SECTION 1E - COCKPIT MODULE

IMPORTANT

Before perfo rming any Service Operation or other procedu re described in this Section , refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

1.1 PRECAUTIONS

GENERAL PRECAUTIONS

INSTALLATION PRECAUTIONS

SAFETY PRECAUTIONS

2. SERVICE OPERATIONS

2.1 DASH PANEL ASSEMBLY

REMOVE

2.2 INSTALLATION PREPARATION

SURFACE PREPARATION

CHECKLIST

MIXING ADHESIVE & CATALYST

2.3 REINSTALL

DASH PANEL ASSEMBLY

COMPONENTS

2.4 DASH PANEL ASSEMBLY REPAIR

PANEL REPAIR

ADHESIVE REPAIR

3. TORQUE WRENCH SPECIFICATIONS

4. SPECIAL TOOLS

1. GENERAL DESCRIPTION

This Section describes the replacement of the dash panel assembly which is part of the cockpit module: a

production line sub-assembly consisting of the instrum ent panel, heater & A/C module assembly, steering colum n,

pedal assembly, wiring, etc. mounted to the dash panel assembly.

During production, the cockpit module is fitted to the vehicle in one operation. It is lowered through the windshield

opening and the dash panel as s embly is fitted into a channel k nown as the glue-tr ack, which is par t of the f r ont f loor

panel extension and hinge pillar inner panel assembly.

The glue track is filled with a special silicone adhesive prior to the cockpit module being installed. The dash panel

assem bly aligns with several dimples and four bolts sec ure it to the vehicle; two through the hinge pillar and two in

the plenum area. Once the adhesive cures, the dash panel assembly becomes an integral part of the body

structure.

The dash panel assembly is clearly visible from within the engine compartment. It is the gloss-black body panel

forming the plenum chamber below the windshield and continuing to the floor panel. The glue-track can be seen

where the dash panel assembly joins the hinge pillars and floor.

The s ilicone adhesive is a specif ic type f or this application and is s uited for the high temperatures generated within

the engine c om partm ent. It has exc ellent bonding, sealing and longevity characterist ics. T his tec hnique has been in

use for many years.

The components of the cockpit module, e.g. instrument panel, steering column, heater & A/C module assembly,

etc. c an be s ervic ed in the nor mal manner. The dash panel as s embly can also be serviced, however due to the f ac t

it is ‘glued-in’, the procedures in this Section must be followed.

Also included in this Sec tion are repair pr ocedures f or a damaged dash panel assem bly and adhesive. As the dash

panel is ‘glued’ to the vehicle, consideration is needed for the adhesive when repair procedures are performed.

1.1 PRECAUTIONS

GENERAL PRECAUTIONS

1. Only the correct two-part silicone adhesive should be used when refitting or repairing the dash panel assembly.

NOTE: Remove as much of the old adhesive as possible from the glue track before installation.

2. As the das h panel as sembly forms par t of the vehicle s tr uctur e, where it has any damage or cr ac ks in the sheet

metal, or if fire damage has occurred, the dash panel assembly must be removed and replaced.

3. Tears, separation or splitting of the adhesive exceeding 300 mm in length requires removal and complete re-

gluing of the dash panel. T he adhesive m ay be repaired where dam age is less than 300 m m in length, ref er to

2.4 DASH PANEL REPAIR.

4. The silicone adhesive used in the glue track must not be replaced with any other type of adhesive or sealant

other than that which is recommended and available from your authorised dealer as the Sealant Kit - Dash

Panel. Urethanes, epoxies, acrylic or ‘normal’ silicones, etc. are not suitable for use in this application. Failure to

correctly seal the cockpit module panel to the vehicle may allow exhaust, fuel or other fumes to enter the

passenger compartment and compromise the structural integrity of the vehicle.

5. The adhesive is best applied with the SAE 677 barrel gun & follower plate. Refer to your authorised dealer for

availability .

INSTALLATION PRECAUTIONS

IMPORTANT: To obtain a satisfactory bond between the two parts, the following procedures must be observed.

1. Prior to installation of the dash panel ass em bly, remove as m uc h of the r em aining adhesive f rom the glue trac k

as possible.

2. After repairing any damaged sheet metal, completely remove the rem aining adhesive in the repaired area and

apply primer and refinish the area according to the paint manufacturer’s specifications.

3. Do not apply paint over any remaining adhesive or allow overs pray to get in the glue-track . Apply mask ing tape

to the track before painting, and install the dash panel assembly after oven baking the paint (where

appropriate).

4. Do not use an adhesive other than which is recommended.

5. Body shell assemblies are available with the cockpit module installed, refer to your authorised dealer for

availability .

6. Before commencing installation of the dash panel assembly, thoroughly read 2.2 INSTALLATION

PREPARATION in this Section.

7. Although the cock pit module is installed as an assem bly on the production line, this method is not practical for

repairing the vehicle.

SAFETY PRECAUTIONS

The silicone adhesive used in the glue track, once cured, requires no special precautions. However, when mixing

the adhesive compound with the catalyst and applying the adhesive, the following precautions should be observed.

1. Do not swallow: the catalyst is a toxic substance, keep away from children.

2. Safety glasses should be worn to avoid contact with eyes. If eye contact occurs, wash the area in clean water

only, and seek immediate medical advice.

3. Wear protective gloves when handing the adhesive and catalyst, as they may cause skin irritation. If irritation

occurs, wipe the adhesive/catalyst off with a clean cloth and wash the affected area thoroughly in clean water.

4. Vapour produced by the adhesive and catalyst may cause breathing difficulties, use only in a well ventilated

area.

5. The catalyst is combustible, keep away from sparks and flame.

2. SERVICE OPERATIONS

2.1 DASH PANEL ASSEMBLY

LT Section No. – 12-425

IMPORTANT: Prior to commencing any of the following procedures, disconnect the battery to disable the SIR

system. Following reconnection of the battery the security PIN code will be required to reinstate the entertainment

system, refer to Section 12D ENTERTAINMENT SYSTEM.

As required, first remove the following components:

1. Hood and hinge assemblies, refer to Section 1A4, 2.5 HOOD & HINGE ASSEMBLIES.

2. Drain the engine coolant, refer to Section 6B1 ENGINE CO OLING – V6 or Section 6B2 ENGINE COO LING –

V6 S/C or Section 6B3 ENGINE COOLING – V8.

3. Discharge the air-conditioning s ystem (Manual or Auto A/C), refer to Section 2C HVAC OCCUPANT CLIMATE

CONTROL (MANUAL A/C) – SERVICE & DIAGNOSIS.

4. Engine, refer to Section 6A1 ENGINE MECHANICAL – V6 or Section 6A2 ENGINE M ECHANICAL – V6 S/C

or Section 6A3 ENGINE MECHANICAL – V8.

5. Plenum Cover assembly and windshield wiper assembly, refer to Section 12N WIPERS/WASHERS & HORN.

6. Windscreen side garnish, refer to Section 1A8 HEADLING & INTERIOR TRIM.

7. Hinge pillar trim, refer to Section 1A8 HEADLING & INTERIOR TRIM.

8. Windshield assembly, refer to Section 1A6 STATIONARY GLASS.

9. Floor console and instrument panel assembly, refer to Section 1A3 INSTRUMENT PANEL & CONSOLE.

10. Passenger airbag assembly, refer to Section 12M OCCUPANT PROTECTION SYSTEM.

11. Fuse panel, refer to Section 12O FUSES & WIRING HARNESS.

12. BCM, refer to Section 12J BODY CONTROL MODULE.

13. Instrument panel brackets and braces, refer to Section 1A3 INSTRUMENT PANEL & CONSOLE.

14. PCM, refer to Section 6C1 POWERTRAIN MANAGEMENT SYSTEM – V6 or Section 6C2 POWERTRAIN

MANAGEMENT SYSTEM – V6 S/C or Section 6C3 POWERTRAIN MANAGEMENT SYSTEM – V8.

15. Heater & A/C module ass embly, refer to Section 2B HVAC OCCUPANT CLIMATE CONTROL (MANUAL A/C)

– REMOVAL & INSTALLATION or Section 2E HVAC OCCUPANT CLIMATE CONTROL (AUTO A/C) –

REMOVAL & INSTALLATION.

16. Steering Column assembly, refer to Section 9A POWER STEERING.

17. Brake master cylinder assembly, brake and accelerator pedal assemblies, refer to Section 5A SERVICE &

PARK BRAKE SYSTEMS.

18. Clutch master cylinder assembly and clutch pedal assembly, if fitted, refer to Section 7A1 CLUTCH – V6

ENGINE.

19. Telematics module and antenna, if fitted, refer to Section 12K TELEMATICS.

20. As required, remove the wiring harnesses from the dash panel and lay out of the way, refer to

Section 12O FUSES & WIRING HARNESS.

NOTE 1: For the RH side, the dash panel assem bly will be cut f rom around the har ness. This saves disconnec tion

of the complete main wiring harness.

NOTE 2: As required, mark and identify the connectors to aid reinstallation.

NOTE: The following fasteners MUST be replaced

when performing this operation:

+

++

+

Dash panel screw (plenum side)

+

++

+

Dash panel bolt (hinge pillar side)

REMOVE

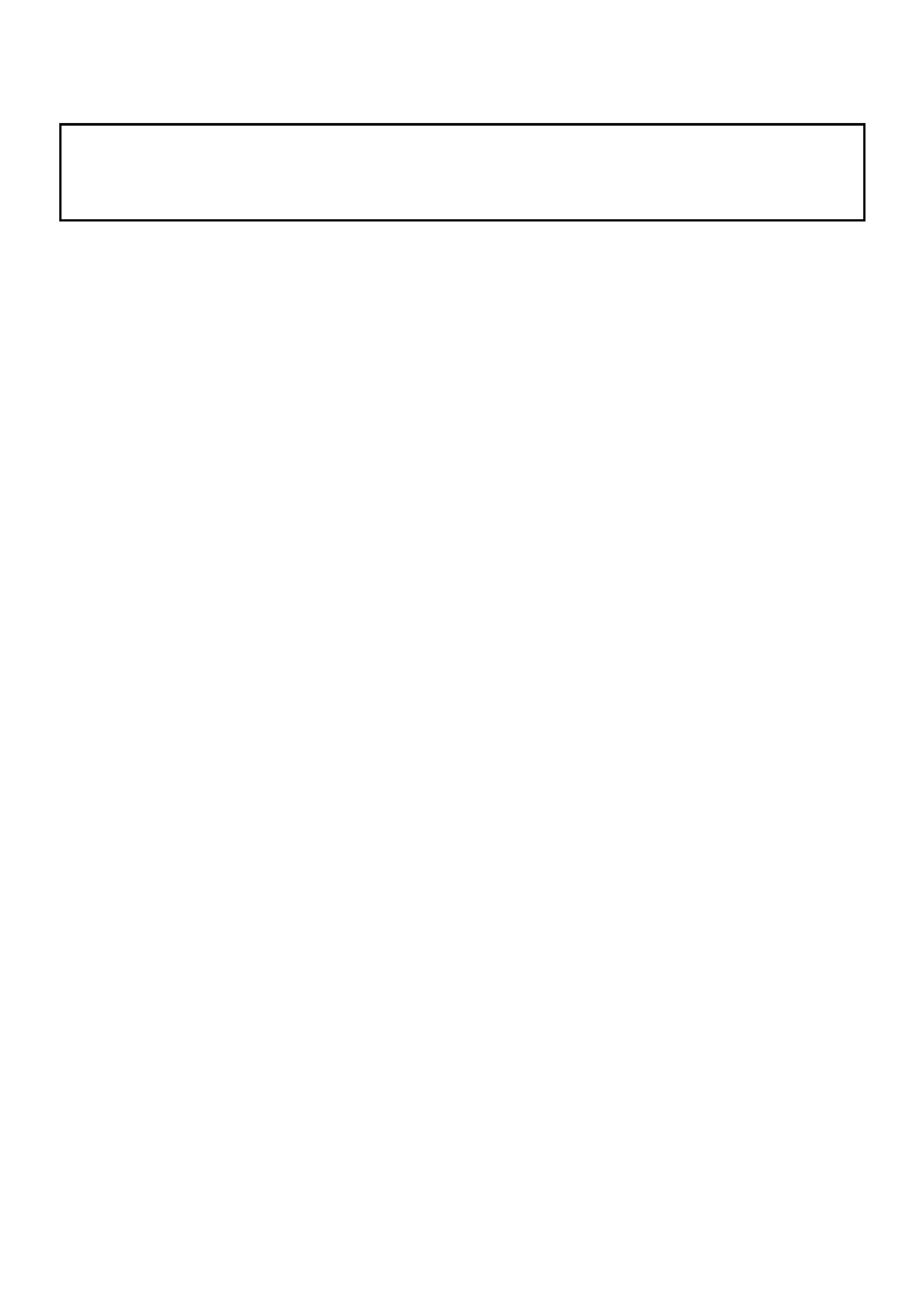

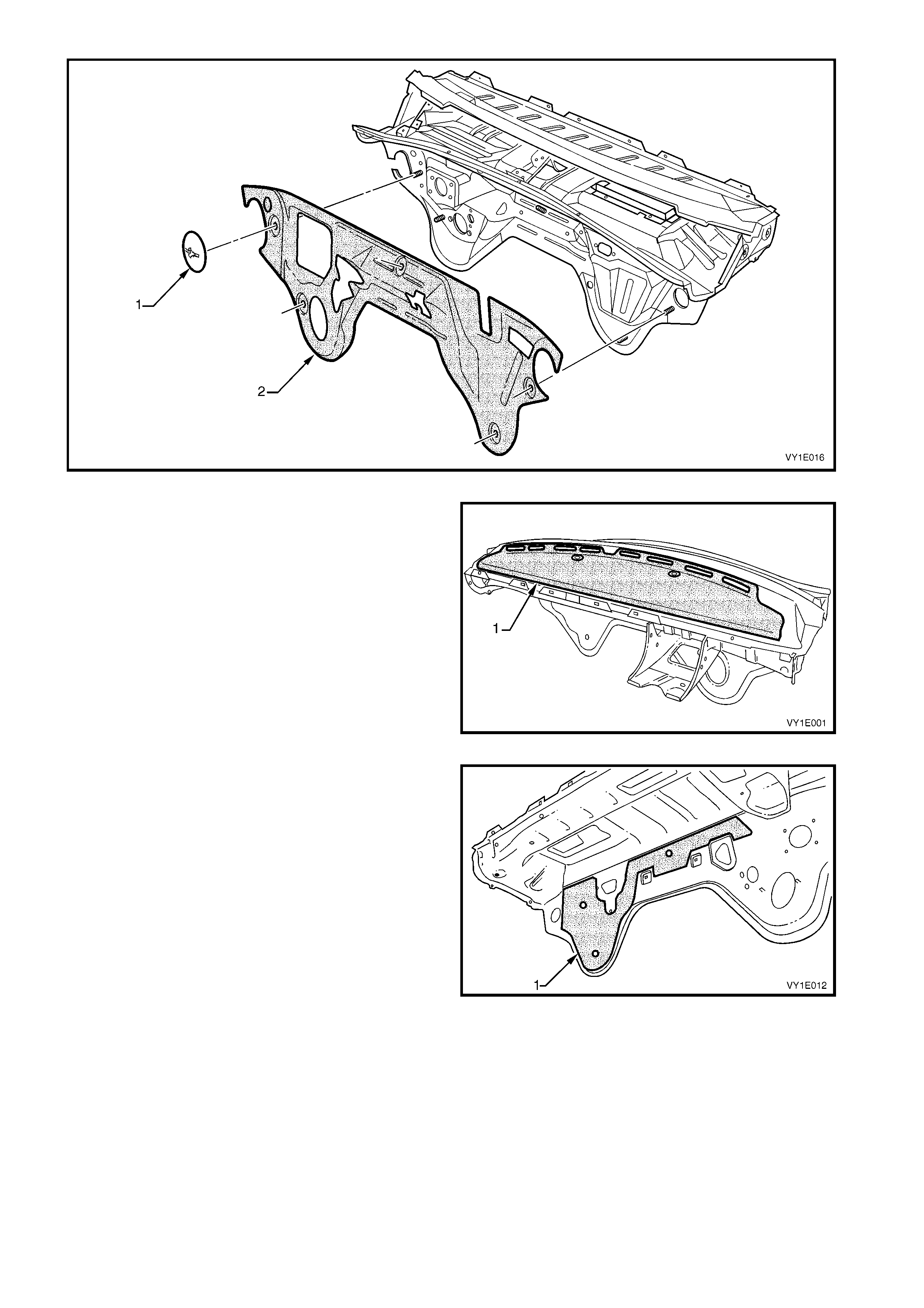

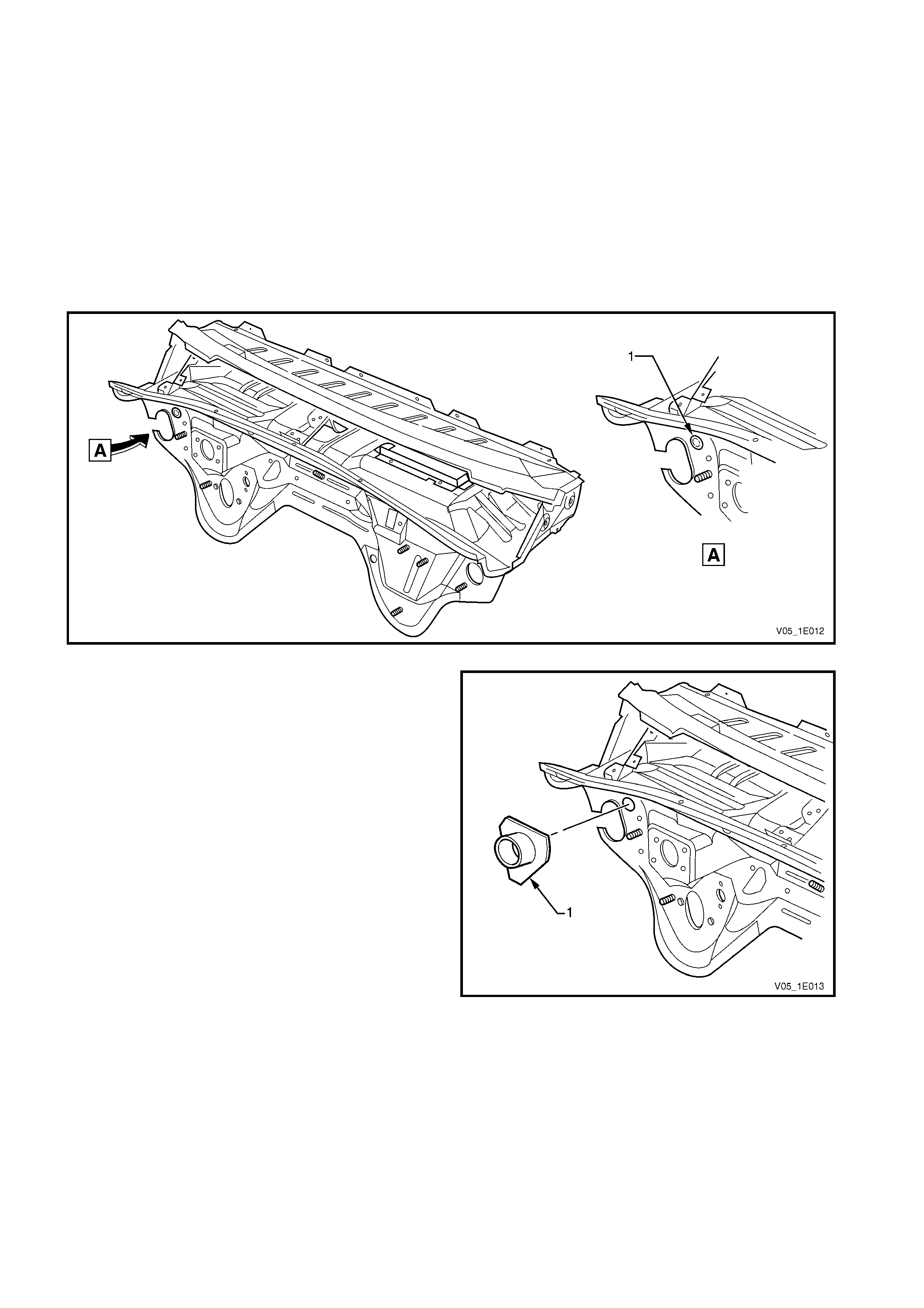

1. Remove the dash panel bolt (1) from each hinge

pillar.

Figure 1E-1

2. From within the plenum chamber, remove the

dash panel screw (1) each side.

Figure 1E-2

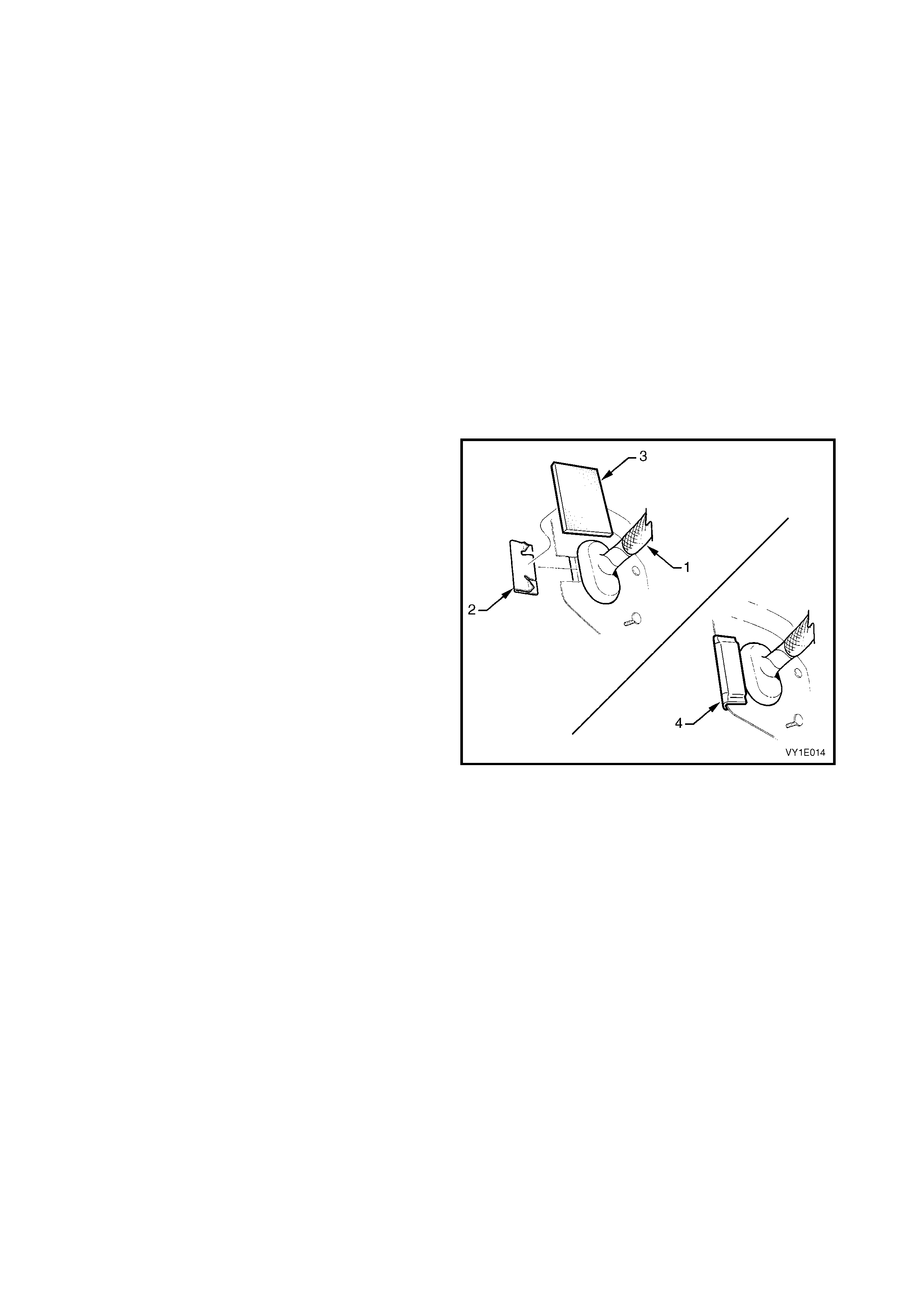

3. Remove the two screws (1) attaching the body

earth strap (2) and remove.

Figure 1E-3

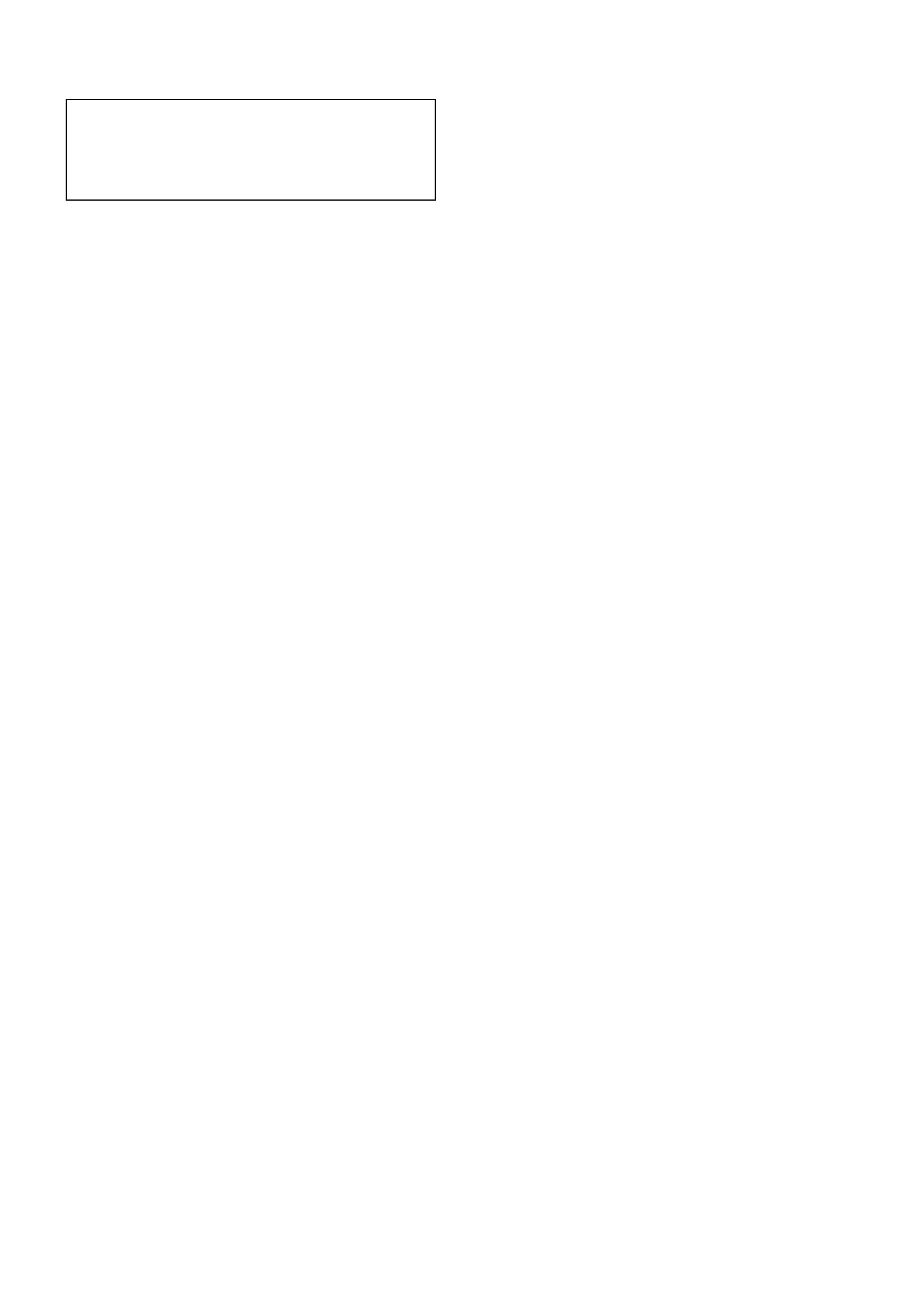

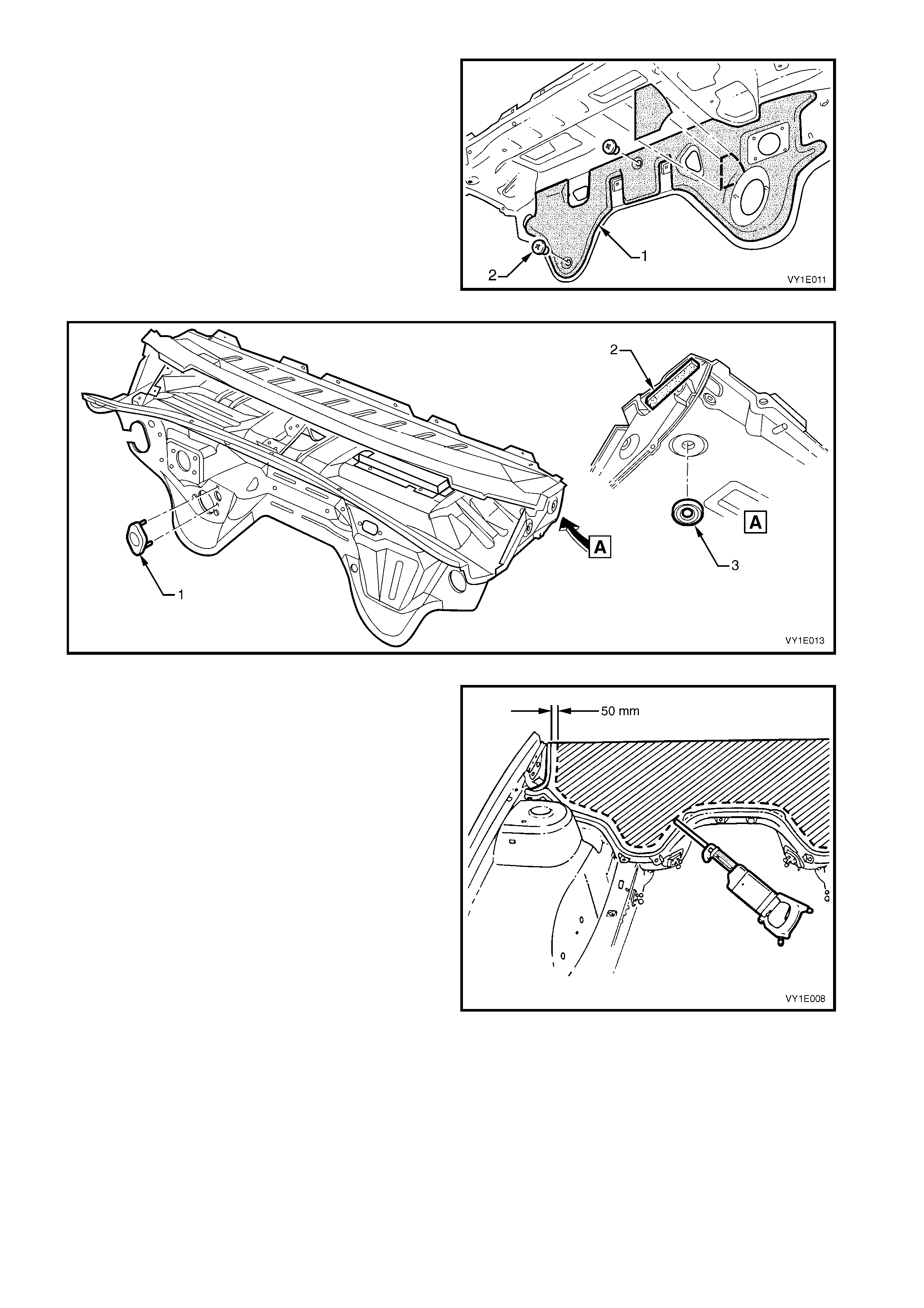

4. Locate the safety compliance plate (1) near the

centre of the dash panel and VIN plate (2) on the

LH side of the dash pane.

5. Using a drill and suitable size drill bit, drill out the

retaining rivets.

Figure 1E-4

6. Transf er the VIN plate (1) onto the new dash panel

assembly.

7. Using a com mercially available hand rivet tool and

two new rosette headed rivets (2), secure the VIN

plate to the new dash panel assembly.

Figure 1E-5

8. Transfer the safety compliance plate (1) onto new

dash panel assembly.

9. Using a com mercially available hand rivet tool and

two new rosette headed rivets (2), secure the

safety compliance plate to the new dash panel

assembly.

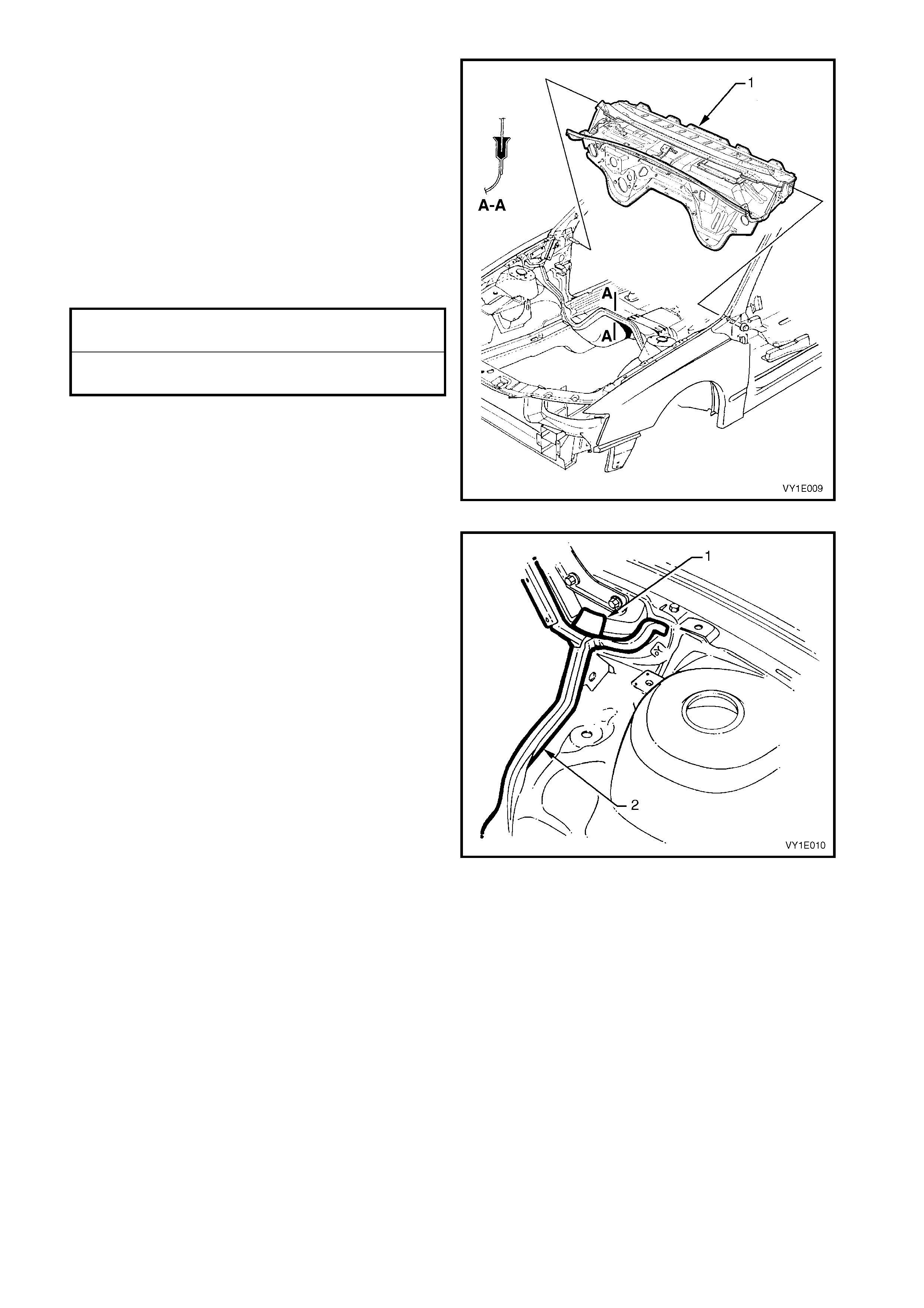

10. Remove the retainer (1) attaching the dash panel

lower insulator outer to the engine compartment

side of the dash panel, refer to Figure 1E-7.

Figure 1E-6

Figure 1E-7

11. Transfer the dash panel upper insulator (1) from

the existing dash panel to the new dash panel.

The insulator is adhered to the dash panel and

care is required during removal. If required, apply

contact adhesive to the insulator prior to affixing it

to the new dash panel and ensure it follows the

form of the dash panel.

If a new insulator is being fitted, remove the

backing paper prior to fitting and apply.

Figure 1E-8

12. The dash panel lower deadener (1) cannot be

transferred to the new dash panel; a new

deadener will be required. Affix the deadener to

the new dash panel now to allow the dash panel

lower insulator to be transferred.

The deadener is a heat-fusible type. Install it in

position with the diamond embossed side to the

panel. Use a heat gun, heat lamps or suc h, to c ure

the deadener. Smooth the deadener with a roller

or such to expel any air bubbles and to maximise

adhesion.

Figure 1E-9

13. Transfer the dash panel lower insulator inner (1)

from the existing dash panel. The insulator is

attached with two retainers (2).

14. Transfer the plug (1), if fitted, spacer (2) and plug

(3), refer to Figure 1E-11.

Figure 1E-10

Figure 1E-11

15. Using a power saw, cut the dash panel assembly

approximately 50 mm above the glue track.

CAUTION: Sparks may ignite petrol in the fuel or

emission control lines if due precautions are not

taken.

NOTE: Take care cutting around the main wiring

harness.

16. Remove the dash panel assembly section.

17. Cut the section of remaining panel to enable

removal of the main wiring harness.

Figure 1E-12

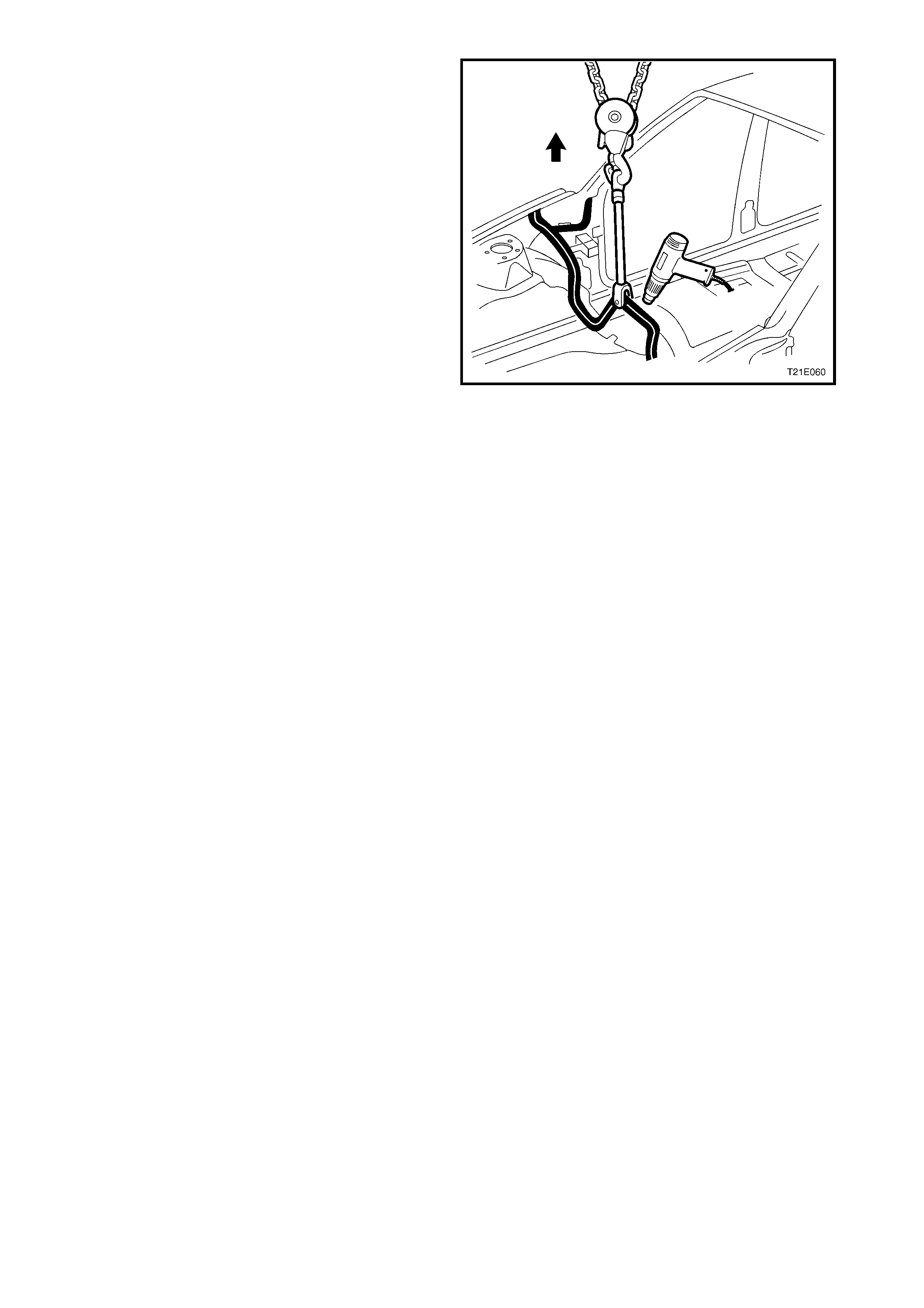

18. Drill a hole in the flange above the transmission

tunnel, and attach a chain block and a clevis.

19. Apply and maintain a light tension to the rem aining

part of the dash panel assembly .

20. Either cut the adhesive with a hot knife or heat the

adhesive us ing a heat gun and pull the panel fr om

the glue track.

NOTE: This may be required in several places.

21. Clean the excess adhesive from the glue track

using a hot knife or a heat gun and tool.

CAUTION: To avoid fire, do not attempt to burn

the remaining adhesive from the glue track using

an oxy / acetylene torch.

Figure 1E-13

2.2 INSTALLATION PREPARATION

NOTE: Do not attempt to install a fully built-up cockpit module assembly.

SURFACE PREPARATION

Clean any remaining adhesive from the glue track using a hot knife or heat gun.

The vehicle should be painted before installation of the dash panel assembly. Before painting the vehicle, apply

masking tape to prevent paint entering the glue track.

The adhesive will not adhere to paint, overspray, oil, grease, etc. The glue track must be free of dirt, dust, grease,

oil and paint or overspray.

W ipe the glue track with a suitable cleaning agent such as Prepsol or equivalent, then clean any residue from the

area with a clean, dry, lint free cloth.

Temporarily install the new dash panel assembly prior to mixing the adhesive to check for correct fit. Rectify any

faults found then remove the panel from the vehicle.

NOTE: Before mixing the adhesive, it is advisable to have the SAE 677 barrel gun & follower plate. Refer to the

latest Spare Parts Information for details.

CHECKLIST

Before mixing the adhesive and installing the dash panel assembly, the following items should be checked:

• Familiarise yourself with the precautions in 1.1 GENERAL PRECAUTIONS.

• Ensure the adhesive being used is the recommended material.

• The vehicle surface should be finished and the paint fully dry before installation.

• Clean any overspray, grease, oil, dir t, etc. f rom the glue trac k using an agent suc h as Pr epsol or equivalent and

a clean, dry, lint-free cloth.

• Test fit the module panel in the glue track BEFORE MIXING THE ADHESIVE.

• Is the adhesive applicator gun clean and ready for use?

• Are the cockpit module bolts readily accessible?

MIXING ADHESIVE & CATALYST

IMPORTANT: This is a two-part, fast cur e adhes ive. Ensur e that the panel is ready for ins tallation bef or e m ixing the

adhesive. The working time is less than 20 minutes.

Part A : Adhesive compound, yellow in colour and supplied in a 1.4 kilogram container.

Part B: Catalyst, used to accelerate the cure time of the adhesive compound and is supplied in a 120 gram tube.

The contents of the Sealant Kit - Dash Panel is sufficient to install the dash panel assembly in a vehicle.

CAUTION: The vapour from the adhesive may cause breathing difficulties, use only in a well ventilated

area. In case of eye contact, flush immediately with clean water. Refer to Safety Precautions in

1.1 GENERAL PRECAUTIONS.

COMBUSTIBLE – keep away from spark and flame.

1. Remove the lid from the adhesive compound container.

2. Rem ove the cap from the catalyst and pierce the end of the tube, then squeeze the entire contents of the tube

into the adhesive compound container.

3. Hold the container securely, and m ix the catalyst into the adhesive using a paint mixer or a flat clean wooden

utensil.

4. Continue to mix until the adhesive is a consistent grey colour without any streaks.

5. Place the follower plate supplied with the applicator gun into the adhesive container.

6. Remove the front end cap and disposable nozzle from the applicator gun.

7. Cut the tip from the nozzle.

8. Place the applicator gun front end over the hole in the follower plate.

NOTE: The eas iest m ethod of drawing the adhesive into the gun is to proceed slowly, allow the downward pressure

on the plate and the suction of the gun to draw the compound.

9. Sim ultaneously push down on the gun and plate with max imum pressure, pres s the gun’s release plate inward

and slowly pull the T-bar (piston) outward. This procedure will slowly suck the mixed adhesive into the

applicator gun.

10. Wipe any excess adhesive f r om the applicator gun, sc r ew the end cap onto the applicator gun and then reinstall

the nozzle.

11. Proceed immediately with installing the panel.

IMPORTANT: After mixing the silicone adhesive, installation of the cockpit module panel should be completed

within 15 – 20 minutes. Under normal conditions, the adhesive will begin to cure in about 25 – 30 minutes. After

installation, the dash panel assembly or vehicle should not be moved or disturbed until the adhesive is fully cured

(about 3 hours).

2.3 REINSTALL

DASH PANEL ASSEMBLY

NOTE: A replacement dash panel assembly may

require a hole to be drilled and a throttle cable bush

and plate assembly to be welded in place to allow

throttle cable installation.

1. If fitting a replacement dash panel:

a. Carefully drill a 3 mm pilot hole through the

centre of the dimple (1). Drill out the hole to

23 mm, refer to Figure 1E-14

b. Remove any burrs and refinish as required.

Figure 1E-14

c. Ensure the throttle cable bush and plate

assembly (1) is centred over the hole and

carefully MIG weld the bush and plate

assembly along the three edges onto the dash

panel.

Figure 1E-15

NOTE: Do not attempt to install a fully built-up cockpit

module assembly.

2. Ensure any remaining adhesive is cleaned off the

glue track using a hot knife or heat gun.

3. Check each item in 2.2 INSTALLATION

PREPARATION – CHECKLIST.

4. Mix the silicone adhesive and fill the applicator

gun as described in 2.2 INSTALLATION

PREPARATION – MIXING ADHESIVE &

CATALYST.

NOTE: Installation is best performed with the aid of

two people.

5. Begin filling the glue track from the lowest points

to prevent air bubbles forming in the adhesive.

Completely fill the channel in a continuous bead.

6. Apply a patch of adhesive approximately 50mm

diameter to the base or the windshield pillar.

7. Hold the dash panel assembly in position slightly

above the glue track.

8. Have an assistant pass the main wiring harness

(1) through the opening in the dash panel.

9. Install the dash panel outer opening cover (2) onto

the dash panel assembly.

10. Affix the dash panel side insulator (3) over the

cover and fold over the back of the panel as

shown (4).

Figure 1E-16

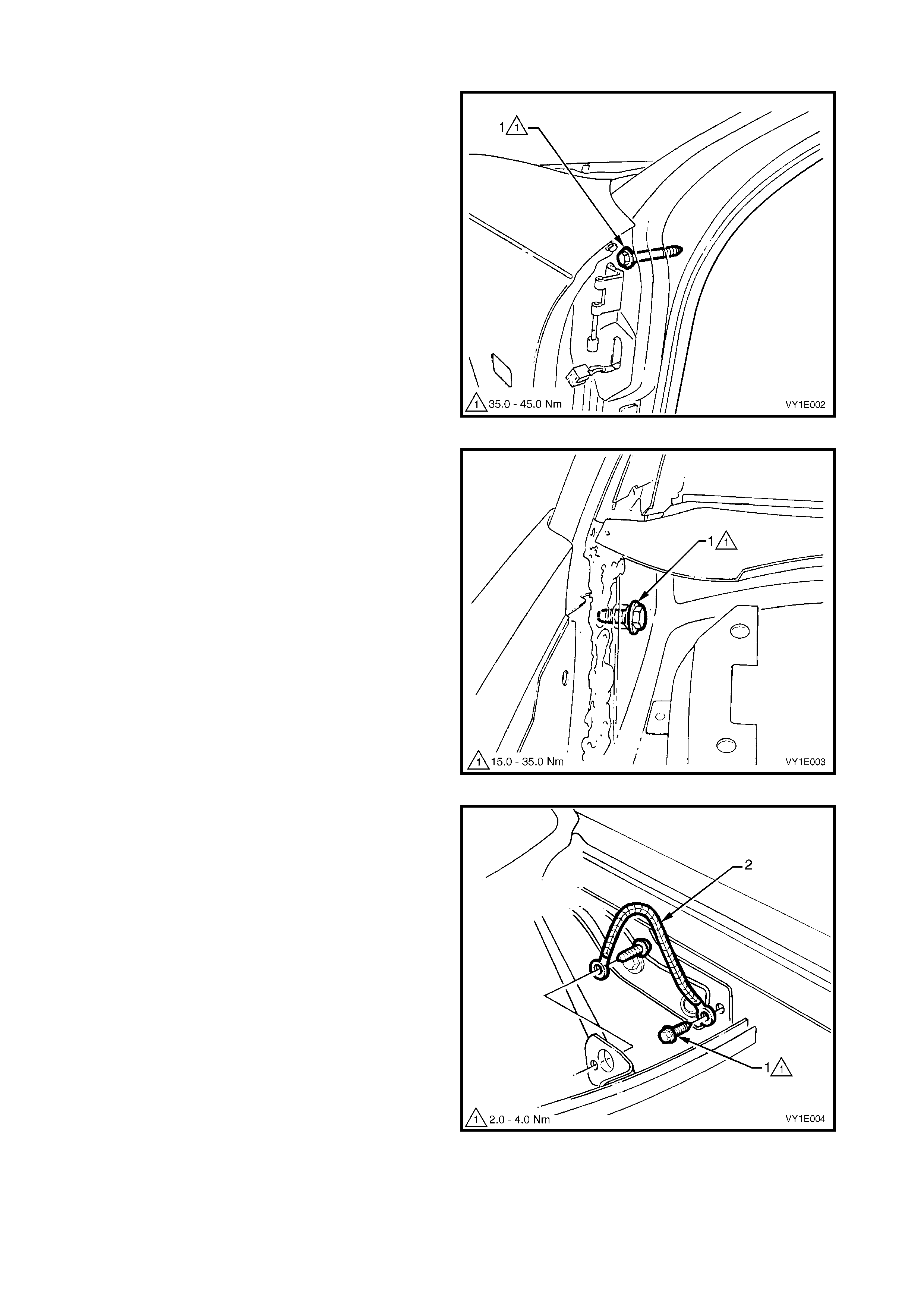

11. Lower the dash panel assembly (1), ensuring the

flange seats correctly in the glue track.

12. Push the panel firmly into the glue track channel

until mounting bolt holes align. Check to ensure

that the section around the main wiring harness

hole is correctly installed.

13. Install two new dash panel bolts through the hinge

pillar and two new screws within the plenum

chamber and hand tighten.

14. Recheck the flanges are correctly seated.

15. Tighten the bolts and screws to the specified

torque.

Figure 1E-17

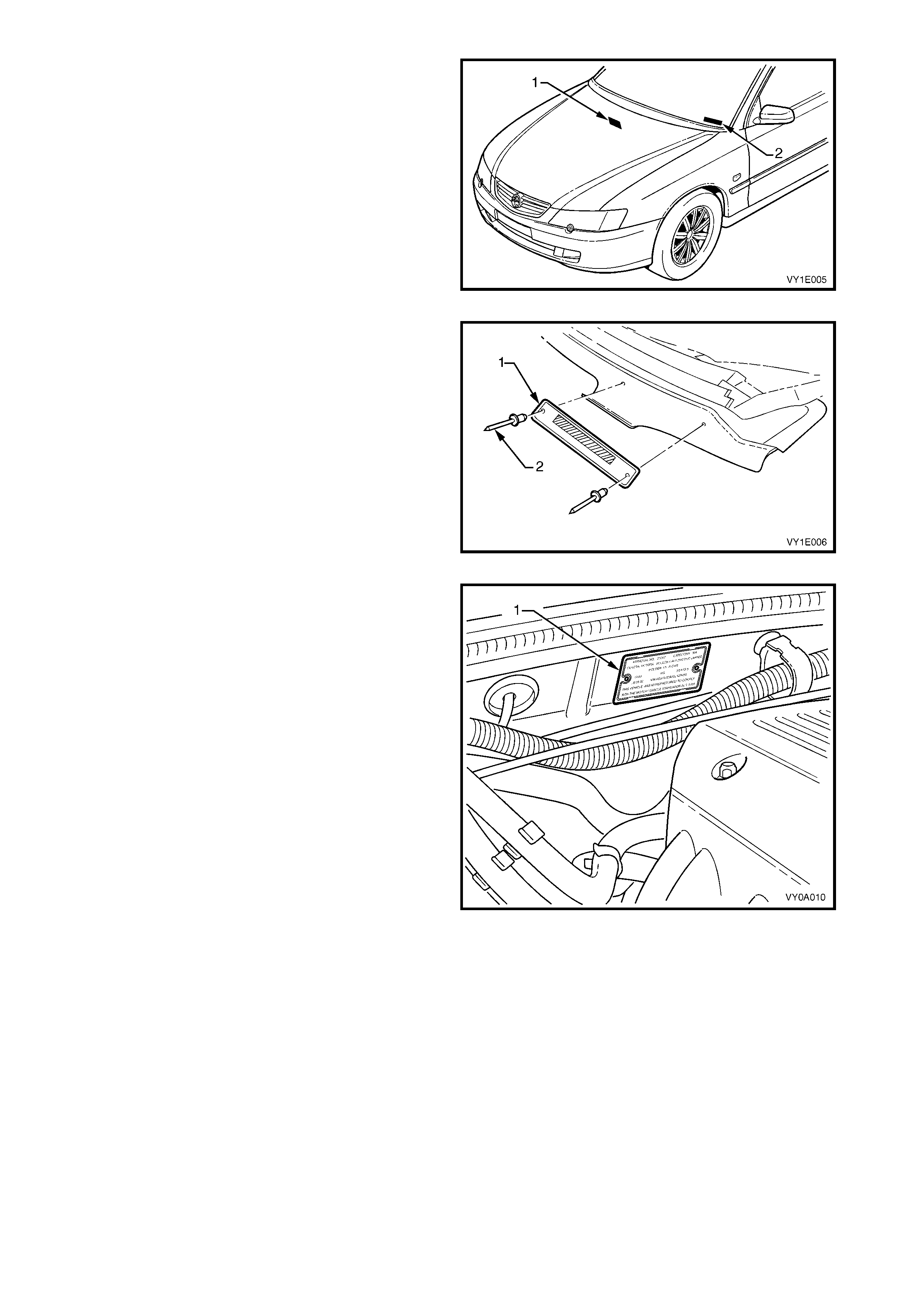

16. Wipe any excess adhesive from the plenum drain

hole (1) each side and the glue track areas (2).

17. Immediately following dash panel assembly

installation, clean any adhesive from the applicator

gun and follower plate.

18. Leave adhesive to cure for a minimum of three

hours.

Figure 1E-18

COMPONENTS

Installation of the cockpit module components is the reverse of the removal, noting the following.

1. Ensure all the rubber grommets and insulation materials are installed onto the dash panel assembly.

2. Ensure all fasteners are tightened to the correct torque specification.

3. Ensure the heater & A/C module assembly drain tube is correctly installed.

4. Ensure that all wiring harnesses are correctly routed and retained correctly, refer to Section 12O FUSES &

WIRING HARNESS.

5. Ensure the stop lamp switch and cruise control release switches are adjusted correctly, refer to Sections 12B

LIGHTING SYSTEM and 12E CRUISE CONTROL.

6. Ensure the throttle and cruise control cables are correctly routed and adjusted.

7. On battery reconnection, check the SIR warning icon for correct operation, refer to Section 12M, OCCUPANT

PROTECTION SYSTEM and reprogram the audio system security PIN, refer to Section 12D

ENTERTAINMENT SYSTEM.

DASH PANEL SCREW (PLENUM SIDE)

TORQUE SPECIFICATION 15.0 – 35.0 Nm

DASH PANEL BOLT (HINGE PILLAR SIDE)

TORQUE SPECIFICATION 35.0 – 45.0 Nm

2.4 DASH PANEL ASSEMBLY REPAIR

PANEL REPAIR

NOTE: The dash panel assembly can only be levered against itself. Levering or pulling from other panels or

external objects may cause the dash panel assembly to separate from the adhesive and glue track.

If the dash panel as s embly is separated from the glue track for les s than 300 mm , due to damage of either the dash

panel assembly or surrounding panels and the dash panel assembly is serviceable, it is permissible to repair the

panel without removal.

1. Disassemble the required components to allow access, refer to 2.1 DASH PANEL ASSEMBLY.

2. Cut the required section of adhesive from the glue track using a hot knife.

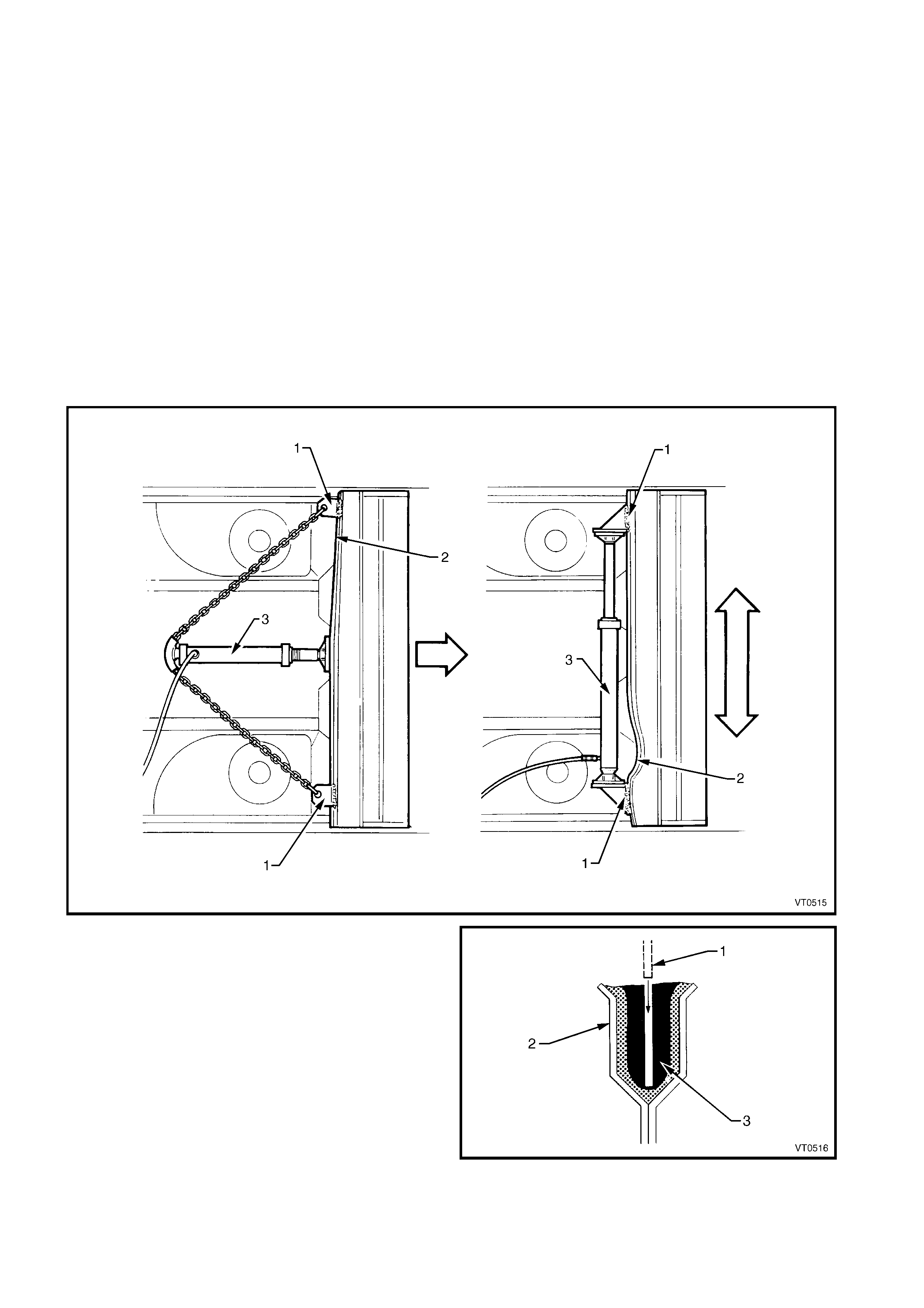

3. Repair the damage to the surrounding panels as required.

4. Secure two clamps or brackets (1) to the dash panel assembly to act as levering points to straighten the

damaged area (2), refer to Figure 1E-17.

NOTE: Depending on the damage, it may be more appropriate to pull the area instead of pushing it.

5. Install a suitable hydraulic ram (3) between the clamps.

6. Make the necessary repairs and adjustments to the module panel to ensure an accurate fit in the glue track.

7. W ith the dash panel assem bly (1) correctly seated

in the glue track (2), fill the glue track with the

approved adhesive (3). Follow the procedures as

required in 2.2 INSTALLATION PREPARATION

and 2.3 INSTALL - DASH PANEL ASSEMBLY.

8. Allow the adhesive at least three hours to cure

before performing any further work or painting the

vehicle.

Figure 1E-18

ADHESIVE REPAIR

Adhesive tears or splits of less than 300 mm in length

may be repaired using single pack silicone adhesive.

Repairing a tear or split longer than 300 mm in length

necessitates removal of the dash panel assembly, as

described pr evious ly, with complete replacement of the

silicone adhesive.

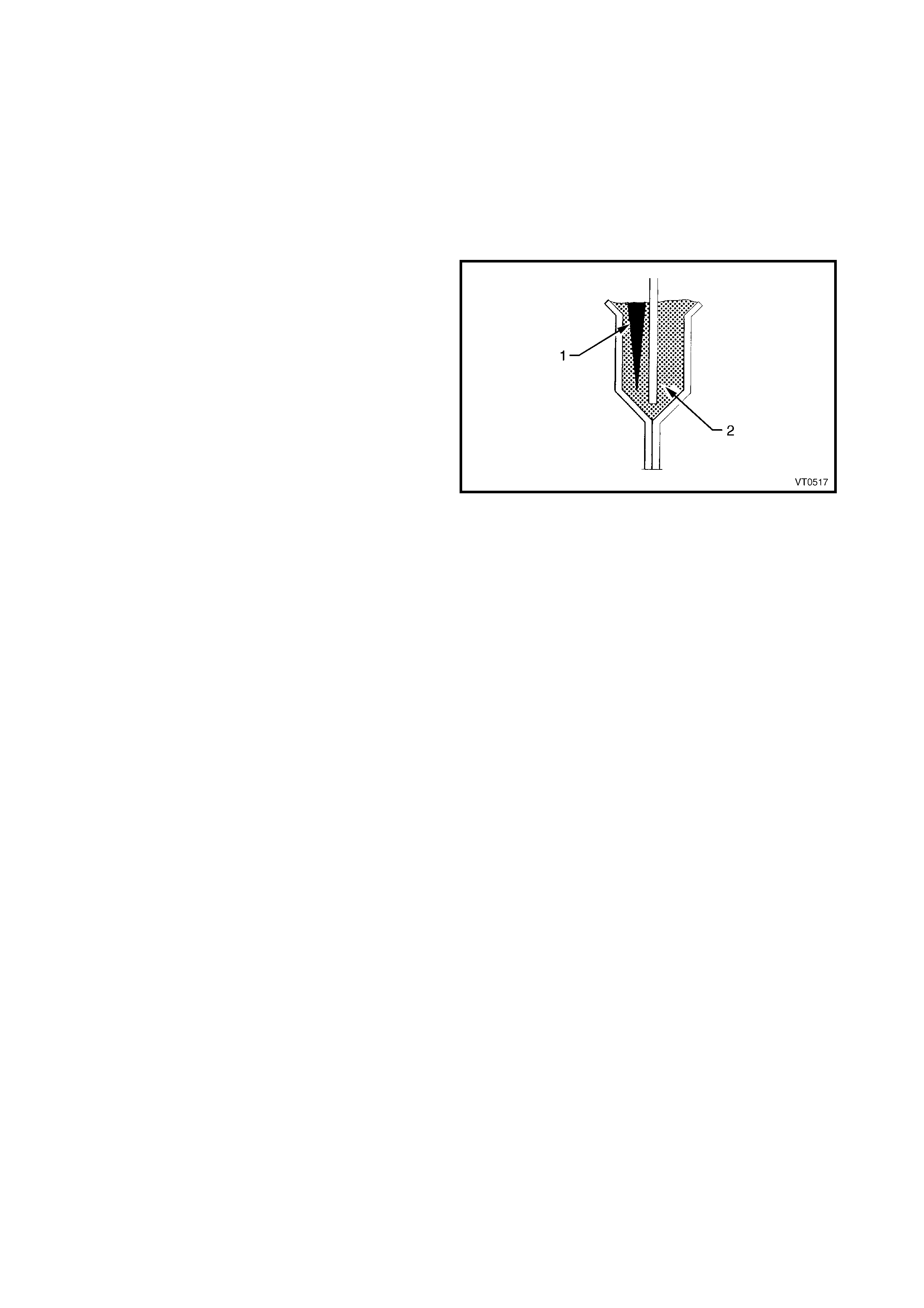

1. Wipe the surrounding area with a cleaning agent

such as Prepsol, then remove any residue from

the area with a dry, lint free cloth.

2. Cut a deep “V” (1) into the adhesive (2),

completely cutting out the torn or split section.

NOTE: The area must be completely clean; free of dirt,

oil, grease, etc. to obtain satisfactory adhesion of the

silicone adhesive.

3. If necessary, wipe the metal area of the glue track

with mineral spir its, then wipe the r esidue from the

surface using clean, dry, lint free cloth.

4. Fill the void with silicone adhesive, ensuring no air

bubbles remain trapped in the adhesive.

5. Smooth out the adhesive flush with adjacent area.

6. Clean up any excess before the adhesive cures,

using mineral spirits.

7. Allow the adhes ive to cure ( up to 24 hours), befor e

performing any further work on the area.

Figure 1E-19

3. TORQUE WRENCH SPECIFICATIONS

Dash panel screw (plenum side) ....................................................................15.0 – 35.0 Nm

Dash panel bolt (hinge pillar side)...................................................................35.0 – 65.0 Nm

Body earth strap screws .................................................................................2.0 – 4.0 Nm

4. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASIFICATION

SAE 677

BARREL GUN &

FOLLOWER

PLATE

Used to apply dash panel assembly

two-part silicone adhesive.

Previously available, refer parts

catalogue

Desirable