SECTION 12H - REAR-VIEW MIRRORS

IMPORTANT

Before p erforming any Serv ice Operation or other procedure d escribed in this Section , refer to Section 00,

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

1.1 INTERIOR MIRROR OPERATION

DAY/NIGHT SETTING

1.2 CONTROL SWITCH OPERATION

TILT DOWNWARDS

TILT UPWARDS

TILT OUTWARDS

TILT INWARDS

LH VS. RH MIRROR OPERATION

2. SERVICE OPERATIONS

2.1 EXTERIOR MIRROR ASSEMBLY

REMOVE

TEST

REINSTALL

2.2 EXTERIOR MIRROR GLASS

REMOVE

REINSTALL

2.3 MIRROR CONTROL SWITCH

REMOVE

TEST THE SWITCH CONTACTS

REINSTALL

2.4 INTERIOR REAR-VIEW MIRROR

REMOVE

REINSTALL

3. DIAGNOSIS

ELECTRIC MOTOR INOPERATIVE

DIAGNOSTIC CHART

EXTERIOR MIRROR LOSS OF FUNCTION

DIAGNOSTIC CHART

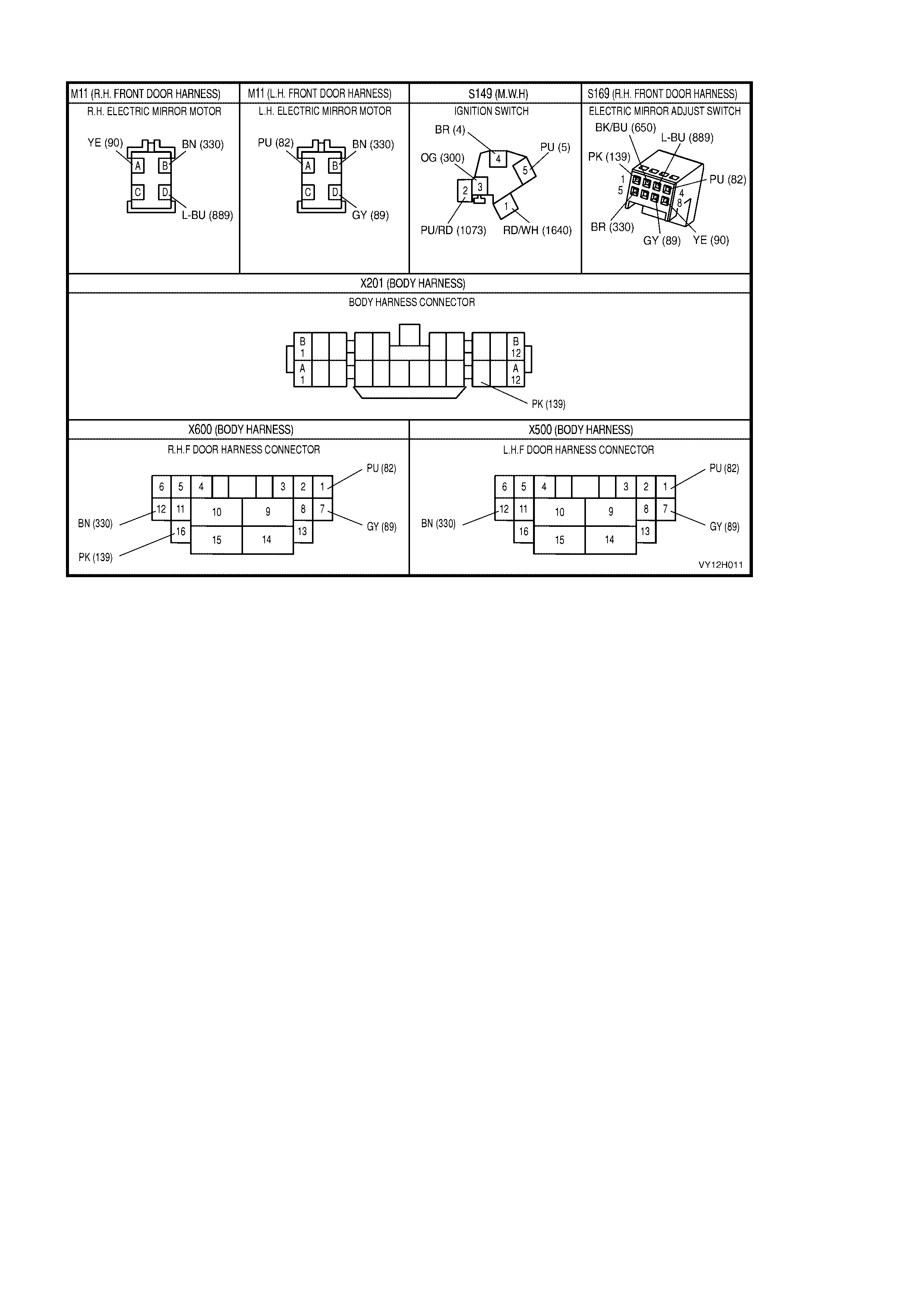

CONNECTOR DIAGRAM – RIGHT-HAND

DRIVE

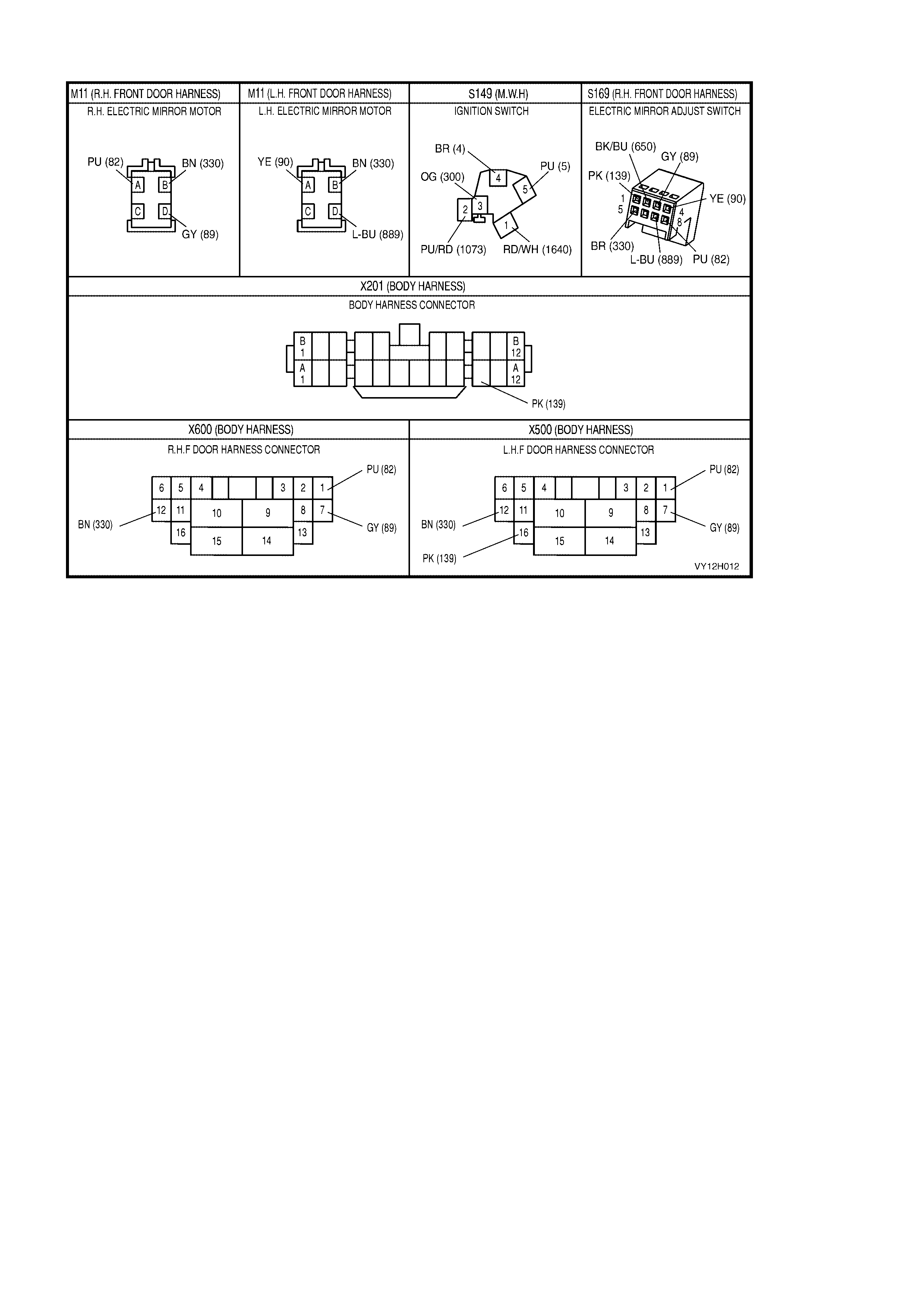

CONNECTOR DIAGRAM – LEFT-HAND DRIVE

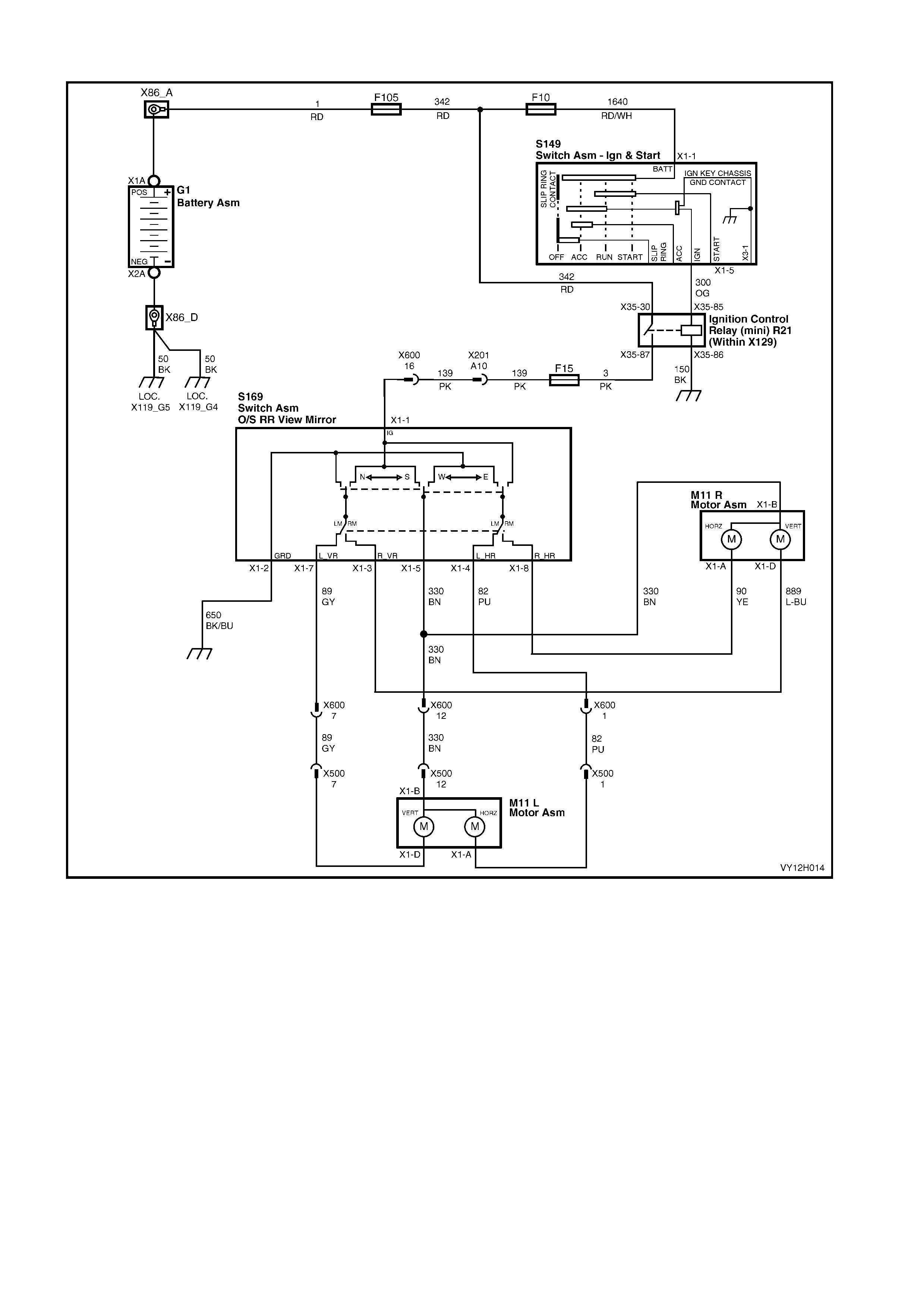

CIRCUIT DIAGRAM – RIGHT-HAND DRIVE

CIRCUIT DIAGRAM – LEFT-HAND DRIVE

4. TORQUE WRENCH SPECIFICATIONS

5. SPECIAL TOOLS

1. GENERAL I NFORMATION

Electrically adjustable exterior rear-view mirrors are fitted as standard equipment on all VY Series Models.

Each exterior mirror assem bly has two reversible m otors: one to tilt the mirror face up and down (vertical position)

and one to tilt the mirror face left and right (horizontal position).

The ex terior rear-view m irrors are adjusted electr ically from ins ide the vehicle using the mirror control switch, whic h

is mounted in the driver’s door pull-handle.

Replacement exterior rear-view mirror assemblies are available in Black. These are made of acrylate styrene

acrylonitrile (ASA) plastic. Replacement assemblies requiring a colour-coded contrast need to be masked and

painted using correct refinishing procedures as outlined by the paint manufacturer.

The interior rear-view mirror is manually adjusted to suit the driving position. Models fitted with production option

UE1 (Comm unication System Te lem atics) have som e c om ponents of this system installed into the rear-view mirror.

Refer to Section 12K, TELEMATICS for service information relating to the interior rear-view mirror of these models.

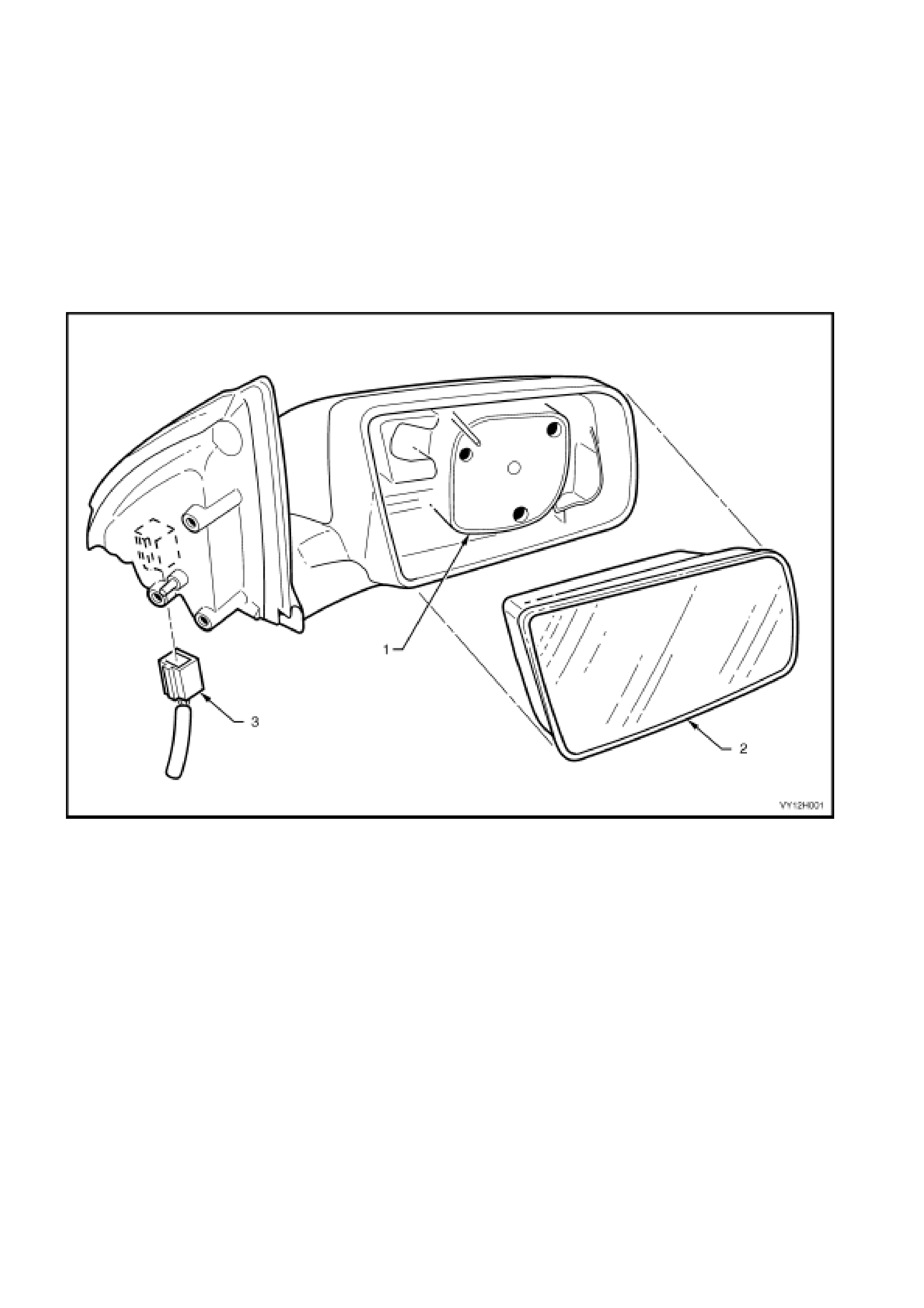

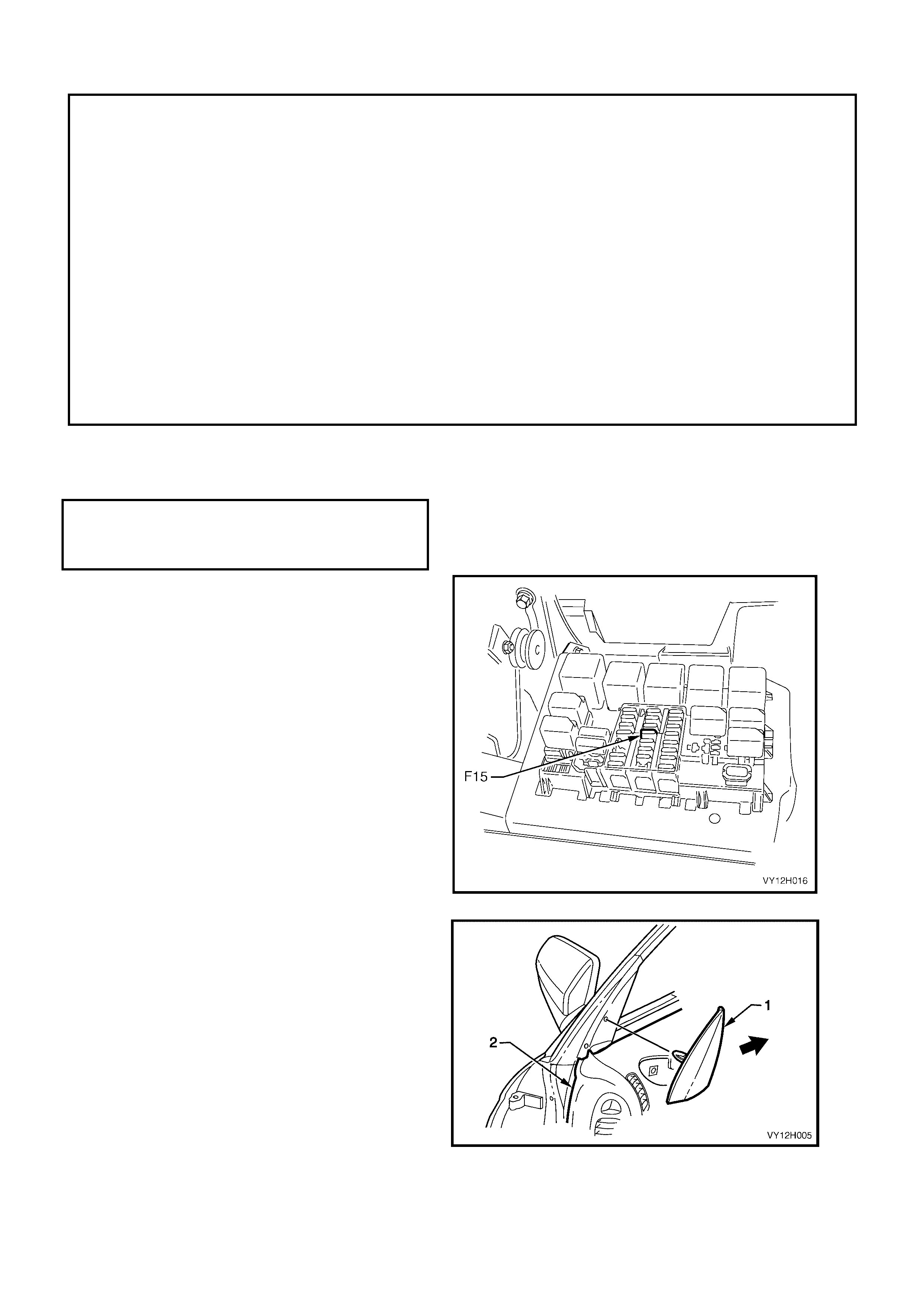

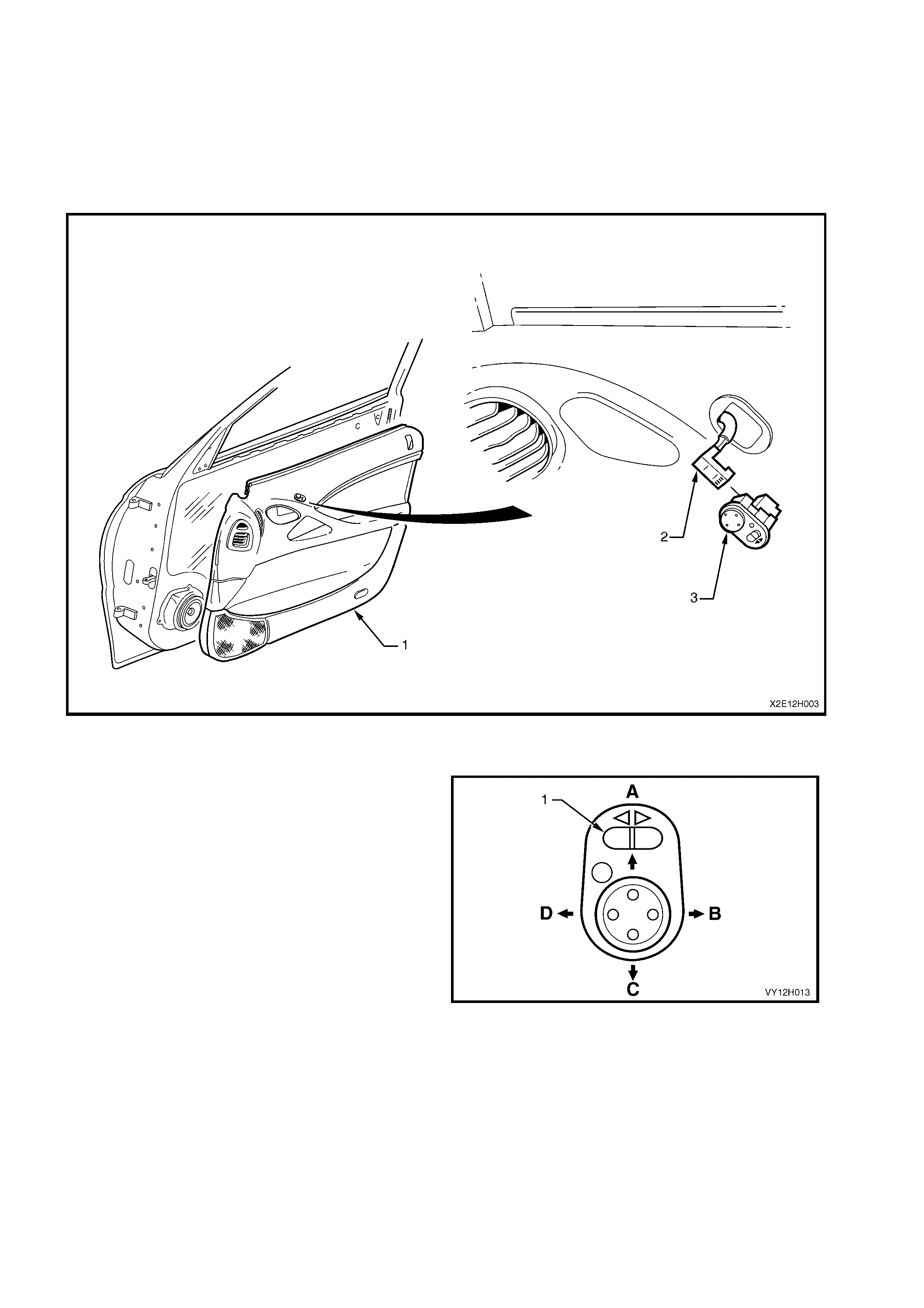

Figure 12H-1

Legend

1. Vertical and horizontal motor housing

2. Mirror glass

3. Mirror harness connector

1.1 INTERIOR MIRROR OPERATION

For vehicle models fitted with production option UE1 (Communication System Telematics), refer to

Section 12K, TELEMATICS.

DAY/NIGHT SETTING

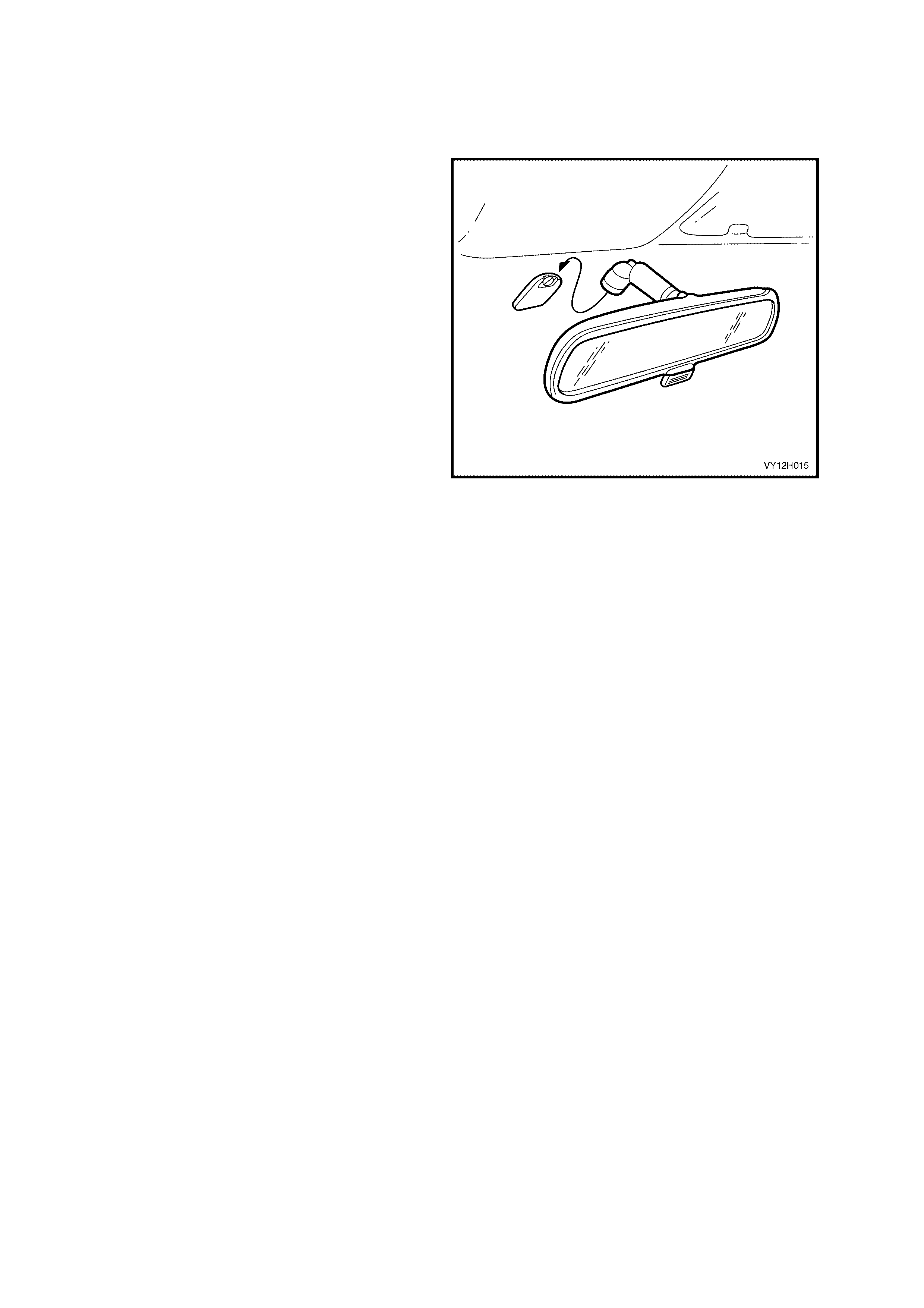

A lever is fitted at the base of the interior rear-view

mirror. When the lever is pulled to the forward

position, the fac e of the m ir ror tilts slightly upwar ds.

This maintains rear vision but reduces the glare of

reflected light for night-time driving. The lever

should be reset to the rearward position for all

daytime driving.

Figure 12H-2

1.2 CONTROL SWITCH OPERATION

The exterior-mirror control switch has two controls:

a slide-select switch (1) (with left mirror and right

mirror positions) and a directional toggle switch (2)

to control the direction of adjustment.

The dire ctional toggle switch is designed to operate

in only one direction at a time and is activated by

pressing the edge of the toggle in the required

direction.

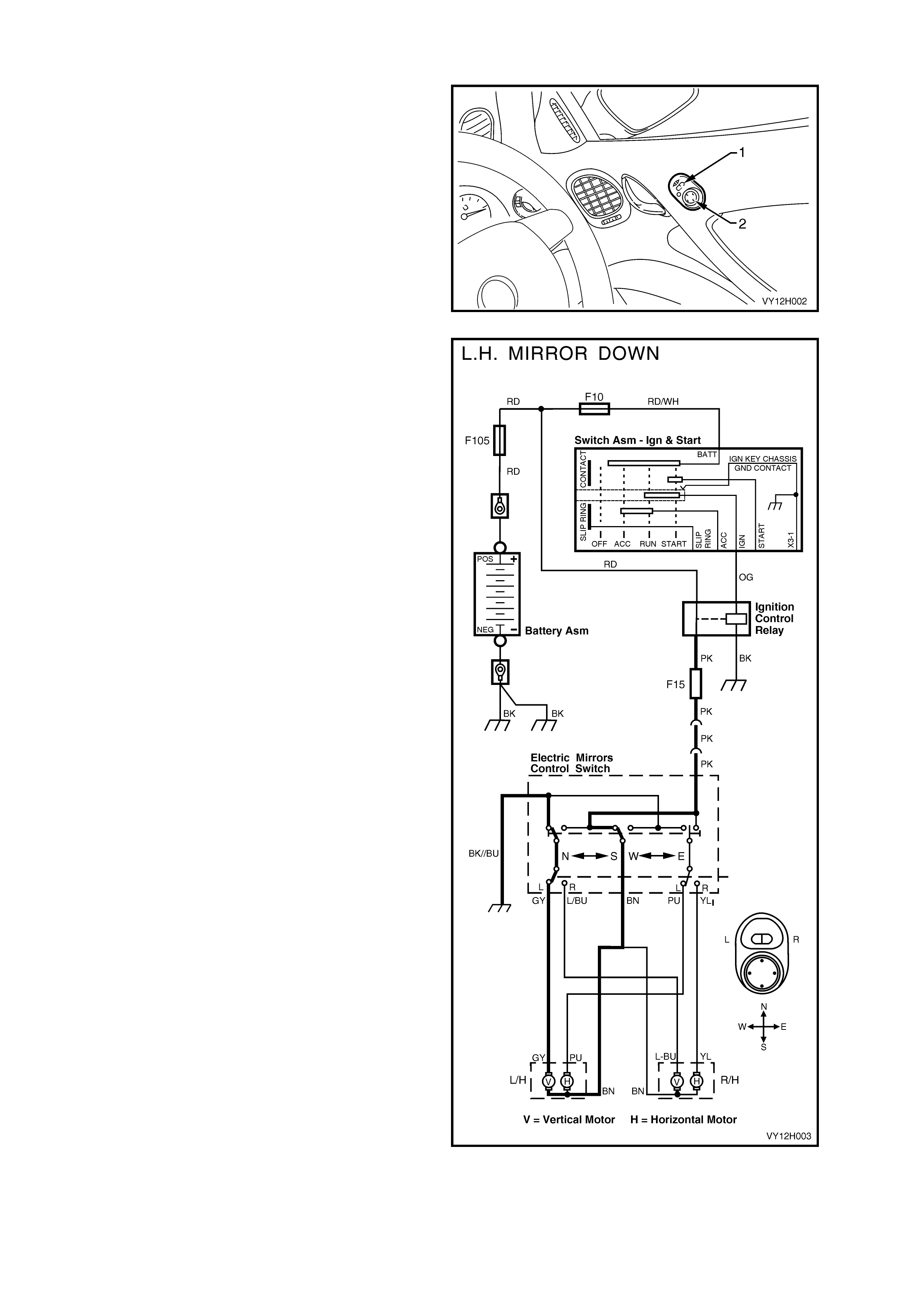

Figure 12H-3

TILT DOWNWARDS

With the switches positioned as shown in

Figure 12H-4, the LH exterior mirr or is selected and

the toggle switch is set to activate the vertical

position motor to tilt the mirror DOWNWARDS.

The following circuit is activated.

Battery voltage is supplied to the toggle switch

contacts via fuse F15. This voltage is applied via

circuit 330 (Brown wire) to one side of the vertical

position motor. The circuit is completed on the

other s ide of the LH ver tic al pos ition motor, with the

following path to ground:

• through circuit 89 (Grey wire)

• to the LH side select-switch contacts

• through the toggle switch directional contacts

and

• circuit 650 (Black / Blue wire) to ground.

This activates the vertical position motor until the

directional toggle switch is released.

TILT UPWARDS

When the toggle switch is pressed to move the

mirror UPWARDS, it switches the circuit so that

voltage is applied to the same motor, but in the

opposite direction.

That is, from fuse F15 to the toggle switch then

through the select s witch c ontacts and via c irc uit 89

to the motor.

The path to ground is now via circuit 330 to the

toggle switch contacts, then through circuit 650 to

ground.

Figure 12H-4

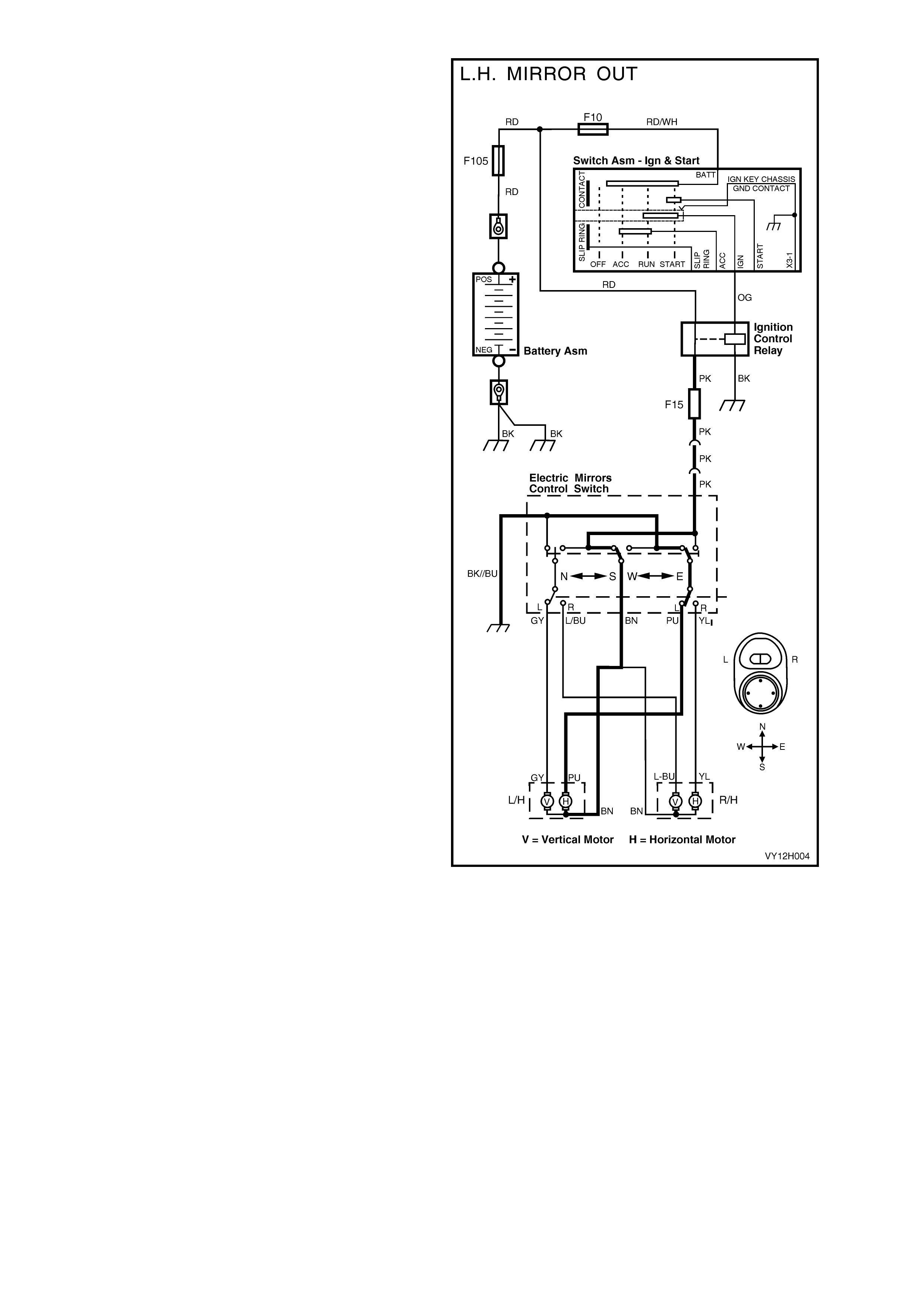

TILT OUTWARDS

When the directional switch is pressed in the

OUTWARD position, the circuit in Figure 12H-5 is

activated as follows:

Battery voltage from fuse F15 is supplied through

the directional centre contacts of the toggle switch

and circuit 330 (Brown wire) to one side of the

horizontal mirror motor.

The LH mirror horizontal position motor has a path

to ground through:

• circuit 82 (Purple wire)

• the LH side select switch contacts

• the directional contacts

• circuit 650 (Black / Blue wire) to ground.

This energises the LH m irror horizontal m otor to tilt

the mirror OUTWARDS until the toggle switch is

released.

TILT INWA RDS

W hen the directional toggle switch is pressed to tilt

the mirror INWARDS, the LH mirror horizontal

motor is supplied voltage in the opposite direction.

Power to the motor is supplied through the

directional and LH side select switch c ontacts, then

through circuit 82 (Purple wire). The motor is

grounded though circuit 330 (Brown wire) and the

directional switch c ontacts, then through circuit 650

(Black / Blue wire).

LH vs. RH MIRROR OPERATION

The RH motors operate by the same principles as

the LH motors (outlined previously).

By moving the side-select switch to adjust the RH

side mirror, power and ground connections are

made as for the LH side, but using different wires

(different circuit numbers).

To tilt the RH mirror DOW N, power is supplied via

circuit 889 (Light Blue wire) and grounded via

circuits 330 (Brown wire) and 650 (Black wire).

To tilt the RH m irror UP, power is supplied through

circuit 330 and grounded via circuits 889 and 650.

To tilt the RH mirror OUT, power is supplied

through circuit 90 and grounded via circuits 330

and 650.

To tilt the RH mirror IN, power is supplied through

circuit 330 and grounded via circuits 90 and 650.

Figure 12H-5

2. SERVICE OPERATIONS

IMPORTANT

All fasteners are important attaching parts as they affect the performance of components and failure

could result in major repair. Where specified in this section, fasteners MUST be replaced with parts of

the same part number or a GM approved equivalent. Do not use fasteners of an inferior quality or

substitute des ign.

Torque values must be used as specified during reassembly to ensure proper retention of the

components.

Throughout this section, fastener torque specifications may be accompanied by the following

identification marks:

+

++

+ Fasteners must be replaced after loosening.

&

&&

& Vehicle must be at curb height before final tightening.

6

66

6 Fasteners either have micro encapsulated sealant applied or incorporate a mechanical thread lock

and

should only be re-used once. If in doubt, replacement is recommended.

These recommendations must be adhered to.

2.1 EXTERIOR MIRROR ASSEMBLY

LT Section No. – 10-400

NOTE: The following fasteners MUST be replaced

when performing this operation:

+

++

+ Exterior-mirror assembly retaining screws.

REMOVE

1. Remove fuse F15 from the interior fuse panel.

Figure 12H-6

2. Remove the mirror inner dress cover (1) by

gently prying the cover away from the door and

sliding it back (towards the side window).

3. Pull the door demist duct (2) up and out of the

door trim panel.

Figure 12H-7

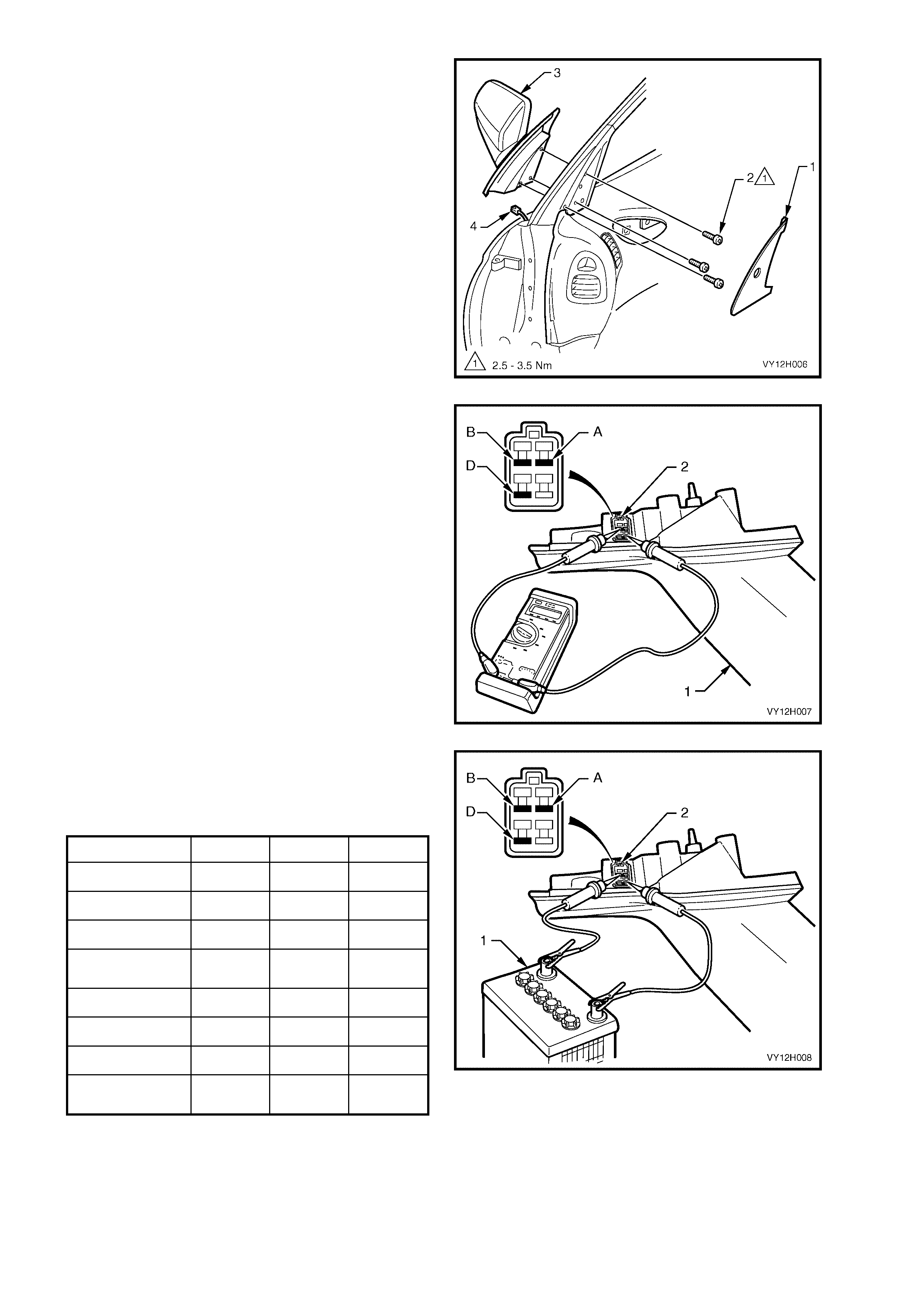

4. Remove the dust cover (1).

5. Remove the door trim to gain access to the

retaining screws. Refer to Section 1A5,

FRONT AND REAR DOOR ASSEMBLIES.

6. Remove the three screws (2) securing the

mirror to the door.

7. While supporting the mirror assembly (3),

disconnect the mirror wiring harness connector

(4).

8. Remove the mirror assembly.

Figure 12H-8

TEST

The following operations are performed with the

mirror assembly (1) removed from the vehicle.

1. Check the mirror assembly horizontal and

vertical motors . If the following operations prove

that a mirror component is faulty, replace the

mirror assembly.

2. Connect an ohmmeter to the electric mirror

connector (2) to check the continuity of the

wiring between the following terminals:

$%A and B

$%A and D

$%B and D.

3. If the ohmmeter indicates an open circuit or a

resistance of more than 200 ohms between

these terminals, replace the mirror assembly.

Figure 12H-9

4. Connect the positive (+) and negative (–) leads

from a 12 volt battery (1) to the connector

terminals, as outlined in the following chart.

5. Observe the mirror movement.

FUNCTION TE RM. A TERM. B TERM . D

LH MIRROR – IN – +

LH MIRROR – OUT + –

LH MIRROR – UP + –

LH MIRROR –

DOWN – +

RH MIRROR – IN + –

RH MIRROR – OUT – +

RH MIRROR – UP + –

RH MIRROR –

DOWN – +

+ = battery positive (12 volts)

– = battery negative

6. If the m ovement of the m ir ror is not as s hown in

the above chart, replace the mirror assembly.

Figure 12H-10

REINSTALL

Installation of the exterior rear-view mirror is the reverse of the removal procedure, noting the following:

1. Ensure that the wiring harness for the mirror is correctly routed.

2. Tighten the three mirror-to-door retaining screws to the correct torque specification.

( + ) EXTERIOR MIRROR ASSEMBLY

RETAINING SCREW

TORQUE SPECIFICATION 2.5 – 3.5 Nm

3. Install the door trim.

4. Install the door demist duct, ensuring that the duct clips into position.

5. Install fuse F15 ensuring that it is positioned into the correct fuse receptacle.

6. Check for correct mirror operation.

2.2 EXTERIOR MIRROR GLASS

LT Section No. – 10-400

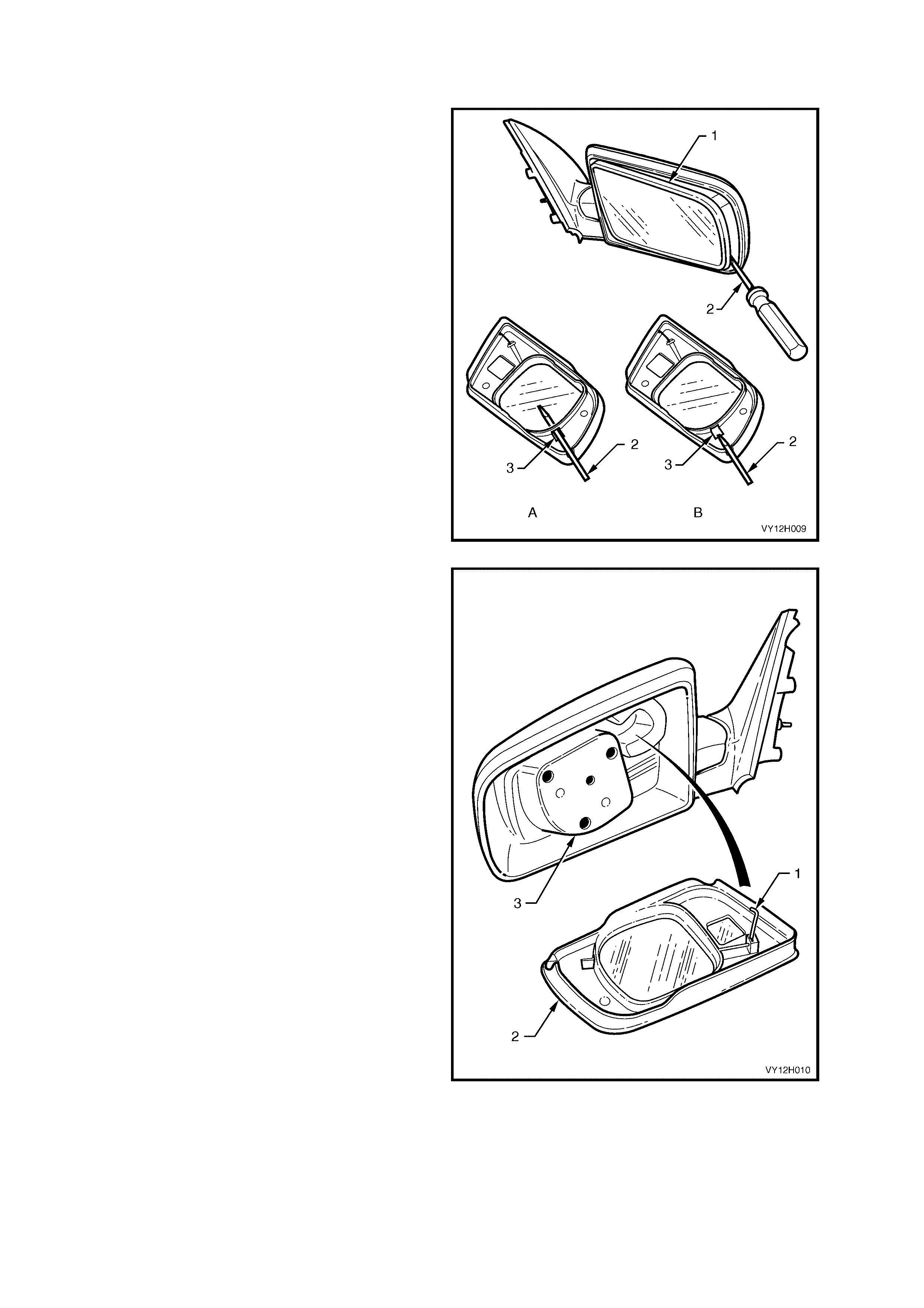

REMOVE

1. Adjust the mirror glass (1) so it is in the fully UP

and fully IN position.

2. Refer to Figur e 12H-11, views A and B. Insert a

screwdriver (2) into the slot (3) on the inside of

the mirror glass.

3. Gently lever the mirror glass away from the

moto r assembly.

4. Remove the mirror glass from the motor

assembly.

Figure 12H-11

REINSTALL

1. Ensure the anti-vibration spring rod (1) is at a

right angle to the mirror glass (2) and that it

aligns with the corresponding aperture in the

mirror housing.

2. Suppor t the mirr or housing and push the m irror

glass squarely onto the motor assembly (3)

until it is firmly seated.

Figure 12H-12

2.3 MIRROR CONTROL SWITCH

LT Section No. – 02-775

REMOVE

1. Remove the door inner trim panel (1). Refer to Section 1A5, FRONT AND REAR DOOR ASSEMBLIES.

2. Disconnect the door electrical harness (2) from the control switch (3).

3. From the inside of the door trim assembly, push the control switch to free it and remove it.

Figure 12H-13

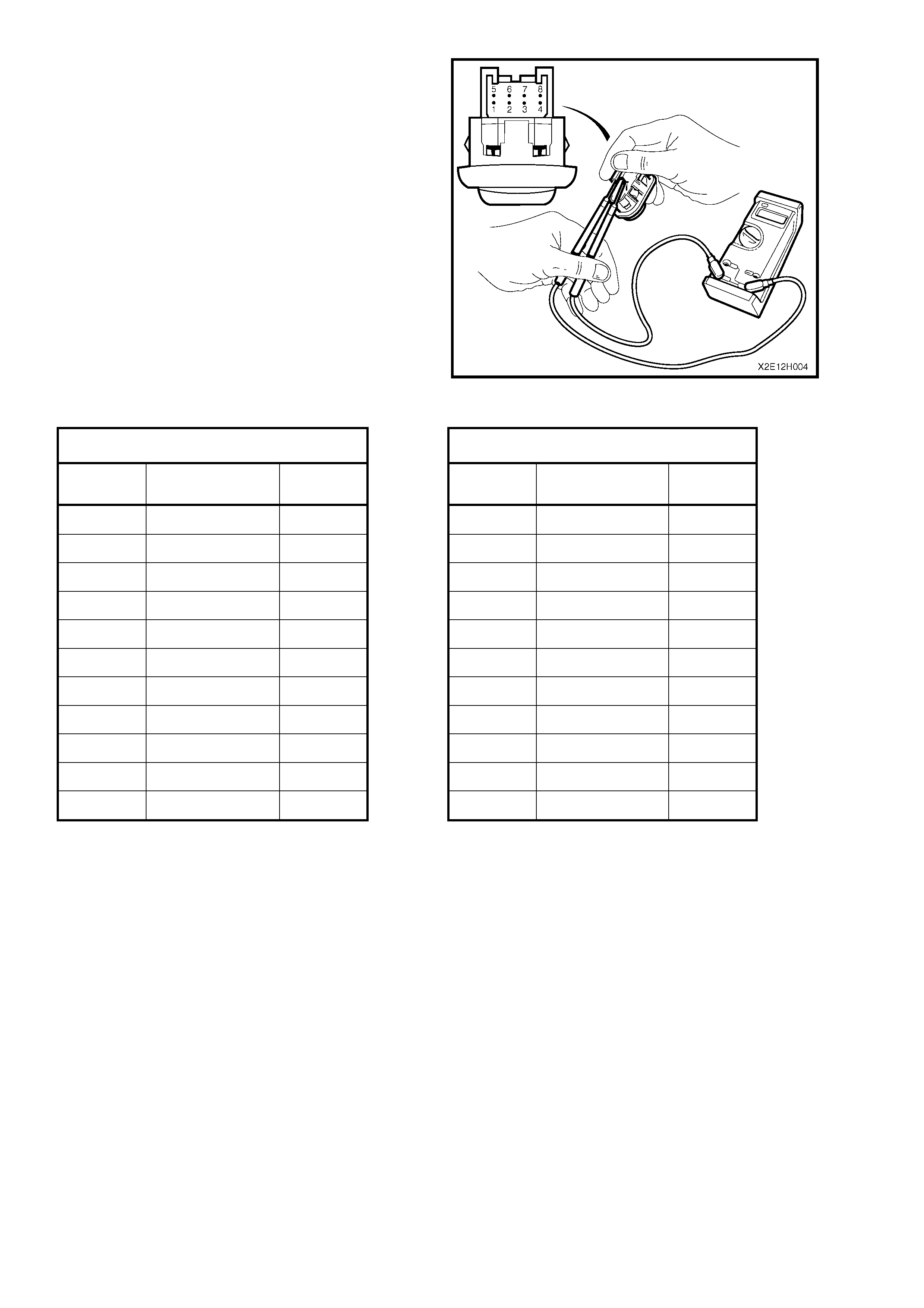

TEST THE SWITCH CONTACTS

1. Using Figures 12H-134and 12H-15 and the

following two charts, use an ohmmeter to

check the mirror control switch contacts for

continuity between terminals.

2. Select the desired mirror with the selector

switch (1).

Legend

A. Tilt UP

B. Tilt OUT – right-hand mirror

Tilt IN – left-hand mirror

C. Tilt DOWN

D. Tilt IN – right-hand mirror

Tilt OUT – left-hand mirror

Figure 12H-14

3. Attach the ohmmeter to the terminals listed in

the following two charts.

4. Press the directional toggle switch as if

adjusting the selected mirror in the direction

indicated in the chart.

The ohmmeter must indicate continuity

between the terminals listed.

Figure 12H-15

LEFT-HAND MIRROR CONNECTIONS RIGHT-HAND MIRROR CONNECTIONS

TILT SWITCH

TERMINALS SUPPLY TILT SWITCH

TERMINALS SUPPLY

IN 1 and 4 + IN 1 and 5 +

2 and 5 – 2 and 8 –

OUT 1 and 5 + OUT 1 and 8 +

2 and 4 – 2 and 5 –

UP 1 and 5 + UP 1 and 5 +

2 and 7 – 2 and 3 –

DOWN 1 and 7 + DOWN 1 and 3 +

2 and 5 –

2 and 5 –

REINSTALL

Installation is the reverse of the removal procedure.

2.4 INTERIOR REAR-VIEW MIRROR

For vehicle models fitted with production option

UE1 (Communication System Telematics), refer to

Section 12K, TELEMATICS.

REMOVE

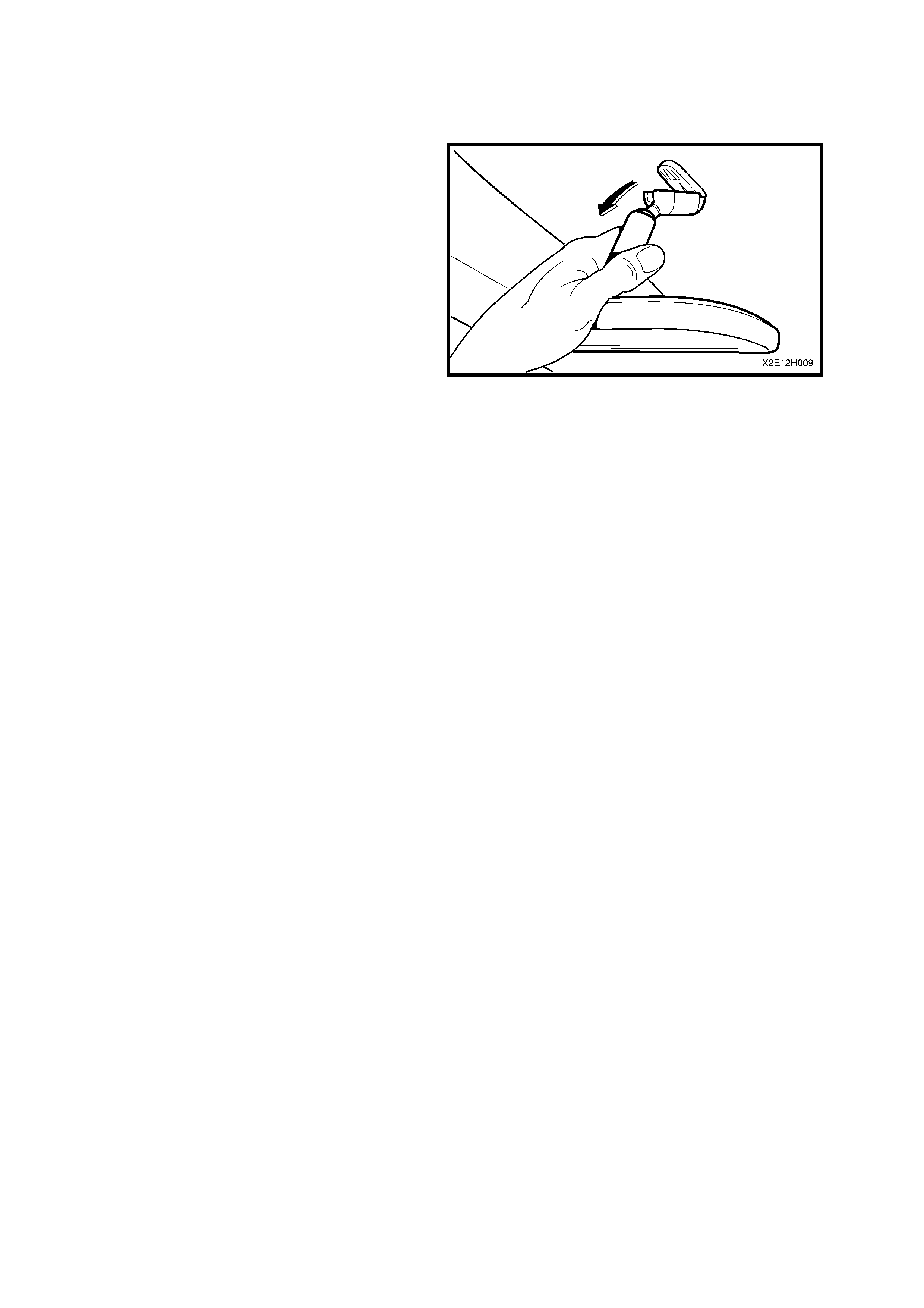

The interior rear-view mirror is held in position by

spring force onto the boss that is fixed to the

windscreen.

1. Disengage the interior mirror from the boss on

the windscreen by grasping the mirror lens

firm ly by hand and peeling the mirror assem bly

downwards towards the lower edge of the

windscreen.

REINSTALL

Installation is the r everse of the removal procedur e,

noting the following:

1. W hen inst alling the mirror onto the boss on the

windscreen, slide the m irror assem bly from the

top of the boss downwards, ensuring that it is

pushed down fully. An audible click should

occur as the mirror assembly locks into

position.

Figure 12H-16

3. DIAGNOSIS

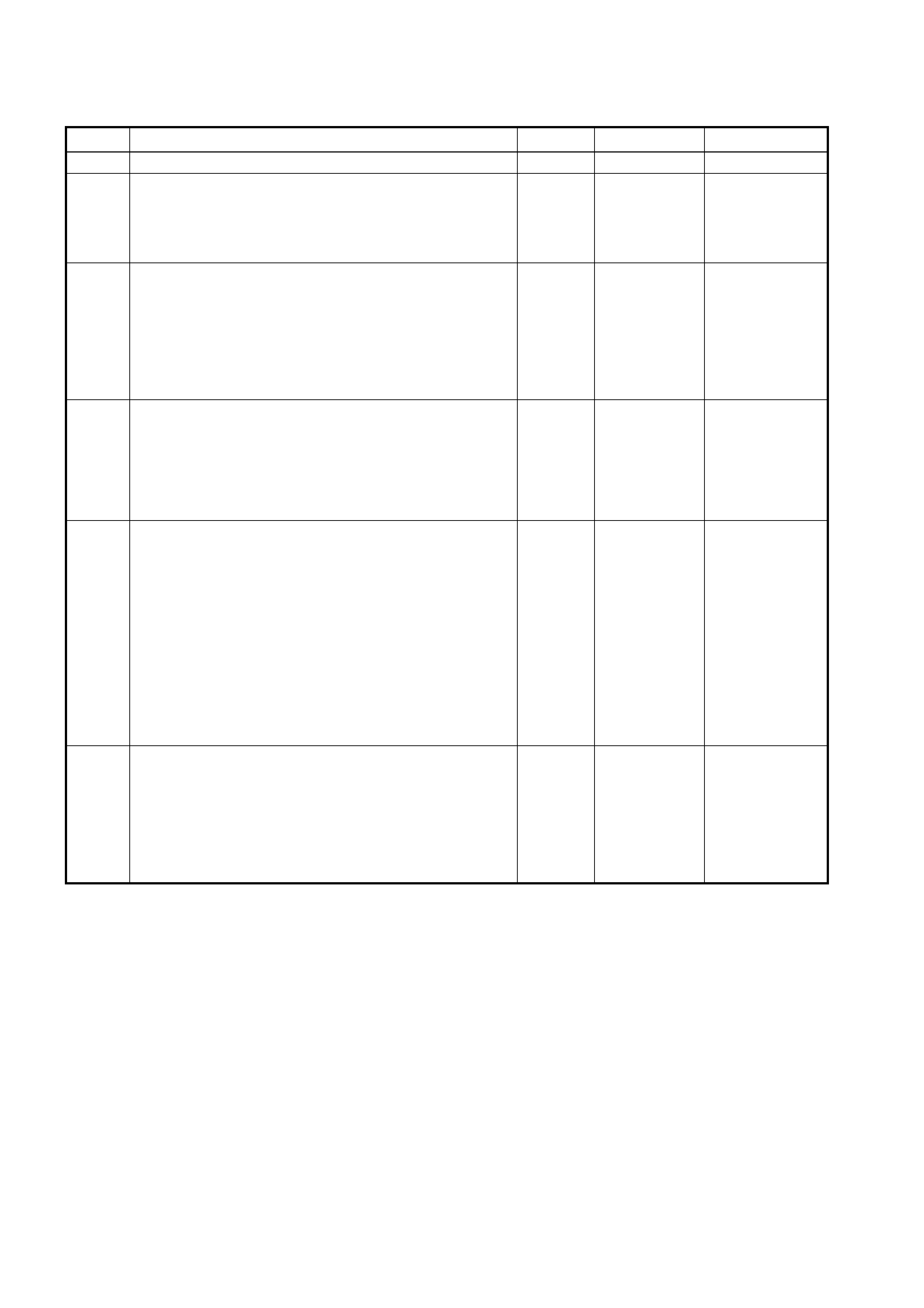

ELECTRIC MOTOR INOPERATIVE DIA GNOSTIC CHART

STEP ACTION VALUE YES NO

1 Are both electric rear-view mirrors inoperative? Go to Step 2. Go to Step 3.

2 Is Fuse F15 (located in fuse panel) OK? Go to Step 3. Replace blown

fuse and check

wiring for cause

of fuse blowing.

Verify repair.

3 Remove the driver’s door inner trim panel, refer to Section

1A5, FRONT AND REAR DOOR ASSEMBLIES.

Reconnect the mirror control switch.

Turn the ignition on.

Using a test light, check for power at connector S169,

terminal X1-1, circuit 139 (Purple wire).

Does the test light illuminate?

Go to Step 4. Check and

repair open

circuit in circuit

139 (Pink wire)

from fuse F15 to

the control

switch. Verify

repair.

4 1. Turn the ignition off.

2. Using an ohmmeter, check circuit 650 (Black / Blue

wire) for continuity between connector S169, terminal

X1-2, and the ground connection at location X118.

Is the wiring OK?

Go to Step 5. Check and

repair open

circuit in ground

circuit 650

(Black / Blue

wire). Verify

repair.

5 1. At connector S169, terminal X1-5, check for continuity

between circuit 330 (Brown wire) and the following

circuits:

• Circuit 82 (Purple wire), terminal X1-4 (LH mirror

horizontal motor).

• Circuit 89 (Grey wire), terminal X1-7 (LH mirror vertical

motor).

• Circuit 90 (Yellow wire), terminal X1-8. (RH mirror

horizontal motor).

• Circuit 889 (Light Blue wire), terminal X1-3 (RH mirror

vertical motor).

Is the wiring OK?

Go to Step 6. Check and

repair open

circuit. Verify

repair.

6 1. Disconnect the mirror control switch connector and test

the switch contacts. Refer to 2.3 MIRROR CONTROL

SWITCH, in this Section.

Is mirror control switch OK?

System OK. Replace mirror

control switch.

Refer to 2.3

MIRROR

CONTROL

SWITCH, in this

Section. Verify

repair.

EXTERIOR MIRROR LOSS OF FUNCTION DIAGNOSTIC CHART

STEP ACTION VALUE YES NO

1 1. Remove the mirror control switch and test the switch

contacts, refer to 2.3 MIRROR CONTROL SWITCH in

this Section.

Are the mirror switch contacts OK?

Go to Step 2. Replace mirror

control switch.

Refer to 2.3

MIRROR

CONTROL

SWITCH, in this

Section. Verify

repair.

2 1. At connector S169, terminal X1-5, check for continuity

between circuit 330 (Brown wire) and the following

circuits:

• Circuit 82 (Purple wire), terminal X1-4 (LH mirror

horizontal motor).

• Circuit 89 (Grey wire), terminal X1-7 (LH mirror vertical

motor).

• Circuit 90 (Yellow wire), terminal X1-8. (RH mirror

horizontal motor).

• Circuit 889 (Light Blue wire), terminal X1-3 (RH mirror

vertical motor).

Is the wiring OK?

Go to Step 3. Check and

repair open

circuit. Verify

repair.

3 1. Check the faulty mirror assembly. Refer to

2.1 MIRROR ASSEMBLY in this Section.

Is the mirror OK?

System OK. Replace mirror

assembly. Refer

to 2.3 MIRROR

CONTROL

SWITCH, in this

Section. Verify

repair.

CONNECTOR DIAGRAM – RIGHT-HAND DRIVE

CONNECTOR DIAGRAM – LEFT-HAND DRIVE

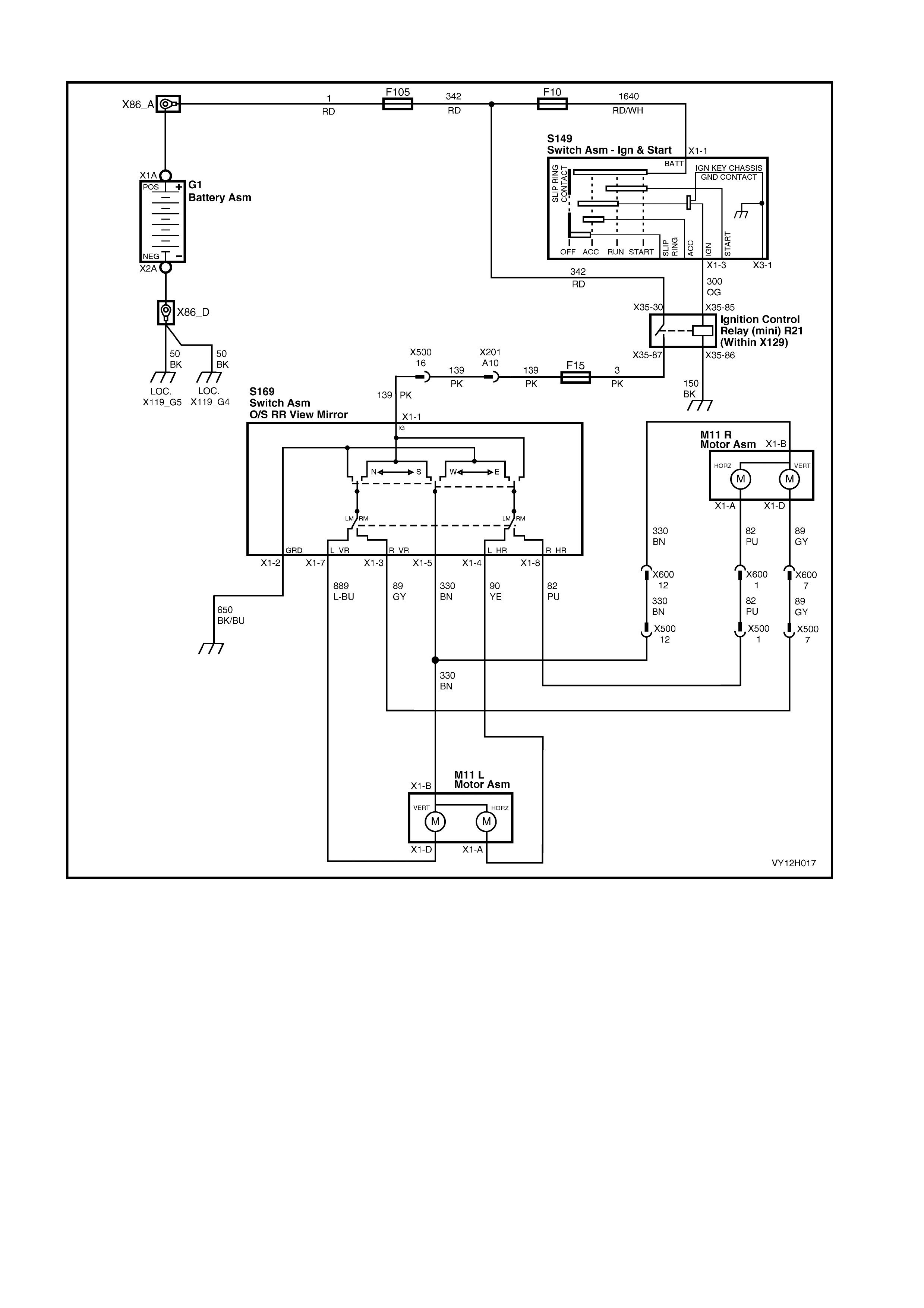

CIRCUIT DIAGRAM – RIGHT-HAND DRIVE

Figure 12H-17

CIRCUIT DIAGRAM – LEFT-HAND DRIVE

Figure 12H-18

4. TORQUE WRENCH SPECIFICATIONS

Mirror to Door Attaching Screws 2.5 – 3.5 Nm

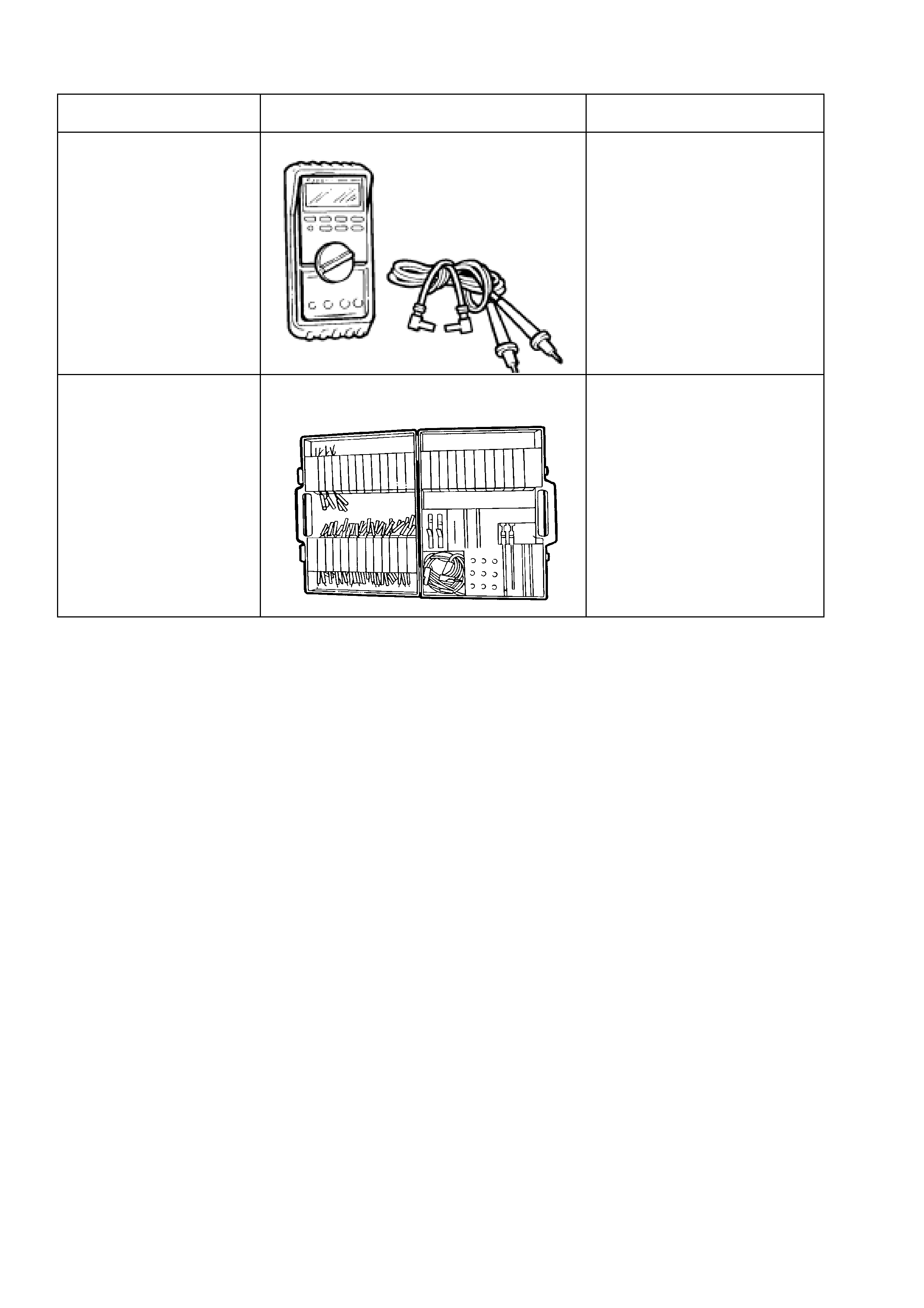

5. SPECIAL TOOLS

TOOL NO. REF IN TEXT TOOL DESCRIPTION COMMENTS

j39200 DIGITAL MULTIMETER TOOL NO. J39200

PREVIOUSLY RELEASED, OR

USE COMMERCIALLY

AVAILABLE EQUIVALENT.

MUST HAVE 10 MEG OHM

INPUT IMPEDANCE OR

GREATER

J35616-A

(KM609) CONNECTOR test ADAPTOR KIT

USED IN CONJUNCTION

WITH A MULTIMETER FOR

MEASURING VOLTAGES AND

RESISTANCES WITHOUT

damaging WIRING HARNESS

CONNECTORS