SECTION 12P - WIRING DIAGRAMS

IMPORTANT

Before p erforming any Serv ice Operation or other procedure d escribed in this Section , refer to Section 00,

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. ELECTRICAL CIRCUIT DIAGNOSIS

PROBLEM EXAMPLE

3. TEST PROCEDURES

3.1 ELECTRICAL FAULT DIAGNOSIS

POSSIBLE ELECTRICAL MALFUNCTIONS

CIRCUIT FAULTS

OPEN

SHORT TO EARTH

SHORT TO VOLTAGE

HIGH RESISTANCE PROBLEMS

3.2 TROUBLESHOOTING TEST EQUIPMENT

JUMPER WIRE

TEST LIGHT

SELF-POWERED TEST LIGHT

MULTIMETERS

3.3 DIGITAL MULTIMETER

USE OF A MULTIMETER

SELECTION OF MULTIMETERS

VOLTAGE MEASUREMENT

RESISTANCE MEASUREMENT

CONTINUITY TESTING

DIODE TESTING

CURRENT MEASUREMENT

4. DIAGNOSTIC TESTS

4.1 TESTING FOR VOLTAGE

4.2 TESTING FOR CONTINUITY

4.3 TESTING FOR VOLTAGE DROP

4.4 TESTING FOR SHORT TO EARTH

USING A TEST LIGHT OR VOLTMETER

USING A SELF-POWERED TEST LIGHT OR

OHMMETER

USING A SHORT FINDER

USING A COMPASS

USING A CIRCUIT BREAKER

4.5 OPERATING A SHORT FINDER

4.6 MEASURING CURRENT

4.7 DETECTING INTERMITTENT ELECTRICAL

FAULTS

DIAGNOSTIC PROCEDURE

CHECKING TERMINAL CONTACT

METER CONNECTIONS

5. WIRING REPAIR PROCEDURES

5.1 GENERAL INFORMATION

5.2 PERFORMING WIRING HARNESS REPAIRS

SOLDERING

THE FIVE POINTS TO SOLDERING

JOINING WIRE

5.3 SPLICING WIRING USING SPLICE CLIPS

5.4 ABS AND SRS WIRING REPAIR

ABS AND SRS WIRE PIGTAIL REPAIR

WIRING REPAIR

ABS AND SRS WIRING SPLICE REPAIR

5.5 SPLICING TWISTED OR SHIELDED CABLE

5.6 SPLICING IN-LINE HARNESS DIODES

5.7 HEATED OXYGEN SENSOR (HO2S) WIRING

REPAIRS

5.8 TERMINAL REMOVAL

REPAIRING PUSH-TO-SEAT AND

PULL-TO-SEAT CONNECTORS

WEATHER PACK CONNECTORS

6. READING 12P WIRING DIAGRAMS

GENERAL

SHEET IDENTIFICATION

WIRE IDENTIFICATION

GRID REFERENCE

CONTINUATION REFERENCE

ASSEMBLY IDENTIFICATION

ASSEMBLY CONTINUATION

ASSEMBLY CONNECTOR IDENTIFICATION

ASSEMBLY CIRCUIT IDENTIFICATION

INFORMATION WITHIN AN ASSEM BLY

HARNESS SPLICES

GROUND LOCATIONS

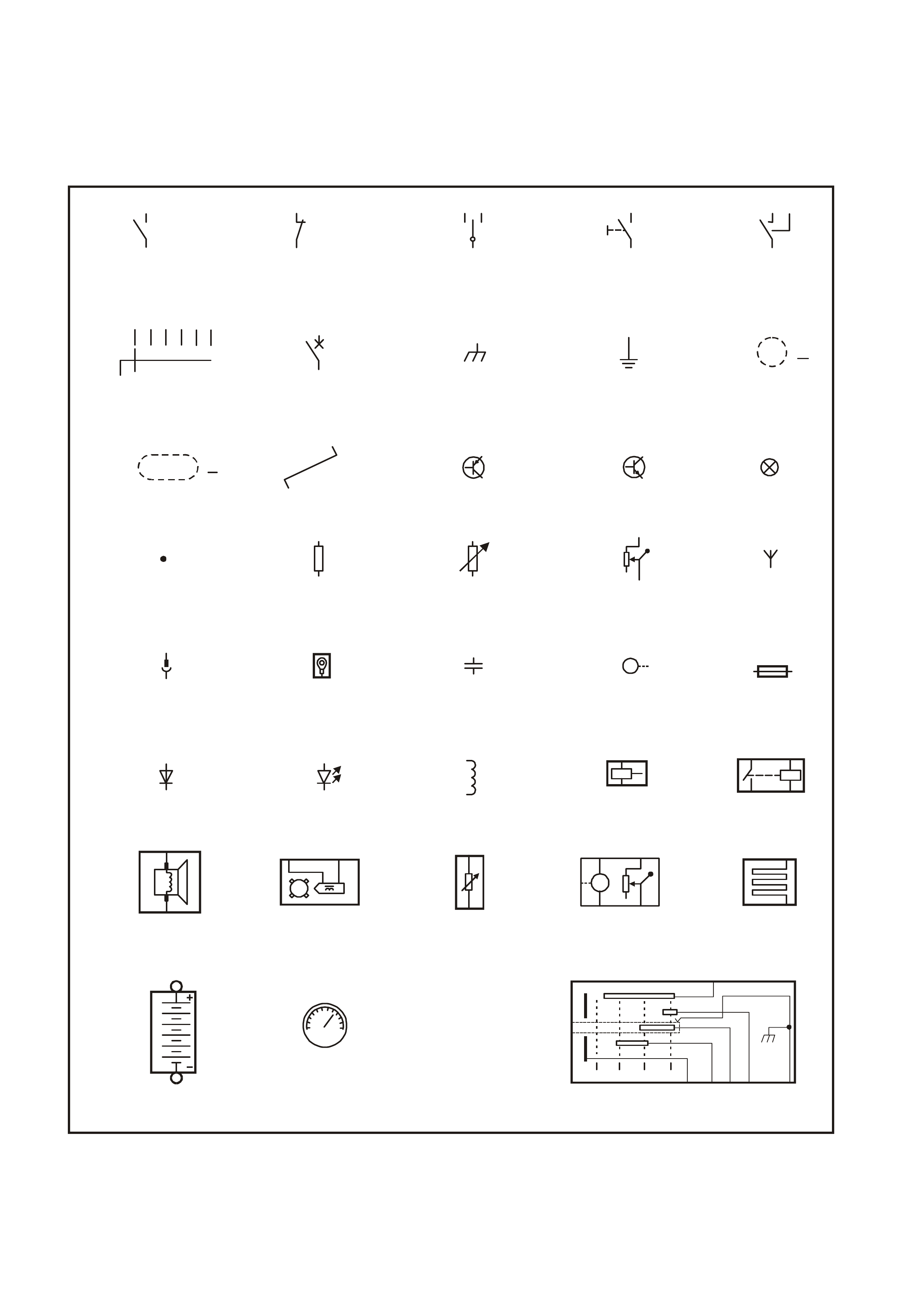

CIRCUIT SYMBOLS

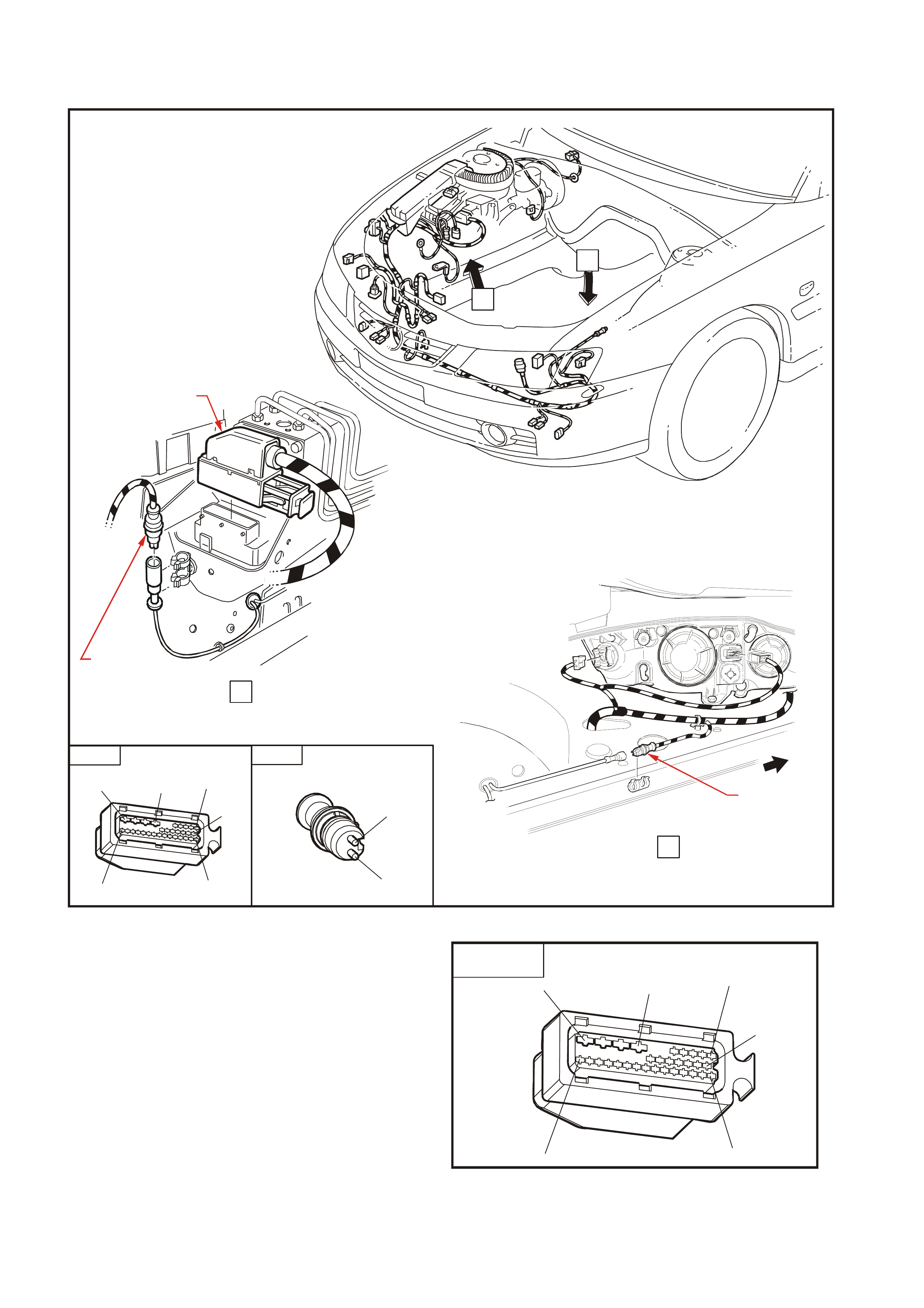

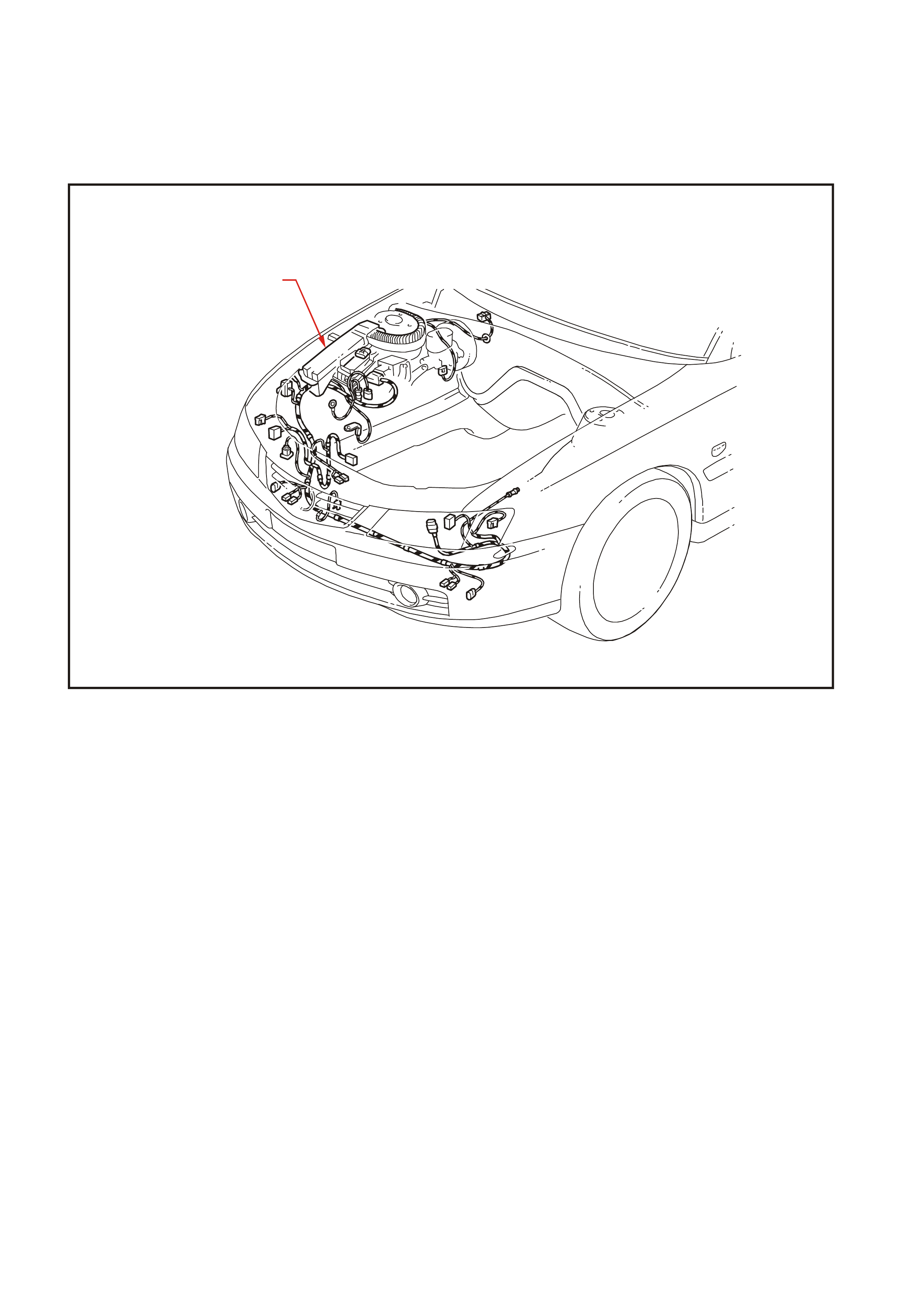

7. CONNECTOR LOCATION ILLUSTRATIONS

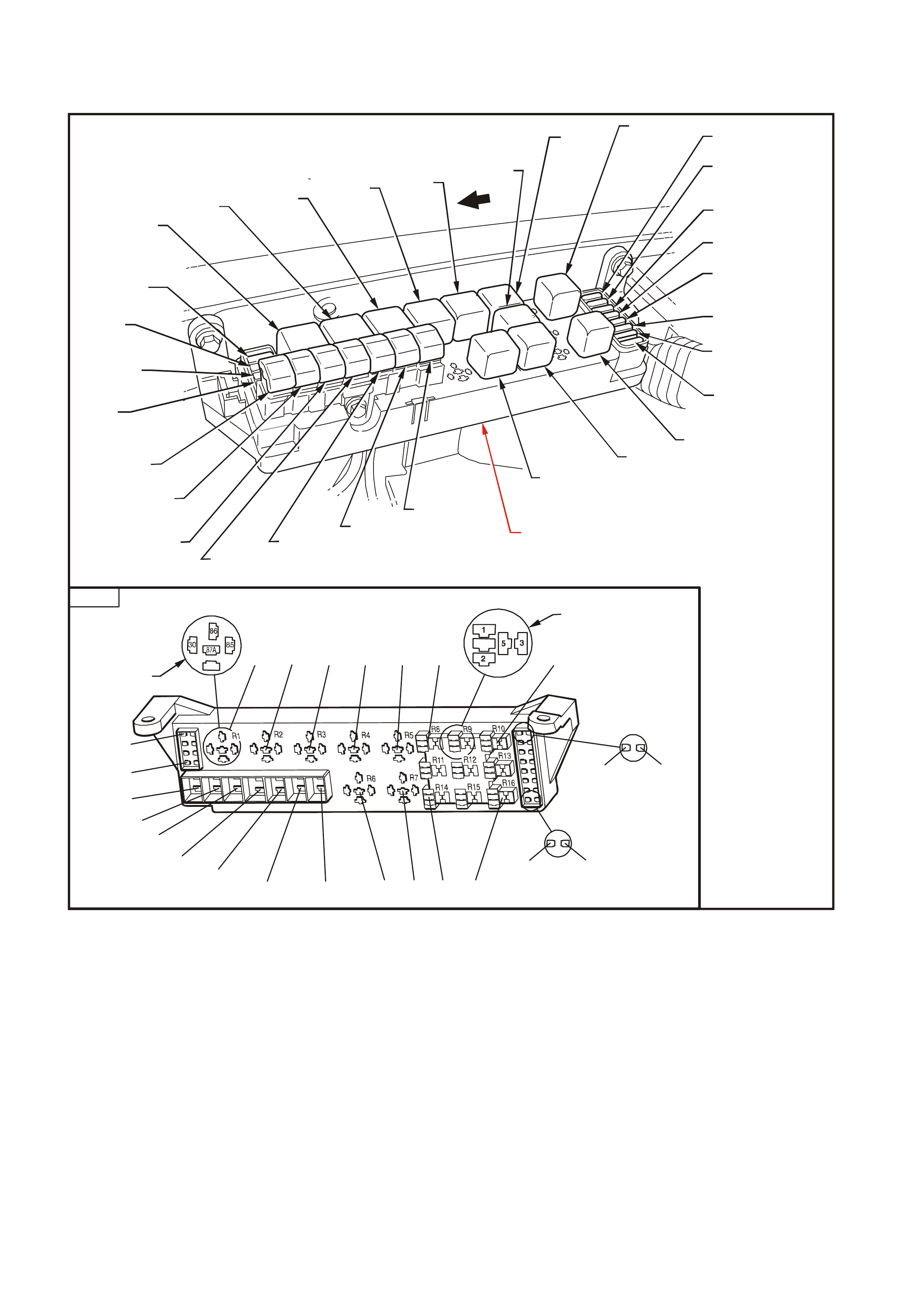

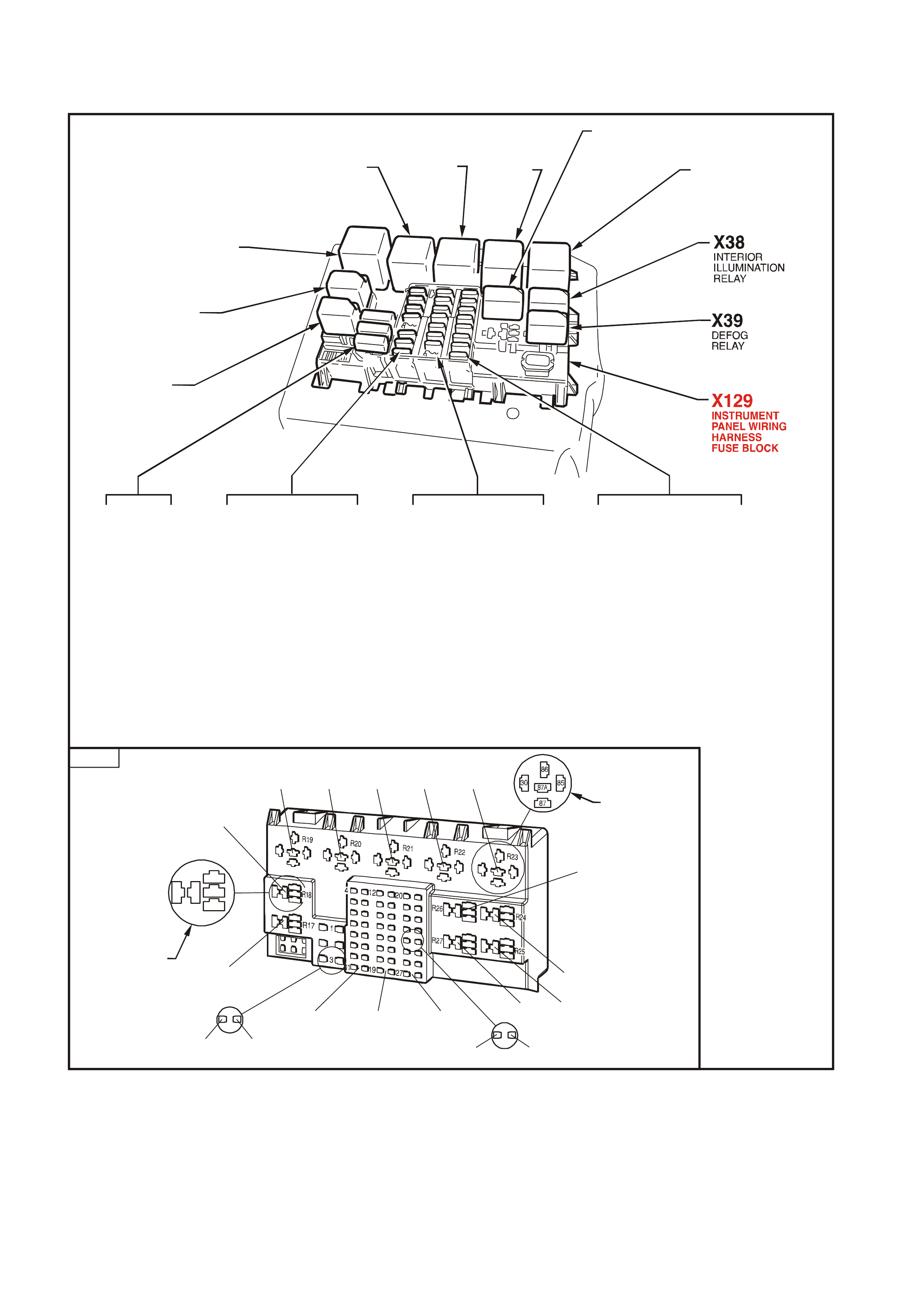

8. FUSE AND RELAY PANEL LOCATIONS

9. IVED ELECTRICAL SCHEMATICS

10. SPECIAL TOOLS

1. GENERAL INFORMATION

Wiring diagrams are found throughout various Sections of the Service Information. The wiring diagrams contained

in this Service Information are the specific systems wiring diagrams for MY2003 VY and V2 Series vehicles. These

wiring diagrams are based on the Integrated Vehicle Electrical Design (IVED) standards. There are two types of

wiring diagrams used in this Service Information:

• Service Information Wiring Diagrams.

• IVED Electrical Schematics.

The Service Information wiring diagrams only refer to the system under discussion and are used to:

• Present the overall circuitry for a total system.

• Assist in explaining the operation of part of a total system.

• Assist in diagnostics.

This Section is designed to assist technicians in understanding both forms of wiring diagrams.

Additional wiring, wiring harness and specific wiring harness installation information is contained in

Section 12O, FUSES, RELAYS AND WIRING HARNESSES in this Service Information. Further information on

developing a diagnostic procedure for electrical circuit diagnosis, electrical circuit test procedures, diagnostic tests

and wiring repair procedures is contained in this Section.

2. ELECTRICAL CIRCUIT DIAG NOSI S

The system wiring diagrams should be referred to when diagnosing vehicle electrical problems.

These diagrams should ALWAYS be the starting point when troubleshooting electrical problems.

The diagrams illustrate how a particular circuit should work by design, and should be understood before trying to

determine why it does not work.

NOTE: It is important to realise that no attempt is made on the diagrams to represent components and wiring as

they appear in the vehicle geographically.

For example, a metre length of wire is treated no differently in a wiring diagram from one which is only a few

centimetres long. Similarly, switches and other components are shown as simply as possible in schematic format

and in an inactivated state, with basic function only being shown.

The following six-step procedure is recommended when diagnosing a vehicle electrical problem.

Step 1. Identify the Problem

Does a problem really exists?

To identify the problem, listen patiently and carefully to the owner/operator of the vehicle.

Step 2. Specify the Problem

Question the owner/operator to establish:

Is there a problem?

What is the problem?

Where is the problem?

How serious or extensive is the problem?

How often does the problem occur?

Does a trend exist?

Perform a system check to be sure you understand what is wrong.

Do not waste time fixing only part of the problem. Do not begin disassembly of components or testing until you have

narrowed down the possible causes.

Step 3. Investigate the Problem

Are you totally familiar with the system?

Read the system wiring diagram.

Study the diagram to understand how the affected circuit should work.

Check circuits that share wiring with the problem circuit. If the shared circuits operate correctly, then the shared

wiring must be OK. The cause of the problem must be within the wiring or components used by the problem circuit.

If several circuits fail at the same time, chances are the power (fuse) or earth circuit is faulty.

Step 4. Develop Possible Causes

Make yourself a mental or written check list.

Ask yourself would this cause the problem?

Use the system wiring diagram to develop a set of test points.

Narrow down the possible causes.

Step 5. Isolate the Most Possible Cause

You must have the knowledge and the special tools/equipment.

Carry out the necessary tests and measurements as given in the appropriate system diagnosis, e.g. ENGINE

MANAGEMENT SYSTEM, CRUISE CONTROL, or at the test points that you have developed from the wiring

diagrams. TEST, DON'T GUESS.

Before replacing a component, check power, signal and earth wires at the component wiring harness connector. If

these check OK, the component is most likely to be faulty. FIND THE CAUSE AND REPAIR.

Step 6. Verify

Test the repair.

Has the problem been fixed?

Ask yourself why did the problem occur/part fail?

Will it happen again?

Have I created any other problems?

CURE THE CAUSE NOT THE EFFECT.

OPERATE THE CIRCUIT AND ROAD TEST THE VEHICLE BEFORE RETURNING IT TO THE CUSTOMER.

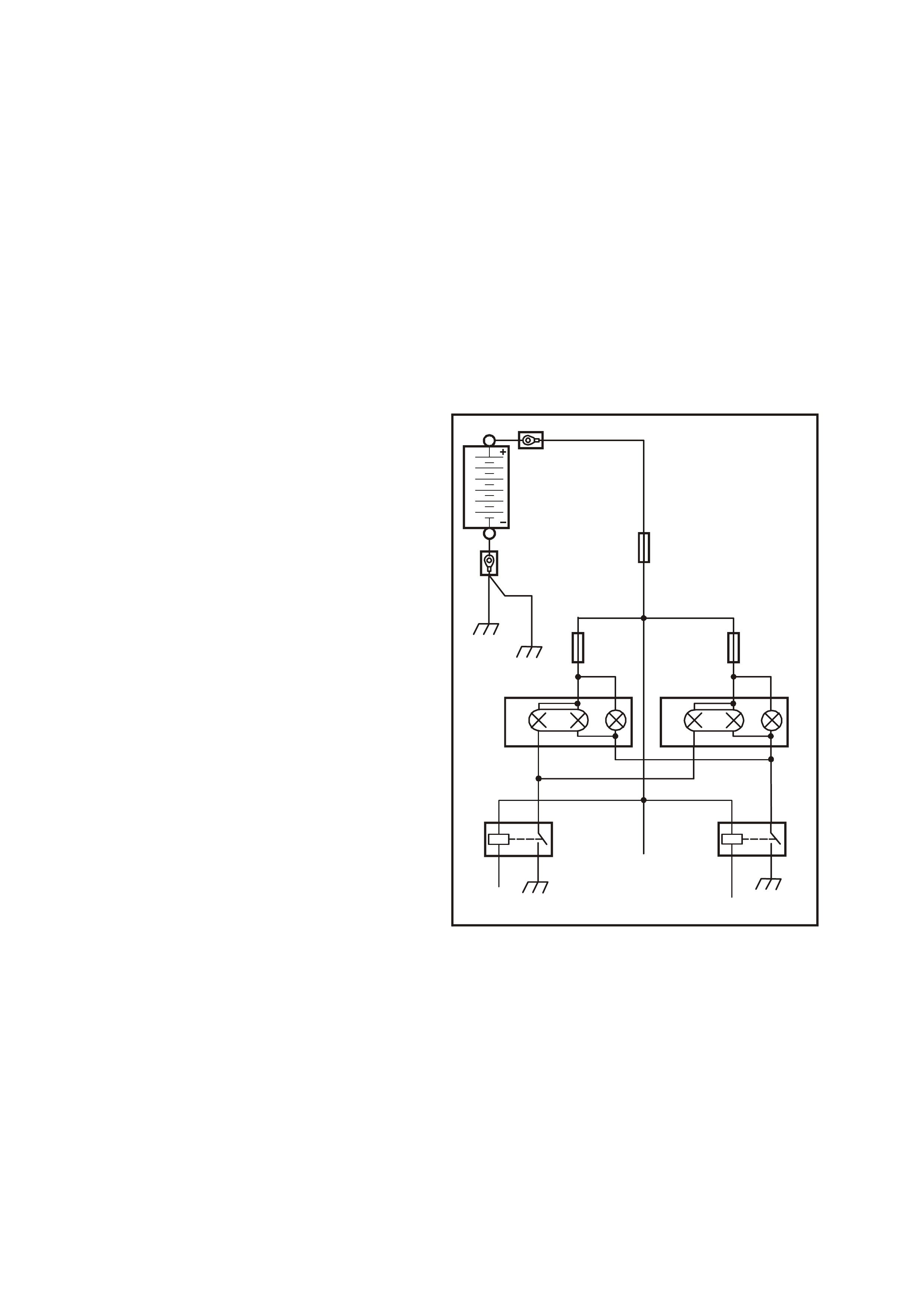

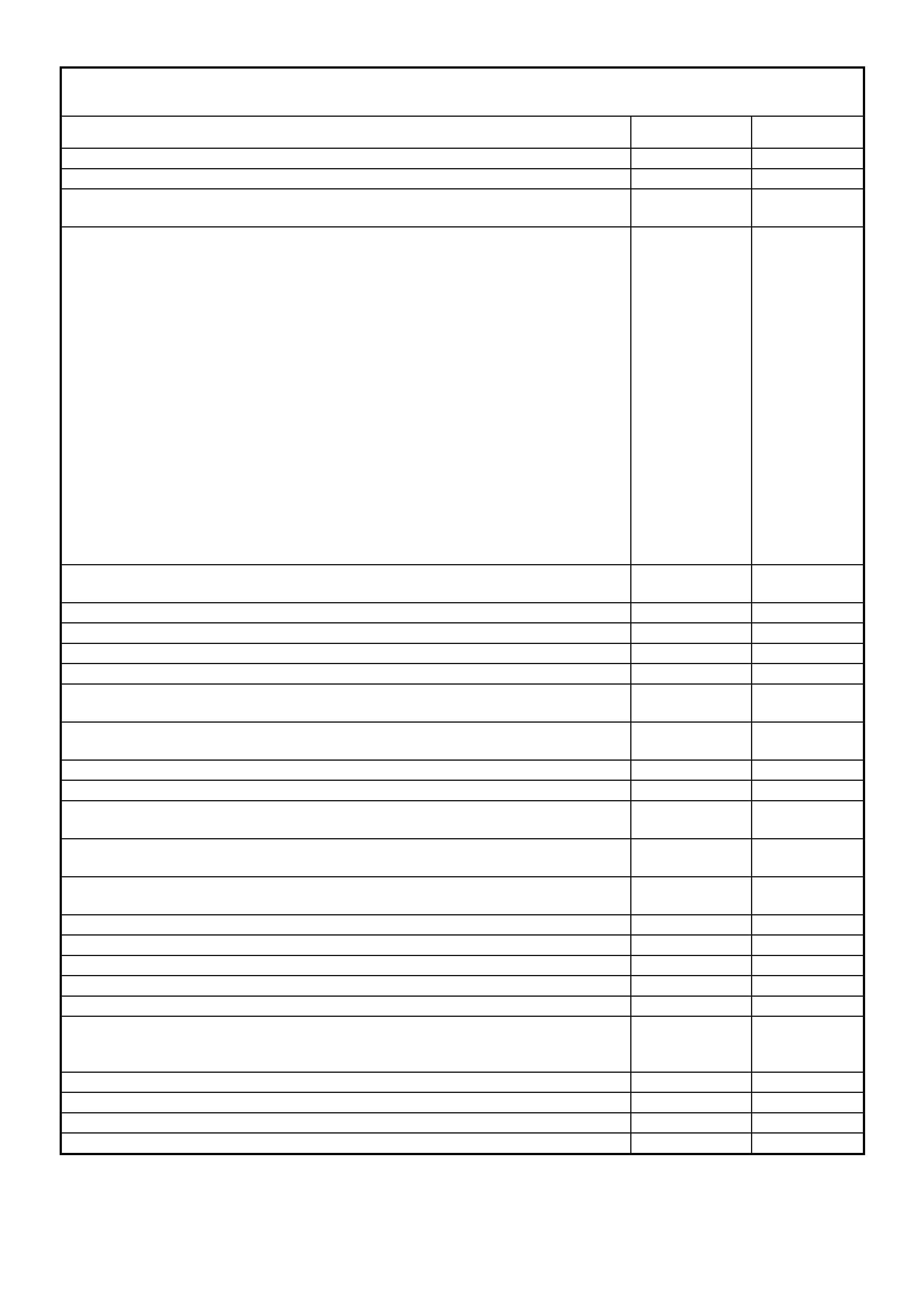

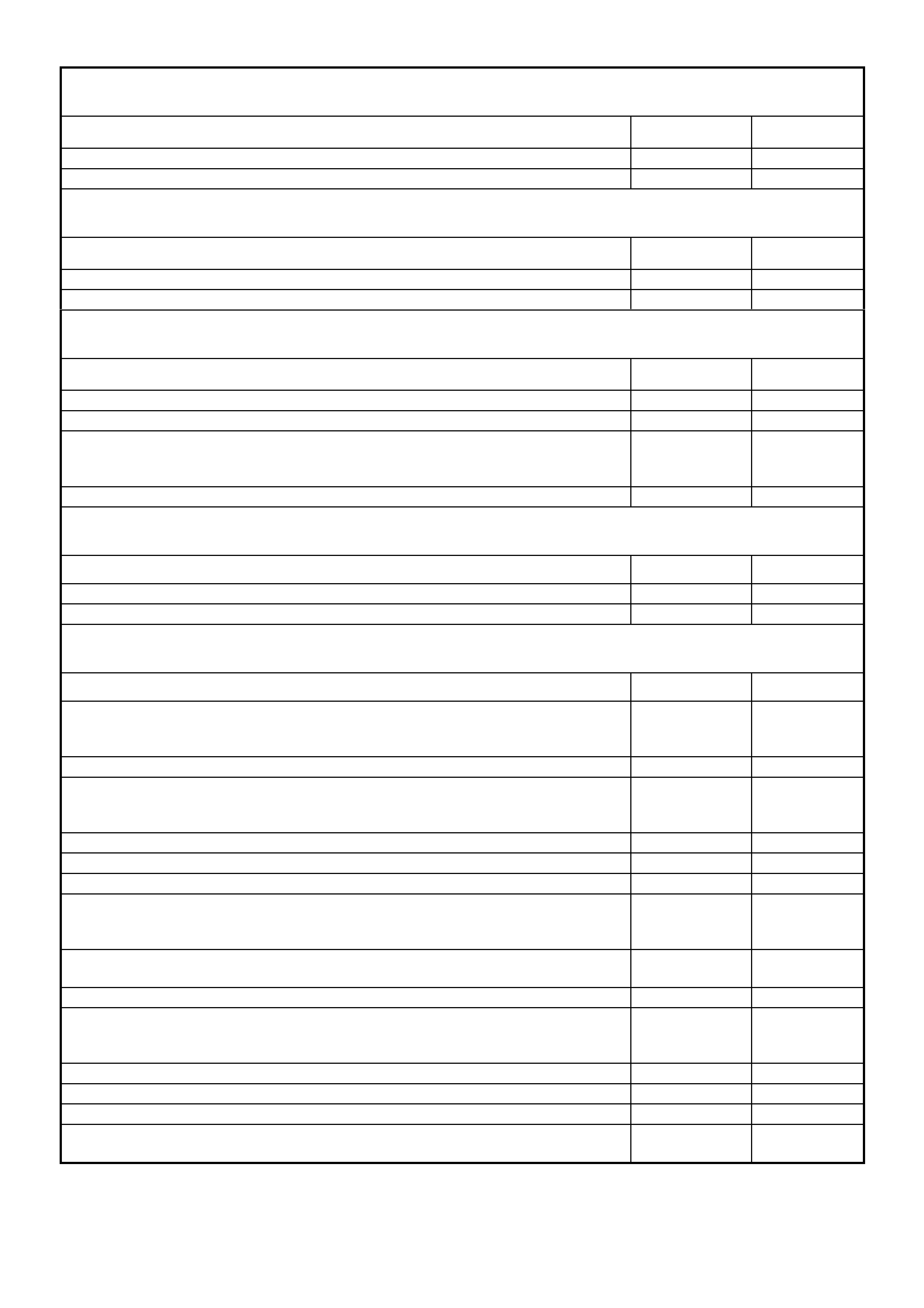

PROBLEM EXAMPLE

Step 1. Identify the Problem

A customer brings in a vehicle reporting that the headlamps are not operating correctly.

Step 2. Specify the Problem

The driver is questioned and it is established that the LHF headlamp is not operating on high beam, or when the

flash switch is operated.

Step 3. Investigate the Problem

Perform a system check on the headlamp circuit. It is noted that:

1. Headlamps operate correctly on low beam.

2. On high beam, the headlamp high beam lamps operate correctly but the left hand headlamp inboard high beam

lamp does not operate on high beam.

3. When the high beam flash switch is operated, the LHF headlamp inboard high beam lamp still does not operate

on high beam.

READ THE SYSTEM WIRING DIAGRAM.

This is the step that will save time and labour. Remember, it is essential to understand how a system should work,

before trying to determine why it doesn't work.

Step 4. Develop Possible Causes

Once the circuit is understood, read the diagram

again, this time keeping in mind what you have

learned by operating the circuit. It is recommended

to read the System Wiring Diagram from the

battery positive terminal or fuse (being the source

of electrical supply) to ground (battery negative

terminal).

As both low beam headlamps work, fuses F102,

F31 and F30, the headlamp switch, low beam

headlamp relay, the low beam ground circuit, and

both low beam headlamp filaments are OK.

Furthermore, since the RHF inboard high beam

lamp works on high beam and flash, the headlamp

and flash switch and the high beam head lamp

relay are OK.

Since the LH outboard high beam headlamp is

working correctly, the lead from the headlamp relay

to the lamp assembly must be OK. Therefore the

fault must be in circuit 2140 between the splice

after fuse F31 and the splice after the LH inboard

high beam bulb in the headlamp assembly.

The cause must be:

1. In wire 2140, from the splice after fuse F31 to

LH connector E83, terminal X1-4.

2. In the lead from LH connector E83, terminal

X1-4 to the LH inboard high beam headlamp

bulb.

3. The LH headlamp high beam bulb.

The possible causes have been quickly narrowed

down to a specific area and done no work on the

vehicle itself.

Read the system wiring diagram again to develop a

set of test points. Start from the positive to the

negative/ground.

X1-A

X2-A

POS

NEG

F102

G1

Battery Asm

1

X86_A

RD

X86_D

LOC.

X119_GP4 LOC.

X119_G4_GP3

50

BK 50

BK

F30F31

442

RD

LO_BM

LO_RET HI_RET

E83 - L

Lamp

Asm

LO_BM

LO_RET HI_RET

E83 - R

Lamp As m

11

L-GN

TN

12

Headlamp

Relay

(High Beam )

Within X100

87

86

30

85

BK/WH

550

LOC. X157_GP2

Headlamp

Relay

(Low Beam)

Within X100

25

13

BK/WH

550

LOC. X157_GP2

VY12P201

20402140

WH/BKWH/BU

55X1 X1

X1 X1

44

Figure 12P-1

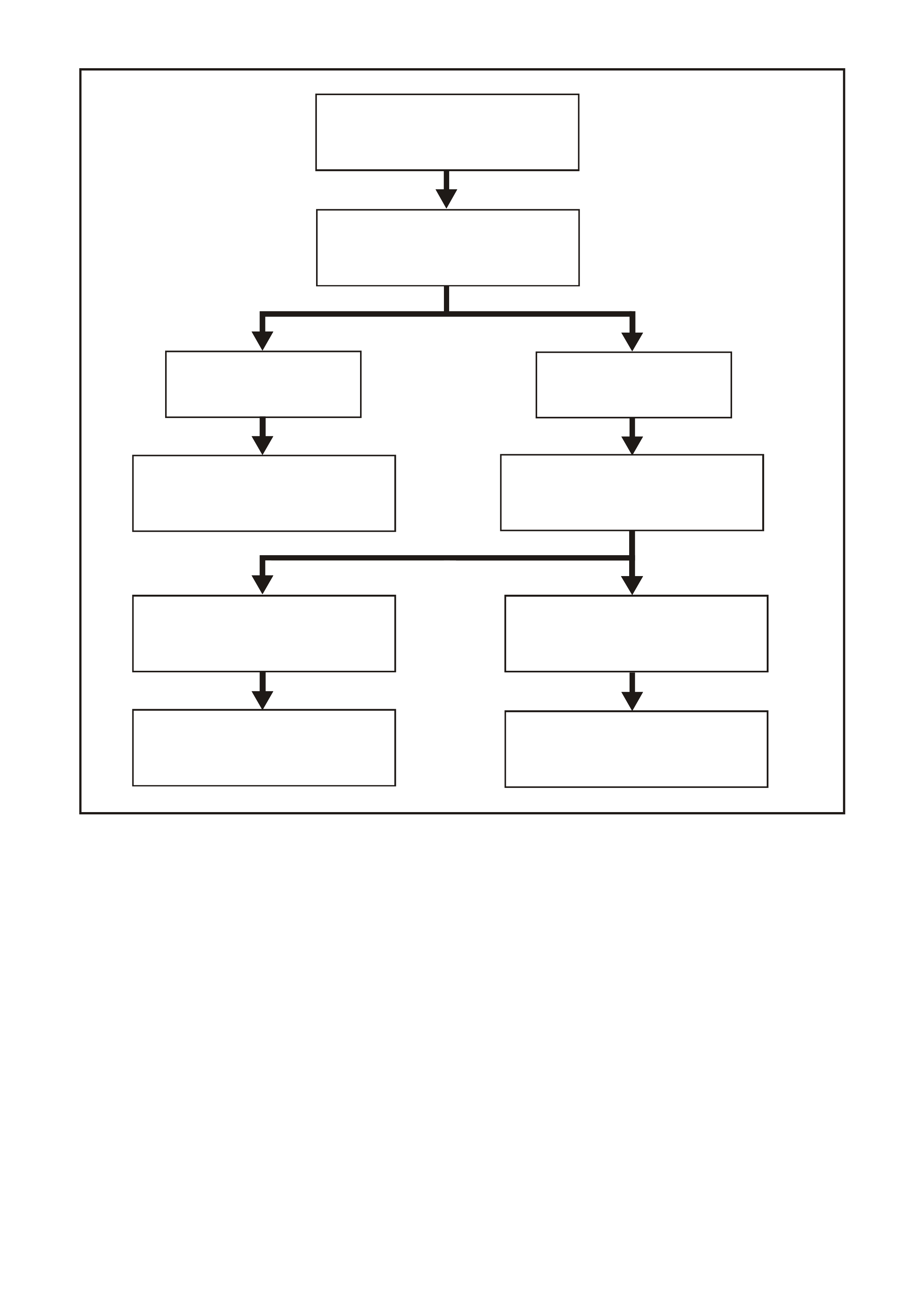

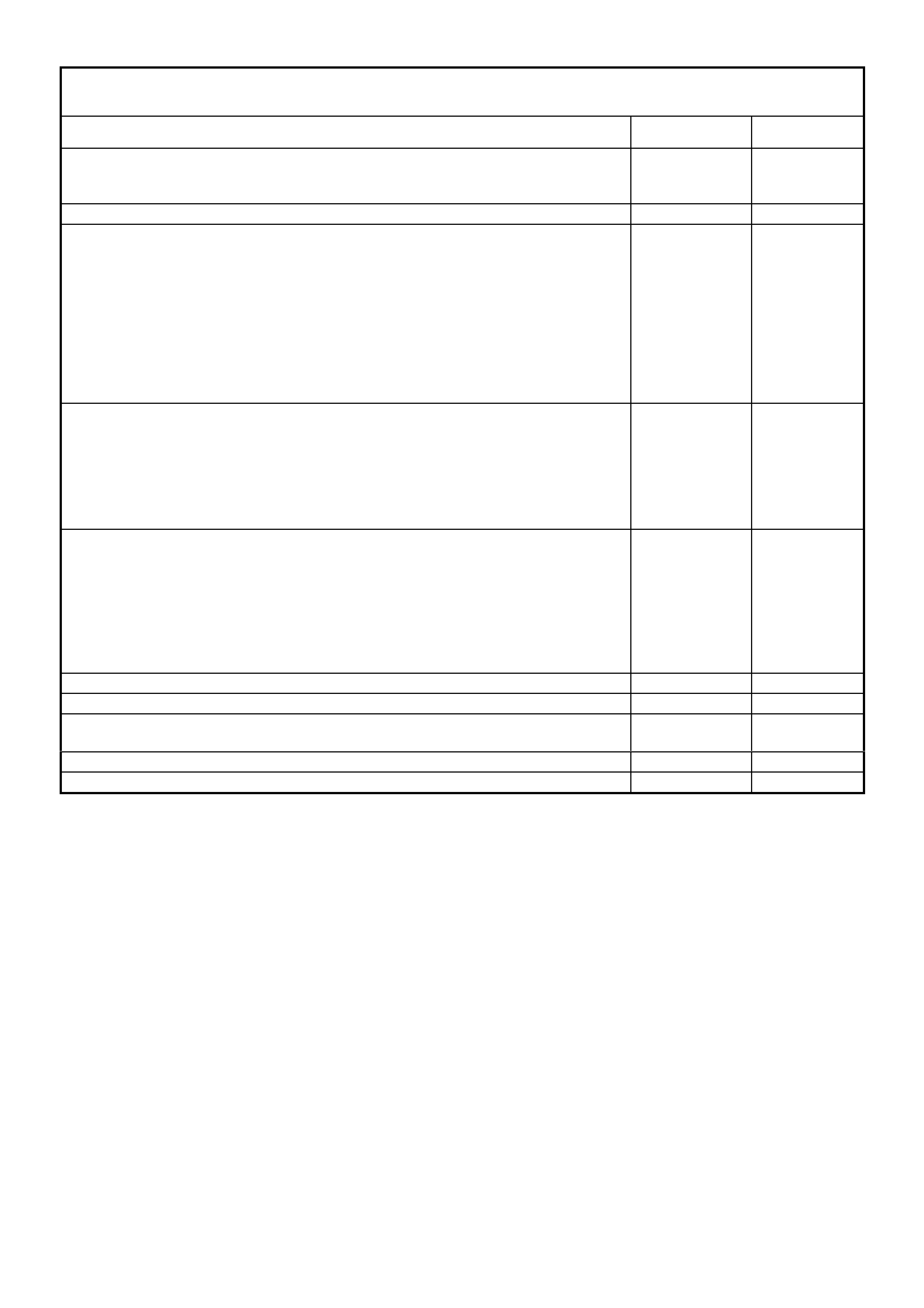

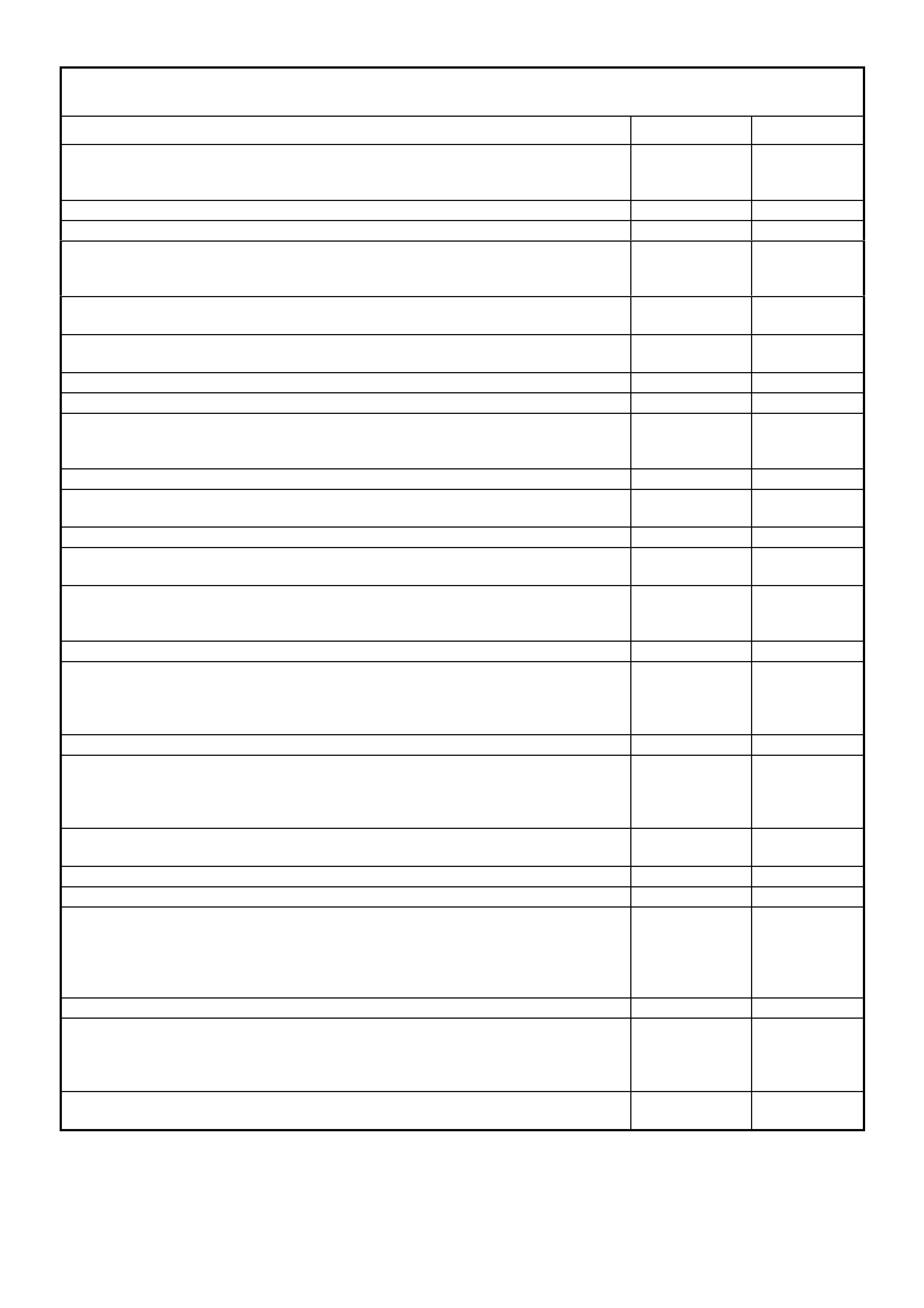

Step 5. Isolate the Most Possible Cause

Figure 12P-2 is an example of how to isolate the

cause of the problem. Remembering it has already

been determined that the fault is between the

splice after fuse F31 and the LH inboard high beam

headlamp bulb, check the simple things first.

NO BATTERY VOLTAGE

AT TE RM INA L X 1-4 BATTERY VOLTAGE

AT TERMINAL X1-4

REMOVE LH INBOARD HEADLAMP

DUST CAP AND CHECK FOR BATTE RY

VOLTAGE AT BULB CONNECTOR

WH /BU WIRE

REPAIR OPEN CIRCUIT BETWEEN

CONN ECTOR E83 TERMINAL X1-4

AND INBOARD HIGH BEAM BULB

CONNECTOR

REPLA CE L H I NBOA RD HEAD L AMP

HIGH BEAM BULB

BATTERY VOLTAGE AT BULB

CONNECTOR WH/BU WIR E NO BATTERY VOL TAGE A T BULB

CONNECTOR WH/BU WIR E

REPAIR WIRING BETWEEN CIRCUI T

2140 SPLICE AND CONNECTOR

E83 TERMINAL X1-4

CHECK FOR BATTERY VOLTAGE

AT LH INBOARD HEADLAMP

CONNECTOR E83 TERMINAL X1-4.

SWITCH HEADLAMPS ON.

SWITCH HEADLAMPS TO

THE HI GH BEA M POSITION

VY12P202

Figure 12P-2

Step 6. Verify

Test the repair by performing a system check on the headlamp circuit. This of course means making sure that both

high beam lamps, both low beam lamps and high beam indicator are all working. Ask yourself:

• Has the problem been fixed?

• Why did the problem occur or why did the part fail?

• Will it happen again?

• Have I created any other problems?

CURE THE CAUSE NOT THE EFFECT.

OPERATE THE CIRCUIT AND ROAD TEST THE VEHICLE BEFORE RETURNING IT TO THE CUSTOMER.

3. TEST PROCEDURES

3.1 ELECTRICAL FAULT DIAGNOSIS

The proper operation of electrical circuits especially low amperage input/output circuits (electronic components etc)

depend upon good continuity between circuit connectors.

It is important before component replacement and/or during normal trouble shooting procedures that a thorough

visual inspection of all terminals or connectors is performed and any questionable mating connector/terminals be

repaired or replaced.

All mating surfaces should be clean, properly formed, clean and making positive contact.

Some typical causes of connector problems are:

1. Improperly formed contacts and/or connector plugs.

2. Damaged contacts or plugs due to improper engagement.

3. Corrosion, body sealer or other contaminants on the contact mating surfaces.

4. Incomplete mating of the connector halves during initial assembly or during subsequent trouble shooting or

repairs.

5. Tendency for connectors to come apart due to vibration and/or temperature cycling.

6. Terminal not fully seated in connector body (terminal backed out).

7. Inadequate terminal crimps to the wire or poor solder joint.

NOTE: When inserting test probes during diagnosis, always try to test from the back of the terminal and avoid

spreading terminals which may cause poor continuity.

IMPORTANT: Do not back probe 'Weather Pack' type connectors as damage to the cable seals will result.

When carrying out wiring checks, rather than probe terminals and connectors with incorrect sized multimeter or test

lead connectors, use adaptors included in kit J35616-A or KM-609. This is will prevent any possibility of spreading

or damaging wiring harness terminals.

POSSIBLE ELECTRICAL MALFUNCTIONS

There are five possible electrical malfunctions, as follows:

1. Loss of battery power (loose connections/corrosion).

2. Defective device.

3. High resistance (dirty, loose or corroded connections).

4. Open circuit.

5. Earthed or short circuit.

Electrical circuits should be tested at:

1. Easily disconnected connections.

2. Easy to reach access points.

CIRCUIT FAULTS

The various failures that occur in a circuit will dictate what must be done to repair the problem. These failures can

be categorised as follows:

OPEN

An open circuit is a physical break in the path of current flow. In a series circuit, the circuit stops operating. In

parallel circuits, an open in one individual circuit will stop the operation of that particular circuit, but other individual

parallel circuits will continue to operate. The ohmmeter is useful in finding an open circuit with continuity checks.

SHORT TO EARTH

A short to earth is where the circuit is earthed due to an insulation breakage. The conductor touches earth, causing

a fuse or fusible link to blow. If there is no fuse, the circuit may burn, and even cause flames. If the short occurs

after the load, circuit control may be lost causing the circuit to operate when it is not wanted. The test light is a good

device in this case. Insert the test light in place of the fuse. Disconnect circuit components in a systematic and

logical manner. When the test light goes out, the part of the circuit with the short to earth will be found.

SHORT TO VOLTAGE

The short to voltage is a condition where a circuit, due to insulation breakage, causes the conductor to contact the

voltage of another circuit. This will cause the circuit (or both circuits) to operate improperly. This problem can cause

odd things to occur and can be difficult to find. To locate this type of problem, a thorough examination, using the

diagnostic procedure described at the beginning of this Section, must be performed. Observe the symptoms to

recognise associated circuits involved. Isolation by removing fuses will help isolate the circuit branches involved.

Then voltage and resistance checks at strategic locations will isolate the problem.

HIGH RESISTANCE PROBLEMS

A high resistance problem is often hardest to find. This is a condition where it is important to use test meters. High

resistance can be caused by loose, dirty or corroded connectors. Current flow will be lowered, which can cause

incorrect circuit operation or inoperative components.

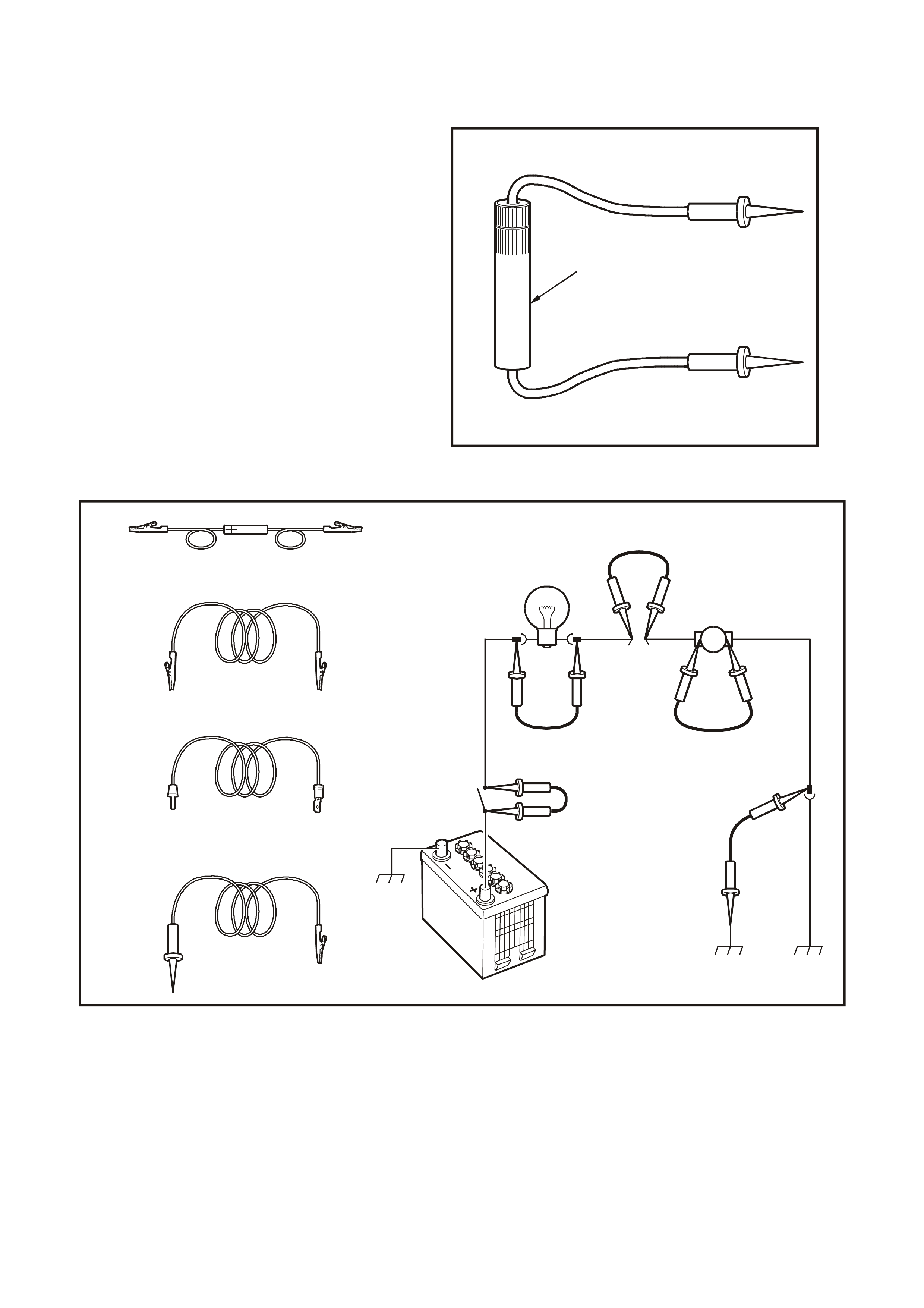

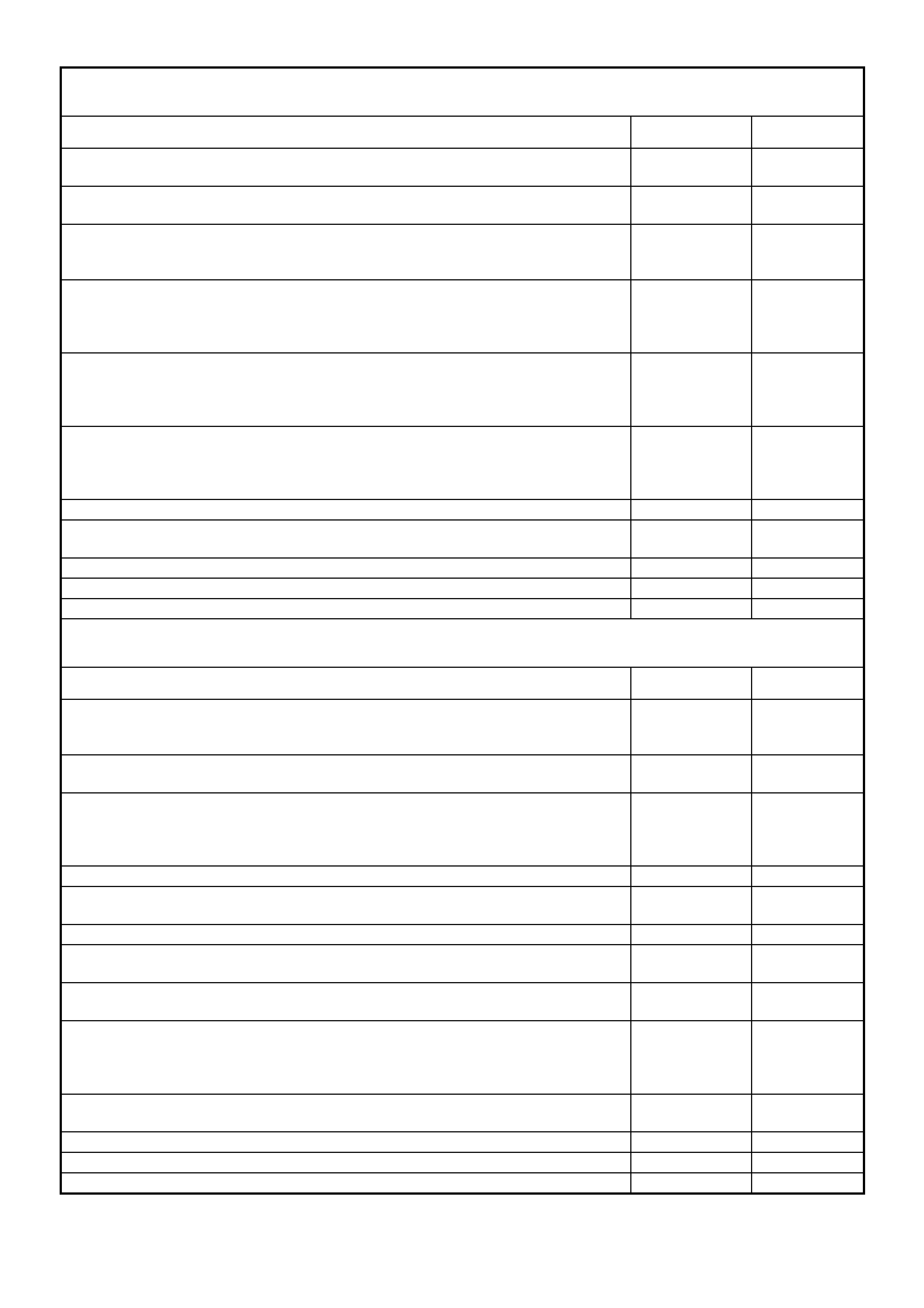

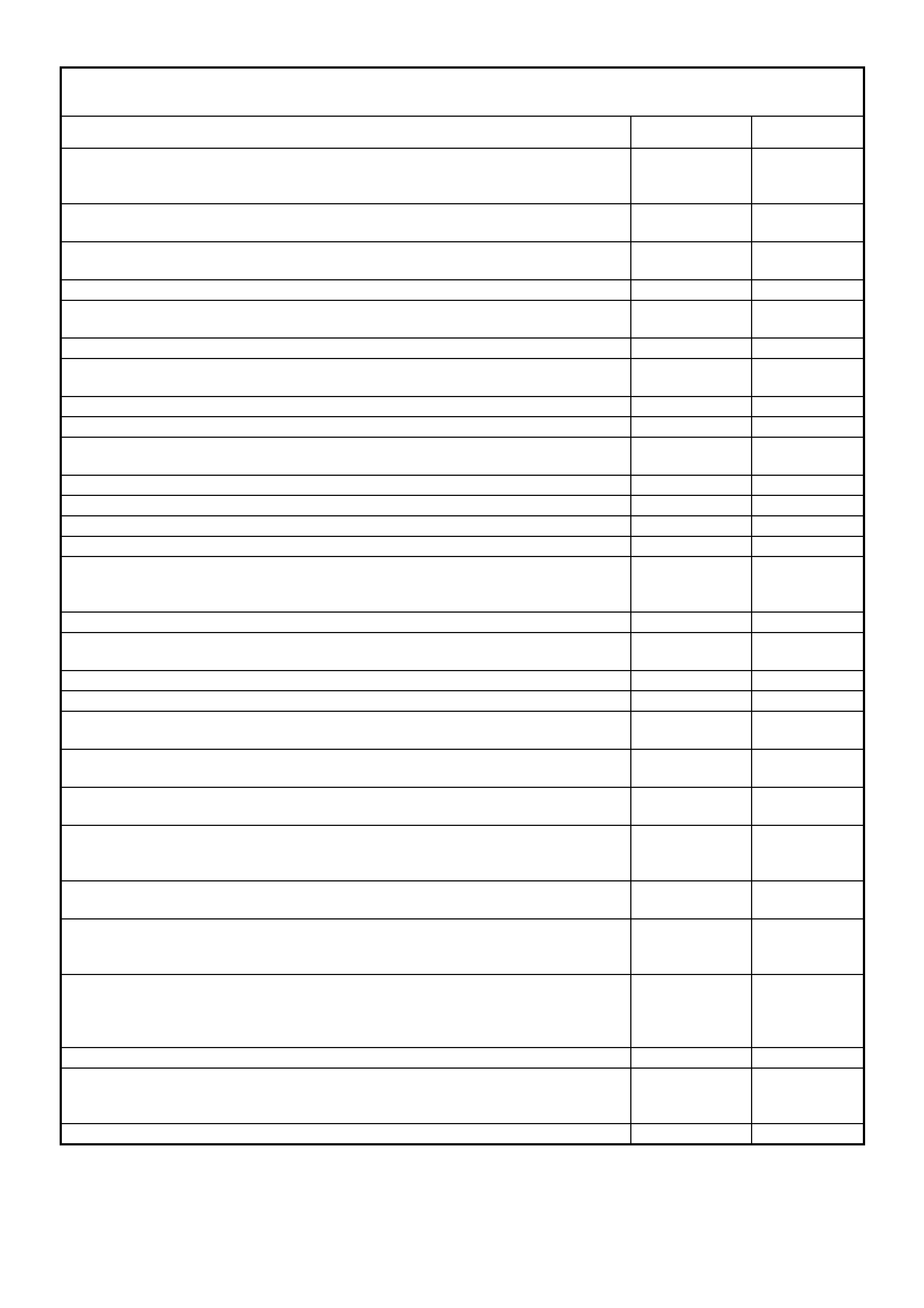

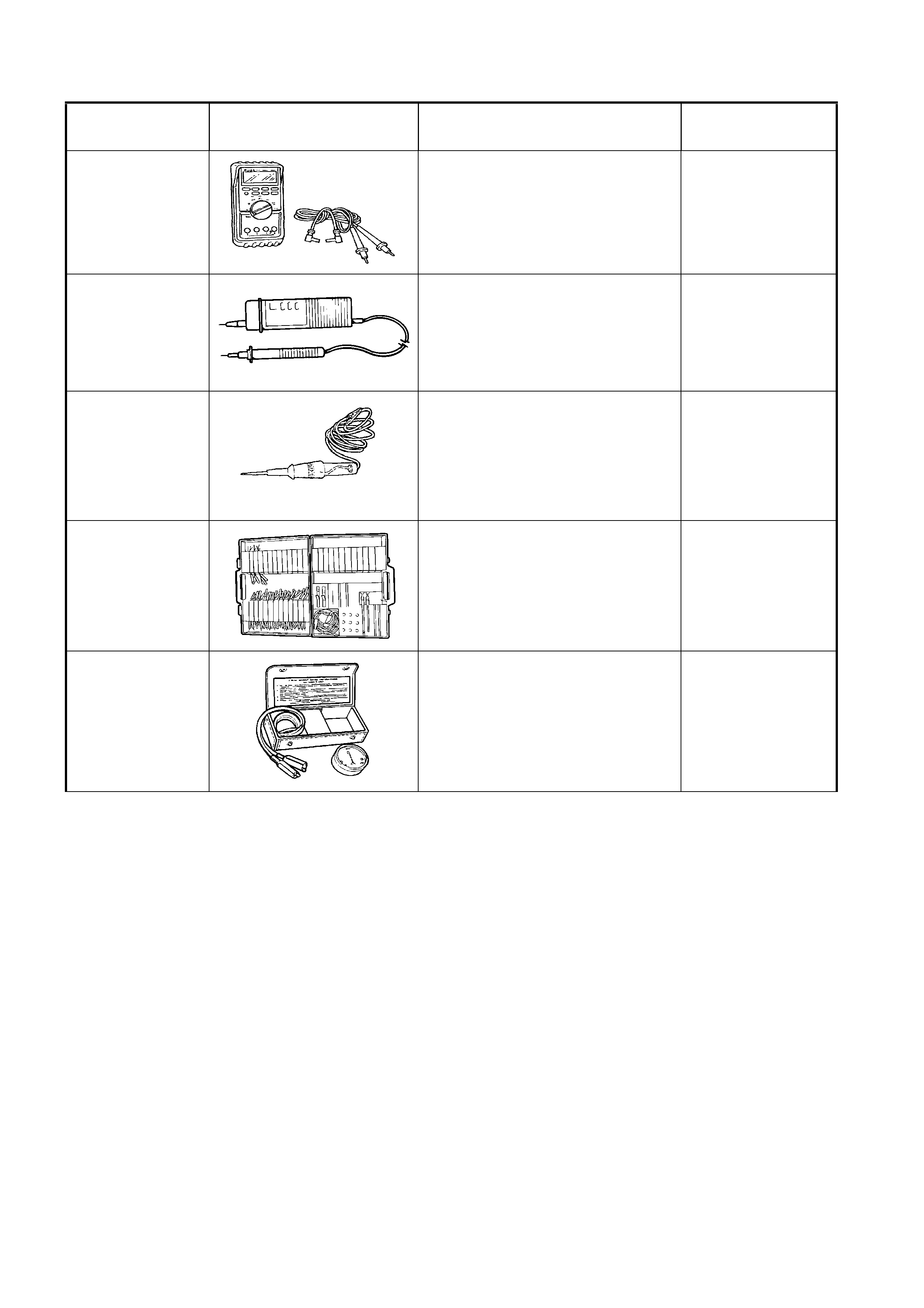

3.2 TROUBLESHOOTING TEST EQUIPMENT

JUMPER WIRE

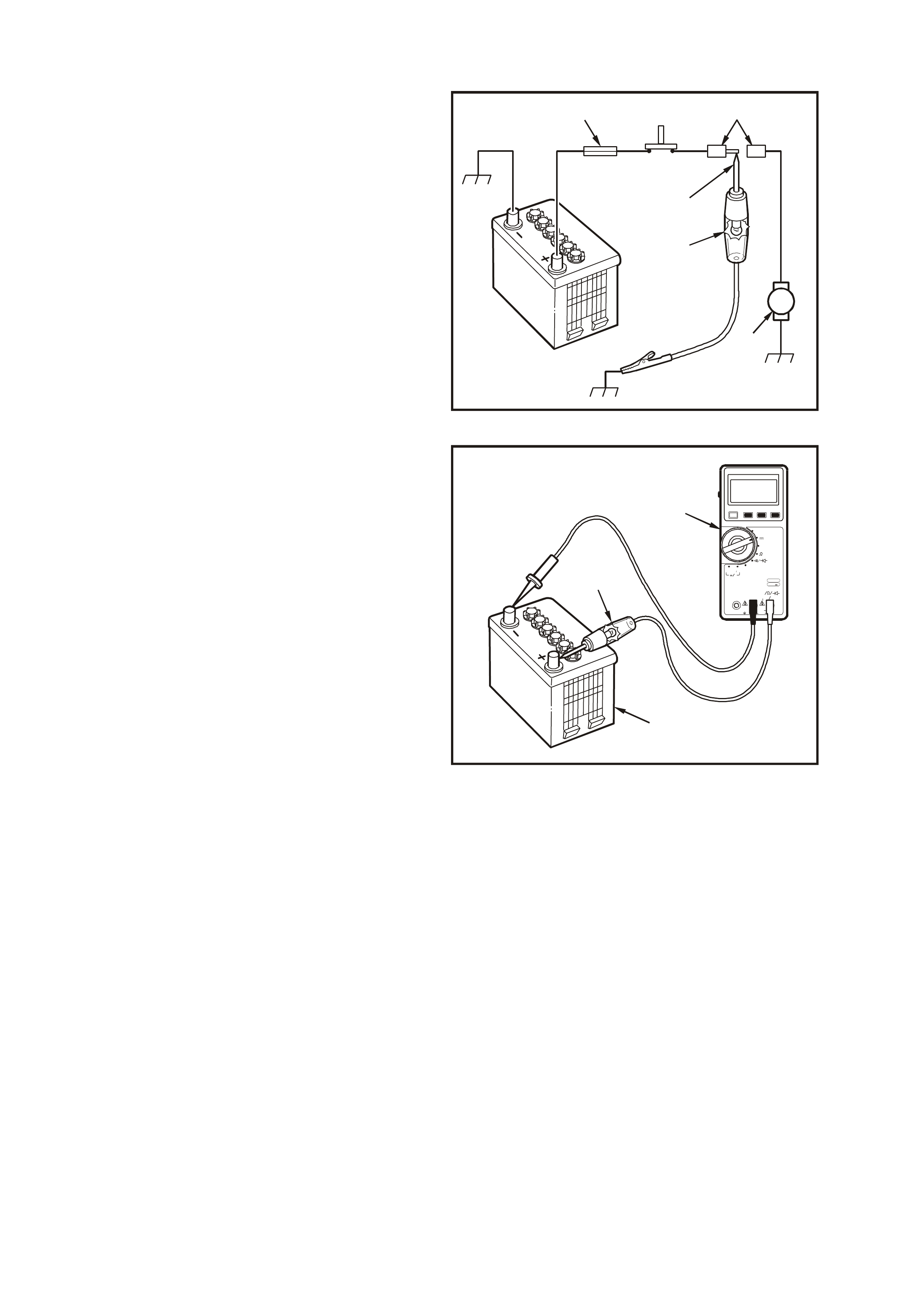

A jumper wire is an in-line fuse holder connected to

a set of test leads and it is use for by-passing open

circuits. The in-line fuse holder (1) should be fitted

with a five-amp fuse. Never use a jumper wire

across any load as this will cause a direct battery

short and blow the fuse. When properly used,

jumper wires are simple, effective testing aids.

They are used to complete a circuit by allowing

current to 'jump' across a suspected open or break,

and so act as a test of continuity.

When a jumper wire is used, it replaces a

suspected faulty portion of a circuit with a known

good conductor. If the circuit works properly when

the jumper wire is in place, but does not work

properly without the jumper wire, an open circuit is

indicated in the area that has been jumped. Use a

jumper wire to by-pass only non-resistive parts of a

circuit, such as switches, connectors and sections

of wiring.

VY12P203

1

Figure 12P-3

VY12P204

1

2

5

6

34

8

7

9

M

3

3

3

88

Figure 12P-4

Legend

1. Alligator clips with in-line fuse 4. Spade terminal 7. Battery

2. Alligator clips 5. Probe tip 8. Switch

3. Pin terminal 6. Alligator clip 9. Motor

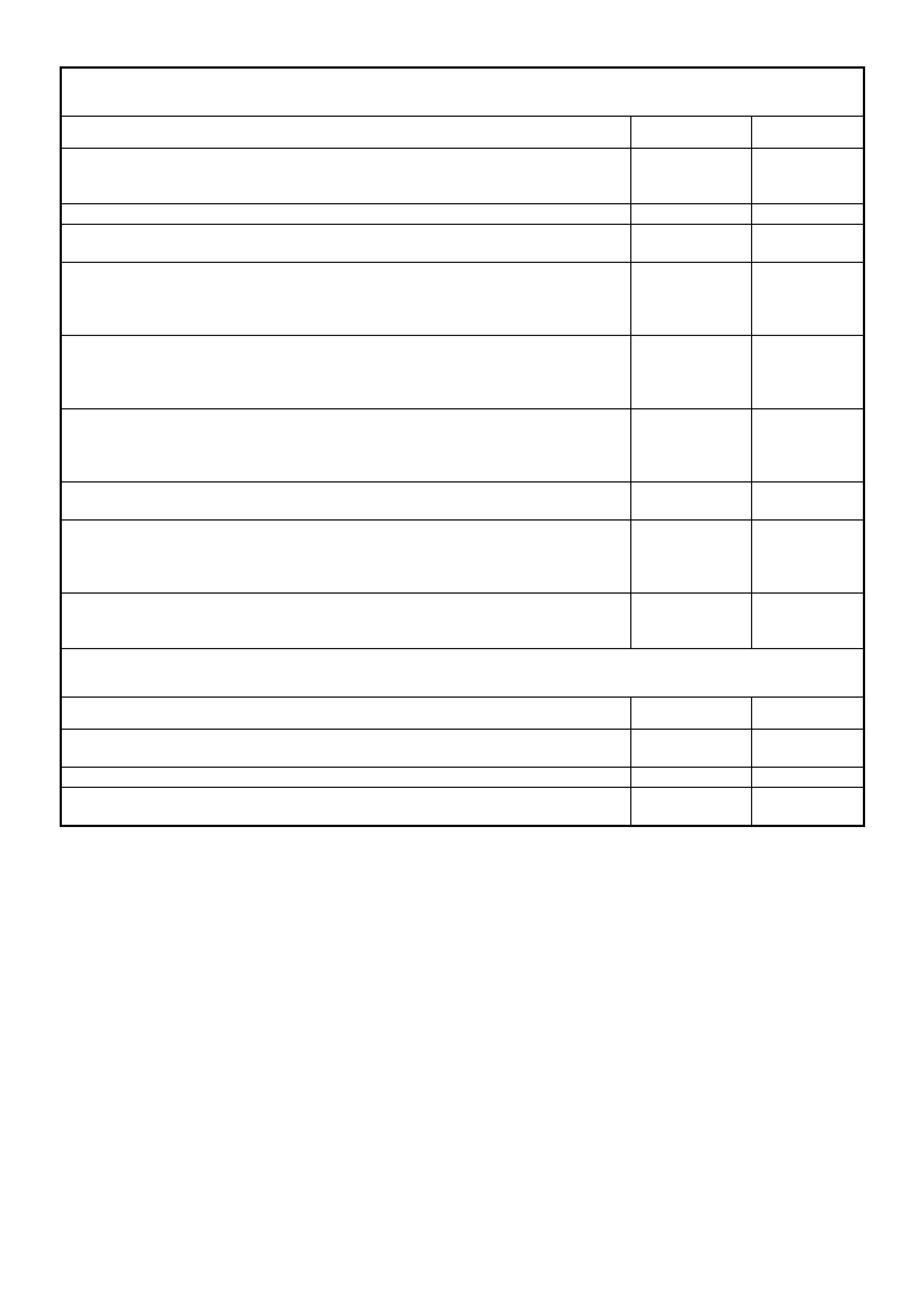

TEST LIGHT

A test light is made up of a 12 volt light bulb with a

pair of leads attached and is used to test for

voltage. After earthing one lead, touch the other

lead to various points along the circuit where

voltage should be present. When the bulb

illuminates, there is voltage present at the point

being tested.

CAUTION: Never use a low-imped ance test ligh t

on circuits that contain solid-state components,

since damage to these components may result.

Legend

1. Fuse 4. Test light

2. Connector 5. Motor

3. Probe

VY12P205

1

3

4

5

2

M

Figure 12P-5

When a test light is specified, a LOW-POWER test

light must be used. Do not use a high wattage test

light. While a particular brand of test light is not

suggested, a simple test on any test light will

ensure it's suitability for circuit testing. Connect an

accurate ammeter such as the high-impedance

digital multimeter (1) in series with the test light (2)

being tested, and power the test light - ammeter

circuit with the vehicle battery (3). If the ammeter

indicates less than 0.3 A (300 mA) current flow, the

test light is OK to use. If more than 0.3 A (300 mA),

DO NOT USE.

VY12P206

1

2

3

~

POW ER

FUSED

1000V

MAX 750V~

1000V---

MAX

10A COM uA mA

V

DATA

HOLD SELECT RANGE

ºC

V

~V

A

DP

mA/A uA

P U SH SE L E C T

PUSH SELECT

1

kHz

0.3% V

~

DC AMPS

Figure 12P-6

SELF-POWERED TEST LIGHT

A self-powered test light is used to check for continuity. This tool is made up of a 3 V light bulb, battery and two

leads. If the leads are touched together, the bulb will illuminate.

A self-powered test light is used only on an unpowered circuit. First, disconnect the vehicle's battery, or remove the

fuse which feeds the circuit being worked on. Select two specific points along the circuit through which there should

be continuity. Connect one lead of the self-powered test light to each point. If there is continuity, the test light's

circuit will be completed and the bulb will illuminate.

An increasing number of circuits include solid state control modules. Voltages in these circuits should be tested

ONLY with a 10 Megohm or higher impedance digital voltmeter or multimeter.

CAUTION: Never use a self-powered test light on circuits that contain solid-state components, since

damage to these components may result.

MULTIMETERS

Analogue versus Digital Meters

Digital multimeters outperform most types of analogue meters for a variety of reasons. Digital multimeters are more

accurate. The internal circuitry is not the only factor affecting analogue meter accuracy. The pointer can appear to

be in different positions when the gauge is viewed from different angles. Digital displays leave no such doubt about

there reading.

The digital multimeter shows a + symbol in front of the reading when the positive meter lead is connected to a

positive power source and the negative lead is connected to earth. If the digital multimeter leads are reversed, a –

symbol appears in front of the reading to indicate reverse polarity.

A digital multimeter, has an electronic digital readout of the value of the measurement being made. This type of

meter has electronic circuitry for precise measurements. It can be accurate within 0.1 percent, much more accurate

than analogue meters. The digital multimeter is becoming the preferred choice for electrical diagnosis and testing,

especially for testing electronic systems.

The impedance of an analogue meter is less than 10 Megohm. A meter with less than 10 Megohm impedance must

not be used on circuits that contain solid state components because:

• The low impedance of the meter could cause incorrect readings.

• The meter could allow too much current to flow through the circuit being tested.

• The excess current could damage sensitive electronic components.

A digital multimeter with at least 10 Megohm input impedance is needed for use on Holden vehicles. This input

impedance applies to the meter only when it is used on the voltage scale. This means that the meter resists loading

down the circuit being measured with a resistance of 10 million ohms. On automotive circuits, this high resistance

permits measurement of very sensitive circuits without damaging or altering them.

NOTE: Impedance is the resistance to current flow through the meter, from one lead to the other lead. High input

impedance provides greater sensitivity, and prevents the meter from affecting the circuit being tested. Resistance is

measured in ohms. Impedance and resistance both mean 'opposition to current flow'.

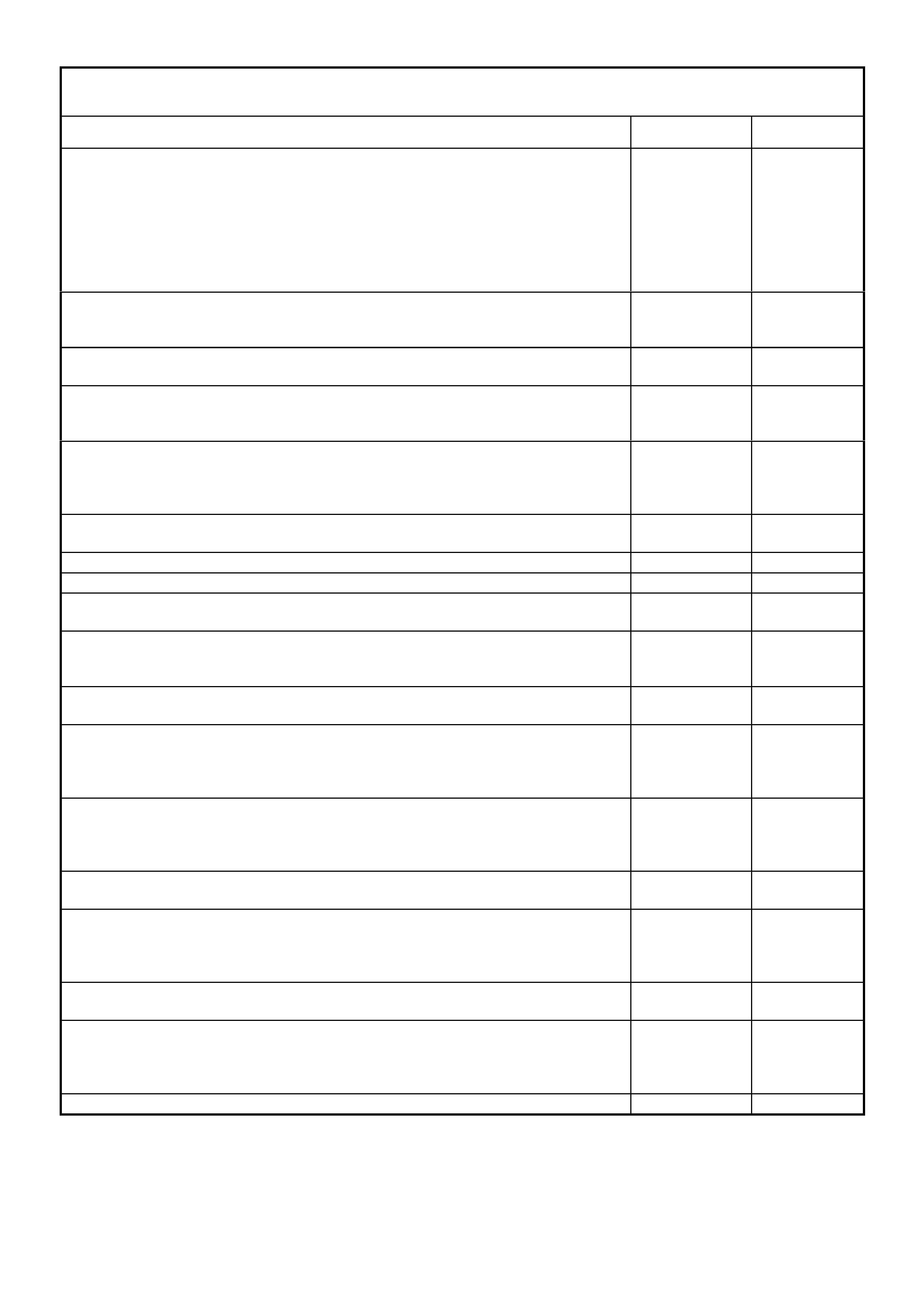

3.3 DIGITAL MULTIMETER

One of the most useful diagnostic tools is the digital multimeter. These basic operating procedures for a multimeter

may vary with the make of meter and the manufacturer's operating instructions should be read and understood

before using the multimeter.

USE OF A MULTIMETER

1. Always turn meter OFF when not in use.

2. Ensure the meter face reads zero.

3. If applicable, touch the leads together then adjust the resistance reading to zero each time a resistance range is

selected or changed.

4. If you are not sure of the reading you expect to get, always select the highest scale, then reduce to allow an

effective reading.

5. When measuring current, ensure the meter can handle the load and that the test leads are in the correct jacks.

6. Treat the instrument with the respect it deserves.

NOTE:

• Voltage readings are taken in parallel (i.e. over the load).

• Current readings are taken in series (i.e. break the circuit and use meter leads to complete the open circuit).

• Resistance: Disconnect all external power, which includes the discharging of capacitors in electronic

components.

SELECTION OF MULTIMETERS

The best type of multimeter is one which has:

• Internal protection so that it cannot be damaged if, for example, voltage is put through when the meter is set on

ohms. The fuse protects the meter and is the only thing that has to be replaced.

• One that you can use to carry out a diode check facility which also provides an audible signal.

• An audible signal when carrying out continuity checks.

• A data hold facility so when a reading is taken that reading will remain on the display after the leads are

removed.

A multimeter today also has to have a high impedance factor. The common analogue type multimeter may be

inadequate and may actually damage sensitive electronic circuitry. Analogue meters, due to their low internal

resistance (input impedance), draw too much power from the device they are testing for use on computers. Many

analogue meters use 9 volts to power the resistance test which is enough to destroy sensitive digital components.

Digital multimeters have an input impedance of about 10 Megohms which is much higher than analogue

multimeters. The high impedance means that the meter will draw very little power from the device under test. This

means the meter will provide a more accurate measurement and will not damage delicate electronic components.

The multimeter used should also be able to test temperature and high amperages. This allows the one tool to do a

vast amount of work in the area of diagnosis.

Auto diagnosis is the art of the mechanical trade. To be able to fault find, rectify the fault and have the vehicle back

to the owner/operator with minimum delay is what leads to repeat business for the workshop. To do this you must

be able to refer to available literature, apply basic theories and use the correct test equipment.

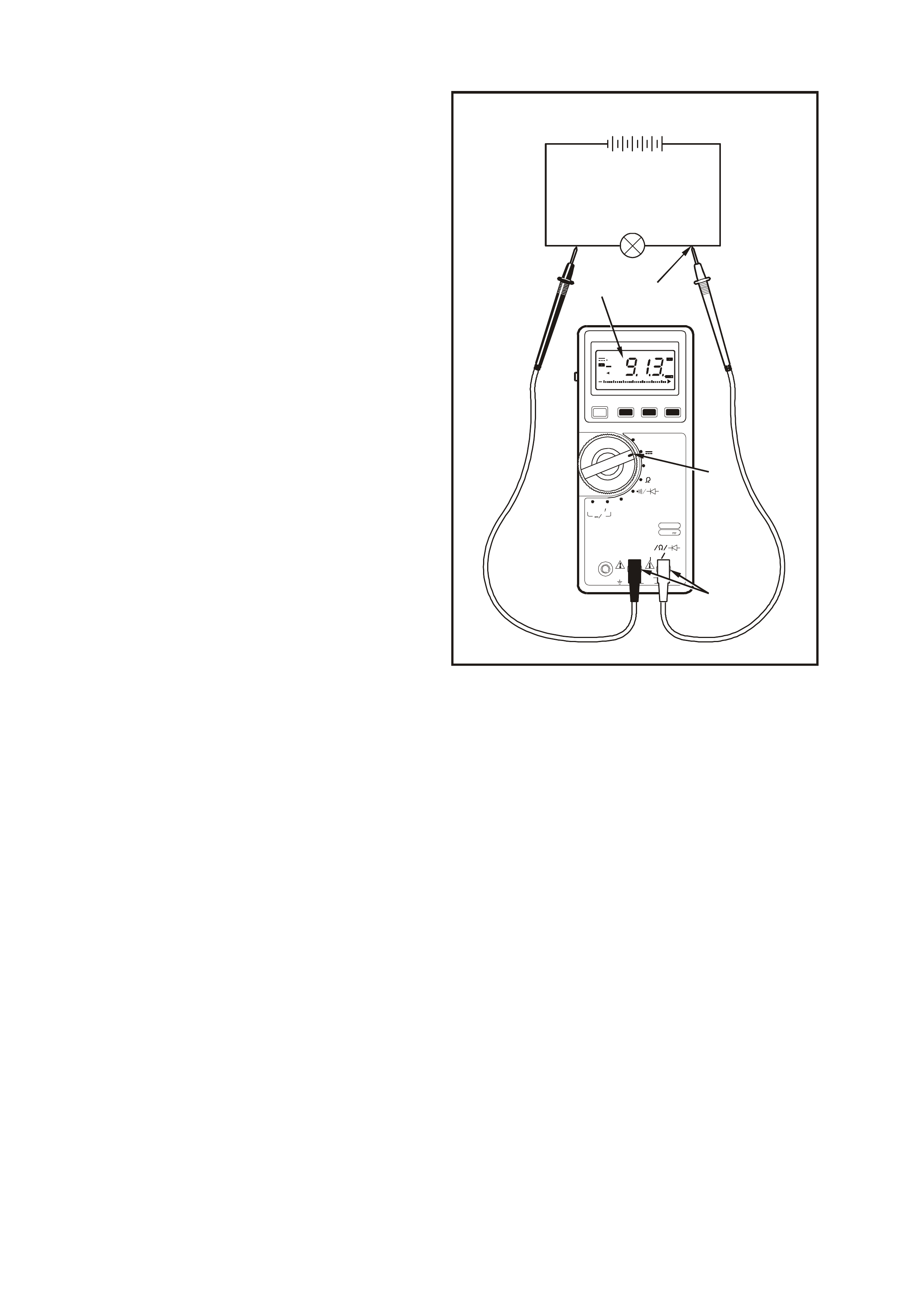

VOLTAGE MEASUREMENT

With the Volts DC mode selected, the digital

multimeter will operate as a voltmeter.

When using a voltmeter, the circuit power must be

ON and the voltmeter must be connected with the

correct polarity. This means the red lead should be

on the positive (+) side of the load or circuit and the

black lead should be on the negative (–) side of the

load or circuit.

The voltmeter must be connected in parallel with

the load or circuit. It has a high internal resistance

and takes only a small amount of current. The

meter will display the voltage difference between

the points where the meter leads are attached. If

the voltmeter is connected in series, the meter's

high internal resistance will reduce the circuit

current, resulting in an incorrect reading.

Testing for correct supply voltage is usually the first

thing measured in a circuit. If there is no voltage

present, or if the supply voltage is too high or too

low, the voltage problem should be corrected

before further testing.

NOTE: Voltage readings should always be taken in

parallel, i.e. across the load.

To make the reading:

1. Select VOLTS DC.

2. Plug the black test probe into the COM input

jack and the red test probe into the V input

jack.

3. Touch the probe tips to the circuit across the

load or power source.

4. View the reading, being sure to note the unit of

measurement.

D H

R H

~

0102030

m V

Mk

+

VY12P208

1

2

34

~

POWER

FUSED

1000V

MAX 750V~

1000V---

MAX

10A COM uA mA

V

DATA

HOLD SELECT RANGE

ºC

V

~V

ADP

mA/A uA

PUSH SELE CT

PUSH SE LE CT

1

kHz

0.3% V

~

Figure 12P-7

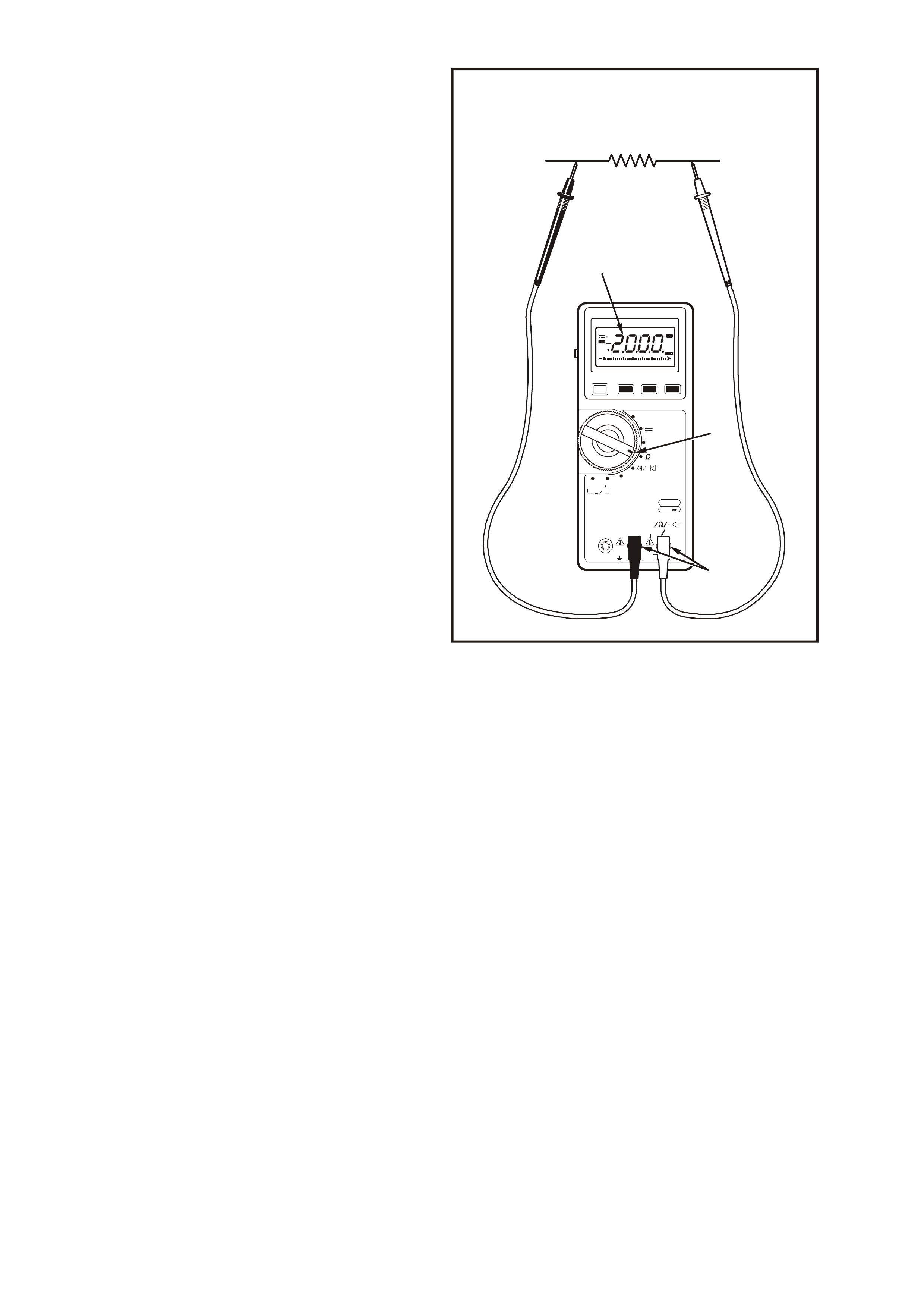

RESISTANCE MEASUREMENT

With the resistance mode selected, the digital

multimeter will operate as an ohmmeter.

The ohmmeter can be connected without regard to

polarity, unless there is a diode in the circuit.

Always remember, however, that an ohmmeter

must NEVER be connected to a live circuit, which

could blow a fuse in the meter or damage the

meter.

The ohmmeter has its own battery, which provides

the necessary voltage for testing. If an ohmmeter is

connected into a 'live' circuit the ohmmeter will be

damaged. Components or circuits MUST BE

DISCONNECTED FROM THE POWER SOURCE

when being tested.

Resistance Testing

Resistance measurements must be made with the

circuit power OFF, otherwise damage to the meter

or the circuit may result.

To make the resistance test:

1. Remove the power from the circuit and select

Ω.

2. Plug the black test probe into the COM input

jack and the red test probe into the Ω input

jack.

3. Touch the probe tips across the component or

the part of the circuit to be tested.

4. View the reading, being sure to note the unit of

measurement.

NOTE: 1000 ohms = 1 kΩ.

1 000 000 ohms = 1 MΩ.

D H

R H

~

0102030

m V

Mk

+

VY12P209

2

1

4

~

POWER

FUSED

1000V

MAX 750V~

1000V---

MAX

10A COM uA mA

V

DATA

HOLD SELECT RANGE

ºC

V

~V

ADP

mA/A uA

PUSH SELE CT

PUSH SE LE CT

1

kHz

0.3% V

~

Figure 12P-8

CONTINUITY TESTING

A continuity test is a quick test that distinguishes between an open and a closed circuit.

A digital multimeter with a continuity beeper allows you to complete many continuity tests easily and quickly as the

meter beeps when it detects a closed circuit. The level of resistance required to trigger the beeper varies from

model to model of meter.

Continuity tests determine:

• Good or blown fuses.

• Open or shorted conductors.

• Operation of switches.

• Circuit paths.

NOTE: Circuits which include any solid state control modules, such as the Powertrain Control Module (PCM),

should be tested only with a 10 Megohm or higher impedance digital multimeter.

Diodes and solid state components in a circuit can cause an ohmmeter to give a false reading. To find out if a

component is affecting a measurement, take a reading once, reverse the leads and take a second reading. If the

readings differ, the solid state component is affecting the measurement.

DIODE TESTING

A diode is like an electronic switch. It can be turned ON if the voltage is above a certain level, generally about 0.6 V

for a silicon diode, and allows current to flow in one direction.

Some meters have a special mode called diode test. In this mode the readings across the diode should be 0.6 V to

0.7 V in one direction and indicate an open circuit in the other. This indicates a good diode. If both readings are

open circuit, the diode is open. If both readings indicate continuity, the diode is shorted.

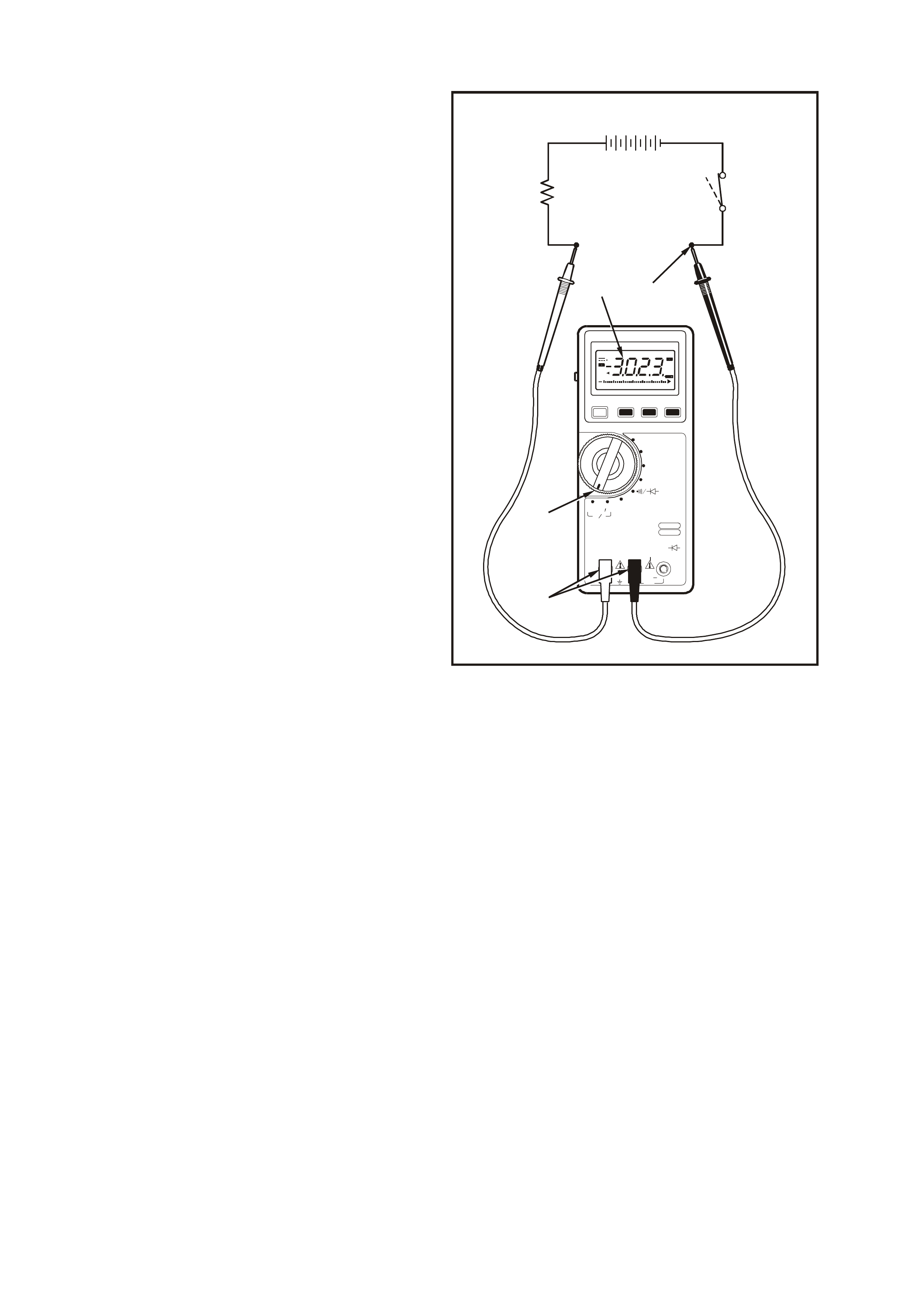

CURRENT MEASUREMENT

With the AMPS DC mode selected, the digital

multimeter will operate as an ammeter.

An ammeter is an instrument that measures

current flow in a circuit. For this reason ammeters

MUST be connected in series. The ammeter must

also be connected into the circuit according to

polarity.

Current measurements are different from other

measurements made with a digital multimeter.

Current measurements are made in series, unlike

voltage or resistance measurements, which are

made in parallel. The entire current being

measured flows through the meter. Also, the tests

probes must be plugged into a different set of input

jacks on the meter.

CAUTION: Do not leave the test leads plugged

into the current input jacks and then attempt a

voltage measurement. This causes a direct

short across the source voltage through the

low-value resistor inside the digital multimeter

and if the meter is not adequately protected,

can cause extreme damage to the meter and to

the circuit, and injury to the operator.

To take a current reading:

1. Remove the power from the circuit, cut or open

the circuit and select A.

2. Plug the black test probe into the COM input

jack and the red test probe into the 10A input

jack.

3. Touch the probe tips across the cut or open

circuit as shown in Figure 12P-9.

4. View the reading, being sure to note the unit of

measurement.

NOTE: If the test leads are reversed, a – sign

shows on the meter display.

D H

R H

~

0102030

m V

Mk

+

VY12P210

1

2

43

~

POWER

FUSED

1000V

MAX 750V~

1000V---

MAX

10A COM uA mA

V

DATA

HOLD SELECT RANGE

ºC

V

~V

ADP

mA/A uA

PUSH SELE CT

PUSH SE LE CT

1

kHz

0.3% V

~

Figure 12P-9

4. DIAGNOSTIC TESTS

4.1 TESTING FOR VOLTAGE

To perform a voltage test:

1. Connect one lead of a test light to a good

ground. If using a voltmeter, ensure the

voltmeter's negative (COM) lead is connected

to ground (battery negative).

2. Switch the meter to V and connect the other

lead of the test light or voltmeter to a selected

test point on a connector or terminal.

3. If the test light illuminates, there is voltage

present. If using a voltmeter, note the voltage

reading. It should be within one volt of the

measured battery voltage, unless otherwise

specified in the system diagnosis.

Legend

1. Power from battery 5. Meter

2. Fuse 6. Voltage test point

3. Switch 7. Voltage test point

4. Relay coil

VY12P211

2

4

3

5

6

7

1

D H

R H

~

0102030

m V

Mk

+

~

POWER

FUSED

1000V

MAX 750V~

10 00V -- -

MAX

10A COM uA mA

V

DATA

HOLD SELECT RANGE

ºC

V

~V

ADP

mA/A uA

PUSH SELECT

PUSH SELECT

1

kHz

0.3% V

~

V

Figure 12P-10

4.2 TESTING FOR CONTINUITY

To test for continuity:

1. Disconnect the battery earth lead.

2. Connect one lead of a self-powered test light or

ohmmeter to one end of the part of the circuit

under test.

3. Switch the meter to Ω and connect the other

lead to the other end of the circuit.

4. If the self-powered test light illuminates, there is

continuity. If you are using an ohmmeter, low or

no resistance means good continuity.

Legend

1. Meter switched to ohms

2. Switch terminal

VY12P212

2

1

D H

R H

~

0102030

m V

Mk

+

~

POWER

FUSED

1000V

MAX 750V~

10 00V -- -

MAX

10A COM uA mA

V

DATA

HOLD S ELECT RANG E

ºC

V

~V

ADP

mA/A uA

PUSH SELECT

PUSH SELECT

1

kHz

0.3% V

~

O

Figure 12P-11

4.3 TESTING FOR VOLTAGE DROP

This test checks for voltage being lost along a wire

or through a connection or switch.

1. Switch the voltmeter to V and connect the

positive lead to the end of the wire (or to one

side of the connection or switch) which is

closest to the battery.

2. Connect the negative lead to the other end of

the wire (or other side of the connection or

switch).

3. Operate the circuit.

4. The voltmeter will show the difference in

voltage between the two points. A difference

(or drop) of more than 1 volt indicates a

problem.

Legend

1. Power from battery 4. Relay coil

2. Fuse 5. Meter

3. Switch

VY12P213

2

3

5

1

D H

R H

~

0102030

m V

Mk

+

~

POWER

FUSED

1000V

MAX 750V~

10 00V -- -

MAX

10A COM uA mA

V

DATA

HOLD SELECT RANGE

ºC

V

~V

ADP

mA/A uA

PUSH SELECT

PUSH SELECT

1

kHz

0.3% V

~

V

4

Figure 12P-12

4.4 TESTING FOR SHORT TO EARTH

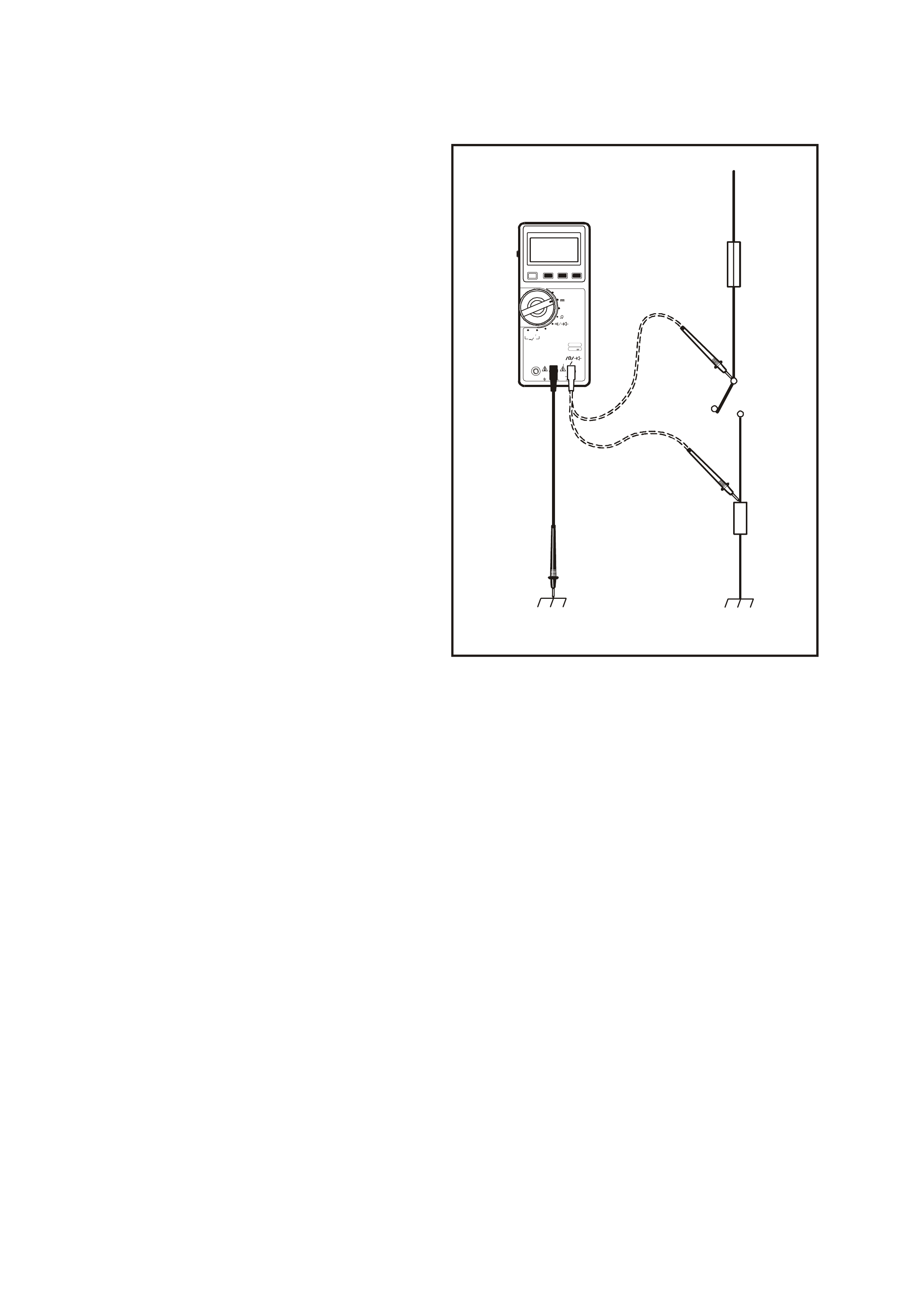

USING A TEST LIGHT OR VOLTMETER

To test for a short to earth using a test light or a

voltmeter:

1. Remove the blown fuse and disconnect the

load.

2. Ensure that fuse block is powered and connect

a test light or voltmeter across the fuse

terminals.

3. Beginning near the fuse block, wiggle the

harness from side to side. Continue this at

convenient points about 150 mm apart while

watching the test light or voltmeter.

4. If the test light illuminates, or the voltmeter

registers, there is a short to earth in the wiring

near that point.

Legend

1. Power from battery with fuse removed

2. Starting test point

3. Switch

4. Disconnected load

5. Meter set to volts

6. Short to earth

VY12P214

1

2

6

3

5

D H

R H

~

0102030

m V

Mk

+

~

POWER

FUSED

1000V

MAX 750V~

10 00V- - -

MAX

10A COM uA mA

V

DATA

HOLD S ELECT RANG E

ºC

V

~V

ADP

mA/A uA

PUSH SELECT

PUSH SELECT

1

kHz

0.3% V

~

V

4

Figure 12P-13

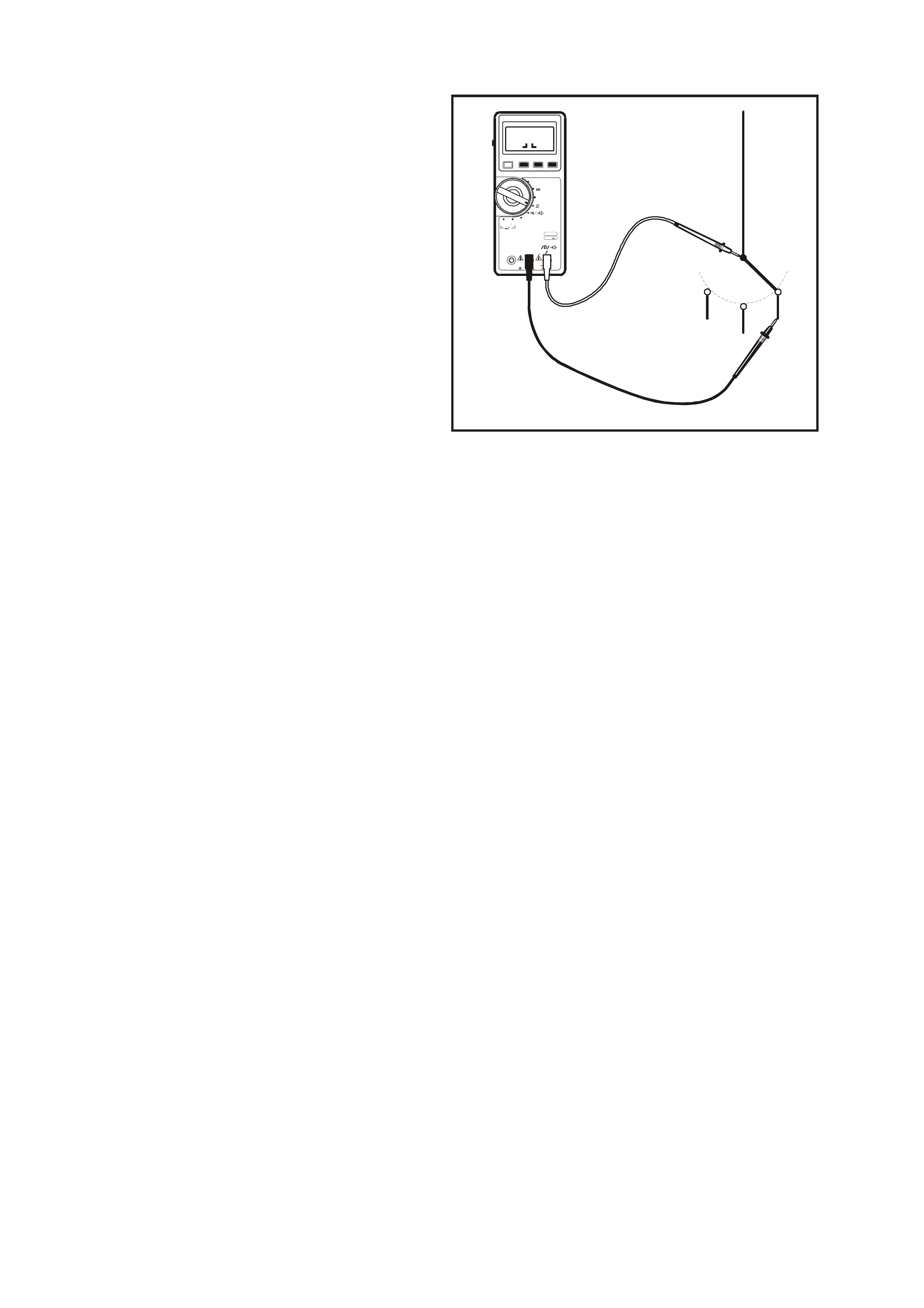

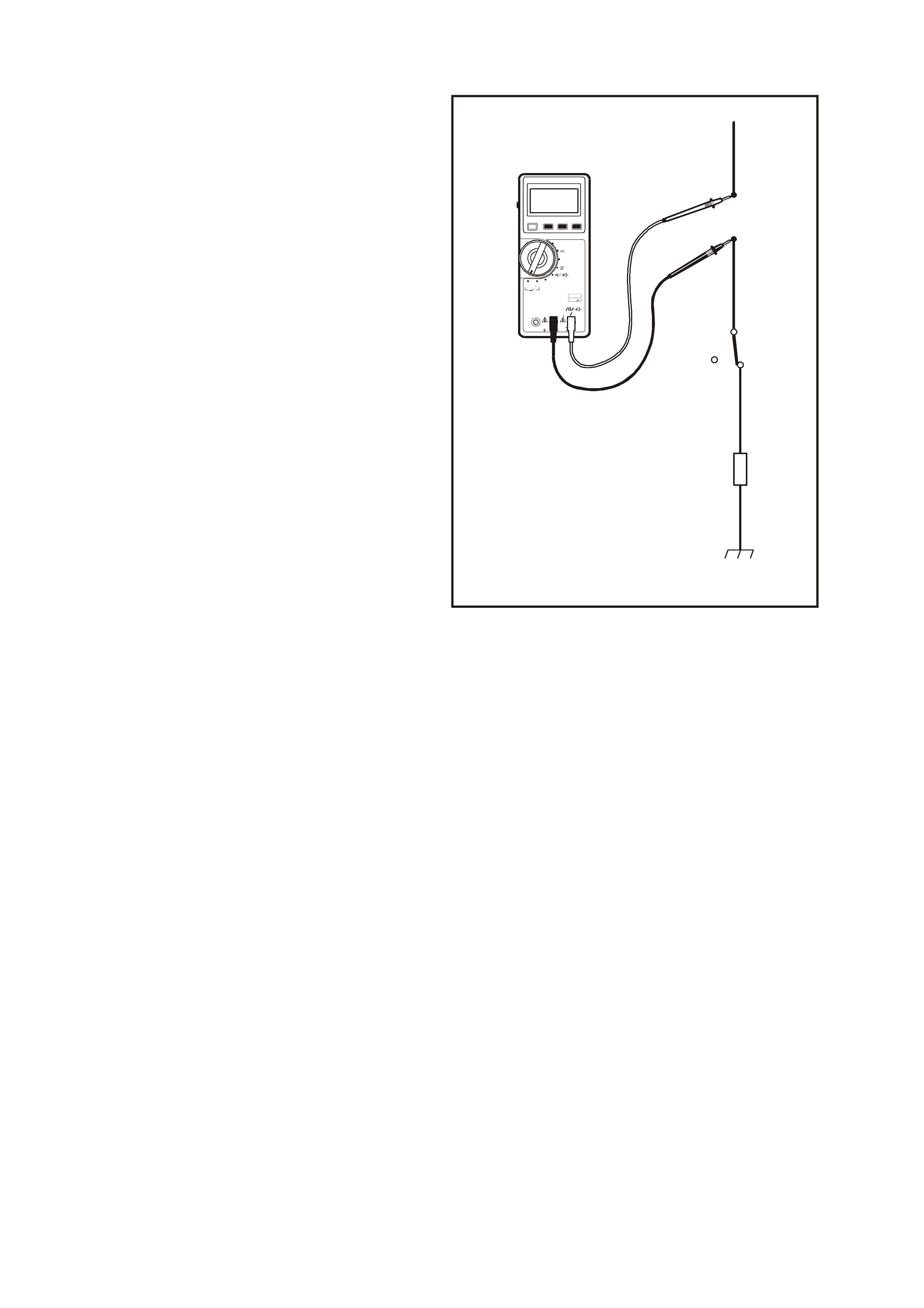

USING A SELF-POWE RED TEST LIGHT OR OHMMETER

To test for a short to earth using a self-powered

test light or an ohmmeter:

1. Remove the blown fuse and disconnect the

battery and load.

2. Connect one lead of a self-powered test light or

ohmmeter to the fuse terminal on the load side.

3. Connect the other lead to a known good earth.

4. Beginning near the fuse block, wiggle the

harness from side to side. Continue this at

convenient points about 150 mm apart while

watching the self-powered test light or

ohmmeter.

5. If the self-powered test light illuminates or

flickers, or the ohmmeter changes or registers,

there is a short to earth in the wiring near that

point.

Legend

1. Power from battery with fuse removed

2. Starting test point

3. Switch

4. Disconnected load

5. Meter set to ohms

6. Short to earth

VY12P215

1

2

6

3

5

D H

R H

~

0102030

m V

Mk

+

~

POWER

FUSED

1000V

MAX 750V~

10 00V- - -

MAX

10A COM uA mA

V

DATA

HOLD S ELECT RANG E

ºC

V

~V

ADP

mA/A uA

PUSH SELECT

PUSH SELECT

1

kHz

0.3% V

~

O

4

Figure 12P-14

USING A SHORT FINDER

A short finder is a device used for locating hidden shorts. These create a magnetic field in the shorted circuit and

allow you to read its location through body trim or sheet metal.

USING A COMPASS

An ordinary magnetic compass may be used to locate earthed circuits. It makes use of the fact that a wire carrying

current creates a magnetic field. In circuits that are protected by a circuit breaker, a short or earth can be quickly

located by use of an ordinary magnetic compass. Turn the circuit breaker on and off and start following the wiring

with the compass, the compass will 'kick' each time the circuit breaker closes. As the compass passes the point of

the short or earth, the compass will stop 'kicking'. Thus, the compass can pinpoint the problem without removing

trim, cover plates or tape. If the circuit is fused, the problem can be found in the same manner by substituting a

circuit breaker for the fuse.

USING A CIRCUIT BREAKER

By using a circuit breaker as a substitute for a fuse, other tools can be more effectively used to find troubles. A turn

signal flasher makes a convenient circuit breaker. Solder a lead to each terminal of the turn signal flasher, and each

lead with a terminal from an old fuse. If this unit is inserted in the junction block in place of a fuse, it may operate too

fast to produce good compass needle deflection. To slow it down, insert a rheostat in series with the flasher. By

cutting in additional resistance, the flashing rate of the unit may be slowed down to produce good compass needle

deflection.

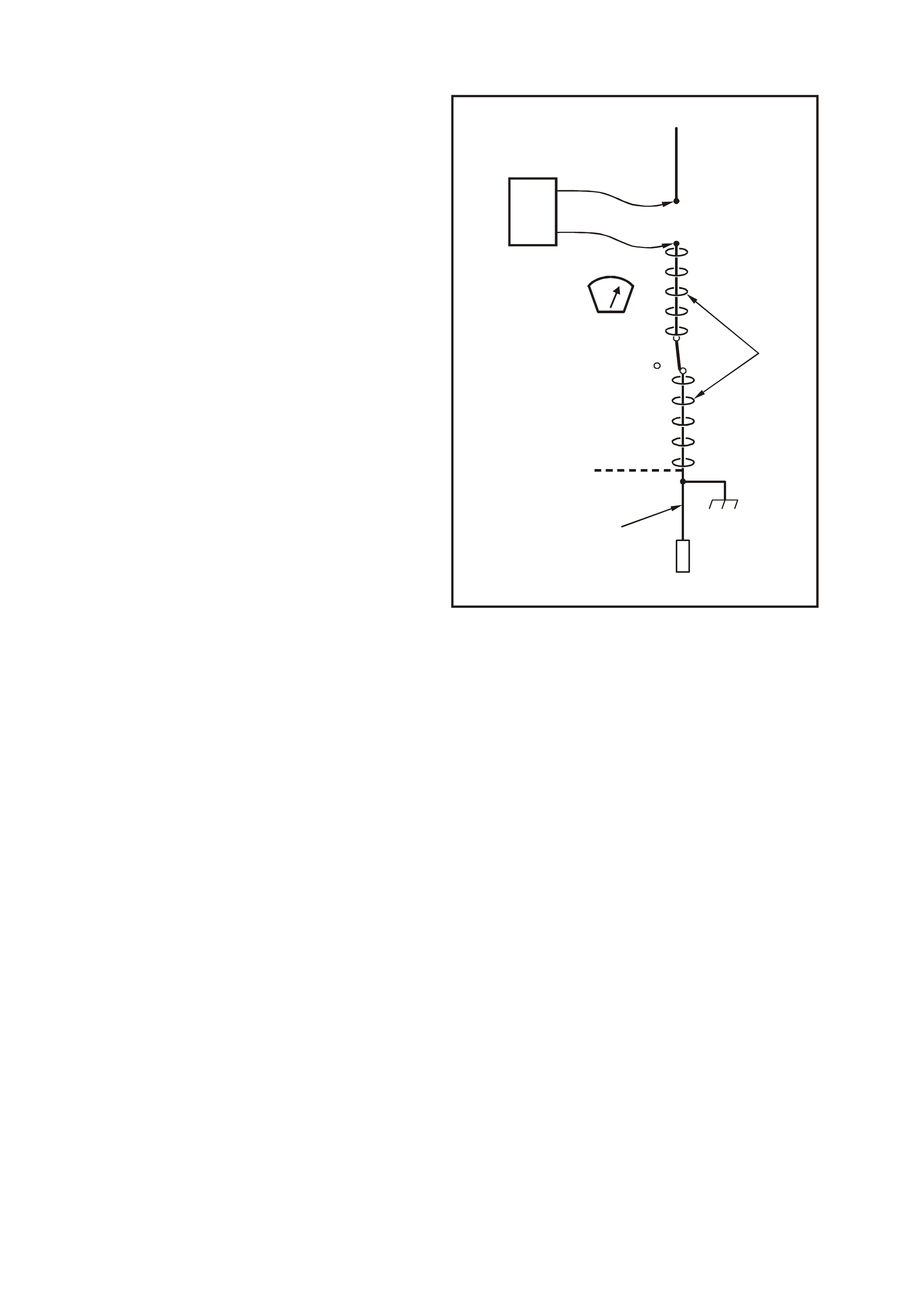

4.5 OPERATING A SHORT FINDER

To use a short finder:

1. Remove the blown fuse, leaving the battery

connected.

2. Connect the short finder (2) across the fuse

terminals.

3. Close all switches (6) in series with the circuit

you are troubleshooting.

4. Operate the short finder. The short finder will

pulse current to the short. This creates a

pulsating magnetic field (5) surrounding the

circuit wiring between the fuse block and the

short.

5. Beginning at the fuse block, slowly move the

short finder meter (4) along the circuit wiring.

The short finder meter will show current pulses

through sheet metal and body trim. As long as

the meter is between the fuse block and the

short, the needle will move with each current

pulse. When you have moved the meter past

the point of the short, the needle will stop

moving (10). Examine the wiring in that area for

the short to earth.

NOTE: Short finders are particularly useful for

'hidden' shorts as the meter will read the short

location through body trim or sheet metal.

CAUTION: Never use a short finder on circuits

that contain solid-state components, since

damage to these components may result.

VY12P216

1

2

4

3

7

6

8

9

5

10

Figure 12P-15

Legend

1. Power from battery with fuse removed 6. Switch

2. Short finder pulse generator 7. Short to earth

3. Fuse panel with fuse removed 8. Solenoid

4. Short finder meter 9. No pulsating magnetic field

5. Pulsating magnetic field 10. Needle stops moving here

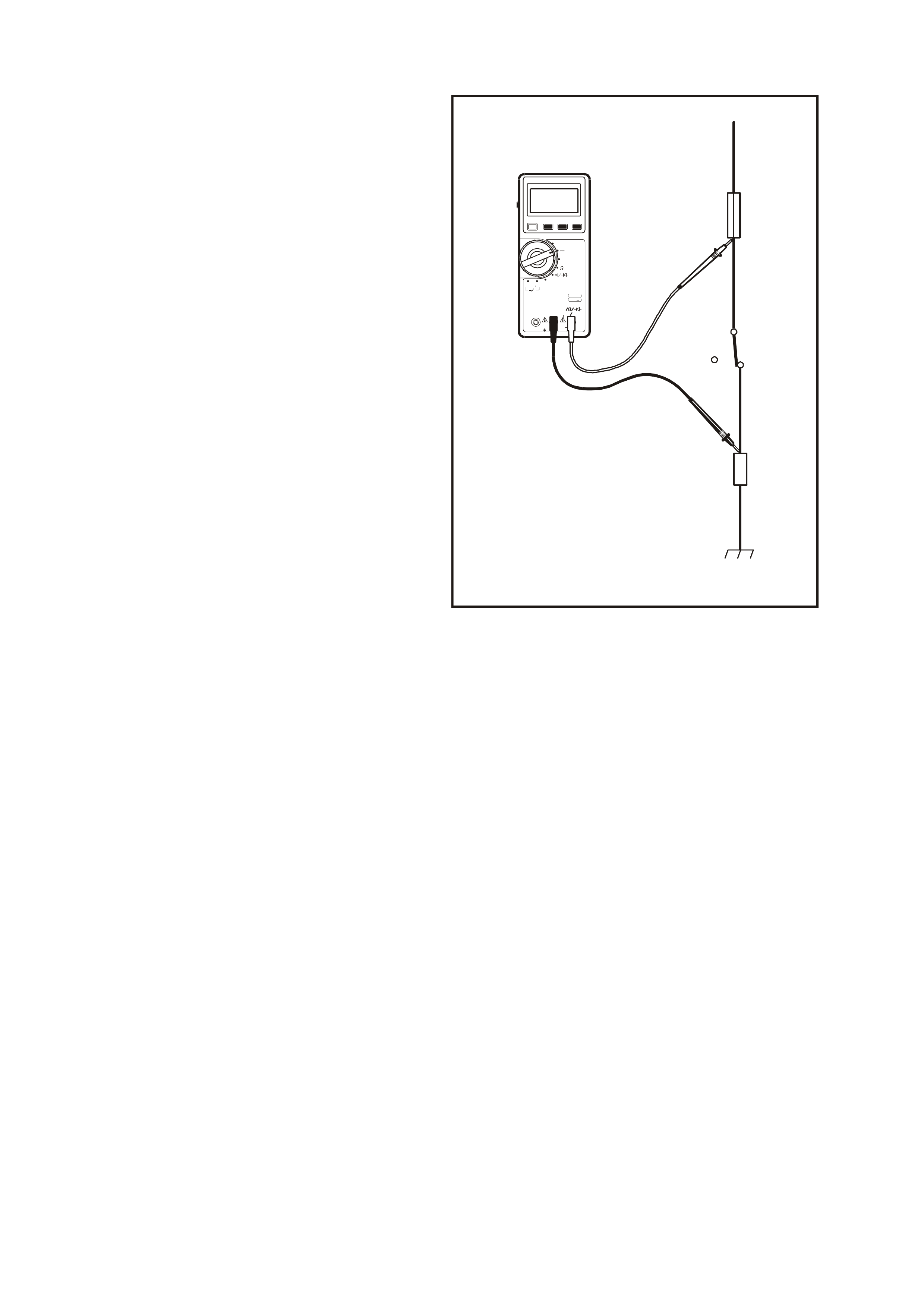

4.6 MEASURING CURRENT

To measure the current flowing in a circuit, the

ammeter must be connected in series in the circuit.

Current measurements always involve a

component being removed or disconnected from

the circuit or the circuit being opened. The circuit

current flows through the meter, which displays the

current in amps or milliamps.

Two commonly used locations for taking current

measurements are at a fuse and at the battery.

CAUTION: Never use a meter set on a current

scale to measure v olt age. Sev ere damage to the

meter, the circuit, or both will result.

Legend

1. Power from battery with fuse removed

2. Fuse block

3. Meter set to ohms

4. Switch

5. Load

VY12P217

1

2

D H

R H

~

0102030

m V

Mk

+

~

POWER

FUSED

1000V

MAX 750V~

10 00V- - -

MAX

10A COM uA mA

V

DATA

HOLD S ELECT RANG E

ºC

V

~V

ADP

mA/A uA

PUSH SELECT

PUSH SELECT

1

kHz

0.3% V

~

A

4

3

5

Figure 12P-16

4.7 DETECTING INTERMITTENT ELECTRICAL FAULTS

DIAGNOSTIC PROCEDURE

This procedure can be used to detect intermittent terminal contact or a broken wire with an intermittent connection

inside its insulation.

Some digital multimeters, such as Tool No. 3588, have the ability to monitor current, resistance or voltage while

recording the minimum (MIN) and maximum (MAX) values measured.

When diagnosing circuits that have voltage applied, use the voltage setting to monitor a connector or part of a

circuit which may have an intermittent connection, but at the time is operating normally. Using Tool No. 3588:

1. Set the digital multimeter to read voltage. Since the MIN MAX mode does not use auto ranging, manually select

the voltage range necessary before proceeding.

2. Connect the meter to both sides of a suspect connector (still connected) or from one end of a suspect circuit to

the other. This will continuously monitor the terminal contacts or length of wire being checked.

3. Press the MIN MAX button. The meter should read 100 ms RECORD (100 millisecond record) and emit a 0.25

second beep. The meter is now ready to record and will generate an audible tone for any change in voltage. At

this point, press the PEAK MIN MAX button, which will record any voltage variations that occur for at least 1

millisecond.

4. Simulate the condition that may be causing an intermittent connection, either by wiggling connections or wiring,

test driving or performing other operations. If an open or resistance is created, a voltage drop will occur and the

meter will emit a tone for as long as the open or resistance exists. Any change in voltage will cause the meter to

emit a tone for no less than 0.25 second.

Use the MIN and MAX values when the meter is out of sight or sound range, in noisy areas or for test driving when

it may not be possible to monitor the meter.

To check the MIN and MAX recorded voltages, press MIN MAX button once for MAX and twice for MIN. A variation

between MIN and MAX recorded voltages (unless nearly 0 volts) suggests an intermittent open or resistance exists

and should be repaired as necessary. Refer to 5. WIRING REPAIR PROCEDURES in this Section for repair

procedures.

NOTE:The 100 ms RECORD mode is NOT the amount of time allowed to perform a specific procedure. It is the

amount of time used to record each snapshot of information used for calculating AVG when in the MIN MAX mode.

CHECKING TERMINAL CONTACT

Before replacing a suspect faulty component, it is important to check terminal contact between a connector and the

component, or between in-line mating connectors.

Frequently, a diagnostic chart leads to a step that reads for example ‘Check for poor connection’. Mating terminals

must be inspected to ensure good terminal contact. A poor connection between the male and female terminals at a

connector may be the result of contamination or deformation.

Contamination is caused by the connector bodies being improperly connected, a missing or damaged connector

seal, or damage to the connector itself, exposing the terminals to moisture and dirt. Contamination, usually in the

engine compartment or underbody connectors, leads to terminal corrosion, causing an open circuit or intermittently

open circuit.

Deformation is caused by probing the mating side of a connector terminal without the proper adaptor, improperly

joining the connector bodies or repeatedly separating and reconnecting the connector bodies together. Deformation,

usually to the female terminal contact tang, can result in poor terminal contact, causing an open or intermittently

open circuit.

To check terminal contact:

1. Separate the connector bodies or the component connector.

2. Inspect the connector bodies or component for contamination. Contamination will result in a white or green

build-up within the connector body or between the terminals, causing high resistance, intermittent contact, or an

open circuit. An engine compartment or underbody connector that shows signs of contamination should be

replaced if it is serviced (refer to VY Parts information for connectors that are serviced) or the relevant wiring

harness should be replaced.

3. Using an equivalent male terminal, check the retention force of the female terminal in question by inserting and

removing the male terminal to the female terminal in the connector body. Good terminal contact will require a

certain amount of force to separate the terminals.

4. Using a known good condition equivalent female terminal, compare the retention force of this terminal to the

female terminal in question by inserting and removing the male terminal. If the retention force is significantly

different between the two female terminals, replace the female terminal in question.

If a visual (physical) check does not reveal the cause of the problem, the vehicle may be able to be driven with a

digital multimeter connected to the suspected circuit. An abnormal voltage reading when the problem occurs

indicates the problem may be in that circuit.

METER CONNECTIONS

The procedure for detecting intermittent faults was based on the digital multimeter set to read voltage. Whether

using current, voltage or resistance settings to detect intermittent faults, it will be necessary to connect the meter

into the circuit.

The following are examples of various methods of connecting the meter into a circuit to be checked.

1. Back probe both ends of the connector and either hold meter leads in place while manipulating the connector

or, tape the leads to the harness for continuous monitoring while performing other operations or while test

driving.

IMPORTANT: Do not back probe 'Weather Pack' type connectors as damage to the cable seals will result.

2. Disconnect the harness at both ends of a suspect circuit where it connects either to a component or to other

harnesses. Use connector test adaptor kit, Tool No. J35616-A or KM-609 to connect the meter onto the circuit.

Additional Information

NOTE: Turn off power to the test circuit before attempting in-circuit resistance measurements to prevent false

readings or damage to the meter. Do not use the meter to measure resistance through a solid state module.

Continuity tests that work well for detecting intermittent shorts to earth can be performed by setting the meter to

ohms when pressing the PEAK MIN MAX button. An audible tone will be heard whenever the meter detects

continuity for at least 1 millisecond.

The instruction manual accompanying the multimeter is often a good source of information and should be read

thoroughly before using the meter as well as kept on hand for reference during new procedures.

5. WIRING REPAIR PROCEDURES

5.1 GENERAL INFORMATION

Except for some specific connector bodies, wiring harness terminals, terminal seals and connector bodies are

generally not serviced individually.

Specific terminals, with seals (if fitted) are serviced only as an assembly with a wiring pigtail attached. Refer to VY

Parts Information for a listing of serviced terminals and connector bodies.

When conducting wiring harness repairs that involve replacement of damaged terminal/s, remove the terminal/s

from the connector body (refer instructions in this Service Information) and splice new terminal/s with wiring pigtail

into the wiring harness (refer instructions in this Service Information).

If a specific wiring harness terminal or connector body is damaged beyond repair, and the terminal or connector

body is not serviced, that particular wiring harness must be replaced.

Specific instructions on how to replace each individual wiring harness are not included in this information.

Installation details of wiring harnesses are included on the wiring installation diagrams in Section 12N, FUSES AND

WIRING HARNESSES.

5.2 PERFORMING WIRING HARNESS REPAIRS

CAUTION: Special wiring repair procedures have been developed for use on the ABS and SRS due to the

sensitive nature of their circuitry. The procedures in 5.4 ABS AND SRS WIRING REPAIR in this Service

Information are the only recommended and approved ABS and SRS wiring repair methods. The following

wiring repair methods are not to be used on ABS or SRS wiring.

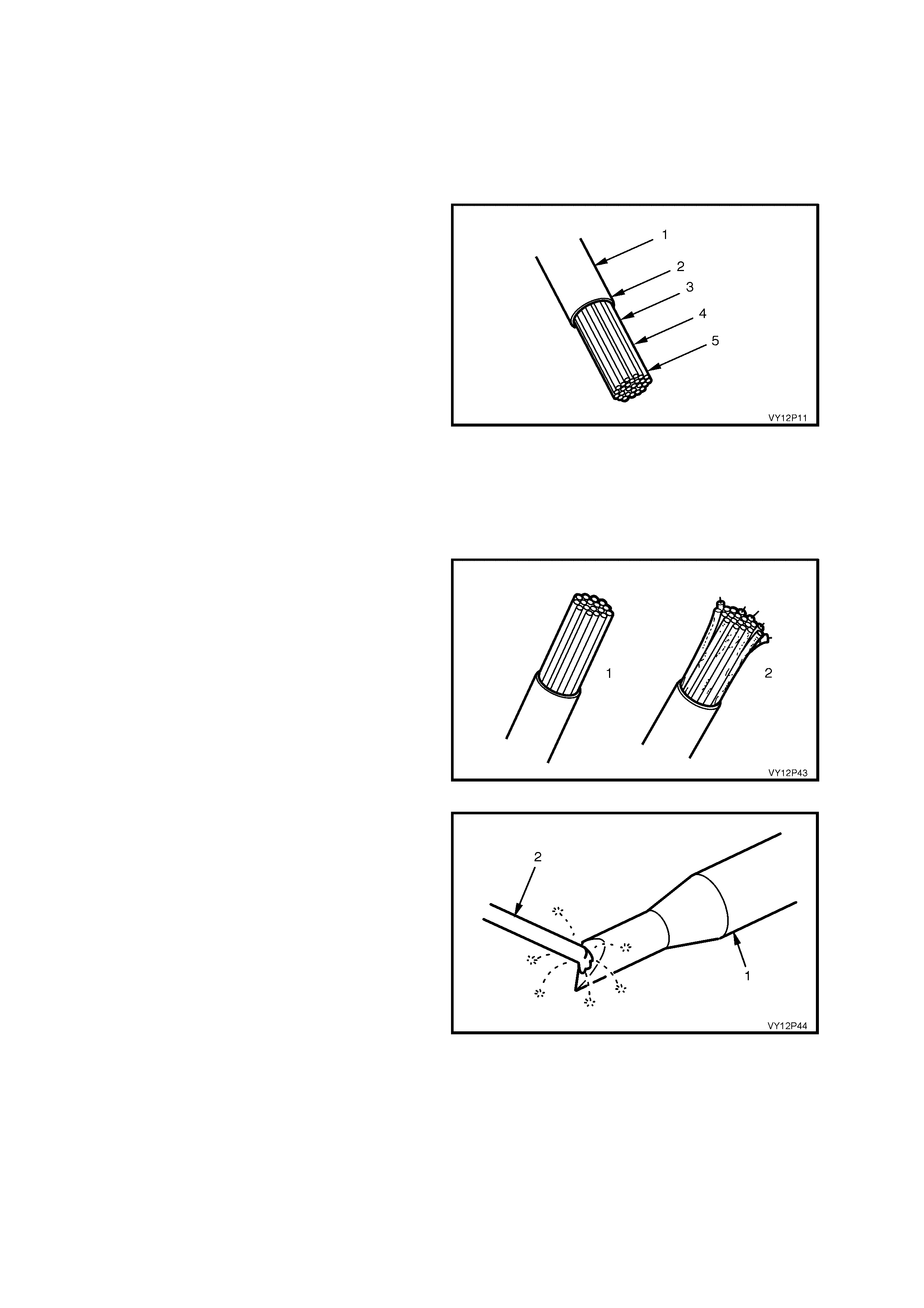

SOLDERING

These are the five points upon which an electrical

soldering joint is judged.

With electrical wiring only resin flux can be used.

Acid flux creates a corrosion problem that makes it

unsuitable for this work.

Do not clean resin flux off after soldering as the

resin acts as an anti-corrosive to protect the

soldered area.

Legend

1. Little or no solder penetration into the insulated

area

2. Undamaged insulation

3. Full solder penetration

4. Smooth, glossy finish

5. No excess solder

Figure 12P-17

THE FIVE POINTS TO SOLDERING

Step 1. Soldering Preparation

The job must be clean and bright (1). Acid corroded

or greasy wiring ends (2) should be stripped back.

Keep the job and your hands clean at all times.

Figure 12P-18

Step 2. Iron Preparation

The soldering iron (1) must be tinned and hot

BEFORE application. Preheat the soldering iron to

slightly above solder melting point before applying

solder (2) or applying it to the job to allow for heat

loss on contact.

The commencement of 'flux spit' is an indication of

correct preheat temperature.

Figure 12P-19

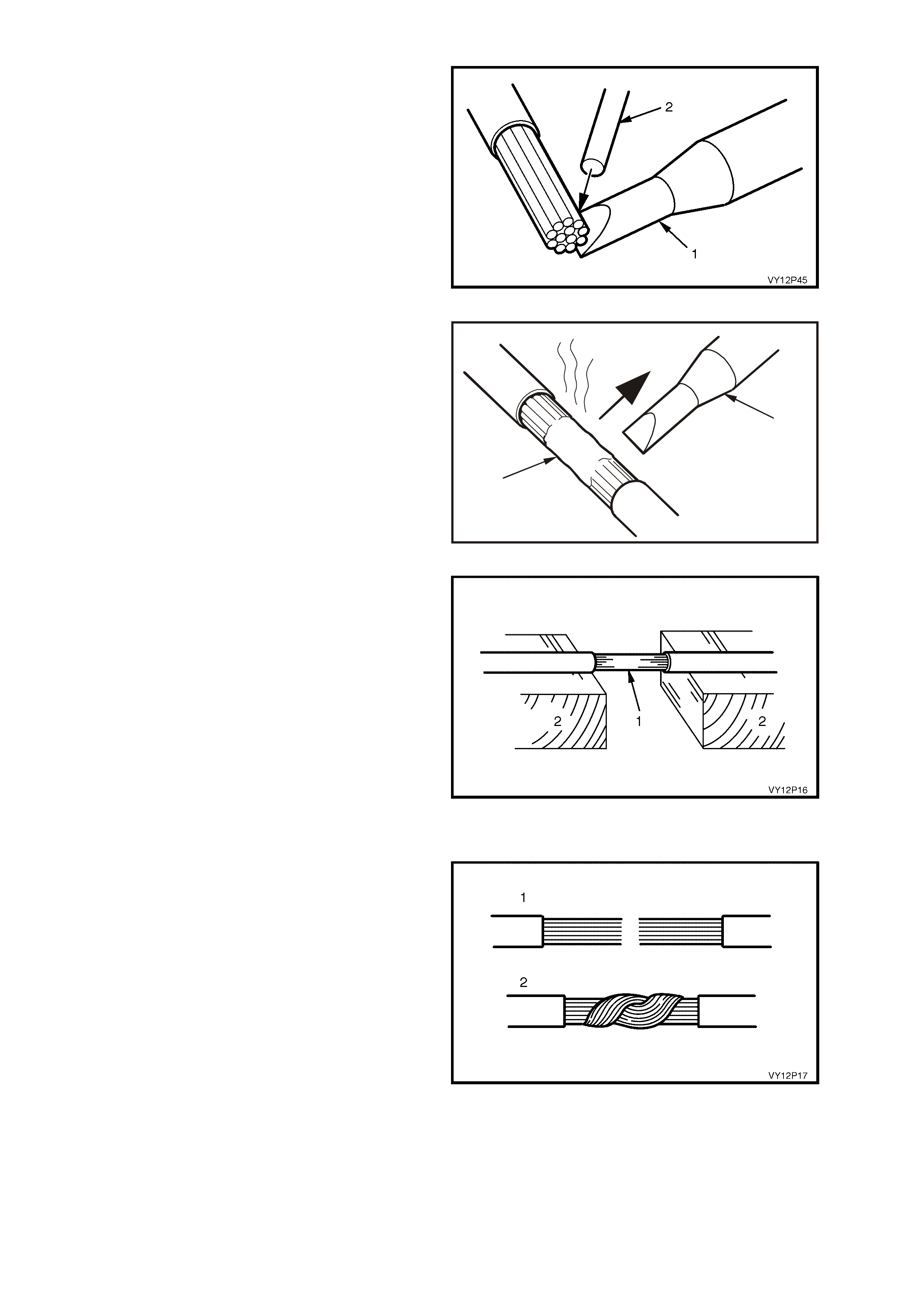

Step 3. Forming a Heat Bridge

Apply the full face of the soldering iron to the job

and immediately add solder to the 'V' formed by the

iron and the job.

This is known as heat bridge where the melting

solder speeds up the heat transfer and cuts down

the job heating time.

Figure 12P-20

Step 4. Soldering Iron Removal

Remove the soldering iron (1) the instant the job is

complete. This prevents the solder (2) travelling

outside the intended deposit area.

VY12P46

2

1

Figure 12P-21

Step 5. Prevent Job Movement

Prevent job movement until the solder cools.

A soldered joint (1) can be weakened if the two

components being joined move in relation to each

other just as the liquid solder changes to a solid

state.

Making a second attempt to solder the joint is

undesirable as prolonged heating is necessary to

remelt the solder.

Arrange support (2) before you start and use it until

the solder cools.

Figure 12P-22

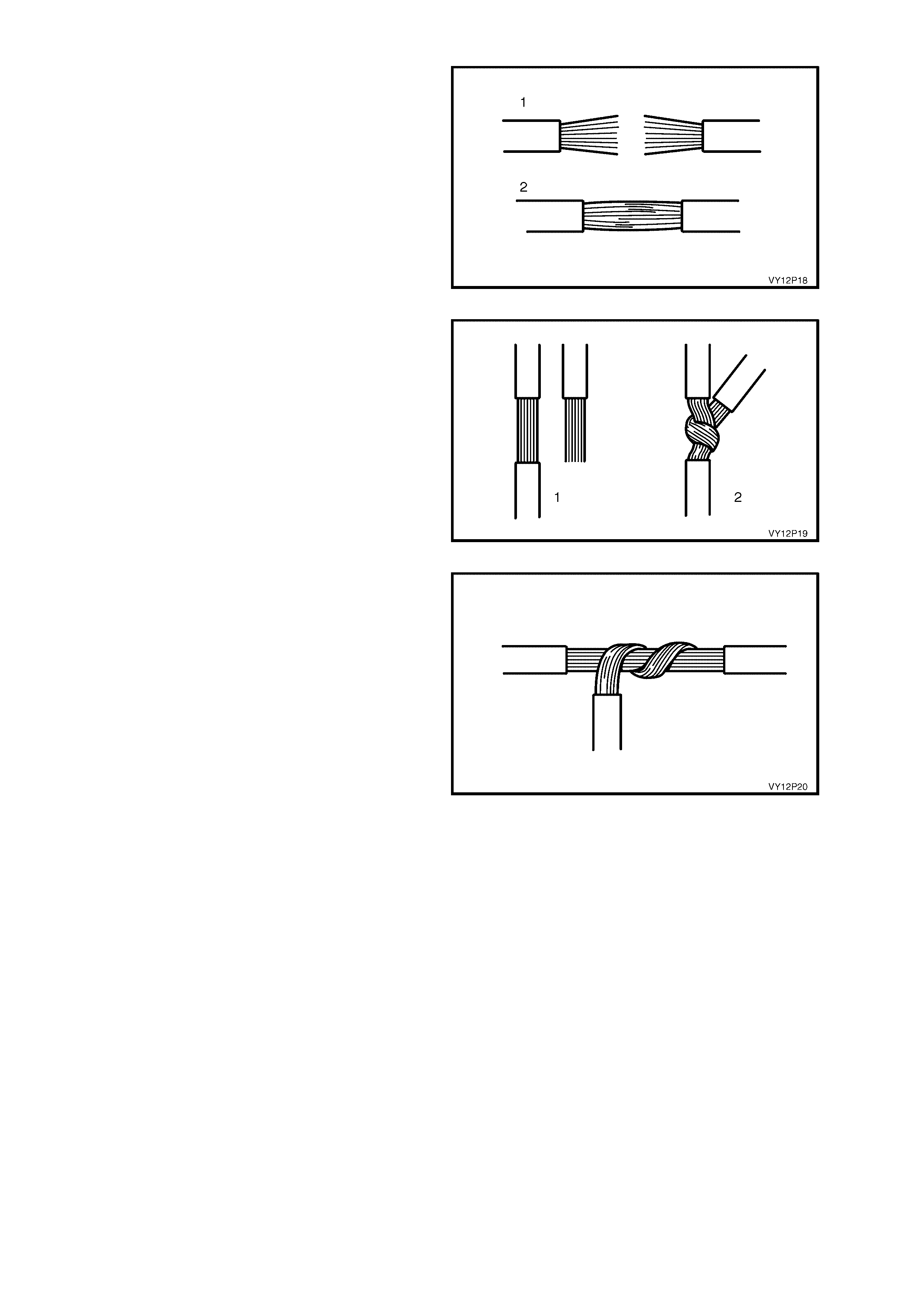

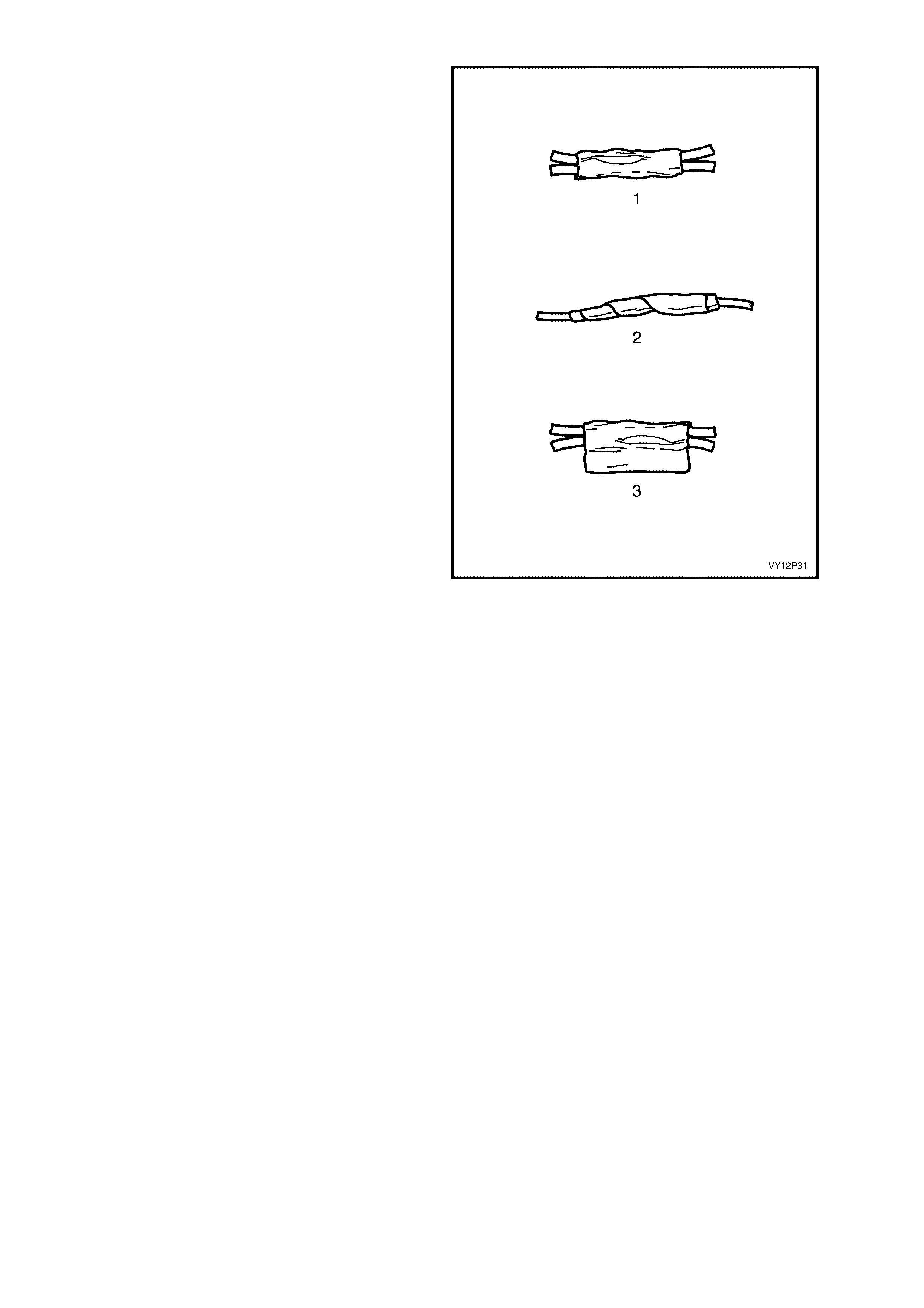

JOINING WIRE

Twist Joint

The twist joint is simple and strong.

1. Strip 20 mm of insulation from each wire (1).

2. Twist the strands to compact them.

3. Join them together by twisting (2).

4. Complete the join by soldering.

5. Use PVC tape to insulate the joint.

NOTE: To prevent a short or earthed circuit,

remove all the 'spikes' from the join before

insulating. Spikes can be formed by wire strands or

solder itself. These can cut through the insulation.

Figure 12P-23

Splice Joint

To splice join conductors:

1. Strip back 20 mm of insulation and spread the

strands (1).

2. Push the strands together and twist the ends in

opposite directions to compact the joint (2).

3. Solder the joint.

4. Use PVC tape to insulate the joint.

NOTE: A good splice may be a little harder to

achieve but it makes a neater join that is less bulky

when taped.

Figure 12P-24

The Y Junction

The Y junction is used to install a branch

connection parallel with the original.

1. Use a sharp blade to remove approximately 20

mm of insulation from the original wire (1).

2. Strip the insulation on the branch wire by

approximately 20 mm.

3. Twist the branch wire around the original wire

(2).

4. Solder the connection.

5. Use PVC tape to insulate the joint.

Figure 12P-25

The T Junction

The T junction is used to achieve a 90 degree

branch connection.

1. Use a sharp blade to remove approximately 20

mm of insulation from the original wire.

2. Strip the insulation on the branch wire by

approximately 20 mm.

3. Twist the branch wire around the original wire.

4. Solder the connection.

Use PVC tape to insulate the joint.

Figure 12P-26

5.3 SPLICING WIRING USING SPLICE CLIPS

Splice clips are included in Terminal Repair Kit,

Tool No. J38125-A. The splice clip is a general-

purpose wire repair device. It may not be

acceptable for applications having special

requirements such as moisture sealing.

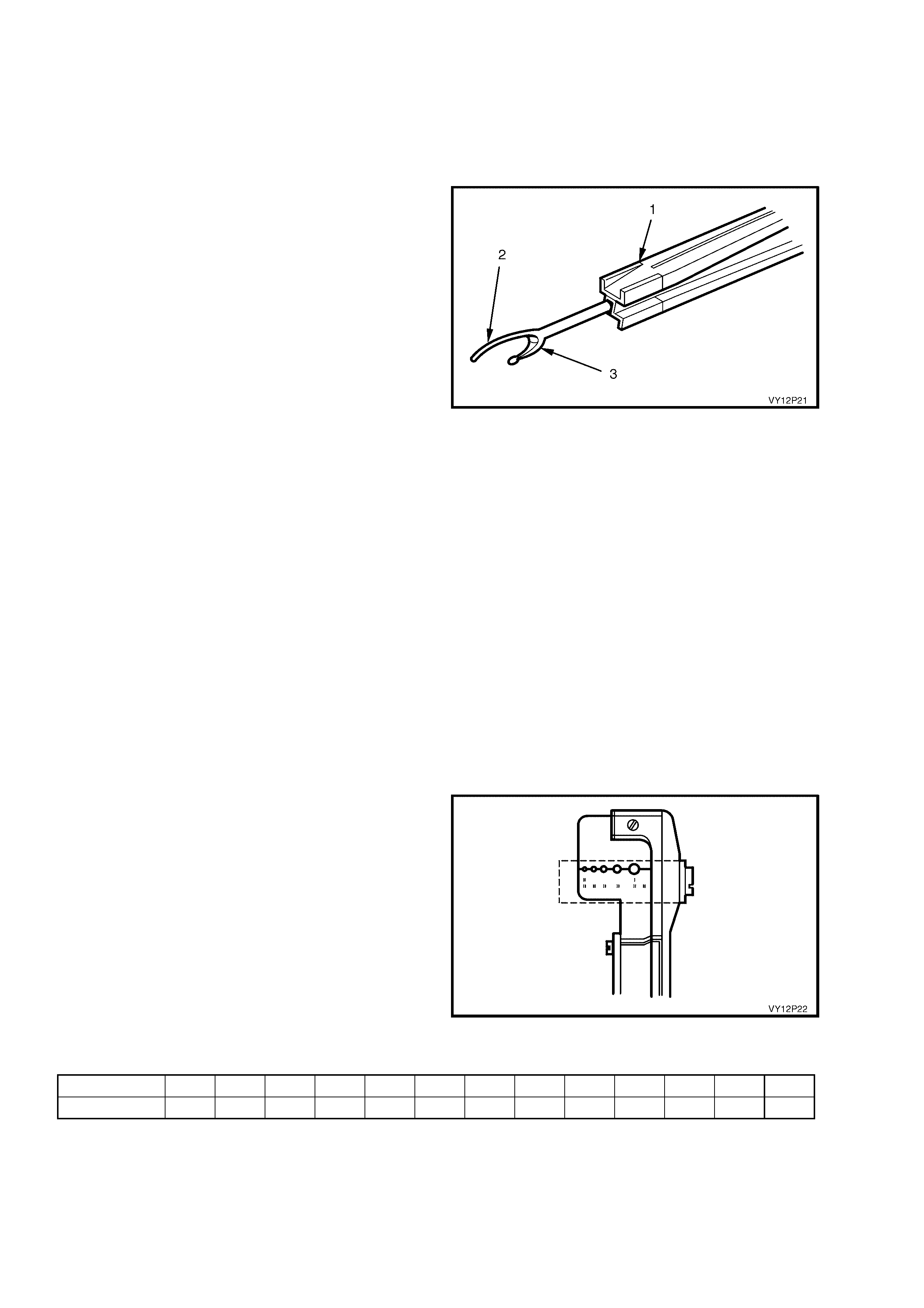

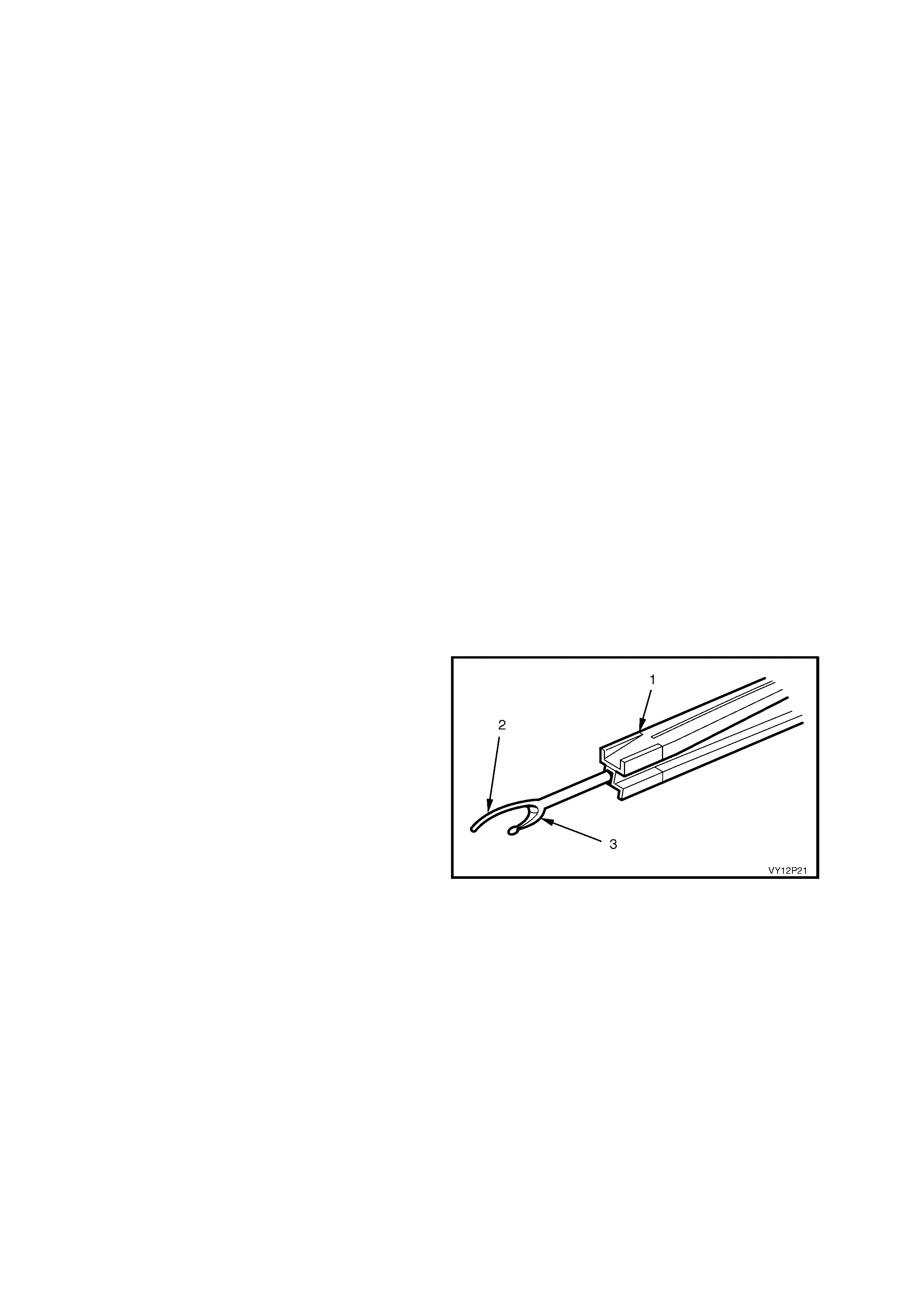

Step 1. Open the Harness

A wiring harness may be wrapped in tape or

enclosed in a plastic conduit.

If it is conduit encased, simply open the conduit and

pull out the desired wire.

If the harness is wrapped in tape, use a seam

splitter (1) to open the harness. This prevents

damage to the insulation of the wire inside the

harness. Seam splitters are readily available from

sewing supply stores.

When using a seam splitter, use the blade with the

pointed end (2) to start a small split in the tape

away from any wires.

Use the blade with the rounded end (3) to slit the

tape as far as necessary. Be careful to avoid

cutting into any wire insulation.

Figure 12P-27

Step 2. Cut the Wire

Leave as much wire on the harness as possible. More can be cut off later to adjust the location of the splice if

necessary.

NOTE: Ensure that each splice is at least 40 mm away from other splices, harness branches and connectors. This

helps prevent moisture from bridging adjacent splices and causing damage.

Do not nick or cut any copper strands as this could limit the current-carrying capabilities of the wire.

Step 3. Select the Correct Size and Type of Wire

The wire must be of a size equal to or greater than the original except for fusible links. The wire insulation must

have the same or higher temperature rating:

General purpose insulation (PVC) is used in areas not subject to high temperatures.

Cross-linked polyethylene (XLPE) insulation wire is used where high temperatures are expected.

NOTE: XLPE insulated wire may be used to replace PVC, but PVC must not be used to replace XLPE. XLPE

insulation is not fuel resistant, so XLPE covered wire must not be used where there is the possibility of fuel contact.

Step 4. Strip the Insulation

Find the wire size using a wire gauge (AWG).

A wire stripper, labelled in AWG sizes, is needed

for stripping away the insulation. If the wire size is

not known, start with the largest stripper hole and

work down until a clean strip of insulation is

removed without nicking or cutting the wire. Set the

stripper guide to a 7.5 mm long strip.

The splice should be at least 40 mm away from any

other splices or outlets.

Figure 12P-28

METRIC SIZE 0.22 0.35 0.5 0.8 1.0 2.0 3.0 5.0 8.0 13.0 19.0 32.0 50.0

AWG 24 22 20 18 16 14 12 10 8 6 4 2 1/0

Use the following procedure when using a wire

stripper:

1. Hold both handles in the right hand, with

gripper jaws to the left.

2. Hold the wire in the left hand and press the end

of the wire against the guide and up into the

correct notch of the upper blade.

3. Close left handle first, to grip the wire firmly

before cutting the insulation.

4. If the stripper castings stick open after stripping

the wire, pull the handles outward to snap the

tool closed.

5. Check the stripped wire for nicks or cut

strands.

If the wire is damaged, repeat the procedure on a

new section of wire. The two stripped sections of

wire to be joined should be of equal length.

CAUTION: Do not place your fingers between

the gripper casting and the cutter casting at any

time. Do not lay these castings against your

hands when open. The stripper castings are

designed to snap shut when fully opened, and

may cause injury.

Legend

1 Gripper jaws 5 Insulation

2 Gripper casting 6 Guide

3 Stripped wire 7 Blades

4 Cutter casting

Figure 12P-29

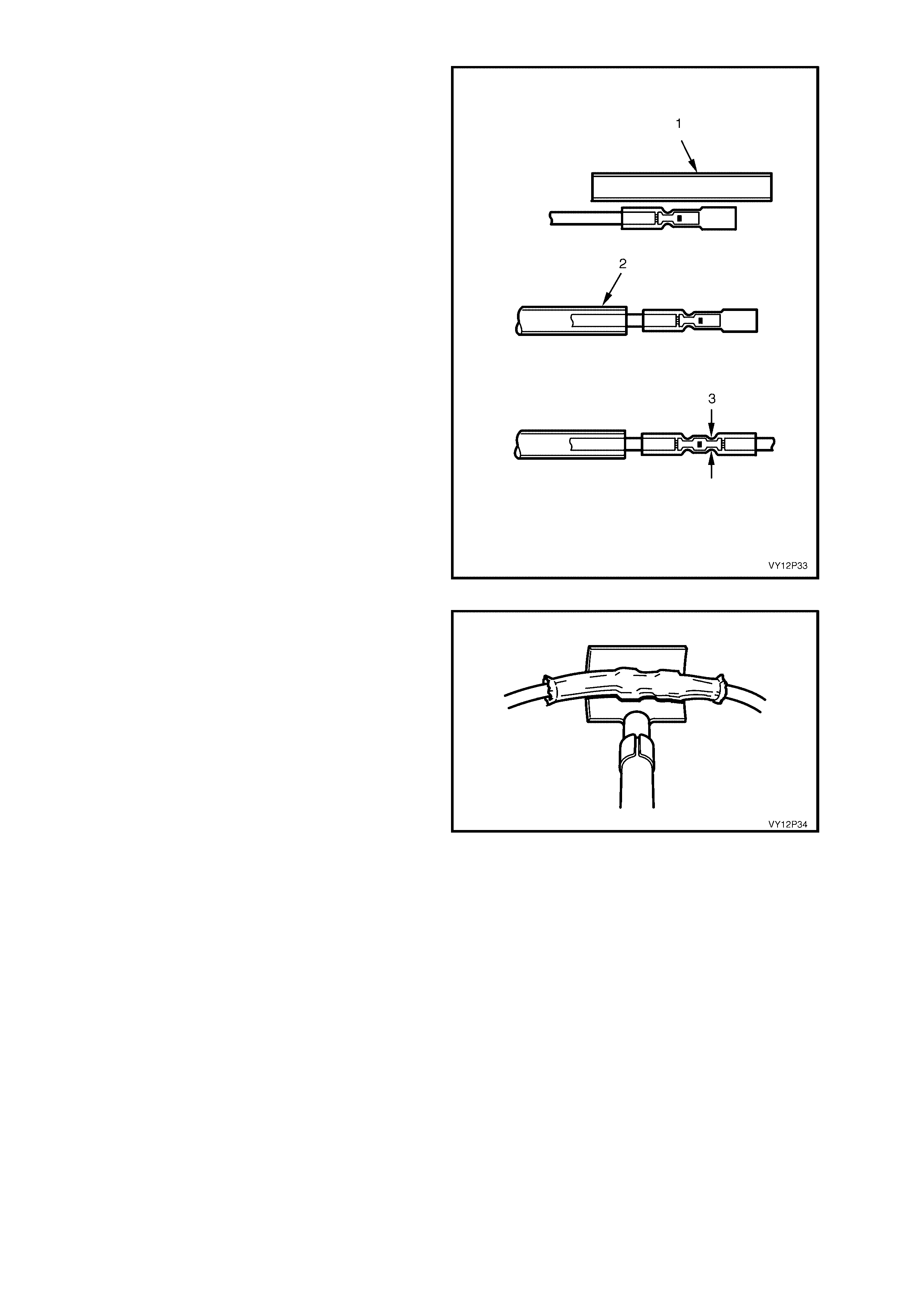

Step 5. Crimping the Joint

1. Select the correct sized clip.

2. Unlock the crimping tool.

3. Slightly close the clip using the nose of the

crimping tool as shown in Figure 12P-30.

4. Select the correct crimper anvil.

Legend

1 Nose 5 Former

2 Former 6 Large anvil

3 Small anvil 7 Clip

4 Lock

Figure 12P-30

5. Overlap the two stripped wire ends (1) and hold

them between the thumb and forefinger as

shown in Figure Figure 12P-31.

6. Centre the splice clip (2) under the stripped

wires and hold in place as shown.

• Ensure that the wires extend beyond the clip in

each direction.

• Ensure no insulation is caught under the clip.

• Strands of wire are not cut or loose.

Figure 12P-31

7. Fully open the crimping tool and rest one

handle on a firm, flat surface.

8. Centre the back of the splice clip on the proper

anvil (2) and close the crimping tool to the point

where the former touches the wings of the clip

(1).

9. Verify the clip and wires are still in the correct

position before closing the crimping tool with

steady pressure.

Figure 12P-32

10. Crimp the splice clip a second and third time,

once at each end (1). Do not let the crimping

tool extend beyond the edge of the clip when

doing so.

Figure 12P-33

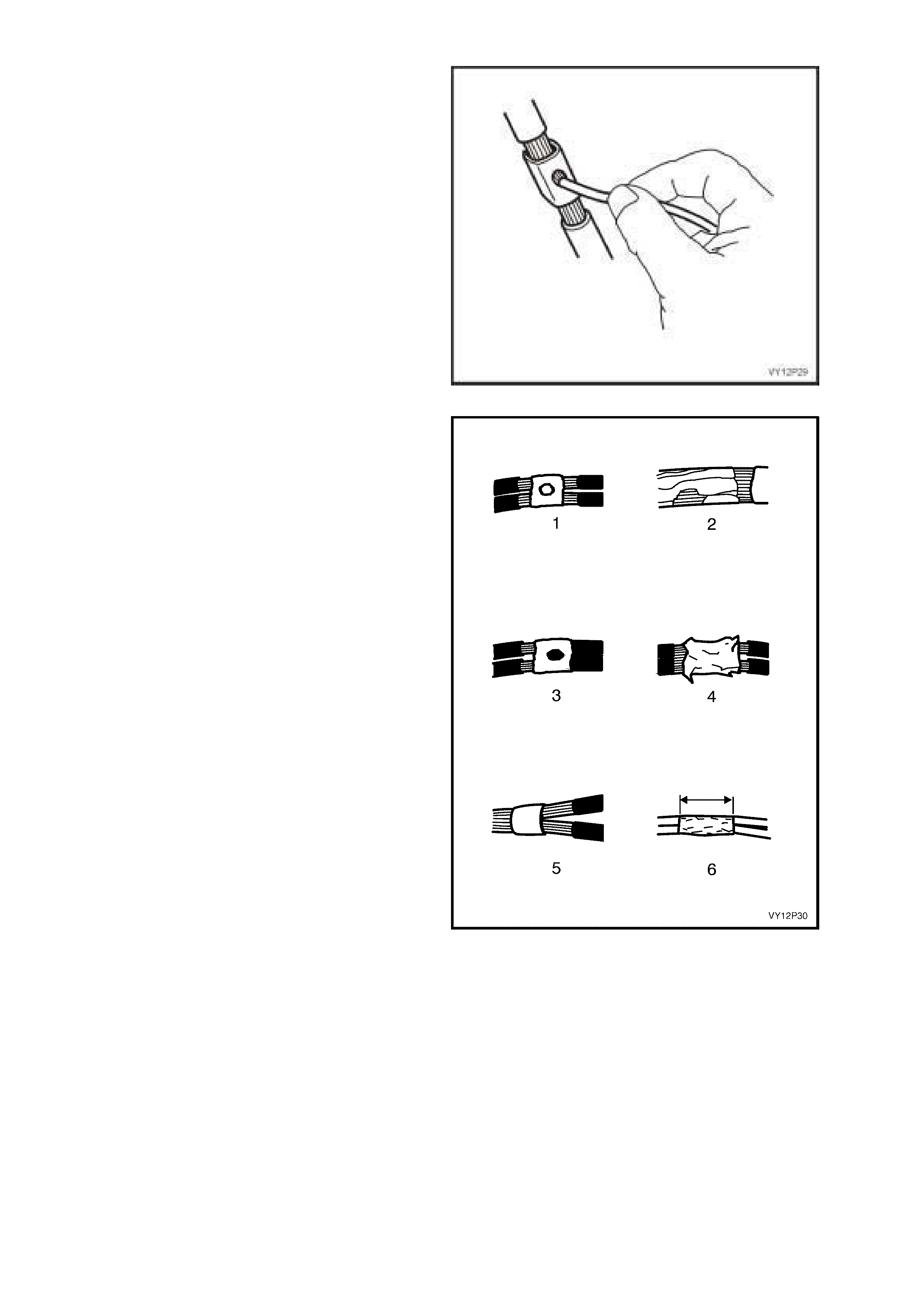

Step 6. Solder

Apply 50/50 resin core solder to the hole in the

back of the clip as shown in Figure 12P-34.

Figure 12P-34

Ensure there are none of the faults shown in

Figure 12P-35.

Legend

1 Poor solder application with bad solder fillets

2 Excessive burning which cannot be covered

with 50 mm splice tape

3 Insulation clamped under the clip

4 Sharp solder spikes

5 Wires not fully inserted into the clip

6 Tape width less than 50 mm

Figure 12P-35

Step 7. Tape the Splice

Centre and roll a 50 mm x 50 mm piece of tape

around the splice joint.

If the wire is not in conduit or another harness

covering, tape it again using a winding motion,

entirely overlapping the first piece.

Legend

1 Example of properly rolled tape

2 Tape again if needed

3 Example of bad (flagged) taping

Figure 12P-36

5.4 ABS AND SRS WIRING REPAIR

Special wiring repair procedures have been developed for use on the Anti-lock Braking System (ABS) and

Supplemental Restraint System (SRS) due to the sensitive nature of the circuitry. These specific procedures and

instructions must be followed when working with ABS and SRS wiring, and wiring components (such as connectors

and terminals). Terminal Repair Kit, Tool No. J38125-A contains special sealed splices for use in repairing ABS and

SRS wiring.

A special crimping tool, heat torch, and instruction manual for these splices are also included.

Two critical features of the sealed splices are a special heat shrink sleeve with sealing adhesive to produce an

environmentally sealed splice and a cross hatched (knurled) core crimp to provide necessary contact integrity for

the sensitive, low energy circuits.

Terminal Repair Kit J38125-A also serves as a generic terminal repair kit. The kit contains a large sampling of

common GM electrical terminals and the correct tools to attach them to wires and remove them from connectors.

The terminals in the kit are NOT to be used to replace damaged terminals in the ABS and SRS wiring.

CAUTION: The following procedure for repairing ABS and SRS wiring is the only recommended and

approved repair method. No alternative repair methods are to be used.

ABS AND SRS WIRE PIGTAIL REPAIR

Read and understand the instruction repair manual before conducting ABS and SRS wiring repairs using this kit.

If a wiring pigtail (a wire or wires attached directly to the device, not by a connector) is damaged, the entire

component (with pigtail) must be replaced.

Examples of pigtail components are the wheel speed sensors or clock spring coil. Absolutely no wire, connector or

terminal repairs are to be attempted on these components, REPLACE THE COMPONENT.

WIRING REPAIR

NOTE: Before conducting SRS wiring repair, disable the SRS, refer to Section 12M, OCCUPANT PROTECTION

SYSTEM.

If any wiring, except the pigtail, is damaged, the wiring should be repaired by splicing in a new section of wire of the

same gauge size (0.5, 0.8, 1.0, etc.). The splices and Splice Crimping Tool from Terminal Repair Kit J38125-A must

be used for these repairs.

The following wiring repair procedures must be used to ensure the integrity of the sealed splice application.

Step 1. Open the Harness

A wiring harness may be wrapped in tape or

enclosed in a plastic conduit.

If it is conduit encased, simply open the conduit and

pull out the desired wire.

If the harness is wrapped in tape, use a seam

splitter (1) to open the harness. This prevents

damage to the insulation of the wire inside the

harness. Seam splitters are readily available from

sewing supply stores.

When using a seam splitter, use the blade with the

pointed end (2) to start a small split in the tape

away from any wires.

Use the blade with the rounded end (3) to slit the

tape as far as necessary. Be careful to avoid

cutting into any wire insulation.

The crimp and sealed splice sleeves may be used

on all types of insulation except tefzel and coaxial

and may only be used to form a one-to-one splice.

Figure 12P-37

Step 2. Cut the Wire

Leave as much wire on the harness as possible. More can be cut off later to adjust the location of the splice if

necessary.

NOTE: Ensure that each splice is at least 40 mm away from other splices, harness branches and connectors. This

helps prevent moisture from bridging adjacent splices and causing damage.

Do not nick or cut any copper strands as this could limit the current-carrying capabilities of the wire.

Step 3. Select the Correct Size and Type of Wire

The wire must be of a size equal to or greater than the original except for fusible links. The wire insulation must

have the same or higher temperature rating:

General purpose insulation (PVC) is used in areas not subject to high temperatures.

Cross-linked polyethylene (XLPE) insulation wire is used where high temperatures are expected.

NOTE: XLPE insulated wire may be used to replace PVC, but PVC must not be used to replace XLPE. XLPE

insulation is not fuel resistant, so XLPE covered wire must not be used where there is the possibility of fuel contact.

Step 4. Strip the Insulation

NOTE: The following procedures must be followed

in the order listed. If wire strands are damaged, the

procedure must be repeated until a clean strip with

all wire strands intact is obtained.

If it is necessary to add a length of wire to the

existing harness, be certain to use the same size

as the original wire.

To find the correct wire size, either find the wire on

the ABS or SRS wiring diagram, or measure it with

a wire gauge.

If unsure about the wire size, begin with the largest

opening in the wire stripper and work down until

achieving a clean strip of the insulation. Strip

approximately 7.5 mm of insulation from each wire

to be spliced. Be careful to avoid nicking or cutting

any of the strands. Check the stripped wire for

nicks or cut strands. If the wire is damaged, repeat

this procedure after removing the damaged

section.

Figure 12P-38

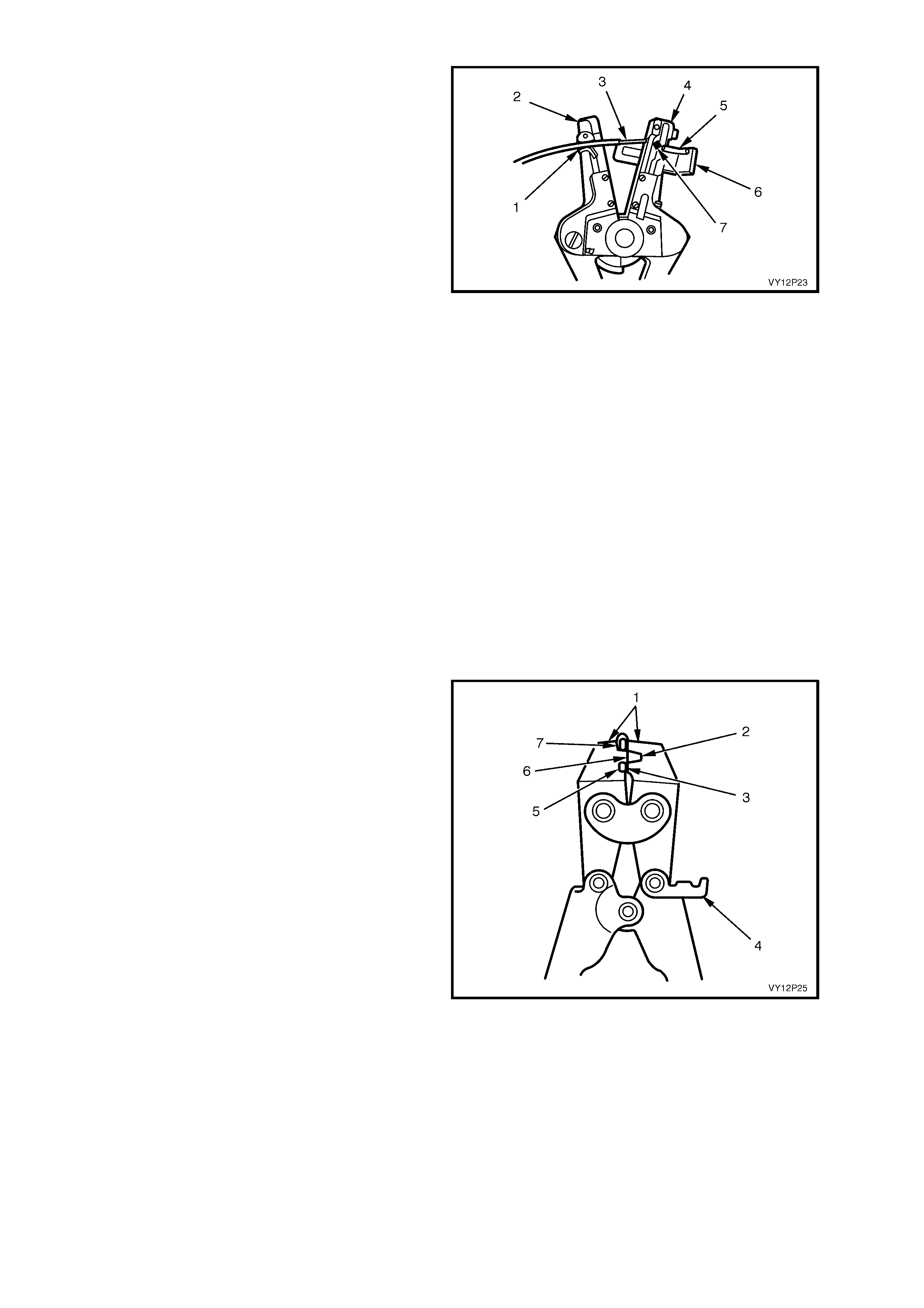

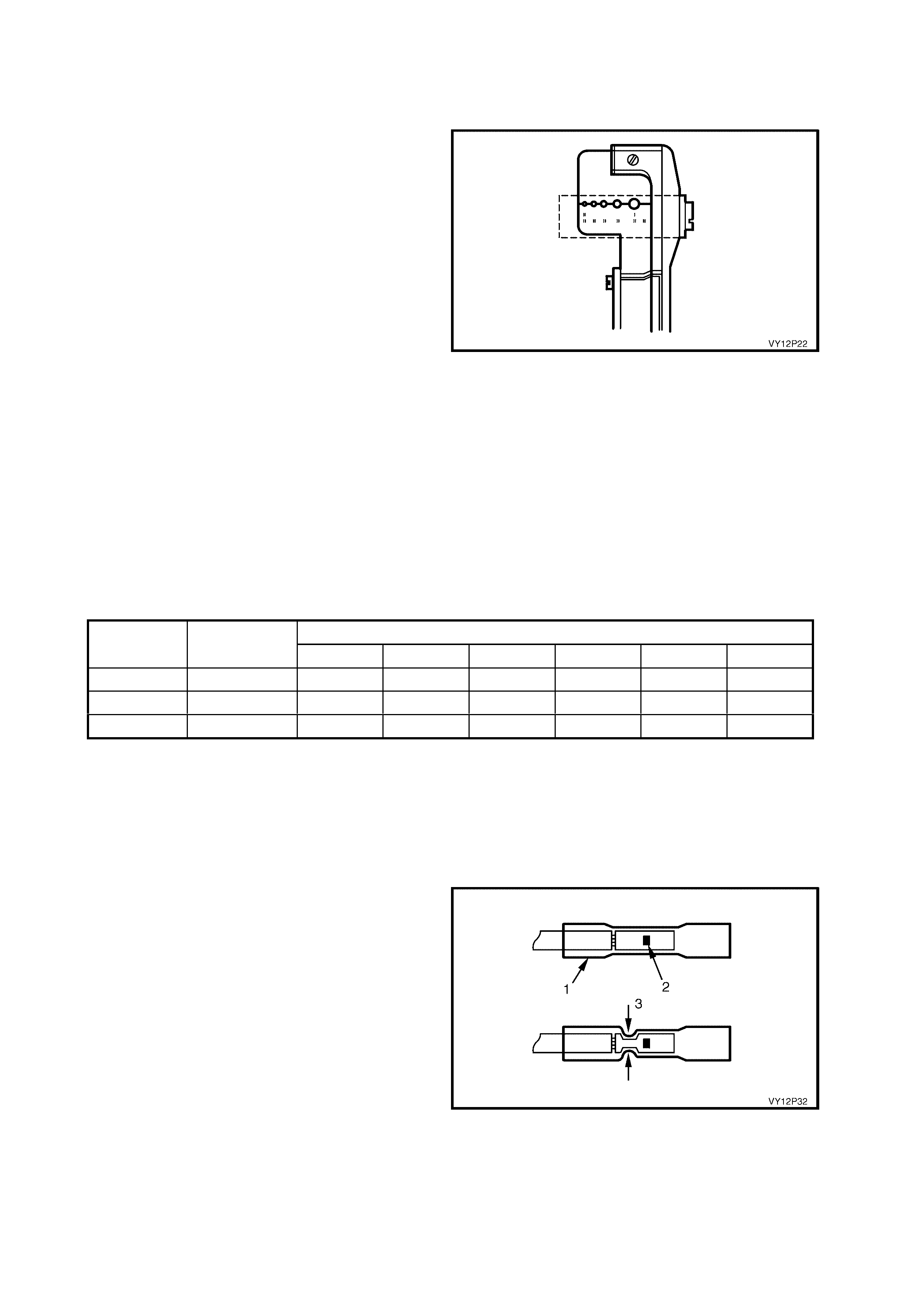

Step 5. Select and Position the Splice Sleeve

Select the proper sealed splice sleeve according to wire size. The splice sleeves and tool nests are colour coded

(refer to Table 12P-1).

Table 12P-1

WIRE SIZE (mm)

SPLICE CRIMP

PART No. CRIMP TOOL

NEST COLOUR 0.5 0.8 1.0 2.0 3.0 5.0

12089189 RED SALMON SALMON

12089190 BLUE BLUE BLUE

12089191 YELLOW YELLOW YELLOW

Using the J38125-A Splice Crimp Tool, position the splice sleeve in the proper colour nest of the hand crimp tool.

Place the splice sleeve in the nest so that the crimp falls midway between the end of the barrel and the stop.

The sleeve has a stop in the middle of the barrel to prevent the wire from going further. Close the hand crimper

handles slightly to hold the splice sleeve firmly in the proper nest.

Step 6. Insert First Wire Into Splice Sleeve and Crimp

1. Insert the wire into the splice sleeve (1) until it

hits the barrel stop (2).

2. Close the handles of the crimp tool tightly at

position (3) until the crimper handles open

when released. The crimper handles will not

open until the proper amount of pressure has

been applied to the splice sleeve.

3. Gently tug the wire to ensure the crimp is

secure.

Figure 12P-39

Step 7. Crimp the Second Wire in the Splice

1. Cut a length of heat shrink tubing (1) which will

allow an overlap of at least 10 mm at each end

of the finally crimped joint.

2. Slide the heat shrink tubing over the harness

wire which has already been crimped (2).

3. Repeat the Step 5 operations for the second

end of the splice (3).

Figure 12P-40

Step 8. Shrink the Insulation around the Splice

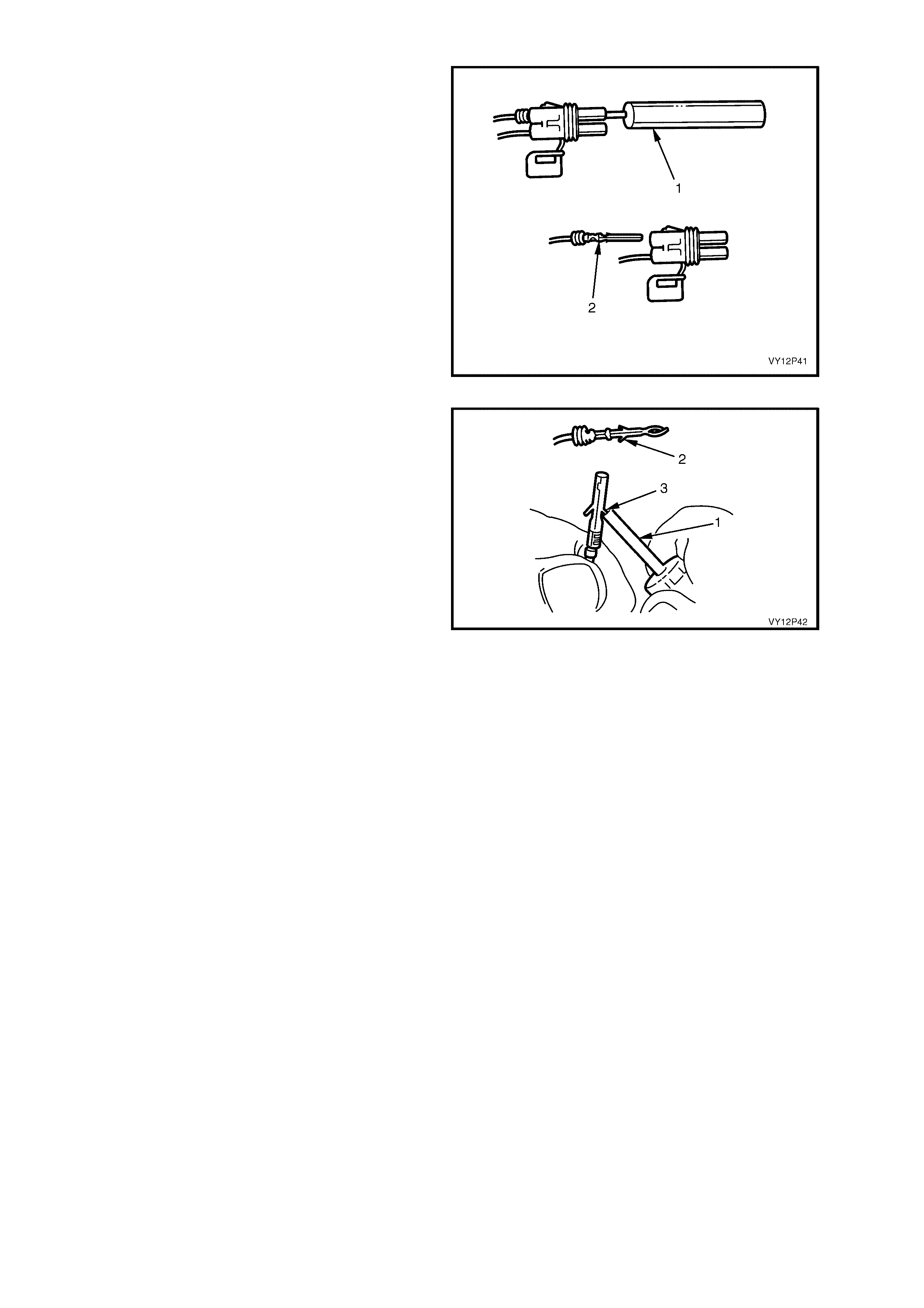

1. Bring the ultratorch (part of J38125-A) to

operating temperature.

2. Using the torch, apply heat where the barrel is

crimped as shown in Figure 12P-41.

3. Gradually move the heat barrel from the centre

toward each end of the tubing, softening and

shrinking the tubing completely as the heat is

moved along the insulation. A small amount of

sealant will come out of the end of the tubing

when sufficient shrinking is achieved.

4. Allow the splice sleeve to cool.

Step 9. Close the Harness

Using a multimeter, check continuity of repaired

wiring. If wiring is OK, tape the harness wires.

Figure 12P-41

ABS AND SRS WIRING SPLICE REPAIR

If any of the original equipment splices (three wires or more) in the ABS and SRS wiring are damaged they should

be repaired by applying a new splice (not sealed) from the Terminal Repair Kit J38125-A. Carefully follow the

instructions included in the kit for proper splice clip application. Cloth duct tape may be substituted for splice tape if

necessary.

5.5 SPLICING TWISTED OR SHIELDED CABLE

Twisted or shielded cable is used to protect wiring from electrical noise. Two-conductor cable is used between the

radio and the Delco-Bose speaker amplifier units and other applications where low level, sensitive signals must be

carried.

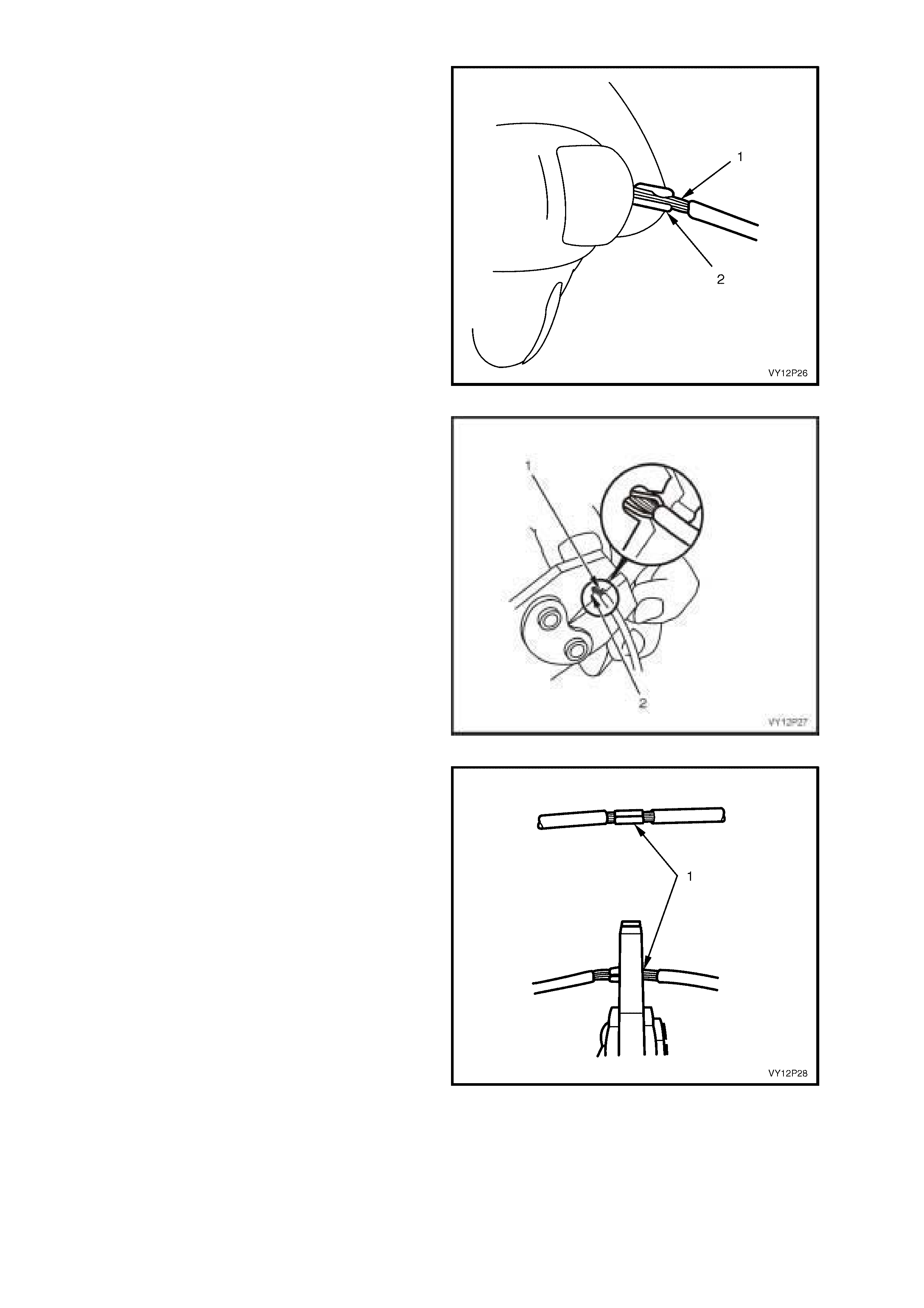

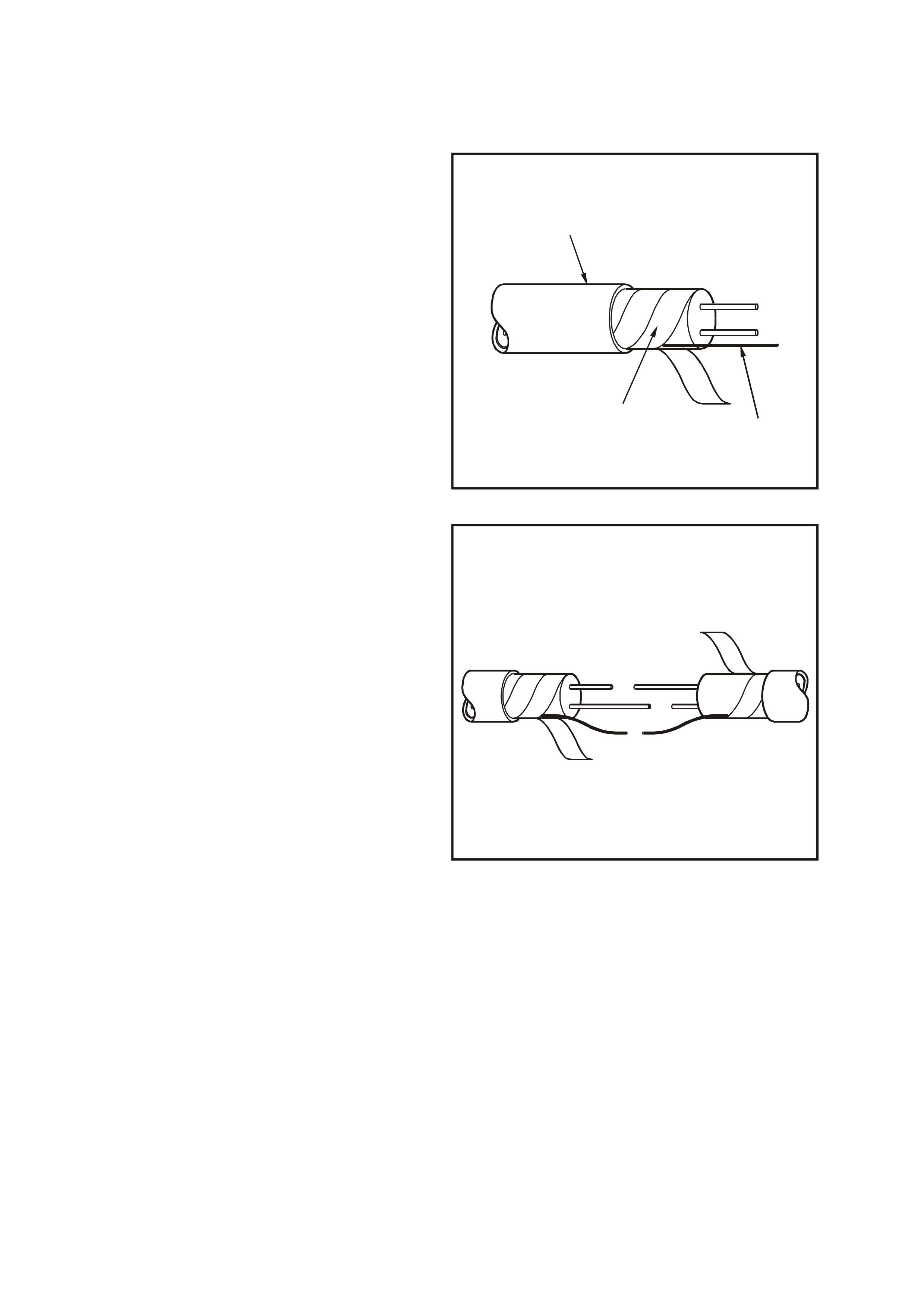

Step 1. Strip the Cable

1. Remove the outer jacket (1). Use care not to

cut into the drain wire (2) of the mylar tape(3).

2. Unwrap the mylar tape. Do not remove the tape

because it will be used to re-wrap the

conductors after the splice has been made.

VY12P47

1

2

3

Figure 12P-42

Step 2. Prepare the Splice

1. Straighten the conductors and stagger the

splices by 65 mm.

2. Follow the instructions for splicing copper wire.

VY12P48

Figure 12P-43

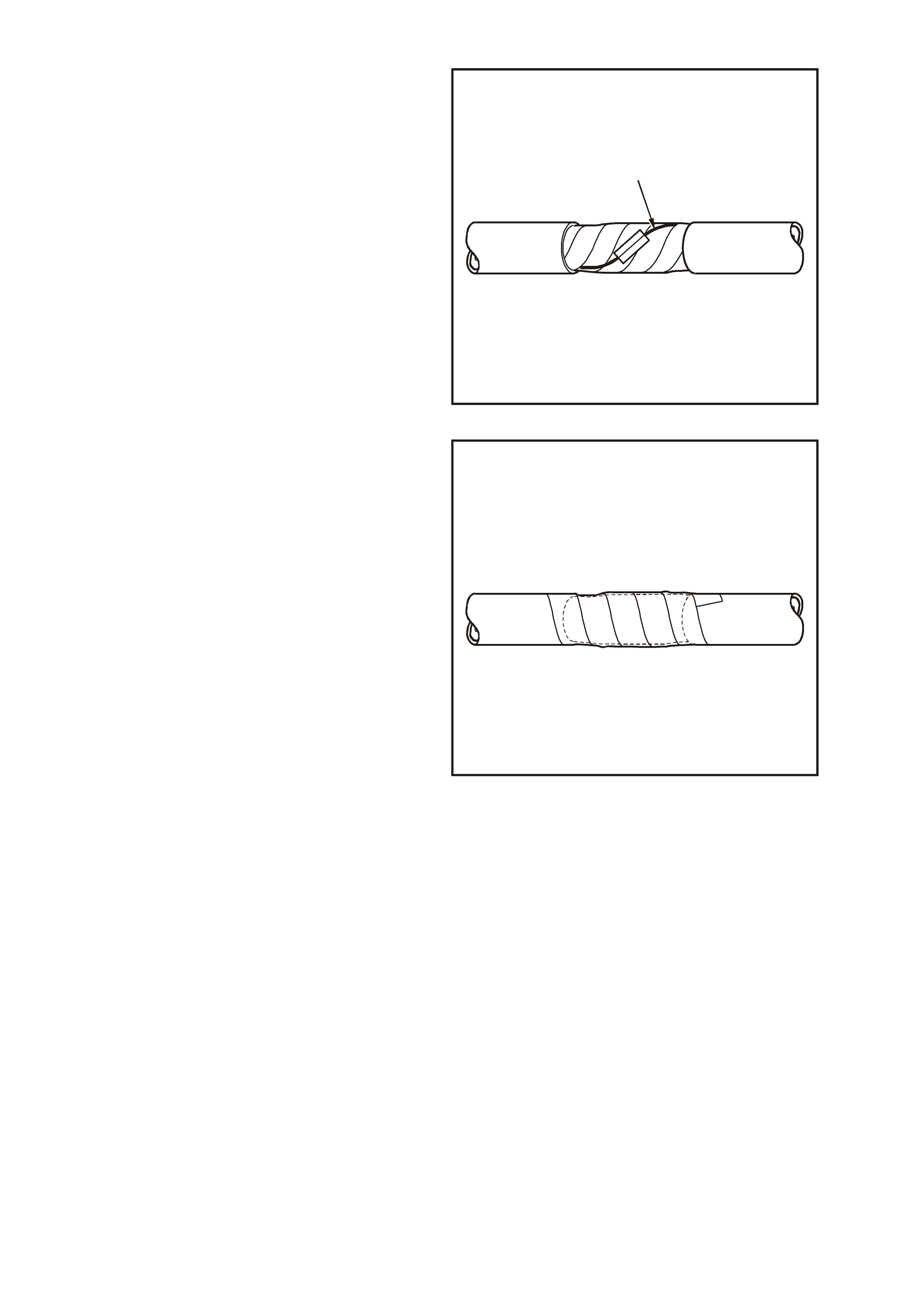

Step 3. Reassemble the Cable

1. Re-wrap the conductors with the mylar tape,

taking care not to wrap the drain wire (1) in the

tape.

NOTE: Apply the mylar tape with the aluminium

side inward to ensure good electrical connection.

2. Follow the instructions for splicing copper wire

and splice the drain wire.

3. Wrap the drain wire around the conductors and

tape with mylar tape.

VY12P49

1

Figure 12P-44

Step 4. Tape the Joint

1. Tape over the entire cable using a winding

motion while applying the tape.

VY12P50

Figure 12P-45

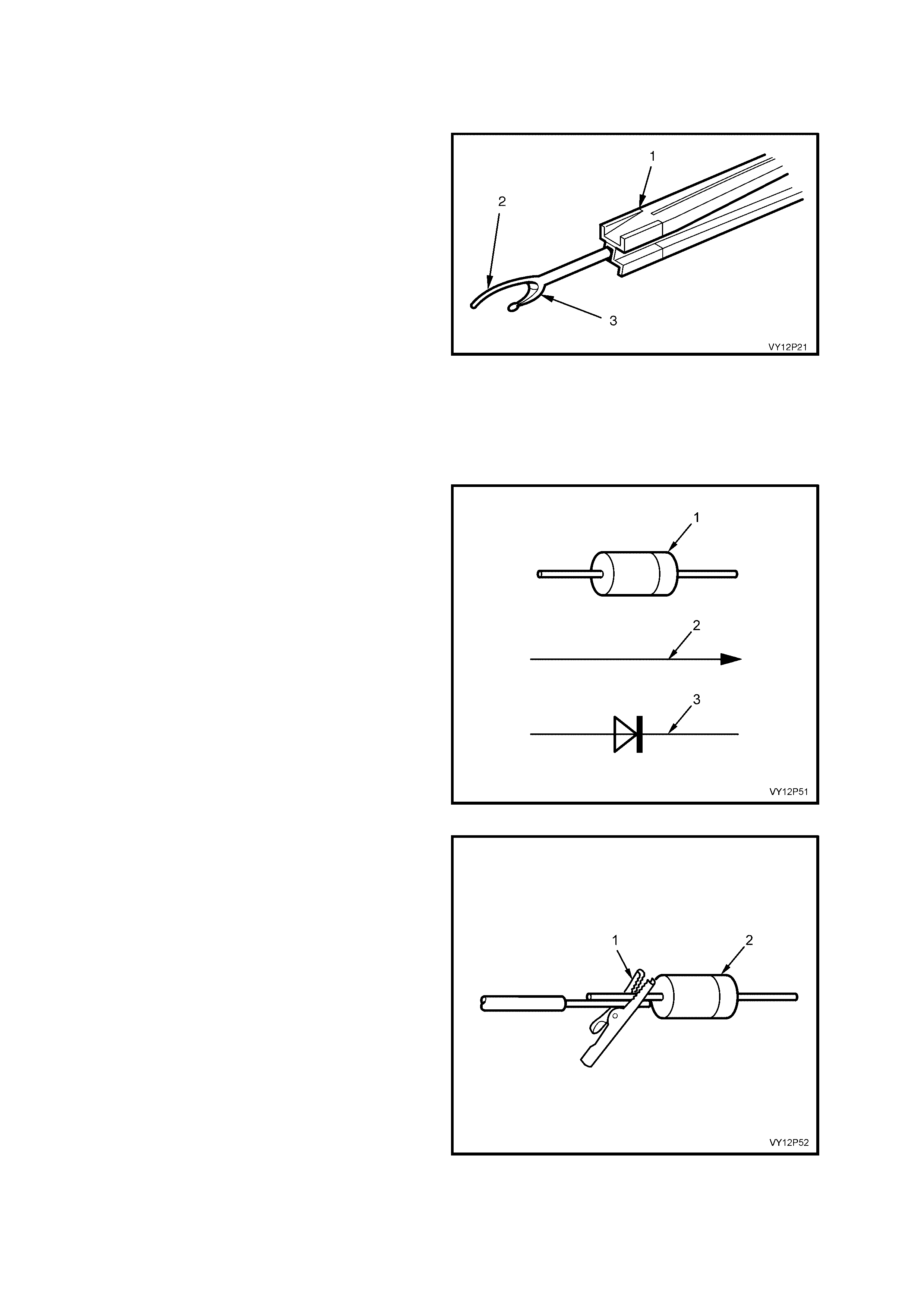

5.6 SPLICING IN-LINE HARNESS DIODES

Many vehicle electrical systems use a diode to isolate circuits and protect the components from voltage spikes. To

install a new diode:

Step 1. Open the Harness

A wiring harness may be wrapped in tape or

enclosed in a plastic conduit.

If it is conduit encased, simply open the conduit and

pull out the desired wire and diode.

If the harness is wrapped in tape, use a seam

splitter (1) to open the harness. This prevents

damage to the insulation of the wire inside the

harness. Seam splitters are readily available from

sewing supply stores.

When using a seam splitter, use the blade with the

pointed end (2) to start a small split in the tape

away from any wires.

Use the blade with the rounded end (3) to slit the

tape as far as necessary. Be careful to avoid

cutting into any wire insulation.

If the diode is taped to the harness, remove all of

the tape.

Figure 12P-46

Step 2. Remove Diode

1. Check and record the orientation and current

flow direction and of the diode.

NOTE: The colour band (1) or the letter K

impressed into the end of the diode indicated the

cathode.

2. Remove the faulty diode from the harness

using a suitable soldering tool.

NOTE: If the diode is located next to a connector

terminal, remove the terminal from the connector to

prevent heat damage from the soldering tool.

3. Strip away as much insulation from the wire as

is needed to attach the new diode.

Figure 12P-47

Step 3. Install the New Diode

1. Check the current flow direction of the new

diode, being sure to install the new diode with

the correct bias.

2. Solder the new diode to the wire using 50/50

resin cored solder.

NOTE: Use heat sinks across the diode wire ends

to protect the diode from excessive heat.

3. If removed, reinstall the terminal into the

connector.

4. To prevent shorts to ground and water

intrusion, completely cover all exposed wire

and diode attachment points with tape.

5. Tape the diode to the harness or connector

using electrical tape.

Figure 12P-48

5.7 HEATED OXYGEN SENSOR (HO2S) WIRING REPAIRS

NOTE: Do not solder repairs as this could result in the air reference being obstructed.

If the heated oxygen sensor pigtail wiring, connector or terminal is damaged, the entire oxygen sensor assembly

must be replaced. Do not attempt to repair the wiring, connector or terminals. For the sensor to function properly, it

must have a clean air reference. The clean air reference is obtained through the oxygen sensor signal and heater

wires. Any attempt to repair the wires, connectors or terminals could result in the obstruction of the air reference

and degrade the oxygen sensor performance.

The following guidelines should be used when servicing the heated oxygen sensor:

• Do not apply contact cleaner or other materials to the sensor or vehicle harness connectors. These materials

may get into the sensor causing poor performance.

• The sensor pigtail and harness wires must not be damaged or the wires inside exposed. This could provide a

path for foreign materials to enter the sensor and cause performance problems.

• Do not sharply bend or kink the sensor or vehicle lead wires. Sharp bends and kinks could block the reference

air path through the lead wire.

• Do not remove or disconnect the oxygen sensor ground wire where fitted. Vehicles with a ground wire sensor

may rely on this ground as the only ground contact to the sensor. Removing the ground wire will also cause

poor engine performance.

• To prevent damage due to water intrusion, ensure the peripheral seal on the vehicle harness connector remains

intact.

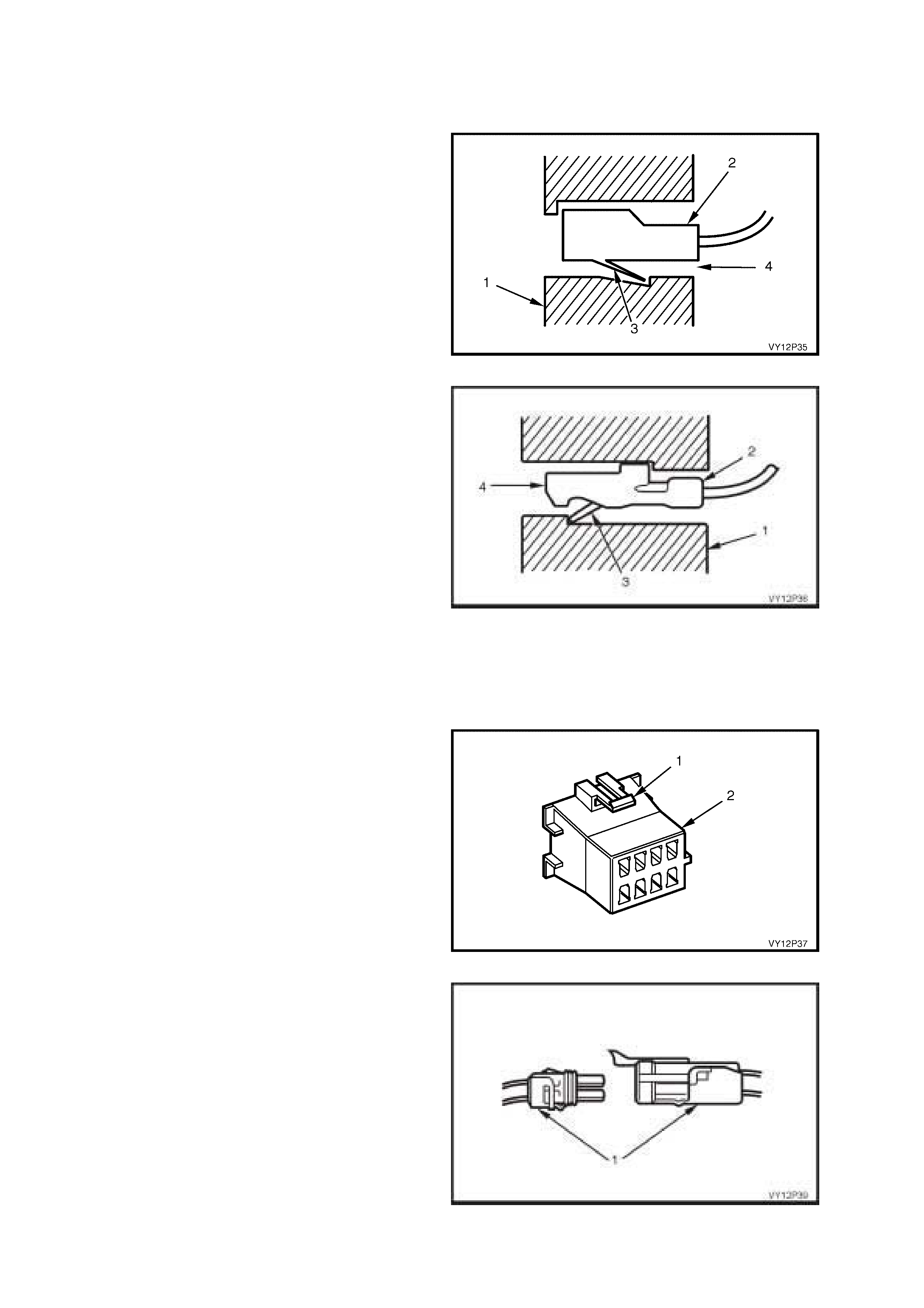

5.8 TERMINAL REMOVAL

The following general terminal removal procedures can be used on most types of connectors. The removal

procedures are divided into three general groups; Push-to-Seat, Pull-to-Seat and Weather Pack ®.

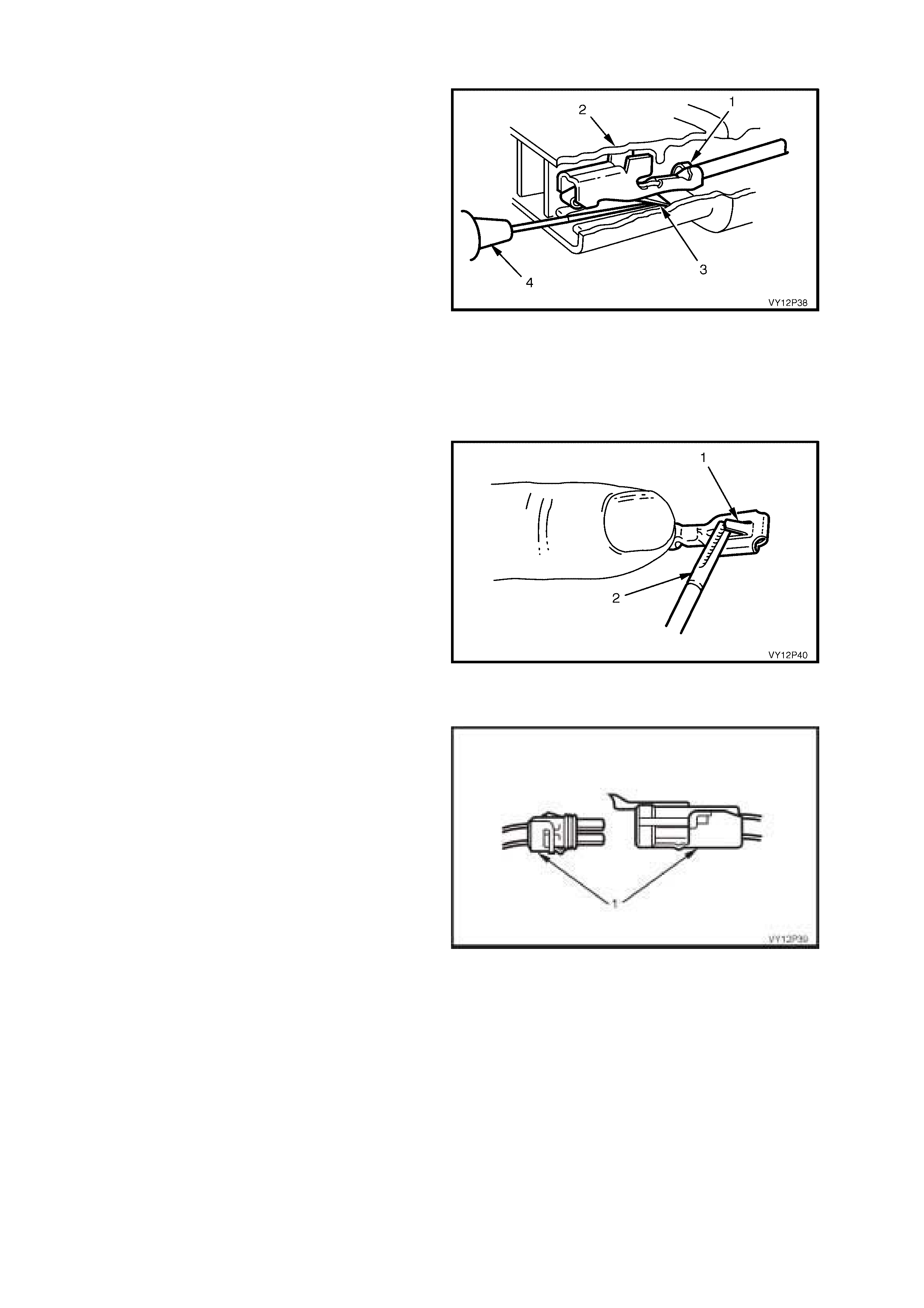

Push-to-Seat connectors, refer to Figure 12P-49,

are those which have the terminal inserted in the

rear of the connector body when assembled.

Legend

1 Connector body

2 Terminal

3 Locking tan

4 Insertion direction

Figure 12P-49

Pull-to-Seat connectors, refer to Figure 12P-50,

have the terminal inserted in the front of the

connector body when assembled.

Use the proper pick(s) or tool(s) that apply to the

appropriate terminal and connector.

Legend

1 Connector body

2 Terminal

3 Locking tang

4 Insertion direction

Figure 12P-50

REPAIRING PUSH-TO-SEAT AND PULL-TO-SEAT CONNECTORS

The following steps will enable repair of Push-to-Seat or Pull-to-Seat type connectors. The steps are illustrated with

typical connectors. A specific connector may differ, but the repair steps are similar. Some connectors do not require

all the steps shown.

To repair a connector:

1. Lift up the connector body retaining tangs (1)

and pull mating connector bodies (2) apart, or

disconnect the connector from the component.

2. Remove any anti - backout combs that may be