SECTION 2E - HVAC OCCUPANT CLIMATE CONTROL

(AUTO A/C) – REMOVAL AND INSTALLATION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. SERVICE OPERATIONS

2.1 OCC CONTROL MODULE

REMOVE

REINSTALL

2.2 SUN LOAD SENSOR

REMOVE

REINSTALL

2.3 IN-CAR TEMPERATURE SENSOR

REMOVE

REINSTALL

2.4 EVAPORATIVE TEMPERATURE SENSOR

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

2.5 ASPIRATOR TUBE AND VENTURI

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

2.6 AM BIENT TEMPERATURE SENSOR

REMOVE

REINSTALL

2.7 VACUUM SOLENOID PACK

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

2.8 WATER VALVE VACUUM SWITCH VALVE

REMOVE

REINSTALL

2.9 BLOWER MOTOR AND FAN

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD

REINSTALL – RHD

2.10 AIR MIX MOTOR

REMOVE – LHD

REINSTALL – LHD

REMOVE – RHD (SINGLE ZONE)

REINSTALL – RHD (SINGLE ZONE)

REMOVE – RHD (DUAL ZONE)

REINSTALL – RHD (DUAL ZONE)

3. TORQUE WRENCH SPECIFICATIONS

4. SPECIAL TOOLS

Techline

Techline

Techline

Techline

Techline

1. GENERAL I NFORMATI O N

The inf or mation that is provided in this Sec tion is to be us ed f or both lef t and r ight-hand dr ive vehicles . Although the

information shown is primarily right-hand drive, it is also applicable to left-hand drive vehicles unless otherwise

specified.

Removal and Installation procedures of the HVAC Occupant Climate Control (Auto A/C) type HVAC unit are not

included in this Section. For this information, refer to Section 2B, 3. HEATING, VENTILATION AND AIR

CONDITIONING (HVAC) UNIT.

2. SERVICE OPERATIONS

2.1 OCC CONTROL MODULE

LT Section – 08-155A

If required, first remove the following components:

1. Navigation remote control cradle, refer to Section 12L, 3.2 NAVIGATION REMOTE CONTROL ASSEMBLY.

2. Navigation monitor escutcheon, refer to Section 12L, 3.3 NAVIGATION DISPLAY ASSEMBLY.

REMOVE

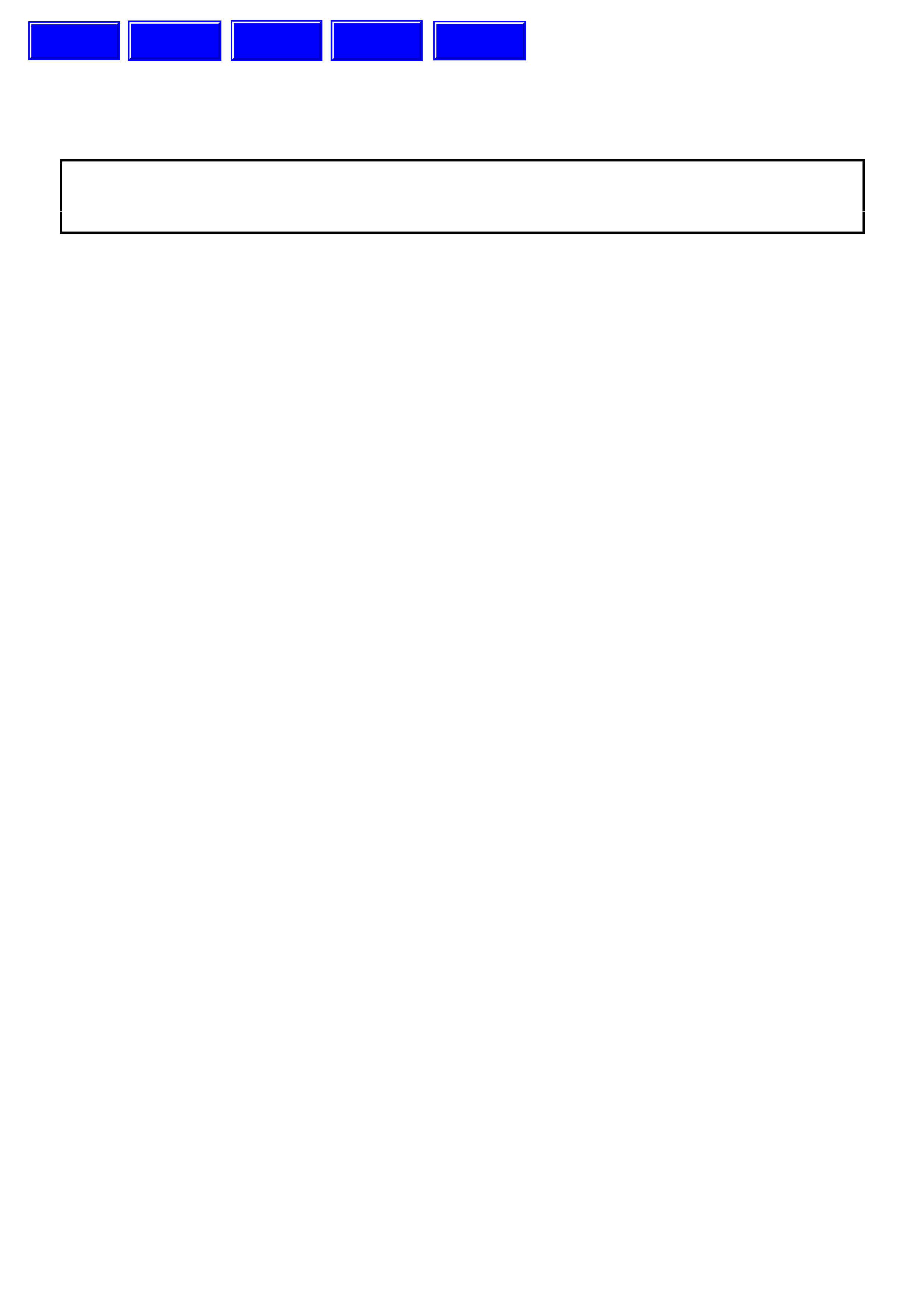

1. Remove the floor console front compartment liner

(1) by lifting upwards to disengage the retaining

lugs.

Figure 2E-1

2. Remove the screw (1) attaching the floor console

cover assembly (2).

3. Prise the cover assembly from the floor console,

six places (3).

4. Lift the cover assembly up from the rear,

disconnect the wiring connector (4) from the side

window switch assembly and any auxiliary

switches if fitted, and remove the cover assembly.

Figure 2E-2

5. Insert Spec ial T ool KM6067 ( 1) into the holes eac h

side of the radio assembly.

6. While holding outward pressure on the tools

(toward each outer side of the vehicle), pull the

radio assembly from the radio housing.

NOTE: The wiring connectors remain attached to the

radio housing and will disconnect on removal of the

radio assembly.

Figure 2E-3

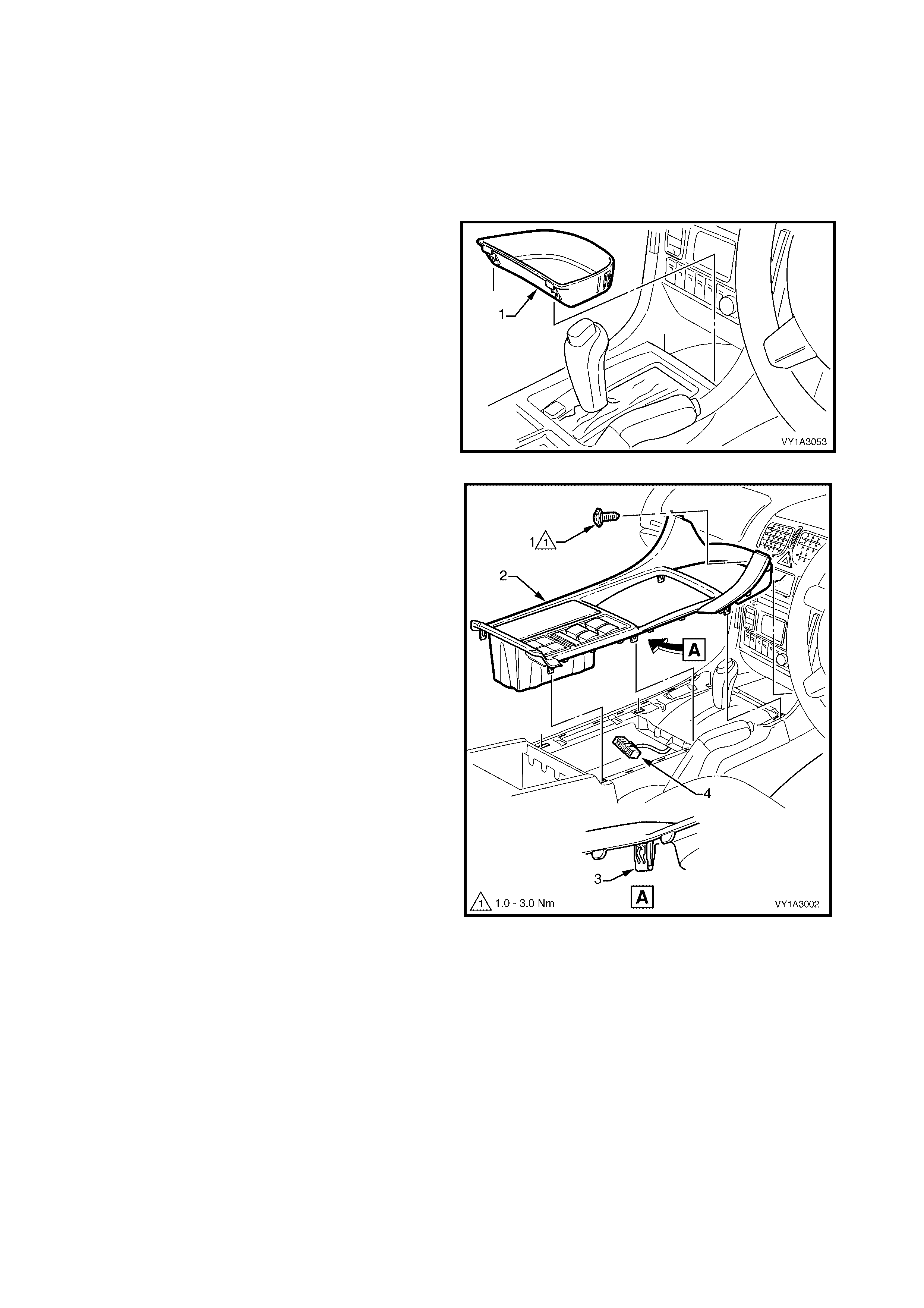

7. Carefully prise the front edge of the instrument panel upper centre trim panel (1) refer to Figure 2E-4, and pull

upward to disengage the retaining clips at each corner from the centre trim assembly (2).

NOTE: A fine flat blade screwdriver may be used; however take steps to ensure the trims are not marked or

damaged.

8. Remove the lower screw (3), two places, attaching the centre trim assembly to the instrument panel.

9. Remove the upper screws (4 and 5), two places each, attaching the centre trim assembly to the instrument

panel.

10. Remove the c entre tr im as s embly, noting the four clips ( 6), far enough to disc onnec t the wiring connector s f rom

the rear of the hazard warning switch.

11. Remove the centre trim assembly.

Figure 2E-4

NOTE: Depending on model not all of the following components will be fitted.

12. Remove the scr ew ( 1) r ef er to Figure 2E- 5, one plac e each s ide, attaching the O CC c ontrol module (2) and c up

holder assembly (3) to the centre trim (4).

13. Remove the screw (5), one place each side, attaching the OCC control module to the centre trim and remove

the control module.

NOTE: For service and diagnosis of the OCC control module refer to Section 2F, HVAC OCCUPANT CLIMATE

CONTROL (AUTO A/C) – DIAGNOSTICS.

Figure 2E-5

REINSTALL

IMPORTANT: If the OCC control m odule has been replaced, the air mix door/motor function must be calibrated to

the new OCC control m odule. Failure to do so may cause poor HVAC system perform ance and result in customer

complaints. Refer to Section 2F, F5: PROGRAM.

Installation of the OCC control module is the reverse of removal procedures. Tighten all screws to the specified

torque.

OCC CONTROL MODULE

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

INSTRUMENT PANEL CENTRE TRIM

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

FLOOR CONSOLE COVER

ASSEMBLY ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.2 SUN LOAD SENSOR

LT Section – 08-155A

REMOVE

1. Remove the instrument panel outer cover from both sides, refer to Section 1A3, 3.17 INSTRUMENT PANEL

OUTER COVER.

2. Remove the windshield defroster grille assembly from both sides, refer to Section 1A3, 3.18 WINDSHIELD

DEFROSTER GRILLE ASSEMBLY.

3. Carefully unclip the receiver and sun load sensor

(1) from the instrument panel.

4. Disconnect the wiring connector (2), unclip the

wiring harness f rom the sun load sensor as sembly

and remove.

NOTE: For service and diagnosis of the sun load

sensor, refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

Figure 2E-6

REINSTALL

Installation of the receiver and sun load sensor assembly is the reverse of removal procedures.

2.3 IN-CAR TEMPERATURE SENSOR

LT Section – 08-200

REMOVE

1. Remove the instrument cluster trim assembly, refer to Section 1A3, 3.12 INSTRUMENT CLUSTER TRIM

ASSEMBLY.

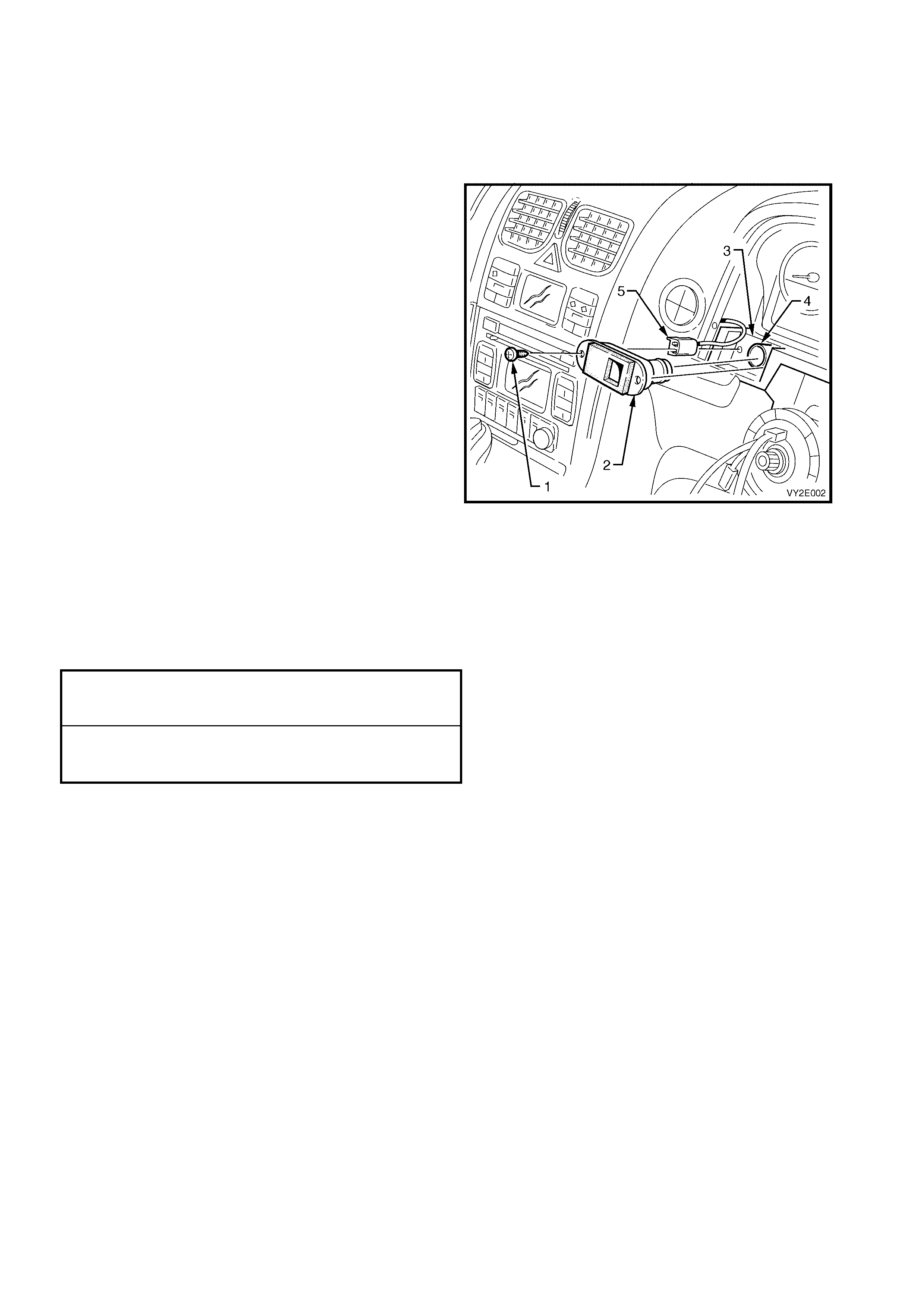

1. Remove the screw (1) attaching the in-car

temperature sensor (2) to the instrument panel (3).

2. Extract the sensor assembly from the cavity and

disconnect the aspirator tube (4) and wiring

connector (5).

3. Remove the sensor assembly.

NOTE 1: Steering wheel is shown removed only for

clarity of detail. Do not remove the steering wheel for

in-car temperature sensor removal.

NOTE 2: For service and diagnosis of the in-car

temperature sensor refer to Section 2F, HVAC

OCCUPANT CLIMATE CONTROL (AUTO A/C) –

DIAGNOSTICS.

Figure 2E-7

REINSTALL

1. Ins tall the in- car tem perature s ensor into the instr ument panel ensur ing that the aspirator tube is f itted correc tly

to the sensor.

2. Install the screw attaching the in-car temperature sensor to the instrument panel. Tighten the screw to the

specified torque.

3. Install the instrument cluster trim assembly. Tighten the screws to the specified torque.

INSTRUMENT CLUSTER TRIM ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

IN-CAR TEMPERATURE SENSOR

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2.4 EVAPORATIVE TEMPERATURE SENSOR

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

2. Access the evaporator core, refer to Section 2B, 4. EVAPORATOR.

Disconnect the evaporative sensor harness connector at the front of the HVAC case.

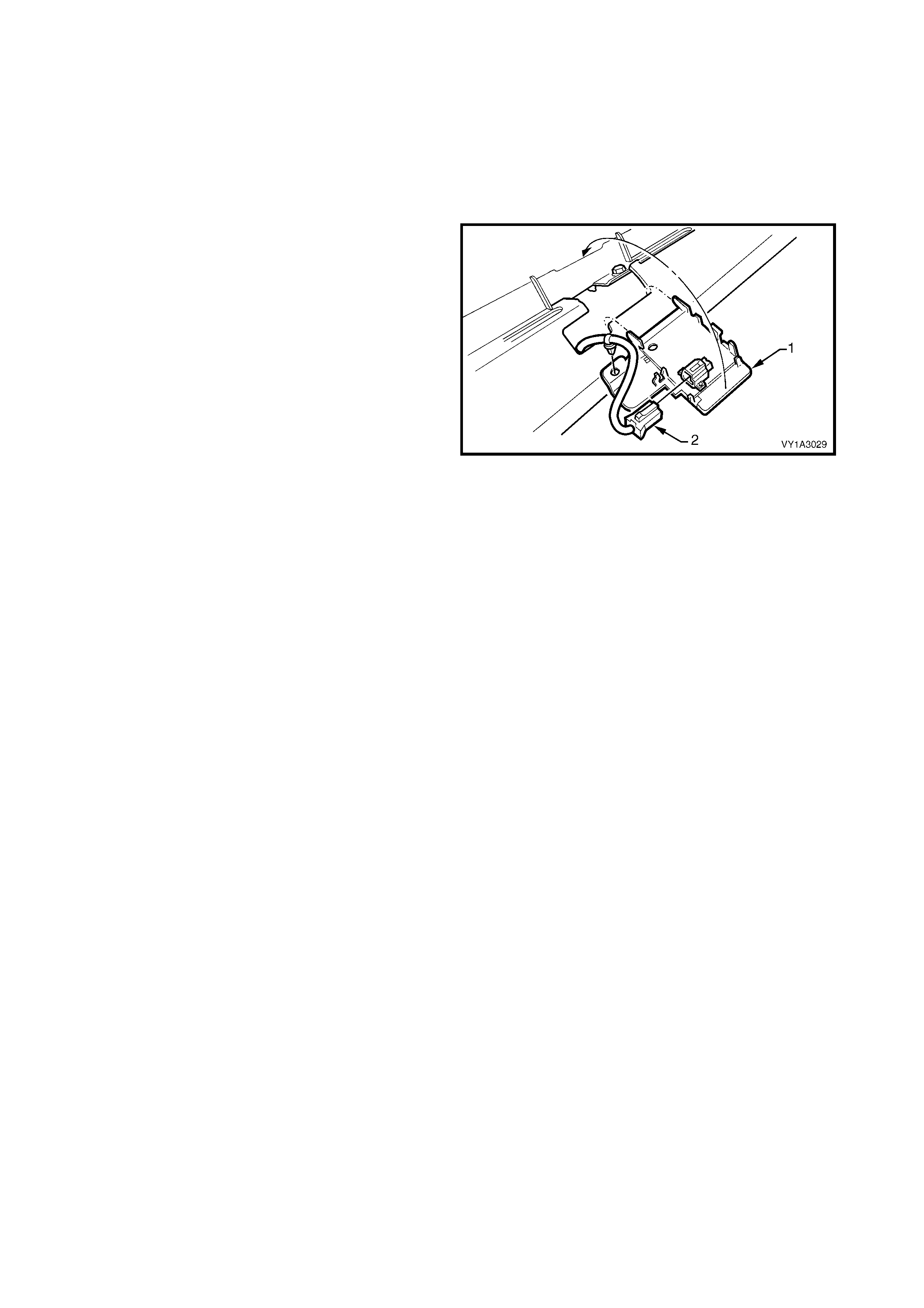

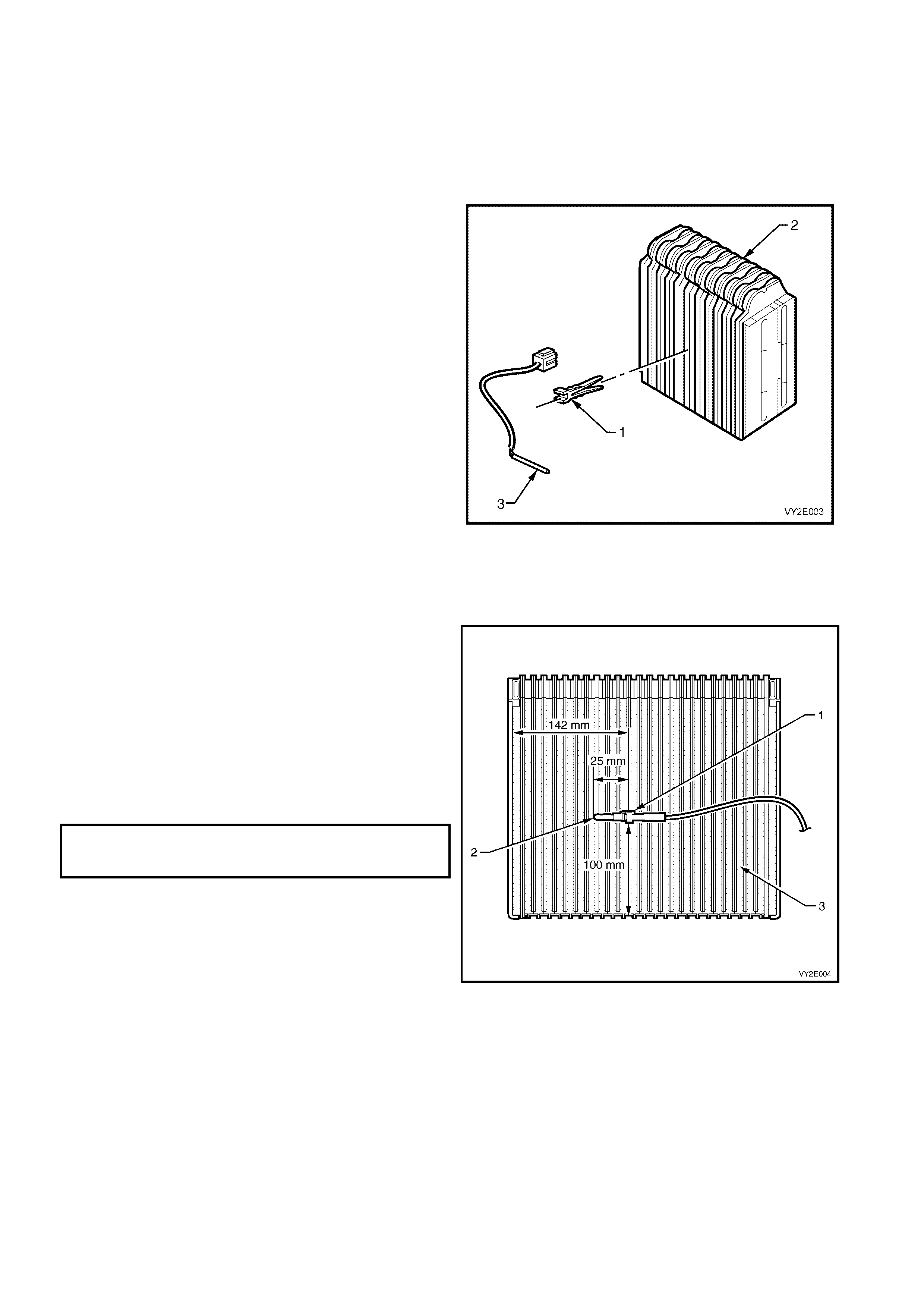

3. Remove the clamp (1) from the evaporator core (2)

and remove the thermistor (3).

NOTE: For service and diagnosis of the evaporator

temperature sensor assembly refer to

Section 2F, HVAC OCCUPANT CLIMATE CONTROL

(AUTO A/C) – DIAGNOSTICS.

Figure 2E-8

REINSTALL – LHD

Install the evaporator temperature in the reverse order

of removal procedures noting the following:

1. When installing the evaporative temperature

sensor, ensure that the clamp (1) is fitted over the

thermistor (2) at 25 mm from the end of the

thermistor. The clamp is firmly inserted into the

core fins (3) at a height and width as shown in

Figure 2E-9.

2. Ensure that the sensor harness is installed

correctly in the hole provided in the HVAC case

when the upper and lower cases are assembled.

3. Tighten all screws to the specified torque.

HVAC CASE

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2E-9

LT Section – 08-025

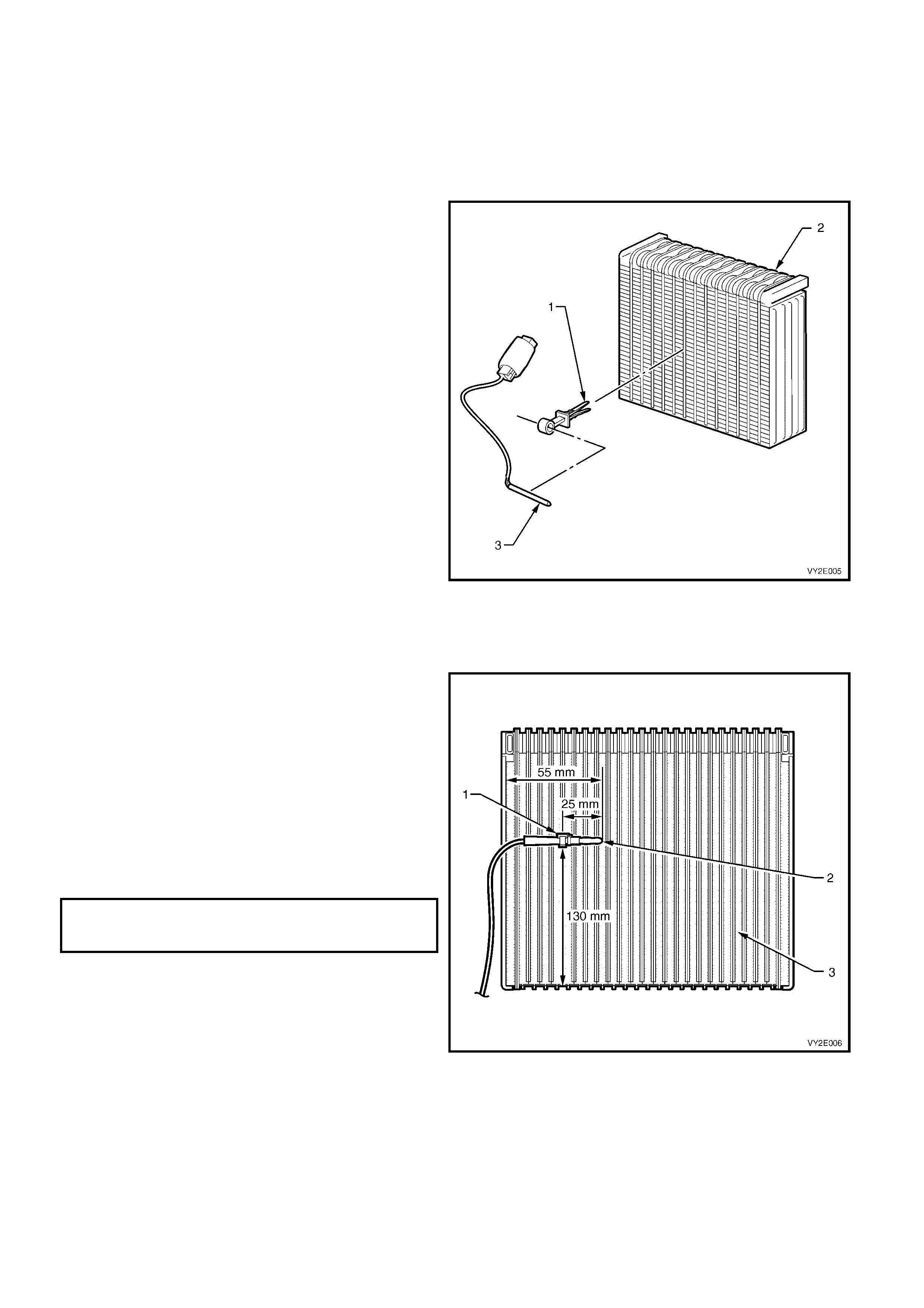

REMOVE – RHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

2. Access the evaporator core, refer to Section 2B, 4. EVAPORATOR.

3. Disconnect the evaporative temperature sensor harness connector at the front of the HVAC case.

4. Remove the clamp (1) from the evaporator core

(2) and remove the thermistor (3).

NOTE: For service and diagnosis of the sensor

assembly refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) –

DIAGNOSTICS.

Figure 2E-10

REINSTALL – RHD

Install the evaporator temperature sensor in the

reverse order of removal procedures noting the

following:

1. When installing the evaporative temperature

sensor, ensure that the clamp (1) is fitted over

the thermistor (2) at 25 mm from the end of the

thermistor. The clamp is firmly inserted into the

core fins (3) at a height and width as shown in

Figure 2E-11.

2. Ensure that the sensor harness is correctly

installed in the recess provided in the evaporator

cover when the cover is assembled to the case.

3. Tighten all screws to the specified torque.

EVAPORATOR COVER

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2E-11

2.5 ASPIRATOR TUBE AND VE NTURI

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

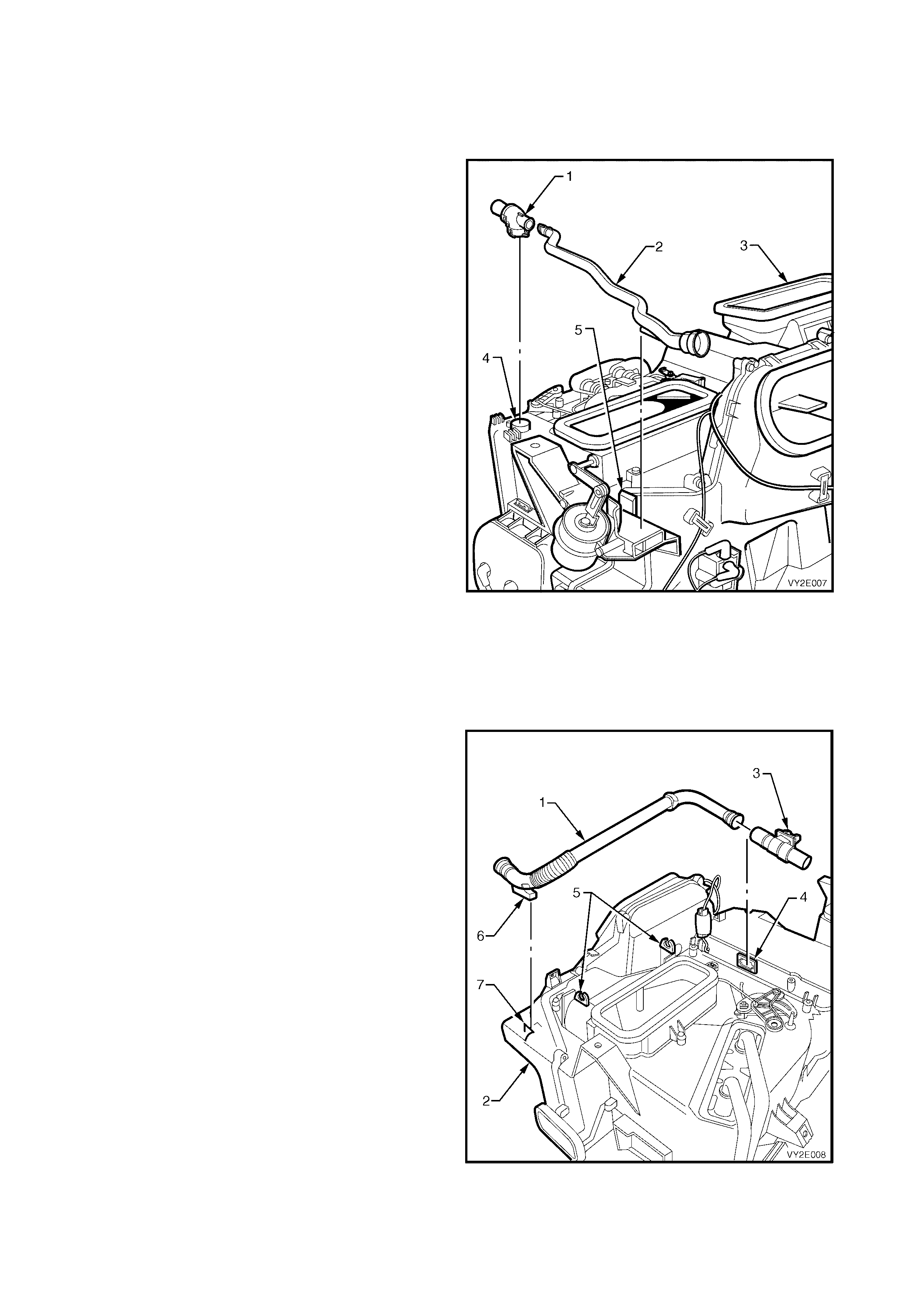

2. Remove the venturi (1) and aspirator tube (2) as

an assembly from the HVAC case (3).

3. Remove the aspirator tube from the venturi.

REINSTALL – LHD

Install the aspirator tube and venturi in the reverse

order of removal procedures noting the following:

1. When inst alling the venturi on to the as pir ator tube,

ensure that the tube is fully engaged into the

venturi.

2. When installing the venturi and aspirator tube

assembly, ensure that the venturi is fully seated to

the HVAC case venturi hole (4) and that aspirator

tube is correctly installed in the aspirator tube

locating recess (5) moulded in the HVAC case.

Figure 2E-12

LT Section – 08-150

REMOVE – RHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

2. Note the location then remove any adhesive tape

retaining the aspirator tube (1) to the HVAC case

(2).

3. Remove the aspirator tube and the venturi (3) as

an assembly from the HVAC case.

4. Remove the aspirator tube from the venturi.

REINSTALL – RHD

Install the aspirator tube and the venturi in the reverse

order of removal procedures noting the following:

1. W hen installing the venturi into the aspirator tube,

ensure that the tube is fully engaged into the

venturi.

2. When installing the venturi and aspirator tube

assembly, ensure that the venturi is fully seated

into the venturi hole (4) of the HVAC case. Ensure

that aspirator tube is correctly installed into the

retaining clips (5) and the retaining lug (6) is

correctly installed into the recess (7) moulded in

the HVAC case.

3. Install adhesive tape to the original locations as

noted.

Figure 2E-13

2.6 AMBIENT TEMPERATURE SENSOR

LT Section – 08-200

REMOVE

1. Raise front of vehicle and support on safety stands. Refer to Section 0A, GENERAL INFORMATION for the

location of jacking and support points.

2. Remove the ambient temperature sensor harness

connector (1) from the sensor (2).

3. Using a flat blade screwdriver carefully lever the

sensor away from the retaining bracket (3).

NOTE 1: The retaining bracket is not to be removed

from the condenser (4).

NOTE 2: For service and diagnosis of the sensor

assembly refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

REINSTALL

Installation of the ambient temperature sensor is the

reverse order of removal procedures.

Figure 2E-14

2.7 VACUUM SOLENOID PACK

REMOVE – LHD

1. Remove the right-hand side instrument panel lower trim plate assembly, refer to

Section 1A3, 3.1 INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

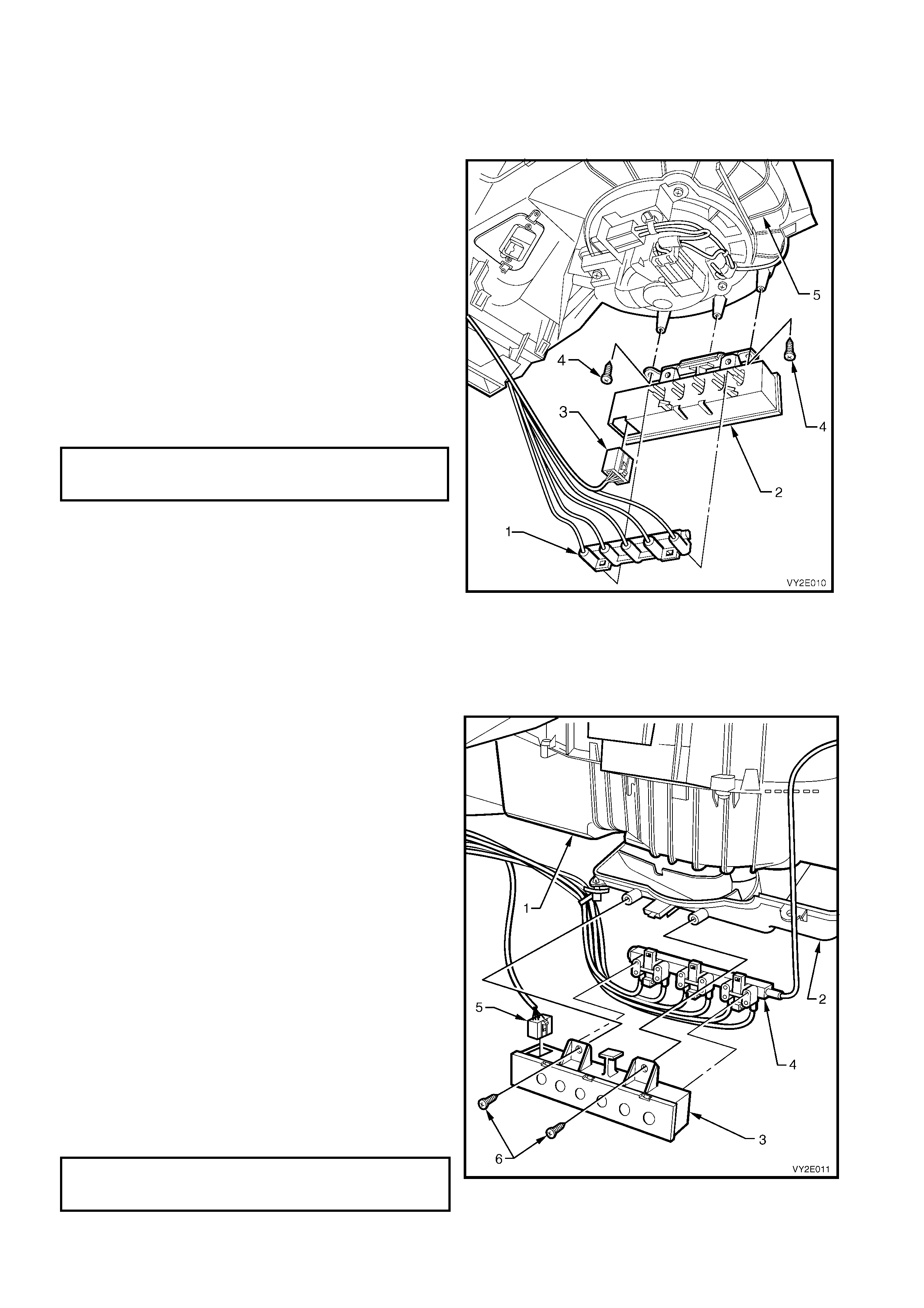

2. Disconnect the vacuum solenoid pack vacuum

manifold (1) from the solenoid pack (2).

3. Disconnect the harness connector (3) from the

solenoid pack.

4. Remove the two screws (4) and detach the

vacuum s olenoid pac k and bracket fr om the HVAC

lower case housing (5).

NOTE: Fo r service and diagnosis of the solenoid pack

assembly refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

REINSTALL – LHD

Installation of the vac uum solenoid pac k is the reverse

order of removal procedures. Tighten all screws to the

specified torque.

VACUUM SOLENOID PACK

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2E-15

LT Section – 08-150

REMOVE – RHD

1. Remove the right-hand side instrument panel lower trim plate assembly, refer to Section 1A3, 3.1

INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Remove the blower motor and fan harness

connector from the blower motor connector (refer

to item 1 in Figure 2E-19) below the HVAC unit (1).

3. Remove the three screws from the blower motor

and fan assembly access cover (refer to item 2 in

Figure 2E-19) and remove the blower motor and

fan assembly access cover (2) with the solenoid

pack (3) attached to the cover.

4. Disconnect the vacuum manifold (4) from the

vacuum solenoid pack.

5. Disconnect the harness connector (5) from the

solenoid pack.

6. Remove the two screws (6) and remove the

vacuum solenoid pack from the blower motor and

fan access cover.

NOTE: For service and diagnosis of the solenoid pack

assembly refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

REINSTALL – RHD

Installation of the vacuum solenoid pack is the reverse

order of removal procedures. Tighten all screws to the

specified torque.

VACUUM SOLENOID PACK

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2E-16

2.8 W ATER VALVE VACUUM SWITCH VALVE

REMOVE

NOTE: The water valve vacuum switch valve is fitted to LHD OCC (Auto A/C) HVAC units only.

1. Remove the radio assembly, refer to Section 1A3, 3.6 RADIO ASSEMBLY.

2. Remove the radio housing and radio bracket assembly, refer to Section 1A3, 3.11 RADIO HOUSING AND

RADIO BRACKET ASSEMBLY.

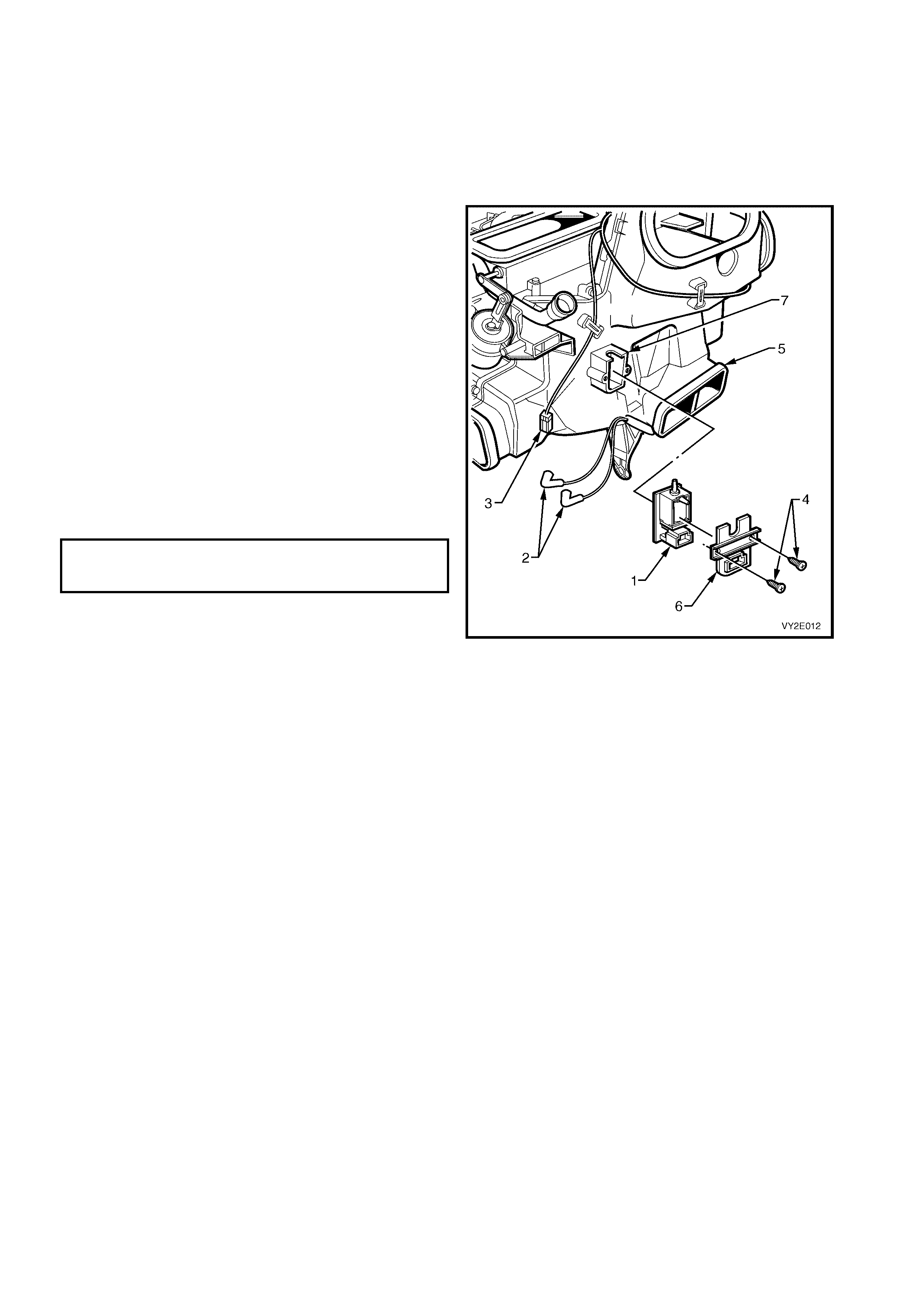

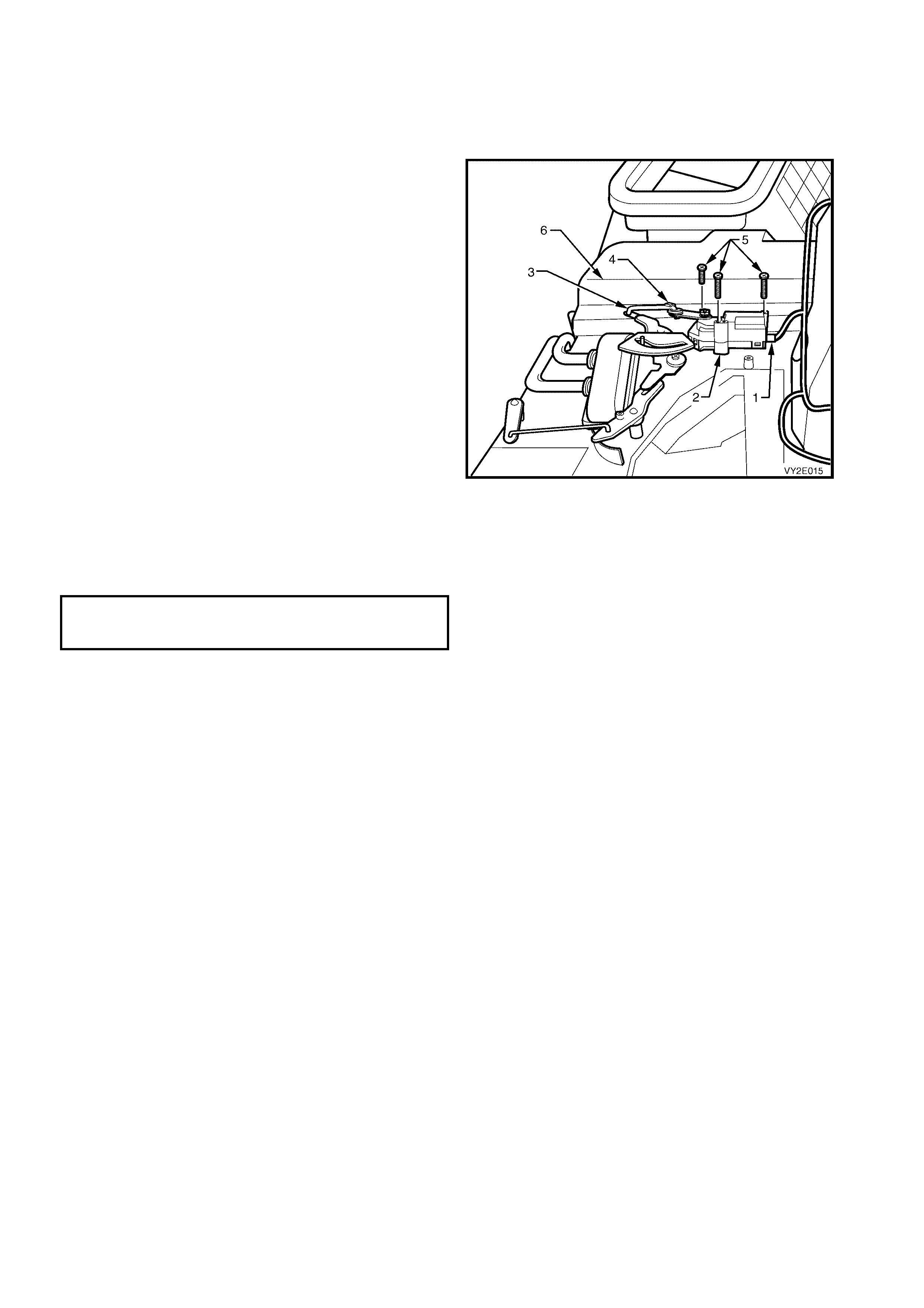

3. Locate the vacuum switch valve (1) and remove

the vacuum hoses (2) noting their installation to

the valve.

4. Remove the harness connector (3) from the valve.

5. Remove the two screws (4) attaching the valve to

the front of the HVAC unit (5).

6. Remove the valve cover (6).

7. Rem ove the vacuum s witc h valve from the front of

the HVAC unit vacuum switch housing (7).

NOTE: For service and diagnosis of the water valve

VSV refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

REINSTALL

1. Ins ert the vacuum switch and c over into the HVAC

unit vacuum s witch hous ing and tighten the sc r ews

to the specified torque.

WATER VALVE VACUUM SWITCH

VALVE ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2. Install the vacuum hoses to their original vacuum

outlets.

3. Install the harness connector to the valve.

4. Install the radio housing and radio bracket

assembly.

Figure 2E-17

2.9 BLOWE R MOTOR AND FAN

REMOVE – LHD

1. Remove the right-hand side instrument panel lower trim plate assembly, refer to Section 1A3, 3.1

INSTRUMENT PANEL LOWER TRIM PLATE ASSEMBLY.

2. Remove the solenoid pack from the HVAC unit, refer to 2.7 VACUUM SOLENOID PA CK in this Section.

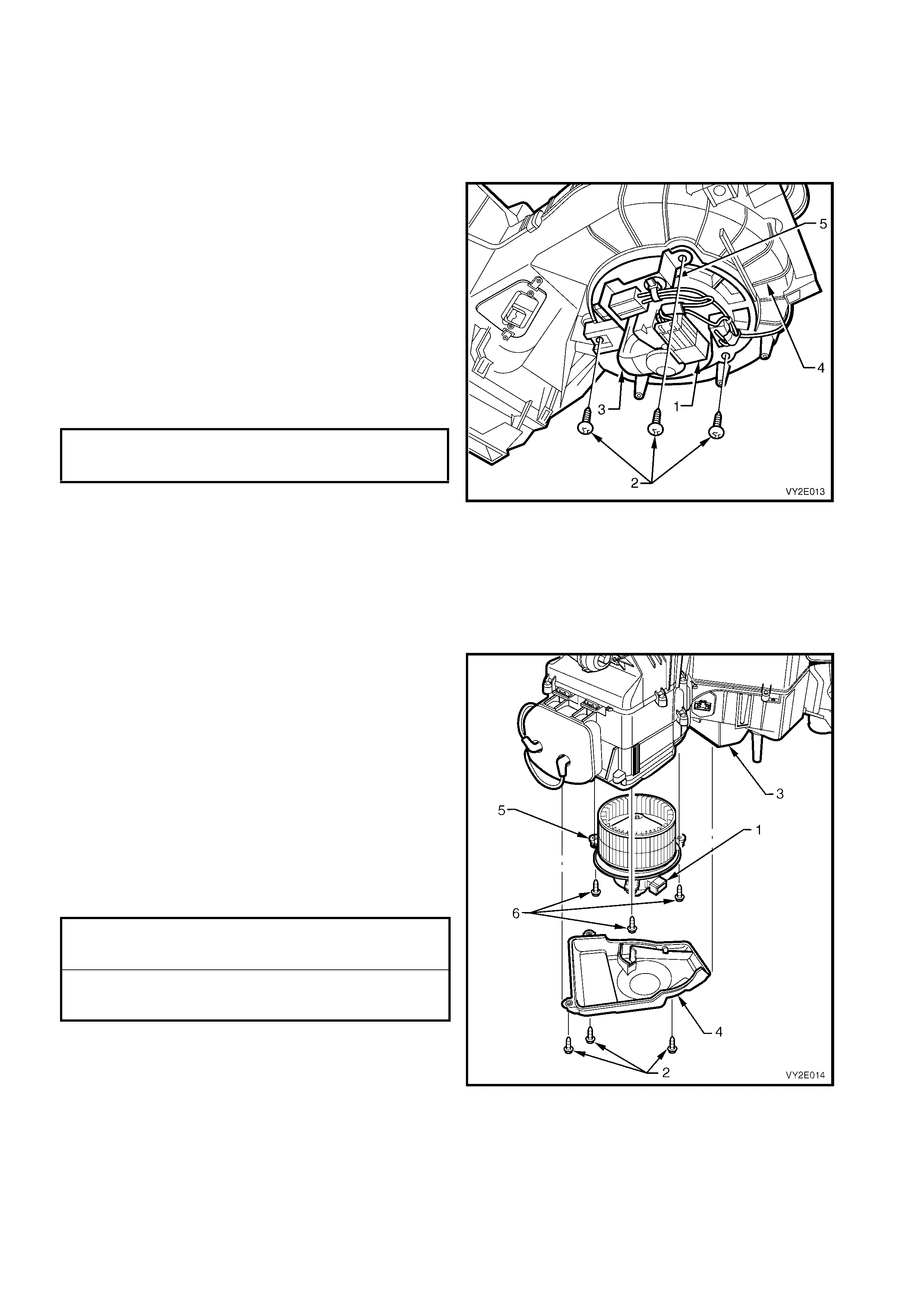

3. Disconnect the body harness connector from the

blower motor and fan assembly sub harness

connector (1).

4. Remove the three screws (2) and remove the

blower motor and fan assembly (3) from the lower

case housing (4).

5. Remove the blower motor and fan assembly sub

harness and bracket (5) from the blower motor.

REINSTALL – LHD

Installation of the blower motor and fan assembly is the

reverse order of removal procedures. Tighten all

screws to the specified torque.

BLOWER MOTOR AND FAN ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2E-18

LT Section – 08-150

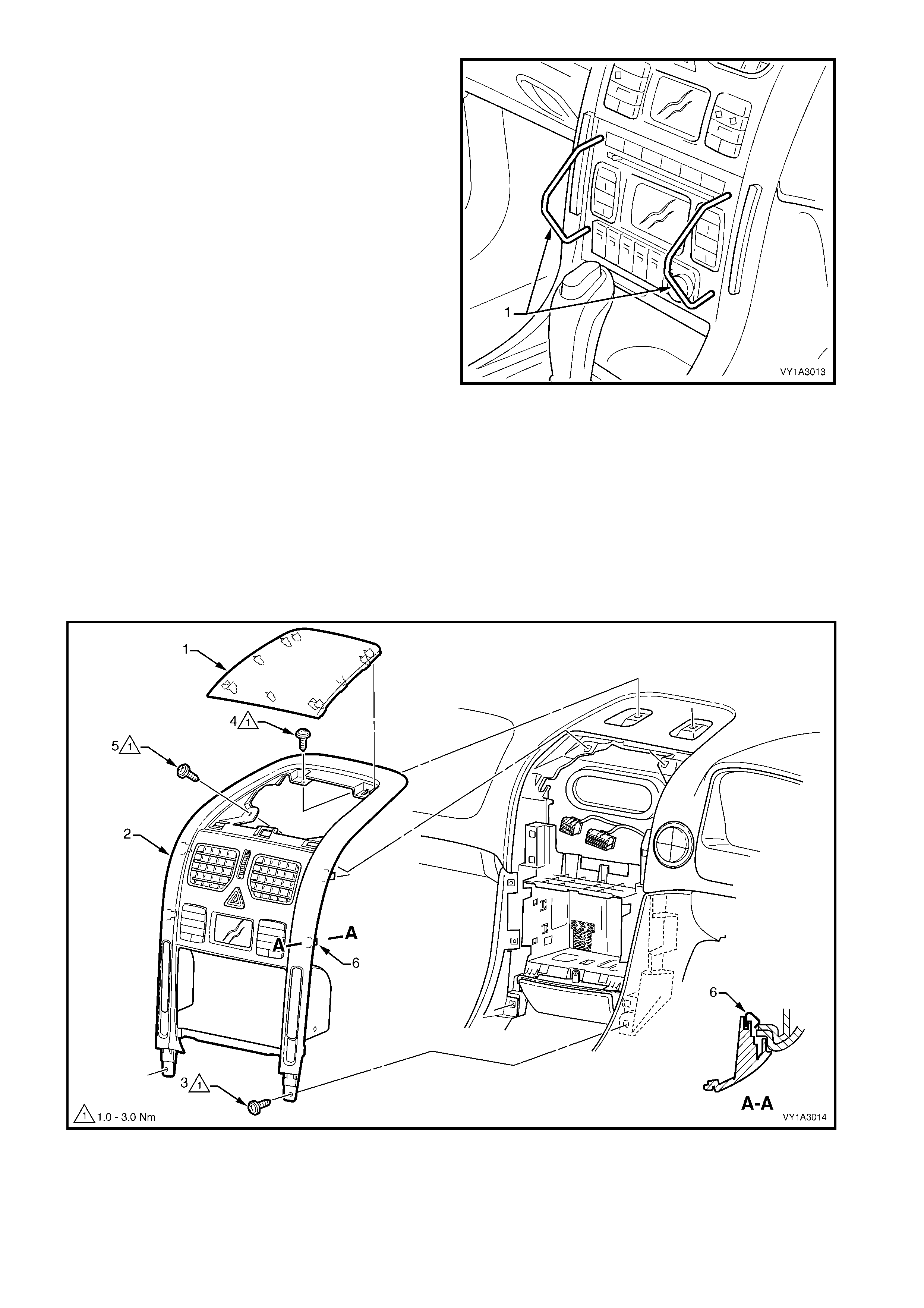

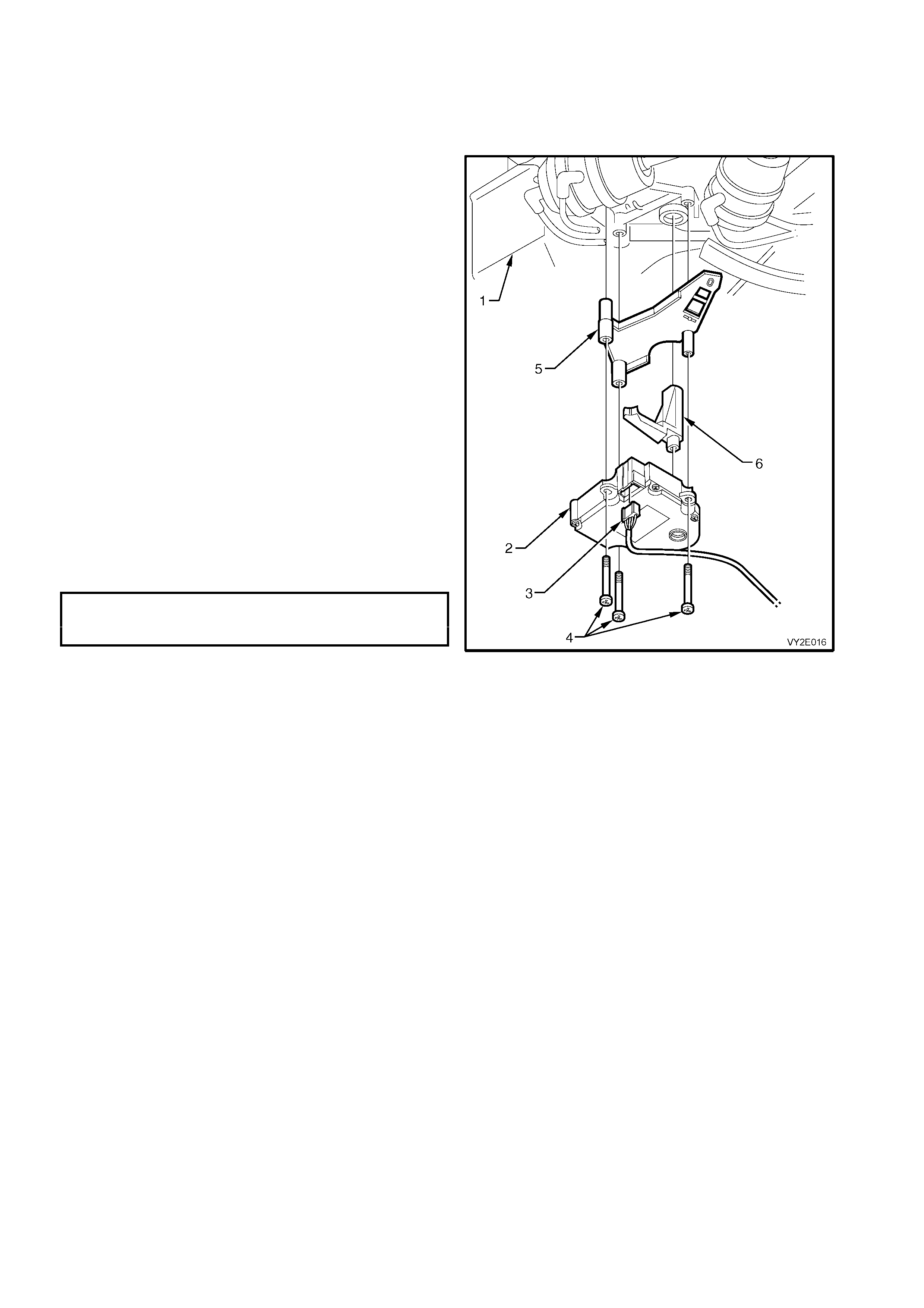

REMOVE – RHD

1. Remove the left-hand side instrument panel lower trim plate assembly, refer to Section 1A3, 3.1 INSTRUMENT

PANEL LOWER TRIM PLATE ASSEMBLY.

2. Disconnect the body harness connector from the

blower motor and fan assembly connector (1).

3. Remove the blower motor and fan cover screws

(2) f rom the HVAC unit (3) and m ove the cover (4)

suff iciently to allow access to the blower m otor and

fan assembly (5).

4. Remove the three blower m otor and f an s cr ews (6)

and remove the blower motor and fan assembly

from the HVAC unit.

REINSTALL – RHD

Installation of the blower motor and f an as s embly is the

reverse order of removal procedures. Tighten all

screws to the specified torque.

BLOWER MOTOR AND FAN ASSEMBLY

COVER ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

BLOWER MOTOR AND FAN ASSEMBLY

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

Figure 2E-19

2.10 AIR MIX MOTOR

REMOVE – LHD

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

2. Disc onnect the wiring harness (1) from the air m ix

motor (2).

3. Remove the actuating rod (3) from the air mix

motor by unfastening but not removing the

actuating rod from the air mix motor retaining clip

(4).

4. Rem ove the three screws (5) securing the air mix

motor to the HVAC unit ( 6) and r emove the air mix

motor.

NOTE: Fo r s ervice and diagnos is of the air m ix m otor ,

refer to Section 2F, HVAC OCCUPANT CLIMATE

CONTROL (AUTO A/C) – DIAGNOSTICS.

REINSTALL – LHD

IMPORTANT: If the air mix motor has been replaced,

the air mix door/motor function must be calibrated to

the OCC control module. Failure to do so may cause

poor HVAC system performance and result in

customer complaints. Refer to

Section 2F, F5: PROGRAM.

1. Install the air mix motor and air mix motor screws

onto the HVAC unit and tighten the screws to the

specified torque.

AIR MIX MOTOR ATTACHING

SCREW ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

2. Ins tall the actuating rod and retaining clip to the air

mix motor.

3. Install the floor console, instrument panel and

HVAC assemblies, refer to Section 2B,

3. HEATING, VENTILATION, AND AIR

CONDITIONING UNIT – REMOVAL AND

INSTALLATION.

4. If required, carry out the air mix door calibration

procedure. Refer to Section 2F, F5: PROGRAM.

Figure 2E-20

LT Section – 08-150

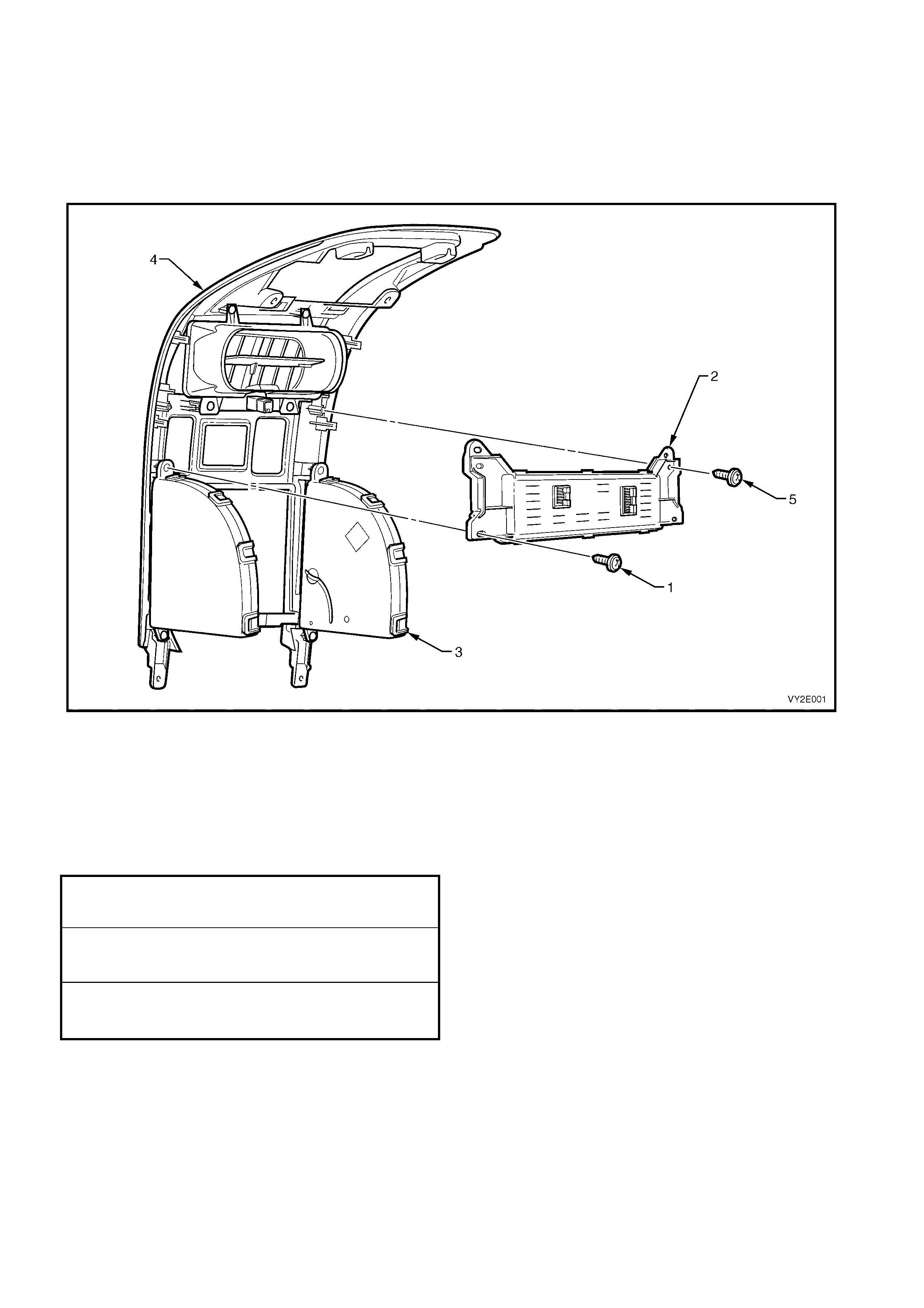

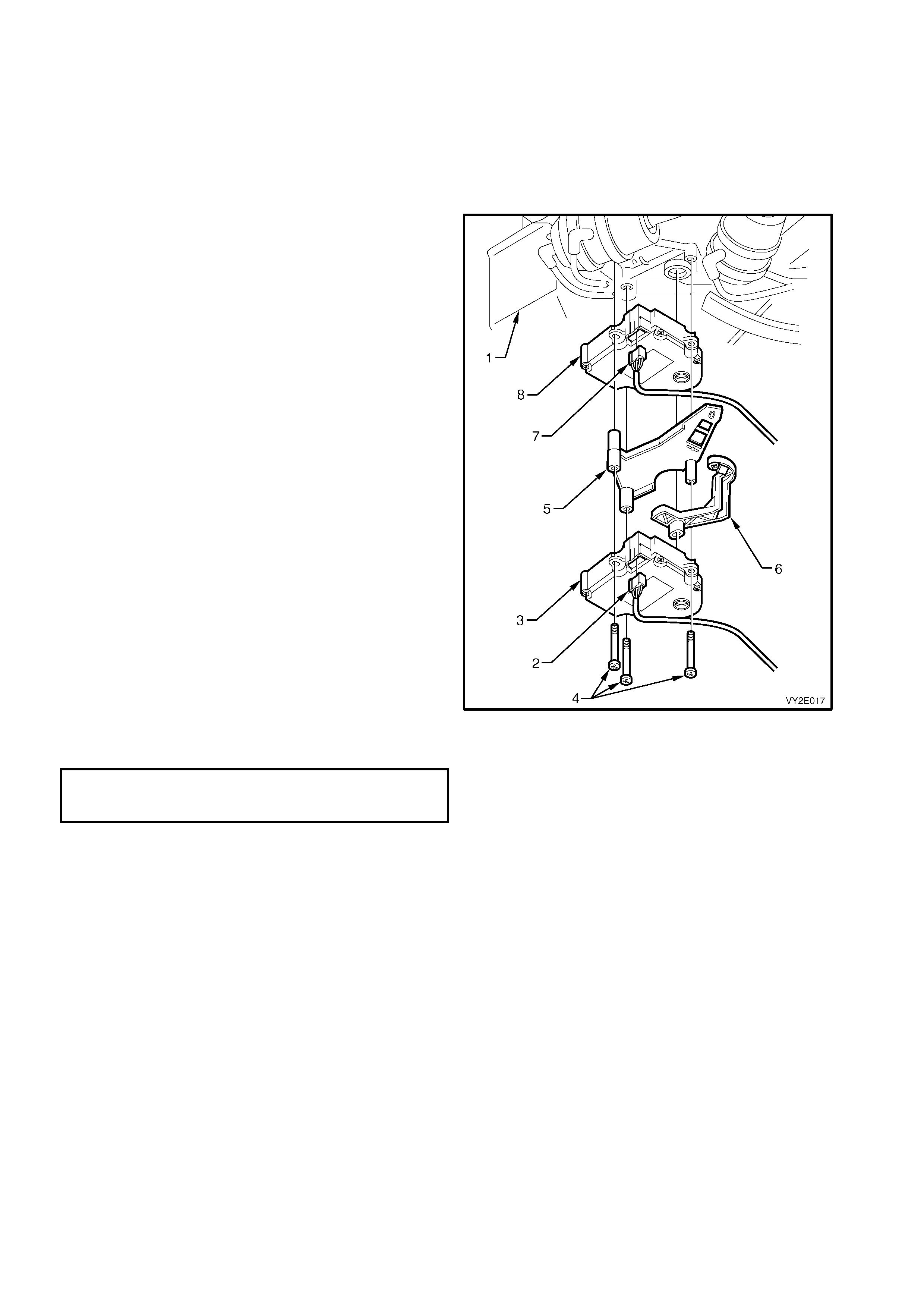

REMOVE – RHD (SINGLE ZONE)

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

2. From the underside of the HVAC unit (1), locate

the air mix motor (2) and remove the harness

connector (3) from the air mix motor.

3. Remove the three screws (4) retaining the air mix

motor to the HVAC unit and remove the motor

along with intermediate mounting plate (5) and

activating lever (6).

NOTE: For service and diagnosis of the air mix

motors, refer to Section 2F, HVAC OCCUPANT

CLIMATE CONTROL (AUTO A/C) – DIAGNOSTICS.

REINSTALL – RHD (SINGLE ZONE)

IMPORTANT: If the air mix motor has been

replaced, the air mix door/motor function must be

calibrated to the OCC control module. Failure to

do so may cause poor HVAC system performance

and result in customer complaints. Refer to

Section 2F, F5: PROGRAM.

1. Install the activating lever into the HVAC case.

2. Assemble the intermediate mounting plate,

activating the lever and air mix motor as shown

and secure with the three screws to the specified

torque.

AIR MIX MOTOR ATTACHING SCREW

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

3. Connect the harness connector to air mix motor.

4. Install the floor console, instrument panel and

HVAC assemblies, refer to Section 2B,

3. HEATING, VENTILATION, AND AIR

CONDITIONING UNIT – REMOVAL AND

INSTALLATION.

5. If required, carry out the air mix door calibration

procedure. Refer to Section 2F, F5: PROGRAM.

Figure 2E-21

LT Section – 08-150

REMOVE – RHD (DUAL ZONE)

1. Remove the floor console, instrument panel and HVAC assemblies, refer to Section 2B, 3. HEATING,

VENTILATION, AND AIR CONDITIONING UNIT – REMOVAL AND INSTALLATION.

IMPORTANT: Prior to removal of the air mix motor harness connectors, note which connector is installed to the

driver’s side air mix motor and which connector is installed to the passenger’s side air mix motor, i.e. do not

transpose air mix motor harness connectors.

2. From the underside of the HVAC unit (1), locate

the driver’s air mix motor harness connector (2).

Remove the harness connector from the driver’s

side air mix motor (3).

3. Remove the three screws (4) retaining the air mix

motors to the HVAC unit and remove the driver’s

side air mix motor along with intermediate

mounting plate (5) and activating lever (6).

4. Remove the harness connector (7) from the

passenger side air mix motor (8).

5. Remove the passenger side air mix motor from

the HVAC unit.

REINSTALL – RHD (DUAL ZONE)

IMPORTANT: If an air mix motor has been

replaced, the air mix door/motor function must be

calibrated to the OCC control module. Failure to

do so may cause poor HVAC system performance

and result in customer complaints. Refer to

Section 2F, F5: PROGRAM.

1. Install the passenger side air mix motor to the

HVAC case and install passenger side air mix

motor harness.

2. Install intermediate mounting plate and activating

lever to the passenger side air mix motor.

3. Install the driver’s side air mix motor to the

mounting plate.

4. Secure the air mix motors with the three scr ews to

the specified torque.

AIR MIX MOTOR ATTACHING SCREW

ATTACHING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

5. Connect the harness connector to driver’s air mix

motor.

6. Install the floor console, instrument panel and

HVAC assemblies, refer to Section 2B,

3. HEATING, VENTILATION, AND AIR

CONDITIONING UNIT – REMOVAL AND

INSTALLATION.

7. If required, carry out the air mix door calibration

procedure. Refer to Section 2F, F5: PROGRAM.

Figure 2E-22

3. TORQUE WRENCH SPECIFICATIONS

Floor console cover assembly attaching screw .......................................................... 1.0 – 3.0 Nm

OCC control module attaching screw ......................................................................... 1.0 – 3.0 Nm

Instrument panel centre trim assembly attaching screw............................................. 1.0 – 3.0 Nm

In-car temperature sensor attaching screw................................................................. 1.0 – 3.0 Nm

Instrument cluster trim assembly attaching screw...................................................... 1.0 – 3.0 Nm

Solenoid pack attaching screw.................................................................................... 1.0 – 3.0 Nm

Water valve vacuum switch valve attaching screw..................................................... 1.0 – 3.0 Nm

Air mix motor attaching screw..................................................................................... 1.0 – 3.0 Nm

Blower motor and fan assembly cover attaching screw.............................................. 1.0 – 3.0 Nm

Blower motor and fan assembly attaching screw........................................................ 1.0 – 3.0 Nm

HVAC case attaching screws...................................................................................... 1.0 – 3.0 Nm

Evaporator cover attaching screws............................................................................. 1.0 – 3.0 Nm

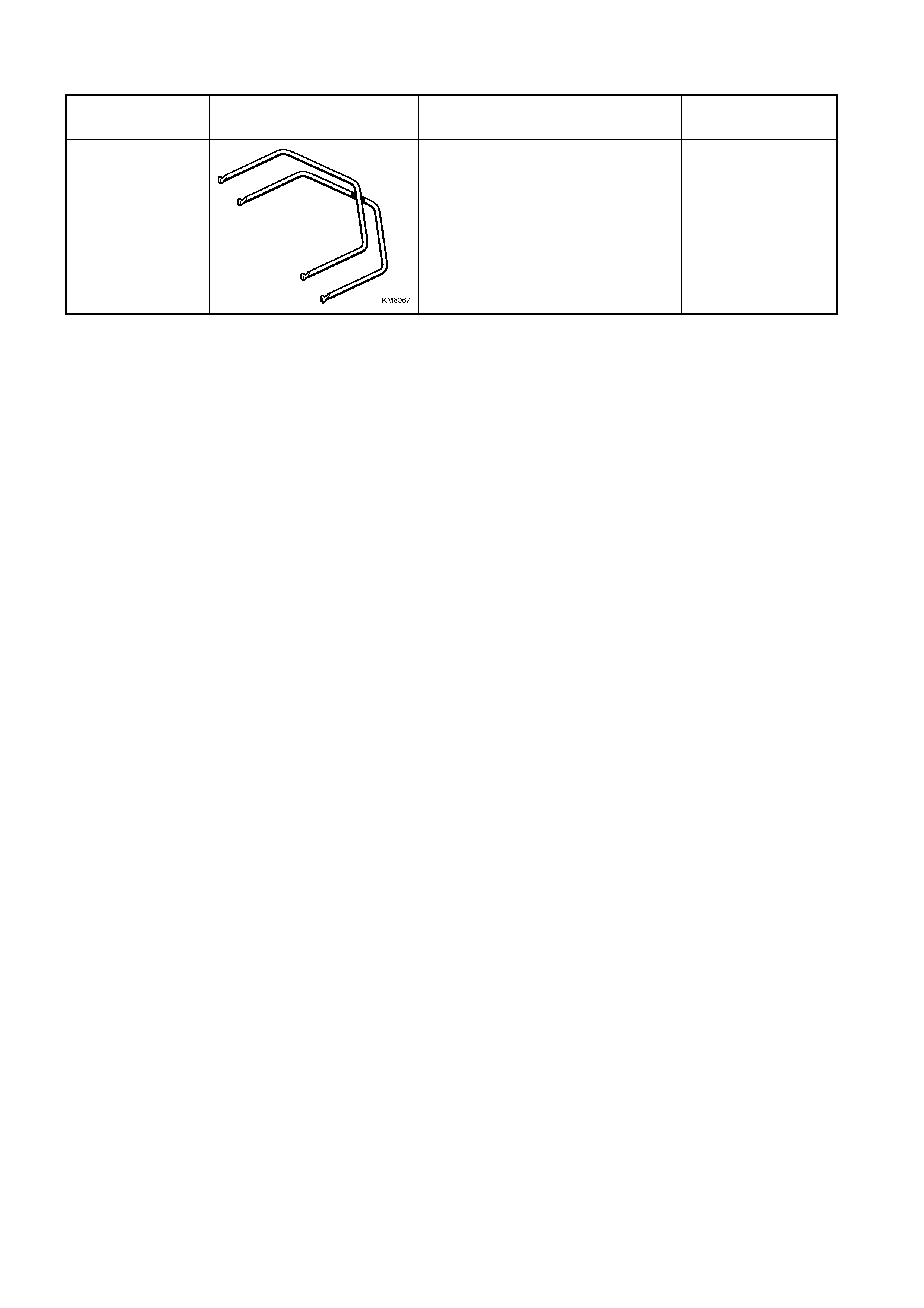

4. SPECIAL TOOLS

TOOL NUMBER ILLUSTRATION DESCRIPTION TOOL

CLASIFICATION

KM6067 RADIO REMOVAL TOOL

Used for removing VY audio unit

from its mounting location.

New tool for VY.

Mandatory