SECTION 12E - CRUISE CONTROL

IMPORTANT

Before perfo rming any Service O peration or oth er procedu re described in t his Sectio n, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 SYSTEM OPERATION

COMPONENTS

CRUISE CONTROL SWITCH OPERATION

2. SERVICE OPERATIONS

2.1 CRUISE CONTROL CABLE

REMOVE

REINSTALL

2.2 CRUISE CONTROL MODULE

REMOVE

REINSTALL

2.3 CRUISE CONTROL SWITCH ASSEMBLY

REMOVE AND REINSTALL

CHECKING SWITCH CONTACTS

2.4 STOP LAMP SWITCH (SWITCH A)

TESTING SWITCH CONTACTS

REMOVE

REINSTALL AND ADJUST

2.5 ELECTRICAL RELEASE SWITCH (SWITCH B)

TESTING SWITCH CONTACTS

REMOVE

REINSTALL AND ADJUST

2.6 CLUTCH PEDAL SWITCH

TESTING SWITCH CONTACTS

REMOVE

REINSTALL AND ADJUST

3. DIAGNOSIS

3.1 PRELIMINARY DIAGNOSIS AND INSPECTION

3.2 CRUISE CONTROL SYSTEM FUNCTIONAL

CHECK

ROAD TEST PROCEDURE

3.3 SELF DIAGNOSTIC TEST

3.4 CRUISE CONTROL SYSTEM CONNECTORS

AND CIRCUIT DIAGRAM

3.5 CRUISE CONTROL SYSTEM DIAGNOSTIC

CHART

TEST DESCRIPTION

4. TORQUE WRENCH SPECIFICATIONS

5. SPECIAL TOOLS

Techline

1. GENERAL I NFORMATION

Cruise control is a vehicle speed control system which maintains a desired vehicle speed without the driver having

to continually apply foot pressure to the accelerator pedal.

Depending on the model var iant, cruis e control is available as either standar d or optional equipm ent on all MY 2003

VY and V2 Series models with either automatic or manual transmission.

The cruise control system is an Electro-motor system, i.e. it uses a stepper motor to control vehicle speed.

On m odels fitted with GEN III V8 engine and traction control, a throttle relaxer servo is f itted as part of the traction

control system to pr ovide engine torque c ontrol. The thr ottle relaxer m om entarily reduces the throttle opening angle

when traction loss occurs.

There is no electronic interface between the throttle relaxer and the cruise control module.

1.1 SYSTEM OPERATION

The main components of the Electro-motor cruise control system are:

• Module Assembly – Cruise Control (cruise control module);

• Switch Assembly – Cruise Control (cruise control switch assembly, incorporated into the turn signal switch

assembly);

• Brake pedal stop lamp switch (Switch A);

• Brake pedal electrical release switch (Switch B);

• Clutch pedal switch and patch harness (manual transmission models);

• Cruise control cable; and

• Electrical wiring (incorporated into the main wiring harness).

The cruise control module also uses an output from the Powertrain Control Module (PCM) for vehicle speed, and

provides an input to the instrument cluster for cruise control status indication.

When the c r uise contr ol module is powered up via the cr uis e c ontrol O N- OF F push- button s witch, the cr uis e contr ol

module activates an input to the instrument cluster. The instrument cluster sees this line as active and sends a

message to the Multi-function Display (MFD) to turn its CRUISE icon on.

W hen the CRUISE switch is rotated to the SET -DECEL position (provided the vehicle s peed is above 40 km/h and

either the brake or clutch pedal is not pressed) the cruise control module activates an input to the instrument

cluster. The instrument cluster sees this line as active and sends a mess age to the MFD to turn its ACTIVE icon on

and in tur n, the instrument c luster inform s the PCM via the serial data interf ace to use a specif ic transm ission shift

pattern. T he transm iss ion s hift pattern is des igned primar ily for cruise m ode, having f ewer trans m ission down shif ts

and reduc ed trans miss ion gear c hange ac tivity. For f urt her inf or mation about the PCM cr uis e contr ol inter f ace, r ef er

to Section 6C, POWERTRAIN MANAGEMENT.

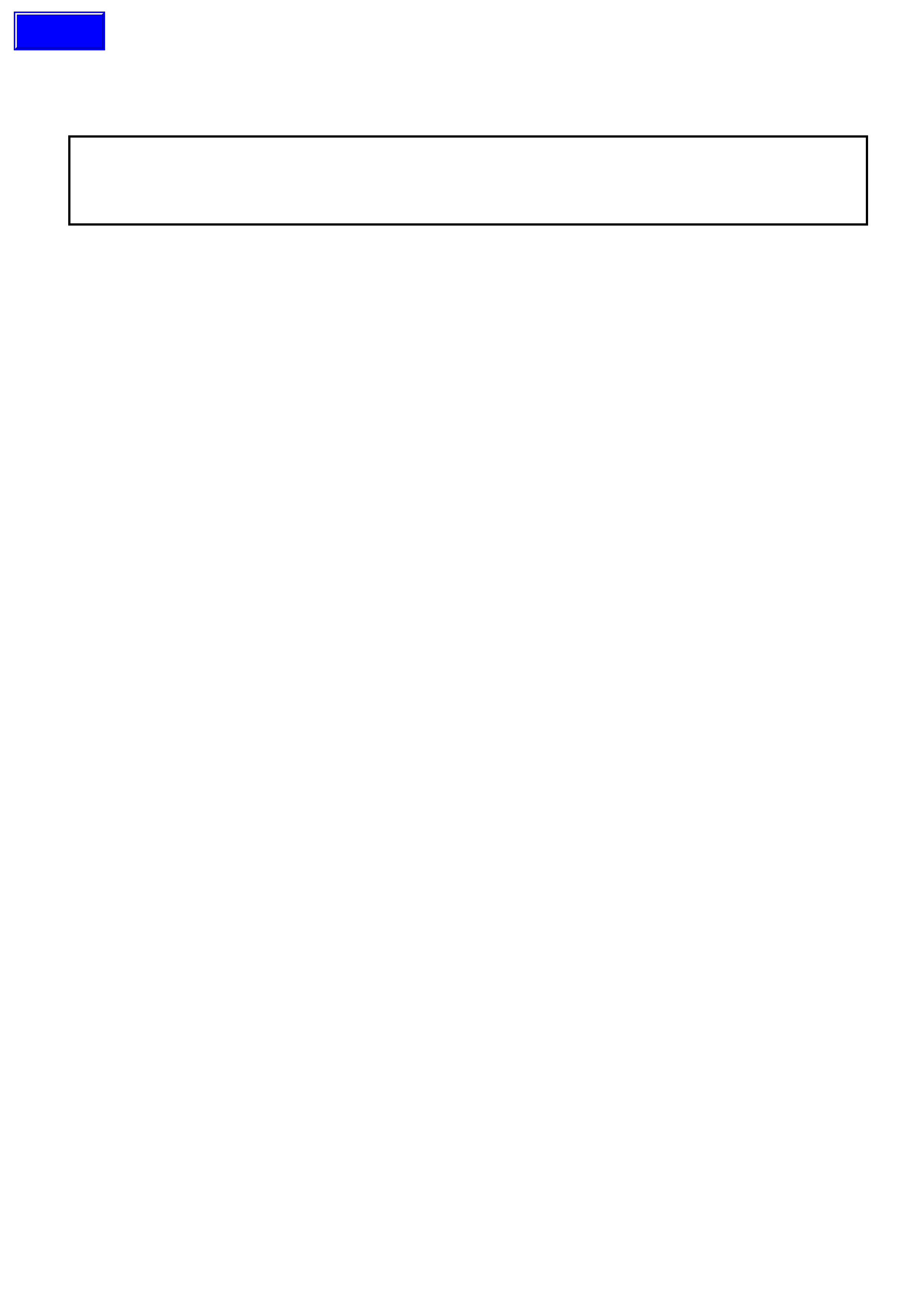

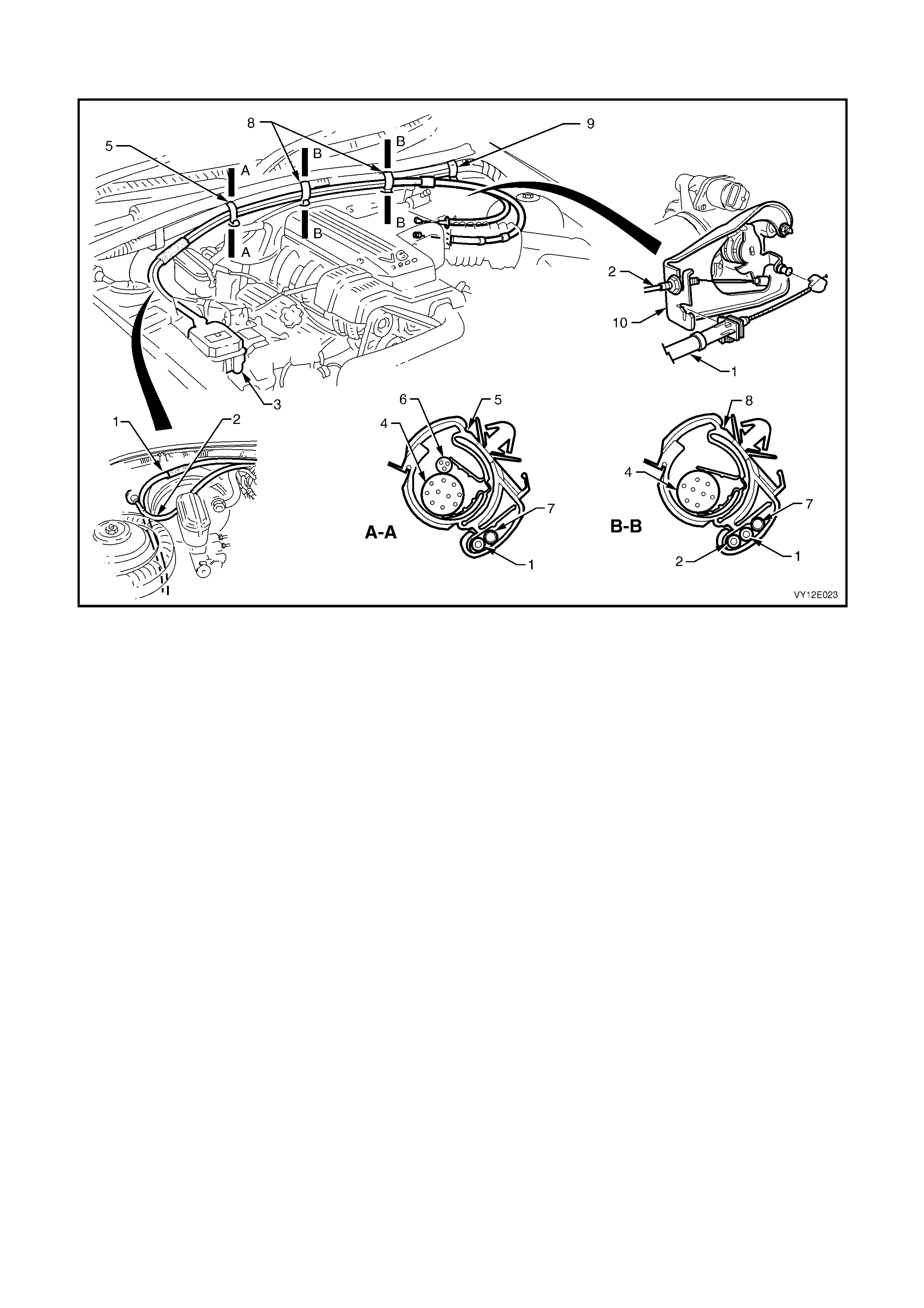

Figure 12E-1 illustrates the component relationship for the cruise control sy stem.

Figure 12E-1

Legend

1. Cruise Control Module 6. Instrument Cluster

2. Brake Pedal Electrical Release Switch (Switch B) 7. Multi-function Display – CRUISE and ACTIVE Icons

3. Brake Pedal Stop Lamp Switch (Switch A) 8. Powertrain Control Module

4. Throttle Body 9. Clutch Switch

5. Cruise Control Switch Assembly

COMPONENTS

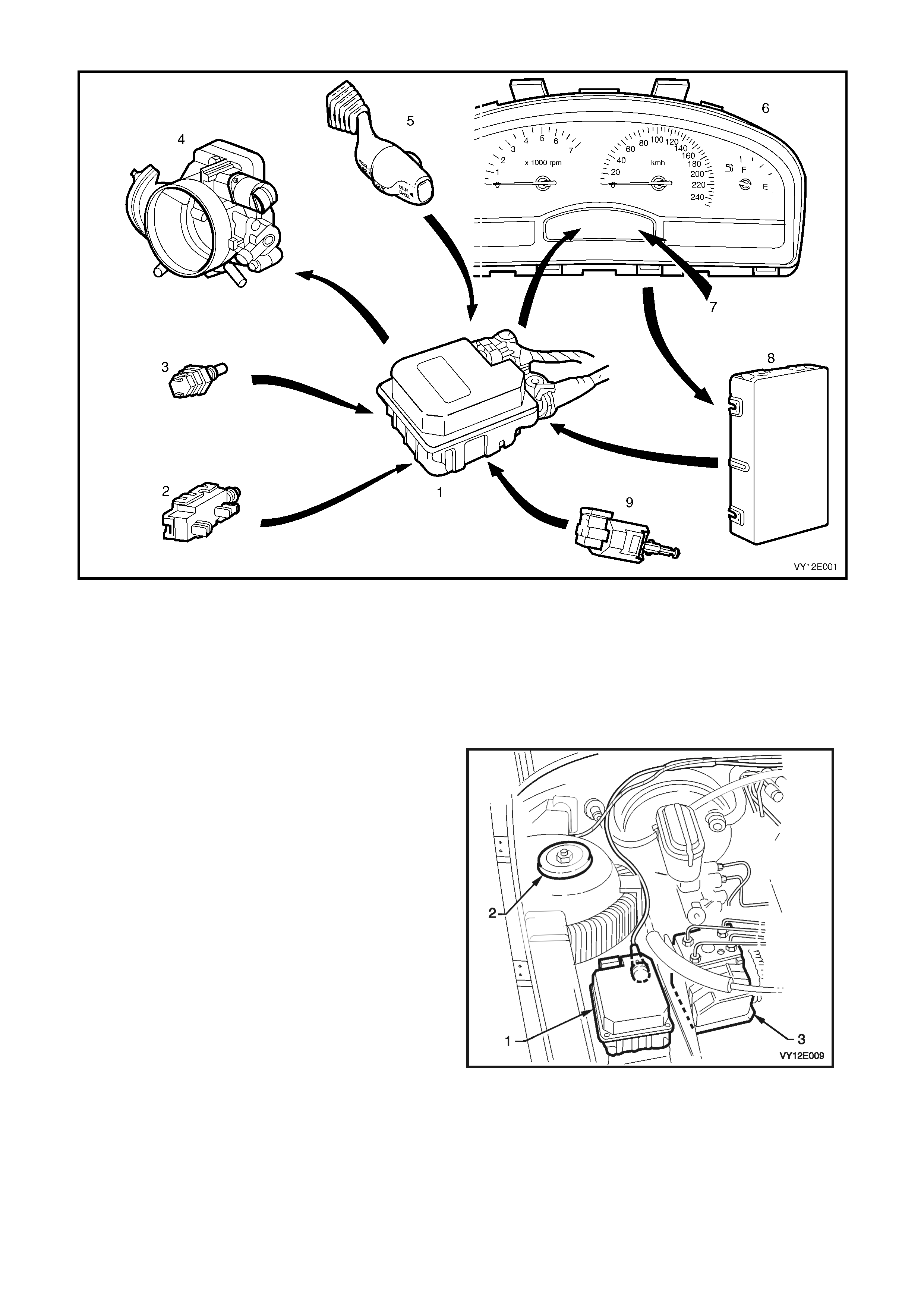

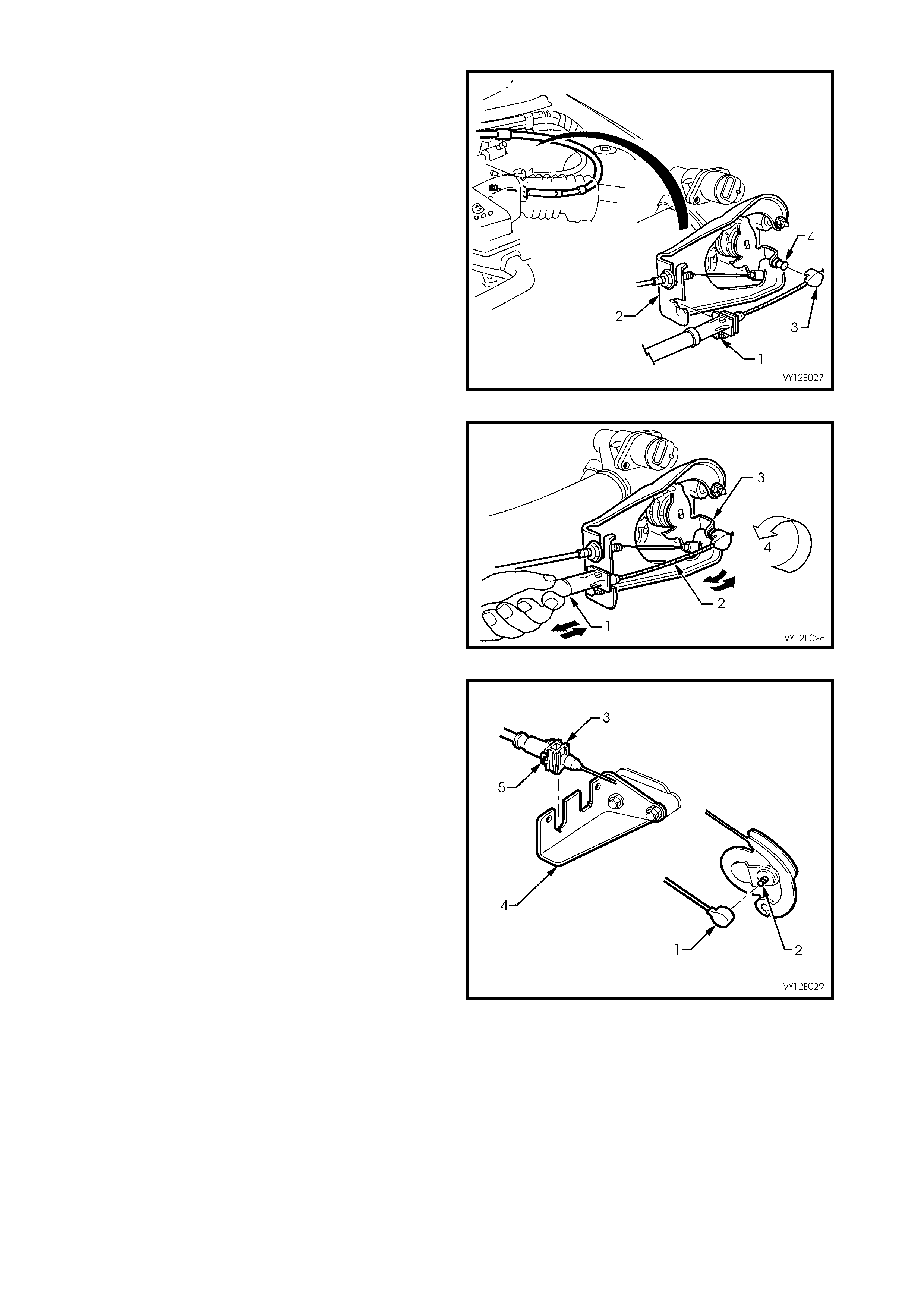

The cruise control module (1) is mounted forward

of the right-hand s trut tower (2) and adjacent to the

optional ABS/TCS module (3), on both LHD and

RHD vehicles, regardless of the engine variant.

Refer to Figure 12E-2, RHD shown.

Figure 12E-2

The c ruis e c ontrol module f unctionally integrates an

electronic controller (1) with an electric stepper

motor (2).

The electronic controller monitors vehicle speed

from a signal generated by the PCM which in turn,

operates the electric stepper motor.

The stepper motor, in response to the electronic

controller, adjusts the throttle position to maintain

the desired vehicle set speed. The electronic

controller is operated by the cruise control system

control switches (3), RHD model shown, located at

the tip of the headlamp and turn signal switch

assembly.

Figure 12E-3

Two switches, mounted on the brake pedal

support (1), disengage the cruise control system

electronically when the brake pedal (2) is pressed.

The upper switch (3) is the cruise control electrical

release switch (Switch B). The two rear terminals

are used for the cruise control system.

NOTE: Us ing the front set of terminals will res ult in

the cruise control not functioning.

The lower switch (4) is the brake pedal stop lamp

switch (Switch A), and is used to illum inate the stop

lamps and signal the cruise control module to

disengage.

With the brake pedal at rest, the stop lamp contacts

in the lower switch are open, and closed when the

brake pedal is pressed.

With the brake pedal at rest, the electrical release

contacts in the upper switch are closed, and open

when the brake pedal is pressed.

Both switches are used to signal the cruise control

module s o that if one should f ail, the second switch

will still generate a signal to the cruise control

module to disengage the cruise control function.

Figure 12E-4

For vehicles with a manual transmission, a clutch

pedal switch (1) mounted on the clutch pedal

support (2), has been incorporated into the cruise

control system. W hen the driver presses the clutch

pedal (3) to change gear, the cruise control is

disengaged.

When the clutch pedal is pressed, a signal is

transmitted to the cruise control module to

disengage the cruise control function.

With the clutch pedal at rest, the contacts of the

clutch switch are c losed, and open when the clutch

pedal is pressed.

Figure 12E-5

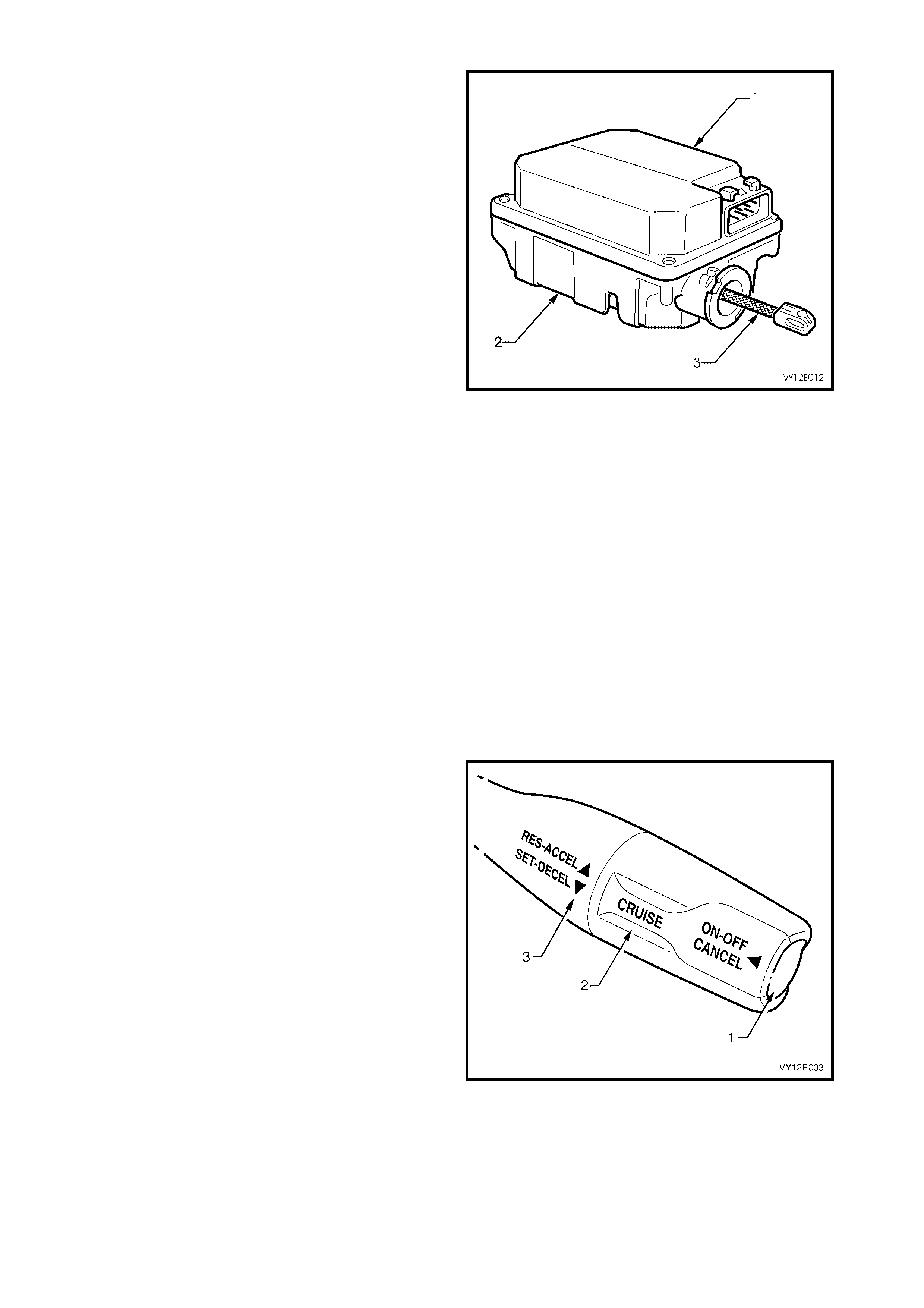

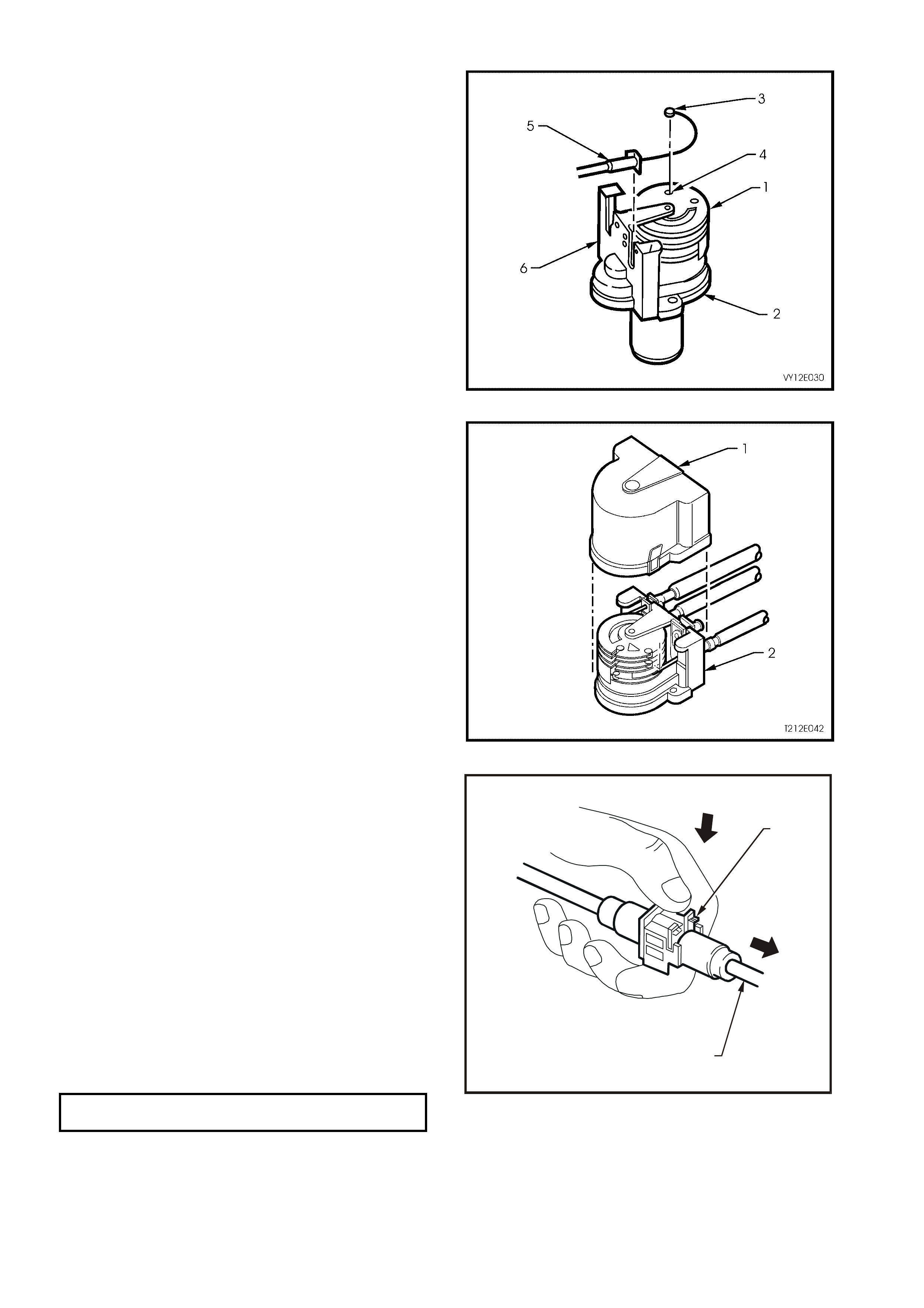

The cruise control module comprises of an

electronic controller (1) and electric stepper motor,

solenoid operated clutch and gear train

assemblies (2), and a connecting strap (3).

The electronic controller receives signals from the

cruise control electrical release switch, stop lamp

switch, clutch pedal switch and vehicle speed

output. It then generates signals to control the

stepper m otor and solenoid operated cr uise control

module clutch.

The electric stepper motor is a brushless type

motor with a four pole perm anent magnet arm ature

and three phase stator. The motor provides torque

through a mechanical gear train to a control cable,

which actuates the throttle linkage.

When the brake pedal electrical release switch is

activated (brake pedal pressed) the stepper motor

begins to spin the motor back to the zero motor

position. If the signal at pin X1-G (refer to

Figure 12E-43) of the cruise control module is

pulled high, it will cause the stepper m otor clutch to

de-energise in about 0.75 second. In most cases,

the stepper motor will be in the zero position when

the module clutch is disengaged. This time delay

period is introduced to prevent the accelerator

pedal from slapping while the throttle is still held

open. The stepper motor relies on the throttle

return s pr ing to r eturn the s tepper motor to the zero

position as the spring on the drum gear is not

strong enough to return the throttle/cruise to zero.

The internal components of the cruise control

module are not serviceable.

CAUTION: Do not attempt to repair the cruise

control module assembly if faulty.

Unauthorised repair of the cruise control

module will affect vehicle safety.

Figure 12E-6

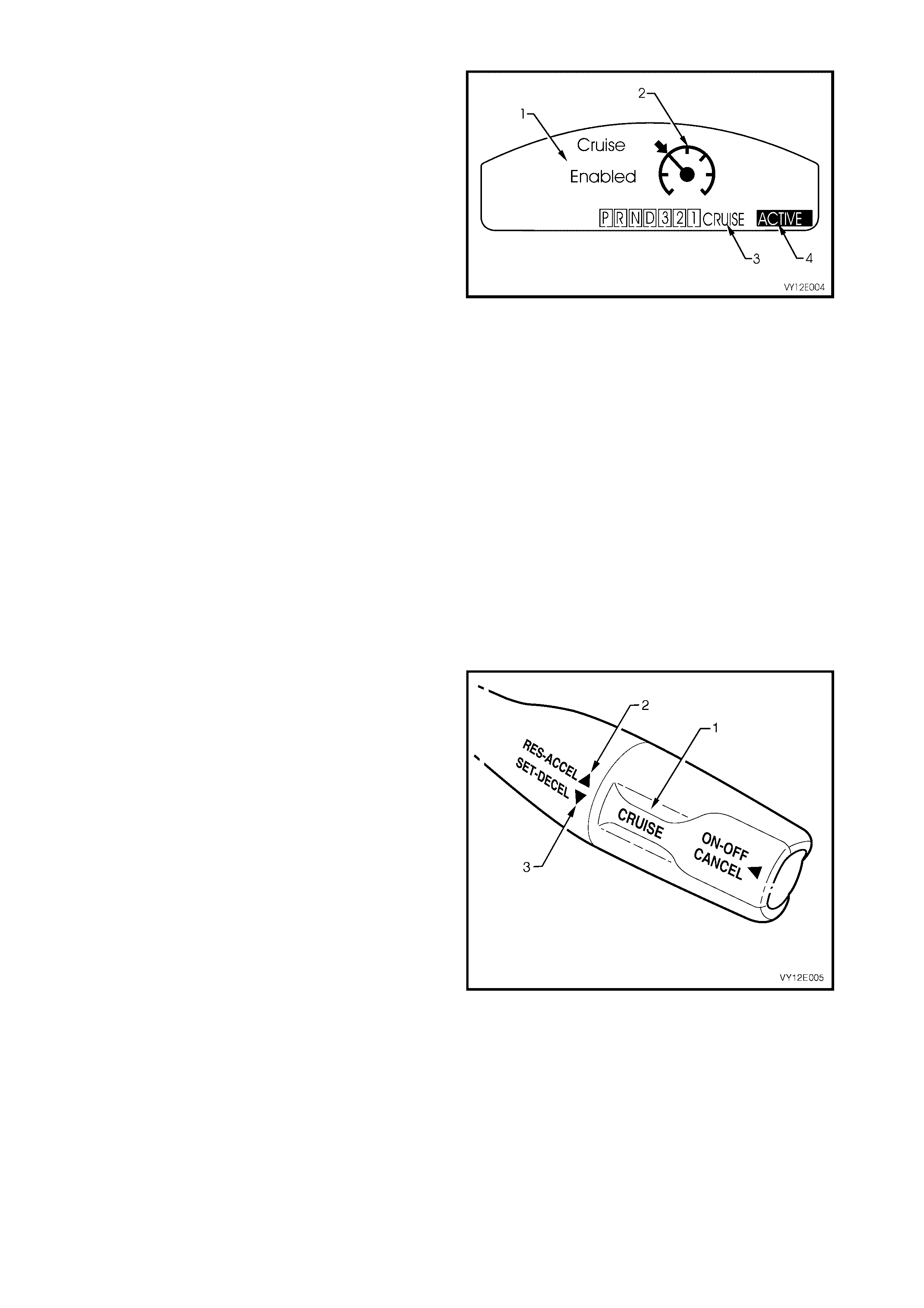

CRUISE CONTROL SWITCH OPERATION

Engaging the Cruise Control

With the ignition switched on, press the CRUISE

ON-OFF push-button (1), RHD model shown. This

will cause the ‘Cruise Enabled’ message to be

displayed for 2 seconds on the instrument cluster

MFD along with the cruise symbol with a flashing

set arrow and the CRUISE icon, refer to

Figure 12E-8. The instrument cluster MFD then

reverts to just the CRUISE icon, indicating that

power is on.

Accelerate the vehicle to the desired cruise speed

(above 40 km/h) and rotate the CRUISE switch (2)

to the SET-DECEL position (3) and release, then

release the accelerator pedal.

Figure 12E-7

The ‘Cruise Enabled’ message (1), the cruise

symbol with a flashing set arrow (2) and the

CRUISE icon (3) will be displayed on the

instrument cluster MFD for 2 seconds when the

cruise control system is turned on at the control

switch located on the turn signal switch assembly.

The instrum ent cluster MFD then reverts to j ust the

CRUISE icon (3) indicating that power is on.

The ACTIVE icon (4) in the instrum ent cluster MFD

will be displayed when the cruise control system is

engaged. The cruise speed will be automatically

maintained, provided the vehicle speed is above

40 km/h.

Figure 12E-8

To Change Cruise Speed

To reset the cruise control to a higher speed,

accelerate the vehicle to the desired speed, rotate

the CRUISE switch (1) to the SET-DECEL

position (3) and release it. Refer to Figure 12E-9,

RHD model shown.

Rotating the CRUISE switch (1) to the RES-ACCEL

position (2) will cause an increase in cruise speed

and the vehicle will accelerate at a controlled rate

until the CRUISE switch is released. The vehicle

will now cruise at this higher set speed.

To decrease the cruise speed, rotate the CRUISE

switch to the SET-DECEL position (3). The vehicle

will decelerate, coasting to a slower speed at a

controlled rate until the CRUISE switch is released.

The vehicle will now continue to cruise at the

reduced set speed.

NOTE: While holding the CRUISE switch in the

SET-DECEL position, the ACTIVE icon (4) in the

instrument cluster MFD (refer to Figure 12E-8) will

turn OFF . The ACTIVE ic on will be displayed again

when the CRUISE switch is released.

The cruise control switches also provide the facility

for TAP UP and TAP DOWN for smaller

incremental adjustments in vehicle cruise speed.

TAP UP is ac hieved by quickly rotating the CRUISE

switch to the RES-ACCEL position and releasing.

The cruise speed will increase by 2.0 km/h for

every TAP UP. Quickly rotating the CRUISE switch

to the SET-DECEL position (TAP DOWN) will

decrease the cruise control speed by 2.0 km/h for

every TAP DOW N. T AP DOW NS are lim ited to the

minimum cruising speed of 40 km/h.

Figure 12E-9

To Override the Cruise Control System

The acceler ator pedal m ay be pressed at any time to overr ide the cruis e control s ys tem . Release of the acceler ator

pedal will return the vehicle to the cruise speed set previously.

To Disengage the Cruise Control System

The system is disengaged when:

1. The brake pedal is pressed.

2. The clutch pedal is pressed (for vehicles with manual transmission).

3. The ON-OFF push-button is pressed switching the cruise control system to the Standby mode.

IMPORTANT: When vehicles fitted with Electronic T raction Control are in a low traction situation, the c ruise control

will disengage.

When the cruise control system is disengaged, the ACTIVE icon goes out but the CRUISE icon remains.

To resume the previously set cruise control memory speed after changing gear, braking, stopping or pressing the

ON-OFF switch once; first accelerate, if required, until the vehicle speed is greater than 40 km/h, then rotate the

CRUISE switch to the RES-ACCEL position ( for less than 1 s econd). The vehicle will then autom atically acceler ate

to the previous cruise speed setting.

The cruise control module will retain the previous set speed in memory for as long as the CRUISE icon is on.

Pressing the clutch pedal or brake pedal, or pressing the ON-OFF switch once while the ACTIVE icon is, will not

erase the vehicle set speed from the cruise control module memory.

Pressing the ON-OFF switch while only the CRUISE icon is on or turning the ignition off, will erase the previous

cruise set speed from the cruise control module memory.

NOTE: Each tim e the ignition is cycled, the CRUISE and ACTIVE icons will go out. To reactivate the cruise control,

the CRUISE ON-OFF switch will have to be pressed.

2. SERVICE OPERATIONS

IMPORTANT

All fasteners are important attaching parts as they affect the performance of vital components and / or

could result in major repair expense. Where specified in this section, fasteners M UST be replaced with

parts of the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality

or substitute design.

Torque values must be used as specified during reassembly to ensure proper retention of all

components.

Through out this section, fastener torque w rench specifications may be accompanied with the follow ing

identification marks:

+

++

+ Fasteners must be replaced after loosening.

&

&&

& Vehicle must be at curb height before final tightening.

6

66

6 Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock

and should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 CRUISE CONTROL CABLE

LT Section No. 03–400

REMOVE

1. On vehicles fitted with the V6 engine, push the

outer cable retaining tang (1) at the throttle

cable bracket (2) away from the throttle body

and pull the outer cable (3) out of the throttle

cable bracket.

2. On vehicles fitted with the V6 engine, remove

the inner cable retaining clip (4) from the

throttle body linkage lever stud by pushing the

retaining clip off the stud with the aid of a

screwdriver.

Figure 12E-10

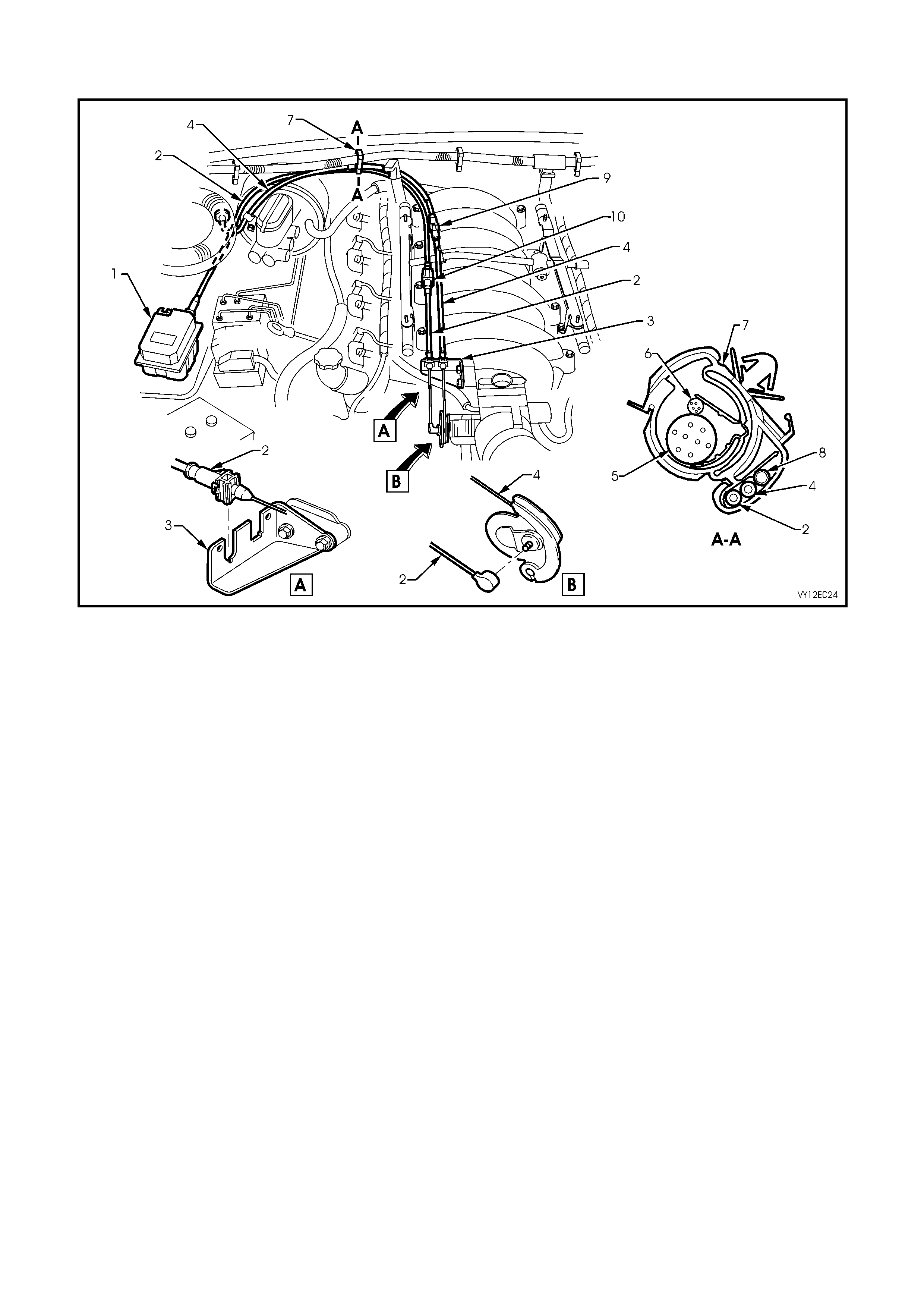

3. On vehicles fitted with the GEN III V8 engine

and without traction control, remove the four

dome nuts (2) securing the engine dress cover

assembly (1) to the intake manifold studs. Lift

and remove the dress cover assembly.

Figure 12E-11

4. On vehicles fitted with the GEN III V8 engine

and without traction control, use a screwdriver

to prise the end of the cruise control inner

cable (1) from the throttle body lever stud (2).

Lever the outer c able r etaining tang (3) at c able

the mounting bracket (4) and pull the outer

cable (5) upwards from the cable mounting

bracket.

Figure 12E-12

5. On vehicles fitted with the GEN III V8 engine

and traction control, remove the cover (1) from

the throttle relaxer (2) by pressing the tabs (3)

on both sides of the cover. Refer to

Figures 12E-13 and 12E-24 for RHD vehicles

and 12E-25 for LHD vehicles.

Figure 12E-13

6. Rotate the top cam (1) of throttle relaxer (2)

and remove the ferrule (3) of the cruise control

inner cable from the locating slot (4) in the

throttle cam . Lever out the retaining tang of the

outer cable (5) then lift the cable away from the

throttle relaxer mounting bracket (6).

Figure 12E-14

7. At the cruise control module (1), turn the outer

control cable (2) towards the engine (approx.

45°) to release the cable lock mechanism (3)

from the cruise control module.

Figure 12E-15

8. Pull the outer cable (1) from the cruise control

module (2) and disconnect the inner cable (3)

from the electric stepper motor strap end

fitting (4) by lifting the cable upward,

approximately 45°, allowing it to be released

from the end fitting.

Figure 12E-16

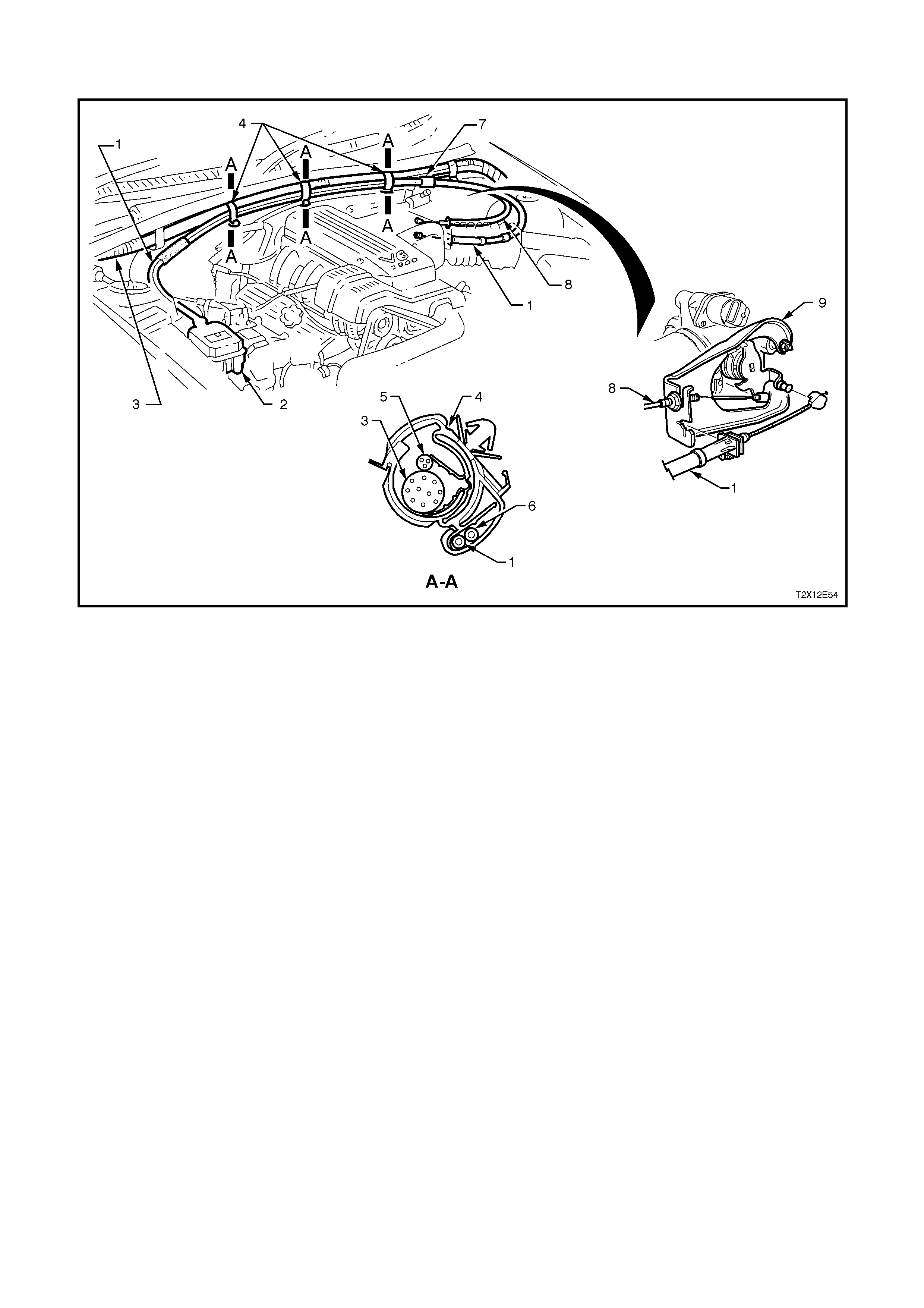

9. On RHD vehicles. Release the cruise control

cable from the main wiring harness/cable

clip (1) by holding the upper retention clip (2)

and then pushing the lower retention clip (3)

inward and down to release the powertrain

wiring harness (4), throttle cable (5), cruise

control cable (6), and for wagon only, the rear

washer hose (7).

NOTE: Depending on the model and harness/c able

clip location, the clip may also retain the accelerator

pedal cable and the wiper motor harness.

Figure 12E-17

10. On LHD vehicles. Release cruise control cable

from main wiring harness/cable clip (1) by

holding the upper retention clip (2) and then

pushing the lower retention clip (3) inward and

down to release the wiper motor harness (4),

powertrain wiring harness (5), throttle cable (6 ),

cruise control cable (7) and engine hood

release cable (8).

NOTE: Depending on the model and harness/c able

clip location, the clip may also retain the accelerator

pedal cable and the wiper motor harness.

Figure 12E-18

11. Remove the cruise control cable.

REINSTALL

1. Ens uring that the motor s trap (1) is not twisted,

attach the inner cable end (2) to the motor

strap end fitting (3) at the cruise control

module (4).

Figure 12E-19

2. While holding the inner cable (1) at the throttle

body linkage lever stud connection end, slide

the outer cable (2) over the motor strap until

the outer cable sits flush with the c ruise control

module housing (3).

3. Turn the outer cable towards the right-hand

fender (approximately 45°) to lock the outer

cable locking mechanism to the cruise control

module.

4. Ensuring that the cruise control cable is routed

correctly, lock the cable into the main wiring

harness/cable clips. Refer to:

• Figure 12E-21 (V6 and V6 S/C, RHD),

• Figure 12E-22 (V6 and V6 S/C, LHD),

• Figure 12E-23 (GEN III V8 without throttle

relaxer, RHD),

• Figure 12E-24 (GEN III V8 with throttle

relaxer, RHD), and

• Figure 12E-25 (GEN III V8 with throttle

relaxer, LHD).

Figure 12E-20

Cable Routing – V6 And V6 Supercharged Engines (RHD)

Figure 12E-21

Legend

1. Cruise Control Cable 6. Wiper Motor Harness

2. Throttle Cable 7. Rear Washer Hose (Wagon Only)

3. Cruise Control Module 8. Harness/Cable Clip (Section B-B, Three Places)

4. Powertrain Wiring Harness 9. Cruise Control Outer Cable Adjuster/Lock

5. Harness/Cable Clip (Section A-A) 10. Throttle Cable Bracket

Cable Routing – V6 And V6 Supercharged Engines (LHD)

Figure 12E-22

Legend

1. Cruise Control Cable 6. Engine Hood Release Cable

2. Cruise Control Module 7. Cruise Control Outer Cable Adjuster/Lock

3. Powertrain Wiring Harness 8. Throttle Cable

4. Harness/Cable Clip (Section A-A, Three Places) 9. Throttle Cable Bracket

5. Wiper Motor Harness

Cable Routing – Gen III V8 Engine Without Throttle Relaxer (RHD)

Figure 12E-23

Legend

1. Cruise Control Module 6. Wiper Motor Harness

2. Cruise Control Cable 7. Harness/Cable Clip (Section A-A)

3. Throttle Cable Bracket 8. Rear Washer Hose (Wagon Only)

4. Throttle Cable 9. Throttle Outer Cable Adjuster/Lock

5. Powertrain Harness 10. Cruise Control Outer Cable Adjuster/Lock

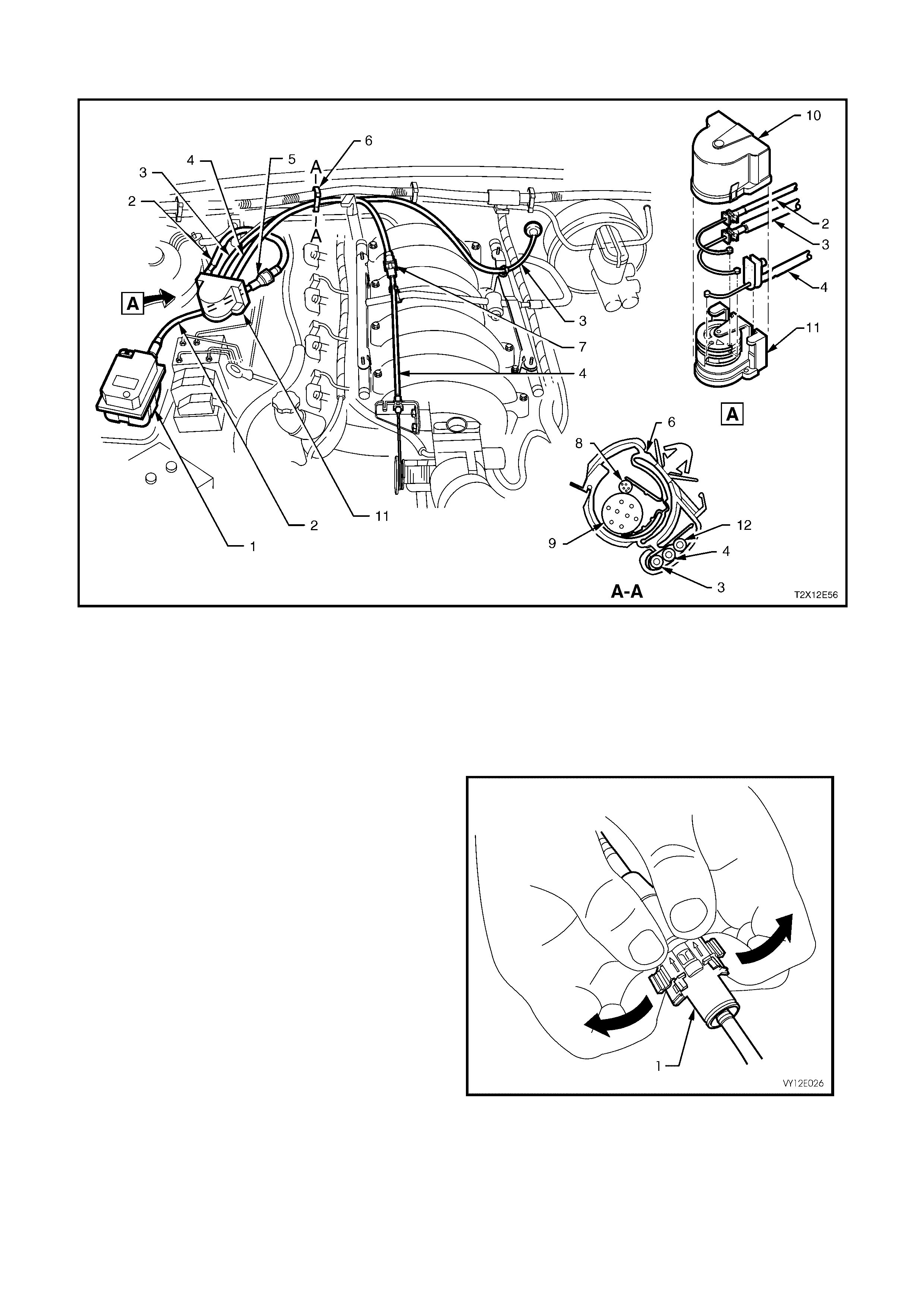

Cable Routing – GEN III V8 Engine With Throttle Relaxer (RHD)

Figure 12E-24

Legend

1. Cruise Control Module 9. Throttle Outer Cable Adjuster/Lock

2. Cruise Control Cable 10. Throttle Cable

3. Accelerator Pedal Cable 11. Harness/Cable Clip (Section B-B)

4. Powertrain Harness 12. Cruise Control Outer Cable Adjuster/Lock

5. Wiper Motor Harness 13. Harness/Cable Clip (Section C-C)

6. Harness/Cable Clip (Section A-A) 14. Throttle Relaxer

7. Rear Washer Hose (Wagon Only) 15. Throttle Relaxer Cover

8. Throttle Cable Bracket

Cable Routing – Gen Iii V8 Engine With Throttle Relaxer (LHD)

Figure 12E-25

Legend

1. Cruise Control Module 7. Throttle Outer Cable Adjuster/Lock

2. Cruise Control Cable 8. Wiper Motor Harness

3. Accelerator Pedal Cable 9. Powertrain Harness

4. Throttle Cable 10. Throttle Relaxer Cover

5. Cruise Control Outer Cable Adjuster/Lock 11. Throttle Relaxer

6. Harness/Cable Clip (Section A-A) 12. Engine Hood Release Cable

5. Unlock the cruise control outer cable by pulling

the lock tangs on the outer cable

adjuster/lock (1) in the direction indicated by

the arrows in Figure 12E-26.

Figure 12E-26

6. On vehicles fitted with the V6 engine, push the

outer cable retainer (1) into the throttle cable

bracket (2).

7. On vehicles fitted with the V6 engine, push the

inner cable retaining clip (3) onto the throttle

body linkage lever stud (4).

Figure 12E-27

8. On vehicles f itted with the V6 engine, adjus t the

cruise control outer cable (1) at the cable

adjuster/lock (refer to Figure 12E-26) to

achieve minimum slack of the inner cable (2)

while ensuring that the throttle lever (3)

remains in the fully closed position (4), refer to

Figure 12E-28.

Figure 12E-28

9. On vehicles fitted with the GEN III V8 engine

without traction control push the inner cable

retainer clip (1) onto the throttle body linkage

lever stud (2). Push the outer cable retainer (3)

into the throttle cable bracket (4) ensuring that

the cable retaining tang (5) locks into the

throttle cable bracket.

Figure 12E-29

10. On vehicles fitted with the GEN III V8 engine

and traction control, rotate the top cam (1) of

the throttle relaxer (2) and install the inner

cable ferrule (3) into the slot in the cam (4).

Ensure that the inner cable is properly in the

groove on the cam. Push the outer cable

retainer (5) onto the throttle relaxer mounting

bracket (6) ensuring that the cable retaining

tang locks into the mounting bracket.

Figure 12E-30

11. On vehicles fitted with the GEN III V8 engine

and traction control, install the cover (1) onto

the throttl e relaxer (2).

Figure 12E-31

12. Allow the internal spring of the cable

adjuster/loc k m echanism ( 1) to tak e up the f ree

play of the outer cable (2). Push down on the

outer cable locking retainer to fix the outer

cable to the correct self adjusted length. Refer

to Figure 12E-32.

NOTE: After the cable is fitted, ensure that the

throttle opens without binding and returns to the

fully closed position under throttle return spring

tension.

13. On vehicles fitted with the GEN III V8 engine

without traction control, install the engine dress

cover. Ensure that the stud grommets in the

dress cover remain in place.

14. Install the engine dress cover dome nuts.

Tighten the dome nuts to the correct torque

specification.

ENGINE DRESS COVER DOME NUT

TORQUE SPECIFICATION 4 – 6 Nm

T212E021

2

1

Figure 12E-32

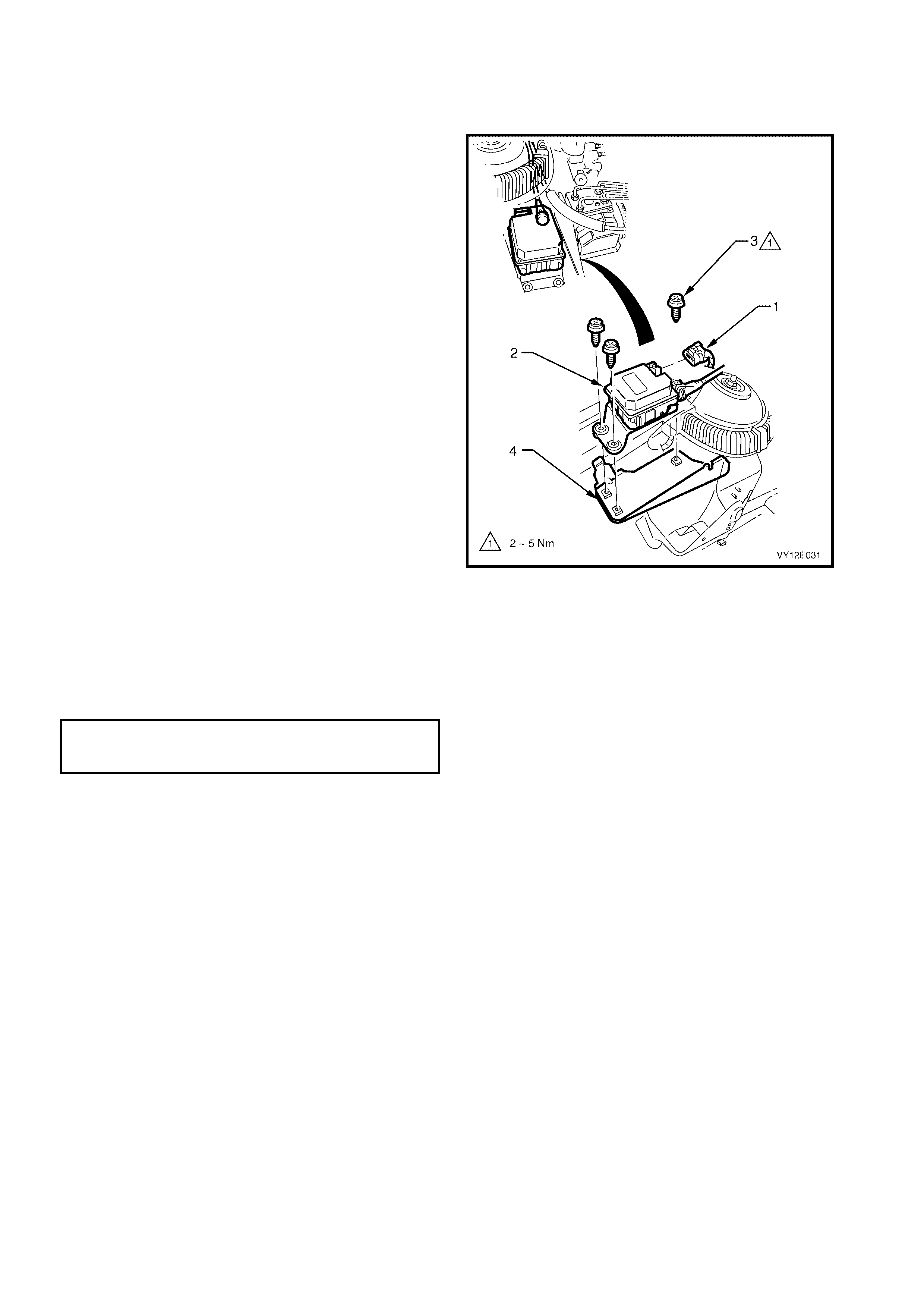

2.2 CRUISE CONTROL MODULE

LT Section No. 03–400

REMOVE

1. Remove the cruise control cable, refer to

2.1 CRUISE CONTROL CABLE in this

Section.

2. Pull up the tang on the wiring harness

connector (1), and pull the connector from the

cruise control module (2).

3. Remove the three screws (3) securing the

cruise control module to the ABS/c ruise control

module mounting bracket (4) and remove the

cruise control module.

Figure 12E-33

REINSTALL

Installation of the cruise control module is the reverse of the removal operation, noting the following:

1. To install the cruise control cable, refer to 2.1 CRUISE CONTROL CABLE in this Section.

2. Tighten all fasteners to the correct torque specification.

CONTROL MODULE

SECURING SCREW

TORQUE SPECIFICATION 2 – 5 Nm

3. Connect the wiring harness connector ensuring that the connector tang is secure.

2.3 CRUISE CONTROL SWITCH ASSEMBLY

LT Section No. 06–250

REMOVE AND REINSTALL

The cruise control switches are incorporated with

the headlamp and turn signal switch assembly

located to the right of the steering column in the

RHD models and to the left of the steering column

in the LHD models.

Removal and installation instructions for the turn

signal switch assembly are described in

Section 12B, LIGHTING SYSTEM.

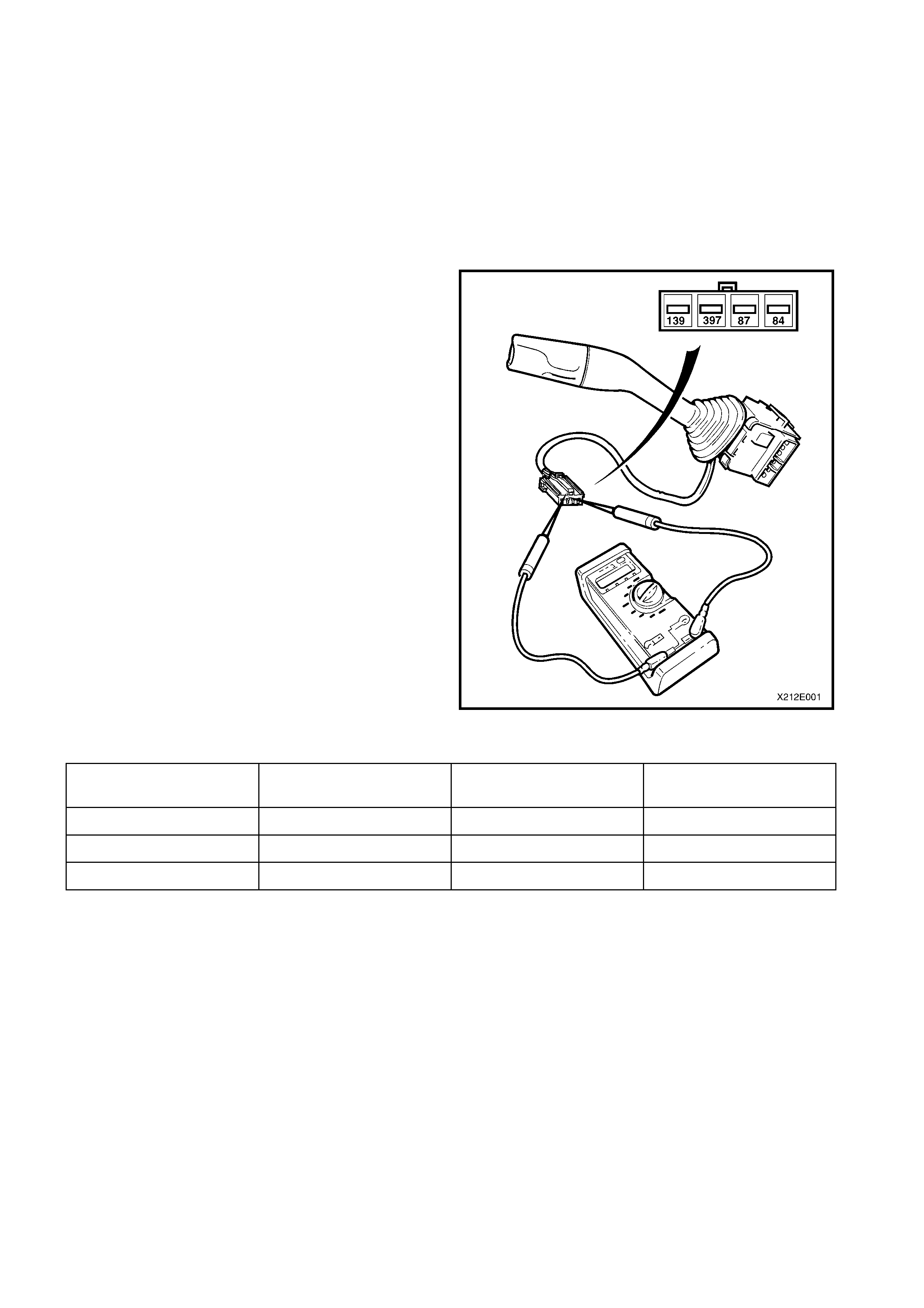

CHECKING SWITCH CONTACTS

With the cruise control switch assembly lead

disconnected from the main wiring harness, check

the cruise control switch contacts as follows:

Attach an ohmmeter to the appropriate terminals

nominated in the following chart and press and hold

button as directed. The ohmmeter will read

approximately 470 ohms resistance when the

button is pressed and show an open circuit when

released.

NOTE: If the resistance is not to specification,

replace the cruise control switch assembly.

Figure 12E-34

SWITCH OHMMETER CONNECTED

BETWEEN TERMINALS RESISTANCE –

SWITCH PRESSED RESISTANCE –

SWITCH RELEASED

ON-OFF 139 and 397 Approximately 470 Ω Open Circuit

SET-DECEL 139 and 84 Approximately 470 Ω Open Circuit

RES-ACCEL 139 and 87 Approximately 470 Ω Open Circuit

2.4 STOP LAMP SWITCH (SWITCH A)

LT Section No. 04B–600

TESTING SWITCH CONTACTS

1. Check the adjustment of the stop lamp

switch (1). Refer to the following switch

installation and adjustment procedure and

adjust the switch as required.

Ensure that the stop lamps ar e operating when

the brake pedal is pressed.

If the stop lamps are not operating, repair as

necessary. Refer to Section 12B, LIGHTING

SYSTEM.

2. Remove the wiring harness connector (2) from

the terminals of the stop lamp switch (1).

3. Connect an ohmmeter across the switch

terminals and the ohmmeter should indicate

open circuit with the brake pedal at rest.

Press the brake pedal and the ohmmeter

should indicate continuity.

4. Replace the switch as per the following

removal procedure if the tests prove the switch

to be faulty.

5. If the test proves the switch to be serviceable,

connect the wiring harness connector to the

switch.

T212E045

2

3

1

Figure 12E-35

REMOVE

1. Remove the instrument panel lower trim

assembly and the instrument panel lower trim

retainer plate. Refer to Section 1A3,

INSTRUMENT PANEL & CONSOLE.

2. Disconnect the wiring harness connectors (2)

from the stop lamp switch (1), refer to

Figure 12E-35.

3. Rotate the switch anticlockwise and remove it

from the mounting nut (3).

REINSTALL AND ADJUST

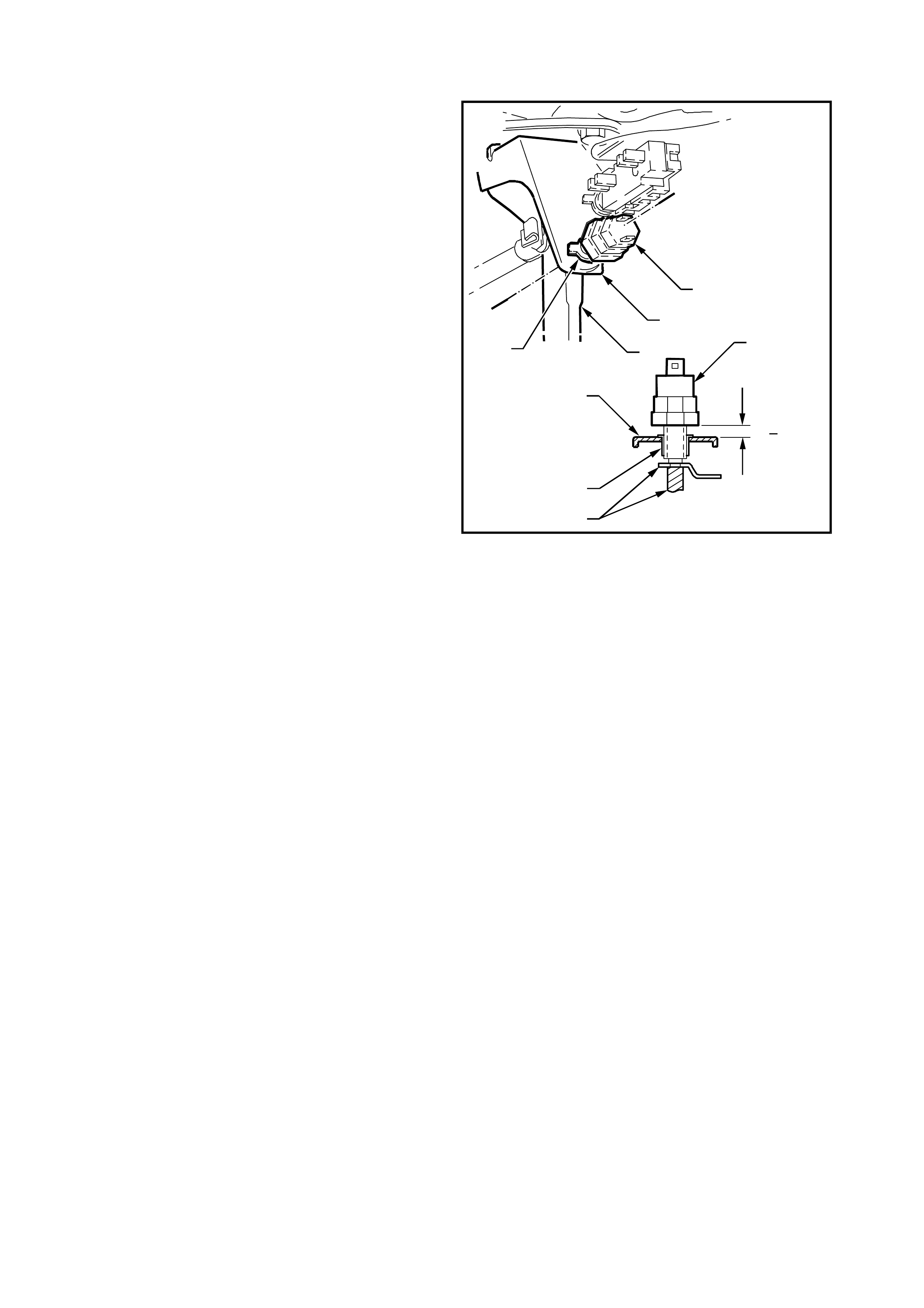

1. Install the stop lamp switch (1) into the

mounting nut (2) on the brake pedal

support (3).

2. With the brake pedal (4) in its rest position,

adjust the switch to the clearance dimension

shown in Figure 12E-36.

3. Connect the wiring harness connector to the

switch.

4. Install the instrument panel lower trim assembly

and the instrument panel lower trim retainer

plate. Refer to Section 1A 3, INSTRUMENT

PANEL & CONSOLE.

T212E046

1

3

2

4

6 0.5mm

A

A

1

3

4

2

A-A

+

Figure 12E-36

2.5 ELECTRICAL RELEASE SWITCH (SWITCH B)

LT Section No. 04B–600

TESTING SWITCH CONTACTS

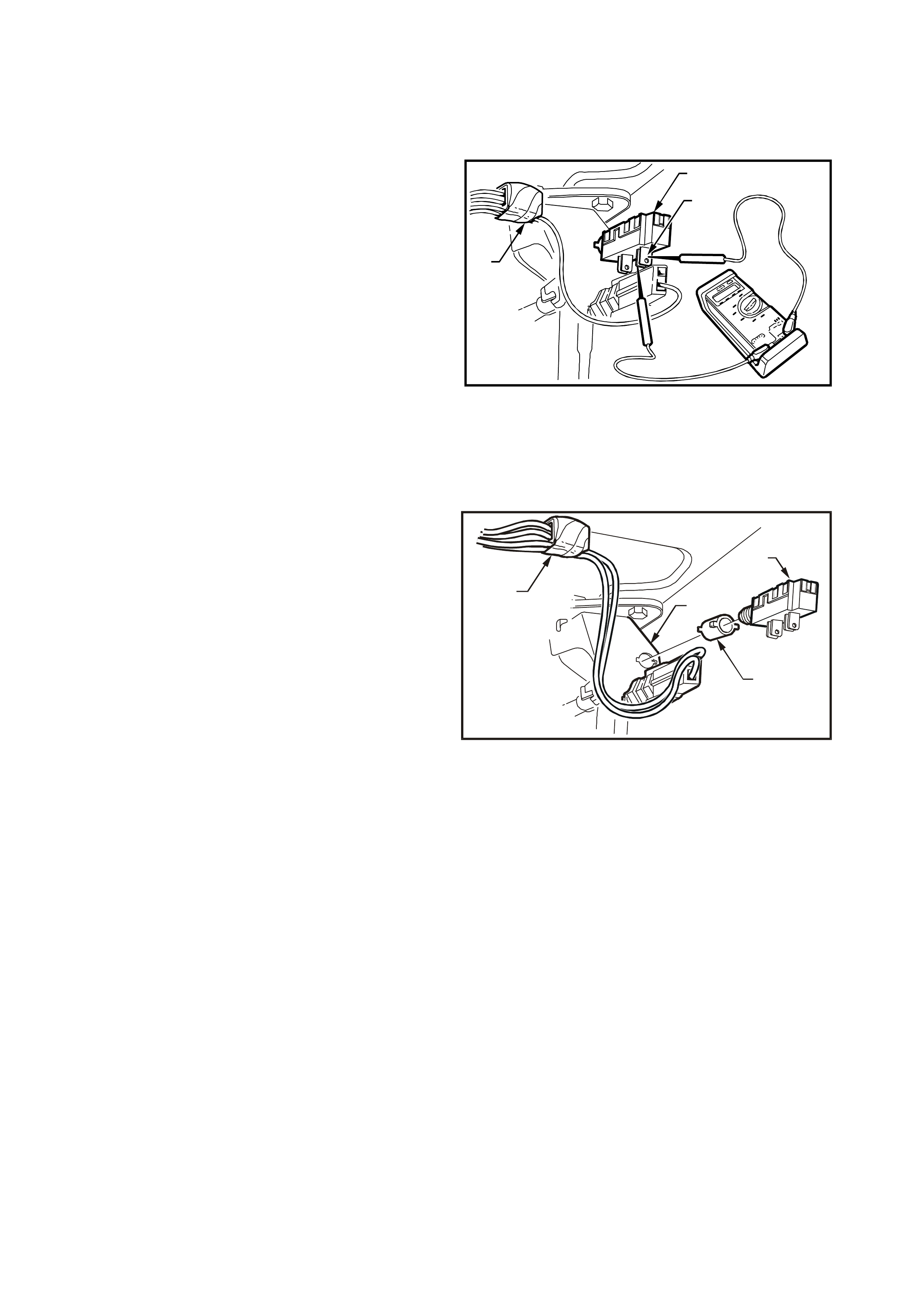

1. Check the adjustment of the electrical release

switch (1), refer to the following switch

installation and adjustment procedure and

adjust the switch as required.

2. Rem ove the wiring harness c onnector from the

rear most terminals (2) of the switch.

3. Connect an ohmmeter across the switch

terminals and the ohmmeter should indicate

continuity with the brake pedal at rest.

Press the brake pedal and the ohmmeter

should indicate an open circuit.

4. Replace the switch as per the following

removal procedure if the tests prove the switch

to be faulty.

5. If the test proves the switch to be serviceable,

connect the wiring harness connector to the

switch.

T212E023

1

3

2

Figure 12E-37

REMOVE

1. Remove the instrument panel lower trim

assembly and the instrument panel lower trim

retainer plate. Refer to Section 1A3,

INSTRUMENT PANEL & CONSOLE.

2. Disconnect the wiring harness connectors (1)

from the electrical release switch (2).

3. Pull the switch from the tubular clip (3).

4. If necessary, remove the clip from the brake

pedal support (4).

T212E024

1

2

4

3

Figure 12E-38

REINSTALL AND ADJUST

1. If removed, install the tubular clip into the mounting hole of the brake pedal support.

2. Holding the brake pedal in its pressed position, install the switch into the tubular clip. Push the switch forward

until the switch body locates in the clip.

NOTE: Audible c licks will be heard as the thr eaded por tion of s witch ass embly is pushed into the tubular c lip toward

the brake pedal.

Pull the brake pedal fully against the pedal stop until audible ‘click’ sounds can no longer be heard. (The switch

assembly is pushed back out from the clip to provide the correct switch position adjustment).

Press the brake pedal again and repeat above procedure to ensure that the switch adjustment is correct (no click

sounds).

3. Connect the wiring harness connector to the switch.

4. Install the instrument panel lower trim assembly and the instrument panel lower trim retainer plate. Refer to

Section 1A3, INSTRUMENT PANEL & CONSOLE.

2.6 CLUTCH PE DAL SWITCH

LT Section No. 04B–600

TESTING SWITCH CONTACTS

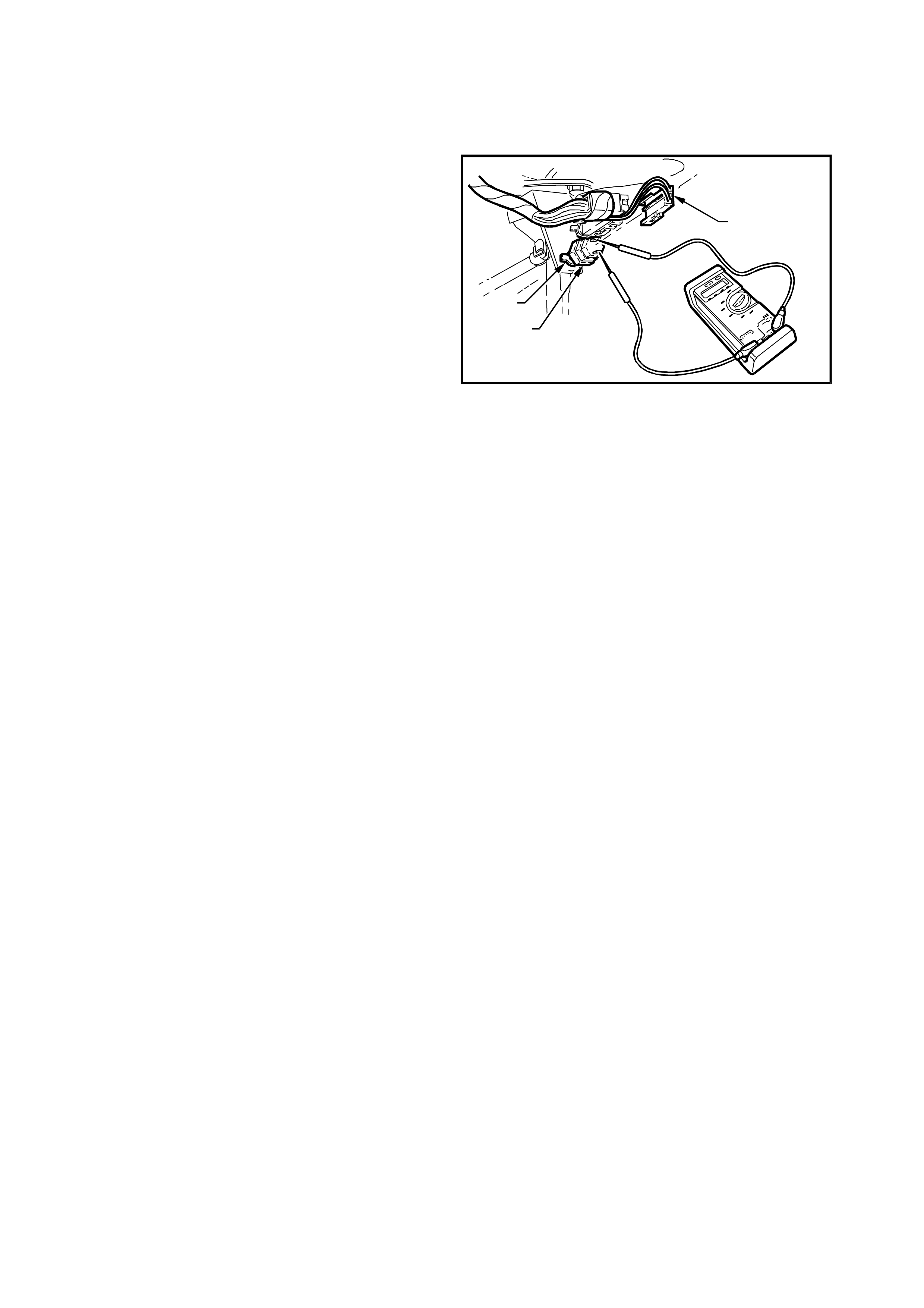

1. Rem ove the wiring harnes s connector fr om the

terminals of the clutch switch.

2. Connect an ohmmeter across the switch

term inals (1) and the ohm m eter should indic ate

continuity with the clutch pedal at rest.

3. Press the clutch pedal and the ohmmeter

should indicate an open circuit.

4. Replace the switch as per the following

removal procedure if the tests prove the switch

to be faulty.

5. If the test proves the switch to be serviceable,

connect the wiring harness connector to the

switch.

T212E040

1

Figure 12E-39

REMOVE

1. Remove the instrument panel lower trim

assembly and the instrument panel lower trim

retainer plate. Refer to Section 1A3,

INSTRUMENT PANEL & CONSOLE.

2. Dis connect the wiring harness c onnectors from

the switch.

3. Turn the switch 90°, then pull the switch

assembly out from the pedal support to

remove.

REINSTALL AND ADJUST

1. Install the new switch by pushing the switch

assembly through the pedal support and

turning the switch 90°.

2. Hold the clutch pedal at its rest position.

3. Connect the wiring harness connectors to the

clutch switch.

4. Install the instrument panel lower trim assembly

and the instrument panel lower trim retainer

plate. Refer to Section 1A 3, INSTRUMENT

PANEL & CONSOLE.

5. Verify the operation of the clutch switch by

operating the cruise control and checking that

the clutch switch stops operation of the cruise

control when the clutch pedal is pressed.

3. DIAGNOSIS

3.1 PRELIMINARY DIAGNOSIS AND INSPECTION

NOTE: If a vehic le is fitted with traction contr ol, the cruise control system will disengage or fail to engage whenever

the LOW TRAC icon is displayed on the instrum ent cluster MFD, and will not engage or re-engage until the LOW

TRAC icon turns off.

When a vehicle is sus pected of having a cruis e control s ystem operation malf unction, it is im portant to carr y out the

following preliminary diagnosis. This diagnosis should be used to determine whether the cruise control system

problem is the result of an actual system defect, or the result of a problem with some other vehicle component.

Also, s om e c ruise control system c om plaints m ay be a misunders tanding by the driver about how the cruise contr ol

system f unctions . In that c as e, the operation of the s ystem should be ex plained in a manner the dr iver unders tands .

A practical demonstration is very useful to explain system operation.

If it is decided the cruise control system is at fault, perform a visual inspection of all components in the system.

Cruise control system malfunctions can be caused by mechanical, electrical, or a combination of both problems.

Things to check are:

1. Switch inputs to the cruise control module.

2. Dirty, corroded, or loose electrical connections.

3. Damaged or incor rectly adjusted stop lam p switch (Switch A). Refer to 2.4 ST OP LAMP SWITCH (SW IT CH A)

in this Section for test and adjustment procedure.

4. Damaged or incorrectly adjusted electrical release switch (Switch B). Refer to 2.5 ELECTRICAL RELEASE

SWITCH (SWITCH B) in this Section for test and adjustment procedure.

5. Damaged or inoper ative clutch pedal s witch. Refer to 2.6 CLUT CH PEDAL SWITCH in this Sec tion f or tes t and

adjustment procedure.

6. Binding or sticking throttle linkage.

7. Broken components (eg. cruise control cable).

8. Bare, broken or disconnected wires.

9. Adjustment of the control cable, refer to 2.1 CRUISE CONTROL CABLE in this Section.

10. On vehicles fitted with GEN III V8 engine and traction control, ensure that the throttle relaxer is functioning

correctly. Refer to Section 12L, ABS AND ABS/ETC.

11. If pr elim inary inspection reveals no problem , and the s ystem is m alfunc tioning, refe r to 3.3 SELF DIAGNOSTIC

TEST in this Section.

NOTE: Verify that the problem exists before attempting any repairs. Sometimes normal operating characteristics

may be misunderstood as a problem.

3.2 CRUISE CONTROL SYSTEM FUNCTIONAL CHECK

The f ollowing procedure s hould be used to chec k the oper ating m odes of the cruis e control s ystem. T his procedure

should always be used after repair work has been completed on the cruise control system.

ROAD TEST PROCEDURE

1. Check ON-OFF activation: Ignition on, press the cruise control ON-OFF push-button to turn the system on;

system CRUISE icon should illuminate.

2. Check the low speed inhibit: Drive the vehicle at 30 km/h. Rotate the CRUISE switch to the SET-DECEL

position and release. Cruise control must not engage and only the CRUISE icon should be illuminated.

3. Check set speed: Drive the vehicle at a steady speed of 60 km/h. Rotate the CRUISE switch to the

SET-DECEL position and release. The cruise control should engage at approximately 60 km/h and both the

CRUISE and ACTIVE icons must illuminate.

4. Check b rake release: With the cruis e c ontrol system engaged, pr ess the br ak e pedal. The c ruise c ontrol m ust

release the throttle, allowing vehicle speed to drop. The system must not re-engage when the brake pedal is

released. The ACTIVE icon must go out but the CRUISE icon should remain on.

5. Check clu tch release (manual t ransmission only): With the cruis e control system engaged, pr ess the clutch

pedal. The c ruise control m ust r elease the throttle, allowing the vehicle speed to drop. The system m ust not re-

engage when the clutch pedal is released. The ACTIVE icon must go out but the CRUISE icon should remain

on.

6. Check resume feature: With the vehicle speed at approximately 50 km/h, rotate the CRUISE switch to the

RES-ACCEL position and release. The vehicle should accelerate to approximately 60 km/h and the CRUISE

and ACTIVE icons should illuminate again.

7. Check coast feature: Rotate the CRUISE switch to the SET-DECEL position and hold. Only the ACTIVE icon

must go out. Allow the vehicle speed to drop to 50 km/h and release the CRUISE switch. The cruise control

should hold the vehicle speed at approximately 50 km/h and both the ACTIVE and CRUISE icons should be

illuminated.

8. Check accelerator feature: Rotate the CRUISE switch to the RES-ACCEL position and hold. The vehicle

speed should begin to increase. Allow the speed to increase to 60 km/h and release the switch. The cruise

control s hould hold the vehicle s peed at approximately 60 km /h. Both the ACT IVE and CRUISE ic ons should be

illuminated.

9. Check coast down mode:

a) Press and release the ON-OFF push-button. The vehicle should begin to slow down (this has the same effect

as holding the CRUISE switch in the SET-DECEL position). In this m ode, the cruise is deactivated and allows

the vehicle to slow down but the CRUISE icon remains illuminated. Allow the vehicle to slow to approximately

50 km/h then rotate the CRUISE switch to the RES-ACCEL position and release. The vehicle must return to

approximately 60 km/h and both the CRUISE and ACTIVE icons should be illuminated.

b) Press and release the ON-OFF push-button and allow vehicle to slow to approximately 50 km/h again then

rotate the CRUISE switch to the SET-DECEL position. The vehicle speed must hold at 50 km/h and both the

CRUISE and ACTIVE icons should be illuminated.

c) Press the ON-OFF pus h-button again and allow the vehicle to coast down. Only the CRUISE icon should be

illuminated.

d) Press the ON-OFF push-button again while in coast down mode (Step c) to fully turn the cruise control

system off. Both the CRUISE and ACTIVE icons must go out.

3.3 SELF DIAGNOSTIC TEST

To provide a means of checking the brake switch, clutch switch, cruise release switch, speed sensor inputs and

electro-motor operation, the cruise control system incorporates a self diagnostic facility.

Following the SELF DIAGNOSTIC TEST CHART is a detailed Diagnostic Chart to pin point the cause of a cruise

control system malfunction. Refer to 3.5 CRUISE CONTROL SYSTEM DIAGNOSTIC CHART in this Section.

Carry out the Self Diagnostic Test as outlined.

Jack up the vehicle and support on saf ety stands. Ref er to Section 0A GENERAL INFORMAT ION f or the location

of jacking points. Ensure that the drive shafts are horizontal.

Follow Steps 1 – 23 in the SELF DIAGNOSTIC TEST CHART and perform each function as requested. If at any

stage during this tes t the system does not func tion as nominated (CRUISE or ACTIVE icon illum ination), repair the

fault as necessary.

NOTE: If at any time during Steps 1 – 23 of the diagnos tic test the ignition is switched off , the cruise control system

will exit diagnostic mode and return to normal operating conditions.

Self Diagnostic Test Chart ICONS

(Refer to Figure 12E-40)

STEP PROCEDURE

CRUISE ACTIVE

COMMENTS

1 Turn ignition OFF OFF OFF Clears memory of any pre-set speed.

2 Press and hold in the ON-OFF push-button OFF OFF

3 Turn ignition ON ON OFF Triggers diagnostic test. ON-OFF push-

button must be held until Step 13.

4 Wait 5 seconds ON OFF Waits for LOW TRAC warning icon to

switch OFF (if fitted).

5 Rotate and hold SET-DECEL position ON ON

6 Release SET-DECEL position ON OFF Tests SET-DECEL function of cruise

control switch assembly.

7 Rotate and hold RES-ACCEL position ON ON

8 Release RES-ACCEL position ON OFF Checks RES-ACCEL function of cruise

control switch assembly.

9 Press and hold brake pedal ON ON

10 Release brake pedal ON OFF Checks cruise control electrical release

switch (switch B).

11 Press and hold clutch pedal (man. trans.)

brake pedal (auto. trans.) ON ON

12 Release clutch pedal (man. trans.) brake

pedal (auto. trans.) ON OFF

This Step is included for vehicles with

manual transmission. If the vehicle is

fitted with automatic transmission, then

the brake pedal must be pressed and

released to enable the completion of

the switch diagnostic test.

13 Release ON-OFF push-button ON ON

14 Press and hold in the ON-OFF push-button OFF OFF Enters the second stage of the

diagnostic mode to check the ON-OFF

switch and cruise control warning

icons.

15 Press and hold brake pedal OFF ON

16 Release brake pedal OFF OFF

17 Press and hold brake pedal OFF ON

18 Release brake pedal OFF OFF

Checks stop lamp switch (switch A)

and cruise control switch inputs to

cruise control module. If not

functioning, repair as necessary.

19 Release ON-OFF push-button OFF ON Enters final stage of diagnostic mode,

allowing vehicle to be road tested

without having to hold cruise control

function buttons.

20 Press and hold brake pedal after motor

stroking OFF

OFF

OFF

ON

Checks stepper motor and cable

operation.

Stepper motor will stroke and return to

rest (closed throttle) state. If not

functioning, repair as necessary.

21 Hold brake pedal and start engine OFF X ACTIVE icon can be either ON or OFF.

22 Select DRIVE, drive vehicle and monitor

ACTIVE icon OFF FLASH ACTIVE icon will flash with vehicle

speed signal.

Checks speed sender input to cruise

control module. If not functioning as

specified, replace cruise control

module.

23 Select PARK (auto. trans.), 1st gear (man.

trans.) and switch engine OFF OFF OFF Ends diagnostic mode. Returns cruise

control to normal operating conditions.

Legend

1. Cruise Text Message

2. Flashing Set Arrow

3. Cruise Symbol

4. CRUISE Icon

5. ACTIVE Icon

Figure 12E-40

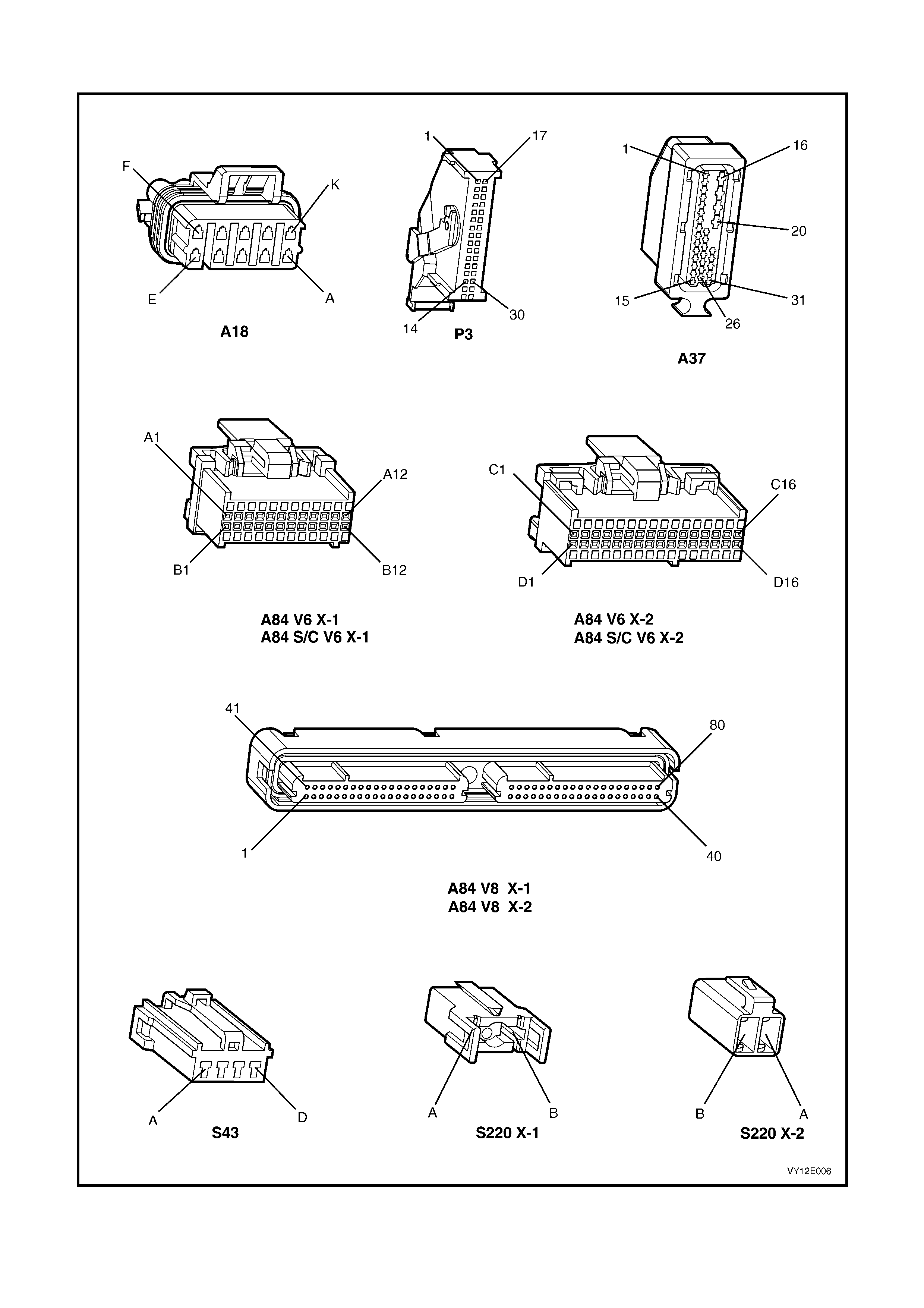

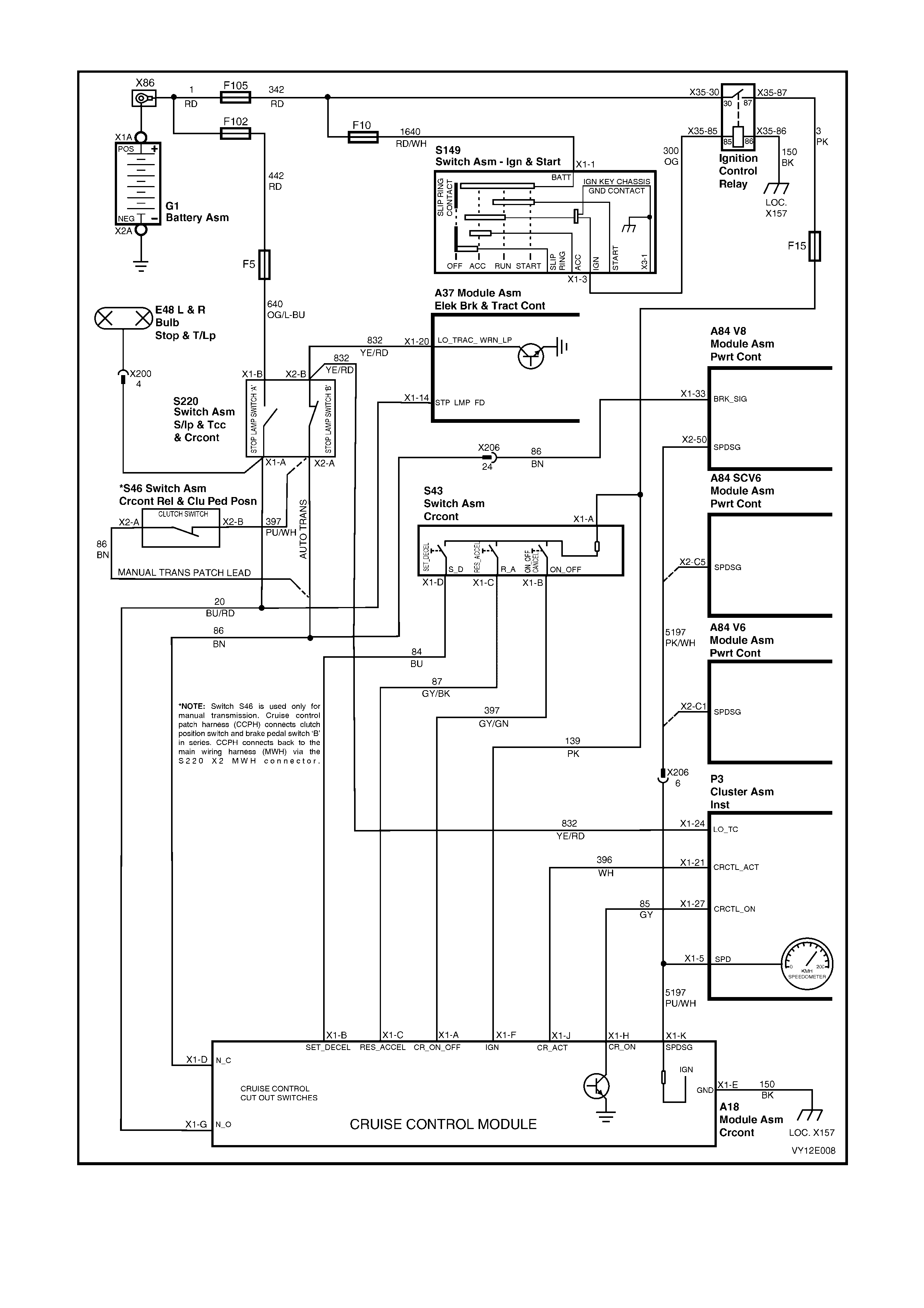

3.4 CRUISE CONTROL SYSTEM CONNECTORS AND CIRCUIT DIAGRAM

Figure 12E-41

Figure 12E-42

Figure 12E-43

3.5 CRUISE CONTROL S YSTEM DIAGNOSTIC CHART

When using the following diagnostic chart, refer also to the cruise control system circuit diagram and connectors

(refer to Figure s 12E-41, 12E-42 and 12E-43).

TEST DESCRIPTION

The numbers below refer to Step numbers in the diagnostic chart for the cruise control system.

1. Checks ignition supply to the cruise control module.

2. Checks for ground circuit 150 to the cruise control module.

3. Checks circuits 84 and 87.

4. Checks if the fault is in circuits 84 and 87, or with the cruise control module.

5. Checks RES-ACCEL function on the cruise control switch assembly.

6. Checks for ignition supply to the cruise control switch.

7. Checks RES-ACCEL function of the cruise control switch.

8. Checks power supply to the cruise control module at SET-DECEL input.

9. Checks SET-DECEL function of the cruise control switch.

10. Determ ines if the f ault is with the cruise c ontrol module to the ins trum ent cluster interface or with the stop lam p

switch inputs.

11. Checks the cruise control interface to the instrument cluster.

12. Checks circuit 85 for an open circuit.

13. Checks for faulty a stop lamp switch (Switch A).

14. Checks for a faulty electrical release switch (stop lamp Switch B) and the clutch switch.

15. Checks operation of the ACTIVE icon.

16. Determines if the fault is in circuit 396 or in the instrument cluster.

17. Checks for a fault in circuit 5197 and/or PCM.

18. Checks the operation of the cruise control system during road test.

19. Visual checks of the cruise control cable for damage and adjustment.

20. Further diagnostic test that can be performed to help isolate any malfunctions within the system.

Cruise Control System Diagnostic Chart

STEP ACTION VALUE(S) YES NO

1 1. Ignition OFF.

2. Disconnect connector A18 from cruise control

module.

3. Ignition ON.

4. Measure voltage between terminal X1-F, circuit 139

(Pink wire) and a good ground.

Is voltage as specified?

Approx.

12 volts Go to Step 2. Check and repair

open in circuit

139 between

(and including)

fuse F15 and

connector A18.

2 1. Ignition OFF.

2. With connector A18 still disconnected from cruise

control module, check for continuity between cruise

control module connector A18, terminal X1-E,

circuit 150 (Black wire) and ground location E3

(connector X157, terminal X1-4).

Does continuity exist?

—

Go to Step 3. Check and repair

open in

circuit 150.

3 1. Ignition ON.

2. Measure voltage at connector A18, terminal X1-B,

circuit 84 (Blue wire) and terminal X1-C, circuit 87

(Grey/Black wire) to ground.

Is voltage as specified at either terminal?

Less than

1 volt Go to Step 5. Go to Step 4.

4 1. Ignition ON.

2. Disconnect cruise control switch assembly

connector S43 and measure voltage at terminals

X1-B and X1-C to ground on connector A18 again.

Is voltage as specified at either terminal?

Less than

1 volt Replace cruise

control switch

assembly, refer

to 2.3 CRUISE

CONTROL

SWITCH

ASSEMBLY in

this Section.

Check and repair

short to voltage

in circuit 84

and/or 87.

STEP ACTION VALUE(S) YES NO

5 1. Ignition ON.

2. Rotate and hold the CRUISE switch in the

RES-ACCEL position on cruise control switch

assembly.

3. Measure voltage between connector A18, terminal

X1-C, circuit 87 (Grey/Black wire) and ground.

Is voltage as specified?

Greater than

9 volts Go to Step 8. Go to Step 6.

6 1. Ignition OFF.

2. Disconnect cruise control switch assembly

connector S43.

3. Ignition ON.

4. Measure voltage between connector S43, circuit

139 (Pink wire) and ground.

Does voltage exist?

Approx.

12 volts Go to Step 7. Check and repair

open in circuit

139 between

(and including)

fuse F15 and

connector S43.

7 1. Ignition OFF.

2. Disconnect cruise control switch assembly

connector S43.

3. Rotate and hold the CRUISE switch in the

RES-ACCEL position and check for continuity

between terminal X1-A (Black wire) and terminal

X1-C (Yellow wire) on cruise control switch

assembly.

Is resistance as specified?

Approx.

470 ohms Check and repair

open in

circuit 87.

Replace cruise

control switch

assembly, refer

to 2.3 CRUISE

CONTROL

SWITCH

ASSEMBLY in

this Section.

8 1. Ignition ON.

2. Connect cruise control switch assembly connector

S43.

3. Rotate and hold the CRUISE switch in the

SET-DECEL position on cruise control switch

assembly.

4. Measure voltage between connector A18, terminal

X1-B, circuit 84 (Blue wire) and a good ground.

Is voltage as specified?

Greater than

9 volts Go to Step 10. Go to Step 9.

9 1. Ignition OFF.

2. Disconnect cruise control switch assembly

connector S43.

3. Rotate and hold the CRUISE switch in the

SET-DECEL position and check for continuity

between terminal X1-A (Black wire) and terminal

X1-D (White wire) on cruise control switch

assembly.

Is resistance as specified?

Approx.

470 ohms Check and repair

open in

circuit 84.

Replace cruise

control switch

assembly, refer

to 2.3 CRUISE

CONTROL

SWITCH

ASSEMBLY in

this Section.

10 1. Ignition OFF.

2. Connect cruise control switch connector S43 and

cruise control module connector A18.

3. Ignition ON.

4. Repeatedly press the cruise ON-OFF push-button.

Does the CRUISE icon, text and symbol in the

instrument cluster MFD toggle between the on and off

representation with switch operating?

—

Go to Step 13. Go to Step 11.

11 1. Ignition OFF.

2. Disconnect connector P3 from the instrument

cluster and probe the instrument cluster connector

P3, terminal X1-27, circuit 85 (Grey wire) with a

voltmeter to ground.

3. Ignition ON.

4. Repeatedly press the cruise ON-OFF push-button

again.

Does the voltage vary as specified?

Switch

pressed:

approx.

12 volts

Switch

released:

approx.

7 volts

Check connector.

Replace

instrument panel

cluster, refer to

Section 12C,

INSTRUMENTS.

Go to Step 12.

12 1. Ignition OFF.

2. Disconnect connector A18 from cruise control

module.

3. Check for continuity between connector A18,

terminal X1-H and connector P3, terminal X1-27,

circuit 85 (Grey wire).

Does continuity exist?

—

Replace cruise

control module

assembly, refer

to 2.2 CRUISE

CONTROL

MODULE

in this Section.

Repair open in

circuit 85.

STEP ACTION VALUE(S) YES NO

13 1. Remove connector A18 from cruise control module.

2. Ignition ON.

3. Measure voltage at connector A18, terminal X1-G,

circuit 20 (Blue/Red wire) to ground.

Is voltage as specified?

Less than

1 volt Go to Step 14. Check operation

of stop lamp

switch (switch A).

In particular, look

for improperly

adjusted stop

lamp switch.

Repair as

necessary.

14 1. With connector A18 still disconnected from cruise

control module and ignition ON, measure voltage at

connector A18, terminal X1-D, circuit 86 (Brown

wire) to ground.

Is voltage as specified?

Approx.

12 volts Go to Step 15. Check operation

of electrical

release switch

(switch B) and

clutch switch. In

particular, look

for improperly

adjusted

switches or

check for open in

circuit 86. Repair

as necessary.

15 1. With connector A18 still disconnected from cruise

control module and ignition ON (using an

appropriate jumper lead from J35616-A) place a

short between cruise control connector A18,

terminal X1-J and ground.

Does the cruise control ACTIVE icon, text and symbol

illuminate in the instrument cluster MFD?

—

Go to Step 17. Go to Step 16.

16 1. Ignition OFF.

2. Disconnect connector P3 from instrument cluster.

3. Check for continuity between connector A18,

terminal X1-J and connector P3, terminal X1-21,

circuit 396 (White wire).

Does continuity exist?

—

Check connector.

Replace

instrument

cluster, refer to

Section 12C,

INSTRUMENTS.

Repair open in

circuit 396.

17 1. Jack up rear of vehicle and support on safety

stands.

2. Back probe cruise control module connector A18,

terminal X1-K, circuit 5197 (Purple/White wire) with

a voltmeter to ground.

3. Ignition ON.

4. Spin rear wheels by hand.

Does voltage vary as specified?

Varies from

less than

1 volt to

greater than

10 volts

Go to Step 18.

Check for open

or short to

ground in circuit

5197

(Purple/White

wire) between

PCM and cruise

control module

connector A18.

NOTE: If circuit

5197 is OK, refer

to PCM

DIAGNOSIS in

Section

6C1 (V6),

6C2 (V6 S/C), or

6C3 (GEN III V8.

18 1. Connect all electrical connectors.

2. Drive vehicle at approximately 50 km/h and rotate

the CRUISE switch to the SET-DECEL position to

set vehicle speed.

Does the cruise fail to hold speed?

Go to Step 19. System OK.

19 1. Check condition and adjustment of cruise control

cable, refer to 2.1 CRUISE CONTROL CABLE in

this Section.

Is cable OK?

Go to Step 20. Adjust or replace

the cruise control

cable as

necessary, refer

to 2.1 CRUISE

CONTROL

CABLE in this

Section.

20 1. Perform switch diagnostic test, refer to 3.3 SELF

DIAGNOSTIC TEST, SWITCH DIAGNOSTIC

TEST CHART in this Section.

Does test highlight a fault with the system?

Repair fault as

necessary. Replace cruise

control module

assembly, refer

to 2.2 CRUISE

CONTROL

MODULE in this

Section.

WHEN ALL DIAGNOSIS AND REPAIRS ARE COM PLETE, VERIFY CORRECT OPERATION

4. TORQUE WRENCH SPECIFICATIONS

Nm

Engine Dress Cover Dome Nut ............................................ 4 – 6

Cruise Control Module Securing Screw................................ 2 – 5

§

Fasteners must be replaced after loosening.

• Vehicle mus t be at curb height before final tightening.

♦ Fasteners either have micro encapsulated sealant applied or incorporate a mechanical

thread lock and should only be re-used once. If in doubt, replacement is recommended.

5. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASSIFICATION

J35616-A

(KM609)

CONNECTOR TEST ADAPTOR

KIT

Used when carrying out electrical

diagnostic circuit checks.

Previously released.

Desirable

3588

(J39200)

DIGITAL MULTIMETER

Must have at least 10 MΩ input

impedance and be capable of

reading frequencies.

Previously released.

Available