SECTION 12B - LIGHTING SYSTEM

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

1.1 HEADLAMP ASSEMBLY

LEVEL 1 VEHICLES

LEVEL 2 AND LEVEL 3 VEHICLES

COUPE

1.2 TAIL LAMP ASSEMBLY

1.3 HIGH MOUNT STOP LAMPS

1.4 INTERIOR ILLUMINATION

LEVEL 1

LEVEL 2 AND 3

COUPE

1.5 INSTRUMENT AND SWITCH ILLUMINATION

HEADLAMP SWITCH

POLICE LIGHTS-OUT SWITCH

2. SERVICE OPERATIONS – EXTERIOR

ILLUMINATION

2.1 HEADLAMP AND FOG LAMP AIMING

HEADLAMP ASSEMBLY AIM

FRONT FOG LAMP ASSEMBLY AIM

2.2 HEADLAMP AND PARK LAMP

ASSEMBLY BULBS

LEVEL 1

LEVEL 2 AND LEVEL 3

COUPE

2.3 FRONT TURN SIGNAL LAMP BULB

REPLACE

2.4 FRONT FOG LAMP BULB ASSEMBLIES

LEVEL 3

SS

COUPE

2.5 TAIL LAMP ASSEMBLY BULBS

SEDAN

WAGON

COUPE

UTILITY

2.6 HEADLAMP ASSEMBLY

REMOVE

REINSTALL

2.7 FRONT FOG LAMP ASSEMBLY

LEVEL 3

SS

COUPE

2.8 TAIL LAMP ASSEMBLY

SEDAN

WAGON

COUPE

UTILITY

2.9 FRONT SIDE TURN SIGNAL LAMP

ASSEMBLY

REMOVE

REINSTALL

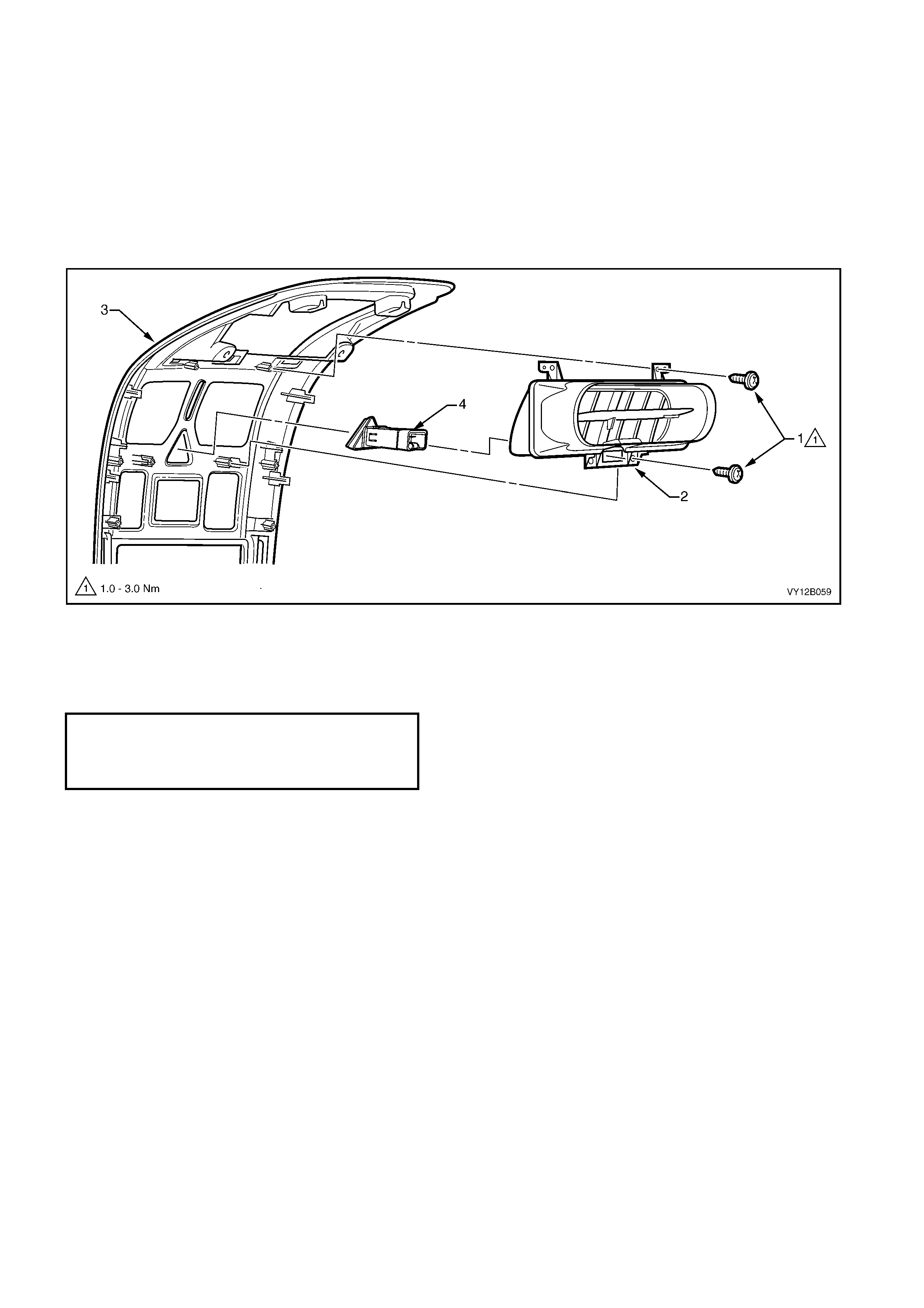

2.10 HIGH MOUNT STOP LAMP ASSEMBLY

SEDAN WITHOUT REAR END SPOILER

SEDAN WITH REAR END SPOILER

WAGON

COUPE

UTILITY

2.11 REAR LICENCE PLATE LAMP ASSEMBLY

REMOVE

REINSTALL

WIRING HARNESS, SEDAN

WIRING HARNESS, WAGON

WIRING HARNESS, COUPE

3. SERVICE OPERATIONS – INTERIOR

ILLUMINATION AND SWITCHING

3.1 SIDE DOOR COURTESY LAMP ASSEMBLY

REMOVE

REINSTALL

3.2 INSTRUMENT PANEL COMPARTMENT

LAMP ASSEMBLY

REMOVE

REINSTALL

3.3 INSTRUMENT PANEL COMPARTMENT

LAMP SWITCH ASSEMBLY

REMOVE

REINSTALL

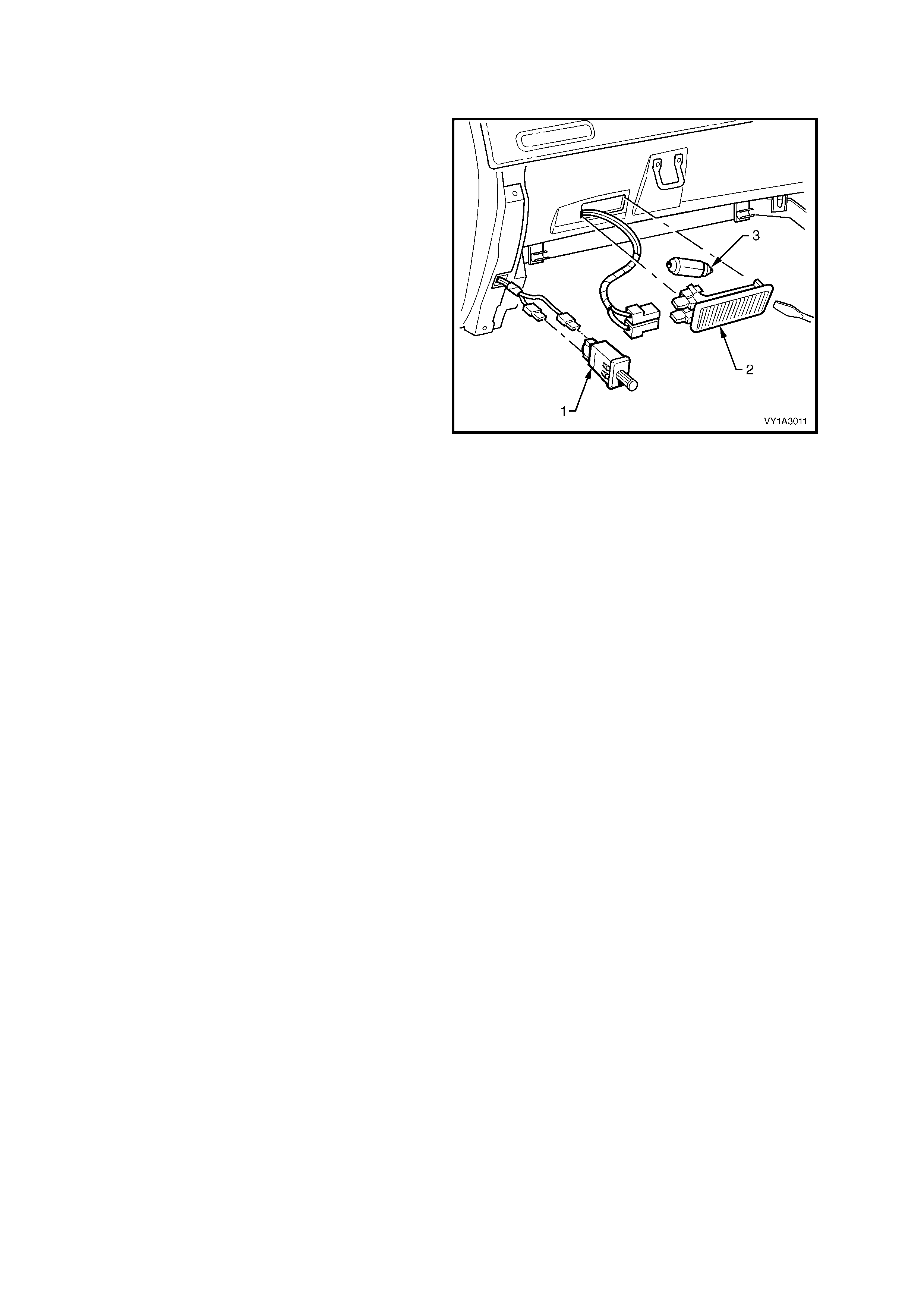

3.4 REAR COMPARTMENT COURTESY

LAMP ASSEMBLY

REMOVE

REINSTALL

3.5 REAR COMPARTMENT COURTESY

LAMP SWITCH ASSEMBLY

REMOVE

REINSTALL

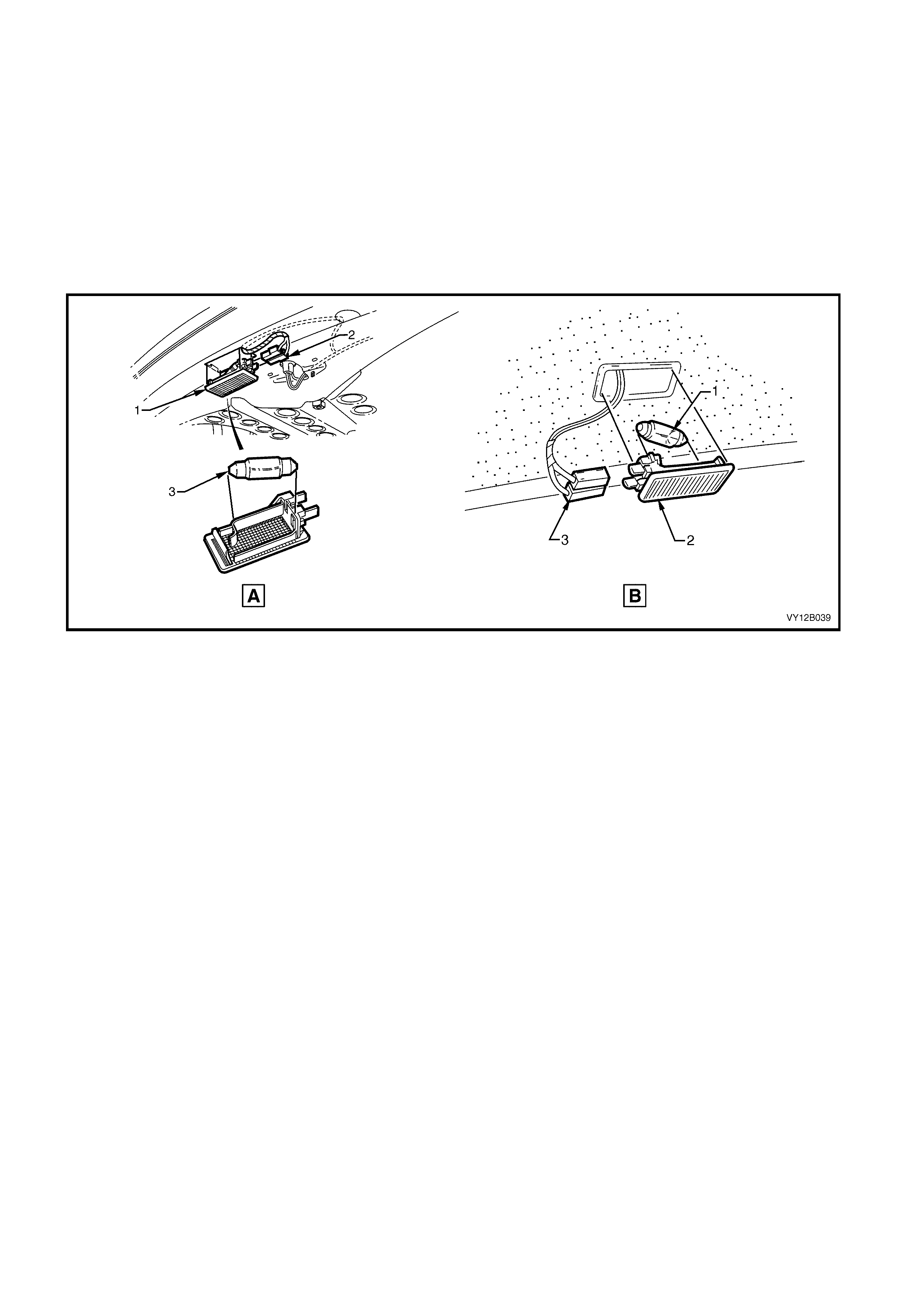

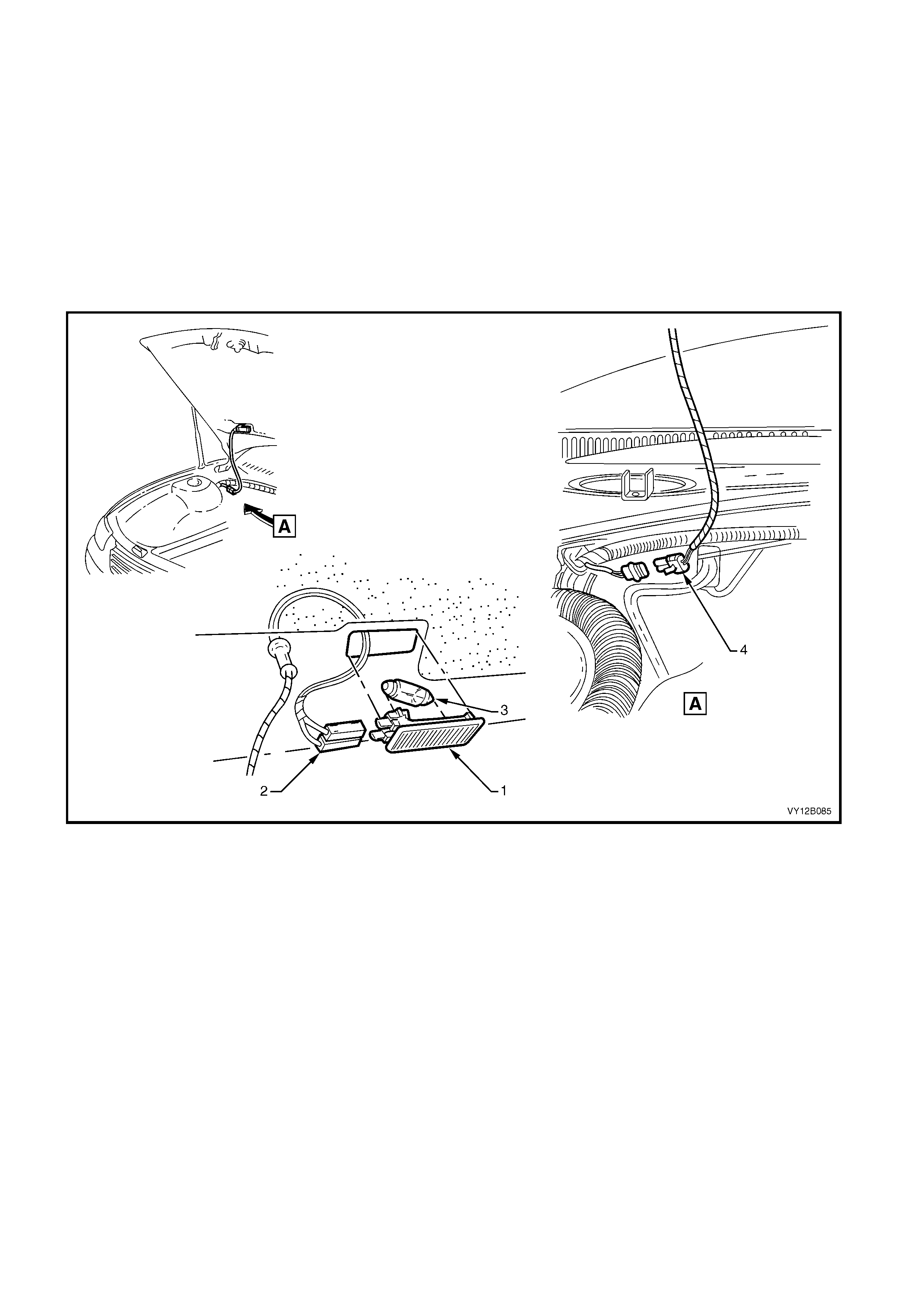

3.6 UNDER-HOOD LAMP ASSEMBLY

REMOVE

REINSTALL

3.7 UNDER-HOOD LAMP ASSEMBLY

WIRING HARNESS

REMOVE

REINSTALL

3.8 DOME LAMP ASSEMBLY

BULB REPLACE

REMOVE

REINSTALL

3.9 DOME AND READING LAMP ASSEMBLY

BULB REPLACE

REMOVE

REINSTALL

3.10 ROOF CONSOLE

BULB REPLACE

REMOVE

REINSTALL

Techline

Techline

Techline

Techline

Techline

Techline

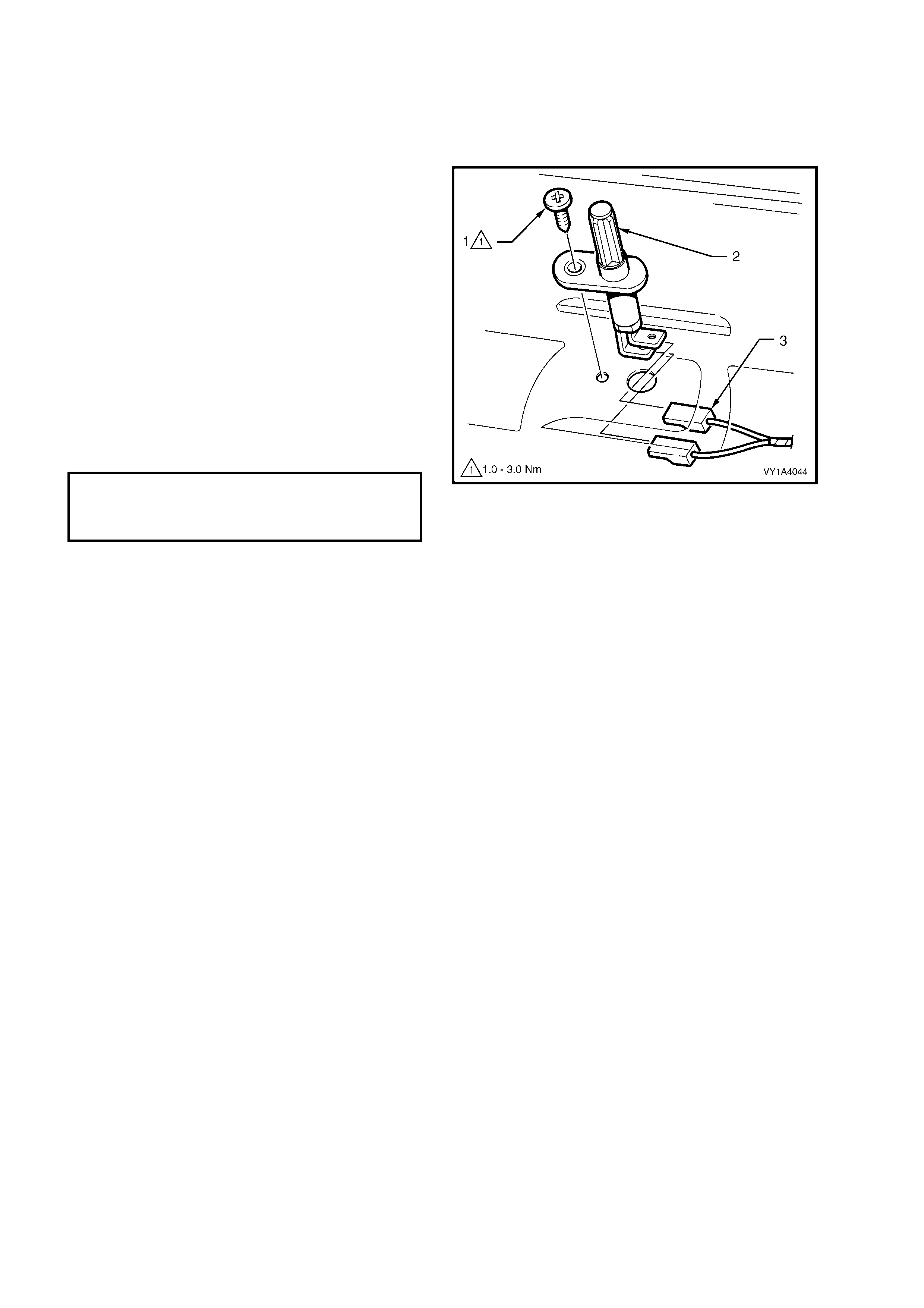

3.11 DOOR JAMB SWITCHES

REMOVE

REINSTALL

3.12 STEPWELL LAMPS

REPLACE

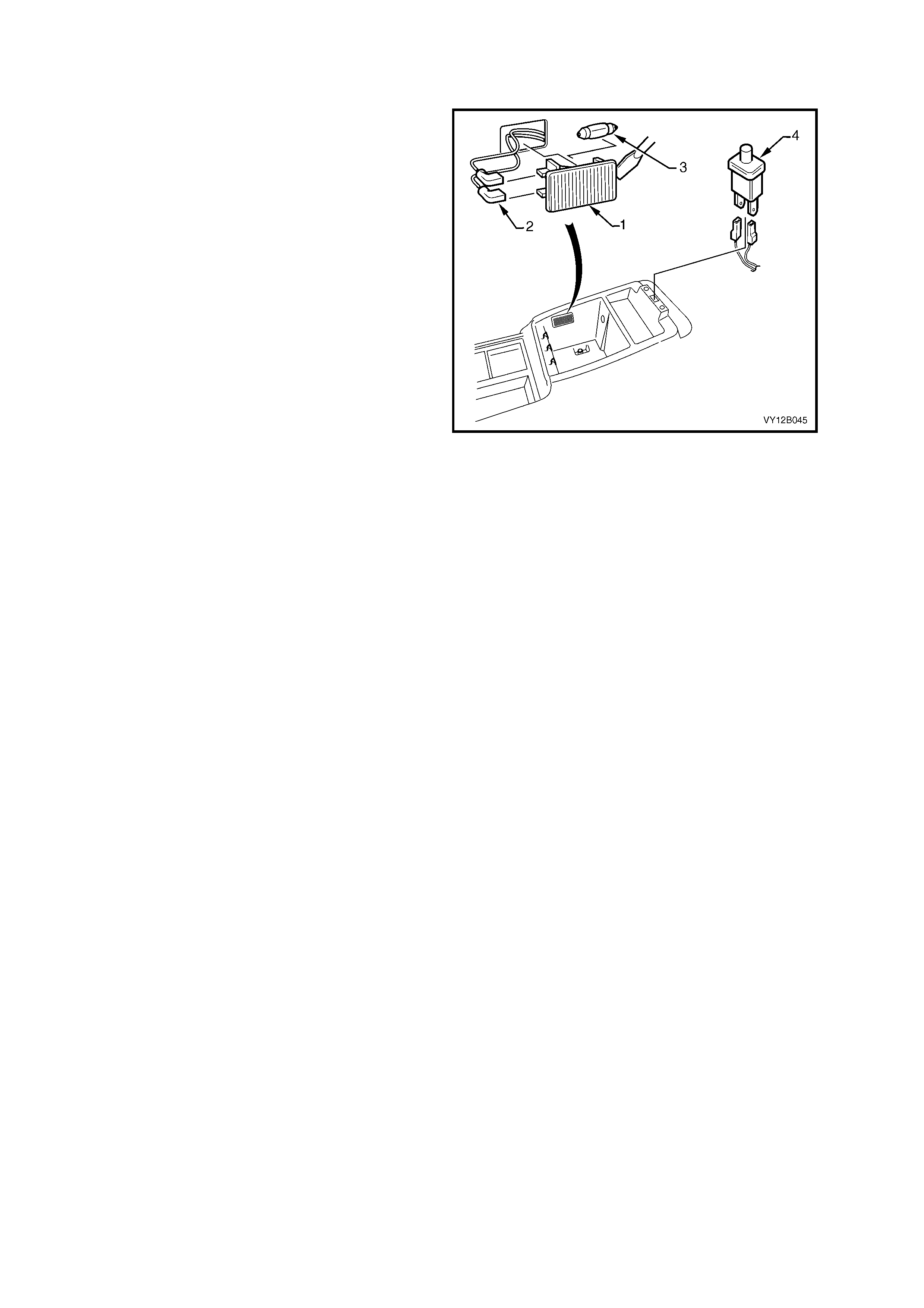

3.13 FLOOR CONSOLE COMPARTMENT

LAMP ASSEMBLY

REMOVE

REINSTALL

3.14 FLOOR CONSOLE COMPARTMENT

LAMP SWITCH ASSEMBLY

REMOVE

REINSTALL

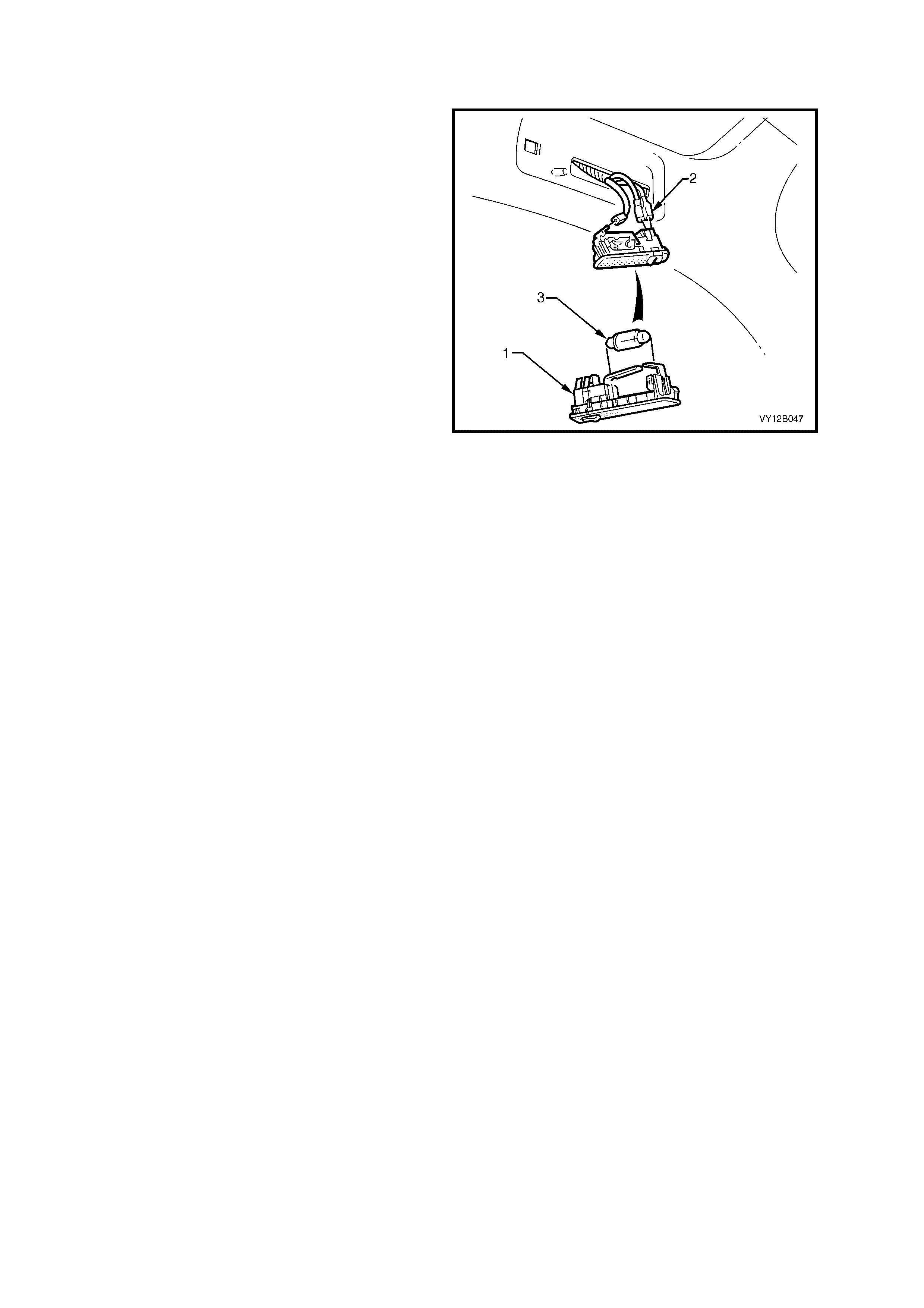

3.15 ROOF RAIL COURTESY AND READING

LAMP ASSEMBLY

REMOVE

REINSTALL

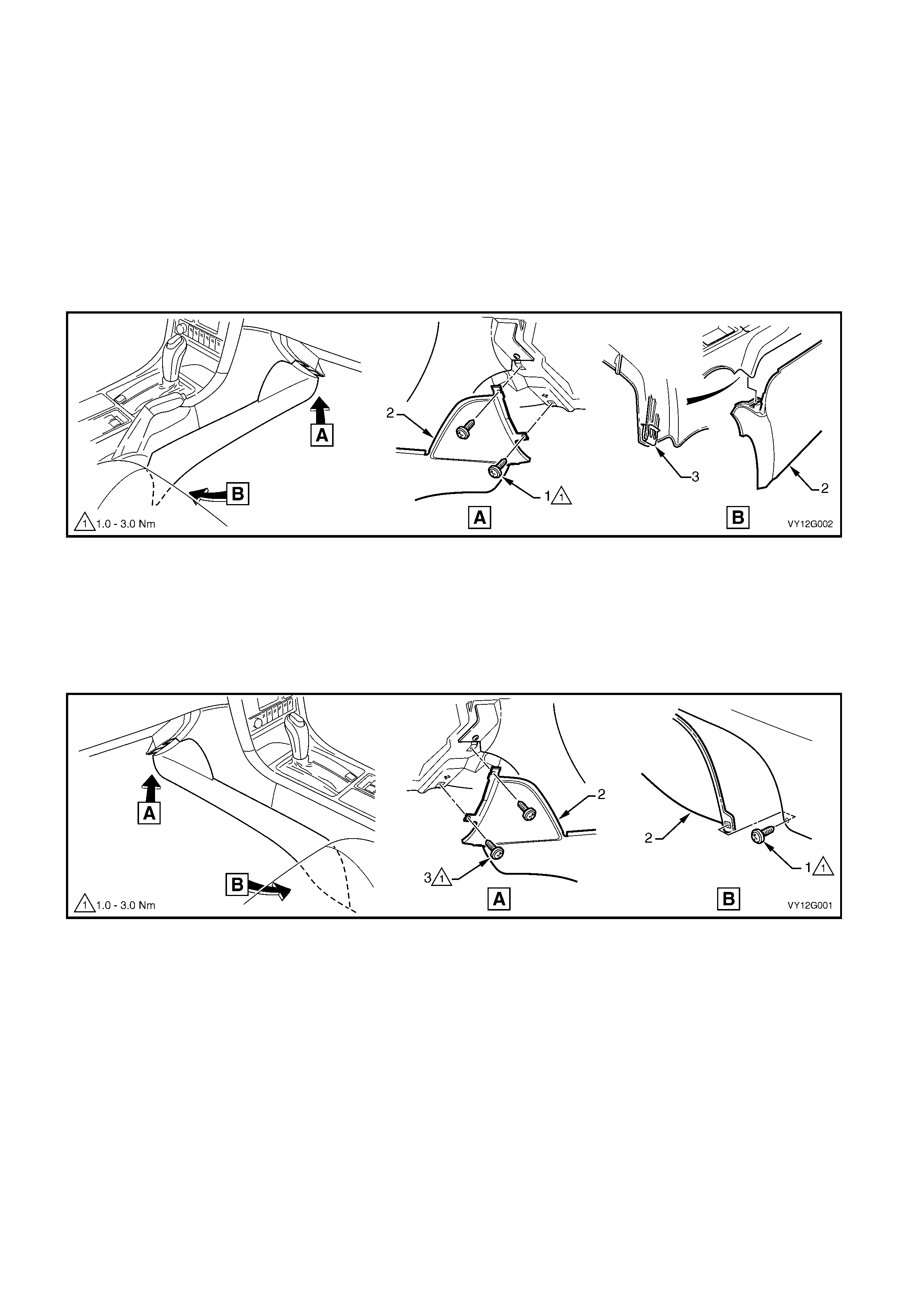

3.16 AUTOMATIC TRANSMISSION

CONTROL POSITION LAMP

REPLACE

3.17 IGNITION LOCK CYLINDER BULB

REPLACE

3.18 STOP LAMP SWITCH ASSEMBLY

REPLACE

TEST

3.19 SWITCH ILLUMINATION

AUXILIARY SWITCH BULBS

POWER AND TRACTION

CONTROL SWITCH BULBS

HAZARD WARNING SWITCH BULB

FUEL TANK FILLER DOOR

LOCK RELEASE SWITCH BULB, LHD

3.20 BACK-UP LAMP SWITCH

3.21 NEUTRAL SAFETY BACK-UP SWITCH

3.22 TURN SIGNAL SWITCH ASSEMBLY

REMOVE

REINSTALL

TESTING

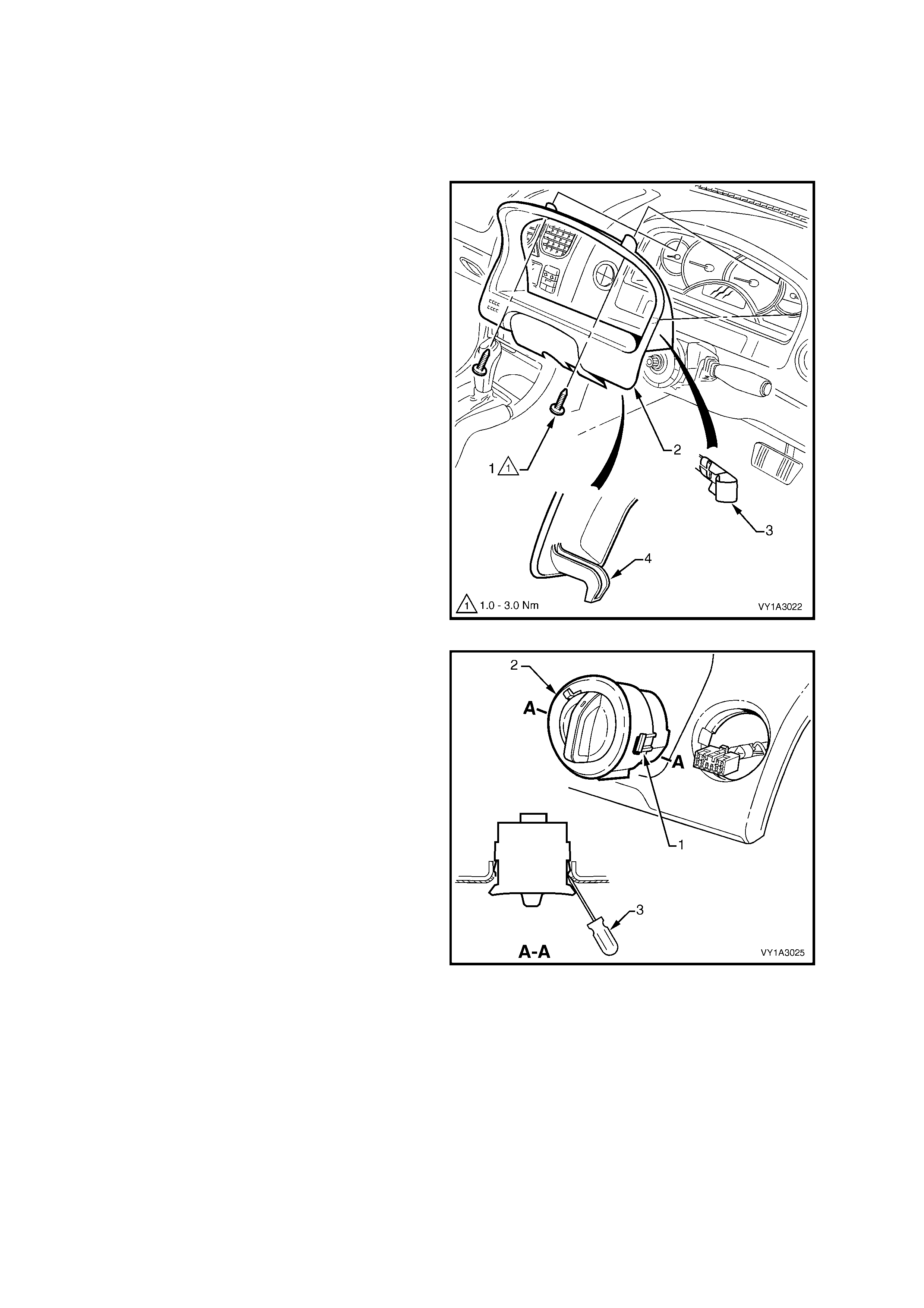

3.23 HEADLAM P SWITCH ASSEMBLY

REMOVE

REINSTALL

TESTING

3.24 DAYLIGHT RUNNING LAMP

ASSEMBLY (OPTION T82)

REMOVE

REINSTALL

TESTING

3.25 HAZARD WARNING SWITCH ASSEMBLY

REMOVE

REINSTALL

TESTING

3.26 PASSENGER COMPARTMENT FUSE

AND RELAY ASSEMBLY

ACCESS

COMPONENT LOCATION

3.27 ENGINE COMPARTMENT FUSE AND

RELAY PANEL ASSEMBLY

ACCESS

COMPONENT LOCATION

4. SPECIFICATIONS

5. TORQUE WRENCH SPECIFICATIONS

1. GENERAL DESCRIPTION

IMPORTANT: All illustrations in this Section represent a right-hand drive vehicle. For left-hand drive vehicles, any

procedure or item that is not a direct mirror of a right-hand drive vehicle in left-hand drive configuration, will be

highlighted and a procedure or illustration produced to accommodate the difference.

1.1 HEADLAMP ASSEMBLY

The headlamp ass emblies fitted to the MY 2003 VY Series vehic les and V2 Ser ies II Coupe inc orpor ate the lates t in

headlamp reflector technology. There are three basic headlamp geometries and each type is applicable to the

following groups of vehicles:

• Level 1

• Level 2 and Level 3 vehicles

• Coupe

Although the headlamp assemblies are visually different, they share the following common features:

• All are equipped with low beam, high beam, park and turn signal lamps.

• Beam movement in the vertical and horizontal axes is controlled by the same type of adjustment device.

• Turn signal bulb holders and main wiring connector are identical.

• Turn signal lamps are located on the outside extremities of the assembly.

• The high beam is located in the inboard side of the assembly.

• The low beam lamp is located outboard of the high beam lamp.

• The headlamp assemblies have common mounting holes, that is, they all require three screws in the same

locations to secure the assemblies to the sheetmetal.

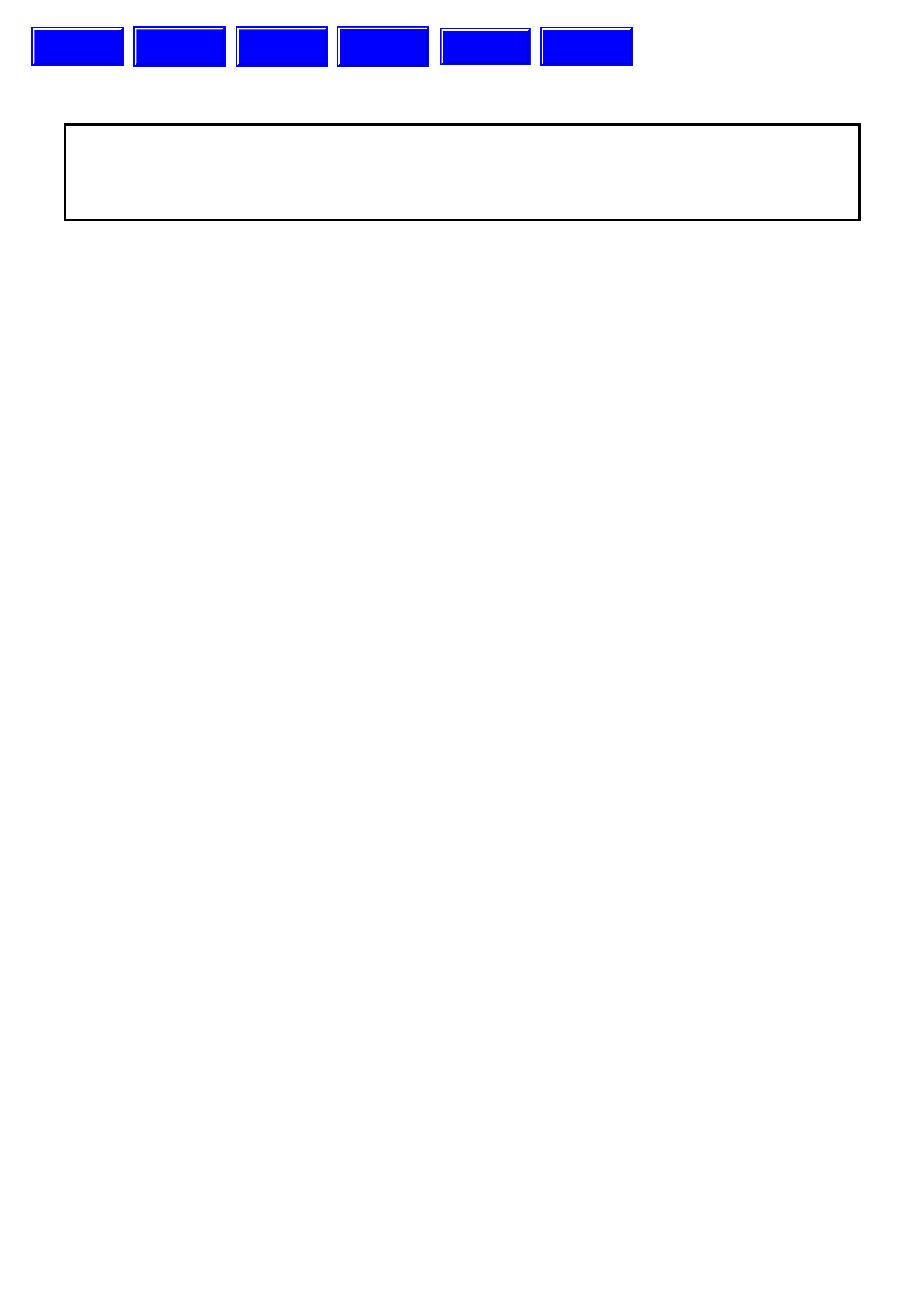

LEVEL 1 VEHICLES

Level 1 vehicle headlamp assemblies (refer to Figure 12B-1) have the following features, depending on particular

model specifications:

• The headlamps use complex reflector technology for low and high beam.

• Distinctive styling to suit the Level 1 vehicle bumper fascia.

• Chrome or black headlamp bezels.

• Single filament H1 and dual filament H4 specification globes are fitted to the inner and outer beam reflector

pockets respectively.

• T he park lamp is located on the lower edge of the assem bly, between the inner and outer reflector pockets, in

its own reflector housing.

Figure 12B-1

Legend

1. Turn Signal Lamp

2. Turn Signal Wiring Connector 3. Headlamp High Beam Bulb (H1)

4. Headlamp Main Wiring Connector 5. Park Lamp

6. Headlamp Low Beam Bulb (H4)

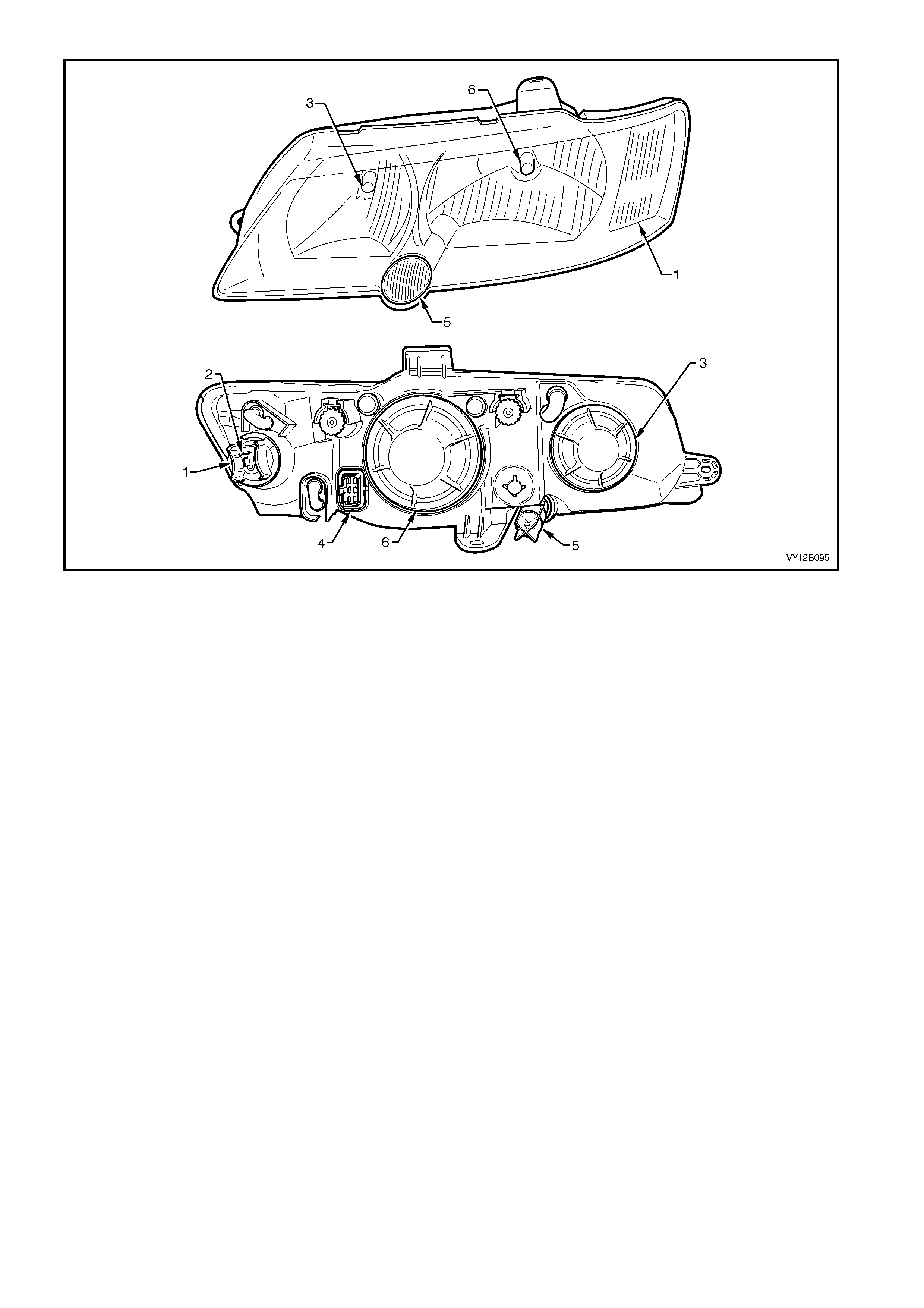

LEVEL 2 AND LEVEL 3 VEHICLES

The Level 2 and 3 vehicle headlamp assemblies (refer to Figure 12B-2) have the following features:

• Distinctive styling to suit the Level 2 and Level 3 vehicle bumper fascia.

• Chrome or black headlamp bezels.

• Single filament H9 and H11 specification globes for high and low beam reflector pockets respectively.

• The low beam uses projector lamp technology to increase illumination and give distinctive styling, whilst high

beam uses complex reflector technology.

• The park lamp is located below the turn signal lamp in its own reflector housing.

Figure 12B-2

Legend

1. Turn Signal Lamp

2. Turn Signal Wiring Connector 3. Headlamp High Beam Bulb (H9)

4. Headlamp Main Wiring Connector 5. Park Lamp

6. Headlamp Low Beam Bulb (H11)

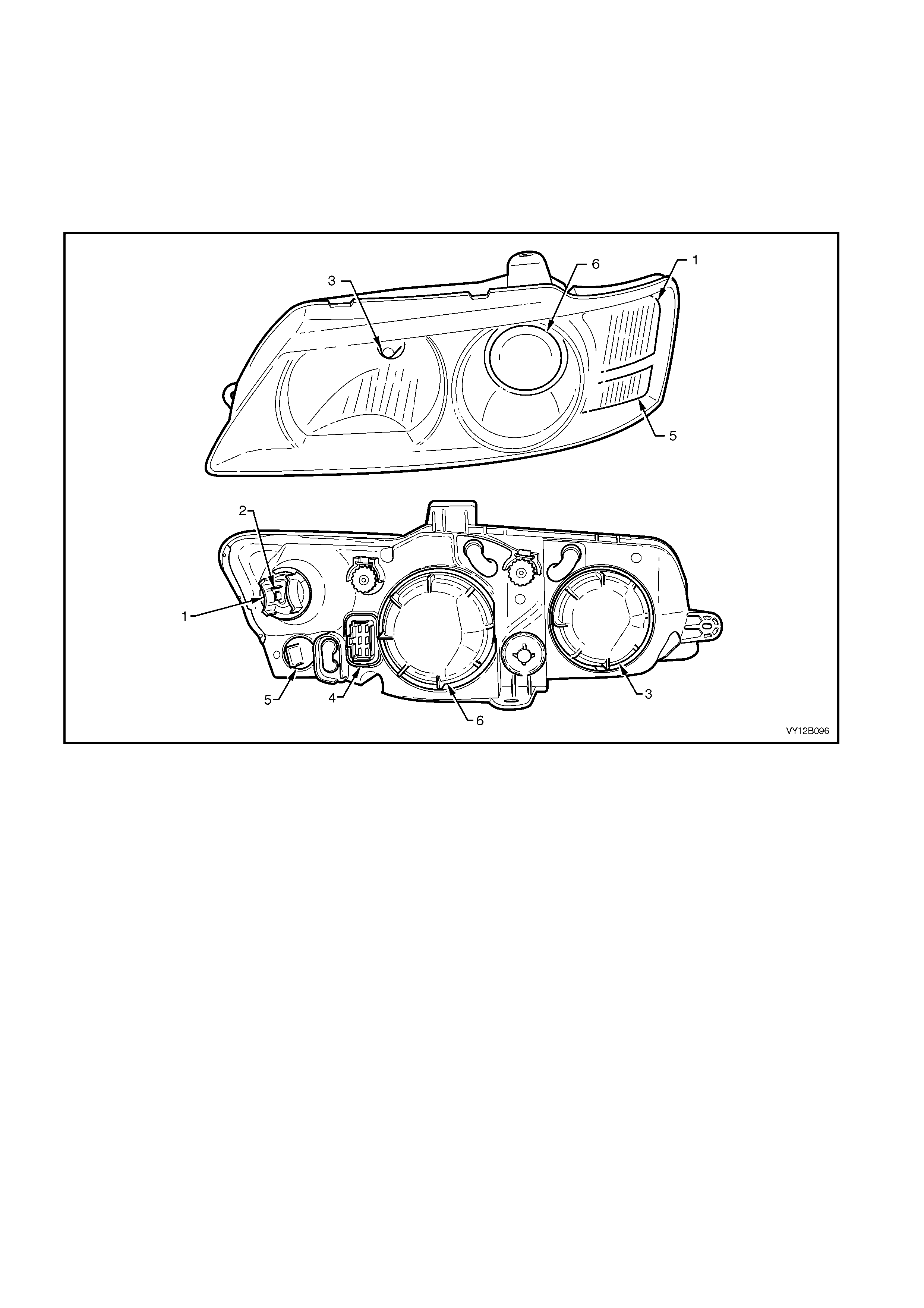

COUPE

The Coupe headlamp assembly (refer to Figure 12B-3) has the following features:

• Distinctive styling to suite the Coupe bumper fascia.

• Single filament H9 and H11 specification globes high and low beam reflector pockets respectively.

• The low beam uses projector lamp technology to increase illumination and give distinctive styling, whilst high

beam uses complex reflector technology.

• The park lamp is located in the high beam reflector and is accessed through the high beam lamp dust cap.

Figure 12B-3

Legend

1. Turn Signal Lamp

2. Turn Signal Wiring Connector 3. Headlamp High Beam Bulb (H9)

4. Headlamp Main Wiring Connector 5. Park Lamp

6. Headlamp Low Beam Bulb (H11)

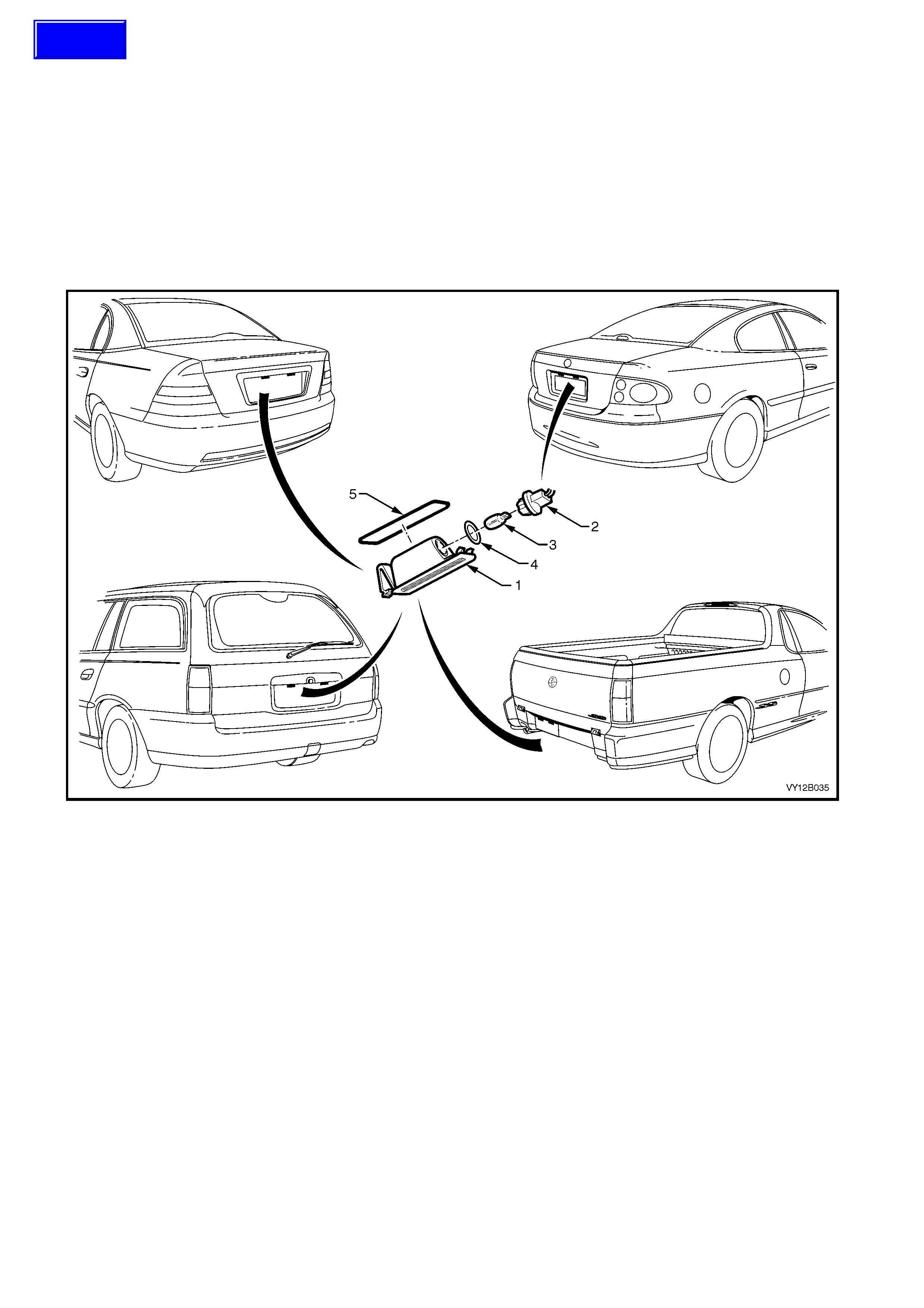

1.2 TAIL LAMP ASSEMBLY

The tail lam ps fitted to the MY 2003 VY Series vehicles and V2 Ser ies II Coupe are designed to be f unctional whilst

providing aesthetically pleasing looks. T here are four basic tail lamp geometries and each type is applicable to the

following groups of vehicles:

• Level 1

• Level 2 and Level 3 Sedan vehicles

• All Utility and Wagon vehicles

• Coupe

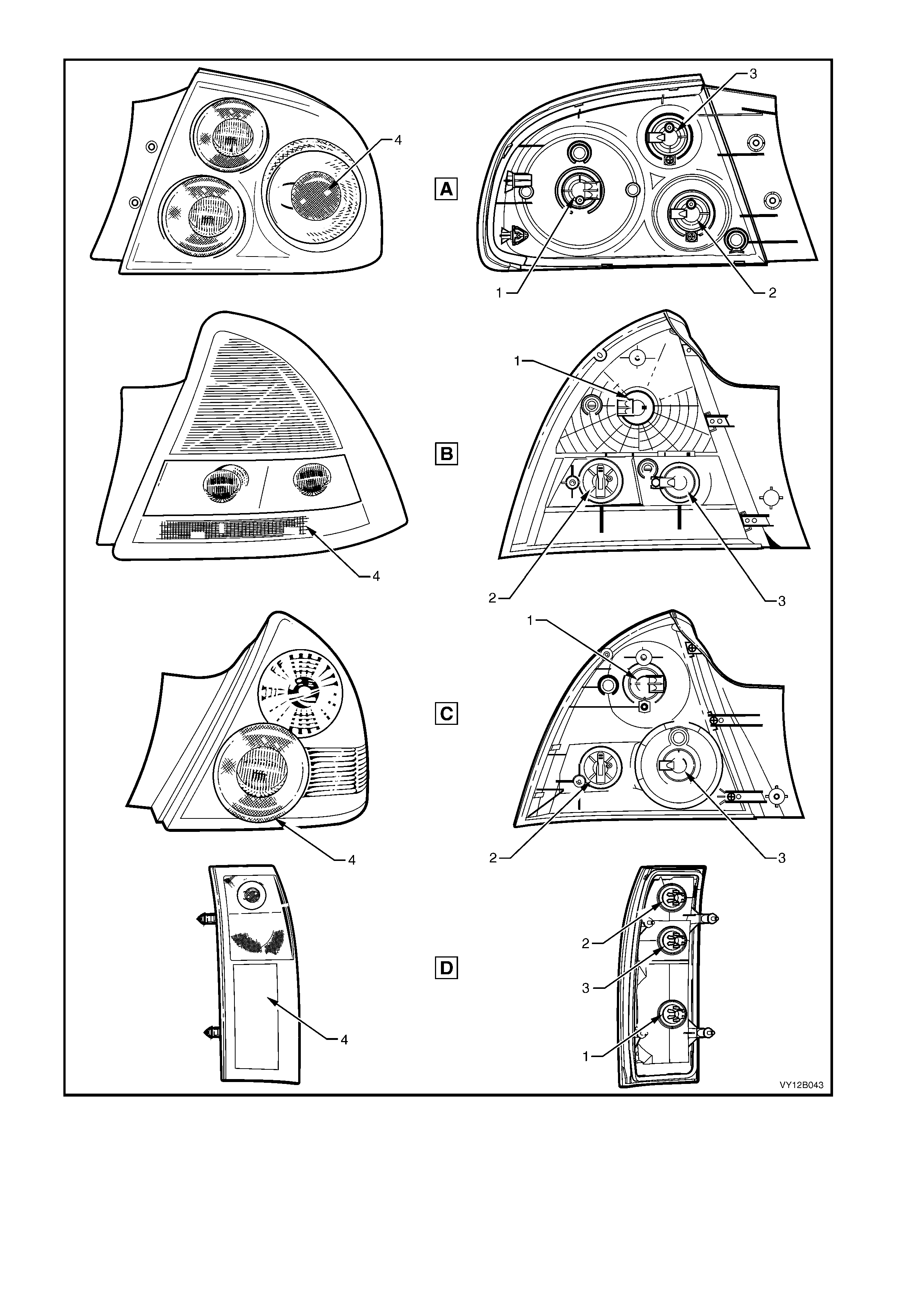

For views of the front and rear of the tail lamp assemblies, refer to Figure 12B-4 where:

• VIEW A – Coupe front and rear views

• VIEW B – Level 2 and Level 3 Sedan vehicle front and rear views

• VIEW C – Level 1 Sedan vehicle front and rear views

• VIEW D – Utility and Wagon front and rear views

All provide the following functions:

• Stop/tail lamps (1)

• Turn signal lamps (2)

• Back-up lamps (3)

• Reflex reflectors (4)

Beside the physical differences between the tail lamp assemblies across the various model levels, Level 1 Sedan

vehicles tail lamp assemblies have chrome or black housings, depending on particular model specifications.

Techline

Figure 12B-4

Legend

A Tail Lamp Assembly – Coupe

B Tail Lamp Assembly – Level 2 and Level 3

C Tail Lamp Assembly – Level 1

D Tail Lamp Assembly – Wagon and Utility

1. Stop/Tail Lamp

2. Turn Signal Lamp

3. Back-up Lamp

4. Reflex Reflector

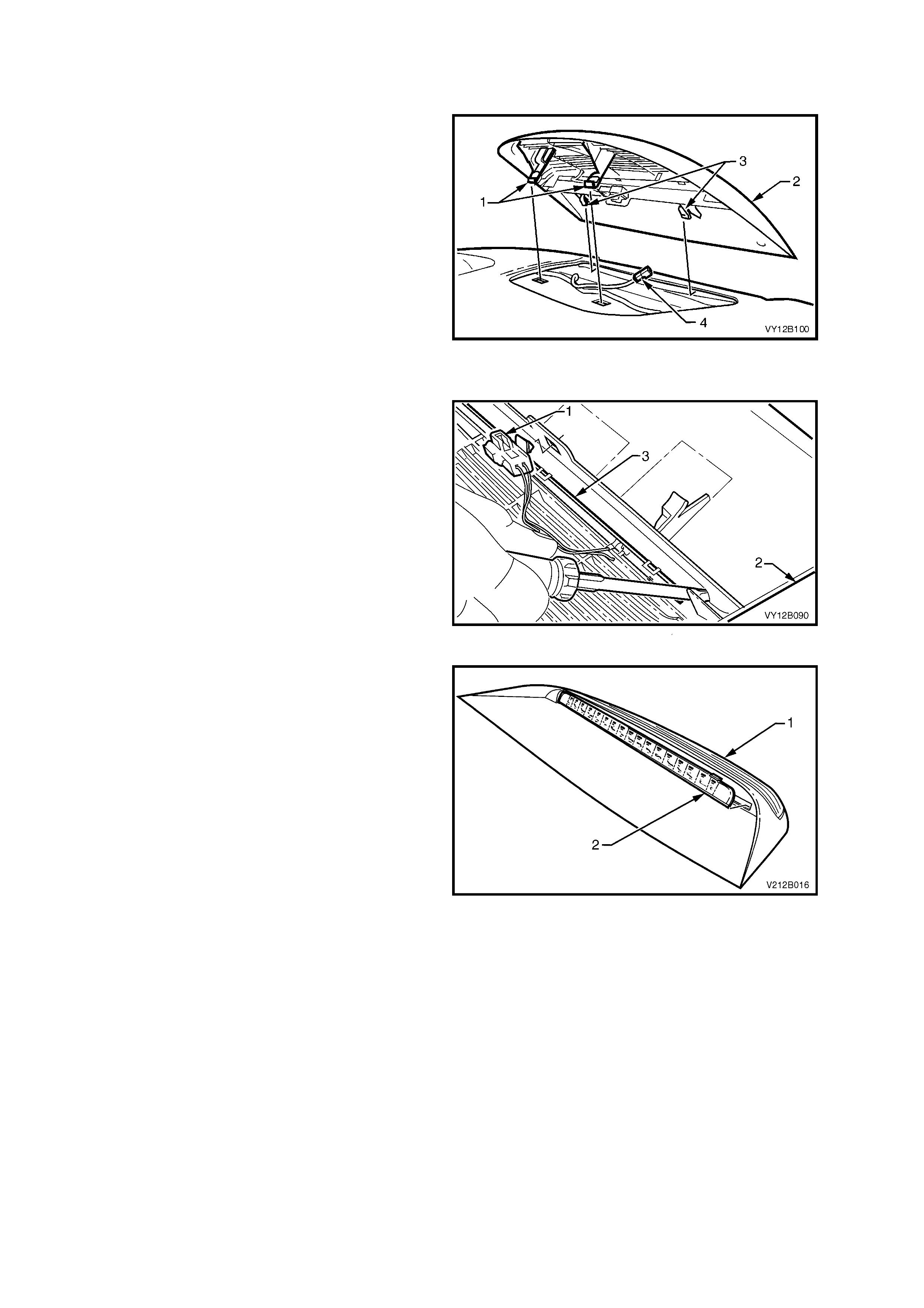

1.3 HIGH MOUNT STOP LAMPS

Five different high mount stop lamp variants are fitted to MY 2003 VY Series vehicles and V2 Series II Coupe. All

high mount stop lamps that are fitted to the inside of the vehicle use bulbs for illumination, except for the Coupe

which uses a strip of Light Em itting Diodes (LED’s) . High mounted stop lam ps that are fitted to s edan rear spoilers

use LED’s.

1.4 INTERIOR ILLUMINATION

The type and amount of interior illumination depends on the model level of the vehicle. All vehicles are fitted with

lamp s adequate to illum inate the c abin ar ea during low light conditions . In addition, all m odels are equipped with an

instrument panel compartment lam p and a rear compartment lam p. Many of the lamps are controlled by the Body

Control Module (BCM). Refer to Section 12J BODY CONTROL MODULE for further information.

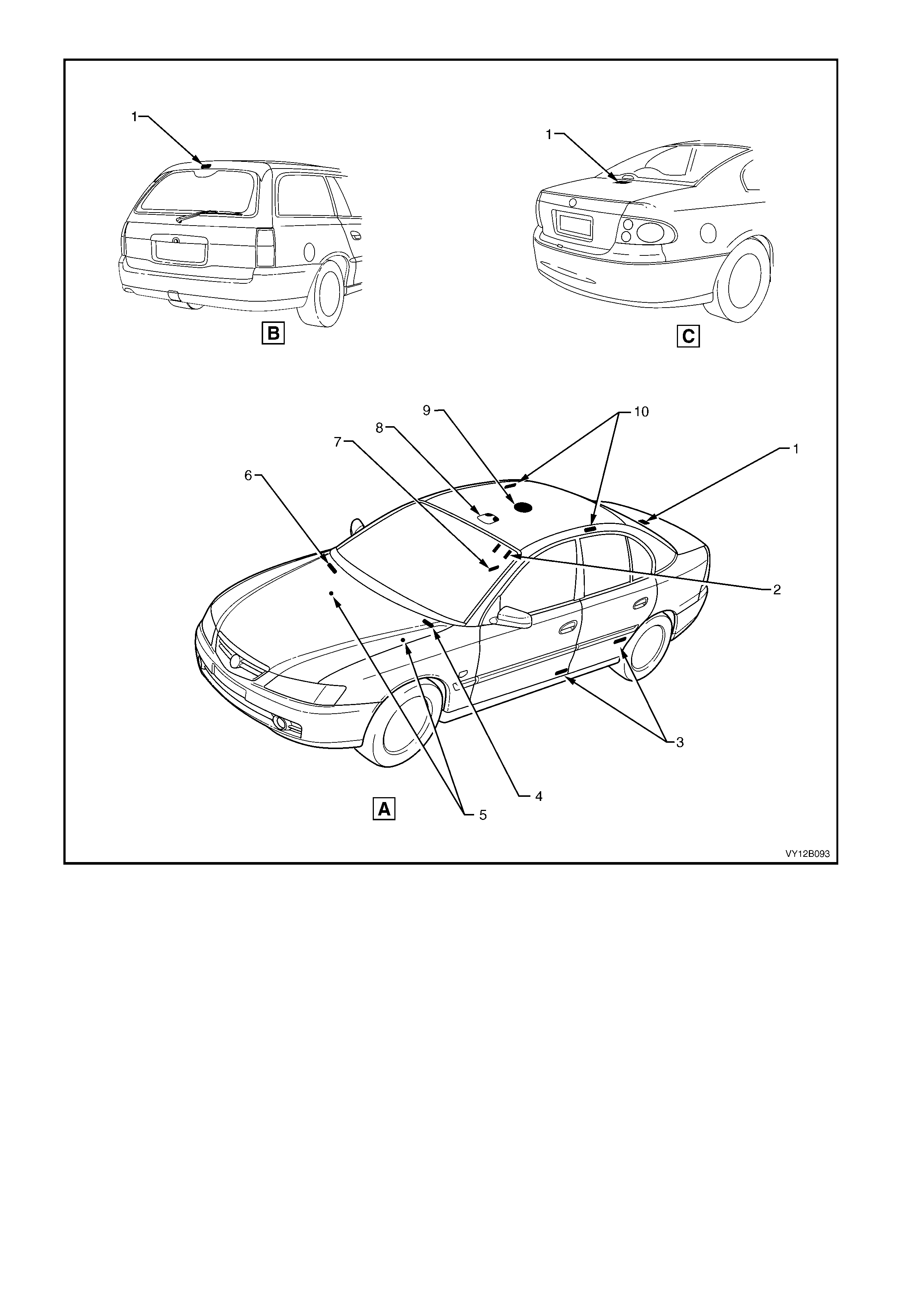

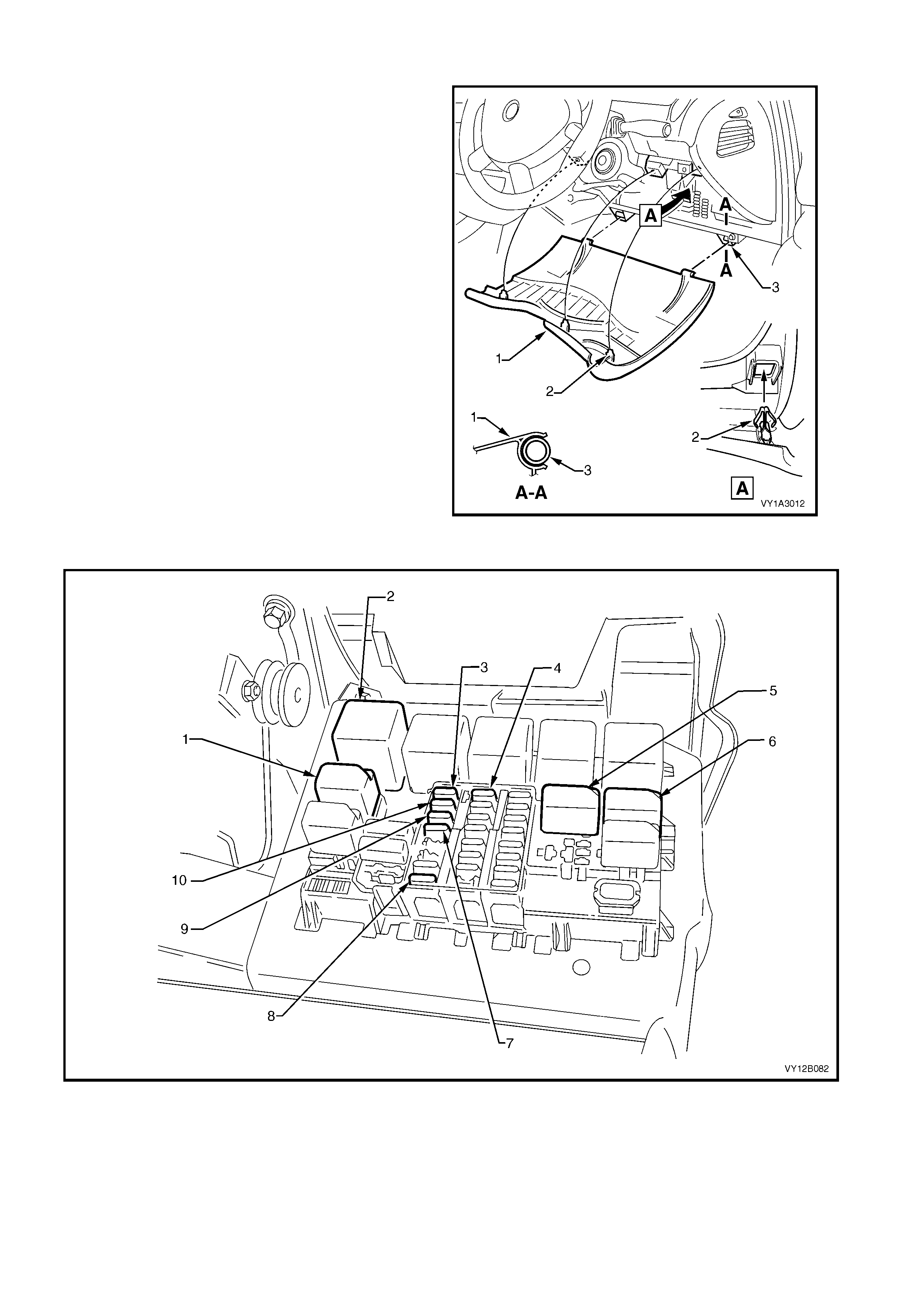

Refer to Figure 12B-5 for interior lighting component locations.

LEVEL 1

• Dome lamp assembly or, dome and reading lamp assembly depending on particular model specification.

LEVEL 2 AND LEVEL 3

• Roof console lamps

• Roof rail courtesy and reading lamp assembly

• Side door courtesy lamps (left-hand drive model only)

• Side door courtesy lamps (right-hand drive Level 3 vehicle only)

• Sunshade vanity mirror lamps (Level 3 only)

• Stepwell lamps

• Floor console compartment lamp (Level 3 only)

COUPE

• Dome lamp assembly (right-hand drive CV6 and left-hand drive Lumina S only)

• Dome and reading lamp assembly (right-hand drive CV8 and left-hand drive Lumina SS only)

• Side door courtesy lamps

• Stepwell lamps

• Sunshade vanity mirror lamps

• Floor console compartment lamp (right-hand drive CV8 and left-hand drive Lumina SS only)

Figure 12B-5

Legend

A Sedan – Interior illumination

B Wagon – Interior Illumination

C Coupe – Interior Illumination

1. Rear Compartment Courtesy Lamp

2. Sunshade Vanity Mi rror Lamps

3. Side Door Courtesy Lamps

4. Instrument Panel Compartment

Courtesy Lamp

5. Stepwell Lamps

6. Under-Hood Lamp (Where Fitted)

7. Floor Console Compartment Lamp

8. Roof Console

9. Dome Lamp

10. Roof Rail Courtesy And Reading

Lamps

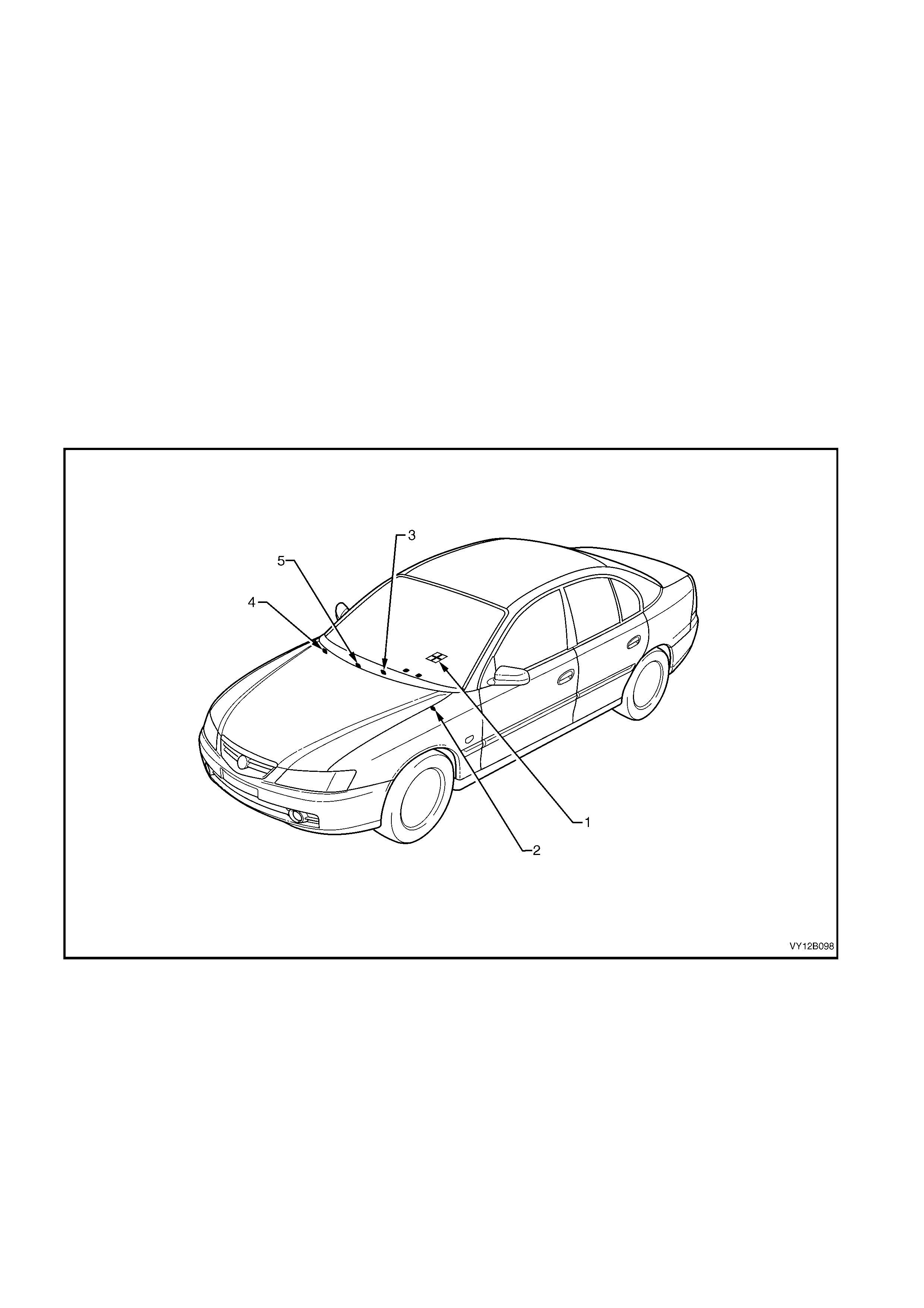

1.5 INSTRUME NT AND SWITCH ILLUMINATION

All instrument and switch illumination is provided by Light Emitting Diodes (LED’s) with the exception of the

following, which are illuminated with conventional bulbs:

• Hazard warning switch

• Left-hand drive fuel filler door lock release switch

• Traction control switch (automatic transmission)

• Traction control switch (manual transmission)

• Power switch selector

• LPG (Liquefied Petroleum Gas) switch

• Headlamp switch

• Trip computer switch

• Side window switch assembly

• Ignition lock cylinder

The LPG and traction control (manual transmission) are located in the auxiliary switches location.

The headlamp, trip computer and side window switches are sealed units and the conventional bulbs cannot be

serviced on these items.

LED’s are used instead of conventional bulbs due to their longevity in operation. If the illumination of any LED

equipped item no longer operates correctly, and the LED is isolated as the fault, replace the assembly in question.

Figure 12B-6

Legend

1. Auxiliary switches

2. Fuel tank filler door lock release switch, LHD

3. Hazard warning switch

4. Headlamp switch

5. Trip computer switch

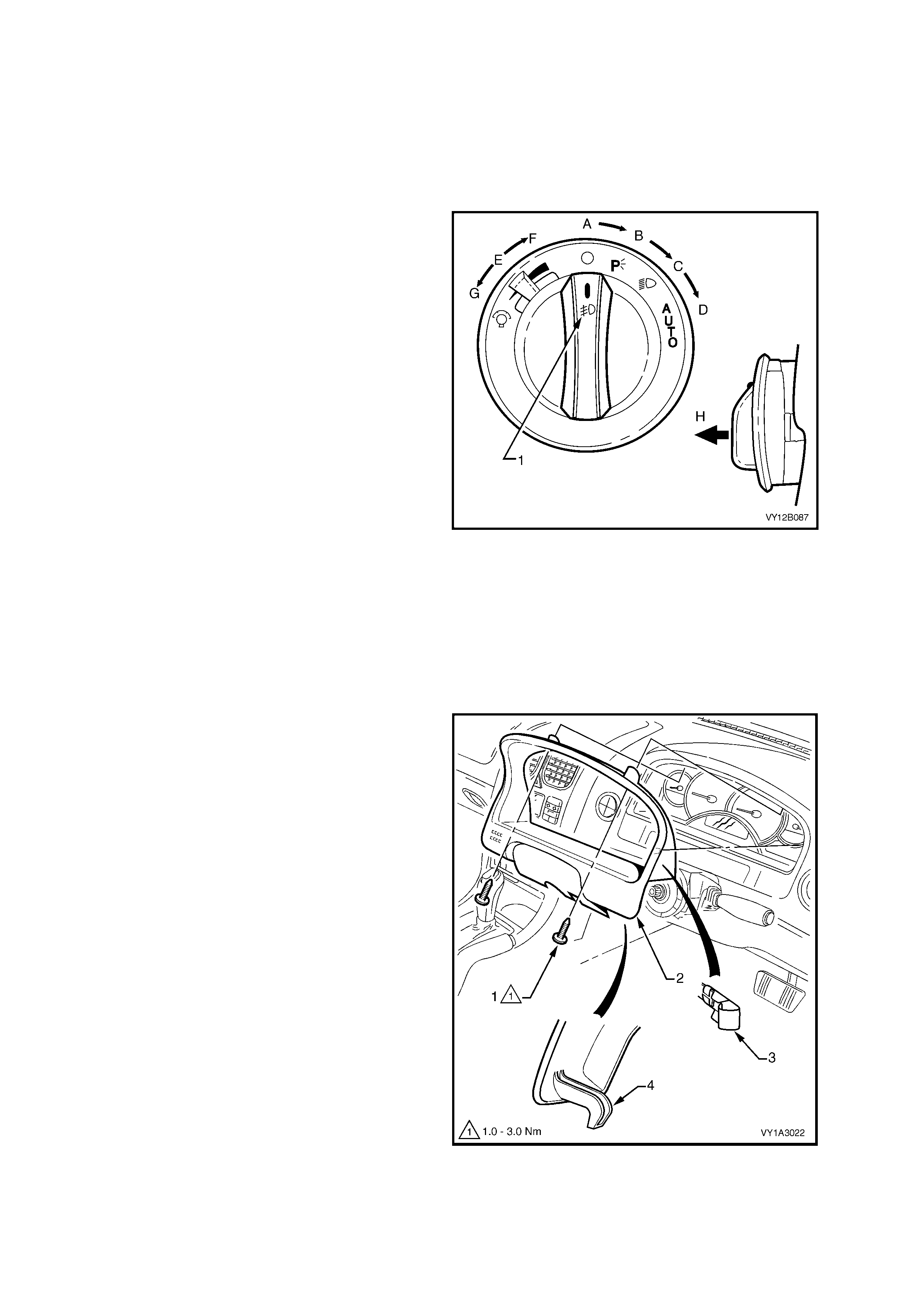

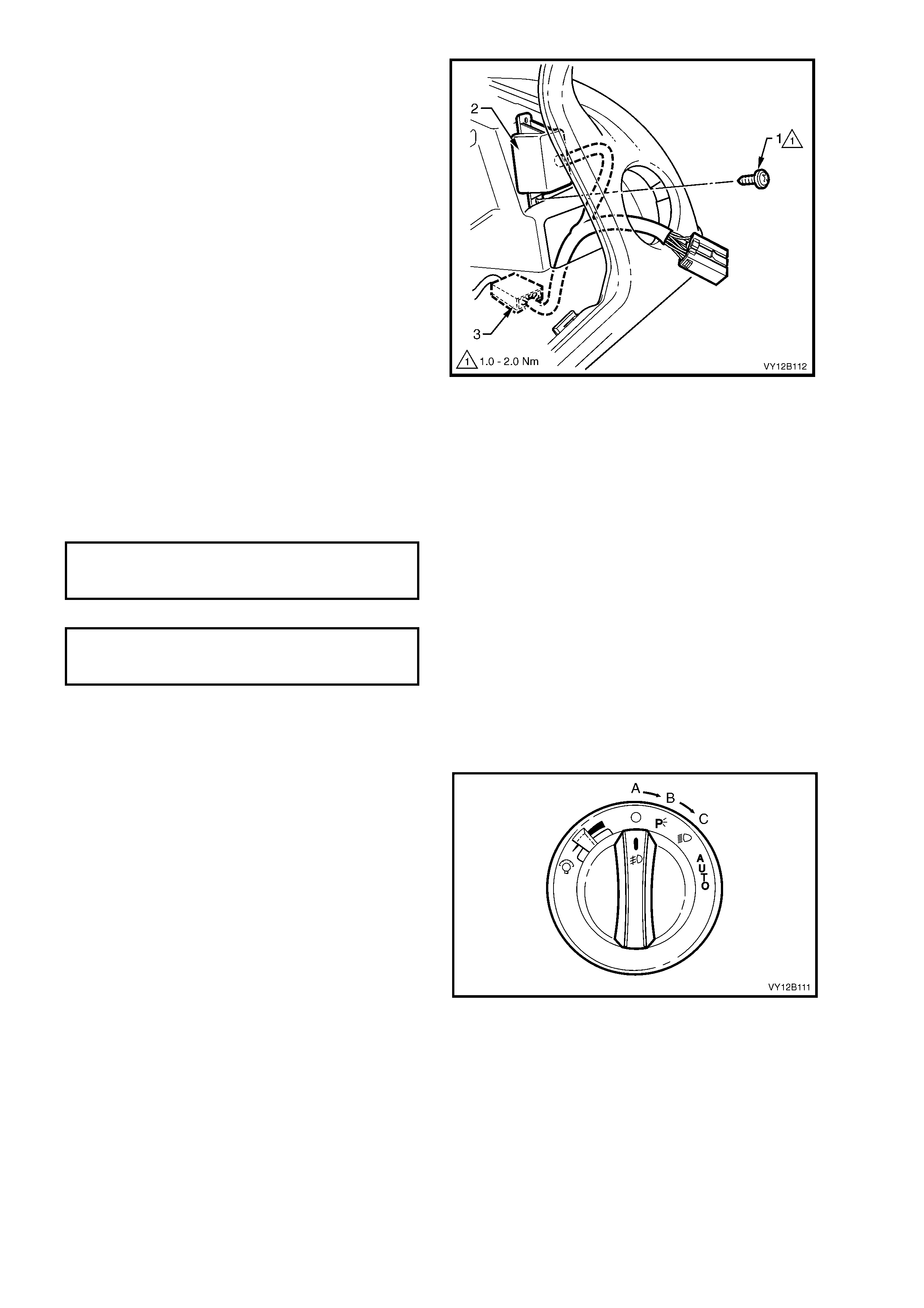

HEADLAMP SWITCH

A feature of the MY 2003 VY Series vehicles and V2 Series II Coupe, is they are equipped with the automatic

headlamp control feature. With the headlamp switch in the AUTO position (refer to Figure 12B-105), the BCM

controls the function of the park and low beam of the headlamps. For further information on this feature, refer to

Section 12J, 1.13 AUTOMATIC LA MP CONTROL.

POLICE LIGHTS-OUT SWITCH

The lights -out switch is f itted to police vehicles when required. T he switch, when on, will inactivate all interior lamps

from operating except reading lamps, which can be operated individually.

NOTE: This switch does not illuminate with the park lamps operating.

2. SERVICE OPERATIONS – EXTERIOR ILLUM I NATION

2.1 HEADLAMP AND FRONT FOG LAMP AIMING

CAUTION: During headlamp assembly aiming procedures, do not use a cloth or similar material to cover

the lens of the headlamp assembly not being adjusted. Damage to the headlamp assembly will result if the

headlamp beam is obstructed in this manner.

The headlamp assemblies and front fog lamp assemblies (if fitted) must be correctly aimed in order to obtain the

max im um road illum ination and saf ety. The headlam ps and f og lam ps m ust be c heck ed f or corr ect aim whenever a

bulb or lamp assembly is replaced, and after any adjustments or repairs to the front-end sheetmetal.

Headlamp aim ing devices are in general use. W hen using one of these devices, ensure that it is in good condition

and carefully follow the instructions of the manufacturer.

Regardless of the method used for check ing headlamp and f og lamp aim, the vehicle must be at kerb weight, that

is, with full fuel level, oil, water and spare tyre but no passengers. The tyres must be uniformly inflated to their

specified pressure.

IMPORTANT: If the vehic le will regularly carry an unusual load in the rear compar tm ent or tow a trailer, these loads

should be on the vehicle when the headlamps/fog lamps are checked.

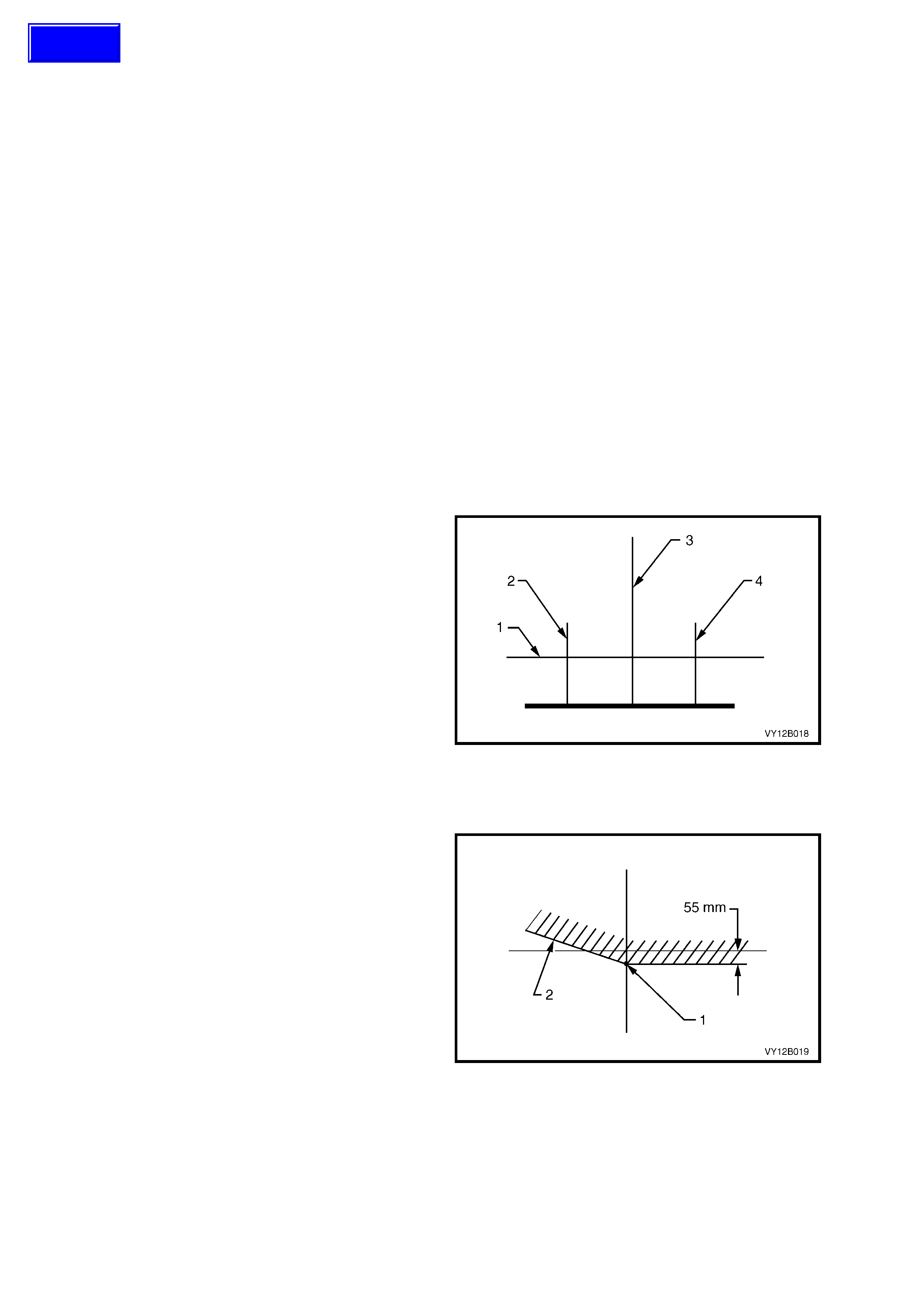

HEADLAMP ASSEMBLY AIM

LT Section –

This procedure is to be used only when suitable test equipment is not available.

1. Set up a screen or use a vertical wall, in

conjunction with a flat horizontal floor. Park the

vehicle im m ediately in front of scr een / wall and

mark the following lines:

a. A vertical c entre line (3) which corres ponds

to the centre of the vehicle.

b. Two vertical lines (2 and 4). These lines

are to correspond to the respective centre

of the low beam bulb on each side of the

vehicle.

c. A horizontal line (1) that corr esponds to the

centre of the low beam bulb.

2. To check whether the marks are correctly

positioned, turn on the headlights.

3. Reverse the vehicle straight back so that the

front is 5 metres in front of the screen or wall,

ensuring that the centre of the vehicle is

aligned with the vehicle centre line m ark (3) on

the screen.

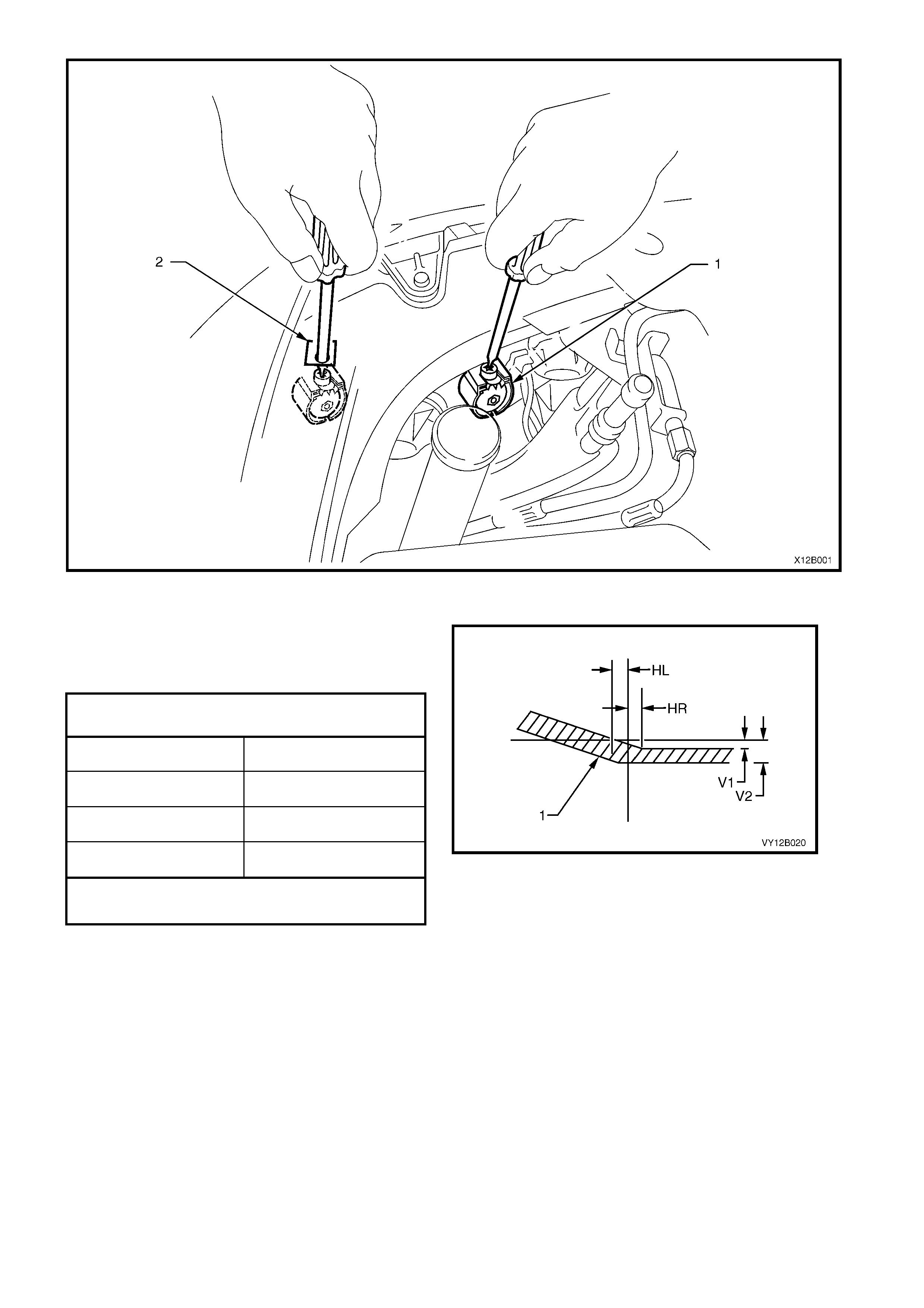

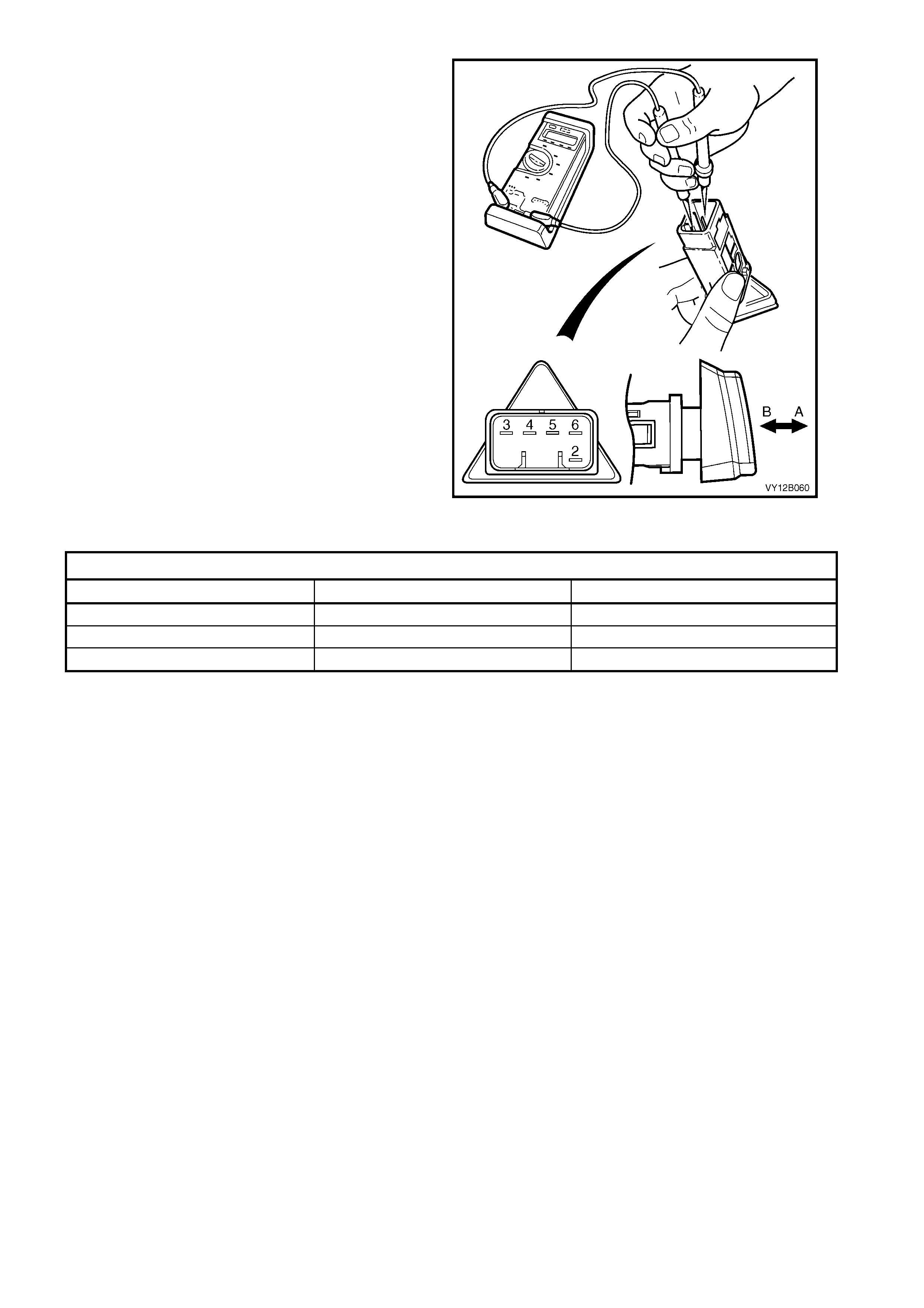

Figure 12B-7

4. Individually aim each headlamp to a point (1)

on its vertical centre line, 55 mm below the

headlamp horizontal centre line. Item 2 is the

cut-off line. To adjust the headlamp assembly

(refer to Figure 12B-9):

a. Rotate the inboard adjuster (1) to move the

beam vertically.

b. Rotate the outboard adjuster (2) to move the

beam horizontally.

Aiming directions for each adjuster are visible on

the headlamp assembly.

Figure 12B-8

Techline

Figure 12B-9

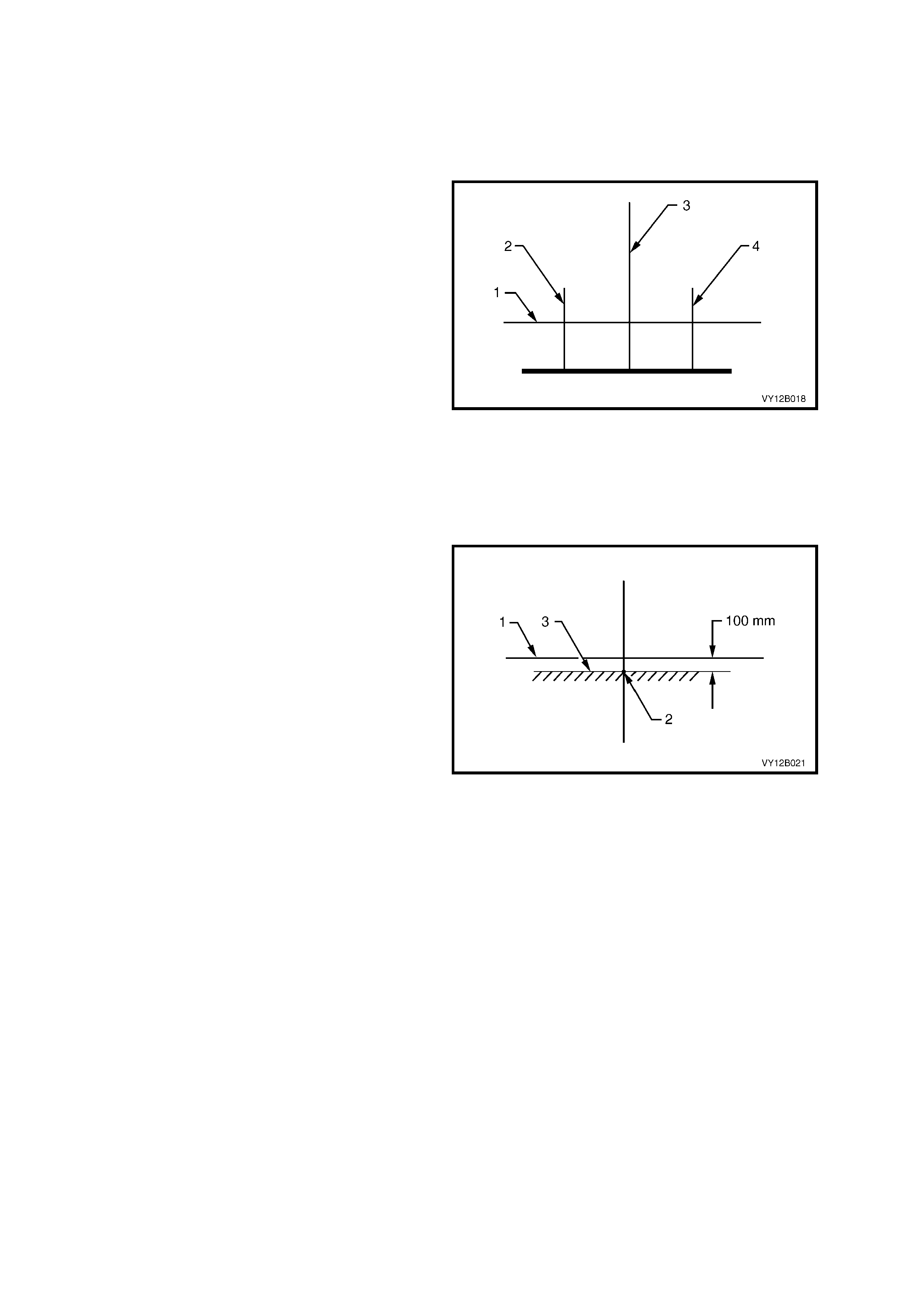

5. The allowable variations on headlamp aiming

point settings shown in Figure 12B-10 are

specified as follows:

NOTE: The cut-off line must be within the shaded

zone (1).

Figure 12B-10

HE ADLAMP AIMING

Acceptable Variations In Headlamp Aiming Points

HL 50 mm

HR 0 mm

V1 50 mm

V2 60 mm

Maximum allowable vertical variation between any

pair of headlamps is not to exceed 10 mm

FRONT FOG LAMP ASSEMBLY AIM

LT Section –

The process for aiming the front fog lamps is the

same for all vehicles fitted with fog lamps. This

procedure is to be used only when suitable test

equipment is not available.

1. Set up a screen or use a vertical wall, in

conjunction with a flat horizontal floor. Park the

vehicle immediately in front of a screen / wall

and mark the following lines on it:

a. A vertical centre line (3), which

corresponds to the centre of the vehicle.

b. Two vertical lines (2 and 4). These lines

are to correspond to the respective centre

of the fog lamp bulb on each side of the

vehicle.

c. A horizontal line (1), that corresponds to

the centre of the fog lamp bulb.

2. To check whether the marks are correctly

positioned, turn on the fog lamps.

3. Reverse the vehicle straight back so the that

front is 5 metres in front of the screen or wall,

ensuring that the centre of the vehicle is

aligned with the vehicle centre line m ark (3) on

the screen.

Figure 12B-11

4. Turn the front fog lamps on. Individually aim

each fog lamp to a point on its vertical centre

line (2), with the cut-off line (3) 100 mm below

fog lamp horizontal centre line (1).

NOTE: There is no provision for horizontal

adjustm ent. Fog lamps are fix ed to a ver tical centre

line.

Figure 12B-12

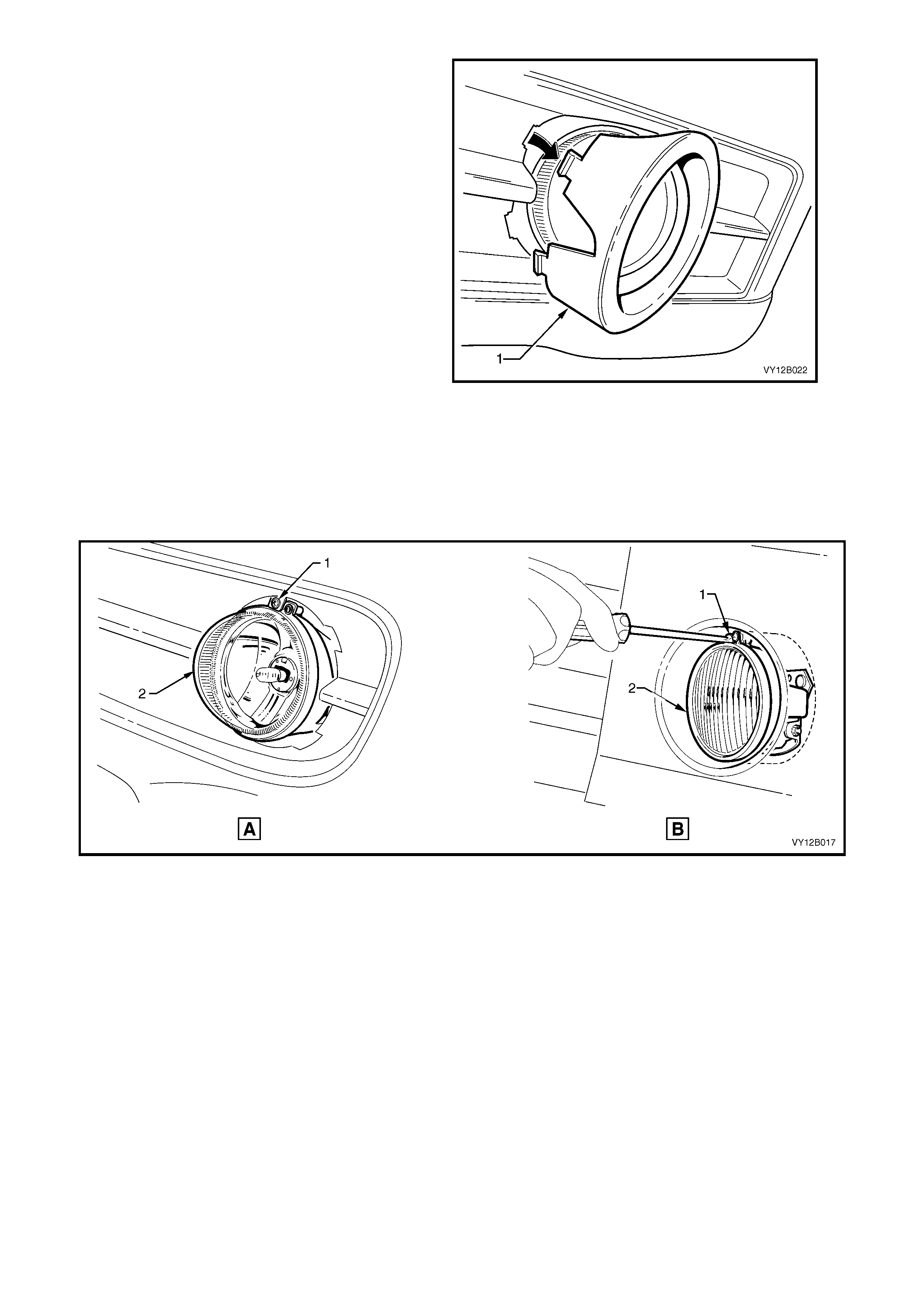

4. For Level 3 vehicles, the front fog lamp bezel

assembly must be removed to access the

adjusting screw. To remove the bezel

assembly:

a. Depress the inboard side of the bezel

assembly and rotate the inboard side

forward.

b. When the inboard side of the bezel

assem bly is clear of the lam p lens, pull the

bezel assembly forward to unclip it from the

outboard side of the bumper fascia.

5. For Coupe, the lower grille m us t be rem oved to

access the adjusting screw. Refer to

Section 1C, 2.5 LOWER RADIATOR GRILLE

– COUPE.

7. Using a No. 2 Philips head screwdriver adjust

the beam of the front fog lamp (2) by rotating

the adjusting screw (1) clockwise to raise the

beam and anti-clockwise to lower the beam.

Refer to Figure 12B-14 where:

A. Level 3.

B. SS and Coupe fog lamp assembly (SS

shown, Coupe is similar.

8. For Level 3 front fog lamp assemblies, install

the bezel assembly.

Figure 12B-13

Figure 12B-14

2.2 HEADLAMP AND PARK LAMP ASSEMBLY BULBS

LT Section – 02-300

LEVEL 1

Replace – Low Beam Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

6. From within the engine compartment, remove

the outboard dust cap (1) from the rear of the

headlamp assembly (2) by turning dust cap

anti-clockwise, and pulling it away from

assembly. If the dust cap seal stays on the

headlamp assembly, remove the seal and

install it onto the cap.

7. Carefully pull the wiring harness connector (3)

from the rear of the bulb (4).

Figure 12B-15

8. Depress and unclip the bulb spring retainer (1)

and pivot clear of the bulb. Remove the bulb (2)

from the reflector.

NOTE: Do not handle the quartz envelope of the

headlamp bulb. If the envelope is touched

accidentally, wipe it immediately with methylated

spirits or the bulb’s performance will be

deteriorated.

9. Install a new bulb into the reflector, ensuring

that the locating tangs mate correctly with the

cutouts in the reflector.

NOTE: The different sized locating tangs on the

bulb and the mating cut-outs in the reflector, allow

the bulb to seat correctly into the reflector in one

orientation only. This ensures correct relationship

of the bulb to the reflector.

10. Install the spring retainer and the wiring

harness connector.

11. Inspect the seal in the dus t c ap to ensur e that it

is not dam aged and that it is s eated corr ectly in

the cap. Replace the seal if it is damaged.

12. Install the cap onto the rear of the headlamp

assembly. Lock the cap into place by turning it

clockwise. Connect the wiring harness

connector to the rear of the headlamp

assembly.

Figure 12B-16

13. As required, install the coolant filler bottle neck, upper radiator shroud and battery.

14. Fit the fusible link F102.

15. Check the headlamp operation and the aim of the headlamps as the bulb filam ent with respect to the reflector

may have changed. Refer to 2.1 AIMING OF HEADLAMPS AND FOG LAMPS in this Section.

Replace – High Beam Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

6. From within the engine compartment, remove

the inboard high beam dust cap (1) from the

rear of the headlamp assembly by turning the

dust cap anti-clockwise, and pulling it away

from the assembly. If the dust cap seal stays

on the headlamp assembly, remove the seal

and install it onto the cap.

Figure 12B-17

7. Carefully pull the wiring harness connector (1)

from the bulb (2). Depress and unclip the bulb

retaining clip (3), and allow to it fall clear of

bulb. Remove the bulb

NOTE: Do not handle the quartz envelope of the

inboard high beam bulb. If touched accidentally,

wipe immediately with methylated spirits or bulb

performance will deteriorate.

8. Install a new bulb into the reflector, ensuring

that the locating lug on the bulb assembly

aligns with the square edge on the reflector.

9. Fit the bulb retaining clip. Connect the wiring

harness connector to the bulb.

10. Inspect the seal in the dus t c ap to ensur e that it

is not damaged and that it is seated correctly.

Replace the seal if it is damaged.

11. Install the dust cap onto the rear of headlamp

assembly and lock it into place by turning the

cap clockwise. Connect the wiring harness

connector to the rear of the headlamp

assembly.

Figure 12B-18

12. As required, install the coolant filler bottle neck, upper radiator shroud and battery.

13. Fit the fusible link F102.

Replace – Park Lamp Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

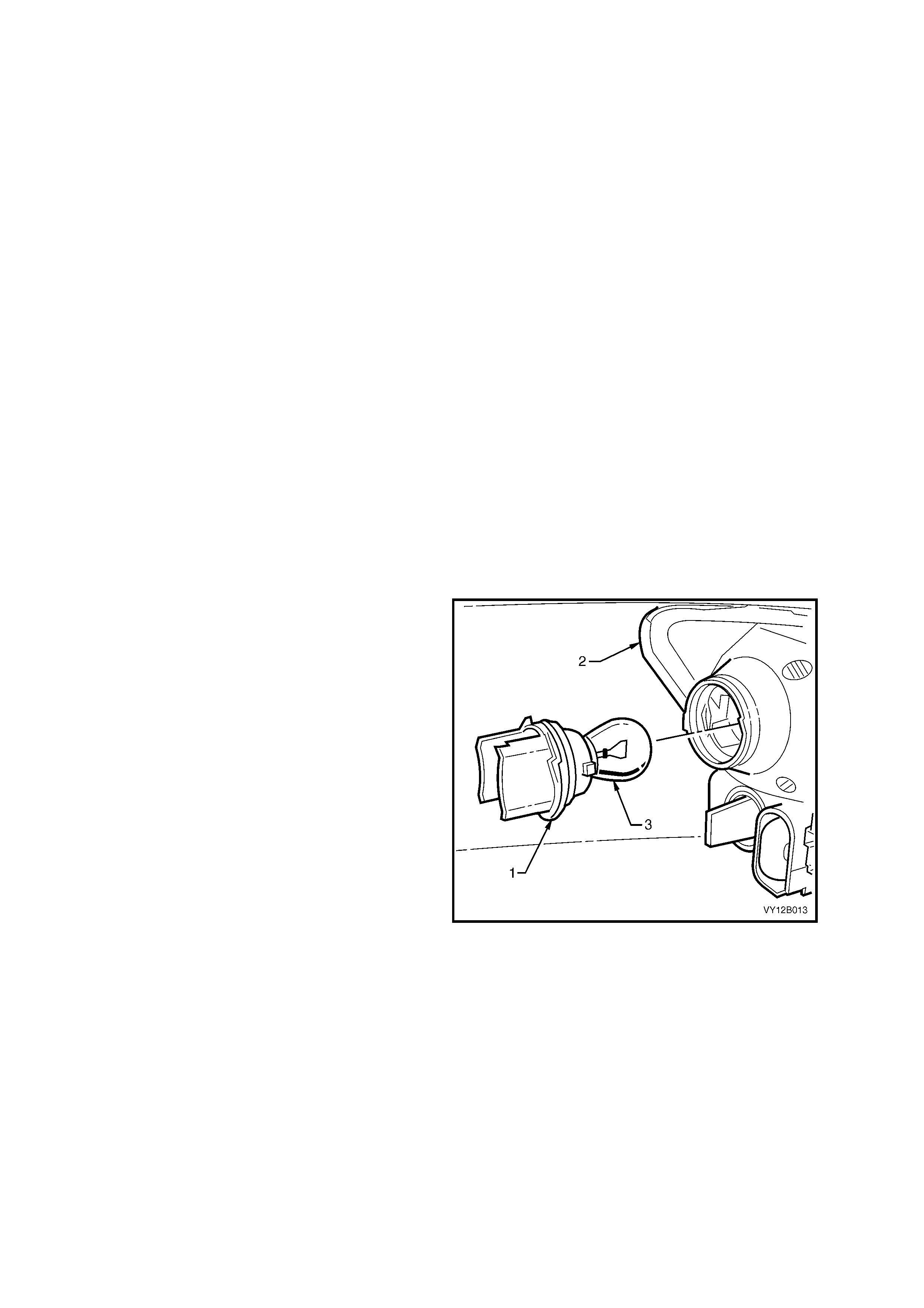

6. From within the engine compartment, remove

the park lamp socket (1) from the headlamp

assembly (2) by rotating it anti-clockwise and

then pulling it away from the headlamp

assembly.

7. Pull the bulb ( 3) away fr om the sock et. Insert a

new bulb into the socket.

8. Inspect the seal on the socket to ensure that it

is not damaged and that it is seated correctly.

Replace the seal if necessary.

9. Install the park lamp socket into the rear of the

headlamp assembly and lock it into place by

turning it clockwise. Ensure that the ‘TOP’ mark

is facing upwards. The socket has a two stage

locking feature. Ensure that the socket is

engaged in the secondary lock (4) and there is

no excess movement.

10. Connect the wiring harness connector to the

rear of the headlamp assembly.

Figure 12B-19

11. As required, install the coolant filler bottle neck, upper radiator shroud and battery.

12. Fit the fusible link F102.

13. Check the park lamp operation.

LEVEL 2 AND LEVEL 3

Replace – Low Beam Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

6. From within the engine compartment, remove

the outboard dust cap (1) from the rear of the

headlamp assembly (2) by turning dust cap

anti-clockwise, and pulling it away from

assembly. If the dust cap seal stays on the

headlamp assembly, remove the seal and

install it onto the cap.

7. Disconnect the wiring connector (3) from the

bulb (4) by squeezing the two tangs together

and pulling the connector down from the bulb.

Figure 12B-20

8. Rotate the bulb (1) anti-clockwise and remove

the bulb from the bulb holder (2).

NOTE: Do not handle the quartz envelope of the

headlamp bulb. If the envelope is touched

accidentally, wipe it immediately with methylated

spirits or the bulb’s performance will be

deteriorated.

9. Install a new bulb into the bulb holder. Lock the

bulb in place by turning it clockwise. Fit the bulb

connector by pushing it into the base of the

bulb until the tangs engage.

NOTE: The dif f erent sized locating lugs on the bulb

base and mating cut-outs in the bulb holder allow

the bulb to seat correctly in one orientation only.

This ensures correct relationship of the bulb to the

reflector.

10. Inspect the seal on the dust cap to ensure that

it is not damaged and that it is seated corr ectly

on the cap. Replace the seal if it is damaged.

11. Install the cap onto the rear of the headlamp

assembly. The different size lugs on the dust

cap and the mating cut-outs on the headlamp

assem bly ensure that the dust cap can only be

installed in one orientation. T he chamf ered f lats

of the cap need to be f ac ing inboard f or the cap

to install. Lock the cap into place by turning it

clockwise.

12. Connect the wiring harness connector to the

rear of the headlamp assembly.

Figure 12B-21

13. As required, install the coolant filler bottle neck, upper radiator shroud and battery.

14. Fit the fusible link F102.

15. Check the headlamp operation and the aim of the headlamps as the bulb filam ent with respect to the reflector

may have changed. Refer to 2.1 AIMING OF HEADLAMPS AND FOG LAMPS in this Section.

Replace – High Beam Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

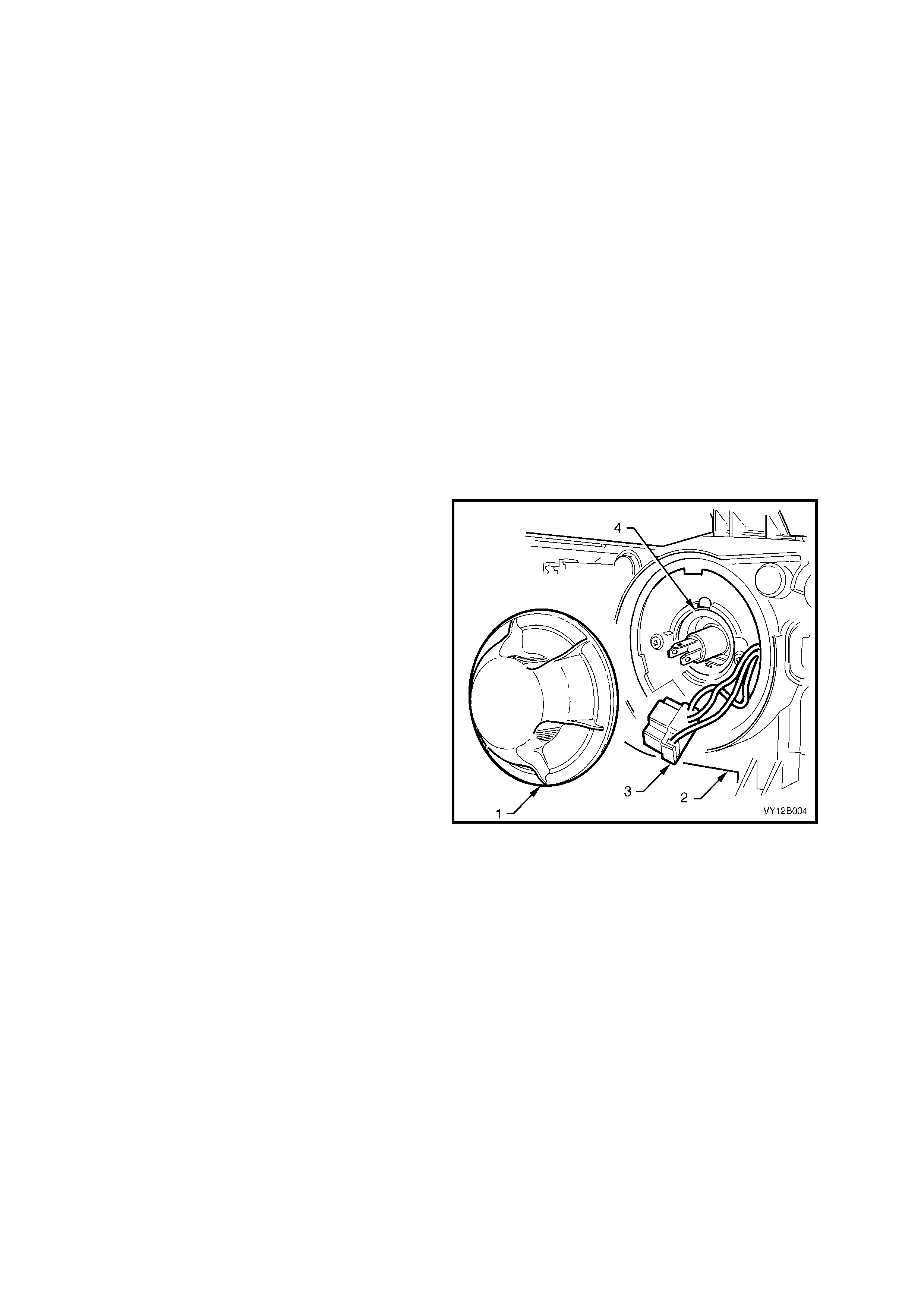

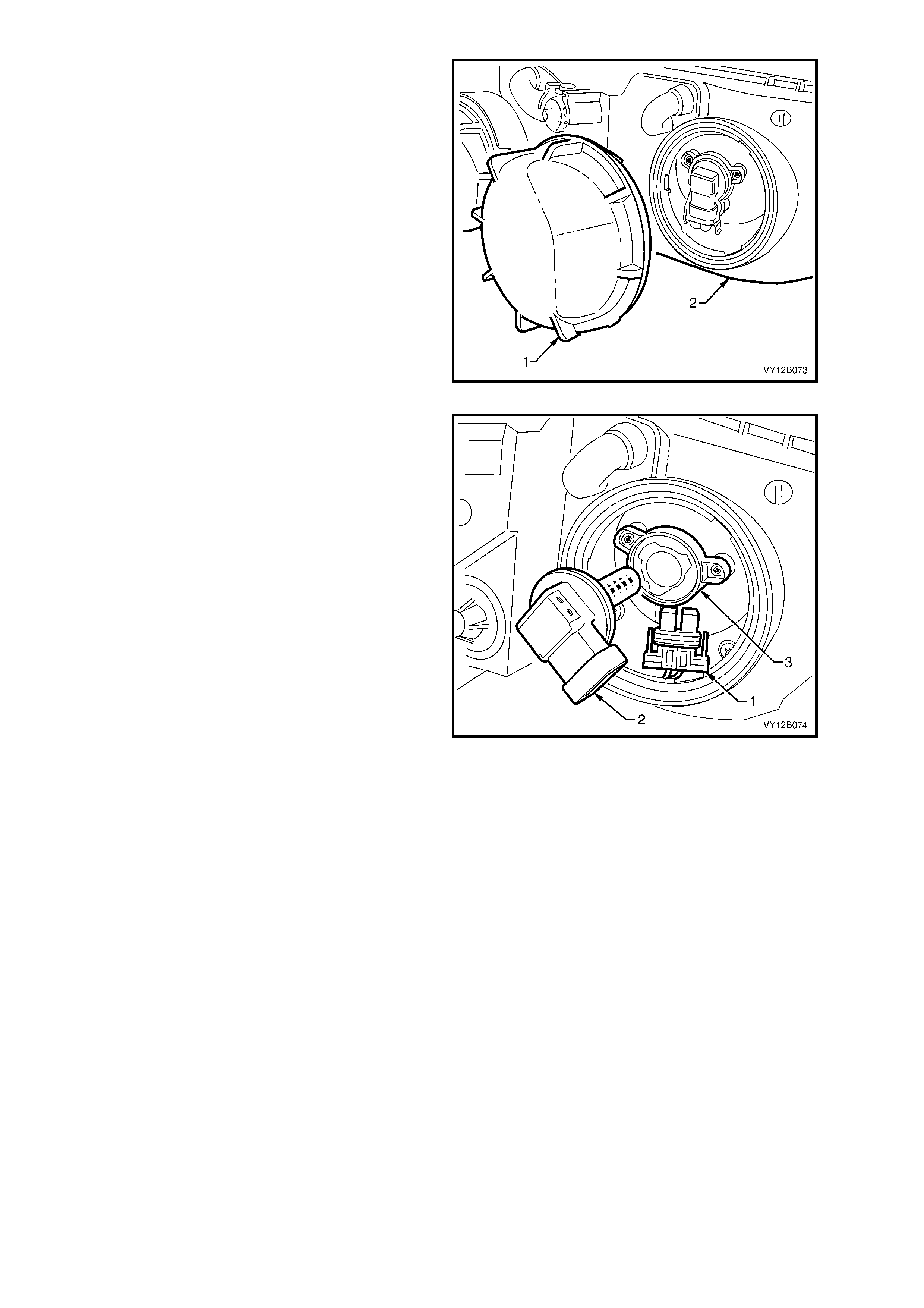

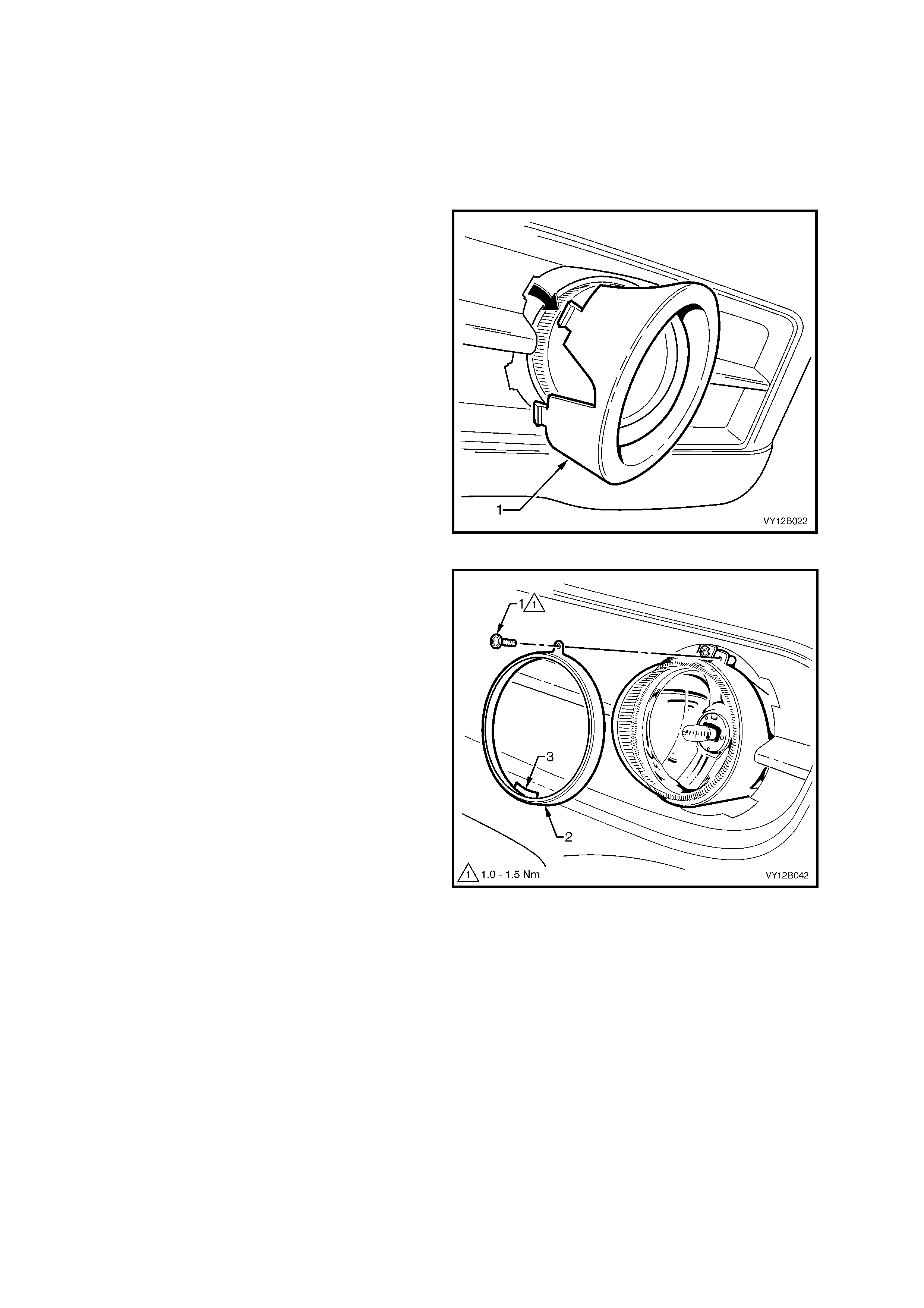

6. From within the engine compartment, remove

the inboard high beam dust cap (1) from the

rear of the headlamp assembly (2) by turning

dust cap anti-clockwise, and pulling it away

from assembly. If the dust cap seal stays on

the headlamp assembly, remove the seal and

install it onto the cap.

Figure 12B-22

7. Disconnect the wiring connector (1) from the

bulb by squeezing the two tangs together and

pulling the connector down from the bulb.

8. Rotate the bulb (2) anti-clockwise and remove

the bulb from the bulb holder (3).

NOTE: Do not handle the quartz envelope of

inboard high beam bulb. If touched accidentally,

wipe immediately with methylated spirits or bulb

performance will deteriorate.

9. Install a new bulb into the bulb holder. Lock the

bulb in place by turning it clockwise. Fit the bulb

connector by pushing it into the base of the

bulb until the tangs engage.

NOTE: The dif f erent sized locating lugs on the bulb

base and mating cut-outs in the bulb holder allow

the bulb to seat correctly in one orientation only.

This ensures correct relationship of the bulb to the

reflector.

10. Inspect the seal on the dust cap to ensure that

it is not damaged and that it is seated corr ectly

on the cap. Replace the seal if it is damaged.

11. Install the dust cap onto the rear of headlamp

assembly. The different size lugs on the dust

cap and the mating cut-outs in the headlamp

assem bly ensure that the dust cap can only be

installed in one orientation. T he chamf ered f lats

of the cap need to be f ac ing inboard f or the cap

to install. Lock it into place by turning the cap

clockwise.

12. Connect the wiring harness connector to the

rear of the headlamp assembly.

Figure 12B-23

13. As r equired, ins tall the c oolant f iller bottle nec k,

upper radiator shroud and battery.

14. Fit the fusible link F102.

Replace – Park Lamp Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

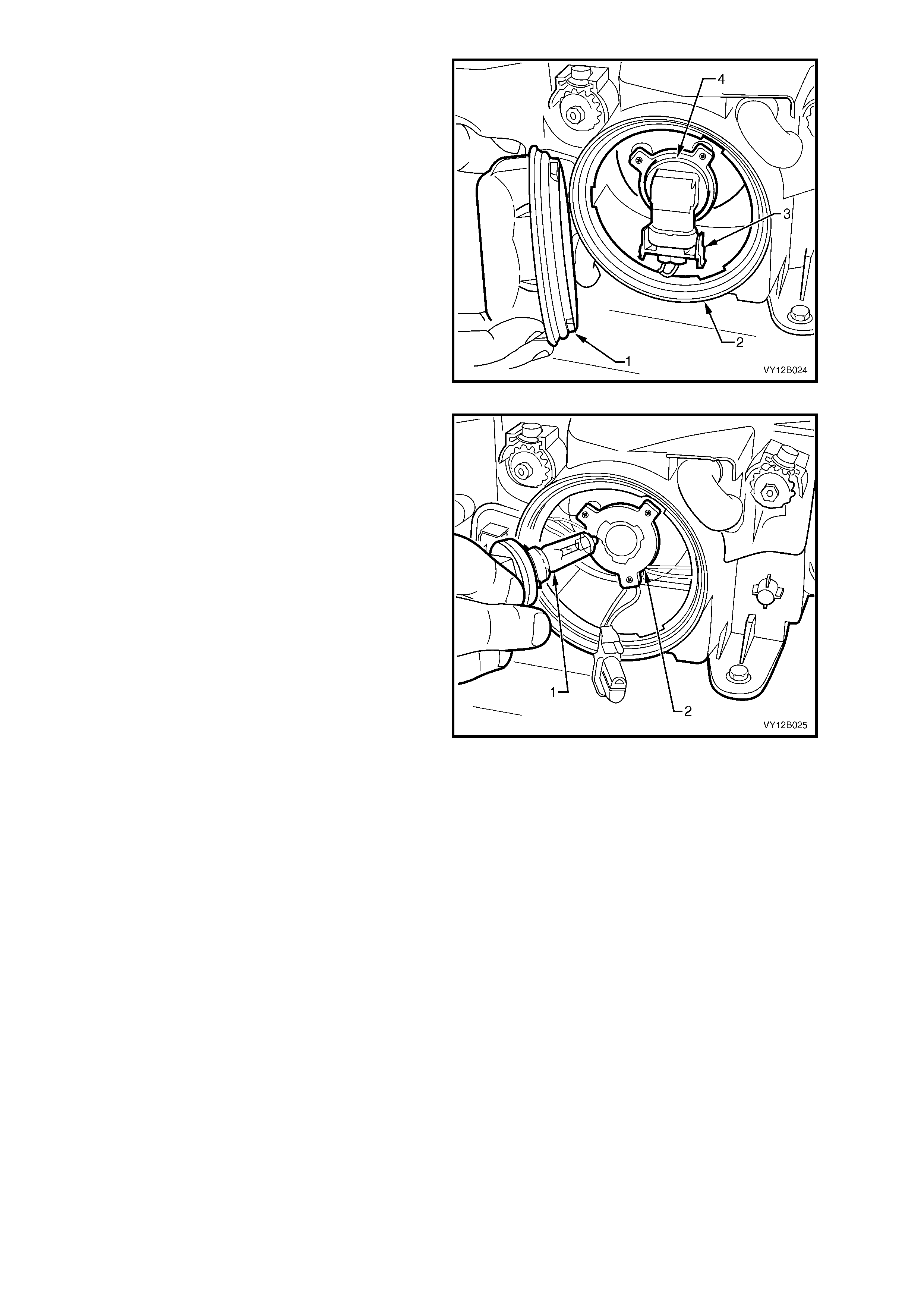

6. From within the engine compartment, remove

the park lamp socket (1) from the headlamp

assembly (2) by rotating it anti-clockwise and

then pulling it away from the headlamp

assembly.

7. Pull the bulb ( 3) away fr om the sock et. Insert a

new bulb into the socket.

8. Inspect the seal on the socket to ensure that it

is not damaged and that it is seated correctly.

Replace the seal if it is damaged.

9. Install the park lamp socket into the rear of the

headlamp assembly and lock into place by

turning it clockwise. Connect the wiring harness

connector to the rear of the headlamp

assembly.

Figure 12B-24

10. As required, install the coolant filler bottle neck, upper radiator shroud and battery.

11. Fit the fusible link F102.

12. Check the park lamp operation.

COUPE

Replace – Low Beam Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

6. From within the engine compartment, remove

the outboard dust cap (1) from the rear of the

headlamp as sembly (2) by turning the dus t cap

anti-clockwise, and pulling it away from the

assembly. If the dust cap seal stays on the

headlamp assembly, remove the seal and

install it onto the cap.

7. Disconnect the wiring connector (3) from the

bulb (4) by squeezing the two tangs together

and pulling the connector down from the bulb.

Figure 12B-25

8. Rotate the bulb (1) anti-clockwise and remove

the bulb from the bulb holder (2).

NOTE: Do not handle the quartz envelope of the

inboard high beam bulb. If touched accidentally,

wipe immediately with methylated spirits or bulb

performance will deteriorate.

9. Install a new bulb into the bulb holder. Lock the

bulb in place by turning it clockwise. Fit the bulb

connector by pushing it into the base of the

bulb until the tangs engage.

NOTE: The dif f erent sized locating lugs on the bulb

base and mating cut-outs in the bulb holder allow

the bulb to seat correctly in one orientation only.

This ensures correct relationship of the bulb to the

reflector.

10. Inspect the seal in the dus t c ap to ensur e that it

is not damaged and that it is seated correctly.

Replace the seal if it is damaged.

11. Install the dust cap onto the rear of headlamp

assembly. The different size lugs on the dust

cap and the mating cut-outs in the headlamp

assem bly ensure that the dust cap can only be

installed in one orientation. T he chamf ered f lats

of the cap need to be f ac ing inboard f or the cap

to install. Lock the cap into place by turning it

clockwise.

12. Connect the wiring harness connector to the

rear of the headlamp assembly.

Figure 12B-26

13. As required, install the coolant filler bottle neck, upper radiator shroud and battery.

14. Fit the fusible link F102.

15. Check the headlamp operation and the aim of the headlamps as the bulb filam ent with respect to the reflector

may have changed. Refer to 2.1 AIMING OF HEADLAMPS AND FOG LAMPS in this Section.

Replace – High Beam Bulb

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring harness connector from the rear of the relevant headlamp assembly.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

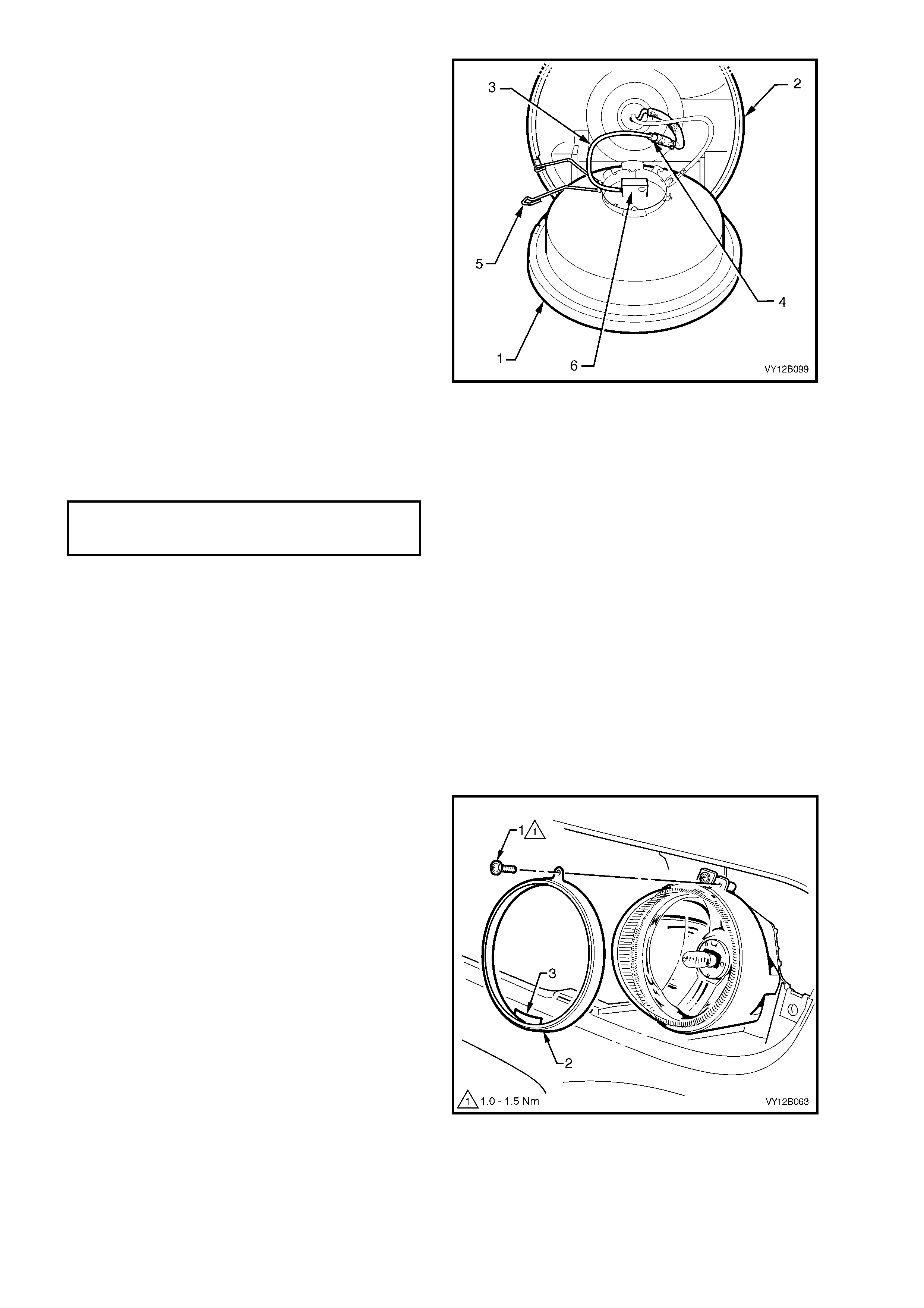

6. From within the engine compartment, remove

the inboard dust cap (1) from the rear of the

headlamp assembly (2) by turning dust cap

anti-clockwise, and pulling it away from the

assembly. If the dust cap seal stays on the

headlamp assembly, remove the seal and

install it onto the cap.

Figure 12B-27

7. Disconnect the wiring connector (1) from the

bulb (2) by squeezing the two tangs together

and pulling the connector down from the bulb.

8. Rotate the bulb anti-clockwise and remove the

bulb from the bulb holder (3).

NOTE: Do not handle the quartz envelope of the

inboard high beam bulb. If touched accidentally,

wipe immediately with methylated spirits or bulb

performance will deteriorate.

9. Install a new bulb into the bulb holder. Lock the

bulb in place by turning it clockwise. Fit the bulb

connector by pushing it into the base of the

bulb until the tangs engage.

NOTE: The dif f erent sized locating lugs on the bulb

base and the mating cut-outs in the bulb holder

allow the bulb to seat correctly in one orientation

only. This ensures correct relationship of the bulb

to the reflector.

10. Inspect the rubber seal in the dust cap to

ensure that it is not damaged and that it is

seated correctly. Replace the seal if it is

damaged.

11. Install the dust cap onto the rear of headlamp

assembly. The different size lugs on the dust

cap and the mating cut-outs in the headlamp

assem bly ensure that the dust cap can only be

installed in one orientation. T he chamf ered f lats

of the cap need to be f ac ing inboard f or the cap

to install. Lock it into place by turning the cap

clockwise.

12. Connect the wiring harness connector to the

rear of the headlamp assembly.

Figure 12B-28

13. As r equired, ins tall the c oolant f iller bottle nec k,

upper radiator shroud and battery.

14. Fit the fusible link F102.

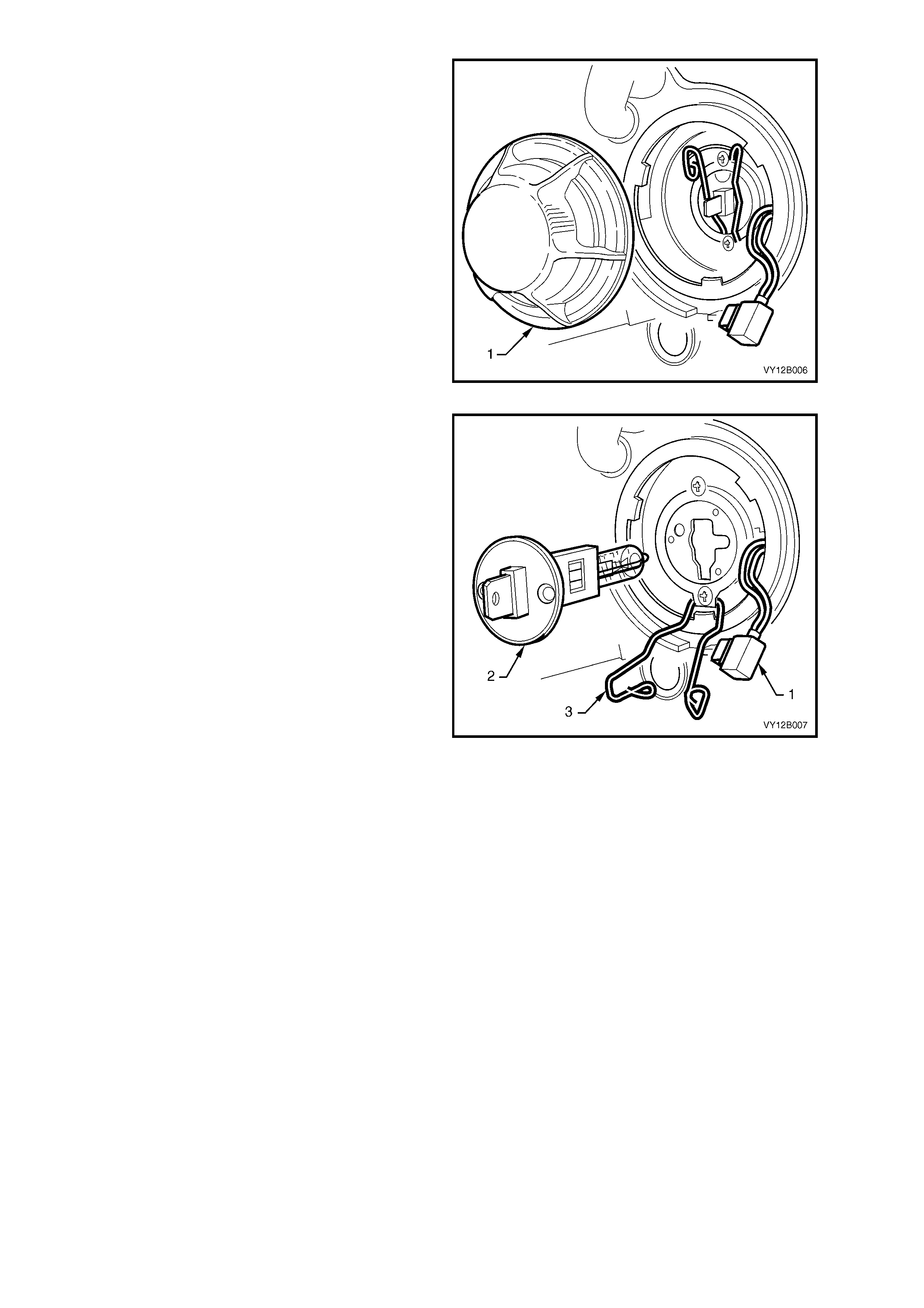

Replace – Park Lamp Bulb

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Open the hood and disconnect the wiring

harness connec tor fr om the rear of the relevant

headlamp assembly.

3. Remove the high beam bulb from the

headlamp assembly, refer REPLACE – HIGH

BEAM BULB, in this Section.

CAUTION: Do not place fingers through the

high beam bulb opening to assist park lamp

socket from assembly.

4. Remove the park lamp socket (1) from the

headlamp assembly high beam reflector by

pulling it firmly rearwards.

5. Pull the bulb (2) from the socket.

6. Inser t a new bulb into the socket and ins tall the

socket into the reflector.

7. Install the high beam bulb into the headlamp

assembly, refer REPLACE – HIGH BEAM

BULB, in this Section.

8. Check the park lamp operation.

Figure 12B-29

2.3 FRONT TURN SIGNAL LAMP BULB

REPLACE

LT Section – 02-300

This Section details the replacement of the turn signal bulb for all models. Although there are dif ferences between

the headlamp assemblies, the turn signal bulb and socket is identical on each. It is situated on the outboard

extremity of each headlamp assembly. The turn signal lamp socket is orange in colour and has a separate wiring

connector to that of the headlamp assembly. To view the rear of the different headlamp assemblies, refer to:

Figure 12B-1 item 1 for Level 1.

Figure 12B-2 item 1 for Level 2 and Level 3 vehicles.

Figure 12B-3 item 1 for Coupe.

1. Open the hood.

2. Remove the turn signal lamp fuse, refer to Figure 12B-116, item 4.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

NOTE: On GEN III V8 engine models, left-hand bulb access can be gained via a hole in the top of the air intake

duct.

5. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

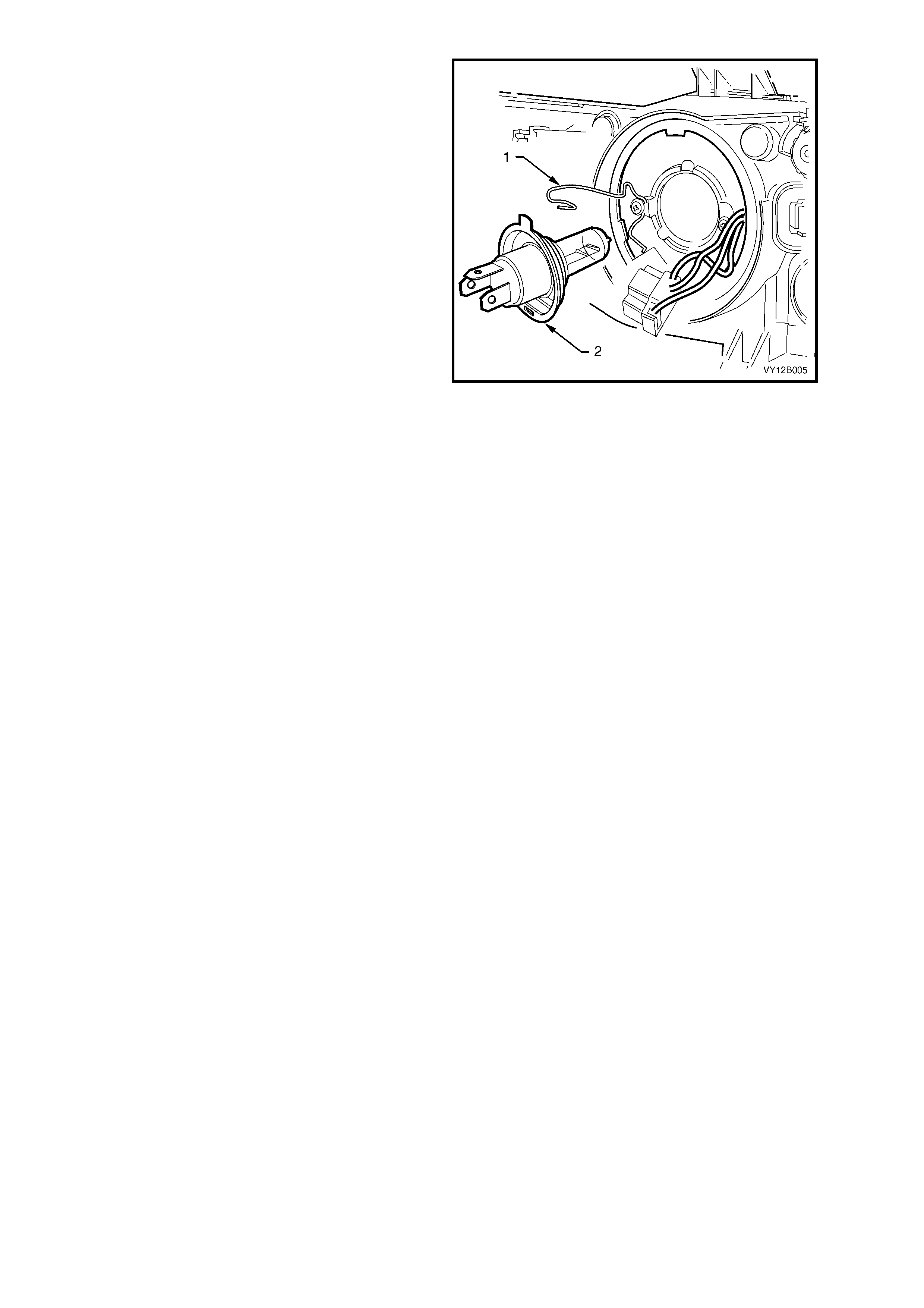

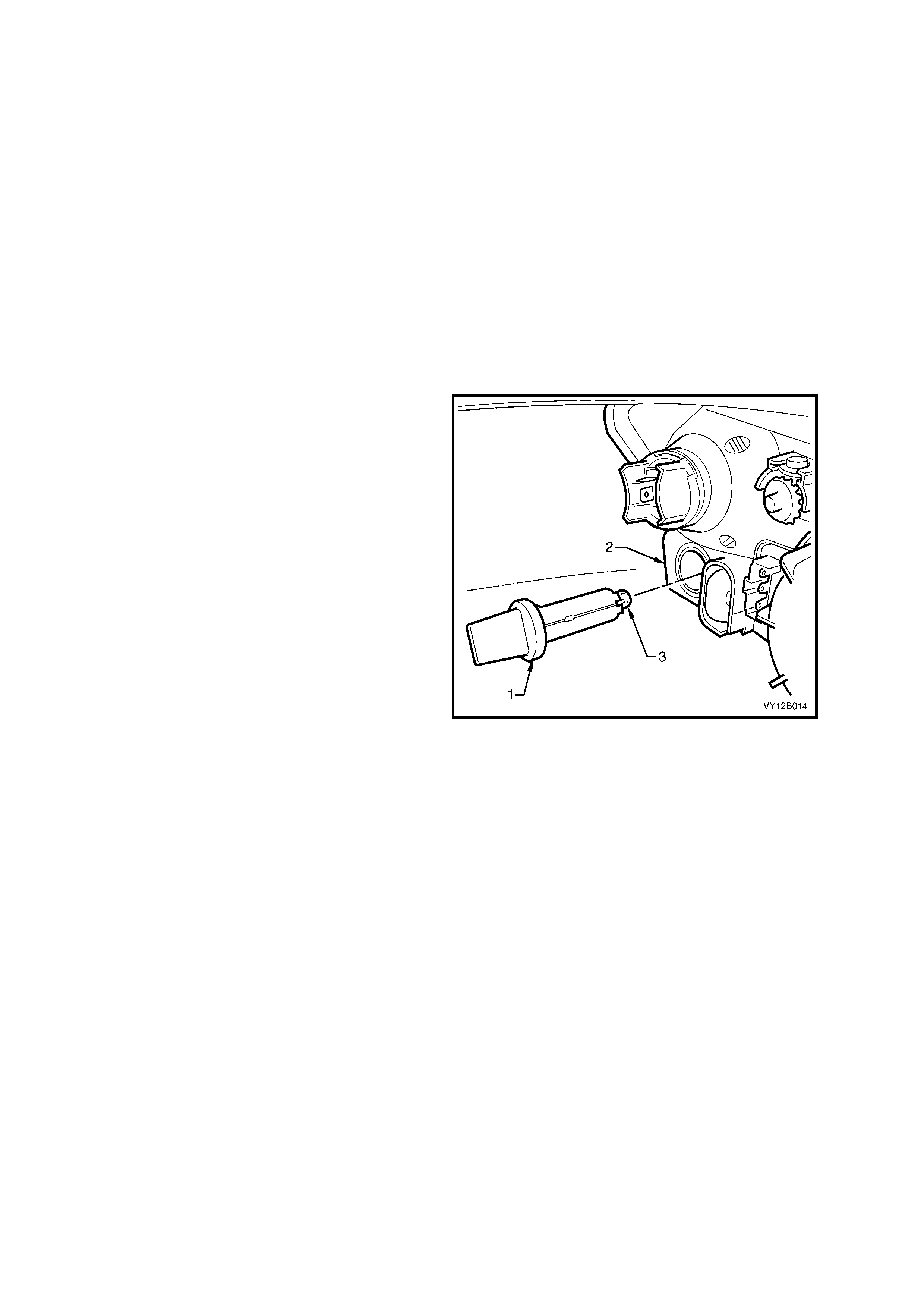

6. Disconnect the turn signal wiring harness

connector from the turn signal socket (1).

7. From within the engine compartment, remove

the turn signal socket from the headlamp

assembly (2) by rotating it anti-clockwise and

then pulling it away from the headlamp

assembly.

8. Depress the bulb (3) into the socket and rotate

anti-clockwise to remove.

9. Inspec t the seal on the bulb soc ket f or damage

and correct seating. Replace the seal if

necessary.

10. Install the new bulb into the socket. Install the

socket into the headlamp assembly and lock

into place by turning it clockwise.

11. Connect the wiring harness connector to the

socket.

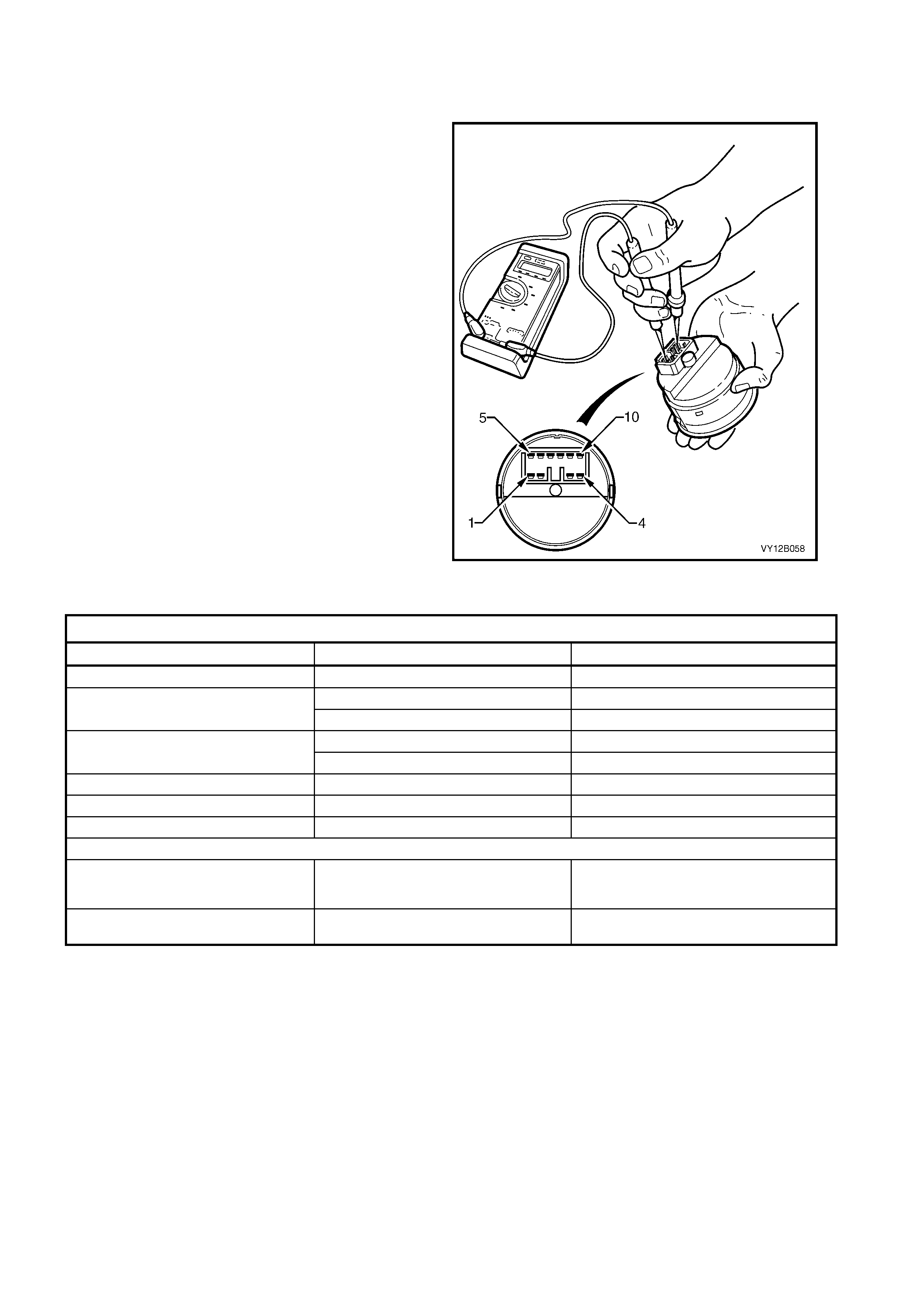

Figure 12B-30

12. As required, install the coolant filler bottle neck,

upper radiator shroud and battery.

13. Fit the turn signal lamp fuse.

14. Check the turn signal operation.

2.4 FRONT FOG LAMP BULB ASSEMBLIES

LT Section – 02-325

LEVEL 3

Replace

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Depress the inner side of the front fog lamp

bezel assembly (1). Rotate the inner side of the

bezel assembly outwards until the tabs are

clear of the bumper fascia. Pull the bezel

assembly away from the bumper fascia.

Figure 12B-31

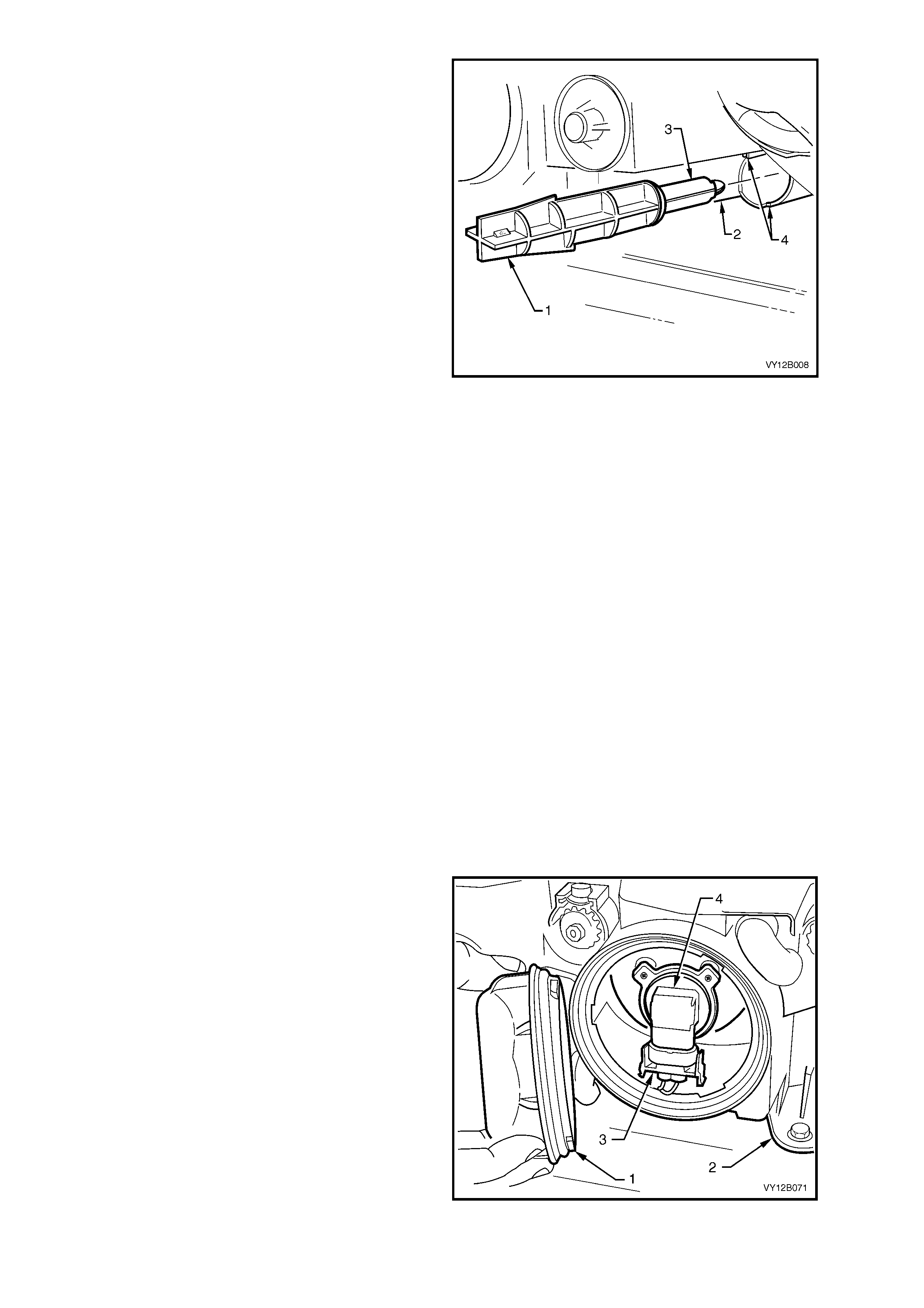

3. Remove the screw (1) to release the clamp

ring (2).

4. Rotate the ring clockwise until the retaining

hook (3) is at the 9 o’clock position. Ease the

ring out of the aperture and away from the fog

lamp.

Figure 12B-32

5. Pull the lens and reflector assembly (1) out

from the lamp housing (2).

6. Disconnect the bulb lead (3) from the wiring

harness connector located inside the insulation

sheath (4).

7. Squeeze the two halves of the spring retainer

(5) together and pivot the spring backward

clear of the bulb. Lif t the bulb (6) out of the lens

and reflector assembly.

NOTE: Do not handle the quartz envelope of the

bulb. If touched, wipe it immediately with

methylated spirits or the bulbs performance will

deteriorate.

8. Install the new bulb into the correct locating

notches in the reflector and insert the spring

retainer. Connect the bulb lead to the wiring

harness connector.

9. Install the lens and reflector assembly into the

housing ensuring that the tabs on the rim of the

lens and reflector assembly correspond with

the cut-outs in the rim of the housing.

10. Secure the lens and r ef lec tor as s embly with the

clamp ring and tighten the screw to the correct

torque specification.

11. Install the fusible link F102.

12. Check fog lamp operation and aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS.

13. Install the fog lamp bezel assembly, ensuring

that the tabs lock securely into the bumper

fascia assembly.

Figure 12B-33

SS

Replace

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Remove the screw (1) to release the clamp

ring (2).

3. Rotate the ring clockwise until the retaining

hook (3) is at the 9 o’clock position. Ease the

ring out of the aperture and away from the fog

lamp.

Figure 12B-34

FRONT FOG LAMP ASSEMBLY

CLAMP RING SECURING SCREW

TORQUE SPECIFICATION 1.0 – 1.5 Nm

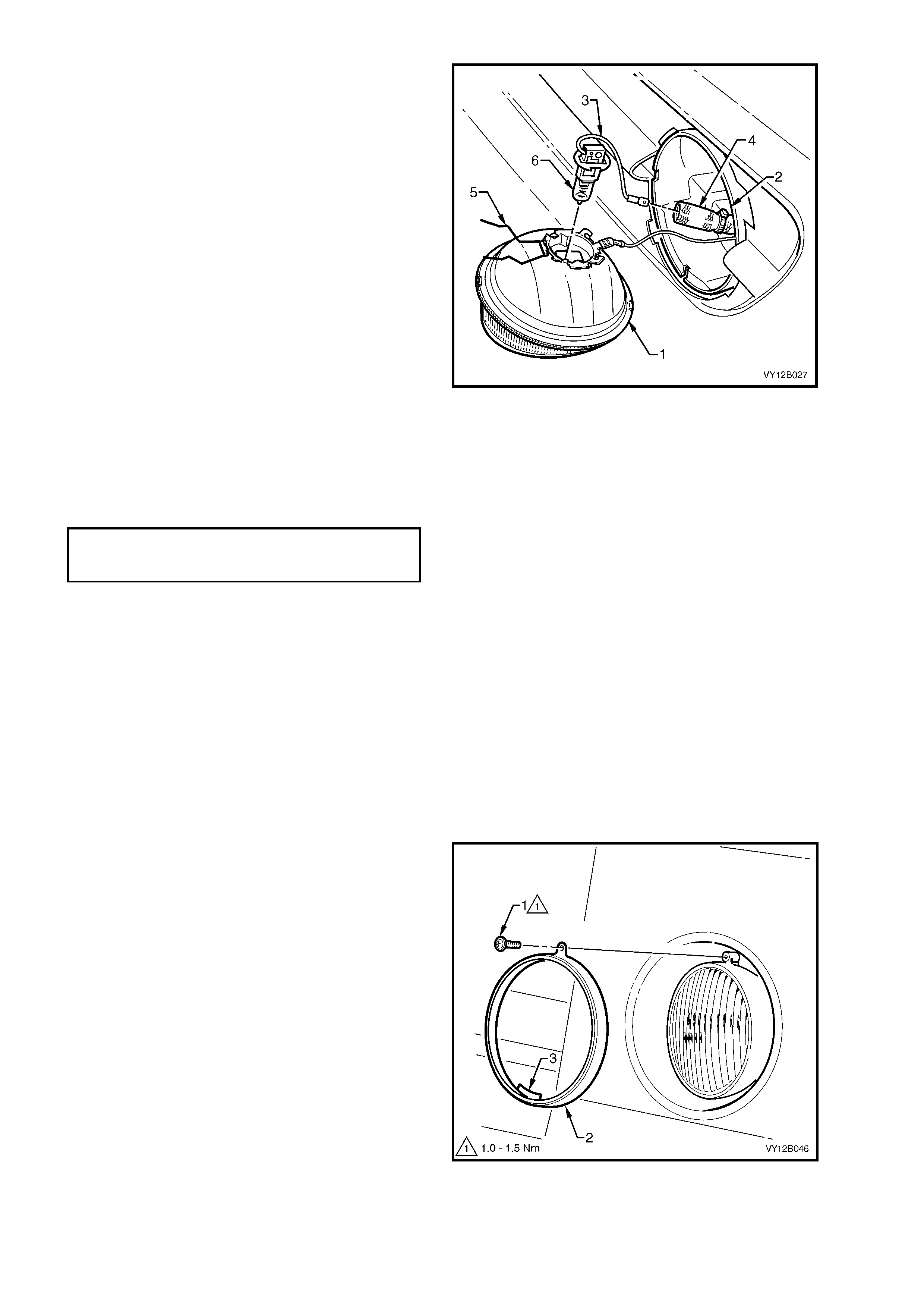

4. Pull the lens and reflector assembly (1) out

from the lamp assembly (2).

5. Disconnect the bulb lead (3) from the wiring

harness connector (4) located inside the

insulating sheath.

6. Squeeze the spring retainer (5) together and

pivot the spring backward clear of the bulb.

Remove the bulb ( 6) f rom the lens and reflector

assembly.

NOTE: Do not handle the quartz envelope of the

bulb. If touched, wipe immediately with methylated

spirits or the bulbs performance will deteriorate.

7. Align the bulb to the notches in the reflector

and install the bulb. Install the spring retainer.

8. Connect the new bulb lead to the wiring

harness connector.

9. Install the lens and reflector assembly into the

housing ensuring that the tabs on the rim of the

lens and reflector assembly correspond with

the cut-outs in the rim of the housing.

10. Install the clamp ring and tighten screw to the

specified torque

11. Install the fusible link F102.

12. Check fog lamp operation and aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS.

Figure 12B-35

COUPE

Replace

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Remove the lower grille, refer to Section 1C,

2.5 LOWER RADIATOR GRILLE, COUPE.

3. Remove the screw (1) to release the clamp

ring (2).

4. Rotate the ring clockwise until the retaining

hook (3) is at the 9 o’clock position. Ease the

ring out of the aperture and away from the fog

lamp.

Figure 12B-36

FRONT FOG LAMP ASSEMBLY

CLAMP RING SECURING SCREW

TORQUE SPECIFICATION 1.0 – 1.5 Nm

5. Pull the lens and reflector assembly (1) out

from the lamp housing (2).

6. Disconnect the bulb lead (3) from the wiring

harness connector located inside the insulation

sheath (4).

7. Squeeze the two halves of the spring retainer

(5) together and pivot the spring backward

clear of the bulb. Lif t the bulb (6) out of the lens

and reflector assembly.

NOTE: Do not handle the quartz envelope of the

bulb. If touched, wipe it immediately with

methylated spirits or the bulbs performance will

deteriorate.

8. Install the new bulb into the correct locating

notches in the reflector and insert the spring

retainer. Connect the bulb lead to the wiring

harness connector.

9. Install the lens and reflector assembly into the

housing ensuring that the tabs on the rim of the

lens and reflector assembly correspond with

the cut-outs in the rim of the housing.

10. Secure the lens and r ef lec tor as s embly with the

clamp ring and tighten the screw to the correct

torque specification.

11. Install the fusible link F102.

12. Check fog lamp operation and aim, refer to

2.1 AIMING OF HEADLAMPS AND FOG

LAMPS.

Figure 12B-37

FRONT FOG LAMP ASSEMBLY

CLAMP RING SECURING SCREW

TORQUE SPECIFICATION 1.0 – 1.5 Nm

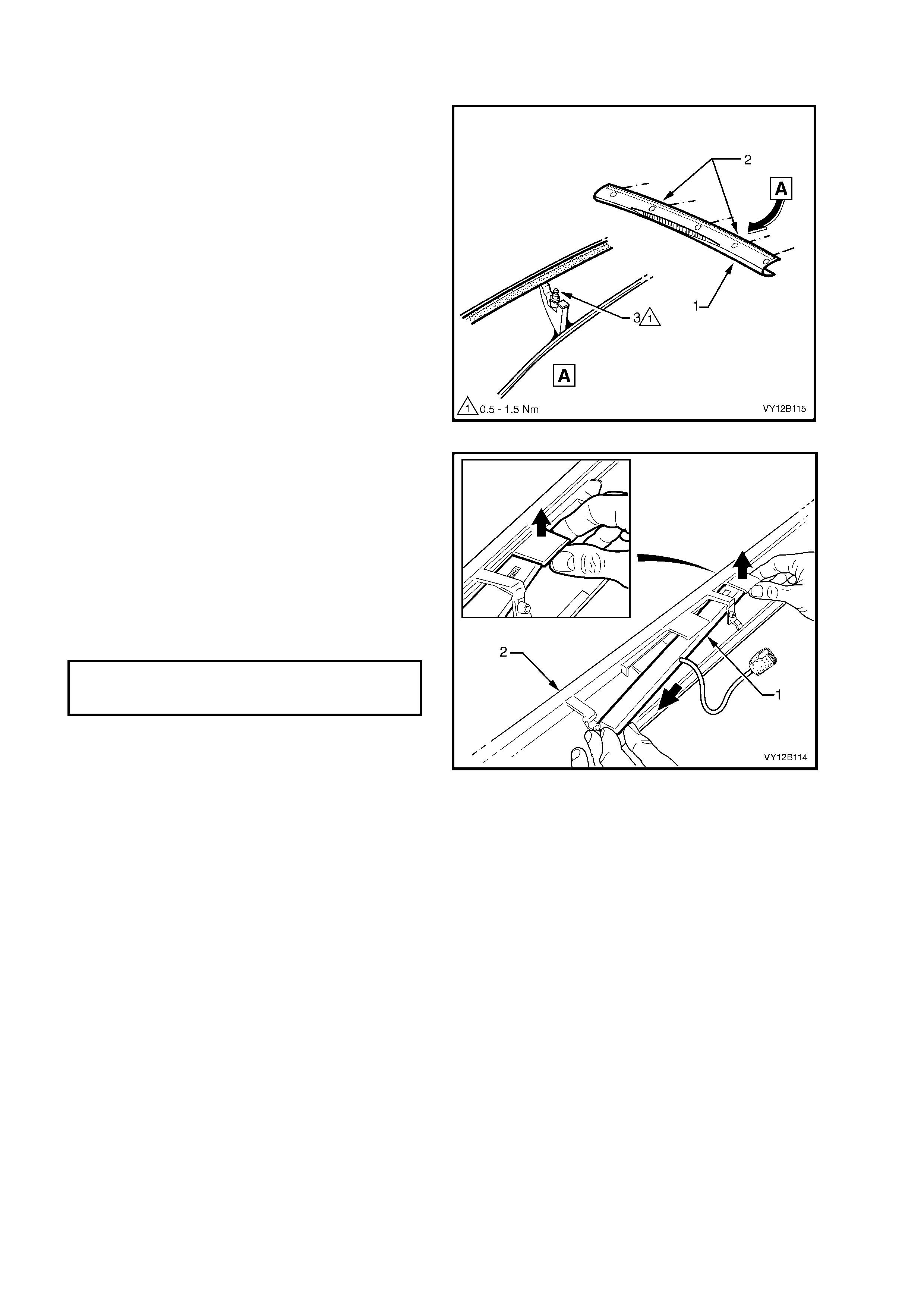

2.5 TAIL LAMP ASSEMBLY BULBS

LT Section – 02-350

SEDAN

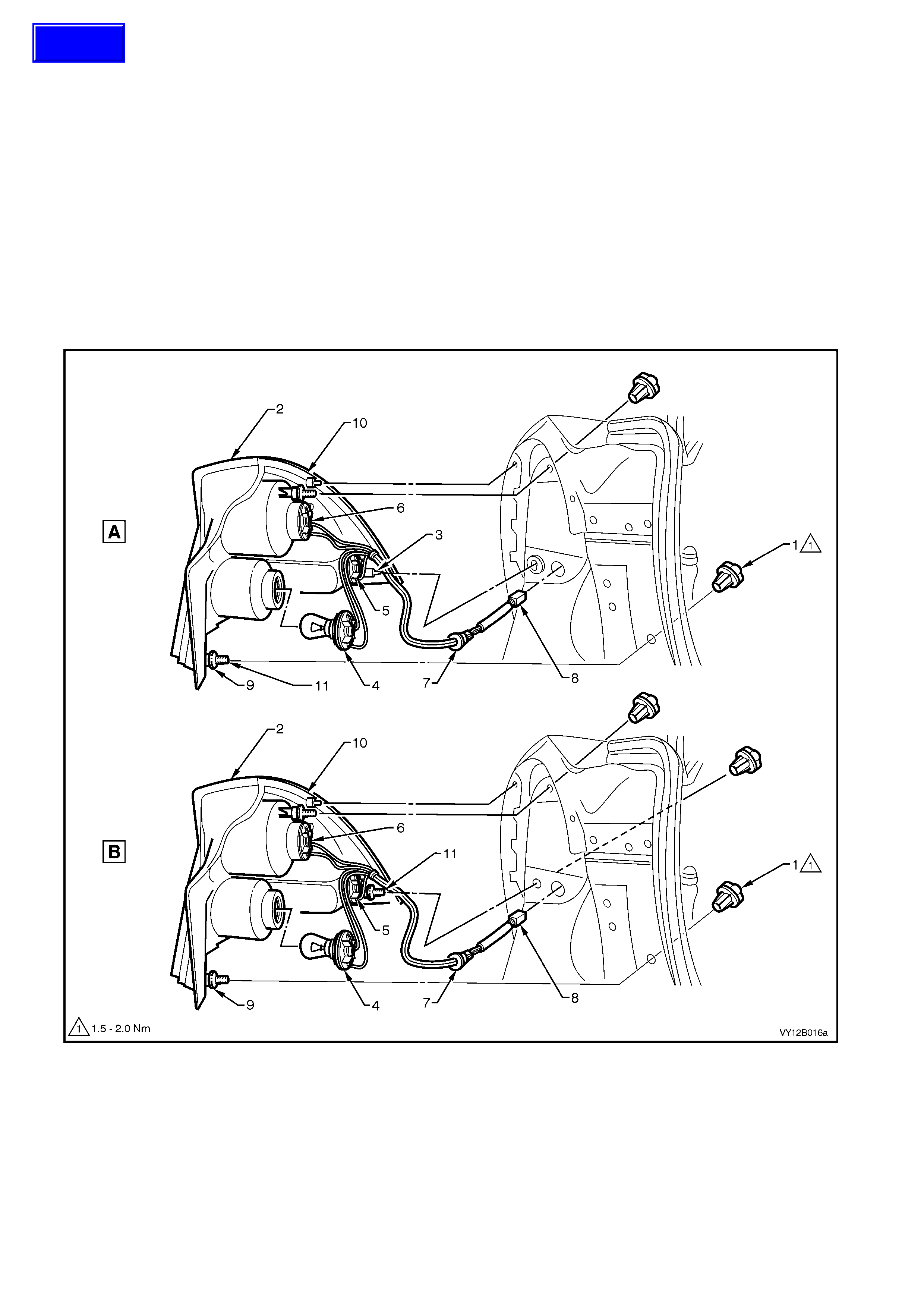

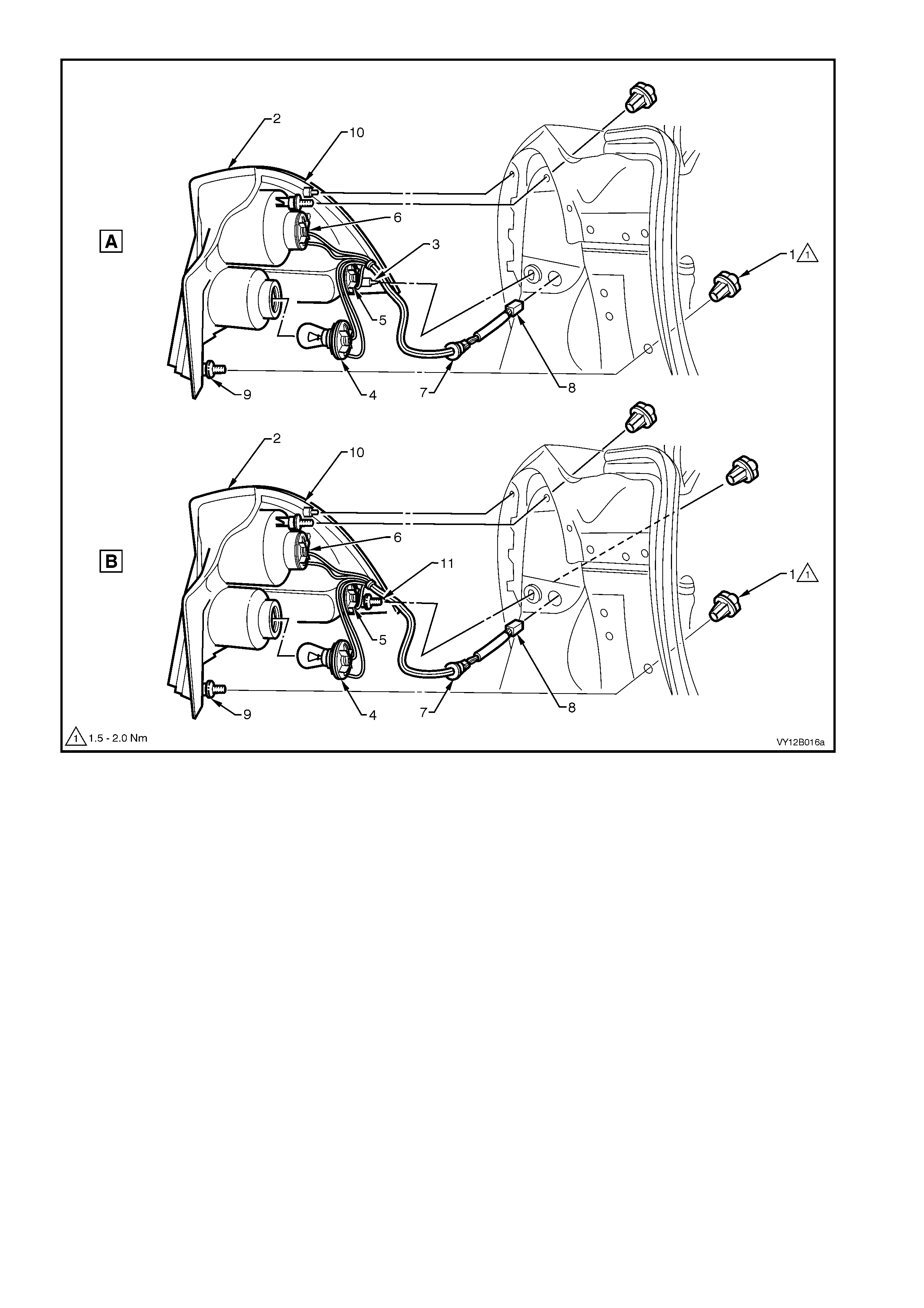

NOTE: During the production of the Sedan, the tail lamp assembly has been modified. The metal locating peg (3,

refer to Figure 12B-38, View A) has been replaced with a threaded stud (11) and attaching nut (1) so to provide a

further securing point for tail lamp assembly to sheetmetal. Therefore some tail lamp assemblies will have three

attaching nuts (View B), and some will have two attaching nuts and a metal locating peg (View A).

Replace

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the rear compartment lid.

3. Pull the quar ter inner r ear s ide car pet f r om the cor ner of the r ear compartment to ex pose the tail lamp attac hing

nuts (1), refer to Figure 12B-38.

NOTE: The tail lamp attaching nuts can be removed by hand or using a 6.0 mm Allen key.

Figure 12B-38

Legend

A Early Type Tail Lamp Assembly

with Two Attachment Studs

B Later Type Tail Lamp Assembly

with Three Attachment Studs

1. Attaching Nut

(two places View A)

(three places View B)

2. Tail lamp assembly

3. Metal locating peg

(one place View A)

4. Back-up Lamp Socket

5. Turn Signal Lamp Socket

6. Stop/Tail Lamp Socket

7. Grommet

8. Electrical Connector

9. Stud Seals

10. Main Seal

11. Attachment Stud

(two places View A)

(three places View B)

Techline

4. Remove the attaching nuts (1), in two places for the early type or three places for the later type tail lamps.

5. Pull the tail lamp away from the vehicle, releasing the metal lock peg (3) from its retainer for early type tail

lamps. Support the tail lamp assembly.

6. Remove the appr opriate bulb soc ket ( 4, 5 or 6) by turning the sock et anti-clock wise and pulling it away f rom the

lamp assembly.

7. Remove the bulb from the socket by depressing the bulb and then rotating it anti-clockwise.

8. Inspect the bulb socket seal for damage and replace if necessary.

9. Insert a new bulb into the socket and install the socket into the lam p assembly, ensuring that the sock et locks

securely into place.

NOTE: Lamp sockets have differing numbers of lugs to prevent installation into the incorrect rear lamp receptacle.

10. Ensure that the main seal (10), stud seals (9) and seal mating areas are clean to prevent any paint damage.

11. Install the lamp assembly onto the vehicle. Apply a firm pressure to the outboard lower corner of the tail lamp so

that the metal locating peg locks into the retainer (early type tail lamps).

12. Install and tighten the tail lamp assembly attaching nuts to the correct torque specification.

TAIL LAMP ASSEMBLY

ATTACHING NUT

TORQUE SPECIFICATION 1.5 – 2.0 Nm

13. Fit the fusible link F102 and check the tail lamp operation.

14. Fit the quarter inner rear side carpet in the rear compartment.

WAGON

Replace

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Open the liftgate.

3. Remove the quarter trim panel vent with

a flat blade screwdriver, taking care not

to damage the surrounding quarter

inner trim panel assembly. Refer to

Section 1A8, 3.11 QUARTER INNER TRIM

PANEL ASSEMBLY – DISASSEMBLE.

4. Remove the appropriate bulb socket (1) by

turning it anti-clockwise and pulling it away from

the lamp assembly.

IMPORTANT: The various sockets are colour

coded to aid in identification:

• Black socket – stop/tail lamp

• Grey socket – back-up lamp

• Orange socket – turn signal

5. Remove the bulb from the socket by

depressing the bulb and then rotating it anti-

clockwise.

6. Inspect the socket to lamp assembly seals for

damage and replace if necessary.

7. Insert a new bulb into the socket and fit the

socket into the lamp assembly, ensuring that

the socket locks securely into place.

8. F it the fus ible link F 102 and check the tail lam p

operation.

9. Fit the quarter trim panel vent.

Figure 12B-39

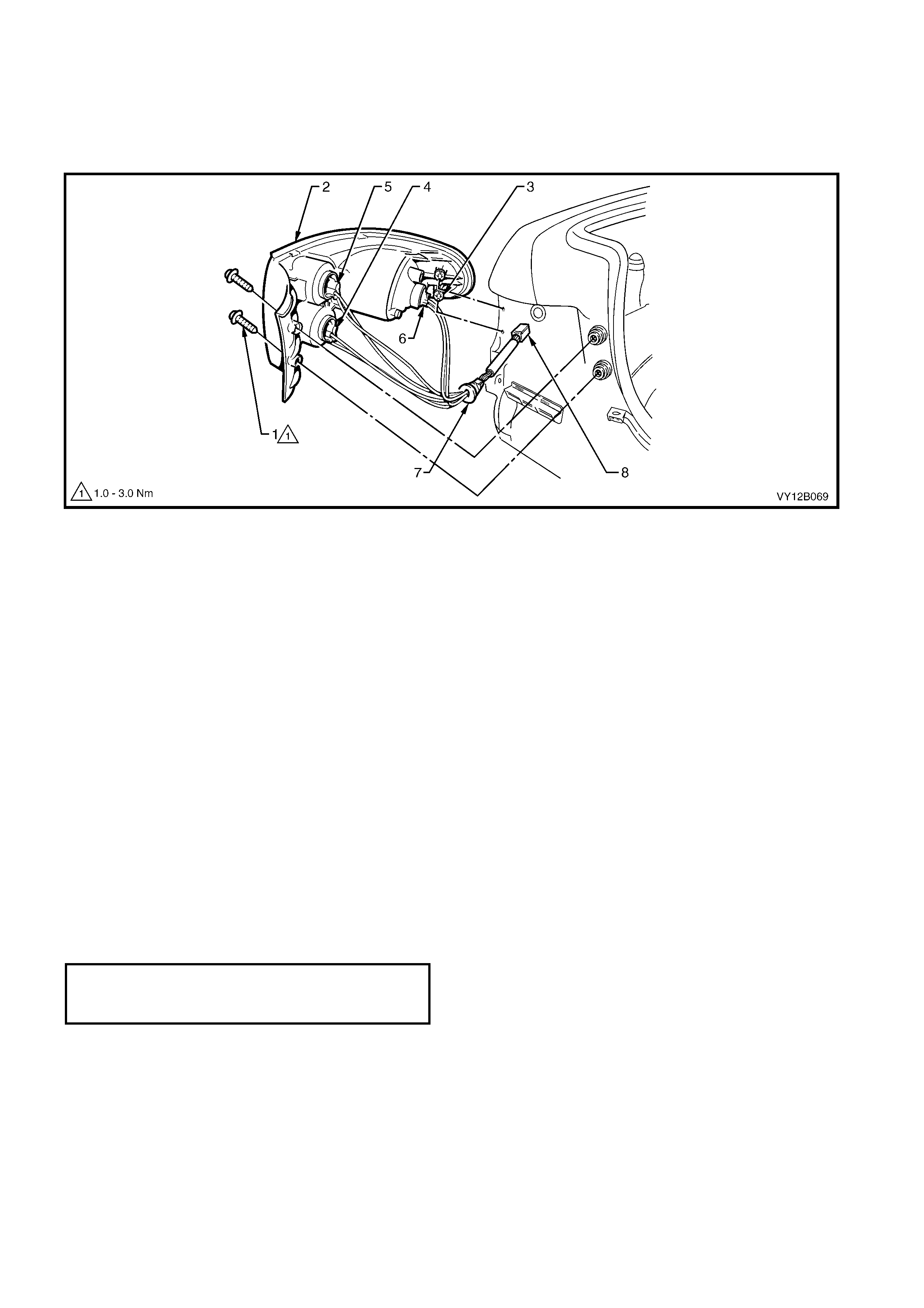

COUPE

Replace

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the rear compartment.

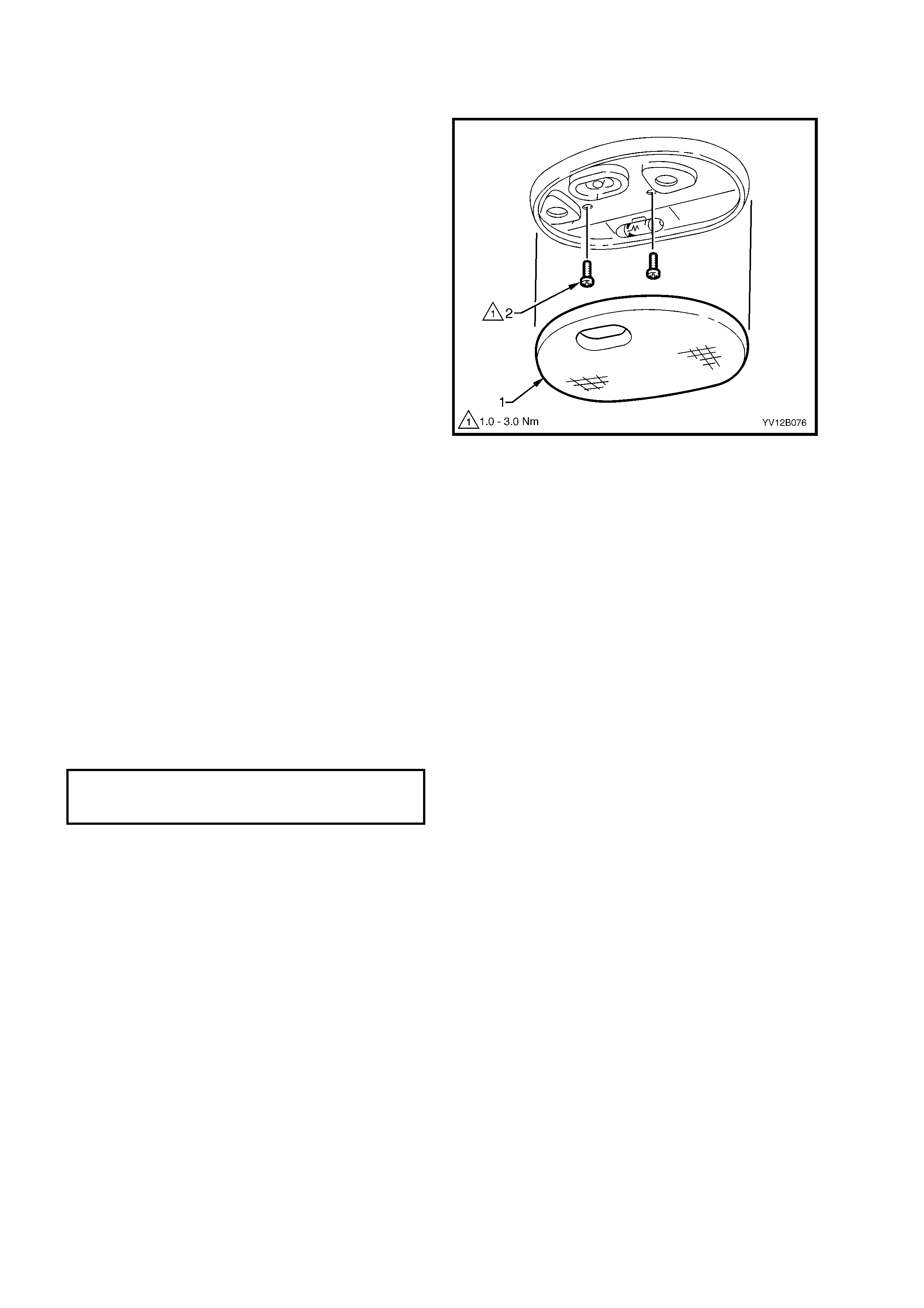

3. Remove the tail lamp assembly attaching screws (1), refer to Figure 12B-40.

Figure 12B-40

Legend

1. Attaching screw (2 places)

2. Tail lamp assembly

3. Locating pegs

4. Back-up lamp socket

5. Turn signal lamp socket

6. Stop/tail lamp socket

7. Grommet

8. Electrical connector

4. Pull the tail lamp assembly (2) sideways and out from the panel so that locating pegs (3) on the side of lamp

assembly snap free from the retainers. Support the assembly.

NOTE: When removing the tail lamp assembly from the panel, take care not to damage the locating pegs.

5. Remove the appr opriate bulb soc ket ( 4, 5 or 6) by turning the sock et anti-clock wise and pulling it away f rom the

lamp assembly.

6. Remove the bulb from the socket by depressing the bulb and then rotating it anti-clockwise.

7. Inspect the socket seal for damage and replace if necessary.

8. Insert a new bulb into the socket and install the socket into the lam p assembly, ensuring that the sock et locks

securely into place.

NOTE 1: Lamp sockets have differing numbers of lugs to prevent installation into the incorrect rear lamp receptacle.

NOTE 2: Harness length will allow the back -up light sock et and the turn signal bulb socket to be fitted into correct

locations only.

9. Ensure that the lamp harness grommet (7) is seated correctly. Fit the tail lamp assembly to the body ensuring

that the locating pegs snap into the retainers.

10. Install and tighten the attaching screws to the correct torque specification.

TAIL LAMP ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

11. Install the fusible link F102 and check the tail lamp operation.

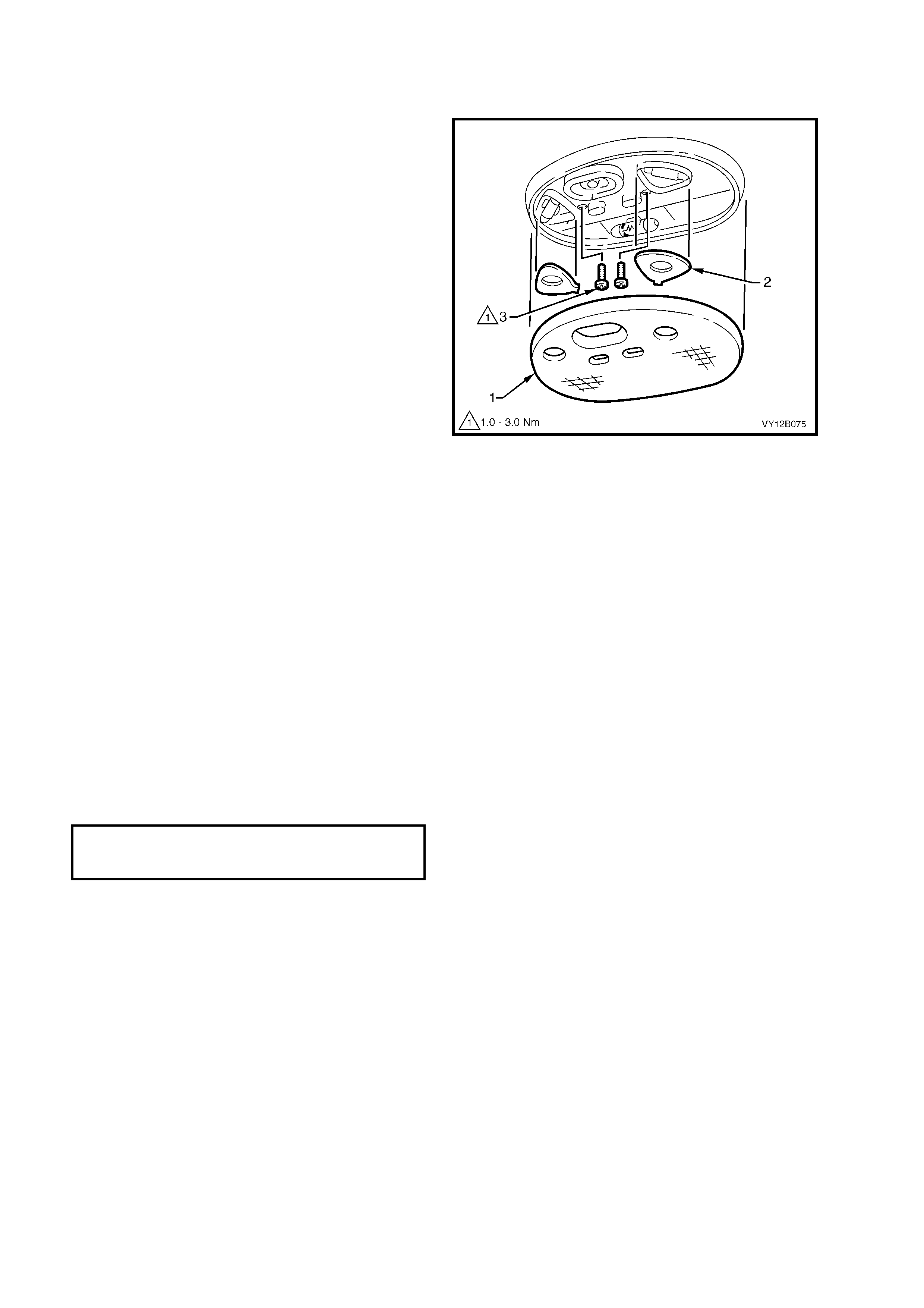

UTILITY

Replace

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Remove the eight screws (1) securing the rear

inner side panel cover (2) and remove the

cover.

NOTE: The cover may require careful prising to

break the seal (3) from the inner side panel.

Figure 12B-41

3. Rem ove the appropriate soc ket (1) by turning it

anti-clockwise and removing the socket from

the tail lamp assembly (2).

IMPORTANT: The various sockets are colour

coded to aid in identification:

• Black socket – stop/tail lamp

• Grey socket – back-up lamp

• Orange socket – turn signal

4. Remove the bulb (3) from the socket by

depressing the bulb and then rotating it anti-

clockwise.

5. Inspect the socket to the lamp assembly seals

for damage and replace if necessary.

6. Insert a new bulb into the socket and fit the

socket into the lamp assembly, ensuring that it

locks securely into place.

7. F it the fus ible link F 102 and check the tail lam p

assembly operation.

8. Check the seal (3) on the rear inner side panel

cover, refer to Figure 12B-41. Fit and tighten

the rear inner side panel cover screws to the

specified torque.

Figure 12B-42

REAR INNER SIDE

PANEL COVER SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

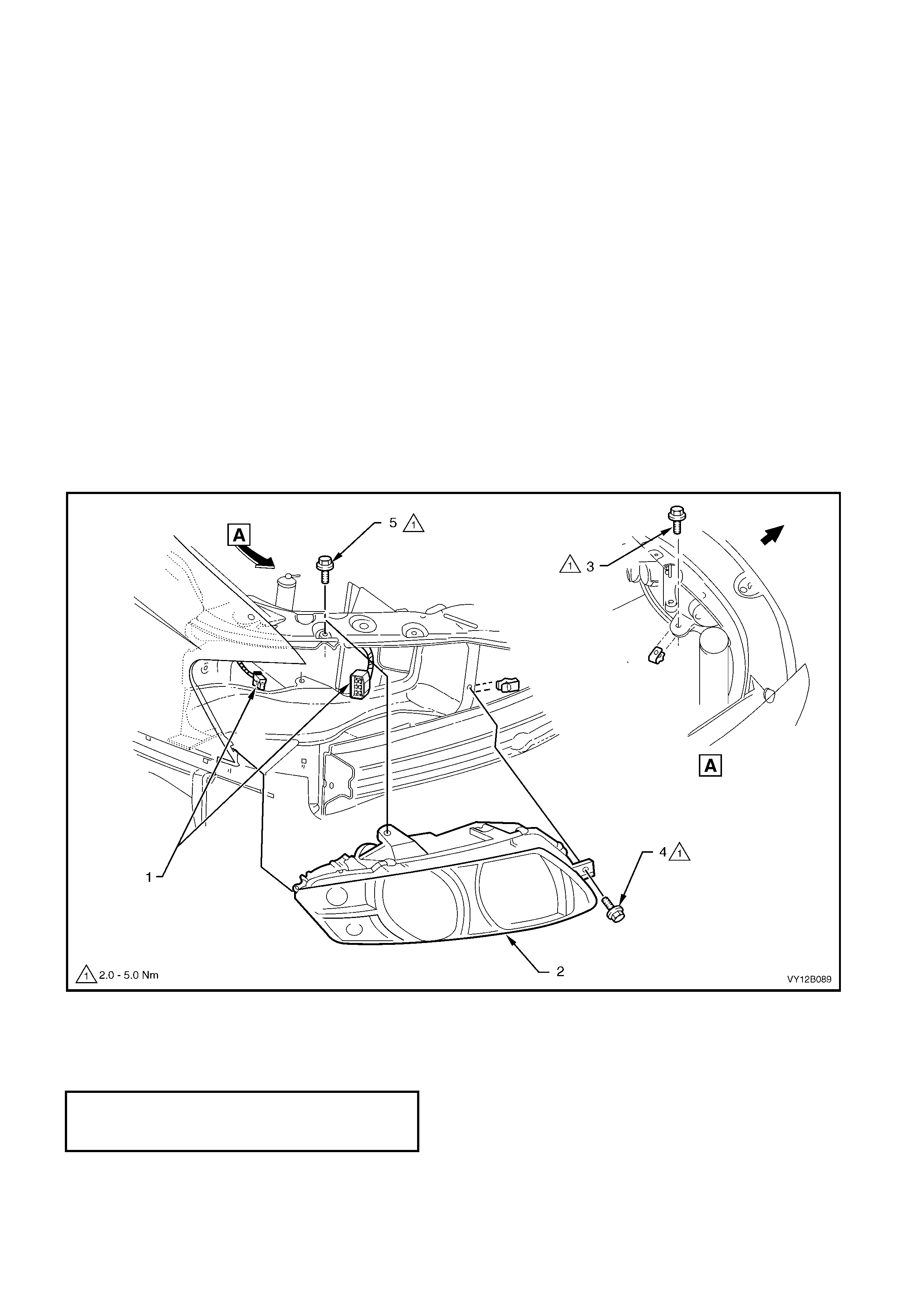

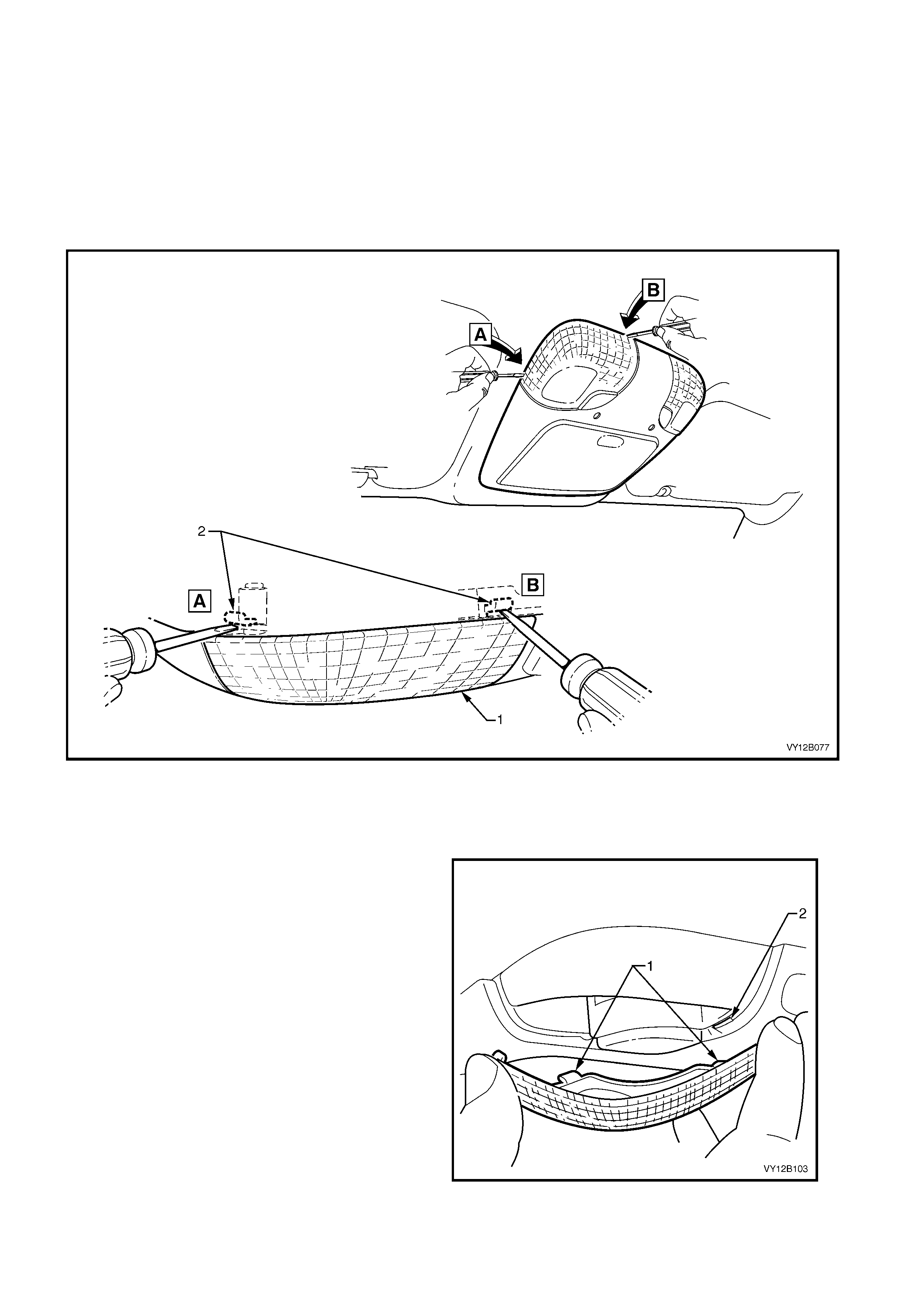

2.6 HEADLAMP ASSEMBLY

The headlamp assemblies all have the same retainer attaching pattern, that is, they all require three screws in the

same locations to secure the assemblies to the sheetmetal.

LT Section – 02-300

REMOVE

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Remove the front bumper fascia assembly . Refer to Section 1D, 2.2 FRONT BUMPER FASCIA ASSEMBLY.

3. If required, for GEN III V8 engine models, remove the four retainers securing the upper radiator shroud and

remove the shroud. Refer to Section 6B3, 2.16 RADIATOR.

4. For the right-hand headlamp assembly, it may be necessary to remove the battery to gain the required access.

a. If required, remove the battery hold-down bracket and move the battery to gain access. Refer to

Section 12A, 2.9 BATTERY.

b. If further access is required, remove the battery terminals from the battery and remove the battery from the

engine compartment. Refer to Section 12A, 2.9 BATTERY.

Important: Disconnection of the battery affects certain vehicle electronic systems. Refer to

Section 00, 5. BATTERY DISCONNECTION PROCEDURES before disconnecting the battery.

4. For lef t- hand headlamp as s embly’s on V6 engine models, remove the c oolant f iller bottle nec k and place to one

side.

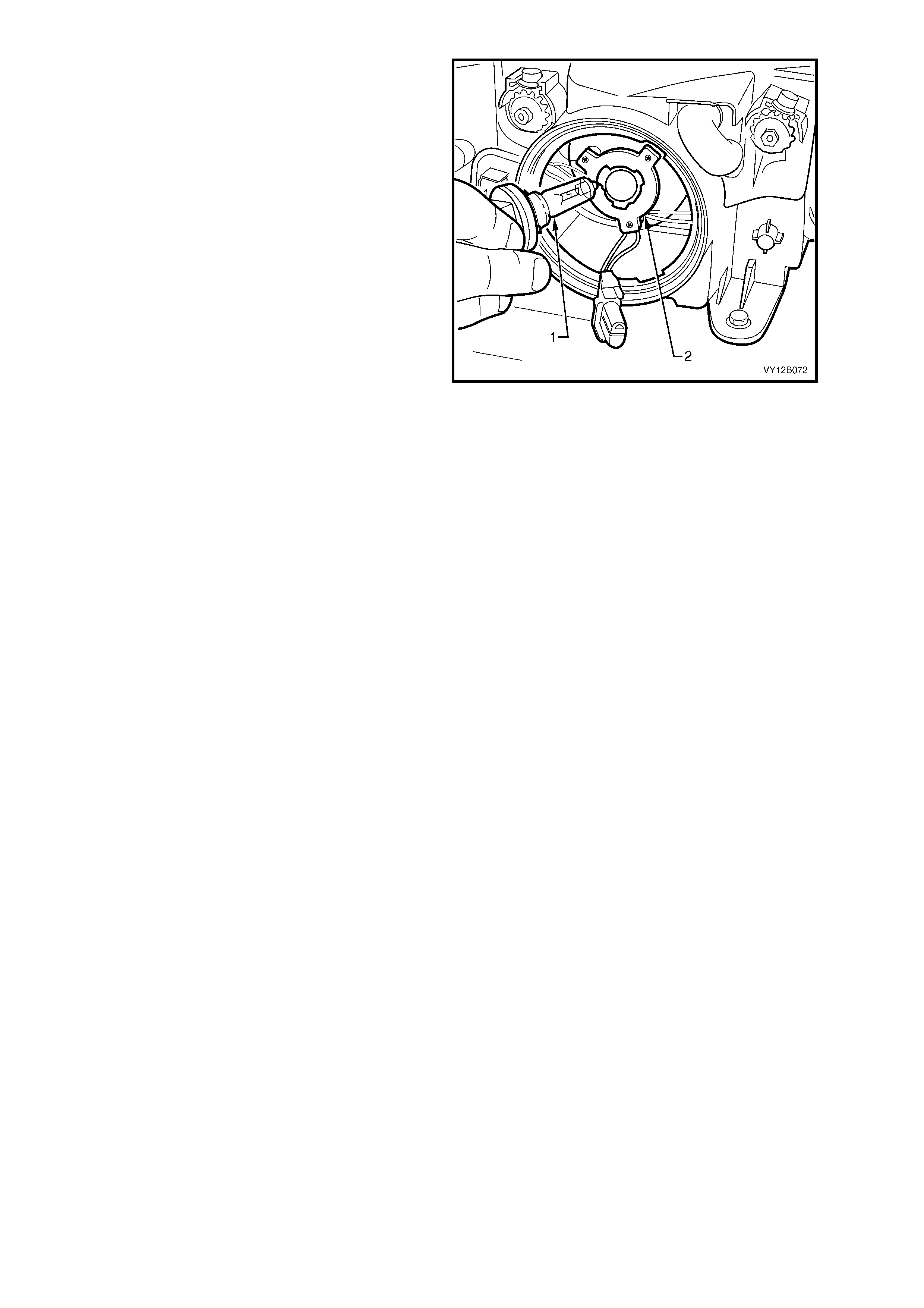

5. Disconnect the turn signal and headlamp wiring harness connectors (1) from the rear of the headlamp

assembly (2).

6. Remove the three headlamp retaining screws (3, 4 and 5) and remove the headlamp assembly.

Figure 12B-43

REINSTALL

Installation of the headlamp assembly is the reverse of the removal procedure, noting the following points:

1. Install the headlamp assembly and tighten the retaining screws to the correct torque specification.

HEADLAMP ASSEMBLY

RETAINING SCREW

TORQUE SPECIFICATION 2.0 – 5.0 Nm

2. Connect all the wiring harness connectors and check the operation of the headlamps and turn signal/parking

lamps.

3. Install the front bumper fascia assembly. Refer to Section 1D, 2.2 FRONT BUMPER FASCIA ASSEMBLY.

4. Check the headlamp (and fog lamps) aim, refer to 2.1 AIMING OF HEADLAMPS AND FOG LAMPS.

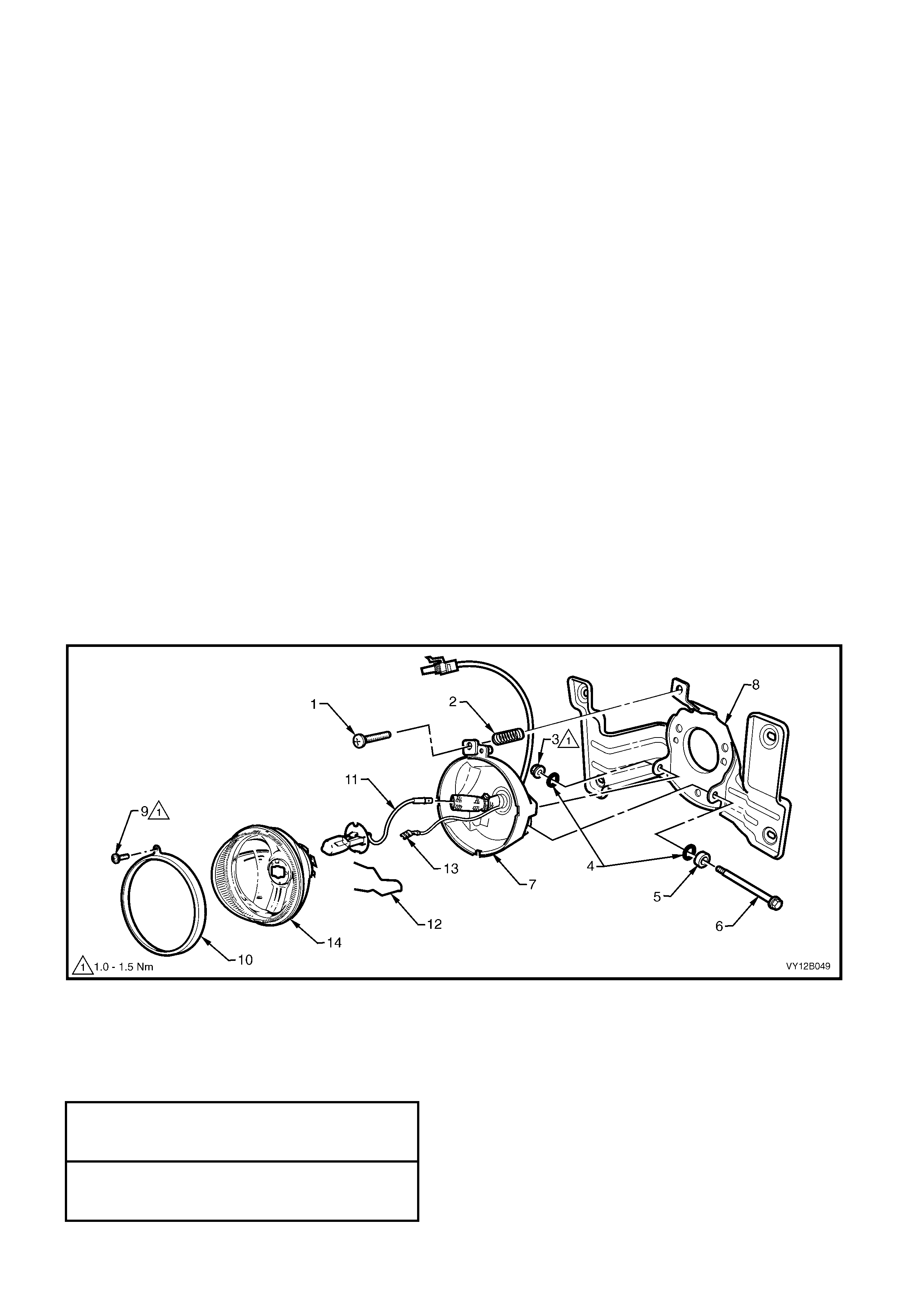

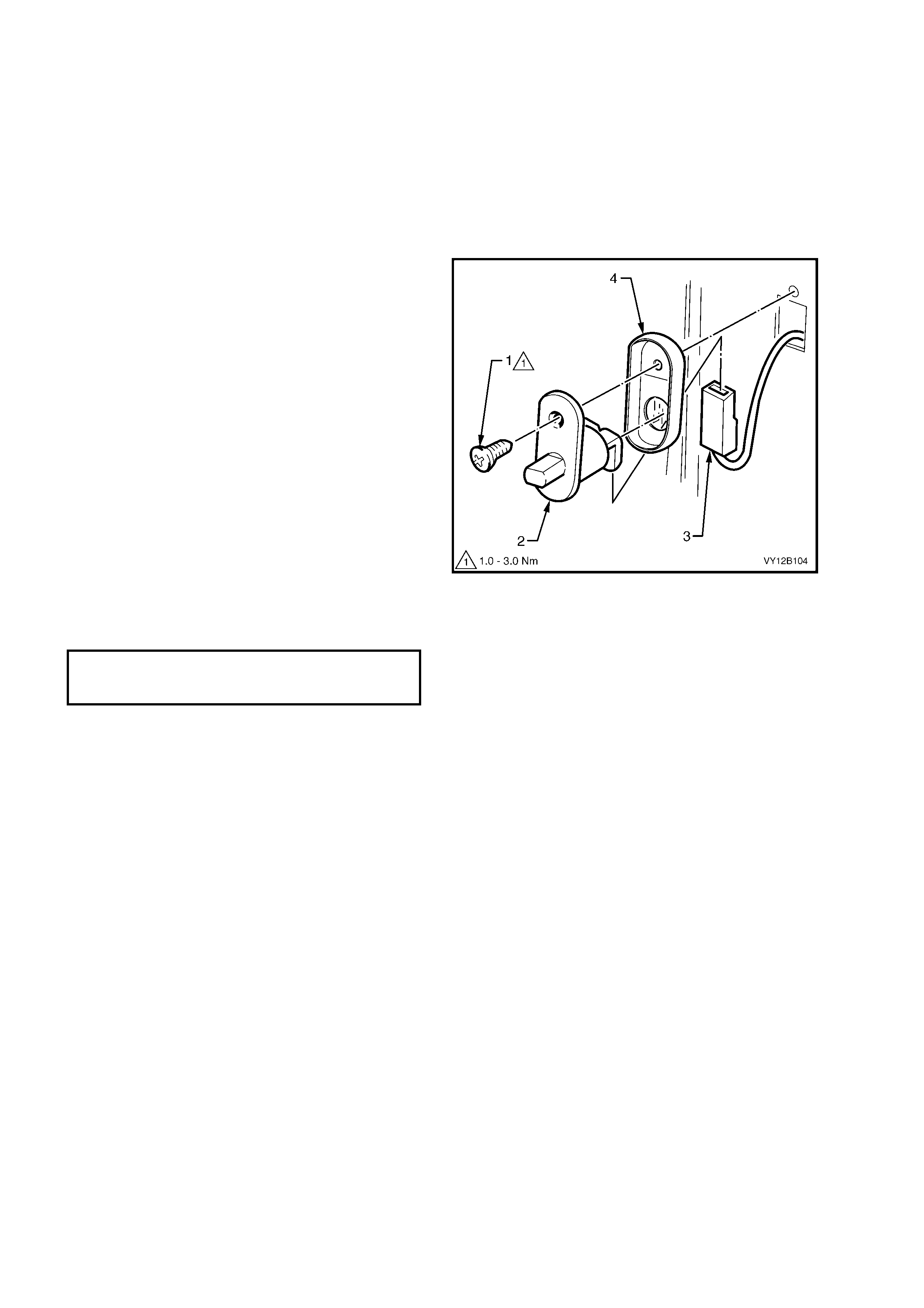

2.7 FRONT FOG LAMP ASSEMBLY

LT Section – 02-325

LEVEL 3

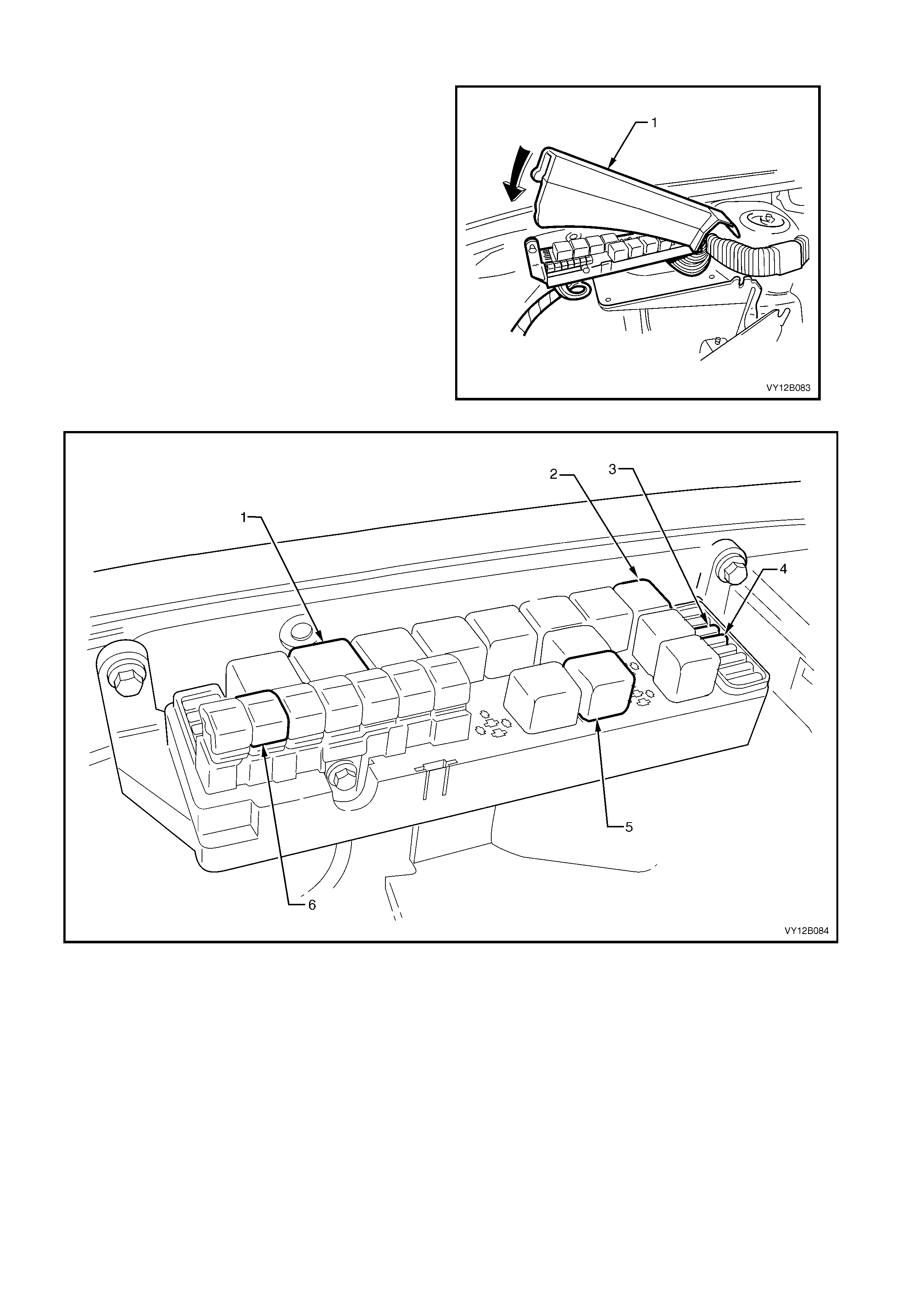

The following parts (refer to Figure 12B-44) may be disassembled from the front fog lamp assembly without

removing the complete unit from behind the lower radiator grille:

• Adjusting screw (1)

• Spring (2 )

• Clamp ring (10)

• Lens and reflector assembly (14)

• Bulb (11)

• Retaining spring (12)

To remove any of these items, refer to 2.4 FRONT FOG LAMP BULB ASSEMBLY – LEVEL 3.

Remove

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Remove the front fog lamp assembly, refer to Section 1C, 2.4 LOWER RADIATOR GRILLE, LEVEL

2 & 3 –DISASSEMBLY.

Disassemble

1. Remove the adjusting screw (1) and the spring (2).

NOTE: Ensure that the spring is contained when the adjusting screw is removed.

2. Remove the nut (3), seals (4), spacer (5) and bolt (6) securing the lens and reflector housing (7) to the

mounting bracket (8). Separate the two items.

3. Remove the screw (9) and clamp ring (10).

4. Disconnect the bulb lead (11) from the wiring harness connector inside the insulation sheath.

5. Remove the earth lead connector (13) from the lens and reflector assembly (14).

6. Squeeze the ends of the retaining spring (12) together and remove the spring. Remove the bulb.

7. Remove the grommet and remove the wiring harness from the lens and reflector housing.

Figure 12B-44

Reassemble

Assembly of the front fog lamp is the reverse of the disassembly procedure, noting the following:

1. Tighten the clamp ring securing screw to the correct torque specification.

2. Tighten the lens and reflector housing hinge bolt nut to the correct torque specification.

FRONT FOG LAMP ASSEMBLY

CLAMP RING SECURING SCREW

TORQUE SPECIFICATION 1.0 – 1.5 Nm

FRONT FOG LAMP ASSEMBLY LENS

AND REFLECTOR HOUSING HINGE

BOLT NUT TORQUE SPECIFICATION 1.0 – 1.5 Nm

Reinstall

Installation of the fog lamp assembly is the reverse of the removal procedure.

SS

The following parts (refer to Figure 12B-44) may be disassembled from the front fog lamp assembly without

removing the complete unit from behind the lower radiator grille:

• Adjusting screw (1)

• Spring (2 )

• Clamp ring (10)

• Lens and reflector assembly (14)

• Bulb (11)

• Retaining spring (12)

To remove any of these items, refer to 2.4 FRONT FOG LAMP BULB ASSEMBLY – SS.

Remove

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

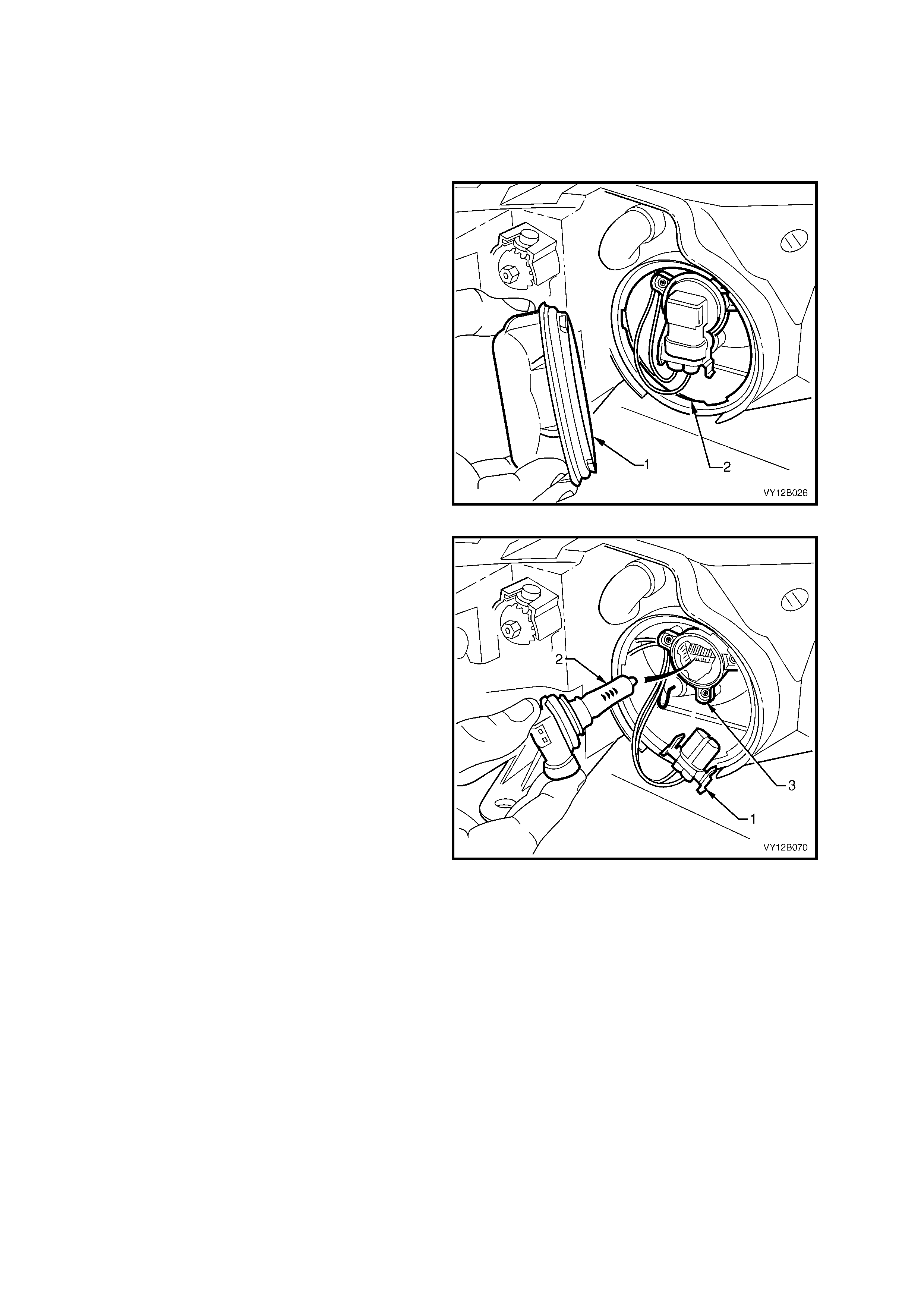

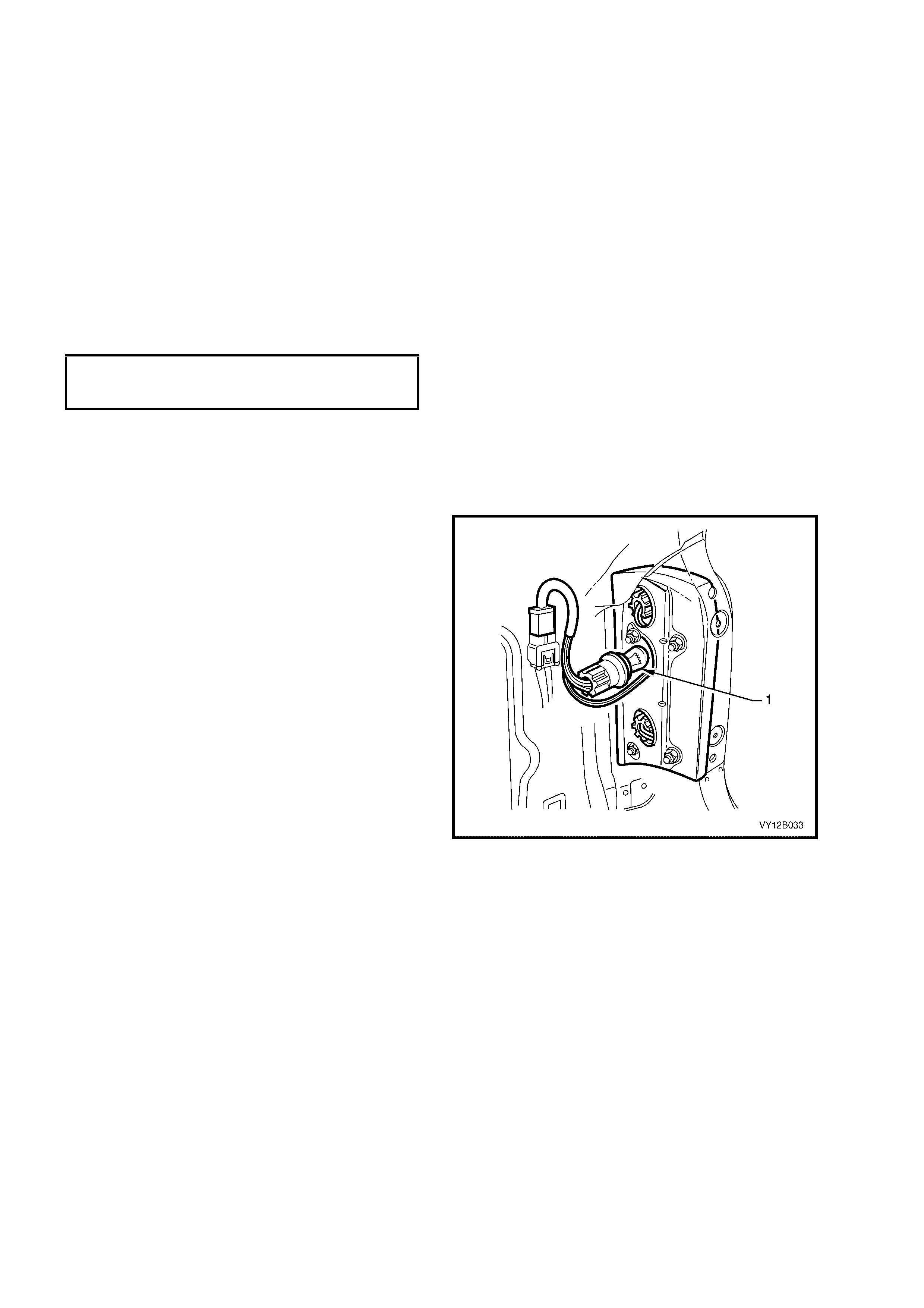

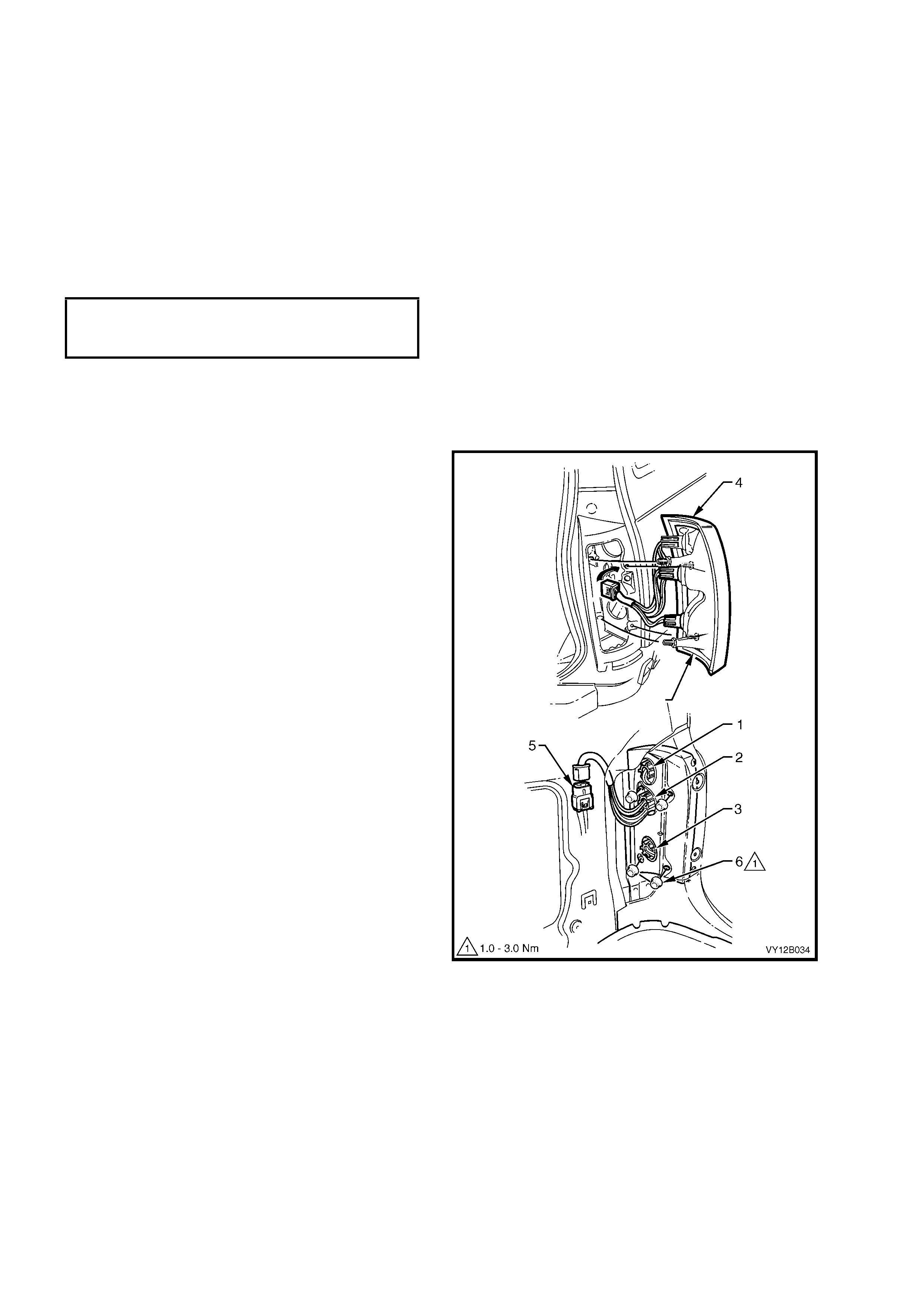

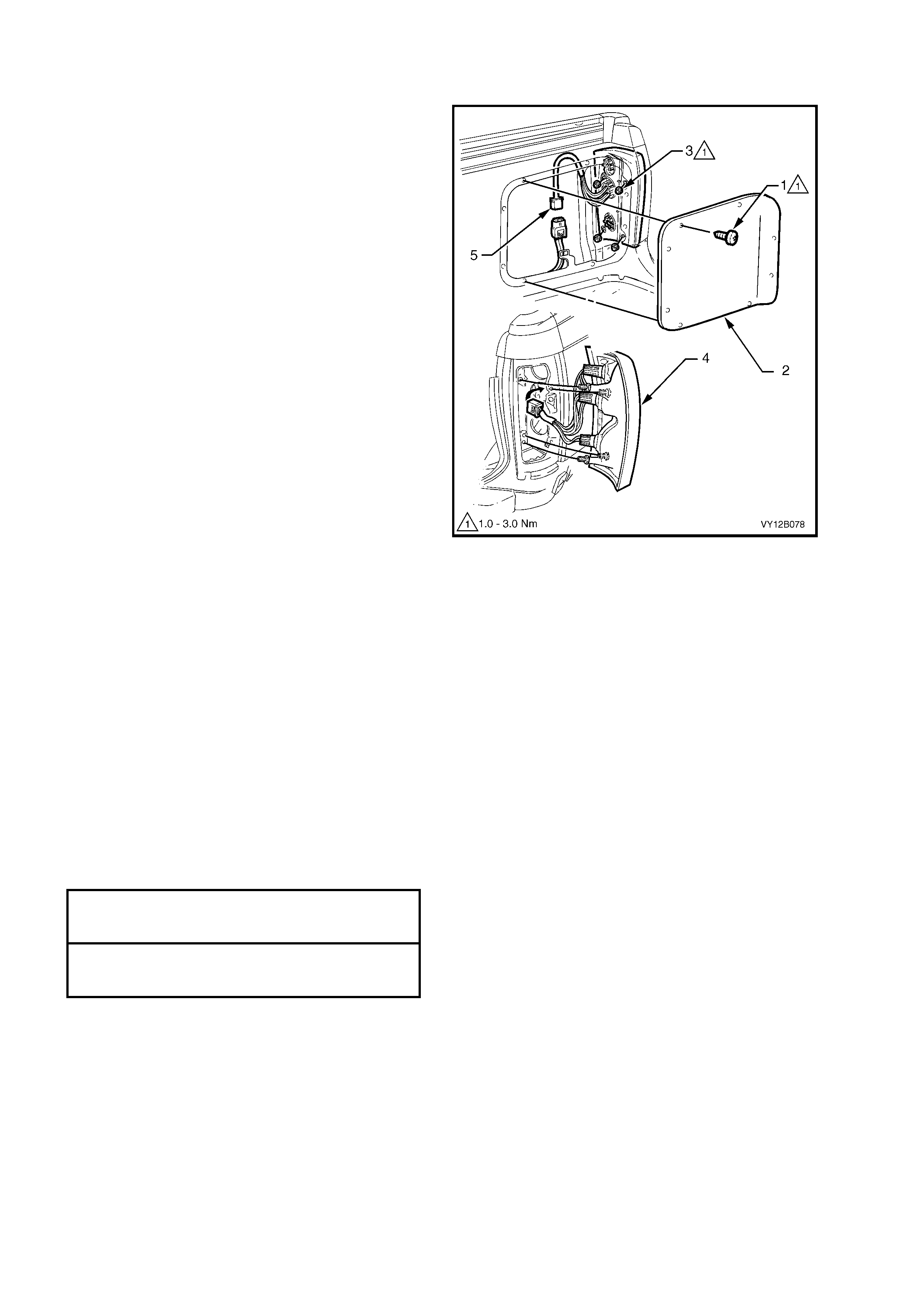

2. From behind the bumper fascia assembly (1),

disconnect the fog lamp harness connector (2).

3. Remove the three nuts (3) securing the front

fog lamp assembly (4) to bumper fascia and

remove the lamp assembly.

Disassemble

Disassembly of the SS front fog lamp is the same

as Level 3, refer to 2.7 FRONT FOG LAMP

ASSEMBLY, LEVEL 3 - DISASSEMBLY.

Reassembly

Assembly of the SS front fog lamp is the same as

Level 3, refer to 2.7 FRONT FOG LAMP

ASSEMBLY, LEVEL 3 – REASSEMBLY.

Reinstall

Installation of the front fog lamp assembly is the

reverse of the removal procedures, noting the

following points:

1. Ensure that the front fog lamp assembly is

correctly orientated with the beam adjustment

screw located to the top.

2. Ensure that the lamp is located on the fascia

datum pins (4). Tighten the nuts securing the

lamp assembly to the bumper fascia assembly

to the correct torque specification.

3. Check the operation and adjust the aim of the

front fog lamps. Refer to 2.1 AIMING OF

HEADLAMPS AND FOG LAMPS in this

Section.

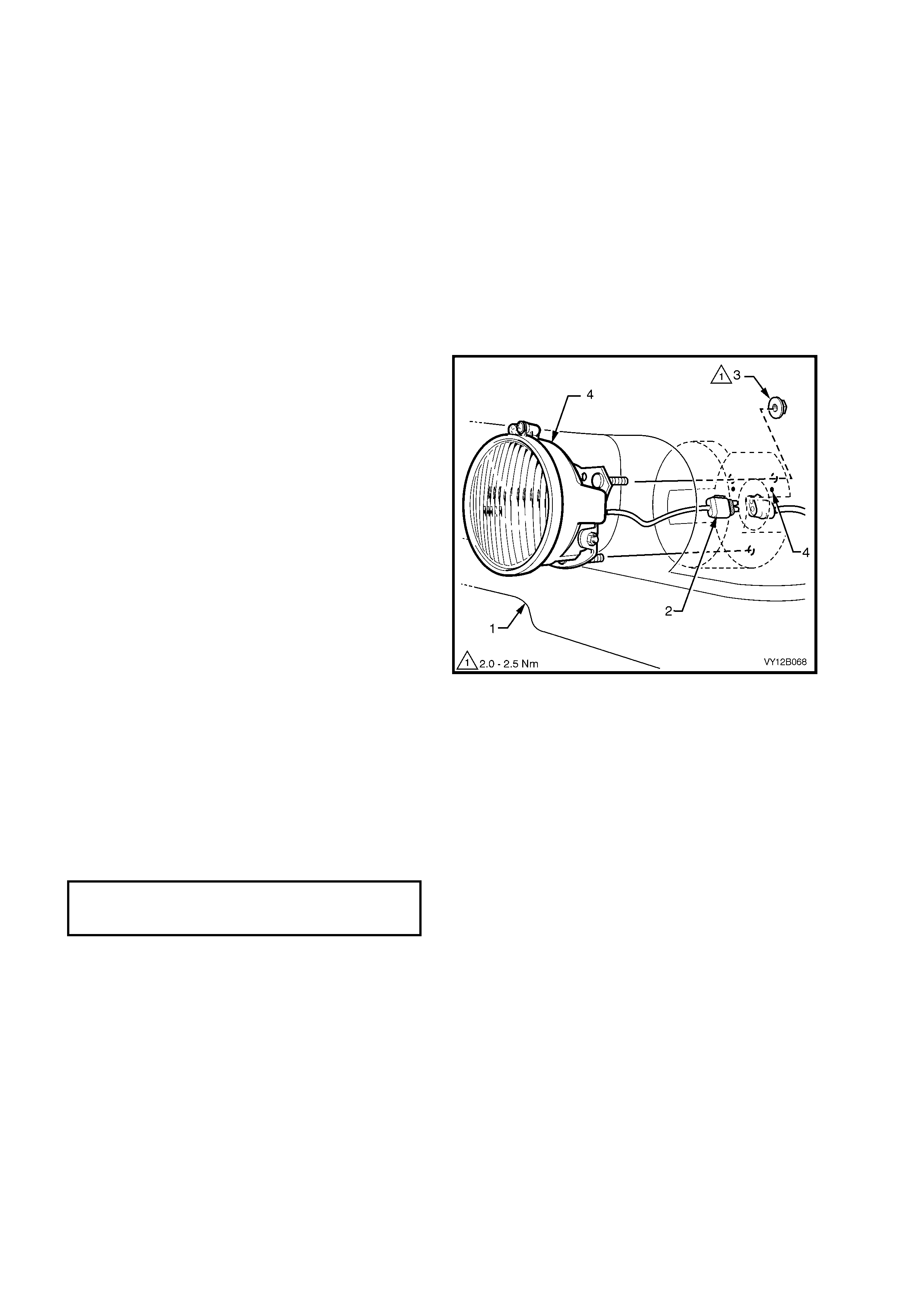

Figure 12B-45

FRONT FOG LAMP

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 2.5 Nm

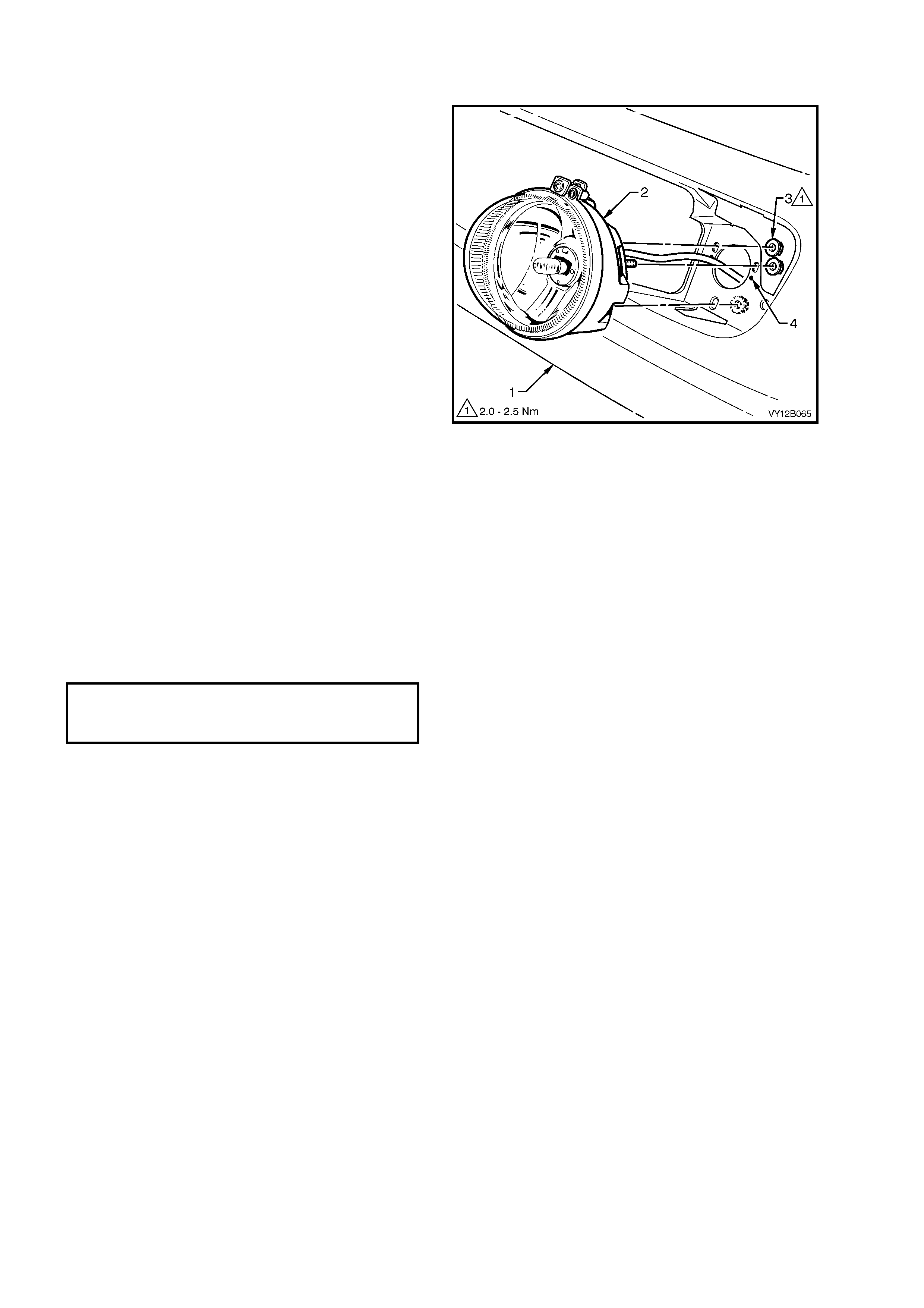

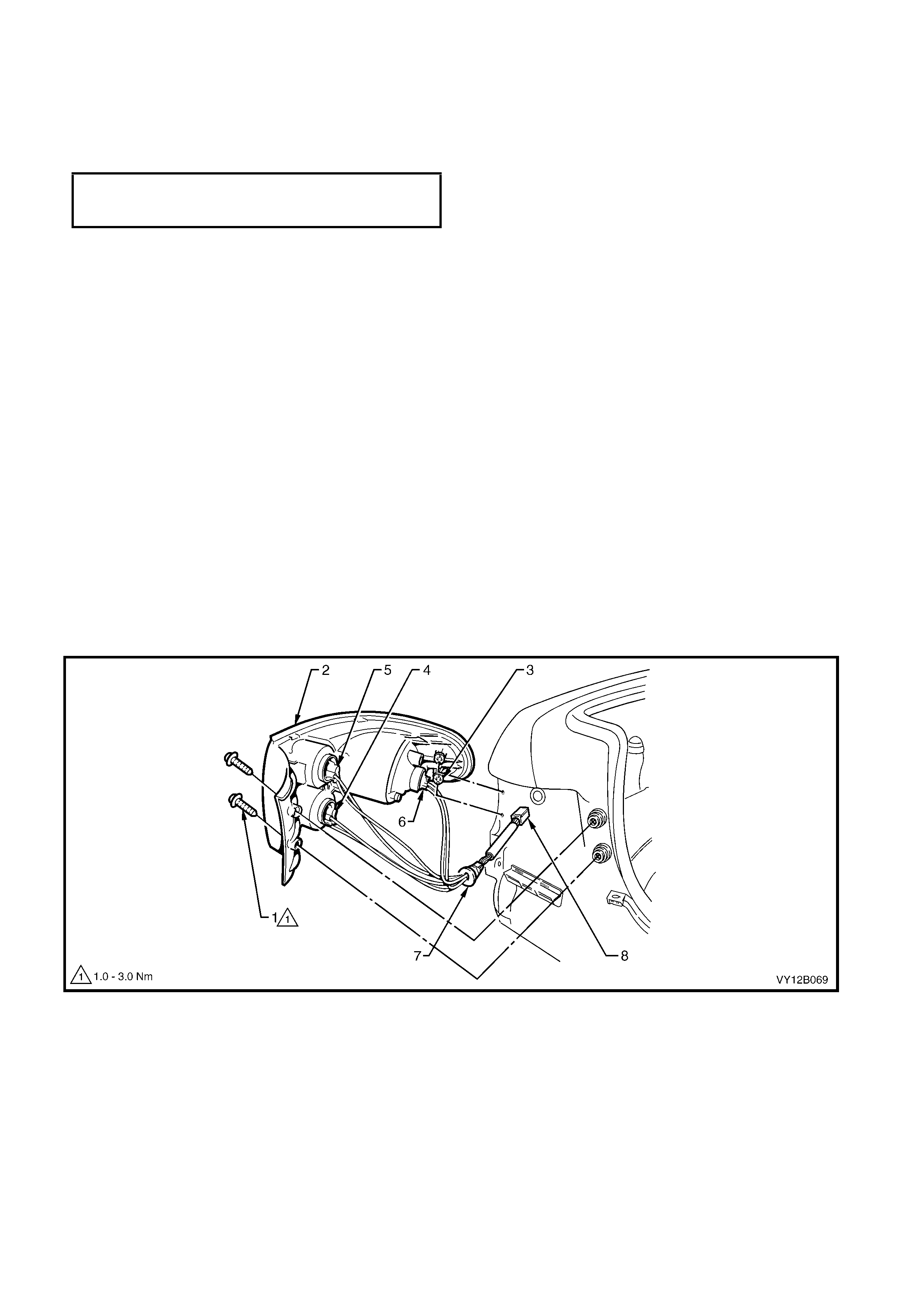

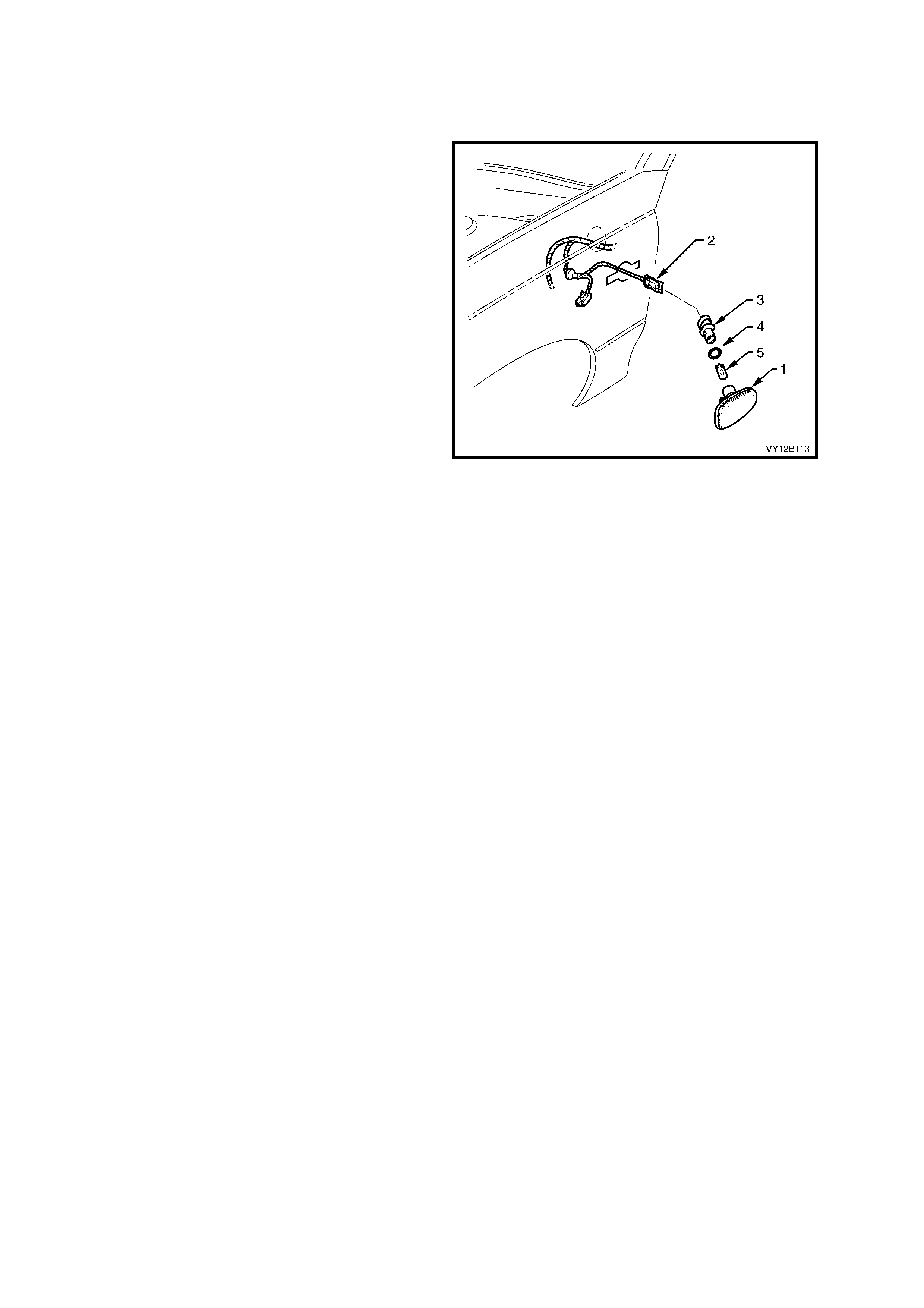

COUPE

Remove

1. Remove the fusible link F102. Refer to

Figure 12B-118, item 6.

2. Remove the lower grille, refer to Section 1C,

2.5 LOWER RADIATOR GRILLE – COUPE.

3. F rom behind the f ront bum per fas cia assem bly,

disconnect the f og lam p harness from the main

wiring harness connector.

4. Remove the three nuts (3) securing the front

fog lamp as s embly (2) to the bumper bar fascia

(1) and remove the lamp assembly.

Disassemble

Disassembly of the Coupe front fog lamp is the

same as Level 3, refer to 2.7 FRONT FOG LAMP

ASSEMBLY, LEVEL 3 - DISASSEMBLY.

Reassembly

Assembly of the Coupe front fog lam p is the same

as Level 3, refer to 2.7 FRONT FOG LAMP

ASSEMBLY, LEVEL 3 – REASSEMBLY.

Reinstall

Installation of the front fog lamp assembly is the

reverse of the removal procedures, noting the

following points:

1. Ensure that the front fog lamp assembly is

correctly orientated with the beam adjustment

screw located to the top.

2. Ensure that the lamp is located on the fascia

datum pins (4). Tighten the nuts securing the

lamp assembly to the bumper fascia assembly

to the correct torque specification.

FRONT FOG LAMP

ASSEMBLY ATTACHING NUT

TORQUE SPECIFICATION 2.0 – 2.5 Nm

3. Check the operation and adjust the aim of the

front fog lamps. Refer to 2.1 AIMING OF

HEADLAMPS AND FOG LAMPS in this

Section.

4. Install the lower grille, refer to Section 1C, 2.5

LOWER RADIATOR GRILLE – COUPE.

Figure 12B-46

2.8 TAIL LAMP ASSEMBLY

LT Section – 02-350

SEDAN

NOTE: During the production of the Sedan, the tail lamp assembly has been modified. The metal locating peg (3,

refer to Figure 12B-38, View A) has been replaced with a threaded stud (11) and attaching nut (1) so to provide a

further securing point for tail lamp assembly to sheetmetal. Therefore some tail lamp assemblies will have three

attaching nuts (View B), and some will have two attaching nuts and a metal locating peg (View A).

Remove

1. Remove the fusible link F102. Refer to Figure 12B-118, item 6.

2. Open the rear compartment lid.

3. Pull the quar ter inner r ear s ide car pet f r om the cor ner of the r ear compartment to ex pose the tail lamp attac hing

nuts (1), refer to Figure 12B-47.

NOTE: The tail lamp attaching nuts can be removed by hand or using a 6.0 mm Allen key.

4. If leaving the wiring harness installed:

a. Remove the attaching nuts (1), in two places for the early type or three places for the later type tail lamps.

b. Pull the tail lamp away from the vehicle, releasing the metal lock peg (3) from its retainer for early type tail

lamps. Support the tail lamp assembly.

c. Rem ove all the bulb sock ets (4, 5 and 6) by turning the sock ets anti-clock wise and pulling them away from the

reflector.

5. If removing the wiring harness:

a. Remove the attaching nuts (1), in two places for the early type or three places for the later type tail lamps.

b. Pull the tail lamp away from the vehicle, releasing the metal lock peg (3) from its retainer for early type tail

lamps. Support the tail lamp assembly.

c. Disconnect the tail lamp wiring harness (8) from the body wiring harness.

d. Pull the grommet (7) out from the sheetmetal and remove the tail lamp assembly and the harness.

Techline

A Early Type Tail Lamp Assembly

with Two Attachment Studs

B Later Type Tail Lamp Assembly

with Three Attachment Studs

1. Attaching Nut

(two places View A)

(three places View B)

2. Tail lamp assembly

3. Metal locating peg

(one place View A)

4. Back-up Lamp Socket

5. Turn Signal Lamp Socket

6. Stop/Tail Lamp Socket

7. Grommet

8. Electrical Connector

9. Stud Seals

10. Main Seal

11. Attachment Stud

(two places View A)

(three places View B)

Replace – Main Seal

The main seal is adhered to the lens cover of the lamp assembly with contact adhesive and double-sided tape.

1. T o r eplace the seal, c arefu lly rem ove the old seal and clean the surf ace lam p assem bly with soapy water . Wipe

any residue of the cleaner from the plastic before applying fresh adhesive and tape.

NOTE: Do not use solvents on the plastic surfaces of the lamp assembly.

2. Apply a small amount of adhesive to the seal and double-sided tape to the lamp assembly.

3. Place the seal on the lamp assembly.

4. Allow time for the adhesive to cure before installing the lamp assembly to the vehicle.

Figure 12B-47

Legend

Reinstall

Installation of the lamp assembly is the reverse on the removal procedure, noting the following points:

1. If required, inspect the socket to lamp assembly seals for damage and replace where necessary.

2. If required, replace the wiring harness.

3. Ensure that the lamp sockets are installed into the lamp assembly correctly and locked into place.

NOTE: Lamp sockets have differing numbers of lugs to prevent installation into the incorrect tail lamp assembly

receptacle.

4. Ensure that the main seal (10), stud seals (9) and seal mating areas are clean to prevent any paint damage.

5. Install the lamp assembly onto the vehicle. Apply a firm pressure to the outboard lower corner of the tail lamp so

that the metal locating peg locks into the retainer (early type tail lamps).

6. Install and tighten the tail lamp assembly attaching nuts to the correct torque specification.

TAIL LAMP ASSEMBLY

ATTACHING NUT

TORQUE SPECIFICATION 1.5 – 2.0 Nm

7. Check the tail lamp operation.

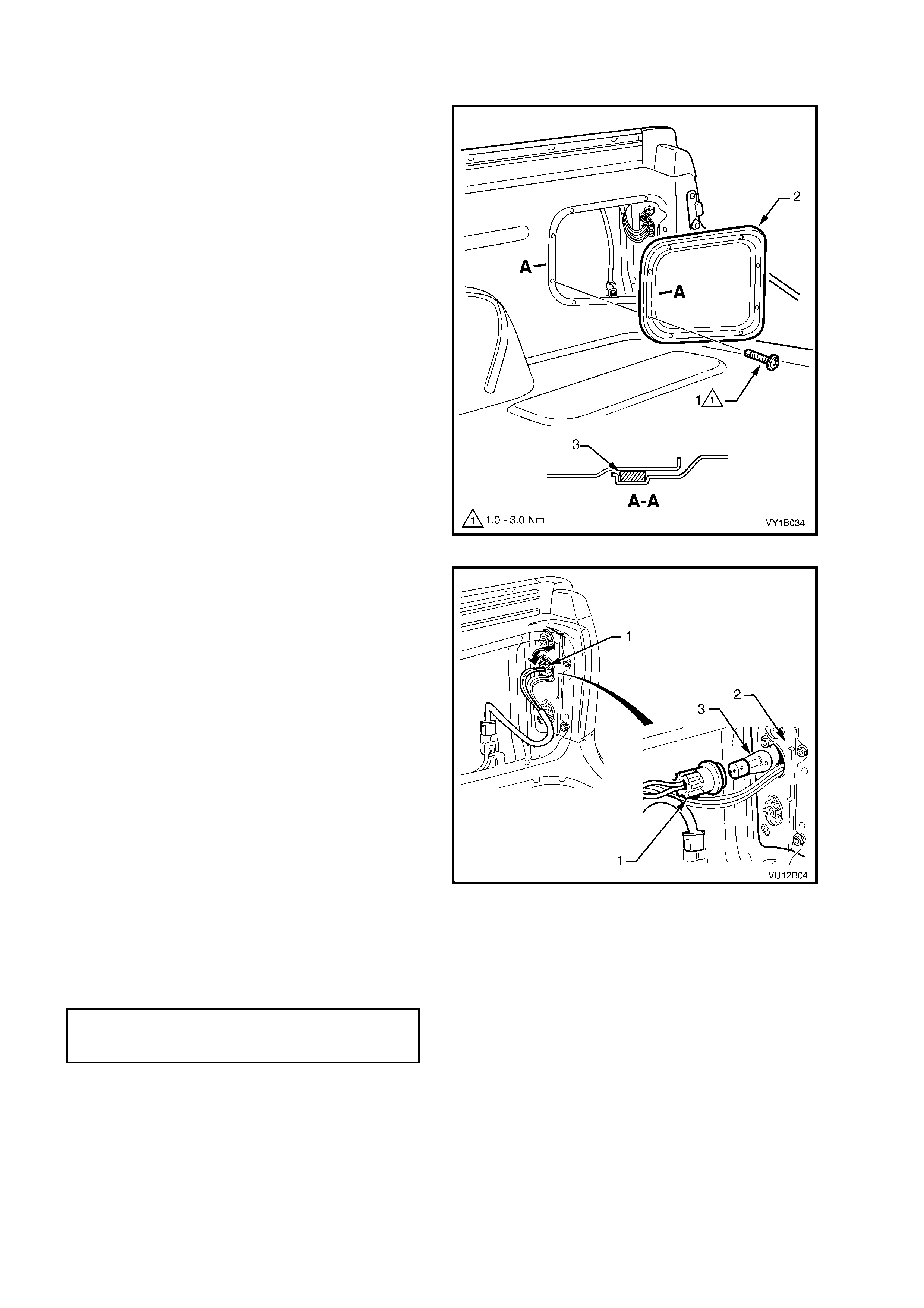

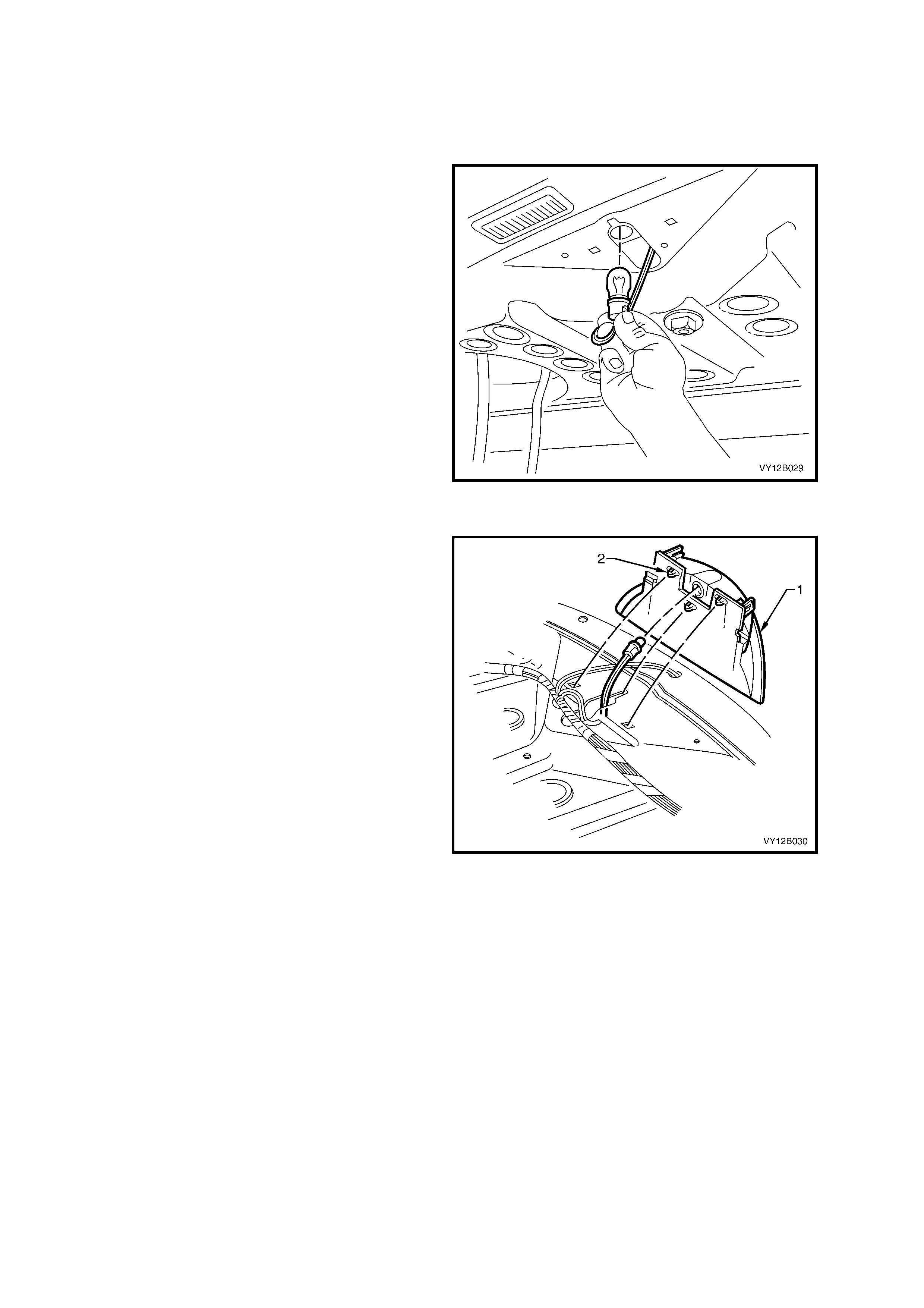

WAGON

Remove

1. Remove the fusible link F102, refer to

Figure 12B-118, item 6.

2. Open the liftgate.

3. If leaving the wiring harness installed:

a. Remove the quarter trim panel vent with

a flat blade screwdriver, taking care not

to damage the surrounding quarter

inner trim panel assembly. Refer to

Section 1A8, 3.11 QUARTER INNER TRIM

PANEL ASSEMBLY – DISASSEMBLE.

b. Remove all three bulb sockets (1, 2 and 3)

from the lamp assembly (4) by turning them

anti-clockwise and pulling them away from the

assembly.

4. If removing the wiring harness:

a. Remove the quarter inner trim

panel assembly, refer to Section 1A8,

3.11 QUARTER INNER TRIM PANEL

ASSEMBLY.

b. Disconnect the tail lamp wiring harness (5)

from the body wiring harness connector.

5. Remove the four nuts (6) retaining the lamp

assembly to the vehicle.

6. Remove the lamp assembly.

Reinstall

Installation of the lamp assembly is the reverse of

the removal procedures, noting the following points:

1. If necessary, install new bulbs into the sockets

and fit the sockets to the lamp assembly.

2. Ensure that the main seal and seal mating

surface is clean to avoid damage to the

paintwork.

Figure 12B-48

IMPORTANT: The various sockets are colour coded to aid in identification:

• Black socket – stop/tail lamp.

• Grey socket – back-up lamp.

• Orange socket – turn signal.

3. Tighten the lamp assembly attaching nuts to the correct torque specification.

4. Check the tail lamp operation.

COUPE

Remove

1. Remove the fusible link F102, refer to Figure 12B-118, item 6.

2. Open the rear compartment lid.

3. Remove the two lamp assembly to body attaching screws (1).

4. If leaving the wiring harness installed:

a. Pull the tail lam p assem bly (2) sideways and out f rom the panel so that the locating peg (3) on the side of lamp

assembly snaps free from the retainer.

NOTE: When removing the tail lamp assembly from panel, take care not to damage the locating pegs (3).

b. Remove all the sockets (4, 5 and 6) by turning the sockets anti-clockwise and pulling them away from the

reflector.

5. If removing the wiring harness:

a. Pull the quarter inner rear side carpet away from the vehicle to expose the tail lamp wiring harness connector

(8).

b. Disconnect the tail lamp wiring harness from the body wiring harness.

c. Pull the tail lamp assembly (2) sideways out from the panel so that the locating peg (3) on side of the lamp

assembly snaps free from the retainer.

d. Pull the grommet (7) out from the sheetmetal and remove and tail lamp assembly and the harness.

Figure 12B-49

Legend

1. Attaching screw (2 places)

2. Tail lamp assembly

3. Locating pegs

4. Back-up lamp socket

5. Turn signal lamp socket

6. Stop/tail lamp socket

7. Grommet

8. Electrical connector

TAIL LAMP ASSEMBLY

ATTACHING NUT

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Replace – Main Seal

The seal is adhered to the lens cover of the lamp assembly with contact adhesive and double-sided tape.

1. T o r eplace the seal, c arefu lly rem ove the old seal and clean the surf ace lam p assem bly with soapy water . Wipe

any residue of the cleaner from the plastic before applying fresh adhesive and tape.

NOTE: Do not use solvents on the plastic surfaces of the lamp assembly.

2. Apply a small amount of adhesive to the seal and double-sided tape to the lamp assembly.

3. Place the seal on the lamp assembly.

4. Allow time for the adhesive to cure before installing the lamp assembly to the vehicle.

Reinstall

Installation of the lamp assembly is the reverse on the removal procedure, noting the following points:

1. If required, inspect the socket to lamp assembly seals for damage and replace where necessary.

2. If required, replace the wiring harness.

3. Ensure that the lamp sockets are installed into the lamp assembly correctly and locked into place.

NOTE: Harness length will allow the back-up light socket and turn signal bulb socket to be fitted to the correct

locations only.

4. Install and tighten the attaching screws to the correct torque specification.

TAIL LAMP ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

5. Check the tail lamp operation.

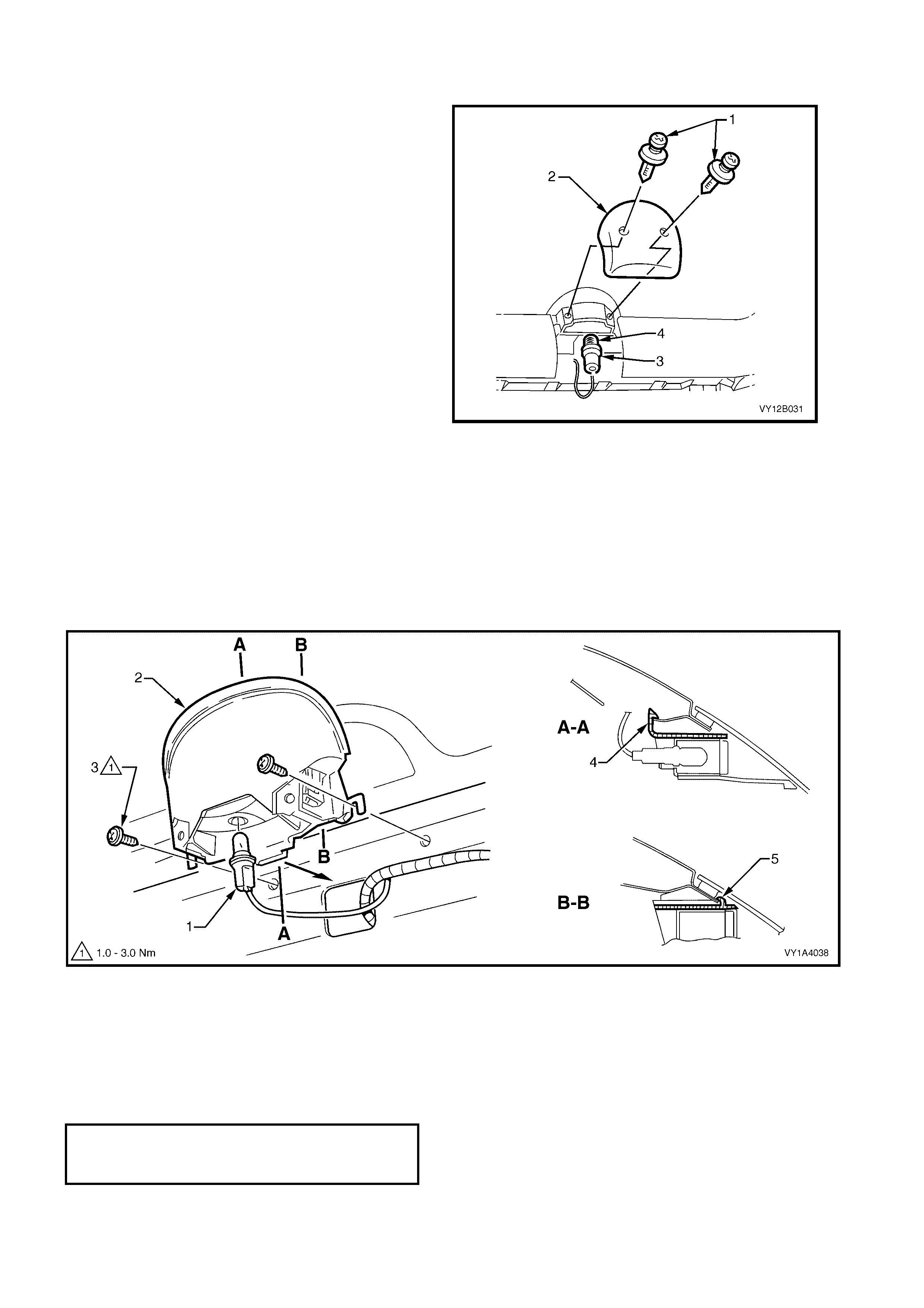

UTILITY

Remove

1. Remove the fusible link F102, refer to

Figure 12B-118, item 6.

2. Remove the eight screws (1) securing the rear

inner side panel cover (2) and remove the

cover.

3. Remove the four nuts (3) retaining the lamp

assembly (4) to the vehicle.

4. Disconnect the tail lamp wiring harness (5)

from the body harness and carefully remove

the lamp assembly.

5. If necess ary, rem ove the bulb sock ets from the

lamp assembly. To remove the sockets, rotate

them anti-clockwise and pull them away from

the reflector.

Reinstall

Installation of the lamp assembly is the reverse of

the removal procedure, noting the following points:

1. If necessary, install new bulbs into the sockets

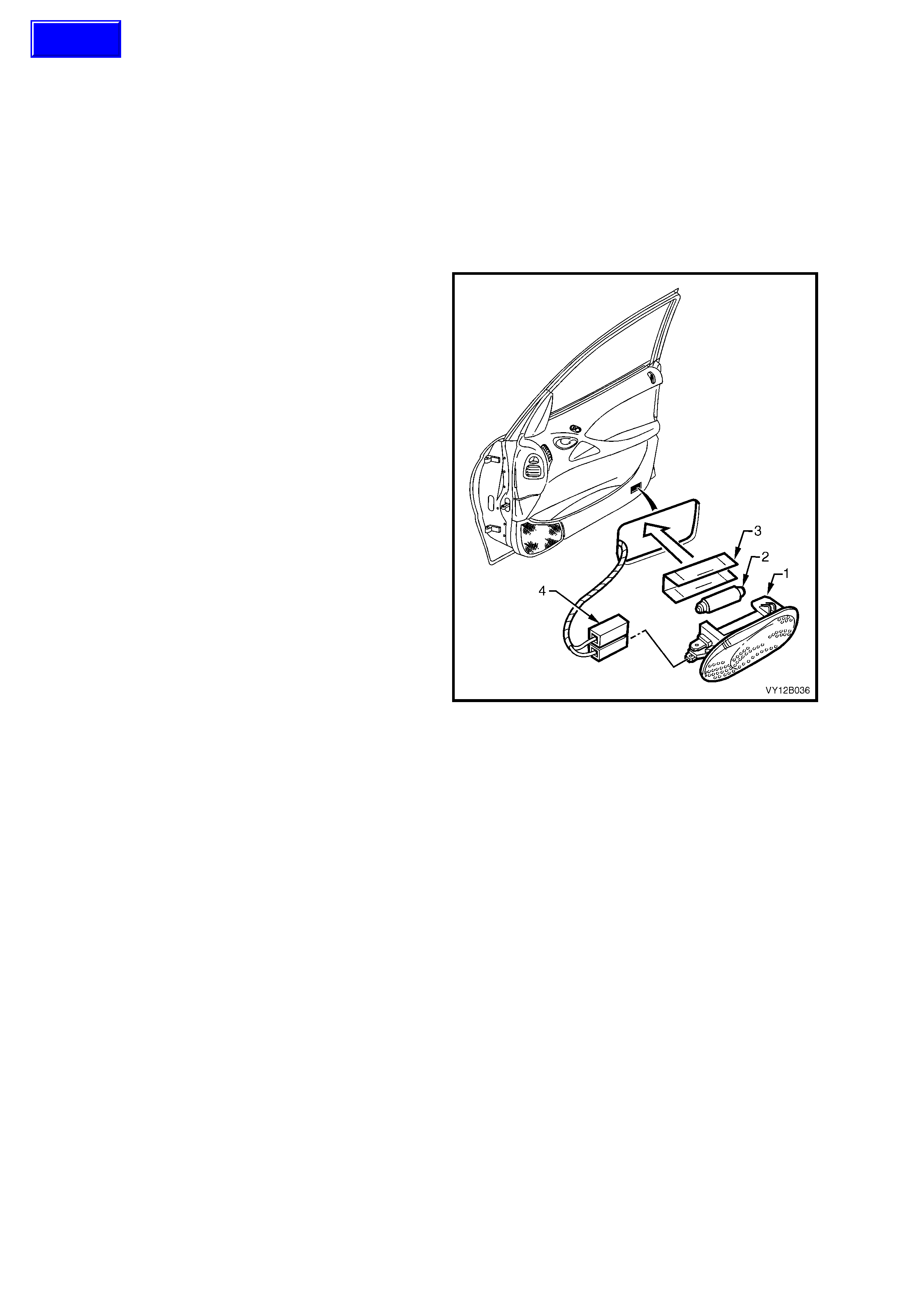

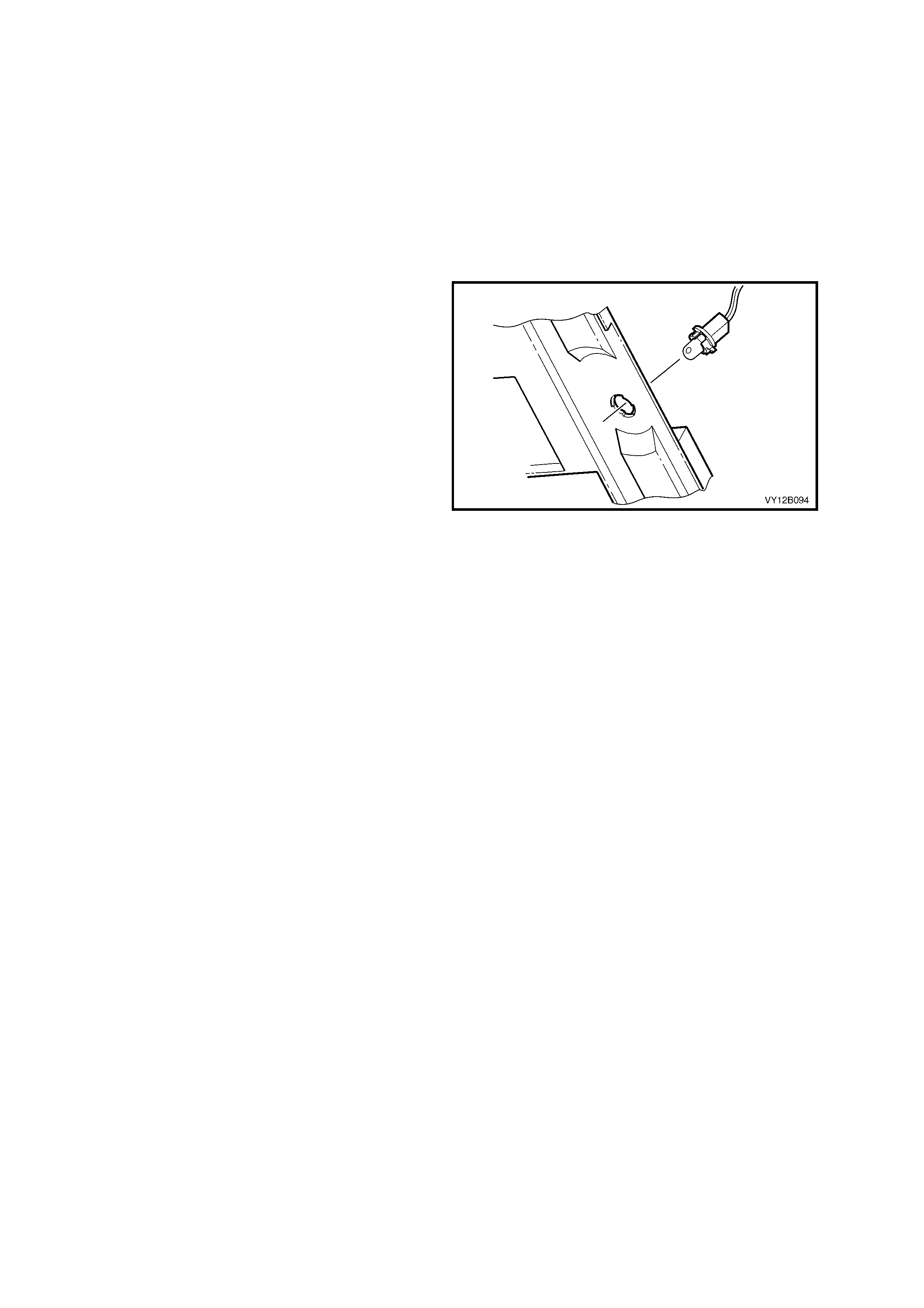

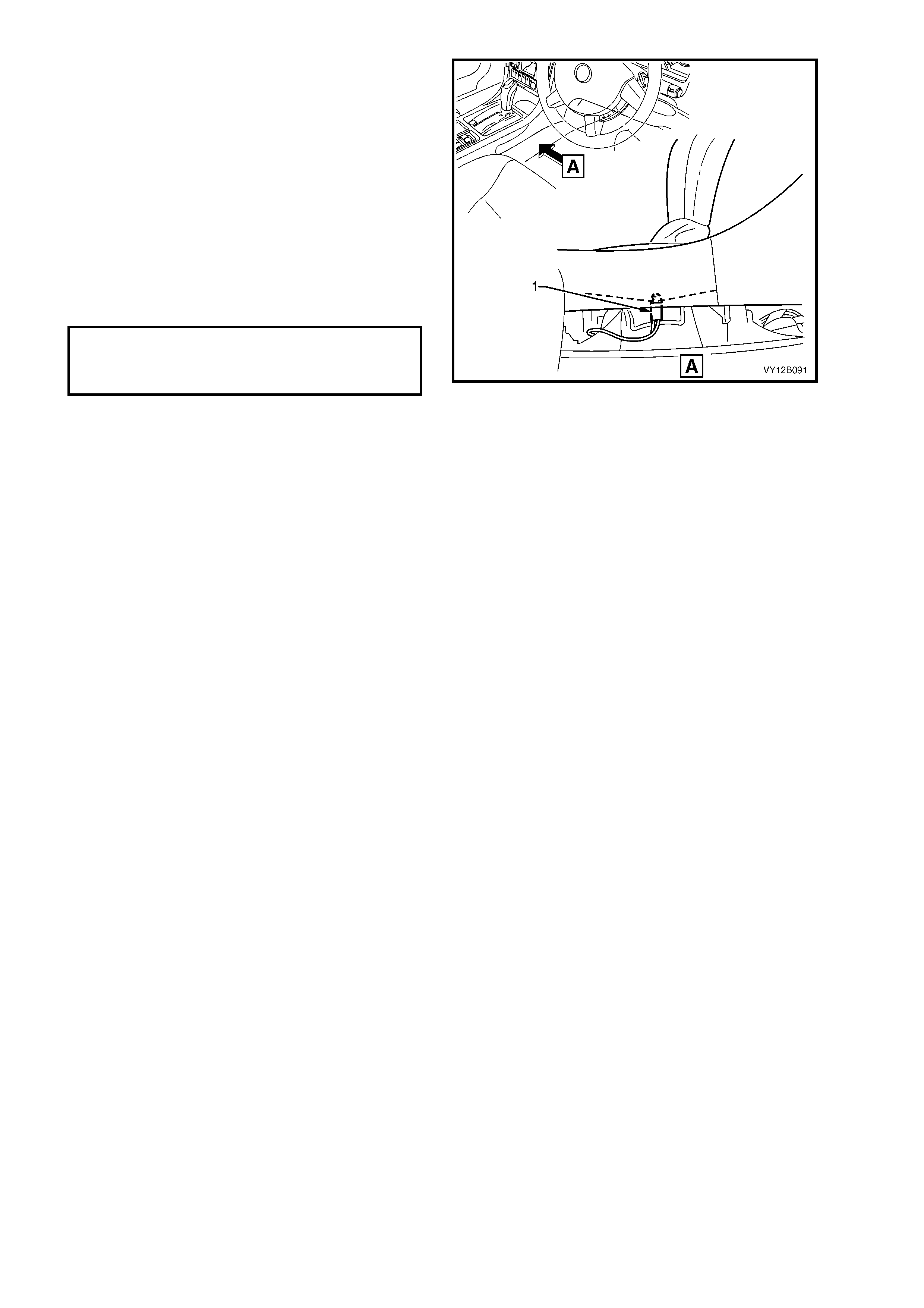

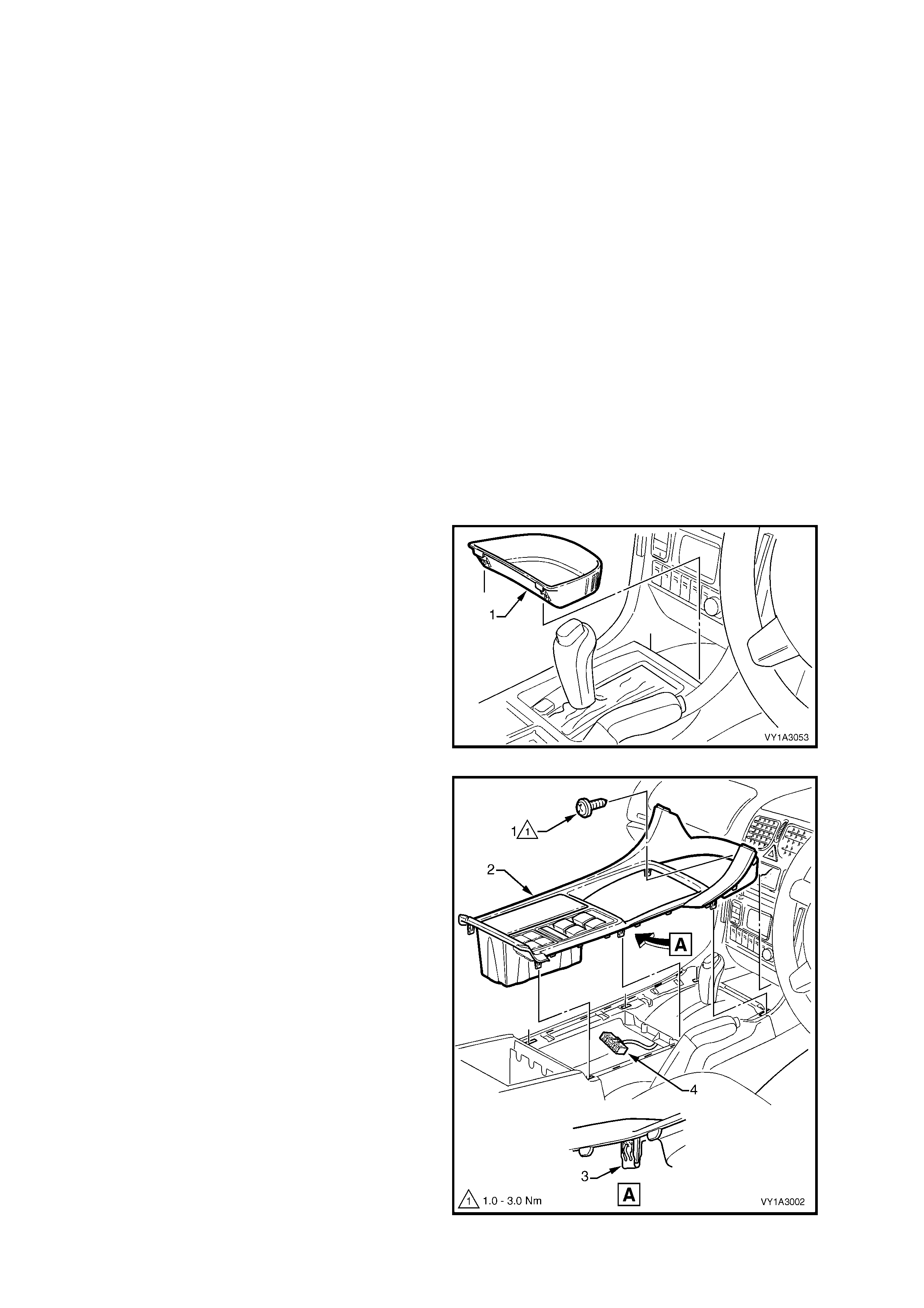

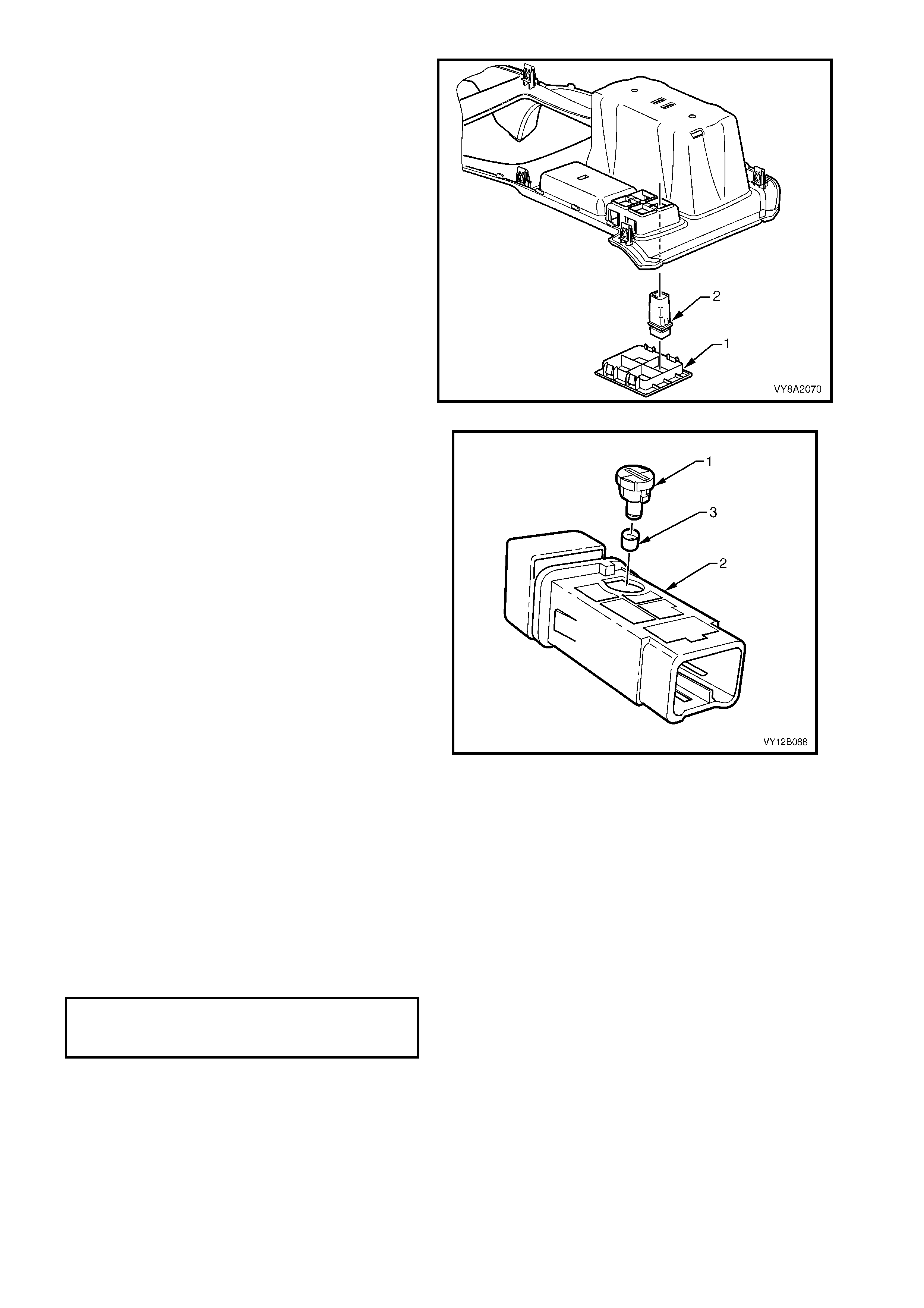

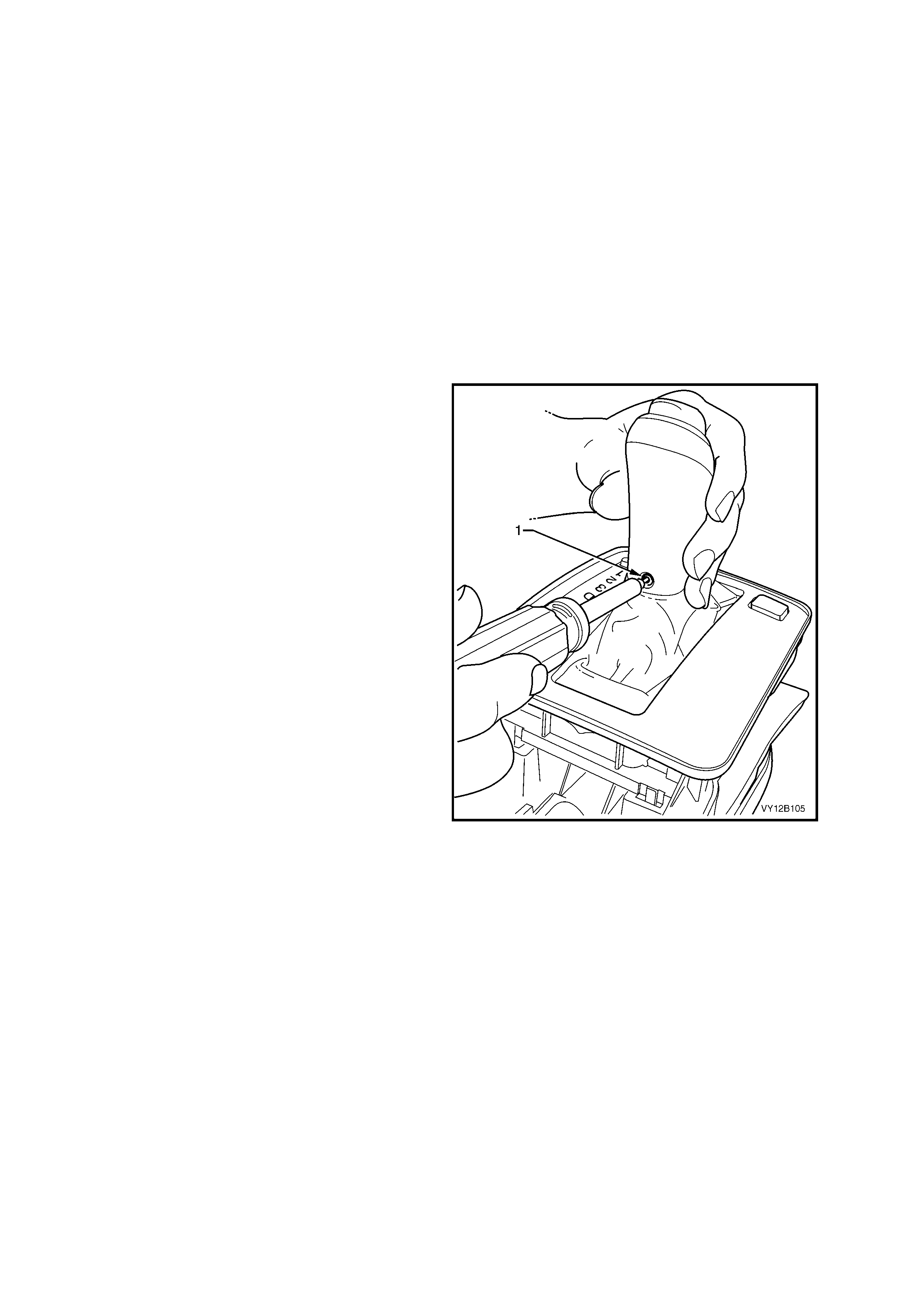

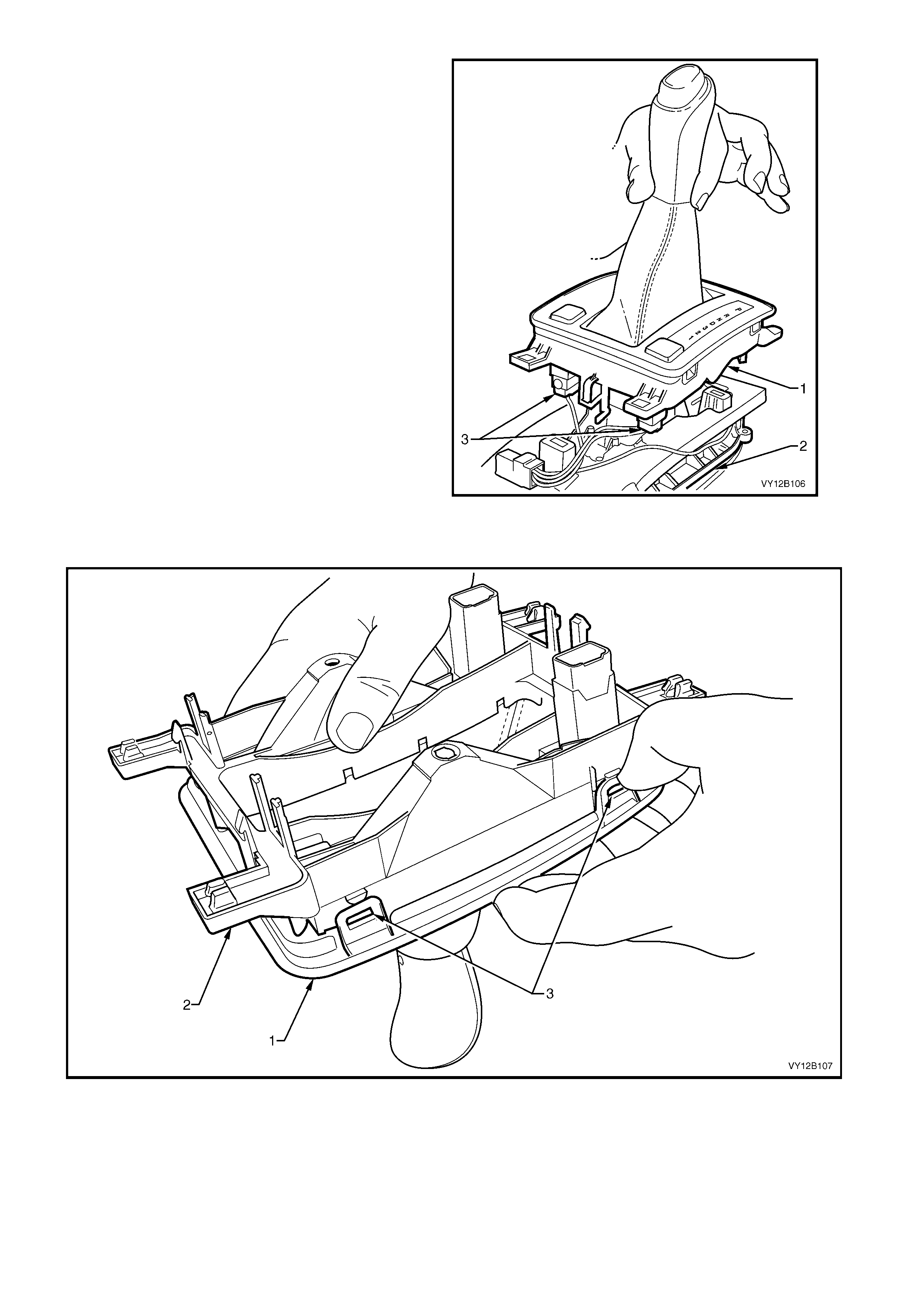

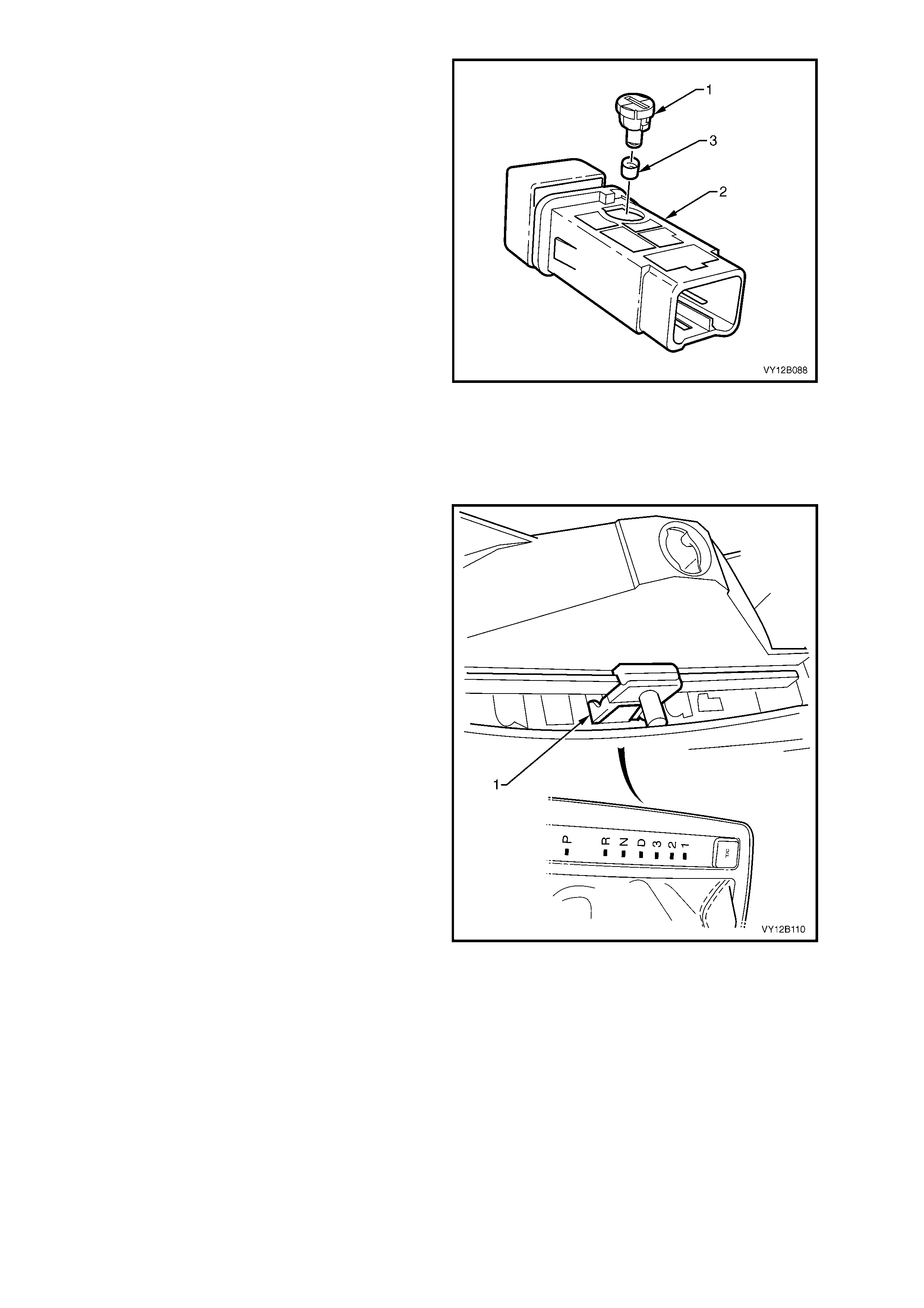

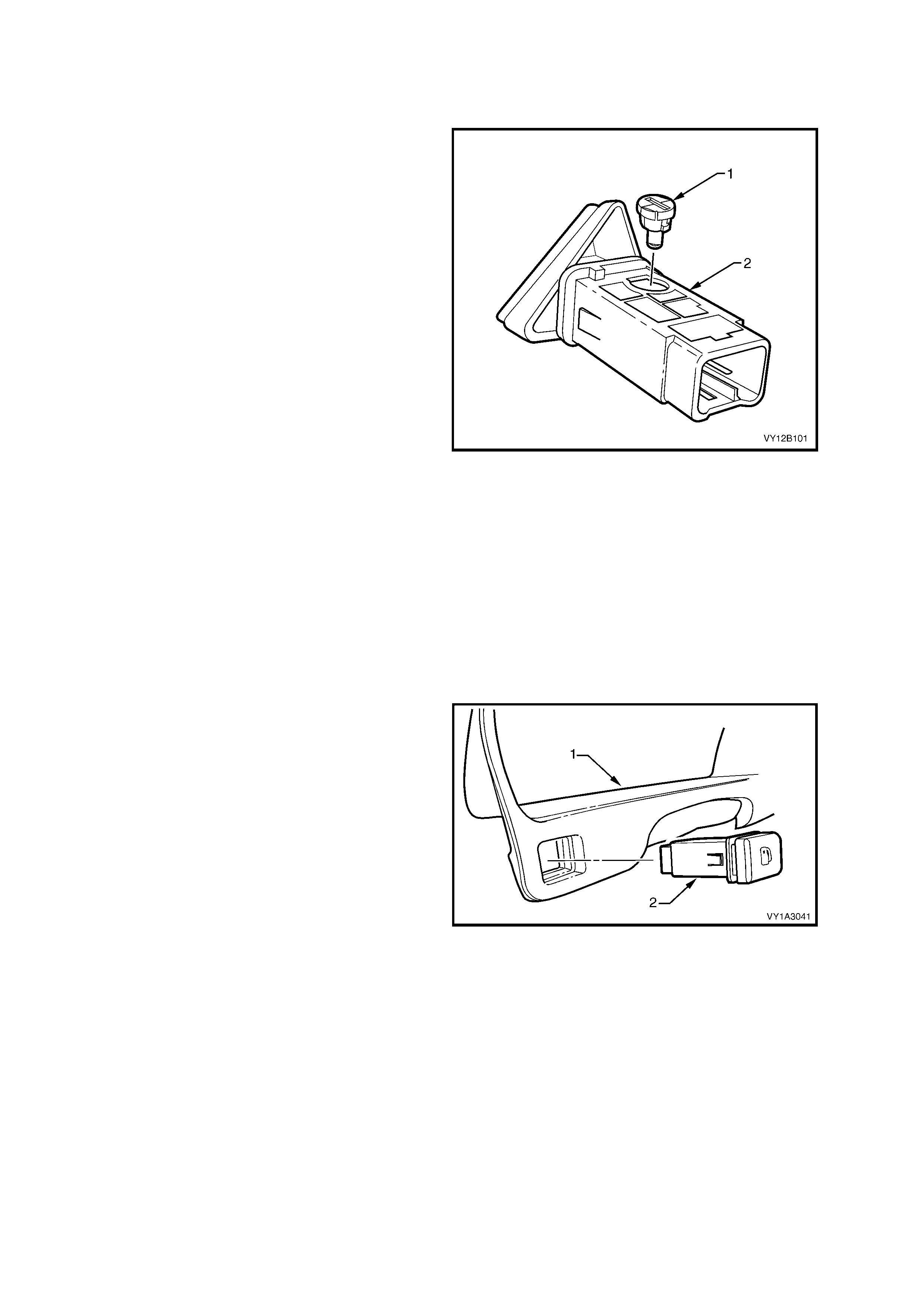

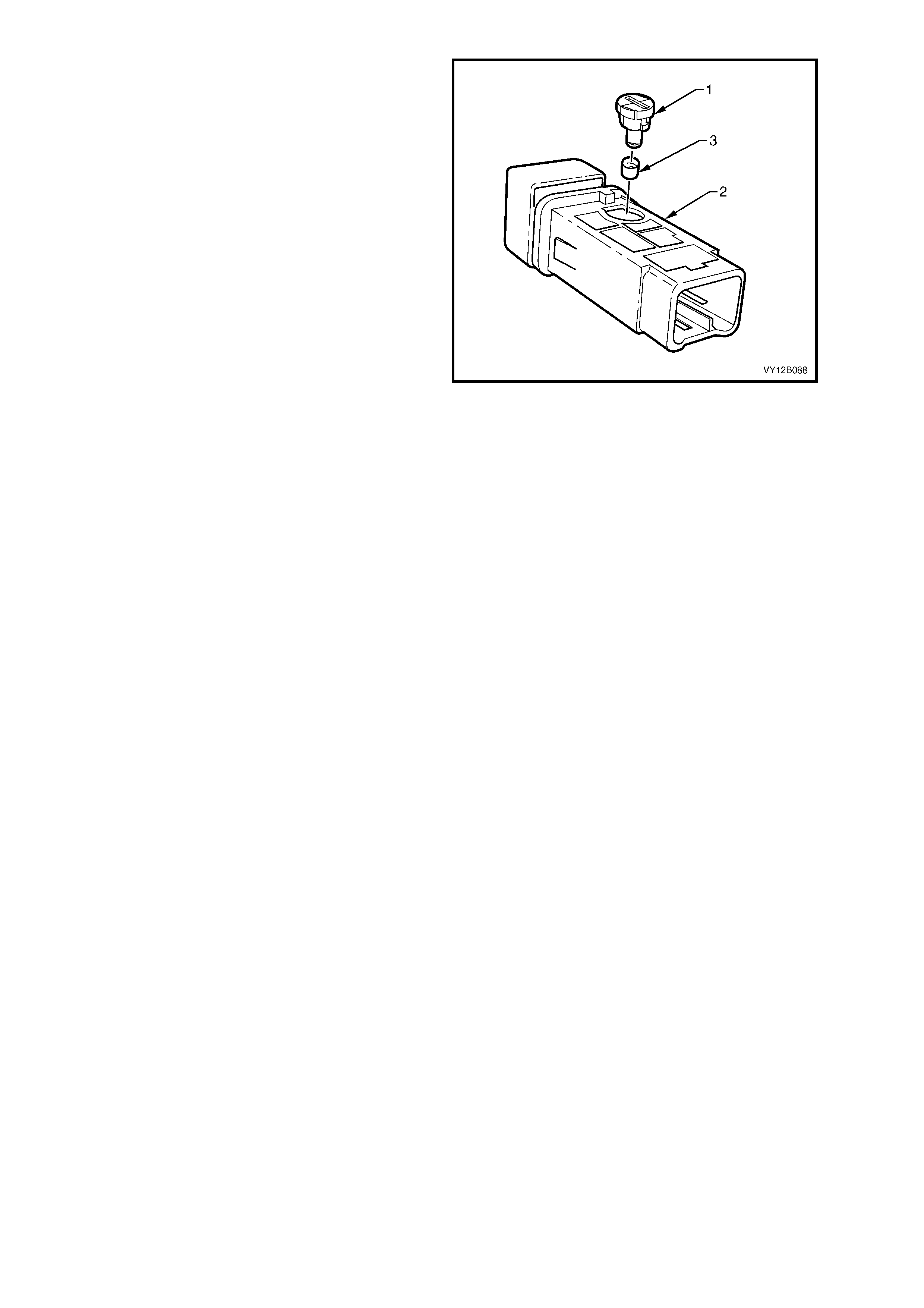

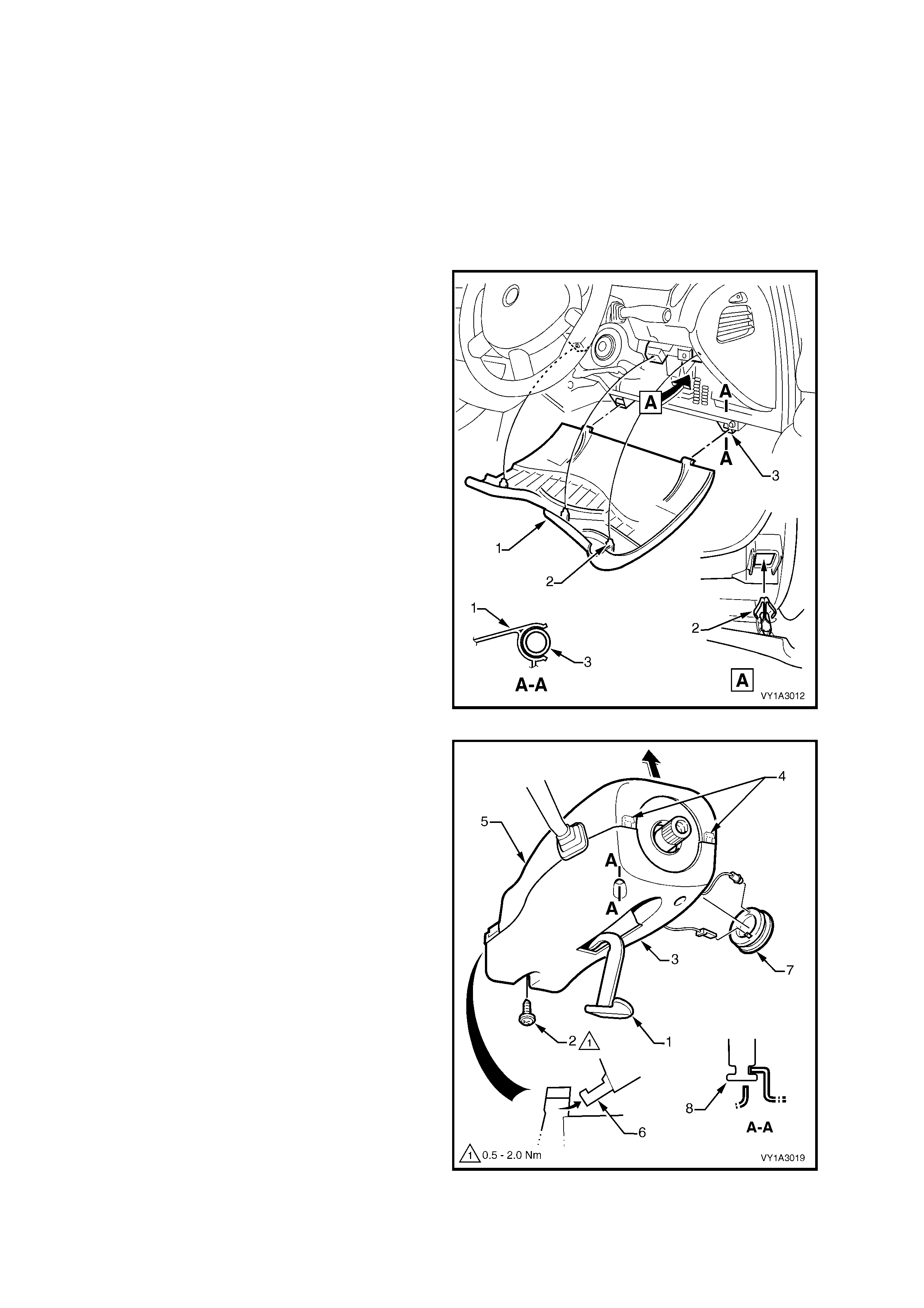

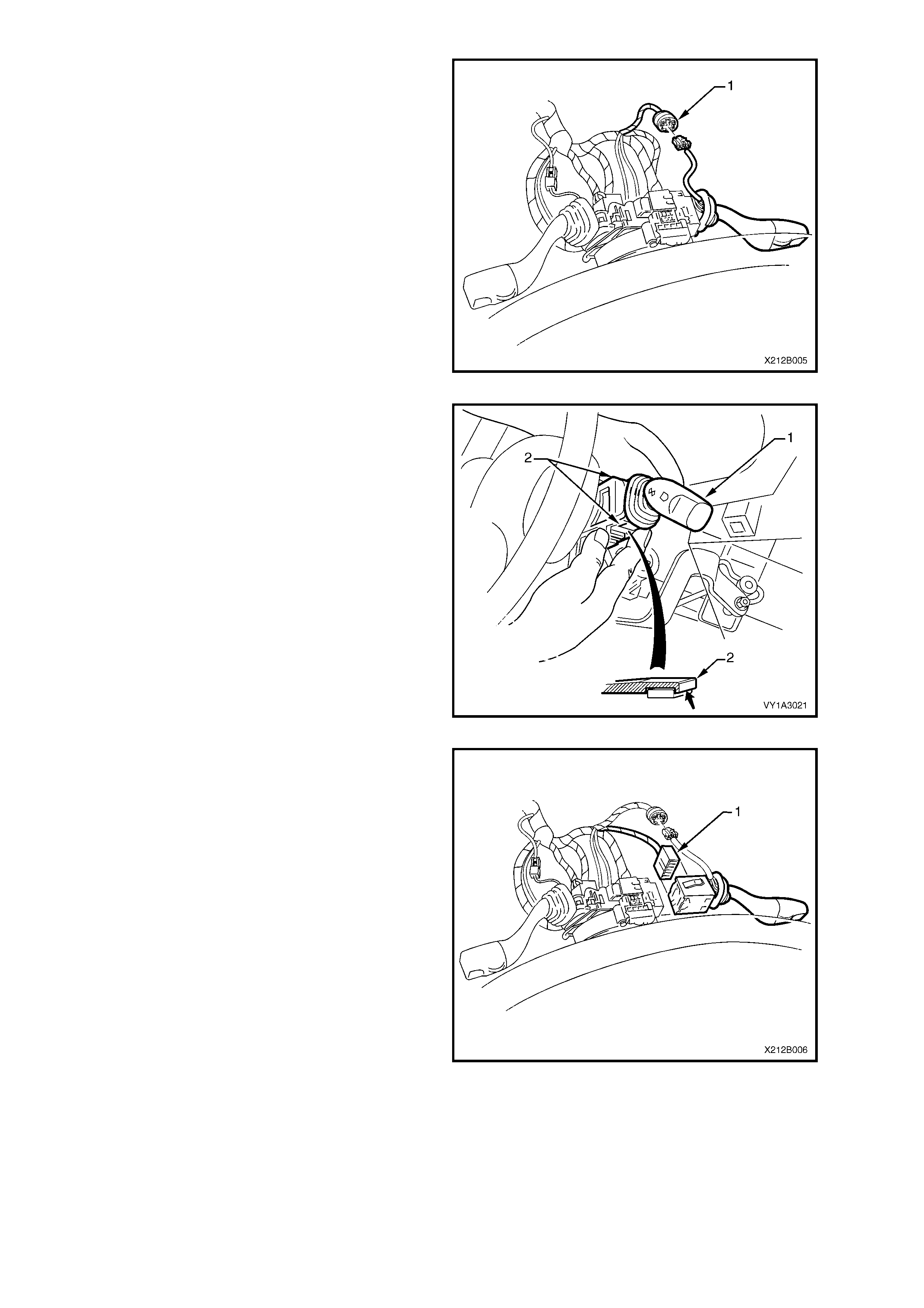

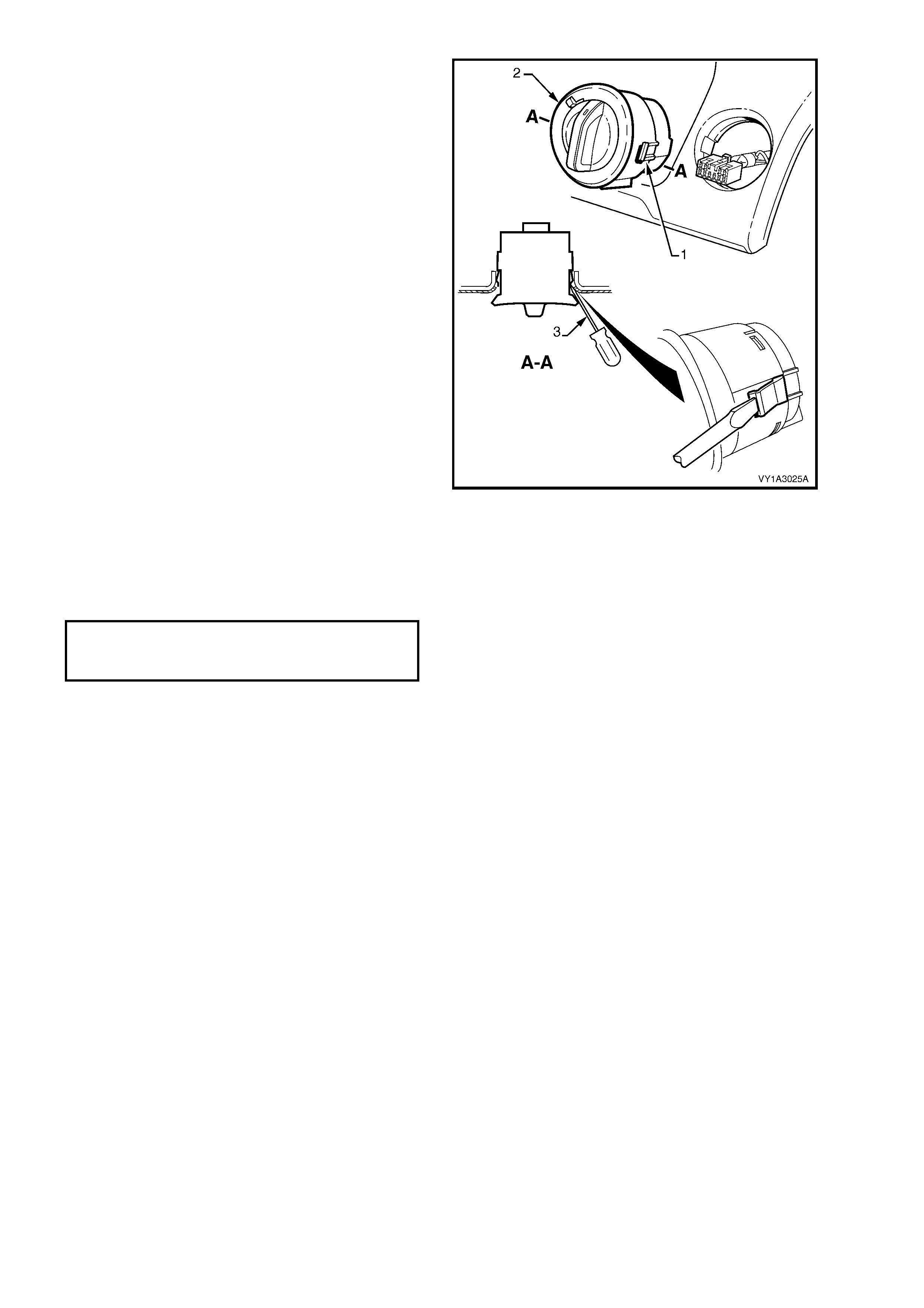

and fit the sockets to the lamp assembly.