SECTION 4A - REAR SUSPENSION

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section

00 CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL INFORMATION

2. SERVICE OPERATIONS

2.1 SERVICE NOTES AND CAUTIONS

2.2 REAR SUSPENSION CONTROL ARM

REMOVE

REAR SUSPENSION CONTROL ARM

PIVOT BUSHING, REPLACE

REINSTALL

2.3 OUTER REAR WHEEL DRIVE SHAFT,

FLANGE OR BEARING

REPLACE

2.4 REAR SUSPENSION CROSSM EMBER

REMOVE

REINSTALL

2.5 REAR SUSPENSION CROSSMEMBER

FRONT MOUNT BUSHING

OFF-CAR REPLACEMENT

ON-CAR REPLACEMENT

2.6 REAR SUSPENSION CROSSMEMBER

MASS DAMPER

REMOVE

REINSTALL

2.7 REAR SUSPENSION CROSSMEMBER

REAR MOUNT

REMOVE

REINSTALL

2.8 STABILISER SHAFT AND/OR MOUNTINGS

REMOVE

STABILISER SHAFT LINK INSULATORS,

REPLACE

REINSTALL

2.9 REAR SPRING AND INSULATORS

REMOVE

REINSTALL

2.10 REAR SHOCK ABSORBERS AND/OR BUSHING

REMOVE

LOWER BUSHING, REPLACE

REINSTALL

2.11 ADDITIONAL CONTROL ARM

INSPECT

REMOVE

DISASSSEMBLE

REASSSEMBLE

REINSTALL

2.12 REAR WHEEL ALIGNMENT CHECKING

CAMBER AND TOE CHECK

2.13 REAR WHEEL TOE ADJUSTMENT

3. DIAGNOSIS

CHECKING AND TESTING SHOCK

ABSORBERS

LEAKAGE CRITERIA

4. SPECIFICATIONS

REAR SUSPENSION SERVICE

ALIGNMENT DATA

REAR SPRING DETAILS

REAR SHOCK ABSORBER DETAILS

REAR STABILISER SHAFT DETAILS

5. TORQUE WRENCH SPECIFICATIONS

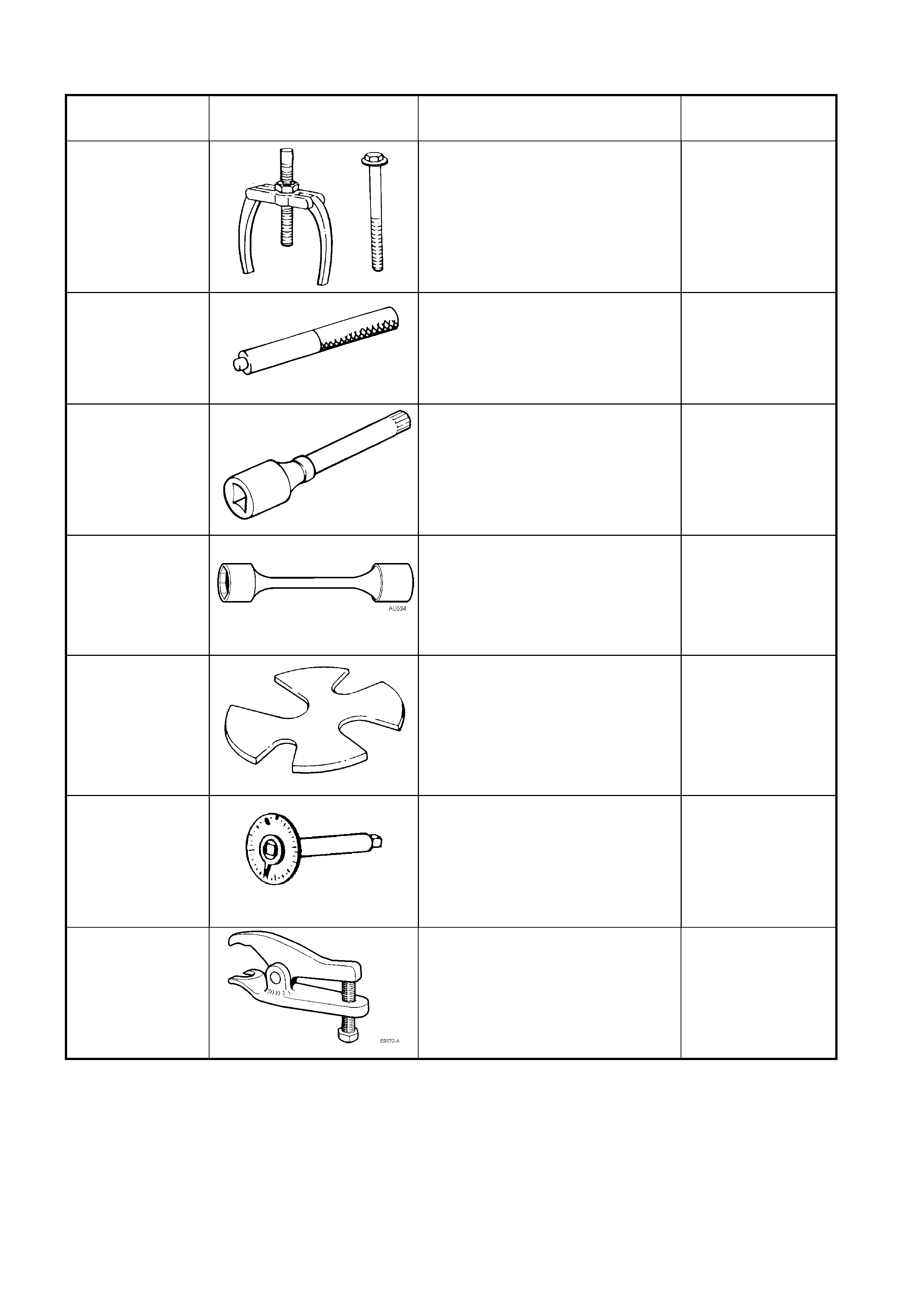

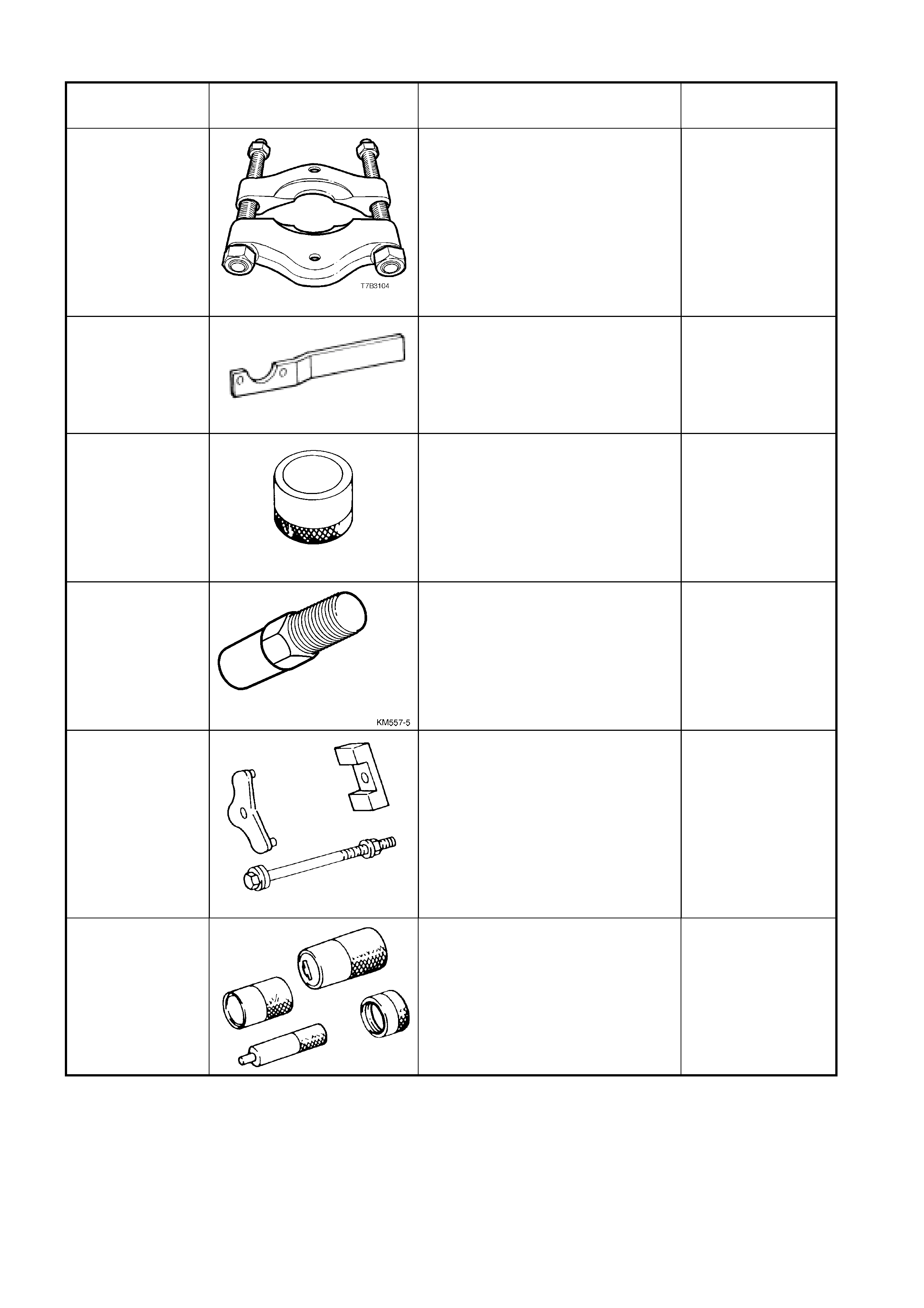

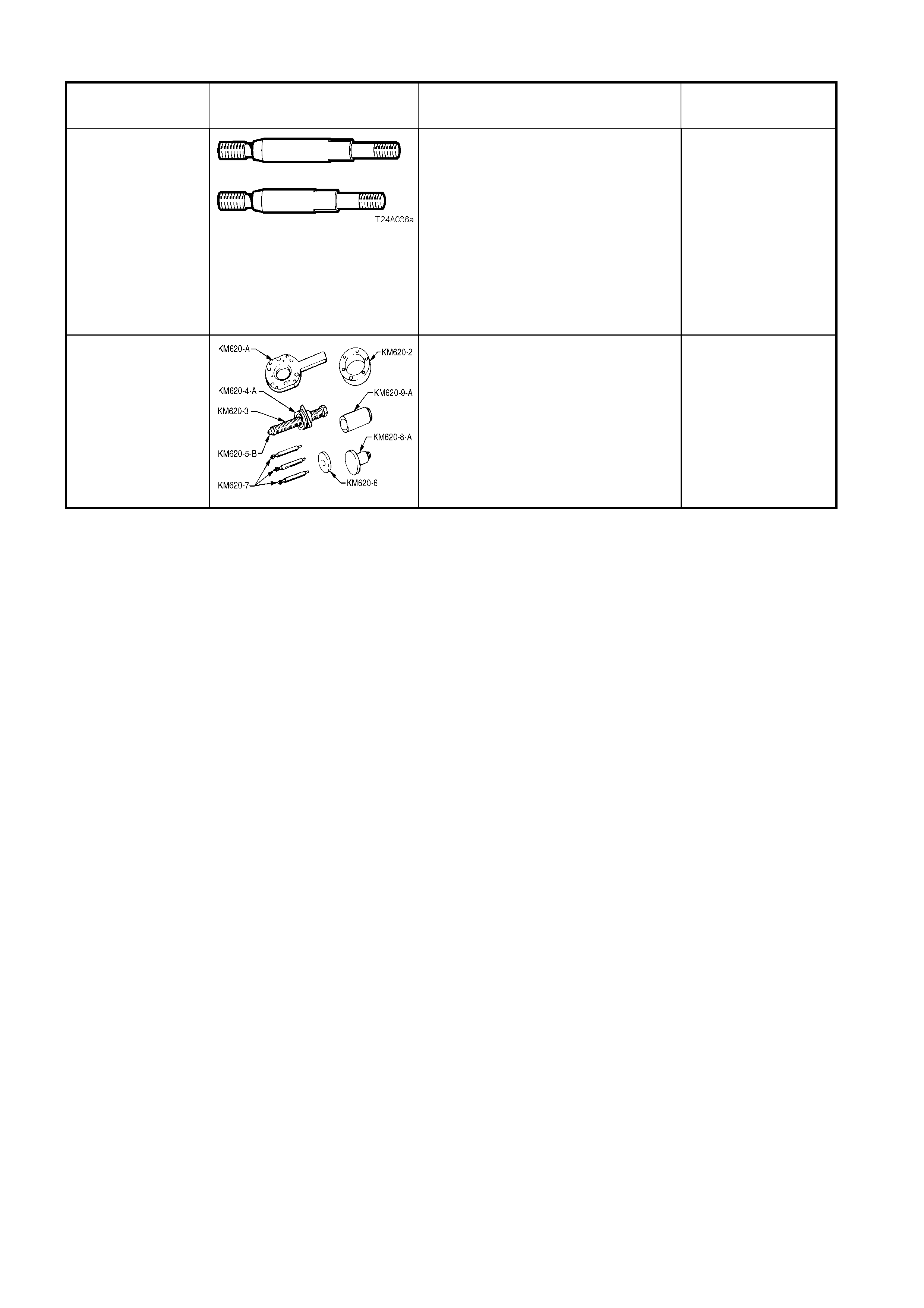

6. SPECIAL TOOLS

Techline

1. GENERAL I NFORMATI O N

Independent rear suspension is fitted as standard equipment on all MY 2003 VY and V2 Series Models, and is

equipped with variable rate minibloc coil rear springs and direct acting shock absorbers.

The r ear s us pension is contained within a rear sus pens ion c ros s mem ber as sembly that is attached by large volume

rubber bus hing at eac h f r ont c orner to the vehic le underbody. Rear location is provided by a rear m ounting bolted to

the differential carrier assembly that is in turn, attached to the crossmember.

W ith the exception of utility vehicles, vehicles that are fitted with a GEN III V8 and automatic transmission, have a

mass damper located on the rear suspension cross member, forward of each of the front mounts.

Two rear suspension control arms are attached to the crossm ember pivot points through rubber bushing. The rear

suspension control arms provide attachment of the additional control arms (where fitted), the rear brake

componentry, rear wheel drive shaft flanges and outer rear wheel drive shaft (rear wheel) bearings.

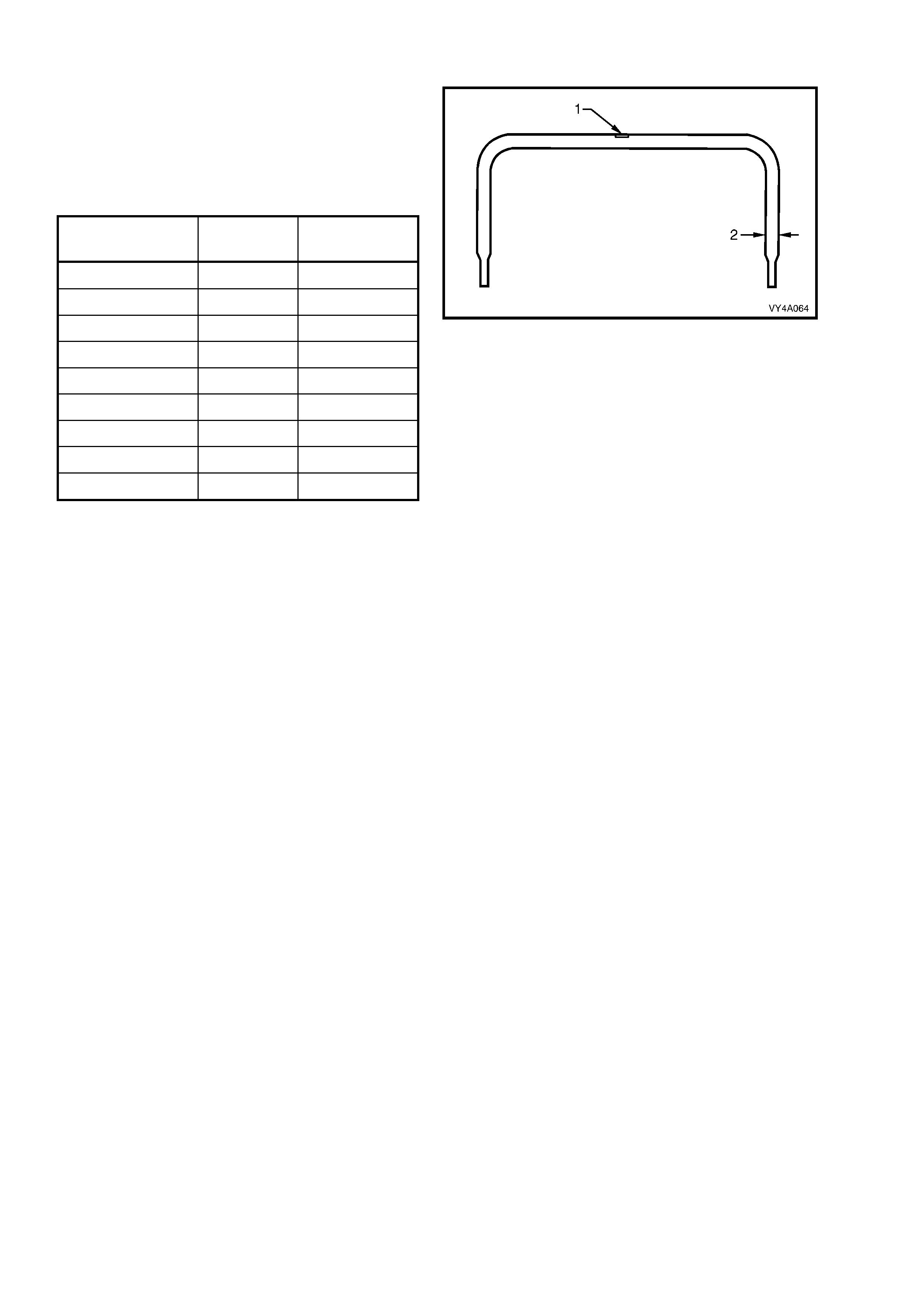

A decoupled type stabiliser shaf t is attac hed to the top of the c ross m em ber by two brackets and ins ulating bushing.

The outer ends of the stabiliser shaft are attached to each rear suspension control arm by a link via insulating

bushing.

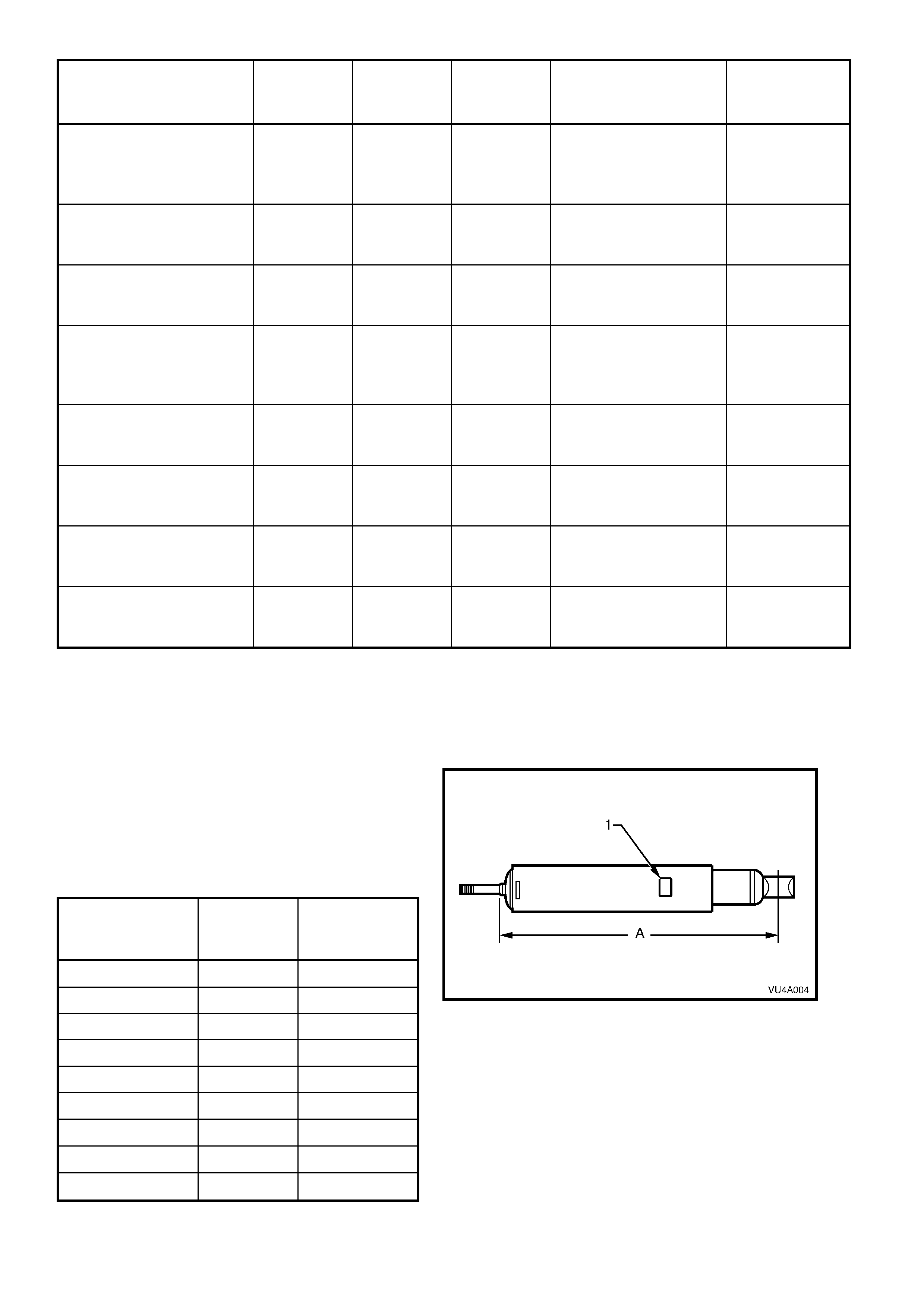

All standard (Production Option FE1) suspension applications utilise twin tube hydraulic shock absorbers that are

double acting and are mounted between the vehicle underbody and each rear suspension control arm . The sports

suspension (Production Option FE2) and country pack (Production Option FR1) applications utilise twin tube, gas

pressurised shock absorbers. Pneumatic adjustable (Superlift) type rear shock absorbers are available as an

accessory or as part of a 2100 kg tow bar package for select MY 2003 VY Series Models.

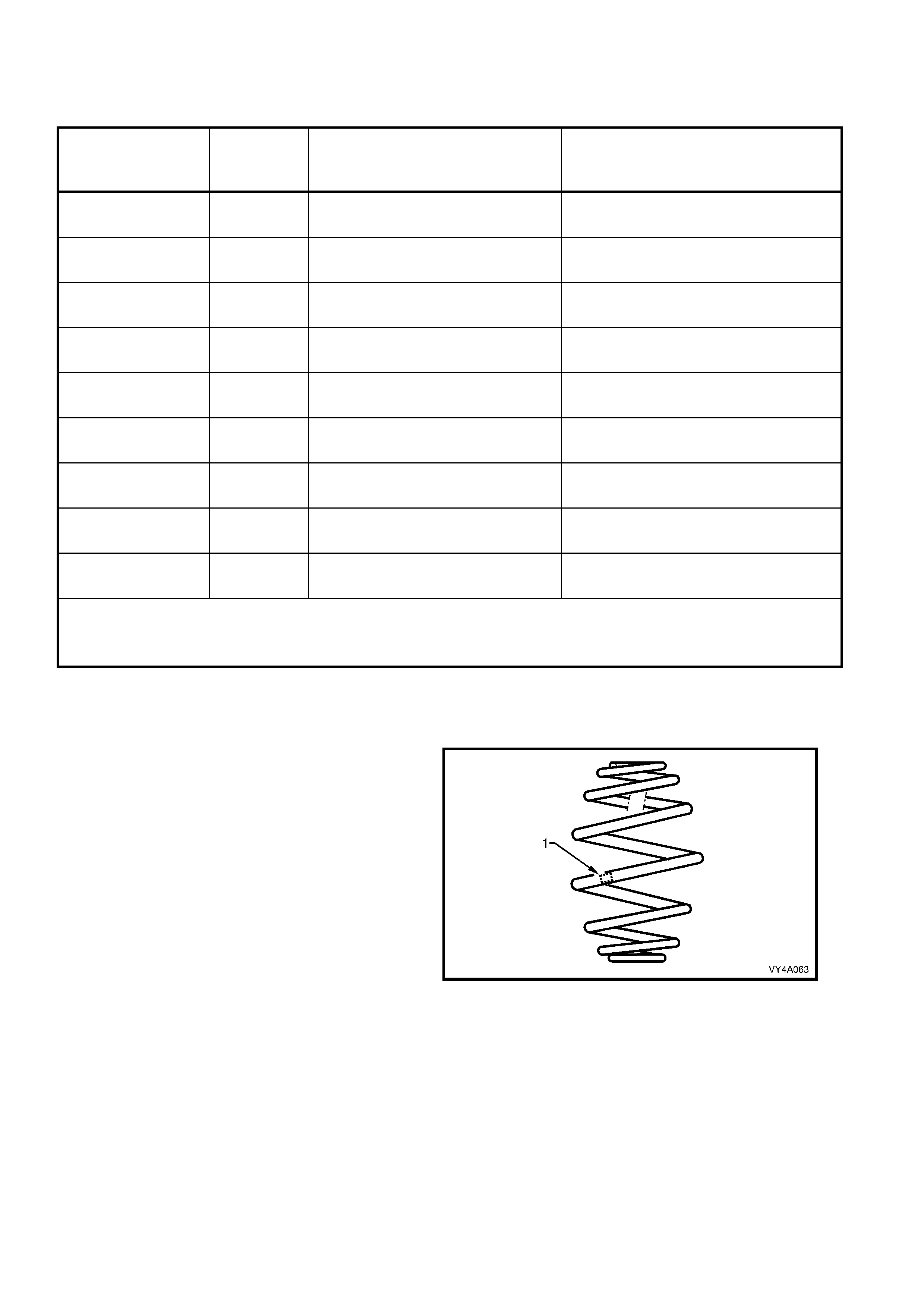

Numerous specifications of variable rate minibloc rear springs are fitted to MY 2003 VY and V2 Series Models,

depending on body type and the suspension option. T he rear springs have insulating pads top and bottom , and are

maintained in the correct location by mounts on the vehicle underbody and the rear suspension control arms.

As part of the KL7 production LPG option, Sedan and Wagon vehicles gain, as par t of the option, an uprated spring

package to compensate for the extra weight of the LPG tank.

All vehicles fitted with the KL7 LPG option are identified by the installation of a Holden By Design (HBD)

identification plate attached to the upper front panel, refer to Section 8A2, 1.2 Identification Plates and Warning

Labels.

An additional control arm is also fitted as standard equipment to all MY 2003 VY and V2 Series Models except

utilities. T he inner ends of the additional control arms contain rubber bushing and are attached to brackets welded

to the rear sus pension cross mem ber. T he outer end of the additional control arm is secured to the rear sus pension

control arm by a sock et assem bly. The purpose of the additional control arm is to m aintain the rear wheel camber

and toe angles during suspension travel, whilst also providing a means of adjusting the rear wheel toe.

NOTE: For further information regarding how to identif y which suspension application (Production Option) is fitted to

a particular vehicle, refer to 9.3 BODY AND OPTION IDENTIFICATION PLATE in Section 0A, GENERAL

INFORMATION.

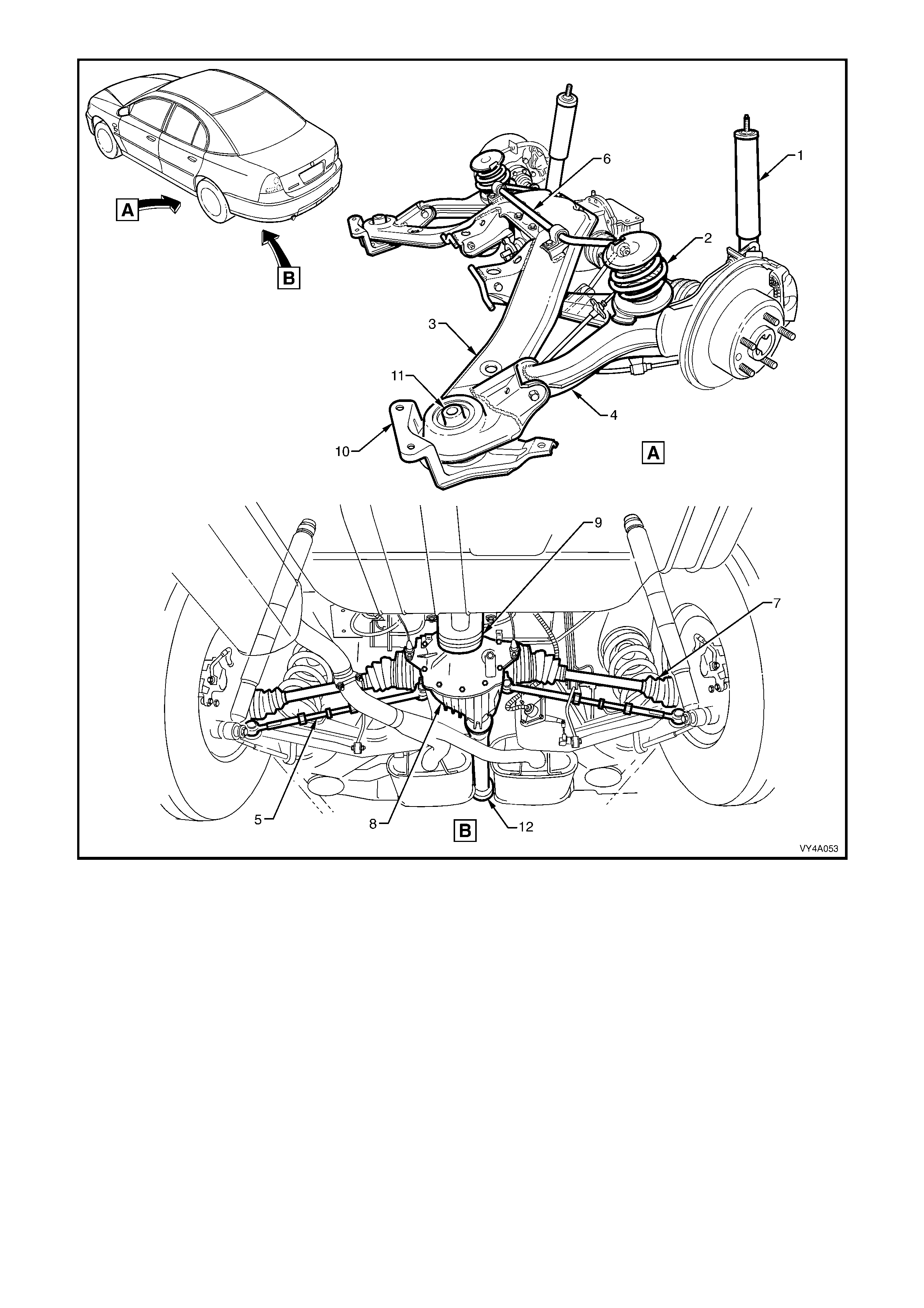

Figure 4A-1

Legend

1. Rear Shock Absorber 7. Driveshaft (2 Places)

2. Rear Spring 8. Rear Suspension Differential Assembly

3. Rear Suspension Crossmember Assembly 9. Rear Suspension Crossmember Rear Mount

4. Rear Suspension Control Arm Assembly 10. Rear Suspension Crossmember Front Mounting Brace

5. Additional Control Arm Assembly 11. Rear Suspension Crossmember Front Mount Bushing

6. Stabiliser Shaft 12. Propeller Shaft Assembly

2. SERVICE OPERATIONS

IMPORTANT

All rear suspension fasteners are important attaching parts as they affect the performance of vital

components and/or could result in major repair expense. Where specified in this Section, fasteners M UST

be replaced w ith part s of the same part nu mber or a GM appro ved equiv alent. Do no t use fasteners o f an

inferior qua lity or substitute des ign.

Torque values must be used as specified during reassembly to ensure proper retention of all rear

suspension components.

Throughout this Section, fastener torque wrench specifications may be accompanied with the following

identification marks:

!

!!

! Fasteners must be replaced after loosening.

"

""

" Vehicle must be at curb height before final tightening.

#

##

# Fasten ers either hav e micro encap sulated sealant app lied or incorporate a mechan ical thread lock and

should only be re-used once. If in doubt, replacement is recommended.

If one of these identification marks is present alongside a fastener torque wrench specification, the

recommendation regarding that fastener must be adhered to.

2.1 SERVICE NOTES AND CAUTIONS

NOTE 1: Whenever a road wheel and/or brake rotor is removed from or installed to a MY 2003 VY or V2 Series

vehicle, it MUST be done in accordance with the procedure provided in 2.3 WHEEL REMOVAL AND

INSTALLATION in Section 10, WHEELS AND TYRES.

NOTE 2: T o ensure proper retention of the additional contr ol arm, the sock et assem bly stud and the corresponding

tapered hole in the rear suspension control arm must be cleaned of dirt and foreign matter prior to installation.

CAUTION: Whenever any component that forms part of the ABS (if fitted) is disturbed during

Service Operat ions, it is v ital th at the co mplete ABS system b e checked, using the pro cedure as detailed in

4.4 ABS & T CS FUNCTION CHECK (V6 engines) or 5.4 ABS & TCS FUNCT ION CHECK (GEN III V8 engines),

in Section 5B ABS & TCS.

2.2 REAR SUSPENSION CONTROL ARM

LT Section No. – 06-212

NOTE 1: The following fasteners have either micro

encapsulation or incorporate a mechanical thread lock

and should only be used once. If in doubt, r eplacement

is recommended when performing this operation:

♦ Brake caliper anchor plate to rear suspension

control arm upper attaching bolt.

♦ Additional control arm socket assembly retaining

nut.

♦ Stabiliser shaft link to rear suspension control arm

attaching nut and bolt.

♦ Rear suspension control arm to rear suspension

crossmember attaching nut.

NOTE 2: The following fasteners MUST be replaced

when performing this operation:

!

!!

!$

$$

$Brake caliper anchor plate lower attaching bolt.

!

!!

!$

$$

$Rear suspension crossmember mount to under

body attaching bolt.

!

!!

!$

$$

$Drive shaft constant velocity joint to rear wheel

drive shaft flange attaching bolt.

NOTE 3: The following fasteners MUST be at curb

height before final tightening:

• Shock absorber lower mounting bolt.

• Stabiliser shaf t link to rear suspension control arm

attaching nut and bolt.

• Rear suspension control arm to rear suspension

crossmember attaching nut.

IMPORTANT: Before disturbing the crossmember rear mounting bolts, an alignment procedure is required on

installation and a spec ial tool is required for this purpose. If this tool is not available, then the crossm em ber c annot

be correctly aligned and steering and/or handling abnormalities will result.

REMOVE

1. Using a floor jack under the centre of the differential carrier, jack up the rear of the vehicle and place safety

stands under the body rear jacking points. Refer to Section 0A GENERAL INFORMATION for the location of

jacking points.

2. On the side of the vehicle where the rear suspens ion control ar m is to be rem oved, mar k the r elationship of the

road wheel to hub (eg. end of wheel stud), with a felt tipped pen or similar. Loosen, and then rem ove the road

wheel attaching nuts. Remove the road wheel.

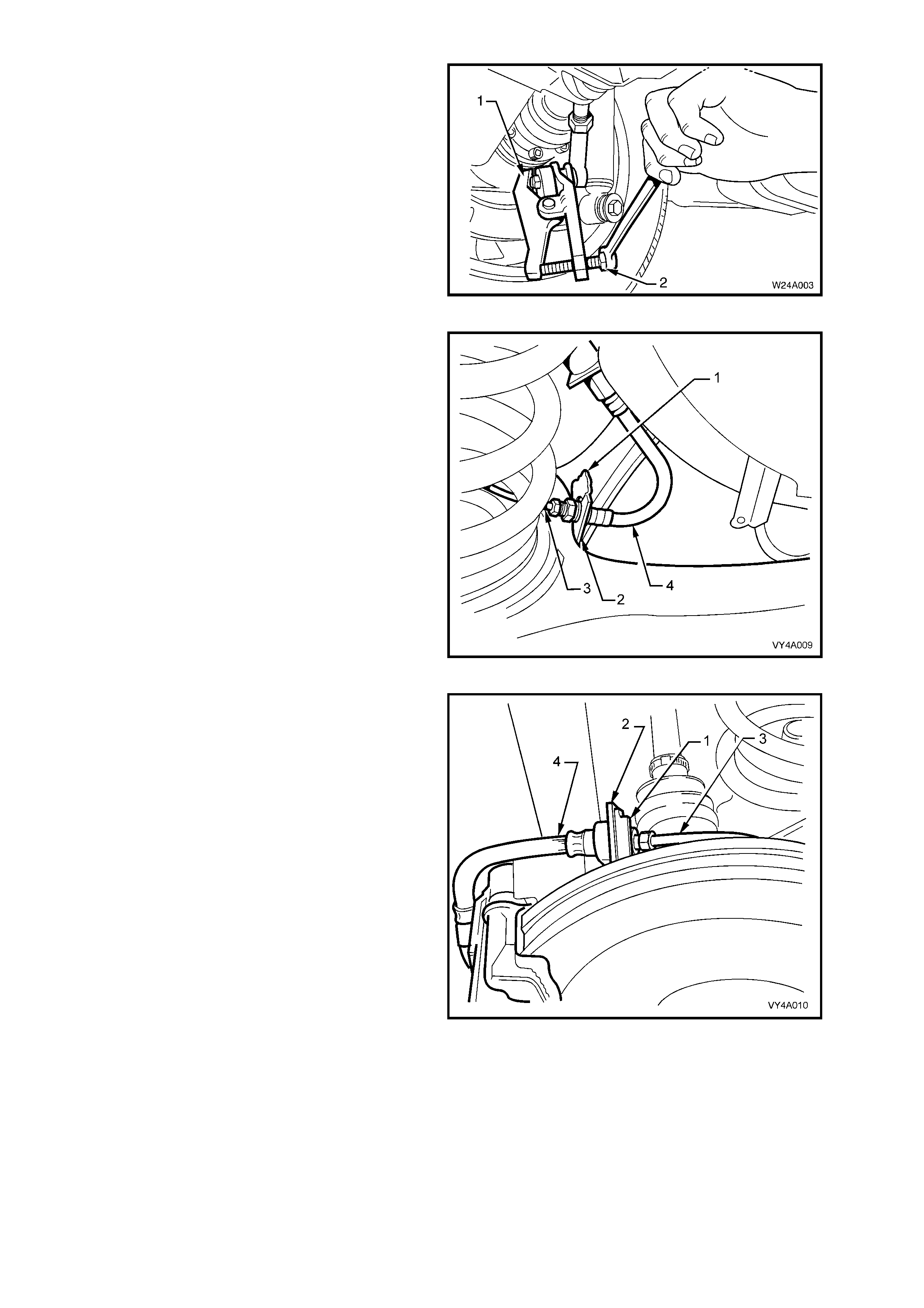

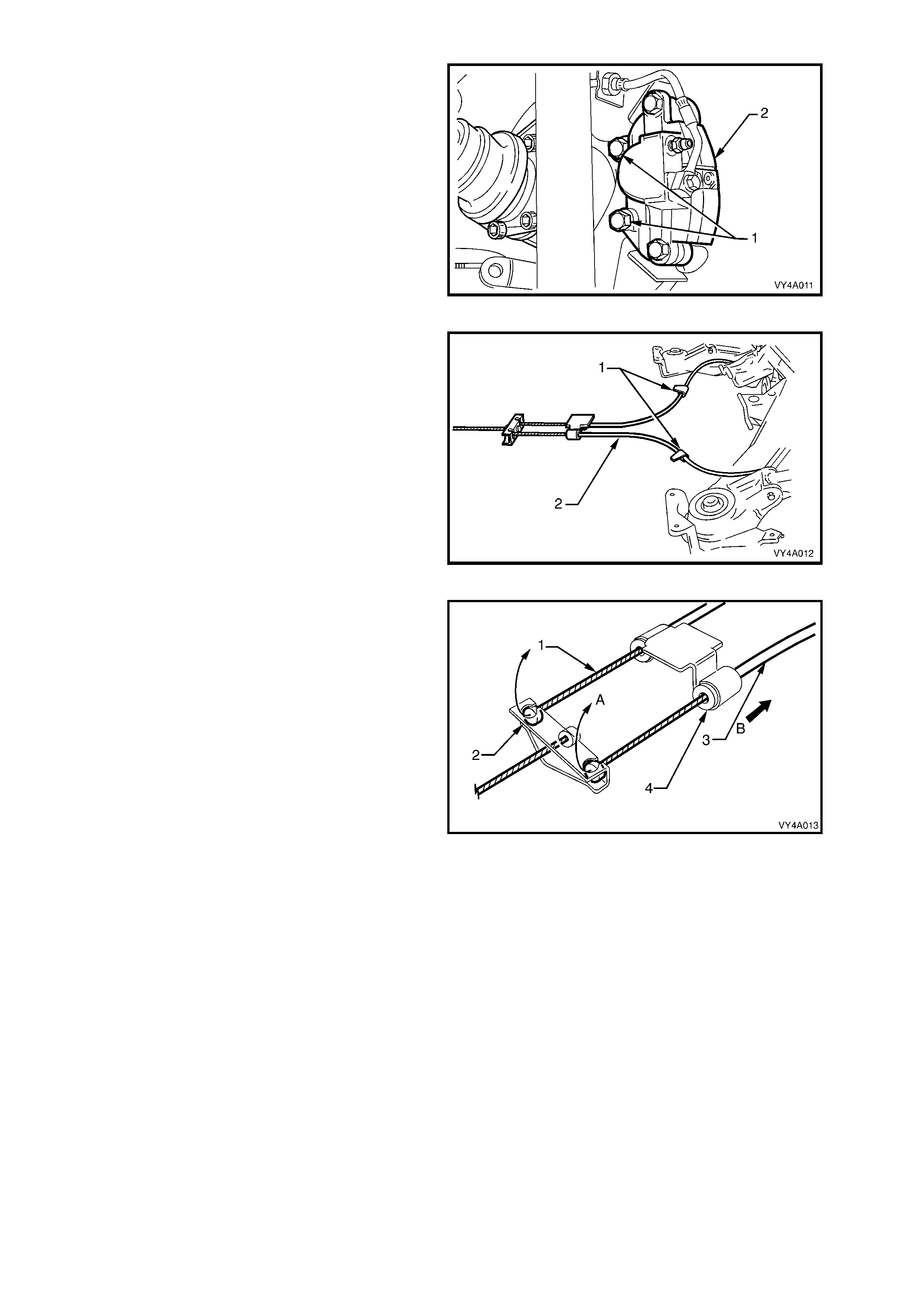

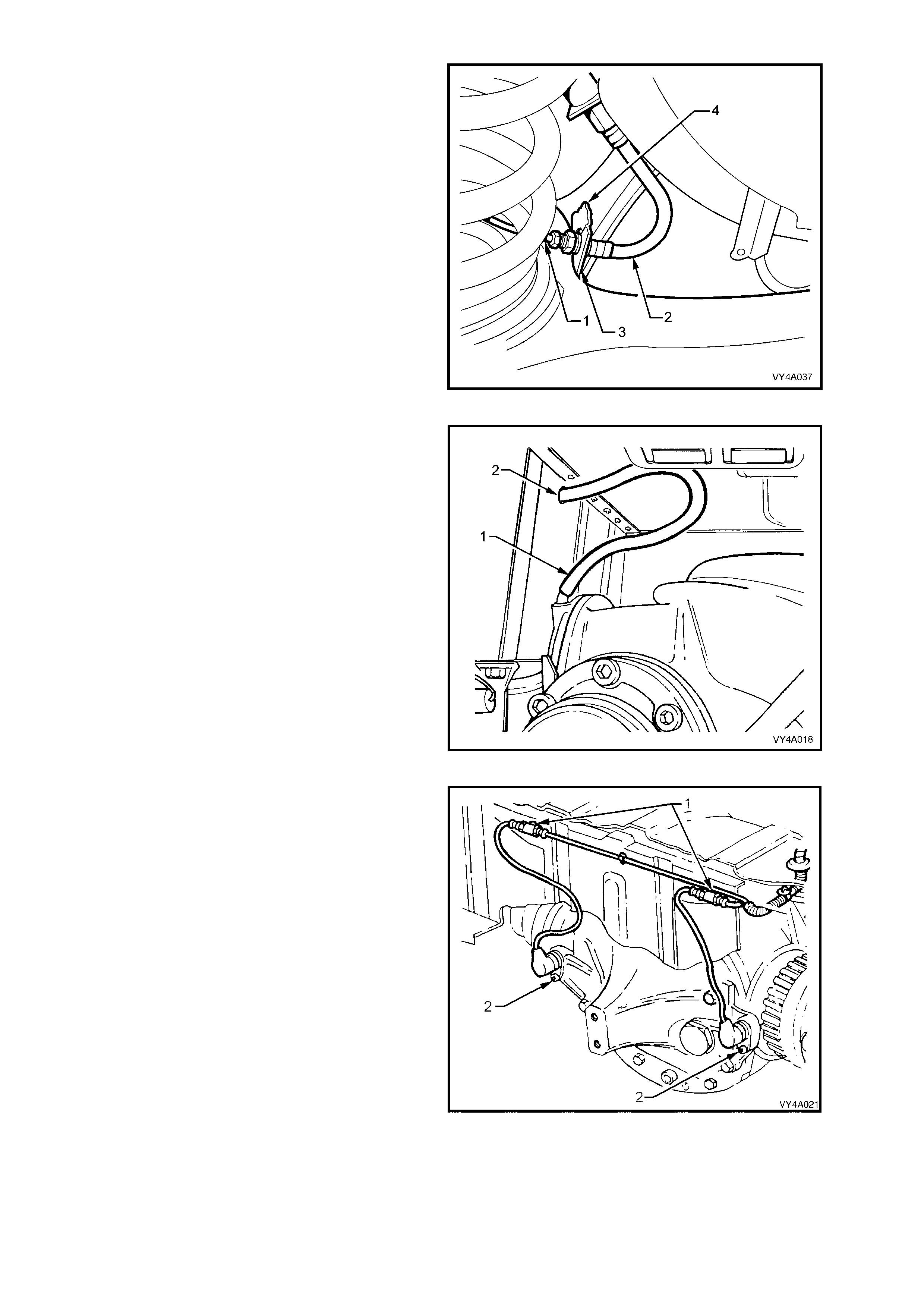

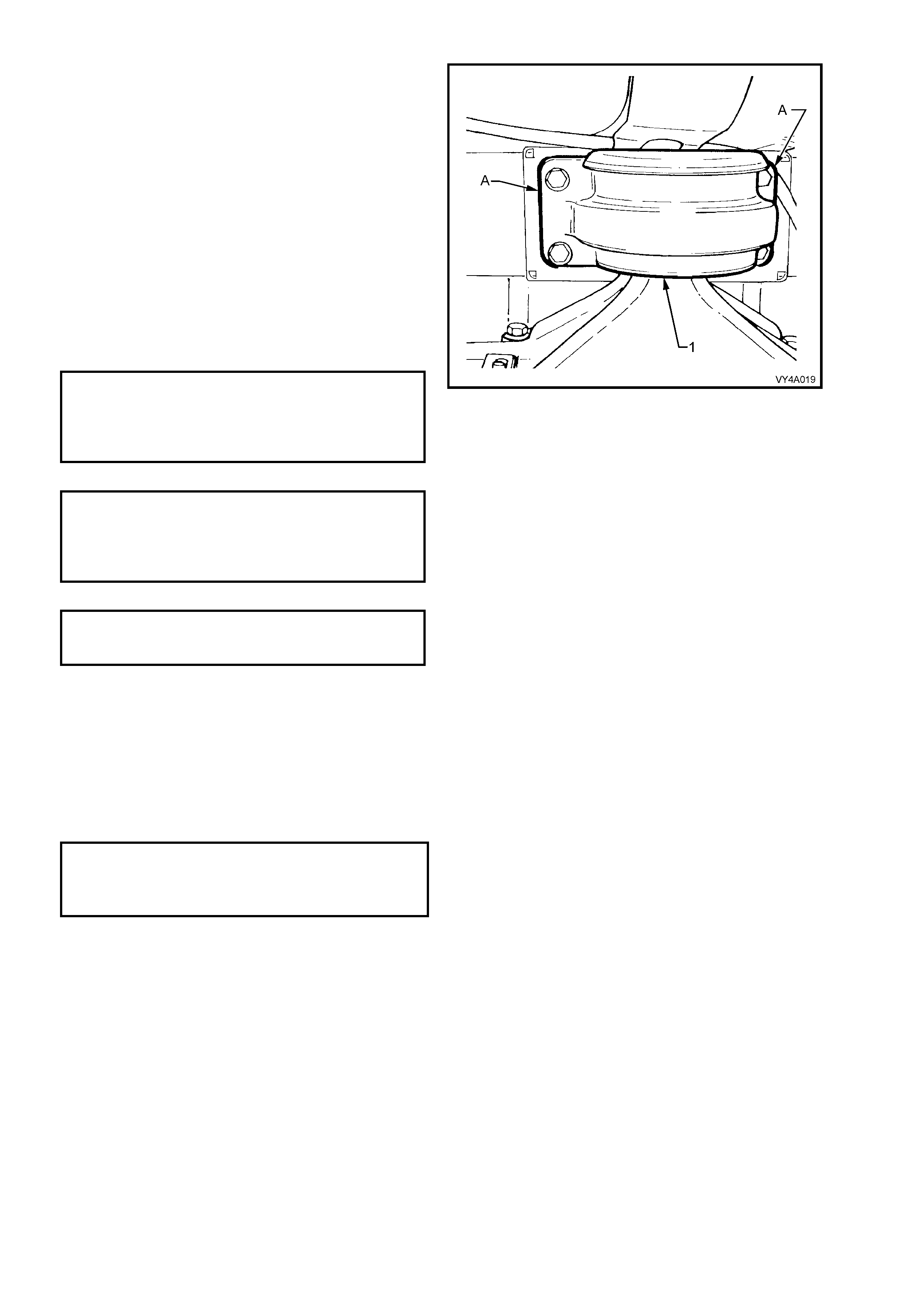

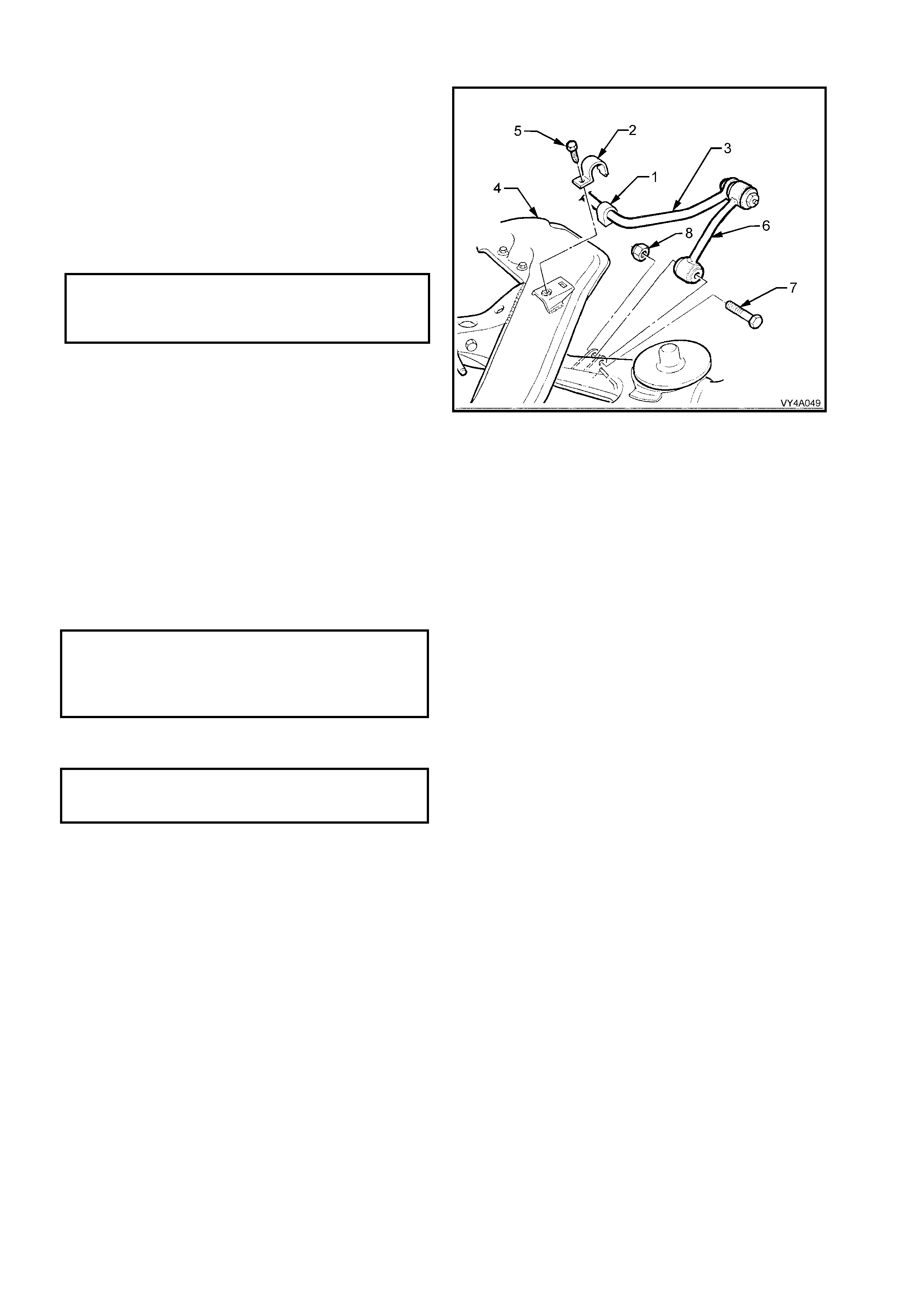

3. Loosen both stabiliser shaft link (1), attaching

bolts (2) and nuts, to reduce stress on the

insulator bushing.

4. Remove the stabiliser link to rear suspension

control arm attaching bolt and nut from side of

vehicle where the rear suspension control arm

is to be removed.

Figure 4A-2

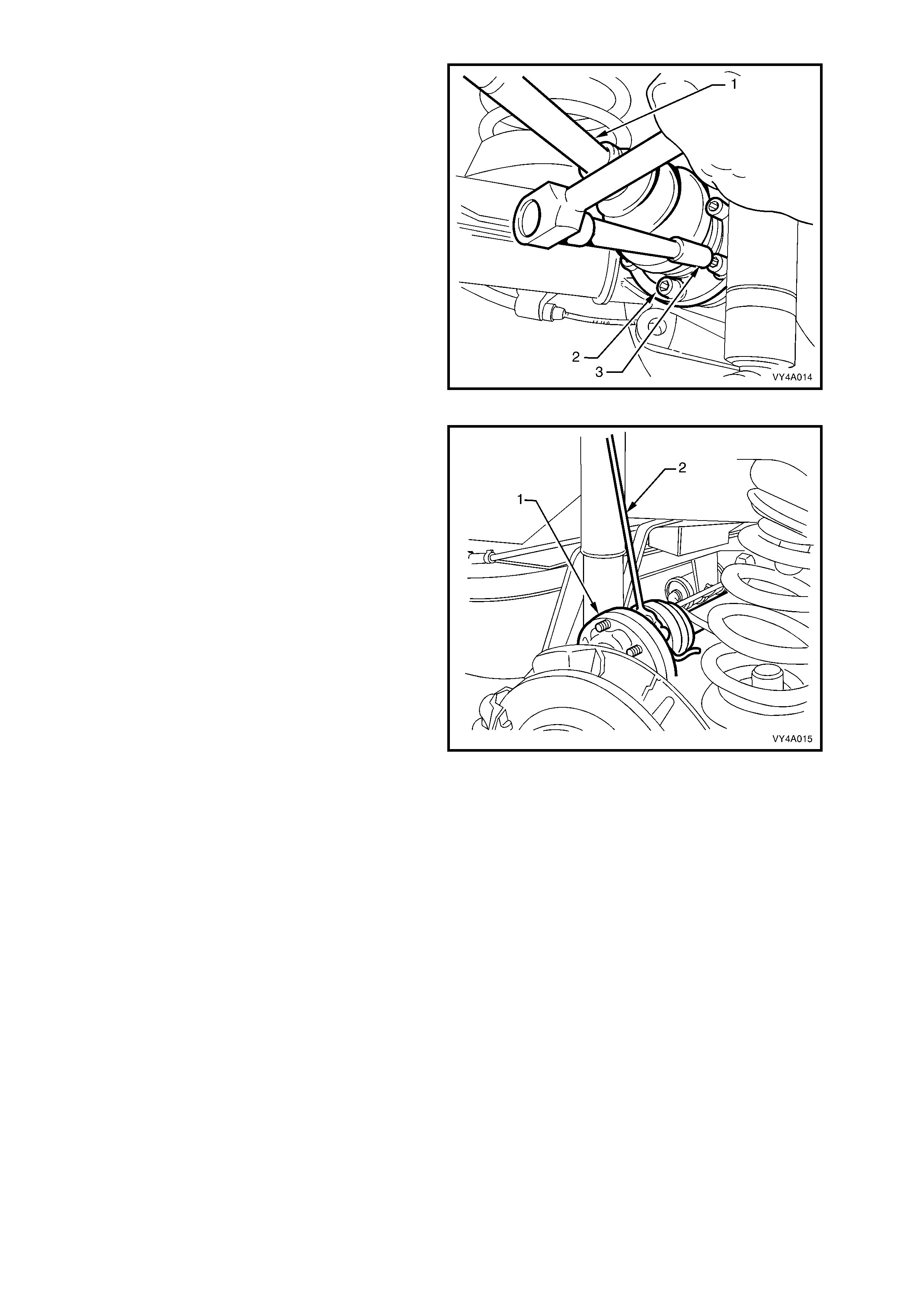

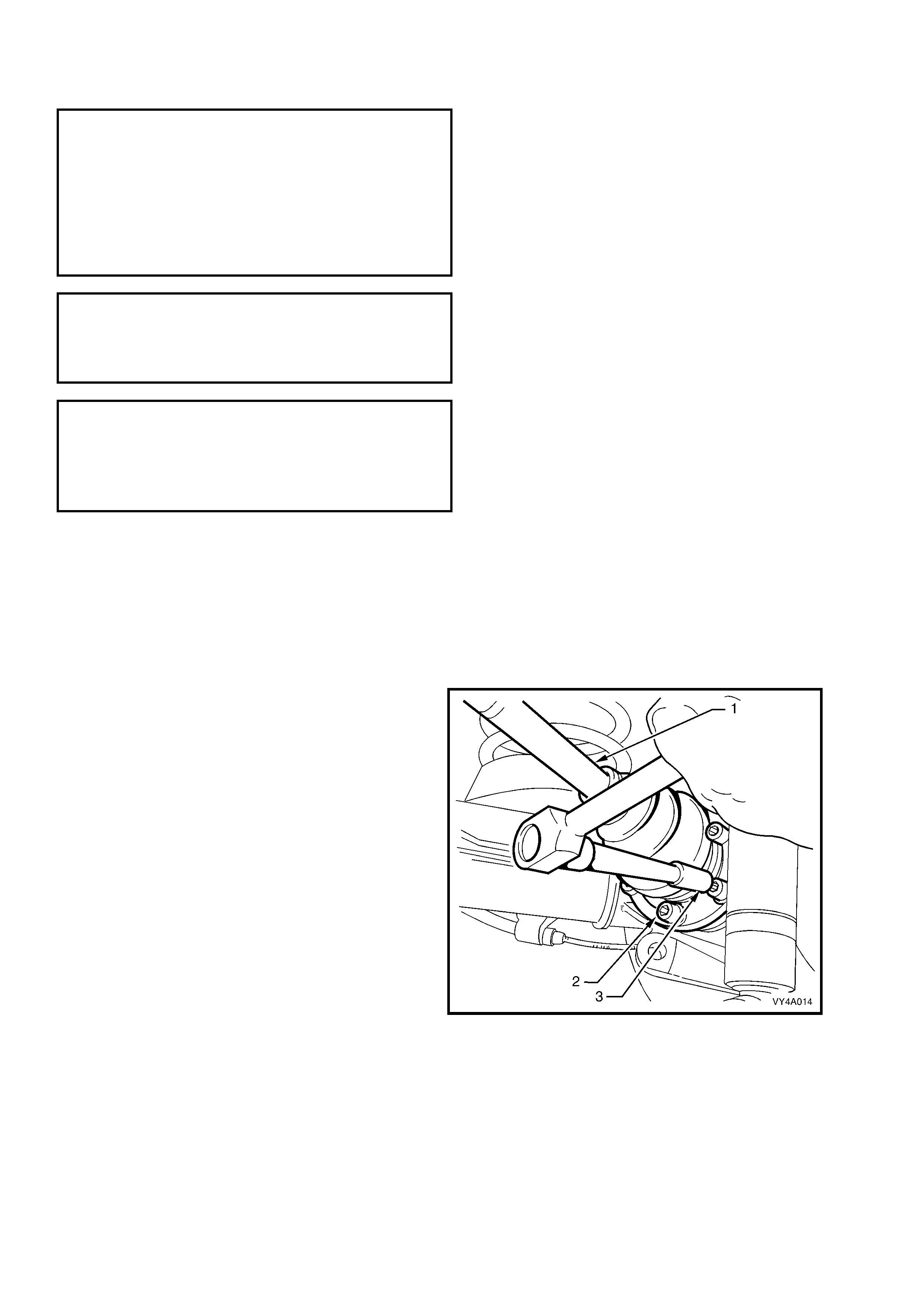

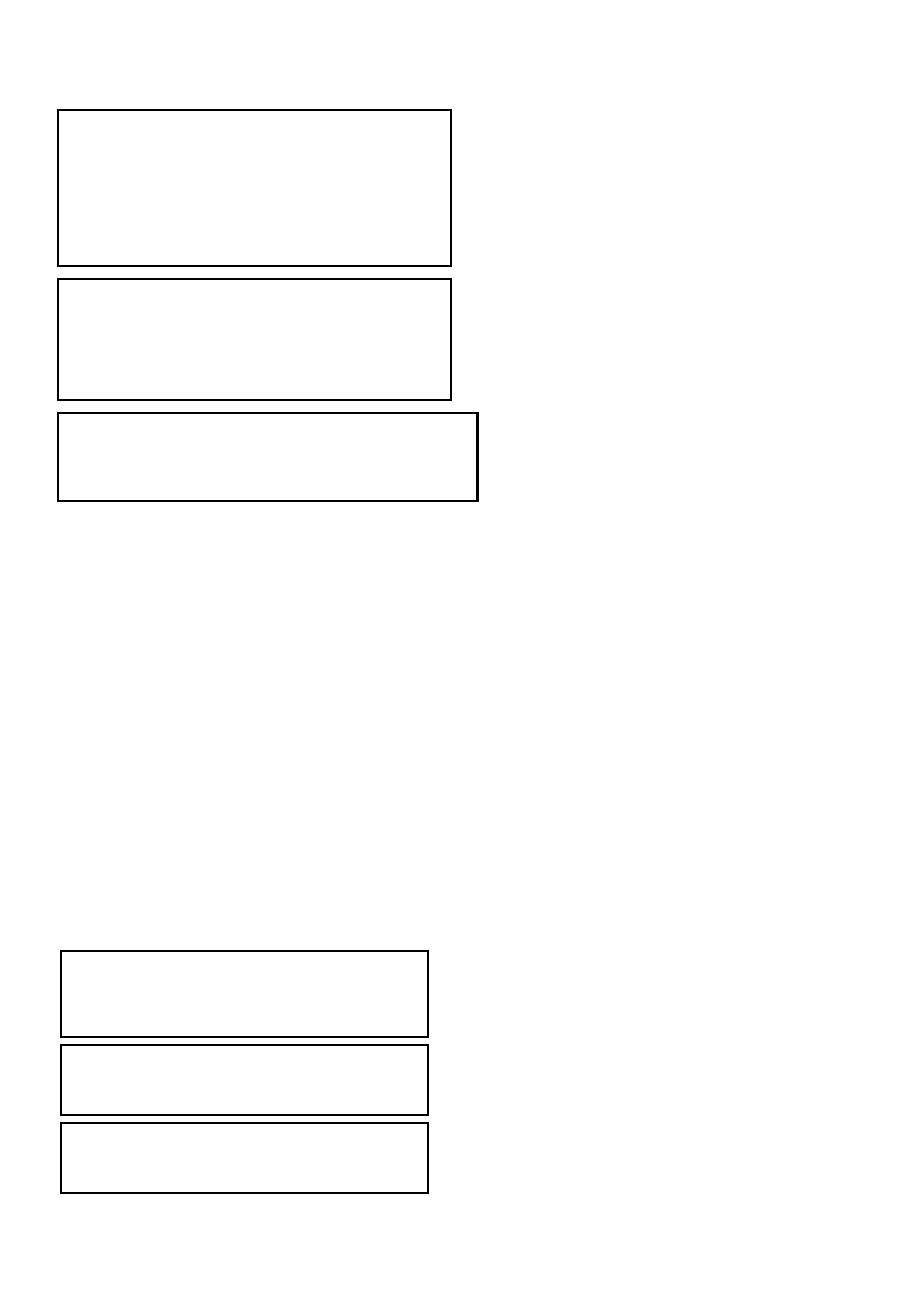

5. Loosen the additional control arm socket

assem bly retaining nut until level with the top of

the socket assembly stud.

6. Using s pecial tool No. E-9332- A (1), tighten the

lever forcing screw (2) to press the socket

assembly stud free from the taper in the rear

suspension control arm, remove socket

assembly retaining nut and discard.

7. Remove the additional control arm socket

assembly from the rear suspension control

arm.

Figure 4A-3

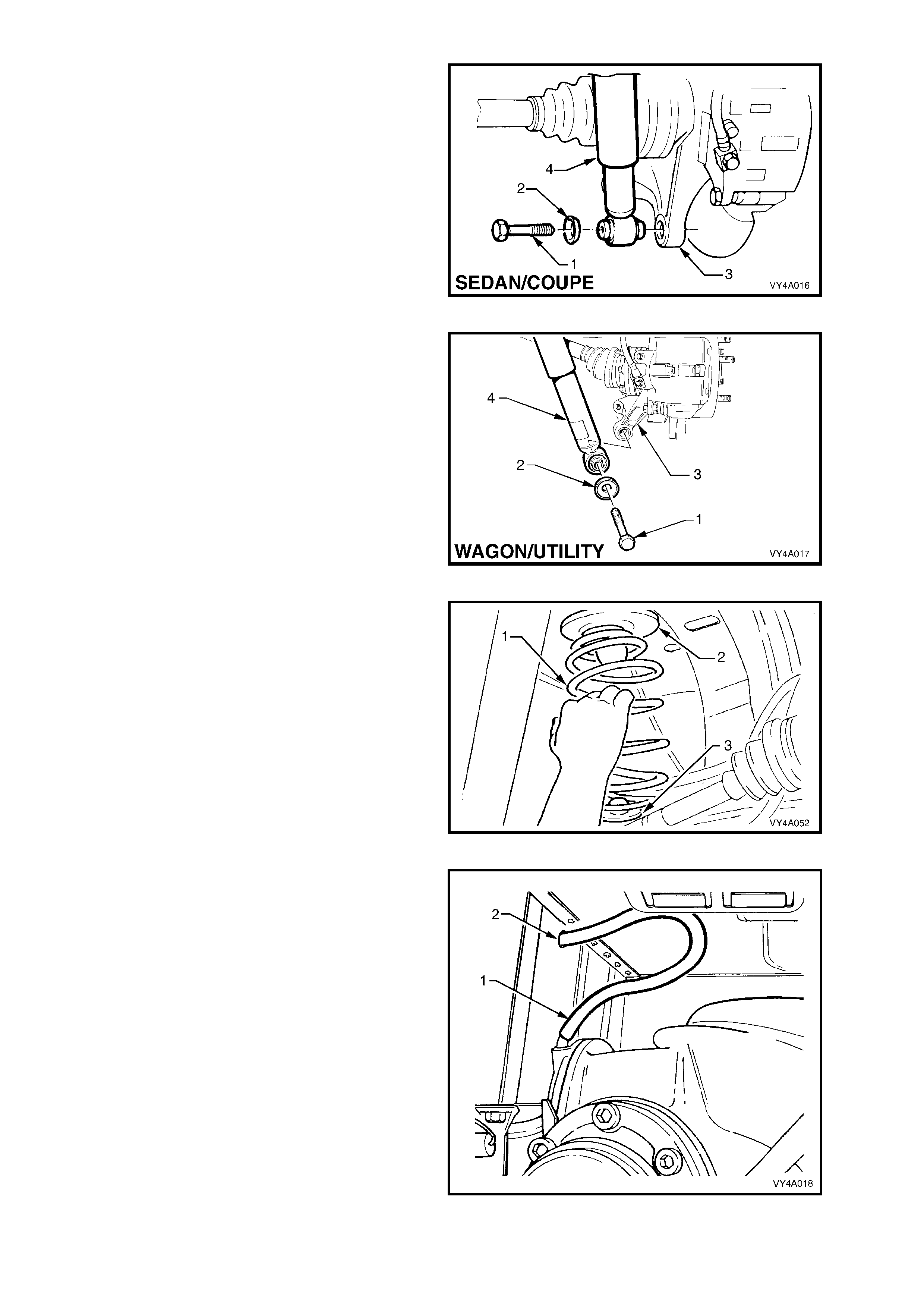

8. Remove the rear brake hose retaining clip (1)

from the rear suspension control arm bracket

(2) on the side to be removed. Pull the brake

pipe (3) and hose ( 4) f orward from the brack et,

and then disconnect from the rear suspension

control arm by lifting the brake pipe up through

the slot in the bracket.

Figure 4A-4

9. Remove the brake hose retaining clip (1) from

the brak e back ing plate brack et (2). Disconnec t

the rear caliper brake pipe (3) from the brake

hose (4) and disconnect the pipe from the

backing plate bracket.

Plug the open ends of the brak e pipe and hose

to prevent fluid loss and foreign matter entry.

Figure 4A-5

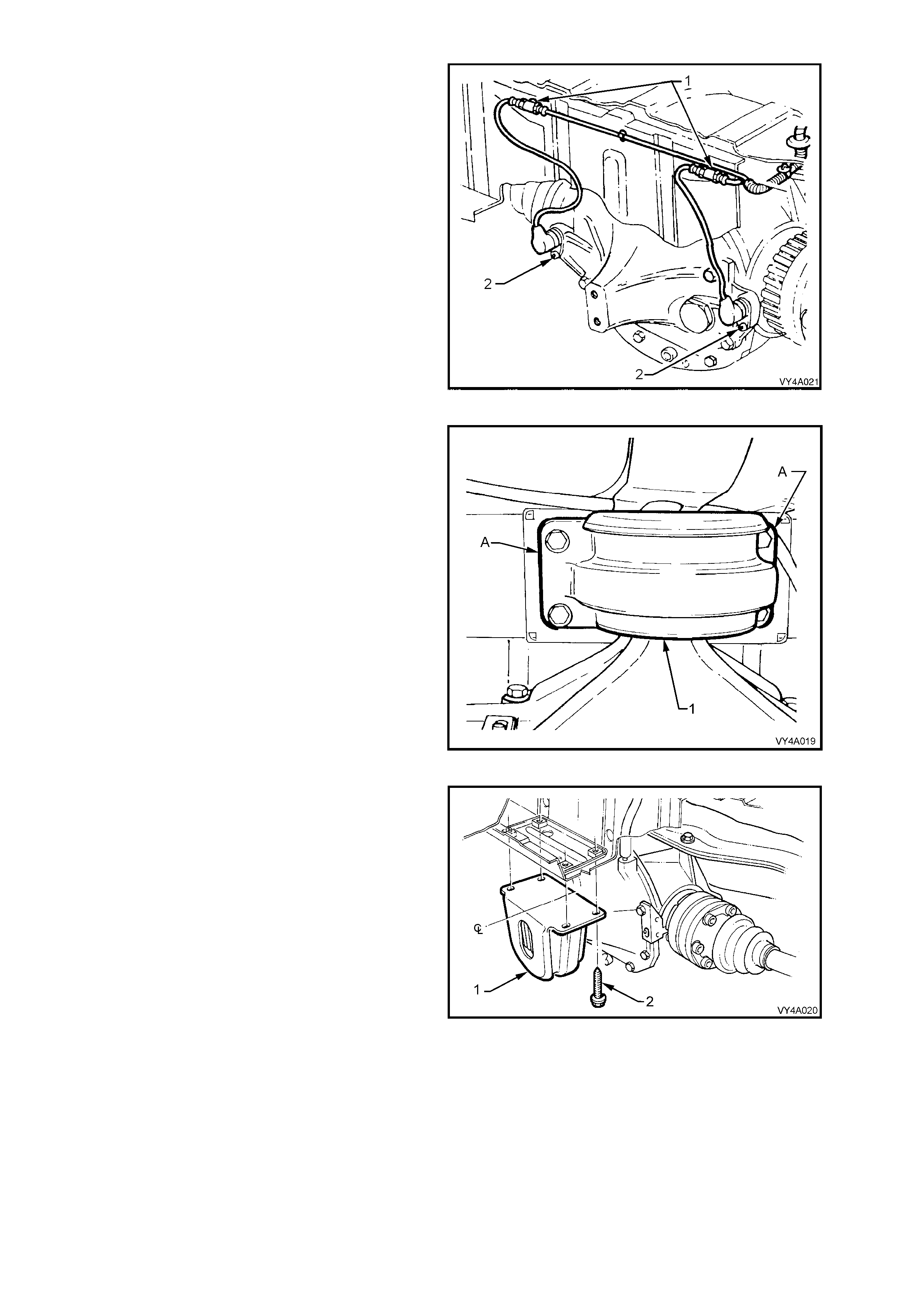

10. Remove the brake caliper anchor plate to rear

suspension control arm attaching bolts (1) and

remove the caliper (2) from the rotor. Set the

brake caliper to one side.

Important: If the brake pipe to hose is not

disconnected, the brake caliper must be supported

with tie wire secured to the vehicle underbody. THE

CALIPER IS NOT TO HANG BY THE BRAKE

HOSE.

Figure 4A-6

11. Set the park brake in the fully released position,

then release each of the underbody to park

brake cable (1) retaining clips (2) and free the

cables.

Figure 4A-7

12. Remove the park brake outer cable retaining

bracket bolt (underbody bracket and bolt are

not shown) from the vehicle underbody.

13. Pull each park brake inner cable (1) forward

and up (A), out of the cable retainer (2) to

release each cable.

14. Pull the outer cable (3) rearward (B) to remove

from the underbody retainer (4).

15. Remove the br ake rotor f r om the wheel bearing

hub.

NOTE 1: While the brake rotor to hub location is

marked in production, ensure that the rotor to hub

position is carefully marked (eg. rotor to end of

wheel stud), with a felt tipped pen or s im ilar. T his is

necess ary to overc ome the poss ibility of inducing a

brake shudder condition after reassembly.

NOTE 2: Should it be necessary to adjust the park

brake shoe to allow the brake rotor to be rem oved,

refer to Section 5A, SERVICE AND PARK

BRAKING SYSTEM for the necessary procedure.

Figure 4A-8

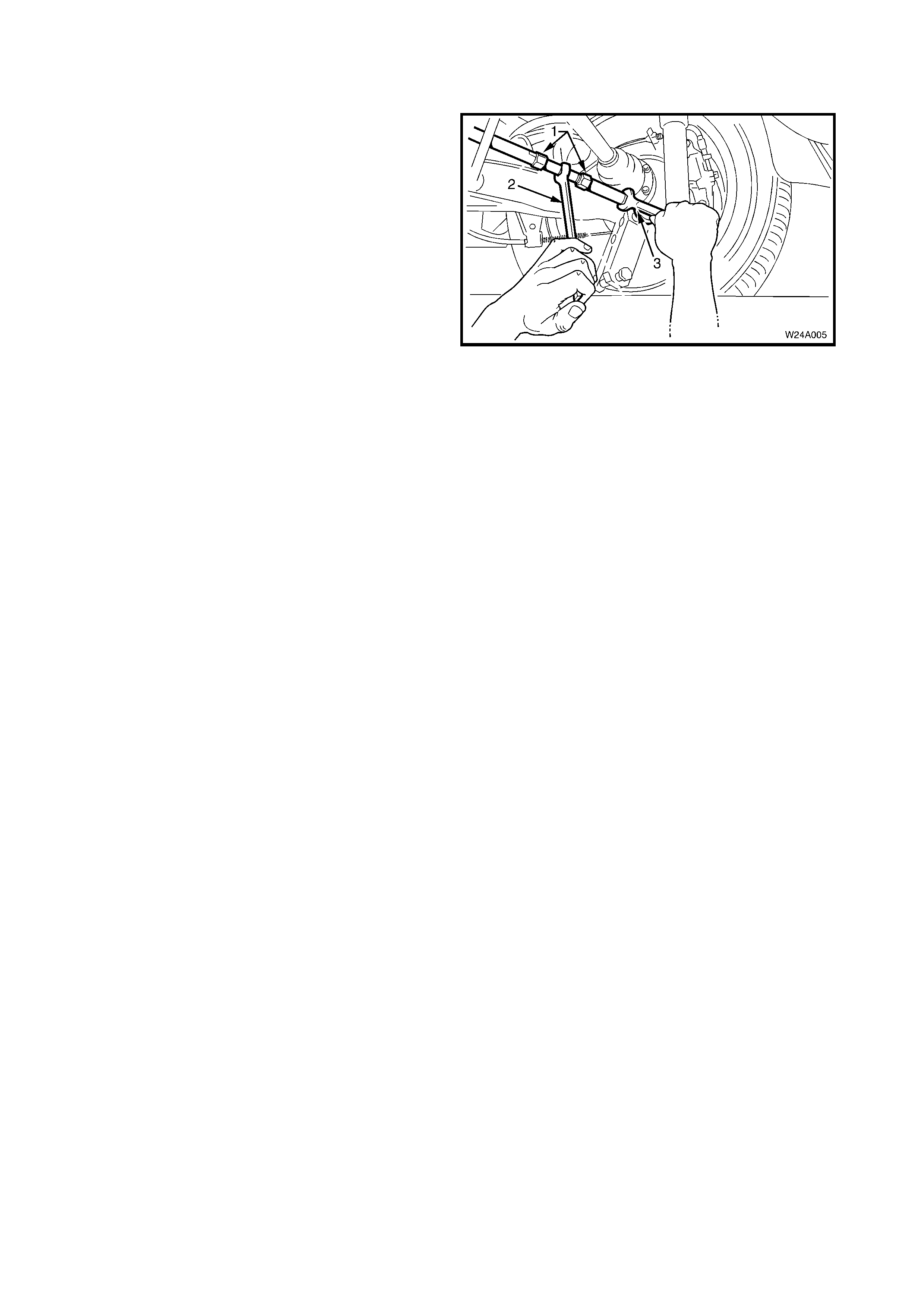

16. Using T ool No. KM468 over the wheel studs to

hold outer rear wheel drive shaft hub from

rotating, loosen the six drive shaft (1) outer

constant velocity joint to rear wheel drive shaft

flange attaching bolts (2), using an 8 mm Allen

key socket (3). Remove and discard the bolts.

Figure 4A-9

17. Disconnect the drive shaft (1) from the flange

and lift upward. While keeping the outer

constant velocity joint in the same plane as the

driveshaf t, use a length of wire (2), to tie up the

drive shaft to the lower end of the shock

absorber upper mounting.

NOTE: Bruising to the inside of the drive shaft

constant velocity joint boots will occur if the rear

suspens ion control arm is lowered. This will lead to

prem ature f ailure of the boot and eventual failure of

the joint.

This is why it is im portant that the constant velocity

joint be disconnected from the rear wheel drive

shaft flange before removing the shock absorber

lower mounting bolt.

Figure 4A-10

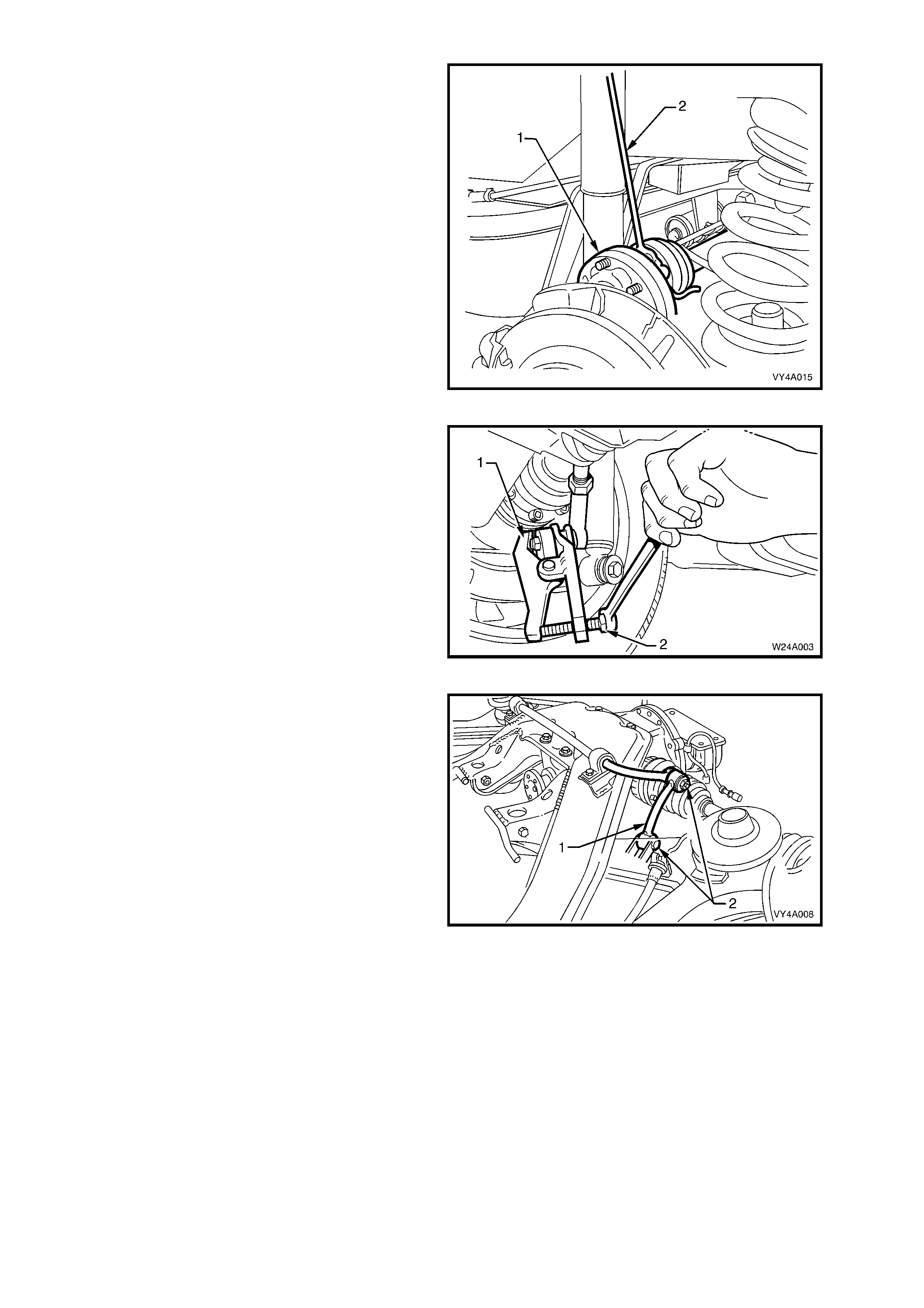

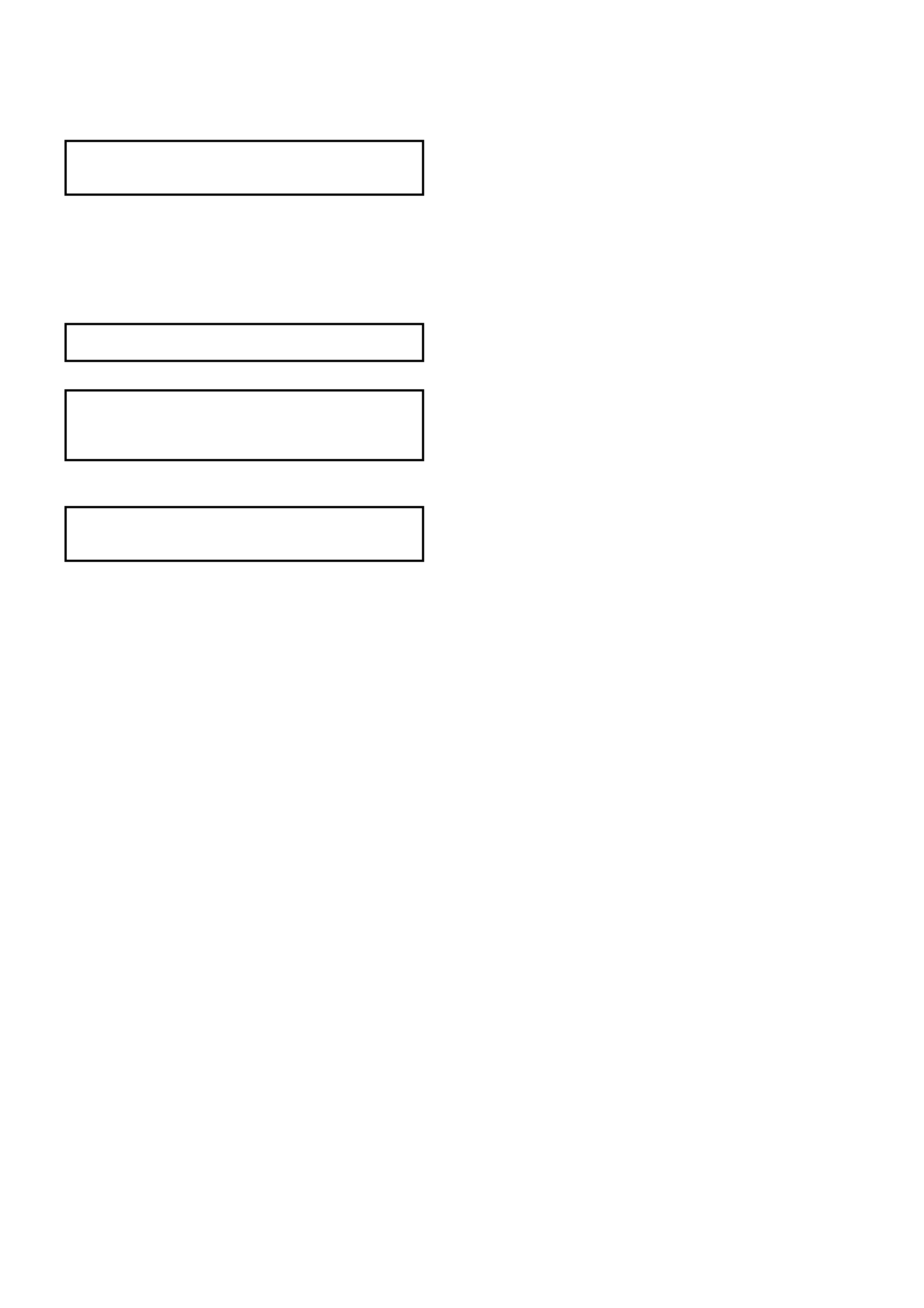

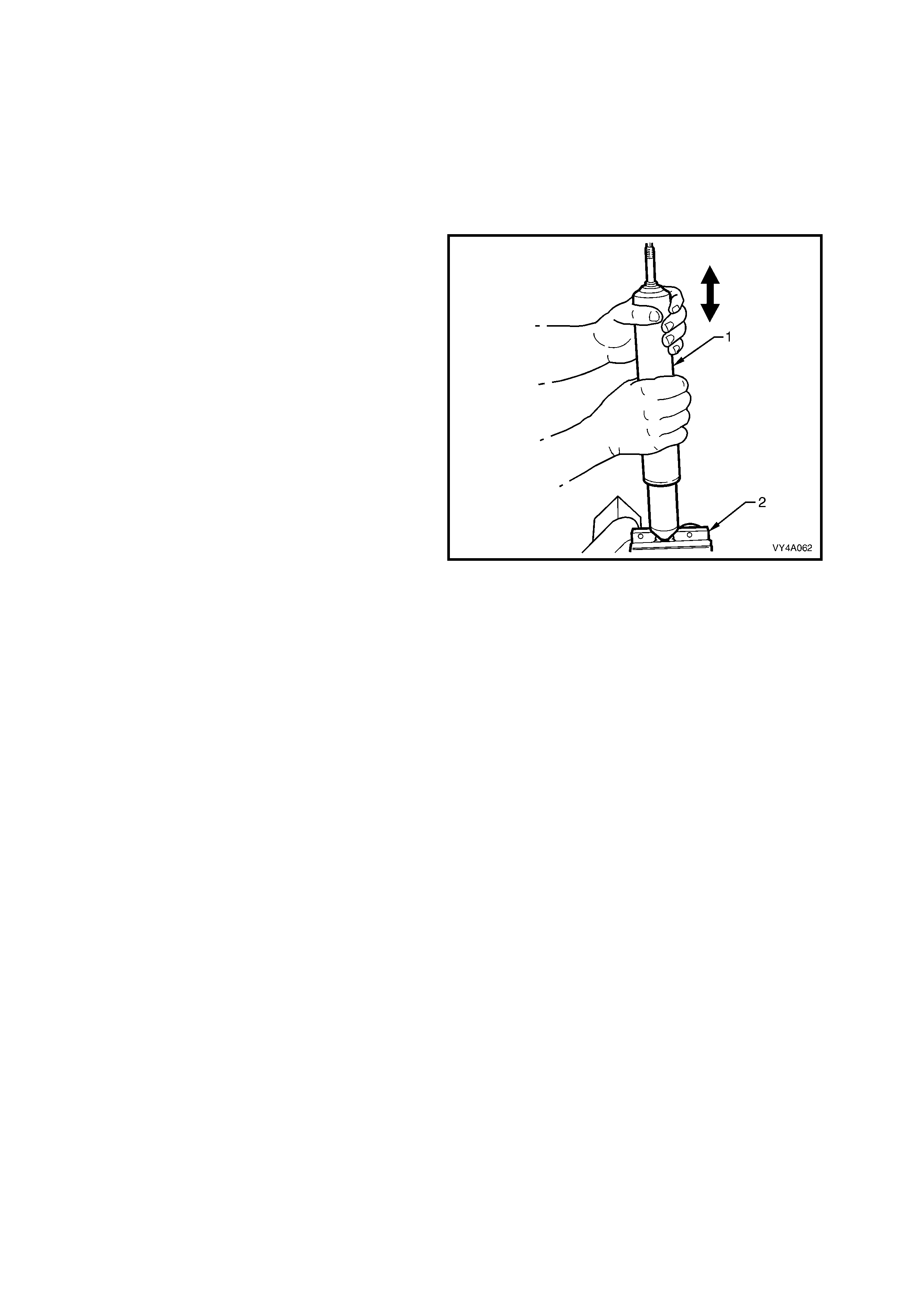

18. Position the floor jack with a block of wood

under the rear suspension control arm. Raise

the jack slightly to take the spring load off the

rear suspension control arm. Remove the rear

shock absorber lower mounting bolt (1) and

washer (2) from the rear suspension control

arm (3), then pull the lower end of the shock

absorber (4) from the rear suspension control

arm.

Figure 4A-11

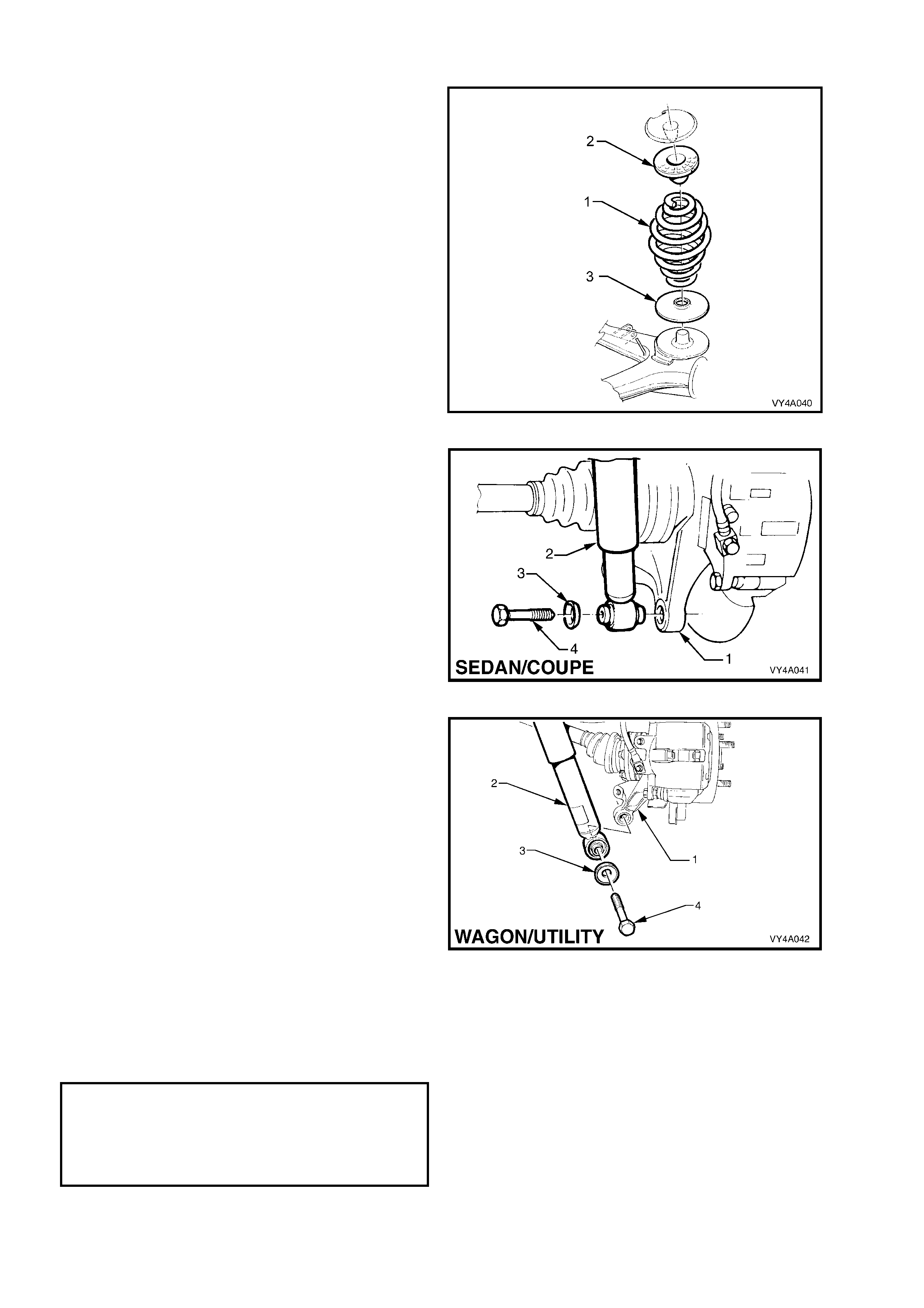

Figure 4A-12

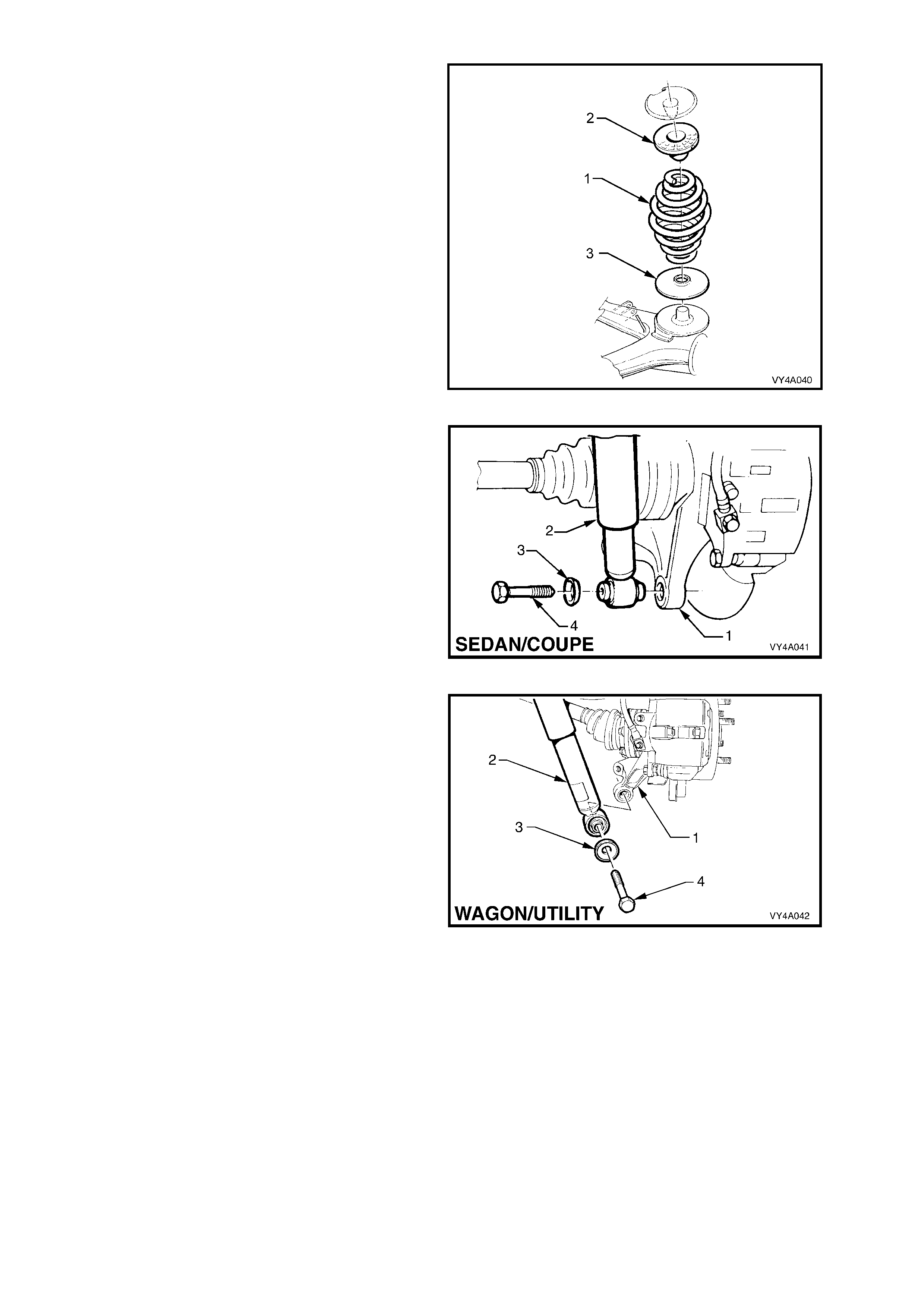

19. Lower the floor jack and if necessary, push

down on the rear suspension control arm and

remove the rear spring (1), upper insulator (2)

and lower insulator (3) from the vehicle

underbody and rear suspension control arm.

Figure 4A-13

20. Pull out the differ ential c arr ier br eather hos e ( 1)

from the vehicle underbody crossmember hole

(2).

Figure 4A-14

21. If the vehicle is f itted with ABS, pull both sensor

lead connectors from the underbody retaining

clips (1). Separate the sensor connectors from

the body harnes s connectors by levering with a

screwdriver.

Figure 4A-15

22. Using a scriber, mark the rear mount (1) to

vehicle under body location (A). T his will assist

in the rear sus pension crossm ember alignm ent

on installation.

23. Support the weight of the differential carrier

with a floor jack.

Figure 4A-16

24. Remove the rear mount (1) to vehicle

underbody attaching bolts (2) and discard.

Lower the differential carrier and rear

suspension crossmem ber assem bly suff iciently

to allow removal of the outboard rear

suspension control arm to front crossmember

attaching bolt and nut.

Figure 4A-17

25. Remove the rear suspension control arm to

rear suspension crossmember attaching bolts

and nuts, remove the rear suspension control

arm and discard the nuts.

Figure 4A-18

REAR SUSPENSION CONTROL ARM PIVOT BUSHING, REPLACE

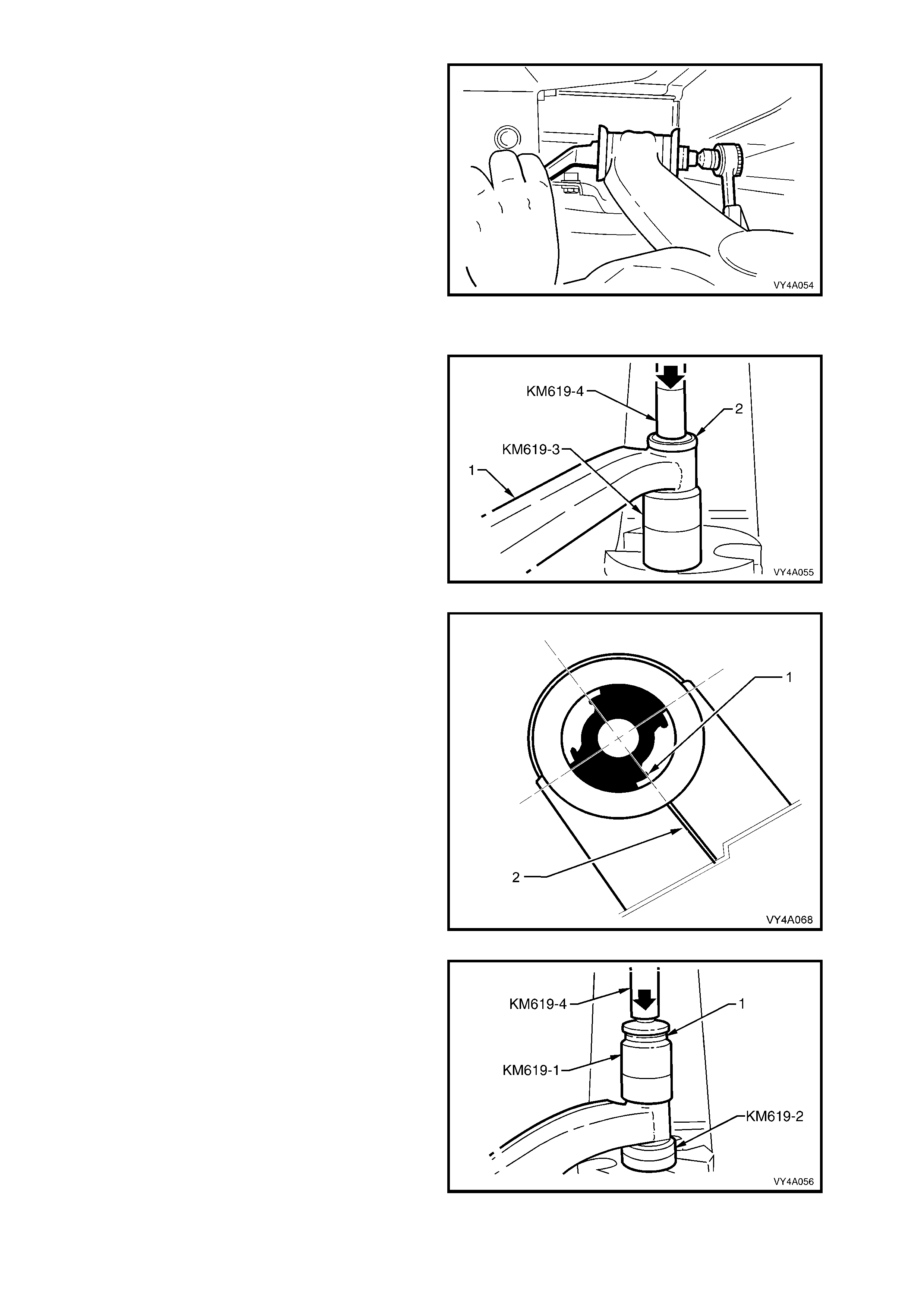

1. With the rear suspension control arm (1)

removed, press the bushing (2) from the rear

suspension control arm using Special tools

number KM619-3 and KM619-4.

Figure 4A-19

2. Lightly coat the outside surface of the new

bushing with a soapy water solution.

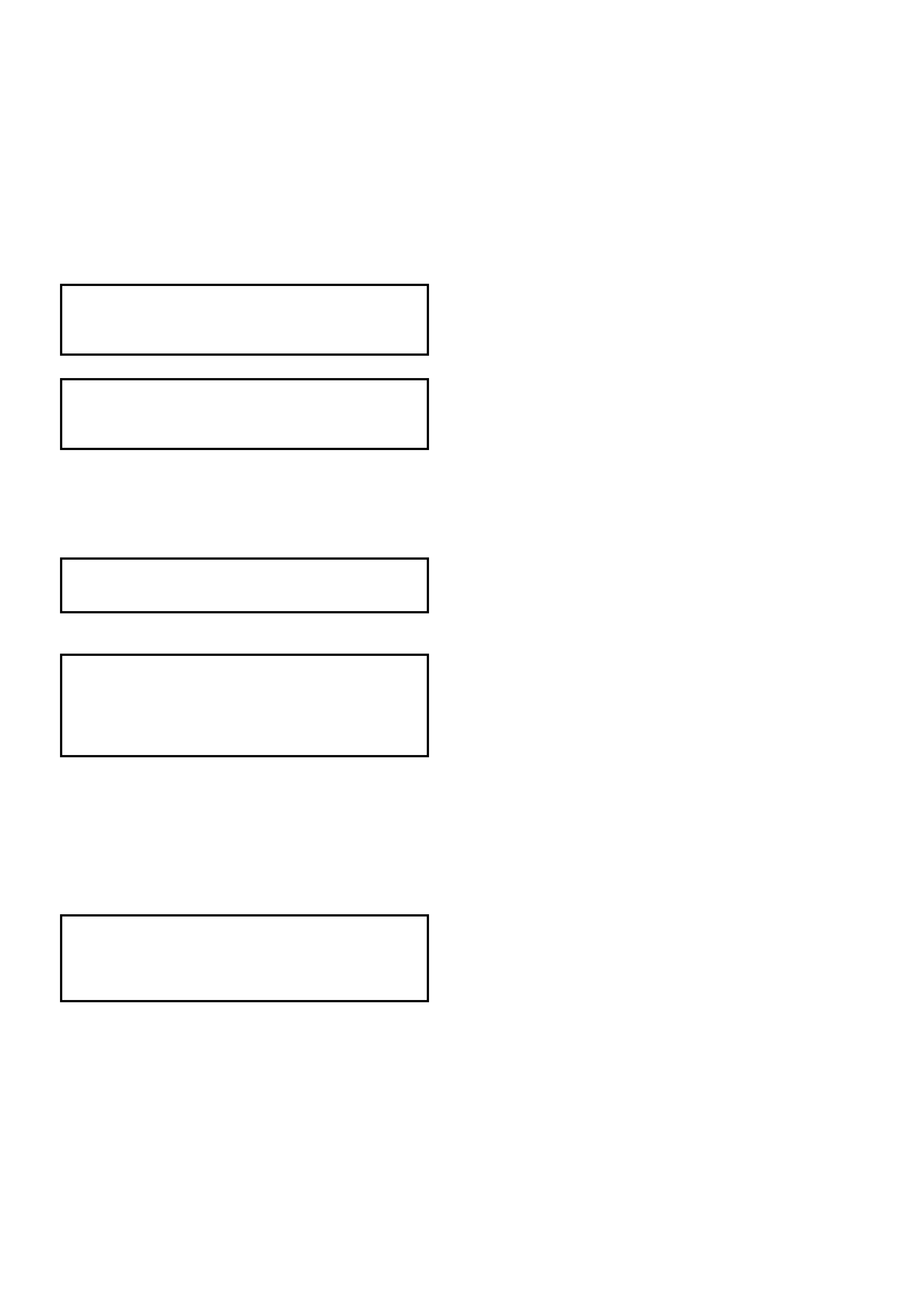

3. Position the new bush into the rear suspension

control arm.

NOTE: If replacing a voided type inner bush as

fitted to all MY 2003 VY Series Models with the

additional control arm, ensure to align the edge of

one of the voids (1), with the welded seam in the

trailing arm (2) as shown in Figure 4A-20.

Figure 4A-20

4. Press the new bushing into rear suspension

control arm (2) using Special tools number

KM619-1, KM619-2 and KM619-4.

Figure 4A-21

REINSTALL

The re installation of the rear sus pension control arm is the reverse of the removal pr ocedure, with the exception of

the following steps:

1. Install the rear suspension c ontrol arm to the r ear suspension cros smem ber, using bolts and NEW nuts but do

not fully tighten at this stage.

2. Install the brake rotor, aligning the marks made before removal.

NOTE: If the r ear wheel drive s haf t f lange or outer rear wheel drive shaf t was r eplac ed, then runout chec k s m us t be

carried out on the installed brake rotor. Refer to Section 5A, SERVICE AND PARK BRAKING SYSTEM for

important information regarding these checks.

3. Ins tall the br ake caliper anc hor plate to the rear s uspens ion c ontrol ar m, install the attaching bolts and tighten to

the correct torque specification.

( # ) BRAKE CALIPER ANCHOR

PLATE TO REAR SUSPENSION

CONTROL ARM UPPER ATTACHING

BOLT TORQUE SPECIFICATION......... 70 – 100 Nm

( ! ) BRAKE CALIPER ANCHOR

PLATE TO REAR SUSPENSION

CONTROL ARM LOWER ATTACHING

BOLT TORQUE SPECIFICATION......... 85 – 90 Nm

4. Support rear suspension control arm with a floor jack and wooden block and raise sufficiently to enable the

shock absorber to be reinstalled.

5. Install the shock absorber and stabiliser shaft link attaching bolts and nuts but do not fully tighten at this stage.

6. Install the additional control arm socket assembly and a NEW nut and tighten to the correct torque wrench

specification.

( # ) ADDITIONAL CONTROL ARM BALL

JOINT RETAINING NUT

TORQUE SPECIFICATION ................... 55 – 70 Nm

7. Install new drive shaft outer constant velocity joint to rear wheel drive shaft flange attaching bolts and plates,

then tighten to the correct torque specification.

( ! ) DRIVE SHAFT CONSTANT

VELOCITY JOINT TO REAR WHEEL

DRIVE SHAFT FLANGE BOLT

TORQUE SPECIFICATION ...................... 50 Nm, then

60° - 75°

turn angle

8. After reconnec ting all brak e line connec tions, bleed the rear brak es and chec k for leaks . For the r ecom m ended

procedure, refer to Section 5A, SERVICE AND PARK BRAKING SYSTEM.

9. Raise the differential carrier and rear suspension crossmember assembly until the rear mount contacts the

vehicle underbody.

10. Align rear suspension crossmember mount with the scribed alignment mark (refer to step 1 in

2.7 REAR SUSPENSION CROSSMEMBER REAR MOUNT, REMOVE in this Section), fit the new rear

suspension crossmember mount to vehicle underbody mounting bolts and tighten to the correct torque

specification.

( ! ) REAR SUSPENSION CROSSMEMBER

MOUNT TO UNDERBODY ATTACHING

BOLT TORQUE SPECIFICATION...... 30 – 40 Nm,

Plus 55° – 65°

turn angle

11. Install the road wheel/s, aligning the marks made prior to removal and secure with the attaching nuts.

12. Lower the vehicle to the ground and bounce the rear of the vehicle several times to settle the suspension

components.

13. W ith the weight of the vehicle on the four wheels and at curb weight, tighten the f ollowing bolts and nuts to the

respective, correct torque specifications.

( " ) SHOCK ABSORBER LOWER

MOUNTING BOL T

TORQUE SPECIFICATION ................ 105 – 125 Nm

( " # ) STABILISER SHAFT LINK

TO REAR SUSPENSION CONTROL

ARM ATTACHING BOLT

TORQUE SPECIFICATION ................... 90 – 105 Nm

( " # ) REAR SUSPENSION CONTROL ARM

TO REAR CROSSMEMBER ATTACHING

NUT TORQUE SPECIFICATION........... 95 – 105 Nm

14. Tighten the road wheel attaching nuts to the correct torque specification, working in a ‘star’ pattern. Refer to

Section 10 WHEELS AND TYRES for detailed information regarding the installation procedure for the road

wheels.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION ................ 100 – 125 Nm

15. Install the wheel cover/centre cap.

2.3 OUTER REAR WHEEL DRIVE SHAFT, FLANGE OR BEARING

LT Section No. – 05-290

NOTE: The following fasteners MUST be replaced

when performing this operation:

!

!!

!$

$$

$Outer rear wheel drive shaft collar nut.

REPLACE

Important: The rear wheel bearing s hould only be rem oved if it is faulty, or the outer rear wheel drive shaft is to be

removed.

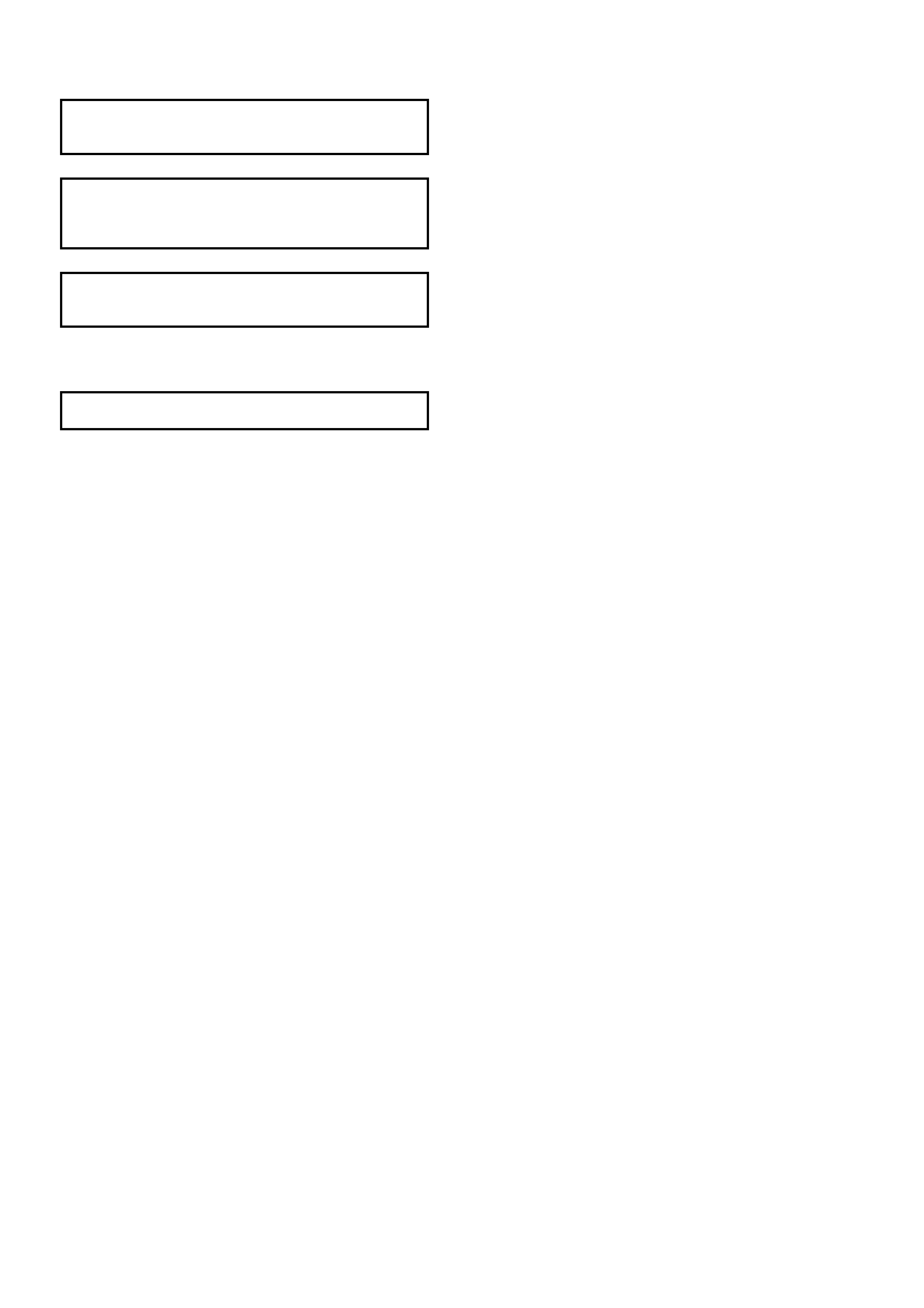

Trunnion Assembly – Sectioned View

Legend:

1. Collar Nut Lock Plate

2. Collar Nut

3. Rear Wheel Drive Shaft Flange

4. Rear Suspension Control Arm

5. Brake Backing Plate

6. Brake Rotor

7. Brake Caliper

8. Rear Wheel Bearing

9. Outer Rear Wheel Drive Shaft

10. Rear Wheel Bearing Retaining Ring

Figure 4A-22

1. Remove the rear suspension control arm.

Refer 2.2 REAR SUSPENSION CONTROL

ARM in this Section for details.

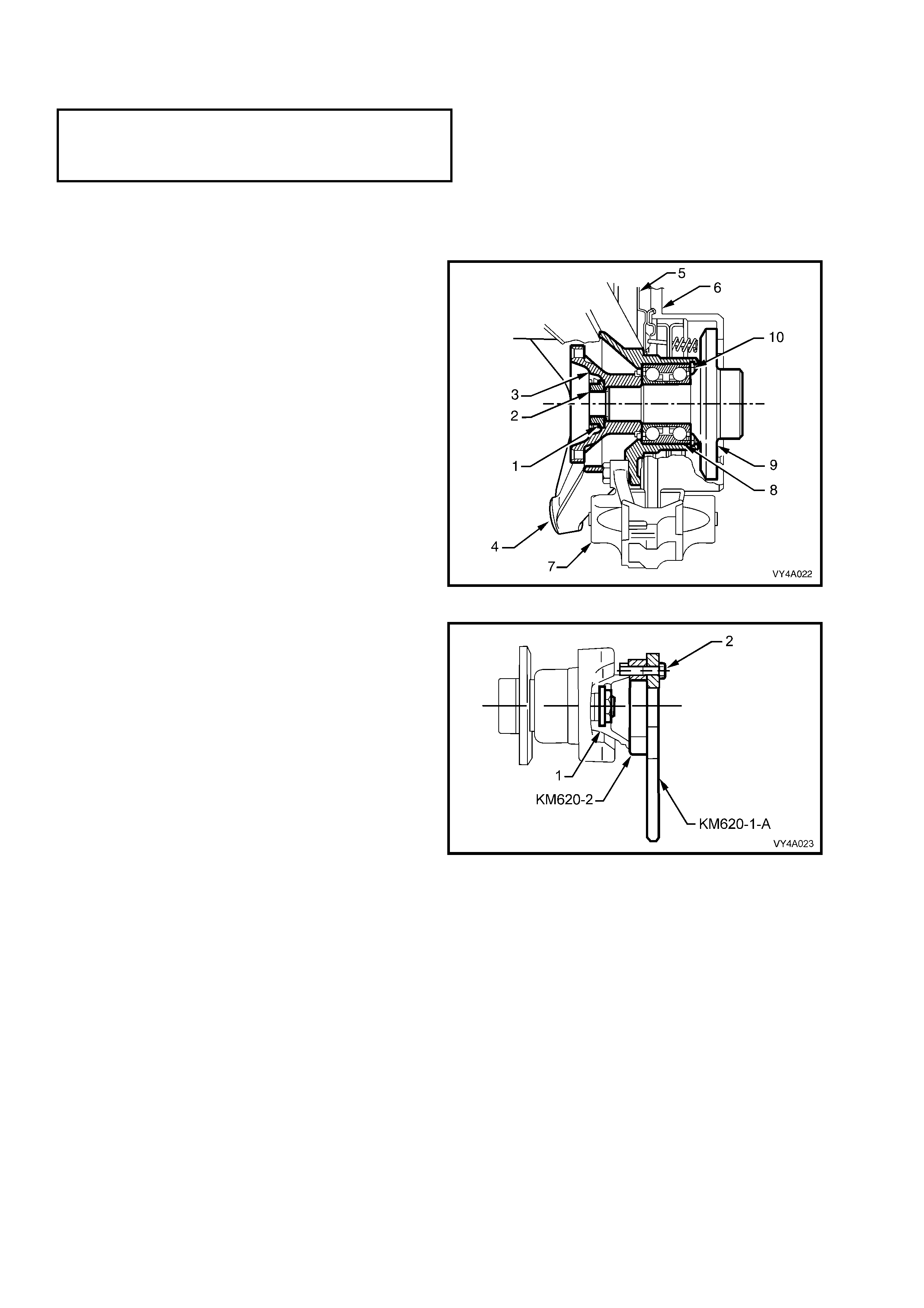

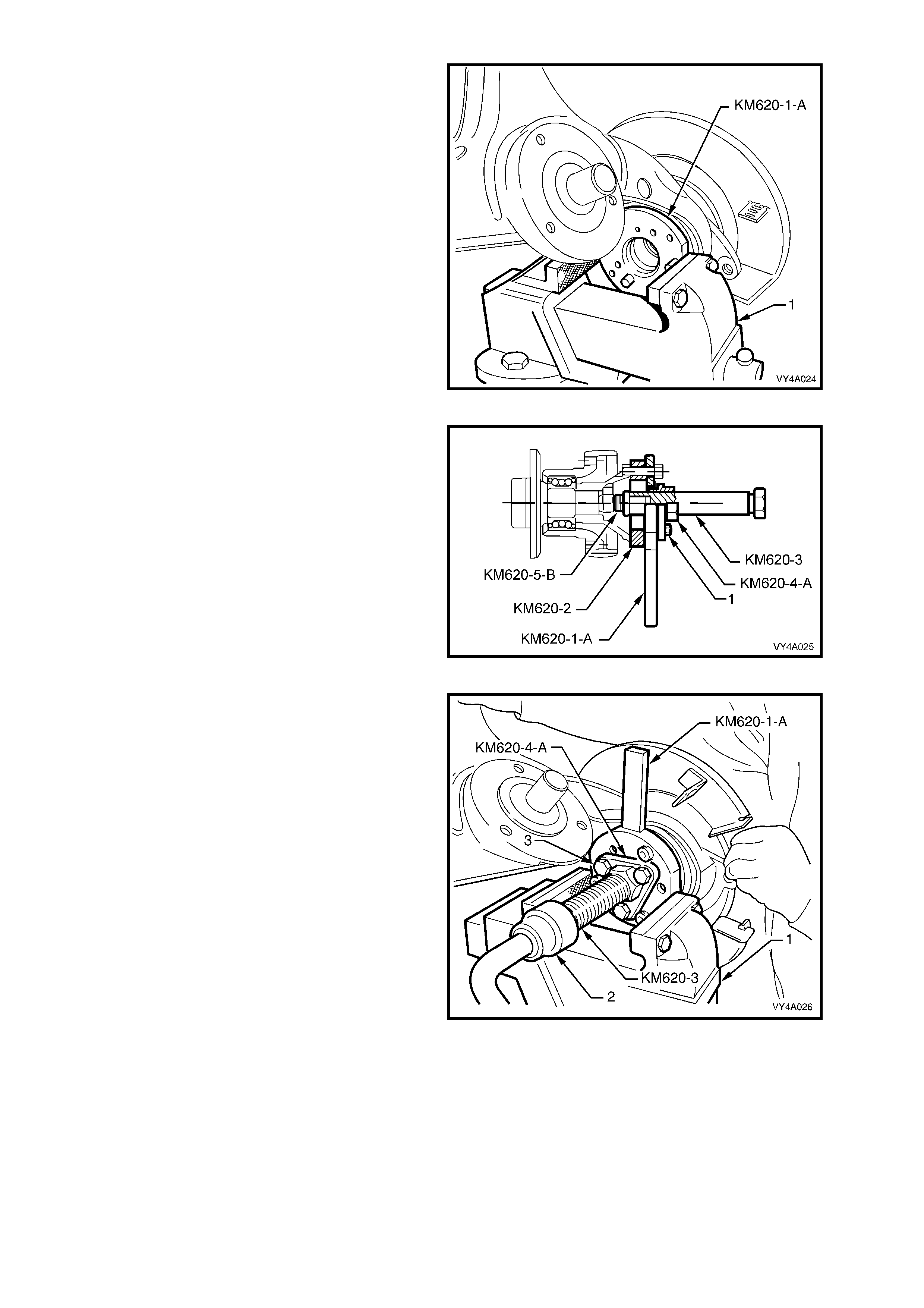

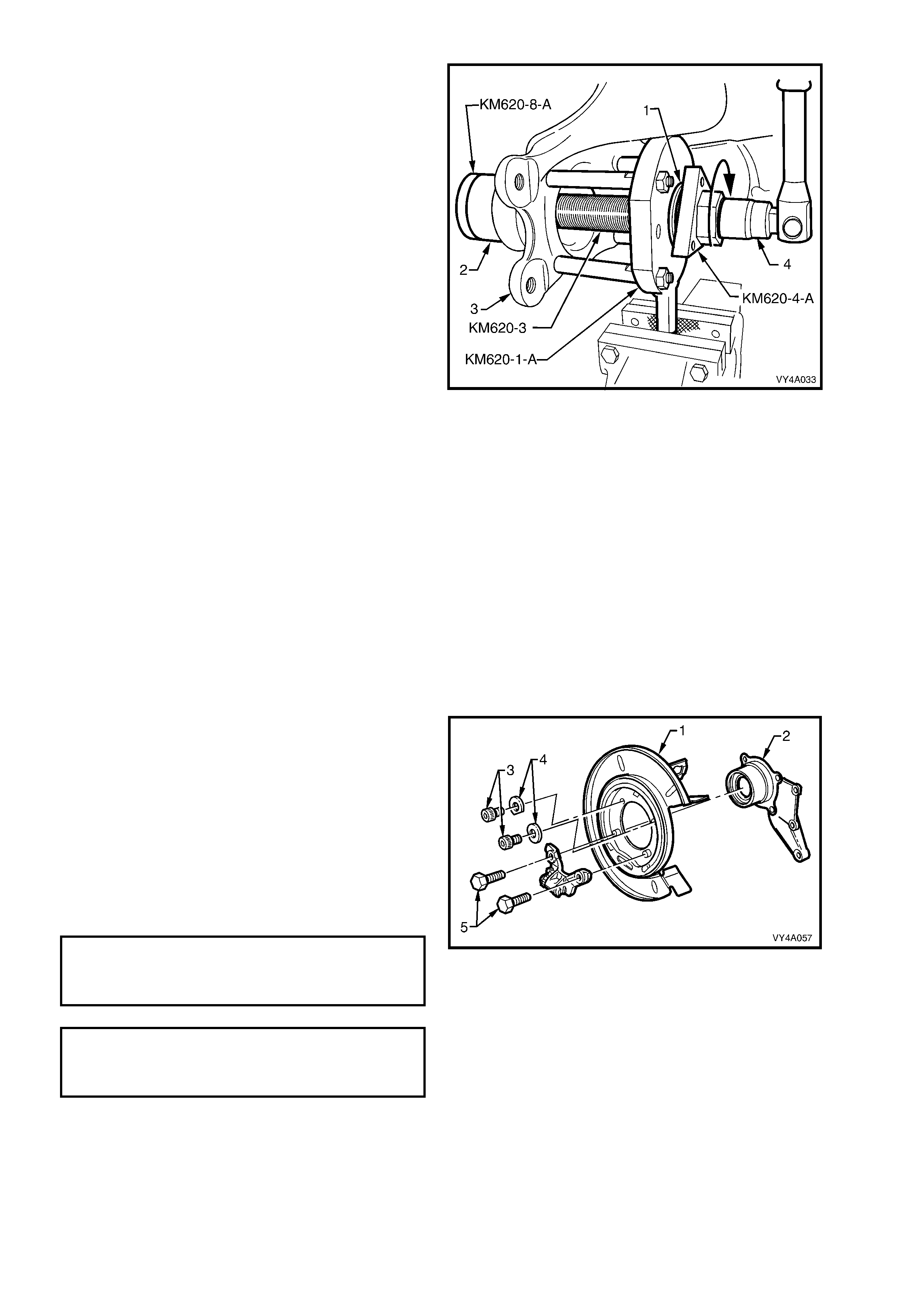

2. Secure the flange holding tool, KM620-1-A and

rear wheel drive shaft f lange ring tool KM620-2

to the rear wheel drive shaft flange (1) with

three of the removed drive shaft constant

velocity joint to rear wheel drive shaft flange

attaching bolts (2).

NOTE: Align holes marked ‘B’ on the flange holding

tool KM620-1-A and KM620-2 with holes in the rear

wheel drive shaft flange before installing and

tightening bolts.

Figure 4A-23

3. Distort the rear wheel drive shaft flange collar

nut lock plate, using a suitable size pin punch

and hamm er , then remove and dis car d the loc k

plate.

4. Mount the assembly in a vice (1), gripping the

handle or the flats of the flange holding tool

KM620-1-A. Loosen, then remove and discard

the rear wheel drive shaft flange to outer rear

wheel drive shaft collar nut and lock plate.

NOTE: The collar nut and the lock plate must be

replaced on reassembly.

5. Leave the holding tool KM620-1-A and the rear

wheel drive shaft flange ring tool KM620-2

assembled to the rear wheel drive shaft flange.

Figure 4A-24

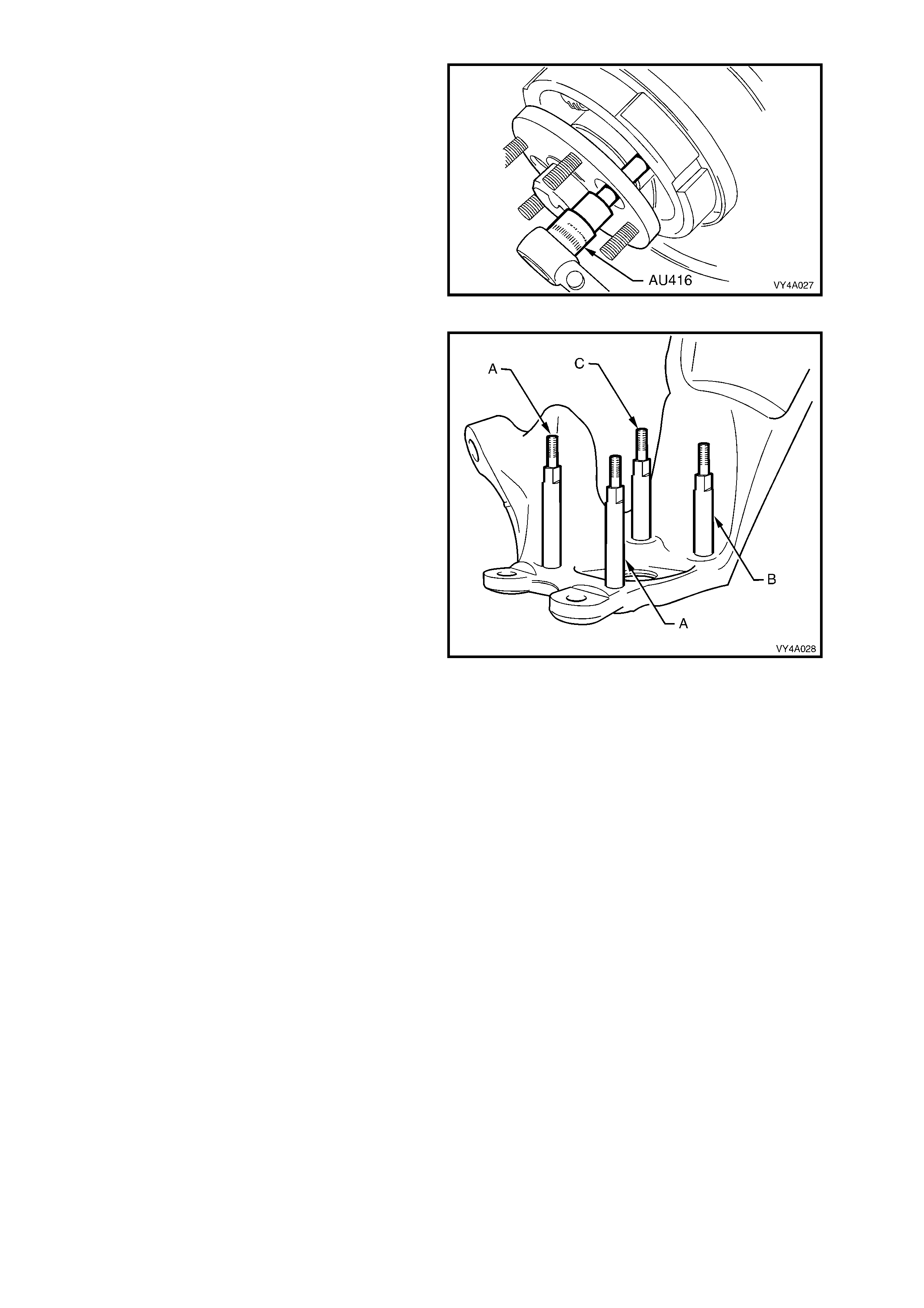

6. Lubricate the threads of the forcing screw

KM620-3, then install the screw to adaptor

KM620-4-A. Apply grease to the ball end of the

plunger, Tool No. KM620-5-B, then install that,

into the end of the forcing screw KM620-3.

7. Install the whole sub-assembly through the

central opening of the flange holding tool

KM620-1-A. Secure the adaptor KM620-4-A to

the flange holding tool KM620-1-A, using three

suitable bolts (1).

NOTE: Adjust the position of the forcing screw

KM620-3 in the adaptor KM620-4-A, to allow the

adaptor to be in full contact with the flange holding

tool KM620-1-A.

Figure 4A-25

8. W ith the flange holding tool KM620-1-A held in

a vice (1) and, with an assistant holding and

supporting the weight of the rear suspension

control arm assembly, turn the forcing screw

(KM620-3) us ing suitable s oc ket equipment (2),

until the flange is f r ee f r om the outer rear wheel

drive shaft, then remove and separate the

special tool components from the rear wheel

drive shaft flange.

Figure 4A-26

9. Using Torx bit s oc k et, Tool No. AU416, remove

the two upper bolts attaching the brake backing

plate to the rear suspension control arm, then,

using suitable socket equipment, remove the

two longer, hexagonal headed, lower bolts.

Figure 4A-27

10. Prior to removing the outer rear wheel drive

shaft and rear wheel bearing from the rear

suspension control arm, use a commercially

available M10 x 1.25 bottoming tap and a

suitable lubricant, clean the four backing plate

to rear suspension control arm bolt threads

working from the outer rear wheel drive shaft

side.

NOTE: This step is necessary to clear any dried

mud, dirt etc, from the exposed portion of the

threads on the inboard side of the rear suspension

control arm. Also, the deepest thread (position ‘C’)

may not be completely formed through to the

inboard side.

11. Install two supports KM620-7-A in positions ‘A’

and two KM620-7- AUS to ‘B’ and ‘C’ in the rear

suspension control arm, as indicated.

As a guide, the two longest supports (KM620-

7-A) are to be installed at the brake caliper

mounting side (position ‘A’). The longer of

KM620-7-AUS supports is installed at position

‘B’ and the shorter is installed at position ‘C’.

12. After installing all four supports in the correct

positions, tighten with a set spanner.

Figure 4A-28

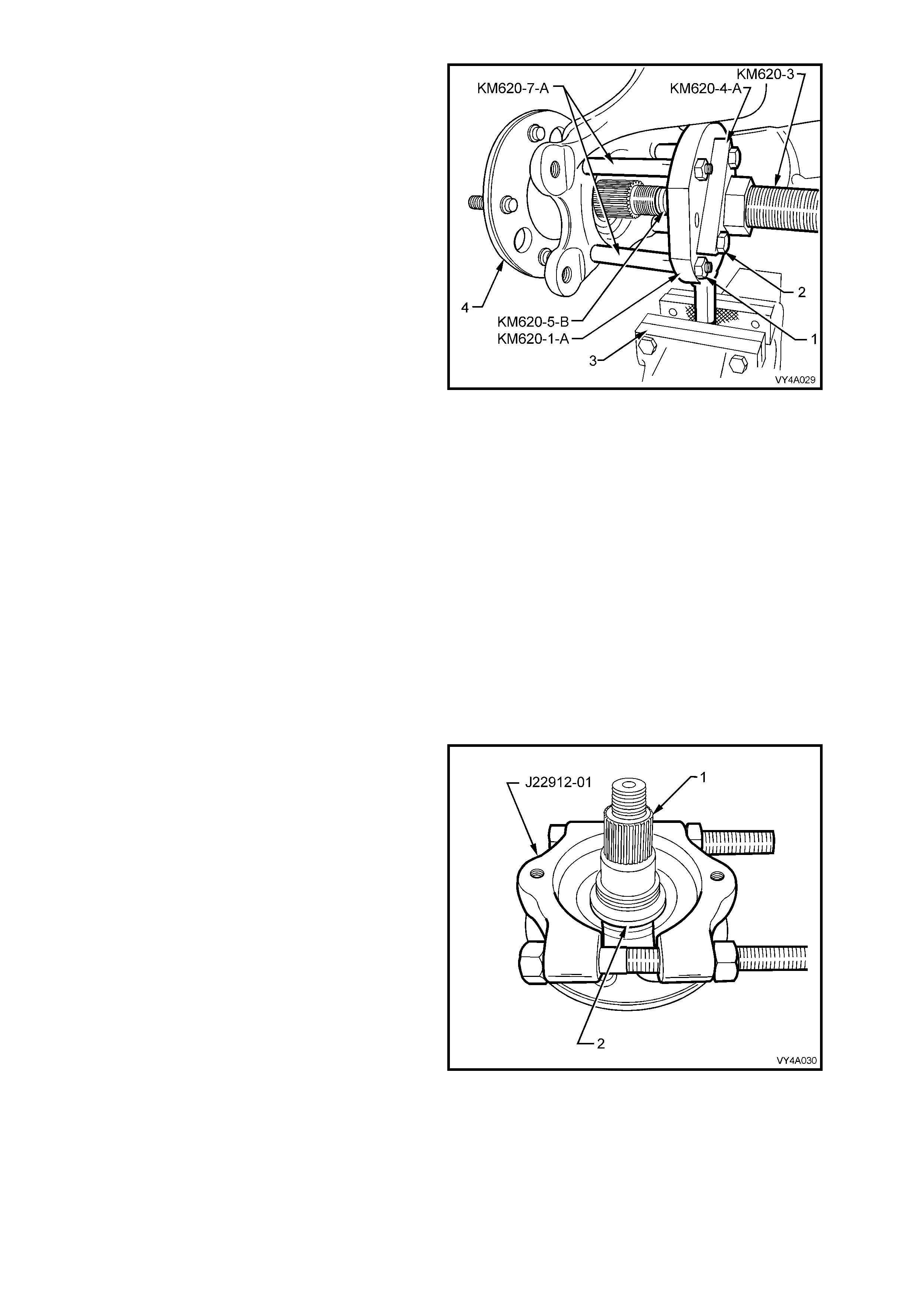

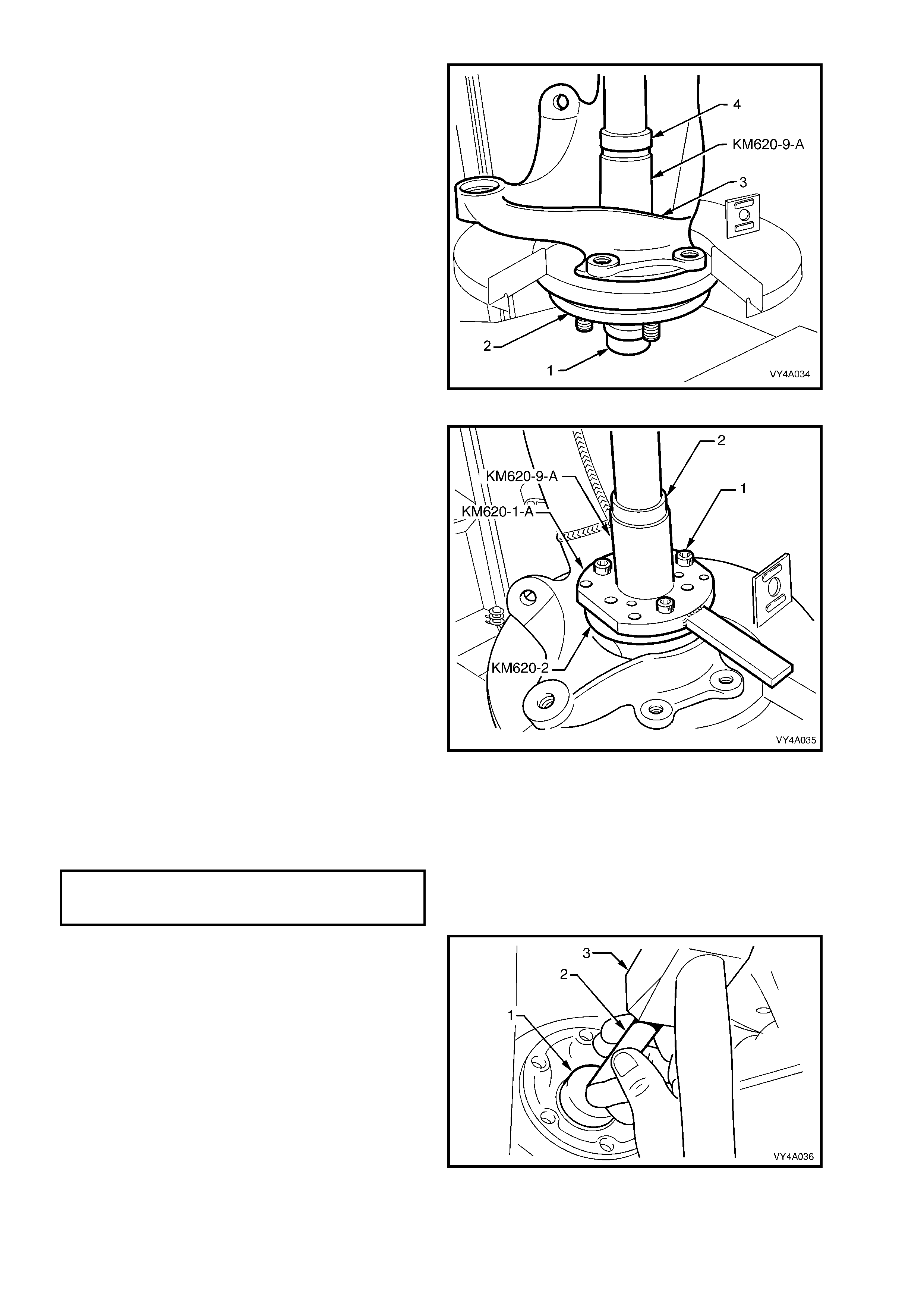

13. Install the flange holding tool KM620-1-A over

the four supports, KM620-7-A (2 places) and

KM620-7-AUS (2 places), install four suitable

nuts (1) and tighten to secure.

14. Pre-assemble the lubricated forcing screw

KM620-3 to the adaptor KM620-4-A. Apply

grease to the ball end of the plunger KM620- 5-

B, then install that, into the end of the forcing

screw KM620-3.

15. Install this sub-assembly through the central

opening of holding tool KM620-1-A. Secure the

adaptor KM620-4-A to the flange holding tool

KM620-1-A, using three suitable bolts (2).

NOTE: Adjust the position of the forcing screw

KM620-3 into the adaptor KM620-4-A, to allow full

contact of the adaptor to the flange holding tool

KM620-1-A.

16. Tighten the three bolts securing adaptor

KM620-4-A to the flange holding Tool KM620-

1-A.

17. Mount the assem bly in a vice (3) by the handle

of the f lange holding tool KM620-1- A as s hown,

then turn the forcing s crew KM620-3 and press

the outer rear wheel drive shaft (4) from the

rear wheel bearing.

18. When the outer rear wheel drive shaft has

been removed, unscrew the forcing screw, as

this same arrangement is used to press the

rear wheel bearing from the rear suspension

control arm.

NOTE: The inner rear wheel bearing cone will

separate from the bearing assembly and be

retained on the outer rear wheel drive shaft.

19. Remove the brake backing plate and park

brake assembly from the rear suspension

control arm and set to one side.

Figure 4A-29

20. If the outer rear wheel drive shaft (1) is to be

re-used, then the outer half of the inner rear

wheel bearing cone ( 2) will need to be removed

from the outer rear wheel drive shaft.

a. Install the press plates J22912-01 over the

bearing cone and tighten the press plate

bolts to grip the bearing cone.

b. Pres s the outer rear wheel drive shaft from

the bearing cone and discard bearing cone.

NOTE 1: If the outer rear wheel drive shaft is to be

replaced, then step 20, is not required.

NOTE 2: A new outer rear wheel drive shaft is

supplied with wheel studs already installed.

Figure 4A-30

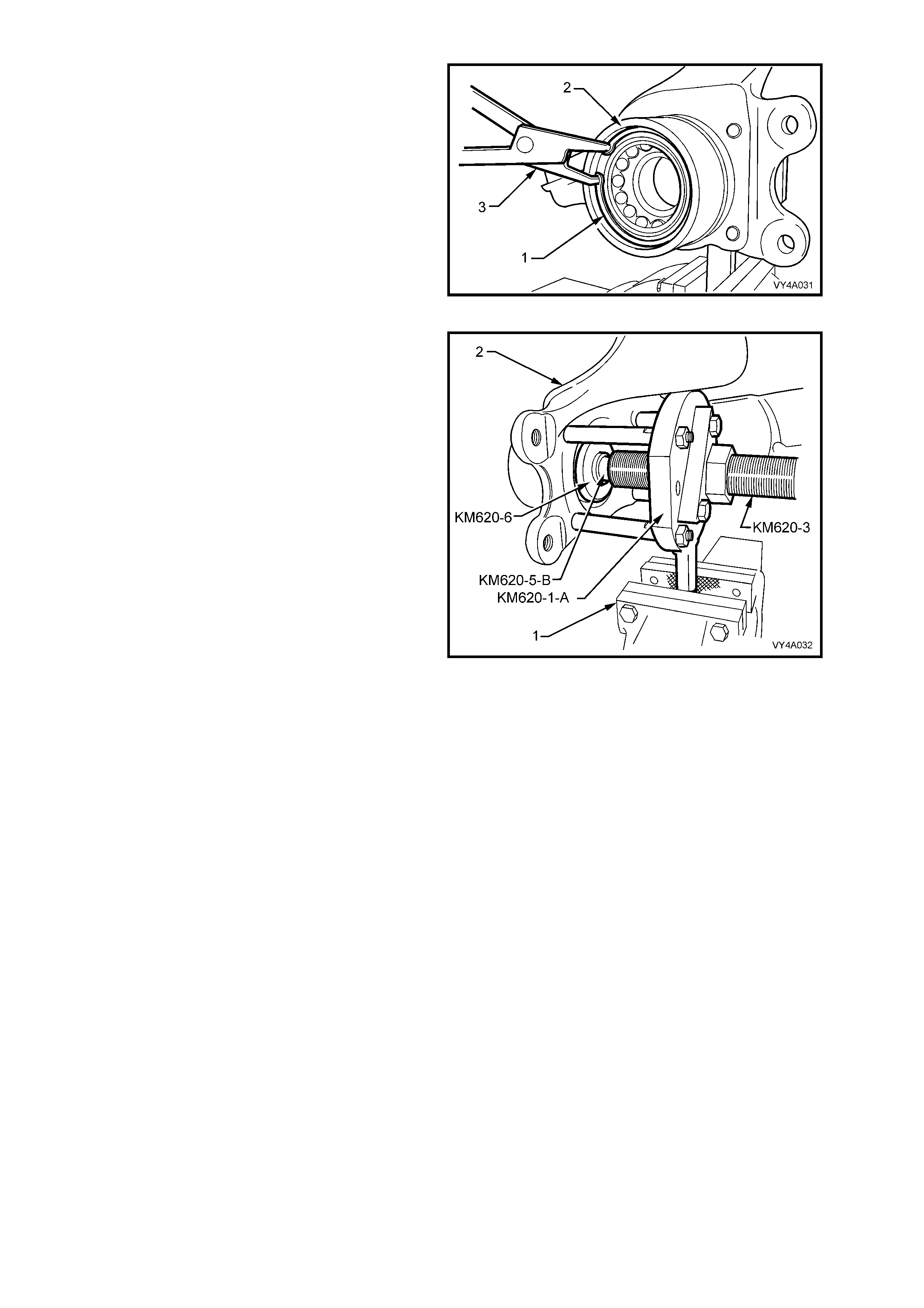

21. Remove the wheel bearing retaining ring (1)

from the rear s uspension contr ol arm (2), using

suitable circlip pliers (3).

Figure 4A-31

22. With the tool components set up as shown in

Figure 4A-29, install the rear axle bearing

removing plate KM620-6 into the rear of the

axle bearing. Reposition the forcing screw

KM620-3 and the adaptor KM620-5-B to retain

the removing plate KM620-6 in place.

23. With KM620-1-A mounted in the vice jaws (1),

turn the forcing screw KM620-3 clockwise to

press the wheel bearing from the rear

suspension control arm (2).

24. If installing a replacement rear suspension

control arm without bushing, install new

bushing. Refer to 2.2 REAR SUSPENSION

CONTROL ARM in this Section.

25. Ensure that the bearing bore of the rear

suspens ion contr ol ar m is c lean and f ree of any

foreign matter.

26. Coat the outside diameter of a new wheel

bearing and the bore of the rear suspension

control arm with lubricant such as Molybond

HB50 (or a commercially available equivalent).

Figure 4A-32

27. Rem ove the bolts secur ing adaptor KM620- 4-A

to the holding tool KM620-1-A, then r emove the

adaptor and forcing screw KM620-3.

28. Lubricate the thrust ball bearing race (1) (part

of KM620-A) with lubricant such as Molybond

HB50 (or commercially available equivalent),

then assemble the bearing onto the flanged

end of adaptor KM620-4-A.

29. Install the forcing screw and adaptor/bearing

assem bly to the flange holding tool KM620-1- A.

Do not install the adaptor (KM620-4-A) to

holding tool (KM620-1-A) attaching bolts.

30. Install the bearing installer KM620-8-A into a

new bearing (2) and install both into the rear

suspension control arm (3).

31. Join the forcing screw (KM620-3), and the

bearing installer (KM620-8-A) by engaging the

screw thread of the forcing screw (KM620-3)

with the installer (KM620-8-B) and tightening

the forcing screw to engage at least 8 full

threads.

32. While holding the forcing screw (KM620-3)

from turning by using suitable socket

equipment ( 4) , rotate the adaptor KM620-4- A in

the direction shown, with a suitable 40 mm

wrench to draw the new bearing (2) fully into

position.

33. Remove the installer KM620-8-A once the

bearing is fully installed, then install the

retaining ring into the rear suspension control

arm using suitable circlip pliers, ensuring that

the ring is seated correctly.

34. Separate all special tool components from the

rear wheel drive shaft flange, after the bearing

has been fully installed.

Figure 4A-33

NOTE 1: T he two upper bolts (3) have washer s (4)

that are installed with the cut-out edge facing

around the rear suspension control arm hub outer

surface.

NOTE 2: Apply Loctite 242 (or a commercially

available equivalent) to the threads of the two

longer, lower hexagon headed bolts (5), before

installation.

35. Install the rear brake shield (1) to rear

suspension control arm (2) bolts and tighten to

the correct torque specification.

REAR BRAKE SHIELD TO REAR

SUSPENSION CONTROL ARM

UPPER ATTACHING BOLT

TORQUE SPECIFICATION ................... 70 – 80 Nm

REAR BRAKE SHIELD TO REAR

SUSPENSION CONTROL ARM

LOWE R ATTACHING BOLT

TORQUE SPECIFICATION ................... 85 – 90 Nm

Figure 4A-34

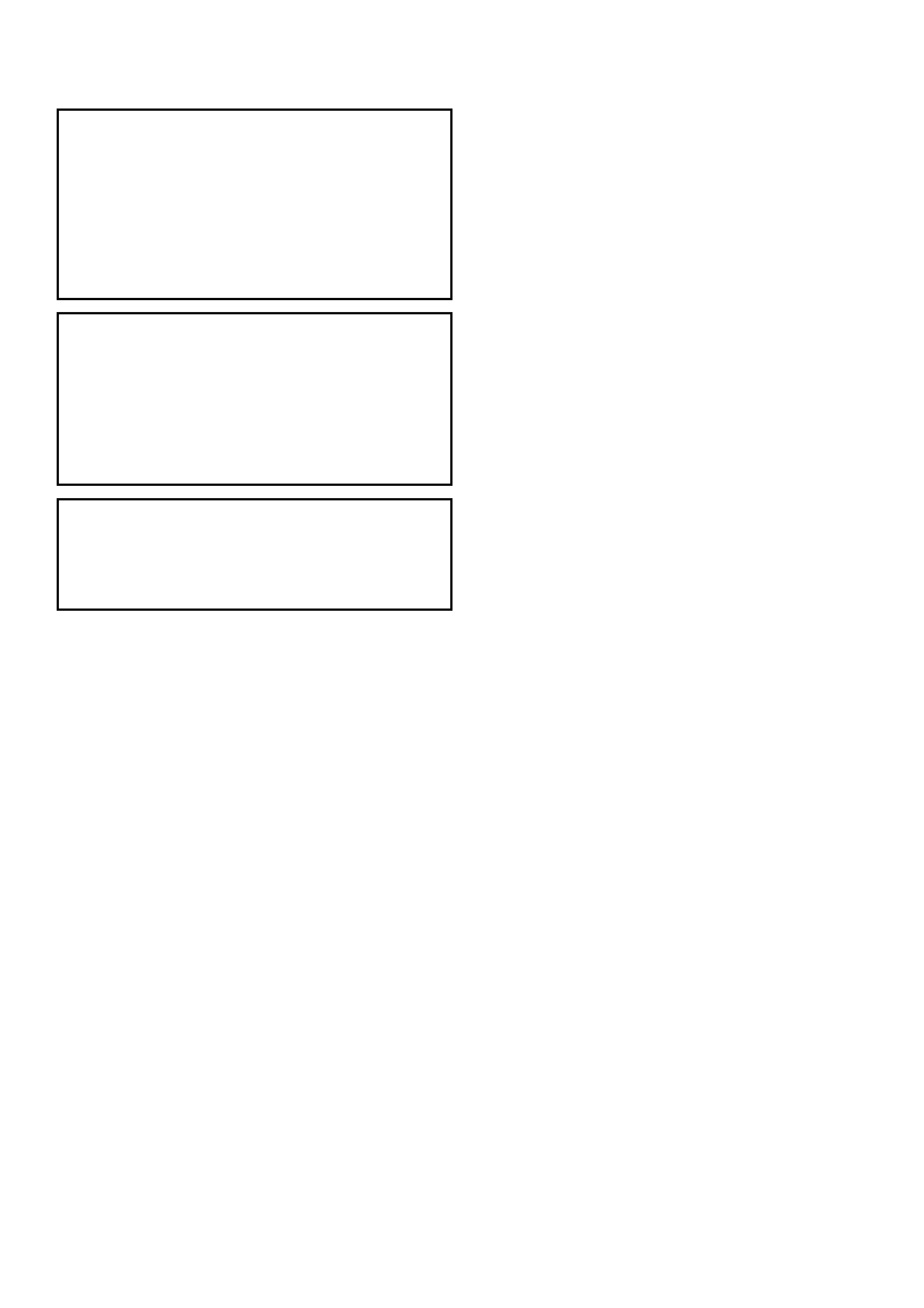

36. Position the outer rear wheel drive shaft (2)

with the centre hub section resting on a

suitable support (1) and press plates, checking

to make sure that the outer rear wheel drive

shaft wheel studs do not contact press plates.

37. Position the rear suspension control arm (3)

with the wheel bearing onto the outer rear

wheel drive shaft. W ith an assistant supporting

the rear suspension control arm assembly in

this position, us e installer KM620-9-A and steel

pipe (4) of suitable length and diameter, press

wheel bearing onto the outer rear wheel drive

shaft.

Figure 4A-35

38. Remove the installer KM620-9-A and steel

pipe. Assemble the flange holding tool KM620-

1-A and rear wheel drive shaft flange ring

KM620-2 to the rear wheel drive shaft flange

using three drive shaft attaching bolts (1).

39. Lubricate the rear wheel drive shaft flange

splines and the outer rear wheel drive shaft

threads with a suitable lubricant such as

Molybond HB50 (or a commercially available

equivalent), then install the rear wheel drive

shaft flange onto the outer rear wheel drive

shaft, aligning the splines on each.

40. W ith the outer rear wheel drive shaf t supported

on press plates, as in step 36, press the rear

wheel drive shaft flange onto the outer rear

wheel drive shaft using installer KM620-9-A

and a suitable steel pipe (2).

41. Remove the rear suspension control arm

assembly from the press and support the

assembly in a vice by the flats on flange

holding tool KM620-1-A.

42. Install a new collar nut to the outer rear wheel

drive shaft and tighten to the correct torque

specification.

( ! ) COLLAR NUT TO OUTER REAR

WHEEL DRIVE SHAFT

TORQUE SPECIFICATION ................ 295 – 305 Nm

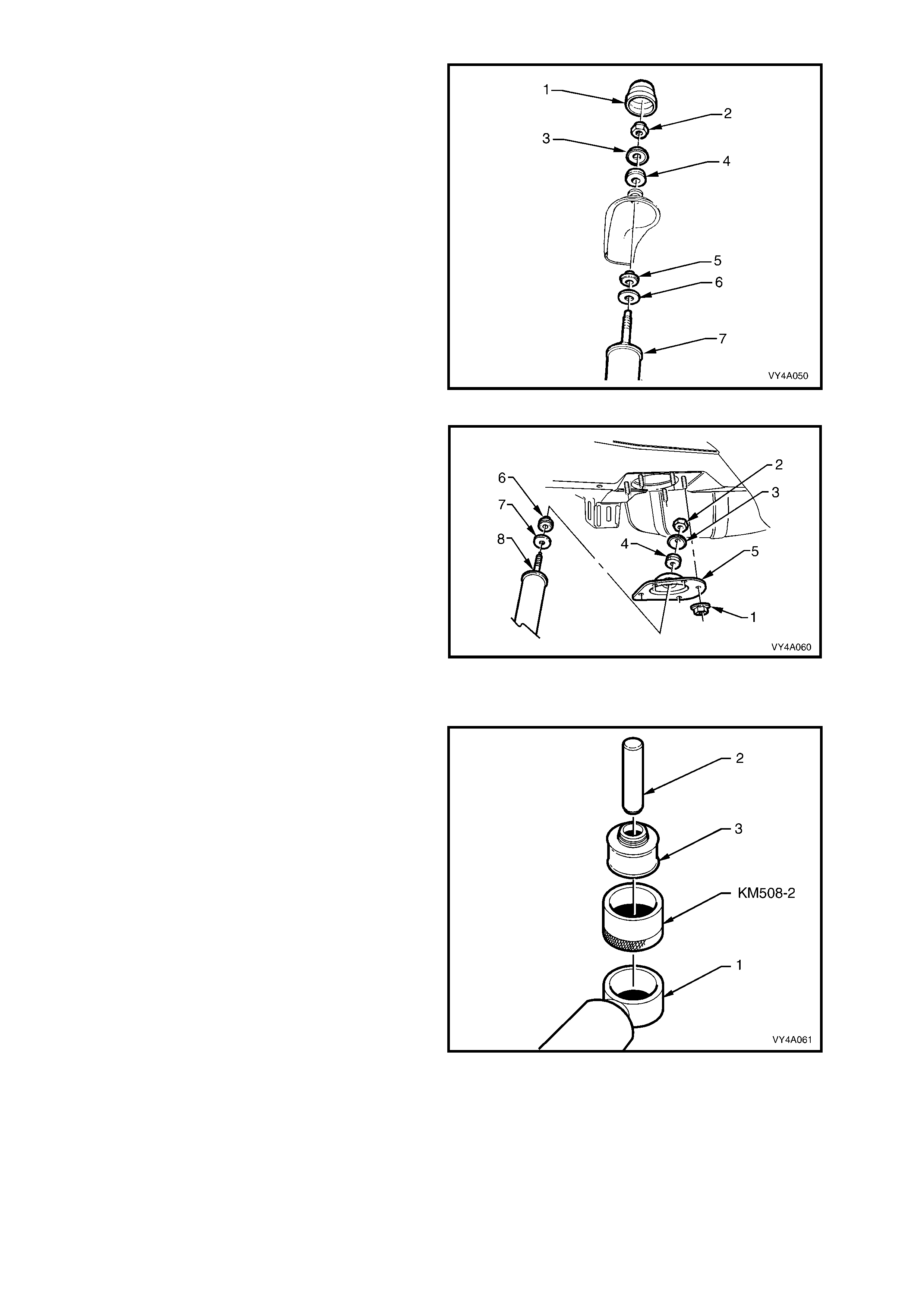

Figure 4A-36

43. Remove the rear suspension control arm

assembly from the vice and remove all the

special tools from the rear wheel drive shaft

flange. Using a suitable diameter socket (1),

150 mm socket shaft (2) and hammer (3),

install a new lock plate over the collar nut.

Figure 4A-37

2.4 REAR SUSPENSION CROSSMEMBER

LT Section No. – 07-150

NOTE 1: The following fasteners have either micro

encapsulation or incorporate a mechanical thread lock

and should only be used once. If in doubt, r eplacement

is recommended when performing this operation:

♦ Rear suspension crossmember front mounting

brace to under body attaching bolts.

♦ Additional control arm inner shaft attaching nut.

♦ Rear suspension control arm to rear suspension

crossmember attaching nut.

NOTE 2: The following fasteners MUST be replaced

when performing this operation:

!!!!$

$$

$ Rear suspension crossmember rear mount to

under body attaching bolt.

!!!!$

$$

$ Rear suspension crossmember front mounting

bolt.

!

!!

!$

$$

$ Differential carrier to rear suspension

crossmember attaching bolts.

NOTE 3: The following fasteners MUST be at curb

height before final tightening:

• Rear suspension control arm to rear suspension

crossmember attaching nut.

• Shock absorber lower mounting bolt.

CAUTION: Whenever any component that forms part of the ABS (if fitted) is disturbed during

Service Operat ions, it is v ital th at the co mplete ABS system b e checked, using the pro cedure as detailed in

4.4 ABS & T CS FUNCTION CHECK (V6 engines) or 5.4 ABS & TCS FUNCT ION CHECK (GEN III V8 engines),

in Section 5B ABS & TCS.

Important: Before dis tur bing the rear s uspens ion c r oss member mounting bolts, an alignment proc edure is r equired

on installation and a special tool is required for this purpose. If this tool is not available, then the crossmember

cannot be correctly aligned and steering and/or handling abnormalities will result.

REMOVE

1. Using a floor jack under the centre of the differential carrier, jack up the rear of the vehicle and place safety

stands under the body rear jacking points. Refer to Section 0A, GENERAL INFORMATION for location of

jacking points.

2. Remove the wheel covers (steel wheels) or centre caps (alloy wheels).

3. Mark the relationship of the road wheels to the hubs (eg. end of wheel stud), with a felt tipped pen or similar.

Loosen then remove the road wheel attaching nuts. Remove the road wheel.

4. Disconnect and remove the exhaust system from the rear of the catalytic converter/s.

5. Remove the intermediate muffler heatshield from the vehicle underbody.

NOTE: For information regarding the removal and installation of the exhaust components (including heatshields),

refer to Section 8B, EXHAUST SYSTEM.

6. To enable the propeller shaft to be installed in

the original position relative to the pinion flange,

use a felt tipped pen or similar to identify the

relationship (‘A’) between the two components.

7. With the transmission in the ‘Park’ position

(automatic transmission) or in first gear

(m anual transm ission and the park brak e firm ly

applied, use Torx socket K04425E20 or a

commercially available E20 Torx socket to

loosen the three T or x headed bolts (1) secur ing

the propeller shaft rear rubber coupling (2) to

the pinion flange (3).

8. Release the park brake to relieve any torque

loading on the rubber coupling, then remove

the three Torx headed bolts.

Figure 4C-38

9. W hile supporting the centre bearing carrier (1),

remove the two bolts (2) securing the centre

bearing carrier to the underbody reinforcement.

10. While supporting the centre bearing section,

slide the propeller shaft assembly forward to

disengage f rom the rear sus pension diff erential

assembly pinion support pin.

11. Install the centre bearing support bolts (do not

tighten) and use a suitable length of wire to tie

the rear of the pr opeller s haf t to a s uitable point

on the vehicle underbody.

Figure 4C-39

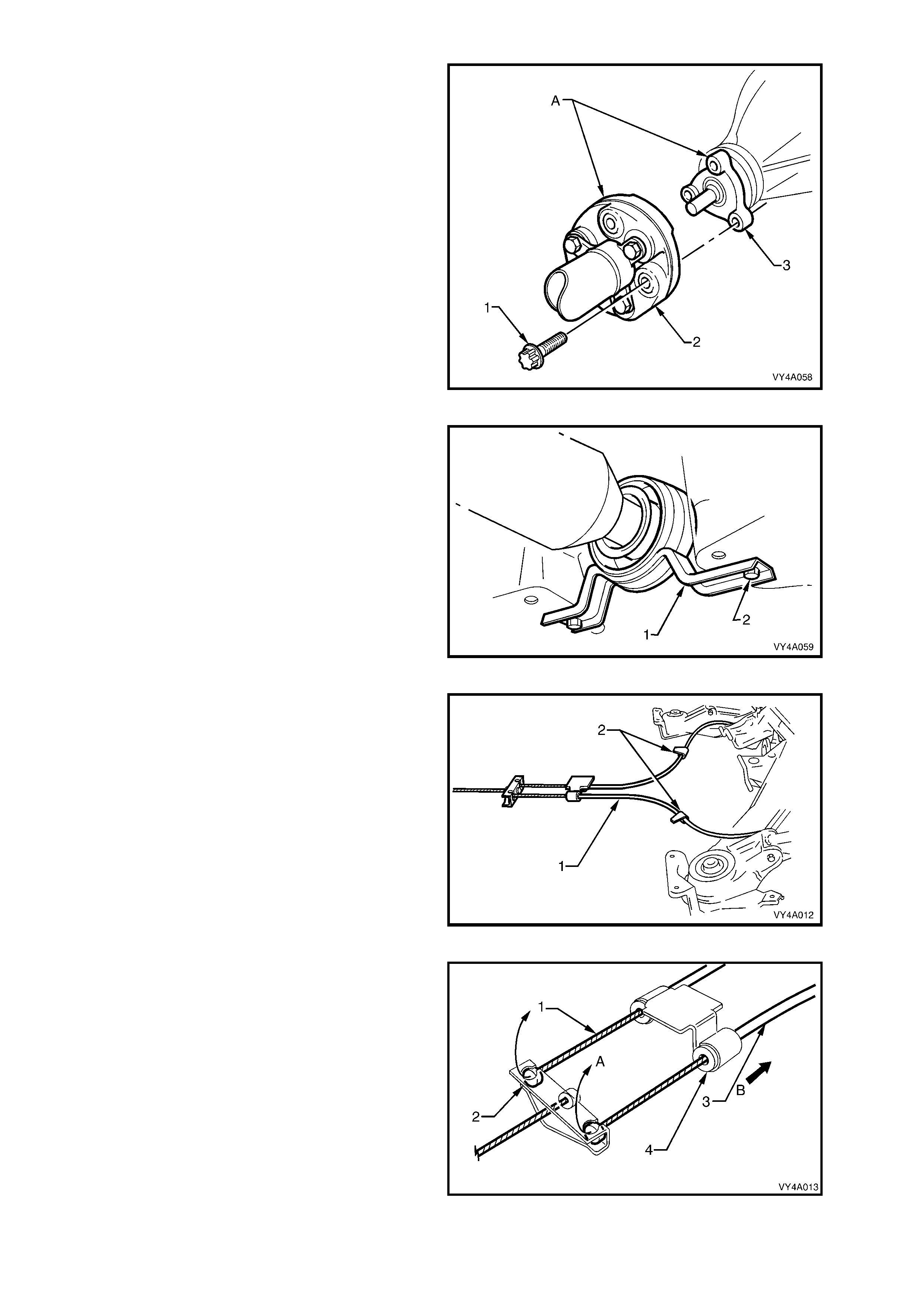

12. Set the park brake in the fully released position,

then release each of the underbody to park

brake cable (1) retaining clips (2) and free the

cables.

Figure 4A-40

13. Remove the park brake outer cable retaining

bracket bolt (underbody bracket and bolt are

not shown) from the vehicle underbody.

14. Pull each park brake inner cable (1) forward

and up in the direction of the arrow (A) and out

of the cable retainer (2) to release each cable.

15. Pull the outer cable (3) rearward (B) to remove

from the underbody retainer (4).

Figure 4A-41

16. Disconnect the brake pipe (1) from the brake

hose (2) at the rear suspension control arm

bracket (3) and remove the brake hose

retaining clip (4).

Plug the open ends of both pipes and hoses to

prevent unnecessary fluid loss and/or foreign

matter entry.

17. Repeat for the other side.

Figure 4A-42

18. Pull the differ ential c arr ier br eather hos e ( 1) out

of the hole (2) in the vehicle underbody rear

suspension crossmember.

Figure 4A-43

19. If the vehicle is f itted with ABS, pull both sensor

lead connectors from the underbody retaining

clips (1). Separate the sensor connectors from

the body harnes s connectors by levering with a

screwdriver.

Figure 4A-44

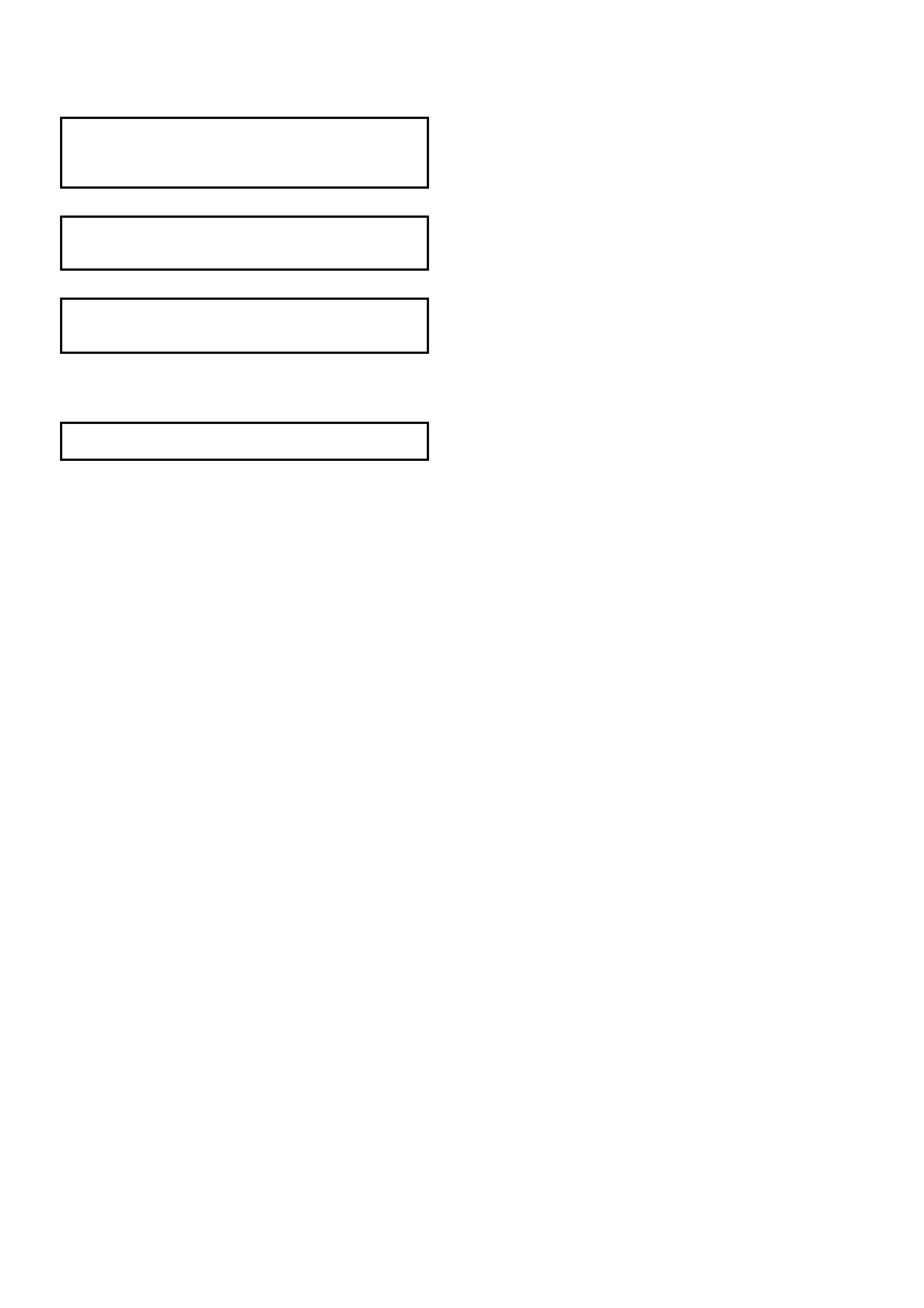

20. Using a scriber, mark the location (A) of the

rear mount (1) to vehicle under body location.

This will assist in rear suspension

crossmember alignment on installation.

21. Support the weight of the differential carrier

with a floor jack.

Figure 4A-45

22. Remove and discard the rear mount (1) to

vehicle underbody attaching bolts (2), the lower

differential carrier and rear suspension

crossmember assembly by at least 60 mm.

Figure 4A-46

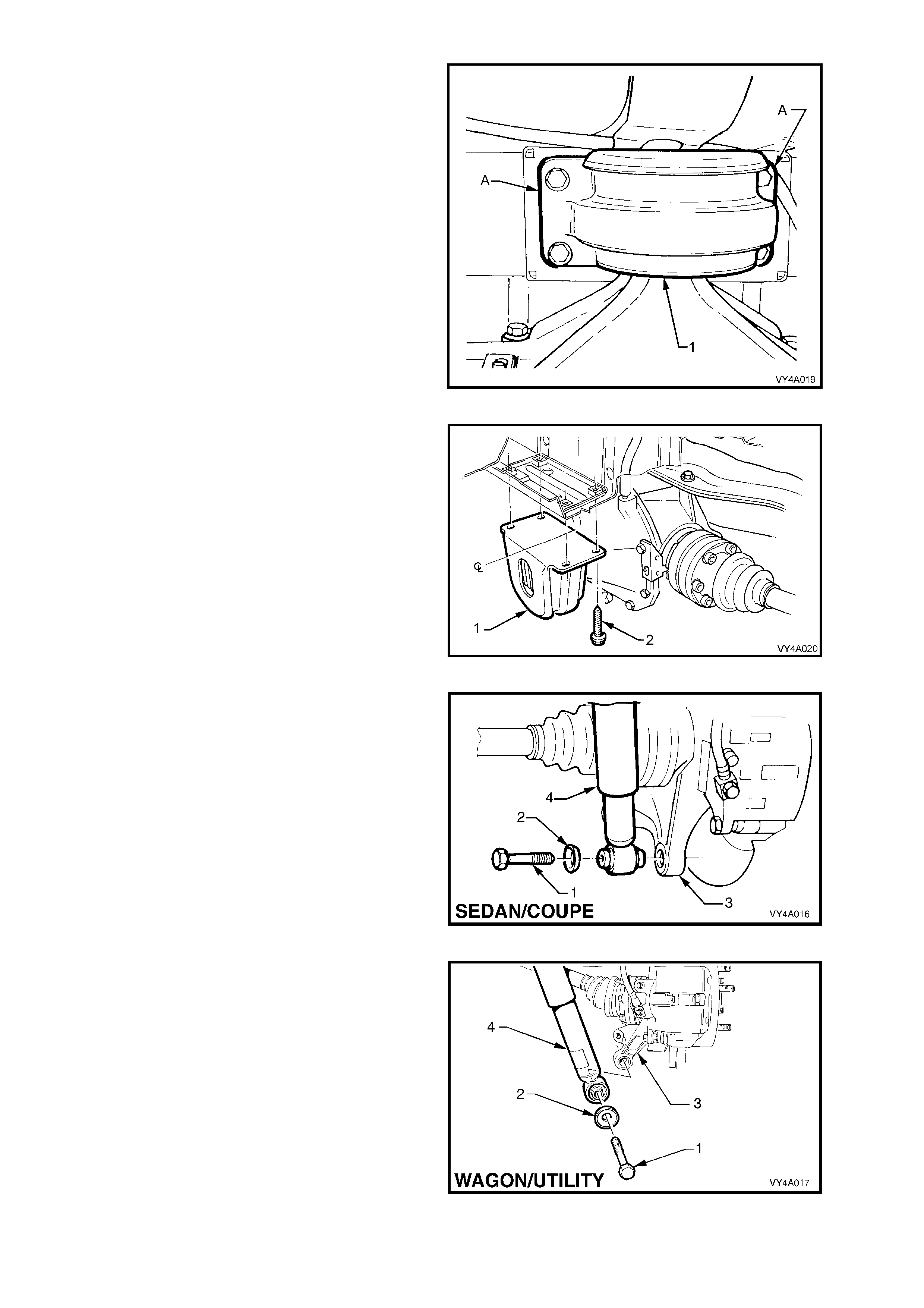

23. Position the floor jack with a block of wood

under the rear suspension control arm. Raise

the jack slightly to take the spring load off the

rear suspension control arm. Remove the rear

shock absorber lower mounting bolt (1) and

washer (2) from the rear suspension control

arm (3), then pull the lower end of the shock

absorber (4) from the rear suspension control

arm.

NOTE: Bruising to the inside of the drive shaft

constant velocity joint boots will occur if the shock

absorber is disconnected f rom the rear suspension

control arm bef ore the r ear of the dif f erential car rier

and crossmember assembly has been lowered by

at least 60 mm. Bruising of the boot will lead to

prem ature f ailure of the boot and eventual failure of

the joint if left unchecked.

Figure 4A-47

Figure 4A-48

24. Remove the rear springs (1), the upper

insulators (2) and the lower insulators (3) from

the vehicle underbody and rear suspension

control arms.

25. Raise the differential carrier and rear

suspension crossmember on a floor jack until

the rear mount contacts the vehicle underbody.

Figure 4A-49

26. Use a floor jac k and a bloc k of wood to support

the differential carrier and crossmember

assembly.

27. Remove the brace to underbody bolts (1)

(3 places) and crossmember to vehicle

underbody attaching bolt (2) from each side.

28. Remove the braces (3) from the vehicle.

29. With an assistant supporting the front end of

the rear suspension crossmember, lower the

assembly on the jack and remove from

beneath the vehicle.

NOTE: If the vehicle is fitted with the GEN III V8

engine and manual transmission, take care not to

lose the is olating r ubbers (4 ) loc ated on top of eac h

rear suspension crossmember front mount

bushing.

30. Remove the differential carrier and

crossmember assembly from the jack and

support the rear suspens ion control ar m s, drive

shafts and differential carrier on wooden

blocks.

Figure 4A-50

31. Remove the stabiliser shaft mounting bracket

attaching bolts (1). Use a screwdriver to lever

up the brackets (2) from the mounting points

and remove the brackets.

32. Remove and discard the differential carrier to

crossmember attaching bolts (3).

33. Remove the rear suspension control arm to

crossmember attaching bolts and nuts (4).

Discard the nuts, as new ones must be used

on reassem bly. Disengage the rear suspens ion

control arms from the crossmember.

34. After loosening the stabiliser link attaching nuts

(5) at each end and on each side to avoid

stres s on the bus hing, s wing the stabilis er s haf t

(6) back from the crossmember.

35. Remove the additional control arm inner shaft

to rear suspension crossmember retaining nut

and bolt and manoeuvre the additional control

arm free from the crossmember.

36. Lift up and remove the crossmember.

Figure 4A- 51

REINSTALL

Installation of the rear suspension crossmember is the reverse of the rem oval procedures, except for the following

steps:

1. If replacing a crossmember that does not have front mount bushing, install new bushing. Refer to

2.5 REAR SUSPENSION CROSSMEMBER FRONT MOUNT BUSHING in this Section, for the required

procedure.

2. Install the crossmember over the differential carrier and rear suspension control arms.

3. Assemble the rear suspension control arms into the crossm ember brackets and install the attaching bolts and

new self-locking nuts.

Do not fully tighten nuts at this stage.

4. Align the crossmember and differential carrier mounting holes, install new attaching bolts and tighten to the

correct torque specification.

( ! ) DIFFERENTIAL ASSEMBLY TO

REAR CROSSMEMBER ATTACHING

BOLT TORQUE SPECIFICATION......... 90 Nm, plus

30° - 45°

turn angle

5. Position the stabilis er shaft onto the cros smem ber, with the insulators located over the cross mem ber m ounting

points.

6. Engage the brackets into the mounting points and install over the insulators, install attaching bolts and tighten to

the correct torque specification.

Stabiliser shaft mounting

bracket TO CROSSMEMBER

ATTACHING BOLT

TORQUE SPECIFICATION ................... 18 – 26 Nm

7. Install the additional control arm into the rear suspension crossmember, install attaching bolt and a NEW nut

and tighten to the correct torque specification.

( # ) ADDITIONAL CONTROL ARM

INNER SHAFT ATTACHING NUT

TORQUE SPECIFICATION ................... 55 – 70 Nm

8. With the aid of two ass istants, place the dif ferential c arrier and rear s uspension cros sm ember assem bly onto a

floor jack.

9. Position the assembly under the vehicle, raise with the jack and, with the aid of the assistants, guide the

crossmember front mounting points into position.

NOTE: During this operation, ensure that rear suspension control arms are also supported on safety stands, to

keep the drive shafts as near to horizontal as possible. Otherwise, bruising to the insides of the constant velocity

joint boots will result, leading to boots splitting and eventually joint failure, if left unchecked.

10. If the vehicle is fitted with the GEN III V8 engine

and manual transmission, an isolating rubber

(4) must be fitted at the top of each

crossmember front mount bushing as shown,

before raising the assembly into place.

11. Install both crossmember front mounting

braces (3), the six mounting brace attaching

bolts (1) and the two rear suspension

crossmember front mounting bolts (2) but do

not fully tighten any of these bolts at this

stage.

Figure 4A-52

12. Lower the differential carrier and rear

suspension crossmember assembly on the

floor jack and s afety stands. Install rear springs

(1) and the upper (2) and lower (3) spring

insulators between the rear suspension control

arm and the vehicle underbody.

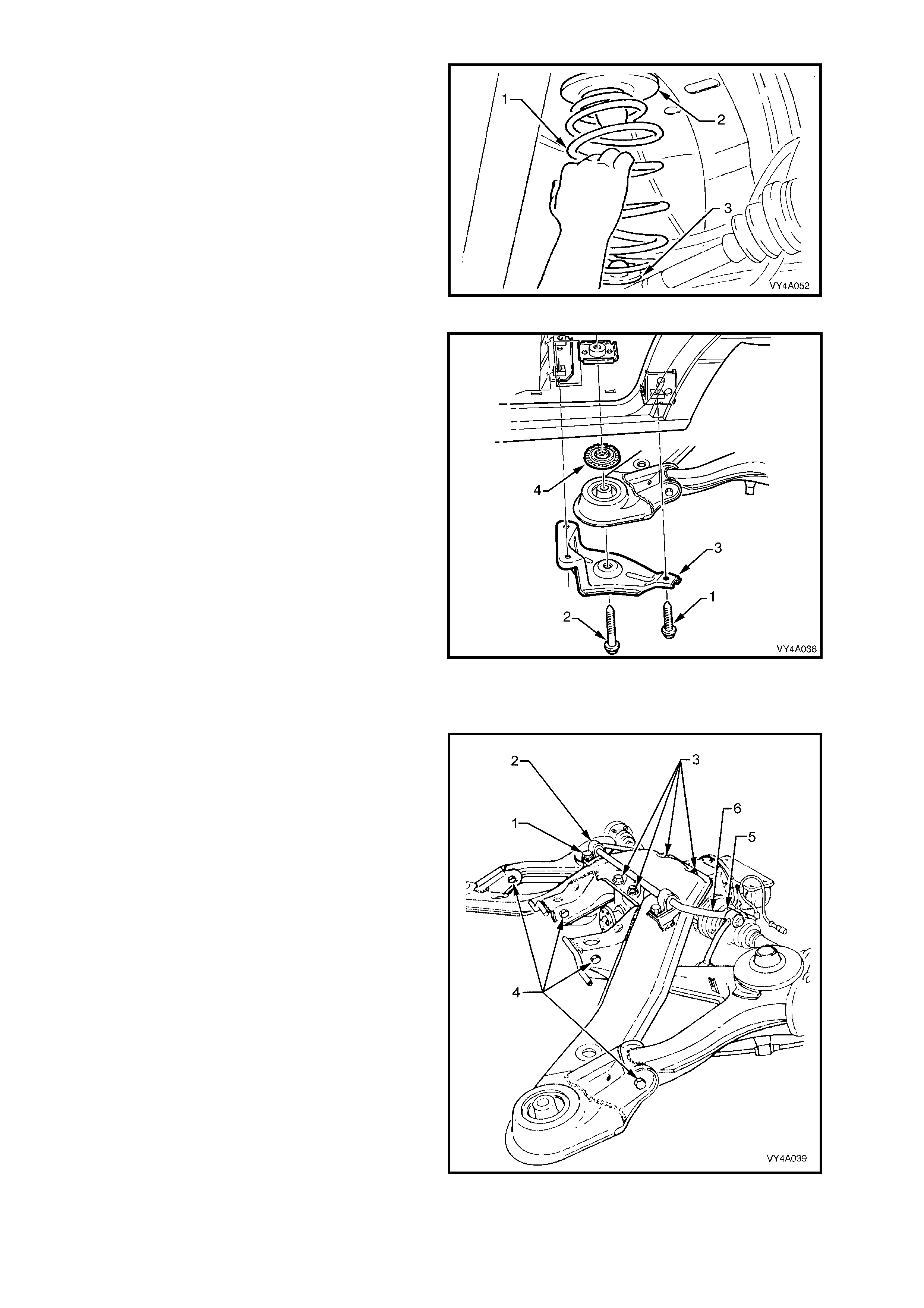

Figure 4A-53

13. With both springs and insulators installed, use

a second floor jack to raise each rear

suspension control arm (1) up sufficiently to

allow shock absorber (2) lower mounting to be

installed to the rear suspension control arm.

14. Install washers (3) and bolts (4) into the shock

absorber lower mounts but do not fully

tighten at this stage. Repeat for the other

side.

NOTE 1: T he torque s pecific ation for Sedan/Coupe

and Station Wagon/Utility are the same.

NOTE 2: Vehicle m ust be at curb weight and on all

four wheels before this the shock absorber lower

mounting bolts are tightened to the correct torque

specification.

Figure 4A-54

Figure 4A-55

15. Raise the assembly until the rear mount

contacts the vehicle underbody.

16. Align the rear mount (1) with the marks (A) on

the underbody, made on disassembly, then

loosely install new attaching bolts but do not

fully tighten at this stage.

17. The rear suspension crossm ember MUST now

be aligned to the vehicle centreline, using the

special tool and procedure as detailed in

Section 1A2, BODY DIMENSIONS.

CAUTION: Failure to correctly align the rear

suspension crossmember to the centreline of

the vehicle will result in steering abnormalities

and uneven tyre wear!

18. Tighten all cros sm em ber m ounting f astener s to

the correct torque specification.

( ! ) CROSSMEMBER REAR MOUNT TO

VEHICLE UNDERBODY ATTACHING

BOLT TORQUE SPECIFICATION...... 30 – 40 Nm,

Plus 55° – 65°

turn angle

( ! ) REAR SUSPENSION CROSSMEMBER

FRONT MOUNTING BOLT

TORQUE SPECIFICATION ................ 125 Nm, plus

30° – 40°

turn angle

( ! ) REAR SUSPENSION CROSSMEMBER

FRONT MOUNTING BRACE BOLT

TORQUE SPECIFICATION ...................... 70 Nm

Figure 4A-56

19. Install the differential carrier breather hose into the hole in the vehicle underbody rear suspension

crossmember, ensuring that the end of the hose is pushed into the hole approximately 25 mm.

20. If equipped with ABS, reconnect the wheel sensor wiring harness connectors and install into the retaining clips.

21. Check the park brake adjustment and bleed the brake hydraulic system, refer to Section 5A, SERVICE AND

PARK BRAKING SYSTEM.

22. Reinstall the exhaust system, using new gasket/seal at the flanges on the catalytic converters.

23. Tighten the intermediate exhaust pipe to catalytic converter bolts to the correct torque specification.

INTERMEDIATE EXHAUST PIPE TO

CATALYTIC CONVERTER BOLT

TORQUE SPECIFICATION ................... 40 – 50 Nm

(All Engines)

24. Check the exhaust clearances as detailed in Section 8B, EXHAUST SYSTEM.

25. Install the road wheel/s, aligning the marks made prior to removal and secure with the attaching nuts but do not

fully tighten at this stage.

26. Remove the safety stands and lower the vehicle.

27. Bounce the rear of the vehicle several times to settle the suspension then, with vehicle in the curb height

position, tighten rear suspension control arm to crossmember attaching nuts, stabiliser shaft link nuts and the

shock absorber lower mounting bolts to the correct torque specifications.

( " # ) REAR SUSPENSION CONTROL

ARM TO REAR CROSSMEMBER

ATTACHING NUT

TORQUE SPECIFICATION ................... 95 – 105 Nm

STABILISER SHAFT LINK, UPPER

AND LOWER MOUNTING NUT

TORQUE SPECIFICATION ...................90 – 105 Nm

( " ) SHOCK ABSORBER

LOWER MOUNTING BOLT

TORQUE SPECIFICATION ................ 105 – 125 Nm

28. Tighten the road wheel attaching nuts to the correct torque specification, working in a ‘star’ pattern. Refer to

Section 10, WHEELS AND TYRES for detailed information regarding installation procedure for the road

wheels.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION ................ 100 – 125 Nm

29. Install the wheel cover/centre cap.

30. Start the vehicle and check the exhaust system for leaks. Repair as necessary.

2.5 REAR SUSPENSION CROSSMEMBER FRONT MOUNT BUSHING

LT Section No. – 07-150A

NOTE 1: The following fasteners have either micro

encapsulation or incorporate a mechanical thread lock

and should only be used once. If in doubt, replacement

is recommended when performing this operation:

♦ Rear suspension crossmember front mounting

brace to under body attaching bolts.

NOTE: The following fasteners MUST be replaced

when performing this operation:

!!!!$

$$

$ Rear suspension crossmember front mounting

bolt.

CAUTION: Whenever any component that forms part of the ABS (if fitted) is disturbed during

Service Operat ions, it is v ital th at the co mplete ABS system b e checked, using the pro cedure as detailed in

4.4 ABS & T CS FUNCTION CHECK (V6 engines) or 5.4 ABS & TCS FUNCT ION CHECK (GEN III V8 engines),

in Section 5B ABS & TCS.

Important: Before removing the rear suspension crossmember, front mounting bolts, an alignment procedure is

required on installation and a special tool is required for this purpose. If this tool is not available, then the

crossmember cannot be correctly aligned and steering and/or handling abnormalities will result.

OFF-CAR REPLACEMENT

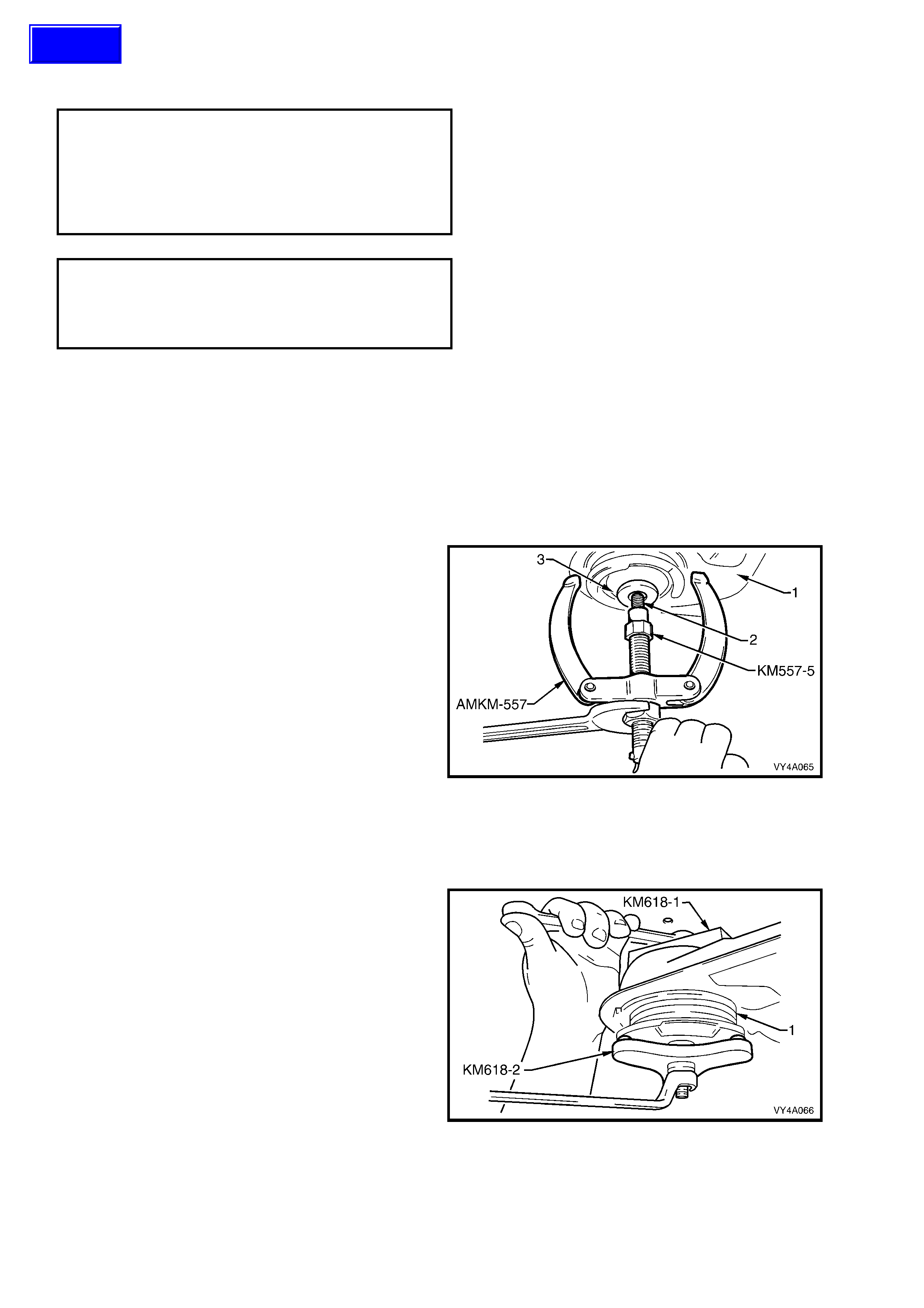

1. With the rear suspension crossmember (1)

removed, install the crossmember to

underbody attaching bolt (2) into the bushing

(3) from above.

NOTE: For information regarding the removal

and installation procedure for the rear

suspension crossmember assembly, refer to

2.4 REAR SUSPENSION CROSSMEMBER in this

Section.

2. Screw the underbody attaching bolt into puller,

Tool No. AMKM-557 and adaptor, Tool No.

KM-557-5 (part of Tool No. AMKM-557).

3. Tighten the forcing nut while holding the

threaded shaft of Tool No. AMKM-557 until the

bushing is removed from the crossmember.

4. Remove the crossmember to underbody

attaching bolt from the puller and adaptor

assembly and discard the bush.

Figure 4A-57

5. Draw the new bushing (1) into the

crossmem ber (2) using Tool No. KM618-1 and

KM618-2.

Figure 4A-58

Techline

ON-CAR REPLACEMENT

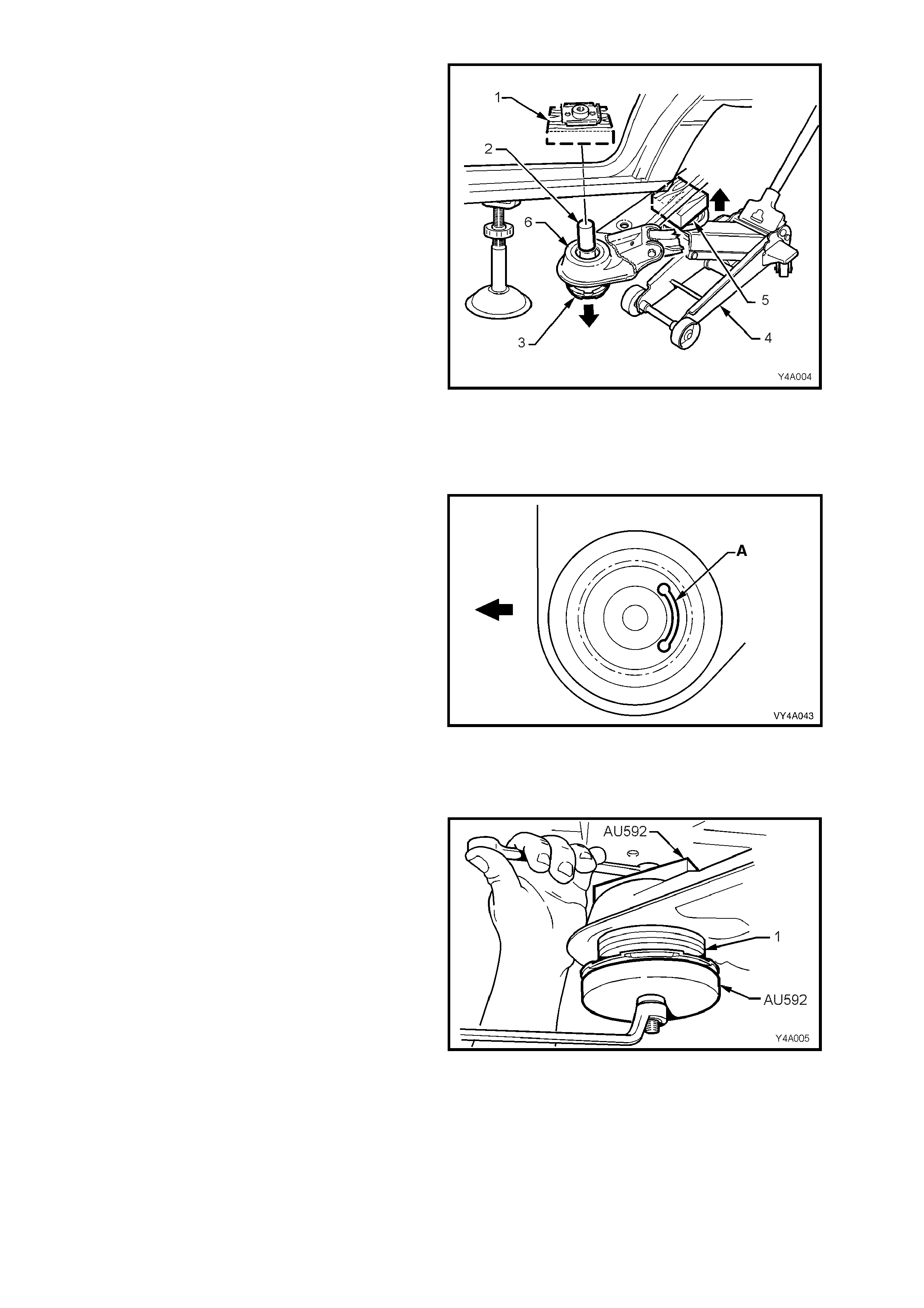

1. Using a floor jack (2) with a suitable wood block

(1) mounted on top of the floor jack to support

and protect the underside of the centre

differential carrier, jack up the rear of the

vehicle.

Figure 4A-59

2. Position s af ety stands (2) to s upport the vehic le

weight at both the LH side and RH side under

body rear jacking points (1). Refer to

Section 0A, GENERAL INFORMATION, for

the detailed information regarding the location

of the vehicle jacking points.

Figure 4A-60

3. Position a floor jack (2) with a suitable block of

wood (1) mounted on top of the jacks’ lifting

pad to support and protec t the rear suspension

cross member as sembly (3) dur ing the f ollowing

procedure.

4. Take up the weight of the crossmember by

raising the floor jack to make contact with the

cross mem ber, nearest to the side on which the

bushing is to be replaced.

5. Rem ove the brac e (6) and the cros smem ber to

vehicle underbody attaching bolts (4 & 5) from

the same side of the vehicle.

6. Lower the floor jack slightly to allow clearance

between the crossmember and the vehicle

underbody.

Figure 4A-61

7. Place a suitable block of wood (1),

approxim ately 50m m in width x 50m m in length

x 25mm in depth, along with a suitable metal

distance piece (2), approximately 50mm in

length x 30mm in diameter, between the

bushing (3) to be removed and the underbody.

8. Raise the floor jack (4) slowly with a suitable

block of wood (5) m ounted on top, allowing the

clearance to reduc e between the crossm em ber

(6) bush, distance piece and the underbody to

apply force in a downward direction on the

bush.

9. Incr ease the pr ess ur e applied by the floor jack ,

gradually pressing the bushing downward and

free of the crossmember. The vehicle weight

and the up-ward movement of the jack will

apply adequate force in a downward direction

to facilitate removal of the bush.

10. Remove and discard the bushing together with

the crossmember front mounting to underbody

bolt.

11. Lower the floor jack to allow clearance for

installation of the new bush.

Figure 4A-62

12. Apply a small amount of petroleum jelly to the

outer diameter area of the new bush, to assist

the installation of the bushing into the

crossmember bushing aperture.

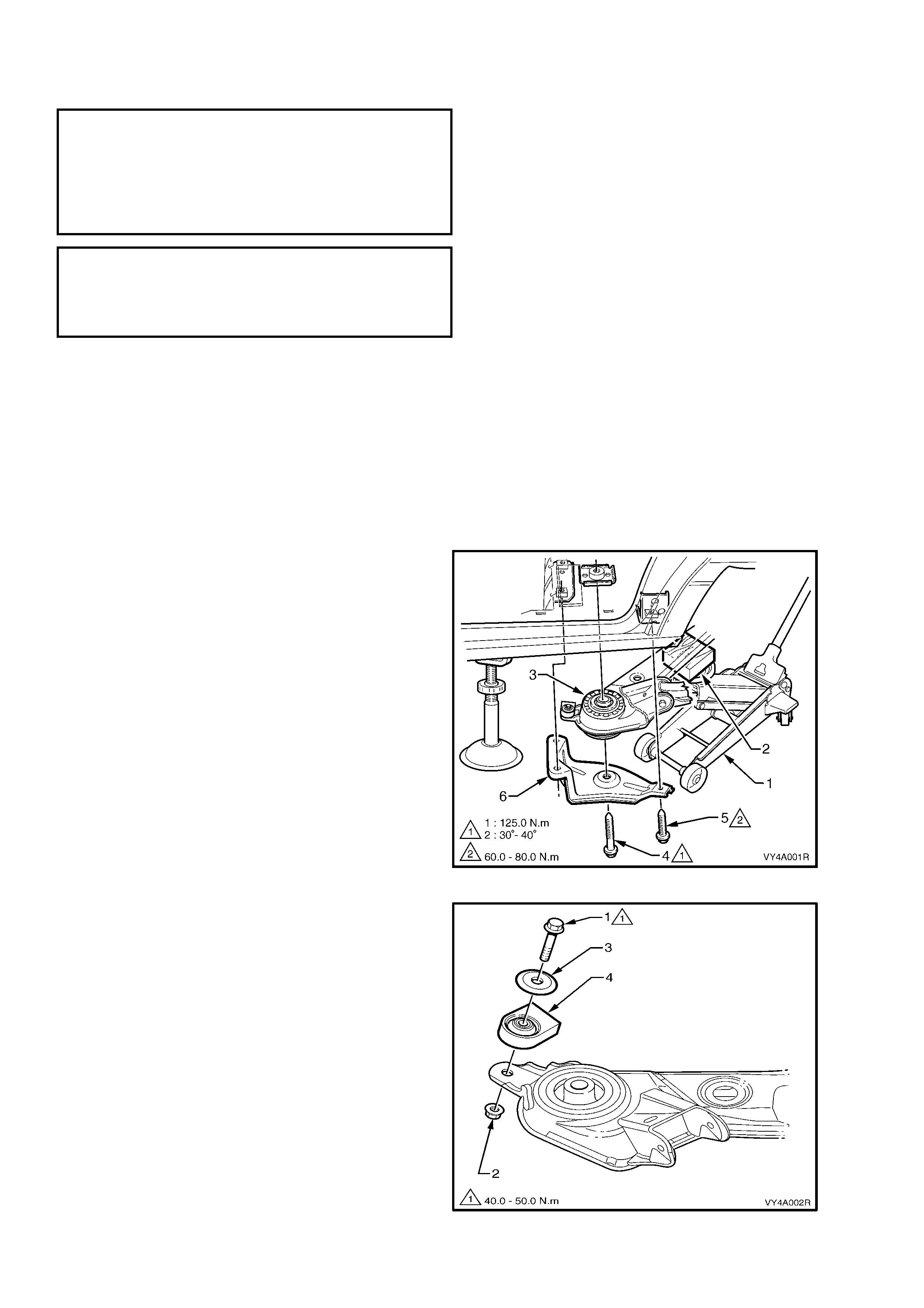

13. For all MY 2003 VY and V2 Series Models

except left-hand drive Lumina, align the new

bushing with the voided section facing the rear

of the vehicle, as shown in Figure 4A-63.

14. For all MY 2003 VY and V2 Series left-hand

drive Lumina Models, position the location

identification mark (Blue) toward the front of the

vehicle, in a 30° inboard direction (toward the

centre line of the vehicle) and apply hand

pressur e to initially start the leading edge of the

bushing into crossmember bushing aperture.

NOTE: Th is installation s tep applies to both LH and

RH side applications respectively.

Figure 4A-63

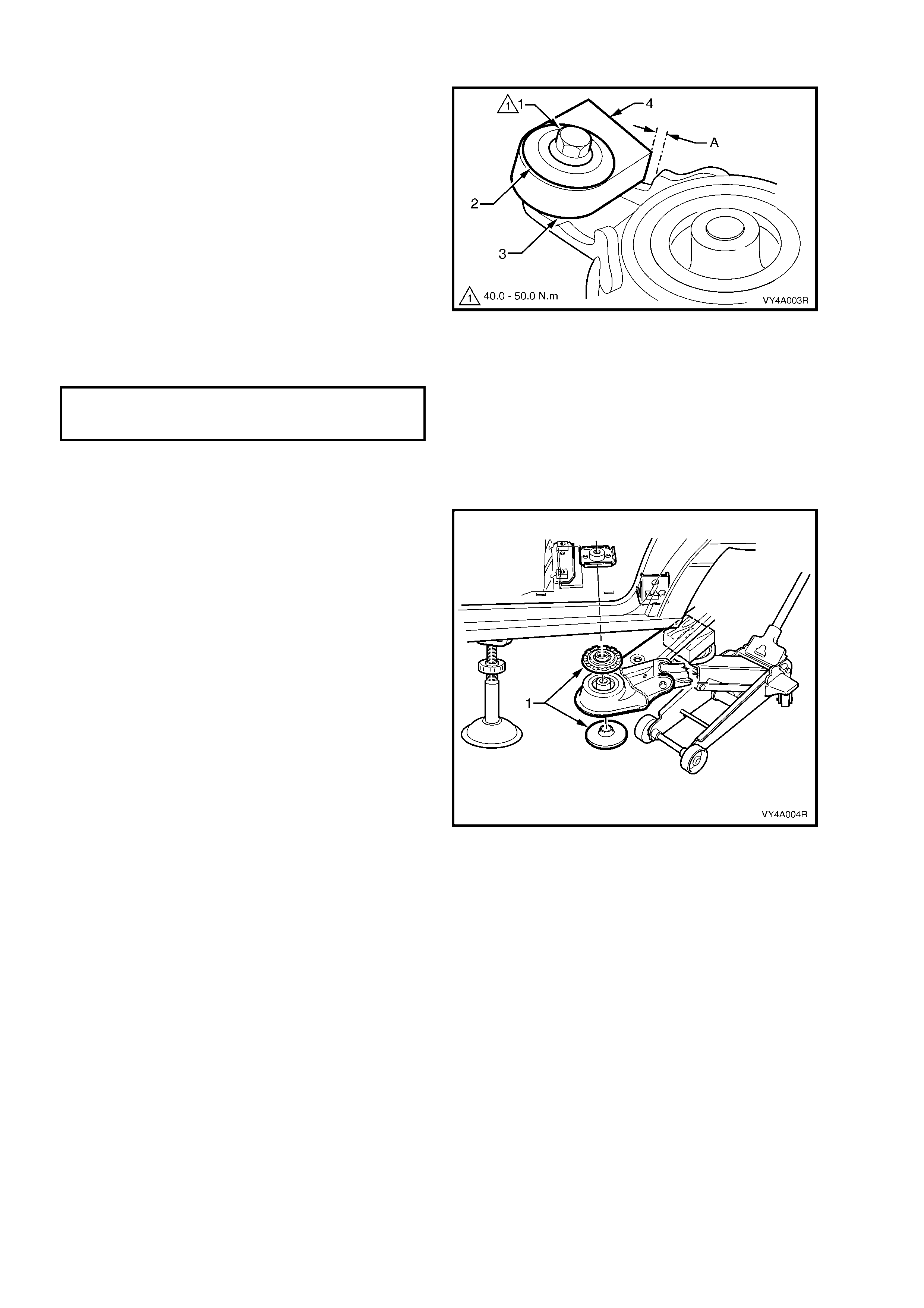

15. Offer the new bushing (1) up to the

crossmember.

16. Apply the installation Tool No. AU592 to the

bushing and crossmember.

17. Draw the remaining exposed section of the new

bushing into the crossmember using Tool No.

AU592.

Figure 4A-64

18. Position the upper insulator pad (1), between

the underbody and the upper part of the

bushing and crossmember (3).

19. With the floor jack still in position to support

and protect the rear suspension crossmember

assembly, raise the crossmember using the

floor jack.

20. Position the lower insulator pad (2), between

the lower part of the bushing and the brace.

Figure 4A-65

21. Install the brace (6), a new crossmember front

mounting to underbody bolt (5), and the three

smaller original brace attaching bolts (4), but do

not tighten the bolts at this stage.

22. If necessary, repeat steps 1 to 21 for the

opposite side.

23. The rear suspension crossm ember MUST now

be chec ked f or correct alignm ent to the vehicle

centreline. Using the special tool and

procedure, as detailed in Section 1A2, BODY

DIMENSIONS.

CAUTION: Failure to correctly align the rear

suspension crossmember to the centreline of

the vehicle will result in steering abnormalities

and or uneven tyre wear.

24. Tighten bolts (4 and 5) to the correct torque

specification.

( ! ) REAR SUSPENSION CROSSMEMBER

TO UNDERBODY FRONT MOUNTING

BOLT TORQUE SPECIFICATION......... 125 Nm, plus

30° - 40°

turn angle

( 6 ) REAR SUSPENSION CROSSMEMBER

BRACE MOUNTING BOLT

TORQUE SPECIFICATION ................... 70 Nm

25. Using a floor jack (2) with a suitable block of

wood (1) mounted on top of the jack lifting pad

to support and protect under the centre of the

differential carrier, raise the rear of the vehicle

from the safety stands.

26. Remove the safety stands, carefully lower the

vehicle to the floor and remove the jack.

Figure 4A-66

2.6 REAR SUSPENSION CROSSMEMBER MASS DAMPER

LT Section No. – 07-150A

NOTE 1: The following fasteners have either micro

encapsulation or incorporate a mechanical thread lock

and should only be used once. If in doubt, replacement

is recommended when performing this operation:

♦ Rear suspension crossmember front mounting

brace to under body attaching bolts.

NOTE: The following fasteners MUST be replaced

when performing this operation:

!!!!$

$$

$ Rear suspension crossmember front mounting

bolt.

CAUTION: Whenever any component that forms part of the ABS (if fitted) is disturbed during

Service Operat ions, it is v ital th at the co mplete ABS system b e checked, using the pro cedure as detailed in

4.4 ABS & T CS FUNCTION CHECK (V6 engines) or 5.4 ABS & TCS FUNCT ION CHECK (GEN III V8 engines),

in Section 5B ABS & TCS.

IMPORTANT: It is necessary to perform an alignment procedure when the front mounting bolts have been loosened

or removed. A special tool is required for this procedure, and if this tool is not available, then the crossmember

cannot be correctly aligned and steering and/or handling abnormalities will result.

REMOVE

1. Raise the vehicle and place on saf ety st ands. Refer to Section 0A, GENERAL INFORM ATION f or the location

of jacking and support points.

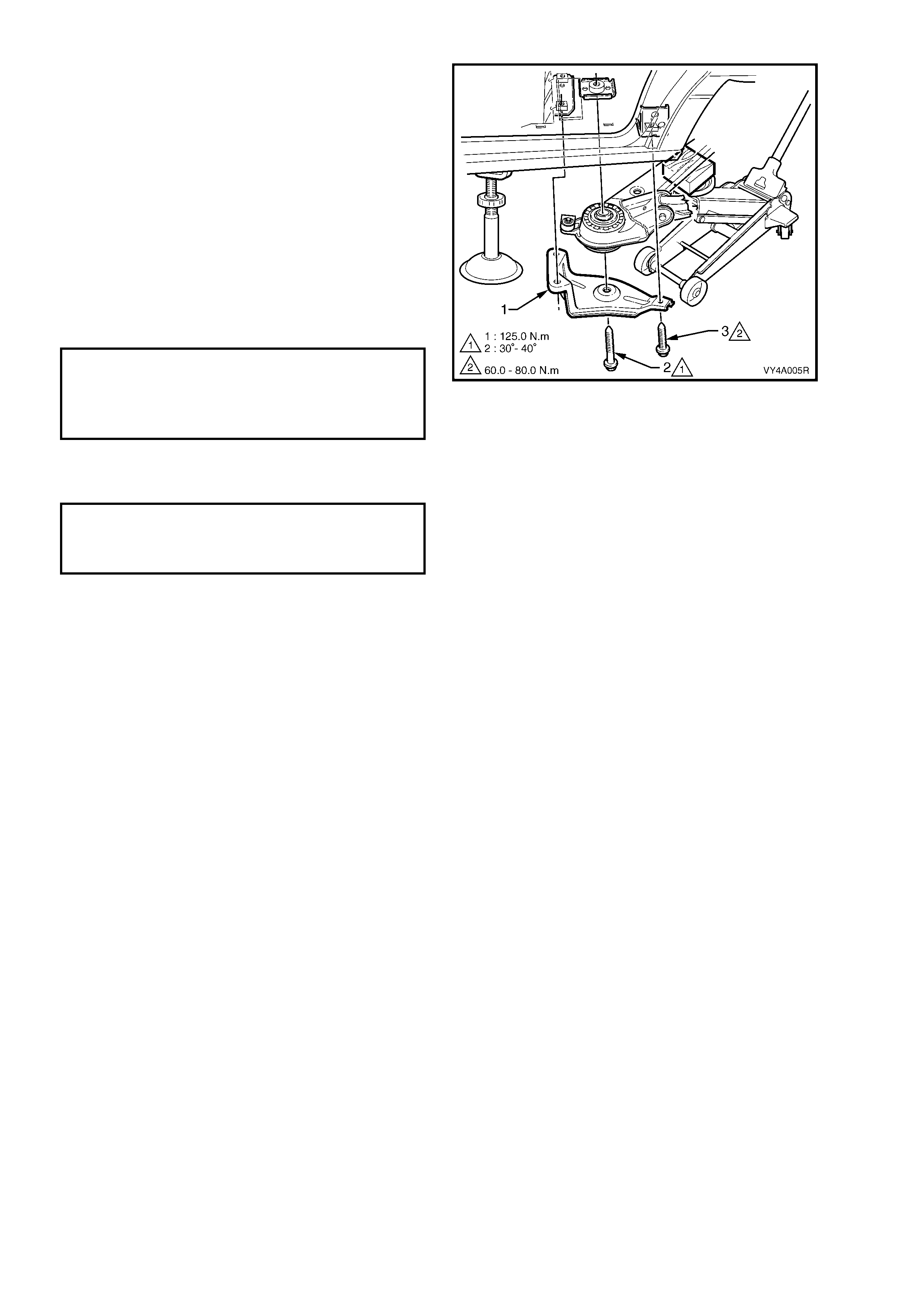

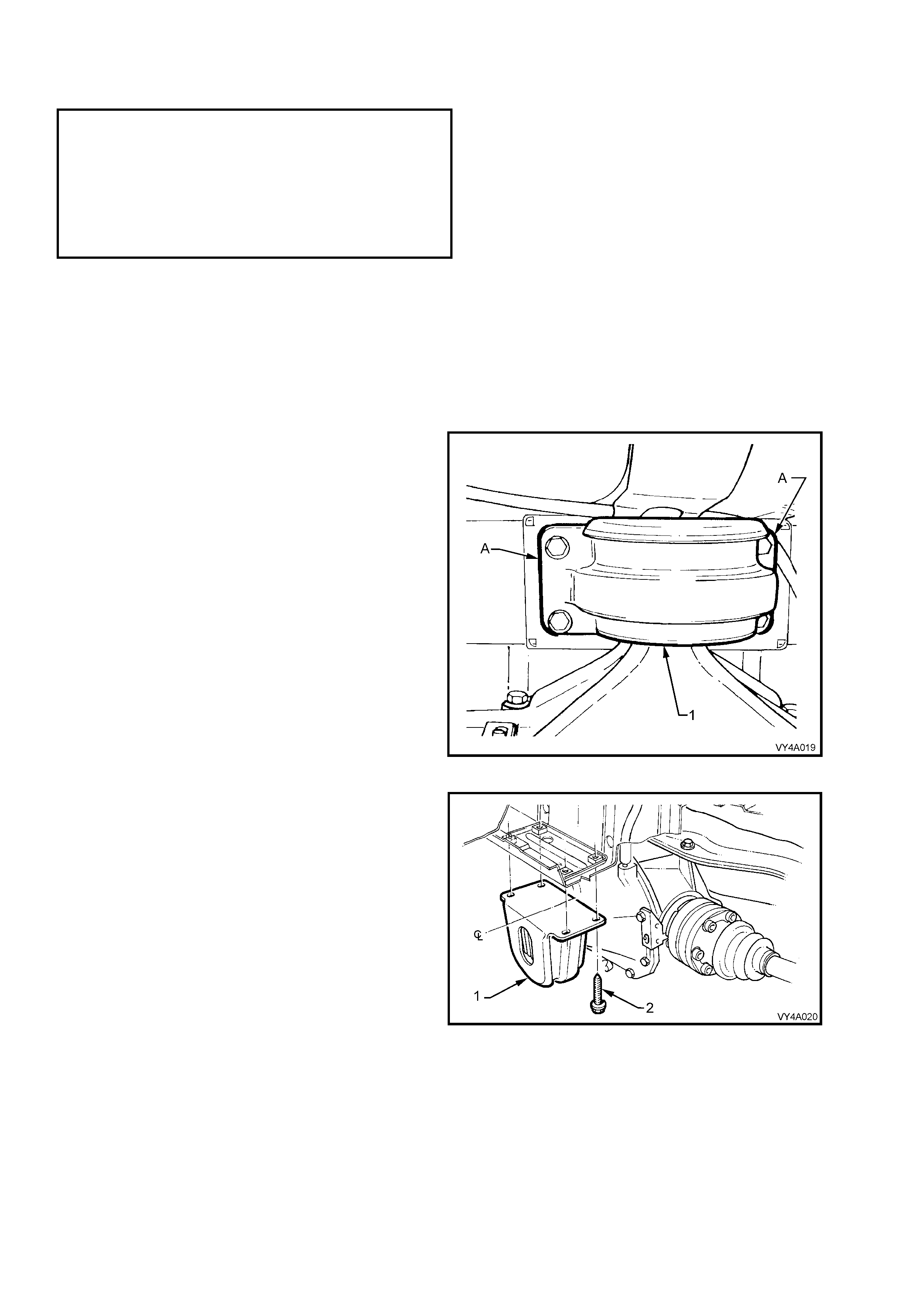

2. Position a floor jack (1) with a suitable block of

wood (2) mounted on top of the jacks’ lifting

pad to support and protec t the rear suspension

cross member as sembly (3) dur ing the f ollowing

procedure.

3. Take up the weight of the crossmember by

raising the floor jack to make contact with the

cross mem ber, nearest to the side on whic h the

rear sus pension cros smem ber m ass damper is

to be replaced.

4. Remove the rear suspension crossmember

front mounting attaching bolt (4). Discard the

removed bolt.

5. Remove the bolt (5), three places, and rem ove

the rear suspension crossmember front

mounting brace (6). Discard the removed bolts.

6. Lower the floor jack slightly to allow clearance

between the crossmember and the vehicle

underbody.

Figure 4A-67

7. Using a back-up spanner on the rear

suspension crossmember mass damper bolt

(1), remove the nut (2).

8. Remove the bolt, washer (3) and rear

suspension crossmember mass damper (4)

from the crossmember.

Figure 4A-68

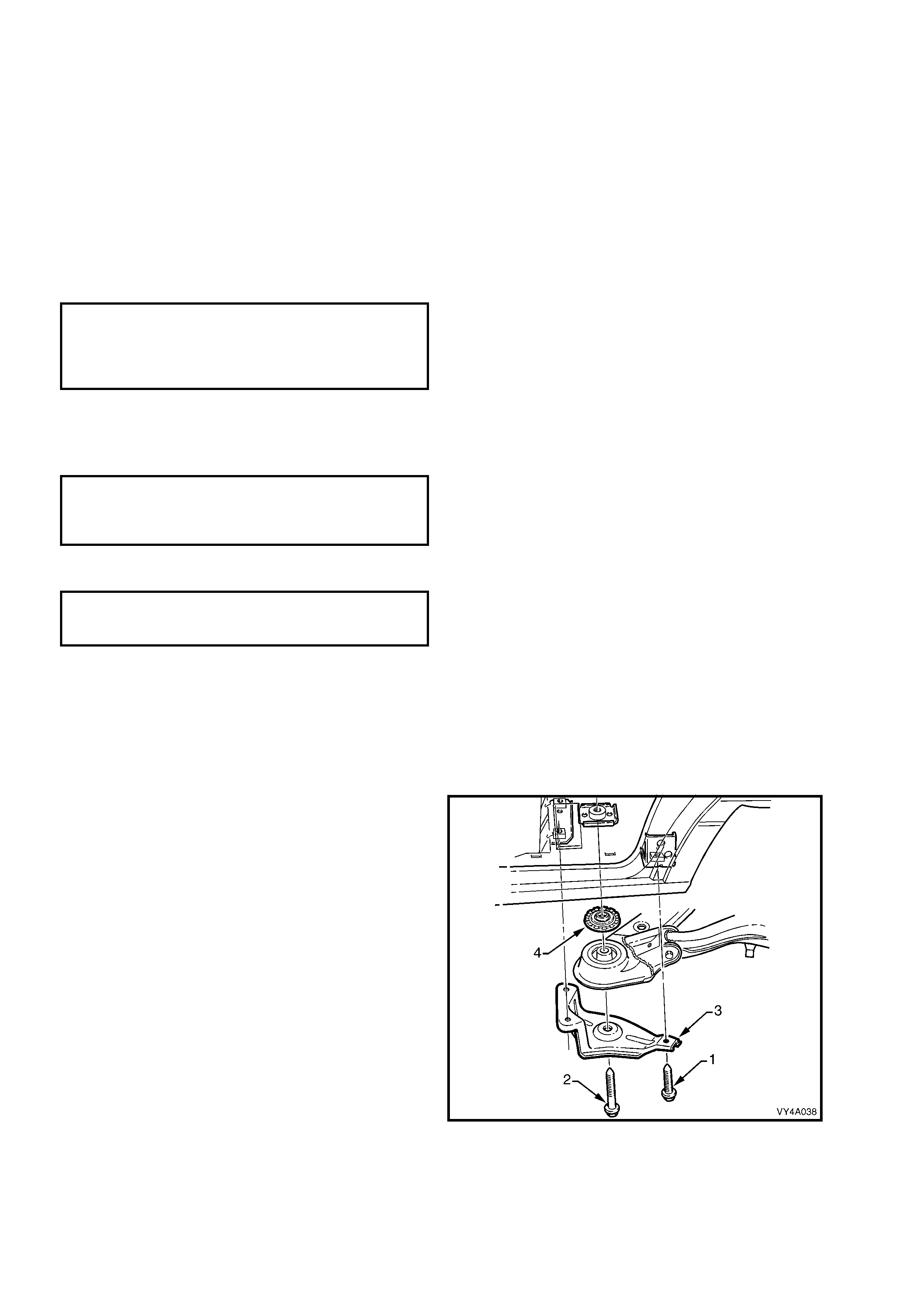

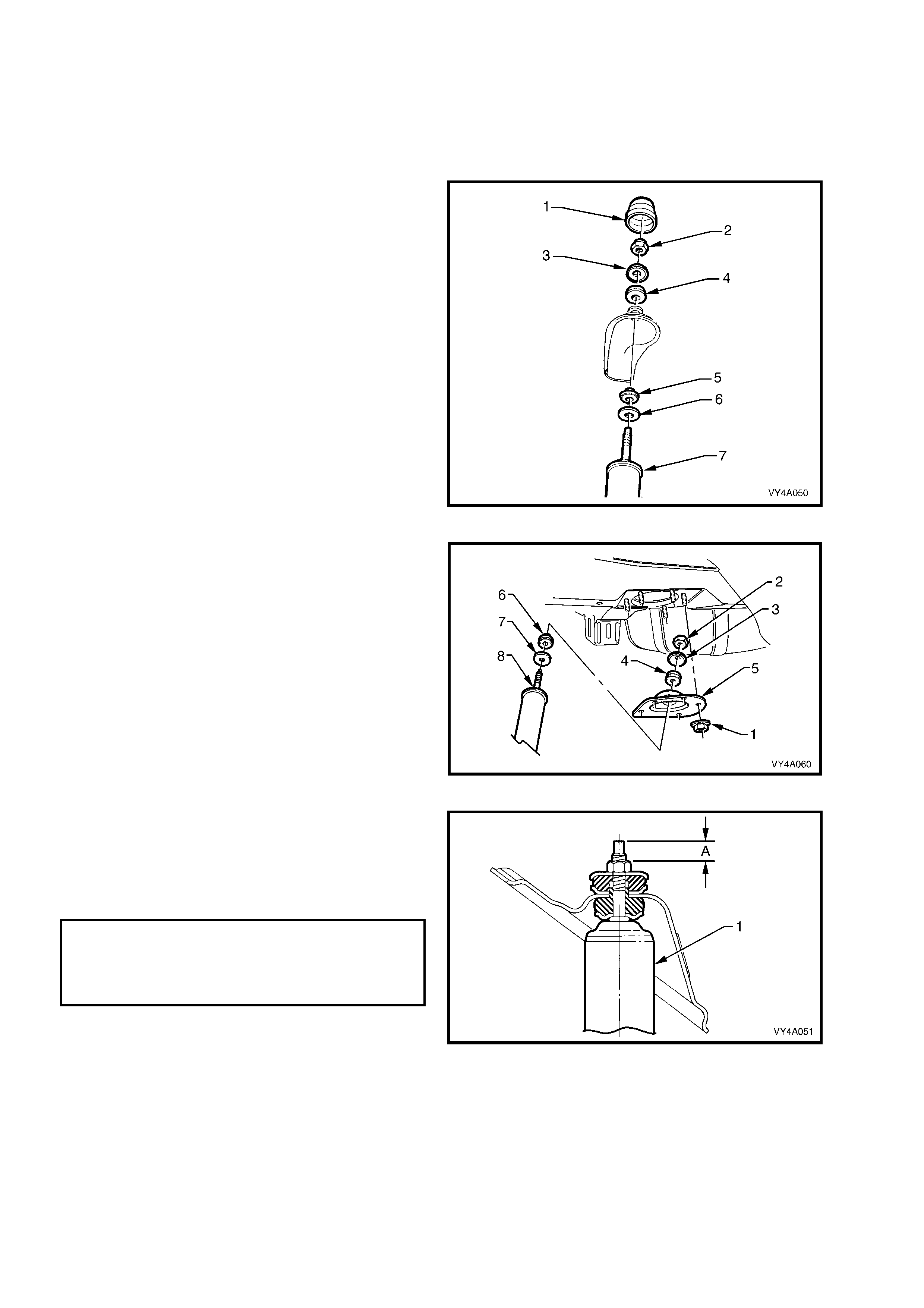

REINSTALL

1. Install the bolt (1), washer (2), rear suspension

crossmember mass damper (3) and nut to the

crossmember. Check that there is a 4 mm

clearance (A) from the rear suspension

crossmember mass damper to the bracket

edge. Do not tighten the retaining nut and bolt

at this stage.

CAUTION: Failure to achieve the correct

clearance may result in driveline vibration.

NOTE: The squared edge (4) of the rear

suspension crossmember mass damper, faces

towards the centre of the vehicle.

2. Using a back-up spanner on the rear

suspension crossmember mass damper bolt,

tighten the nut to the correct torque

specification.

REAR SUSPENSION CROSSMEMBER

MASS DAMPER BOLT

TORQUE SPECIFICATION 40.0 - 50.0 Nm

NOTE: Care must be taken when tightening the

retaining nut to prevent the mass damper from

rotating.

Figure 4A-69

3. Check that the upper and lower insulator pads

(1) are correctly positioned on the

crossmember front mounting bush.

4. With the floor jack still in position to support

and protect the rear suspension crossmember

assembly, raise the crossmember using the

floor jack.

Figure 4A-70

5. Install the brace (1), a new rear suspension

crossmember front mounting bolt (2), and the

rear suspension crossmember front mounting

brace attaching bolt (3), three places. Do not

tighten the bolts at this stage.

6. Check the rear suspension crossmember

alignment. Refer to Section 1A2, BODY

DIMENSIONS for this procedure.

CAUTION: Failure to correctly align the rear

suspension crossmember to the centreline of

the vehicle will result in steering abnormalities

and or uneven tyre wear.

7. Tighten the rear suspension crossmember

front mounting bolt to the correct torque

specification.

( ! ) REAR SUSPENSION

CROSSMEMBER FRONT MOUNTING

TO UNDERBODY BOLT

TORQUE SPECIFICATION 125 N.m, plus

30° - 40° turn angle

8. Tighten the rear suspension crossmember

front mounting brace attaching bolts to the

correct torque specification.

( 6 ) REAR SUSPENSION

CROSSMEMBER BRACE

MOUNTING BOL T

TORQUE SPECIFICATION 70 Nm

9. Remove the safety stands and lower the

vehicle.

Figure 4A-71

2.7 REAR SUSPENSION CROSSMEMBER REAR MOUNT

LT Section No. – 07-150A

NOTE: The following fasteners MUST be replaced

when performing this operation:

!

!!

!$

$$

$Rear suspension crossmember rear mount to

under body attaching bolt.

!

!!

!$

$$

$Rear suspension crossmem ber rear mount to rear

suspension differential assembly rear cover

attaching bolts.

CAUTION: Whenever any component that forms part of the ABS (if fitted) is disturbed during

Service Operat ions, it is v ital th at the co mplete ABS system b e checked, using the pro cedure as detailed in

4.4 ABS & T CS FUNCTION CHECK (V6 engines) or 5.4 ABS & TCS FUNCT ION CHECK (GEN III V8 engines),

in Section 5B ABS & TCS.

Important: Before disturbing the crossmember rear mounting bolts, an alignment procedure is required on

installation and a spec ial tool is required for this purpose. If this tool is not available, then the crossm em ber c annot

be correctly aligned and steering and/or handling abnormalities will result.

REMOVE

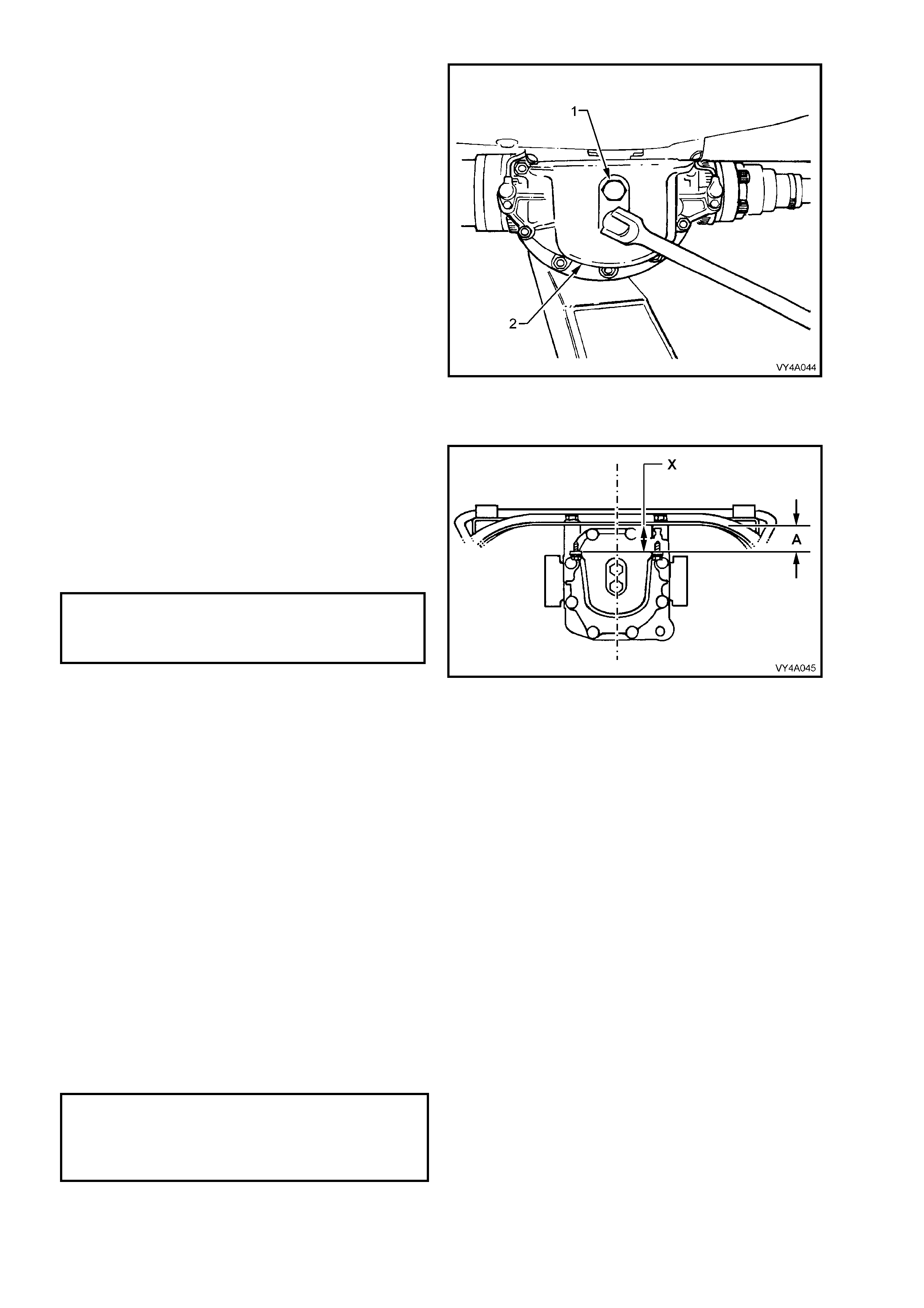

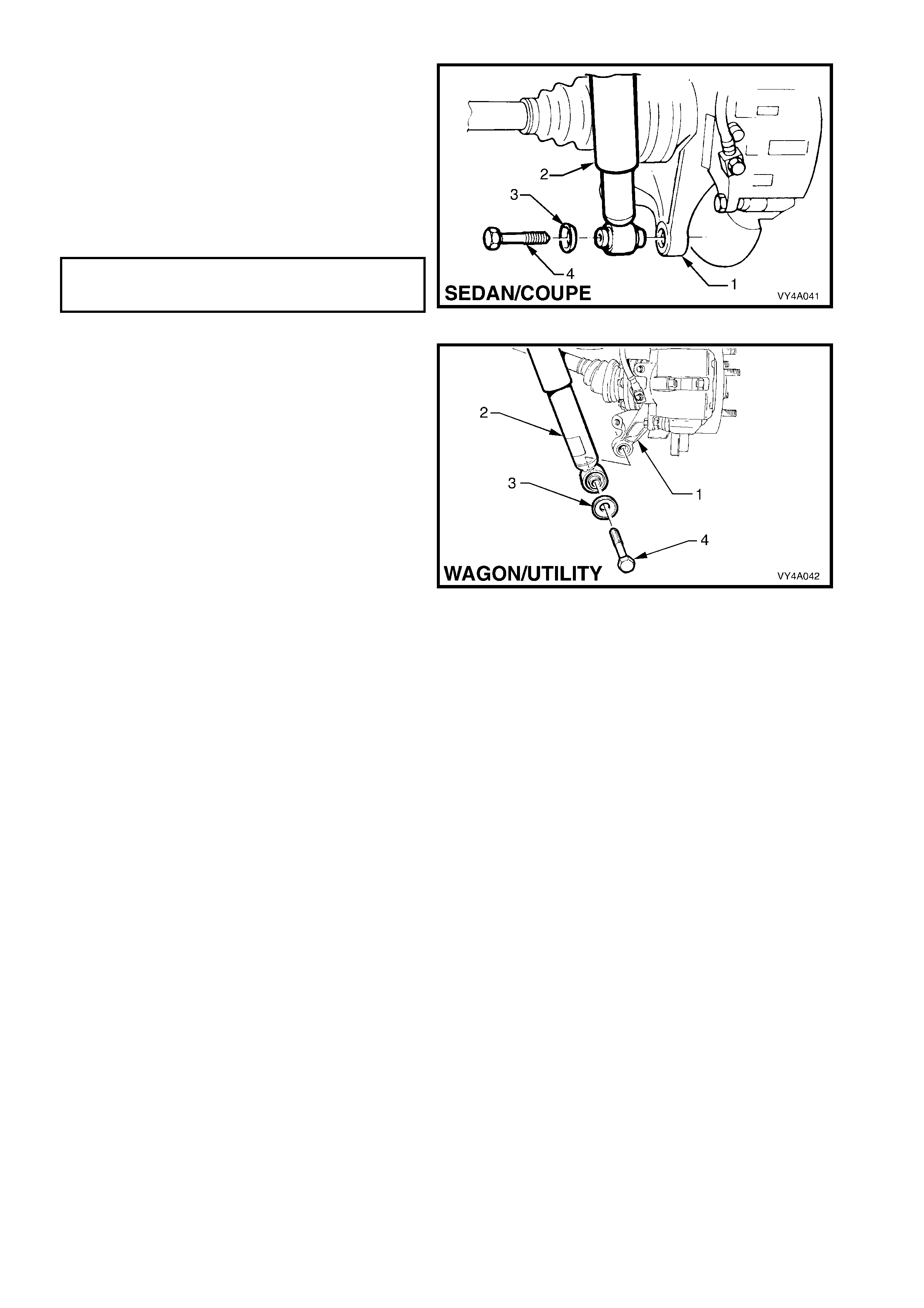

1. Using a scriber, mark the rear mount (1) to the

vehicle under body location (A). This will aid

with the rear suspension crossmember

alignment on installation.

2. Support the weight of the differential carrier

with a floor jack.

Figure 4A-72

3. Remove and discard the rear mount (1) to

vehicle underbody attaching bolts (2). Lower

the differential carrier and rear suspension

crossmember assembly by at least 60 mm.

Figure 4A-73

4. Remove and discard the rear mount to

differential carrier attaching bolts (1) and

remove the rear mount (2).

Figure 4A-74

REINSTALL

1. Install the rear mount and new attaching bolts

to differential carrier rear cover.

2. Tighten the attac hing bolts to the c or rec t tor que

specification, and at same time ensure that

mount does not twist, as the mount to vehicle

underbody mating su rface should be parallel to

within 1 mm (‘X’) of the rear suspension

crossmember,.

( ! )REAR MOUNT TO REAR SUPENSION

DIFFEREENTIAL ASSEMBLY

REAR COVER ATTACHING BOLT

TORQUE SPECIFICATION ................... 85 – 105 Nm

NOTE: Use a spirit level on the rear mount to

underbody surface and the top surface of the

crossmember to ensure that both surfaces are

parallel. Dimension ‘A’ is to be 56.7 mm.

3. Raise the differential carrier and rear

suspension crossmember assembly until the

rear mount contacts vehicle underbody.

4. Align the mount with the marks made on the

underbody during disassembly and install new

attaching bolts but do not tighten at this

stage.

5. The rear suspension crossmem ber MUST now

be aligned to the vehicle centreline, using the

special tool and procedure as detailed in

Section 1A2, BODY DIMENSIONS.

CAUTION: Failure to correctly align the rear

suspension crossmember to the centreline of

the vehicle will result in steering abnormalities

and uneven tyre wear!

Figure 4A-75

6. T ighten the rear sus pension cr ossm em ber rear

mount to underbody bolts to the correct torque

specification.

( ! )REAR SUSPENSION CROSSMEMBER REAR

MOUNT TO VEHICLE UNDERBODY ATTACHING

BOLT TORQUE SPECIFICATION......... 30 – 40 Nm,

then 55° - 65°

turn angle

7. Remove the safety stands and lower the vehicle.

2.8 STABILISER SHAFT AND/OR MOUNTINGS

LT Section No. – 07-150A

NOTE 1: The following fasteners have either micro

encapsulation or incorporate a mechanical thread lock

and should only be used once. If in doubt, r eplacement

is recommended when performing this operation:

♦ Stabiliser shaft link attaching nuts and bolts.

NOTE 2: The following fasteners MUST be replaced

when performing this operation:

!

!!

!$

$$

$Rear suspension crossmember rear mount to

under body attaching bolt.

NOTE 3: The following fasteners MUST be at curb

height before final tightening:

• Stabiliser shaft link attaching nuts and bolts.

CAUTION: Before disturbing the crossmember rear mount to underbody bolts, an alignment procedure is

required on installation and a special tool is required for this purpose. If this tool is not available, then the

crossmember cannot be correctly aligned and steering and/or handling abnormalities will result.

REMOVE

1. Using a floor jack under the centre of the differential carrier, jack up the rear of the vehicle then place safety

stands under the body rear jack ing points. Refer to Section 0A, GENERAL INFORMATION for the location of

the jacking points.

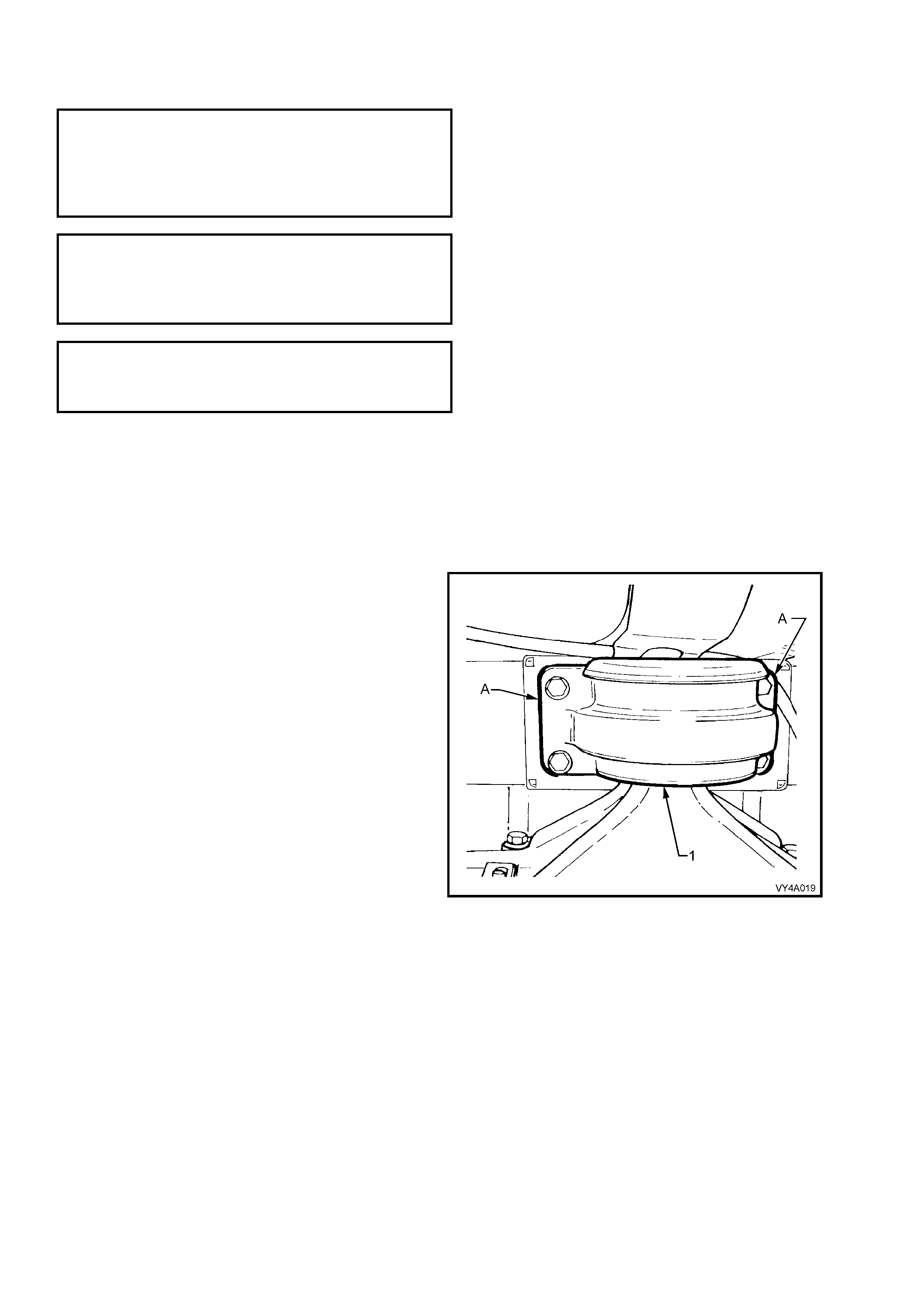

2. Using a scriber, mark the rear mount (1) to

vehicle under body location (A). T his will assist

in the rear sus pension crossm ember alignm ent

on installation.

3. Support the weight of the differential carrier

with a floor jack.

4. Remove and discard the rear mount to vehicle

underbody attaching bolts (2).

5. Lower the differential carrier and rear

suspension crossmem ber assem bly suff iciently

to gain access to the brackets securing the

stabiliser shaft to the rear suspension

crossmember.

NOTE: Do not allow the propeller s haft or left-hand

side drive shaft to rest on the exhaust system.

Figure 4A-76

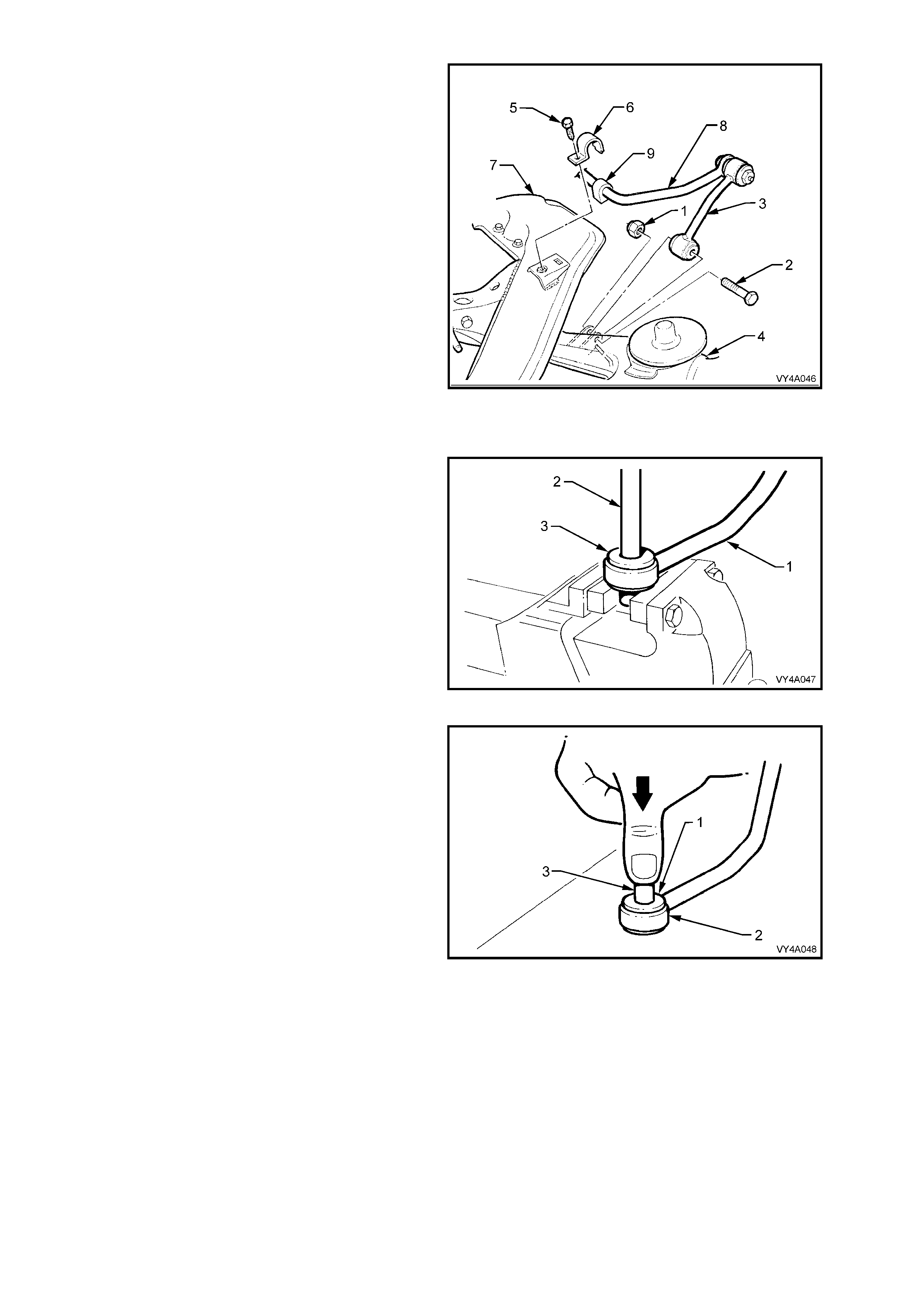

6. Remove both stabiliser shaft link to rear

suspension control arm attaching nuts (1) and

bolts (2).

7. Rotate links (3) until clear of the rear

suspension control arms (4).

8. Remove the stabiliser shaft to the

crossmember bracket attaching bolts (5).

9. Using a screwdriver, lever the brackets (6) up

and out of the crossmember (7).

10. Remove the stabiliser shaft (8) from the

vehicle.

11. Remove the insulators (9) from the stabiliser

shaft.

12. Remove the stabiliser shaft to link mounting

bolts and nuts.

13. Separate the links from the stabiliser shaft.

Figure 4A-77

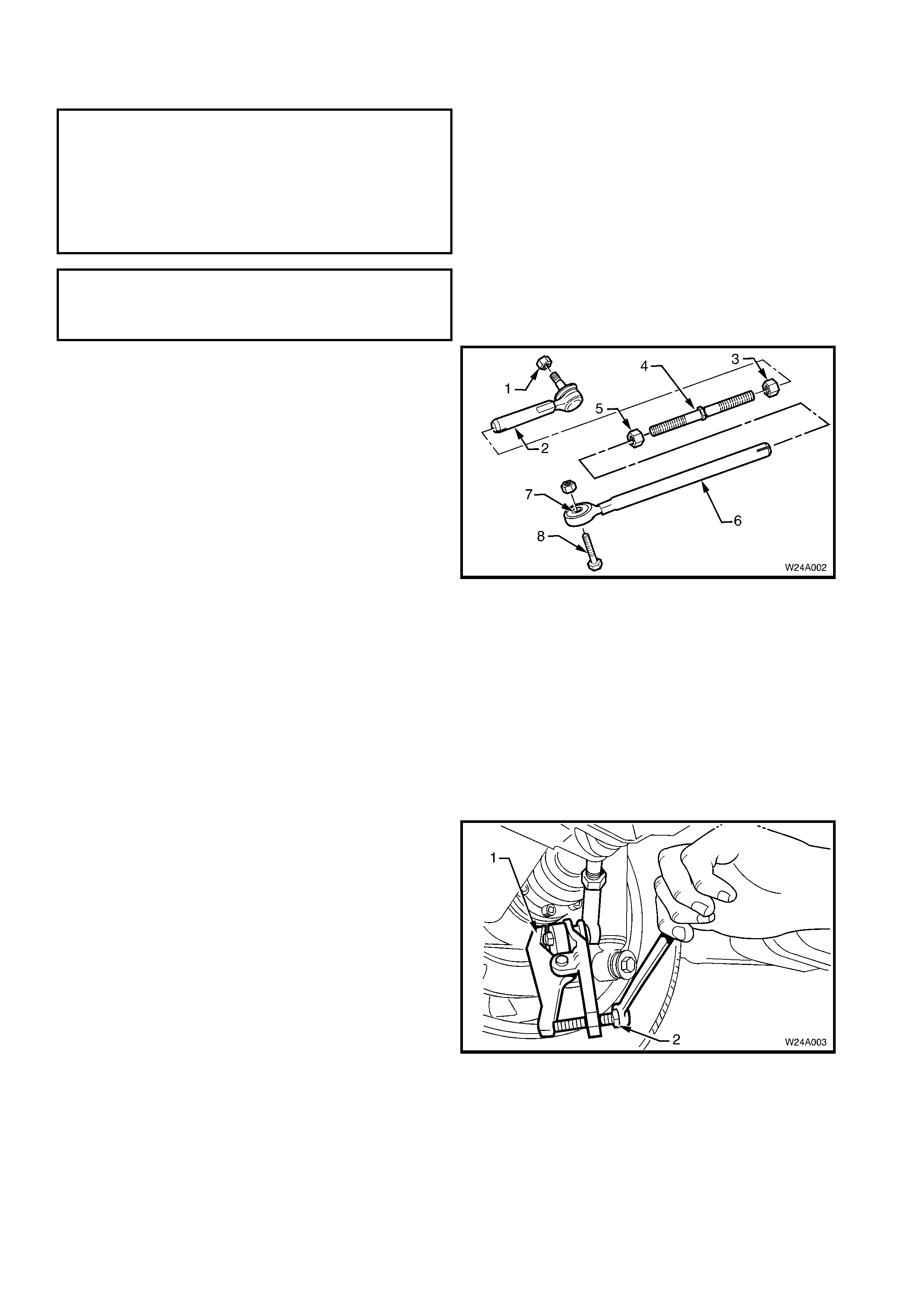

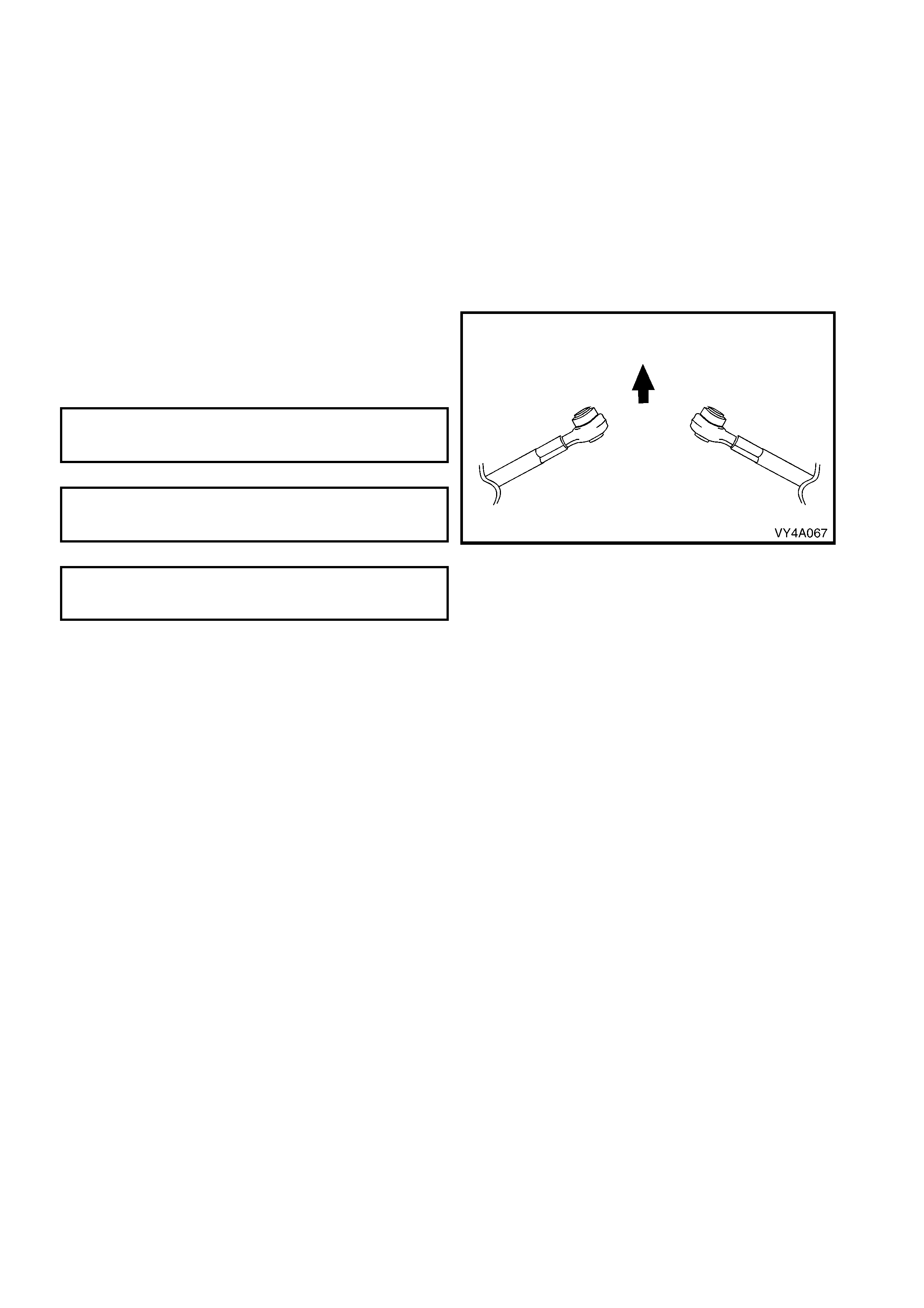

STABILISER SHAFT LINK INSULATORS, REPLACE

NOTE: The same procedure is used to replace

both the upper and lower insulator.

1. While supporting link (1) on open vice

jaws, use a suitable drift (2) and hammer to

remove the steel sleeve from the centre of the

insulator (3).

2. Distort the flanged edge of the insulator and

remove from the link.

Repeat the procedure for the remaining

insulator if required.

Figure 4A-78

3. To ease installation, apply petroleum jelly such

as Vaseline or equivalent, to insulator (1), then

install into the eye of the link (2).

4. Apply a smear of petroleum jelly to the steel

inner sleeve (3), then insert into the insulator

until the sleeve is centralised.

Figure 4A-79

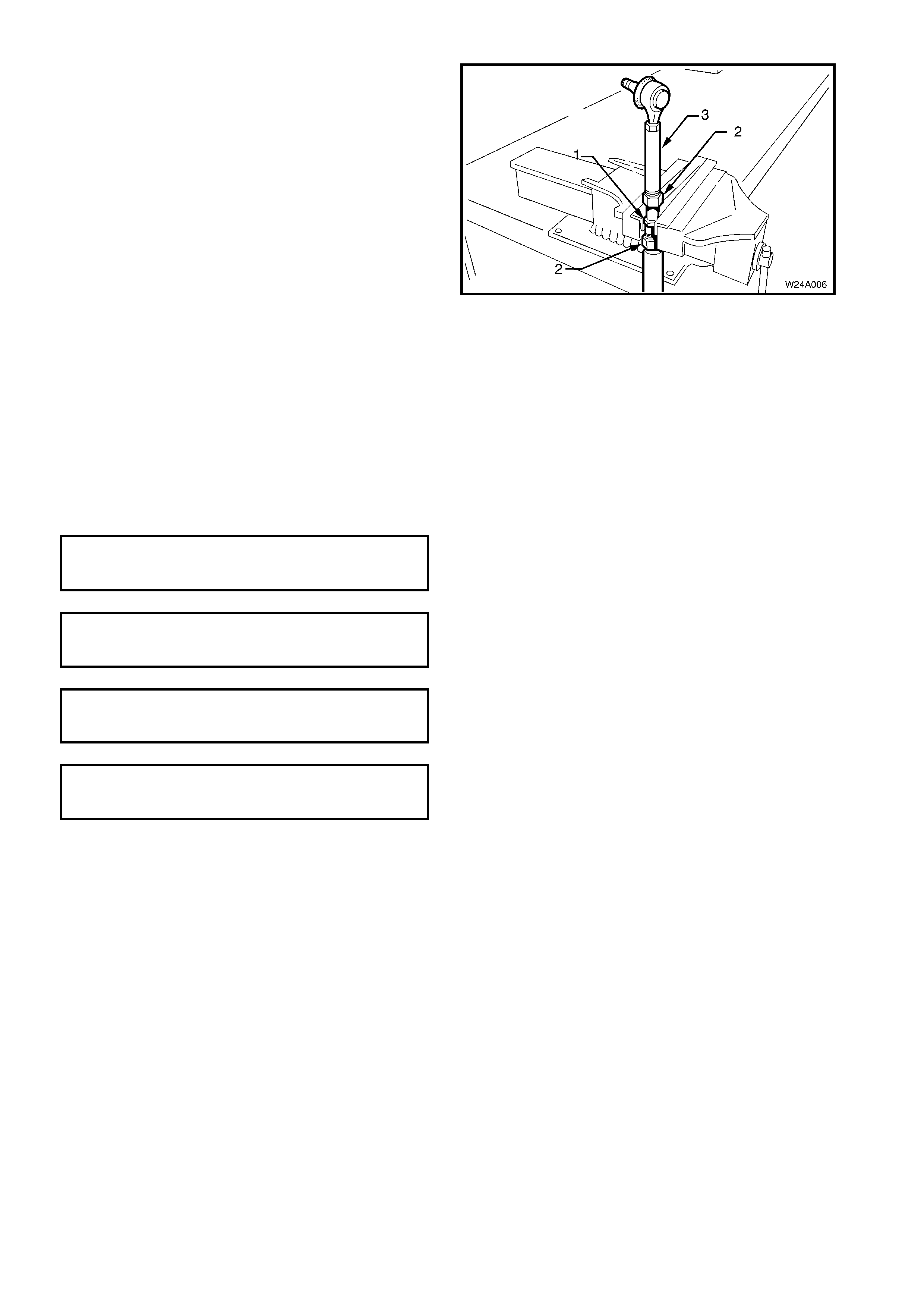

REINSTALL

1. Loosely install the stabiliser shaft link to

stabiliser shaft bolts and nuts but do not fully

tighten at this stage.

2. Install the insulators (1) and brackets (2) to the

stabiliser shaft (3). Position the stabiliser shaft

onto the crossmember (4), engaging the tangs

on the brackets with the slots in the mounting

points on the rear suspension crossmember.

3. Install and tighten the bracket attaching bolts

(5) to the correct torque specification.

STABILISER SHAFT MOUNTING

BRACKET TO CROSSMEMBER

ATTACHING BOLT

TORQUE SPECIFICATION.................. 18 – 26 Nm

4. Install the links (6) into position between the

rear suspension control arm brackets and

loosely install the attaching bolts (7) and nuts

(8), but do not fully tighten at this stage.

Figure 4A-80

5. Raise the differential carrier and rear suspension crossmember assembly until the rear mount contacts the

vehicle underbody.

6. Align the mount with the m ar ks m ade on the under body during disassem bly, and install new attaching bolts but

do not tighten at this stage.

7. The rear suspension crossmember MUST now be aligned to the vehicle centreline, using the special tool and

procedure as detailed in Section 1A2, BODY DIMENSIONS.

CAUTION: Failure to correctly align the rear suspension crossmember to the centreline of the vehicle will

result in steering abnormalities and uneven tyre wear!

8. Tighten the rear suspension crossmember, rear mount to underbody bolts to the correct torque specification.

( ! ) REAR SUSPENSION CROSSMEMBER

MOUNT TO UNDERBODY ATTACHING

BOLT TORQUE SPECIFICATION......... 30 – 40 Nm,

then 55° - 65°

turn angle

9. Lower the vehicle, then bounce the rear of the vehicle several times to settle the suspension.

10. Tighten the stabiliser shaft link mounting bolts and nuts to the correct torque specification.

( " # ) STABILISER SHAFT LINK

ATTACHING BOLTS AND NUTS

TORQUE SPECIFICATION ................... 90 – 105 Nm

2.9 REAR SPRING AND INSULATORS

LT Section No. – 07-150

NOTE 1: The following fasteners have either micro

encapsulation or incorporate a mechanical thread lock

and should only be used once. If in doubt, r eplacement

is recommended when performing this operation:

♦ Additional control arm socket assembly retaining

nut.

♦ Stabiliser shaft link to rear suspension control arm

attaching nut and bolt.

NOTE 2: The following fasteners MUST be replaced

when performing this operation:

!

!!

!$

$$

$Drive shaft constant velocity joint to rear wheel

drive shaft flange attaching bolt.

NOTE 3: The following fasteners MUST be at curb

height before final tightening:

• Shock absorber lower mounting bolt.

• Stabiliser shaf t link to rear suspension control arm

attaching nut and bolt.

REMOVE

1. Using a floor jack under the centre of the differential carrier, jack up the rear of the vehicle and place safety

stands under the body rear jack ing points. Refer to Section 0A, GENERAL INFORMATION for the location of

the jacking points.

2. Remove the wheel cover (steel wheels) or centre cap (alloy wheels) from the rear wheel on the side of the

vehicle where the spring is to be removed.

3. Mark the relationship of the wheel to the mounting flange. Remove the road wheel attaching nuts and rem ove

the wheel.

4. Using Tool No. KM468 to hold the outer rear

wheel drive shaft hub from rotating, loosen the

six drive shaft (1) outer constant velocity joint to

rear wheel drive shaf t flange attaching bolts (2)

with an 8 mm Allen key socket (3). Remove

and discard the bolts.

Figure 4A-81

5. Disconnect the drive shaft (1) from the flange

and lift upward. Keeping the drive shaft vertical

and, using a length of wire (2), tie up the drive

shaft to the lower end of the shock absorber

upper mounting.

NOTE: Bruising to the inside of the drive shaft

constant velocity joint boots will occur if the rear

suspens ion control arm is lowered any further. This

will lead to premature failure of the boot and

eventual failure of the joint if left unchecked.

For this reason, it is important that the constant

velocity joint is disconnected from the rear wheel

drive shaft flange before removing the shock

absorber lower mounting bolt.

Figure 4A-82

6. Loosen the additional control arm socket

assem bly retaining nut until level with the top of

the socket assembly stud.

7. Using s pecial tool No. E-9332- A (1), tighten the

lever forcing screw (2) until the socket

assembly stud breaks f r ee f r om the taper in the

rear suspension control arm, then remove and

discard the socket assembly retaining nut.

8. Remove the additional control arm socket

assembly from the rear suspension control

arm.

Figure 4A-83

9. Remove the stabiliser shaft link (1) to rear

suspension control arm attaching bolt (2) and

nut from the side of the vehicle where the

spring is being removed.

Figure 4A-84

10. Position a floor jack under the rear suspension

control arm. Raise the jack slightly to take the

spring load of f the rear suspension control arm .

Disconnect rear shock absorber lower

mounting bolt (1) and washer (2) from rear

suspension control arm (3), then remove the

lower end of the shock absorber (4) from the

rear suspension control arm.

Figure 4A-85

Figure 4A-86

11. Lower the jack and remove the rear spring (1),

upper insulator (2) and lower insulator (3) from

between the vehicle underbody and the rear

suspension control arm.

NOTE 1: It may be necessary to push the rear

suspension control arm downward by hand slightly

to provide sufficient space for the spring to be

removed.

NOTE 2: Ensure that the rear brake hose is not

pulled tight while pushing down on the rear

suspension control arm.

Figure 4A-87

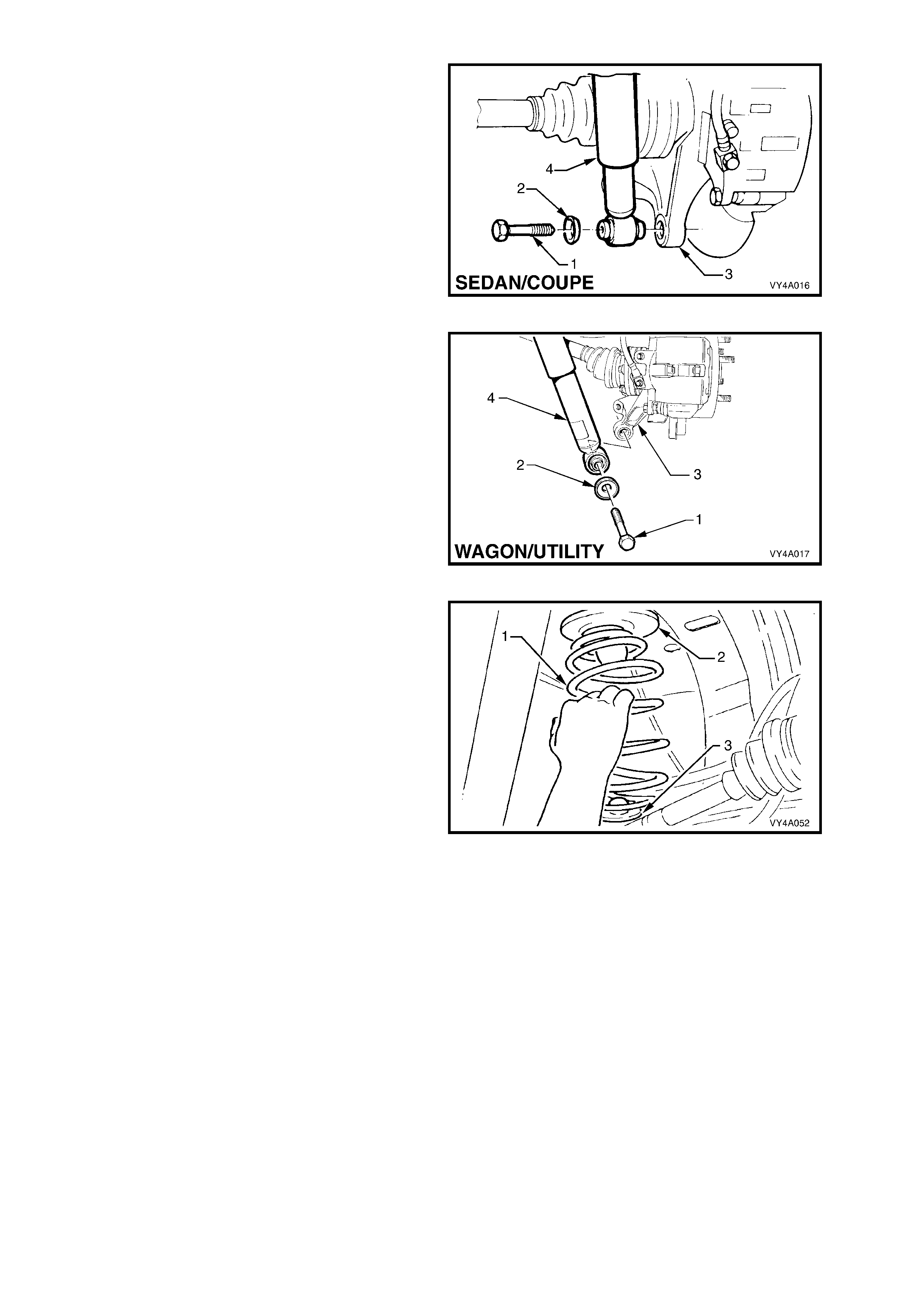

REINSTALL

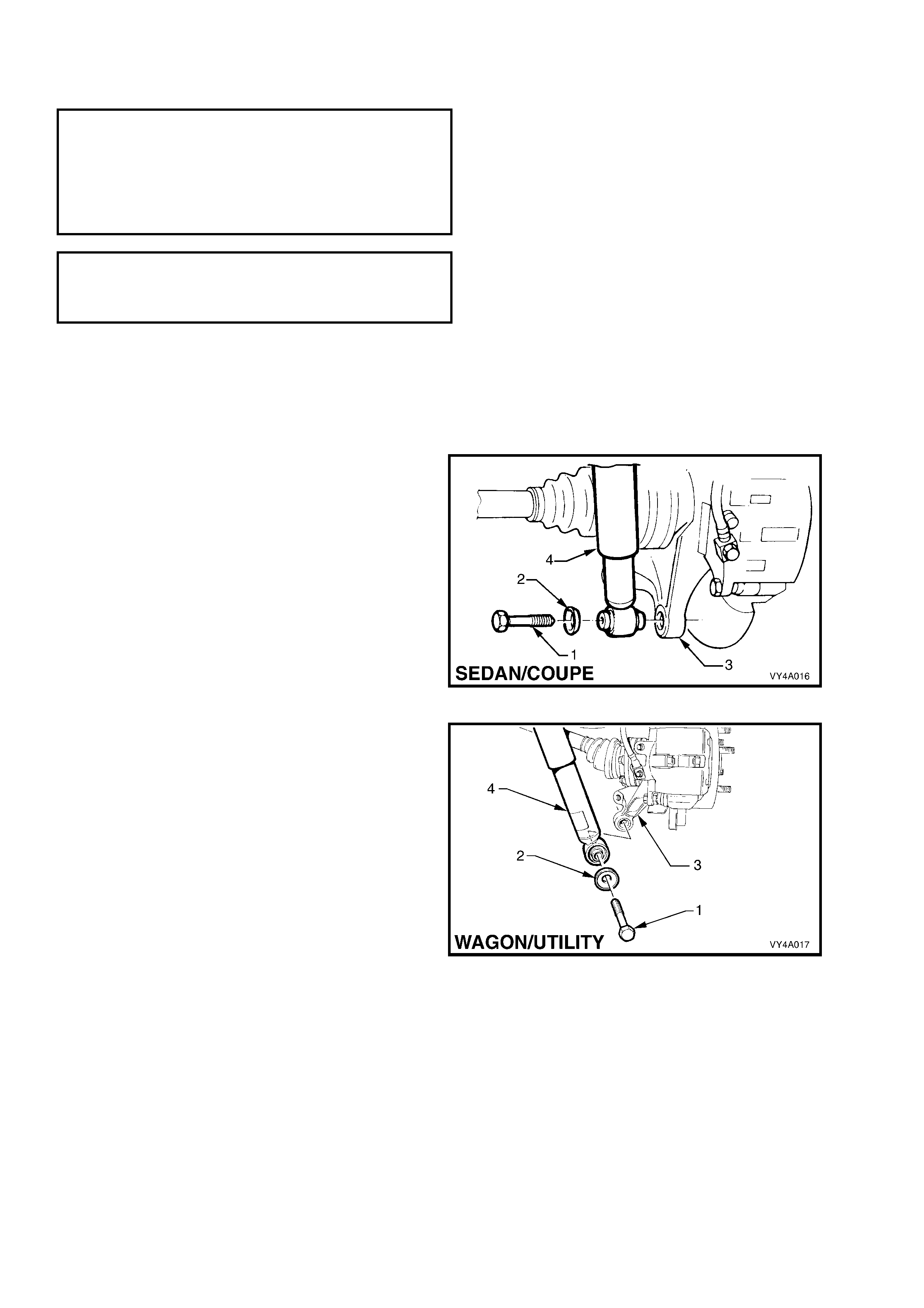

1. Install the lower insulator (3) onto the rear

suspension control arm. Assemble the upper

insulator (2) into the spr ing (1) then push down

on the rear suspension control arm and install

the spring and upper insulator.

Figure 4A-88

2. Position the jack under the rear suspension

control arm (1) and raise it sufficiently to allow

the shock absorber (2) lower mounting washer

(3) and bolt (4) to be installed.

3. Install the washer and bolt on to the shock

absorber lower mount and into the rear

suspension control arm, but do not tighten at

this stage.

Figure 4A-89

Figure 4A-90

4. Remove the wire from the drive shaft and shock absorber upper mount. Lower the drive shaft and align the

drive shaft constant velocity joint to rear wheel drive shaft flange, then fit new attaching bolts into the

corresponding holes in the rear wheel drive shaft flange

5. Tighten the drive shaft constant velocity joint to rear wheel drive shaft flange attaching bolts to the correct

torque specification.

( ! ) DRIVE SHAFT CONSTANT VELOCITY

JOINT TO REAR WHEEL DRIVE SHAFT

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION ................... 50 Nm, then

60° - 75°

turn angle

7. Rotate the stabiliser shaft link into position over the rear suspension control arm bracket. Install the attaching

bolt and nut.

8. Install the additional control arm socket assembly and a new nut and tighten to the correct torque wrench

specification.

( # ) ADDITIONAL CONTROL ARM

SOCKET ASSEMBLY RETAINING NUT

TORQUE SPECIFICATION ................... 55 – 70 Nm