SECTION 1D - BUMPER BARS

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

2. SERVICE OPERATIONS

2.1 PAINT SYSTEMS

GENERAL

REVERSE PARKING AID (RPA)

RECOMMENDED MATERIALS

REFINISHING OF REPLACEMENT

PARTS

REPAIRING COLOUR COAT

HARDENER PRECAUTIONS

PAINT MASKING

2.2 FRONT BUMPER FASCIA ASSEMBLY

REMOVE

DISASSEMBLE

REINSTALL

2.3 FRONT BUMPER FASCIA GUIDE

ASSEMBLY

SEDAN, WAGON & UTILITY

COUPE

2.4 FRONT BUMPER IMPACT BAR

ASSEMBLY

REMOVE

REINSTALL

2.5 REAR BUMPER FASCIA ASSEMBLY,

SEDAN & COUPE

REMOVE

DISASSEMBLE

REVERSE PARKING AID

COMPONENTS

REINSTALL

2.6 REAR BUMPER FASCIA ASSEMBLY,

WAGON

REMOVE

DISASSEMBLE

REINSTALL

2.7 REAR BUMPER FASCIA, UTILITY

REMOVE

REINSTALL

2.8 REAR BUMPER FASCIA GUIDE ASSEMBLY

REMOVE

REINSTALL

2.9 REAR BUMPER FASCIA CENTRE

SUPPORT, SEDAN & COUPE

REMOVE

REINSTALL

2.10 REAR BUMPER SUPPORT FASCIA

UPPER, WAGON

REMOVE

REINSTALL

2.11 REAR BUMPER IMPACT BAR, EXCEPT

UTILITY

REMOVE

REINSTALL

3. TORQUE WRENCH SPECIFICATIONS

1. GENERAL DESCRIPTION

The bumper fascia assemblies fitted to MY2003 VY and V2 series vehicles are constructed from polypropylene

resin. Four styles of fr ont bumper f ascia are available depending on the m odel level: Level 1, Level 2 & 3, S Sedan

& SS, and Coupe.

NOTE: For model level designations, refer to Section 0A GENERAL INFORMATION.

All of the front bumper fascias, with the exception of Coupe, feature a separate radiator grille assembly which is

described in Section 1C RADIATOR GRILLE. The Coupe the radiator grille is moulded as part of the bumper

fascia.

With the exception of S Sedan and SS models, all front bumper fascias feature a separate lower radiator grille,

which is also described in Section 1C RADIATOR GRILLE.

Seven rear bumper fascias are available depending on model level and body type:

• Sedan: one each for Level 1, Level 2 & 3 and S & SS, all with or without Reverse Parking Aid (RPA) sensor

assemblies,

• Wagon: one for all Levels,

• Coupe: one for all Levels, with or without RPA sensor assemblies, and

• Utility: separate bumper fascias each side of the vehicle, one for Level 1 & S and one for SS.

The Level 1, S & SS Sedan rear bumper fascias feature a separate lower insert which has a black finish to match

the paint masking area.

Removable towbar opening covers ar e fitted to Sedan and Wagon rear bum per fas cias. Coupe f asc ias do not have

a cover and if a towbar is fitted, the fascia must be modified by cutting an opening and fitting a surround. This

procedure is included in this Section.

A steel front bumper impact bar assembly is installed behind the front bumper fascia assembly and is attached

directly to the front side rails . T he bar ass em bly is designed to assist in the dis persion of crash energy and plays an

integral role with the vehicle’s safety systems.

A steel rear bumper impact bar is also installed behind the rear bumper fascia on all models except utility.

As mentioned, the Sedan and Coupe rear fascia assemblies may include four rear sensor assemblies for Reverse

Parking Aid (RPA).

W hen reverse gear is selected, the sensors emit an ultra-sonic signal which is monitored by a control module. As

the sensors detect an object within their field of range, the system warns the driver by emitting an audible sound,

which increases in frequency, as the object becomes closer.

NOTE: If the vehicle is fitted with RPA, a new rear bumper fascia service part will require modification prior to

painting and installation, ref er to 2.5 REAR BUM PER FASCIA ASSEMBLY , SEDAN & COUPE – Reverse Park ing

Aid Components.

IMPORTANT: The sensors are supplied pre-painted in the vehicle’s body colour and must not be painted, refer to

2.1 PAINT SYSTEM S and Revers e Par k ing Aid Components in 2.5 REAR BUMPER FASCIA ASSEMBLY, SEDAN

& COUPE.

Further information on RPA can be found in Section 12F REVERSE PARKING AID.

2. SERVICE OPERATIONS

2.1 PAINT SYSTEMS

GENERAL

The paint s ystem f o r the bumper fascias and other painted plastic c omponents is relatively straightf or ward providing

the correct materials are used. Normal refinish lacquers will not adhere to plastic components unless the correct

primers and/or additives are used.

NOTE: Thorough cleaning and the use of approved paint and additives or their equivalent is required. Incorrect

materials and methods may damage the plastic or lead to premature paint failure.

The f ollowing s er vice r ecommendations ar e c ompiled to guide repair ers on the c orr ec t materials and methods to be

employed when refinishing bum per f asc ias and preparing new parts for service ins tallation. If another paint brand is

chosen, refer to the manufacturer’s latest technical data for the appropriate materials and procedures required.

REVERSE PARKING AID (RPA)

Where fitted, the rear bumper fascia assembly contains four sensor assemblies for Reverse Parking Aid (RPA).

The exposed end of the sensor assembly is painted the vehicle’s body colour. New service sensor assemblies are

supplied pre-painted in the vehicle’s body colour and must not have any further paint applied.

IMPORTANT: If r epainting a fascia as sem bly, the s ensors and rings MUST be rem oved. Paint m ust not be applied

to any part of a sensor, including the exposed coloured surface. Paint film applied to the exposed surface will render

the sensor inoperable as the paint film restricts the sensor’s ultra-sonic signal. If a sensor is damaged, it must be

replaced.

Replacement housings are supplied unpainted. As they are partially exposed when installed, they will require

painting using the same procedures for painting the bumper fascia, described below.

NOTE: It is preferable to paint the housings and bumper fascia separately to avoid adhesion problems. Assemble

the housings onto the bum per fasc ia once the paint has cured, ref er to 2.5 REAR BUM PER FASCIA ASSEM BLY,

SEDAN & COUPE – Reverse Parking Aid Components.

For further information on reverse parking aid, refer to Section 12F REVERSE PARKING AID.

RECOMMENDED MATERIALS

Front and rear bumper fascias are made from high impact strength Polypropylene (PP).

It is essential that only approved materials, paints, etc. or their equivalent are employed when paint repair

operations are performed and when preparing new parts for installation to the vehicles.

The approved materials are:

- PPG Bodykleen 920-30509

- PPG Plastpak Universal Anti Static Cleaner 920-39237

- PPG Plastpak Universal Primer 499-38571

- PPG Plastpak Flexible Additive for Two Component Products 499-35484

- PPG Cobra Basecoat - Colour 534 Line

- PPG Basecoat Thinner 920-34926

- PPG 2K Clearcoat 455-30900

- PPG 2K Acrylic Enamel Solid Colour 426 Line

- PPG 2K MS Hardener Normal 980-35239

- PPG 2K Reducer Fast 920-9148

REFINISHING OF REPLACEMENT PARTS

Replacement parts will require priming and coating with approved topcoat colour before installation to the vehicle.

1. Order part and paint materials.

2. Read all safety data material relative to the paint system chosen from the paint manufacturer and the

HARDENER PRECAUTIONS further in this Section.

3. Obtain the required respiration and safety equipment recommended by the paint manufacturer, in this

publication or required by regulations.

4. Wash the unpainted bumper fascia all over with a made-up solution of 9 parts fresh water to 1 part PPG

Bodykleen 920-39237. Apply with a clean, non-metallic pad (recommended Scotchbrite** 448) to scuff the

surface.

5. Rinse with fresh cold water.

6. Use a clean cloth saturated with PPG Plastpak Universal Anti-static Cleaner 920-39237. W ash the entire part

allowing contact for a minimum 15 seconds.

7. Dry thoroughly using a separate, clean, dry cloth.

8. Repeat steps five and six another three times. Use a separate, clean dry cloth each time.

NOTE: If a static charge has built up on the bum per surface ( after com pleting all cleaning operations) dam pen the

surface with Plastpak Universal Anti Static Cleaner and allow to evaporate dry. This will impart full anti-static

properties to the bumper fascia.

Priming

1. Fit an air-supplied respirator.

2. Apply one light double coat (approx imately 3-8 m D.F. B. uniformly wet) of PPG Plastpak Univers al Pr imer 499-

38571 to the bumper surface intended for topcoat. Recommended air pressure range is 320-420 kPa.

3. Allow to air dry 15-20 minutes at 20°C. DO NOT SAND.

** Scotchbrite is a trademark of 3M Co.

PAINT – 2K SYSTEM

1. To the matched colour, add Flexible Additive then Hardener and Reducer in the following ratios:

- 246 line colour - 5 parts by volume

- Flexible Additive 499-35484 - 1 part by volume

- 2K MS Hardener 980-35239 - 3 parts by volume

- 2K Reducer 920-19148 - 10-20% by volume

2. Stir thoroughly and strain.

3. Fit an air-supplied respirator.

4. Using a 1.4 – 1.8 mm fluid nozz le on a standard spray gun, apply one medium wet coat.

5. Apply a further one or two coats to achieve coverage (correct film thickness is 40-50 microns) allowing a 3-5

minute flash-off time between coats.

6. If low baking, this can be done im mediately after the last coat, but do not allow more than 5 minutes flash-off.

Bake at 60°C for 40 minutes.

7. If air drying, allow 16 hours.

PAINT – COBRA BASECOAT, METALLIC, PEARL OR SOLID COLOUR SYSTEM

1. Thin the matched basecoat colour with Cobra Basebuilder, 920 line at a 1:1 mix ratio and stir thoroughly.

2. Strain material.

3. Fit an air supplied respirator.

4. Using a 1.4 - 1.6 mm gravity feed spray gun, apply one medium, wet even coat. Allow to flash-off for five

minutes before applying the next coat.

5. Apply one or two further coats to achieve a uniform and even coverage with 5 minutes flash-off between coats.

6. Allow 10-20 minutes drying

7. Mix the 2K Clearcoat with flexible additive, then hardener and reducer in the following ratios:

- 2K Clearcoat 455-30900 - 5 parts by volume

- Flexible Additive 499-35484 - 1 part by volume

- 2K MS Hardener 980-35239 - 3 parts by volume

- 2K Reducer 920-19148 - 20% by volume

Stir thoroughly and strain.

8. Using a 1.4-1.8 fluid nozzle spray gun set up, apply one medium wet coat.

9. Apply a further one or two wet coats after a 3-5 minutes flash-off between coats.

10. If low baking, this can be done immediately after the last coat, but do not allow more than 5 minutes flash-off.

Bake at 60°C for 40 minutes.

11. If air drying, allow 16 hours.

REPAIRING COLOUR COAT

Sanding and repainting may rectify superficial damage to the paint film and/or plastic surfaces. Parts having deep

gouges in the plastic s urface should be r eplaced as repair m ethods using filling m aterials and thinning down of the

plastic section may reduce overall impact strength.

For shallow paint damage, follow the procedure listed under “Colour Finishing of Replacement Parts” in this Section,

using P800 paper to sand down imperfections and using a Scotchbrite 448 pad or P1200 paper, scuff and key

existing paintwork.

Basecoat and Clearcoat can be spot repaired by blending away the basecoat colour and spraying the complete

bumper with Clearcoat. Solid colours are best sprayed as complete panels. If the damage extends through the

paintwork to the plastic surface, this must be primed with Plastpak Universal Primer after the correct cleaning

procedure.

NOTE: Drying of all products m ay be accelerated by heat. But to avoid distortion, uns upported bumper s should not

be heated in an oven or by lamp above 60°C.

HARDENER PRECAUTIONS

The following instructions relate to the safe handling of all paints containing PPG 2K MS Hardener, which contains

not more than 0.3% isocyanate monomer.

CAUTION: This product is for automotive and industrial use only. It requires professional equipment and

experience for safe handling. It is not for use by the general public.

Read and understand the instr uc tions and warnings c ontained in Material Saf ety Data s heets and on the label of the

can containing the base product before opening. Follow all directions and warnings carefully, otherwise do not use

this product. Warnings and precautions on the label also apply to the mixture of hardener and base.

Inhalation of vapour, spray mist and dust from sanding is harmful and may cause lung irritation and allergic

respiratory reaction. The vapour also irritates the skin and eyes.

W hen m ixed with the appropriate base, apply in a spray booth fitted with an effective exhaust system. Com ply with

local legislation applicable to spray painting of motor vehicles. Wear a positive pressure air supplied full face

respirator (complying with any relevant Standards) and gloves while spraying and during all subsequent use. The

spray booth area should be isolated from other people while spraying is in progress and until all spray mist has been

effectively evacuated.

If affected by inhalation of vapour or spray mist, move to a location with plenty of fresh air.

If breathing difficulty persists or occurs later, consult a doctor and have the label information available. In the case

of eye contact, flush immediately with plenty of water for 15 minutes and call a doctor.

In case of skin contact, remove contaminated clothing and wash skin thoroughly with soap and water. Immerse

contaminated clothing in water for 24 hours and do not re-use until it has been laundered.

In case of spillage, absor b the liquid onto dry sand or earth. Rem ove the spillage from the work area and cover with

water for 24 hours before disposal. Treat the empty hardener cans in the same manner.

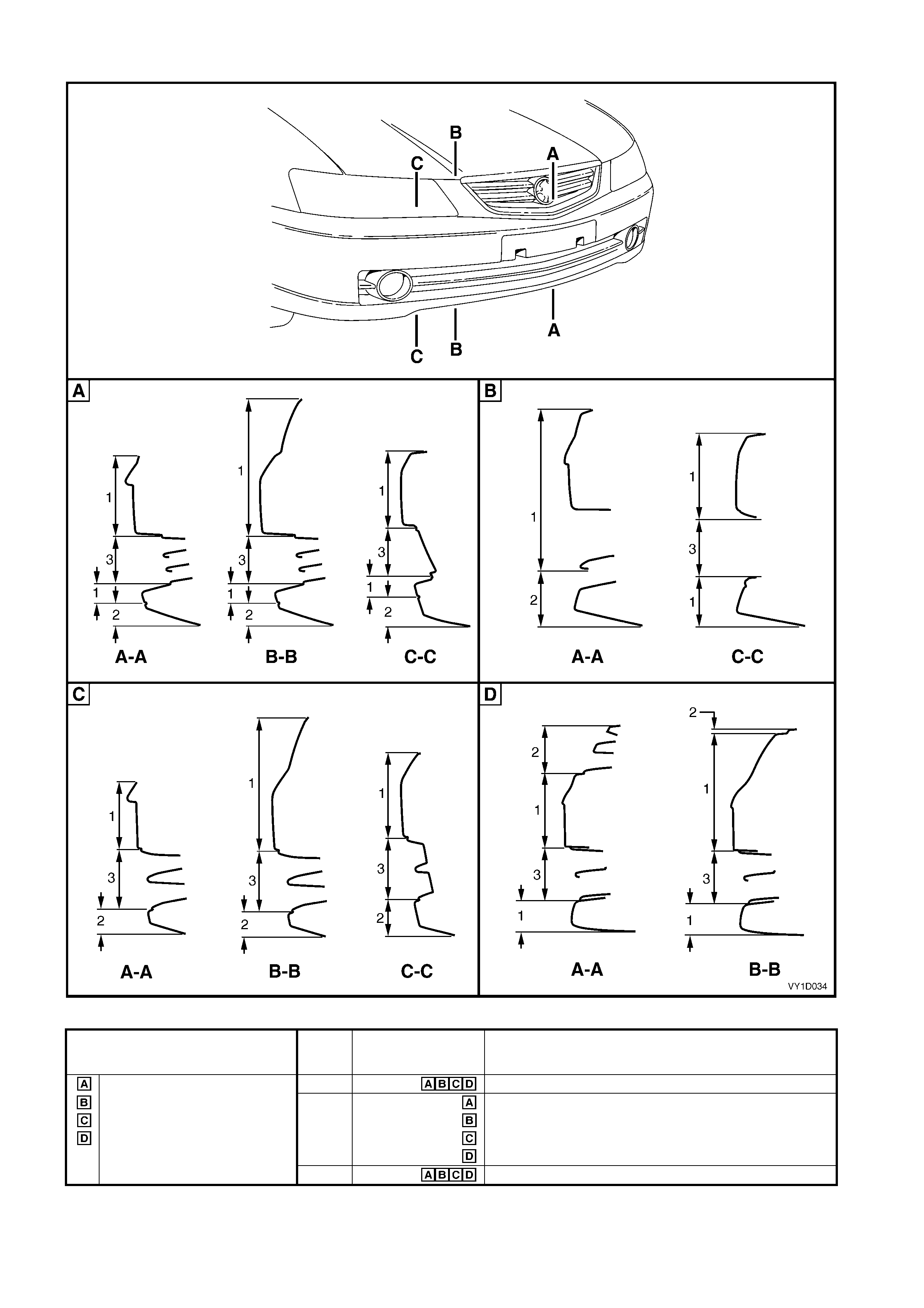

PAINT MASKING

The following illustrations show the front and rear bumper fascia paint masking areas for each vehicle model and

are provided to assist when painting a bumper fascia to match the factory finish.

For further information on the specific model levels, refer to Section 0A.

Front Bumper

Figure 1D-1

Model Area Applicable

Model Finish

Level 1, except S sedan and SS 1 Body Colour

S sedan and SS 2 Unpainted, except Ac claim, SV8 and S ut ility – body colour

Level 2 and 3 Unpainted

Coupe Body colour

Unpainted

3 Fog lamp / Lower grille / Ins ert – finish of supplied part

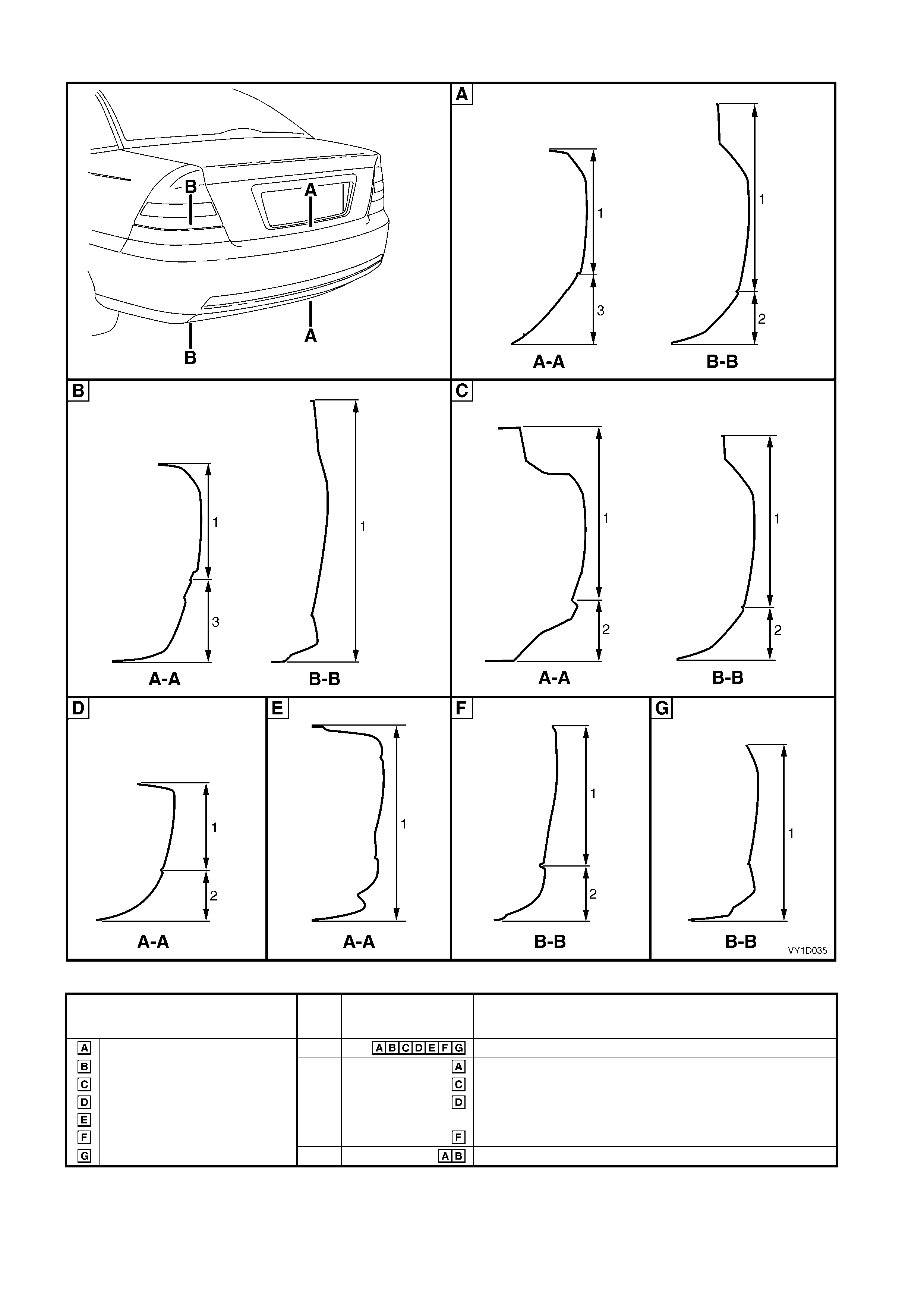

Rear Bumper

Figure 1D-2

Model

A

rea Applicable

Model Finish

Level 1 sedan, except S and SS 1 Body Colour

S sedan and SS 2 Unpainted, except Acclai m and SV 8 – body colour

Level 2 and 3 sedan Body colour

Wagon

Coupe Level 1 – unpainted, except A cclaim

Level 2 and Acclaim – body colour

Utility, except SS Unpainted, except S – body colour

Utility SS 3 Insert – f i ni sh of suppl i ed part

2.2 FRONT BUMPER FASCIA ASSEMBLY

LT Section – 07-500

NOTE: Although different in appearance and minor detail, the procedure for removal of the front bumper fascia

assembly is the same for all models.

REMOVE

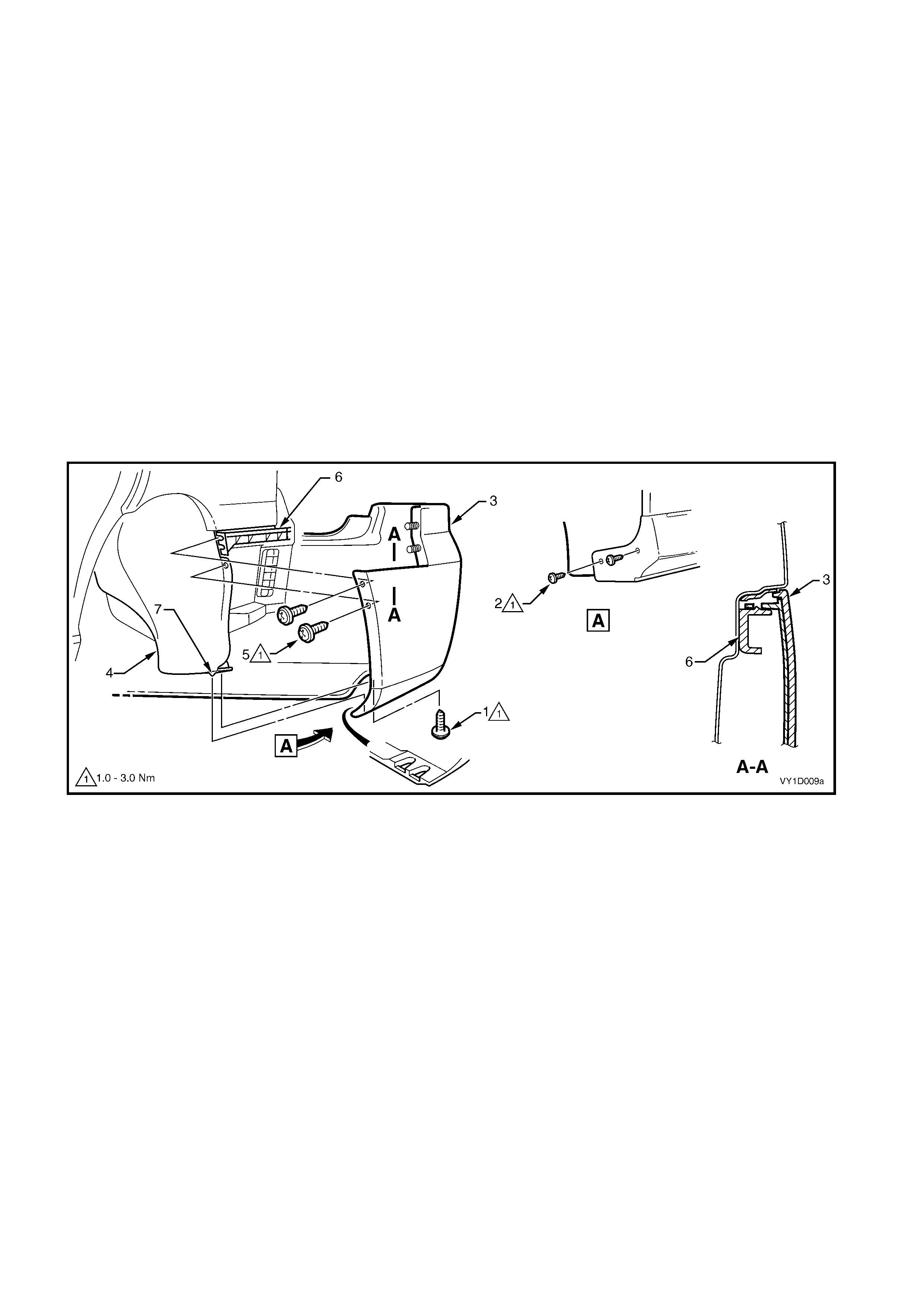

1. From each side of the vehicle:

a. Remove the screw (1), or for S and SS vehicles (2), attaching the front bumper fascia assembly (3) to

the front wheelhouse liner (4), refer to Figure 1D-3.

b. Remove the screw (5) attaching the front bumper assembly to the fascia guide assembly (6).

c. Carefully unclip the fascia assembly from the guide assembly by grasping the upper end of the fascia

and pulling away from the vehicle.

Figure 1D-3

2. If fitted, disconnect the front fog lamp wiring connector (1), one place each side of the vehicle, refer to Figure

1D-4.

3. Remove the two retainers ( 2) f r om the rec es ses ( behind the licenc e plate) , attaching the fascia as s embly (3)

to the front bumper impact bar assembly (4).

4. Remove the three screws (5) attaching the fascia assembly to the front upper panel.

NOTE: For S Sedan and SS, these screws also attach the radiator grille.

5. With the aid of an assistant remove the fascia assembly and store in a safe place.

Figure 1D-4

DISASSEMBLE

For all vehicles exc ept Coupe, as required rem ove the

radiator grille assembly and lower radiator grille, refer

to Section 1C, RADIATOR GRILLE.

For Coupe, as required remove the grille emblem,

refer to Section 1A9, 5.1 RADIATOR GRILLE

EMBLEM and the lower radiator grille, refer to

Section 1C RADIATOR GRILLE.

FRONT BUMPER ACCESS HOLE COVER, LEVEL 1

Remove

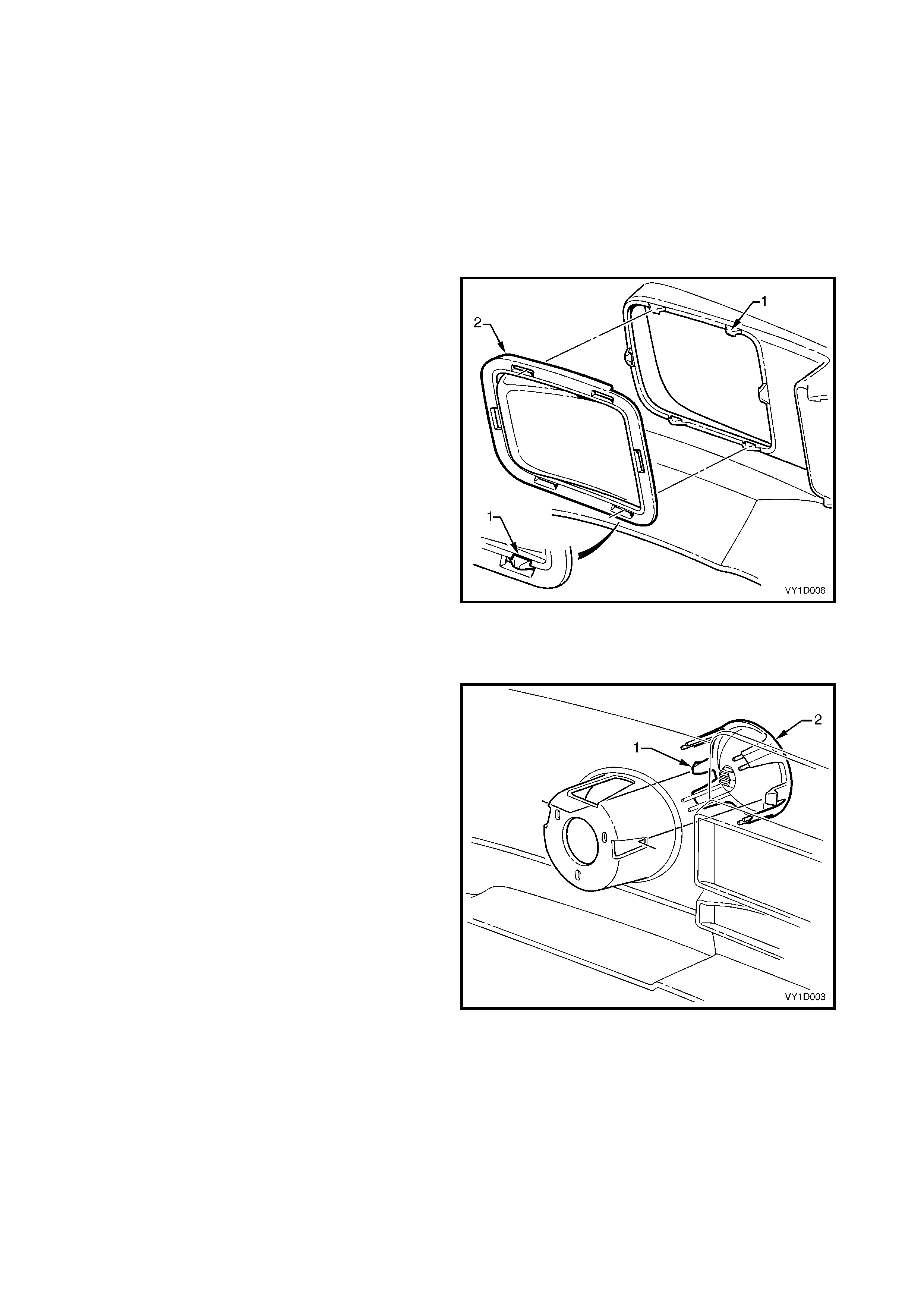

1. Unclip the six retainers (1) securing the cover (2)

to the bumper fascia.

2. Remove the cover.

Reinstall

1. F it the cover into pos ition and clip onto the bumper

fascia.

2. Ensure the retainers are seated correctly.

Figure 1D-5

FRONT FOG LAMP OPENING COVER, S SEDAN

Remove

1. Depress the two retaining tabs (1) securing the

cover (2) to the bumper fascia.

2. W ithdraw the cover f rom the recess to the front of

the bumper fascia.

Reinstall

1. Fit the cover into position and ensure that the

retaining tabs are seated correctly.

Figure 1D-6

FRONT FOG LAMP ASSEMBLY, SS & COUPE

Remove

1. For Coupe, remove the lower radiator grille, refer

to Section 1C, 2.5 LOWER RADIATOR GRILLE.

2. Remove the three nuts (1) attaching the lamp

assembly (2) to the bumper fascia.

NOTE: SS model shown, Coupe similar.

3. W ithdraw the lam p assembly and wiring connector

from the recess the front of the bumper fascia.

NOTE: For further service of the front fog lamp

assembly refer to Section 12B, 2.7 FRONT FOG

LAMP ASSEMBLY.

Reinstall

Installation is the reverse of removal. Tighten the nuts

to the specified torque.

NOTE: Following installation of the bumper fascia

assembly, aim the fog lamps, refer to Section 12B,

2.1 HEADLAMP AND FOG LAMP AIMING.

Figure 1D-7

FRONT BUMPER FASCIA REINFORCEMENT

Two reinforcements are attached to the inner side of the front bumper fascia.

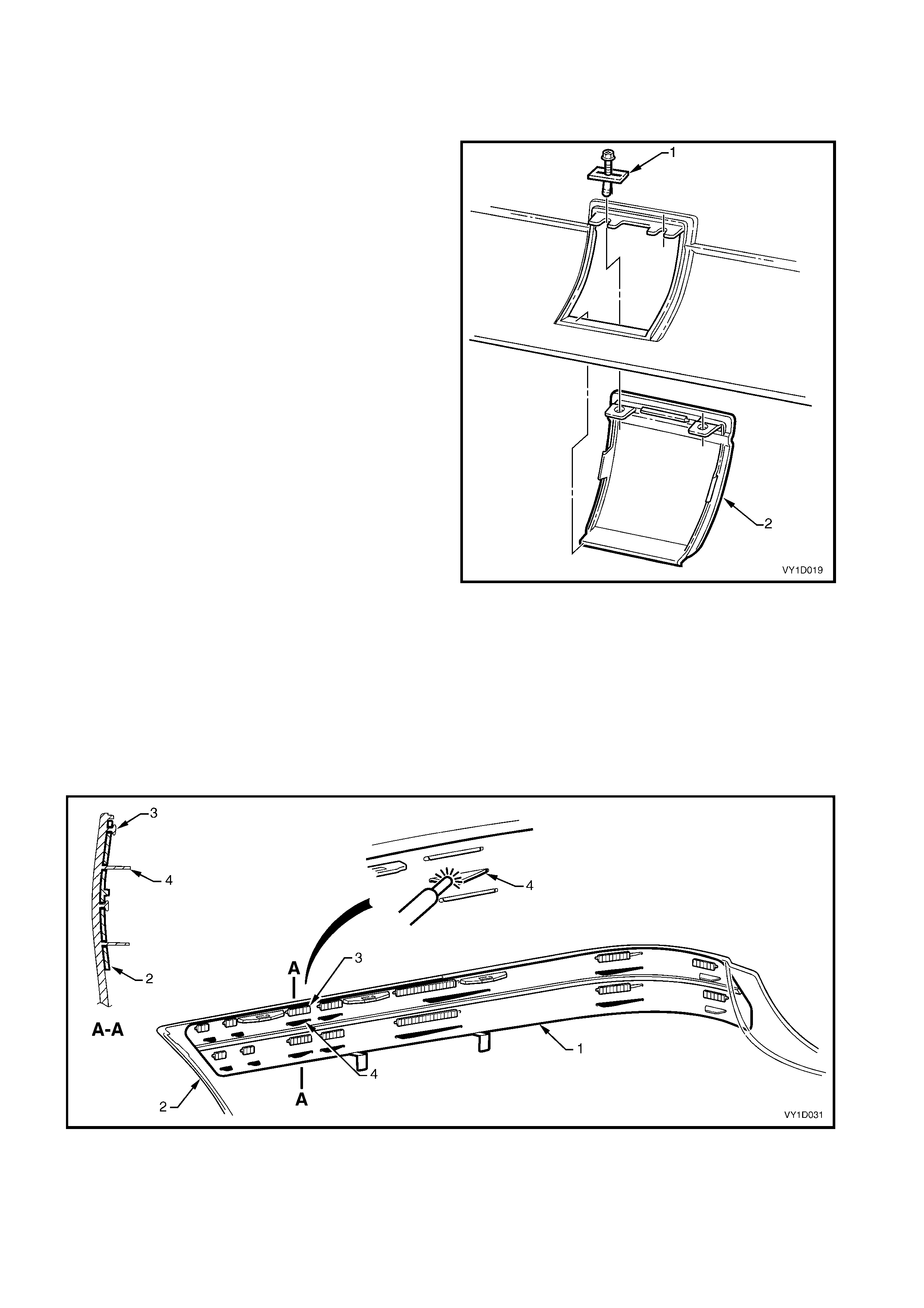

Referr ing to Figure 1D-8 – typical front bum per f asc ia assem bly, the r einforc em ent (1) is attached to the bum per

fasc ia (2) with the heat stakes (3). If the bum per fasc ia assembly is damaged, a replacement reinf orcem ent can

be fitted, or if the heat stakes are broken, a repair can be made.

If the heat stakes are broken, melt over the adjacent heat stakes (4) with a soldering iron.

If the reinf orcem ent is being replaced, c ut the heat stak es (3) with a knif e and rem ove the old reinforc ement. Fit

the new reinforcement in position and using a soldering iron, melt over the adjacent heat stakes (4).

Figure 1D-8

REINSTALL

1. Refinish the bumper fascia assembly in accordance with the procedures in 2.1 PAINT SYSTEMS.

2. With the aid of an assistant, fit the front bumper fascia assembly onto the vehicle.

3. Start the three screws (5) attaching the fascia assembly to the front upper panel, refer to Figure 1D-4.

4. Install the two retainers (2) in the recesses (behind the licence plate).

5. Align the side of the fasc ia assem bly to the f ender, clip the f ascia assem bly into the guide assem bly ( 6) and

install the screw (5), refer to Figure 1D-3. Repeat for the opposite side.

6. Install the screw (1), or for S and SS vehicles (2), attaching each side of the fascia assembly to the front

wheelhouse liner, refer to Figure 1D-3.

7. Tighten the screws to the specified torque.

8. Reconnect the fog lamp wiring connectors if fitted, refer to (1) Figure 1D-4.

FRONT BUMPER FASCIA ASSEMBLY TO

FRONT WHEELHOUSE LI NER SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT BUMPER FASCIA ASSEMBLY

TO FRONT BUMPER FASCIA

GUIDE ASSEMBLY SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FRONT BUMPER FASCIA ASSEMBLY TO

FRONT UPPER PANEL SCREW

TORQUE SPECIFICATION 2.5 – 4.0 Nm

2.3 FRONT BUMPER FASCIA GUIDE ASSEMBLY

SEDAN, WAGON & UTILITY

Remove

1. Remove the f ront bumper f as c ia assembly, refer to

2.2 FRONT BUMPER FASCIA ASSEMBLY.

NOTE: It is poss ible to rem ove one side of the bumper

fascia and carefully move it out to gain access to the

guide assembly.

2. Using a fine flat-blade screwdriver, lever and hold

the tab (1) outwards.

3. Slide the guide assembly (2) forward and out to

detach it from the fender.

Figure 1D-9

Reinstall

1. Align the guide assembly with the slots in the

fender and while pushing in s lightly, s lide the guide

rearwards until it ‘clicks’ into place.

2. Reinstall the bumper fascia as required, refer to

2.2 FRONT BUMPER FASCIA ASSEMBLY.

COUPE

Remove

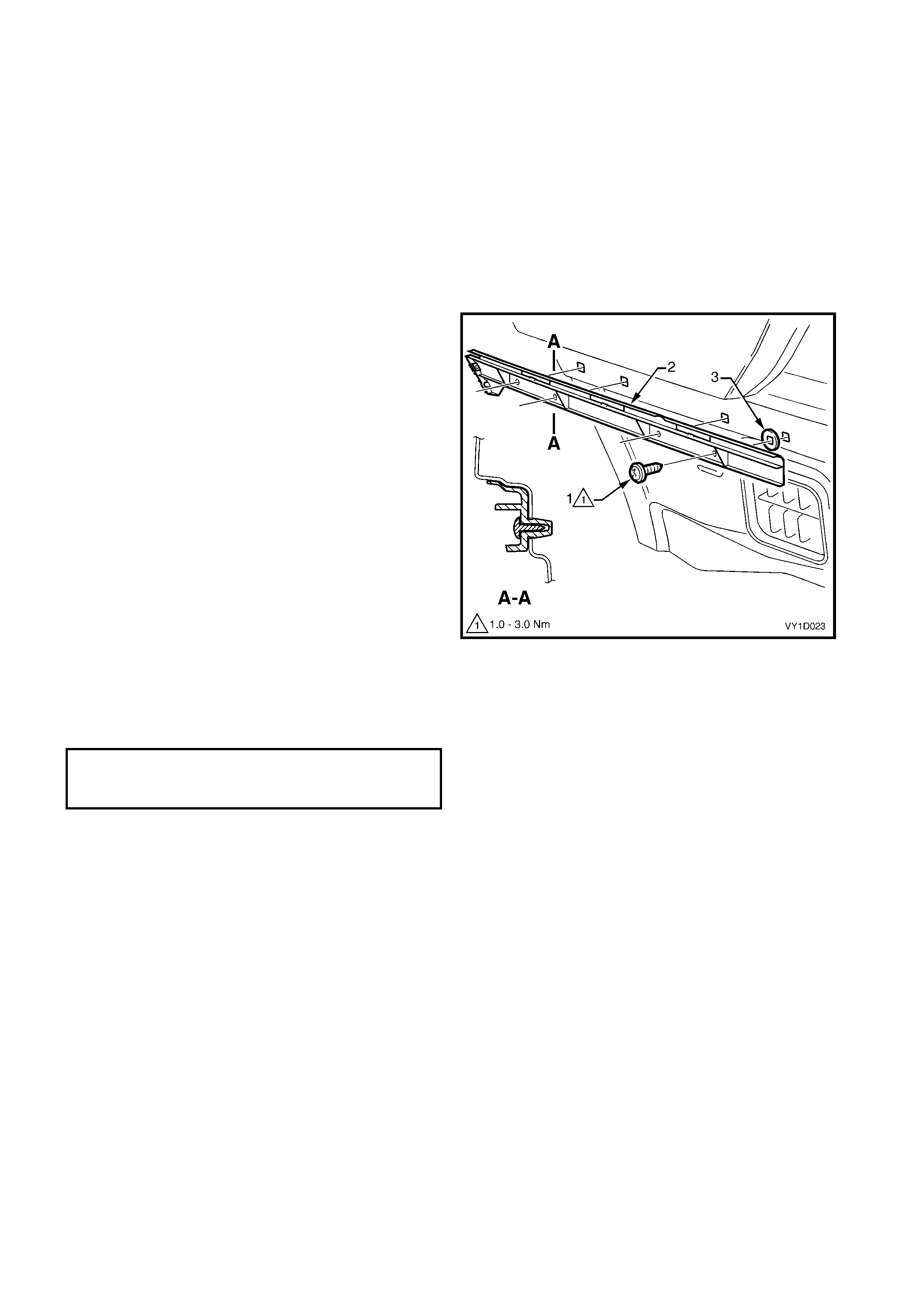

1. Remove the front bumper fascia assembly, refer to 2.2 FRONT BUMPER FASCIA ASSEMBLY.

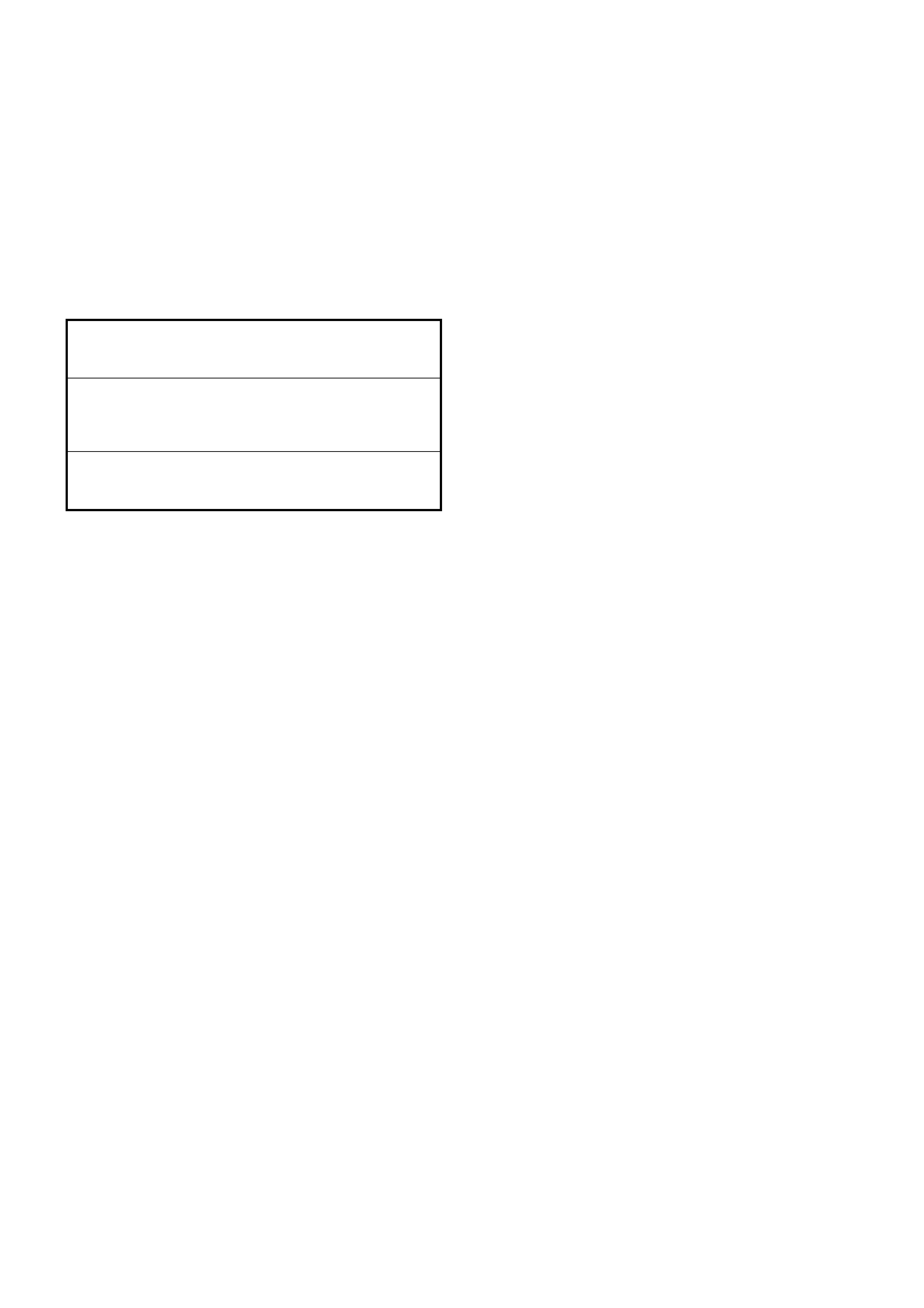

2. Remove the screw (1), three places, attaching the front bumper fascia guide assembly (2) to the vehicle,

refer to Figure 1D-10.

3. Using a fine flat-blade screwdriver, lever and hold the retaining tab (3).

4. Remove the guide outwards to detach it from the fender.

Figure 1D-10

Reinstall

1. Align the guide assembly with the holes in the fender push in to locate it in place.

2. Install the screws and tighten to the specified torque.

3. Reinstall the bumper fascia as required, refer to 2.2 FRONT BUMPER FASCIA ASSEMBLY.

FRONT BUMPER FASCIA GUIDE

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.4 FRONT BUMPER IMPACT BAR ASSEMBLY

The front bumper impact bar assembly not only acts as a m ount and support for the bum per fascia, but is also

critical in the dispersion of crash energy. Hence, it plays an integral role in the operation of the vehicle’s safety

systems.

Repair of the bar assembly should be limited to replacement, as straightening and/or heating can weaken the

bar assembly, resulting in incorrect airbag and seatbelt pretensioner operation.

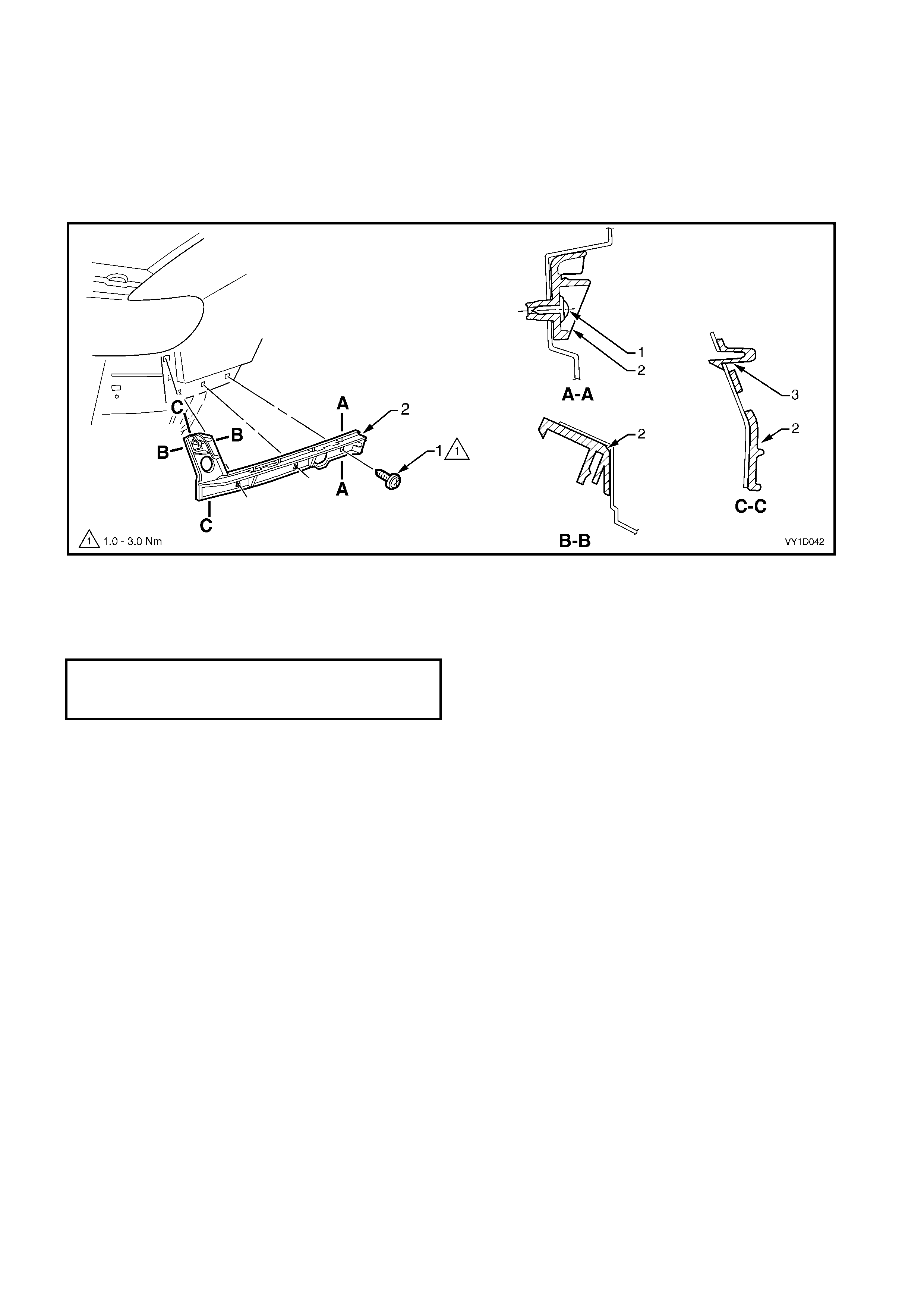

REMOVE

1. Remove the f ront bumper f as c ia assembly, refer to

2.2 FRONT BUMPER FASCIA ASSEMBLY.

2. If fitted, remove the radiator air lower baffle, refer

to Section 6B1.

3. Remove the nuts (1), three places each side,

attaching the bar assembly (2) to the vehicle.

4. Remove the bar assembly.

Figure 1D-11

REINSTALL

NOTE: Check the vehicle’s front body dimensions as

required to ensure correct alignment, refer to

Section 1A2 BODY DIMENSIONS.

1. Fit the bar assembly in position and attach each

nut. Do not tighten.

2. Ensure the bar assembly is correctly positioned

centrally and tighten the nuts to the specified

torque.

3. Refit the front bumper fascia assembly, refer to

2.2 FRONT BUMPER FASCIA ASSEMBLY.

FRONT BUMPER IMPACT BAR

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 20.0 – 30.0 Nm

2.5 REAR BUMPER FASCIA ASSEMBLY, SEDAN & COUPE

LT Section No. – 07-525

NOTE: Although different in appearance, the procedure for removal of the rear bumper fascia assembly is the

same for both Sedan and Coupe.

If required, first remove the following components:

1. Rear end trim panel, refer to Section 1A8, 2.15 REAR END PANEL, SEDAN or 4.12 REAR END TRIM

PANEL, COUPE.

2. Quarter inner rear s ide c arpet, ref er to Section 1A8, 2.17 QUARTER INNER REAR SIDE CARPET, SEDAN

or 4.14 QUARTER INNER REAR SIDE CARPET, COUPE.

REMOVE

1. From each side of the vehicle:

a. Rem ove the screw (1) one place Sedan or two places Coupe, or f or S and SS vehicles (2) two places,

attaching the rear bumper fascia assembly (3) to the rear wheelhouse liner (4), refer to Figure 1D-12.

b. Remove the screw (5) two places, attaching the rear bumper fascia assembly to the liner and rear

bumper fascia guide assembly (6).

c. Carefully unclip the fascia assembly from the guide assembly by grasping the upper end of the fascia

and pulling away f rom the vehicle, als o disconnecting the liner lug (7) from the bum per fascia assem bly

for Sedan except S & SS.

Figure 1D-12

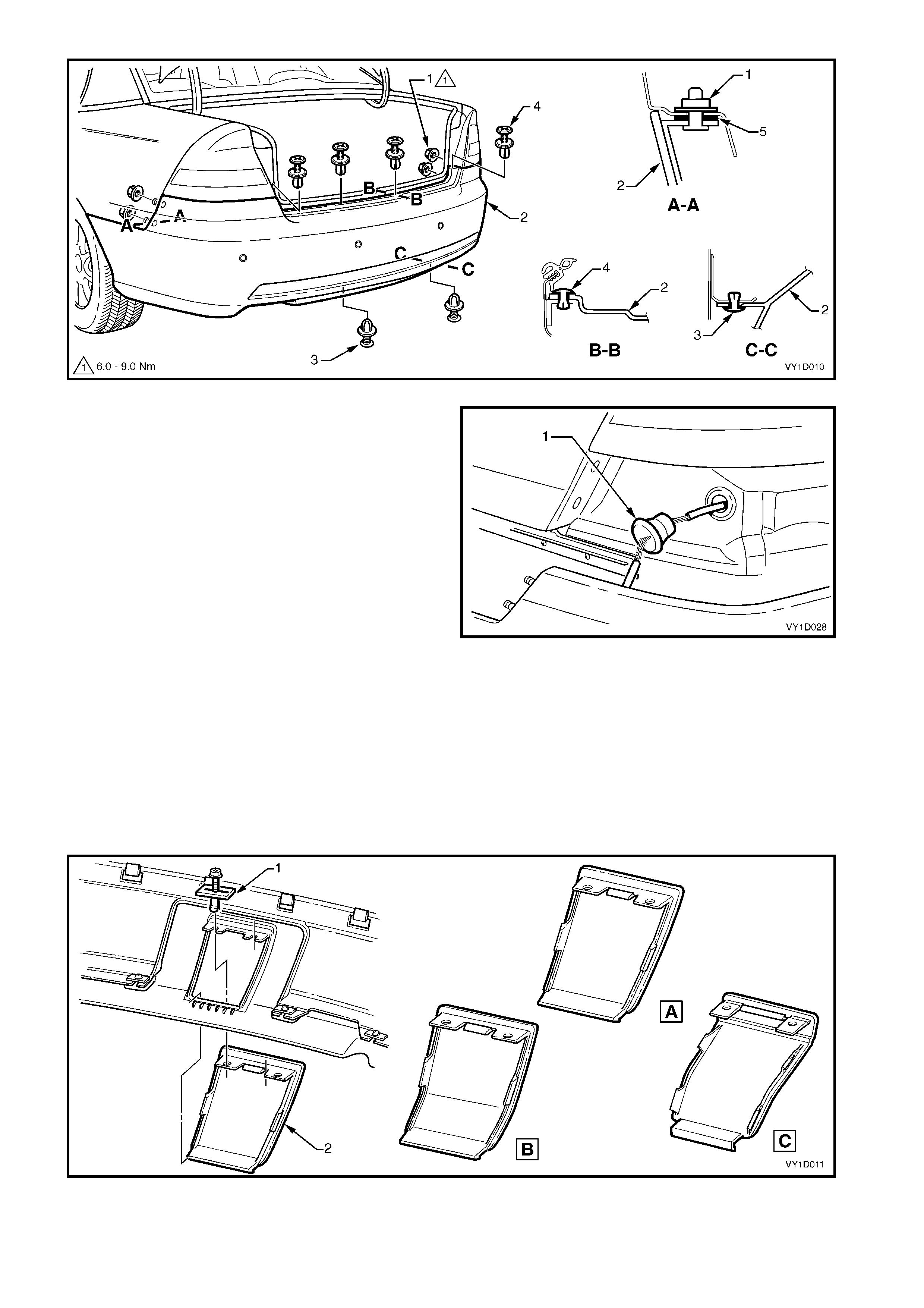

2. Remove the two nuts (1) each side, attaching the fascia assembly (2) to the vehicle, refer to Figure 1D-13.

3. Remove the two retainers (3) from below the fascia assembly.

4. Remove the centre section of the rear compartment lid weatherstrip to allow access to the four upper

retainers (4).

5. Remove the four upper retainers attaching the fascia assembly to the rear bumper fascia centre support

assembly.

Figure 1D-13

6. If f itted, disconnec t the Reverse Park ing Aid (RPA)

wiring connector from within the rear compartment.

7. With the aid of an assistant, withdraw the fascia

assembly, push the RPA wiring harness grommet

(1) through the side panel for Sedan or rear panel

for Coupe, and withdraw the RPA harness thr ough

the panel.

NOTE: Sedan shown, Coupe is similar except located

below the tail lamp housing on the rear of the vehicle.

8. Remove the fascia assembly ensuring the seals

(5, Figure 1D-13) remain with the fascia assembly.

Figure 1D-14

DISASSEMBLE

NOTE: For the disassembly of Reverse Parking Aid (RPA) components, refer to REVERSE PARKING AID

COMPONENTS, following this procedure.

TOWBA R OPENING COVER, EXCEPT COUPE

Remove

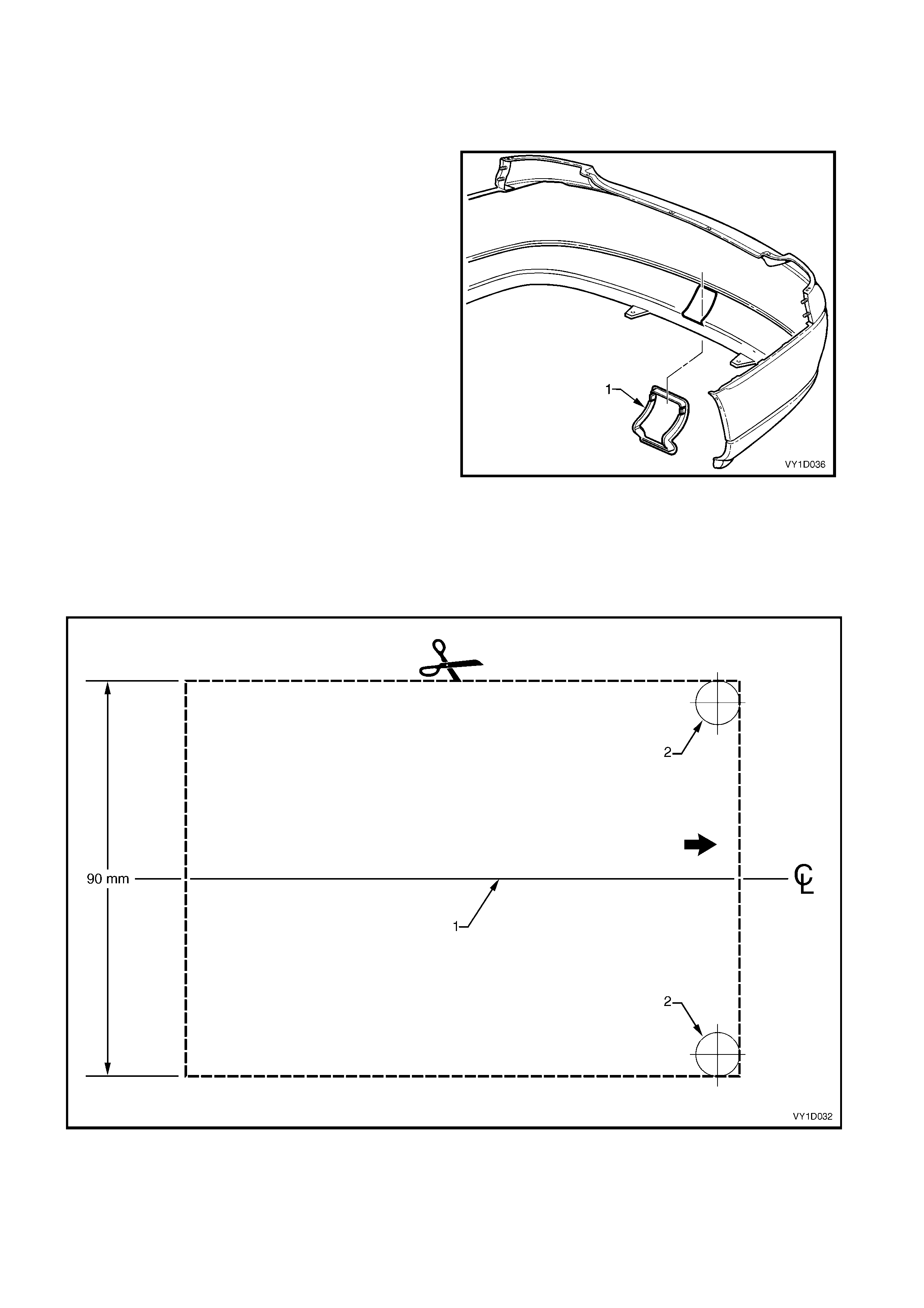

1. Remove the r etainer (1), two places, sec uring the towbar opening cover ( 2) to the bumper fas cia assem bly,

refer to Figure 1D-15.

2. Depress the retaining tabs and remove the cover from the bumper fascia. Note the different styles:

A – Level 1, B – S & SS, C – Levels 2 & 3.

Figure 1D-15

Reinstall

1. Clip the cover in place ensuring the retaining tabs are seated correctly and install the two retainers.

TOWBAR OPENING SURROUND, COUPE

Remove

1. Carefully prise the surround (1) from the bumper

fascia.

Figure 1D-16

Reinstall

1. If the bumper fascia has not been replaced, proceed to Step 9.

2. Print and accurately cut out the towbar opening template in Figure 1D-17.

IMPORTANT: W hen pr inting, in the PRINT DIALOG BOX ensure the ‘SHRINK OVERSIZE PAGES TO PAPER

SIZE’ box is NOT ticked. Always check the scale on the template to ensure it has printed the correct size.

Figure 1D-17

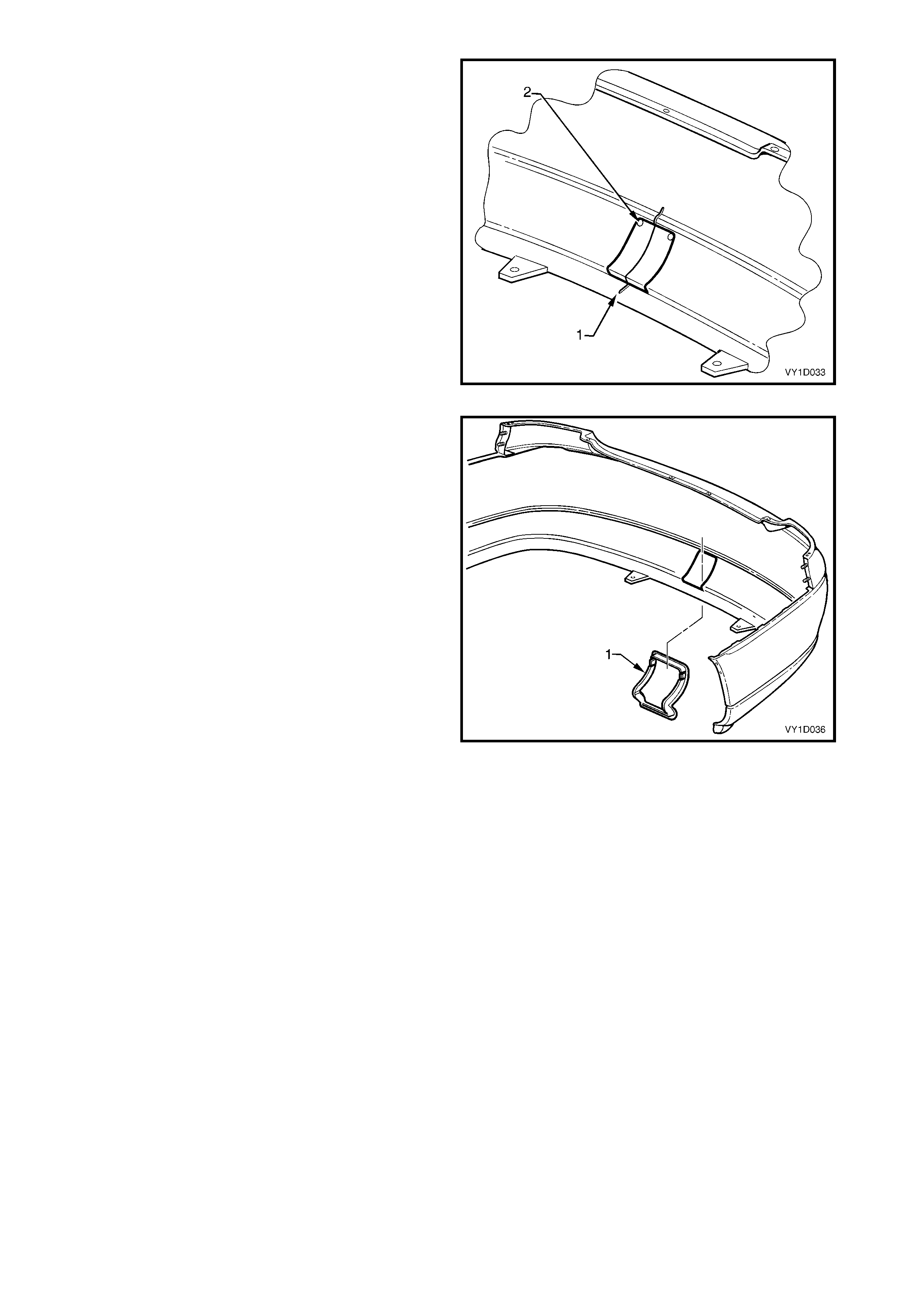

3. Place the template on the rear side of the bum per

fascia and align the template centreline (1) with the

centreline embossed in the fascia.

4. Mark the perimeter of the template on the fascia

and scribe the pilot hole (2) centre points.

5. Rem ove the template and drill a 3.0 m m pilot hole

at each scribed centre point on the inside surface

of the bumper fascia.

6. Enlarge the holes to 10.0 mm.

IMPORTANT: Do not drill outs ide the perim eter line as

the surround will not cover this area.

7. Cut between the drilled holes with a sm all sharp or

serrated knife, taking care not to deviate from the

guidelines.

NOTE: The width of the opening m ust not exceed 90.0

mm.

8. Remove the section of bumper fascia.

Figure 1D-18

9. Clean up the opening and install the towbar

surround (1) to the fascia once the fascia has been

painted.

Figure 1D-19

REAR BUMPER FASCIA INSERT, LEVEL 1, S & SS

Remove

1. Remove the retainer s (1) , s ix plac es f or Level 1 or f ive plac es for S and SS, sec ur ing the rear bumper f as c ia

insert (2) to the bumper fascia.

2. Apply downward pressure on the insert while unclipping the eight tabs (3), for Level 1 or seven tabs for S

and SS.

3. Manoeuvr e the insert downward and out of the bum per fas cia, disengaging the loc ating tabs (4) each end of

the insert.

Figure 1D-20

Reinstall

Installation is the reverse of removal. Ensure the retainers and tabs are seated correctly.

REAR BUMPER FASCIA ANCHOR PLATE ASSEMBLY, COUPE

Remove

1. Using a 3mm drill-bit, remove the four rivets (1)

attaching the plate assembly (2) to the fascia

assembly.

NOTE: If r eusing the fasc ia assem bly, tak e care not to

enlarge the rivet holes.

2. Remove the plate ass embly and if required the two

seals (3).

Reinstall

Installation is the reverse of removal.

Figure 1D-21

REAR BUMPER FASCIA BRACKET ASSEMBLY, SEDAN

A brack et as s embly, which also acts as a reinforcement, is attached to eac h inner side of the rear bumper fas cia

for Sedan models.

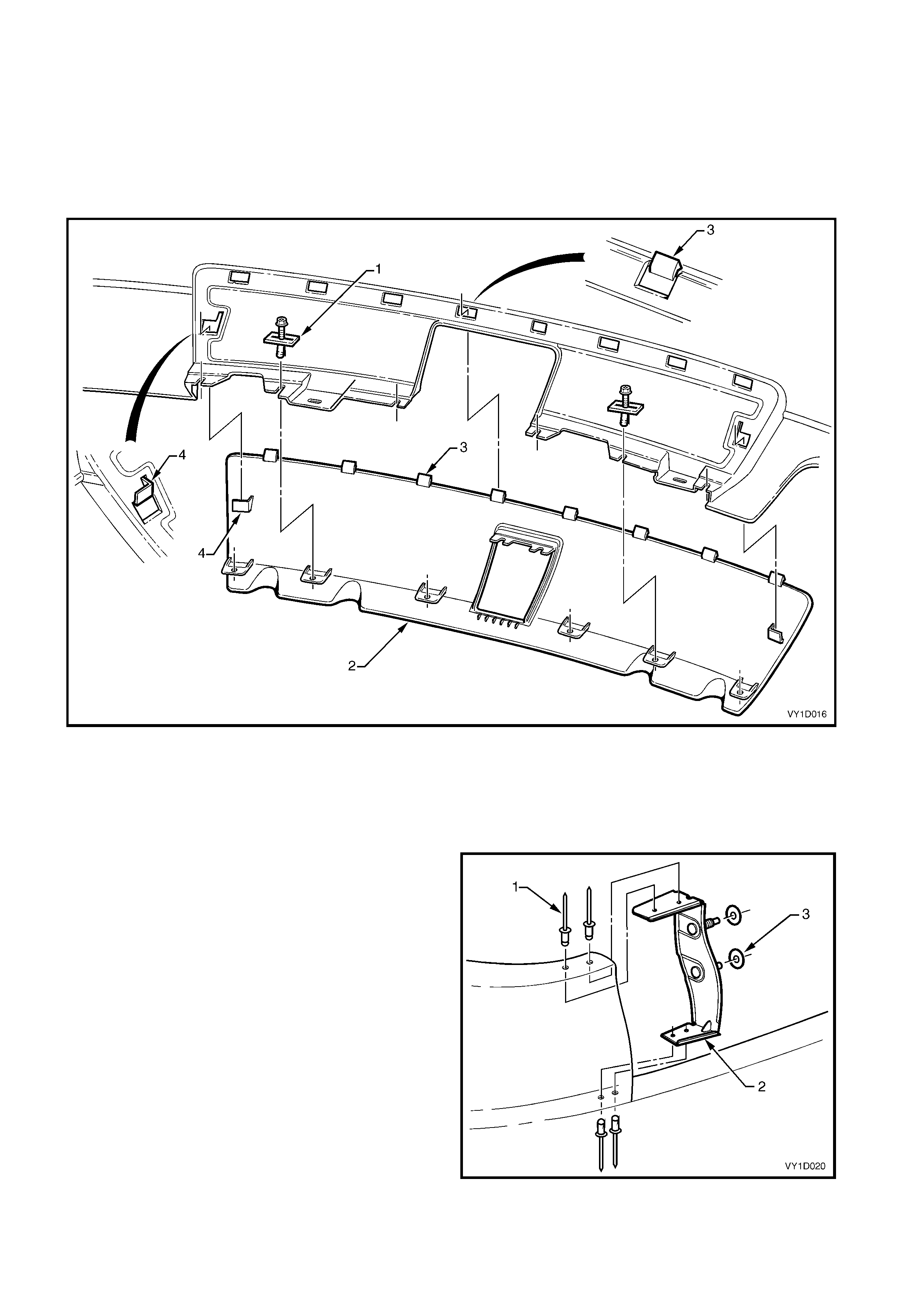

Referring to Figure 1D-22 – typical rear bumper fascia assembly, the bracket assembly (1) is attached to the

bumper fascia (2) with the heat stakes (3). If the bumper fascia assembly is damaged a replacement bracket

assembly can be fitted, or if the heat stakes are broken, a repair can be made.

If the heat stakes are broken, melt over the adjacent heat stakes (4) with a soldering iron.

If the bracket assembly is being replaced, cut the heat stakes (3) with a knife and remove the old bracket

assembly. Fit the new bracket assembly in position and using a soldering iron, melt over the adjacent heat

stakes (4).

Figure 1D-22

REVERSE PARKING AID COMPONENTS

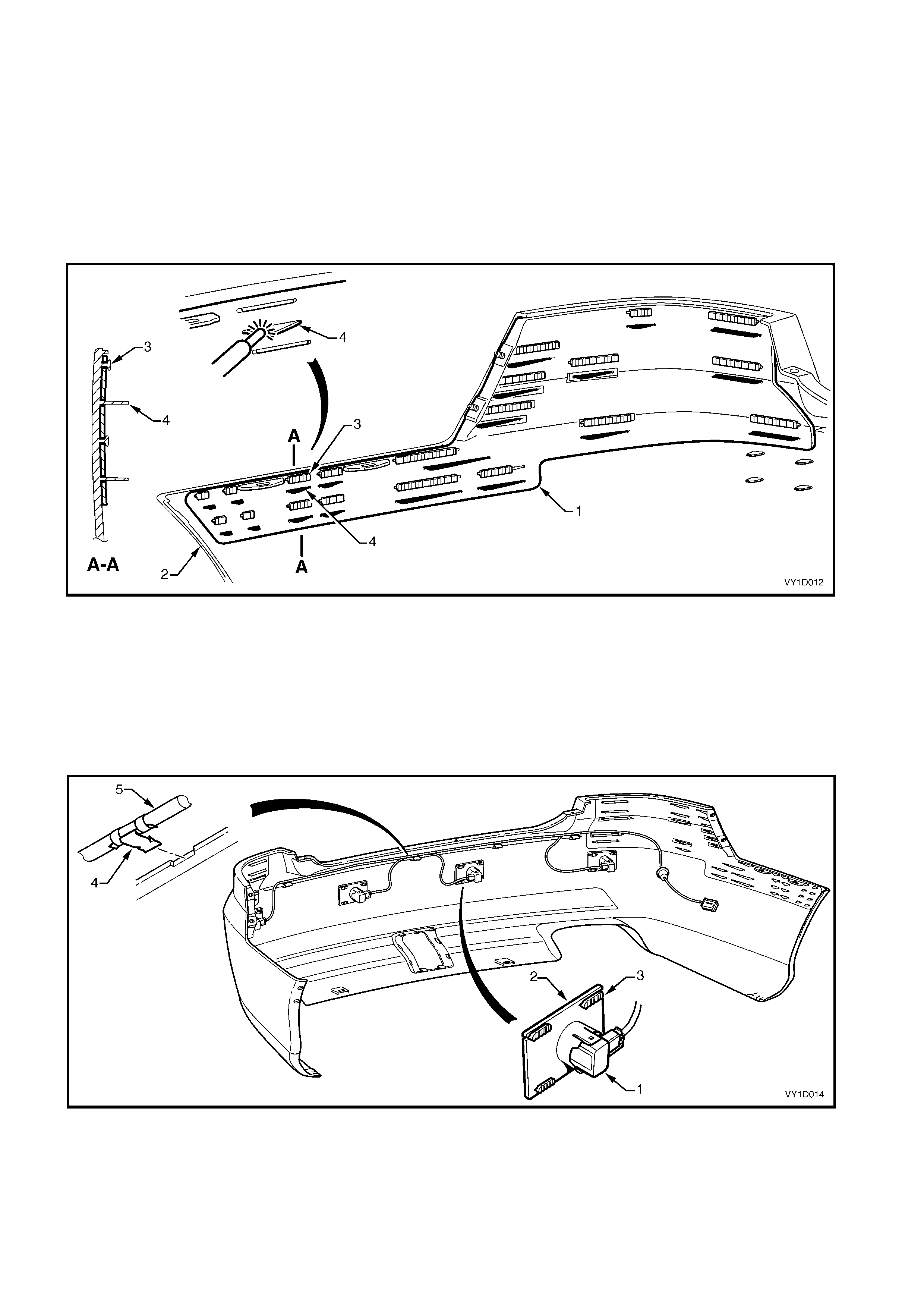

Where fitted, four sensor assemblies and their associated wiring are fitted to the rear bumper fascia assembly

as part of the Reverse Parking Aid (RPA), refer to Figure 1D-23. Sedan shown, Coupe is similar.

Each rear object sensor assembly (1) is fitted into a rear object sensor housing (2) which is attached to the

fascia assembly with four heat-stakes (3). Holes in the fascia expose the sensor and housing faces. Four

retaining clips (4) secure the rear object sensor wiring harness assembly (5) to the fascia assembly which is

routed across to the left-hand side.

Figure 1D-23

IMPORTANT: The fascia assem bly and sensors m ust be correctly aligned if the system is to operate correctly.

Sensors may be damaged if dropped or subjected to temperatures above 80° C.

If repainting a f ascia as sem bly, the sensor s and rings MUST be rem oved. Paint m ust not be applied to any part

of a sensor, including the exposed coloured surface. Paint film applied to the exposed surface will render the

sensor inoperable as the paint film restricts the sensor’s ultra-sonic signal. If a sensor is damaged, it must be

replaced.

Replacement housings are supplied unpainted. As they are partially exposed when installed, they will require

painting using the same procedures for painting the bumper fascia, refer to 2.1 PAINT SYSTEMS.

NOTE: It is preferable to paint the housings and bumper fascia separately to avoid adhesion problems.

Assemble the housings onto the bumper fascia once the paint has cured.

Replacement bumper fascias are supplied without holes and must be modified by following the procedures in

New Facia Modification.

For further information on reverse parking aid, refer to Section 12F REVERSE PARKING AID.

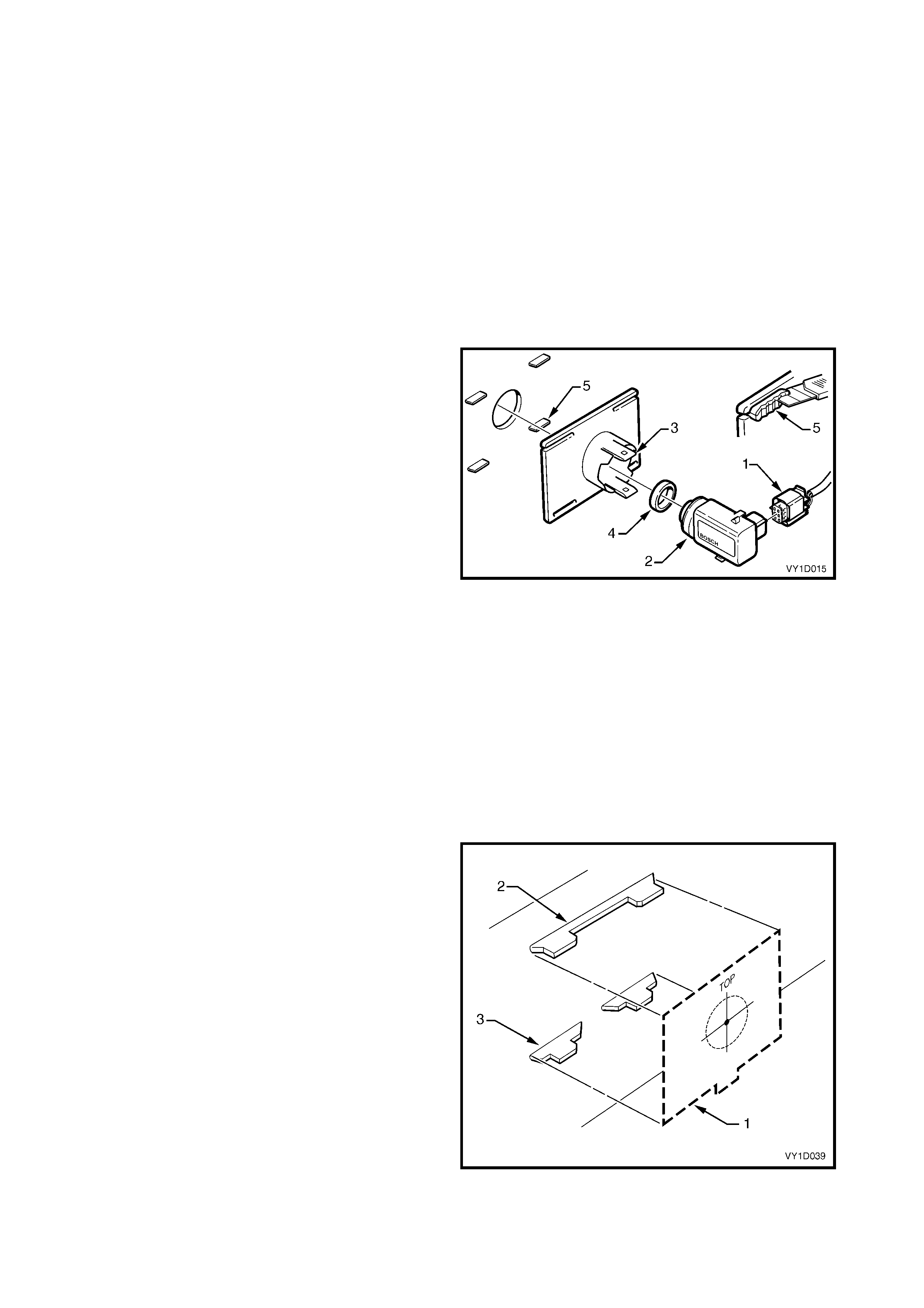

Disassemble

1. Remove the wiring connector (1) from the rear

object sensor assembly (2).

2. Using a fine blade screwdriver, lever the upper and

lower tabs (3) of the rear object sensor housing

and slide the sensor from the housing.

3. If required, remove the rear object sensor ring (4)

from the sensor.

4. Remove the housing from the bumper fascia by

cutting the heat-stakes (5).

NOTE: If the housing is to be reinstalled on the same

bumper fascia, only cut the minimum amount of

material to enable removal, ensuring enough remains

to reattach the housing.

5. Remove the wiring harness from the bumper

fascia by prising the four retaining clips from the

bumper fascia with a fine flat blade screwdriver.

Figure 1D-24

New Fascia Modification

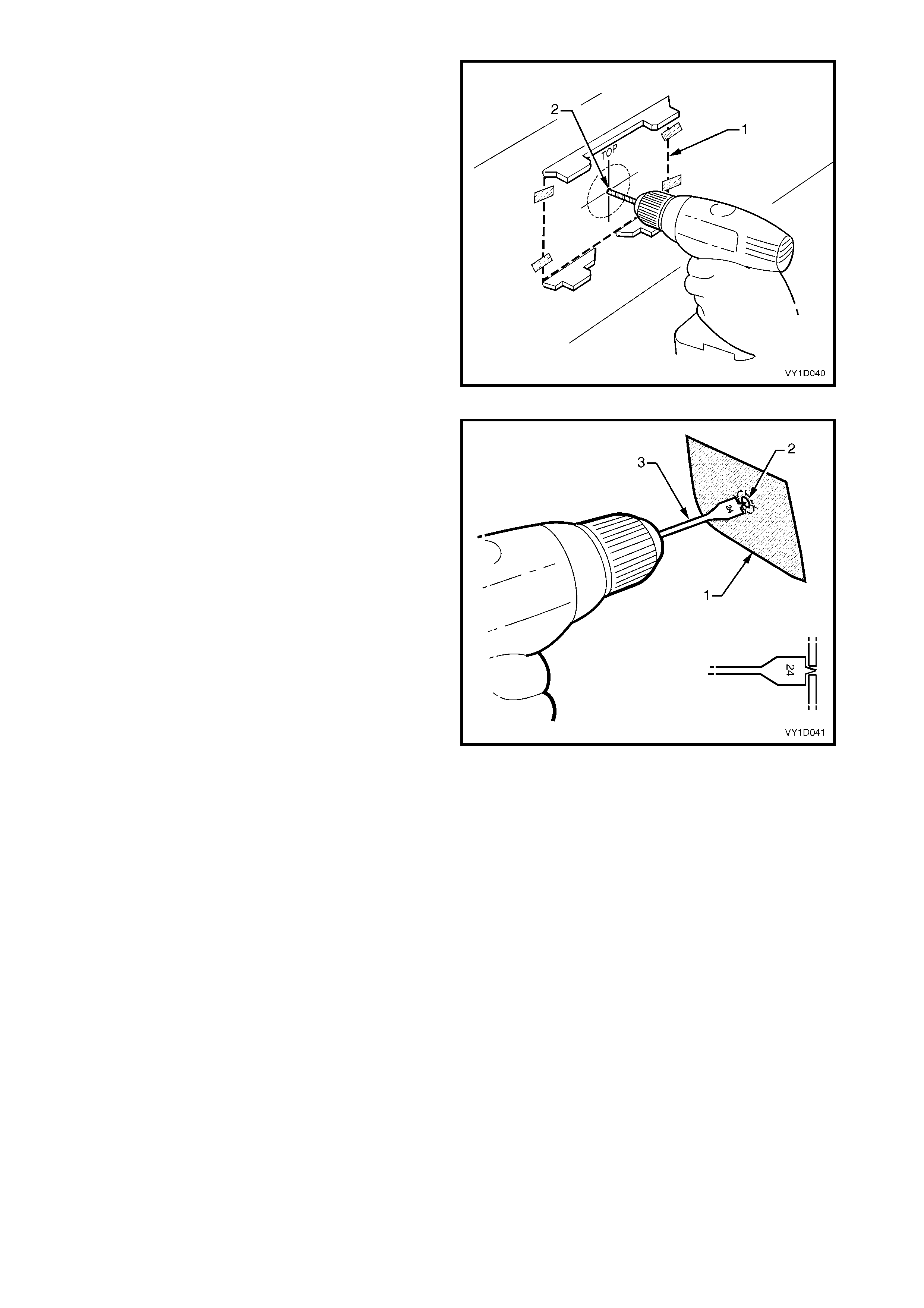

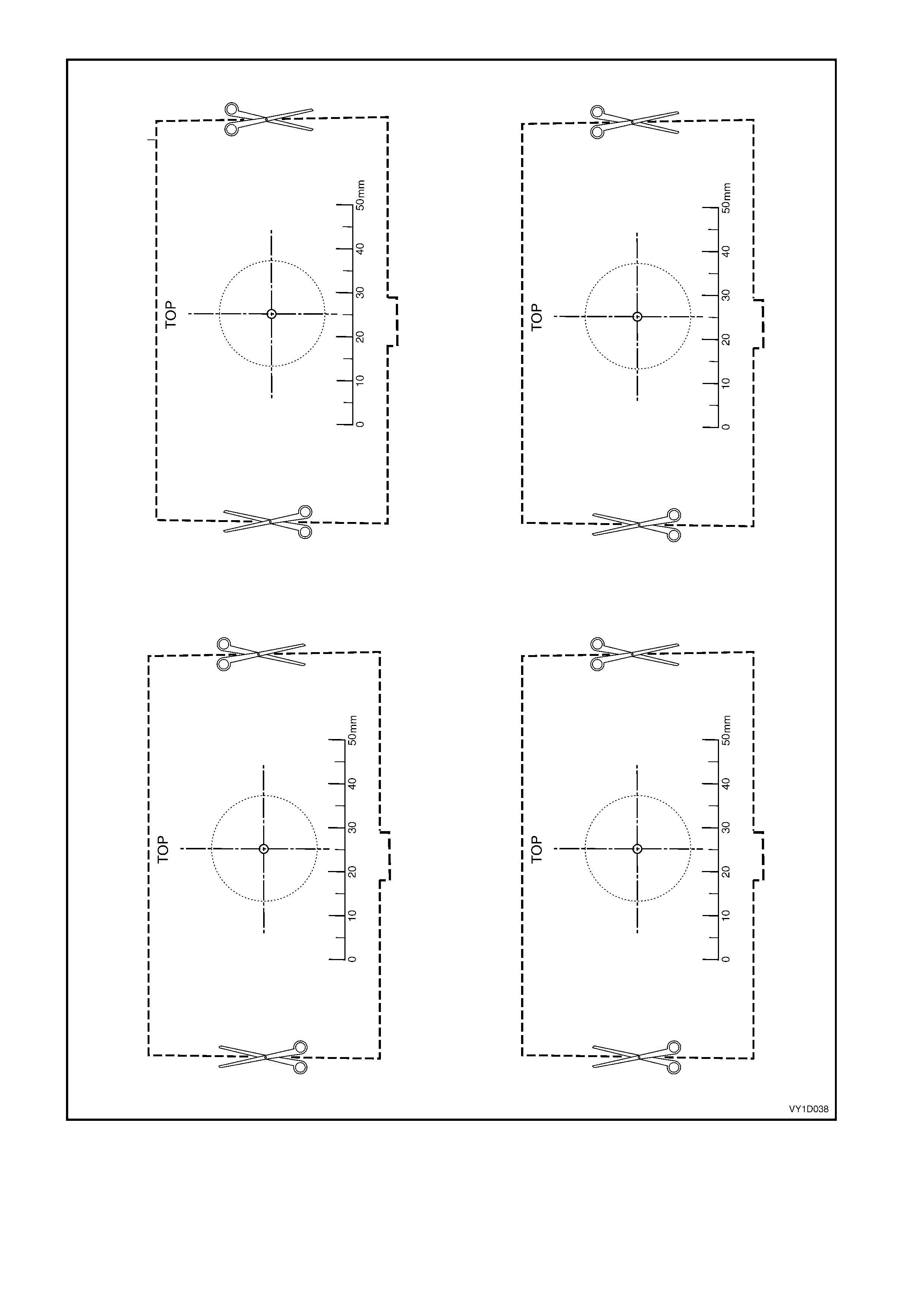

1. Print and cut-out the templates in Figure 1D-28.

IMPORTANT: When printing, in the PRINT DIALOG

BOX ensure the ‘SHRINK OVERSIZE PAGES TO

PAPER SIZE’ box is NOT ticked. Always check the

scale on the template to ensure it has printed the

correct size.

2. Perform the following instructions at the four

reverse parking aid module mounting locations.

3. Tape the template (1) to the inside of the rear

fascia, aligning the edges between the upper (2)

and lower (3) reverse parking aid heat stakes.

Figure 1D-25

4. From the inside of the fascia, drill a 2 mm diameter

pilot hole at the template (1) centre point (2).

Figure 1D-26

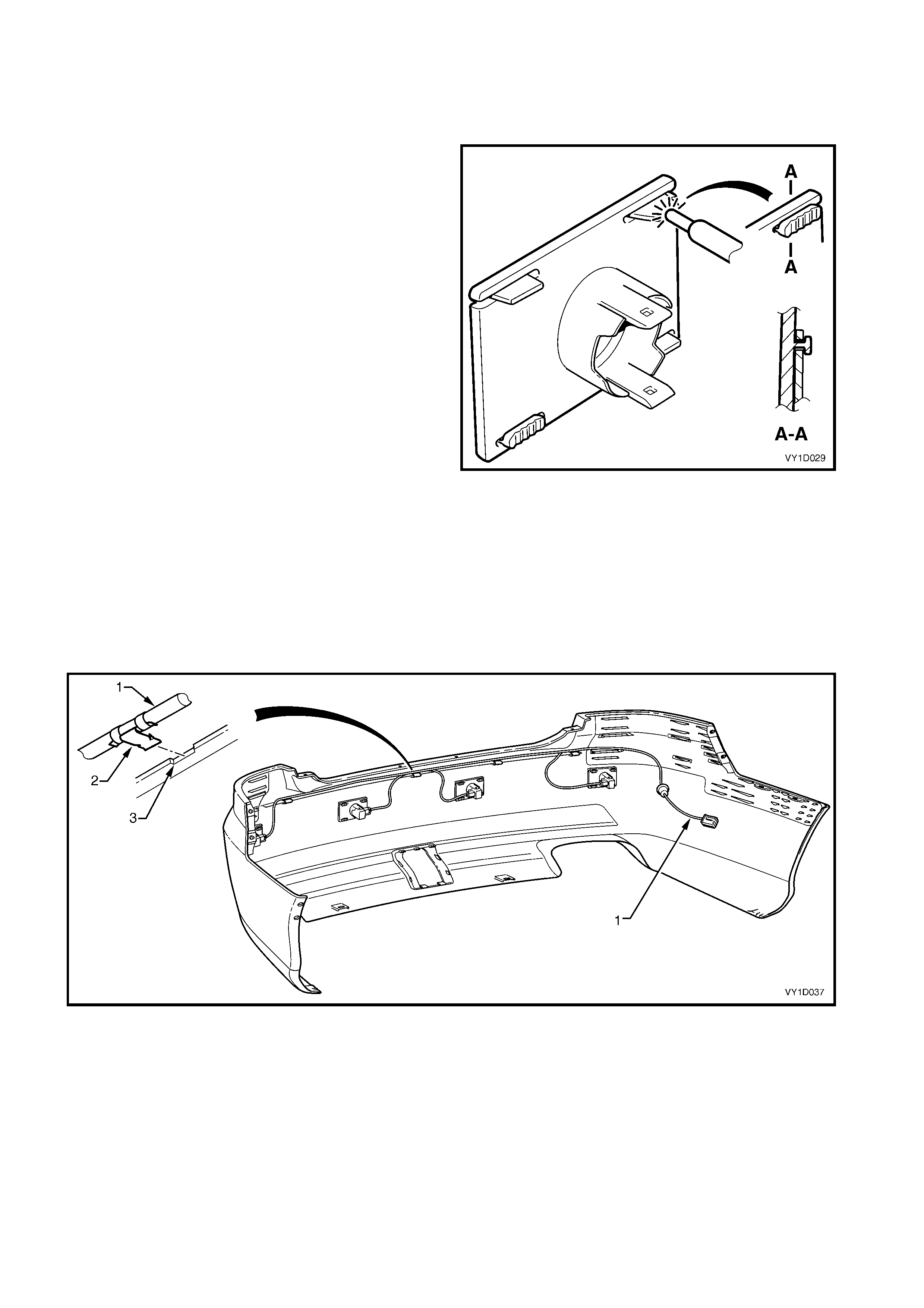

5. Place masking tape (1) on the outside surface of

the fascia in the area to be drilled.

6. From the outside of the fascia, enlarge the pilot

hole (2) to 24 mm using a wood spade drill bit (3).

IMPORTANT:

• Only use a wood spade drill bit as a normal drill bit

or hole saw may damage the rear fascia.

• Ensure the spade drill bit remains square with the

rear fascia.

• Use a slow drill speed to avoid damaging the rear

fascia.

7. Debur the edges of the hole if necessary.

8. As required, paint the bumper fascia and

sensor housings prior to reassembly, refer to

2.1 PAINT SYSTEMS.

Figure 1D-27

Figure 1D-28

Reassemble

NOTE: It is advisable to paint the bumper fascia and

housings prior to attachment to the bumper fascia,

refer to 2.1 PAINT SYSTEMS.

1. Position the housing onto the four stakes, ens ur ing

it is seated against the f asc ia surf ace and correc tly

protrudes through the hole.

2. Using a soldering iron, melt the end of the heat-

stakes. Hold the housing in position until the

plastic has cooled.

NOTE 1: Do not over- melt the m aterial and ensure the

housing is fixed securely.

NOTE 2: If the housing is being reinstalled onto the

same bumper fascia, ensure there is enough material

to provide secure attachment. If required, cut a thin

piece of bumper m aterial from an inconspicuous place

and use as a filler, melting it into the heat-stake.

3. Fit the ring onto the end of the sensor, refer to

Figure 1D-24.

4. Insert the sensor into the housing firmly, ensuring

that the tabs are locked into the sensor.

5. Repeat as required.

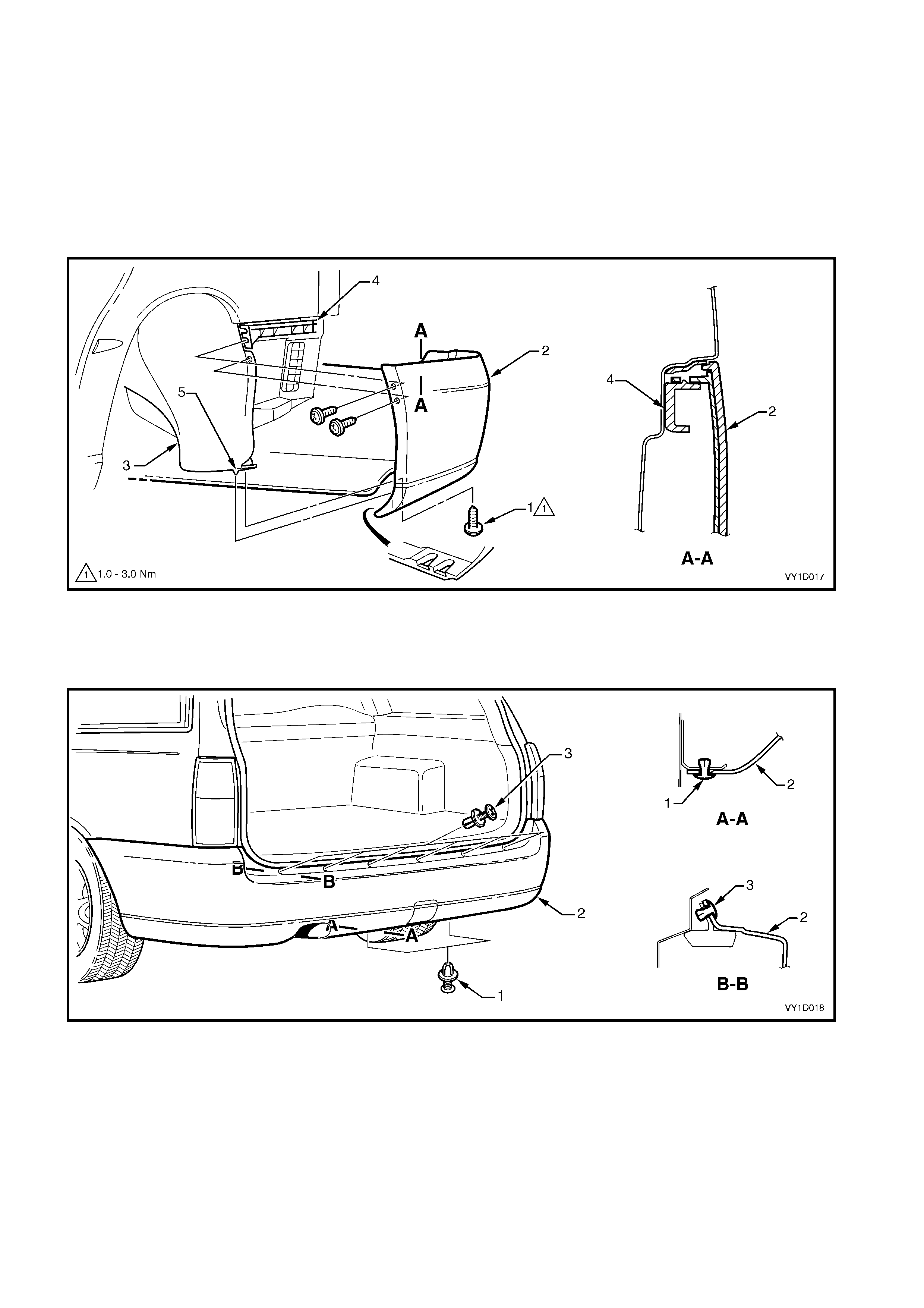

6. Route the wiring harness (1) to the LH side of the

vehicle and connect the wiring harness connectors

to each sensor, refer to Figure 1D-30.

7. Attach the harness to the upper side of the bumper

fascia rib, aligning each clip (2) at the notch (3).

8. Following installation of the bumper fascia

assembly, test the reverse parking aid for correct

operation, refer to Section 12F REVERSE

PARKING AID.

Figure 1D-29

Figure 1D-30

REINSTALL

1. For Sedan, if the vehicle is fitted with a towbar remove the towbar opening cover.

2. Refinish the bumper fascia assembly in accordance with the procedures in 2.1 PAINT SYSTEMS.

3. For Coupe, if the vehicle is fitted with a towbar install the towbar opening surround.

4. With the aid of an assistant, install the rear bumper fascia assembly onto the vehicle, inserting the RPA

wiring connector, if fitted, through its hole in the side panel.

5. Securely fit the RPA wiring harness grommet (1) into the side panel hole, refer to Figure 1D-14.

6. Install the two nuts (1) attac hing the fascia assem bly to the vehicle each side, refer to Figure 1D-13. Do not

tighten.

7. Insert the four retainers (4) across the rear compartment lid opening.

8. Insert the two retainers (3) below the fascia assembly.

9. Align the side of the f ascia assem bly to the quarter panel and clip the fascia assem bly into the rear bum per

fascia guide assem bly (6), also ensuring the wheelhouse liner lug (7) for Sedan except S & SS is engaged

into the fascia, refer to Figure 1D-13. Repeat for the opposite side.

10. Install the two screws each s ide (5), attaching the f a sc ia ass embly to the rear bum per fas c ia guide assem bly

and rear wheelhouse liner, refer to Figure 1D-12.

11. Install the screw (1) one place Sedan or two places Coupe, or for S and SS Vehicles (2) two places,

attaching the fascia assembly to the rear wheelhouse liner.

12. Tighten the two nuts each side and then the screws to the specified torque.

13. If fitted, test the reverse parking aid for correct operation, refer to Section 12F REVERSE PARKING AID.

REAR BUMPER FASCIA ASSEMBLY

TO REAR WHEELHOUSE

LINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA ASSEMBLY

TO REAR BUMPER FASCIA GUIDE

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 6.0 – 9.0 Nm

2.6 REAR BUMPER FASCIA ASSEMBLY, WAGON

LT Section No. – 07-525

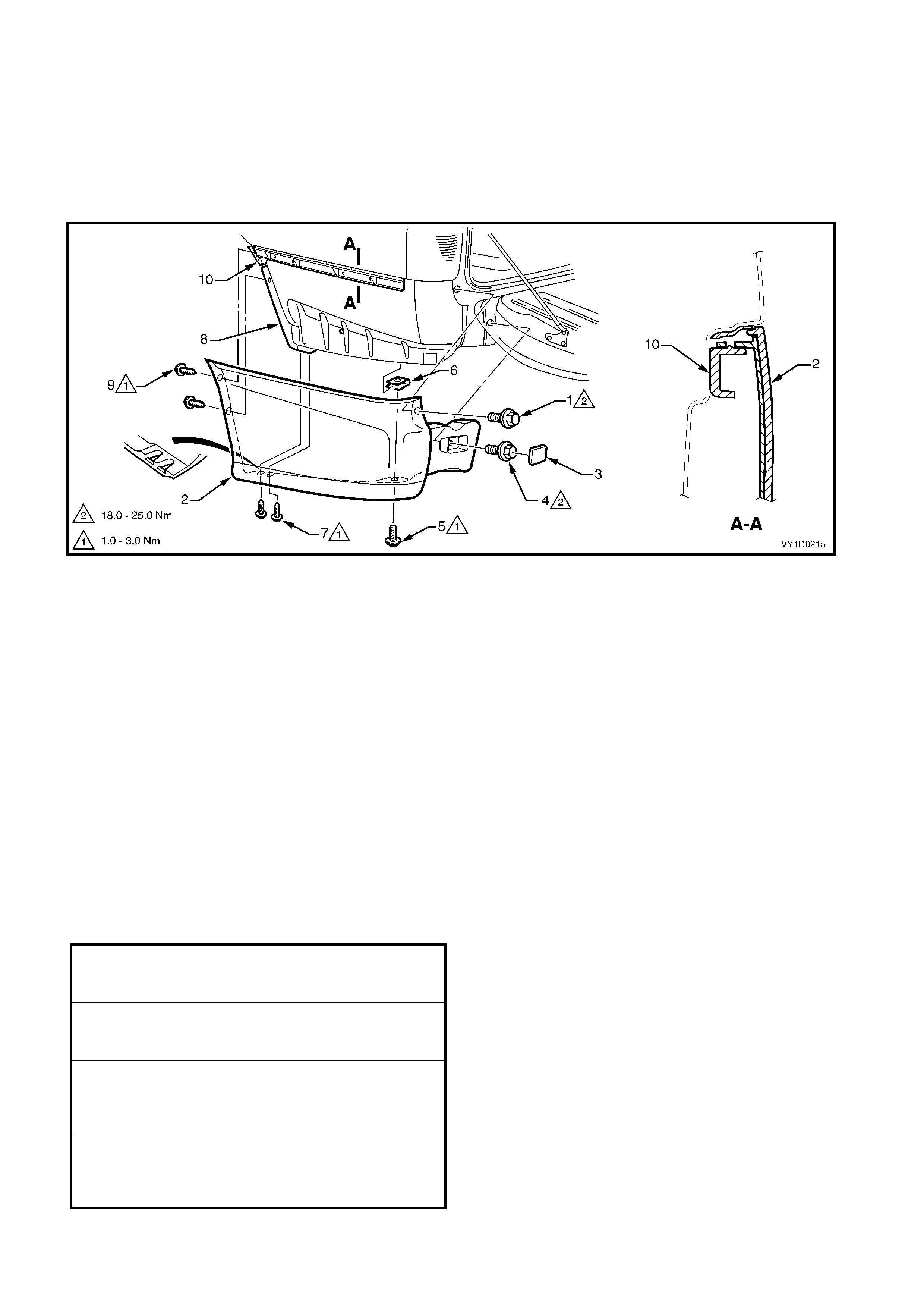

REMOVE

1. Remove the screws (1), three places on each side, attaching the rear bumper fascia assembly (2) to the rear

wheelhouse liner (3) and rear bumper fascia guide assembly (4), refer to Figure 1D-31.

2. Disconnect the lug (5) from the liner.

3. Carefully unclip the fascia assembly from the guide assembly by grasping the upper end of the fascia

assembly and pulling away from the vehicle.

Figure 1D-31

4. Remove the two retainers (1) from below the fascia assembly (2), refer to 1D-32.

5. Remove the six retainers (3) from across the liftgate opening.

6. With the aid of an assistant remove the fascia assembly, sliding it rearward.

Figure 1D-32

DISASSEMBLE

TOWBAR OPENING COVER

Remove

1. Remove the retainer (1), two places, securing the

towbar opening cover (2) to the bumper fascia

assembly.

2. Depress the retaining tabs and remove the cover

from the bumper fascia.

Reinstall

1. Clip the cover in place ensuring the retaining tabs

are seated correctly and install the two retainers.

Figure 1D-33

REAR BUMPER FASCIA BRACKET

A bracket assembly, which also acts as a reinforcement, is attached to each inner side of the rear bumper

fasc ia. Ref erring to Figure 1D-34, the brac ket ( 1) is attac hed to the bum per fas cia (2) with the heat stak es ( 3). If

the bum per f asc ia assem bly is damaged a r eplacem ent brac ket c an be fitted, or if the heat stak es are brok en, a

repair can be made.

If the heat stakes are broken, melt over the adjacent heat stakes (4) with a soldering iron.

If the bracket assembly is being replaced, cut the heat stakes (3) with a knife and remove the old bracket

assembly. Fit the new bracket assembly in position and using a soldering iron, melt over the adjacent heat

stakes (4).

Figure 1D-34

REINSTALL

1. Refinish the bumper fascia assembly in accordance with the procedures in 2.1 PAINT SYSTEMS.

2. If the vehicle is fitted with a towbar, remove the towbar opening cover.

3. With the aid of an assistant, install the rear bumper fascia assembly, ensuring that it is seated correctly.

4. Install the six retainers (3) around the liftgate opening, refer to Figure 1D-32.

5. Insert the two retainers (1) from below the fascia assembly.

6. Align the side of the fascia assembly to the quarter panel and clip the fascia assembly into the guide

assembly (6), refer to Figure 1D-31. Repeat for the opposite side.

7. Install the three screws on each side, attaching the fascia assembly to the guide assembly and rear

wheelhouse liner and tighten to the specified torque.

REAR BUMPER FASCIA ASSEMBLY

TO REAR WHEELHOUSE LINER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA ASSEMBLY

TO REAR BUMPER FASCIA GUIDE

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.7 REAR BUMPER FASCIA, UTILITY

LT Section No. – 07-525

REMOVE

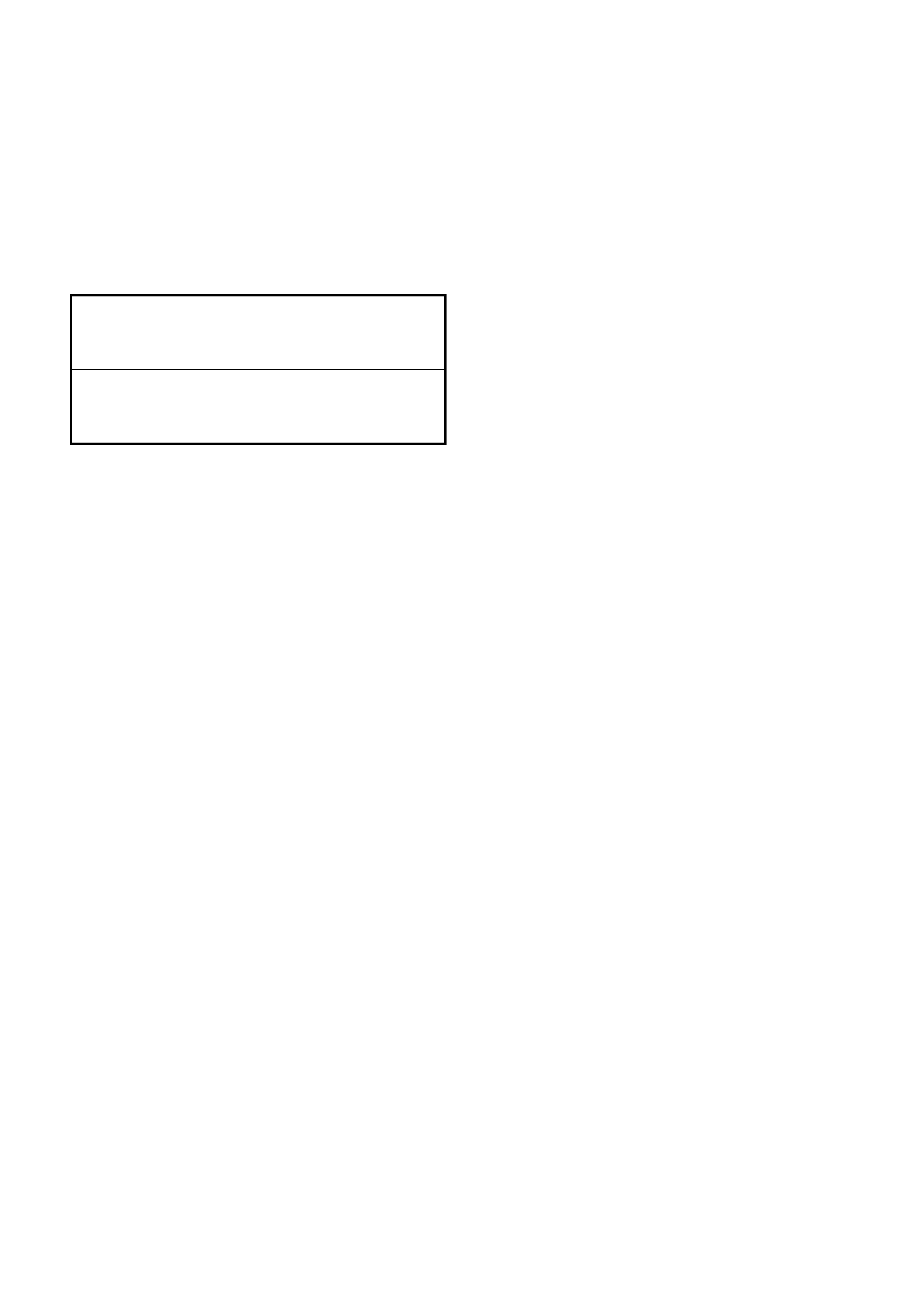

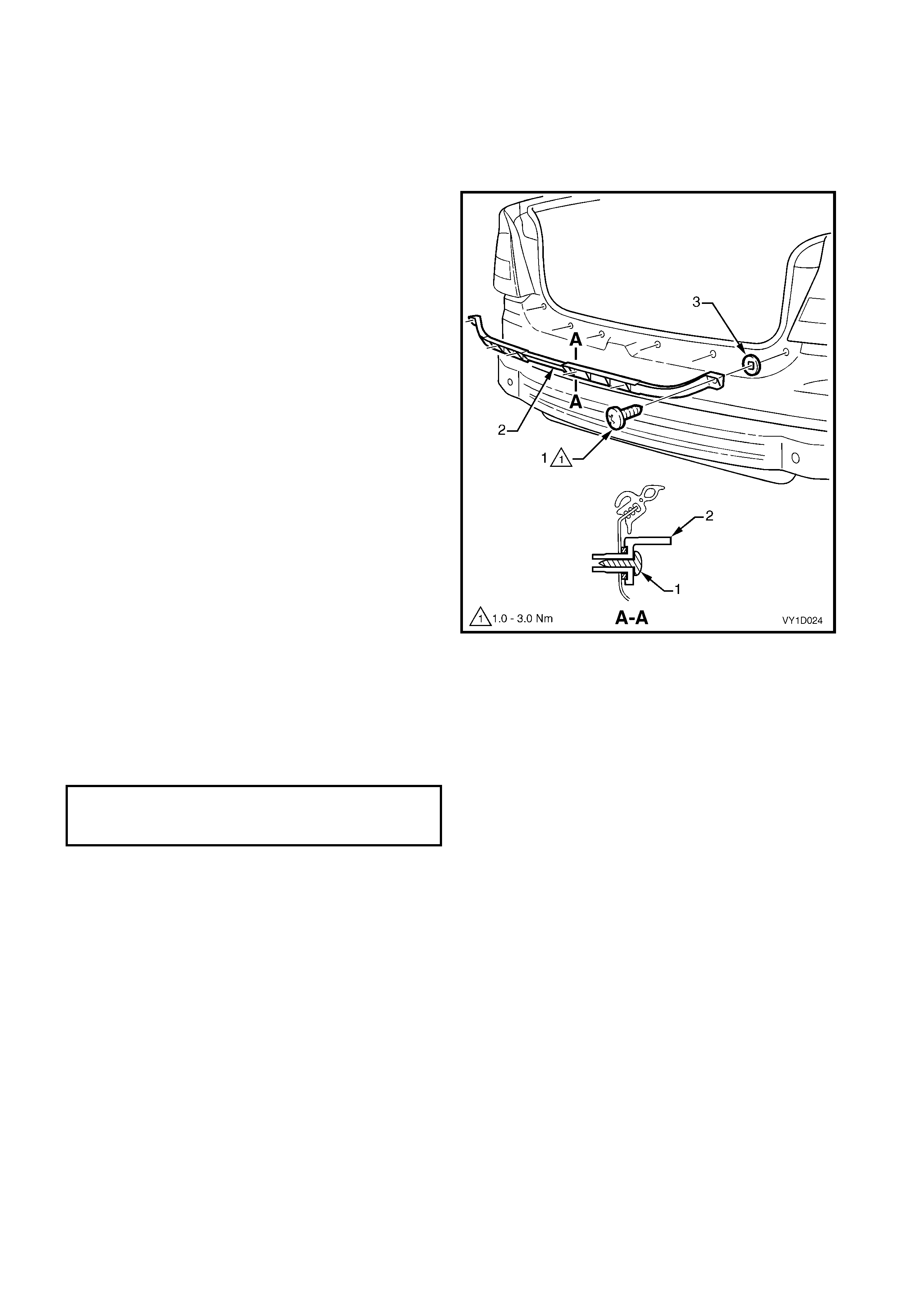

Referring to Figure 1D-35:

1. Open the endgate and remove the screw (1) attaching the bumper fascia (2).

2. Close the endgate.

Figure 1D-35

3. Insert a fine flat-blade screwdriver and clean shop-rag between the outer edge of the rear bumper fascia cap

(3) and fascia and prise off the cap.

4. Remove the screw (4) attaching the fascia.

5. Remove the screw (5) attaching the underside of the fascia to the J-nut (6).

6. Remove the screw (7) attaching the lower forward edge of the fascia to the rear wheelhouse liner (8).

7. Remove the two screws (9) attaching the forward edge of the fascia to the rear bumper fascia guide

assembly (10) and liner.

8. Carefully unclip the f as cia f r om the guide ass embly by gras ping the upper end of the fas c ia and pulling away

from the vehicle.

9. Remove the fascia from the vehicle.

10. If required, remove the J-nut (6) from the outer side panel.

REINSTALL

1. Refinish the bumper fascia assembly in accordance with the procedures in 2.1 PAINT SYSTEMS.

2. Align the side of the fascia to the outer side panel and clip into the guide assembly (10), refer to

Figure 1D-35.

3. Install the screws attaching the fascia and tighten to the specified torque.

REAR BUMPER FASCIA TO REAR END

PANEL ATTACHING SCREW

TORQUE SPECIFICATION 18.0 – 25.0 Nm

REAR BUMPER FASCIA TO J-NUT

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA TO

REAR WHEELHOUSE

LINER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

REAR BUMPER FASCIA TO REAR

BUMPER FASCIA GUIDE ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

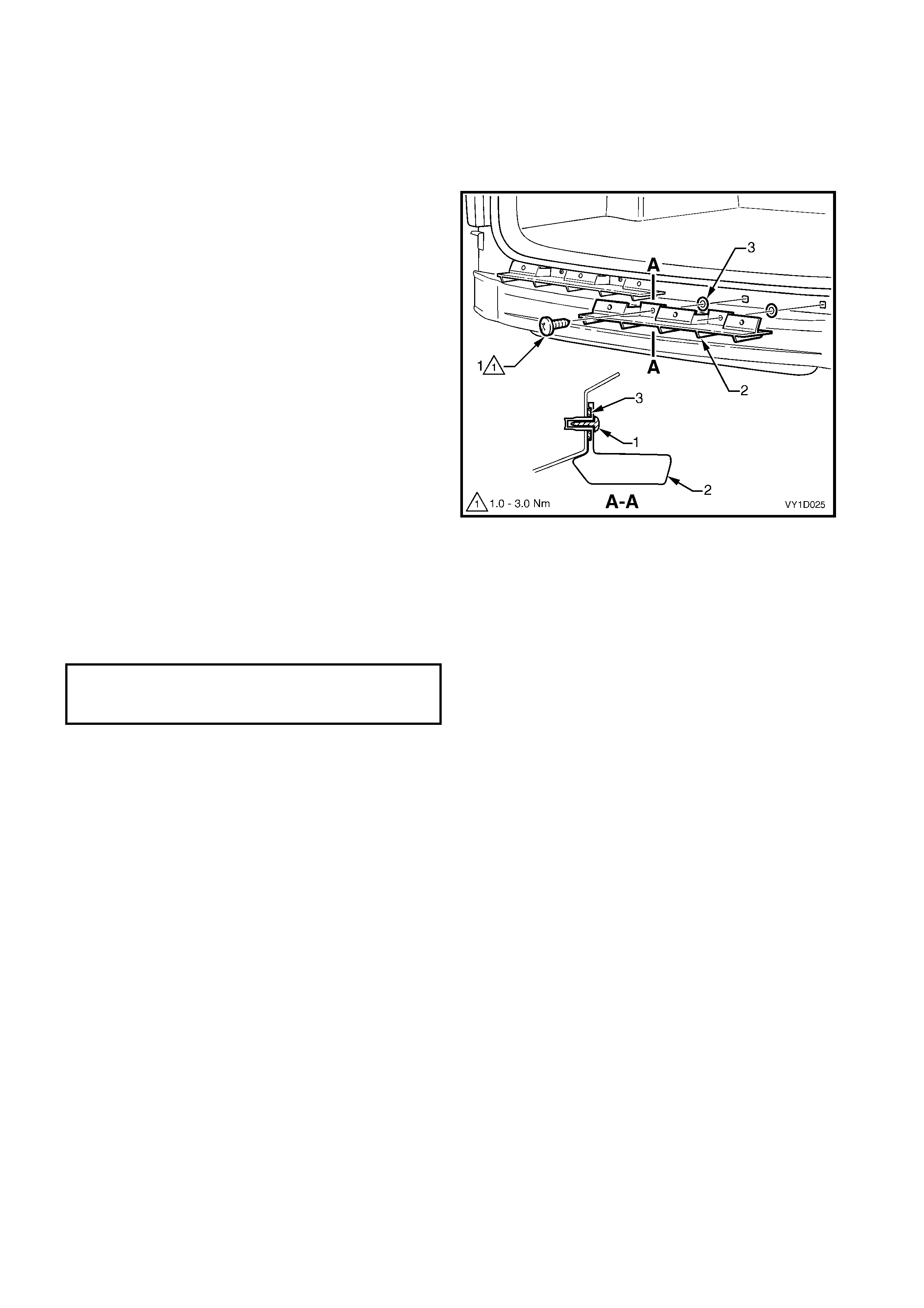

2.8 REAR BUMPER FASCIA GUIDE ASSEMBLY

REMOVE

1. Remove the rear bumper fascia, refer to:

2.5 REAR BUMPER FASCIA ASSEMBLY, SEDAN &

COUPE,

or

2.6 REAR BUMPER FASCIA ASSEMBLY, WAGON,

or

2.7 REAR BUMPER FASCIA, UTILITY.

NOTE: It may be possible to remove one side of the

bumper fascia and carefully move it out far enough to

gain access to the guide assembly.

2. Remove the four screws (1) attaching the guide

assembly (2).

3. Prise the guide assembly out to detach it from the

vehicle.

NOTE: Ensure the seal (3), four places, is removed

with the guide assembly.

Figure 1D-36

REINSTALL

Installation is the reverse of removal. Tighten the

screws to the specified torque.

REAR BUMPER FASCIA GUIDE

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.9 REAR BUMPER FASCIA CENTRE S UP PORT, SEDAN & COUP E

REMOVE

1. Rem ove the rear bum per fasc ia assem bly, r efer to

2.5 REAR BUMPER FASCIA ASSEMBLY,

SEDAN & COUPE.

2. Remove the six screws (1), attaching the support

(2) to the vehicle.

3. Prise the support from the vehicle, ensuring the

seals (3) remain with the support.

Figure 1D-37

REINSTALL

1. Installation is the reverse of removal.

NOTE: Ensure the seals are correctly fitted to the

support prior to installation. Tighten the screws to the

specified torque.

REAR BUMPER FASCIA CENTRE

SUPPORT ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.10 REAR BUMPER FASCIA UPPER SUPPORT, WAGON

REMOVE

1. Remove the rear bumper fascia, refer to

2.6 REAR BUMPER FASCIA ASSEMBLY,

WAGON.

2. Remove the screw (1), two places, attaching the

support (2) to the vehicle.

3. Prise the support from the vehicle ensuring the

seals (3) remain with the support.

4. Repeat for the opposite support as required.

Figure 1D-38

REINSTALL

1. Installation is the reverse of removal.

NOTE: Ensure the seals are correctly fitted to the

support prior to installation. Tighten the screws to the

specified torque.

REAR BUMPER FASCIA UPPER

SUPPORT ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

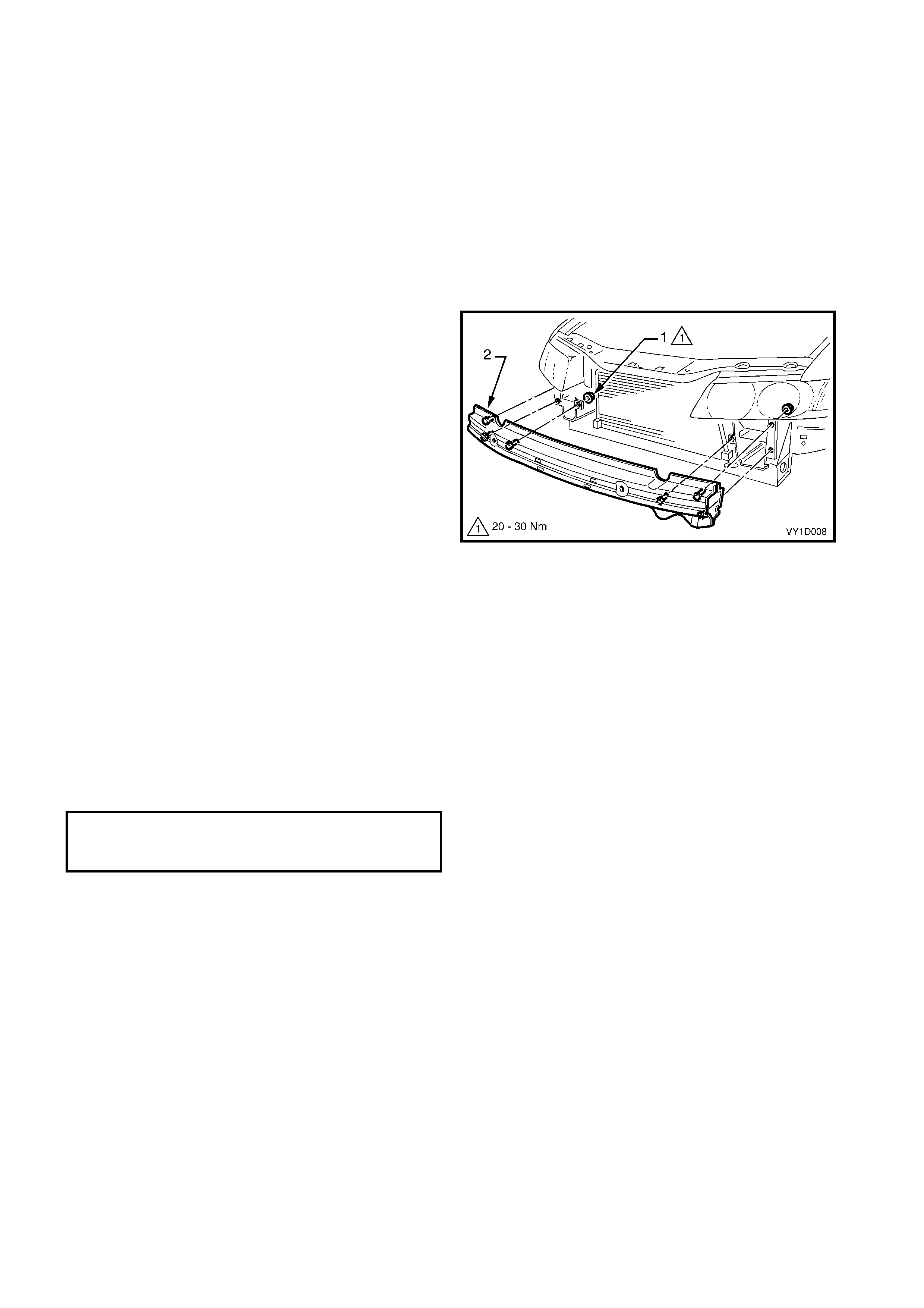

2.11 RE AR BUMPER IMPACT BAR, EXCEPT UTILITY

REMOVE

1. Remove the rear bumper fascia assembly, refer to:

2.5 REAR BUMPER FASCIA ASSEMBLY, SEDAN &

COUPE

or

2.6 REAR BUMPER FASCIA ASSEMBLY, WAGON.

2. Remove the screws (1), two places each side,

attaching the rear bumper impact bar (2) to the

rear bumper impact bar bracket assembly (3).

3. Remove the bar.

4. If required, remove the two nuts (4), attaching the

bracket assembly to the vehicle and remove the

bracket.

Figure 1D-39

REINSTALL

1. Fit the bracket assemblies in position and attach

the nuts. Tighten to the specified torque.

2. Fit the bar to the bracket assemblies and fit each

screw. Do not tighten.

3. When all screws are installed, check the bar is

centralised. Tighten the bolts to the specified

torque.

4. Refit the rear bumper fascia, refer to:

2.5 REAR BUMPER FASCIA ASSEMBLY, SEDAN &

COUPE

or

2.6 REAR BUMPER FASCIA ASSEMBLY, WAGON.

REAR BUMPER IMPACT BAR BRACKET

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 49.0 – 65.0 Nm

REAR BUMPER IMPACT BAR

ATTACHING SCREW

TORQUE SPECIFICATION 35.0 – 52.0 Nm

3. TORQUE WRENCH SPECIFICATIONS

Front fog lamp assembly nut..................................................................................................2.0 – 5.0 Nm

Front bumper fascia assembly to front wheelhouse liner screw ............................................1.0 – 3.0 Nm

Front bumper fascia assembly to front bumper fascia guide assembly screw ......................1.0 – 3.0 Nm

Front bumper fascia assembly to front upper panel screw....................................................2.5 – 4.0 Nm

Front bumper fascia guide assembly screw...........................................................................1.0 – 3.0 Nm

Front bumper impact bar assembly nut .................................................................................20.0 – 30.0 Nm

Rear bumper fascia assembly to rear wheelhouse liner screw..............................................1.0 – 3.0 Nm

Rear bumper fascia assembly to rear bumper fascia guide assembly screw........................1.0 – 3.0 Nm

Rear bumper fascia assembly nut, Sedan & Coupe..............................................................6.0 – 9.0 Nm

Rear bumper fascia to rear end panel screw, Utility ..............................................................18.0 – 25.0 Nm

Rear bumper fascia to J-nut screw, Utility..............................................................................1.0 – 3.0 Nm

Rear bumper fascia to rear wheelhouse liner screw, Utility...................................................1.0 – 3.0 Nm

Rear bumper fascia to rear bumper fascia guide assembly screw, Utility .............................1.0 – 3.0 Nm

Rear bumper fascia guide assembly screw ...........................................................................1.0 – 3.0 Nm

Rear bumper fascia centre support screw, Sedan & Coupe..................................................1.0 – 3.0 Nm

Rear bumper fascia upper support screw, Wagon ................................................................1.0 – 3.0 Nm

Rear bumper impact bar bracket assembly nut.....................................................................49.0 – 65.0 Nm

Rear bumper impact bar screw..............................................................................................35.0 – 52.0 Nm