SECTION 12L - NAVIGATION SYSTEM

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

VEHICLE SPEED & DIRECTION

GLOBAL POSITI ONING SYSTEM

DIGITAL ROAD MAP

1.1 GENERAL OPERATION

1.2 COMPONENT LAYOUT

2. OPERATING INSTRUCTIONS

3. SERVICE OPERATIONS

3.1 PROCESSOR ASSEMBLY

PROCESSOR

MOUNTING BRACKETS

3.2 REMOTE CONTROL ASSEMBLY

REMOTE CONTROL CRADLE

WITH PRESENTER

PRESENTER MOUNTING WEDGE

3.3 DISPLAY ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3.4 NAVIGATION SPEAKER ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

3.5 NAVIGATION WIRING HARNESS

REMOVE

REINSTALL

3.6 COCKPIT NAVIGATION WIRING

HARNESS

REMOVE

REINSTALL

3.7 GPS ANTENNA ASSEMBLY

REMOVE

REINSTALL

3.8 FITTING A NEW FLOOR CONSOLE

COVER ASSEMBLY

3.9 FITTING A NEW FLOOR CONSOLE

ASSEMBLY

3.10 NAVIGATION SYSTEM CALIBRATION

4. SYSTEM DIAGNOSIS

PREREQUISITES

4.1 WIRING DIAGRAM

4.2 CONNECTOR CHART

4.3 NAVIGATION SYSTEM DOES

NOT START

CONDITION ONE

CONDITION TWO

CONDITION THREE

4.4 NO RESPONSE FROM REMOTE

CONTROL

NO RESPONSE FROM REMOTE

CONTROL

CONDITION ONE

CONDITION TWO

4.5 CD–ROM ERROR

CONDITION ONE

CONDITION TWO

CONDITION THREE

4.6 AUDIO PROBLEMS

4.7 GUIDANCE PROBLEMS

CONDITION ONE

CONDITION TWO

CONDITION THREE

CONDITION FOUR

4.8 DISPLAY QUALITY

4.9 DISPLAY DIMMING INOPERATIVE

4.10 VEHICLE DIRECTION INCORRECT

5. PROCESSOR DIAGNOSTICS

5.1 ACCESSING DIAGNOSTIC MENU

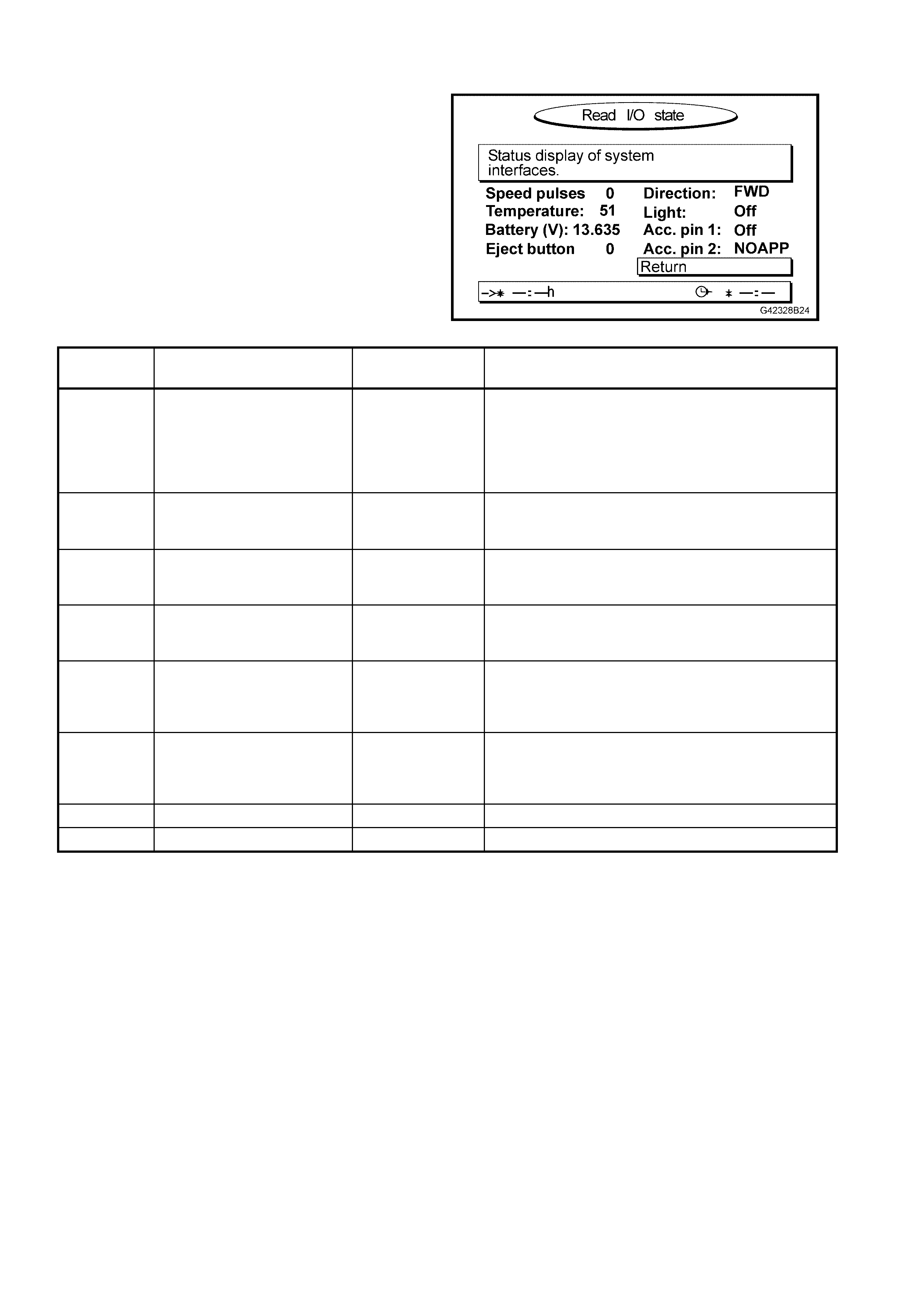

5.2 READ I/O STATE

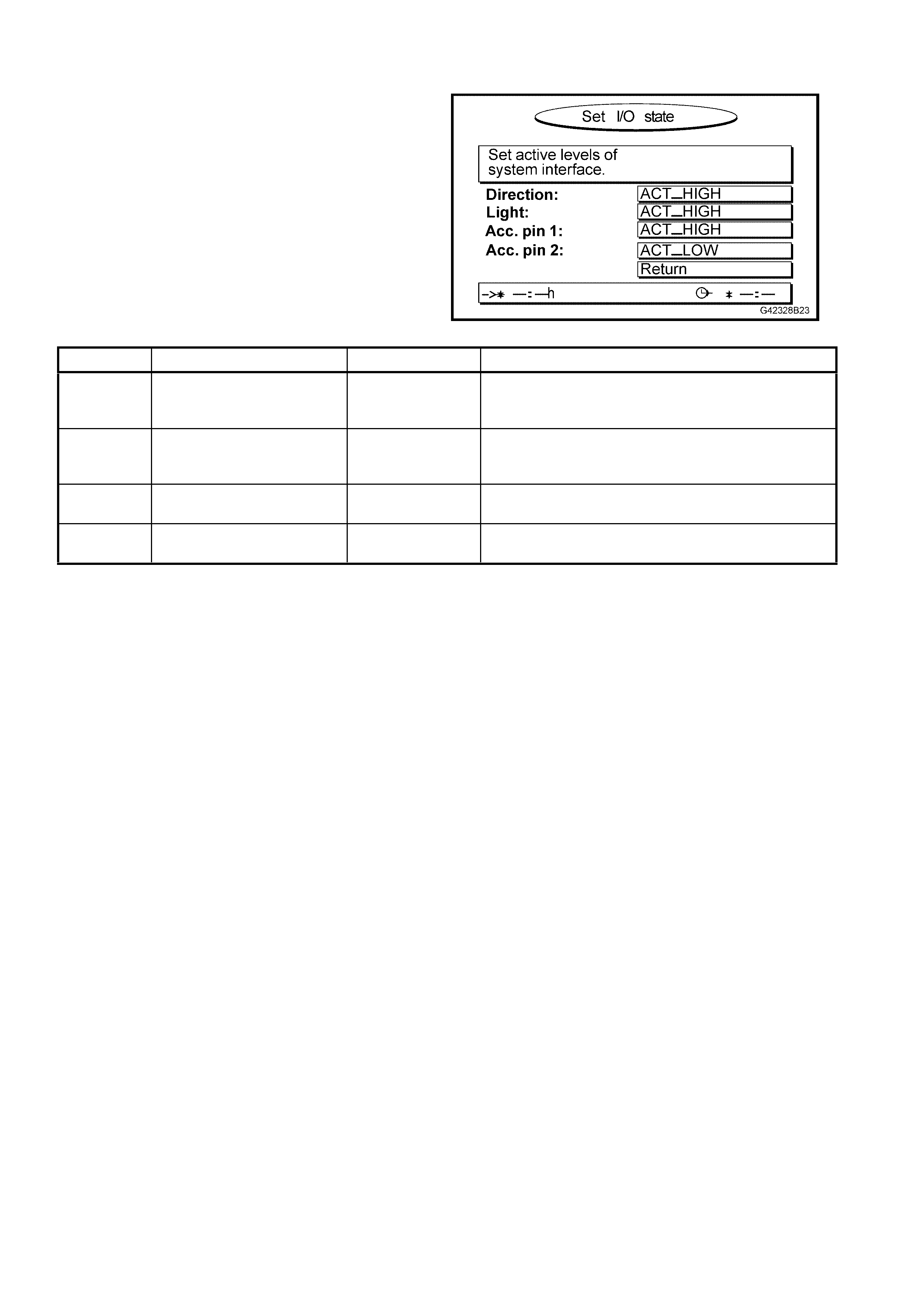

5.3 SET I/O STATE

5.4 READ GPS DATA

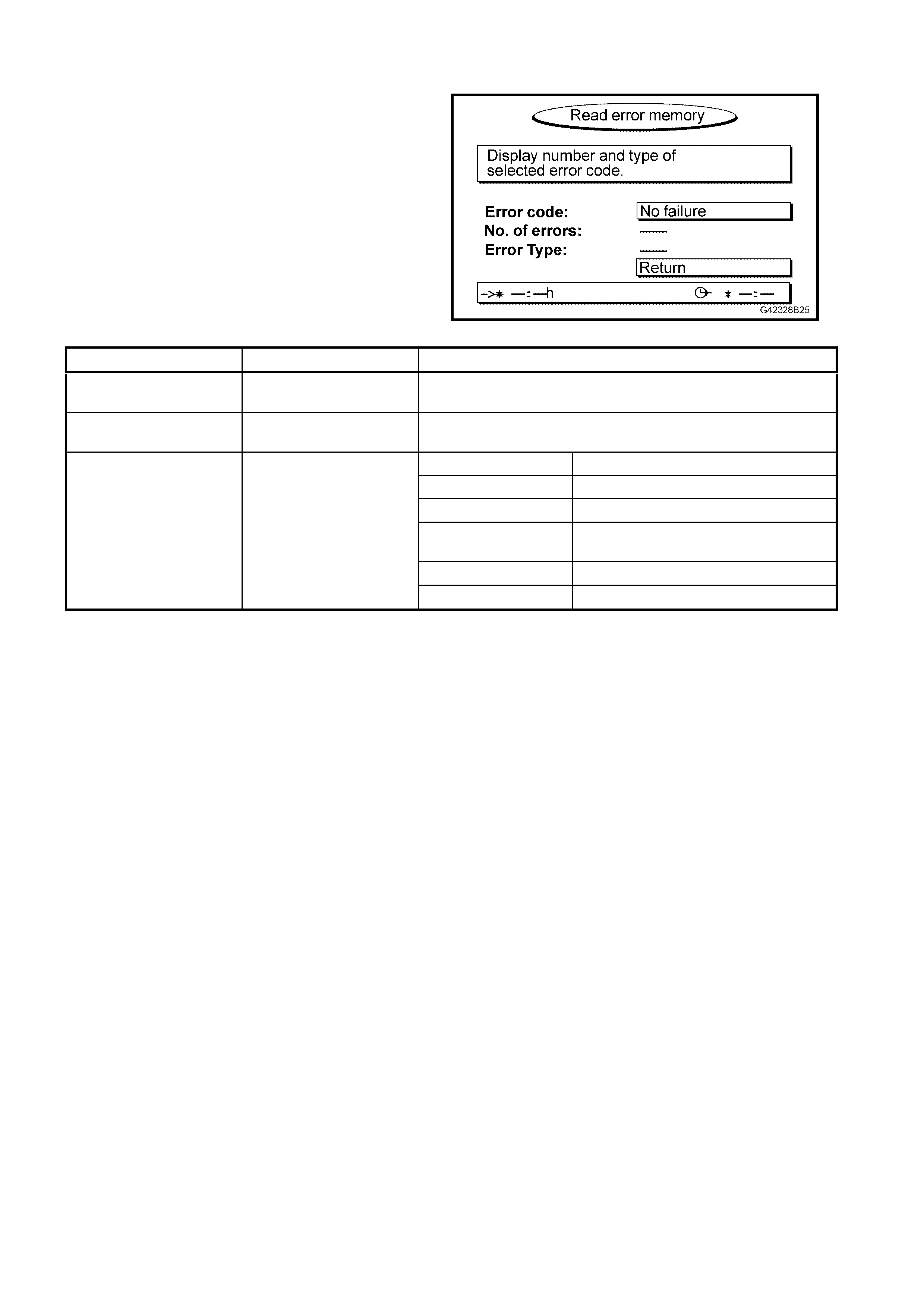

5.5 READ ERROR MEMORY

6. TORQUE WRENCH SPECIFICATIONS

7. SPECIAL TOOLS

1. GENERAL DESCRIPTION

The Occupant Information Navigation System (navigation system) fitted to the MY 2003 VY Series Sedan and V2

Series II Coupe vehicles is adapted from the Siemens VDO Dayton MS 5000 Navigation System. The MS 5000 has

been modified to Holden specifications for easy vehicle installation. The navigation system is a production option

and is fitted by Holden B y Design (HBD).

The navigation system uses three principal technologies:

• The navigation processor uses the vehicle speed signal (VSS) and an internal gyroscope.

• Global Pos it io nin g S ystem (GPS).

• Digital road mapping.

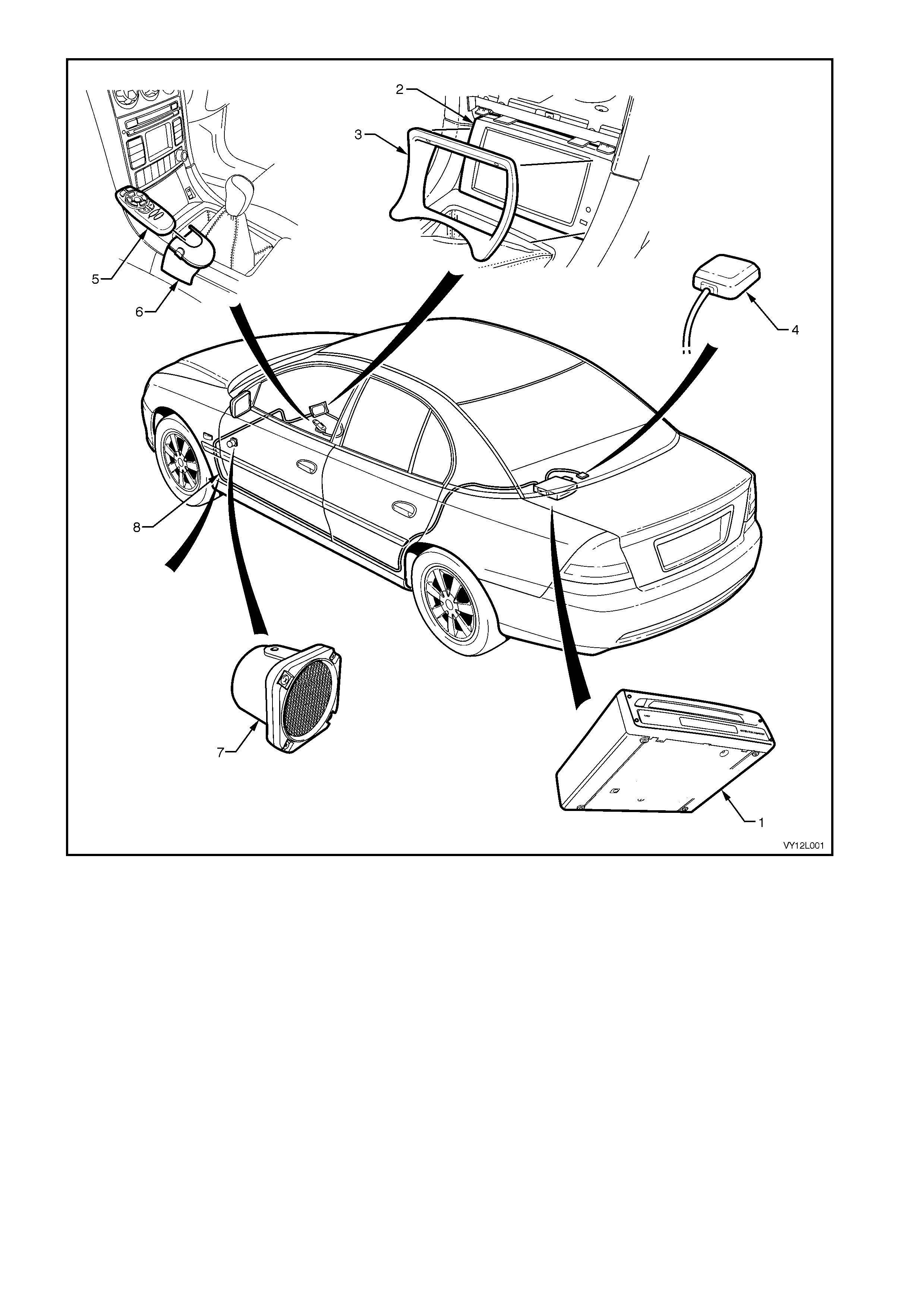

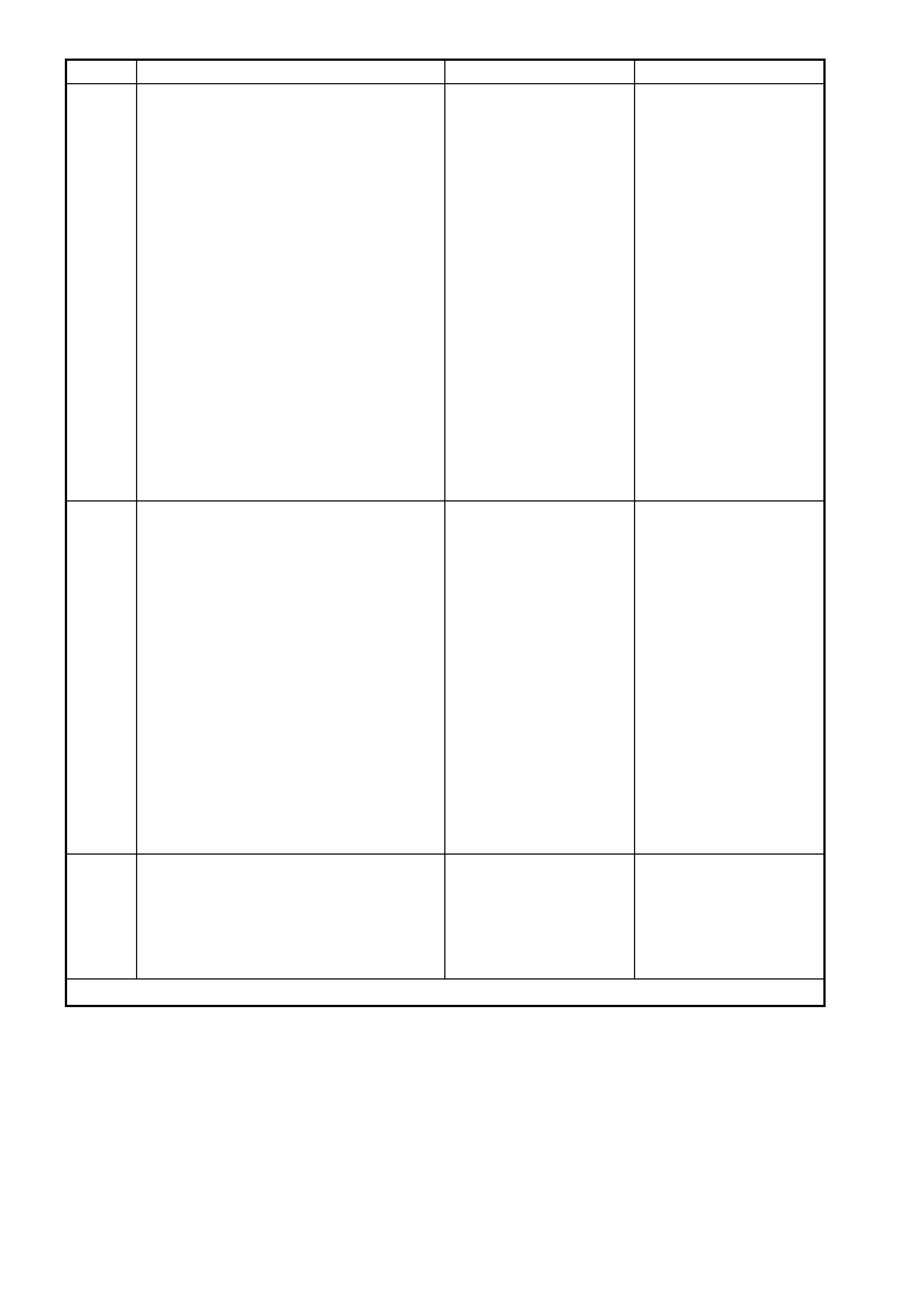

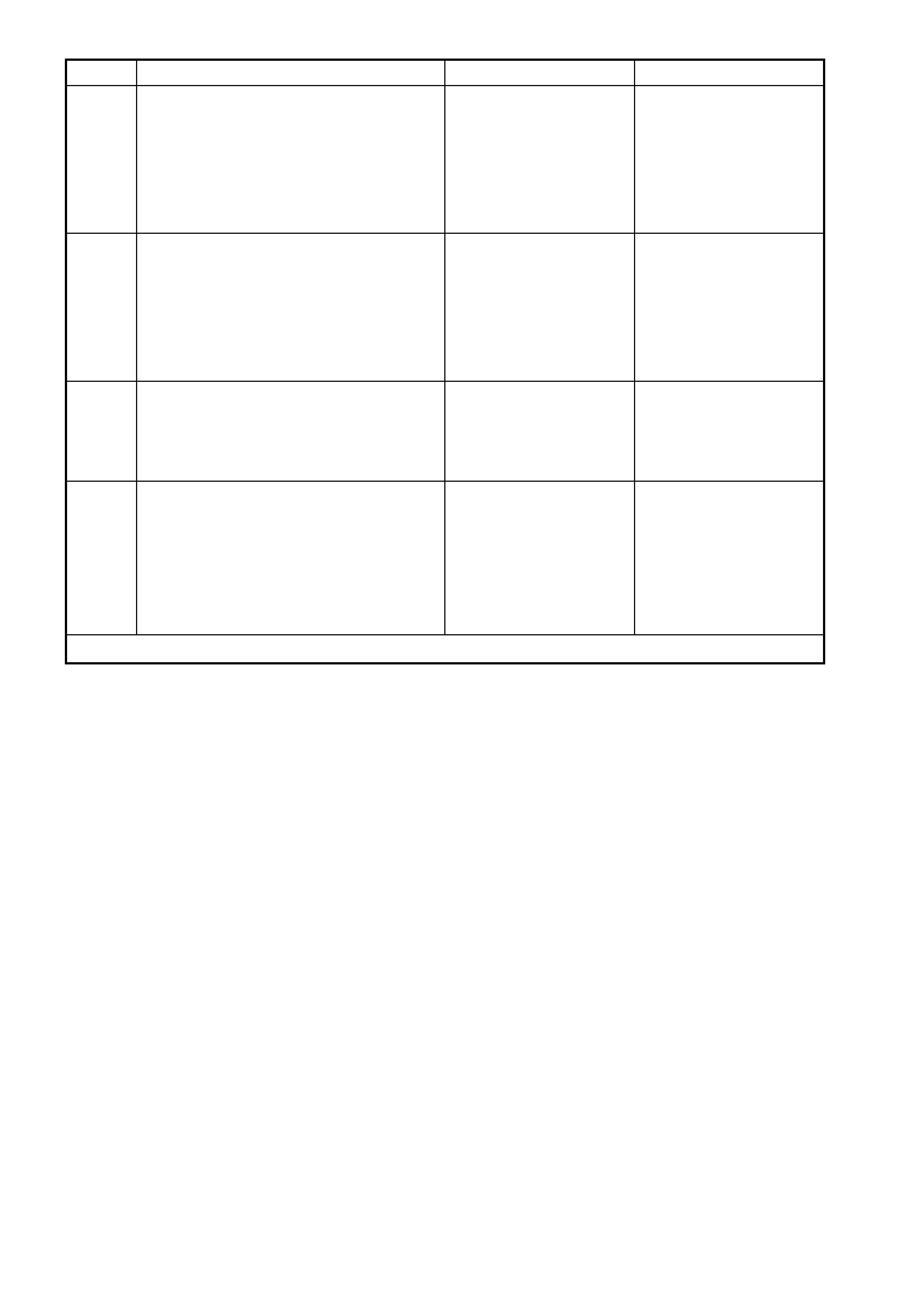

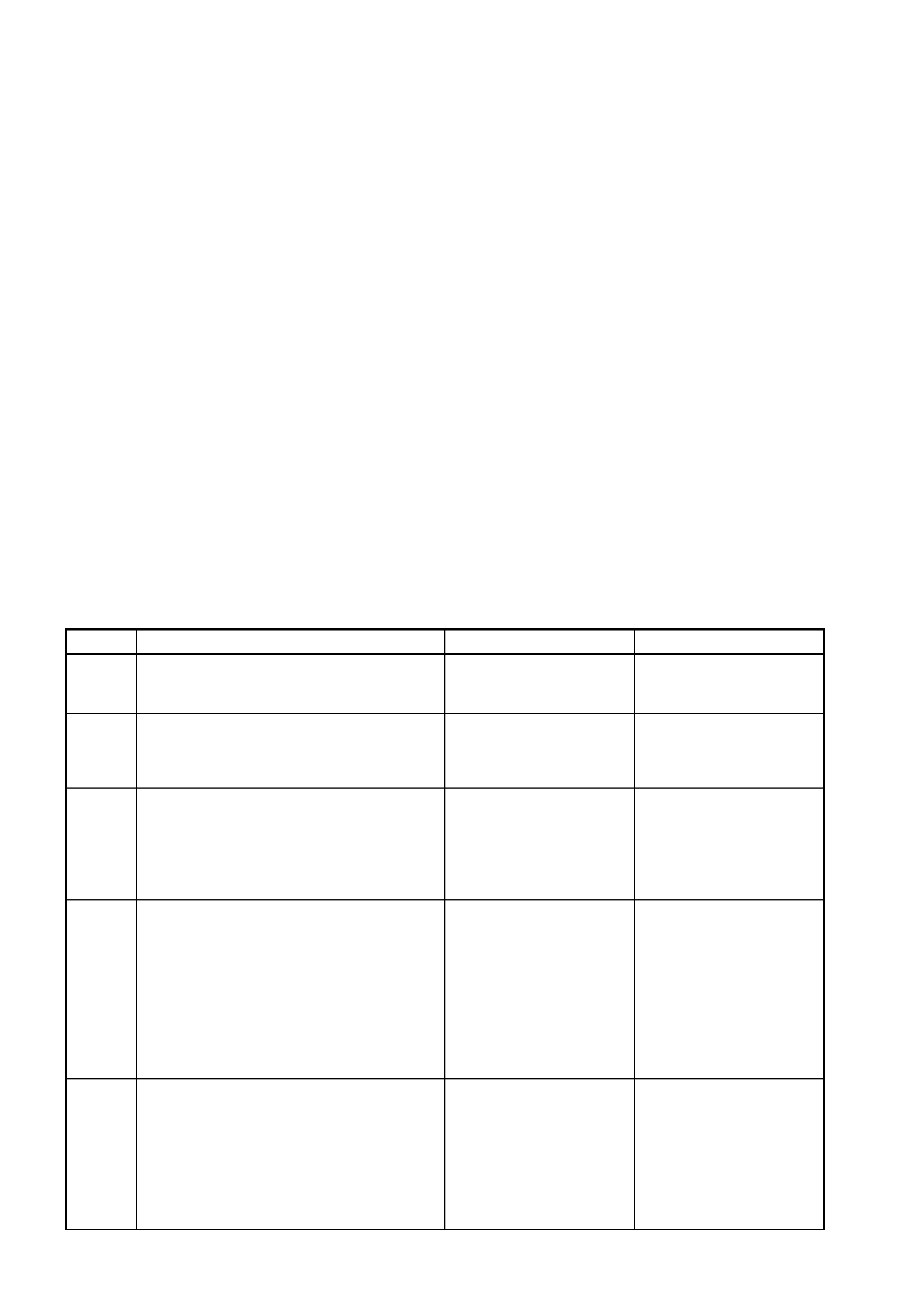

The navigation system consists of the following components:

• Proce ssor assembly (1)

• Display assembly (2) and escutcheon (3)

• GPS antenna assembly (4)

• Remote control assembly (5) with presenter (6)

• Speaker assembly (7)

• Wiring harness and cockpit wiring harness (8)

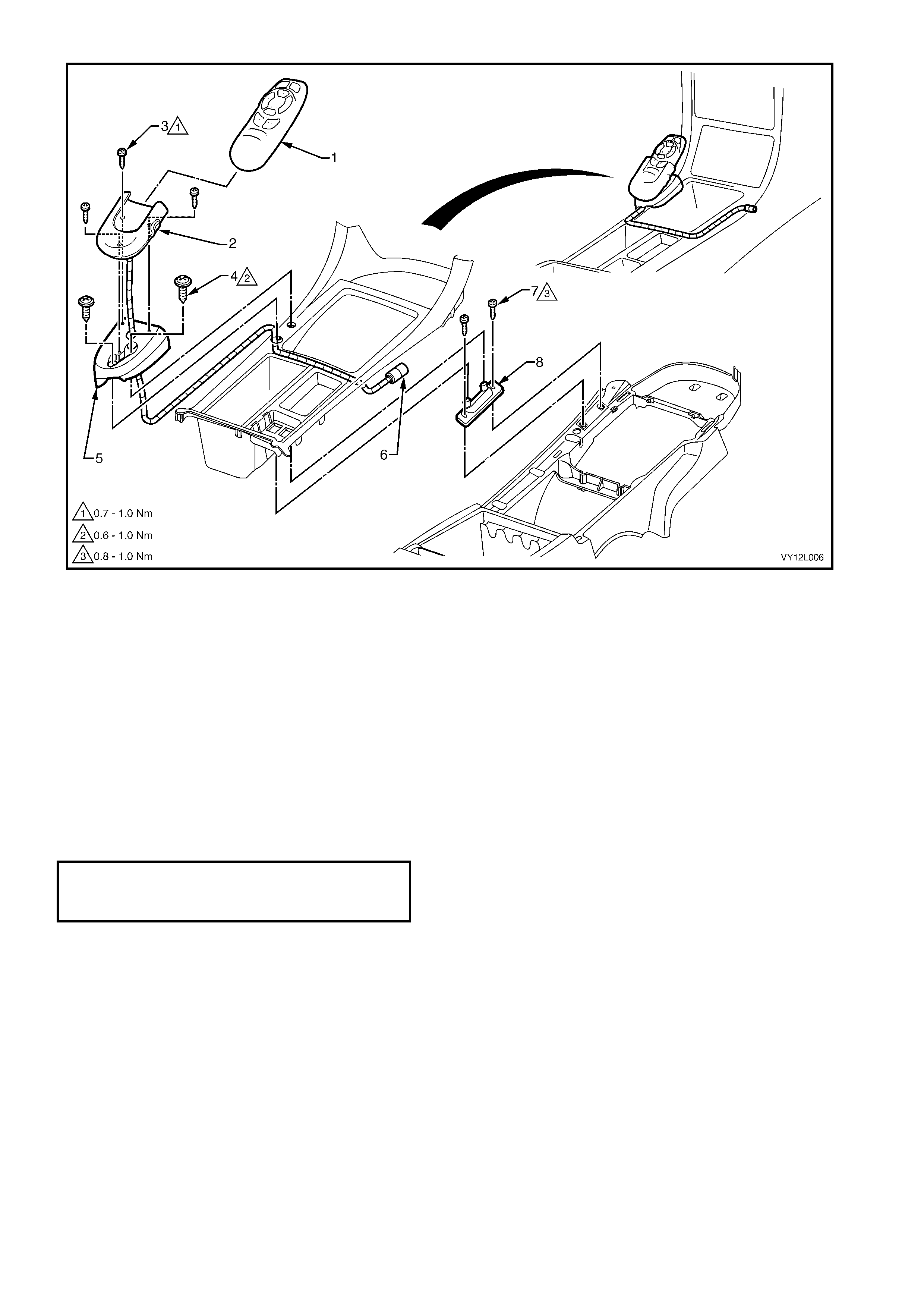

The following modifications are made to the floor console cover assembly to accommodate the navigation system:

• Holes are drilled in the floor console cover assembly so that the navigation remote control assembly and

presenter can be fitted.

• The f loor c ons ol e c o ver as s em bl y is c ut to s p ec if ic atio n to al lo w f or the ins t al lat io n of the nav igat io n d is pl ay

assem bly.

NOTE: Although there are obvious interior trim and body shape differences between the Sedan and Coupe, the

navigation system remains the same for both except for the harness lengths and harness clips.

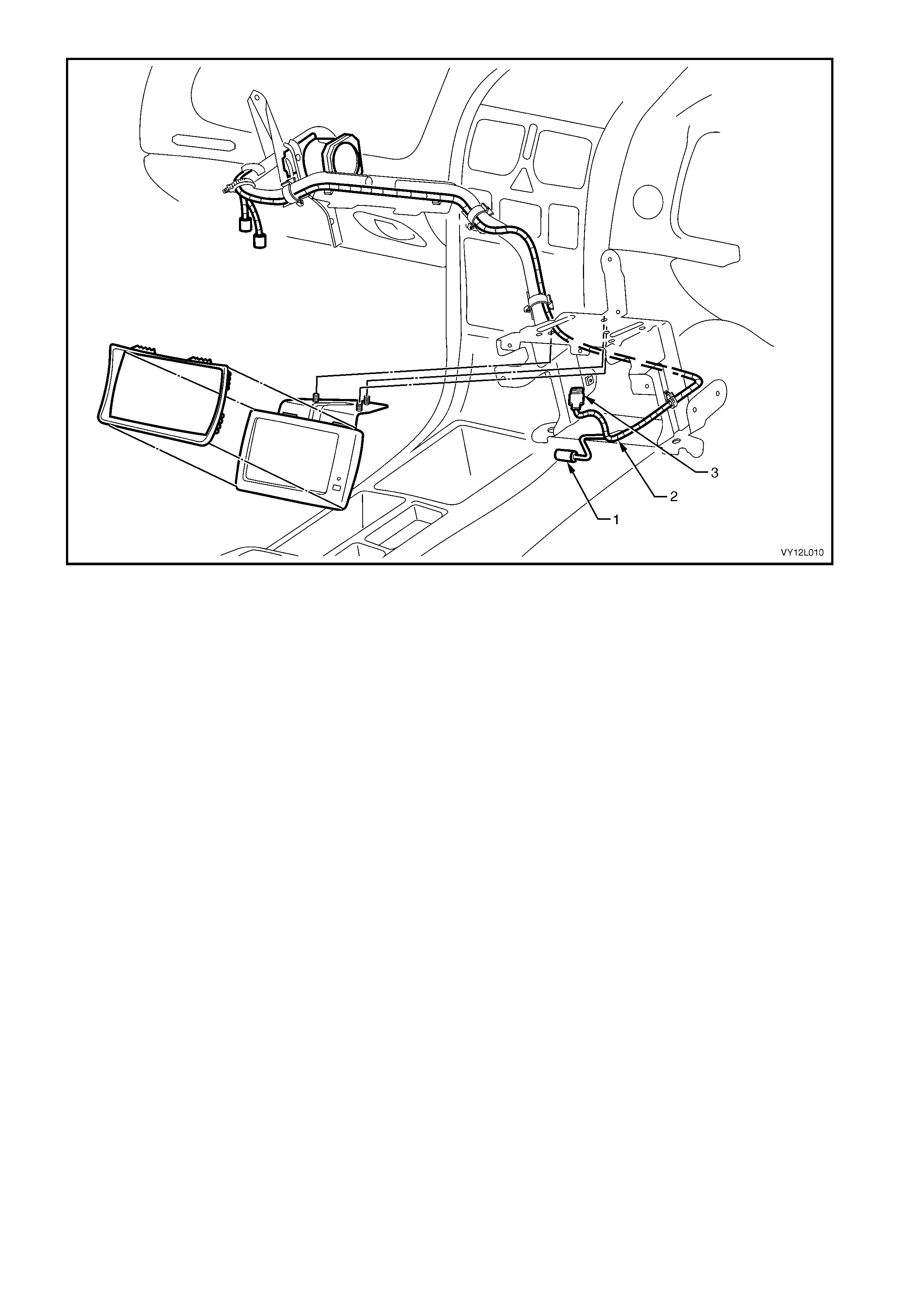

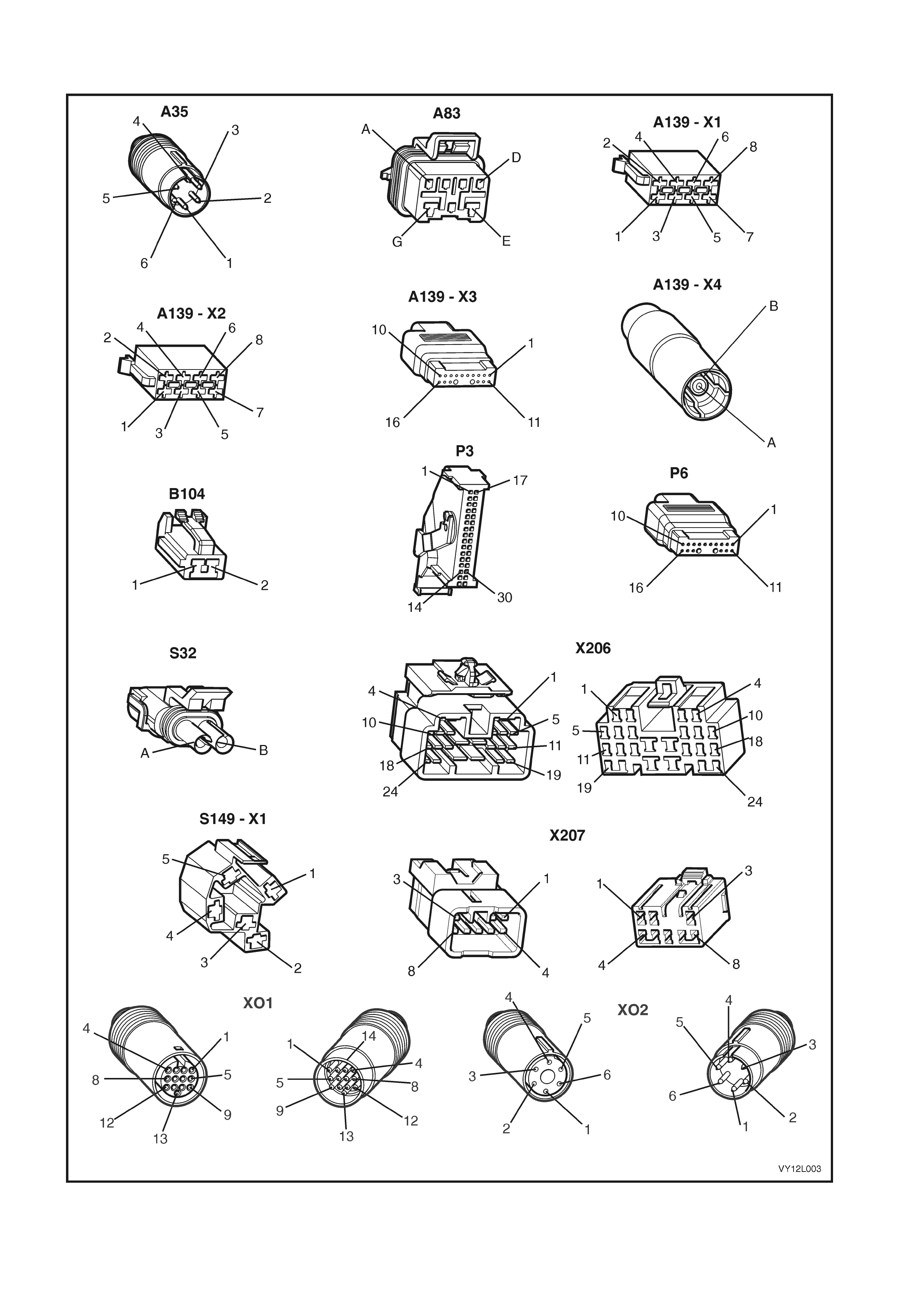

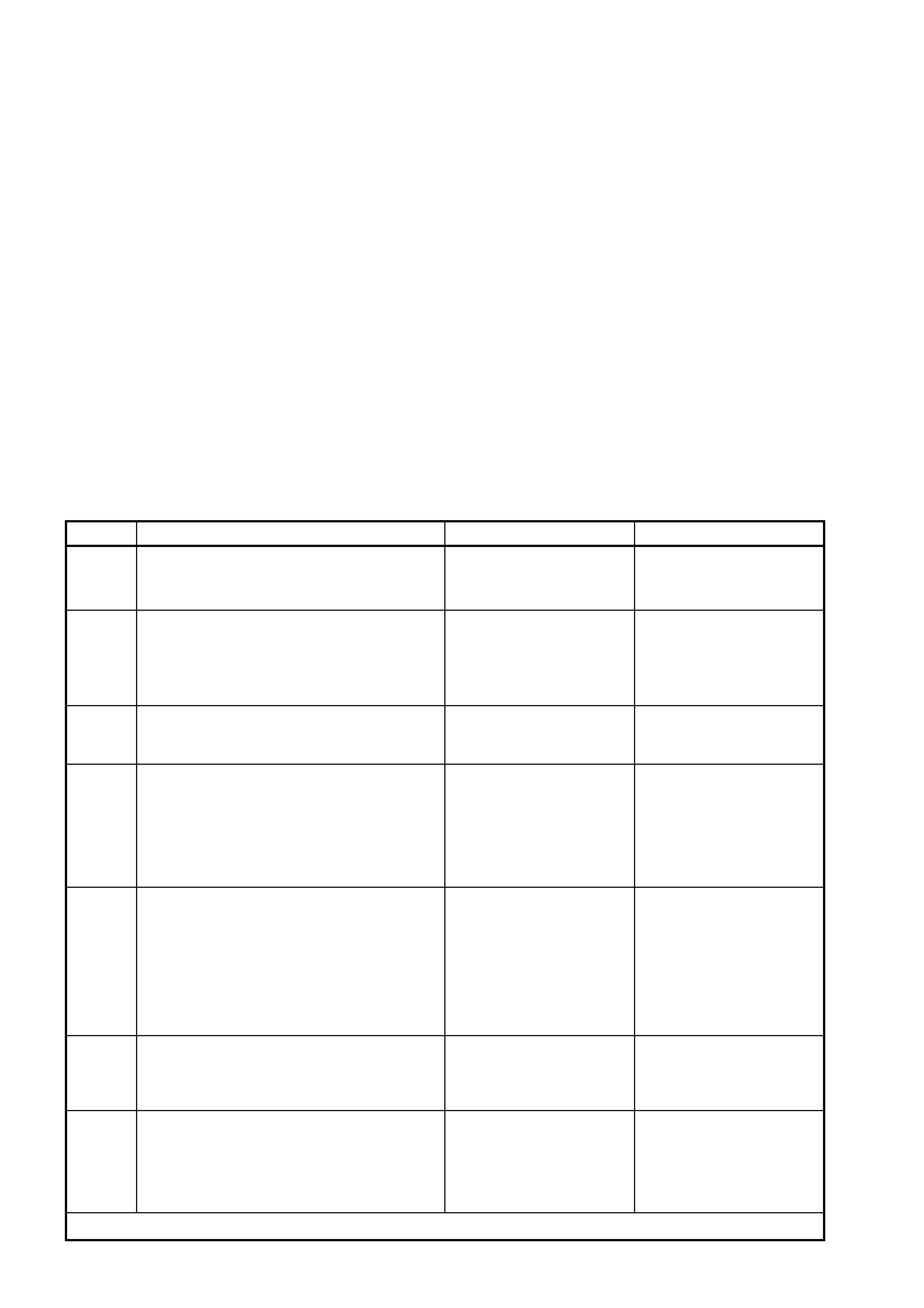

Figure 12L–1

Legend

1. Processor Assembly

2. Display Assembly

3. Escutcheon

4. GPS Antenna

5. Remote Control Assembly

6. Remote Control Cradle and Presenter

7. Speaker Assembly

8. Wiring Harness and Cockpit Wiring Harness

VEHICLE SPEED AND DIRECT ION

The veh icle spe ed sensor and the gyroscope work together to provide direct ion and s peed. I n conjunc tion with the

position signal received from the GPS, the vehicle speed sensor and gyroscope provide the processor with the

necessary information to produce vehicle navigation to the user.

GLOBAL POSITIONING SYSTEM

The GPS is a series of 27 satellites (nominally 24) which orbit the earth at an altitude of 20 372 km. The signals

from f our satellites m ust be r eceived b y a GPS rece iver to get an ac curate thr ee-dim ensional pos ition. If only three

satellit e signals are re ceived a posit ion is attaine d, but with reduced ac curacy. The pos ition calc ulated by the GPS

receiver is acc ur ate to bet w een 30 a nd 1 00 metr es. GPS r ec ept io n ma y be interrupte d, es pec i al ly due to t he natur e

of the navigation system, in the following instances:

• between tall buildings

• in car parks, tunnels or under bridges

• in forests or avenues

• during storms

• in valleys and mountains

• If the GPS antenna assembly and the position of the satellites are not favourable due to the satellite’s orbit

DIGITAL ROAD MAP

The digital road map is supplied b y Siemens VDO Da yton. The map is contained on a Com pact Disc (CD–ROM),

which is read b y the proces sor assem bly. This CD mus t be inserted into the pr ocessor as sembly for the s ystem to

work. Update versions of the map are available from Holden Spare Parts Organisation (HSPO).

1.1 GENERAL OPERATION

NOTE: For inf ormation on t he navigat ion s yst em operatio n, refer to the Satellite Navigatio n Handbook Supplem ent

supplied with the navigation system.

The navigation system works in the following manner:

• Initially, with power supplied, the navigation display activates and the receiver acquires a GPS signal. This

provides a position accurate to within 30 to 100 metres. This position is translated onto the digital road map

and shown o n the n aviga tion dis pla y in the f orm of an ar row. Initi ally, the vehic le m ay not be s ho wn in its exac t

position, as the navigation system may not be calibrated.

• The user can now enter a destination using the navigation system menus. The remote control, which can be

used whil e i n its cr ad le or p oint ed a t th e dis p lay, is use d to n a vig ate t hr oug h th e n av igat io n system m enus . The

map screen highlights the route to be taken.

• The navigation system begins calibration automatically when the vehicle moves. The VSS provides electrical

pulses which are converted into distance signals; the gyroscope detects and measures any change in direction.

The GPS signal continues to be received and is used as a reference by the navigation system.

• After the na vigation s ystem is calibrat ed, the arro w will be dis pla yed on the map i n the correct position and t he

correct direction. To get to this stage, one or two changes of direction of the vehicle may be necessary. The

navigation system supplies audio commands to the user during this time for any direction changes required.

Audio commands are supplied through the speaker assembly, mounted under the instrument panel assembly

on the instrument panel lower bracket.

• If the driver does not take a recommended turning point, the navigation system calculates an alternate route

and supply audio command for that route.

Further:

• Calibration takes longer if the vehicle is driven along a straight road for some distance.

• The vehic le’s posit ion is sto red by the proces sor after the v ehic le’s ign ition is turn ed off . T he navigati on s ystem

requires 30 seconds to shut down properly.

• If the veh icle ’s posit ion h as been s tored previ ousl y, the na vigat ion s ystem operat es with out G PS rec eptio n and

still be accurate.

• The vehicle’s position remains in memory after the battery has been disconnected, but only if the navigation

system has been allowed 30 seconds to shut down properly before disconnection.

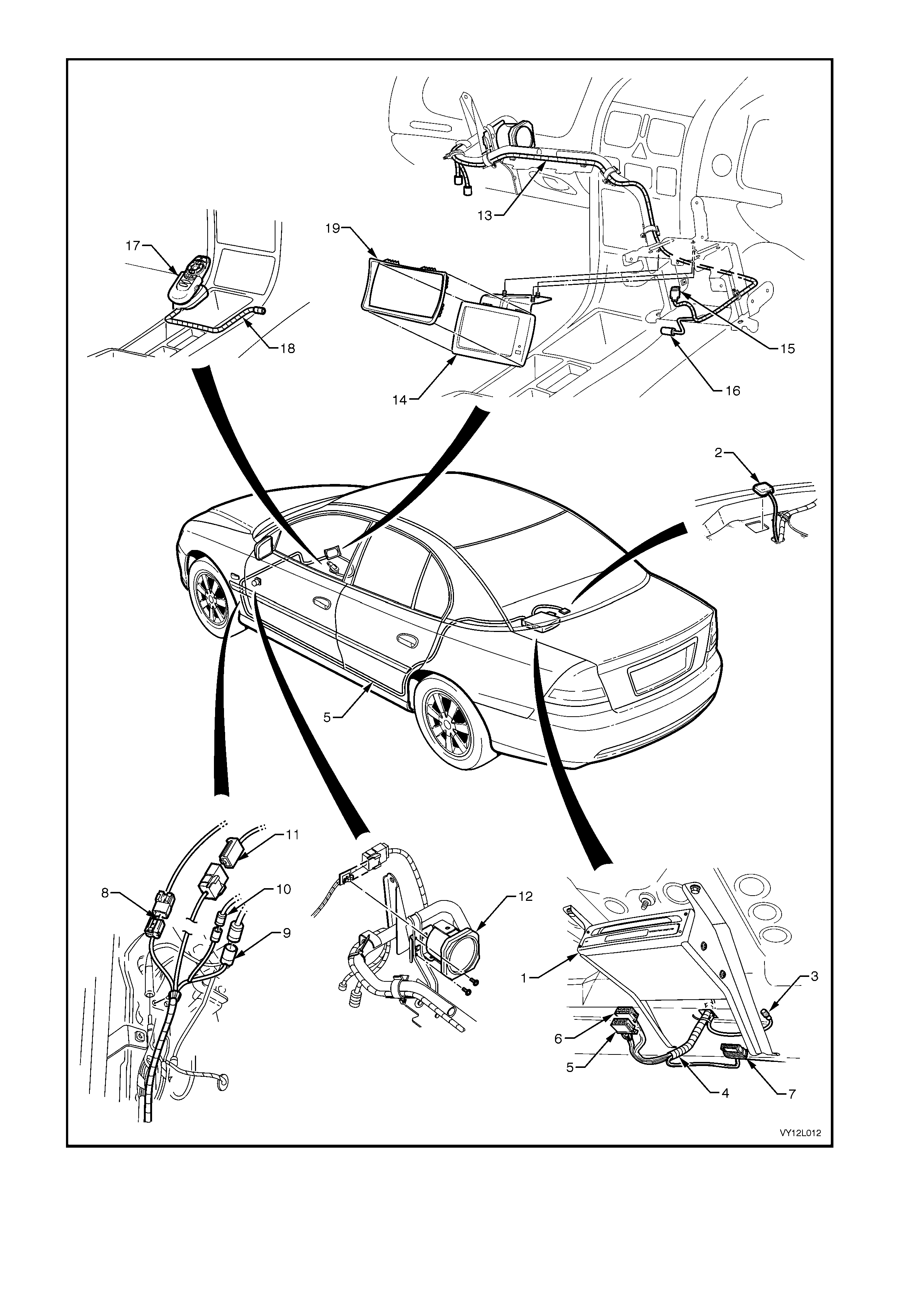

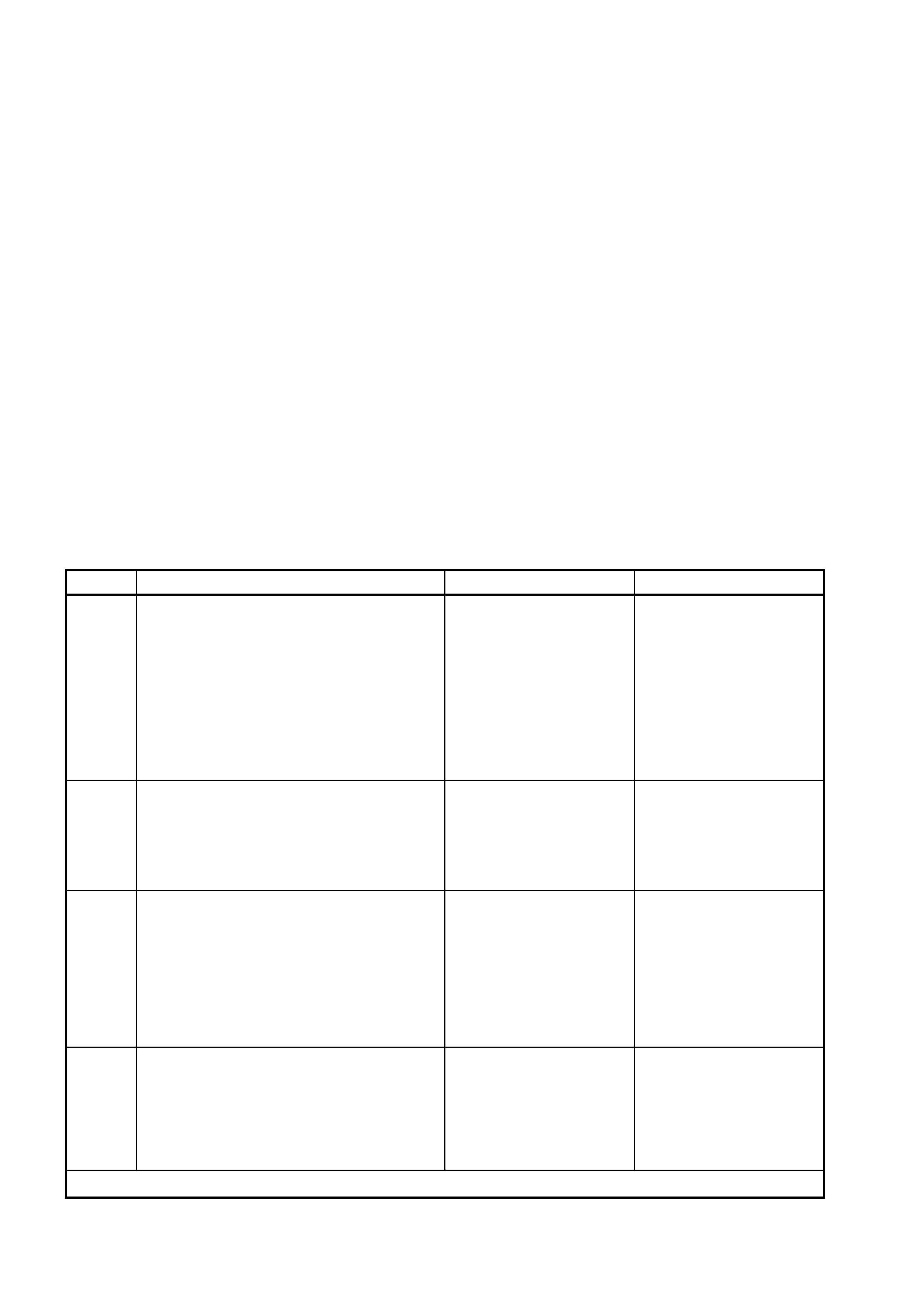

1.2 COMPONENT LAYOUT

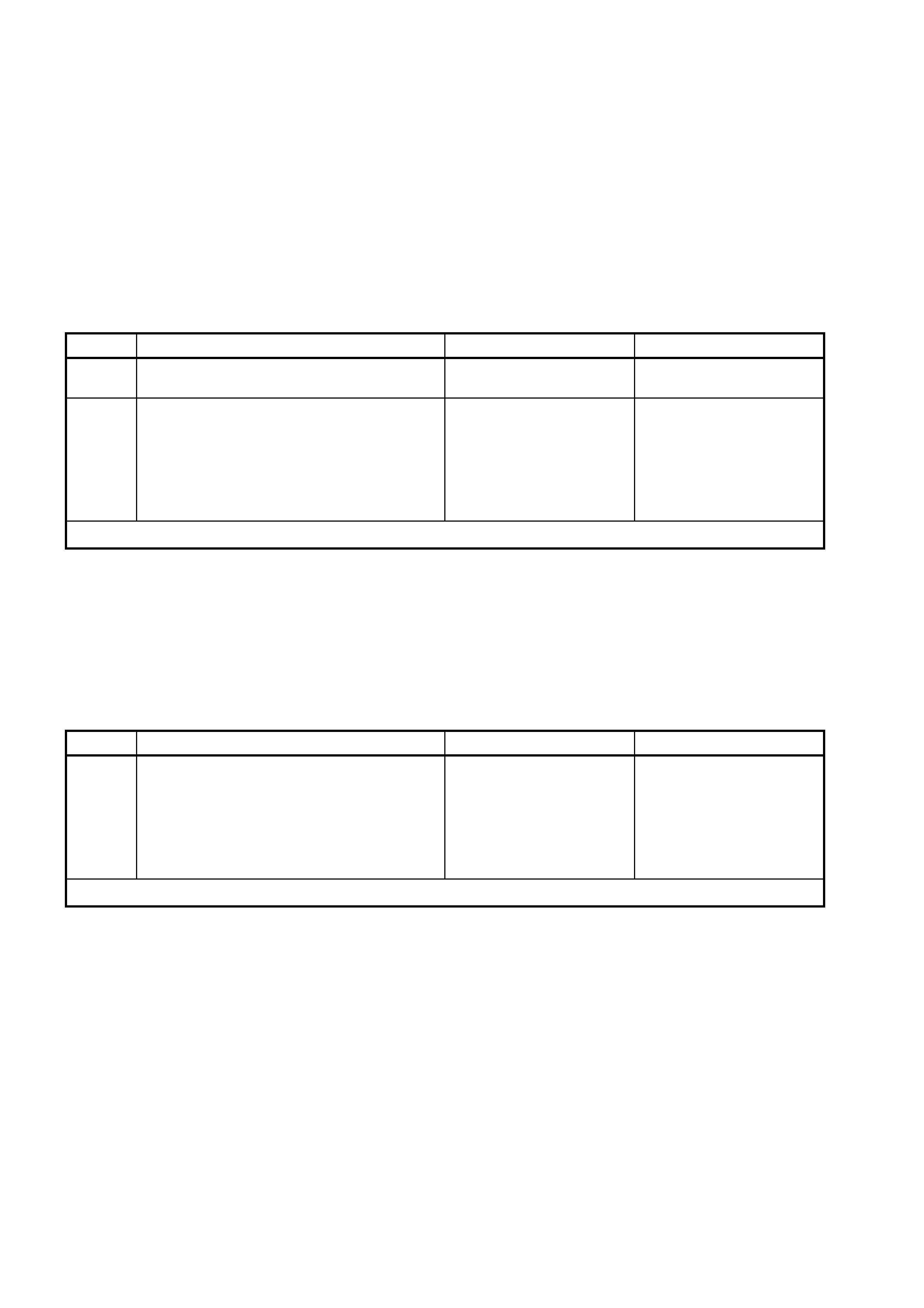

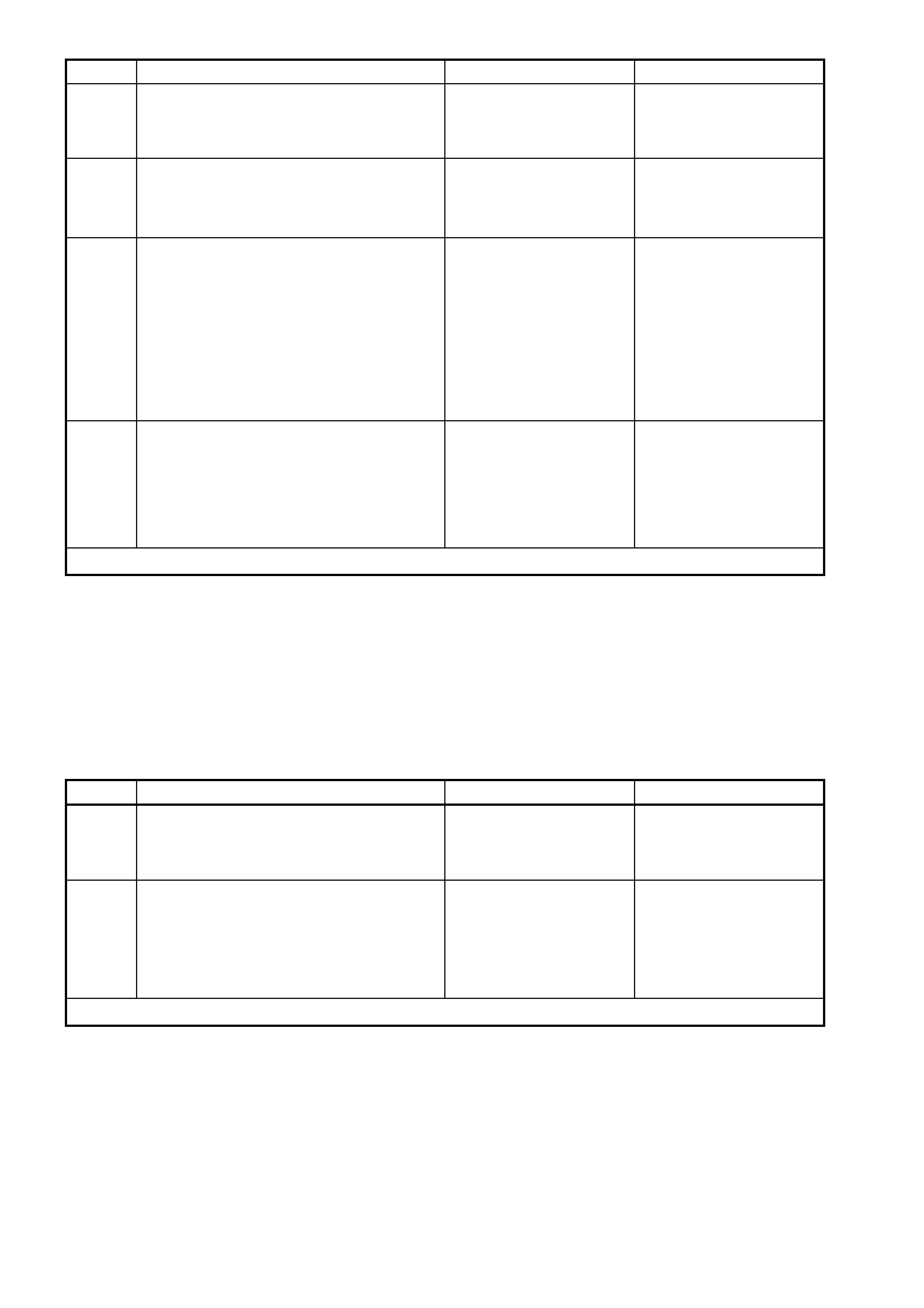

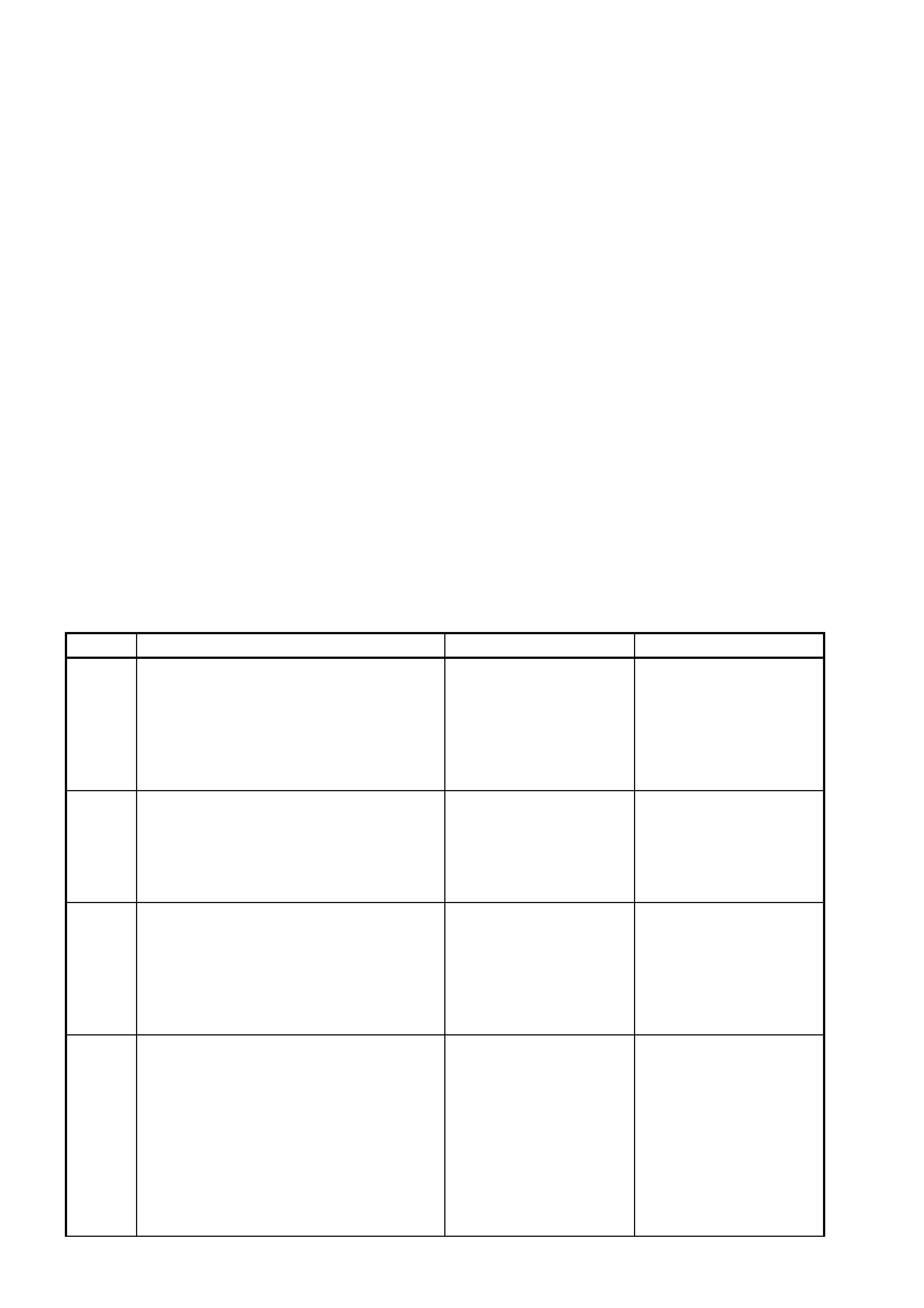

The navigation s ystem is provided by Siem ens VDO Dayton to Holden specif ications. This is a brief description of

the layout and functions of equipment, refer to Fi gure 12L –2.

The processor assembly (1) is mounted in the rear compartment below the rear window panel assembly. The

processor assembly contains a CD–ROM and other components required for the navigation system to operate.

The G PS antenna assem bly (2) is mounted on top of the rear window pan el asse mbly with doub le-sid ed tape. T he

harness is routed through the panel and connects to the processor assembly with connector A139 – X4 (3).

The navigation wiring harness (4) is connected at the processor assembly by three connectors, A139 – X1 (5),

A139 – X2 (6) and A139 – X3 (7). The navigation wiring harness leads from the processor assembly , down the left-

hand side of the vehicle and terminates at the left-hand hinge pillar trim assembly. At this point, the navigation

wiring harness is split into connectors X207 (8), XO1 (9), XO2 (10) and B104 (11).

Connector X207 connects the navigation wiring harness to the body harness. Through this connection, the

navigation system uses the following vehicle resources:

• X207 pin 3 — constant battery power to the processor in all states. This is the supply of power for the

navigation system.

• X207 pin 2 — supplies a signal to the processor assembly when the vehicle is in use. This is active only

when the ignition switch is in the ON or ACC position.

• X207 pin 7 — park lamp relay signal which informs the navigation system when the vehicles headlamps

are turn ed on. This dat a is used to c ontrol the i llumination level of the displa y dur ing da ytim e or night-tim e

operation

• X207 pin 5 — back-up lamp signal which supplies a signal to the navigation system when the vehicle is

moving in the reverse. This uses either the back-up lamp switch (manual transmission) or the

neutral / safety back-up switch (automatic transmission) to supply this signal.

• X201 pin 6 — c luster ass em bl y data, which pro vides VS S puls es f or the navigat ion s ystem . The navi gation

system uses this signal to calculate the speed at which the vehicle is travelling.

• X201 pin 8 — earth.

Connector B104 is attached to the speaker assembly (12) by a clip. B104 connects the speaker assembly to the

navigati on wirin g har nes s.

Connector s XO 1 and XO2 c onnect th e navigat io n wiring harn ess to the cock pit n avigatio n wiri ng harnes s (1 3). T he

cock pit navigat ion wiring h arness c ontains two se parate har nesses of connector XO1 and XO 2 which are wrapped

together. This harness is routed behind the instrument panel and attached to the instrument panel bracing.

The cockpit navigation wiring harness terminates at the navigation display assembly (14), and connects to the

displa y with connec tor P6 ( 15) .

The cockpit navigation wiring harness terminates under the instrument panel lower extension side trim with

connector A35 (16).

The remote control assembly with presenter (17) is secured to the front console assembly. The remote control

cradle wiring harness (18) is routed under the presenter, behind the transmission selector and to under the right-

hand console extension where it connects to the cockpit navigation wiring harness at connector A35.

The display assembly is mounted to the radio housing with a bracket. The display assembly has an

escutcheon (19) placed in front of this to blend it into the centre instrument console. The front console cover is

modified to allow for the display assembly and escutcheon.

Figure 12L–2

Legend

1. Processor Assembly

2. GPS Antenna Assembly

3. Connector A139 – X4

4. Navigation Wiring Harness

5. Connector A139 – X1

6. Connector A139 – X2

7. Connector A139 – X3

8. Connector X207

9. Connector XO1

10. Connector XO2

11. Connector B104

12. Speaker Assembly

13. Cockpit Navigation Wiring Harness

14. Display Assembly

15. Connector P6

16. Connector A35

17. Remote Control Assembly with

Presenter

18. Remote Control Cradle Wiring

Harness

19. Escutcheon

2. OPERATING INSTRUCTIONS

For a detailed description of operation of the navigation system, refer to the Satellite Navigation Handbook

Supplement supplied with the navigation system.

3. SERVICE OPERATIONS

The f ollowing S ectio n cont ains th e proced ures requir ed to r em ove and re insta ll th e navig ation s ystem com ponents.

Modification procedures are included for the front floor console cover if a replacement cover is being fitted.

3.1 PROCESSOR ASSEMBLY

LT Section –

The processor assembly is located inside the rear compartment.

PROCESSOR

Remove

The processor can be removed from the vehicle without removing the processor case and assembly mounting

brackets.

1. Remove the following fuses from the passenger compartment fuse and relay assembly :

a. radio fuse F23.

b. radio cellular phone fuse F16. Refer to Section 12O, 1.1 FUSES for location details .

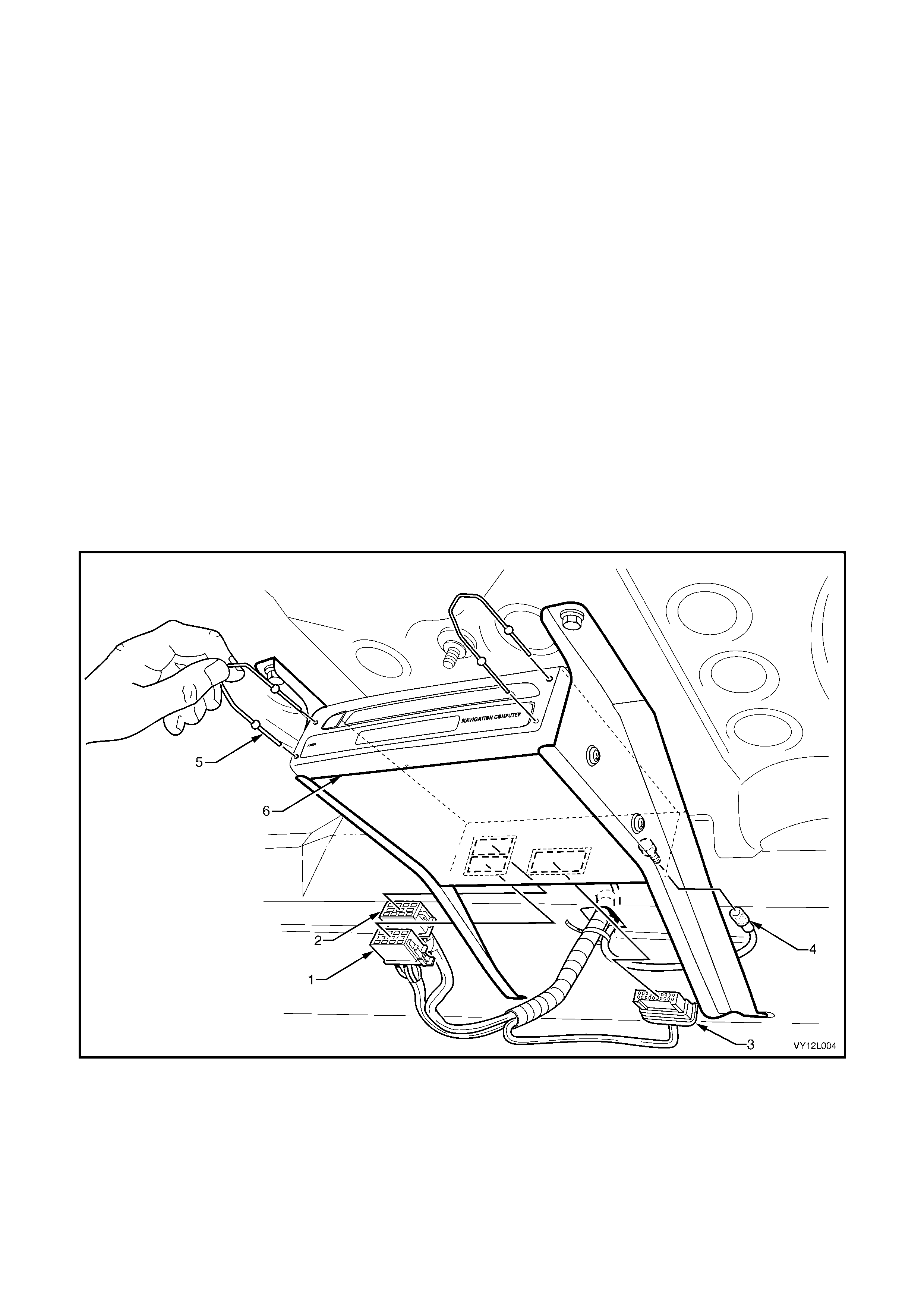

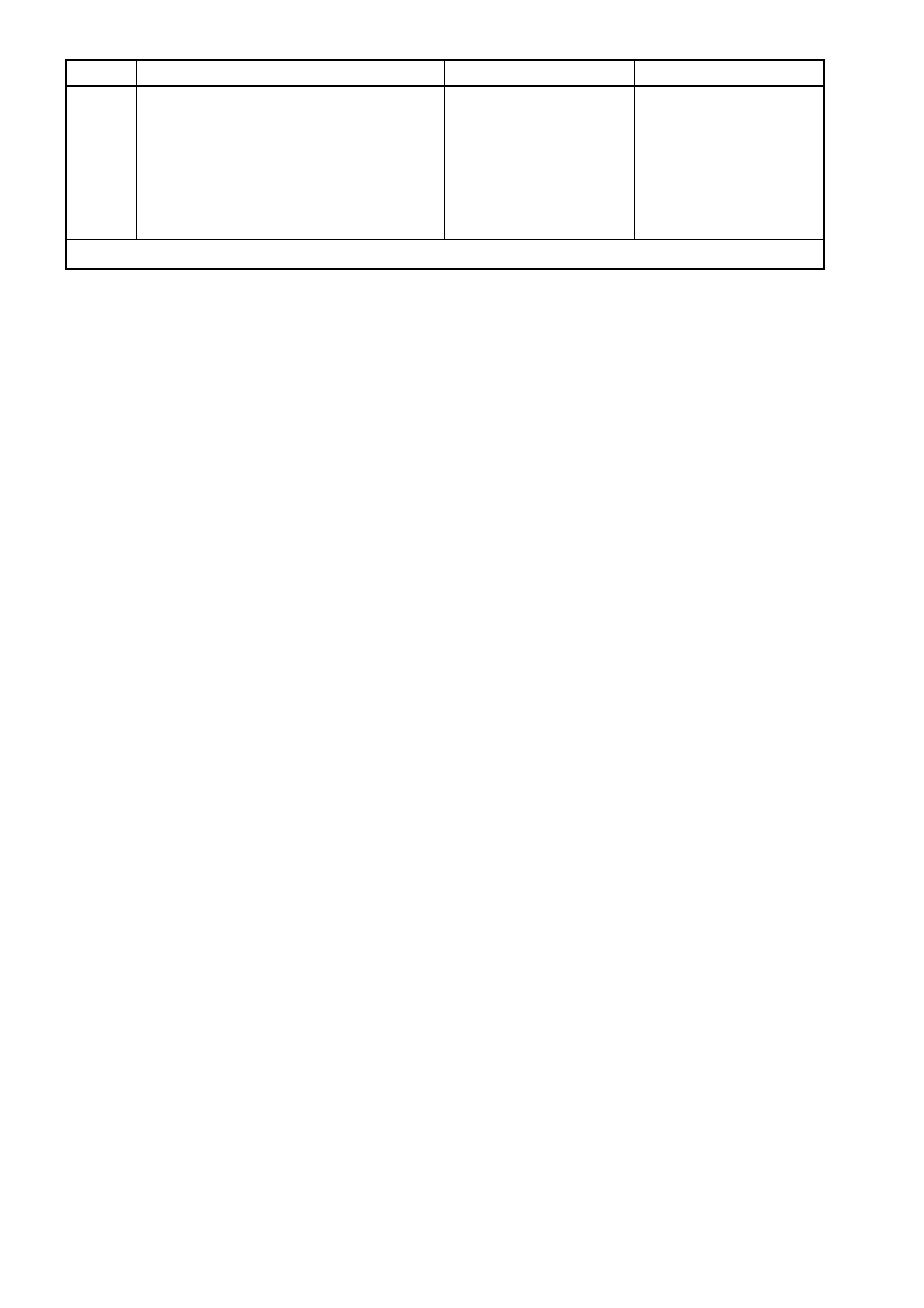

2. Open the rear compartment lid and remove the following from the rear of the processor, refer to Figure 12L–3:

a. Connector A139 – X1 (1).

b. Connector A139 – X2 (2).

c. Connector A139 – X3 (3).

d. Connector A139 – X4 (4).

3. Using the processor assembly removal tools (5) inserted as shown, carefully pull the processor assembly out of

the processor assembly case (6). The processor assembly removal tool can be obtained from Siemens VDO

Dayton or alternatively, the radio/CD removal tool (service tool 179 1308 0000) can be used.

Figure 12L–3

Legend

1. Connector A139 – X1

2. Connector A139 – X2 3. Connector A139 – X3

4. Connector A139 – X4 5. Processor Assembly Removal

Tool

6. Processor Assembly Case

Reinstall

Reinstallation of the processor is the reverse of the removal procedure noting the following. Upon completion of

installation, check the operation of the navigation system.

MOUNTING BRACKETS

Remove

The mounting brackets can be removed or reinstalled with the processor installed.

1. Remove the following fuses from the passenger compartment fuse and relay assembly :

a. radio fuse F23.

b. radio cellular phone fuse F16. Refer to Section 12O, 1.1 FUSES for location details .

2. Open the rear compartment lid and, referring to Figure 12L–3, remove the following from the rear of the

processor:

a. Connector A139 – X1 (1).

b. Connector A139 – X2 (2).

c. Connector A139 – X3 (3).

d. Connector A139 – X4 (4).

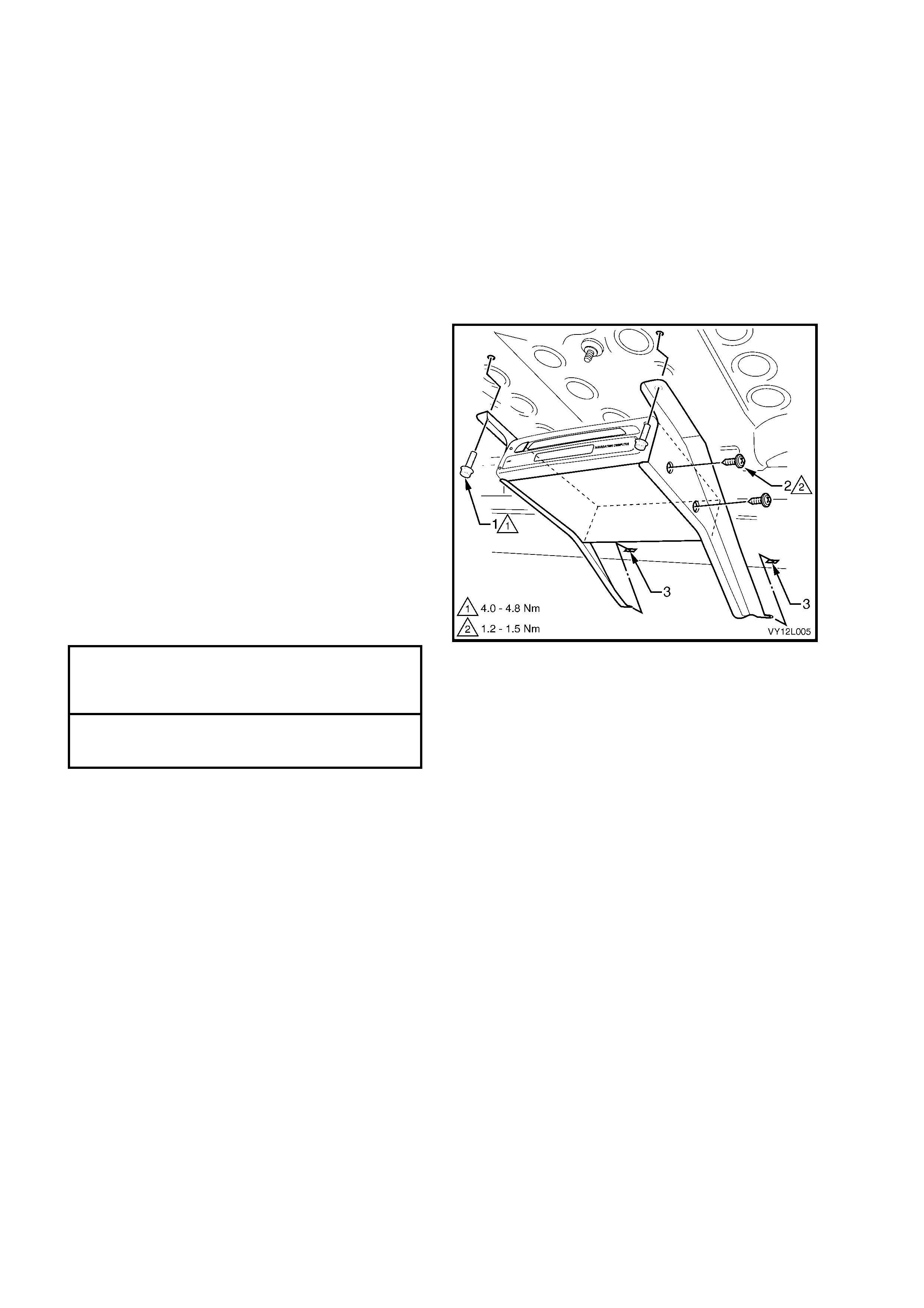

3. Remove the two screws (1) securing the

brackets to the rear window panel assembly.

NOTE: Support the processor assembly and

brackets when removing the screws (1). After

removing these screws, the processor assembly

drops away from the rear window panel assembly

unless supported.

4. Lower the processor assembly and pull away

from the retaining holes (3).

5. If required, remove the screws (2) in two

places attaching either bracket to the

processor assembly case.

Reinstall

Reinstallation of the brackets is the reverse of the

removal procedure. Tighten the screws to the

specified torque.

Figure 12L–4

PROCESSOR ASSEMBL Y MOUNTING

BRACKET TO REAR WINDOW PANEL

ASSEMBLY ATTACHING SCREWS

TORQUE SPECIFICATION 4.0 – 4.8 Nm

PROCESSOR ASSEMBL Y TO

MOUNTING BRACKET ATTACHING

SCREWS TORQUE SPECIFICATION 1.2 – 1.5 Nm

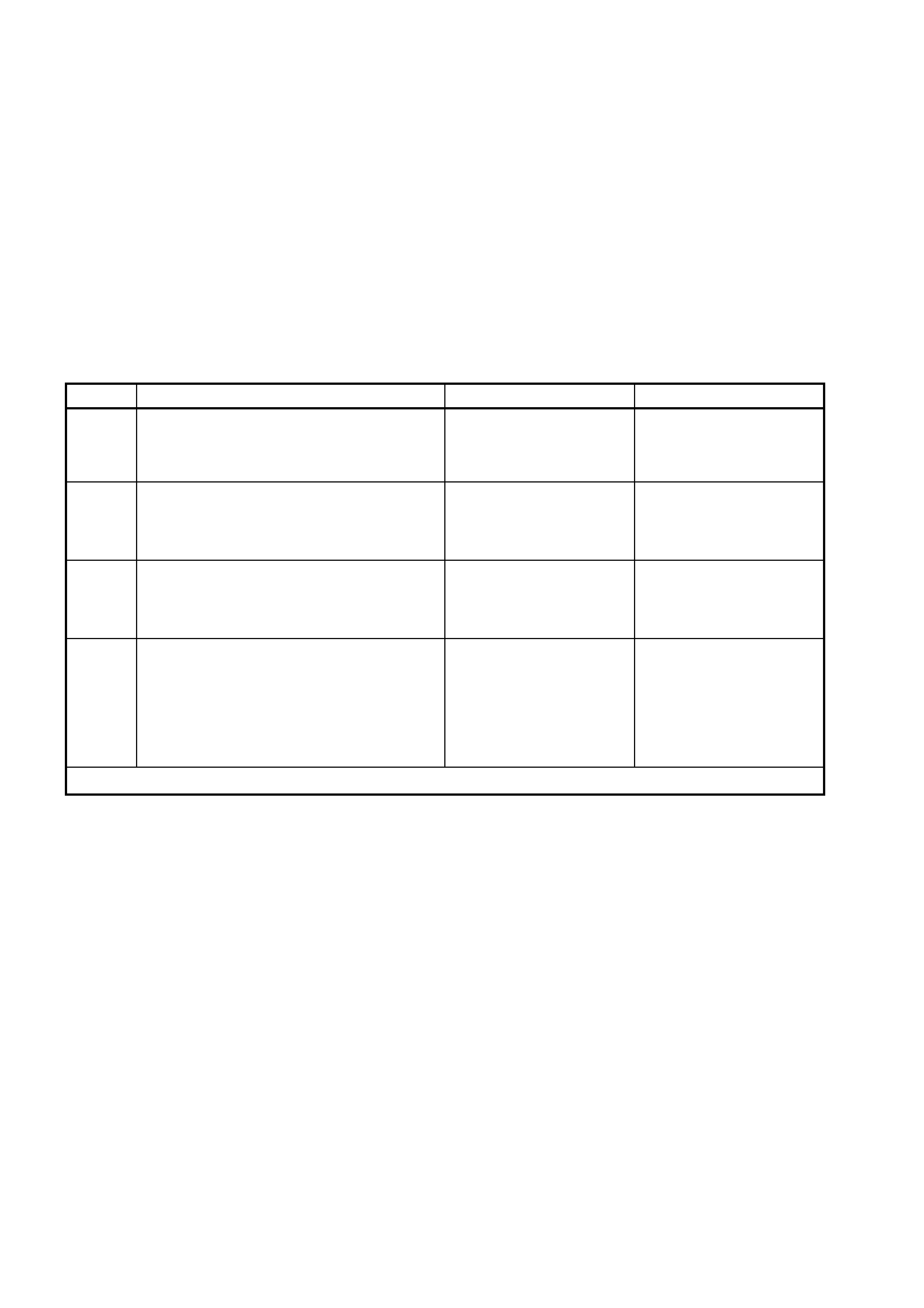

3.2 REMOTE CONTROL ASSEMBLY

LT Section –

The remote control assembly is located on the floor

console assembly, next to the automatic transmission

selector / manual gear lever assembly and consists of

the following items, refer to Figure 12L–8:

a. Remote control (1)

b. Remote control cradle (2)

c. Presenter (5)

d. Presenter m ounting wed ge ( 8)

REMOTE CONTROL CRADLE WITH PRESENTER

Remove

1. Remove the following fuses from the passenger compartment fuse and relay assembly :

a. Radio fuse F23.

b. Radio cellular phone fuse F16. Refer to Section 12O, 1.1 FUSES for location details.

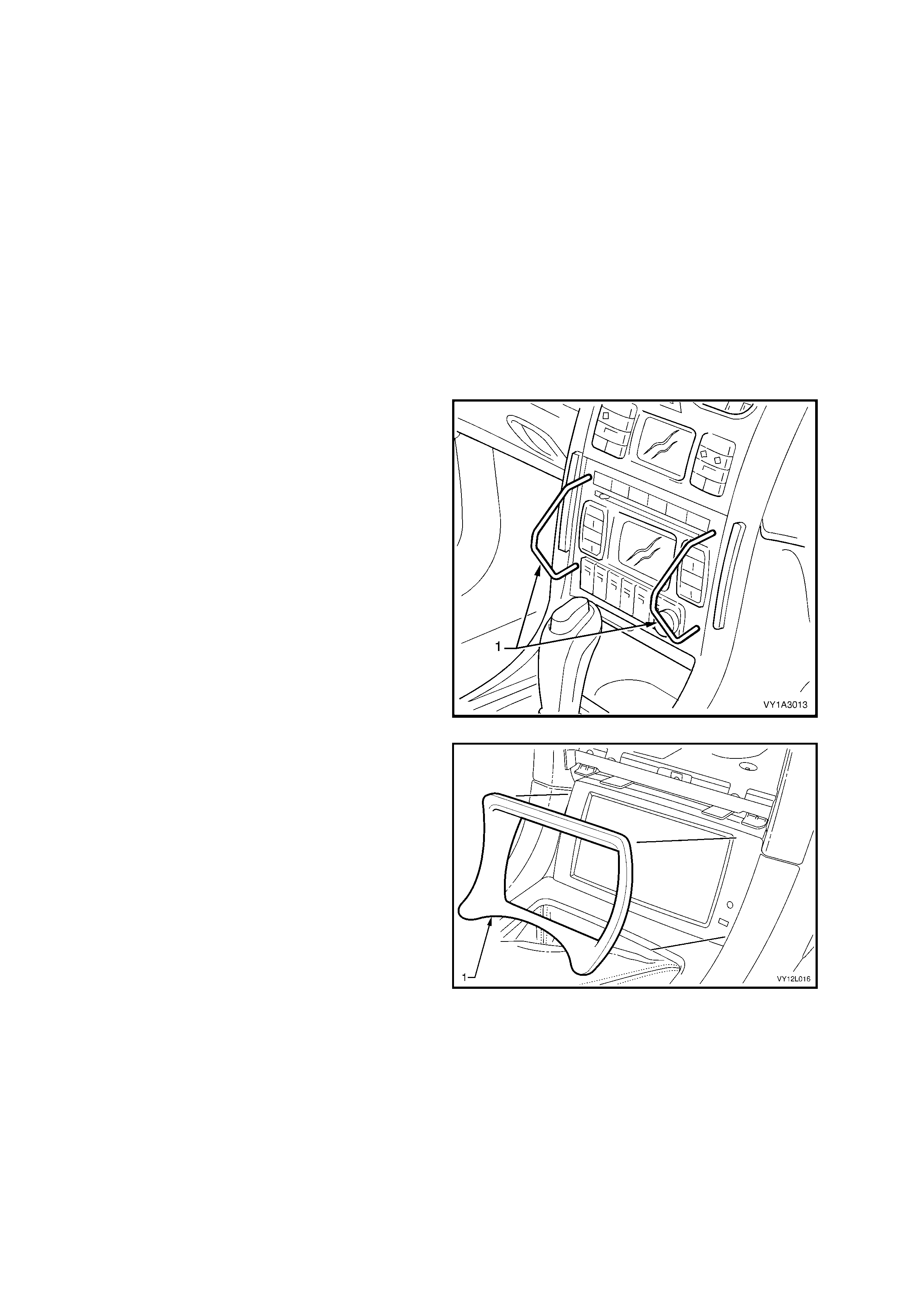

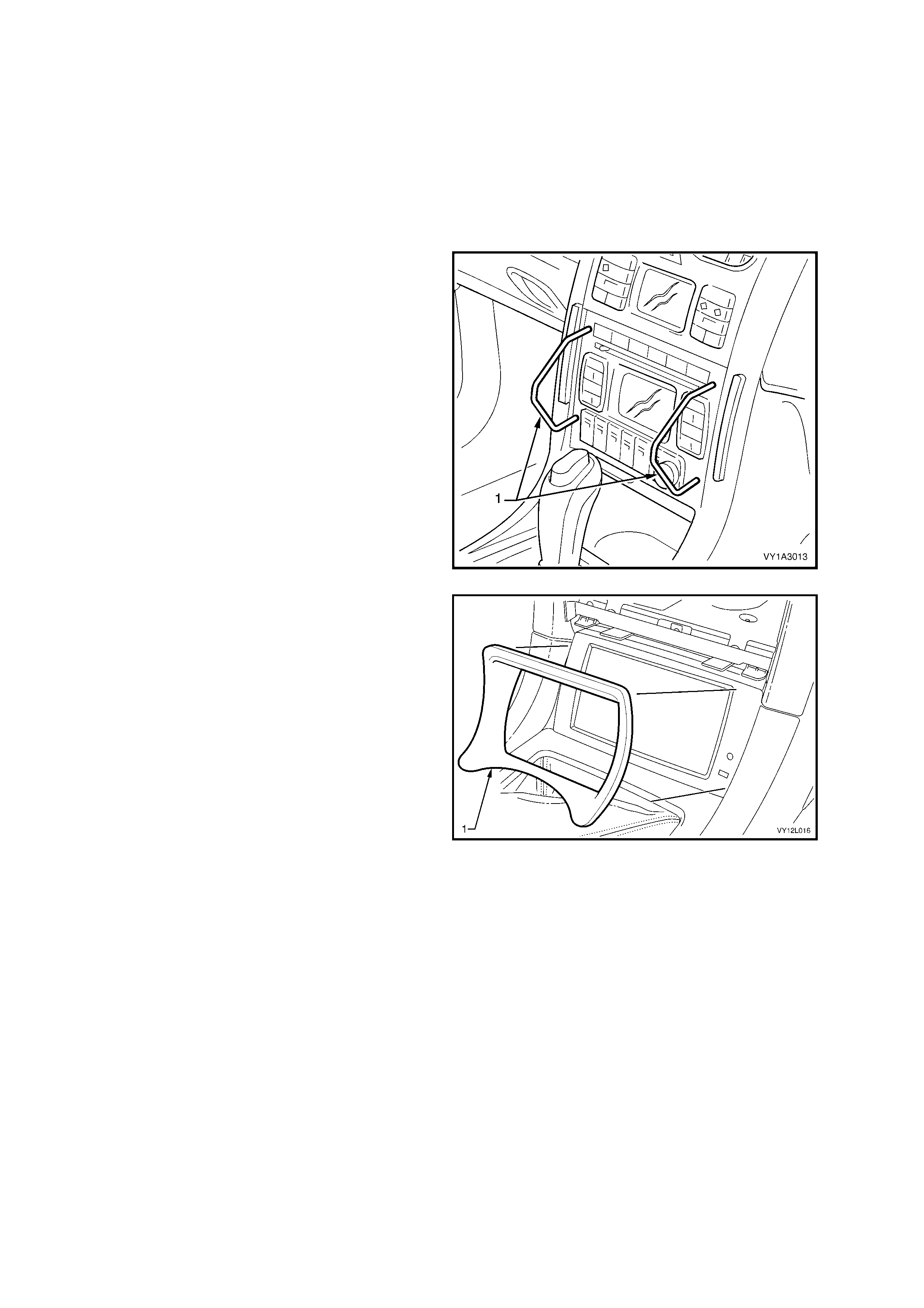

2. Insert the special tools KM6067 (1) into the

holes on each side of the radio assembly.

3. While applying outwards pressure on the tools

(towards each outer side of the vehicle), pull

the radio assembly out of the radio housing.

NOTE: The wiring connectors remain attached to

the radio housing and disconnect when the radio

assembly is removed.

Figure 12L–5

4. Remove the escutcheon (1).

5. Inspect the foam tape on the escutcheon for

serviceability.

Figure 12L–6

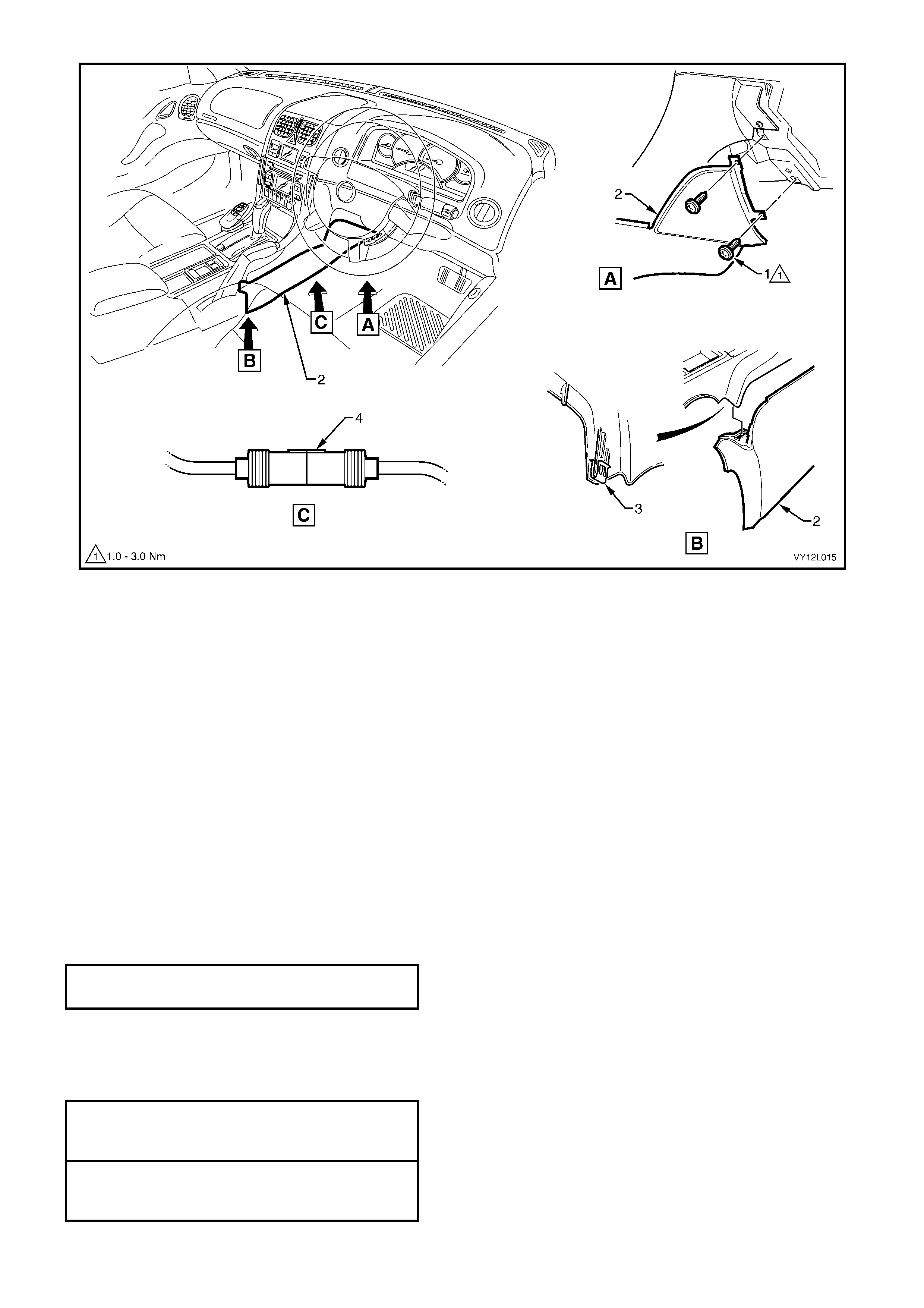

Refer to Figure 12L–7 for the following steps:

6. Open the instrument panel lower trim panel and remove the two screws (1) attaching the instrument panel

lower extension side trim (2) to the instrument panel.

7. Prise the rear of the extension side trim downward to disengage it from the floor console retaining clip (3).

8. Remove the extension side trim.

9. Disconnect the navigation wiring harness from the cockpit navigation wiring harness connector A35 (4).

Figure 12L–7

Legend

1. Screw

2. Instrument Panel Lower Extension Side Trim, Right-

hand Side

3. Floor Console Retaining Clip

4. Connector A35

Refer to Figure 12L–8 for the following steps:

10. Remove the remote control (1) from the remote control cradle (2).

Important: Do not pull or tug on the remote control cradle wiring harness.

11. Remove the three screws (3) and lift the cradle and place to one side.

12. Remove the two screws (4) and lift the presenter (5) and place to one side.

13. Remove the floor console cover, refer to Section 1A3, 2.1 FLOOR CONSOLE COVER ASSEMBLY.

14. Feed the remote control cradle wiring harness and connector (6) through the aperture in the floor console cover

assem bly.

Reinstall

Reinstallation of the remote control cradle with presenter is the reverse of the removal procedure noting the

following:

1. Replace the escutcheon foam tape if required.

2. Tighten the presenter attaching screws to the specified torque.

PRESENTER ATTACHING SCREWS

TORQUE SPECIFICATION 0.6 – 1.0 Nm

3. Do not pull or tug on the remote control cradle cable wiring harness when routeing to the navigation main wiring

harness connector.

4. Tighten the remote control cradle attaching screws to the specified torque.

5. Tighten the instrument panel lower extension side trim attaching screw to the specified torque.

REMOTE CONTROL CRADLE

ATTACHING SCREWS

TORQUE SPECIFICATION 0.7 – 1.0 Nm

INSTRUMENT PANEL LOWER EXTENSION

SIDE TRIM PANEL ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 12L–8

Legend

1. Remote Control

2. Remote Control Cradle

3. Screw

4. Screw

5. Presenter

6. Connector A35

7. Screw

8. Presenter Mounting Wedge

PRESENTER MOUNTING WEDGE

Remove

1. Remove the remote control cradle with presenter as detailed in this Section.

2. Remove the two screws (7) that secure the presenter mounter wedge (8) to the floor console cover assembly

and remove the presenter mounter wedge, refer to Figure 12L–8.

Reinstall

Reinstallation of the presenter mounter wedge is the reverse of the removal procedure. Tighten the screws to the

specified torque.

PRESENTER MOUNTING W EDGE

ATTACHING SCREWS

TORQUE SPECIFICATION 0.8 – 1.0 Nm

3.3 DISPLAY ASSEMBLY

LT Section –

The display assembly is located in the floor console assembly.

REMOVE

1. Remove the following fuses from the passenger compartment fuse and relay assembly :

a. Radio fuse F23.

b. Radio cellular phone fuse F16. Refer to Section 12O, 1.1 FUSES AND CIRCUIT BREAKERS for location

details.

2. Insert the special tools KM6067 (1) into the

holes on each side of the radio assembly.

3. While applying outwards pressure on the tools

(towards each outer side of the vehicle), pull

the radio assembly out of the radio housing.

NOTE: The wiring connectors remain attached to

the radio housing and disconnect when the radio

assembly is removed.

Figure 12L–9

4. Remove the escutcheon (1).

5. Inspect the foam tape on the escutcheon for

serviceability.

Figure 12L–10

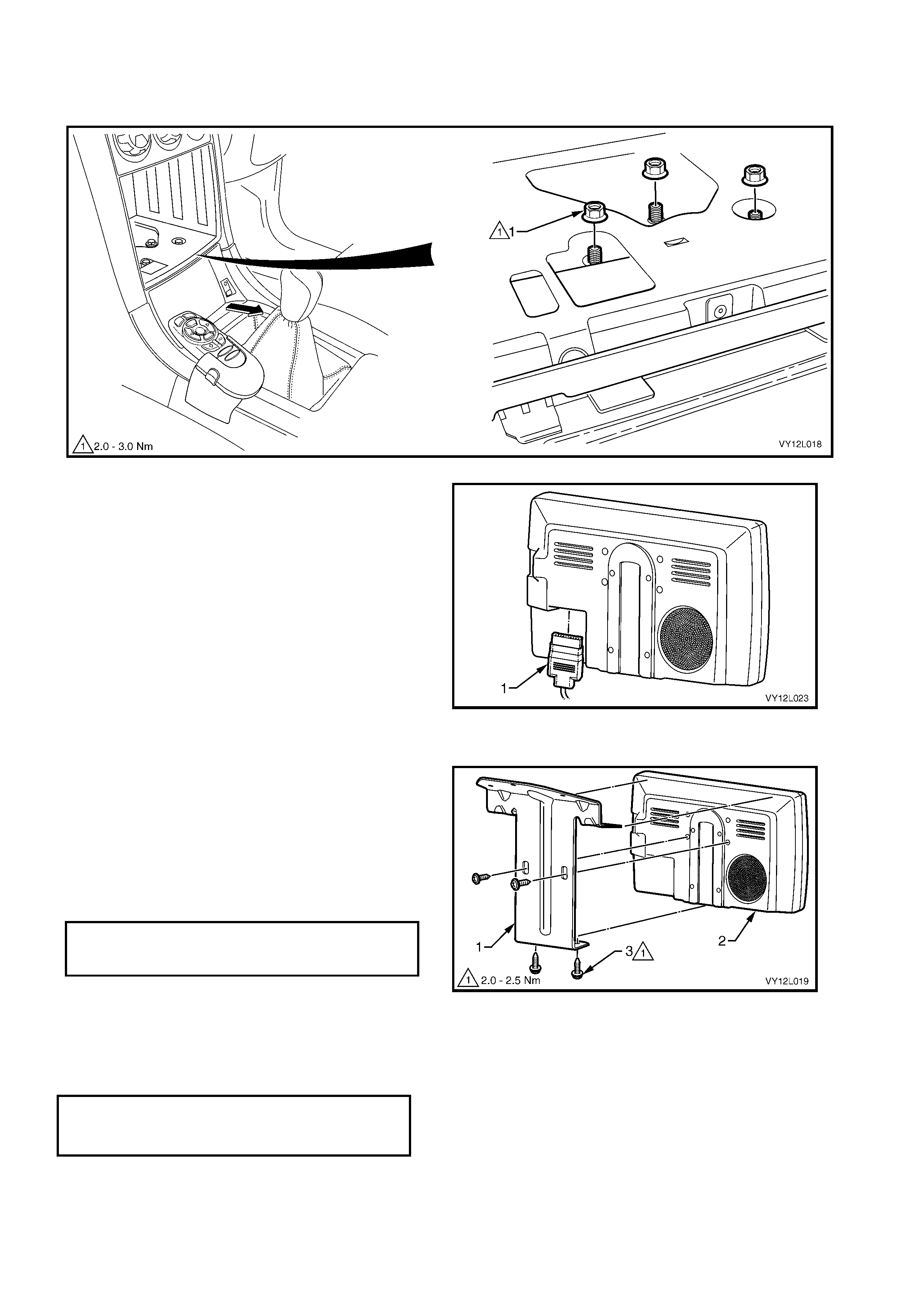

6. Remove the three nuts (1) securing the display assembly mounting bracket to the radio housing, refer to

Figure 12L–11 .

7. Slowly pivot the lower part of the display assembly up and to the rear of the vehicle.

Figure 12L–11

8. Disconnect the cockpit navigation wiring

harness connector P6 (1), from the display

assem bly.

9. Remove the display assembly.

Figure 12L–12

DISASSEMBLE

1. Remove the three screws (3) securing the

display assembly mounting bracket (1) to the

display assem bly (2).

REASSEMBLE

Reassem bly of the displa y assem bly is th e reverse

of the disassembly procedure. Tighten the screws

to the specified torque.

Figure 12L–13

REINST ALL

Reinstallation of the display assembly is the reverse of the removal procedure noting the following:

1. Tighten the three nuts to the specified torque.

DISPLAY ASSEMBLY MOUNTING

BRACKET ATTACHING NUTS

TORQUE SPECIFICATION 2.0 – 3.0 Nm

2. Check for the correct operation of the display.

DISPLAY ASSEMBLY MOUNTING

BRACKET TO DISPLAY ATTACHING

SCREW TORQUE SPECIFICATION 2.0 – 2.5 Nm

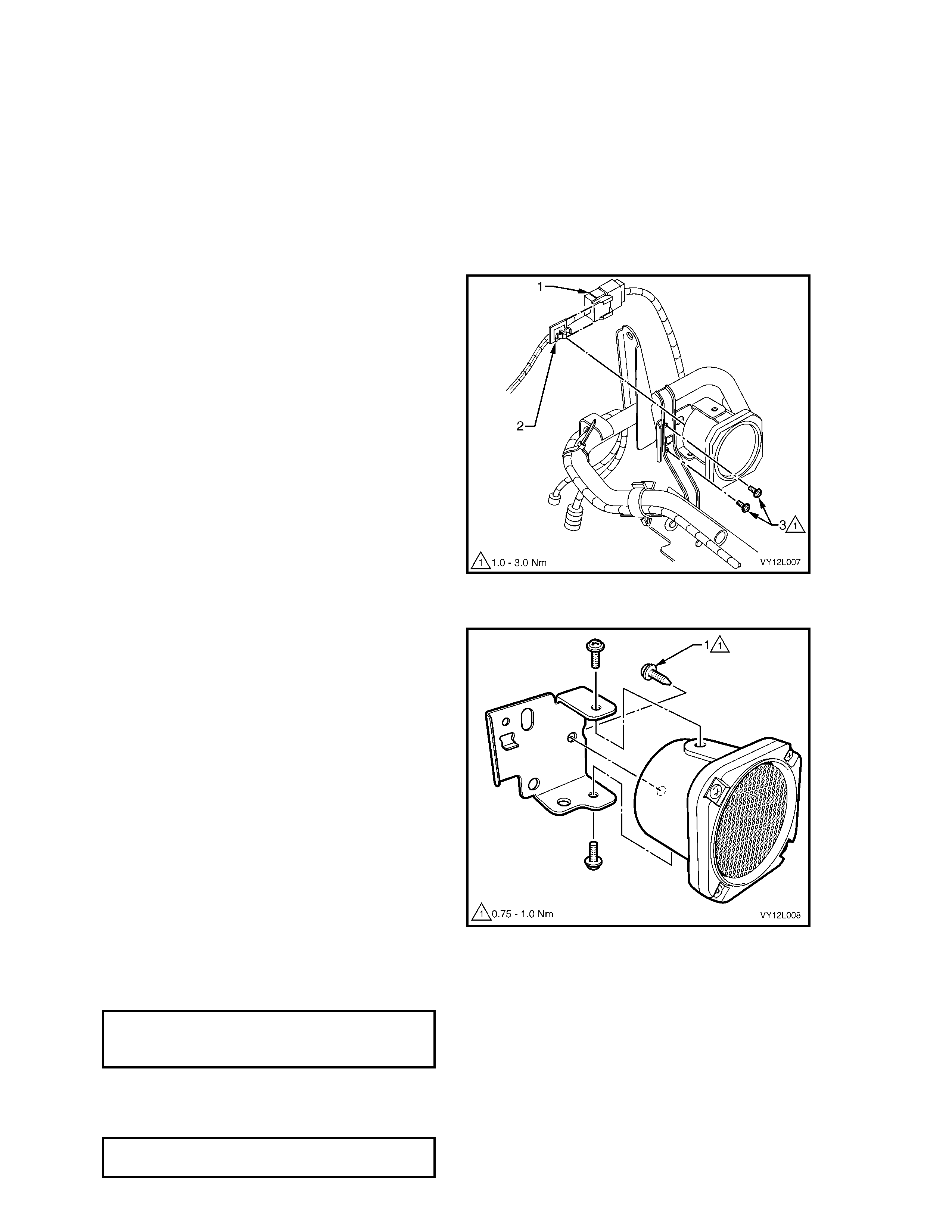

3.4 NAVIGATION SPEAKER ASSEMBLY

LT Section –

REMOVE

1. R em ove the follow ing fuses from the passenger compartment fu se and relay asse m bly:

a. Radio fuse F23.

b. Radio cellular p hone fuse F16. Refer to Section 12O, 1.1 FUSES for location details.

2. Remove the left-hand instrument panel lower trim plate assembly, refer to Section 1A3, 3.1 INSTRUMENT

PANEL LOWER TRIM PLATE ASSEMBLY .

3. Remove the instrument panel compartment assembly, refer to Section 1A3, 3.2 INSTRUMENT PANEL

COMPARTMENT ASSEM BLY.

4. Disconnect the speaker connector B104 (1)

from the navigation wiring harness.

5. Remove the clip (2) from the speaker assembly

plate.

6. Remove th e speaker assem bl y attach ing scr ew

(3) and rem ove the speaker assembly.

Figure 12L–14

DISASSEMBLE

1. Remove the screws (1 and 2) securing the

speaker to the speaker assembly plate and

separate the two items.

Figure 12L–15

REASSEMBLE

Reassembly of the speaker assembly is the reverse of the disassembly procedure. Tighten the screws to the

speci fied torqu e.

SPEAKER TO SPEAKER ASSEMBLY

PLATE ATTACHING SCREWS

TORQUE SPECIFICATION 0.75 – 1.0 Nm

REINSTALL

Reinstallation of the navigation speaker assembly is the reverse of the removal procedure. Tighten the screws to

the spe cif ied to rque.

SPEAKER ASSEMBLY ATTACHING

SCREW TORQUE SPECIFICATION 1.0 – 3.0 Nm

3.5 NAVIGATION WIRING HA RNESS

LT Section –

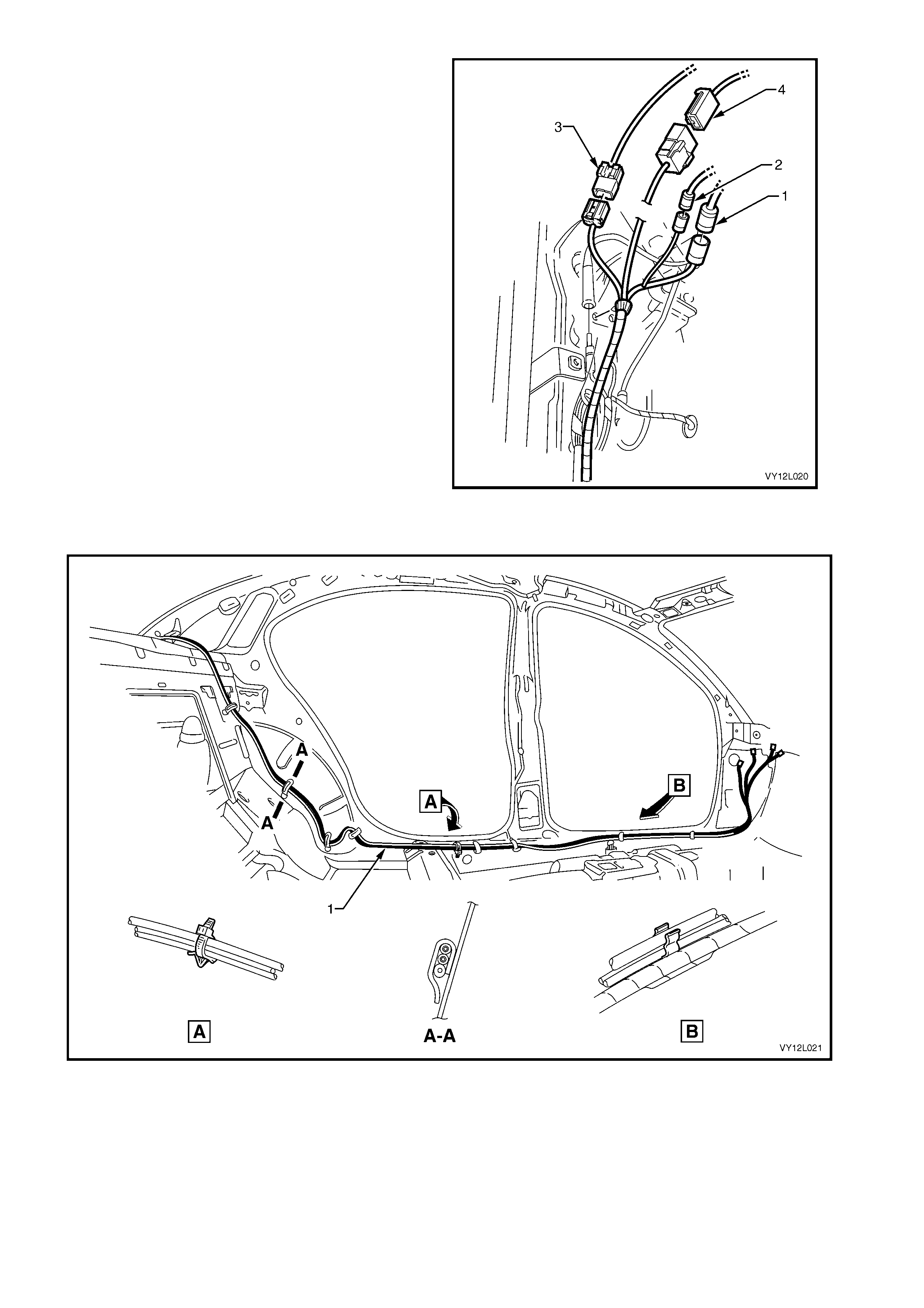

The na vigation wiring har ness (1) is rout ed from t he rear com partment , along the lef t-hand sid e of the veh icle and

termi nate s at the h inge pilla r trim a ssembl y, ref er to Fi gure 12L– 16. Her e, the h ar ness con nects to the bo dy w iring

harne ss of the ve hicle at co nne ctor X207 and t he cock pit naviga tion wiring h arne ss with conn ectors XO 1, XO 2 and

B104.

Figure 12L–16

REMOVE

1. R em ove the follow ing fuses from the passenger compartment fu se and relay asse m bly:

a. Radio fuse F23.

b. Radio cellular p hone fuse F16. Refer to Section 12O, 1.1 FUSES for location details.

2. Open the rear compartment lid and, referring to Figure 12L–3 , remove the following from the rear of the

processor:

a. Conn e cto r A139 – X1 (1).

b. Conn e cto r A139 – X2 (2).

c. Conne ctor A139 – X3 (3).

d. Conn e cto r A139 – X4 (4).

3. Remove the rear seat cushion and seat back. Refer to Section 1A7:

a. 6.2 REAR SEAT CUSHION ASSEMBLY for the sedan rear seat cushion assembly, and

b. 6.3 REAR SEAT — BACK ASSEMBLY for the sedan rear seat back assembly. Or

c. 8.1 REAR SEAT CUSHI ON ASSEMBLY for th e coupe rear seat cushion a ssembly, and

d. 8.2 REAR SEAT — BACK ASSEMBLY for the cou pe rear back assembly.

4. R em ove the left- hand side sill t rim and plate, refer to Section 1A8, 2. 4 S IDE SILL TRIM AND PLATE.

5. Remove the left-hand hinge pillar trim assembly, refer to Section 1A8, 2.8 HINGE PILLA R TRIM ASSEMBLY.

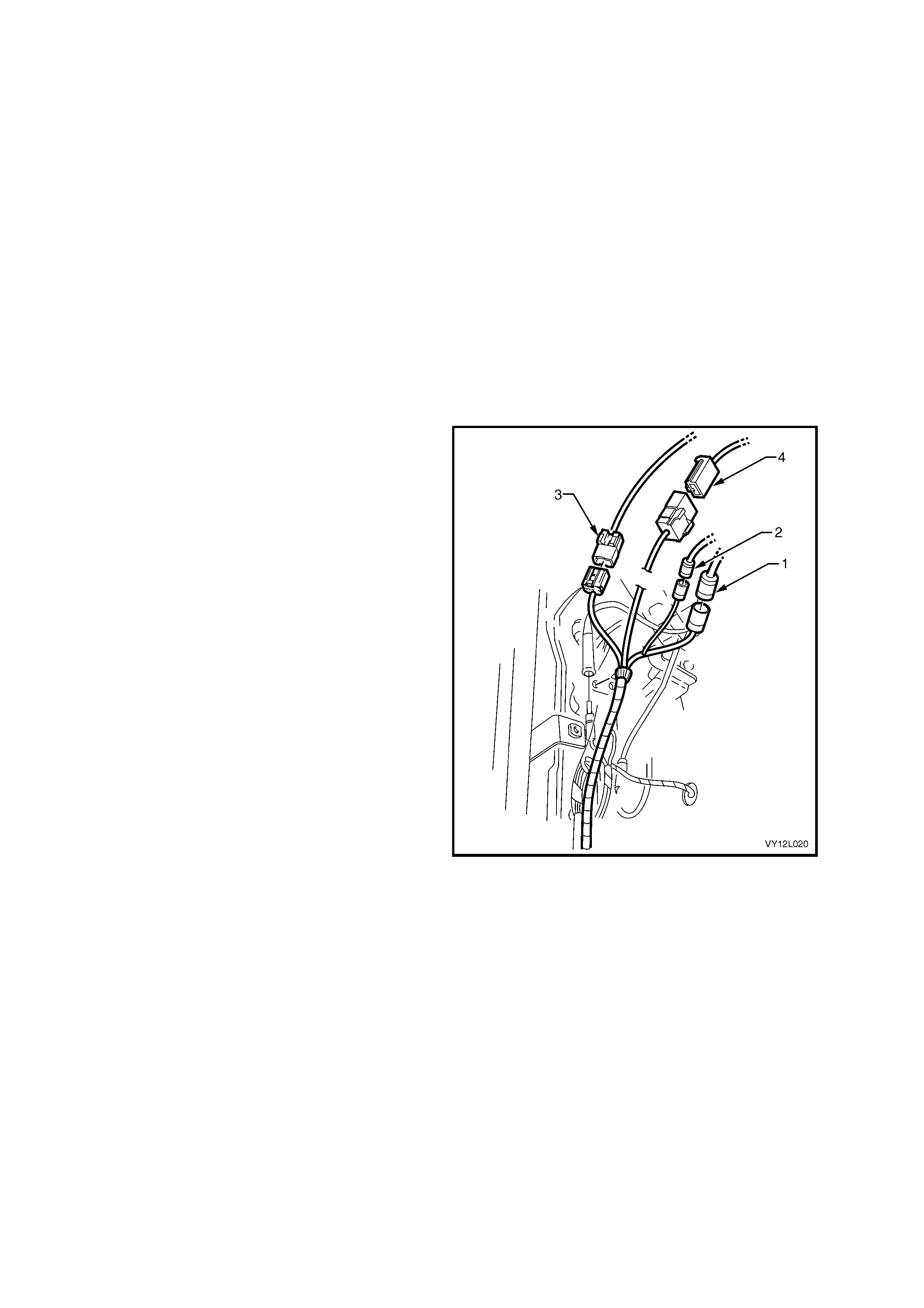

6. Disconnect the following at the left-hand hinge

pillar trim assembly:

a. XO1 (1).

b. XO2 (2).

c. X207 (3).

d. B104 (4).

Figure 12L–17

7. As required, cut the cable ties securing the navigation wiring harness (1) to the sheetmetal, refer to

Figure 12L–18 for Sedan and Figure 12L–19 for Coupe.

Figure 12L–18

Figure 12L–19

8. For Sedan, remove all clips attaching the

navigation wiring harness (1) to the rear

window panel assembly. Feed the navigation

wiring harness through the rear window panel

assem bly.

NOTE: The navigation wiring harness is too long

for Sedan vehicl es. Any exc ess har nes s is car ef ull y

looped and tied together, and placed through the

panel assembly at the designated point (2).

Figure 12L–20

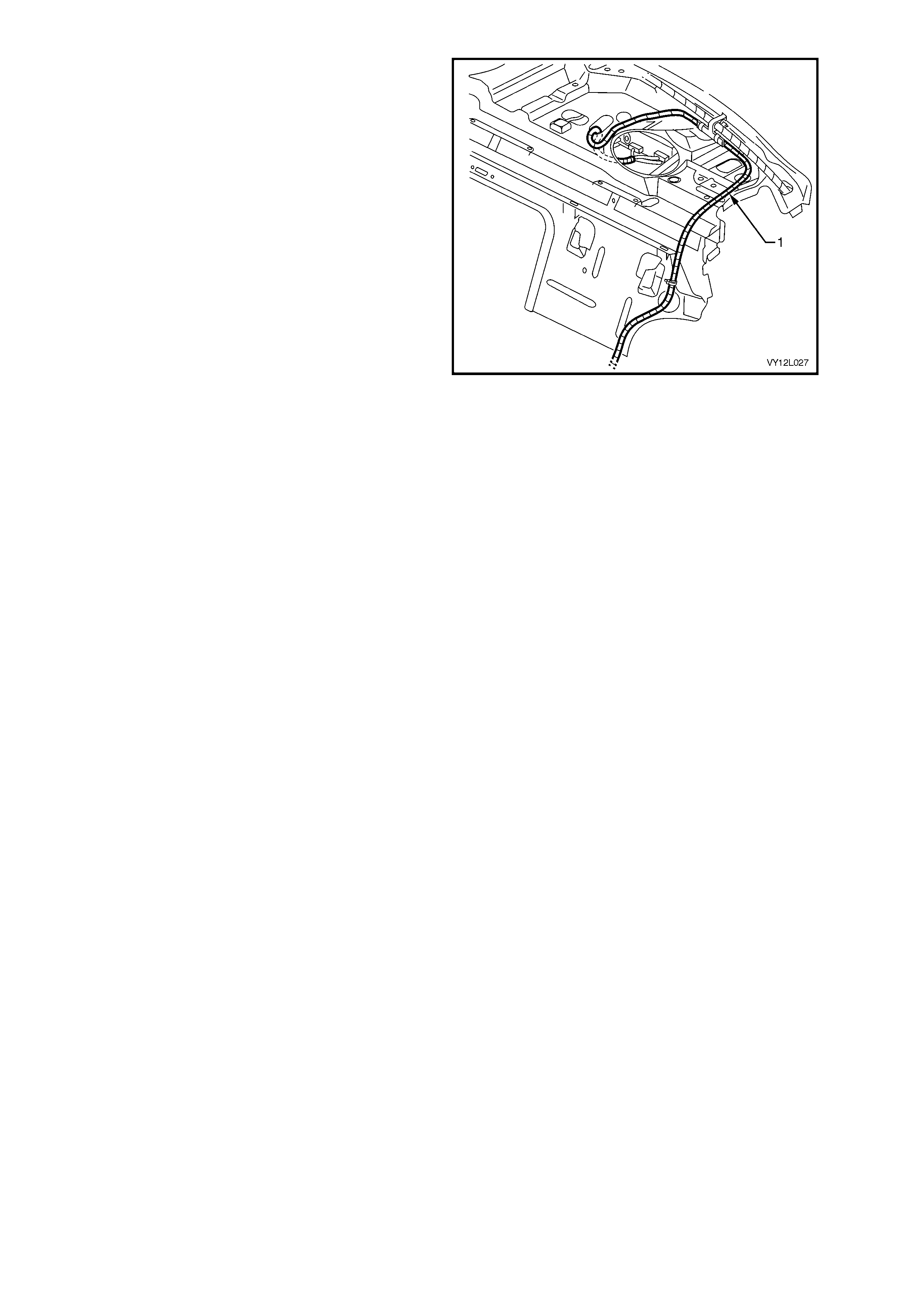

9. For Coupe:

a. Lift the rear window panel insulator to gain

access to the navigation wiring harness

b. Remove all clips attaching the navigation

wiring harness to the rear window panel

assem bly.

c. Feed the naviga tion wiring har ness thr ough t he

rear windo w panel assembly.

10. Rem ove the na v igat io n wir ing harness f r om the

vehicle.

Figure 12L–21

REINST ALL

Reinstallation of the navigation wiring harness is the reverse of the removal procedure noting the following:

1. Replace all the clips and ties where required.

2. Ensure that excess wiring harness is looped, tied and placed through t he rear window panel assem bly (at the

designated point (2), refer to Figure 12L–20).

3. Connect all electrical connectors and check the operation of the navigation system before installing the seat

and trim assemblies.

3.6 COCKPIT NAVIGATION WIRING HARNESS

LT Section –

The cockpit navigation wiring harness connects to the navigation wiring harness under the left-hand hinge pillar trim

assembly, using connectors XO1 and XO2. The cockpit navigation wiring harness is then routed under the hinge

pillar trim assembly, along the instrument panel lower bracket, behind the radio housing and terminates under the

front right-hand side of the floor console cover assembly.

REMOVE

1. Remove the display assembly, refer to 3.3 DISPLAY ASSEMBLY.

2. Remove both the ins tr ument panel lo wer ex tensi ons , r ef er to Sectio n 1 A3, 3.9 IN ST RUM ENT P ANEL LOWER

EXTENSION.

3. Remove the right-hand instrument panel lower extension side trim, refer to Section 1A3, 2.2 INSTRUMENT

PANEL LOWER EXTENSION SIDE TRIM.

4. Remove the left-hand instrument panel lower trim plate assembly, refer to Section 1A3, 3.1 INSTRUMENT

PANEL LOWER PLATE ASSEMBLY.

5. Remove the instrument panel compartment assembly, refer to Section 1A3, 3.2 INSTRUMENT PANEL

COMPARTMENT ASSEMBLY.

6. Remove the left-hand hinge pillar trim assembly, refer to Section 1A8, 2.8 HINGE PILLAR TRIM ASSEMBLY.

7. Disconnect the following from beneath the left-

hand hinge pillar trim assembly:

a. XO1 (1).

b. XO2 (2).

c. X207 (3).

Figure 12L–22

Refer to Figure 12L–23 for the following steps:

8. Disconnect the remote control cradle from the cockpit wiring harness connector A35 (1).

9. As requir ed cut the cable t ies secur ing the cockpit nav igation wiring har ness (2) to the v ehicle and rem ove the

harness.

Figure 12L–23

Legend

1. Connector A35

2. Cockpit Navigation Wiring Harness 3. Connector P6

REINST ALL

Reinstallation of the cockpit navigation wiring harness is the reverse of removal procedure, noting the following:

1. Ensure that all clips and ties are installed in the correct locations.

2. Check the operation of the navigation system.

3.7 GPS ANTENNA ASSEMBLY

LT Section –

REMOVE

1. Remove the following fuses from the passenger compartment fuse and relay assembly :

a. Radio fuse F23.

b. Radio cellular phone fuse F16. Refer to Section 12O, 1.1 FUSES AND for location details.

2 Disconnect the navigation antenna connector A139 – X4 from the rear of the processor assembly, refer to

Figure 12L–3.

3. Remove the rear window trim panel assembly, refer to Section 1A8, 2.9 REAR WINDOW TRIM PANEL

ASSEM BLY.

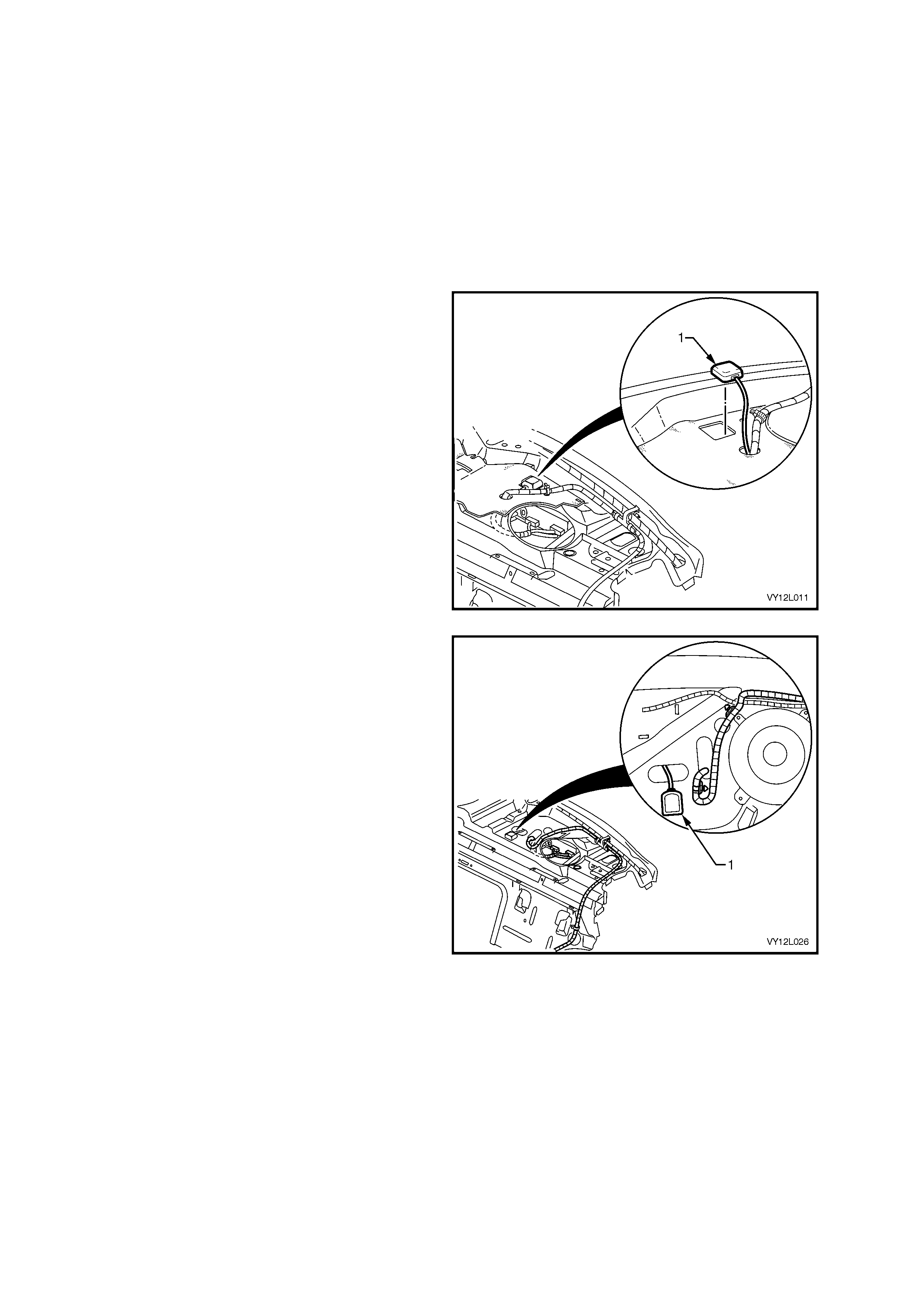

4. For Sedan, using a flat blade screwdriver,

carefully prise the antenna (1) from the rear

window panel assembly.

IMPORTANT: The GPS antenna assembly is

secured in place with dou bl e-s ided tap e.

Figure 12L–24

5. For Coupe:

a. Lift the rear window panel insulator to gain

access to the navigation wiring harness.

b. Using a flat blade screwdriver, carefully prise

the antenna (1) from the rear window panel

assem bly.

IMPORTANT: The GPS antenna assembly is

secured in place with dou bl e-s ided tap e.

6. Pull the GPS antenna assembly cable through

the rear window panel assembly and remove

the antenna.

Figure 12L–25

REINST ALL

Reinstallation of the GPS antenna assembly is the reverse of the removal procedure, noting the following:

1. Clean the rear window panel assembly to remove any residue of the double-sided tape.

2. If required, replace the double-sided tape on the navigation antenna with 3M® brand 4428 or equivalent.

3. Ensure the GPS antenna assembly is secured to the rear window panel assembly.

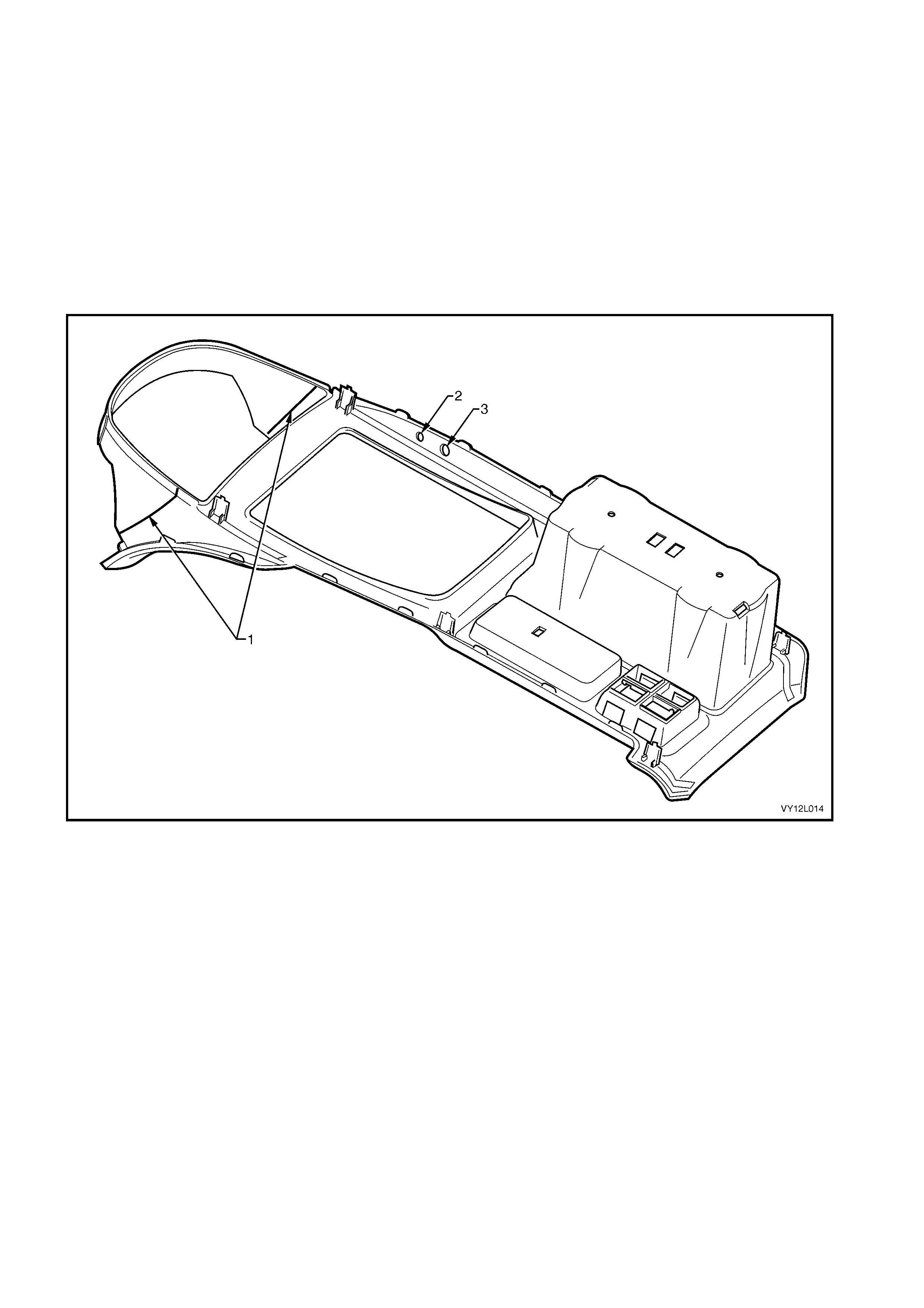

3.8 FITTING A NEW FLOOR CONSOLE COVER ASSEMBLY

LT Section –

The following procedure details how to modify the floor console cover assembly to allow for installation of the

navigation system.

1. Cut through the two lines (1) marked on the underside of the floor console cover assembly.

IMPORTANT: Use blunt drill bits to avoid the plastic splitting.

2. Drill two pilot holes thr ough the floor c onsole cover as sembly at the m arks (2 and 3) on th e underside, ref er to

Figure 12L–26 .

3. Enlarge the hole (2) to 10 mm and the hole (3) to 14 mm.

4. Remove any burrs from both holes.

5. To install the new floor console cover assembly, refer to 3.2 REMOTE CONTROL ASSEMBLY in this Section.

Figure 12L–26

3.9 FITTING A NEW FLOOR CONSOLE ASSEMBLY

LT Section –

If a floor console assembly needs to be replaced on a navigation s ystem-equipped vehicle, the new floor console

assembly does not have the nutserts required for the attachment of the presenter mounting wedge. Two nutserts

and scre ws ar e used to att ac h the pr ese nter mounting wed ge, r ef er to F ig ure 12L –8, t o th e f loor co ns ol e assembly.

The nutserts can be used from the previous console assembly or new nutserts can be ordered.

3.10 NAVIGATION SYSTEM CALIBR ATION

LT Section –

The navigation system requires calibration only if the vehicle has been moved without the navigation system

activate d or if the vehic le’s batter y had been dis connected withou t allowing th e system to shut down properl y. T he

navigation system requires 30 seconds to shut down before disconnection.

Calibrat ion of the n aviga tion s ystem is per form ed auto m aticall y when t he ve hicl e m oves and the navi gation system

activated. Calibration does not need to be performed by the technician, but if the customer is unaware of

calibration requirements, he/she may believe the system is not functioning correctly.

For the system to calibrate, the following must be performed:

• The navigation system must be activated.

• The vehicle must be driven until the arrow representing the vehicle is correctly aligned with the digital map

displayed on the monitor.

NOTE: The more turns taken during calibration, the faster the system calibrates.

4. SYSTEM DIAGNOSIS

Diagnostic tables contained in this Section, list both t echnical problems and comm on faults found due to im proper

use of the navigation system. 4.1 WIRING DIAGRAM and 4.2 CONNECTOR CHART should be used with the

diagnostic tables to fault-find the navigation system.

It is advantageous to read the Satellite Navigation Handbook Supplement supplied with the navigation system

before performing diagnosis on the system.

NOTE: If the proc essor ass em bly needs t o be r em oved or disc onnec ted f rom the veh icle p ower s uppl y, ensu re the

processor assembly has shut down completely. The red LED on the processor assembly extinguishes when the

processor assembly is shut off. Allow approximately 30 seconds after the ignition is turned off for the processor

assembly to shut down.

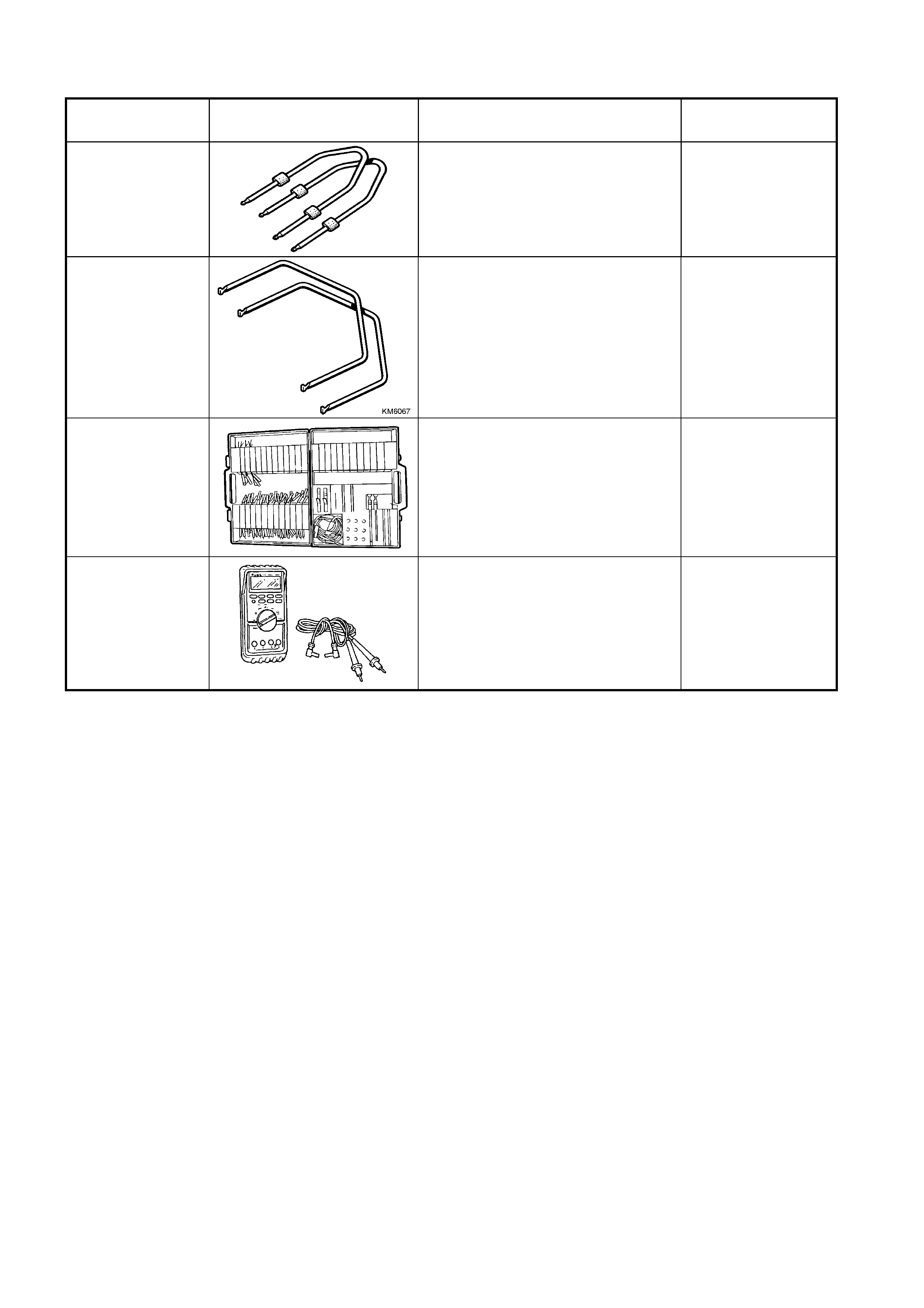

PREREQUISITES

Safety Requirements

When operating the navigation s ystem as part of any of the Steps in the diagnos is charts, ensure tha t fingers and

limbs are clear of moving parts.

Equipment

The following equipment is required to diagnose the navigation system:

1. An unpowered test lamp with a current draw of less than 3 A.

2. A digital multimeter with a minimum impedance of 10 MΩ.

Testing Proc e dur es

Adhere to the following points when performing diagnostic testing on navigation system components:

1. Care must be taken when using testing equipment to diagnose wiring harness connectors. The technician

should back-probe the connector to avoid terminal damage.

2. When tests are required on connector terminals, use the adapters in the connector adapter kit KM–609 to

prevent damage to the terminals.

3. Unless the multimeter being used has an auto-ranging function, ensure the correct range is selected.

4. When back-probing connectors, ensure the test lamp earth lead is connected to a suitable earth point on the

vehicle. Ensure this earth point is not part of the circuit being tested.

Important:

When following the Steps in the diagnosis charts, ensure work is performed in the order in which they are

presented. If the required nominal value or result is not achieved, rectify the problem before proceeding.

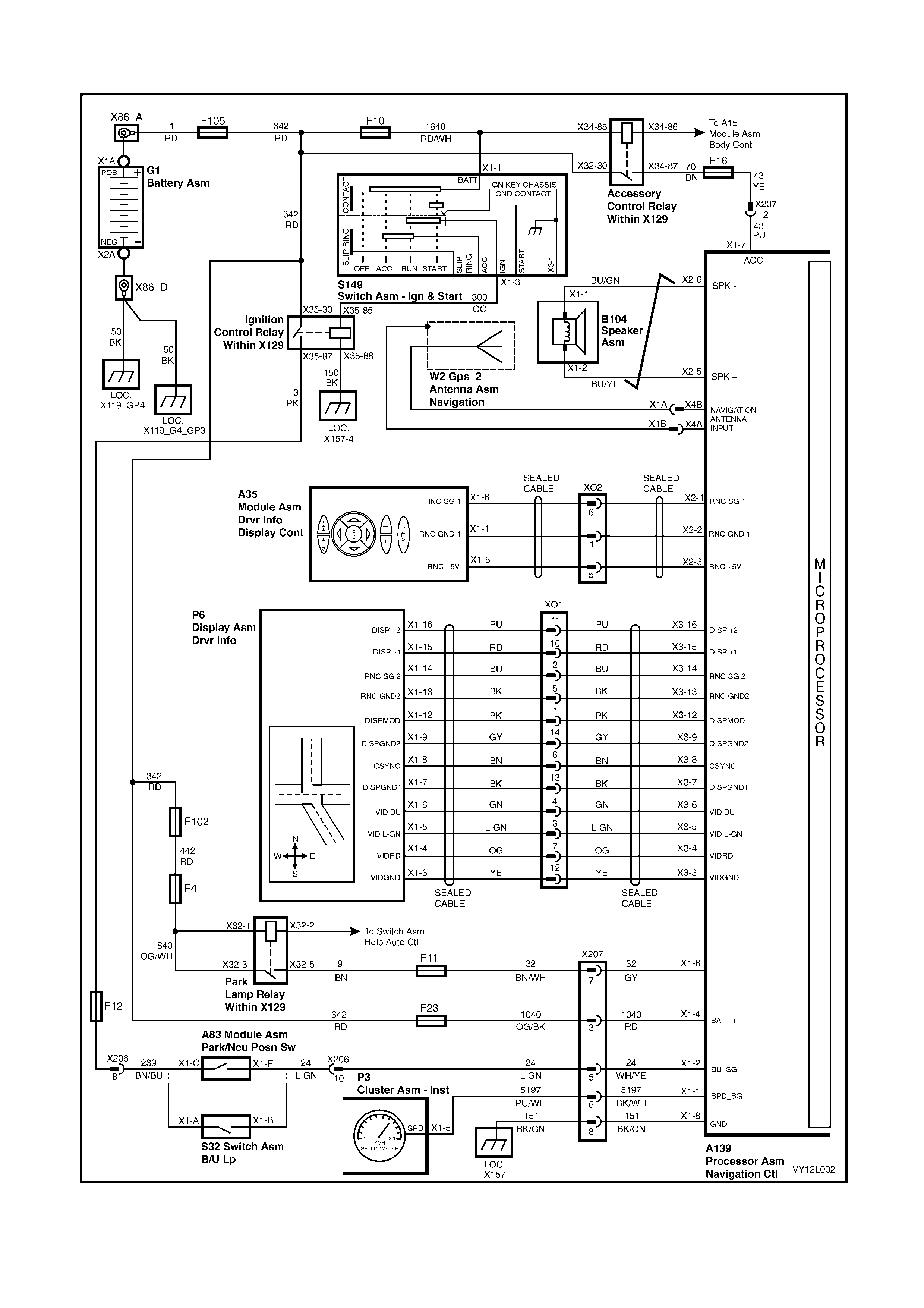

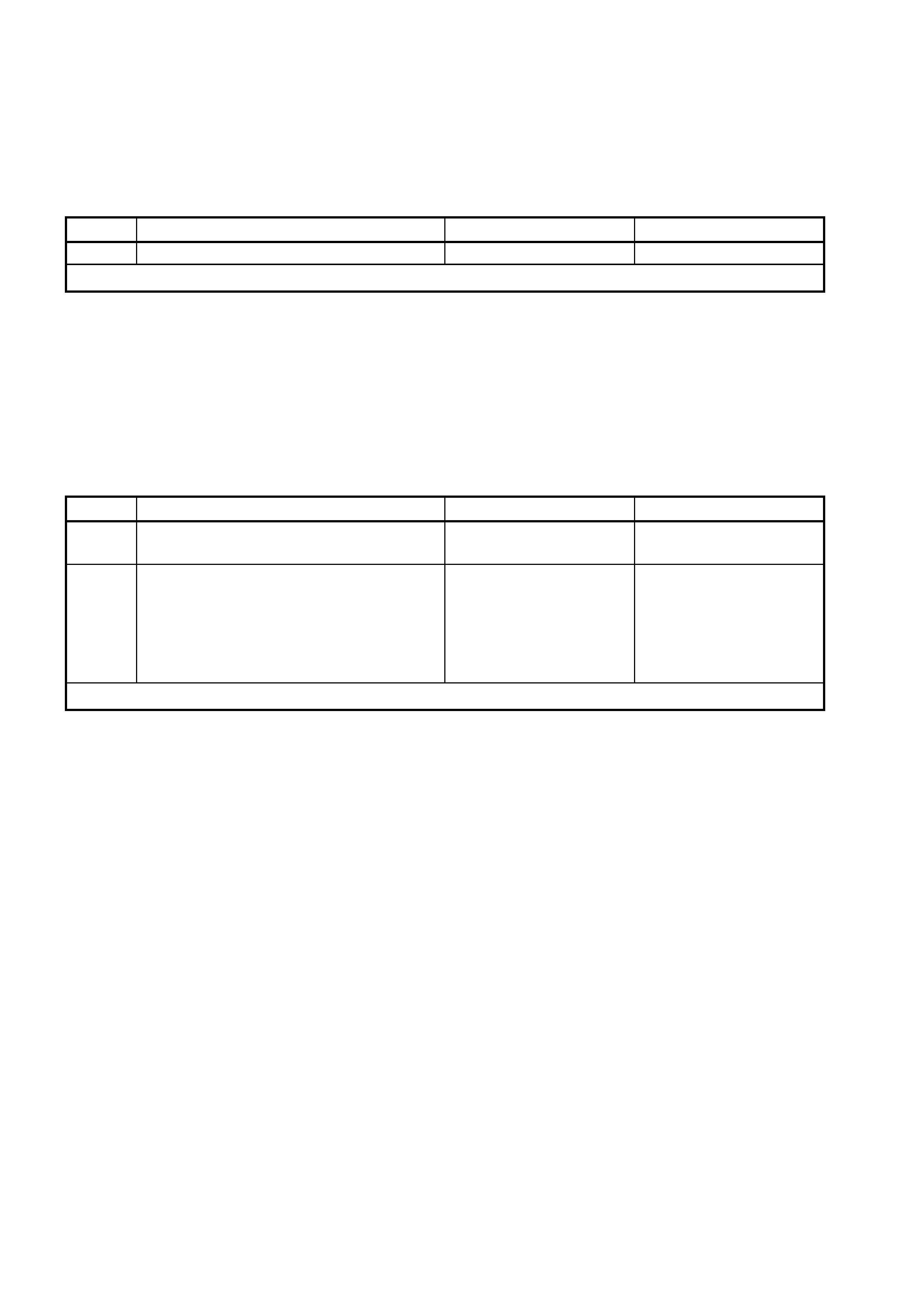

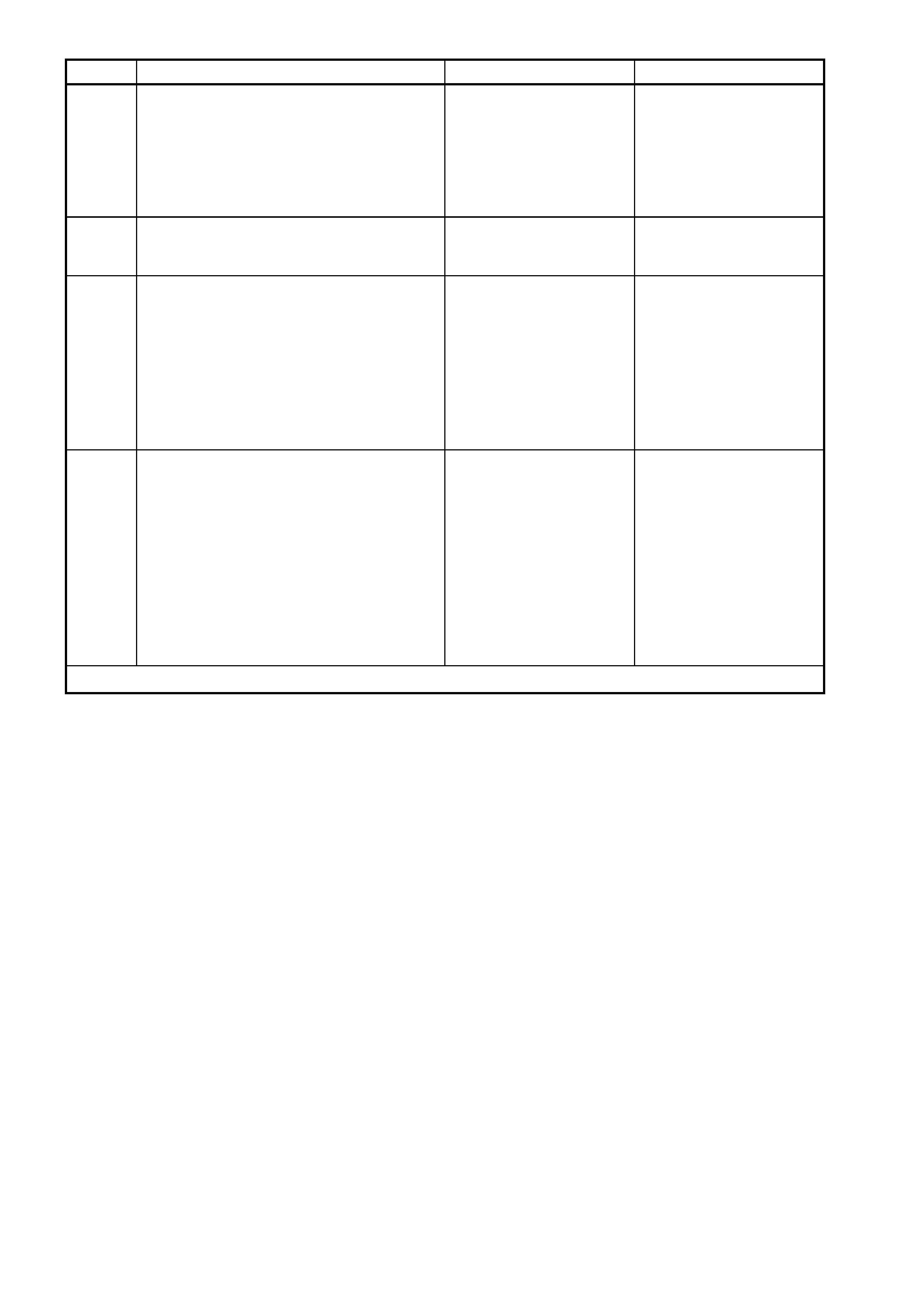

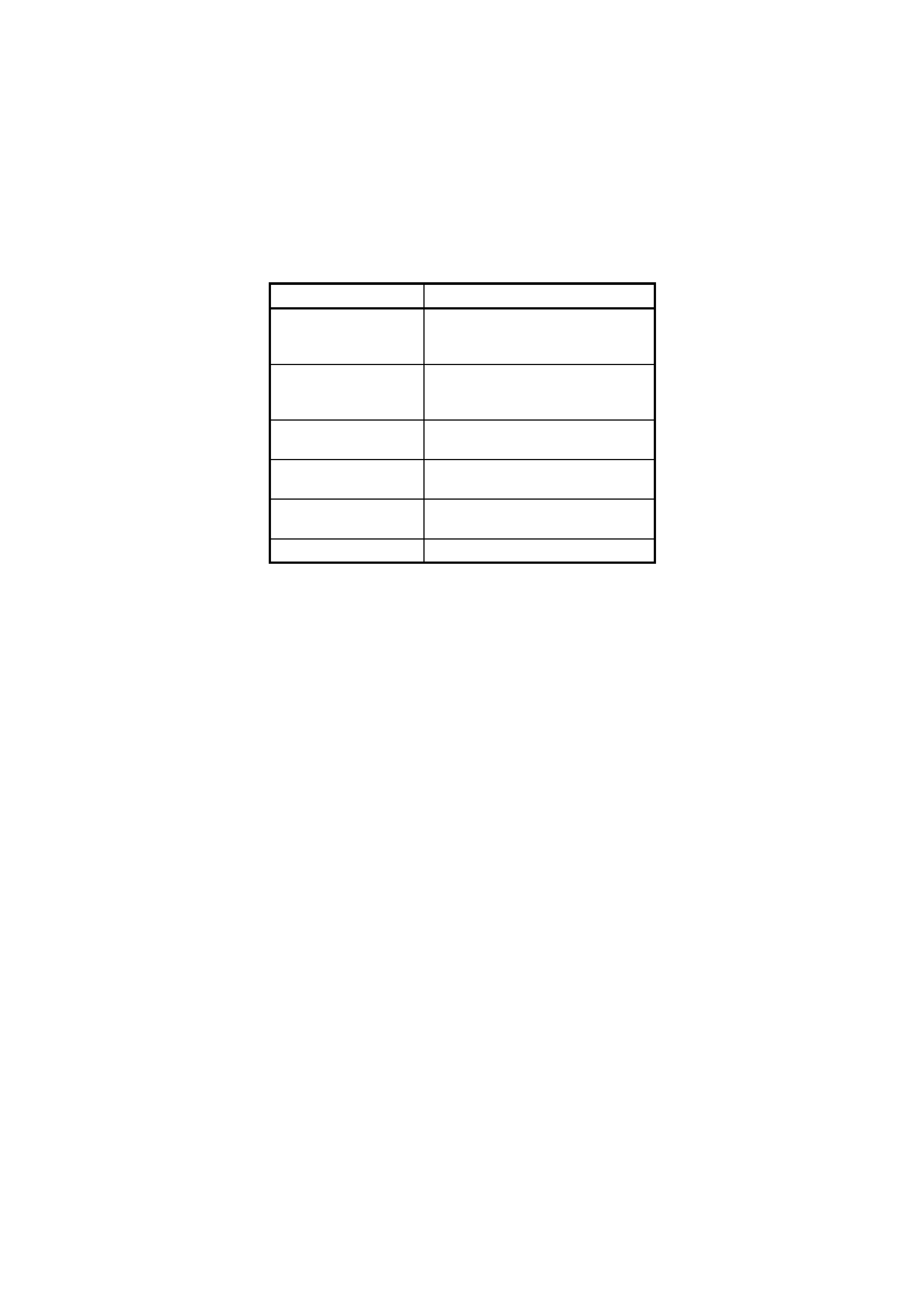

4.1 WIRING DIAGRAM

Figure 12L–27

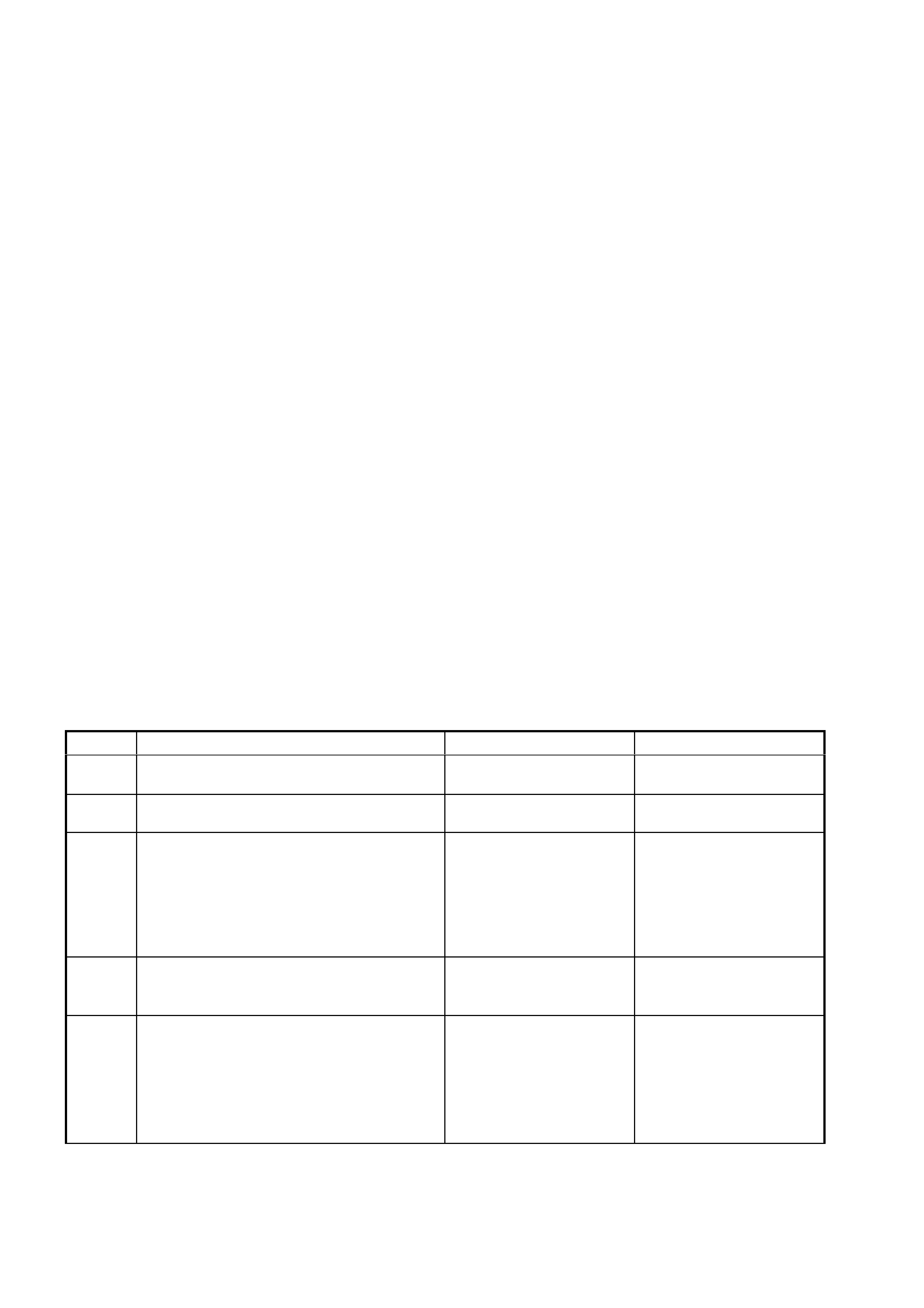

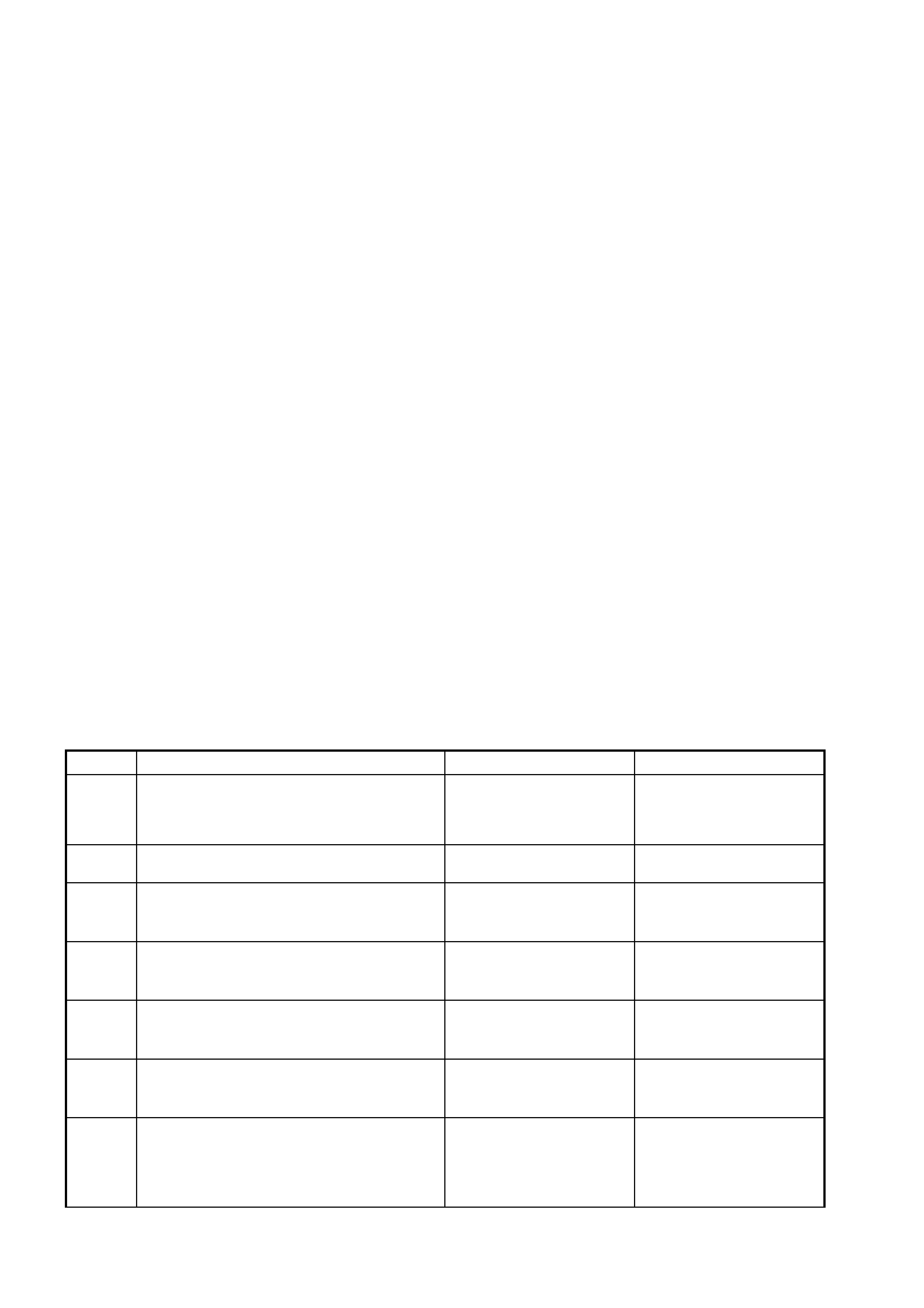

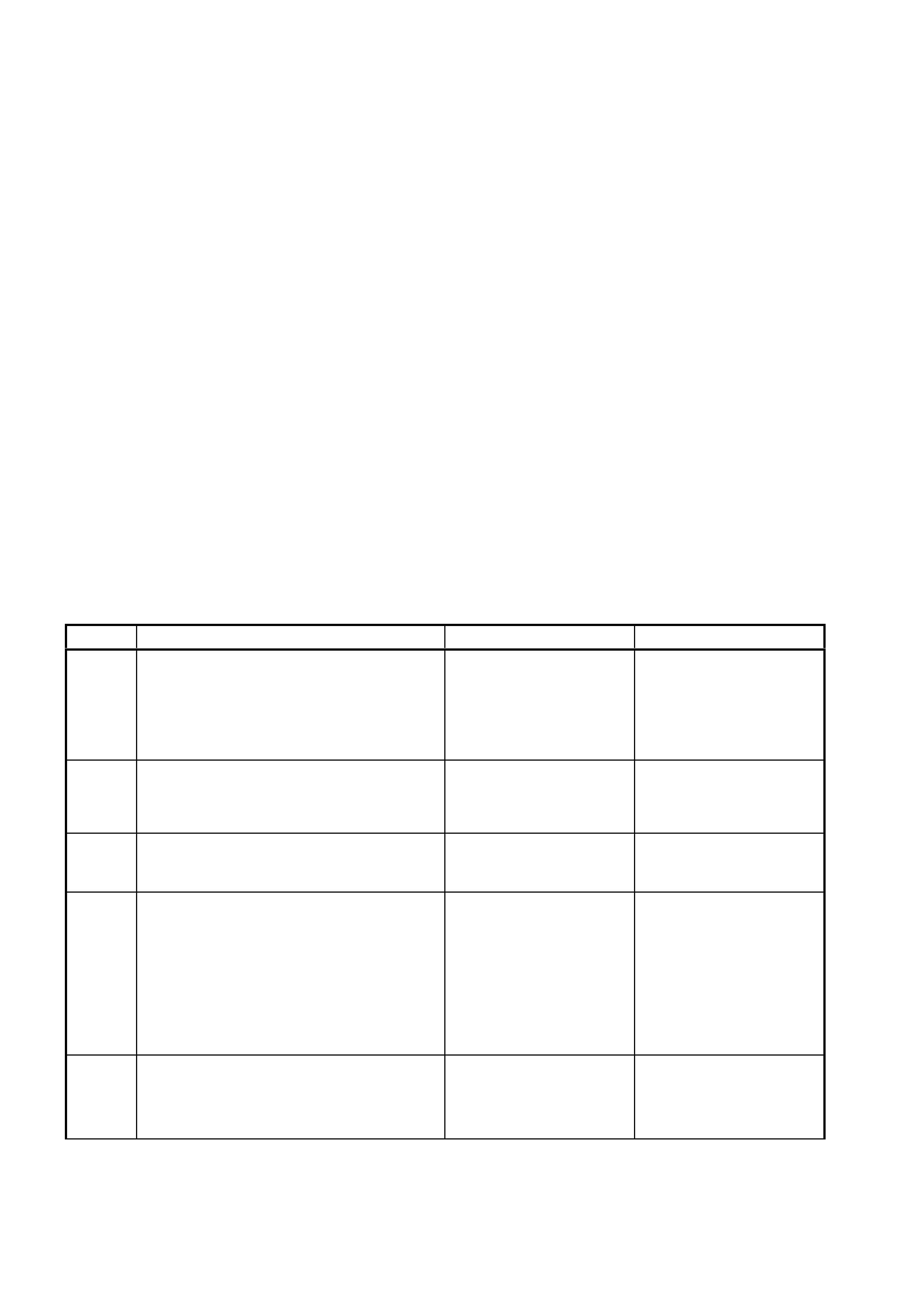

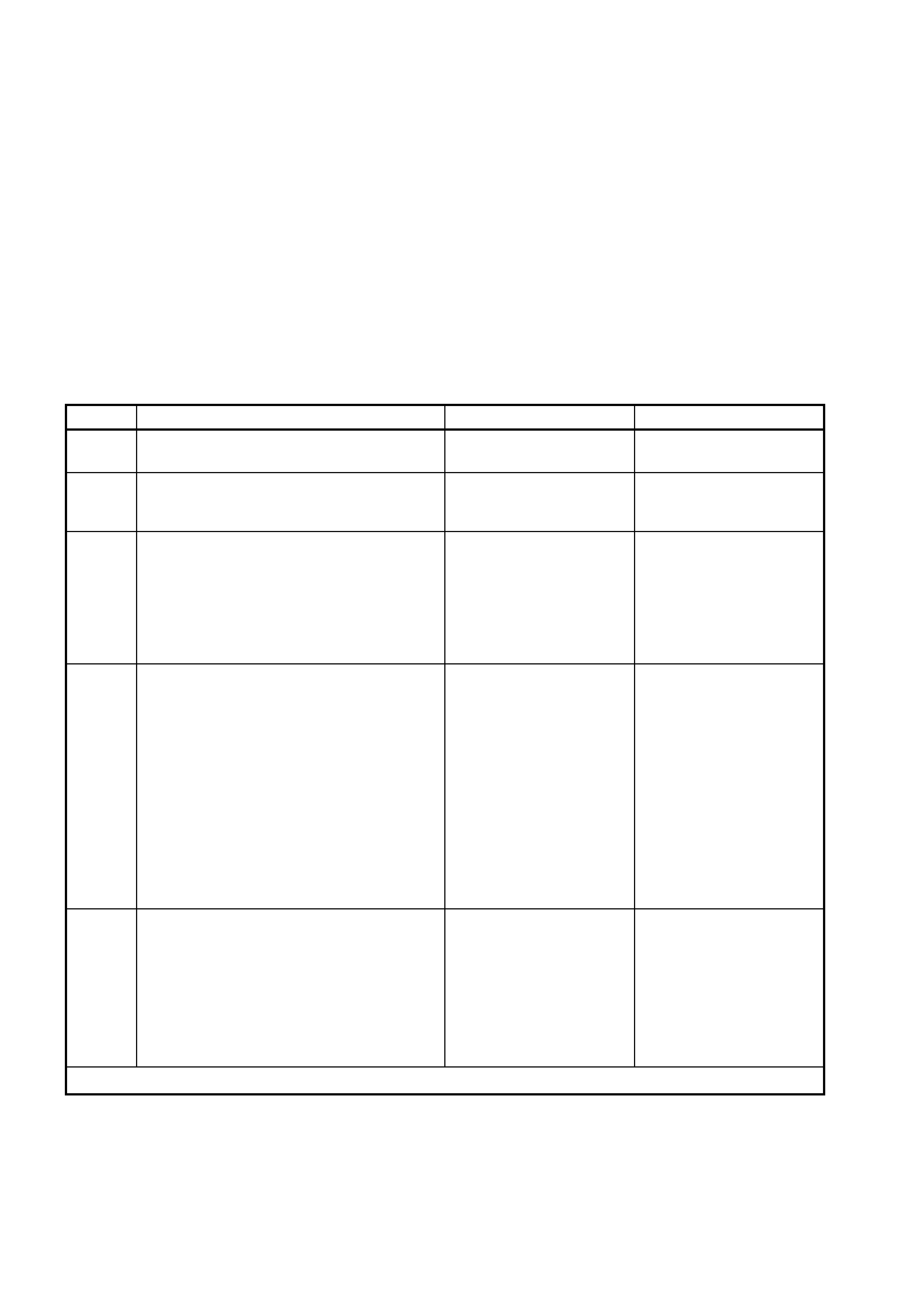

4.2 CONNECTOR CHART

Figure 12L–28

4.3 NAVIGATION SYSTEM DOES NOT START

CONDITION ONE

Introduction

Accessory power supplied to the processor assembly is used by the processor only as an indication that the vehicle

is in use and the navigation system is required. The battery supply provides power for the navigation system to

operate. If the processor does not receive accessory power, the navigation system can not operate because the

navigation system can not determine if the vehicle is in use.

The following symptoms are presented when accessory power is not supplied to the processor assembly with the

ignition switch in either the ACC or IGN position:

• There is no picture on the display.

• The red power LED on the processor assembly is flashing.

• The system does not respond to commands from the remote control.

If the red power LED flashes on the processor assembly, battery power and an earth circuit are present and

serviceable.

To assist in the diagnosing the navigation system, refer to 4.1 WIRING DIAGRAM and 4.2 CONNE CT OR CHART.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the ignition switch is in the ACC or IGN position to supply accessory power to the vehicle. If

access ory power is not s upplied to the vehicle when t he ignition s witch is in the ACC or IGN position, t he fault

does not lie with the navigation system. Refer to Section 12J, 4.4 ACCESSORY POWER CIRCUIT for further

diagnosis.

2. Checks that the connector required for accessory power to be supplied to the processor assembly is in place

and positiv ely connecte d.

3. Check s if there is ac cess ory power at the proc essor assem bly. Isolates whether t he supp ly of acc essor y power

or the processor assembly is at fault.

4. Checks if fuse F16 on the passenger compartment fuse and relay panel assembly is serviceable. Isolates

whether the fuse is the fault affecting the circuit between the accessory control relay and the processor

assem bly.

5. Checks if there is accessory power at the connector X207. Isolates whether the fault in the circuit is between

connector X207 and the processor, or X207 and the accessory control relay.

6. Checks if there is accessory power at fuse F16. Isolates whether the fault in the circuit is between fuse F16 and

connector X207, or between fuse F16 and the accessory power circuit.

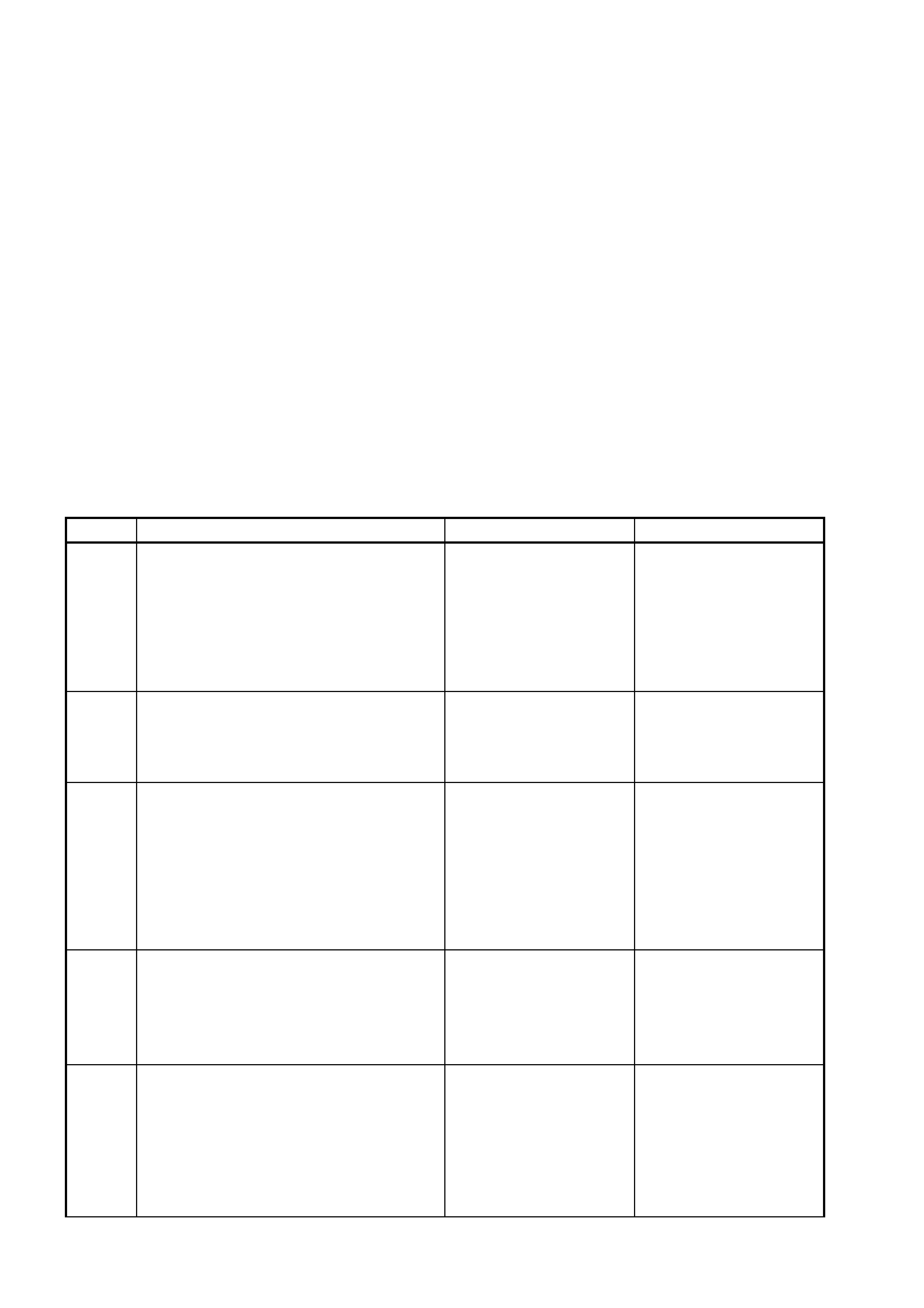

STEP POSSIBLE CAUSE / REMEDY YES NO

1. Is the ignition switch in the ACC or IGN

position? Go to Step 2. Turn the ignition switch to

the ACC or IGN position.

2. Is connector A139 – X1 secure? Go to Step 3. Ensure that connector

A139 – X1 is secure.

3. 1. Back-probe connector A139 – X1 pin 7

with a test lamp.

Does the test lamp illuminate?

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282

Go to Step 4.

4. 1. Inspect fuse F16, refer to Section 12O,

2.1 FUSES.

Is fuse F16 blown? Replace fuse F16. Go to Step 5.

5. 1. Remove the left-hand hinge pillar trim

assembly to gain access to connector

XO1, refer to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

2. Back-probe connector X207 pin 2 with a

test lamp.

Does the test lamp illuminate?

There is a fault in circuit 43

between connectors

A139 – X1 pin 7 and X207

pin 2. Repair or replace

circuit 43.

Go to Step 6.

STEP POSSIBLE CAUSE / REMEDY YES NO

6. 1. Remove fuse F16 from the passenger

compartment fuse and relay panel

assembly, refer to Section 12O,

2.1 FUSES.

2. Using a multimeter with the negative lead

to earth, check if there is battery voltage at

connector X129 – X43 pin 16.

Is there battery voltage across the connector

X129 – X43 pin 16?

A fault exists in circuit 43

between connector X207

pin 2 and connector

X129 – X43 pin 16. Repair

or replace circuit 43.

A fault exists in circuit 70

that supplies acc es sory

power for the navigation

system. Refer to Section

12J, 4.4 ACCESSORY

POWER CIRCUIT for

further diagnosis .

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION TWO

Introduction

The batter y power connection provides two functions to the navigation system . When the vehicle ignition s witch is

in the ACC or IGN position, the processor determines that the vehicle is in use. The processor draws its power

through the battery supply circuit to supply the navigation system.

When the vehicle’s ignition is in the OFF position, the battery supply circuit provides power to the processor

assembly to allow the processor assembly to store data such as current location etc.

The following symptoms are presented when battery power is not supplied to the processor assembly:

• There is no picture on the display until the ignition switch is in either the ACC or IGN position.

• The red power LED on the processor assembly is extinguished.

To assist in diagnosing the navigation system, refer to 4.1 WIRING DIAGRAM and 4.2 CONNECTOR CHART.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. The red power LED illuminates if the 12 volt battery power and chassis earth are OK.

2. Check s that the connector required for battery power to be s upplied to the proc essor ass em bly is in place and

positively connected.

3. Checks that battery voltage is more than 12 volts. The navigation system requires more than 12 volts to

operate correctly.

4. Checks if the fuse located on the rear of the processor assembly has not blown.

5. Checks if fuse F23 located on the passenger compartment fuse and relay panel assembly has not blown.

6. Checks if there is battery voltage to the processor assembly. Isolates whether there is a fault between the

battery and the processor assembly, or the fault is in the earth circuit or processor assembly.

7. Checks if connec tor X207 i s in plac e an d pos i tive l y connec te d. Co nnector X 20 7 i s par t of the batt ery circuit and

earth circuit for the processor assembly.

8. Check s if there is battery voltage a t connector X207 p in 3. Isolates whether there is a f ault between c onnector

X207 and the processor assembly.

9. Checks if there is battery voltage at fuse F23 on the passenger compartment fuse and relay panel assembly.

Isolates whether there is a fault bet ween fuse F 23 and connec tor X207 pin 3, or bet ween fusible link F105 an d

fuse F23.

10. Checks if there is battery voltage at connector X139 – X1 pin 8. Isolates if there is a fault with the processor

assem bly.

11. Checks if there is battery voltage at connector X207 pin 8. Isolates whether the fault is in earth circuit 151

(between connector X207 and the processor assembly), or between connectors X207 and X157.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Press the EJECT button on the processor.

Does the red LED illuminate? If there is still no response

from the system, refer to

CONDITION THREE in this

Section.

Go to Step 2.

2. Is connector A139 – X1 secure? Go to Step 3. Ensure that connector

A139 – X1 is secure.

3. 1. Check the battery voltage, refer to Section

12A, 2.9 BATTERY.

Is the battery voltage more than 12 V? Go to Step 4. Refer to Section 12A,

2.9 BATTERY for further

diagnosis.

4. 1. Inspect the fuse on the rear of the

processor assembly.

Is the fuse on the rear of the processor blown? Replace the fuse. Go to Step 5.

5. 1. Inspect fuse F23, refer to Section 12O, 2.1

FUSES.

Is fuse F23 blown? Replace the fuse. Go to Step 6.

6. 1. Back-probe connector A139 – X1 pin 4

with a test lamp.

Does the test lamp illuminate? Go to Step 10. Go to Step 7

7. 1. Remove the left-hand hinge pillar trim

assembly to gain access to connector

XO1, refer to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

Is connector X207 secure?

Go to Step 8. Ensure that connector

X207 is se cure.

STEP POSSIBLE CAUSE / REMEDY YES NO

8. 1. Back-probe connector X207 pin 3 with a

test lamp.

Does the test lamp illuminate? Go to Step 9.

A fault exists in circuit 1040

between connectors X207–

3 and A139 – X1–4. Repair

or replace circuit 1040.

9. 1. Remove fuse F23 from the passenger

fuse and relay panel assembly.

2. Back-probe connector X129 – X42 pin 23

with a test lamp.

Does the test lamp illuminate?

A fault exists in circuit 1040

between the connector

X129 – X42 pin 23 and

X207. Repair or replace

circuit 1040.

A fault exists in circuit 342

between fusible link F105

and connect or

X129 – X42 pin 23. Repair

or replace circuit 342.

10. 1. Back-probe connector A139 – X1 pin 8

with a test lamp.

Does the test lamp illuminate? Go to Step 11.

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further diagnosi s.

Contact Siemens VDO

Customer Service on

1800 335 – 282.

11. 1. Back-probe connector X207 pin 8 with a

test lamp.

Does the test lamp illuminate?

A fault exists in circuit 151

between connector X207

pin 8 and X157. Repair or

replace circuit 151.

A fault exists in circuit 151

between connector A139 –

X1 pin 8 and X207 pin 8.

Repair or replace circuit

151.

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION THREE

Introduction

When the vehicle ignition switch is in the ACC or IGN position and the battery, accessory and earth circuits are

serviceable, the red LED on the processor assembly illuminates continuously.

The following conditions exist when there is power to the processor assembly, but there is no picture on the

display:

• No picture on the display.

• Red power LED on the processor is illuminated.

To assist in diagnosing the navigation system, Refer to 4.1 WIRING DIAGRAM and 4.2 CONNECTOR CHART.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the system is in an idle state. Attempts to restore system operation by using the remote control.

2. Checks if the system is in a n i dle s tate . Attem pts to r es t ore system oper a tio n by u sing the r emote contr ol. If t he

system is restored, there is a fault in the remote control assembly when it is being used outside the cradle.

3. Checks that the battery voltage is above 12 V. The navigation system requires more than 12 V to operate

correctly.

4. Navigation control buttons are located on top of the display. If the system responds when these buttons are

pressed, there is a problem with the remote control and associated circuits when the control is operated.

5. Checks if all the connectors required for the navigation system display to function correctly are in place and

positively connected.

6. Checks if there is continuity between connectors A139 – X3 and XO1 which is part of the navigation wiring

harness. This isolates whether the navigation wiring harness that supplies power to the display is at fault.

7. Checks if there is continuity between connectors P6 – X1 and XO1 which is part of the cockpit navigation wiring

harness. This isolates whether the cockpit navigation wiring harness that supplies power to the display is at

fault.

8. Checks if the dis p lay ass embly is th e f au lt in the system. Isolates wheth er th e f a ult is with the d is pl a y ass e mbly

or the processor assembly.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Remove the remote control from the

remote control cradle.

2. Point the remote control at the display and

press the OK button to restore display

operation.

Does this activate the display?

System serviceable. Go to Step 2.

2. 1. Seat the remote control in the remote

control cradle and press the OK button on

the remote control.

Does this activate the display?

Refer to 4.4 NO

RESPONSE FROM

REMOTE CONTROL,

Condition One.

Go to Step 3.

3. 1. Check the battery voltage, refer to Section

12A, 2.9 BATTERY.

Is the battery voltage more than 12 V? Go to Step 4. Refer to Section 12A,

2.9 BATTERY for further

diagnosis.

4. 1. Remove the display assembly and the

display assembly mounting bracket, refer

to 3.3 NAVIGATION DISPLAY

ASSEMBLY.

2. Connect the connector P6 to the back of

the display.

3. Operate the navigation system using the

keys on top o f the display.

Does this activate the display?

Refer to 4.4 NO

RESPONSE FROM

REMOTE CONTROL. Go to Step 5.

5. Are the following connections secure:

• A139 – X3

• X01

• P6

Go to Step 6. Ensure the connectors

are secure.

STEP POSSIBLE CAUSE / REMEDY YES NO

6. 1. Remove the left-hand hinge pillar trim

assembly to gain access to connector

XO1, refer to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

2. Using a multimeter, check for continuity

between the following connectors:

• A139 – X3 pin 16 and X01 pin 11

• A139 – X3 pin 15 and X01 pin 10

• A139 – X3 pin 14 and X01 pin 2

• A139 – X3 pin 13 and X01 pin 5

• A139 – X3 pin 12 and X01 pin 1

• A139 – X3 pin 9 and X01 pin 14

• A139 – X3 pin 8 and X01 pin 6

• A139 – X3 pin 7 and X01 pin 13

• A139 – X3 pin 6 and X01 pin 4

• A139 – X3 pin 5 and X01 pin 3

• A139 – X3 pin 4 and X01 pin 7

• A139 – X3 pin 3 and X01 pin 12

Is there continuity between all of the terminals

of connectors A139 – X3 and X01? Ensure

resistance is minimal and consistent across all

pins checked.

Go to Step 7.

A fault exists in the display

cable which is part of the

navigation wiring harness.

Repair or replace the

navigation wiring harness

as required.

7. 1. Remove the display assembly, refer to 3.3

NAVIGATION DISPLAY ASSEMBLY.

2. Using a multimeter, check for continuity

between the following connectors:

• P6 – X1 pin 16 and X01 pin 11

• P6 – X1 pin 15 and X01 pin 10

• P6 – X1 pin 14 and X01 pin 2

• P6 – X1 pin 13 and X01 pin 5

• P6 – X1 pin 12 and X01 pin 1

• P6 – X1 pin 9 and X01 pin 14

• P6 – X1 pin 8 and X01 pin 6

• P6 – X1 pin 7 and X01 pin 13

• P6 – X1 pin 6 and X01 pin 4

• P6 – X1 pin 5 and X01 pin 3

• P6 – X1 pin 4 and X01 pin 7

• P6 – X1 pin 3 and X01 pin 12

Is there continuity between all of the terminals

of connectors P6 – X1 and X01?

Go to Step 8.

A fault exists in the display

cable which is part of the

cockpit navigation wiring

harness. Repair or replace

the cockpit navigation

wiring harness as required.

8. 1. Replace the display assembly.

Does the display now operate?

System servic eabl e.

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282.

When all diagnosis and repairs are completed, check the system for correct operation.

4.4 NO RESPONSE FROM REMOTE CONTROL

NO RESPONSE FROM REMOTE CONTROL

Introduction

The rem ote control sends signals to t he process or assembly in e ither of two m ethods. In the f irst method, with t he

rem ote control rem oved from the r emote control c radle and pointe d at the disp lay assem bly, the signal is received

by the display assembly, then transmitted through the display wiring harness to the processor assembly. In this

case the power to transmit the signal is from the remote control batteries.

The second method is with the remote control situated in the remote control cradle. In this case, signals from the

rem ote c ontrol tr ans mit dire ctl y through the r emote con tr ol cr adl e a nd its wiring ha r ness to the pr oces s or as s embly.

The power to tr ansm it the sign al from the rem ote control is pro vided b y the vehic le via the pr ocess or ass embl y and

remote control cradle.

The following conditions exist when the remote control is inoperative:

• The navigation system is operational, with the title screen on the display.

• The navigation system does not respond to commands from the remote control.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Chec ks if there is an y response f rom the rem ote control i n any of its operating c onditio ns. Isola tes whether the

remote control or the system that transmits the signal to the processor is at fault.

2. Checks if the r em ote c ontro l f unc tions c orr ectly when operate d f rom the cradle. Is o lates wheth er the c radle an d

associated circuitry is at fault.

3. Checks if the remote control functions correctly when operated through the display. Isolates whether the

display and associated circuitry is at fault.

4. Repl aces the rem ote contr ol with a ser viceabl e item . Isolates wheth er the rem ote control or th e processor is at

fault.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Place the remote control in the remote

control cradl e.

2. Press the ‘OK’ button on the remote

control.

3. Remove the remote control from the

remote control cradle.

4. Point the remote control at the display

assembly and press the ‘OK’ button.

Does the system respond to the remote control

during any part of the procedure?

Go to Step 2. Go to Step 4.

2. 1. Place the remote control in the remote

control cradl e.

2. Press the ‘OK’ button on the remote

control.

Does the system respond when the remote

control is operated from the cradle?

Go to Step 3.

Refer to 4.4 NO

RESPONSE FROM

REMOTE CONTROL,

Condition Two.

3. 1. Remove the remote control from the

remote control cradle.

2. Point the remote control at the display

assembly and press the ‘OK’ button.

Does the system respond when the remote

control is operated though the display (that is,

when it is not seated in the cradle)?

System servic eabl e

Refer to 4.4 NO

RESPONSE FROM THE

REMOTE CONTROL,

Condition One.

4. 1. Replace the remote control with a

serviceable item.

2. Repeat the processes in Step 1 and 2.

Does the system respond when the remote

control is operated? System servic eabl e.

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION ONE

Introduction

In this con dition t he titl e scr een appe ars when th e vehi cle ignit ion s witch is i n the ACC or IGN pos ition. T he syst em

does not respond when the remote control is operated via the display (that is, when it is not seated in the remote

control cradle).

To assist in diagnosing the navigation system, Refer to 4.1 WIRING DIAGRAM and 4.2 CONNECTOR CHART.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if anything is preventing the transmission of commands between the remote control and the infrared

screen that is part of the display assembly.

2. After the batteries are changed, checks if the system responds when the remote control is operated via the

display.

3. Check s that all the c onnectors required for the remote c ontrol to oper ate effec tively are in place and p ositively

connected.

4. Check s if there is c ontin uit y between the r ele vant p ins on t he navig ation wiring harnes s that transm it the s ignal

from the display assembly to the processor. Isolates whether the navigation wiring harness is at fault.

5. Checks if there is continuity between the relevant pins on the cockpit navigation wiring harness that transmit

the signa ls from the dis play assem bly to the pr ocessor . Isolates wh ether the co ckpit navi gation wiring harness

is at fault.

6. Isolates whether the remote control as at fault.

7. Replac es th e d isp lay asse mbl y with a s erv ic eab le it e m. Is olates wh ether the dis play asse mbly or th e proc e s s or

is at fault.

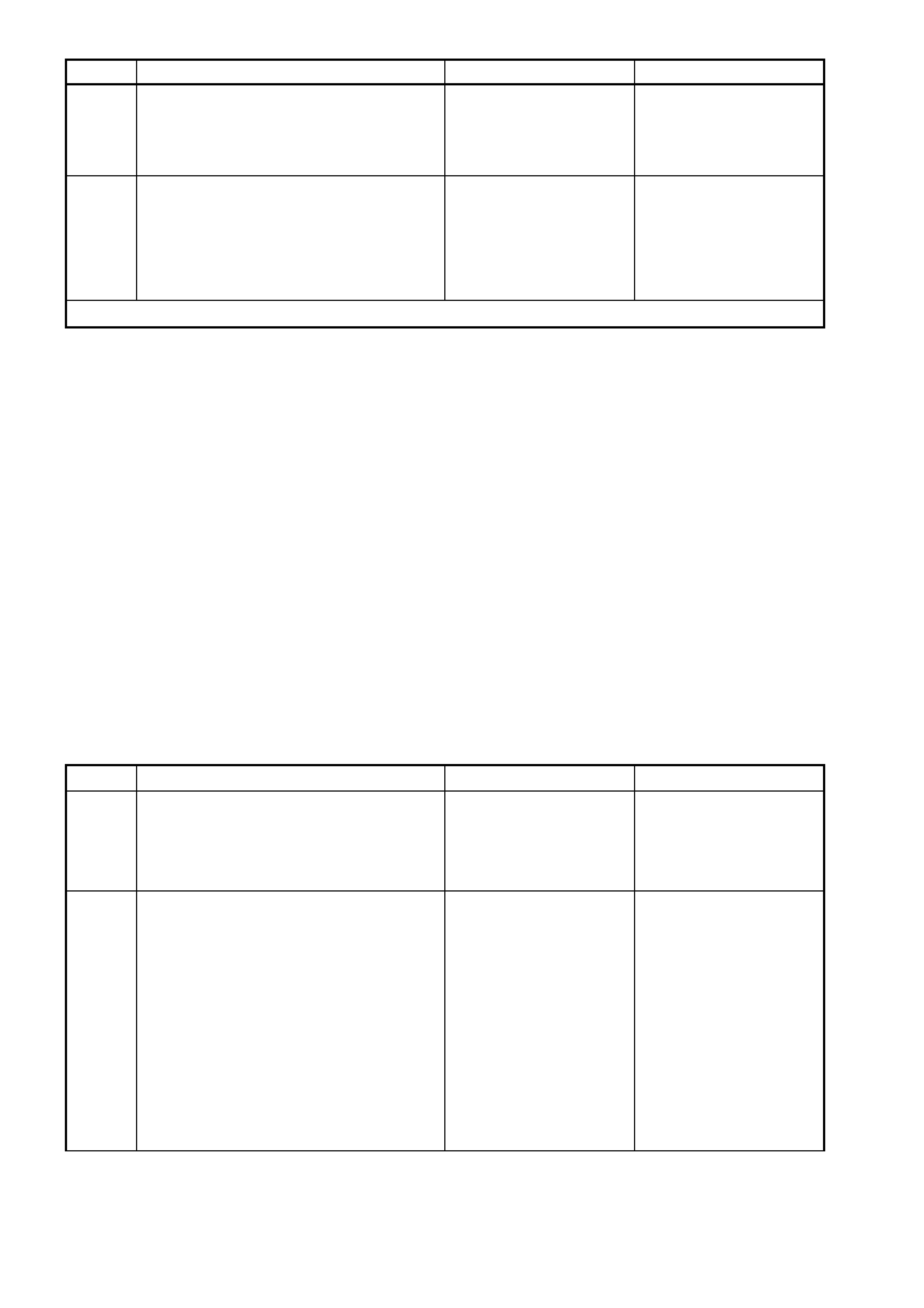

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Remove any obstructions in front of the

infrared screen on the display.

2. Clean the infrared screen on the display.

3. Clean the infrared screen on the remote

control.

Does the system respond when the remote

control is operated though the display (that is,

when it is not seated in the cradle)?

System serviceable. Go to Step 2.

2. 1. Replace the batteries in the remote

control.

Does the system respond when the remote

control is operated though the display (that is,

when it is not seated in the cradle)?

System serviceable. Go to Step 3.

3. 1. Remove the left-hand hinge pillar trim

assembly to gain access to connector

XO1, refer to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

2. Check the following connectors are

secured:

• A139 – X3

• XO1

• P6

Go to Step 4. Ensure the connectors are

secure.

4. 1. Perform continuity checks on the

following:

• A139 – X3 pin 14 to XO1 pin 10

• A139 – X3 pin 13 to XO1 pin 2

Is there continuity between connectors

A139 – X3 and XO1?

Go to Step 5. Repair or replace the

navigation wiring harness

as required.

5. 1. Remove the display assembly, refer to 3.3

NAVIGATION DISPLAY ASSEMBLY.

2. Perform continuity checks on the

following:

• P6 – X1 pin 14 to XO1 pin 10

• P6 – X1 pin 13 to XO1 pin 2

Is there continuity between connectors P6 –

X1 and XO1?

Go to Step 6. Repair or replace the

cockpit navigation wiring

harness as requir ed.

STEP POSSIBLE CAUSE / REMEDY YES NO

6. 1. Replace the remote control with a

serviceable unit.

Does the system respond when the remote

control is operated though the display (that is,

when it is not seated in the cradle)?

System serviceable. Go to Step 7.

7. 1. Replace the display with a serviceable

item.

Does the system respond when the remote

control is operated though the display (that is,

when it is not seated in the cradle)? System servic eabl e.

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION TWO

Introduction

In this condition the title screen appears when the vehicle ignition switch is in the ACC or IGN position.

The following conditions are presented:

• Title screen appears.

• System does not respond when the remote control is operated when installed correctly in the cradle.

To assist in diagnosing the navigation system, Refer to 4.1 WIRING DIAGRAM and 4.2 CONNECTOR CHART.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the contacts between the remote control and the remote control cradle are clean and serviceable.

2. Checks that all connectors required for the remote control to operate effectively are in place and positively

connected.

3. Check s if there is c ontin uit y between the r ele vant p ins on t he navig ation wiring harnes s that transm it the s ignal

from the remote control cradle to the processor. Isolates whether the navigation wiring harness is at fault.

4. Checks if there is continuity between the relevant pins on the cockpit navigation wiring harness that transmit

signals from the remote c ontrol cradle to the proc essor. Isolates whether the cock pit navigation wir ing harness

is at fault.

5. Isolates whether the remote control as at fault.

6. Replaces the remote control cradle with a serviceable item. Isolates whether the remote control cradle or the

processor is at fault.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Inspect the contacts on the base of

the remote control and the

corresponding contacts in the remote

control cradle

Are the contacts clean and serviceable?

Go to Step 2. Clean the contacts. If the

contacts are damaged,

replace the af f ec ted part.

2. 1. Rem ove the left-hand hinge pillar trim

assembly to gain access to connector

XO1, ref er to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

2. Remove the right-hand instrument

panel ex tension si de trim , refer to 3.2

REMOTE CONTROL ASSEMBLY

within this Section.

3. Check the following connectors are

secured:

• A139 – X2

• XO2

• A35

Go to Step 3. Ensure that the

connectors are secure.

STEP POSSIBLE CAUSE / REMEDY YES NO

3. 1. Perform continuity checks on the

following:

• A139 – X2 pin 1 to XO2 pin 6

• A139 – X2 pin 2 to XO2 pin 1

• A139 – X2 pin 3 to XO2 pin 5

Is there continuity between connectors

A139 – X3 and XO2?

Go to Step 4. Repair or replace the

navigati on wir ing

harness as required.

4. 1. Perform continuity checks for the

following:

• A35 – X1 pin 6 to XO2 pin 6

• A35 – X1 pin 1 to XO2 pin 1

• A35 – X1 pin 5 to XO2 pin 5

Is there continuity between connectors

A35 – X1 and XO2?

Go to Step 5. Repair or replace the

cockpit navigation wiring

harness as required.

5. 1. Replace the remote control with a

serviceable unit.

Does the system respond when the

remote control is operated via the remote

control cradle?

System serviceable. Go to Step 6.

6. 1. Replace the remote control cradle

assembly with a serviceable item,

refer to 3.2 REMOTE CONTROL

ASSEMBLY.

Does the system respond when the

remote control is operated via the remote

control cradle?

System serviceable.

The processor assembly

is faulty. Send the

processor assembly to

the vendor for further

assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282

When all diagnosis and repairs are completed, check the system for correct operation.

4.5 CD–ROM ERROR

The CD–ROM is supplied as part of the navigation system. It contains all map and relevant information for

Australia. The CD–ROM must be inserted correctly in the processor for the navigation system to operate correctly.

CONDITION ONE

Introduction

When the vehicle ignition switch is in the ACC or IGN position and the navigation system is operational, the

NAVIGATION and ADDRESS book can not be selected via the remote control.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if there is a CD–ROM inserted in the processor.

2. Checks if the CD–ROM is inserted correctly, or is dirty or damaged in some way. Isolates whether the CD–

ROM or the processor is at fault.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. Is the map CD–ROM inserted in the processor

assembly? Go to Step 2. Insert the CD–ROM in the

processor.

2. 1. Remove the CD–ROM from the

processor.

2. Inspect the CD–ROM surface.

Is the map CD–ROM scratched, dirty,

damaged or inser ted ups ide d own?

Clean the CD–ROM.

Replace the CD–ROM as

required.

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 –282

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION TWO

Introduction

With the vehicle ignition switch in the ACC or IGN position, the CD–ROM ejects from the processor without

somebody pressing the EJECT button.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the CD–ROM is inserted correctly, or is dirty or damaged in some way. Isolates whether the CD–

ROM or the processor is at fault.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Remove the CD–ROM from the

processor.

2. Inspect the CD–ROM surface.

Is the map CD–ROM scratched, dirty,

damaged or inser ted ups ide d own?

Clean the CD–ROM.

Replace the CD–ROM as

required.

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 –282

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION THREE

Introduction

With the vehicle ignition switch in the ACC or IGN position, a message of “Please insert CD” or “Please insert

correct CD” is displayed.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the CD–ROM is inserted correctly, or is dirty or damaged in some way. Isolates whether the CD–

ROM or the processor is at fault.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. Is the map CD–ROM scratched, dirty,

fault y or insert ed upsid e down? Clean the CD–ROM.

Replace the CD–ROM

as required.

The processor assembly

is faulty. Send the

processor assembly to

the vendor for further

assessment.

Contact Siemens VDO

Customer Service on

1800 335 –282

When all diagnosis and repairs are completed, check the system for correct operation.

4.6 AUDIO PROBLEMS

Introduction

With the vehicle ignition switch in the ACC or IGN position and the system operational and in use, there are no

audio commands through the speaker, but the system is displaying the guidance arrow.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Press the ‘+’ button on the rem ote c ontrol inc reases the au dio l evel of the navig ation s ystem . If the s ystem has

been muted, pressing the ‘+’ button will resort audio guidance. When the system is muted, there will be a

symbol in the form of a loudspeaker with a red diagonal line through it on the display.

2. Checks that all the connectors required for the speaker to operate effectively are in place and positively

connected.

3. Checks if there is continuity in the navigation wiring harness that supplies power from the processor to the

speaker. Isolates whether the navigation wiring harness is at fault.

4. Check if the speaker has a resistance of 8 Ω across its terminals. Isolates whether the speaker or the

processor is at fault.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Press the ‘+’ button on the remote control

eight times.

Is the word ‘louder’ audible through the

navigation spe aker?

System serviceable. Go to Step 2.

2. 1. Check the following connectors are

secure:

• A139 – X2

• B104

Go to Step 4. Ensure the connectors are

secure.

3. 1. Perform continuity checks on the

following:

• A139 – X2 pin 6 to B104 – X1 pin 1

• A139 – X2 pin 5 to B104 – X1 pin 2

Go to Step 5. Repair or replace the

navigation wiring harness

as required.

4. 1. Disconnect connector B104 from the

navigation wiring harness.

2. Using a multimeter, measure the

resistance across terminals B104 – X1

pin 1 and pin 2 on the speaker side.

Is there a resistance of 8 Ω across the B104 –

X1 pin 1 and pin 2?

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 –282

Replace the speaker

assembly.

When all diagnosis and repairs are completed, check the system for correct operation.

4.7 GUIDANCE PROBLEMS

The proc es s or c ontin uously c alcul ates th e veh ic le posit ion. When a destinati on is enter e d, t he process or c alculates

the best pos sible rout e depending on the user's preferences. If the user do es not follo w the directions provided b y

the processor, the processor must recalculate another route, then provide the user with new directions. Problems

may occur in guidance when the user does not follow the processor route instructions and makes a number of

changes in directions before the processor can recalculate the route. The processor eventually calculates the

correct route, but must be given som e time. In this case, the user has obviously strayed from processor guidance

instructions; the processor always maintains the correct location of the vehicle.

CONDITION ONE

Introduction

With the navigation system operational and in use, incorrect guidance instructions are given by the processor.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. W ith the navigation s ystem operat ional and in M AP mode, the s cale is not a t a level that ca n show the corr ect

position of the vehicle. A change of scale may show a more accurate position.

2. If the system has been driven along straight long roads for excessive periods or has been recently disabled,

the navigation system may need calibrating.

3. Checks that the DIRECTION option in the SET I/O STATE menu is set to ACT_HIGH.

4. Checks that the processor is receiving an adequate GPS signal to ensure an accurate calculation of the

position of the vehicle. Isolates whether the GPS antenna is at fault.

5. Check that the processor’s internal gyroscope is not faulty.

6. Checks if the CD–ROM is out of date. This will especially affect people who travel into newly-developed areas.

7. Checks that the processor is receiving VSS. Isolates whether there is a VSS fault or the processor is faulty. If

there is a VSS fault, the check isolates whether it is contained in the navigation system or within the other

systems of the vehicle.

8. Checks for continuity between X207 and A139 at the processor. Isolates whether the fault is in the processor or

the navigation wiring harness.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Switch the system display to MAP mode in

100M scale.

Is the vehicle position now accurate? System serviceable. Go to Step 2.

2. 1. Calibrate the navigation system, refer to

3.10 NAVIGATION SYSTEM

CALIBRATION

Is the vehicle position now accurate?

System serviceable. Go to Step 3.

3. 1. Using the remote control, access the SET

I/O STATE menu, refer to 5.3 SET I/O

STATE.

2. Check that the DIRECTION is set to

ACT_HIGH.

Is the DIRECTION set to ACT_HIGH?

Go to Step 4. Change the DIRECTION to

ACT_HIGH, refer to 5.3

SET I/O STATE.

4. 1. Check that the connector A139 – X4 is

secure to the rear of the processor.

2. Ensure that the vehicle is outside with no

major structures around it that might

cause a disruption in GPS reception.

3. Using the remote control, access the

READ GPS DATA menu, refer to

5.4 READ GPS DATA.

Is the receiver state in either 3D or 2D

POSITION?

Go to Step 5. Replace the antenna, refer

to 3.7 NAVIGATION GPS

ANTENNA.

5. 1. Using the remote control, switch the

system to MAP mode

Does the position arrow rotate while the

vehicle is stationary?

Disconnect the power from

the processor assembly

and allow the system to

reset.

If the vehicle position arrow

still rotates after the system

has been reset, send the

processor assembly to the

vendor for further

Go to Step 6.

STEP POSSIBLE CAUSE / REMEDY YES NO

assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282.

6. 1. Replace the CD–ROM.

2. Calibrate the system, refer to 3.10

NAVIGATION SYSTEM CALIBRATION.

Is the vehicle position now accurate?

System serviceable. Go to Step 7.

7. 1. Using the remote control, access the

READ I/O STATE menu, refer to

5.2 READ I/O STATE.

2. Drive the vehicle at a speed greater than

5 km/h.

Is the SPEED PULSES reading greater

than 0?

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282.

Check the VSS circuit.

Refer to:

• Section 6C1-2A for V6.

• Section 6C2-2A for

V6 S/C.

• Section 6C3-2A for

GEN III.

• Go to Step 8 if there is

no fault found with the

VSS circuit.

8. 1. Remove the left-hand hinge pillar trim

assembly to gain access to connector

XO1, refer to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

2. Check the continuity between the

following:

• A139 – X1 pin 1 to X207 pin 6

The processor assembly is

faulty. Send the processor

assembly to the vendor for

further assessment.

Contact Siemens VDO

Customer Service on

1800 335 – 282.

Repair or replace the

navigation wiring harness

as required.

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION TWO

Introduction

W ith the naviga ti on s ystem operatio nal a nd i n us e, a d es tina tio n (eg CITY or ROAD etc .) is entered with th e r emote

control, but is not recognised by the system.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the destination has been correctly entered.

2. Checks if the street number being entered is correct. Isolates whether the CD–ROM is out of date or the

number being entered is on a road that extends through more than one suburb.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Change the search criteria. Search by a

region (eg Sydney) and then by the road

name.

Is the destination now recognised?

System serviceable. Go to Step 2.

2. 1. Replace the CD–ROM with the current

version.

Is the destination now recognised? System servic eabl e.

When a long road

continue s from one sub urb

to the next the house

number may restart in the

new suburb or continue in

sequence from the original

suburb.

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION THREE

Introduction

With the navigation system operational, the GUIDANCE function can not be selected.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. There is only one instance when, with all other functions operating correctly, guidance can not be selected.

This occurs if a destination has not been entered.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Enter the destination. System serviceable.

When all diagnosis and repairs are completed, check the system for correct operation.

CONDITION FOUR

Introduction

With the navigation system operational, there are no guidance instructions after the destination has been entered

and the GUIDANCE function selected.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if the GUIDANCE function has been selected and activated.

2. Ensures that, if the ve hicle is on a road held withi n the navig ation system database, the appr opriate secti on of

map is displayed. The system does not give guidance instructions until the vehicle is on such a road.

STEP POSSIBLE CAUSE / REMEDY YES NO

1. 1. Activate the GUIDANCE function.

Are guidance instructions restored? System serviceable. Go to Step 2.

2. 1. Ensure the vehicle is on a road held within

the navigation system database. If the

vehicle is not on such a road, an arrow

appears in the top right-hand corner of the

map screen.

Are guidance instructions restored?

If the location of the vehicle

is incorrect when it has

been moved to a digitised

road, calibrate the

navigation system, refer to

3.10 NAVIGATION

SYSTEM CALIBRATION.

When all diagnosis and repairs are completed, check the system for correct operation.

4.8 DISPLAY QUALITY

Introduction

With the navigation system operational, the display quality is poor.

Test Description

The numbers following refer to the Step numbers in the diagnostic chart.

1. Checks if there is a problem in the dimm ing circuit for the display. The display is designed to be bright during

the day and is dimmed when the park lights are turned on.

2. Checks the battery voltage is above 12 V. The navigation system requires more than 12 V to operate correctly.

3. Checks if the brightness of the display as at its maximum. Brightness can not be controlled by the remote

control; this is controlled from the top of the display.