SECTION 2D - HVAC OCCUPANT CLIMATE CONTROL

(AUTO A/C) – DESCRIPTION AND OPERATION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. GENERAL DESCRIPTION

3. DESCRIPTION

3.1 OCC CONTROL MODULE

OCC CONTROL MODULE CONFIGURATIONS

SWITCHES – SINGLE ZONE

SWITCHES – DUAL ZONE

LIQUID CRYSTAL DISPLAY SCREEN

OCC CONTROL MODULE COMPONENTS

OCC CONTROL MODULE ELECTRICAL

CONNECTION

3.2 HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT:

CONSTRUCTION, COMPONENTS AND

ASSOCIATED SENSORS

HVAC UNIT – LEFT-HAND DRIVE

HVAC UNIT – RIGHT-HAND DRIVE

AIR MIX DOORS AND AIR MIX MOTORS

BLOWER MOTOR RESISTOR

VACUUM SOLENOID PACK

WATER VALVE VACUUM SWITCHING

VALVE

ASPIRATOR TUBE AND VENTURI

IN-CAR TEMPERATURE SENSOR

EVAPORATIVE TEMPERATURE SENSOR

AMBIENT TEMPERATURE SENSOR

SUN LOAD SENSOR

3.3 HVAC UNIT AIRFLOW MODES

RECIRCULATION MODE – LHD

FACE MODE – LHD

BI-LEVEL MODE – LHD

FLOOR MODE – LHD

BLEND MODE – LHD

DEMIST MODE – LHD

DEFAULT MODE – LHD

RECIRCULATION MODE – RHD

FACE MODE – RHD

BI-LEVEL MODE – RHD

FLOOR MODE – RHD

BLEND MODE – RHD

DEMIST MODE – RHD

DEFAULT MODE – RHD

3.4 VACUUM CIRCUIT

SOLENOID PACK AND VACUUM

LINES – LHD

VACUUM CIRCUIT SCHEMATIC – LHD

SOLENOID PACK AND VACUUM

LINES – RHD

VACUUM CIRCUIT SCHEMATIC – RHD

4. OPERATION

RECOMMENDED SETTINGS

EVAPORATOR TEMPERATURE CONTROL

BLOWER FAN CONTROL

AIR DISTRIBUTION CONTROL

AIR INLET CONTROL

VENT AIR TEMPERATURE CONTROL

OCC COLD START-UP ROUTINES

SENSOR MALFUNCTION INDICATOR

DEFAULT MODE: VACUUM LEAK

AUTOMATIC OPERATION

OCC SYSTEM ACTIVATION

OCC SINGLE ZONE OPERATION

OCC DUAL ZONE OPERATION

5. SPECIFICATIONS

Techline

Techline

Techline

1. GENERAL I NFORMATI O N

HVAC Occupant Climate Control (Auto A/C) is fitted to m id and high level MY2003 VY and V2 Series vehicles . It

will be generally referred to as ‘O cc upant Climate Control ( O CC)’ or ‘OCC (Auto A/C)’ air conditioning in this Section

and the following Sections:

• Section 2E HVAC OCCUPA NT CLIMATE CONTROL (AUTO A/C) – REMOVAL AND INSTALLATION

• Section 2F HVAC OCCUPANT CLIMATE CONTROL (AUTO A/C) – DIA GNOSTICS

Inform ation in this Sec tion, Section 2E and Section 2F is relevant to HVAC Occupant Climate Control (Auto A/C)

only. For information relating to the HVAC Occupant Climate Control (Auto A/C) system not covered in this

Section, Section 2E or Section 2F, refer to the following Sections:

• Section 2A HVAC CLIMATE CONTROL (MANUAL A/C) – DESCRIPTION AND OPERATION

• Section 2B HVAC CLIMATE CONTROL (MANUAL A/C) – REMOVAL AND INSTALLATION

• Section 2C HVAC CLIMATE CONTROL (MANUAL A/C) – SERVICING AND DIAGNOSIS

2. GENERAL DESCRIPTION

The Occupant Climate Control system as fitted to MY2003 VY and V2 Series uses the same basic components as

fitted to models equipped with manual air conditioning. Major components such as the condenser, filter drier

receiver, compressor, evaporator, heater core, blower fan, cooling fans and water valve are common to both

manual and OCC (Auto A/C) air conditioning systems.

Sensors and components, which are fitted to the auto air conditioning system and not the manual air conditioning

system, include the following:

• Push button Occupant Climate Control module

• In-car temperature sensor

• Sun load sensor

• Ambient temperature sensor

• Evaporative temperature sensor

• Vacuum solenoid pack

• Water valve vacuum switch valve (LHD models only)

• Air mix door motor/s

NOTE: Sun load sensing is an additional function of the ambient light sensor / remote receiver. Accordingly this

sensor is still fitted to vehicles with manual type air conditioning.

The major operational difference between the manual and OCC (Auto A/C) air conditioning systems is that the OCC

(Auto A/C)) system can maintain a preset level of cooling or heating regardless of inside or outside temperature

fluctuations. The electronic sensing devices listed above allow the system to respond to various changes in ambient

temperature, evaporator temperature, interior cabin temperature and sun load. Another key difference is that unlike

the manual system, the OCC (Auto A/C) system has the capability to use recirculated air in conjunction with all

other ventilation modes. The OCC (Auto A/C) system will adjust automatically to any climate and temperature

changes to maintain the vehicle cabin interior within the selected temperature range. This is achieved by

automatically controlling:

• Heater water valve opening and closing

• Air mix door movement

• Fresh/recirculation door position

• Blower fan speeds

• Ventilation mode selection

Similar to manual A/C system, the A/C compressor cycling is controlled by the PCM in accordance to the pressure

signal sent to it by the A/C pressure transducer and serial data communication with the BCM. Also similar to the

manual A/C system, engine cooling/condenser fan operation is controlled by the BCM and PCM.

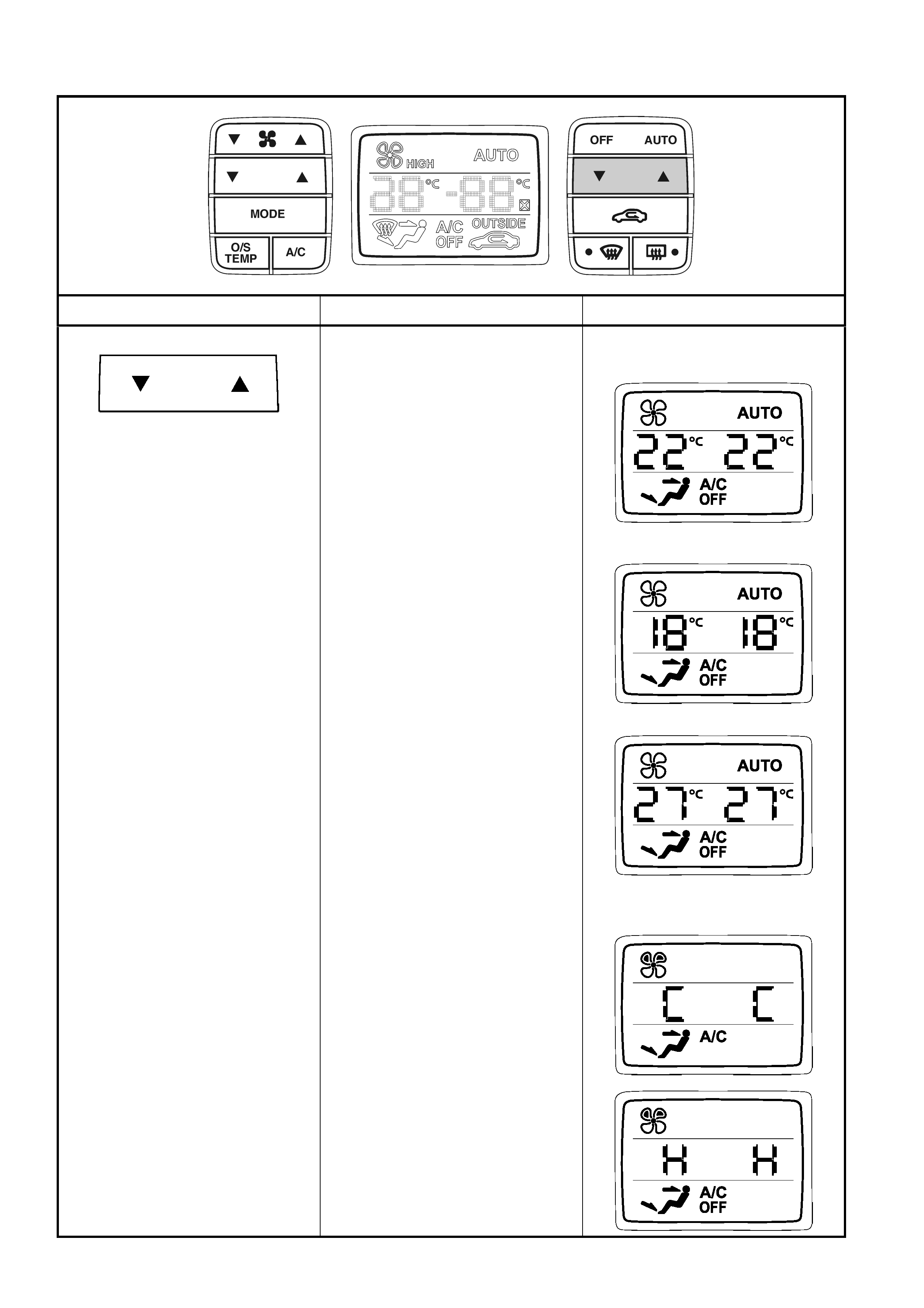

Where an OCC (Auto A/C) system is fitted to MY2003 VY and V2 Series vehicles, it may be either single zone or

dual zone. Dual zone is available on right-hand drive models only.

Single zone OCC control modules are fitted with one temperature control button, refer to Figure 2D-8 and

Figure 2D-9. Dual zone OCC control modules are fitted with two temperature control buttons, refer to

Figure 2D-10. This allows both the driver and the front seat passenger to individually select their desired comfort

level of temperature setting. When dual zone mode is operating, the temperature of the air flowing from the

passenger’s floor, face and side vents will be different to that of the driver’s floor, face and side vents. For

information on the operation of single zone and dual zone OCC control modules refer to 4. OPERATION in this

Section.

OCC SYSTEM SENSORS

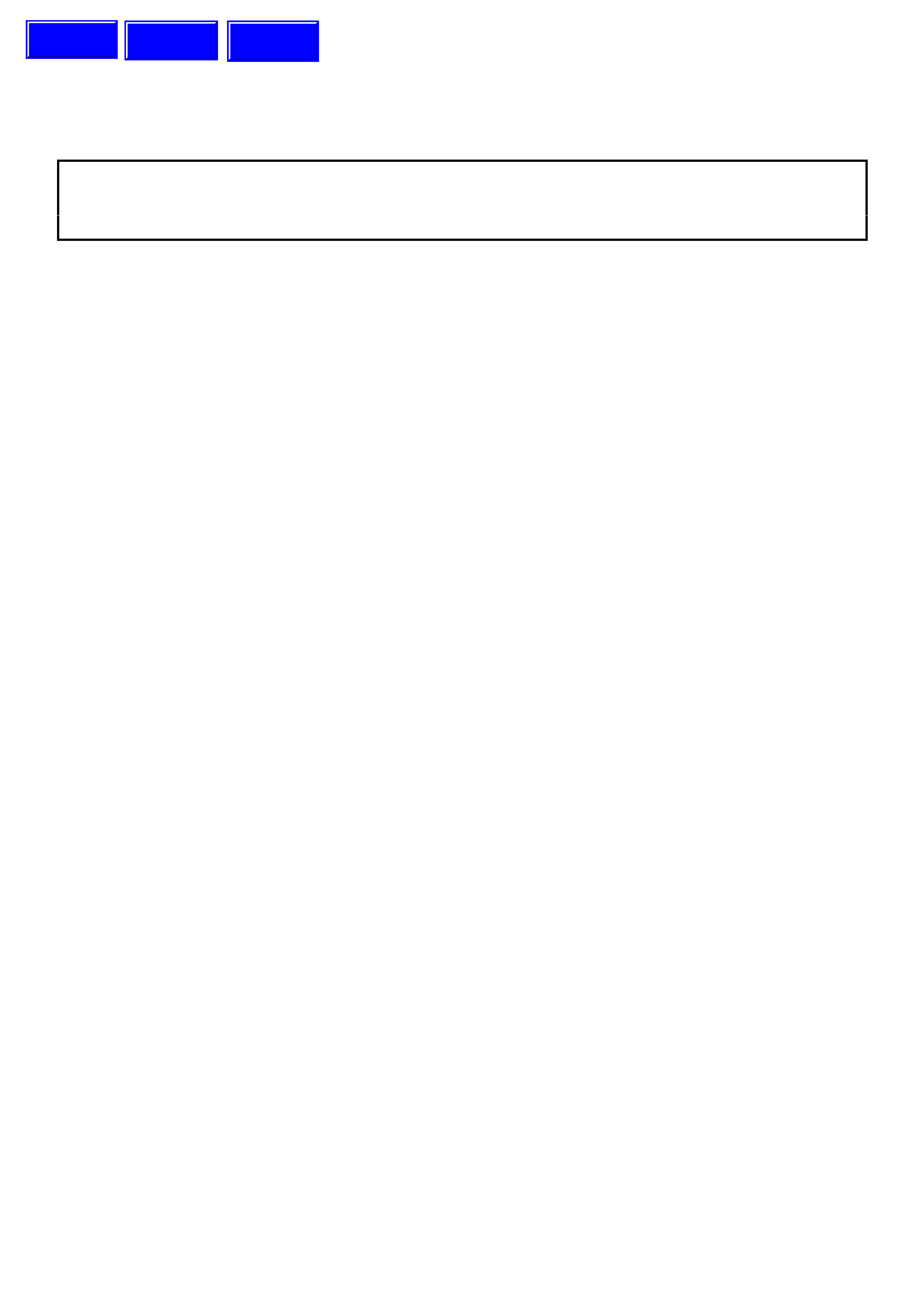

Figure 2D-1 shows the four sensors that the OCC control module uses to automatically control cabin temperature.

Figure 2D-1

Legend

1. Sun Load Sensor – located between defroster grilles and installed to top of instrument panel.

2. In-car Temperature Sensor – attached to instrument panel behind instrument cluster trim assembly.

3. Ambient Temperature Sensor – mounted to lower right-hand side front of condenser.

4. Evaporative Temperature Sensor – located inside HVAC unit and attached to downstream side of evaporator core.

3. DESCRIPTI O N

3.1 OCC CONTROL MODULE

The Occupant Climate Control system as fitted to MY2003 VY and V2 Series vehicles uses an electronic ‘soft

touch’, push button type control module to select the desired HVAC functions, operating modes and cabin

temperature. Included in its functions are switches for activating the Outside Temperature indicator, windscreen

demisting mode and the heated rear window. LED switch illumination is provided when the windscreen demister

and heated rear window are activated. All wording and icons on the soft touch buttons are illuminated when the park

lights are activated. Their illumination level is adjusted by the same means and to the same level as the

instrumentation illumination.

A Liquid Crystal Display (LCD) screen is located between the two switch clusters and provides information regarding

the current HVAC settings as well as the Outside Temperature when selected. In the event that the OCC system

develops a fault, an X symbol for OCC system Self Diagnosis can also be displayed on the LCD. The illumination

level of the LCD is also adjusted by the same means and to the same level as the instrumentation illumination.

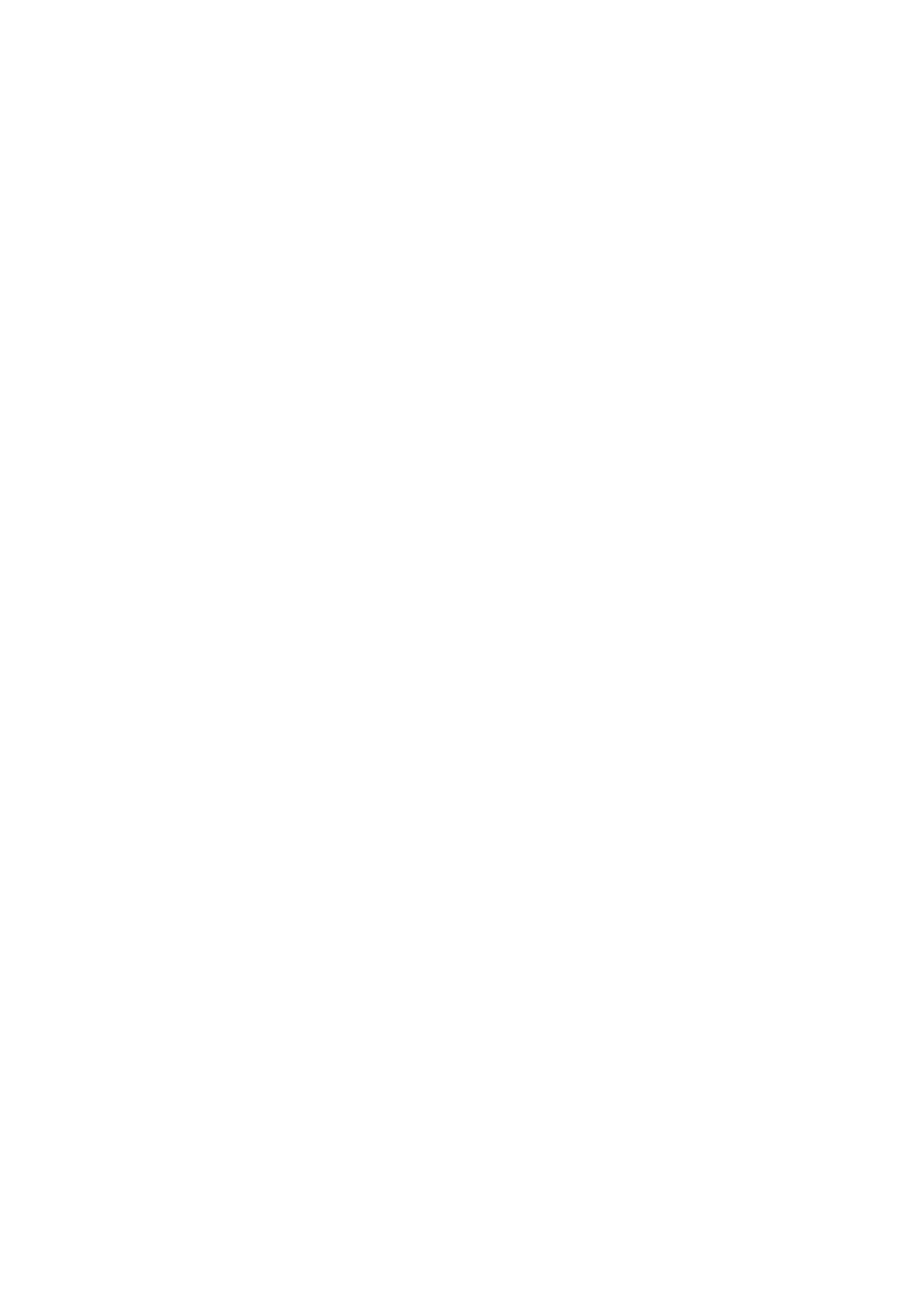

The O CC contr ol module (1) is loc ated below the hazard switch (2) and face level c entre vents (3). Contained within

the module is all s of tware and s witching hardware r equired to c ontr ol the HVAC sys tem in conjunction with the Body

Control Module (BCM) and Powertrain Control Module (PCM).

The module is installed behind the instrument bezel (4) and is attached to the bezel at four points.

Figure 2D-2

Four types of OCC control modules are fitted across the MY2003 VY and V2 Series vehicle range:

• a single zone module specific to left-hand drive models

• a single zone module specific to right-hand drive models

• a dual zone module for all dual zone systems excluding V2 Coupe models

• a dual zone module for all dual zone systems for V2 Coupe models

OCC CONTROL MODULE CONFIGURATIONS

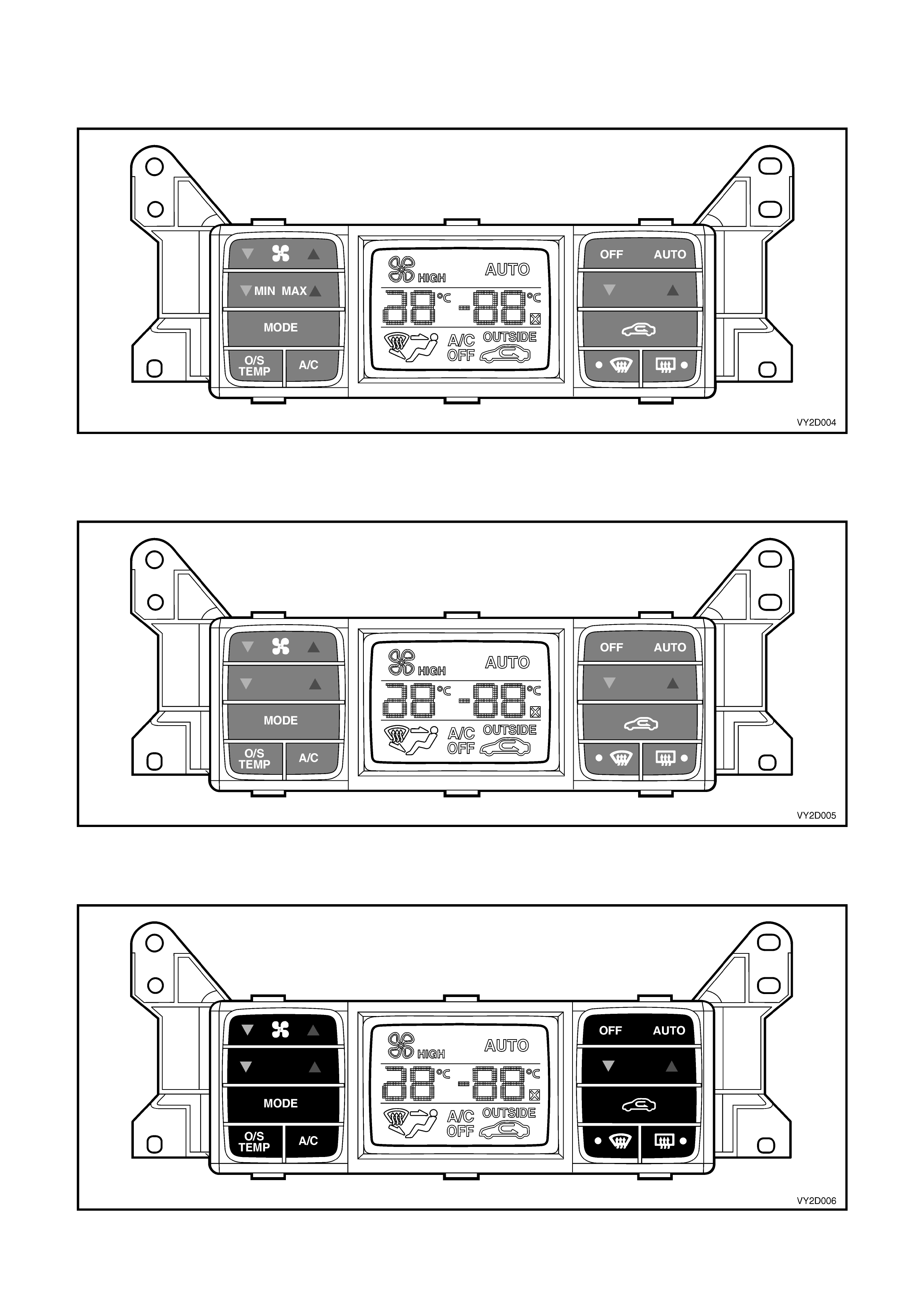

Figure 2D-3 shows the OCC control module for all single zone systems. All switches are grey.

Figure 2D-3

Figure 2D-4 shows the O CC control m odule f or all dual zone systems excluding V2 Coupe m odels. All switches are

grey.

Figure 2D-4

Figure 2D-5 shows the OCC control module for all dual zone systems as fitted to V2 Coupe models. All switches

are black.

Figure 2D-5

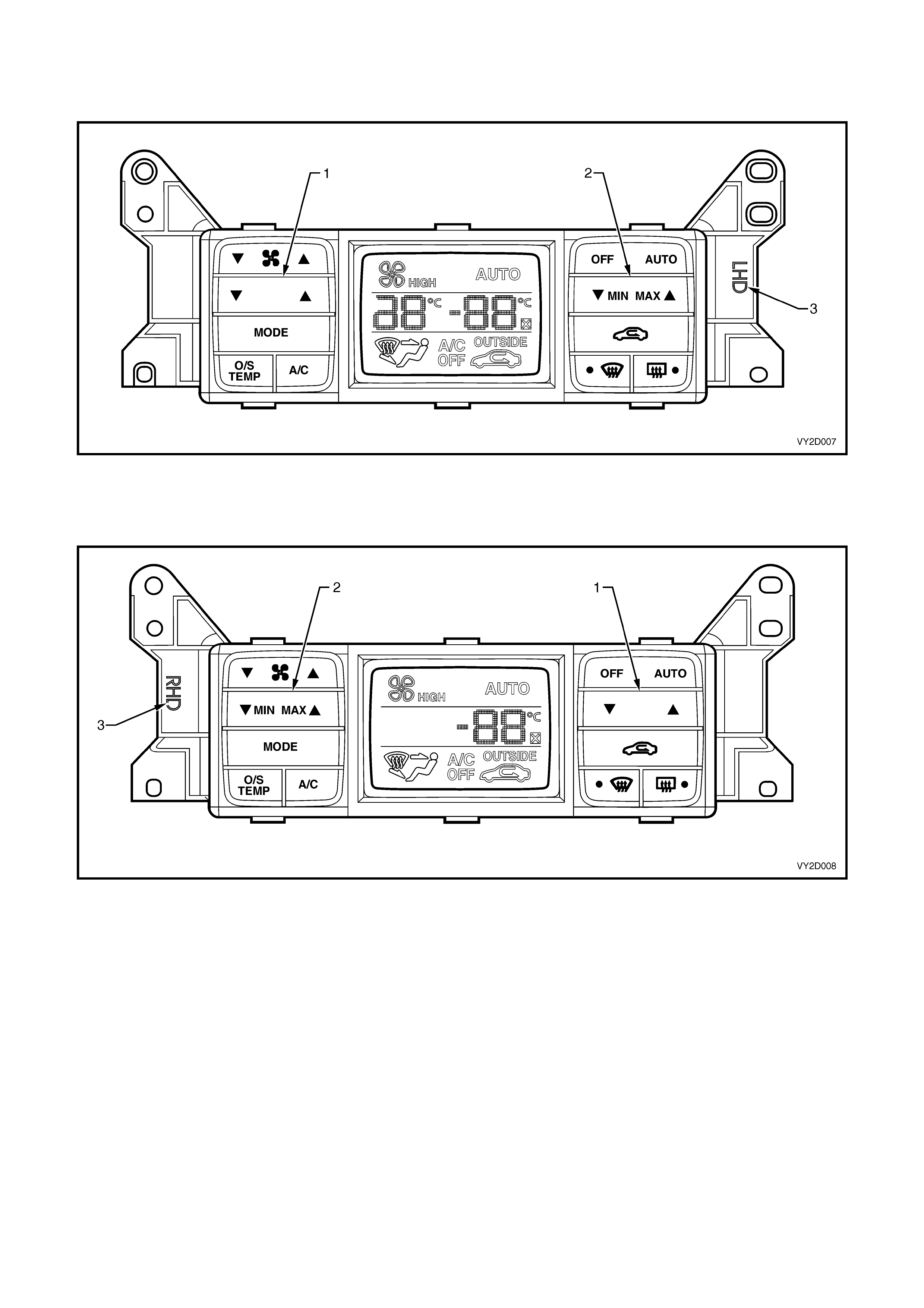

Figure 2D-6 shows the single zone OCC control module as fitted to left-hand drive models. The set temperature

switch (1) is on the left- hand side and the MIN/MAX unc ontrolled tem perature s witch (2) is on the right-hand side. A

‘LHD’ marking (3) is moulded to the facia to indicate that the module is for LHD application.

Figure 2D-6

Figure 2D-7 shows the single zone OCC control module as fitted to right-hand drive models. The set temperature

switch (1) is on the right-hand side and the MIN/MAX uncontrolled tem per ature switch ( 2) is on the lef t-hand side. A

‘RHD’ marking (3) is moulded to the facia to indicate that the module is for RHD application.

Figure 2D-7

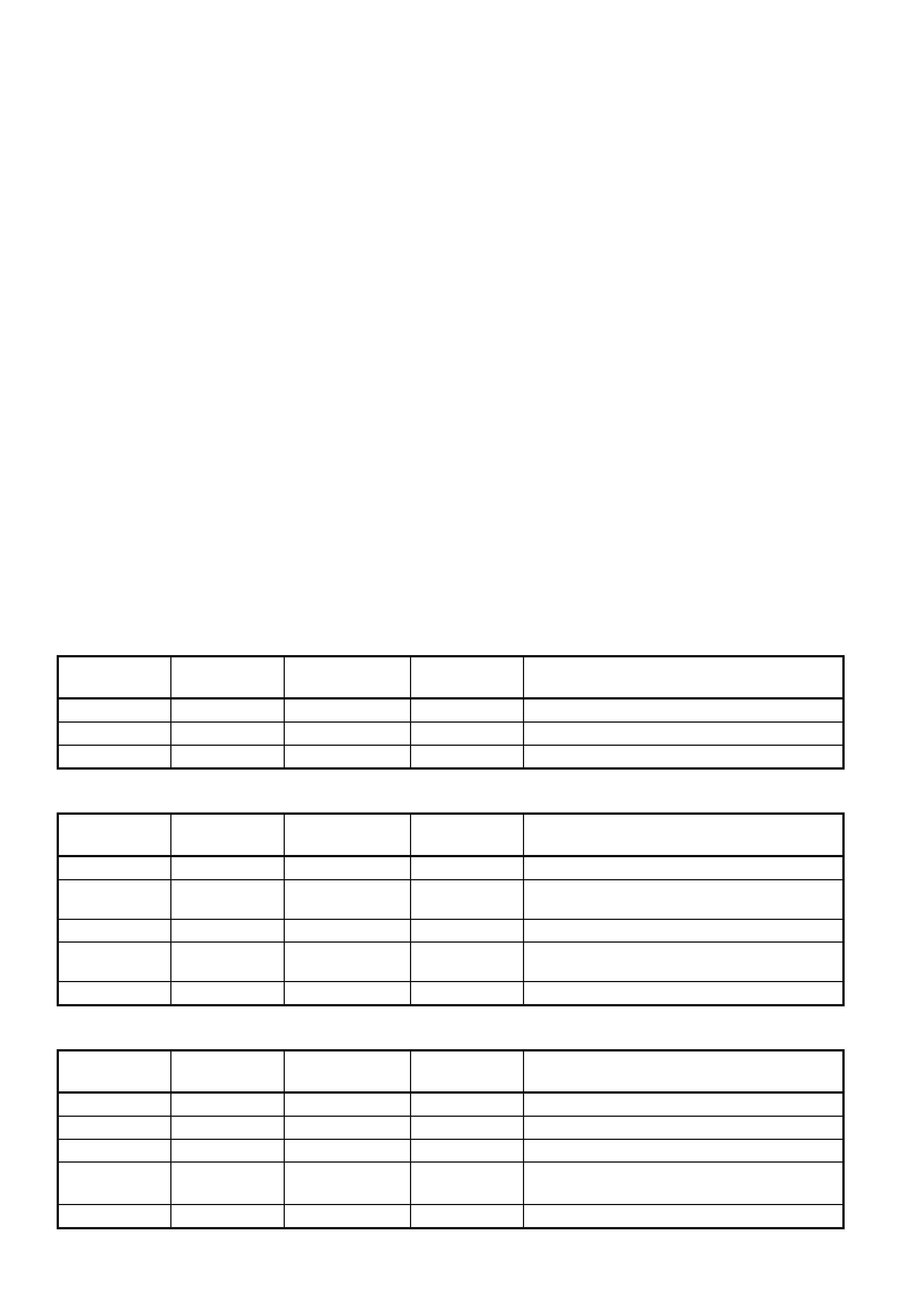

SWITCHES – SINGLE ZONE

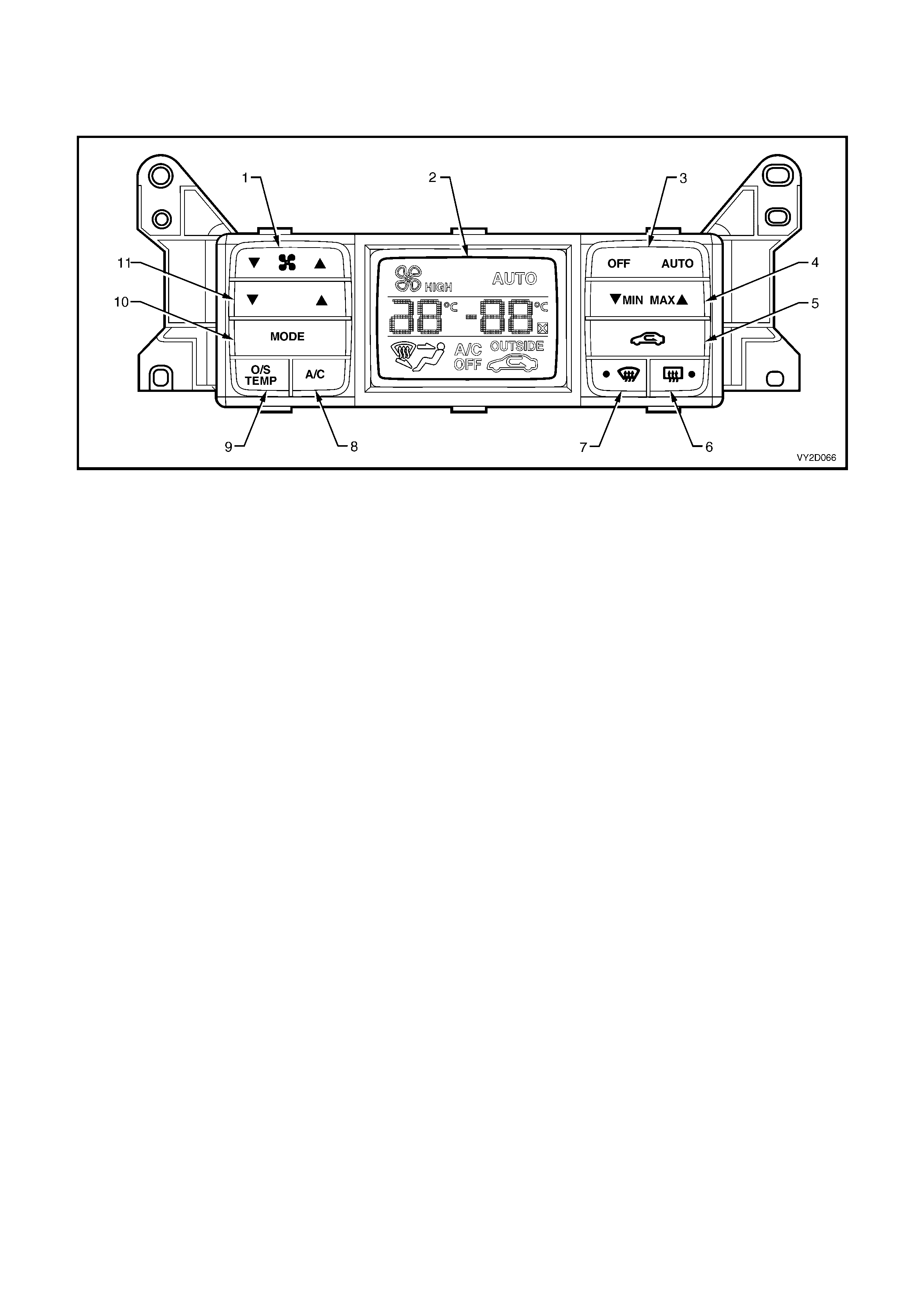

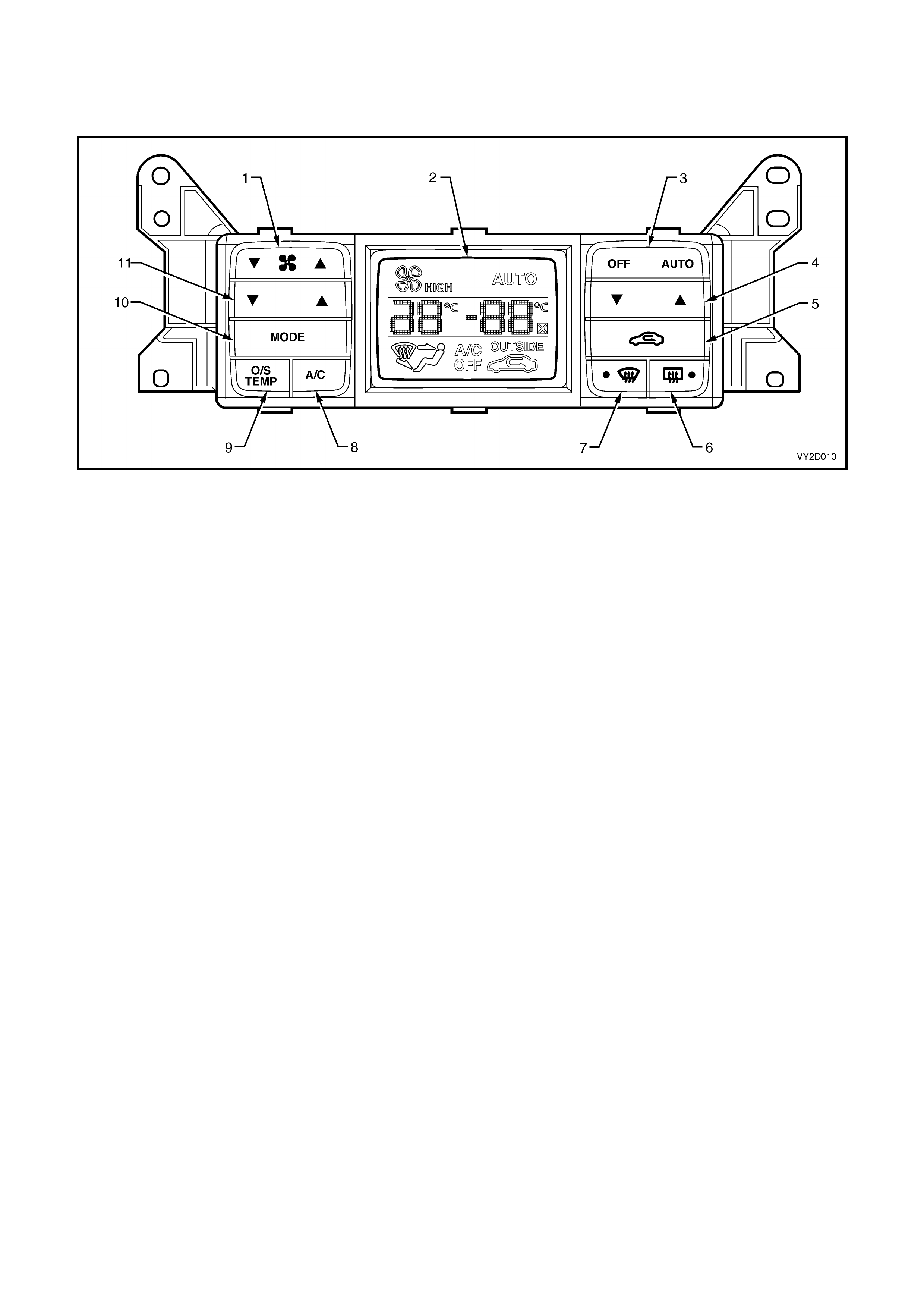

Figure 2D-8 shows the single zone OCC control module switch configuration as applicable to left-hand drive

models.

Figure 2D-8

Legend

1. Blower Fan Speed Switch 7. Windscreen Demist Mode Switch And Indicator LED

2. Liquid Crystal Display (LCD) Screen 8. Air Conditioning ON/OFF Switch

3. OCC ON/OFF, Auto Function ON Switch 9. Outside Temperature Indicator Select Switch

4. Min (Cold), Max (Hot), Uncontrolled Temperature Setting 10. Ventilation Mode Selection Switch

5. Fresh/Recirculation Mode Position Switch 11. Set Temperature Switch

6. Heated Rear Window Switch And Indicator LED

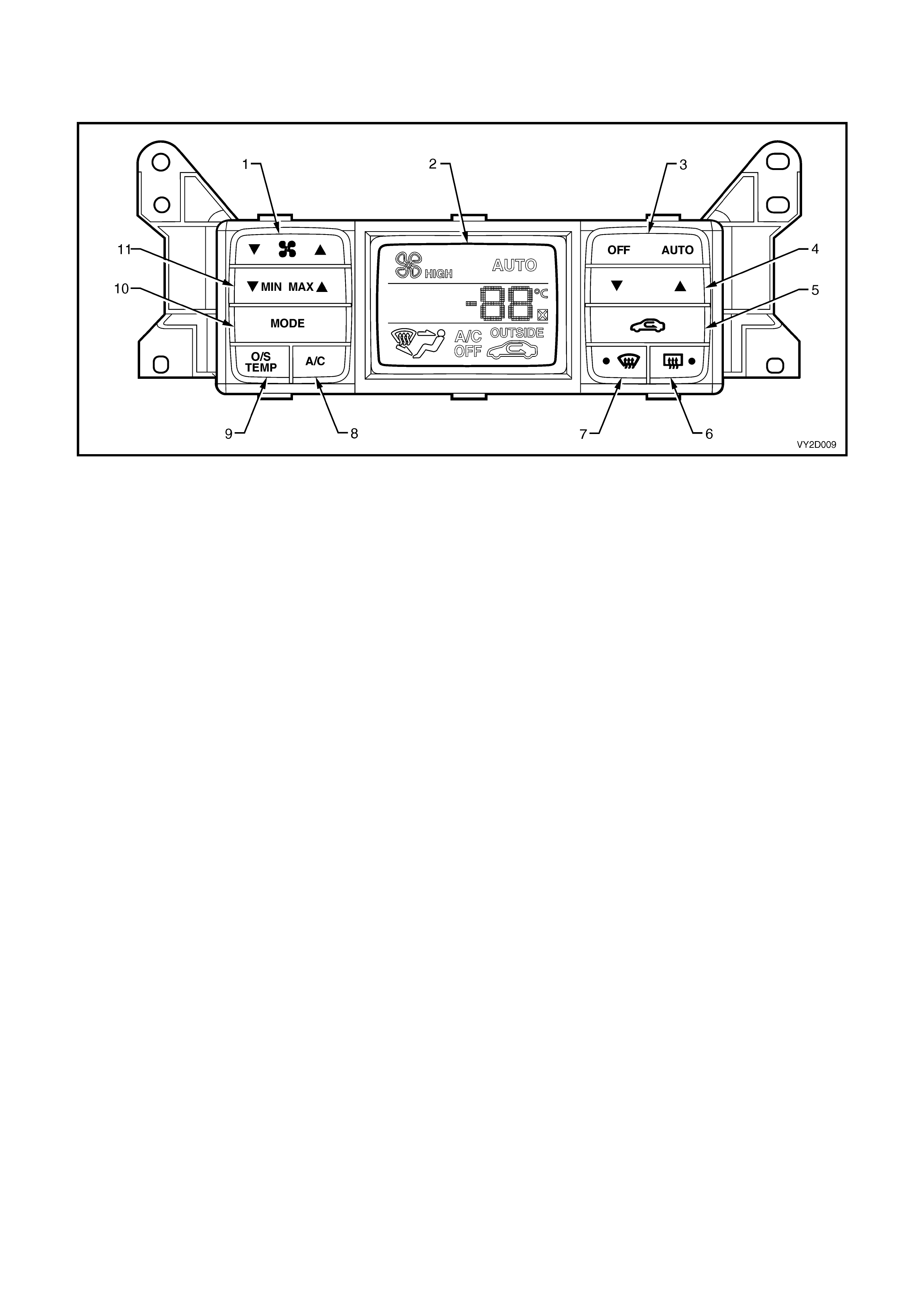

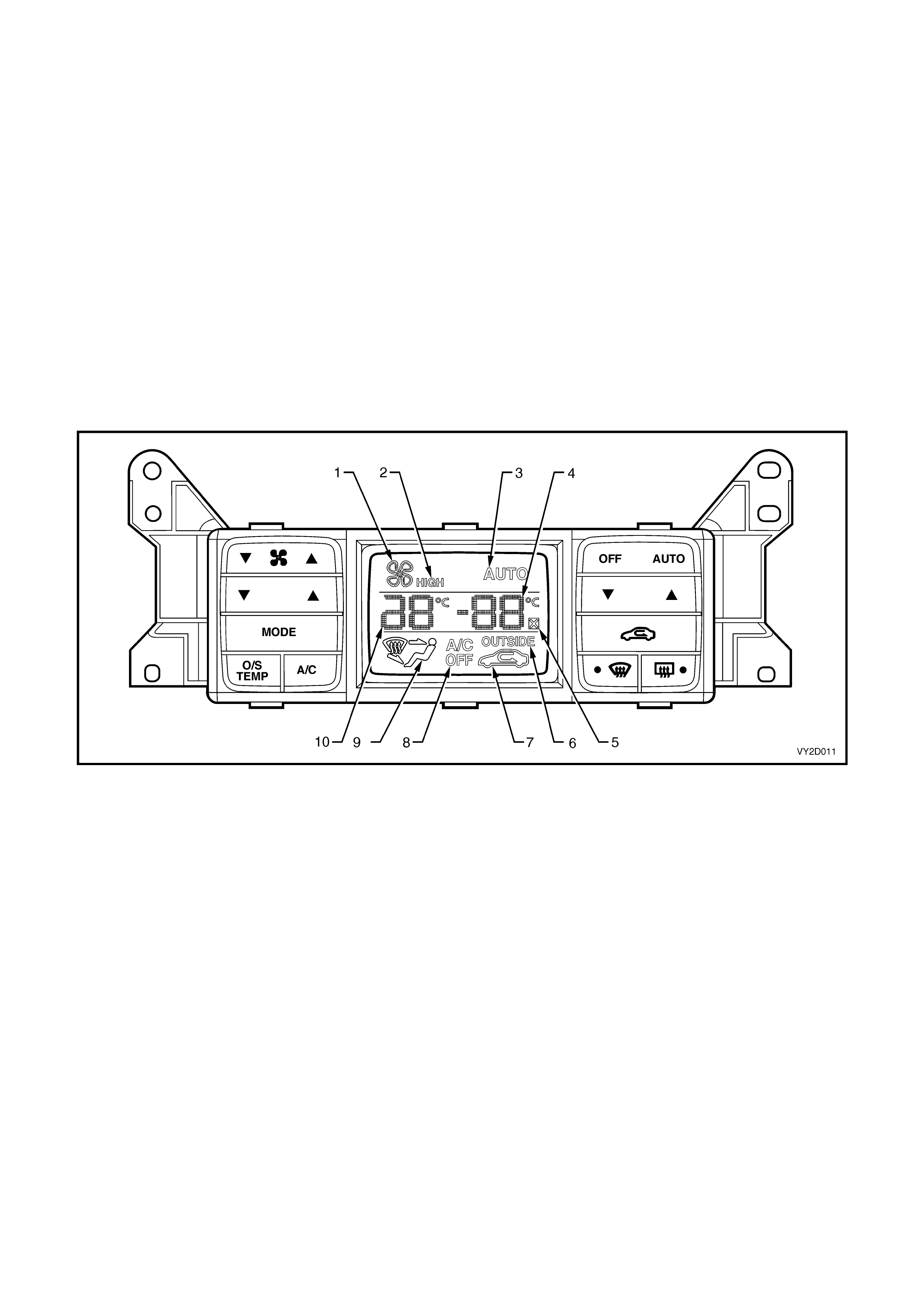

Figure 2D-9 shows the single zone OCC control module switch configuration as applicable to right-hand drive

models.

Figure 2D-9

Legend

1. Blower Fan Speed Switch 7. Windscreen Demist Mode Switch And Indicator LED

2. Liquid Crystal Display (LCD) Screen 8. Air Conditioning ON/OFF Switch

3. OCC ON/OFF, Auto Function ON Switch 9. Outside Temperature Indicator Select Switch

4. Set Temperature Switch 10. Ventilation Mode Selection Switch

5. Fresh/Recirculation Mode Position Switch 11. Min (Cold), Max (Hot), Uncontrolled Temperature Setting

6. Heated Rear Window Switch And Indicator LED

SWITCHES – DUAL ZONE

Figure 2D-10 shows the dual zone OCC control module switch configuration. Dual zone is applicable to right-hand

drive models only.

Figure 2D-10

Legend

1. Blower Fan Speed Switch 7. Windscreen Demist Mode Switch And Indicator LED

2. Liquid Crystal Display (LCD) Screen 8. Air Conditioning ON/OFF Switch

3. OCC ON/OFF, Auto Function ON Switch 9. Outside Temperature Indicator Select Switch

4. Set Temperature Switch – Driver’s Side 10. Ventilation Mode Selection Switch

5. Fresh/Recirculation Mode Position Switch 11. Set Temperature Switch – Passenger’s Side

6. Heated Rear Window Switch And Indicator LED

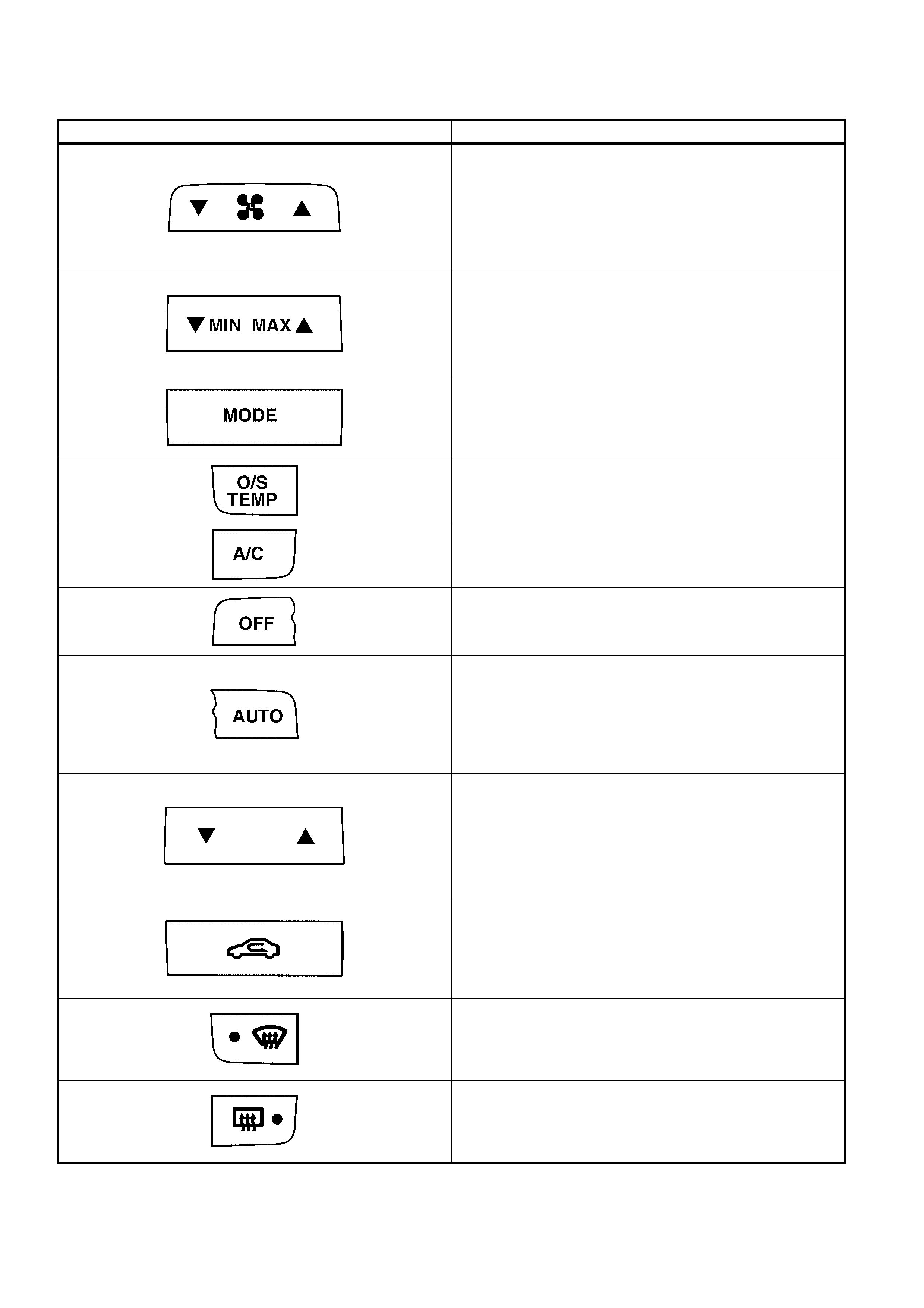

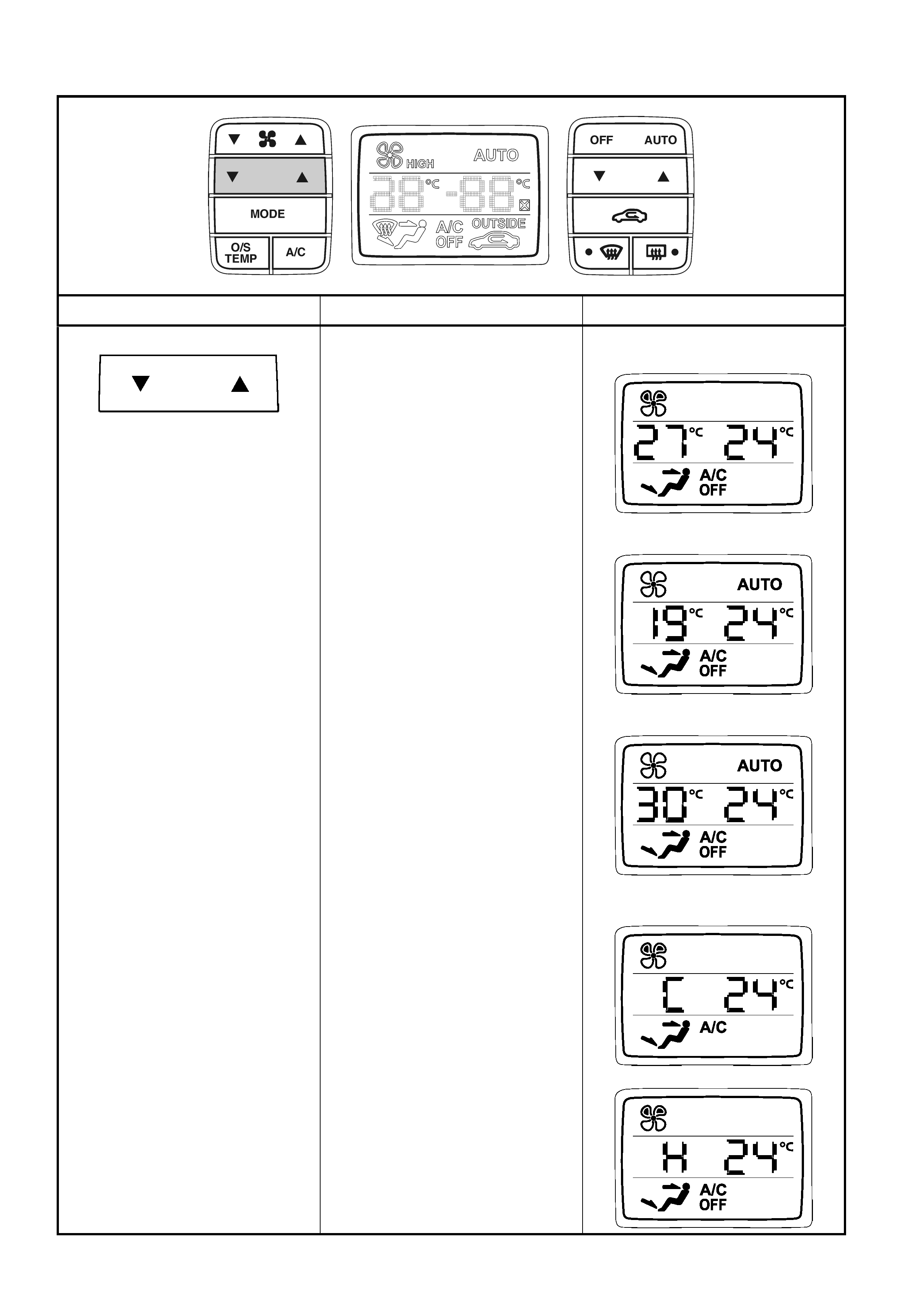

LIQUID CRYSTAL DISPLAY SCREEN

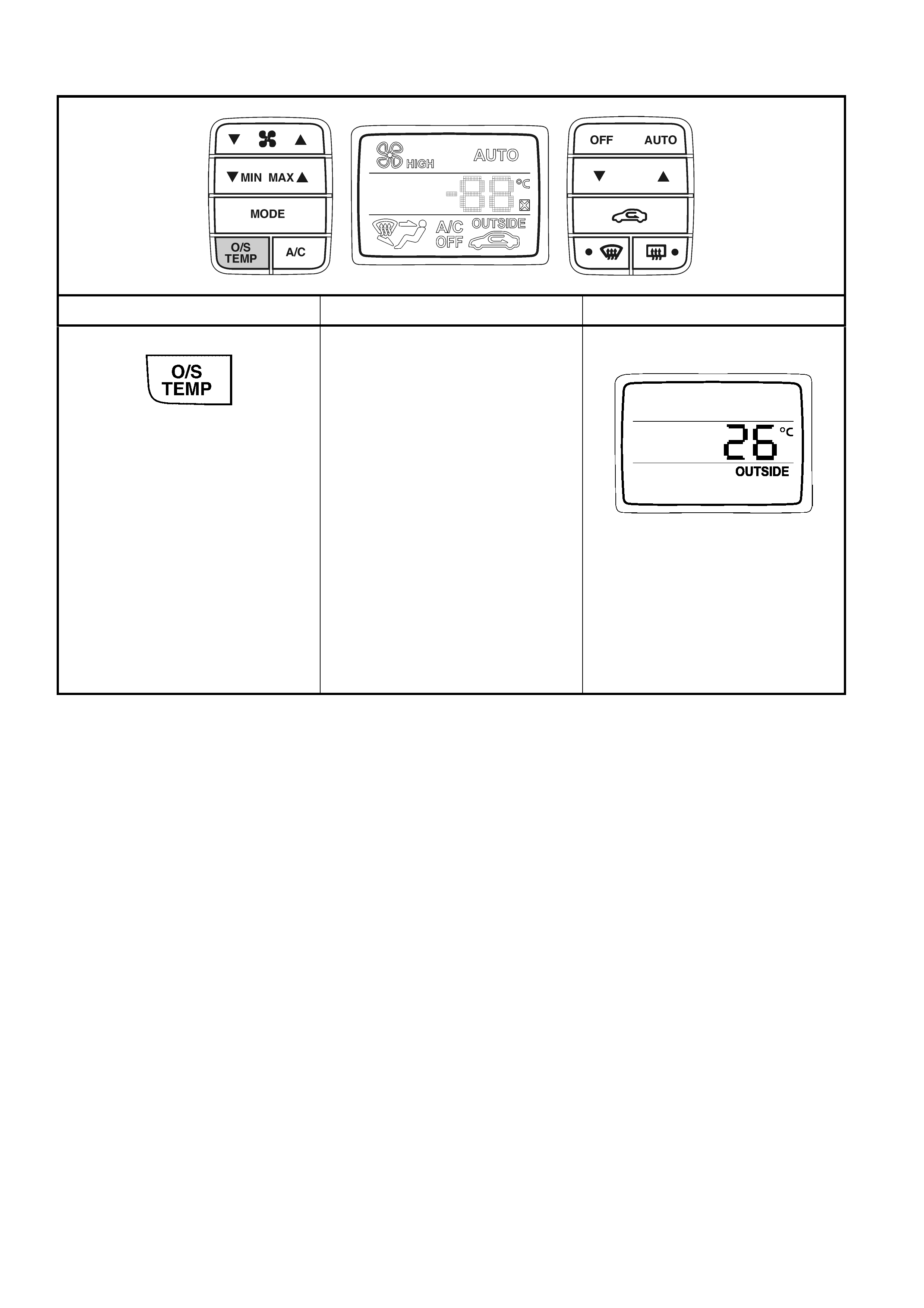

In the centre of the OCC control module is a Liquid Crystal Display (LCD) screen to indicate which modes and

functions have been selected. Depending on the mode chosen, the LCD will also display the vehicle cabin

temperature as selected by the driver, the vehicle cabin temperature as selected by the front passenger on a dual

zone system , or the tem perature as s et by the OCC s ystem when in Auto mode. An Outside Tem perature indicator

will be displayed when the O/S T EMP button is held on. T his f unction will operate whether the OCC s ystem is on or

off . When selected, the Rec irculation m ode s ymbol will be displayed on the LCD even if the OCC system is off . For

further information on the LCD screen and to view typical screen displays, refer to 4. OPERATION in this Section.

The illumination level of the LCD is controlled by the BCM via the auxiliary serial bus. The LCD brightness is

maintained at a similar level to the instruments (dials and Multi Function Display) and audio system displays. It is

adjusted simultaneously with these systems when the driver adjusts the brightness up or down, at the headlight

switch. Along with these systems, the illumination level will be dependant upon Priority 1 or Priority 2 remote key

usage. For further information, refer to Section 12J, BODY CONTROL MODULE.

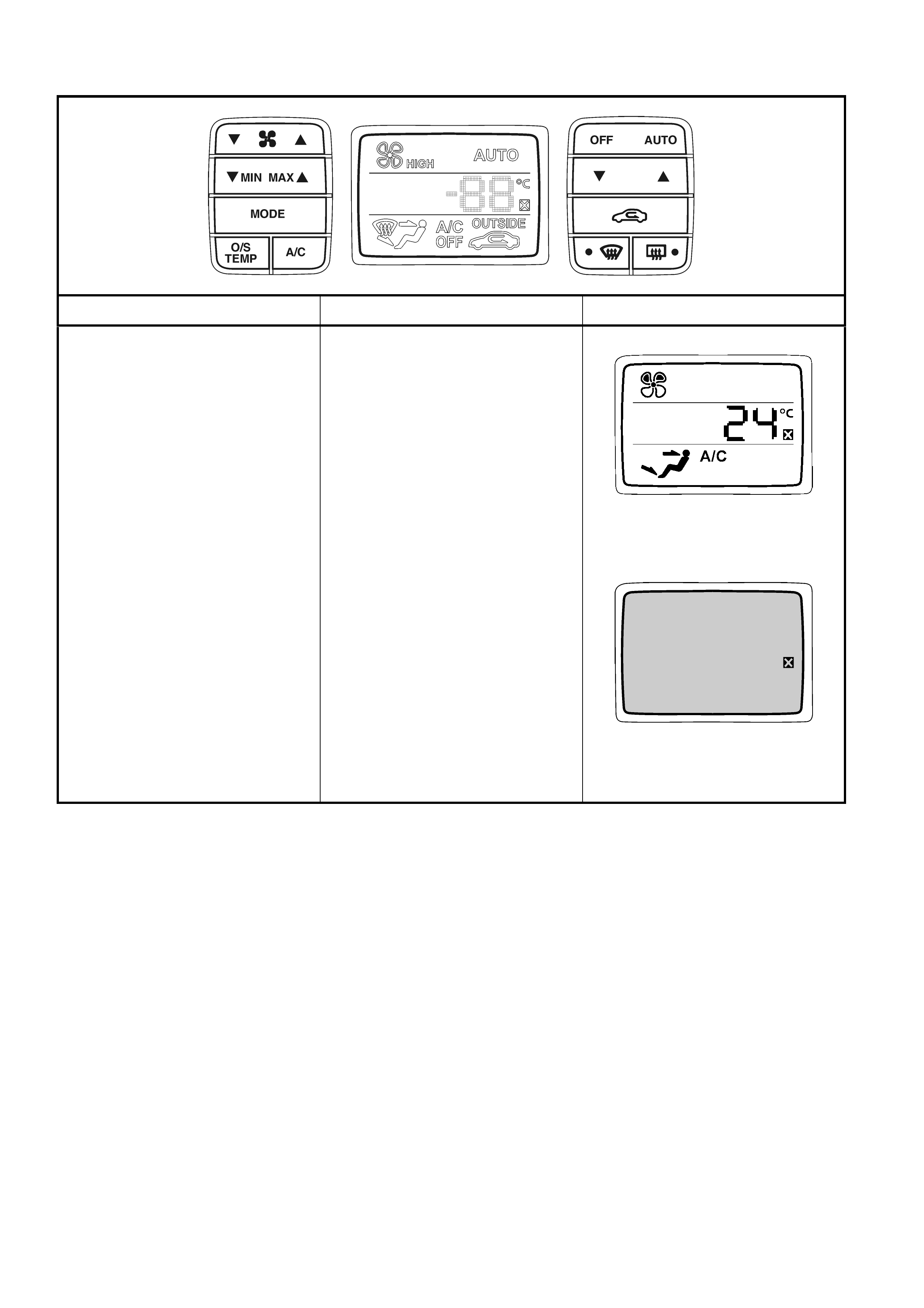

The LCD is also capable of displaying a self-diagnostic message if the OCC system develops a fault. When an

OCC sensor input is not received due to an open circuit or damaged wiring, an X symbol will appear on the LCD

screen beside the right-hand side tem perature numerals. This X symbol will rem ain displayed on the LCD whether

the OCC system is on or of f . It will disappear once the pr oblem has been r ec tif ied. Fo r f ur ther inf ormation relating to

OCC self-diagnosis, refer to Section 2F, HVAC OCCUPANT CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

Figure 2D-11

Legend

1. Blower Fan Active 6. Outside Temperature Indicator

2. Blower Fan High Speed 7. Recirculation Mode Position Indicator

3. OCC System In Auto Mode 8. Air Conditioning OFF Indicator

4. Temperature Setting And Outside Temperature 9. Ventilation Mode Indicator

5. Self Diagnostic Symbol 10. Temperature Setting

Note 1: Item 4 – Temperature setting will be for the cabin on RHD single zone models or for the driver only on RHD

dual zone models.

Note 2: Item 10 – Temperature setting will be for the cabin on LHD vehicles or for the passenger only on RHD dual

zone models.

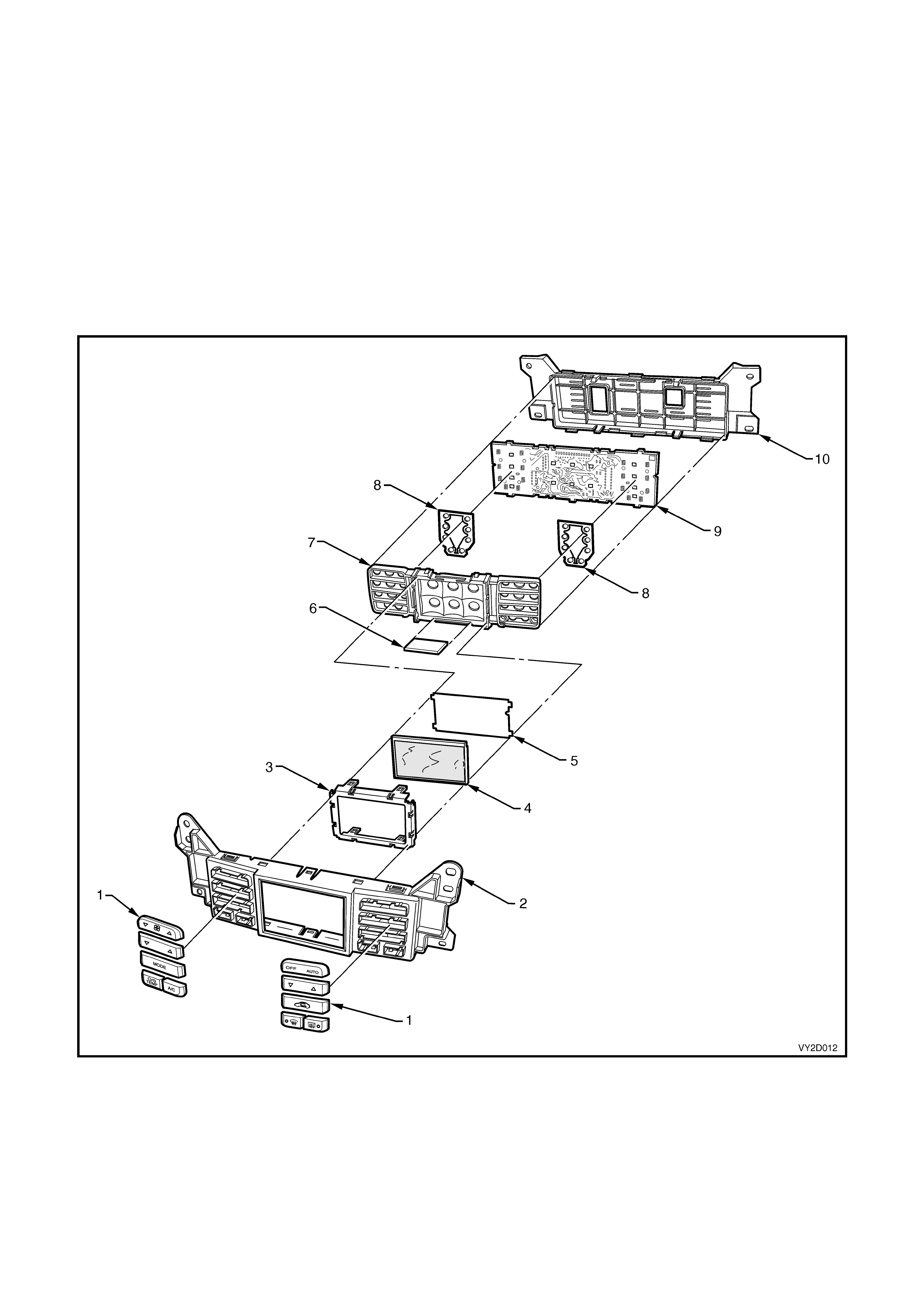

OCC CONTROL MODULE COMPONENTS

The module is designed for ease of assembly and no screws are used in its construction. The f ront facia and rear

housing of the module are constructed of plastic. The ten control buttons are also plastic and clip into and are

retained by the f ront f acia. The f ront f acia clips over the rear hous ing at four loc ations. Contained within the m odule

is a printed circuit board with the LCD screen clipped to it in four locations. Information from the circuit board is

transf erred to the LCD scr een through a carbon ‘zebra strip’. A 12 pin and a 20 pin electric al connector are bonded

directly to rear of the circuit board and protrude through apertures of the module’s rear housing. The circuit board

and LCD as sembly is c lipped to the front facia in s ix locations. At each cor ner, the complete m odule is attached to

the rear of the instrum ent bezel by four screws. T he installation of these s crews als o serves to clam p the front facia

and the rear housing of the module together, ensuring that the module remains in an assembled state when

installed to the instrument panel.

There are no replaceable bulbs contained within the OCC control module. LEDs are used to provide illumination

where necessary. The module has no serviceable items. If any component fails to function, including LCD, the

module must be replaced.

Figure 2D-12

Legend

1. Control Buttons 6. Carbon Zebra Strip

2. Front Facia 7. LCD and Silicone Switch Carrier

3. LCD Frame 8. Silicone Switches

4. LCD Screen 9. Circuit Board

5. LCD Diffuser 10. Rear Housing

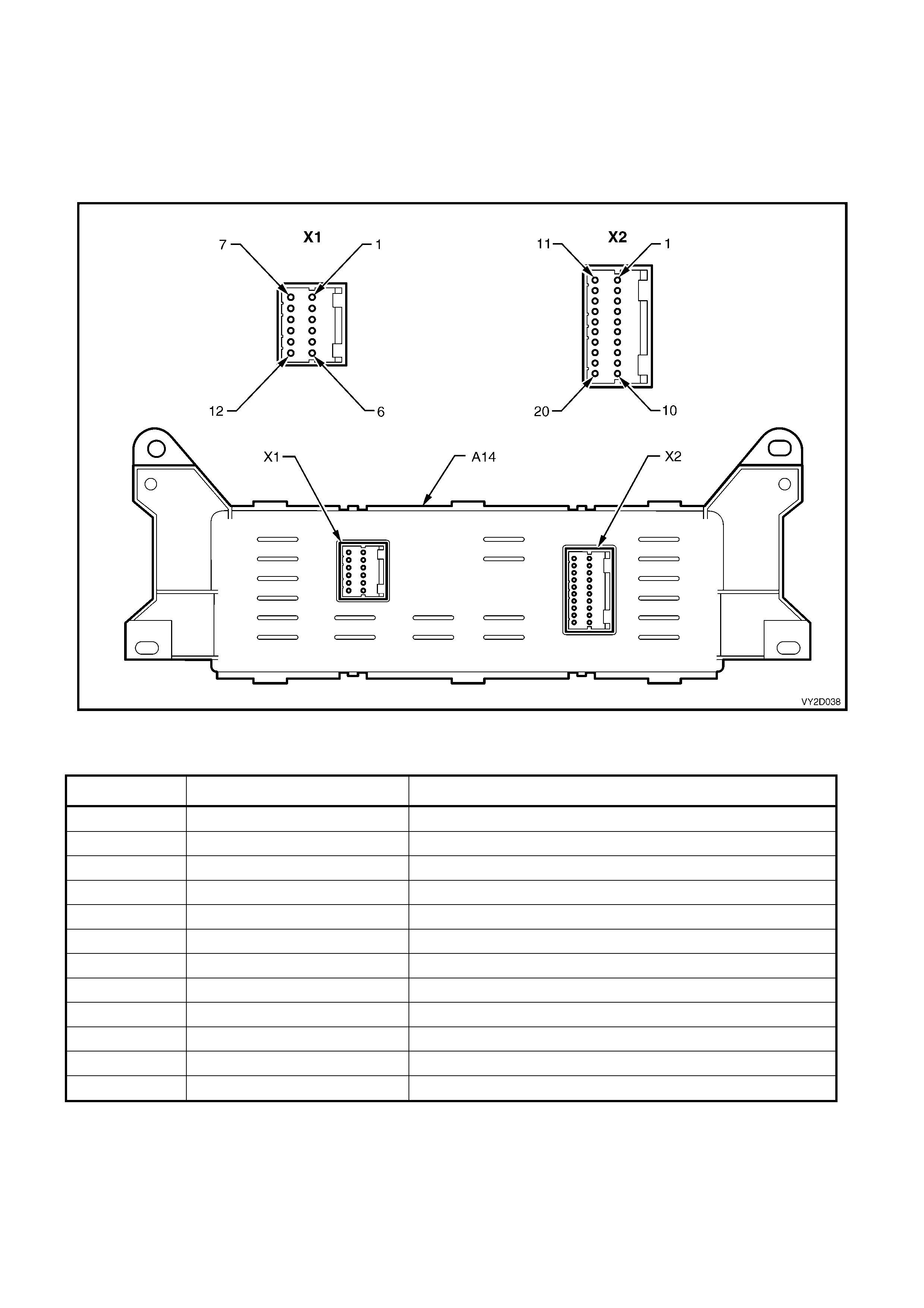

OCC CONTROL MODULE ELECTRICAL CONNECTION

Two electric al connectors are loc ated to the rear of the m anual HVAC controller. In accor dance with the Integrated

Vehicle Electrical Design (IVED) standard as applied to MY 2003 VY and V2 Series vehicles, the controller is

designated as A14 and the connectors are designated as Connector X1 and Connector X2. Both connectors are

bonded to the rear of the printed circuit board.

Figure 2D- 13 provides a view of the connector term inal assignm ents and the tables following it provide inf ormation

on their function.

Figure 2D-13

Connector X1 – RHD and LHD

PIN NUMBER WIRE COLOUR FUNCTION

X1-1 Black / Red Rear window demister select to HRW relay

X1-2 Black / Yellow Ground (X157)

X1-3 Orange / Yellow Fuse F21 – Power for OCC Switc hi ng and LE D i ndi cation

X1-4 Pink / B l ue Fuse F13 – Power for solenoid pack switching and LED illumi nation

X1-5 Yellow / Black Fan speed high – Bl ower Relay

X1-6 Green / White Serial data line

X1-7 Yellow Fan speed feedback

X1-8 Black / Red Fan speed cont rol

X1-9 Brown / White Fuse F11 – Power for instrument illumination

X1-10 Blue / Blac k In-car air temperat ure sensor signal

X1-11 – Not connected

X1-12 Light Green / B l ack Ambi ent air temperature sens or signal

Connector X2 – LHD

PIN NUMBER WIRE COLOUR FUNCTION

X2-1 Red Air m ix door motor + ve

X2-2 Black Air mix door motor – ve

X2-3 – Not connected

X2-4 – Not connected

X2-5 Red / White Power for sol enoi d pack sol enoi ds and water VSV

X2-6 Dark Green Foot 1 select – No.1 s ol enoi d, solenoid pack

X2-7 Black / Whit e Defog select – No.2 s ol enoi d, solenoid pac k

X2-8 Pink Fresh / rec i rc select – No.5 solenoi d, solenoid pac k

X2-9 Yellow Face 1 select – No.4 s ol enoi d, solenoid pack

X2-10 Blue / Red Face 2 select – No.3 s ol enoi d, solenoid pac k

X2-11 Brown Power for air m i x motor positi on signal

X2-12 – Not connected

X2-13 – Not connected

X2-14 – Not connected

X2-15 White Ground for sens ors and air mi x m ot or signal

X2-16 – Not connected

X2-17 – Not connected

X2-18 Green / Whit e Air mi x motor positi on signal

X2-19 Whit e / Black Evaporative temperat ure sensor signal

X2-20 Red / Black Water valve – Vac uum switch valve

Connector X2 – RHD (Single Zone)

PIN NUMBER WIRE COLOUR FUNCTION

X2-1 Red Air m ix door motor + ve

X2-2 Black Air mix door motor – ve

X2-3 – Not connected

X2-4 – Not connected

X2-5 Red / Whit e Power for sol enoi d pack sol enoi ds

X2-6 Dark Green Foot 1 select – No.4 s ol enoi d, solenoid pack

X2-7 Black / White Foot 2 select – No.5 solenoid, solenoid pack

X2-8 Pink Fres h/recircul ation selec t – No.1 solenoi d, solenoid pac k

X2-9 Yellow Fac e 1 select – No.2 solenoid, solenoid pack

X2-10 Blue / Red Fac e 2 select – No.3 solenoid, solenoid pack

X2-11 White P ower for air mix mot or position s i gnal

X2-12 – Not connected

X2-13 – Not connected

X2-14 – Not connected

X2-15 Tan Ground for sensors and ai r mix mot or signal

X2-16 – Not connected

X2-17 – Not connected

X2-18 Green / White Ai r mix motor position signal

X2-19 White / Black Evaporative temperature s i gnal

X2-20 Purple Water val ve – No. 6 solenoid, s o l enoi d pack

Connector X2 – RHD (Dual Zone)

PIN NUMBER WIRE COLOUR FUNCTION

X2-1 Red Driver’s s i de ai r mix door moto r + ve

X2-2 Black Driver’s si de ai r mix door mot or – ve

X2-3 Brown Passenger side air mix door motor + ve

X2-4 Blue Passenger s i de ai r mix door mot or – ve

X2-5 Red / White Power for solenoid pack solenoi ds

X2-6 Dark Green Foot 1 select – No. 4 solenoid, s ol enoi d pack

X2-7 Black / White Foot 2 select – No.5 sol enoi d, solenoid pac k

X2-8 Pink Fresh/recirculat i on select – No.1 solenoid, solenoid pack

X2-9 Yellow Face 1 select – No.2 s ol enoi d, solenoid pack

X2-10 Blue / Red Face 2 select – No.3 s ol enoi d, solenoid pac k

X2-11 White Power for air mix m otor positi on signal

X2-12 – Not connected

X2-13 – Not connected

X2-14 – Not connected

X2-15 Tan Ground for sens ors and air mi x motor signals

X2-16 – Not connected

X2-17 Yellow / Blue Passenger si de ai r mix motor position s i gnal

X2-18 Green / White Driver’s s i de ai r mix motor position signal

X2-19 White / B l ack Evaporative temperature s i gnal

X2-20 Purple Water valve – No.6 solenoid, solenoid pack

3.2 HEATING, VENTILATION AND AIR CONDITIONING (HVAC) UNIT:

CONSTRUCTION, COMPONENTS AND ASSOCIATED SENSORS

There are three different types of Occupant Climate Control (OCC) HVAC units fitted across the MY2003 VY and

V2 Series vehicle range:

• Left-hand drive single zone system – HVAC Occupant Climate Control

• Right-hand drive single zone system – HVAC Occupant Climate Control

• Right-hand drive dual zone system – HVAC Occupant Climate Control

While similar in function and performance, the OCC HVAC units fitted to left and right-hand drive vehicles differ

significantly in ter ms of their case constr uction as well as their internal and external c omponents. Dual zone HVAC

units differ from the single zone units in that two air mix motors (not visible in the following diagram) are fitted to

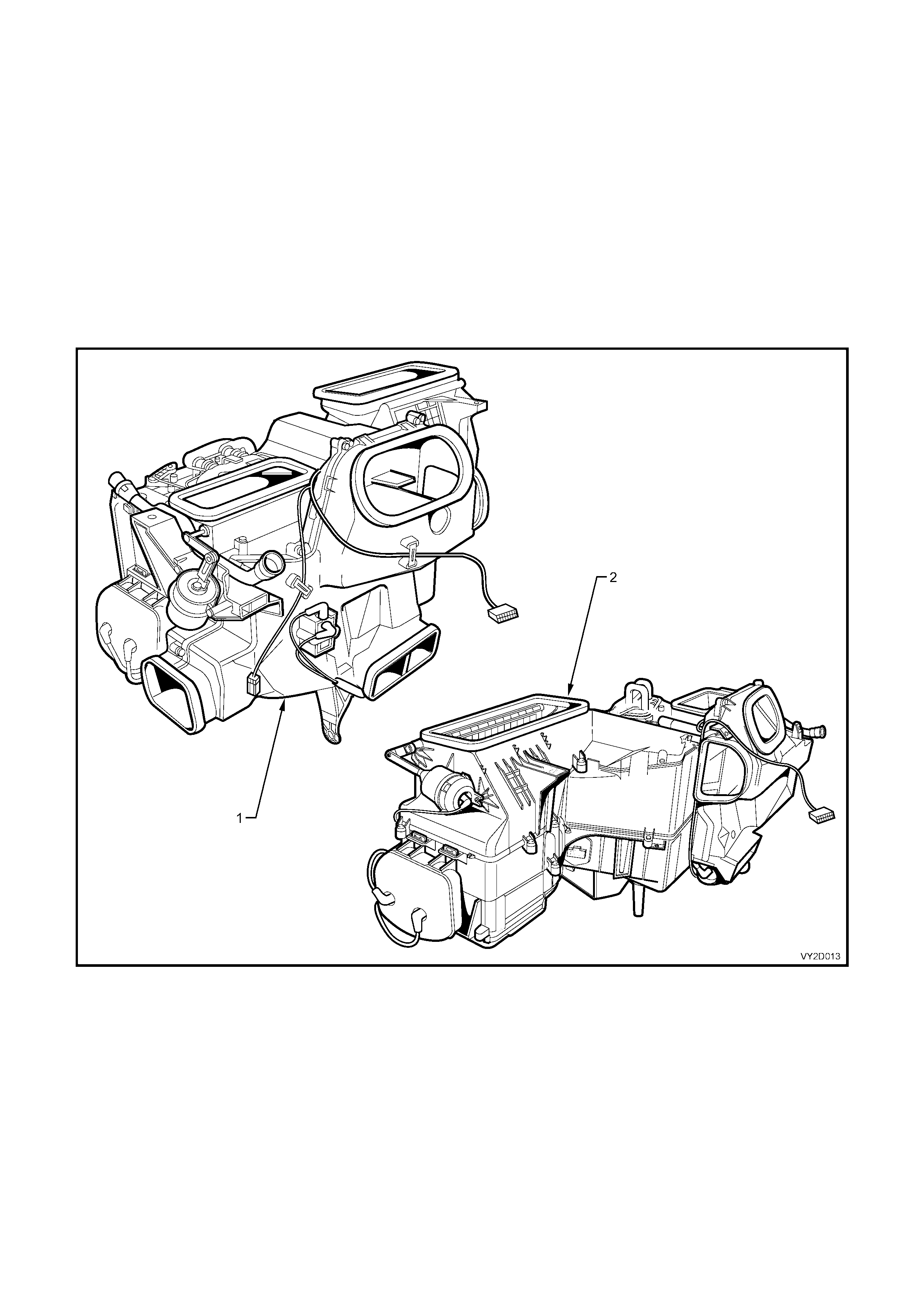

provide independent operation of the passenger and driver side air m ix doors. Figure 2D-14 compares the left and

right-hand drive OCC HVAC units, Views are shown as viewed from a left-hand side of cabin perspective.

Figure 2D-14

Legend

1. OCC HVAC Unit – Left-hand Drive 2. OCC HVAC Unit – Right-hand Drive

HVAC UNIT – LEFT-HAND DRIVE

The HVAC unit as fitted to left-hand drive vehicles is of a four piece case construction and is fitted with four

externally mounted vacuum actuators to provide the selected operating modes. A five-solenoid vacuum solenoid

pack , controlling vacuum to the actuators, is fitted under the RHS of the HVAC unit to the r ear of the blower m otor.

An additional solenoid for water valve control is mounted to the front of the HVAC unit.

Two recirculation doors are used to control airflow into the HVAC unit. Two individual air mix doors are used to

control the airflow through the heater core. A single air mix motor is fitted above the HVAC unit to operate the air

mix doors.

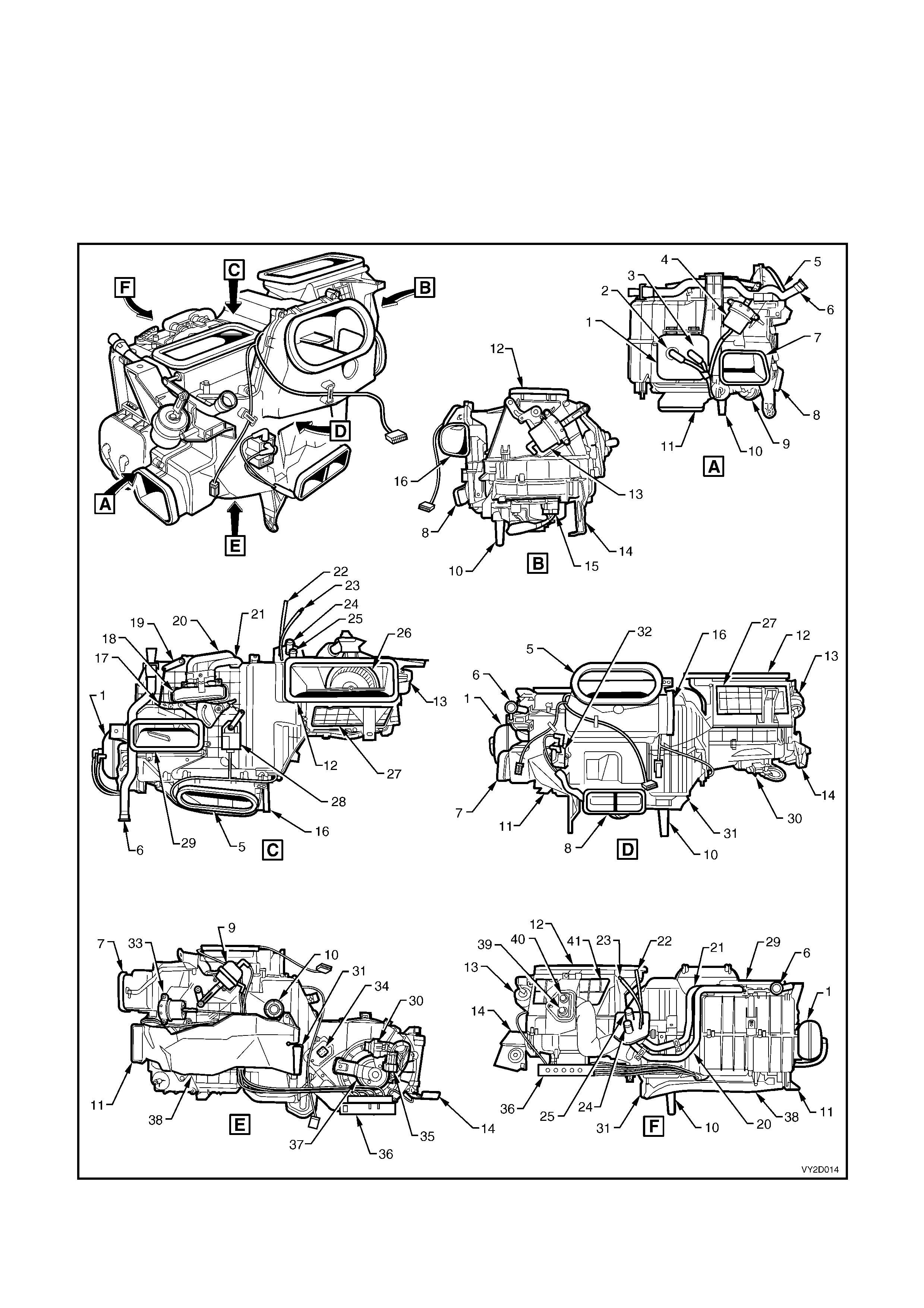

Left-hand drive HVAC unit – assembled views

Figure 2D-15

Legend (for Figure 2D-15)

1. Vacuum Tank 22. Vacuum Line (To water valve)

2. Vacuum Connector (From inlet manifold) 23. Vacuum Line (To inlet manifold)

3. Vacuum Connector (To solenoid pack) 24. Heater Core Outlet

4. Demist Vacuum Actuator 25. Heater Core Inlet

5. Face Vent Outlet 26. Blower Fan

6. Aspirator Tube 27. Front Recirculation Door

7. Side Duct Outlet – LHS 28. Air Mix Motor

8. Rear Duct Outlet 29. Demist Outlet

9. Face Vacuum Actuator 30. In-line Fuse Holder

10. Drain Tube 31. Foot Vent Outlet – RHS

11. Foot Vent Outlet – LHS 32. Water Valve Vacuum Switch Solenoid Valve

12. HVAC Inlet 33. Foot Vacuum Actuator

13. Intake Vacuum Actuator 34. Blower Resistor Assembly

14. BCM Bracket 35. Blower Motor Harness Connector

15. Blower Motor Connector 36. Solenoid Pack

16. Side Duct Outlet – RHS 37. Blower Motor

17. Front Air Mix Door Lever 38. Foot Duct

18. Heater Core 39. A/C High Pressure Port

19. Rear Air Mix Door Lever 40. A/C Low Pressure Port

20. Heater Core Pipe – Outlet 41. Rear Recirculation Door

21. Heater Core Pipe – Inlet

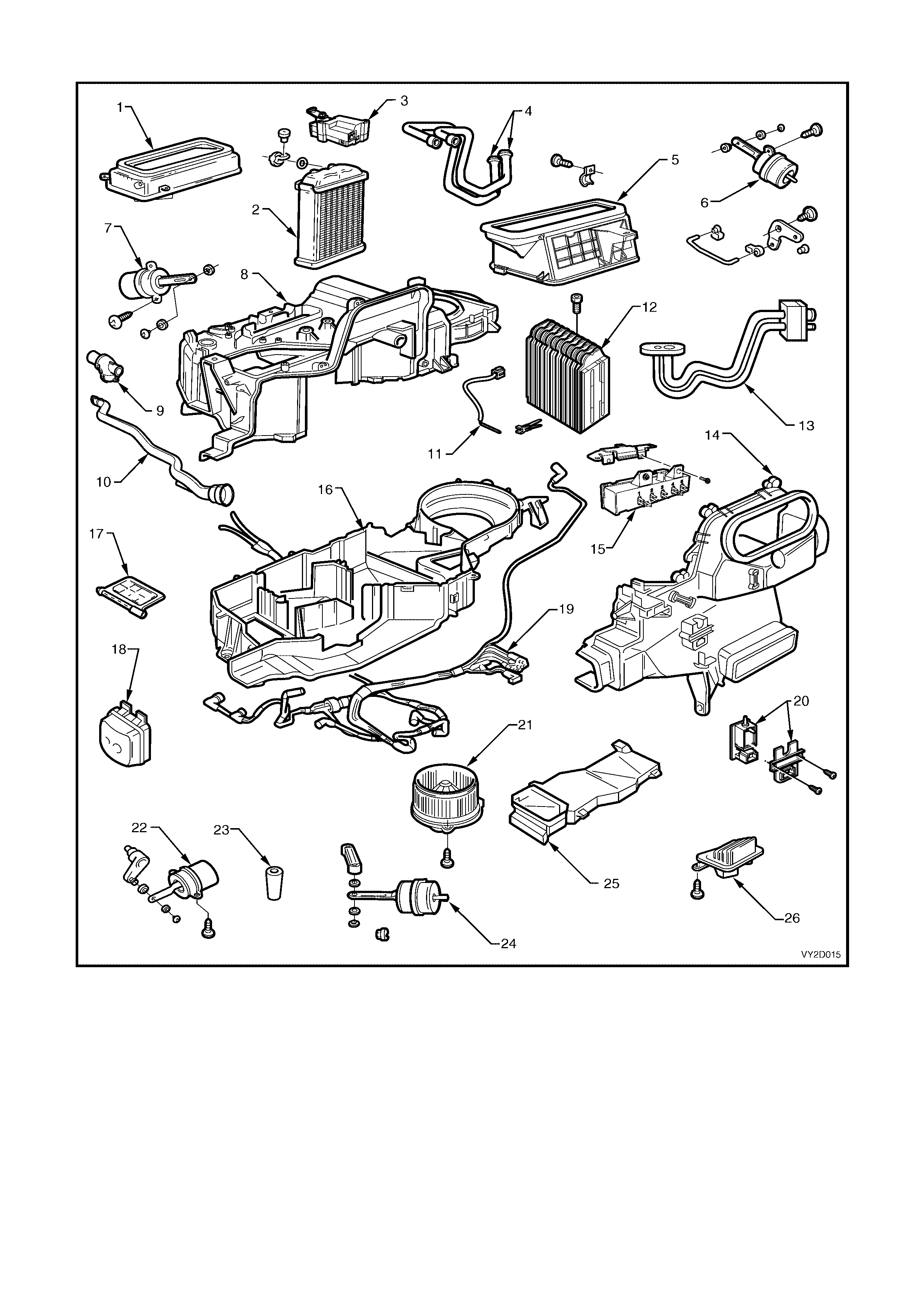

Left-hand drive HVAC unit – exploded view

Figure 2D-16

Legend

1. Demister Housing 10. Aspirator Tube 19. Vacuum Tube Harness

2. Heater Core 11. Evaporative Temperature Sensor 20. Water Valve VSV

3. Air Mix Motor 12. Evaporator Core 21. Blower Fan And Motor

4. Heater Core Pipes 13. Evaporator Core Pipes 22. Foot Vacuum Actuator

5. Fresh/Recirculation Housing 14. HVAC Case – Front 23. Drain Hose

6. Fresh/Recirculation Vacuum Actuator 15. Vacuum Solenoid Pack 24. Face Vacuum Actuator

7. Demist Vacuum Actuator 16. HVAC Case – Lower 25. Foot Duct

8. HVAC Case – Upper 17. Foot Door 26. Blower Motor Resistor

9. Aspirator Venturi 18. Vacuum Tank

HVAC UNIT – RIGHT-HAND DRIVE

The HVAC unit as fitted to right-hand drive vehicles is of a four piece case construction and is fitted with three

externally mounted vacuum actuators to provide the selected operating modes. A six-solenoid vacuum solenoid

pack, controlling vacuum to the actuators, is fitted under the LHS of the HVAC unit to the rear of the blower m otor

cover.

A single recirculation door is used to control airflow into the HVAC unit. A single two piece air mix door is used to

control the airflow through the heater core. On Single Zone units, a single air mix motor is fitted below the HVAC

unit to operate the air m ix door. On Dual Zone units, two air mix motors are f itted below the HVAC unit to operate

the two independent air mix doors.

Right-hand drive HVAC unit – assembled views

Figure 2D-17

Legend (for Figure 2D-17)

1. Vacuum Tank 18. Heater Core Outlet

2. Vacuum Connector (From inlet manifold) 19. Blower Fan

3. A/C High Pressure Port 20. Heater Core

4. Vacuum Line (To water valve) 21. Heater Core Pipe – Outlet

5. Vacuum Line (To inlet manifold) 22. Heater Core Pipe – Inlet

6. A/C Low Pressure Port 23. Demist Outlet

7. HVAC Inlet 24. Air Mix Door Rod

8. Intake Vacuum Actuator 25. Foot Vent Outlet – RHS

9. Face Vent Outlet 26. Face/Bi-level Vacuum Actuator

10. Side Duct Outlet – LHS 27. Foot Vent Outlet – LHS

11. Rear Duct Outlet 28. Blower Resistor Assembly

12. Vacuum Connector (From Solenoid Pack) 29. Blower Motor Connector

13. Drain Tube 30. Blower Motor Cover

14. Solenoid Pack 31. Air Mix Motor

15. Side Duct Outlet – RHS 32. Demist/Foot Actuator

16. Aspirator Tube 33. Foot Duct

17. Heater Core Inlet 34. Recirculation Door

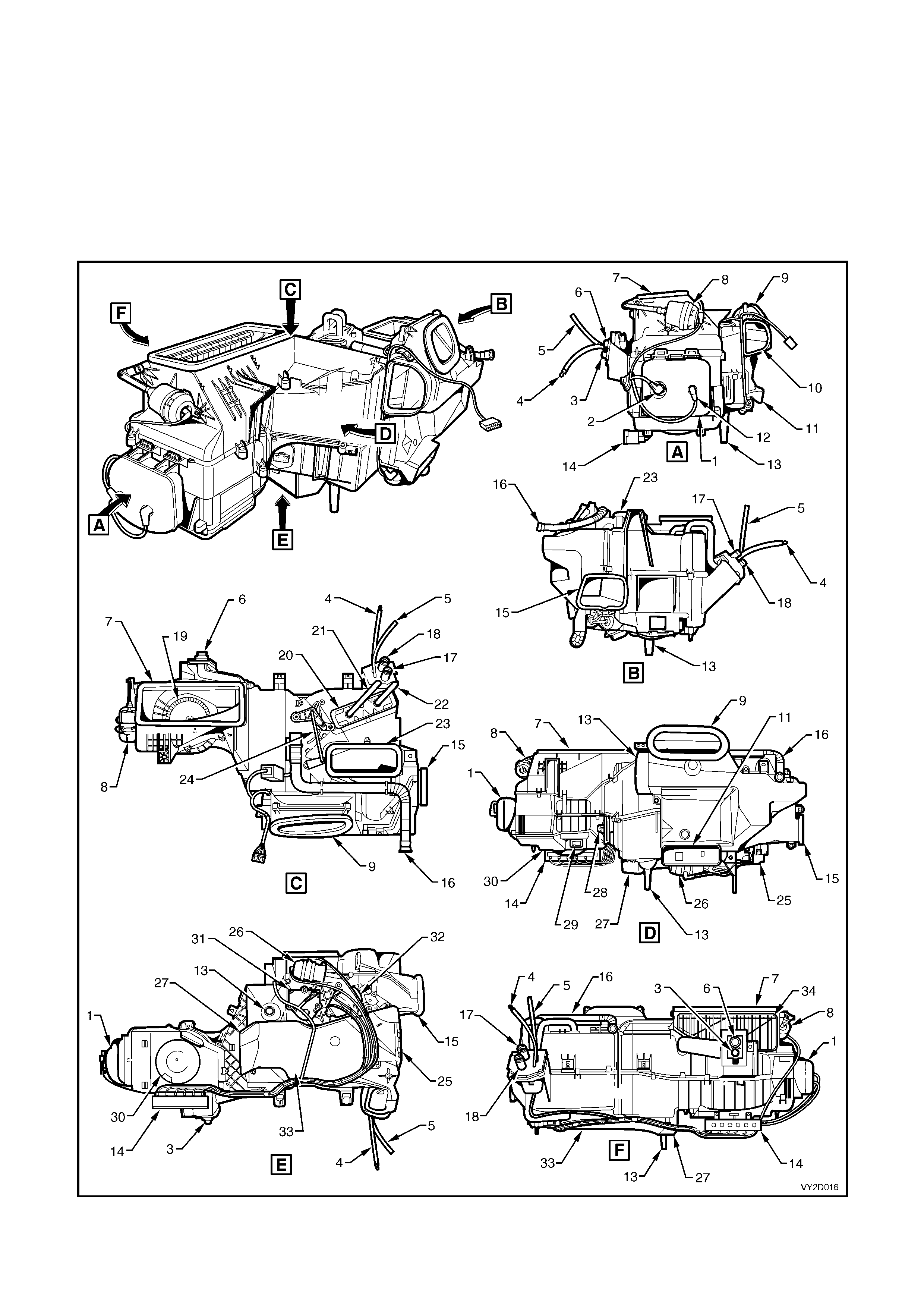

Right-hand drive HVAC unit, single zone and dual zone – exploded view

Figure 2D-18

Legend

1. Fresh/Recirculation Housing 11. Evaporator Core 21. Air Mix Motor Mounting Bracket

2. Evaporative Temperature Sensor 12. Lower Insulator – Evaporator 22. Lever – Dual Zone

3. Aspirator Venturi 13. Vacuum Solenoid Pack 23. Lever – Single Zone

4. Aspirator Tube 14. HVAC Case 24. Foot Duct

5. Evaporator Cover 15. Vacuum Tube Harness 25. Cover – Blower Fan And Motor

6. Fresh/Recirculation Vacuum

Actuator 16. Vacuum Tank 26. Drain Hose

7. Upper Insulator – Evaporator 17. Blower Fan And Motor 27. Air Mix Motor – Passenger

8. Heater Pipe Seal 18. Blower Motor Resistor 28. Face/Bi-level Vacuum Actuator

9. Heater Pipe Retainer 19. Air Mix Motor – Single Zone,

Driver – Dual Zone

10. Heater Core 20. Demist/Foot Vacuum Actuator

AIR MIX DOORS AND AIR MIX MOTORS

AIR MIX DOORS

Air mix doors control airflow through the heater core and thereby raising or lowering the vehicle’s cabin temperature.

Two air mix doors are fitted to all OCC HVAC units across the MY2003 VY and V2 Series vehicle range. However

three different configurations are across the MY2003 VY and V2 model range.

AIR MIX MOTORS

The air mix motor is a small electric stepper motor used to operate air mix doors which control airflow through the

heater core and thereby raising or lowering the vehicle’s cabin temperature.

Air mix motor movement is achieved by sending a 12 volt signal between the OCC control module to the air mix

motor causing the motor to turn and open the air mix doors. The motor’s direction can be changed to close the

doors by the OCC reversing the polarity of the voltage signal.

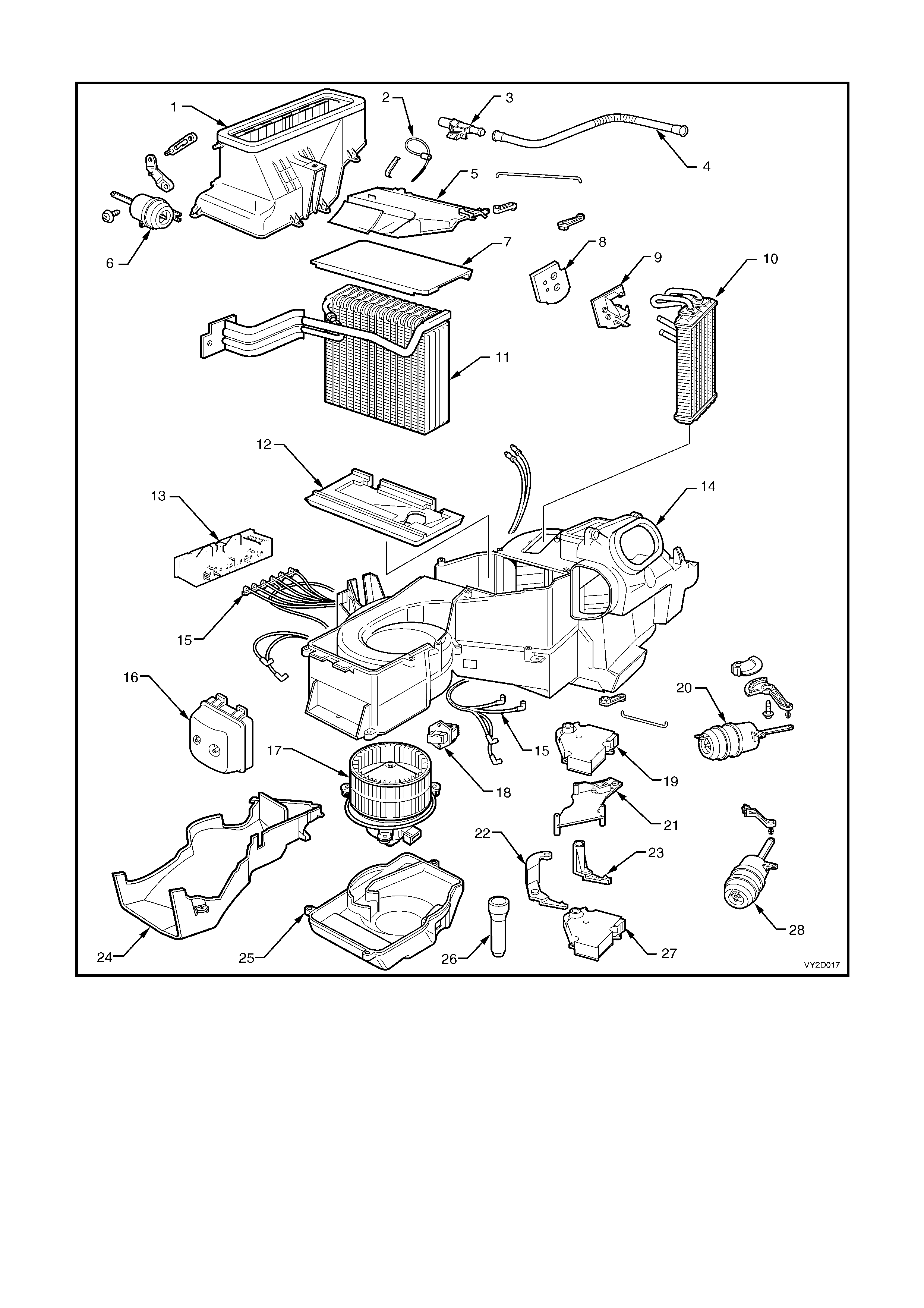

AIR MIX MOTOR/DOOR CALIBRATION

The air m ix m otor is als o fitted with a potentiom eter to send a 3.6 ± 0.2 volt ‘f eedbac k’ signal f rom the air mix motor

to the OCC control module as to the location of the air mix doors in relation to air mix motor drive location. To

maintain the correct working relationship between the OCC control module and the air mix motor/s, the air mix

motor and door f unc tion must be ‘c alibr ated’ to the OCC c ontr ol module. A variation of more than 5% f r om the base

calibration value may cause customer complaints e.g. cabin slow to heat, poor demist performance, etc.

Air mix door calibration can be carried out with

TECH 2 and is part of the ‘Program’ function

contained within the ‘2003 VY Commodore

Occupant Climate Control’ software. This can be

accessed by selecting ‘Occupant Climate Control’

from the Body menu on Tech 2.

For further information on air mix door calibrating,

refer to Section 2F, F5: PROGRAM.

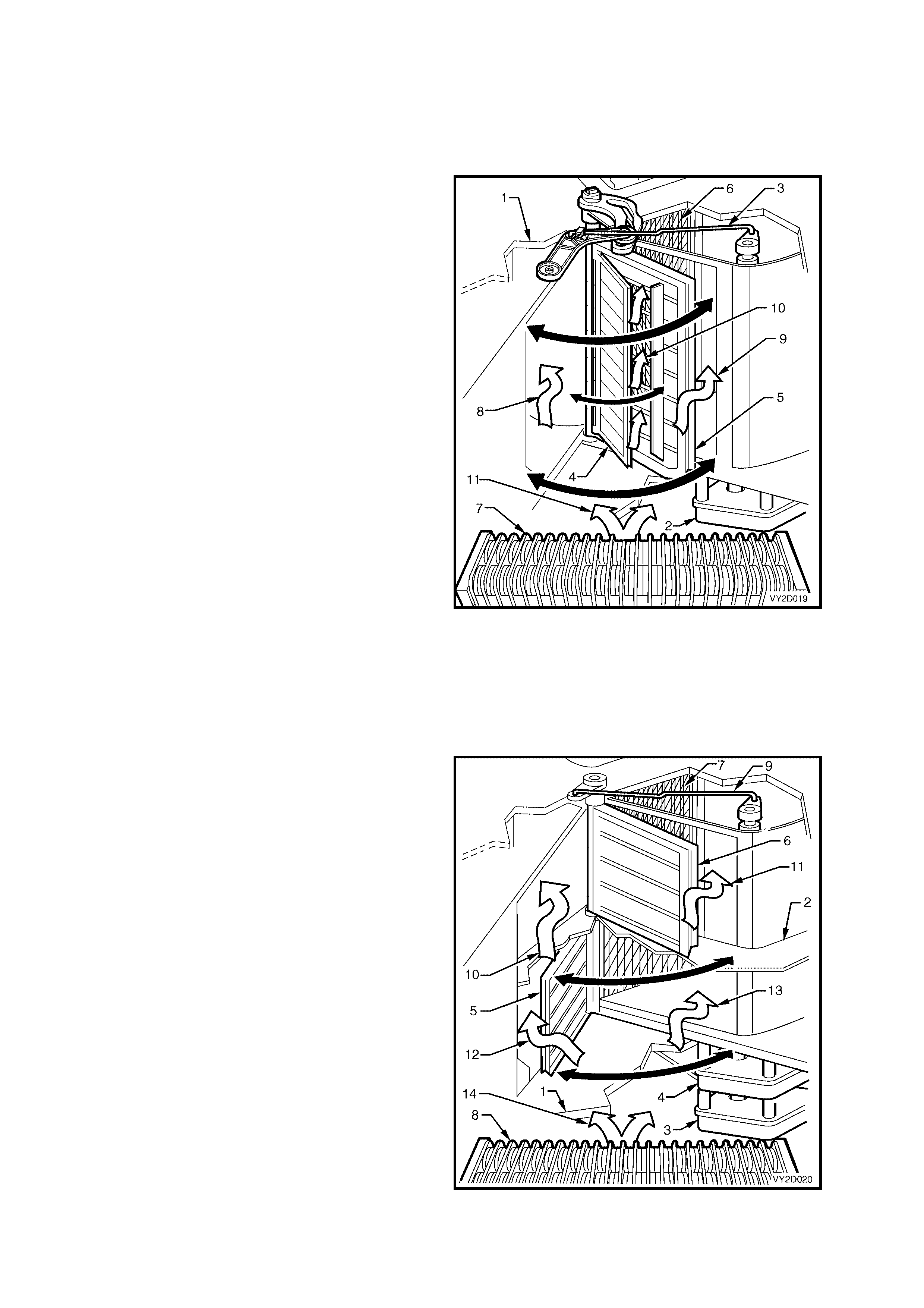

Figure 2D-19

AIR MIX MOTOR/DOOR CONFIGURATIONS

Left-hand drive

All left-hand drive OCC HVAC units have two

unequally s ized air mix door s fitted. An air mix door

is located in front of, and behind the heater core.

A single air mix motor is located on top of the

HVAC unit. It opens and closes the two air mix

doors through a series of rods and levers in

response to OCC control module output signals.

Legend

1. HVAC Case

2. Air Mix Motor

3. Air Mix Motor Actuating Rod

4. Air Mix Door – Front

5. Air Mix Door – Rear

6. Heater Core

Figure 2D-20

Right-hand drive – Single zone

All right-hand drive single zone HVAC units use a

large and small air mix door on one side of the

heater core.

One air mix motor is fitted to operate the air mix

door assem bly in response to OCC control module

output signals. The air mix motor is located under

the HVAC unit and is connected to the air mix door

lever via a relay lever and rod.

Legend

1. HVAC Case

2. Air Mix Motor

3. Air Mix Motor Actuating Rod

4. Air Mix Door – Small

5. Air Mix Door – Large

6. Heater Core

7. Evaporator

8. Air To Heater Core

9. Air Bypassing Heater Core

10. Air Bypassing Heater Core Through

Large Air Mix Door

11. Air Leaving Evaporator

Figure 2D-21

Right-hand drive – Dual zone

All right-hand drive dual zone HVAC units use an

equally sized upper and lower air mix door on one

side of the heater core to provide the temperature

differentiation between the driver’s side and front

passenger’s side of the cabin

Two air mix motors located under the HVAC unit

are fitted to operate the two air mix doors in

response to OCC control module output signals.

The air mix motors function independently during

dual zone operation. Their operating state is

identical during single zone operation.

Legend

1. HVAC Case

2. Dual Zone Partition

3. Air Mix Motor – Driver

4. Air Mix Motor – Passenger

5. Air Mix Door – Driver

6. Air Mix Door – Passenger

7. Heater Core

8. Evaporator

9. Air Mix Motor Actuating Rod – Passenger

10. Air To Heater Core – Passenger

11. Air Bypassing Heater Core – Passenger

12. Air To Heater Core – Driver

13. Air Bypassing Heater Core – Driver

14. Air Leaving Evaporator

Figure 2D-22

BLOWER MOTOR RESISTOR

To provide the different fan speeds a variable resistor using a large scale power transistor is wired into the blower

motor circuit. T he resistor is located inside the HVAC unit and is exposed to the internal airf low between the blower

fan and the evaporator.

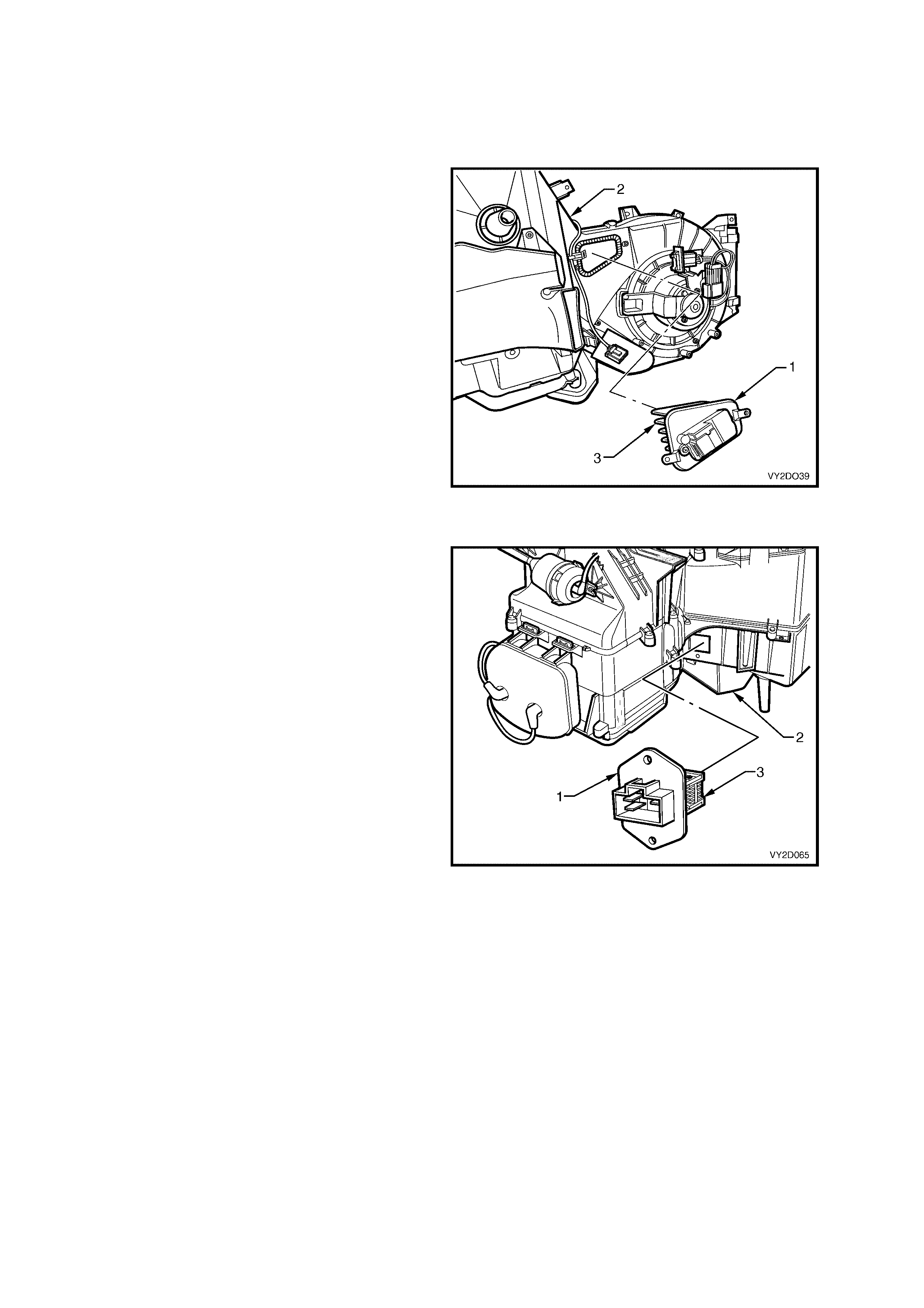

Left-hand drive

The blower motor resistor (1) is located on the

underside of the HVAC unit ( 2) to the lef t-hand side

of the blower motor housing.

It uses a large s cale power transistor to provide the

fixed and var iable fan speeds. An alum inium finned

heat sink (3) is used to dissipate the heat from the

power transistor.

Figure 2A-23

Right-hand drive

The blower motor res is tor ( 1) is loc ated to the cabin

side of the HVAC unit (2) beside the blower motor

housing.

It uses large scale power transistor to provide the

fixed and variable fan speeds. An aluminium heat

sink (3) is used to dissipate the heat from the

power transistor.

Figure 2A-24

VACUUM SOLENOID PACK

Left-hand drive

On left-hand drive HVAC units, the vacuum

solenoid pack (1) is located on the lower rear of

blower motor housing (2). It consists of a band of

five electronically activated vacuum solenoids used

to apply or remove vacuum to the vacuum

actuators and alter air distribution positions.

Power is us ed to engage these solenoids and allow

vacuum to flow to an actuator. Removing this

power de-energises the solenoid and allows any

vacuum contained in the actuator and line to vent

through the front section of the solenoid.

Figure 2D-25

Right-hand drive

On right-hand drive HVAC units, the vacuum

solenoid pack (1) is located on the lower rear of

blower motor housing (2). It consists of a band of

six electronically activated vacuum solenoids. Five

are used to apply or remove vac uum to the vacuum

actuators altering the air distribution positions. The

remaining solenoid is used to actuate the heater

water valve.

Power is supplied to these solenoids through the

OCC control module. When a mode switch is

selected on the OCC control module, current flows

through appropriate solenoids and allows vacuum

to flow to the actuators. Rem oving this current flow

de-energises the solenoids and allows any vacuum

contained in the actuator and line to vent through

the front section of the solenoid.

Figure 2D-26

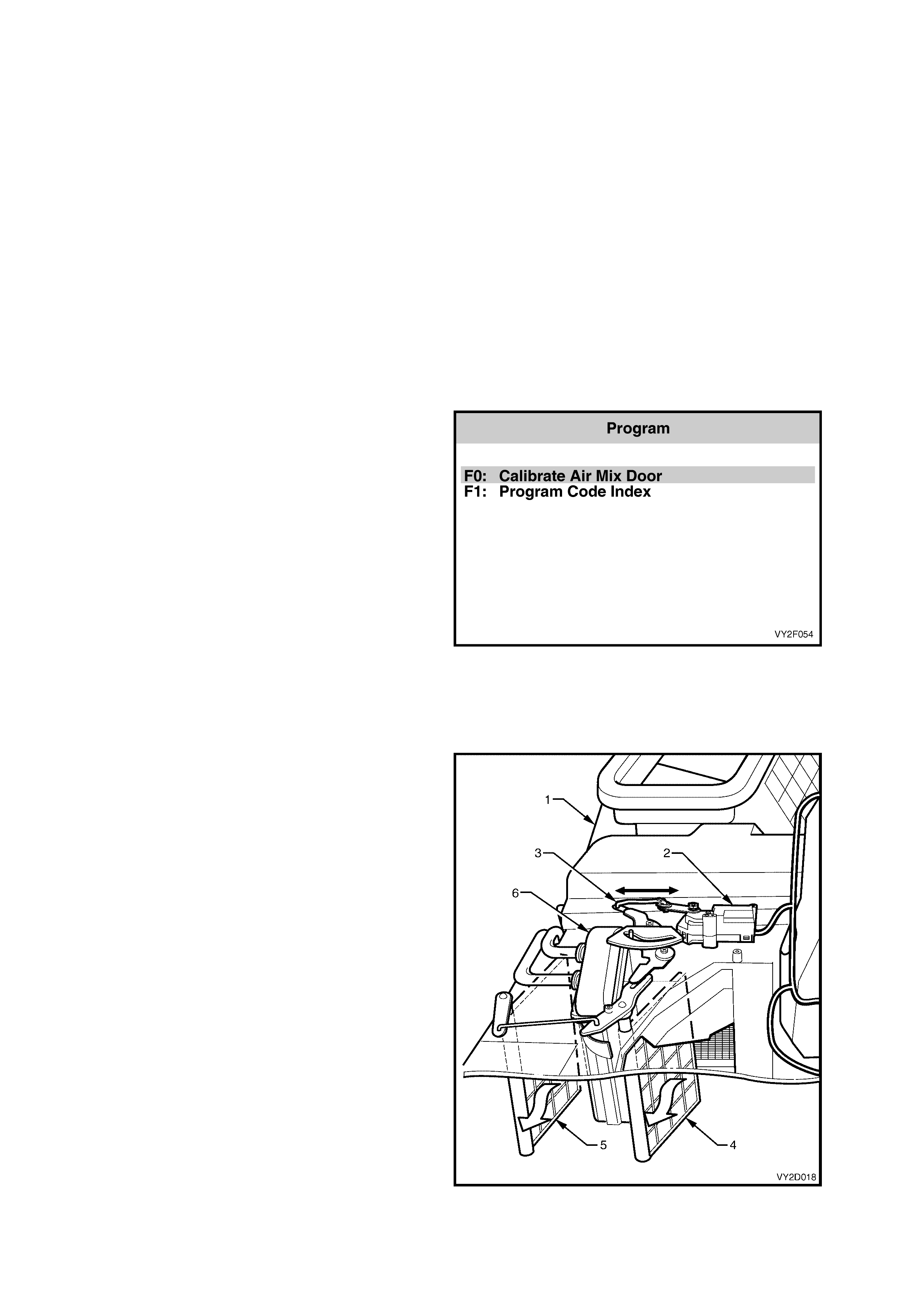

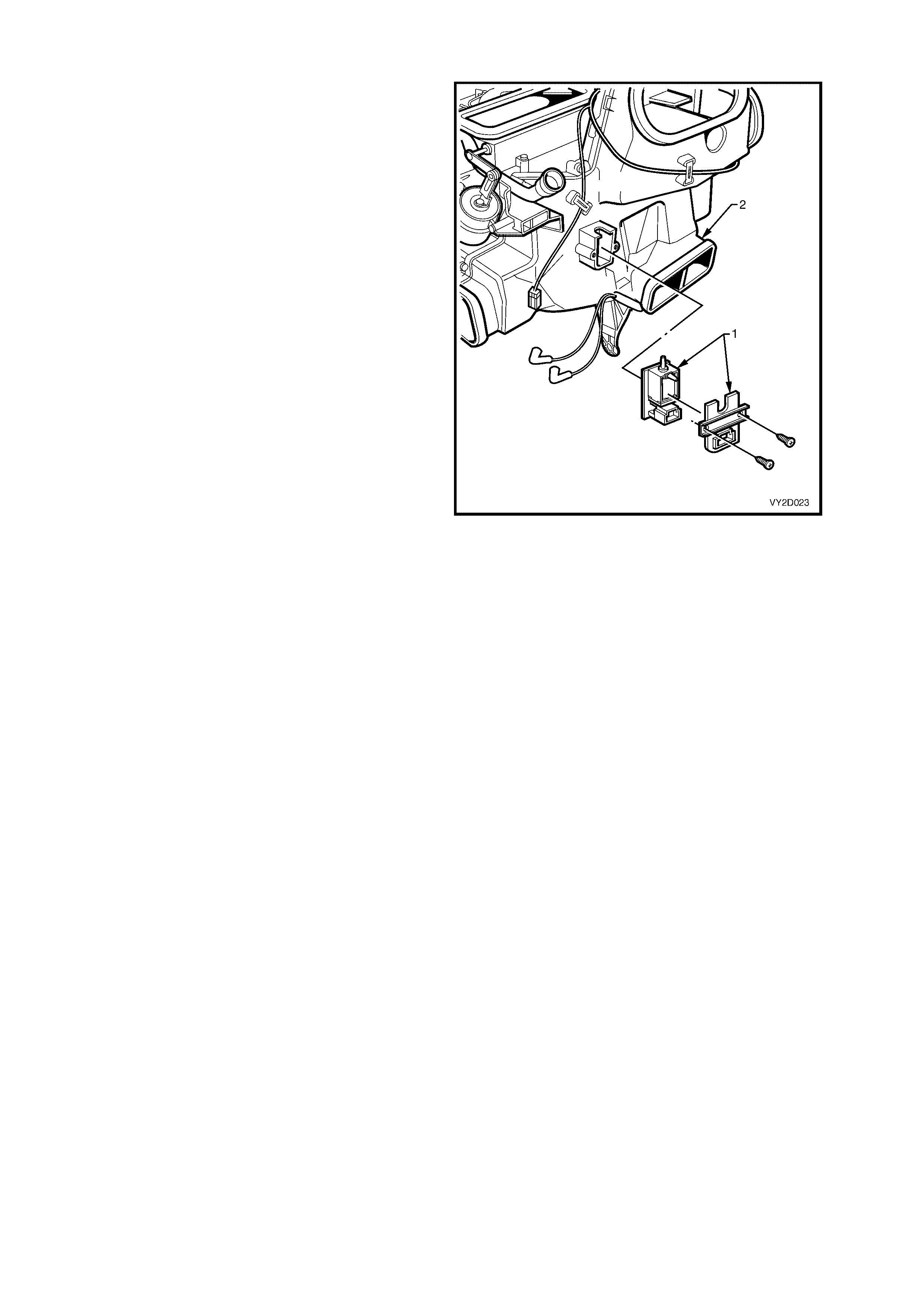

WATER VALVE VACUUM SWITCHING VALVE

Left-hand drive only

On left-hand drive HVAC units, an electrically

operated vacuum switching valve (1) for heater

water valve control is fitted and is located on the

front of the HVAC unit (2). The OCC control module

activates the vacuum switching valve in accordance

to a manually selected, or an automatically

controlled temperature setting.

The water valve is held in the off position by

vacuum. When a cold setting is selected either

manually or automatically, the vacuum switching

solenoid valve will maintain vacuum to the heater

water valve so that no hot water enters the heater

core.

Figure 2D-27

ASPIRATOR TUBE AND VENTURI

The aspirator tube is a formed plastic tube and is installed between the in-car temperature sensor (located behind

the instrument trim assembly) and a venturi, which is fitted to the top of the HVAC case. When the blower fan is

operating, positive air pressure is forced through the venturi. This causes air to be drawn from the vehicle interior

through the in-car tem perature s ensor to the venturi via the as pirator tube. T he induc ted air is used to aid the in- car

temperature sensor to react quickly to any temperature changes taking place within the vehicle interior.

Refer to IN-CAR TEMPERATURE SENSOR in this Section for further information.

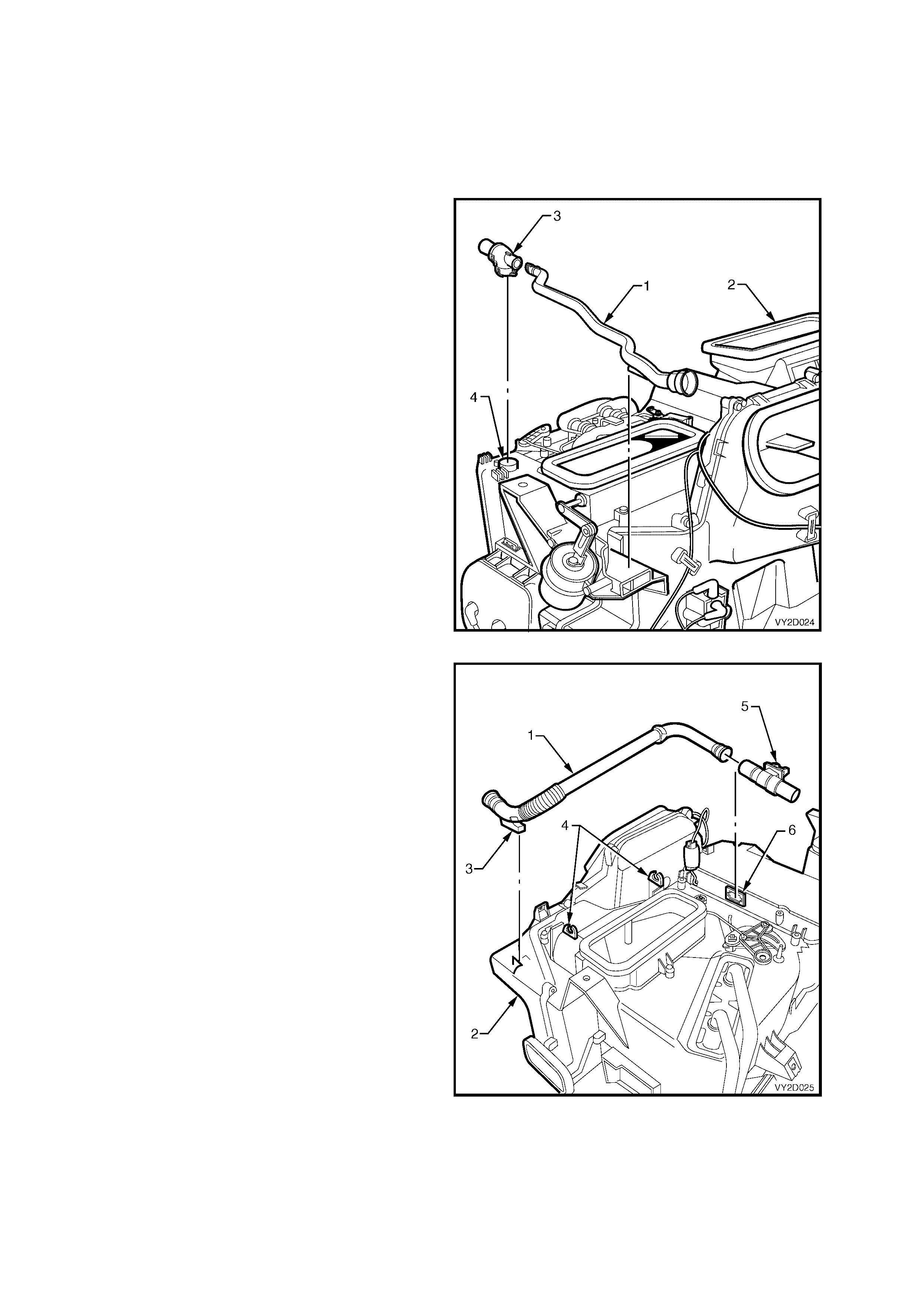

Left-hand drive

On left-hand drive HVAC units, the aspirator tube

(1) is located on the top of the HVAC case (2) on

the left-hand side. The front section of the tube is

retained to the case within a moulded recess. The

rear of the tube is fitted into the induction port of the

venturi (3) The base of the venturi (inlet port) is

installed to the HVAC unit at the venturi air hole (4)

located at the left rear corner of the HVAC case.

Figure 2D-28

Right-hand drive

On right-hand drive HVAC units, the aspirator tube

(1) is located on the top of the HVAC c ase (2). T he

front s ection of the tube is retained to the case by a

locating lug (3), which locks into the HVAC case.

Two retaining clips (4) moulded to the case retain

the centre section of the tube.

The rear of the tube is fitted into the induction port

of the venturi ( 5) The base of the venturi ( inlet port)

is installed to the venturi air hole (6) located in the

evaporator cover of the HVAC case.

Figure 2D-29

IN-CA R TEMPERATURE SENSOR

The in-c ar temperature s ens or is a ther mistor type (NTC ) r esis tor used to monitor the vehic le’s inter ior temperatur e.

Resistance s ignals are c onstantly monitored by the OCC control m odule and are used f or subsequent control of the

OCC system.

It is essential that the ventur i and aspirator tube assem b ly be properly connected to the in-car temper ature sensor if

the sensor is to provide correct information to the OCC control module.

Refer to ASPIRATOR TUBE AND VENTURI in this Section for further information.

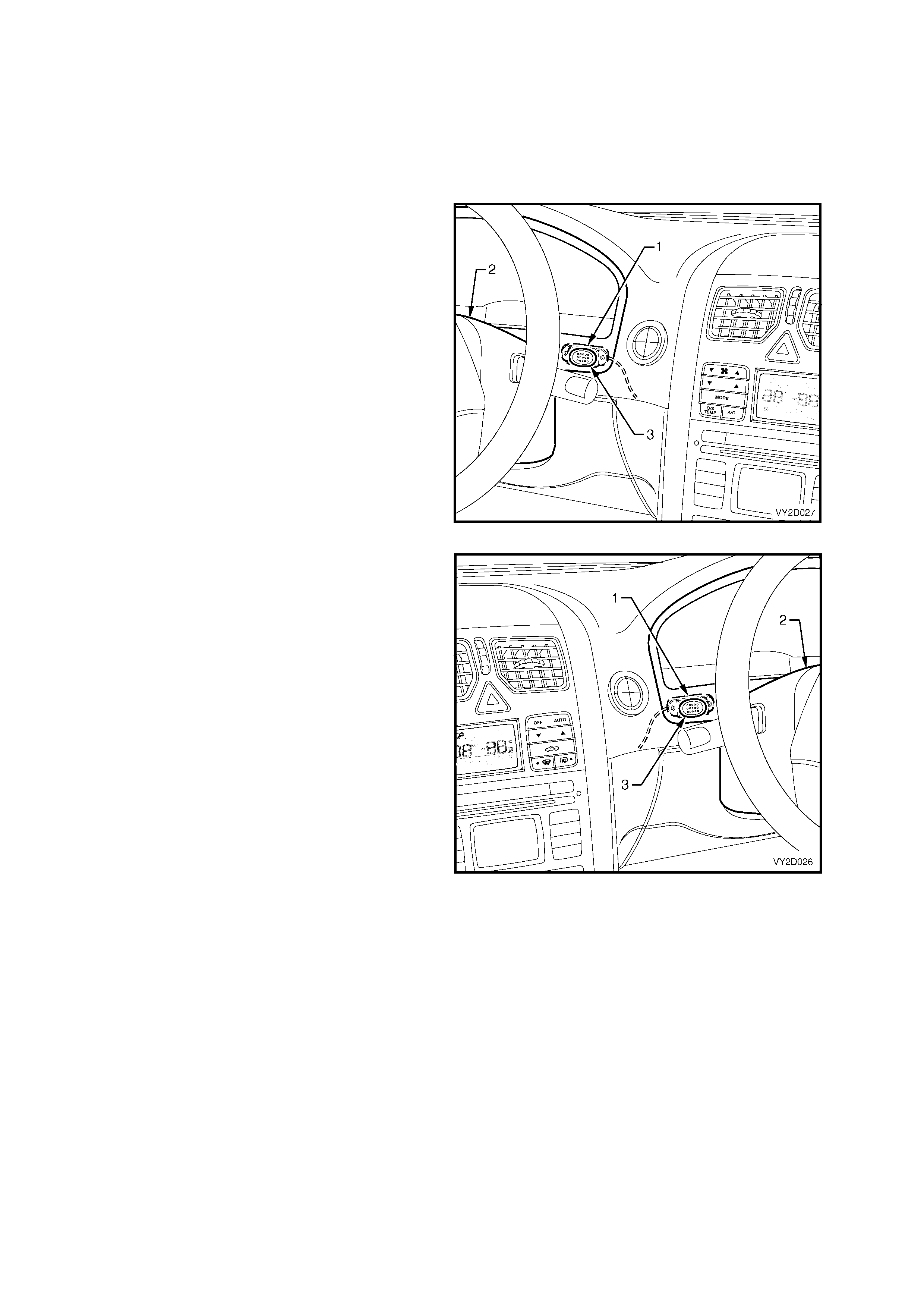

Left-hand drive

On left-hand drive vehicles, the in-car temperature

sensor (1) is located on the right-hand side of the

steering column (2) behind the sensor inlet air

holes (3) on the instrument cluster trim assembly.

Figure 2D-30

Right-hand drive

On right-hand drive vehic les , the in-car temper ature

sensor (1) is located on the left-hand side of the

steering column (2) behind the sensor inlet air

holes (3) on the instrument cluster trim assembly.

Figure 2D-31

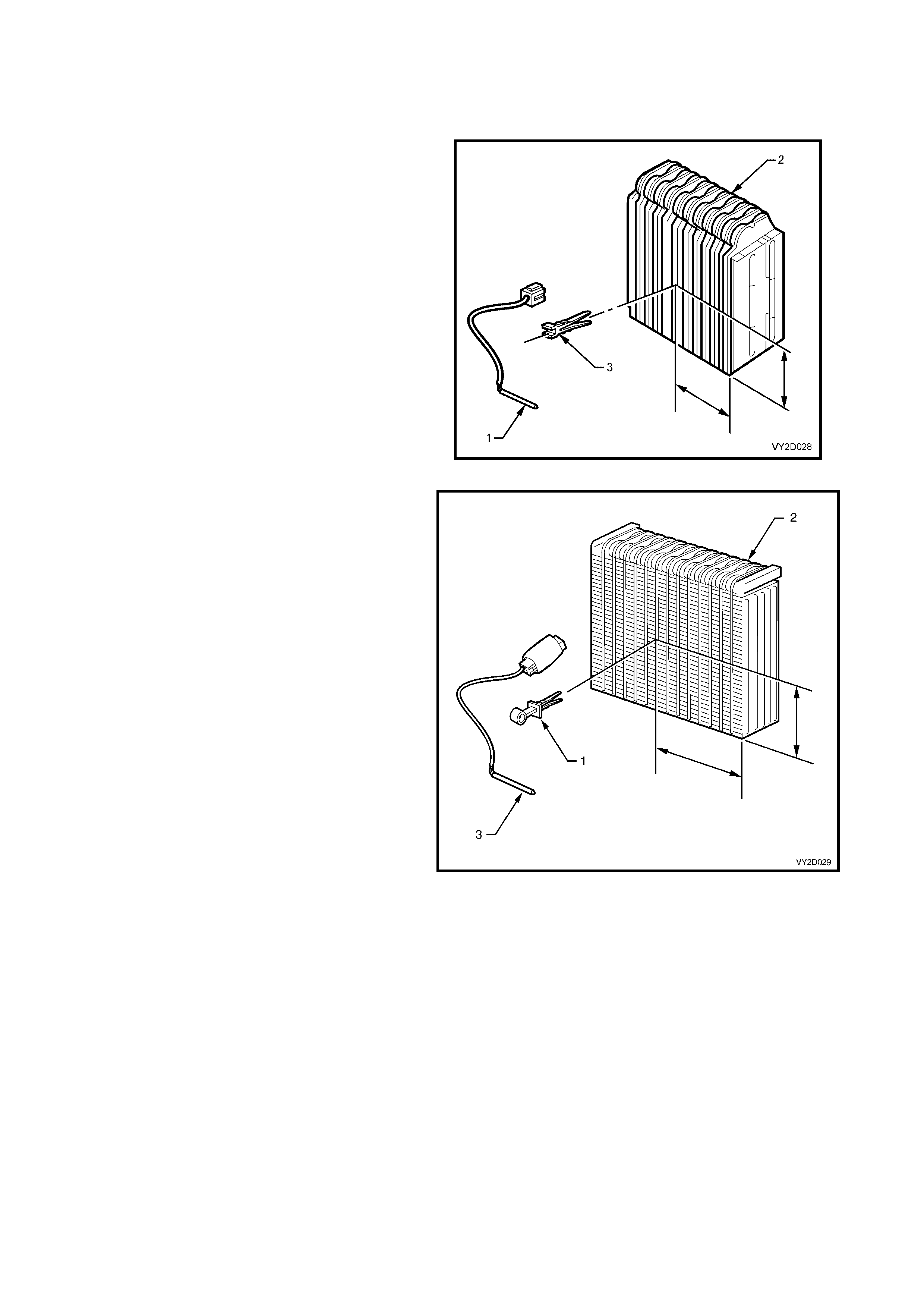

EVAPORATIVE TEMPERATURE SENSOR

The Evaporative T em per ature Sens or is a therm istor type (NTC) resistor used to m onitor the tem per ature of the air

into the HVAC unit after it has passed through the evaporator cor e. Resistance values are c onstantly m onitored by

the OCC control module and are used for subsequent control of the OCC system.

Left-hand drive

On left-hand drive HVAC units, the evaporative

temperature sensor (1) is located on evaporator

core (2) by a plastic retaining clip (3). The

installation point of the sensor to the evaporator is

critical f or correct OCC system performance. Refer

to Section 2E, 2.4 EVAPORATIVE

TEMPERATURE SENSOR for the specified

installation dimensions of the LHD evaporator

temperature sensor.

Figure 2D-32

Right-hand drive

On right-hand drive HVAC units, the evaporative

temperature sensor (1) is located on evaporator

core (2) by a plastic retaining clip (3). The

installation point of the sensor to the evaporator is

critical f or correct OCC system performance. Refer

to Section 2E, 2.4 EVAPORATIVE

TEMPERATURE SENSOR for the specified

installation dimensions of the RHD evaporative

temperature sensor.

Figure 2D-33

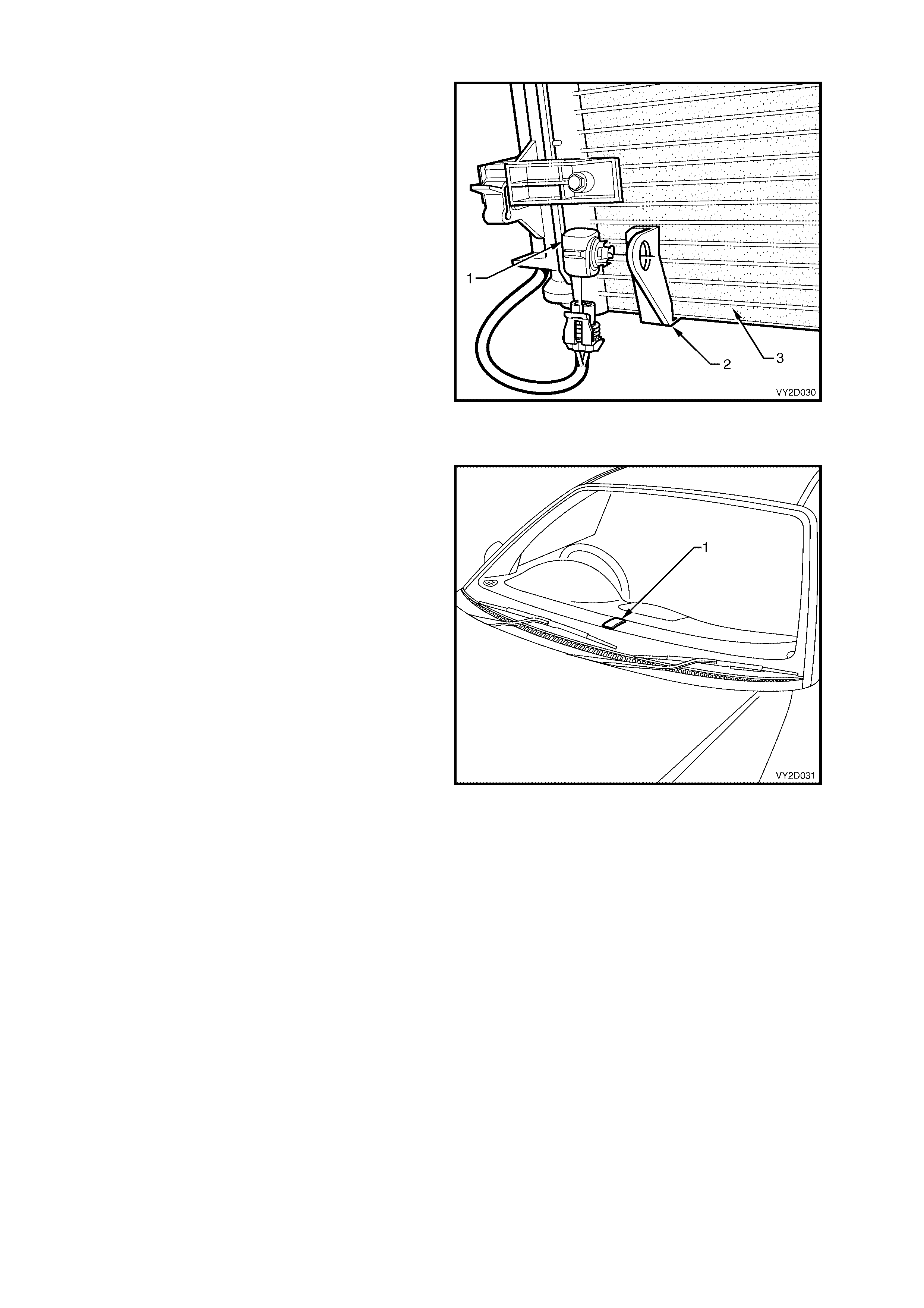

AMBIENT TEMPERATURE SENSOR

The Am bient T em peratur e Sensor ( 1) is ins talled to

a bracket (2) that is permanently attached to the

front of the A/C condenser (3) on the lower right-

hand side.

It is a thermistor type (NTC) resistor used to

monitor the ambient (outside) temperature. This

sensor is slow reacting due to the dense plastic

housing surrounding it. The OCC takes into

account road speed before updating the

temperature display to avoid false readings in

heavy traffic or extended idle conditions.

Resistance signals are sent directly from the

ambient temperature sensor to the OCC control

module for interpretation.

Figure 2D-34

SUN LOAD SENSOR

The Sun Load Sensor (1) incorporates the remote

receiver module and is located in the centre of the

demis t panel. F or the pur poses of the OCC sys tem,

it is used to monitor the sun load upon the vehicle.

It is a photochemical type sensor, meaning that a

small electrical current will be created depending

on the sun load (strength) over it. When the sun

load is high, the OCC control module will select a

higher blower fan speed and increased cooling

automatically. Likewise, when the sun load is low,

such as going into an underground car park, the

OCC control module will automatically reduce the

fan speeds and increase heating slightly.

Signals are sent from the sun load sensor directly

to the BCM then to the OCC control m odule via the

serial data line input.

Figure 2D-35

3.3 HVAC UNIT AIRFLOW MODES

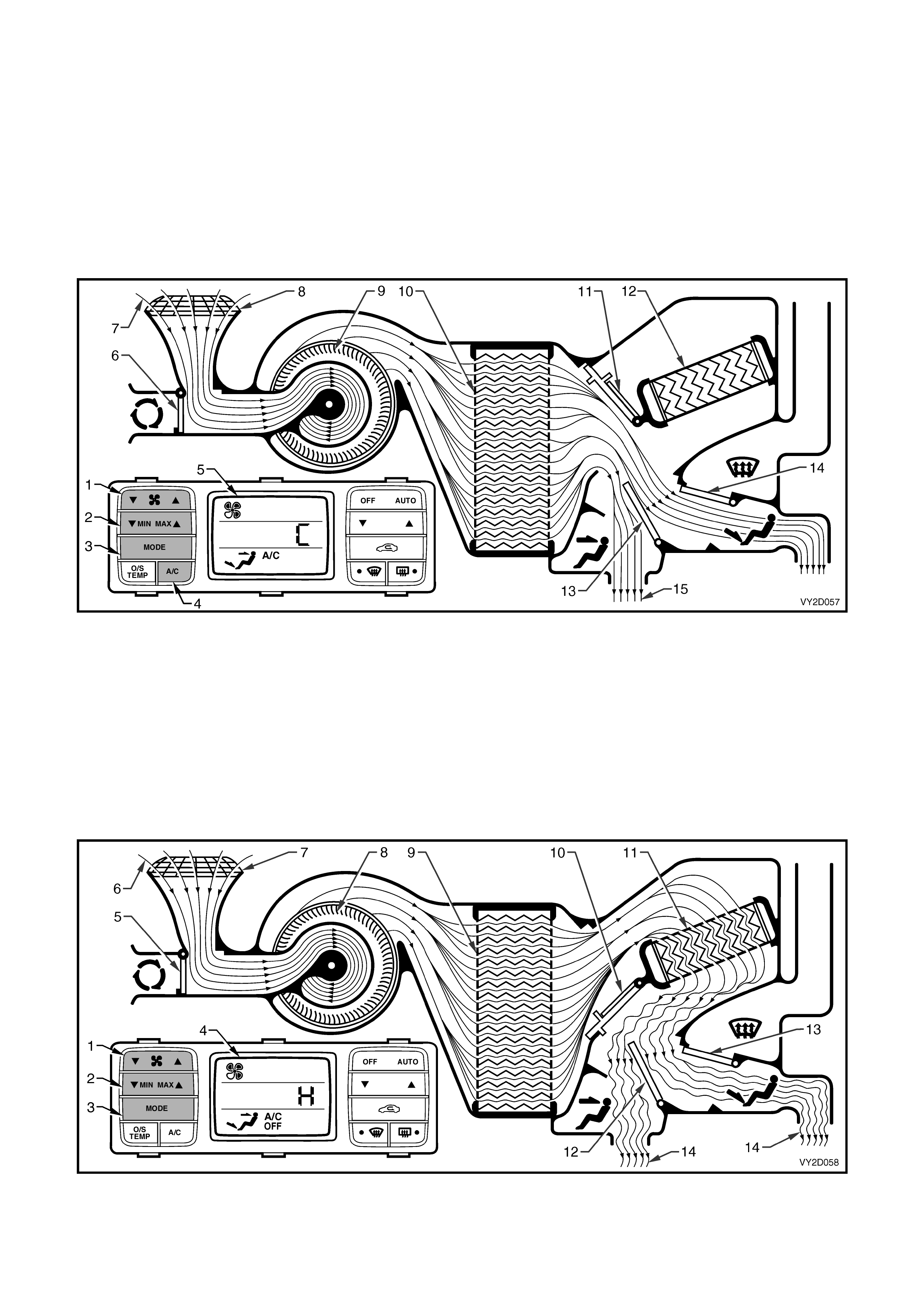

The following airflow mode diagrams (Figure 2D-37 to Figure 2D-60) provide a schematic representation of how

cold and heated air f lows thr ough the HVAC unit during the seven differ ent pos sible m odes. Each schem atic has a

graphic representation of the OCC control module with the LCD screen matching the given mode.

Because of the differ ent design characteristic s and configurations of the left-hand drive and r ight-hand drive HVAC

units, schematics are provided specific to left-hand drive and right-hand drive applications.

LEFT-HAND DRIVE

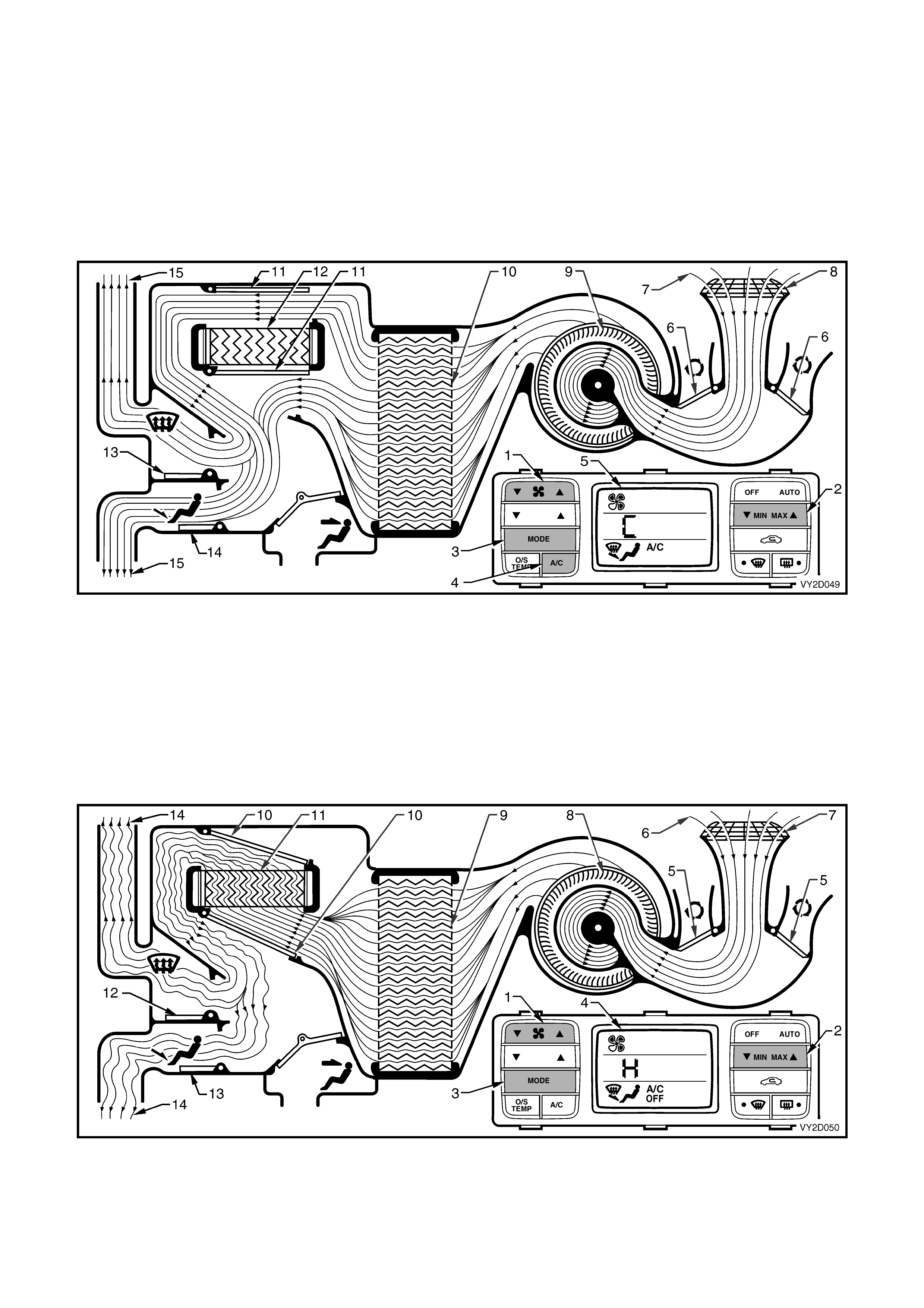

• Recirculation Mode Refer to Figure 2D-37 (Full cold) and Figure 2D-38 (Full heat)

• Face Mode Refer to Figure 2D-39 (Full cold) and Figure 2D-40 (Full heat)

• Bi-level Mode Refer to Figure 2D-41 (Full cold) and Figure 2D-42 (Full heat)

• Floor Mode Refer to Figure 2D-43 (Full cold) and Figure 2D-44 (Full heat)

• Blend Mode Refer to Figure 2D-45 (Full cold) and Figure 2D-46 (Full heat)

• Demist Mode Refer to Figure 2D-47

• Default Mode Refer to Figure 2D-48

RIGHT-HAND DRIVE

• Recirculation Mode Refer to Figure 2D-49 (Full cold) and Figure 2D-50 (Full heat)

• Face Mode Refer to Figure 2D-51 (Full cold) and Figure 2D-52 (Full heat)

• Bi-level Mode Refer to Figure 2D-53 (Full cold) and Figure 2D-54 (Full heat)

• Floor Mode Refer to Figure 2D-55 (Full cold) and Figure 2D-56 (Full heat)

• Blend Mode Refer to Figure 2D-57 (Full cold) and Figure 2D-58 (Full heat)

• Demist Mode Refer to Figure 2D-59

• Default Mode Refer to Figure 2D-60

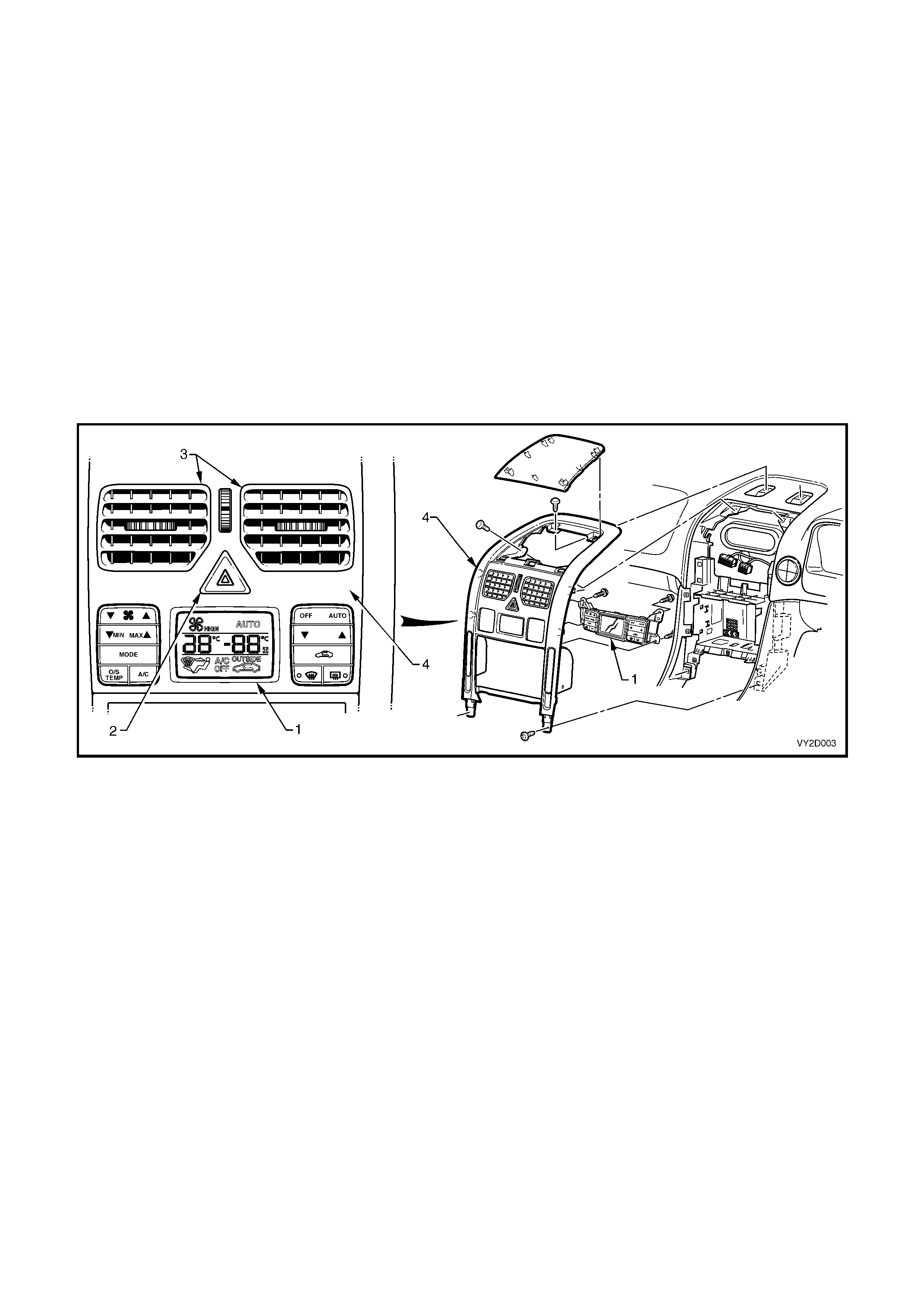

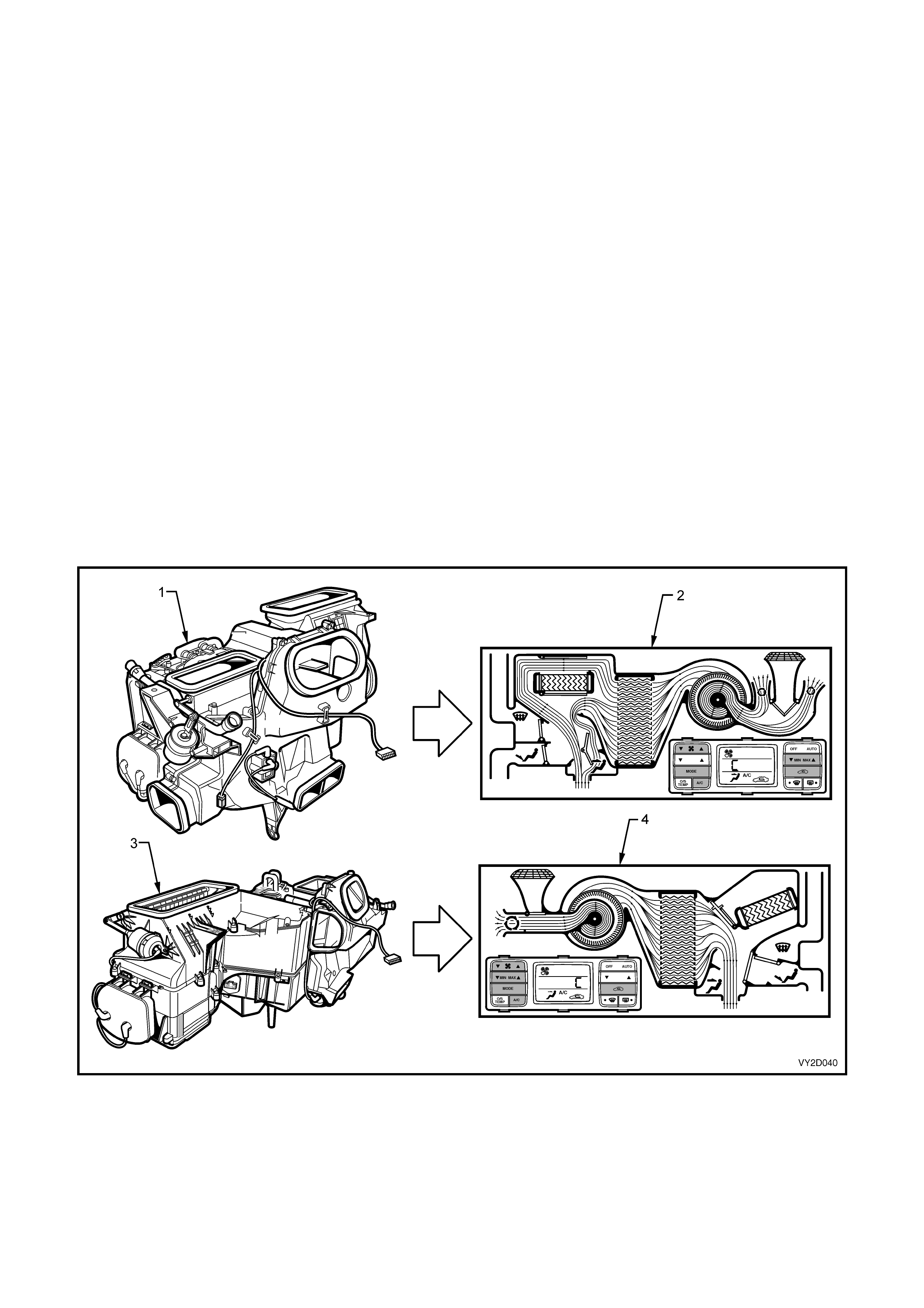

Figure 2D-36

Legend

1. HVAC Unit – LHD 3. HVAC Unit – RHD

2. HVAC Unit Airfl ow Schematic – LHD 4. HVAC Unit Airfl ow Schematic – RHD

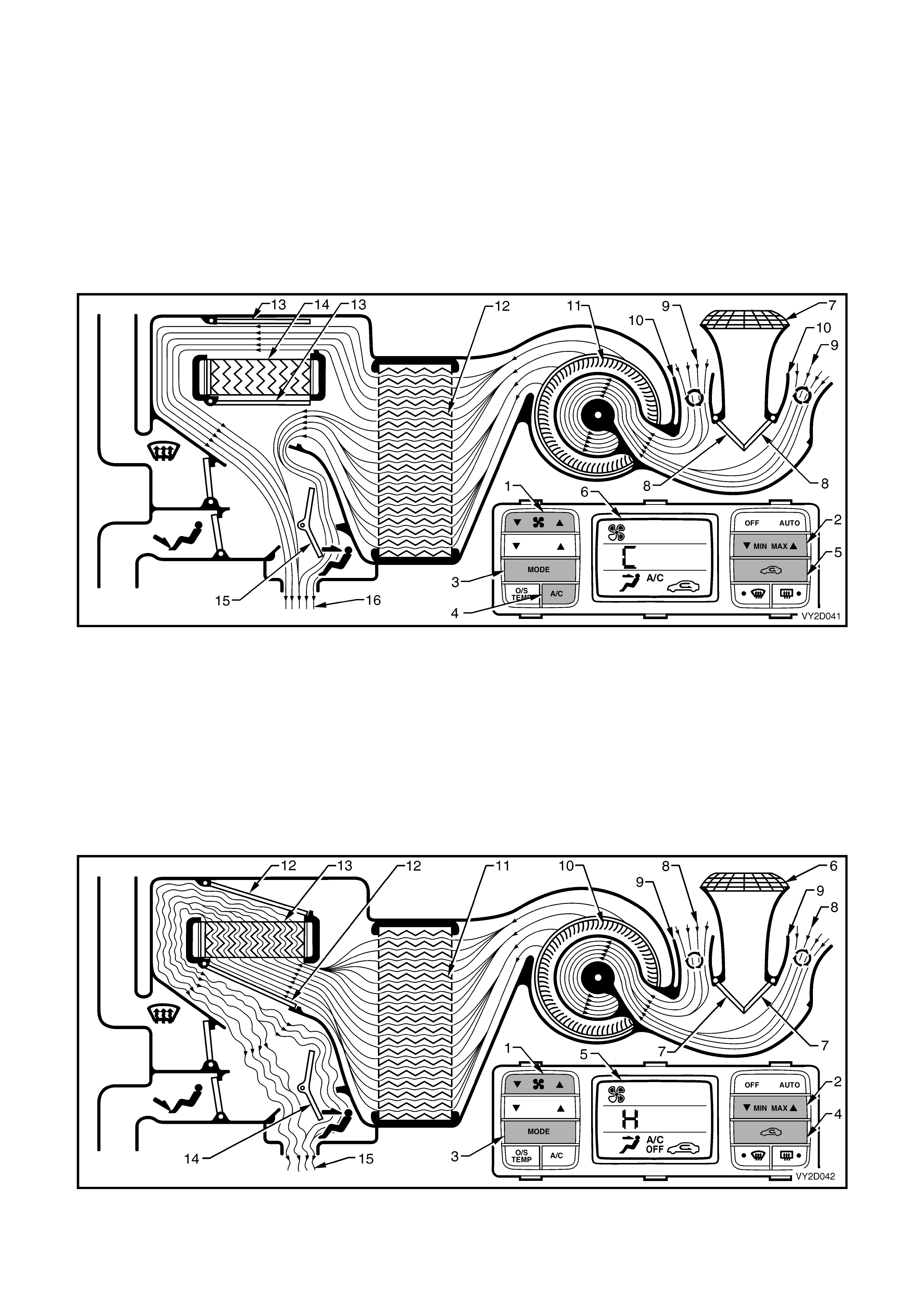

RECIRCULATION MODE – LEFT-HA ND DRIVE

Full cold

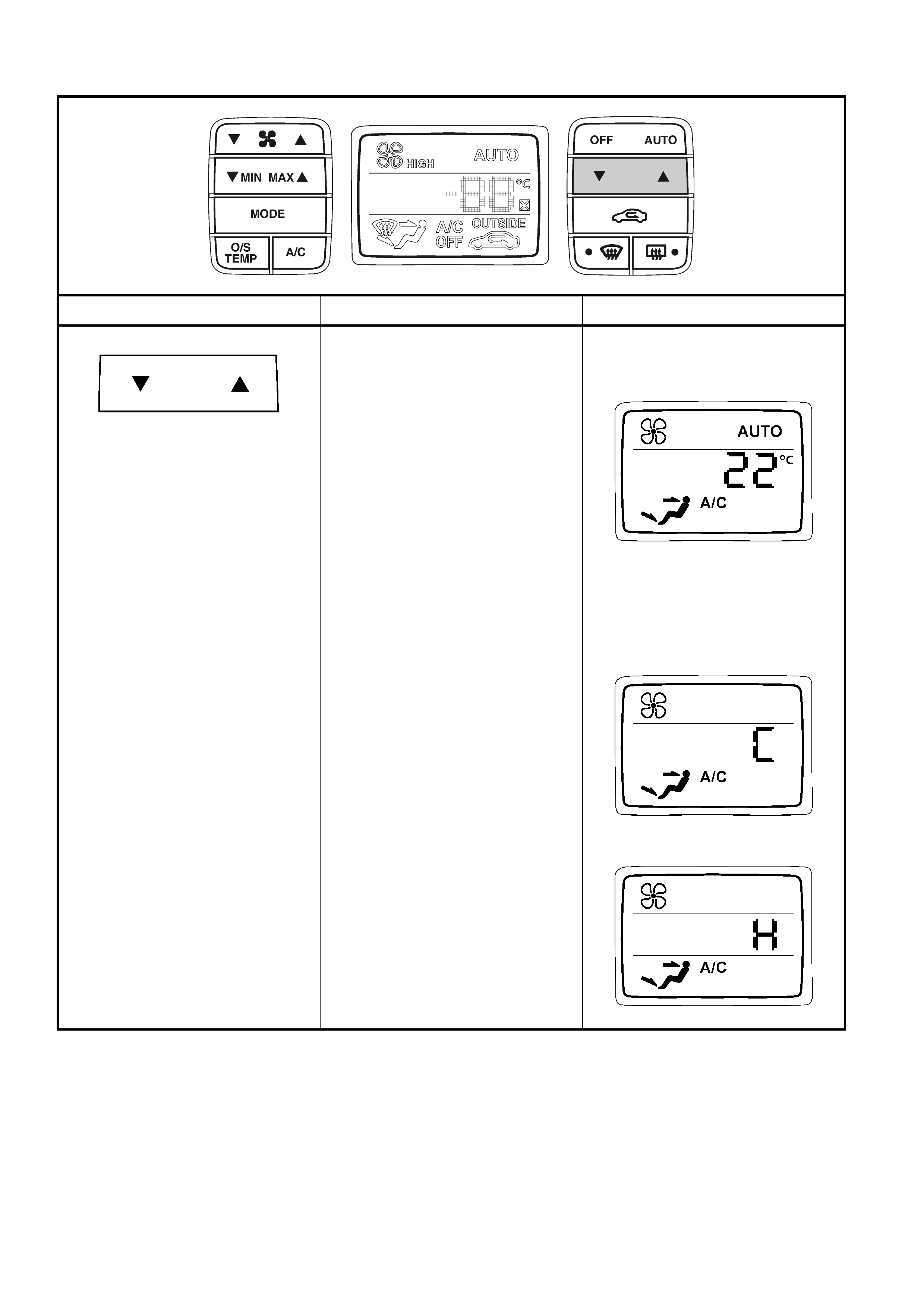

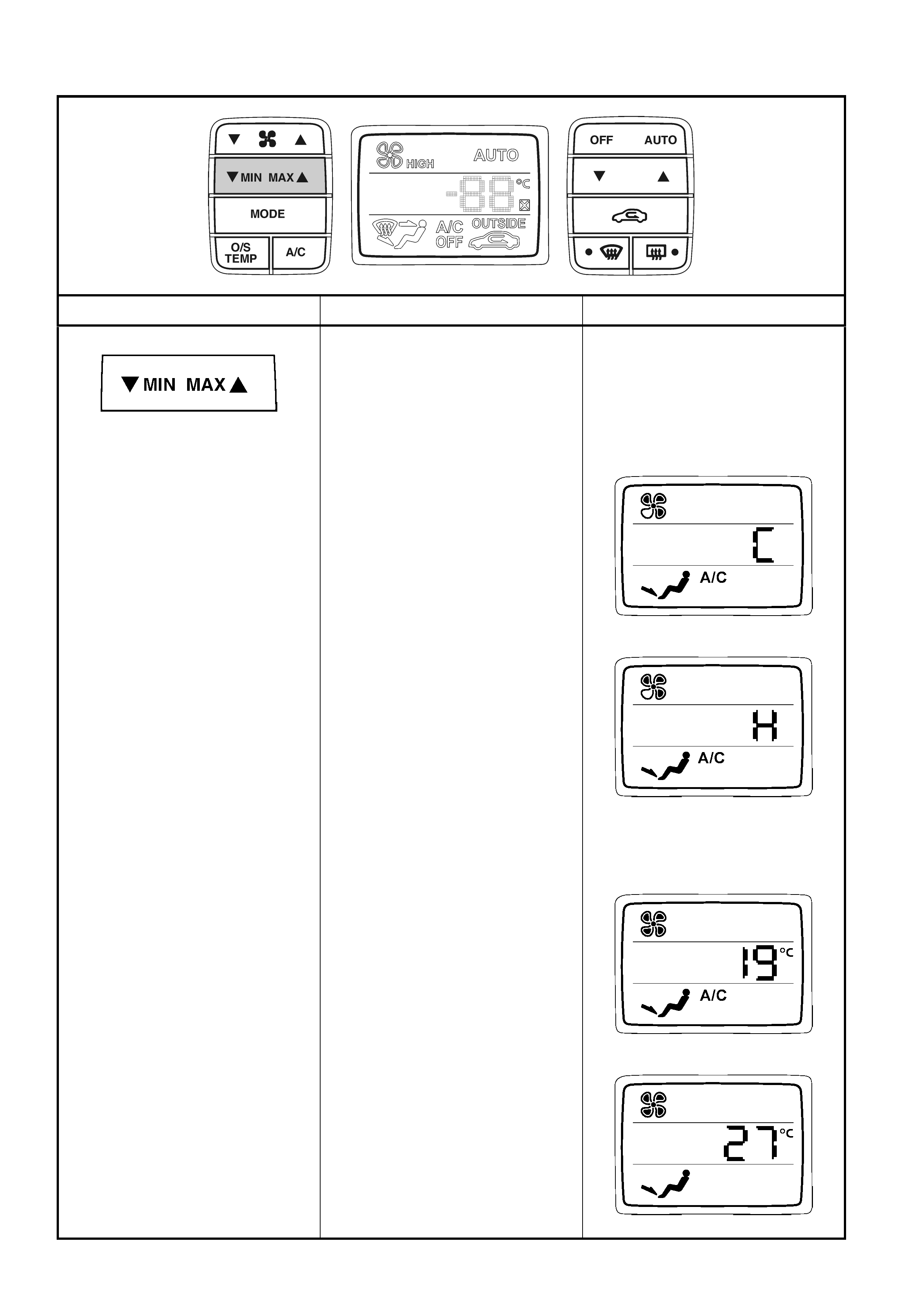

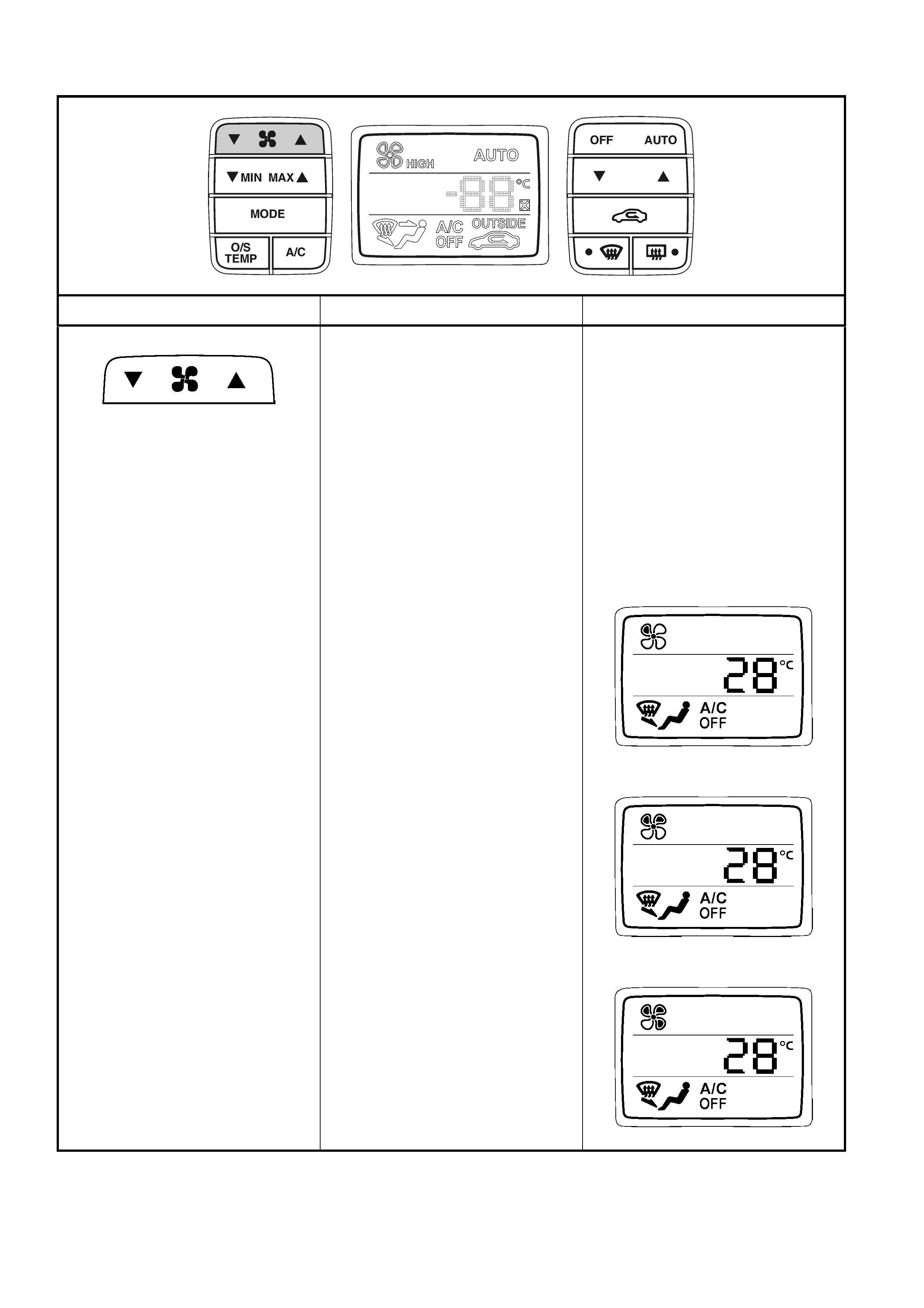

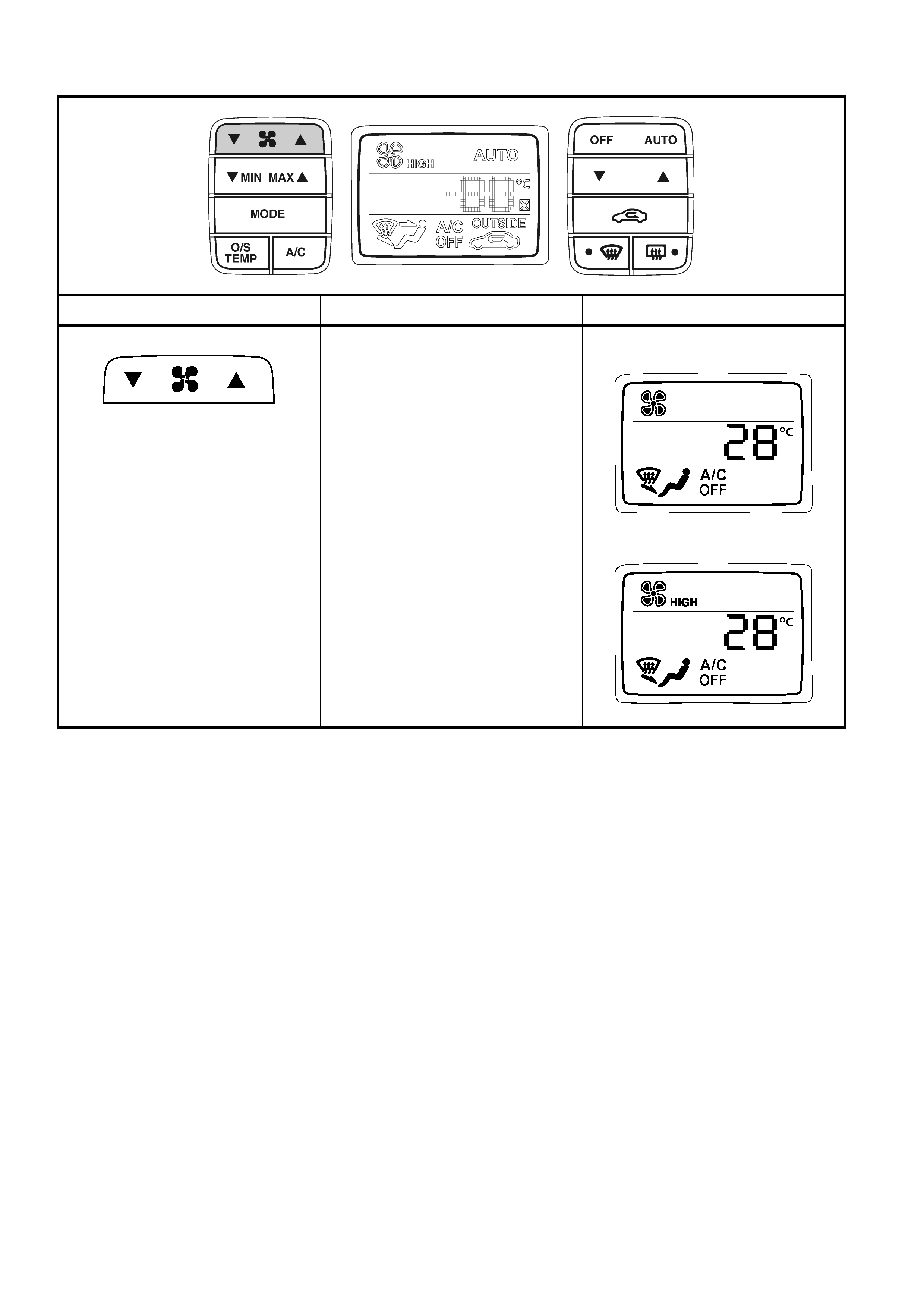

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled cooling. The mode control switch (3) is set to face mode. The A/C switch (4) is

on and the recirculation switch (5) has also been selected. All of these settings are displayed on the LCD screen (6).

NOTE: Recirculation mode can be selected independently of all other air distribution modes excluding demist mode.

The plenum chamber (outside air) inlet (7) to the HVAC unit is closed off by the recirculation doors (8). Interior air

(9) is dr awn into the HVAC unit through the recirculation inlets ( 10) by the blower motor fan (11), and is then f orced

through the cold evaporator f ins (12) . In f ull c old mode the air mix doors ( 13) ar e positioned to allow all air to bypass

the heater core (14). The air travels through the open face door (15). The cold air (16) is then directed out of the

HVAC unit to the centre and side vents.

Figure 2D-37

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The mode control switch (3) has been switched to face mode. The

recirculation switch (4) has been selected. All of these settings are displayed on the LCD screen (5).

NOTE: Recirculation mode can be selected independently of all other air distribution modes excluding demist mode.

The plenum chamber (outside air) inlet (6) to the HVAC unit is closed off by the recirculation doors (7). Interior air

(8) is drawn into the HVAC unit through the recirculation inlets (9) by the blower motor fan (10), and is then forced

through the evaporator f ins (11) . In f ull heat mode, the air mix door s (12) will be positioned s o that all incoming air is

directed through the heater core (13). The air travels through the open face door (14). The heated air (15) is then

directed out through the centre and side vents.

Figure 2D-38

FACE MODE – LEFT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected r esulting in f ull, unc ontr olled cooling. The m ode c ontrol s witch ( 3) has been s witched to f ac e mode and the

A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation doors (6) are closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). T he air travels through the open fac e door (13). The c old air (14) is then directed through the centre and side

vents.

Figure 2D-39

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The m ode control switch (3) has been switched to face mode. All of

these settings are displayed on the LCD screen (4).

The recirculation doors (5) are closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater core (11). The air travels through the open face door (12). The heated air (13) is then directed

out through the centre and side vents.

Figure 2D-40

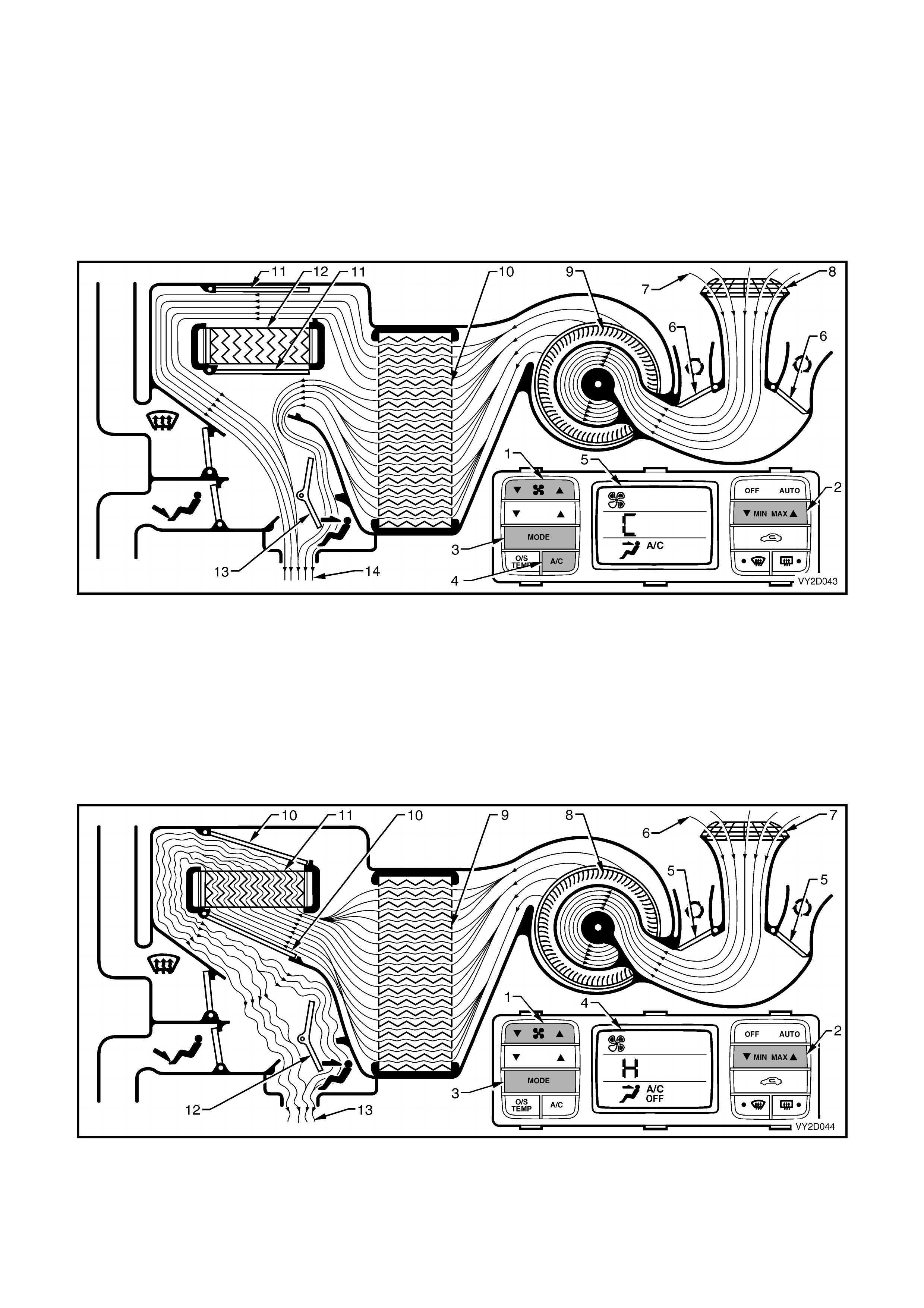

BI-LEVEL MODE – LEFT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected r esulting in full, uncontrolled c ooling. The mode c ontrol switch (3) has been s witc hed to bi-level mode and

the A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation doors (6) are closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). T he air travels through the half opened face door (13) and the fully opened foot door (14) . The cold air (15) is

then directed through the centre and side vents as well as to the floor ducts.

Figure 2D-41

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The mode control s witc h (3) has been switched to bi-level m ode. All

of these settings are displayed on the LCD screen (4).

The recirculation doors (5) are closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater core (11). The air travels through the half opened face door (12) and the fully opened foot door

(13). The heated air (14) is then directed through the centre and side vents as well as to the floor ducts.

Figure 2D-42

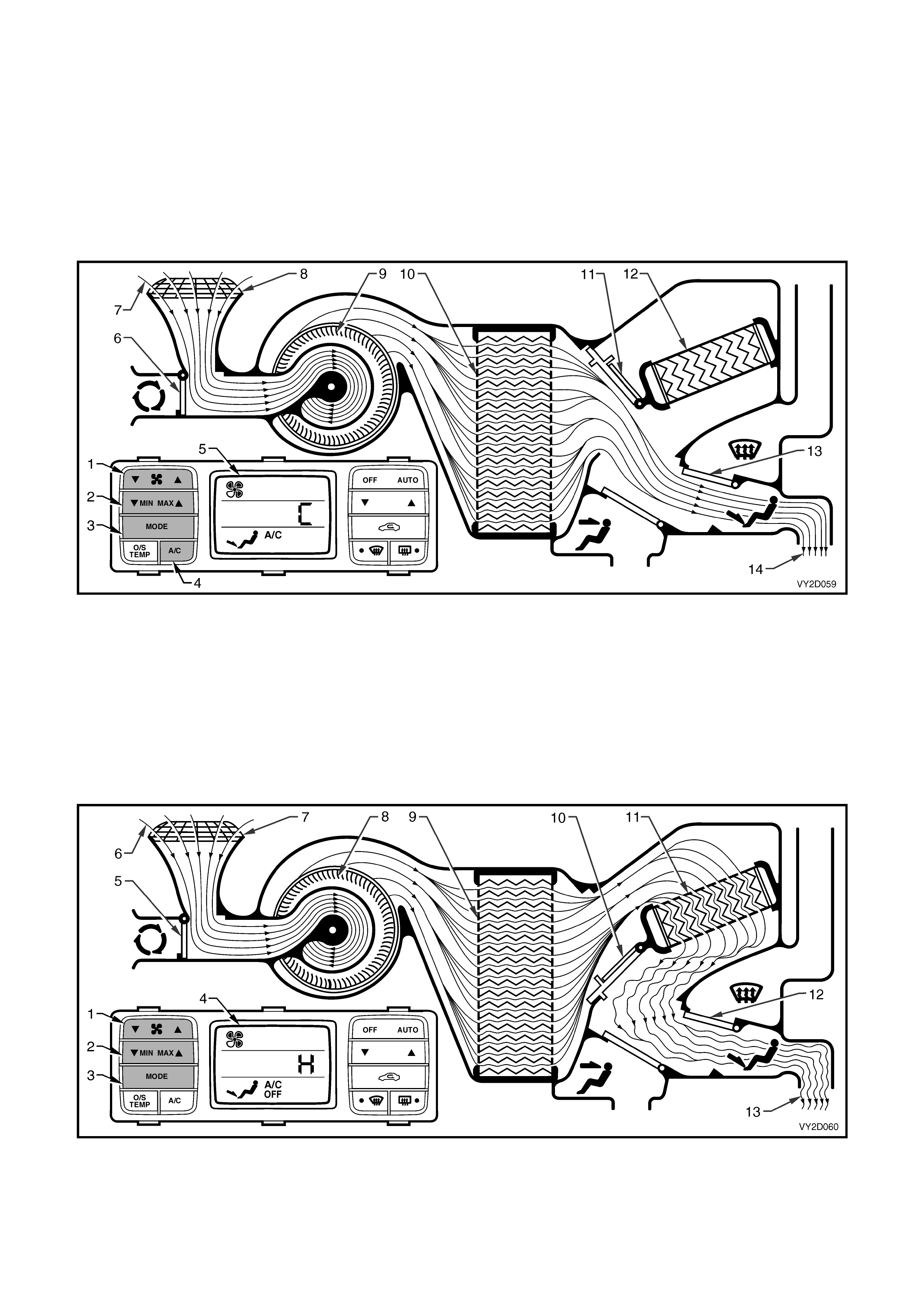

FLOOR MODE – LEFT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected r esulting in f ull, unc ontr olled cooling. The m ode c ontr ol s witch (3) has been switched to f loor mode and the

A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation doors (6) are closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). The air travels through the foot door (13). The cold air (14) is then directed to the floor ducts.

Figure 2D-43

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The m ode control switch (3) has been switched to floor mode. All of

these settings are displayed on the LCD screen (4).

The recirculation doors (5) are closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater core (11). The air travels through the foot door (12). The heated air (13) is then directed to the

floor ducts.

Figure 2D-44

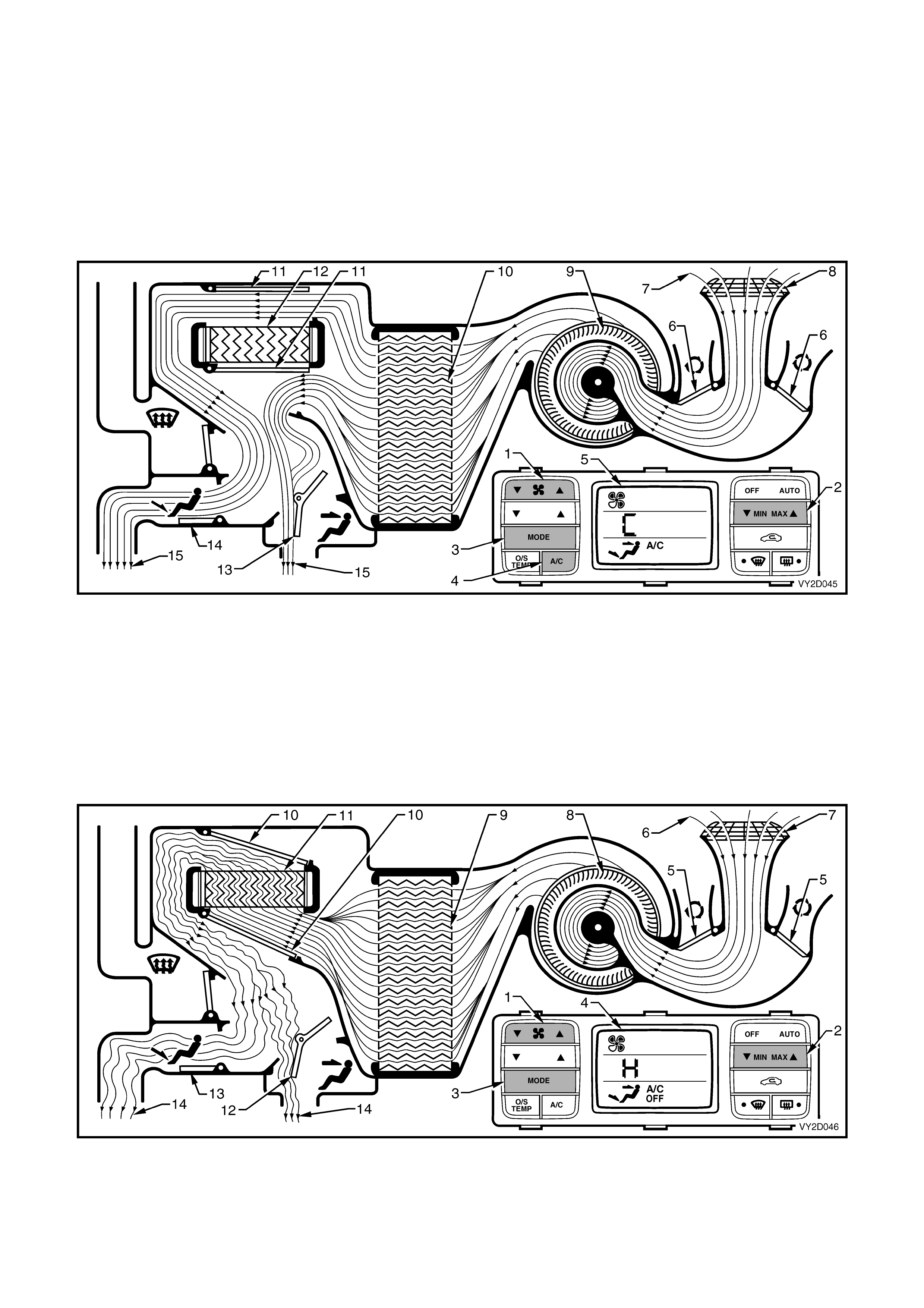

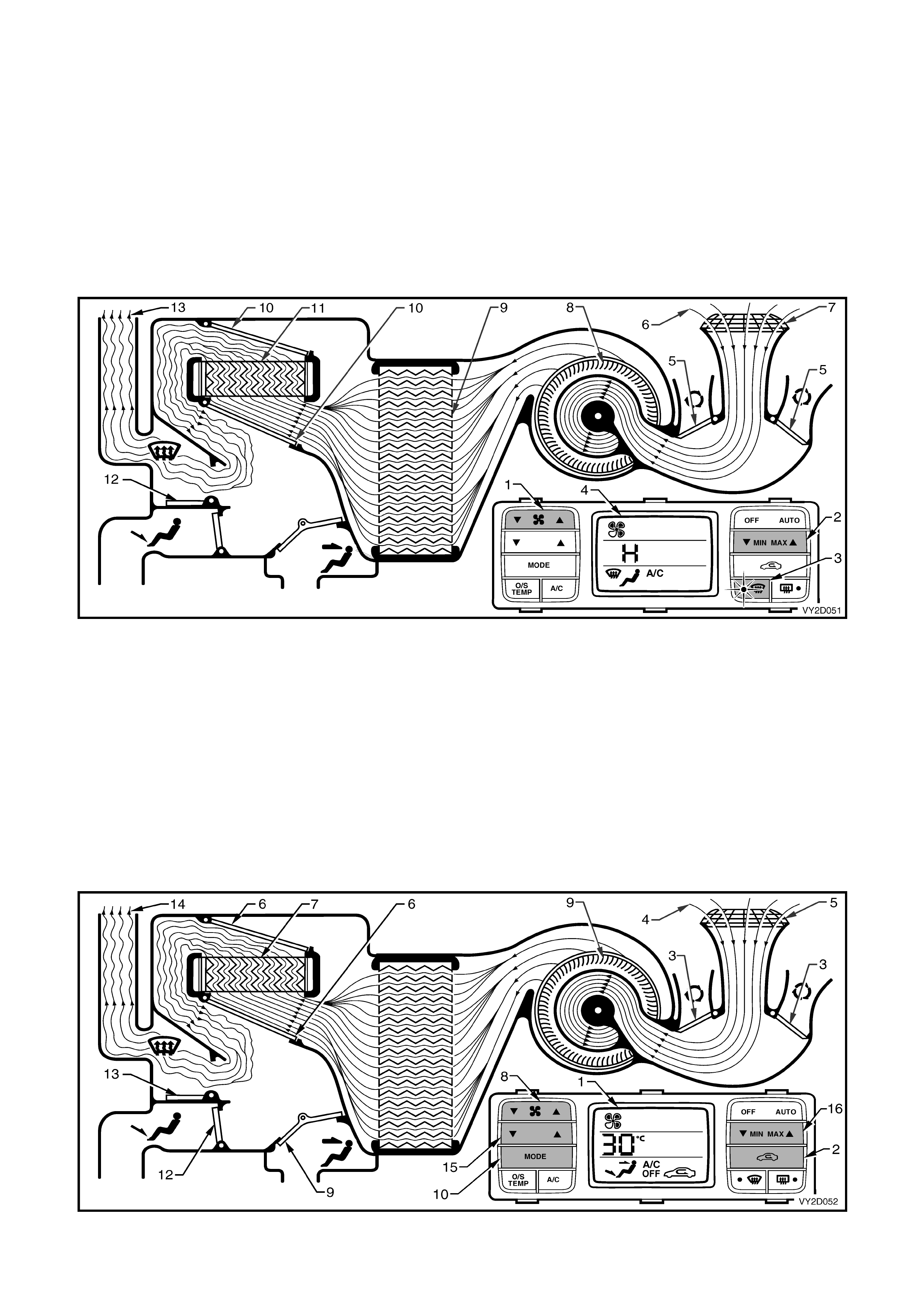

BLEND MODE – LEFT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled cooling. The mode control switch (3) has been switched to blend mode and

the A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation doors (6) are closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). T he air travels through the open dem ist door (13) and foot door ( 14). The c old air (15) is then direc ted to both

the front windscreen and the floor ducts.

Figure 2D-45

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in f ull, uncontrolled heating. T he m ode control s witch (3) has been switched to blend m ode. All of

these settings are displayed on the LCD screen (4).

The recirculation doors (5) are closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater core (11). The air travels through the open demist door (12) and foot door (13). The heated air

(14) is then directed to both the front windscreen and the floor ducts.

Figure 2D-46

DEMIST MODE – LEFT-HAND DRIVE

Full heat and A/C activated

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in f ull, uncontr olled heating. The dem is t switch (3) has been switched on and the A/C s ystem has

been switched on automatically. All of these settings are displayed on the LCD screen (4).

The recirculation doors (5) are closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the cold

evaporator core fins (9) removing moisture from the air. In full heat m ode, the air mix doors (10) are positioned to

direct this dehumidified incoming air through the heater core (11). The air travels through the open demist door (12).

The heated air (13) is then directed to the front windscreen via the demist vents.

NOTE: By turning on the A/C system in this mode, dehumidification of incoming air will take place, demisting the

front windscreen and side windows in a shorter period.

Figure 2D-47

DEFAULT MODE – LEFT-HA ND DRIVE

Loss of vacuum supply to HVAC unit

If a loss of vacuum occurs within the OCC (Auto A/C) system, the HVAC unit will default to the following settings.

The ventilation mode settings will remain constant regardless of what is displayed on the LCD screen (1).

Regardless of rec irculation s witch (2) s election, the rec irculation door s (3) will rem ain closed allowing outside air ( 4)

to enter and flow into the HVAC unit via the plenum chamber inlet (5). The position of the air mix doors (6) will

remain controllable as their function is electrically operated by the air mix motor. Heated coolant will flow through the

heater core (7), as vacuum is required to m aintain the water valve in the cold (closed) position. The f an switch (8)

will operate the blower fan (9) as normal. In any position of the mode switch (10), the face door (11) and the floor

door ( 12) will remain c losed. The dem is t door (13) will be positioned s o that all air (14) leaving the HVAC unit will be

directed to the demist ducts. Depending on the selected setting of temperature switch (15) and/or the MIN MAX

switch (16), this air may be cold, warm or hot air.

Figure 2D-48

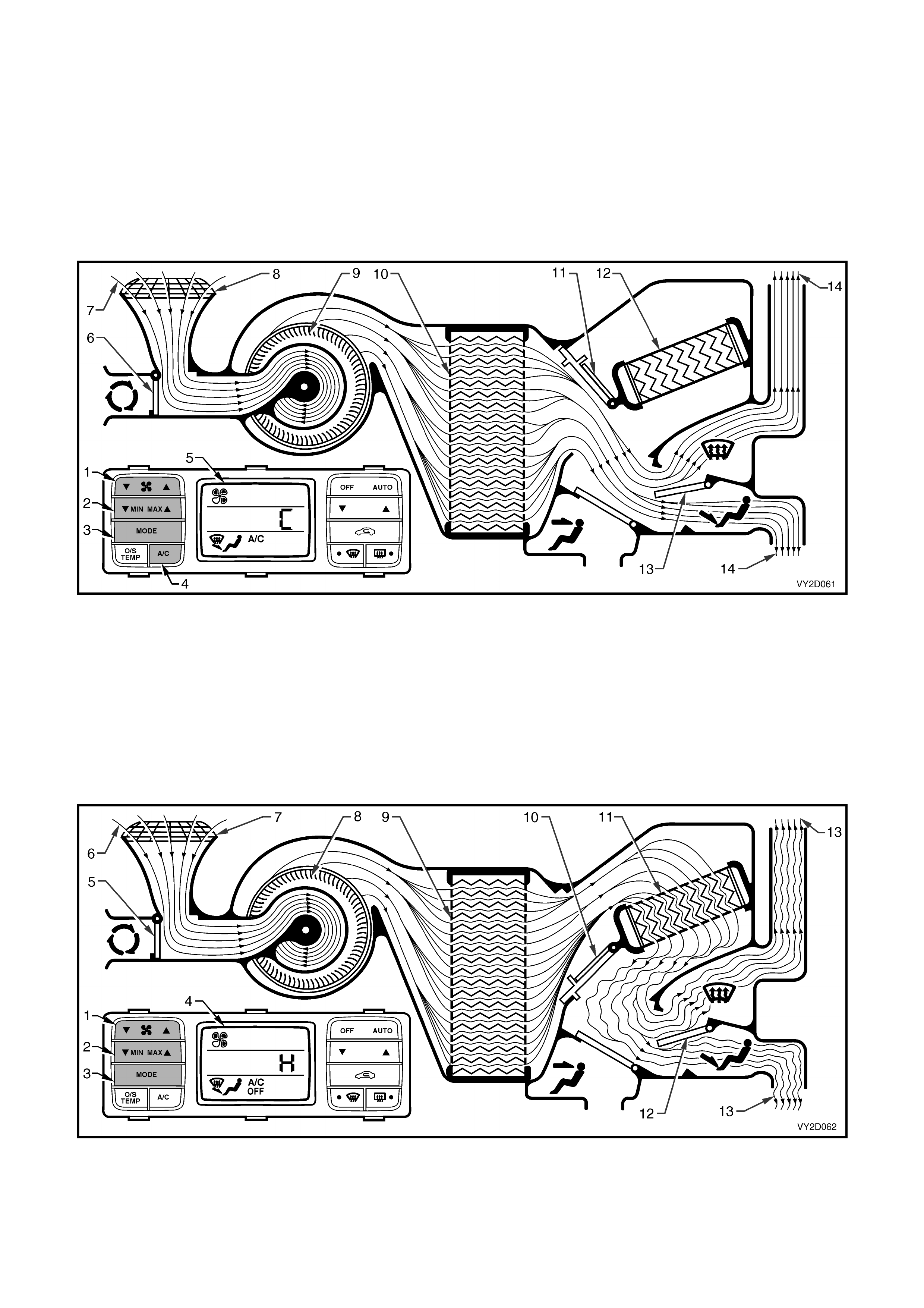

RECIRCULATION MODE – RIGHT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled cooling. The mode control switch (3) is set to face mode. The A/C switch (4) is

on and the recirculation switch (5) has also been selected. All of these settings are displayed on the LCD screen (6).

NOTE: Recirculation mode can be selected independently of all other air distribution modes excluding demist mode.

The plenum chamber ( outs ide air ) inlet (7) to the HVAC unit is c losed of f by the recirculation door (8) . Inter ior air (9)

is drawn into the HVAC unit through the recirculation inlet (10) by the blower motor fan (11), and is then forced

through the cold evaporator f ins (12) . In f ull c old mode the air mix doors ( 13) ar e positioned to allow all air to bypass

the heater core (14). The air travels through the open face door (15). The cold air (16) is then directed out of the

HVAC unit to the centre and side vents.

Figure 2D-49

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The mode control switch (3) has been switched to face mode. The

recirculation switch (4) has been selected. All of these settings are displayed on the LCD screen (5).

NOTE: Recirculation mode can be selected independently of all other air distribution modes excluding demist mode.

The plenum chamber ( outs ide air ) inlet (6) to the HVAC unit is c losed of f by the recirculation door (7) . Inter ior air (8)

is drawn into the HVAC unit through the recirculation inlet (9) by the blower motor fan (10), and is then forced

through the evaporator f ins (11) . In f ull heat mode, the air mix door s (12) will be positioned s o that all incoming air is

directed through the heater core (13). The air travels through the open face door (14). The heated air (15) is then

directed out through the centre and side vents.

Figure 2D-50

FACE MODE – RIGHT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected r esulting in f ull, unc ontr olled cooling. The m ode c ontrol s witch ( 3) has been s witched to f ac e mode and the

A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation door (6) is closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). T he air travels through the open fac e door (13). The c old air (14) is then directed through the centre and side

vents.

Figure 2D-51

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The m ode control switch (3) has been switched to face mode. All of

these settings are displayed on the LCD screen (4).

The recirculation door (5) is closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater core (11). The air travels through the open face door (12). The heated air (13) is then directed

out through the centre and side vents.

Figure 2D-52

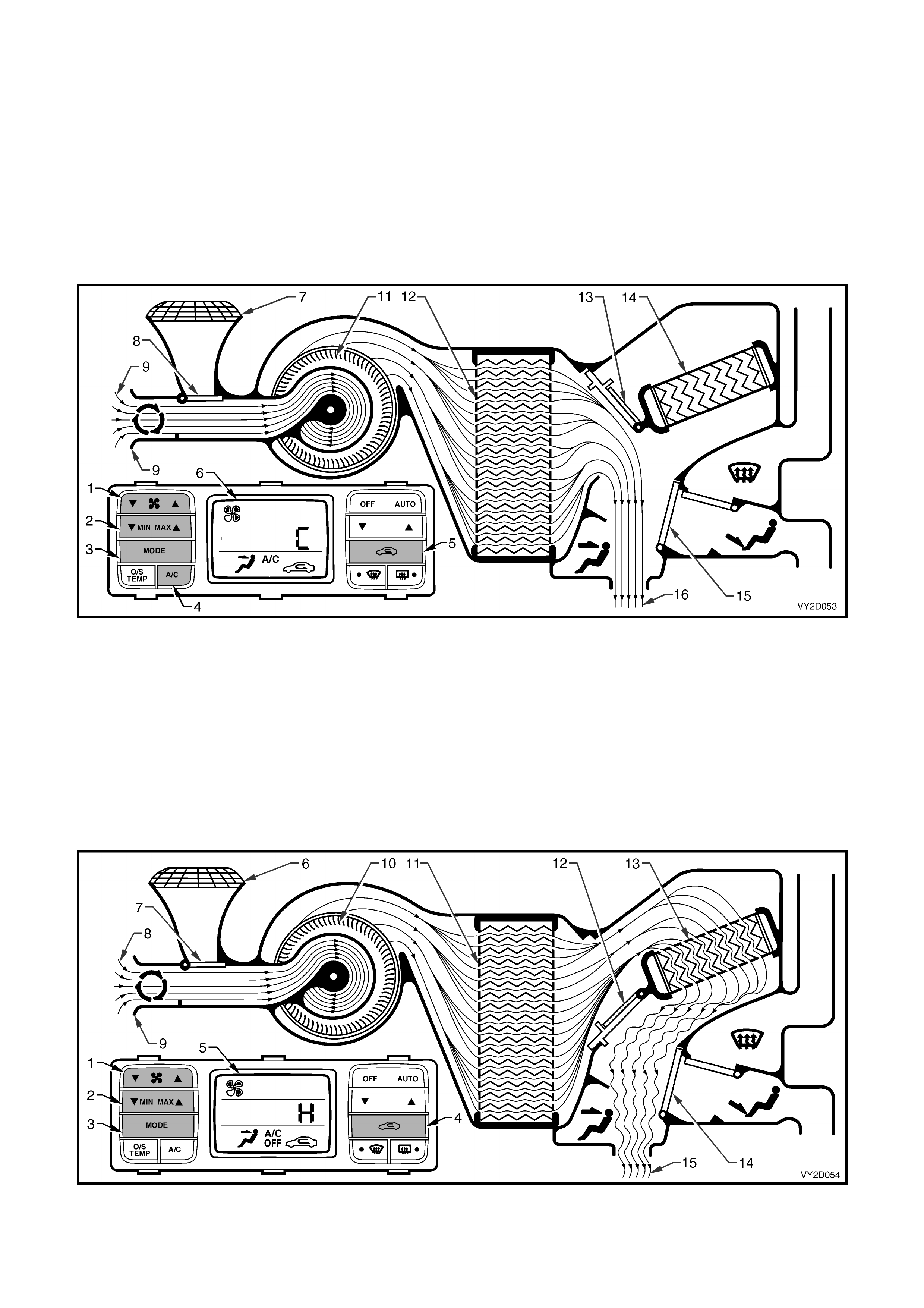

BI-LEVEL MODE – RIGHT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected r esulting in full, uncontrolled c ooling. The mode c ontrol switch (3) has been s witc hed to bi-level mode and

the A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation door (6) is closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). T he air travels through the half opened face door (13) and the through the dem ist/floor door (14) which is fully

open in the floor mode. The cold air (15) is then directed through the centre and side vents as well as to the floor

ducts.

Figure 2D-53

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The mode control s witc h (3) has been switched to bi-level m ode. All

of these settings are displayed on the LCD screen (4).

The recirculation door (5) is closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater core (11). The air travels through the half opened face door (12) and through the demist/floor

door (13), which is fully open in the floor mode. The heated air (14) is then directed through the centre and side

vents as well as to the floor ducts.

Figure 2D-54

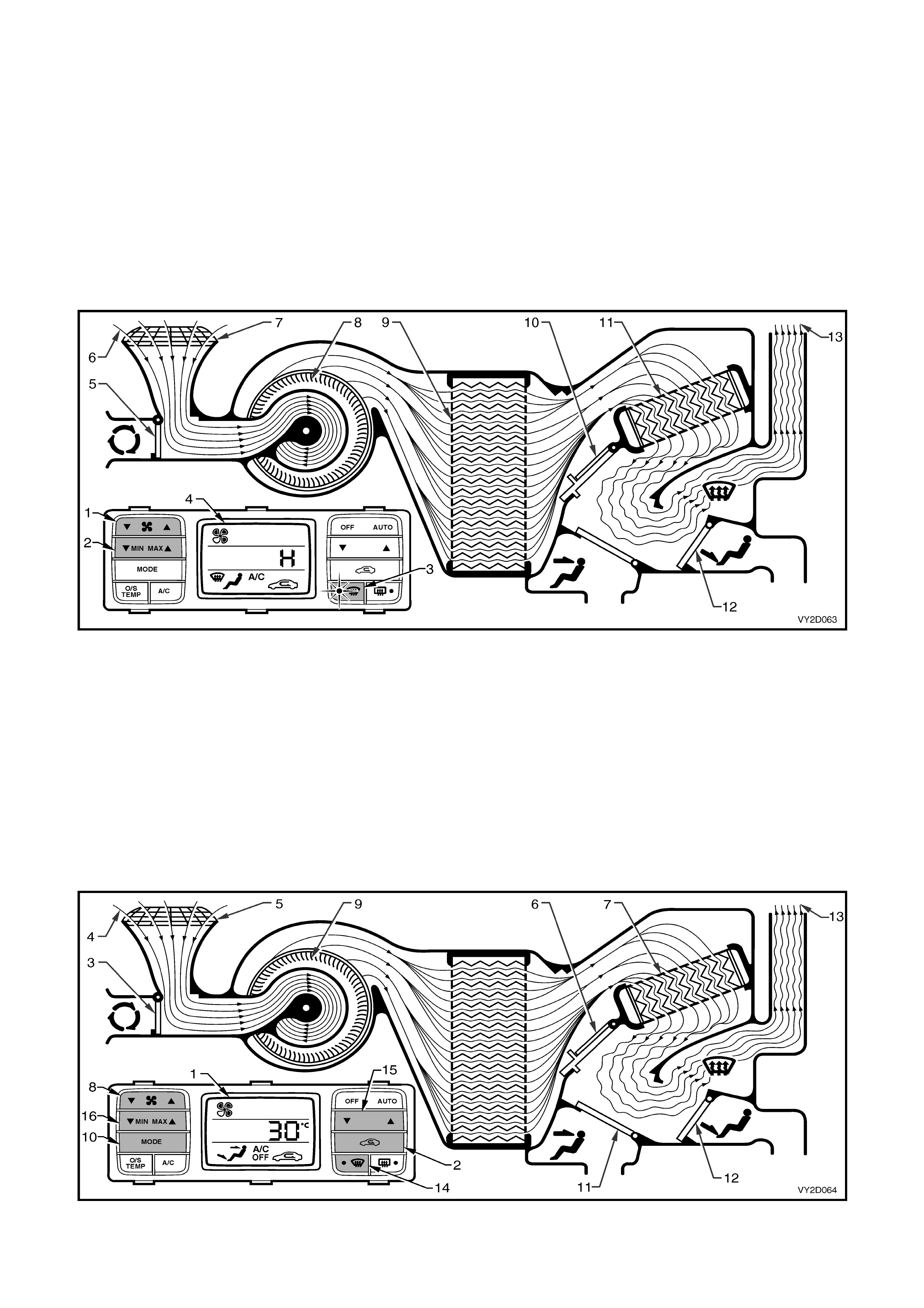

FLOOR MODE – RIGHT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected r esulting in f ull, unc ontr olled cooling. The m ode c ontr ol s witch (3) has been switched to f loor mode and the

A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation door (6) is closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). The air travels through the demist/floor door (13), which is fully open in the floor mode. The cold air (14) is then

directed to the floor ducts.

Figure 2D-55

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled heating. The m ode control switch (3) has been switched to floor mode. All of

these settings are displayed on the LCD screen (4).

The recirculation door (5) is closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater cor e (11). T he air tr avels through the dem is t/floor door (12) which is fully open in the floor mode.

The heated air (13) is then directed to the floor ducts.

Figure 2D-56

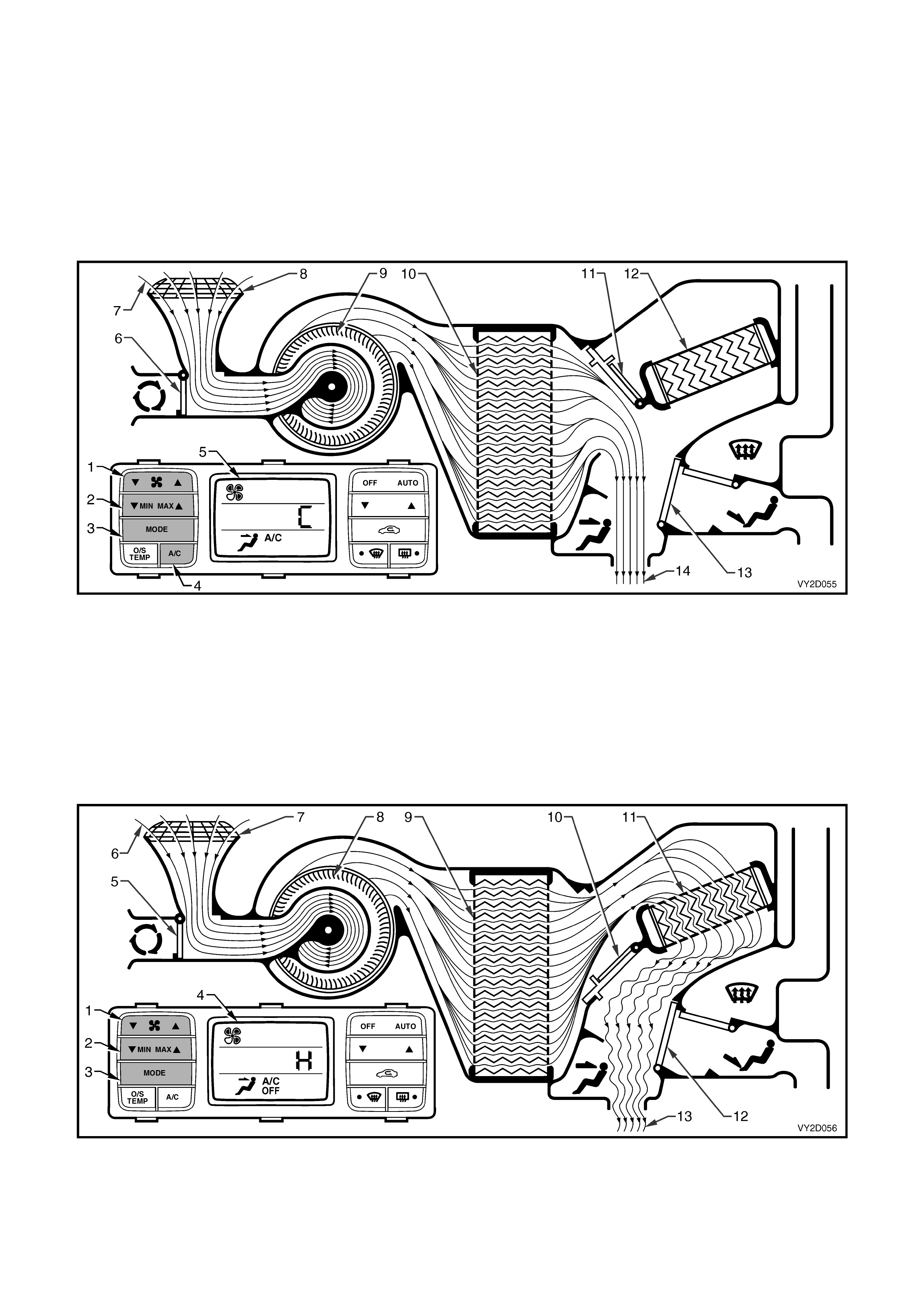

BLEND MODE – RIGHT-HAND DRIVE

Full cold

The fan switch (1) is used to select any one of five speeds. The side G of the MIN MAX switch (2) has been

selected resulting in full, uncontrolled cooling. The mode control switch (3) has been switched to blend mode and

the A/C switch (4) is on. All of these settings are displayed on the LCD screen (5).

The recirculation door (6) is closed allowing outside air (7) to enter and flow into the HVAC unit via the plenum

chamber inlet (8). Air is drawn into the HVAC unit by the blower motor (9), and is then forced through the cold

evaporator f ins ( 10). In full c old mode, the air mix door s ( 11) are pos itioned to allow all air to bypass the heater cor e

(12). The air travels through the demist/floor door (13) which is positioned half way between demist and floor

modes. The cold air (14) is then directed to both the front windscreen and the floor ducts.

Figure 2D-57

Full heat

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in f ull, uncontrolled heating. T he m ode control s witch (3) has been switched to blend m ode. All of

these settings are displayed on the LCD screen (4).

The recirculation door (5) is closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the

evaporator core fins (9). In full heat mode, the air mix doors (10) will be positioned so that all incoming air is directed

through the heater cor e (11) . The air travels through the demis t/f loor door (12) which is positioned half way between

demist and floor modes. The heated air (13) is then directed to both the front windscreen and the floor ducts.

Figure 2D-58

DEMIST MODE – RIGHT-HAND DRIVE

Full heat and A/C activated

The fan switch (1) is used to select any one of five speeds. The side F of the MIN MAX switch (2) has been

selected resulting in f ull, uncontr olled heating. The dem is t switch (3) has been switched on and the A/C s ystem has

been switched on automatically. All of these settings are displayed on the LCD screen (4).

The recirculation door (5) is closed allowing outside air (6) to enter and flow into the HVAC unit via the plenum

chamber inlet (7). Air is drawn into the HVAC unit by the blower motor (8). This air is then forced through the cold

evaporator core fins (9) removing moisture from the air. In full heat m ode, the air mix doors (10) are positioned to

direct this dehumidif ied incom ing air through the heater core ( 11). The air travels through the dem ist/floor door (12)

which is fully open in the demist mode. The heated air (13) is then directed to the front windscreen via the demist

vents.

NOTE: By turning on the A/C system in this mode, dehumidification of incoming air will take place, demisting the

front windscreen and side windows in a shorter period.

Figure 2D-59

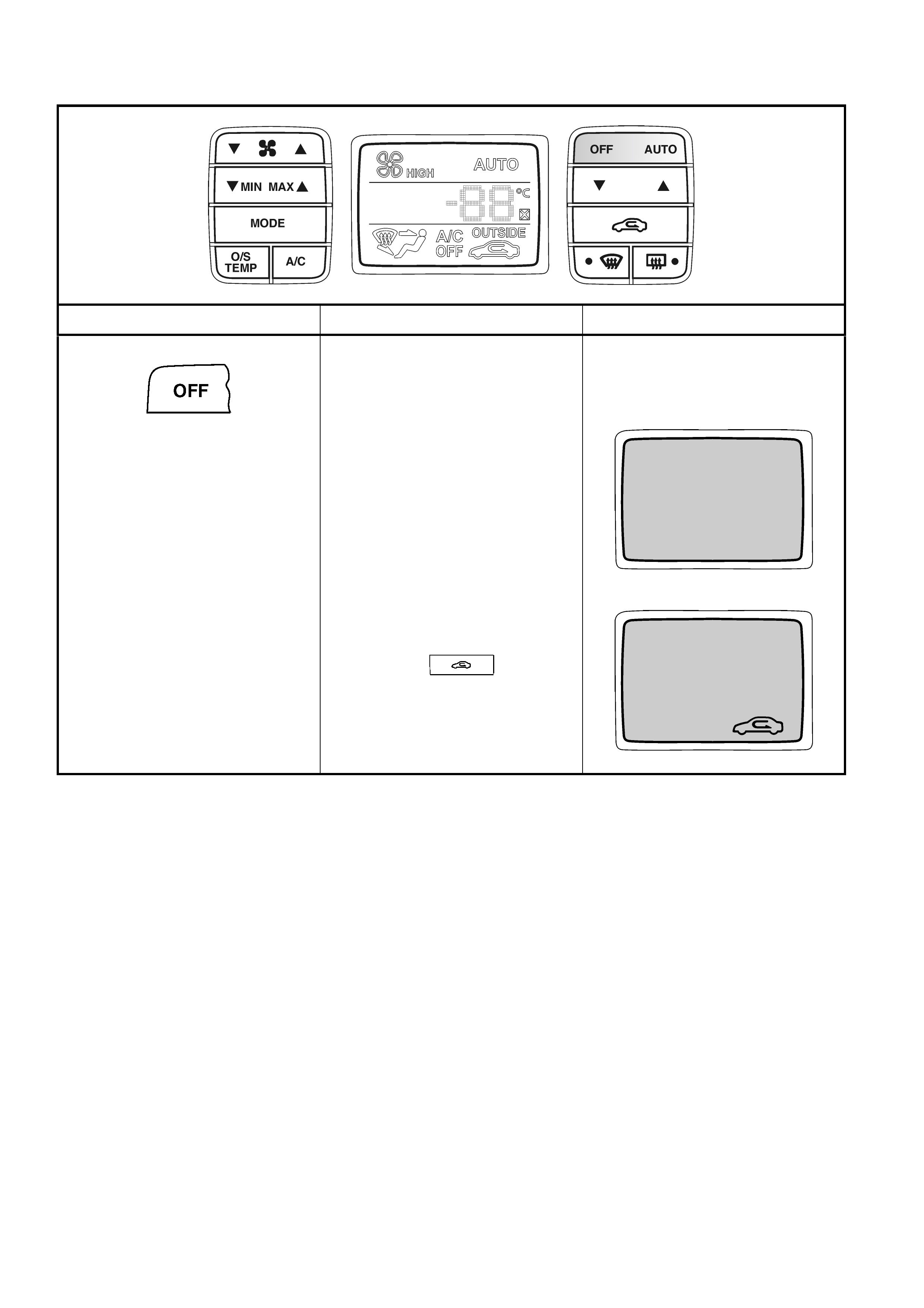

DEFAULT MODE – RIGHT-HAND DRIVE

Loss of vacuum supply to HVAC unit

If a loss of vacuum occurs within the OCC (Auto A/C) system, the HVAC unit will default to the following settings.

The ventilation mode settings will remain constant regardless of what is displayed on the LCD screen (1).

Regardless of rec irculation switch (2) selec tion, the recirculation door (3) will remain c losed allowing outside air (4)

to enter and flow into the HVAC unit via the plenum chamber inlet (5). The position of the air mix doors (6) will

remain controllable as their function is electrically operated by the air mix motor. Heated coolant will flow through the

heater core (7), as vacuum is required to maintain the water valve in the cold (closed) position. The fan switch (8)

will operate the blower fan (9) as normal. In any position of the mode switch (10), the face door (11) will remain

closed. The dem ist/f loor door (12) will be positioned so that all air (13) leaving the HVAC unit will be directed to the

demist ducts whether or not the demist switch (14) is selected. Depending on the selected setting of temperature

switch (15) and/or the MIN MAX switch (16), this air may be cold, warm or hot air.

Figure 2D-60

3.4 VACUUM CIRCUIT

SOLENOID PACK AND VACUUM LINES - LEFT-HAND DRIVE

The vacuum generated within the engine inlet manifold is used to operate the HVAC vacuum actuators and the

water valve.

A vacuum tank located on the left-hand side of the HVAC unit is used to store vacuum for times when engine

vacuum is low such as at full engine throttle. A check valve is fitted on the supply line between the inlet manifold and

the vacuum tank to ensure that vacuum is maintained within the system at all times.

A five solenoid vacuum solenoid pack is used to direct vacuum to the vacuum actuators. The solenoid pack is

connected to the vac uum tank through a white plastic vacuum hos e. An additional rem ote solenoid/ vacuum switch

valve is used to operate the water valve. T he OCC control module turns the solenoids on and off to direct vacuum

to the vac uum ac tuators and water valve when r equired. This alters the position of the water valve and the various

doors within the HVAC unit to bring about the desired heating, demisting or cooling affect.

Vacuum is vented f r om the vacuum actuator /plast ic hos e onc e an OCC c ontr ol module m ode s witch or temperature

switch is used to select a different setting. When vacuum is applied to the water valve, the valve remains closed and

no water will flow through the heater core.

This white plastic hose is also teed off to the heater water valve vacuum switching solenoid valve. From the

switching valve, vacuum moves into an orange coloured plastic hose and then that is connected to a black hose

(inside the cabin at the das h panel), which in turn is connected to the vac uum operated heater water valve. Refer to

Figure2D-63.

The five vacuum hoses between the solenoid pack and the vacuum actuators are also colour keyed.

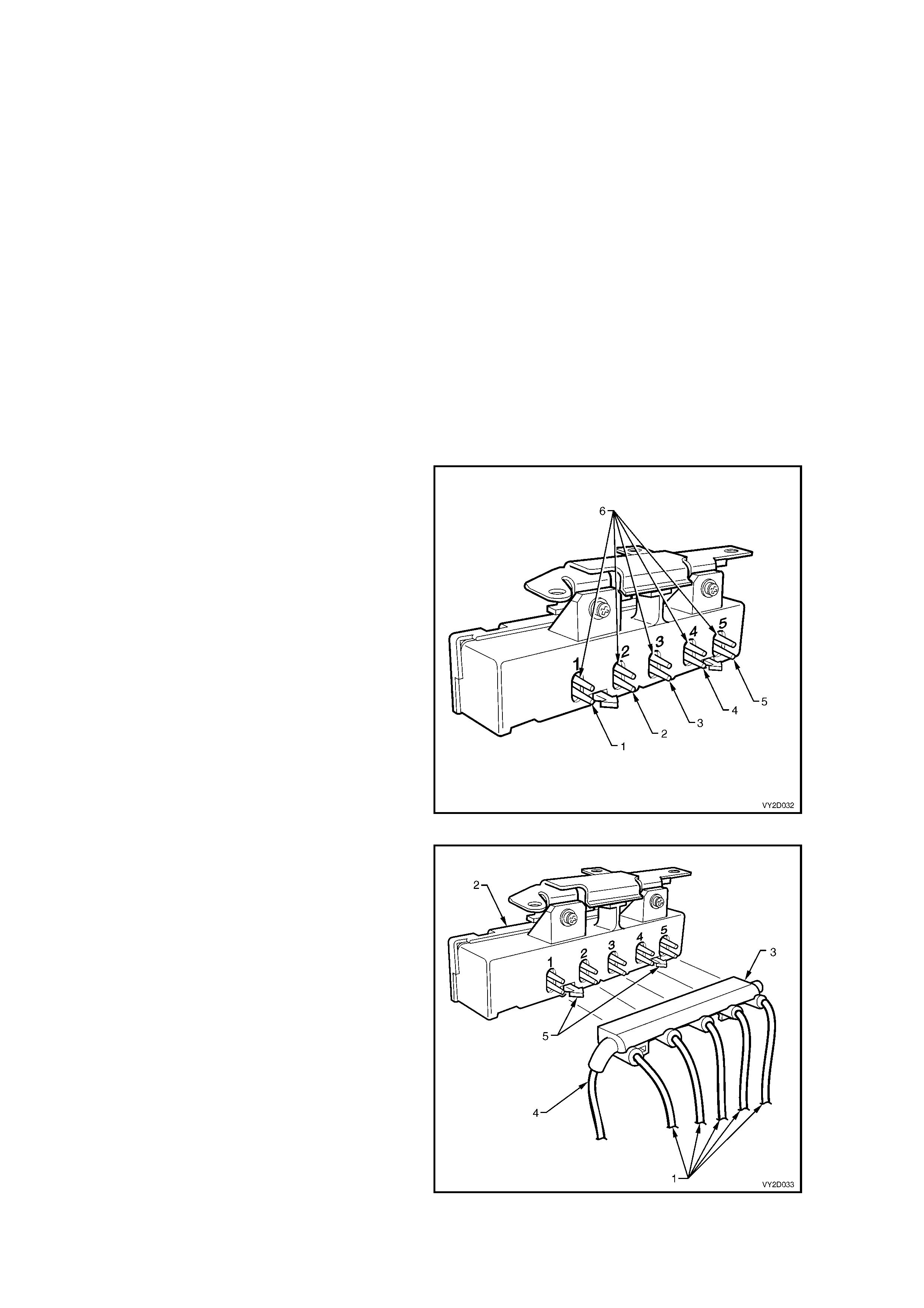

Figure 2D-61 shows the solenoid outlets from the

left-hand drive HVAC vacuum solenoid pack. The

function of the s olenoid connections and the colour

of the attached vacuum lines are listed below:

Legend

1. Foot (Red)

2. Demist (Green)

3. Face 2 (Brown)

4. Face 1 (Blue)

5. Fresh/Recirculation (Yellow)

6. Vacuum Supply (White)

Figure 2D-61

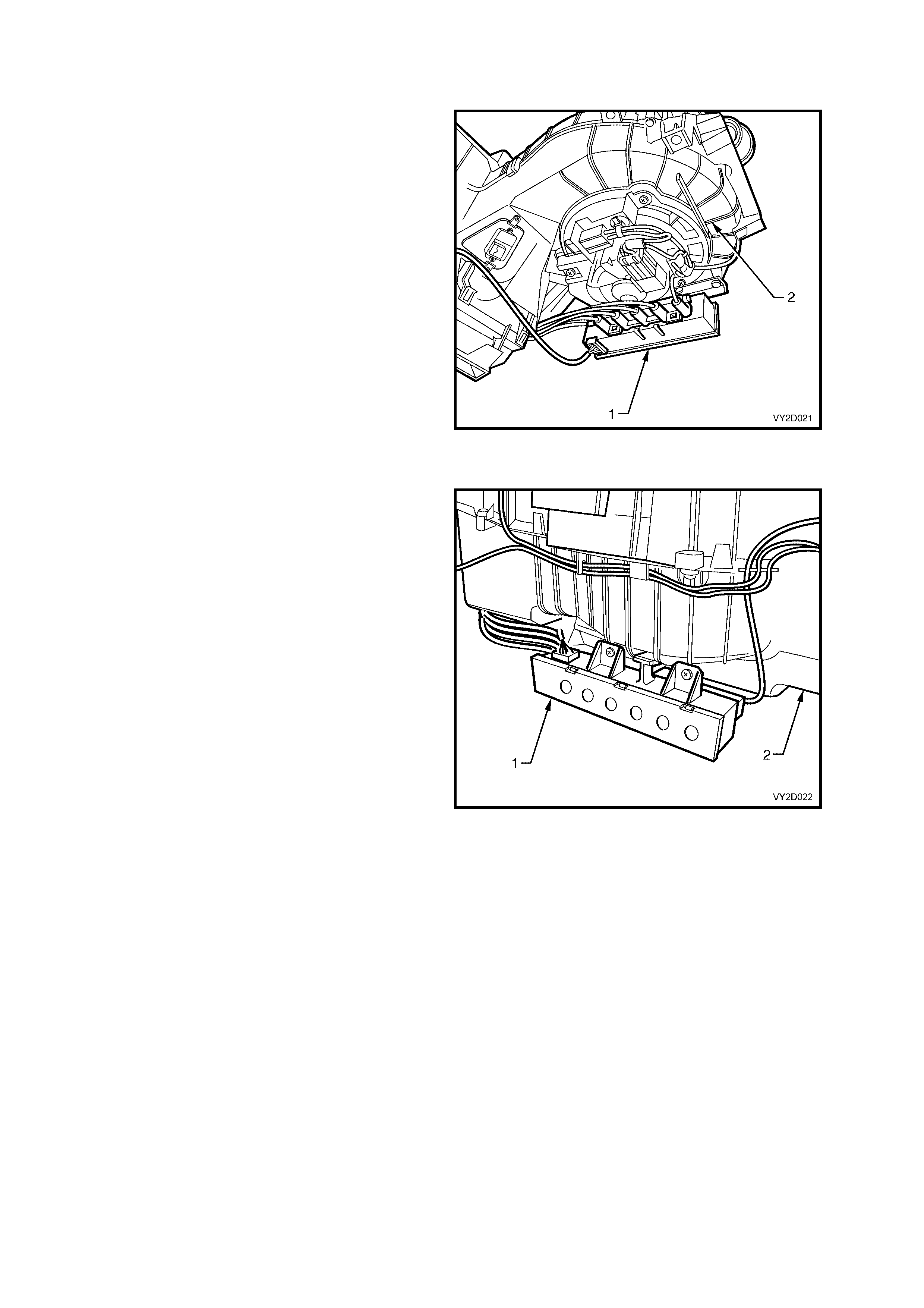

All actuator vacuum hoses (1) at the solenoid pack

(2) are permanently connected to a common, soft

plastic m anifold (3) , which is installed to the f ront of

the solenoid pack.

The white hose (4) at the left-hand side of the

manifold is the vacuum supply line from the

vacuum tank and is also permanently connected.

The manifold is locked into its installed position by

two retaining tangs (5) protruding fr om the so lenoid

pack housing.

Figure 2D-62

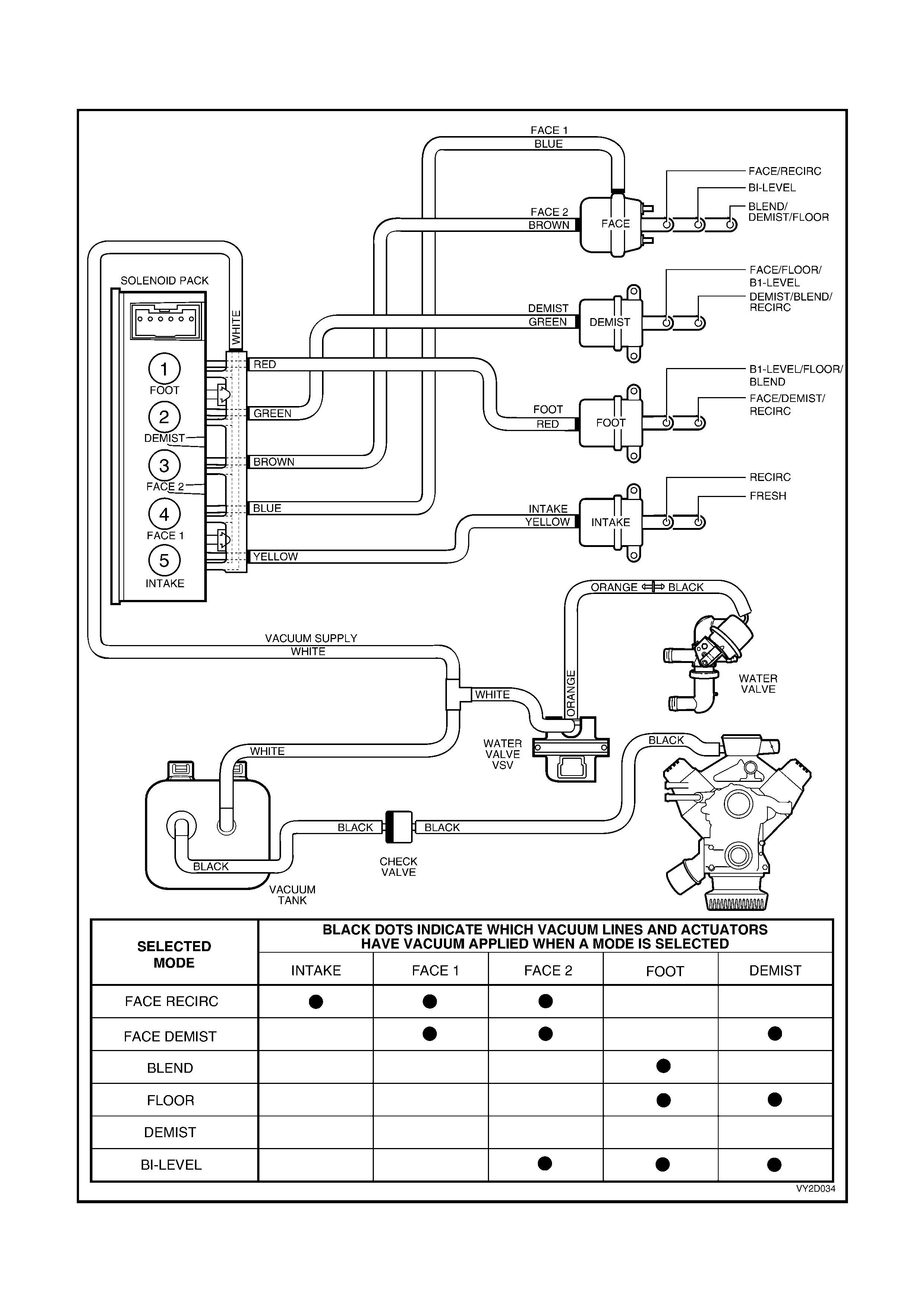

VACUUM CIRCUIT SCHEMATIC – LEFT-HAND DRIVE

Figure 2D-63 shows, which vacuum actuators are applied with vacuum in a certain mode.

Figure 2D-63

SOLENOID PACK AND VACUUM LINES - RIGHT-HAND DRIVE

The vacuum generated within the engine inlet manifold is used to operate the HVAC vacuum actuators and the

water valve.

A vacuum tank located on the left-hand side of the HVAC unit is used to store vacuum for times when engine

vacuum is low such as at full engine throttle. A check valve is fitted on the supply line between the inlet manifold and

the vacuum tank to ensure that vacuum is maintained within the system at all times.

A six solenoid vacuum solenoid pack is used to direct vacuum to the vacuum actuators and the water valve The

solenoid pack is connected to the vacuum tank through a black plastic vacuum hose. The OCC control module

turns the solenoids on and of f to direct vac uum to the vacuum actuator s and water valve when required. T his alter s

the position of the water valve and the various doors within the HVAC unit to bring about the desired heating,

demisting or cooling affect.

Vacuum is vented f r om the vacuum actuator /plast ic hos e onc e an OCC c ontr ol module m ode s witch or temperature

switch is used to select a different setting. When vacuum is applied to the water valve, the valve remains closed and

no water will flow through the heater core.

For water valve control, vacuum is directed to the yellow coloured plastic hose that is connected to a black hose

(inside the cabin at the das h panel), which in turn is connected to the vac uum operated heater water valve. Refer to

Figure 2D-66.

The six vacuum hoses between the solenoid pack and the vacuum actuators are also colour keyed.

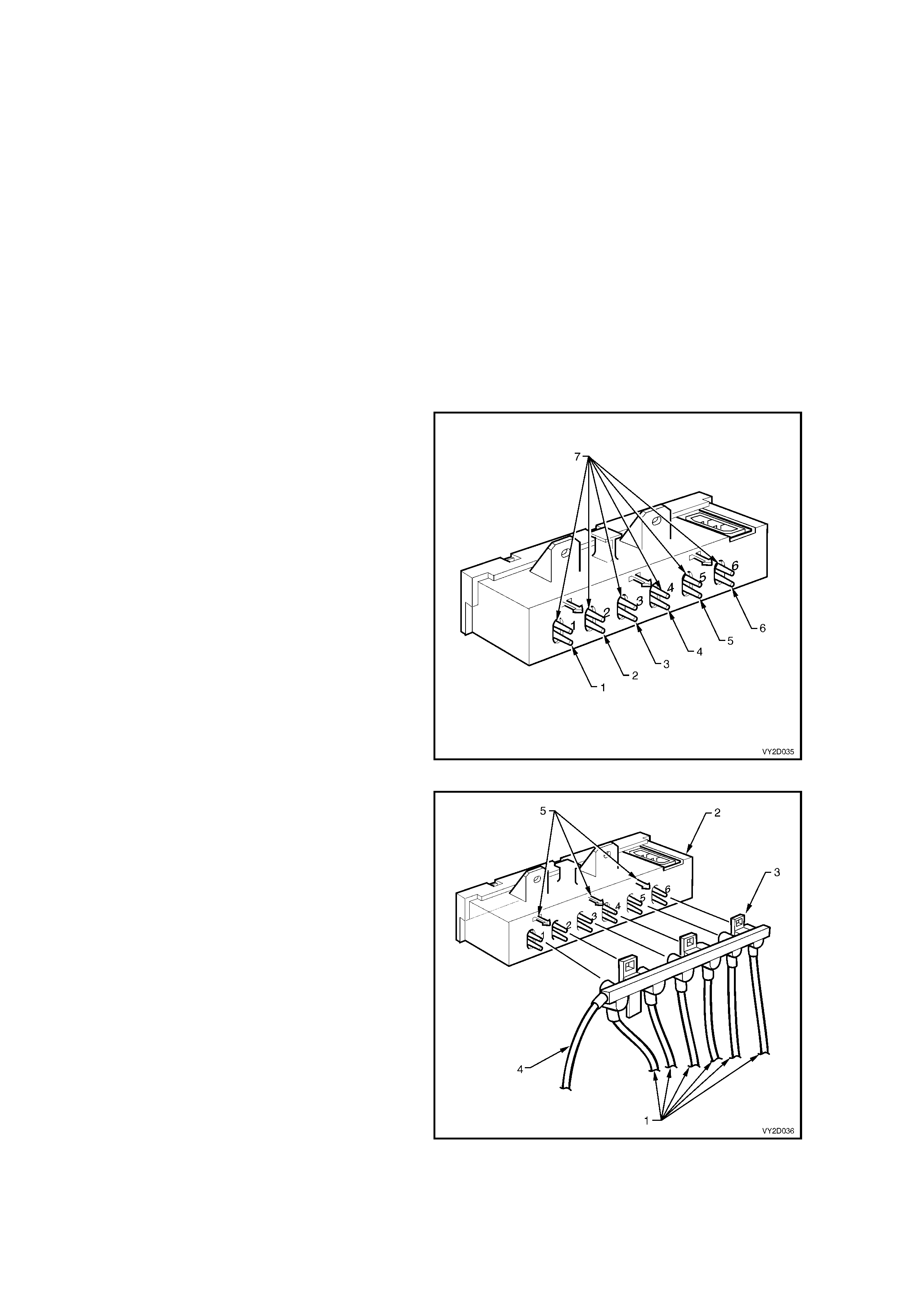

Figure 2D-64 shows the solenoid outlets from the

right-hand drive HVAC vacuum solenoid pack. The

function of the s olenoid connections and the colour

of the attached vacuum lines are listed below:

Legend

1. Fresh/Recirculation (Blue)

2. Face 1 (White)

3. Face 2 (Green)

4. Foot 1 (Pink)

5. Foot 2 (Orange)

6. Water valve (Yellow)

7. Vacuum supply (Black)

Figure 2D-64

All actuator vacuum hoses (1) at the solenoid pack

(2) are permanently connected to a common, soft

plastic m anifold (3) , which is installed to the f ront of

the solenoid pack.

The black hose (4) at the left-hand side of the

manifold is the vacuum supply line from the

vacuum tank and is also permanently connected.

The manifold is locked into its installed position by

three retaining tangs (5) protruding from the

solenoid pack housing.

Figure 2D-65

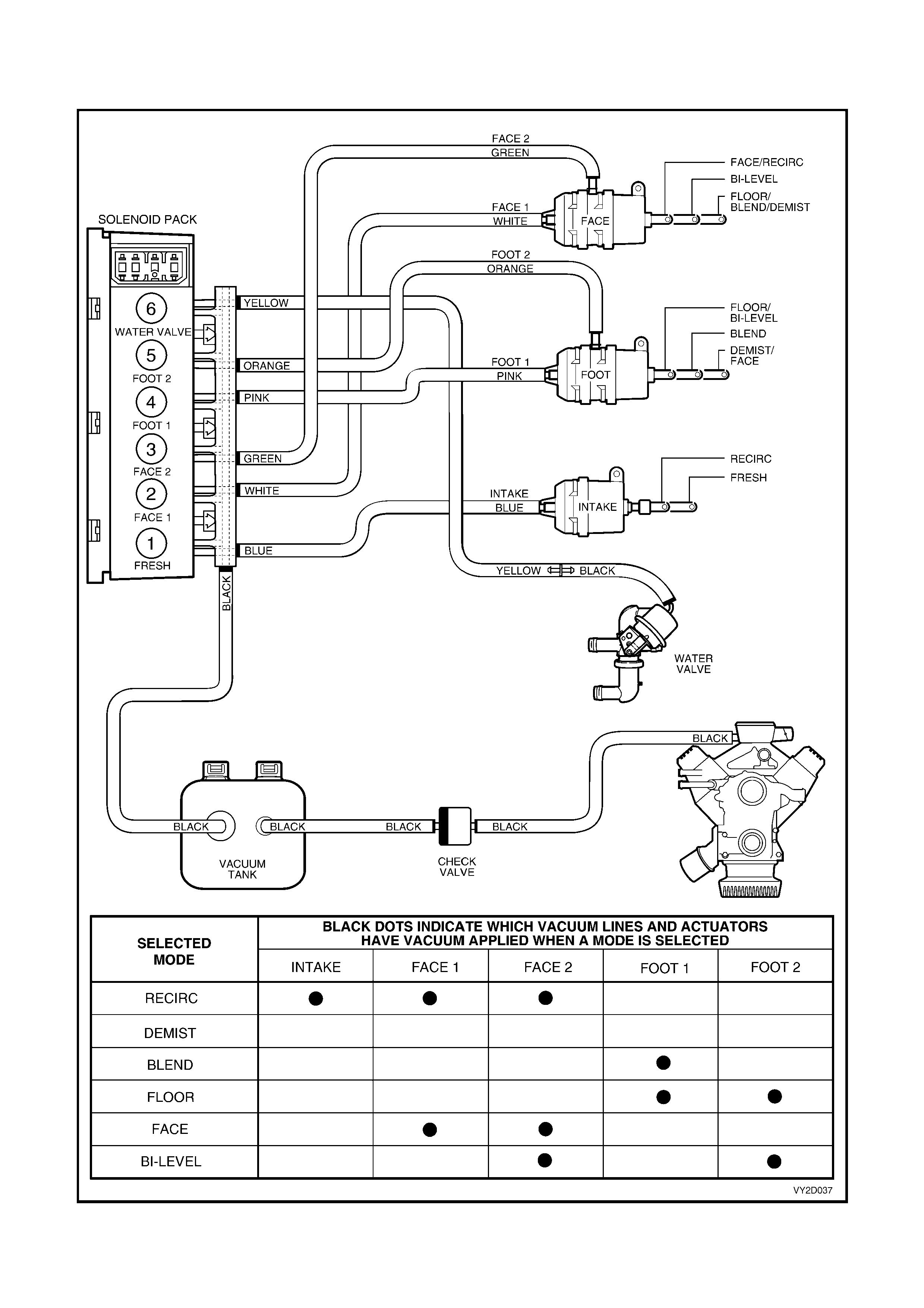

VACUUM CIRCUIT SCHEMATIC – RIGHT-HAND DRIVE

Figure 2D-66 shows, which vacuum actuators are applied with vacuum in a certain mode.

Figure 2D-66

4. OPERATION

The OCC control module uses a microprocessor to monitor inputs, process data and thus control outputs.

The inputs used by the OCC are as follows:

• Serial Data information:

Sunlight level, Priority Key user and Ignition Off time f rom BCM, Engine RPM, c oolant temperature, road speed

and A/C pressure from PCM.

• In-car temperature sensor.

• Ambient temperature sensor.

• Evaporative temperature sensor.

• Air mix potentiometer (PBR) (2 for dual zone systems).

• Ignition Voltage.

• Blower Fan Voltage.

• Customer settings by way of the OCC buttons.

The outputs controlled by the OCC control module controls are as follows:

• Serial Data information:

Sunlight level for Instrument dimming of cruise and Power indicators, A/C request to the PCM.

• Air Distribution Mode – demist, foot, foot and face (bi level), face – by controlling the logic of 4 vacuum

solenoids.

• Vent Air Temperature by controlling the position of the Air mix doors (2 independent doors for dual zone

systems) (between approx. 5°C (with A/C on) and approx. 70°C (with warm engine).

• Air Inlet Mode (i.e. Fresh or Recirculated) by controlling a vacuum solenoid.

• Water valve operation by controlling a vacuum solenoid.

• Blower fan s peed by an analogue signal s ent to the Blower speed controller which am plif ies this signal and thus

controls the blower voltage.

• Maximum Blower relay.

• Rear Window Demist relay.

• OCC LCD screen and LEDs to indicate OCC status.

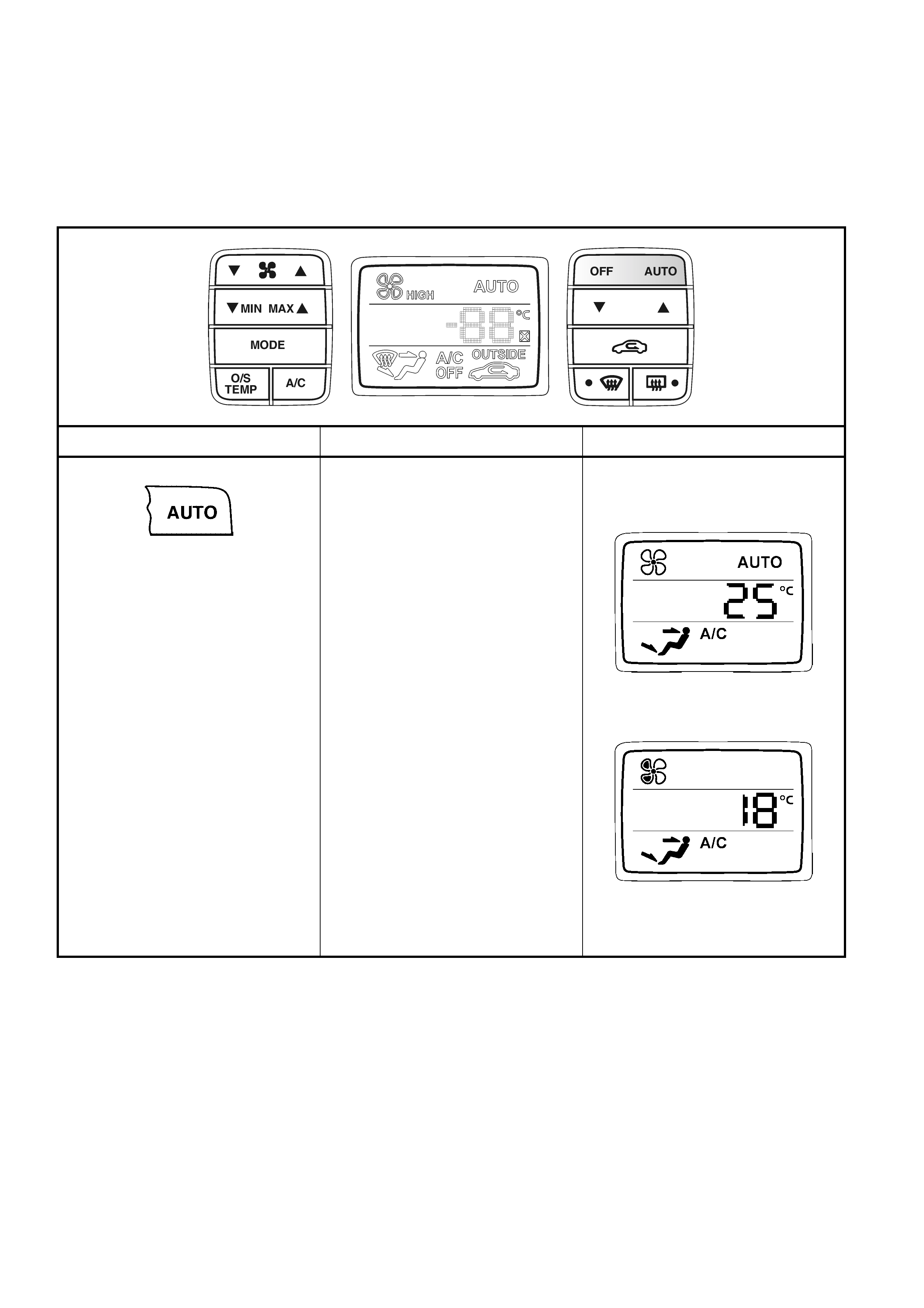

RECOMMENDED SETTINGS

The customer should be encouraged to use the OCC in full Auto mode (orange Auto LED ON) and a set

temperature of 23°C.

Changing the set temperature to suit dif ferent conditions could cause the OCC to behave differently from what the

custom er expects (eg. setting to 17°C on a hot day could cause the customer to com plain the blower speed is too

high on hot days). This should be discouraged.

EVAPORATOR TEMPERATURE CONTROL

As the A/C system us es a Delphi V5 variable strok e compres sor, there is NO need f or an evaporative tem perature

sensor in the manual A/C system. In the OCC system an evaporator air off sensor does not exist, but is only used to

sense A/C temperature for OCC software calculations, not to cycle the compressor on or off. Anti ice-up is

governed by the evaporator pressure control valve located within the compressor.

BLOWER FAN CONTROL

There ar e s teples s var ying blower fan speeds available in the automatic mode and five speeds in the manual mode.

Manual fifth speed is the same as highest automatic blower fan speed.

When the engine is not running, the actual blower s peed will not be higher than approxim ately fan speed 3, in order

to improve battery life.

AUTOMATIC MODE

The blower speed will vary according to:

• In-car Temperature

• Ambient Temperature

• Sun load

• Driver Set Temperature

• Coolant Temperature

• Air Distribution Mode

If the cabin is at the required temperature, the blower will be at a minimum. An increase in sun load in these

conditions would cause the blower to increase.

If heating of the cabin is required (eg. After a cold night), the blower would gradually increase as the coolant

temperature increased to approximately 70°C. Then, as the In-car temperature increased, the blower would

decrease.

If extreme cooling of the cabin were required, the blower would increase to maximum speed (over about 15

seconds). Then, as the In-car temperature decreased, the blower would also decrease.

If cooling of the cabin is required, an increase in sun load will cause the blower speed to increase. If heating up of

the cabin is required, an increase in sun load will normally cause the blower speed to decrease.

If the air distribution mode changes, (eg. From Face to Face/Floor) the fan speed may also change.

In order to maintain a constant airflow, the blower voltage compensated for:

• Road Speed

• Air Inlet mode

• Ignition Voltage

AIR DISTRIBUTION CONTROL

There are 5 distribution modes that can be selected either automatically or manually. These are:

• Demist

• Blend (Foot/Demist)

• Foot

• Bi-level (Foot/Face)

• Face

AUTOMATIC MODE

The air distribution mode selected will vary according to:

• In-car Temperature

• Ambient Temperature

• Sun load

• Driver’s Set Temperature

• Start Up conditions

If the cabin is at the desired temperature, the OCC will select either Foot/Face of Face (depending on if the cabin

needed to be warmed up or cooled down).

If cooling of the cabin were required, Foot mode may be selected for a short time (A/C purge), followed by Face

mode.

If heating of the cabin is r equired, dem ist m ode would be selec ted until the coolant is warm enough (Demis t Delay),

followed by Foot/Demist. Then, as the In-car temperature increased, the mode should change to Foot/Face.

If heating is requires and the coolant is warm, Foot mode may be selected for a short time (Purge), followed by

Foot/Face mode (or Foot/Demist mode depending on conditions).

AIR INLET CONTROL

W hen recirculate is selected either Manually or Automatically, the OCC will return the Inlet to Fresh Air mode after

approxim ately 40 minutes. T his is to avoid ‘stuf finess ’ in the car. T he c ustom er c an return to r ecirculate by pressing

the recirculate button.

AUTOMATIC MODE

The Air Inlet mode selected will vary according to:

• In-car Temperature

• Ambient Temperature

• Sun load

• Driver’s Set Temperature

• Start Up conditions

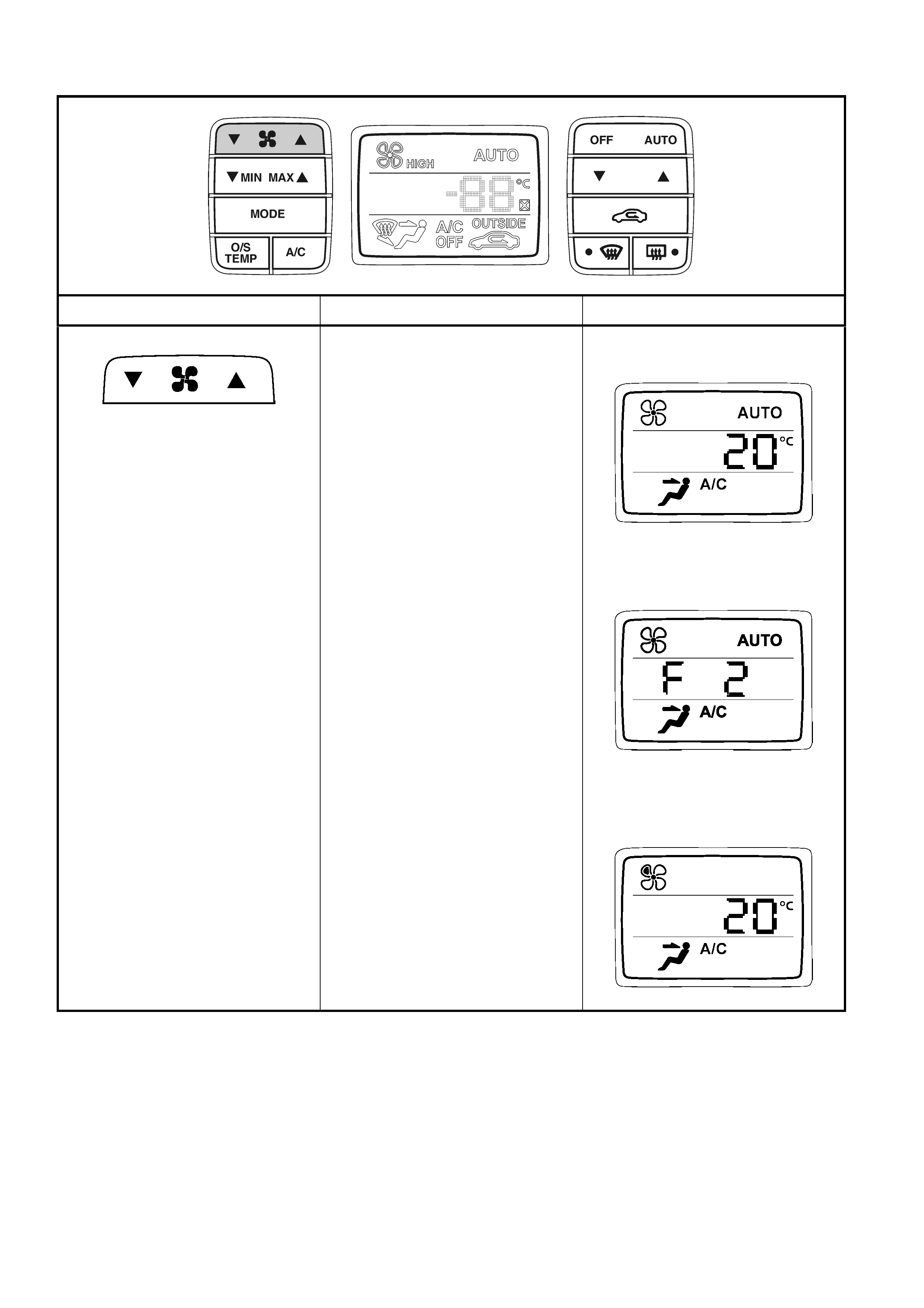

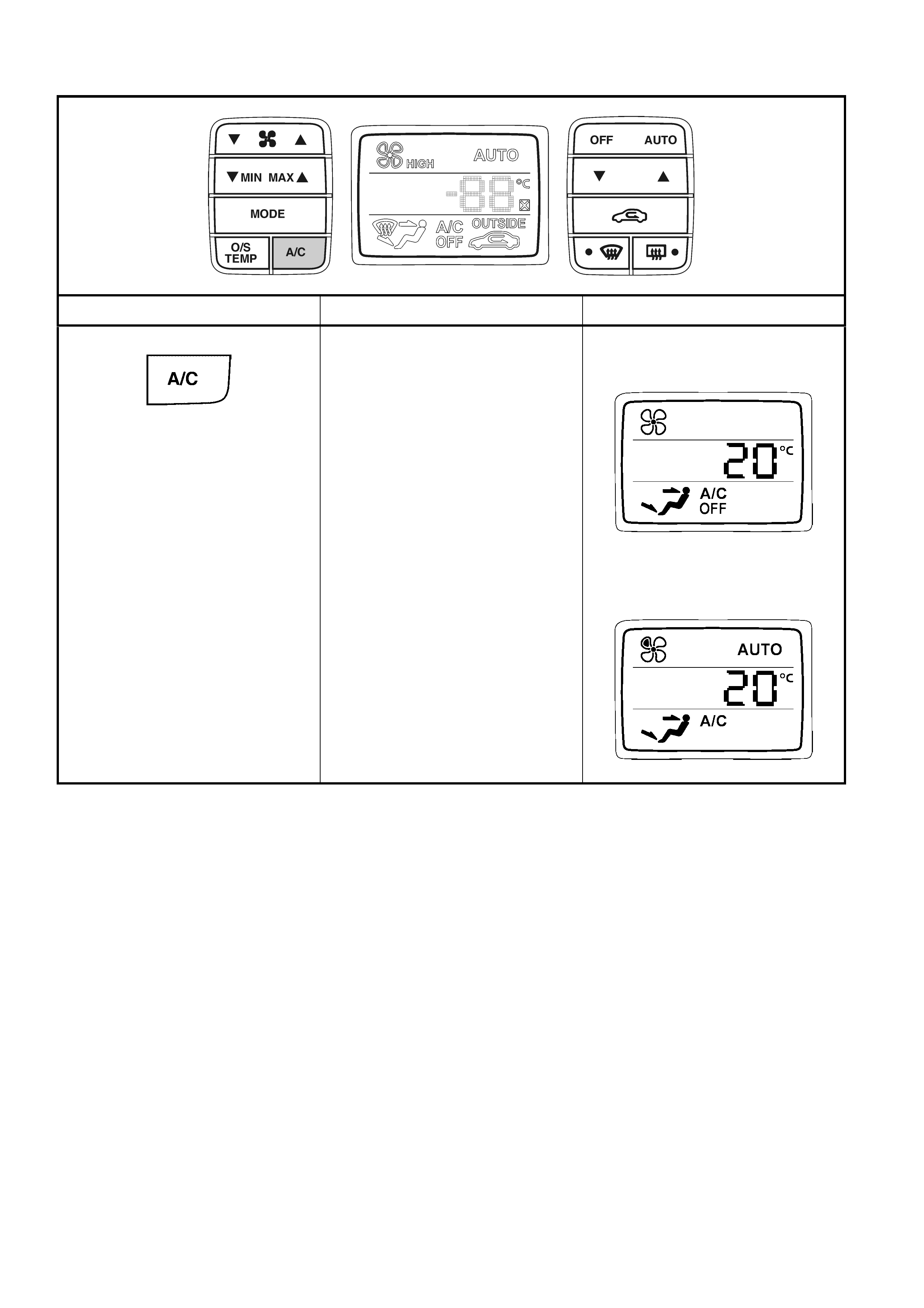

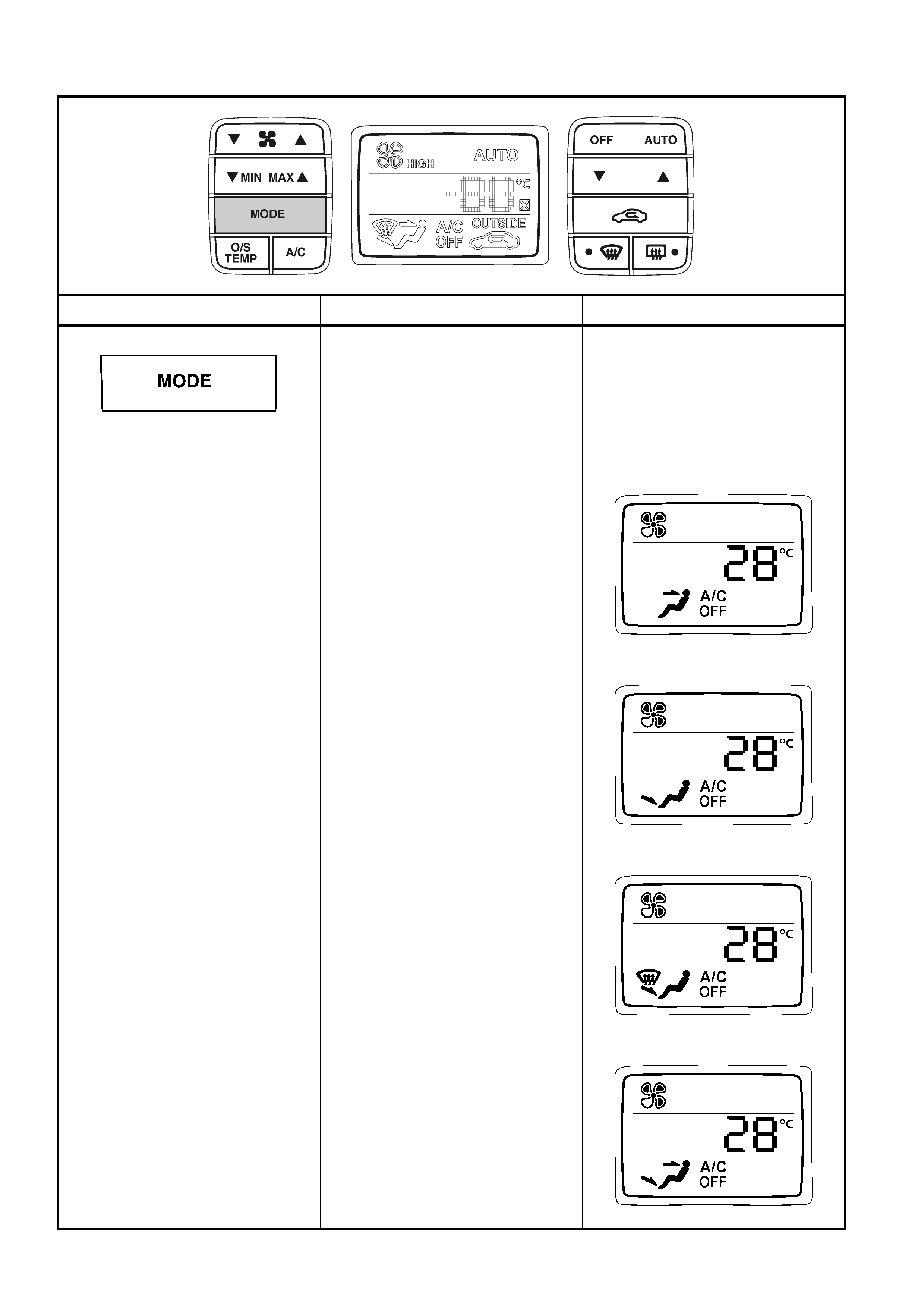

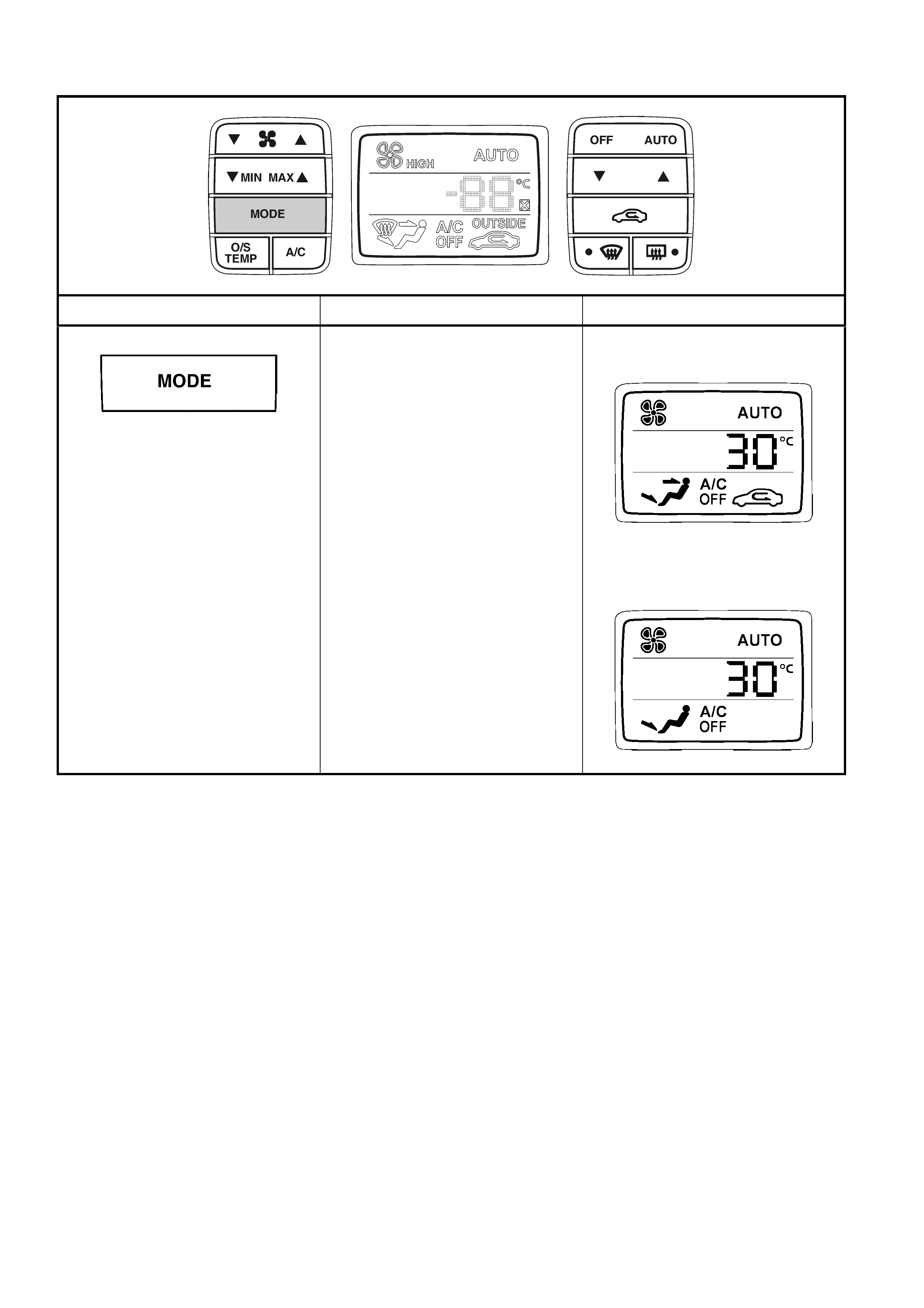

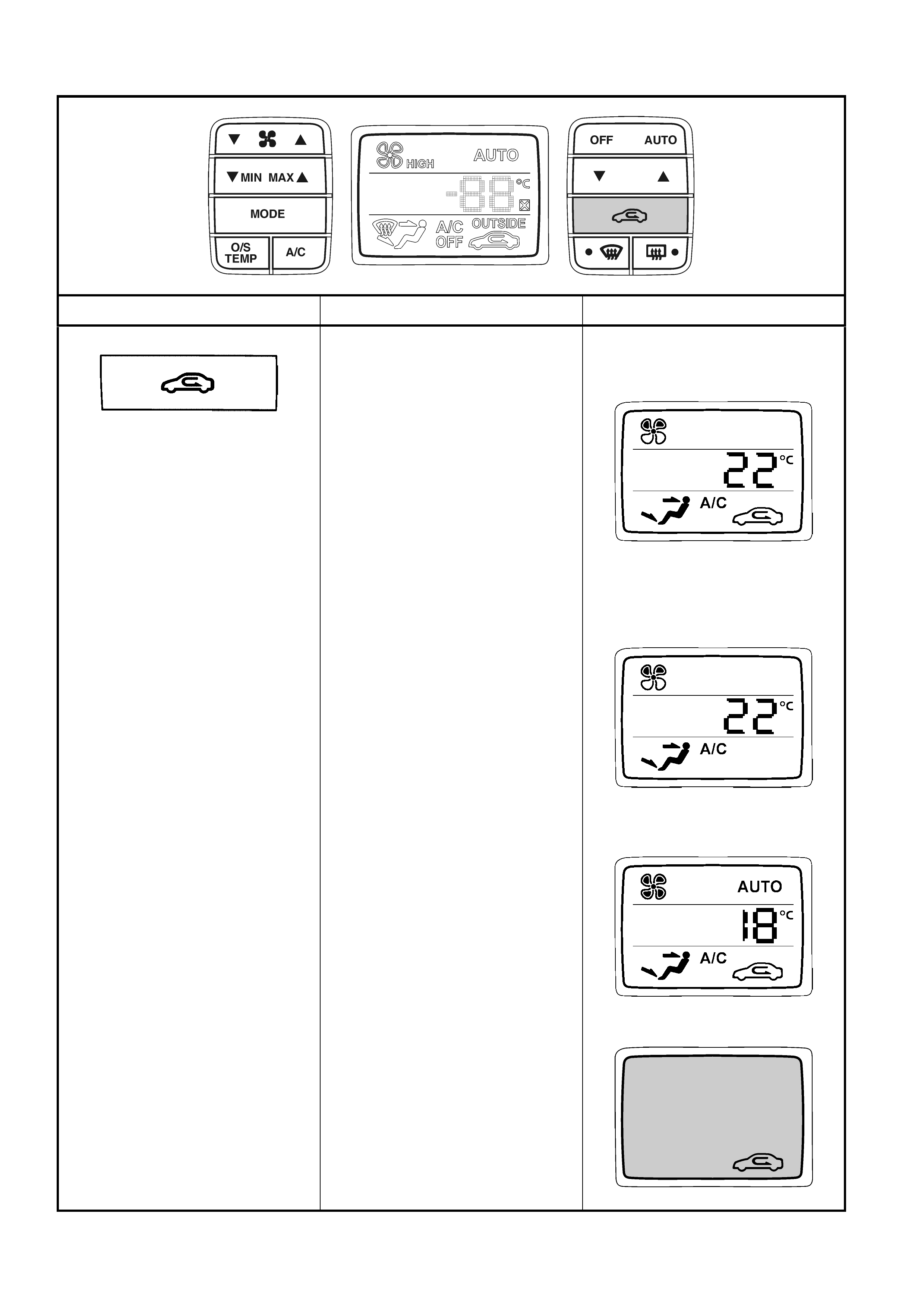

• Evaporator Temperature