SECTION 4B - FINAL DRIVE AND DRIVE SHAFTS

IMPORTANT

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

CAUTIONS AND NOTES for correct workshop practices with regard to safety and/or property damage.

CONTENTS

1. GENERAL DESCRIPTION

1.1 FINAL DRIVE ASSEMBLY IDENTIFICATION

1.2 FINAL DRIVE ASSEMBLY MAINTENANCE

MAINTENANCE

LIMITED SLIP DIFFERENTIAL

PRECAUTIONS

LUBRICATION

2. MINOR SERVICE OPERATIONS

2.1 GENERAL

IMPORTANT SERVICE REQUIREMENTS

2.2 CHECKING DIFFERENTIAL CARRIER

LUBRICANT LEVEL

2.3 CHANGING/FLUSHING REAR AXLE

LUBRICANT LEVEL

2.4 TRAILING ARM TRUNNION ASSEMBLY HUB

CHECK FOR RUN-OUT

2.5 TRAILING ARM TRUNNION ASSEMBLY

HUB STUDS

REPLACE

2.6 LIMITED SLIP DIFFERENTIAL

TORQUE CHECK

2.7 DRIVE SHAFT ASSEMBLY

REMOVE

REINSTALL

2.8 DRIVE SHAFT AND/OR CONSTANT

VELOCITY JOINTS

DISASSEMBLE

INSPECT

REASSEMBLE

2.9 INNER AXLE SHAFT SEAL

REPLACE

2.10 PINION OIL SEAL

REPLACE

2.11 PINION FLANGE

REPLACE [USING OLD OIL SEAL]

REPLACE [USING NEW OIL SEAL]

3. MAJOR SERVICE OPERATIONS

3.1 TRAILING ARM TRUNNION FLANGE,

TRUNNION ASSEMBLY AND/OR

WHEEL BEARING

REMOVE

REINSTALL

3.2 FINAL DRIVE ASSEMBLY

REMOVE

REINSTALL

3.3 REMOVED FINAL DRIVE ASSEMBLY

DISASSEMBLE

INSPECT

REASSEMBLE

3.4 LIMITED SLIP DIFFERENTIAL

DISASSEMBLE

INSPECT

REASSEMBLE

3.5 REAR AXLE

REASSEMBLE

4. DIAGNOSIS

4.1 GENERAL INFORMATION

4.2 FINAL DRIVE ASSEMBLY NOISE

GEAR RELATED NOISE

BEARING RELATED NOISE

4.3 LSD NOISE

4.4 FINAL DRIVE BEARING DIAGNOSIS

5. SPECIFICATIONS

6. TORQUE WRENCH SPECIFICATIONS

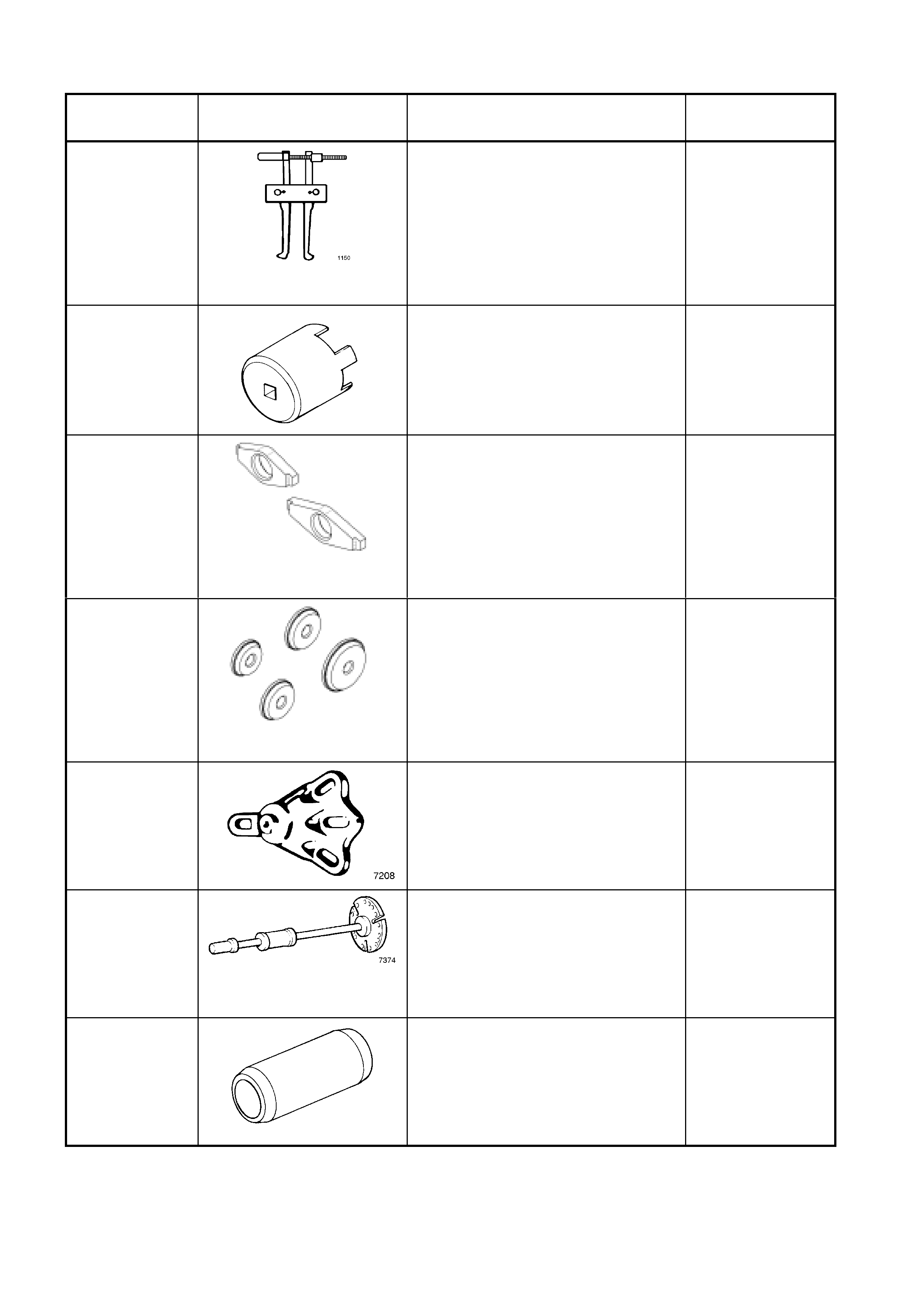

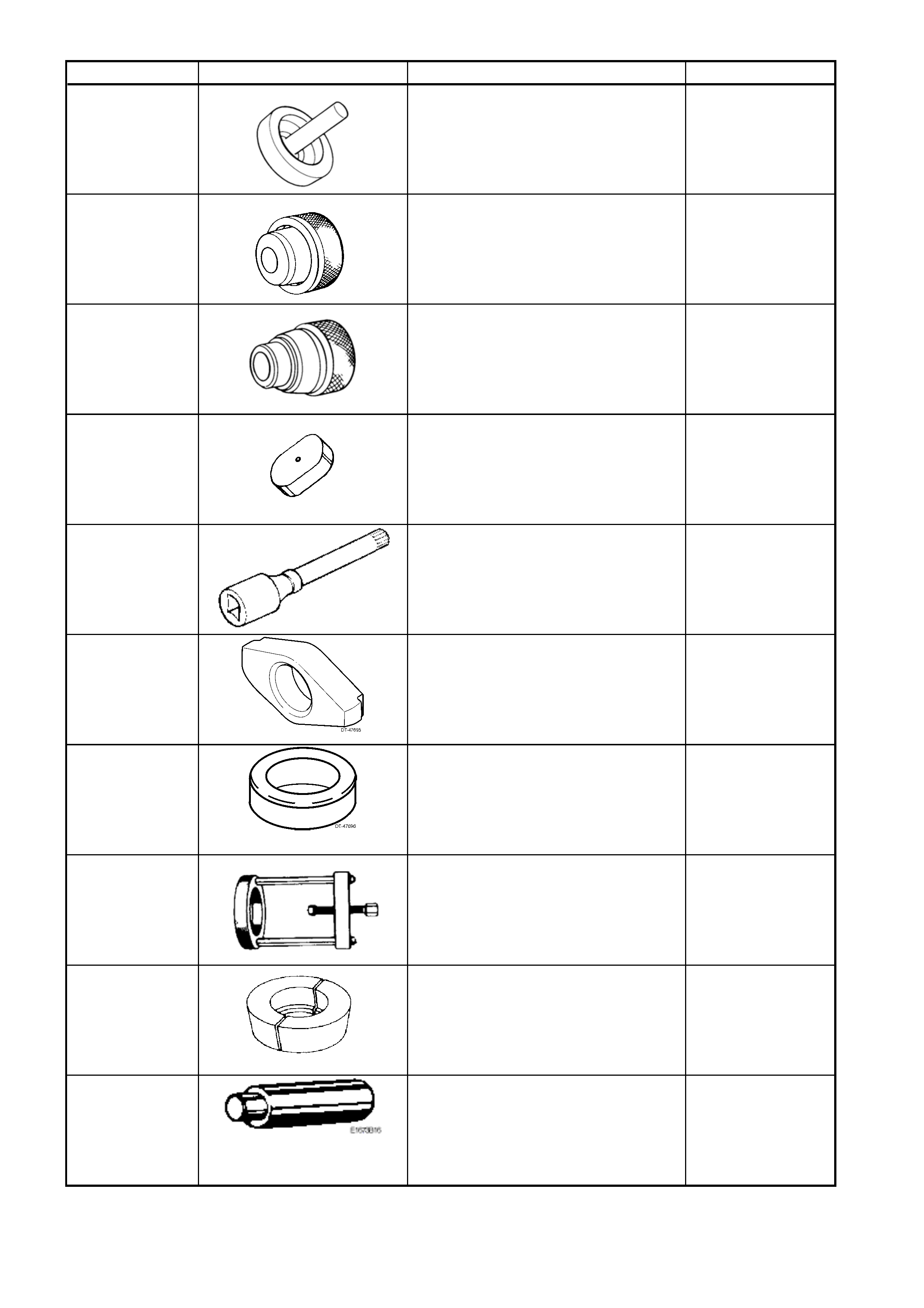

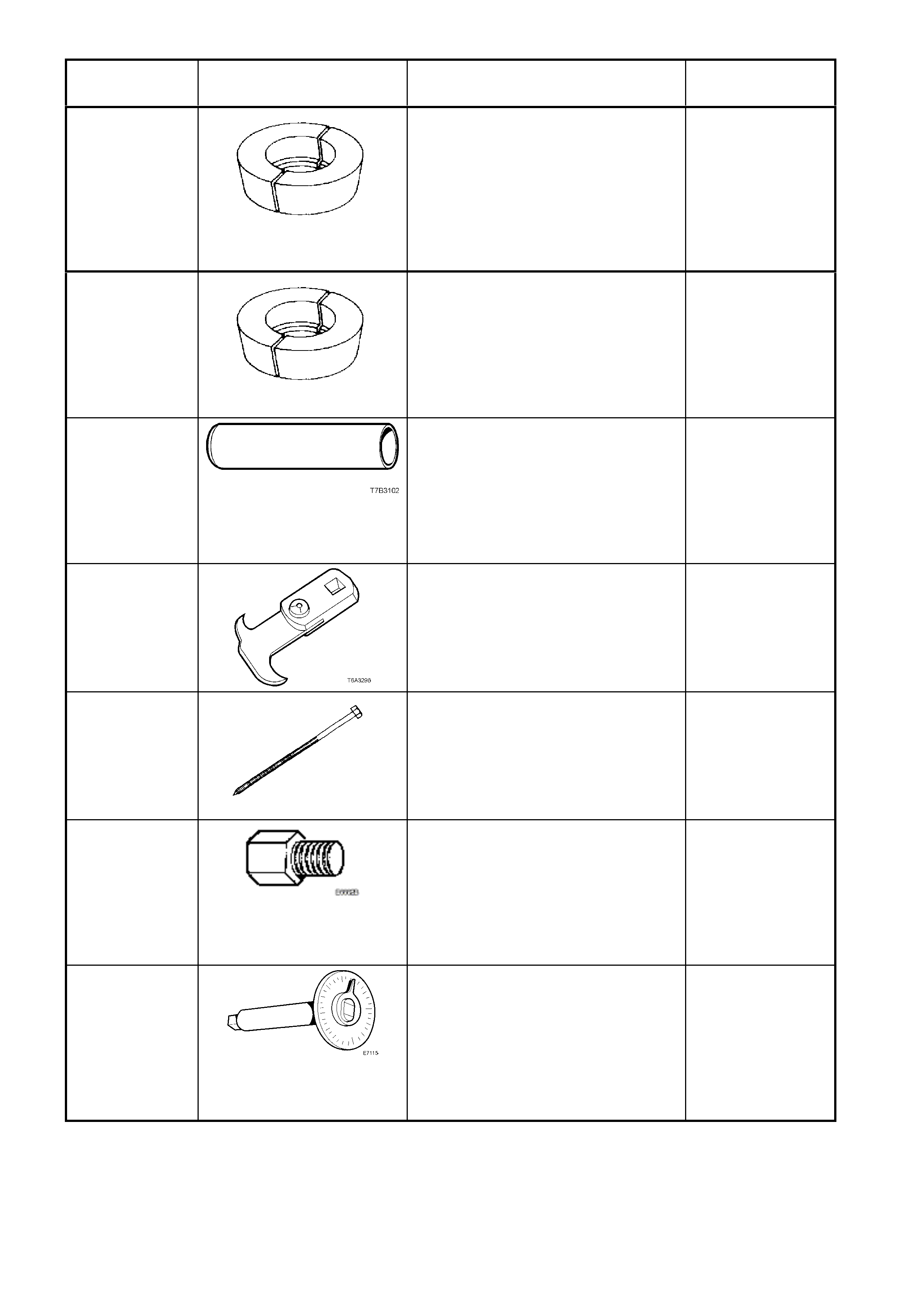

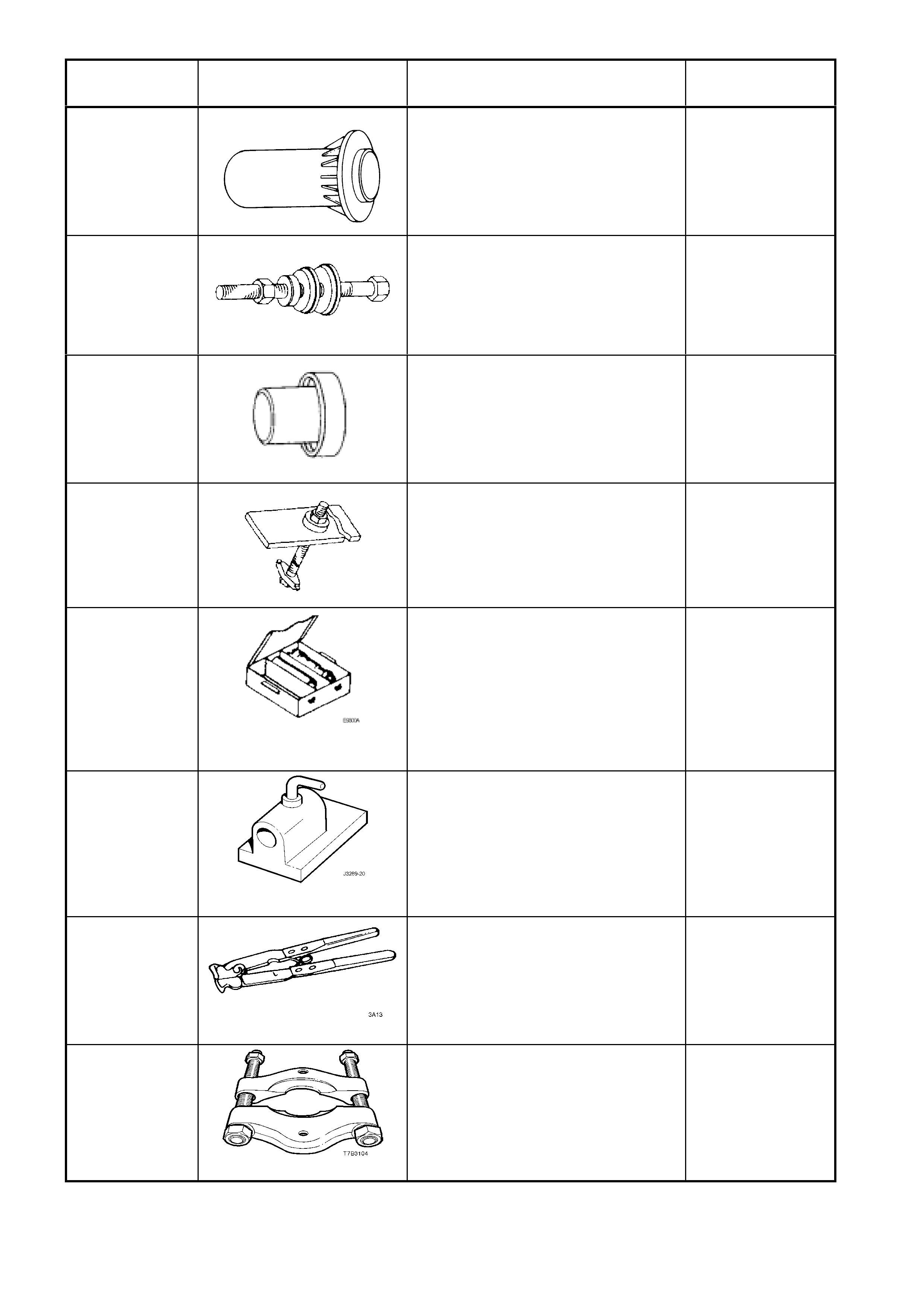

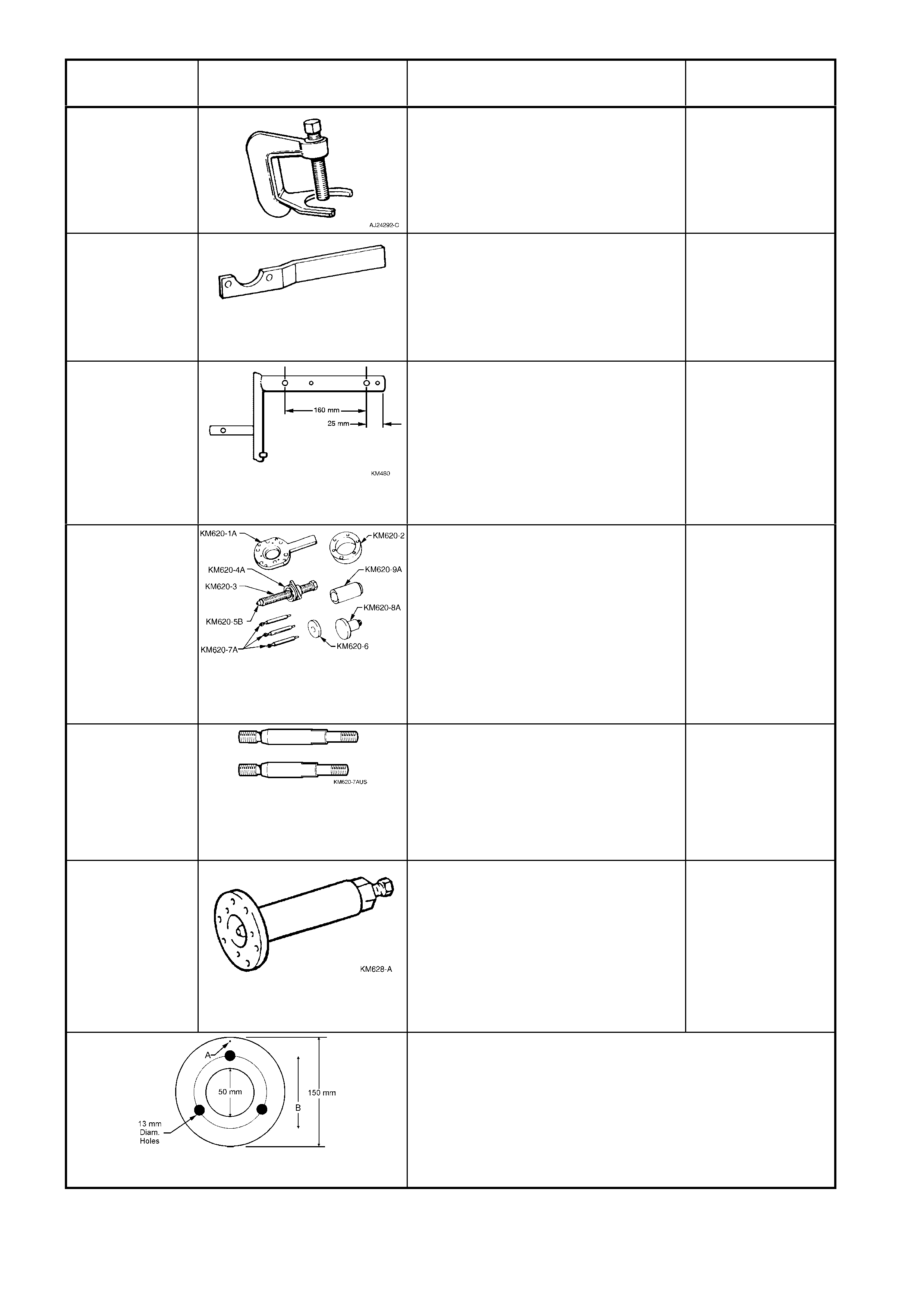

7. SPECIAL TOOLS

Techline

Techline

Techline

Techline

Techline

Techline

Techline

Techline

1. GENERAL DESCRIPTION

Independent rear suspension is fitted as standard equipment on all MY2003 VY Series vehicles and all are fitted

with a f inal dr i ve ass embly that h as a f our -pin ion type rear dif f er entia l as sembl y. The rin g ge ar di ameter varie s f r om

190.5 m m to 203.2 mm and 205 mm . Applicat ion of each r atio is pro vided in a s ummar y of usage in table form on

page 4B-5.

Production option G80, Limited Slip Differential (LSD), (also referred to as Spin Resistant Differential - SRD) is

availab le on a ll models. While the m aj orit y of illust rations shown in th is Sec ti on rel ate to v eh ic les f itted with th e AB S

braking system, service procedures are the same for vehicles equipped with standard brakes, unless otherwise

noted.

The final dr ive assem bly is mounted directl y to a crossm em ber which is rubber mounted to th e vehicle un derbod y.

The differential case and drive p inion are m ounted in opposed taper roller bearings in the carrier. Differentia l case

side beari ng pre- load adj us tm ent is provi ded b y screw adjusters in the s ides of the cas e. Pinion b earing pr e- load is

provided by a collapsible spacer. Torque is transferred from the propeller shaft to the final drive assem bly via the

pinion flange which is splined to the hypoid pinion. The torque is then transferred from the pinion through the ring

gear, differential case, differential pinion cross shafts, differential pinions, side gears and then via splines, to the

inner axle shafts and drive shafts.

The Limited Slip Differential performs the same functions as the conventional type differential but in addition,

transfers driving force to the wheel with traction, should the opposite wheel begin to spin. The differential case

houses t wo co ne t ype clutc hes b ehind the s ide gears t hat, wit h V6 m odels, ar e sp lined to the inner axl e shaf ts and

their tapered faces contact corresponding faces in the differential case.

The cones for V8 and V6 supercharged models however, form an integral part of the side gears. The four pinion

type Limited Slip Differential has three pre-load springs enclosed in the centre of the pinion cross shaft. The Limited

Slip Diff erential dir ects the m ajor drivin g forc e to the wheel with the gr eater am ount of trac tion, but will not inter fere

with steer ing char acteristic s or dif ferentia l action. T he partia l lock ing action, due t o the sprin g load on th e cones , is

automatic ally incr eased by the i nherent separa ting f orces bet ween the side gear s and pinions , which pro gressive ly

increases the resistance in the differential as applied torque is increased.

W hen the rear wh eels are under ex trem ely unbalanc ed condit ions, s uch as a wheel on a dr y road and t he other in

mud or ice, with the standa rd differential, wheel spin eas ily occ urs if over-ac celeration is attem pted. Howeve r, with

a Limited Slip Differential, when the tendency for wheel spin occurs, the friction generated inside the case, transfers

drivin g force to the non-s pinning wheel. In the event o f continu ed spin ning, a whirring so und fr om the ov er-runnin g

cones is produced but this condition/sound does not indicate failure of the unit.

The f inal dri ve as sembl y shoul d be r emoved f rom the vehicl e f or all s ervice oper at i ons other than for the remova l of

the inner axle shafts, inner axle shaft oil seals, pinion oil seal or the rear cover. Two drive shaft assemblies are

used, each consisting of a shaft which is splined at each end into a ball type constant velocity joint. The inner

constant velocit y joint is bolted to the inner axle shaft flange at the differential ca rrier, with the outer joint bolted to

the trunnion flange at the rear trailing arm.

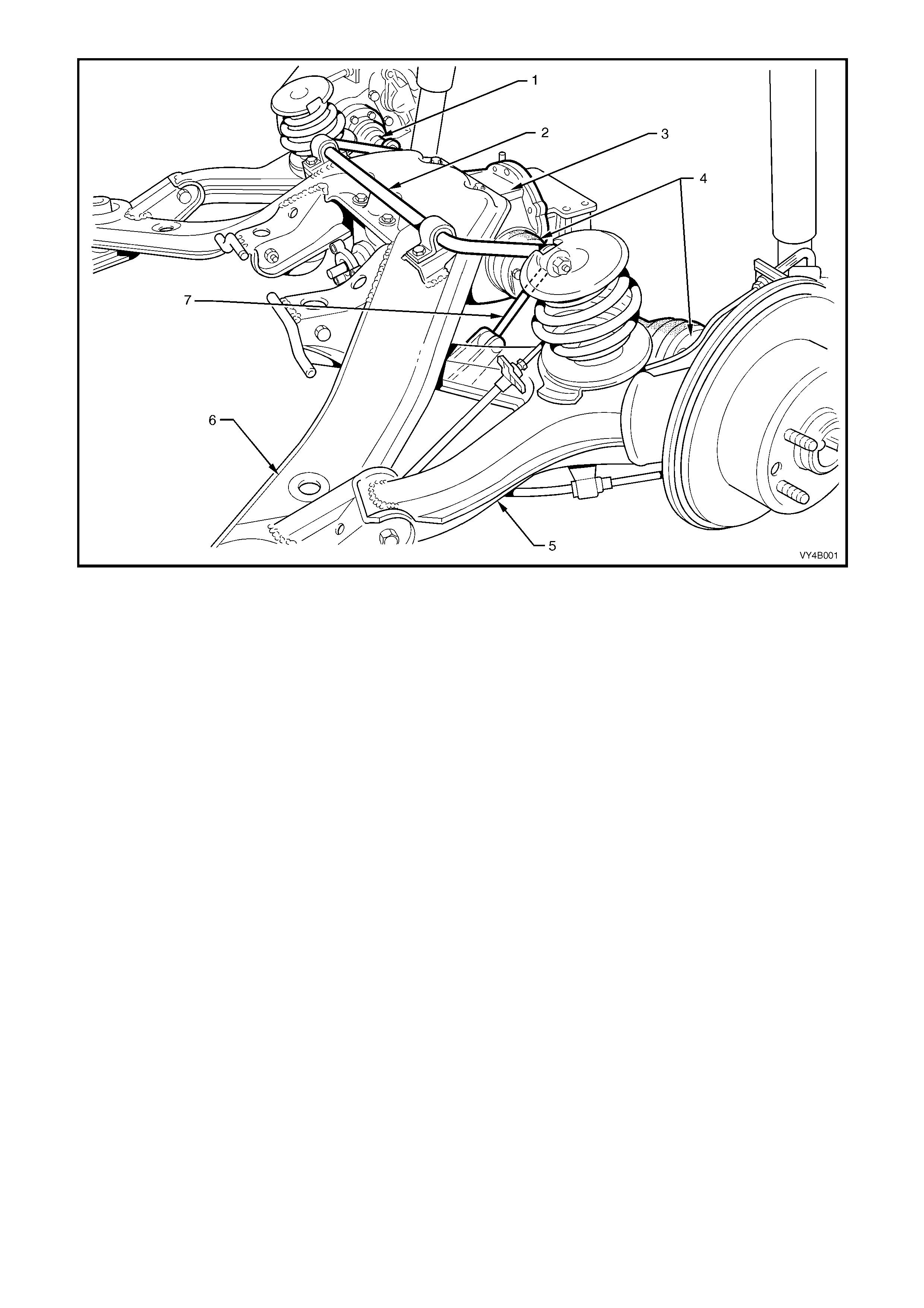

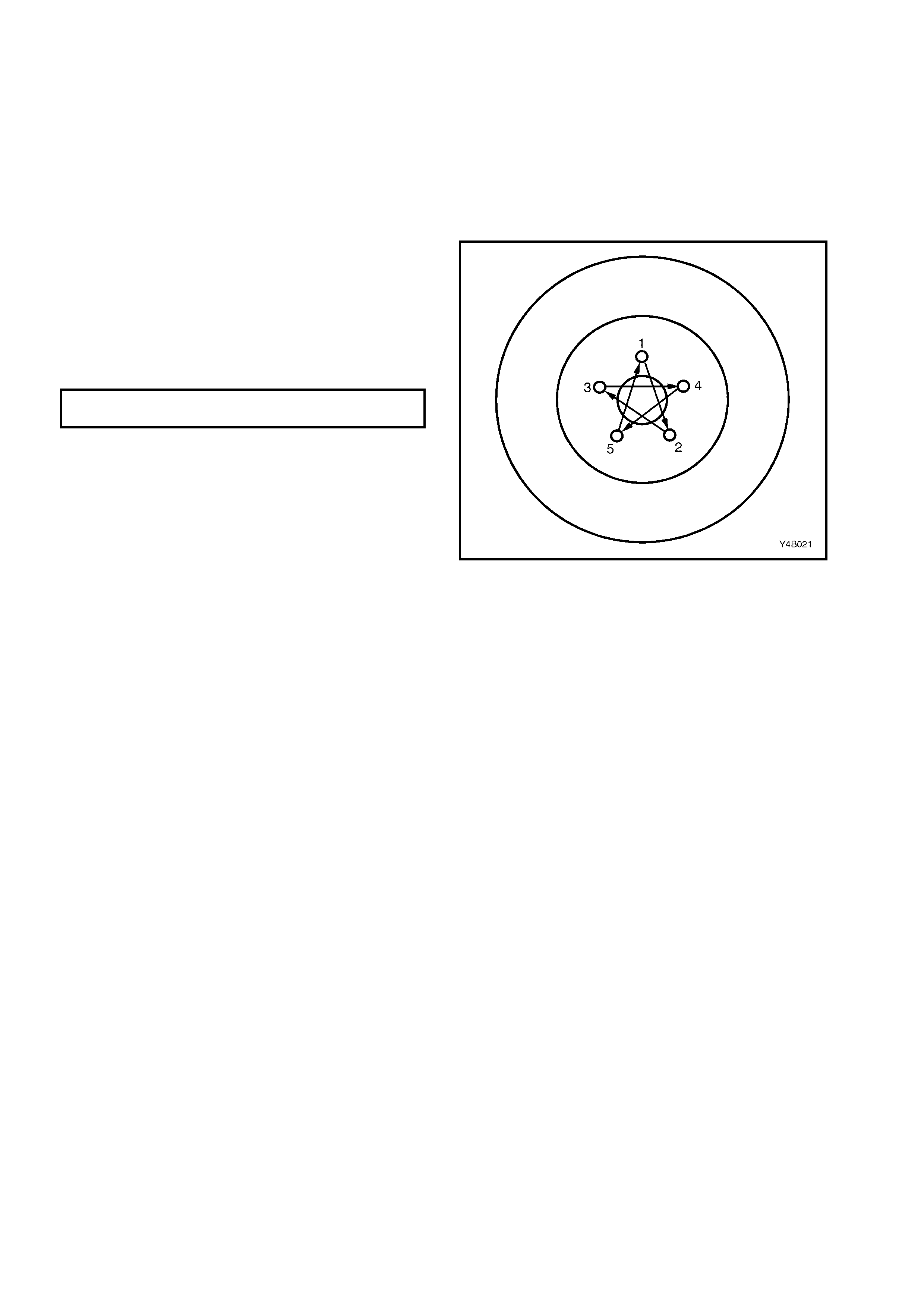

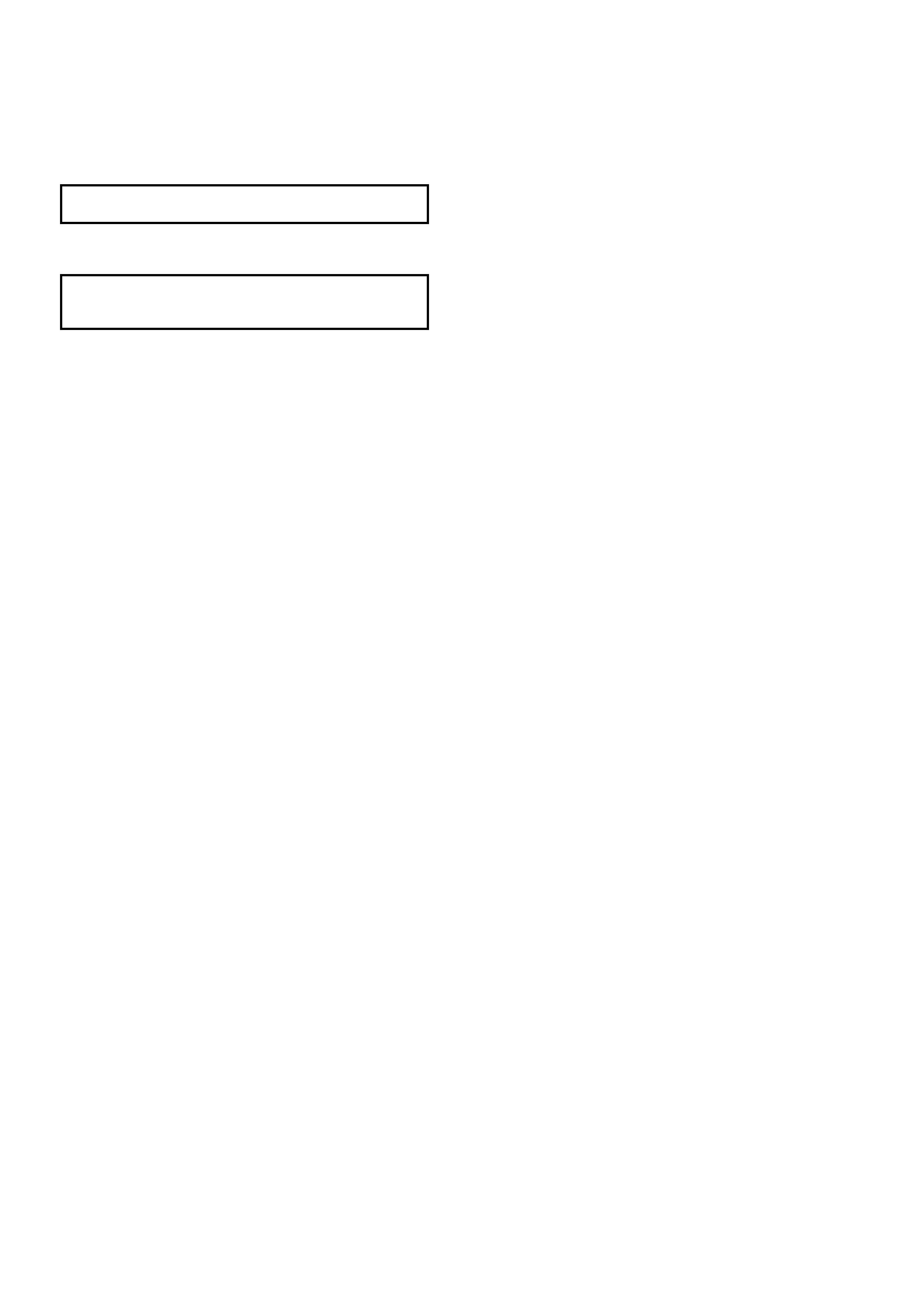

Figure 4B-1

Legend

1. Drive Shaft

2. Rear Suspension Stabiliser Bar

3. Final Drive Assembly

4. Constant Velocity Joints

5. Trailing Arm

6. Rear Suspension Crossmember

7. Rear Stabiliser Bar to Trailing Arm Link

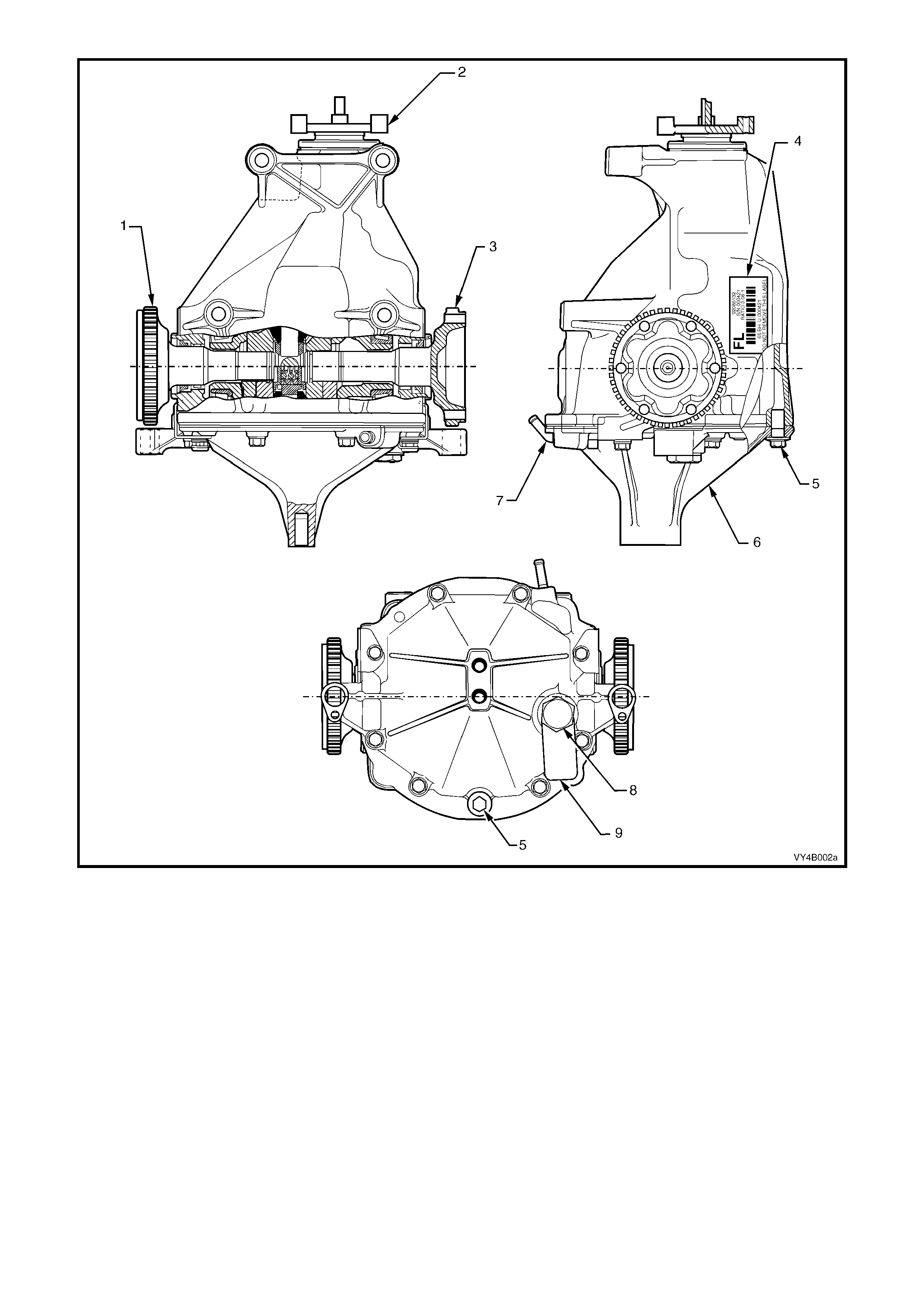

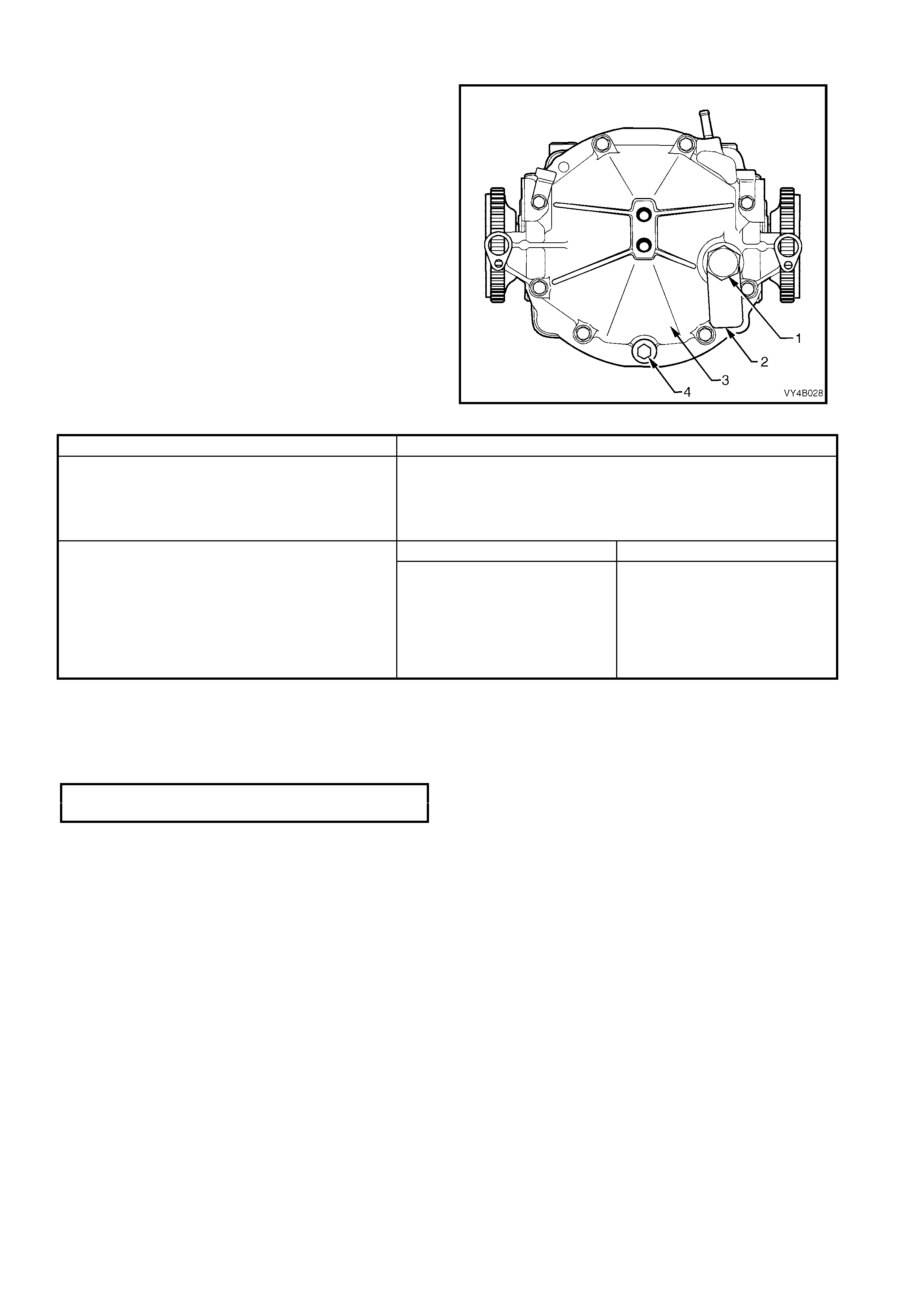

Legend

1. LH Inner Axle Shaft

2. Pinion Flange

3. RH Inner Axle Shaft

4. Identification Label

5. Drain Plug

6. Rear Cover

7. Breather

8. Filler Plug

9. Lubrication Tag

Figure 4B-2

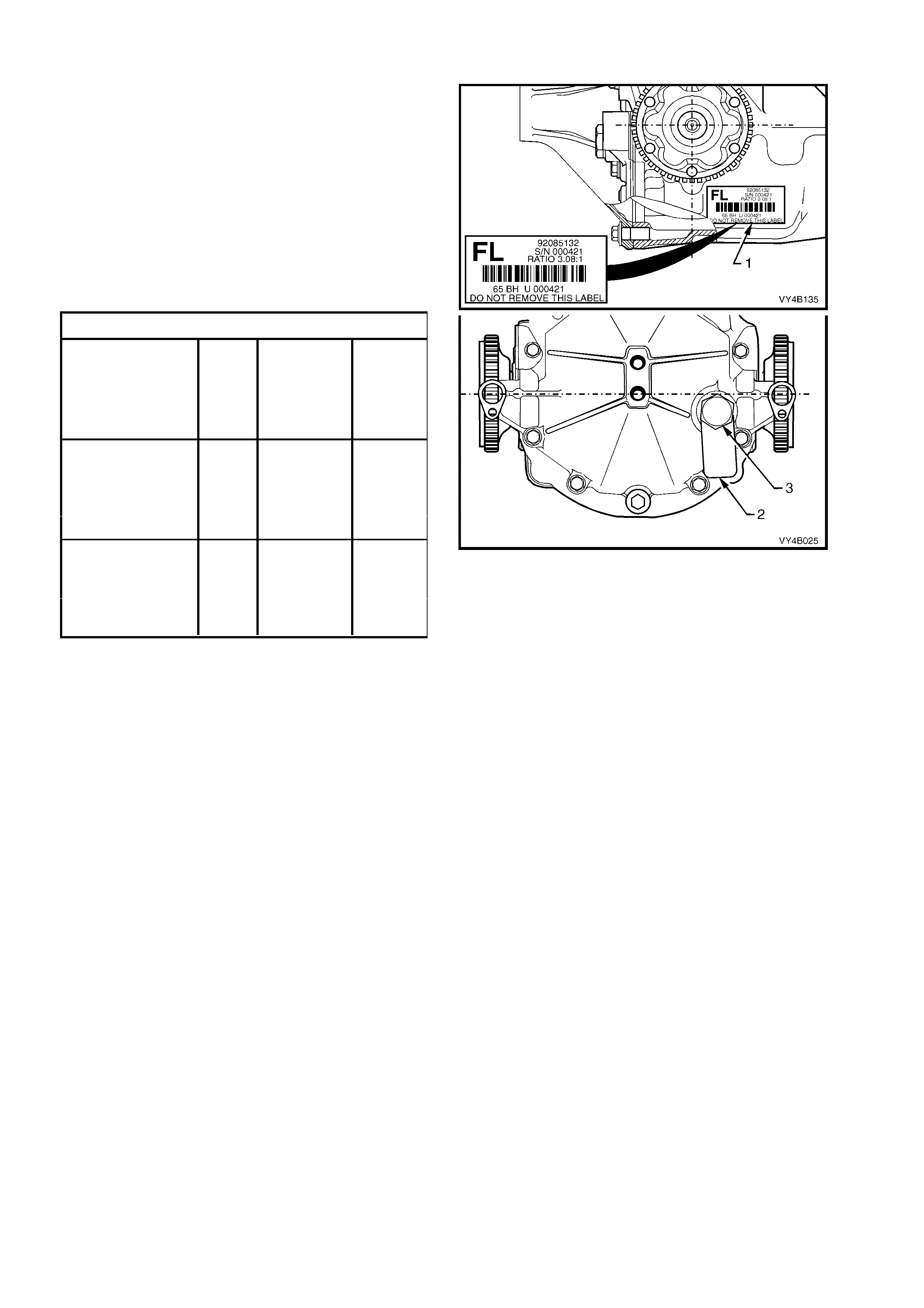

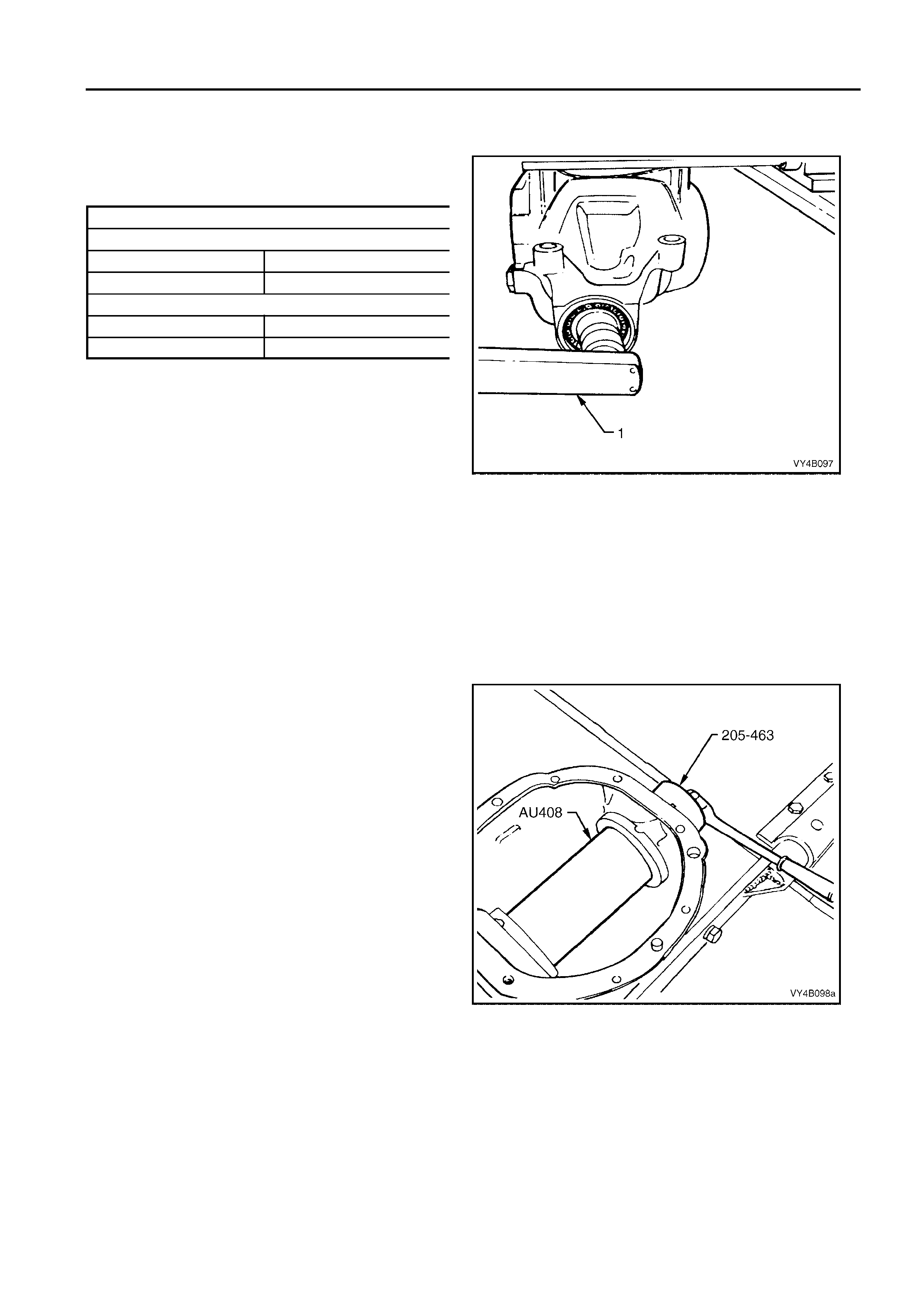

1. 1 FINAL DRIVE ASSEMBLY IDENTIFICATION

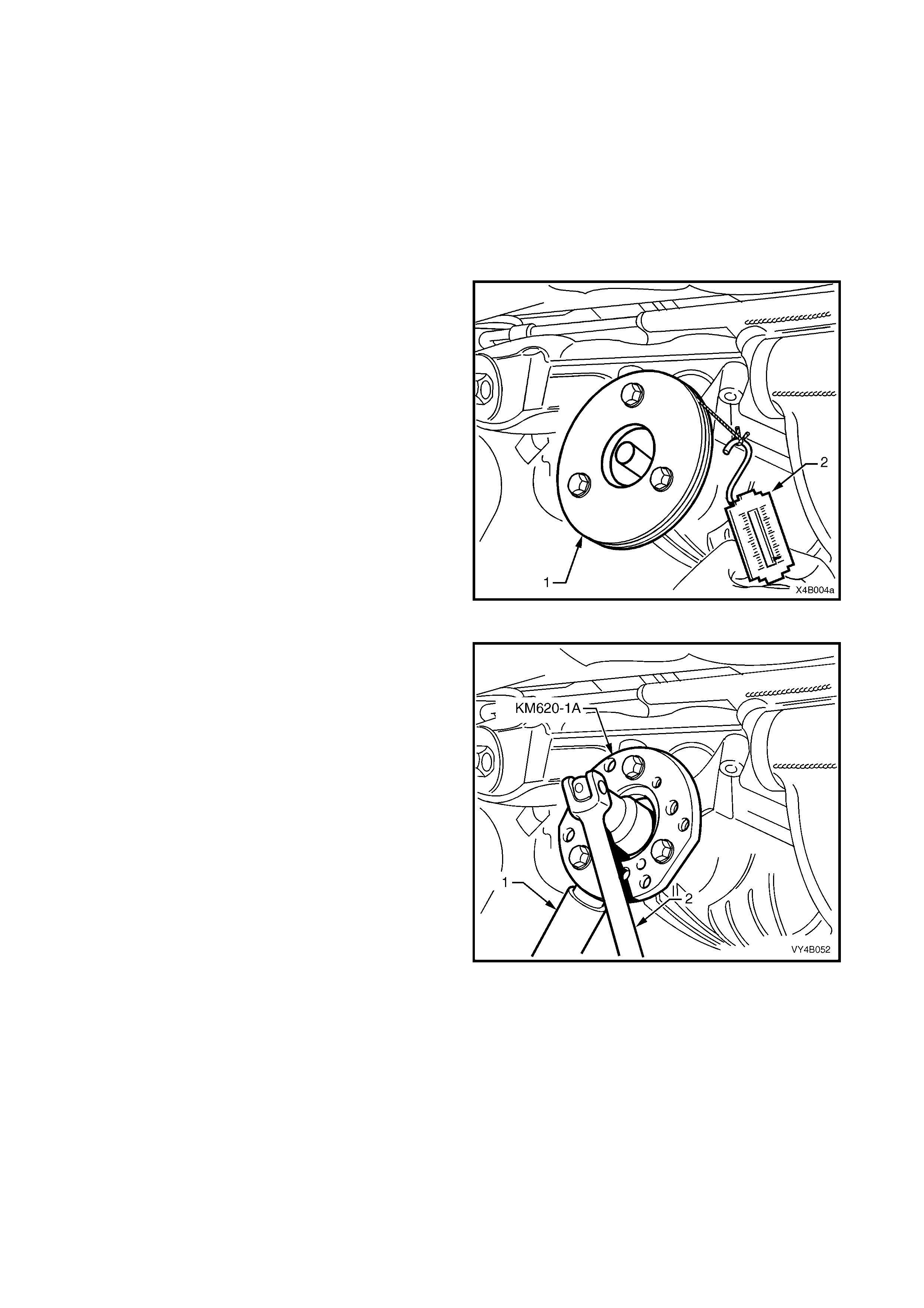

The type of differential fitted to this final drive

assembly can be identified by referring to the

identification label (1) attached to the RHS of the

carrier housing and the lubrication tag (2) under the

filler plug (3) on the rear cover.

The locations of the identification label and

lubrication tag are as shown in Figure 4B-3.

The identification label (1) carries the final drive

assembly part number for the final drive ratio and

the serial number of the assembly.

The code number and bar code is used for

production identification of the final drive assembly.

Usage Ratio Type I.D. Code

GEN III V8 or Standard FB

V6 Engined Ut il ity LSD FA

with 3.46:1 ABS (Std) FT

Manual LSD & ABS FC

Transmission

GEN III V8 &V6 Standard FD

Superc harge d with LSD FE

Automatic Trans. / 3.07:1 ABS (Std) FF

V6 Statio n Wagon LSD & ABS FH

with Manual Tr ans .

All V6 Engined Standard FJ

Sedans, Utility and LSD FK

Station Wagon 3.08:1 ABS (Std) FL

with Aut omatic LSD & ABS FM

Transmission

When fitted, the information on the lubrication tag

(2) under the filler plug (‘3’ in Figure 4B-3), will be:

Figure 4B-3

• With V6 and LSD; “SPIN RESISTANT DIFF. USE APPROVED LUBRICANT ONLY”

• With GEN III V8, V6 Supercharged (with Automatic Transmission), V6 Station Wagon and V6 Utility (with

Manual Transmission), fitted with the conventional differential; “HIGH PERFORMANCE. USE APPROVED

LUBRICANT ONLY”

• With GEN III V8, V6 Supercharged (with Automatic Transmission), V6 Station Wagon and V6 Utility (with

Manual Transmission), fitted with LSD; “LSD - HIGH PERFORMANCE. USE APPROVED LUBRICANT AND

FRICTION MODIFIER”

1.2 FIN AL DRIVE ASSEMBLY MAINTENANCE

MAINTENANCE

Drive Shaft Bearings and Constant Velocity Joints

The drive shaft outer bearings and constant

velocity joints are lubricated for life and therefore

require no periodic maintenance.

The constant velocity joint boots are to be

inspected at every maintenance service. If there is

any evidence of damage to boots, remove drive

shaft and inspect constant velocity joints, refer to

2.7 DRIVE SHAFT ASSEMBLY and to

2.8 DRIVE SHAFT AND/OR CONSTANT

VELOCITY JOINTS in this Section.

Differential Carrier Assembly

Check for lubricant leaks at every maintenance

service. If there is evidence of leakage, c orrect the

leak and add lubricant as necessary. (Refer to

2 MINOR SERVICE OPERATIONS in this

Section).

At the tim e or distance interval specified in the MY

2003 VY and V2 Ser ies Owner's Handbook , check

to ensur e that the lubr icant le vel is to the bottom of

the filler plug hole when the differential carrier

assembly is COLD.

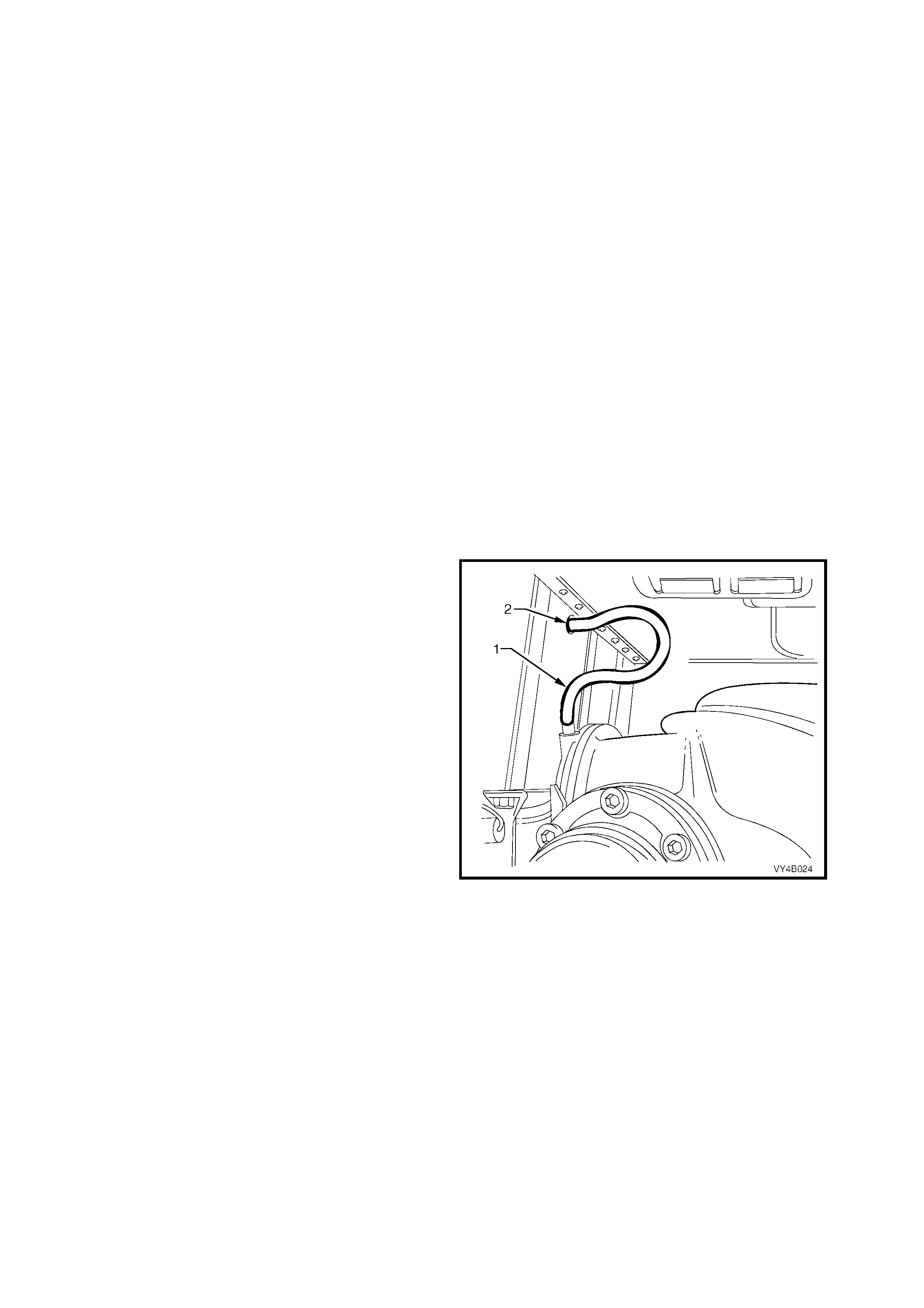

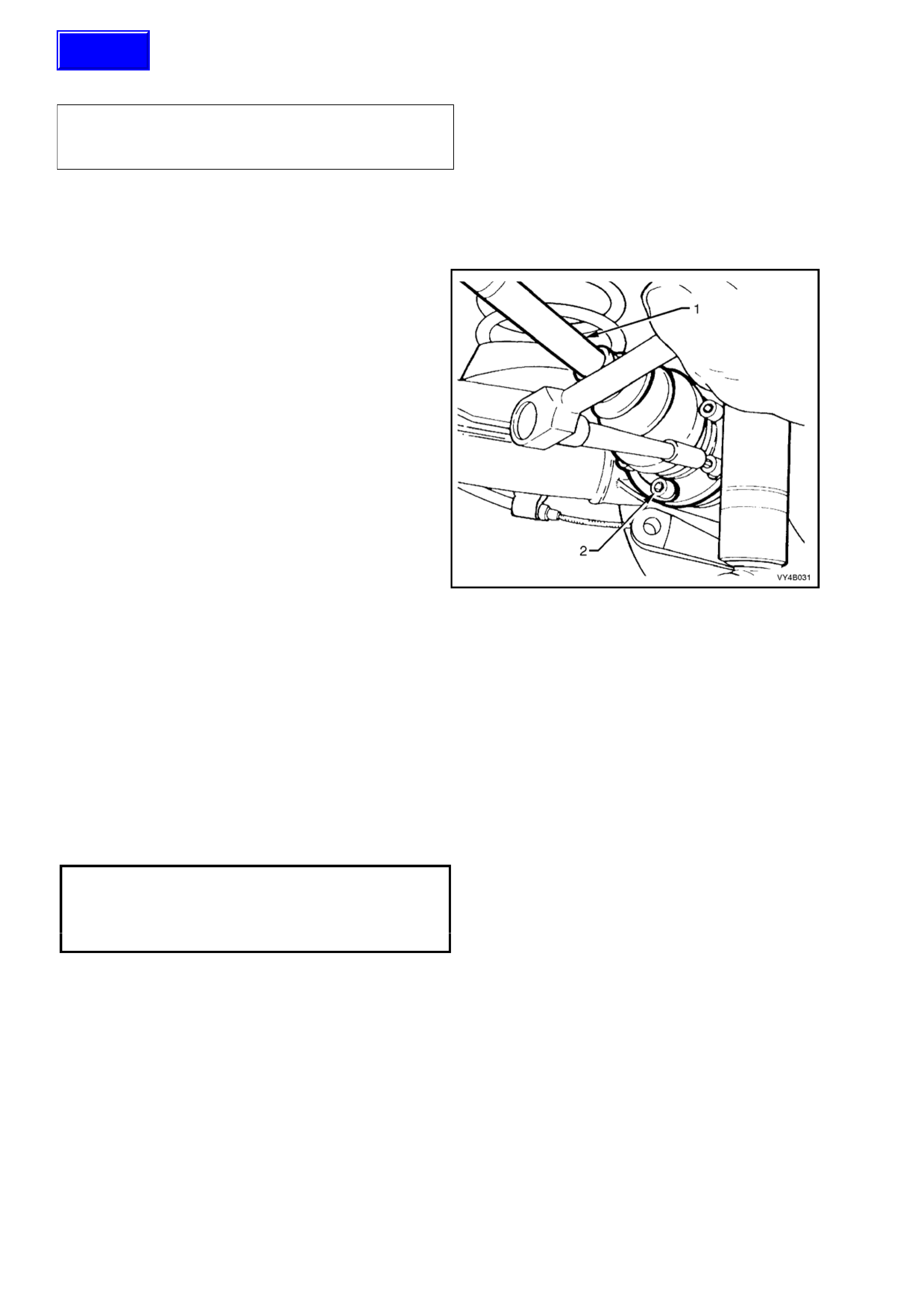

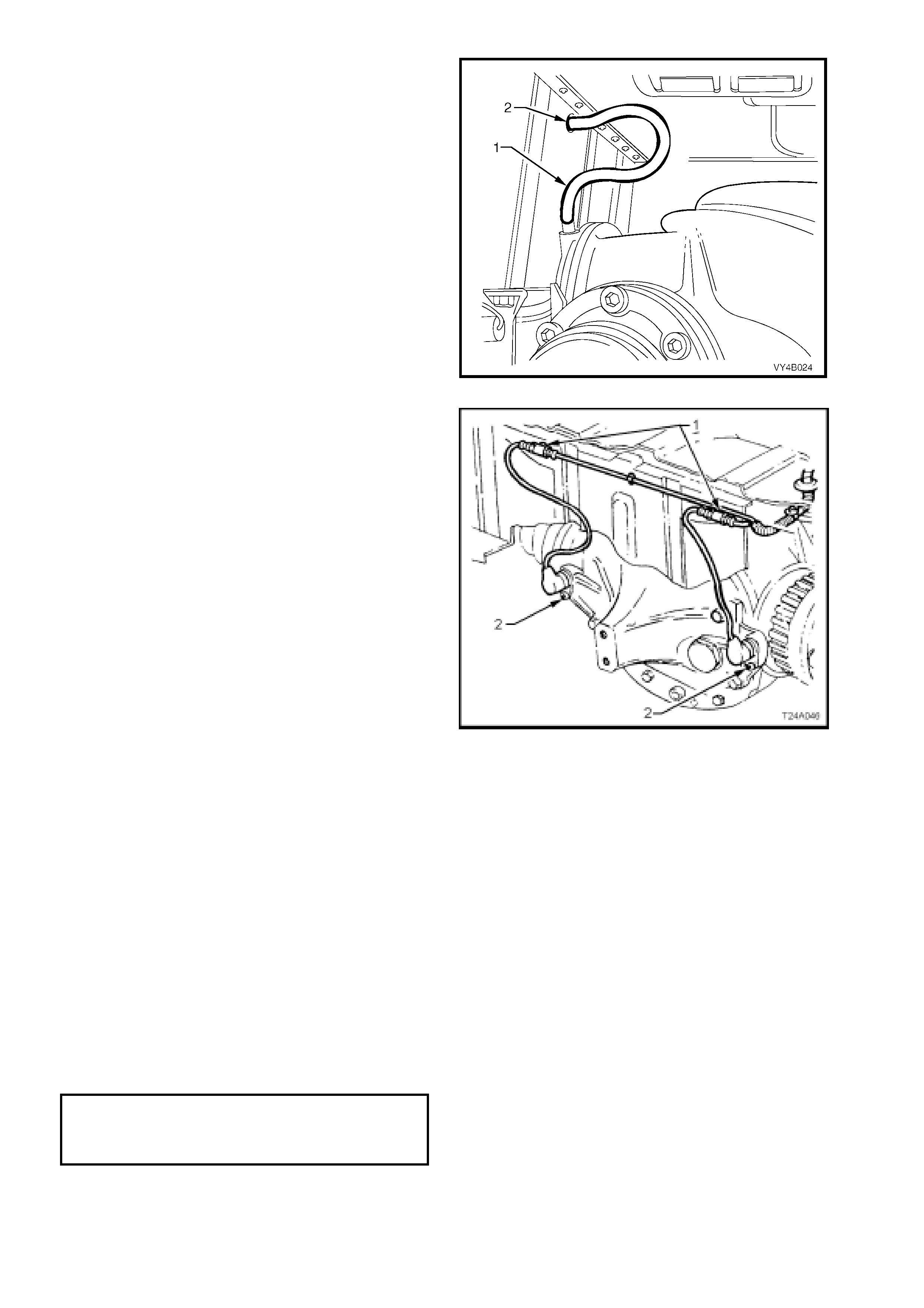

Final Drive Assembly Breather

The breath er hose ( 1) shou ld be check ed regular ly

to ensure that it is correctly routed and not kinked.

The top end of the breather hose should be

inserted at least 25 mm into the vehicle underbody

crossmember hole (2).

Figure 4B-4

LIMITED SLIP DIFFERENTIAL PRECAUTIONS

CAUTION: When servicing a vehicle fitted with a Limited Slip Differential, never run the engine with the

transmission in gear and one wheel raised. The driving force to the wheel on the ground may cause the

vehicle to move.

NOTE: 'On Car' type wheel balancers are not recommended for use on the rear wheels of cars equipped with a

Limited Slip Differential. One rear wheel will drive if in contact with the ground when the opposite wheel is raised

and rotated.

This type of bal ancer ma y be used b y rem oving the road wheel opposit e to the one bein g spun, the veh icle raised

and supported on safety stands. Refit wheel nuts, reversed, to retain brake disc.

LUBRICATION

The lubricant level should be checked and topped up (if required), at the time or distance intervals outlined in the

MY2003 V Y Series Owner' s Handbook with the differ ential carr ier COLD ; refer to 2.2 C HECKING DIFF ERENT IAL

CARRIER LUBRICANT LEVEL in this Sec t ion . At th is temperatur e, th e l ubr ica n t s hould be le ve l with the bott om of

the filler plug hole. Operation 2.2 also details the recommended lubricants for all final drives fitted to MY2003 VY

Series vehicles.

NEVER USE ANY OTHER THAN THE STATED AND RECOMMENDED LUBRICANT.

NOTE 1: The lubricant for vehicles with the 3.08:1 ratio assembly, with either the standard or Limited Slip

Differential (LSD) differential, is an approved mineral, LSD compatible lubricant and MUST be used. Using a

straight run mineral oil in an LSD final drive assembly, will cause ‘stick-slip’ chatter to occur when turning corners.

Alternatively, if a synthetic type lubricant is used in any rear axle of a 3.08:1 ratio assembly, oil seal deterioration

with the possibility of lubricant leakage may occur.

NOTE 2: T he lubr icant used i n the r ear ax les of al l 3.0 7 and 3.46:1 rat io as sem bli es, is a s ynthetic pr oduc t. The oil

seals of the 3.07 and 3.46 :1 ratio as semblies ha ve been speci ally form ulated to tolerat e this lubr icant. It mus t also

be noted that, using a m ineral t ype lubricant in any final drive f itted to a 3.07 or 3.46:1 ratio assem bly, may cause

gear set and/or bearing damage under high load driving conditions.

NOTE 3: With rear axles of 3.07 and 3.46:1 ratio assemblies, with LSD, an approved additive such as Sturaco

7098 MUST also be used, in conjunction with a synthetic hypoid gear oil.

NOTE 4: If the incorrect lubricant is accidentally used in the rear axle of any MY2003 VY Series vehicle, then the

rear axle should be drained, flushed (with the recommended lubricant) and then refilled with the correct lubricant.

The procedure for this operation is detailed in 2.3 CHANGING/FLUSHING REAR AXLE LUBRICANT, in this

Section.

2. MINOR SERVICE OPERATIONS

2.1 GENERAL

IMPORTANT SERVICE REQUIREMENTS

1. Whenever a road wheel and/or brak e disc is removed from the vehicle, the relationship of the road wheel and

the disc to th e hub MUST be mark ed with a felt ti ppe d pen or similar, in or d er f or those parts to be re ins ta ll ed in

their original positions. This is critical to maintain the brake disc and road wheel runout dimension to a

minimum.

2. When reinstalling road wheels, do not use an

impact gun to tighten wheel nuts unless the

impact gun is fitted with a torque limiter socket

(Tool No. AU534 or a commercial equivalent).

Failure to correctly tighten wheel nuts to the

correct torque specification and in the correct

order, may result in a distorted brake disc,

leading to the development of brake shudder.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 – 140 Nm

For a complete description of the method

used to measure both brake disc and

trunnion assembly runout and correction, refer to

3.5 REAR BRAKE DISC, Brake Disc and Hub

Indexing Procedure, in Section 5A SERVICE AND

PARK BRAKING SYSTEMS in the MY 2003 VY

and V2 Series Ser v ice Infor mation

Figure 4B-5

3. All rear suspension fasteners are important

attaching parts because they affect the

performance of vital components and/or could

result in major repair expense. Where

specified in this Section, fasteners MUST be

replace d with ones of the s am e par t num ber or

with an equivalent part. Do not use a

replacement part of inf erior qua lity or substitute

design.

4. Torque values must be used as specified

during reassembly to ensure proper retention

of all rear suspension components.

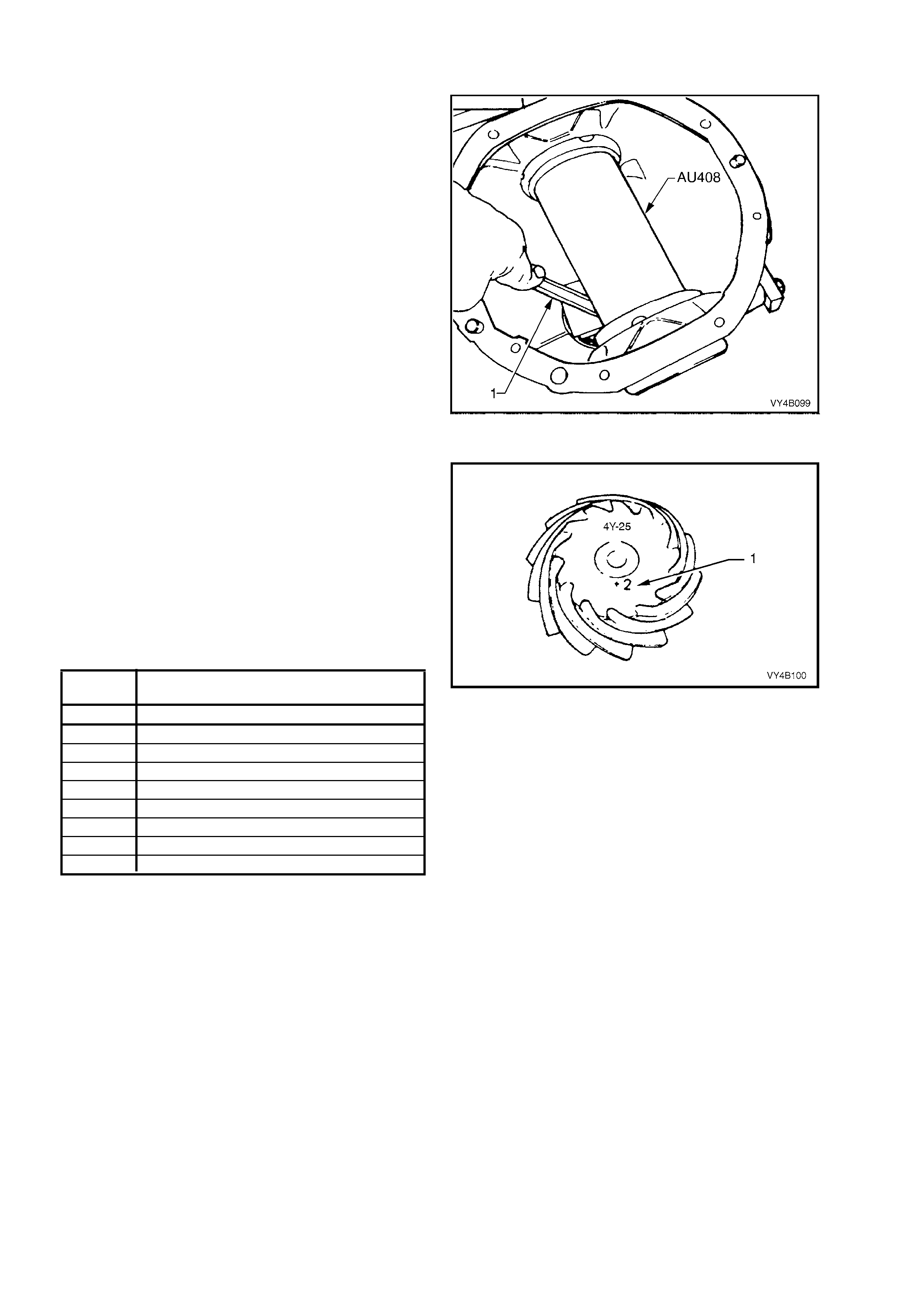

2.2 CHECKING DIFFERENTIAL CARRIER LUBRICANT LEVEL

1. Ensure ve hic l e is le vel.

2. Clean area around filler plug (1).

3. Remove filler plug (1) from rear cover (3) (do

not lose the lubrication tag (2) from the plug, if

fitted).

4. The lubricant level is to be maintained at the

bottom edge of the filler plug hole, WHEN

COLD. Use only the recommended lubricant,

detailed as follows:

Figure 4B-6

ENGINE & AXLE TYPE RECOMMENDED LUBRICANT

ALL V6 Sedan with Manual or Automatic

Transmission,

V6 Station Wagon or Utility with Automatic

Transmission

Mineral Hypoid Gear Oil SAE 90 LSD such as;

AMPOL Gear Lube LSD 90,

CASTROL LSX90,

SHELL Helix Limited Slip Diff. Oil

VALVOLINE HP Gear Oil LS90

ALL NON-LSD AXLES ALL LSD AXLES

ALL GEN III V8 V6 Supercharged and V6 Station

Wagon or Utility with Manual Transmission Synthetic Hypoid Gear Oil, SAE

80W-140 such as;

MOBIL Mobilube SHC ID or

CASTROL SAF-XA Only

Synthetic Hypoid Gear Oil, SAE

80W-140 such as;

MOBIL Mobilube SHC ID,

CASTROL SAF-XA

With LSD (G80), also add;

0.1 litre of Sturaco 7098 Oil

Additive

5. Inspect filler plug (1) for damage, if OK,

reinstall to the rear cover (3) (including the

lubrication tag (2). If damaged, replace plug.

6. Tighten filler plug (1) to the correct torque

specification.

FILLER PLUG

TORQUE SPECIFICATION 23 - 31 Nm

2.3 CHANGING/FLUSHING REAR AXLE LUBRICANT

1. To drain lubrican t from diff er entia l c arr ier as s embly, re move filler ( 1) and dr ai n p lu gs (4 ) ( refer Figur e 4B-6) a nd

allow (preferably warm) lubricant to drain into a suitable container.

2. If flushing is required, use an undiluted quantity of the recommended lubricant for the operation.

3. When the draining and flushing (if required), operation is completed, apply thread sealing tape to rear cover

drain plug (4) thread. Install and tighten drain plug (4) to the correct torque specification.

REAR AXLE DRAIN PLUG

TORQUE SPECIFICATION 23 - 31 Nm

4. Fill the f in al dr iv e as sembl y with eith er 1.6 litr es of the r ec om m ended l ubric an t or 1.5 litr es of the r ec om mended

lubricant plus 0.1 litre of Sturaco 7098 oil additive. Install the filler plug (1) and lubrication tag (2) (if fitted) and

tighten to the correct torque specification.

REAR AXLE FILLER PLUG

TORQUE SPECIFICATION 23 - 31 Nm

2.4 TRAILING ARM TRUNNION ASSEMBLY HUB

CHECK FOR RUN-OUT

1. Using a floor jack under centre of differential carrier, jack up rear of vehicle, then place safety stands under

trailing arms to support weight of vehicle.

2. Remove rear wheel cover (steel wheels) or wheel nut covers (alloy wheels) on that side of the vehicle where

the trunnion is to be checked.

3. Mark relationship of wheel to mounting flange. Remove road wheel attaching nuts and remove wheel.

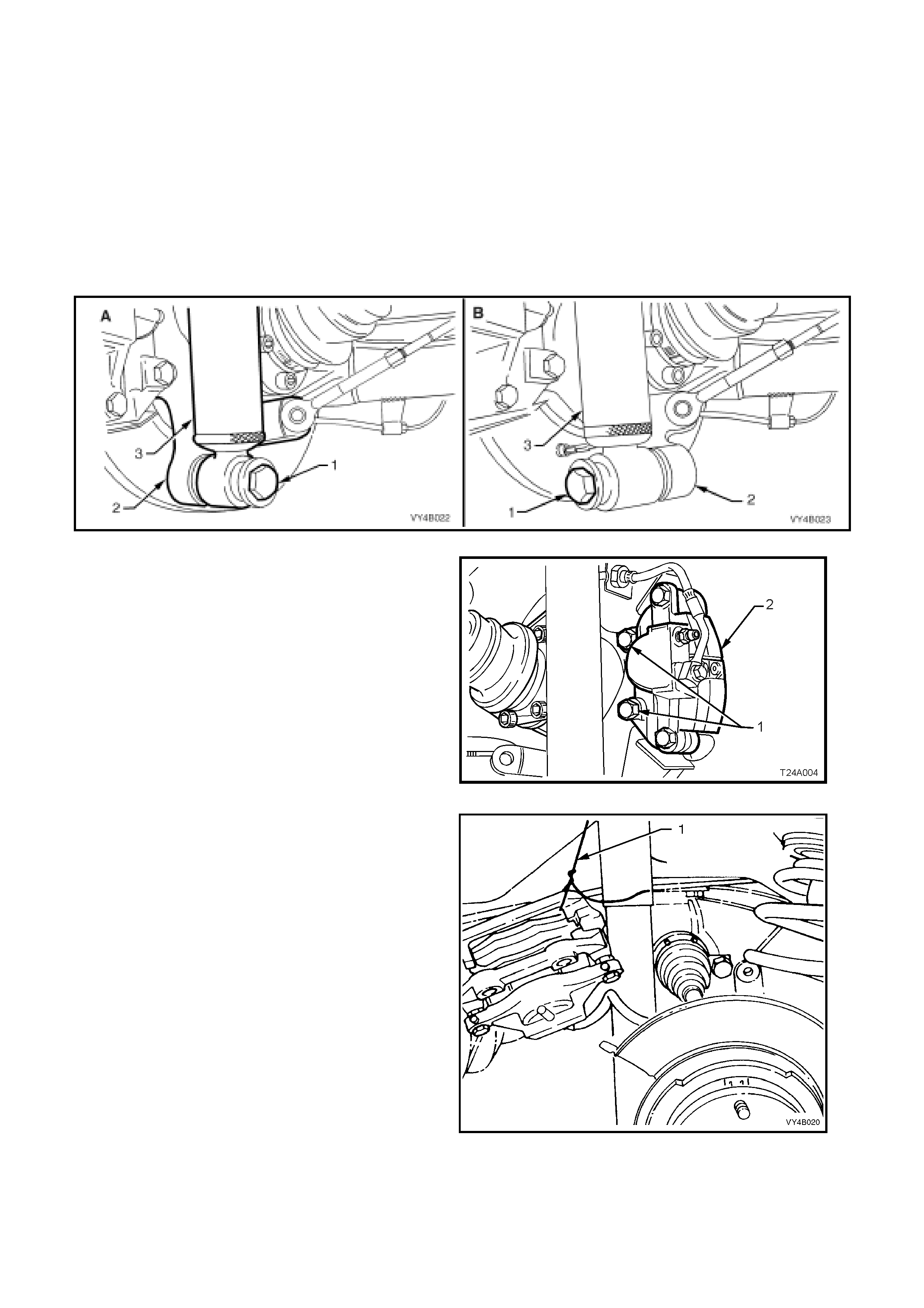

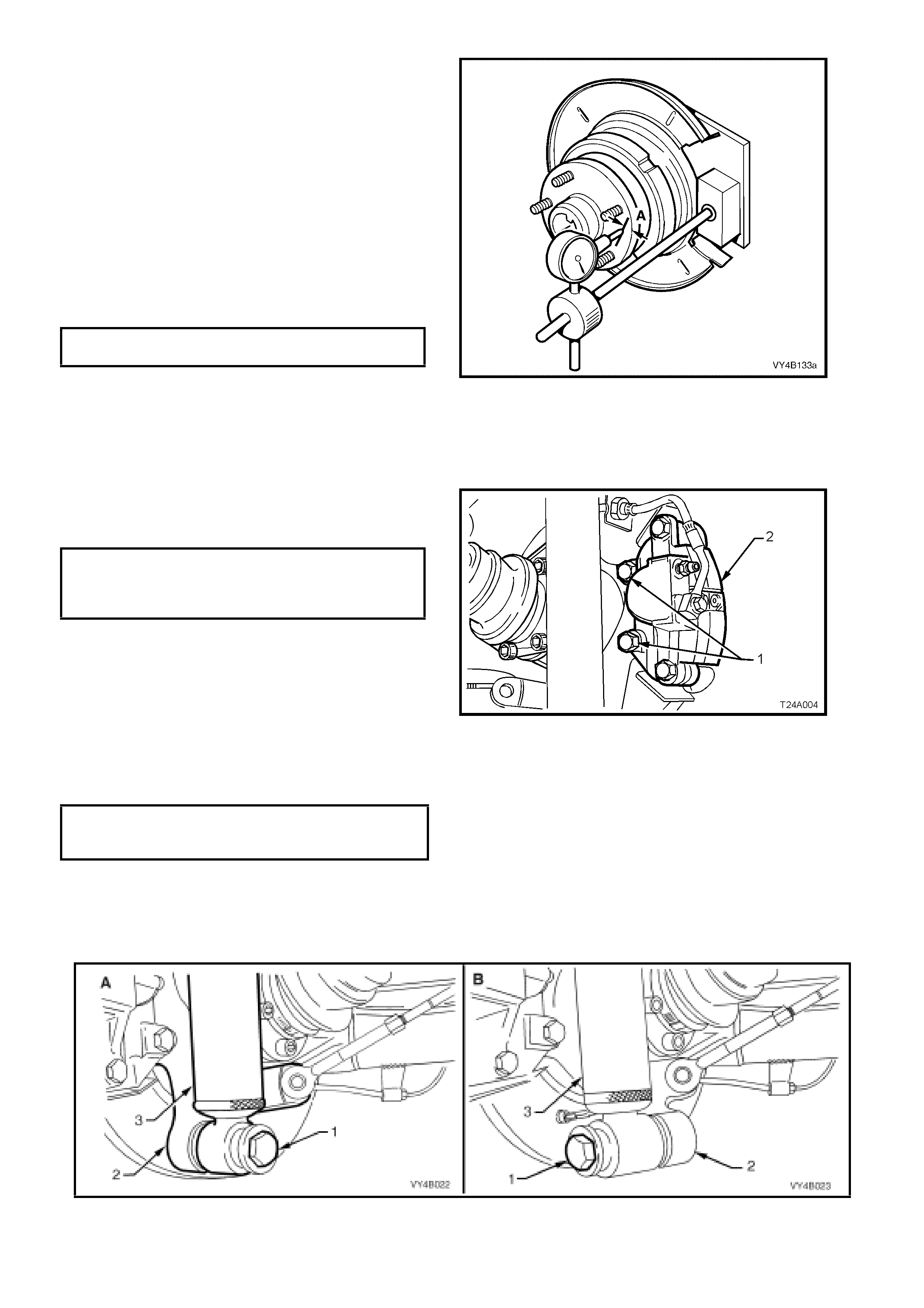

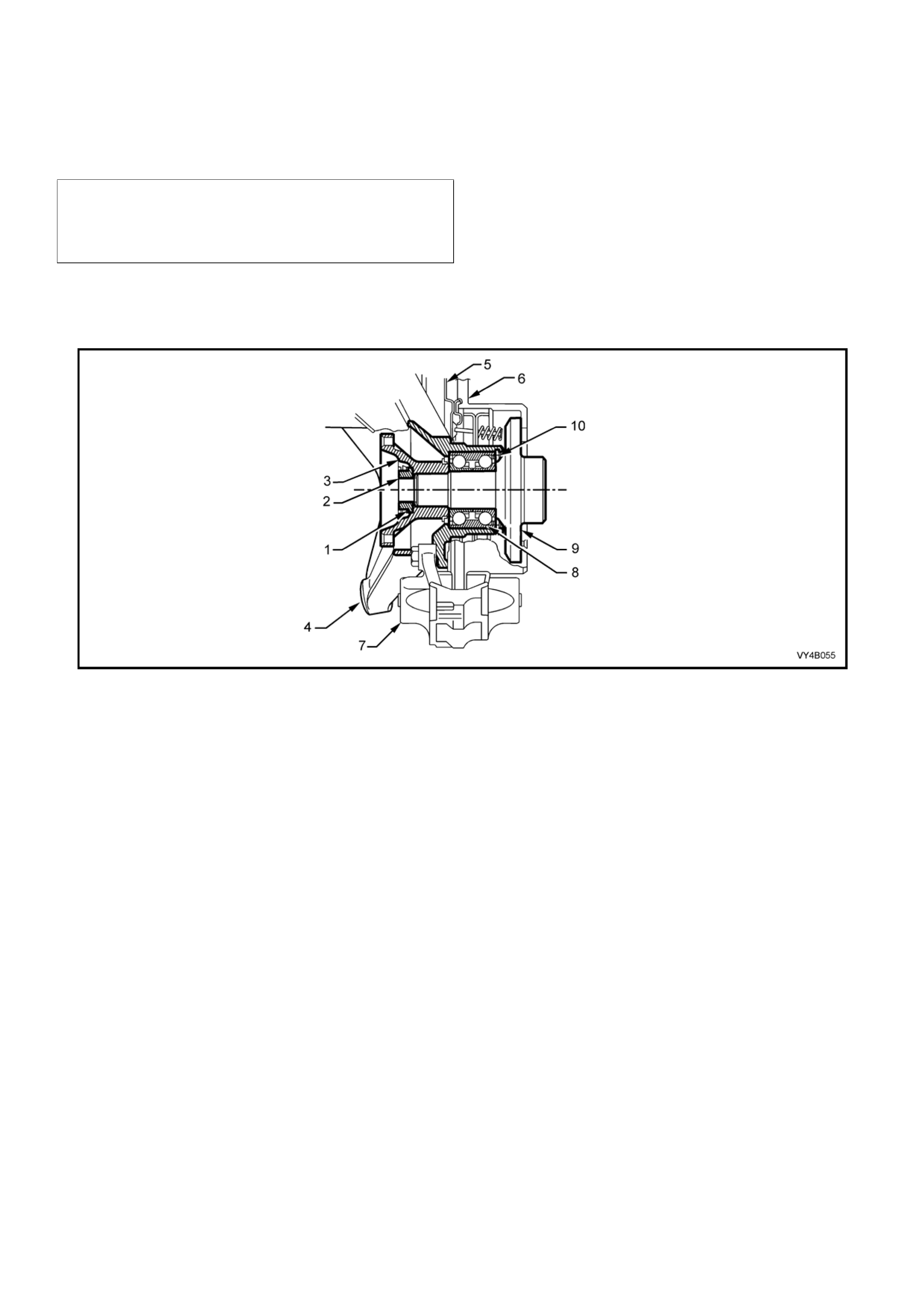

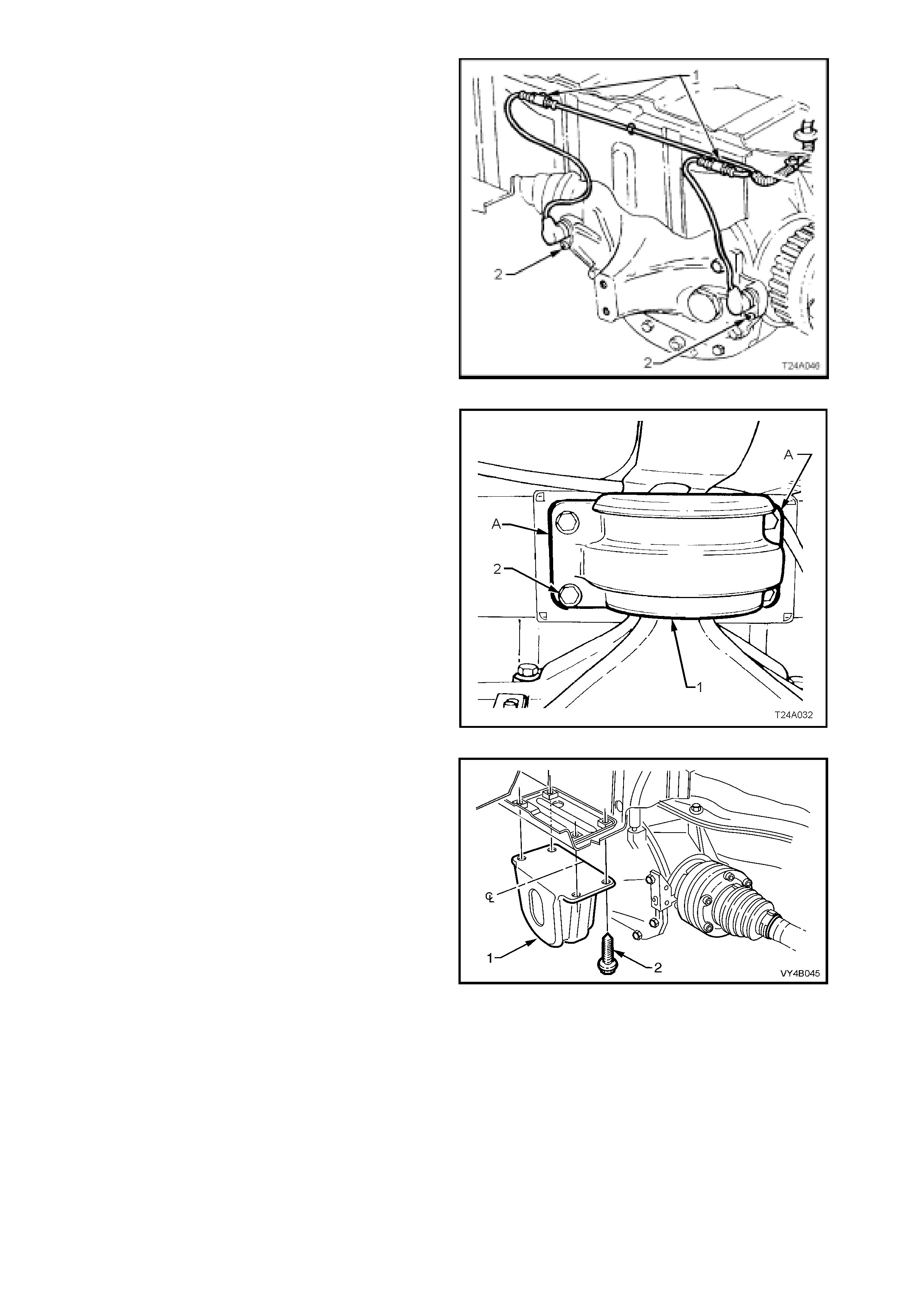

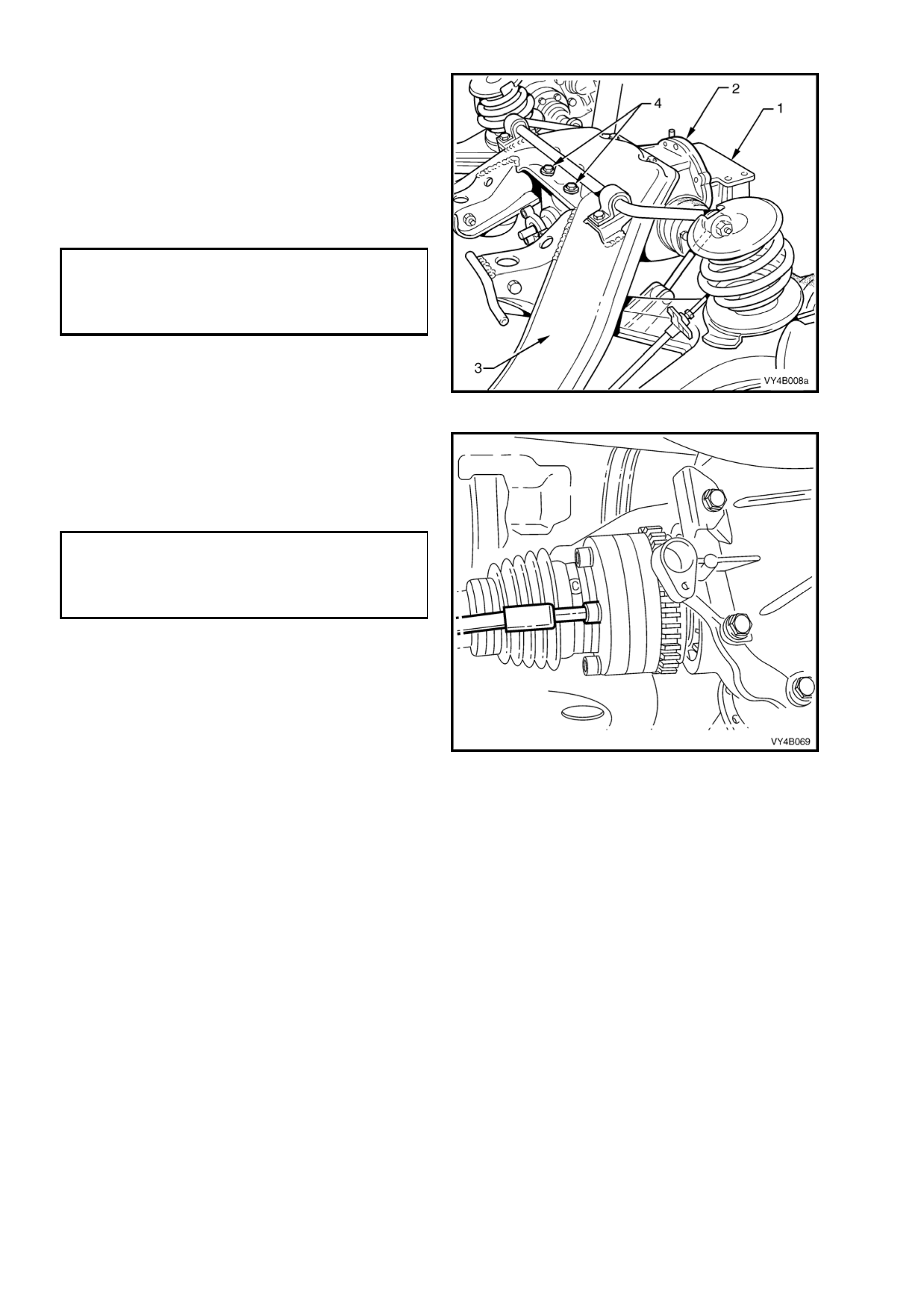

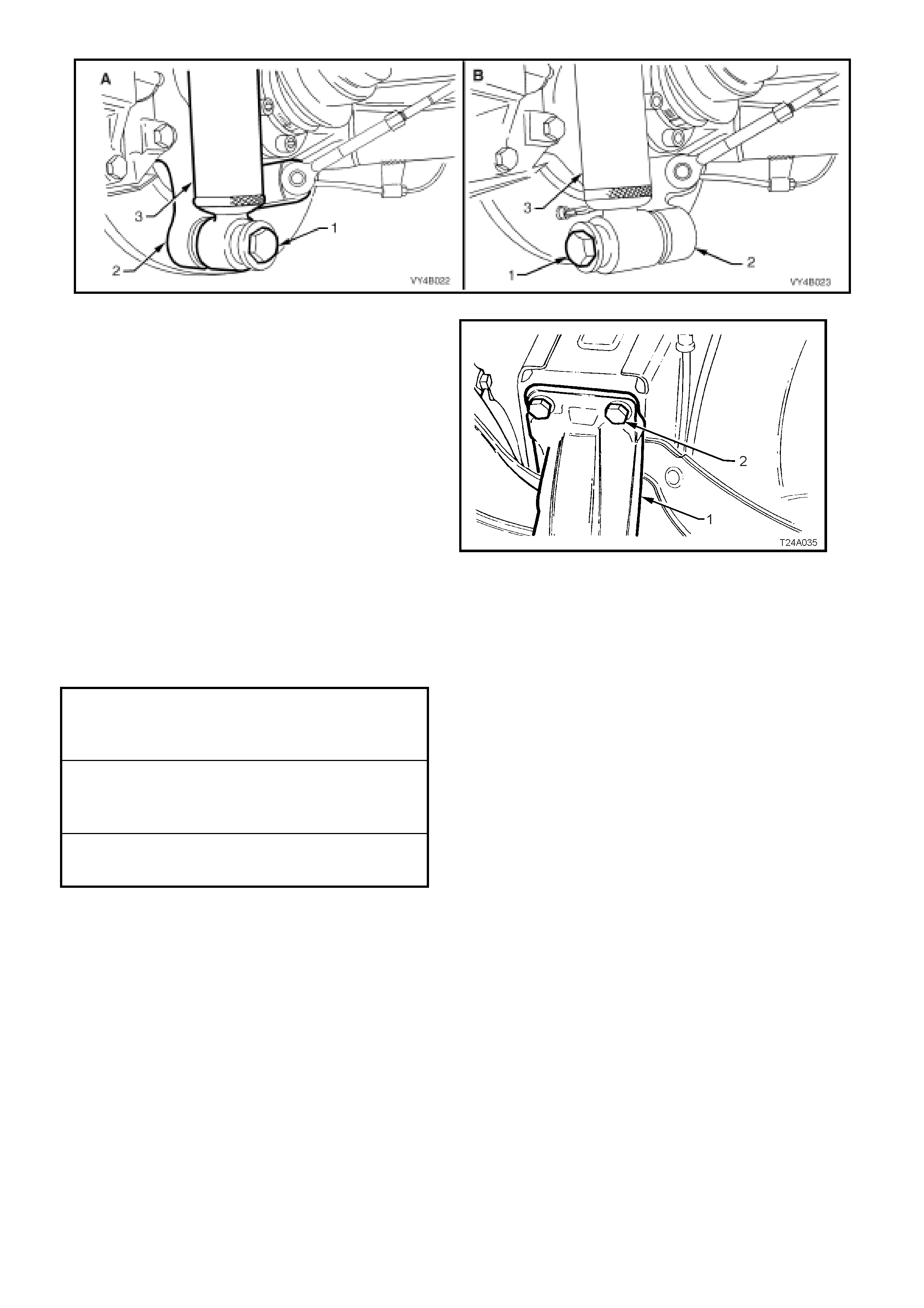

4. Disconnect rear shock absorber lower mounting bolt (1) from trailing arm (2), and pull lower end of shock

absorber (3) from trailing arm.

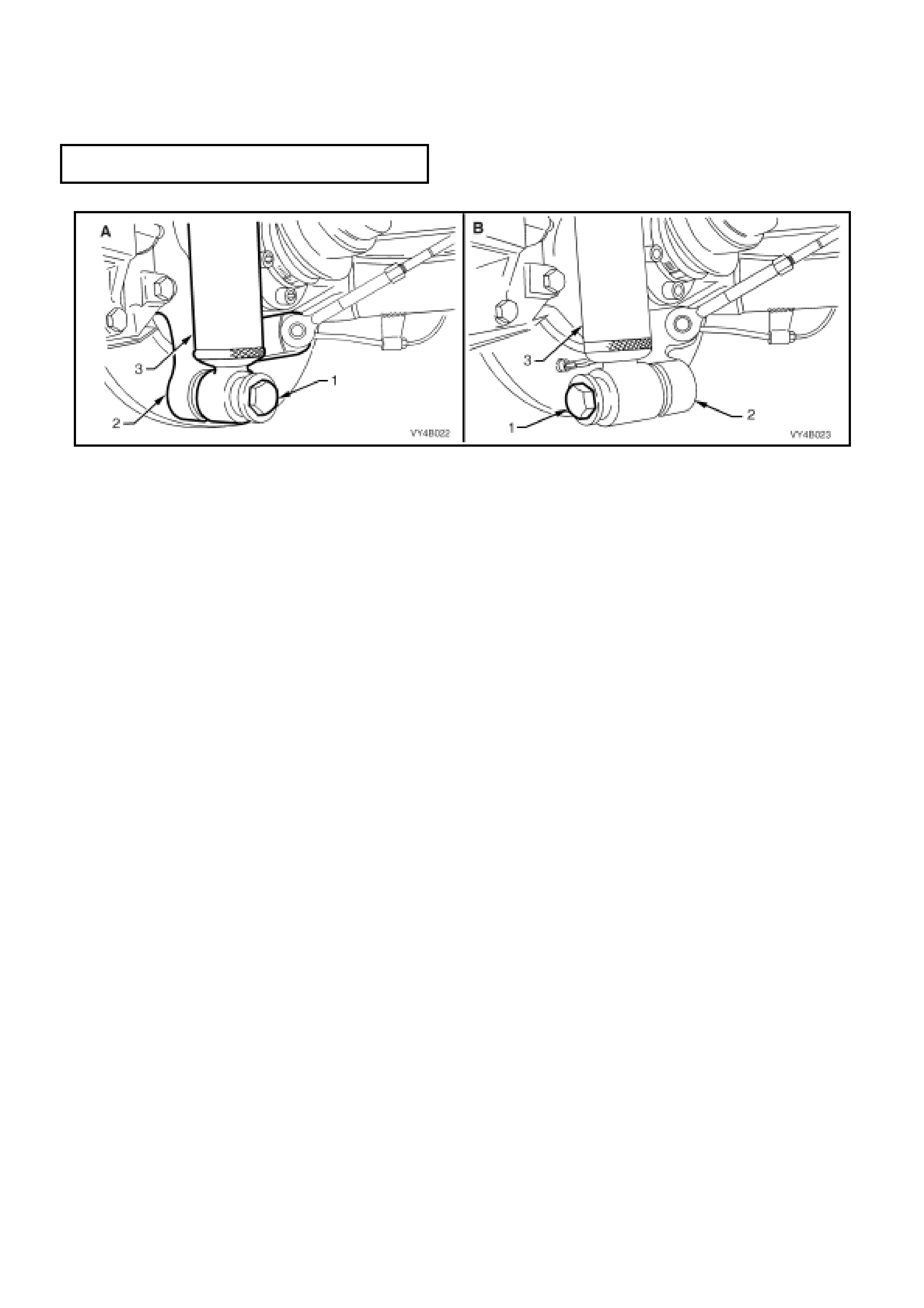

NOTE: View ‘A’ i n Figure 4B-7 s hows the sedan, lower s hock absorber m ounting, whil e view ‘B’ sho ws the station

wagon arrangement.

Figure 4B-7

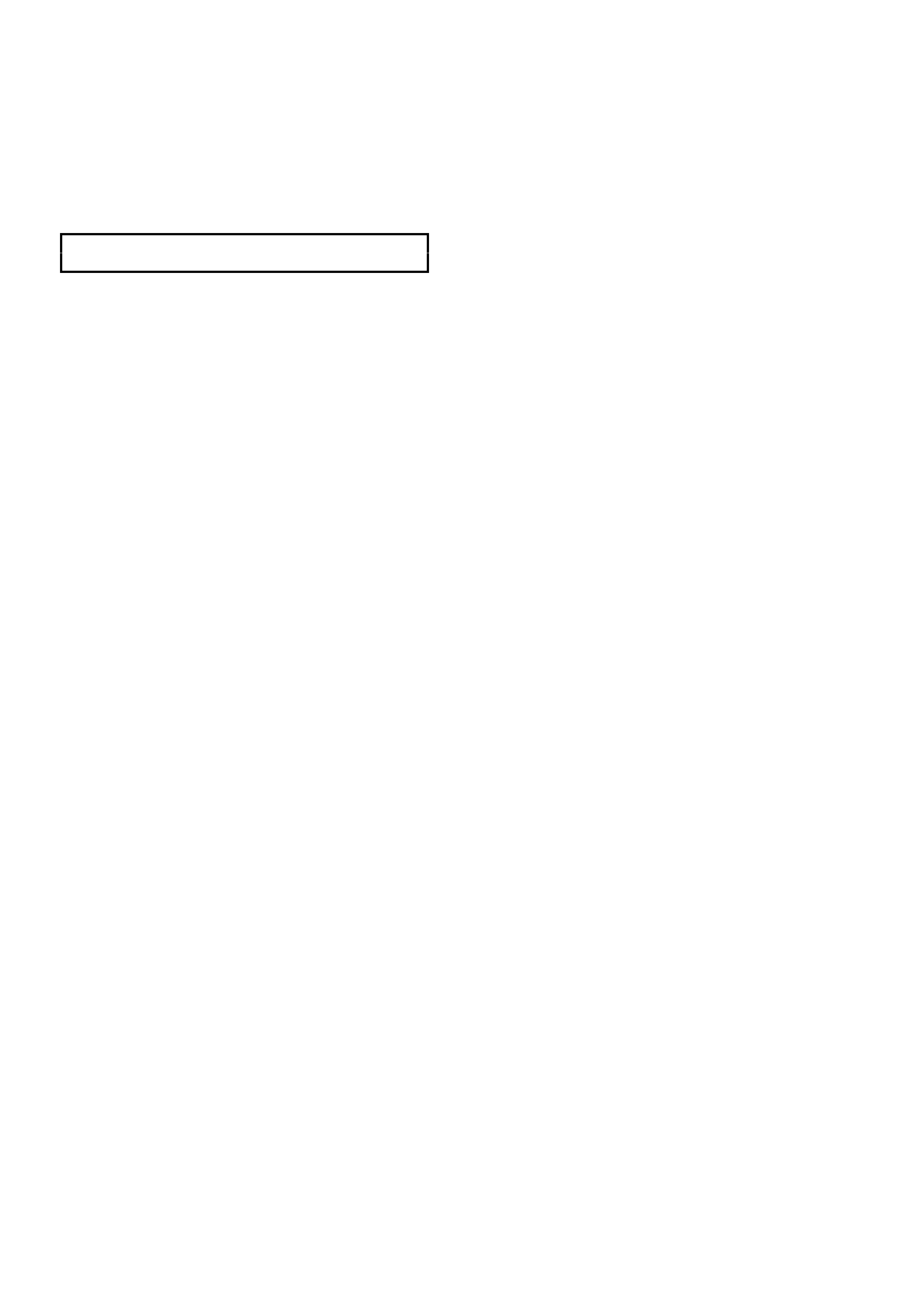

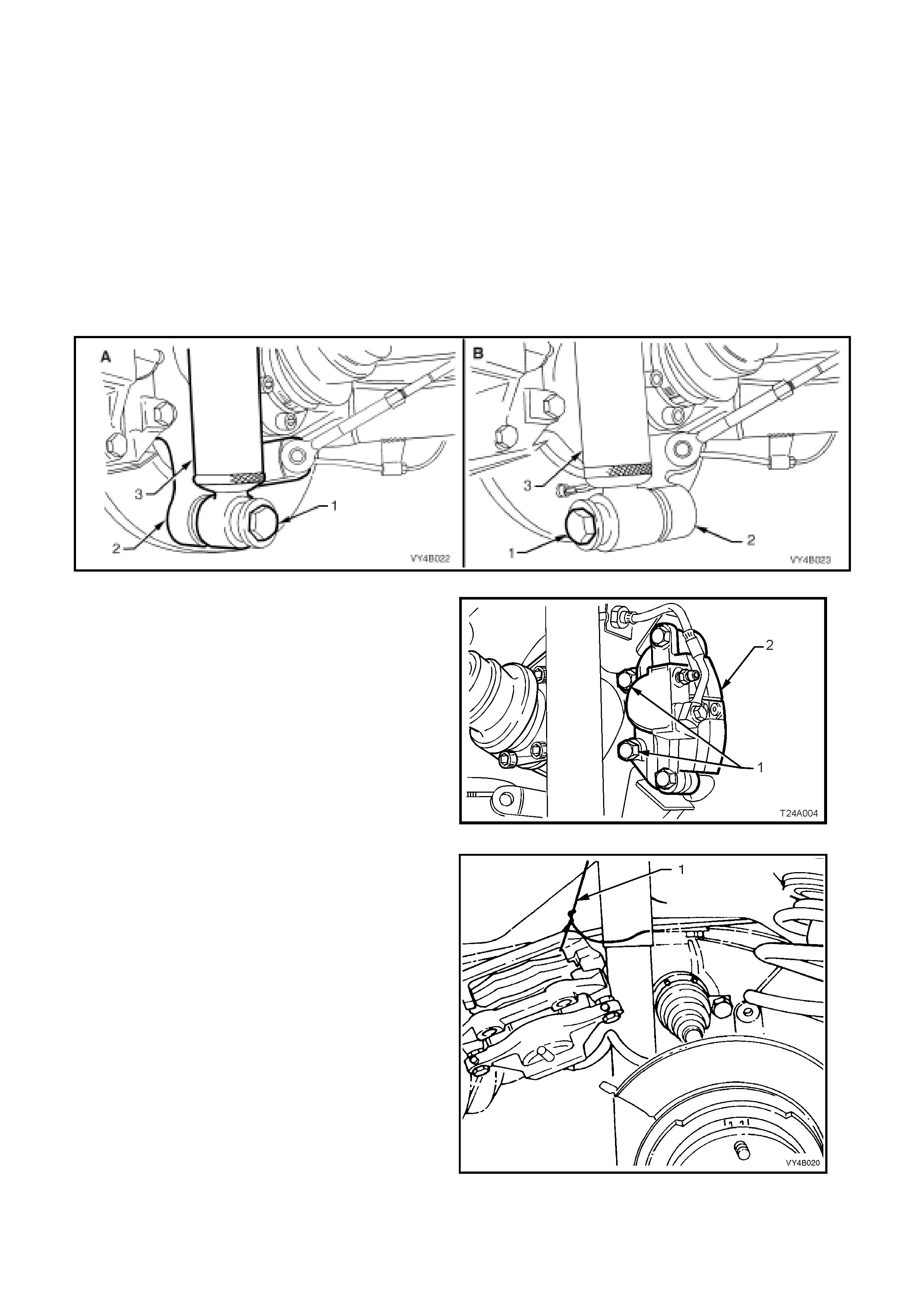

5. Remove brake caliper anchor plate to trailing

arm attac hing bo lts ( 1), rem ove c aliper (2) fr om

disc.

Figure 4B-8

6. Using tie wire (1), secure caliper to lower end

of shock absorber upper mounting. DO NOT

ALLOW CALIPER TO HANG BY BRAKE

HOSE.

7. Mark the brake disc position to trunnion

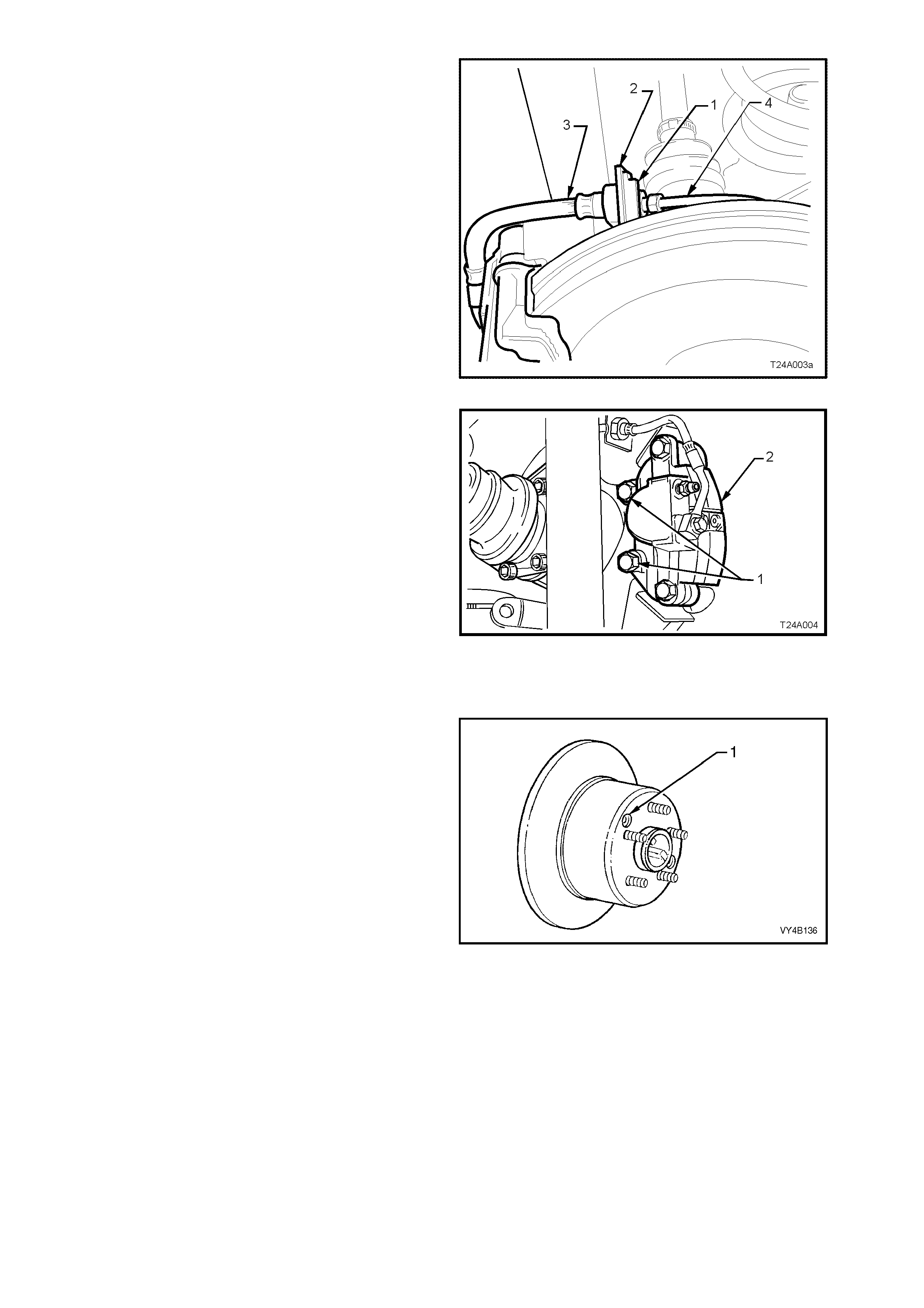

assembly, using a felt tipped pen or similar,

then remove the brake disc from the trunnion

assembly (Shown already removed in

Figure 4B-9).

Figure 4B-9

8. Clean the rear trunnion face by rubbing lightly

with fine emery paper.

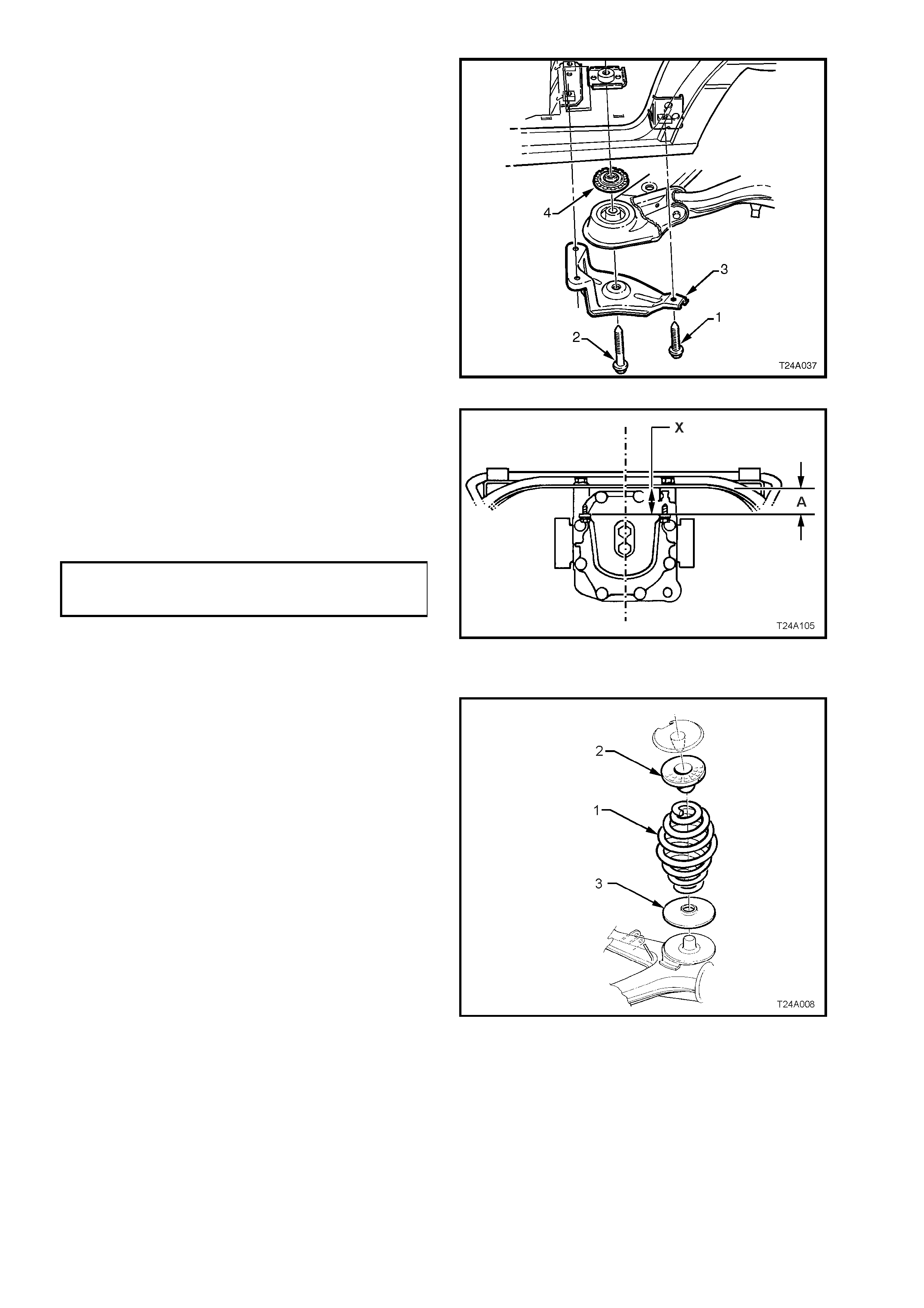

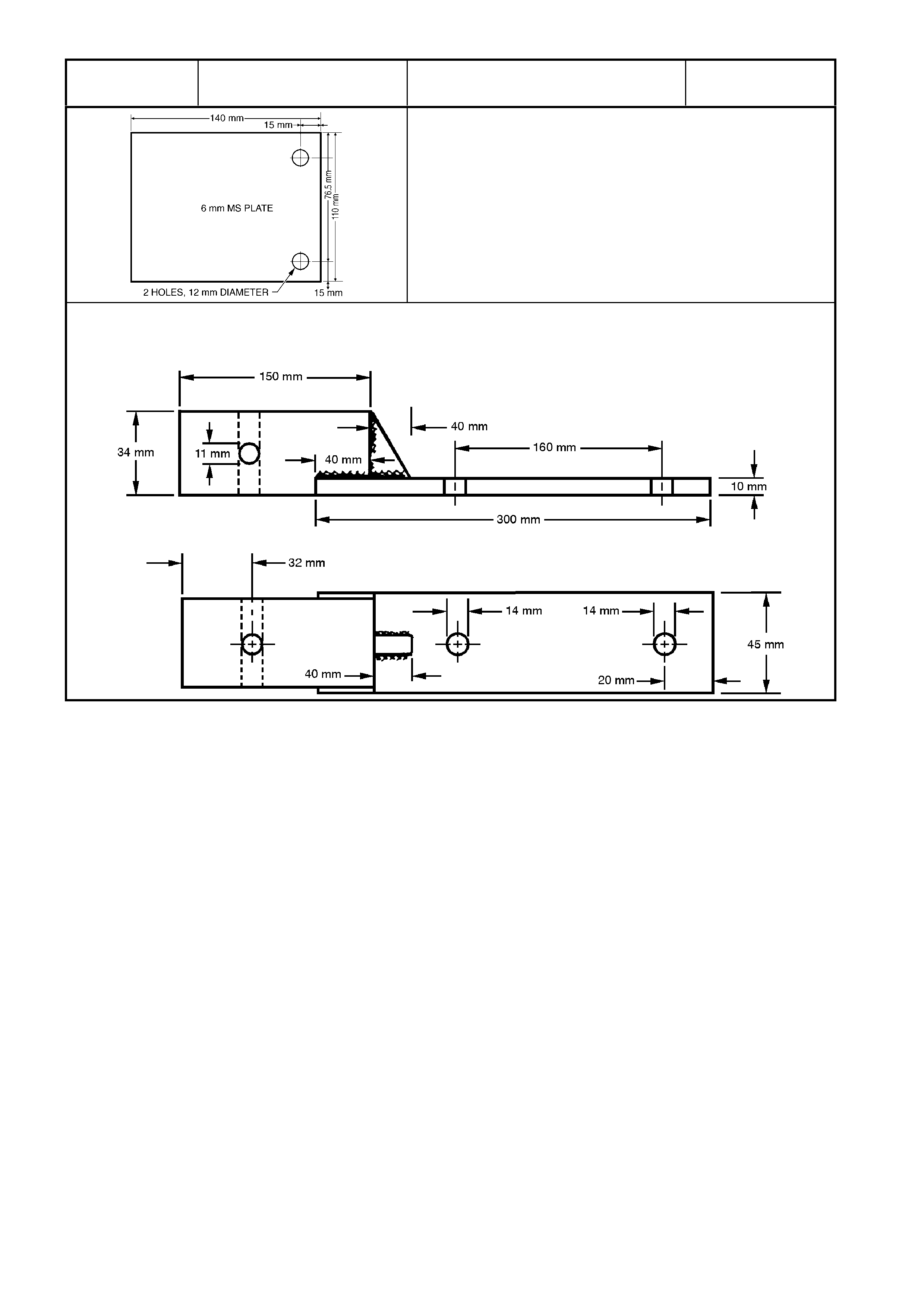

9. Mount the pre-fabricated mounting plate (refer

7. SPECI AL TOOLS in th is Section f or details )

to the brake caliper mounting points on the rear

trailing arm, using the caliper mounting bolts.

10. Mount a magnetic based dial indicator stand,

install a dial in dicat or, posit ioning the pointer at

a distance of 5 mm in from the outer edge (‘A’).

11. Using the wheel studs , carefull y rotate trunn ion

assembly hub, noting the points of maximum

and minimum lateral run-out. The difference

between these two dimensions is the total

indicated runout.

MAXIMUM TRUNNION ASSEMBLY HUB,

TOTAL INDICATED RUN-OUT 0.060 mm

Figure 4B-10

If Run-out is Within Specification:

12. Reinstall brake disc over the trunnion wheel

studs, ensur ing that th e ali gnm ent marks made

prior to disassembly, are aligned.

13. Reinstall brake caliper (2) anchor plate to

trailing arm attaching bolts (1) and tighten to

the correct torque specification.

BRAKE CALIPER ANCHOR

PLATE TO TRAILING

ARM ATTACHING BOLT

TORQUE SPECIFICATION 70 – 100 Nm

Figure 4B-11

14. Install shock absorber to trailing arm, fit

washer to the lower mounting bolt, install bolt

and tighten to the correct torque specification.

SHOCK ABSORBER LOWER

MOUNTING BOLT

TORQUE SPECIFICATION 105 - 125 Nm

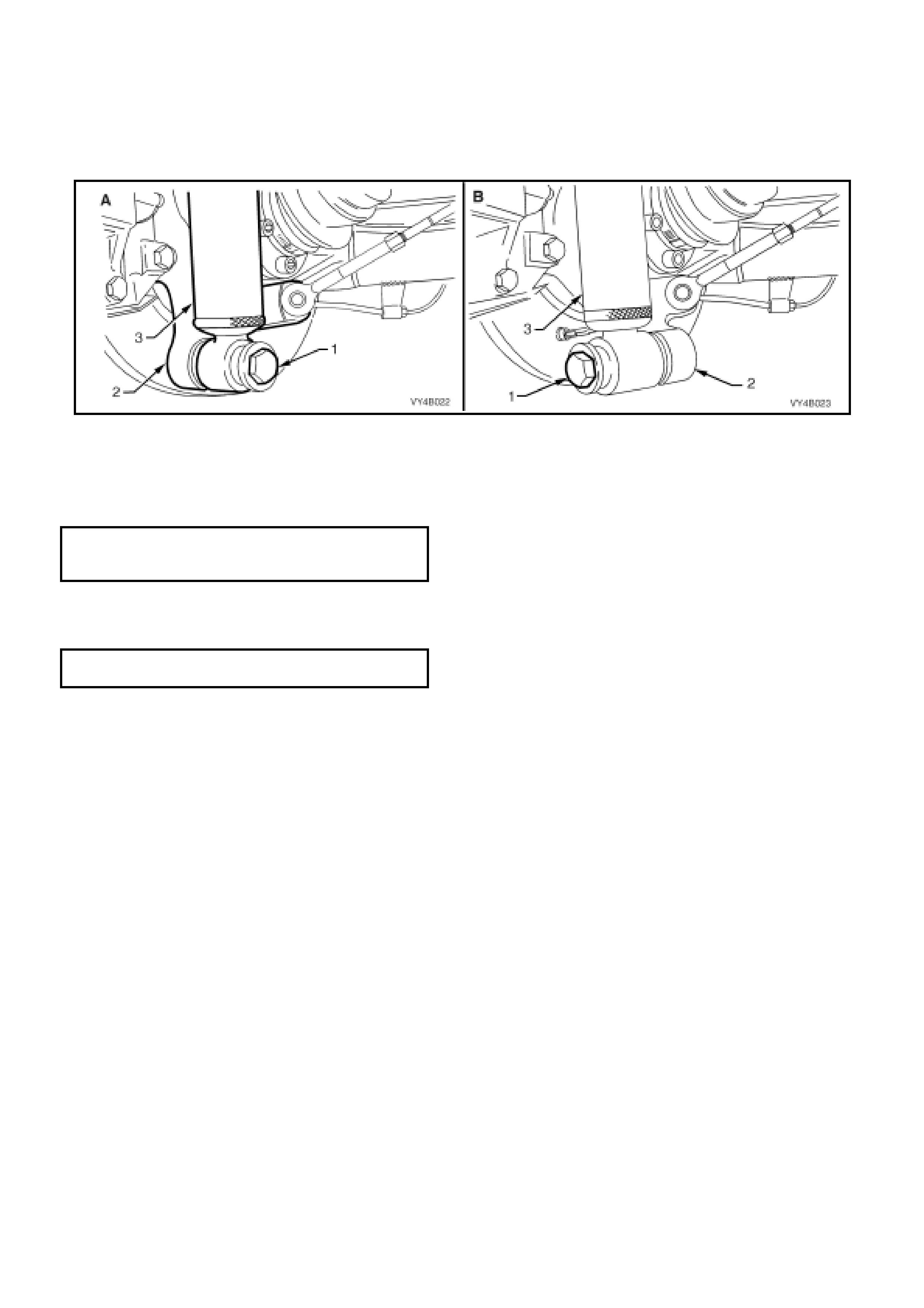

NOTE 1: Vehic le m ust be at c urb we ight an d on al l

four wheels before this torque is applied.

NOTE 2: View ‘A’ in Figure 4B-12 shows the

sedan, lower shock absorber mounting, while view

‘B’ shows the station wagon arrangement.

Figure 4B-12

15. Reinstall road wheel, aligning marks made

prior to removal, install and tighten attaching

nuts.

16. Remove safety stand and lower vehicle.

17. Tighten road wheel attaching nuts to the

correct torque specification and in the correct

sequence (refer ‘IMPORTANT SERVICE

REQUIREMENTS’ in 2.1 GENERAL, in this

Section).

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

18. Refit wheel cover/ whe el nut caps.

If the Run-out Check, Exceeds Specification:

19. The tr unnion assem bly mus t be replace d, refer

to 3.1 TRAILING ARM TRUNNION FLANGE,

TRUNNION ASSEMBLY AND/OR WHEEL

BEARING in this Sect ion.

2.5 TRAILING ARM TRUNNION ASSEMBLY HUB STUDS

LT Section No: E006500 / E006600

REPLACE

1. Using a floor jack under centre of differential carrier, jack up rear of vehicle, then place safety stands under

trailing arms to support weight of vehicle.

2. Rem ove rear wheel cover (steel whee ls) or whee l nut caps (alloy whee ls) on that side of the veh icle where th e

stud/s are to be replaced.

3. Mark relationship of wheel to mounting flange. Loosen then remove road wheel attaching nuts. Remove the

road wheel.

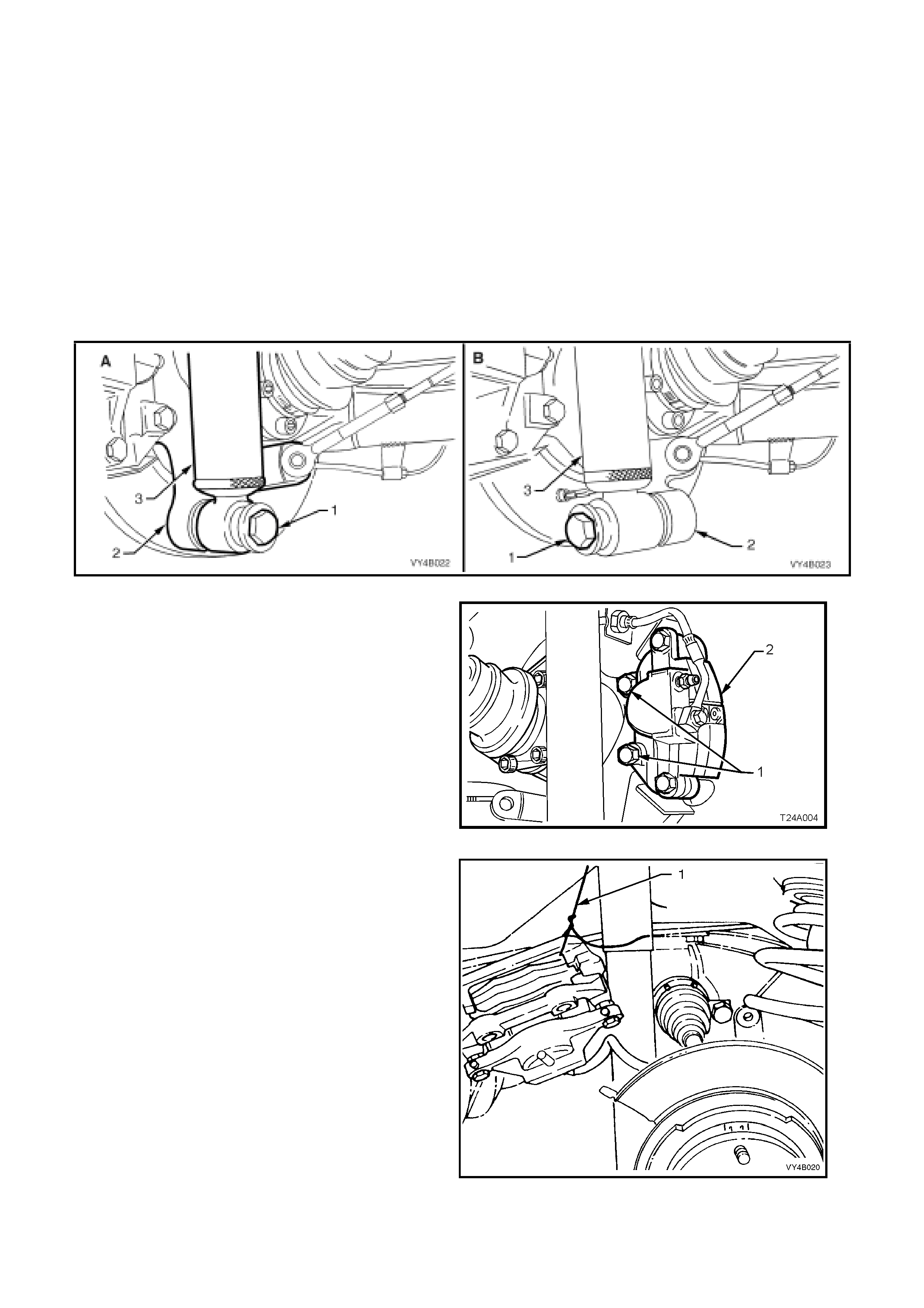

4. Loosen and disconnec t rear shock absorber lo wer mounting bolt ( 1) from trailing arm (2) and pull lo wer end of

shock absorber (3) from trailing arm (2).

NOTE: View ‘A ’ in Figure 4 B-13 s h o ws th e s eda n, lower shoc k absor ber mountin g, whil e vie w ‘ B’ s ho ws t he s tatio n

wagon arrangement.

Figure 4B-13

5. Loosen and remove brake caliper anchor plate

to trailing arm attaching bolts (1) and remove

caliper (2) from disc.

Figure 4B-14

6. Using tie wire (1), secure the brake caliper to

lower end of shock absorber upper mounting.

DO NOT ALLOW CALIPER TO HANG BY

BRAKE HOSE.

7. Mark the brake disc position to trunnion

assembly, using a felt tipped pen or similar,

then remove the brake disc from the trunnion

assembly (Shown already removed in Figure

4B-15).

Figure 4B-15

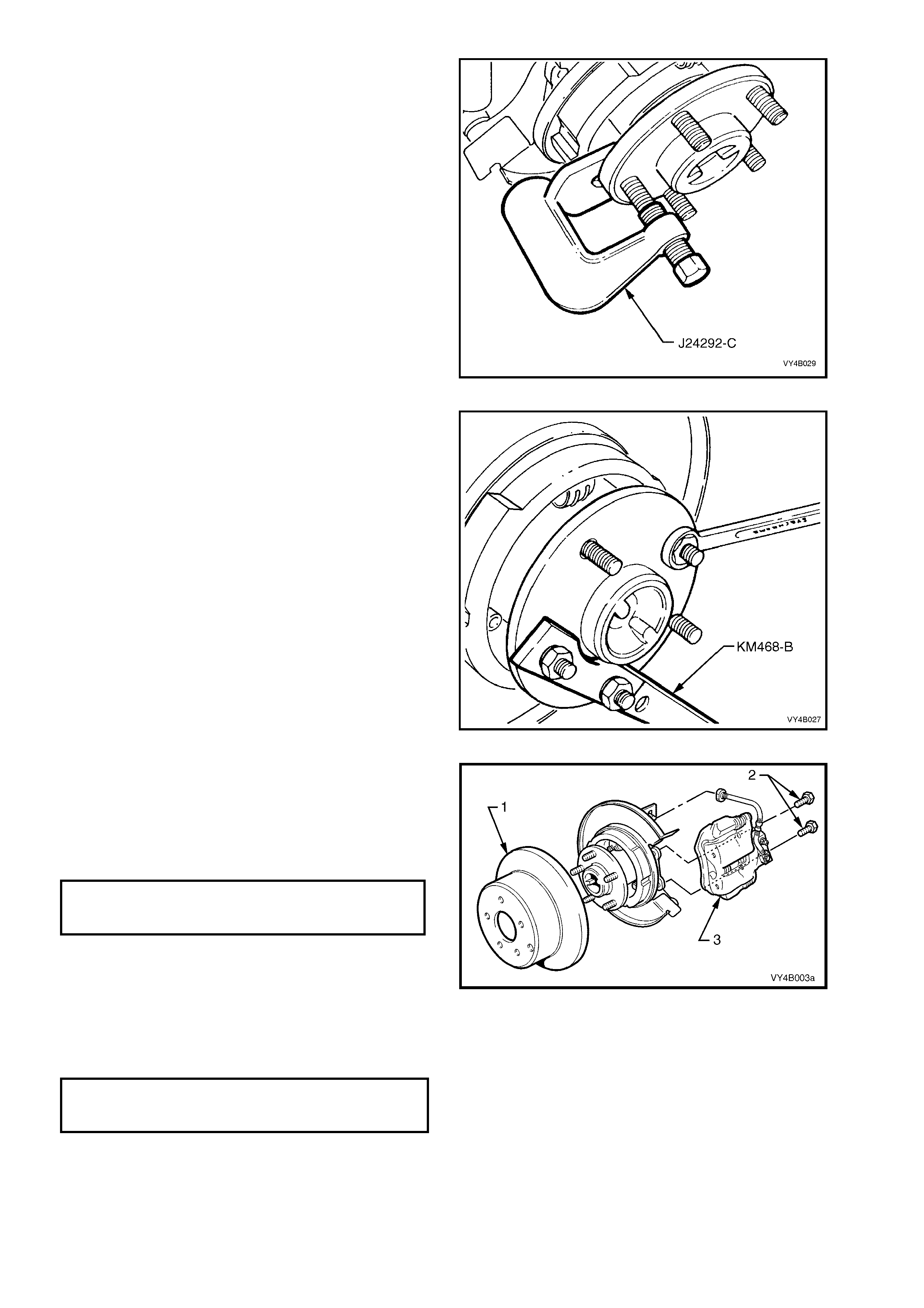

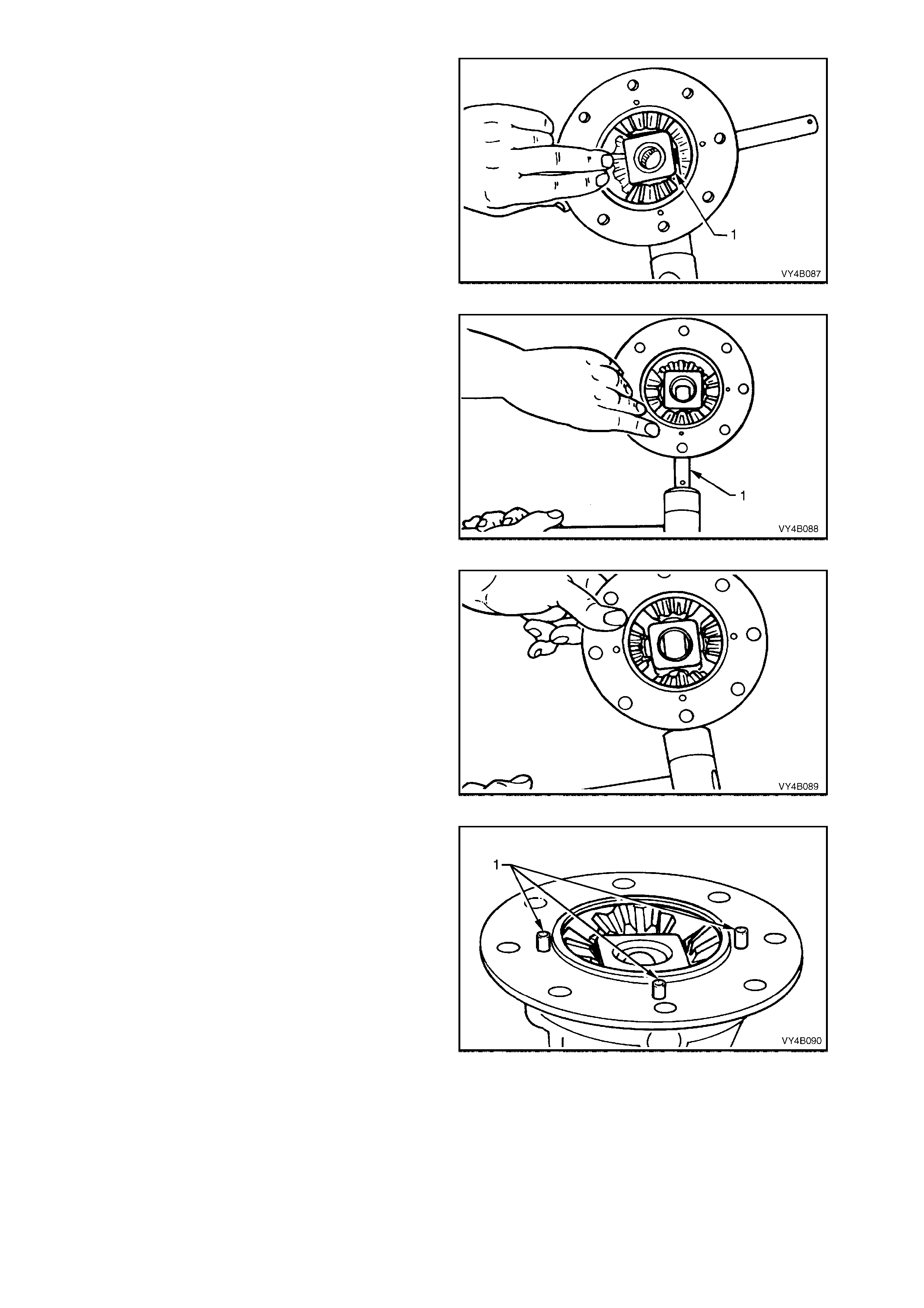

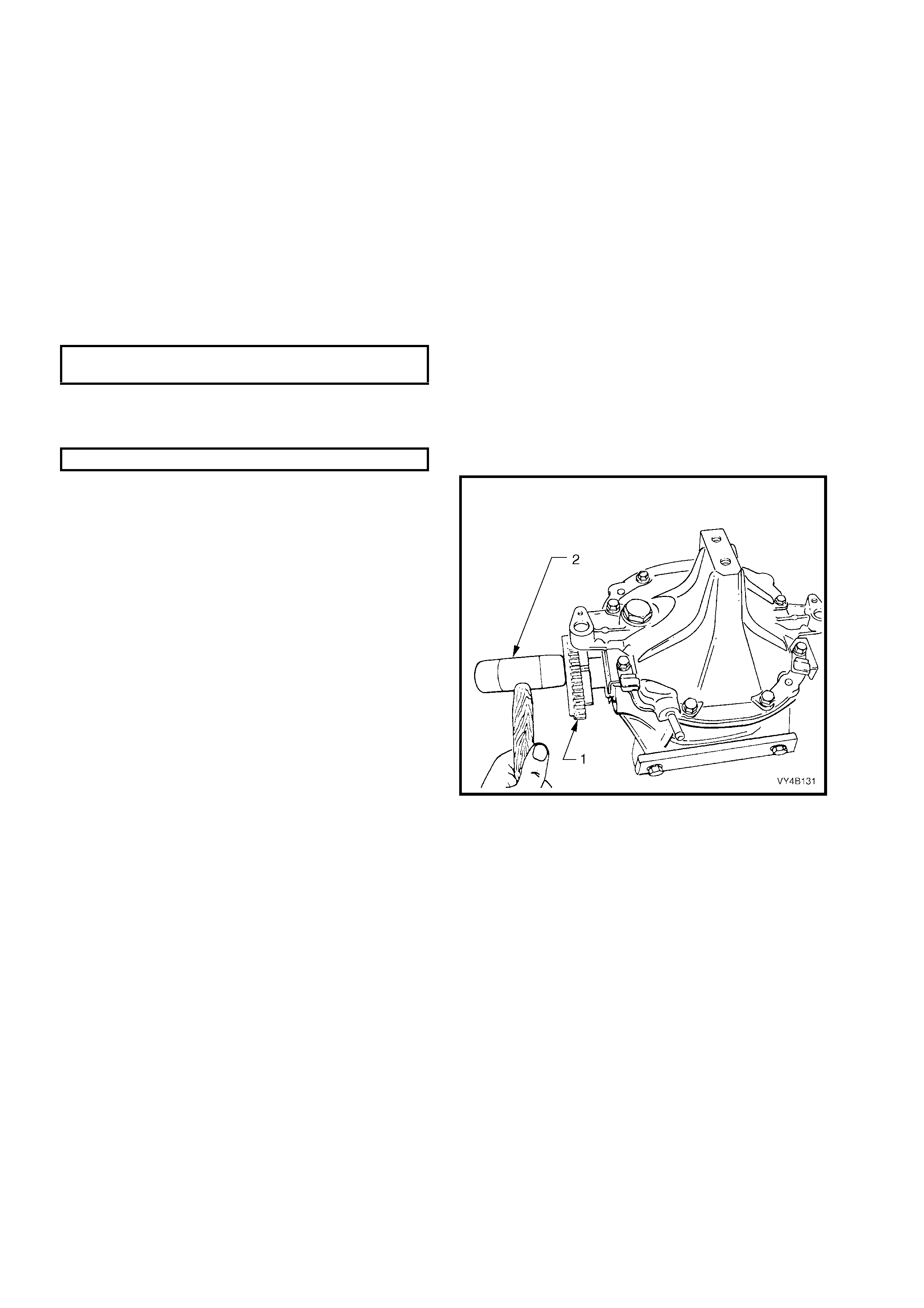

8. Using Tool No. J24292-C or equivalent, press

stud/s from hub.

Figure 4B-16

9. Install Tool No. K M-46 8-B hol ding bar, with tw o

wheel nuts to t he trun nion assem bly hub studs .

Install new stud into hub. Assemble some

suitable size washers and a reversed wheel

nut, onto stud. Tighten wheel nut to draw in

stud. When stud is fully installed, remove

wheel nut and washers.

10. Install any remaining studs in the same

manner.

11. Remove Tool No. KM468-B.

Figure 4B-17

12. Reinst all br ak e disc ( 1) over the trunnion wheel

studs, ensuring that the marks made prior to

disassembly, are aligned.

Reinstall brake caliper (3) anchor plate to

trailing arm attaching bolts (2) and tighten to

the correct torque specification.

BRAKE CALIPER ANCHOR PLATE

TO TRAILING ARM ATTACHING

BOLT TORQUE SPECIFICATION 70 – 100 Nm

Figure 4B-18

13. Reinstall shock absorber to trailing arm, fit

washer to the lower mounting bolt, install bolt

and tighten to the correct torque specification.

SHOCK ABSORBER LOWER

MOUNTING BOLT

TORQUE SPECIFICATION 105 - 125 Nm

NOTE 1: Vehic le m ust be at c urb we ight an d on al l

four wheels before this torque is applied.

NOTE 2: View ‘A’ in Figure 4B-19 shows the

sedan, lower shock absorber mounting, while view

‘B’ shows the station wagon arrangement.

14. Install road wheel, aligning marks made prior to removal, install and tighten attaching nuts.

15. Remove safety stand and lower vehicle.

16. Tighten road wheel attaching nuts to the correct torque specification and in the correct sequence (refer

‘IMPORTANT SERVICE REQUIREMENTS’ in 2.1 GENERAL, in this Sec ti on).

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

17. Refit wheel cover/wheel nut caps.

Figure 4B-19

2.6 LIMITED SLIP DIFFERENTIAL

TORQUE CHECK

1. Place transmission in neutral with engine turned OFF.

2. Jack up one rear wheel and support trailing arm on a safety stand. Release park brake lever to fully OFF

position.

3. Rem ove rear wheel cover (steel whee ls) or whee l nut caps (alloy whee ls) on that side of the veh icle where th e

stud/s are to be replaced.

4. Mark relationship of wheel to mounting flange. Loosen then remove road wheel attaching nuts. Remove the

road wheel.

5. Loosen and disconnect rear shock absorber lower mounting bolt from trailing ar m and pull lower end of shock

absorber from trailing arm.

NOTE: View ‘A ’ in Figure 4 B-20 s h o ws th e s eda n, lower shoc k absor ber mountin g, whil e vie w ‘ B’ s ho ws t he s tatio n

wagon arrangement.

Figure 4B-20

6. Loosen and remove brake caliper anchor plate

to trailing arm attaching bolts (1) and remove

caliper (2) from disc.

Figure 4B-21

7. Using tie wire (1), secure the brake caliper to

lower end of shock absorber upper mounting.

DO NOT ALLOW CALIPER TO HANG BY

BRAKE HOSE.

8. Mark the brake disc position to trunnion

assembly, using a felt tipped pen or similar,

then remove the brake disc from the trunnion

assembly (Shown already removed in

Figure 4B-2 2).

Figure 4B-22

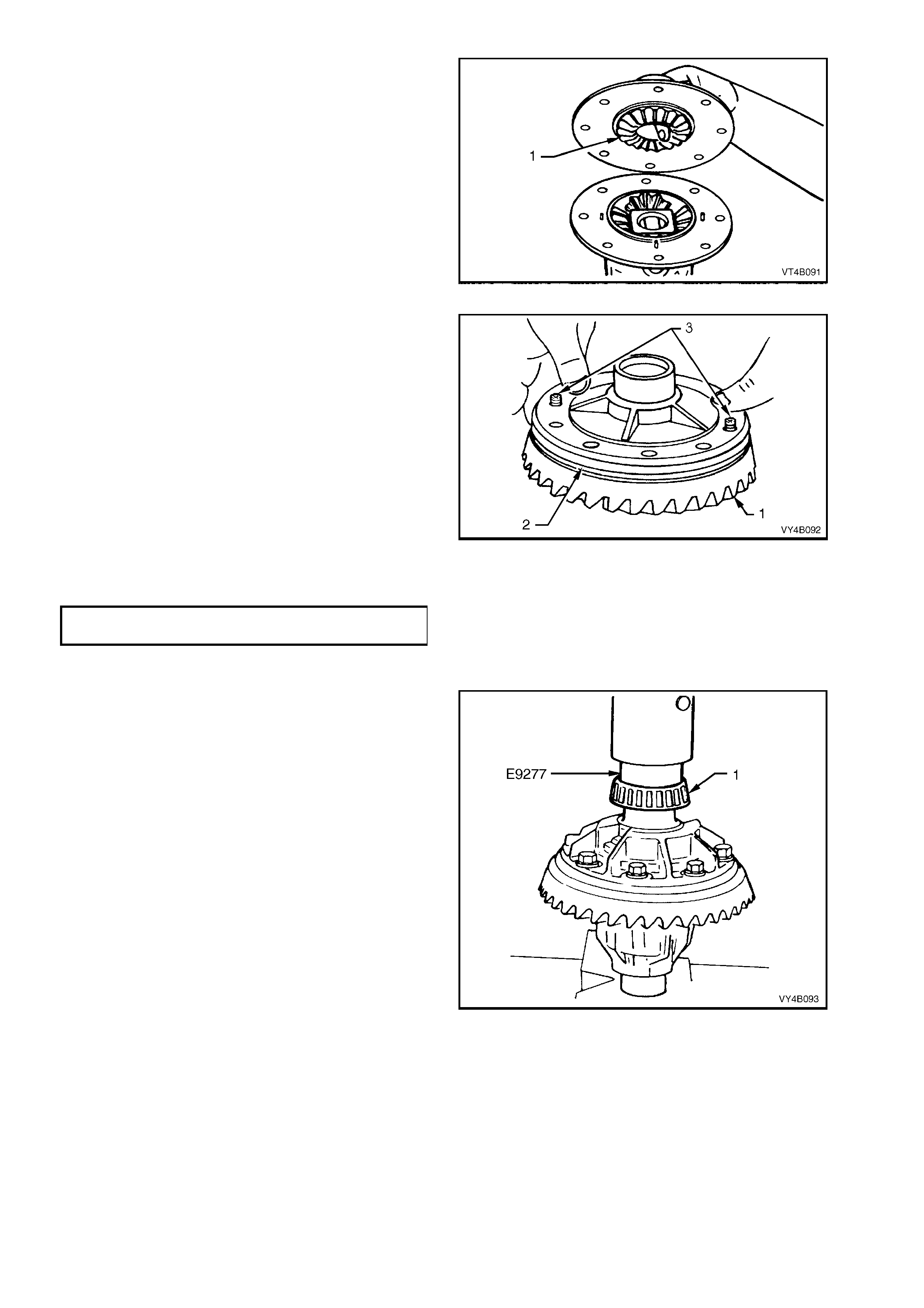

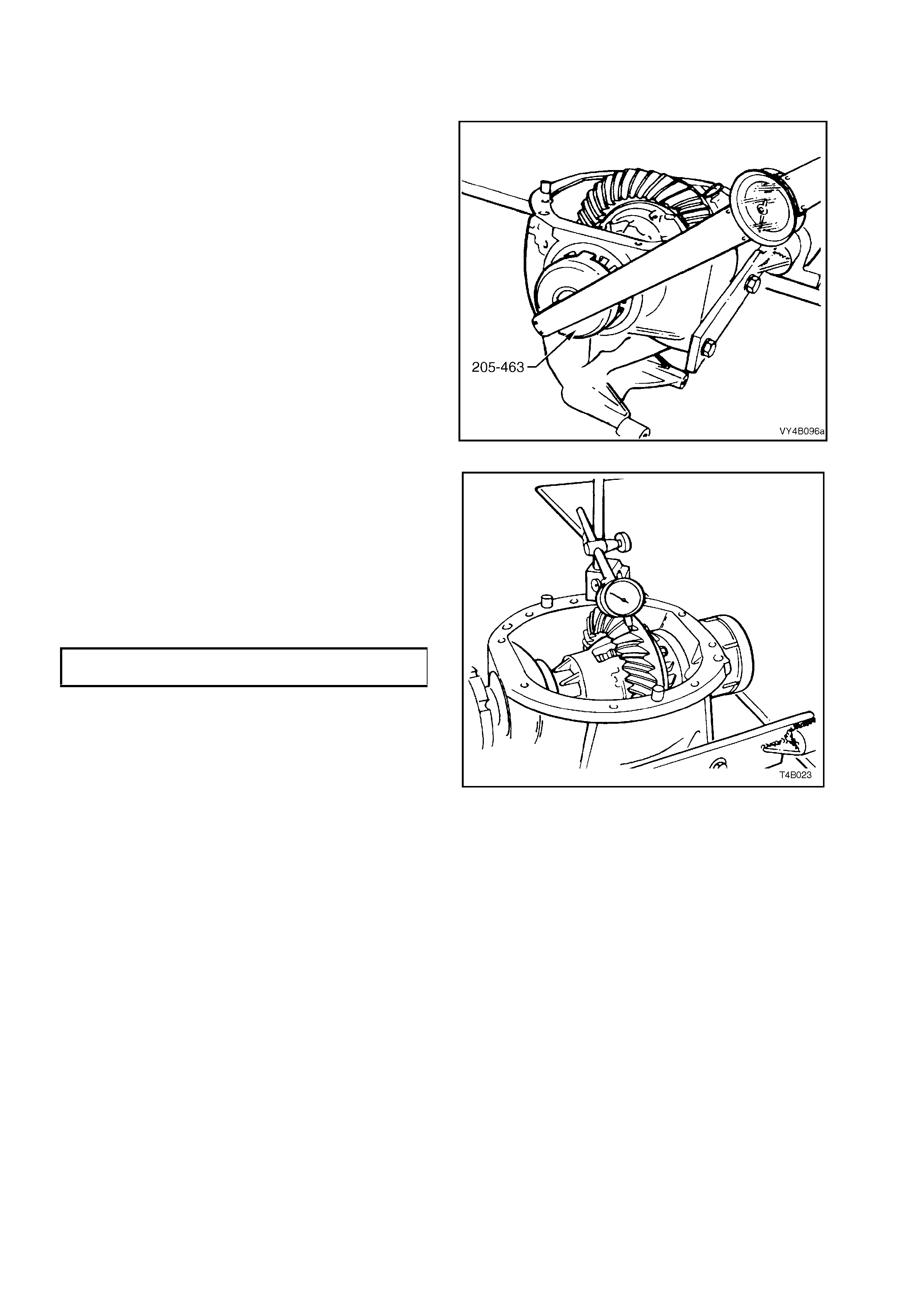

9. Using a torque wrench in conjunction with

adaptor, Tool No. 7208, and torque wrench

adaptor E6662B, rotate trunnion assem bly in a

forward direction. If the unit is operating

satisf ac toril y, a torque rea di ng of appr ox imately

70 Nm should be obtained while turning the

trunnion assembly, with the opposite wheel

remaining stationary.

If a torque reading of less than 45 Nm

is obtained, remove differential case

and inspect case internal components

and repair as necessary, refer to

3.4 LIMITED SLIP DIFFERENTIAL in this

Section.

Figure 4B-23

10. Reinst all br ak e disc ( 1) over the trunnion wheel

studs, ensuring that the marks made prior to

disassembly, are aligned.

Reinstall brake caliper (3) anchor plate to

trailing arm attaching bolts (2) and tighten to

the correct torque specification.

BRAKE CALIPER ANCHOR PLATE

TO TRAILING ARM ATTACHING

BOLT TORQUE SPECIFICATION 70 – 100 Nm

Figure 4B-24

11. Reinstall shock absorber to trailing arm, fit washer to the lower mounting bolt, install bolt and tighten to the

correct torque specification.

SHOCK ABSORBER LOWER

MOUNTING BOLT

TORQUE SPECIFICATION 105 - 125 Nm

NOTE 1: Vehicle must be at curb weight and on all four wheels before this torque is applied.

NOTE 2: View ‘A’ in Figure 4B-25 shows the sedan, lower shock absorber mounting, while view ‘B’ shows the

station wagon ar rangem ent.

Figure 4B-25

12. Install road wheel, aligning marks made prior to removal, install and tighten attaching nuts.

13. Remove safety stand and lower vehicle.

14. Tighten road wheel attaching nuts to the correct torque specification and in the correct sequence (refer

‘IMPORTANT SERVICE REQUIREMENTS’ in 2.1 GENERAL, in this Sec ti on).

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 110 - 140 Nm

15. Refit wheel cover/wheel nut caps.

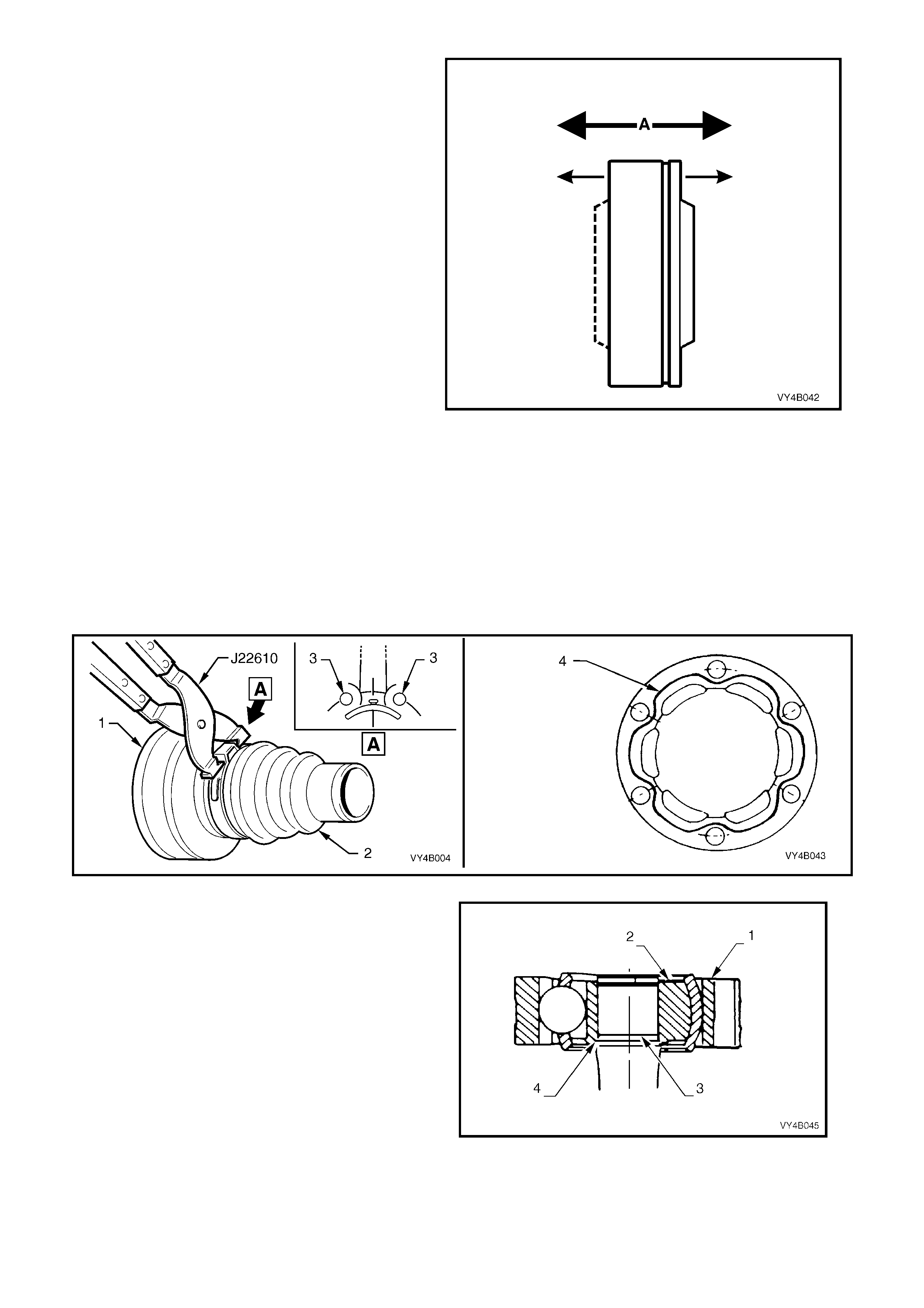

2.7 DRIVE SHAFT ASSEMBLY

LT Reference No: F50400 / F504100 / F504200

NOTE: The following fasteners MUST be replaced when

performing this operation:

Drive shaft constant velocity joint to trunnion flange and

inner axle shaft attaching bolt.

REMOVE

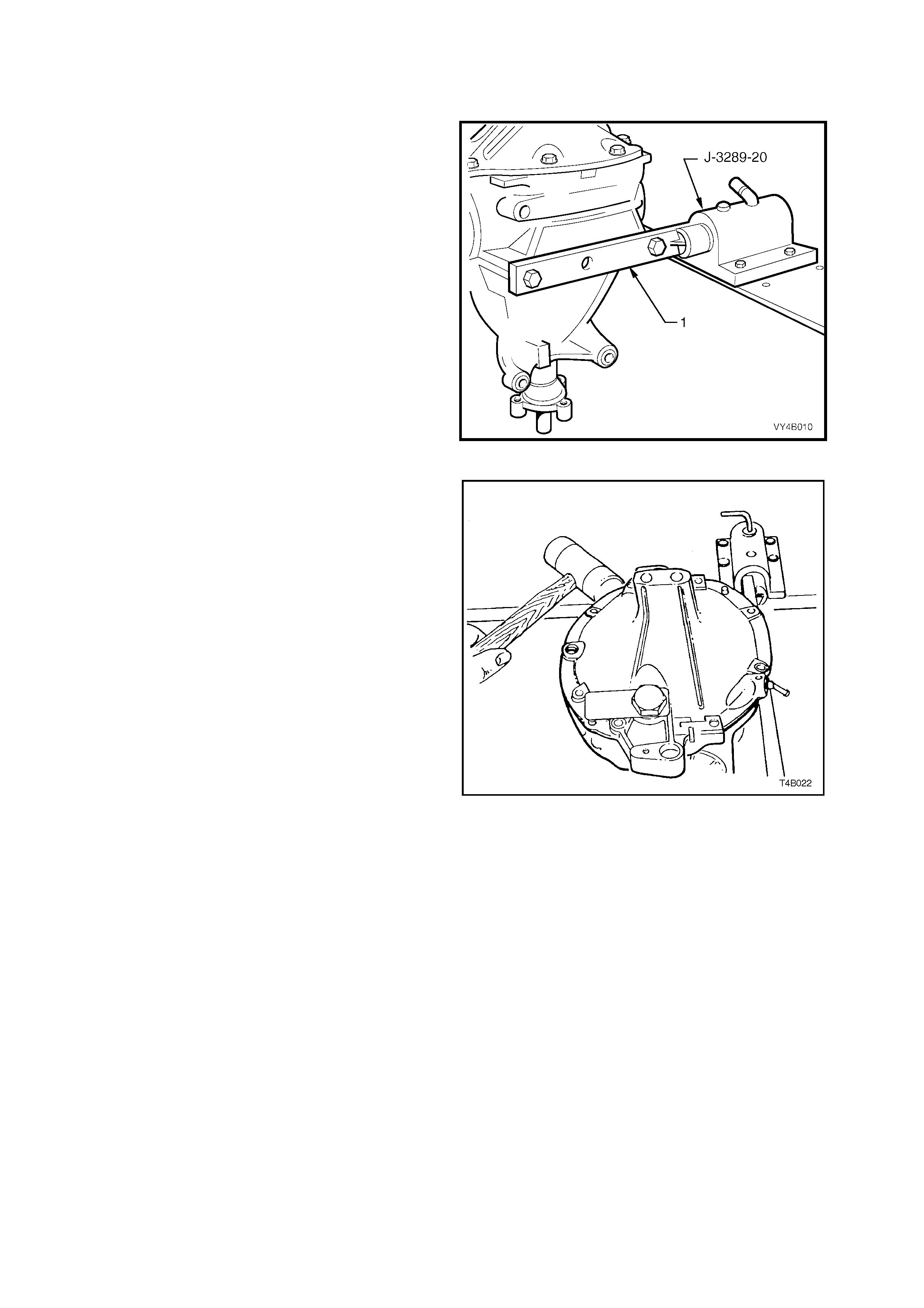

1. Using a floor jack under centre of differential

carrier, jack up rear of vehicle then place safety

stands under trailing arms.

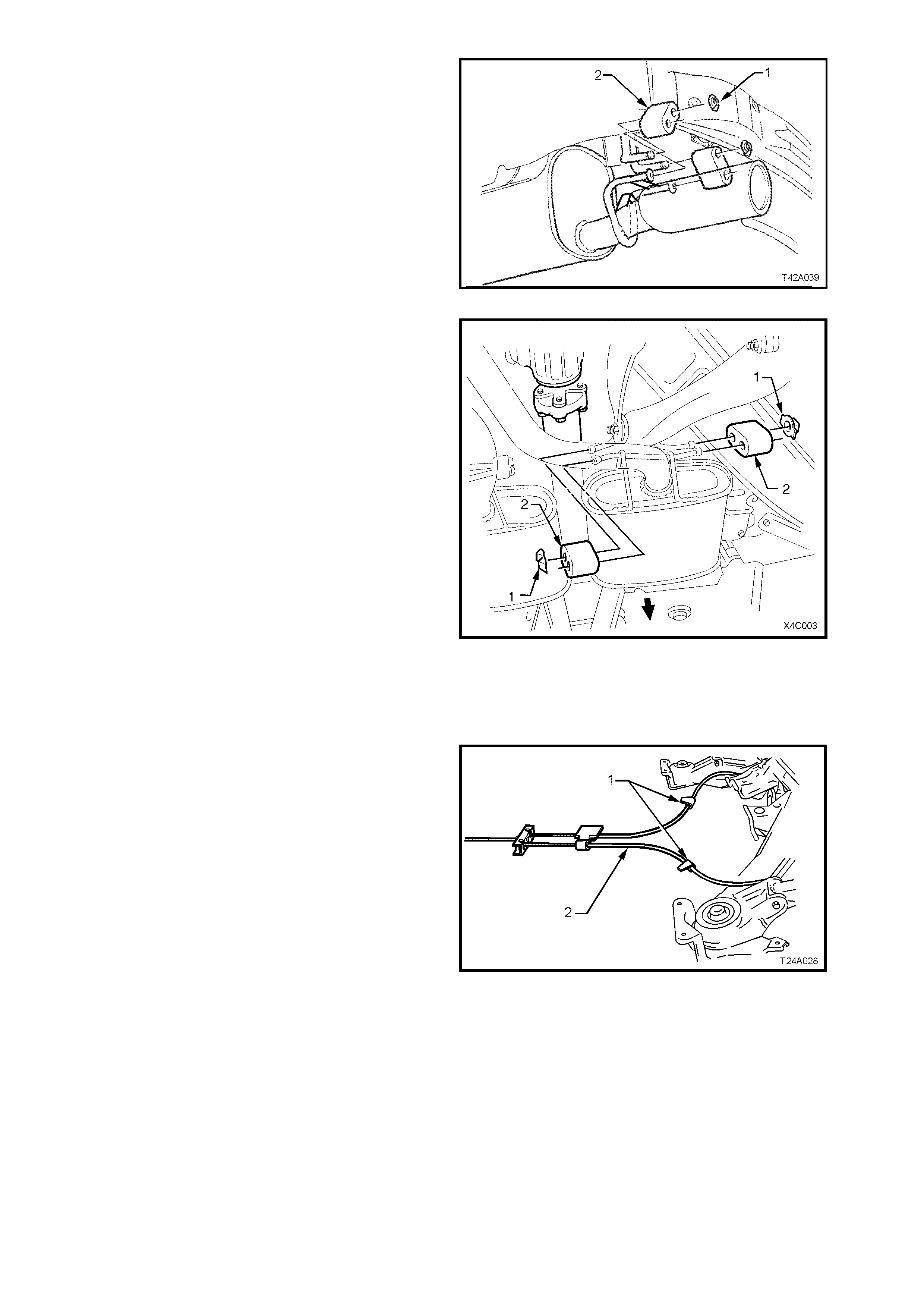

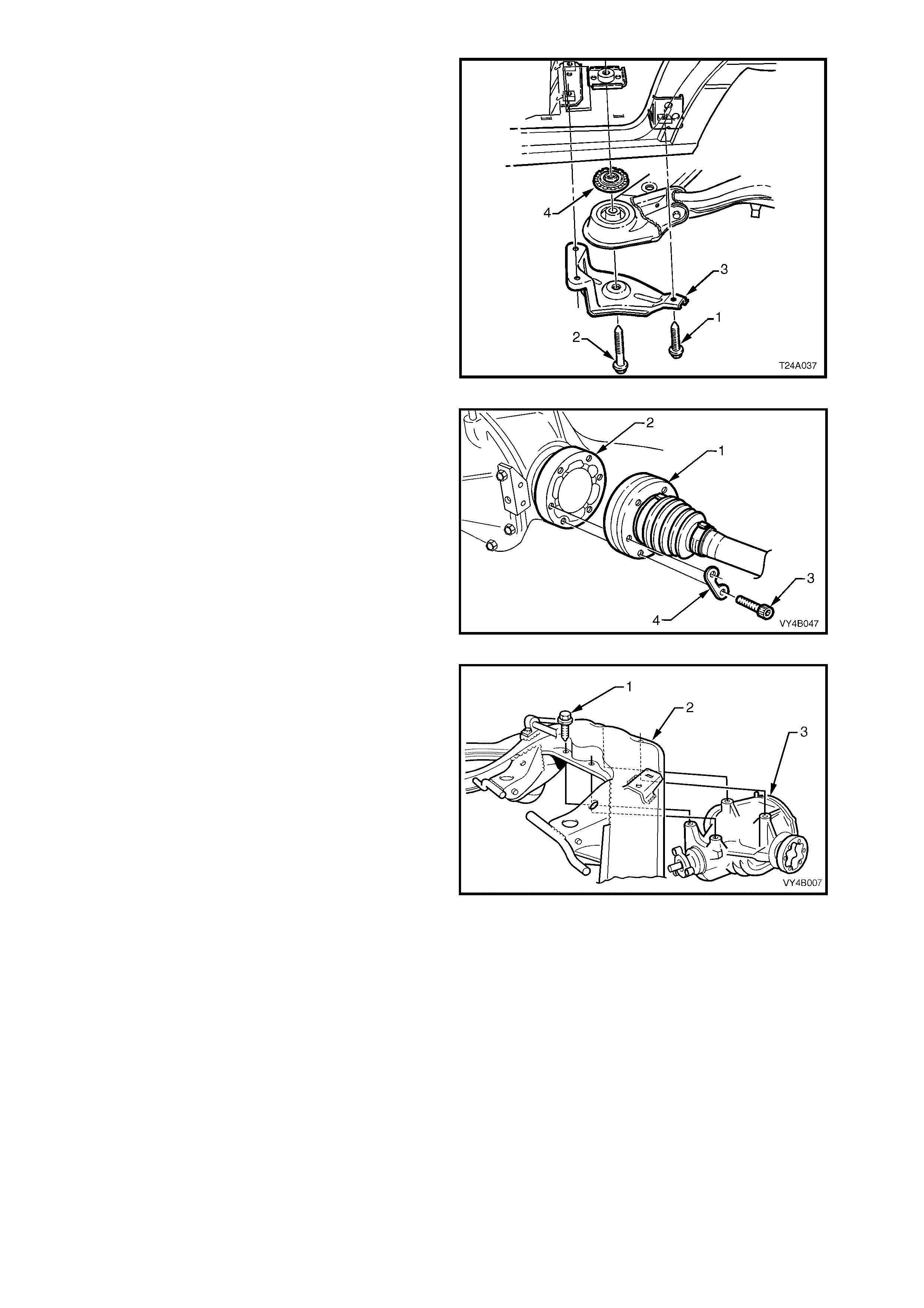

2. Using an 8 mm Allen key socket, remove drive

shaft inner constant velocity joint to inner axle

shaft and outer constant velocity joint to

trunnion flange attaching bolts (2) (six places)

and plates, remove drive shaft (1).

NOTE 1: As it is only the inner, constant velocity

joint that is a plunge joint, it is important that the

drive shaft orientation is remembered for correct

installation.

NOTE 2: During drive shaft removal and

installation, keep drive shaft supported so that it

does not hang on one end because drive shaft joint

deflection must be kept to within the angular

movement of an installed drive shaft.

Figure 4B-26

REINSTALL

Reinstallation of the drive shaft is reversal of the

removal procedure, noting the following points.

NOTE: A label is attached to each drive shaft, to

indicate which joint faces outward. The outer CV joint

is also marked with a groove, while the inner, plunge

joint has none. It is important that the drive shaft is

installed correctly.

1. Tighten drive shaft to trunnion flange and inner

axle shaft attaching bolts to the correct torque

specification.

DRIVE SHAFT CONSTANT VELOCITY

JOINT TO TRUNNION FLANGE AND

INNER AXLE SHAFT ATTACHING

BOLT TORQUE SPECIFICATION 50 Nm, then

90° turn angle

Techline

2.8 DRIVE SHAFT AND/OR CONSTANT VELOCITY JOINTS

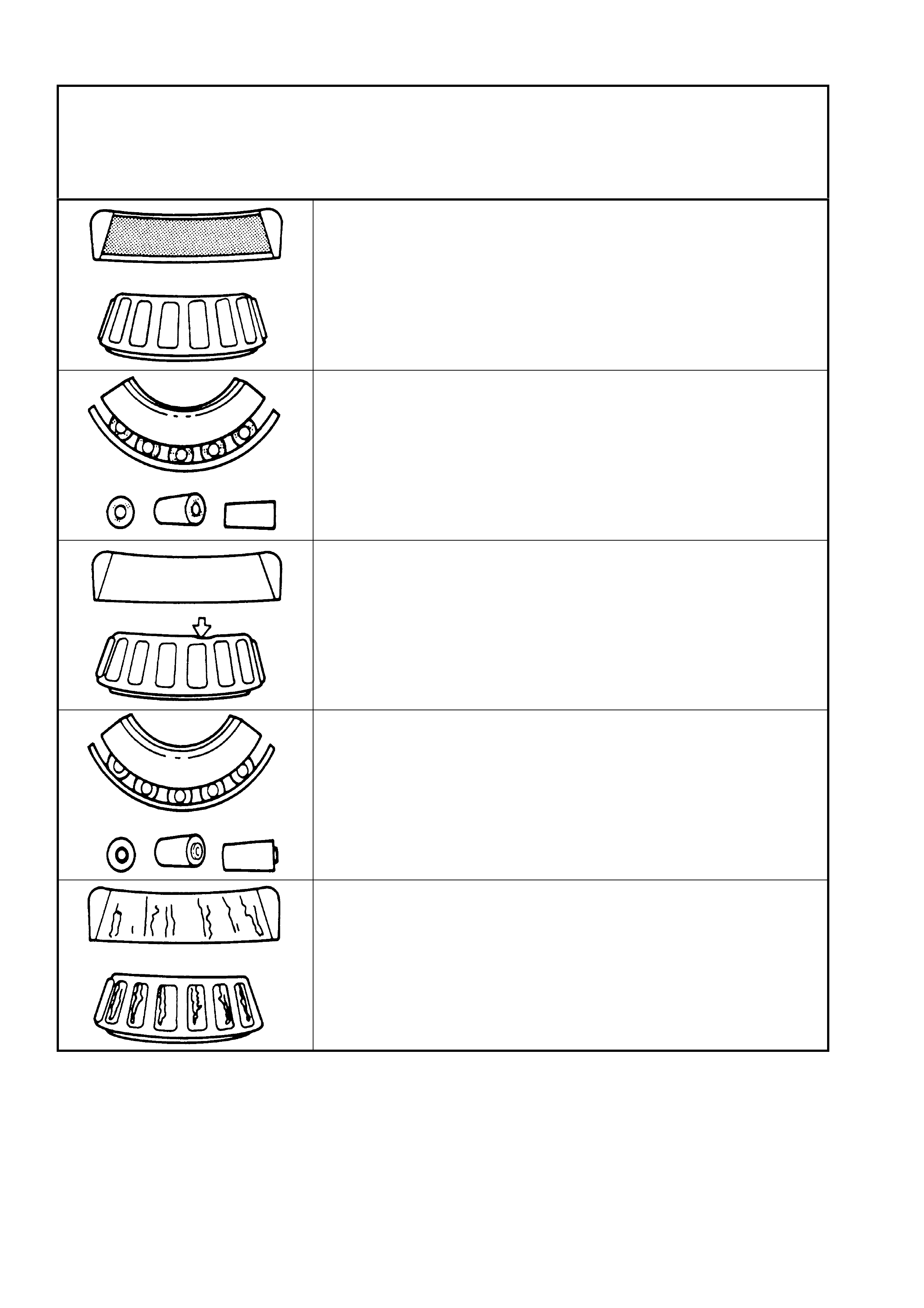

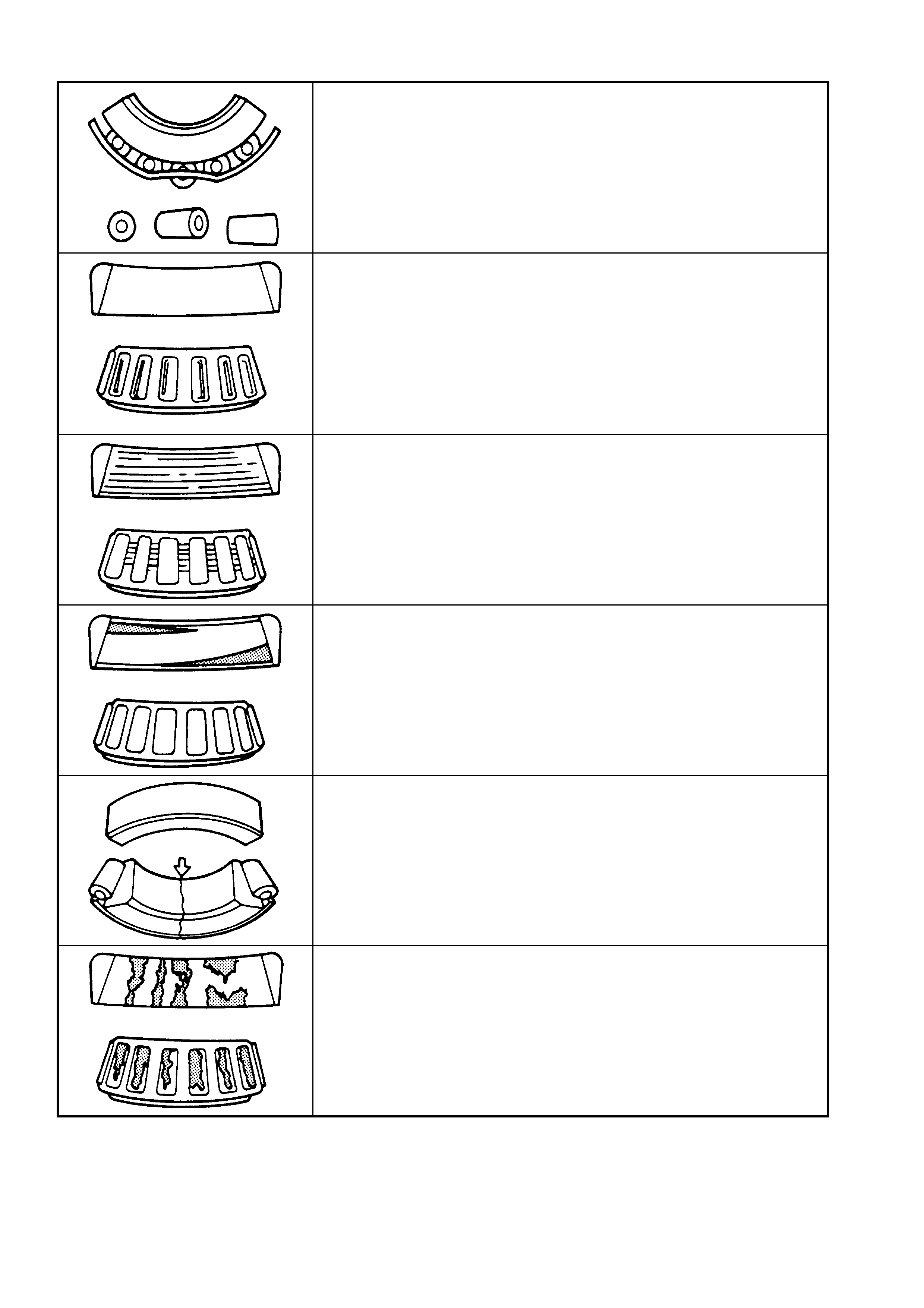

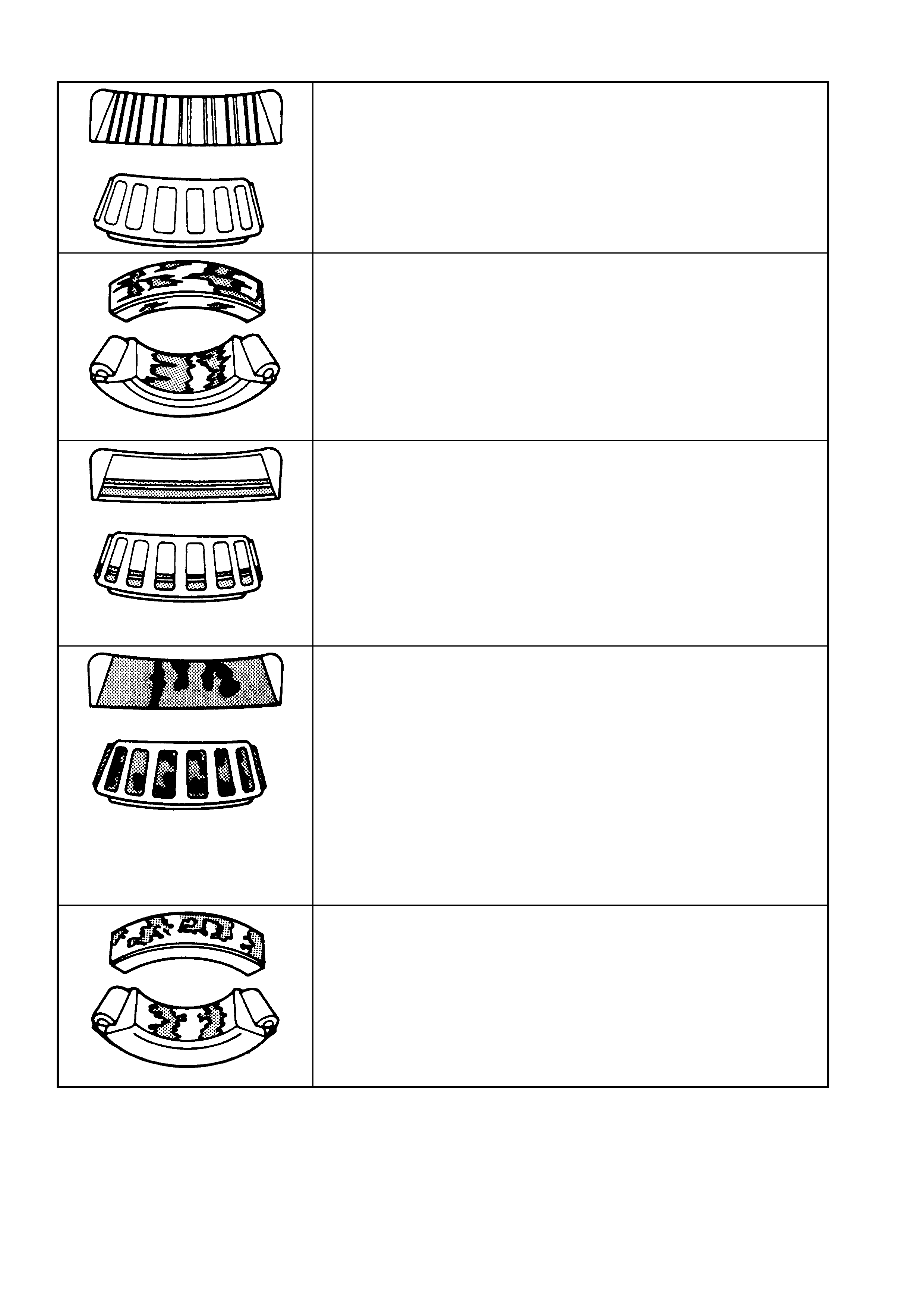

There are four repair kits available for drive shaft constant velocity joint repairs.

1. A ‘BOOT KIT’, which consists of a boot, boot clamps, snap ring and two tubes of grease.

2. A ‘CONSTANT VELOCITY JOINT KIT’, which contains the same items as the BOOT KIT plus the inner,

constant ve locity joint.

3. A ‘CONSTANT VELOCITY JOINT KIT’, which contains the same items as the BOOT KIT plus the outer,

constant ve locity joint.

4. A ‘DUST CAP REPAIR KIT’, which is common to both the inner and outer constant velocity joints.

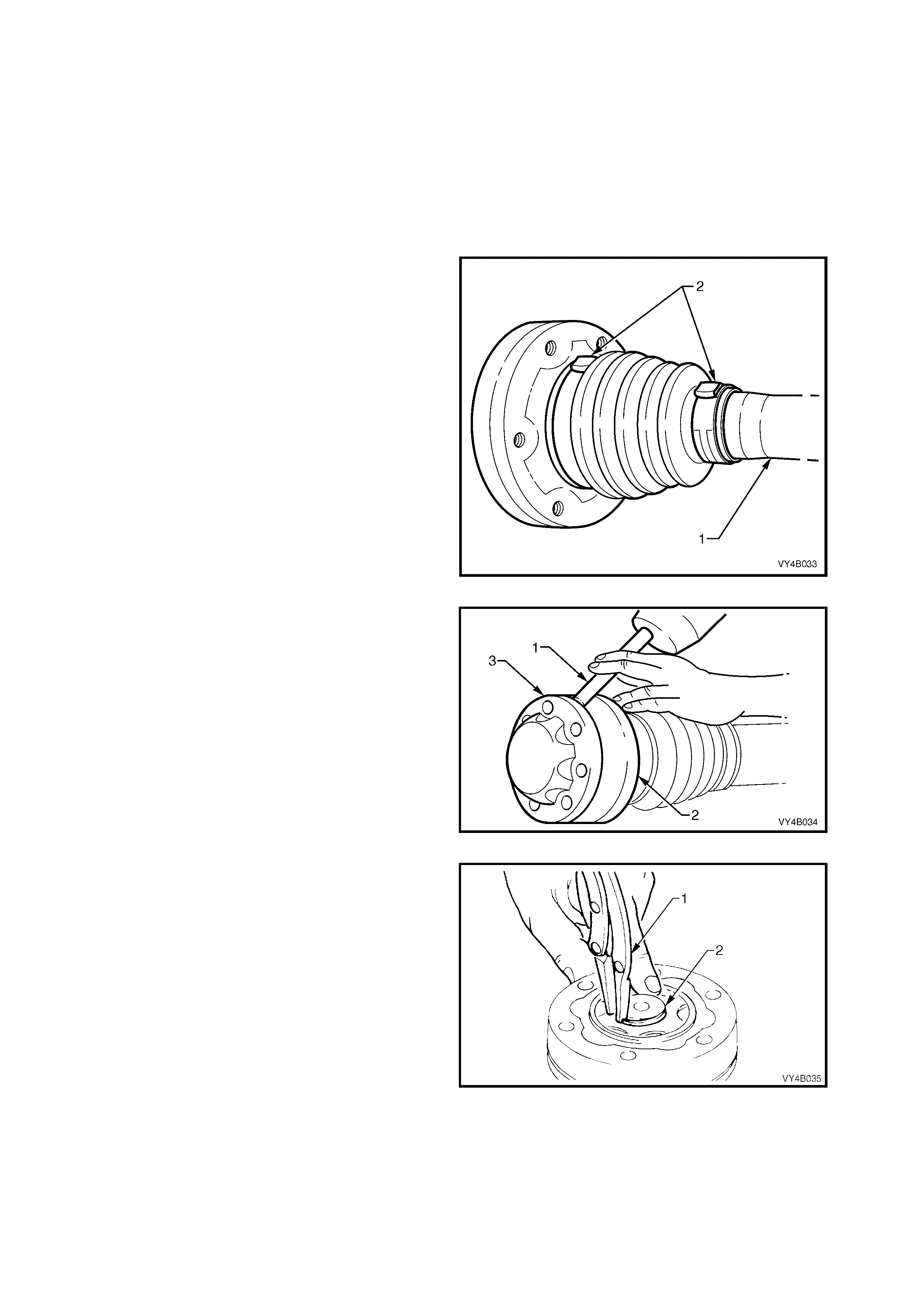

DISASSEMBLE

1. Remove drive shaft assembly, refer to

2.7 DRIVE SHAFT ASSEMBLY in this Section.

2. Clean outside of assembly with a suitable

solvent before disassembling.

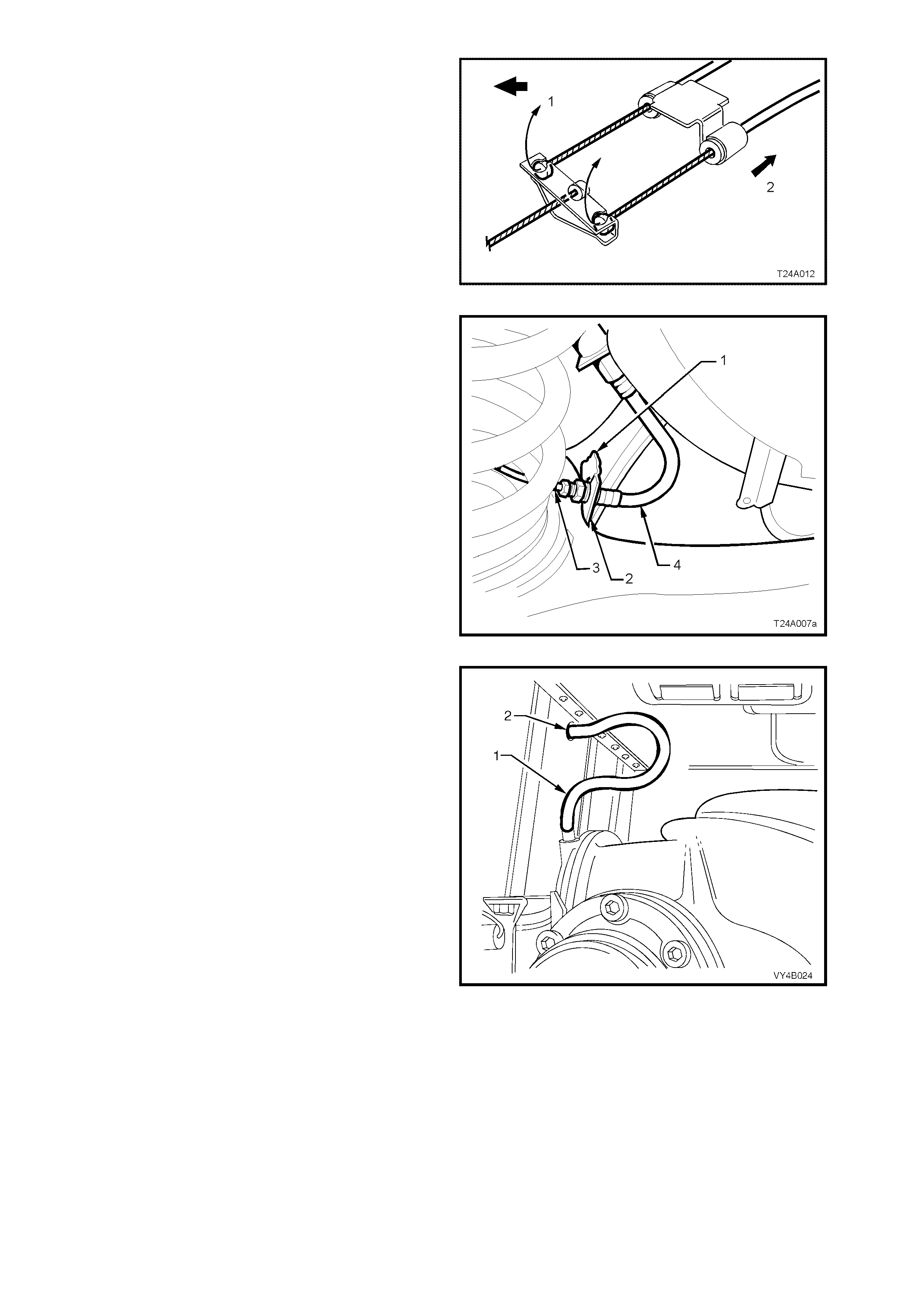

3. Clamp assembly, by drive shaft (1), in a vice

fitted with soft metal jaws.

4. Using tin snips or other suitable cutting tool, cut

boot clamps (2) in raised crimped area and

remove clamps.

Figure 4B-27

5. Using a suitable dr ift (1) a nd hamm er, tap dust

shields (2) and caps (3) from both sides of

constant velocity joints.

Figure 4B-28

6. Using suitable snap ring pliers (1), remove the

snap ring (2) from each end of drive shaft and

discard.

NOTE: Do not use s na p rin gs once they have be en

removed. Always use new snap rings on

reassembly.

7. Remove assembly from vice. Slide dust shield

and boots towards centre of shaft.

Figure 4B-29

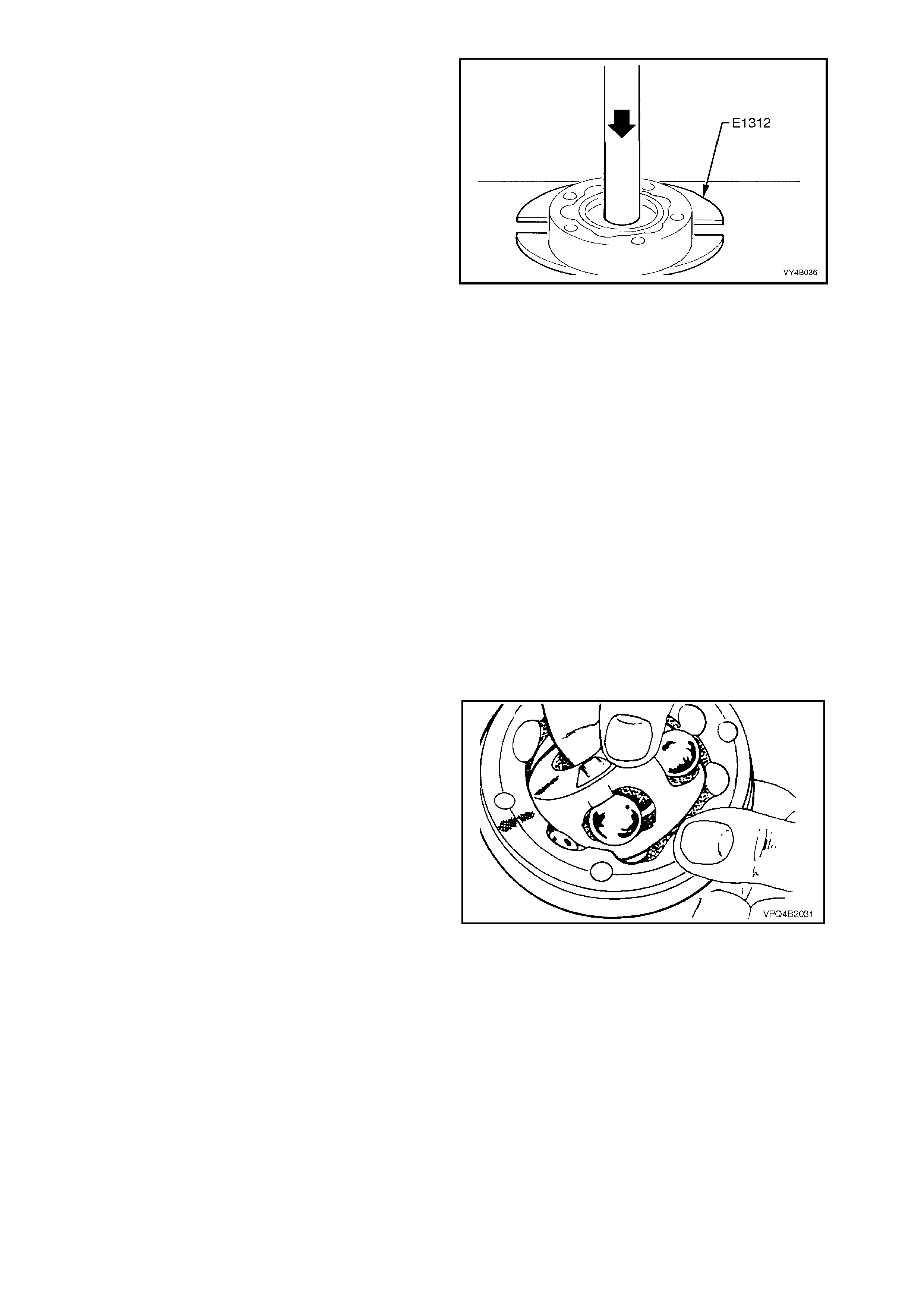

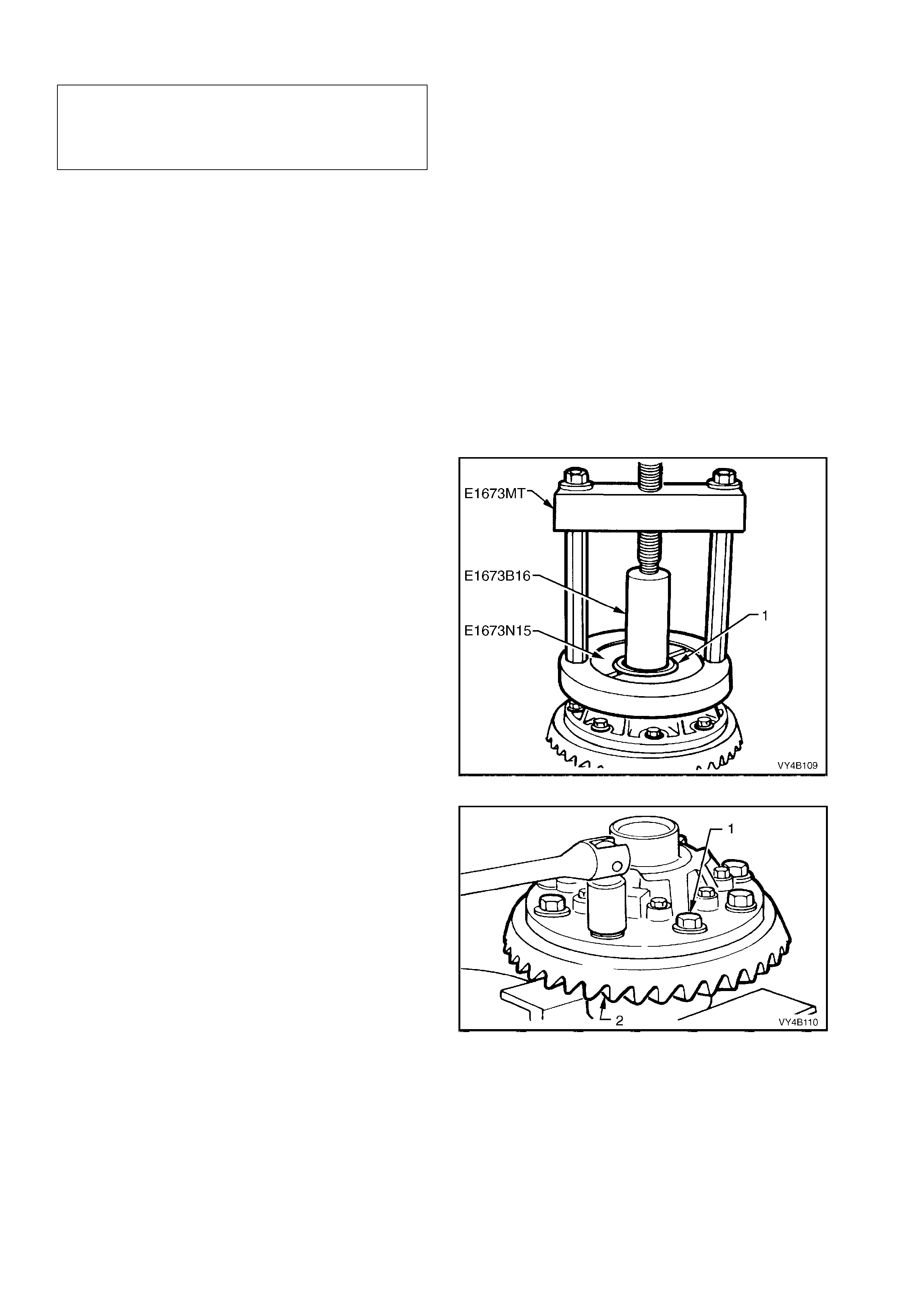

8. Using suitable press plates (such as Tool No.

E1312), supporting inner race, press drive

shaft from constant velocity joint.

9. Repeat process to remove remaining constant

velocity joint.

10. Remove boots and dust shields from drive

shaft, ensuring boots are not damaged on

edges of shaft.

Figure 4B-30

INSPECT

Drive Shaft and Boots

1. Clean shaft and boots in a suitable cleaning

solvent.

2. Inspect drive shaft for twisting, cracking or

excessive spline wear.

NOTE: As the interc onnecting shaft is not serv iced

separately, if the interconnecting shaft is found to

be defective, then the driveshaft must be replaced

as an assembly.

3. Inspect boots and replace if split, fatigued,

cracked or worn.

Constant Velocity Joints

NOTE: Complete disassembly of the constant

velocity joints is not recommended. The internal

components are a precision fit and develop their

own characteristic wear patterns. Intermixing

components could result in looseness, binding

and/or premature failure of the joint.

1. Inspect grease in joint, and if obviously

contaminated with and/or been subjected to

dirt ingress, the joint has in all likelihood

suffered damage and should be replaced.

2. If ins pection reveals that the joint h as not been

contaminated, clean joint by soaking in a

suitable cleaning solvent.

3. Once grease has been removed, inspect

internal c ompone nts by tilti ng inner race to one

side to expose each ball.

4. Replace joint assembly if there is severe

pitting, galling, play between balls and the cage

windows, any cracking or damage to cage,

pitting or galling or chips in raceways.

Figure 4B-31

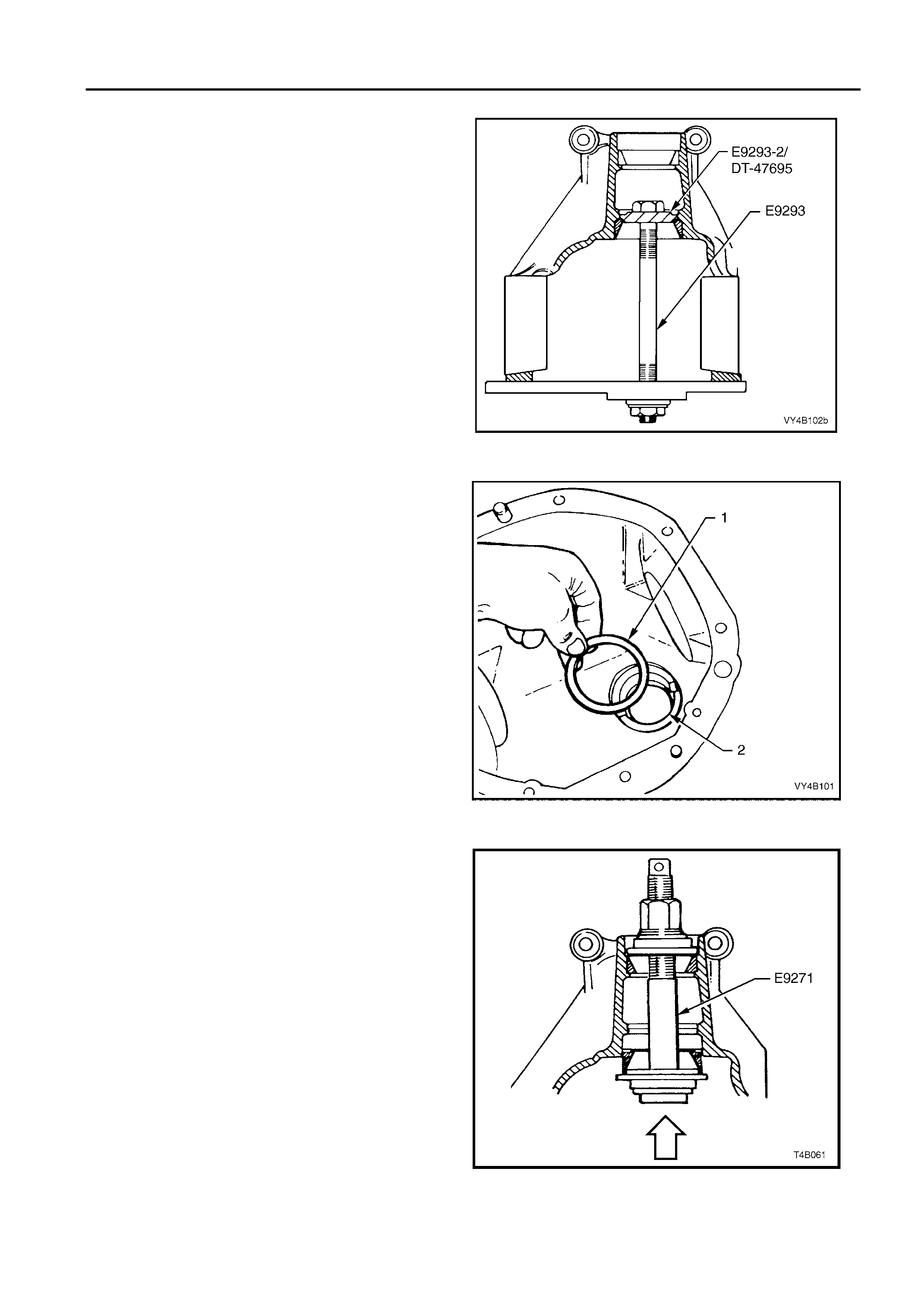

REASSEMBLE

Constant Velocity Joints

NOTE 1: During the removal, cleaning, inspection

or replacement of a constant velocity joint, it is

possible for the joint to become disassembled.

Should an inadvertent disassembly of a constant

velocity (CV) joint occur, and notwithstanding the

earlier recommendation, it is possible to

reassemble the CV joint, provided the following

procedure is followed EXACTLY.

NOTE 2: Ideally, the inner race (1) and cage (2),

together with the individual balls (3), should be

maintained in their original locations to minimise

the creation of a noisy joint.

NOTE 3: Und er no circum stances are components

from one constant velocity joint to be mixed with

components from another CV joint.

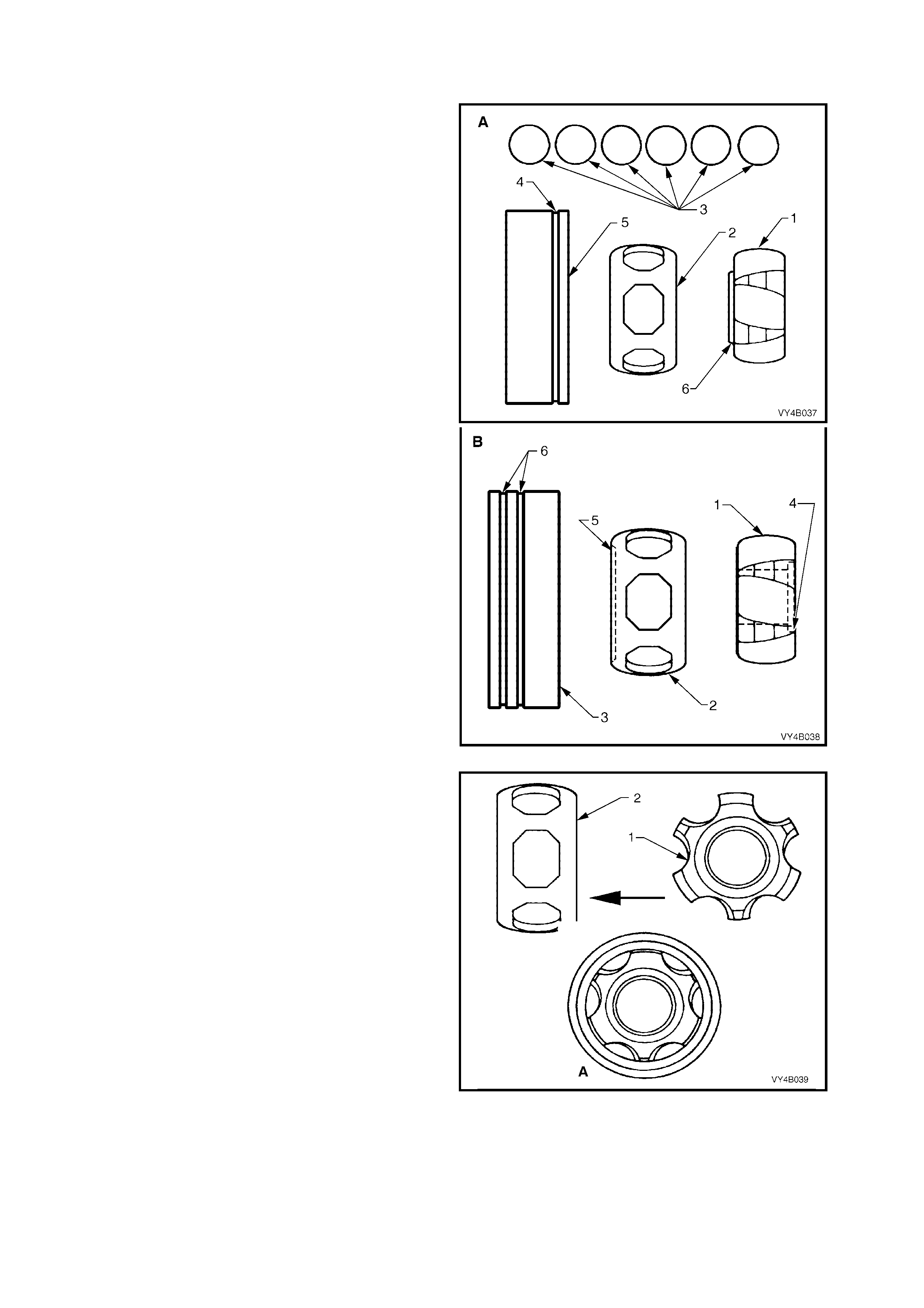

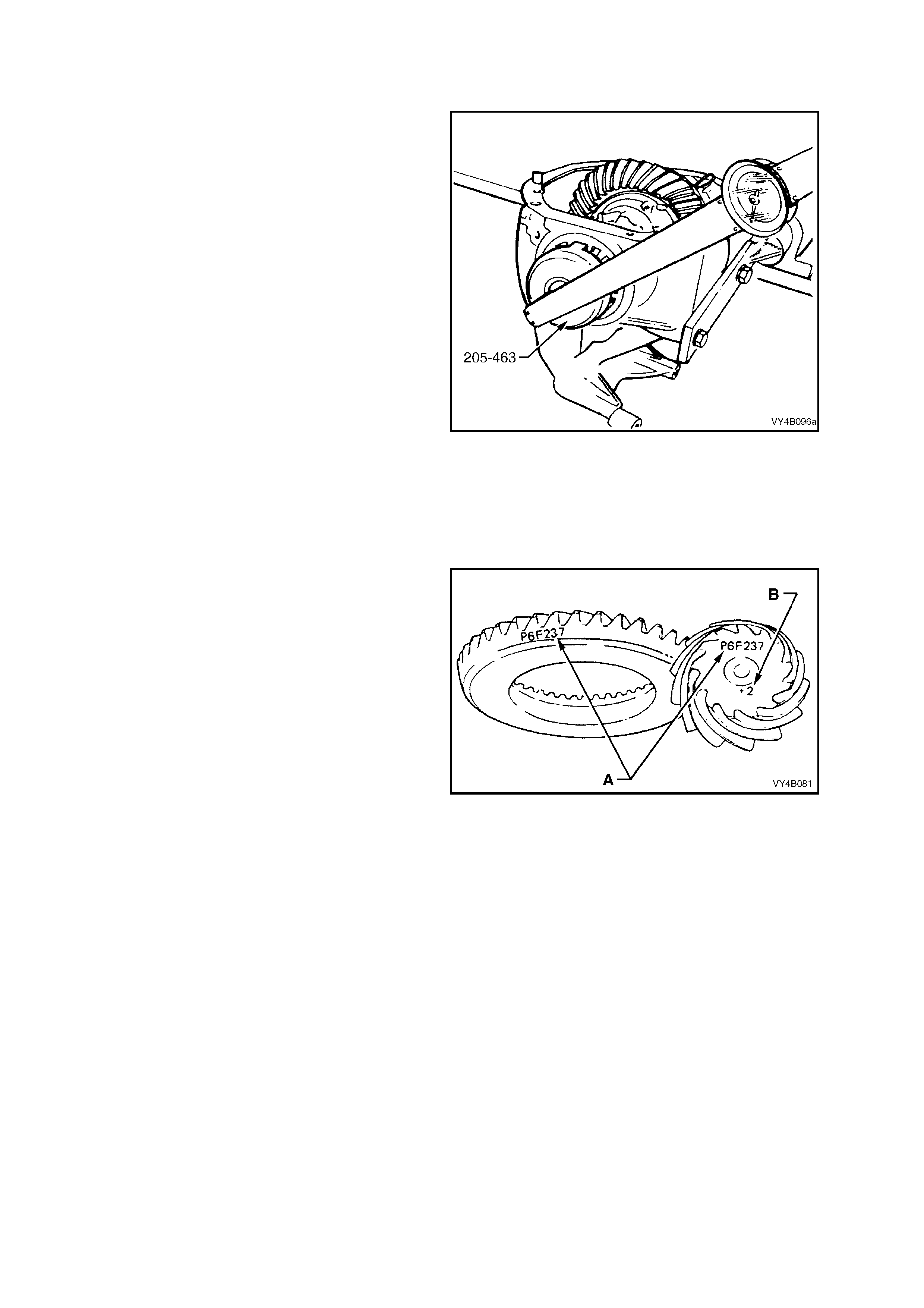

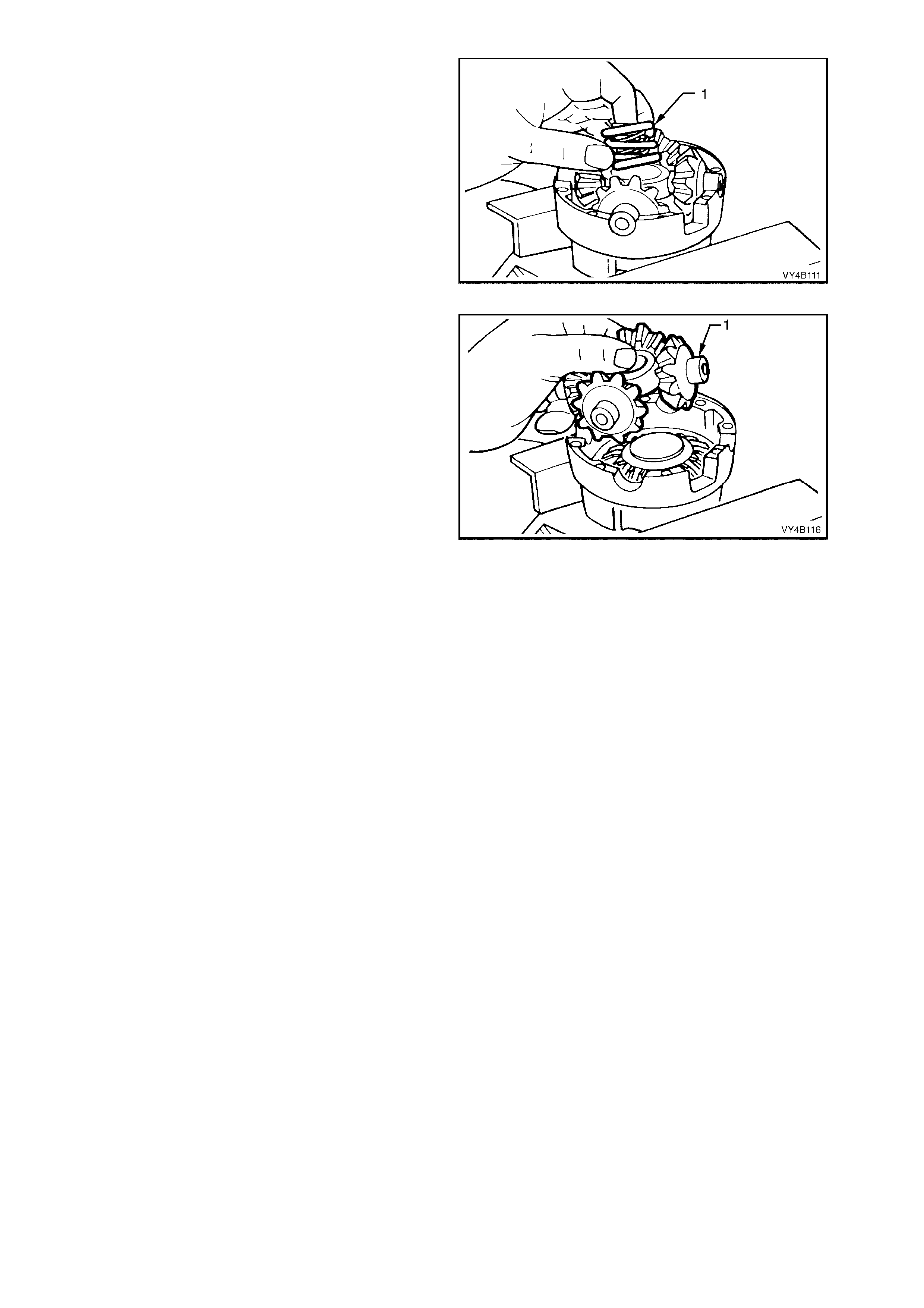

Shown are exploded views of each constant

velocity joint; view “A” is the inner joint, while view

“B” shows the outer.

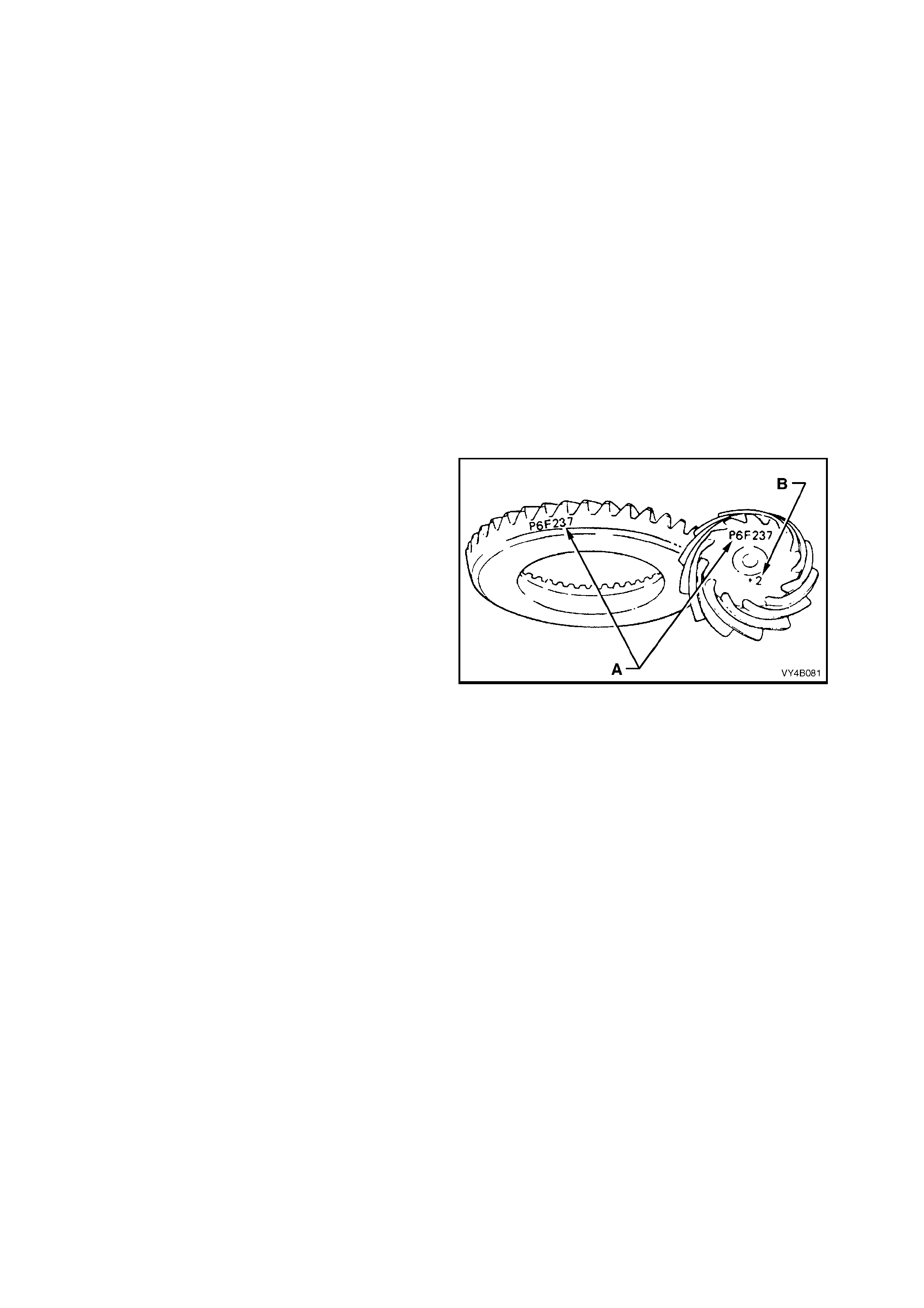

With the inner joint, note the single identification

groove (4) on the outer race (5) and the

identification step (6) on the inner race.

Conversely, the outer joint has two grooves (6) on

the outer race, a chamfer (5) on the cage and a

recess (4) on the inner race (1).

Figure 4B-32

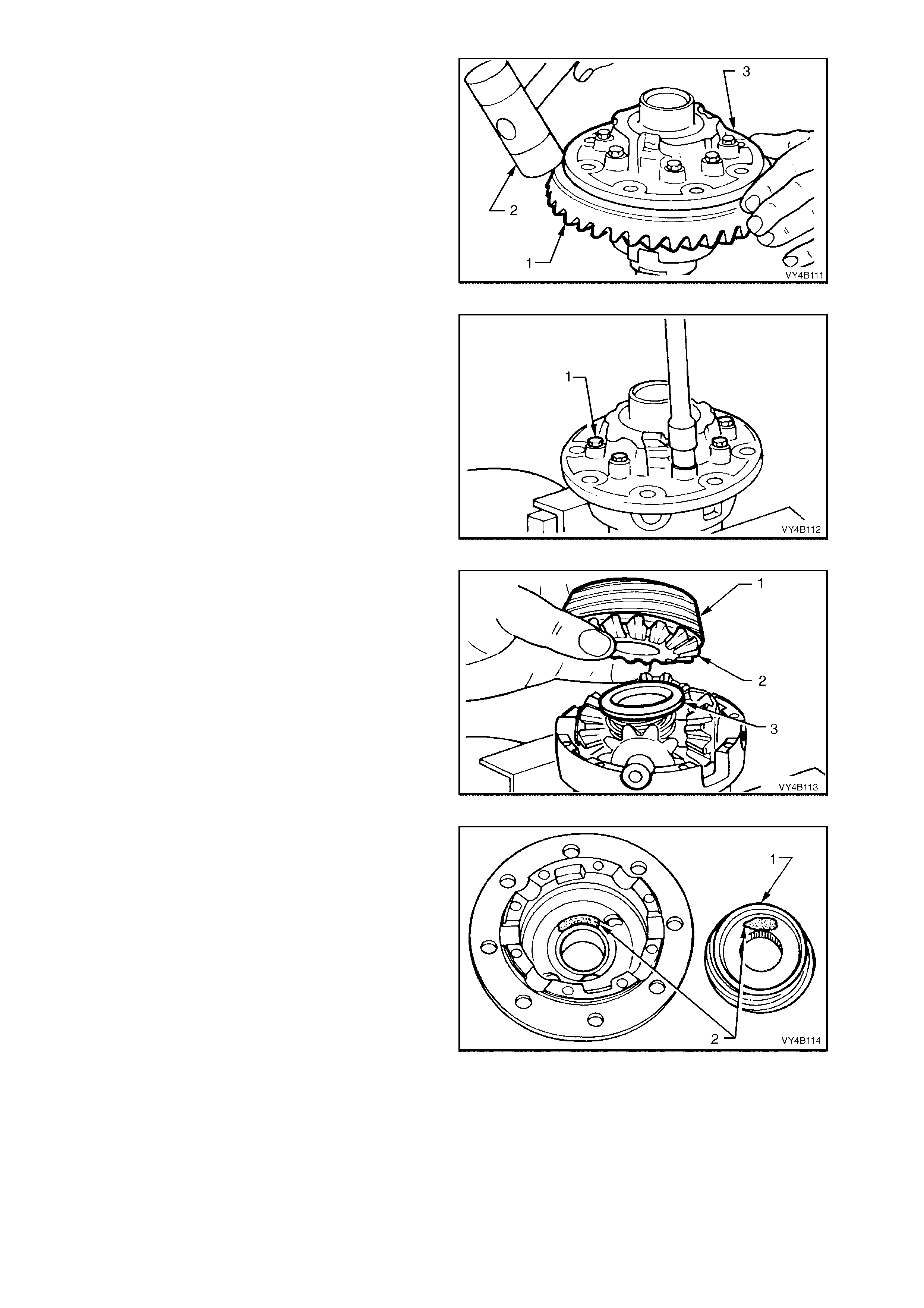

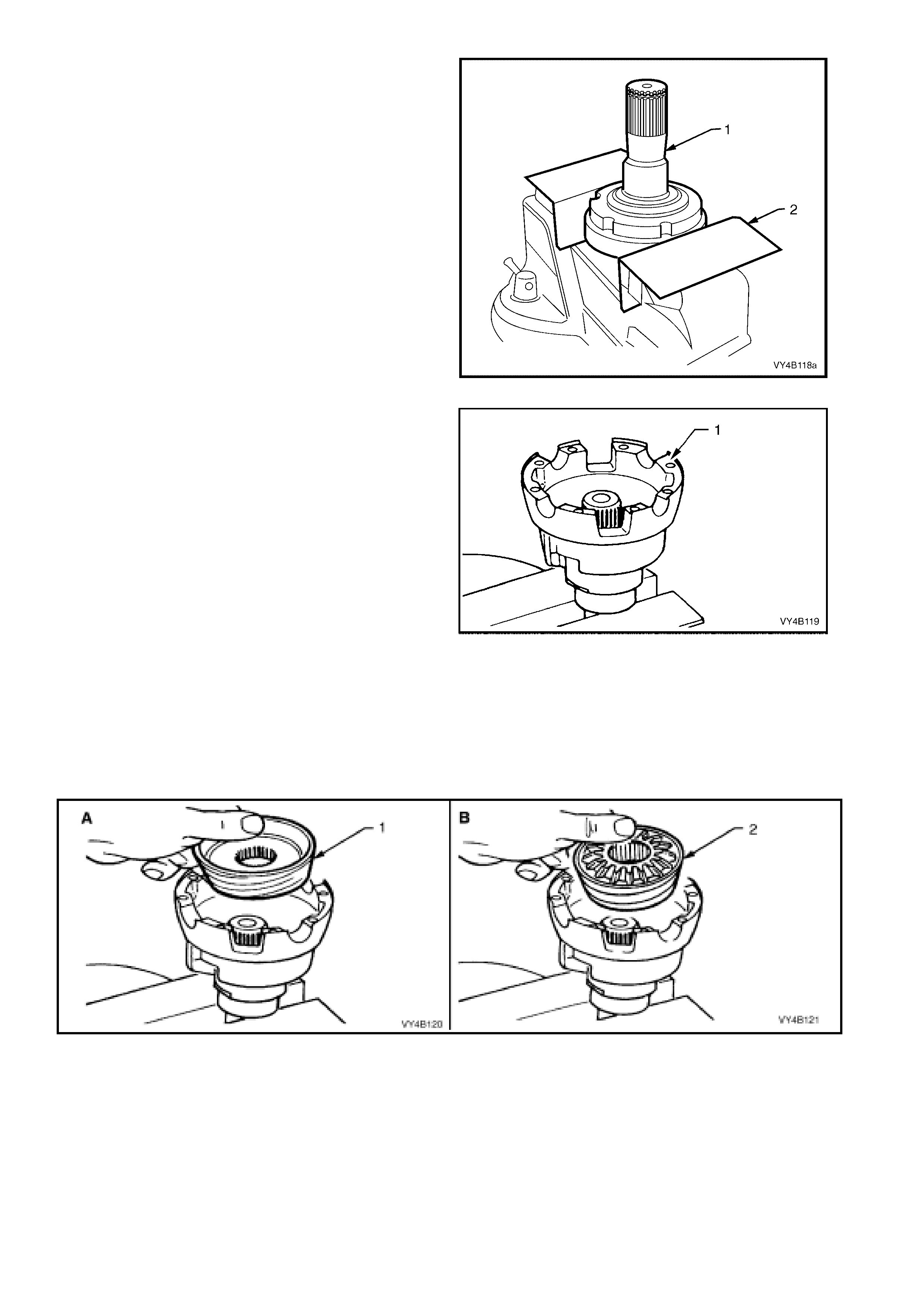

1. Place the inner race (1) into the cage (2) and

position centrally.

Figure 4B-33

2. Place the inner race and cage assembly (2)

into the outer race (1). Make sure that the

identification groove (1) and step (2) are on

opposite sides of the assembly, as shown.

Figure 4B-34

3. Align the thick sections (1) on the outer race,

with the narrow ones (2) on the inner race.

Figure 4B-35

4. Tilt the cage and inner race, as shown and fit

one ball.

Repeat this process for the remaining five

balls.

Figure 4B-36

5. When assembly of the CV joint is complete,

check for plunge movement of the inner

members, as indicated by ‘A’. If NO plunge

movement can be achieved, then the

constant velocity joint has been incorrectly

assembled.

If suc h a situation occurs, t he CV joint m ust be

disassembled and the assembly process

repeated until such time that the required

plunge movement is achieved.

NOTE: This check only applies to the inner plunge

joint. The outer CV joint should have no plunge

movement.

Figure 4B-37

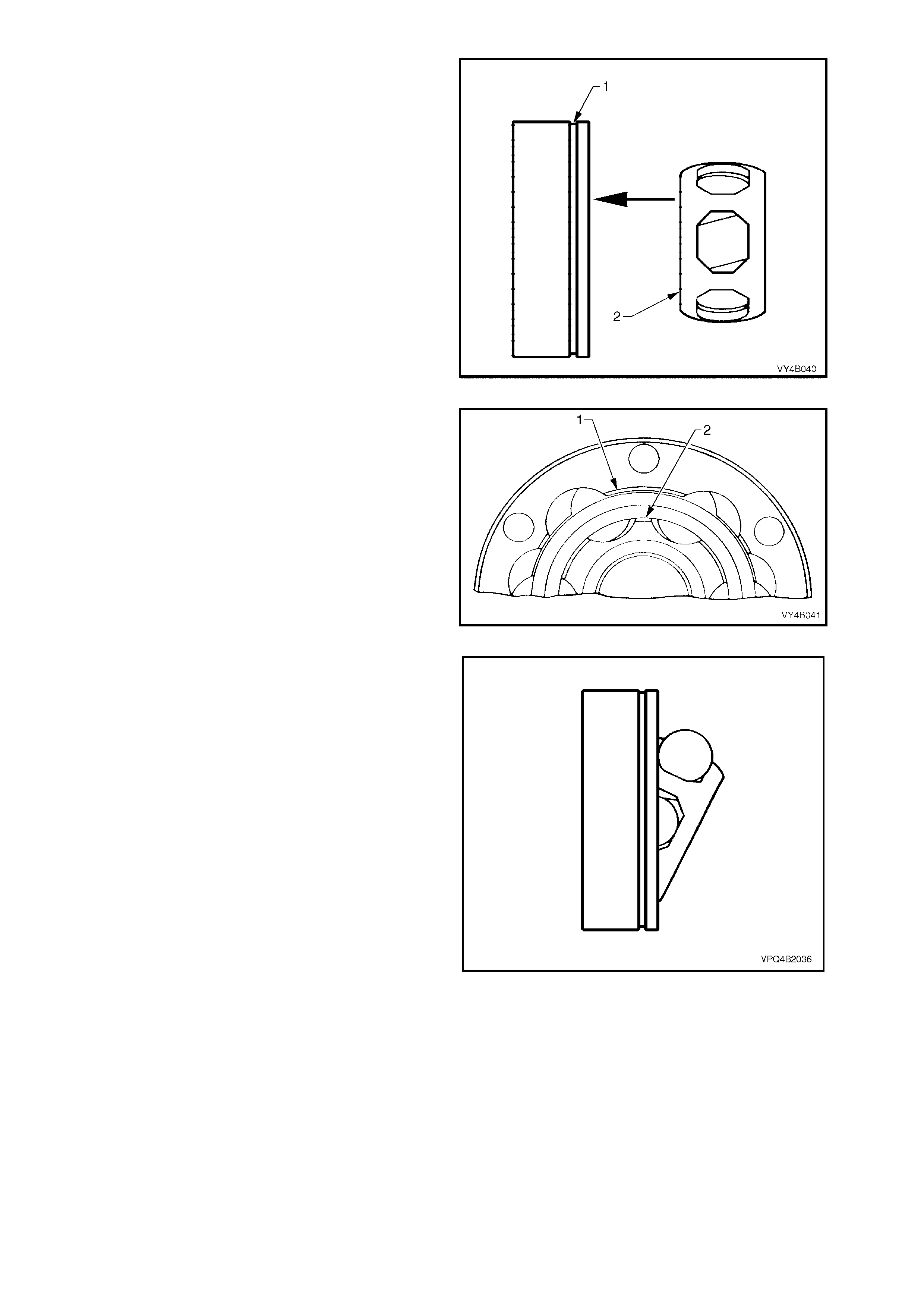

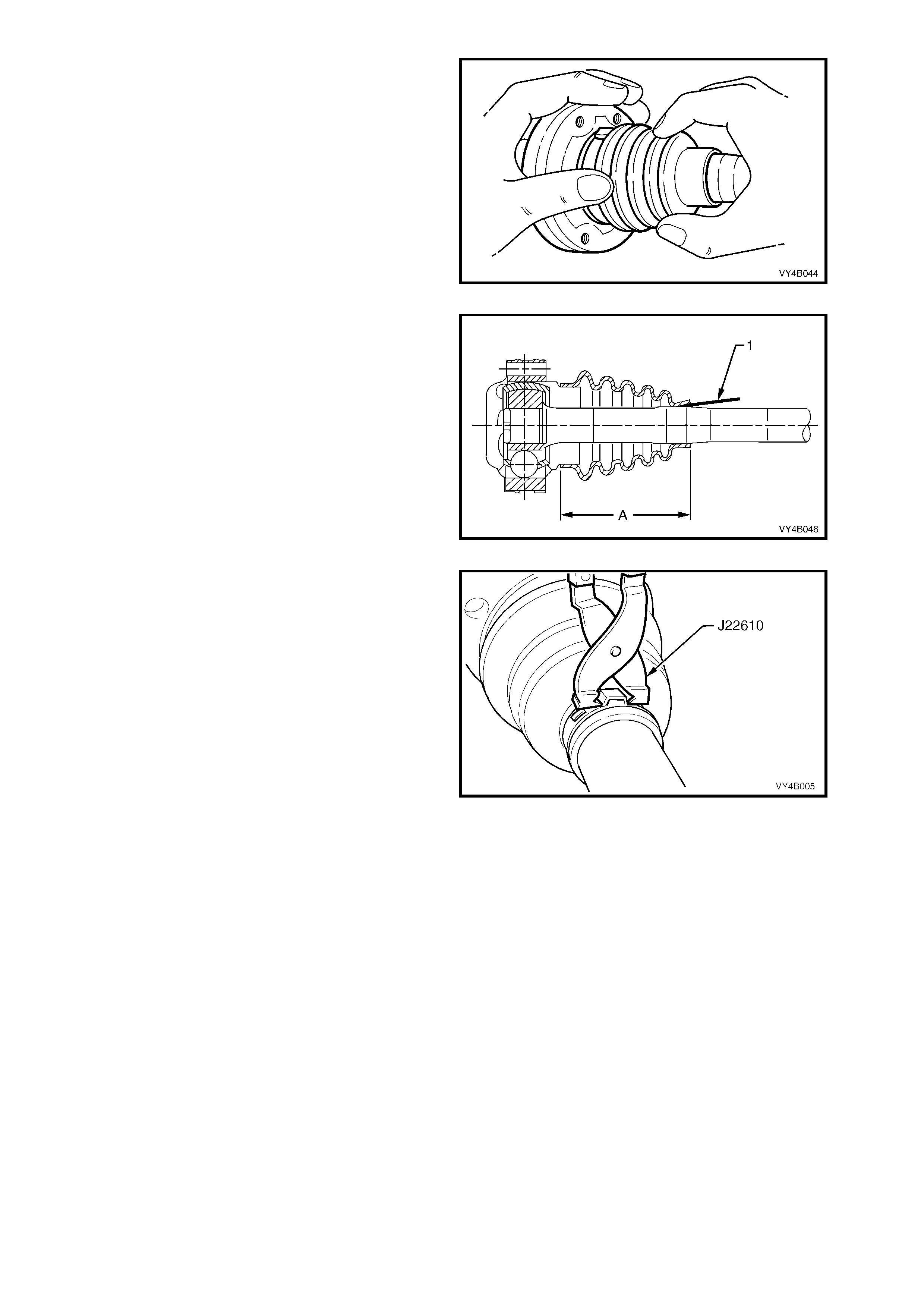

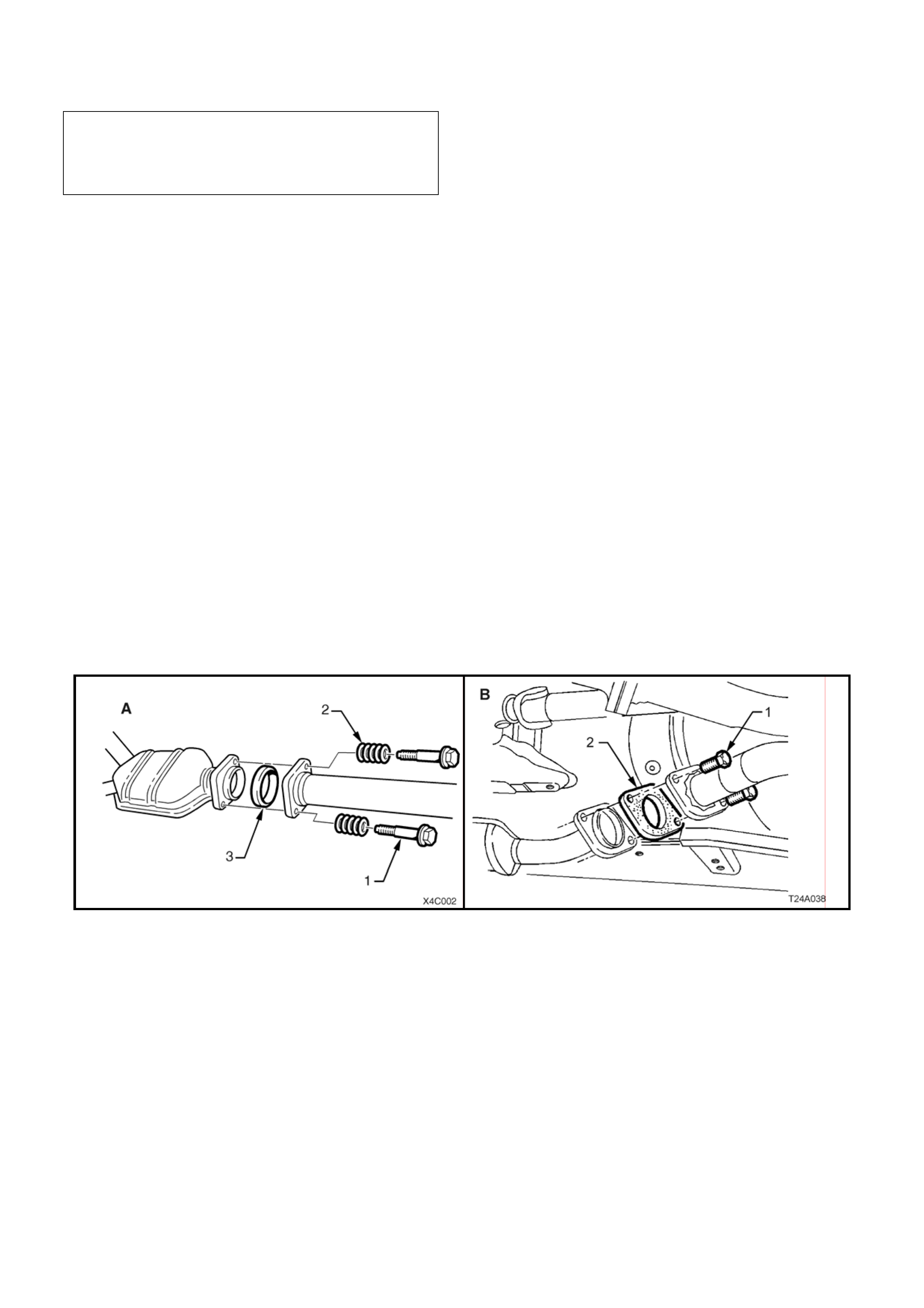

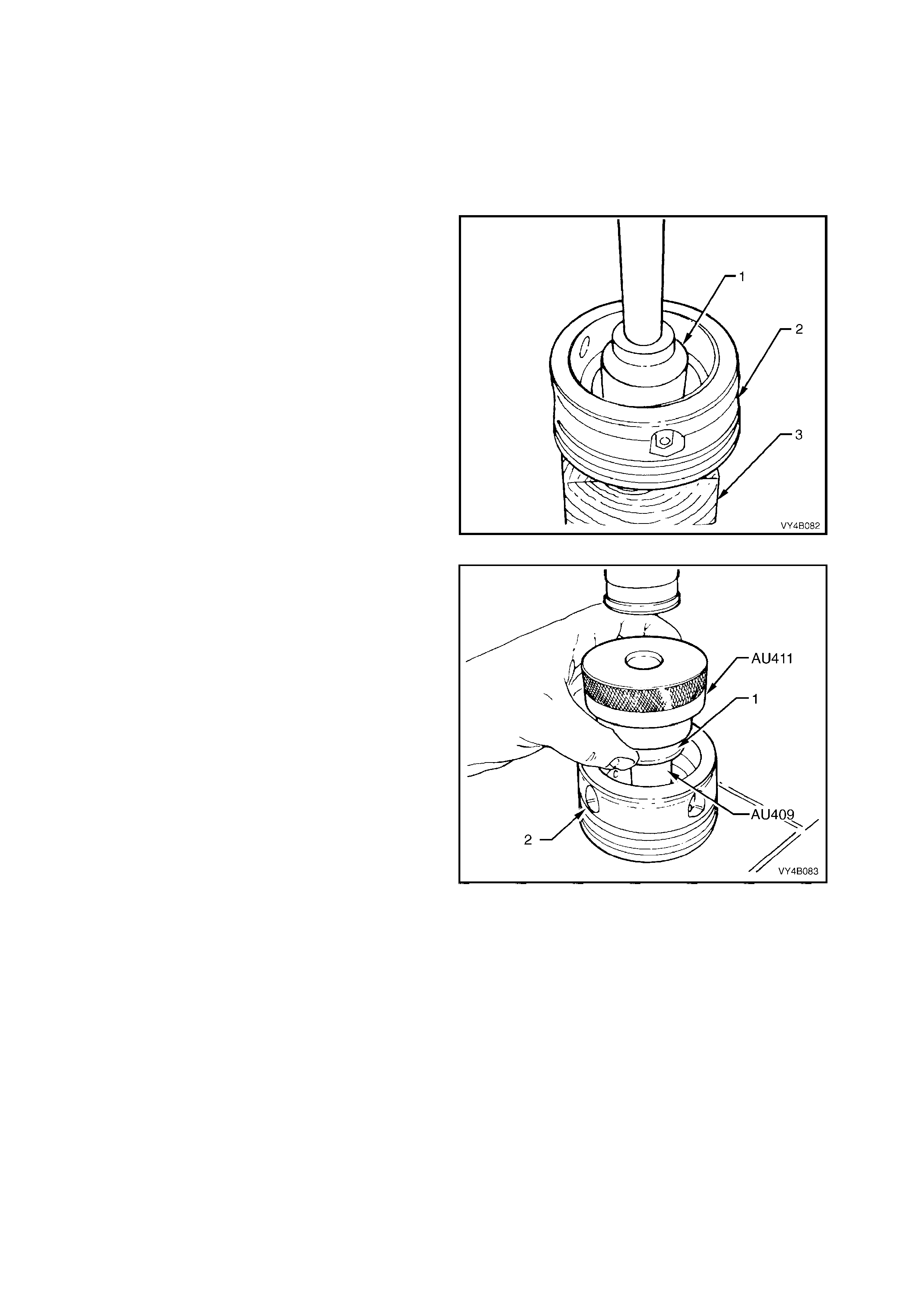

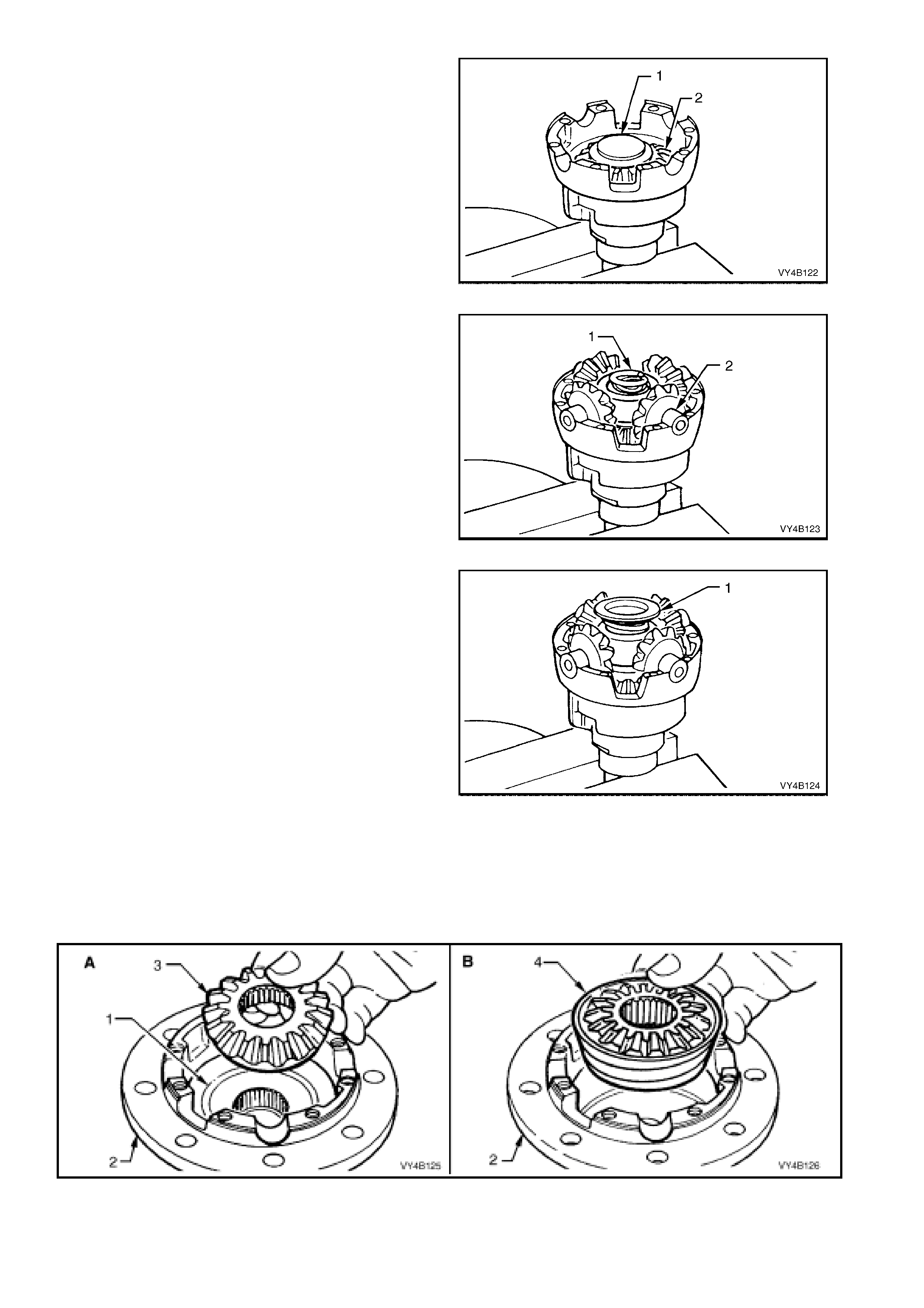

Drive Shaft And Boots

1. Remove old sealing bead of silicon from dust shields, dust caps and constant velocity joints.

2. Position new large boot clamp over boot (2) and place boot over dust shield (1). Using Tool No. J22610,

securely crimp boot clamp, ensuring the crimp is positioned mid-way between two bolt holes (3, in view ‘A’).

3. Apply a 2 mm diameter bead (4) of commercially available RTV 732 sealant to dust caps/shields and allow

approximately one hour to cure.

4. Place new small boot clamps onto drive shaft.

5. Place both dust shield and boot assemblies onto drive shafts, ensuring that boots are not damaged by sharp

edges on each end of shaft.

Figure 4B-38

6. Only for the inner constant velocity joint (1),

reinsta ll the joi nt (1) onto s haft with step (3) on

the inner race (2) facing toward the shoulder

(4) on the shaft.

NOTE: The recess on the inner race of the outer

CV joint, also faces the drive shaft.

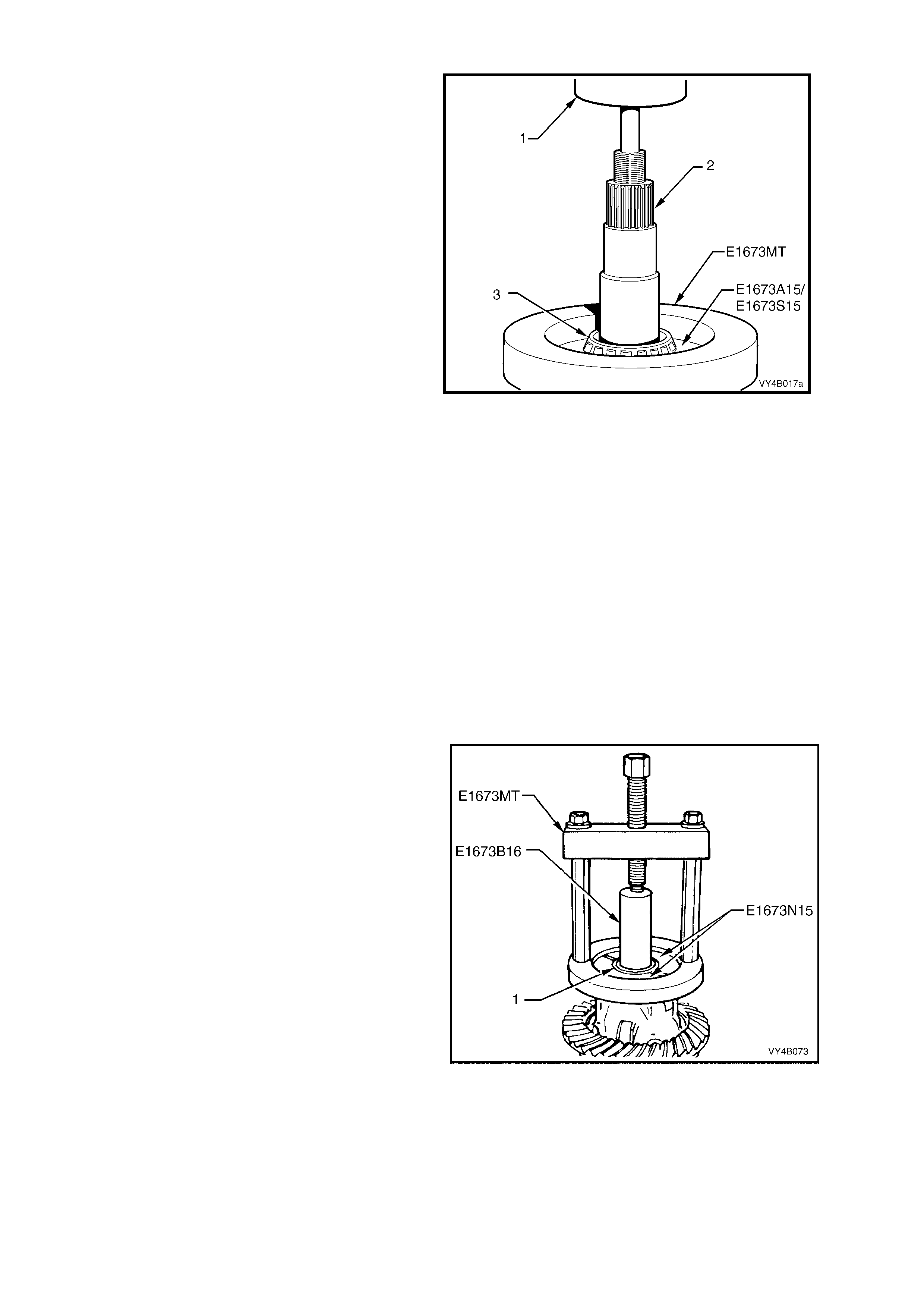

7. Press constant velocity joints onto shaft and

install a NEW circlip at each end.

NOTE: When pressing joints onto shaft, ensure

that the joint inner races (2) take the press load.

Figure 4B-39

8. Pack inside section of joint and boot with one

tube of grease (40 grams) and pack half tube

(20 grams) to outside section of joint.

9. Position dust caps and dust shields onto

constant velocity joints, ensuring that all bolt

holes align.

10. Using a suitable punch and hammer, tap caps

and shields into place.

Figure 4B-40

11. Locate small ends of boots into boot grooves

on drive shafts, ensuring that boots are not

twisted.

W ith both j oin t, pr y up s mall ends of b oots f rom

shaft (1) to equalise air pressure inside and

outside of boots and work out any dimples

before applying new small clamps.

IMPORTANT: The location distance ’A’, ONLY

applies to the inner, plunge joint and should be set

at 81 mm before applying the small clamp.

Figure 4B-41

12. Position small clamps over ends of boots and

using Tool No. J22610, crimp ends of clamps.

13. Reinstall drive shaft, refer 2.7 DRIVE SHAFT

ASSEMBLY - REINSTALL in this Section.

Figure 4B-42

2.9 INNER AXLE SHAFT SEAL

REPLACE

1. Using a floor jack under centre of differential

carrier, jack up rear of vehicle then place

safety stands under body rear jacking points.

Refer to Section 0A GENERAL

INFORMATION for location of jacking points.

2. Remove drive shaft from side of vehicle

which seal is to be replaced, refer to

2.7 DRIVE SHAFT ASSEMBLY – REMOVE,

in this Section.

NOTE 1: During drive shaft removal, keep drive

shaft supported so that it does not hang on one

end.

NOTE 2: Drive s haft j oint def lection sho uld be k ept

to a minimum.

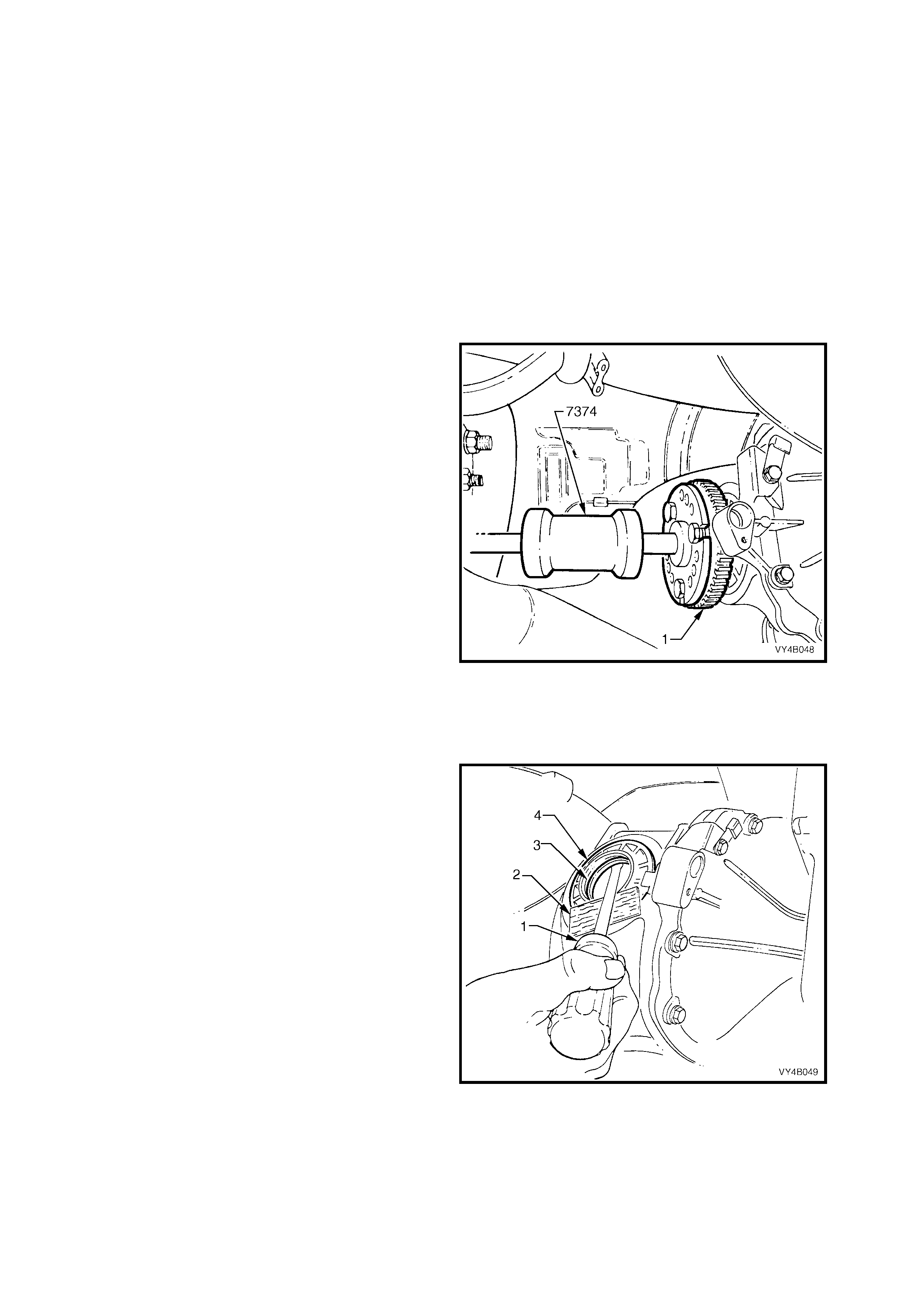

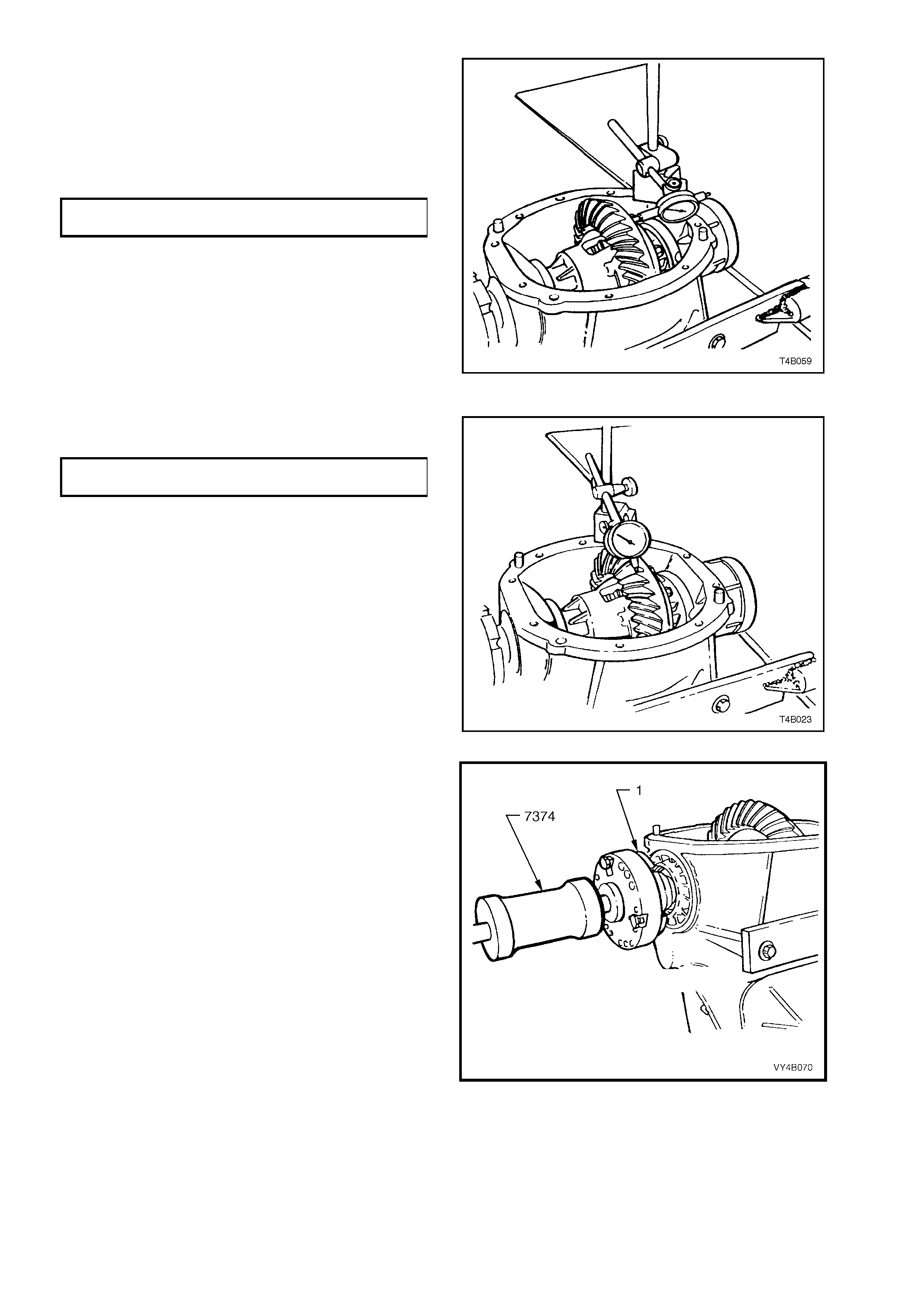

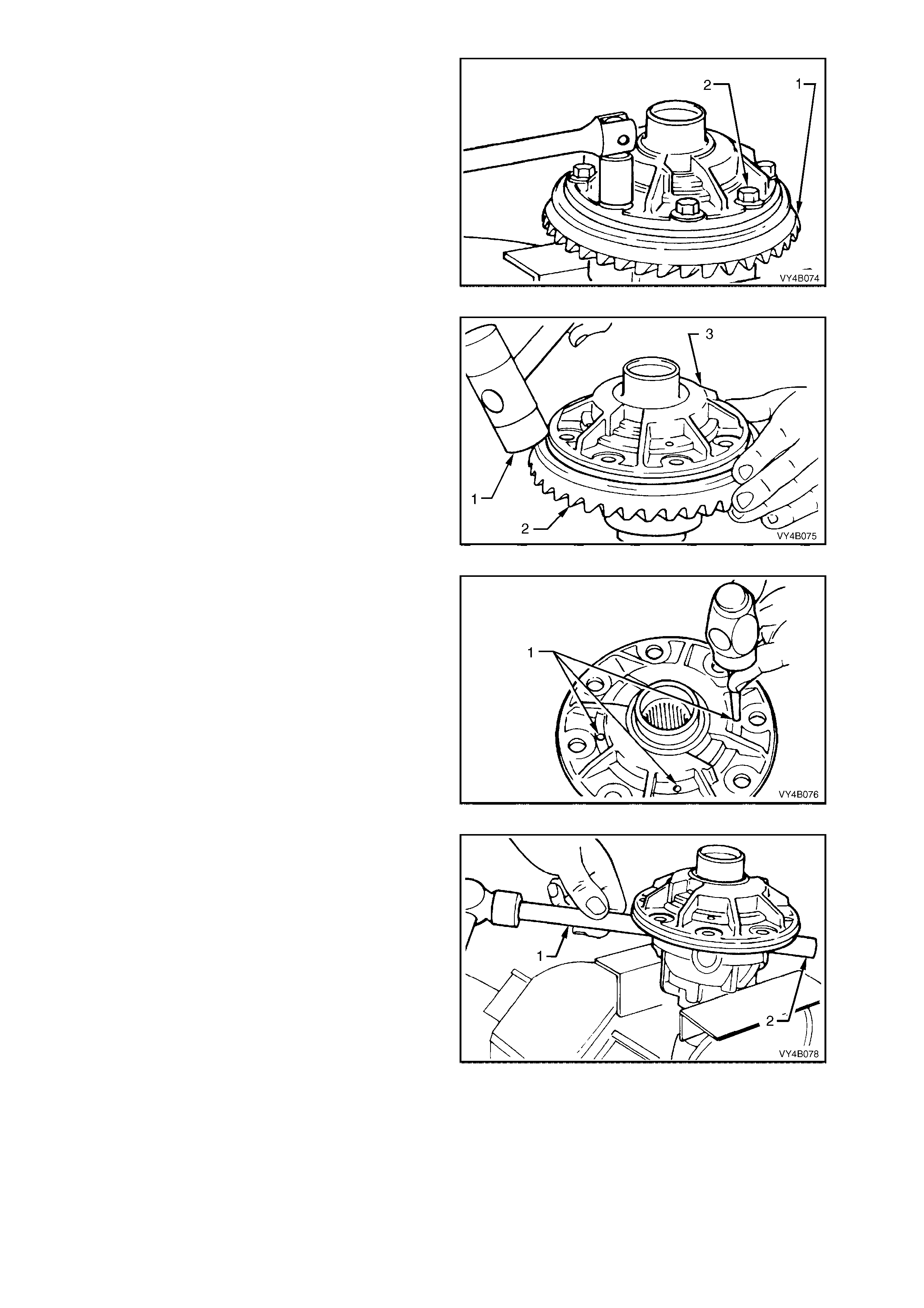

3. Remove inner axle shaft (1) by installing a slide

hammer, Tool No. 7 374 with three suit abl e s i ze

bolts to axle flange. Use slide hammer to

release axle shaft spring clip.

As the axle shaft is removed, a small amount

of lubricant may leak from differential carrier.

CAUTION: If a 3.08:1 ratio final drive is fitted

with LSD, do not rotate the opposite axle shaft,

as side gear and clutch cone splines will

become misaligned. Then the axle shaft cannot

be reinstalled without removing differential

case, dismant ling and realigning g ear and cone

splines.

NOTE: The above ‘Caution’ does not apply to

either the 3.07:1 or 3.46:1 ratio final drives,

because the side gear and LSD cone is an

integrated component.

4. Clean around seal bore and housing area to

make sure that no foreign matter enters axle

shaft needle bearing in the scr ew adjust er.

Figure 4B-43

5. Using a suitable screwdriver (1) and a block of

wood (2), lever seal (3) from screw adjuster

bore (4).

NOTE: Take care not to damage the screw

adjuster's aluminium housing (4) with the

screwdriver blade (1), as this could cause oil leaks

to occur, after a new oil seal was fitted.

Figure 4B-44

6. Before installation of new seal, examine seal

surface of inner axle shaft and remove any

nick s or bur rs. Shoul d th is i ns pection sho w that

the surface is marked, a new inner axle shaft

should be fitted.

NOTE 1: The left hand in n er ax le sh aft is shor ter in

length than the right hand shaft.

NOTE 2: If veh icle is e quipped with AB S, the inner

axle shafts are unique for this application.

NOTE 3: Check spring clip in end of axle shaft to

ensure that it is not damaged and moves freely in

groove. Replace spring clip if necessary, by

expanding ends of clip and removing from shaft.

Only expand the ends of a new clip sufficiently to

allow installation into shaft groove.

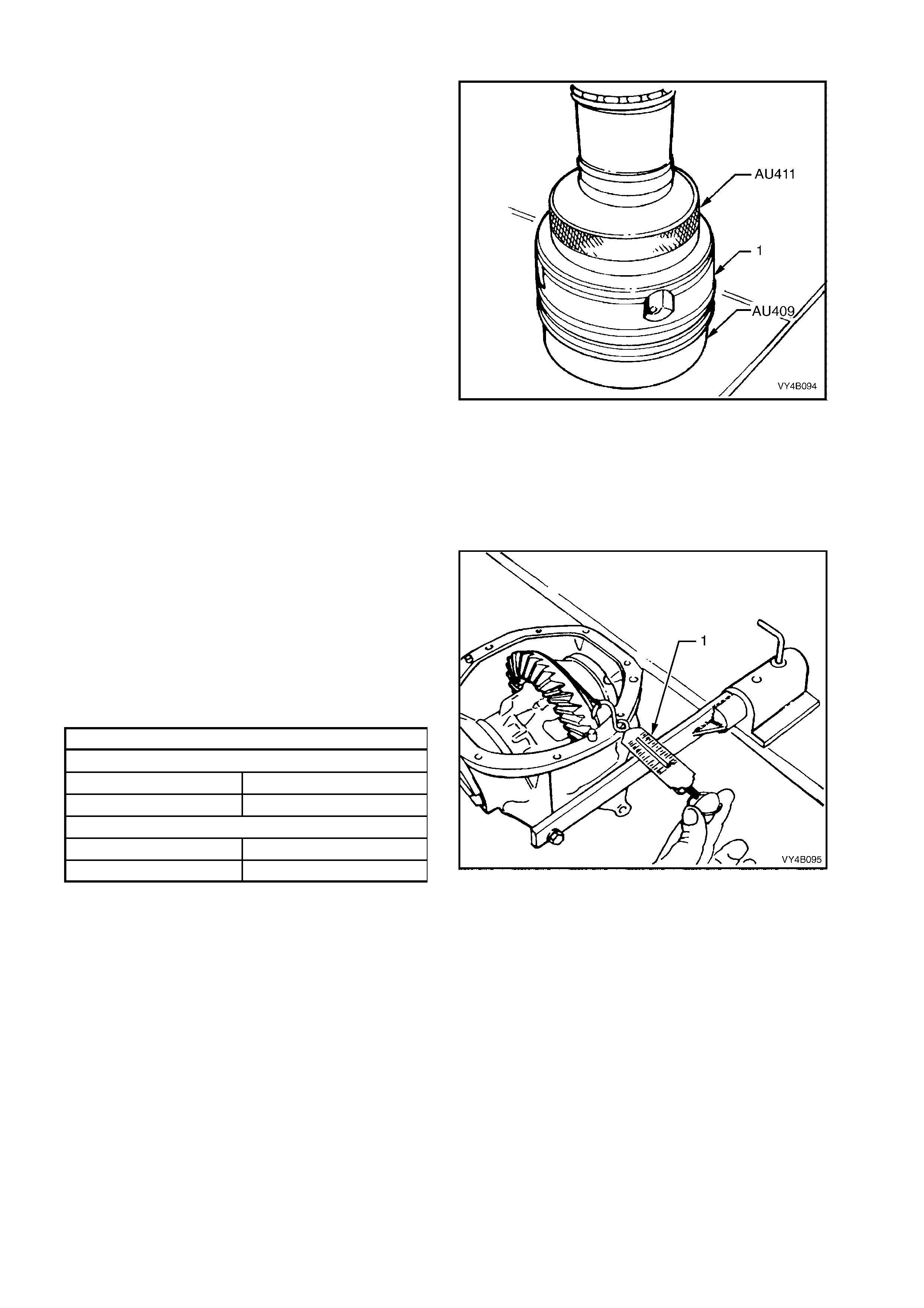

7. Examine seal bore in screw adjuster and

remove any nicks or burrs.

8. Lubricate seal lips and outside diameter with

lithium soap grease. Insta ll seal usin g Tool No.

AU410, until seal bottoms in bore.

Figure 4B-45

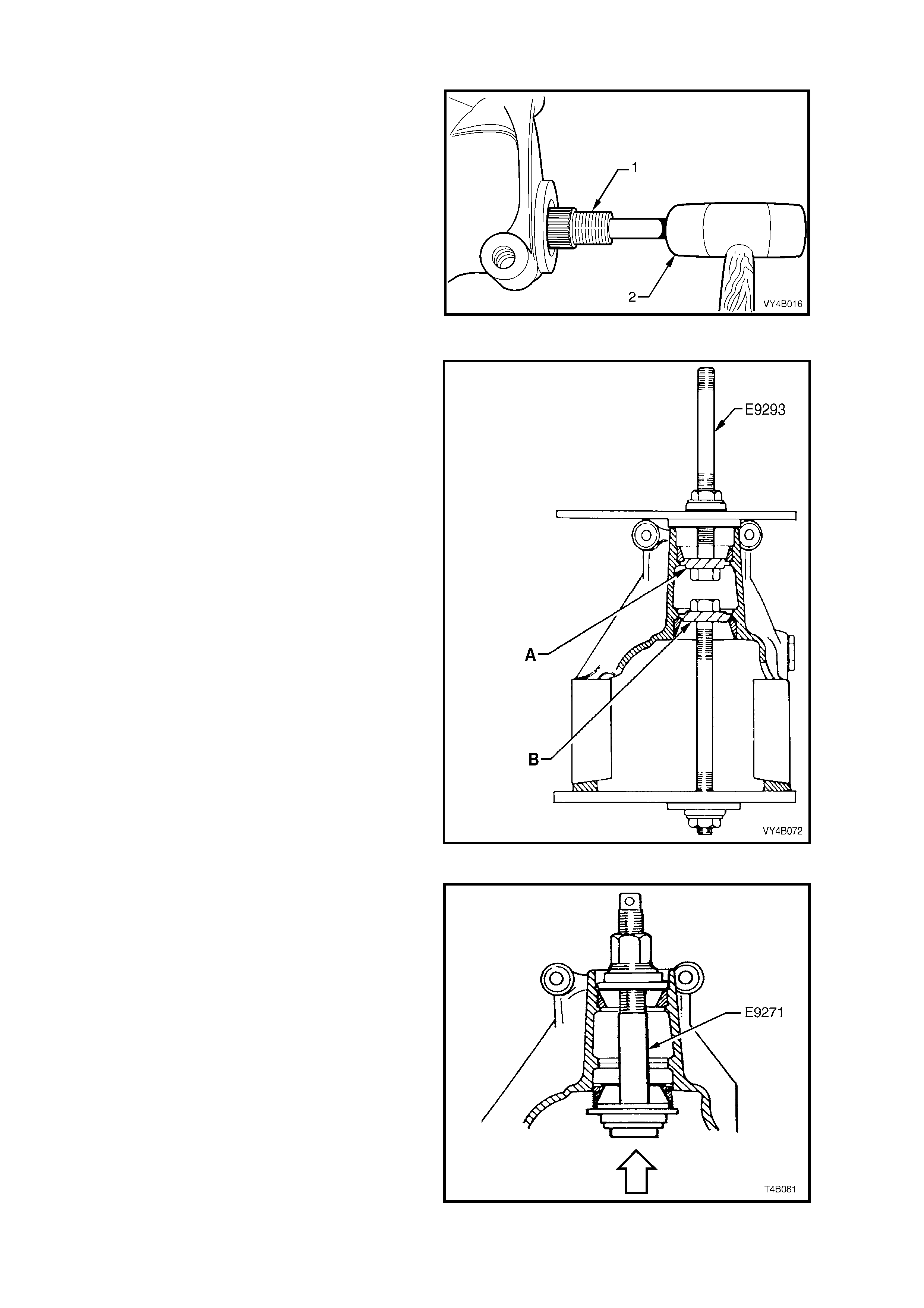

9. Reinstall inner axle shaft (1), aligning splines

with clutch cone (if fitted with a Limited Slip

Diff erential) and side ge ar .

NOTE: To avoid premature seal failure, ensure

axle shaft splines or securing clip do not score or

damage the seal lips during installation.

10. Lightl y hit on end of axle shaf t flange (1) with a

soft faced hammer (2) to compress spring clip

on shaft in to cl utch con e and s ide g ear splin es.

Fully engage shaft (1) until clip snaps in to side

gear groove.

Figure 4B-46

11. Reinstall drive shaft, refer to

2.7 DRIVE SHAFT ASSEMBLY in this

Section.

12. Remove safety stands and lower vehicle.

13. Check and f il l dif f er entia l carrier to c orr ec t le vel

with specified lubricant. Refer to

2.2 CHECKING DIFFERENTIAL CARRIER

LUBRICANT LEVEL in this Section.

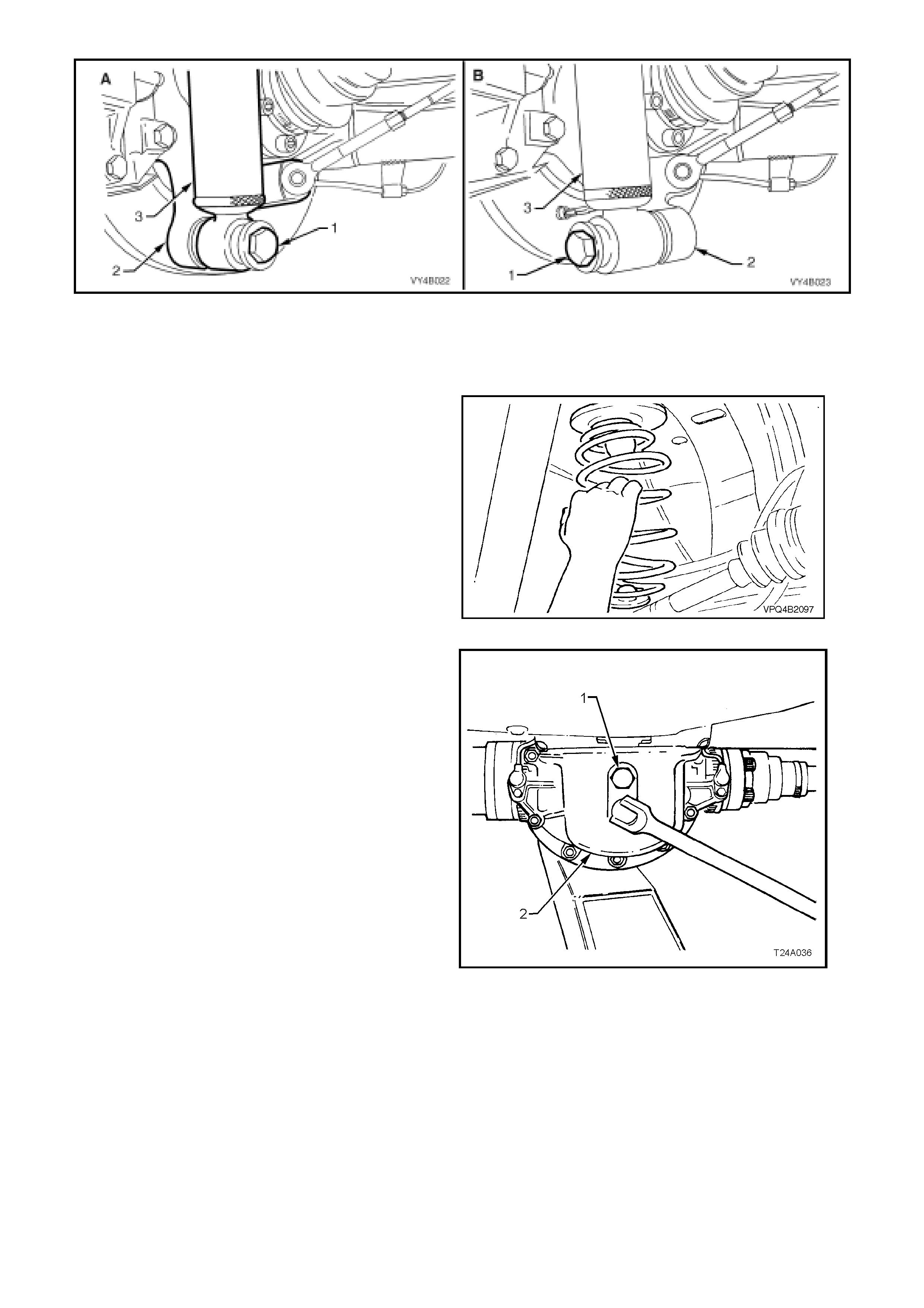

2.10 PINION OIL SEAL

LT Reference No: F502100

REPLACE

1. Using a floor jack under centre of differential carrier, jack

up rear of vehicle, then place safety stands under trailing

arms.

2. Mark the position of the propeller shaft rear coupling to

pinion flange, using a felt tipped pen or similar.

3. Remove propeller shaft, refer to 4C PROPELLER

SHAFT AND UNIVERSAL JOINTS in the MY 2003 VY

and V2 Series Service Information. This operation may

also require partial exhaust system removal.

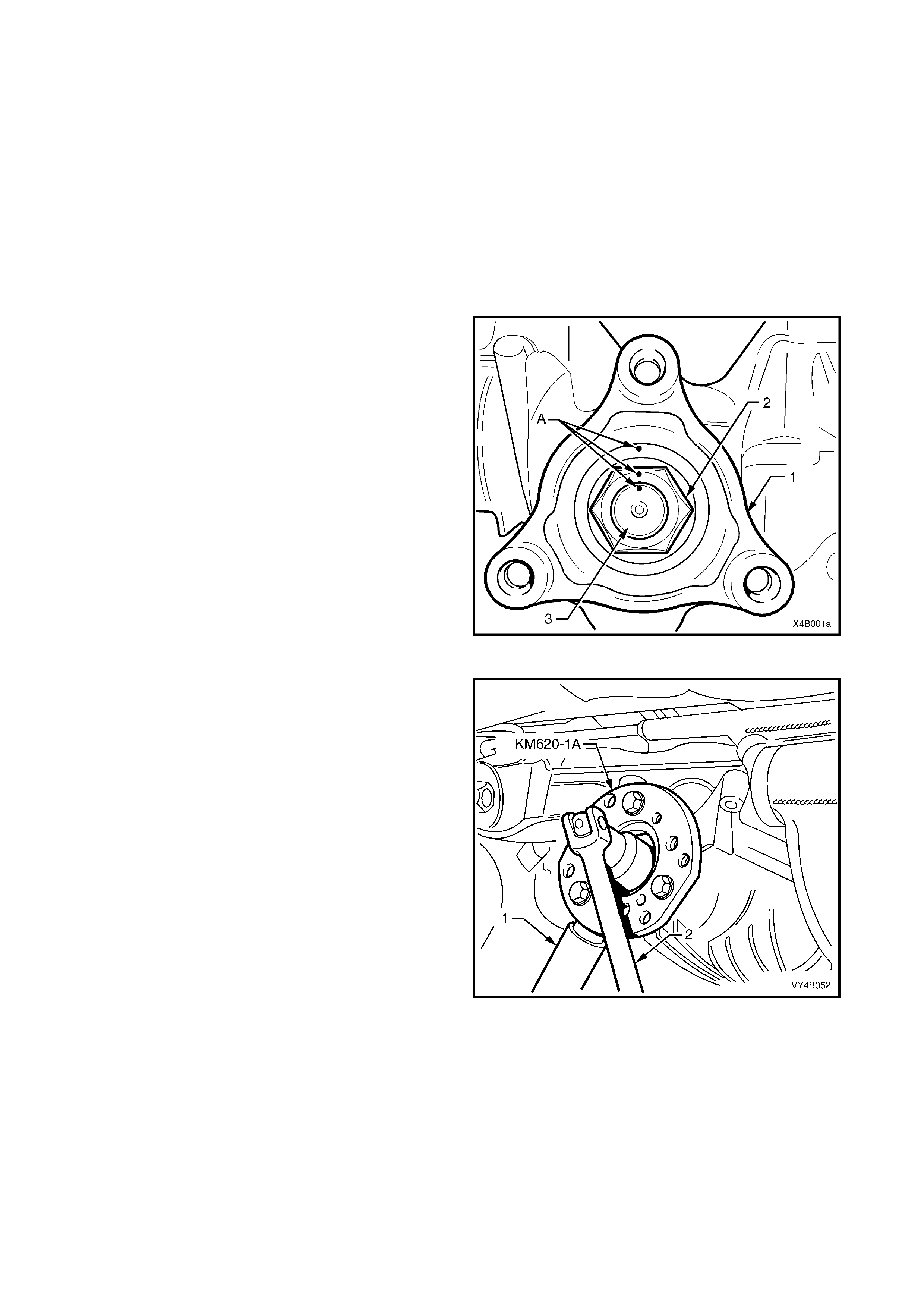

4. Lightly centre-punch alignment marks (A) on the

pinion flange (1), flange nut (2) and pinion end (3) as

an aid for reassembly.

By reassembling to the original position, the flange

run-out will be minimised and the pinion bearing

preload will be maintained.

Figure 4B-47

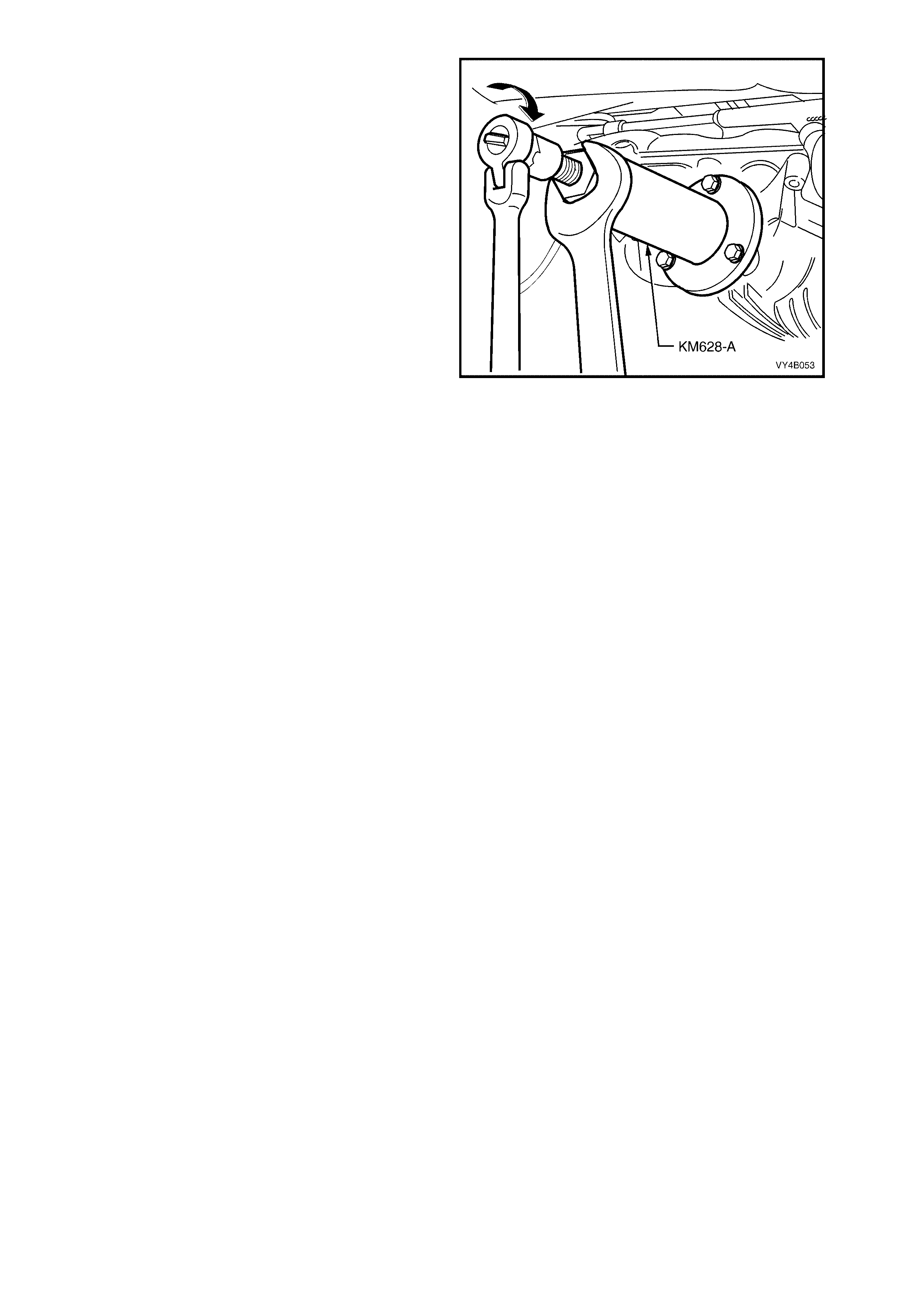

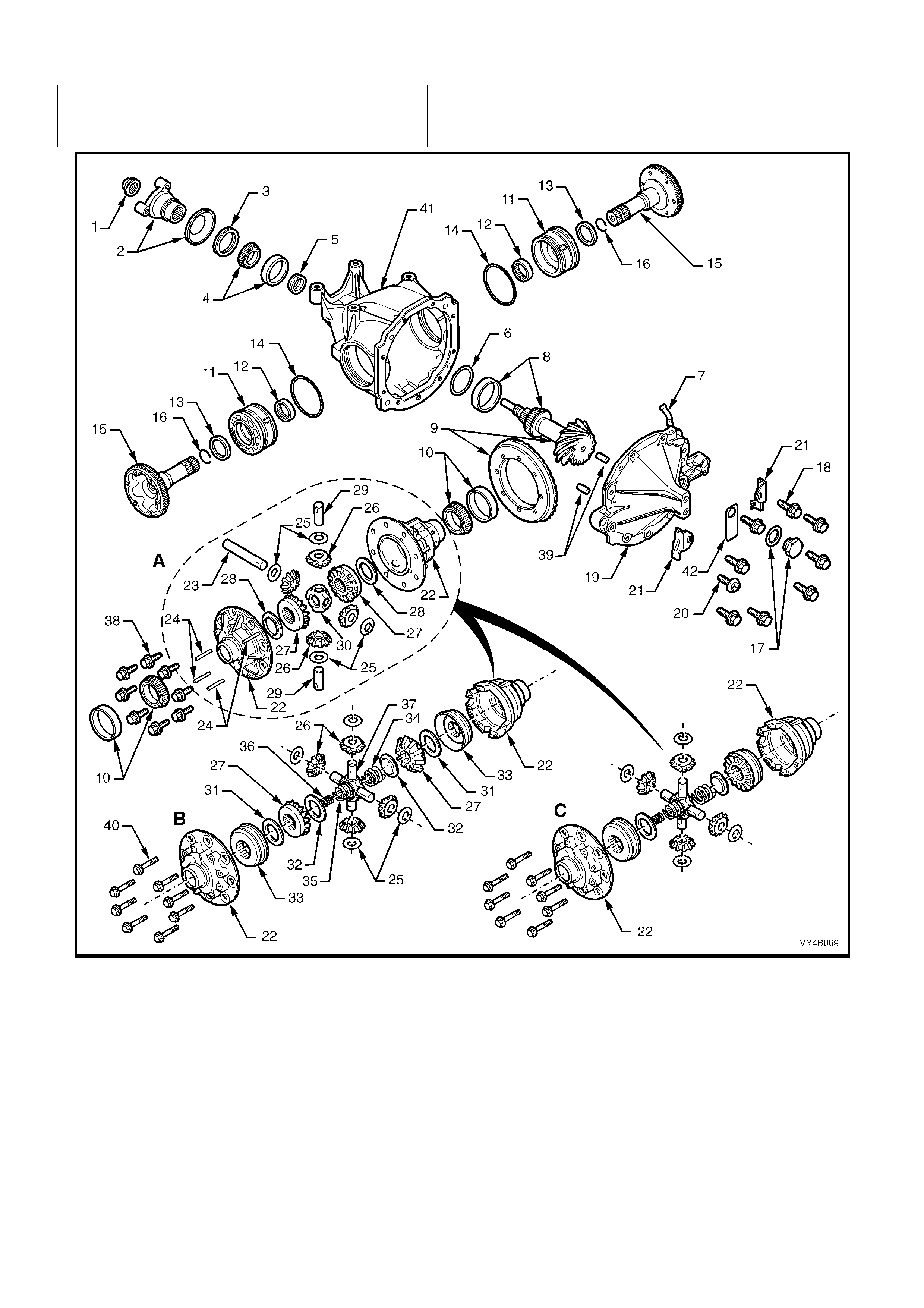

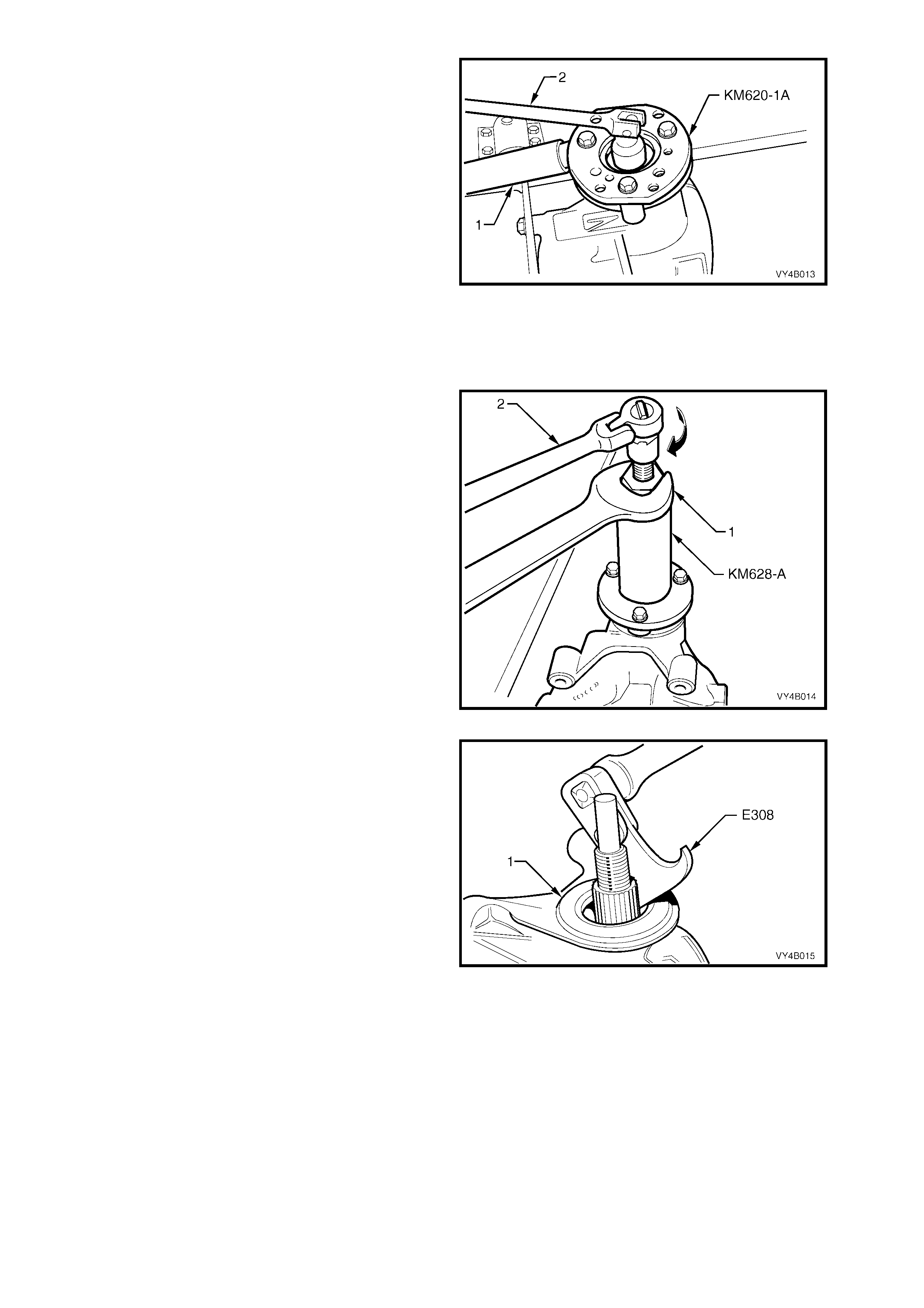

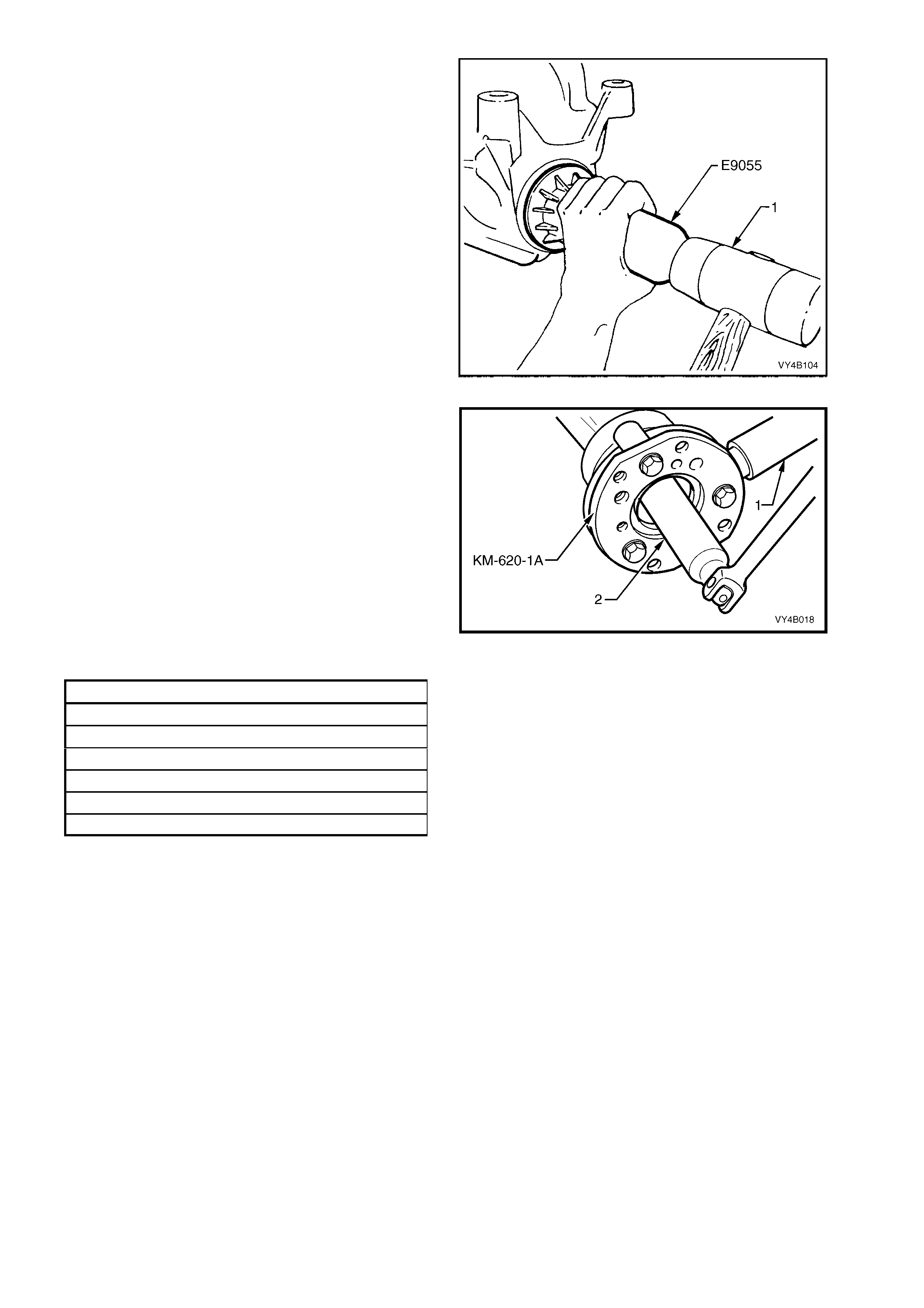

5. Attach Tool No. KM620-1A to the pinion flange,

using three suitable bolts to hold pinion flange.

NOTE 1: If not previously done so, drill out holes

stamped ‘B’ on Tool No. KM620-1A to 12.5 mm.

NOTE 2: Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat washers)

installed first or use three bolts M12 x 1.5 x 40, with the

thread extending to w ithin 12 mm of the head.

6. Insert a suitable length of pipe (1) over the tang of

the installed tool for leverage, then remove the

pinion flange retaining nut, using a commercially

available, 30 mm deep socket and socket bar (2).

7. Remove Tool No. KM620-1A from the pinion flange.

Figure 4B-48

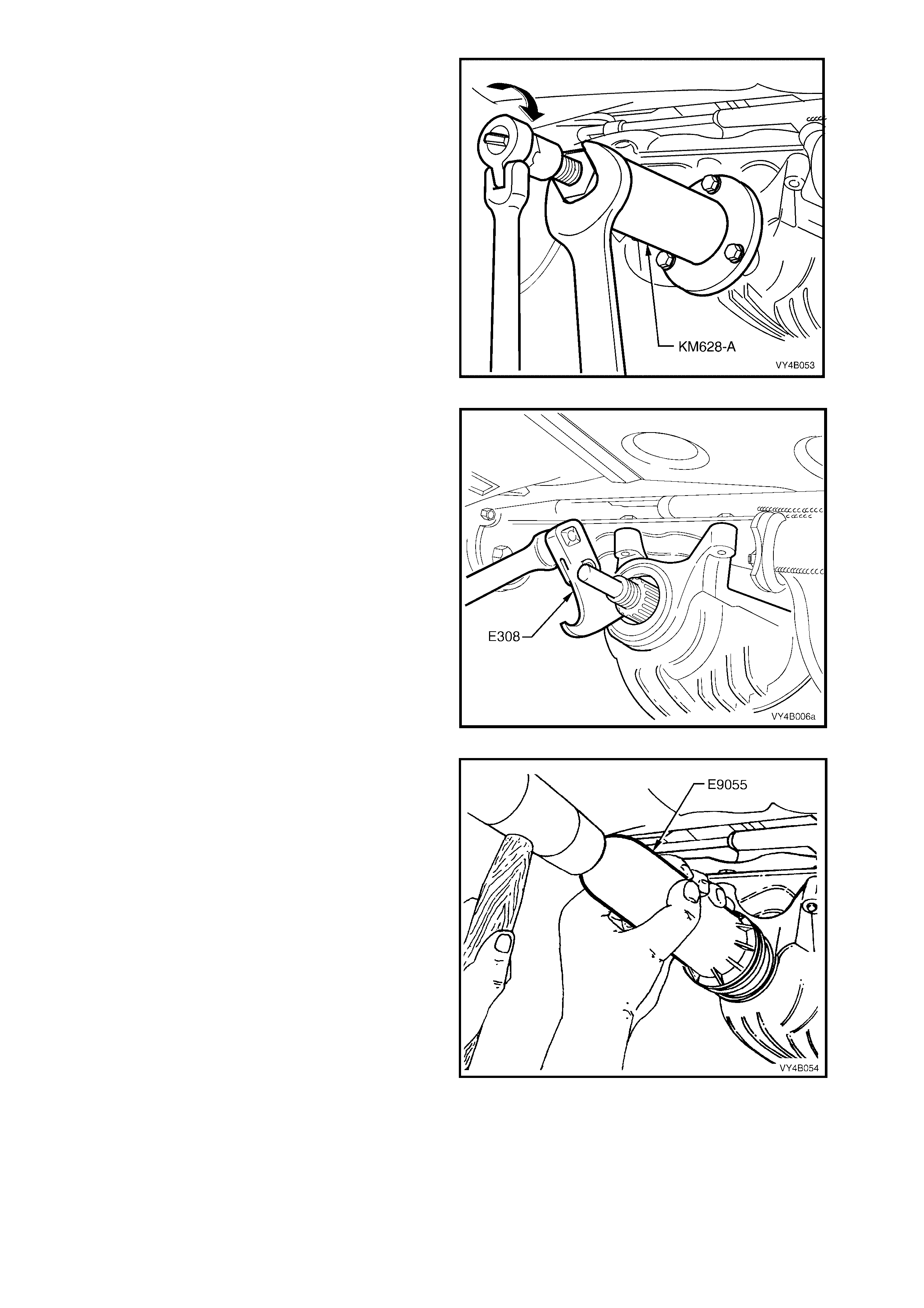

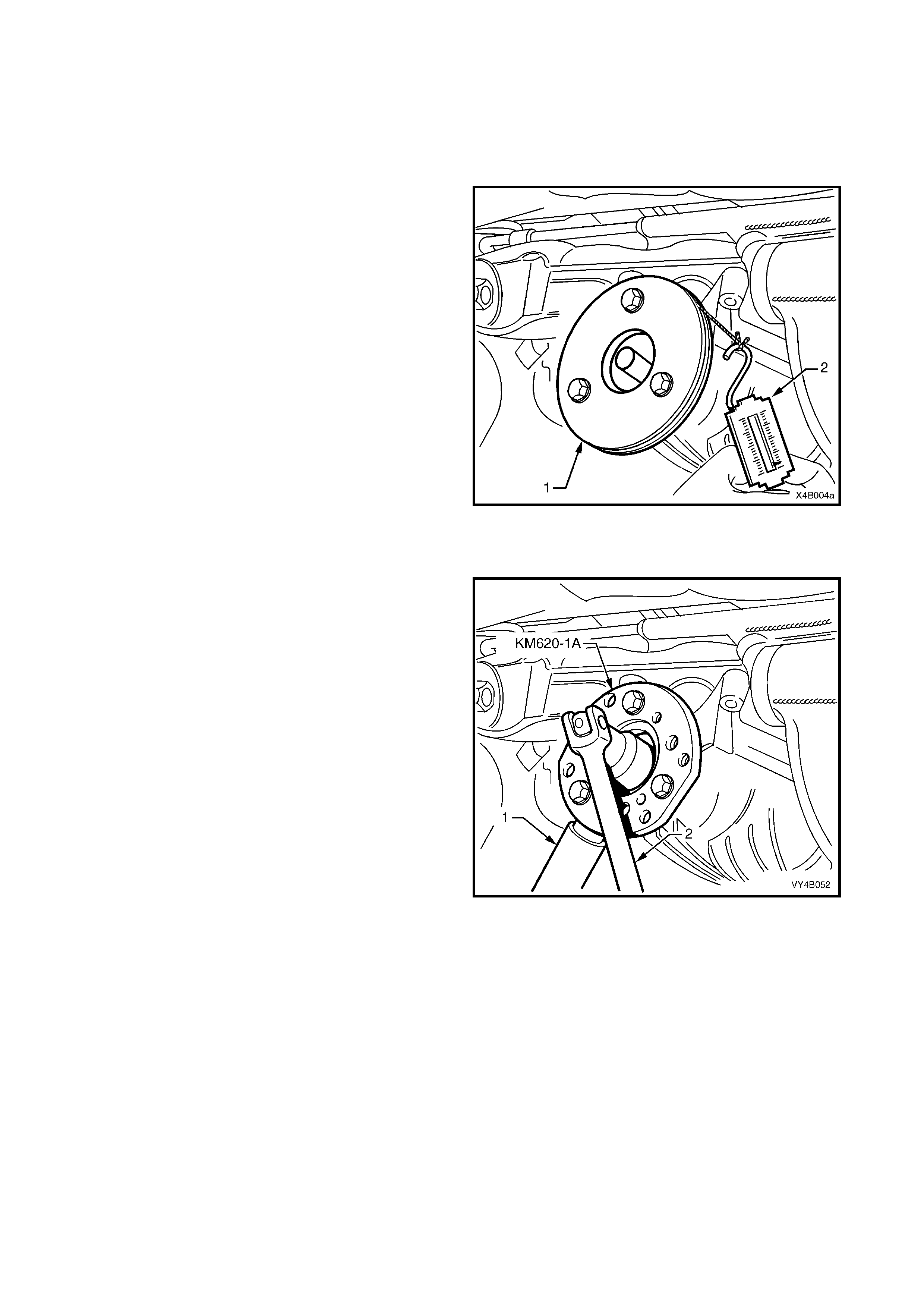

8. Place drain tray beneath differential carrier.

9. Install extractor, Tool No. KM628-A to the

pinion flange using the same three bolts used

to secure the flange holding tool, KM620-1A

(refer Figure 4B-48).

NOTE: If not previo us l y done s o, dr ill out the flan ge

holes on Tool No. KM628-A to 12.5 mm.

IMPORTANT: If using the original propeller shaft

coupling bolts, they must have a 25 mm spacer

fitted to each, so the tool is clamped to the pinion

flange. If this is not done, the screw thread on the

extractor Tool No. KM628-A will not be long

enough to fully remove the pinion flange.

10. While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening

the forcing screw in the direction indicated.

Figure 4B-49

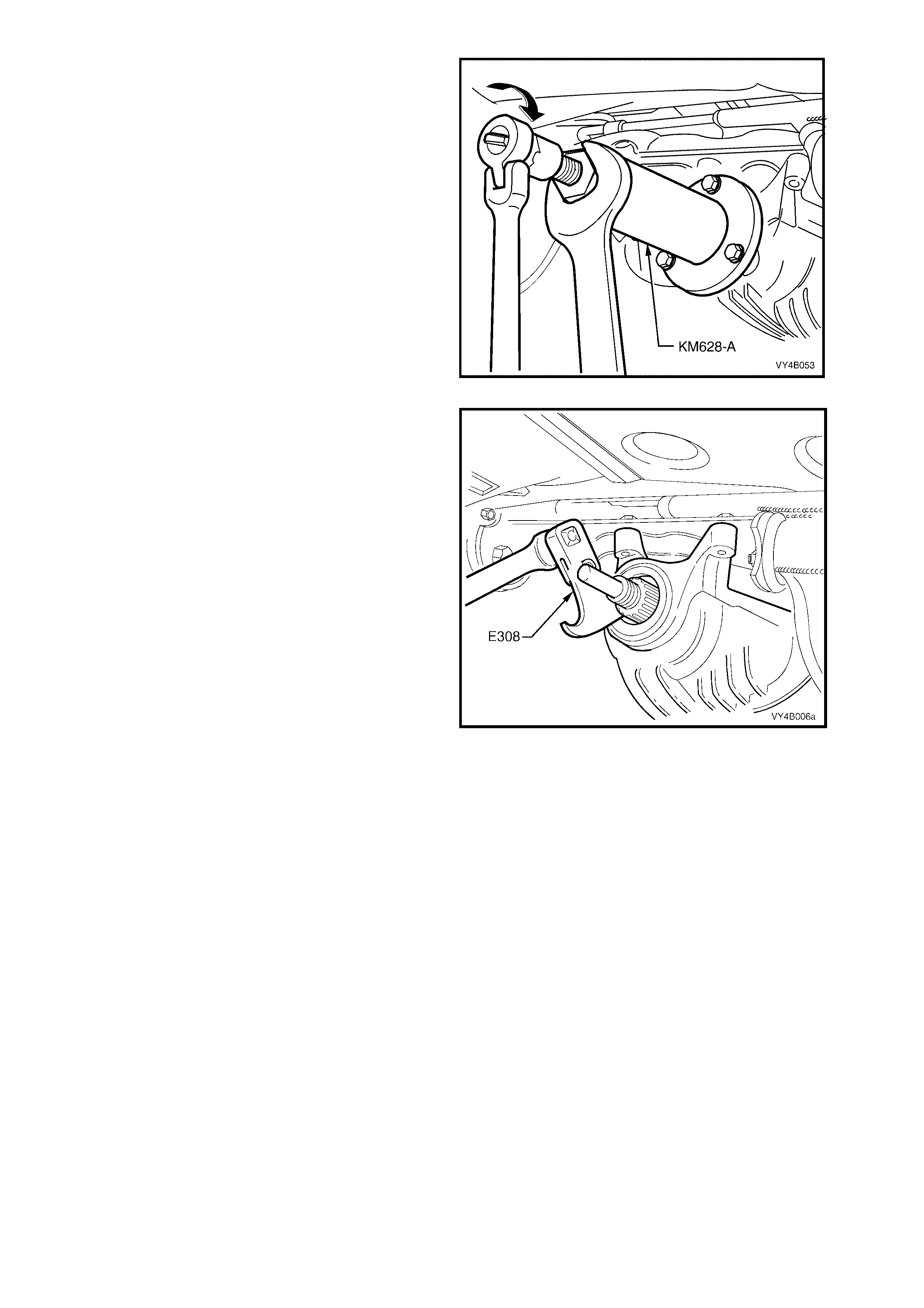

11. Prise pinion oil seal from carrier bore using

Tool No. E308 or a universal seal removing

tool.

Figure 4B-50

12. Lubricate a new pinion oil seal lips and the

outer diameter with the recommended rear

axle lubr ic ant.

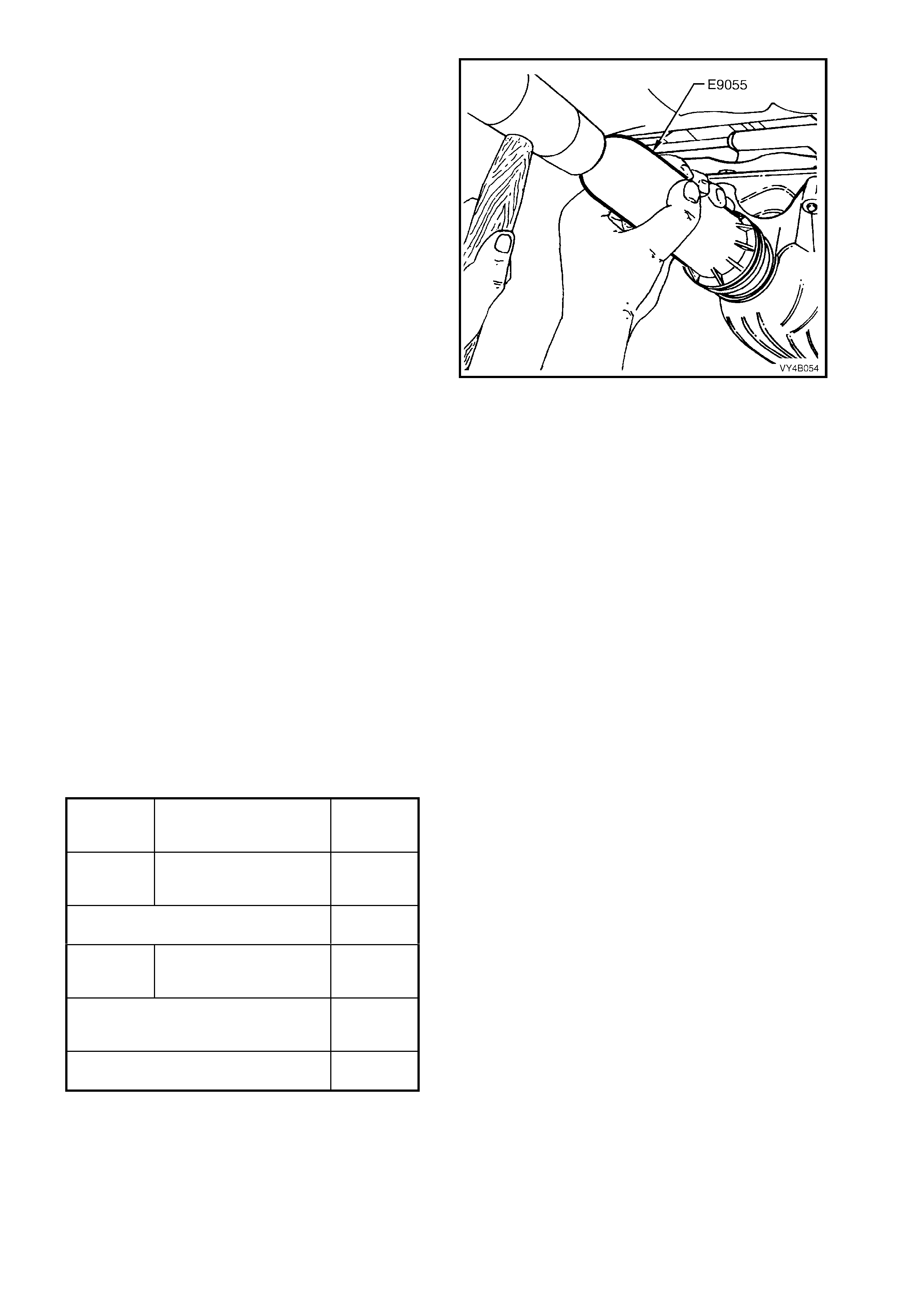

13. Start oil seal into differential carrier housing

and dri ve seal squ arel y into pos ition usin g T ool

No. E9055. Seal fits flush to 0.25 mm below

carrier housing surface.

14. Ensure that pinion shaft is free from burrs and

that flange oil seal surface is free from

damage.

Figure 4B-51

15. Clean the threads of the pinion shaft and the flange retaining nut, removing any oil, dirt or grease.

16. Coat splines and s eal s urface of pinion f lan ge with dif f er enti al g ear lubricant , and ins ta ll flange ont o pi nio n shaft

splines. Ensure that centre-punch marks are aligned.

17. Reinstall holding tool KM620-1A to the pinion flange.

18. Apply a thread locking compound such as Loctite 243 or equivalent, to the threads of the pinion flange retaining

nut, then reinstall the nut.

19. Tighten the flange retaining nut until all centre-punch marks align. Then carefully tighten the nut to a position

not more than 5° past the aligned setting.

NOTE: The pinion flange is an interference fit on pinion shaft splines and should only be pulled into place by

tightening the retaining nut. DO NOT, UNDER ANY CIRCUMSTANCES, USE FORCE OR HAMMER THE

FLANGE DURING INSTALLATION ONTO PINION FLANGE.

CAUTION: Should the retaining nut be over-tightened and pre-load exceeded, it will be necessary to

remove the pinion from the carrier and install a new collapsible spacer. Under no circumstances must the

retaining nut be backed off to decrease the pre-load reading.

20. Reinstall propeller shaft rear coupling to the pinion flange, refer Section 4C PROPELLER SHAFT AND

UNIVERSAL JOINTS in the MY 2003 VY and V2 Series Service Information.

21. If removed previously, reconnect exhaust system, in the reverse to the removal procedure. Refer to

3.2 FINAL DRIVE ASSEMBLY, in this Section, for details.

22. Remove safety stands and lower vehicle.

23. Check lubricant le vel and t op up as necessar y. Refer 2.2 CH ECKING D IFFER ENTIAL CARRIER LUBRICANT

LEVEL in this Section

24. Start vehicle and check for exhaust leaks.

2.11 PINION FLANGE

LT Reference No: F501100

REPLACE (USING OLD OIL SEAL)

NOTE: Due to production tolerances in the length of the pinion flange, it is essential that the following method be used when

installing a new pinion flange. .

1. Using a floor jack under centre of differential carrier, jack up rear of vehicle then place safety stands under trailing arms.

2. Remove propeller shaft, refer 2.1 PROPELLER SHAFT in 4C PROPELLER SHAFT AND UNIVERSAL JOINTS in the

MY 2003 VY and V2 Series Service Information.

3. Remove both drive shafts, refer 2.7 DRIVE SHAFTS in this Section.

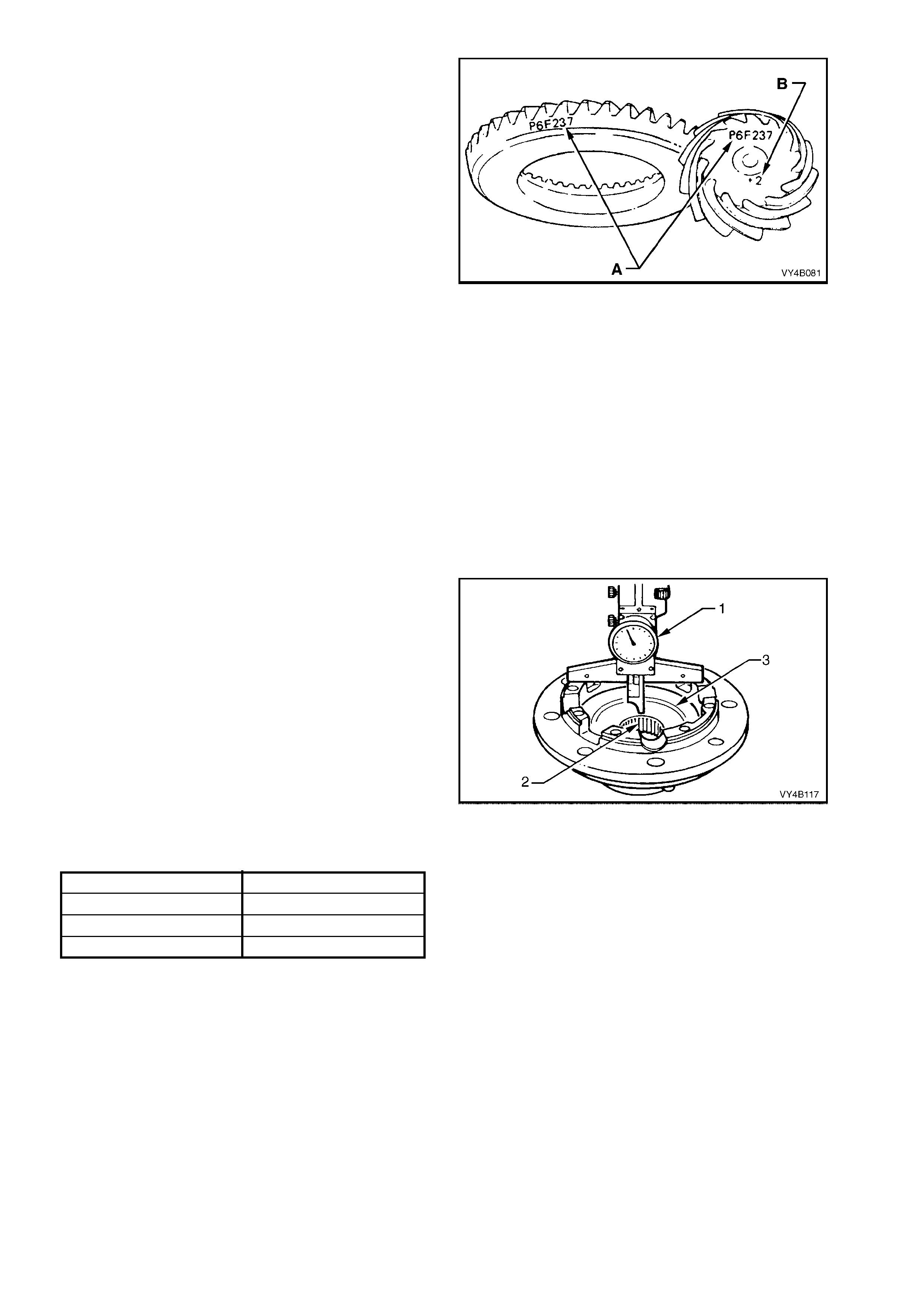

4. Check and record pre-load at pinion flange as follows:

a. Fit a pulley (1) to pinion flange, using three

suitable bolts and attach a cord around pulley

and to a spring scale (2).

NOTE 1: Use either the rear coupling to pinion

flange retaining bolts with a 25 mm spacer (e.g.

flat washers) installed first or use three bolts

M12 x 1.5 x 40, with the thread extending to

within 12 mm of the head.

NOTE 2: For details of the fabricated pulley,

refer 7 Special Tools at end of this Section.

b. Start rotation of pulley and whilst in motion

(approximately 50-60 rpm) note and record

reading of spring balance.

This pre-load reading includes pinion bearings,

side bearings, meshing effect of gear set and

pinion oil seal.

To determine pre-load, multiply reading on

spring balance by radius of pulley.

EXAMPLE: With a pulley diameter of 152 mm, the radius

is 76 mm, which equals 0.076 m. With a spring balance

reading of 25 N, the pre-load equals 0.076 m x 25 N =

1.9 Nm.

5. Remove pulley from pinion flange.

Figure 4B-52

6. Attach Tool No. KM620-1A to the pinion flange,

using three suitable bolts to hold pinion flange.

NOTE 1: If not previously done so, drill out holes

stamped ‘B’ on Tool No. KM620-1A to 12.5 mm.

NOTE 2: Use either the rear coupling to pinion

flange retaining bolts with a 25 mm spacer (e.g. flat

washers) installed first or use three bolts M12 x 1.5

x 40, with the thread extending to within 12 mm of

the head.

7. Insert a suitable length of pipe (1) over the tang of

the installed tool for leverage, then remove the

pinion flange retaining nut, using a commercially

available, 30 mm deep socket and socket bar (2).

8. Remove Tool No. KM620-1A from the pinion flange.

Figure 4B-53

9. Place drain tray beneath differential carrier.

10. Install extractor, Tool No. KM628-A to the

pinion flange using the same three bolts used

in step 6.

NOTE: If not previo us l y done s o, dr ill out the flan ge

holes on Tool No. KM628-A to 12.5 mm.

IMPORTANT: If using the original bolts, they must

have the 25 mm spacers fitted so the tool is

clam ped to the pinion f lang e. If this is not don e, the

screw thread on the extractor Tool No. KM628-A

will not be long enough to fully remove the pinion

flange.

11. While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening

the forcing screw in the direction shown.

Figure 4B-54

12. Ensure that pinion shaft thread is free from burrs, oil, dirt or grease, then coat splines and seal surface of a new

pinion flange with the recommended rear axle lubricant.

13. Install the new pinion flange and a new retaining nut.

NOTE: The new flange will be an interference fit on pinion shaft splines and should only be pulled into place by

tightening retaining nut. DO NOT, UNDER ANY CIRCUMSTANCES, USE FORCE OR HAMMER FLANGE

DURING INSTALLATION ONTO PINION FLANGE.

14. Tighten flange retaining nut gradually until pinion shaft end play is reduced to approximately 0.50 mm.

15. Attach pull ey to the ne w pi nion flange and using sprin g balance, chec k pre-load . Continue ti ghtening nut while

alternatively turning pinion to seat bearings, until the pre-load figure recorded previousl y (Step 4b) is reached.

Further increase this original pre-load reading by 0.5 Nm.

ROTATE PINION AN EXTRA 30-40 TURNS AND RE-CHECK THE PRE-LOAD TO ENSURE THAT NO

CHANGE HAS OCCURRED.

CAUTION: Should the retaining nut be over-tightened and the pre-load exceeded, it will be necessary to

remove the differential carrier assembly and install a new collapsible spacer. Under no circumstances

must the retaining nut be backed off to decrease the pre-load setting.

16. Reinstall drive shafts, refer to 2.7 DRIVE SHAFTS in this Section.

17. Reinstall pro peller s haf t, ref er to Se ction 4C P ROP EL LER SHAFT AND UNIVERS AL JOINT S in th e M Y 20 03

VY and V2 Series Service Information.

18. If removed previously, reconnect exhaust system, in reverse to the removal procedure. Refer to

3.2 FINAL DRIVE ASSEMBLY, in this Section, for details.

19. Remove safety stands and lower vehicle.

20. Check lubricant level and top up as necessary with the recommended lubricant, refer to

2.2 CHECKING DIFFERENTIAL CARRIER LUBRICANT LEVEL in this Section.

21. Start vehicle and check for exhaust leaks.

REPLACE (USING NEW OIL SEAL)

1. Using a floor jack under centre of differential carrier, jack up rear of vehicle then place safety stands under trailing arms.

2. Remove propeller shaft, refer to 4C PROPELLER SHAFT AND UNIVERSAL JOINTS in the MY 2003 VY and V2

Series Service Information.

3. Remove both drive shafts, refer to 2.7 DRIVE SHAFTS in this Section.

4. Check and record pre-load at pinion flange as

follows:

a. Fit a pulley (1) to pinion flange, using three

suitable bolts and attach a cord around pulley

and to a spring balance (2).

NOTE 1: Use either the rear coupling to pinion

flange retaining bolts with a 25 mm spacer (e.g.

flat washers) installed first or use three bolts

M12 x 1.5 x 40, with the thread extending to

within 12 mm of the head.

NOTE 2: For fabricated pulley details, refer to

7. Special Tools at the end of this Section.

b. Start rotation of pulley and whilst in motion

(approximately 50-60 rpm), note and record the

spring balance reading.

This pre-load reading includes pinion bearings,

side bearings, meshing effect of gear set and

pinion oil seal.

To determine pre-load, multiply reading on

spring balance by radius of pulley.

EXAMPLE: With a pulley diameter of 152 mm, the radius

is 76 mm which equals 0.076 m. With a spring balance

reading of 25 N, the pre-load equals 0.076 m x 26 N =

1.9 Nm.

5. Remove pulley from pinion flange.

Figure 4B-55

6. Attach Tool No. KM620-1A to the pinion flange,

using three suitable bolts to hold pinion flange.

NOTE 1: If not previously done so, drill out holes

stamped ‘B’ on Tool No. KM620-1A to 12.5 mm.

NOTE 2: Use either the rear coupling to pinion flange

retaining bolts with a 25 mm spacer (e.g. flat washers)

installed first or use three bolts M12 x 1.5 x 40, with the

thread extending to w ithin 12 mm of the head.

7. Insert a suitable length of pipe (1) over the tang of

the installed tool for leverage, then loosen the pinion

flange retaining nut, using a commercially available,

30 mm deep socket and socket bar (2) until end play

can be felt in the pinion shaft.

8. Check the oil seal and differential side bearing pre-

load using the spring scale and pulley, as detailed in

steps 4a and 4b, Record oil seal and side bearing

pre-load for later use.

9. Remove Tool No. KM620-1A from the pinion flange.

Figure 4B-56

10. Place drain tray beneath differential carrier.

11. Install extractor, Tool No. KM628-A to the

pinion flange using the same three bolts used

previously.

NOTE: If not previo us l y done s o, dr ill out the flan ge

holes on Tool No. KM628-A to 12.5 mm.

IMPORTANT: If using the original bolts, they must

have the 25 mm spacers fitted so the tool is

clam ped to the pinion f lang e. If this is not don e, the

screw thread on the extractor Tool No. KM628-A

will not be long enough to fully remove the pinion

flange.

12. While holding the extractor tool with a suitable

spanner, withdraw pinion flange by tightening

the forcing screw in the direction shown.

Figure 4B-57

13. Prise pinion oil seal from carrier bore using

Tool No. E308 or a universal seal removing

tool.

Figure 4B-58

14. Lubricate a new pinion oil seal lips and the

outer diameter with the recommended rear

axle lubr ic ant.

15. Start oil seal into differential carrier housing

and dri ve seal squ arel y into pos ition usin g T ool

No. E9055. Seal fits flush to 0.25 mm below

carrier housing surface.

16. Ensur e that pin ion shaf t is free f rom burrs , then

clean the threads of the pinion shaft, removing

any oil, dirt or grease.

17. Coat splines and seal surface of pinion flange

with differential gear lubricant, then reinstall

flange to the pinion shaft splines.

18. Install a new flange retaining nut, then tighten

to draw the pinion flange onto the pinion shaft

splines.

NOTE: The ne w flang e will be an int er f er enc e f it on

pinion shaft splines and should only be pulled into

place by tightening the retaining nut. DO NOT,

UNDER ANY CIRCUMSTANCES, USE FORCE

OR HAMMER FLANGE DURING INSTALLATION

ONTO PINION FLANGE.

19. Continue to tighten the flange retaining nut

gradually until pinion shaft end play is reduced

to approximately 0.5 mm.

20. Check new oil seal and differential assembly

pre-load using spring balance as previously

outlined in steps 4a and 4b. Record pre-load

for reassembly reference.

Figure 4B-59

21. The pre-load reading for differential assembly

obtained in step 8, is subtracted from pre-load

reading obtained in step 20. The difference

between these figures represents extra lip

tension of new seal expressed as a Nm pre-

load figure. The difference between the pre-

load readings obtained in steps 8 and 20 must

be added to pre-load reading obtained in step

4b to obtain a total pre-load reading.

THEORETI CAL EXAMPLE

STEP 20 NEW OIL SEAL AND SIDE

BEARIN G PR E- L OAD

SETTING

1.47 Nm

STEP 8 OLD OIL SE AL AND SIDE

BEARING

PRE-LOAD READING

1.02 Nm

SUBTR AC T STEP 8

FROM STEP 20

0.45 Nm

STEP 4b COMPLETE

DIFFER EN TIAL ASSEM BLY

PRE-LOAD READING

1.47 Nm

THE PRE-L O AD READIN G

COMBINATION WILL BE

THE SUM OF:-

1.47 Nm

plus

0.45 Nm

WHICH GI VE S A TO TAL

PRE-LOAD READING OF:-

1.92 Nm

22. Continue tightening retaining nut while

alternately turning pinion to seat bearings until

total pre-load figure obtained in step 21 is

achieved, then increase this pre-load reading

by 0.11 to 0.34 Nm. Further rotate pinion an

extra 30-40 turns and recheck pre-load to

ensure that no change has occurred.

CAUTION: Should the retaining nut be over-tightened and the pre-load exceeded, it will be necessary to

remove the differential carrier assembly and install a new collapsible spacer. Under no circumstances

must the retaining nut be backed off to decrease the pre-load setting.

NOTE: It must be realised that the pre-load readings in the example are only theoretical. In practice, the figures

could differ greatly, so the readings obtained when performing the actual operations, are the ones to use.

23. Reinstall drive shafts, refer to 2.7 DRIVE SHAFTS in this Section.

24. Reinstal l propeller shaf t, refer to Sect ion 4C PROPELL ER SH AFT AND UNIVER SAL JOINT S in the MY2003

VY and V2 Series Service Information.

25. If removed previously, reconnect exhaust system, in the reverse to the removal procedure. Refer to

3.2 FINAL DRIVE ASSEMBLY, in this Section, for details.

26. Remove safety stands and lower vehicle.

27. Check lubricant level and top up as necessary, refer to 2.2 CHECKING DIFFERENTIAL CARRIER

LUBRICANT LEVEL in this Section.

28. Start vehicle and check for exhaust leaks.

3. MAJOR SERVICE OPERATIONS

3.1 TRAILING ARM TRUNNION FLANGE, TRUNNION ASSEMBLY

AND/OR WHEEL BEARING

LT Reference No: F201350 / F201450 / F701100 / F701200 / F201300 / F21400

NOTE: The following fastener MUST be replaced when

performing this operation:

Collar nut to trunnion assembly.

Drive shaft constant velocity joint to trunnion flange and

inner axle shaft attaching bolt.

NOTE 1: The following procedure involves the removal of the trunnion flange, trunnion and/or wheel bearing with

the trailing arm installed in the vehicle. A similar procedure is included in Section 4A REAR SUSPENSION in

the MY2003 VY Series Service Information, when the trailing arm is rem oved from the vehicle.

NOTE 2: The rear wheel bearin g should only be removed if it is faulty, or if the trunnion assembly is to be removed.

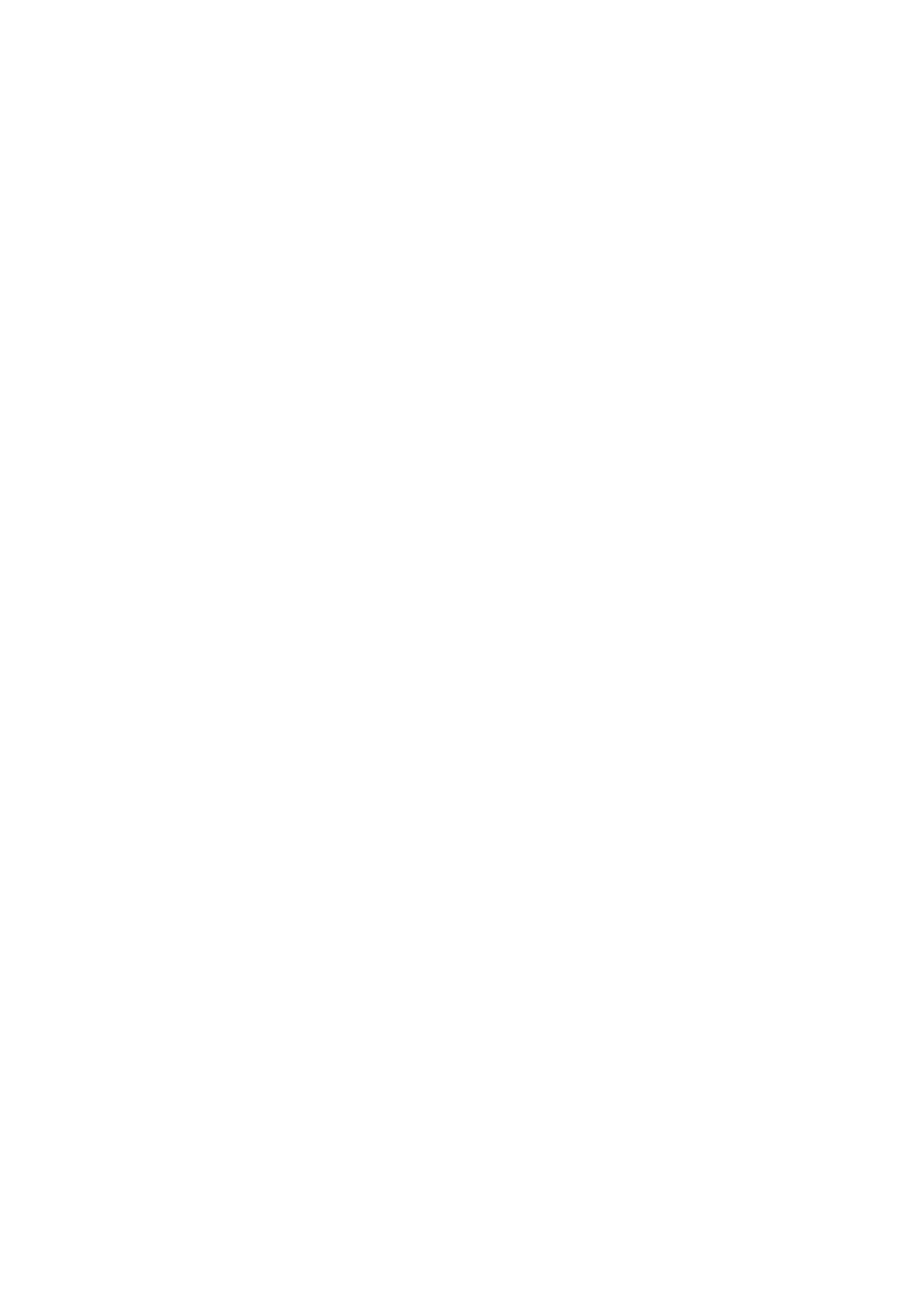

Legend

1. Collar Nut Lock Plate.

2. Collar Nut.

3. Trunnion Flange.

4. Trailing Arm.

5. Brake Backing Plate.

6. Brake Disc.

7. Brake Caliper.

8. Rear Wheel Bearing.

9. Trunnion Assembly.

10. Rear Wheel Bearing Retai ning Ring.

Figure 4B-60

REMOVE

1. Using a floor jack under centre of differential carrier, jack up rear of vehicle and place safety stands under body

rear jacking points. Refer to Section 0A GENERAL INFORMATION in the MY2003 VY Series Service

Information for location of jacking points.

2. On the side of the vehicle where the trailing arm is to be removed, remove the wheel trim or wheel nut covers,

mark relationship of road wheel to hub (e.g. end of wheel stud), with a felt tipped pen or similar. Loosen then

remove road wheel attaching nuts. Remove the road wheel.

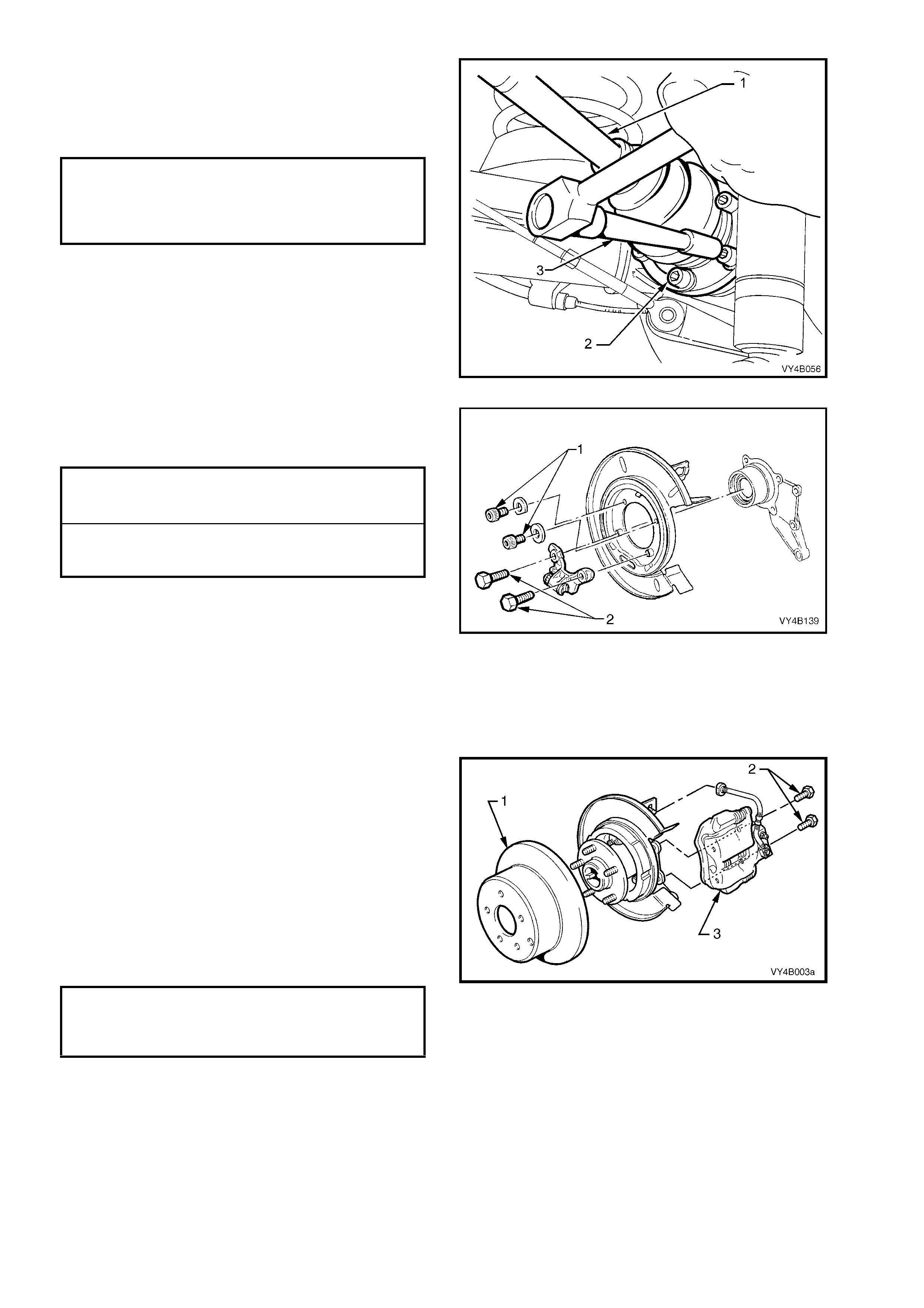

3. Remove brake hose retaining clip (1) from

brake backing plate bracket (2). Disconnect

rear caliper brake hose (3) from brake pipe (4)

and disc on nec t p ipe from bac king plate brack et

(2).

Plug open ends of brake pipe (4) and hose (3)

to prevent fluid loss and foreign matter entry.

Figure 4B-61

4. Remove brake caliper anchor plate to trailing

arm attaching bolts (1) and remove caliper (2)

from disc.

Important: If the brake pipe to hose is not

disconn ected, t he brak e caliper mus t be secur ed to

the vehicle underbody. THE CALIPER IS NOT TO

HANG BY THE BRAK E HOSE.

5. Remove brake disc from the wheel bearing

hub.

NOTE 1: While the brake disc to hub location is

marked in production, ensure that the disc to hub

position is carefully marked (e.g. disc to end of

wheel stud), with a f elt ti pp ed p en or similar. This is

necessar y to overcom e the possibil ity of inducin g a

brake shudder condition after reassembly.

Figure 4B-62

NOTE 2: Should it be necessar y to adjust the park

brake shoe to allow the brake disc to be removed,

the following method should be adopted.

6. Remove one of the access hole plugs (1) from

either of the two access holes provided in the

disc. Using a suitable lever such as a

screwdriver, loosen the par k brake shoe screw

adjuster, until the disc is freed.

7. After disc removal, reinstall the access hole

plug to prevent loss.

Figure 5A-63

8. Position floor jack with a block of wood under the trailing arm (2). Raise jack slightly to take spring load off

trailing arm.

9. Disconnect rear shock absorber lower mounting bolt (1) from trailing arm (2), and pull lower end of shock

absorber (3) from trailing arm. Leave the supporting jack and wooden block in position.

NOTE: View ‘A ’ in Figure 4 B-65 s h o ws th e s eda n, lower shoc k absor ber mountin g, whil e vie w ‘ B’ s ho ws t he s tatio n

wagon arrangement.

Figure 4B-64

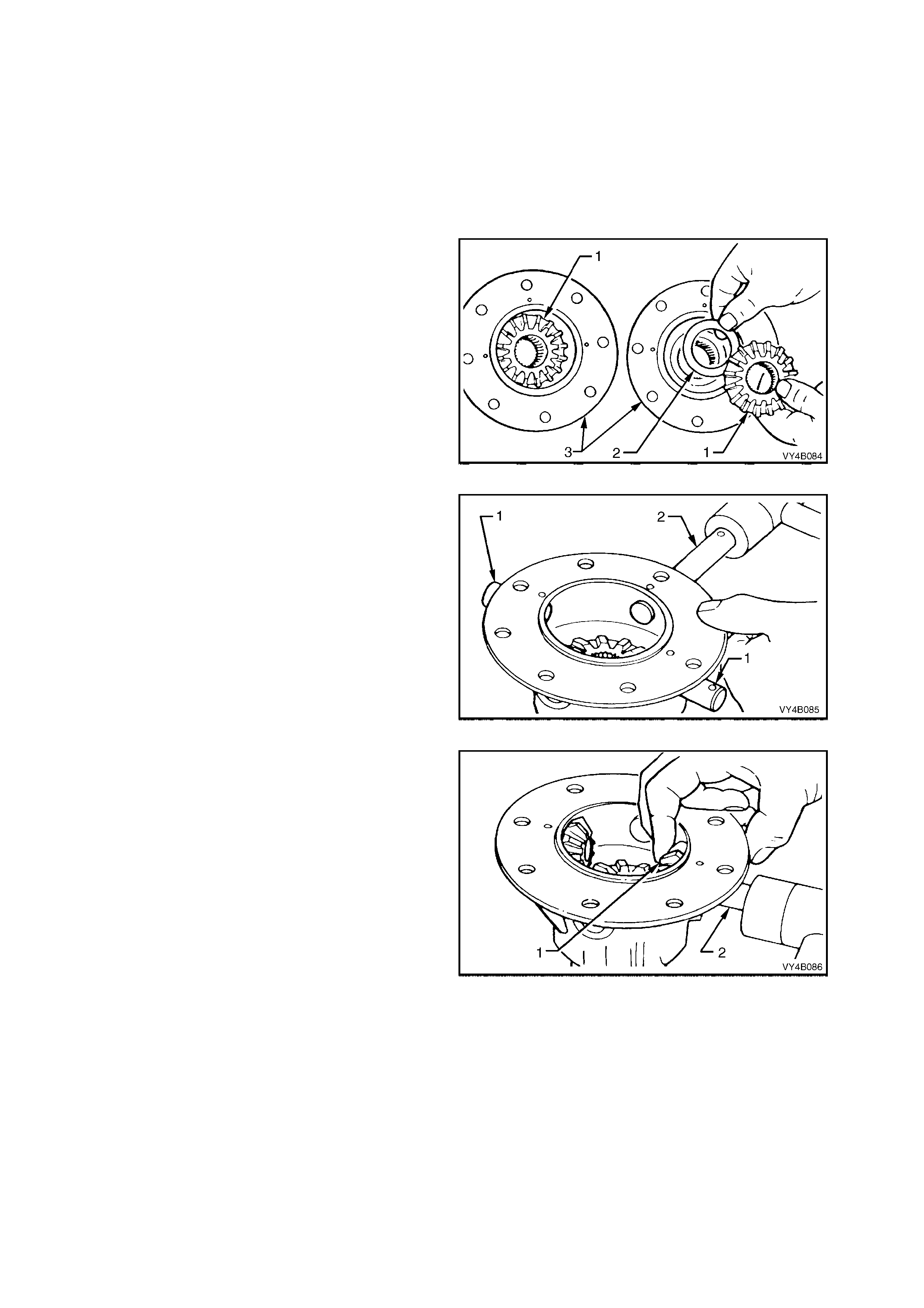

10. Using holding bar, Tool No. KM468 over the

wheel studs to hold trunnion assembly from

rotating, loosen and remove the six drive shaft

(1) constant velocity joint to trunnion flange

attaching bolts (2) and plates, using an 8 mm

Allen key socket and suitable socket

equipment (3).

Figure 4B-65

11. Separate drive shaft from flange and lift

upward. While keeping the outer constant

velocity joint (1) in the same plane as the

driveshaft, use a piece of wire (2) and tie up

the drive shaft assembly to lower end of shock

absorber upper mounting.

NOTE: Bruising to the inside of the drive shaft

constant velocit y joint boots will occur if the trailing

arm is lowered. This will lead to premature failure

of the boot and eventual failure of the joint if left

unchecked.

12. The supporting jack may now be lowered and

the wooden block removed.

Figure 4B-66

13. Remove park brake shoe by grasping each

end as shown. Push up on one end of the

shoe, dislodging the end from the actuator pin

and the shoe from the retaining clip.

Figure 5A-67

14. Using a scre wing motion, rotate t he park brak e

shoe around the trunnion flange to remove it

from the vehicle.

15. Rem ove the park brak e s hoe spring retai ner b y

prising from the rear disc shield, with a

screwdriver or similar lever.

16. Using suitable socket equipment, loosen then

remove the two lower bolts securing the park

brake adjuster and brake backing plate to the

trailing arm.

17. Using Tool No. AU416 and suitable socket

equipment, loosen then remove the two upper

brak e backing plate to the trail ing arm , Tor x bit

headed bolts

Figure 5A-68

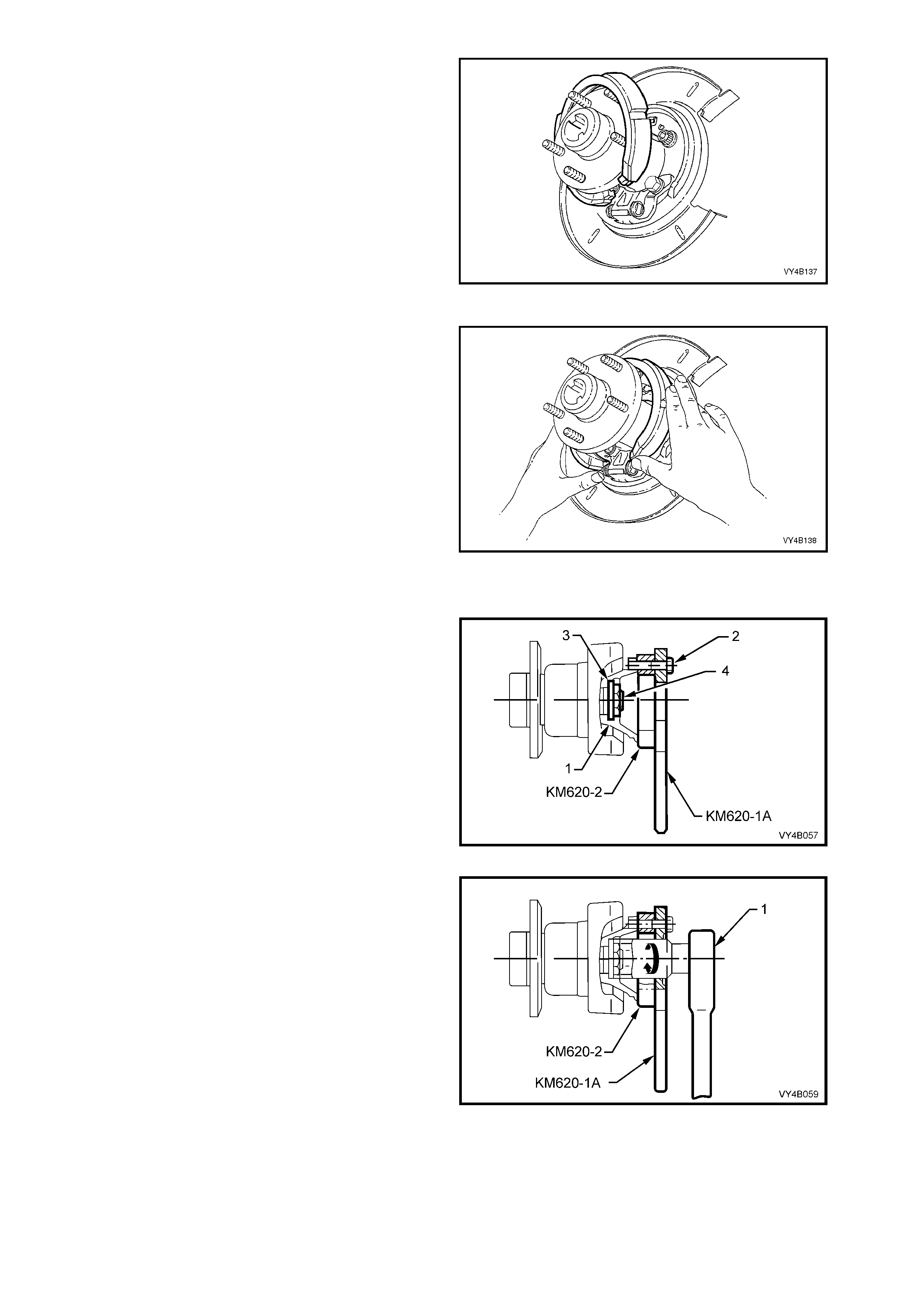

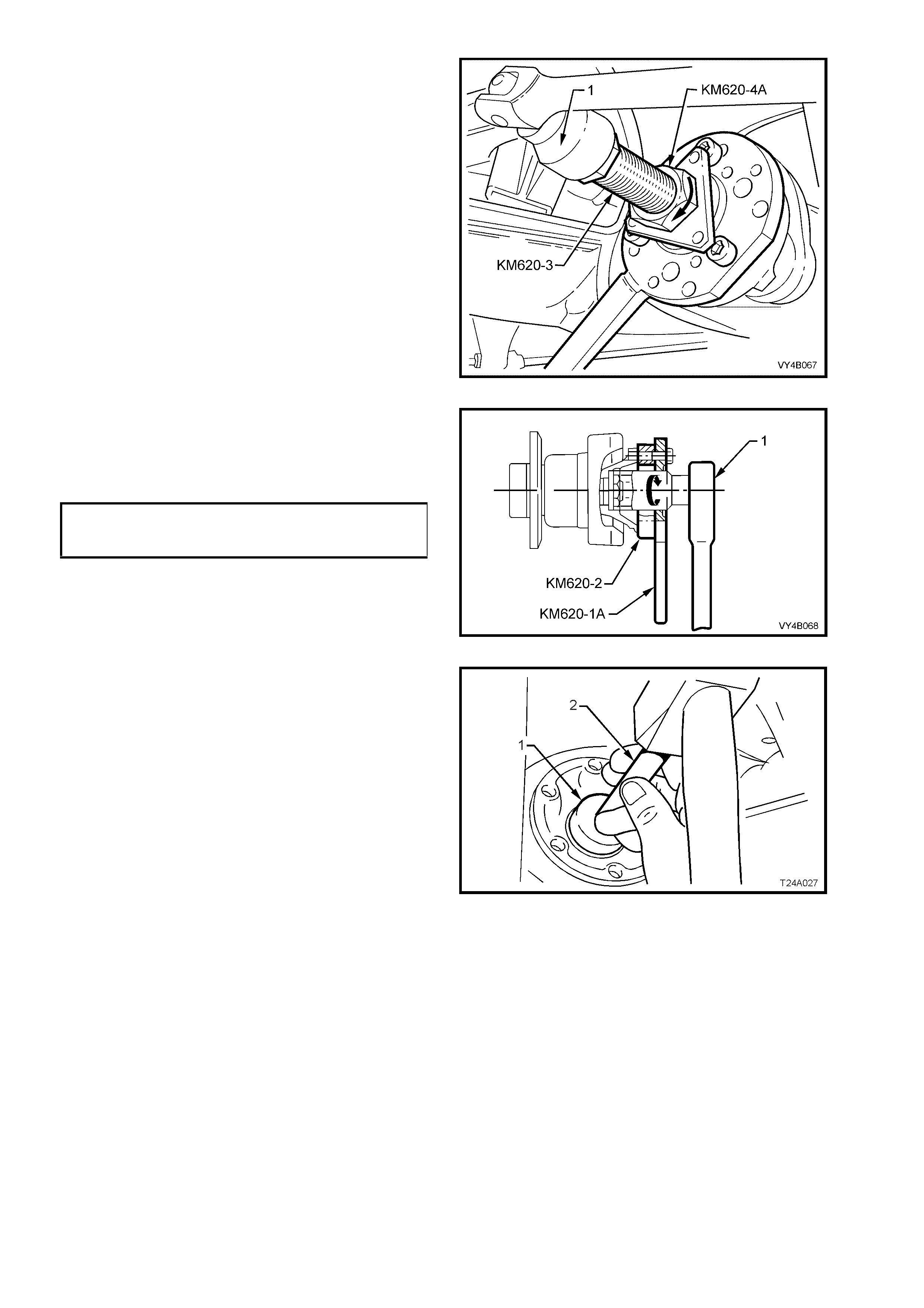

18. Secure flange holding tool, KM620-1A and

trunnion flange ring tool KM620-2 to trunnion

flange (1) with thr ee of the rem oved drive shaf t

constant velocity joint to trunnion flange

attaching bo lts (2).

NOTE: Align holes marked ‘B' on the flange

holding tool KM620-1A and KM620-2 with holes in

the trunnion flange before installing and tightening

bolts.

Figure 4B-69

19. Install a su ita ble le ngth and diameter s teel tub e

over handle of KM620-1A to stop it from

rotating, then use suitable socket equipment

(1) to loosen and remove the collar nut and

lock plate.

NOTE: Once collar nut and lock plate have been

removed, they must be discarded as they are only

to be used once.

Figure 4B-70

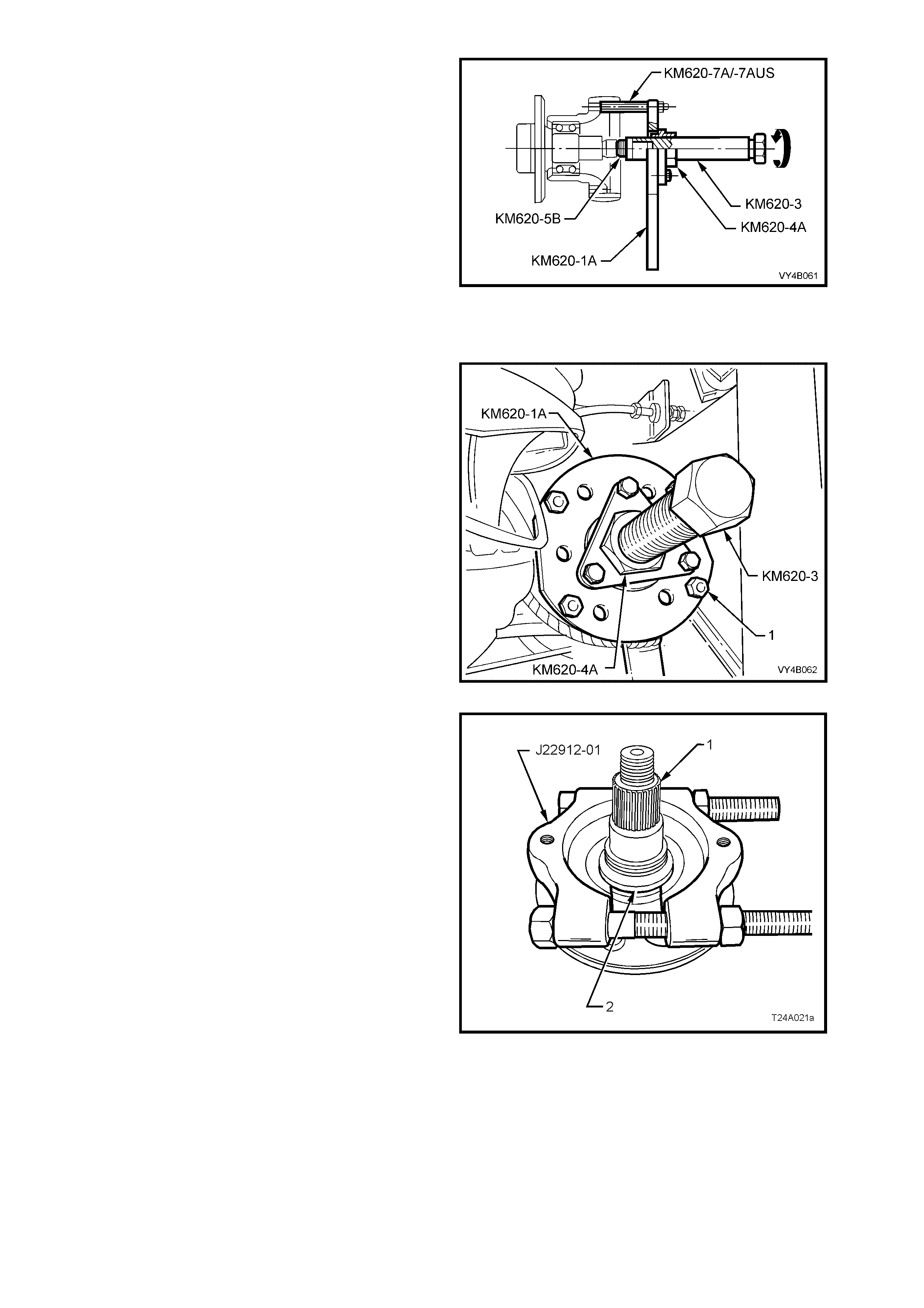

20. Lubricate the threads of forcing screw KM620-

3, then install to adaptor KM620-4-A. Apply

grease to ball end of plung er, T ool No. KM 620-

5B, then install that, into the end of forcing

screw KM620-3.

21. Install the whole sub-assembly through the

central opening of flange holding tool KM620-

1-A. Secure the adaptor KM620-4A to the

flange holding tool KM620-1A, using three

suitable bo lts (1) .

NOTE: Adjust the position of the forcing screw

KM620-3 in the adaptor KM620-4A, to allow

adaptor to be in full contact with the flange holding

tool KM620-1A.

Figure 4B-71

22. While hold ing KM 620-1A f rom r otating, tur n the

screw KM620-3, forcing the flange free from

the trunnion.

Separate tool components from flange once it

has been removed.

Figure 4B-72

23. Prepara tory to rem oving th e trunni on assem bly

and rear wheel bearing from the trailing arm,

use a commercially available M10 x 1.25

bottoming tap and clean the four backing plate

to trailing arm bolt threads, using a suitable

lubricant and working from the trunnion

assembly side.

NOTE: This step is necessary to clear any dried

mud, dirt etc, from the exposed portion of the

threads on the inboard side of the trailing arm.

Also, the deepest thread (position ‘C’) may not be

completely formed through to the inboard side.

24. Install two supports KM620-7A in positions ‘A’

and two KM620-7AUS to ‘B’ and ‘C’ in the

trailing arm, as indicated.

As a guide, the two longest supports (KM620-

7A) are to be installed at the brake caliper

mounting side (position ‘A’). The longer of

KM620-7AUS supports is installed at position

‘B’ and the shorter is installed at position ‘C’.

25. After installing all four supports in the correct

positions, tighten with a set spanner.

Figure 4B-73

26. Install flange holding tool KM620-1A over the

four supports, KM620-7A (2 places) and

KM620-7AUS (2 places), install four suitable

nuts (1) and tighten to secure.

27. Pre-assem ble lubricated forcing screw KM620-

3 to adaptor KM620-4A. Apply grease to ball

end of plunger KM6 20-5B, then i nstall th at, into

the end of forcing screw KM620-3.

28. Install this sub-assembly through the central

opening of holding tool KM620-1A. Secure the

adaptor KM620-4A to the flange holding tool

KM620-1A, using three suitable bolts (2).

NOTE: Adjust the position of the forcing screw

KM620-3 into the adaptor KM620-4A, to allow full

contact of the adaptor to the flange holding tool

KM620-1A.

Figure 4B-74

29. Insert a s uitable le ngth of tube over the handle

of holding tool KM620-1A to stop it from

rotating and turn the forcin g screw KM620-3 to

press trunnion from rear wheel bearing.

30. W hen the trunnion has be en removed, rem ove

nuts (1) holding KM620-1A assembly to the

distance pieces, KM620-7A and KM620-7-

AUS. Rem ove KM620-1A, and r emove KM620-

5B from the end of KM620-3.

31. Unscrew the forcing screw (KM620-3), as this

same arrangement is used to press the rear

wheel bearing from the trailing arm.

NOTE: The rear wheel bearing inner cone will

separate from the bearing assembly and be

retained on the trunnion assembly.

32. Remove the brake backing plate and park

brak e assem bly from the trailin g arm and s et to

one side.

Figure 4B-75

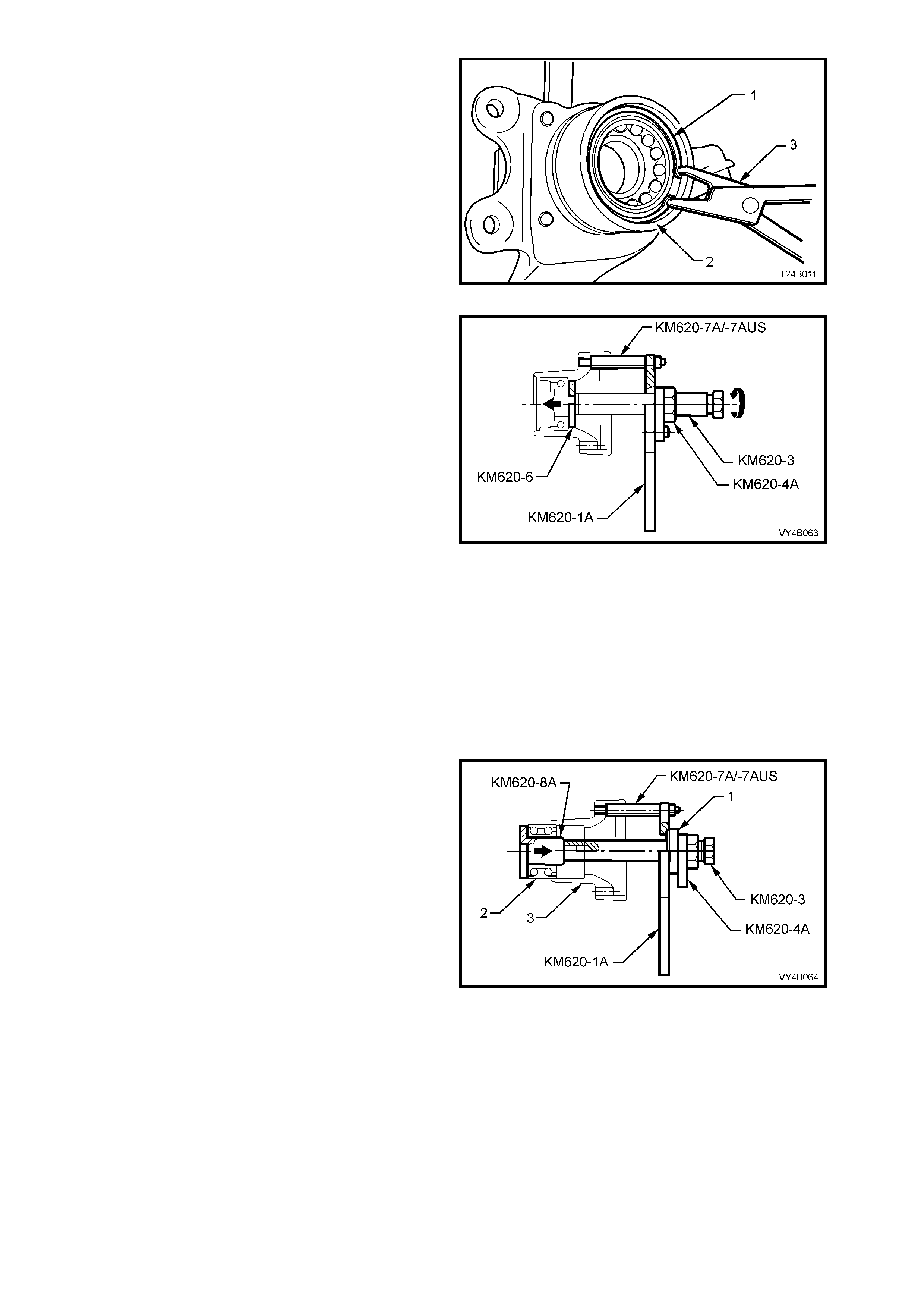

33. If the trunnio n assem bly (1) is to be reins talled,

then the outer half of the inner rear wheel

bearing cone (2) will need to be removed from

the trunnion assembly (1).

a. Ins tall press plates J2291 2-01 over the b earing

cone (2) and tighten the press plate bolts to

grip the bearing cone.

b. Press the trunnion assembly (1) from the

bearing cone (2) and discard bearing cone.

NOTE 1: If the tru nn ion is t o be r ep laced , th en s t ep

27 will not be required.

NOTE 2: A new trunnio n assem bly is supplied with

wheel studs already installed.

Figure 4B-76

34. Remove wheel bearing retaining ring (1) from

trailing arm (2), using suitable circlip pliers (3).

Figure 4B-77

35. With the tool components set up in the same

arrangement as for step 20 (and as shown in

Figure 4B-73), install rear axle bearing

removing plate KM620-6 to rear of the axle

bearing. Reposition the for cing scre w KM620-3

to hold the removi ng pl ate KM6 20-6 in pl ac e.

36. Insert a s uitable le ngth of tube over the handle

of holding tool KM620-1A to stop it from

rotating, then turn the forcing screw KM620-3

to press the wheel bearing from the trailing

arm.

37. If installing a replacement trailing arm without

bushes, install new bushes. Refer to

2.7, TRAILING ARM BUSHES in Section 4A

REAR SUSPENSION in MY2003 VY and V2

Series Service Information.

Figure 4B-78

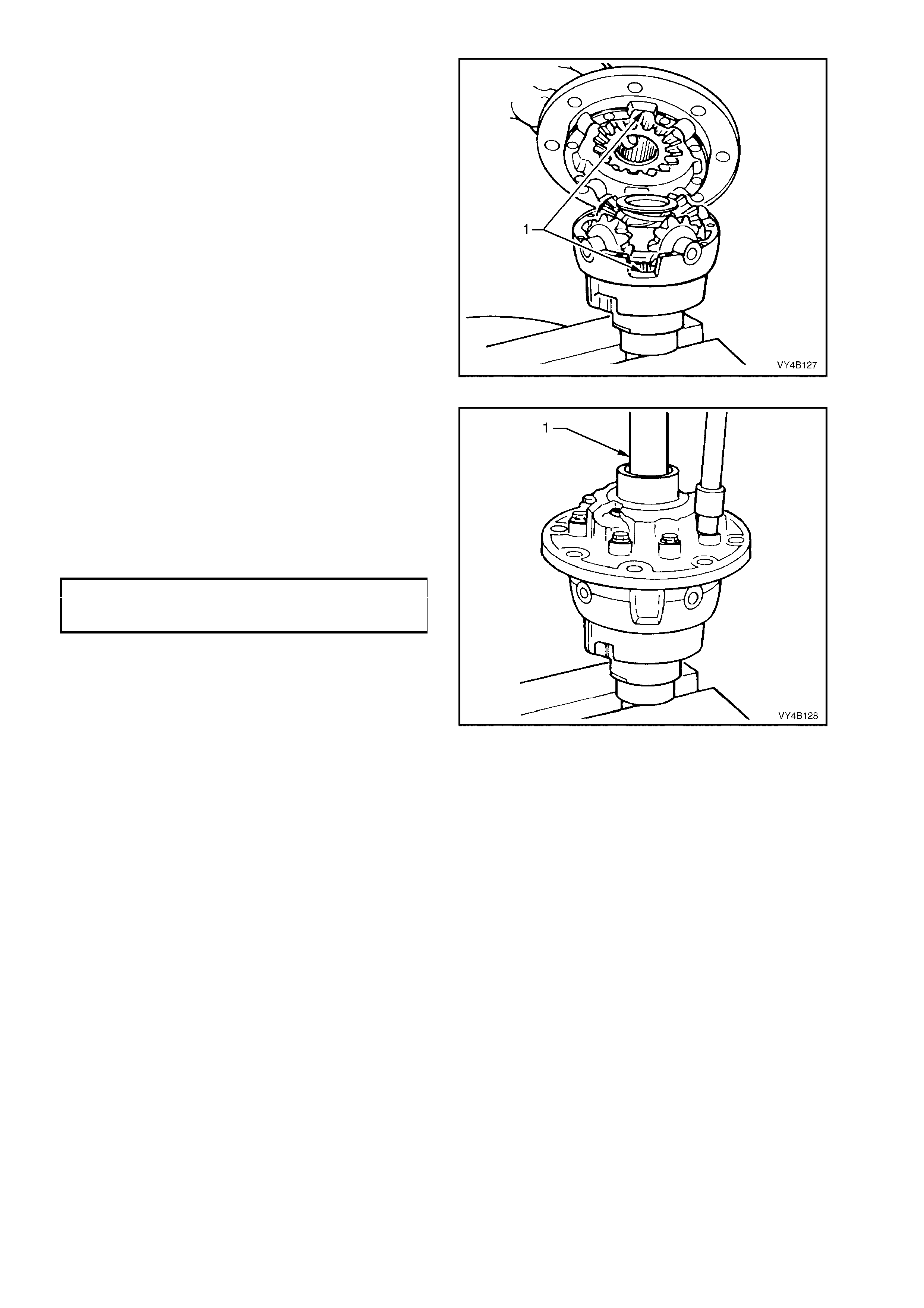

REINSTALL

To Install A New Bearing:

1. Ensure that bearing bore of trailing arm is clean and free of any foreign matter.

2. Coat outside diam eter of ne w wheel bear ing an d bor e of traili ng arm with lubric a nt such as M ol ybond HE50 , or

equivalent.

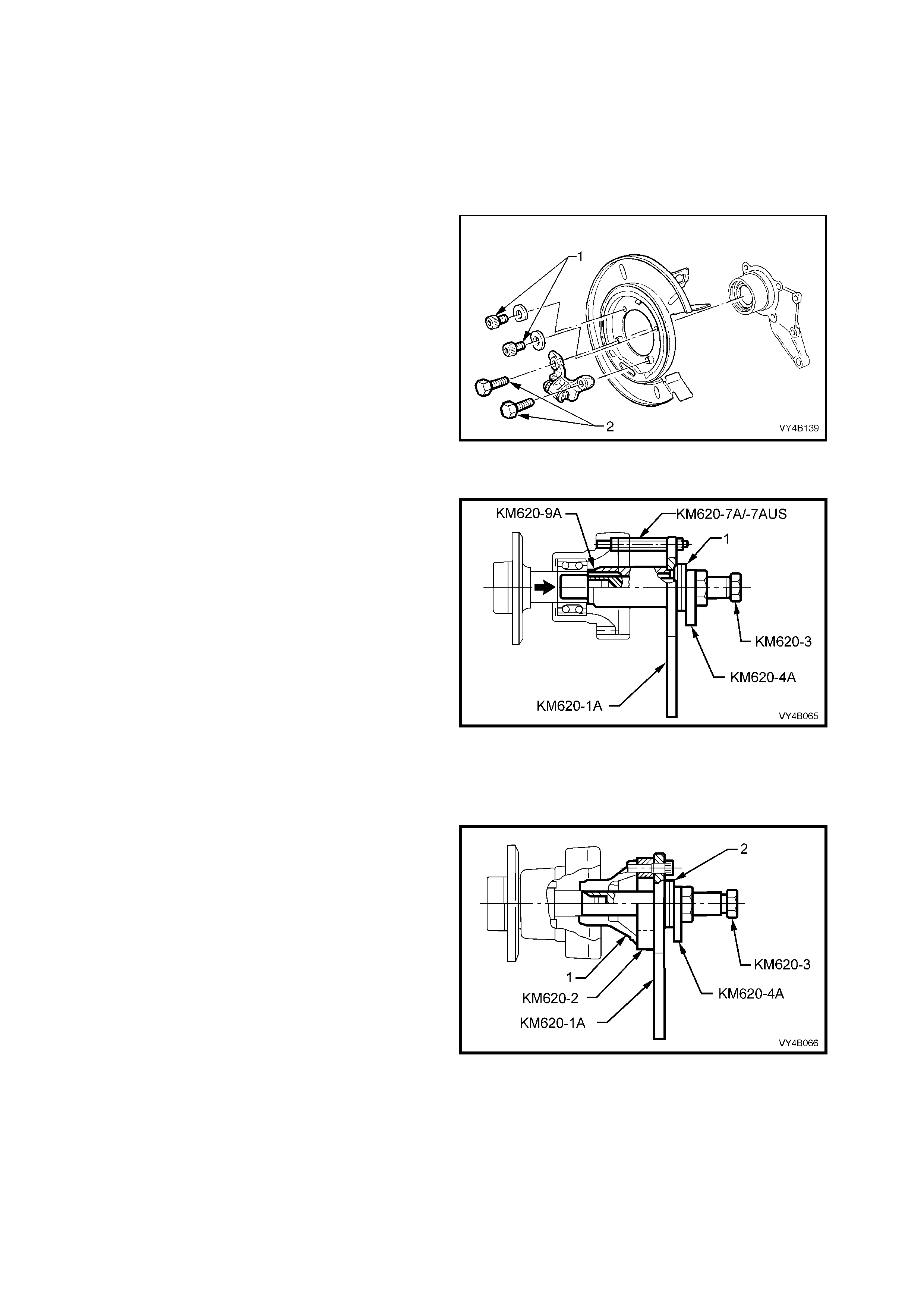

3. Remove bolts securing adaptor KM620-4-A to

the holding tool KM620-1A, then remove the

adaptor and forcing screw KM620-3 from the

holding tool KM620-1A.

4. Lubricate the thrust ball bearing race (1) (part

of KM620-A) with lubricant such as Molybond

HB50, or equivalent, then assemble the

bearing onto the flanged end of adaptor

KM620-4A.

5. Reinstal l t he f or c in g s cr e w and ad aptor / bearing

assem bly to t he flange ho lding tool KM620-1A.

Do not reinstall the adaptor (KM620-4A) to

holding tool (KM620-1A) attaching bolts.

6. Install bearing installer KM620-8A into a new

bearing (2) and install both into the trailing

arm (3).

7. Join the forcing screw (KM620-3), and bearing

installer (KM620-8A) by engaging the screw

thread of the forcing screw (KM620-3) with

installer (KM620-8A) and tightening the forcing

screw to engage at least eight full threads.

Figure 4B-79

8. While holding the forcing screw (KM620-3) from turning by using suitable socket equipment (4), rotate the

adaptor KM620-4A in a clockwise direction, using a suitable 40 mm wrench to draw the new bearing (2) fully

into position.

9. W hen the bearing is f ully installed, separ ate instal ler KM620-8A f rom the forcing s crew KM620-3, the n remove

the instal ler and f orc ing scre w (KM620- 3), adap tor (K M620- 4A) and be arin g, from the holdin g tool (KM 620- 1A).

Leave remaining tools installed.

10. Using s uitab le circ lip pl iers, ins tall a new bear ing ret ainin g ring into tra iling arm , ensuring t hat the r ing is s eat ed

correctly.

11. Install rear disc brake shield to trailing arm but

do not inst all fastener s (‘1’ and ‘2’) at this tim e,

as the s upports, K M620-7A and KM620- 7-AUS

could not be fully installed in the threaded

holes on the opposite side.

Figure 4B-80

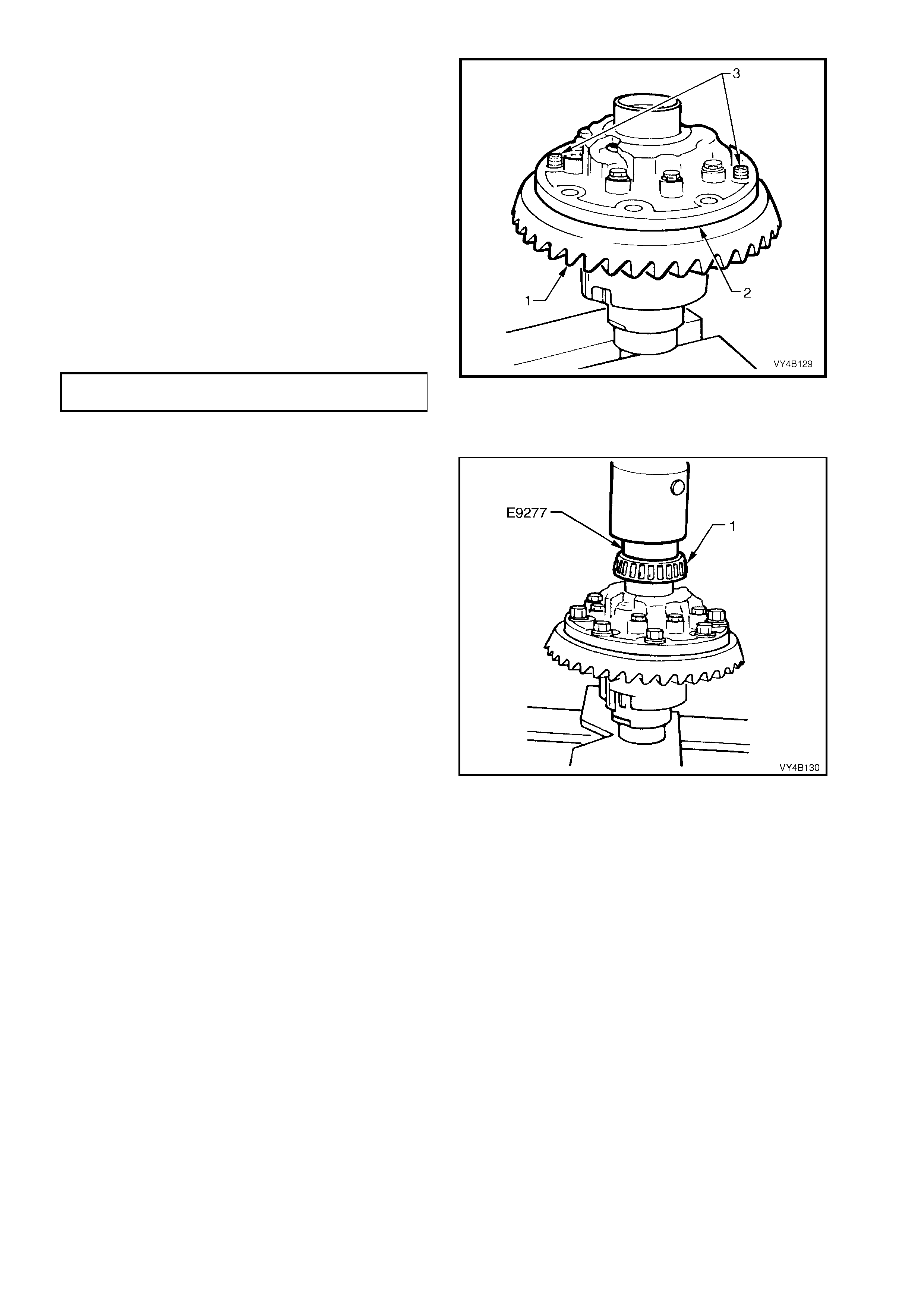

To Reinstall Trunnion:

1. Remove KM620-1A from distance pieces,

KM620-7A and KM620-7AUS. Install sleeve

KM620-9A over KM620-3, with the stepped

shoulder facing away from the trunnion

bearing. Reinstall KM620- 1A to K M620-7A a nd

KM620-7AUS, tightening the attaching nuts.

2. Screw the threaded end of the trunnion into

KM620-3. W hile ho ld ing K M620-3 f rom tur ning,

rotate KM620-4A to draw trunnion into wheel

bearing.

3. Unscrew for cing sc rew KM620-3 fr om trunni on,

then rem ove t he nuts h old i ng to ol KM 620- 1 A t o

the distance pieces KM620-7A and KM620-

7AUS.

4. Remove the distance pieces KM620-7A and

KM620-7AUS from the trailing arm.

Figure 4B-81

5. Assem ble KM620-2 and KM620-1A to trunnion

flange using three drive shaft constant velocity

joint to flange bolts.

6. Lubricate trunnion flange splines and trunnion

threads with the recommended differential

carrier lubricant.

7. With KM620-4A, thrust ball bearing race (2)

and KM620-3 assembled to KM620-1A, screw

the internal thread of KM620-3 onto the

trunnion ass embly.

Figure 4B-82

8. While holding the forcing screw (KM620-3)

from turning with suitable socket equipment

(1), use a suitable 40 mm wrench to rotate the

adaptor KM620-4A in the direction shown, to

install the trunnion flange onto trunnion.

9. Unscrew KM620-3 from the trunnion, then

remove it and adaptor KM620-4A from the

holding tool KM620-1A. Leave the holding tool

KM620-1A and trunnion flange ring tool

KM620-2 installed to the trunnion flange.

Figure 4B-83

10. Install N EW c ollar nut to t he trunnio n assem bly

and, using a suitable length and sized pipe

over the handle of KM620-1A to hold trunnion

assembly from turning, tighten collar nut to the

correct torque specification.

COLLAR NUT TO

TRUNNION ASSEMBLY

TORQUE SPECIFICATION 295 – 305 Nm

11. Remove the holding tool KM620-1A and

trunnion flange ring tool KM620-2 from the

trunnion flange.

Figure 4B-84

12. Using a 1.25 inch socket (1), 150 mm socket

bar (2) and a soft faced hammer, install new lock

plate over collar nut.

Figure 4B2-85

13. Assem ble driveshaft ( 1) outer c onstant veloc ity

joint to trunnion flange, aligning bolt holes.

14. Reinstall six attaching bolts (2) with plates and

tighten bo lts to the c orrect torque specific ation,

using suitable socket equipment (3).

DRIVESHAFT CONSTANT

VEL O CI T Y JO I NT TO TRUNNIO N

FLANGE ATTACHING BOLT

TORQUE SPECIFICATION 50 Nm, then

90° turn angle

Figure 4B-86

15. Reinst all t he f our br ak e back ing plat e t o trail ing

arm bolts (‘1’ a nd ‘2’) and tighte n to the c orrect

torque specification.

REAR DISC BRAKE SHIELD TO

TRAILING ARM UPPER BOLT (‘1’)

TORQUE SPECIFICATION 70 - 80 Nm

REAR DISC BRAKE SHIELD TO

TRAILING ARM LOWER BOLT (‘2’)

TORQUE SPECIFICATION 85 - 90 Nm

NOTE 1: The upper Torx headed bolts have

washers with cut-outs that are to be installed with

the cut-o ut ed ge f ac ing ar o und t he trailing arm hub,

outer surface.

NOTE 2: Apply Loctite 242 thread sealant or

equivalent (to GM Specification 998 5283) to the

threads of the two longer, lower hexagon headed

bolts, befor e instal lat io n.

Figure 4B-87

16. Reinst all br ak e disc ( 1) to trunnion, align ing the

marks made before removal.

NOTE: If the trunnion has been replaced, then

runout checks must be carried out on the trunnion

flange and the installed brake disc (1). Refer to

2.4 TRAILING ARM TRUNNION ASSEMBLY, in

this Section for important information regarding

these checks.

17. Reinstall the brake caliper (3) to the trailing

arm, reinstall brake caliper anchor plate to

trailing ar m attac hing bolts (2 and tig hten to the

correct torque specification.

BRAKE CALIPER ANCHOR

PLATE TO TRAILING ARM

ATTACHING BOLT

TORQUE SPECIFICATION 70 – 100 Nm

18. After reconnecting the brake line to the caliper

hose and installing the brake hose retaining

clip, bl eed the rear brak es and ch eck f or leaks.

For the recommended procedure, refer to

Section 5A SERVICE AND PARK BRAKING

SYSTEMS, in the MY 2003 VY and V2 Series

Service Information.

Figure 4B-88

19. Support the trailing arm with a floor jack and wooden block, sufficient to enable the shock absorber to be

reinstalled.

20. Reinstall shock absorber (3) to trailing arm (2), install the lower mounting bolt (1) but do not torque to

specification at this stage.

NOTE 1: View ‘A’ in Figure 4B-89 shows the sedan, lower shock absorber mounting, while view ‘B’ shows the

station wagon ar r ang ement.

Figure 4B-89

21. Install road wheel, aligning marks made before removal and reinstall attaching nuts.

22. Remove safety stands and lower vehicle to the ground and bounce the rear of the vehicle several times to

settle the suspension components.

23. Tighten the lower shock absorber bolt to the correct torque specification.

SHOCK ABSORBER LOWER

MOUNTING BOL T

TORQUE SPECIFICATION 105 - 125 Nm