SECTION 1F1 - SUNROOF

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

PRE-PROGRAMMED FUNCTIONS

OPTIONAL PROGRAMMABLE FUNCTION

INTERIOR TRIM

POWER HARNESS

SUNROOF CONTROL UNIT (SCU)

SUNROOF COMPONENTS

2. SERVICE OPERATIONS

2.1 DRIVE MOTOR

REMOVE

REINSTALL

2.2 DRIVE GEAR

REMOVE

REINSTALL

2.3 SUNROOF CONTROL UNIT (SCU)

REMOVE

REINSTALL

2.4 CALIBRATING THE SUNROOF

CONTROL UNIT

2.5 GLASS PANEL

REMOVE

REINSTALL AND ADJUST

2.6 ADJUSTMENT BRACKETS

REMOVE

REINSTALL

2.7 EXTERIOR COVERS

REMOVE

REINSTALL

2.8 RUBBER SEAL

REMOVE

REINSTALL

ADJUSTMENT

2.9 WIND DEFLECTOR

REMOVE

REINSTALL

2.10 DRAIN CHANNEL

REMOVE

REINSTALL

2.11 SUNSHADE

REMOVE

REINSTALL

2.12 DRIVE CABLES

REMOVE

REINSTALL

2.13 TIMING OF DRIVE CABLES

2.14 RETRACTION MECHANISM

REMOVE

REINSTALL

2.15 GUIDE RAIL MECHANISM

REMOVE

REINSTALL

2.16 BLOCKING CATCH

REMOVE

REINSTALL

2.17 SUNROOF POWER HARNESS

REMOVE

REINSTALL

2.18 SUNROOF HARNESS

REMOVE

REINSTALL

2.19 SUNROOF CONTROL HARNESS

REMOVE

REINSTALL

2.20 SUNROOF SWITCH

REMOVE

REINSTALL

2.21 REAR DRAIN TUBE – SEDAN

REMOVE

REINSTALL

2.22 REAR DRAIN TUBE – WAGON

REMOVE

REINSTALL

2.23 FRONT DRAIN TUBE

REMOVE

REINSTALL

3. DIAGNOSIS

3.1 FAULT DIAGNOSIS CHARTS

INTRODUCTION

PREREQUISITES

FUNCTIONAL TEST

ELECTRICAL TEST

SUNROOF SWITCH AND SUNROOF

CONTROL HARNESS TEST

REPAIR ADVICE FOR MECHANICAL

FAILURES

REPAIR ADVICE FOR ELECTRICAL

FAILURES

REPAIR ADVICE FOR RATTLING NOISES

REPAIR ADVICE FOR WIND NOISES

REPAIR ADVICE FOR WATER LEAKS

3.2 WIRING DIAGRAM – SUNROOF

3.3 CONNECTOR DIAGRAMS – SUNROOF

4. TORQUE WRENCH SPECIFICATIONS

5. SPECIAL TOOLS

6.

1. GENERAL DESCRIPTION

This section describes the service procedures required for the Holden By Design (HBD) sunroof installed in MY

2003 VY Series Sedans and Wagons.

The HBD s unroof c an be identif ied by the presence of a rubber tr im ring located ar ound the sunr oof and attac hed to

the roof panel.

The HBD sunroof is an electronically operated, two-way design allowing either tilting or sliding actions. It features

tinted glass with a separate internal s unshade and a f ront edge wind deflector . T he sunroof is operated via a s witch

panel located in the roof console, for ward of the sunroof opening. The Sunroof Control Unit (SCU) provides several

pre-programmed functions and the option to program an additional function.

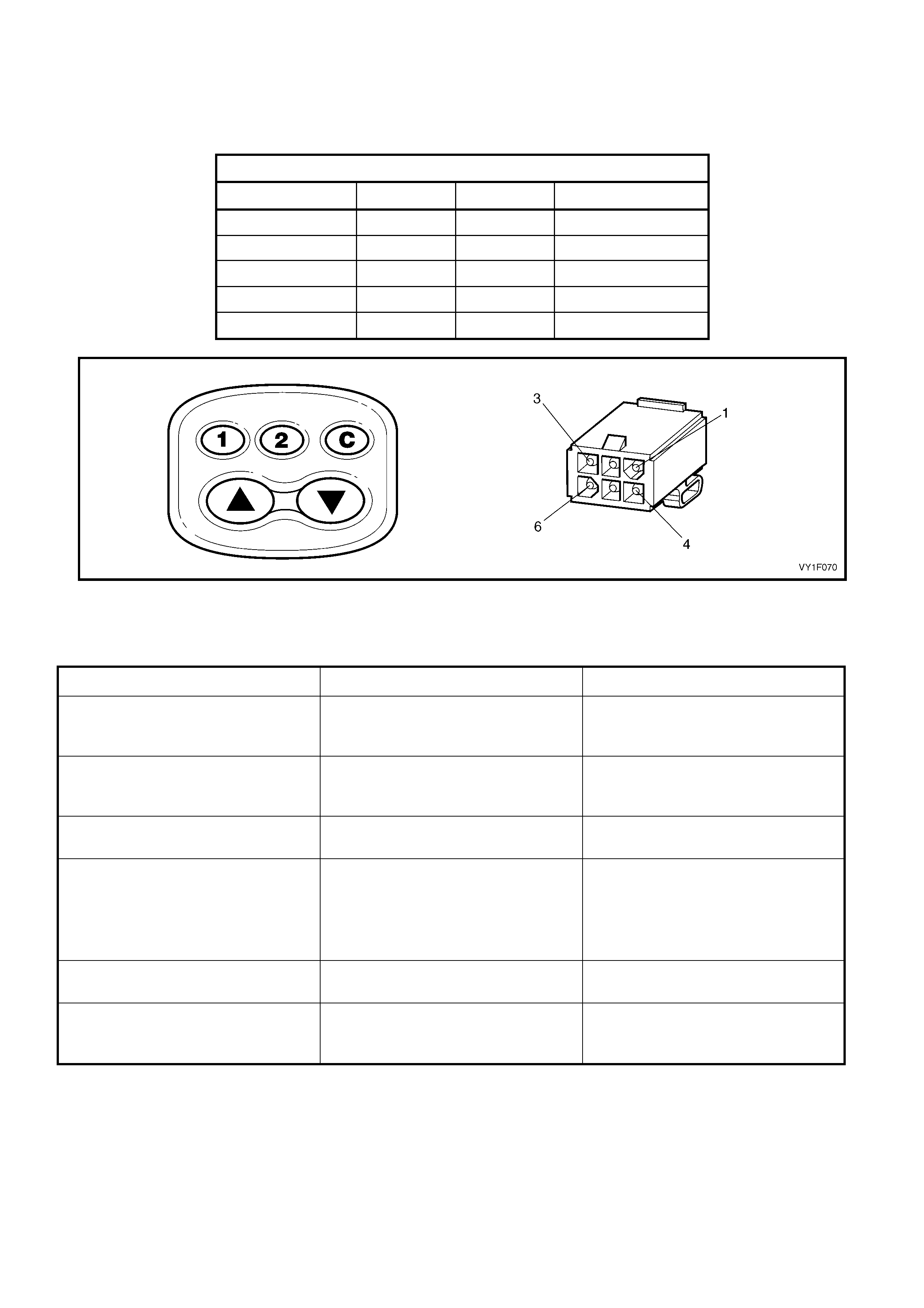

PRE-PROGRAMMED FUNCTIONS

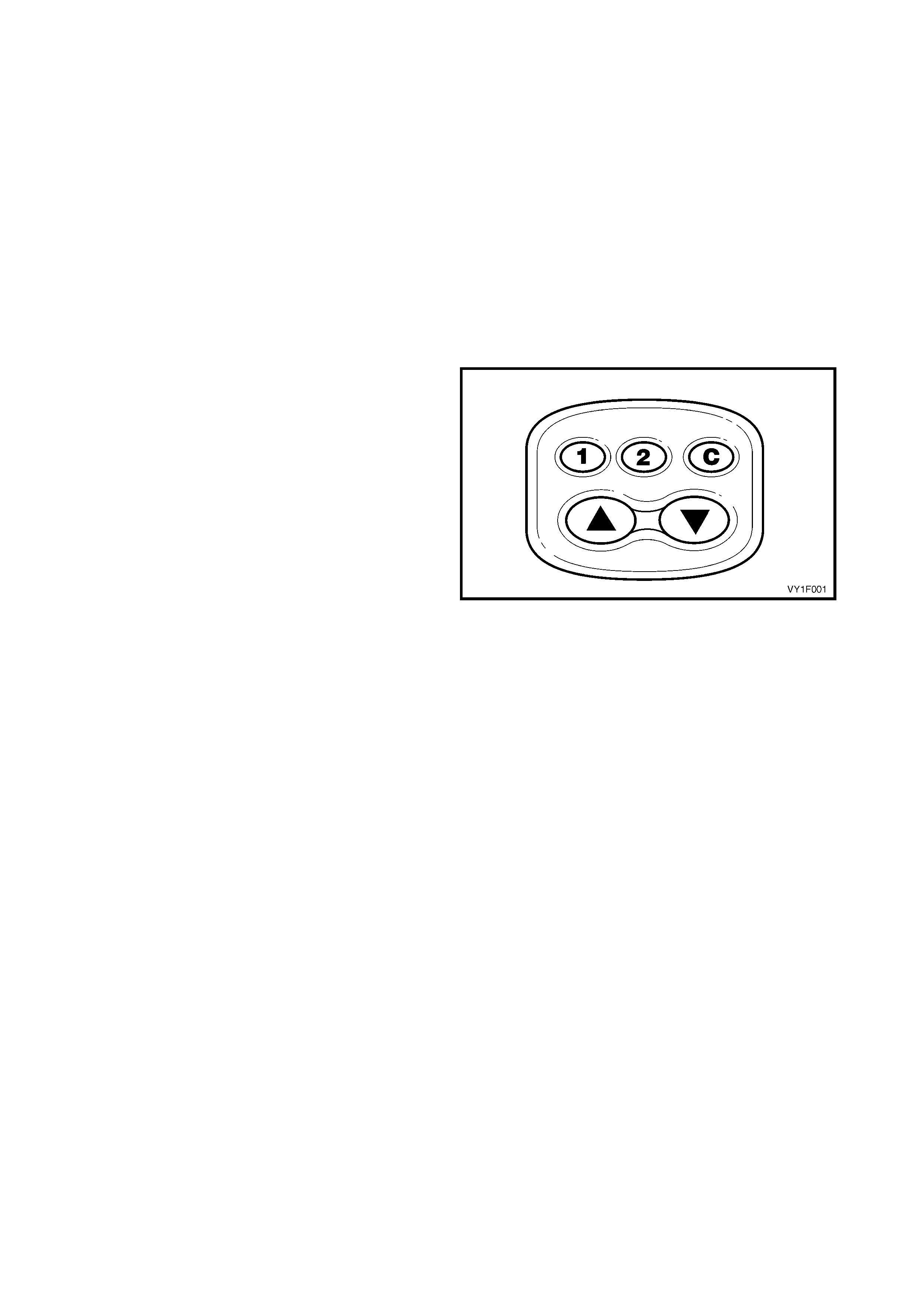

NOTE: If only the sunroof switch button ! and button

" are operating, the sunroof switch has to be reset,

refer to 2.20 SUNROOF SWITCH.

SOFT TOUCH

With the ignition switch ON, briefly pressing the

sunroof button ! will open the sunroof to the

maximum slide position. Briefly pressing the sunroof

button " will open the sunroof to the maximum tilt

position. Movement of the sunroof can be stopped at

any time by briefly pressing the button ! or " again.

CLOSING THE SUNROOF

Briefly pressing the button C will cause the sunroof to

close from any open position.

VARIABLE TILT POSITION

NOTE: Sunroofs installed until June 2003 can be

opened to four tilt positions, sunroofs installed after

June 2003 open to three tilt positions only.

The sunroof can be lowered from maximum tilt

opening in three/four intermediate tilt positions. Press

and hold the sunroof button ! until the glass panel

reaches the next tilt position. Alternatively hold the

button pressed and then r elease it at the desired glass

panel tilt position.

Figure 1F-1

JAMMING PROTECTION (SAFETY FEATURE)

W hen c losing the sunroof using Soft T ouch or Auto-C lose, the sunroof will automatically re-open if it enc ounters

an obstacle and then try to close again. This cycle will continue until the obstacle is removed.

AUTO-CLOSE FUNCTION

Three seconds after the ignition has been turned OFF, the sunroof will close automatically. To override this

action, br iefly pres s the sunroof button ! or " when the sunroof has reached the desir ed position or during the

three second interval to maintain the sunroof position, refer to Figure 1F-1.

The sunroof can be closed when the ignition is OFF but it cannot be opened.

ONE-WAY CLOSING

This automatic f eatur e always closes the sunroof fr om above lowering the glass panel in the clos e position, even

when closed from a slide position, assuring correct positioning of the glass panel.

OPTIONAL PROGRAMMABLE FUNCTION

COMFORT POSITION

This feature allows the sunroof to be opened to two preset positions in the sliding range.

PROGRAMMING THE COMFORT POSITION

To program the two preset positions:

1. Position the sunroof in the desired location.

2. Press and hold button 1 until a beep is heard (approx. 3 seconds).

3. Position the sunroof in the second desired location.

4. Press and hold button 2 until a beep is heard (approx. 3 seconds).

Refer to Figure 1F-1.

To select either preset position, press button 1 or 2. (Pressing either button again will open the sunroof fully).

INTERIOR TRIM

SUNSHADE

The sunshade c an be opened and closed manually when the sunroof is closed but is c ontrolled autom atically in

the following conditions:

• Opening the sunroof in a tilt position, automatically opens the sunshade to a vent position. The sunshade

can then be fully opened manually.

• When the sunroof is opened in slide m ode, the s unshade opens along with it. The s unshade can be opened

further manually.

The sunshade can only be closed fully when the sunroof is closed, and can only be closed manually.

WIND DEFLECTOR

The wind deflector is designed to reduce high frequency noise. The wind deflector is automatically raised when

the sunroof is opened in slide mode. It retracts when the sunroof is closed.

GLASS PANEL

The sunroof glass panel is heat and UV resistant. Clean the glass panel using mild, non-scratching detergent

and a chamois.

RUBBER SEAL

Two types of rubber seal can be fitted to the glass panel assembly. They both have the same function despite

the physical and cross-section differences.

The first r ubber seal type can be identified by its outer surfac e of velvet-like appear ance. The outer edge of the

seal body is open- ended to allow adjus tm ents, with foam st rips, that m ay be necessary to ensure proper s ealing

when the glass panel is in the closed position.

The second rubber seal type is an optional design to the first type and can be identified by its outer surface of

smooth appearance. The outer section of the seal body is hollow with the external surface covered by an anti-

friction coating. No adjustment is necessary for this rubber seal type.

POWER HARNESS

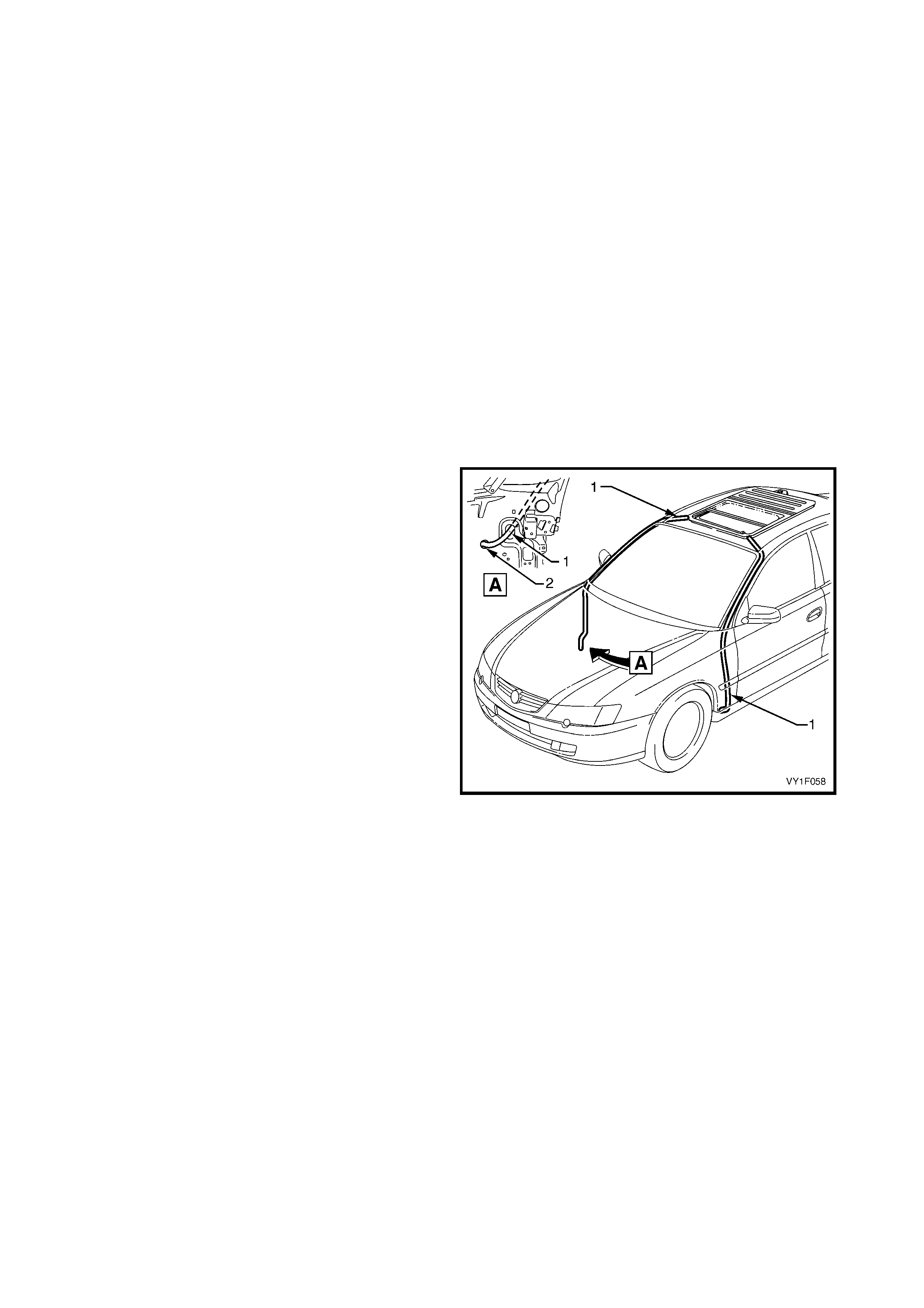

CONFIGURATION ONE

The configuration one power harness is connected to sunroofs installed on all wagon vehicles, and until March

2003 on sedan vehicles.

The configuration one power harness is routed around the sunroof frame, along the hinge pillar, and is

connected to the passenger compartment fuse and relay panel assembly.

CONFIGURATION TWO

The configuration two power harness is connected to sunroofs installed after March 2003, on sedan vehicles.

The configuration two power harness is routed along the C pillar and is connected to the body harness, behind

the quarter inner rear side carpet in the rear compartment.

SUNROOF CONTROL UNIT (SCU)

The SCU is located at the rear of the sunr oof fram e and controls a drive m otor to activate the m ovement of the

glass panel.

The SCU detec ts the position of the glass panel by using an internal position counter. This counter is inc reased

and decreased every time the SCU controls the drive motor.

The c ounter mus t first be s et (calibrated) to detec t the end position of the glas s panel, in full tilt and full slide, by

running to a mechanical block.

If the SCU determines that the glas s panel is in the inc orr ec t pos ition, as def ined by the internal position counter,

it responds by entering the non-calibrated state.

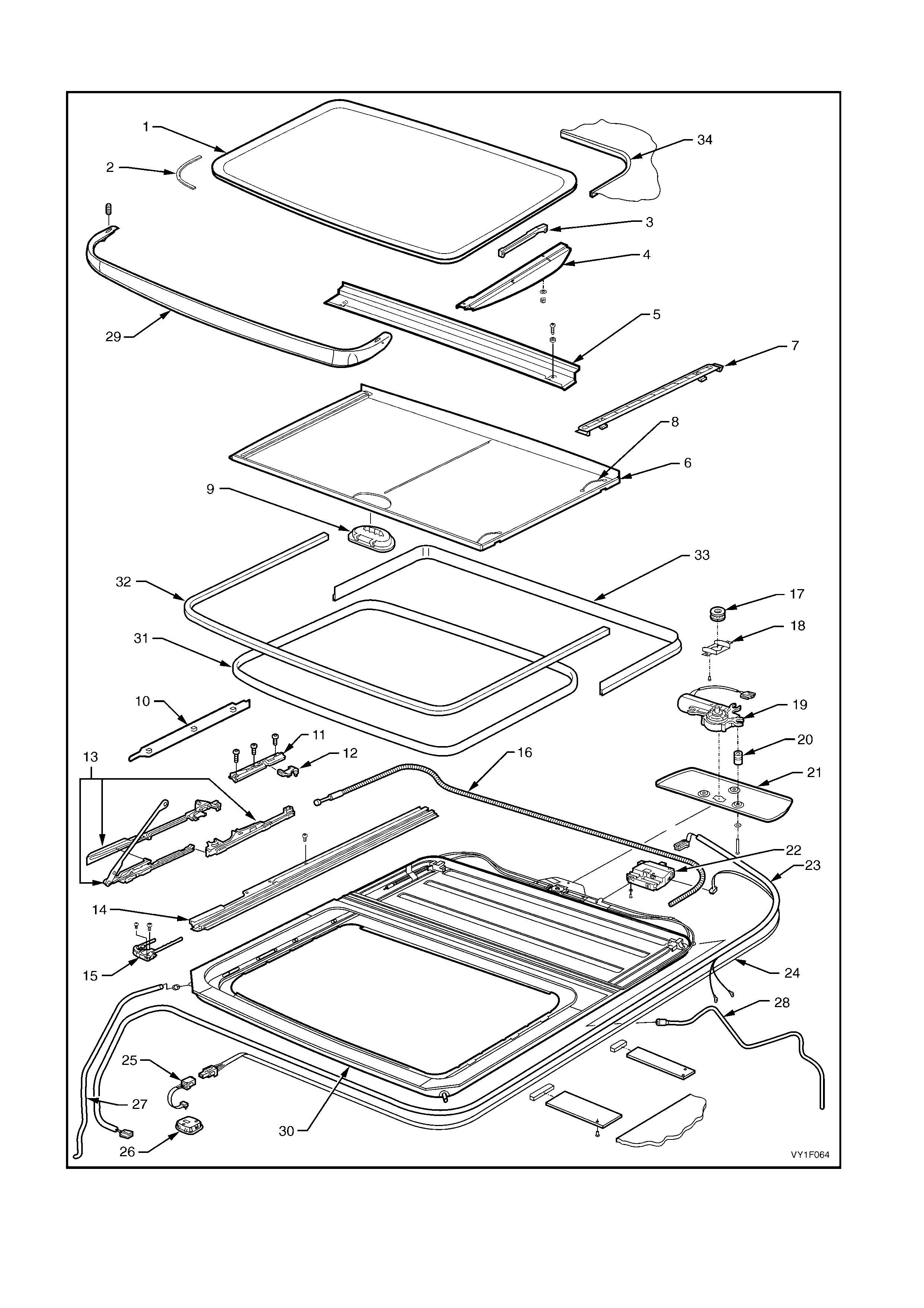

SUNROOF COMPONENTS

Figure 1F-2

Legend

1. Glass Panel 13. Guide Rail Mechanism 25. Sunroof Control Harness

2. Rubber Seal 14. Guide Rail 26. Sunroof Switch

3. Adjustment Bracket 15. Retraction Mechanism 27. Front Drain Tube

4. Exterior Cover 16. Drive Cable 28. Rear Drain Tube

5. Drain Channel 17. Drive Gear 29. Wind Deflector

6. Sunshade 18. Drive Gear Box Retainer 30. Sunroof Assembly

7. Sunshade Guide 19. Drive Motor 31. Opening Seal

8. Sunshade Spring 20. Spacer 32. Front Roof Seal

9. Sunshade Handle 21. Drive Cover 33. Rear Roof Seal

10. Mechanism Cover 22. Sunroof Control Unit (SCU) 34. Trim Ring

11. Locator 23. Sunroof Power Harness

12. Blocking Catch 24. Sunroof Harness

2. SERVICE OPERATIONS

The following service operations detail the service procedures that can be performed by the general service

technician with the sunroof fitted to the vehicle.

The proc edure for the r emoval and ins tallation of the sunroof assembly has been deliber ately om itted due to the

sk ills and special tools required, which would be beyond the s cope of the general r epair technician. The sunr oof

assem bly is chemically bonded to the vehicle’s roof panel and any attem pt to remove it m ay c ause damage the

sunroof and / or the roof panel.

NOTE: W hen a sunroof is fitted, a new headlining is created using pieces of the original headlining and a new

piece of cloth.

The headlining is then installed with adhesive. Removal may damage the headlining and extreme care is

required.

2.1 DRIVE MOTOR

LT Section No. -

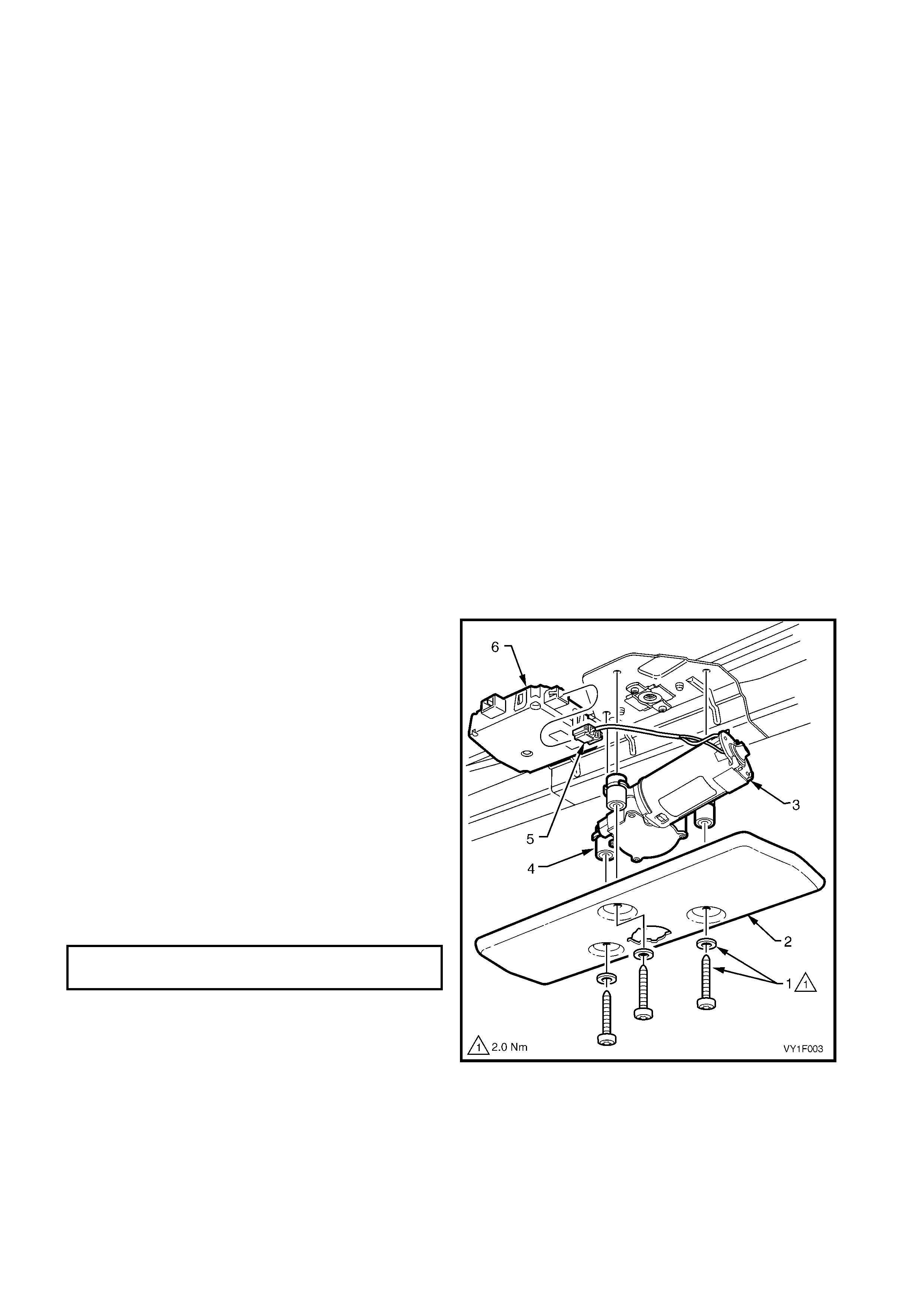

REMOVE

IMPORTANT: Take extreme care when removing the

headlining which has been modified and installed using

adhesive.

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the headlining to gain access to the drive

motor cover. Refer to Section 1A8,

• 2.12 HEADLINING ASSEMBLY – SEDA N

• 3.15 HEADLINING ASSEMBLY – WAGON

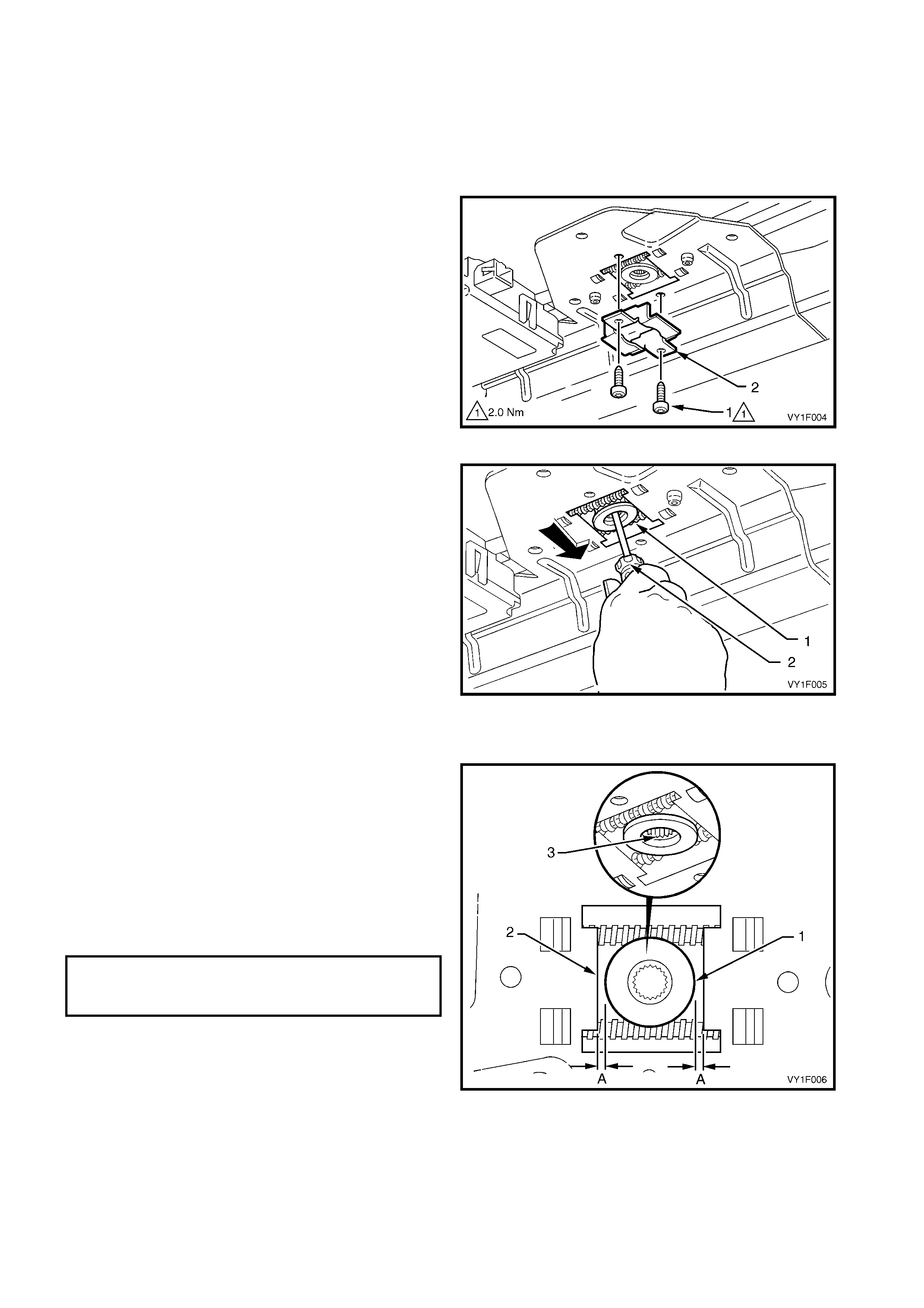

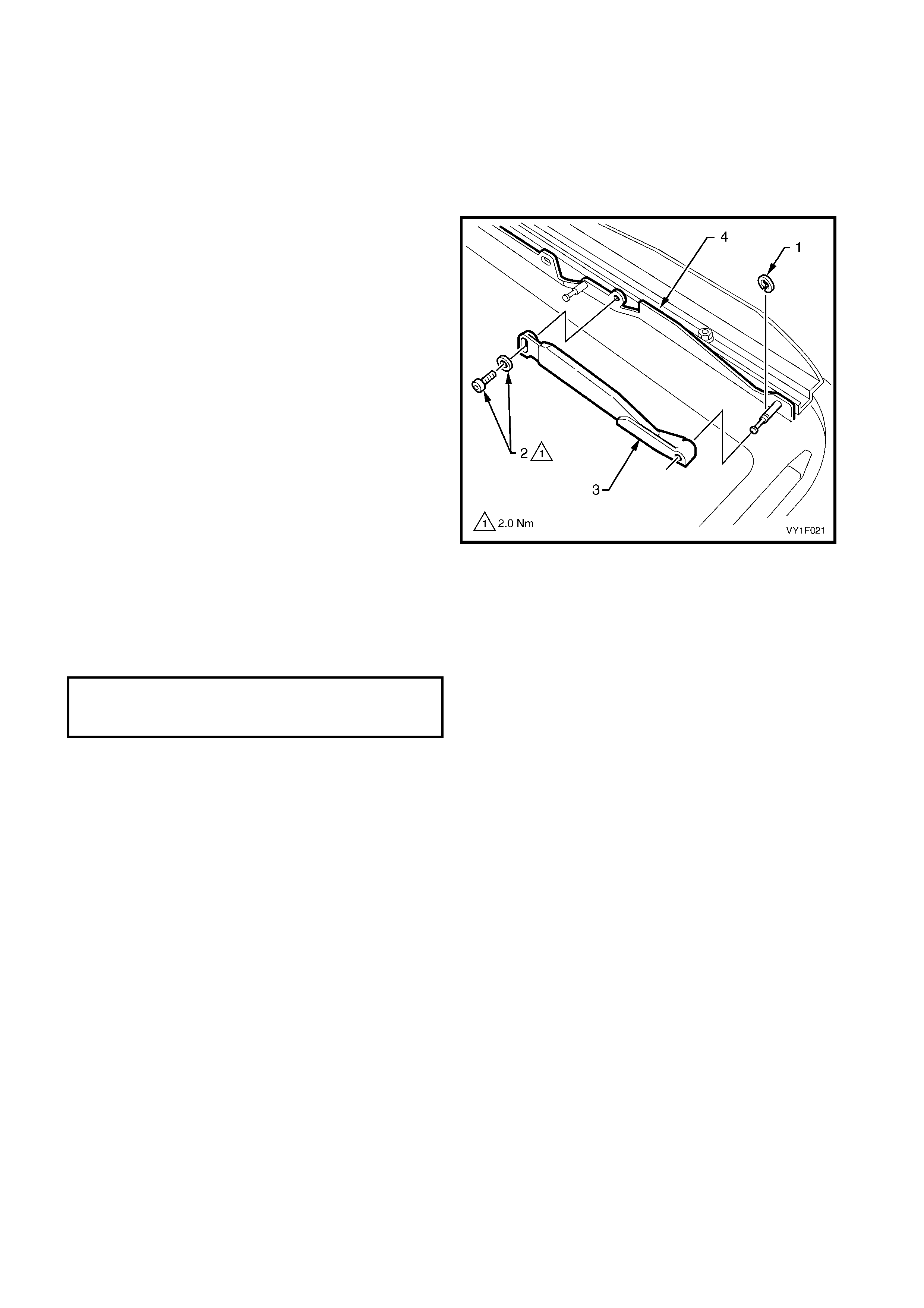

3. Remove the three Torx screws and washers (1)

securing the drive motor cover (2). Carefully lower

the drive motor cover with the drive motor (3) and

spacers (4).

4. Disconnect the drive motor connector (5) from the

sunroof control unit (6).

REINSTALL

Installation of the drive motor is the reverse of the

removal procedure noting the following:

1. Chec k the drive m otor f or correc t operation in both

directions, refer to 3.1 FAULT DIAGNOSIS

CHARTS.

2. Ensure that the three spacer s are f itted to the drive

motor before installing it.

3. Tighten all fasteners to the specified torque.

Figure 1F-3

DRIVE MOTOR COVER TORX SCREWS

TORQUE SPECIFICATION 2.0 Nm

2.2 DRIVE GEAR

LT Section No. -

REMOVE

1. Remove the drive motor cover and the drive

motor, refer to 2.1 DRIVE MOTOR.

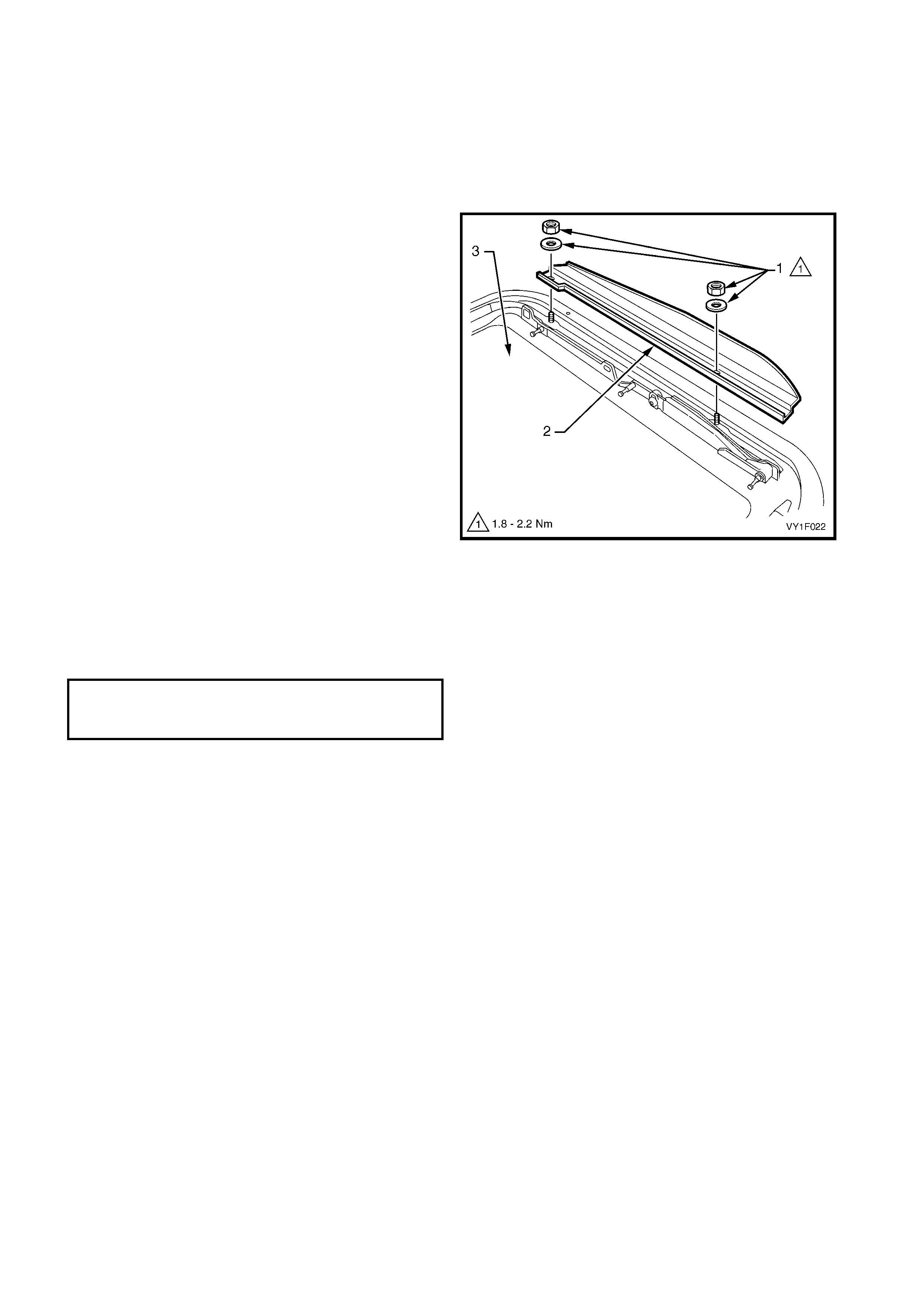

2. Remove the two Torx screws (1) retaining the

drive gear box retainer (2).

3. Remove the drive gear box retainer.

Figure 1F-4

4. Remove the gear wheel (1) by inserting a

screwdriver (2) and pushing forward to allow the

drive gear to drop down.

Figure 1F-5

REINSTALL

Installation of the drive gear is the reverse of the

removal procedure noting the following:

1. Install the drive gear (1), ensur ing that it is centred

(A) in the opening in the drive motor bracket (2).

Note that the core of the centre of the gear has

splines (3). The splines do not extend completely

to one side of the drive gear inner core. This side

faces downward when fitted.

2. Tighten all fasteners to the specified torque.

Figure 1F-6

DRIVE GEAR BOX

RETAINER TORX SCREWS

TORQUE SPECIFICATION 2.0 Nm

2.3 SUNROOF CONTROL UNIT (SCU)

LT Section No. -

REMOVE

1. Remove the drive motor cover and drive motor,

refer to 2.1 DRIVE MOTOR.

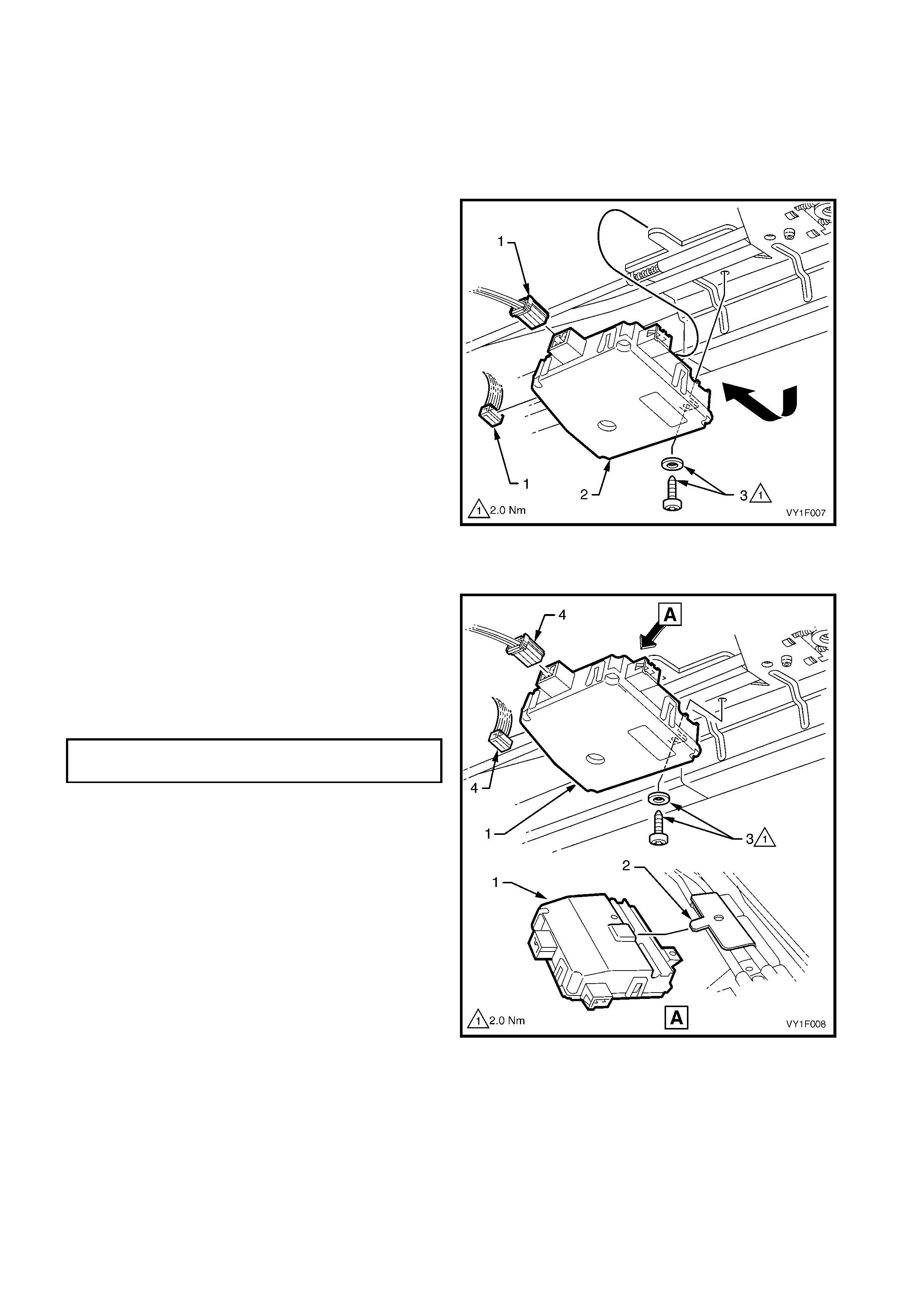

2. Disc onnect the wiring harness connectors (1) f rom

the SCU (2).

3. Remove the SCU retaining Torx screw and

washer (3), lower the front of the SCU and slide

the unit back to remove.

Figure 1F-7

REINSTALL

Installation of the SCU is the reverse of the removal

procedure noting the following:

1. Install the SCU (1) by lowering the unit at the front,

engaging the tang (2) on the cable plate with the

slot on the top of the SCU then slide forward into

position. Secure with Torx screw and washer (3).

2. Tighten the Torx screw to the specified torque.

3. Connect the wiring harness connectors (4).

4. Install the drive motor, refer to

2.1 DRIVE MOTOR.

NOTE: If the SCU installed is a new unit, it must be

calibrated. Refer to 2.4 CALIBRATING THE

SUNROOF CONTROL UNIT.

Figure 1F-8

SCU RETAINING TORX SCREW

TORQUE SPECIFICATION 2.0 Nm

2.4 CALIBRATING THE SUNROOF CONTROL UNIT

LT Section No. -

The SCU is calibrated when the sunroof is installed onto the vehicle, however it needs to be calibrated again if

the glass panel stops at an unexpected position related to the sunroof switch function, the end position cannot

be reached, or one or more buttons of the sunroof switch do not operate properly any more.

If the SCU fails and is replaced with a new unit, the first tim e the new SCU is connected to the power supply it

must be calibrated.

NOTE: The calibration sequence of the sunroof control unit (SCU) m ust be fully completed before the power is

removed from the SCU. Failing to do so causes the SCU to enter the non-calibrated state.

The SCU must be calibrated as follows:

1. Turn the ignition ON.

2. Open the sunroof to the m axim um tilt pos ition (until it reaches the m echanic al block) by pr essing the tilt soft

touch switch continuously, refer to 1. GENERAL DESCRIPTION.

3. The maximum tilt position is now stored in the SCU memory and all electrical functions are now available.

4. To com plete the calibration the sunroof m ust be fully opened in slide mode (until it reaches the mechanical

block) by pressing the slide soft touch switch, refer to 1. GENERAL DESCRIPTION.

5. Check that the sunroof operates correctly.

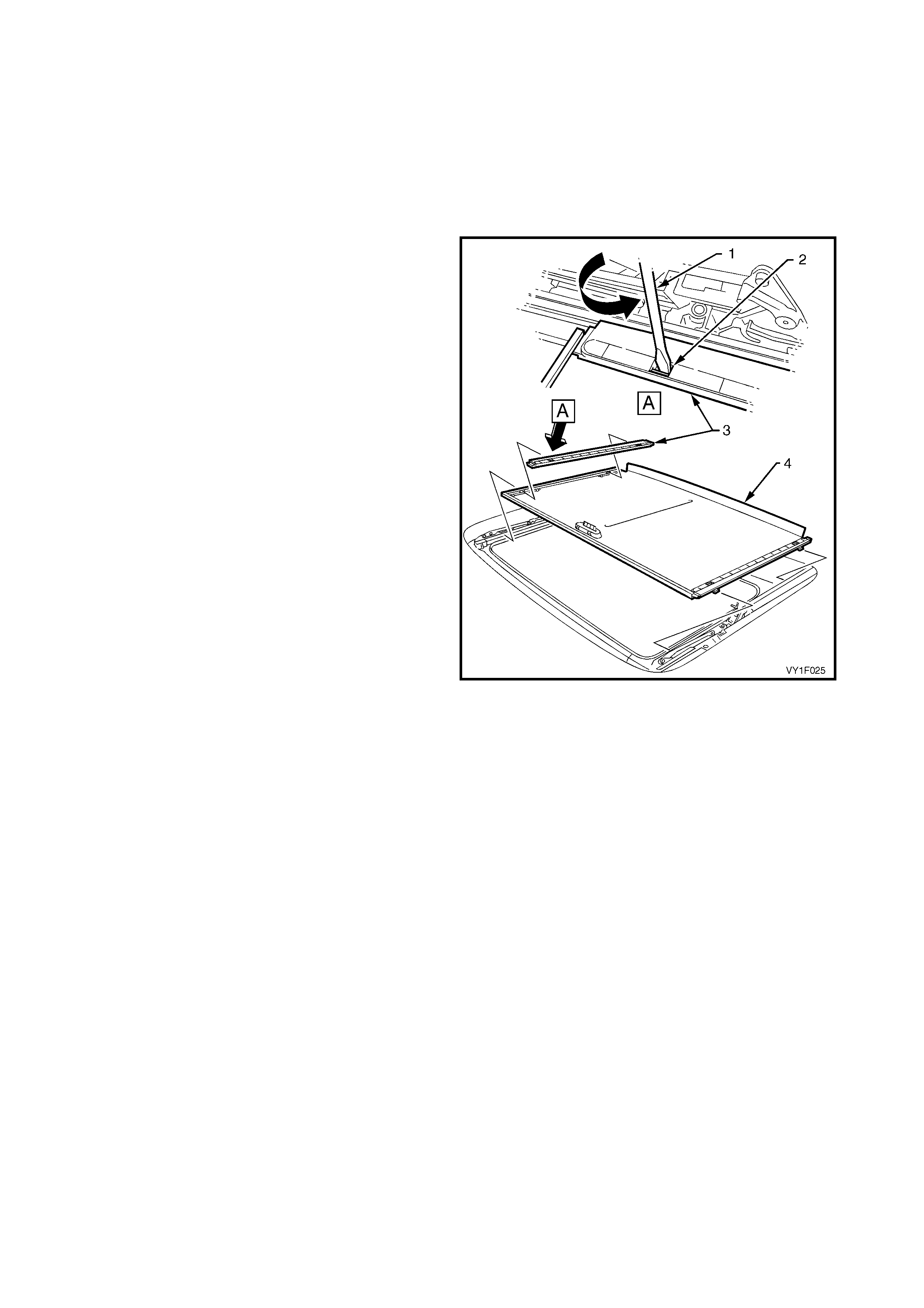

2.5 GLASS PANEL

LT Section No. -

REMOVE

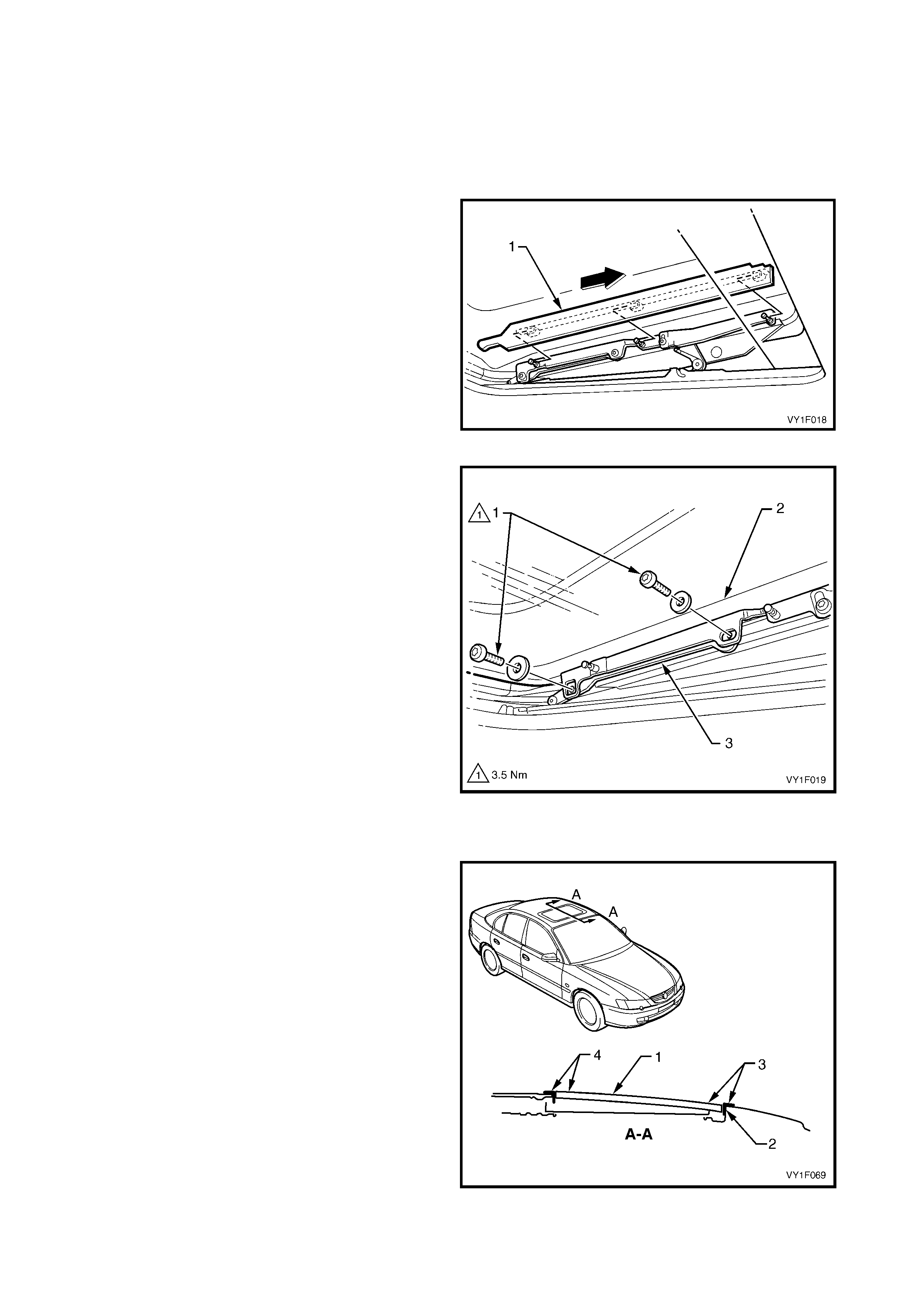

1. Position the sunroof in the full tilt position, refer to

Figure 1F-21.

2. Remove the left-hand and right-hand mechanism

covers (1) by grasping them by hand and sliding

towards the rear of the sunroof assembly.

Figure 1F-9

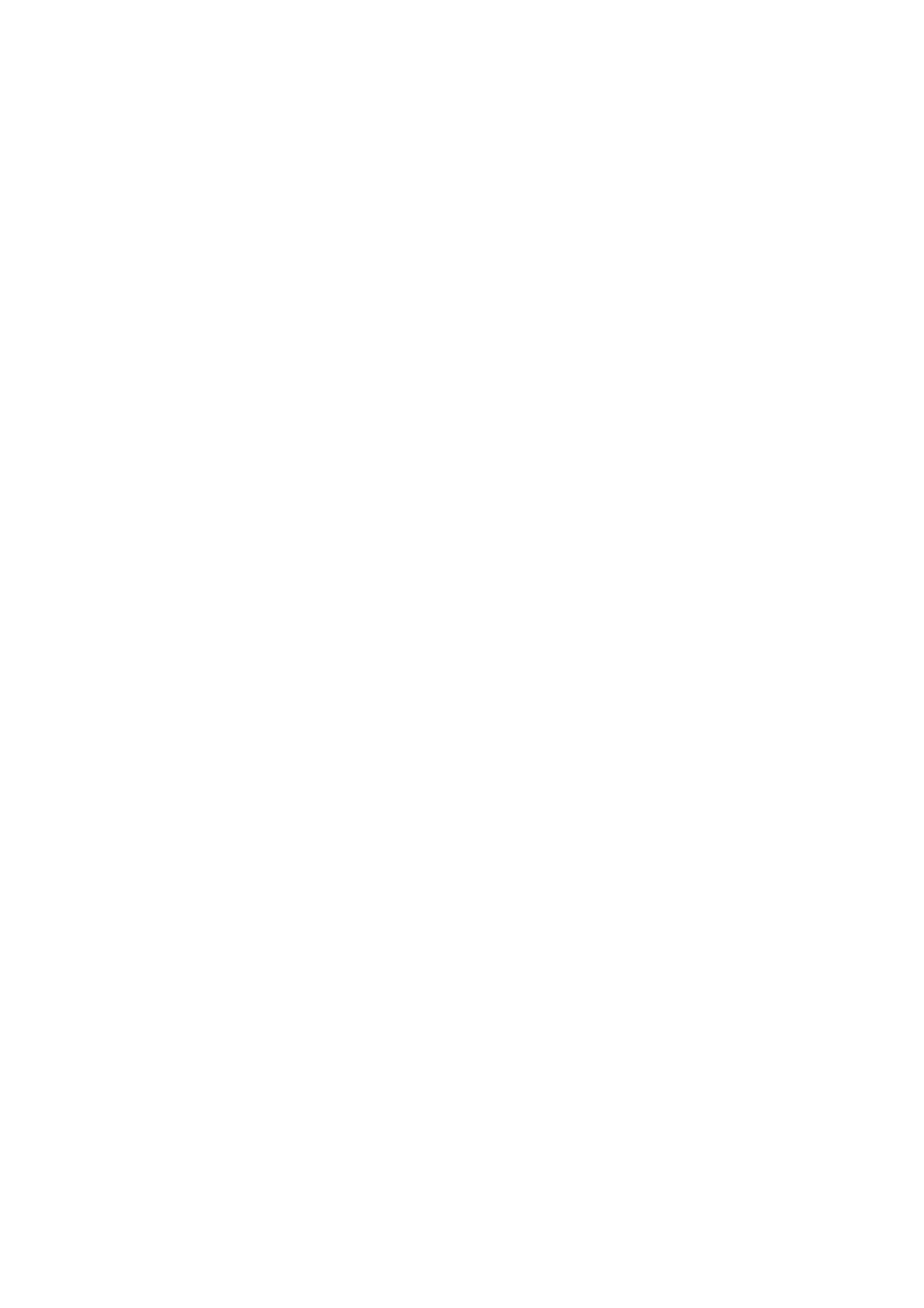

3. Remove the two Torx screws and washers (1) on

each side of the glass panel (2) securing it to the

guide rail mechanism (3), noting the size and

position of the washers.

4. Carefully lift out the glass panel, releasing the

locating tabs from the sliding mechanism and

place in a safe place.

Figure 1F-10

REINSTALL AND ADJUST

NOTE: To avoid wind noise (whistling), the glass

panel (1) must be installed level with the trim ring (2)

within the following limits:

• Front, location (3) flushness 0 to –1 mm

• Rear, location (4) flushness +1 to 0 mm

Figure 1F-11

1. Position the mechanism in the full tilt position, refer to Figure 1F-21.

2. Place the glass panel locating tabs (1) in the sliding mechanism guides (2) then align the glass panel

mounting bracket holes with the threaded holes of the sliding mechanisms, refer to Figure 1F-12.

3. Secure the glass panel with four Torx screws and washers (3, 4 and 5), with the large washers (5) at the

front locations. Do not tighten the Torx screws at this point.

4. Position the sunroof in the closed position.

5. Adj ust the glas s panel against the front of the roof panel opening trim ring, checking the tens ion of the seal

using a business card or s imilar. T he card s hould not fit easily between the roof panel opening trim ring and

the glass panel.

6. Tighten the centre mounting Torx screws (3) to the specified torque.

7. Adj ust the height of the glass panel at the fr ont, flush with the roof trim ring, then tighten the front m ounting

Torx screws (4) to the specified torque.

8. Loos en the left- hand and right-hand adjustment br acket T orx screws (6) . Adjust the glass panel s o that it is

level with the r oof trim ring, ref er to NOTE, and tighten the adj ustment brac ket Torx screws to the specif ied

torque, refer to 2.6 ADJUSTMENT BRACKETS.

9. Check the operation of the m echanis m and the adj ustment of the glass panel. Repeat Steps 4 to 8 if further

adjustments are required.

10. Install the left-hand and right-hand mechanism covers, by sliding them towards the front of the sunroof

assembly.

Figure 1F-12

GLASS PANEL RETAINING TORX

SCREWS TORQUE SPECIFICATION 3.5 Nm

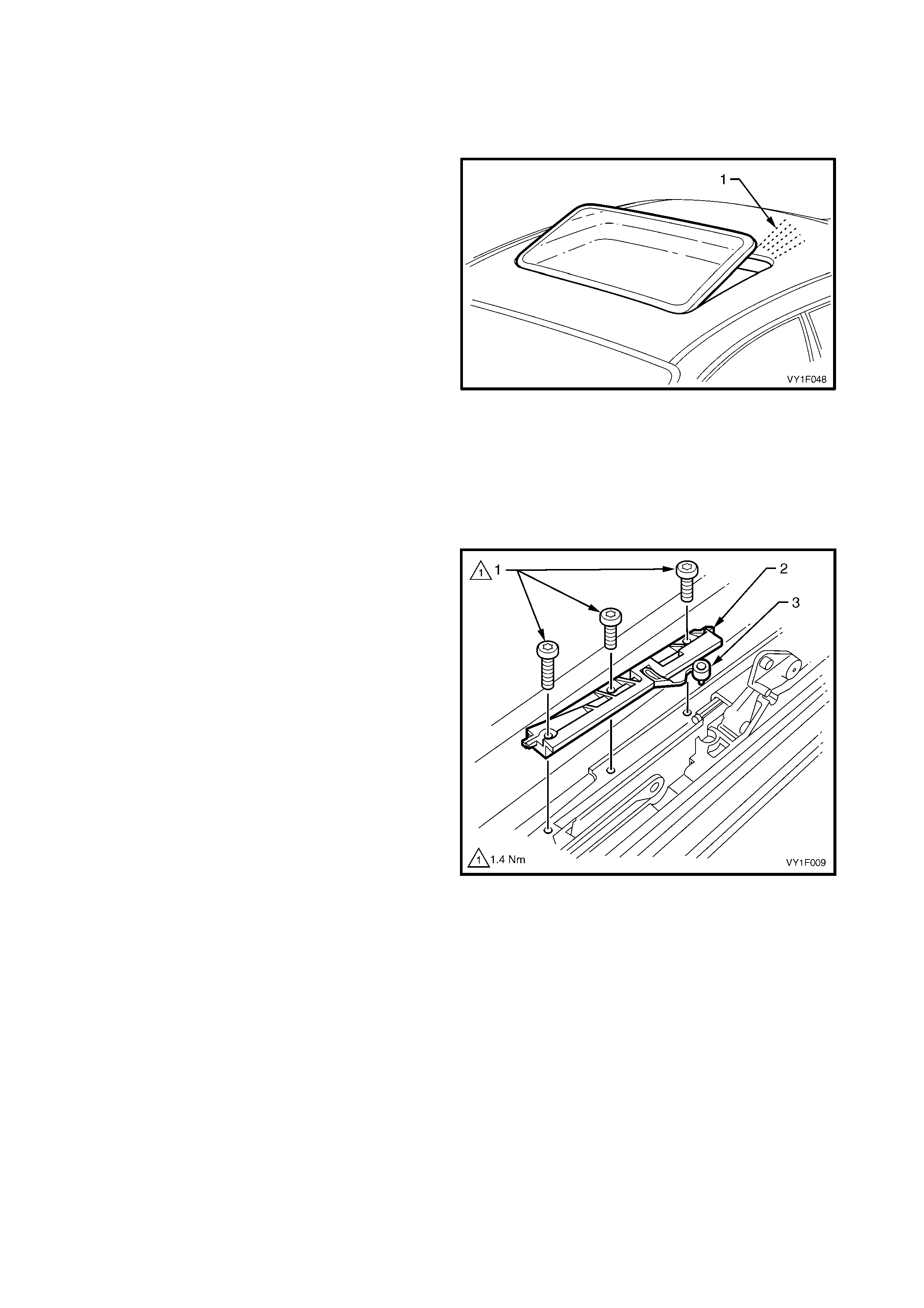

2.6 ADJUSTMENT BRACKETS

LT Section No. -

REMOVE

1. Remove the left-hand and right-hand

mechanism covers and glass panel, refer to

2.5 GLASS PANEL.

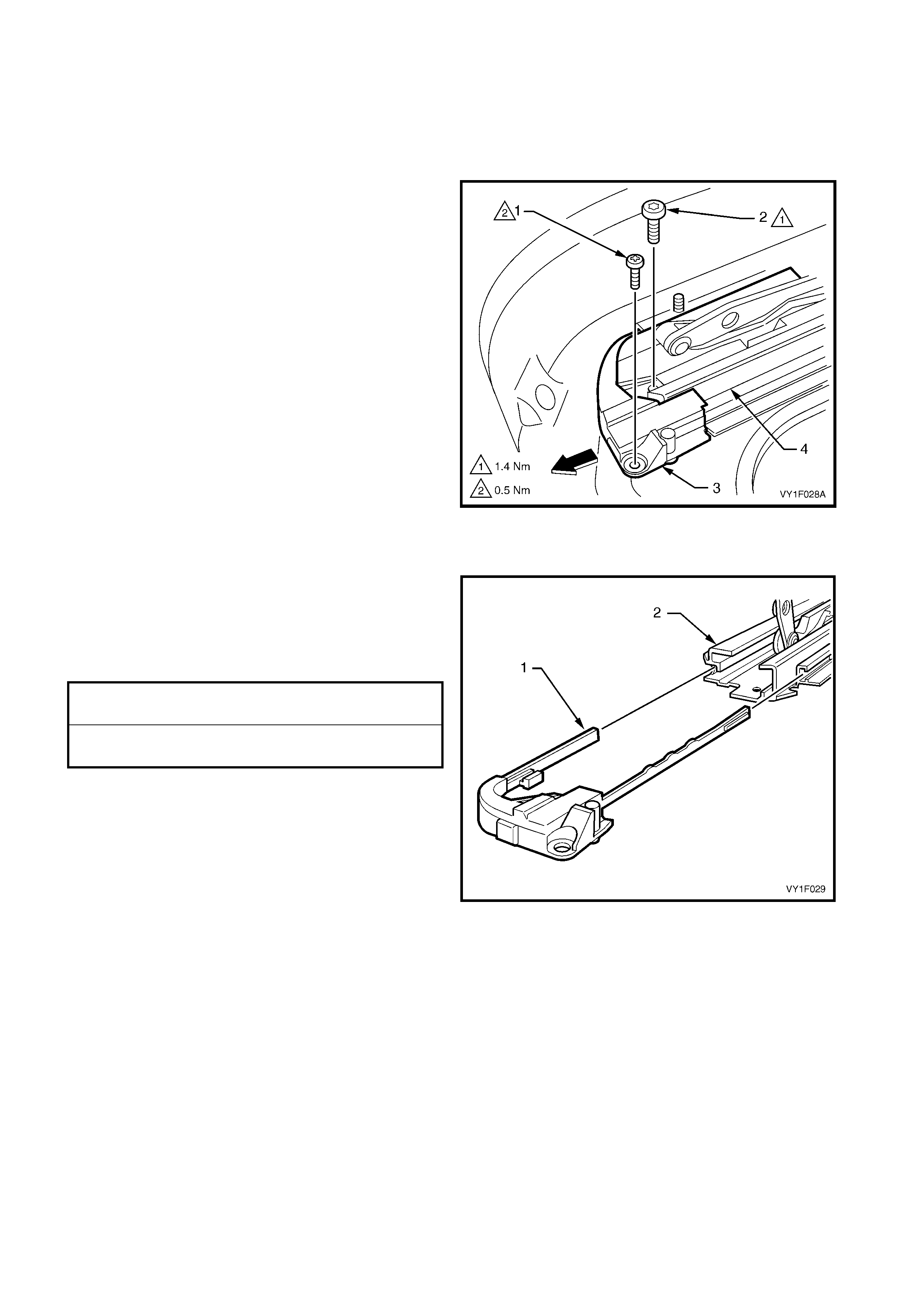

2. Remove the circlip (1) and Torx screw and

washer (2) securing each adjustment bracket (3)

to the glass panel mounting bracket (4). Slide the

bracket off the locating pin.

Figure 1F-13

REINSTALL

Installation of the adjustment bracket is the reverse of

the removal procedure. Tighten the screw to the

specified torque.

ADJUSTMENT BRACKET

RETAINING TORX SCREWS

TORQUE SPECIFICATION 2.0 Nm

2.7 EXTERIOR COVERS

LT Section No. -

REMOVE

1. Remove the left-hand and right-hand

mechanism covers and glass panel, refer to

2.5 GLASS PANEL.

2. Remove the two nuts and washers (1) securing

each exterior cover (2) to the glass panel (3).

Figure 1F-14

REINSTALL

Installation of the exterior covers is the reverse of the

removal procedure. Tighten the nuts to the specified

torque.

EXTERIOR COVER

MOUNTING NUTS

TORQUE SPECIFICATION 1.8 – 2.2 Nm

2.8 RUBBER SEAL

LT Section No. -

REMOVE

1. Remove the left-hand and right-hand

mechanism covers and glass panel, refer to

2.5 GLASS PANEL.

2. Remove the exterior covers, refer to

2.7 EXTERIOR COVERS.

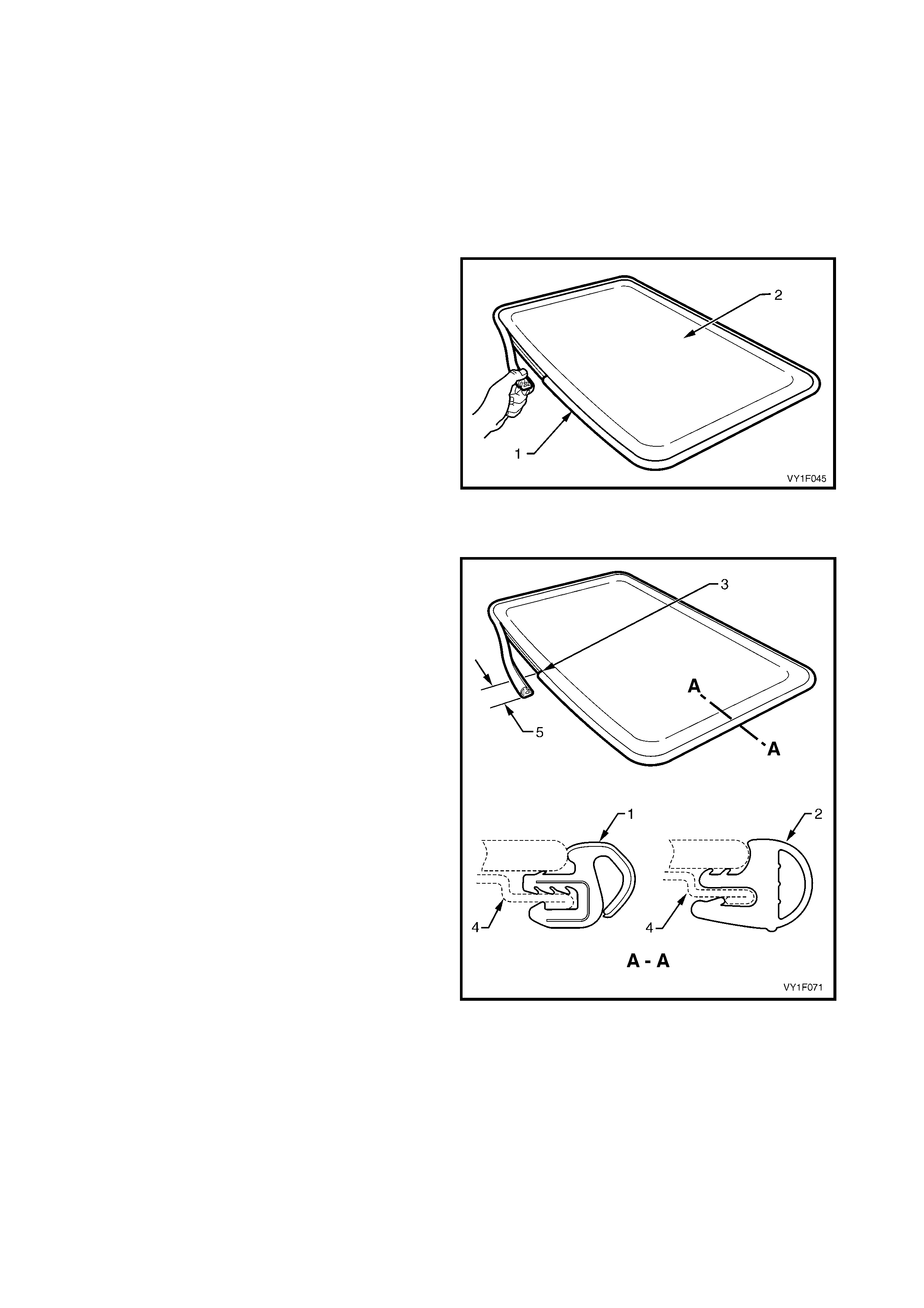

3. Remove the rubber seal (1) from the glass panel

(2).

4. Remove any dirt or debris and clean the glass

panel, refer to 1. GENERAL INFORMATION.

Figure 1F-15

REINSTALL

IMPORTANT: Ensure that the glass and frame are

clean and free of debris before fitting the new rubber

seal.

NOTE: There are two rubber seal configurations that

can be fitted to the glass panel. The installation

procedure is the same for both configurations.

1. Install the new rubber seal configuration one (1) or

alternatively configuration two (2), beginning at the

centre front of the glass frame retaining channel

(3).

2. Insert the new rubber seal in the glass frame

retaining channel (4) with enough pressure to have

a flush fit with the glass.

3. Trim the new rubber seal with approxim ately 6 m m

overlap (5), then work into the retaining channel.

4. Install the glass panel and the mechanism covers,

refer to 2.5 GLASS PANEL.

5. Check that the new rubber seal f irmly contacts the

trim ring attached to the roof panel opening, with

the sunroof in the closed position.

6. Check the sunroof for correct operation.

Figure 1F-16

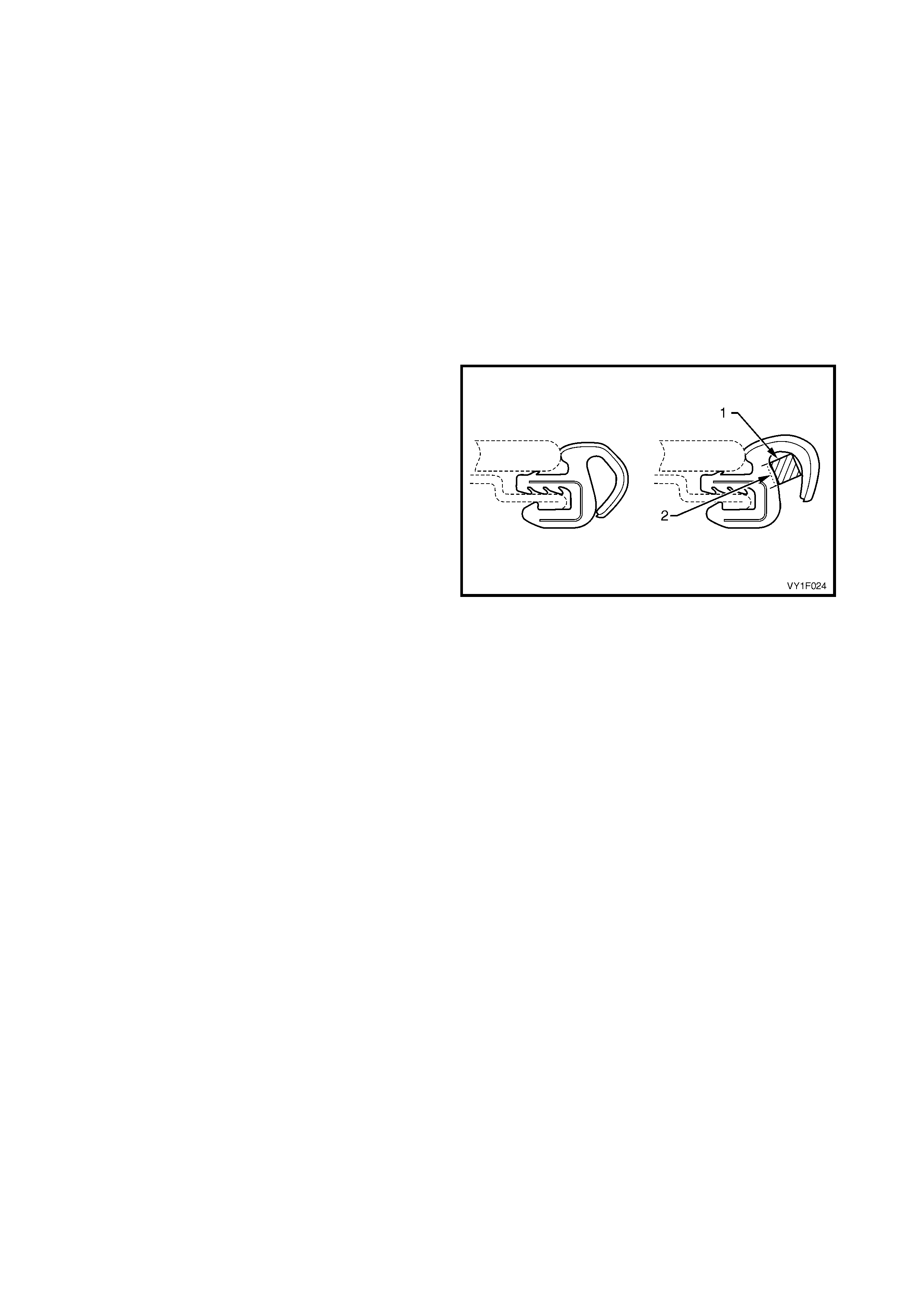

ADJUSTMENT

NOTE: T he adjustm ent is applicable to the rubber seal

configuration one (1) only, refer to Figure 1F-16.

With the glass panel positioned correctly, the rubber

seal should firmly contact the EPDM trim ring on the

sunroof opening. If the glass panel fits correctly but

gaps r emain between the seal and the EPDM trim ring

on the sunroof opening, adjust as follows:

1. Adjus t the glass panel correctly against the rear of

the EPDM trim ring, refer to 2.5 GLASS PANEL.

2. With a grease pencil or similar, mark the areas

where the rubber seal does not make sufficient

contact with the front of the EPDM trim ring.

3. Remove the glass panel, refer to

2.5 GLASS PANEL.

4. In the areas m arked, ins ert a spacer (1) ins ide the

rubber seal as shown (use a 3mm square section

foam strip with adhesive backing).

5. Peel the backing off the foam spacer and stick to

the inner surface of the seal (2).

6. Install the glass panel and adjust, refer to

2.5 GLASS PANEL.

Figure 1F-17

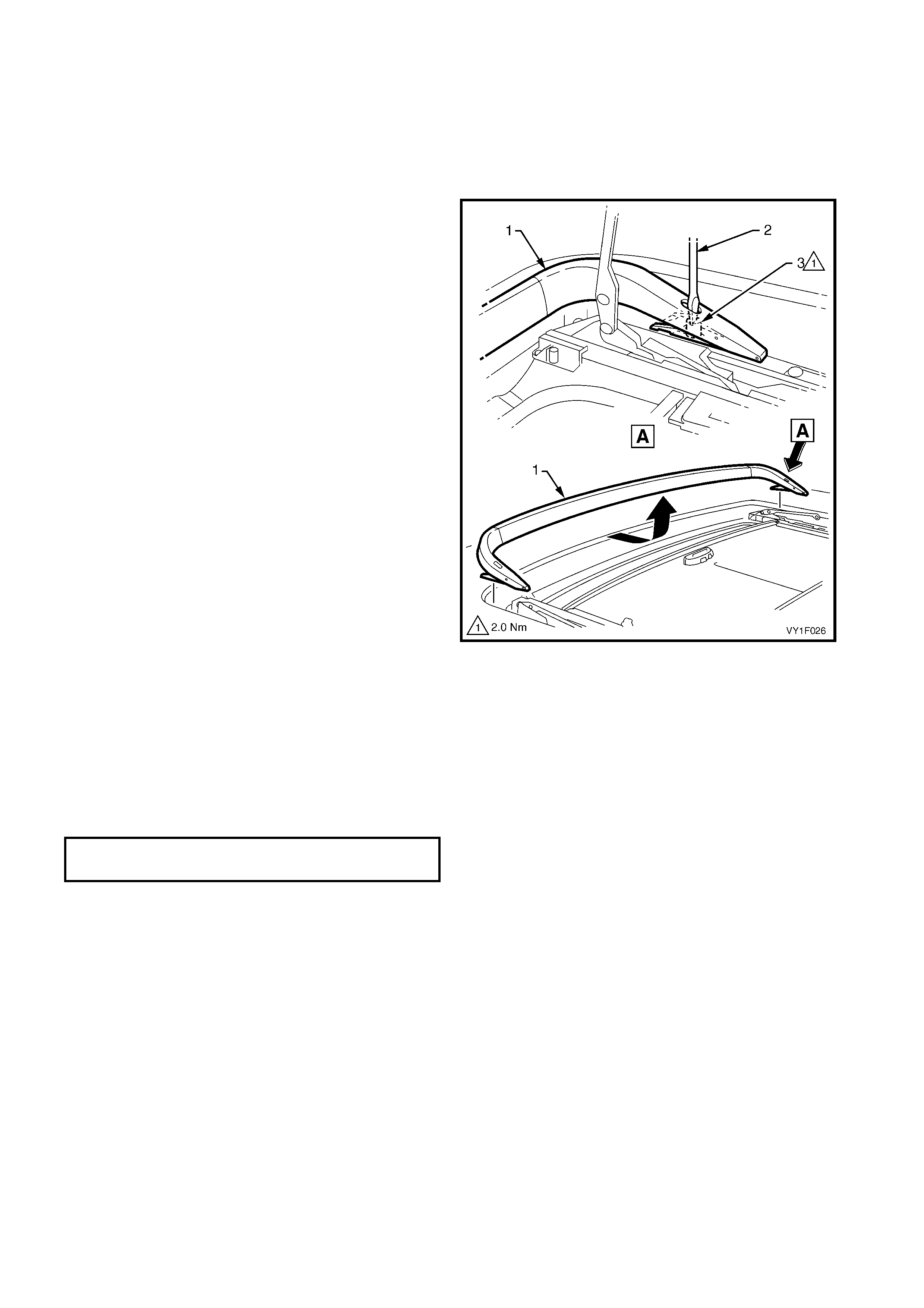

2.9 W IND DEFLECTOR

LT Section No. -

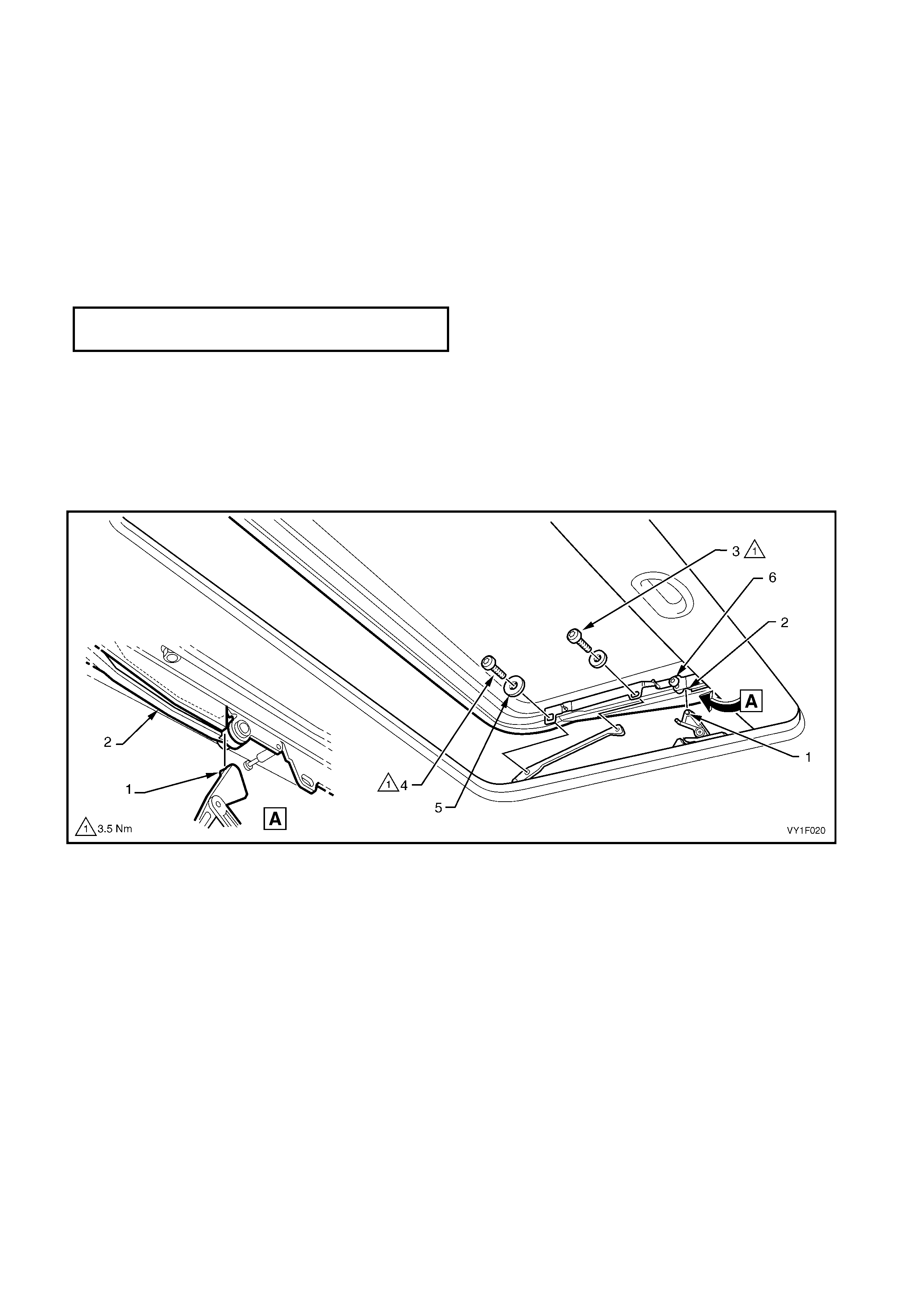

REMOVE

1. Remove the exterior covers and glass panel, refer

to 2.5 GLASS PANEL.

2. Insert a flat blade screwdriver (2) in the wind

deflector mounting hole and loosen the left-hand

and right-hand securing nuts (3).

3. Slide the wind deflector (1) towards the rear and lift

it out.

Figure 1F-18

REINSTALL

Installation of the wind deflector is the reverse of the

removal procedure, noting the following:

1. Always fit the wind deflector to the maximum

forward position.

2. Secure the wind deflector with the two attaching

nuts. Tighten the nuts to the specified torque.

3. Check the glass panel and wind deflector for

correct operation, adjust if necessary.

WIND DEFLECTOR ATTACHING NUTS

TORQUE SPECIFICATION 2.0 Nm

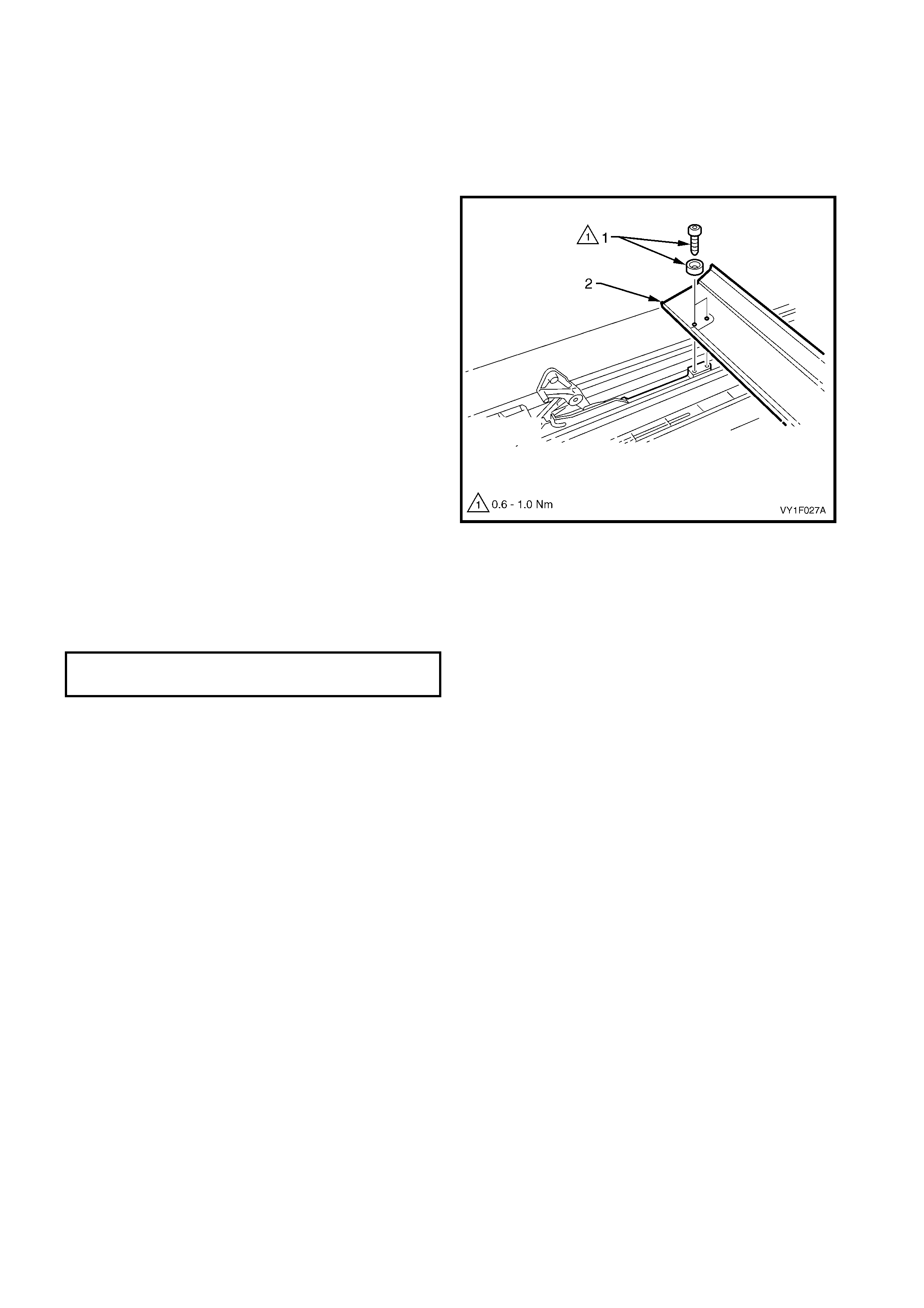

2.10 DRAIN CHANNEL

LT Section No. -

REMOVE

1. Rem ove the exterior covers and glass panel, refer

to 2.5 GLASS PANEL.

2. Rem ove the two lef t-hand and right-hand retaining

Torx screws and washers (1) and lift out the drain

channel (2).

Figure 1F-19

REINSTALL

Installation of the drain channel is the reverse of the

rem oval pr ocedur e. Tighten the scr ews to the specified

torque.

DRAIN CHANNEL TORX SCREWS

TORQUE SPECIFICATION 0.6 – 1.0 Nm

2.11 SUNSHADE

LT Section No. -

REMOVE

1. Rem ove the exterior covers and glass panel, refer

to 2.5 GLASS PANEL.

2. Remove the drain channel, refer to

2.10 DRAIN CHANNEL.

3. Using a flat blade screwdriver (1) or similar,

release the front and rear spring clips (2) from the

sunshade guide (3) by inserting the screwdriver

blade in the slot and twisting as shown in the

figure.

4. Slide the sunshade guide towards the c entre of the

vehicle and lift out.

NOTE: It is only necessary to remove the sunshade

guide on one side of the sunshade to allow

sunshade (4) removal.

5. Lift the sunshade clear of the guide rails.

Figure 1F-20

REINSTALL

Installation of the sunshade is the reverse of the

removal procedure, noting the following:

1. If the suns hade guide was rem oved from one side

only, ensure the tabs on the sunshade guide still

fitted locate correctly in the guide rail when the

sunshade is placed in position.

2. When fitted, check for smooth operation before

continuing with installation.

2.12 DRIVE CABLE S

LT Section No. -

REMOVE

1. Position the sunroof in the maximum tilt position

(1).

2. Remove the mechanism covers and glass panel,

refer to 2.5 GLASS PANEL.

3. Remove the wind deflector, refer to

2.9 WIND DEFLECTOR.

4. Remove the drain channel, refer to 2.10 DRAIN

CHANNEL.

5. Remove the sunshade, refer to 2.11 SUNSHADE.

6. Close the sunroof mechanism.

IMPORTANT: Take extreme care when removing the

headlining which has been modified and installed using

adhesive.

7. Remove the drive motor cover and drive motor,

refer to 2.1 DRIVE MOTOR.

8. Remove the SCU, refer to 2.3 SUNROOF

CONTROL UNIT (SCU)

9. Remove the drive gear retainer and drive gear,

refer to 2.2 DRIVE GEAR.

Figure 1F-21

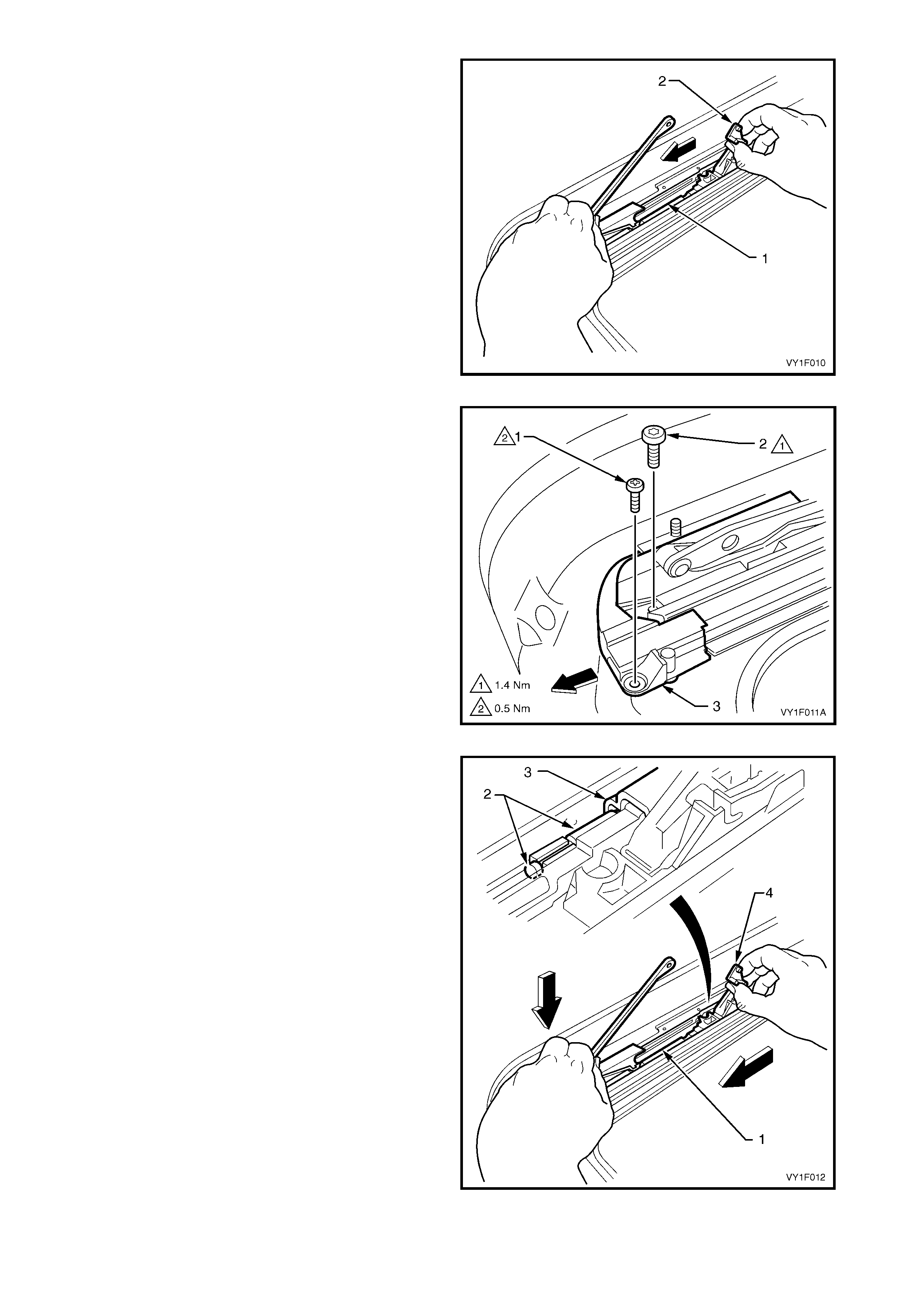

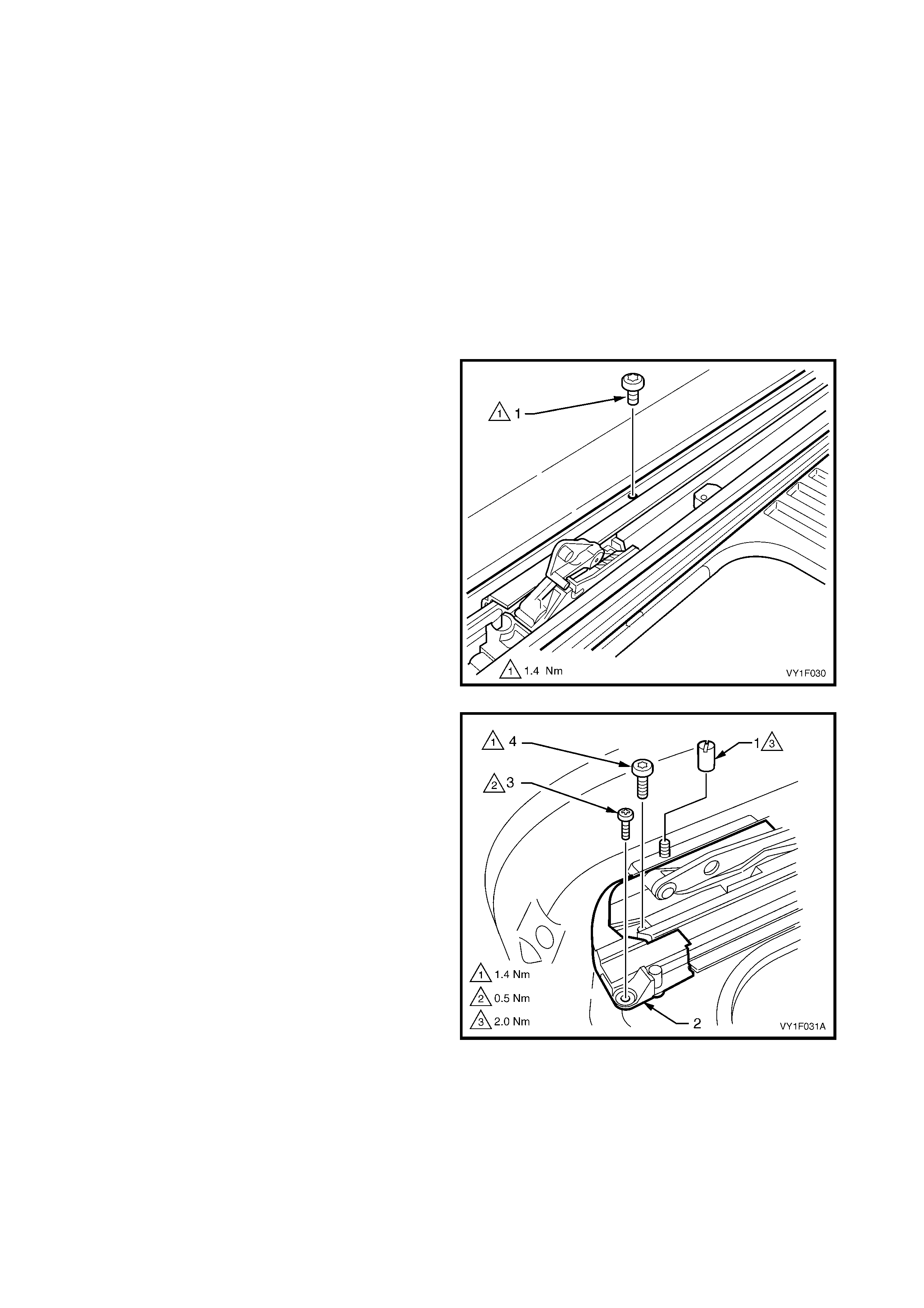

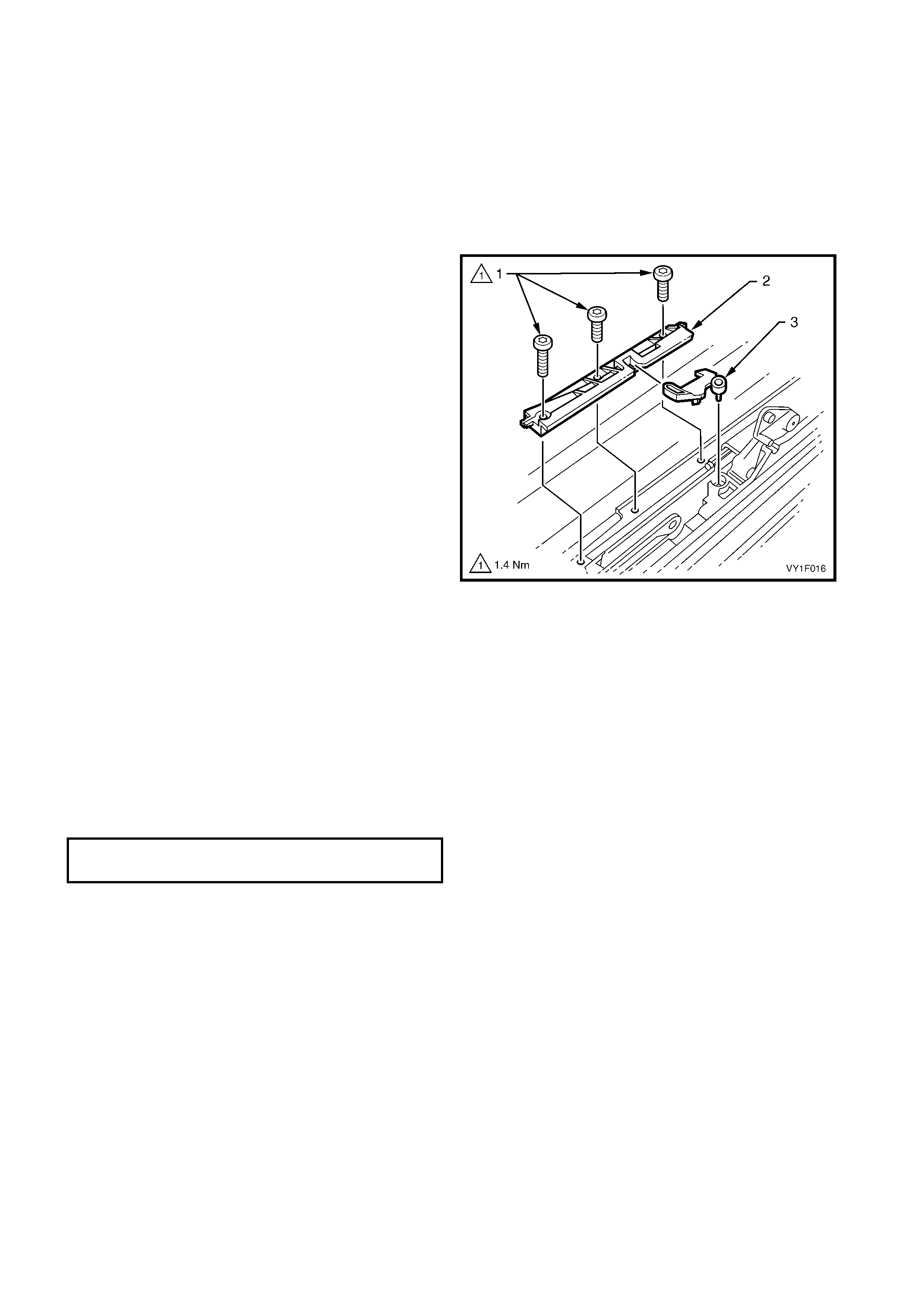

10. Remove the three Torx screws (1) securing the

locator (2) noting the length and position of the

screws. Lift off the locator and the blocking

catch (3) noting the orientation of the blocking

catch.

Figure 1F-22

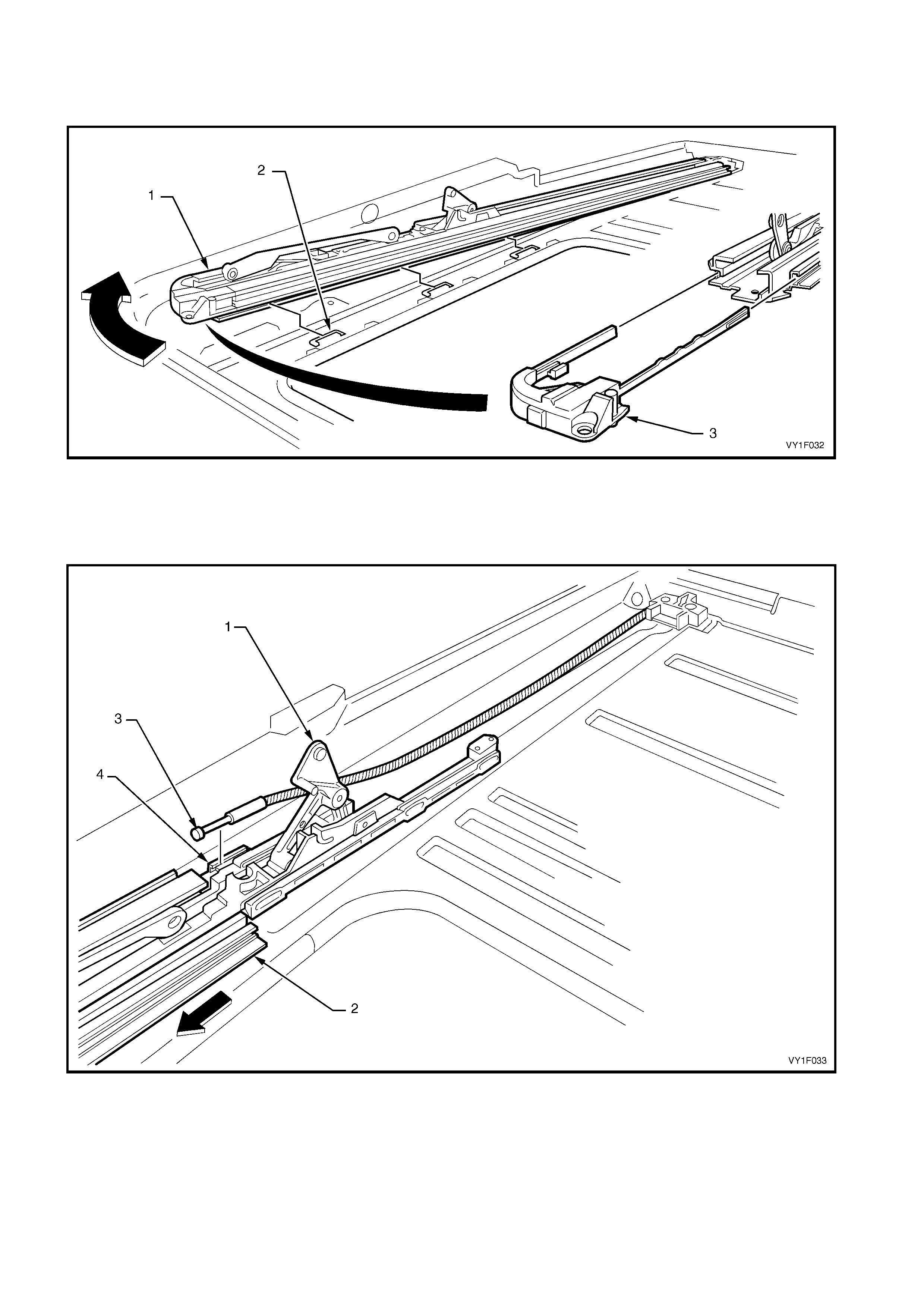

11. Pull the guide r ail m echanis m (1) as far for ward as

possible.

12. Push the guide rail mechanism into the full tilt

position (2).

Figure 1F-23

13. Remove the Phillips head screw (1) and the Torx

screw (2) from the retraction m echanism (3). Slide

the retraction mechanism forward but do not

remove.

Figure 1F-24

14. Push the guide rail mechanism (1) further forward

until the drive cable brass end fitting (2) is fully

forward of the drive cable channel (3). While

pushing forward, apply downward pressure on the

front of the guide rail mec hanism and m aintain the

tilt mechanism in the raised position (4).

Figure 1F-25

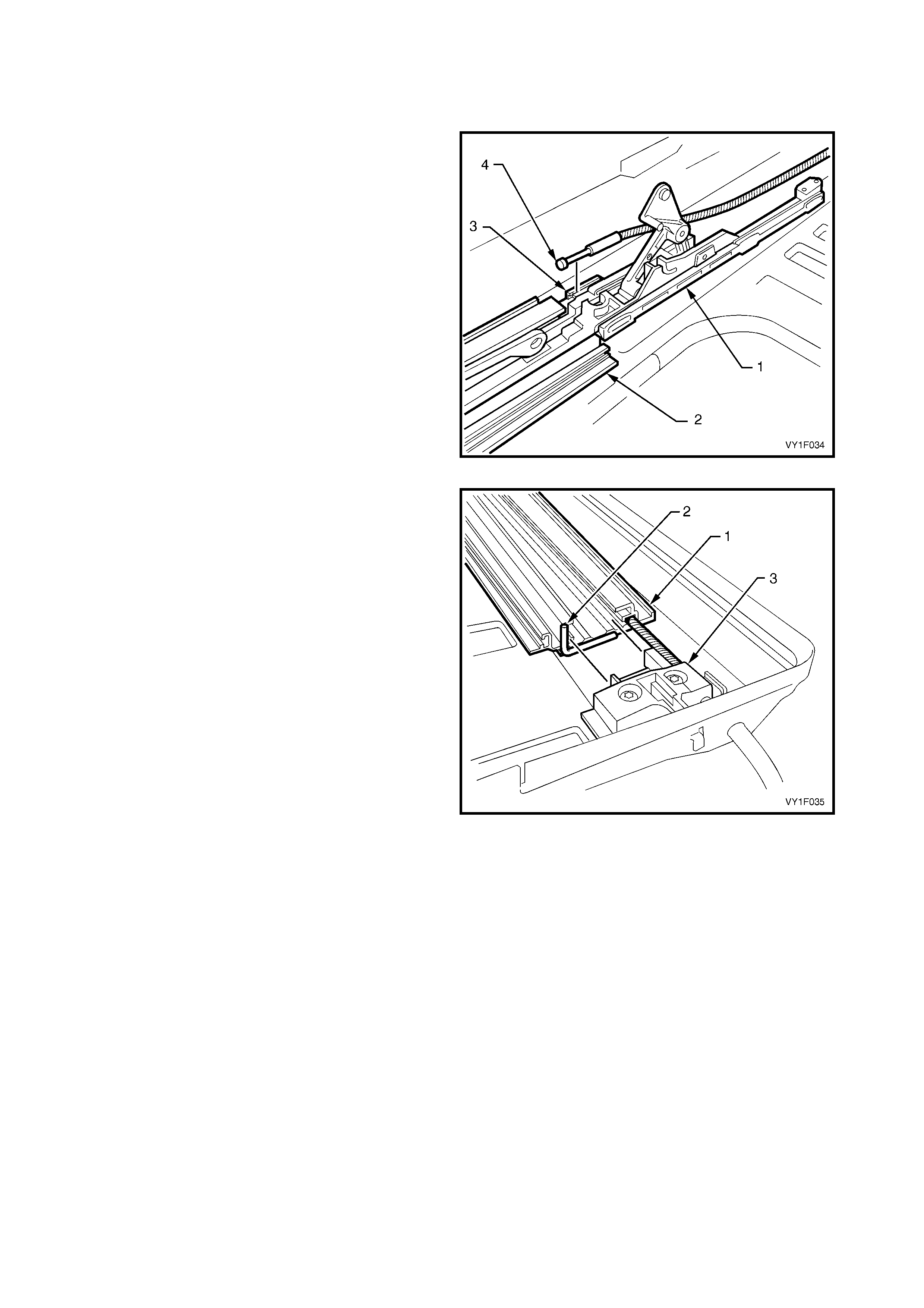

15. Lift the drive cable (1) out of the retaining slot (2) in

the guide rail track and carefully withdraw the

cable.

Figure 1F-26

REINSTALL

Installation of the drive cable is the reverse of the

removal procedure, noting the following:

1. Check that the new cable is the correct length. Oil

the cable using Applied Chemicals Tefoil +PTFE,

Part No. 8-830.

2. Carefully feed the drive cable into the guide rail

opening until the copper head aligns with the

retaining slot in the guide rail track. Do not force

the cable and avoid kinking or bending the cable

excessively.

Figure 1F-27

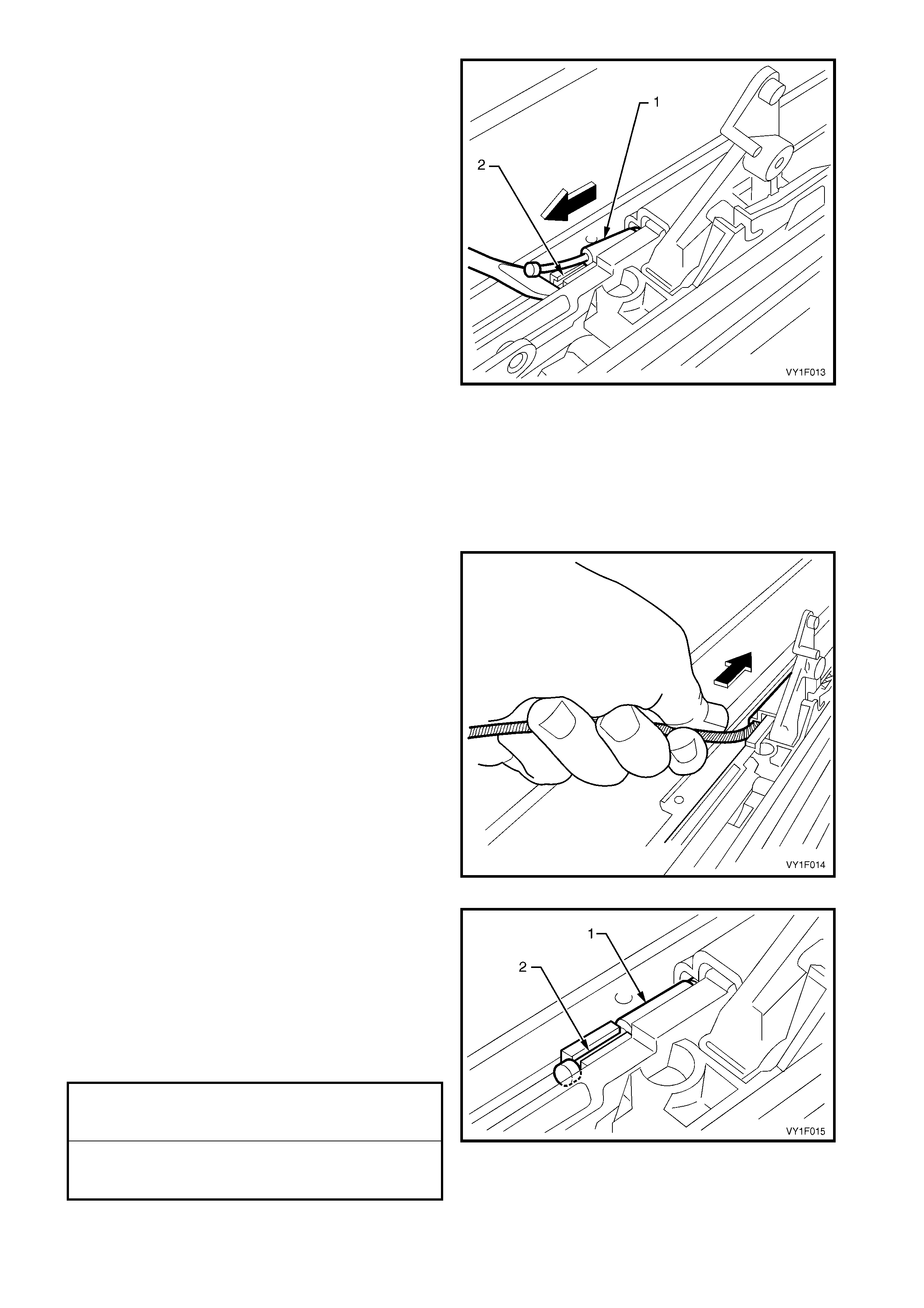

3. Ensure the copper head (1) of the cable seats

securely in the retaining slot (2) in the guide rail

track.

4. To install the retraction mechanism, push the

guide rail mechanism towards the rear slightly,

refer to Figure 1F-24. Position the retraction

mechanism with the locating Phillips head screw

and secure with the Torx screw. Tighten the

screws to the specified torque.

Figure 1F-28

RETRACTION MECHANISM

TORX SCREW

TORQUE SPECIFICATION 1.4 Nm

RETRACTION MECHANISM

LOCATING SCREW

TORQUE SPECIFICATION 0.5 Nm

5. Ensure the blocking catch (3) is correctly fitted to

the locator (2). Position the guide rail mechanism

(by pushing back wards or forwards) so the locator

and blocking catch can be fitted with the blocking

catch mating correctly with the guide rail

mechanism. Secure with three Torx screws (1).

Push the guide rail mechanism to the fully closed

position. Tighten all fasteners to the specified

torque.

6. To replace the opposite cable, repeat the

procedure from Step 10 – REMOVE.

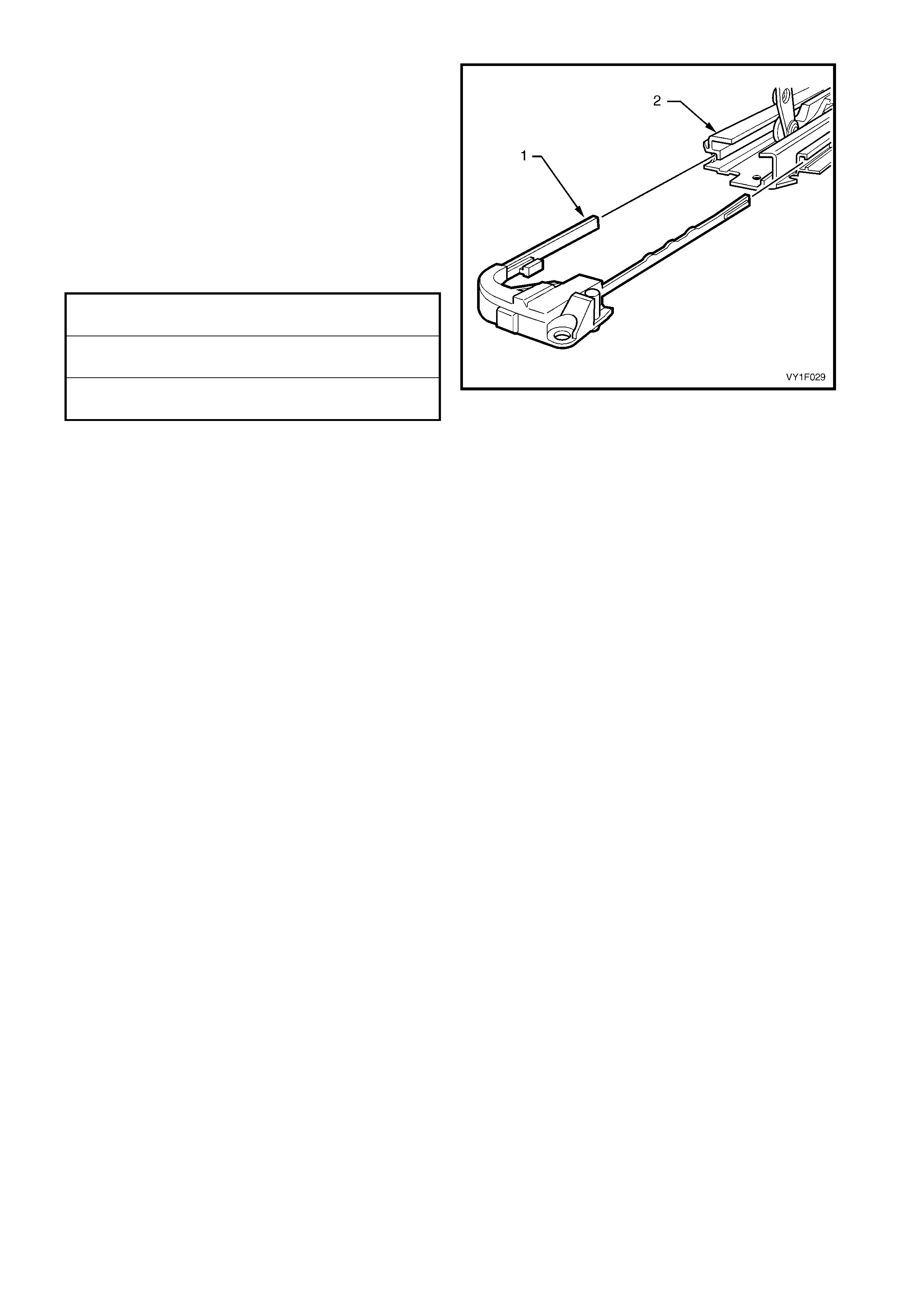

Figure 1F-29

7. Push the left-hand and right-hand mechanisms to

the closed position. Insert a pin (1) in the 2.5 mm

hole in the left-hand and right-hand tilt levers (2).

Slide the mechanisms forward until the pins stop

the mechanisms movement.

8. Install the gearwheel and gearwheel retainer, refer

to 2.2 DRIVE GEAR in this Section.

9. Install the SCU, refer to 2.3 SUNROOF

CONTROL UNIT (SCU).

10. Install the drive m otor and drive motor cover, refer

to 2.1 DRIVE MOTOR.

11. Remove the pins installed in Step 7.

12. Check the sunroof for correct electrical and

mechanical operation before installing the

adjustment bracket, drain c hannel, sunshade, wind

deflector, glass panel and mechanism covers.

13. Check the sunroof for correct operation before

fitting the headlining.

Figure 1F-30

LOCATOR RETAINING

TORX SCREWS

TORQUE SPECIFICATION 1.4 Nm

2.13 TIMING OF DRIVE CABLES

LT Section No. -

1. Open the sunroof in the full tilt position, refer to Figure 1F-21.

2. Remove the left-hand and right-hand mechanism covers and the glass panel, refer to 2.5 GLASS PANEL.

3. Fully close the sunroof.

4. Remove the drive motor cover and drive motor, refer to 2.1 DRIVE MOTOR.

5. Remove the SCU, refer to 2.3 SUNROOF CONTROL UNIT (SCU).

6. Remove the drive gear retainer and the drive gear, refer to 2.2 DRIVE GEAR.

7. Push the left-hand/right-hand mechanisms to the closed position. Insert a pin in the 2.5 mm hole in the

left-hand/right-hand tilt levers. Slide the m echanism forward until the pins stop the mechanism s movement,

refer to Figure 1F-18.

8. Install the drive gear and drive gear retainer, refer to 2.2 DRIVE GEAR.

9. Install the SCU, refer to 2.3 SUNROOF CONTROL UNIT (SCU).

10. Install the drive motor and drive motor cover, refer to 2.1 DRIVE MOTOR.

11. Remove the pins installed in Step 7.

12. Check the sunroof for correct electrical and mechanical function.

13. Install the left-hand and right-hand mechanism covers.

14. Check the sunroof for correct operation before fitting the headlining.

2.14 RE TRACTION MECHANISM

LT Section No. -

REMOVE

1. Retract the sunroof fully.

2. Remove the wind deflector, refer to

2.9 WIND DEFLECTOR.

3. Remove the Phillips head screw (1) and the Torx

screw (2) from the retraction mechanism (3).

4. Withdraw the retraction mechanism forwards out

of the guide rail (4).

Figure 1F-31

REINSTALL

1. Install the new retraction mechanism (1) in the

guide rail (2).

2. Position the retrac tion mechanis m with the locating

Phillips head screw and secure with the Torx

screw. Tighten the screws to the specified torque.

3. Install the wind deflector, refer to

2.9 WIND DEFLECTOR.

4. Check the sunroof for correct operation.

Figure 1F-32

RETRACTION MECHANISM SCREW

TORQUE SPECIFICATION 1.4 Nm

RETRACTION MECHANISM LOCATING

SCREW TORQUE SPECIFICATION 0.5 Nm

2.15 GUIDE RAIL MECHANISM

LT Section No. -

REMOVE

1. Remove the left-hand and right-hand mechanism

covers and glass panel, refer to

2.5 GLASS PANEL.

2. Remove the wind deflector, refer to

2.9 WIND DEFLECTOR.

3. Remove the drain channel, refer to

2.10 DRAIN CHANNEL.

4. Remove the sunshade, refer to 2.11 SUNSHADE .

5. Remove the locator and blocking catch, refer to

2.16 BLOCKING CATCH.

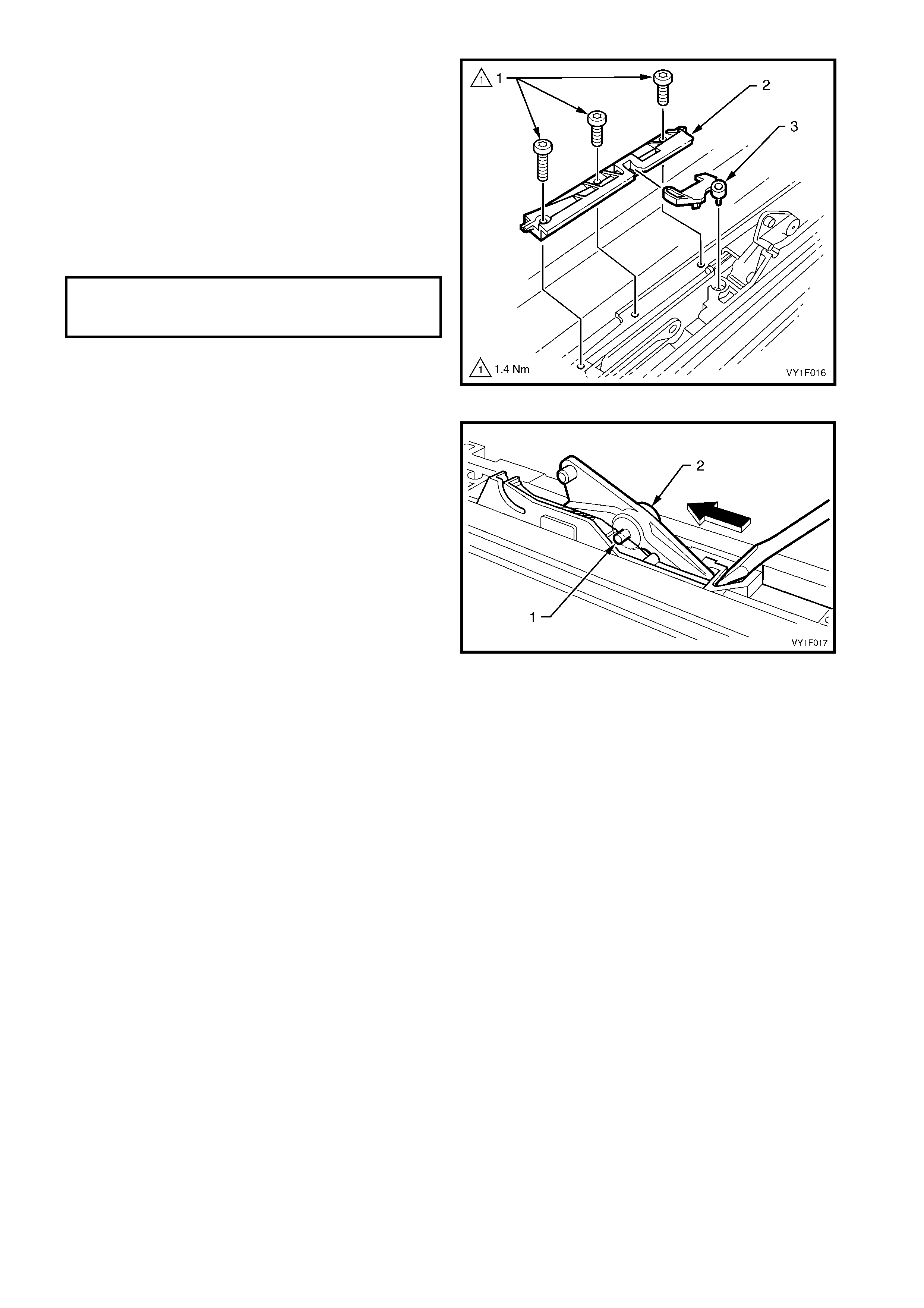

6. Remove the guide rail retaining screw (1) noting

the length and position of the screw.

Figure 1F-33

7. Remove the wind deflector mounting nuts (1).

8. Remove the retraction mechanism (2) locating

Phillips head screw (3) and retaining Torx

screw (4 ).

Figure 1F-34

9. Slide the mechanism guide rail (1) sideways to unlock from the locating tabs (2), refer to Figure 1F-35.

10. Lift the front of the mechanism guide rail and withdraw the retraction mechanism (3).

11. Fully close the mechanism.

Figure 1F-35

12. While holding the guide rail mechanism (1), gently pull the guide rail (2) forward over the guide rail

mechanism until the front of the drive cable (3) becomes visible, refer to Figure 1F-36.

13. Lift the drive cable out of the locating slot (4) then carefully lift out the guide rail and guide rail mechanism.

Figure 1F-36

REINSTALL

1. Check that the guide ra il mechanis m and guide rail

are clean and complete.

2. Slide the guide r ail mec hanism (1) out of the guide

rail (2) until the drive cable locating slot (3) is

visible.

3. Fit the drive c able (4) into the locating slot. Ensur e

the copper head of the drive cable seats securely

in the retaining slot, refer to Figure 1F-28. While

holding the guide rail mechanism (1) in position,

push the guide rail towards the rear locating

position gently to avoid damaging the drive cable.

Figure 1F-37

4. Apply a bead of butyl mastic sealer (2) to the end

of the guide rail (1).

5. While holding the guide r ail mechanis m in position,

push the guide rail towards the rear locating

position gently to avoid damaging the drive cable.

Then push into the rear locating bracket (3).

Figure 1F-38

6. Lift the front of the guide rail (2) and replace the

retraction mechanism (1).

7. Ensure the guide rail is pos itioned c orr ec tly against

the rear locating bracket then slide sideways to

lock into position.

8. Install the retraction mechanism and guide rail

retaining scr ews ensur ing the c orr ec t sc r ews noted

during removal are used. Tighten the guide rail

screw to the specified torque. Position the

retraction mechanism with the locating Phillips

head screw and secure with the Torx screw.

Tighten the screws to the specified torque.

9. Install the locator and blocking catch, refer to

2.16 BLOCKING CATCH.

10. Fully tilt the mechanism.

11. Ensure the mechanism functions correctly.

12. Install the sunshade, refer to 2.11 SUNSHADE .

13. Install the drain channel, refer to

2.10 DRAIN CHANNEL.

14. Install the wind deflector, refer to

2.9 WIND DEFLECTOR.

15. Install the glass panel and mechanism covers,

refer to 2.5 GLASS PANEL.

16. Check the sunroof for correct operation.

Figure 1F-39

GUIDE RAIL TORX SCREW

TORQUE SPECIFICATION 1.4 Nm

RETRACTION MECHANISM TORX SCREW

TORQUE SPECIFICATION 1.4 Nm

RETRACTION MECHANISM LOCATING

SCREW TORQUE SPECIFICATION 0.5 Nm

2.16 BLOCKING CATCH

LT Section No. -

REMOVE

1. Open the sunroof in the full tilt position, refer to

Figure 1F-21. Remove the left-hand and

right-hand m echanism covers and the glass panel,

refer to 2.5 GLASS PANEL.

2. Fully retract the mechanism.

3. Rem ove the three locator retaining screws (1) and

the locator (2) noting the length and position of the

screws.

4. Fully tilt the mechanism.

5. Lift out the blocking catch (3).

6. If replacing a broken blocking catch, make sure

that any debris is removed.

Figure 1F-40

REINSTALL

1. Ensure the blocking catch is correctly fitted to the

locator (2), refer to Figure 1F-40. Position the

guide rail mechanism (by pushing backwards or

forwards) so the locator and bloc king catch can be

fitted with the blocking catch mating correctly with

the guide rail mechanism. Secure the locator and

blocking catch with three Torx screws in the

positions noted during removal. Push the

mec hanism to the fully closed position. T ighten the

locator retaining screws to the specified torque.

2. Check for correct mechanical operation.

3. Install the glass panel and the left-hand and

right-hand mechanism covers, refer to

2.5 GLASS PANEL in this Section.

LOCATOR RETAINING TORX SCREWS

TORQUE SPECIFICATION 1.4 Nm

2.17 SUNROOF POWER HARNESS

LT Section No. -

REMOVE

IMPORTANT: Take extreme care when removing the

headlining which has been modified and installed using

adhesive.

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the headlining. Refer to Section 1A8,

• 2.12 HEADLINING ASSEMBLY – SEDAN

• 3.15 HEADLINING ASSEMBLY – WAGON

3. Remove the front windshield side garnish, refer to

Section 1A8,

• 2.5 WINDSHIELD SIDE GARNISH – SEDAN

• 3.5 WINDSHIELD SIDE GARNISH – WAGON

Configuration One

NOTE: This power harness configuration applies to

sunroofs installed on all wagon vehicles, and until

March 2003 on sedan vehicles.

1. Remove the right-hand hinge pillar trim assembly,

refer to Section 1A8,

• 2.8 HINGE PILLAR TRIM ASSEMBLY –

SEDAN

• 3.12 HINGE PILLAR TRIM ASSEMBLY –

WAGON

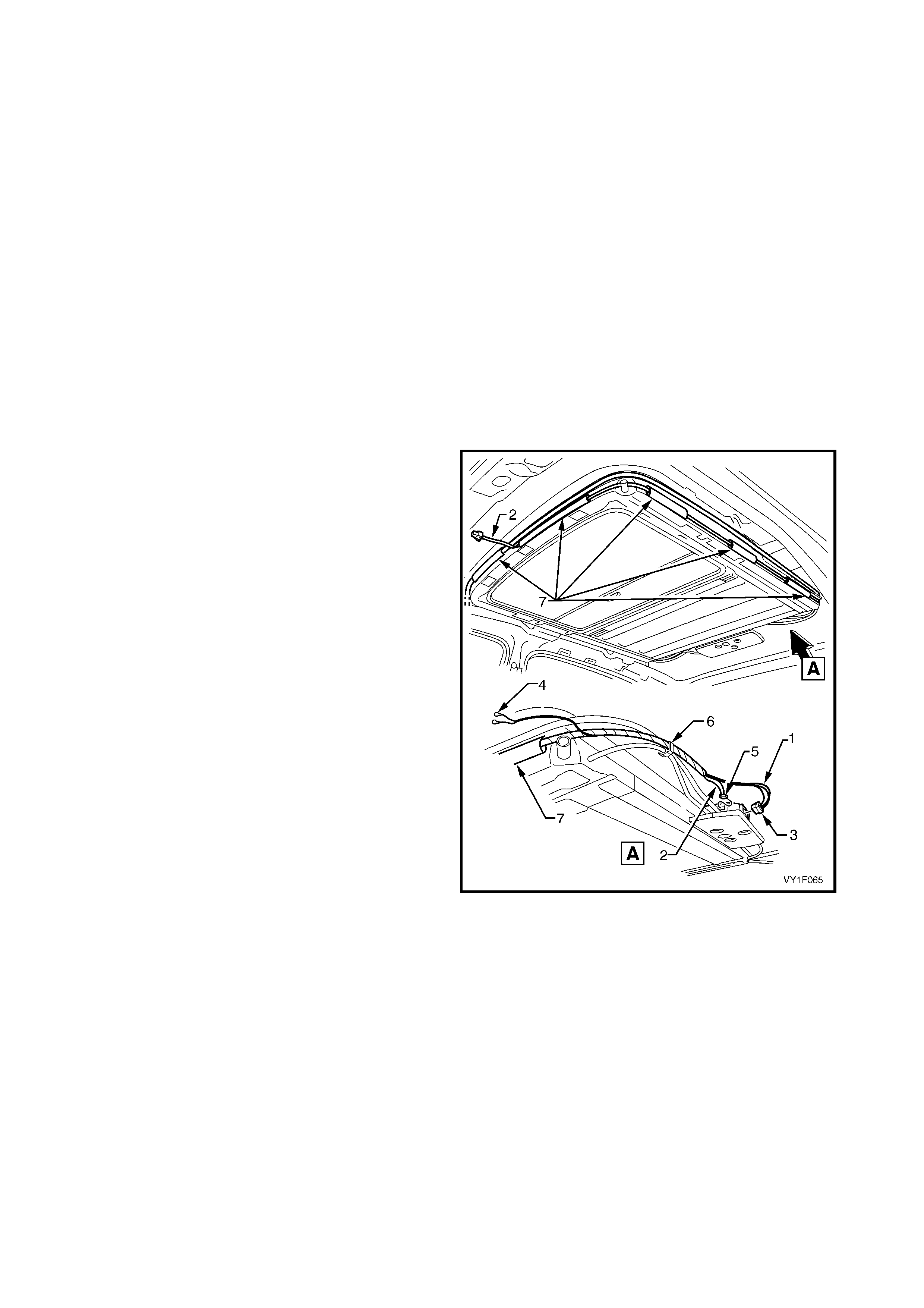

NOTE: The sunroof power harness (1) and the sunroof

harness (2) ar e taped together and should be r eplaced

as an assembly.

2. Disconnect the sunroof power harness

connector (3) from the SCU.

3. Remove the sunroof power harness ground

connections (4) from the left-hand inner side

panel.

4. Disconnect the sunroof harness connector (5)

from the SCU.

5. Unclip the wiring harnes ses from the sunroof drive

cable guides plastic support clip (6).

6. Open the guide tubes (7) attached to the side of

the sunroof to release the wiring harnesses.

Figure 1F-41

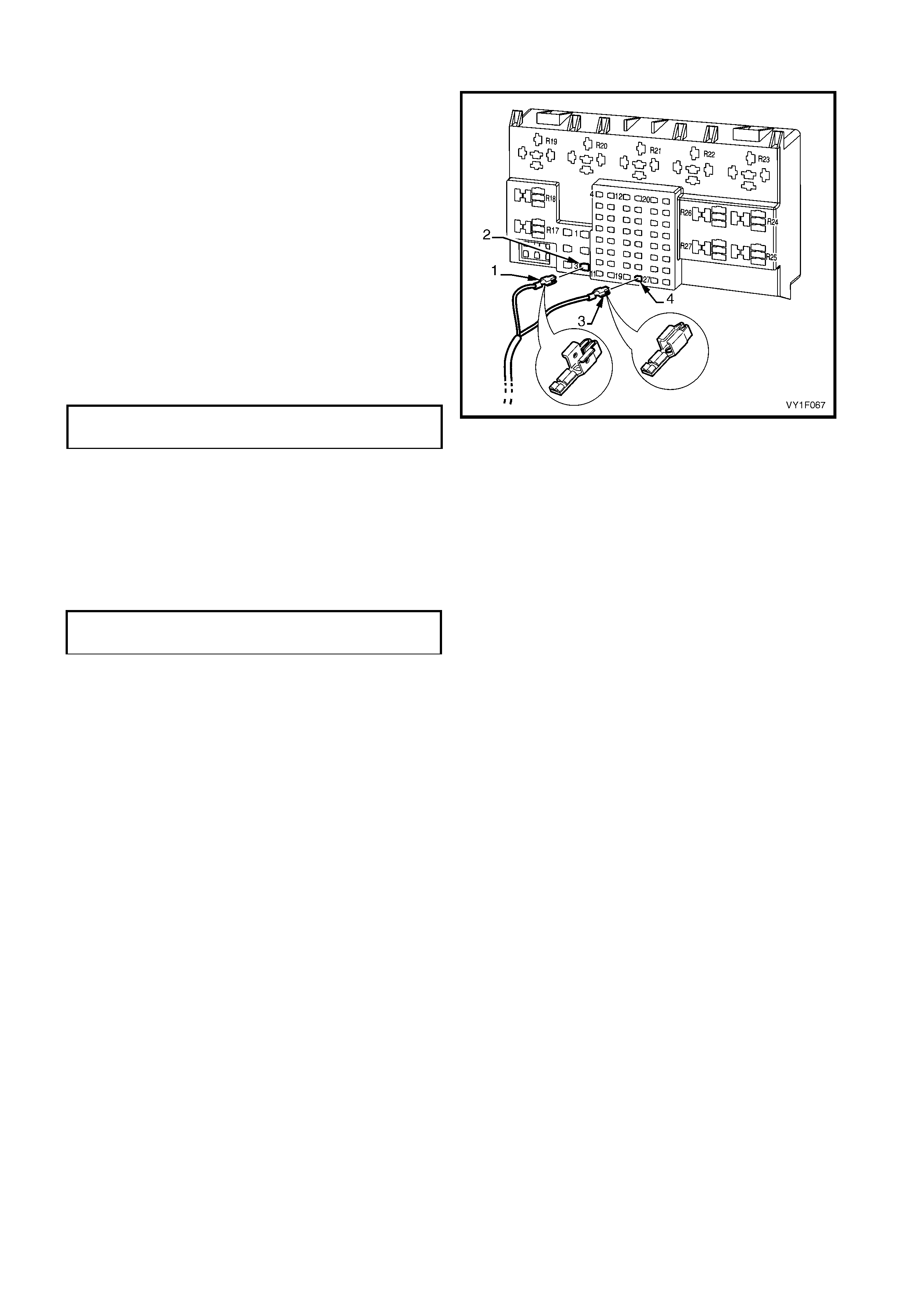

7. Gain access to the passenger compartment

fuse and relay panel assembly, refer to

Section 1A3, 3.4 INSTRUMENT PANEL LOWER

TRIM PANEL.

8. Disconnect the sunroof power harness

connectors (1 and 2) from the passenger

compartment fuse and relay panel assembly.

9. Remove the tape holding the sunroof power

harness (3) to the hinge pillar and remove the

harnesses.

Figure 1F-42

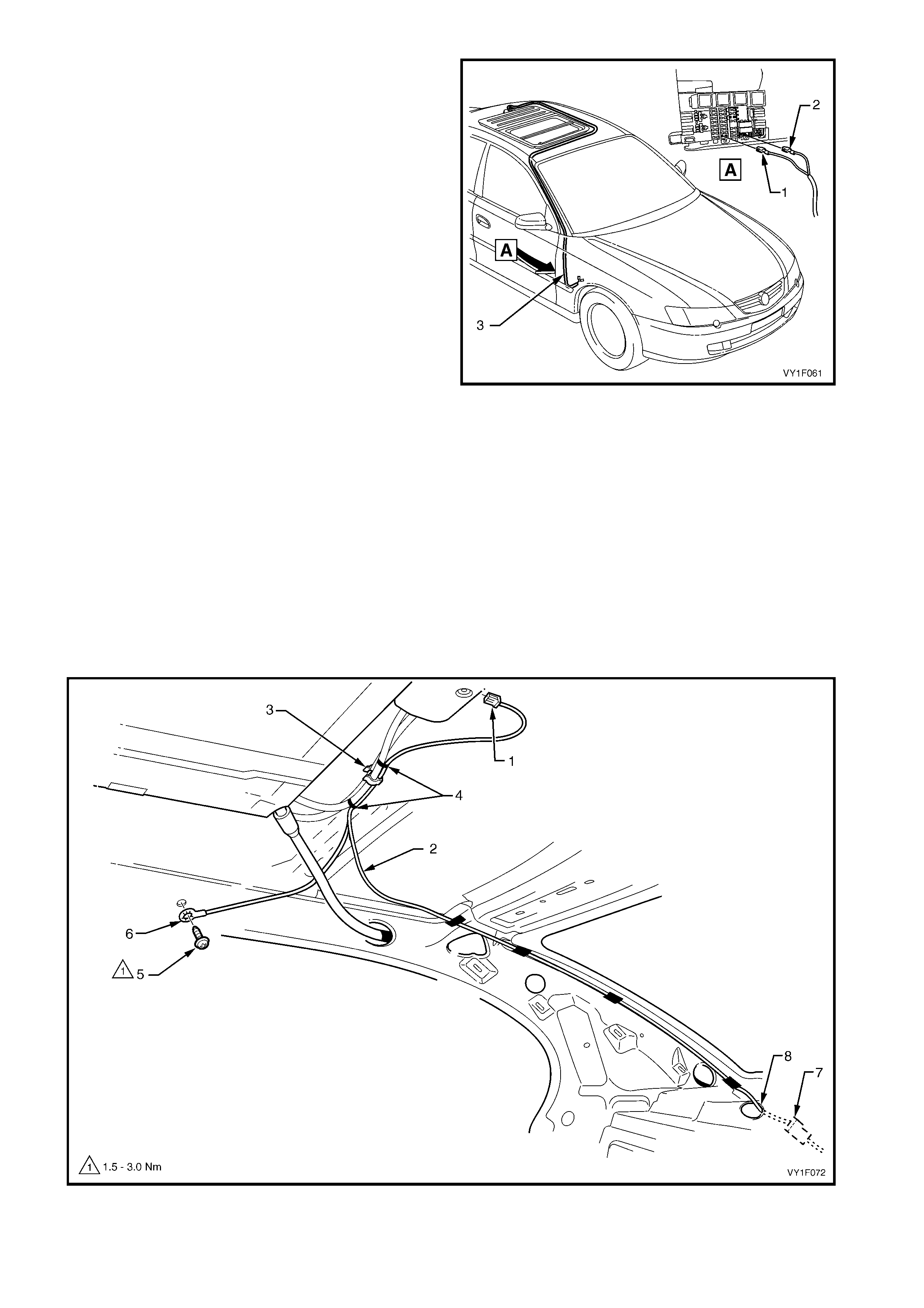

Configuration Two

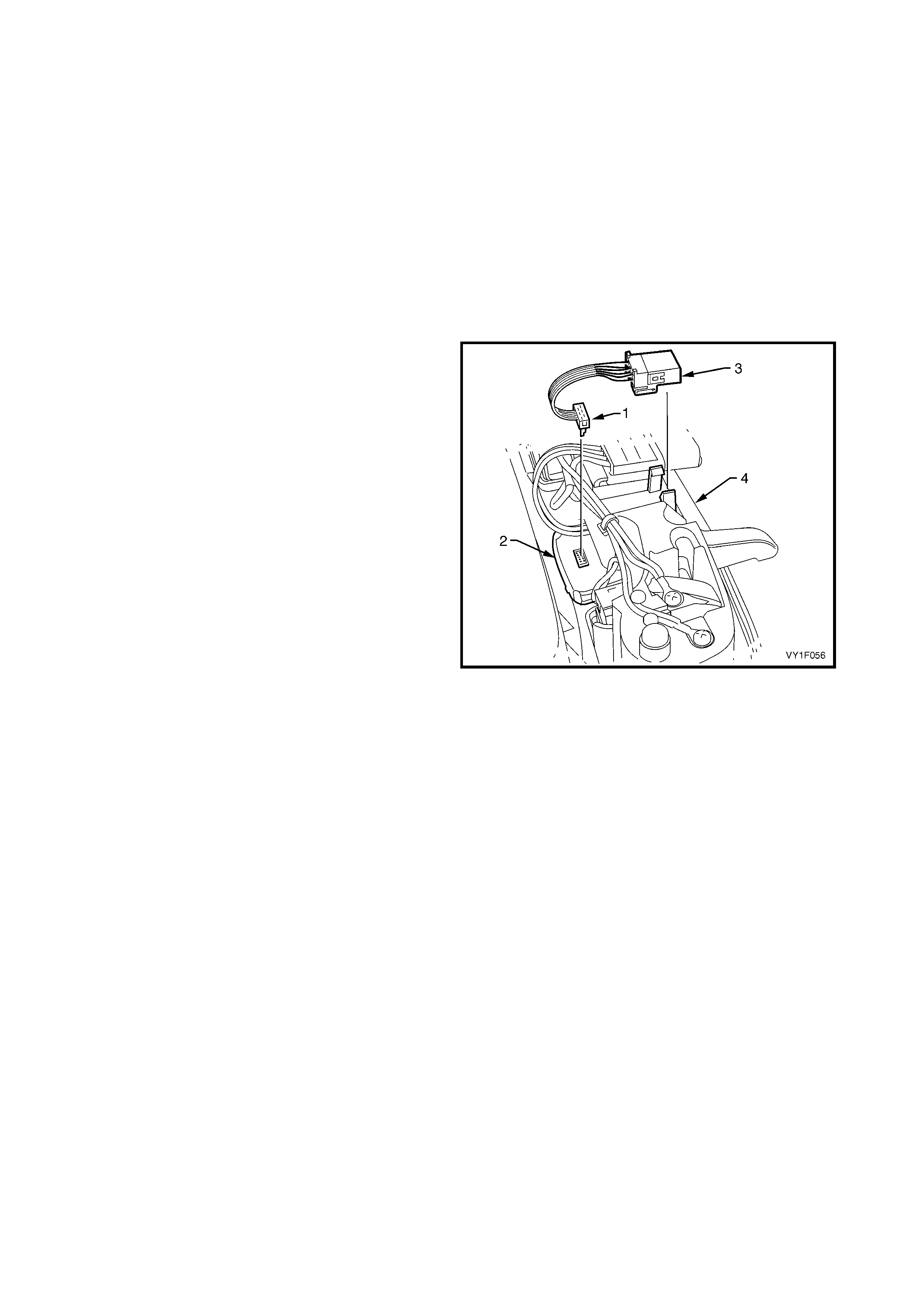

NOTE: This power harness configuration applies to HBD sunroofs installed after March 2003 on sedan vehicles

only .

1. Disconnect the SCU connector (1) from the SCU, refer to Figure 1F-43.

2. Unclip the sunroof power harness (2) from the sunroof drive cable guides plastic support clip (3) and remove

the cable ties (4).

3. Remove the self-tapping screw (5) securing the ground wire (6) to the inner side panel.

4. Untape the sunroof power harness from the C pillar, noting the position of the tape.

5. Partially remove the quarter inner rear side carpet from the rear compartment to expose the sunroof power

harness connector, refer to Section 1A 8, 2.17 QUARTER INNER REAR SIDE CARPET.

6. Disconnect the sunroof power harness connector (7) from the body harness connector.

7. Feed the sunroof power harness through the hole (8) in the parcel tray and remove.

Figure 1F-43

REINSTALL

Configuration One

Installation of the s unr oof power harnes s is the rever se

of the removal, noting the following:

1. Connect the harness to the passenger

compartment fuse and relay panel assembly with:

a. Winged terminal (1) (red wire) to circuit

breaker #3, port (2) X45 3_1

b. Non-winged terminal (3) (white wire) to spare

fuse #19, port (4) X43_19_1

Refer to 3.2 WIRING DIAGRAM – SUNROOF.

3. T ape the s unroof power harness to the hinge pillar

in the same way noted during removal.

4. Ensure that the ground connections are securely

attached to the left-hand inner side panel. Tighten

the screw to the specified torque.

Figure 1F-44

Configuration Two

Installation of the sunroof power harness is the reverse of the removal, noting the following:

1. Tape the sunroof power harness to the C pillar as noted during removal.

2. Sec ure the sunroof power harness to the sunroof drive cable guides plas tic support c lip (3) and c able tie to the

drive cable guides, refer to Figure 1F-43.

3. Ensure the ground connection is securely attached to the right-hand inner side panel. Tighten the screw to the

specified torque.

SUNROOF POWER HARNESS GROUND

SCREW TORQUE SPECIFICATION 1.5 – 3.0 Nm

SUNROOF POWER HARNESS GROUND

SCREW TORQUE SPECIFICATION 1.5 – 3.0 Nm

2.18 S UNROOF HARNESS

LT Section No. -

REMOVE

NOTE: The sunroof harness and the sunroof power harness are taped together and should be replaced as an

assembly.

1. Remove the sunroof harness with the sunroof power harness, refer to 2.17 SUNROOF POWER HARNESS.

REINSTALL

NOTE: The sunroof harness and the sunroof power harness are taped together and should be installed as an

assembly.

1. Install the sunroof harness with the sunroof power harness, refer to 2.17 SUNROOF POWER HARNESS.

2.19 SUNROOF CONTROL HARNESS

LT Section No. -

REMOVE

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the roof console. Refer to:

• Section 1A8, 2.11 ROOF CONSOLE –

SEDAN

• Section 1A8, 3.14 ROOF CONSOLE –

WAGON

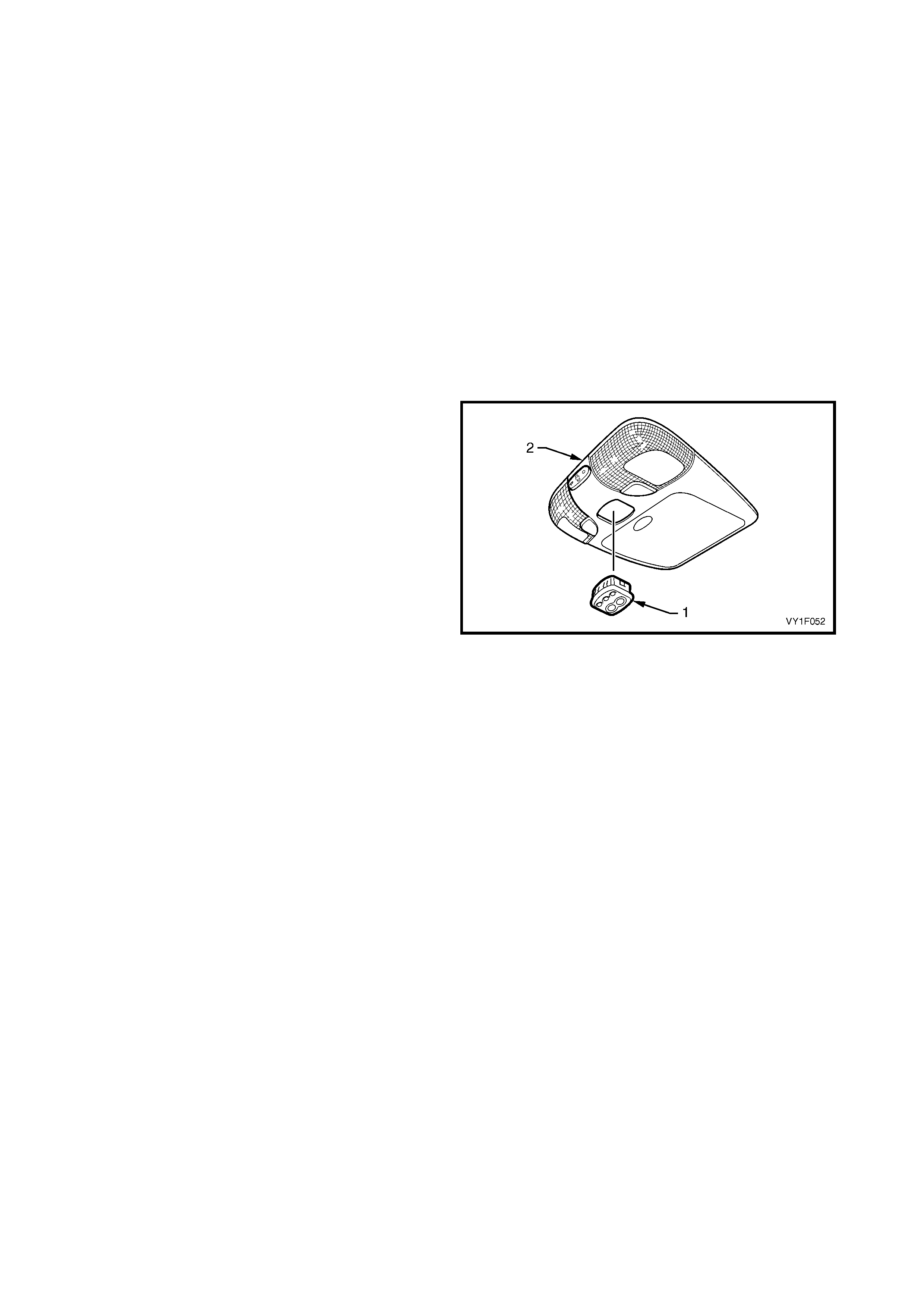

3. Disconnect the sunroof control harness connector

(1) from the sunroof switch (2) and unclip the

connector (3) from the roof console (4).

Figure 1F-45

REINSTALL

Installation of the sunroof control harness is the

reverse of the removal procedure.

2.20 SUNROOF SWITCH

LT Section No. -

REMOVE

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the roof console. Refer to:

• Section 1A8, 2.11 ROOF CONSOLE –

SEDAN

• Section 1A8, 3.14 ROOF CONSOLE –

WAGON

3. Remove the sunroof control harness from the roof

console, refer to 2.19 SUNROOF CONTROL

HARNESS.

4. Carefully unclip the sunroof switch (1) from the

roof console (2).

Figure 1F-46

REINSTALL

Installation of the sunroof switch is the reverse of the

removal procedure.

NOTE : Should the situation arise where the battery

power is supplied to the sunroof before the sunroof

switch is connected to the SCU, only the sunroof

switch button ! and button " will operate. With the

ignition switch in the OFF position, the sunroof switch

has to be reset by removing and inserting the sunroof

circuit breaker F3 on the passenger com partment f use

and relay panel assembly, refer to Section 12O,

2.2 CIRCUIT BREAKERS.

2.21 REAR DRAIN TUBE – SEDAN

LT Section No. -

REMOVE

IMPORTANT: Take extreme care when removing the

headlining which has been modified and installed using

adhesive.

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the headlining, the body lock pillar garnish

and the rear window trim panel assembly, refer to

Section 1A8 HEADLINING AND INTERIOR

TRIM.

3. Partially remove the relevant rear compartment

side trim, refer to Section 1A8, 2.17 QUARTER

INNER REAR SIDE CARPET.

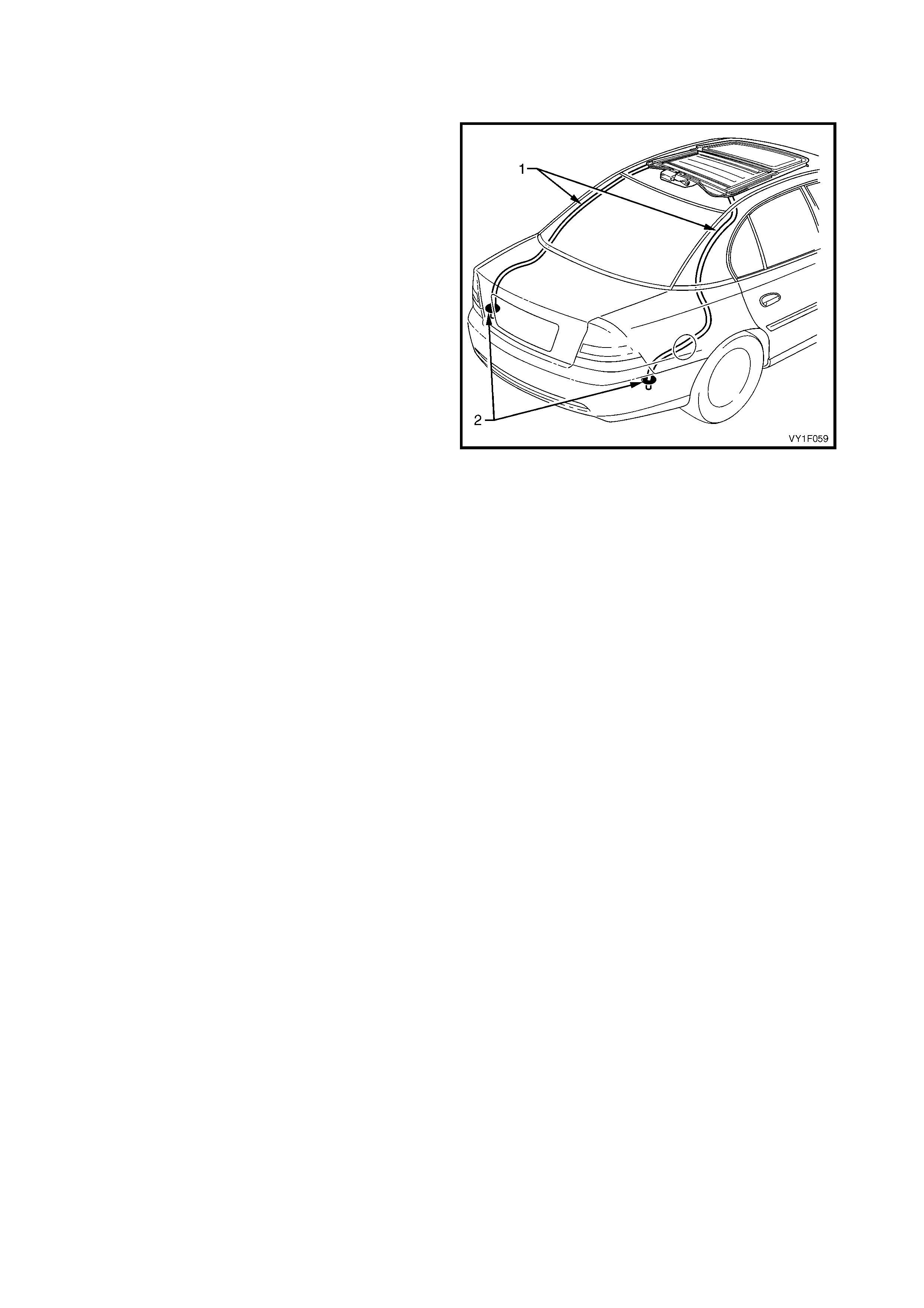

4. Remove the silicone from the rear drain tube exit

hole (2) in the quarter panel and pull the rear drain

tube (1) from the hole.

5. From within the passenger compartment,

disconnect the rear drain tube from the sunroof

assembly.

6. Pull the rear drain tube through the pillar and

remove.

Figure 1F-47

REINSTALL

Installation of the r ear drain tubes is the rever se of the

removal procedure, noting the following:

1. Ensure the rear drain tubes are clear from dirt and

debris and that they are free of kinks.

2. Apply non-acidic silicone to seal the rear drain tube

exit hole.

NOTE: Chlorinated rubber paint is applied to the panel

at the entry holes of the rear drain tubes, touch-up if

needed.

2.22 REAR DRAIN TUBE – WAGON

LT Section No. -

REMOVE

IMPORTANT: Take extreme care when removing the

headlining which has been modified and installed using

adhesive.

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the headlining and the body lock pillar

garnish, refer to Section 1A8 HEADLINING AND

INTERIOR TRIM.

3. Remove the relevant quarter inner tr im panel, ref er

to Section 1A8, 3.11 QUARTER INNER TRIM

PANEL ASSEMBLY.

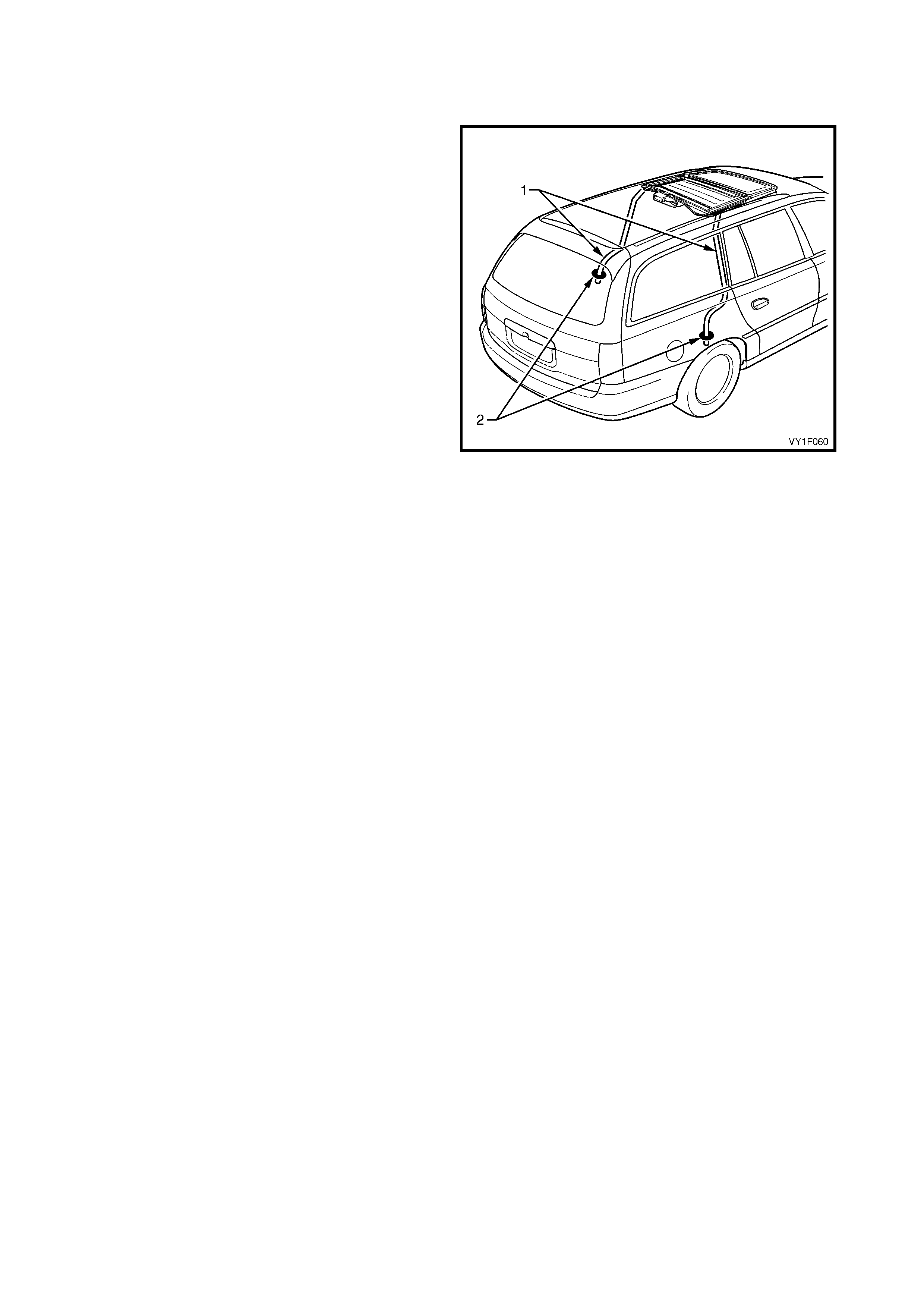

4. Remove the silicone from the rear drain tube exit

hole (2) in the wheel house liner and pull the rear

drain tube (1) from the hole.

5. From within the passenger compartment,

disconnect the rear drain tube from the sunroof

assembly.

6. Pull the rear drain tube through the pillar and

remove.

Figure 1F-48

REINSTALL

Installation of the r ear drain tubes is the rever se of the

removal procedure, noting the following:

1. Ensure the rear drain tubes are clear from dirt and

debris and that they are free of kinks.

2. Apply non-acidic silicone to seal the rear drain tube

exit hole.

NOTE: Chlorinated rubber paint is applied to the panel

at the entry hole of the rear drain tube in the pillar,

touch-up if needed.

2.23 FRONT DRAIN TUBE

LT Section No. -

REMOVE

IMPORTANT: Take extreme care when removing the

headlining which has been modified and installed using

adhesive.

1. Remove the sunroof circuit breaker F3 from the

passenger compartment fuse and relay panel

assembly, refer to Section 12O, 2.2 CIRCUIT

BREAKERS.

2. Remove the headlining, the front windshield side

garnish, and the hinge pillar tr im ass embly, refer to

Section 1A8 HEADLINING AND INTERIOR

TRIM.

NOTE: If required remove the PCM on V6 vehicles,

refer to Section 6C1-3, 2.1 POWERTRAIN CONTROL

MODULE, or remove the PIM on V8 vehicles, refer to

Section 6C3-3, 2.1 POWERTRAIN INTERFACE

MODULE (PIM).

3. Remove the silicone from the front drain tube exit

hole in the hinge inner pillar assembly (2) and pull

the front drain tube (1) from the hole.

4. From within the passenger compartment,

disconnect the front drain tube from the sunroof

assembly.

5. Pull the front drain tube through the upper side

panel and remove.

Figure 1F-49

REINSTALL

Installation of the front drain tube is the reverse of the

removal procedure, noting the following:

1. Ensure the f ront dr ain tubes are c lear f r om dirt and

debris and that they are free of kinks.

2. Apply non-acidic silicone to seal the front drain

tube exit hole in the hinge inner pillar assembly.

NOTE: Chlorinated rubber paint is applied to the panel

at the entry hole of the front drain tube in the upper

side panel, touch-up if needed.

3. DIAGNOSIS

IMPORTANT: The following diagnosis is applicable to HBD sunroofs equipped with a configuration one power

harness, r efer to 1. GENERAL INFORMAT ION. The diagnosis f or HBD sunroof s equipped with a configuration two

power harness and Online sunroofs are identical, refer to Section 1F2, 3. DIAGNOSIS.

3.1 FAULT DIAGNOSIS CHARTS

LT Section No.

INTRODUCTION

The s unroof is operated via a contr ol unit and a switch. T he control unit and the s witch are connec ted to each other

by two harnes ses that each have s ix wires. The glas s panel is activated by a drive motor which is connected to the

control unit. Battery voltage is supplied to the control unit through the ignition switch in the ON position or a circuit

breaker when the ignition switch is in the OFF position. These tests confirms the correct operation of the sunroof

and the serviceability of the switch, the control unit, the drive motor and associated circuits. For a complete wiring

diagram of the sunroof circuits , refer to 3.2 WIRING DIASGRAM - SUNROOF. For connec tor pin locations , ref er to

3.3 CONNECTOR DIAGRAM _ SUNROOF.

NOTE 1: The drive motor has an inbuilt thermal cut-out device that automatically switches the motor off during

period of overload. After a cool down period, the motor will function normally again.

NOTE 2: If the SCU fails and is replaced with a new unit, the first time the new SCU is connected to the power

supply it must be calibrated, refer to 2.4 CALIBRATING THE SUNROOF CONTROL UNIT.

NOTE 3: On completion of the electrical test and/or if the situation arise where only the sunroof switch button ! and

button " are operating, the sunroof switch has to be reset, refer to 2.20 SUNROOF SWITCH.

PREREQUISITES

SAFETY REQUIREMENTS

When operating the sunroof as part of any of the Steps in the diagnosis charts, ensure that fingers are clear of

moving parts.

EQUIPMENT

The following equipment is required to diagnose the sunroof:

1. An unpowered test lamp with a current draw of less than 3 A.

2. A digital multimeter with a minimum impedance of 10 MΩ.

TESTING PROCEDURES

The following points must be adhered to when performing diagnostic testing on components:

1. Care must be taken when using testing equipment to diagnose wiring harness connectors. It is preferred that

the technician back probe the connector to avoid terminal damage.

2. When tests are required on connector terminals, utilise the adapters in the connector adaptor kit KM–609 to

prevent damage to the terminals.

3. Unless the multimeter being used has an auto-ranging function, ensure that the correct range is selected.

4. When back-probing connectors, ensure the test lamp earth lead is connected to a suitable earth point on the

vehicle. Ensure that this earth point is not part of the circuit being tested.

IMPORTANT: When following the Steps in the diagnosis c harts , the exac t or der of Steps s hould be obs erved. If the

required nominal value or result is not achieved at any stage, the pr oblem m ust be rectified bef ore proceeding any

further.

FUNCTIONAL TEST

NOTE: If the glass panel stops at an unexpected position related to the sunroof switch function, the end position

cannot be reached, or one or more buttons of the sunroof s witc h do not operate properly any m ore, it is necessary

to recalibrate the SCU, refer to 2.4 CALIBRATING THE SUNROOF CONTROL UNIT.

TEST DESCRIPTION

The following numbers refer to the Steps in the diagnostic chart.

For functions description and a view of the sunroof switch buttons refer to 1. GENERAL DESCRIPTION and

Figure 1F-1.

1. Checks whether the sunroof operates correctly in the slide open and close mode.

2. Checks whether the sunroof operates correctly in the maximum tilt open and close mode.

3. Checks whether the sunroof operates correctly in the variable tilt mode.

4. Checks whether the sunroof operates correctly in the soft touch mode.

5. Checks whether the sunroof operates correctly in the auto-close mode.

6. Checks whether the sunroof operates correctly in the auto-close override mode.

7. Checks whether the sunroof operates correctly in the jamming protection mode.

8. Checks whether the sunroof operates correctly in the comfort position mode.

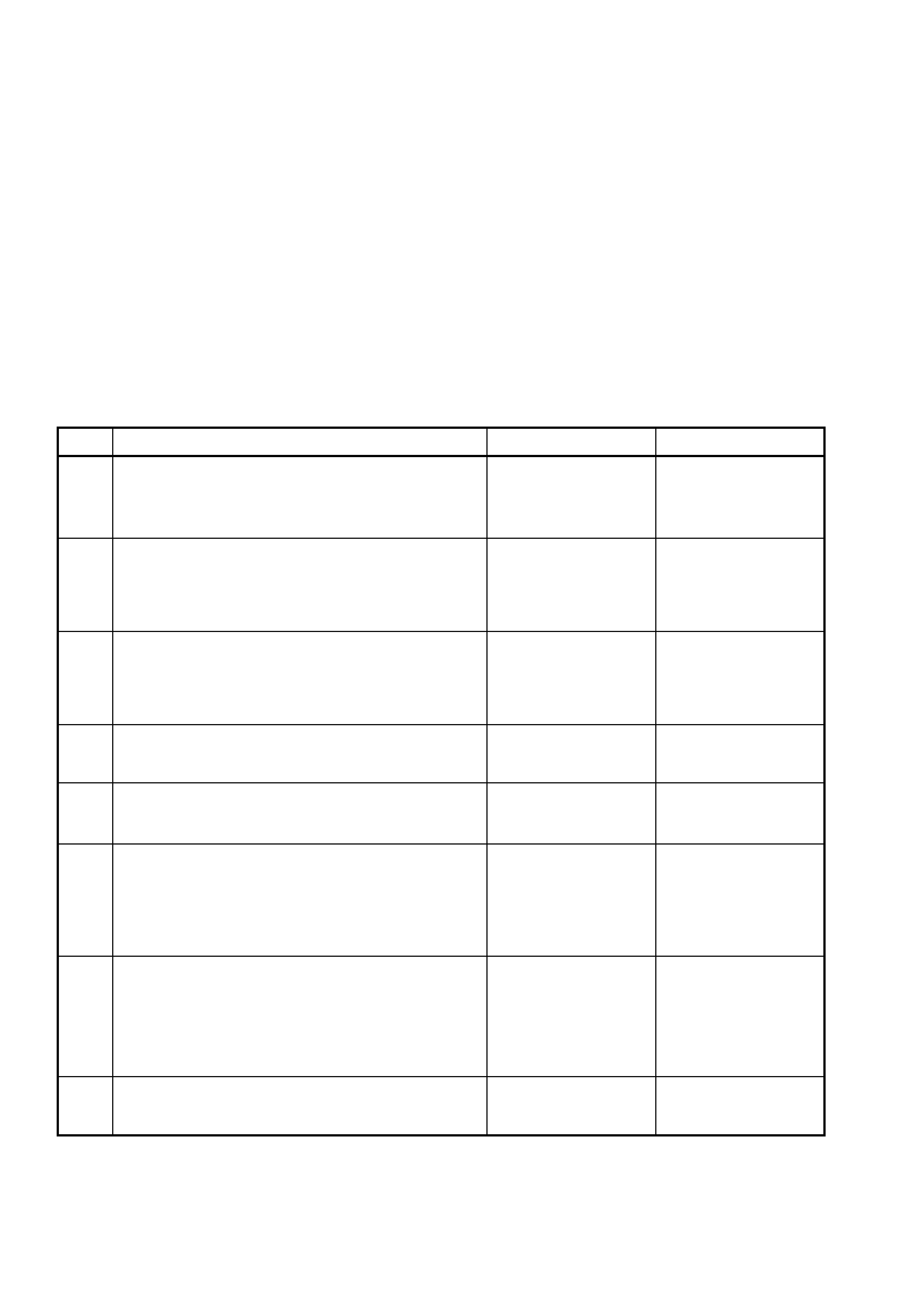

STEP ACTION YES NO

1. 1. Turn the ignition switch to the ON position.

2. Briefly press the ! button to open the glass panel.

3. Briefly press the C button to close the glass panel.

Does the glass panel slide fully open and then close?

Go to Step 2. Go to ELECTRICAL

TEST DESCRIPTION.

2. 1. Briefly press the " button to open the glass panel to

maximum tilt position.

2. Briefly press the C button to close the glass panel.

Does the glass panel open to maximum tilt position and

then close?

Go to Step 3. Go to ELECTRICAL

TEST DESCRIPTION.

3. 1. Briefly press the " button to open the glass panel to

maximum tilt position.

2. Press and hold the ! button, release it at the next

tilt position, repeat for all three/four tilt steps.

Does the variable tilt operation function correctly?

Go to Step 4. Go to ELECTRICAL

TEST DESCRIPTION.

4. 1. Perform the soft touch operation, refer to

1. GENERAL DESCRIPTION.

Does the soft touch operation function correctly ? Go to Step 5. Go to ELECTRICAL

TEST DESCRIPTION.

5. 1. Briefly press the ! button to open the glass panel.

2. Turn the ignition switch to the OFF position.

Does the sunroof close after three seconds? Go to Step 6. Go to ELECTRICAL

TEST DESCRIPTION.

6. 1. Briefly press the ! button to open the glass panel.

2. Turn the ignition switch to the OFF position.

3. Perform the auto-close override operation, refer to

1. GENERAL DESCRIPTION.

Does the auto-close override operation function

correctly?

Go to Step 7. Go to ELECTRICAL

TEST DESCRIPTION.

7. 1. Turn the ignition switch to the ON position.

2. Briefly press the ! button to open the glass panel.

3. Place an obstacle in the glass panel travel path.

4. Briefly press the C button to close the glass panel.

Does the glass panel automatically open when

encountering the obstacle and then try to close again?

Go to Step 8. Go to ELECTRICAL

TEST DESCRIPTION.

8. 1. Perform the comfort position operation, refer to

1. GENERAL DESCRIPTION.

Does the comfort position operation function correctly?

System serviceable.

Go to ELECTRICAL

TEST DESCRIPTION.

ELECTRICAL TEST

TEST DESCRIPTION

The following numbers refer to the Steps in the diagnostic chart.

1. Checks whether the sunroof operates correctly in any mode.

2. Checks that battery voltage is more than 11.5 V. The sunroof requires more than 11.5 V to operate correctly.

3. Checks that circuit breaker F3 within the passenger compartment fuse and relay panel assembly is not tripped.

4. Checks that fusible link F105 within the engine compartment fuse and relay panel assembly is serviceable.

5. Checks that fuses F10 and F19 within the passenger compartment fuse and relay panel assembly are

serviceable.

6. Checks whether there is battery voltage at connector A108 – X1 pin 1. Isolates whether the power supply

electrical circuits are at fault.

7. Checks whether there is battery voltage at connector A108 – X1 pin 3. Isolates whether the power supply

electrical circuits are at fault, with the ignition switch in the ON position.

8. Checks whether there is battery voltage at connector A108 – X1 pin 2. Isolates whether the ground circuit is at

fault.

9. Chec ks whether ther e is battery voltage at circuit breaker F3. Isolates whether sunroof power harness between

circuit breaker F3 and connector A108 – X1 pin 1 is at fault.

10. Chec ks whether there is battery voltage at fuse F19. Isolates whether sunr oof power harnes s between fuse F19

and connector A108 – X1 pin 3 is at fault.

11. Checks that the sunroof switch and sunroof control harness are serviceable.

12. Checks that the sunroof control harness is serviceable. Isolates whether the sunroof control harness or the

sunroof switch is at fault.

13. Checks whether there is correct voltage values at connector X321, with the ignition switch in the ON position.

14. Checks whether there is correct voltage values at connector X321, with the ignition switch in the OFF position.

15. Checks that the sunroof harness is serviceable. Isolates whether the sunroof harness or the SCU is at fault.

16. Checks whether there is battery voltage at connector A108 – X2 pin 2. Isolates whether the SCU is at fault.

17. Checks whether there is battery voltage at connector A108 – X2 pin 1. Isolates whether the drive motor or the

SCU is at fault.

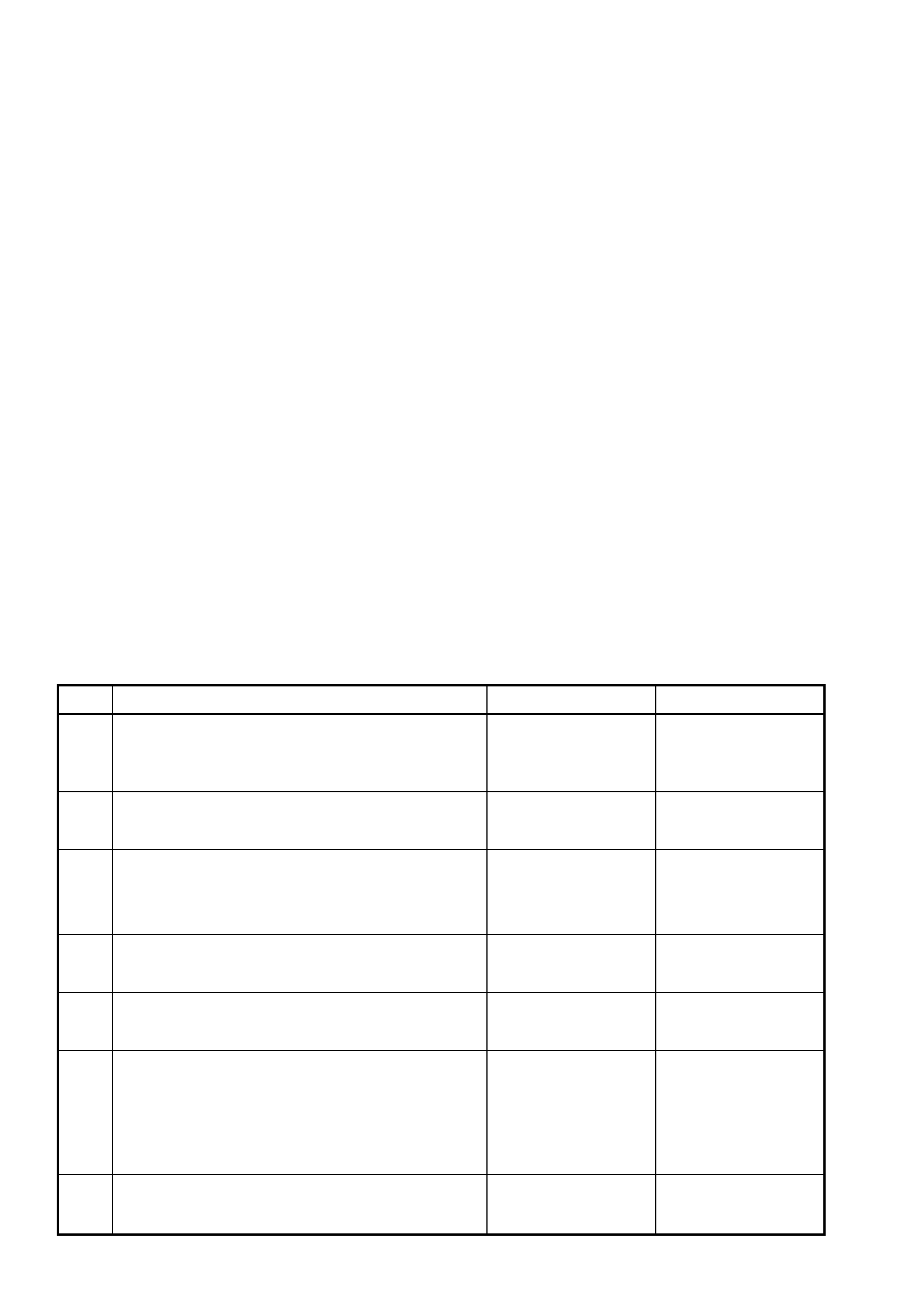

STEP ACTION YES NO

1. 1. Turn the ignition switch to the ON position.

2. Perform the sunroof functional test, refer to

FUNCTIONAL TEST DESCRIPTION.

Does the sunroof operate correctly in any mode?

Go to Step 11. Go to Step 2.

2. 1. Check the battery voltage, refer to Section 12A,

2.9 BATTERY.

Is the battery voltage more than 11.5 V? Go to Step 3. Refer to Section 12A,

2.9 BATTERY for

further diagnosis.

3. 1. Check the circuit breaker F3, refer to Section 12O,

2.2 CIRCUIT BREAKERS.

Is the circuit breaker F3 tripped?

Allow circuit breaker to

reset, refer to

Section 12O,

2.2 CIRCUIT

BREAKERS.

Go to Step 4.

4. 1. Check the fusible link F105, refer to Section 12O,

2.3 FUSIBLE LINKS.

Is the fusible link F105 serviceable? Go to Step 5. Replace the fusible link.

5. 1. Check fuses F10 and F19, refer to Section 12O,

2.1 FUSES.

Are the fuses F10 and F19 serviceable? Go to Step 6. Replace the fuse.

6. 1. Remove the headlining, refer to Section 1A8,

! 2.12 HEADLINING ASSEMBLY (sedan)

! 3.15 HEADLINING ASSEMBLY (wagon)

2. Back probe SCU connector A108 – X1 pin 1 with a

test lamp.

Does the test lamp illuminate?

Go to Step 7. Go to Step 9.

7. 1. Back probe SCU connector A108 – X1 pin 3 with a

test lamp.

Does the test lamp illuminate? Go to Step 8. Go to Step 10.

STEP ACTION YES NO

8. 1. Back probe SCU connector A108 – X1 pin 2 with a

test lamp.

Does the test lamp illuminate?

There is a fault in

sunroof power harness

ground circuit.

Repair or replace

sunroof power harness

ground circuit.

Go to Step 11.

9. 1. Probe connector X129 – X45 pin 2 with a test lamp.

Does the test lamp illuminate? There is a fault in

sunroof power harness

circuit between circuit

breaker F3 and

connector A108 – X1

pin 1.

Repair or replace

sunroof power harness

circuit.

There is a fault in

circuits 342 or 1.

Repair or replace

circuits 342 or 1.

10. 1. Probe connector X129 – X43 pin 2 with a test lamp.

Does the test lamp illuminate? There is a fault in

sunroof power harness

circuit between

fuse F19 and connector

A108 – X1 pin 3.

Repair or replace

sunroof power harness

circuit.

There is a fault in

circuits 4, 1640, 342, 1

or switch S149.

Repair or replace

circuits 4, 1640, 342, 1

or switch S149.

11. 1. If not previously carried out, remove the roof

console, refer to Section 1A8,

• 2.11 ROOF CONSOLE – SEDAN

• 3.14 ROOF CONSOLE – WAGON

2. Check the sunroof switch and sunroof control

harness for continuity, refer to ERROR! NOT A

VALID BOOKMARK SELF-REFERENCE..

Are the sunroof switch and sunroof control harness

serviceable?

Go to Step 13. Go to Step 12.

12. 1. Remove the sunroof control harness, refer to 2.19

SUNROOF CONTROL HARNESS.

2. W ith a multimeter, check for continuity of the sunroof

control harness, between connectors X321 and

S228 – X1.

Is the sunroof control harness serviceable?

Replace the sunroof

switch.

Refer to 2.20

SUNROOF SWITCH.

Replace the sunroof

control harness.

Refer to 2.19

SUNROOF CONTROL

HARNESS.

13. 1. Turn the ignition switch to the ON position.

2. With a multimeter, attach the negative lead to a

suitable earth point.

3. Probe the multimeter positive lead successively to

each pin of sunroof harness connector X321 and

take a reading.

Do the readings indicate:

• battery voltage on pin 1,

• 6.5 V on pin 2,

• 0 V on pins 3 and 4, and

• 6 V on pins 5 and 6?

Tolerances are +/- 0.1 V.

Go to Step 14. Go to Step 15.

14. 1. Turn the ignition switch to the OFF position.

2. With a multimeter, attach the negative lead to a

suitable earth point.

3. Ten seconds after the ignition switch has been

turned to the OFF position, probe the multimeter

positive lead successively to each pin of sunroof

harness connector X321 and take a reading.

Do the readings indicate:

• 1.7 V on pin 1,

• 0.3 V on pin 2, and

• 0 V on pins 3, 4, 5 and 6?

Tolerances are +/- 0.1 V.

Go to Step 16. Go to Step 15.

STEP ACTION YES NO

15. 1. Disconnect sunroof harness connector A108 – X3

from the SCU.

2. W ith a multimeter, check for continuity of the sunroof

harness, between connectors A108 – X3 and X321.

Is the sunroof harness serviceable?

Replace the SCU.

Refer to

2.3 SUNROOF

CONTROL UNIT (SCU).

Replace the harness.

Refer to

2.18 SUNROOF

HARNESS.

16. 1. With a test lamp, back probe connector M16 – X2

pin 2.

2. Briefly press the ! button on the sunroof switch.

Does the test lamp illuminate?

Go to Step 17.

Replace the SCU.

Refer to

2.3 SUNROOF

CONTROL UNIT (SCU).

17. 1. With a test lamp, back probe connector M16 – X2

pin 1.

2. Briefly press the " button on the sunroof switch.

Does the test lamp illuminate?

Replace the motor.

Refer to

2.1 DRIVE MOTOR.

Replace the SCU.

Refer to

2.3 SUNROOF

CONTROL UNIT (SCU).

When all diagnosis and repairs are completed, check the system for correct operation.

SUNROOF SWITCH AND SUNROOF CONTROL HARNESS TEST

Depress the switch buttons and place the multimeter probe tips onto the pins of sunroof control harness

connector X321. Ensure reading is as indicated in the chart below. Refer to Figure 1F-50.

Dimension

Sunroof Switch and Sunr oof Control Harness

Depress Switch + Lead – Lead Indication

! button Pin 3 Pin 5 Continuity

" button Pin 3 Pin 2 Continuity

C button Pin 6 Pin 4 Continuity

1 button Pin 6 Pin 5 Continuity

2 button Pin 6 Pin 2 Continuity

Figure 1F-50

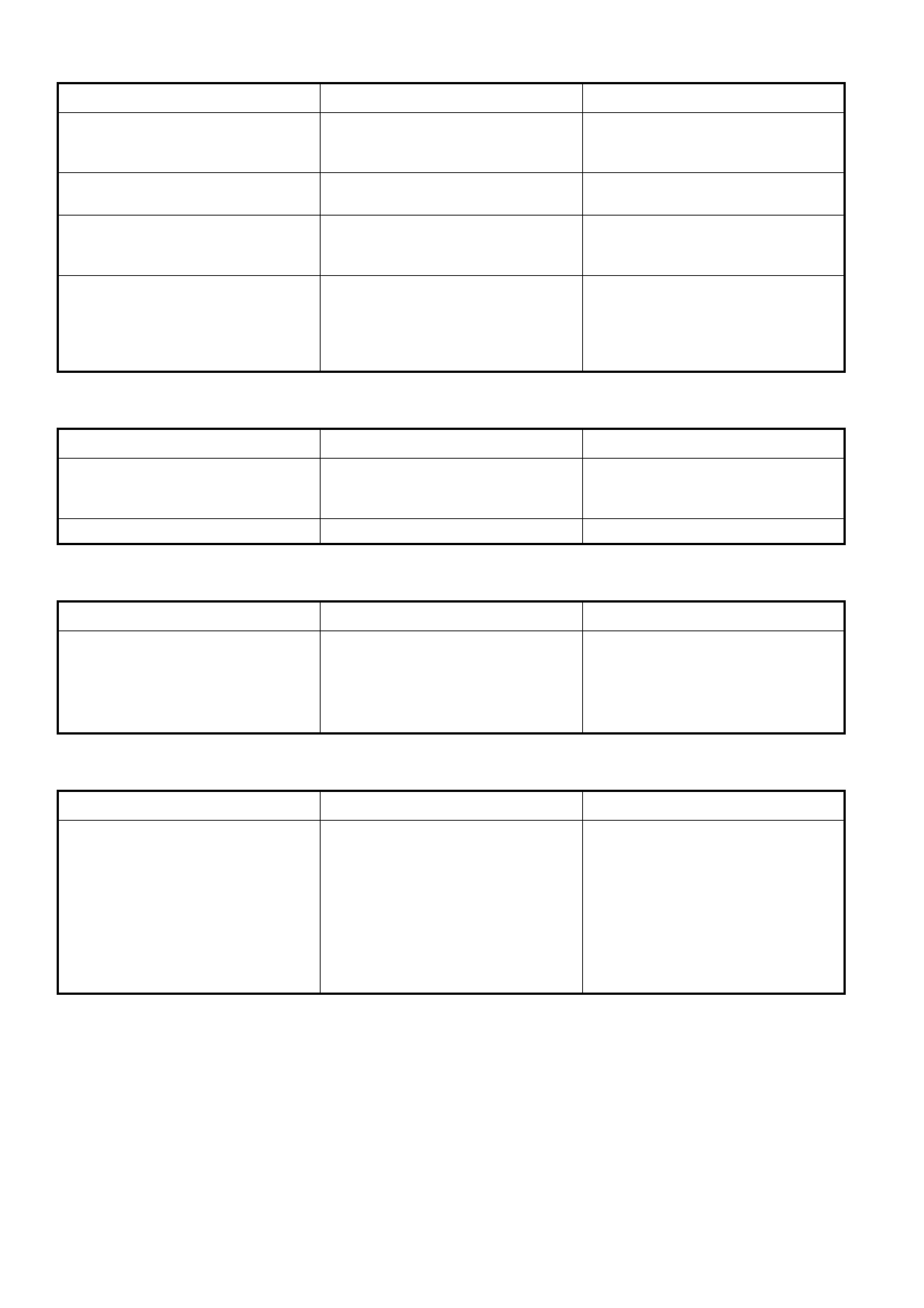

REPAIR ADVICE FOR MECHANICAL FAILURES

Problem Possible Cause Solution

While closing the panel from the tilt

position, the panel begins to slide

rearward.

Blocking catch is broken. Replace blocking catch, refer to

2.16 BLOCKING CATCH.

While closing the panel from the

fully opened position, the panel

begins to tilt under the roof skin.

Blocking catch is broken. Replace blocking catch, refer to

2.16 BLOCKING CATCH.

Panel is misaligned side to side. Timing of drive cables is incorrect. Re-time drive cables, refer to

2.13 TIMING OF DRIVE CABLES.

Panel is sliding too slowly. With a

13.5 V power supply, the panel

should not take more than 7

seconds to close from the fully

opened position.

1. Misaligned panel creating drag

or friction.

2. Dirty mechanism.

1. Re-time drive cables, refer to

2.13 TIMING OF DRIVE

CABLES.

2. Clean and grease mechanism

or replace if necessary.

Glass panel stops prematurely. Obstacle in mechanism or guide

rail. Remove obstacle.

Sunshade fails to open when the

glass panel is opened to tilt

position.

Retraction mechanism is broken. Replace retraction mechanism,

refer to 2.14 RETRACTION

MECHANISM.

REPAIR ADVICE FOR ELECTRICAL FAILURES

Problem Possible Cause Solution

The sunroof operates but the

auto-close and soft touch functions

do not operate.

Voltage-drop in power supply

(battery changed or bad battery ). Check power supply/battery, refer

to Section 12A, 2.9 BATTERY.

Clicking noises from the SCU and

the panel does not slide. Voltage too low. Check power supply /battery, refer

to Section 12A, 2.9 BATTERY.

SCU clicking in open position, but

the sunroof does not close with

continuous pressing of the button.

Voltage drop in power supply. Cut off power supply briefly

(remove fuse F105), reset

programmable positions.

Panel is sliding too slowly. With a

13.5 V power supply, the panel

should not take more than 7

seconds to close from the fully

opened position.

1. Weak battery.

2. Weak motor. Test as detailed

in this Section.

1. Charge or replace the battery.

2. Replace the drive motor, refer

to 2.1 DRIVE MOTOR.

REPAIR ADVICE FOR RATTLING NOISES

Problem Possible Cause Solution

Drain channel rattles. Check if insulator tape is applied

between drain channel and

mechanism.

Add insulator tape.

Rattling in motor area. Drive motor cover screws loose. Tighten drive motor cover screws.

REPAIR ADVICE FOR WIND NOISES

Problem Possible Cause Solution

Excessive wind noise when the

glass panel is in the closed

position.

1. Glass panel seal not fitting

securely against roof panel.

2. Blocking catch broken.

1. Adjust glass panel seal, refer to

2.8 RUBBER SEAL.

2. Replace the blocking catch,

refer to 2.16 BLOCKING

CATCH.

REPAIR ADVICE FOR WATER LEAKS

Problem Possible Cause Solution

Water coming through panel

opening area. 1. Blocked drain tube/s.

2. Misaligned or kinked drain

tubes.

1. Inspect drain tubes outlet. Blow

out drain tubes.

2. Correct routing of drain tubes,

refer to:

2.21 REAR DRAIN TUBE –

SEDAN,

2.22 REAR DRAIN TUBE –

WAGON,

2.23 FRONT DRAIN TUBE.

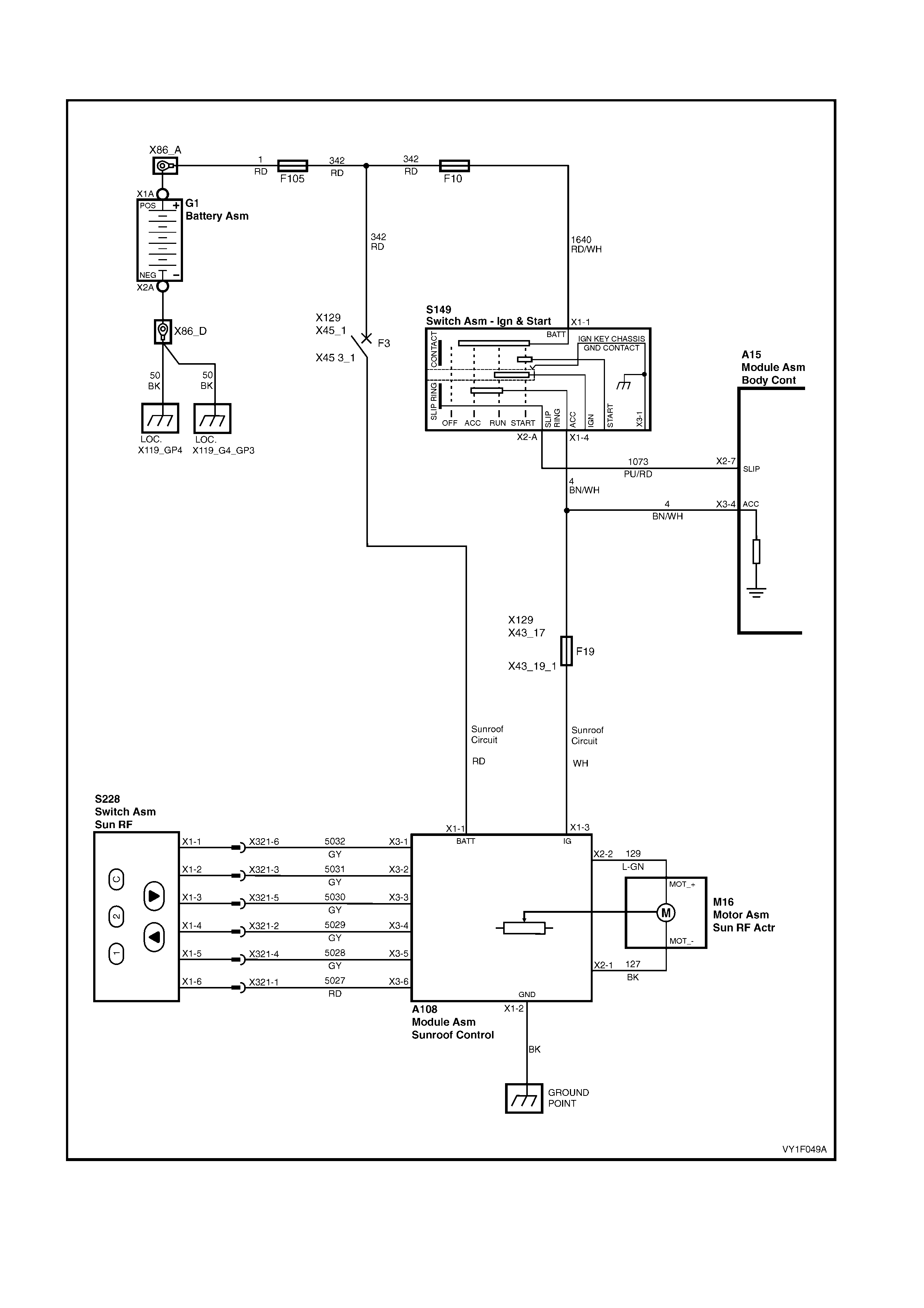

3.2 WI RING DIAGRAM – SUNROOF

Figure 1F-51

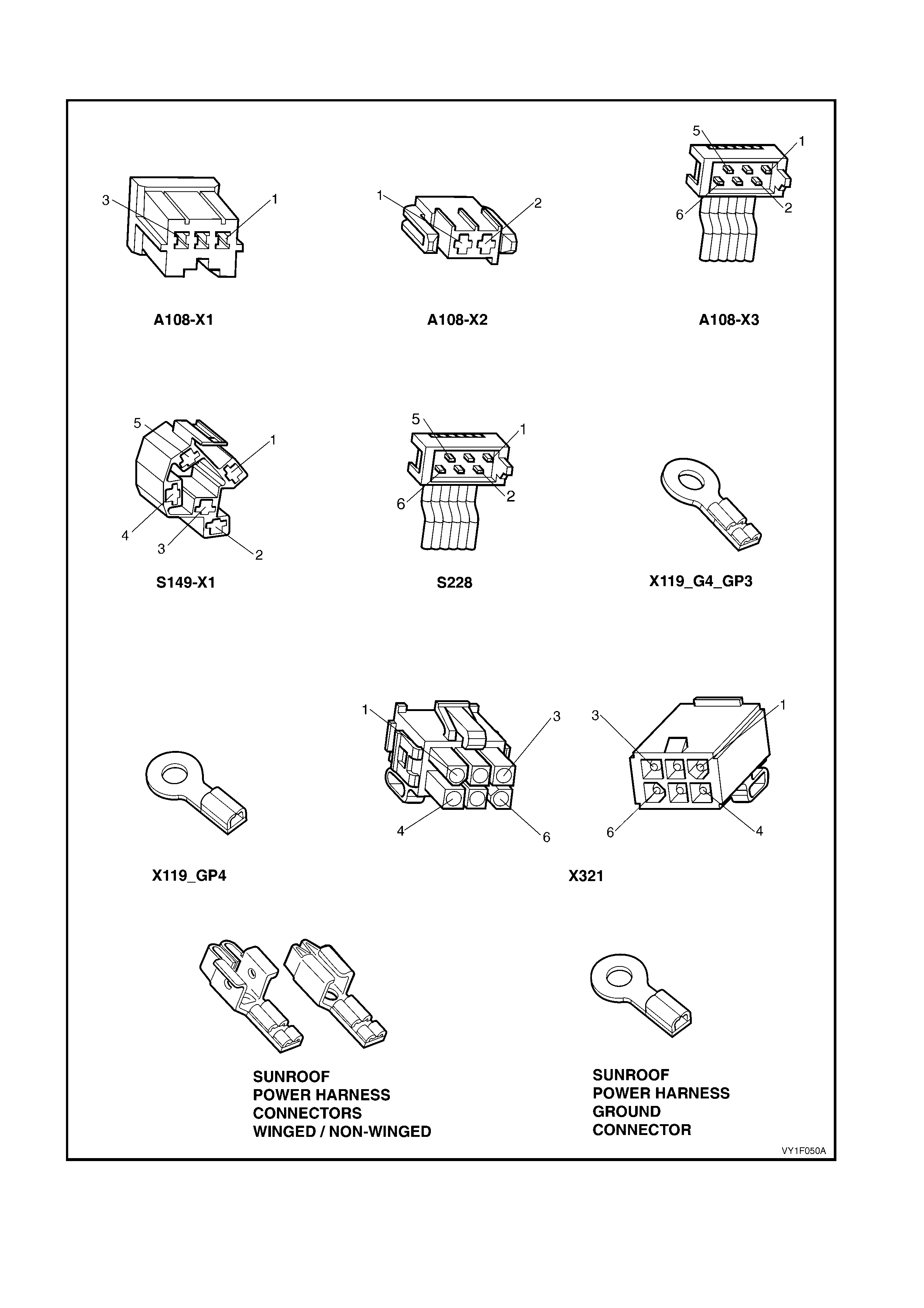

3.3 CONNECTOR DIAGRAMS – SUNROOF

Figure 1F-52

4. TORQUE WRENCH SPECIFI CATIONS

Drive motor cover Torx screw...............................................2.0 Nm

Drive gear box retainer Torx screw.......................................2.0 Nm

SCU retaining Torx screw.....................................................2.0 Nm

Glass panel retaining Torx screw..........................................3.5 Nm

Adjustment bracket retaining Torx screw..............................2.0 Nm

Exterior cover mounting nut..................................................1.8 – 2.2 Nm

Wind deflector attaching nut.................................................2.0 Nm

Drain channel Torx screw.....................................................0.6 – 1.0 Nm

Retraction mechanism Torx screw.......................................1.4 Nm

Retraction mechanism locating screw..................................0.5 Nm

Locator retaining Torx screw.................................................1.4 Nm

Sunroof power harness ground screw..................................1.5 – 3.0 Nm

Guide rail Torx screw............................................................1.4 Nm

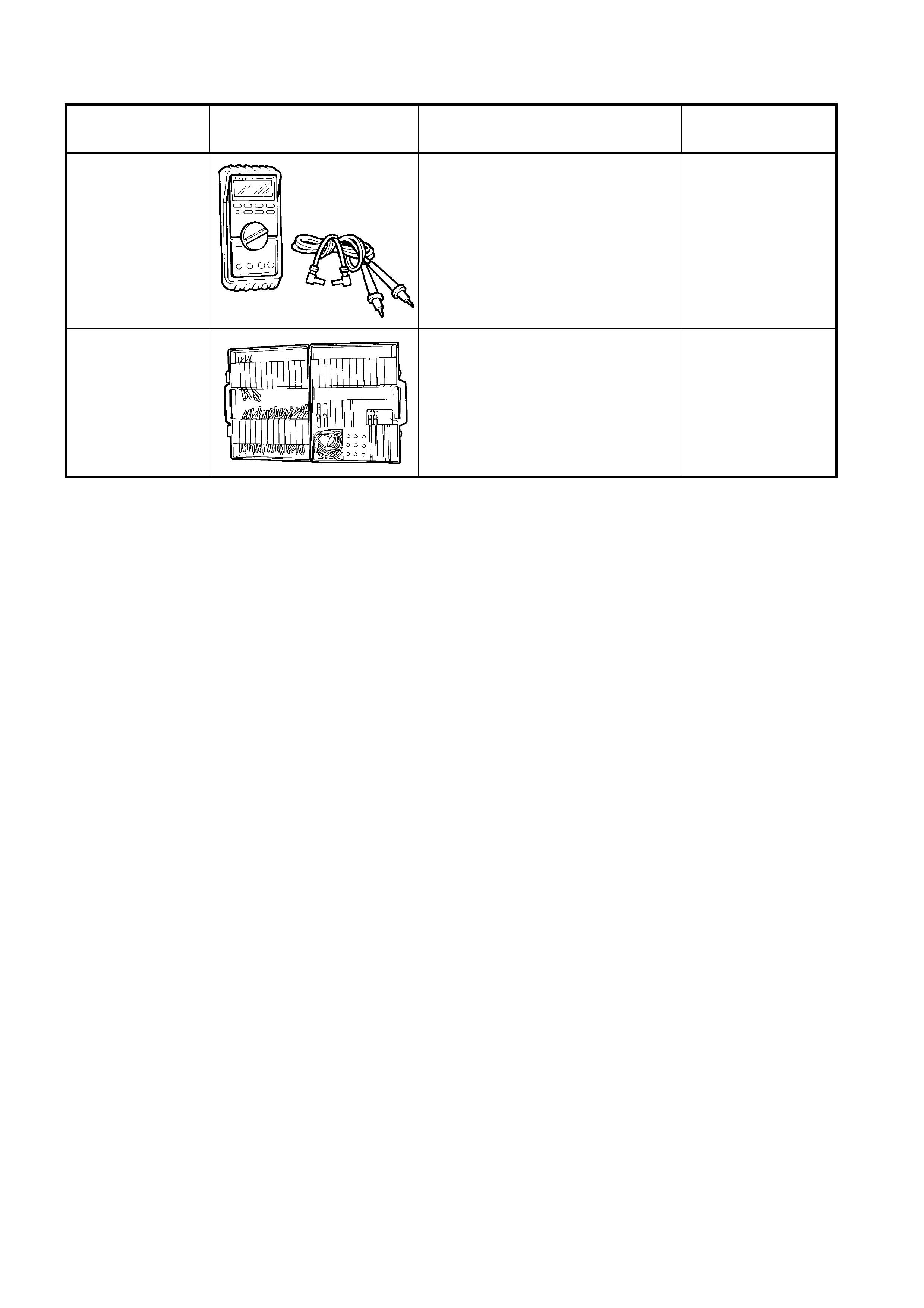

5. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J39200

(3588)

DIGITAL MULTIMETER

Tool no. J39200 previously

released, or use commercially

available equivalent. Must have 10

meg ohm input impedance.

Available

KM-609

(J35616-A)

ELECTRONIC KIT

Used in conjunction with a

multimeter for measuring voltages

and resistances without damaging

wiring harness connectors.

Desirable