SECTION 1A9 - EXTERIOR ORNAMENTATION

IMPORTANT

Before perfo rming any Service O peration or oth er procedu re described in t his Sectio n, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

1.1 PICTORIAL INDEX – DOMESTIC

SEDAN: EXECUTIVE & ACCLAIM

SEDAN: SV8

SEDAN: S

SEDAN: SS

SEDAN: BERLINA

SEDAN: CALAIS

WAGON: EXECUTIVE & ACCLAIM

WAGON: BERLINA

UTILITY

UTILITY: S

UTILITY: SS

COUPE: MONARO CV6 & CV8

1.2 PICTORIAL INDEX – EXPORT

COUPE: MONARO CV6 & CV8

SEDAN: LUMINA LS

SEDAN: S

SEDAN: SS

SEDAN: LUMINA LTZ

SEDAN: OMEGA CD

WAGON: LUMINA LS

UTILITY: SS

COUPE: LUMINA S & SS

2. SERVICE OPERATIONS, SEDAN

2.1 RADIATOR GRILLE EMBLEM

REMOVE

REINSTALL

2.2 FENDER NAME PLATE

REMOVE

REINSTALL

2.3 REAR DOOR NAME PLATE

SS

CALAIS

2.4 REAR COMPARTMENT LID EMBLEM

HOLDEN, CHEVROLET

2.5 REAR COMPARTMENT LID NAME

PLATE, LH

COMMODORE, LUMINA, OMEGA CD

2.6 REAR COMPARTMENT LID NAME

PLATE, RH

EXECUTIVE, ACCLAI M, S, SV8, SS,

BERLINA, CALAIS, LUMINA LS,

LUMINA LTZ, 3.8 V6

2.7 ROOF JOINT MOULDING

REMOVE

REINSTALL

2.8 DOOR OPENING MOULDING

REMOVE

REINSTALL

2.9 CENTRE PILLAR UPPER FINISHER

ASSEMBLY

REMOVE

REINSTALL

2.10 QUARTER PANEL BELT MOULDING

REMOVE

REINSTALL

2.11 BODY SIDE MOULDINGS

REMOVE

REINSTALL

2.12 ROCKER PANEL MOULDING

ASSEMBLY

REMOVE

REINSTALL

3. SERVICE OPERATIONS, WAGON

3.1 RADIATOR GRILLE EMBLEM

REMOVE

REINSTALL

3.2 FENDER NAME PLATE

REMOVE

REINSTALL

3.3 LIFTGATE EMBLEM

HOLDEN, CHEVROLET

3.4 LIFTGATE NAME PLATE, LH

COMMODORE, CHEVROLET

3.5 LIFTGATE EMBLEM, RH

EXECUTIVE, ACCLAIM, BERLINA,

LUMINA LS

3.6 ROOF JOINT MOULDING

REMOVE

REINSTALL

3.7 ROOF BARS

REMOVE

REINSTALL

3.8 ROOF SIDE RAILS

REMOVE

REINSTALL

3.9 DOOR OPENING MOULDING

REMOVE

REINSTALL

3.10 CENTRE PILLAR UPPER FINISHER

ASSEMBLY

REMOVE

REINSTALL

3.11 ROOF JOINT FINISHER

REMOVE

REINSTALL

3.12 BODY SIDE MOULDINGS

REMOVE

REINSTALL

3.13 ROCKER PANEL MOULDING

ASSEMBLY

REMOVE

REINSTALL

4. SERVICE OPERATIONS, UTILITY

4.1 RADIATOR GRILLE EMBLEM

REMOVE

REINSTALL

4.2 FENDER NAME PLATE

REMOVE

REINSTALL

4.3 QUARTER PANEL NAME PLATE

SS

4.4 ENDGATE EMBLEM

HOLDEN, CHEVROLET

4.5 ENDGATE NAME PLATE, RH

S, SS

4.6 ROOF JOINT MOULDING

REMOVE

REINSTALL

4.7 DOOR OPENING MOULDING

REMOVE

REINSTALL

4.8 CENTRE PILLAR UPPER FINISHER

ASSEMBLY

REMOVE

REINSTALL

4.9 ROCKER PANEL MOULDING

ASSEMBLY

REMOVE

REINSTALL

4.10 REAR WINDOW UPPER MOULDING

REMOVE

REINSTALL

4.11 REAR WINDOW SIDE MOULDING

REMOVE

REINSTALL

4.12 QUARTER WINDOW MOULDING

REMOVE

REINSTALL

4.13 QUARTER PANEL RAILS

REMOVE

REINSTALL

4.14 TONNEAU COVER BOW RETAINER

REMOVE

REINSTALL

5. SERVICE OPERATIONS, COUPE

5.1 RADIATOR GRILLE EMBLEM

REMOVE

REINSTALL

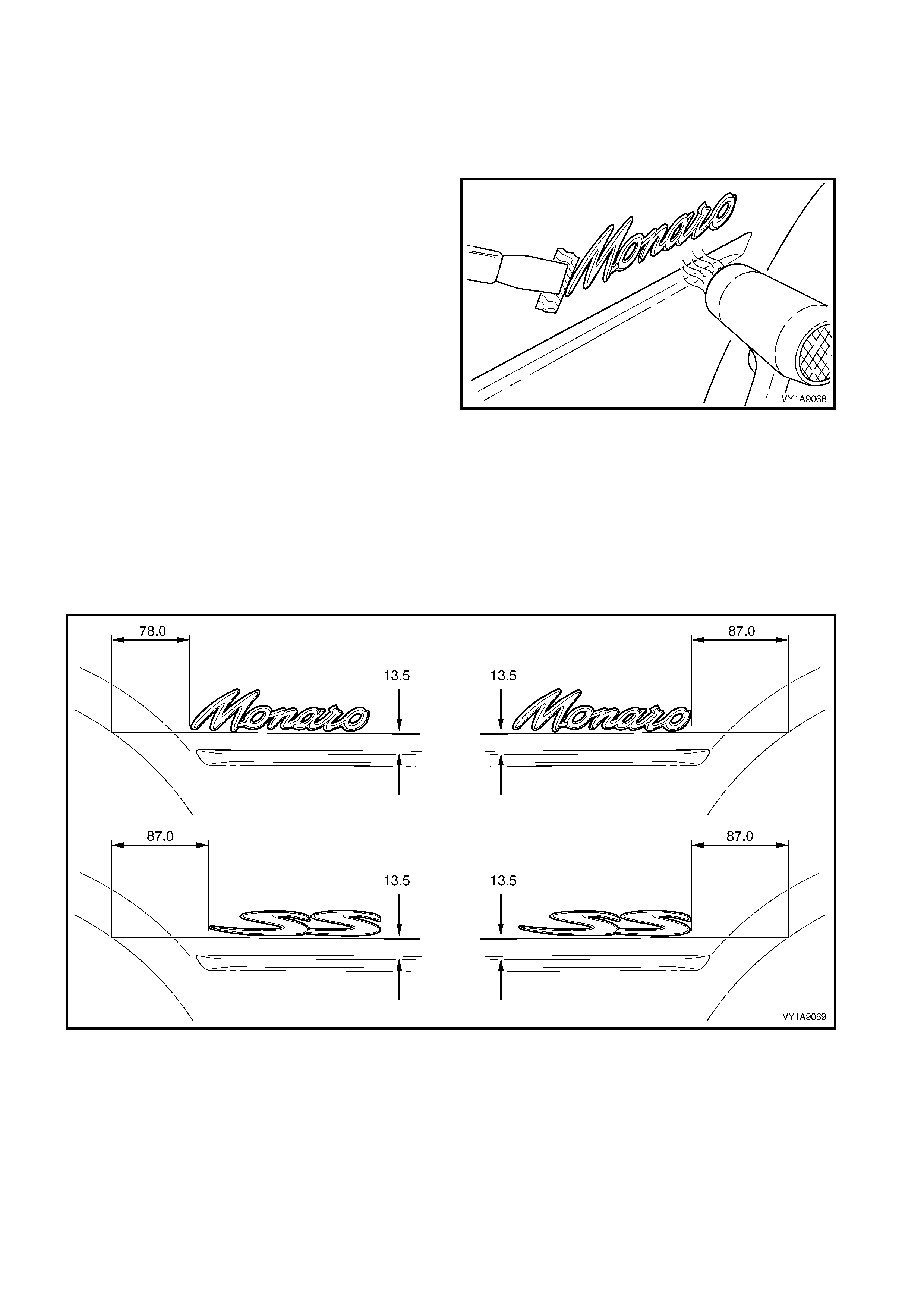

5.2 QUARTER PANEL NAME PLATE

MONARO, SS

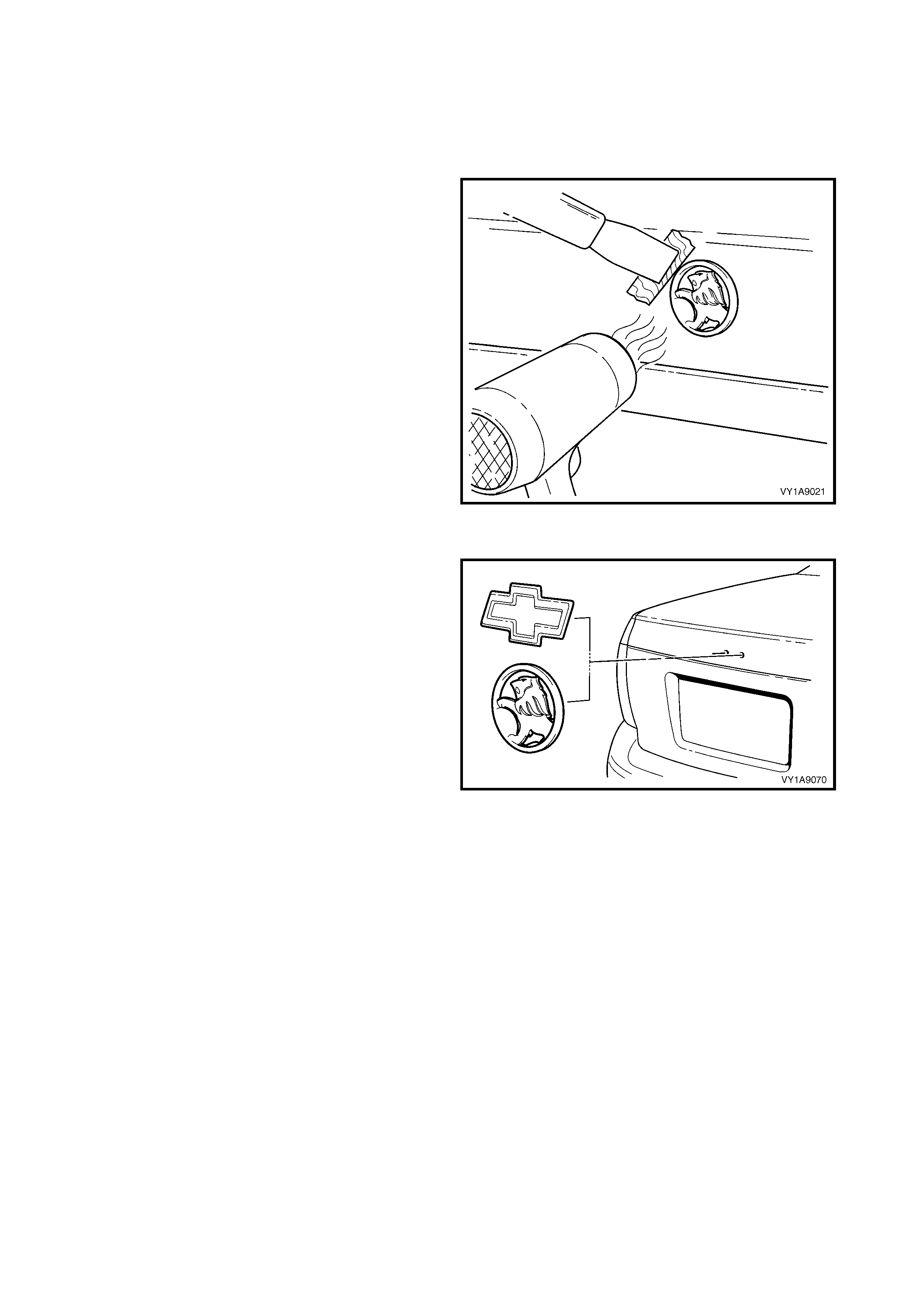

5.3 REAR COMPARTMENT LID EMBLEM

HOLDEN, CHEVROLET

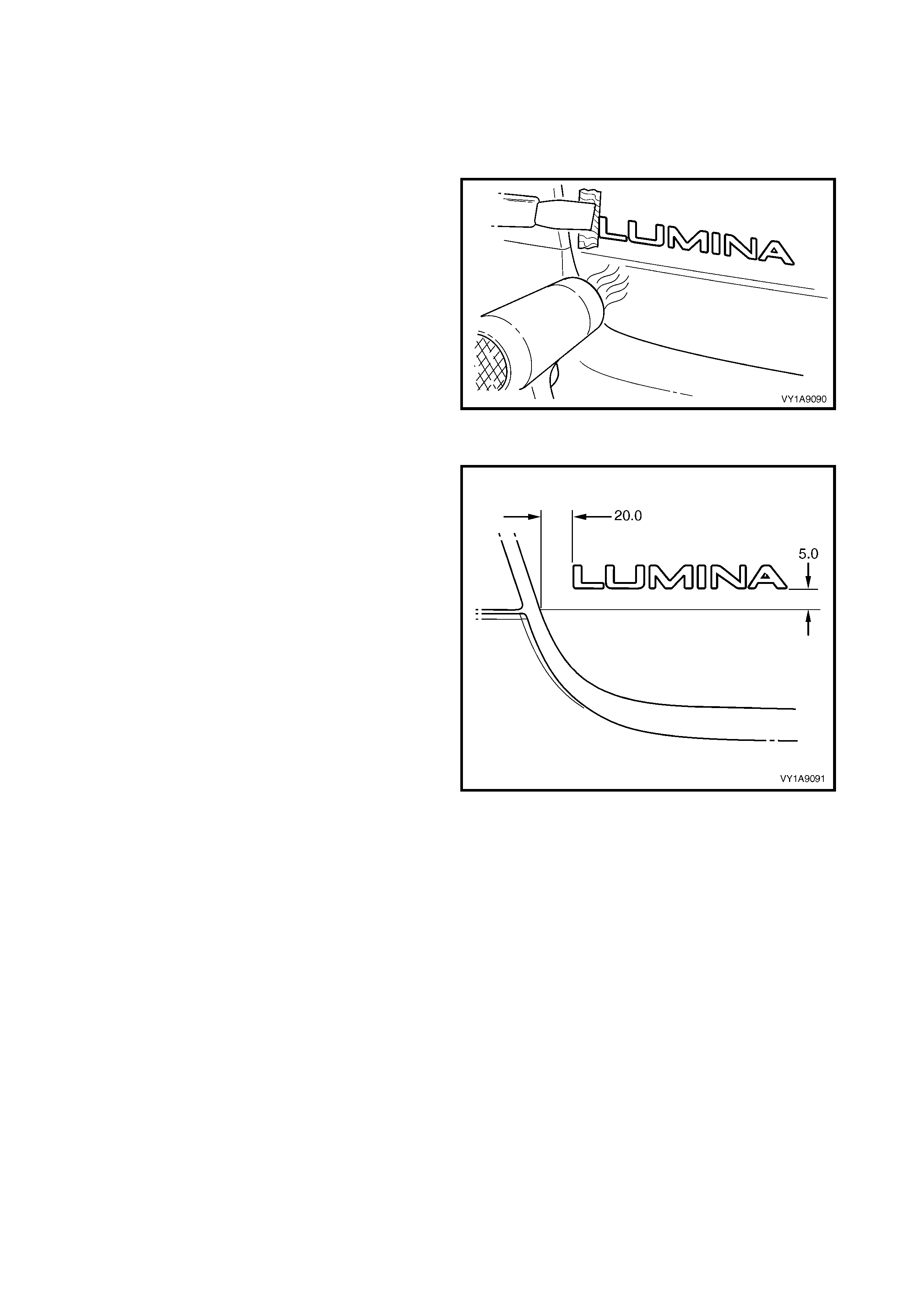

5.4 REAR COMPARTMENT LID NAME

PLATE, LH

LUMINA

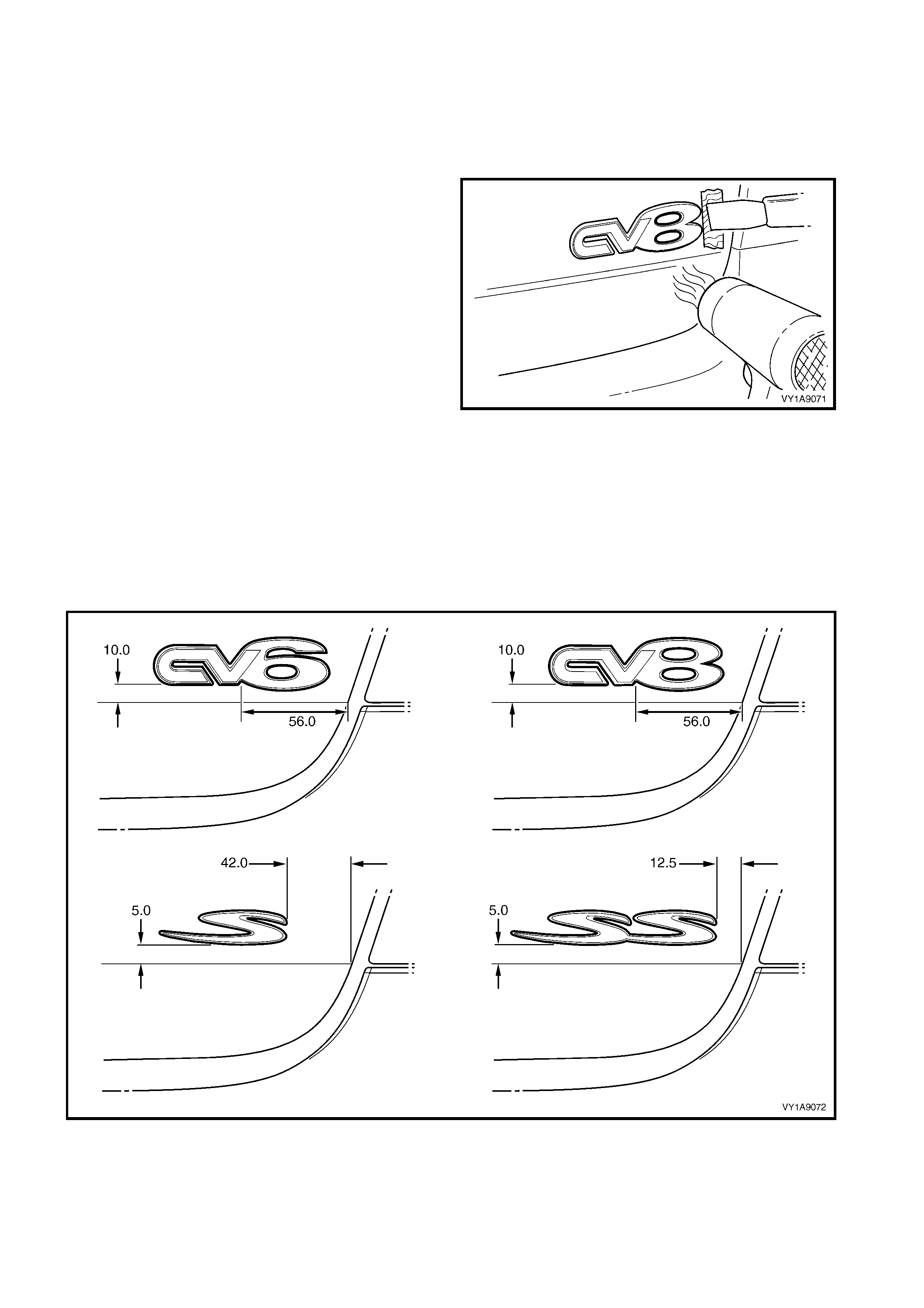

5.5 REAR COMPARTMENT LID NAME

PLATE, RH

CV6, CV8, S, SS

5.6 ROOF JOINT MOULDING

REMOVE

REINSTALL

5.7 DOOR OPENING MOULDING

REMOVE

REINSTALL

5.8 CENTRE PILLAR UPPER FINISHER

ASSEMBLY

REMOVE

REINSTALL

5.9 ROCKER PANEL MOULDING

ASSEMBLY

REMOVE

REINSTALL

6. TORQUE WRENCH SPECIFICATIONS

1. GENERAL DESCRIPTION

This Section describes the service procedures for the ornamentation components such as emblems, name plates,

mouldings and finishers. Also included are the Wagon roof bars, and the Utility quarter panel rails and tonneau

cover bow retainer.

Several components previously in this Section have been moved to other Sections, these are:

• Rear spoiler, refer to Section 1A4, 3.4 REAR SPOILER ASSEMBLY,

• Liftgate air deflector, refer to Section 1A4, 4.9 LIFTGATE AIR DEFLECTOR ASSEMBLY.

Domestic Calais vehicles feature a hood front moulding assembly which is not included in this Section, refer to

Section 1A4. 2.1 HOOD FRONT MOULDING ASSEMBLY.

Many of the components in this Section are affixed to the vehicle with double-sided tape or urethane adhesive. It is

imperative that the correct materials are used when reinstalling these parts, as specified in this Section. Use of

materials other than those specified may lead to premature failure.

To aid in identification and service procedure location, refer to the pictorial index diagrams on the following pages.

NOTE: For information regarding the exterior ornamentation for domestic merchandising packs such as the Berlina

International Wagon and right-hand drive (Holden) Lumina, refer to the MERCHANDISING PACK Section in this

Service Information.

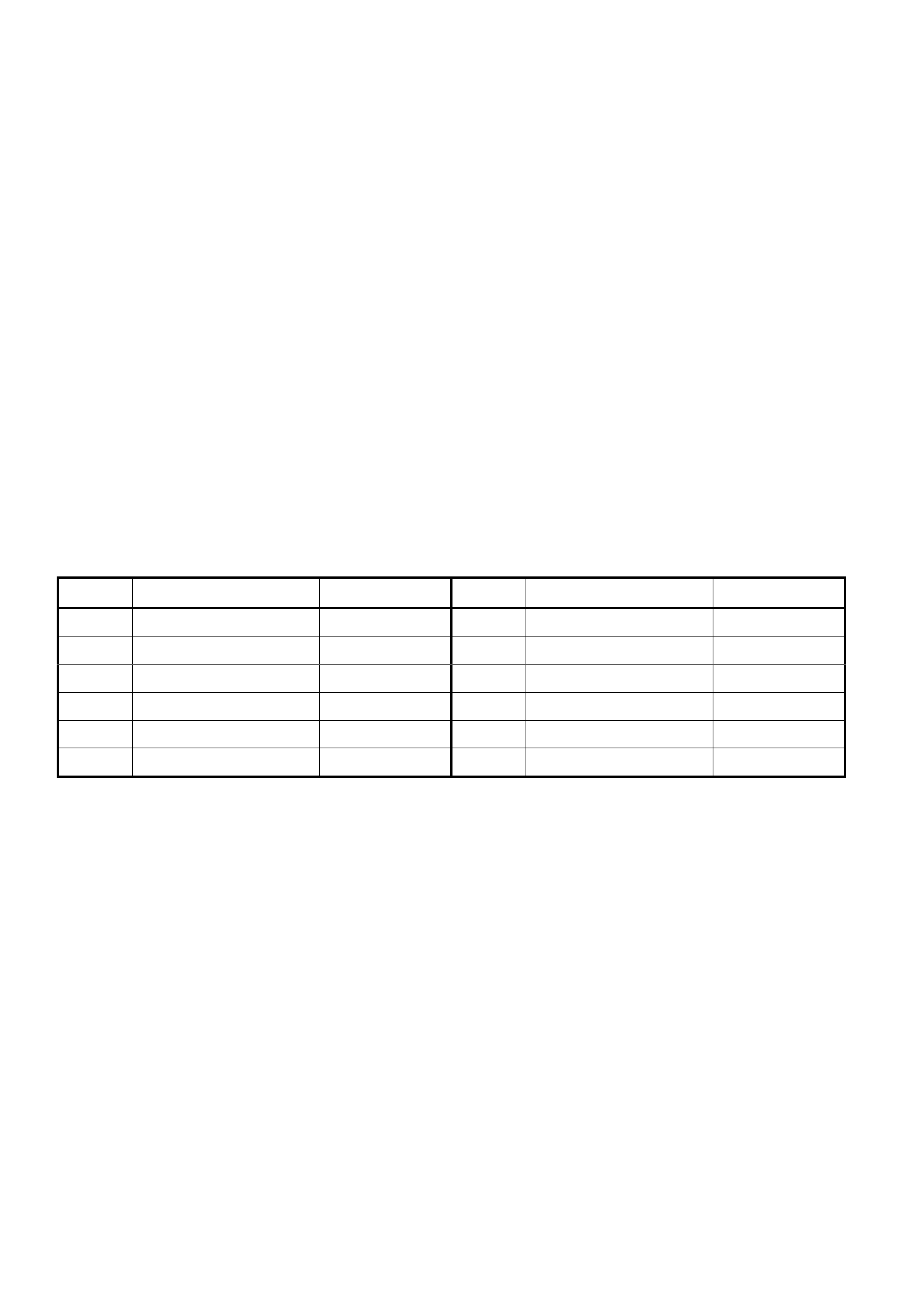

1.1 PICTORIAL INDEX – DOMESTIC

The following diagrams provide a quick reference to the correct service procedures for the exterior ornamentation

components relevant to each vehicle model.

Simply refer to the vehicle model by using the table below, locate the component on the Figure, cross-reference it in

the accompanying table below the Figure and go to the appropriate service procedure.

BODY MODEL REFER TO BODY MODEL REFER TO

Sedan Executive & Acclaim Figure 1A9-1 Wagon Executive & Acclaim Figure 1A9-7

SV8 Figure 1A9-2 Berlina Figure 1A9-8

S Figure 1A9-3 Utility Figure 1A9-9

SS Figure 1A9-4 S Figure 1A9-10

Berlina Figure 1A9-5 SS Figure 1A9-11

Calais Figure 1A9-6 Coupe Monaro CV6 & CV8 Figure 1A9-14

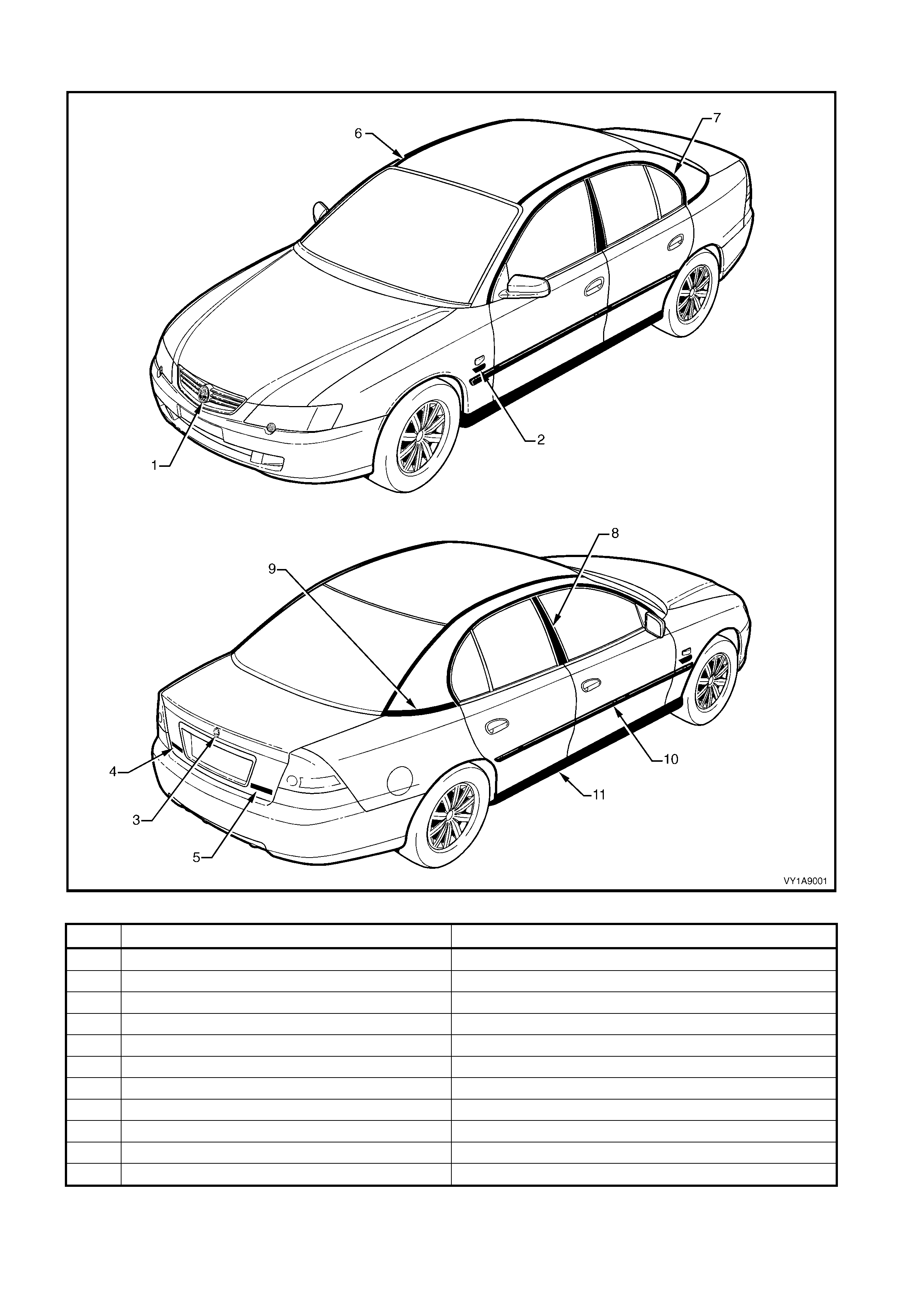

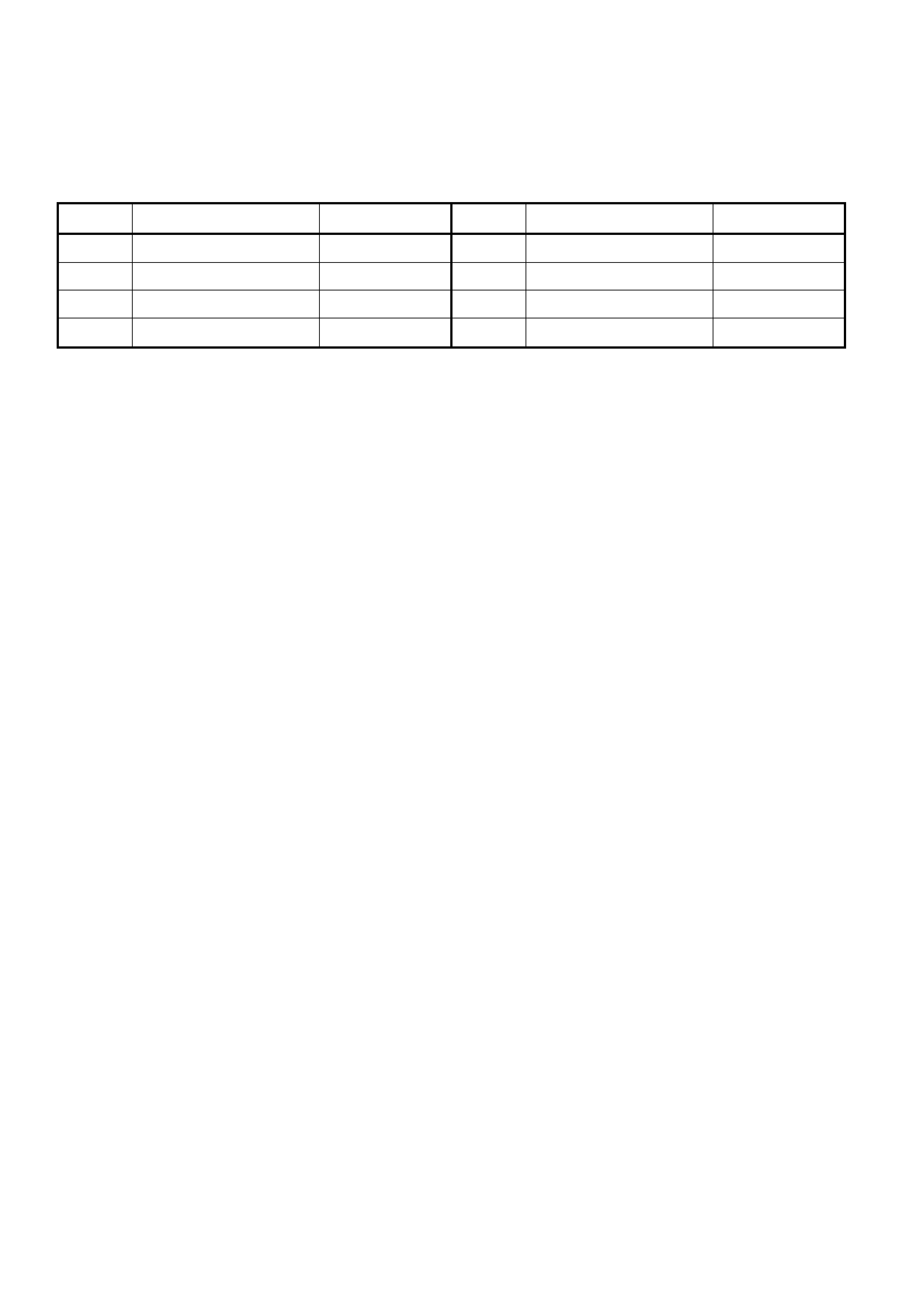

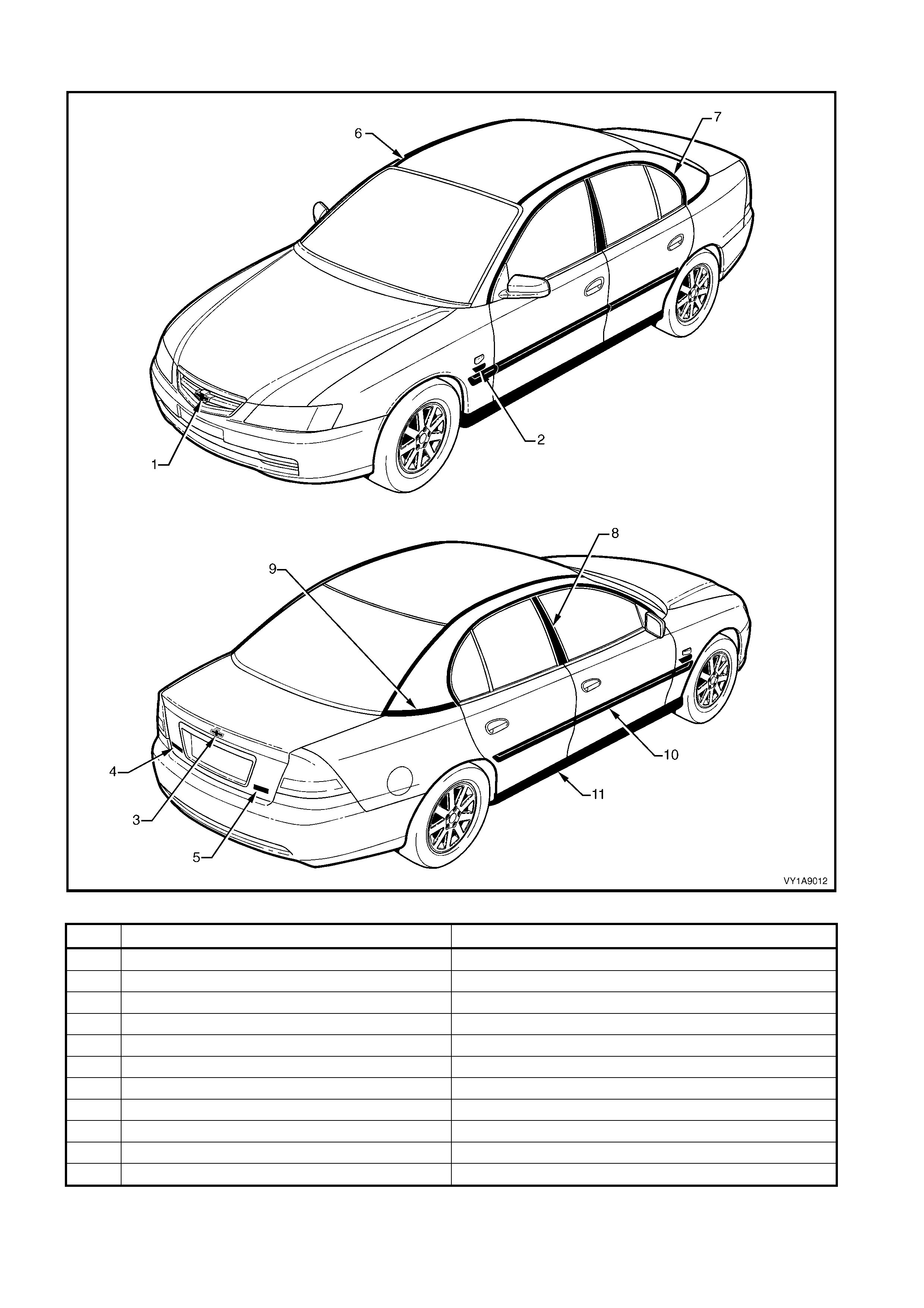

SEDAN: EXECUTIVE & ACCLAIM

Figure 1A9-1

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 2.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, S upercharged, V8 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Holden 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid: Commodore 2.5 REAR COMPA RTMENT LI D NAME PLATE, LH

5 Rear Compart ment Lid Name Plate: Executive, Acclaim 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Body Side Moulding 2.11 BODY SIDE MOULDINGS

11 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

SEDAN: SV8

Figure 1A9-2

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 2.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V8 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Holden 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Comm odore 2.5 REAR COMPA RTMENT LI D NAME PLATE, LH

5 Rear Compart ment Lid Name Plate: SV8 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

NOTE: For service procedures of the rear spoiler refe r t o Section 1A 4, 3.4 REAR S P OILER ASS EMBLY

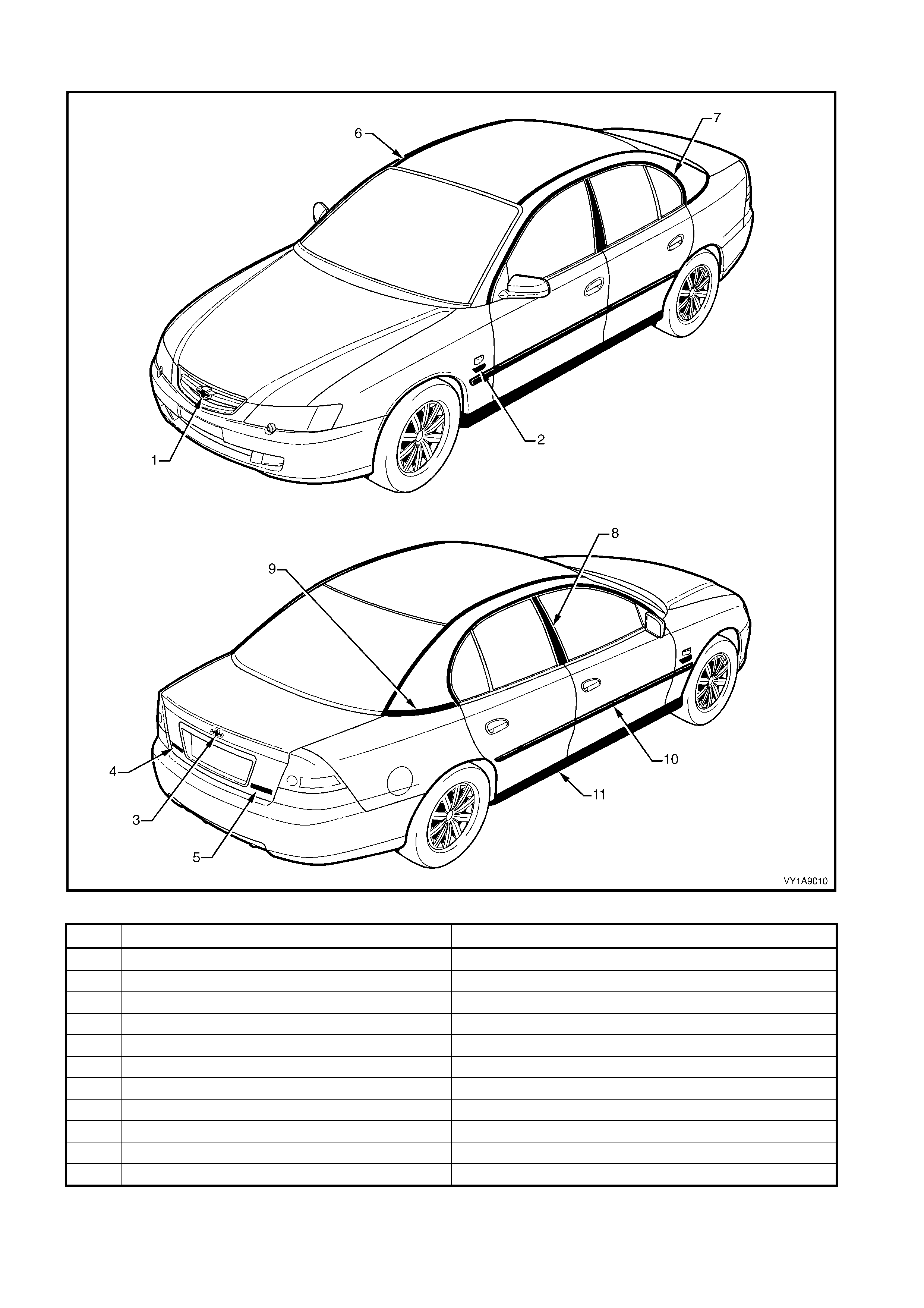

SEDAN: S

Figure 1A9-3

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 2.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, S upercharged 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Holden 2.4 REAR COMPARTMENT LI D EMBLEM

4 Rear Compart ment Lid Name Plate: Comm odore 2.5 REAR COMPA RTMENT LI D NAME PLATE, LH

5 Rear Compart ment Lid Name Plate: S 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

NOTE: For service procedures of the rear spoiler refe r t o Section 1A 4, 3.4 REAR S P OILER ASS EMBLY.

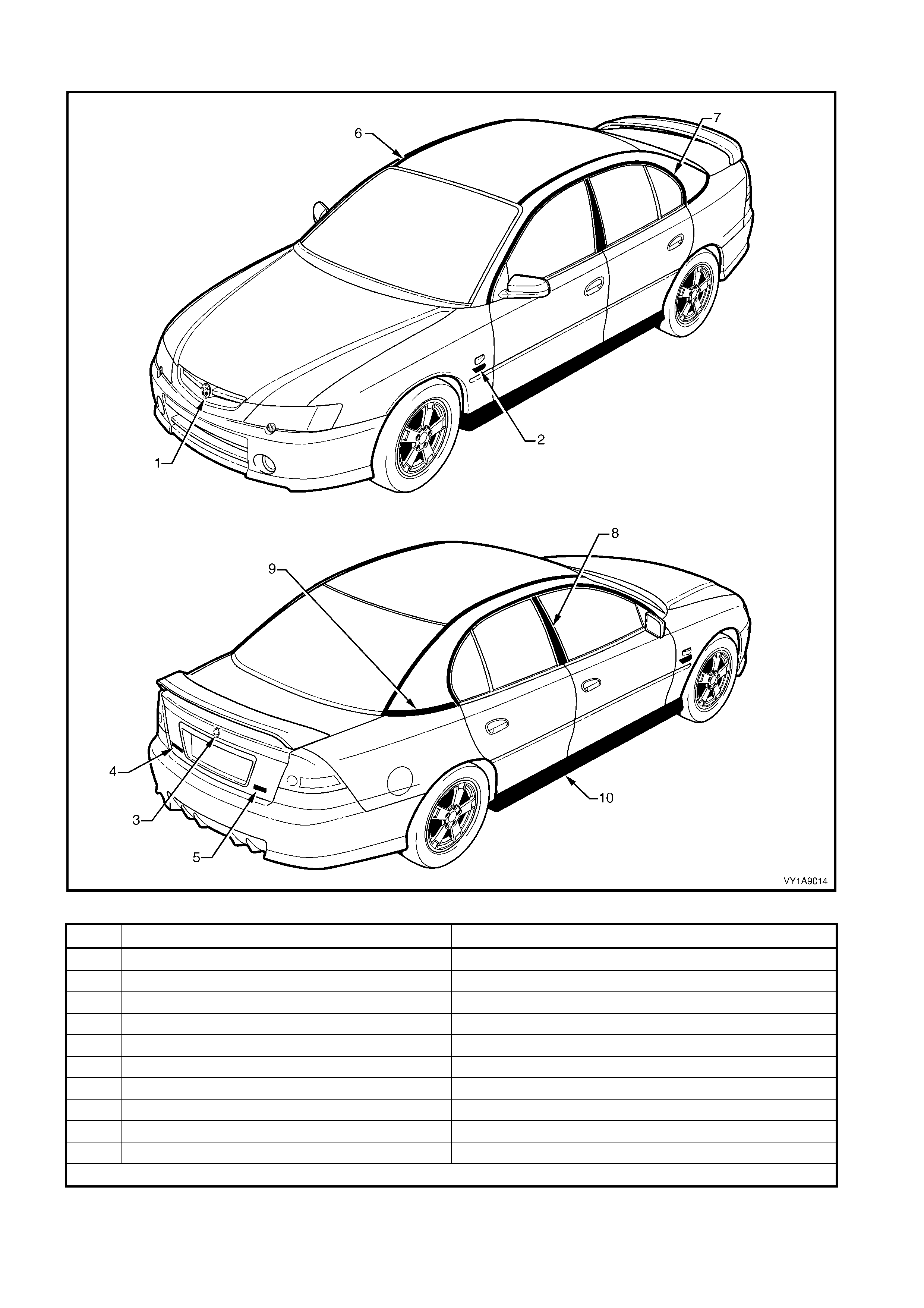

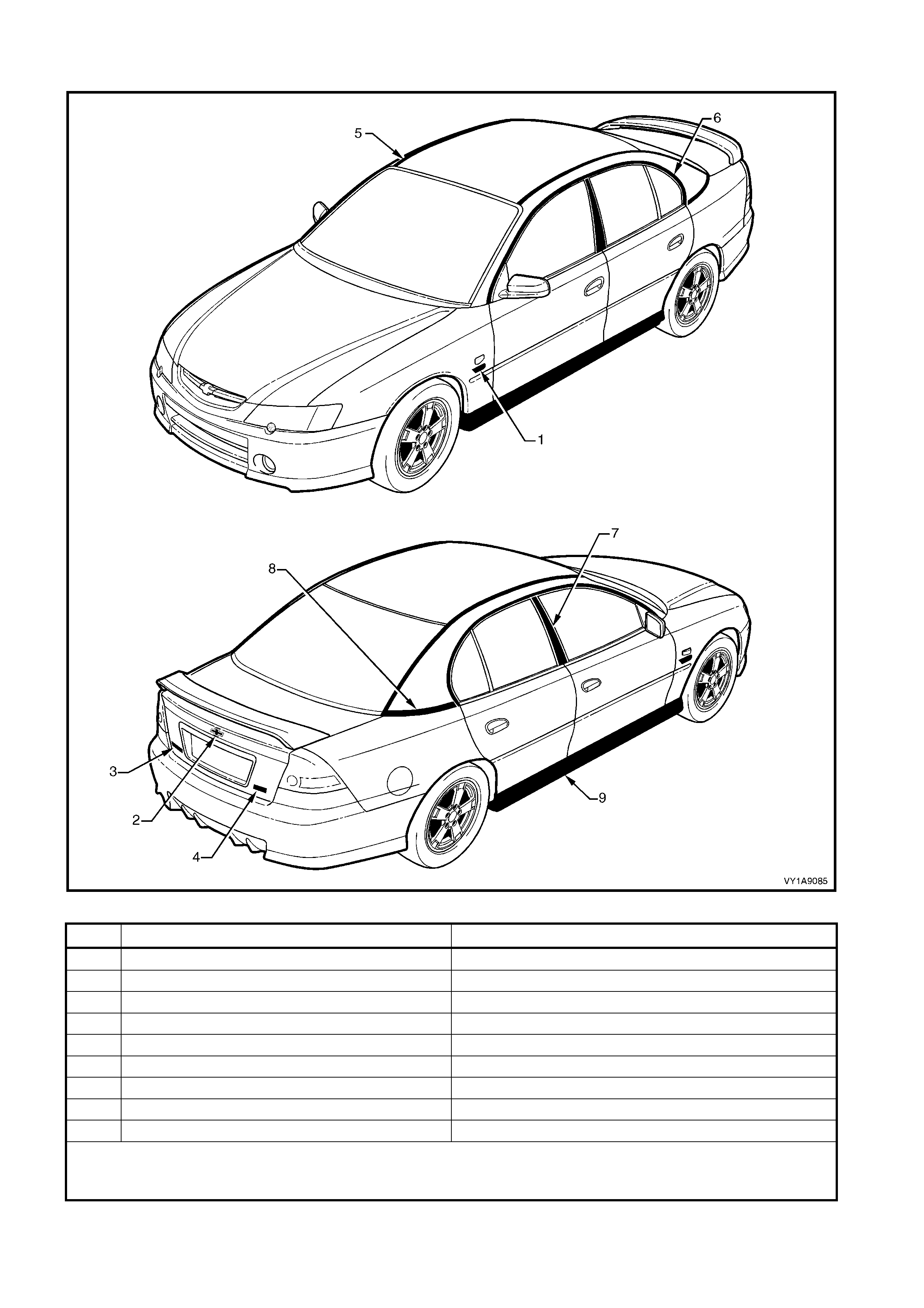

SEDAN: SS

Figure 1A9-4

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 2.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V8 2.2 FENDER NA ME PLATE

3 Rear Door Name P l at e: SS 2.3 REAR DOOR NA ME P LATE

4 Rear Compart ment Lid E mblem : Holden 2.4 REAR COMPARTMENT LI D EMBLEM

5 Rear Compart ment Lid Name Plate: Comm odore 2.5 REAR COMPA RTMENT LI D NAME PLATE, LH

6 Rear Compart ment Lid Name Plate: SS 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

7 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

8 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

9 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

10 Quarter Panel Belt Mouldi ng 2. 10 QUARTER PANEL B E LT MOULDI NG

11 Body Side Moulding 2.11 BODY SIDE MOULDINGS

12 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

NOTE: For service procedures of the rear spoiler refe r t o Section 1A 4, 3.4 REAR S P OILER ASS EMBLY

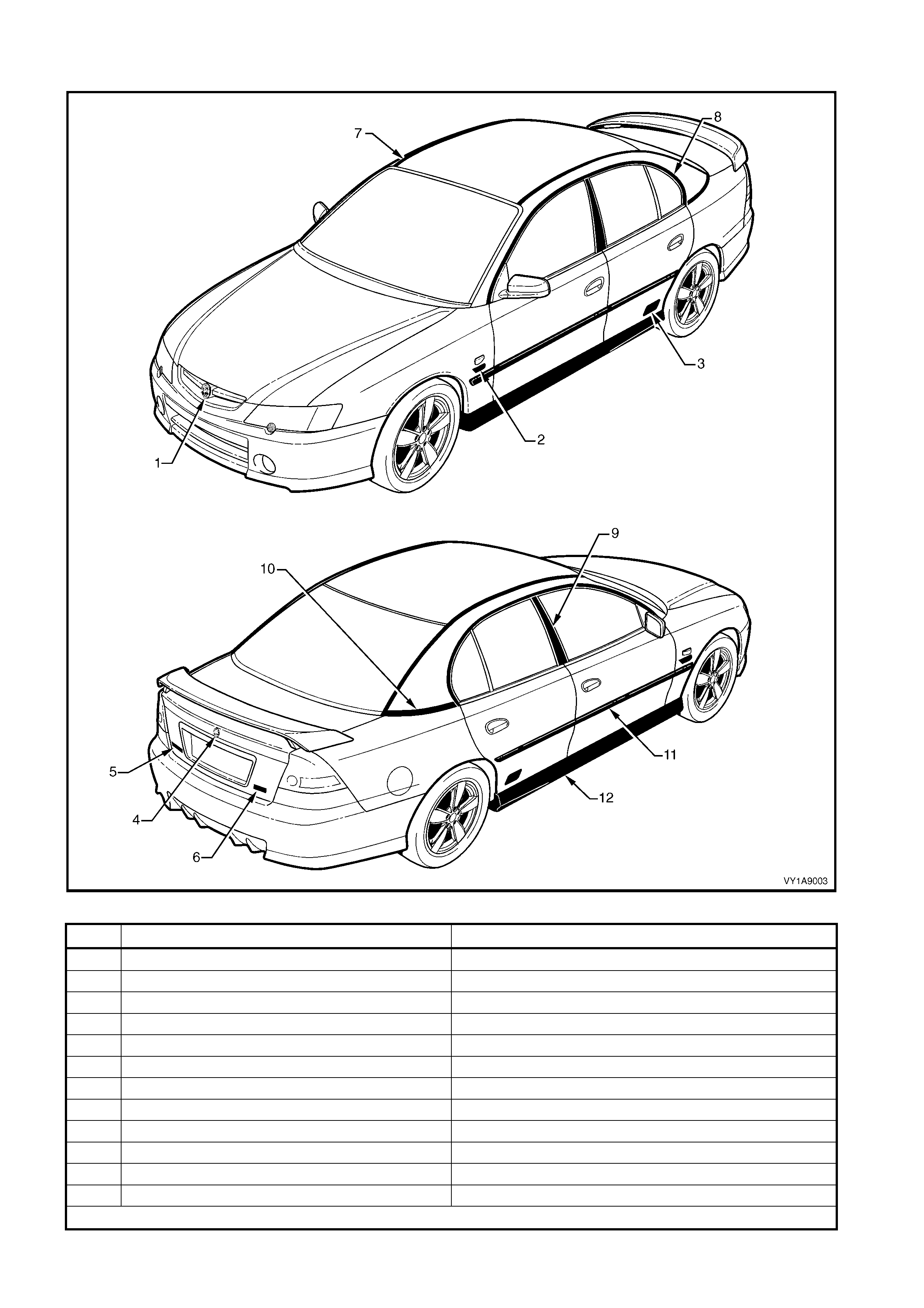

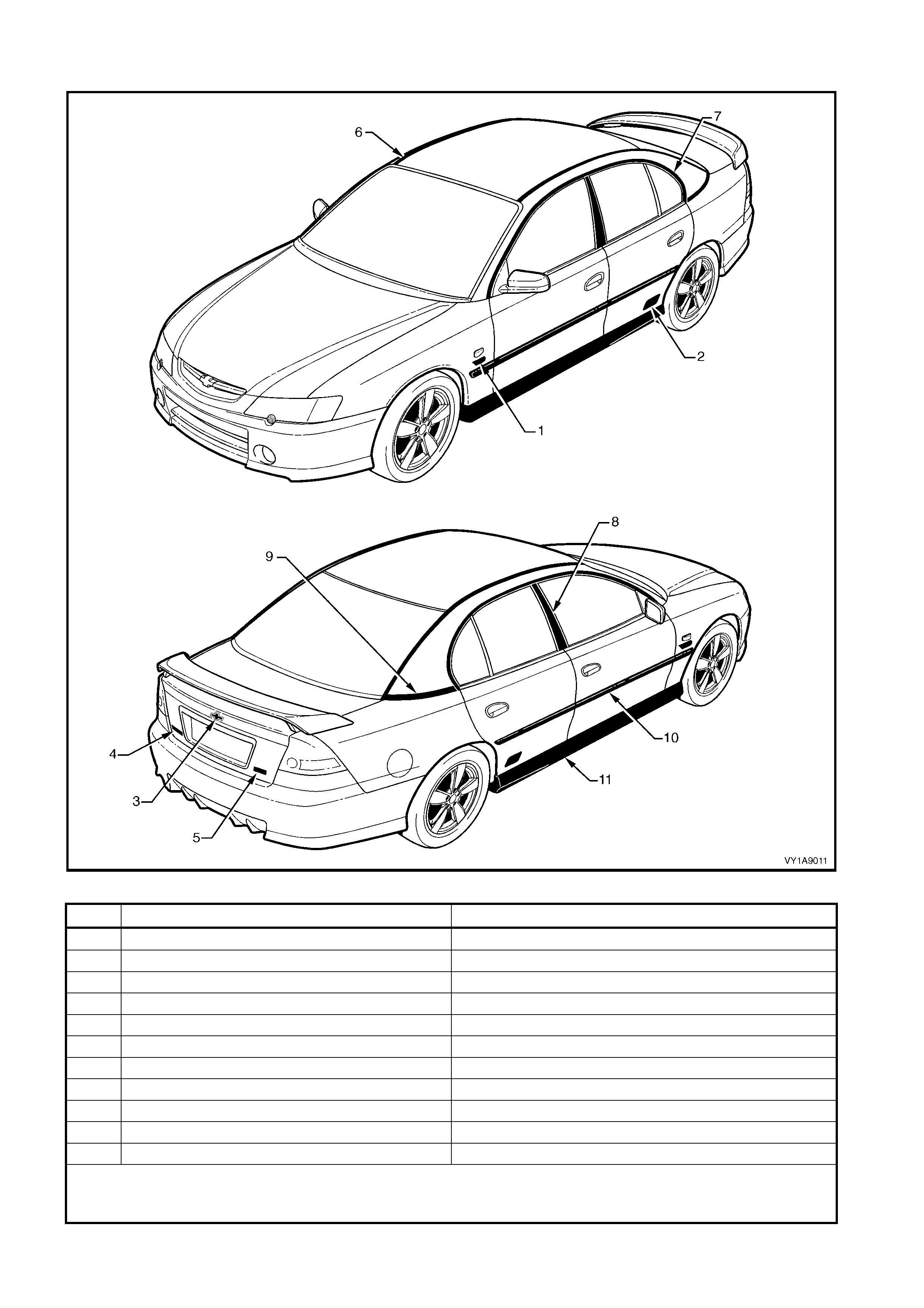

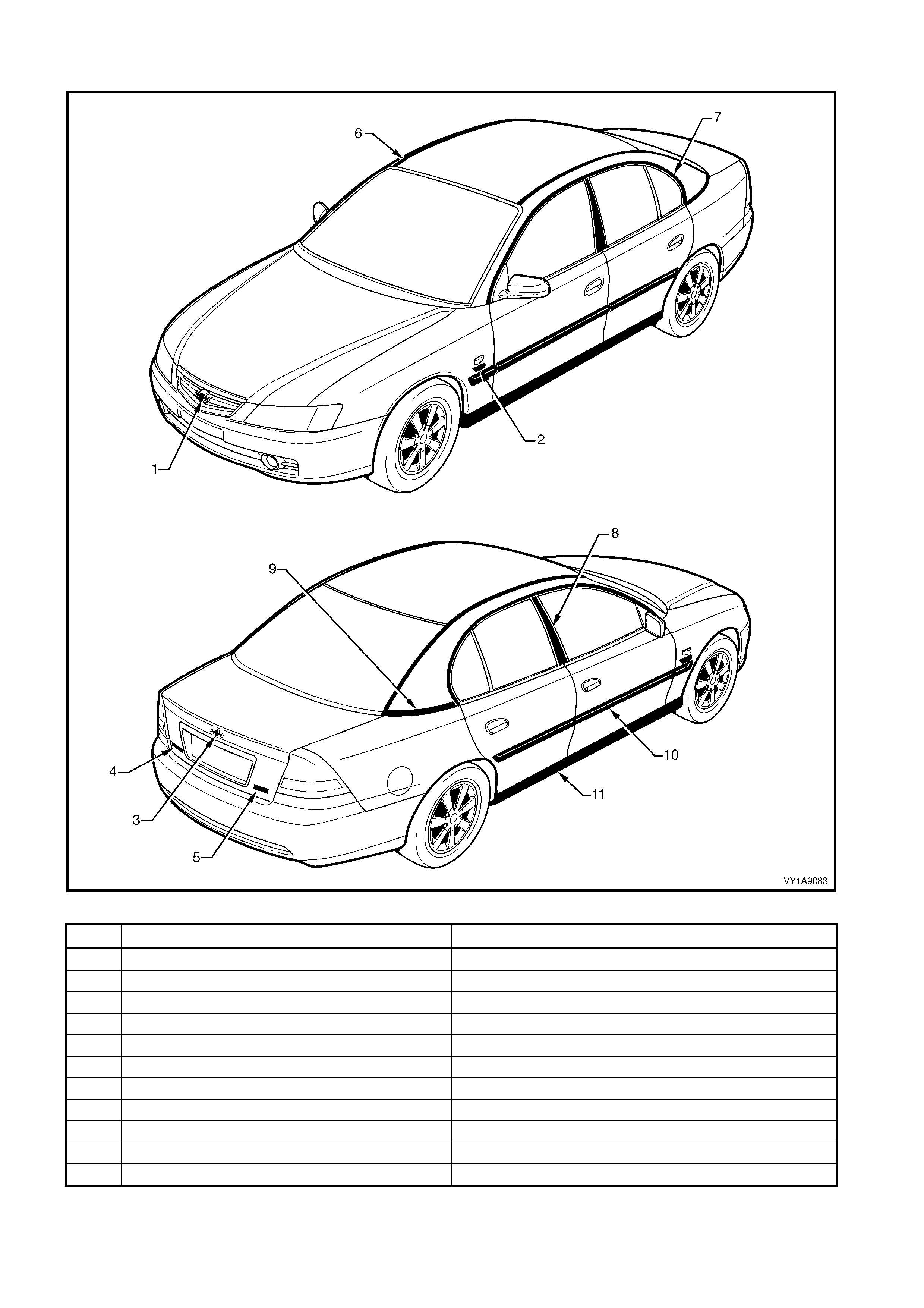

SEDAN: BERLINA

Figure 1A9-5

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 2.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, S upercharged, V8 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Holden 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Berlina 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

5 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

6 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

7 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

8 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

9 Body Side Moulding 2.11 B ODY SIDE MOULDI NGS

10 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

SEDAN: CALAIS

Figure 1A9-6

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 2.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, S upercharged, V8 2.2 FENDER NA ME PLATE

3 Rear Door Name Plate: Calais 2.3 REAR DOOR NAME PLATE

4 Rear Compart ment Lid E mblem : Holden 2.4 REAR COMPARTMENT LID EMBLEM

5 Rear Compart ment Lid Name Plate: Calais 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Body Side Moulding 2.11 BODY SIDE MOULDINGS

11 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

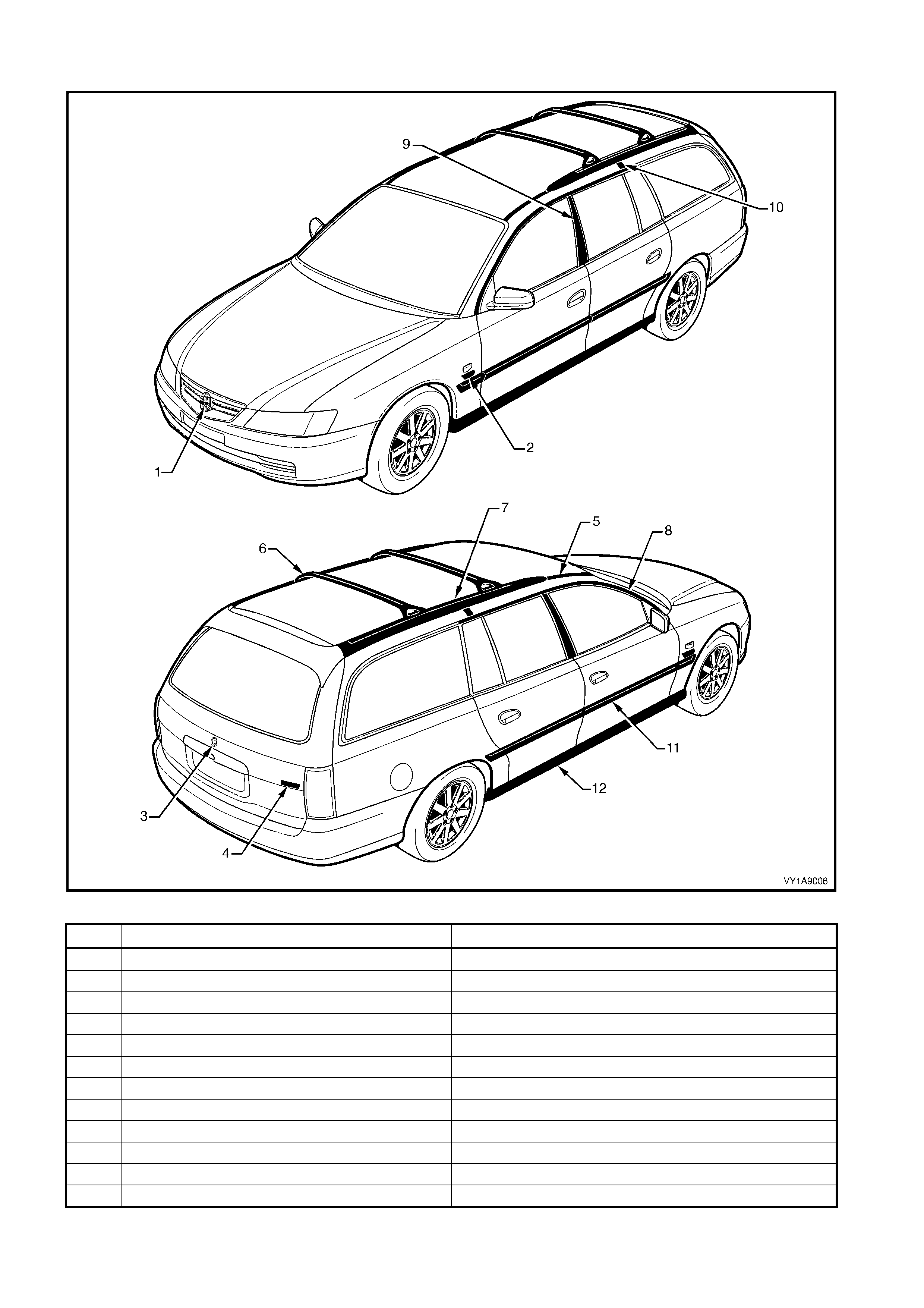

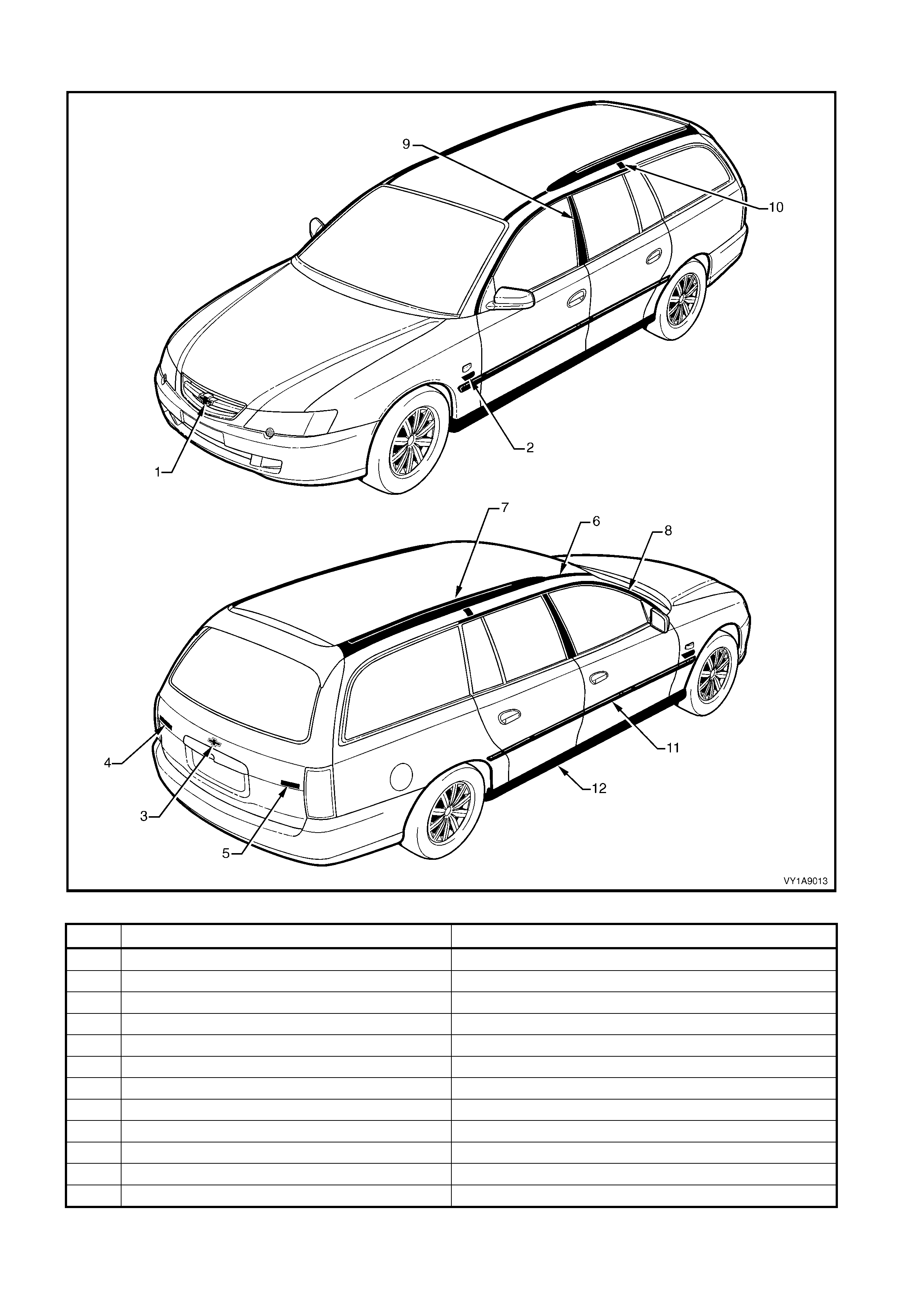

WAGON: EXECUTIVE & ACCLAIM

Figure 1A9-7

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 3.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, V 8 3.2 FENDER NA ME PLATE

3 Liftgate Emblem: Holden 3.3 LIFTGATE EMBLEM

4 Liftgat e Name Plat e: Comm odore 3.4 LIFTGAT E NAME PLATE, LH

5 Liftgat e Name Plat e: Executive, Ac claim 3.5 LIFTGAT E NAME PLATE, RH

6 Roof Joint Moulding 3.6 ROOF JOI NT MOULDING

7 Roof Side Rail s 3.8 ROOF SIDE RAILS

8 Door Opening Moulding 3.9 DOOR OPENI NG MOULDING

9 Centre Pillar upper Finisher Assembly 3.10 CENTRE PILLAR UPPER FINISHER ASSEMBLY

10 Roof Joint Finis her 3.11 ROOF JOINT FI NISHER

11 Body Side Moulding 3.12 BODY SIDE MOULDINGS

12 Rocker Panel Moulding A ssem bl y 3.13 ROCKER P ANEL MOULDING ASS EMBLY

WAGON: BERLINA

Figure 1A9-8

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 3.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, V 8 3.2 FENDER NA ME PLATE

3 Liftgate Emblem: Holden 3.3 LIFTGATE EMBLEM

4 Liftgat e Name Plat e: Berlina 3.5 LIFTGAT E NAME PLATE, RH

5 Roof Joint Moulding 3.6 ROOF JOI NT MOULDING

6 Roof Bars 3.7 ROOF BARS

7 Roof Side Rail s 3.8 ROOF SIDE RAILS

8 Door Opening Moulding 3.9 DOOR OPENI NG MOULDING

9 Centre Pillar upper Finisher Assembly 3.10CENTRE PILLAR UPPER FINISHER ASSEMBLY

10 Roof Joint Finis her 3.11 ROOF JOINT FI NISHER

11 Body Side Moulding 3.12 BODY SIDE MOULDINGS

12 Rocker Panel Moulding A ssem bl y 3.13 ROCKER P ANEL MOULDING ASS EMBLY

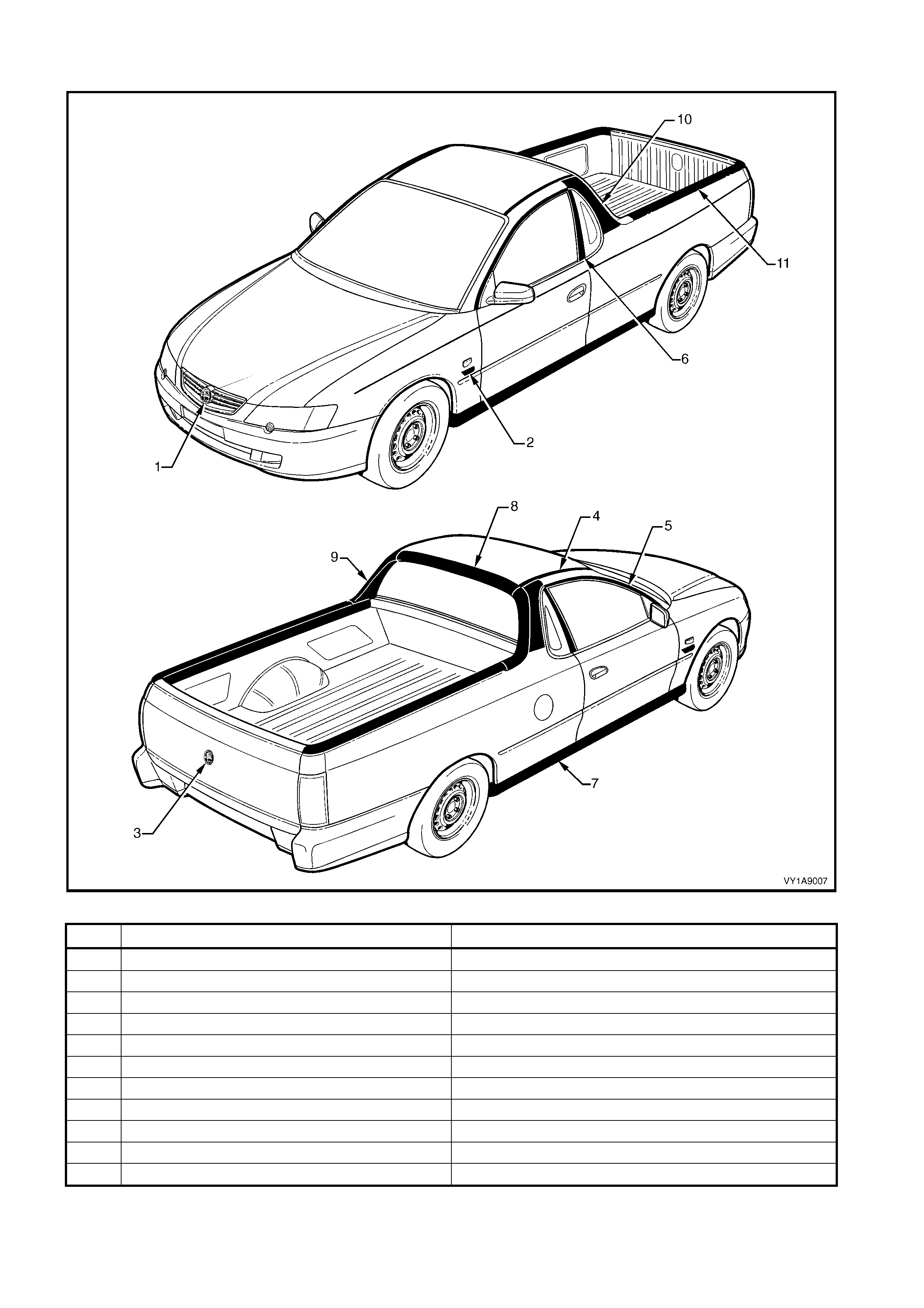

UTILITY

Figure 1A9-9

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 4.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, V 8 4.2 FENDER NA ME PLATE

3 Endgate Emblem: Holden 4.4 ENDGATE EMBLEM & NAME PLATES

4 Roof Joint Moulding 4.6 ROOF JOI NT MOULDING

5 Door Opening Moulding 4.7 DOOR OPENI NG MOULDING

6 Centre Pillar upper Finisher A ssembly 4.8 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

7 Rocker P anel Moulding Assembly 4.9 ROCKER PANE L MOULDING ASSEMBLY

8 Rear Window Upper Moulding 4.10 REAR WINDOW UPPER MOULDING

9 Rear Window Side Moulding 4.11 REAR WINDOW SIDE MOULDI NG

10 Quarter Window Moulding 4.12 QUARTER WINDOW MOULDING

11 Quarter Panel Rails 4.13 QUARTER P A NEL RAILS

UTILITY: S

Figure 1A9-10

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 4.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V6, V 8 4.2 FENDER NA ME PLATE

3 Endgate Emblem: Holden 4.4 ENDGATE EMBLEM

4 Endgate Name Plate: S 4.5 ENDGATE NAME PLATE, RH

5 Roof Joint Moulding 4.6 ROOF JOI NT MOULDING

6 Door Opening Moulding 4.7 DOOR OPENI NG MOULDING

7 Centre Pillar upper Finisher A ssembly 4.8 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

8 Rocker P anel Moulding Assembly 4.9 ROCKER PANE L MOULDING ASSEMBLY

9 Rear Window Upper Moulding 4.10 REAR WINDOW UPPER MOULDING

10 Rear Wi ndow Side Mouldi ng 4.11 RE A R WINDOW SIDE MOULDING

11 Quarter Window Moulding 4.12 QUARTER WINDOW MOULDING

12 Quarter Panel Rails 4.13 QUARTER P A NEL RAILS

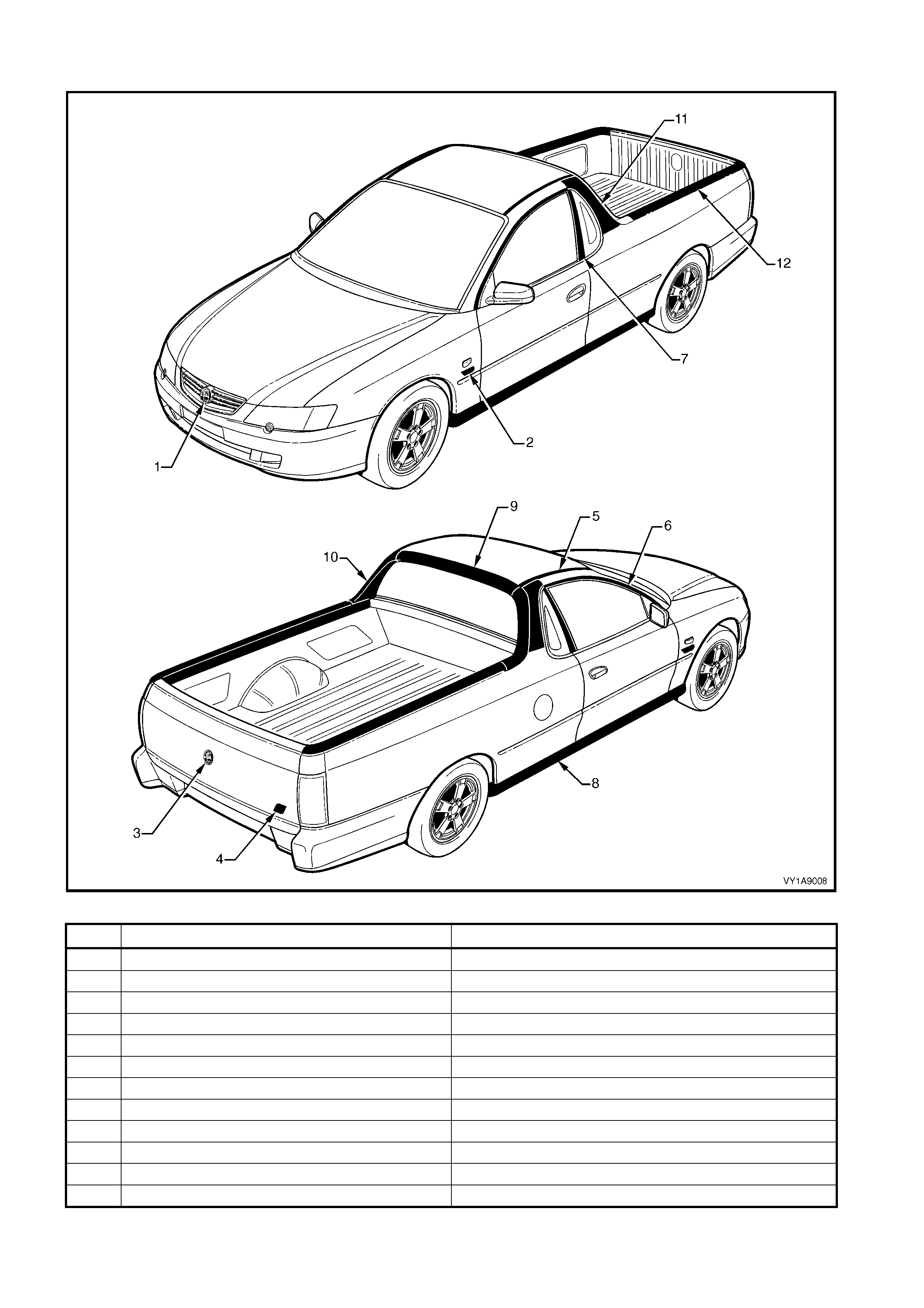

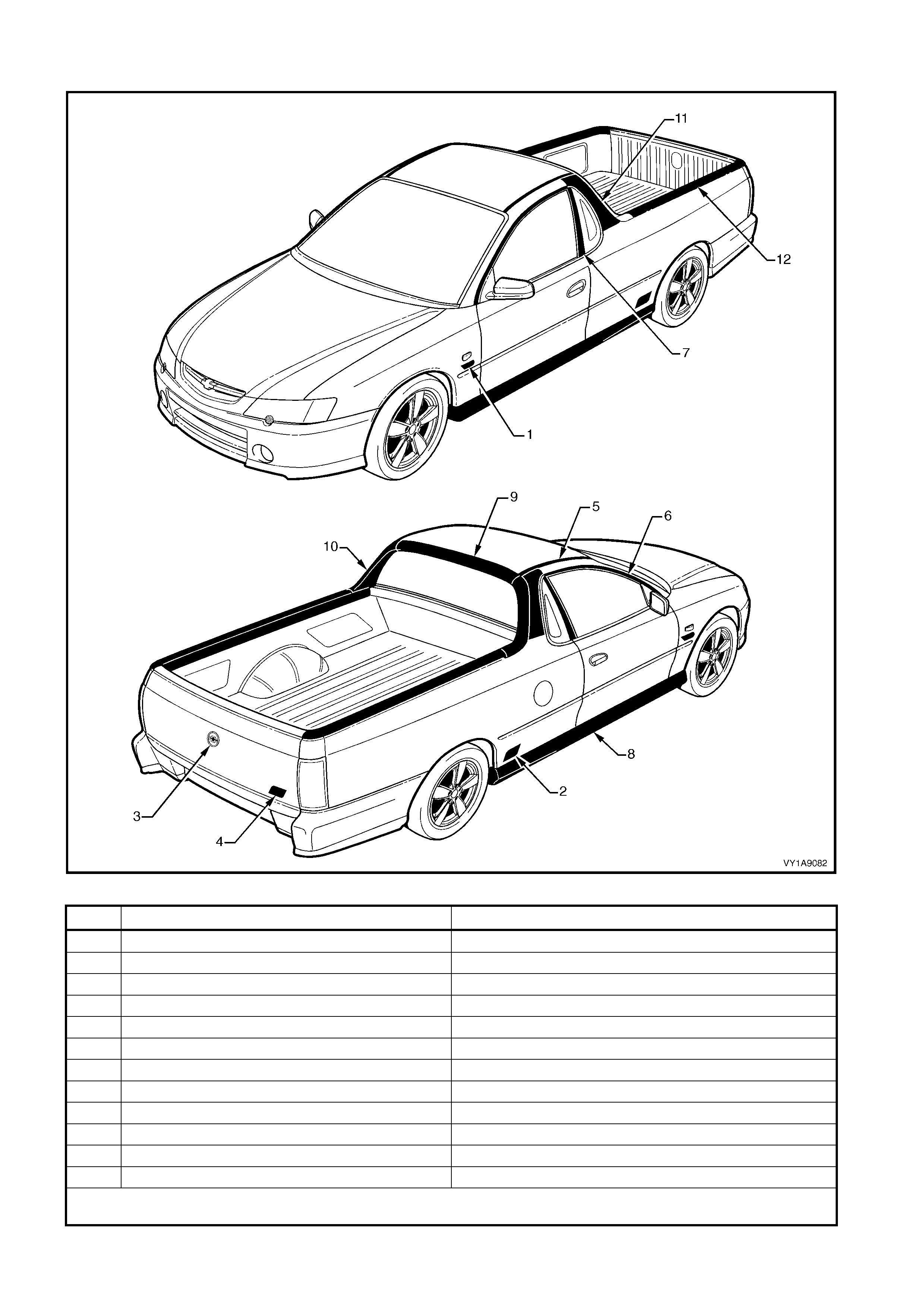

UTILITY: SS

Figure 1A9-11

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 4.1 RADIA T OR GRI LLE EMBLEM

2 Fender Name Pl ate: V8 4.2 FENDER NA ME PLATE

3 Quarter Panel Name Plate: SS 4.3 QUARTER P A NEL NAME PLATE

4 Endgate Emblem: Holden 4.4 ENDGATE EMBLEM

5 Endgate Name Plate: SS 4.5 ENDGAT E NAME PLATE , RH

6 Roof Joint Moulding 4.6 ROOF JOI NT MOULDING

7 Door Opening Moulding 4.7 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 4.8 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Rocker P anel Moulding Assembly 4.9 ROCKER PANE L MOULDING ASSEMBLY

10 Rear Wi ndow Upper Moulding 4.10 REAR WINDOW UP PER MOULDING

11 Rear Wi ndow Side Mouldi ng 4.11 RE A R WINDOW SIDE MOULDING

12 Quarter Window Moulding 4.12 QUARTER WINDOW MOULDING

13 Quarter Panel Rails 4.13 QUARTER P A NEL RAILS

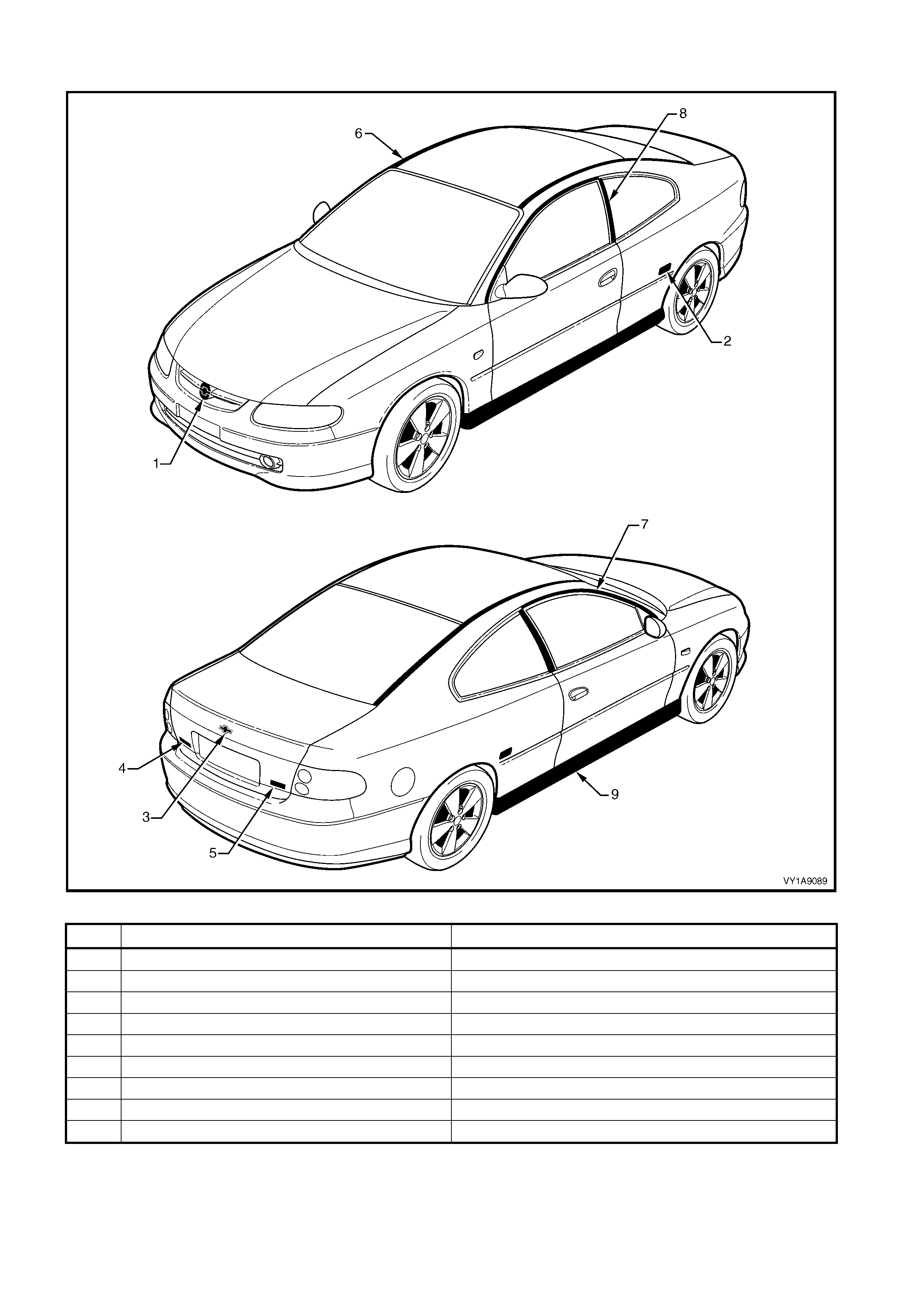

COUPE: MONARO CV6 & CV8

Figure 1A9-12

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Holden 5.1 RADIA T OR GRI LLE EMBLEM

2 Quarter Panel Name Plate: Monaro 5.2 QUARTER P A NEL NAME PLATE

3 Rear Compart ment Lid E mblem : Holden 5.3 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: CV6, CV8 5.5 REAR COMPA RTMENT LI D NAME PLATE , RH

5 Roof Joint Moulding 5.6 ROOF JOI NT MOULDING

6 Door Opening Moulding 5.7 DOOR OPENI NG MOULDING

7 Centre Pillar upper Finisher A ssembly 5.8 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

8 Rocker P anel Moulding Assembly 5.9 ROCKER PANE L MOULDING ASSEMBLY

1.2 PICTORIAL INDEX – EXPORT

The following diagrams provide a quick reference to the correct service procedures for the exterior ornamentation

components relevant to each vehicle model.

Simply refer to the vehic le m odel by using the table below, locate the component on the Figure and c ross -ref erenc e

it in the table below the Figure and go to the appropriate service procedure.

BODY MODEL REFER TO BODY MODEL REFER TO

Sedan Lumina LS Figure 1A9-13 Omega CD Figure 1A9-17

Lumina S Figure 1A9-14 Wagon Lumina LS Figure 1A9-18

Lumina SS Figure 1A9-15 Utility SS Figure 1A9-19

Lumina LTZ Figure 1A9-16 Coupe Lumina S & SS Figure 1A9-20

SEDAN: LUMINA LS

Figure 1A9-13

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Chevrolet 2.1 RADIATOR GRILLE EMBLEM

2 Fender Name Pl ate: V6 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Chevrolet 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Chevrolet 2.5 REAR COMPA RTMENT LI D NAME PLATE, LH

5 Rear Compart ment Lid Name Plate: Lumina LS 2.6 REA R COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Body Side Moulding 2.11 BODY SIDE MOULDINGS

11 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

SEDAN: LUMINA S

Figure 1A9-14

ITEM DESCRIPTION REFER TO

1 Fender Name Pl ate: V6 2.2 FENDER NA ME PLATE

2 Rear Compart ment Lid E mblem : Chevrolet 2.4 REAR COMPARTMENT LID EMBLEM

3 Rear Compart ment Lid Name Plate: Lumina 2.5 RE AR COMPARTMENT LID NAME PLATE, LH

4 Rear Compart ment Lid Name Plate: S 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

5 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

6 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

7 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

8 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

9 Rocker P anel Moulding Assembly 2.12 ROCKER PANE L MOULDING ASSEMBLY

NOTE 1: S vehicles are not fitted with a radiator grille emblem. For servicing of the radiator grille escutcheon refer to Section 1C, 2.2

RADIATOR GRILLE ASSEMBLY, S SEDAN & SS.

NOTE 2: For service procedures of the rear spoiler refer to Secti on 1A4, 3.4 REA R SPOILER A SSEMBLY.

SEDAN: LUMINA SS

Figure 1A9-15

ITEM DESCRIPTION REFER TO

1 Fender Name Pl ate: V8 or High Out put V8 2.2 FENDER NA ME PLATE

2 Rear Door Name P l at e: SS 2.3 REAR DOOR NA ME P LATE

3 Rear Compart ment Lid E mblem : Chevrolet 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Lumina 2.5 RE AR COMPARTMENT LID NAME PLATE, LH

5 Rear Compart ment Lid Name Plate: SS 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Body Side Moulding 2.11 BODY SIDE MOULDINGS

11 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

NOTE 1: SS vehicles are not f itted with a radiator grille emblem . For servicing of the radiator grille esc utcheon refer to Section 1C, 2.2

RADIATOR GRILLE ASSEMBLY, S SEDAN & SS.

NOTE 2: For service procedures of the rear spoiler refer to Secti on 1A4, 3.4 REA R SPOILER A SSEMBLY.

SEDAN: LUMINA LTZ

Figure 1A9-16

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Chevrolet 2.1 RADIATOR GRILLE EMBLEM

2 Fender Name Pl ate: V6 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Chevrolet 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Chevrolet 2.5 REAR COMPA RTMENT LI D NAME PLATE, LH

5 Rear Compartment Lid Name Plate: Lumina LTZ 2.6 REAR COMPA RTMENT LI D NA ME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Body Side Moulding 2.11 BODY SIDE MOULDINGS

11 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

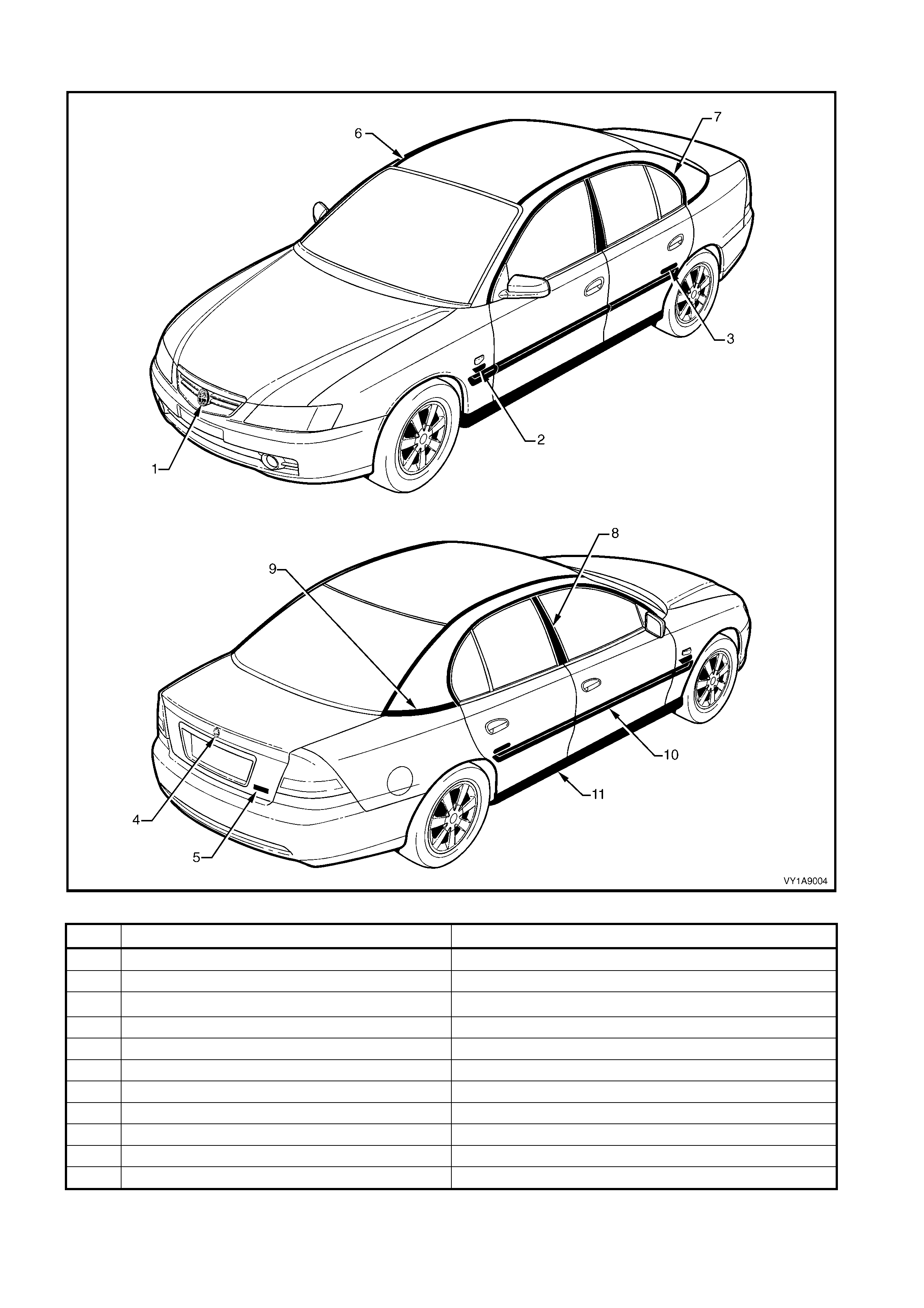

SEDAN: OMEGA CD

Figure 1A9-17

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Chevrolet 2.1 RADIATOR GRILLE EMBLEM

2 Fender Name Pl ate: V6 2.2 FENDER NA ME PLATE

3 Rear Compart ment Lid E mblem : Chevrolet 2.4 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Omega CD 2.5 RE AR COMPARTMENT LID NAME PLAT E, LH

5 Rear Compart ment Lid Name Plate: 3.8 V6 2.6 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 2.7 ROOF JOI NT MOULDING

7 Door Opening Moulding 2.8 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 2.9 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Quarter Panel Bel t Moulding 2.10 QUARTER P A NE L BELT MOULDING

10 Body Side Moulding 2.11 BODY SIDE MOULDINGS

11 Rocker Panel Moulding A ssem bl y 2.12 ROCKER P ANEL MOULDING ASS EMBLY

WAGON: LUMINA LS

Figure 1A9-18

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Chevrolet 3.1 RADIATOR GRILLE EMBLEM

2 Fender Name Pl ate: V6 3.2 FENDER NA ME PLATE

3 Liftgate Emblem: Chevrolet 3.3 LIFTGAT E E MBLE M

4 Liftgat e Name Plat e: Chevrolet 3.4 LI FTGA T E NAME PLATE , LH

5 Liftgat e Name Plat e: Lumina LS 3.5 LIFTGAT E NAME PLATE, RH

6 Roof Joint Moulding 3.6 ROOF JOI NT MOULDING

7 Roof Side Rail s 3.8 ROOF SIDE RAILS

8 Door Opening Moulding 3.9 DOOR OPENI NG MOULDING

9 Centre Pillar upper Finisher Assembly 3.10 CENTRE PILLAR UPPER FINISHER ASSEMBLY

10 Roof Joint Finis her 3.11 ROOF JOINT FI NISHER

11 Body Side Moulding 3.12 BODY SIDE MOULDINGS

12 Rocker Panel Moulding A ssem bl y 3.13 ROCKER P ANEL MOULDING ASS EMBLY

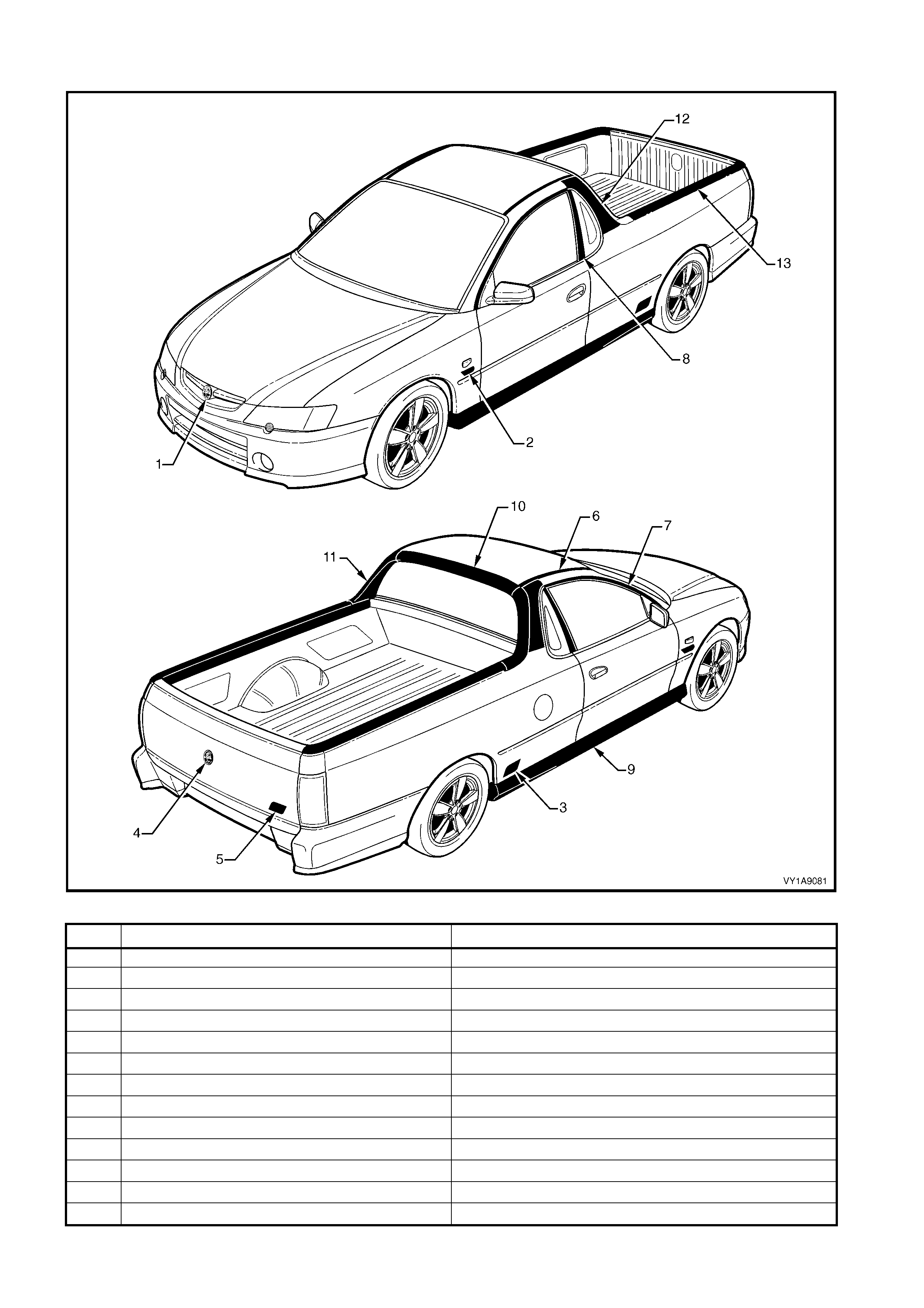

UTILITY: SS

Figure 1A9-19

ITEM DESCRIPTION REFER TO

1 Fender Name Pl ate: V8 4.2 FENDER NA ME PLATE

2 Quarter Panel Name Plate: SS 4.3 QUARTER P A NEL NAME PLATE

3 Endgate Emblem: Chevrolet 4.4 ENDGATE EMBLEM

4 Endgate Name Plate: SS 4.5 ENDGAT E NAME PLATE , RH

5 Roof Joint Moulding 4.6 ROOF JOI NT MOULDING

6 Door Opening Moulding 4.7 DOOR OPENI NG MOULDING

7 Centre Pillar upper Finisher A ssembly 4.8 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

8 Rocker P anel Moulding Assembly 4.9 ROCKER PANE L MOULDING ASSEMBLY

9 Rear Window Upper Moulding 4.10 REAR WINDOW UPPER MOULDING

10 Rear Wi ndow Side Mouldi ng 4.11 RE A R WINDOW SIDE MOULDING

11 Quarter Window Moulding 4.12 QUARTER WINDOW MOULDING

12 Quarter Panel Rails 4.13 QUARTER P A NEL RAILS

NOTE: S S Utility vehicles are not fitted with a radiator grille em blem. For servicing of the radiator grille escut cheon refer to Section 1C,

2.2 RADIATOR GRILLE ASSEMBLY, S SEDAN & SS.

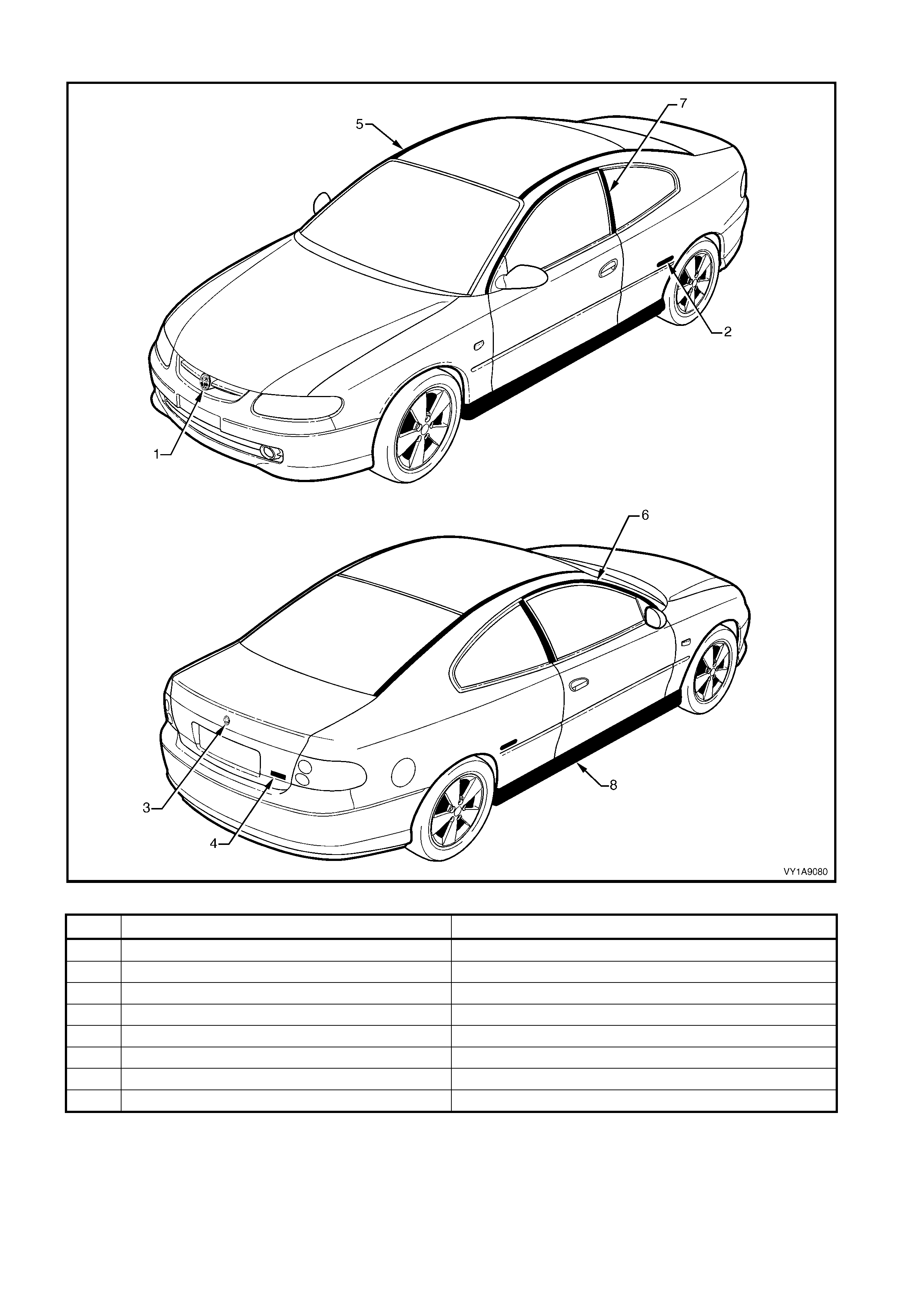

COUPE: LUMINA S & SS

Figure 1A9-20

ITEM DESCRIPTION REFER TO

1 Radiator Grille Emblem: Chevrolet 5.1 RADIATOR GRILLE EMBLEM

2 Quarter Panel Name Plate: SS 5.2 QUARTER P A NEL NAME PLATE

3 Rear Compart ment Lid E mblem : Chevrolet 5.3 REAR COMPARTMENT LID EMBLEM

4 Rear Compart ment Lid Name Plate: Lumina 5.4 RE AR COMPARTMENT LID NAME PLATE, LH

5 Rear Compart ment Lid Name Plate: S or SS 5.5 REAR COMPA RTMENT LI D NAME PLATE, RH

6 Roof Joint Moulding 5.6 ROOF JOI NT MOULDING

7 Door Opening Moulding 5.7 DOOR OPENI NG MOULDING

8 Centre Pillar upper Finisher A ssembly 5.8 CENTRE P I LLAR UPPER FINI SHER ASSE MBLY

9 Rocker P anel Moulding Assembly 5.9 ROCKER PANE L MOULDING ASSEMBLY

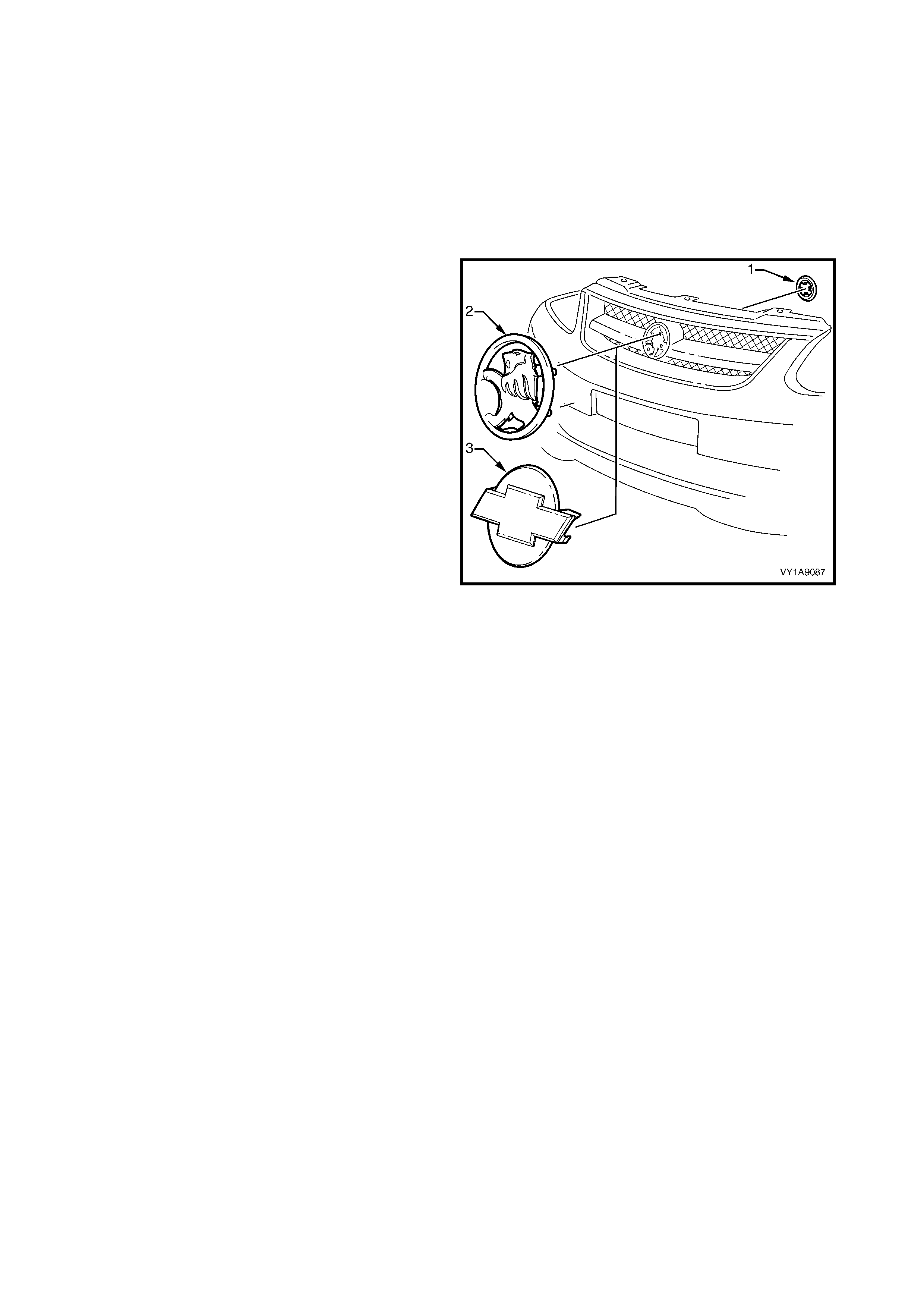

2. SERVICE OPERATIONS, SEDAN

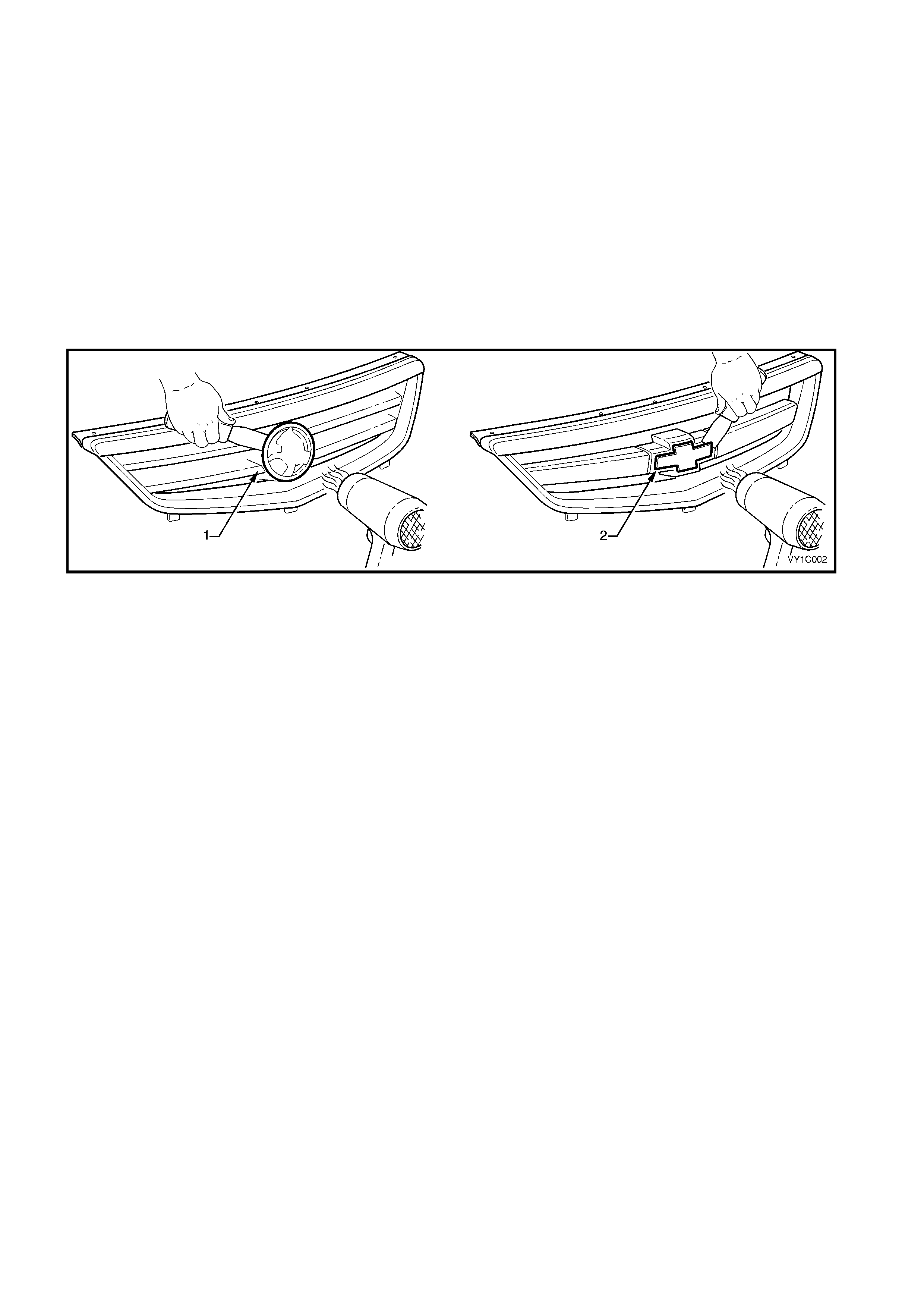

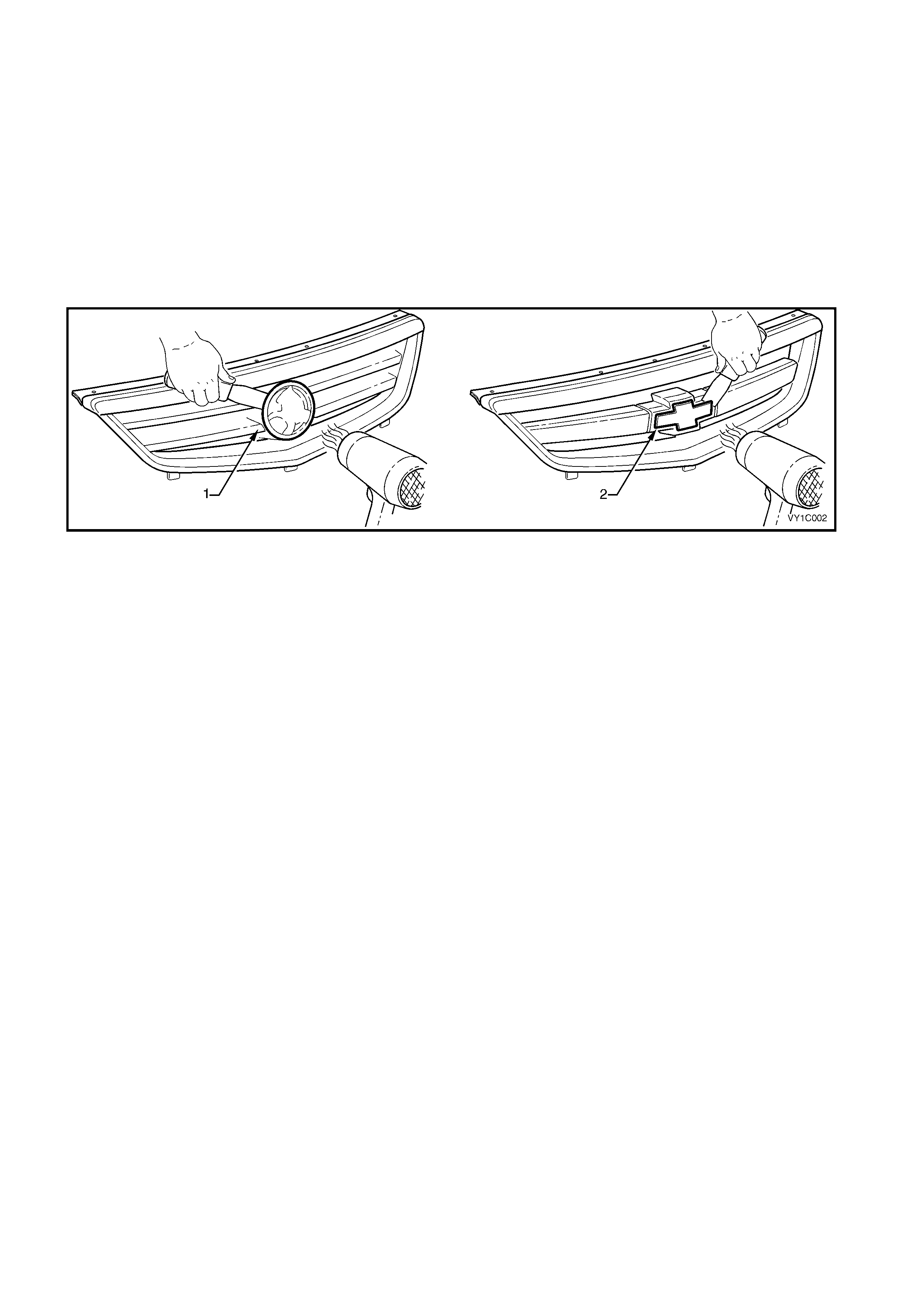

2.1 RADIATOR GRILLE EMBLEM

LT Section No. – 10-150

NOTE: Export S and SS vehicles are not fitted with a radiator grille emblem. For servicing of the radiator grille

escutcheon refer to Section 1C, 2.2 RADIATOR GRILLE ASSEMBLY, S SEDAN & SS.

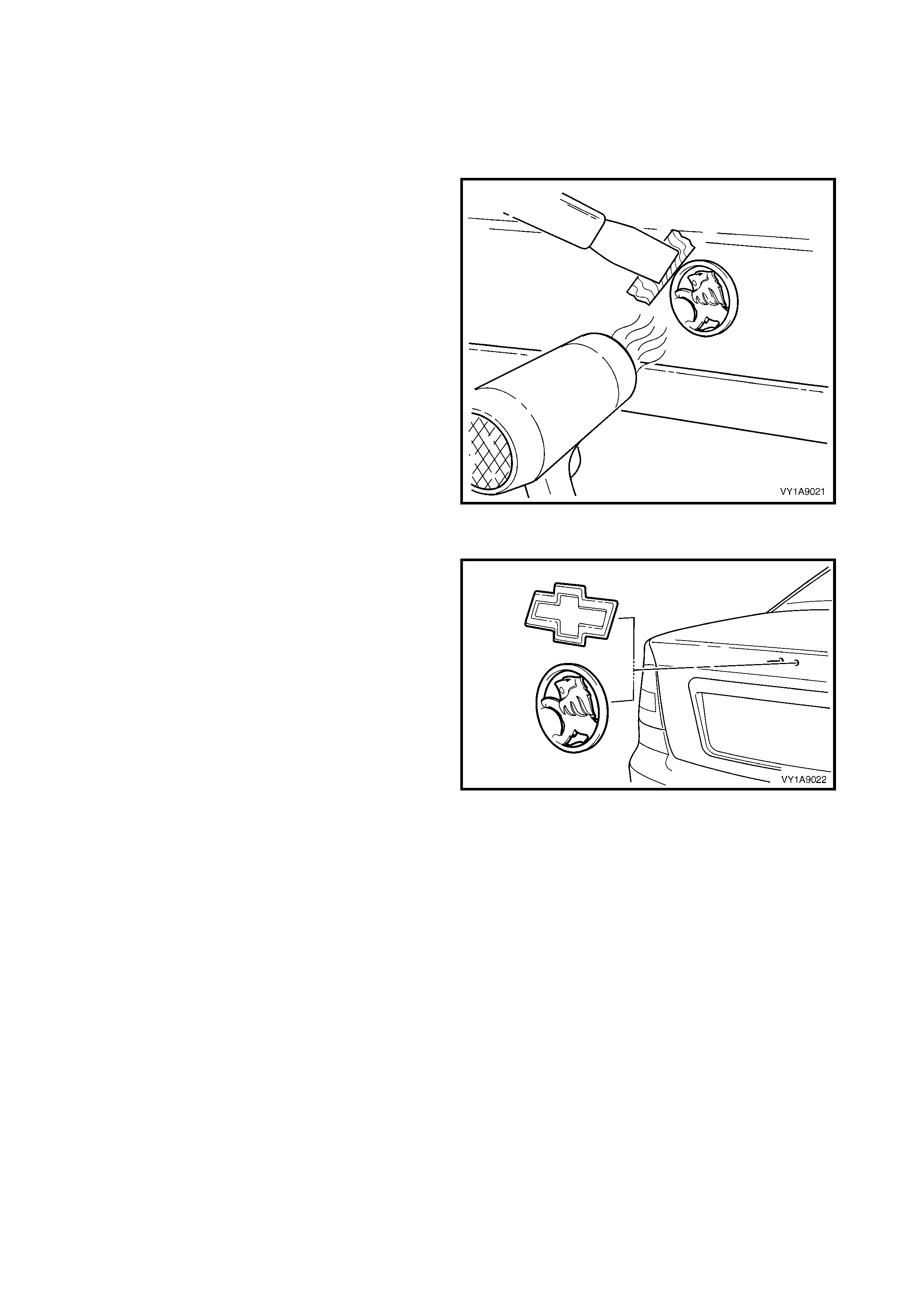

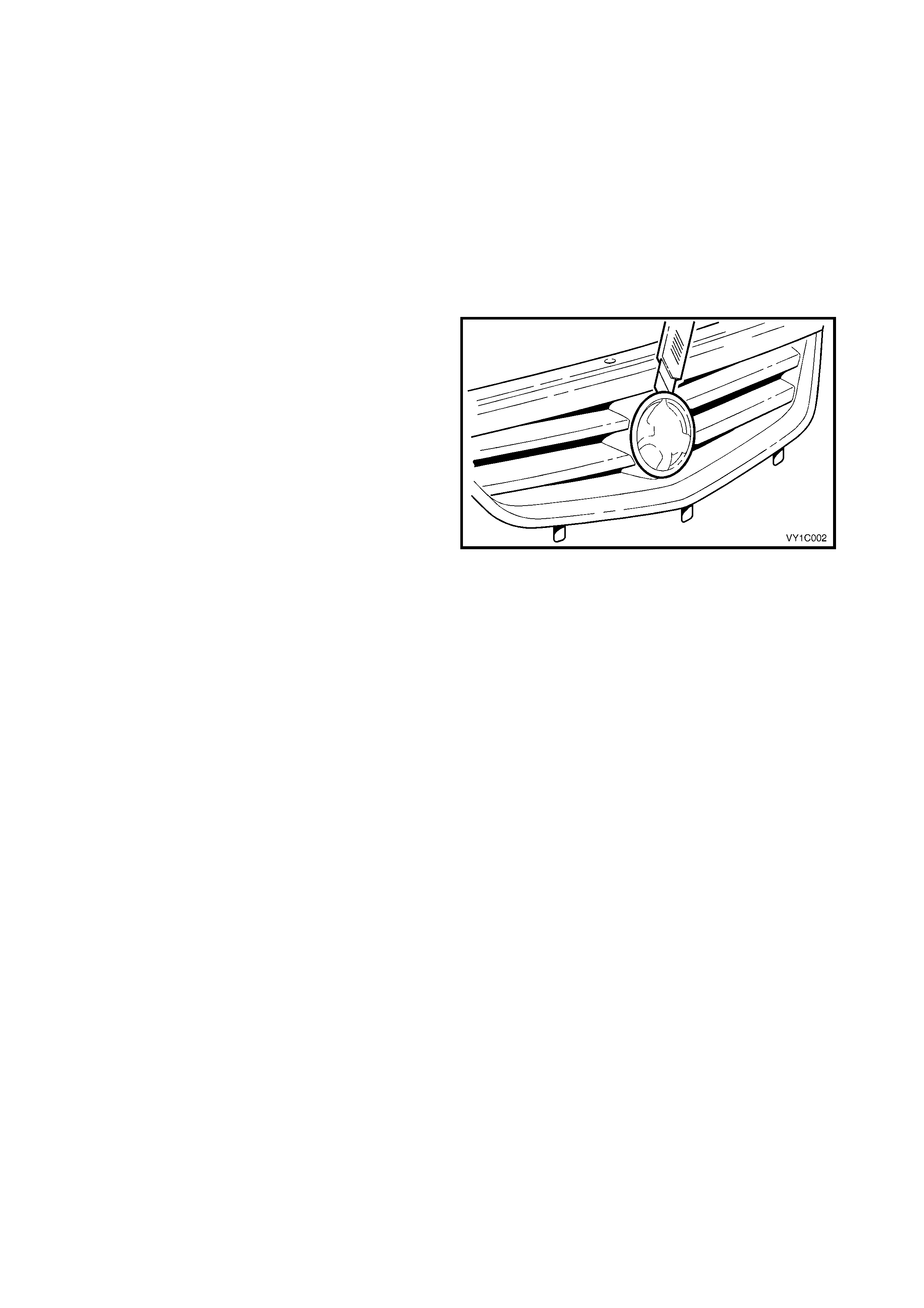

REMOVE

1. To assist removal, warm the emblem with a heat-lamp or heat-gun to soften the adhesive.

2. Using a knife or paint scraper, carefully remove the emblem assembly (1–domestic or 2–export) from the

grille assembly, cutting the double-sided tape, refer to Figure 1A9-21.

NOTE: The domestic emblem has two locating lugs which must not be cut if the emblem is to be reused.

3. Remove any remaining double-sided tape as required.

Figure 1A9-21

REINSTALL

1. If reinstalling the existing emblem, remove the existing double-sided tape and clean the surface with wax

and grease remover such as Prepsol or equivalent. Apply new polyethylene double-sided tape such as 3M

4428 or equivalent.

2. Clean the surface of the grille assembly with wax and grease remover such as Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Align the emblem. For domestic vehicles, locate the lugs with their corresponding holes in the grille

assembly. For export vehicles, align the emblem within its recess in the grille assembly.

5. Affix the emblem and press firmly over the entire emblem for at least 10 seconds to ensure sound adhesion.

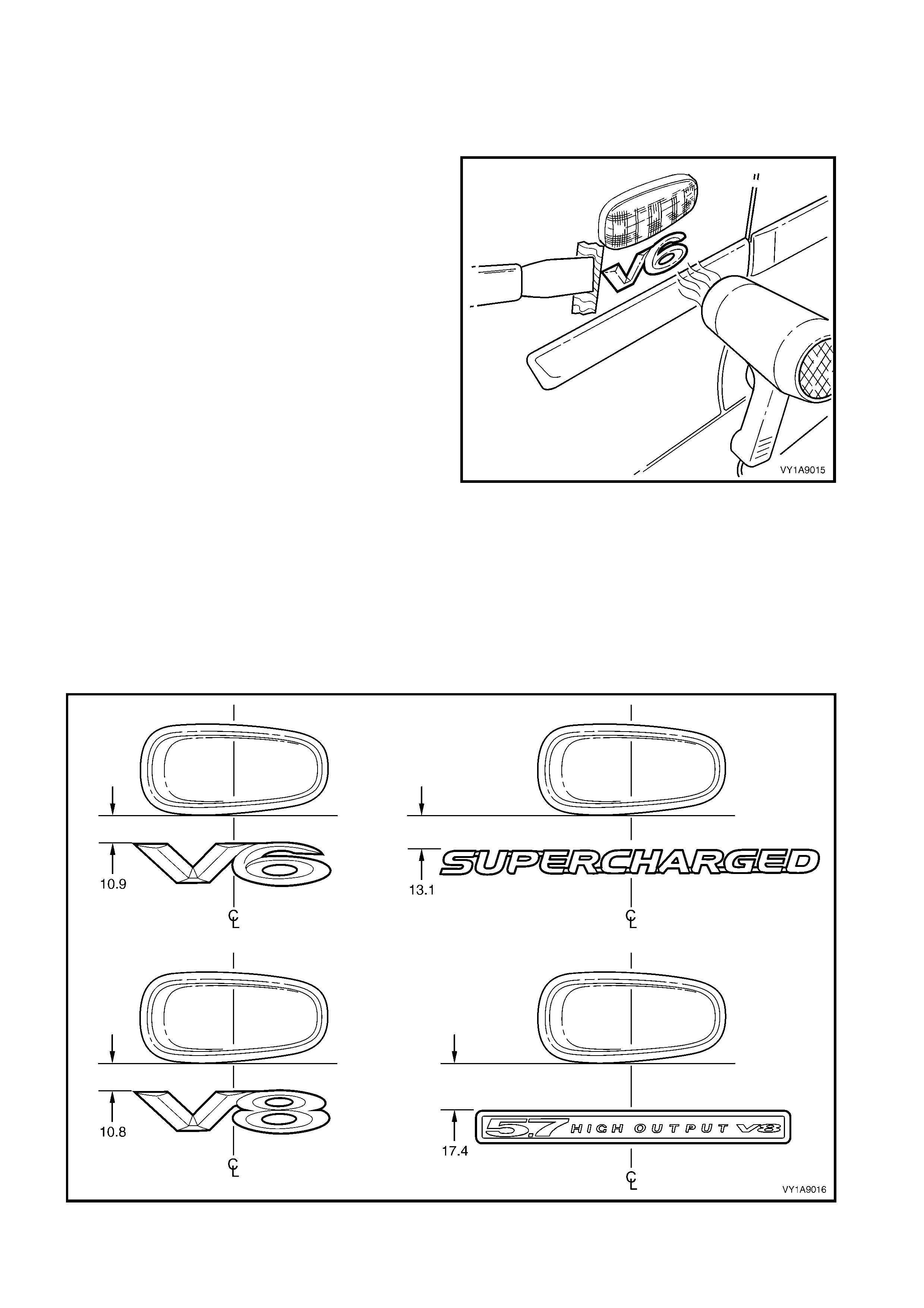

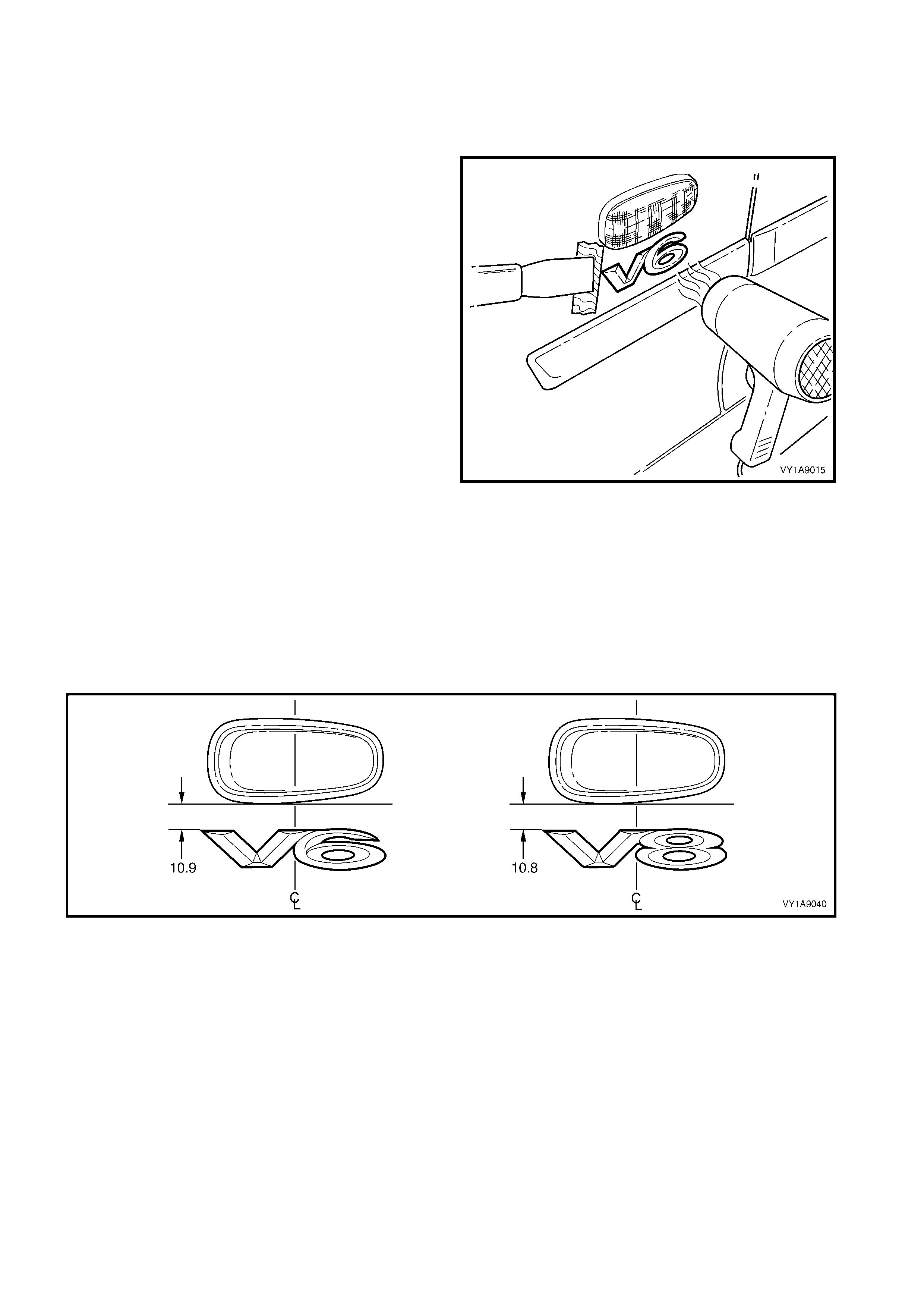

2.2 FENDER NAME PL ATE

LT Section No. – 10-150

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the plate with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

plate from the fender.

4. Remove any remaining double- sided tape from the

plate and/or fender and clean the surfaces with

Prepsol or equivalent.

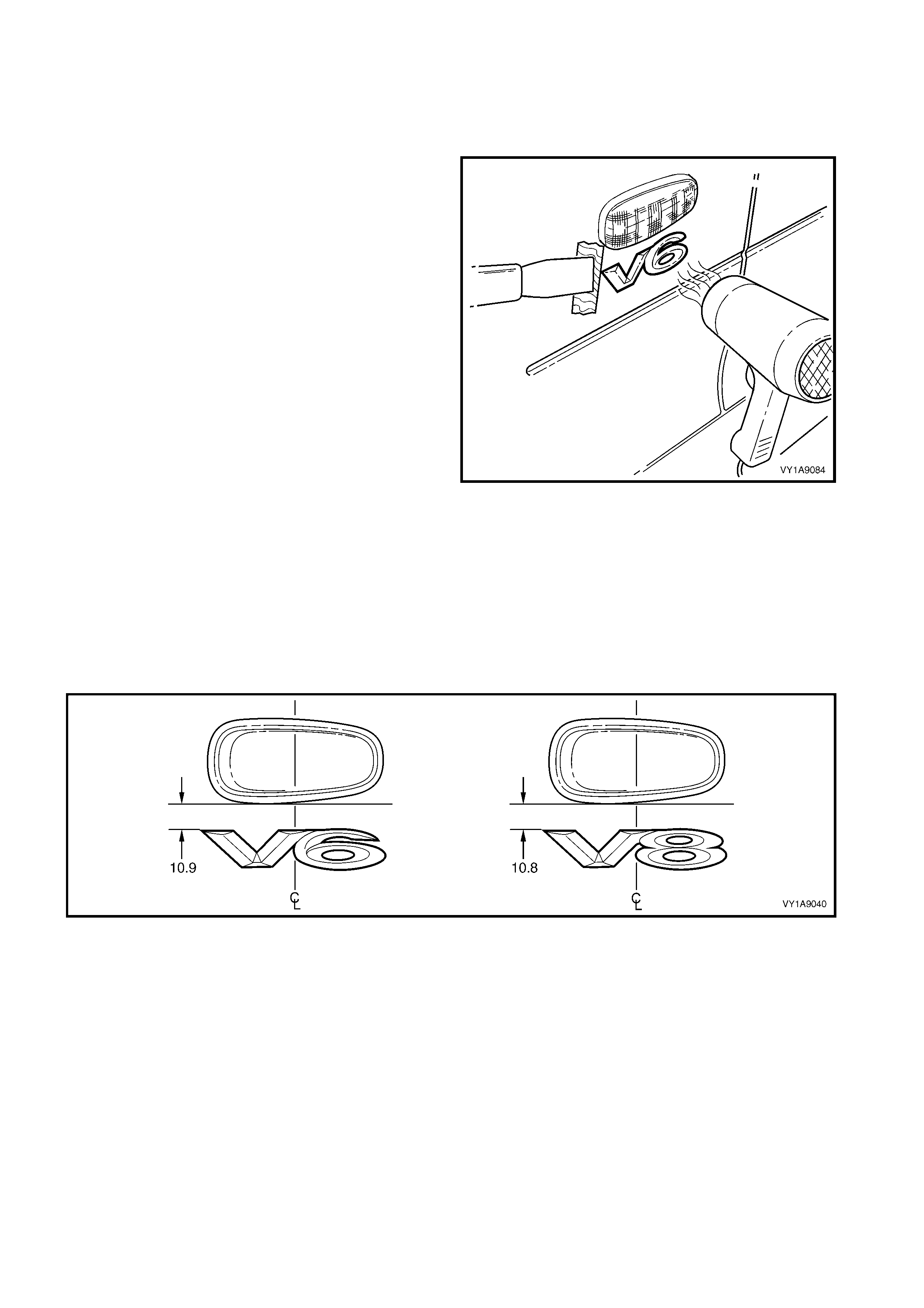

Figure 1A9-22

REINSTALL

1. If reusing the plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the back

and trim the edges of the tape slightly in from the edge of plate.

2. Clean the fender surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the plate in the position shown, measuring from the front side turn signal lamp hole, refer to Figure

1A9-23. Ensure it is positioned parallel to the body side moulding or style line.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-23

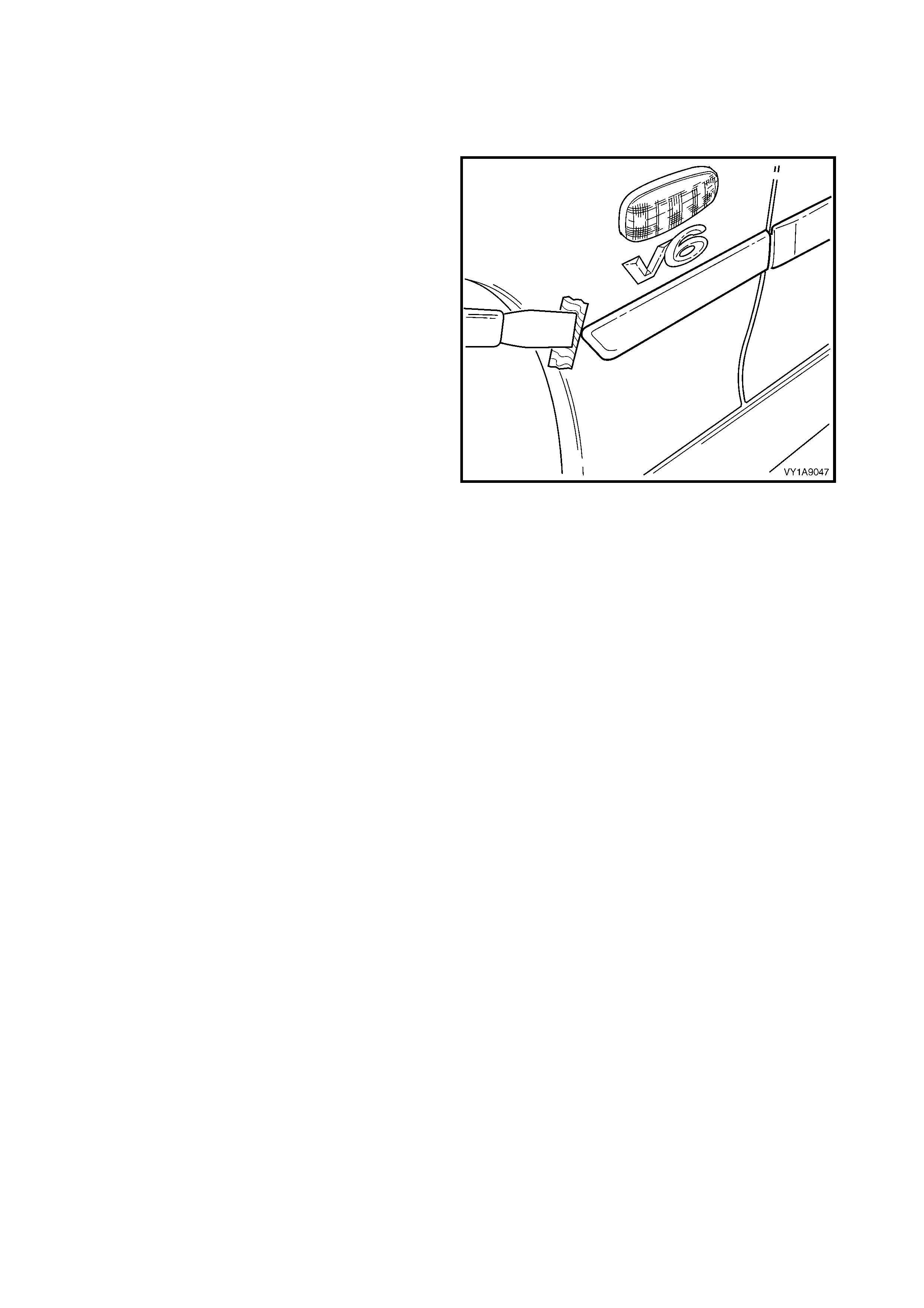

2.3 REAR DOOR NAME PLATE

LT Section No. – 10-150

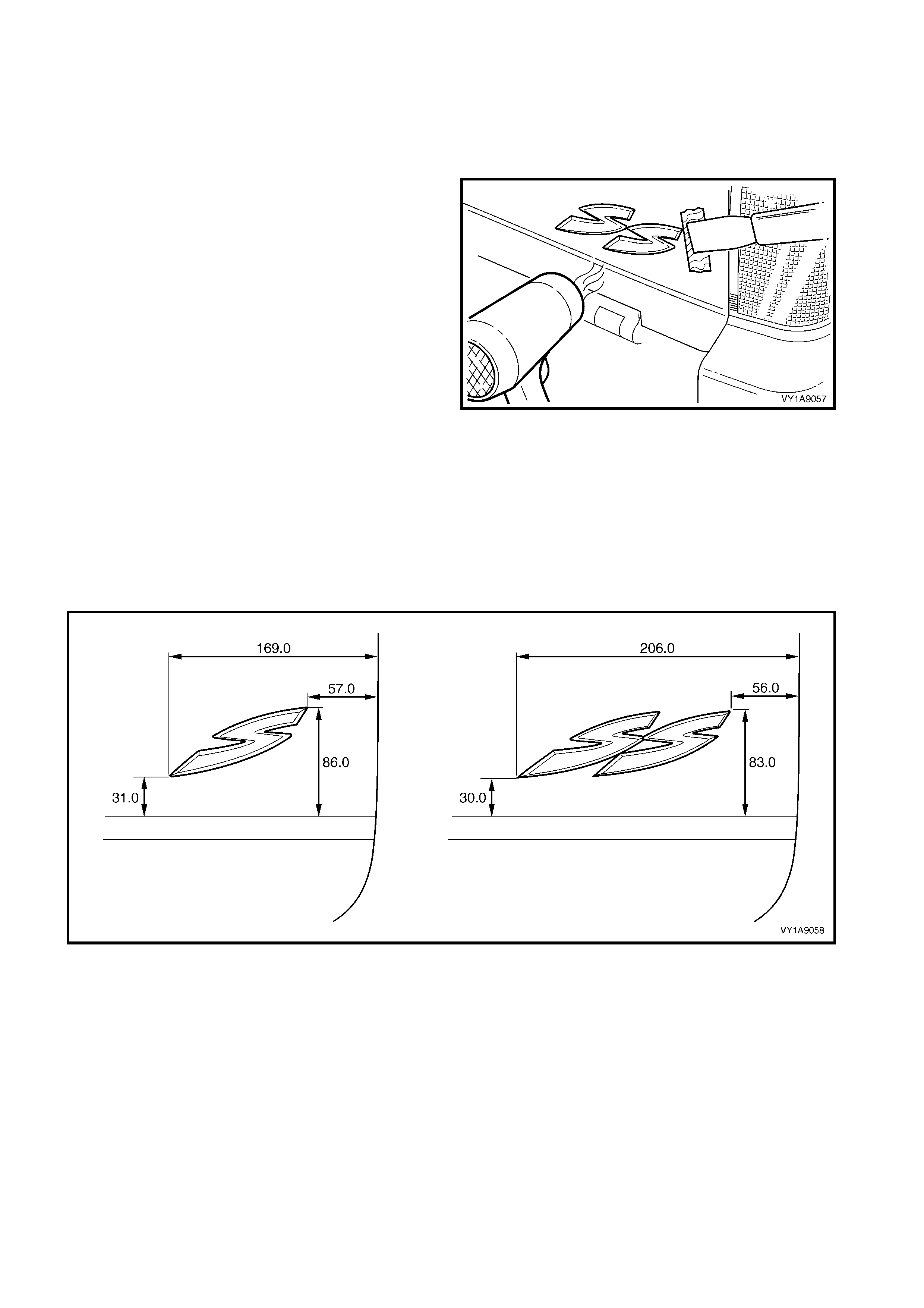

SS

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the door panel.

4. As required, remove any remaining double-sided

tape from the name plate and/or door panel and

clean the surfaces with Prepsol or equivalent.

Figure 1A9-24

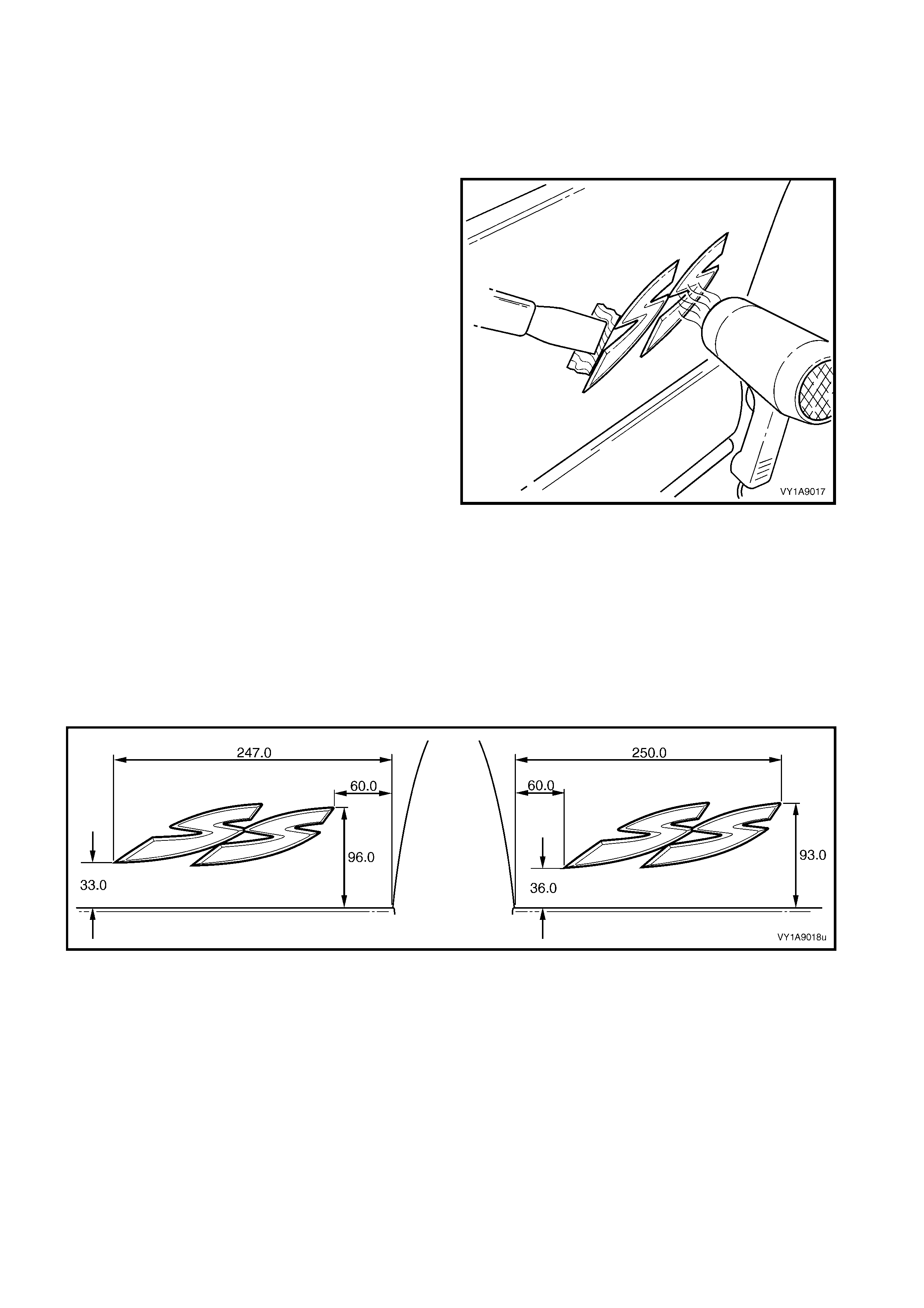

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the door surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the nam e plate on to the lower section of the rear door in the position shown, m easuring up from the

lower edge of the door and in from the rear edge of the door, refer to Figure 1A9-25.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-25

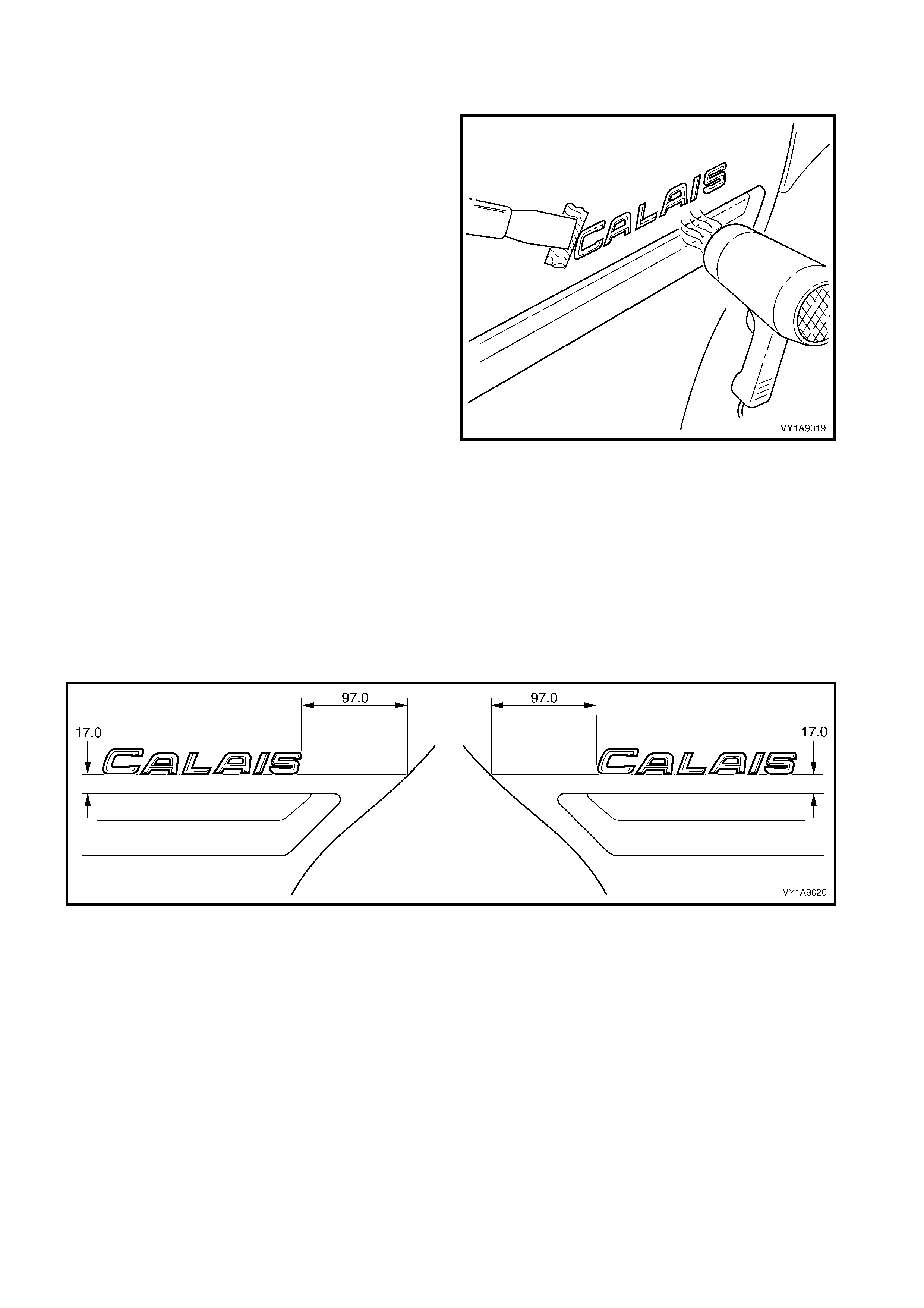

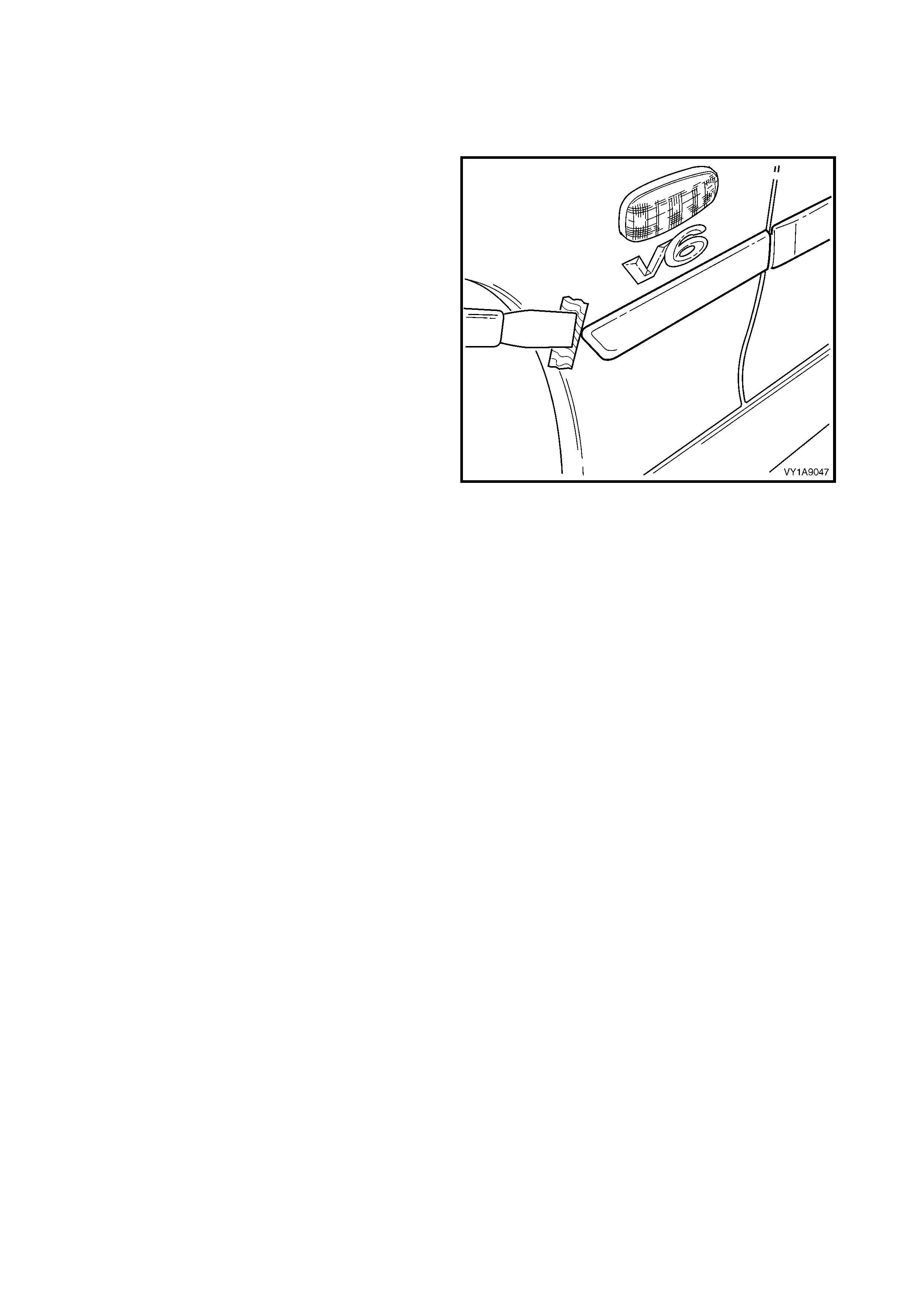

CALAIS

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the door panel.

4. As required, remove any remaining double-sided

tape from the name plate and/or door panel and

clean the surfaces with Prepsol or equivalent.

Figure 1A9-26

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the door surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the nam e plate on to the rear door in the position shown, measuring up from the body side moulding

and in from the rear edge of the door. Ensure it is positioned parallel to the body side moulding, refer to

Figure 1A9-27.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

6. Remove the plastic carrier.

Figure 1A9-27

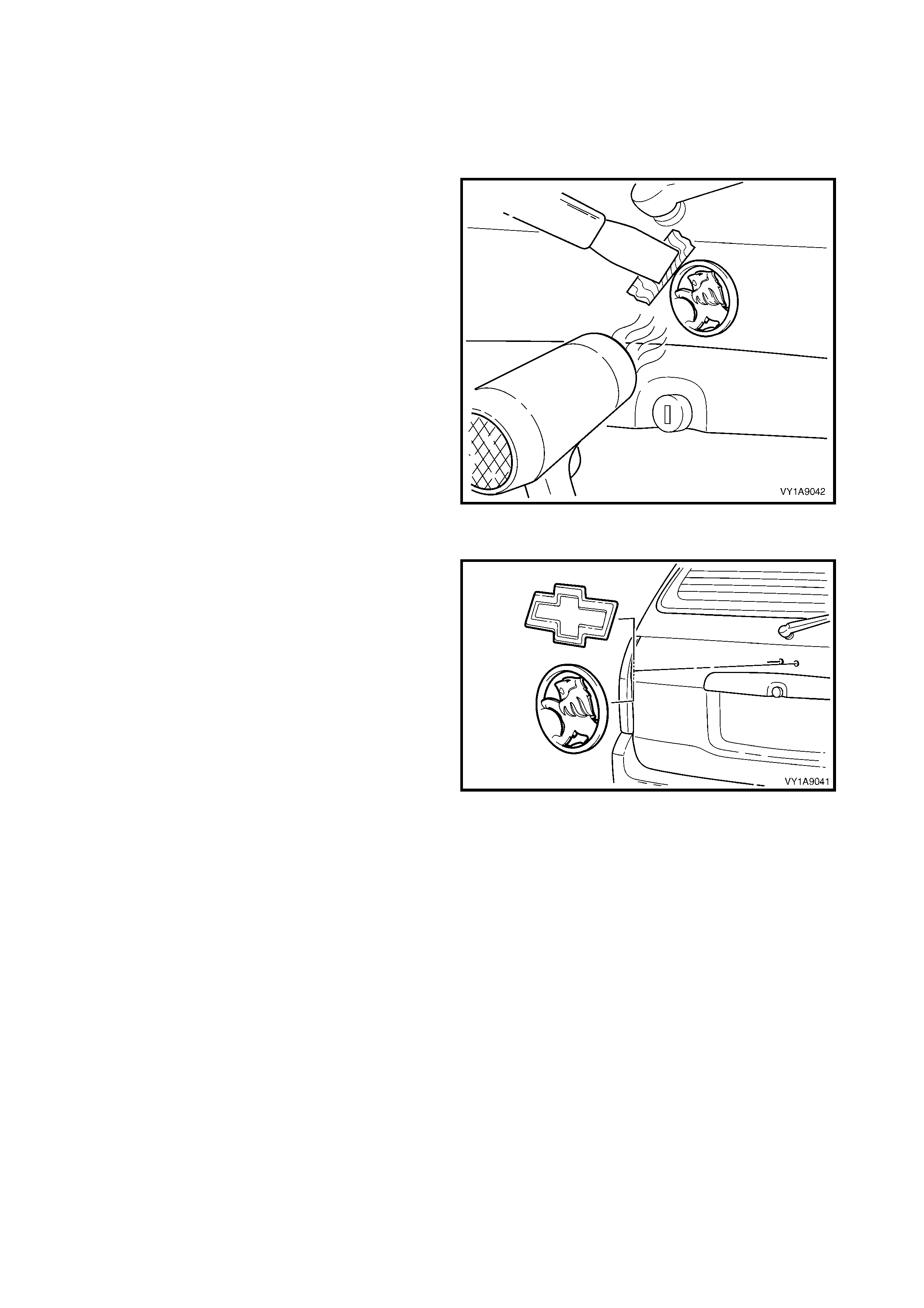

2.4 REAR COMPARTMENT LID EMBLEM

LT Section No. – 10-150

HOLDEN, CHEVROLET

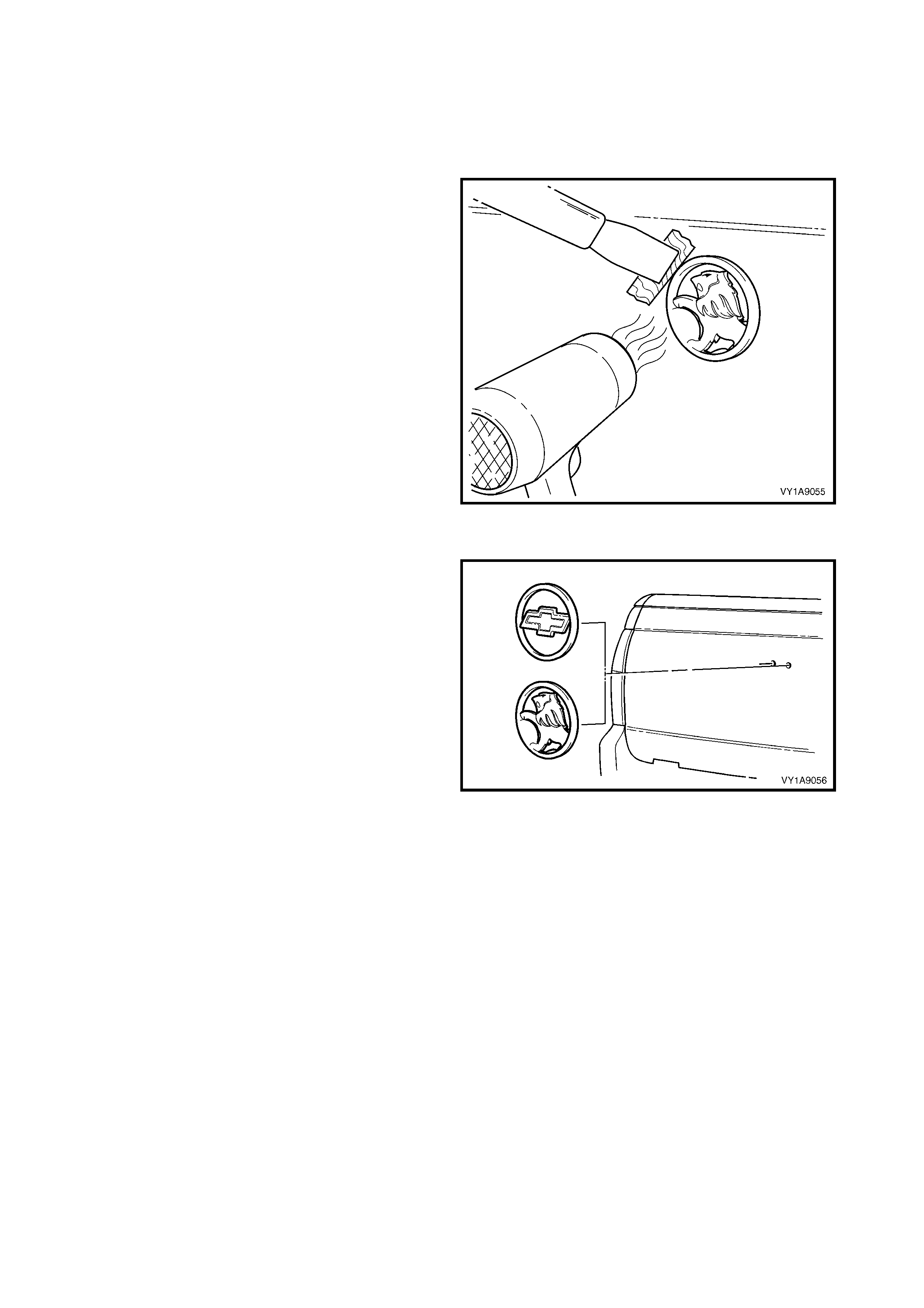

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the emblem with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

emblem from the rear compartment lid.

NOTE: The emblem has two locating pins, take care

not to break them if the emblem is to be reused.

4. As required, remove any remaining double-sided

tape f rom the em blem and/or rear com partm ent lid

and clean the surfaces with Prepsol or equivalent.

Figure 1A9-28

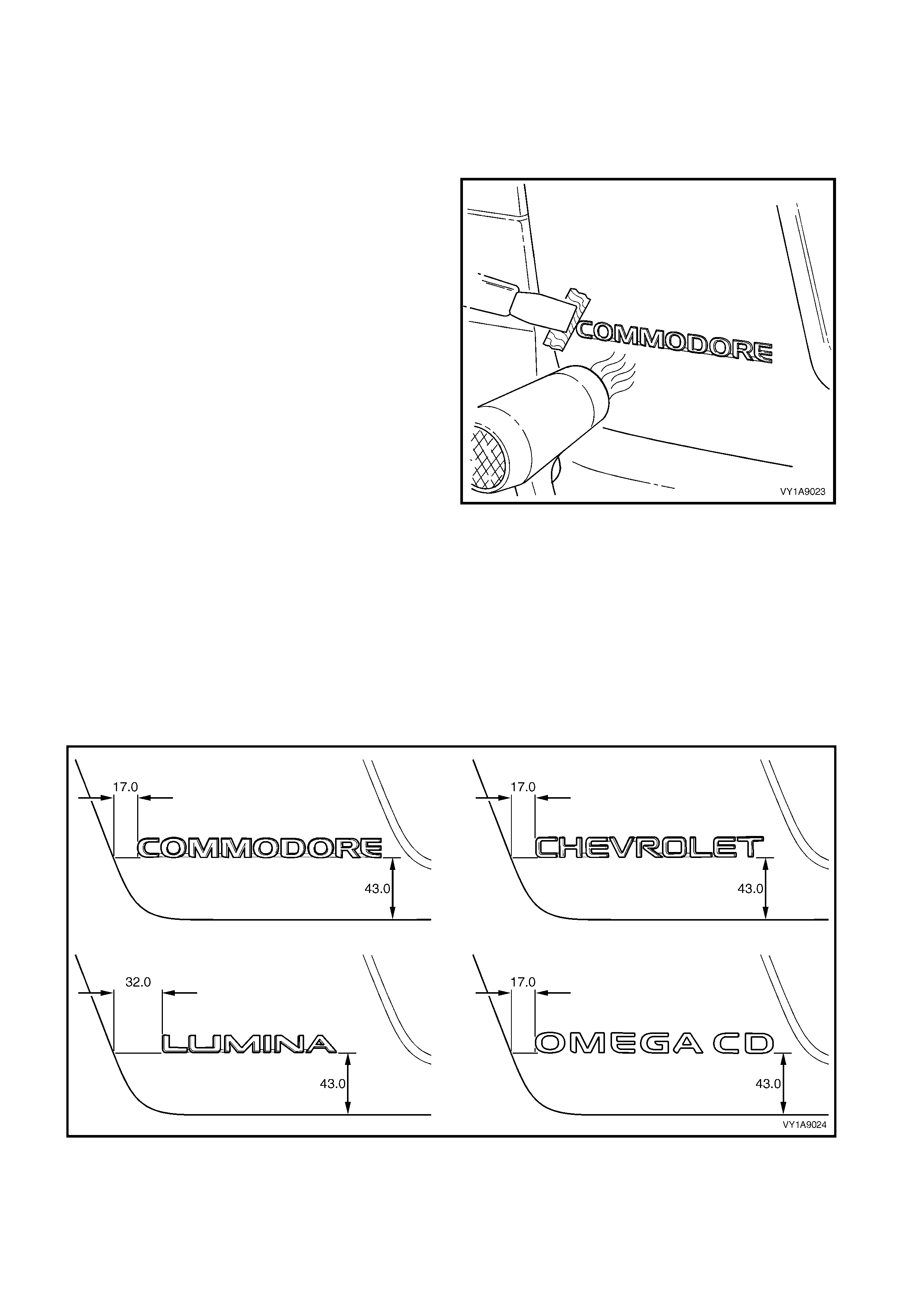

REINSTALL

1. If reusing the emblem, apply new polyethylene

double-sided tape such as 3M 4428 or equivalent

to the back and the trim edges of the tape slightly

in from the edge of the emblem.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided

tape.

4. Apply the emblem in the position shown, ensuring

the locating pins are correctly orientated with the

locating holes in the panel surface.

5. Press firm ly over the entire emblem for at leas t 10

seconds to ensure maximum adhesion.

Figure 1A9-29

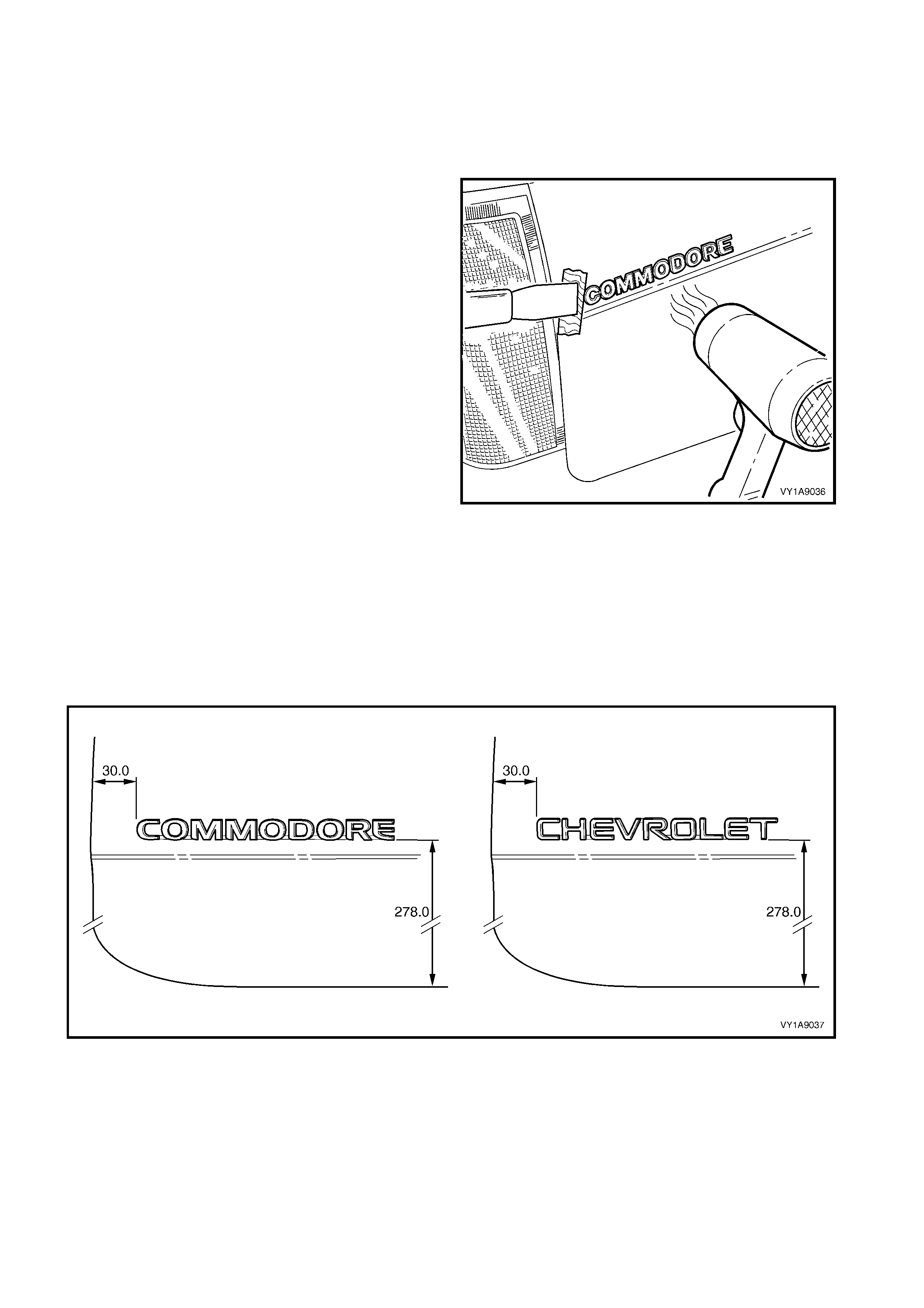

2.5 REAR COMPARTMENT LID NAME PLATE, LH

LT Section No. – 10-150

COMMODORE, CHEVROLET, LUMINA, OMEGA CD

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the rear compartment lid.

4. As required, remove any remaining double-sided

tape from the nam e plate and/or rear c ompartment

lid and clean the surfaces with Prepsol or

equivalent.

Figure 1A9-30

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

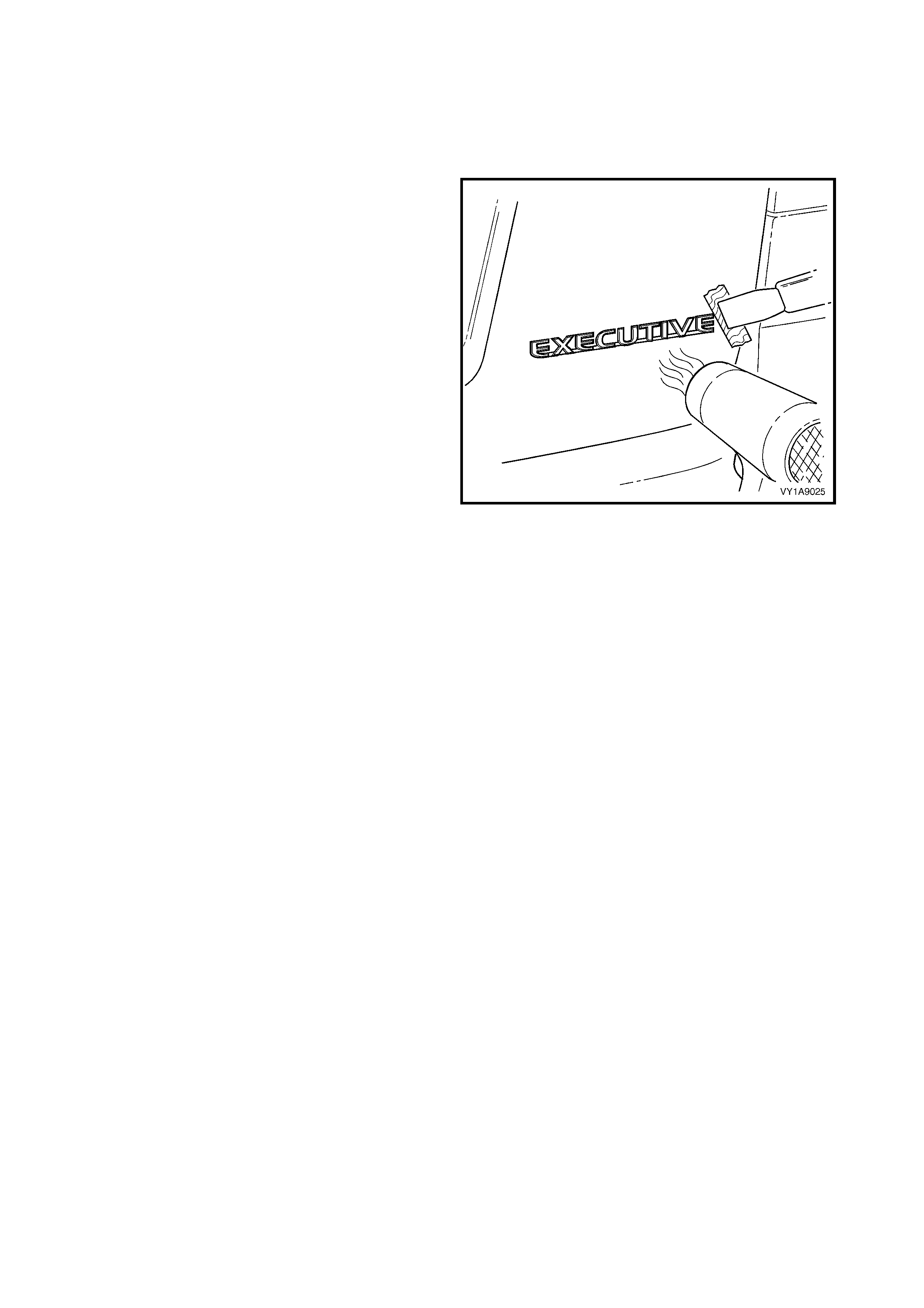

4. Apply the name plate onto the left-hand side of the rear compartment lid in the position shown, measuring

from the edge of the r ear com partment lid. Ens ure it is positioned parallel to the lower edge, ref er to Figure

1A9-31.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

6. If required, remove the plastic carrier.

Figure 1A9-31

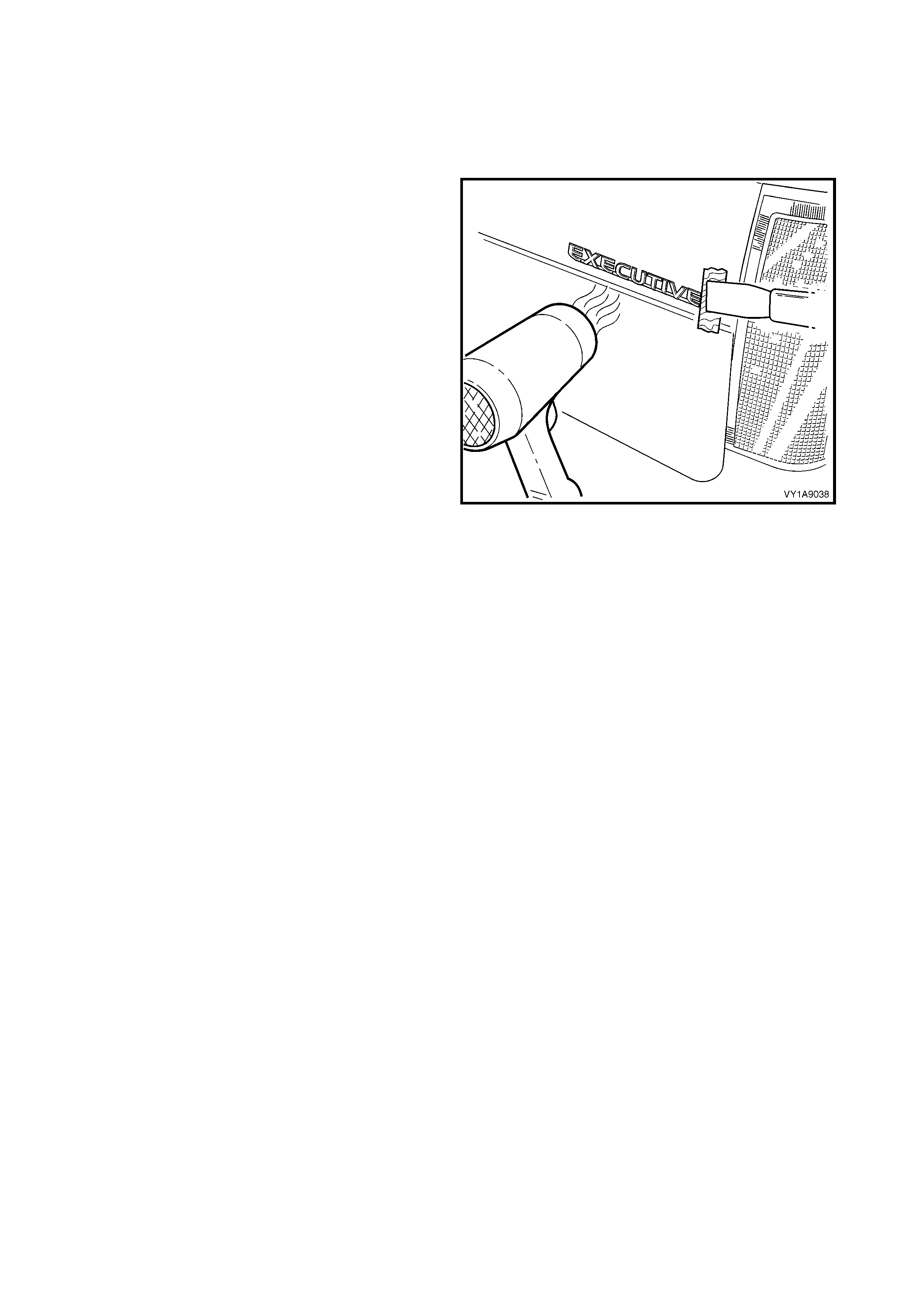

2.6 REAR COMPARTMENT LID NAME PLATE, RH

LT Section No. – 10-150

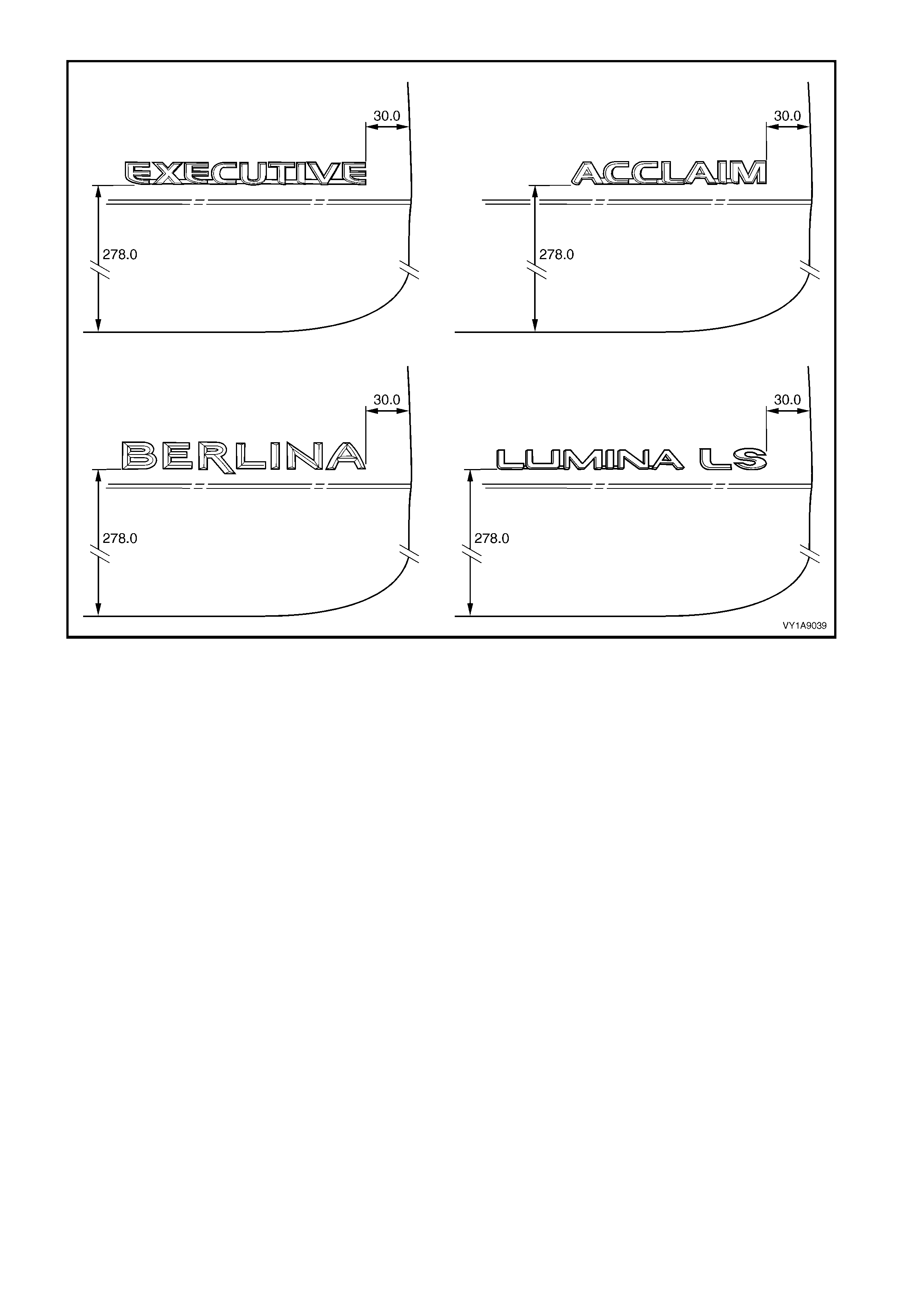

EXECUTIVE, ACCLAIM, S, SV8, SS, BERLINA, CALAIS, LUMINA LS, LUMINA LTZ, 3.8 V6

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the rear compartment lid.

4. As required, remove any remaining double-sided

tape from the nam e plate and/or rear c ompartment

lid and clean the surfaces with Prepsol or

equivalent.

Figure 1A9-32

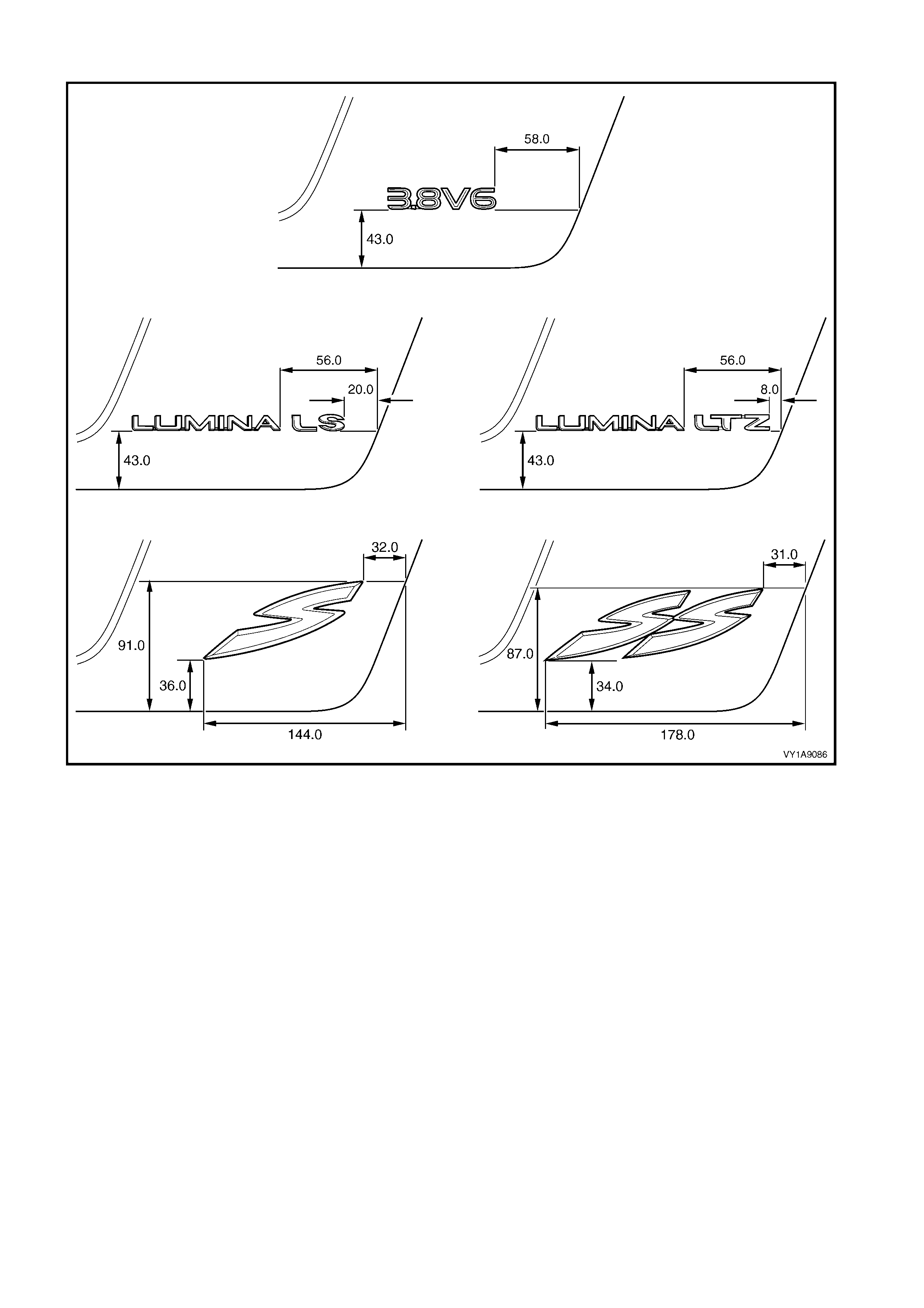

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the name plate onto the r ight-hand side of the rear com partm ent lid in the position shown, measuring

from the edge of the r ear com partment lid. Ens ure it is positioned parallel to the lower edge, ref er to Figure

1A9-33 for domestic vehicles or Figure 1A9-34 for export vehicles.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

6. Where required remove the plastic carrier.

DOMESTIC VEHICLES

Figure 1A9-33

EXPORT VEHICLES

Figure 1A9-34

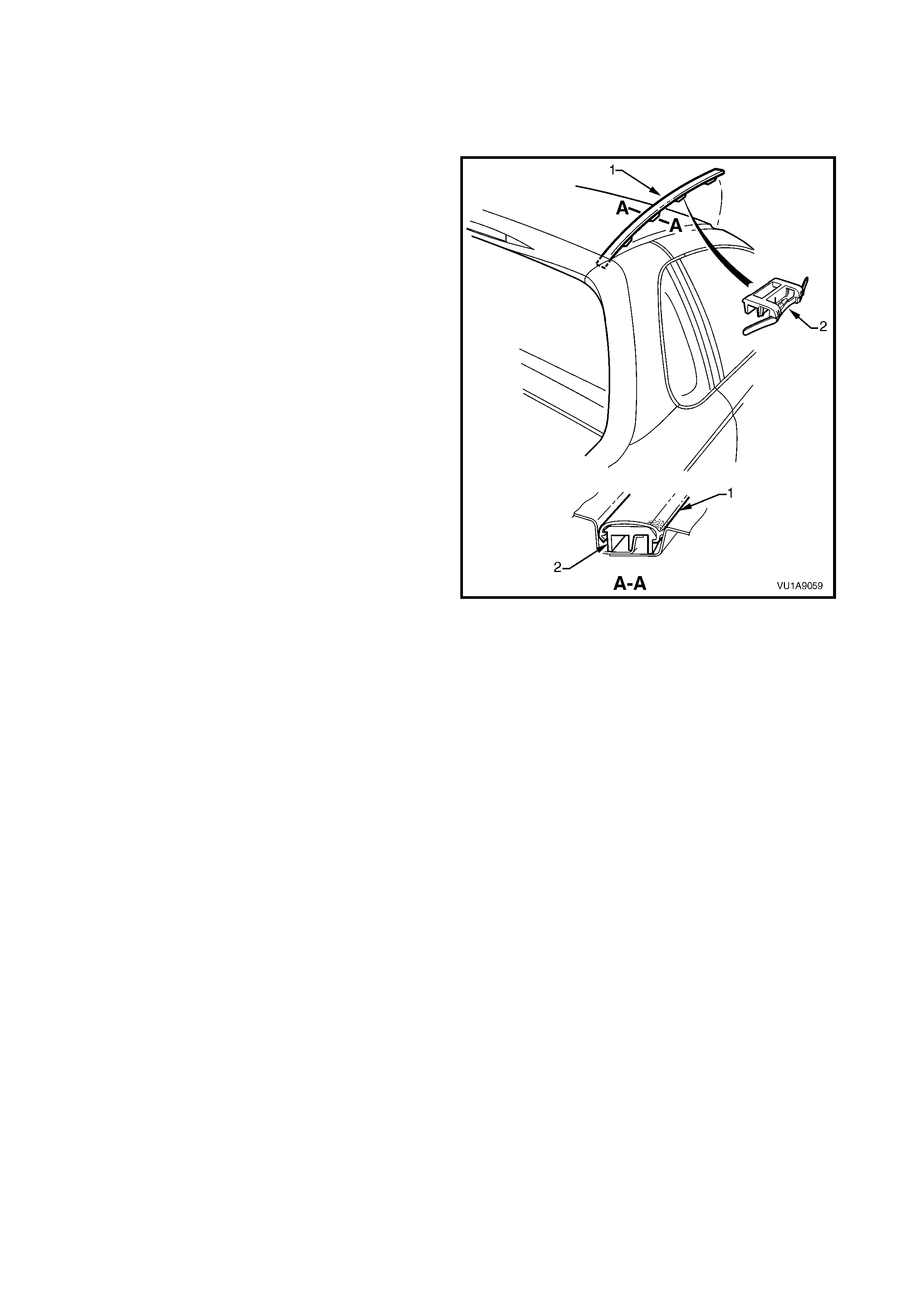

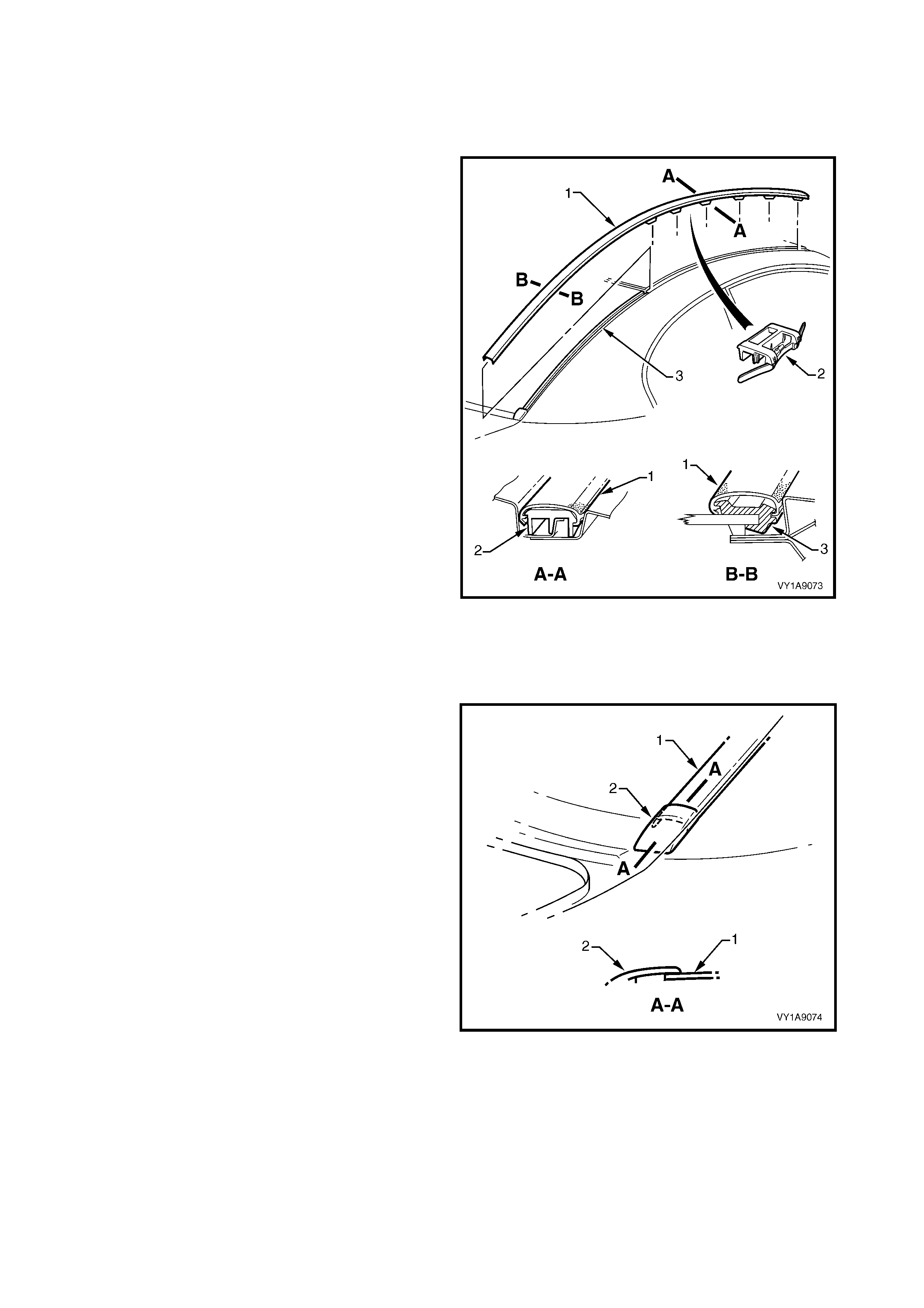

2.7 ROOF JOINT MOULDING

LT Section No. – 10-250

REMOVE

1. Beginning at the front of the vehicle, use a

screwdriver to carefully prise the roof joint

moulding (1) from the roof channel, disengaging

the retaining clips (2) at seven places.

IMPORTANT: Take care as the retaining clips can

easily break. Protect the paintwork with a shop rag.

2. Slide the joint moulding from the rear window side

moulding retainer (3) and remove.

NOTE: For removal of the rear window side moulding

retainer, refer to Section 1A6, 5.1 REAR WINDOW

ASSEMBLY, SEDAN & COUPE.

Figure 1A9-35

REINSTALL

1. As required, s eat the seven retainers onto the roof

joint moulding, evenly spaced.

2. Engage the roof joint moulding (1) onto the rear

window side moulding retainer, refer to Figure

1A9-35, and slide along until the roof joint

moulding sits under the endcap (2).

3. Seat the roof joint moulding in the roof channel

and beginning at the rear, clip it in place.

4. At the f ront, ensure the m oulding is installed under

the windshield moulding cover.

Figure 1A9-36

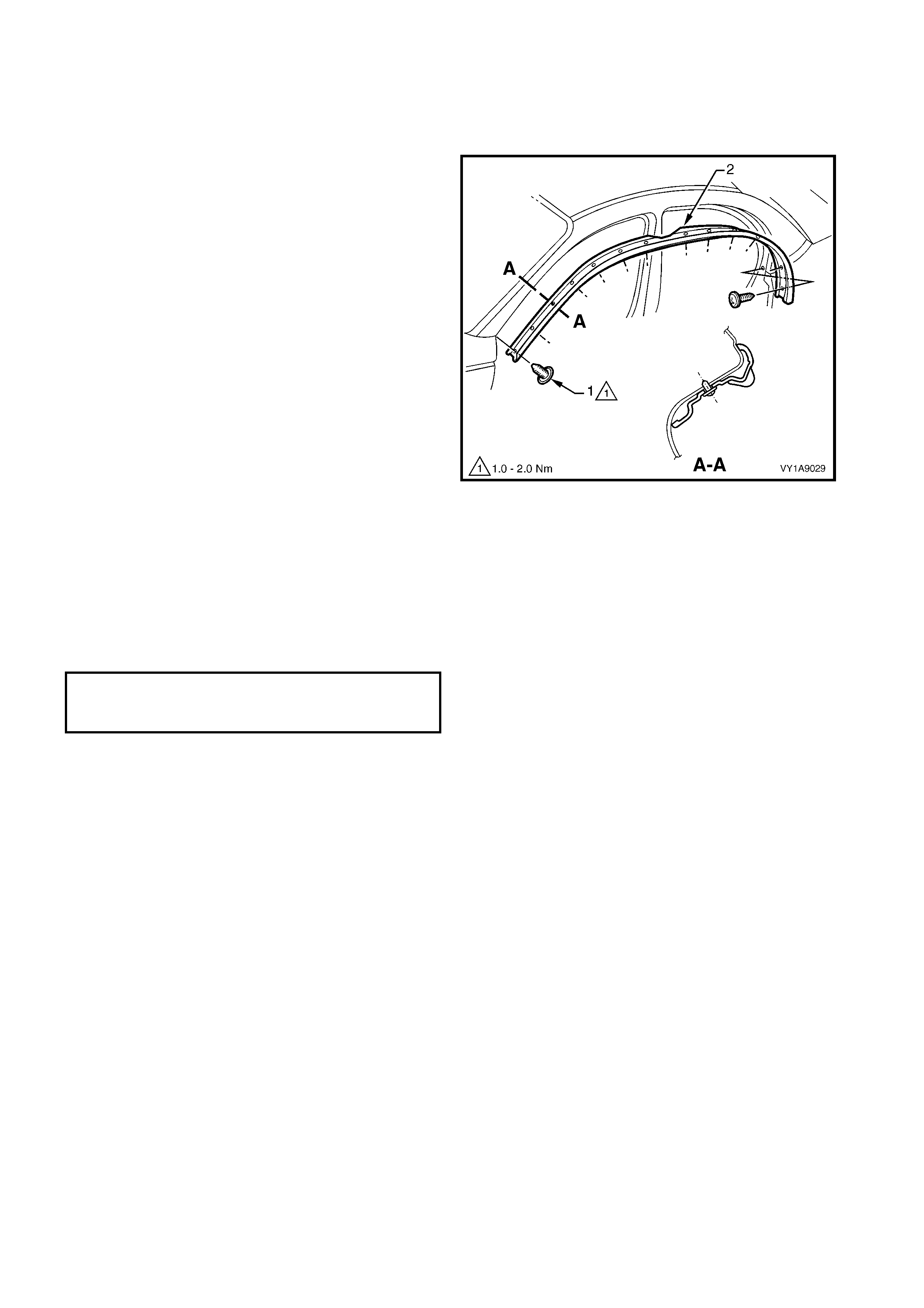

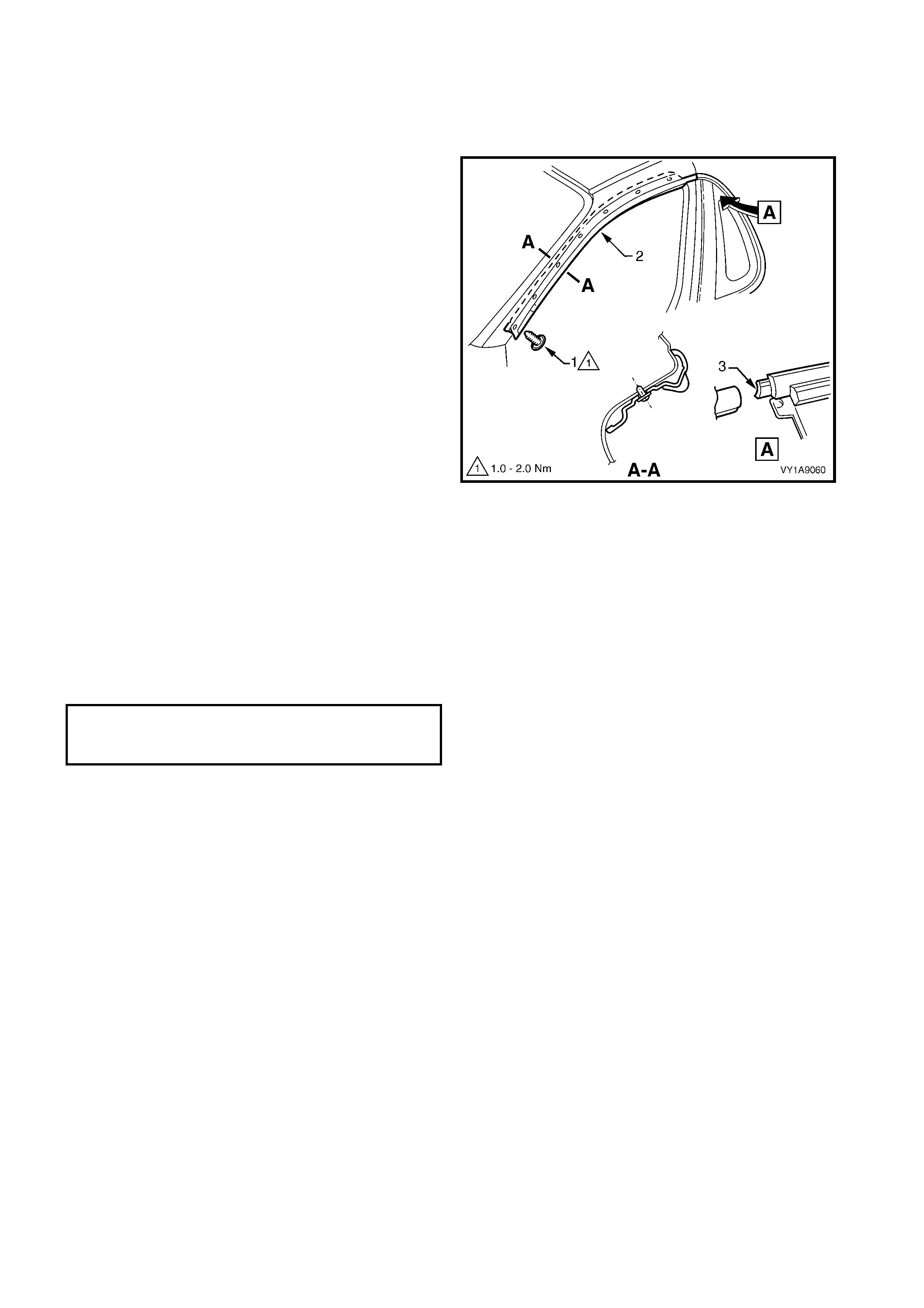

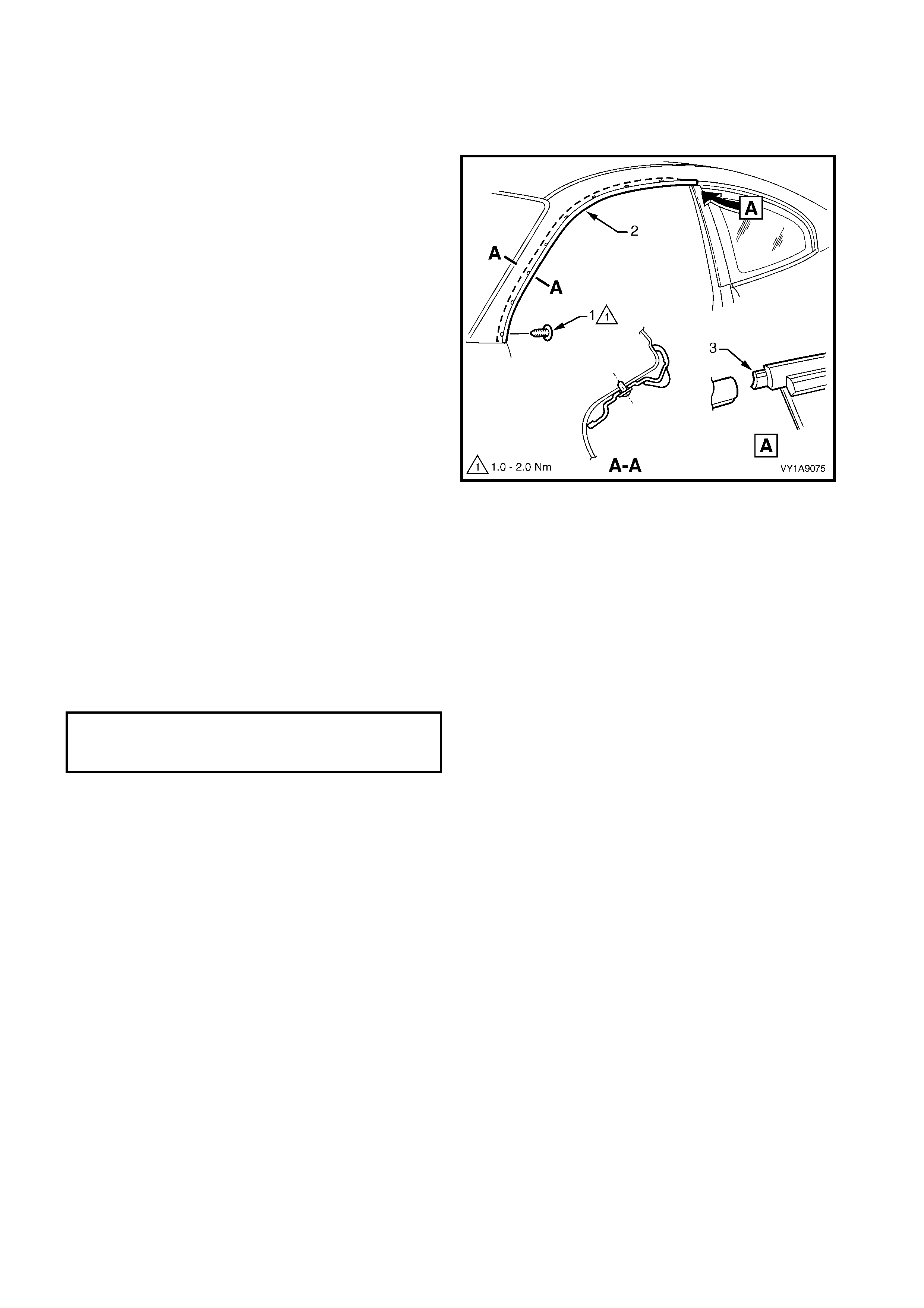

2.8 DOOR OPENING MOULDING

LT Section No. – 10-250

REMOVE

1. Open the fr ont and rear doors on the relevant side

of the vehicle.

2. Beginning at each end and working towards the

middle, rem ove the s crew (1), 13 plac es, attaching

the door opening moulding (2) to the vehicle.

3. Carefully remove the moulding.

Figure 1A9-37

REINSTALL

Reinstallation is the reverse of the removal.

NOTE: The screws are encapsulated with a wax

sealer. It is r ecom mended that the sc rews be replaced

once removed, however if this is impractical, apply a

small amount of sealer to the end of the thread.

Tighten the screws to the specified torque.

DOOR OPENING MOULDING

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 2.0 Nm

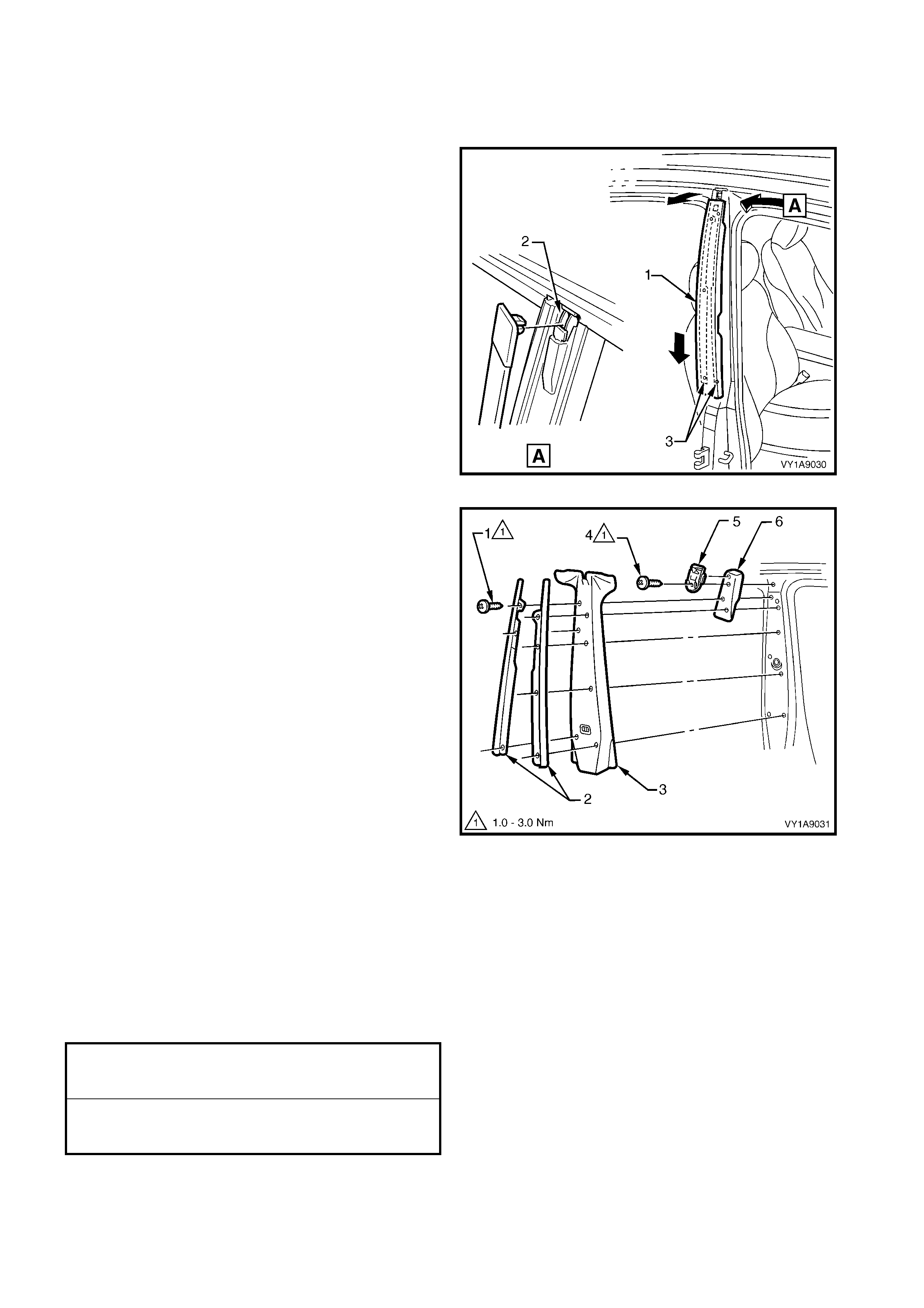

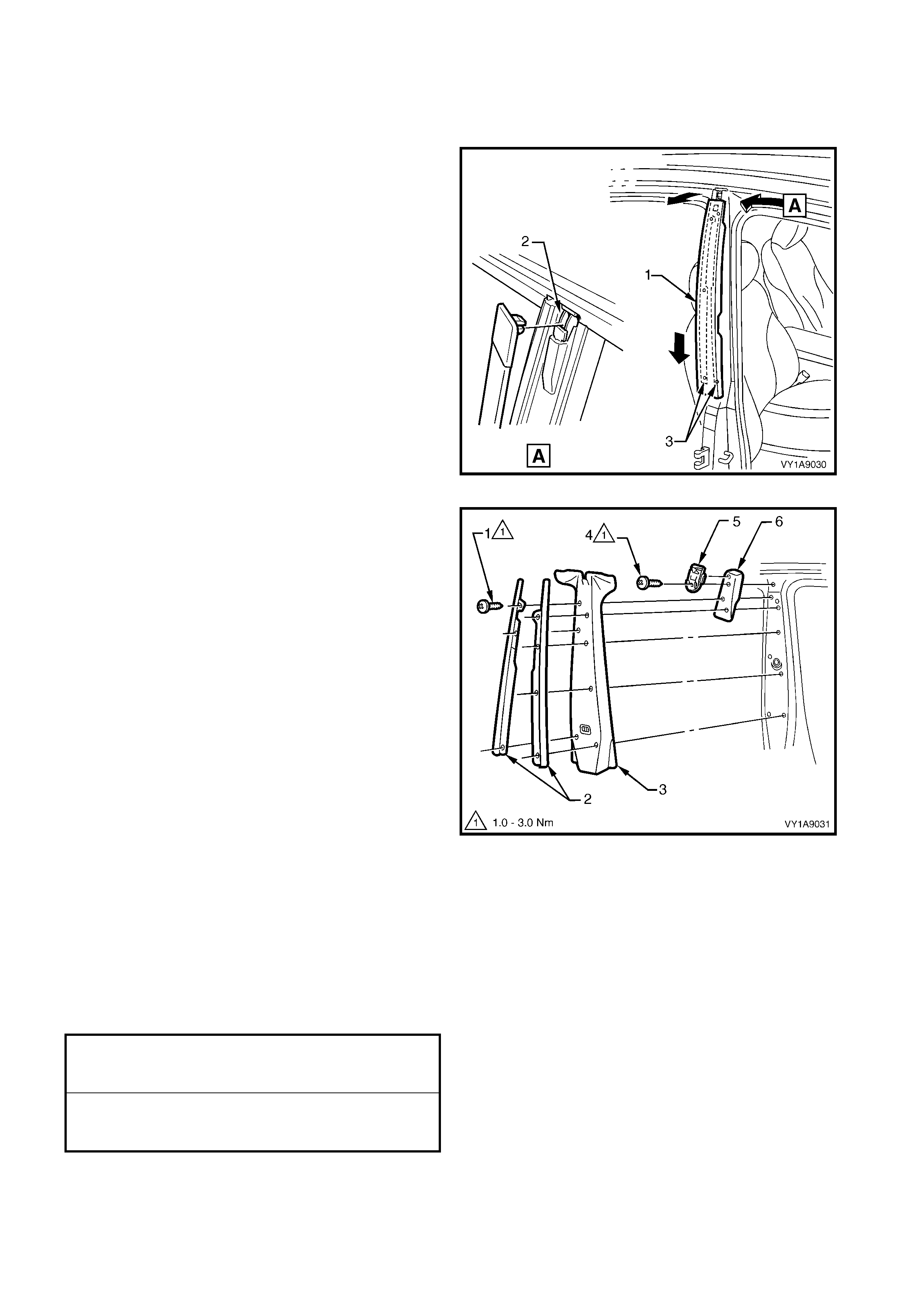

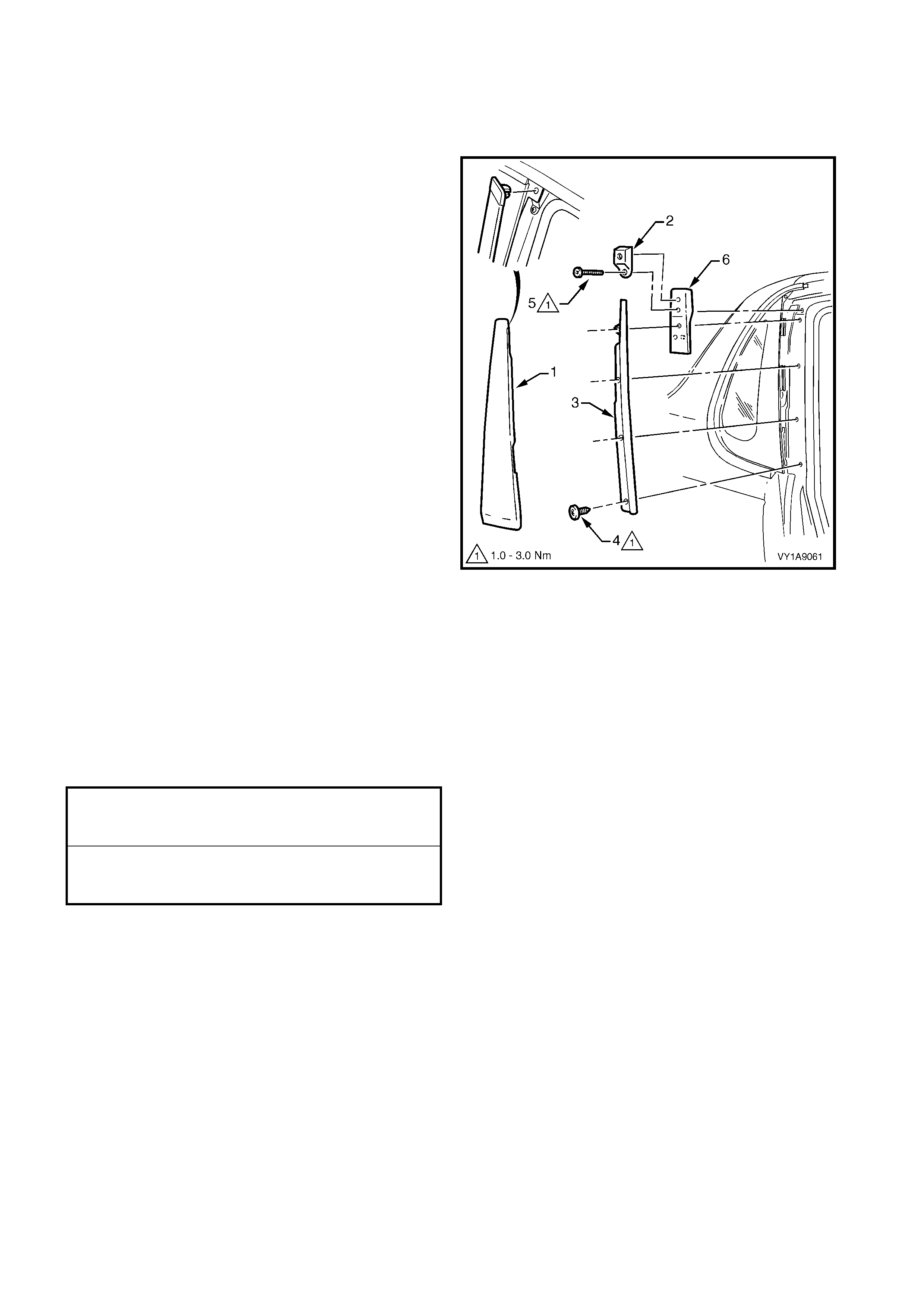

2.9 CENTRE PILLAR UPPER FINISHER ASSEMBLY

LT Section No. – 10-250

REMOVE

1. Open the fr ont and rear doors on the relevant side

of the vehicle.

2. Gently prise the top of the centre pillar upper

finisher (1) out to disengage it from the centre

pillar upper finisher retainer (2).

3. Holding the top of finisher out, slide it down the

centre pillar outer sealing strips (3) until it rests on

rear door hinge.

4. Manoeuvre the finisher f rom the s ealing strips and

remove.

Figure 1A9-38

5. Remove the screw (1) seven places, securing the

centre pillar sealing strips (2) to the pillar and

remove the strips.

6. Partially rem ove the door fram e opening moulding,

refer to 2.8 DOOR OPENING MOULDING in this

Section.

7. Remove centre pillar upper trim panel (3) by

pulling away from the pillar.

8. Remove the screw (4) securing the centre pillar

upper finisher retainer (5) and centre pillar upper

trim mount plate (6) to the pillar and remove.

Figure 1A9-39

REINSTALL

Reinstallation of the centre pillar upper finisher

assembly is the reverse of the removal procedure,

noting the following:

1. Ensure the centre pillar upper trim panel is seated

correctly under the door opening weatherstrips.

2. Ensure all fasteners are tightened to the correct

torque specification.

3. Slide the centre pillar upper f inisher up and press it

in at the top to engage into the retaining clip.

CENTRE PILLAR UPPER FINISHER

RETAINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

CENTRE PILLAR SEALING STRIP

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

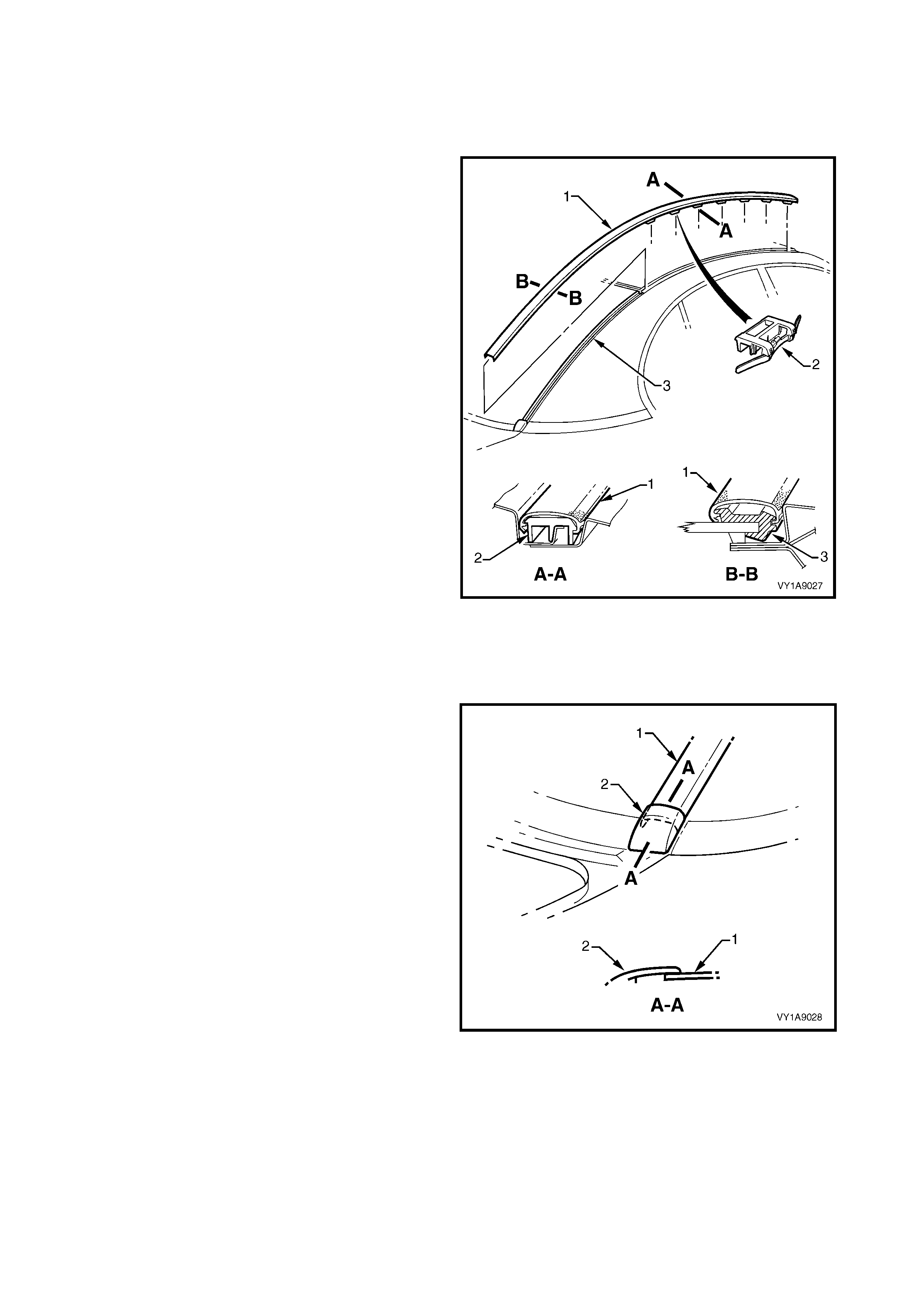

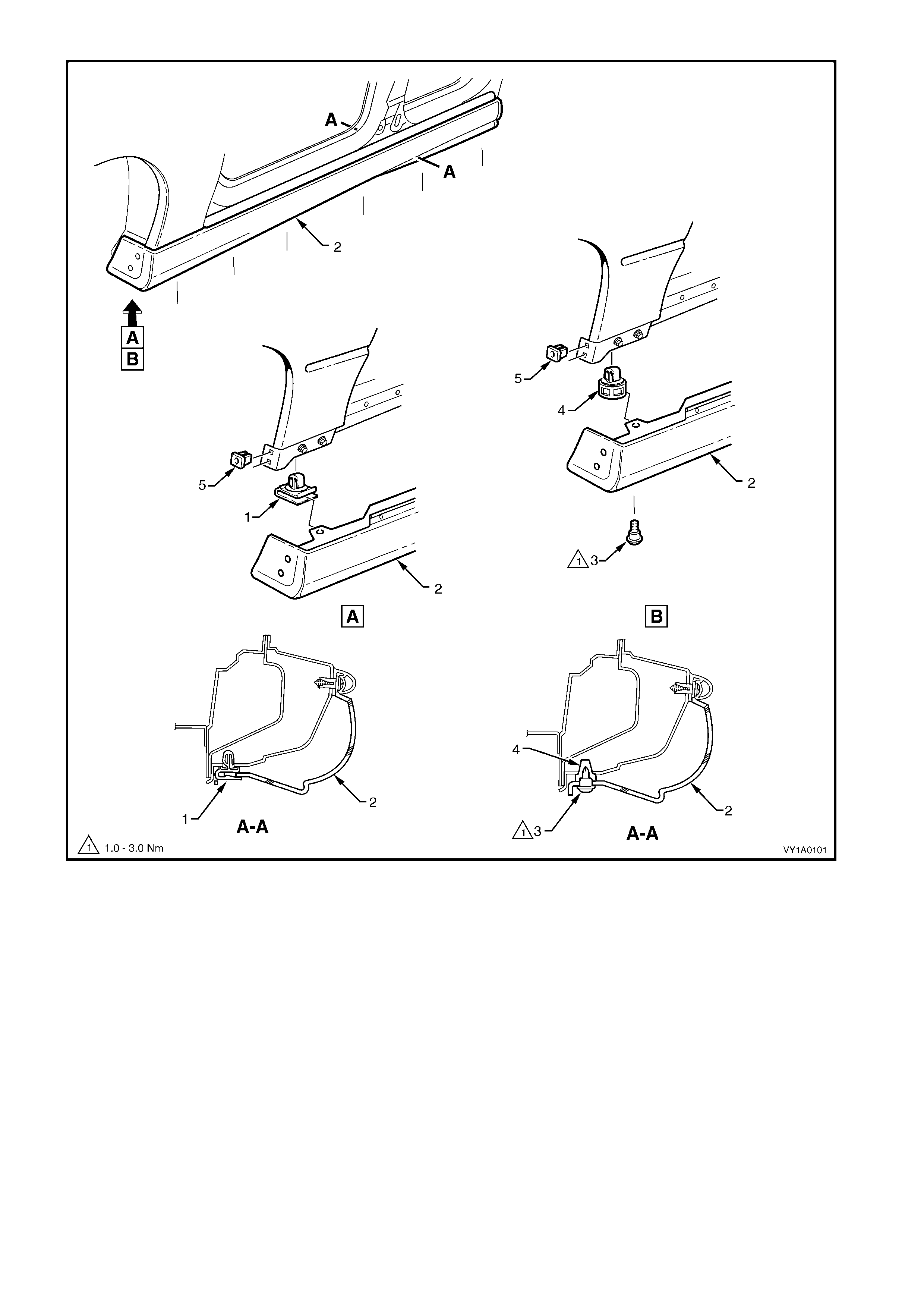

2.10 QUARTER PANEL BELT MOULDING

LT Section No. – 10-250

REMOVE

1. Partially remove the body lock pillar garnish far

enough to access the quarter panel belt moulding

retaining nut, refer to Section 1A8, 2.6 BODY

LOCK PILLAR GARNISH.

2. Remove the retaining nut (1) securing the quarter

panel belt moulding (2) to the vehicle.

3. Using a length of piano wire, carefully cut the

double sided tape (3) and bead of polyurethane

adhesive (4) from the back of the moulding, two

places, noting to rem o ve and reinsert piano wire to

get around the attaching stud (5).

IMPORTANT: Take care not to damage the adjacent

paintwork.

4. Carefully prise the moulding from the vehicle and

remove.

Figure 1A9-40

REINSTALL

Reinstallation of the quarter panel belt moulding is the

reverse of the removal noting the following:

1. Apply two lengths of new acr ylic double-sided tape

such as 3M 5344 or equivalent to the back of the

moulding, refer to Section A-A in Figure 1A9-40.

2. Apply an 8.0 mm bead of urethane adhesive such

as Expandite Betaseal 554.02, Sikaflex Drive or

equivalent to the back of the moulding, between

and for the length of, the ribs in two places, refer to

Section B-B in Figure 1A9-40.

3. Tighten the retaining nut to the specified torque.

QUARTER PANEL BELT

MOULDING RETAINING NUT

TORQUE SPECIFICATION 1.0 – 3.0 Nm

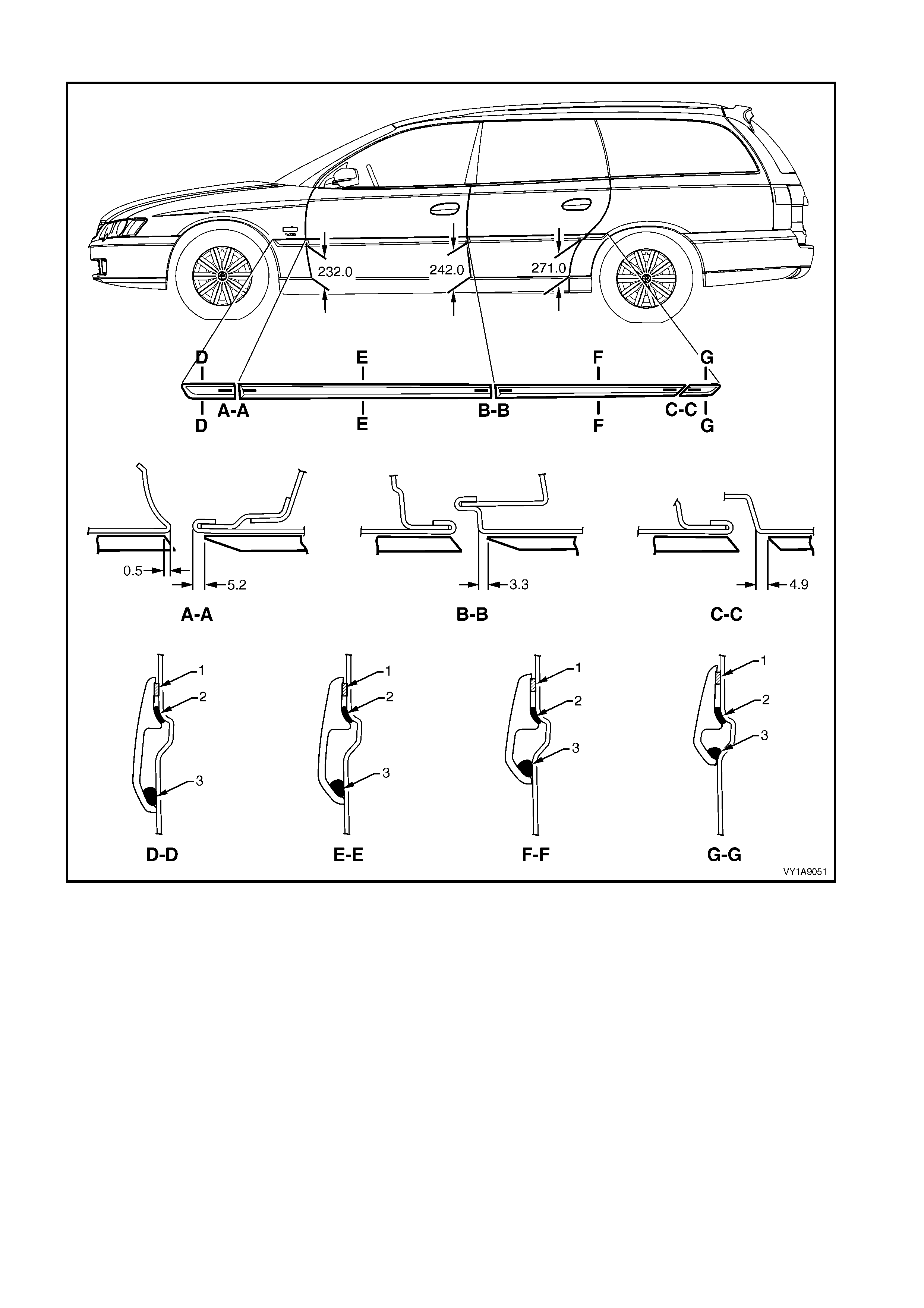

2.11 BODY SIDE MOULDINGS

LT Section No. – 10-250

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. Using a paint scraper or similar, begin at one end

and carefully prise the moulding from the panel,

cutting through the double sided tape and

adhesive.

NOTE: As an alternative, carefully use a length of

piano wire to cut the adhesive in a similar way to

removing a windshield.

3. As required, remove any remaining double-sided

tape and adhesive from the moulding and/or panel.

Clean the surfaces with Prepsol or equivalent.

Figure 1A9-41

REINSTALL

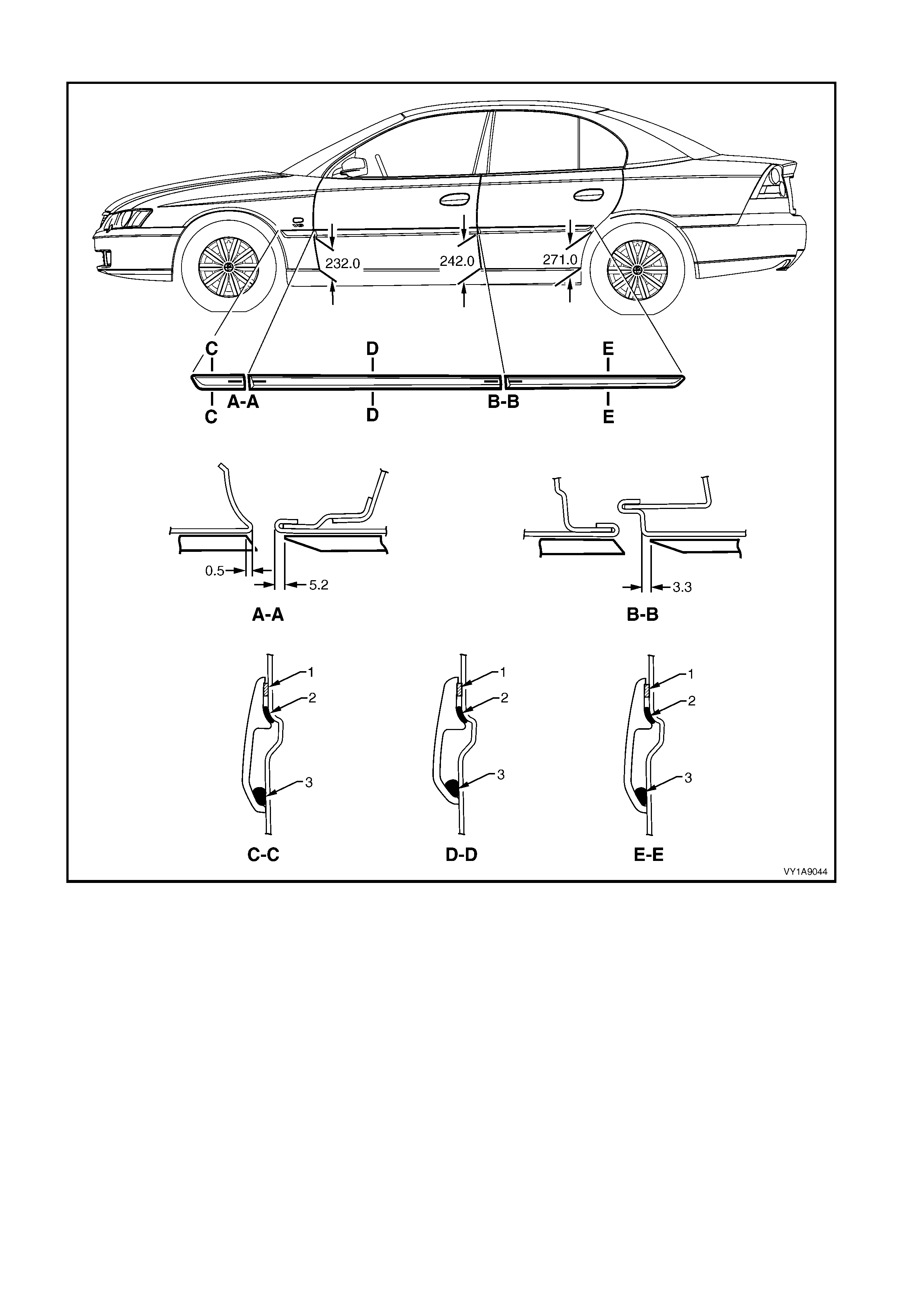

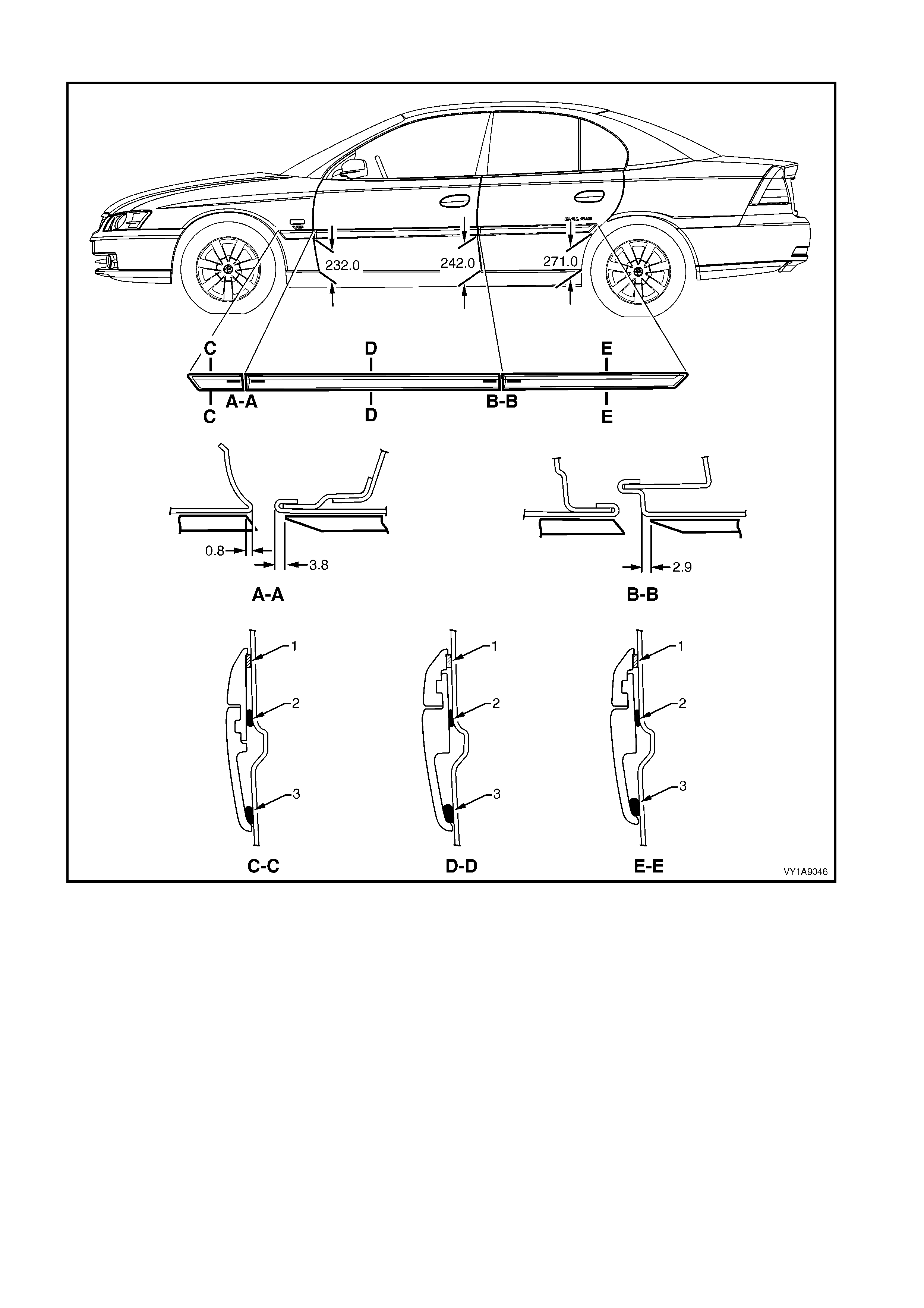

Refer to Figure 1A9-42 for Executive, Acclaim , SS or Lumina LS vehicles, Figure 1A9-43 for Berlina or Lum ina

LTZ vehicles or to Figure 1A9-44 for Calais or Omega CD vehicles.

1. Place a mark on the rear edge of the fender and/or door panels at the three points shown in the relevant

Figure as required. Measure in a straight line from the lower edge of each panel:

2. If a complete moulding set is to be f itted, or as r equir ed, apply a length of mas king tape along the side of the

vehicle, level with the marks. Begin by affixing the tape at the rear of the rear door, hold it taut and away

from the vehicle, and affix it to each panel. Ensure it is straight and then smooth it down along its length.

3. If reusing the moulding, apply new acrylic double-sided tape (1) such as 3M 5344 or equivalent along the

back of the moulding.

4. Apply a 3.0 m m diam eter bead of urethane adhesive such as Expandite Betaseal 554.02, Sikaflex Drive or

equivalent over the entire length of moulding (2) and for 50mm in several places (3).

NOTE: Refer to any further directions supplied with the urethane adhesive.

5. Affix the moulding to the vehicle in the correct positions, aligning the lower edge with the masking tape (if

fitted) and:

• For the fender moulding begin at the rear edge of the fender, aligning to the dimension at Section A-A.

• For the f ront door moulding begin at the fr ont edge of the f r ont door, aligning to the dimension at Section

A-A.

• For the rear door moulding begin at the f ront edge of the rear door, aligning to the dim ension at Section

B-B.

6. Press firmly over the length of the moulding(s) at the double-sided tape to ensure maximum adhesion.

EXECUTIVE, ACCLAIM, SS, LUMINA LS

Figure 1A9-42

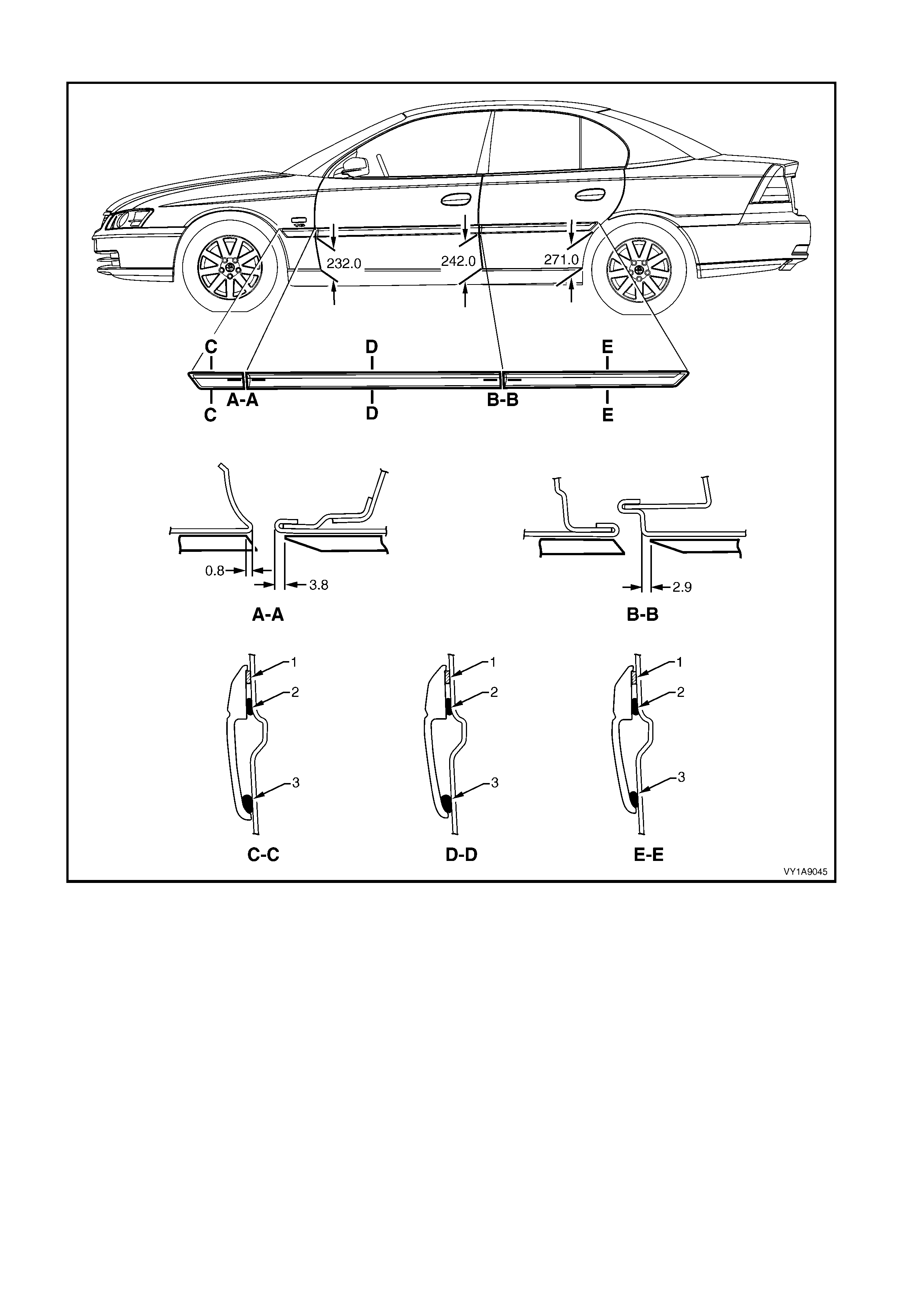

BERLINA, LUMINA LTZ

Figure 1A9-43

CALAIS, OMEGA CD

Figure 1A9-44

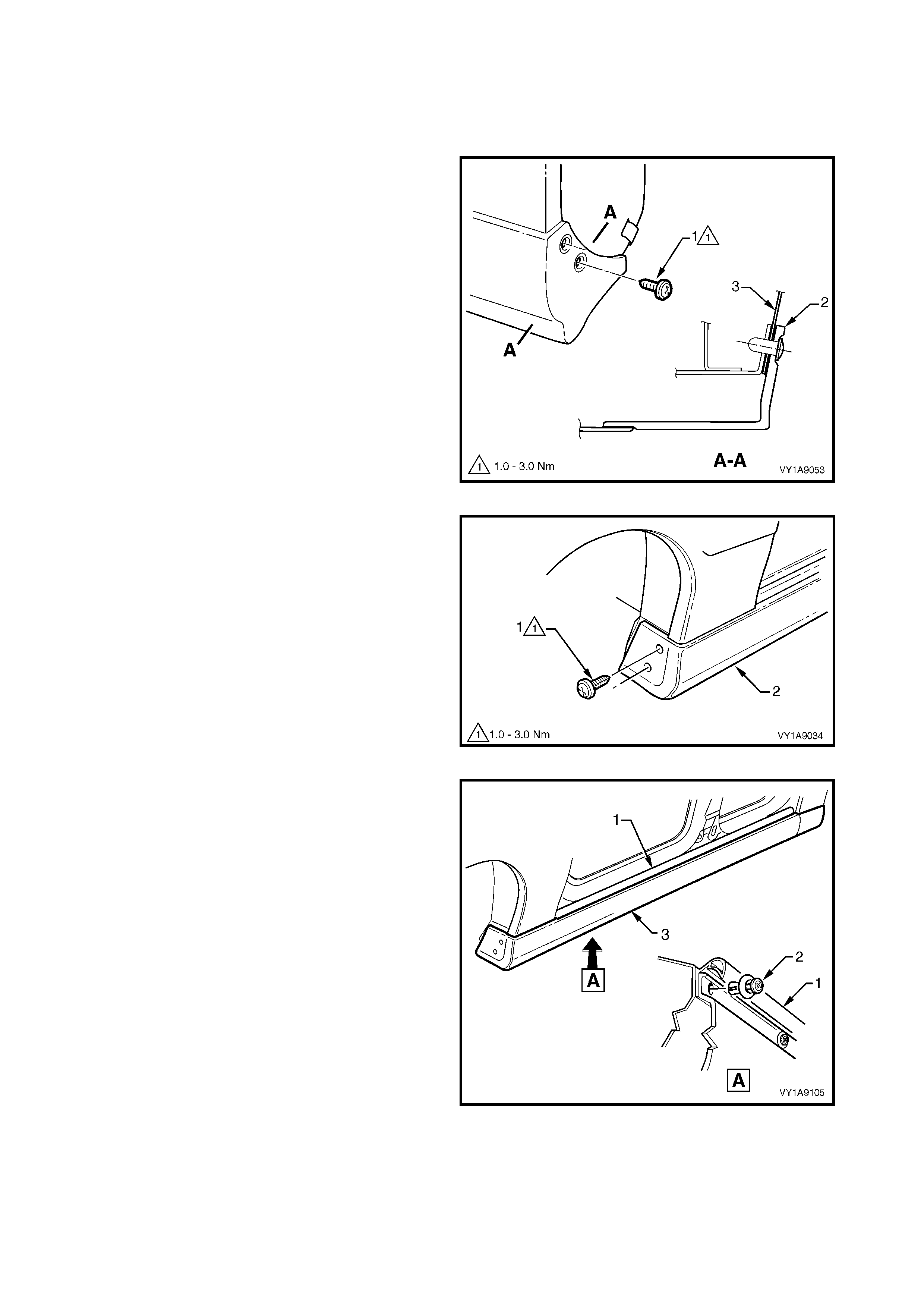

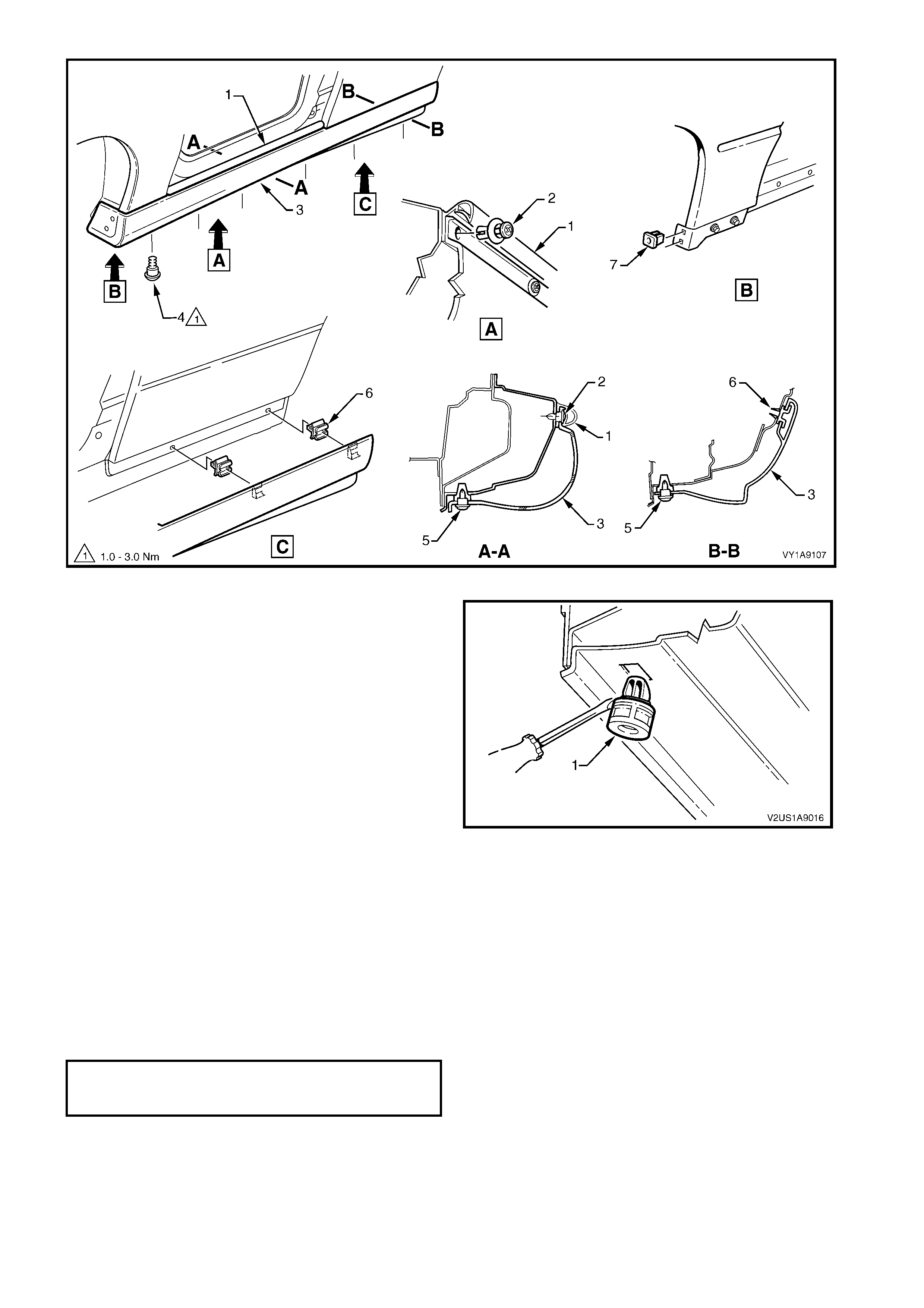

2.12 ROCKER PANEL MOULDING ASSEMBLY

LT Section No. – 10-300

REMOVE

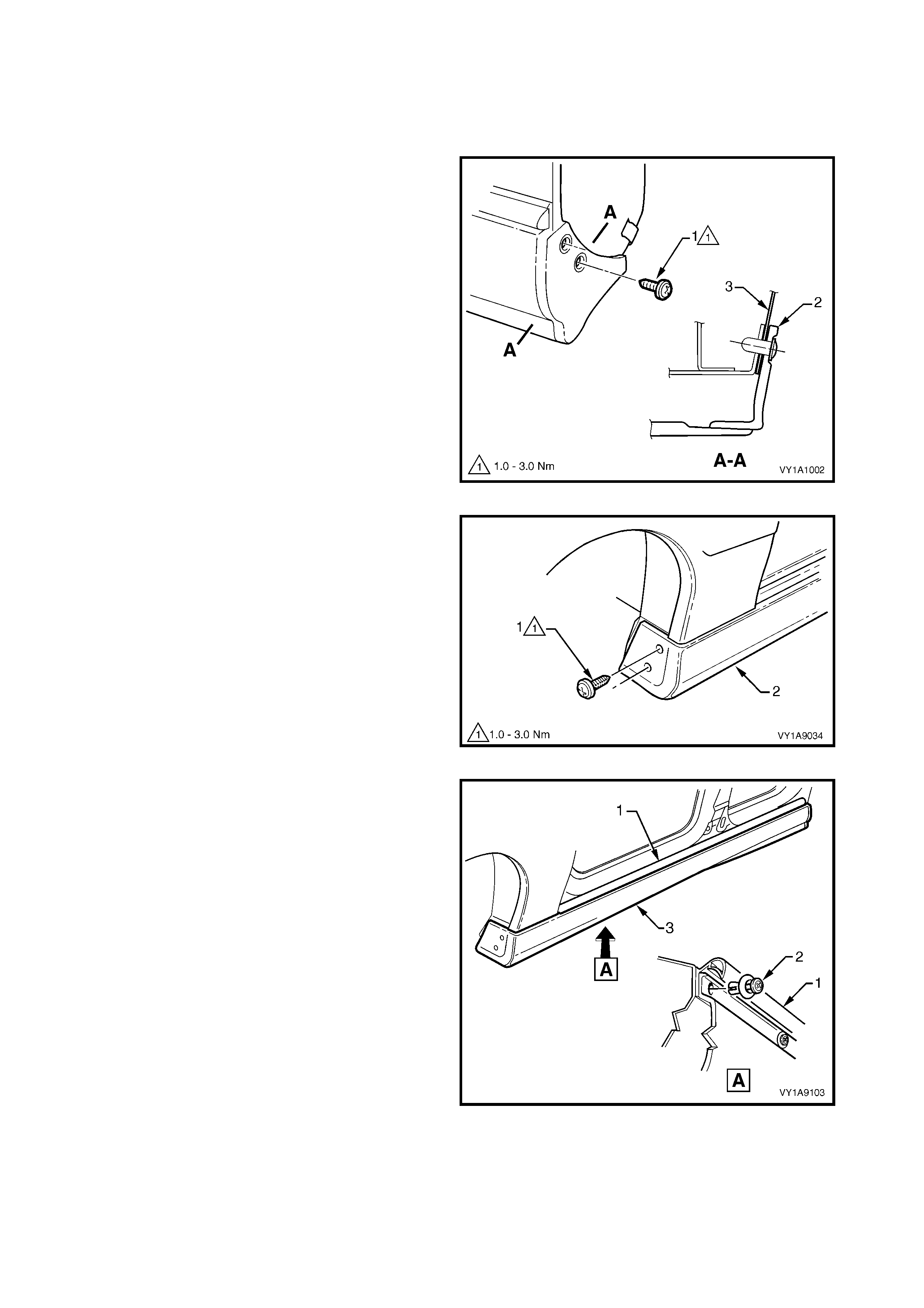

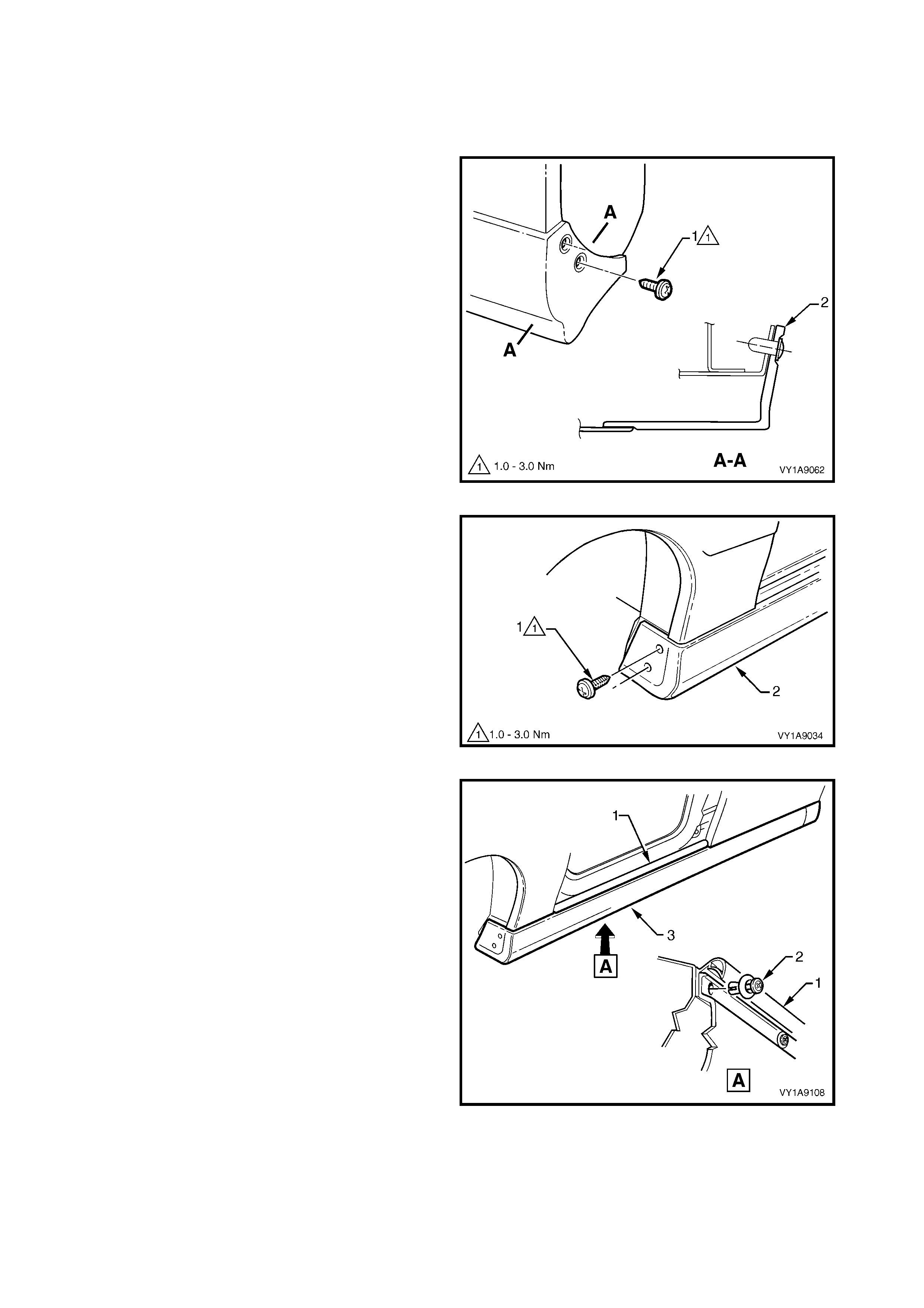

1. Remove the screw (1), two places, attaching the

rear rocker panel moulding (2) and wheelhouse

liner (3 ).

NOTE: If required, the r ear rocker panel moulding can

be removed at this stage by sliding it rearward from the

front rocker panel moulding.

Figure 1A9-45

2. Remove the screw (1), two places, attaching the

front rocker panel moulding (2) to the fender and

liner.

Figure 1A9-46

3. Lift up the rocker panel weatherstrip (1) to gain

access and remove the retainer (2), nine places,

attaching the rocker panel moulding (3).

4. From underneath the vehicle, refer to Figure 1A9-

48:

• For earlier build vehicles f itted with the retainer

(1), beginning at one end of the moulding (2),

use a flat blade screwdriver to spread the

retainer apart slightly while holding outward

pressure on the moulding, disengaging it from

the retainer.

• For later build vehicles fitted with the screw

arrangement, remove the screw (3), six

places, from the retainer under the moulding

(4).

5. Remove the moulding.

6. If required, prise the nut (5), two places, from the

fender.

Figure 1A9-47

Figure 1A9-48

7. If required:

• For earlier build vehicles , remove the retainer ( 1), s ix plac es , by gently levering out f r om the body, tak ing

care not to damage paint work, refer to View A, Figure 1A9-49.

• For later build vehicles, remove the retainer (2), six places, by gently levering out from the body, taking

care not to damage paint work, refer to View B, Figure 1A9-49.

Figure 1A9-49

REINSTALL

Reinstallation of the rocker panel front and rear

mouldings is the reverse of the removal operation

noting the following.

1. Ensure the front moulding is c or re ctly seated in the

retaining clips.

2. Tighten all fasteners to the correct torque

specification.

3. Ensure the weatherstrip is seated correctly.

ROCKER PANEL MOULDING

ATTACHING SCREW

TORQUE SPE CIFICATI ON 1.0 – 3.0 Nm

3. SERVICE OPERATIONS, WAGON

3.1 RADIATOR GRILLE EMBLEM

LT Section No. – 10-150

REMOVE

1. To assist removal, warm the emblem with a heat-lamp or heat-gun to soften the adhesive.

2. Using a knife or paint scraper, carefully remove the emblem assembly (1–domestic or 2–export) from the

grille assembly, cutting the double-sided tape, refer to Figure 1A9-49.

NOTE: The domestic emblem has two locating lugs which must not be cut if the emblem is to be reused.

3. Remove any remaining double-sided tape as required.

Figure 1A9-49

REINSTALL

1. If reinstalling the existing emblem, remove the existing double-sided tape and clean the surface with wax

and grease remover such as Prepsol or equivalent. Apply new polyethylene double-sided tape such as 3M

4428 or equivalent.

2. Clean the surface of the grille assembly with wax and grease remover such as Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Align the emblem. For domestic vehicles, locate the lugs with their corresponding holes in the grille

assembly. For export vehicles, align the emblem within its recess in the grille assembly.

5. Affix the emblem and press firmly over the entire emblem for at least 10 seconds to ensure sound adhesion.

3.2 FENDER NAME PL ATE

LT Section No. – 10-150

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the plate with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

plate from the fender.

4. Remove any remaining double- sided tape from the

plate and/or fender and clean the surfaces with

Prepsol or equivalent.

Figure 1A9-50

REINSTALL

1. If reusing the plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the back

and trim the edges of the tape slightly in from the edge of plate.

2. Clean the fender surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the plate in the position shown, measuring from the front side turn signal lamp hole, refer to Figure

1A9-51. Ensure it is positioned parallel to the body side moulding.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-51

3.3 LIFTGATE EMBLEM

LT Section No. – 10-150

HOLDEN, CHEVROLET

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the emblem with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

emblem from the liftgate.

NOTE: The emblem has two locating pins, take care

not to break them if the emblem is to be reused.

4. As required, remove any remaining double-sided

tape from the em blem and/or liftgate and c lean the

surfaces with Prepsol or equivalent.

Figure 1A9-52

REINSTALL

1. If reusing the emblem, apply new polyethylene

double-sided tape such as 3M 4428 or equivalent

to the back and the trim edges of the tape slightly

in from the edge of the emblem.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided

tape.

4. Apply the emblem in the position shown ensuring

the locating pins are correctly orientated with the

locating holes in the panel surface.

5. Press firm ly over the entire emblem for at leas t 10

seconds to ensure maximum adhesion.

Figure 1A9-53

3.4 LIFTGATE NAME PLATE, LH

LT Section No. – 10-150

COMMODORE, CHEVROLET

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the emblem with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

emblem from the liftgate.

4. As required, remove any remaining double-sided

tape from the name plate and/or liftgate and clean

the surfaces with Prepsol or equivalent.

Figure 1A9-54

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the name plate onto the left- hand s ide of the lif tgate in the position s hown, ensur ing it is s tr aight and is

correctly aligned to the measurements, refer to Figure 1A9-55.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-55

3.5 LIFTGATE NAME PLATE, RH

LT Section No. – 10-150

EXECUTIVE, ACCLAIM, BERLINA, LUMINA LS

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the liftgate.

4. As required, remove any remaining double-sided

tape from the name plate and/or liftgate and clean

the surfaces with Prepsol or equivalent.

Figure 1A9-56

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the name plate onto the right-hand s ide of the liftgate in the position s hown, ensuring it is straight and

is correctly aligned to the measurements, refer to Figure 1A9-57.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

6. Where required remove the plastic carrier.

Figure 1A9-57

3.6 ROOF JOINT MOULDING

LT Section No. – 10-250

REMOVE

1. Beginning at the front of the vehicle, use a

screwdriver to carefully prise the roof joint

moulding (1) from the roof channel, disengaging

the retaining clips (2), three places.

IMPORTANT: Take care as the retaining clips can

easily break. Protect the paintwork with a shop rag.

2. Slide the joint moulding from under the roof side

rail and remove.

Figure 1A9-58

REINSTALL

1. As required, seat the three retainers onto the roof

joint moulding, evenly spaced.

2. Slide the moulding under the roof side rail.

3. Seat the moulding in the roof channel and

beginning at the rear, clip it in place.

4. At the f ront, ensure the m oulding is installed under

the windshield moulding cover.

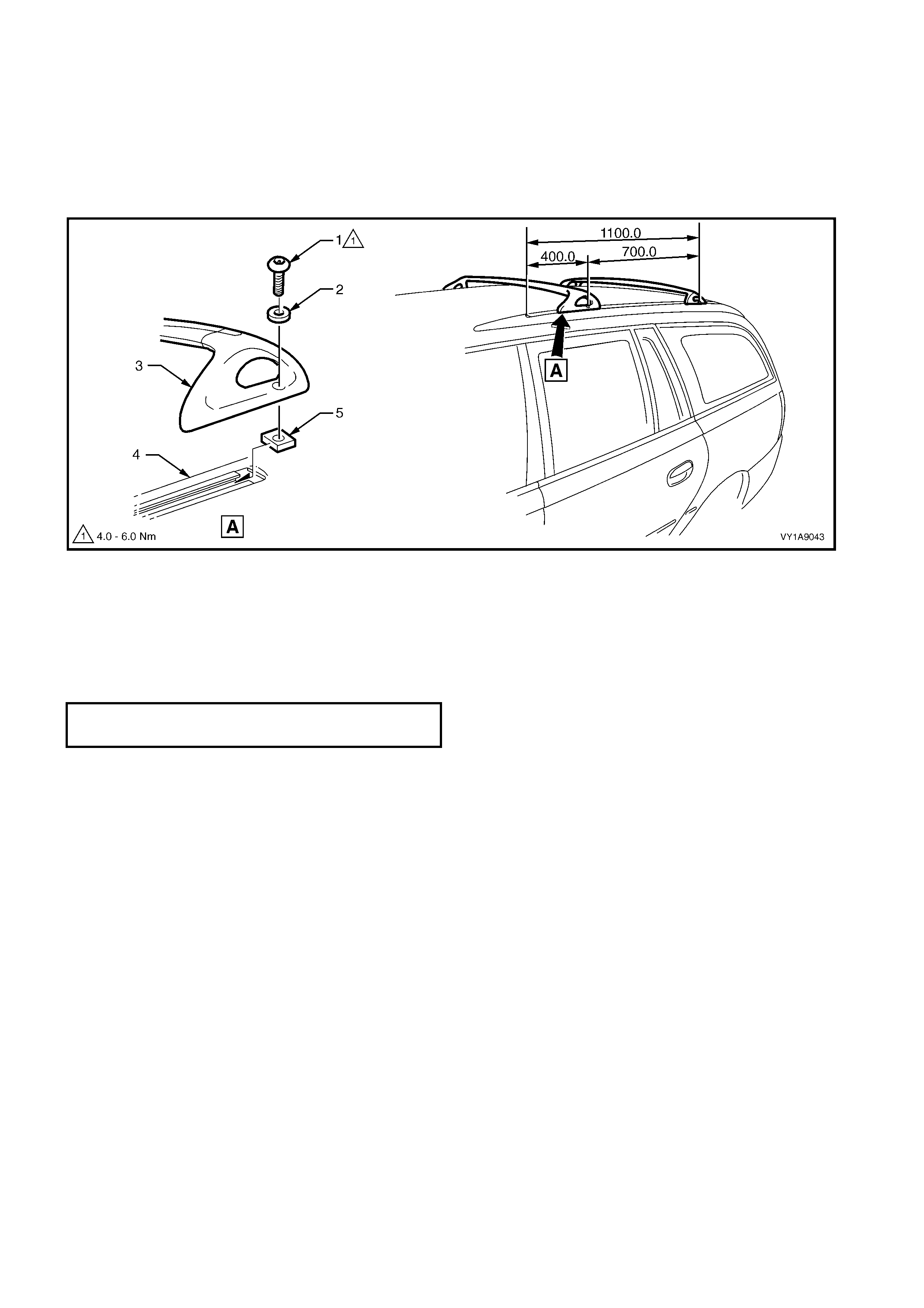

3.7 ROOF BARS

LT Section No. – AA-005

REMOVE

1. Using the key tool (supplied with vehicle) or an appropriate Allen key, loosen and remove the two locking

screws (1) and washers (2) securing each roof bar (3) to the roof side rail (4), refer to Figure 1A9-59.

2. If required, slide the roof bar securing nuts (5) out of the rear of the roof side rail.

Figure 1A9-59

REINSTALL

Reinstallation of the roof bars is the reverse of the removal procedure, noting the following:

1. Position the roof bars in the production standard position as shown, refer to Figure 1A9-59.

2. Tighten the fasteners to the correct torque specification.

ROOF BAR ATTACHING SCREW

TORQUE SPECIFICATION 4.0 – 6.0 Nm

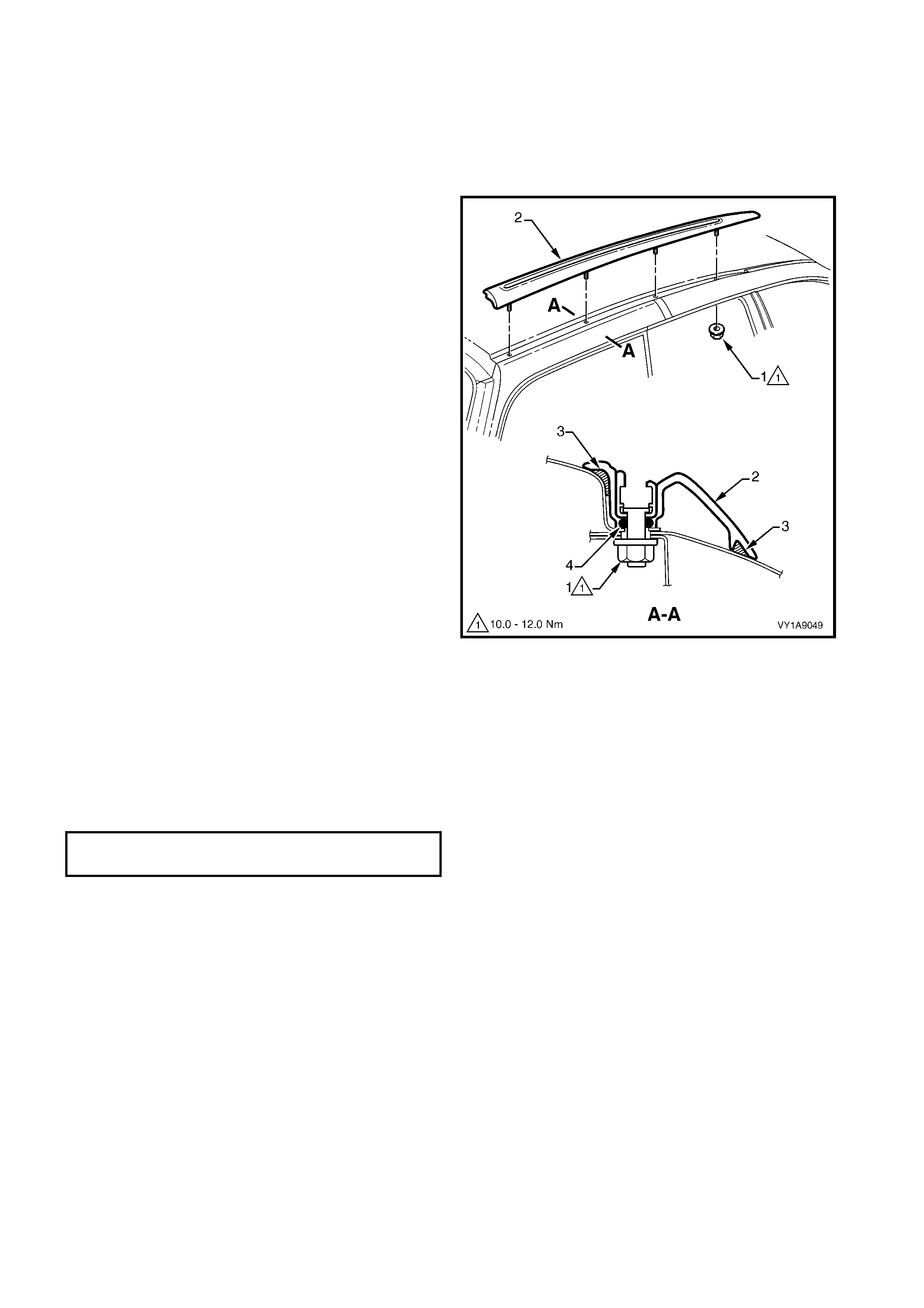

3.8 ROOF SIDE RAILS

LT Section No. – 10-250

REMOVE

1. Remove the headlining from the vehicle, refer to

Section 1A8, HEADLINING.

2. Rem ove the nut (1), f our places, attaching the roof

side rail (2) to the roof panel.

3. Remove the roof side rail up until the studs are

free and then slide the rail rearward.

Figure 1A9-60

REINSTALL

Reinstallation of the roof side rail is the reverse of the

removal procedure, noting the following:

1. Ensure the foam seal (3) is not damaged and is

correctly seated and that the O-ring seals (4) are

fitted to each of the studs, refer to Figure 1A9-60.

2. Tighten the nuts to the specified torque.

ROOF SIDE RAIL ATTACHING

NUT TORQUE SPECIFICATION 10.0 – 12.0 Nm

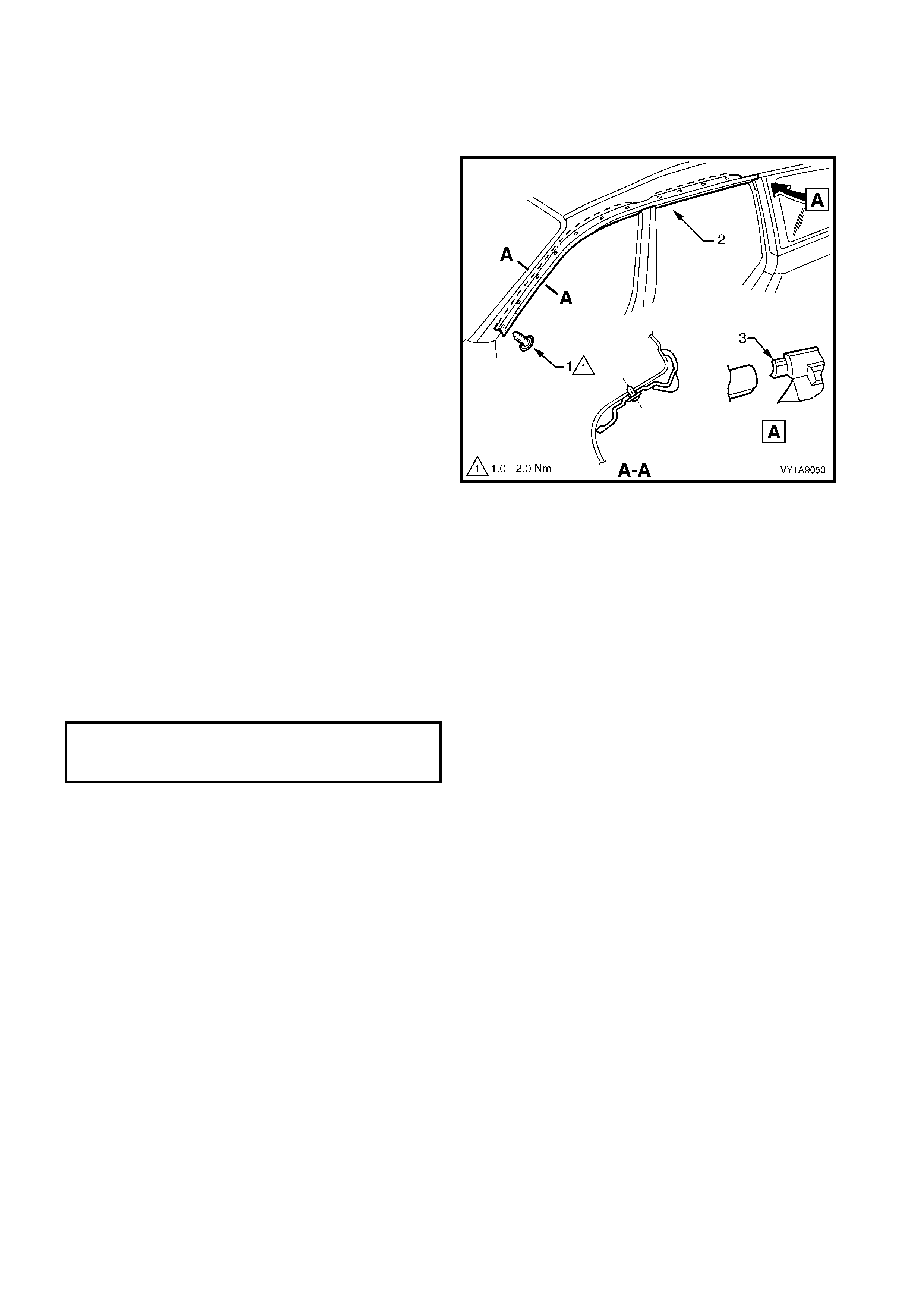

3.9 DOOR OPENING MOULDING

LT Section No. – 10-250

REMOVE

1. Open the fr ont and rear doors on the relevant side

of the vehicle.

2. Beginning at each end and working towards the

middle, rem ove the s crew (1), 11 plac es, attaching

the door opening moulding (2) to the body.

3. Carefully remove the moulding, disengaging the

quarter window assembly tab (3).

Figure 1A9-61

REINSTALL

Reinstallation is the reverse of the removal. When

installing the screws, begin at the rear and work

forward.

NOTE: The screws are encapsulated with a wax

sealer. It is r ecom mended that the sc rews be replaced

once removed, however if this is impractical, apply a

small amount of sealer to the end of the thread.

Tighten the screws to the specified torque.

DOOR OPENING MOULDING

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 2.0 Nm

3.10 CENTRE PILLAR UPPER FINISHER ASSEMBLY

LT Section No. – 10-250

REMOVE

1. Open front and rear doors on relevant side of the

vehicle.

2. Gently prise top of centre pillar upper finisher (1)

out to disengage it from the centre pillar upper

finisher retainer (2).

3. Holding the top of finisher out, slide it down the

centre pillar outer sealing strips (3) until it rests on

rear door hinge.

4. Manoeuvre the finisher f rom the s ealing strips and

remove.

Figure 1A9-62

5. Remove the screw (1), seven places, sec uring the

centre pillar sealing strips (2) to the pillar and

remove the strips.

6. Partially rem ove the door fram e opening moulding,

refer to 3.9 DOOR OPENING MOULDING in this

Section.

7. Remove centre pillar upper trim panel (3) by

pulling away from the pillar.

8. Remove the screw (4) securing the centre pillar

upper finisher retainer (5) and centre pillar upper

trim mount plate (6) to the pillar and remove.

Figure 1A9-63

REINSTALL

Reinstallation of the centre pillar upper finisher

assembly is the reverse of the removal procedure,

noting the following:

1. Ensure the centre pillar upper trim panel is seated

correctly under door opening weatherstrips.

2. Ensure all fasteners are tightened to the correct

torque specification.

3. Slide the centre pillar upper f inisher up and press it

in at the top to engage into the retaining clip.

CENTRE PILLAR UPPER FINISHER

RETAINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

CENTRE PILLAR SEALING STRIP

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

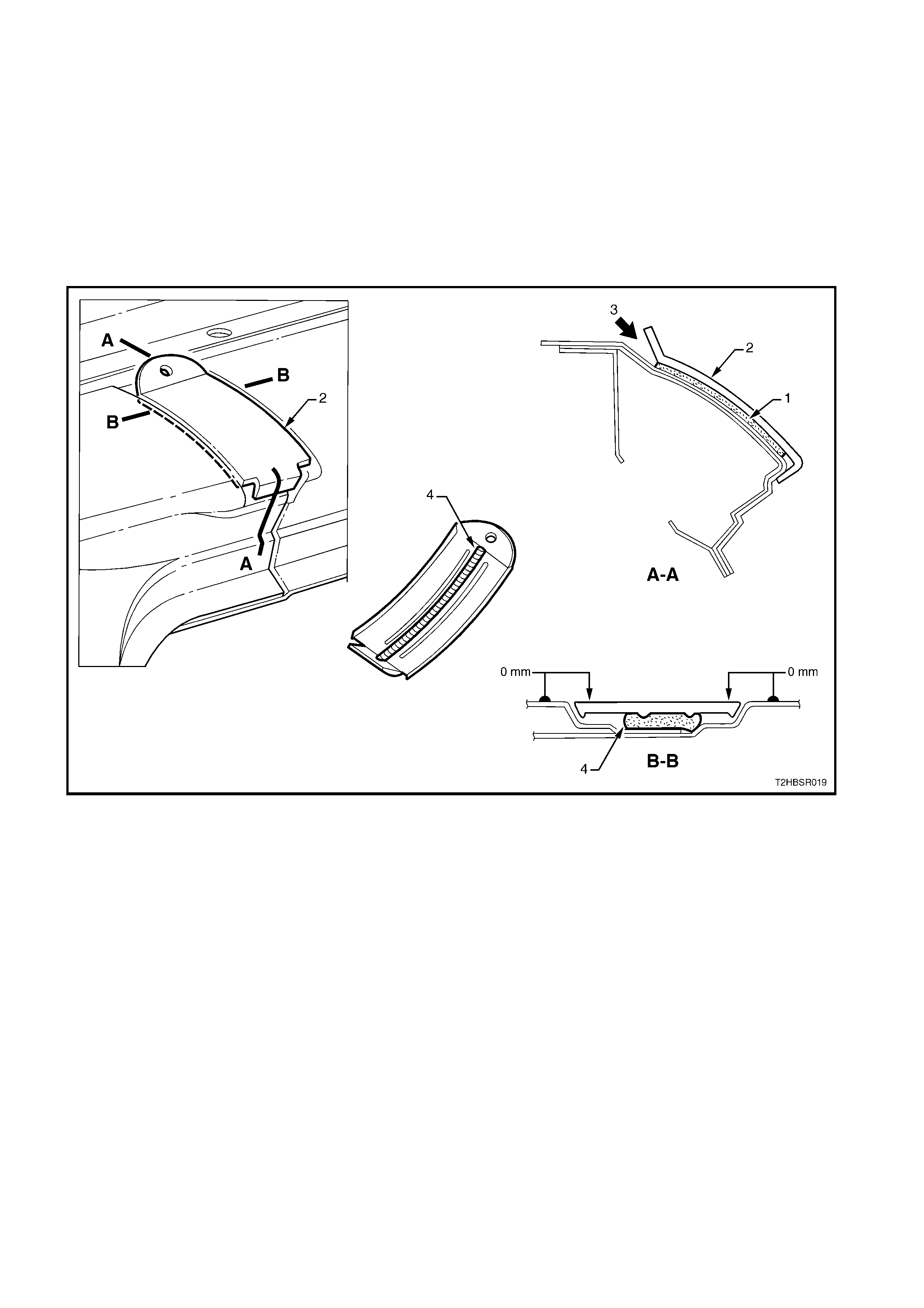

3.11 ROOF JOINT FINISHER

LT Section No. –

As required, first remove the following components:

1. Roof side rails, refer to 3.8 ROOF SIDE RAILS.

2. Door opening moulding, refer to 3.9 DOOR OPENING MOULDING.

REMOVE

1. Car efully cut the adhesive (1) attac hing the roof joint f inisher (2) , while prising the top of the finis her (3) f rom

the vehicle, refer to Figure 1A9-64.

2. Clean off any residual adhesive as required.

Figure 1A9-64

REINSTALL

1. The surface is to be clean and painted.

2. Apply an 8 m m bead of urethane adhesive such as Expandite Betaseal 554.02, Sik aflex Drive or equivalent

(4) along the back of the moulding, between the ribs.

3. Fit the finisher, ensuring the outer surface is flush with the panel surfaces and the side gaps are even.

4. If required, temporarily secure finisher with tape.

5. Allow adhesive to cure overnight.

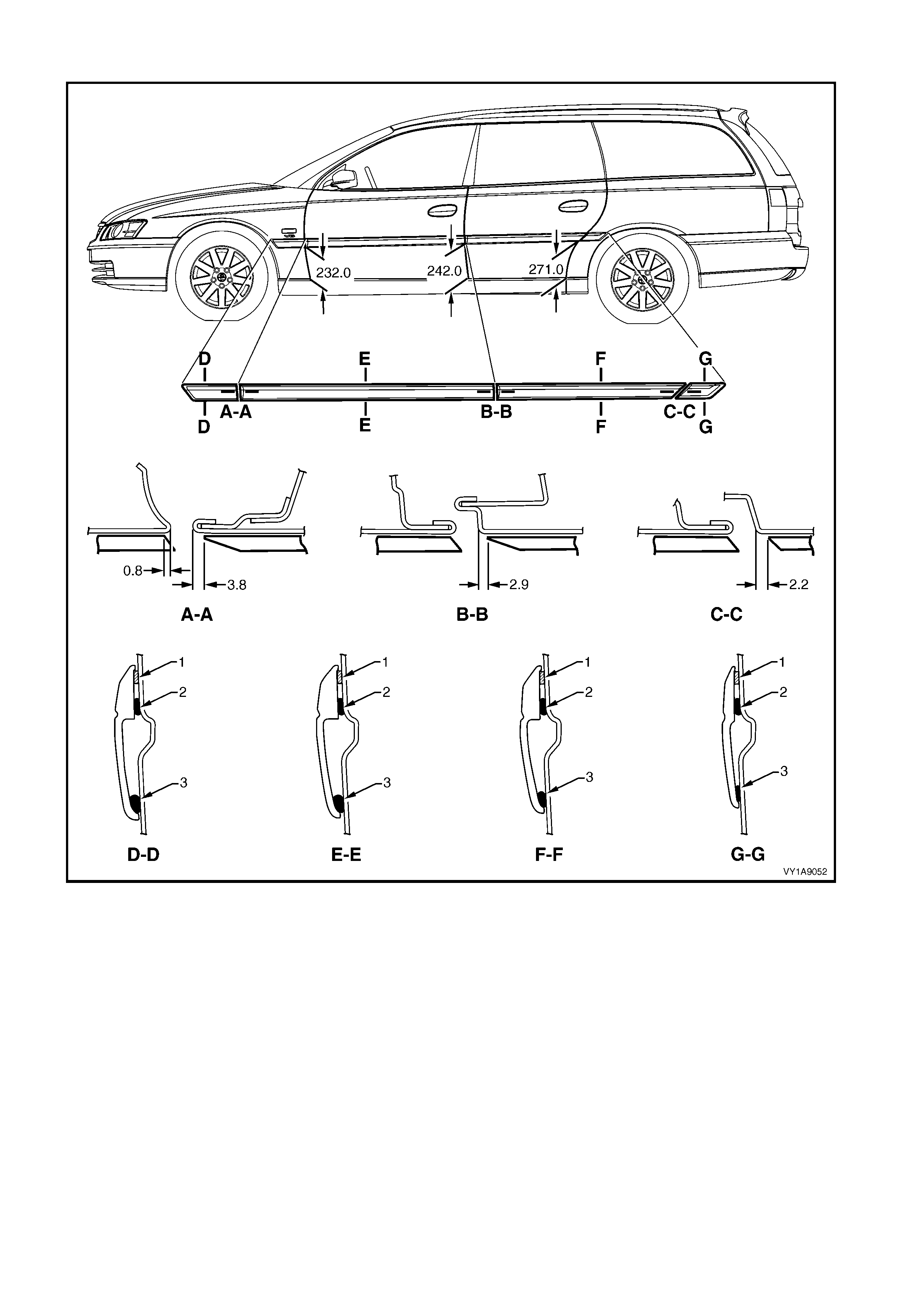

3.12 BODY SIDE MOULDINGS

LT Section No. – 10-250

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. Using a paint scraper or similar, begin at one end

and carefully prise the moulding from the panel,

cutting through the double sided tape and

adhesive.

NOTE: As an alternative, carefully use a length of

piano wire to cut the adhesive in a similar way to

removing a windshield.

3. As required, remove any remaining double-sided

tape and adhesive from the moulding and/or panel.

Clean the surfaces with Prepsol or equivalent.

Figure 1A9-65

REINSTALL

Refer to Figure 1A9-66 for Executive, Acclaim or Lumina LS vehicles or to Figure 1A9-67 for Berlina vehicles.

1. Place a mark on the rear edge of the fender and/or door panels at the three points shown in the relevant

Figure as required. Measure in a straight line from the lower edge of each panel:

2. If a complete moulding set is to be f itted, or as r equir ed, apply a length of mas king tape along the side of the

vehicle, level with the marks. Begin by affixing the tape at the rear of the rear door, hold it taut and away

from the vehicle, and affix it to each panel. Ensure it is straight and then smooth it down along its length.

3. If reusing the moulding, apply new acrylic double-sided tape (1) such as 3M 5344 along the back of the

moulding.

4. Apply a 3.0 m m diam eter bead of urethane adhesive such as Expandite Betaseal 554.02, Sikaflex Drive or

equivalent over the entire length of moulding (2) and for 50mm in several places (3).

NOTE: Refer to any further directions supplied with the urethane adhesive.

5. Affix the moulding to the vehicle in the correct positions, aligning the lower edge with the masking tape (if

fitted) and:

• For the fender moulding begin at the rear edge aligning to the dimension at Section A-A.

• For the f ront door moulding begin at the fr ont edge of the f r ont door, aligning to the dimension at Section

A-A.

• For the rear door moulding begin at the f ront edge of the rear door, aligning to the dim ension at Section

B-B.

• For the quarter panel m oulding begin at the f ront edge of the quarter panel, aligning to the dim ension at

Section C-C.

6. Press firmly over the length of the moulding(s) at the double-sided tape to ensure maximum adhesion.

EXECUTIVE, ACCLAIM, LUMINA LS

Figure 1A9-66

BERLINA

Figure 1A9-67

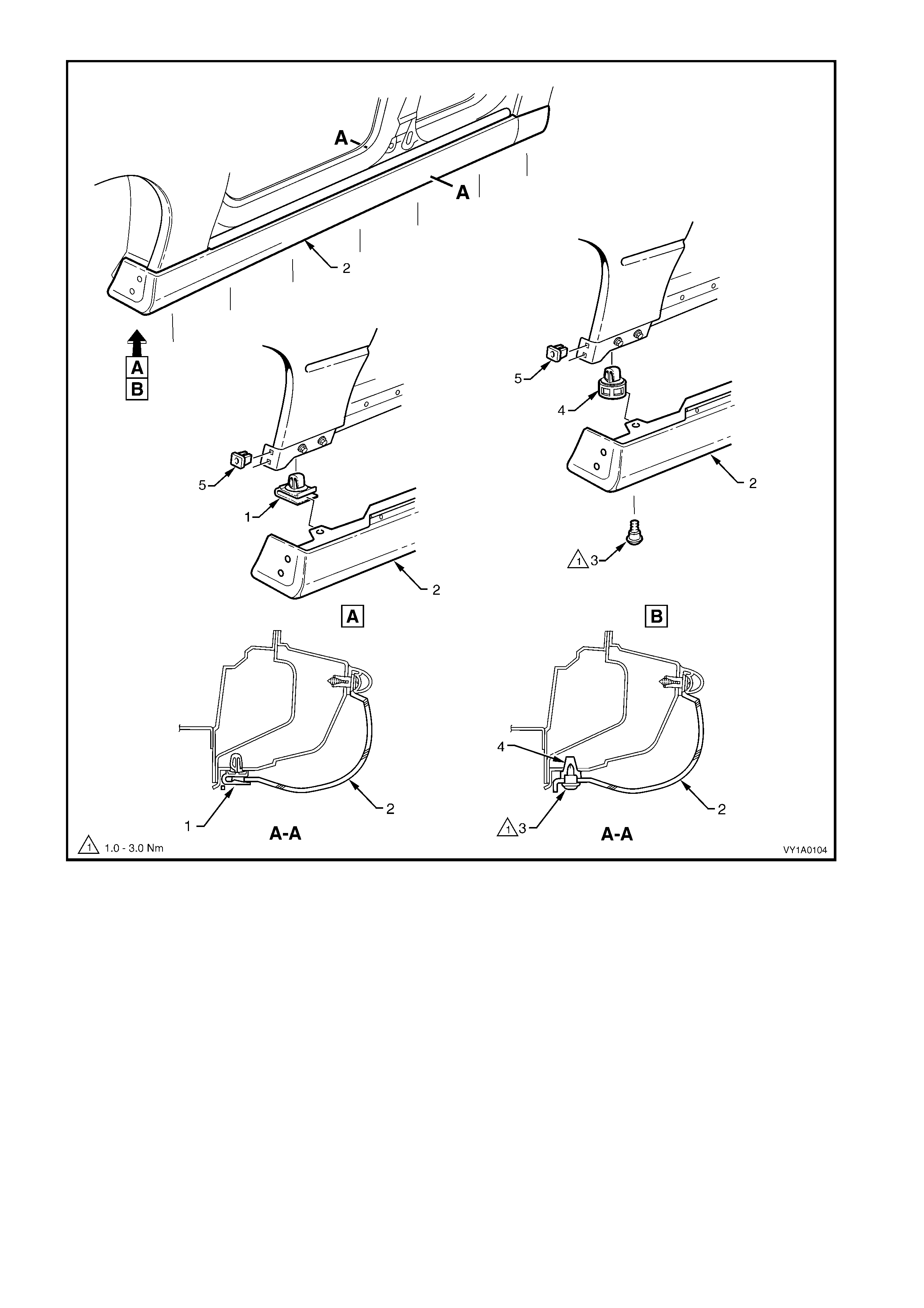

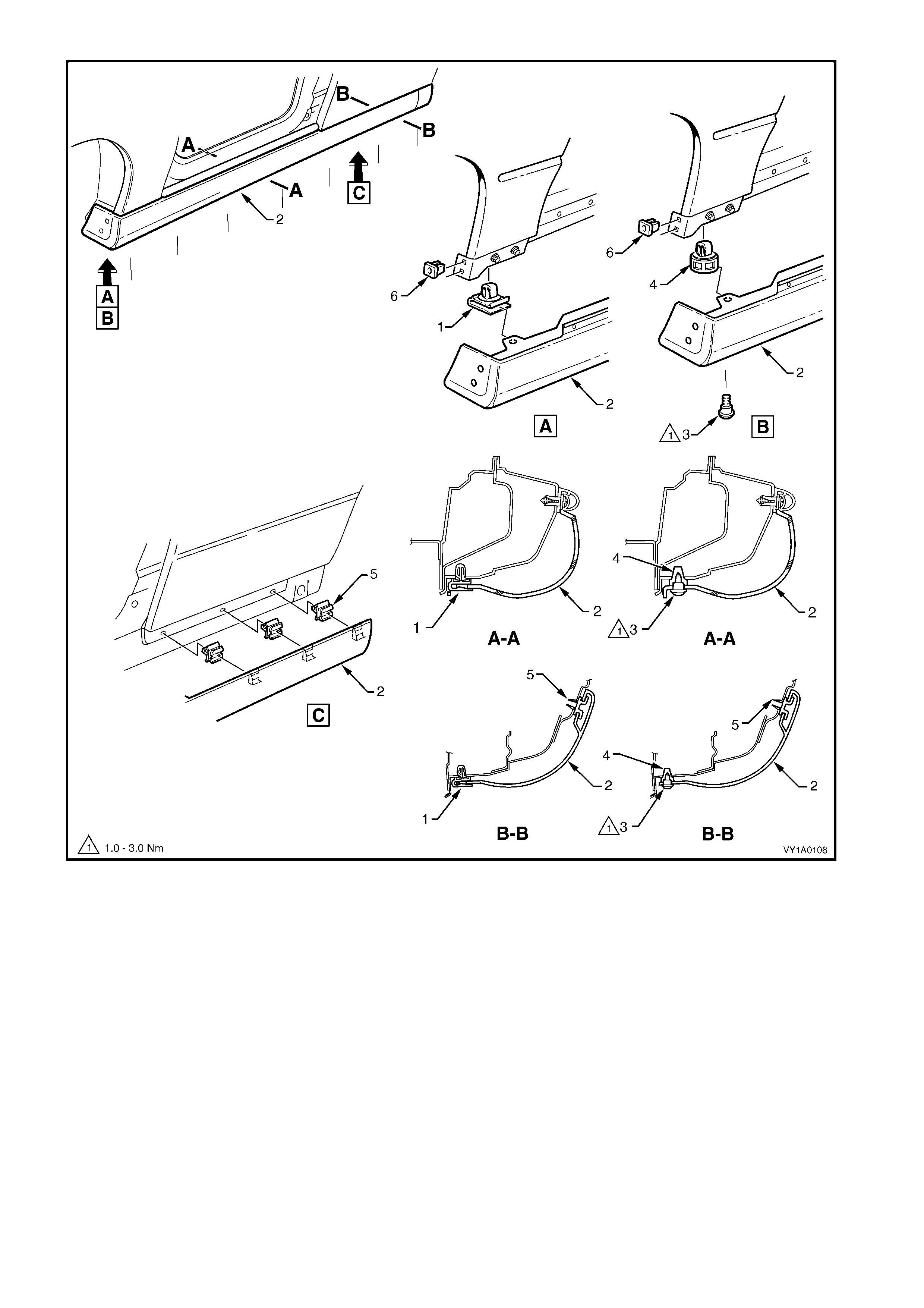

3.13 ROCKER PANEL MOULDING ASSEMBLY

LT Section No. – 10-300

REMOVE

1. Remove the screw (1), two places, attaching the

rear rocker panel moulding (2) and wheelhouse

liner (3 ).

NOTE: If required, the r ear rocker panel moulding can

be removed at this stage by sliding it rearward from the

front rocker panel moulding.

Figure 1A9-69

2. Remove the two screw (1), two places, attaching

the front rocker panel moulding (2) to the fender

and liner.

Figure 1A9-70

3. Lift up the rocker panel weatherstrip (1) to gain

access and remove the retainer (2), nine places,

attaching the rocker panel moulding (3).

4. From underneath the vehicle, refer to Figure 1A9-

72:

• For earlier build vehicles f itted with the retainer

(1), beginning at one end of the moulding (2),

use a flat blade screwdriver to spread the

retainer apart slightly while holding outward

pressure on the moulding, disengaging it from

the retainer.

• For later build vehicles fitted with the screw

arrangement, remove the screw (3), seven

places, from the retainer under the moulding

(4).

5. Remove the moulding.

6. If required, prise the nut (5), two places, from the

fender.

Figure 1A9-71

Figure 1A9-72

7. If required:

• For earlier build vehicles, remove the retainer (1), seven places, by gently levering out from the body,

taking care not to damage paint work, refer to View A, Figure 1A9-73.

• For later build vehicles, remove the retainer (2), seven places, by gently levering out from the body,

taking care not to damage paint work, refer to View B, Figure 1A9-73.

Figure 1A9-73

REINSTALL

Reinstallation of the rocker panel front and rear

mouldings is the reverse of the removal operation

noting the following.

1. Ensure the front moulding is c or re ctly seated in the

retaining clips.

2. Tighten all fasteners to the correct torque

specification.

3. Ensure the weatherstrip is seated correctly.

ROCKER PA NEL MOULDING

ATTACHING SCREW

TORQUE SPE CI FICATION 1.0 – 3.0 Nm

4. SERVICE OPERATIONS, UTILITY

4.1 RADIATOR GRILLE EMBLEM

LT Section No. – 10-150

NOTE: Export SS Utilities are not fitted with a radiator

grille emblem. For servicing of the radiator grille

escutcheon refer to Section 1C, 2.2 RADIATOR

GRILLE ASSEMBLY, S SEDAN & SS.

REMOVE

1. To assist removal, warm the emblem with a heat-

lamp or heat-gun to soften the adhesive.

2. Using a knife or paint scraper, carefully remove

the emblem as sem bly from grille as sem bly, cutting

the double-sided tape.

NOTE: The em blem has two locating lugs which must

not be cut if the emblem is to be reused.

3. Remove any remaining double-sided tape as

required.

Figure 1A9-72

REINSTALL

1. If reinstalling the existing emblem, remove the

existing double-sided tape and clean the surface

with wax and grease remover such as Prepsol or

equivalent. Apply new polyethylene double-sided

tape such as 3M 4428 or equivalent.

2. Clean the surface of the grille assembly with

Prepsol or equivalent.

3. Remove the backing paper from the double-sided

tape.

4. Align the emblem locating lugs with their

corresponding holes in the grille assembly and

affix the emblem.

5. Press firm ly over the entire emblem for at leas t 10

seconds to ensure maximum adhesion.

4.2 FENDER NAME PL ATE

LT Section No. – 10-150

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the plate with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

plate required, remove any rem aining double-sided

tape from the plate and/or fender and clean the

surfaces with Prepsol or equivalent.

Figure 1A9-73

REINSTALL

1. If reusing the plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the back

and trim the edges of the tape slightly in from the edge of plate.

2. Clean the fender surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the plate in the position shown, measuring from the front side turn signal lamp hole, refer to Figure

1A9-74. Ensure it is positioned parallel to the style line.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-74

4.3 QUARTER PANEL NAME PLATE

LT Section No. – 10-150

SS

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the quarter panel.

4. As required, remove any remaining double-sided

tape f rom the nam e plate and/or quarter panel and

clean the surfaces with Prepsol or equivalent.

Figure 1A9-75

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the quarter panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the nam e plate on to the lower section of the quarter panel in the position shown, meas uring up from

the lower edge of the quarter panel and in from the wheel arch, level with the lower edge of the plate, refer to

Figure 1A9-76.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-76

4.4 ENDGATE EMBLEM

LT Section No. – 10-150

HOLDEN, CHEVROLET

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the emblem with a heat-

lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

emblem from the endgate.

NOTE: The emblem has two locating pins, take care

not to break them if the emblem is to be reused.

4. As required, remove any remaining double-sided

tape from the emblem and/or endgate and clean

the surfaces with Prepsol or equivalent.

Figure 1A9-77

REINSTALL

1. If reusing the emblem, apply new polyethylene

double-sided tape such as 3M 4428 or equivalent

to the back and the trim edges of the tape slightly

in from the edge of the emblem.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided

tape.

4. Apply the emblem in the position shown ensuring

the locating pins are correctly orientated with the

locating holes in the panel surface.

5. Press firm ly over the entire emblem for at leas t 10

seconds to ensure maximum adhesion.

Figure 1A9-78

4.5 ENDGATE NAME PLATE, RH

LT Section No. – 10-150

S & SS

REMOVE

1. Protect the paint and bodywork with tape or a rag.

2. To assist removal, warm the name plate with a

heat-lamp or heat-gun to soften the adhesive.

3. Using a paint s craper or sim ilar, caref ully pris e the

name plate from the endgate.

4. As required, remove any remaining double-sided

tape from the name plate and/or endgate and

clean the surfaces with Prepsol or equivalent.

Figure 1A9-79

REINSTALL

1. If reusing the name plate, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

back and the trim edges of the tape slightly in from the edge of the name plate.

2. Clean the panel surface with Prepsol or equivalent.

3. Remove the backing paper from the double-sided tape.

4. Apply the name plate onto the right-hand side of the endgate in the position shown, ensuring it is straight and

is correctly aligned to the measurements, refer to Figure 1A9-80.

5. Press firmly over the entire plate for at least 10 seconds to ensure maximum adhesion.

Figure 1A9-80

4.6 ROOF JOINT MOULDING

LT Section No. – 10-265

REMOVE

1. Beginning at the front of the vehicle, use a

screwdriver to carefully prise the roof joint

moulding (1) from the roof channel, disengaging

the retaining clips (2) at four places.

IMPORTANT: Take care as the retaining clips can

easily break. Protect the paintwork with a shop rag.

2. Disengage the roof joint m oulding rear loc ating lug

from the rear window upper moulding by lifting the

moulding at the front until it slides freely from its

location in the rear window upper moulding.

Figure 1A9-81

REINSTALL

1. As required, seat the four retainers onto the roof

joint moulding, evenly spaced.

2. Position the roof joint moulding locating lug in

position in the rear window upper moulding.

3. Seat the roof joint moulding in the roof channel

and beginning at the rear, clip it in place.

4. At the f ront, ensure the m oulding is installed under

the windshield moulding cover.

4.7 DOOR OPENING MOULDING

LT Section No. – 10-265

REMOVE

1. Open the door on the relevant side of the vehicle.

2. Remove the scr ew (1), s even places , attac hing the

door opening moulding (2) to the body.

3. Carefully remove the moulding, disengaging the

quarter window assembly tab (3).

Figure 1A9-82

REINSTALL

Reinstallation is the reverse of the removal. When

installing the screws, begin at the rear and work

forward.

NOTE: The screws are encapsulated with a wax

sealer. It is r ecom mended that the sc rews be replaced

once removed, however if this is impractical, apply a

small amount of sealer to the end of the thread.

Tighten the screws to the specified torque.

DOOR OPENING MOULDING

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 2.0 Nm

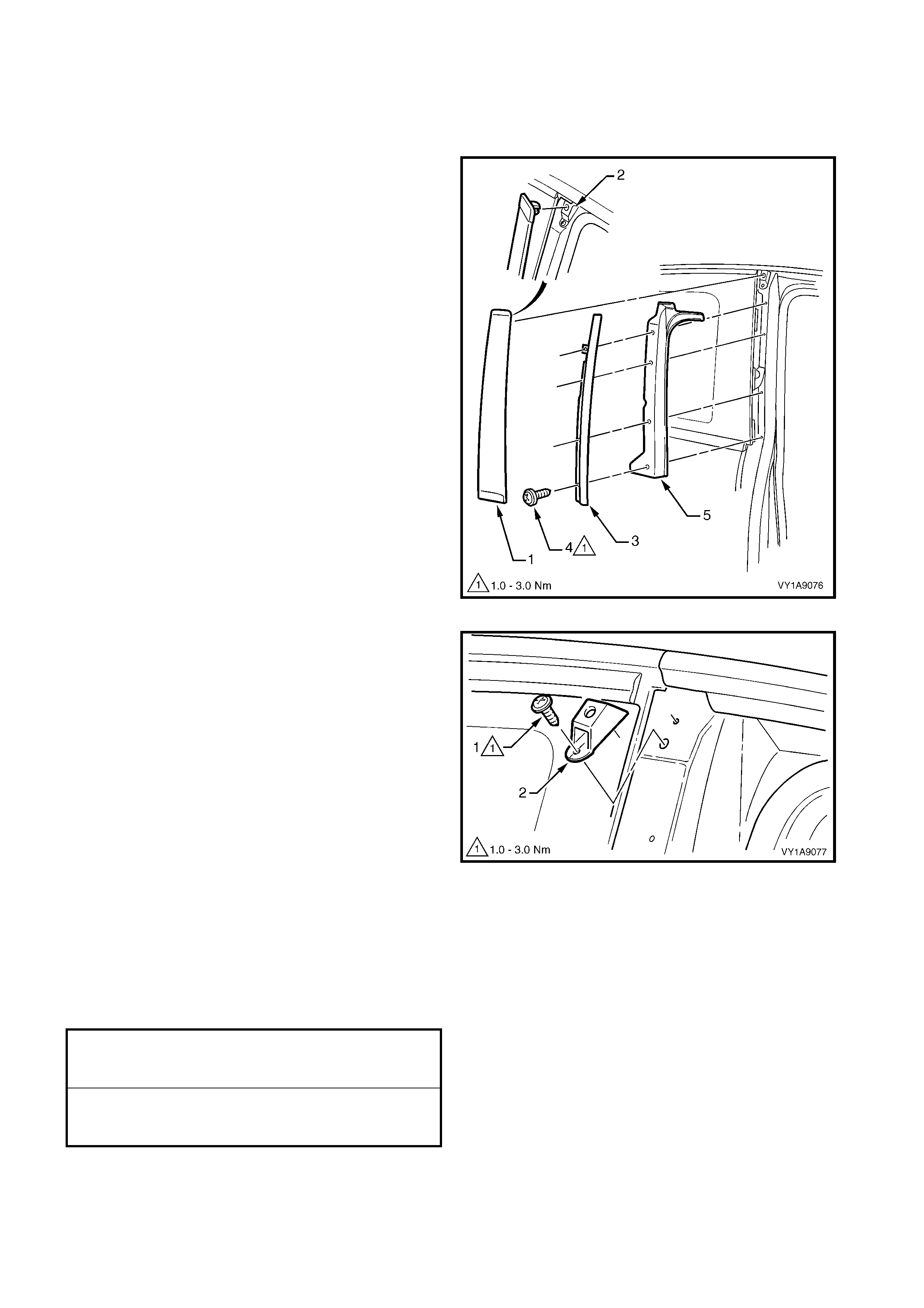

4.8 CENTRE PILLAR UPPER FINISHER ASSEMBLY

LT Section No. – 10-265

REMOVE

1. Open the door on the relevant side of the vehicle.

2. Gently prise the top of the centre pillar upper

finisher (1) out to disengage it from the centre

pillar upper finisher retainer (2).

3. Holding the top of the finisher out, slide it up the

centre pillar outer sealing strip (3).

4. Manoeuvre the rear edge and then the front edge

of the finisher from the sealing strip and remove.

5. Remove the screw (4), four places, securing the

centre pillar sealing strip to the pillar and remove

the strip.

6. Remove the screw (5) securing the centre pillar

upper finisher retainer and centre pillar upper trim

mount plate (6) to the pillar and remove.

Figure 1A9-83

REINSTALL

Reinstallation of the centre pillar upper finisher

assembly is the reverse of the removal procedure,

noting the following:

1. Ensure the centre pillar upper trim panel is seated

correctly under the door opening weatherstrip

2. Ensure all fasteners are tightened to the correct

torque specification.

3. Engage the front edge of the finisher into the

sealing strip and then the rear edge into the

window assembly

4. Slide the centre pillar upper finisher down and

press it in at the top to engage it into the retaining

clip.

CENTRE PILLAR UPPER FINISHER

RETAINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

CENTRE PILLAR SEALING STRIP

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

4.9 ROCKER PANEL MOULDING ASSEMBLY

LT Section No. – 10-300

REMOVE

1. Remove the screw (1), two places, attaching the

rear rocker panel moulding (2).

NOTE: If required, the r ear rocker panel moulding can

be removed at this stage by sliding it rearward from the

front rocker panel moulding.

Figure 1A9-86

2. Remove the screw (1), two places, attaching the

front rocker panel moulding (2) to the fender and

liner.

Figure 1A9-87

1. Lift up the rocker panel weatherstrip (1) to gain

access and remove the retainer (2), five places,

attaching the rocker panel moulding (3).

2. From underneath the vehicle, refer to Figure 1A9-

89:

• For earlier build vehicles f itted with the retainer

(1), beginning at one end of the moulding (2),

use a flat blade screwdriver to spread the

retainer apart slightly while holding outward

pressure on the moulding, disengaging it from

the retainer.

• For later build vehicles fitted with the screw

arrangement, remove the screw (3), seven

places, from the retainer (4) under the

moulding.

3. Carefully remove the moulding from the vehicle,

unclipping the three retainers (5).

4. If required, prise the nut (6), two places, from the

fender.

Figure 1A9-88

Figure 1A9-89

5. If required:

• For earlier build vehicles, remove the retainer (1), seven places, by gently levering out from the body,

taking care not to damage paint work, refer to View A, Figure 1A9-90.

• For later build vehicles, remove the retainer (2), seven places, by gently levering out from the body,

taking care not to damage paint work, refer to View B, Figure 1A9-90.

Figure 1A9-90

REINSTALL

Reinstallation of the rocker panel front and rear

mouldings is the reverse of the removal operation

noting the following.

1. Ensure the front moulding is c or re ctly seated in the

retaining clips.

2. Tighten all fasteners to the correct torque

specification.

3. Ensure the weatherstrip is seated correctly.

ROCKER PANEL MOULDING

ATTACHING SCREW

TORQUE SPE CIFICATI ON 1.0 – 3.0 Nm

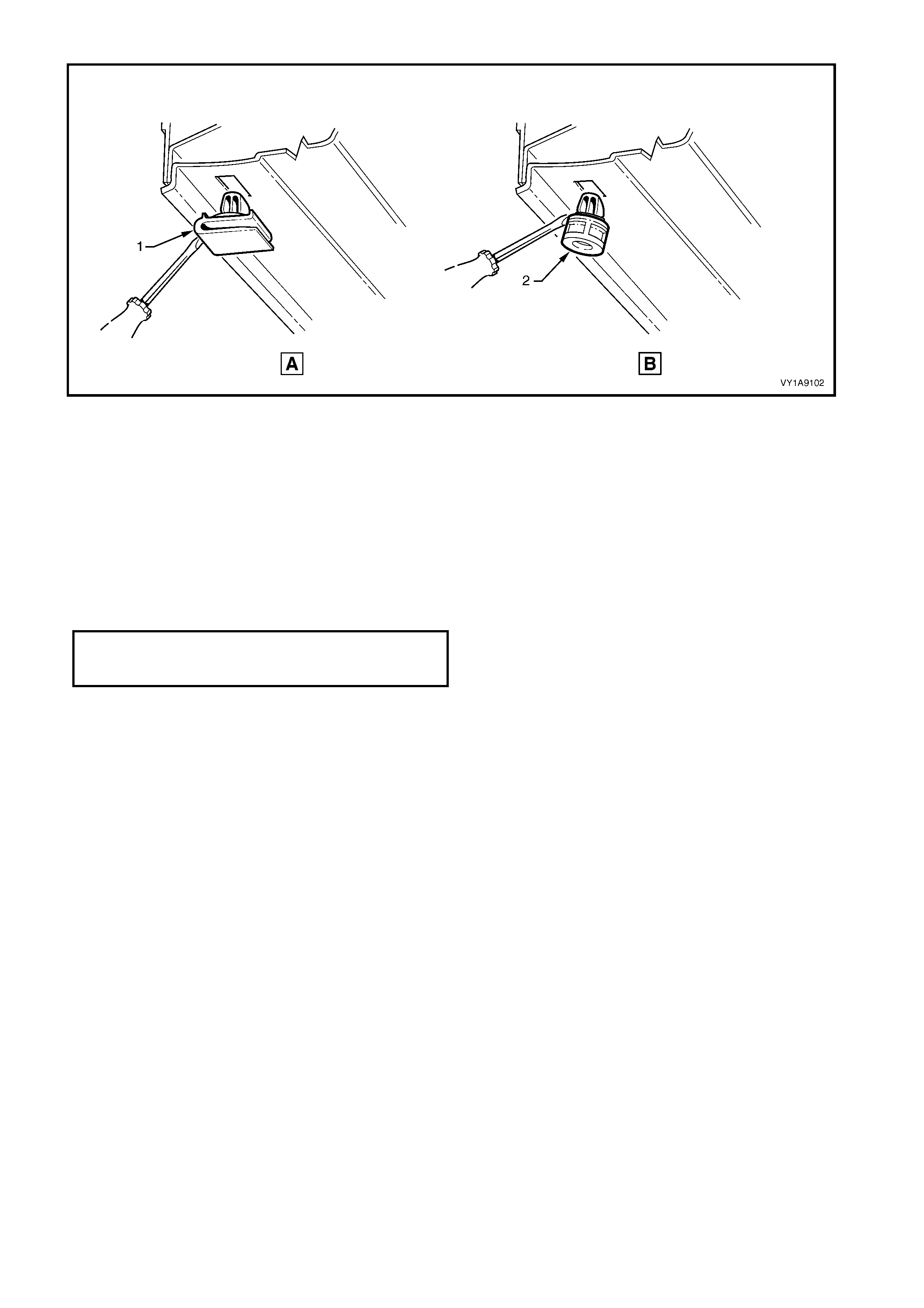

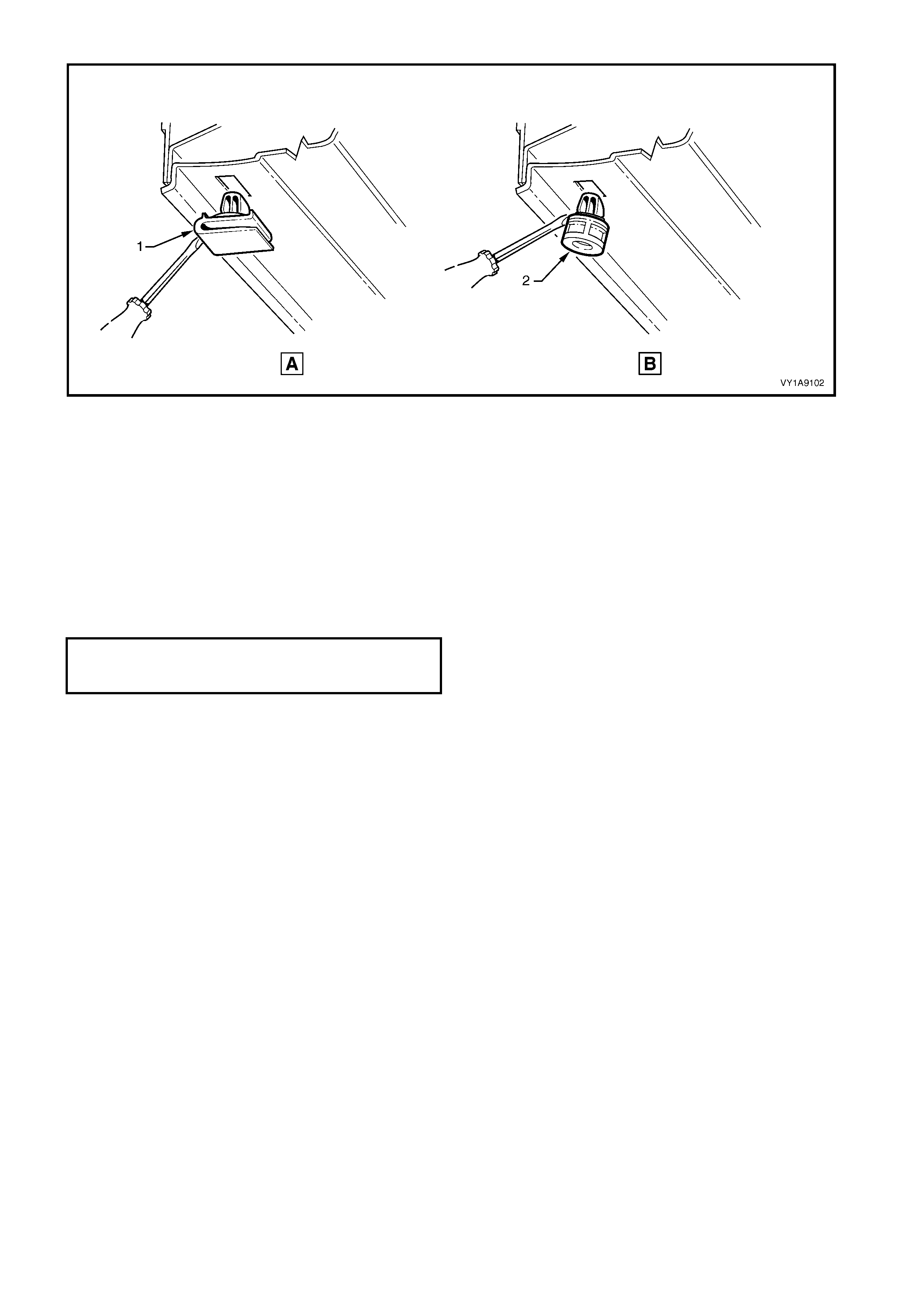

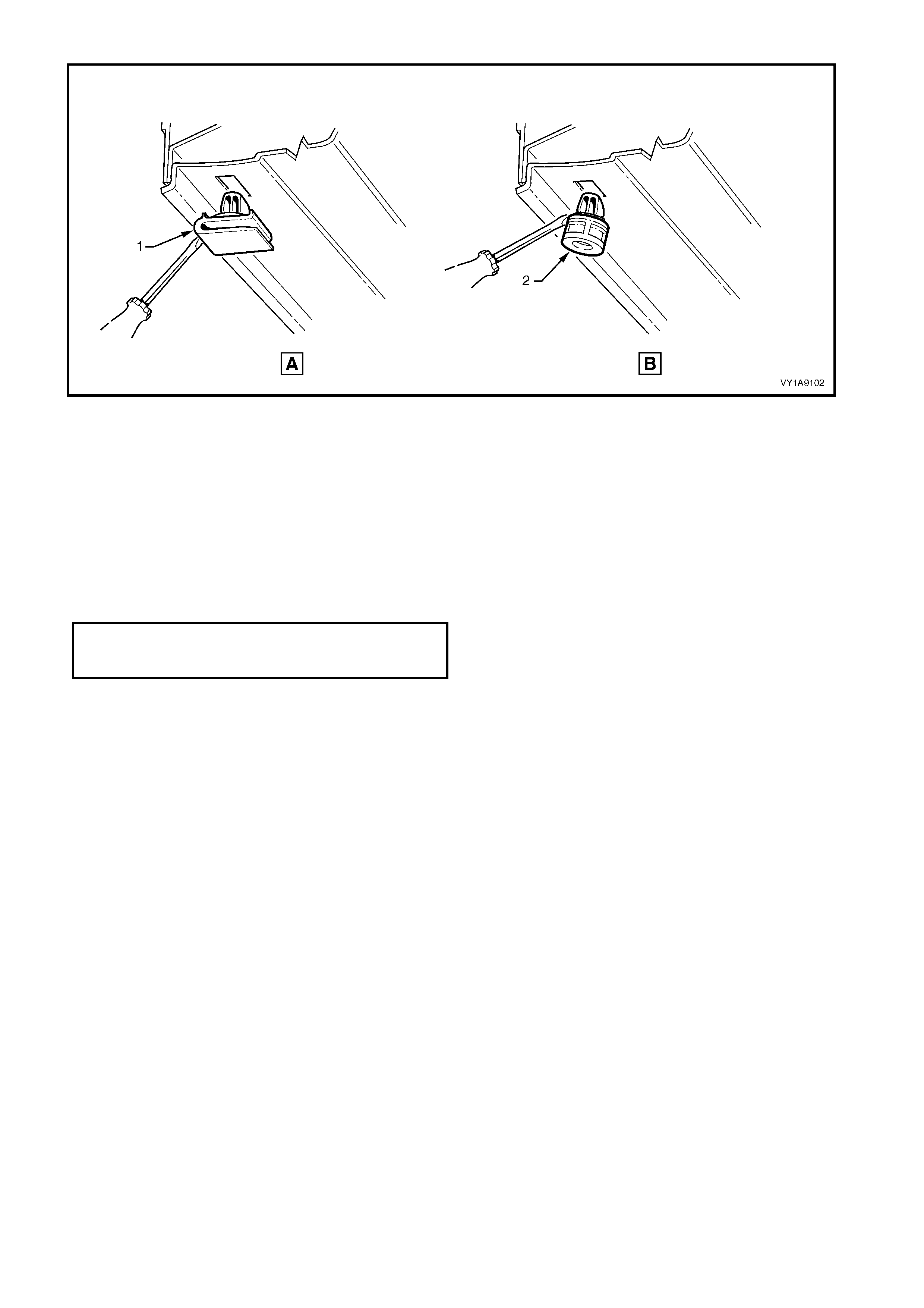

4.10 REAR WINDOW UPPER MOULDING

LT Section No. – 10-265

REMOVE

1. Carefully spread each end of the rear window upper m oulding (1) to disengage the locking tabs (2), ref er to

Figure 1A9-88.

2. Insert a flat-blade screwdriver and clean shop rag between the lower edge of the moulding and the rear

window.

3. Ensur ing the lock ing tabs are disengaged, pr ise the moulding of f in a rear ward and slightly upward direction

to disengage the retaining studs (3), five places.

NOTE: The upper edge of the moulding is attached with double-sided tape (4), remove the moulding carefully.

4. Where f itted, disconnec t the high mount stop lam p connec tor from the rear of the moulding and r emove the

moulding.

5. Remove any remaining double-sided tape from the moulding and/or panel as required and clean the

surfaces with Prepsol or equivalent.

6. If required, remove the five retainers (5) and seals (6) by inserting a flat-blade screwdriver between the

upper edge of the retainer and the panel. W hile pressing down on the screwdriver, ease the retainer out of

its location.

NOTE: Take care not to damage the paintwork.

Figure 1A9-88

DISASSEMBLE

1. Where fitted, carefully disengage the retaining

tangs fr om the high m ount stop lam p assem bly (1)

and manoeuvre the lamp assembly free from the

moulding (2).

Figure 1A9-89

REINSTALL

1. If fitted, install the high mount stop lamp assembly using the reverse of the removal procedure.

2. Check the retainers and seals are in sound condition. Replace as required.

3. If removed, fit the retainers and seals.

4. If reusing the moulding, apply new polyethylene double-sided tape such as 3M 4428 or equivalent to the

upper surface.

5. Clean the panel surface with Prepsol or equivalent.

6. Connect the high mount stop lamp connector, if fitted, and check its operation prior to installing the cap. Fit

the connector into its recess in the rear of the moulding.

7. Remove the backing paper from the double-sided tape.

8. Align the r etaining studs with their respec tive retainers on the vehicle and pus h home, ensuring the double-

sided tape does not contact until the moulding is fully seated.

9. Push-in each end to engage the locking tabs.

10. Press down along the upper surface of the moulding to ensure the tape is correctly adhered to the panel.

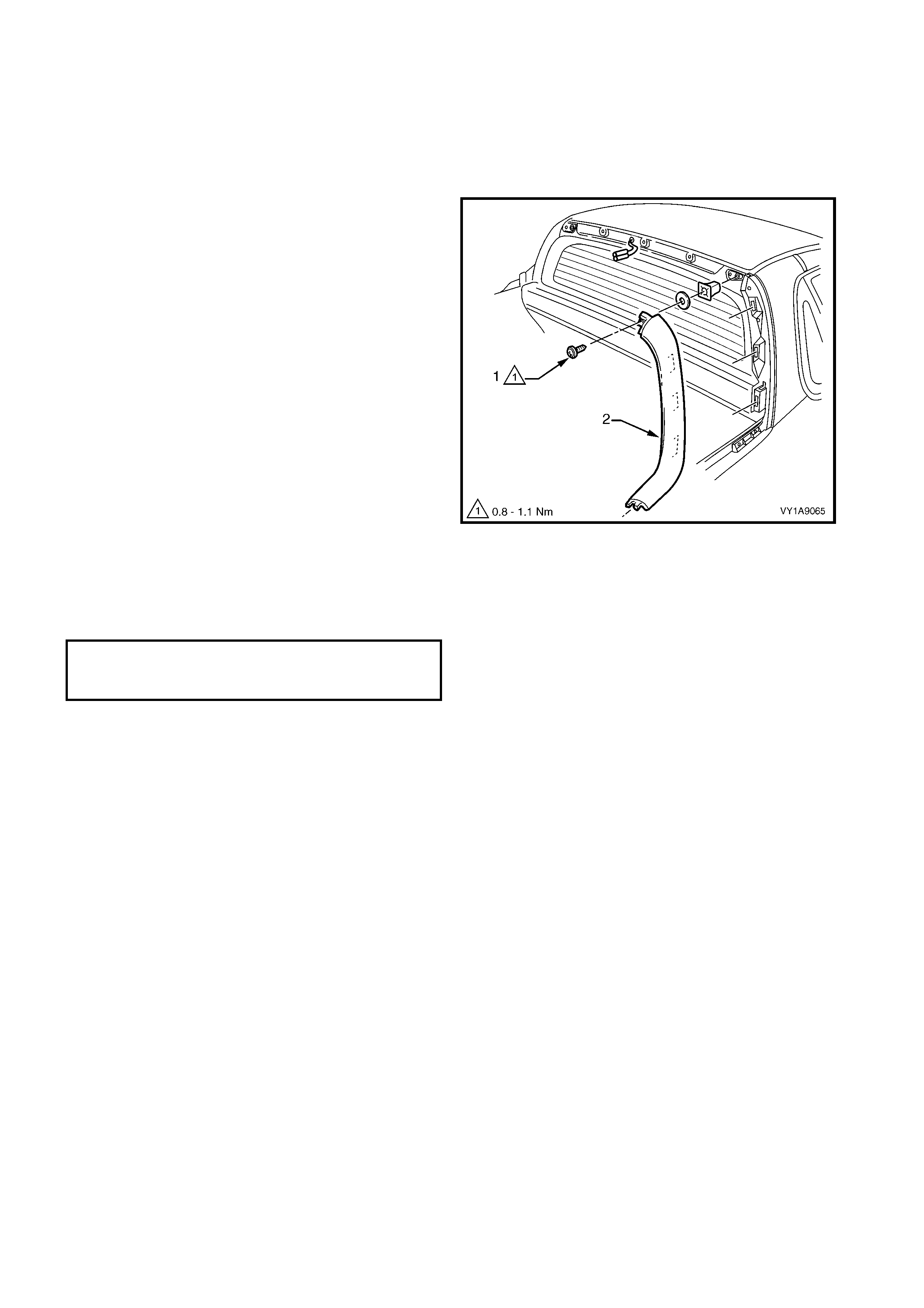

4.11 REAR WINDOW SIDE MOULDING

LT Section No. – 10-265

REMOVE

1. Remove the rear window upper moulding, refer to

4.10 REAR WINDOW UPPER MOULDING.

2. Remove the screw (1) attaching the rear window

side moulding (2).

3. Rotate the upper end of the moulding rearward to

disengage the three retainers.

4. Ease the lower end of the moulding forward to

disengage it from the quarter panel outer rail.

5. As required, remove the seal and retainer.

Figure 1A9-90

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screw to the specified torque.

TORQUE SPEC

REAR WINDOW SIDE MOULDING

ATTACHING SCREW

TORQUE SPECIFICATION 0.8 – 1.1 Nm

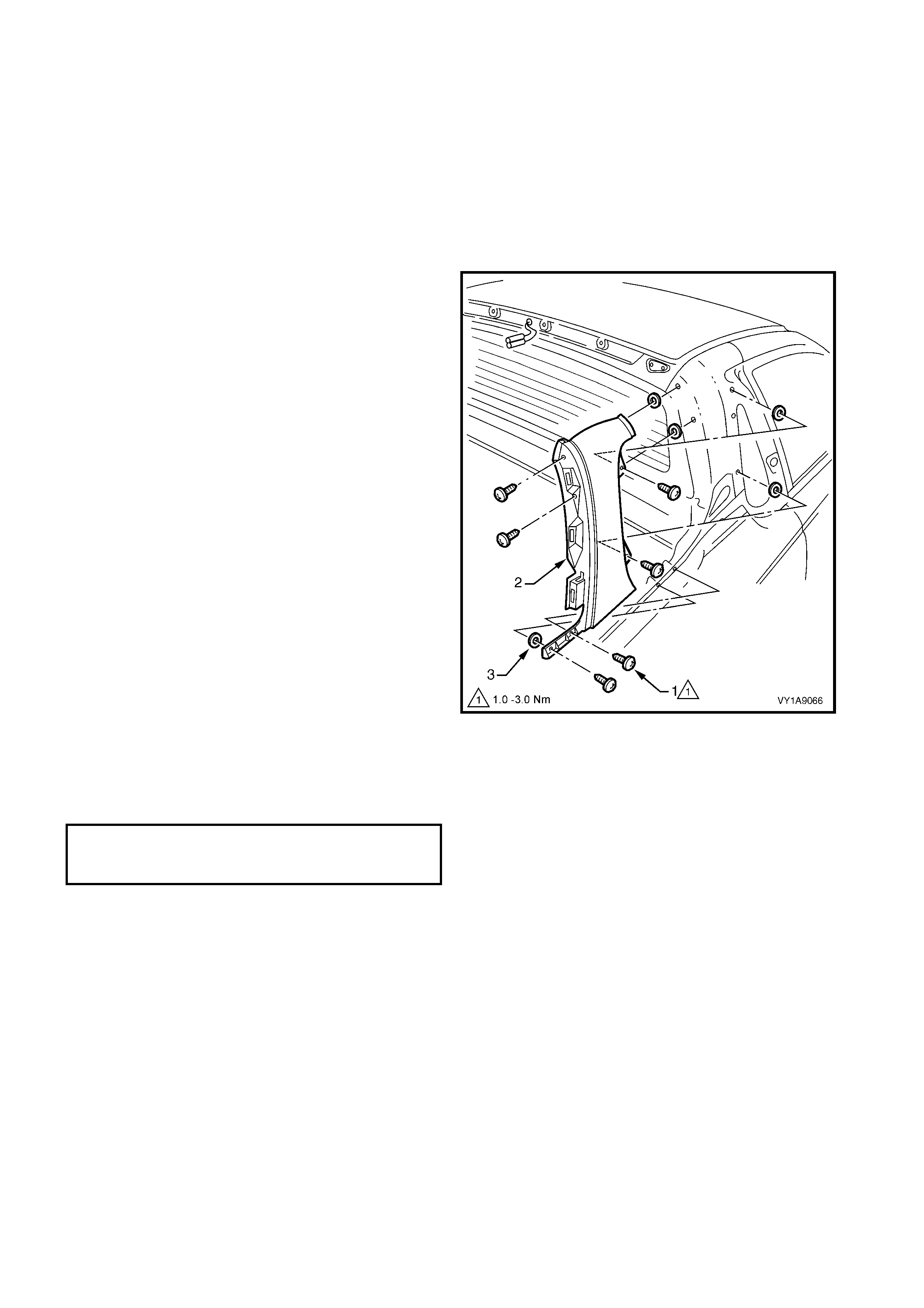

4.12 QUARTER WINDOW MOULDING

LT Section No. – 10-265

As required, first remove the following components:

1. Body lock pillar upper trim, refer to Section 1A8, 5.3 BODY LOCK PILLAR UPPER TRIM.

2. Quarter window assembly, refer to Section 1A6, 4.2 QUARTER WINDOW ASSEMBLY, UTILITY.

3. Rear window upper moulding, refer to 4.10 REAR WINDOW UPPER MOULDING.

4. Rear window side moulding, refer to 4.11 REAR WINDOW SIDE MOULDING.

REMOVE

1. Remove the screw (1), six places, attaching the

quarter window moulding (2) to the vehicle.

2. Remove the moulding rearwards, disengaging the

front upper edge.

3. If required, carefully peel the seals (3) from the

vehicle.

Figure 1A9-91

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

QUARTER WINDOW MOULDING

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

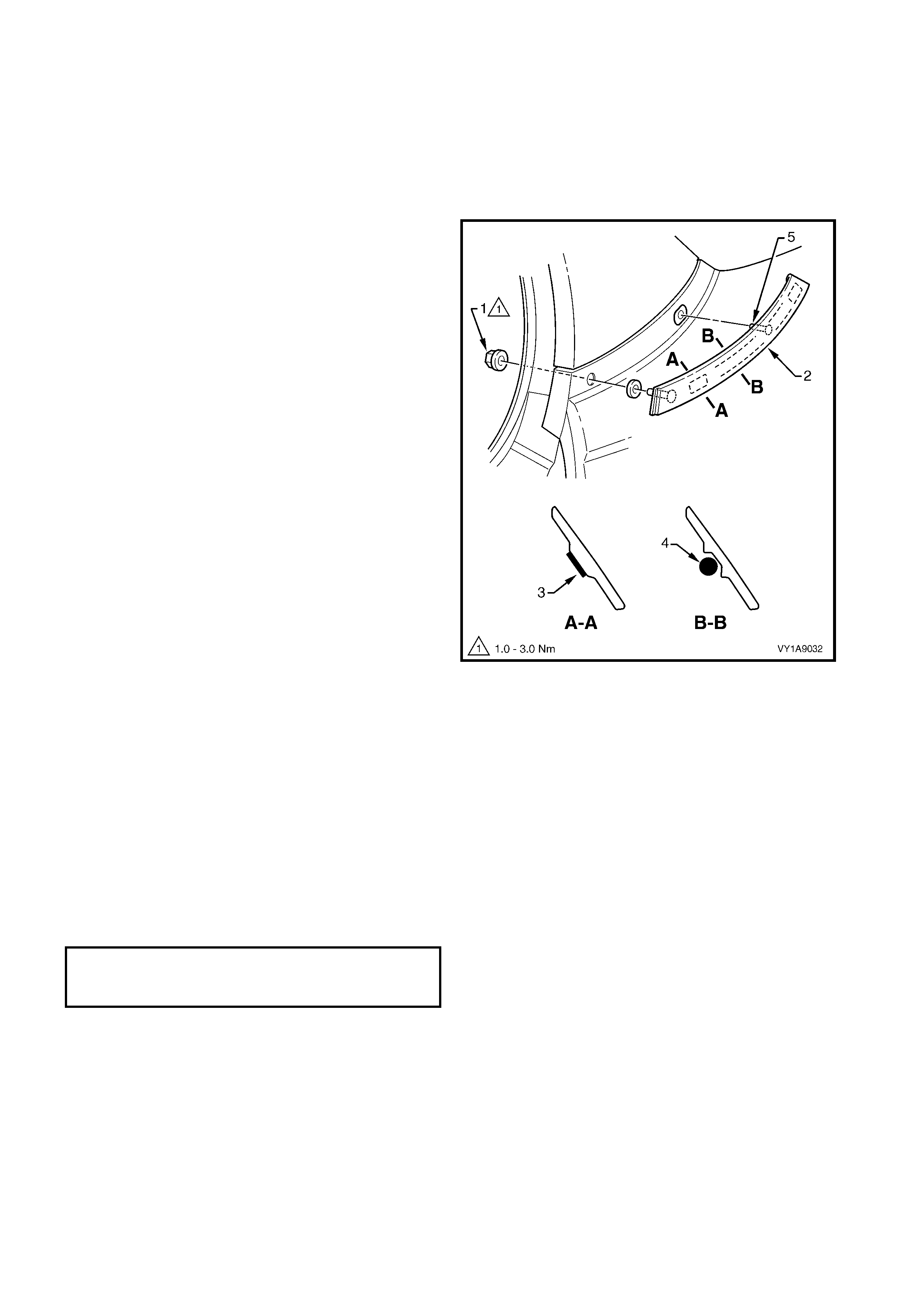

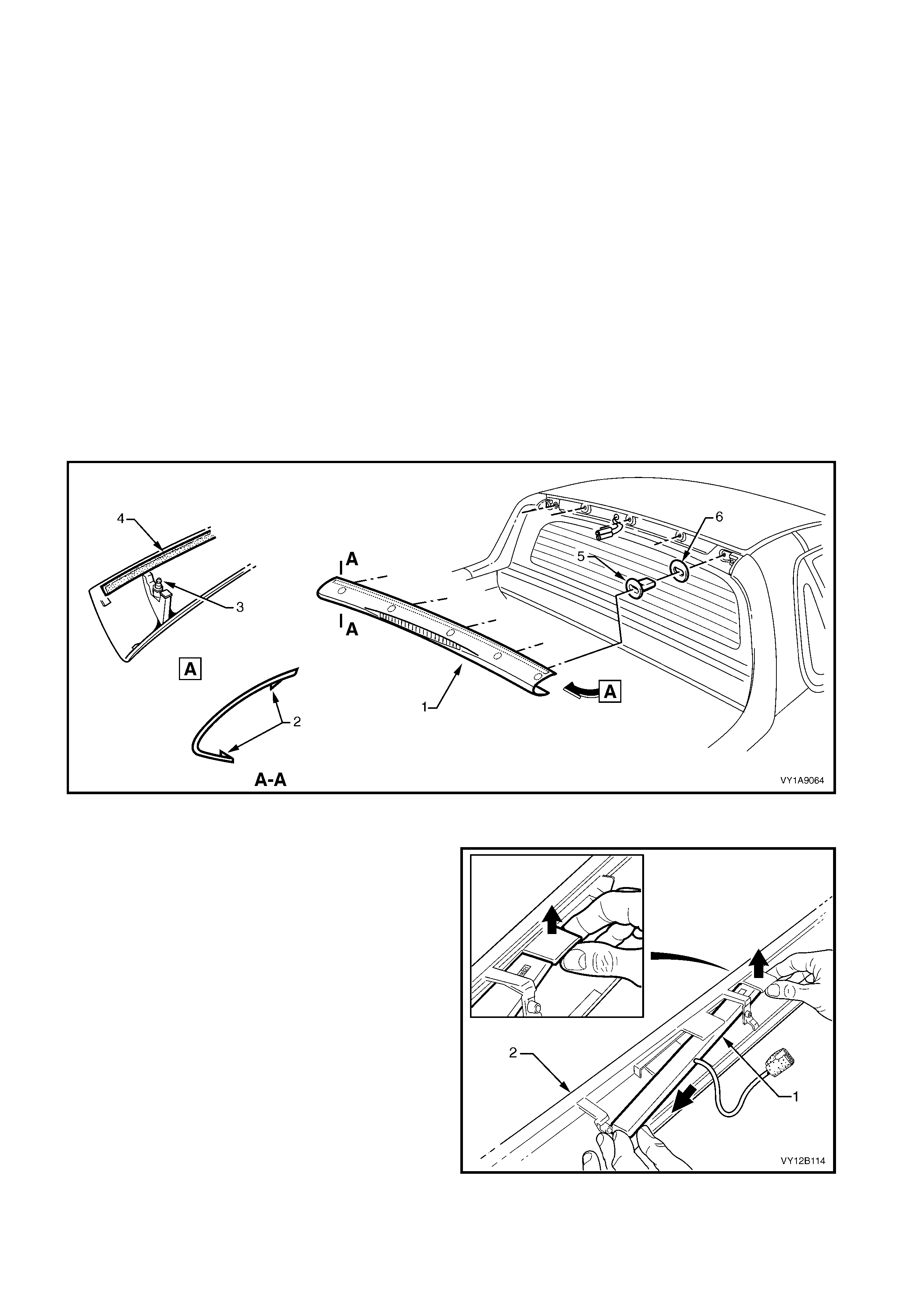

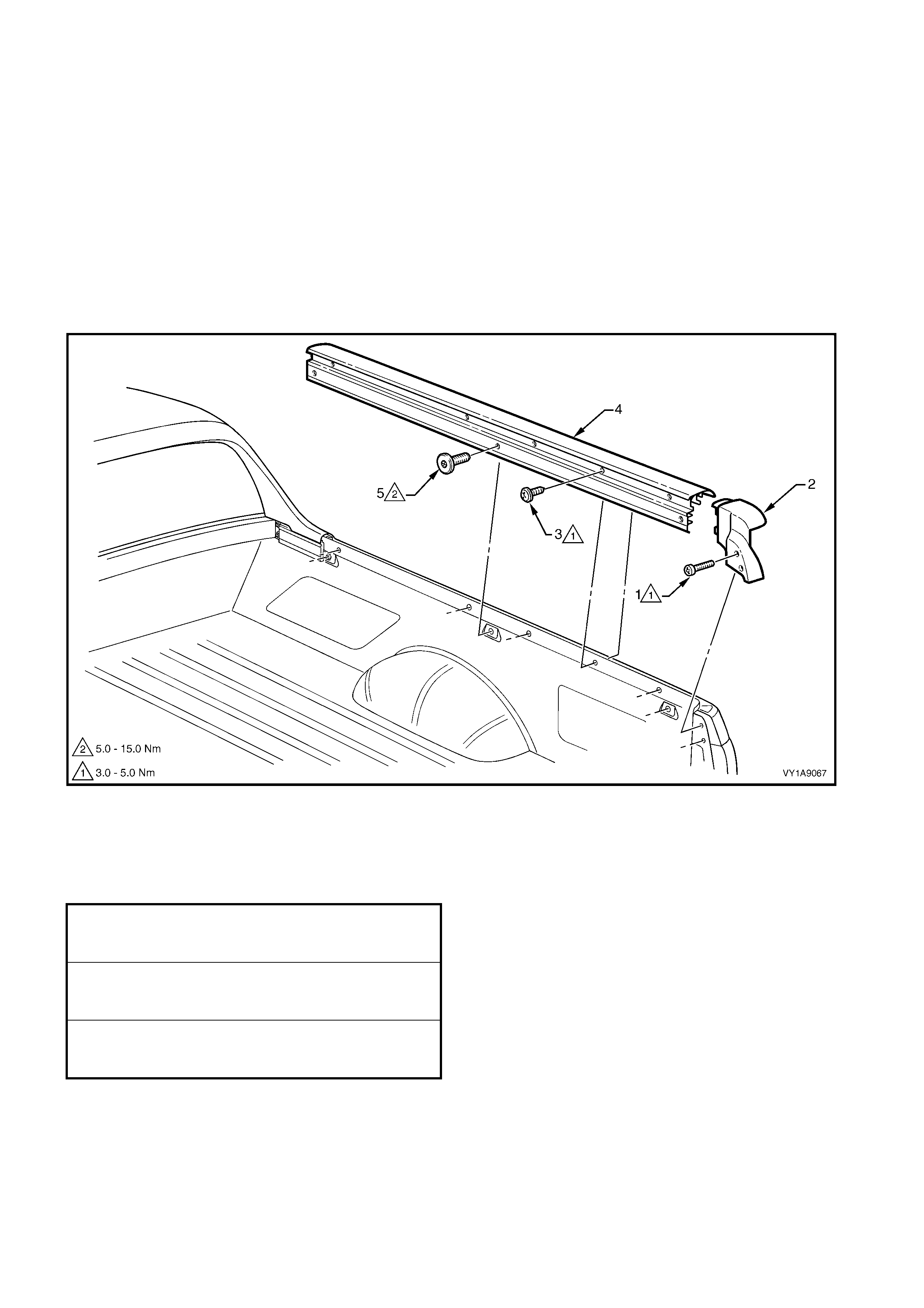

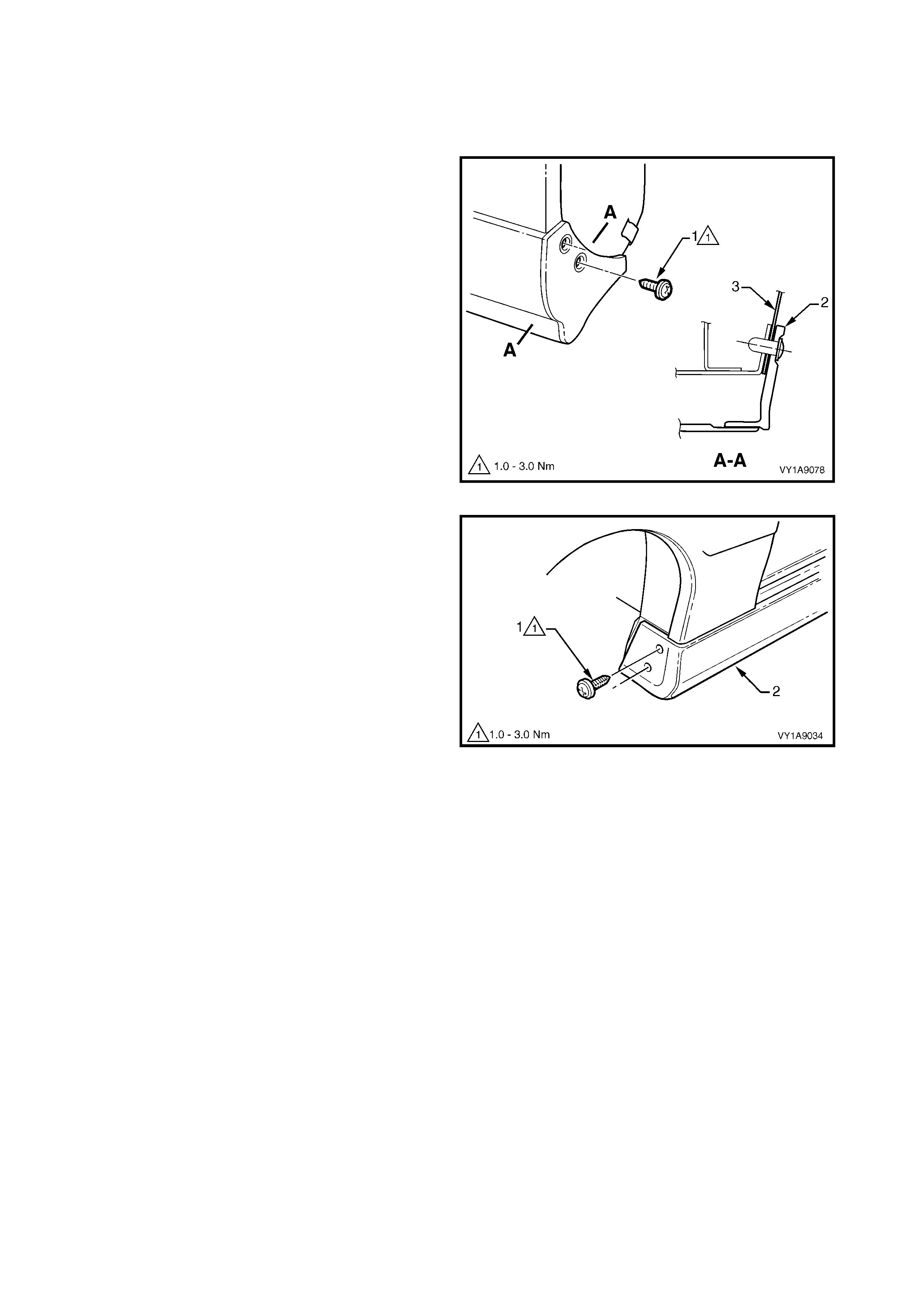

4.13 QUARTER PANEL RAILS

LT Section No. – 12-480

REMOVE

1. Remove the screw (1), two places, attaching the

quarter panel rear moulding (2) to the vehicle, refer

to Figure 1A9-92.

2. Remove the screw (3), five places, attaching the

quarter panel outer rail (4) to the vehicle.

3. Remove the torx-head screw (5), three places

attaching the quarter panel outer rail.

4. Carefully lift the moulding and rail from the vehicle

and remove.

Figure 1A9-92

REINSTALL

Reinstallation is the reverse of removal. Tighten the

screws to the specified torque.

QUARTER PANEL REAR MOULDING

ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 8.0 Nm

QUARTER PANEL OUTER RAIL

ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 8.0 Nm

QUARTER PANEL OUTER RAIL

ATTACHING TORX SCREW

TORQUE SPECIFICATION 5.0 – 15.0 Nm

4.14 TONNEAU COVER BOW RETAINER

LT Section No. – 12-480

REMOVE

1. Remove the rear window side moulding, refer to

4.11 REAR WINDOW SIDE MOULDING.

2. Remove the quarter panel rails, refer to

4.13 QUARTER PANEL RAILS.

3. Remove the screw (1) attaching the quarter

window moulding to the tonneau cover bow

retainer (2 ).

4. Remove the torx-head screw (3), two places,

attaching the tonneau cover bow retainer.

5. Remove the retainer from the vehicle.

NOTE: The torx-head screw (4) should not be