SECTION 2B - HVAC CLIMATE CONTROL

(MANUAL A/C) – REMOVAL AND INSTALLATION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. MANUAL HVAC CONTROLLER

REMOVE

REINSTALL

2.1 WATER VALVE VACUUM SWITCH

REMOVE

REINSTALL

2.2 AIR MIX DOOR ROD RETAINER

REMOVE

REINSTALL

2.3 FRONT HOUSING/SWITCH ASSEMBLY

AND PRINTED CIRCUIT BOARD

REMOVE

REINSTALL

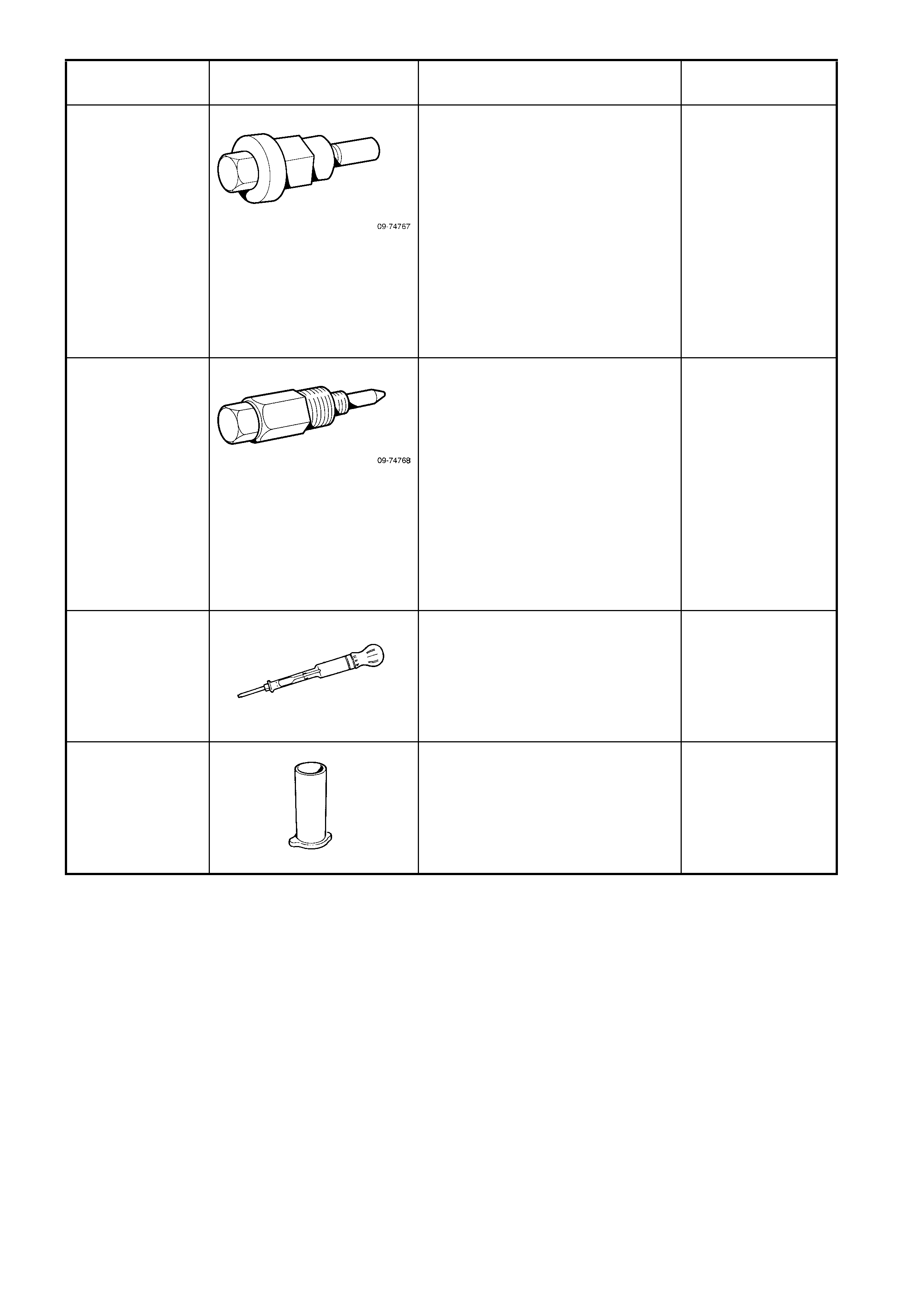

2.4 MODE SWITCH VACUUM VALVE

REMOVE

REINSTALL

3. HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT

REMOVE

REINSTALL

4. EVAPORATOR CORE

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

5. HEATER CORE

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

6. BLOWER MOTOR AND

FAN ASSEMBLY

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

7. BLOWER MOTOR RESISTOR

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

8. VACUUM TANK AND VACUUM

ACTUATORS

8.1 VACUUM TANK

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

8.2 FRESH/RECIRCULATION (INTAKE)

ACTUATOR

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

8.3 FACE ACTUATOR

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

8.4 FOOT ACTUATOR

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

8.5 DEMIST ACTUATOR – LHD ONLY

REMOVE

REINSTALL

9. A/C HOSE AND PIPE CONNECTIONS

AND RETAINERS

REMOVE AND REINSTALL

10. THERMAL EXPANSION VALVE (TXV)

REMOVE

REINSTALL

11. A/C PRESSURE TRANSDUCER

REMOVE AND REINSTALL

12. CONDENSER

12.1 V6 AND V6 SUPERCHARGED ENGINE

REMOVE

REINSTALL

12.2 GEN III V8 ENGINE

REMOVE

REINSTALL

13. FILTER DRIER RECEIVER

REMOVE

REINSTALL

14. A/C DRIVE BELT AND PULLEYS

14.1 V6 ENGINE

REMOVE

REINSTALL

14.2 V6 SUPERCHARGED ENGINE

REMOVE

REINSTALL

14.3 GEN III V8 ENGINE

REMOVE

REINSTALL

14.4 A/C DRIVE BELT IDLER PULLEY

ASSEMBLY – V6 AND V6 S/C ENGINE

REMOVE

REINSTALL

14.5 A/C DRIVE BELT IDLER PULLEY

ASSEMBLY – GEN III V8 ENGINE

REMOVE

REINSTALL

14.6 A/C DRIVE BELT TENSIONER PULLEY

ASSEMBLY – GEN III V8 ENGINE

REMOVE

REINSTALL

Techline

Techline

Techline

15. A/C COMPRESSOR

15.1 V6 AND V6 SUPERCHARGHED ENGINE

REMOVE

REINSTALL

15.2 GEN III V8 ENGINE

REMOVE

REINSTALL

16. MINOR A/C COMPRESSOR REPAIR

PROCEDURES

16.1 A/C COM PRESSOR CONTROL VALVE

REMOVE

REINSTALL

16.2 A/C CLUTCH DRIVE PLATE AND HUB

ASSEMBLY

REMOVE

REINSTALL

16.3 A/C CLUTCH PULLEY AND BEARING

ASSEMBLY

REMOVE

REINSTALL

17. UNDER HOOD HEATER COMPONENTS

17.1 WATER VALVE

REMOVE

REINSTALL

17.2 HEATER HOSES AND VACUUM LINES

REMOVE AND REINSTALL

18. HVAC INLET, DUCTS AND

VENTILATION OUTLETS

18.1 HVAC INLET SCREEN

REMOVE

REINSTALL

18.2 HVAC SYSTEM DUCTS

REMOVE – DRIVER’S SIDE OUTER DUCT

REINSTALL – DRIVER’S SIDE OUTER DUCT

REMOVE – DRIVER’S SIDE INNER DUCT

REINSTALL – DRIVER’S SIDE INNER DUCT

REMOVE – PASSENGER SIDE DUCT

REINSTALL – PASSENGER SIDE DUCT

REMOVE – FLOOR CONSOLE REAR DUCT

REINSTALL – FLOOR CONSOLE REAR DUCT

REMOVE – FLOOR CONSOLE FRONT DUCT

REINSTALL – FLOOR CONSOLE FRONT

DUCT

REMOVE – FOOT DUCT, LHD

REINSTALL – FOOT DUCT, LHD

REMOVE – FOOT DUCT, RHD

REINSTALL – FOOT DUCT, RHD

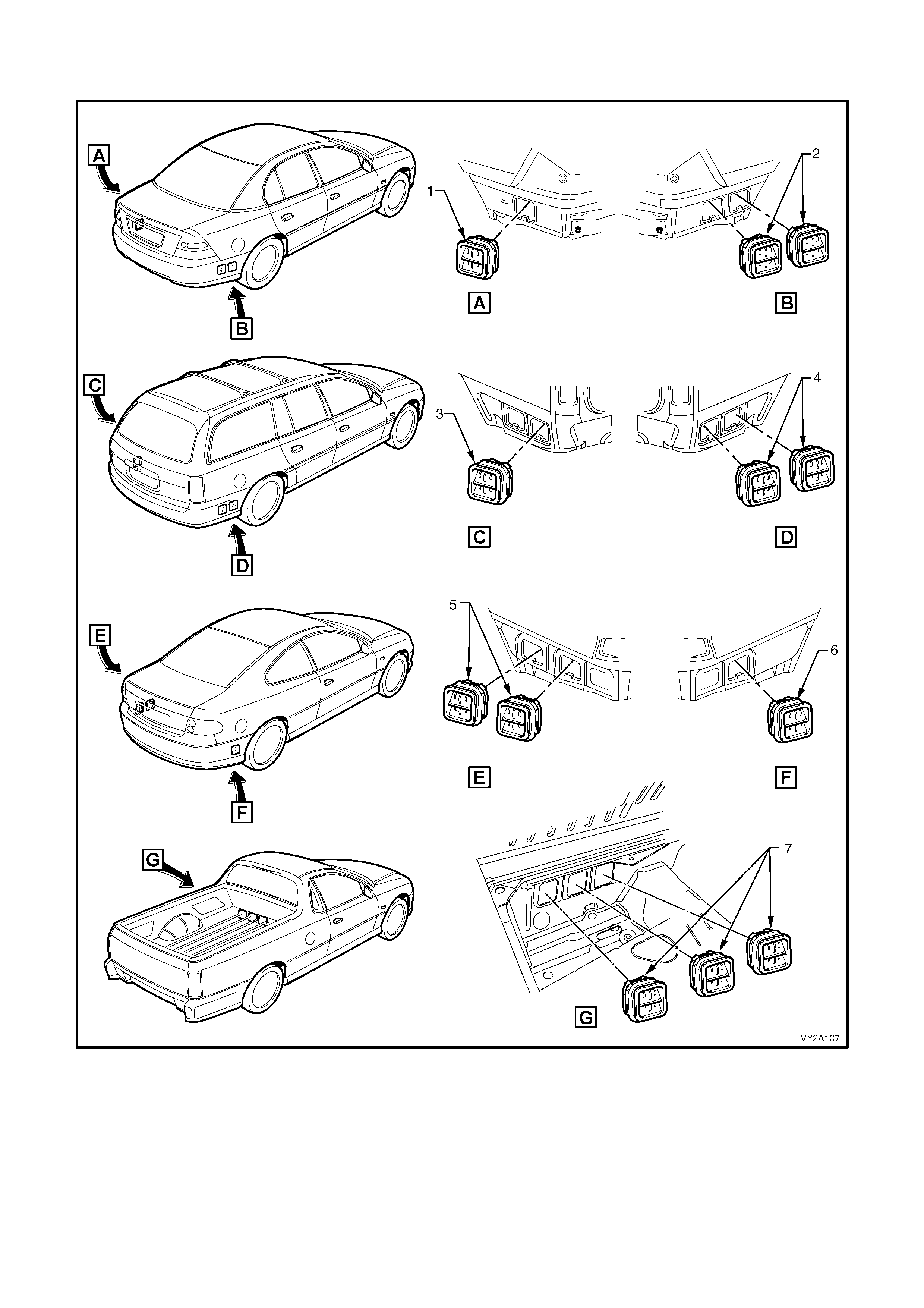

18.3 CABIN VENTILATION OUTLETS

REMOVE AND REINSTALL

18.4 BODY VENTILATION OUTLETS

REMOVE – SEDAN AND COUPE

REINSTALL – SEDAN AND COUPE

REMOVE – WAGON

REINSTALL – WAGON

REMOVE – UTILITY

REINSTALL – UTILITY

19. TORQUE WRENCH SPECIFICATIONS

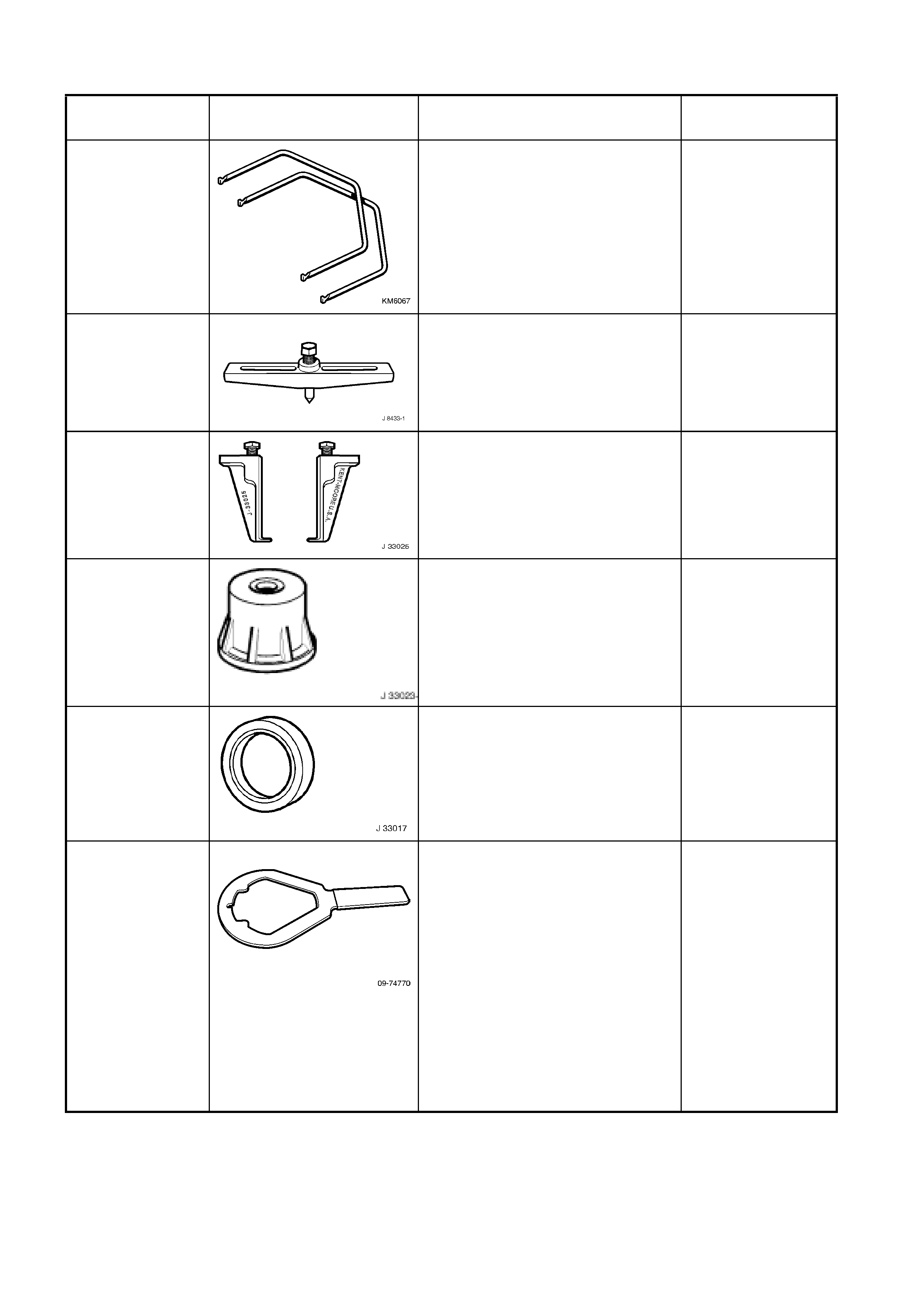

20. SPECIAL TOOLS

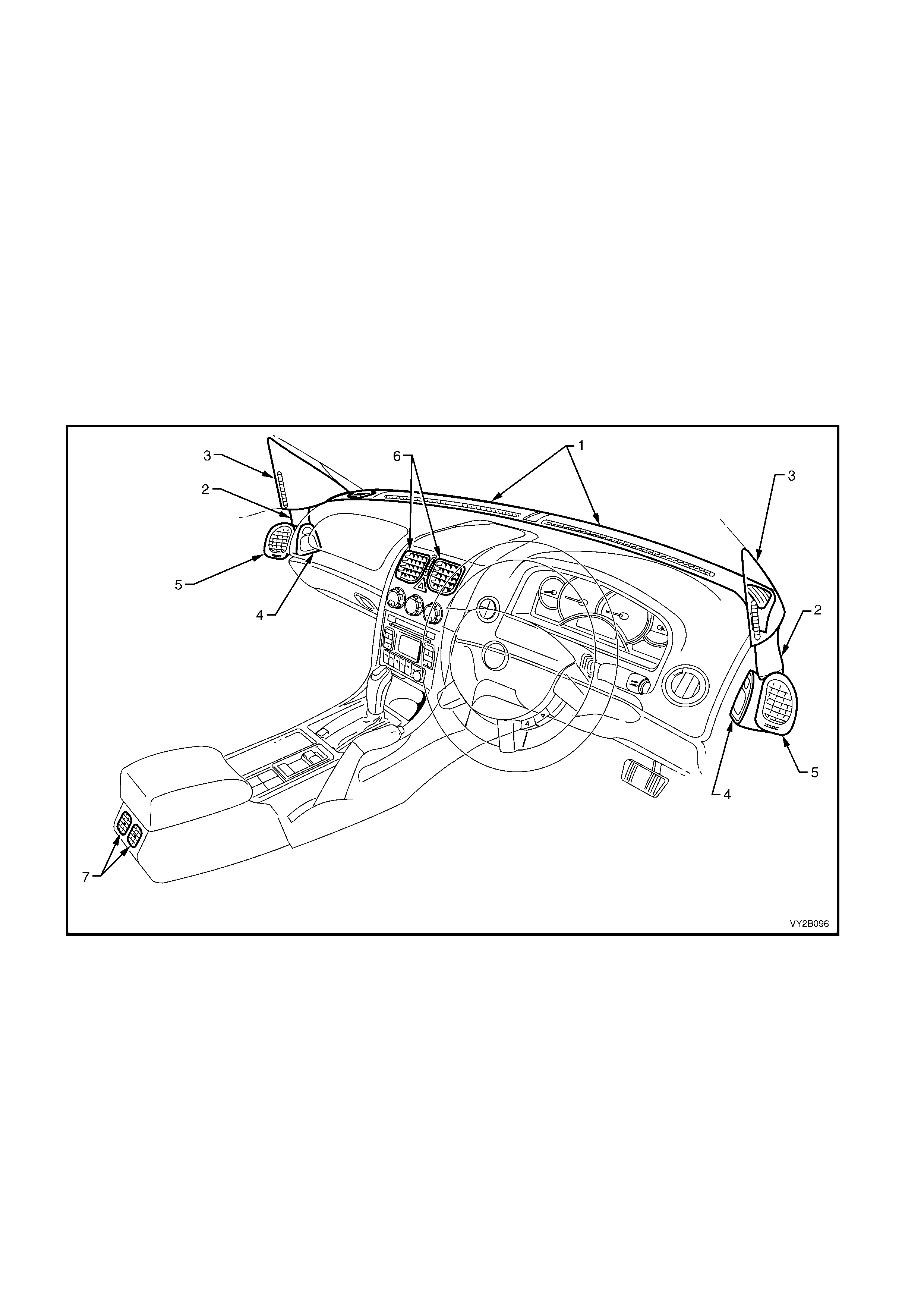

1. GENERAL I NFORMATI O N

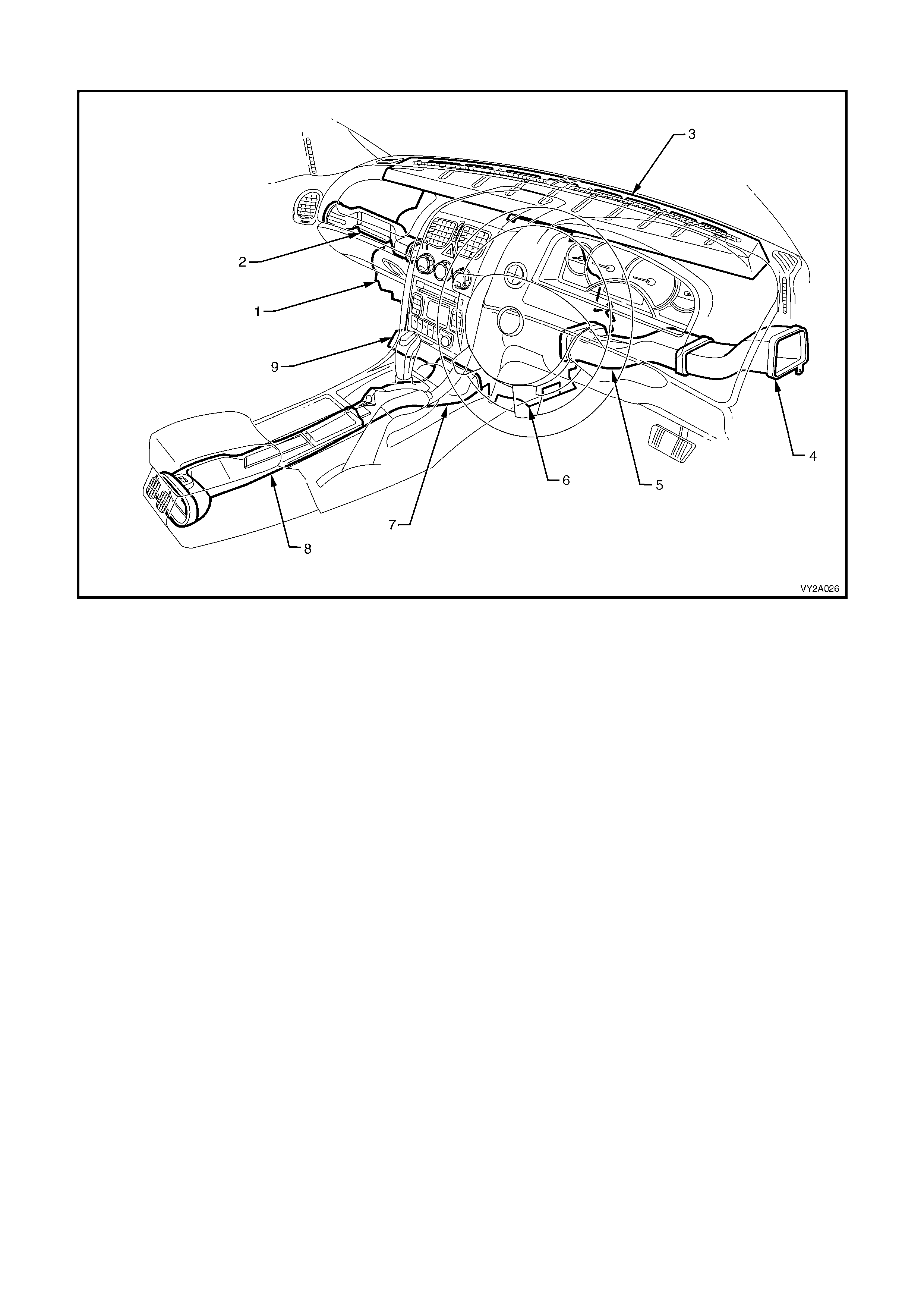

The inf or mation that is provided in this Sec tion is to be us ed f or both lef t and r ight-hand dr ive vehicles . Although the

information shown is primarily right-hand drive, it also applies to left-hand drive vehicles unless otherwise specified.

The instrument panel for left-hand drive vehicles is a mirror of the right-hand drive instrument panel, with a few

exceptions. The body control module r emains on the r ight-hand s ide of the vehic le, mounted vertically for right-hand

drive or horizontally for left-hand drive. A fuel filler door release switch is m ounted in the left-hand drive instrument

cluster trim.

While similar in function and performance, the HVAC units fitted to left and right-hand drive vehicles differ

significantly in terms of their case construction as well as their internal and external components. Accordingly,

certain Remove and Reinstall procedures in this area are specific to left and right-hand drive application and are

detailed in this Section.

The Remove and Reinstall procedures in this Section relating to the HVAC unit removal can be used for both the

HVAC Climate Control (Manual A/C) type system and the HVAC Occupant Climate Control (Auto A/C) type system.

The m anual HVAC controller Remove and Reins tall procedures in this Section relate only to HVAC Climate Control

(Manual A/C) type system. For Remove and Reinstall procedures of the OCC control module used to control the

HVAC Occupant Climate Control (Auto A/C) type system refer to Section 2E, 2. OCC CONTROL MODULE.

2. MANUAL HVAC CONTROLLER

LT Section – 08-155A

REMOVE

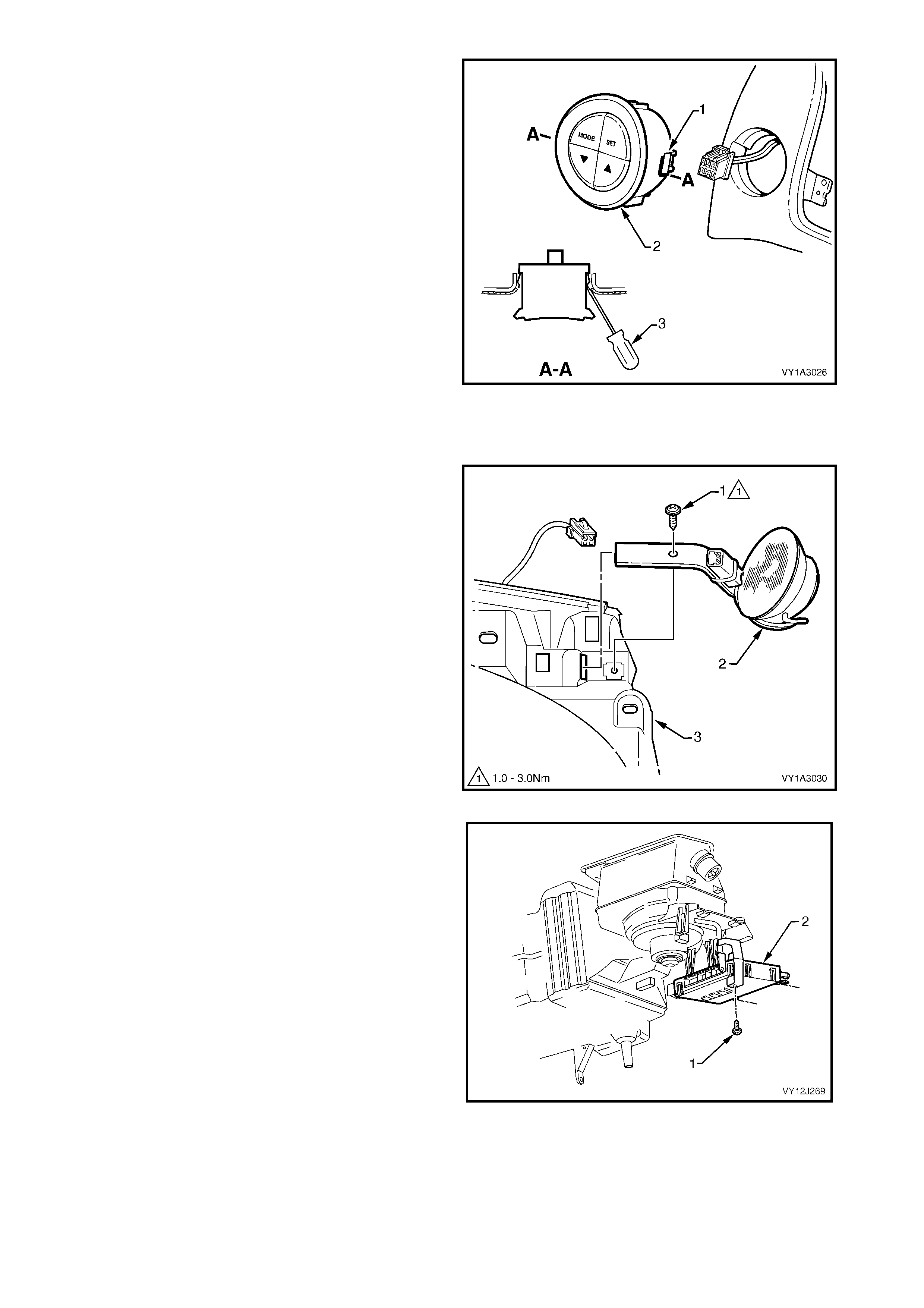

1. If fitted, remove the navigation remote control cradle. Refer to Section 12L, 3.2 NAVIGATION REMOTE

CONTROL ASSEMBLY.

2. If fitted, remove the navigation monitor escutcheon. Refer to Section 12L, 3.3 NAVIGATION DISPLAY

ASSEMBLY.

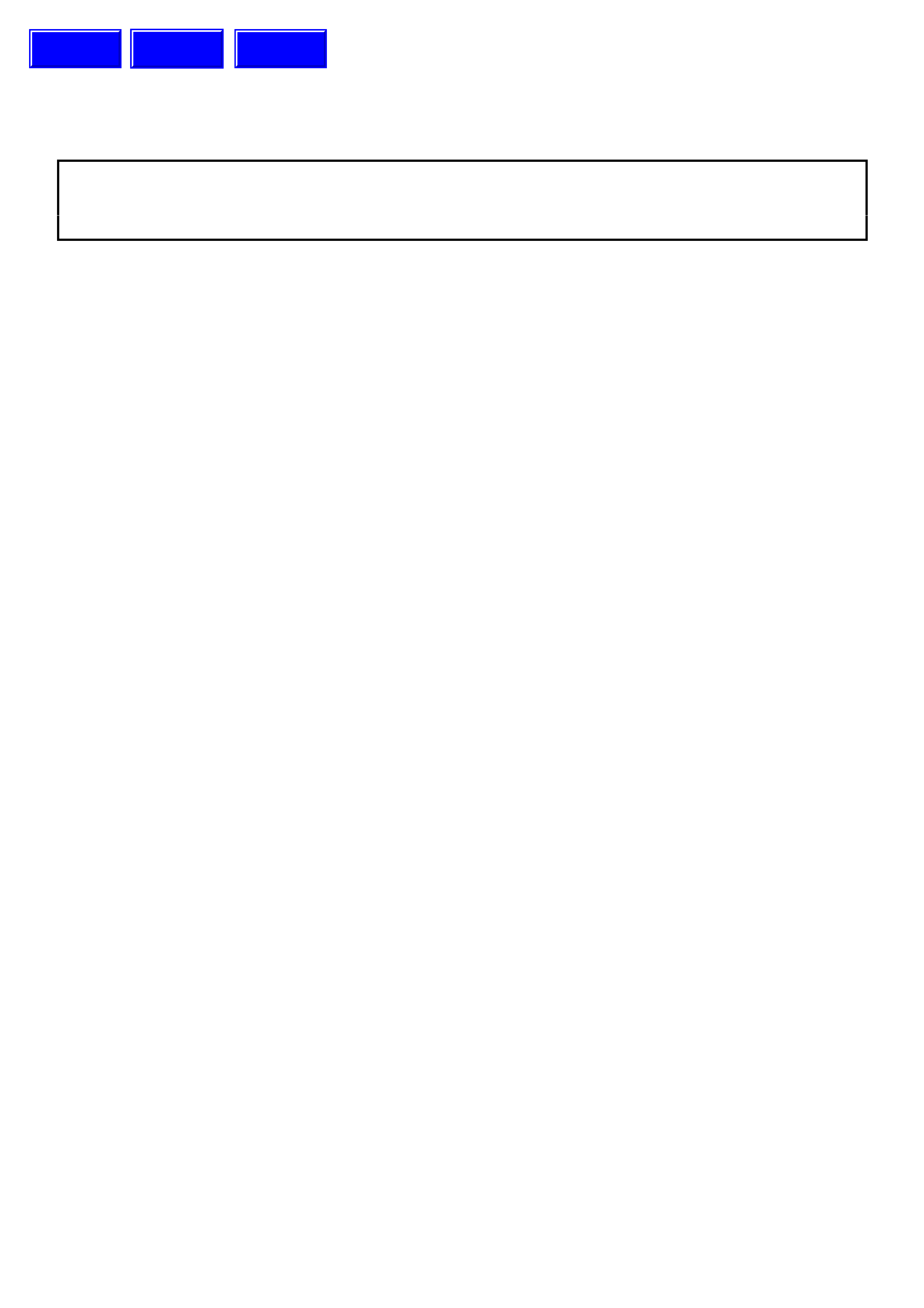

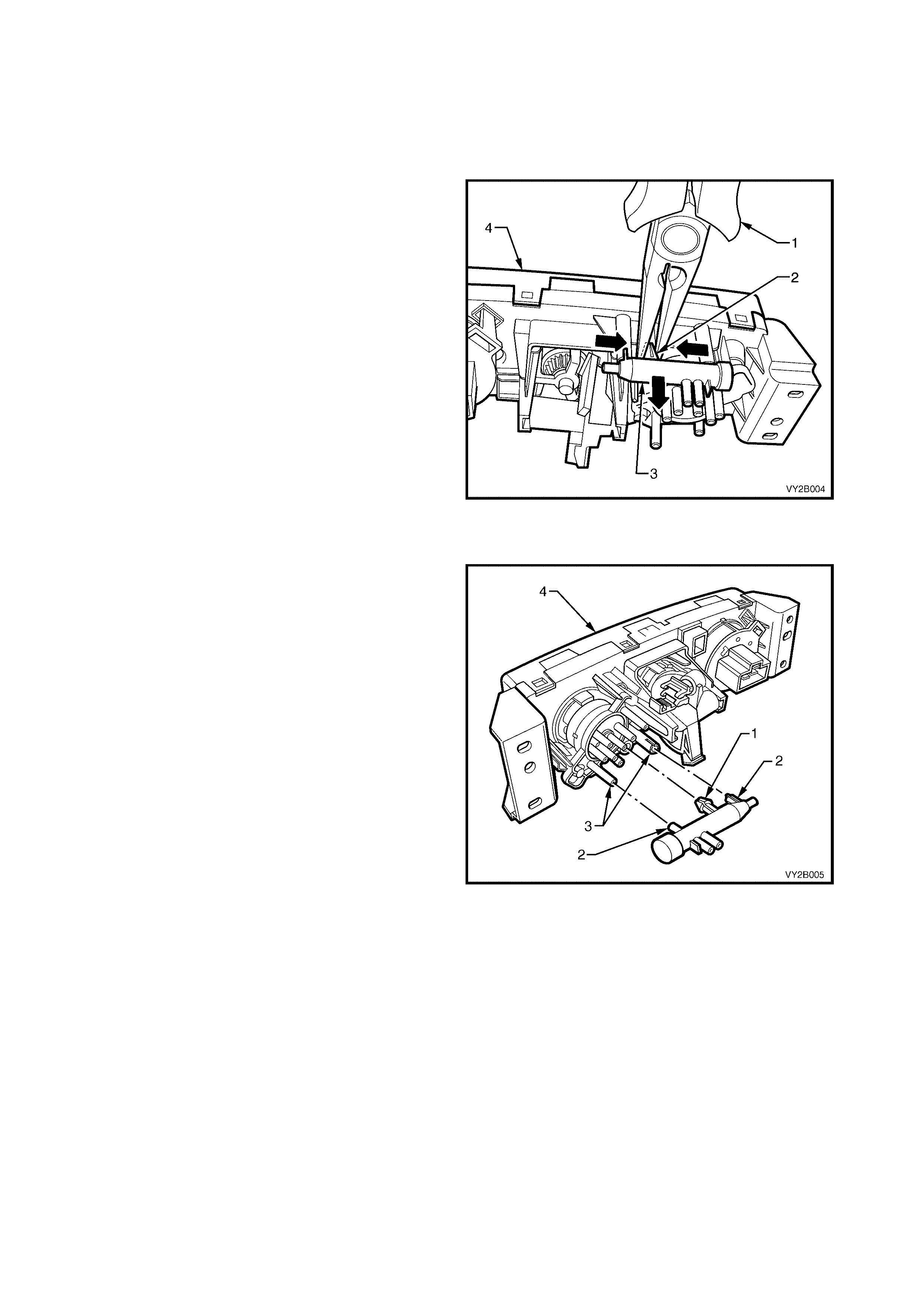

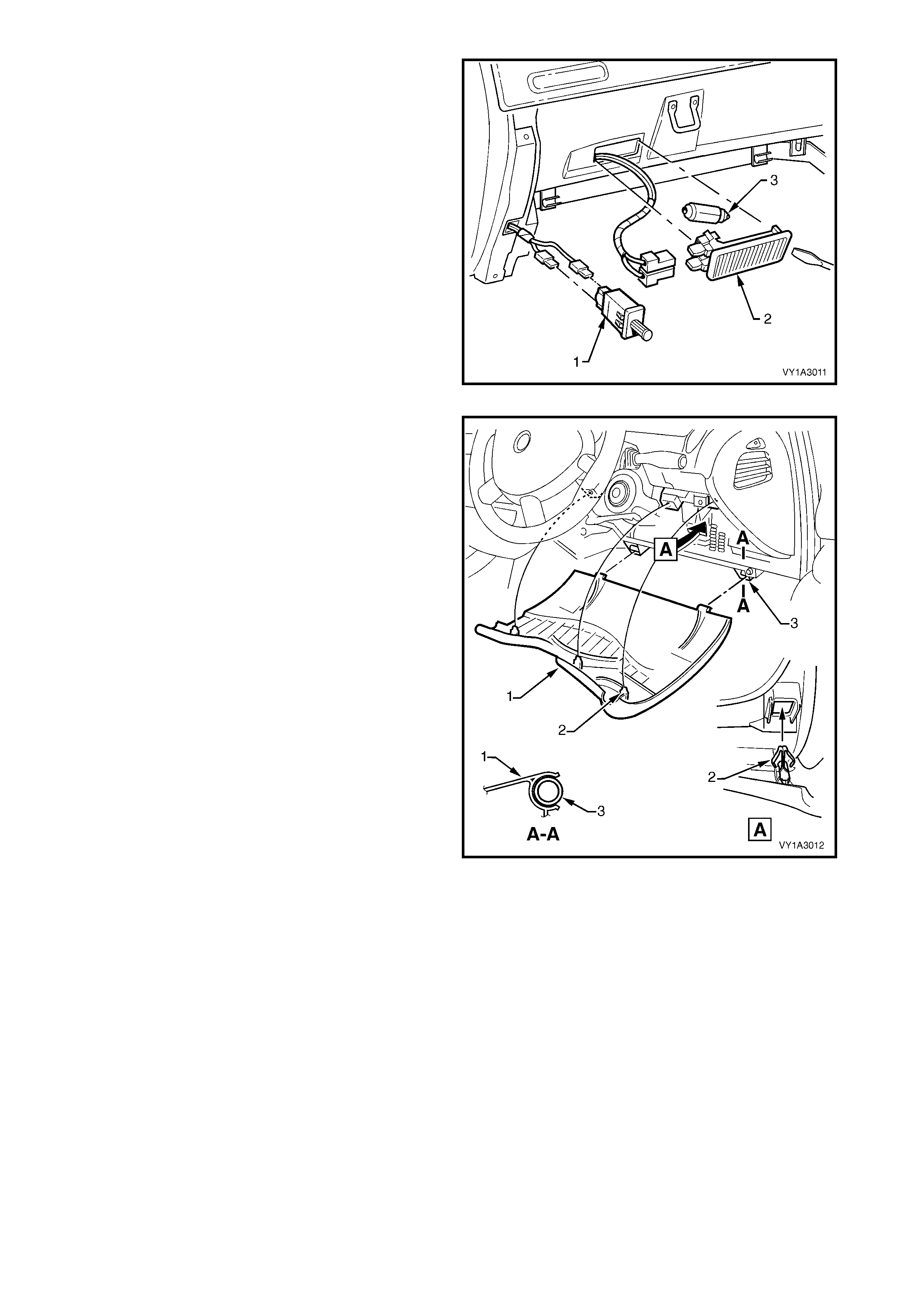

3. Remove the floor console front compartment liner

(1) by lifting upwards to disengage it from the

console cover.

Figure 2B-1

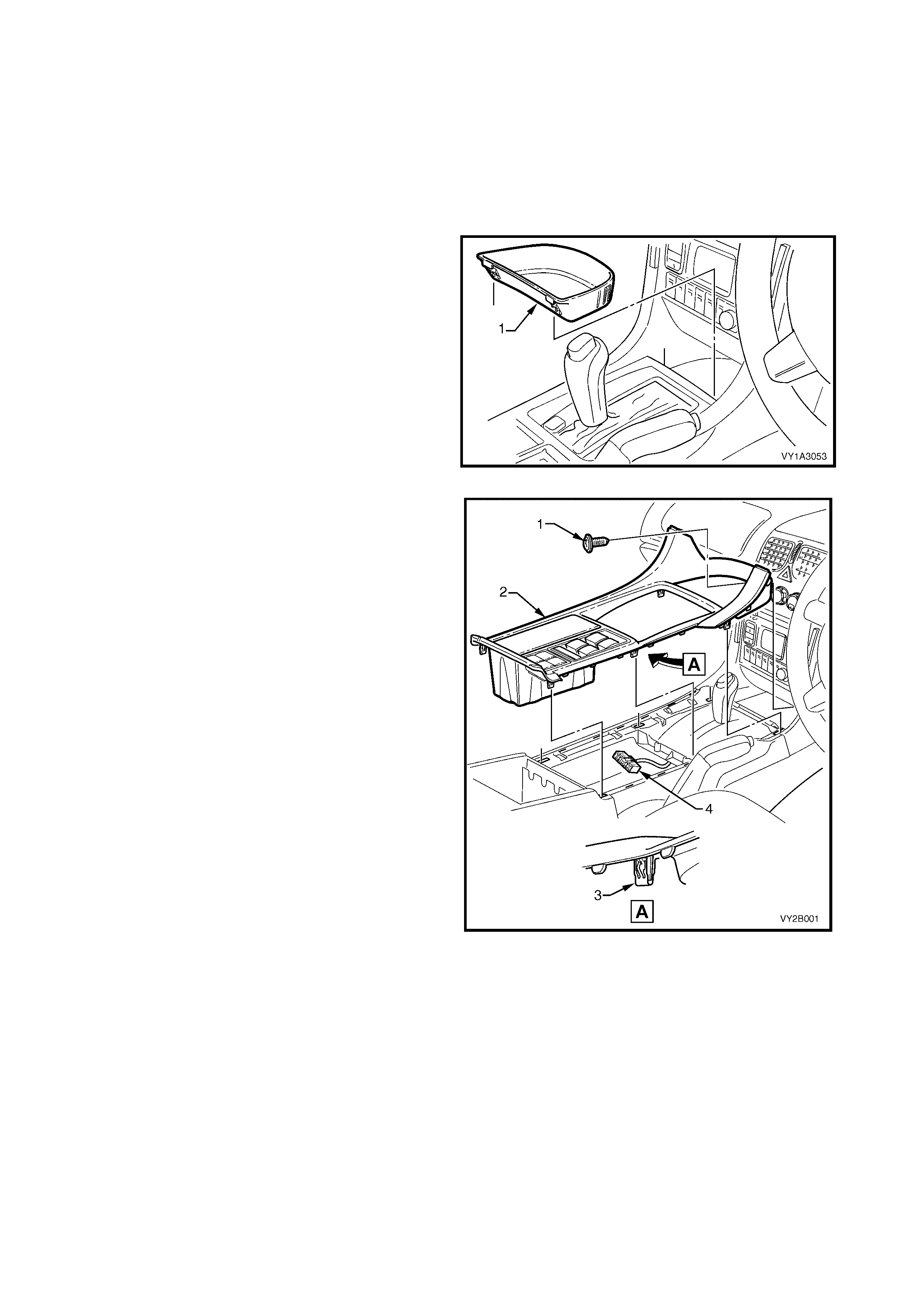

4. Remove the screw (1) slightly to the right of centre,

attaching the floor console cover assembly (2).

NOTE: Vehicles fitted with Navigation System do not

have this screw.

5. Prise the cover assembly from the floor console,

six places (3).

6. Lift the cover assembly up from the rear,

disconnect the wiring connector (4) from the side

window switch assembly and any auxiliary

switches if fitted, and remove the cover assembly.

Figure 2B-2

7. Insert Spec ial T ool KM6067 ( 1) into the holes eac h

side of the radio assembly.

8. While holding outward pressure on the tools

(toward each outer side of the vehicle), pull the

radio assembly from the radio housing.

NOTE: The wiring connectors remain attached to the

radio housing and will disconnect on removal of the

radio assembly.

Figure 2B-3

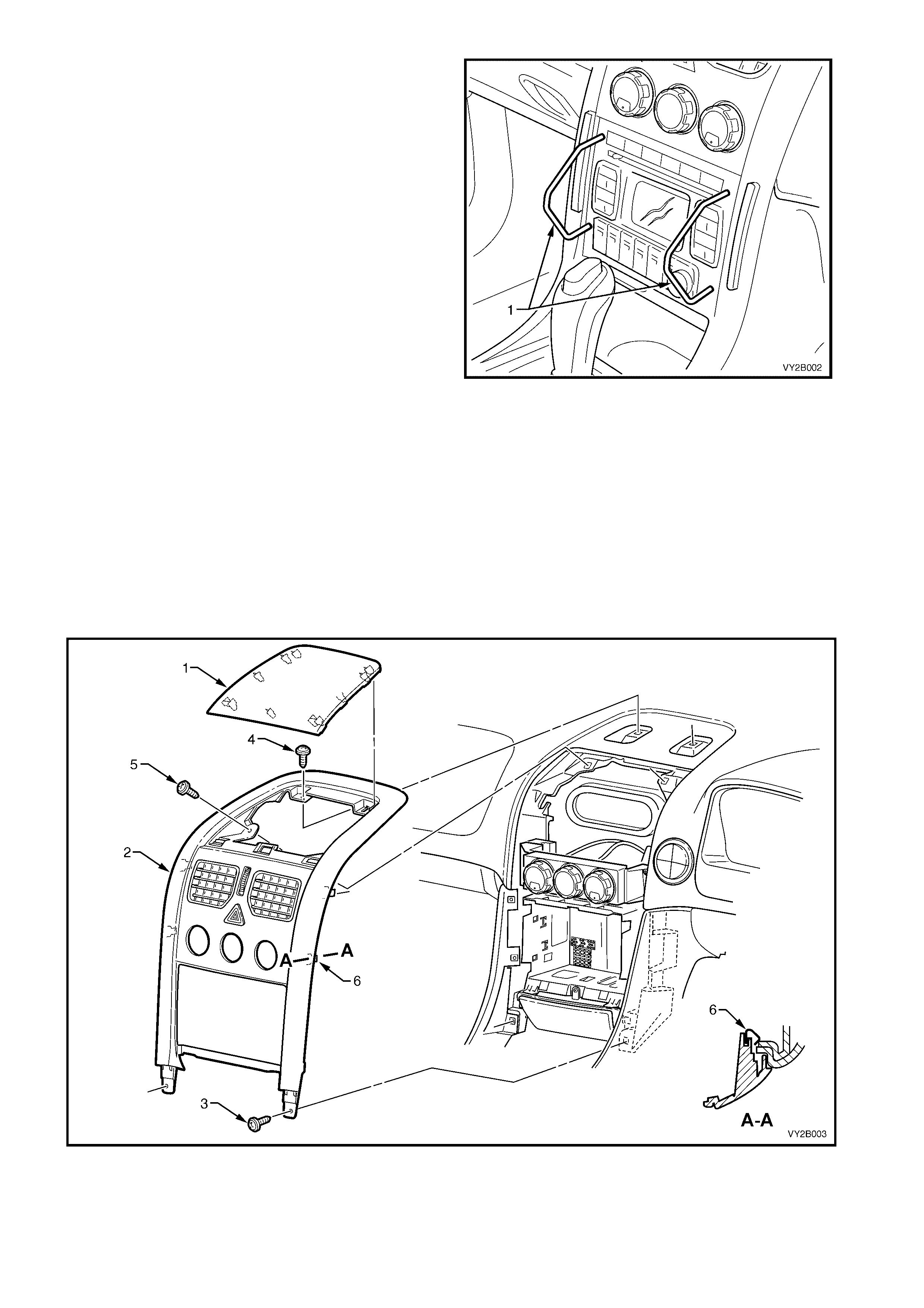

Referring to Figure 2B-4:

9. Carefully prise the front edge of the instrument panel upper centre trim panel (1), and pull upward to

disengage the retaining clips at each corner from the centre trim assembly (2).

NOTE: A fine flat blade screwdriver may be used; however take steps to ensure the trims are not marked or

damaged.

10. Remove the lower screw (3), two places, attaching the centre trim assembly to the instrument panel.

11. Remove the upper s crews (4 and 5), two places eac h, attaching the centre trim assem bly to the instrum ent

panel.

12. Remove the centre trim assembly, noting the four clips (6), far enough to disconnect the wiring connectors

from the rear of the hazard warning switch.

13. Remove the centre trim assembly.

Figure 2B-4

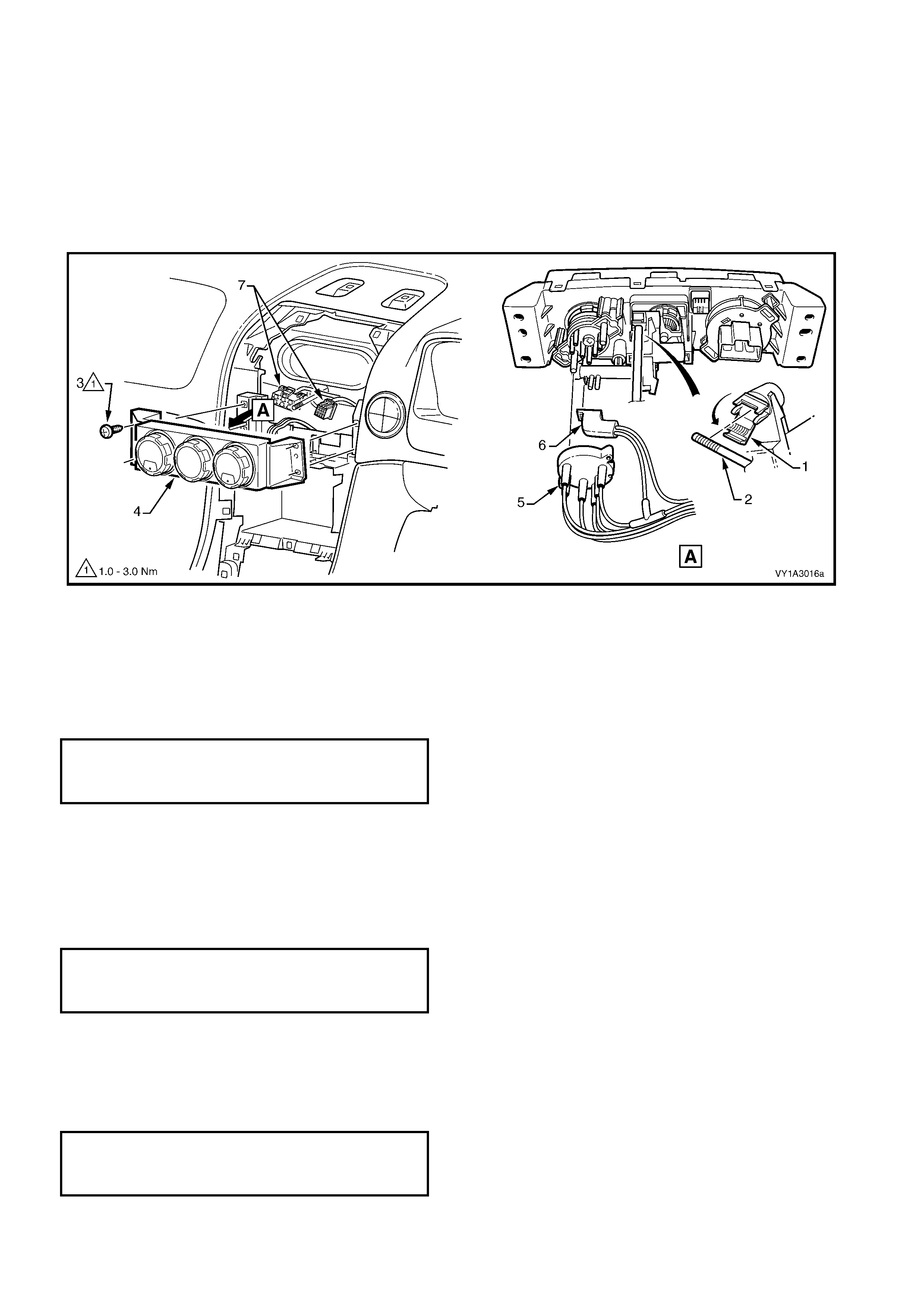

Referring to Figure 2B-5:

14. From the rear of the HVAC controller, open the air mix door rod retainer (1) and disconnect the rod (2).

15. Remove the screw (3), two places each side, attaching the HVAC controller (4) to the instrument panel.

16. Partially remove the HVAC c ontro ller as s embly outwards f rom the ins trument panel to ac ce ss the r ear of the

controller.

17. Disconnect the two vacuum hose connections (5 and 6) and two wiring connectors (7).

18. Remove the HVAC controller assembly.

NOTE: For service and diagnosis of the manual HVAC controller, refer to Section 2C, 7. ELECTRICAL

COMPONENT TESTS and Section 2C, 8. VACUUM RETENTION TESTS.

Figure 2B-5

REINSTALL

1. Install the two wiring connectors and the lower then upper vacuum hose connections.

2. Push the control rod toward the HVAC unit (front of vehicle) fully.

3. Seat the control assembly in position.

4. Install the four screws and tighten to the specified torque.

MANUAL HVAC CONTROLLER

ATTACHING SCREW TORQUE

TORQUE SPECIFICATION 1.0 – 3.0 Nm

5. Rotate the temperature switch to the full cold position.

6. Position the air mix door rod retainer so that it will close upward.

7. Connect the rod to the air mix door rod retainer.

8. Close and lock the rod retainer over the rod.

9. Check for correct operation of the temperature switch.

10. Install the instrument panel centre trim assembly. Tighten all screws to the specified torque.

INSTRUMENT PANEL CENTRE TRIM

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

11. Insert the radio assembly into the housing.

12. Push the unit home to engage the retaining clips and wiring connectors.

NOTE: The Special Tool is not required.

10. Install the floor console cover assembly. Installation is the reverse of removal. Tighten the screw to the

specified torque.

FLOOR CONSOLE COVER ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

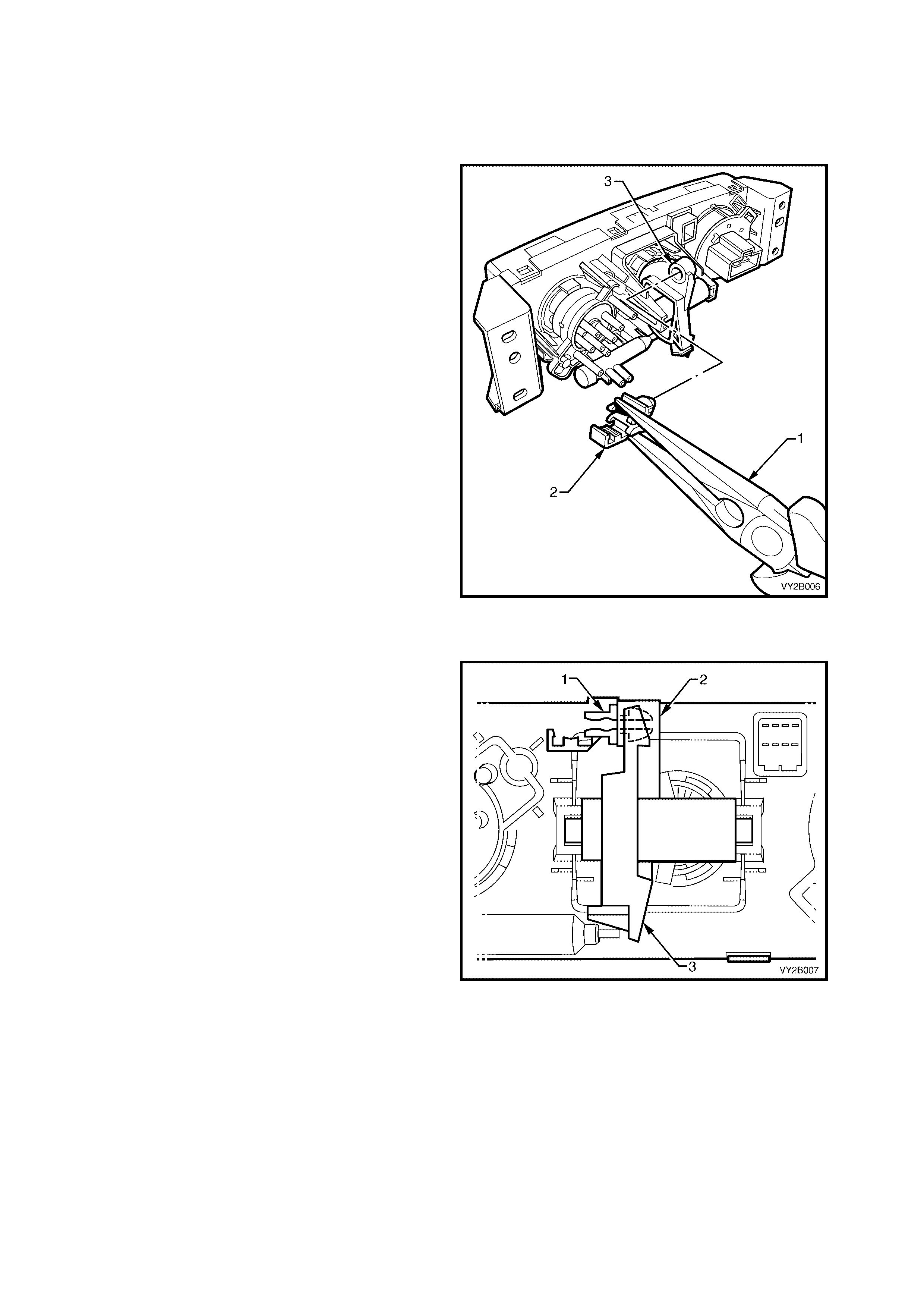

2.1 WATER VALVE VACUUM SWITCH

LT Section – 08-155A

REMOVE

1. Remove the manual HVAC controller. Refer to 2. MANUAL HVAC CONTROLLER in this Section.

2. Turn the temper ature s witch to the f ull hot pos ition.

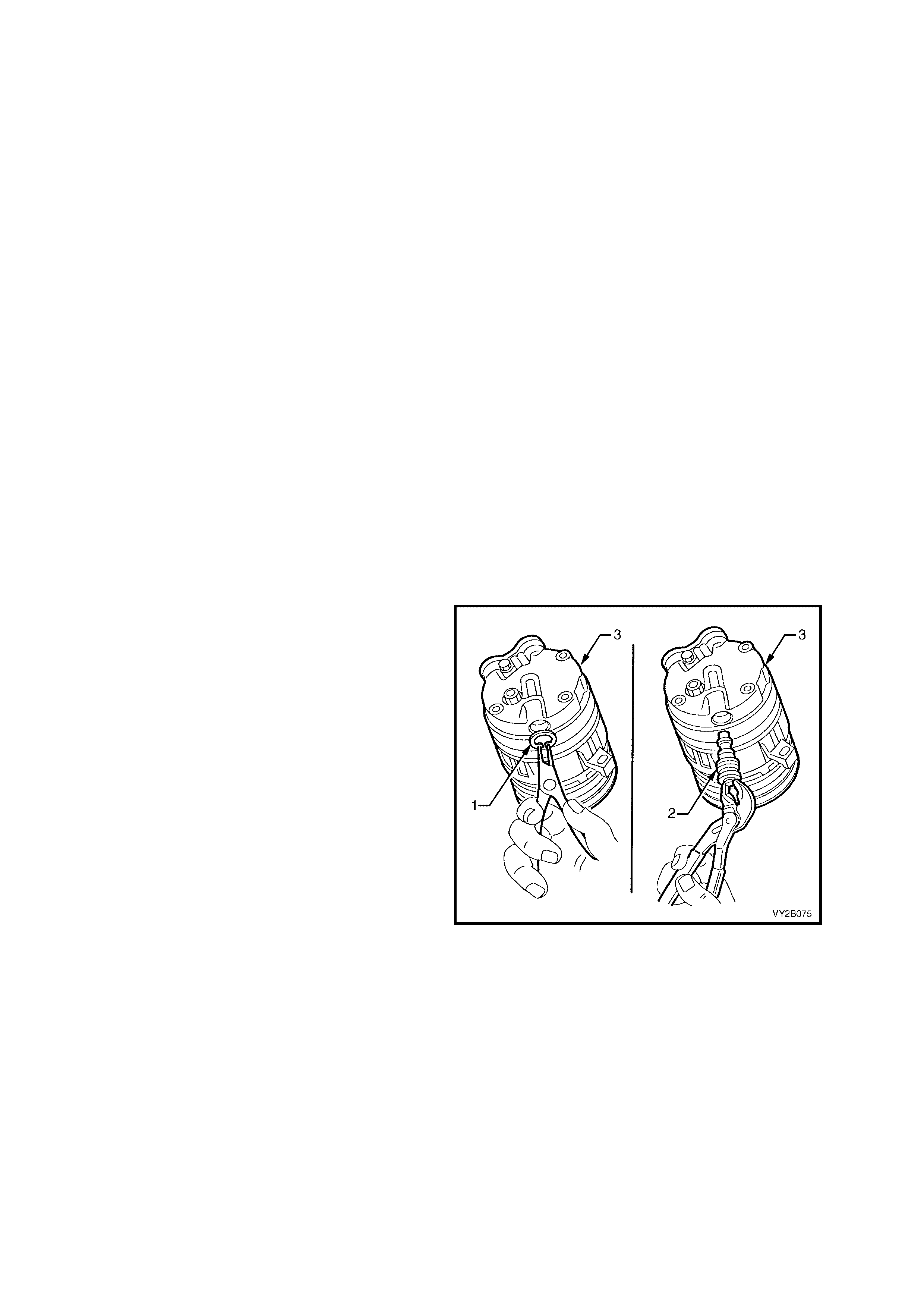

Using needle nose pliers (1), carefully compress

the locking legs (2) of the vacuum switch (3)

together and withdraw the switch from the rear

housing (4) of the controller.

Figure 2B-6

REINSTALL

1. Insert the vacuum switch locking legs (1) through

the rear housing ensuring that the locating

dowels (2) are installed into the two dowel

locators (3) of the rear housing (4).

2. Push the vacuum switch into position ensuring the

lock ing legs lock into position and retain the switch

in the rear housing.

3. Install the controller to the instrument panel. Refer

to 2. MANUAL HVAC CONTROLLER in this

Section.

Figure 2B-7

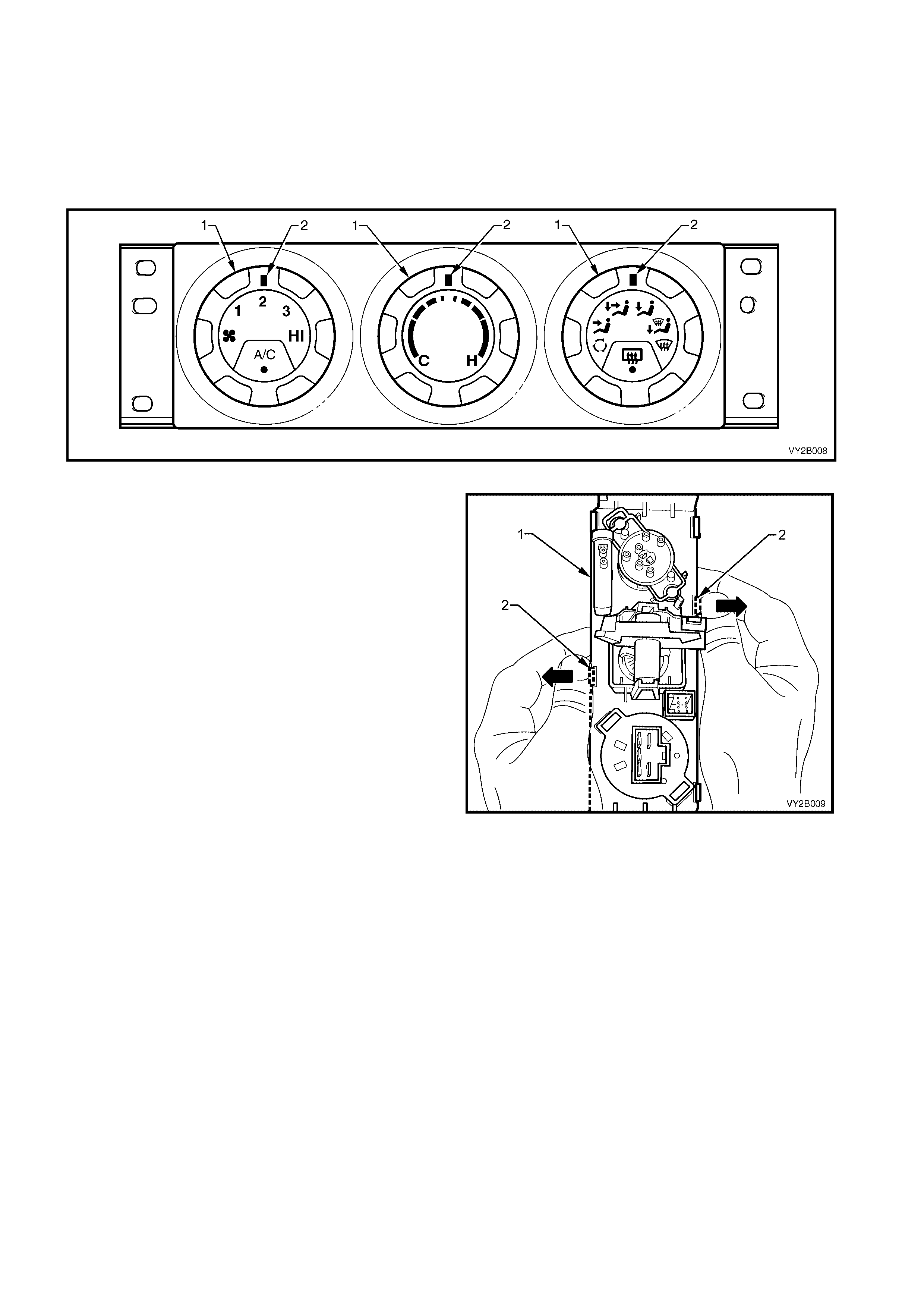

2.2 AIR MIX DOOR ROD RETAINER

LT Section – 08-155A

REMOVE

1. Remove the manual HVAC controller. Refer to 2. MANUA L HVAC CONTROLLER in this Section.

2. Using needle nose pliers (1), carefully compress

the rod retainer ( 2) together and withdraw the rod

retainer from the crescent gear (3) of the

controller.

Figure 2B-8

REINSTALL

1. Insert the rod retainer (1) into the pivot hole ( 2) of

the crescent gear (3) ensuring it locks into

position.

2. Install the controller to the instrument panel.

Refer to 2. MANUAL HVAC CONTROLLER in

this Section.

Figure 2B-9

2.3 FRONT HOUSING/SWITCH ASSEMBLY

AND PRINTED CIRCUIT BOARD

LT Section – 08-155A

REMOVE

1. Remove the manual HVAC controller. Refer to 2. MANUA L HVAC CONTROLLER in this Section.

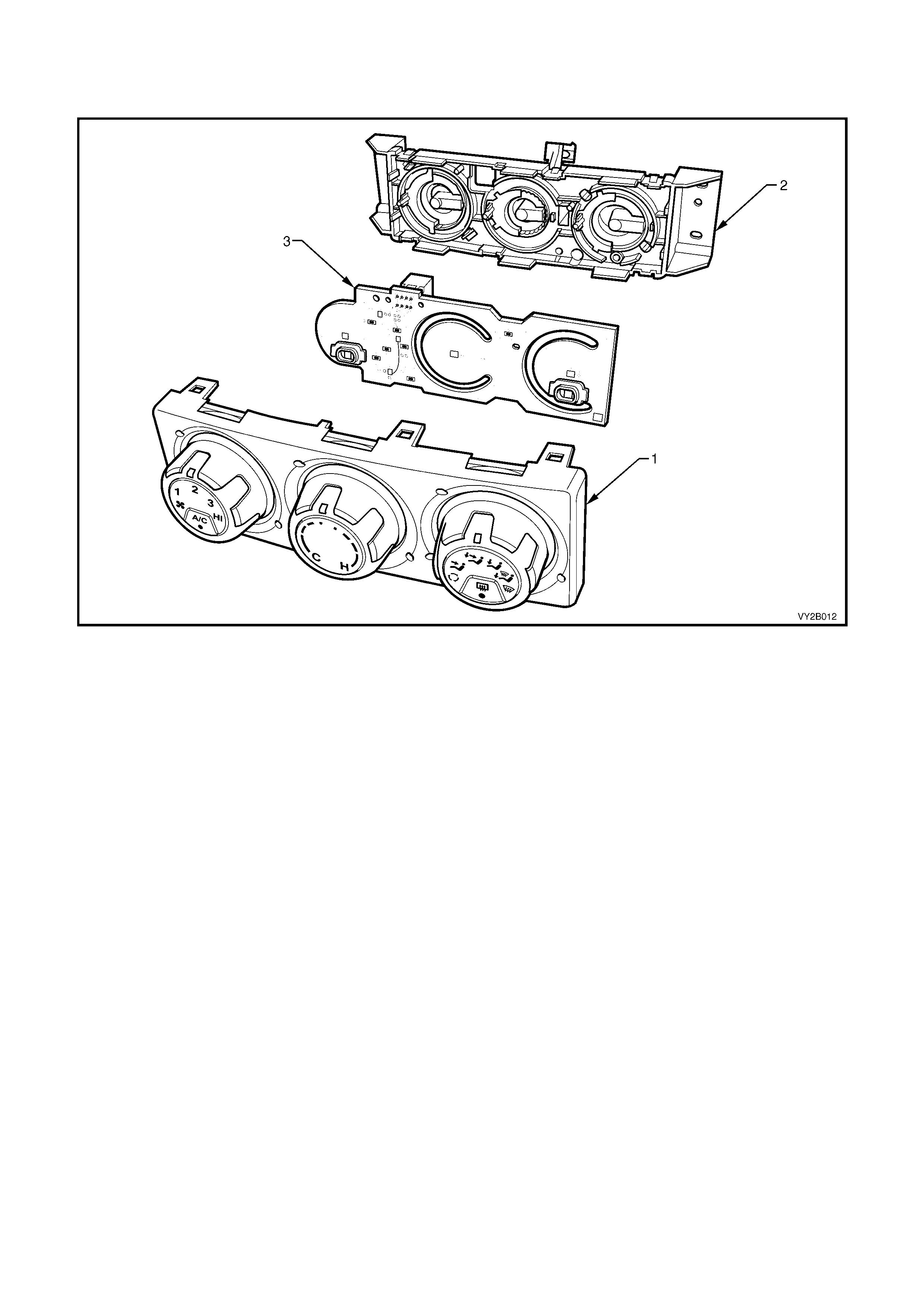

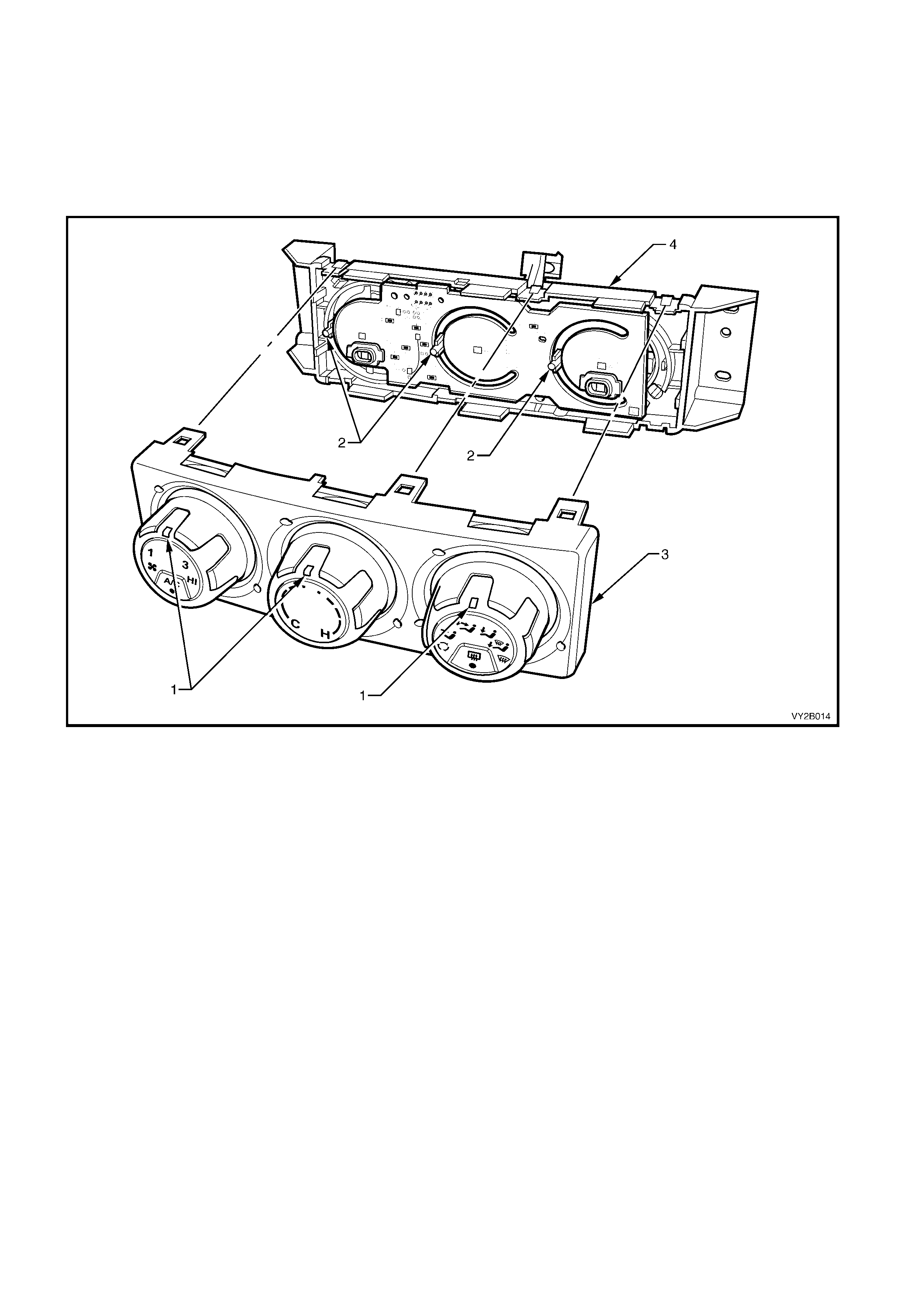

2. Rotate the switches (1) so that all switch position indicators (2) are at the 12 o’clock position.

Figure 2B-10

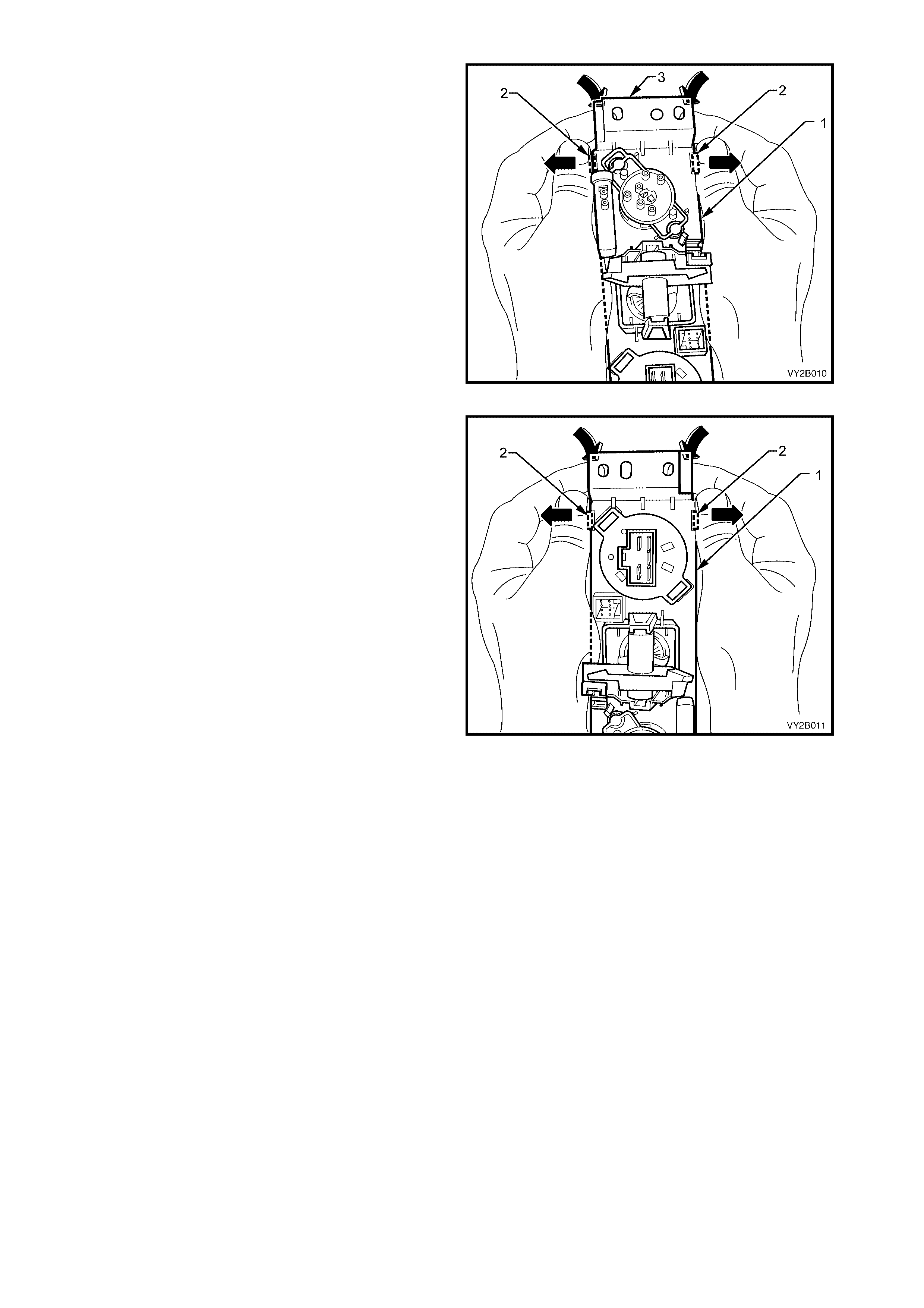

3. Holding the controller (1) as shown in Figure 2B-

11, disengage the middle retaining tangs of the

front housing/switch assembly from the rear

housing by caref ully m oving the retaining tangs (2)

of the front housing outwards with thumb pressure.

Figure 2B-11

4. Holding the controller (1) as shown in Figure 2B-

12, continue to disengage the front housing/switch

assem bly from the rear housing by m oving the end

retaining tangs (2) of the front housing outwards

with thumb pressure while simultaneously

separating the rear housing from the front

housing/switch assembly using index finger

pressure at the mounting flange (3) of the

controller.

Figure 2B-12

5. Rotate the controller (1) through 180° and

disengage retaining tangs (2) at the other end of

the controller by using the same technique as

described in Step 4.

Figure 2B-13

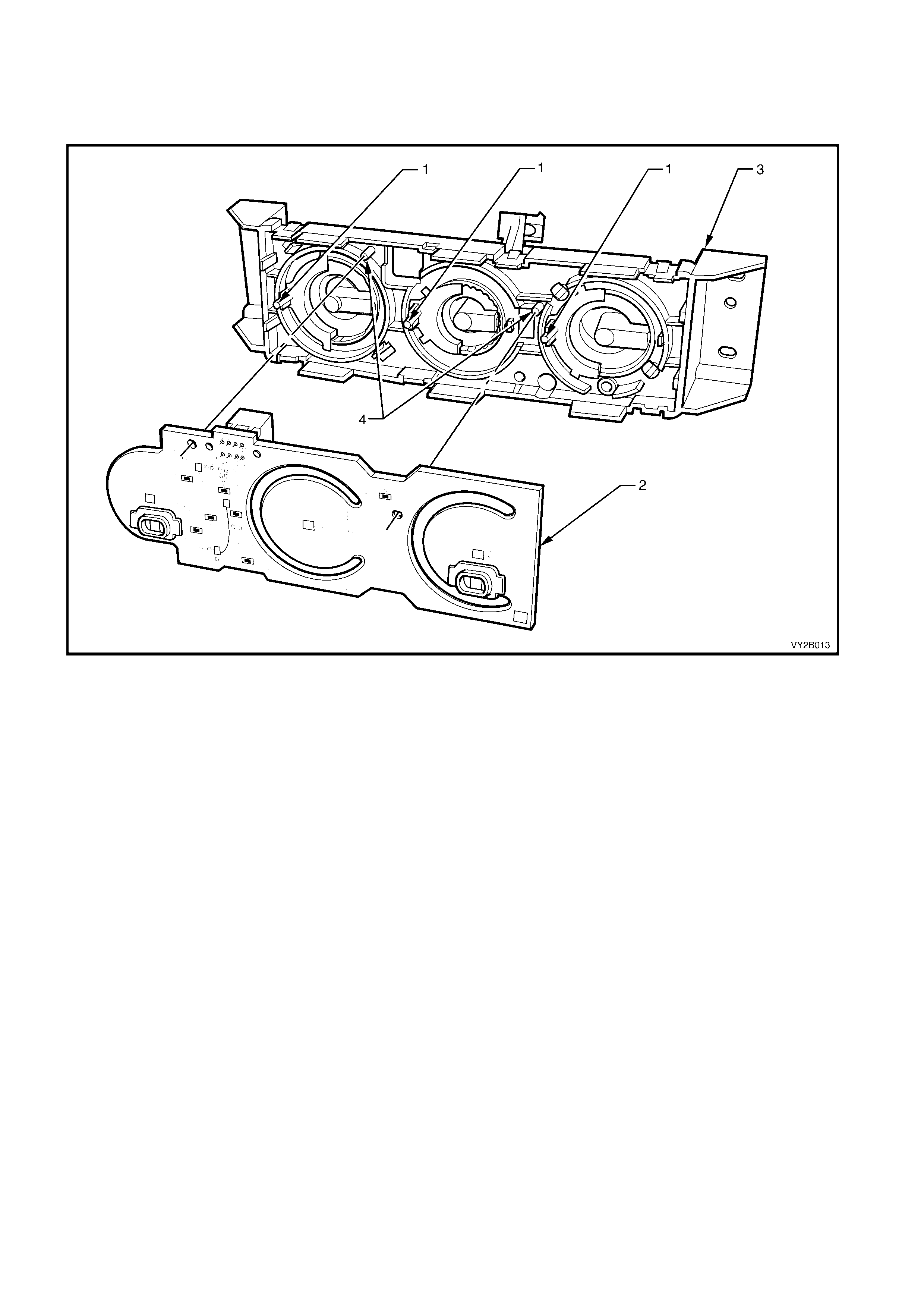

6. Remove the front housing/switch assembly (1) from the rear housing (2).

7. Remove the printed circuit board (3) from the rear housing.

Figure 2B-14

REINSTALL

1. Ensure that the switch shaft pins (1) are located at the 9 o’clock position.

2. Install the printed circuit board (2) to the rear housing (3). Ensure that the circuit board locating pins (4) are

aligned with the corresponding holes of the circuit board prior to installation.

Figure 2B-15

3. Rotate the switches so that all switch position indicators (1) are at the 12 o’clock position. Ensure that all

three of the shaft pins (2) are still located at exactly the 9 o’clock position.

4. Install the front housing/switch assembly (3) to the rear housing (4) ensuring that its six retaining tangs are

fully engaged over the rear housing tang protrusions.

5. Ensure that all the s witches rotate f reely and that the s witc h position indicators align cor rectly with all switch

positions. Ensure that all switches do not rotate past intended rotation limits.

6. Install the controller to the instrument panel. Refer to 2. MA NUAL HVAC CONTROLLER in this Section.

Figure 2B-16

2.4 MODE SWITCH VACUUM VALVE

LT Section – 08-155A

REMOVE

1. Remove the manual HVAC controller. Refer to 2. MANUAL HVAC CONTROLLER in this Section.

2. Remove the front housing/switch assembly and printed circuit from the rear housing. Refer to

2.3 FRONT HOUSING/SWITCH ASSEMBLY AND PRINTED CIRCUIT BOARD in this Section.

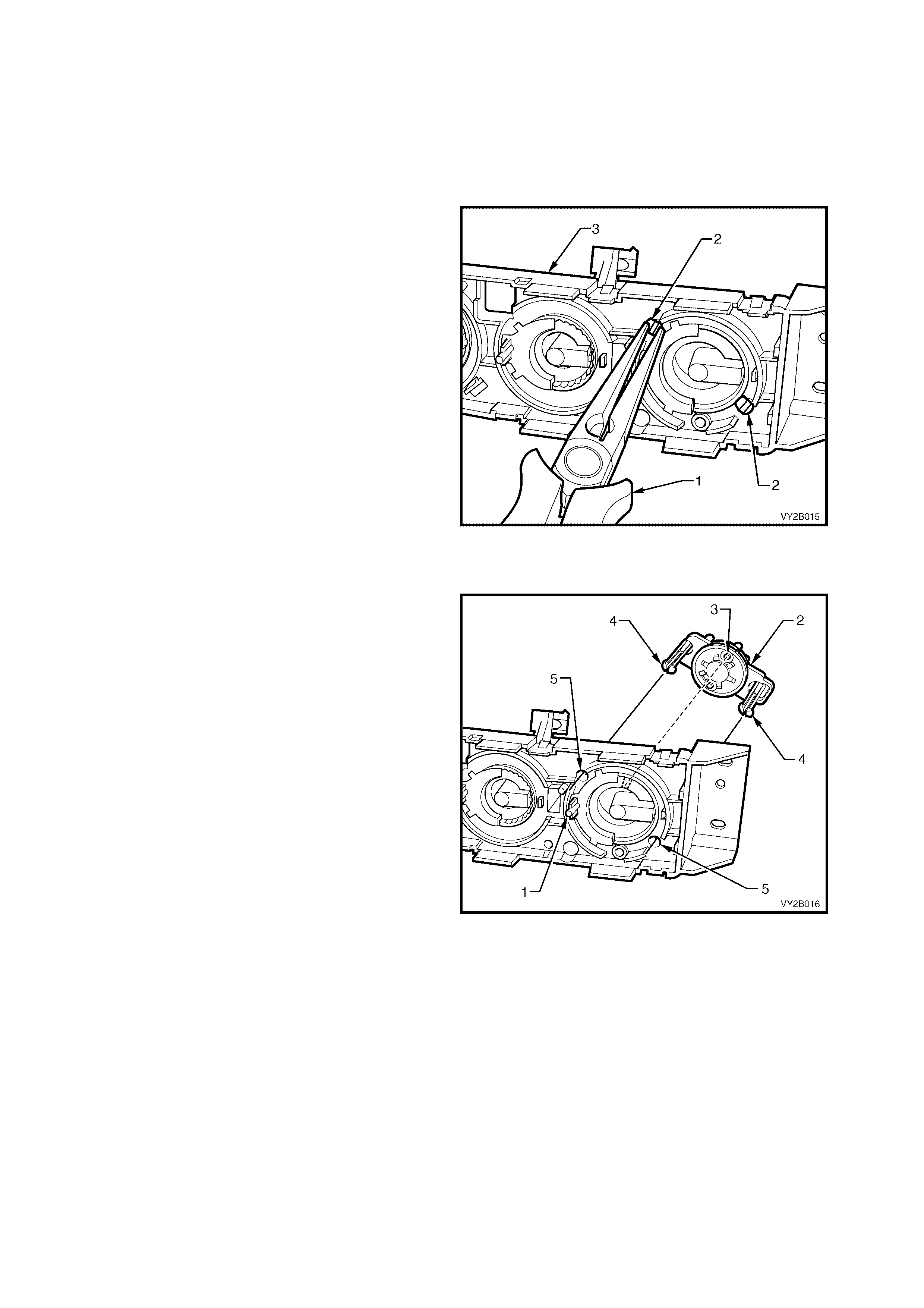

3. Using needle nose pliers (1), carefully compress

both pairs of locking tangs (2) on the mounting

dowels on the mode switch vacuum valve and

withdraw the switch assembly from the rear

housing (3) of the controller.

Figure 2B-17

REINSTALL

1. Ensure that the mode shaft pin (1) is located at

the 9 o’clock position. On the mode switch valve

assembly (2) ensure that the larger drive pin (3)

is positioned at the 12 o’clock position.

2. Align the mounting dowels (4) to the

corresponding holes (5) in the rear housing and

install the switch assembly ensuring that the

locking tangs of the mounting dowels engage

fully into the rear housing

3. Install the front housing/switch assembly and

printed circuit to the rear housing. Refer to

2.3 FRONT HOUSING/SWITCH ASSEMBLY

AND PRINTED CIRCUIT BOARD in this Section.

4. Ensure that all switches rotate freely and that all

the switch position indicators align correctly with

all switch positions. Ensure that all switches do

not rotate past intended rotation limits.

5. Install the controller to the instrument panel.

Refer to 2. MANUAL HVAC CONTROLLER in

this Section.

Figure 2B-18

3. HEATI NG, VENTILATION AND AIR CONDITIONING (HVAC) UNIT

LT Section – 08-150

REMOVE

NOTE: Disconnection of the battery affects certain vehicle electronic systems. Refer to Section 00, 5. BATTERY

DISCONNECTION PROCEDURES prior to disconnecting the battery.

1. Disconnect the battery ground lead. Refer to Section 00, 5. BATTERY DISCONNECTION PROCEDURES.

2. Disable the OPS, SRS system. Refer to Section 12M, 2.2 SYSTEM DISABLING AND ENABLING

PROCEDURE.

3. Discharge the A/C system. Refer to Section 2C, 2. DISCHARGING SYSTEM – REFRIGERANT

RECOVERY.

4. Drain engine coolant into a suitable, clean container. For GEN III V8 engines, refer to Section 6B-3, 2.3

DRAINING AND FILLING COOLING SYSTEM.

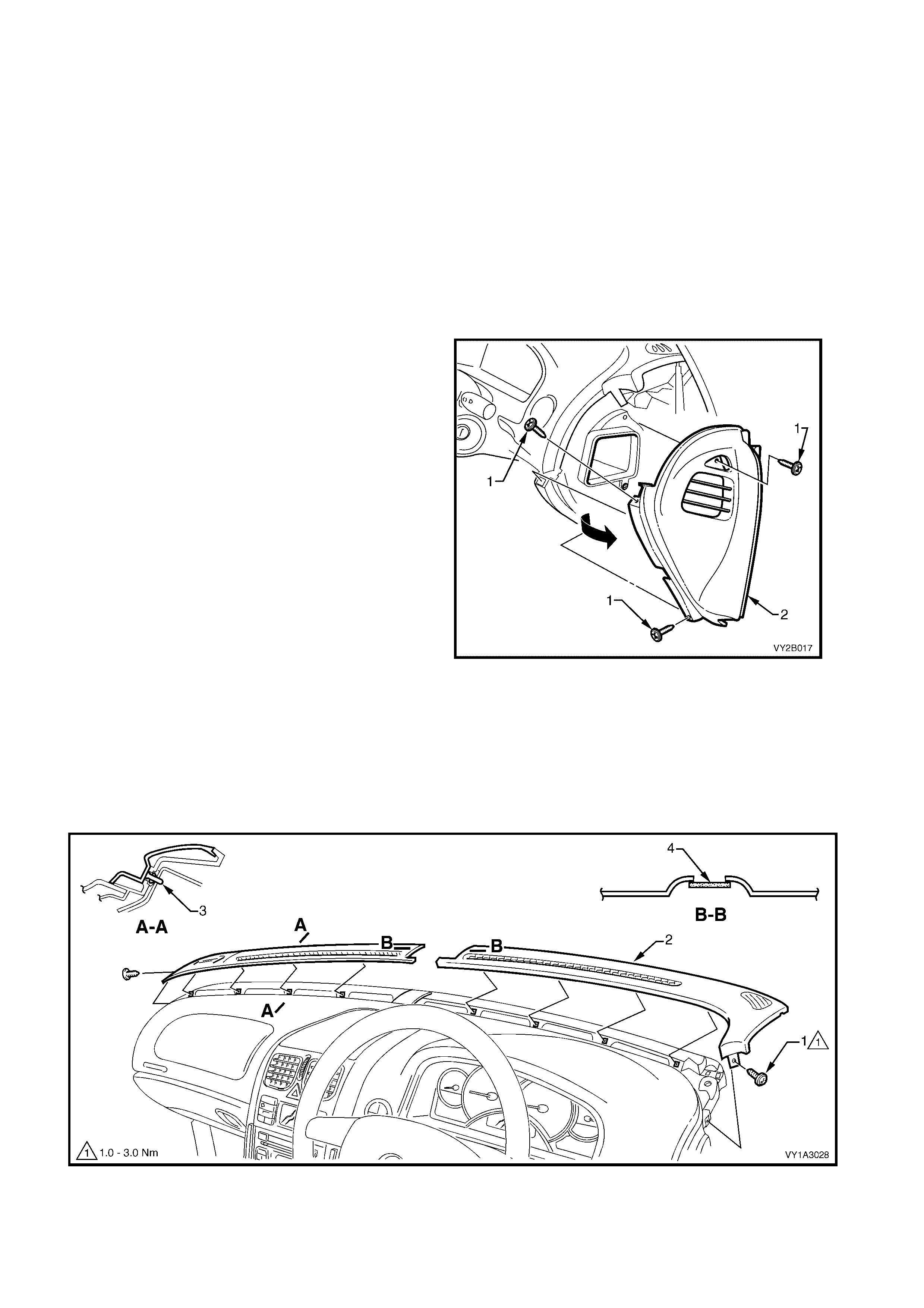

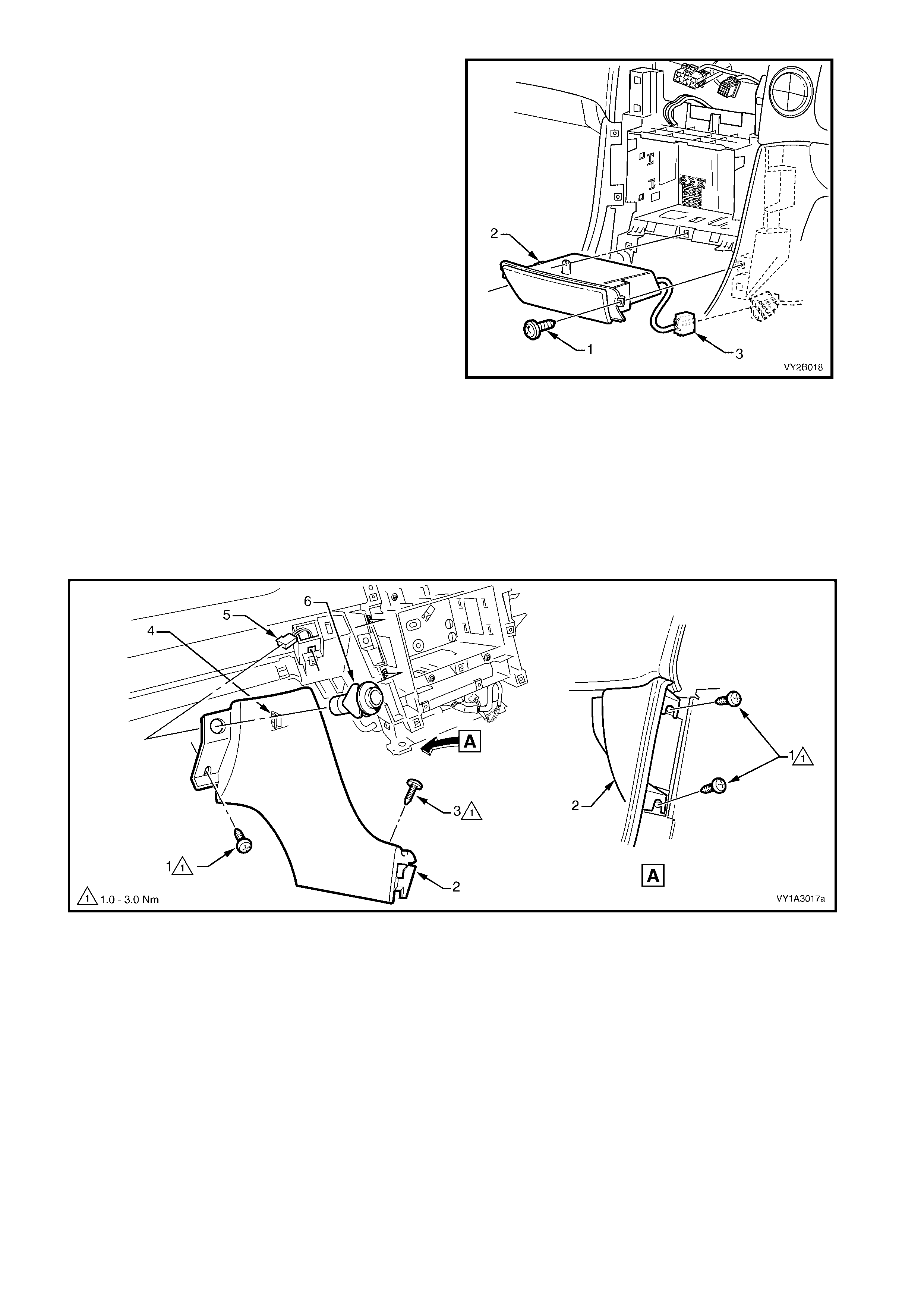

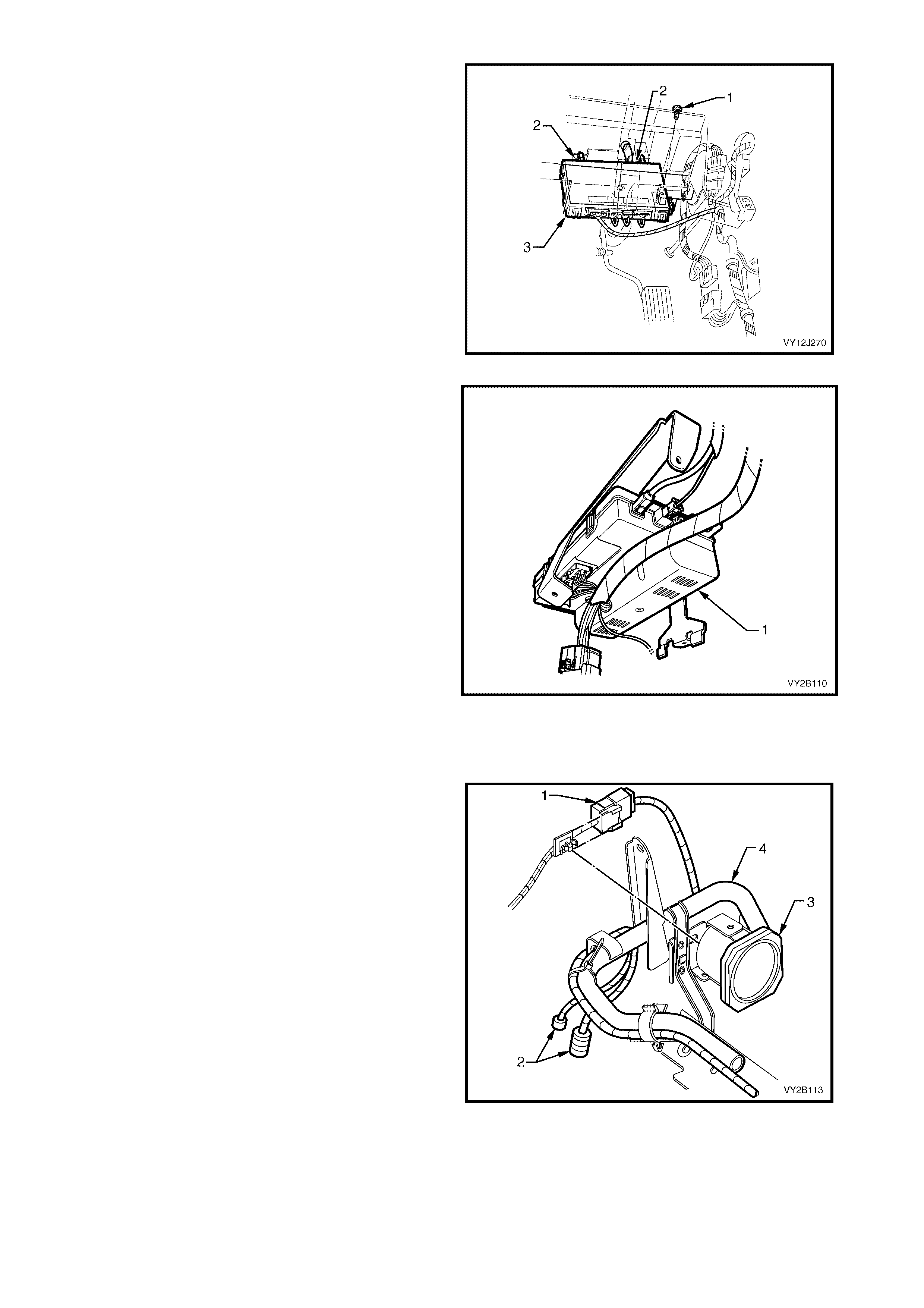

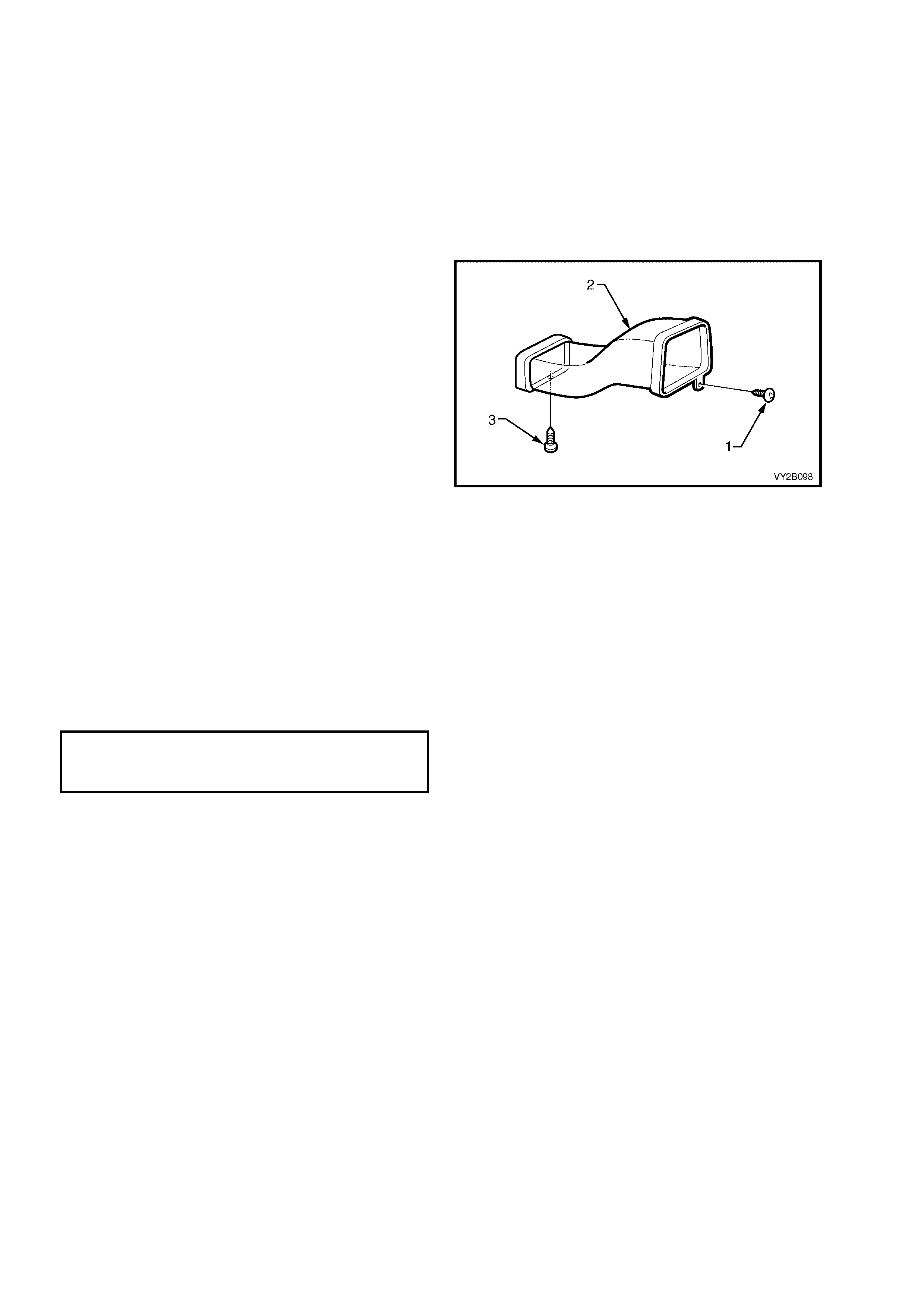

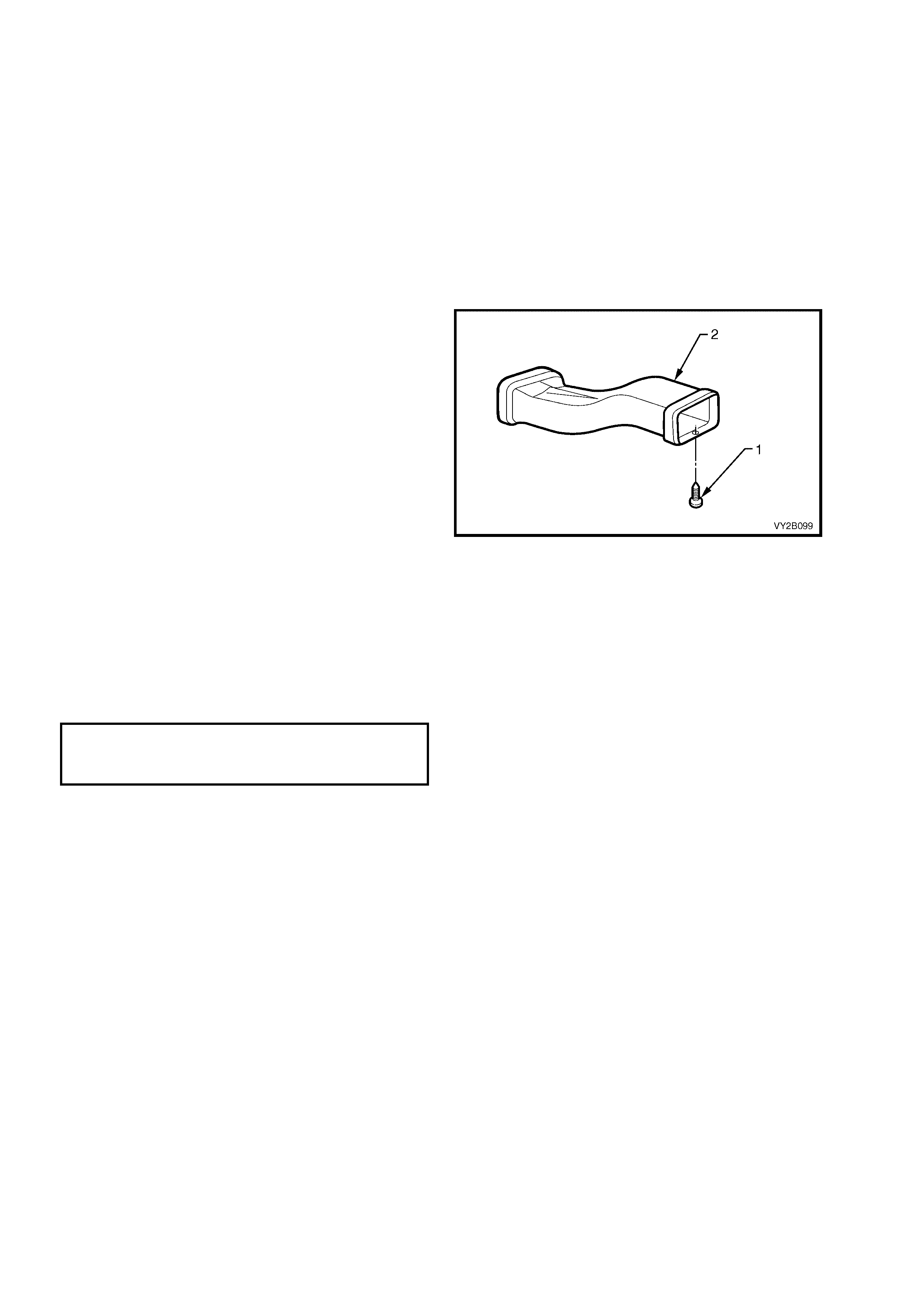

5. Remove the three screws (1) attaching the

right-hand side (shown) and left-hand side

instrument panel outer cover (2) to the

instrument panel.

6. Remove the cover by rotating outward to

disengage the ventilation duct.

Figure 2B-19

Referring to Figure 2B-20:

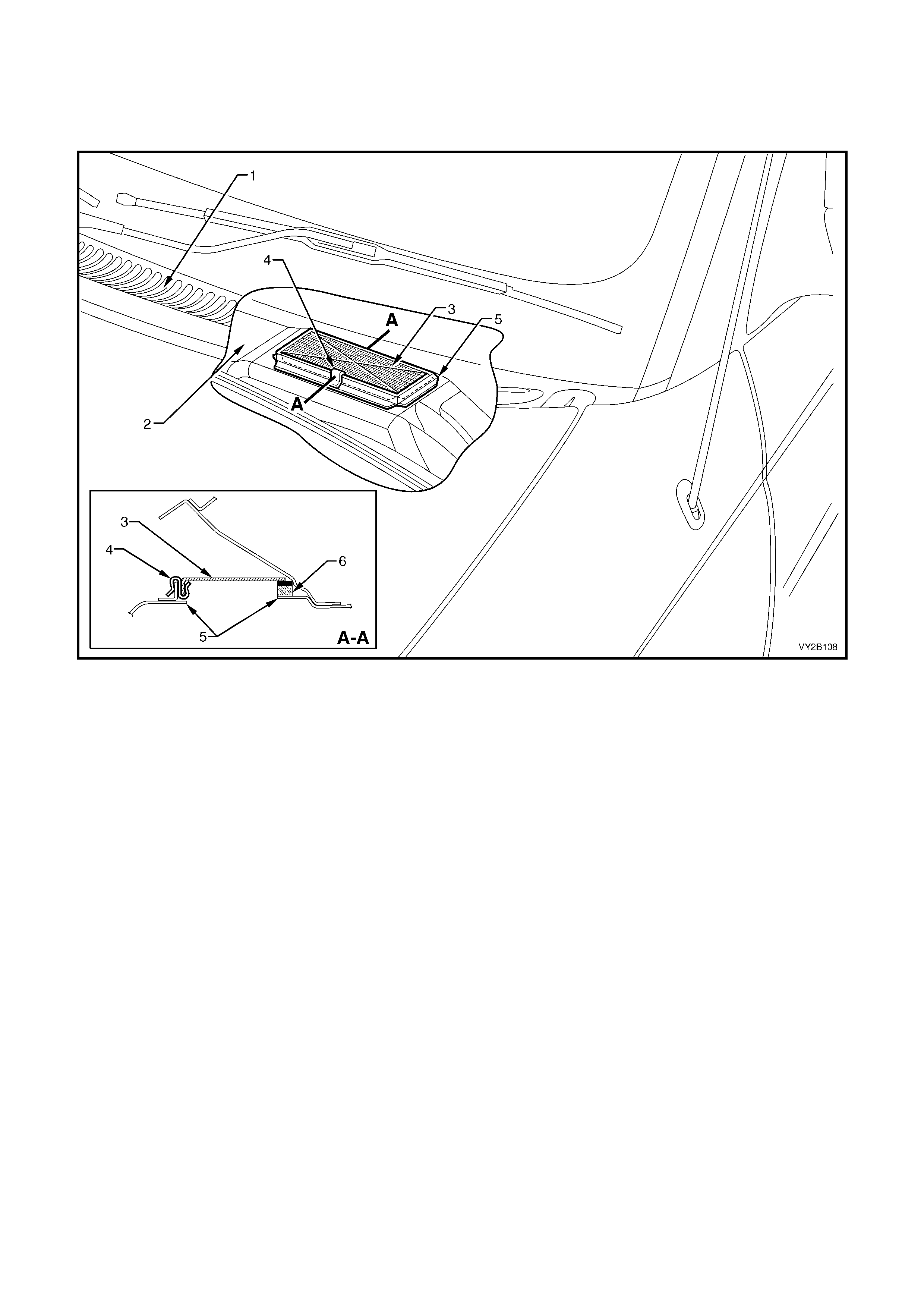

7. Remove the screw (1) attaching each windshield defroster grille (2) to the instrument panel.

8. Carefully remove the grille by unclipping (3), four places, at an angle equal to the windshield.

NOTE: As the grille is retained securely, removal may prove difficult. If required, a hook (such as an Allen key

held with vice- grips) can be used to assist in removal of the grille. Insert the hook at the inner then outer end of

the vent opening. Ensure it is hooked under the grille and not the sheetmetal below. Do not attempt to remove

the grilles by placing any removal tools between the grilles and the sun load sensor (4).

Figure 2B-20

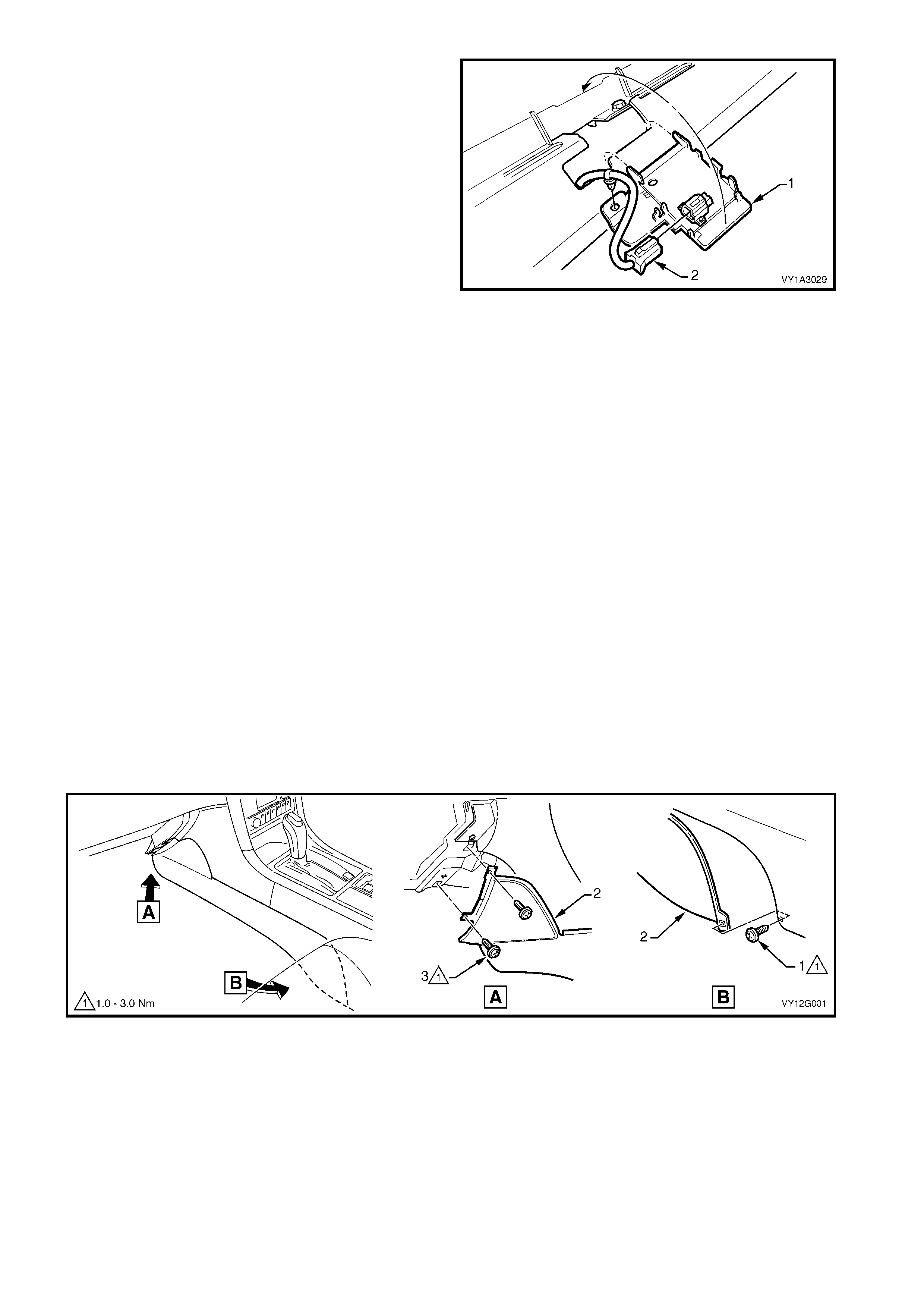

9. Carefully unclip the sun load sensor (1) from the

instrument panel.

10. Disconnect the wiring connector (2), unclip the

wiring harness from the sensor assembly and

remove.

NOTE 1: The sun load sensor also functions as the

remote key receiver and provides data for headlamp

auto control.

NOTE 2: For diagnosis of the remote key receiver

and headlamp auto control functions, refer to

Section 12J, BODY CONTROL MODULE.

NOTE 3: For diagnosis of the sun load sensor

function, refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

Figure 2B-21

11. Referr ing to information in 2. M ANUAL HVAC CONT ROLLER in this Section, rem ove in order, the f ollowing

items:

• Navigation remote control assembly (if fitted)

• Navigation display assembly (if fitted)

• Floor console front compartment liner

• Floor console cover assembly

• Radio assembly

• Instrument panel upper trim assembly

• Instrument panel centre trim assembly

• Manual HVAC controller (for manual A/C systems)

NOTE 1: If the HVAC unit to be removed is an Occupant Climate Control (Auto A/C) type, the OCC

control module will have been removed with the instrument panel centre trim assembly. If required, refer to

Section 2E, 2.1 OCC CONTROL MODULE for additional removal information.

NOTE 2: T he O CC c ontrol m odule does not have to be removed f r om the instr ument panel centr e trim ass embly

for HVAC unit removal purposes.

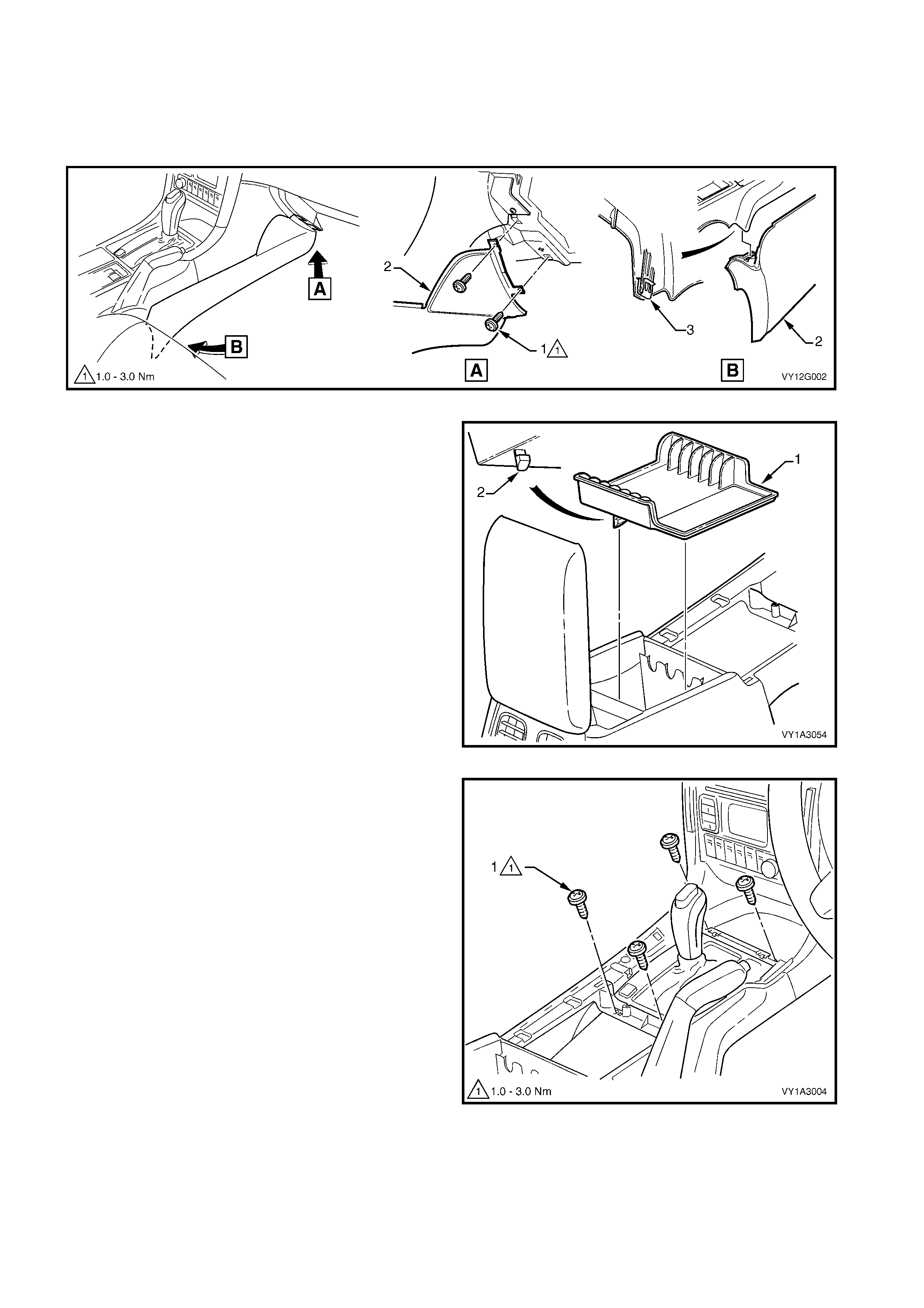

12. Referring to Figure 2B-22 for the left-hand side of the floor console:

a. Remove the screw (1) attaching the instrument panel lower extension side trim (2) to the floor console.

b. Open the instrum ent panel compartm ent (RHD) or instrument panel lower trim panel (LHD) and remove

the two screws (3) attaching the side trim to the instrument panel.

c. Remove the side trim.

Figure 2B-22

13. Referring to Figure 2B-23 for the right-hand side of the floor console:

a. Open the instrum ent panel lower trim panel (RHD) or instrum ent panel compartm ent (LHD) and remove

the two screws (1) attaching the instrument panel lower extension side trim (2) to the instrument panel.

b. Prise the rear of the trim panel downward to disengage it from the floor console retaining clip (3).

c. Remove the side trim.

Figure 2B-23

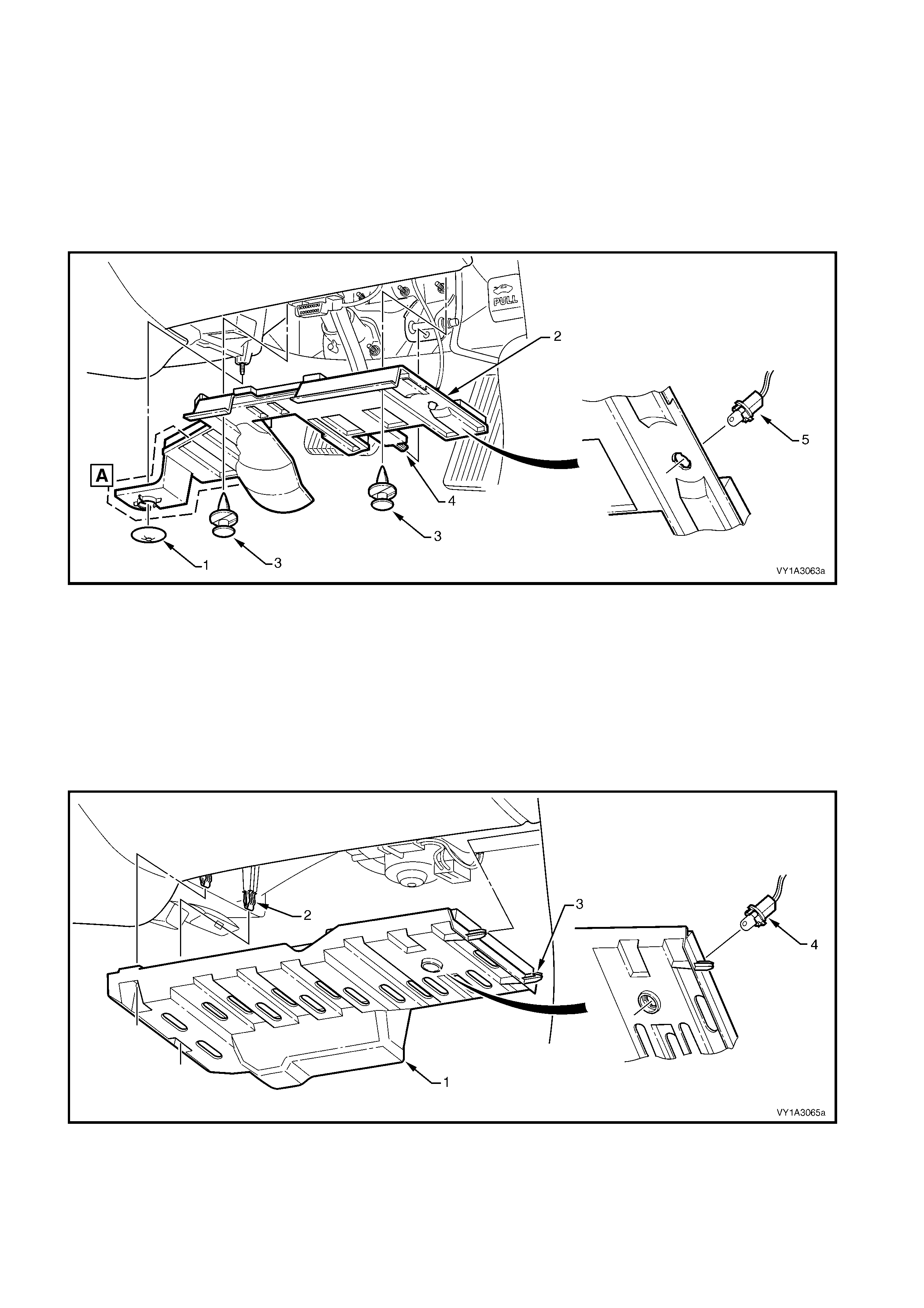

14. Remove the f loor c onsole c ompartment liner (1) by

carefully grasping the liner and disengaging the

two lugs (2).

Figure 2B-24

15. For automatic transmission models, remove the

screw (1), four places , attaching the console to the

automatic transmission selector assembly.

Figure 2B-25

16. For manual transmission models, use a fine flat-

blade screwdriver to disengage the lug (1),

attaching the manual transmission gear lever boot

assembly (2) to the console, two places front and

rear.

17. Remove the boot assembly from the console and

raise it over the gear knob. Remove the console

over the boot assembly when the remaining

fasteners are removed.

IMPORTANT: Do not attem pt to r emove the gear knob

from the gear lever shaft as it is glued in place. The

gear knob, boot assembly and lever shaft can be

removed from the transmission if required, refer to

Section 7B, MANUAL TRANSMISSION.

Figure 2B-26

18. Disconnect the console wiring connector (1) from

the front of the console storage bin.

Figure 2B-27

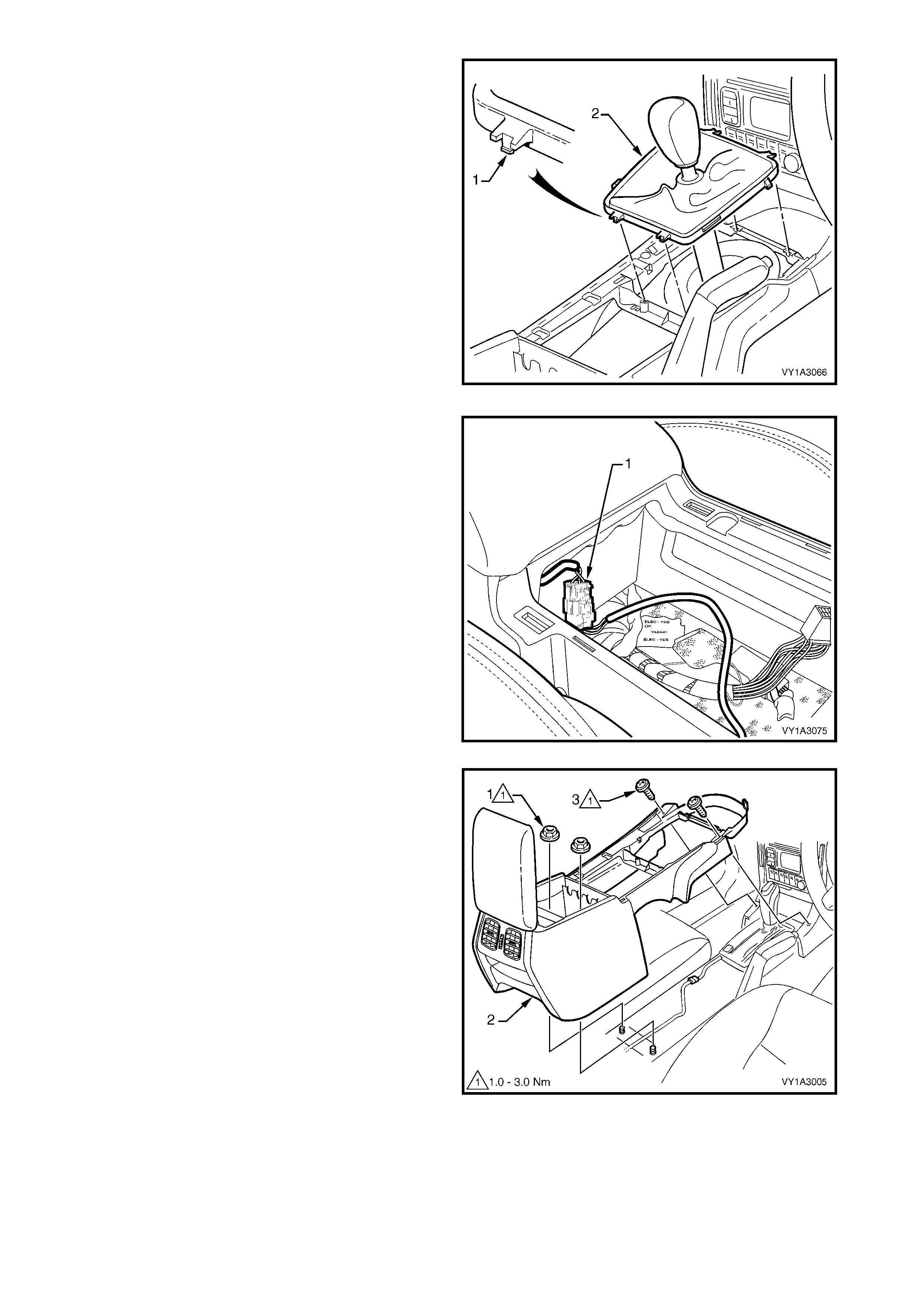

19. Remove the two nuts (1) attaching the floor

console (2) to the vehicle floor.

20. Remove the two screws (3) attaching the front of

the console to the instrument panel assembly.

21. As required disconnect any console wiring

connectors.

22. Lift the rear of the console upward and remove.

NOTE: The console rear air duct will disconnect from

the console front air duct during removal. The rear air

duct will remain with the console.

Figure 2B-28

NOTE: Where fitted, an instrument panel ashtray

assembly replaces the instrument panel lower

compartment. Removal of both components is the

same.

23. Remove the screw (1), three places, attaching the

instrument panel lower compartment assembly or

ashtray assembly (2) to the instrument panel.

24. Slide the compartment or ashtray assembly

outward to remove.

NOTE: If an ashtray assembly is fitted, disconnect the

wiring connector (3).

Figure 2B-29

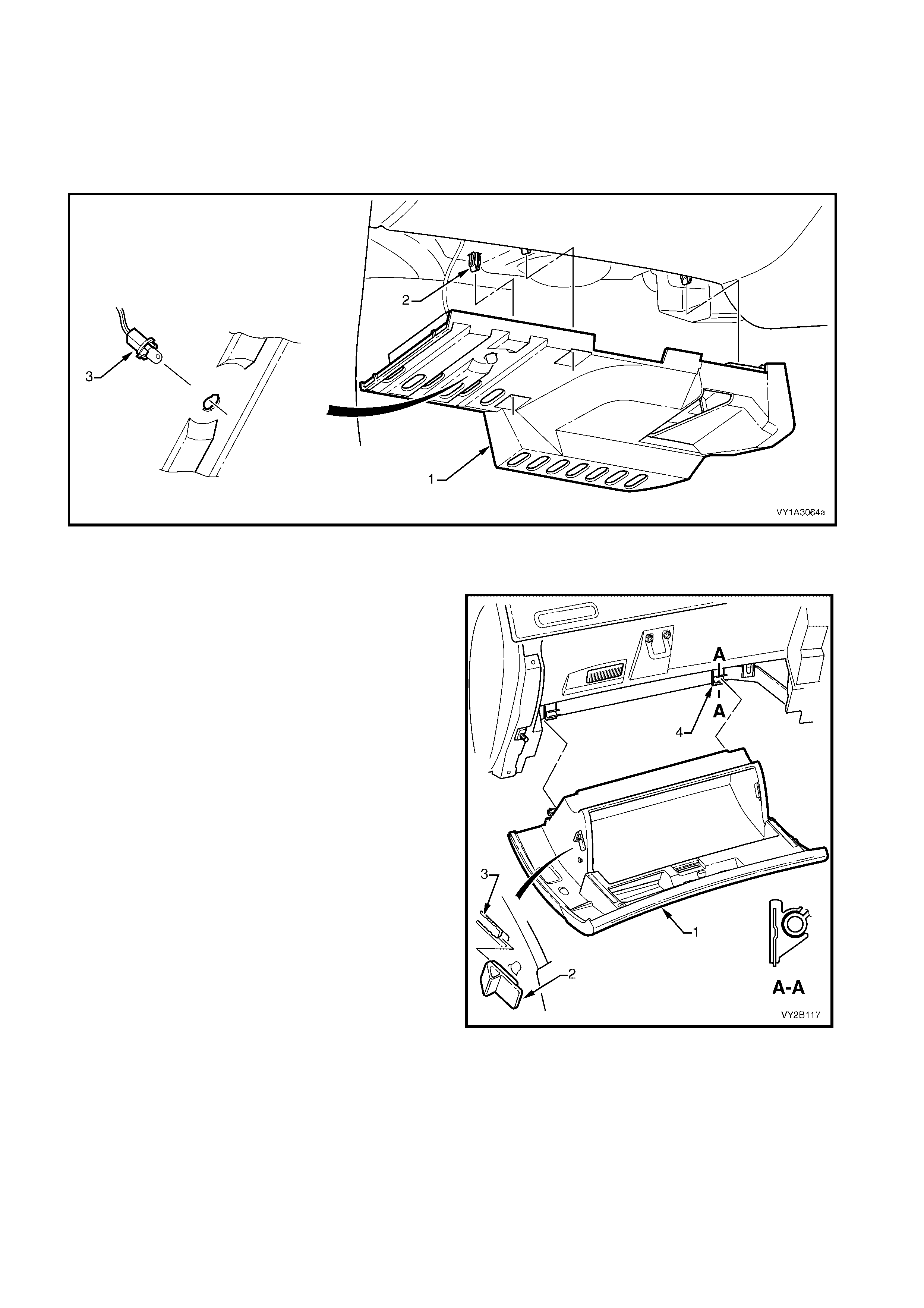

Referring to Figure 2B-30:

25. Remove the two screws (1) attaching the instrument panel lower extension (2) to the instrument panel.

26. For the left-hand side, remove the screw (3) attaching the floor console front duct.

27. Grasp the top of the extension and pull rearwards to release the clip (4).

28. Rem ove the floor console front duct from the HVAC unit. Refer to item 6 in Figure 2B-55 for left-hand drive

models or Figure 2B-56 for right-hand models.

29. If f itted, disconnect the wiring connec tor (5) f rom the r ear com par tm ent lid release switch (6) and rem ove the

panel.

Figure 2B-30

Referring to Figure 2B-31:

30. Remove the screw (1) from the rear face of the radio housing (2) attaching the housing to the instrument

panel.

31. Remove the screw (3), two places, attaching the front edge of the radio housing.

32. Lift the retaining tab (4), two places in the top of the housing and one place at the bottom.

33. Withdr aw the hous ing from the br ack et ass em bly far enough to allow access to the r adio and antenna wiring

connectors.

NOTE: If ther e is not s uff icient length in the radio harness , either unclip the c onnector f rom within the housing or

remove the passenger side instrument panel lower extension side trim and unclip the harness from the vehicle

floor.

34. From the rear of the housing, unclip the radio wiring connector (5), if not previously done, the antenna

connector (6) and if fitted, the diversity antenna connector (7) from the housing.

35. Disconnect the antenna lead(s) and remove the housing.

Figure 2B-31

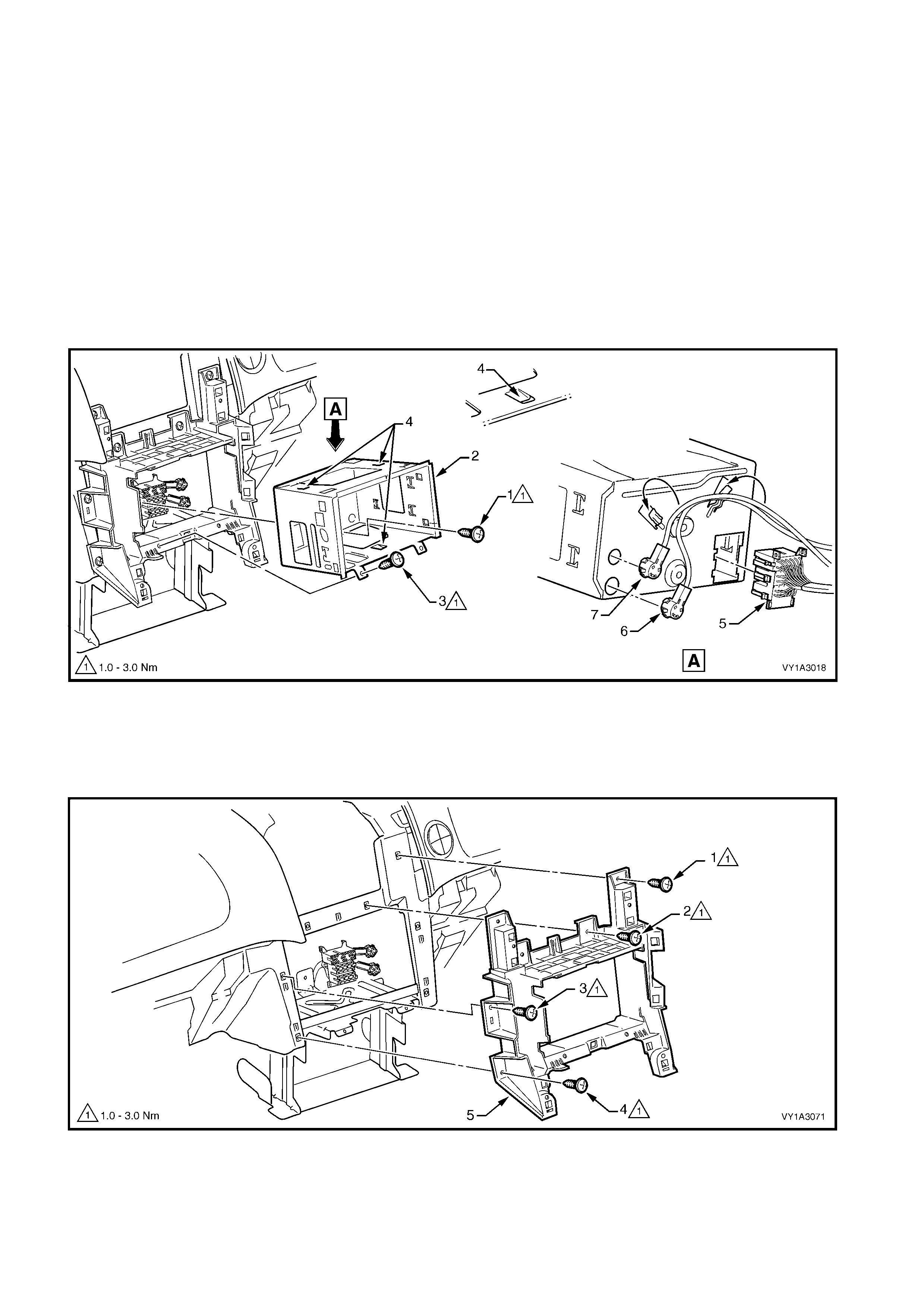

Referring to Figure 2B-32:

36. Remove the screws (1, 2, 3 and 4), two places each side, attaching the radio bracket assembly (5) to the

instrument panel.

37. Remove the bracket assembly from its locating tabs.

Figure 2B-32

38. For automatic transmission models, remove the retainer (1) attaching the driver’s side instrument panel

lower trim plate assembly (2) to the HVAC unit, refer to Figure 2B-33.

NOTE: The area shown A is removed for manual transmission models.

39. Prise the insert and remove the retainer (3), two places, attaching the plate assembly to the instrument

panel.

40. Lower the plate assembly slightly and withdraw the lug (4) from the pedal bracket.

41. If fitted, remove the stepwell lamp (5) by rotating the socket and removing from the plate assembly.

42. Remove the driver’s side plate assembly.

Figure 2B-33

Left-Hand Drive Vehic les

43. Grasp the inner end of the passenger side instrum ent panel lower trim plate assembly (1) and carefully pull

downwards to disengage the retaining clip (2), two places, refer to Figure 2B-34.

44. Withdraw the plate assembly from the hinge pillar trim panel, disengaging the lug (3), two places.

NOTE: The rear lug has a hook that engages the hinge pillar trim panel.

45. Lower the passenger side plate assem bly slightly and, if f itted remove the stepwell lamp (4), by rotating the

socket and removing from the plate assembly.

46. Remove the passenger side plate assembly.

Figure 2B-34

Right-Hand Drive Vehicles

47. Grasp the passenger side instrument panel lower trim plate assembly (1).

48. Carefully pull downw ard to disengage the retaining clip (2), three places, refer to Figure 2B-35.

49. Lower the plate assembly slightly and, if fitted remove the stepwell lamp (3), by rotating the socket and

removing from the plate assembly.

50. Remove the passenger side plate assembly.

Figure 2B-35

All Vehicles

51. O pen the instrument panel c om partm ent assem bly

(1).

52. Using a fine flat-blade screwdriver, flatten the

instrument panel compartment bumper stop (2)

each side, and carefully open the compartment

assembly fully.

53. From the inside of the compartment assembly,

push outwards on the bumper stop (2), and slide

the bumper from the lug (3). Repeat for the

opposite side.

54. Close the compartment assembly a third of the

way and grasping each side pull rearward to

disengage the compartment assembly from each

instrument panel compartment hinge (4).

IMPORTANT: T ake c are when disengaging the hinges

as removing the com partment assem bly on the wrong

angle may cause damage.

Figure 2B-36

55. From either side of the instrument panel

compartment lamp switch (1), carefully insert a

fine flat blade screwdriver and prise the switch

from the instrument panel.

56. Disconnect the wiring harness connectors and

remove the switch.

57. From the right-hand side of the instrument panel

compartment lamp (2), carefully insert a fine flat

blade screwdriver.

58. Pr ise the lam p fr om the instrum ent panel and s lide

it out of its cavity.

59. Disconnect the wiring harness connectors.

60. Remove the lamp ensuring that the globe (3) is not

dislodged or damaged during the removal

procedure.

Figure 2B-37

61. Grasp the upper edge of the instrument panel

lower trim panel assem bly ( 1) and pull outward s to

disengage the three retaining clips (2).

62. Swing the panel assembly open.

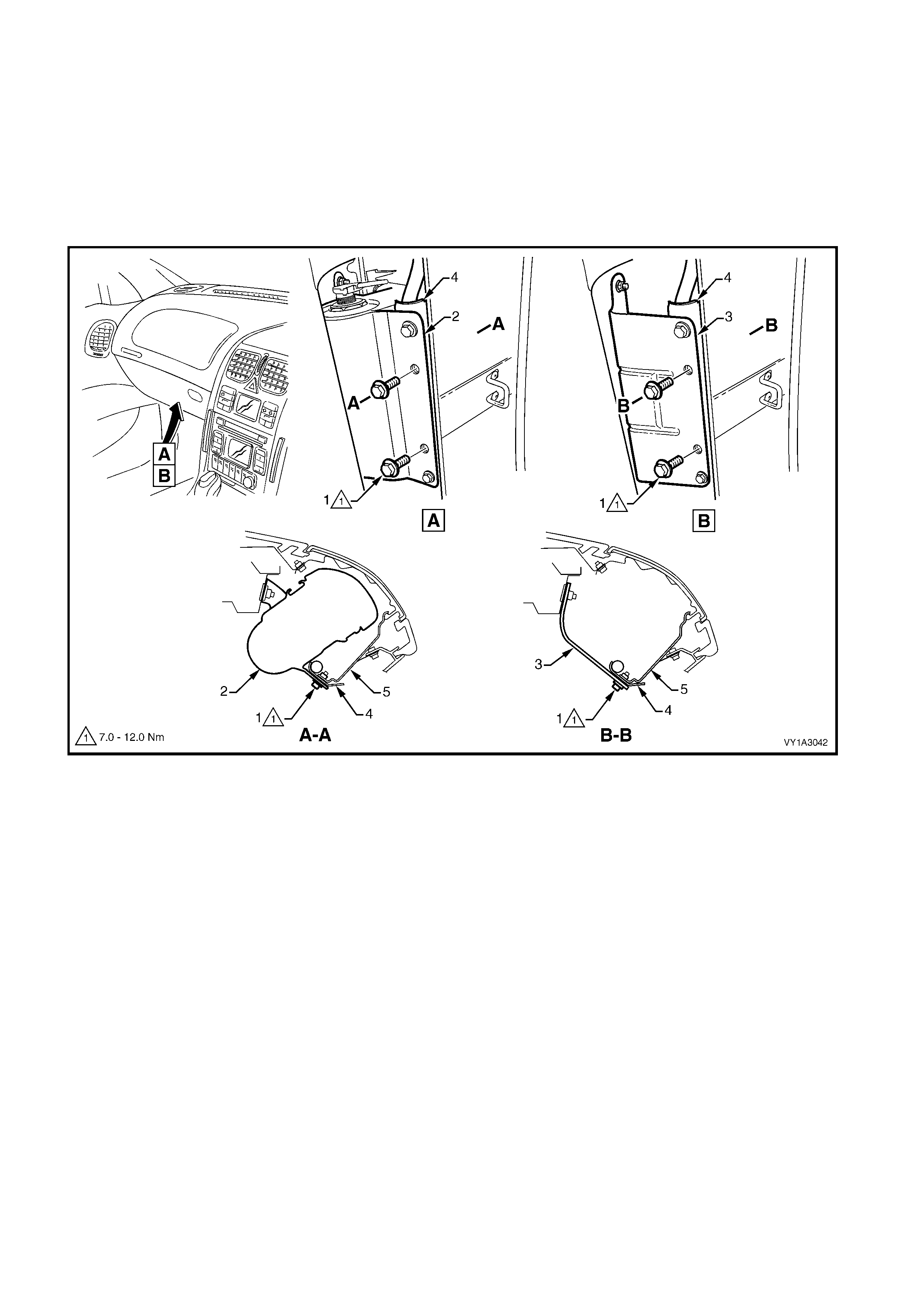

63. Holding each side of the panel assembly, pull

rearwards to disengage it from the instrument

panel lower trim panel retainer (3), two places.

Figure 2B-38

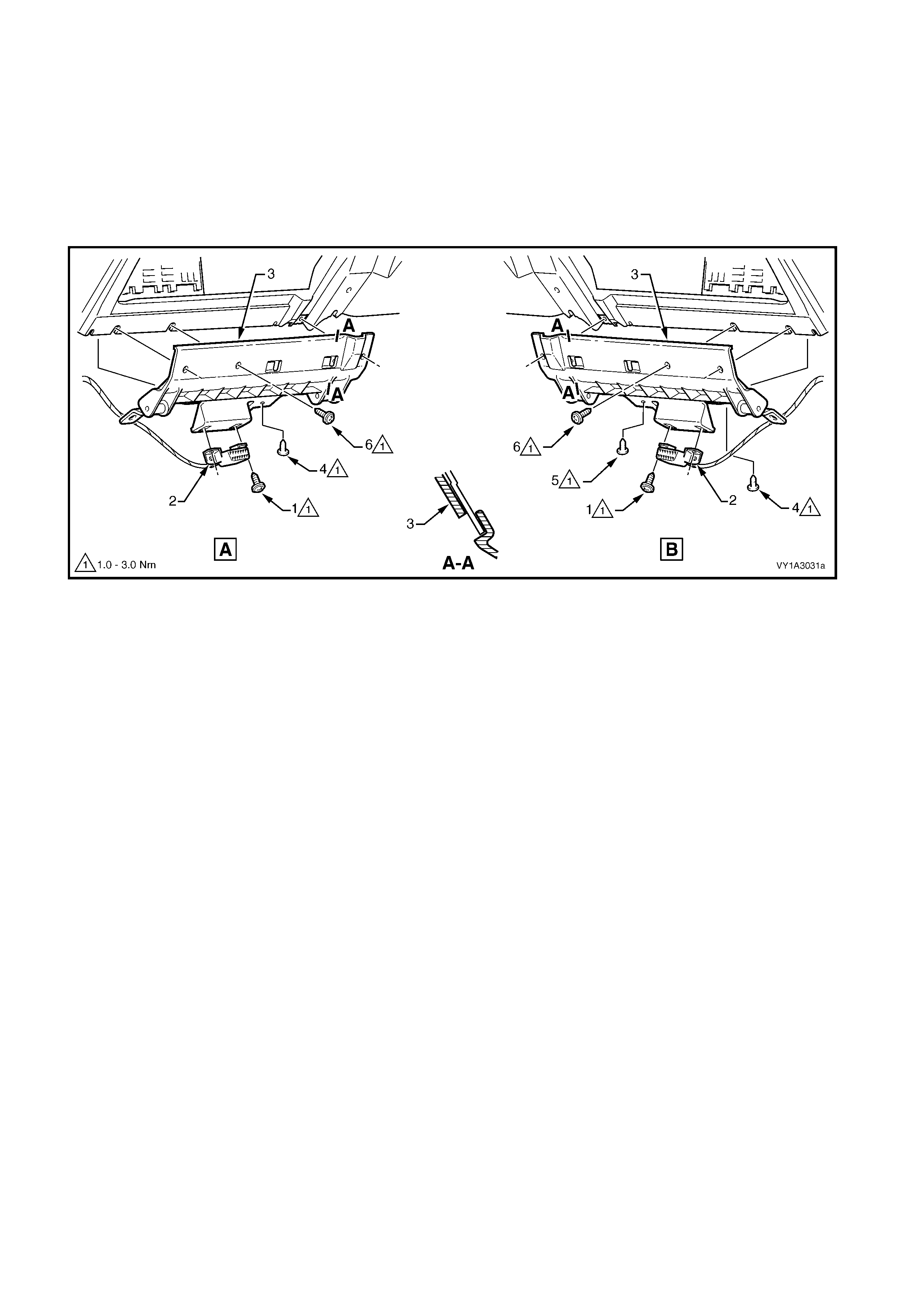

64. Remove the screw (1), two places, attaching the data link connector (2) to the instrument panel lower trim

panel retainer (3), refer to Figure 2B-39, A – left-hand drive or B – right-hand drive.

65. For left-hand drive vehicles, remove the screw (4) attaching the retainer to the driver’s side inner air duct.

66. For r ight-hand drive vehicles, r emove the sc rew (4) attaching the retainer to the driver’s s ide inner and outer

air duct joint.

67. Remove the screw (5), attaching the driver’s side inner duct to the retainer.

68. Remove the screw (6), three places, attaching the retainer to the instrument panel.

69. Slide the retainer downward to disengage the two lugs from the instrument panel assembly as shown at

Section A-A and remove the retainer.

Figure 2B-39

70. Remove the screw (1) attaching the driver’s side outer duct (2) to the instrument panel.

NOTE: The lower retaining screw (3) and (4) are removed during removal of the instrument panel lower trim

panel retainer at Step 65 or Step 66. On left-hand drive models this screw retains only the inner duct (4) to the

instrum ent panel. On right-hand drive models, this screw retains both the inner and outer duct to the instrum ent

panel. For left-hand drive models refer to item 5 in Figure 2B-55. For right-hand drive m odels refer to item 5 in

Figure 2B-56.

71. Raise the steering column to its highest adjustment position.

72. Separate the dr iver’s side outer duc t and the driver’s side inner duct by partially withdrawing the driver’s side

outer duct through the end cavity of the instrument panel.

73. Remove the driver’s side inner duct through the instrument panel lower trim plate assembly cavity.

74. Remove the driver’s side outer duct through the instrument panel lower trim plate assembly cavity.

75. Remove the screw (6) attaching the passenger side duct (7) to the instrument panel.

NOTE 1: The floor console front duct retaining screw (8) is removed at Step 25 and duct (9), at Step 28.

NOTE 2: The floor console rear duct (10), is removed with the floor console at Step 22.

Figure 2B-40

76. Release the steering column adjustment lever (1)

and move the column to its lowest position.

77. From below the steering column, remove the

screw (2) attaching the lower cover (3).

NOTE: The covers can be removed with the steering

wheel installed; however, it is not shown for clarity.

78. Depress the face of the lower cover inwards to

disengage the tabs (4) and lift the steering column

upper cover (5).

79. Raise the upper cover as high as possible to

disengage the lugs (6) and remove the cover.

80. Slide the lower cover rearward to disengage it from

the lugs (7) and remove the cover.

81. Remove the steering wheel inflatable restraint

module, refer to Section 12M, OCCUPANT

PROTECTION SYSTEM.

NOTE: Special Tool required.

Figure 2B-41

82. Place the road wheels in the straight-ahead

position and lock the steering column.

83. Remove the screw (1).

84. Remove the steering wheel, disconnecting and

feeding the wires through the aperture as required.

NOTE: A puller should not be required, however if the

wheel assembly cannot be removed fairly easily, use

puller J1859-A and legs E1408.

85. Check that the green indicator (2) on the inflatable

restraint module coil assembly has engaged the

inner clock spring to lock it in the central position.

Figure 2B-42

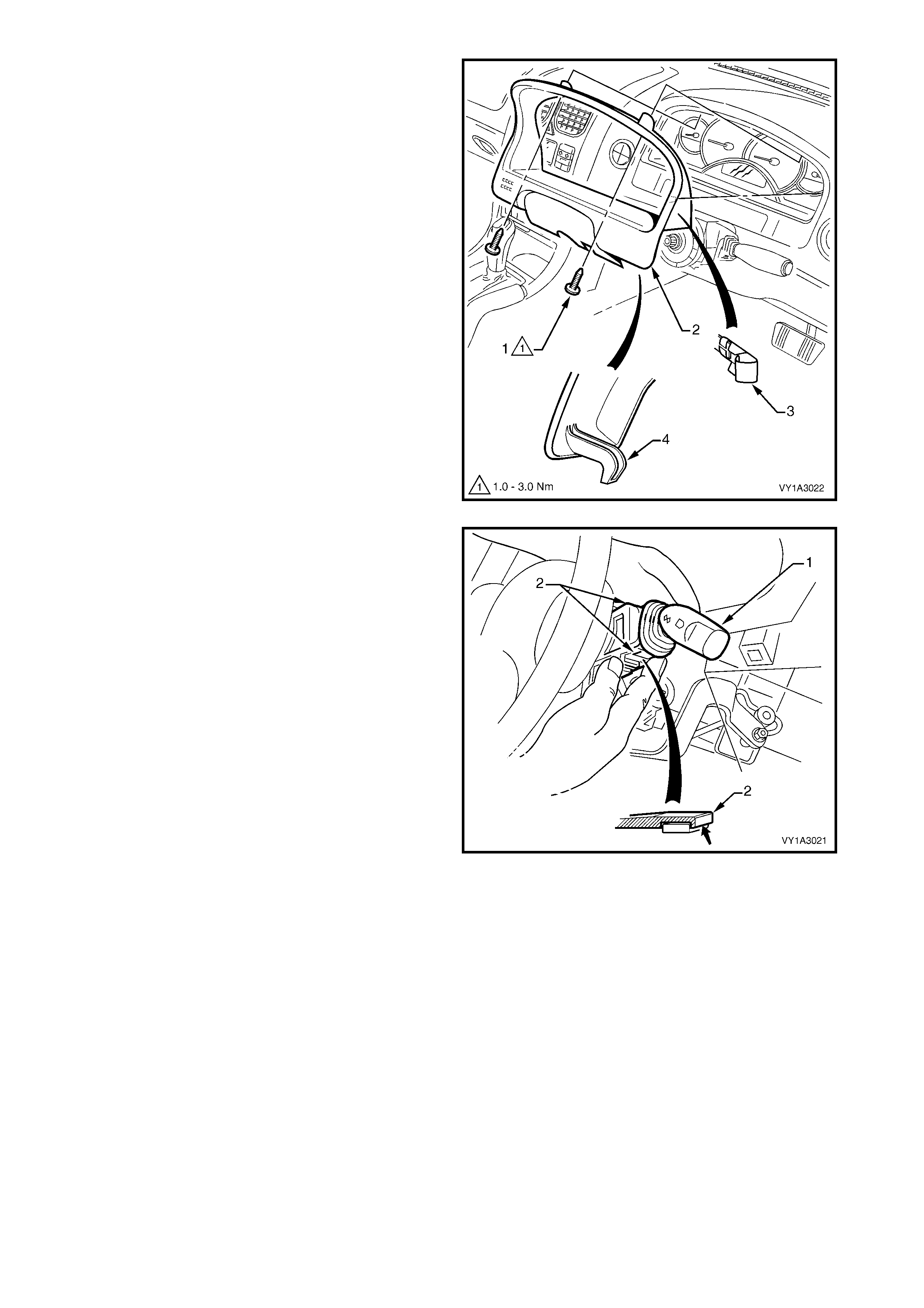

86. Remove the two screws (1) attaching the

instrument cluster trim assembly (2) to the

instrument panel.

87. Depress the top of the trim assembly slightly and

tilt the top of the trim assembly out of the

instrument panel pad, disengaging the retaining

clips (3) each side.

88. Unhook each lug (4) from the instrument panel

pad.

89. For left-hand drive models, disconnect the fuel

tank filler door lock release switch wiring

connector.

90. Remove the trim assembly.

Figure 2B-43

91. Disconnect the wiring connectors from the rear of

the turn signal switch assembly (1) and windshield

wiper and washer switch assembly.

92. Depress the two tabs (2) securing the switch and

slide from the steering column assembly. Repeat

for the other switch.

Figure 2B-44

93. Remove the four screws (1) attaching the

instrument cluster (2) to the instrument panel.

94. Roll the top of the cluster from its cavity.

95. Using a f ine flat blade scr ewdriver, open the wiring

connector locking tab (3) on the back of the

cluster.

96. Remove the cluster assembly.

Figure 2B-45

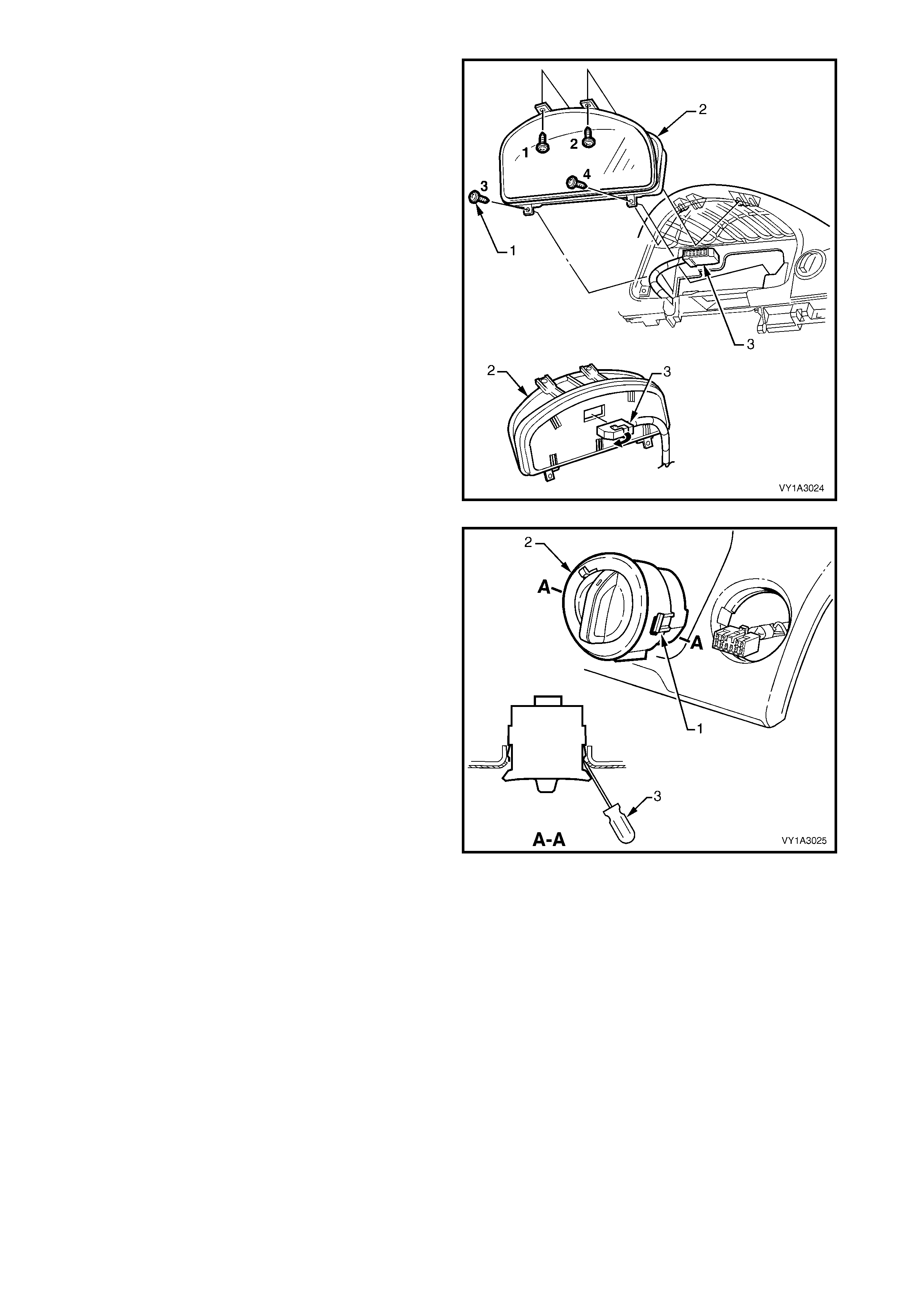

IMPORTANT: Care m ust be exercis ed when removing

the headlamp switch as the retaining clip and locating

guide will catch and damage the instrument panel

outer material.

NOTE: Complete switch assembly removal is not

necessar y for HVAC unit rem oval. Figure 2B-46 shows

the switch assembly removed only for clarity of detail.

97. From behind the instrument panel pad, depress

the retaining clips (1). Use a fine, flat blade

screwdriver if required.

98. Carefully push the headlamp switch assembly (2)

part way from its cavity.

99. Insert a fine, flat-blade screwdriver (3) as shown

and hold the retaining clip depres sed, while slowly

manipulating the s witch from its cavity. Repeat for

the opposite side and for the locating guide

underneath as required.

100. Disconnect the wiring connector but do not

remove the switch assembly, as complete

removal is not necessary.

Figure 2B-46

IMPORTANT: Care m ust be exercis ed when removing

the trip computer switch as the retaining clip and

locating guide will catch and damage the instrument

panel outer material.

NOTE: Complete switch assembly removal is not

necessar y for HVAC unit rem oval. Figure 2B-47 shows

the switch assembly removed only for clarity of detail.

101. From behind the instrument panel pad, depress

the retaining clips (1). Use a fine, flat blade

screwdriver if required.

102. Carefully push the trip computer switch

assembly (2) part way from its cavity.

103. Insert a fine, flat-blade screwdriver (3) as shown

and hold the retaining clip depressed, while

manipulating the s witch from its cavity. Repeat for

the opposite side and for the locating guide

underneath as required.

104. Disconnect the wiring connector but do not

remove the switch assembly, as complete

removal is not necessary.

Figure 2B-47

105. Remove the screw (1) attaching the instrument

panel speaker (2) to the instrument panel (3).

106. Disconnect the wiring connector and remove the

speaker by withdrawing it from the slot in the

instrument panel.

Figure 2B-48

Left-Hand Drive Vehic les

107. Remove the screw (1) attaching the BCM (2) to

the HVAC BCM bracket.

108. Release the rear retaining tang and gently

manoeuvre the BCM from the mounting bracket.

Figure 2B-49

Right-hand Drive Vehicles

109. Remove the screw (1) attaching the BCM (3) to

the instrument panel bracket outer brace.

110. Release the two rear retaining tangs (2) and

gently manoeuvre the BCM f r om the top mounting

bracket.

Figure 2B-50

111. If fitted, remove the telematics module (1). Refer

to Section 12K, TELEMATICS.

Figure 2B-51

112. If the vehicle is fitted with a satellite navigation

system, remove the passenger side hinge pillar

trim assembly. Refer to Section 1A8, 2.8 HINGE

PILLAR TRIM ASSEMBLY.

113. Disconnect the satellite navigation speaker

connector (1) and the satellite navigation system

connectors (2).

NOTE: Rem oval of the navigation s peaker (3) fr om the

instrument panel lower bracket (4) is not necessary.

The brac ket and s peaker are r emoved as an as s embly

at a latter stage.

Figure 2B-52

All Vehicles

114. Remove the four BCM wiring harness connectors from the module and remove the module.

115. Remove the antenna lead from the retaining clips loc ated on the underside of the RHD HVAC unit or at the

case join on the LHD HVAC unit.

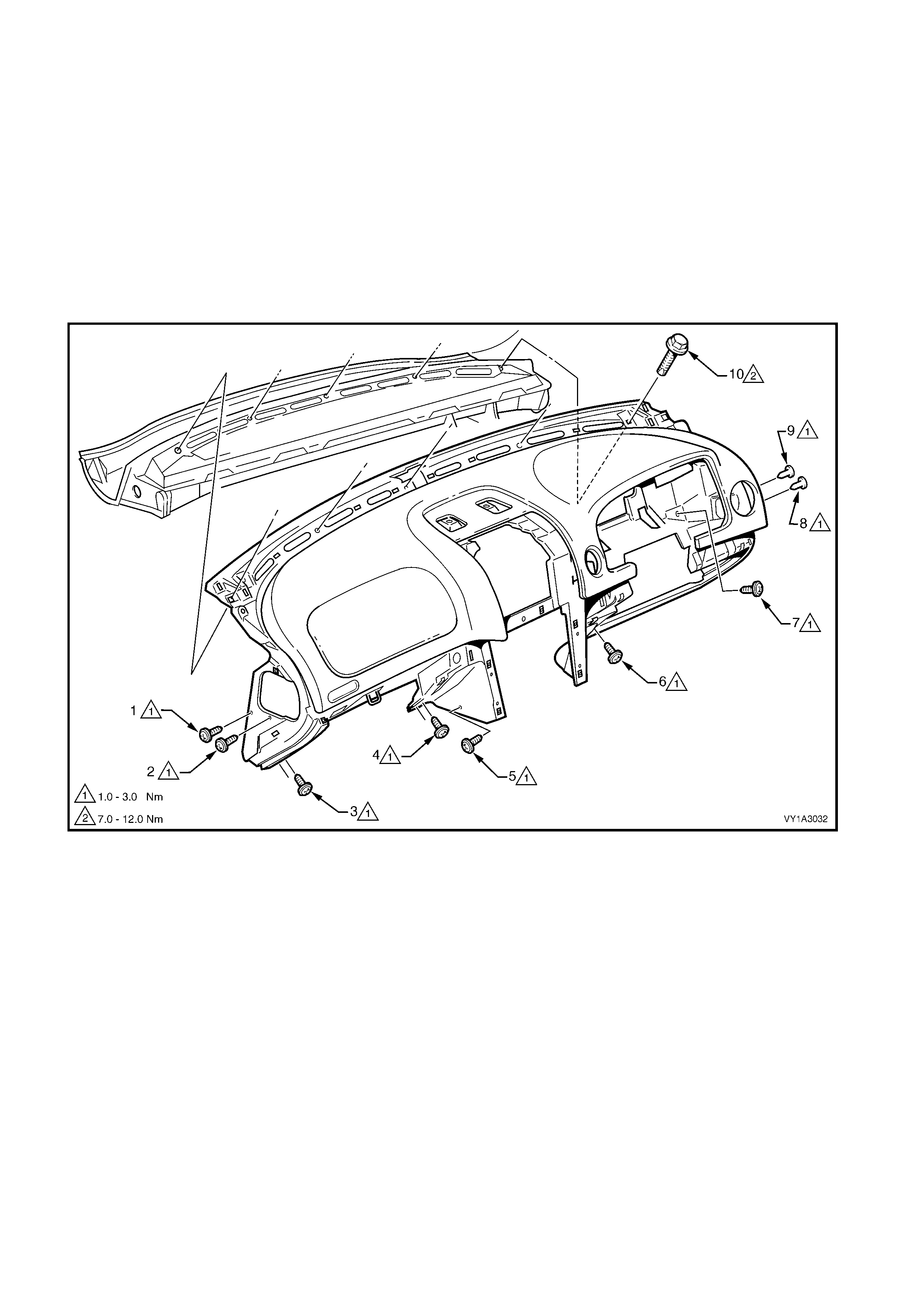

116. Remove the two inner screws (1) attaching the instrument panel inflatable restraint (2) or instrument panel

outer upper bracket (3) and instrument panel lower bracket (4) to the instrument panel inflatable restraint

bracket (5), refer to Figure 2B-53.

NOTE: View A is for models with an instrument panel inflatable restraint. View B is for models without an

instrument panel inflatable restraint.

Figure 2B-53

117. Prior to instrum ent panel pad rem oval, refe r to Figure 2B-54 and ensur e that the following screws attaching

the instrument pad assembly are removed:

a. left-hand end (1) one place,

b. to the passenger side air duct (2) one place, (removed previously at Step 75)

c. passenger side lower (3 and 4) two places each,

d. left of centre (5) one place,

e. driver side lower (6) one place,

f. behind instrument cluster (7) one place,

g. to the driver’s side outer air duct (8) one place, (removed previously at Step 70)

h. right-hand end (9) one place,

i. along the upper edge (10), five places.

With the aid of an assistant, carefully lift the pad assembly out of the vehicle and place on a soft surface.

Figure 2B-54

118. If fitted, remove the instrument panel inflatable restraint module assembly. Refer to Section 12M, 2.4

INSTRUMENT PANEL INFLATABLE RESTRAINT MODULE ASSEMBLY.

119. Remove the passenger side HVAC duct from the HVAC unit. Refer to item 9 in Figure 2B-55 for left-hand

drive models or Figure 2B-56 for right-hand models.

NOTE: At this stage, all ducting required for HVAC unit removal, should have been removed.

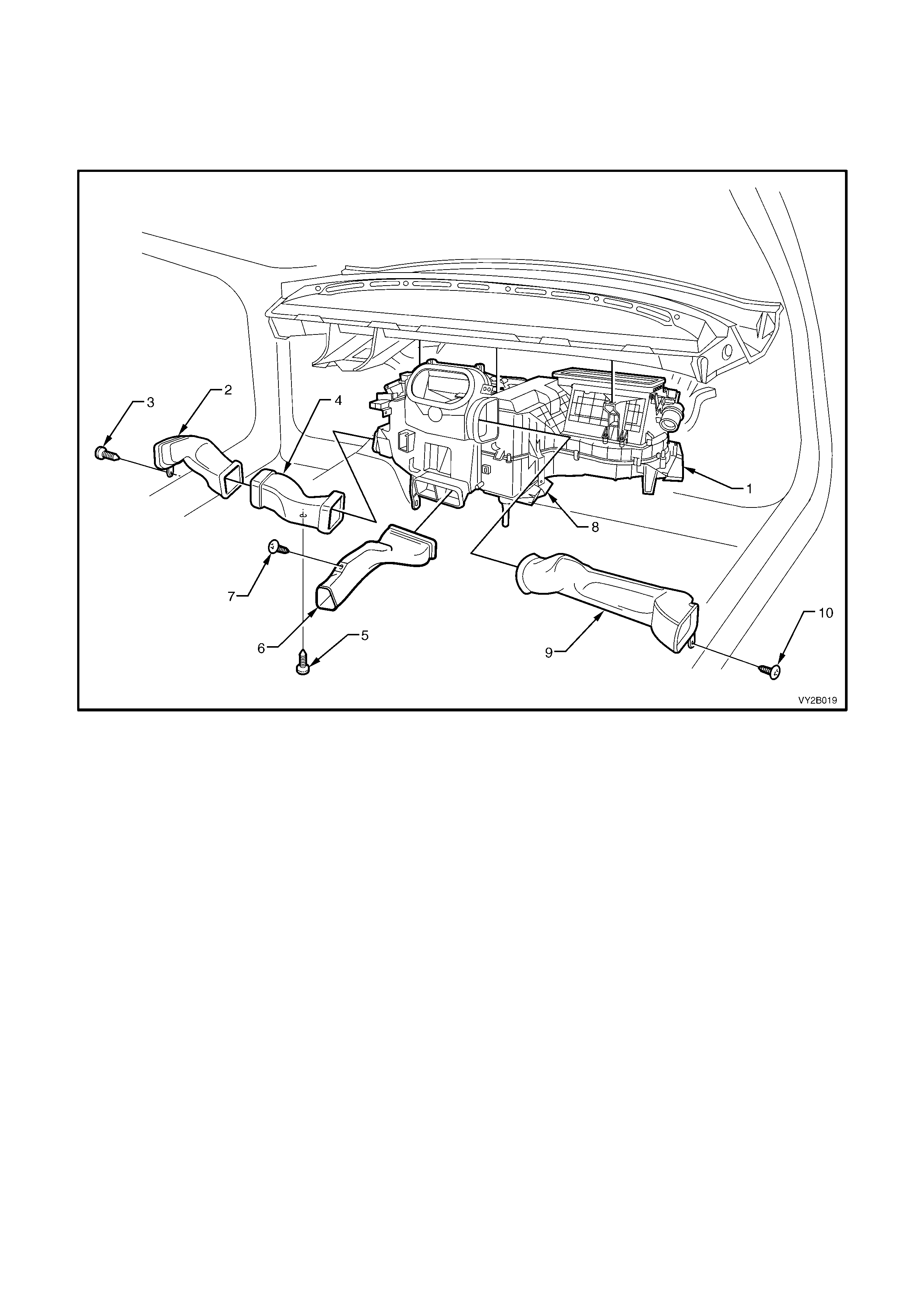

Figure 2B-55

Legend

1. HVAC Unit 6. Floor Console Front Duct, removed at Step 28

2. Driver’s Side Outer Duct, removed at Step 74 7. Screw (1 place), removed at Step 25

3. Screw (1 place), removed at Step 70 8. Foot Duct

4. Driver’s Side Inner Duct, removed at Step 73 9. Passenger’s Side Duct, removed at Step 118

5. Screw (1 place), removed at Step 65 10. Screw (1 place), removed at Step 75

NOTE 1: The foot duct remains attached when the HVAC unit is removed.

NOTE 2: The floor console rear duct (not shown) is removed and installed with the floor console assembly.

NOTE 3: The steering column (not shown) does not have to be removed for HVAC unit removal.

NOTE 4: The floor console front duct is not applicable to utility models.

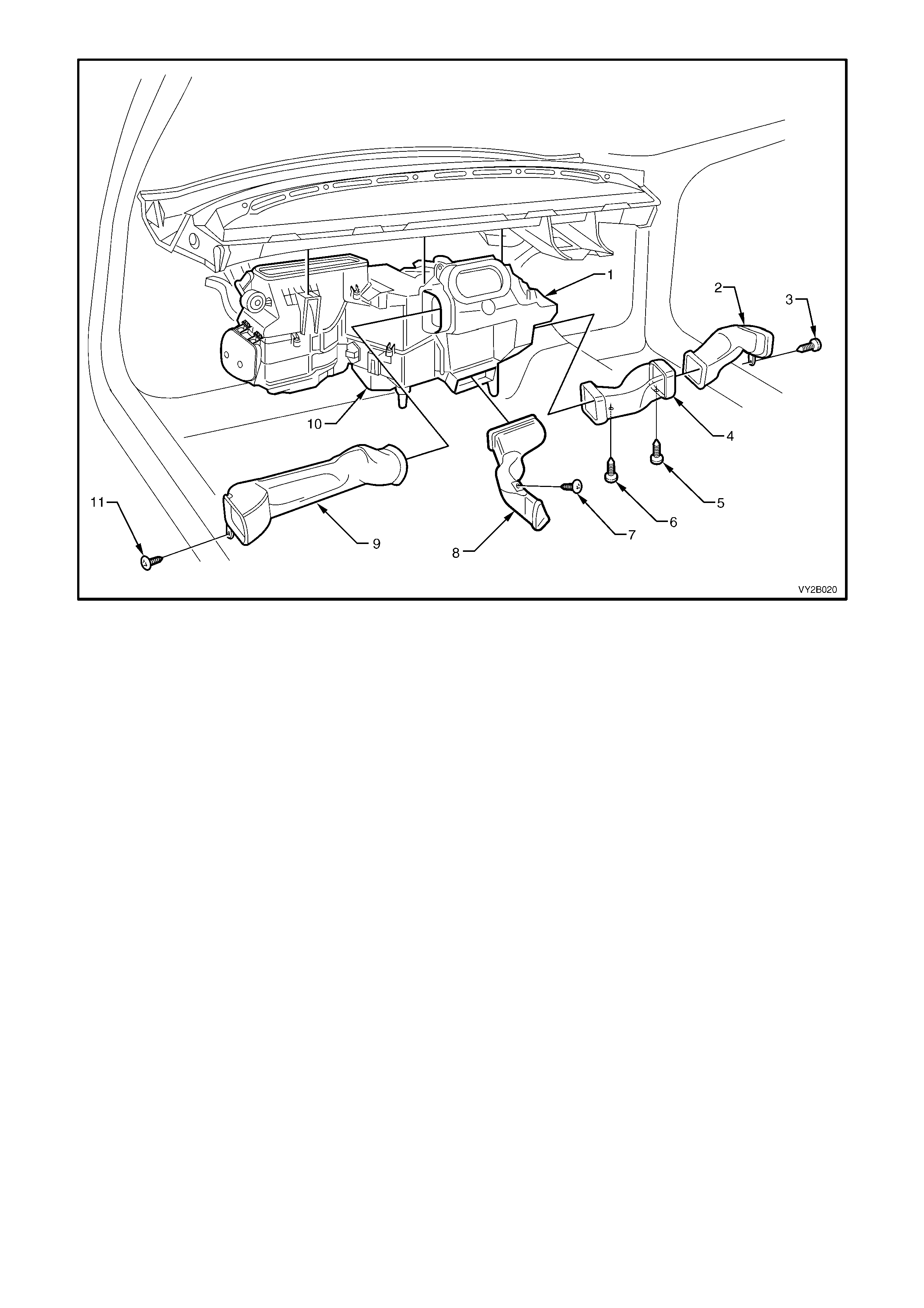

Figure 2B-56

Legend

1. HVAC Unit 7. Screw (1 place), removed at Step 25

2. Driver’s Side Outer Duct, removed at Step 74 8. Floor Console Front Duct, removed at Step 28

3. Screw (1 place), removed at Step 70 9. Passenger’s Side Duct, removed at Step 118

4. Driver’s Side Inner Duct, removed at Step 73 10. Foot Duct

5. Screw (1 place), removed at Step 66 11. Screw (1 place), removed at Step 75

6. Screw (1 place), removed at Step 67

NOTE 1: The foot duct remains attached when the HVAC unit is removed.

NOTE 2: The floor console rear duct (not shown) is removed and installed with the floor console assembly.

NOTE 3: The steering column (not shown) does not have to be removed for HVAC unit removal.

NOTE 4: The floor console front duct is not applicable to utility models.

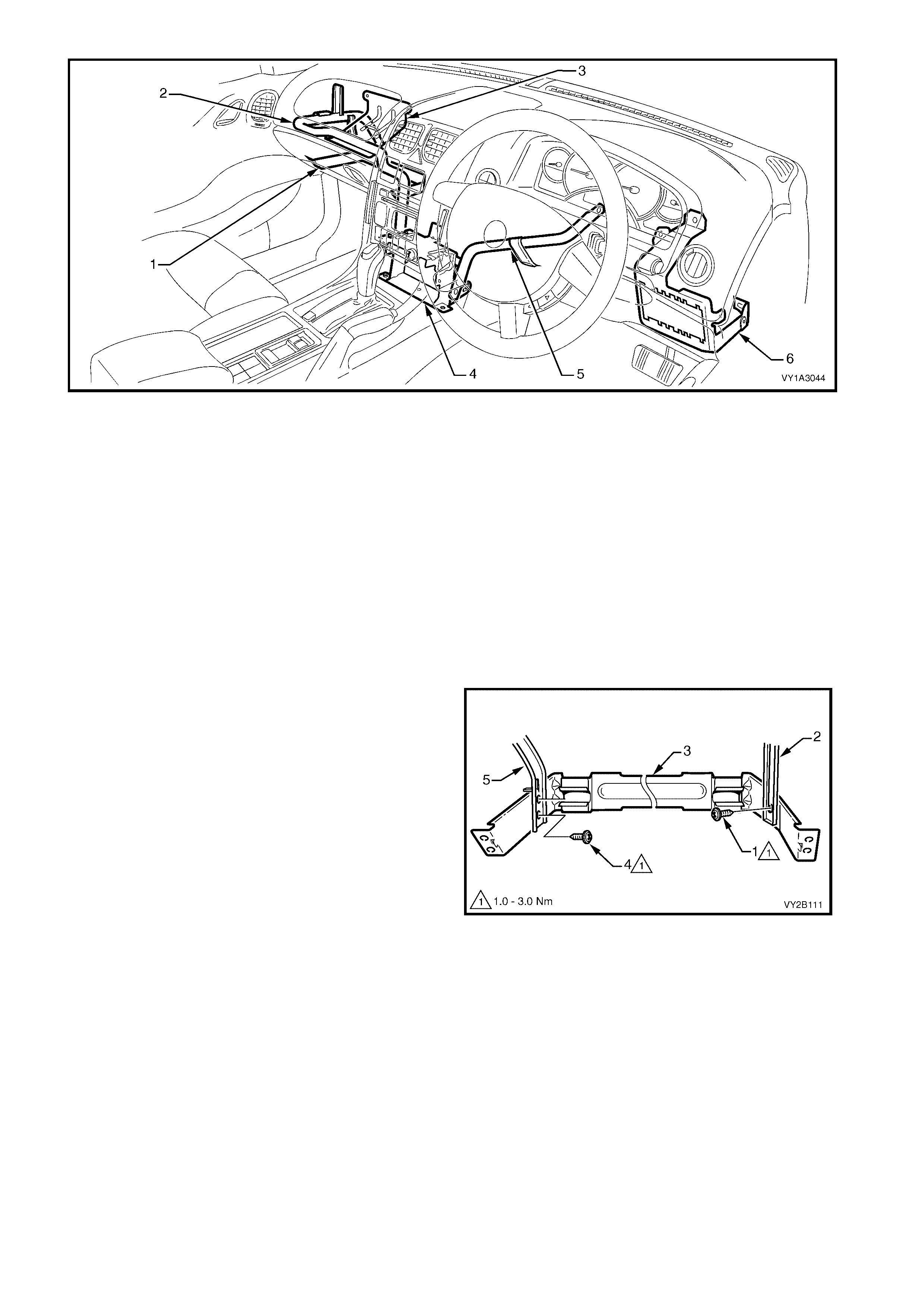

Figure 2B-57

Legend

1. Instrument Panel Compartment Bracket, refer to Step 117 c, and Step 120 through to Step 121

2. Instrument Panel Lower Bracket, refer to Step 122 through to Step 124

3. Instrument Panel Outer Upper Bracket, refer to Step 124 and Step 125

4. Lower Radio Bracket, refer to Step 122, Step 126, Step 127, Step 130 and Step 131

5. Steering Column Bracket Inner Brace, refer to Step 127 through to Step 129

6. Steering Column Bracket Outer Brace, do not remove

NOTE1: Item 3, the instrument panel outer upper bracket, is fitted only to models not fitted with an instrument panel

inflatable restraint module assembly.

NOTE 2: Item 2 and 3 are removed as an assembly.

NOTE 3: If the vehicle is fitted with a satellite navigation system, the navigation speaker will be attached to, and removed

with Item 2. Refer to Figure 2B-52.

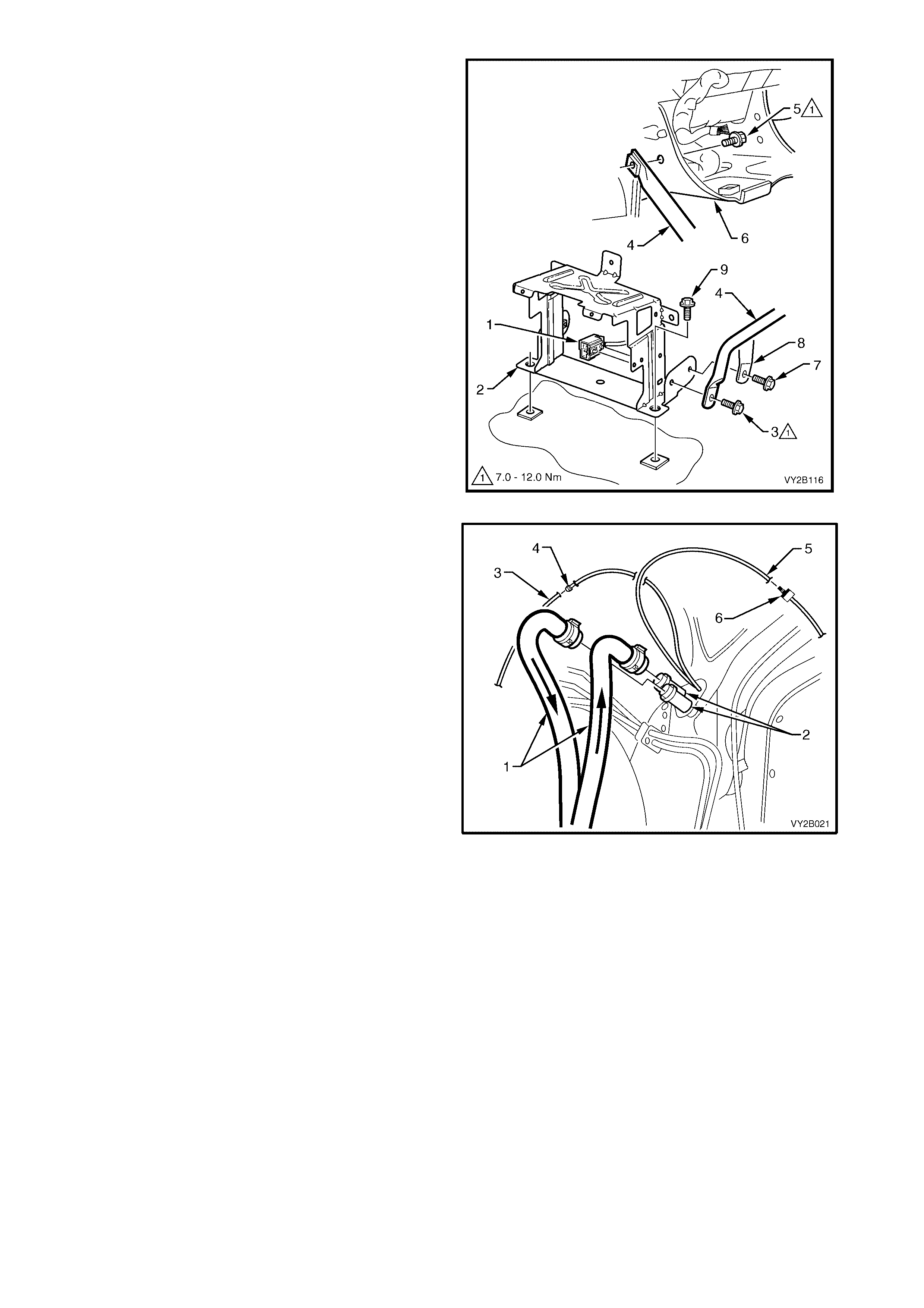

120. Remove the screw (1) attaching the HVAC unit (2)

to the instrument panel compartment bracket (3).

121. Remove the screw (4), two places, attaching the

bracket to the instrument panel lower bracket (5)

and remove the bracket.

Figure 2B-58

Referring to Figure 2B-59:

122. Remove the screws (1 and 2) attaching the instrument panel lower bracket (3) to the lower radio bracket.

123. Remove the screws (4 and 5) attaching the bracket to the vehicle.

IMPORTANT: If the vehicle is fitted with a satellite navigation system, exercise caution when removing the

instrument panel lower bracket to ensure that the attached satellite navigation speaker is not damaged.

124. Remove the outer upper bracket (6) and lower bracket as an assembly.

Figure 2B-59

125. Remove the nut (1), two places, attaching the

outer upper bracket to the dash panel assembly .

Figure 2B-60

126. Unclip the wiring connector (1) from the lower

radio bracket (2).

127. Remove the screw (3) attaching the steering

column bracket inner brace (4) to the lower radio

bracket.

128. Remove the screw (5) attaching the brace to the

steering column bracket (6).

129. Remove the brace.

130. Remove the screw (7), attaching the HVAC

unit (8) to the radio bracket.

131. Remove the screw (9), two places, attaching the

radio bracket to the vehicle and remove the

bracket.

Figure 2B-61

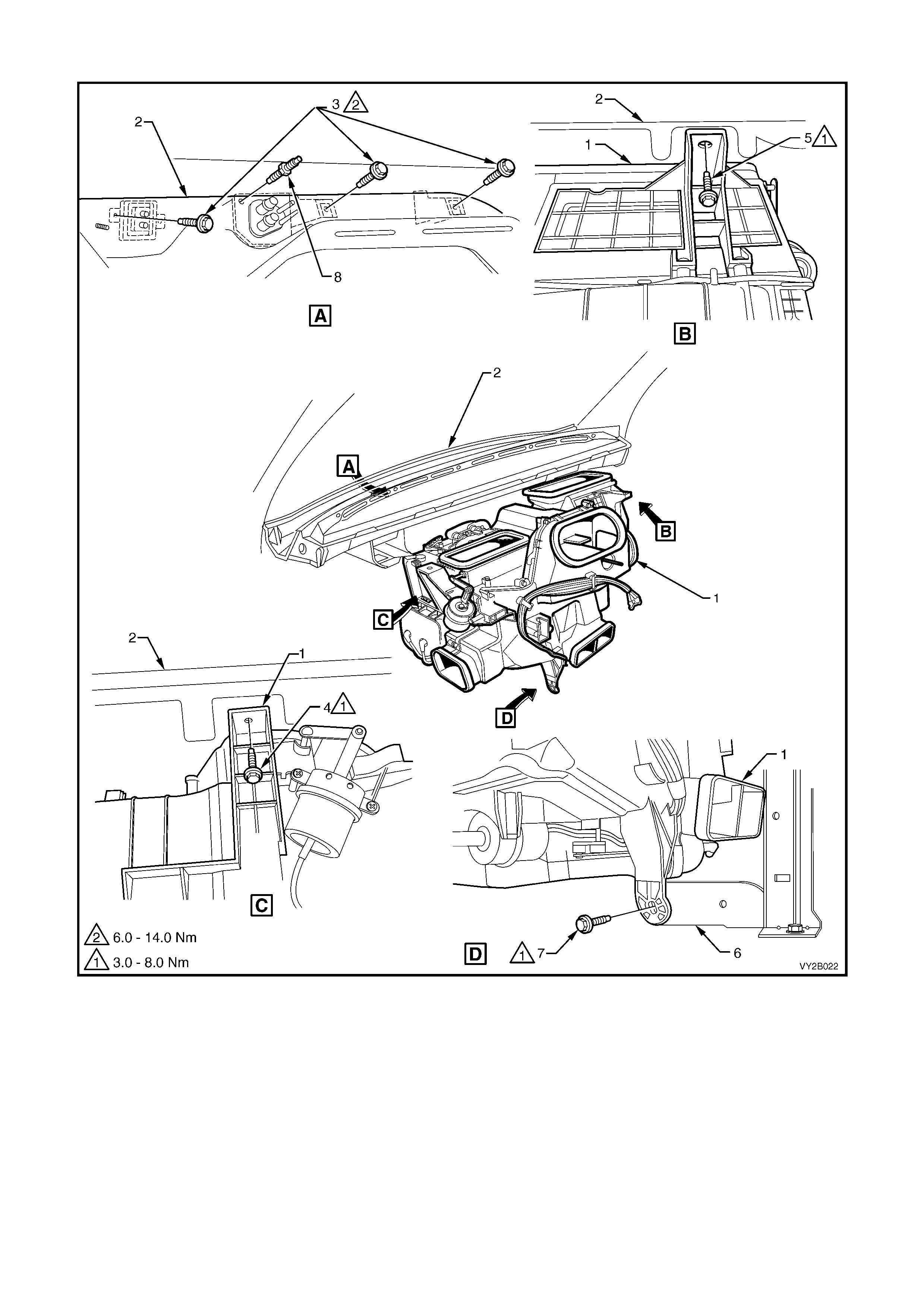

132. Mark the heater hoses (1) in relation to the heater

core pipes (2) to maintain correct coolant flow.

Remove the heater hoses from the heater core

pipes.

133. Disconnect the water valve vacuum hose (3) at

the joiner (4).

134. Disconnect the vacuum supply hose (5) at the

check valve (6).

Figure 2B-62

135. Remove the suc tion and liquid tubes (one bolt) and the ther mal expans ion valve (two cap scr ews). Refer to

10.THERMAL EXPANSION VALVE (TXV) in this Section.

136. On GEN III V8 models, remove the fuel line retaining bracket attached to the HVAC mounting stud. For

location, refer to item 8 in Figure 2B-63 for left-hand drive models and Figure 2B-64 for right-hand drive

models.

137. Remove the screws retaining the HVAC unit to the dash panel. Refer to Figure 2B-63 for left-hand drive

models and Figure 2B-64 for right-hand drive models.

NOTE: Item 7 will have been removed during previous Steps.

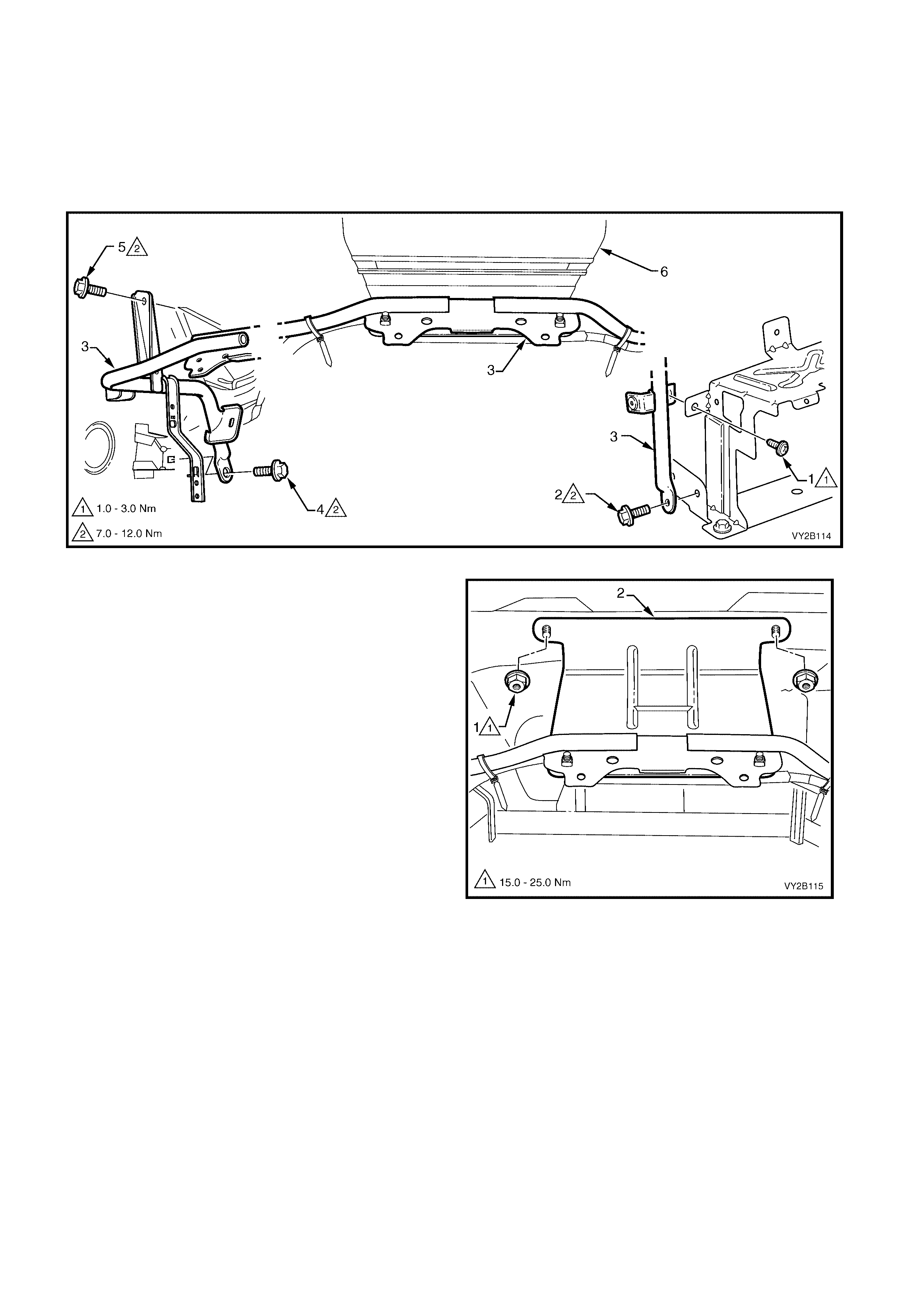

HVAC UNIT FASTENER LOCATION – LHD

Figure 2B-63

Legend

1. HVAC Unit 5. Screw – Dash Panel, Cabin on Passenger’s Side

2. Dash Panel 6. Lower Radio Bracket Assembly

3. Screw – Dash Panel, Engine Bay (3 places) 7. Screw – Lower Radio Bracket Assembly, removed at Step 130

4. Screw – Dash Panel, Cabin on Driver’s Side 8. Screw for V6, Stud for GEN III V8 – Dash Panel, Engine Bay

NOTE: The steering column (not shown) does not have to be removed for HVAC unit removal.

HVAC UNIT FASTENER LOCATION – RHD

Figure 2B-64

Legend

1. HVAC Unit 5. Screw – Dash Panel, Cabin Driver’s Side

2. Dash Panel 6. Lower Radio Bracket Assembly

3. Screw – Dash Panel, Engine Bay (3 places) 7. Screw – Lower Radio Bracket Assembly, removed at Step 130

4. Screw – Dash Panel, Cabin Passenger Side 8. Screw for V6, Stud for GEN III V8 – Dash Panel, Engine Bay

NOTE: The steering column (not shown) does not have to be removed for HVAC unit removal.

IMPORTANT: W hen r emoving the HVAC unit from the vehicle take c are not to strain the heater cor e tubes and

evaporator core tubes.

NOTE: Figure 2B-65 shows the right-hand drive HVAC unit and corresponding drain tube / hole location offset

towards the left of the transmission tunnel. The left-hand drive HVAC unit drain tube / hole location is offset

towards the right of the transmission tunnel.

138. Remove the HVAC unit (1) from the vehicle by disengaging the drain tube (2) from the body grommet (3)

installed in the transmission tunnel (4).

139. Carefully lift the HVAC unit away from the dash panel (5).

Figure 2B-65

REINSTALL

Installation of the heating, ventilation and air conditioning (HVAC) unit is in the reverse order of removal noting the

following points and references:

1. Tighten all fasteners to the specified torque. Refer to 19. TORQUE WRENCH SPECIFICATIONS in this

Section.

2. Enable the OPS, SRS in accordance to the correct procedure. Refer to Section 12M, 2.2 SYSTEM

DISABLING AND ENABLING PROCEDURE.

3. Fill the cooling system with the correct specification and quantity of coolant. Pressure test the cooling system.

As applicable refer to:

• Section 6B1, ENGINE COOLING – V6 ENGINE

• Section 6B2, ENGINE COOLING – V6 ENGINE SUPERCHARGED

• Section 6B3, ENGINE COOLING – GEN III V8 ENGINE

4. Evacuate and charge the system with 775 – 825 g of R134a refrigerant, refer to Section 2C, 2.1 SYSTEM

CHARGING AND EVACUATION.

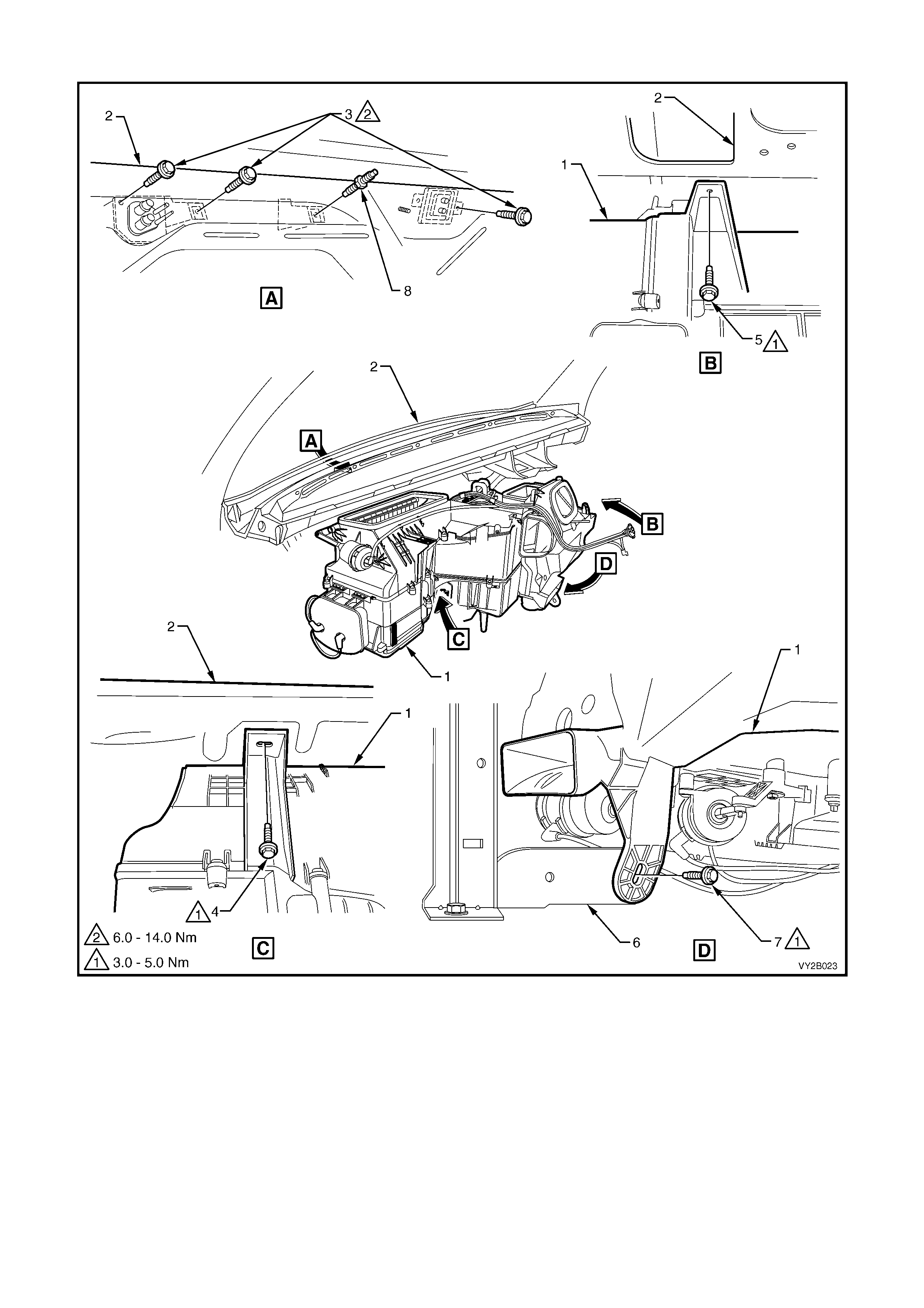

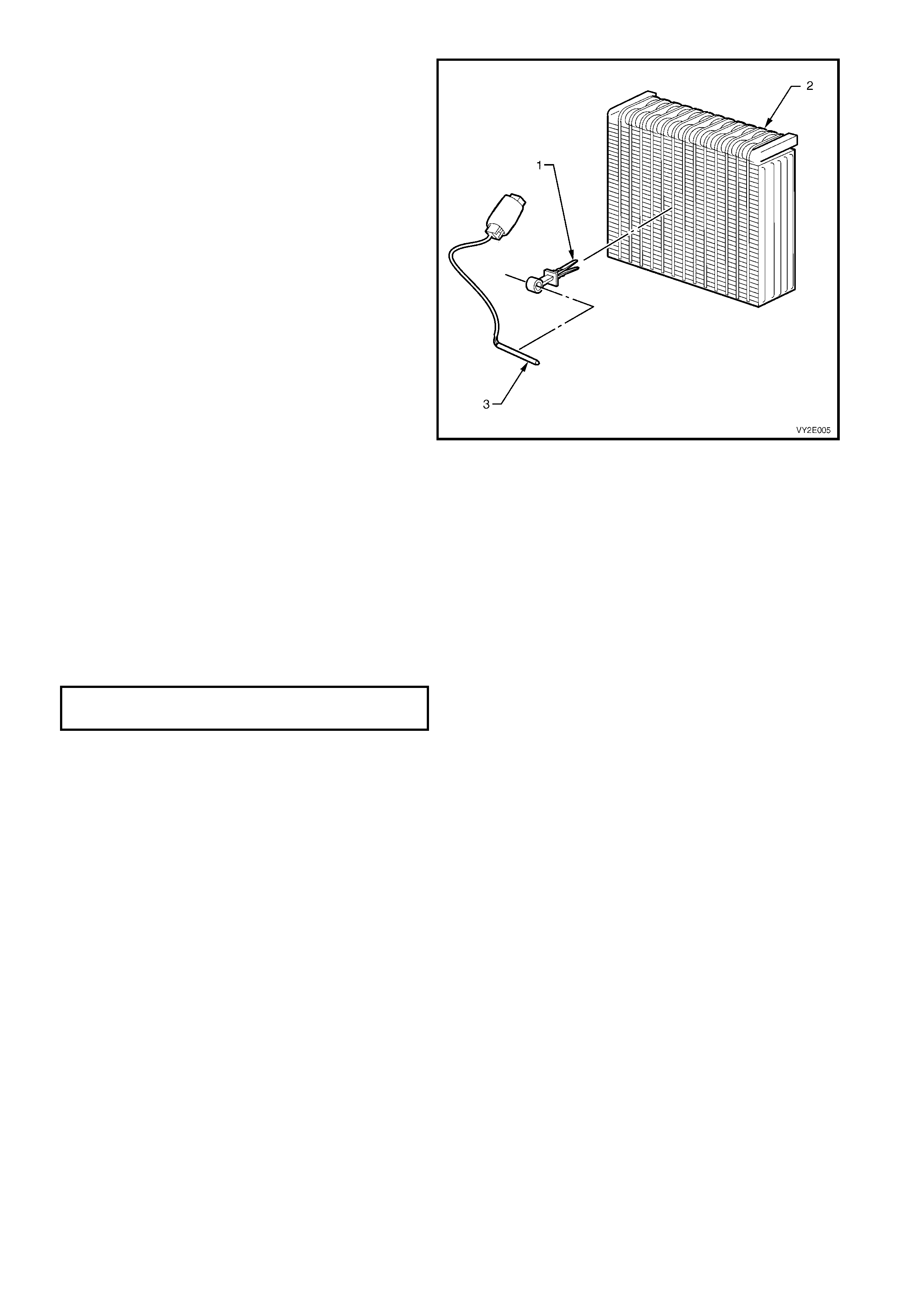

4. EVAPORATOR CORE

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

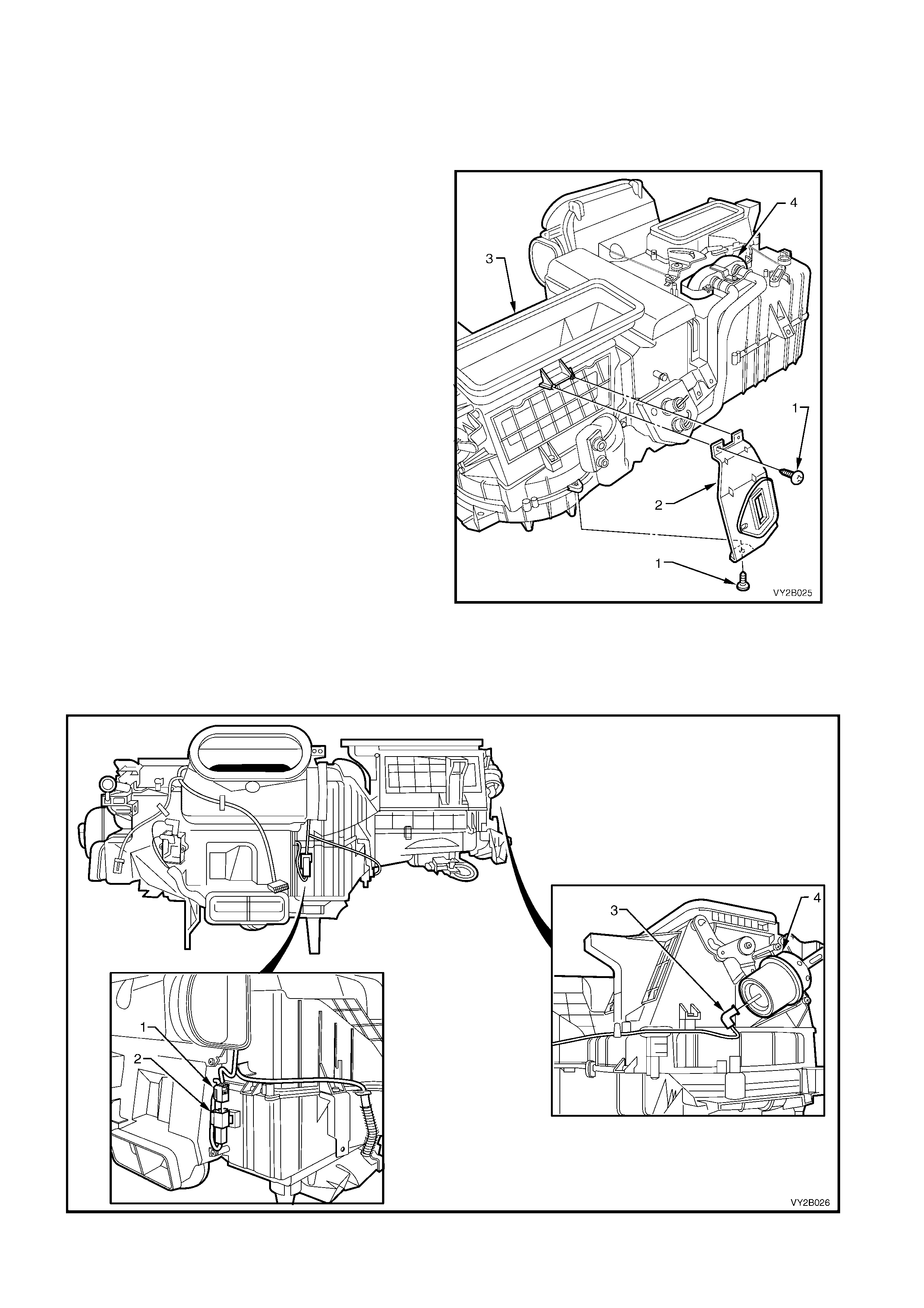

2. Remove TXV joint bracket screws (1) and

remove the bracket (2) from the HVAC unit (3).

3. Remove the heater core (4). Refer to

5. HEATER CORE in this Section.

Figure 2B-66

4. On O CC (Auto A/C) HVAC units rem ove the HVAC harness c onnector (1) f rom the evaporative temperatur e

sensor harness connector (2).

5. On both manual A/C and OCC (Auto A/C) type HVAC units, remove the vacuum line (3) to the intake

actuator (4).

Figure 2B-67

6. On manual HVAC units remove the vacuum

line retainers (1) and remove the vacuum lines

(2) from the front case (3). Remove the intake

actuator vacuum line (4) from the front and

upper case.

7. On both types of HVAC units remove

the demist actuator (5). Refer to

8.5 DEMIST ACTUATOR in this Section.

Figure 2B-68

8. On OCC (Auto A/C) HVAC units remove the

harness retainers (1) and remove the

harness (2) from the front case (3).

9. On OCC (Auto A/C) HVAC units remove the

vacuum lines (4) from the water valve VSV (5).

10. On OCC (Auto A/C) HVAC units remove the

aspirator tube and venturi assembly (6). Refer

to Section 2E, ASPIRATOR TUBE AND

VENTURI.

Figure 2B-69

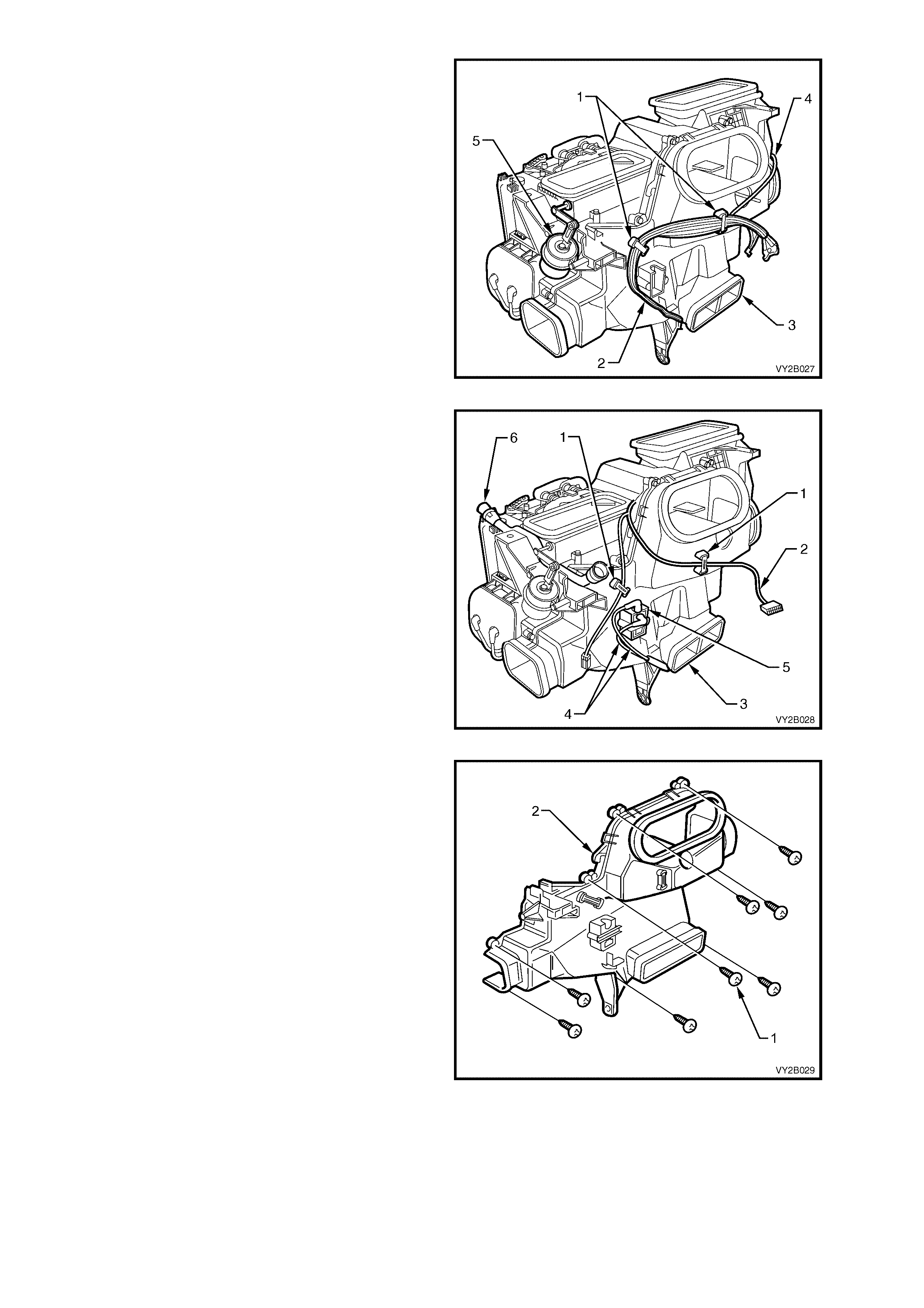

11. Remove the eight s cr ews (1) attaching the f ront

case (2) to the upper and lower case assembly.

Figure 2B-70

12. To access the evaporator (1) separate the

lower case (2) from the upper case (3) by

removing the ten screws (4) installed through

the upper case, one s crew (5) installed thr ough

the lower case, and four clips (6). Do not

remove air doors from either case.

NOTE: Two clips ar e located ins ide the HVAC case

and are accessible after the front case is removed.

Figure 2B-71

13. On OCC (Auto A/C) HVAC units, if the

evaporator is to be replaced, remove the

evaporative temperature sensor clip (1) from

the evaporator (2) and remove the sensor (3).

14. Carefully remove the evaporator core from the

upper case. Pull tubes away from the upper

case to facilitate removal.

Figure 2B-72

15. Rotate the evaporator core (1) and remove

evaporator pipes (2) after removing the

retaining scr ew (3). Remove and discar d the O-

rings (4) from the evaporator pipes.

Figure 2B-73

REINSTALL – LHD

Installation of the evaporator core is in the reverse order of removal procedures noting the following points:

IMPORTANT: The total quantity of lubricating oil in the air conditioning system must be maintained. If a

compressor, evaporator, condenser, filter drier receiver, hose or pipe is to be replaced, a specified quantity of

lubricating oil must be added to the system to compensate for oil removed with the original component. Refer to

Section 2C, 2.4 LUBRICATING OIL COMPENSATION.

NOTE 1: Install new O-rings at the evaporator to evaporator pipe joint.

NOTE 2: On OCC (Auto A/C) evaporator assemblies, install the evaporative temperature sensor in the correct

location on the evaporator core. Refer to Section 2E, 2.4 EVAPORATIVE TEMPERATURE SENSOR.

1. Tighten evaporator to evaporator pipe screw to the correct torque specification.

EVAPORATOR PIPE SCREW

TORQUE SPECIFICATION 5.0 Nm

2. Tighten the HVAC case screws to the correct torque specification.

HVAC CASE SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3. Install the heating, ventilation and air conditioning (HVAC) unit, refer to 3. HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

4. Evacuate and charge the system with 775 – 825 g of R134a refrigerant, refer to Section 2C, 2.1 SYSTEM

CHARGING AND EVACUATION.

LT Section – 08-150

REMOVE – RHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

2. On OCC (Auto A/C) HVAC units, remove the

HVAC harness connector (1) from the

evaporative temperature sensor harness

connector (2). Remove the venturi (3) from the

evaporator cover (4).

Figure 2B-74

3. Remove the vacuum hose (1) from the fresh/

recirculation actuator (2).

4. Remove the five screws (3) from the

fresh/recirculation housing (4) and remove the

fresh/recirculation housing.

5. Disconnect the vacuum tube harness retaining

clips (5) above the evaporator core cover (6).

Figure 2B-75

6. On OCC (Auto A/C) HVAC units remove the

aspirator tube and venturi. Refer to

Section 2E, 2.5 ASPIRATOR TUBE AND

VENTURI.

7. On manual HVAC units disconnect the air mix

door actuator rod (1) and quadrant screw (2)

and remove the quadrant (3)

8. Remove the four screws from the evaporator

core cover (4) and remove the evaporator

cover (5).

Figure 2B-76

9. Remove the upper insulator (1) and carefully

rem ove the evapor ator c ore (2) f rom the m iddle

cavity of the HVAC case (3).

Figure 2B-77

10. On OCC (Auto A/C) HVAC units, disconnect

the evaporative tem perature sensor harness. If

the evaporator is to be replaced, remove the

evaporative temperature sensor clip (1) from

the evaporator (2) and remove the sensor (3).

Figure 2B-78

REINSTALL – RHD

Installation of the evaporator core is in the reverse order of removal procedures noting the following points:

IMPORTANT: The total quantity of lubricating oil in the air conditioning system must be maintained. If a

compressor, evaporator, condenser, filter drier receiver, hose or pipe is to be replaced, a specified quantity of

lubricating oil must be added to the system to compensate for oil removed with the original component. Refer to

Section 2C, 2.4 LUBRICATING OIL COMPENSATION.

NOTE: On OCC (Auto A/C) evaporator assemblies install the evaporative temperature sensor in the correct location

on the evaporator core. Refer to Section 2E, 2.4 EVAPORATIVE TEMPERATURE SENSOR.

1. Tighten the HVAC case screws to the correct torque specification.

HVAC CASE SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2. Install the heating, ventilation and air conditioning (HVAC) unit, refer to 3. HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

3. Evacuate and charge the system with 775 - 825 g of R134a refrigerant, refer to Section 2C, 2.1 SYSTEM

CHARGING AND EVACUATION.

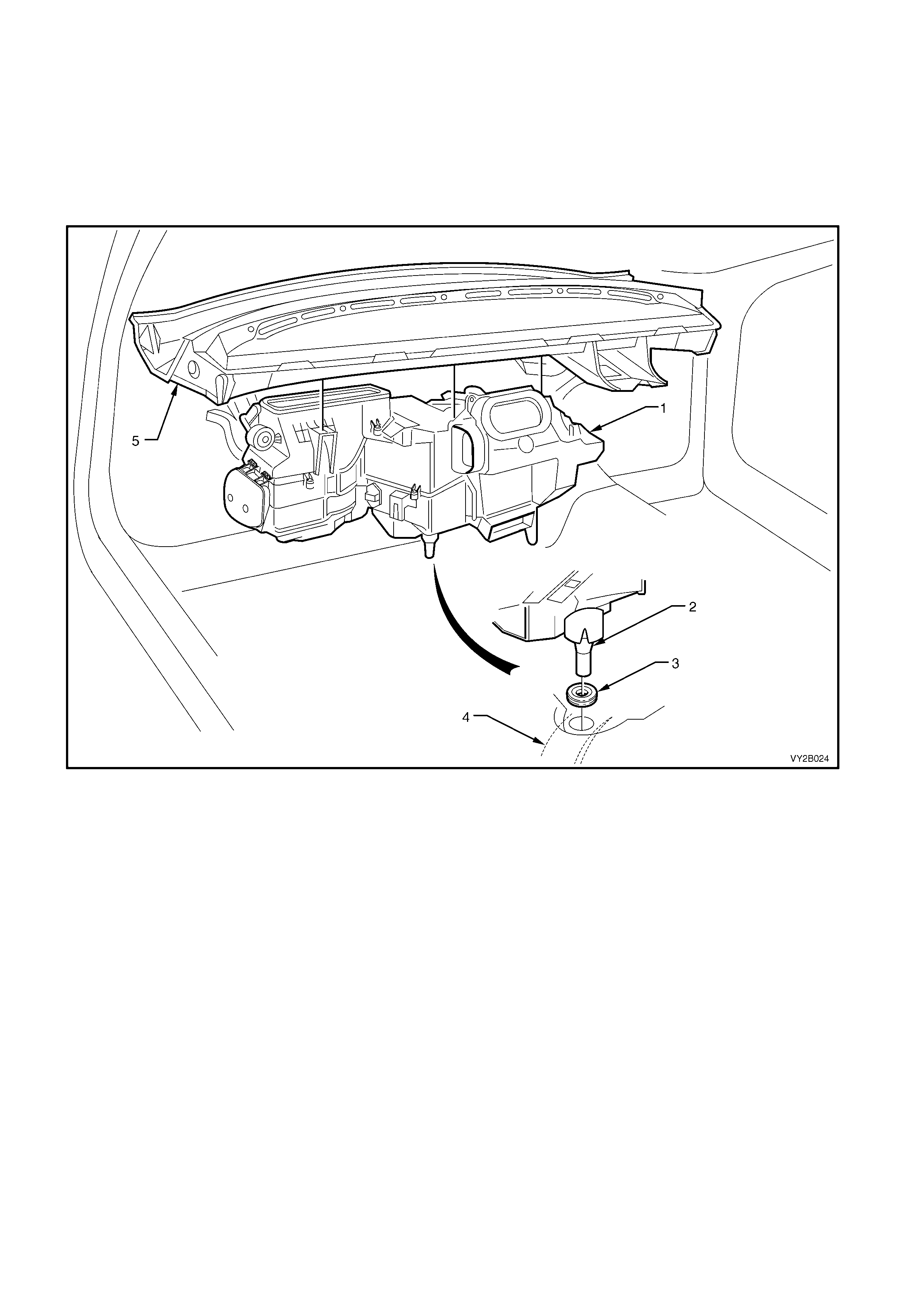

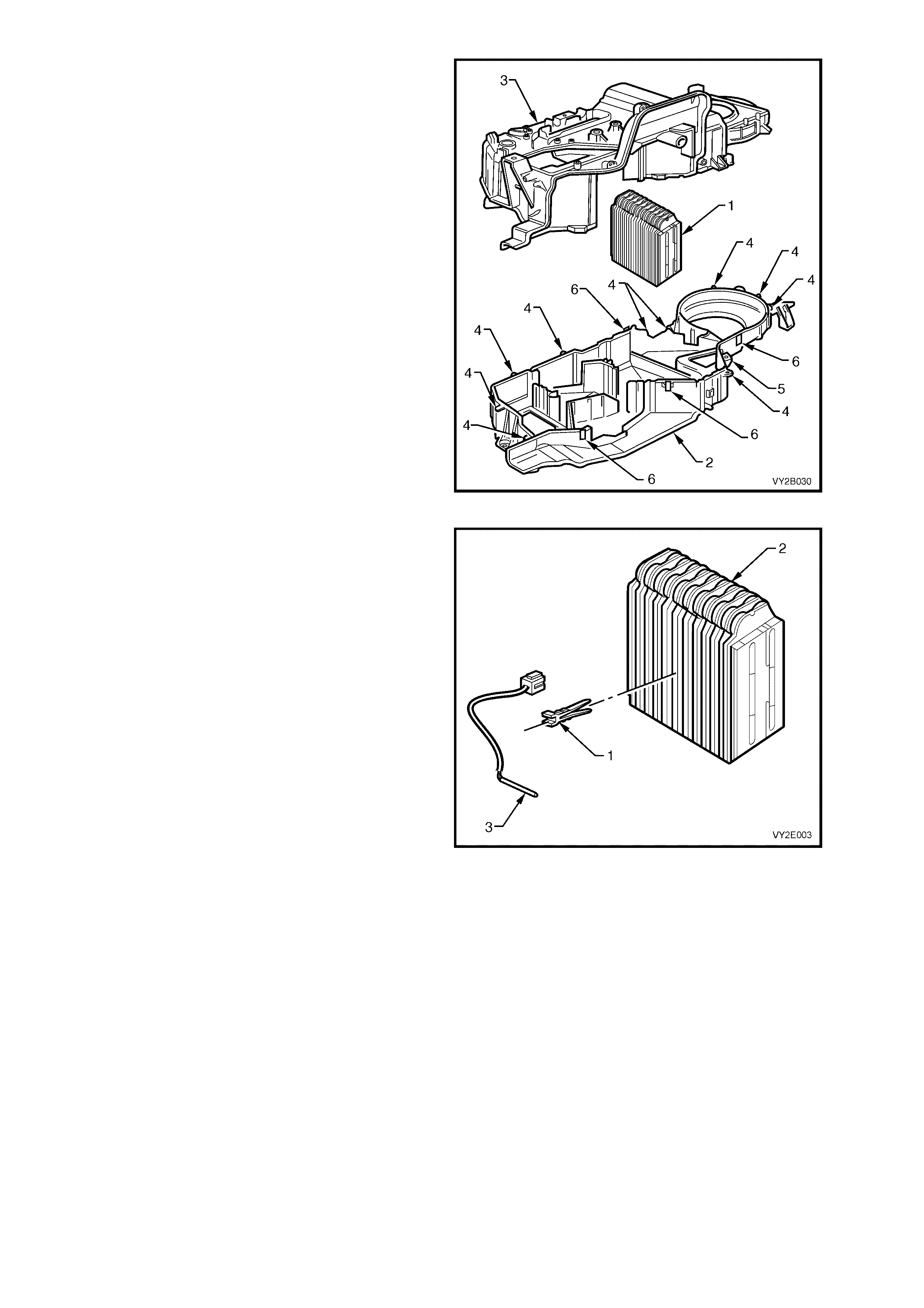

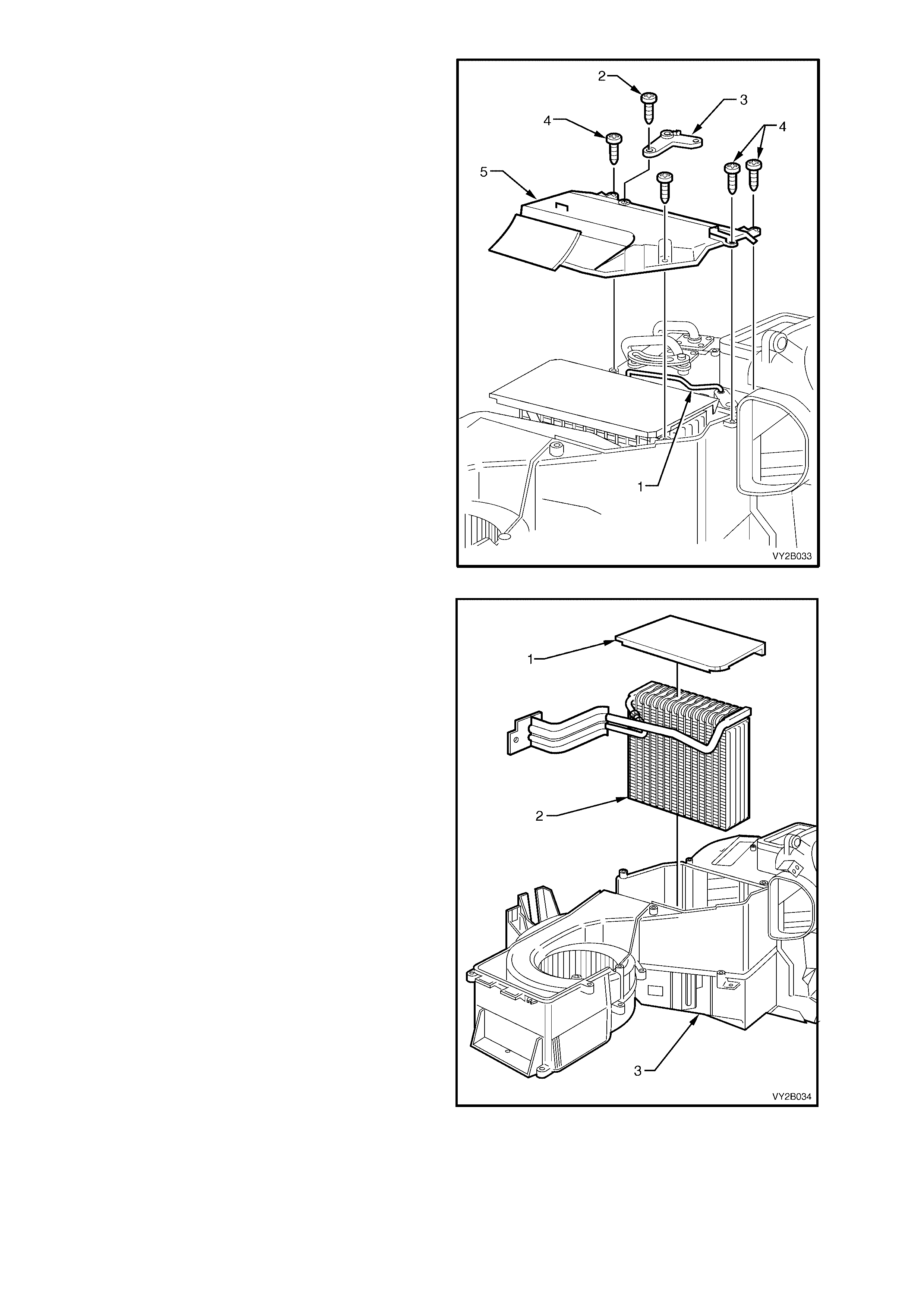

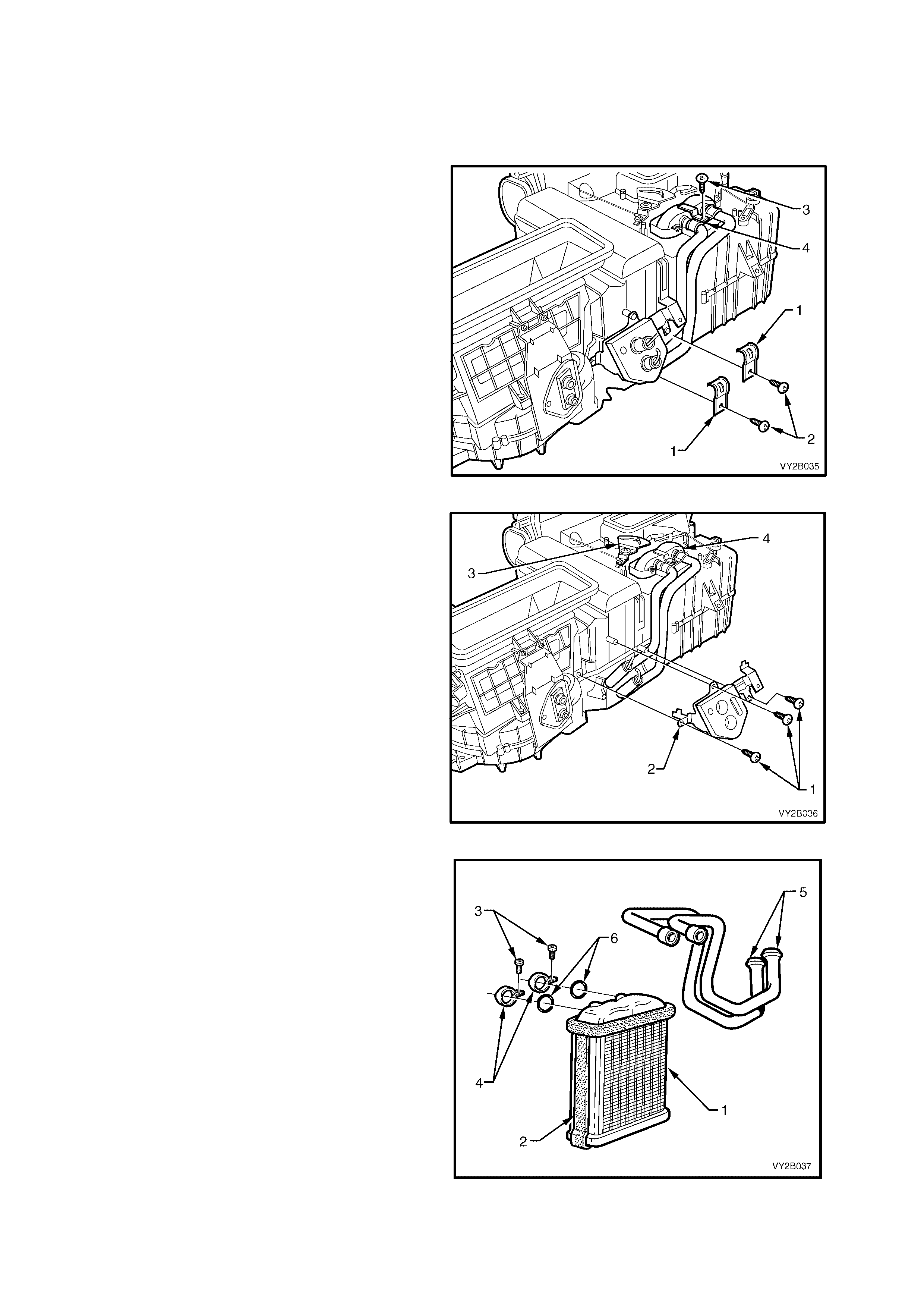

5. HEATER CORE

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

2. Remove heater the two heater core pipe

clamps (1) and screws (2).

3. Remove heater core retaining strap mounting

screw (3) and retaining strap (4).

Figure 2B-79

4. Remove heater pipe bracket mounting

screws (1) and the bracket (2).

5. Position the air mix door mechanism (3) clear

of the top of the heater core (4).

Figure 2B-80

6. Remove the heater core (1) from the HVAC

case without damaging the foam seal (2)

located on top and on both sides of the heater

core.

7. Remove the screw (3) and retainer clip (4)

retaining each heater pipe (5) to the heater

core and remove the pipes from the heater

core. Discard the O-rings (6).

Figure 2B-81

REINSTALL – LHD

Installation of the heater core is in the reverse order of removal procedures noting the following points:

NOTE 1: Install new O-rings at the heater core pipe joints.

NOTE 2: Ensure the foam seals are not damaged when installing heater core to the HVAC case.

1. Tighten all fasteners to the correct torque specification.

HEATER CORE PIPE

RETAINING SCREWS

TORQUE SPECIFICATION 3.0 – 5.0 Nm

HVAC CASE SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2. Install the heating, ventilation and air conditioning (HVAC) unit, refer to 3. HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

3. Evacuate and charge the system with 775 - 825 g of R134a refrigerant, refer to Section 2C, 2.1 SYSTEM

CHARGING AND EVACUATION.

LT Section – 08-150

REMOVE – RHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

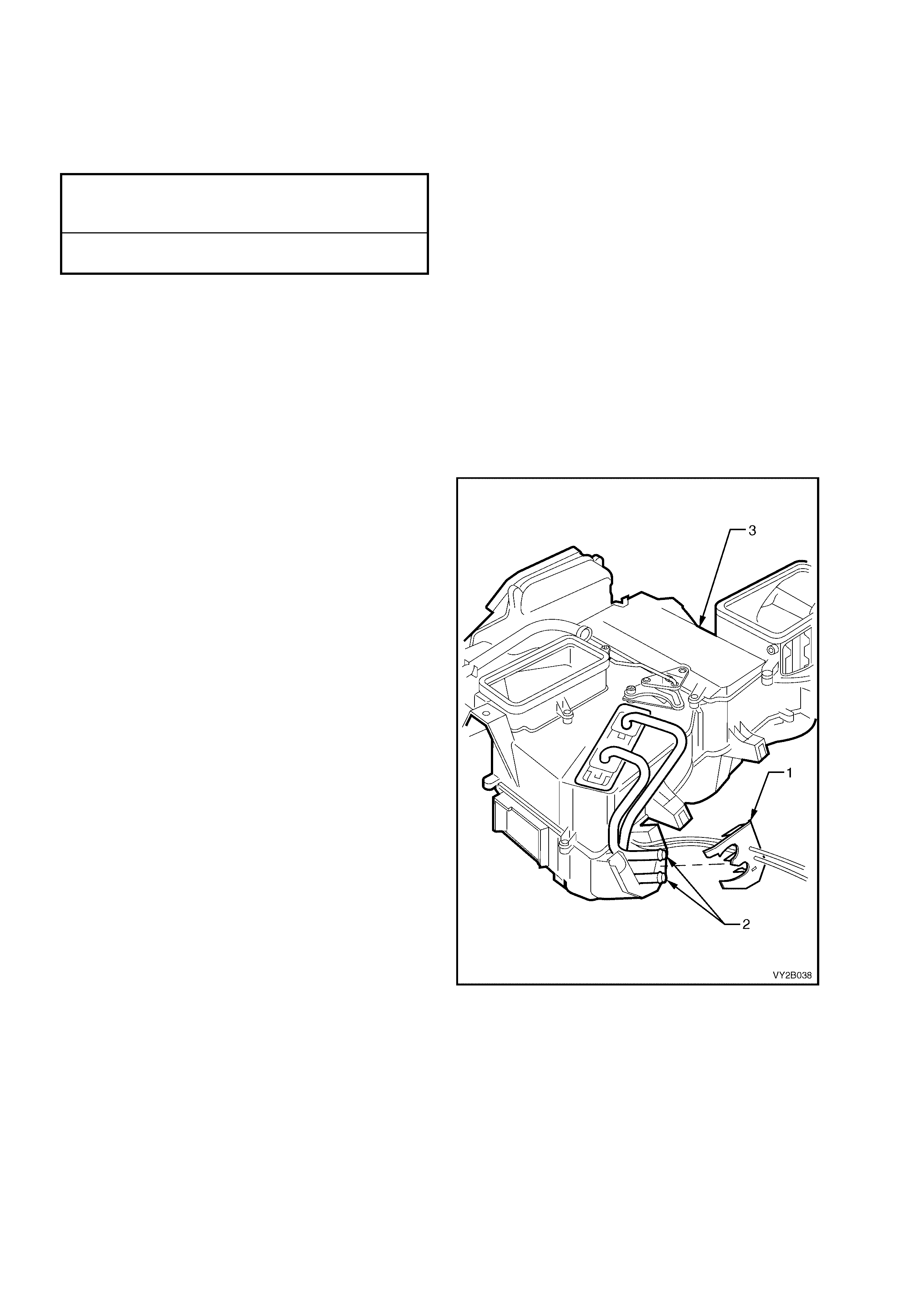

2. Unclip and remove plastic retainer (1) from the

heater pipes (2) at the rear of the HVAC unit

(3).

Figure 2B-82

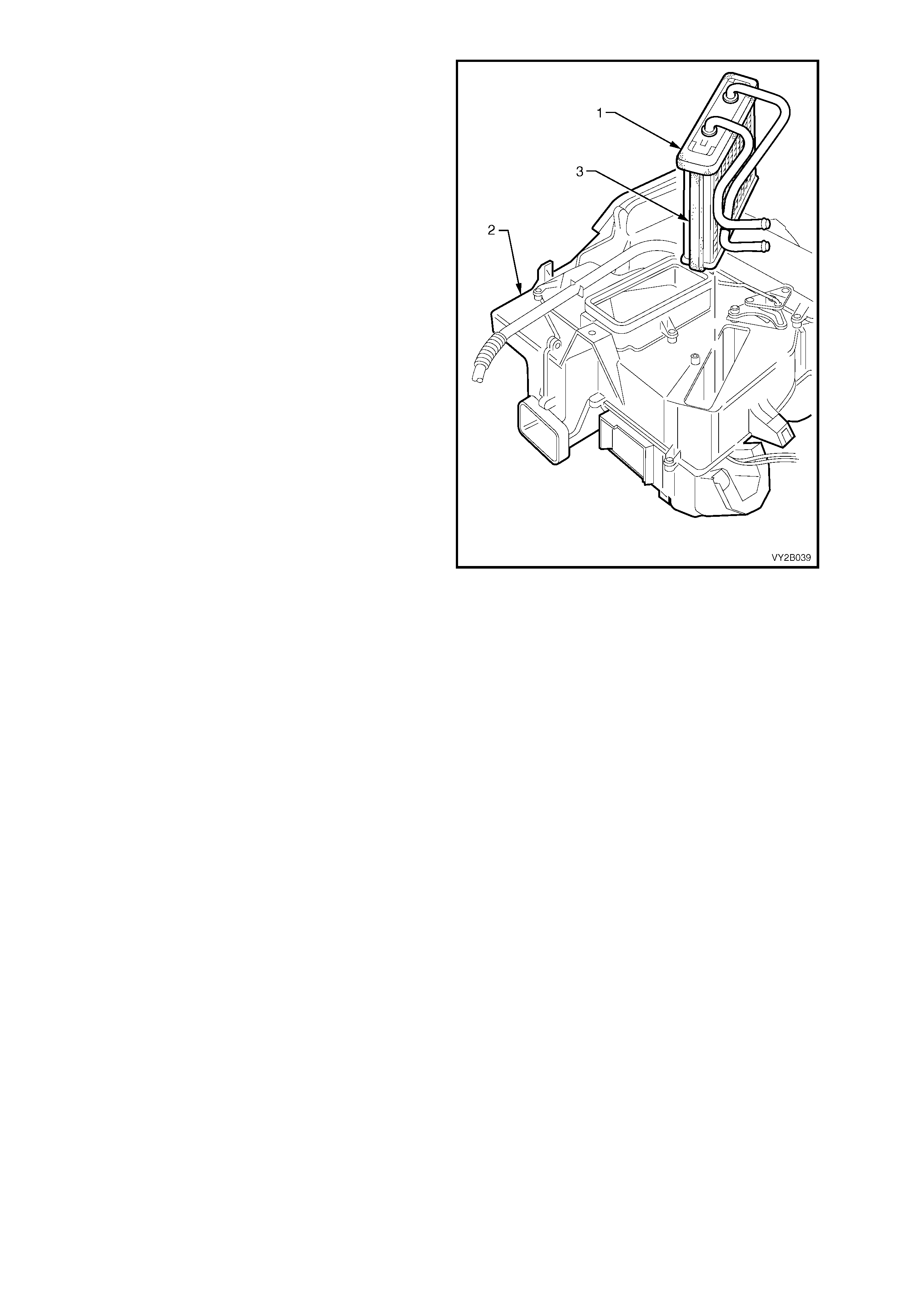

3. Remove the heater core (1) from the HVAC

case (2) without damaging the foam seal (3)

located on top and on both sides of the heater

core.

Figure 2B-83

REINSTALL – RHD

Installation of the heater core is in the reverse order of removal procedures noting the following points:

NOTE: Ensure the foam seals are not damaged when installing heater core to the HVAC case.

1. Install the heating, ventilation and air conditioning (HVAC) unit, refer to 3. HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT in this Section.

2. Evacuate and charge the system with 775 – 825 g of R134a refrigerant, refer to Section 2C, 2.1 SYSTEM

CHARGING AND EVACUATION.

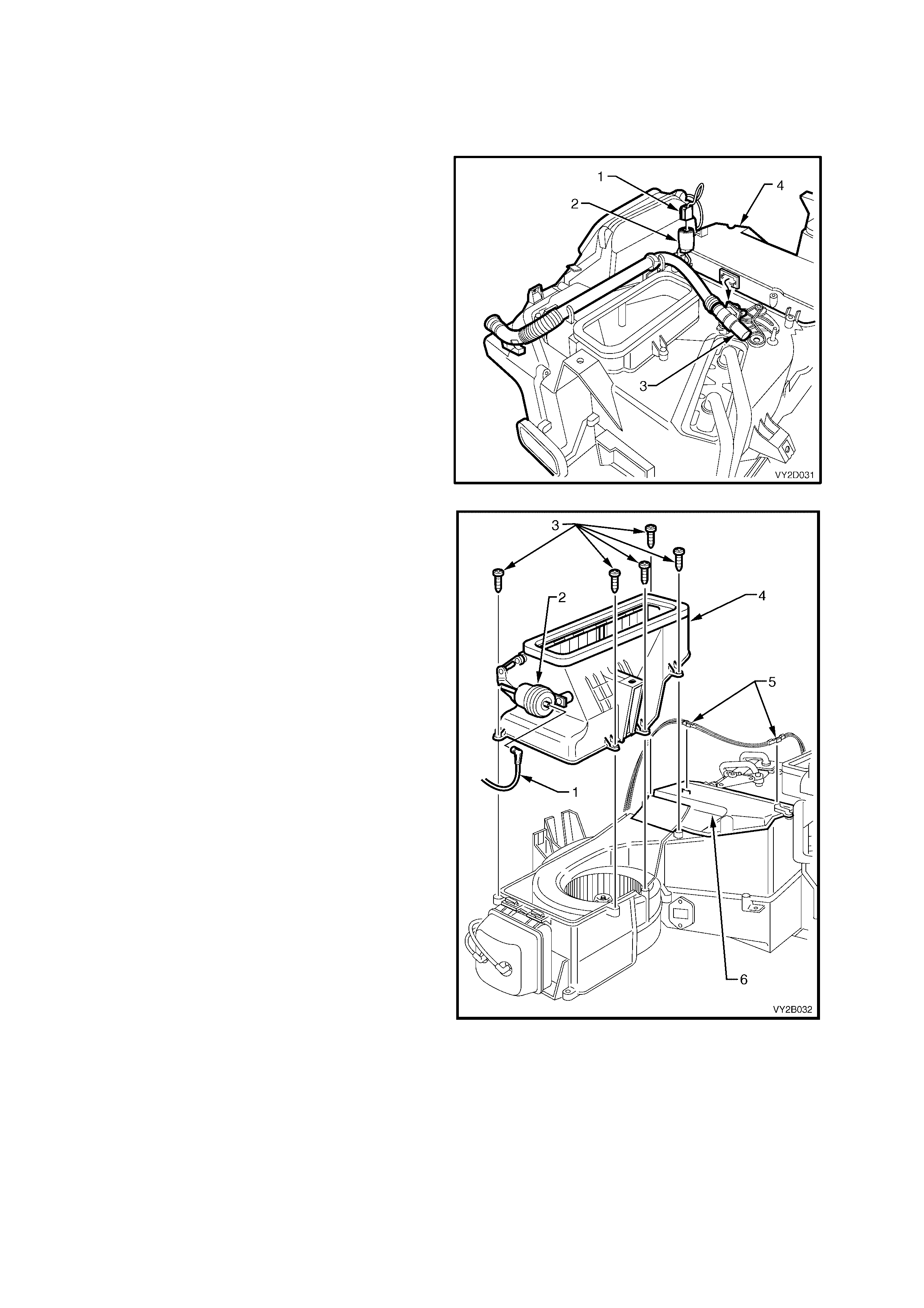

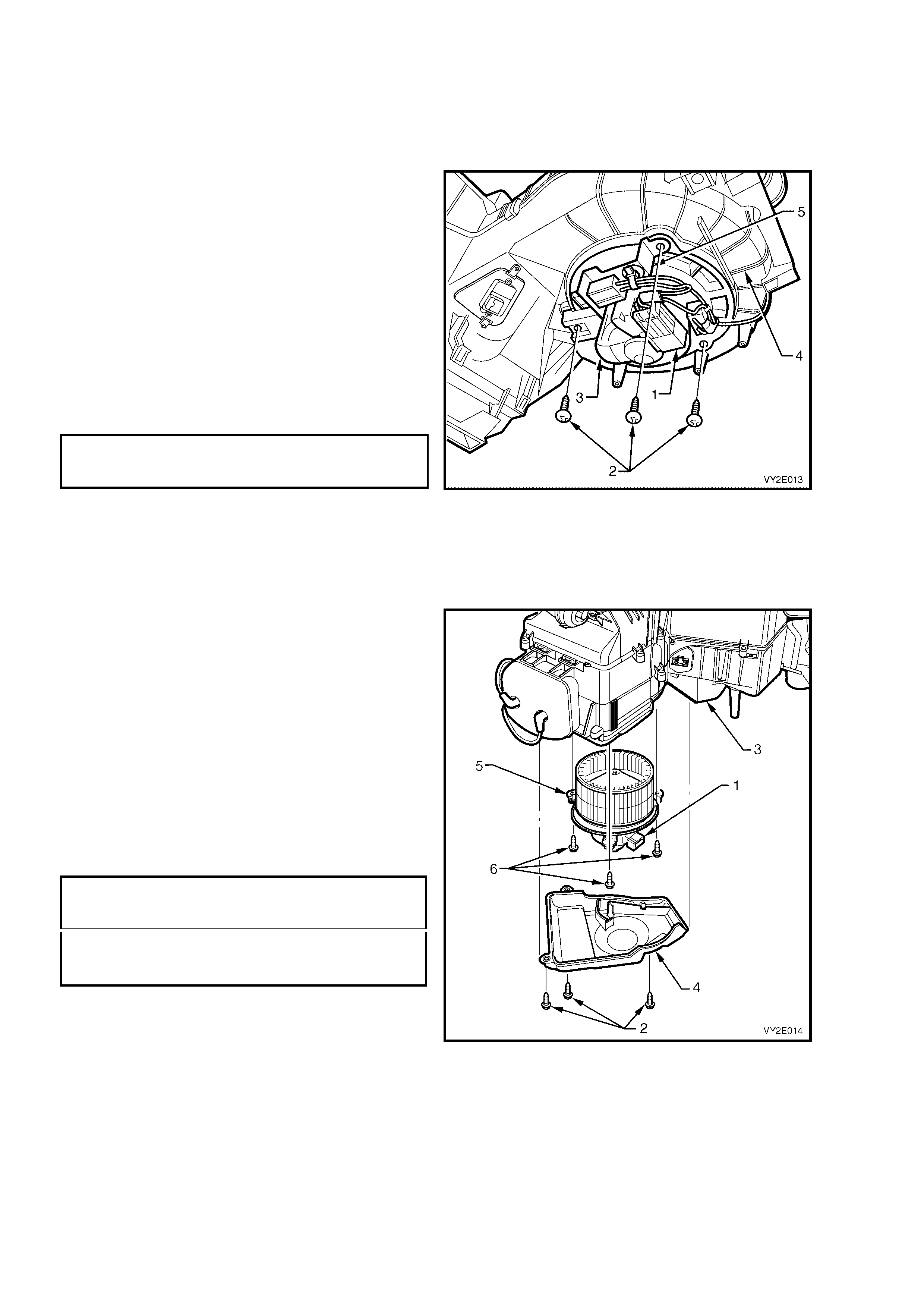

6. BLOWER MOTOR AND FAN ASSEMBLY

REMOVE – LHD

1. Remove the right-hand side instrument panel lower trim plate assembly, refer to Section 1A3,

3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Disconnect the body harness connector to the

blower motor and fan assembly sub harness

connector (1).

3. Remove the three screws (2) and remove the

blower motor and fan assembly (3) from the

lower case housing (4)

4. Remove the blower motor and fan assembly

sub harness and bracket (5) from the blower

motor.

REINSTALL – LHD

Installation of the blower m otor and f an ass em bly is

the reverse order of removal procedures. Tighten

all screws to the specified torque.

BLOWER MOTOR AND FAN

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2B-84

LT Section – 08-150

REMOVE – RHD

1. Remove the left-hand side instrument panel lower trim plate assembly, refer to Section 1A3, 3.1

INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Disconnect the body harness connector to the

blower motor and fan assembly connector (1).

3. Remove the blower motor and fan assembly

cover screws (2) from the HVAC unit (3) and

move the cover (4) sufficiently to allow access

to the blower motor and fan assembly (5).

4. Remove the three blower motor and fan

assembly screws (6) and remove the blower

motor and fan assembly from the HVAC unit.

REINSTALL – RHD

Installation of the blower m otor and fan assem bly is

the reverse order of removal procedures. Tighten

all screws to the specified torque.

BLOWER MOTOR AND FAN ASSEMBLY

COVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

BLOWER MOTOR AND FAN ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2B-85

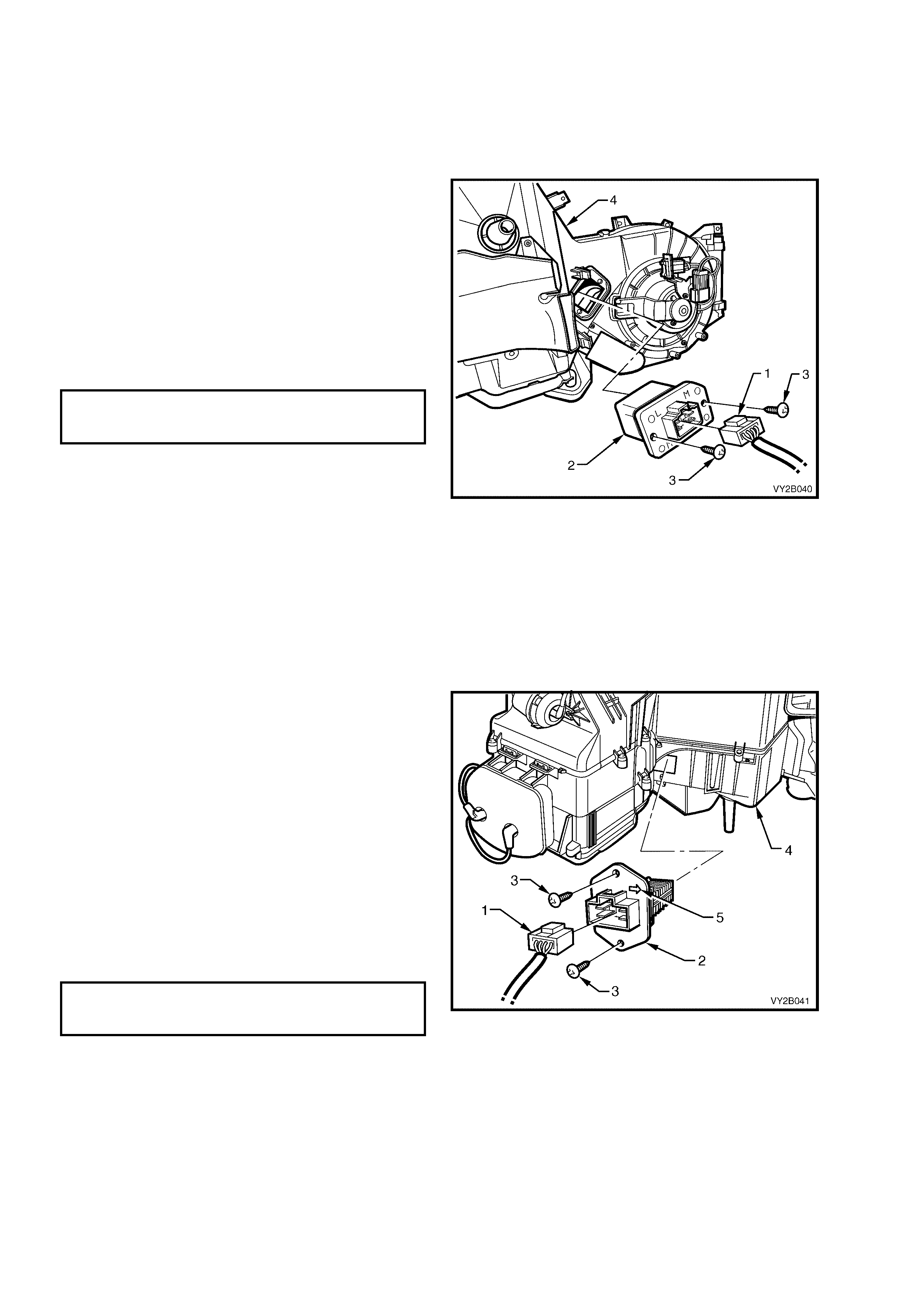

7. BLOWER MOTOR RESISTOR

REMOVE – LHD

1. Remove the right-hand side instrument panel lower trim plate assembly. Refer to

Section 1A3, 3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Remove the harness connector (1) from the

blower motor resistor (2).

3. Remove the two screws (3) retaining the

blower motor resistor to the HVAC unit (4).

4. Remove the blower motor resistor from below

the HVAC unit.

REINSTALL – LHD

Installation of the blower motor resistor is the

reverse order of removal procedures. Tighten all

screws to the specified torque.

BLOWER MOTOR RESISTOR

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2B-86

LT Section – 08-150

REMOVE – RHD

1. Remove the left-hand side instrument panel lower trim plate assembly. Refer to

Section 1A3, 3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Remove the instrument panel compartment assembly. Refer to Section 1A3, 3.2 INSTRUMENT PANEL

COMPARTMENT ASSEMBLY.

3. Remove the harness connector (1) from the

blower motor resistor (2).

4. Remove the two screws (3) attaching the

blower motor resistor to the side of the HVAC

unit (4).

5. Remove the blower motor resistor from the

HVAC unit.

REINSTALL – RHD

Installation of the blower motor resistor is the

reverse order of removal procedures noting the

following points:

1. Install the resistor with the arrow (5) pointing

towards the rear of the vehicle.

2. Tighten all screws to the specified torque.

BLOWER MOTOR RESISTOR

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2B-87

8. VACUUM TANK AND VACUUM ACTUATORS

8.1 VACUUM TANK

REMOVE – LHD

1. Remove the left-hand side instrument panel lower trim plate assembly. Refer to

Section 1A3, 3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

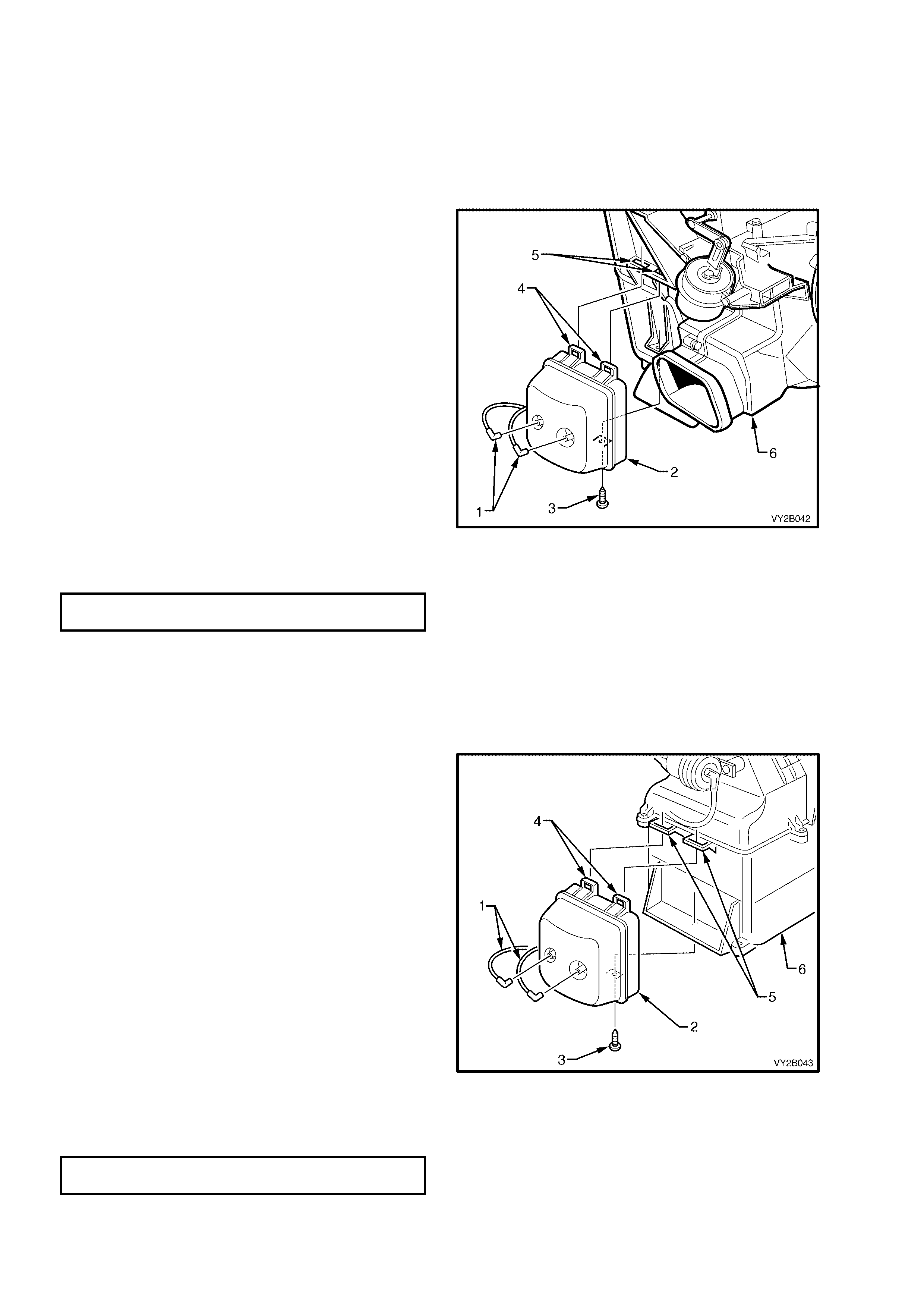

2. Remove the two vacuum lines (1) from the

vacuum tank (2).

3. Remove the screw (3) located under the

vacuum tank.

4. Move the lower section of the vacuum tank

outwards and move the tank downwards to

disengage the retaining tangs (4) from the

locating slots (5) on the side of the HVAC

case (6).

5. Remove the vacuum tank.

REINSTALL – LHD

Installation of the vacuum tank is the reverse order

of removal procedures noting the following points:

NOTE: Ensure that the vacuum lines are installed

correctly. The black vacuum line (vacuum source)

is connected to tank port closer to the engine bay.

The white vacuum line is c onnected to the tank port

closer to the cabin.

1. Tighten all screws to the specified torque.

VACUUM TANK ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2B-88

LT Section – 08-125

REMOVE – RHD

1. Remove the left-hand side instrument panel lower trim plate assembly. Refer to

Section 1A3, 3.1. INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY

2. Remove the two vacuum lines (1) from the

vacuum tank (2).

3. Remove the screw (3) located under the

vacuum tank.

4. Move the lower section of the vacuum tank

outwards and move the tank downwards to

disengage the retaining tangs (4) from the

locating slots (5) on the side of the HVAC

case (6).

5. Remove the vacuum tank.

REINSTALL – RHD

Installation of the vacuum tank is the reverse order

of removal procedures noting the following points:

NOTE: Ensure that the vacuum lines are installed

correctly. The vacuum line with larger connecting

elbow (vacuum source) is connected to tank port

closer to the engine bay. The vacuum line with the

smaller connecting elbow is connected to the tank

port closer to the cabin.

1. Tighten all screws to the specified torque.

VACUUM TANK ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2B-89

8.2 FRESH/RECIRCULATION (INTAKE) ACTUATOR

REMOVE – LHD

1. Remove the left-hand side instrument panel lower trim plate assembly. Refer to

Section 1A3, 3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Remove the BCM. Refer to Section 12J, 2.1 BODY CONTROL MODULE.

3. Remove the vacuum line (1) from the vacuum actuator (2).

4. Remove the e-clip (3), bushes (4) and actuator rod (5) from the lever (6).

5. Remove the vacuum actuator attaching screws (7).

6. Remove the vacuum actuator.

Figure 2B-90

REINSTALL – LHD

Installation of the fresh/recirculation (intake) vacuum actuator is in the reverse order of removal procedures noting

the following points:

1. Tighten all screws to the specified torque.

FRESH/RECIRCULATION

ACTUATOR ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

REMOVE – RHD

LT Section – 08-150

1. Remove the left-hand side instrument panel lower trim plate assembly. Refer to

Section 1A3, 3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Rem ove the left-hand s ide instrum ent panel outer cover. Ref er to Section 1A3, 3.17 INSTRUMENT PANEL

OUTER COVER.

3. Remove the vacuum tank. Refer to 8.1 VACUUM TANK in this Section.

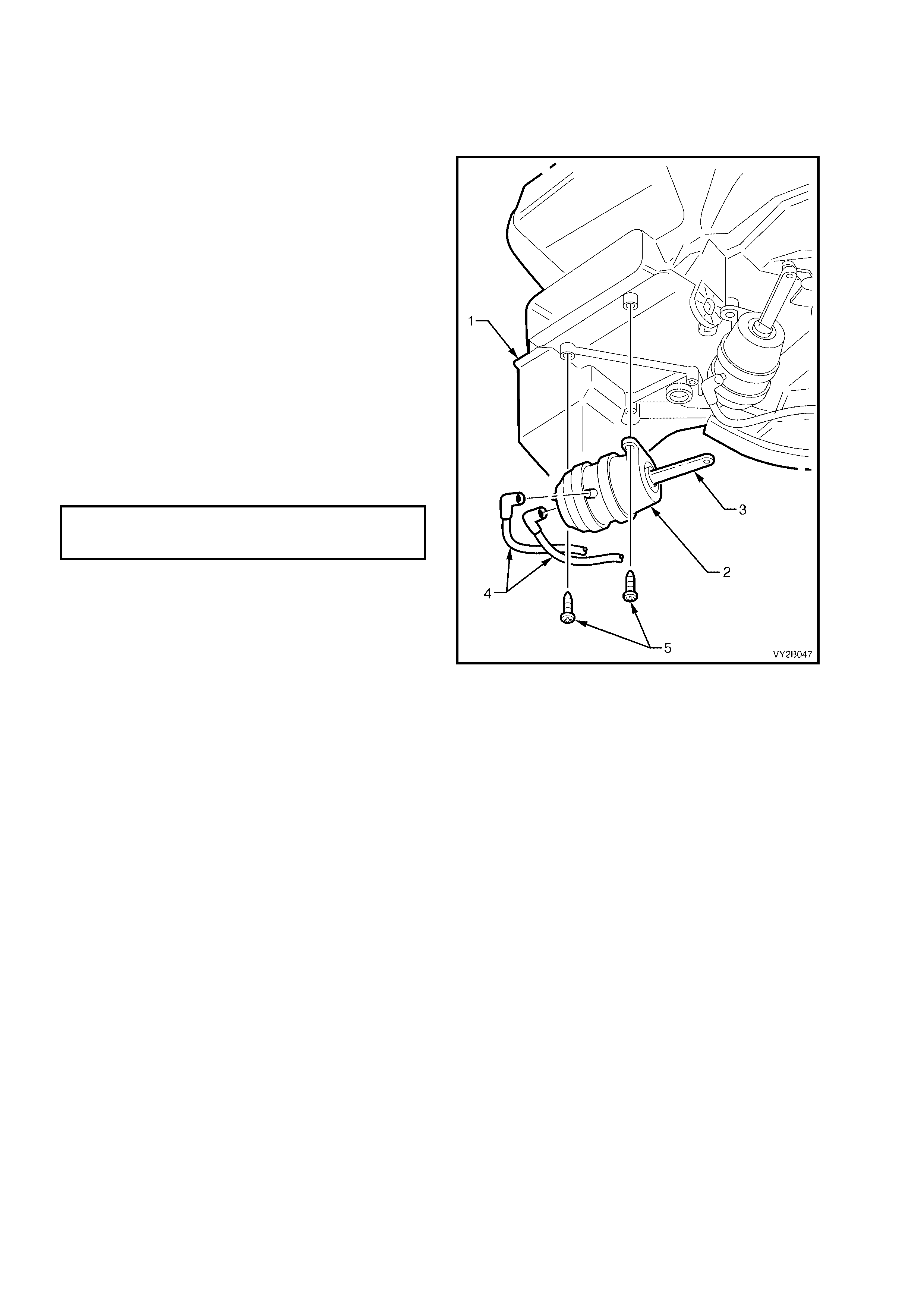

4. Remove the vacuum line (1) at the vacuum

actuator (2).

5. Remove the vacuum actuator rod (3) from the

vacuum actuator lever (4).

6. Remove the two screws (5).

7. Remove the vacuum actuator.

REINSTALL – RHD

Installation of the fresh/recirculation vacuum

actuator is the r ever se or der of re moval procedur es

noting the following:

1. Tighten all screws to the specified torque.

FRESH/RECIRCULATION

ACTUATOR ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

Figure 2B-91

8.3 FACE ACTUATOR

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

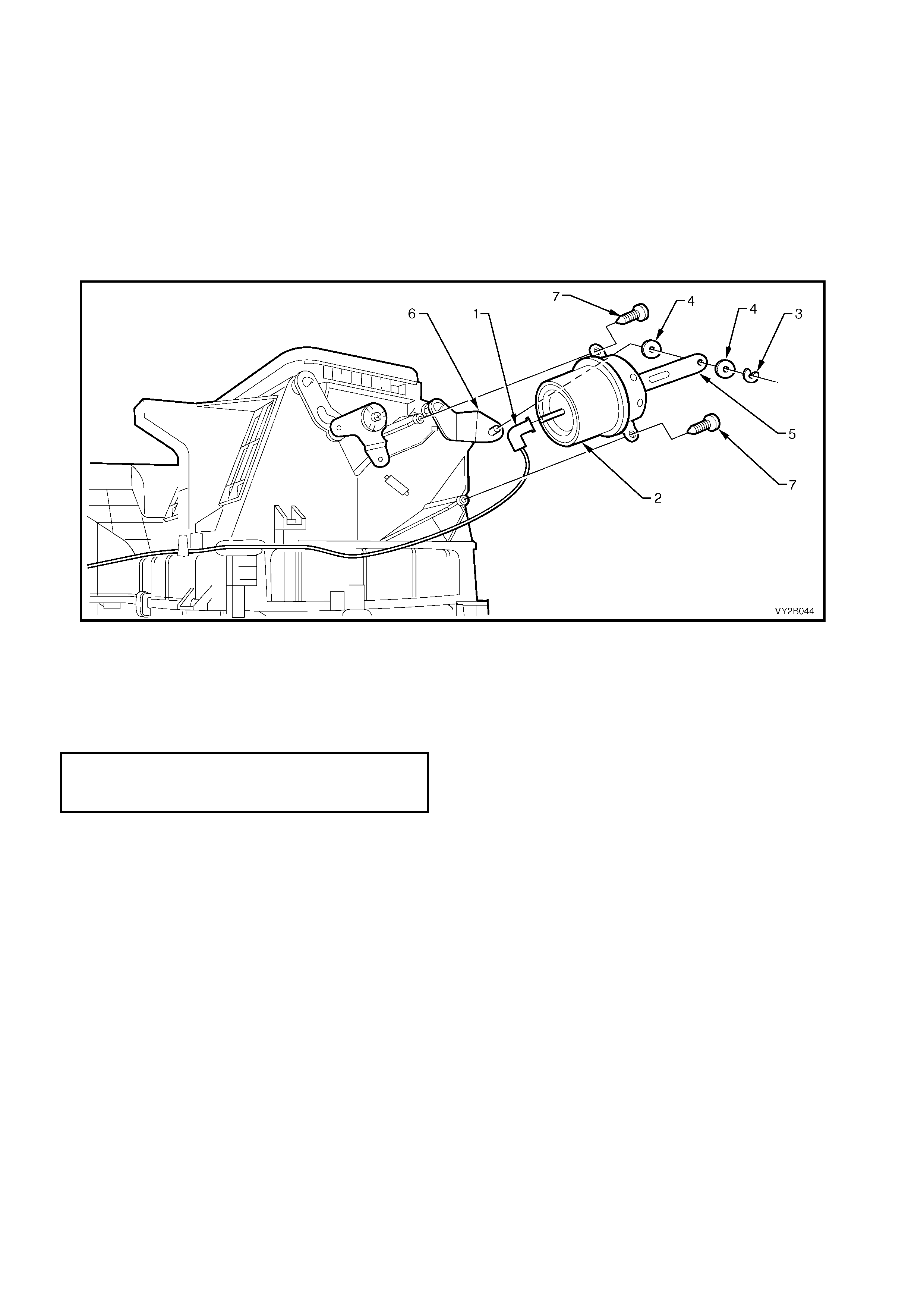

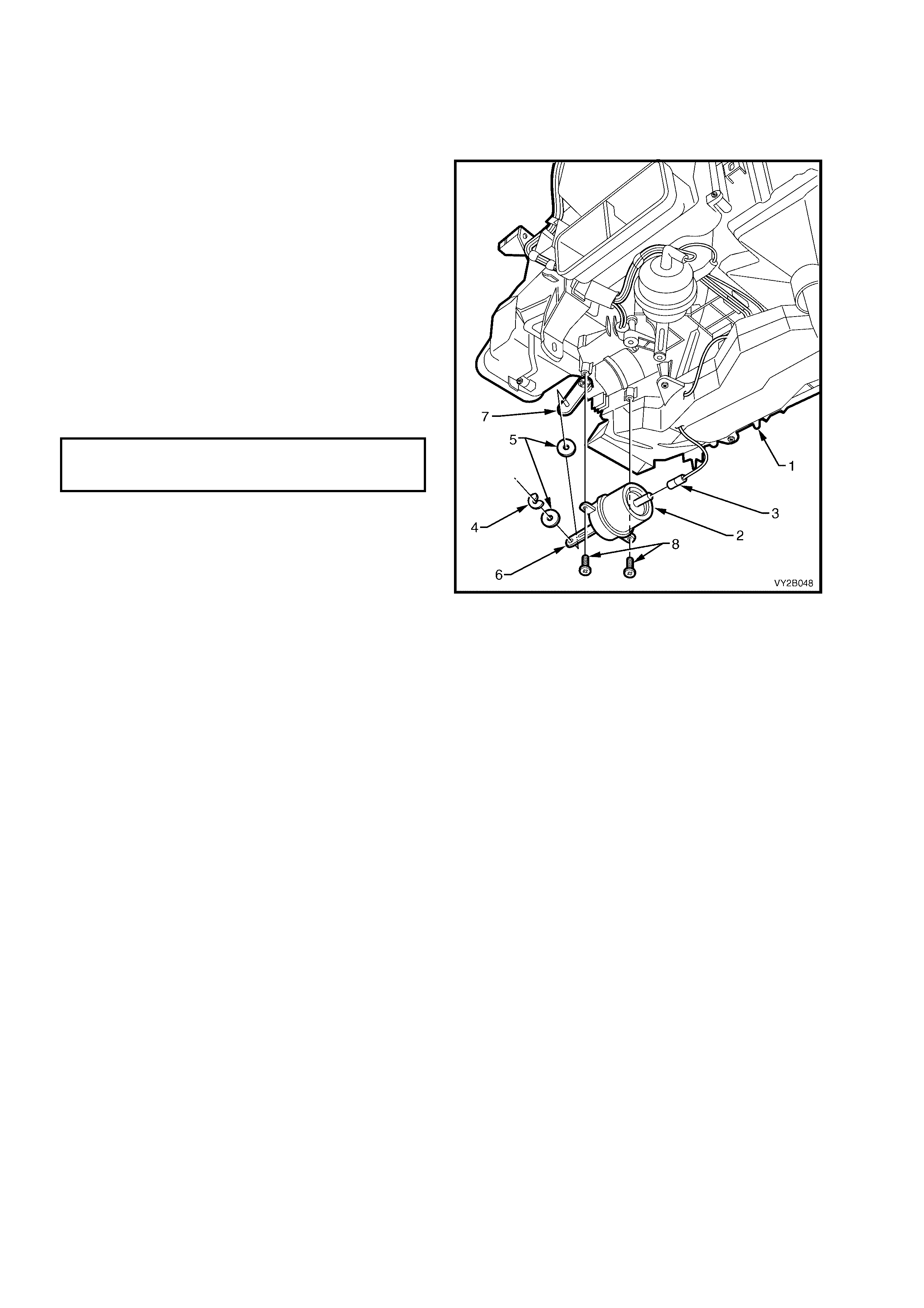

2. From the underside of the HVAC unit (1),

locate the face actuator (2).

3. Remove the vac uum lines (3) from the vacuum

actuator.

4. Remove the e-clip (4), rod bushes (5) and the

actuator rod (6) from the lever (7).

5. Remove the two vacuum actuator nuts (8).

6. Remove the vacuum actuator.

REINSTALL – LHD

Installation of the face vacuum actuator is the

reverse order of removal procedures noting the

following points:

NOTE: Ensure that the vacuum lines are installed

correc tly. The blue vac uum line is c onnected to the

side of the face actuator. The white vacuum line is

connected to the back of the face actuator.

1. Tighten the nuts to the specified torque.

FACE ACTUATOR

ATTACHING NUT

TORQUE SPECIFICATION 3.0 – 5.0 Nm

Figure 2B-92

LT Section – 08-150

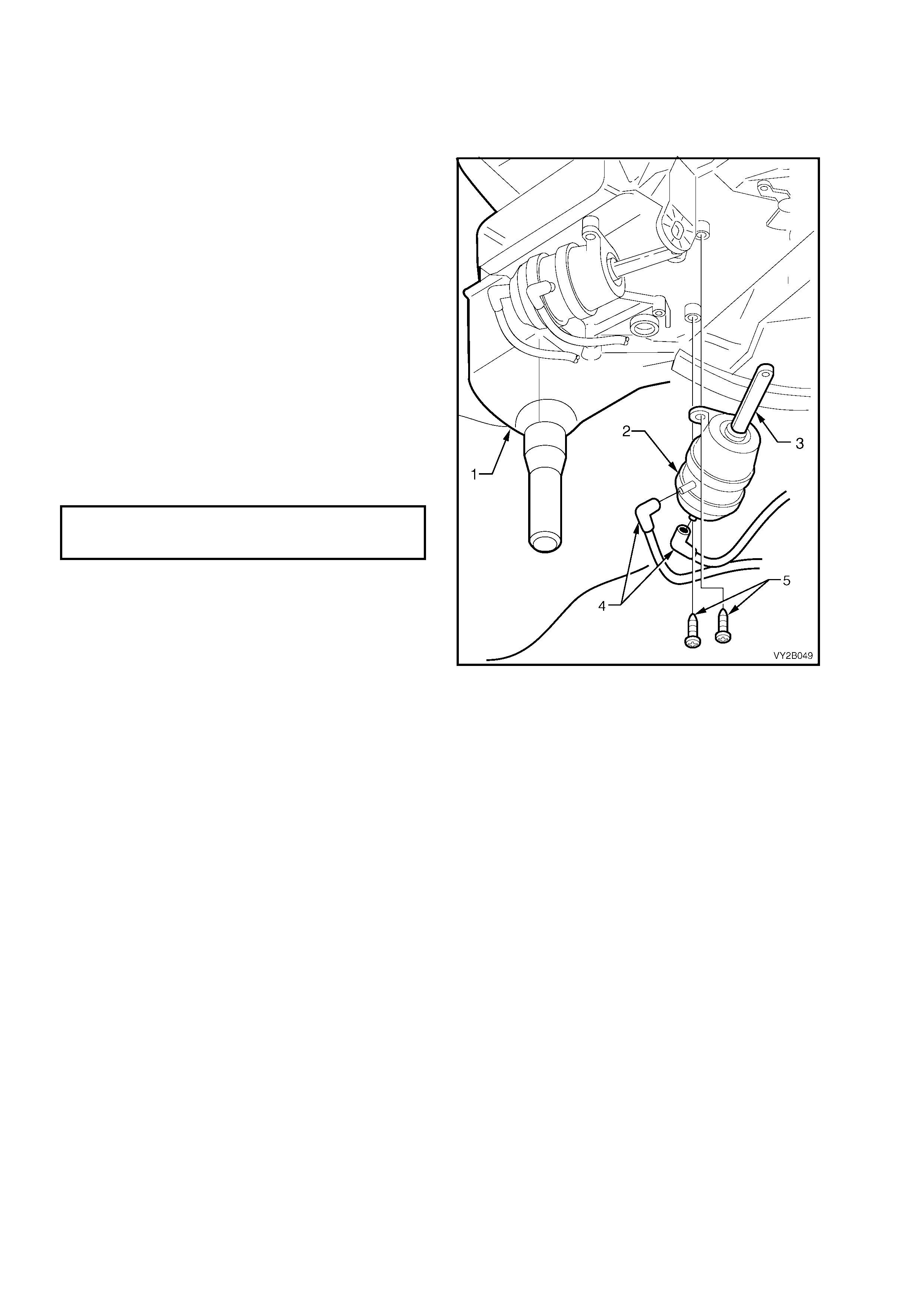

REMOVE – RHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

2. From the underside of the HVAC unit (1),

locate the face actuator (2).

3. Remove the vacuum actuator rod (3) from the

door lever.

4. Remove the vac uum lines (4) from the vacuum

actuator.

5. Remove the two vacuum actuator attaching

screws (5).

REINSTALL – RHD

Installation of the face vacuum actuator is the

reverse order of removal procedures noting the

following points:

NOTE: Ensure that the vacuum lines are installed

correctly. The green vacuum line is connected to

the side of the face actuator. The white vacuum line

is connected to the back of the face actuator.

1. Tighten the screws to the specified torque.

FACE ACTUATOR

ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

Figure 2B-93

8.4 FOOT ACTUATOR

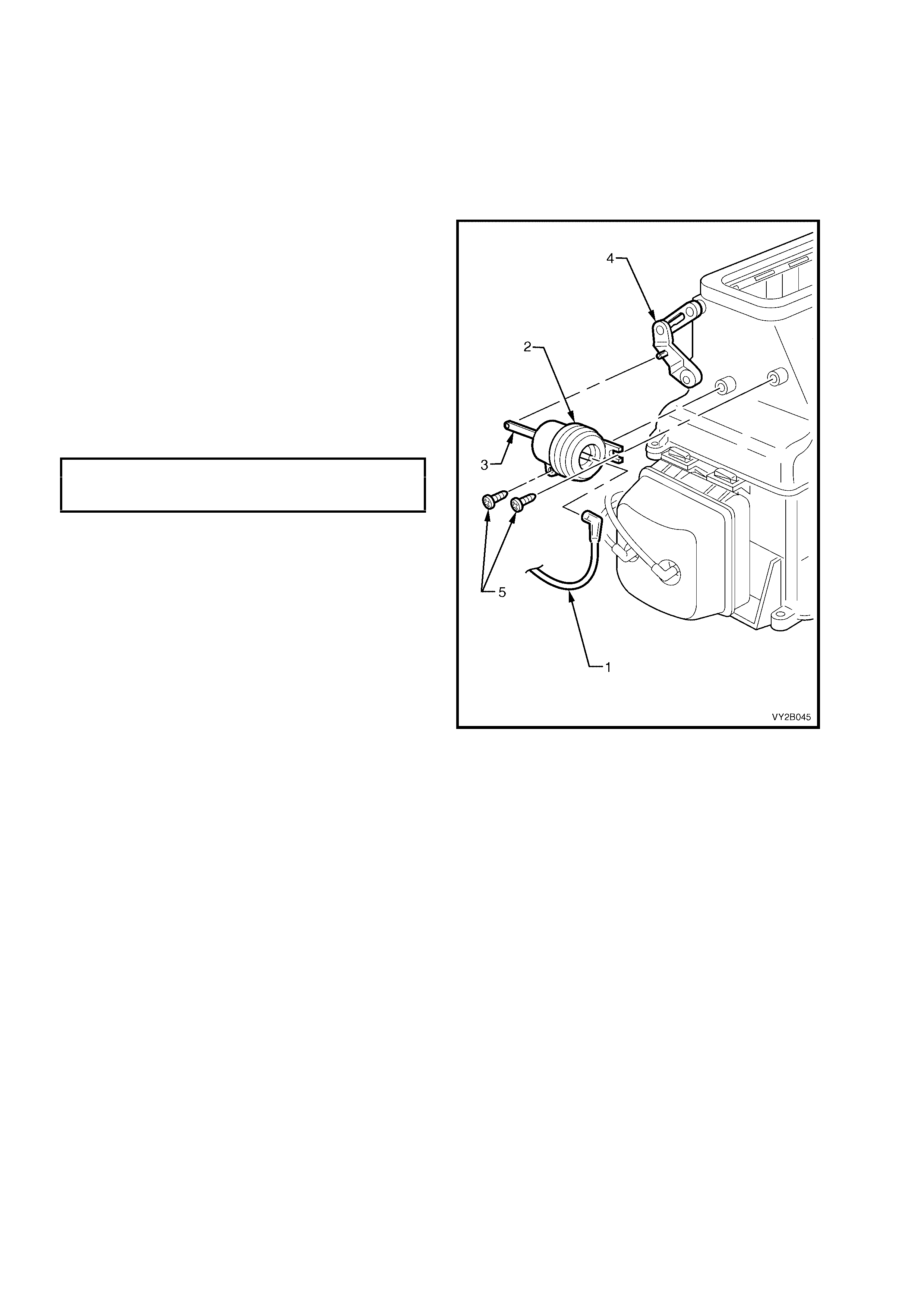

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

2. From the underside of the HVAC unit (1),

locate the foot actuator (2).

3. Remove the vacuum line (3) from the vacuum

actuator.

4. Remove the e-clip (4), rod bushes (5) and the

actuator rod (6) from the lever (7).

5. Remove the vacuum actuator two screws (8).

5. Remove the vacuum actuator.

REINSTALL – LHD

Installation of the foot vacuum actuator is the

reverse order of removal procedures noting the

following:

1. Tighten the screws to the specified torque.

FOOT ACTUATOR

ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

Figure 2B-94

LT Section – 08-150

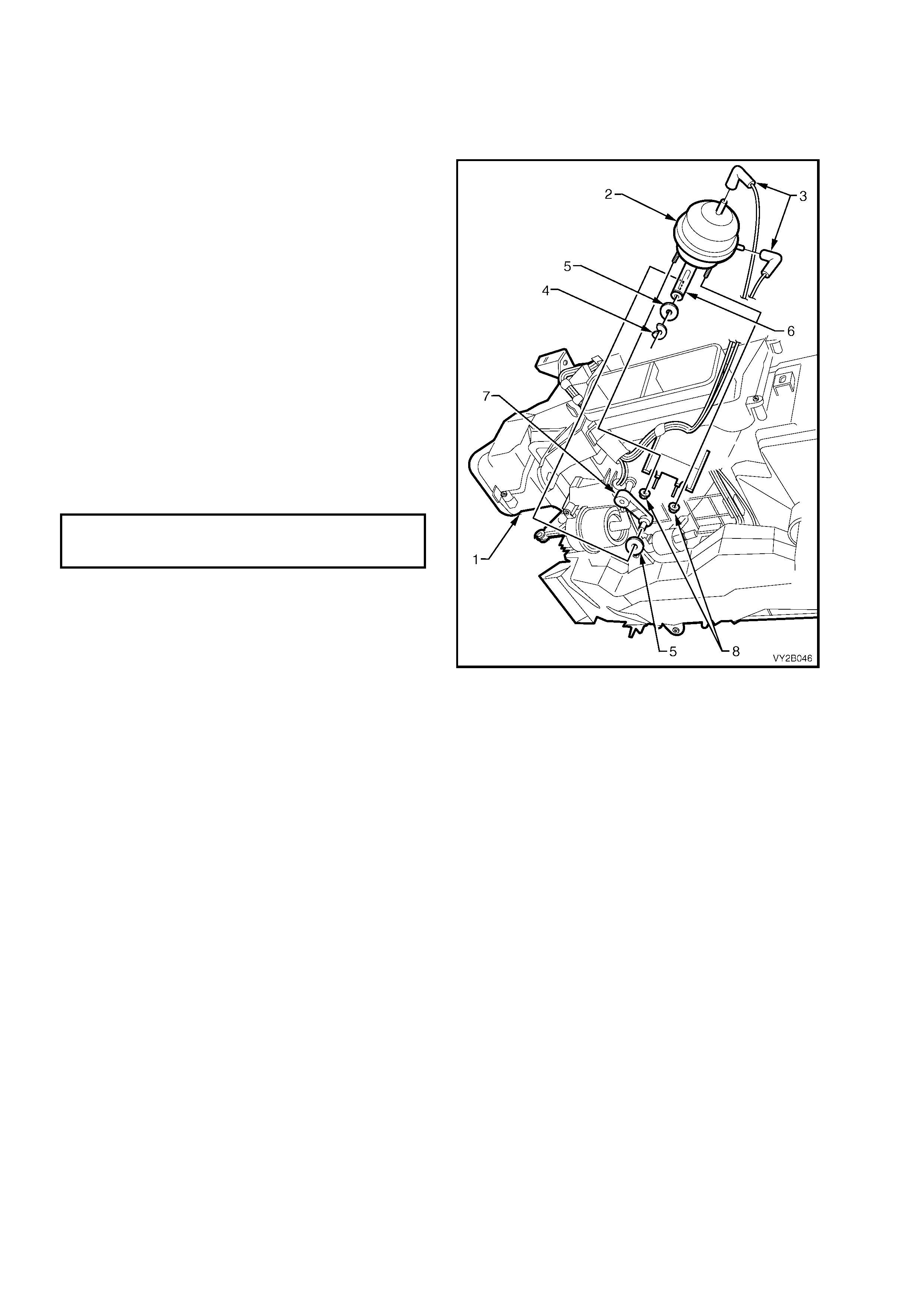

REMOVE – RHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to 3. HEATING, VENTILATION

AND AIR CONDITIONING (HVAC) UNIT in this Section.

2. From the underside of the HVAC unit (1),

locate the foot actuator (2).

3. Remove the vacuum actuator rod (3) from the

door lever.

4. Remove the vac uum lines (4) from the vacuum

actuator.

5. Remove the two vacuum actuator attaching

screws (5).

REINSTALL – RHD

Installation of the foot vacuum actuator is the

reverse order of removal procedures noting the

following points:

NOTE: Ensure that the vacuum lines are installed

correctly. The orange vacuum line is connected to

side of the foot actuator. The pink vacuum line is

connected to the back of the foot actuator.

1. Tighten all screws to the specified torque.

FOOT ACTUATOR

ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

Figure 2B-95

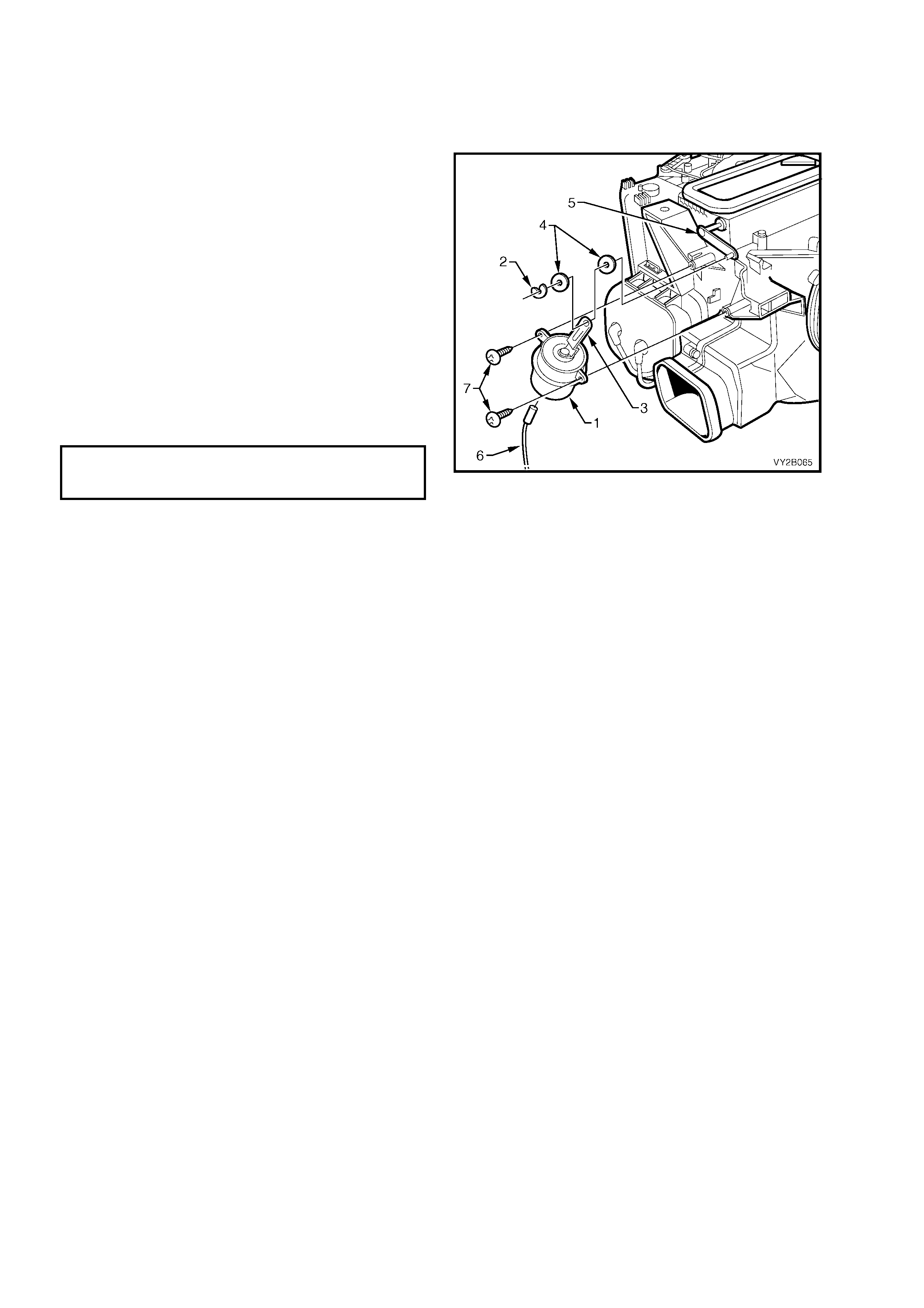

8.5 DEMIST ACTUATOR – LHD ONLY

REMOVE

1. Remove instrument cluster. Refer to Section 1A3, 3.14 INSTRUMENT CLUSTER.

2. Lower the instrument panel lower trim panel assembly.

3. Through the aperture in the instrument panel,

locate the vacuum actuator (1) and remove the

e-clip (2) and the actuator rod (3), rod

bushes (4) from the lever (5).

4. Remove the vacuum line (6) from the vacuum

actuator.

5. Remove the two vacuum actuator attaching

screws (7).

6. Remove the vacuum actuator.

REINSTALL

Installation of the demist vacuum actuator is the

reverse order of removal procedures noting the

following:

1. Tighten all screws to the specified torque.

DEMIST ACTUATOR

ATTACHING SCREW

TORQUE SPECIFICATION 3.0 – 5.0 Nm

Figure 2B-96

9. AI R CONDI TIONING HOSE AND PI PE CONNECTI O NS AND RETAI NERS

LT Section – 08-200

REMOVE AND REINSTALL

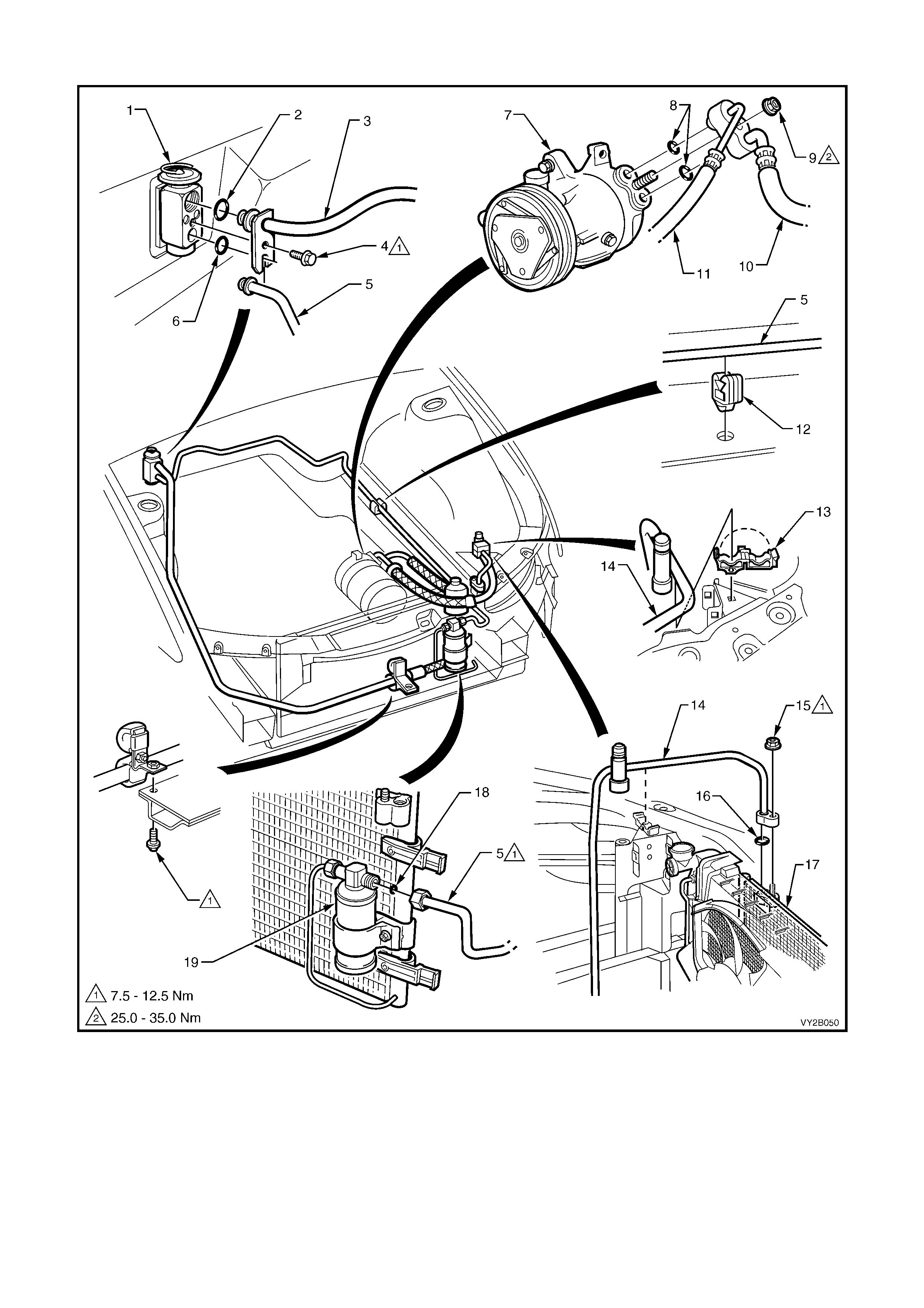

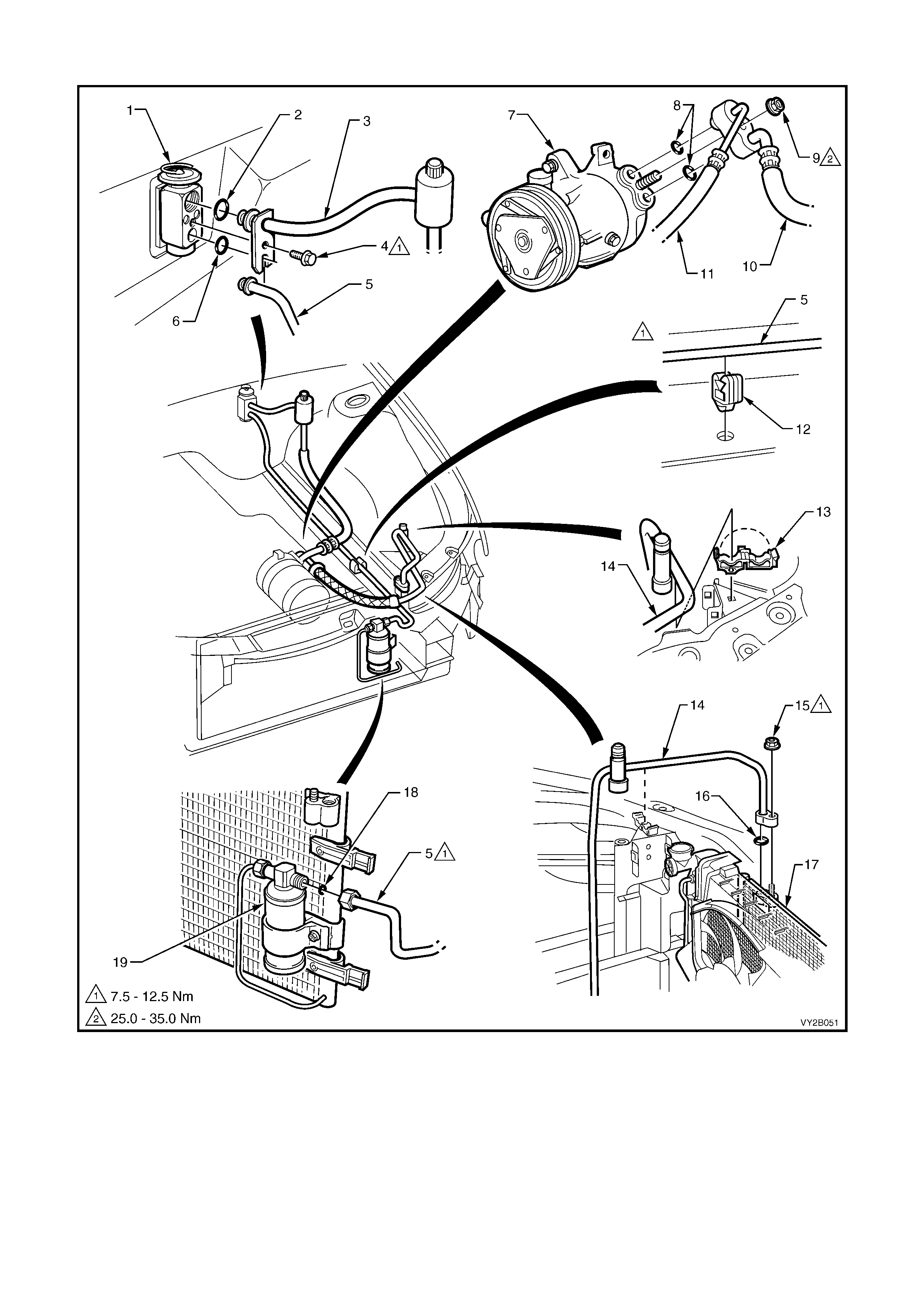

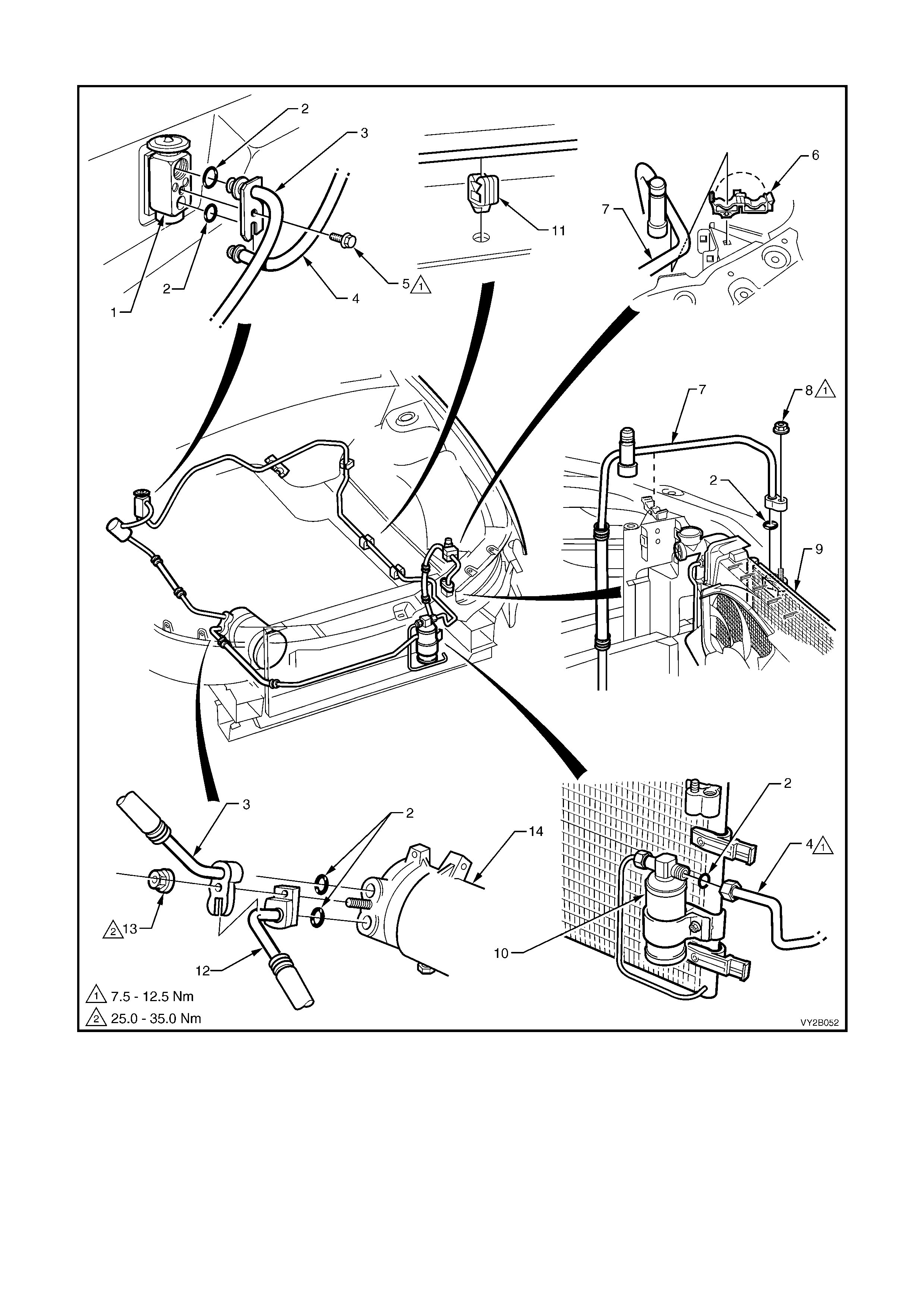

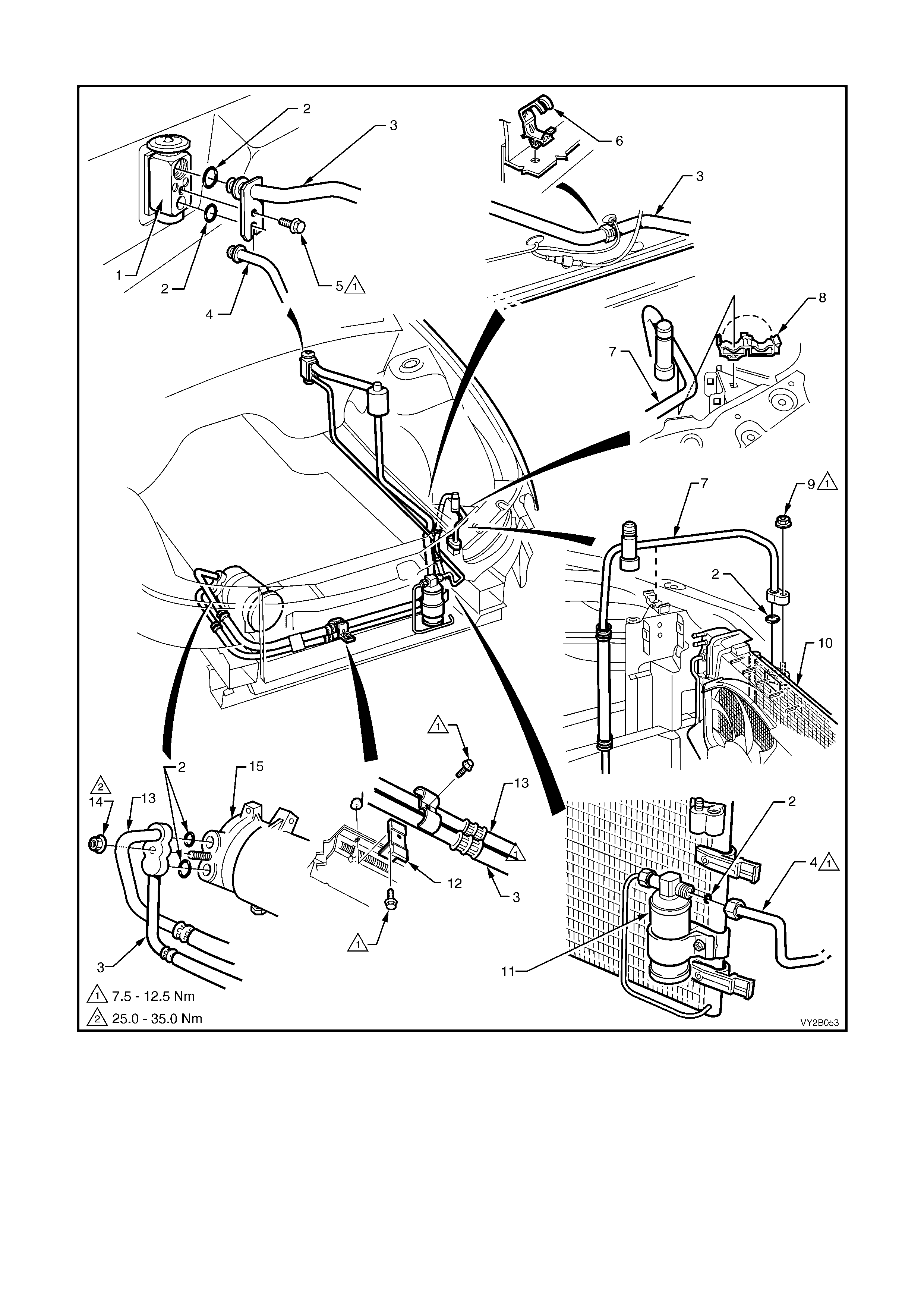

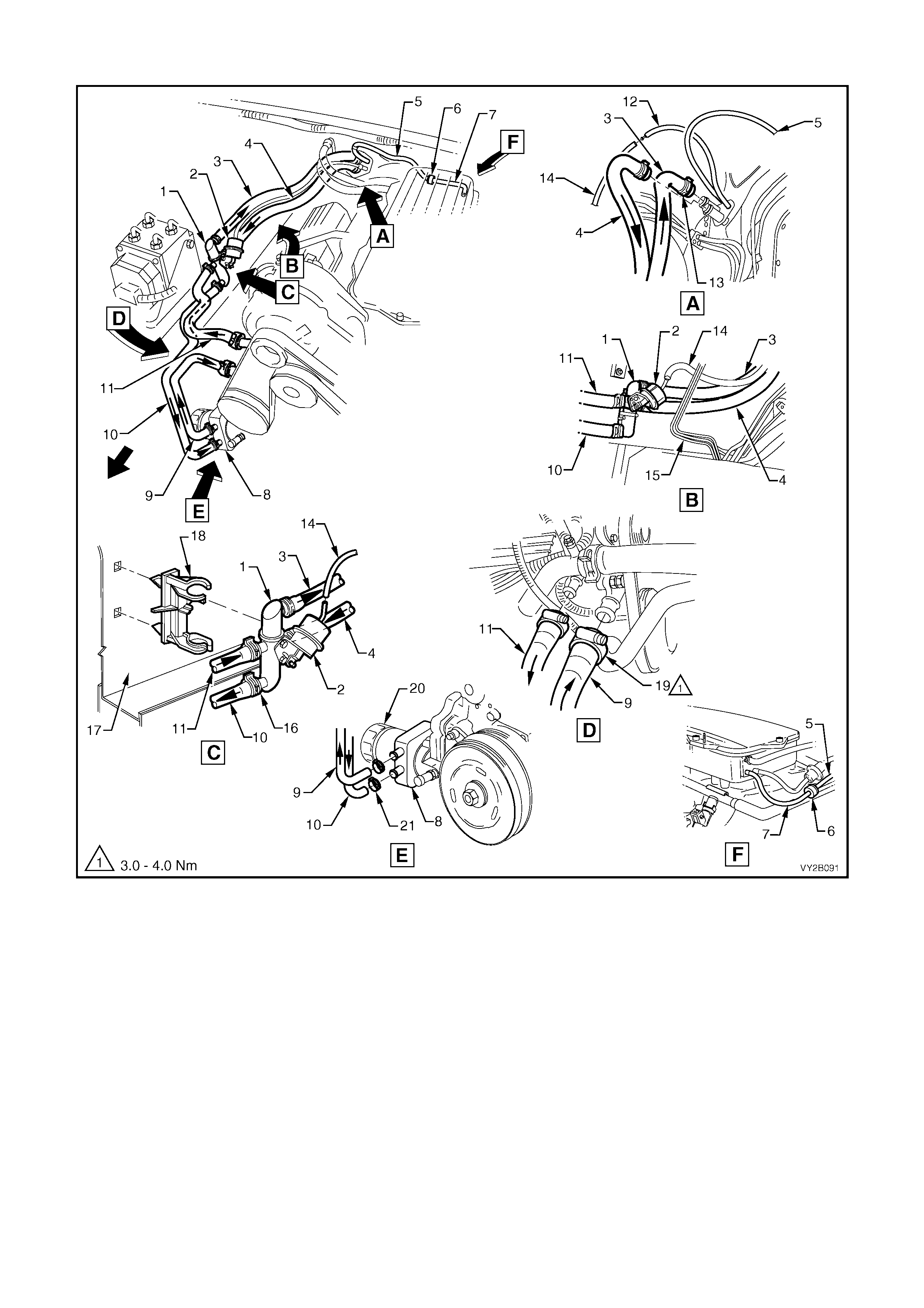

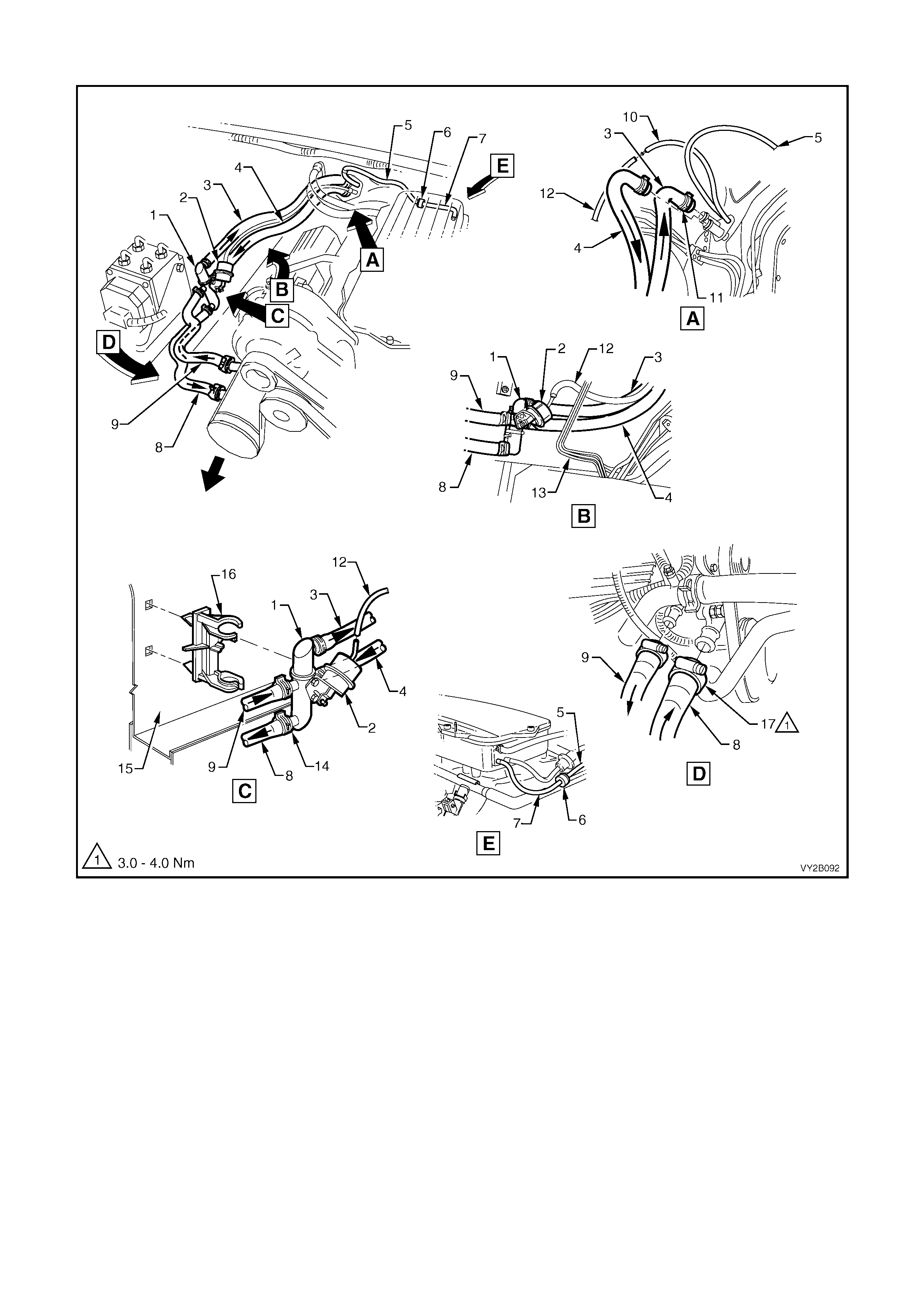

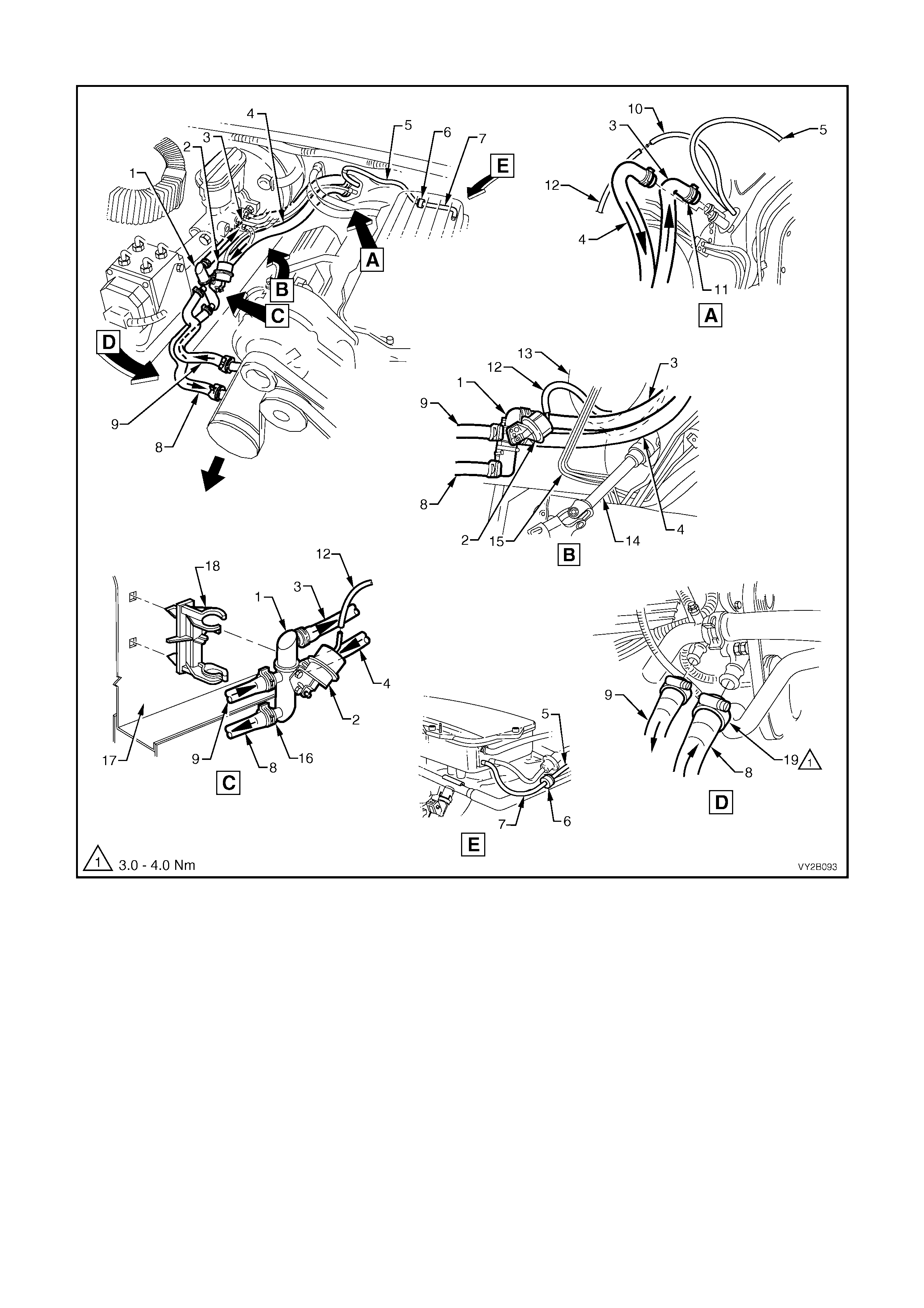

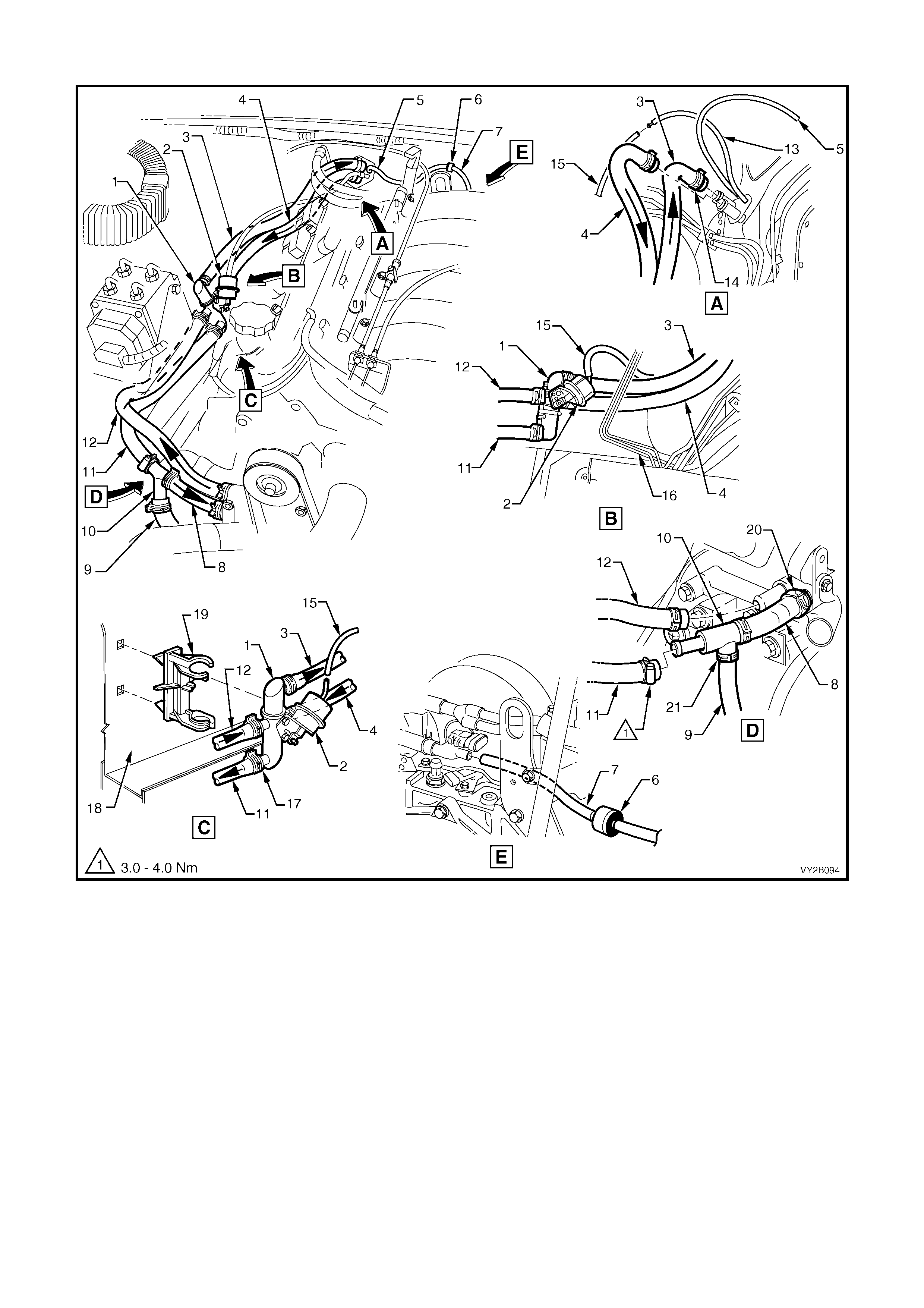

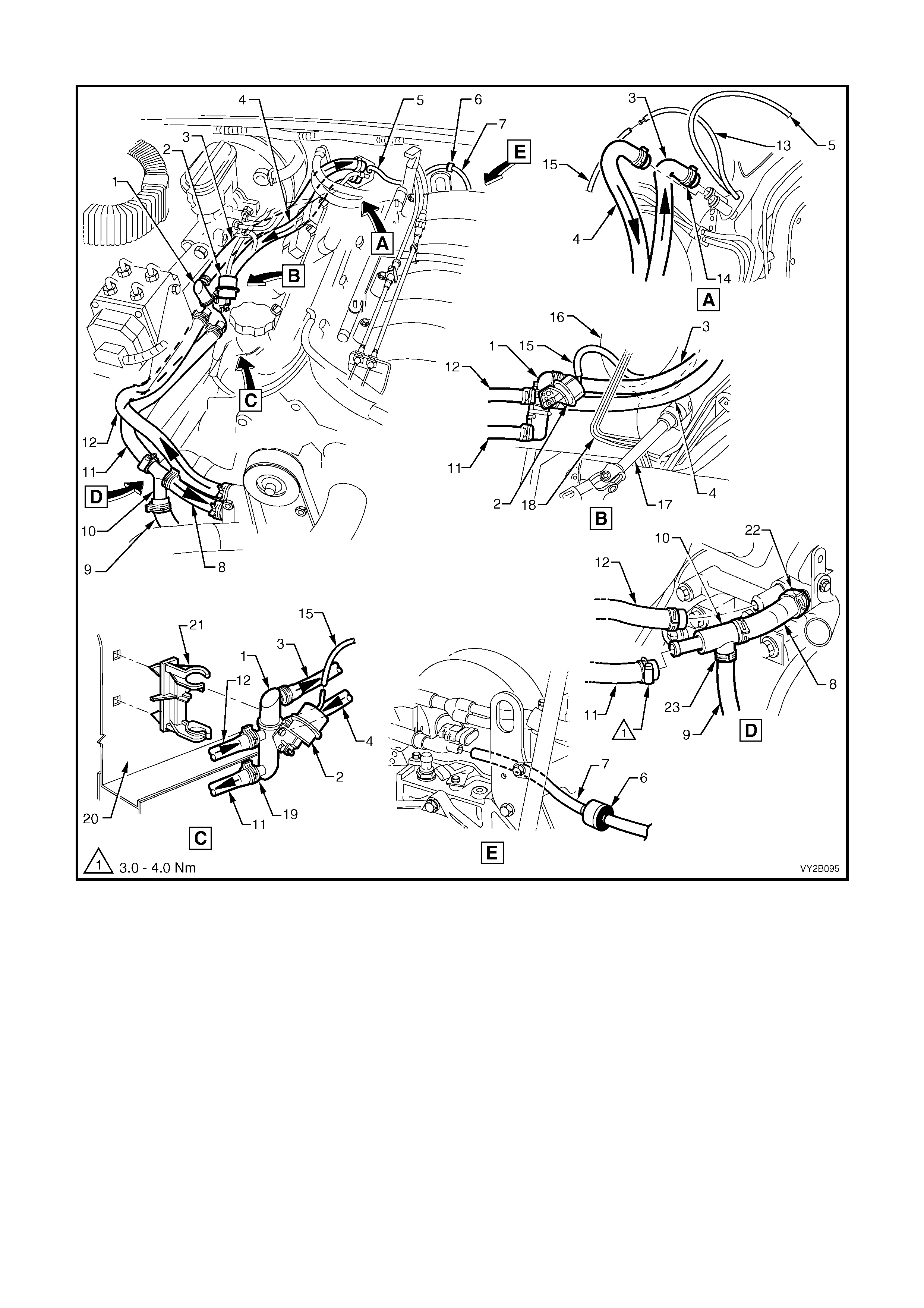

The following four Figures provide under hood views of the air conditioning hose and pipe connections, and

retainers. Refer to these Figures when removing and installing these components.

• For V6 left-hand drive models, refer to Figure 2B-62

• For V6 and V6 Supercharged right-hand drive models, refer to Figure 2B-63

• For GEN III V8 left-hand drive models, refer to Figure 2B-64

• For GEN III V8 right-hand drive models, refer to Figure 2B-6 5

IMPORTANT: The total quantity of lubricating oil in the air conditioning system must be maintained. If a

compressor, evaporator, condenser, filter drier receiver, hose or pipe is to be replaced, a specified quantity of

lubricating oil must be added to the system to compensate for oil removed with the original component. Refer to

Section 2C, 2.4 LUBRICATING OIL COMPENSATION.

Techline

A/C HOSE AND PIPE CONNECTIONS, AND RETAINERS – V6 ENGINE LHD

Figure 2B-97

Legend

1. Thermal Expansion Valve

(TXV) 6. O-ring – TXV

Discharge 11. Discharge Hose/

Tube 16. O-ring – Condenser

2. O-ring – TXV Suction 7. Compressor 12. Liquid Tube Clip 17. Condenser

3. Suction Tube 8. O-ring – Compressor 13. Discharge Tube Clip 18. O-ring – FDR

4. Screw 9. Nut 14. Discharge Tube 19. Filter Drier Receiver

5. Liquid Tube 10. Suction Hose/Tube 15. Nut (FDR)

A/C HOSE AND PIPE CONNECTIONS, AND RETAINERS – V6 AND V6 SUPERCHARGED ENGINES RHD

Figure 2B-98

Legend

1. Thermal Expansion Valve

(TXV) 6. O-ring – TXV

Discharge 11. Discharge Hose/

Tube 16. O-ring – Condenser

2. O-ring – TXV Suction 7. Compressor 12. Liquid Tube Clip 17. Condenser

3. Suction Tube 8. O-ring – Compressor 13. Discharge Tube Clip 18. O-ring – FDR

4. Screw 9. Nut 14. Discharge Tube 19. Filter Drier Receiver

5. Liquid Tube 10. Suction Hose/Tube 15. Nut (FDR)

A/C HOSE AND PIPE CONNECTIONS, AND RETAINERS – GEN III V8 ENGINE LHD

Figure 2B-99

Legend

1. Thermal Expansion Valve (TXV) 6. Discharge Tube Retaining Clip 11. Retaining Clamp

2. O-Ring 7. Discharge Tube 12. Discharge Hose/Tube

3. Suction Hose/Tube 8. Discharge Tube Retaining Nut 13. Retaining Nut

4. Liquid Tube 9. Condenser 14. Compressor

5. Retaining Screw 10. Filter Drier Receiver (FDR)

A/C HOSE AND PIPE CONNECTIONS, AND RETAINERS – GEN III V8 ENGINE RHD

Figure 2B-100

Legend

1. Thermal Expansion Valve (TXV) 6. Suction Tube Retaining Clip 11. Filter Drier Receiver (FDR)

2. O-Ring 7. Discharge Tube 12. Retaining Clamp

3. Discharge Hose/Tube 8. Discharge Tube Retaining Clip 13. Suction Hose/Tube

4. Liquid Tube 9. Discharge Tube Retaining Nut 14. Retaining Nut

5. Retaining Screw 10. Condenser 15. Compressor

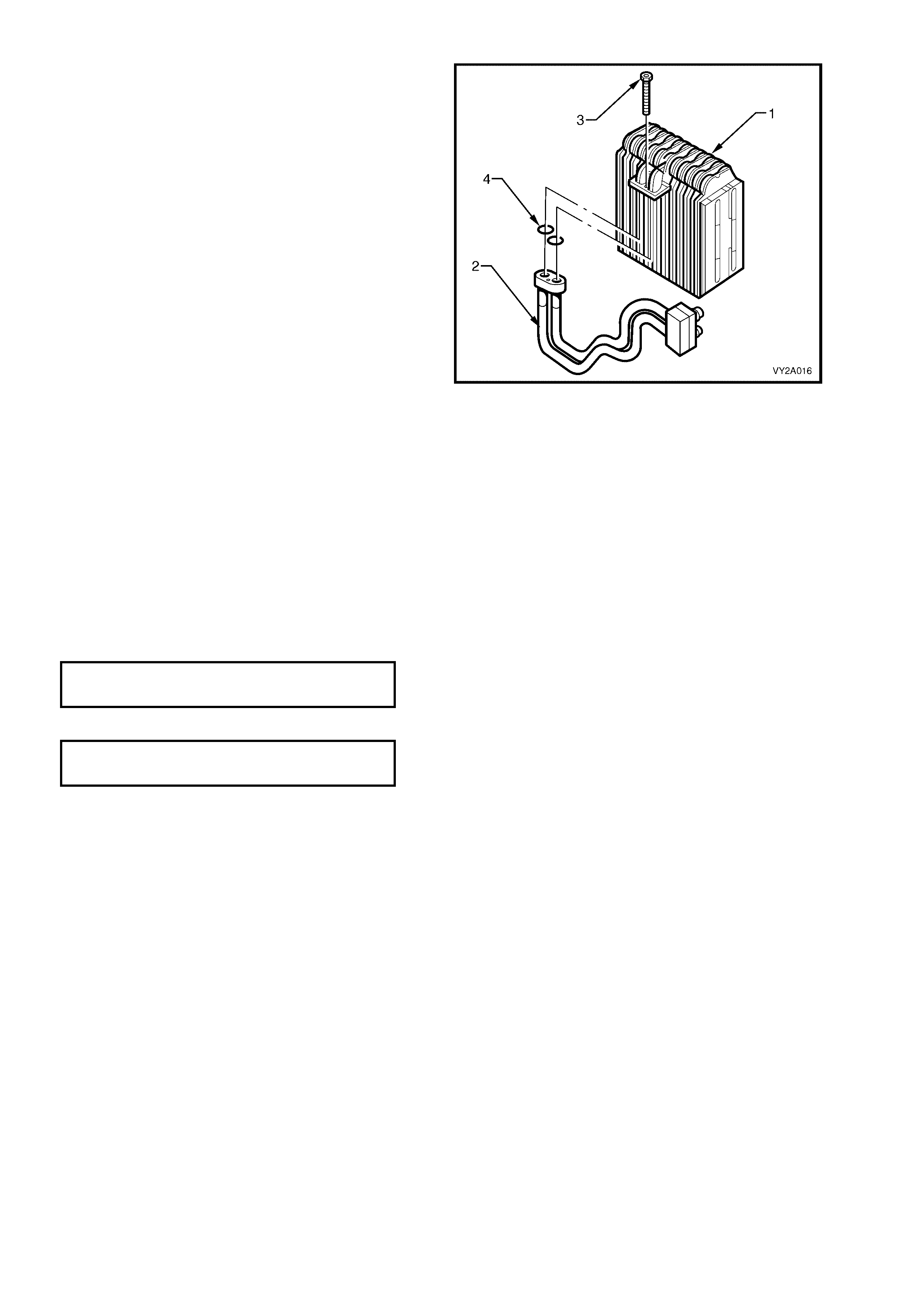

10. THERMAL EXPANSION VALVE (TXV)

LT Section – 08-200

REMOVE

1. Recover the refrigerant from the A/C system, refer to Section 2C, 2.1 SYSTEM CHARGING AND

EVACUATION.

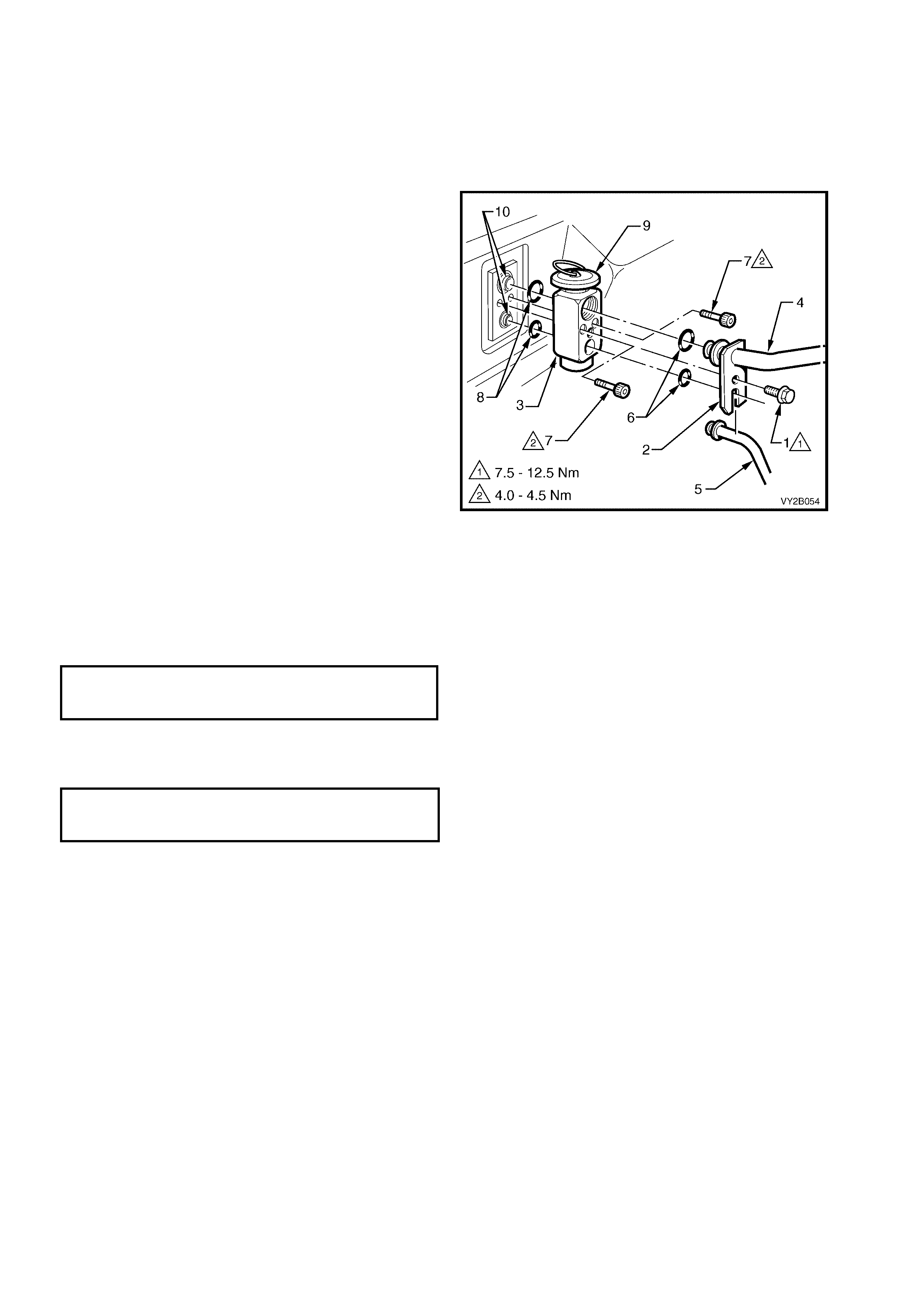

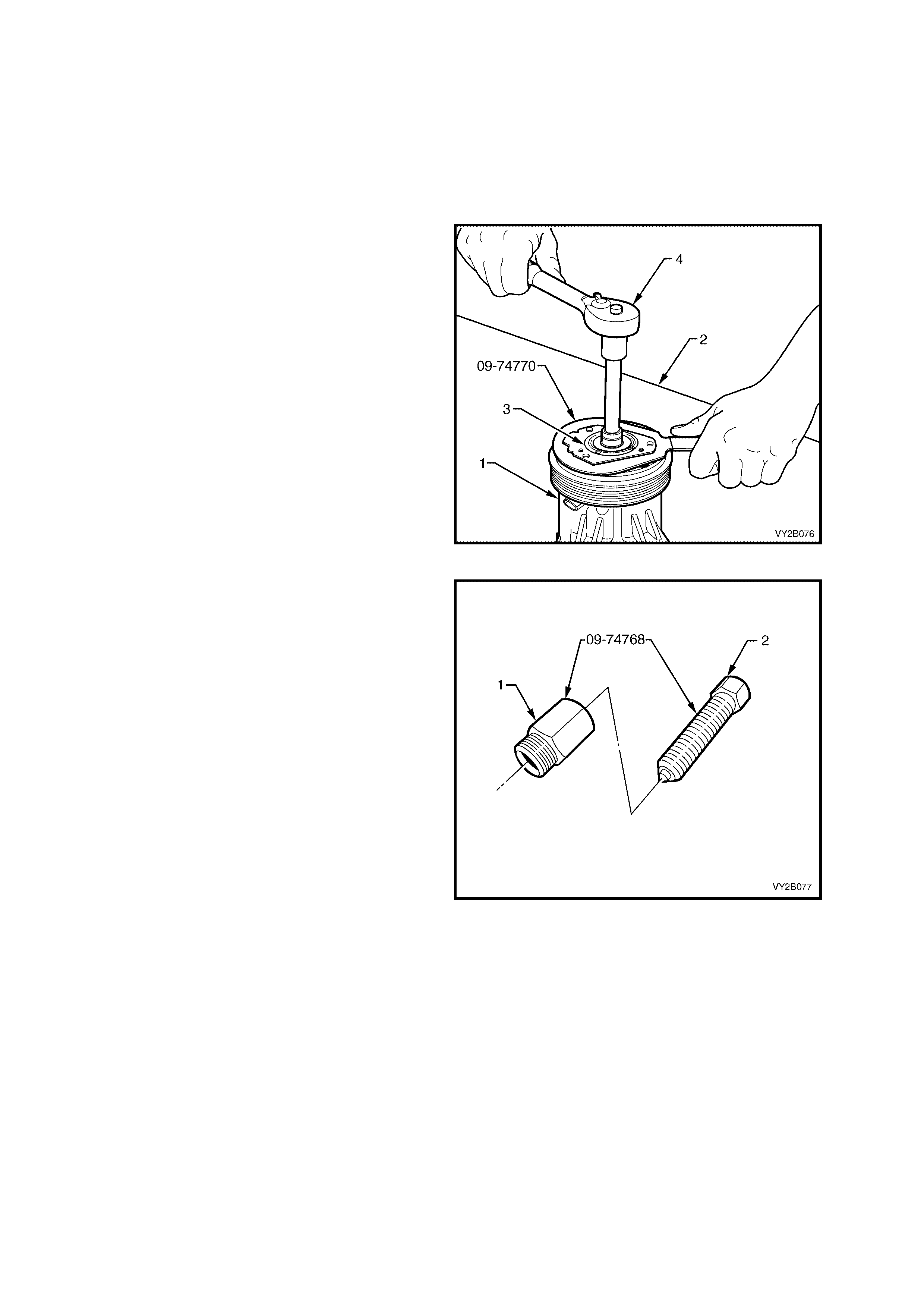

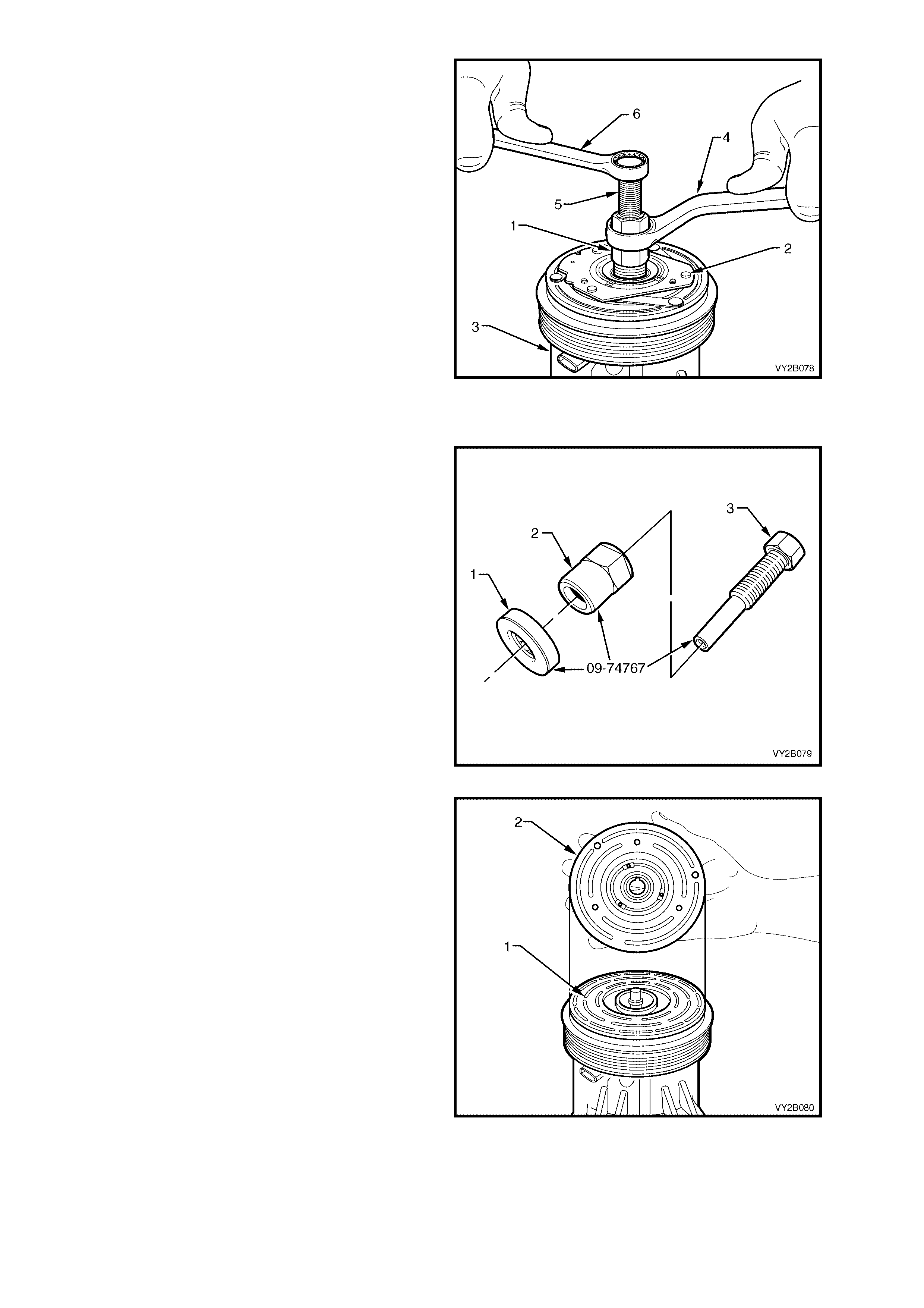

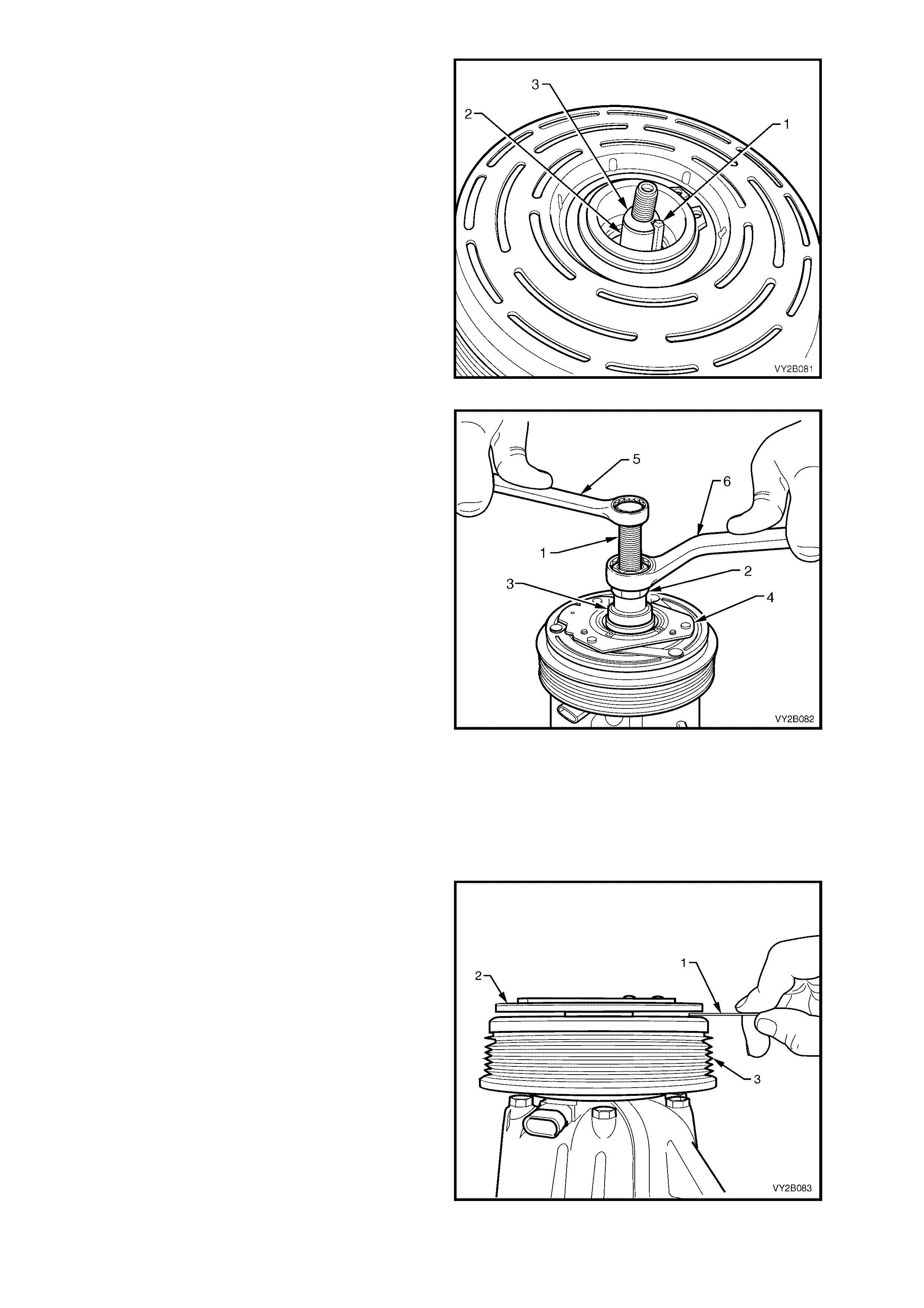

2. Remove the washer f ac ed sc r ew (1) retaining the

tube plate (2) to the Thermal Expansion

Valve (TXV) (3).

3. Remove the plate/suction tube (4) and the liquid

tube (5).

4. Remove and discard the liquid and suction line

O-rings (6).

5. Unscrew the two cap screws (7) and remove the

TXV.

6. Remove and discard the evaporator tube

O-rings (8).

REINSTALL

NOTE: The total quantity of lubricating oil in the air

conditioning system must be maintained. If

lubricating oil loss has occurred during TXV

replacement, oil must be added to the system to

compensate.

1. Lubricate and fit two new O-rings to the

evaporator tubes.

2. Install the TXV with the diaphragm (9) facing

upwards, onto the evaporator tubes (10).

3. Secure the TXV to the evaporator tube plate

using the two cap screws.

TXV TO EVAPORATOR TUBES

SECURING SCREWS

TORQUE SPECIFICATION 4.0 – 4.5 Nm

Figure 2B-101

4. Fit two new lubricated O-rings to the suction tube and liquid tube.

5. Install the liquid and suction tubes and retaining plate onto the TXV.

6. Secure using original washer faced screw.

LIQUID AND SUCTION TUBE

RETAINING PLATE TO TXV SCREW

TORQUE SPECIFICATION 7.5 – 12.5 Nm

7. Evacuate and charge the A/C system with 775 – 825 g of R134a refrigerant, refer to

Section 2C, 2.1 SYSTEM CHARGING AND EVACUATION.

11. A/ C PRESSURE TRANSDUCER

LT Section – 08-200

REMOVE AND REINSTALL

To remove and install the A/C pressure transducer, refer to the following:

• For V6 engines: Section 6C1-3, 6.4 A/C REFRIGERANT SENSOR.

• For V6 Supercharged engines: Section 6C2-3, 6.6 A/C REFRIGERANT SENSOR

• For GEN III V8 engines: Section 6C3-3, 5.3 A/C REFRIGERANT SENSOR

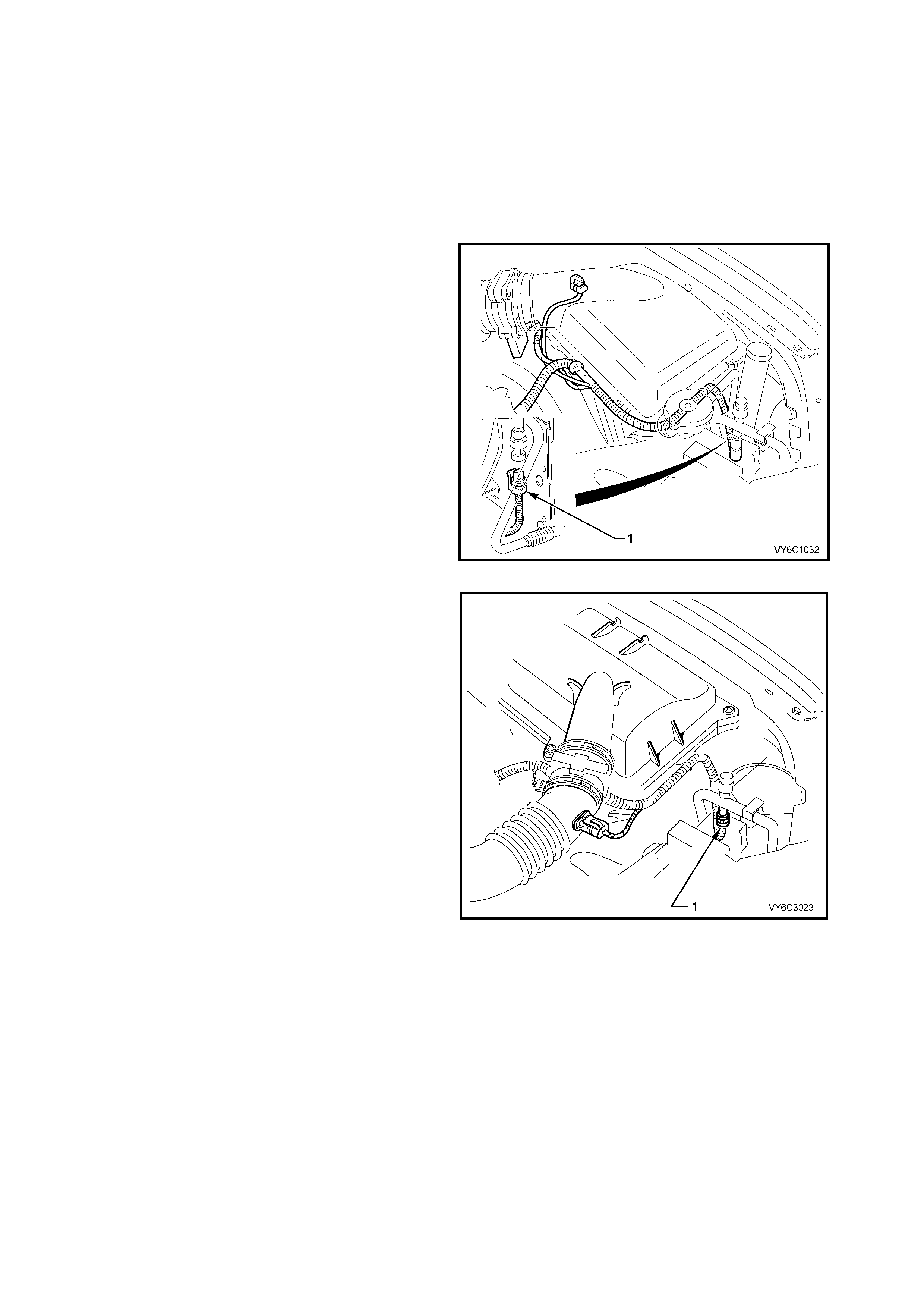

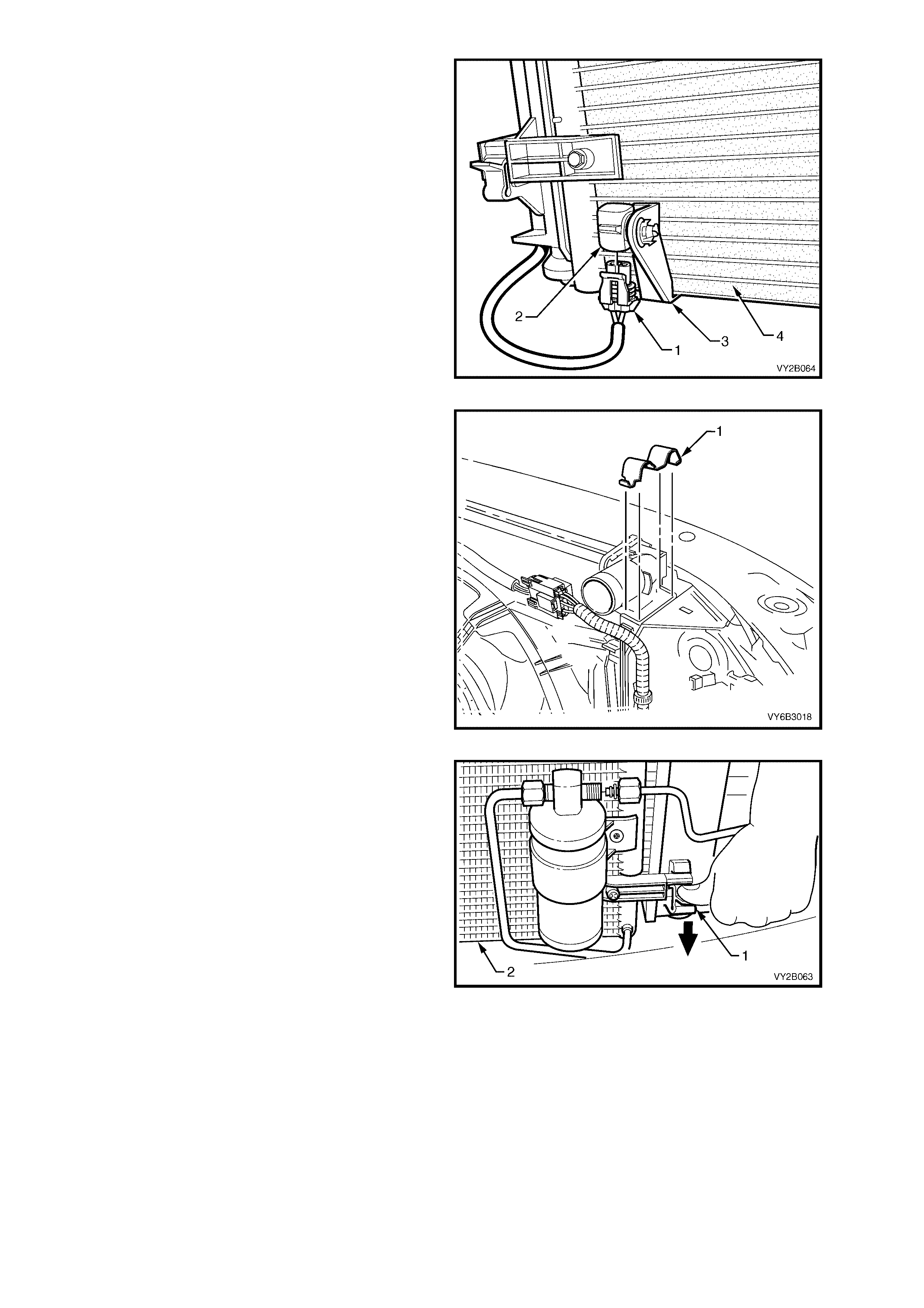

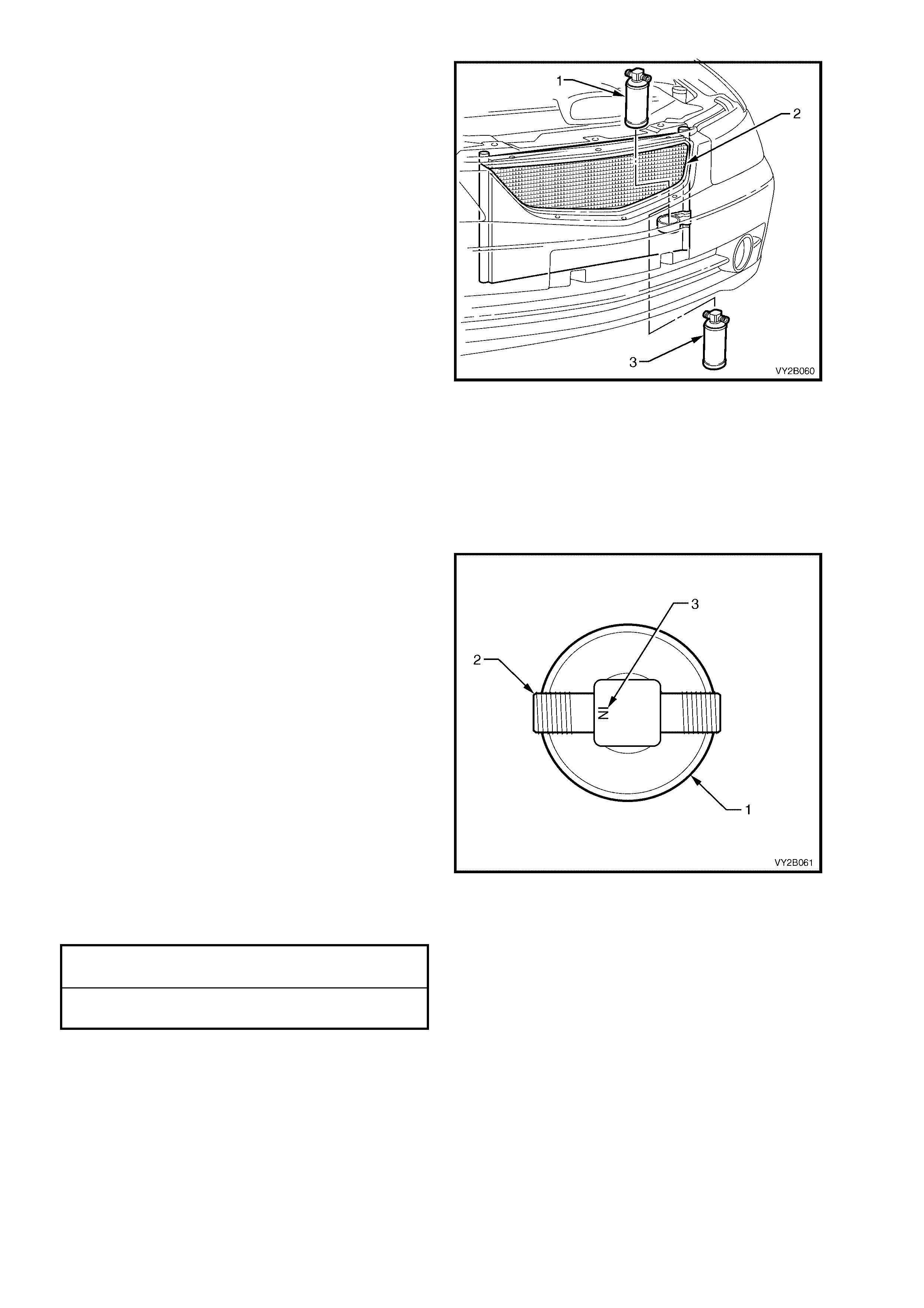

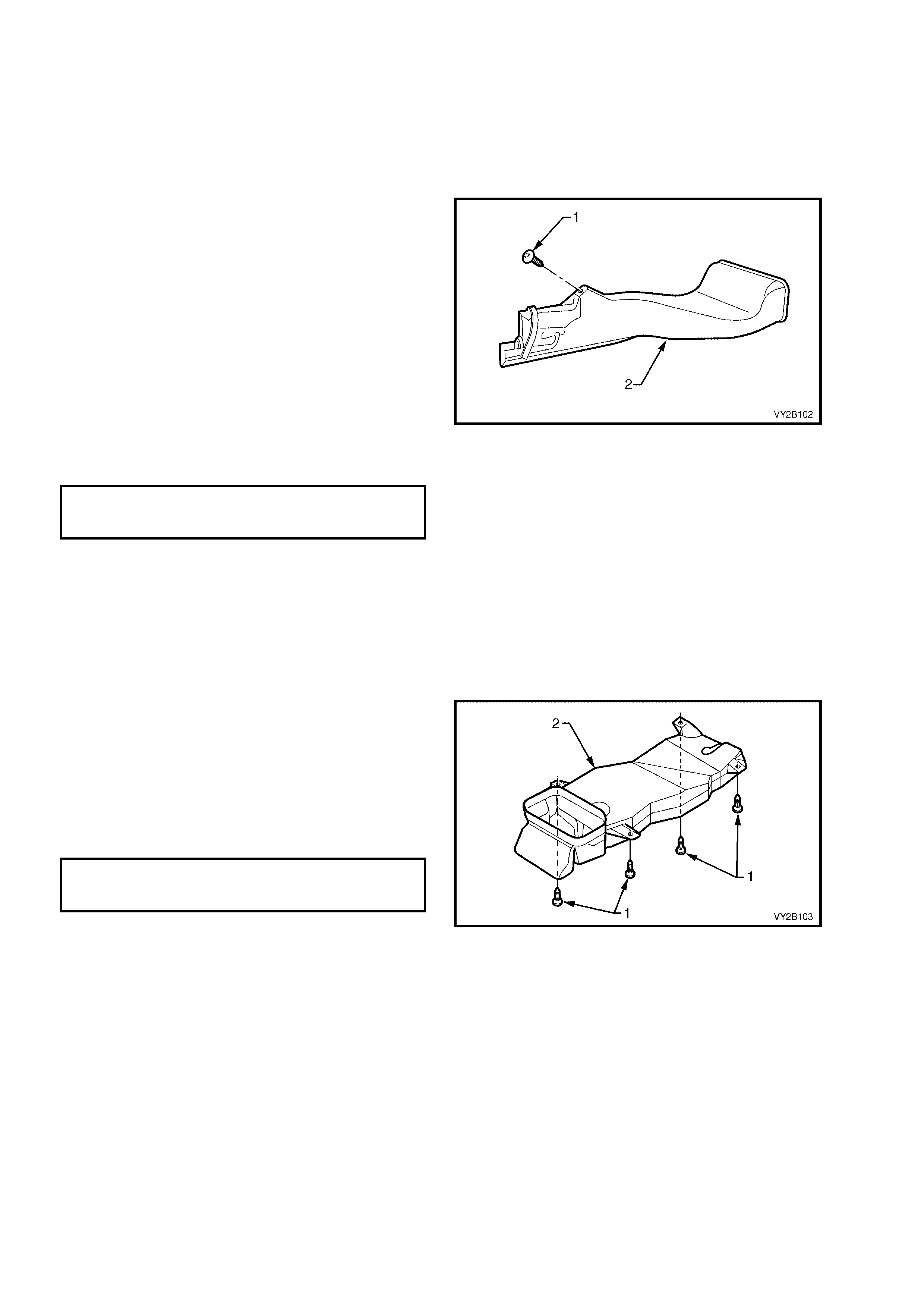

Figure 2B-102 shows the location of the A/C

pressur e transducer (1) f or V6 and V6 Superchar ged

engines.

Figure 2B-102

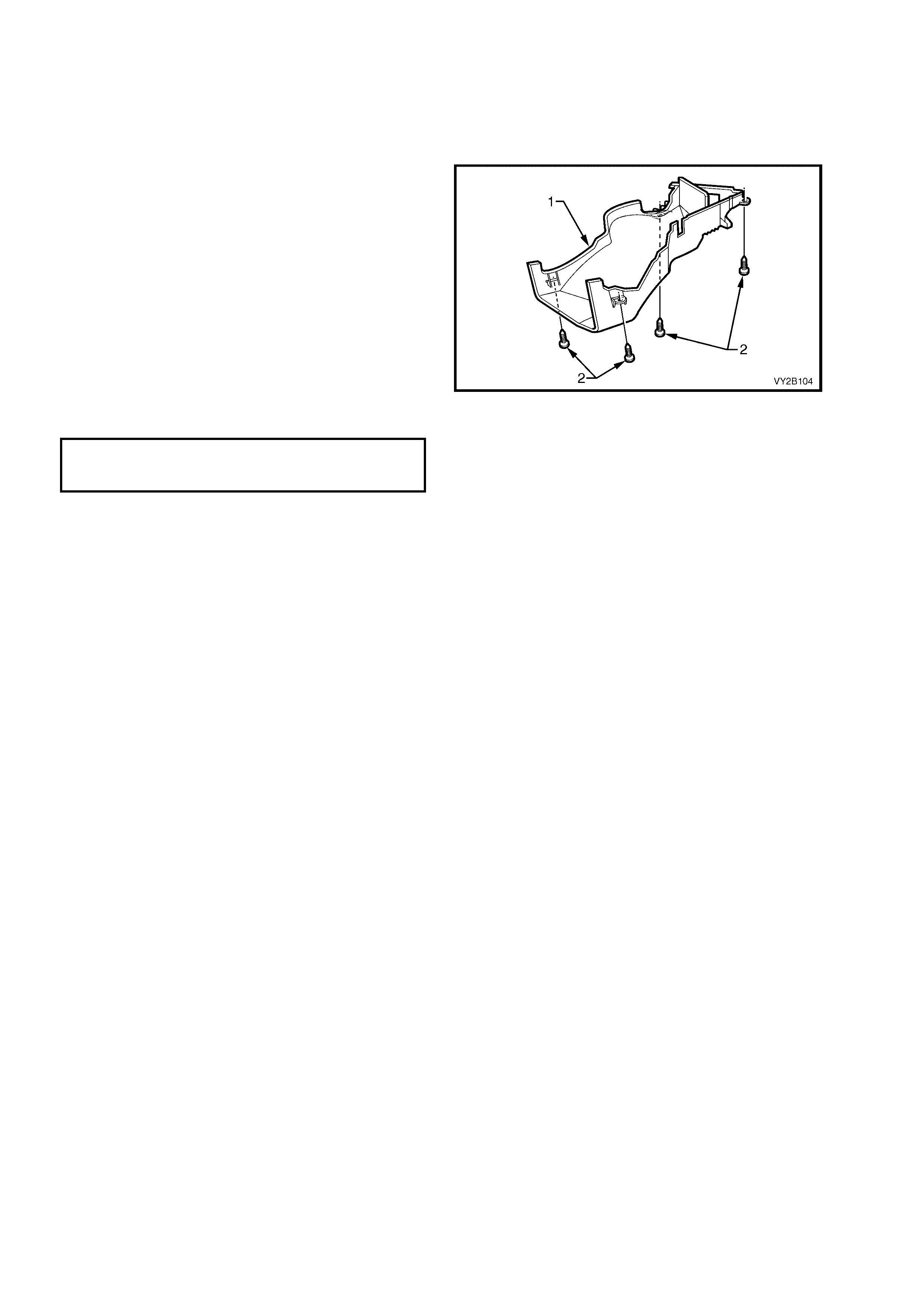

Figure 2B-103 shows the location of the A/C

pressure transducer (1) for GEN III V8 engines.

Figure 2B-103

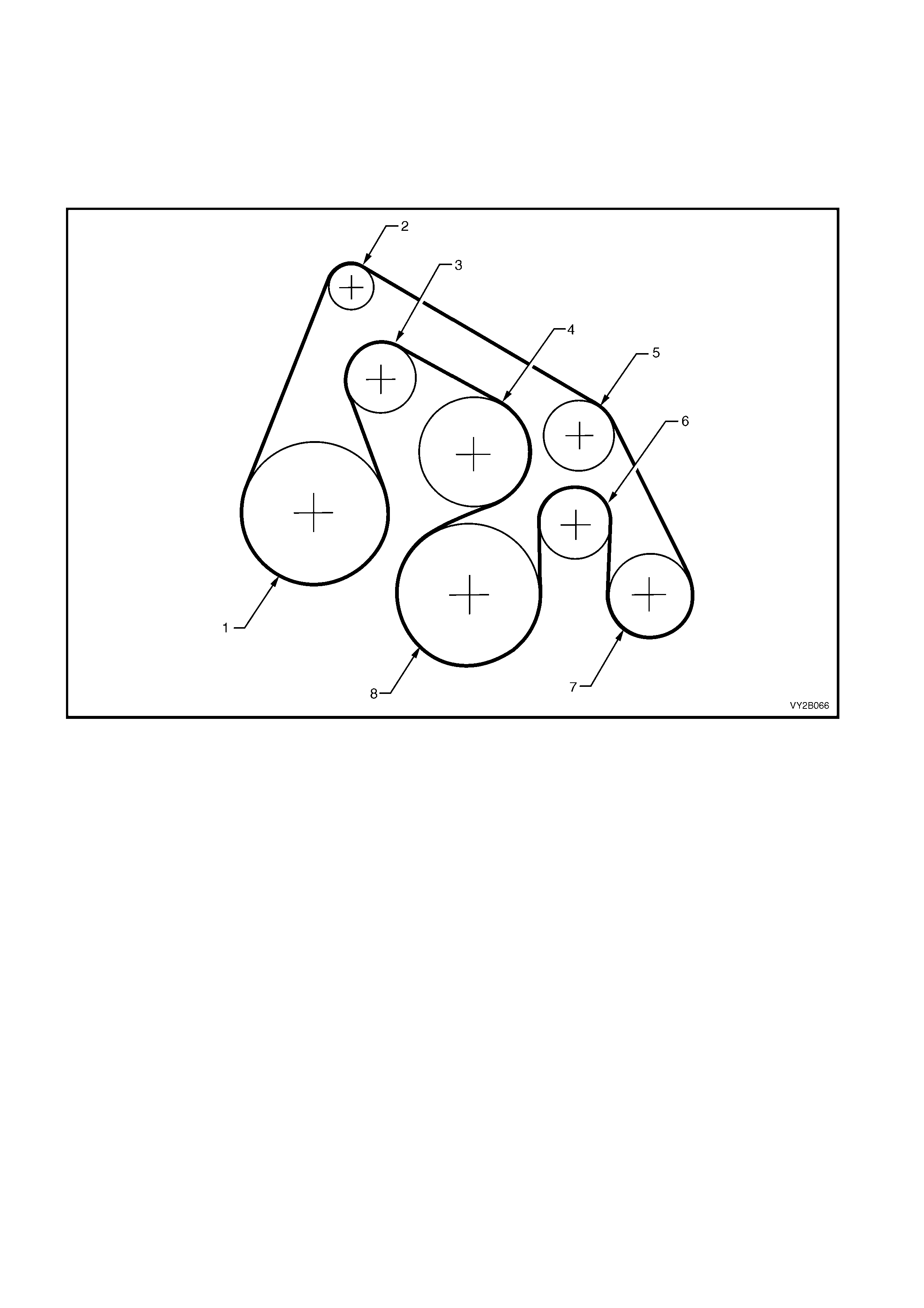

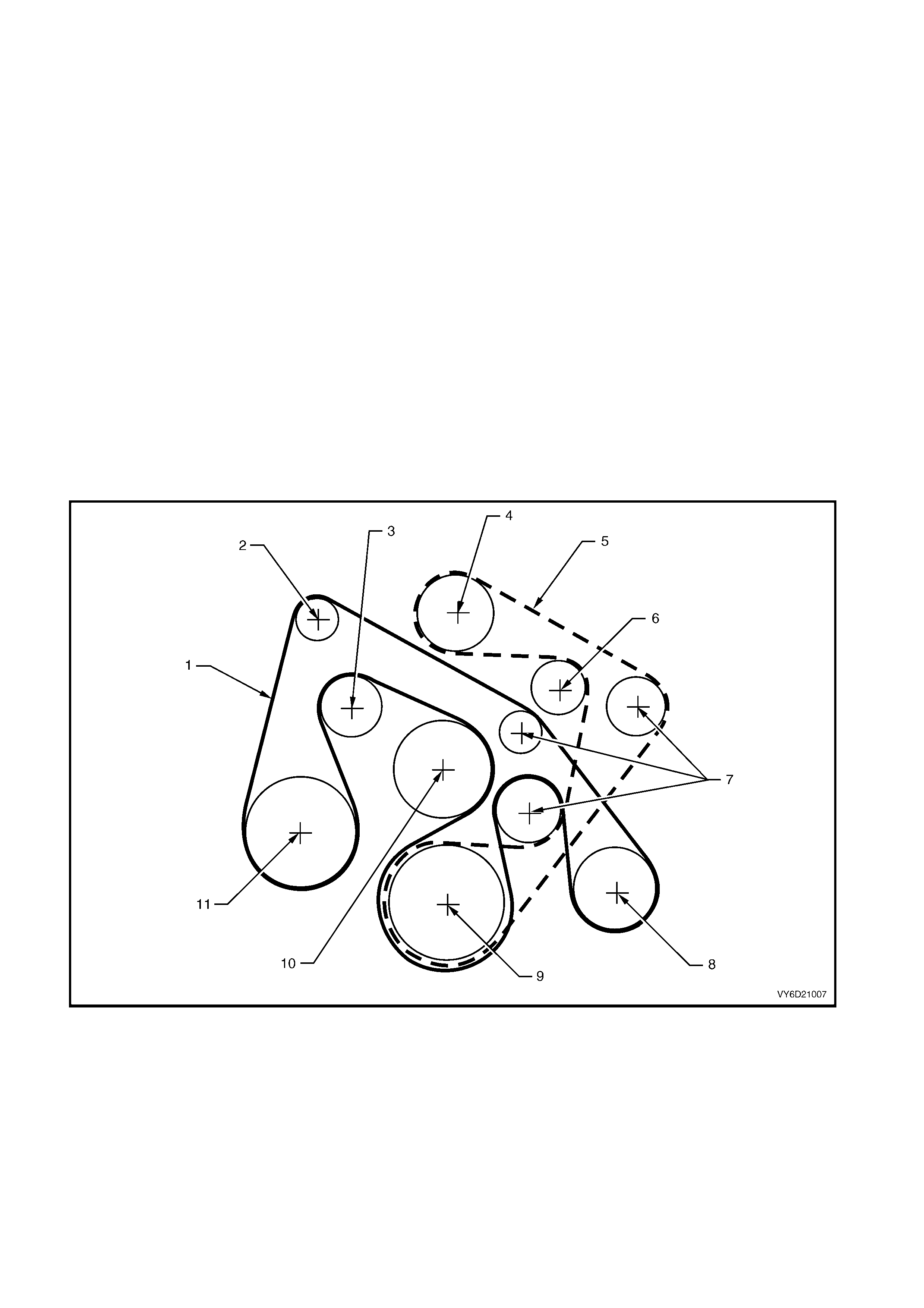

12. CONDENSER

12.1 V6 AND V6 SUPERCHARGED ENGINE

LT Section – 08-200

REMOVE

1. Recover the refrigerant from the A/C system, refer to Section 2C, 2.1 SYSTEM CHARGING AND

EVACUATION.

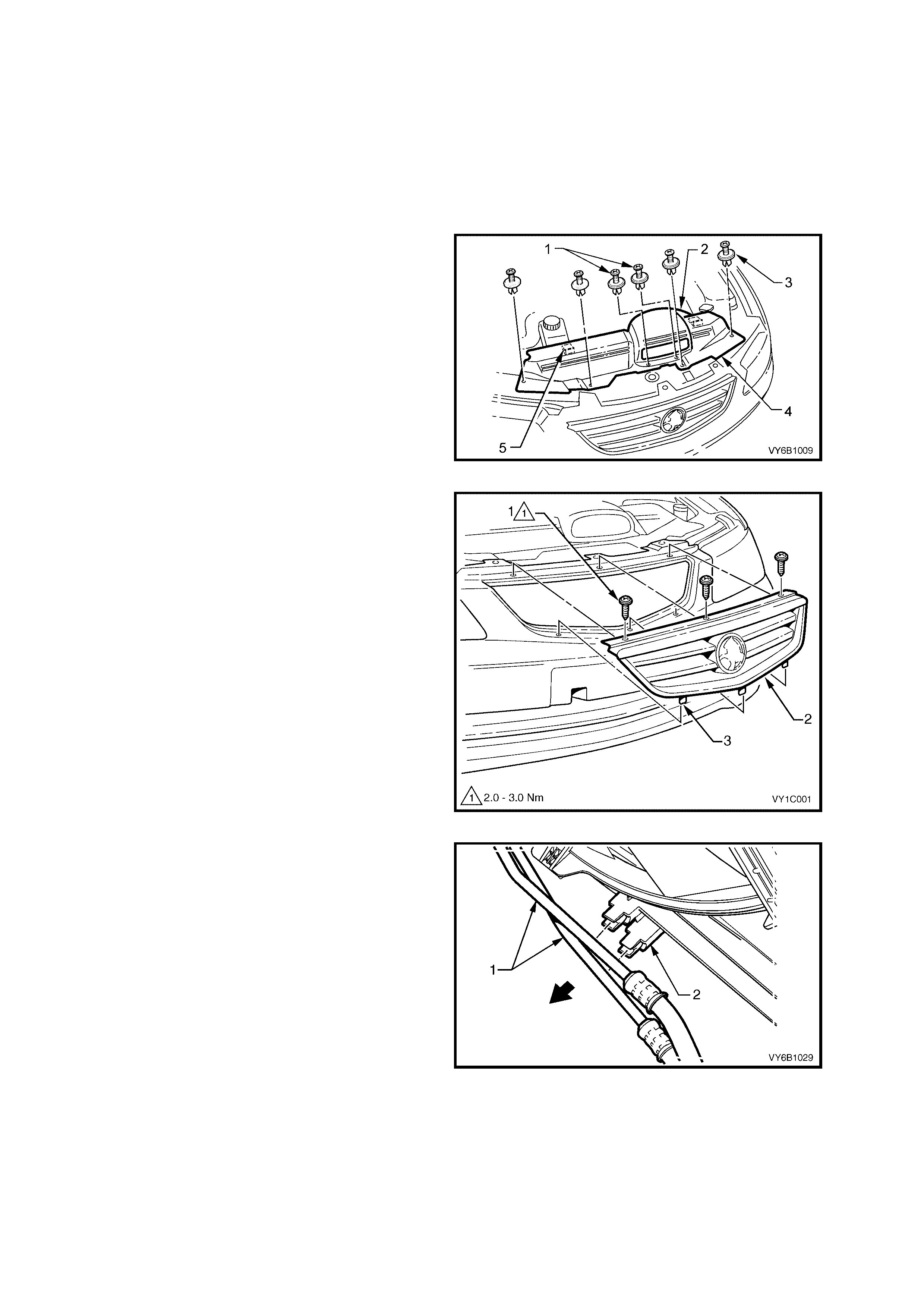

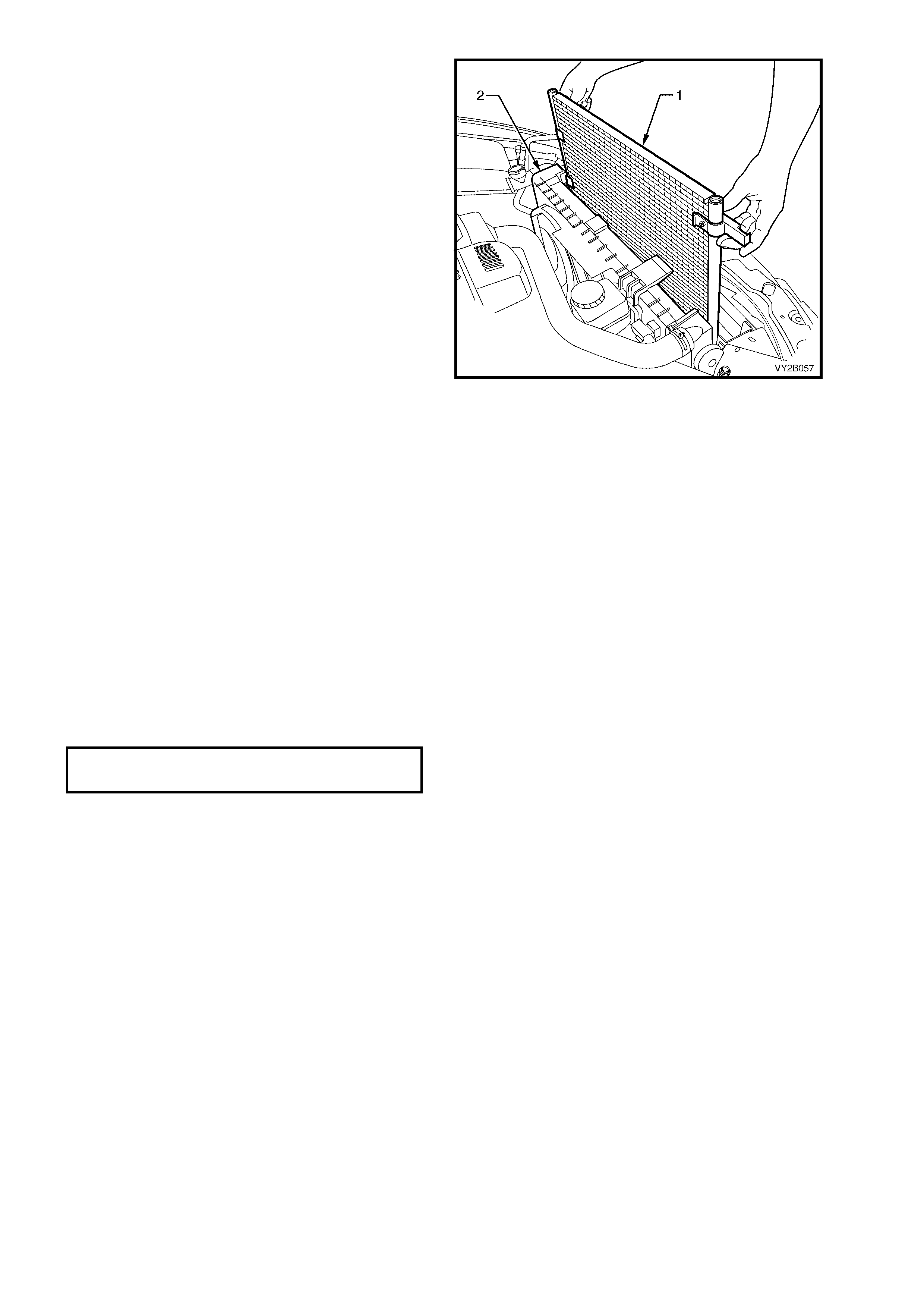

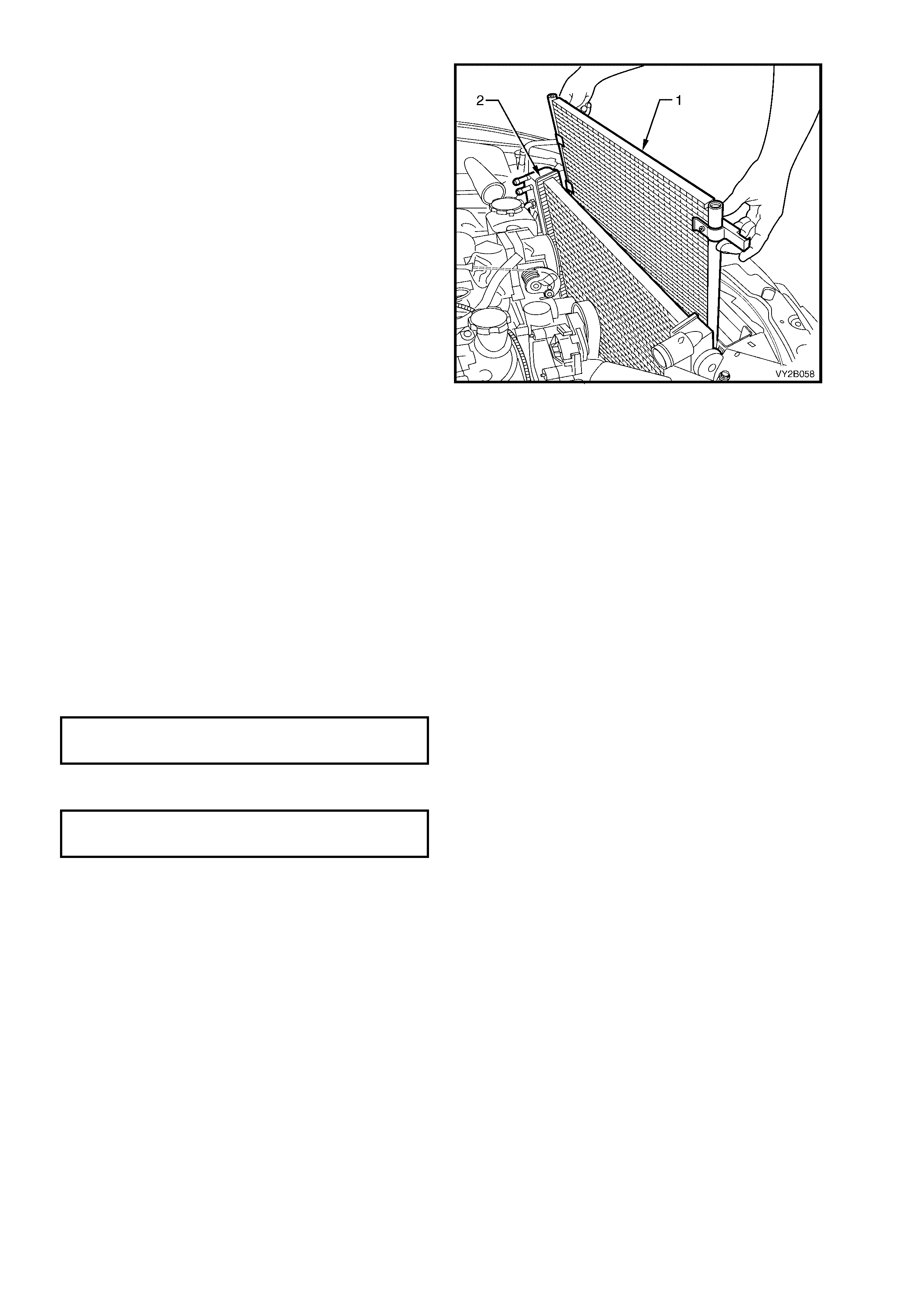

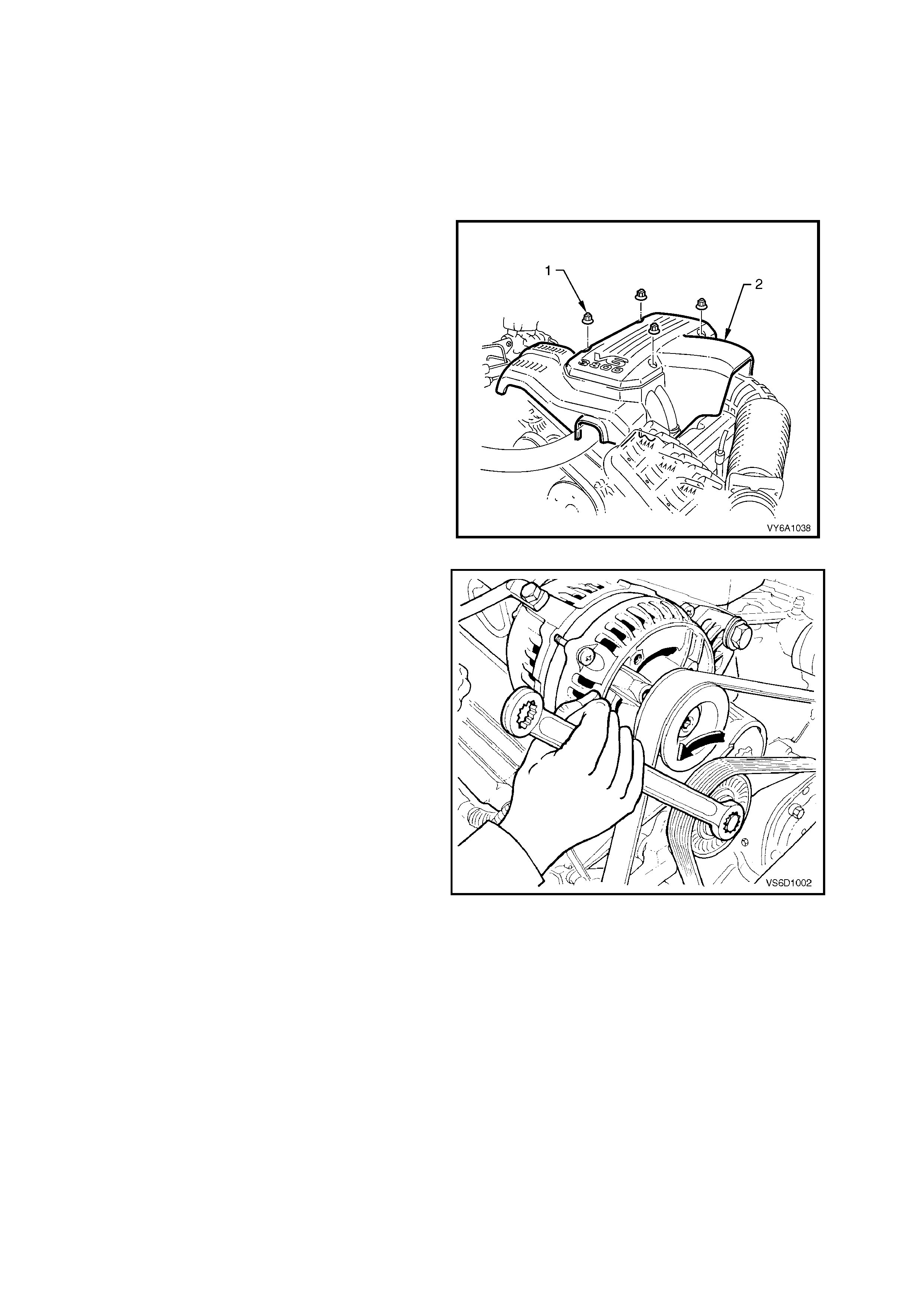

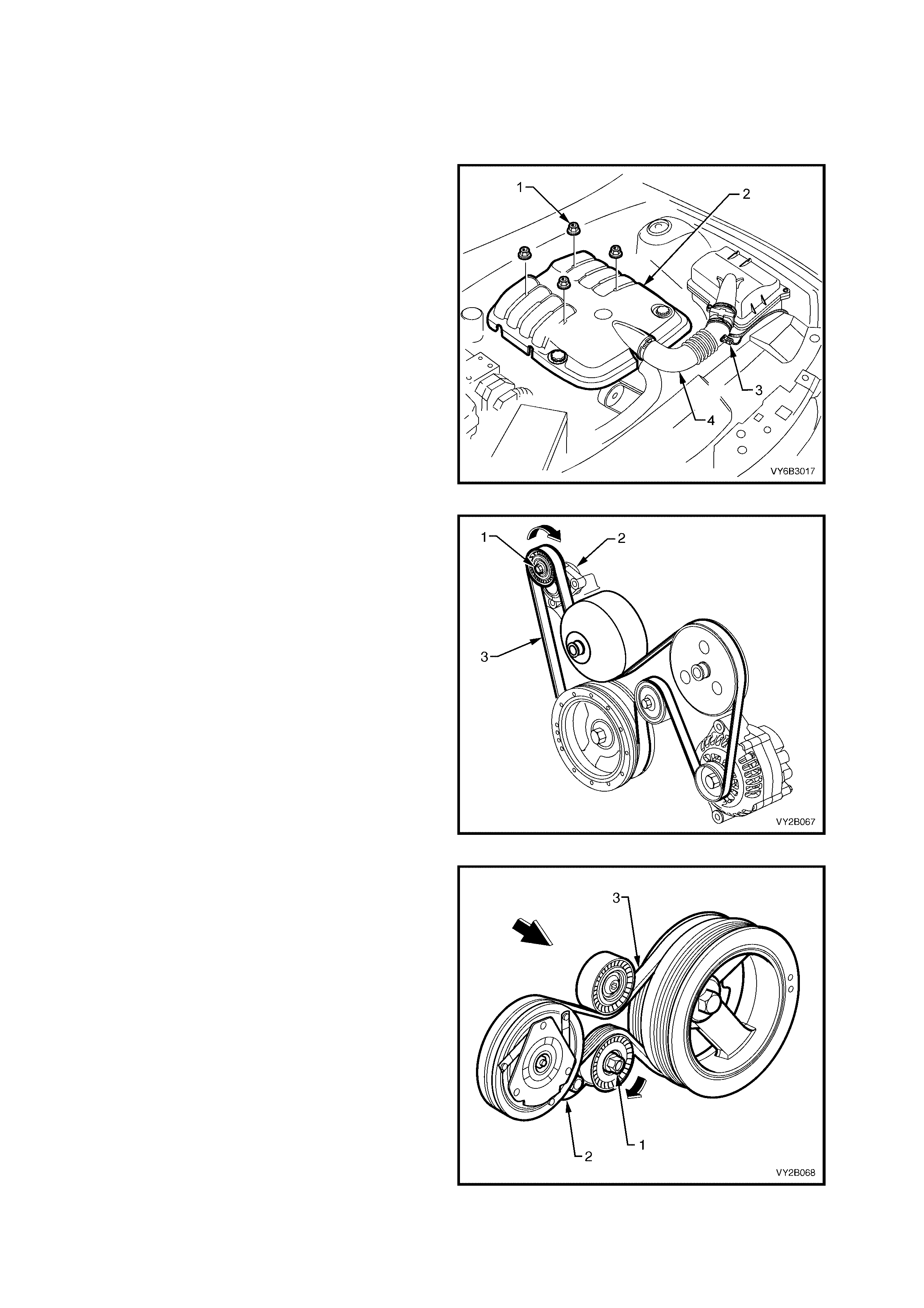

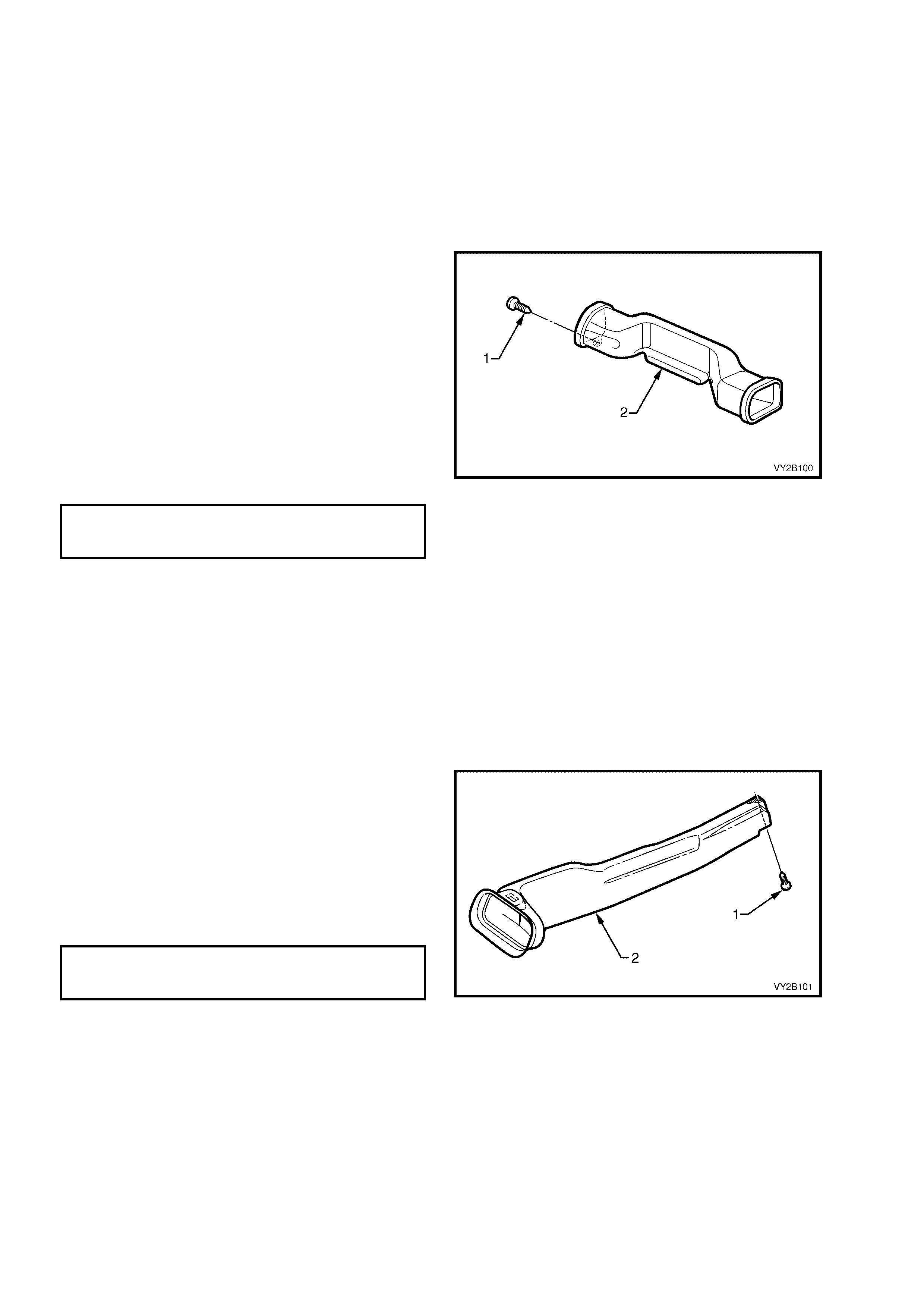

2. Remove the cold air intake duct and radiator

upper shroud retainers (1 and 2). Remove the

cold air intake duct (2), then disengage the

shroud locating tabs (5) by pulling the

shroud (4) towards front of vehicle, prior to

removal.

Figure 2B-104

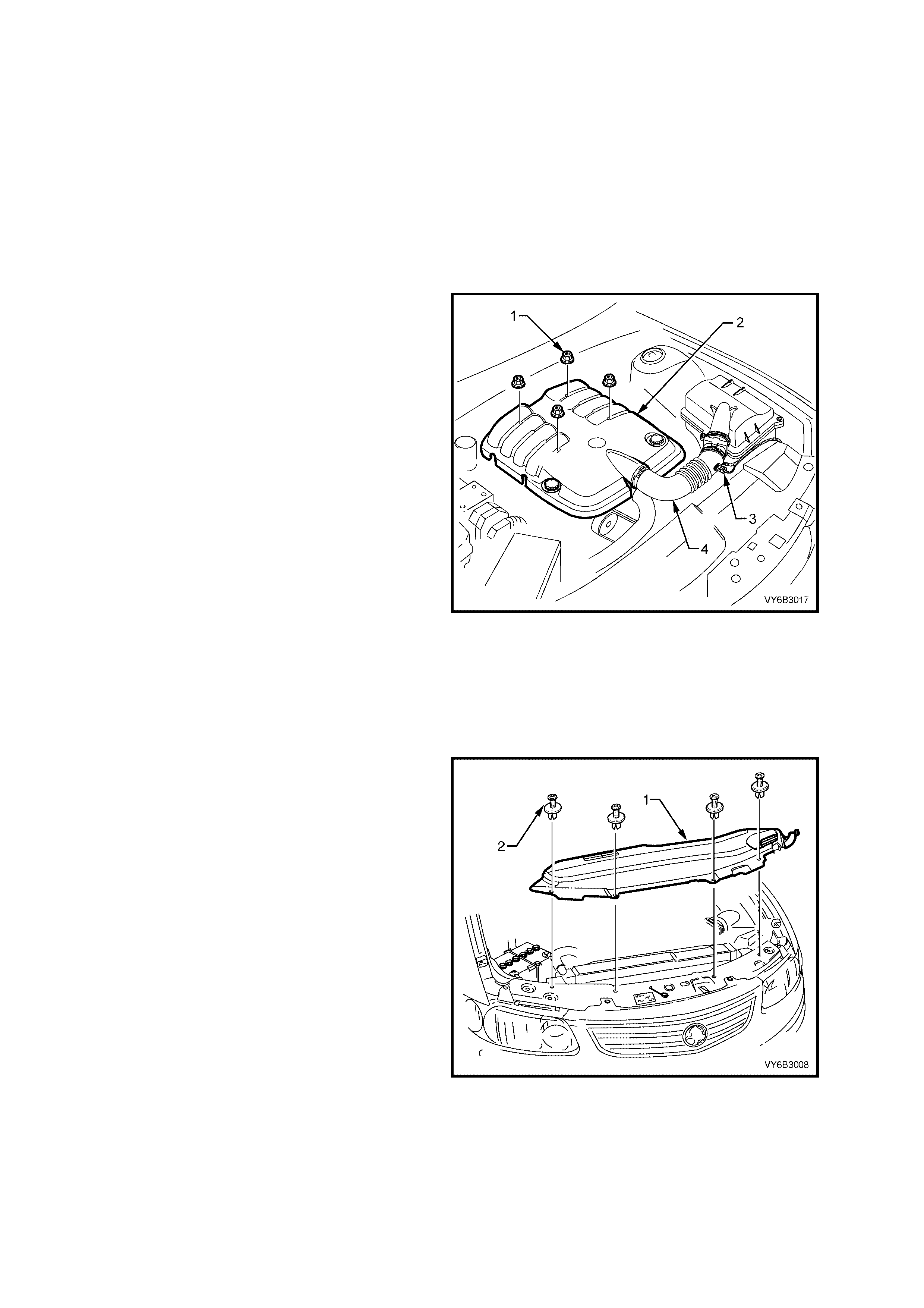

3. On models with removable grille, remove the

three screws (1) securing the radiator grille

assembly (2) and raise that grille so that

locating tabs (3) disengage from the bumper

fascia and remove.

NOTE: To access air conditioning components in

front of the condenser on V2 Coupe models, it will

be necessary to raise the vehicle and remove the

under vehicle air baffles. Refer to

Section 0A, GENERAL INFORMATION for the

location of jacking and support points. Refer to

Section 6B-3, 2.13 AIR BAFFLES.

Figure 2B-105

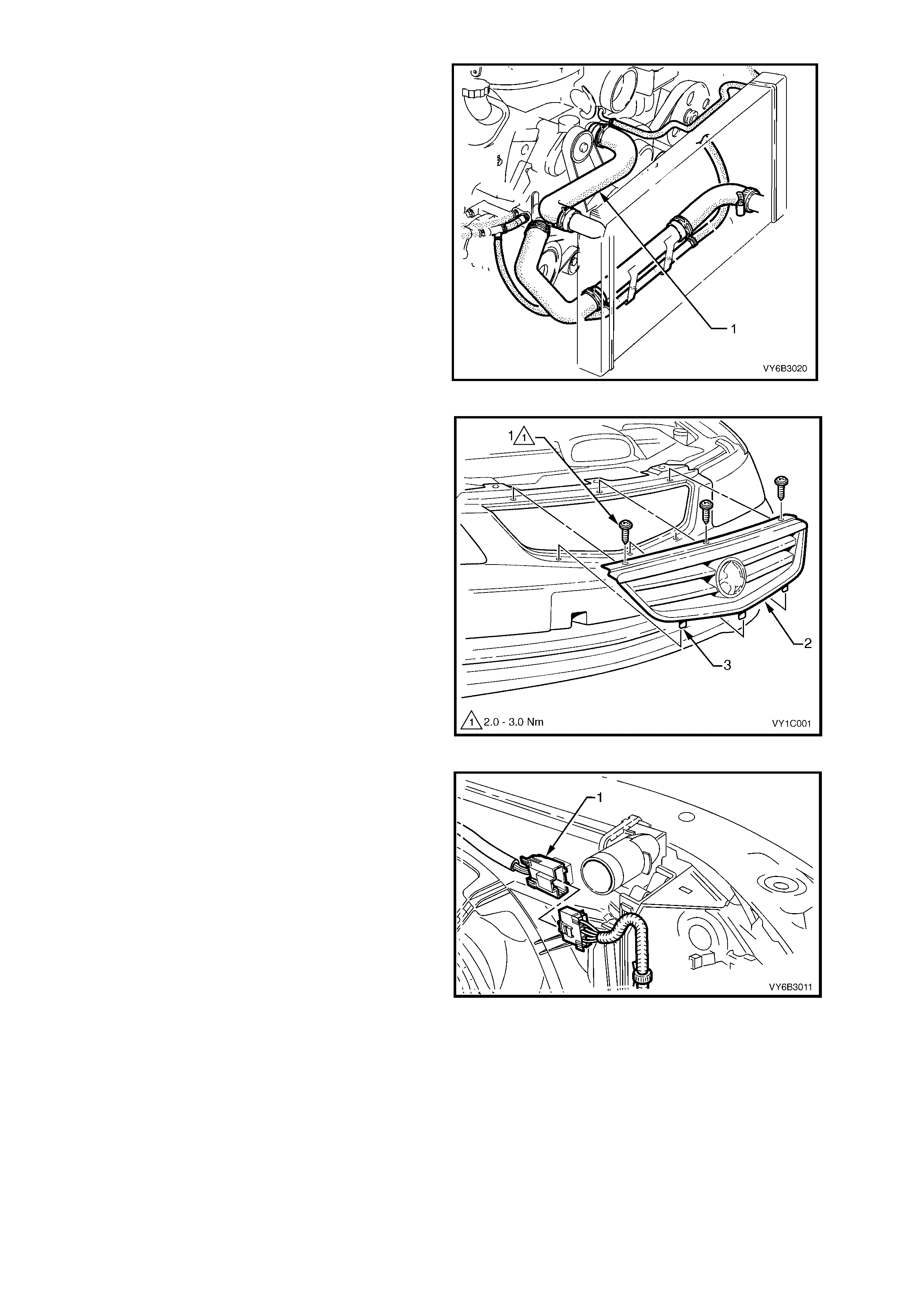

4. If fitted, release each of the automatic

transm ission cooling pipes (1) from the integral

clips (2) on the fan shroud.

Figure 2B-106

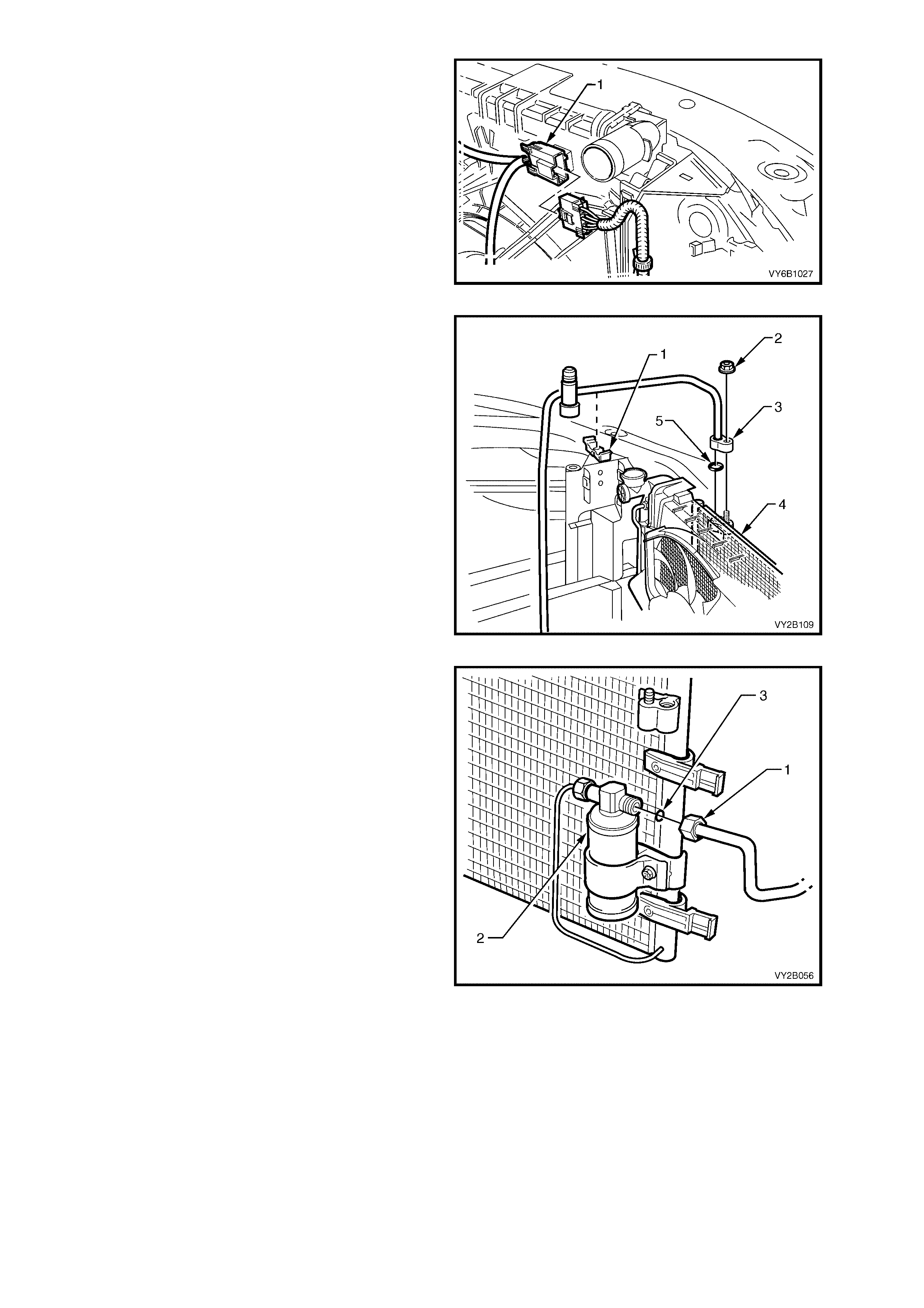

5. Depress tang on main wiring harness to cooling

fan motor wiring harness connector (1) and

separate the connector.

Figure 2B-107

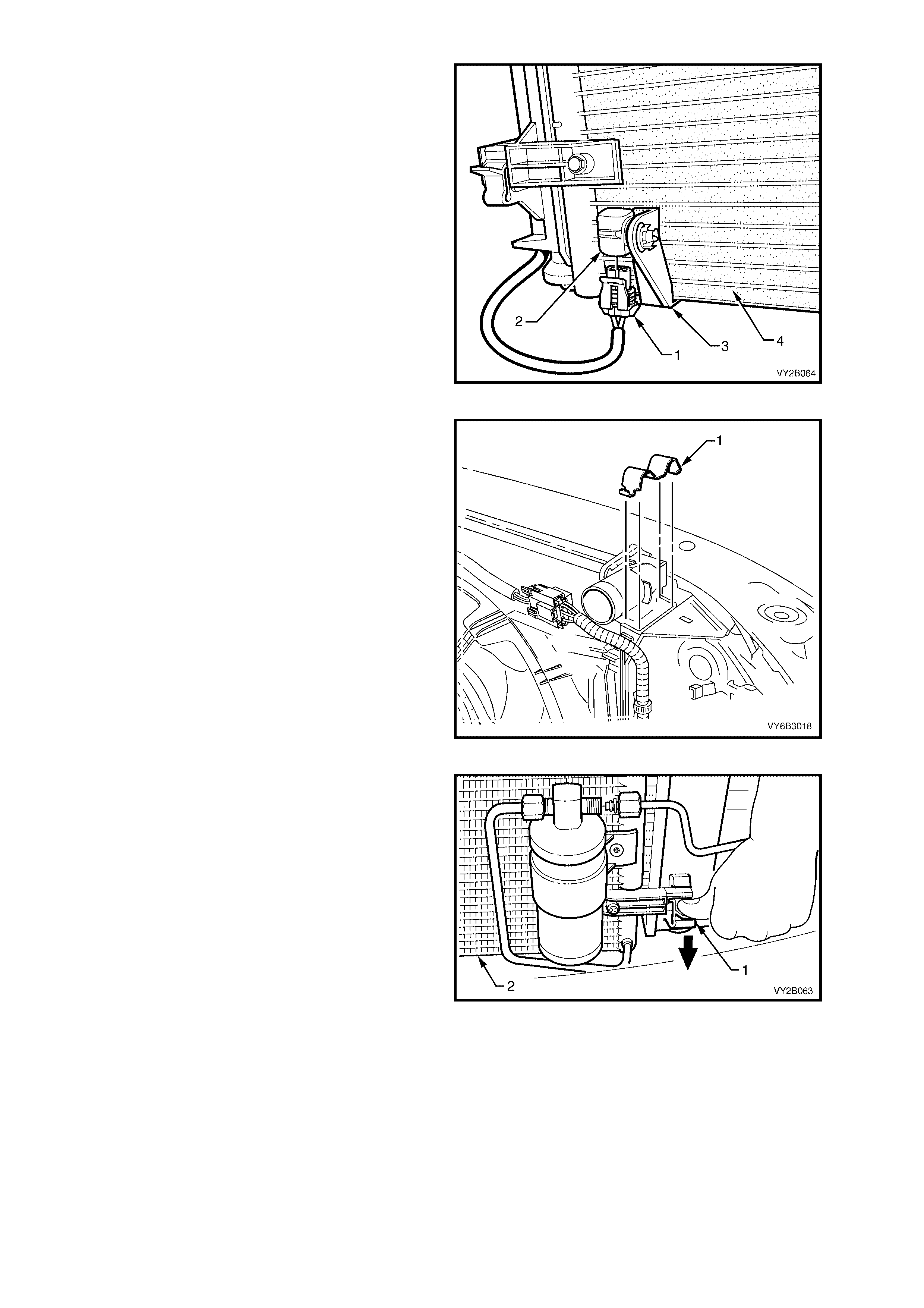

6. Release the discharge tube retaining clip (1).

7. Remove the nut (2) retaining the discharge

hose pad fitting (3) to the condenser (4).

8. Cap all open tubes/hoses to avoid moisture

from entering the system.

9. Discard the O-ring (5).

Figure 2B-108

10. Remove the liquid tube union (1) from the

FDR (2) and discard the O-ring (3).

Figure 2B-109

11. On OCC (Auto A/C) equipped models

disconnect the harness connector (1) from the

ambient temperature sensor (2). Do not

attempt to remove the bracket (3) from the

condenser (4).

Figure 2B-110

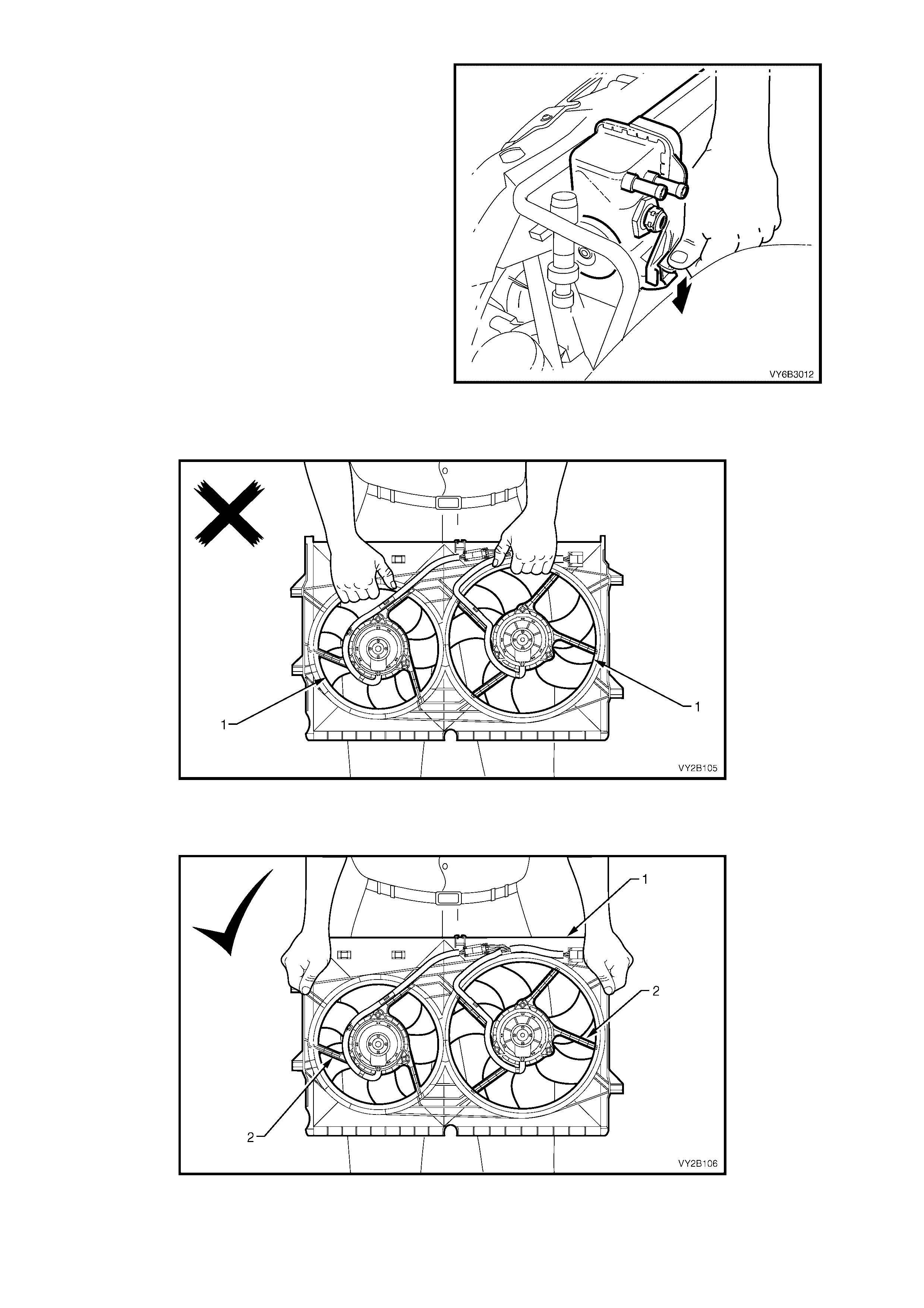

12. Using a screwdriver, compress and lever out

radiator retaining clips (1) from radiator upper

mounting brackets.

IMPORTANT: Do not lift the radiator assembly by

lifting on the fan rings as this will bend the fan

motor shaft and create an unnecessary vibration.

13. Lift radiator assembly upwards out of lower

insulators. Slant the upper section of the

assembly behind the radiator support sheet

metal work and allow it to remain there.

Figure 2B-111

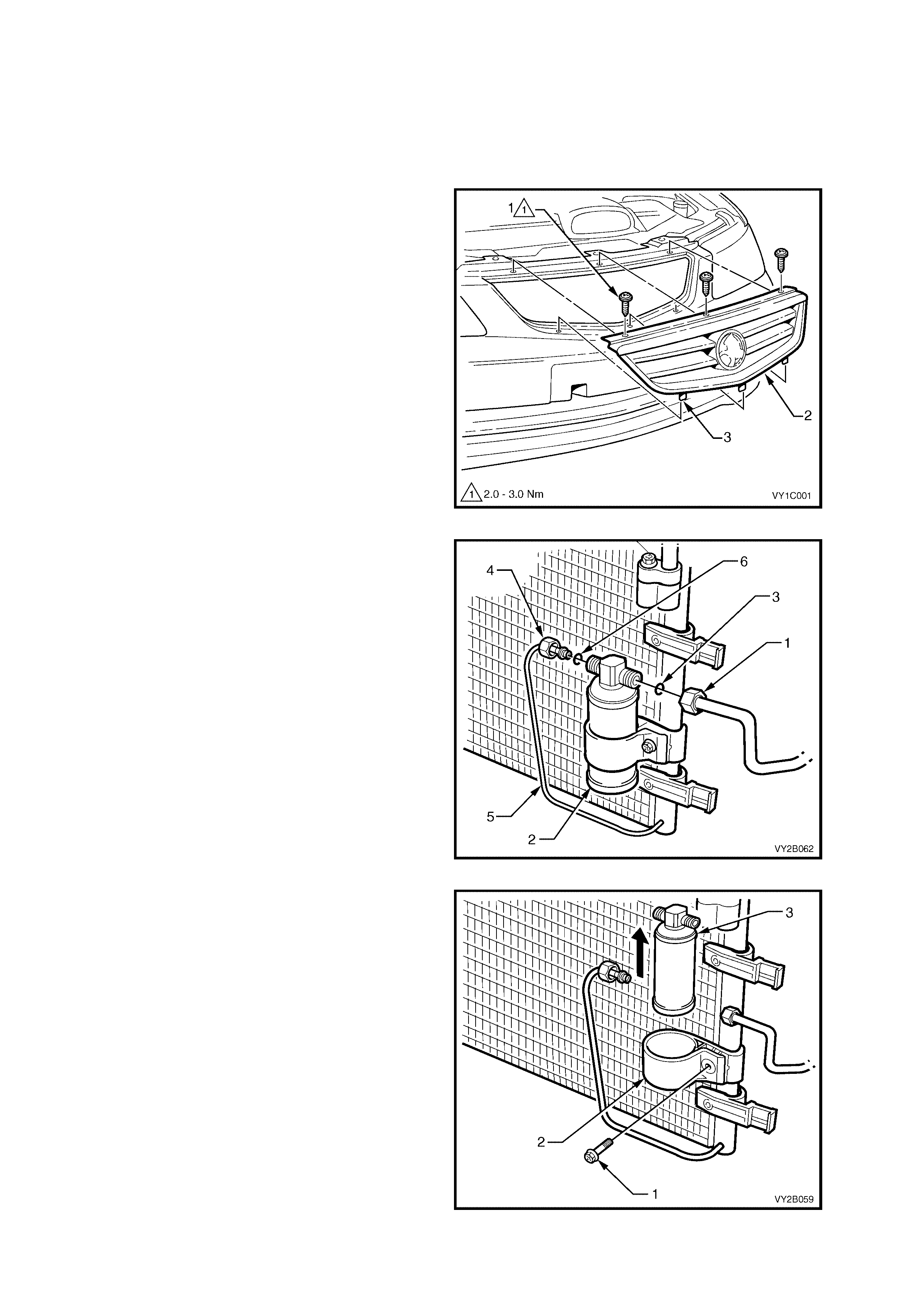

14. Release one of the clips securing the

condenser to the radiator Do this by pressing

down as indicated by the arrow, on the locking

retainer (1) with the fingers of one hand, while

lifting the condenser assembly (2) with the

other hand. Repeat for the other side.

Figure 2B-112

15. Lift the condenser assembly (1) upwards

suff ic iently to clear the mounts moulded to f r ont

of the radiator (2). Rem ove the condenser from

engine bay with the FDR attached.

NOTE: If the FDR is to be removed from the

condenser mark the mounting position of the FDR

in relation to the mounting bracket for correct

positioning when installing, and note the IN mar king

on the filter head for the correct flow direction. For

FDR installation information, refer to 13. FILTER

DRIER RECEIVER in this Section.

Figure 2B-113

REINSTALL

IMPORTANT: The total quantity of lubricating oil in the air conditioning system must be maintained. If a

compressor, evaporator, condenser, filter drier receiver, hose or pipe is to be replaced, a specified quantity of

lubricating oil must be added to the system to compensate for oil removed with the original component. Refer to

Section 2C, 2.4 LUBRICATING OIL COMPENSATION.

Installation of the condenser is the reverse of removal procedures, noting the following points:

1. Before installing radiator, inspect cor e to ensure that there is no for eign matter in cor e fins. Clean out between

core fins with compressed air, blowing from rear to front.

2. Ensure that radiator lower mounting insulators are correctly located in the radiator support panel.

3. Ensure that upper insulators are installed on each of the upper mounting pins and radiator retainers are

correctly installed on each side of the radiator by checking that the clips engage on both sides of the channel

support bracket.

4. If removed ins tall the FDR, ensuring that the union thread with the word IN is connected to the c ondenser side

of the FDR. Tighten the FDR unions and the FDR mounting bracket screw.

5. Ins tall the liquid tube and the dis charge hos e using new lubricated O -rings to the c ondenser. T orque the unions

to specification.

FDR TUBE UNION

TORQUE SPECIFICATION 7.5 – 12.5 Nm

6. Evacuate and charge the A/C system with 775 – 825 g of R134a refrigerant, refer to

Section 2C, 2.1 SYSTEM CHARGING AND EVACUATION.

7. Ensure that fan and shroud assembly to radiator attaching clips are all fully engaged and that the two locking

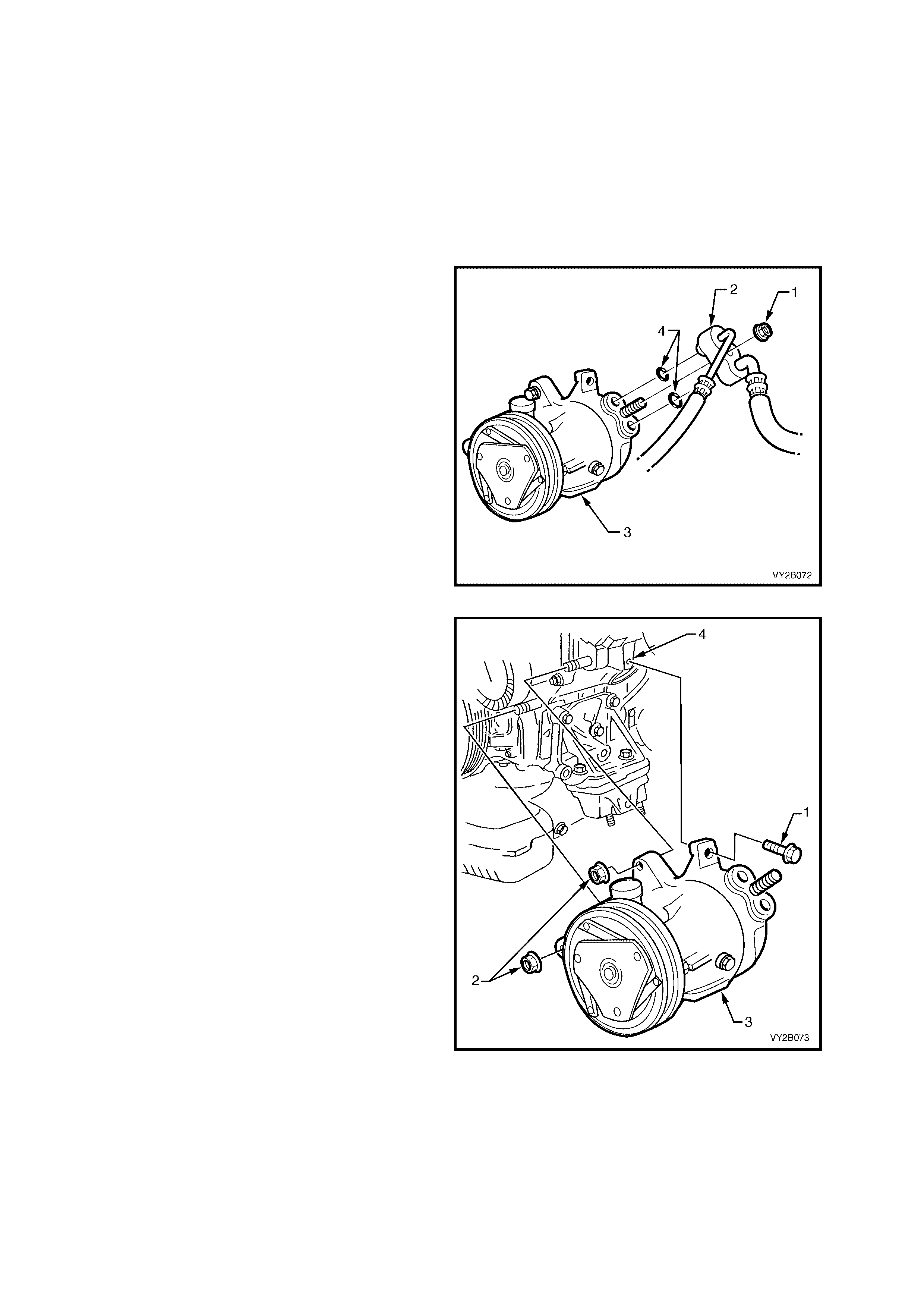

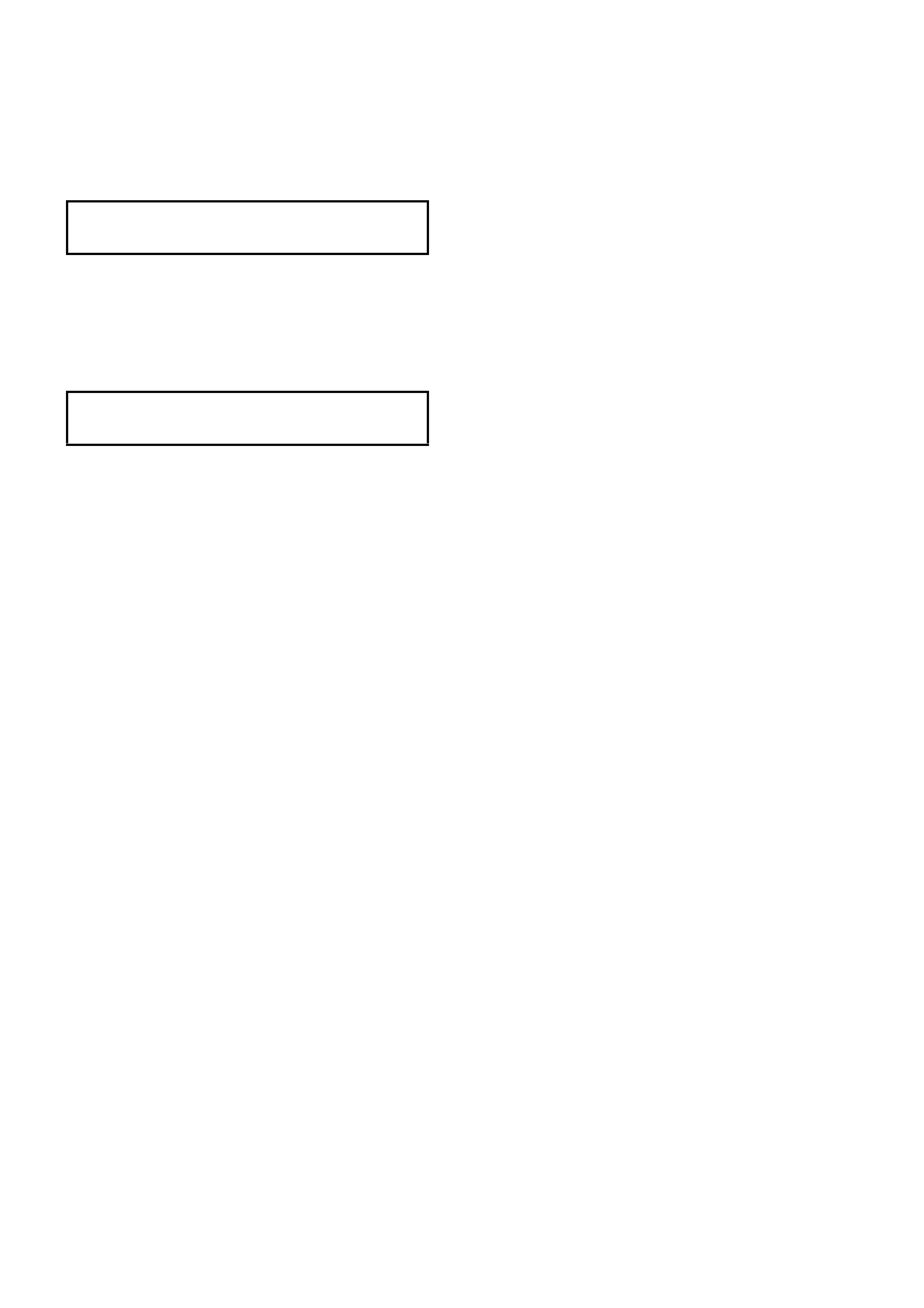

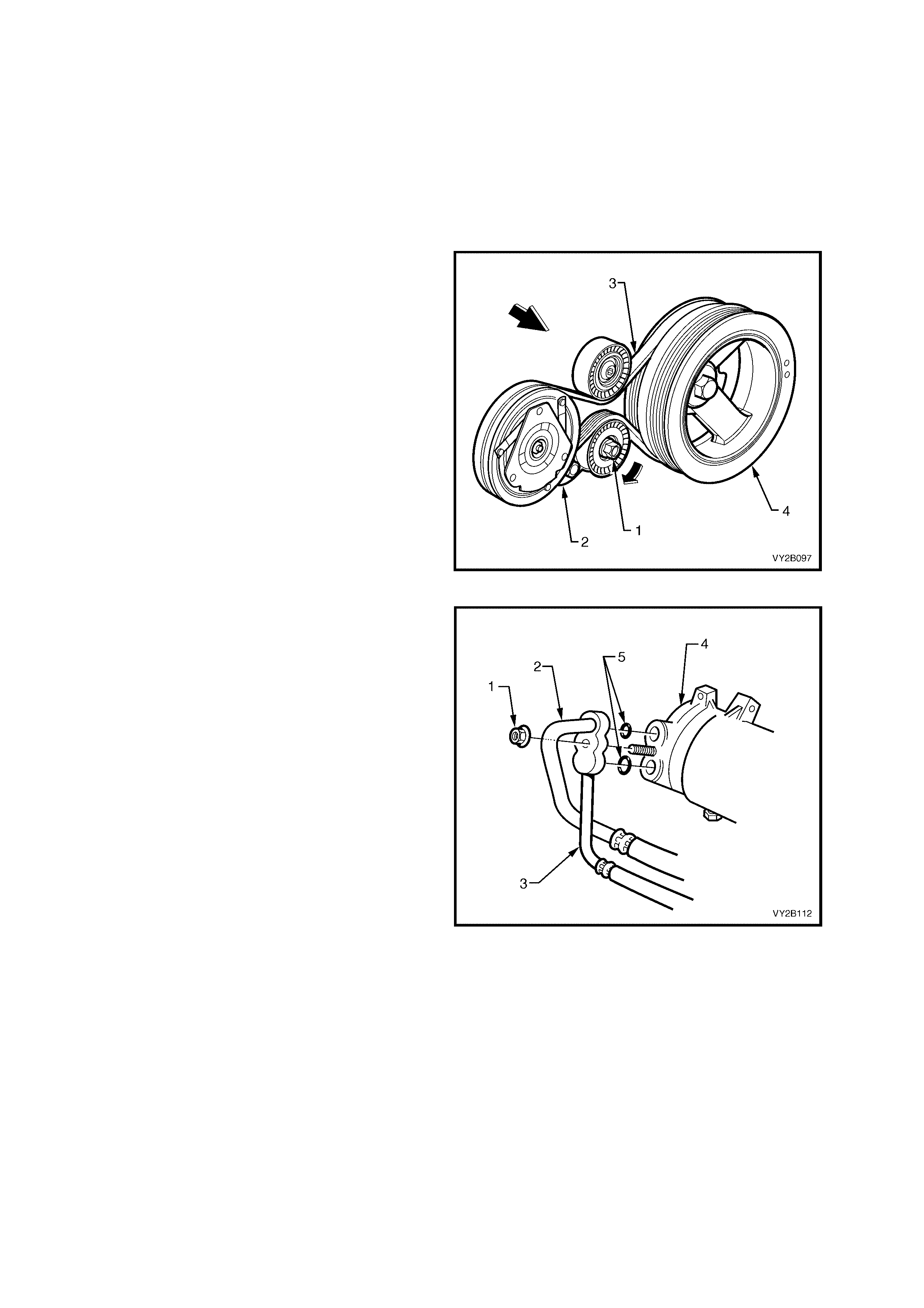

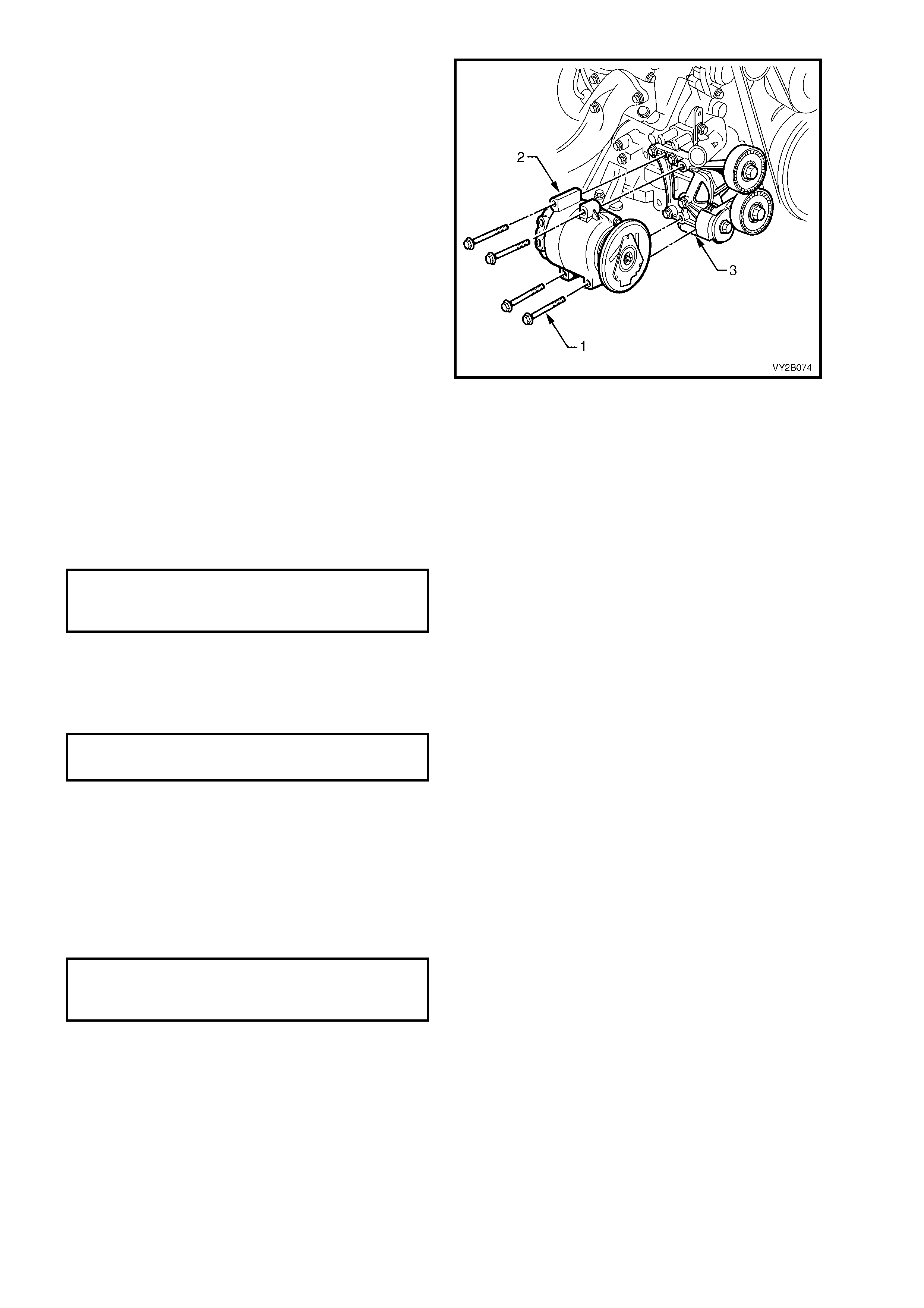

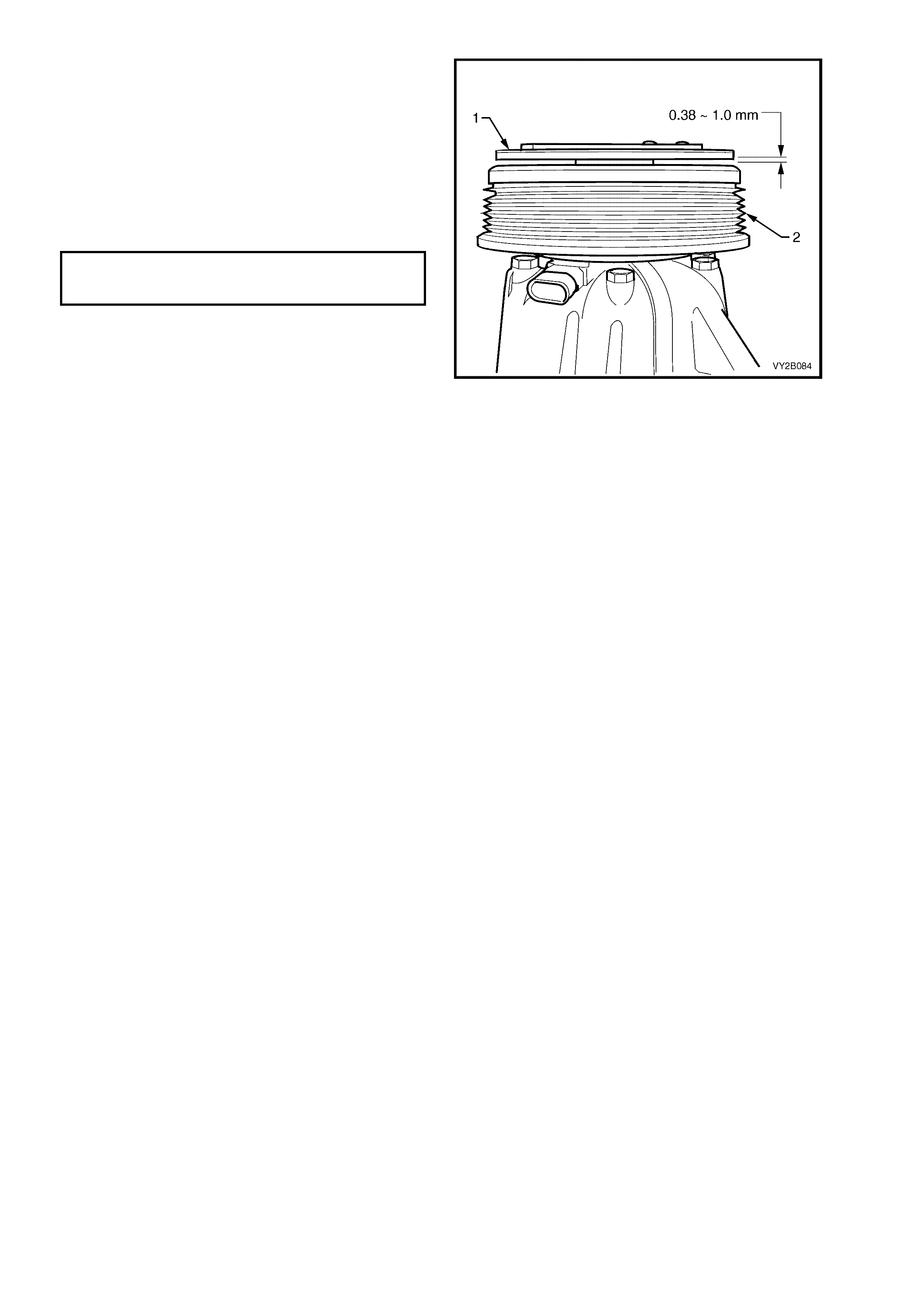

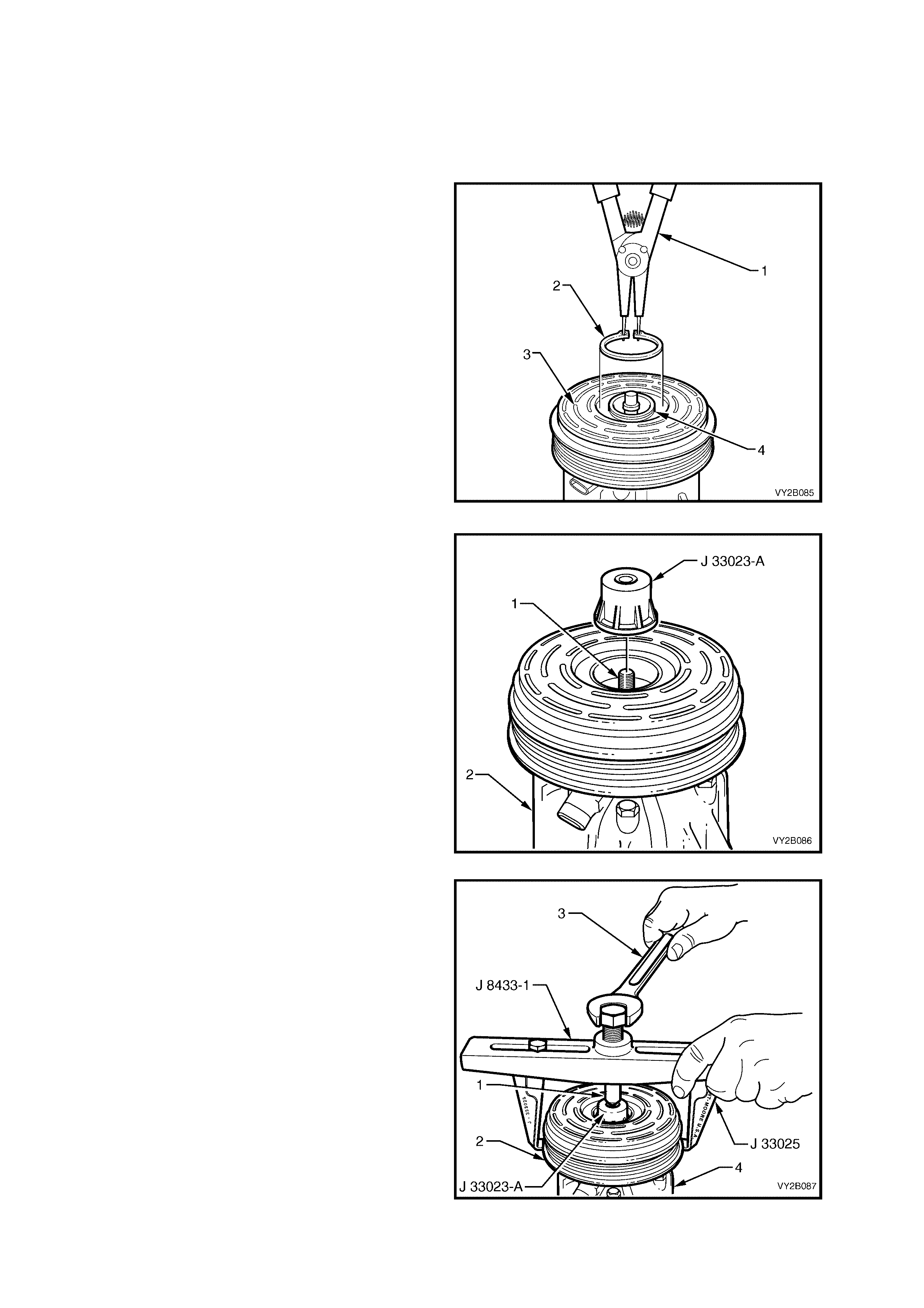

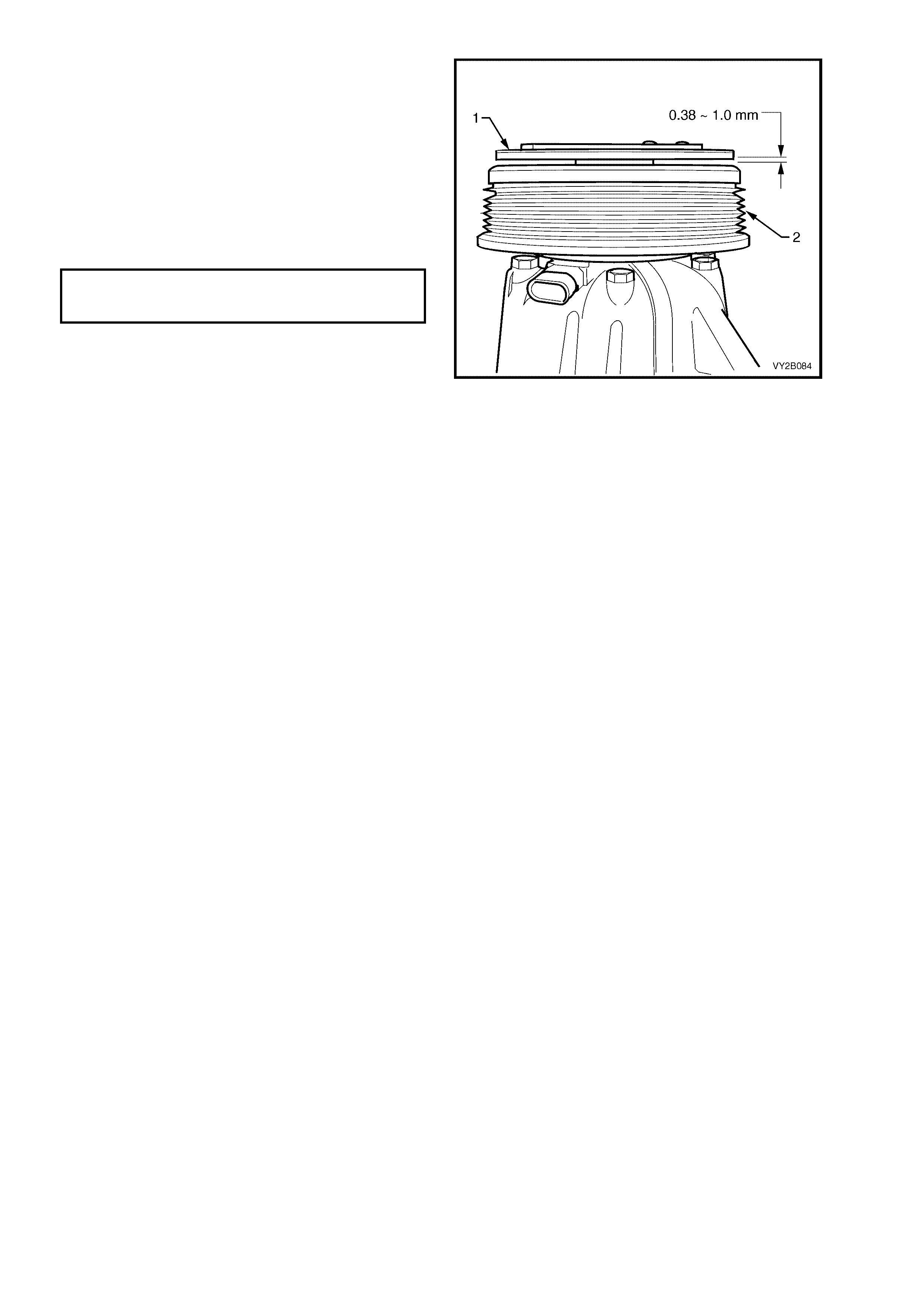

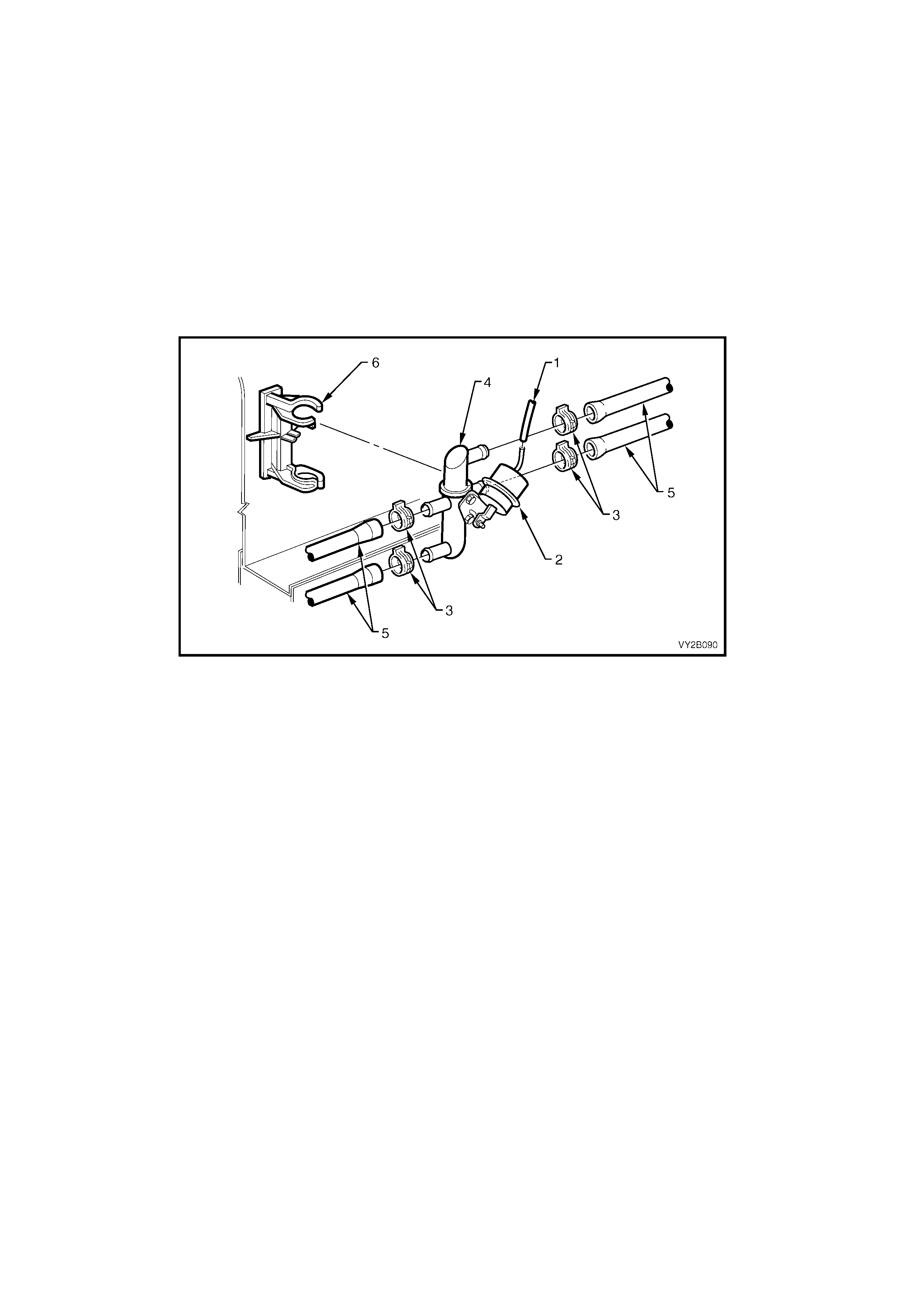

tangs on the upper clips are securing the shroud correctly.