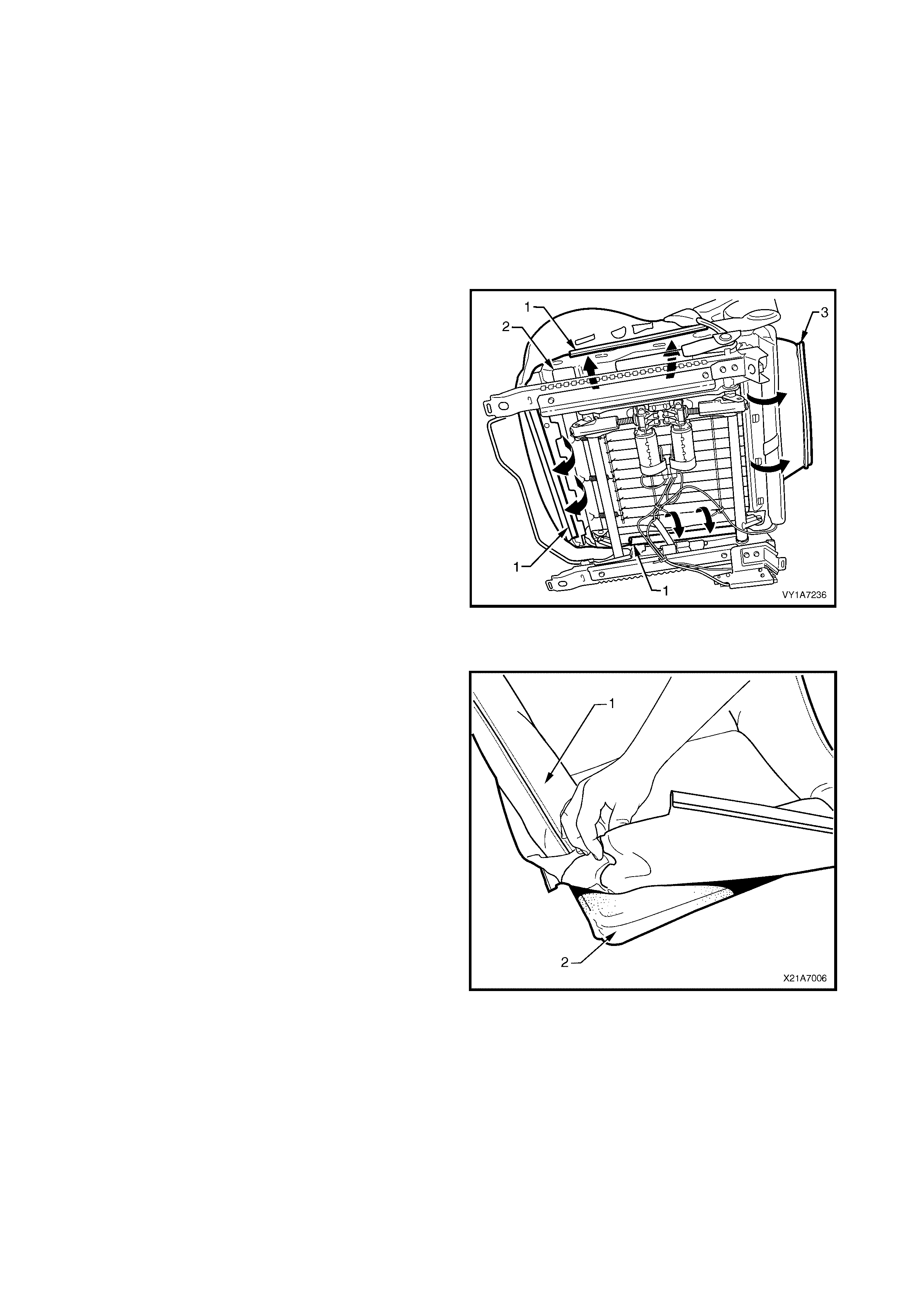

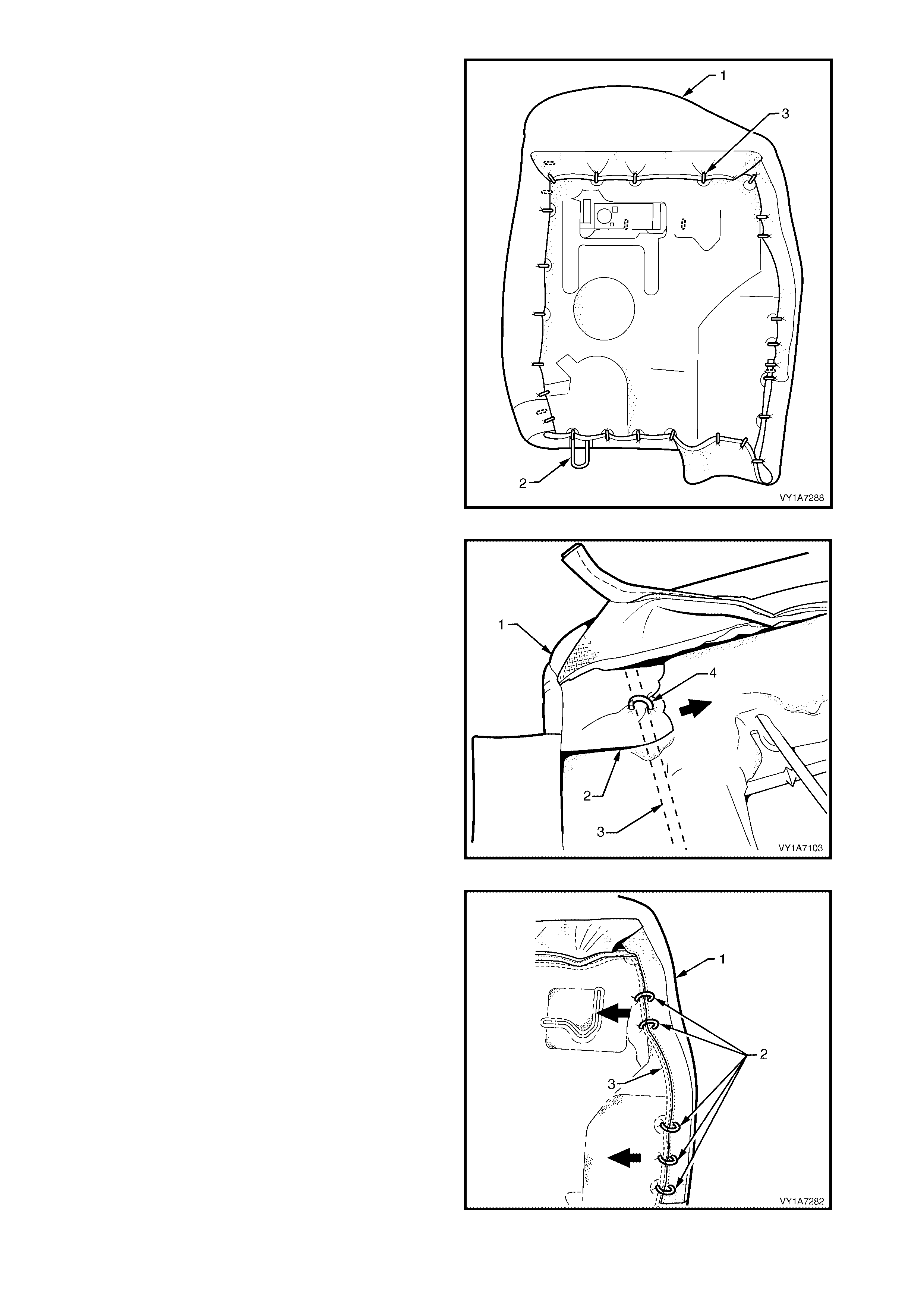

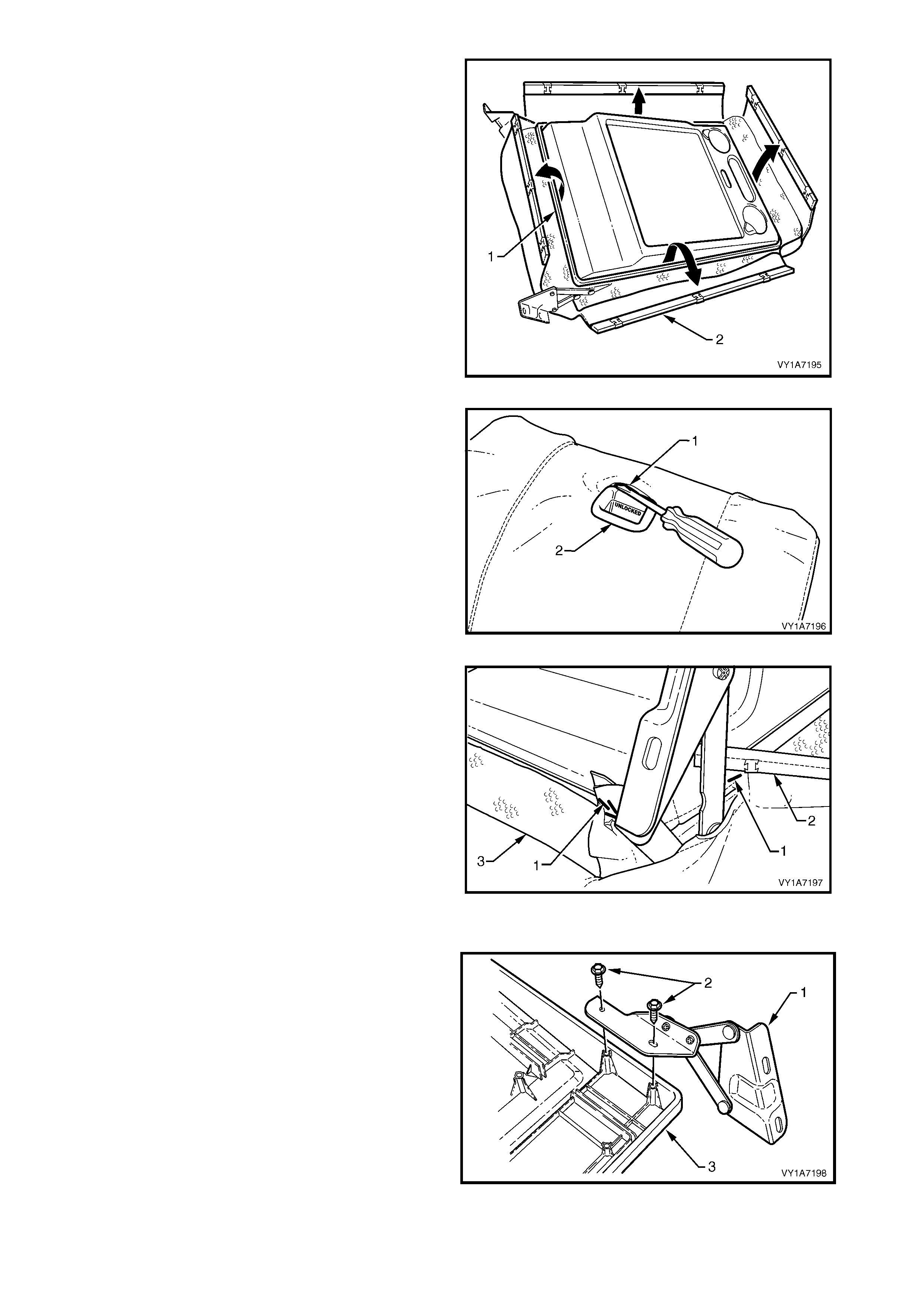

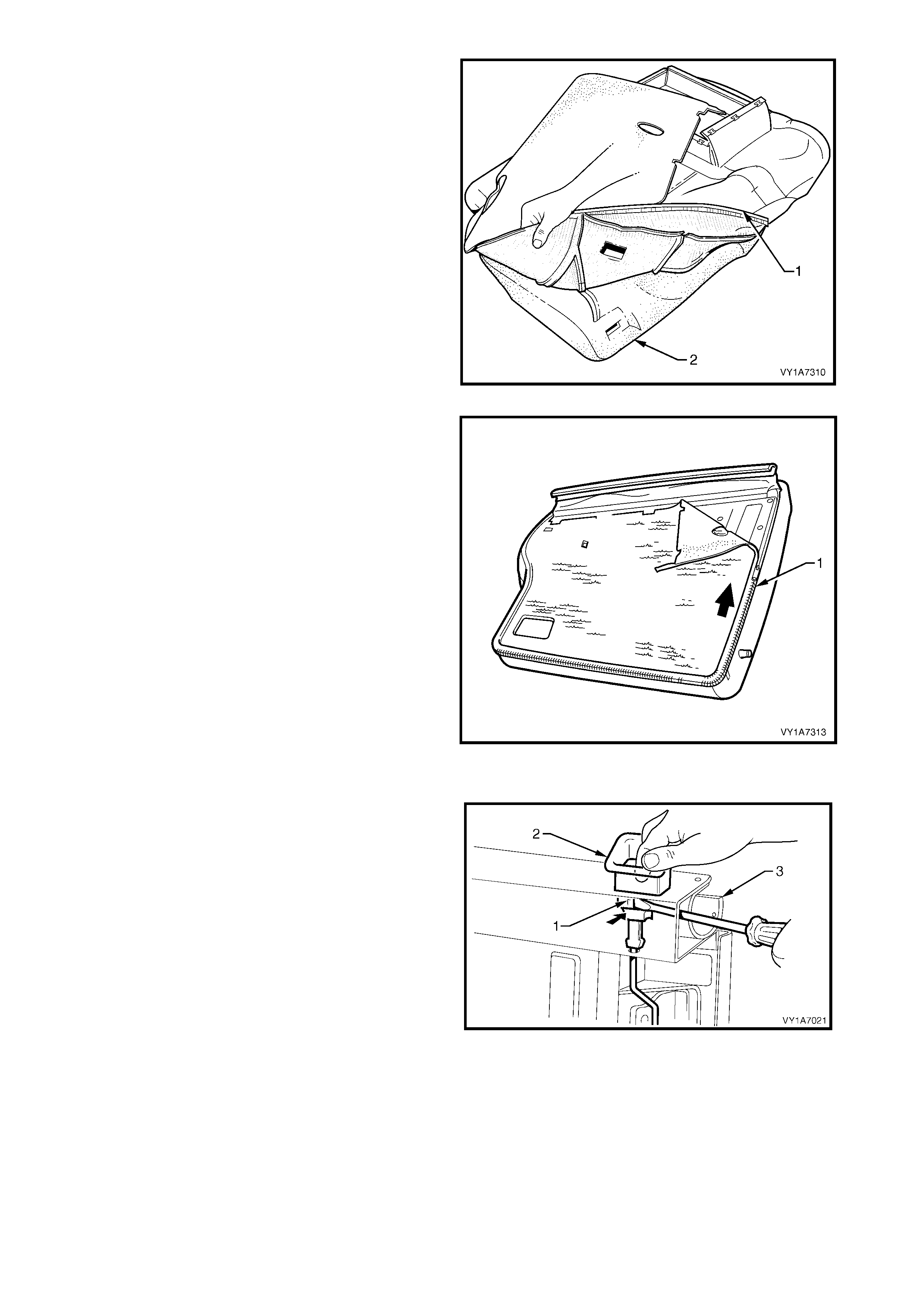

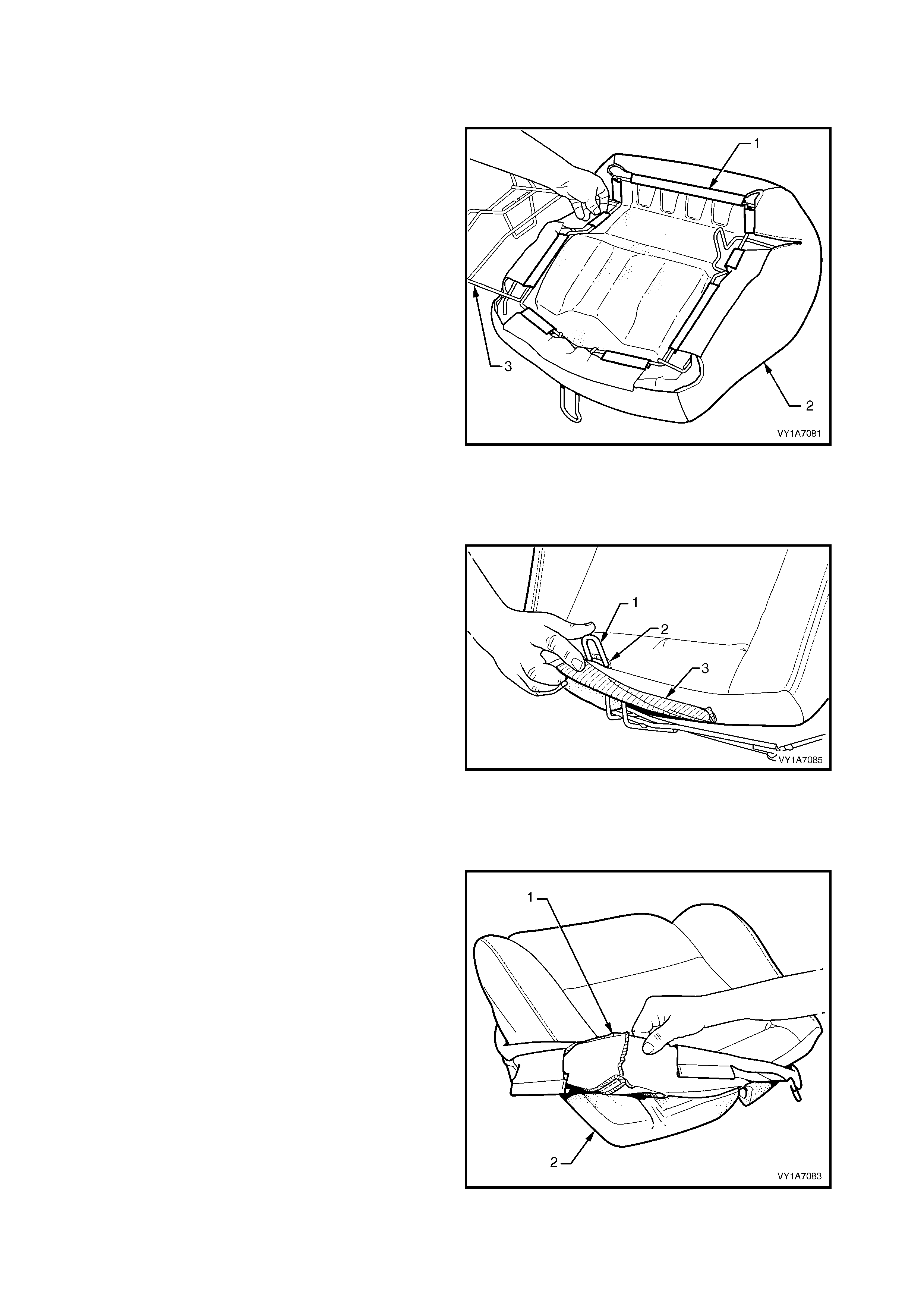

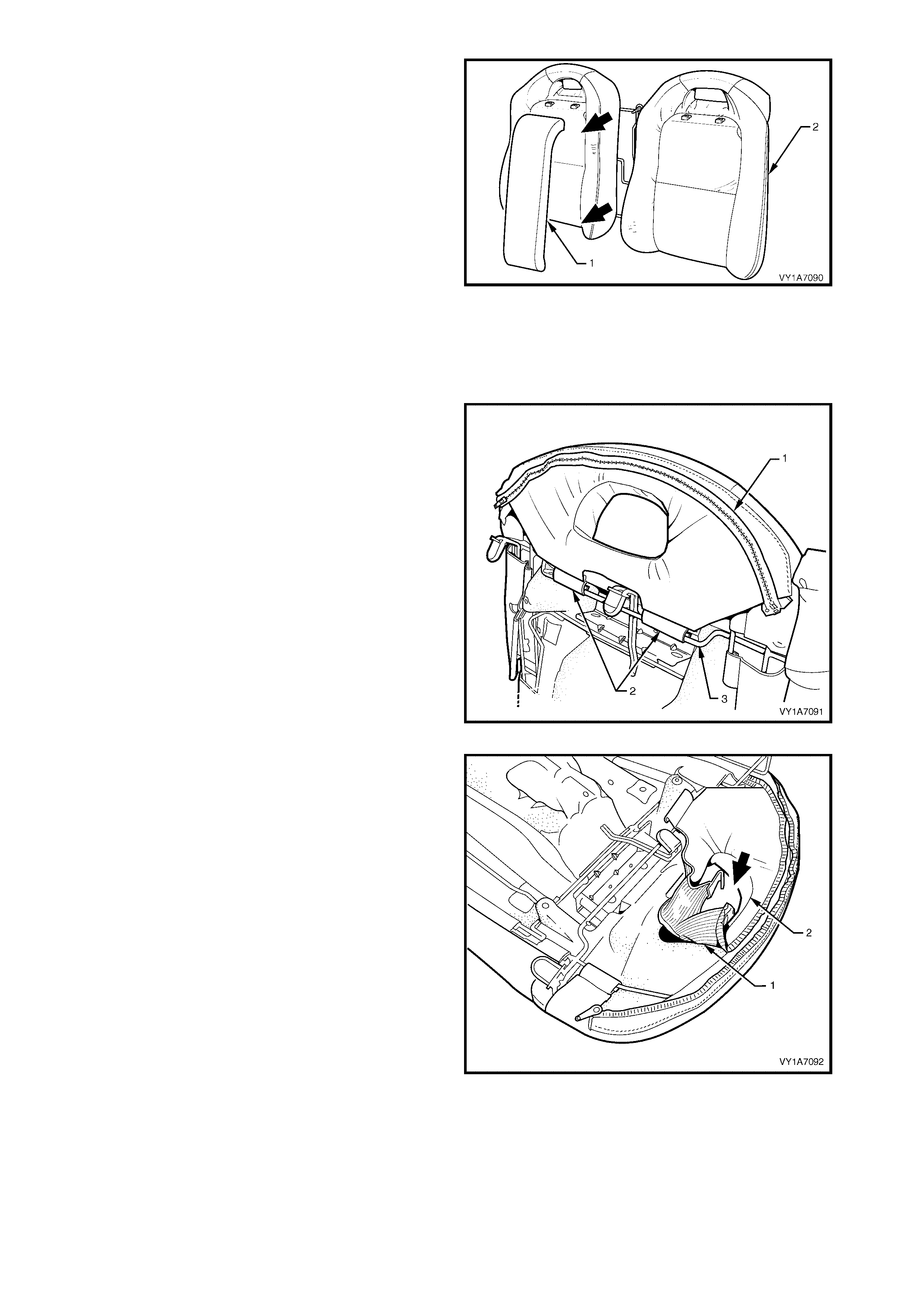

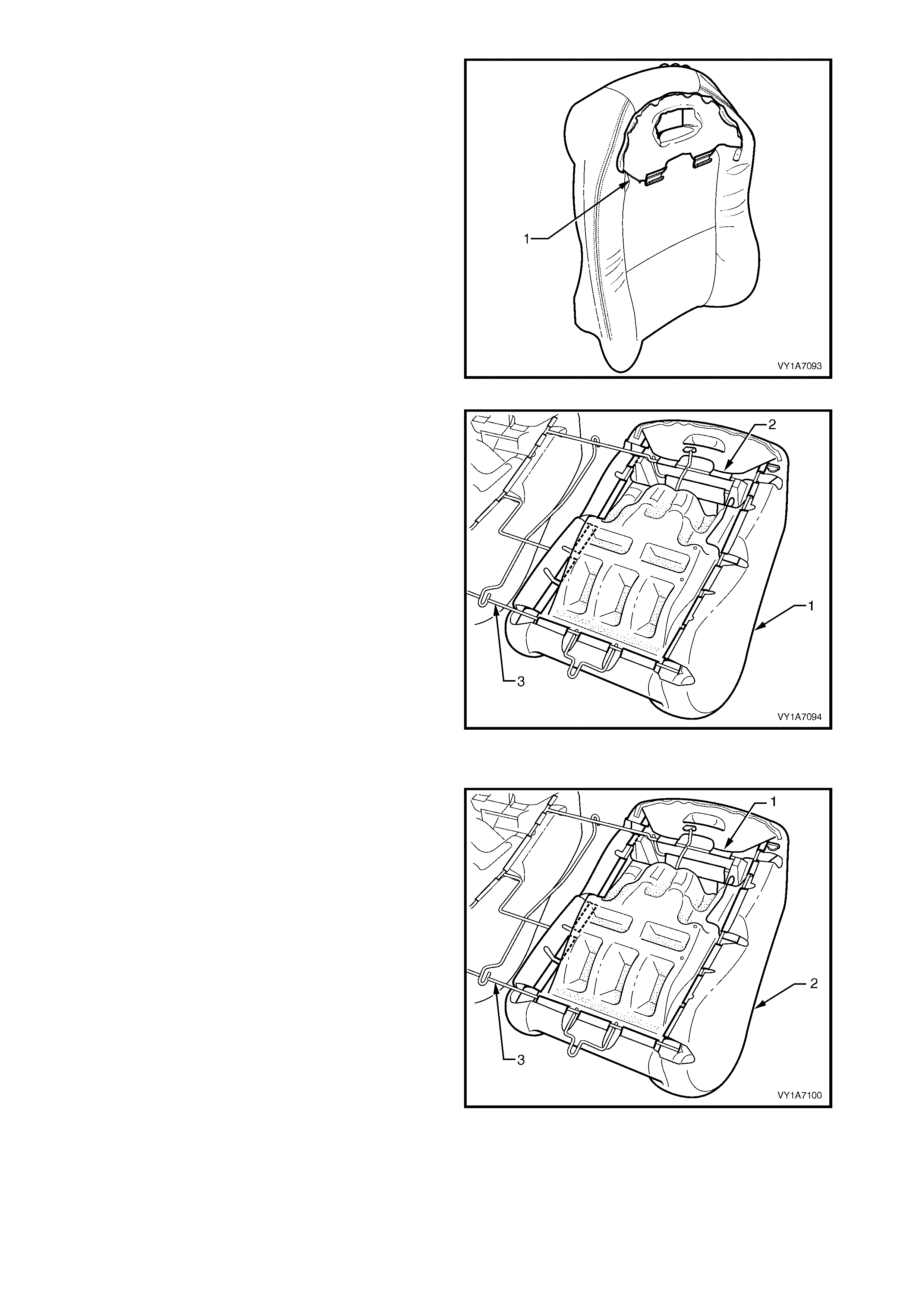

1. Remove the front seat-back pad and cover

assembly (1) by pulling the four J-strips (2) away

from the seat frame.

2. Lift the cover and pad assem bly up and away f rom

the seat-back frame.

Figure 1A7-49

DISASSEMBLE

NOTE 1: The following procedure only applies to

vehicles fitted with seat covers attached to the seat-

back pad with the fully serviced Hook and Loop. For

model reference chart, refer to 2.1 FRONT SEAT

USAGE CHART - EXCEPT COUPE.

NOTE 2: Surebond cover assemblies are not serviced

as they are glued to the seat-back pad, for model

reference chart, refer to 2.1 FRONT SEAT USAGE

CHART - EXCEPT COUPE.

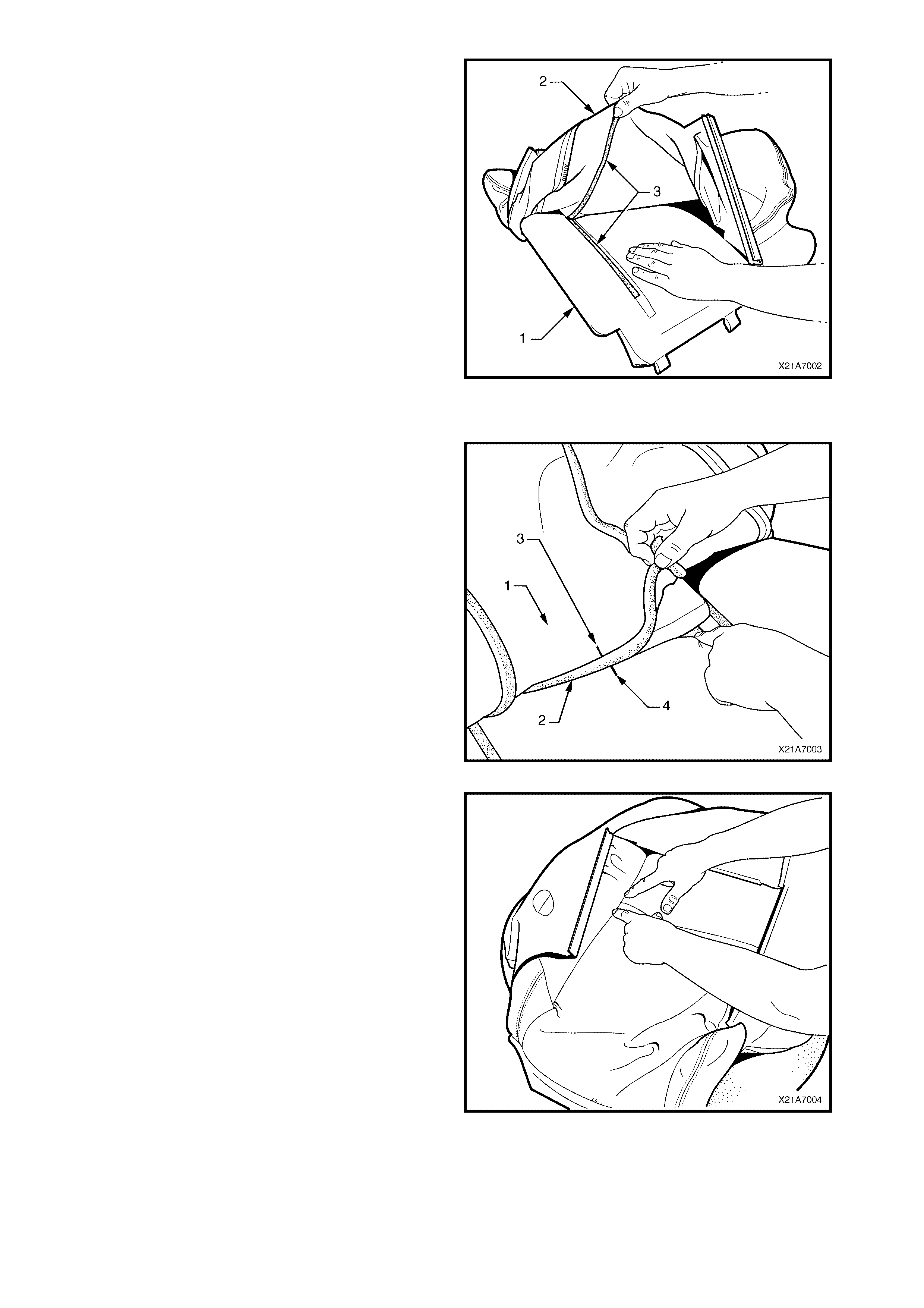

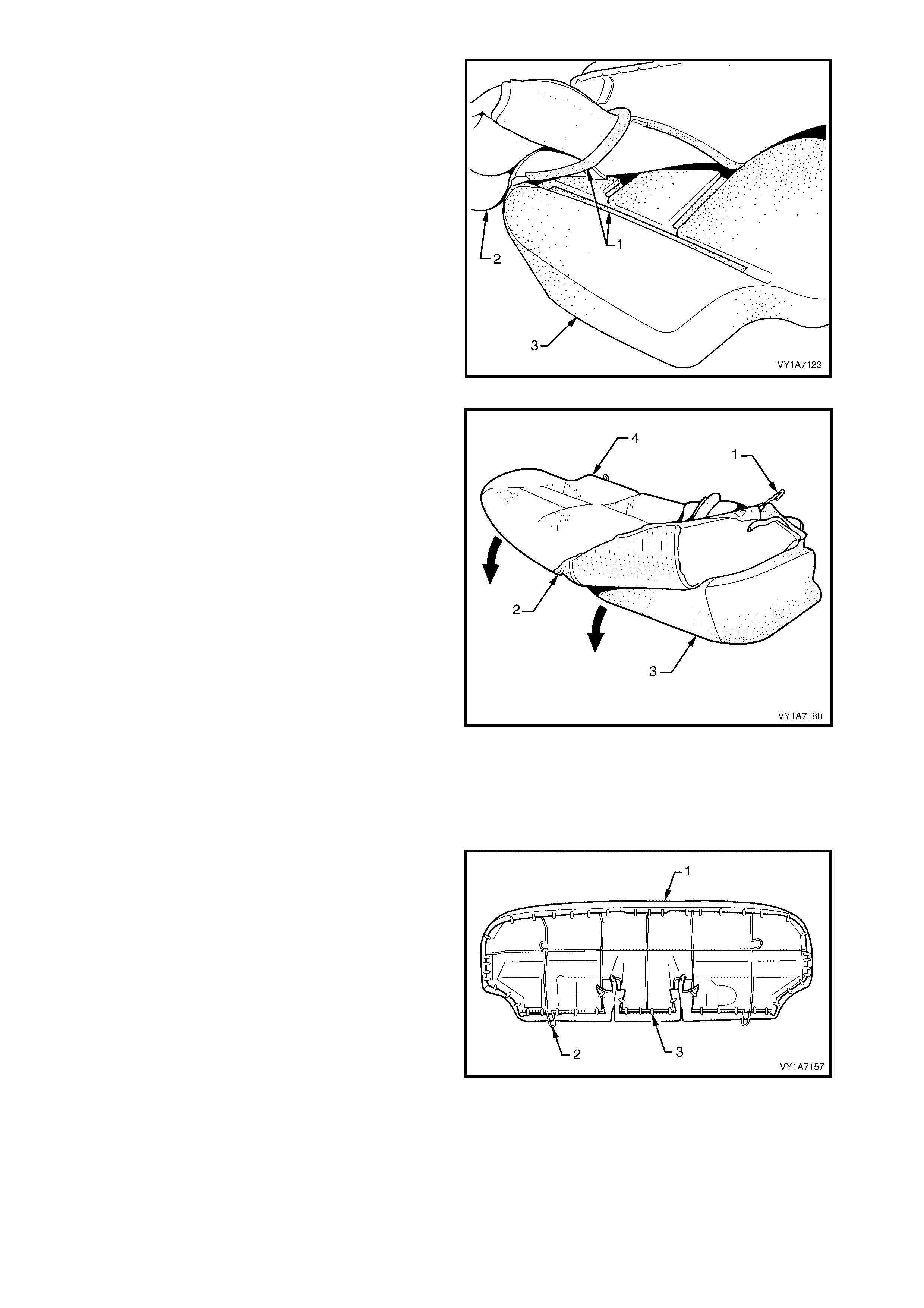

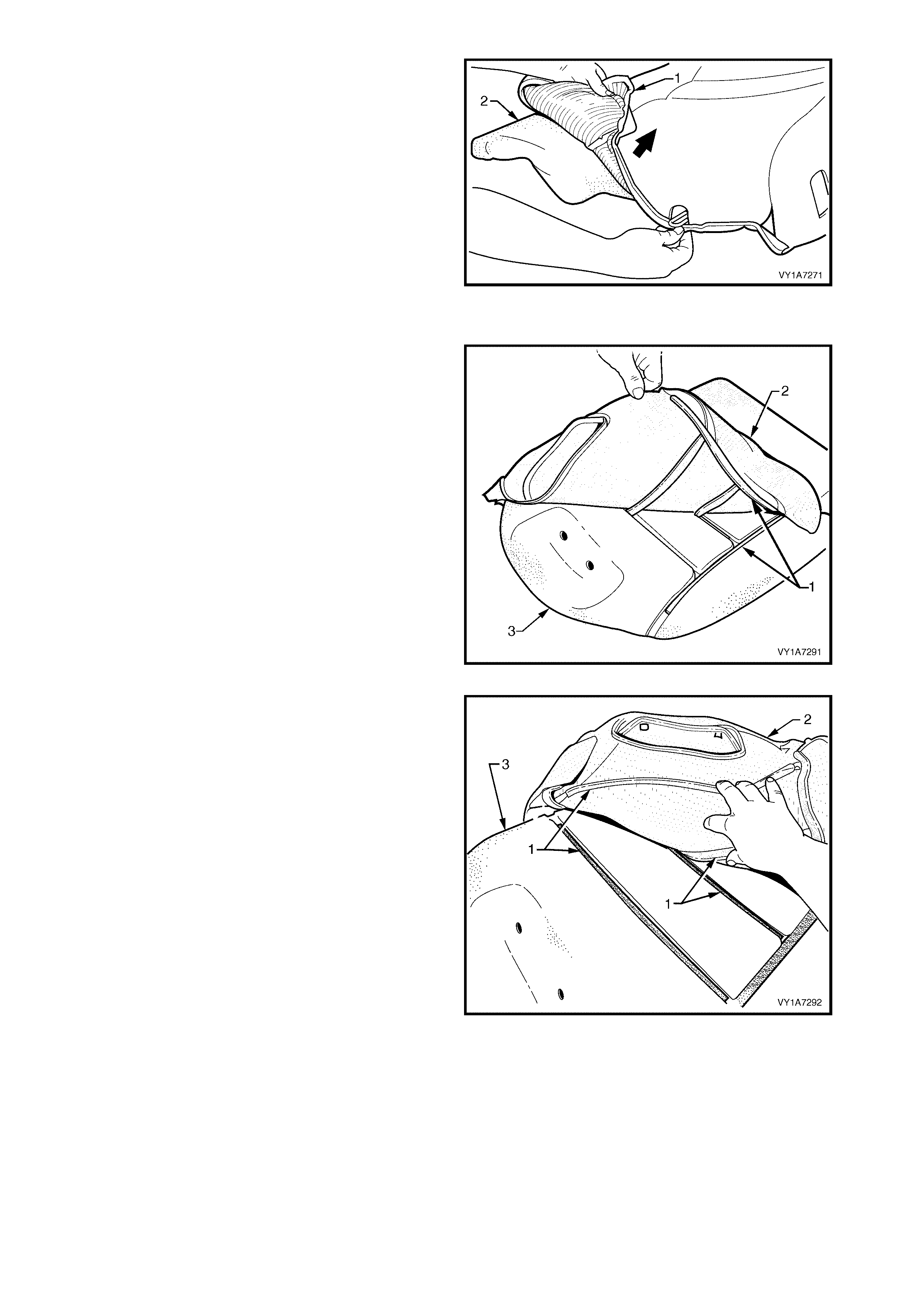

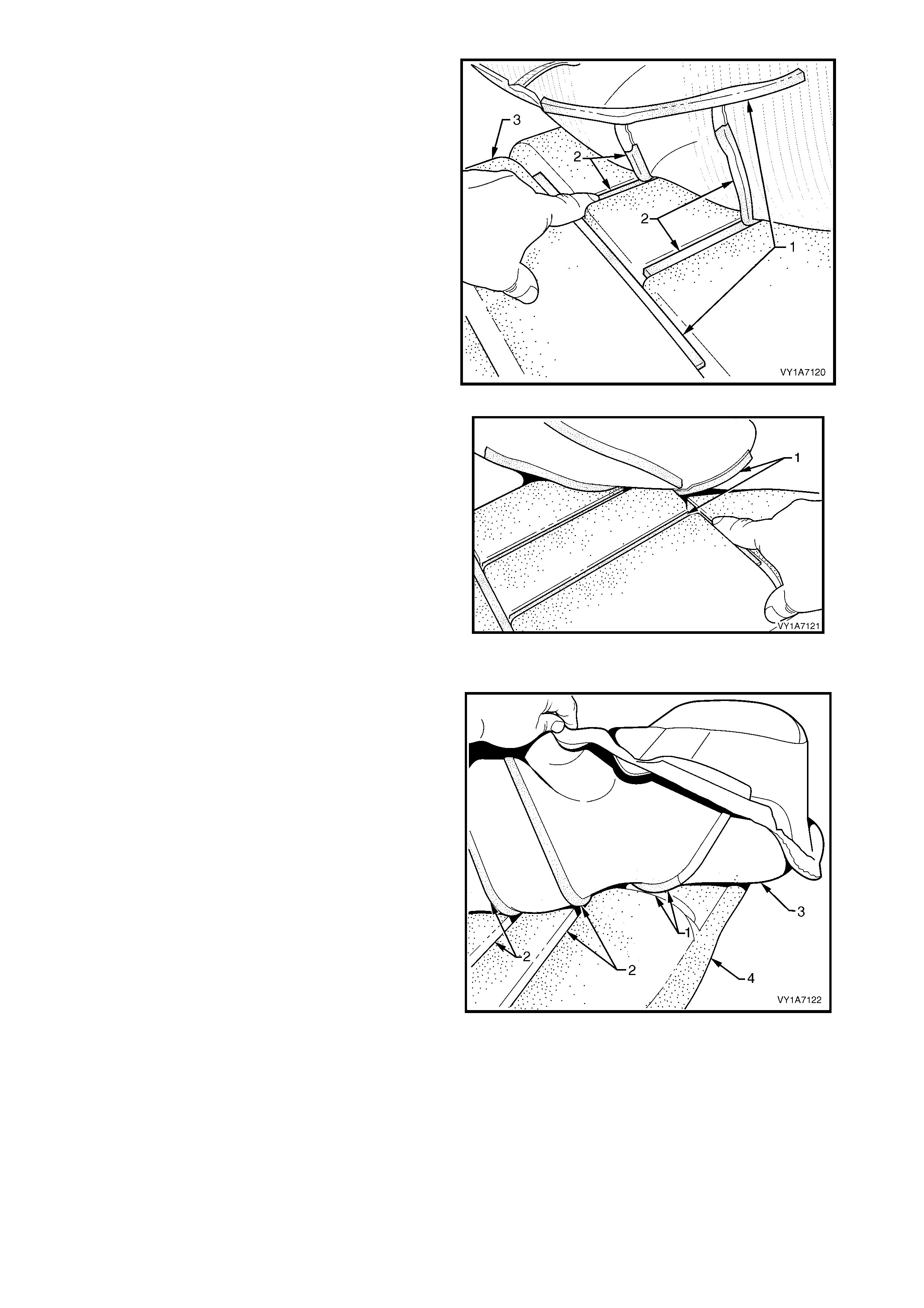

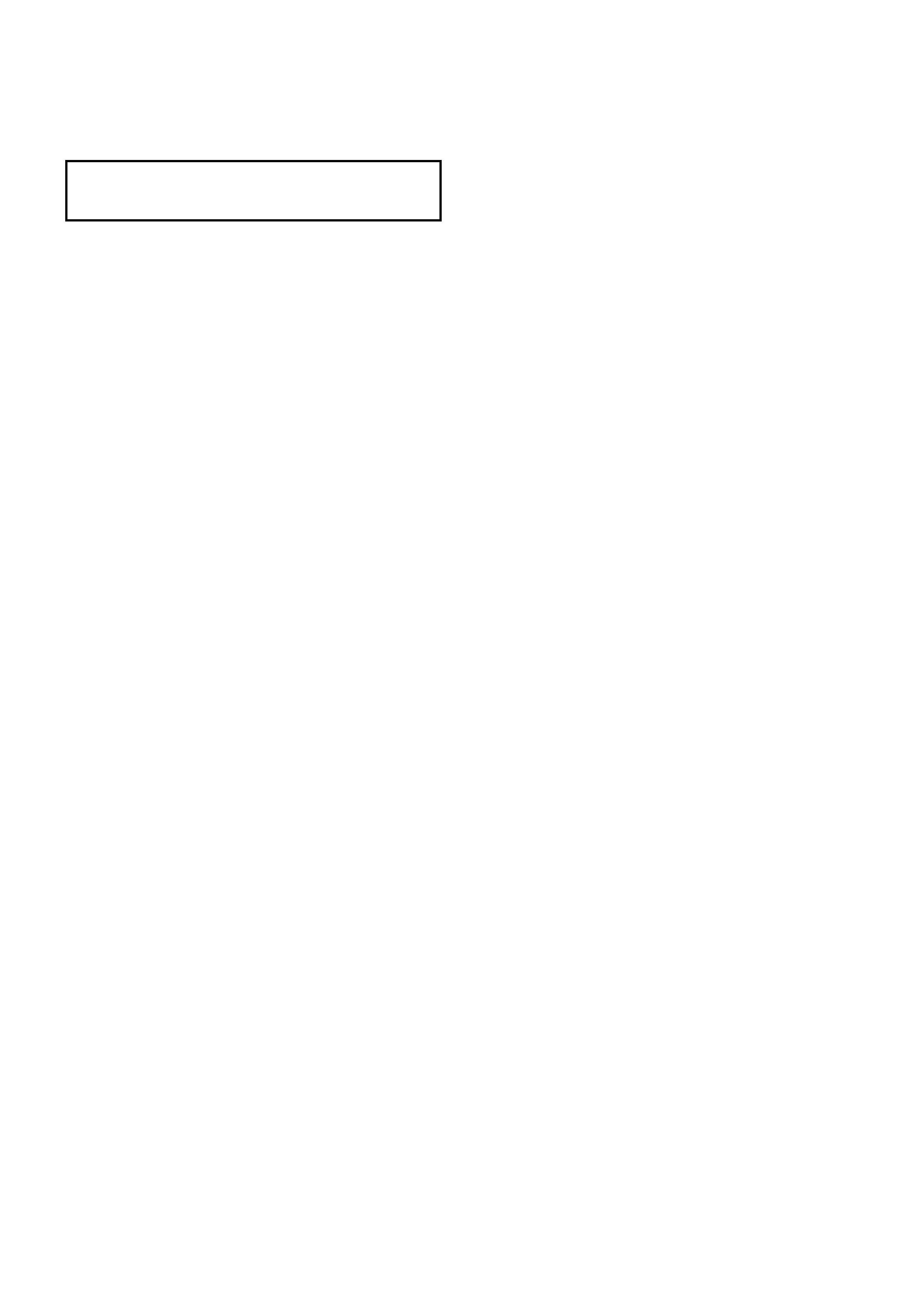

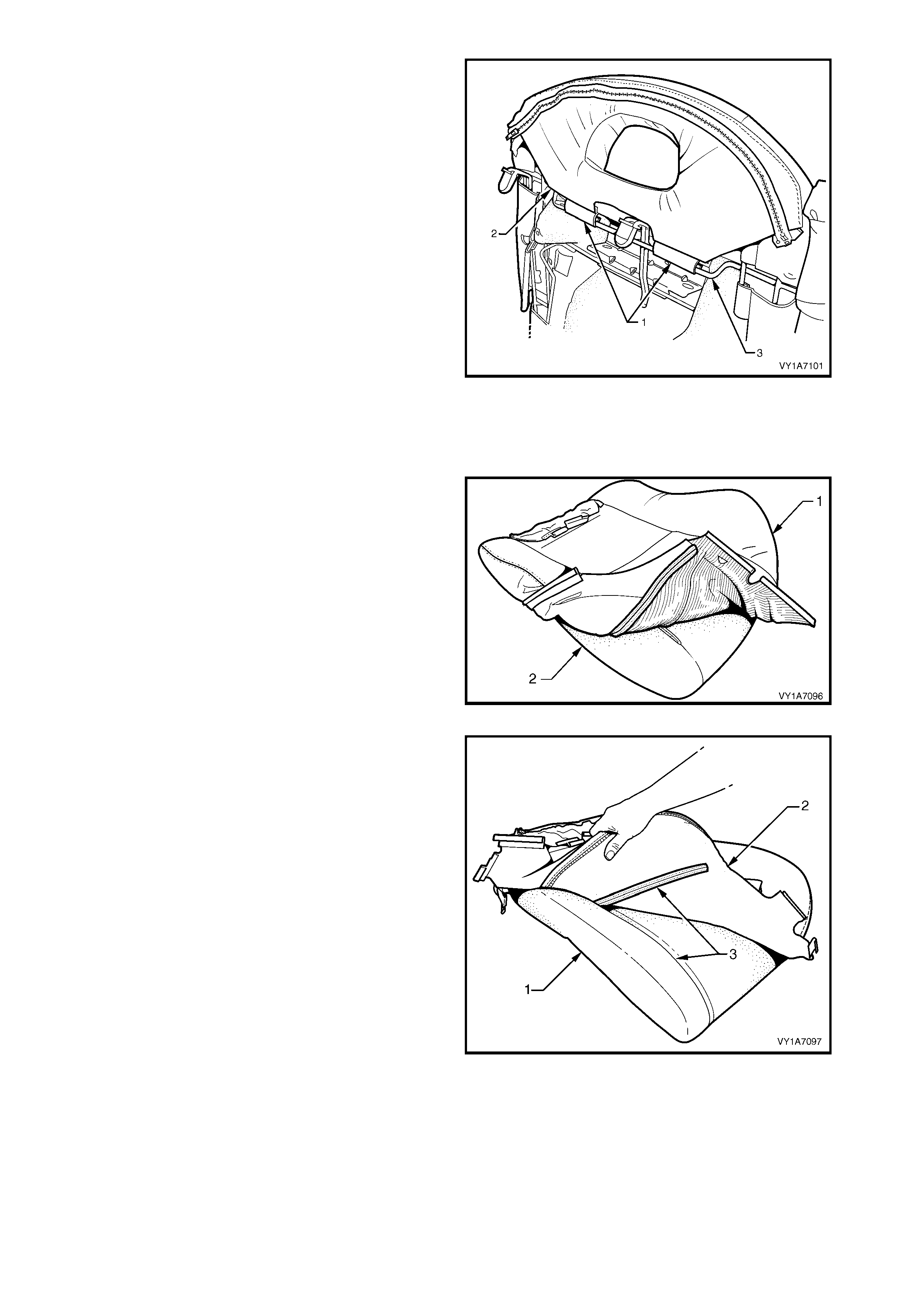

1. Fold the lower corners of the seat-back cover (1)

over the seat-back pad (2).

Figure 1A7-50

2. While holding the front seat-back pad (1), pull the

lower corners of the seat-back cover (2), upwards

and away from the front seat pad to disengage the

hook and loop strips (3).

3. Pull the front seat-back cover up and over the

upper edge of the front seat-back pad.

Figure 1A7-51

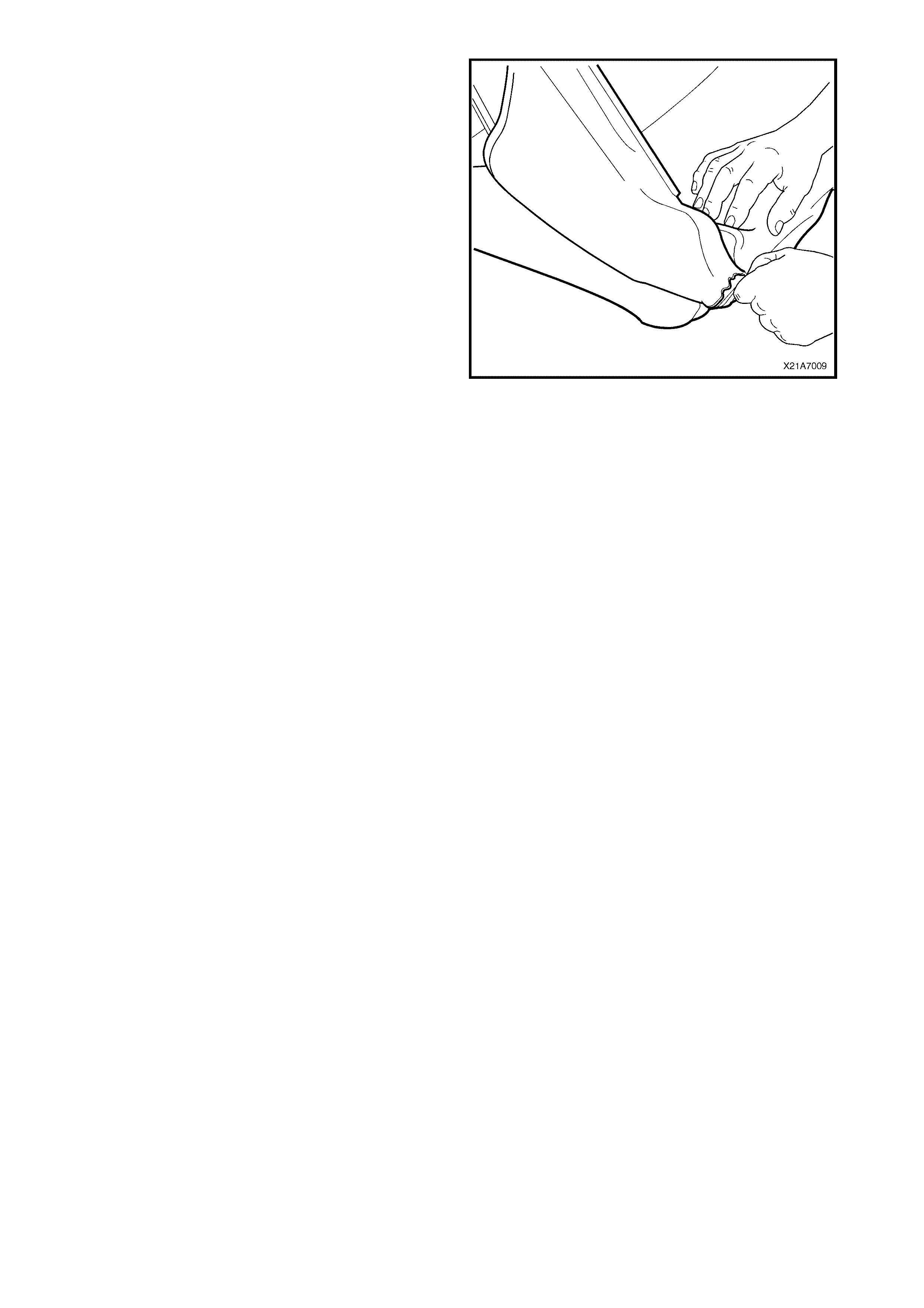

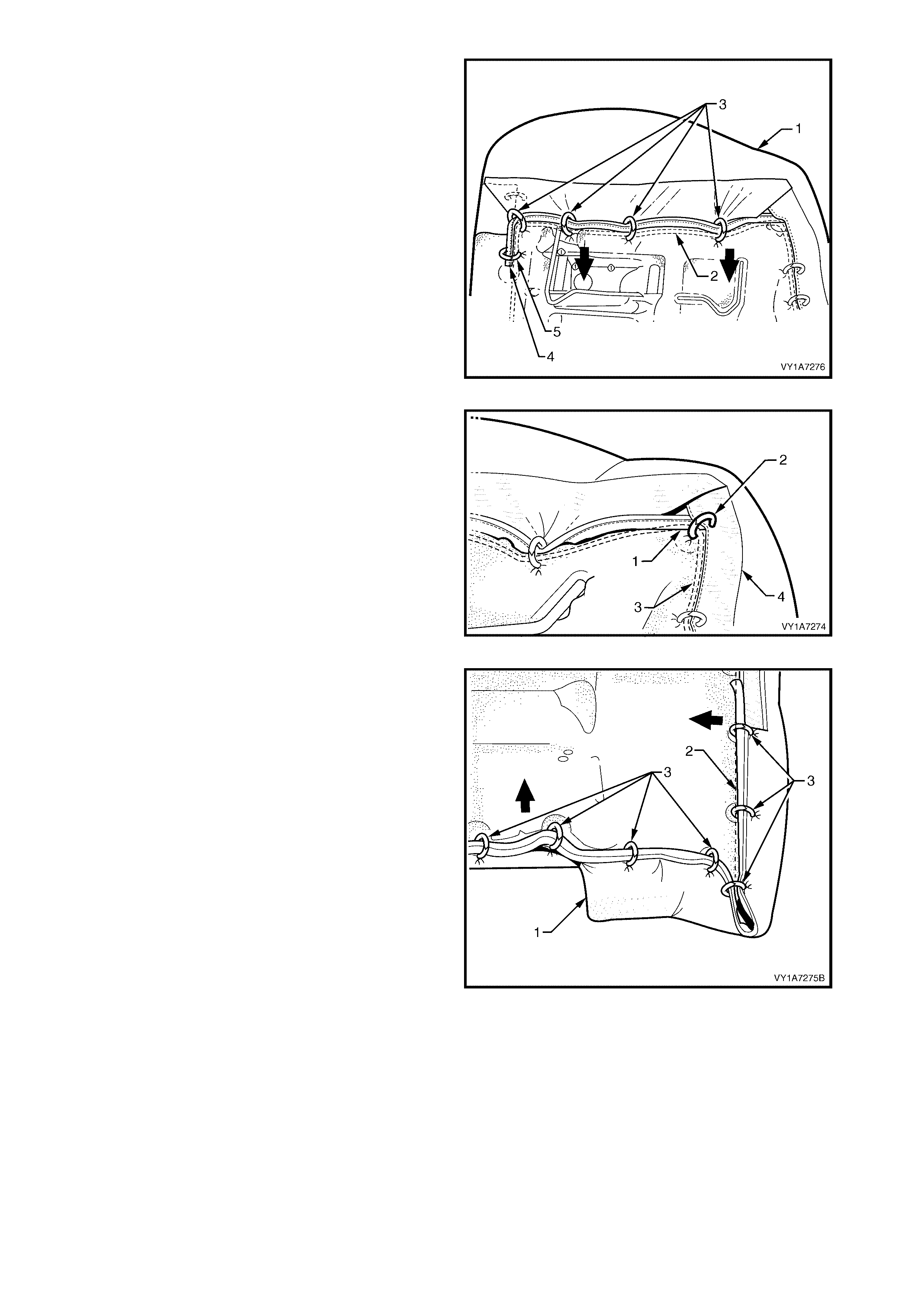

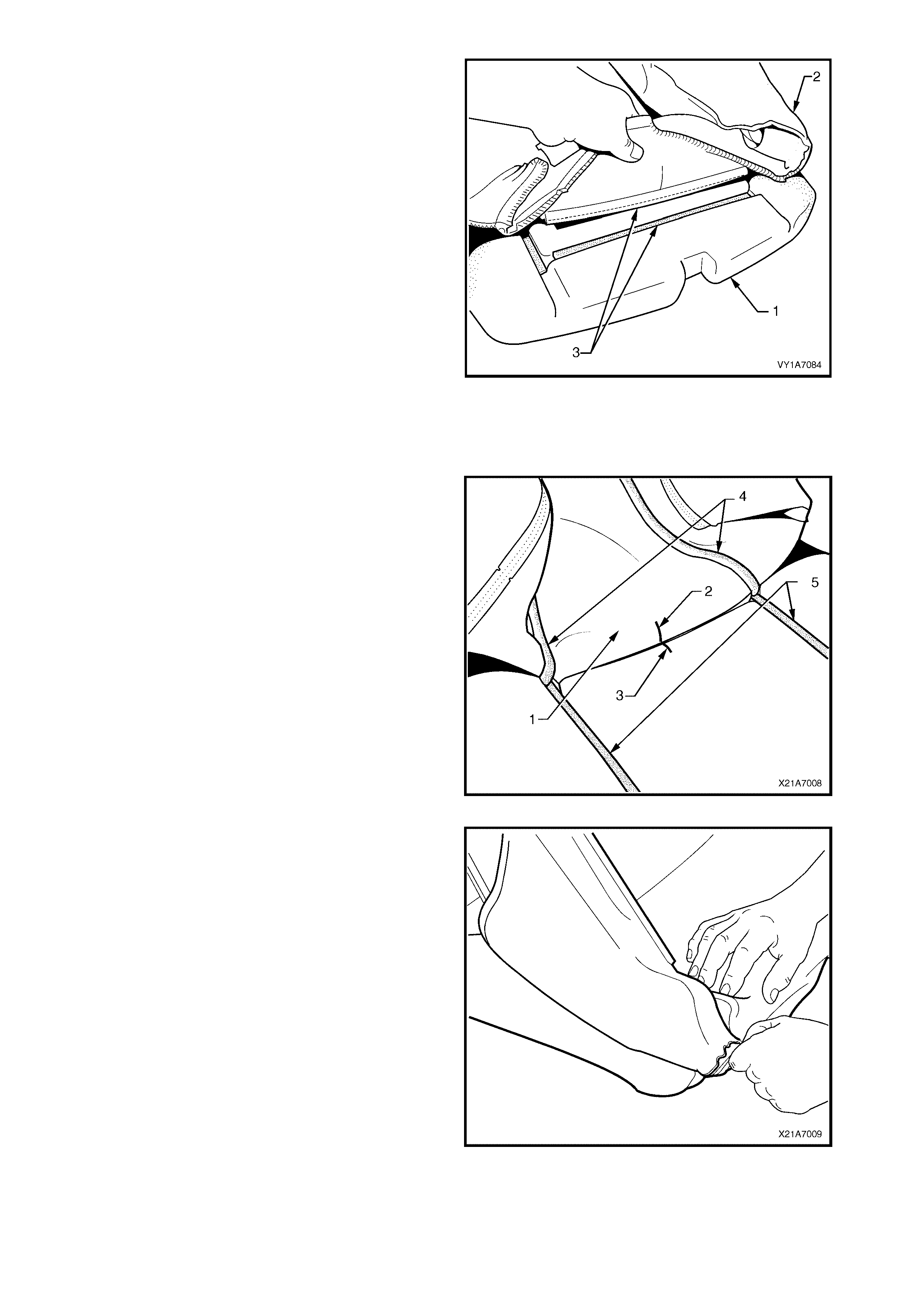

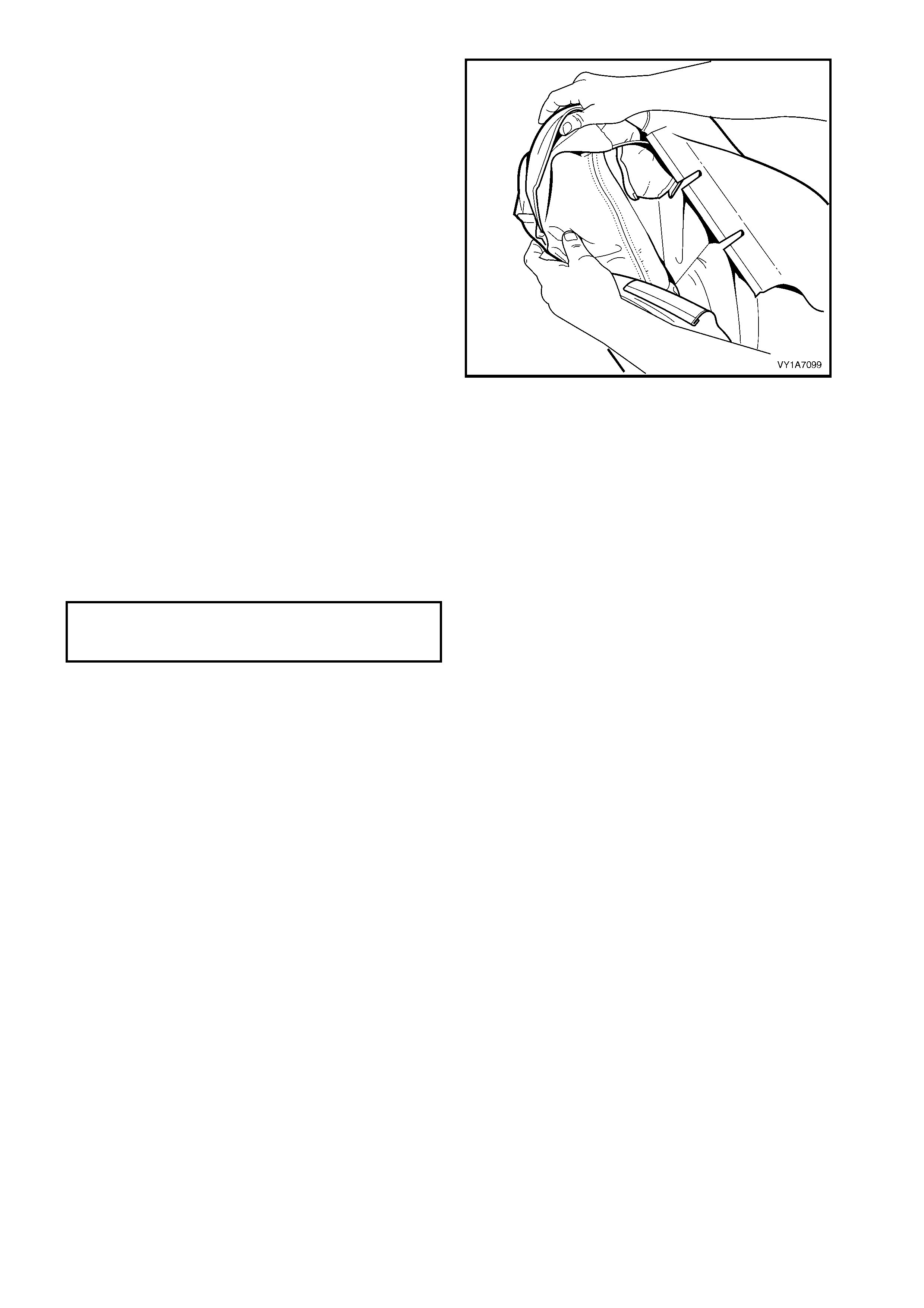

REASSEMBLE

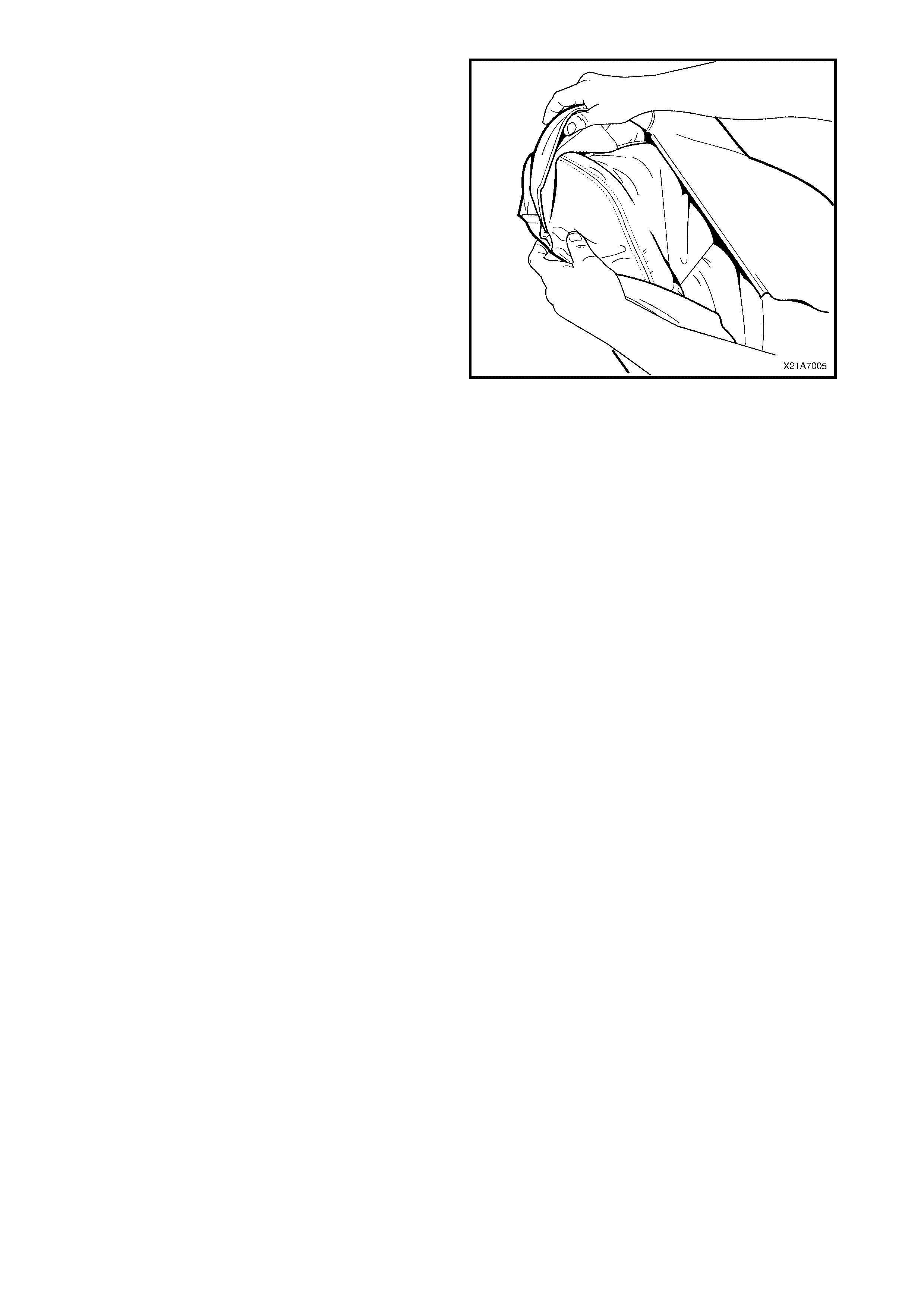

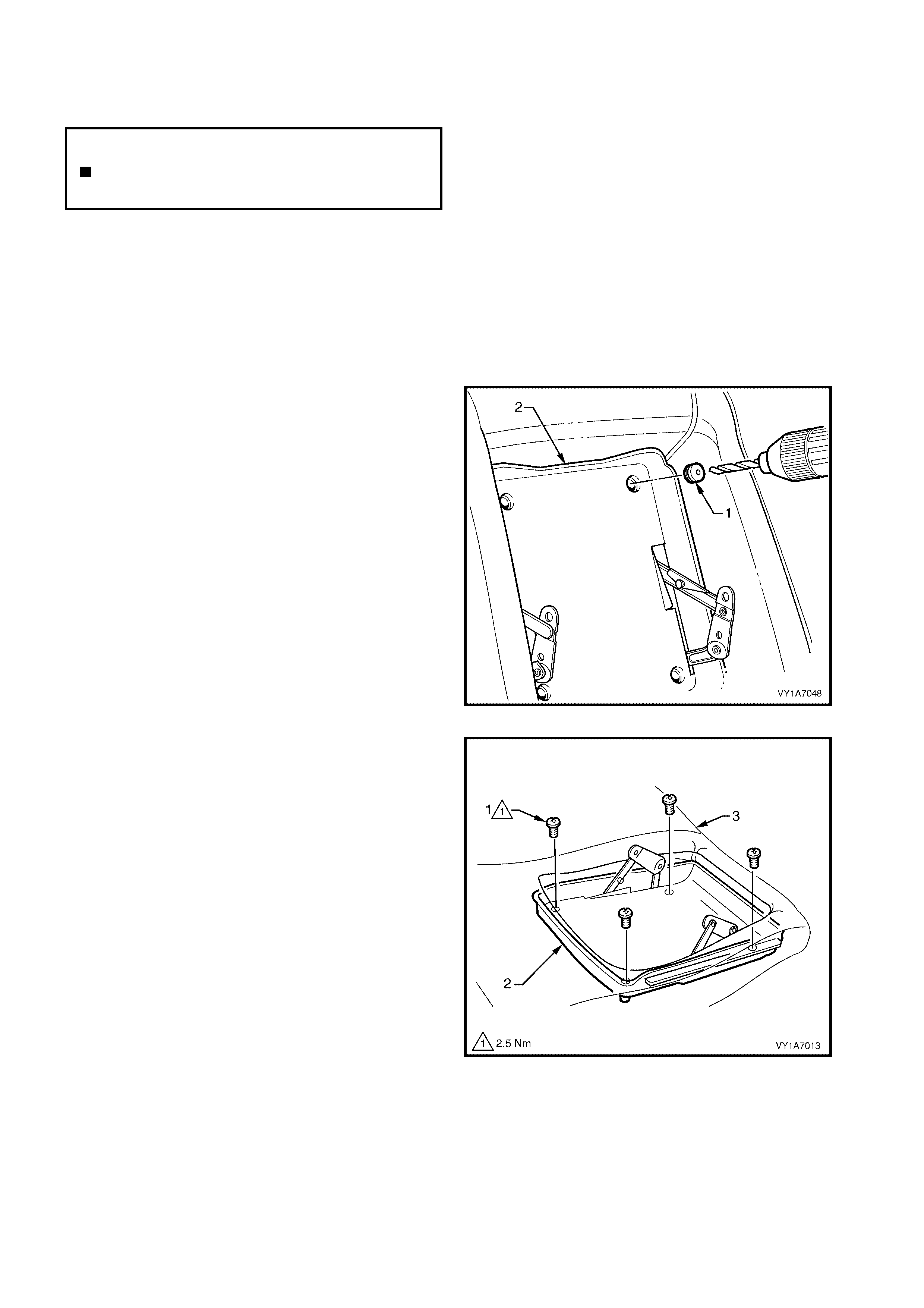

1. With the seat-back cover (1) folded at the central

horizontal strip of hook and loop (2), align the

centre mark (3) on the front seat-back cover with

the centre mark (4) on the seat-back pad.

2. Press the seat-back cover firmly into the

corresponding groove in the seat-back pad to

engage the hook and loop.

Figure 1A7-52

3. W ith the seat cover folded at the two vertical strips

of the hook and loop, press the seat-back cover

firmly into the corresponding grooves in the seat-

back pad.

Figure 1A7-53

4. Roll the upper corners of the front seat-back cover

over the seat-back pad.

5. Roll the s ides of the seat-bac k c over over the s eat-

back pad.

6. Roll the lower corners of the seat-back cover over

the seat-back pad.

NOTE: Make sure the cover is fitted neatly by hand into

all corners and contours of the seat pad.

Figure 1A7-54

REINSTALL

Reinstallation of the rear seat-back assembly is the

reverse of the removal operation.

2.10 FRONT SEAT-BACK FRAME ASSEMBLY

LT Section No. – 14-275

CAUTION: When carrying a live (undeployed) side airbag assembly, make sure the airbag opening is

pointed away from you. Never carry the side airbag assembly by the wiring harness or connectors. In

case of an accidental deployment, the airbag will then deploy with minimal chance of injury.

When p lacing a liv e side airb ag assemb ly on a ben ch or o th er surf ace, alw ays face th e airbag openin g up,

away from t he surface. Never rest th e airbag assembly with th e opening face do wn. Th is is necessary so

that a free sp ace is provid ed to allo w t he airbag t o expand in the un likely event of accid ental dep loyment.

Otherwise, personal injury may result.

1. Remove the front seat assembly, refer to 2.2 FRONT SEAT ASSEMBLY.

2. Remove the front seat outer side cover, refer to 2.3 FRONT SEAT OUTER SIDE COVER.

3. Remove the front seat inner side cover, refer to 2.5 FRONT SEAT INNER SIDE COVER.

4. Remove the front seat-back lower cover assembly, refer to 2.6 FRONT SEAT-BACK LOWER COVER

ASSEMBLY AND LUMBER SUPPORT ADJUSTER KNOB.

5. Remove the front seat head restraint assembly, refer to 2.7 FRONT SEAT HEAD RESTRAINT ASSEMBLY.

6. Remove the front seat head restraint guide, refer to 2.8 FRONT SEAT HEAD RESTRAINT GUIDE.

7. Remove the front seat-back pad and cover assembly, refer to 2.9 FRONT SEAT-BACK PAD AND COVER

ASSEMBLY.

REMOVE

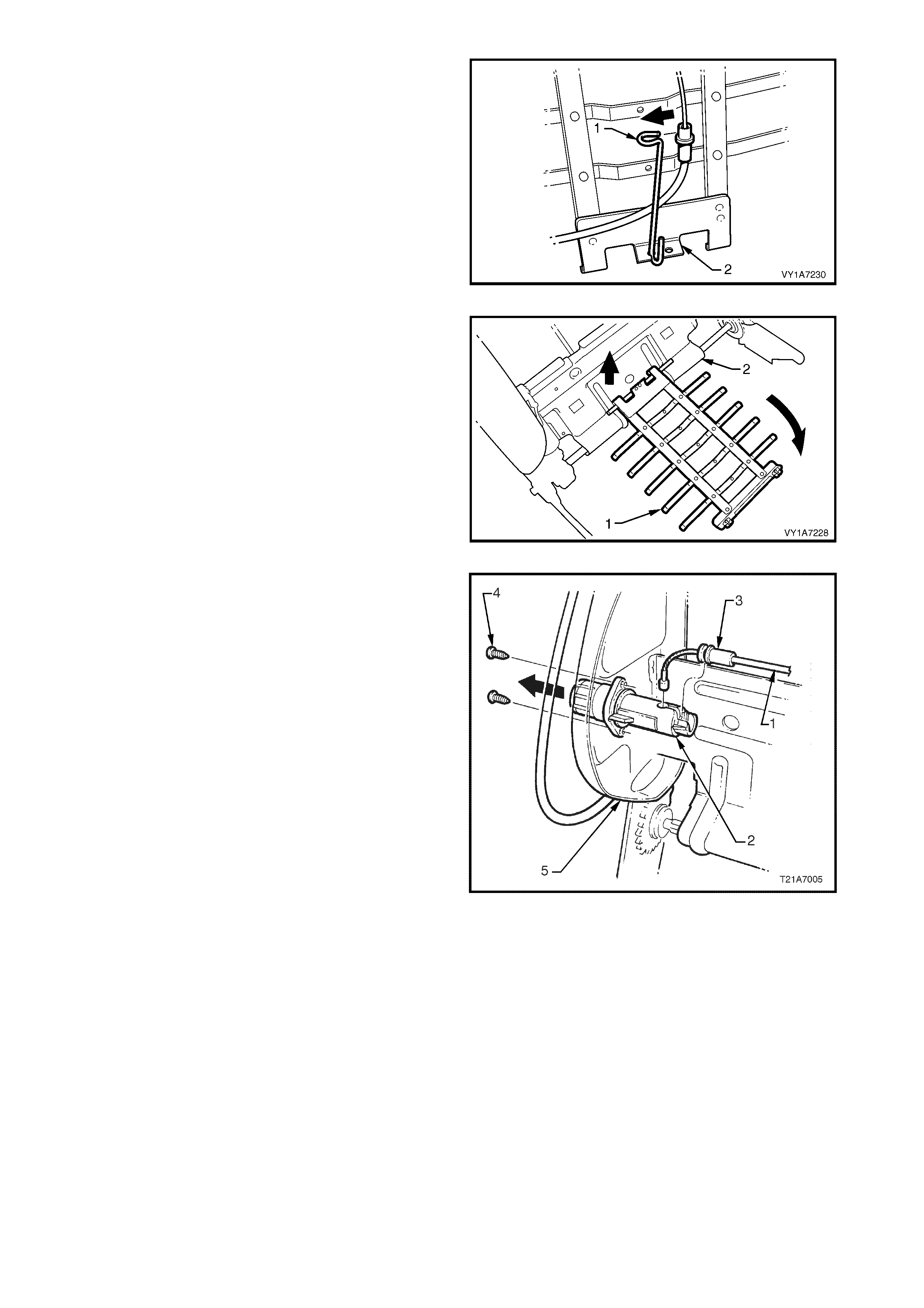

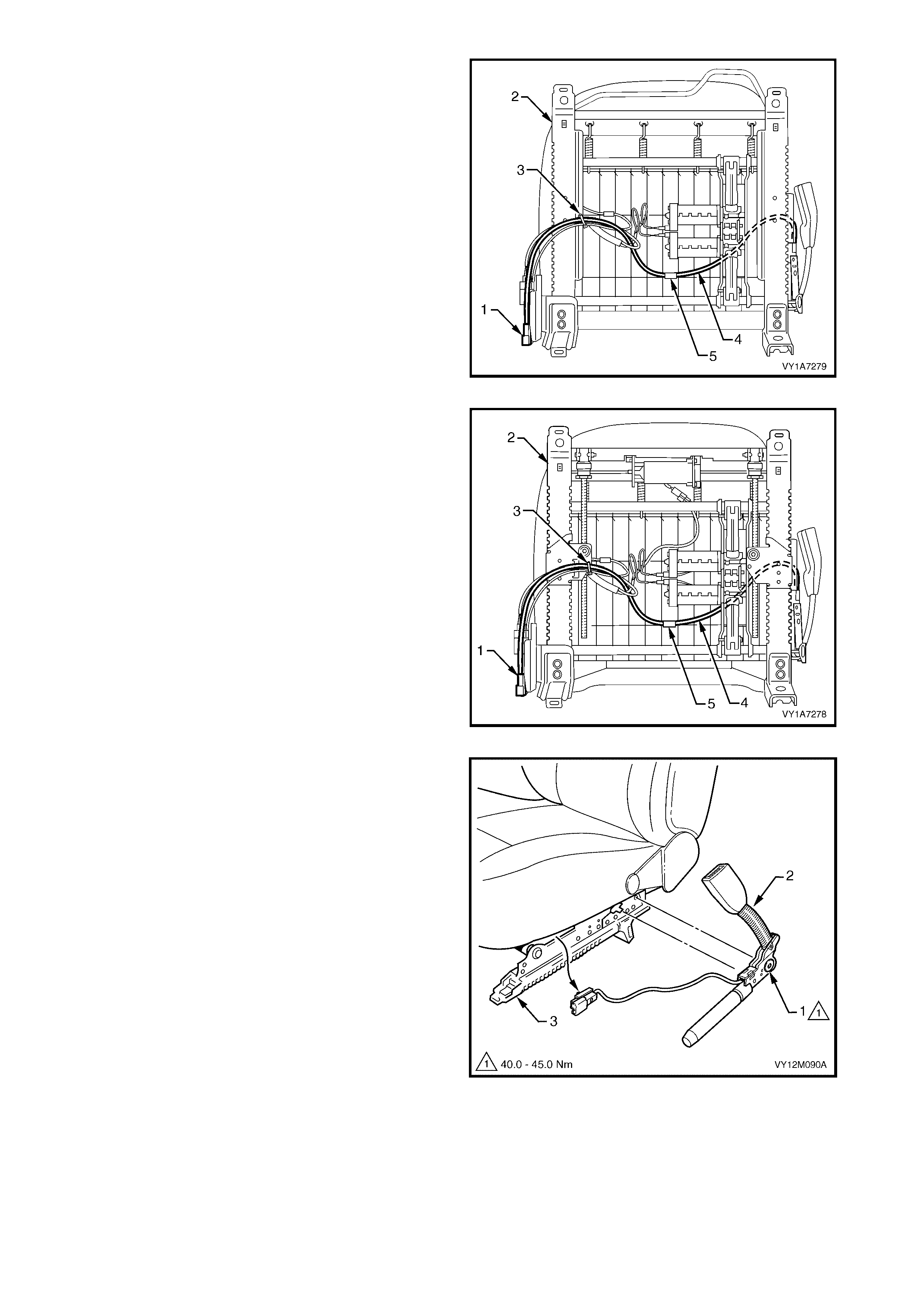

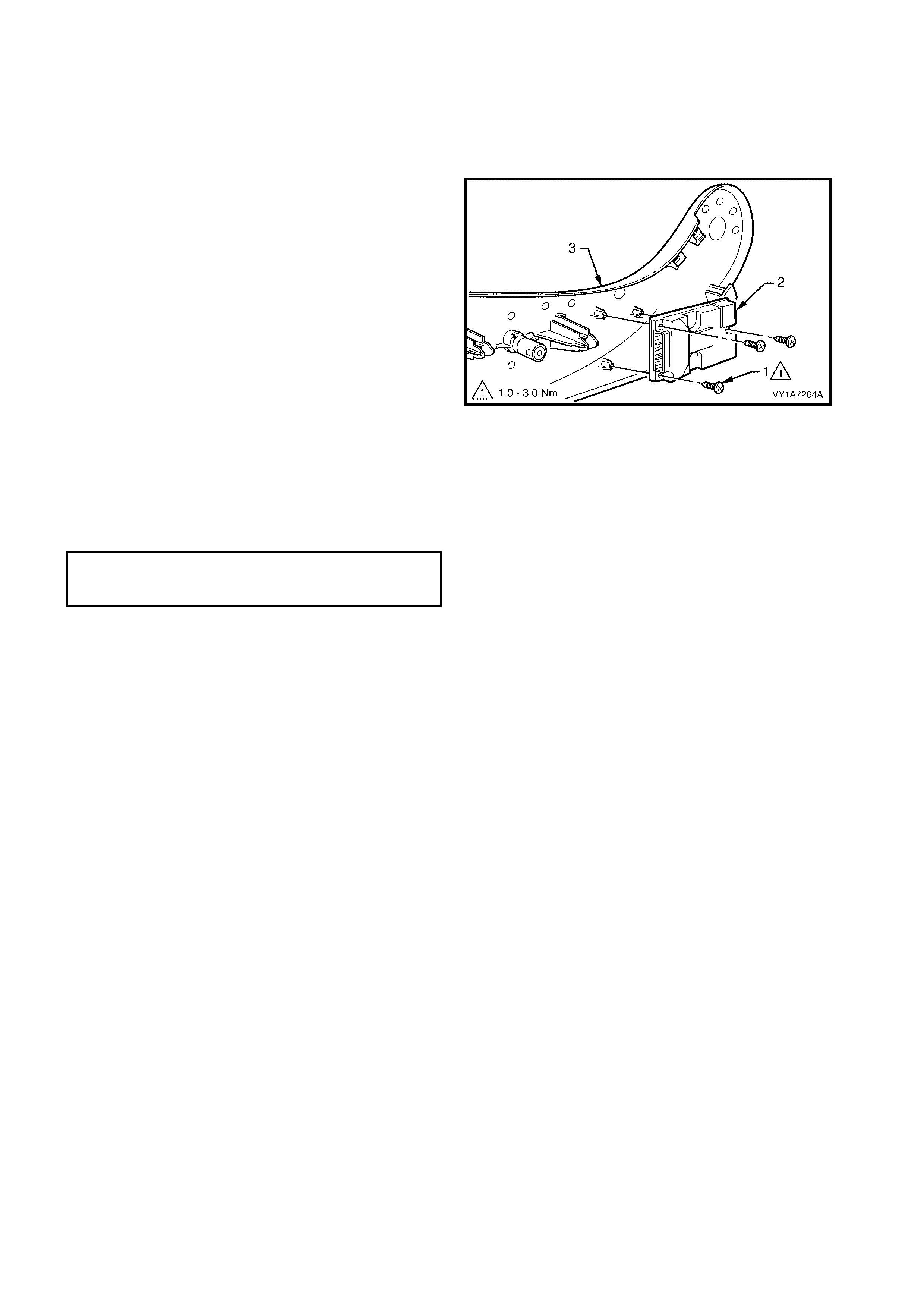

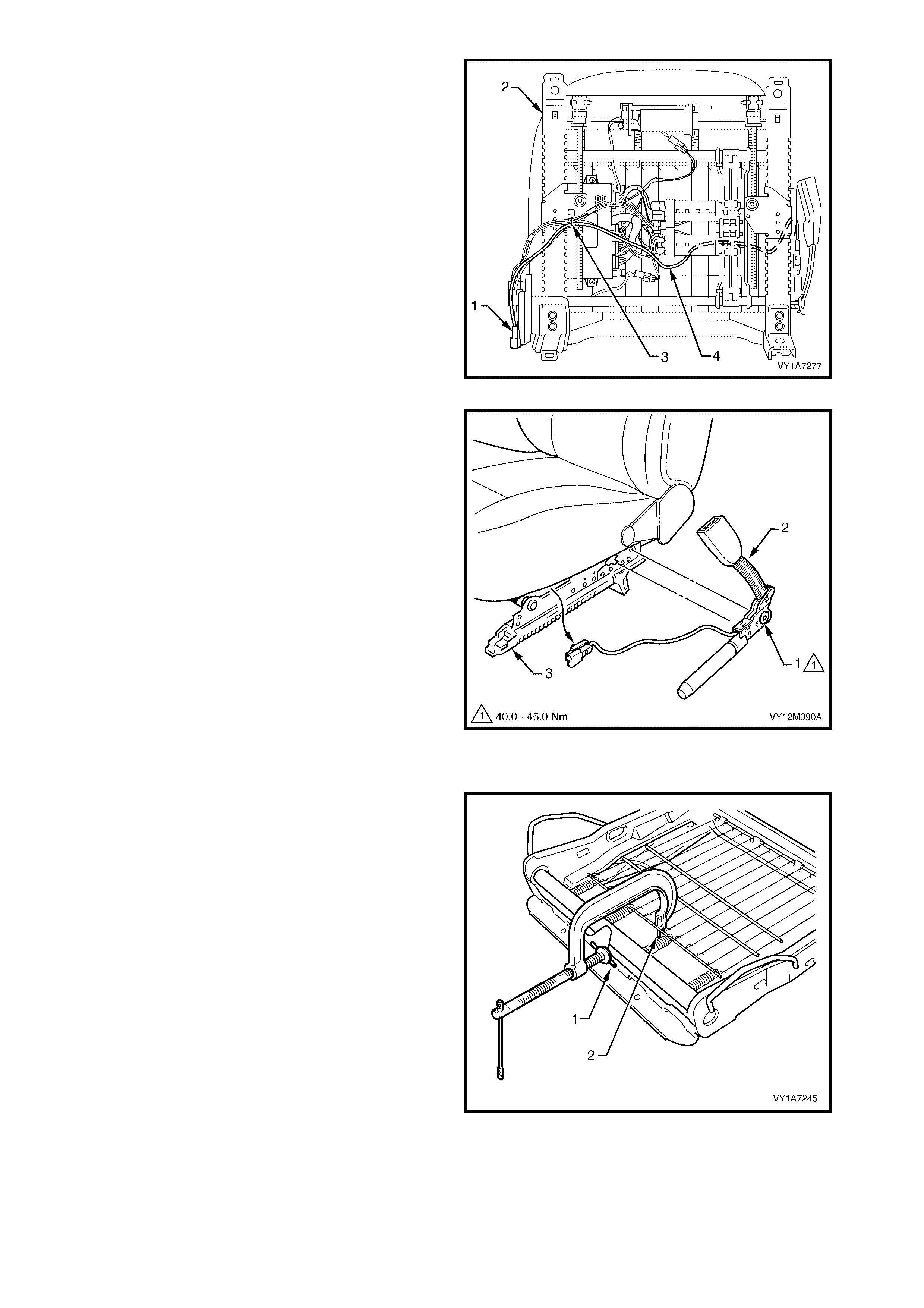

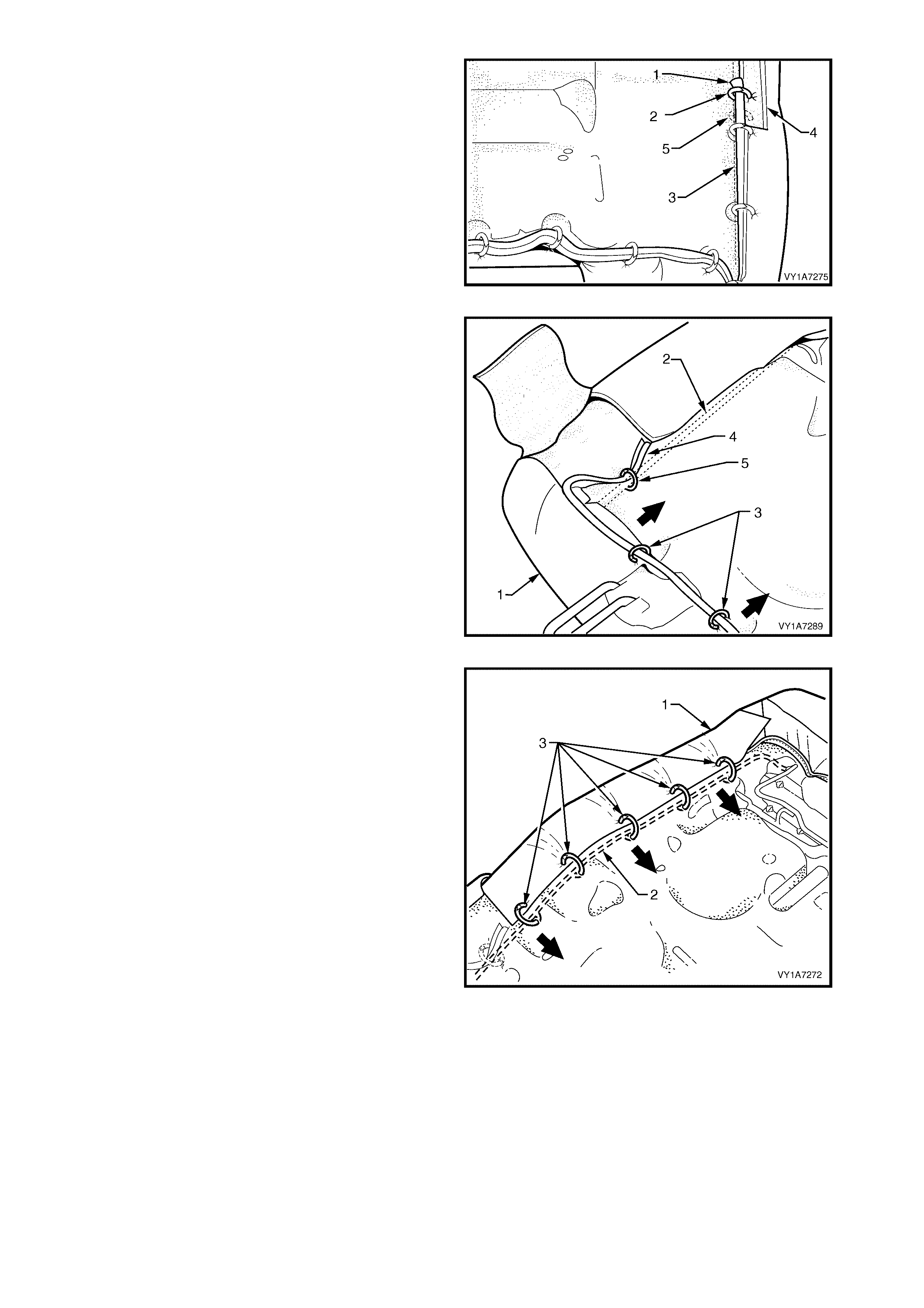

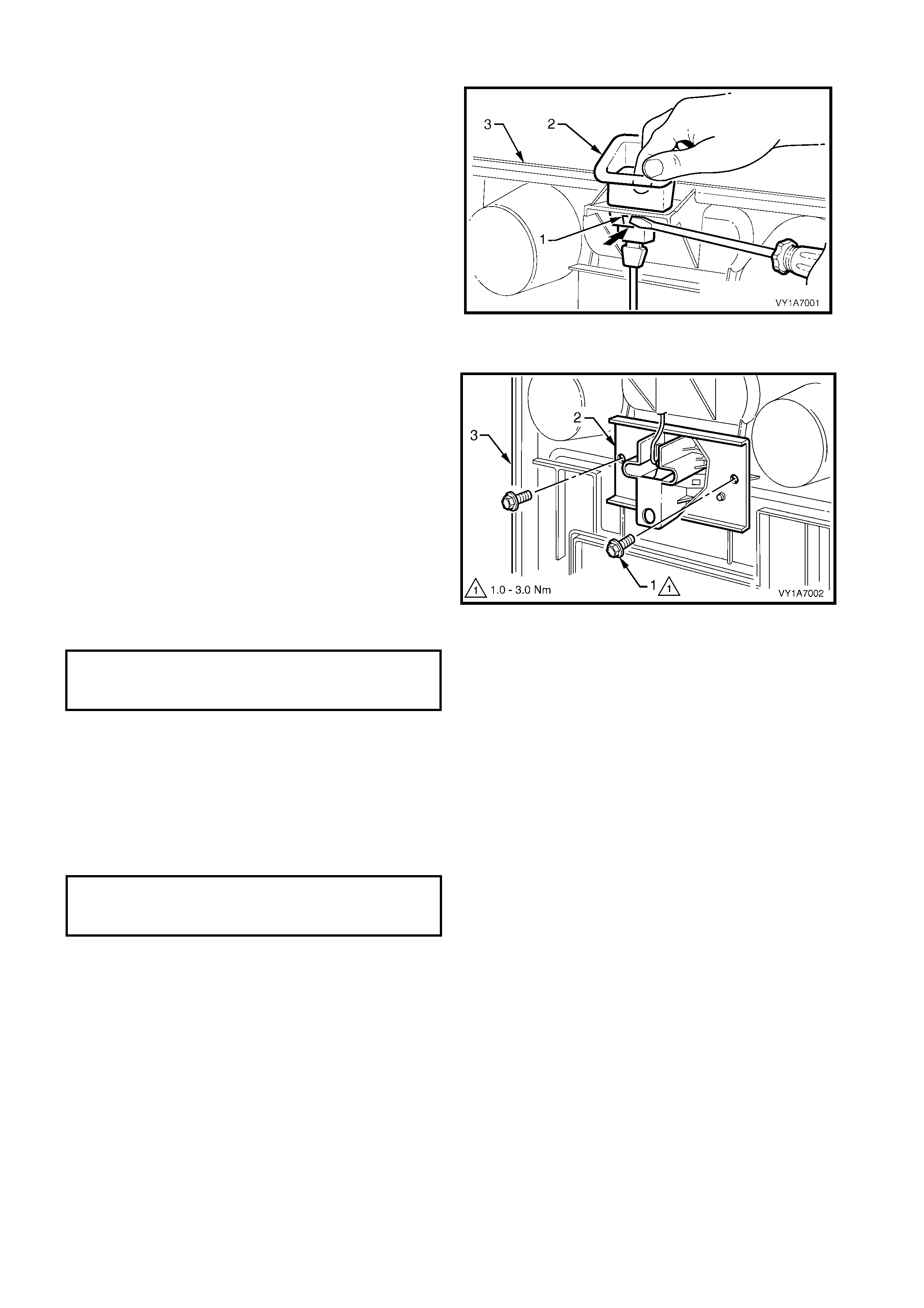

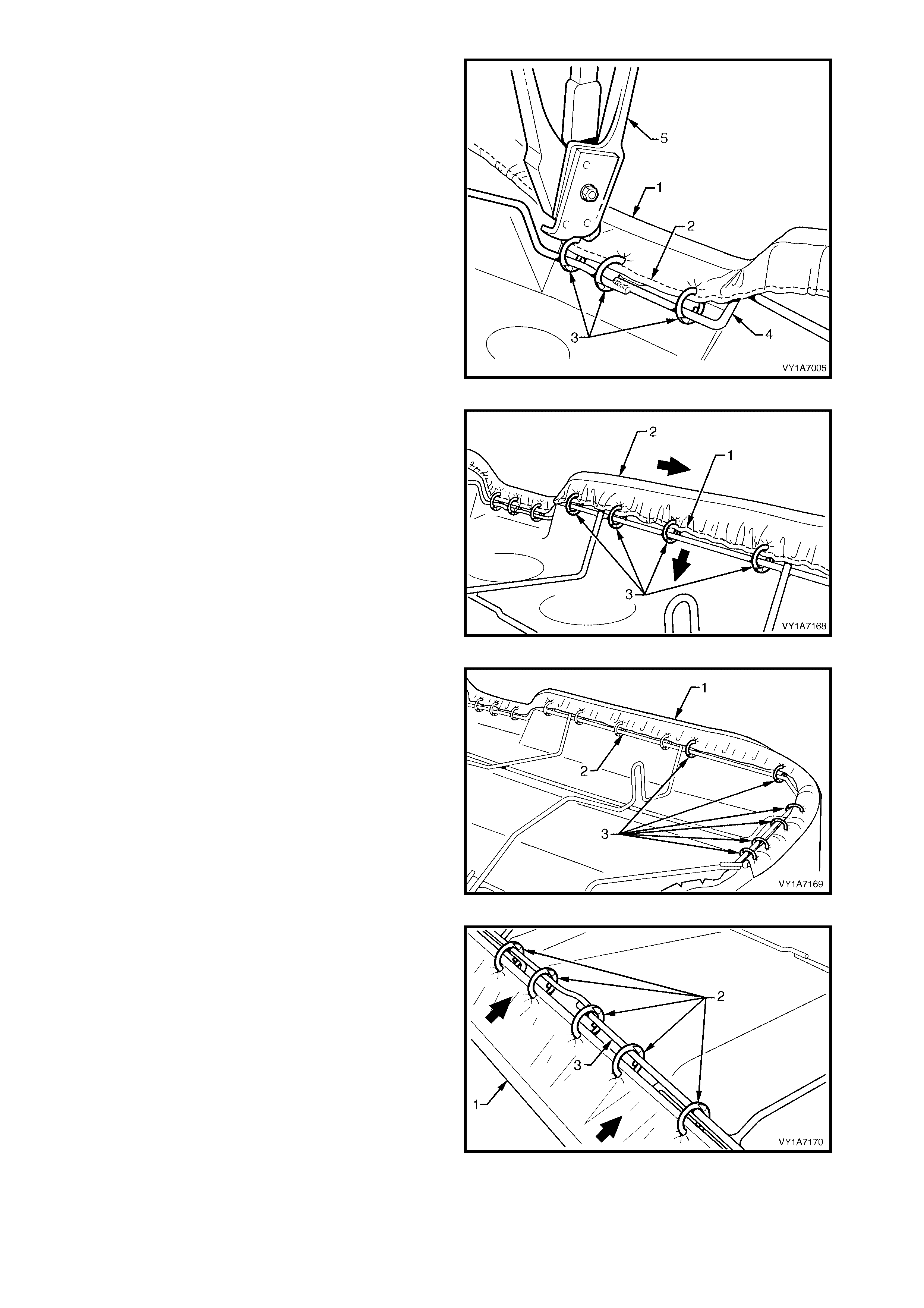

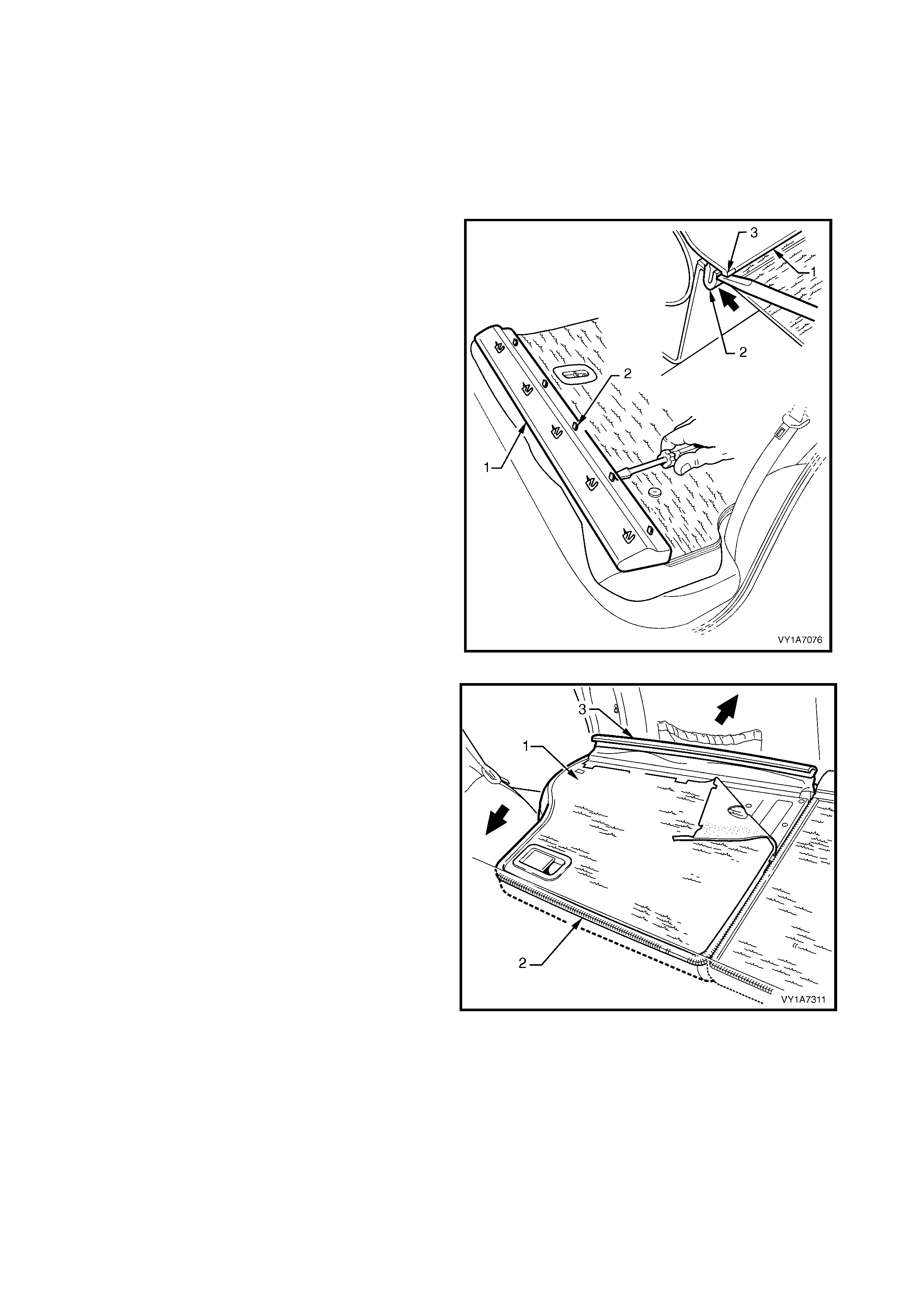

1. Where fitted, unclip the side impact airbag pigtail

wiring harness (1) from the retaining clip (2) and

cut the cable tie (3) securing the side airbag

harness to the front seat cushion frame assembly,

taking care not to damage the wiring harness.

2. Unclip the wiring harness connector (4) from the

adjuster and guide rail assembly (5).

Figure 1A7-55

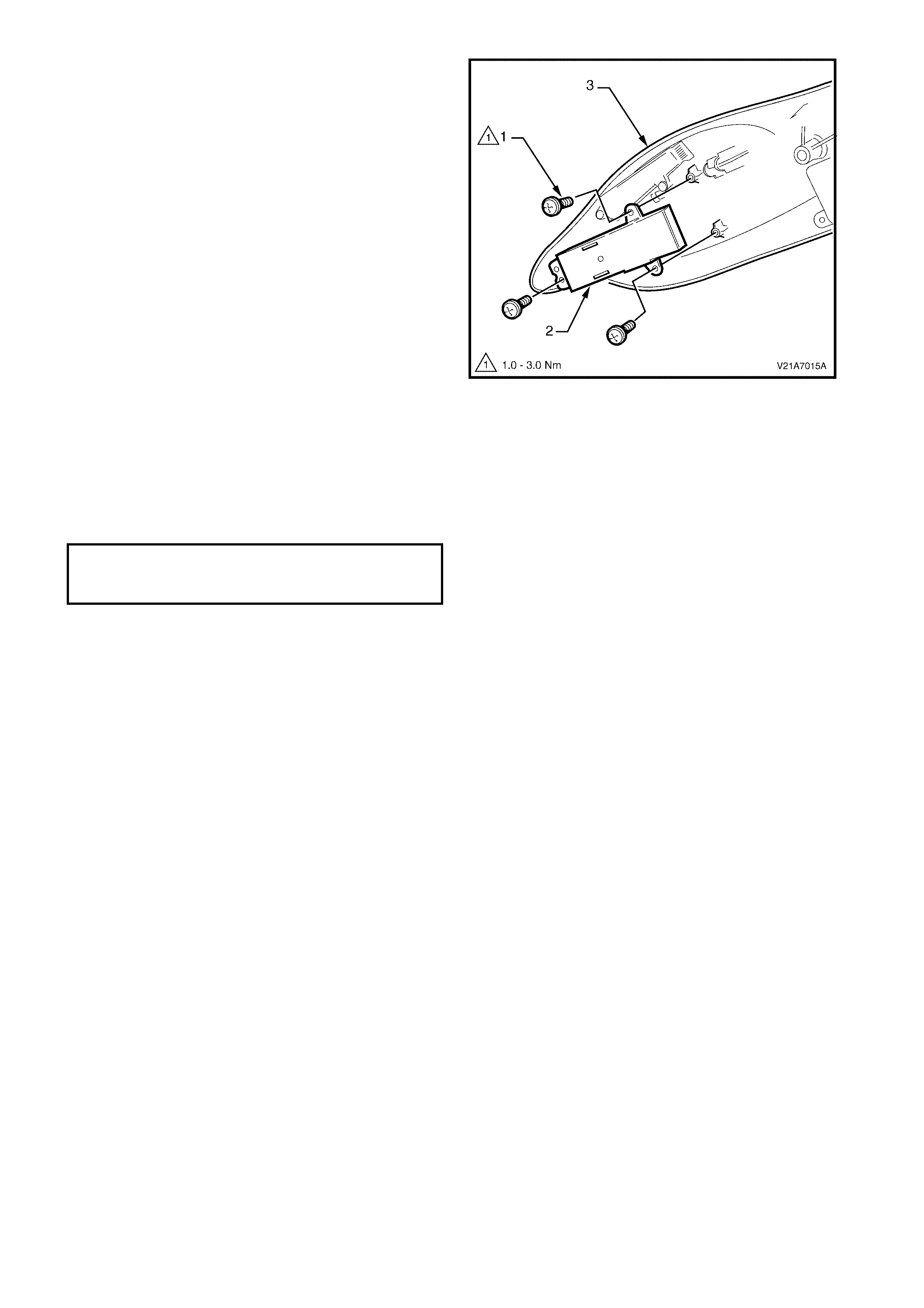

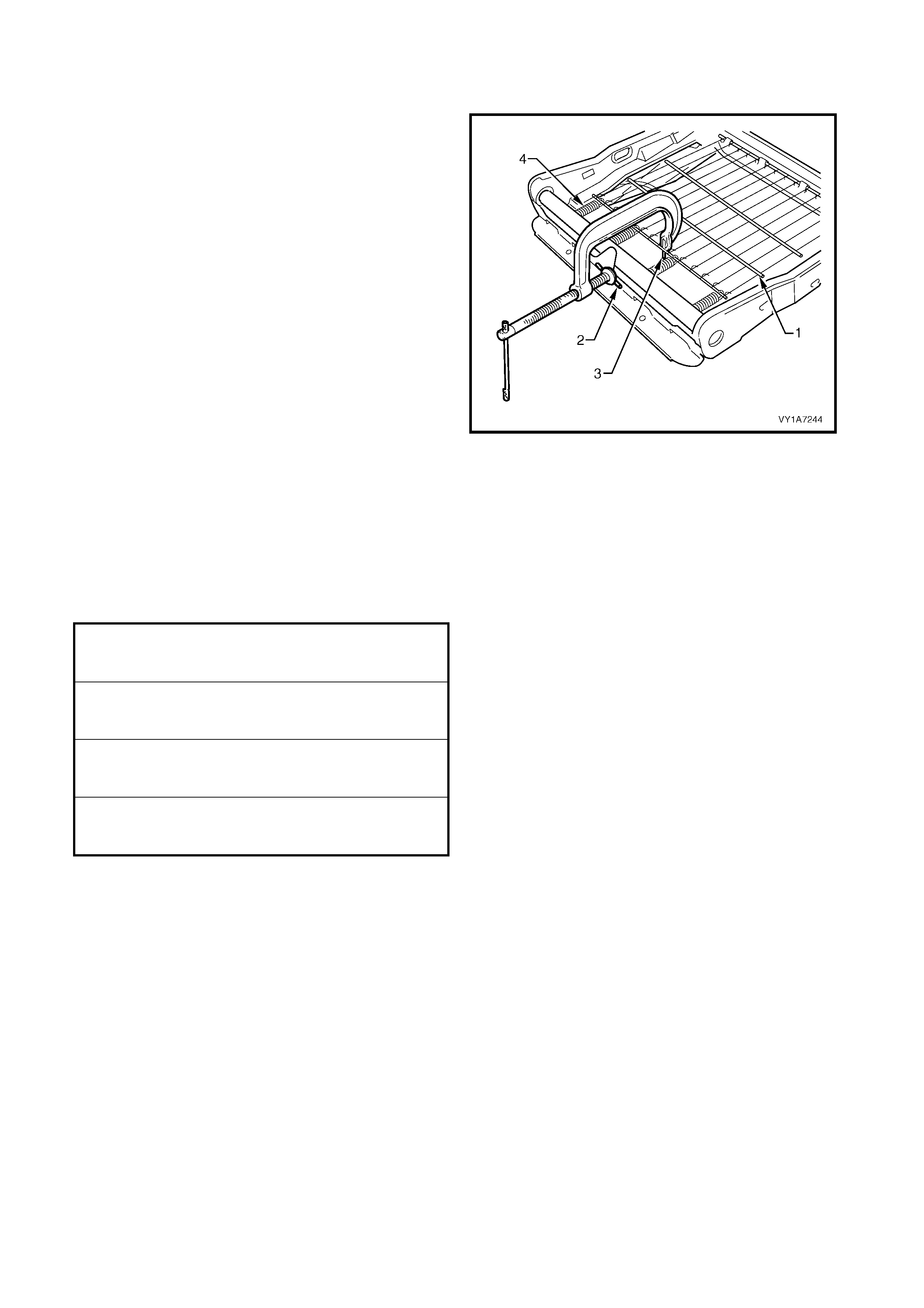

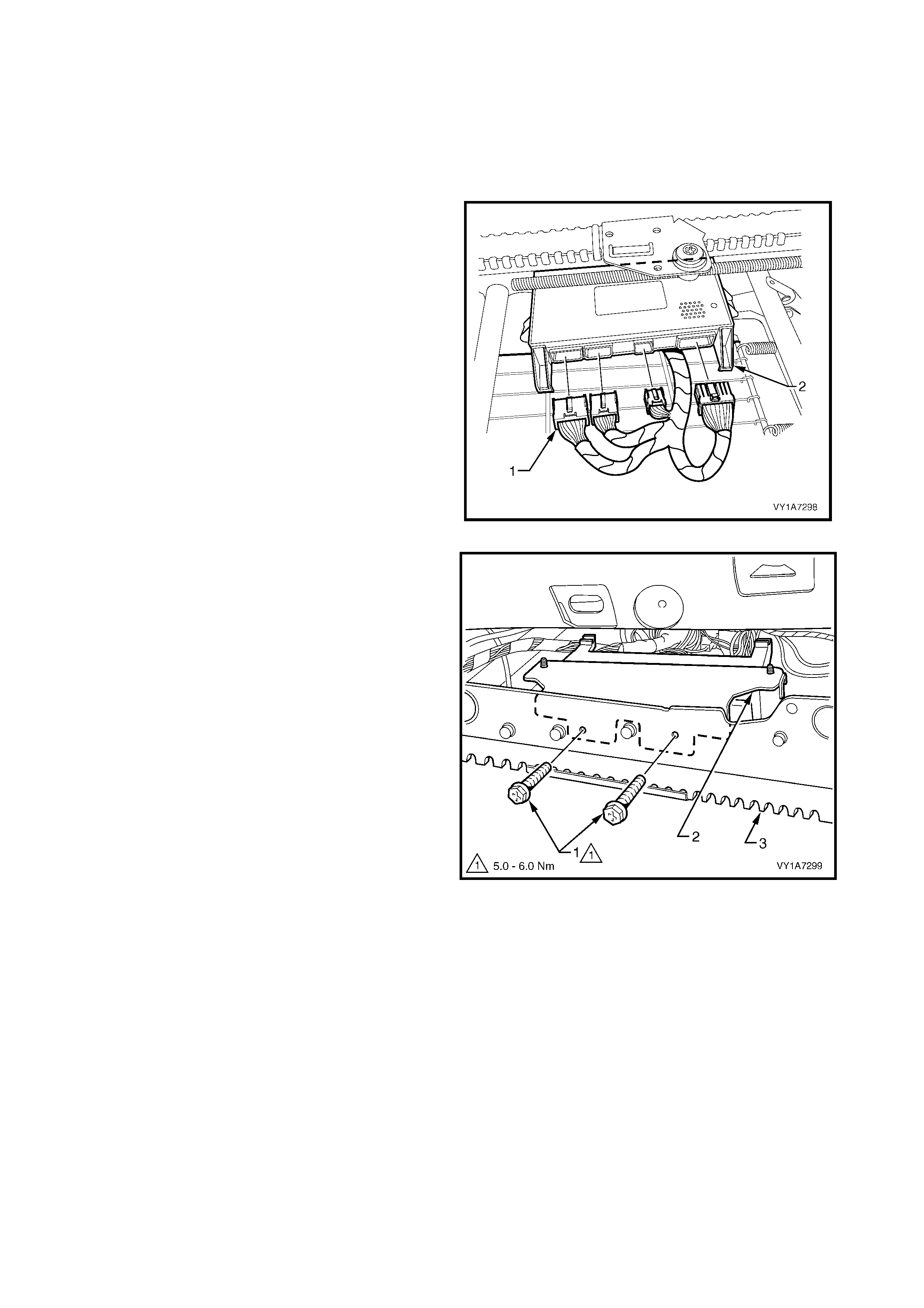

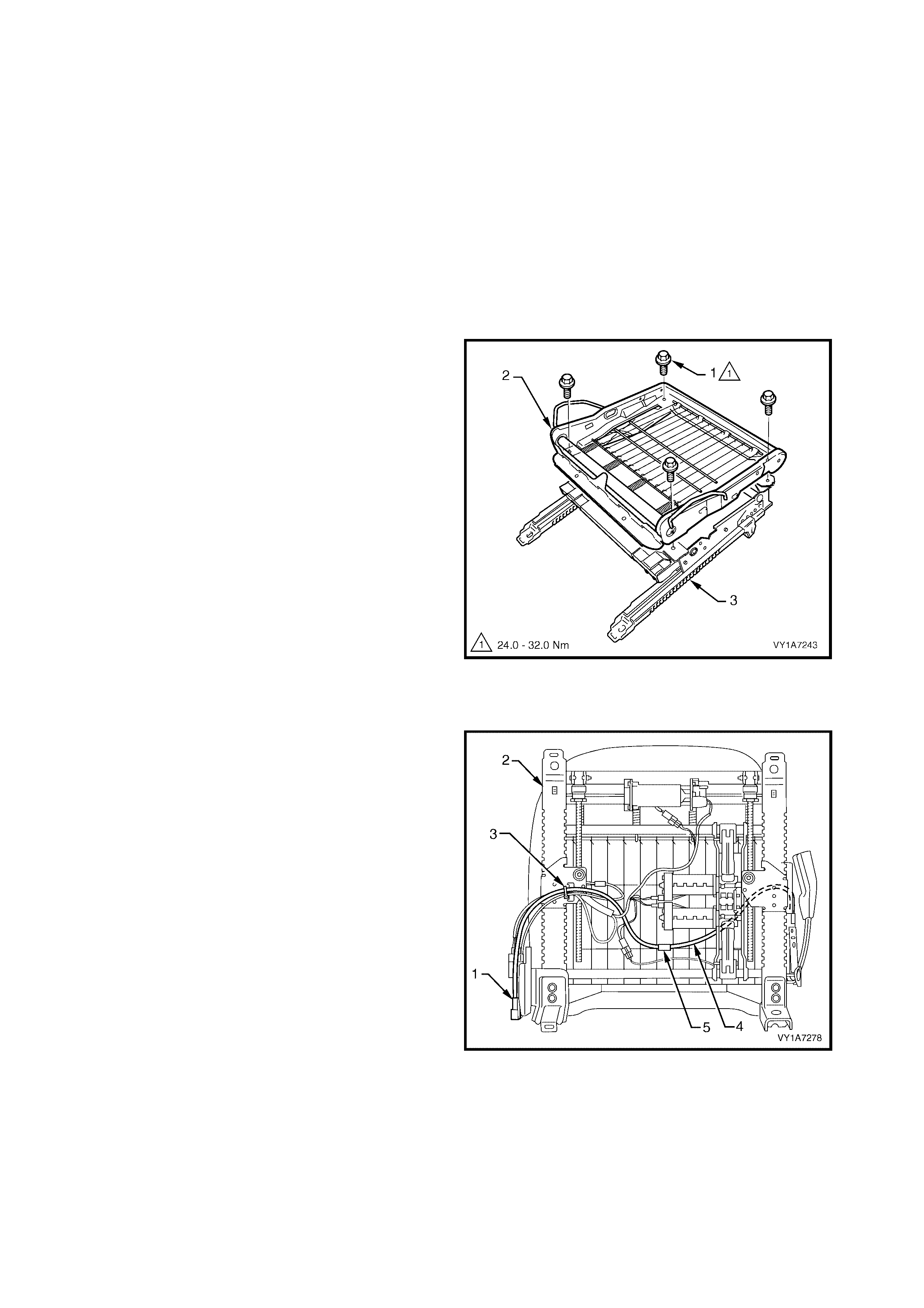

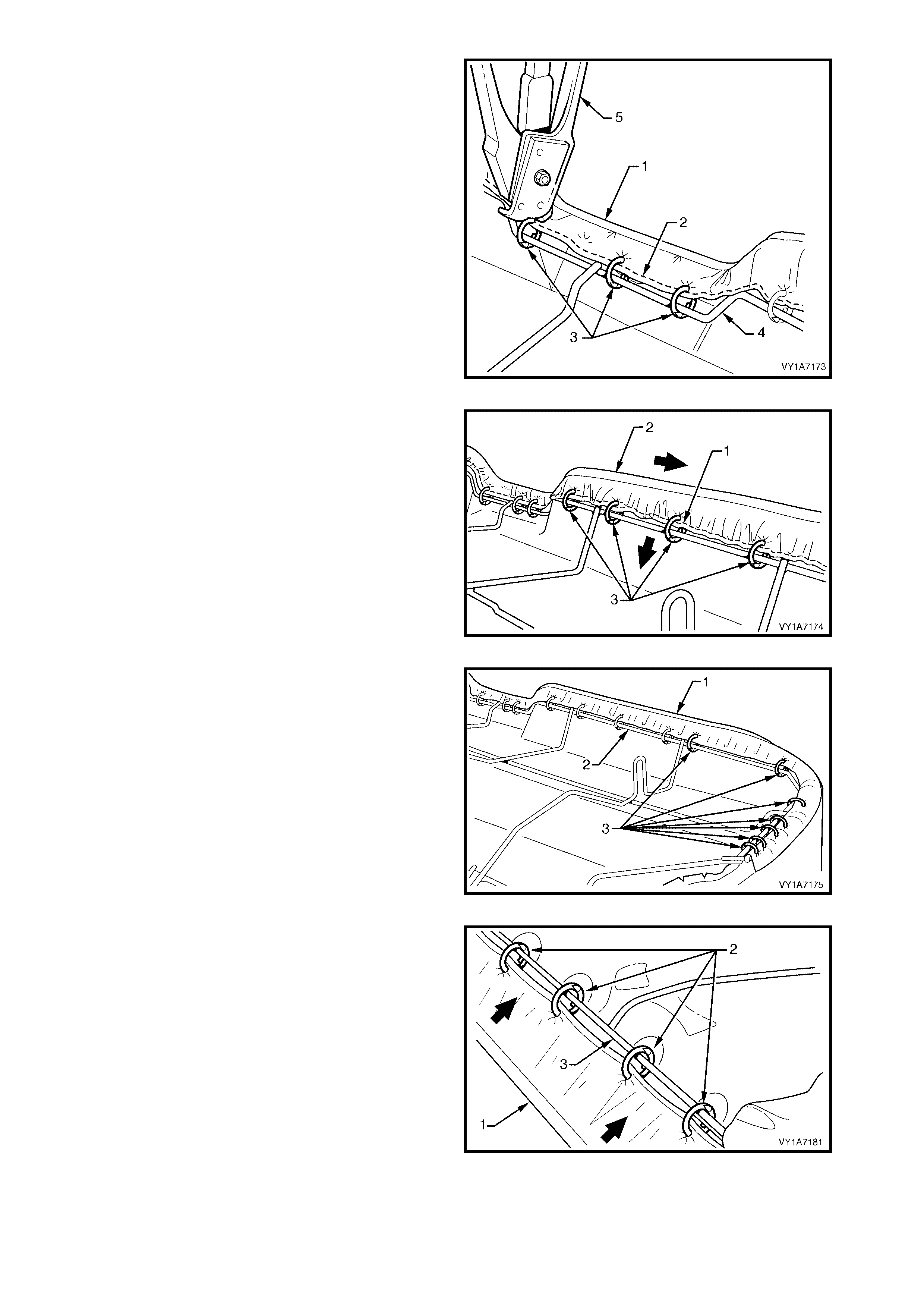

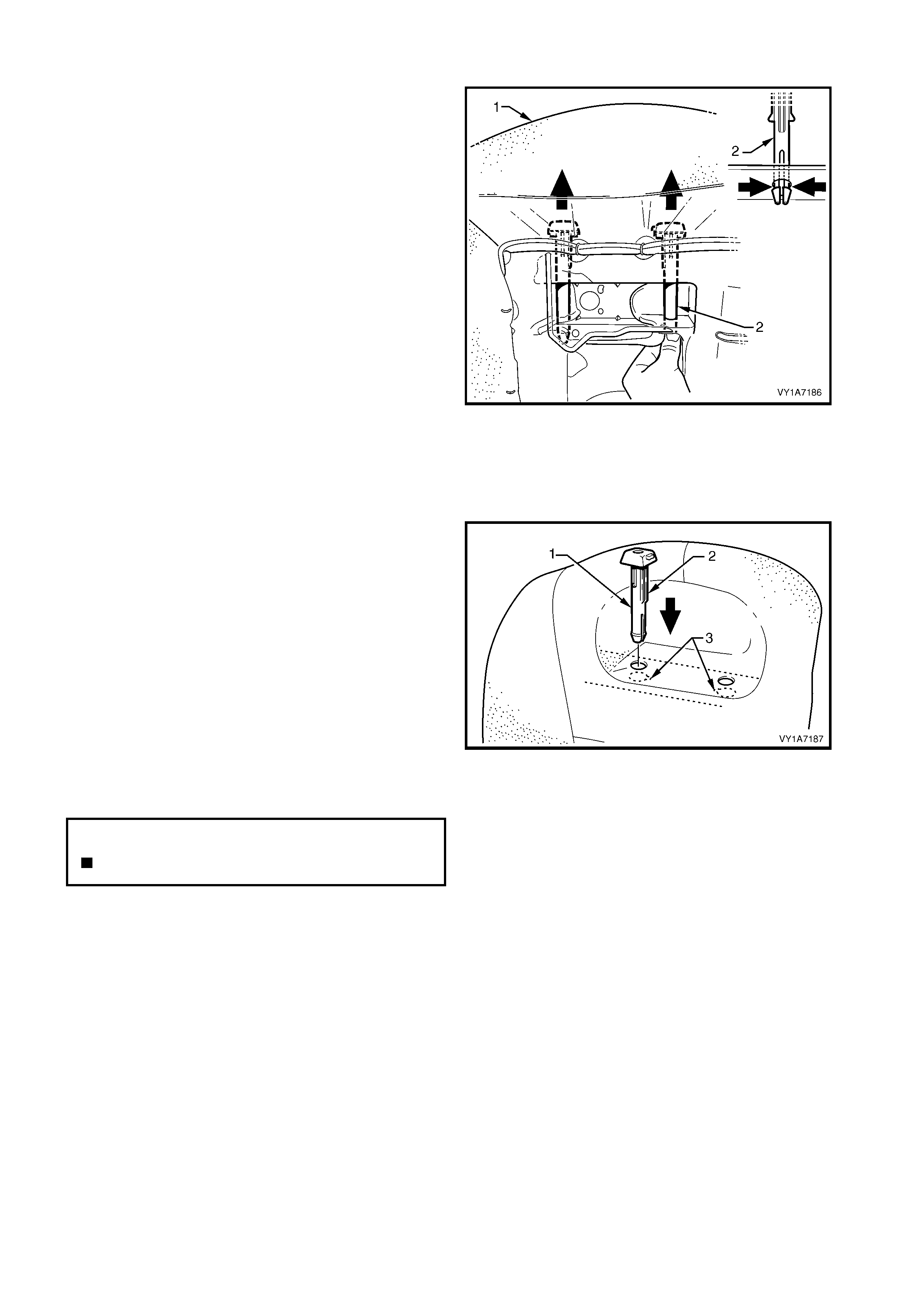

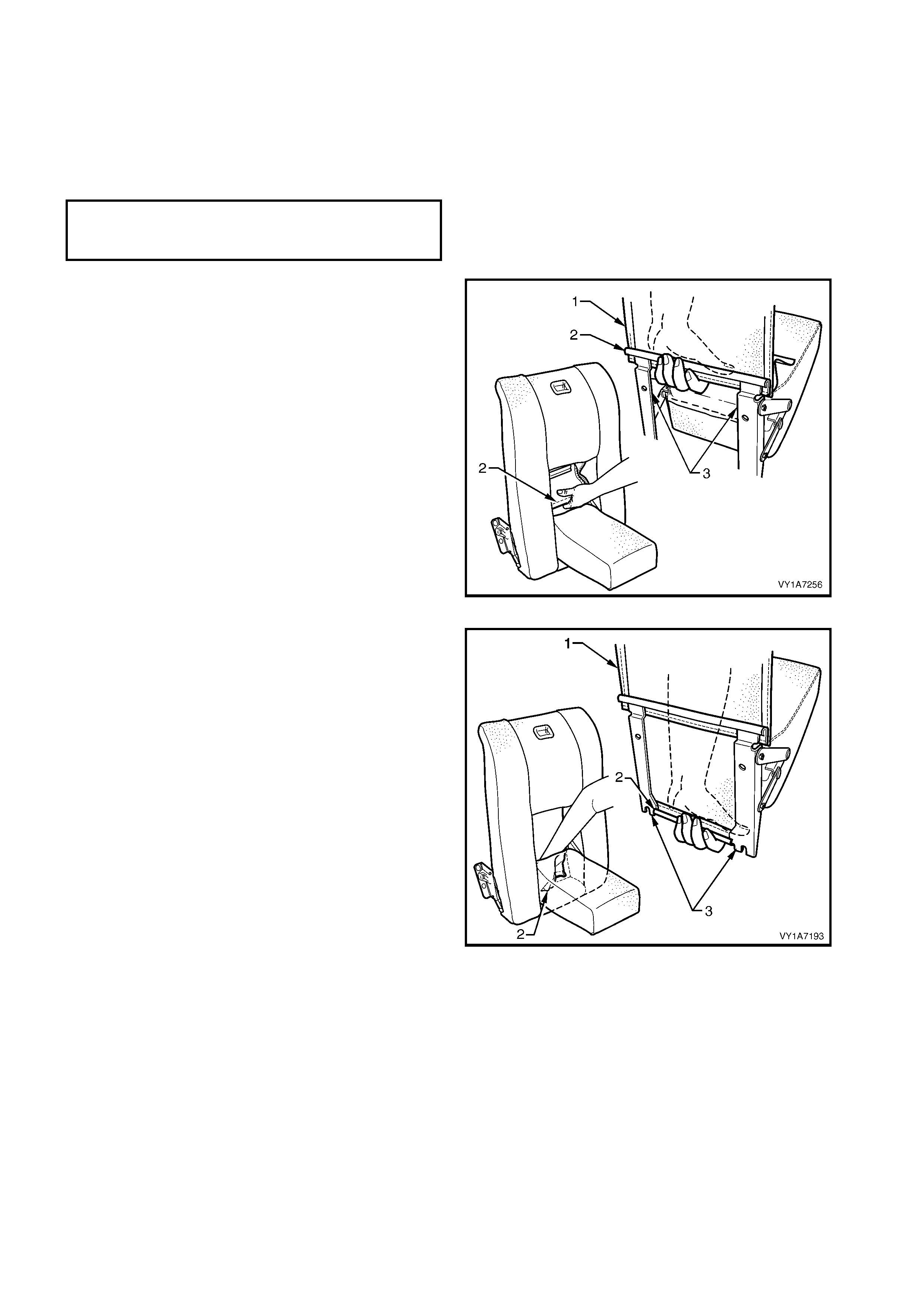

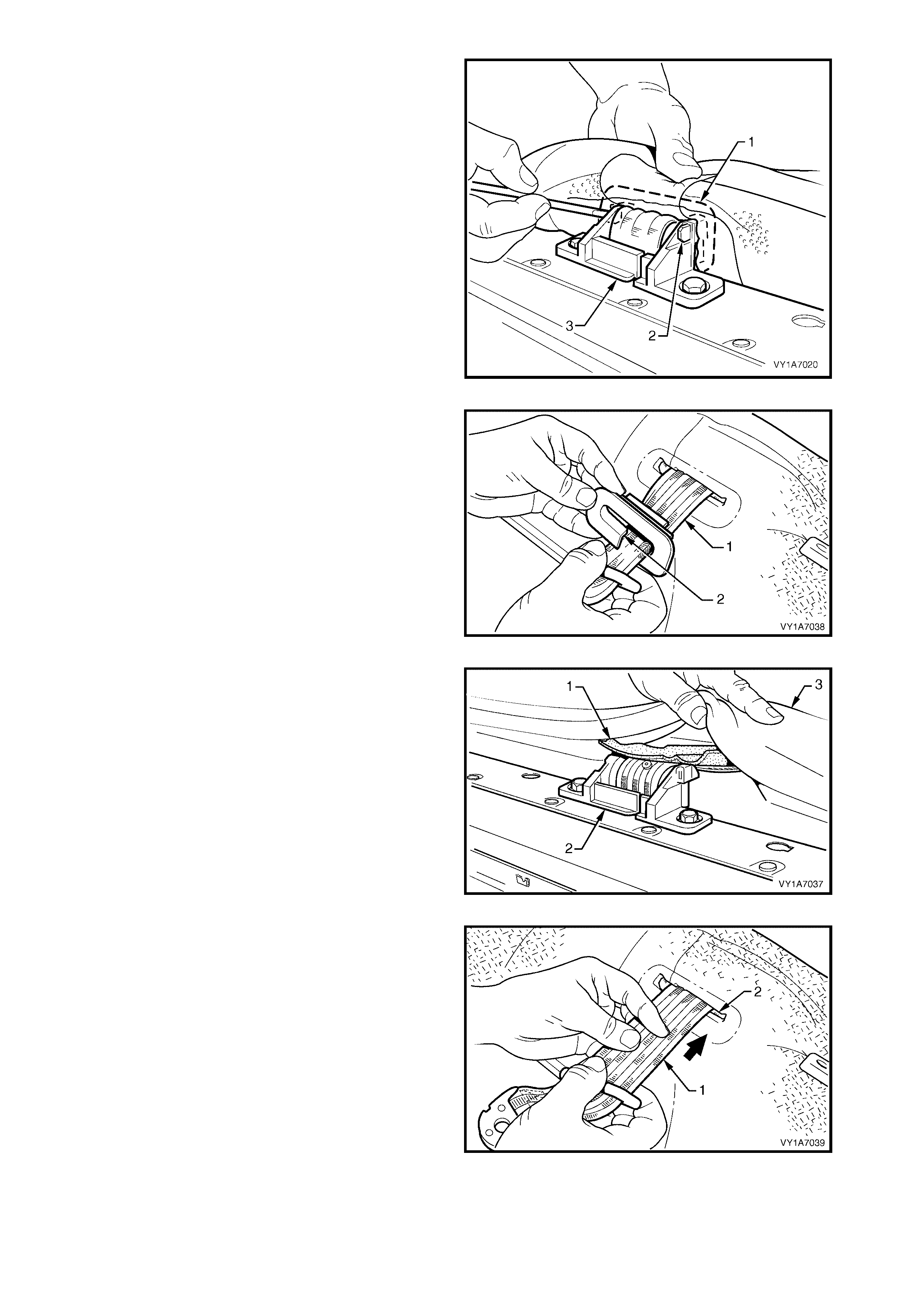

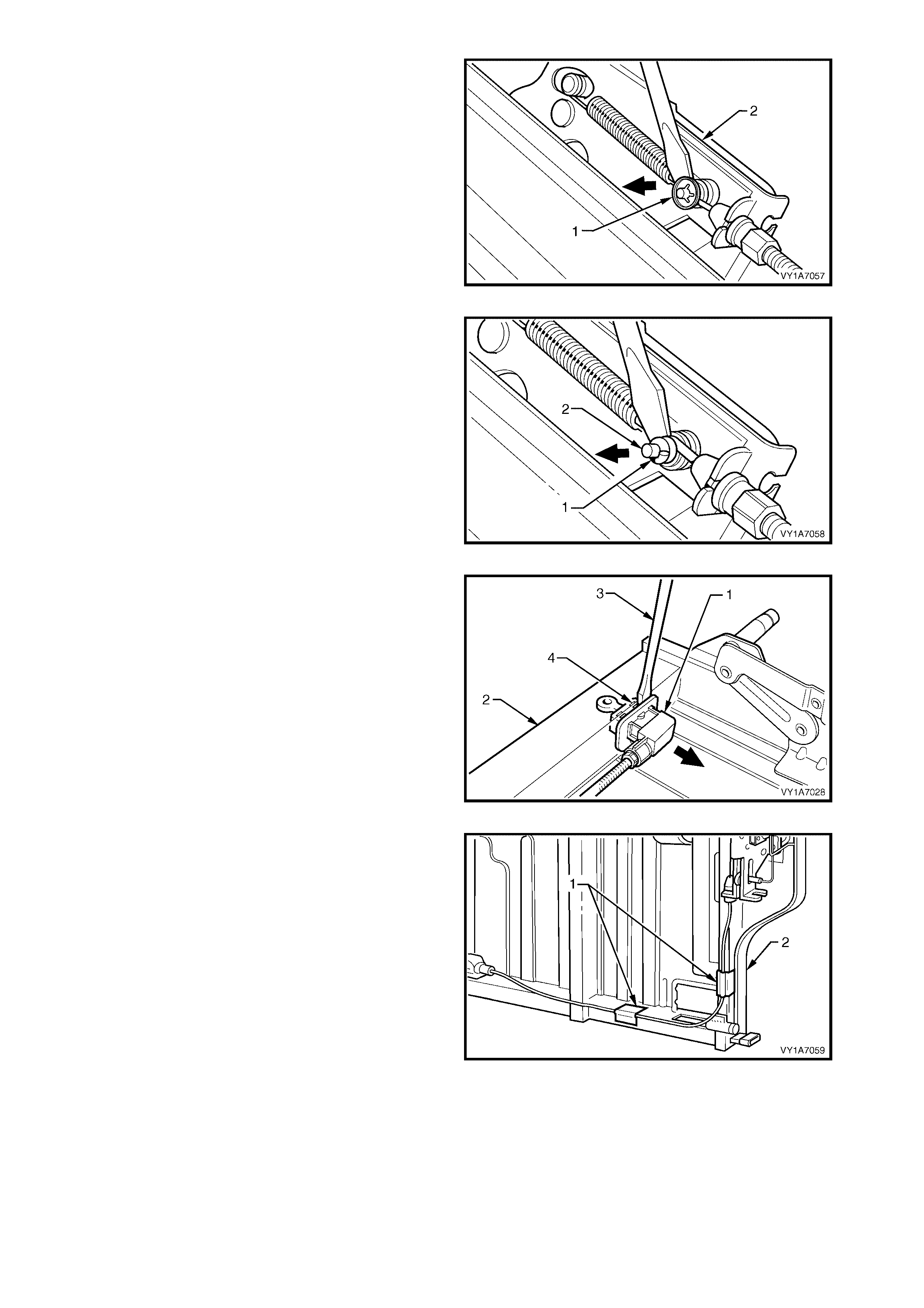

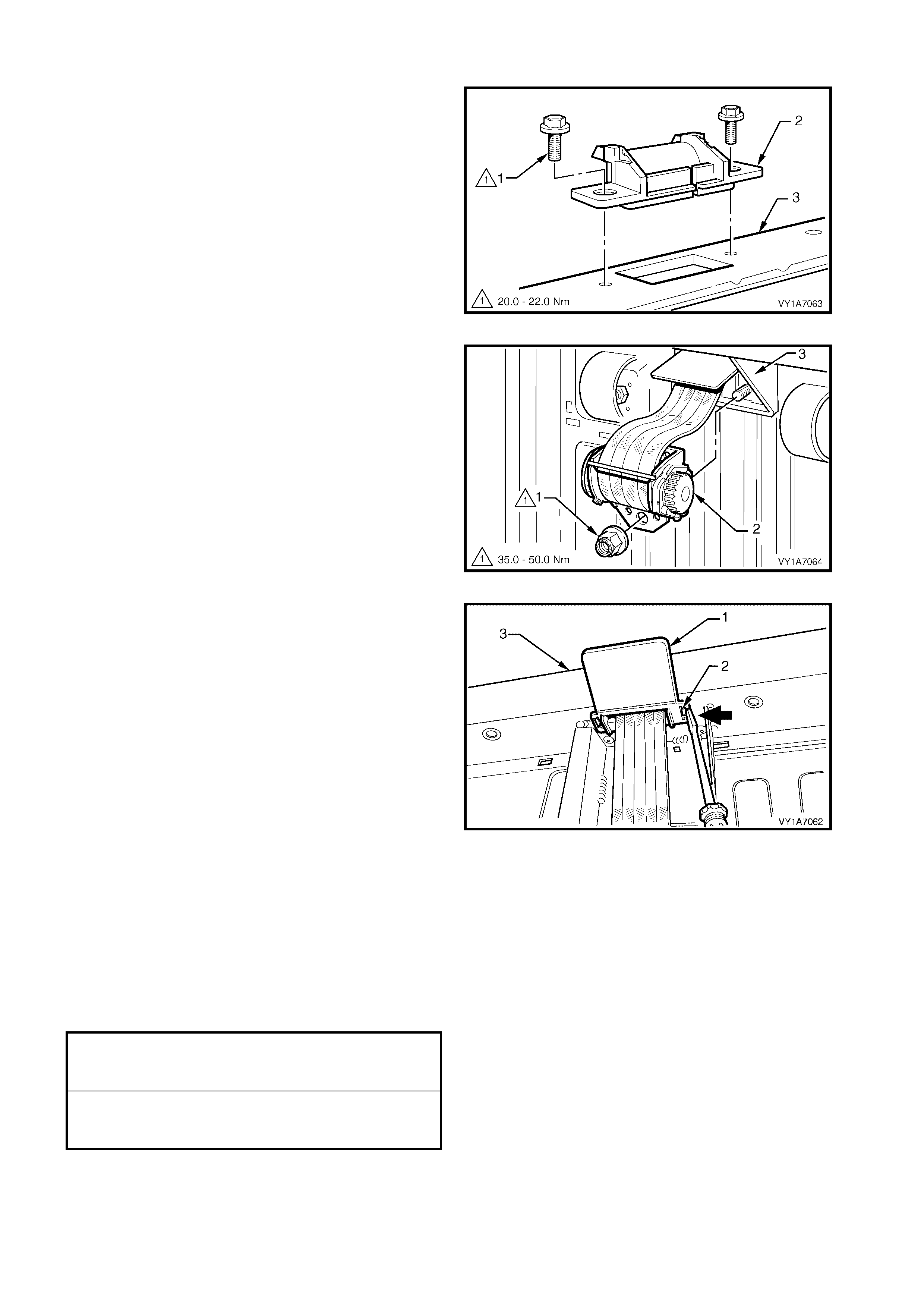

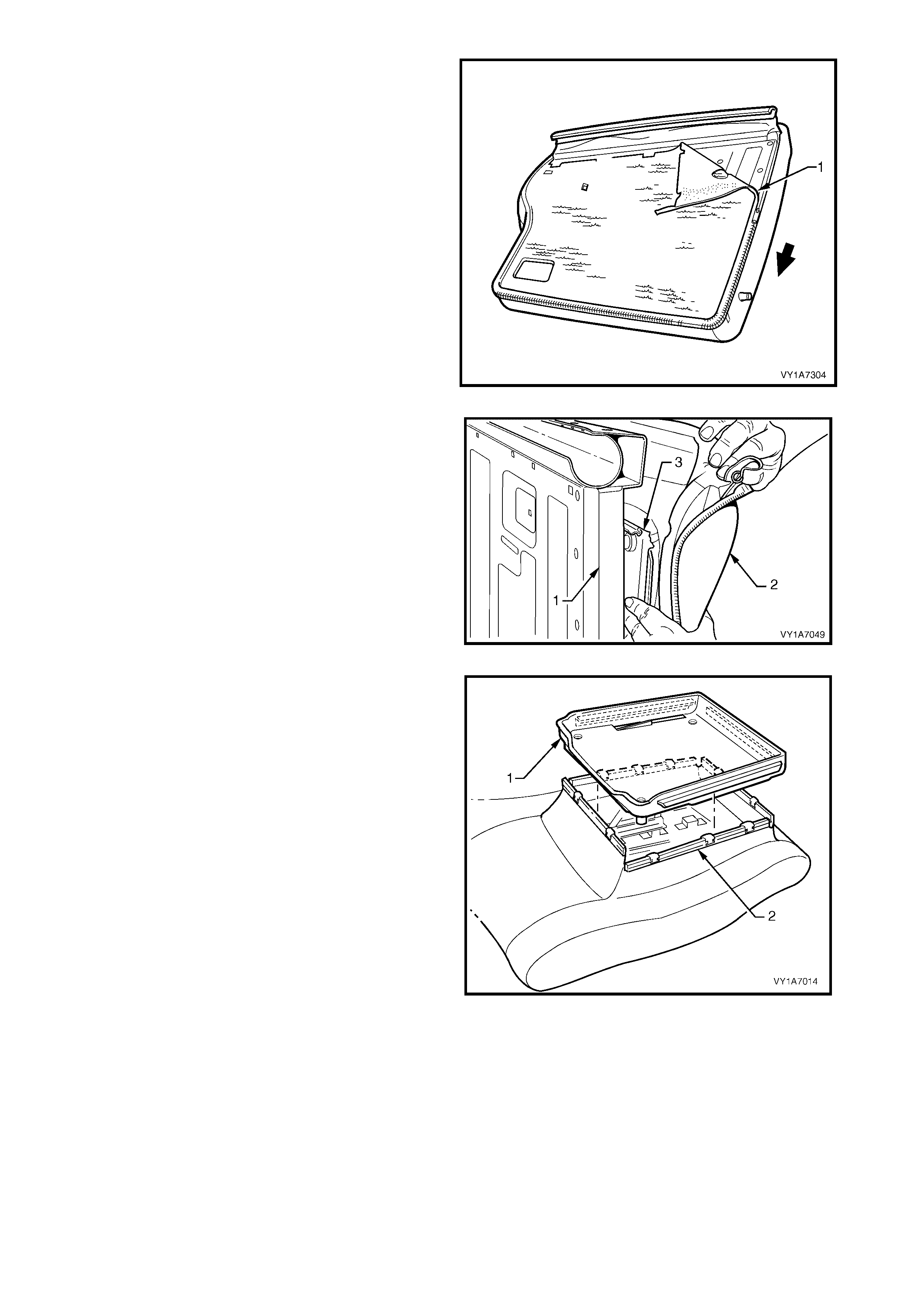

3. Remove the two screws (1), each side, attaching

the seat-back assembly (2) to the seat height

adjuster and cushion frame assembly (3).

4. Remove the seat-back assembly.

Figure 1A7-56

DISASSEMBLE

Remove - Lumbar Support and Adjuster Assembly – Where Fitted

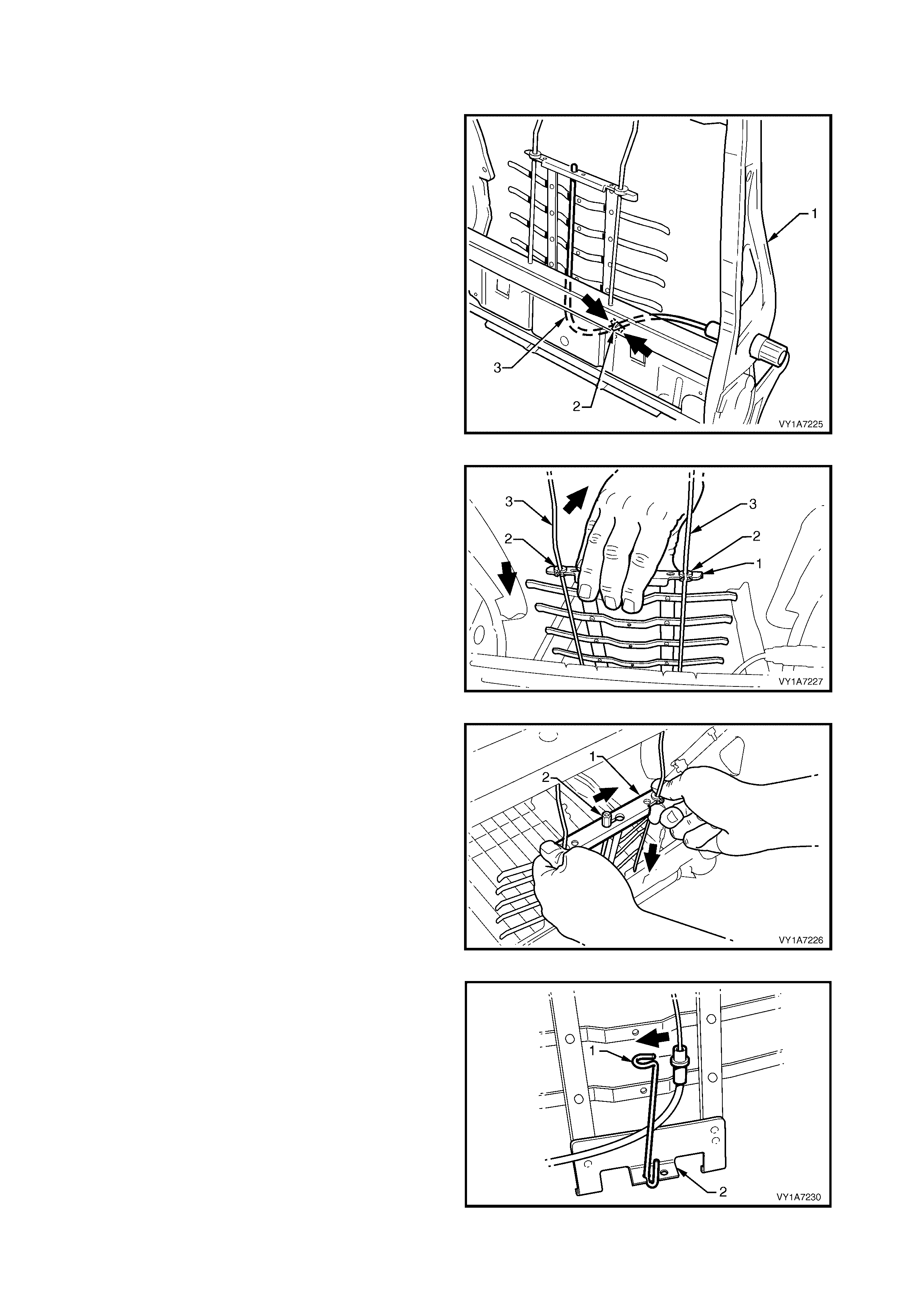

1. From the rear of the front seat-back frame (1),

disengage the clip (2) securing the lumbar support

adjuster cable (3). Squeeze the tangs on the tie clip

together and push the clip through the seat-back

frame.

Figure 1A7-57

2. Push down the top of the lum bar s upport assem bly

(1) to disengage the two retainers (2) from the

guide rails (3) on the seat-back f rame, allowing the

lumbar support to swing freely.

Figure 1A7-58

3. Slightly com press the lum bar support assembly (1)

by hand to release the cable (2) tension,

disengaging the cable from the top of the lumbar

support.

Figure 1A7-59

4. Unclip the lower cable retainer (1) from the lower

lumbar bracket (2).

Figure 1A7-60

5. Lower the lumbar support assembly (1) until it

becomes disengaged from the seat back frame

assembly (2).

6. Remove the lumbar support assembly.

Figure 1A7-61

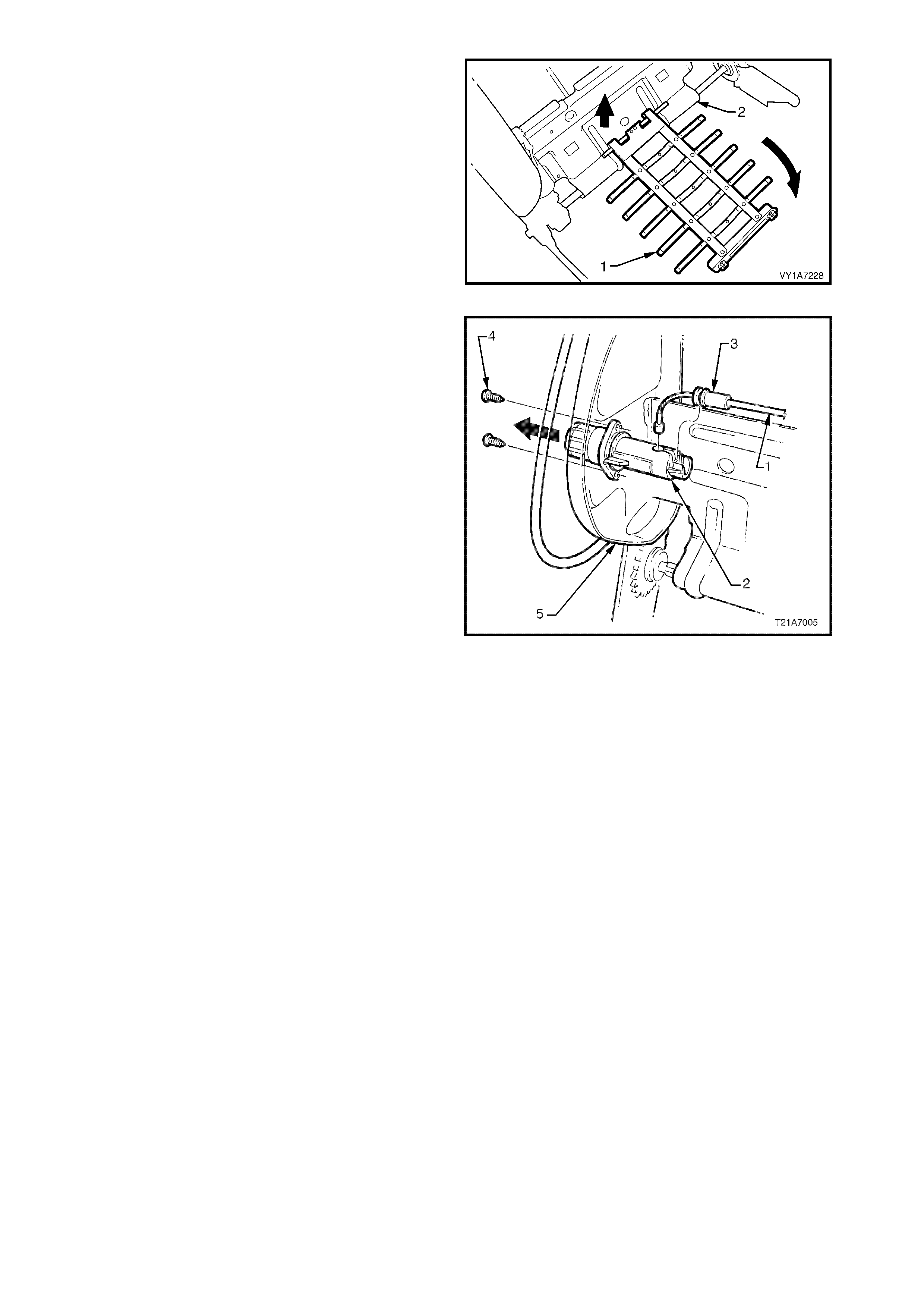

7. Remove the adjusting cable (1) from the adjuster

(2) by unclipping the outer casing (3) of the cable

from the adjuster and removing the cable

assembly.

NOTE: The right-hand seat back is shown. The left-

hand seat back is opposite, with the cable fitting the

adjuster from the under-side.

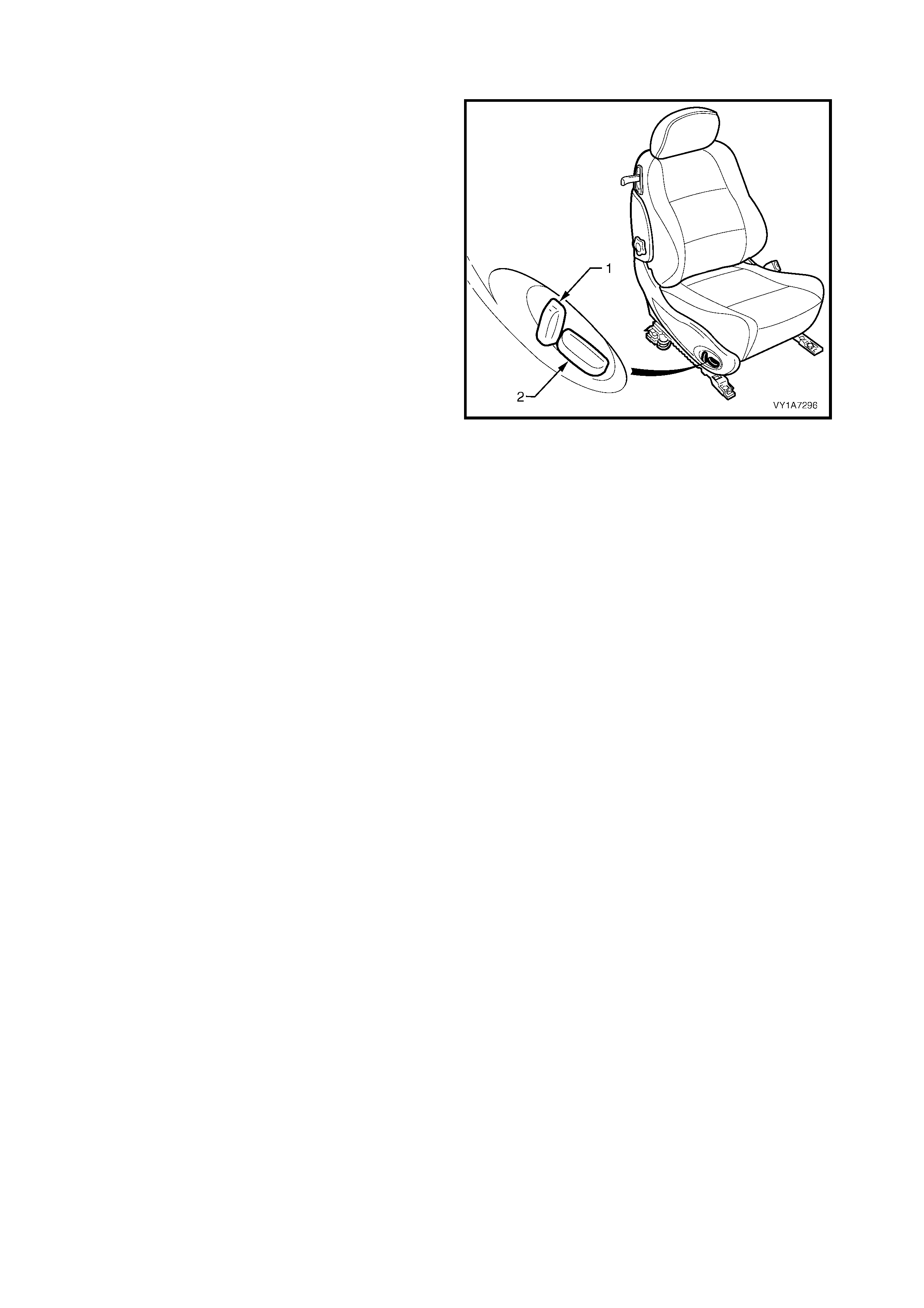

8. Remove the two screws (4) securing the lumbar

support adjuster to the seat-back frame (5) and

remove the adjuster.

Figure 1A7-62

Reinstall - Lumbar Support and Adjuster Assembly

Reinstallation of the lumbar support and adjuster

assembly is the reverse of the removal procedure,

noting the following:

1. Align the hole in the adj us ter f or the adj us ting c able

ball by turning the adjuster , insert the c able into the

adjuster and pus h the outer cas ing of the c able into

the locking seat of the adjuster until it clicks.

NOTE: On the right-hand seat, the cable fits into the

adjuster from the top. On the left-hand seat, the cable

fits into the adjuster from the under-side.

2. Ensure all screws are tightened securely.

Remove – Side Impact Airbag Assembly – Where fitted

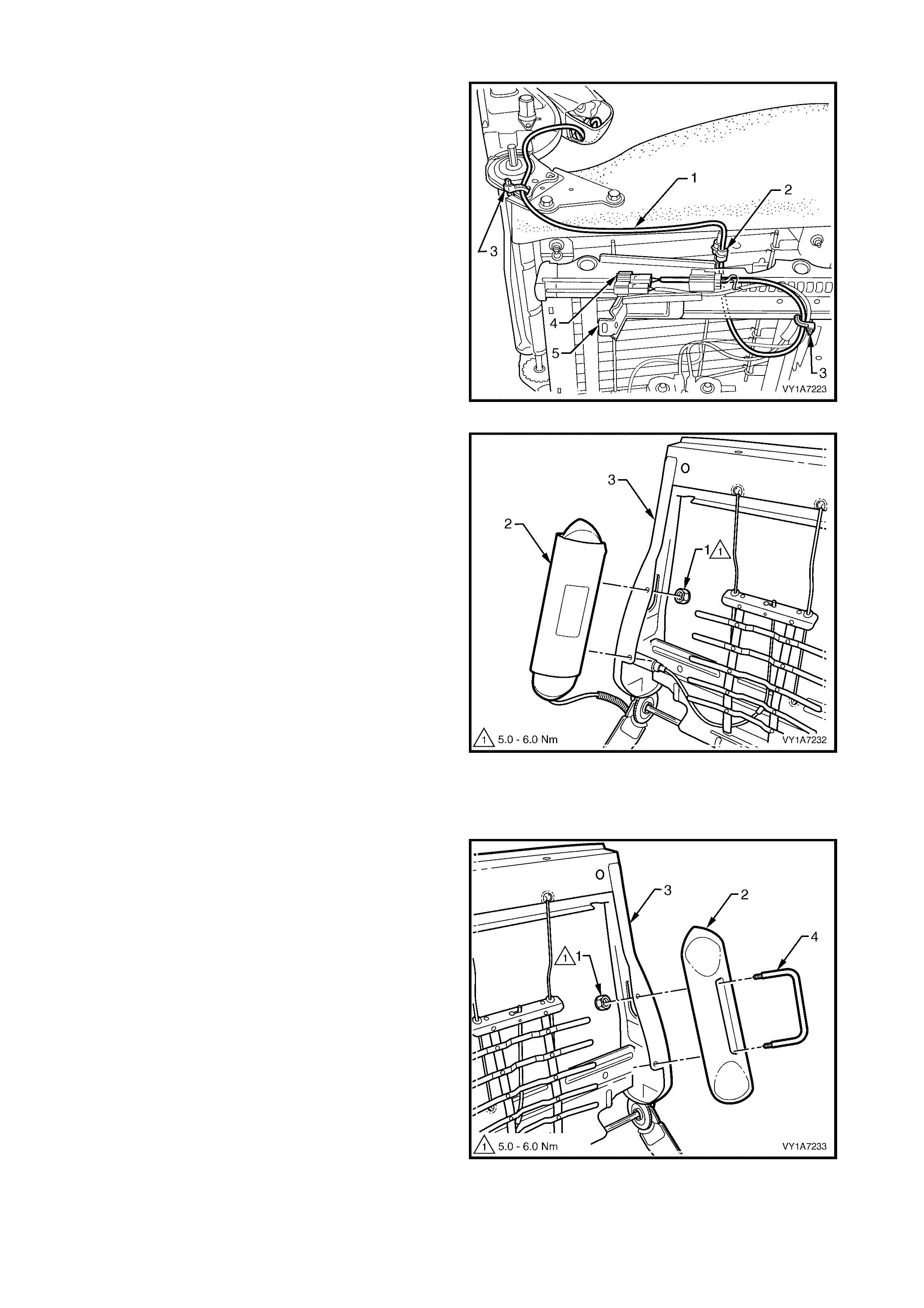

1. Unclip the pigtail wiring harness (1) from the

retaining clip (2) and cut the two cable ties (3),

securing the harness to the front seat cushion

frame assembly, taking care not to damage the

wiring harness.

2. Unclip the wiring harness connector (4) from the

adjuster and guide rail assembly (5).

Figure 1A7-63

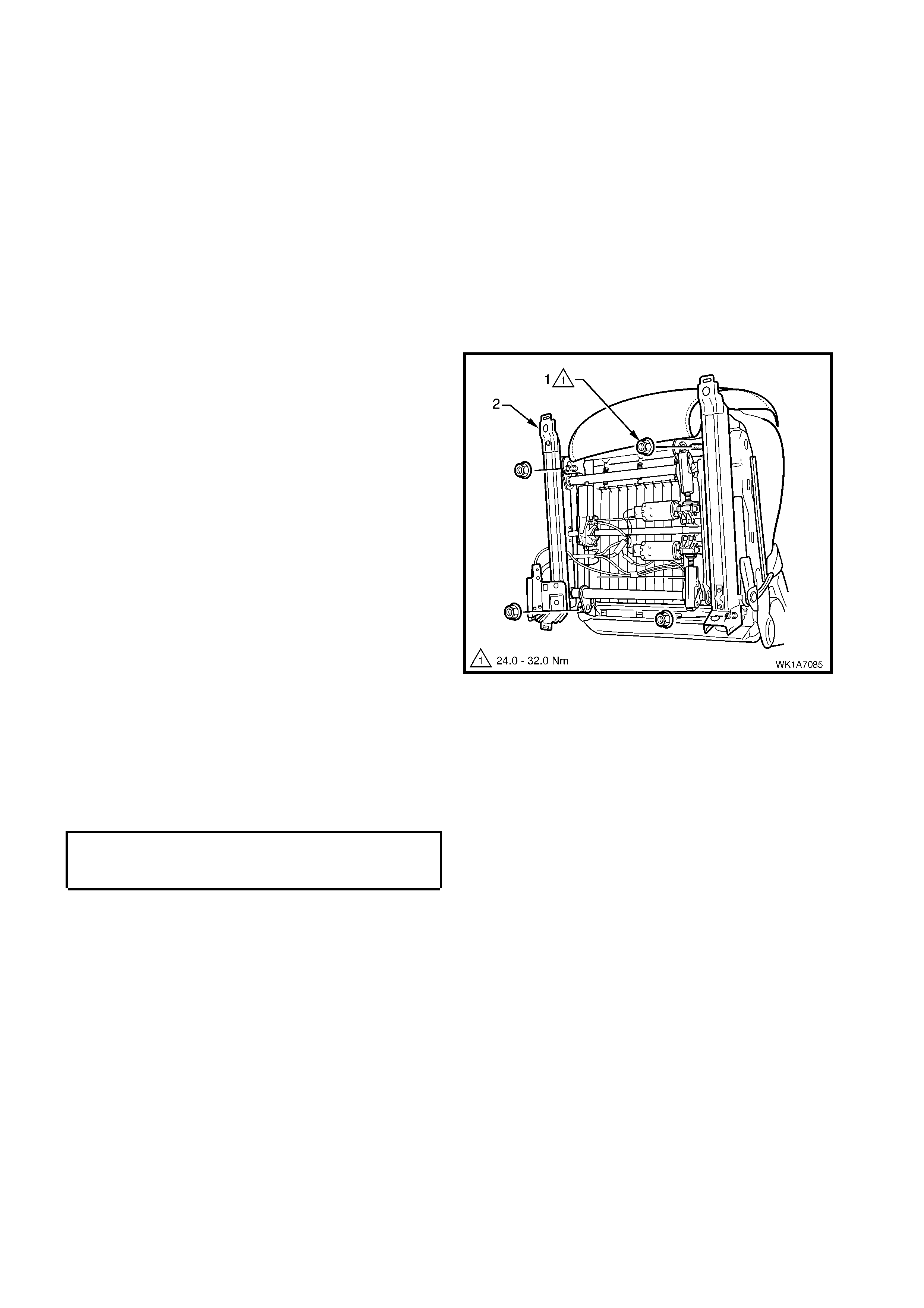

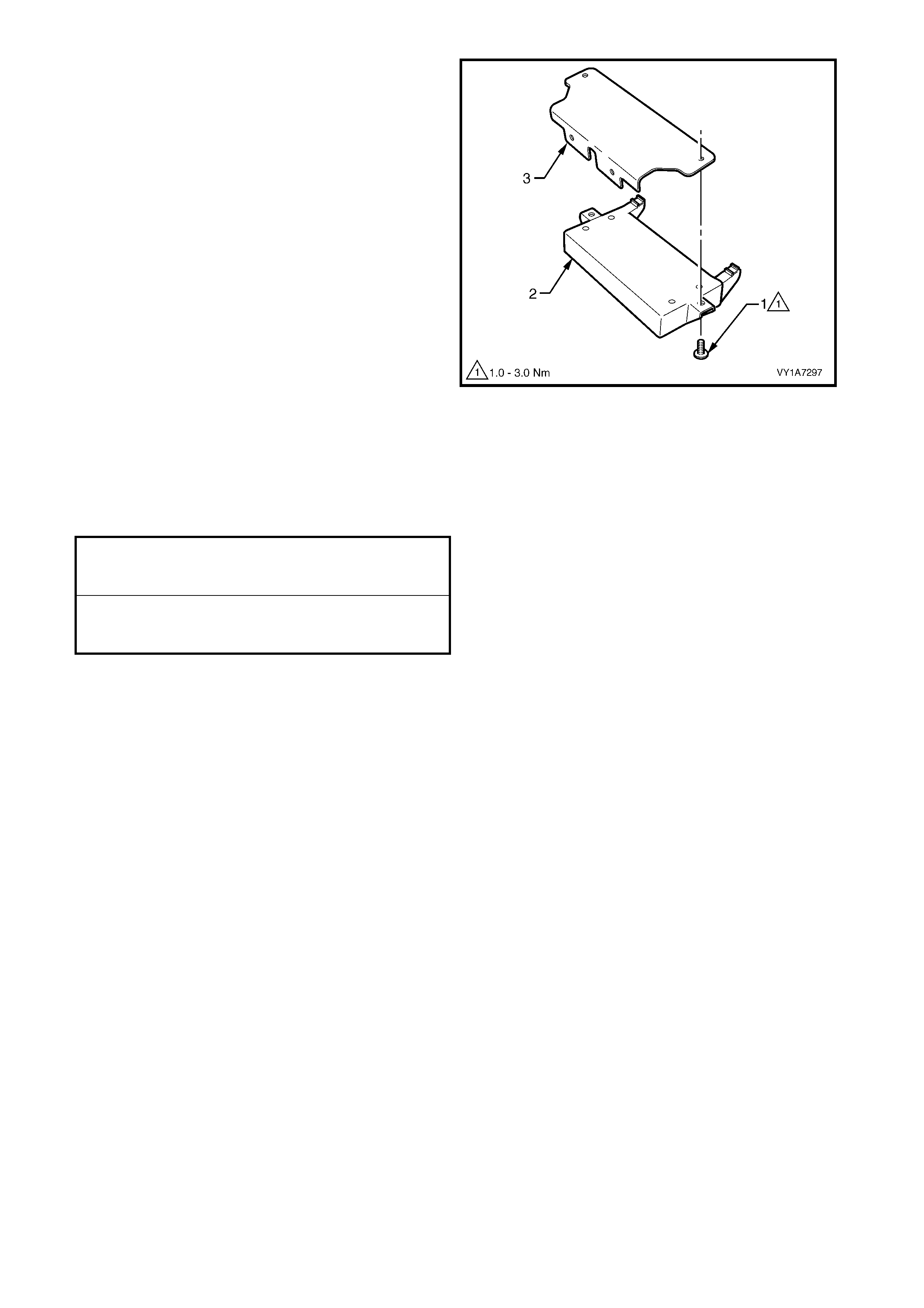

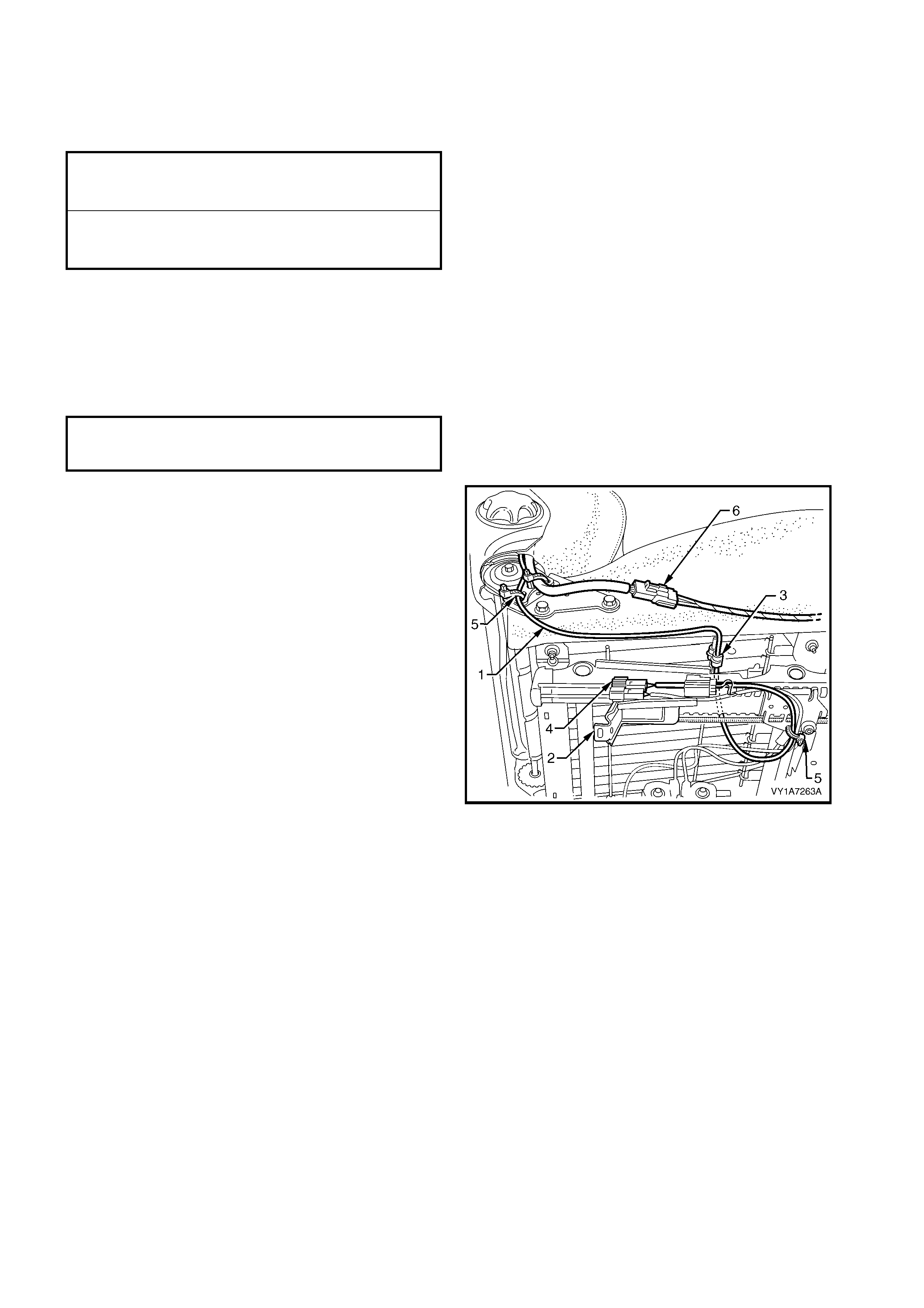

3. Remove the two lock nuts (1), securing the side

impact airbag assembly (2) to the front seat-back

frame (3).

4. Remove side airbag assembly and pigtail wiring

harness assembly from front seat-back frame.

CAUTION: When carrying a live (undeployed) side

airbag assembly, make sure the bag opening is

point ed aw ay from you. Never carry the sid e airbag

assembly by the wiring harness or connectors. In

case of an accidental deployment, the bag will th en

deploy with minimal chance of injury.

When placing a live side airbag assembly on a

bench or other surface, always face the airbag

opening up, away from the surface. Never rest the

airbag inflator module assembly with the opening

face dow n . This is necessary so that a free space is

provided to allow the airbag to expand in the

unlikely event of accidental deployment. Otherwise,

personal injury may result.

Figure 1A7-64

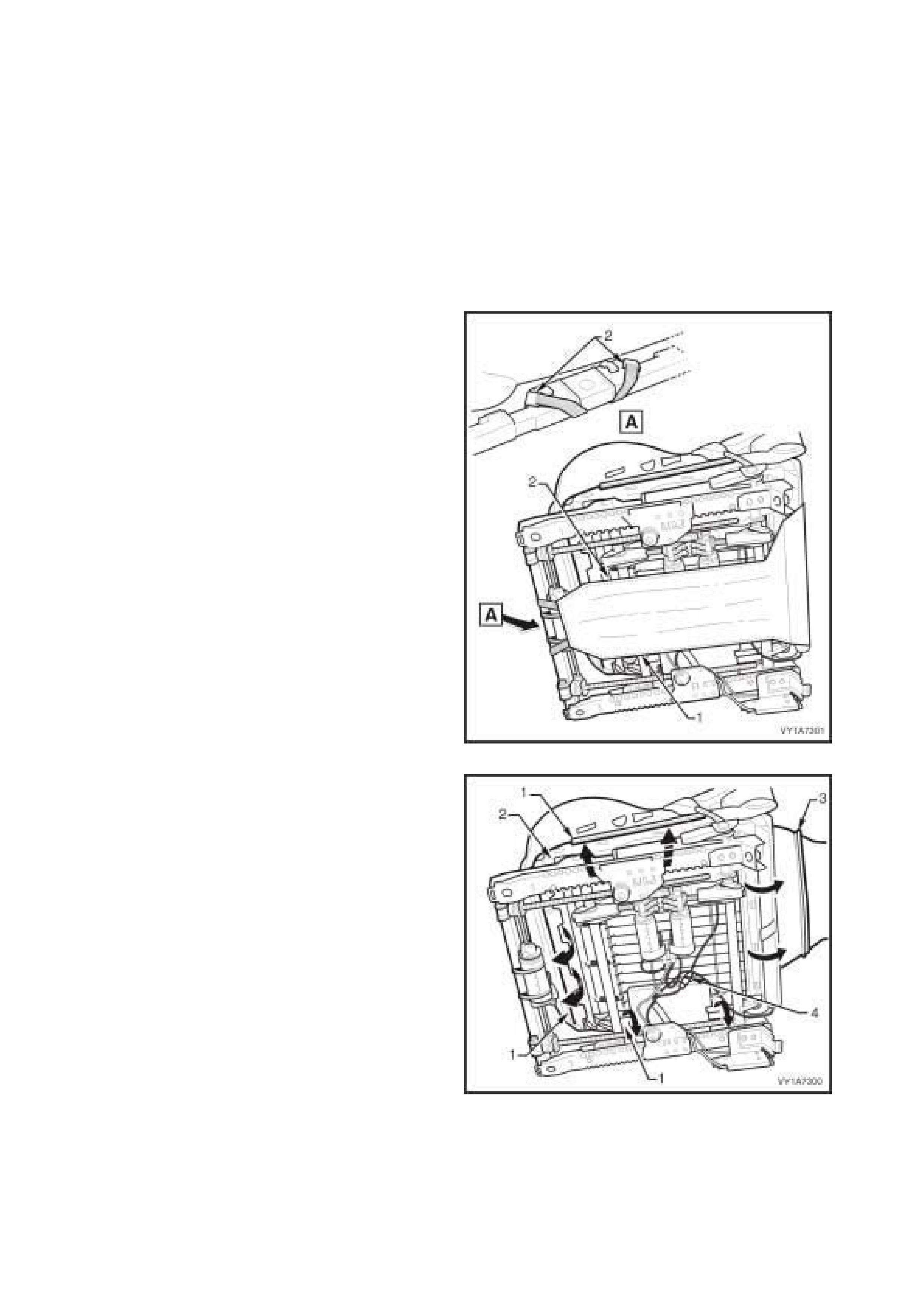

5. If required, remove the two lock nuts (1) retaining

the front s eat foam block ins ert assem bly ( 2) to the

seat-back frame (3) and remove the foam block

inse rt assembly.

6. If required, remove the foam block insert retaining

bracket (4) from the foam block insert assembly.

Figure 1A7-65

Reinstall – Side Impact Airbag Assembly

Reinstallation of the side impact airbag assembly and the foam block insert assembly, is the reverse of the removal

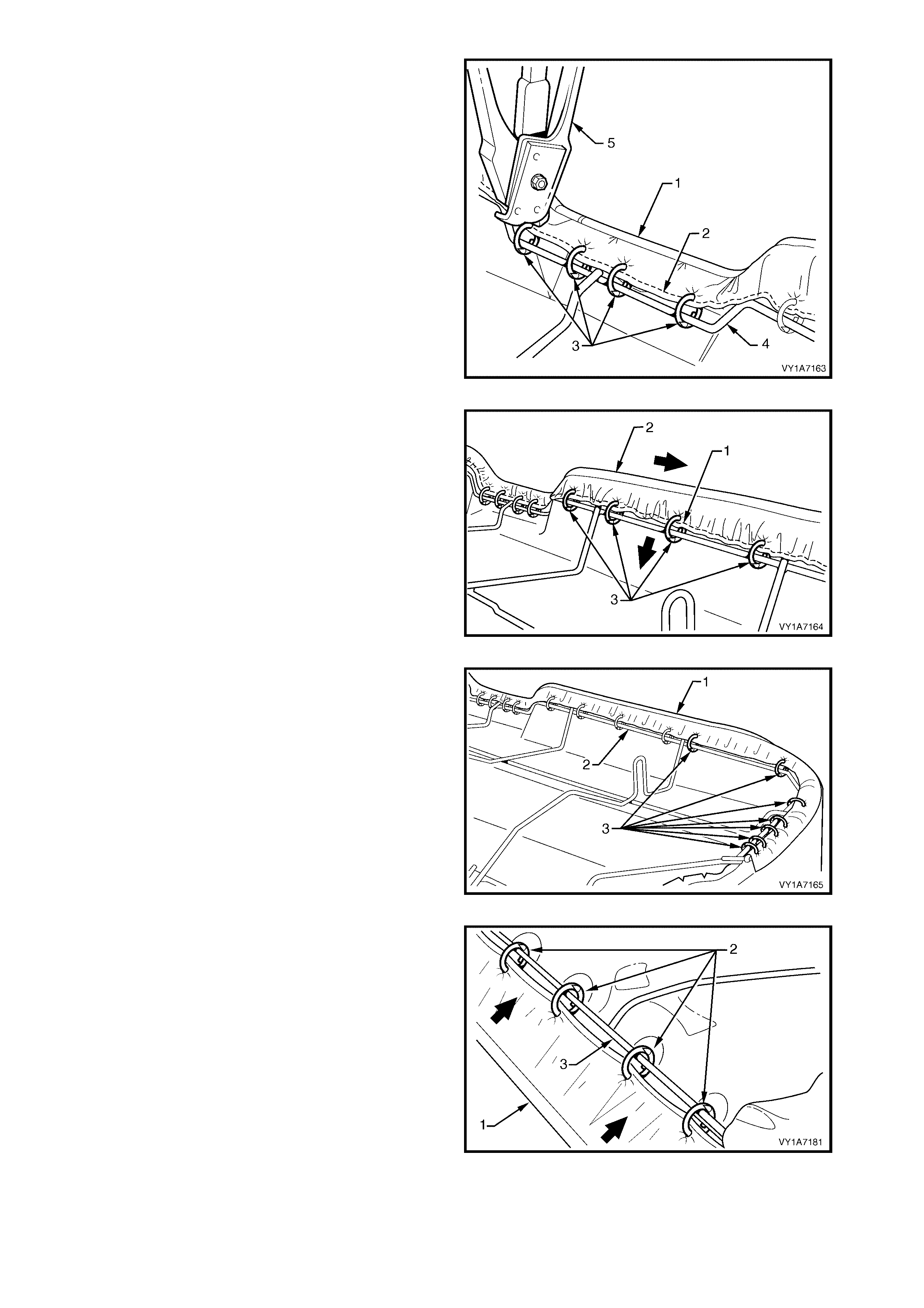

procedure, noting the following:

1. Ensure all fasteners are tightened to the correct torque specification.

REINSTALL

Reinstallation of the front seat-back frame assembly is the reverse of the removal procedure, noting the following:

1. Ensure all fasteners are tightened to the correct torque specification.

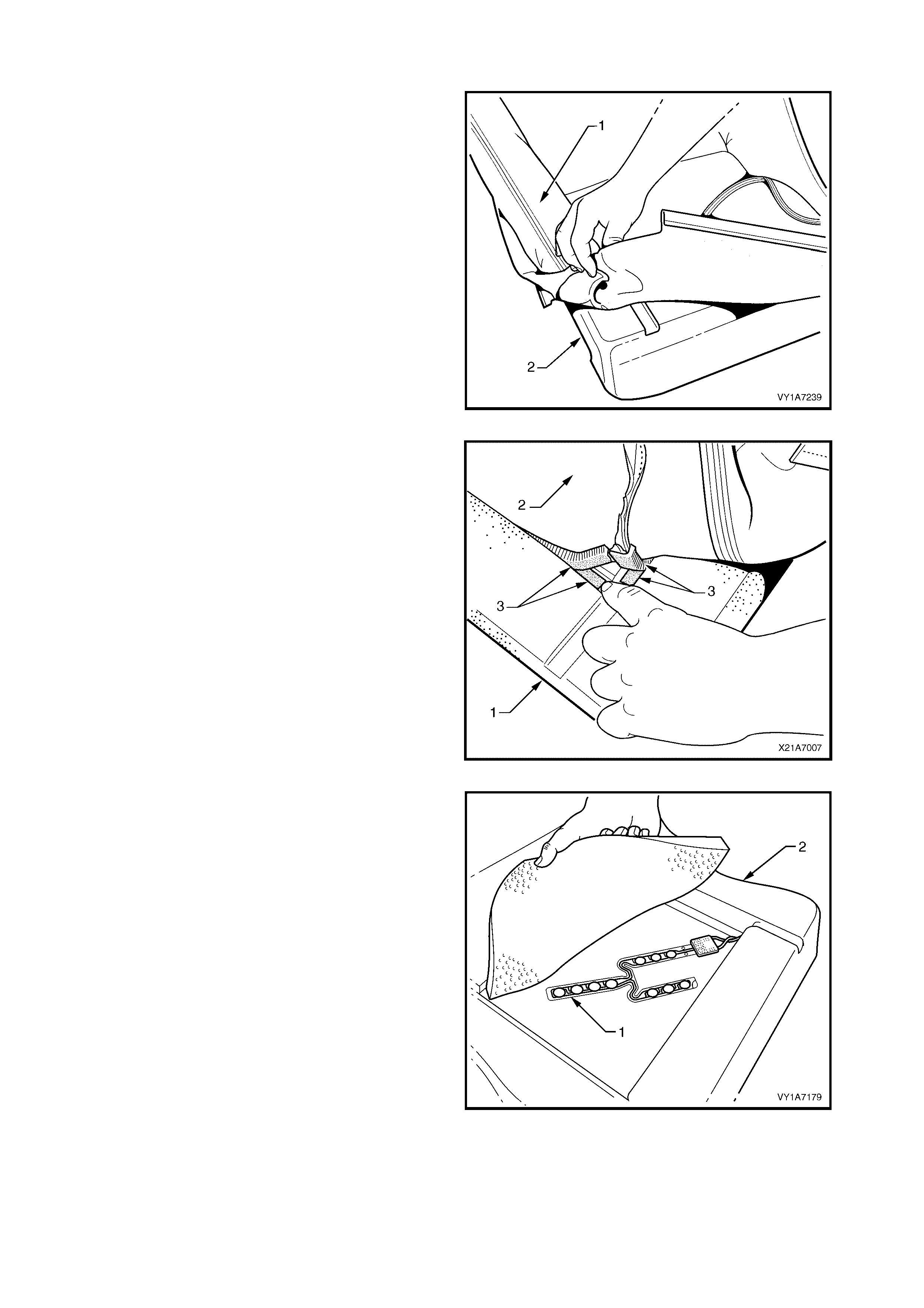

2. If the side impact airbag is fitted, route the wiring

harness (1) through to the side of the adjuster and

guide rail assembly (2) and secure in the retaining

clip (3). Fit the connector (4) to the adjuster and

guide rail assem bly, and attach with two new cable

ties (5).

NOTE 1: If the wiring harness is not routed correctly,

damage to the har ness m ay occur, resulting in the side

impact airbag becoming inoperative and setting a

Diagnostic Trouble Code (DTC) (SRS warning lamp

on).

NOTE 2: The wiring harness that connects to the side

impact airbag module assembly, is not serviced

separately from the side airbag inflator module due to

the design of the anti-back-out connector on the

module assembly.

NOTE 3: If this wiring harness, as with any other SRS

pigtail type wiring harness becom es damaged, no wire,

connector or terminal repairs are to be attempted.

REPLACE THE SIDE AIRBAG MODULE AND

PIGTAIL WIRING HARNESS ASSEMBLY.

Figure 1A7-66

3. Reconnect the battery earth and the positive leads, if the seat is fitted with a side impact airbag, switch the

ignition ON and observe the SRS warning indicator in the instrument cluster.

• If no fault is detected, the SRS warning indicator should illuminate for approximately five seconds while

the system performs a self-test, and then go off.

• If a fault is present, the SRS warning indicator will remain illuminated and a warning chime may sound

after approximately three seconds. The warning message ‘SRS Airbag Fault’ is also displayed in the

instrument cluster multi-function display. To diagnose the fault, refer to Section 12M, 4. DIAGNOSTICS.

4. Check operation of front seat mechanical and electrical adjustments / operation. While checking the seat

adjustm ent / operation, also check to ensure that the side airbag harness does not foul with any of the seats

moveable components (ie. seat motor drive shafts, etc.).

SIDE IMPACT AIRBAG

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 5.0 – 6.0 Nm

FRONT SEAT FOAM BLOCK

INSERT ATTACHING NUT

TORQUE SPECIFICATION 5.0 – 6.0 Nm

FRONT SEAT-BACK FRAME

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 30.0 – 45.0 Nm

2.12 FRONT SEAT CUSHION PAD AND COVER ASSEMBLY

LT Section No. – 14-295

1. Remove the front seat assembly, refer to 2.2 FRONT SEAT ASSEMBLY.

2. Remove the front seat outer side cover, refer to 2.3 FRONT SEAT OUTER SIDE COVER.

3. Remove the front seat inner side cover, refer to 2.5 FRONT SEAT INNER SIDE COVER.

4. Remove the front seat-back lower cover assembly, refer to 2.6 FRONT SEAT-BACK LOWER COVER

ASSEMBLY AND LUMBER SUPPORT ADJUSTER KNOB.

5. Remove the front seat-back frame assembly, refer to 2.10 FRONT SEAT-BACK FRAME ASSEMBLY.

REMOVE

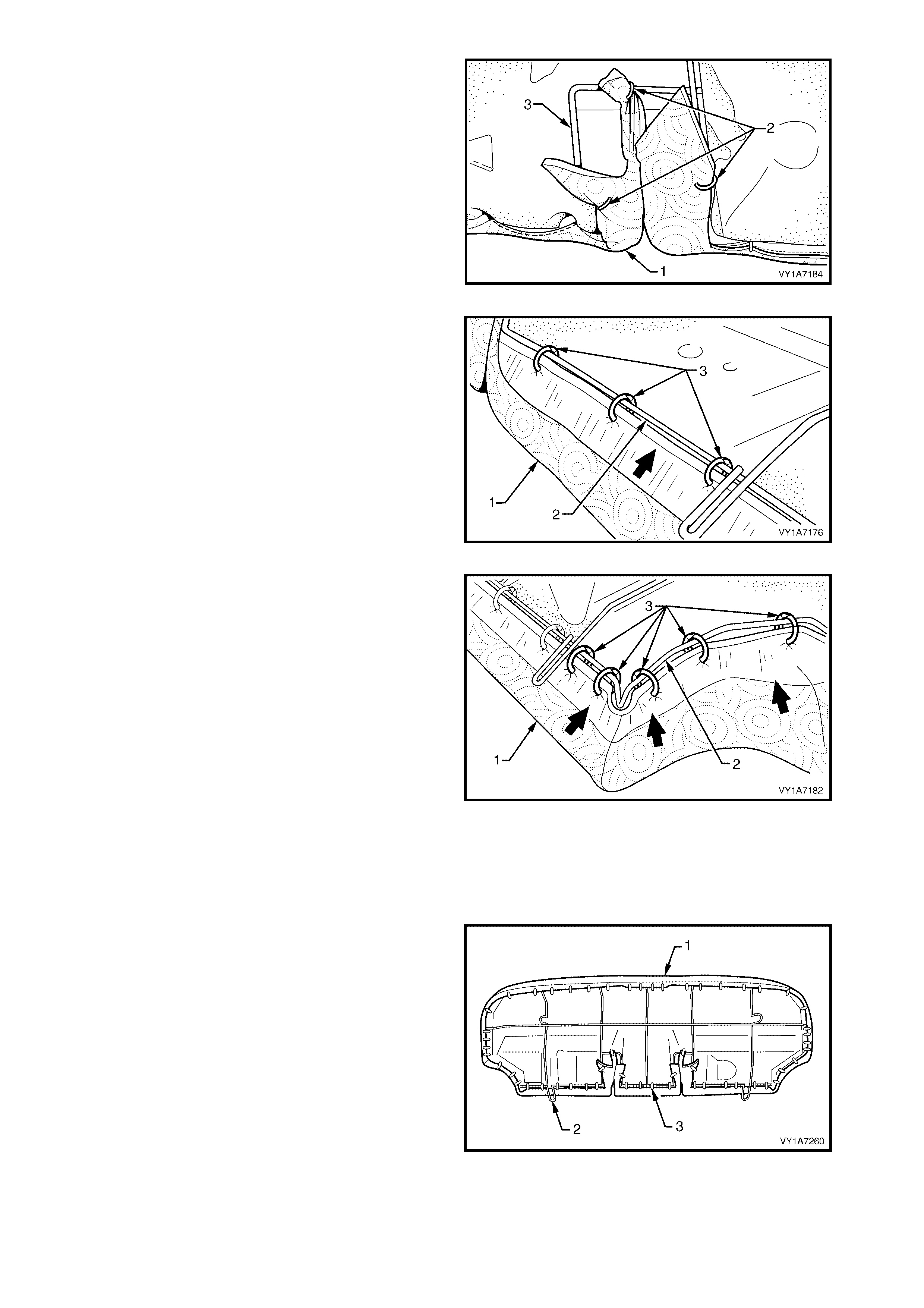

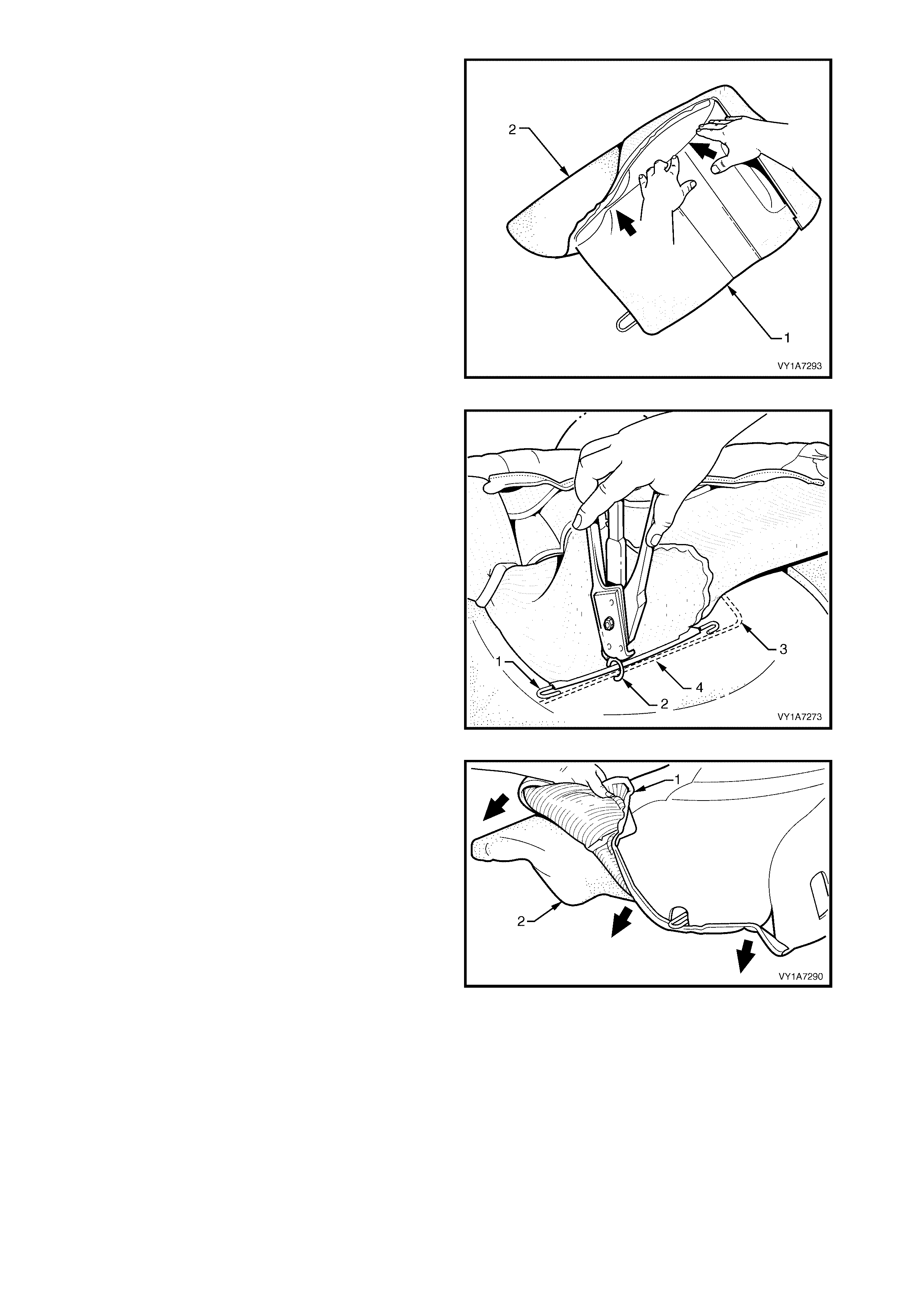

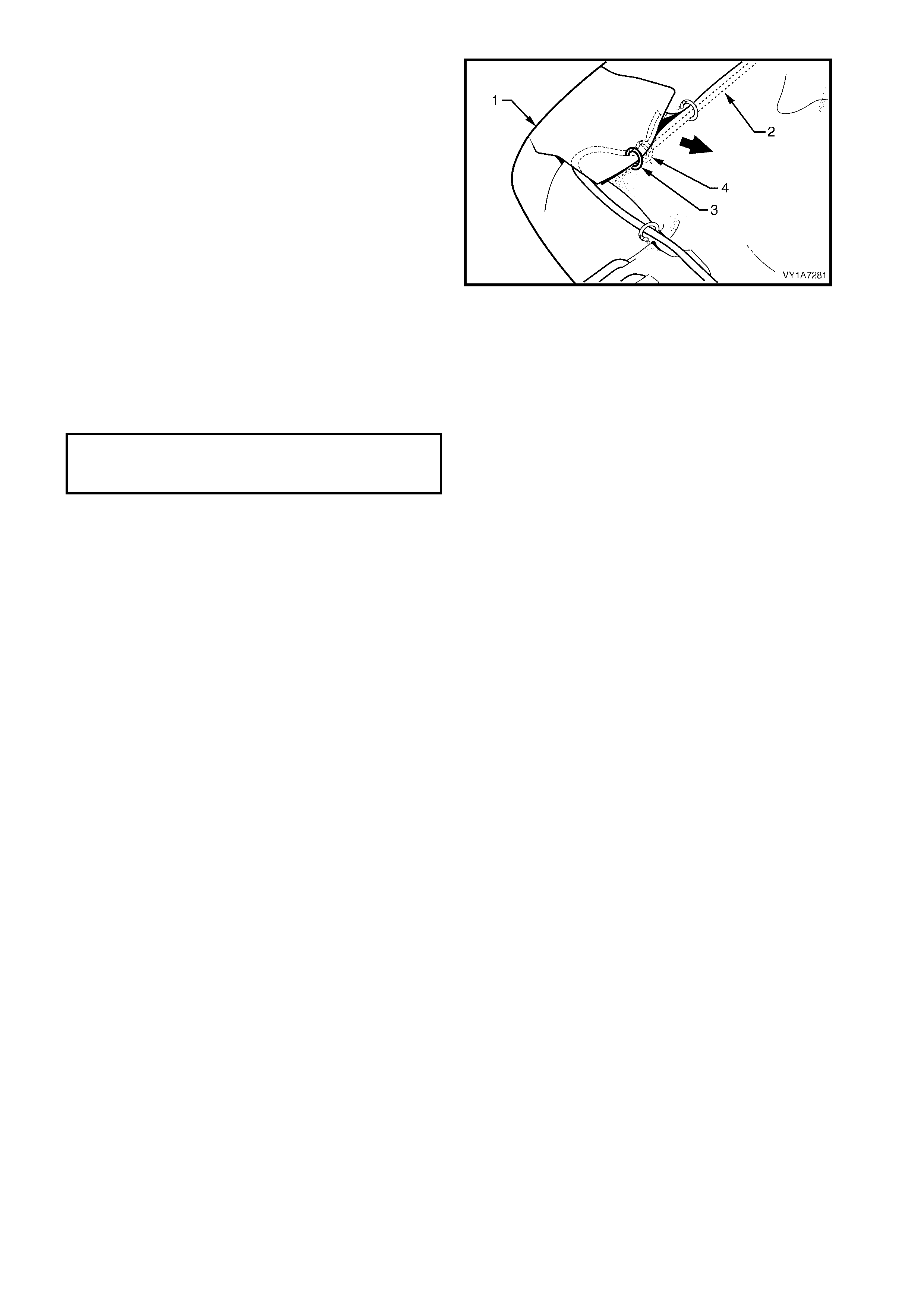

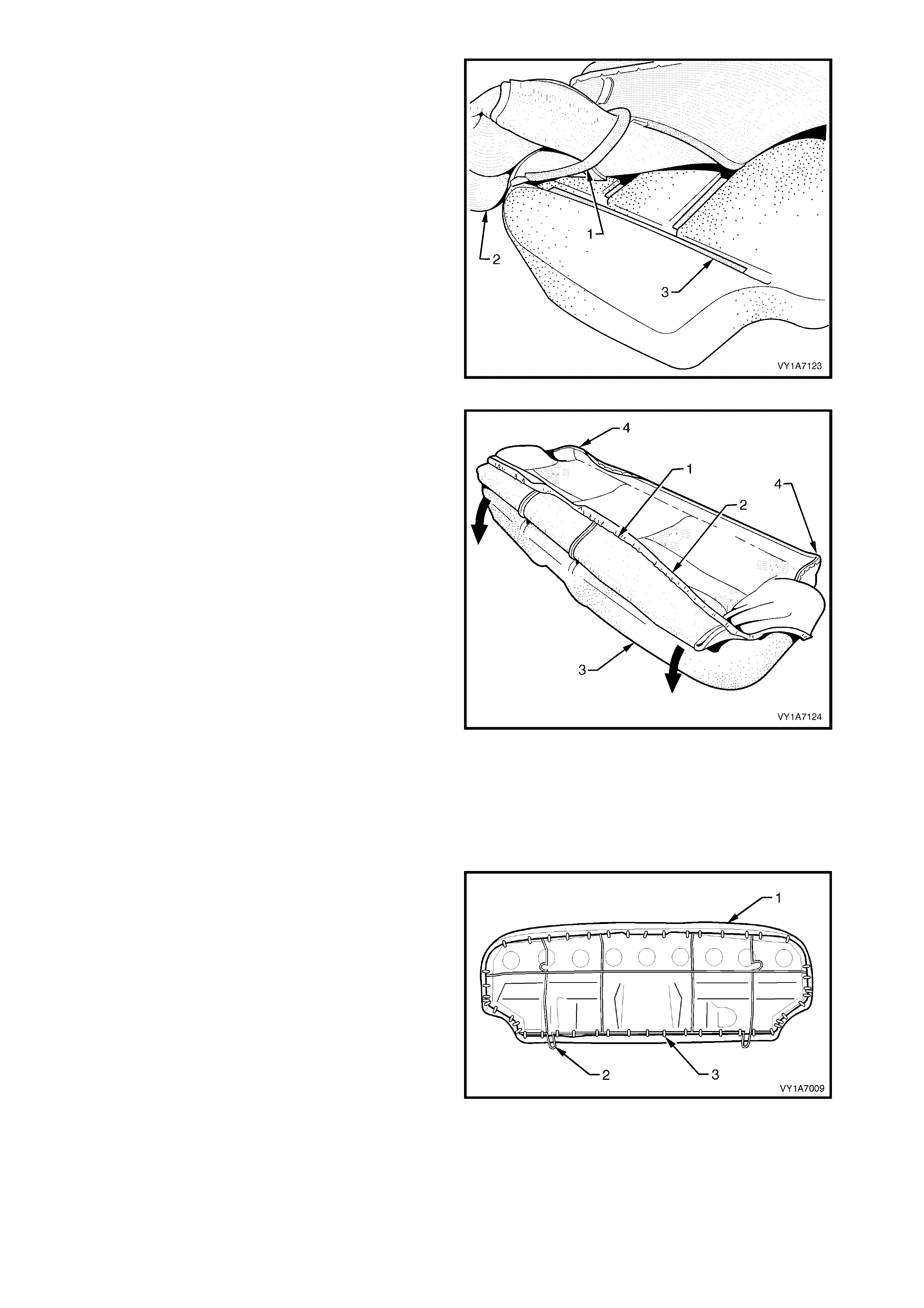

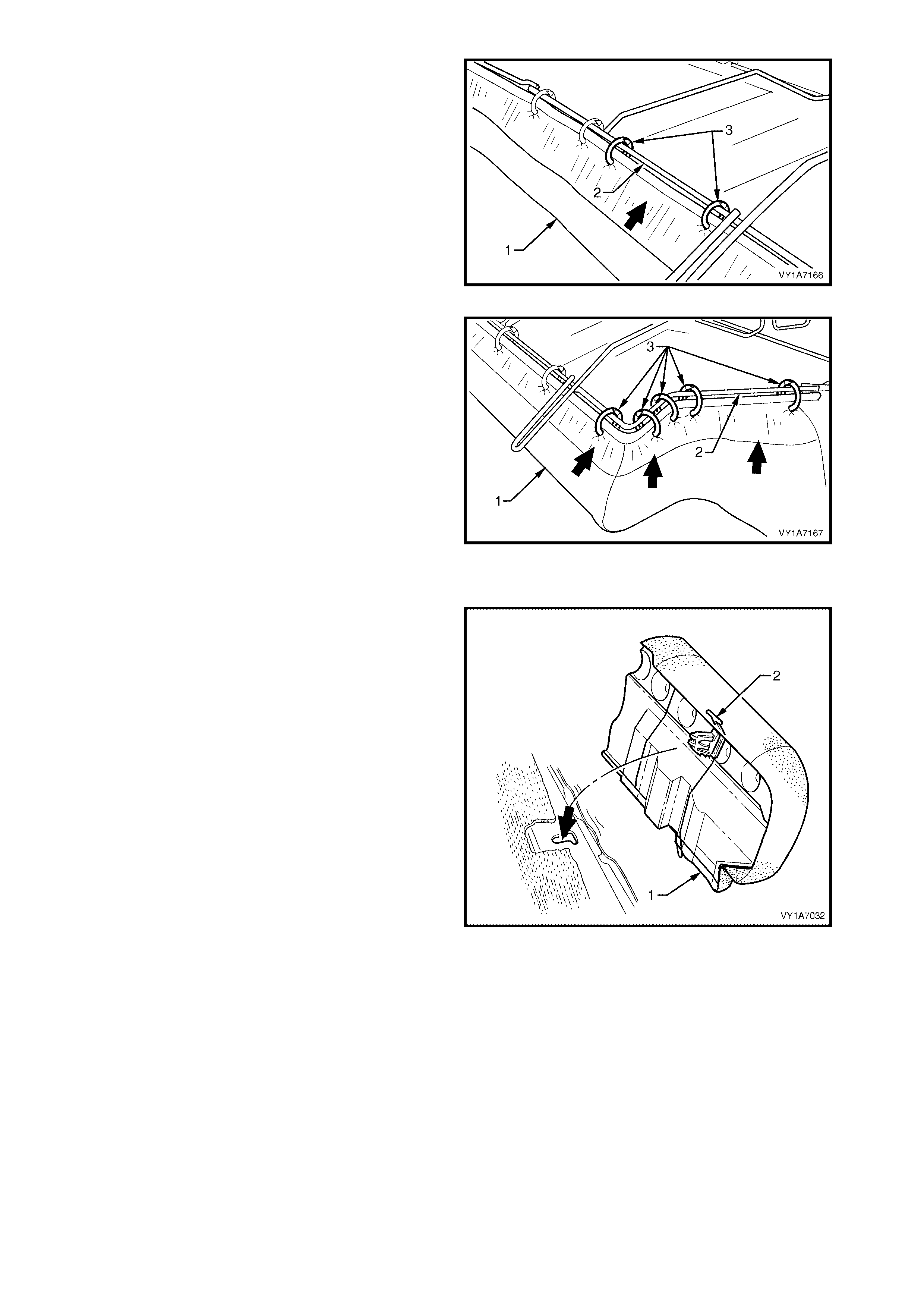

1. From under the front seat cushion, pull the front

and side J-strips (1) away from the seat frame (2).

2. Lift cover and pad assembly away from seat frame

and then release the rear J-strip (3).

Figure 1A7-67

DISASSEMBLE

1. Fold the rear corners of the front seat cushion

cover (1) over the seat cushion pad (2).

Figure 1A7-68

2. While holding the front seat cushion pad (1), pull

the rear corners of the seat cushion cover (2)

forward and away from the front seat cushion pad

to disengage the hook and loop strips (3).

3. Pull the front seat cover up and over the forward

edge of the front seat cushion pad.

Figure 1A7-69

REASSEMBLE