SECTION 5A - SERVICE AND PARK

BRAKING SYSTEMS

IMPORTANT:

Before performing any Service Operation or other procedure described in this Section, refer to Section 00

Cautions And Notes for correct workshop practices with regard to safety and/or property damage.

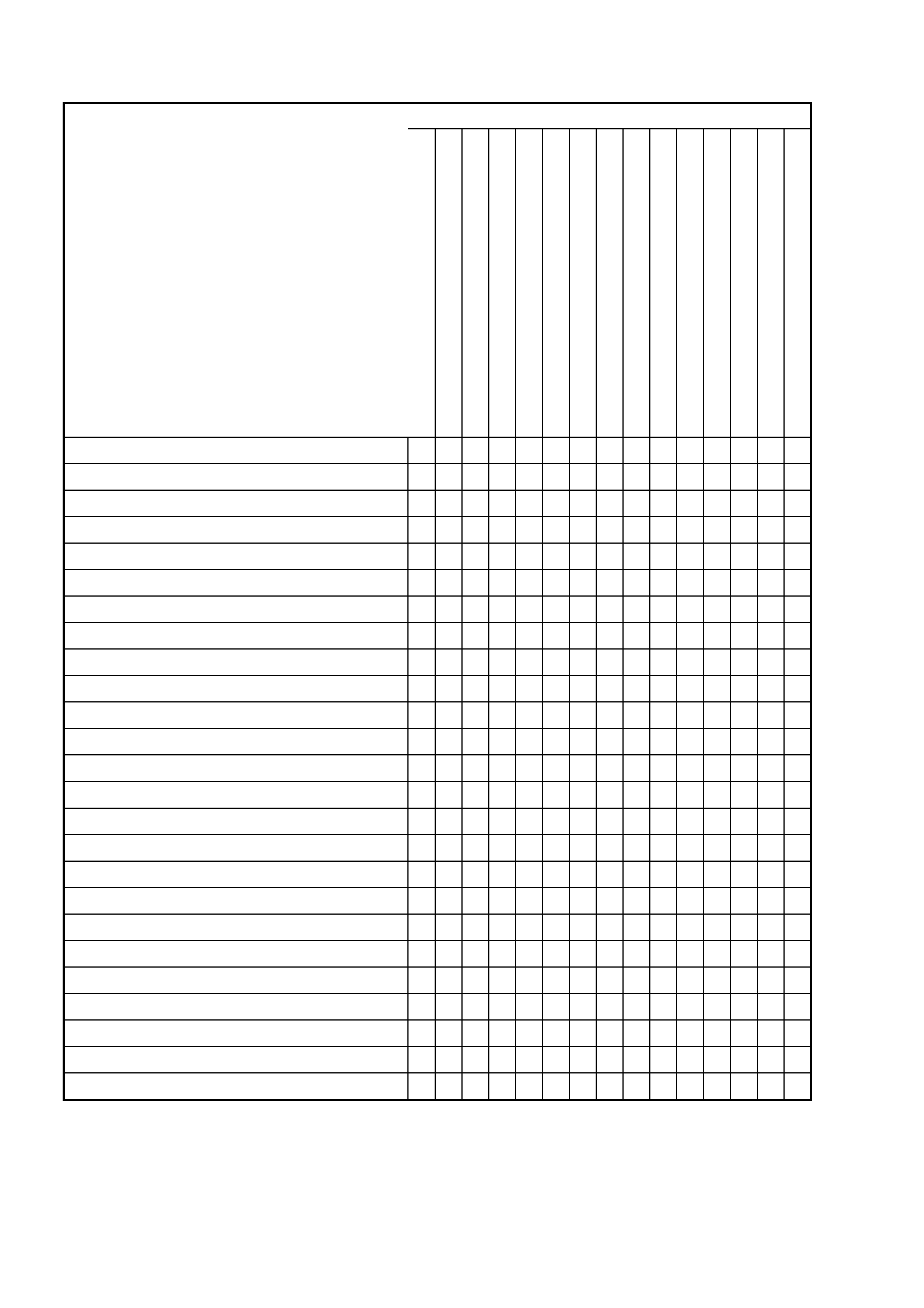

CONTENTS

1. GENERAL INFORMATION

1.1 GENERAL DESCRIPTION

1.2 MASTER CYLINDER

DESCRIPTION

CONSTRUCTION

OPERATION

1.3 PROPORTIONIN G VALVE OPERATION

ALL EXCEPT UTILITY

UTILITY LOAD SENSING PROPORTIONING

VALVE

1.4 FRONT AND REAR BRAKES

2. MINOR SERVICE OPERATIONS

2.1 SERVICE NOTES AND CAUTIONS

2.2 PARK BRAKE CABLE, ADJUST

2.3 BRAKE FLUID LEVEL CHECK

2.4 BRAKE SYSTEM BLEED

2.5 BRAKE FLUID, CHANGE

2.6 BRAKE PAD WEAR, CHECK

2.7 BRAKE PADS, REPLACE

BRAKE PAD REMOVAL

FRONT BRAKE PAD INSTALLATION

REAR BRAKE PAD INSTALLATION

BRAKE PAD BEDDING-IN PROCEDURE

2.8 BRAKE PEDAL ASSEMBLY

REMOVE

DISASSEMBLE

REASSEMBLE

REINSTALL

2.9 PARK BRAKE LEVER

REMOVE

REINSTALL

2.10 PARK BRAKE WARNING LAMP

SWITCH

REMOVE

INSPECT

REINSTALL

2.11 FRONT PARK BRAKE CABLE

REMOVE

REINSTALL

2.12 REAR PARK BRAKE CABLE /S

REMOVE

REINSTALL

2.13 FRONT BRAKE HOSE

REMOVE

REINSTALL

2.14 REAR CALIPER BRAKE HOSE

REMOVE

REINSTALL

2.15 REAR BRAKE HOSE

REMOVE

REINSTALL

2.16 BRAKE BOOSTER HOSE & VALVE

ASSEMBLY – V6 ENGINE

REPLACE

2.17 BRAKE BOOSTER HOSE & VALVE

ASSEMBLY – GEN III V8 ENGINE

REPLACE

2.18 LOAD SENSING PROPORTIONING

VALVE – UTILITY

REMOVE

REINSTALL

2.19 BRAKE PRESSURE DIFFERENTIAL

WARNING SWITCH

REMOVE

INSPECT

REINSTALL

3. MAJOR SERVICE OPERATIONS

3.1 MASTER CYLINDER

REMOVE

DISASSEMBLE

CLEAN AND INSPECT

REASSEMBLE

REINSTALL

3.2 BRAKE BOOSTER

REMOVE

REINSTALL

3.3 BRAKE CALIPER (FRONT AND REAR)

REMOVE

DISASSEMBLE

CLEAN AND INSPECT

REASSEMBLE

REINSTALL

3.4 FRONT BRAKE DISC

REMOVE

INSPECT

BRAKE DISC AND HUB INDEXING

PROCEDURE

REINSTALL

3.5 REAR BRAKE DISC

REMOVE

INSPECT

BRAKE DISC AND HUB INDEXING

PROCEDURE

REINSTALL

3.6 PARK BRAKE LINING WEAR, CHECK

3.7 PARK BRAKE SHOE, ADJUST

3.8 PARK BRAKE SHOE

REMOVE

REINSTALL

3.9 FRONT DISC BRAKE SHIELD

REMOVE

REINSTALL

3.10 REAR DISC BRAKE SHIELD

REMOVE

REINSTALL

4. DIAGNOSIS

5. SPECIFICATIONS

6. TORQUE WRENCH SPECIFICATIONS

7. SPECIAL TOOLS

Techline

Techline

Techline

1. GENERAL INFORMATION

1.1 GENER AL DESCRIPTION

Some illustrations in this Section may show components that are not fitted to all vehicles. Where differences in

service procedures apply, then relevant information relating to those differences are made.

Except f or thos e v eh icles e qui ppe d with A BS as s tand ar d equ ipment, the f r ont an d rear disc br ak es on M Y20 03 V Y

and V2 Series vehicles, are served by separate brake circuits by means of a tandem master cylinder, working

through a vacuum booster. T he dual brake circuit arrangement is designed to provide adequate braking, should a

fault occur in either circuit.

All MY200 3 VY and V2 Series vehicles are f itted with a Steppe d Tandem , Vacuum Suspended t ype brak e booster

and a 25.4 mm bore master cylinder, regardless of the brake system used. The brake booster is not able to be

serviced and must be replaced if proven to have become defective.

All MY2003 VY and V2 Series vehicle are fitted with ventilated discs at the front and solid discs at the rear. The

brake calipers are the sliding, reaction type, with twin pistons in the front calipers and single in the rear.

The front disc brake caliper is attached to the steering knuckle support by two bolts, as is the front wheel bearing

hub, using three bolts. The front dust shield is also attached to the steering knuckle support by three pop rivets.

The rear brake backing plate assembly is bolted to the trailing arm, as is the disc brake caliper. The machined inner

surface of the disc hub acts as the brake drum for the park brake.

The single shoe, Banksia park brake is a drum type with a manual adjustment incorporated into the design. The

park brake is operated by two separate cables at the rear, connected to an equaliser bracket. Park brake

application force is applied to this equaliser bracket, via a single cable, connected to the floor mounted, button

release, park brake lever. Adjustment of the parking brake cables is provided for, by a threaded end on the front,

single cable, at the park brake lever end.

For servici ng deta ils of the ABS Br aking System , ref er to Section 5B in this Service Information.

1.2 MASTER CYLINDER

DESCRIPTION

A ma ster cylinder with a 25 .4 mm (1”) diameter bore is used on all MY2003 V Y and V2 Ser ies vehicl es, regar dless

of the braking system fitted. The only differences being:

a. The m aster cylinder used with ABS has a sc rew in blank ing plug i nstalled into the lower of the two front brake

outlets in the master cylinder.

b. The master cylinder fitted to MY2003 VY Series Utility vehicles does not have a brake proportioning valve

incorpora t ed in to t he master cylinder but us es a s eparate, lo ad sensing pr o porti o nin g val ve , c ou ple d t o the rear

suspension. This ensures that the front to rear braking balance, relative to vehicle load, is maintained.

The master cylinder is a tandem, centre valve design, incorporating a fast fill valve that provides a reduced pedal

travel. T he m aster cylinder is m ounted to th e vacuum brak e booster whic h in turn, is m ounted to t he eng ine side of

the dash panel.

CONSTRUCTION

This tandem m aster cylinde r arr angement prov ides s e p arate hydraulic c irc u its f or the applic at io n of the brakes, in a

front to rear split arrangement.

Both of these circuits are fed by separate fluid feed and compensating ports, through a common fluid reservoir,

sealed by a diaphragm fitted inside the reservoir cover. This diaphragm provides an effective seal against any

atmospheric moisture coming into contact with the hygroscopic brake fluid. This provision maintains the brake

fluid's boiling point, for a maximum period of time.

The internal parts of the master cylinder comprise a primary piston with an L type seal and an O-ring seal, a

secondary valve which incorporates a centre valve, a caged spring and two L type seals, a return spring, a

secondary piston stop pin, and a fast fill valve.

In all vehicles except MY2003 VY Series Utility, a proportioning valve is located in a parallel bore in the same

casting of the master cylinder. This valve is used to maintain the front to rear hydraulic pressure balance. Should

one of the two separate systems fail, a separate piston and brake pressure differential warning switch is

incorporated into the design so that the vehicle operator can be warned of a system malfunction.

The MY20 03 VY Series Ut ilit y has a load s ensing pro portioning valve locat ed at the rear of the veh icle. A pr essure

diff erential spool va l ve replaces the propor tioni ng va l v e, n or mally locat ed in the s ec ond bor e of the master cylind er .

This spool valve can move back and forth to operate the brake pressure differential warning switch, should a

pressure loss occur in either the front or rear brake circuits.

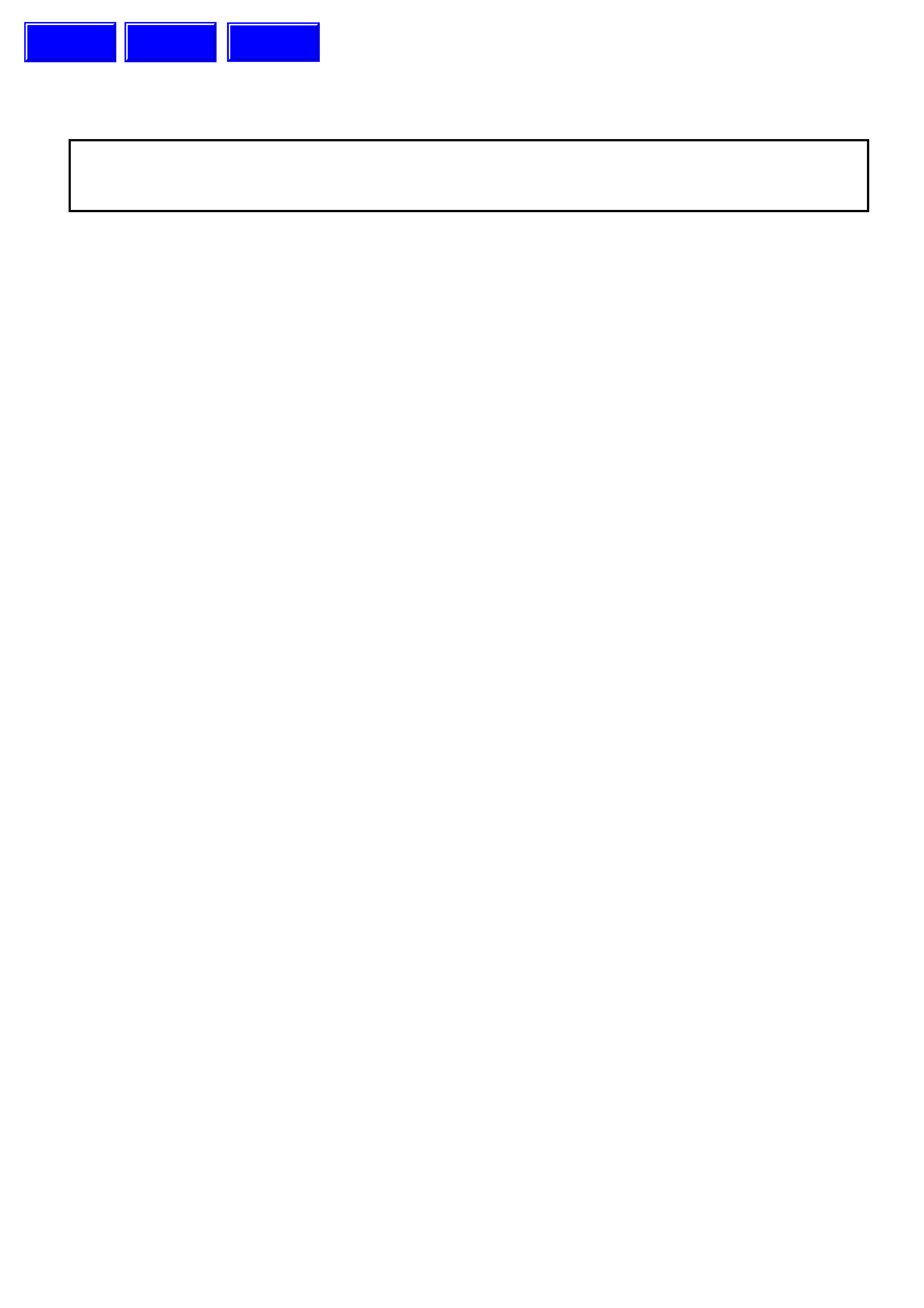

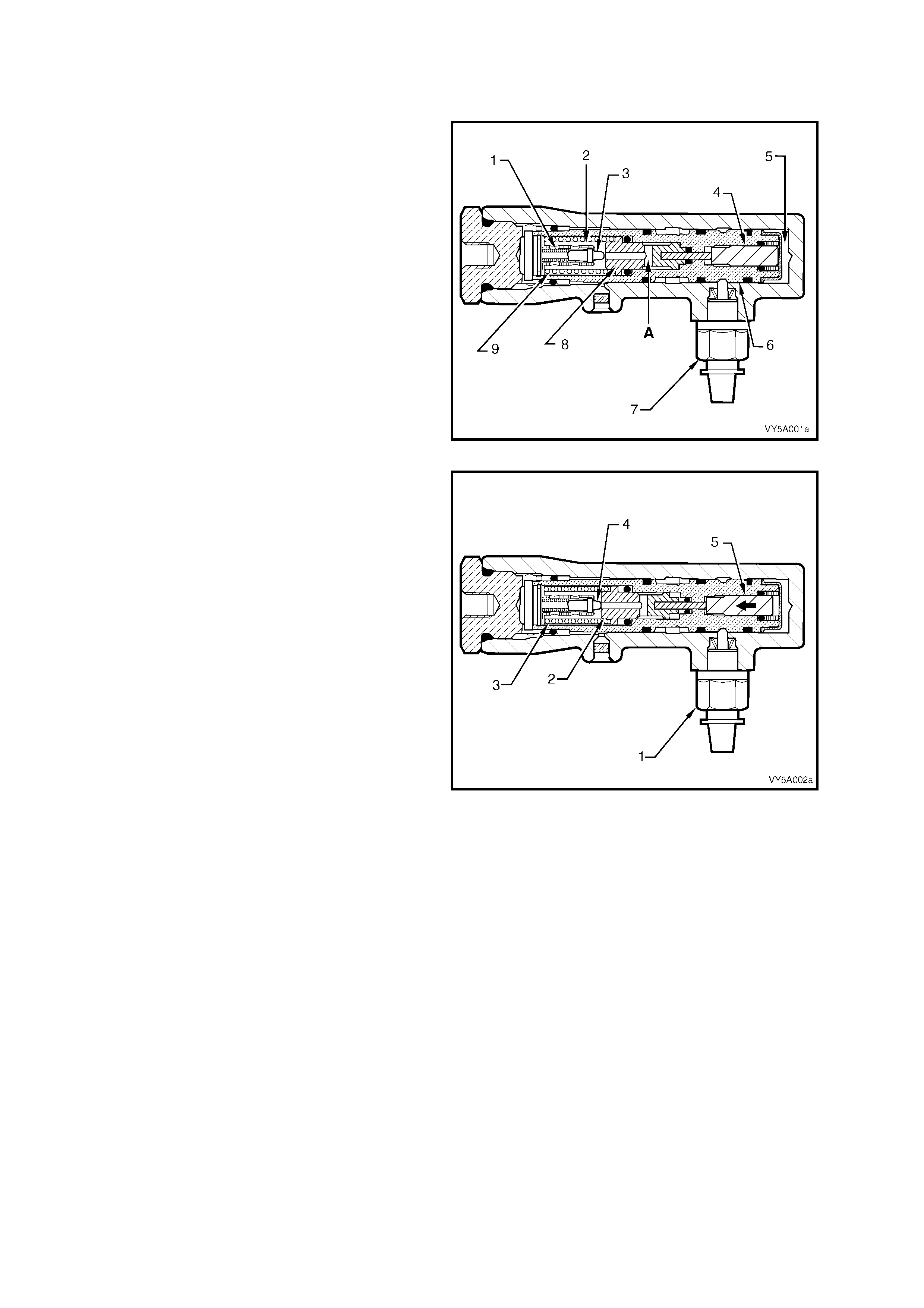

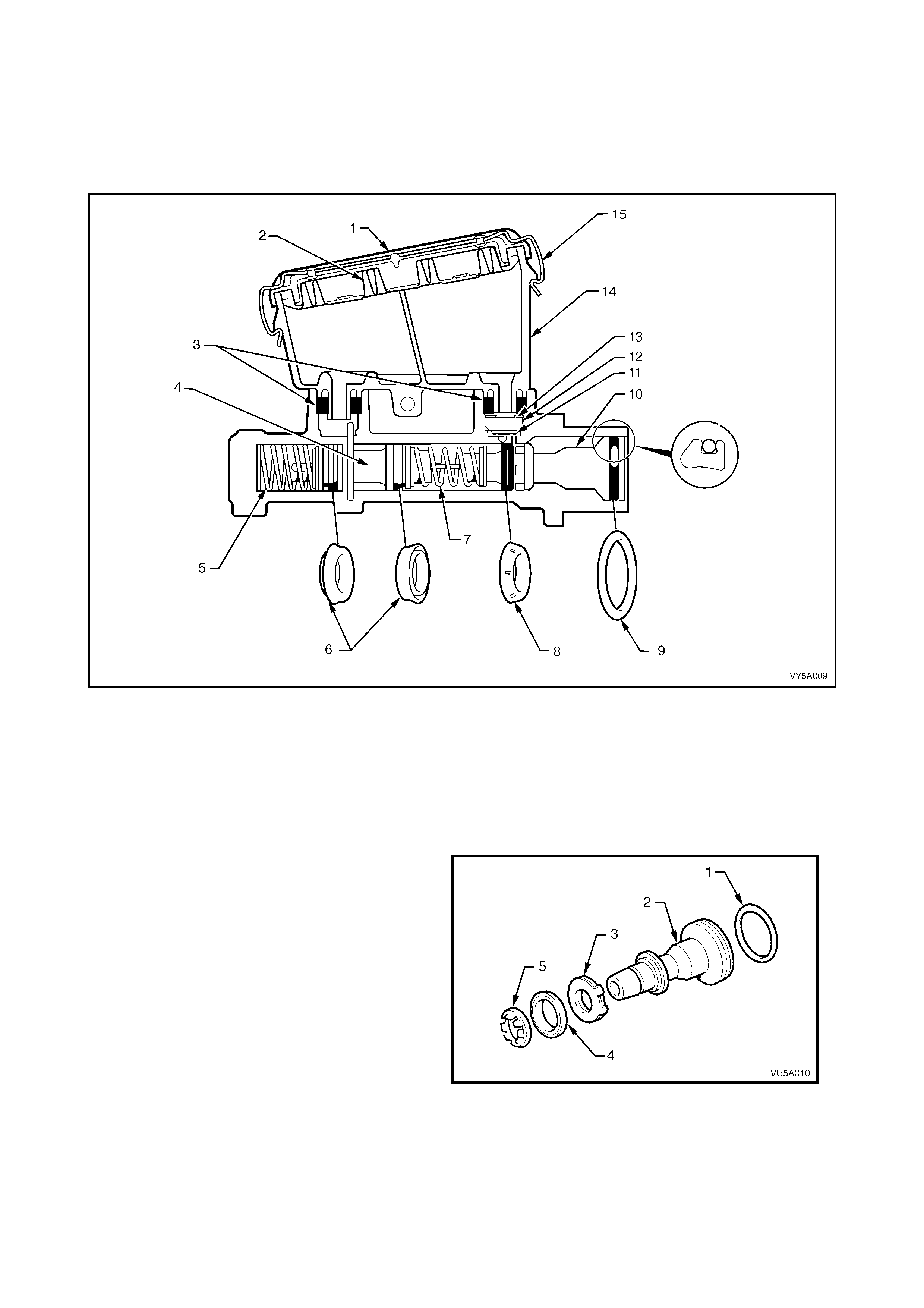

Figure 5A - 1

Legend

1. Reservoir Cap

2. Reservoir Cap Seal

3. Reservoir Sealing Grommets

4. Reservoir Retaining Screw

5. Primary Seal Retainer

6. Primary Seal (L type)

7. Recuperating Guide

8. Primary Piston

9. Primary Piston O-ring

10. Caged Spring

11. Secondary Seals (L type)

12. Secondary Piston

13. Secondary Piston Stop Pin

14. Return Spring

15. Master Cylinder Body

16. Fast Fill Valve O-ring

17. Fast Fill Valve

18. Fast Fill Valve Circlip

19. Brake Pressure Differential

Warning Switch

20. Proportioning Valve (Utility:

Differential Spool Valve)

21. Spool Valve Sleeve

22. Spool Valve Sleeve O-ring

23. End Plug O-ring

24. End Plug

OPERATION

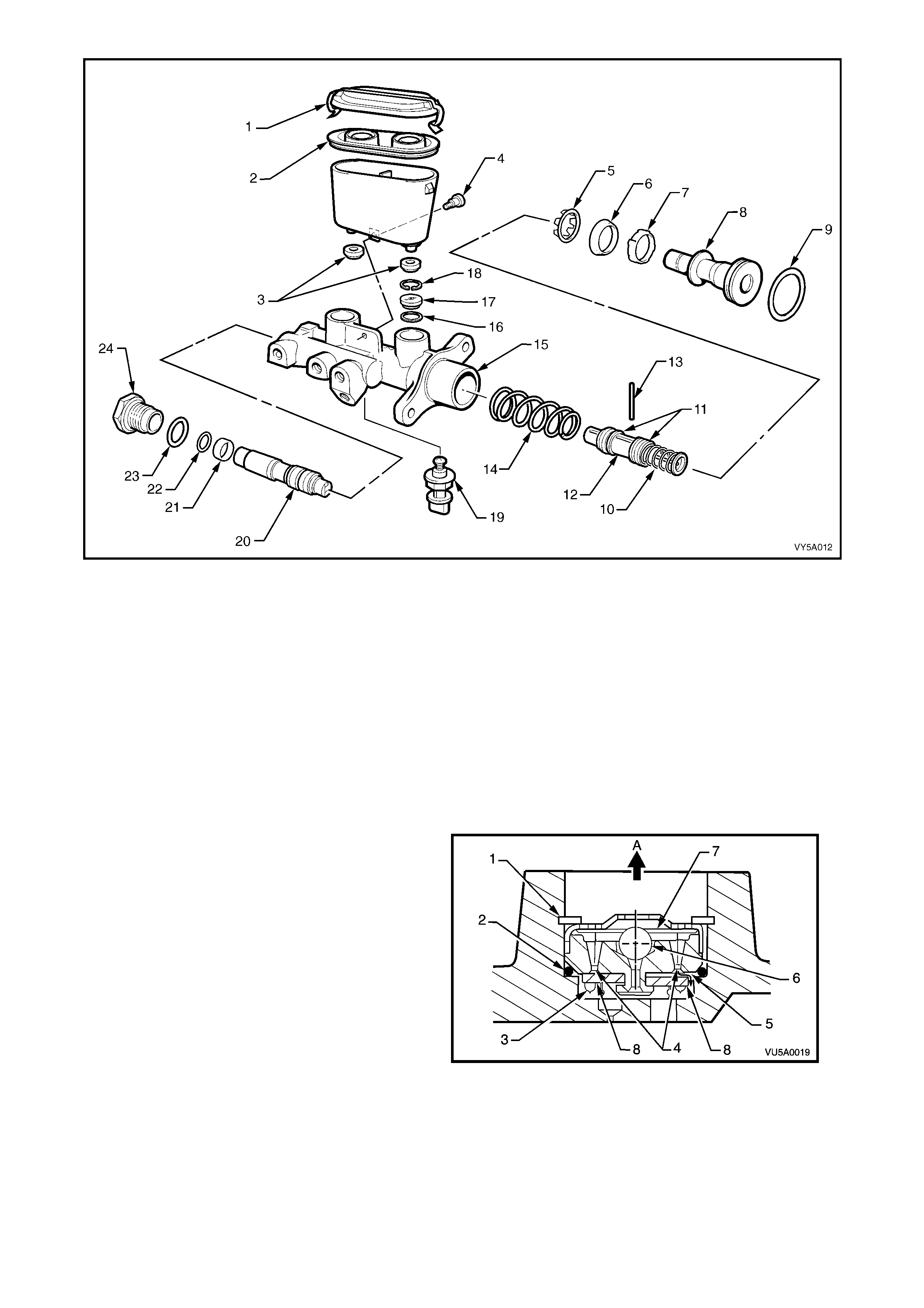

The fast fill (fast pressure build up) valve

incorporated into the master cylinder provides

reduced pedal travel by rapidly overcoming large

low pressure displacements, such as the

advancement of brake pads against the disc with

minimal primary piston travel.

Legend

1. Fast Fill Valve Retaining Circlip

2. Fast Fill Valve O-ring

3. One Way Flap Valve

4. Replenishing Holes

5. Compensating Passage

6. Bal l Va lv e and Seat

7. Ball Valve, Pre Load Disc Spring

8. Rubber Flaps

A To Reservoir

Figure 5A - 2

Initial primary piston movement produces pressure

in the larger bore of the master cylinder which

forces closed the flap on the fast fill valve and

prevents fluid from entering the reservoir port.

This high volum e, lo w pres sure f luid, f lows over th e

primary piston primary L type seal and into the

smaller bore and ou t to the brak e calipers , catering

for most of the low pressure brake system

displacement with minimal primary piston travel.

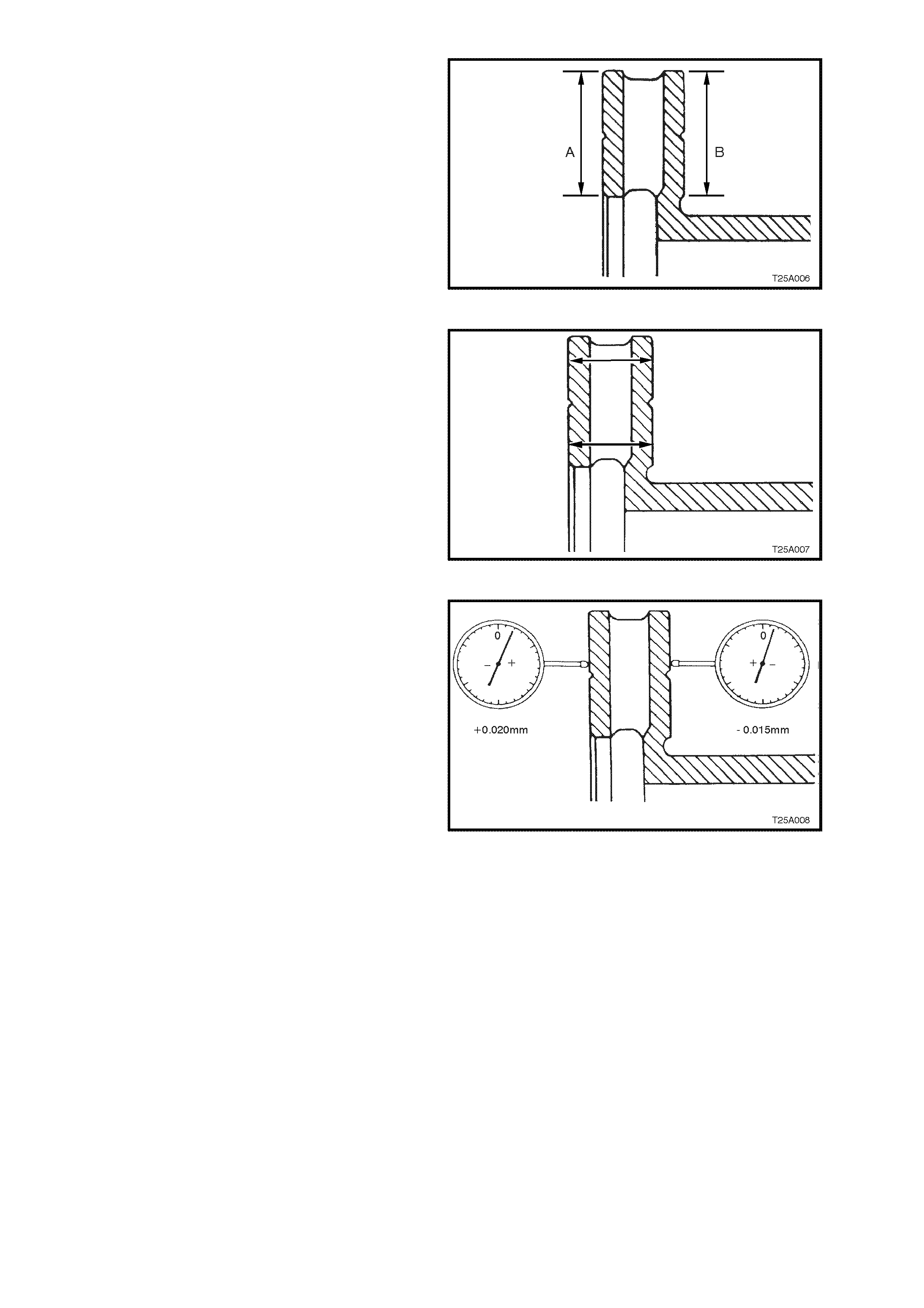

Figure 5A - 3

Further primary movement increases the pressure

in the larger bore and, at a pre-determined

pressure, the ball and seat feature incorporated in

the fast fill valve unloads, preventing additional

pressure rise and allowing fluid to flow from the

larger bore into the reservoir port.

At this point, the small bore section of the master

cylinder functions as a conventional master

cylinder, producing high operating line pressures,

with minimal primary piston travel.

Figure 5A - 4

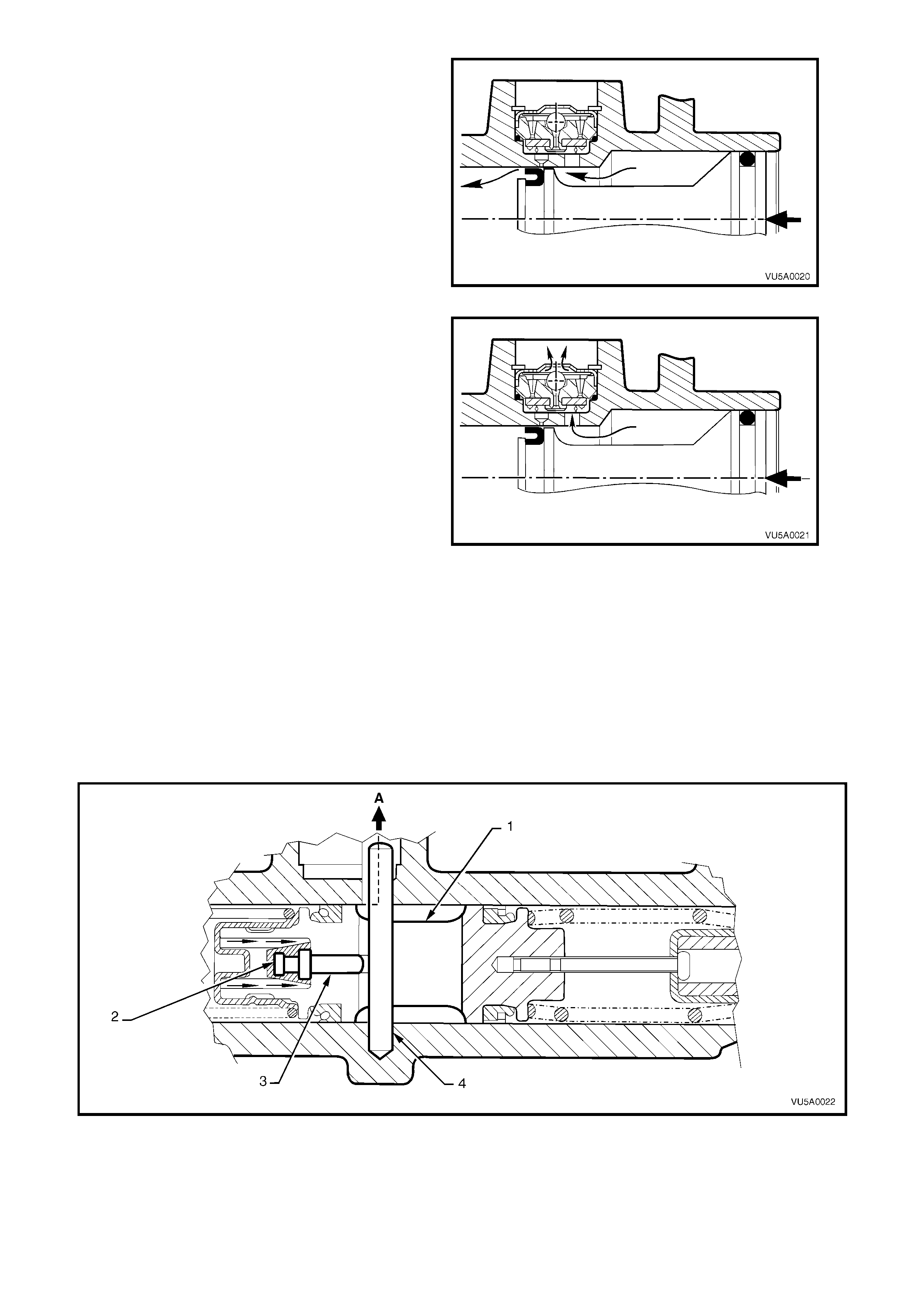

The combination of hydraulic pressure and the force of the primary piston acting on the secondary piston spring

causes the secondary piston to move forward.

This action on the seco ndar y piston m oving forward r eleases th e centre va lve pin fr om contact with the seco ndary

piston st op pin. W ith the for ce of the centr e valve s pring, and th e releas e of the centre valve pin, the r ubber centre

valve seal is pushed against the front of the secondar y piston inner bore, effectively blocking off the fluid from the

rear brake system compensating port.

At the same time, the primary piston L type seal passes the front brake system compensating port, closing it off

from the reservoir and thus the high operating fluid pressure is produced.

The high operating f luid pressur e influence is t hen registered on the proport ioning valve, then to the fr ont and rear

brake calipers, where the brakes are applied.

Figure 5A - 5

Legend

1. Secondary Piston

2. Centre Valve Seal 3. Centre Valve Pin

4. Secondary Piston Stop Pin A To Reservoir

Front Brake System: When the brake pedal is

released and the secondary piston returns, fluid

recuperation will occur from the reservoir through

the reple nishing ho les in the f ast fill val ve, over the

rubber flap and into the larger and smaller piston

bores.

When the primary piston has fully returned, the

compensating hole in the master cylinder will be

uncovered, allowing fluid returning from the wheel

cylinders to flow into the reservoir via the fast fill

valve compensating passage, thus relieving all

pressur e in the brak e s ystem.

Figure 5A - 6

Rear Brake System: When the brake pedal is released and the secondary piston returns, fluid recuperation will

occur from the reservoir and through the centre valve when the centre valve rubber seal becom es unseated from

the secondary piston bore.

Figure 5A - 7

In all vehicles except the MY2003 VY Ser ies Utility vehicles, brake fluid pressure is equal in each system until the

proportioning valve reaches its designed crack point. If the master cylinder pressure then continues to rise, the

proportioning valve operation changes the front to rear braking pressures, to maintain the designed front to rear

braking balance.

1.3 PROPORTIONING VALVE OPERATION

ALL EXCEPT UTILITY

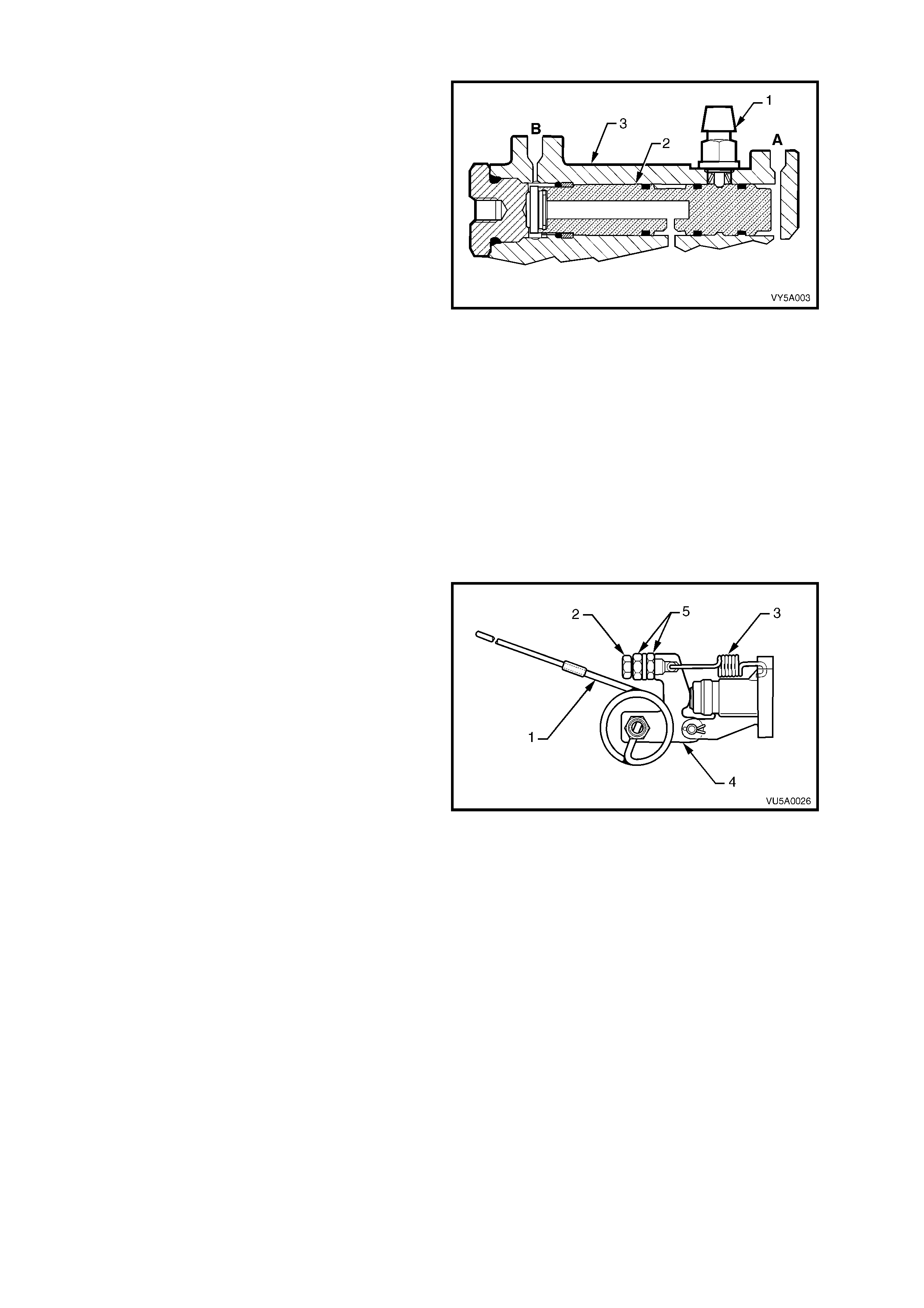

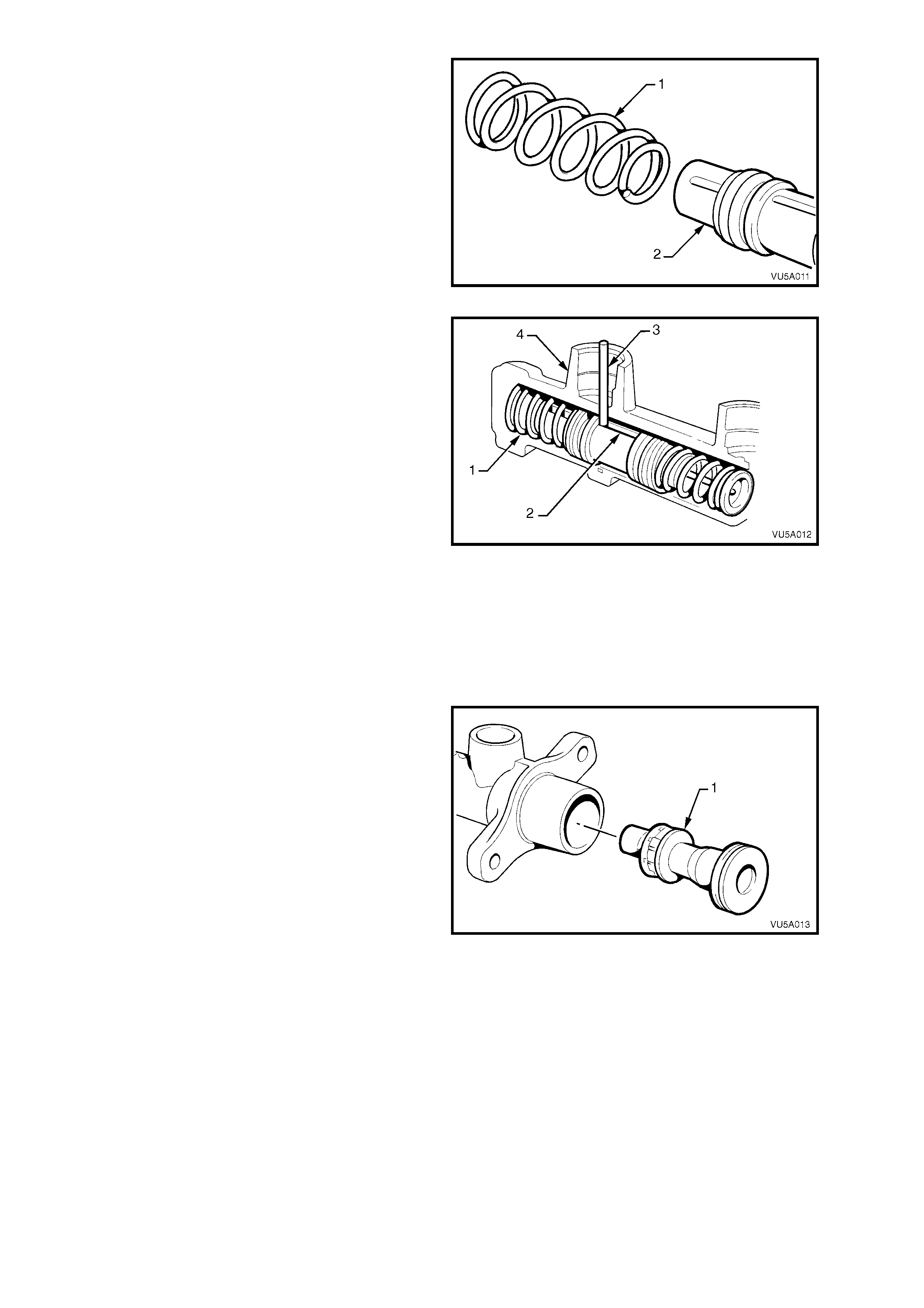

In the relaxed position, the proportioning valve

piston (8) is held in the valve housing (6) by the

large proportioning spring (9).

The poppet valve (3) is held against the end of its

retainer (2) by a light return spring (1) and brake

fluid is free to pass from the master cylinder,

through the bore of the proportioning valve piston

(6) to the rear brakes at A.

Figure 5A - 8

When master cylinder pressure is increased to the

proportioning valve crack point, brake fluid

pressure from the primary section of the master

cylinder acting on the control piston (5), forces the

proportioning valve piston (2) to move to the plug

end, overcoming the large proportioning spring (3)

and seals against the poppet valve (4). This

prevents any further increase in pressure to the

rear brakes until master cylinder pressure is

increased.

Once seated, the proportioning valve piston (2)

now has a larger diameter than the control piston

(5). As a consequence of this differential area, the

output to t he rear brakes after c rack point has bee n

reached, is less than that applied to the front

brakes.

As master cylinder pressure is further increased

above crack point, the piston (2) oscillates against

the poppet va lve (4) a nd pr oportions the r ear br ak e

pressure to a value lower than the front brakes.

Figure 5A - 9

When the brake pedal is released and the fluid pressure from the master cylinder drops, the pressure of the rear

brake fluid unseats the poppet valve (3), allowing the fluid to return to the master cylinder, refer to Figure 5A - 8.

The large propor tioning s pring (9) then returns the propor tioning valve pis ton and control p iston (4) to the ir relaxe d

positions.

Should a loss of pressure occur in either the front or rear brake system, when the brake pedal is applied, the

proport ioning val ve hous ing (6) will m ove withi n the m aster c ylinder bod y, closi ng the sw itch contac ts on the brak e

pressur e diff er entia l war ni n g switch (7) and thus il luminating the brake fail warnin g light on the instrument panel.

After r epairs have been m ade, applicat ion of a reaso nable f orce to the brak e pedal will autom aticall y centralis e the

proport ioning valve h ousing, opening th e contacts in t he brake pres sure differ ential warning s witch and turning the

brake warning light off.

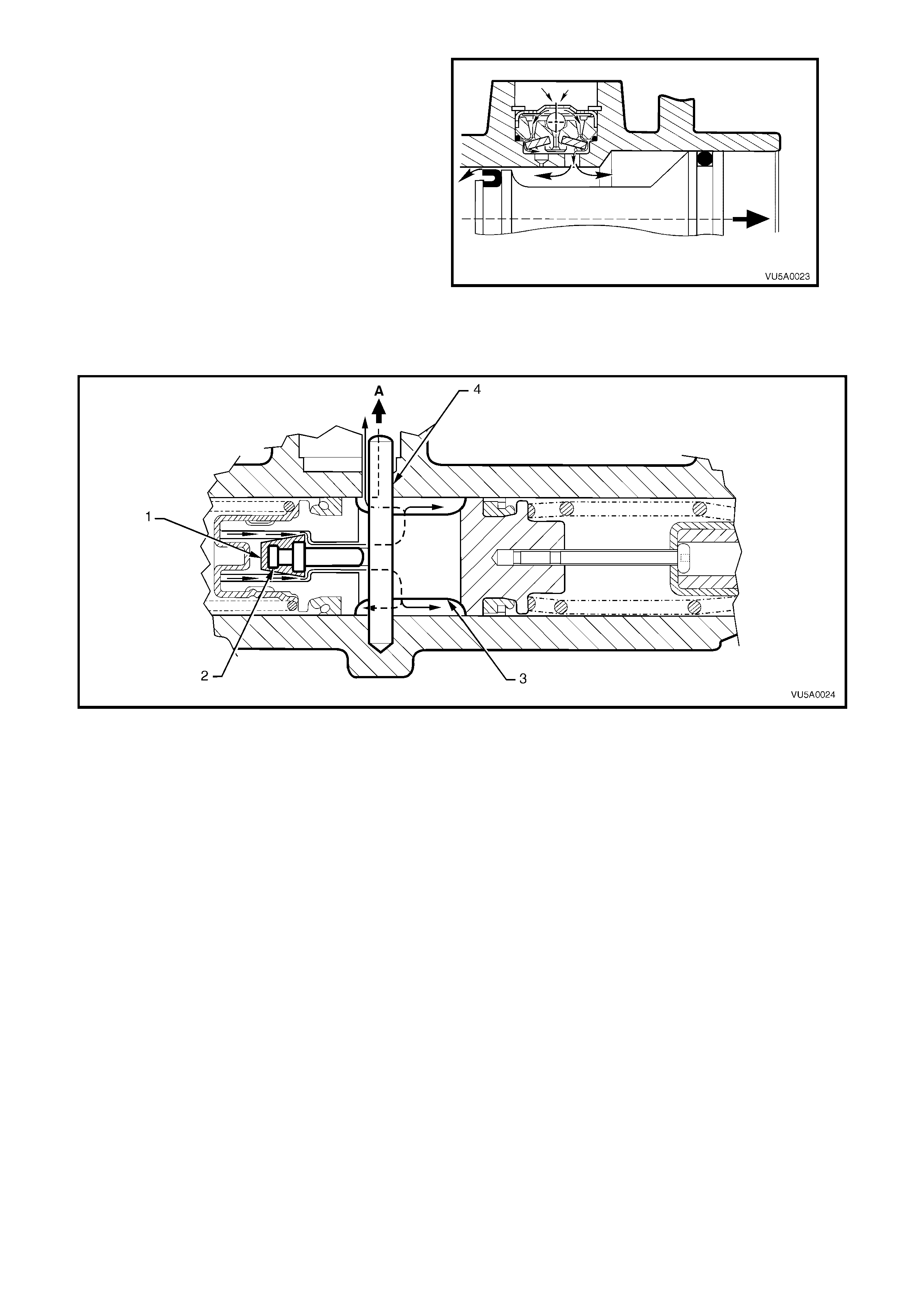

Utility Pressure Differential Spool Valve

As previously stated, the master cylinder fitted to

Utility vehicles is not fitted with a proportioning

valve. In al l other respec ts, it is similar to that f itted

to other MY2003 VY and V2 Series vehicles.

Instead of a proportioning valve, Utility vehicles

have a differential spool valve (2).

The brake pressure differential warning switch (1)

is m ounted in the mas ter cylinder bo dy (3) with the

spring loaded plunger located in a tapered groove

in the centre of the spool valve (2). With the spool

in a centralised position, the switch contacts

remain open.

Should there be a loss of pressure in either the

front (A) or rear (B) brake system when the brake

pedal is applied, the spool valve will move off

centre, closing the switch contacts and activating

the warning light on the instrument panel.

After repairs have been made and the brake

system has been bled, the pressure in the front

and rear brake systems will equalise (when the

brakes are applied), centralising the spool and

opening the contacts in the brake pressure

differential warning switch (1), turning the brake

warning lig ht off .

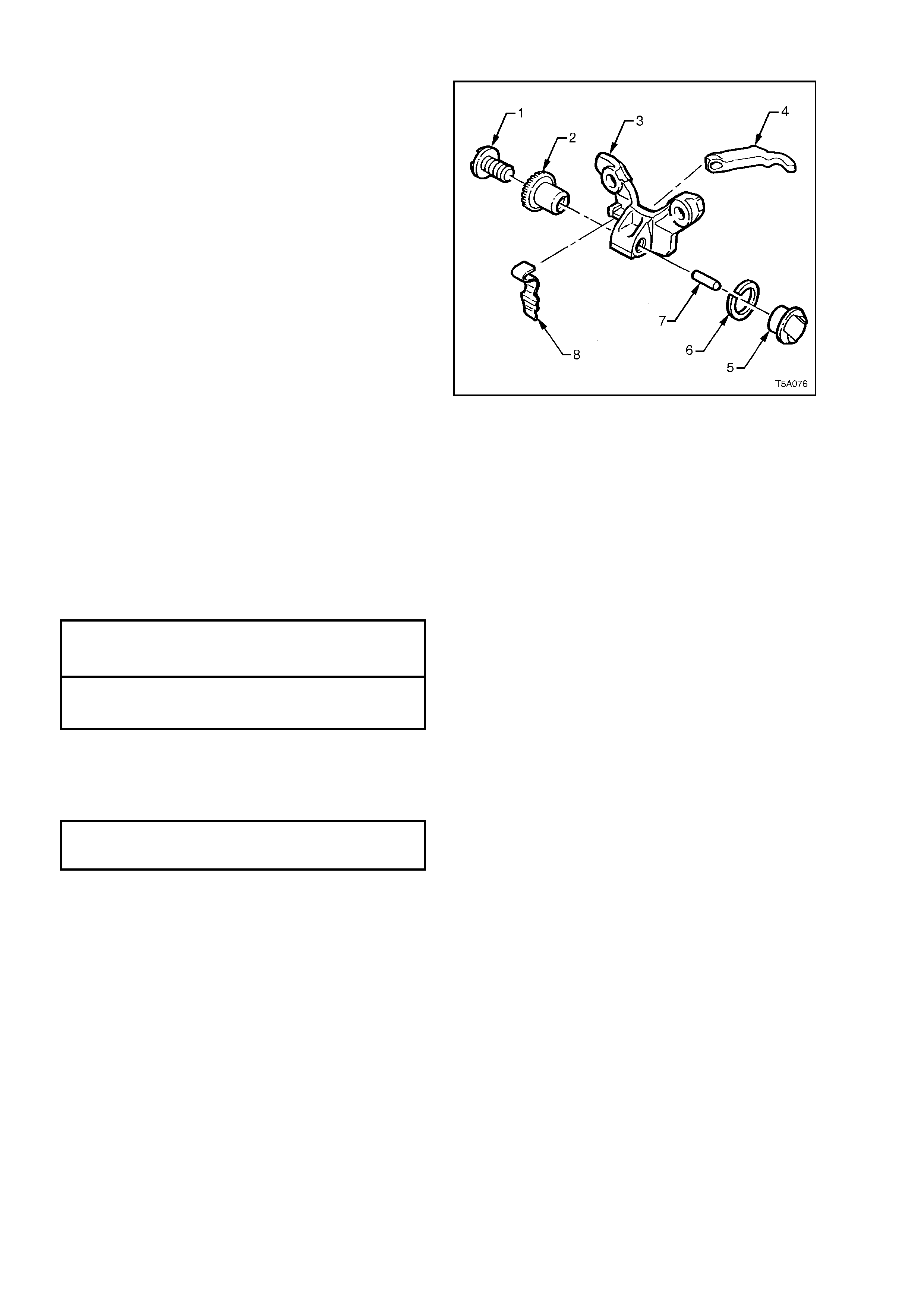

Figure 5A - 10

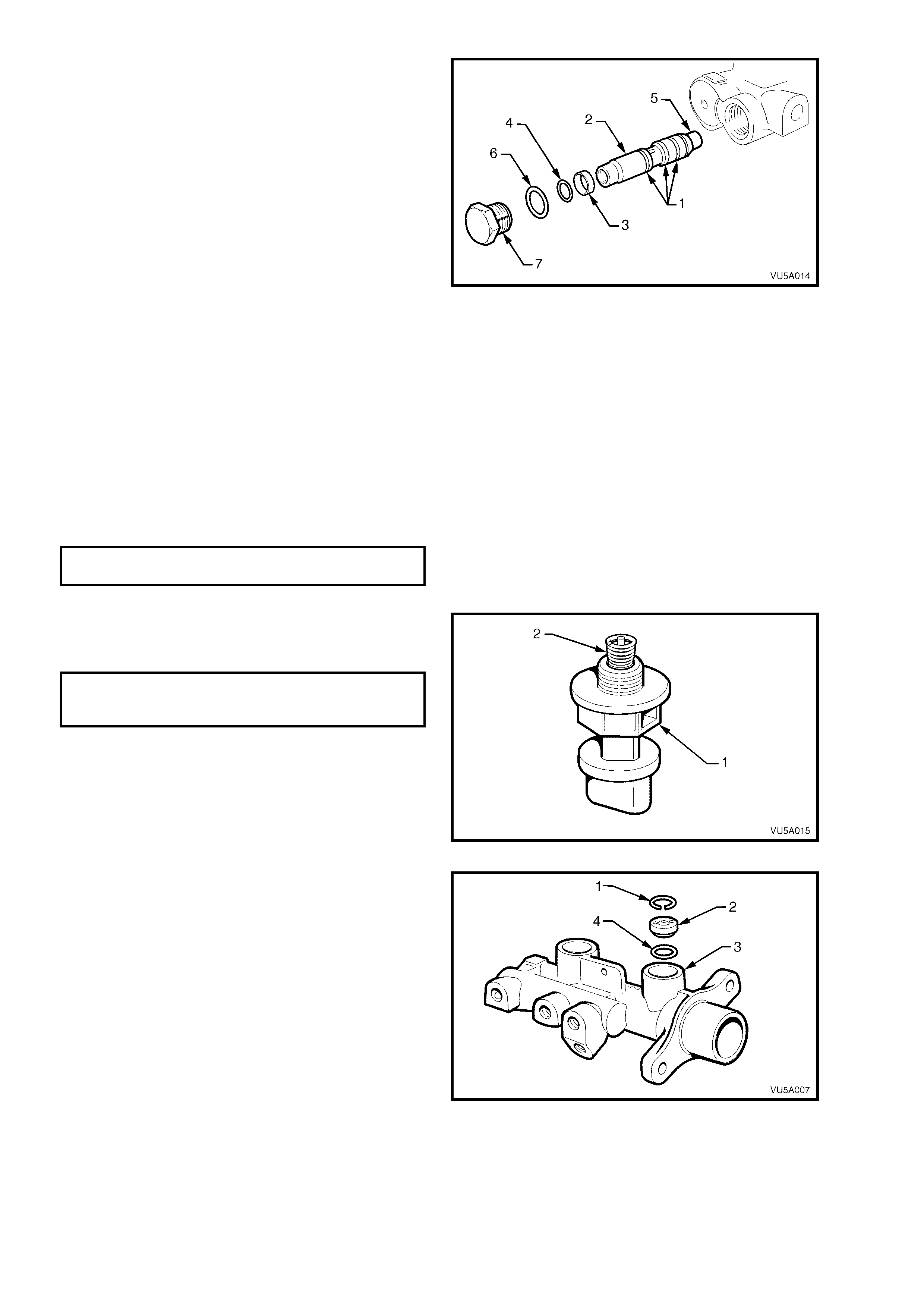

UTILITY LOAD SENSING PROPORTIONING VALVE

Construction

The loa d sens ing propor tio ning valv e is attac hed to

the right hand frame, above the final drive

assembly. The valve torsion spring lever (1) is

attached to the right hand trailing arm rod with a

bracket, cable and hook.

The load sensing proportioning valve senses load

by monitoring the rear suspension ride height, to

regulate the pressure applied to the rear brake

calipers. Maximum line pressure is supplied to the

rear brakes when the vehicle is fully laden, while

lightly loaded conditions provide minimum line

pressure; i.e. line pressure varies in relation to the

weight of the load.

The static spring (3) exerts a force on the end of

the spool valve by means of a lever (4), while a

torsion type sensing spring (1) is attached to the

right-hand trailing arm rod, modifying this applied

force, depending on the axle load.

IMPORTANT: Under no c ircum stances is the st atic

spring tens ion adjustin g sc rew (2) and lock nuts (5 )

to be disturbed nor adjusted, as this adjustment is

set in manufacture.

Figure 5A - 11

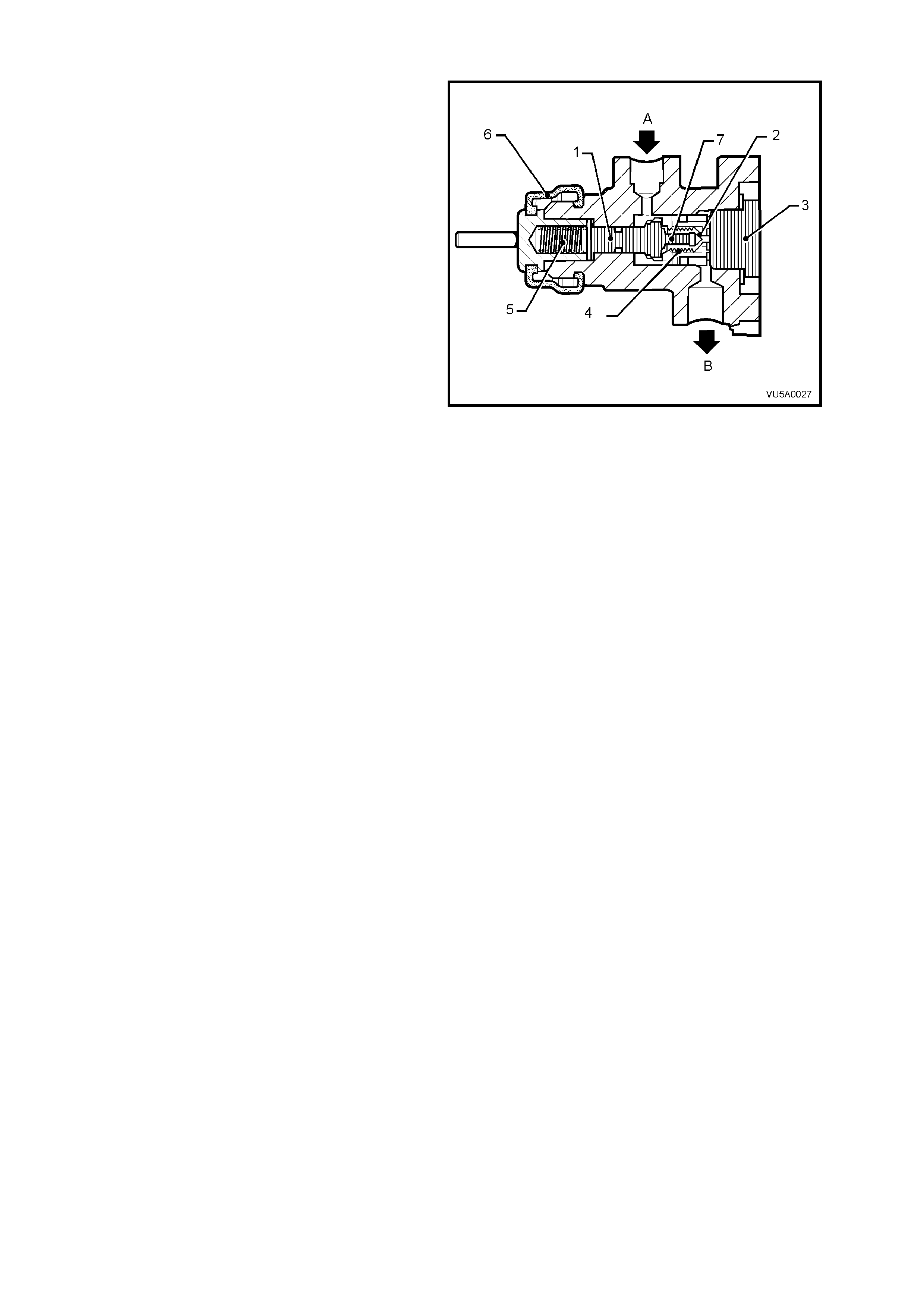

Operation

When the vehicle is unladen or lightly loaded, the

torsion spring has the maximum effect and,

together with the static spring f orce, the total apply

force on the plunger and load sensing valve spool

(1) is l o west. This app l y for c e is a ble to position t he

load sensing valve spool (1) to restrict the flow of

fluid through the outlet port (B) to the rear brakes.

However, when the vehicle is loaded, the load

sensing valve spool is positioned so that fluid can

flow unrestricted through the inlet port (A), through

the spool sub-assembly, around the poppet valve

(7) and out via the spool sub assembly sealing seat

(2) and outlet port (B) to the rear wheel brake

calipers.

When the brake pedal is released, inlet pressure

drops, allowing the higher pressure on the rear

wheel side of the sensing valve to force upon the

poppet valve (7), such that the brake fluid can flow

almost unrestricted, back to the master cylinder.

Eventually, the load sensing valve spool (1) is

forced into its released position by the external

spring set up, to fully open the passage between

the front and rear circuit.

Figure 5A - 12

Legend

1. Load sensing valve s pool

2. Load sensing valve s pool sealing seat

3. Load sensing valve end plug

4. Secondary spring

5. Primary spring

6. Load sensing valve boot

7. Load sensing valve poppet and valve

A. Brake fluid inlet

B. Brake fluid outlet

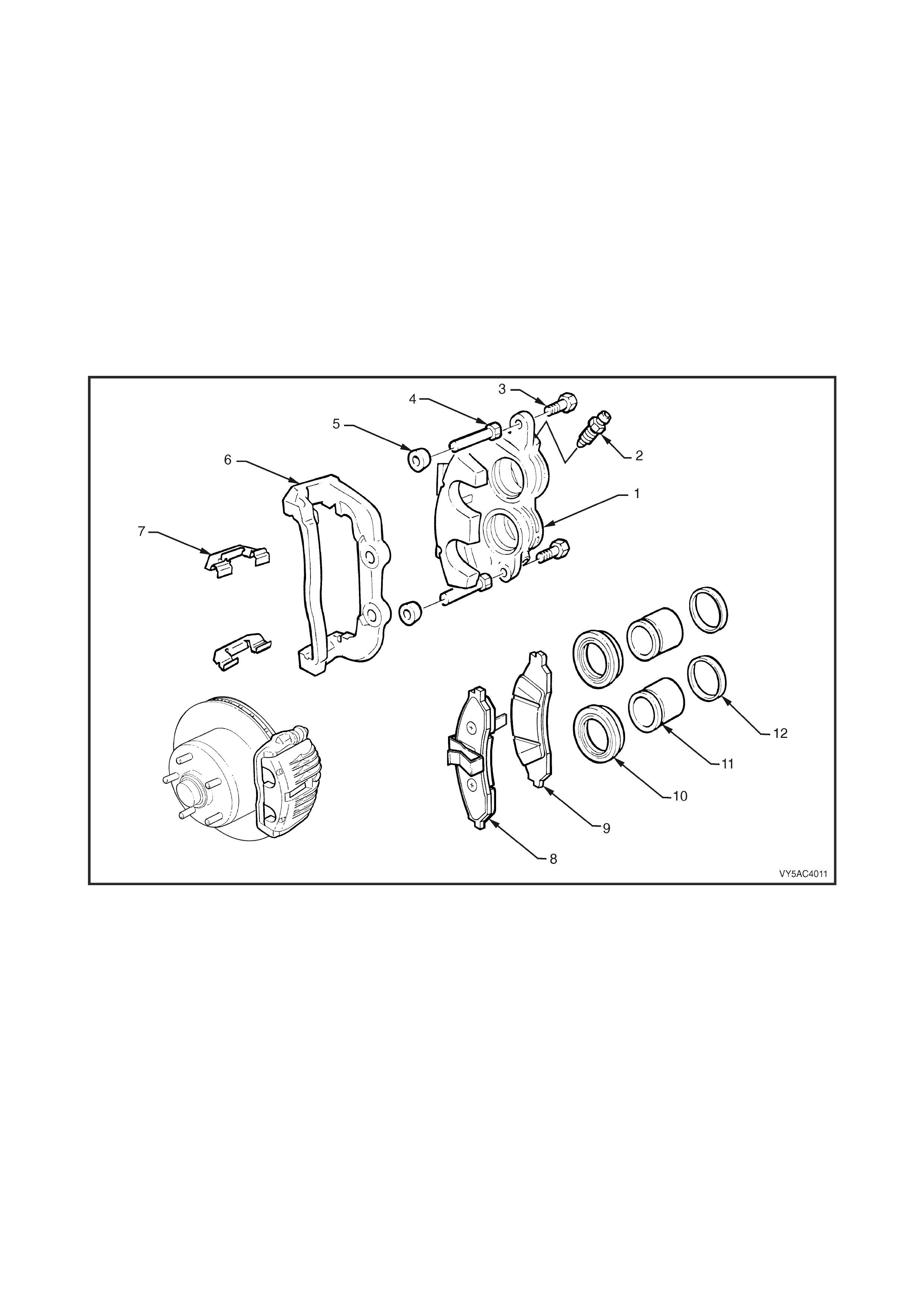

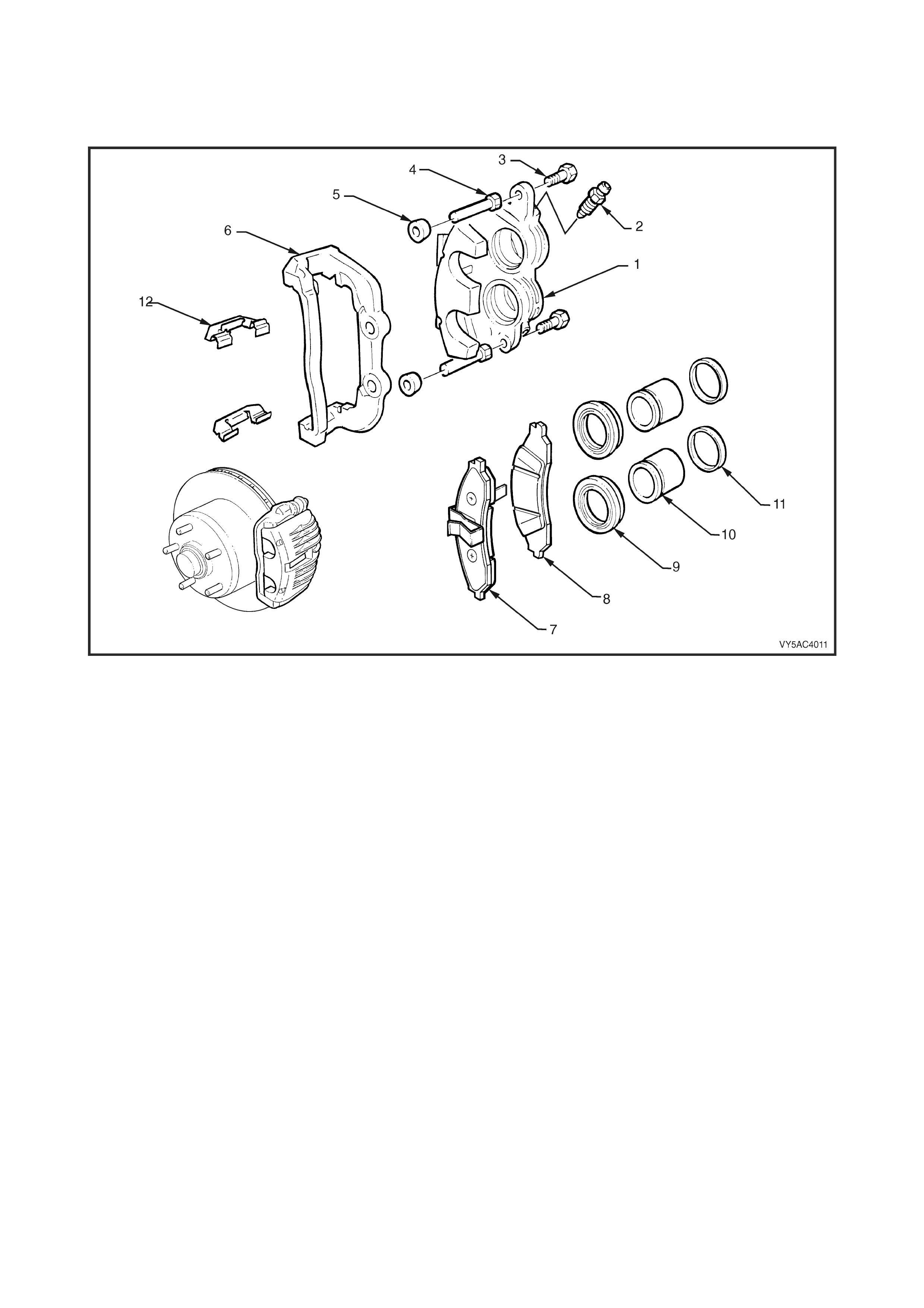

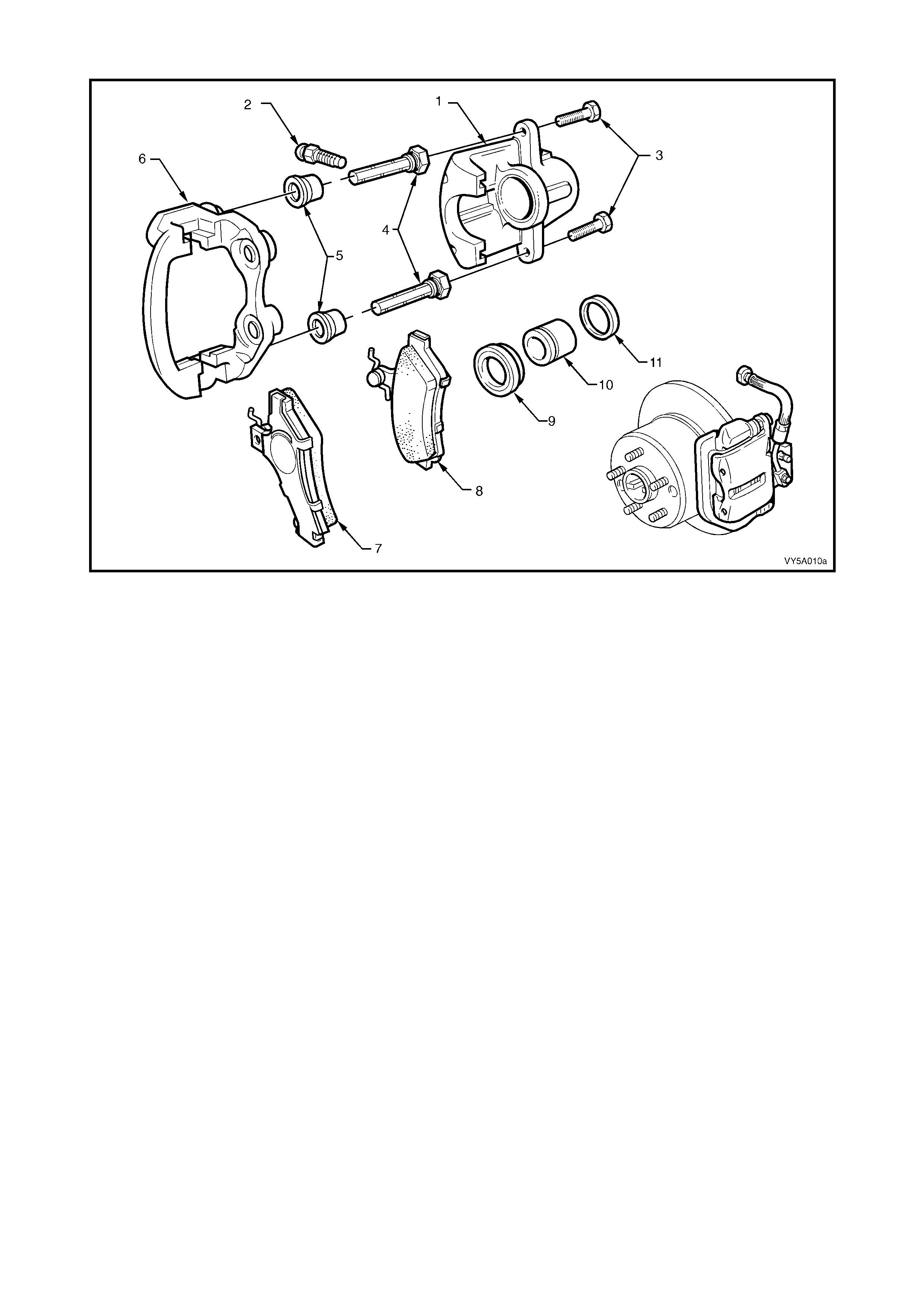

1.4 FRONT AND REAR BRAKES

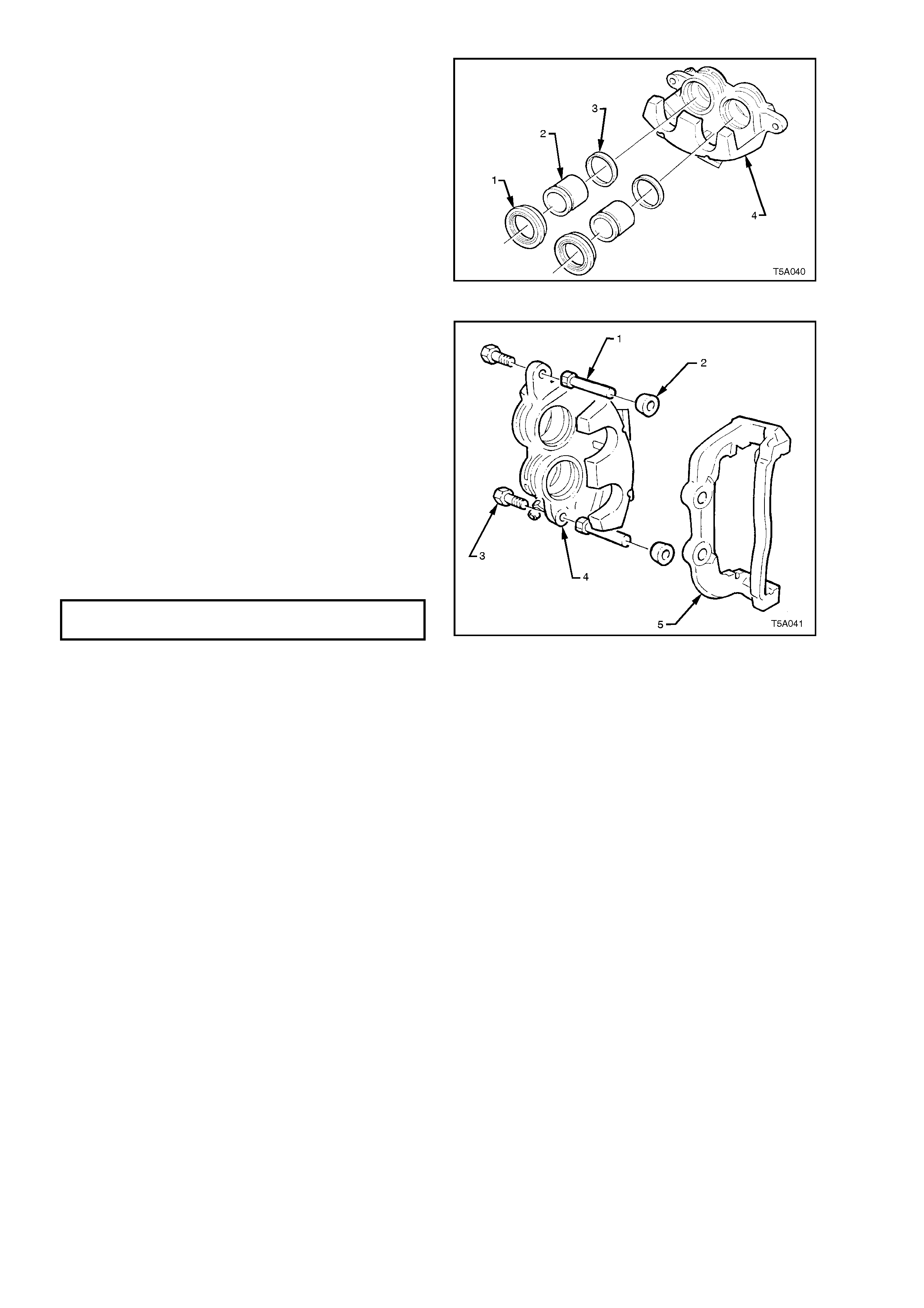

Both front an d r ear br ake assem blies are c om mon for the stand ard an d AB S systems . An ex plod ed vie w of the twin

piston front caliper is shown in Figure 5A - 13.

For the front brakes, the anchor plate is rigidly fixed to the steering knuckle support arm, while the housing slides

within t he anchor p late b y m eans of two gu ide pins b olted to the housing. R ubber boots are f itted to the gu ide pins

to exclude moisture, dirt and foreign matter.

The rear br ak e c aliper anc h or plates are bo lte d to th e t r ailing ar m and also ha ve a f loatin g ho us ing , s lid in g o v er two

guide pins that are fitted with rubber dust boots.

The housing incorporates either twin (front) or a single hydraulic piston (rear), each with a seal. When hydraulic

pressur e is applied, the pis ton forces the inner pad against the dis c and the reaction of the housing pul ls the outer

pad against the disc. The forces of the pads on each side of the disc are therefore equal.

When the hydraulic pressure is released, the piston seal/s retracts the piston/s a small amount, allowing the moving

parts to re lax s uff icientl y for the pads to rem ain in clos e prox im ity to th e disc without dr agg ing. Adj ustm ent for wear

is automatic.

Refer to 2.7 BRAKE PADS, REPLACE, in this Section, for further information regarding brake pad application.

Figure 5A - 13

Legend

1. Caliper Housing

2. Bleed Screw

3. Self Locking Bolt (2 places)

4. Guide Pin (2 places)

5. Guide Pin Boot

6. Anchor Plate

7. Clip ( 2 places)

8. Outer Brake Pad

9. Inner Brake Pad

10. Piston Boot (2 plac es)

11. Piston (2 pl aces)

12. Cylinder Seal (2 pl aces )

2. MINOR SERVICE OPE RATIONS

2.1 SERVICE NOTES AND CAUTIONS

IMPORTANT ITEMS

a. While Holden's wheel brake parts are not asbestos based in their material composition, a danger exists that

non-genuine parts replacement may contain asbestos.

NOT ONLY IS IT IN THE INTERESTS OF PERSONAL SAFETY BUT ALSO THE SAFE AND RELIABLE

OPERATION OF T HE BRA KING S YSTEM, THAT ONLY GENUINE PARTS ARE USED F O R REPLACEM ENT

PURPOSES.

Even so, when s er vic ing whee l br ake parts, do not cr eate dus t by grin di ng or s an din g br ake linings, b y clean ing

wheel brak e parts with a dry brush or with com pressed air. Breathing in dust that may contain asbestos fibr es

can cause serious bodily harm over a protracted period of time.

A water dampened cloth or water based solution should be used to remove any dust on brake parts.

Equipment is commercially available to perform this washing function. These wet methods prevent brake

component fibres from becoming airborne.

b. The polyglycol brake fluid used in MY2003 VY and V2 Series vehicles is hygroscopic and absorbs moisture

from the air through the br ake hoses etc. The boilin g resistance of the f luid decreases as the moistur e content

increases and so the possibility of a vapour lock under heavy braking conditions increases with the age of the

fluid. Therefore, for maximum brake effectiveness, a two yearly change of brake fluid is mandatory, refer to

2.5 BRAKE FLUID, CHANGE, in this Section.

To prevent the absorption of moisture from the air or other contamination, it is recommended that the brake

fluid be stored in small (500 ml) containers and that any surplus fluid remaining in a container after use be

discarded.

NOTE: The only approved brake fluid is Super DOT 4 Plus and is available in 250 and 500 ml containers. If

pressure bleeding equipment is used, it m ust be of an approved type with a diaphragm separating the brake fluid

from the air.

CAUTION: Brake fluid is extremely damaging to paint. If fluid should accidentally come into contact with a

painted surface, immediately wash the fluid from the paint and clean the painted surface.

c. W henever an y component that forms part of the ABS (if fitted) is dis turbed d uring Ser vice Operat ions, it is vital

that the complete ABS system be checked, refer to 4.4 ABS & TCS FUNCTION CHECK (V6 engines) or

5.4 ABS & TCS FUNCTION CHECK (GEN III V8 engines), in Section 5B, ABS & TCS.

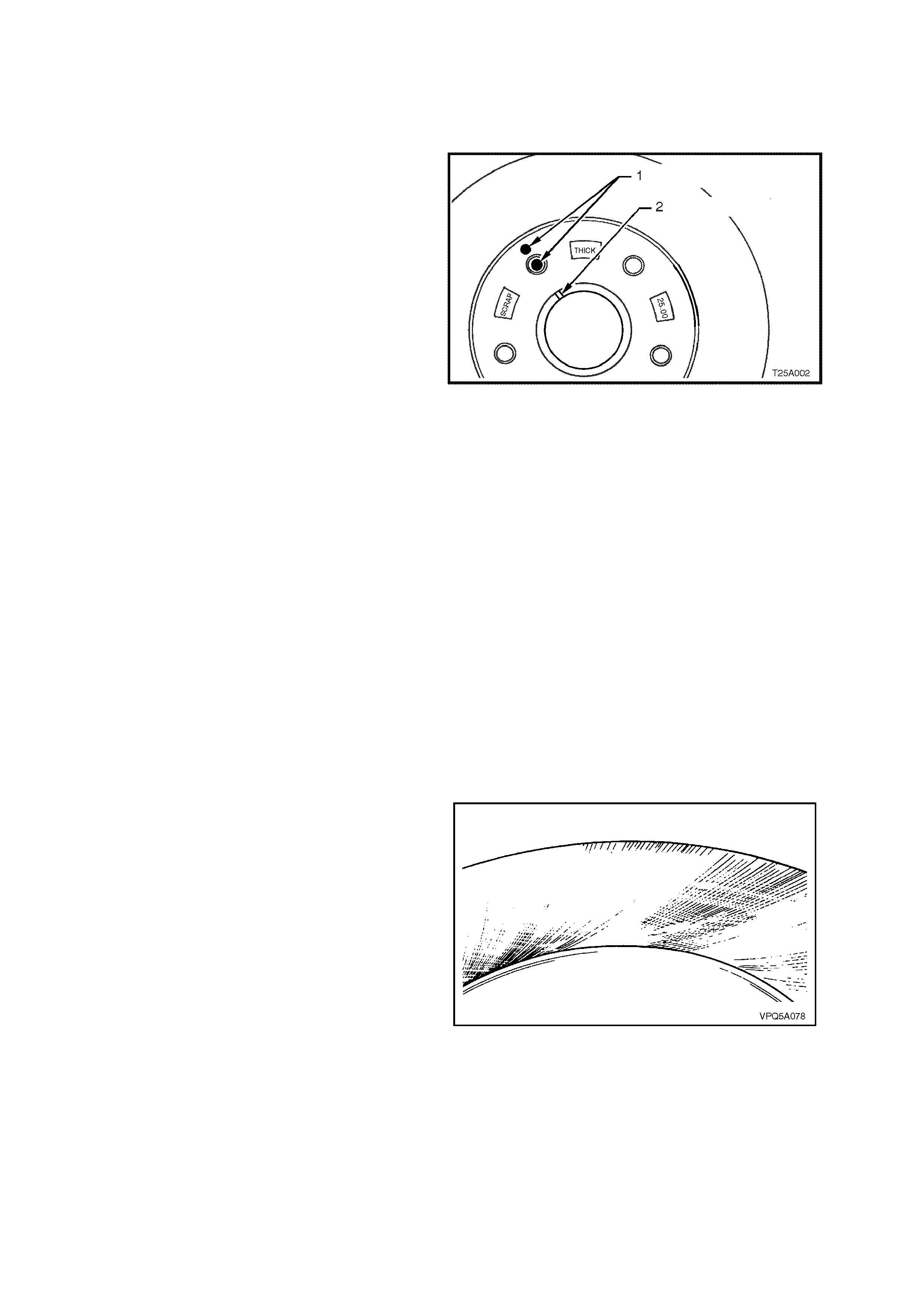

d. W henever a r oad whee l an d/or brake rotor is r em oved f r om or ins talled to a MY2003 V Y or V2 Ser ies ve hic le, it

MUST be done in accorda nce with the procedure provided in 2.3 WHEEL REMOVAL AND INSTALL ATION in

Section 10, WHEELS AND TYRES.

e. W henever a road wheel and/or brake disc is removed from the vehicle, the relat ionship of the road wheel and

the disc to th e hu b MU ST be m ark ed with a felt ti pp ed pen or s imilar, in ord er f or those par ts to b e r eins ta lled in

their original positions. This is critical to maintain the brake disc and road wheel runout dimension to a

minimum.

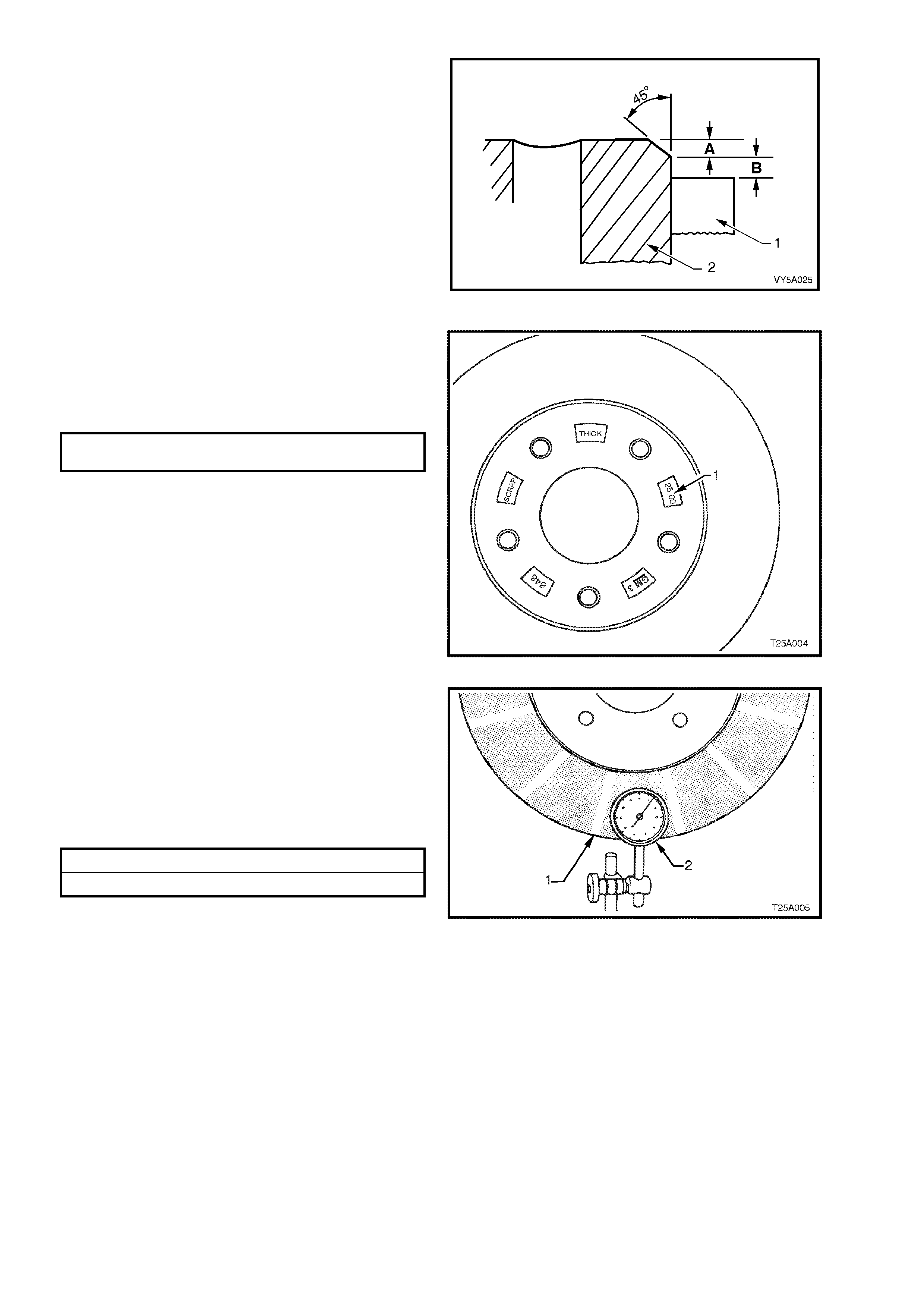

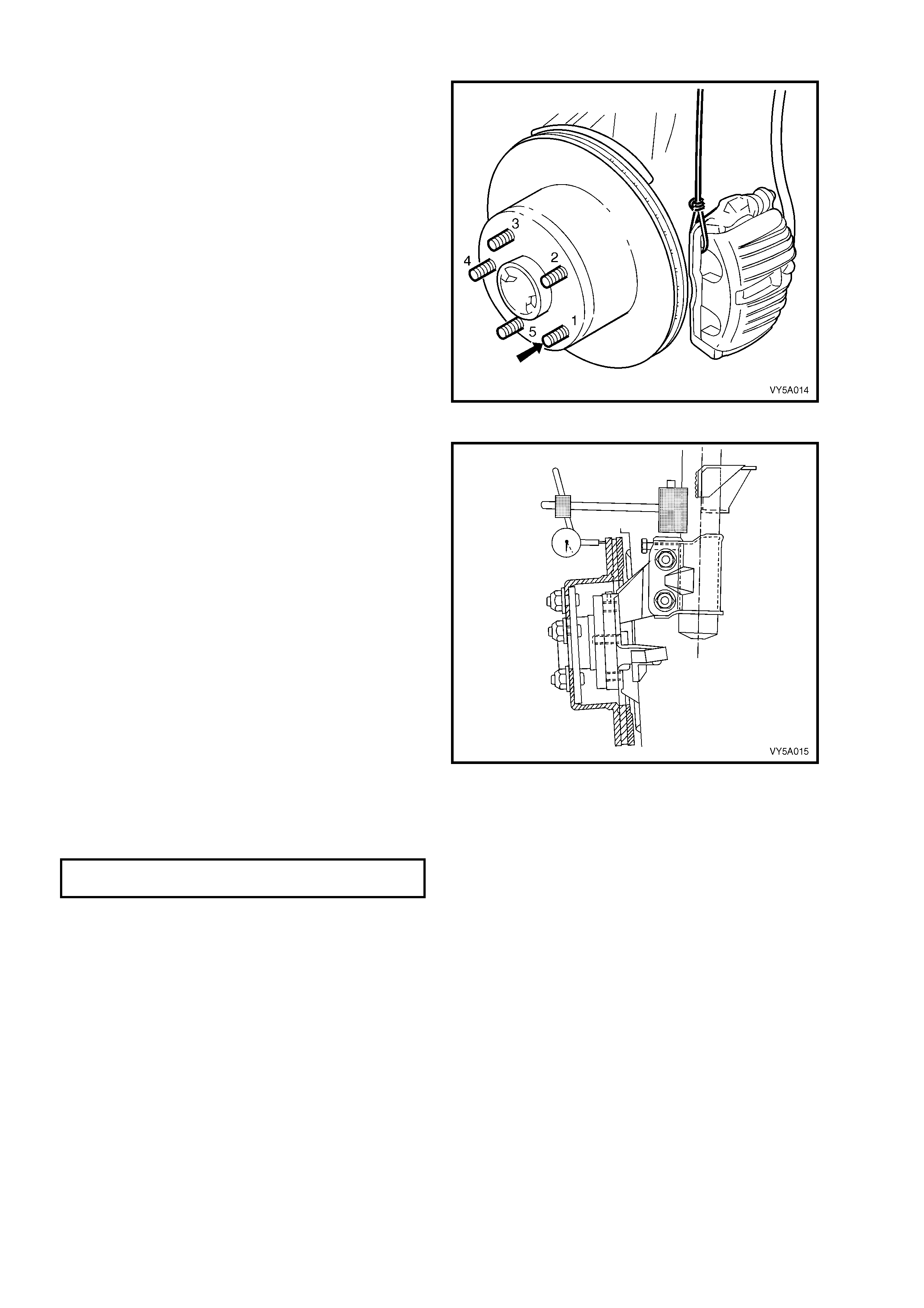

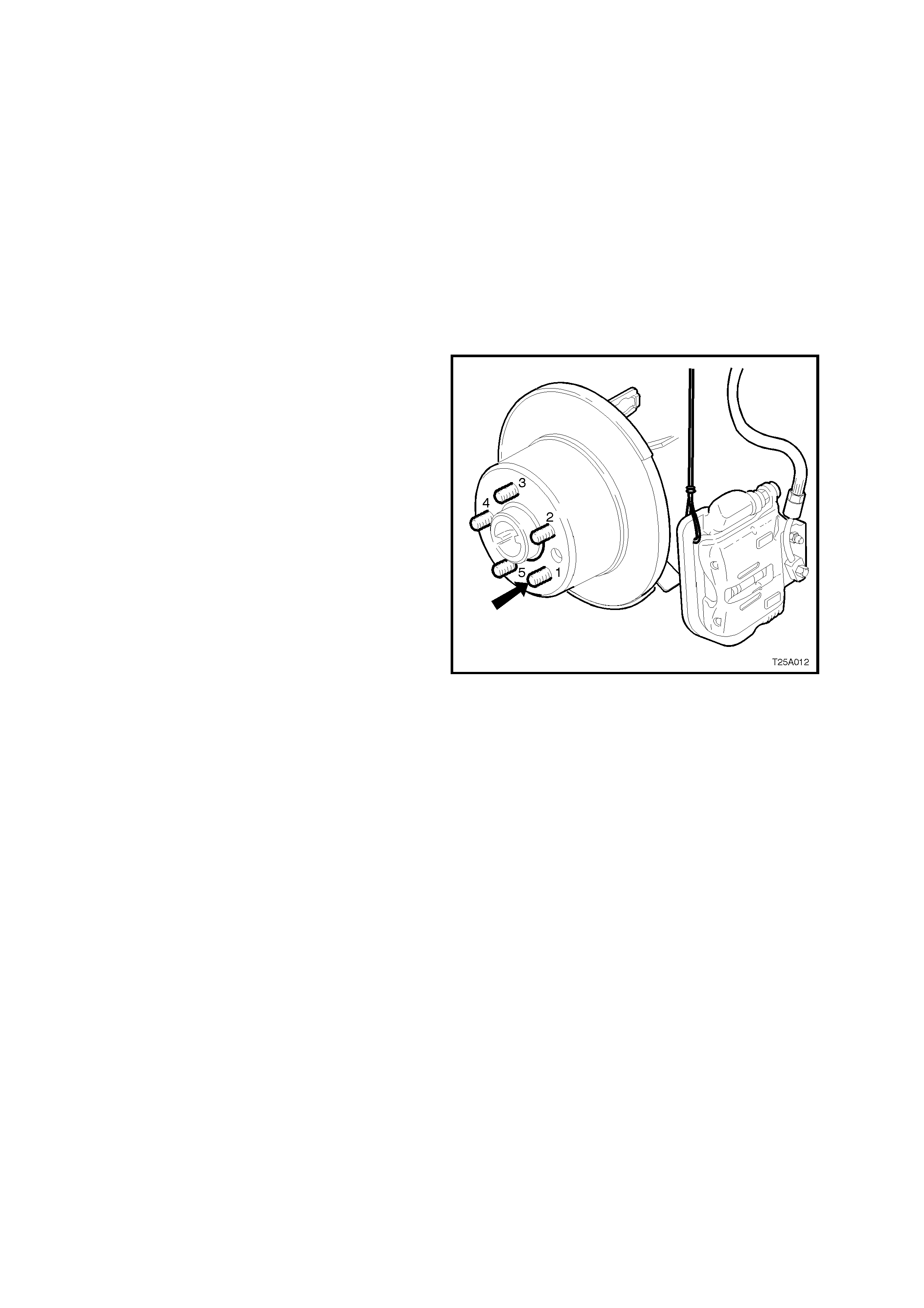

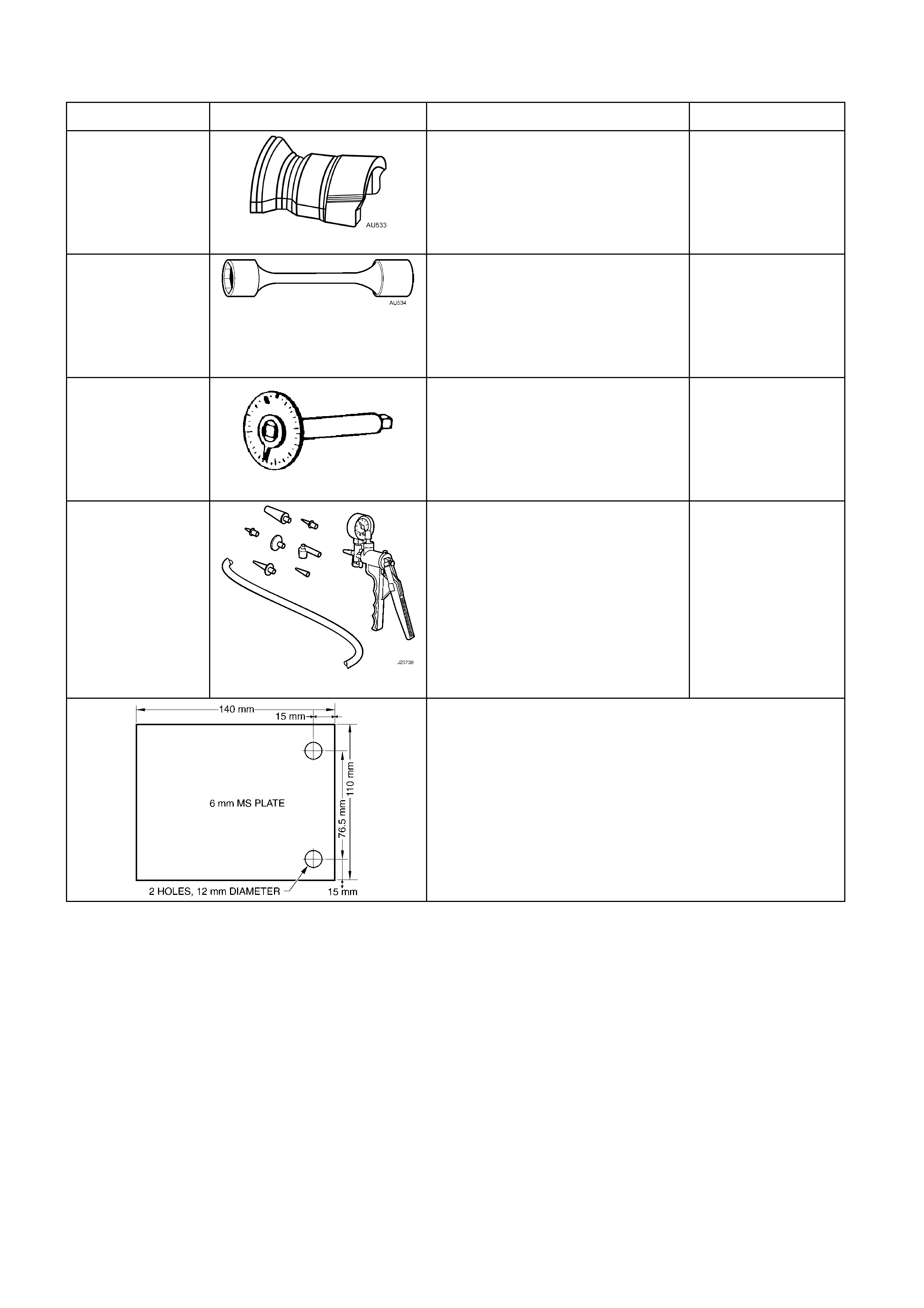

When reinstalling road wheels, do not use an

impact gun to tighten wheel nuts unless the

impact gun is fitted with a torque limiter socket

(Tool No. AU534 or a commercial equivalent).

Failure to correctly tighten wheel nuts to the

correct torque specification and in the correct

order, may result in a distorted brake disc,

leading to the development of brake shudder.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 100 – 125 Nm

For a com plete desc ription of the method used

to measure both brake disc and trunnion

assembly runout and correction, refer to

3.4 FRONT BRAKE DISC or 3.5 REAR

BR AKE DISC, in this Sec ti on.

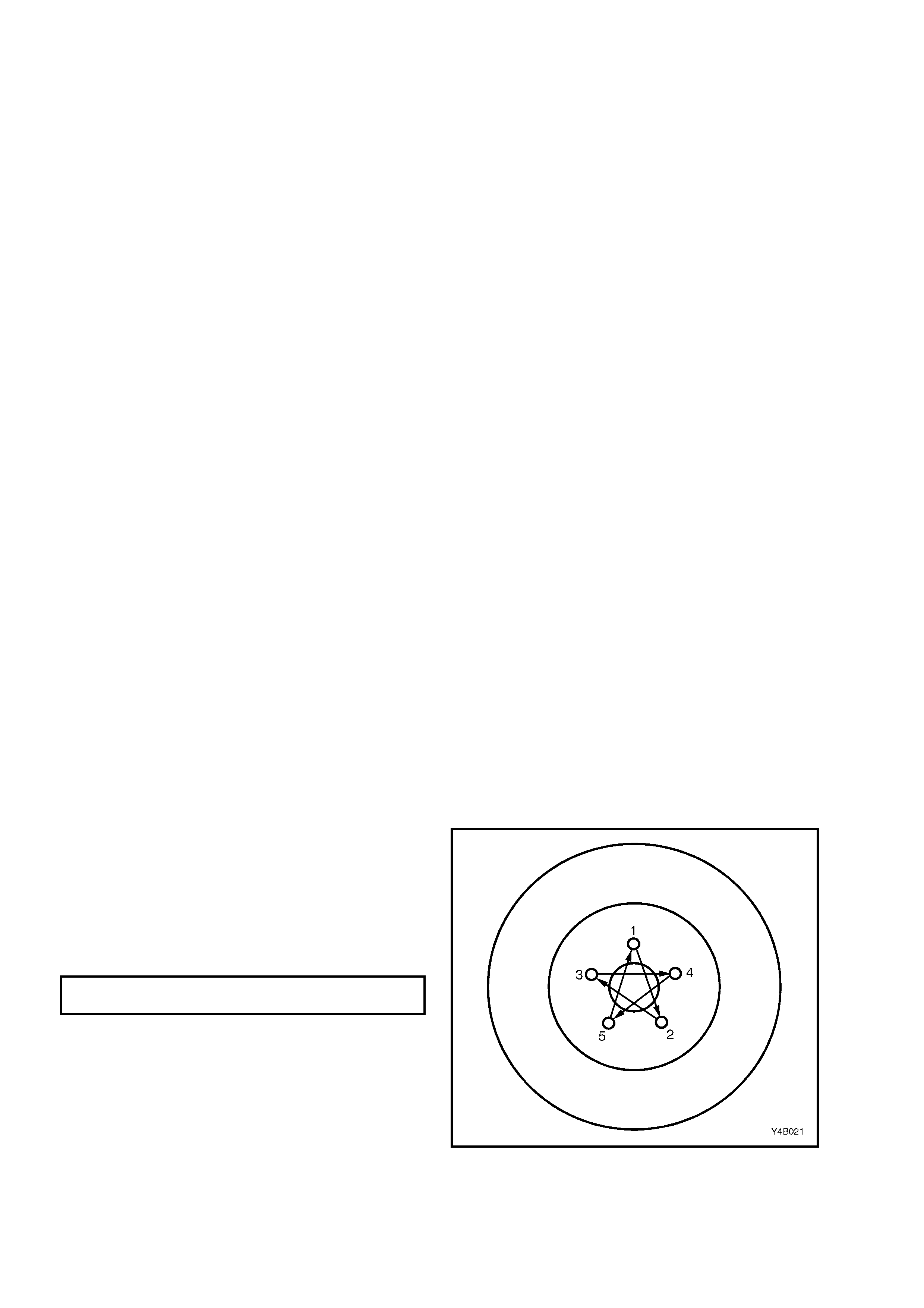

Figure 5A - 14

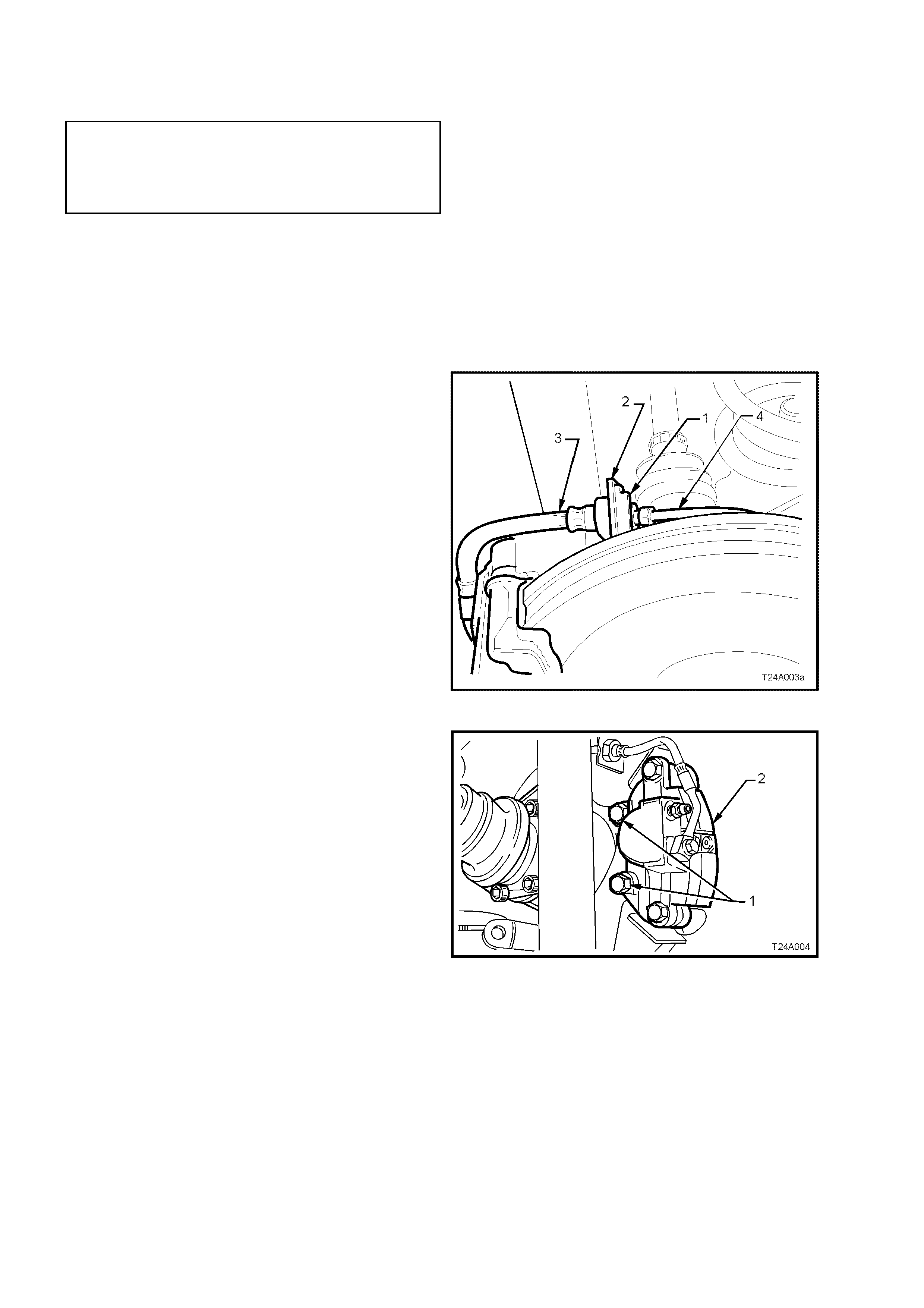

2.2 PARK BRAKE CABLE, ADJUST

1. Raise rear of vehicle and support on jack

stands under each lower control arm, to

maintain the correct suspension attitude.

2. Loosen the park brake cable adjustment nut

several turns.

3. App ly the park brak e until the l ever is extende d

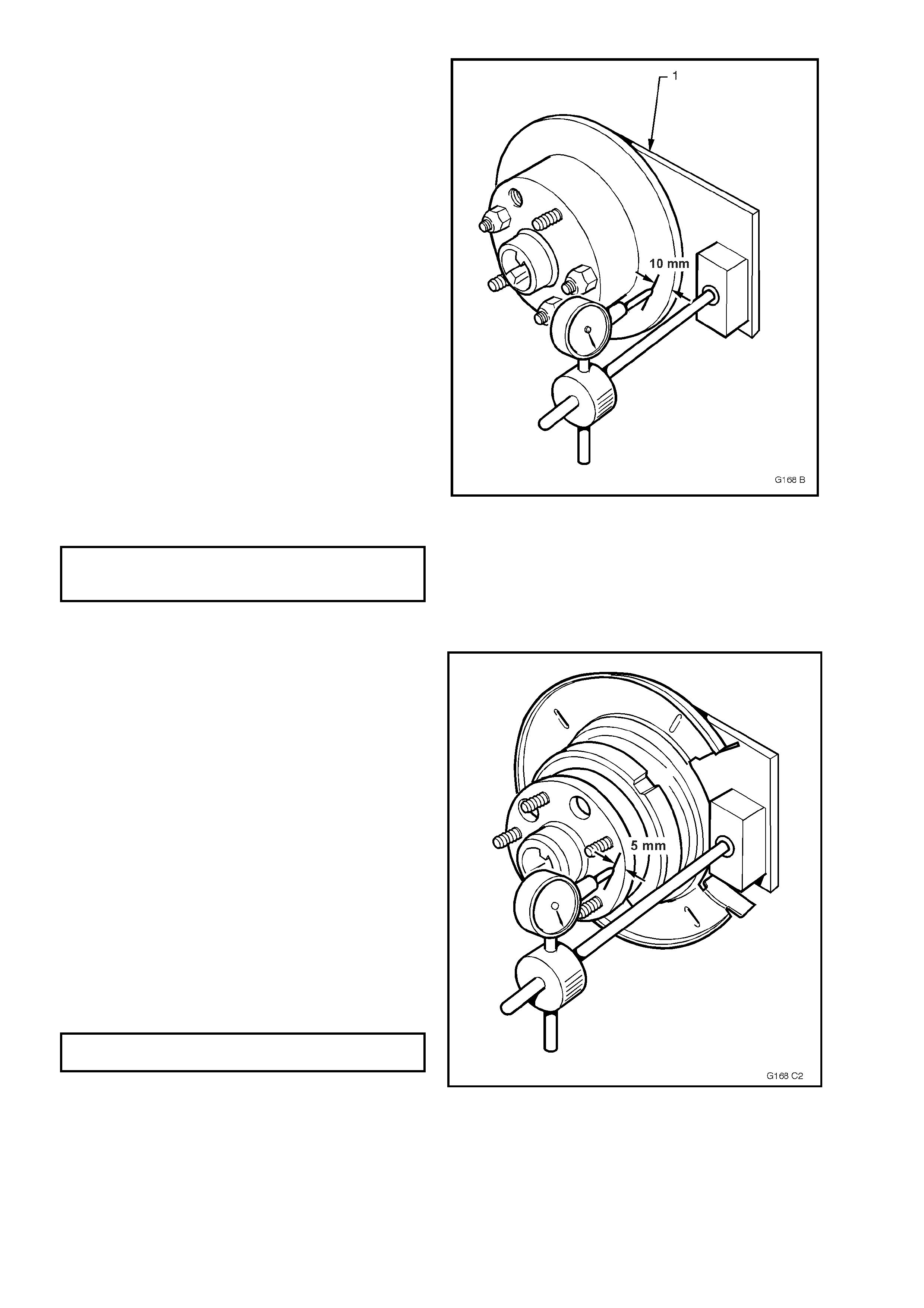

4 - 6 clicks.

4. Using a dial type torque wrench and a deep

socket, tighten the cable adjustment nut

(arrow) until a torque of 2 Nm is applied.

5. Check that this adjustment applies the park

brake shoes to a firm drag torque, by turning

each rear wheel.

NOTE 1: With a new park brake installation or one

that has the correct park brake shoe adjustment,

the thread on the front cable should protrude

through the adjustment nut by 15 - 20 mm.

NOTE 2: If the park brake cannot be satisfactorily

adjusted b y the above m ethod, it will be necessary

to refer to 3.7 PARK BRAKE SHOE, ADJUST in

this Section.

Figure 5A - 15

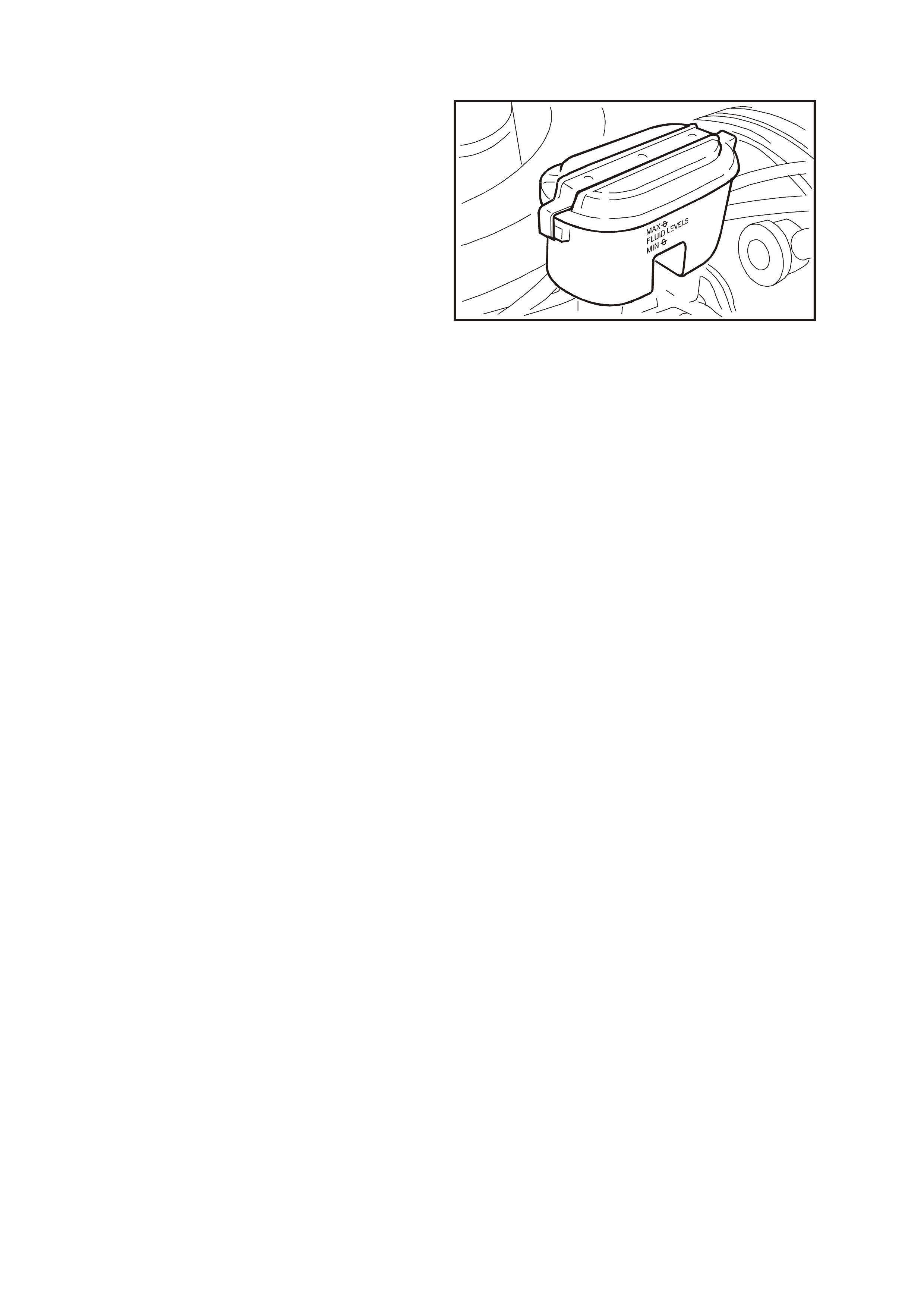

2.3 BRAKE FLUID LEVEL CHECK

Check that the fluid level is between the MIN and

MAX level markings on the translucent reservoir

housing.

NOTE: If the fluid is between the markings, do not

remove reservoir cap, as brake fluid exposed to the

atmosphere will quickly absorb moisture.

Should the addition of f luid be required, wipe clean

the sides of the reservoir cover, then unclip and

rem ove the res ervoir cap . T op up fluid using h eavy

duty brake fluid that complies with DOT 4 Plus

(SAE J1704).

T20B014

Figure 5A - 16

2.4 BRAKE SYSTEM BLEED

LT Section No. – 04-725

The f r ont chamber of the m as ter cylinder can be b led b y lo oseni ng the pi pe to t h e LHF br ak e at th e master c ylinder

(2) and allowing brake fluid to drip from the connection for approximately one minute, ensuring that spilled fluid

drips into a suitab le conta iner. Do not r e-use dra ined fluid and do not operate the brak e pedal or a pply press ure to

the master cylinder during this operation.

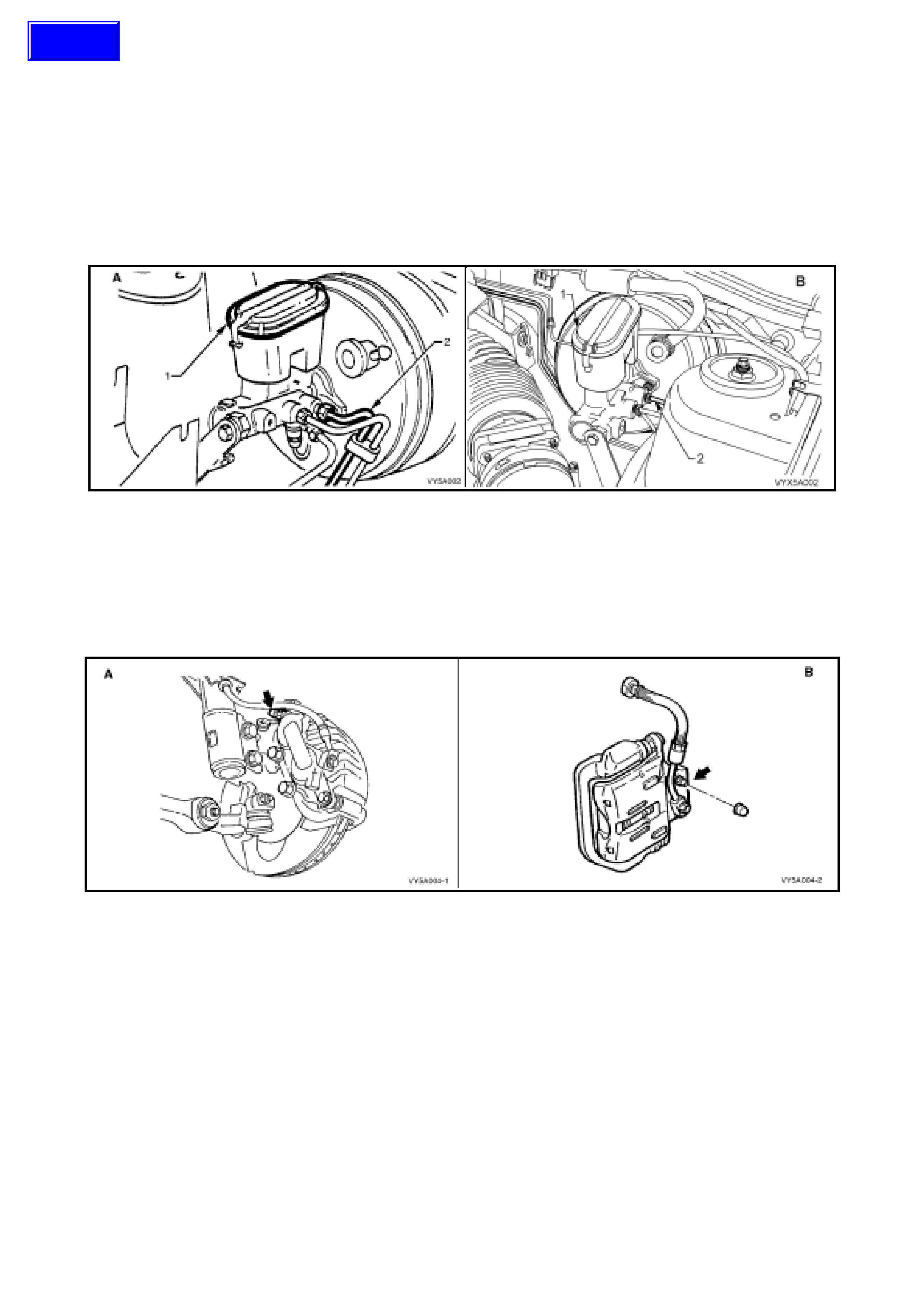

Remove air from other components of the brake system as follows:

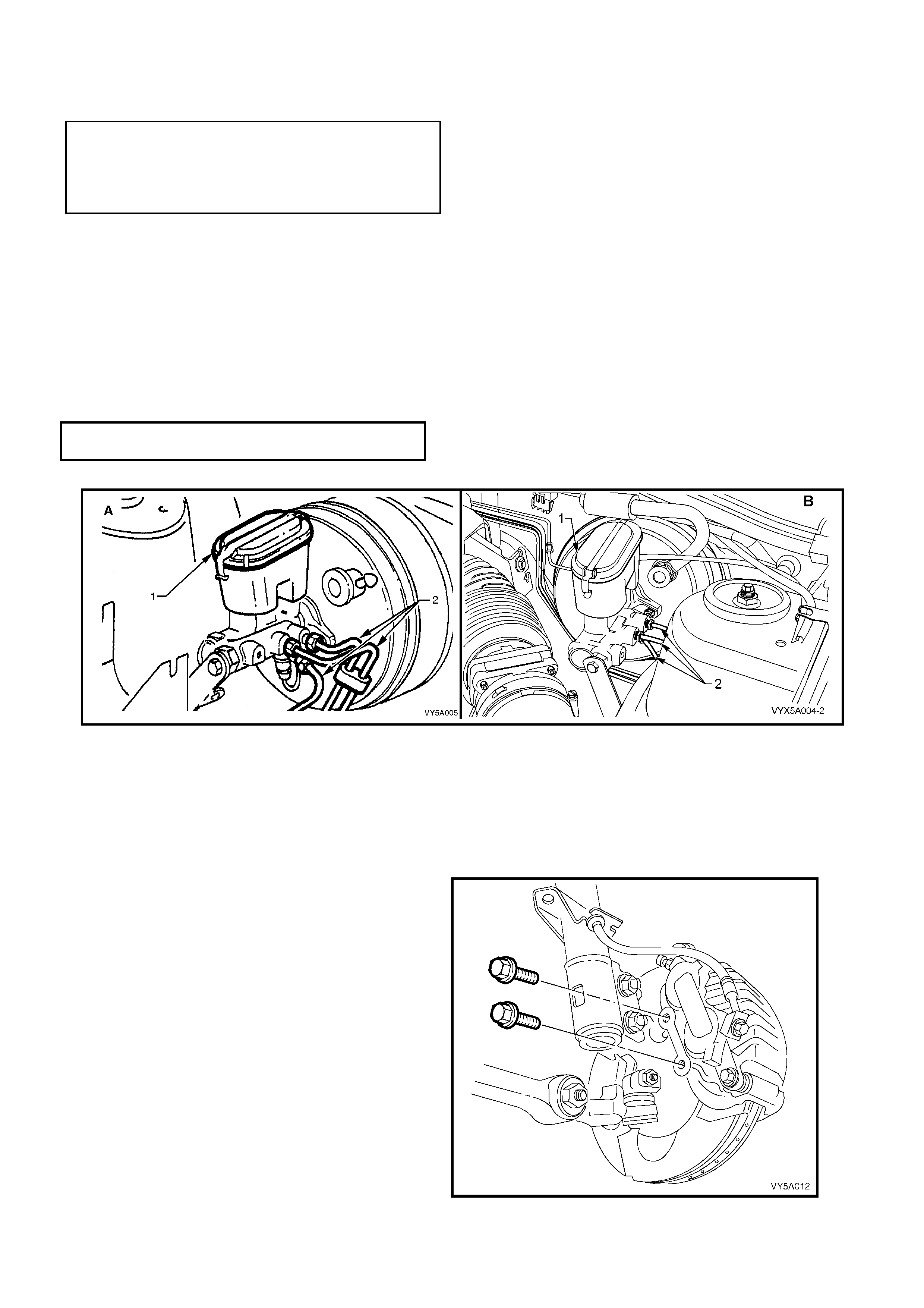

1. Remove master cylinder reservoir cap (1) and fit a commercially available pressure bleed cap.

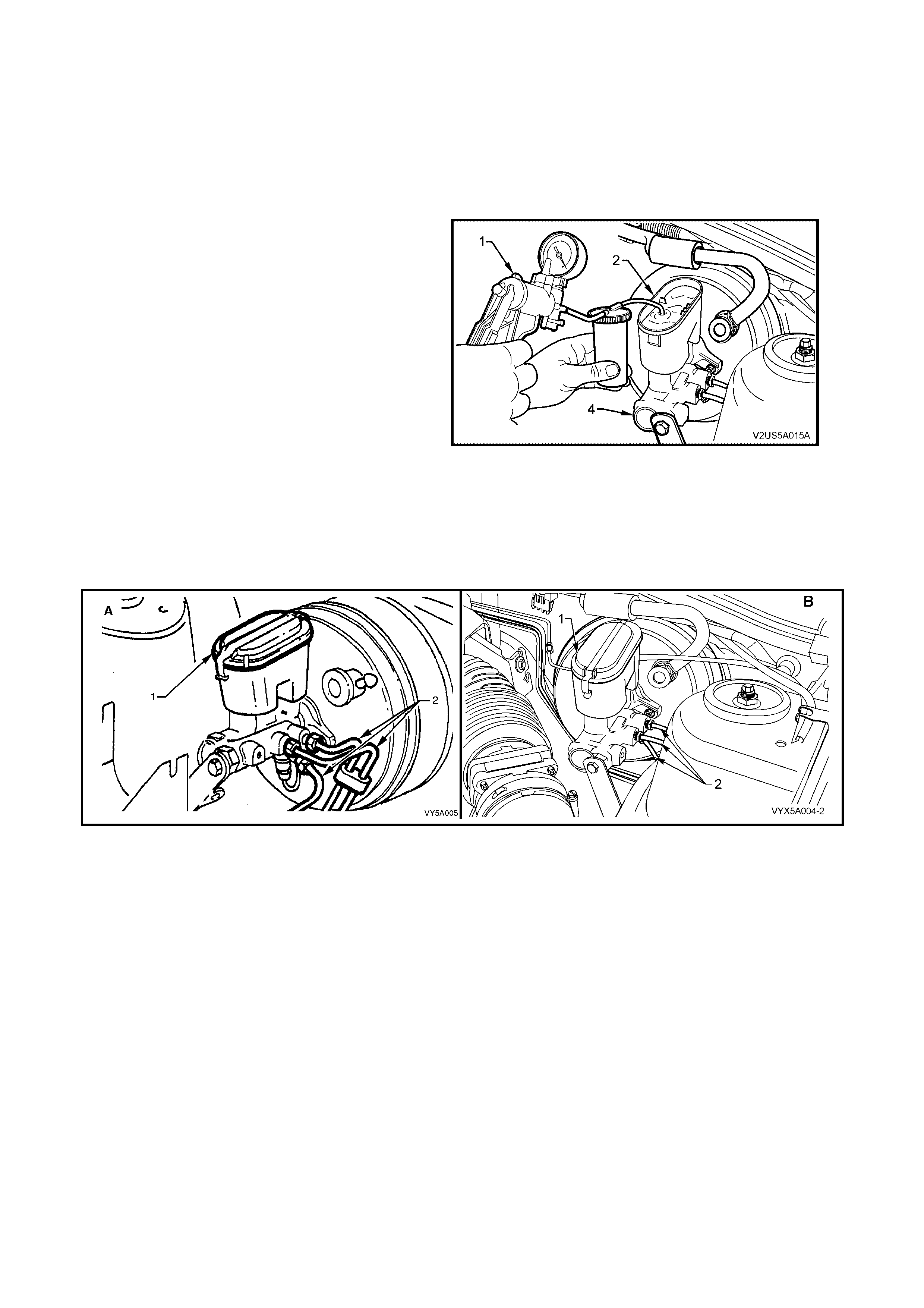

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 17

2. Connect cap to pressure bleed pump and pressurise system to no more than 345 kPa.

3. Open brake bleeder of line to be bled and pump brake pedal one stroke/second for approxim ately 10 strokes,

then close ble eder . Dur ing t his oper a tio n the pres s ure bleeder to th e master c ylinder s hould not b e tur ne d of f. It

is essential that this volume and rate of flow is maintained to ensure air trapped in pipes is carried out of the

system with the flow of the fluid and not allowed to retreat between strokes of the brake pedal.

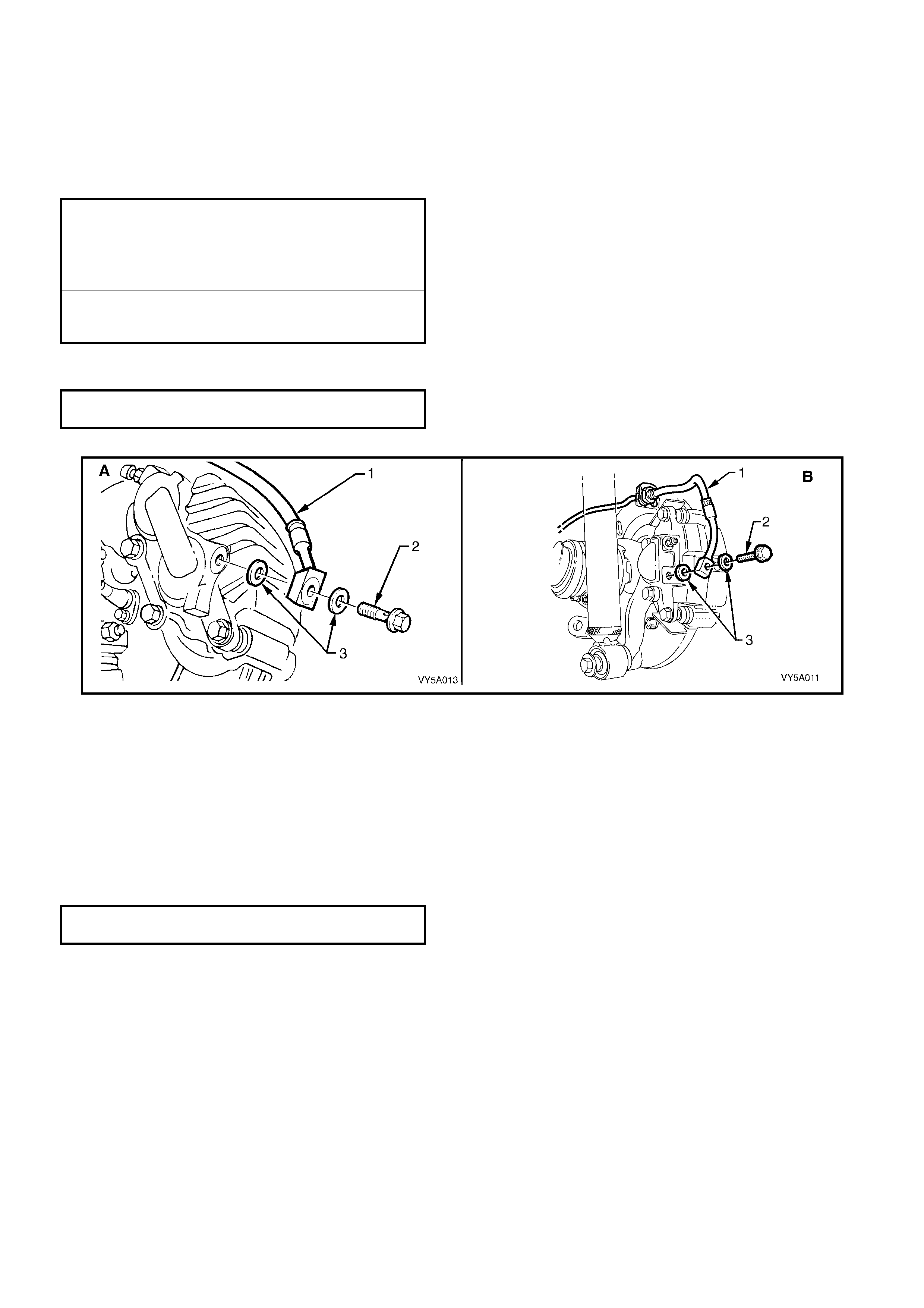

NOTE: View A shows the brake bleeder location for the front brake caliper, while View B is for the rear.

Figure 5A - 18

Techline

2.5 BRAKE FLUID, CHANGE

NOTE: The following fastener MUST be replaced

(!

!!

!) when performing this operation :

!

!!

!

Front brake caliper anchor plate to steering

knuckle attaching bolt

REMOVE

1. Thoroughly clean master cylinder, especially around wheel brake line connections.

2. Disconnect wheel brake lines from master cylinder (2) and remove reservoir cap (1).

3. Allow master cylinder to drain into a container until empty.

4. Fill master cylinder reservoir with fresh, specified brake fluid from a sealed 500 ml container and ensure

reservoir is maintained at least half full for remainder of procedure.

5. Allow fluid to flow from open connection ports until fluid is free of air. Collect discharged fluid in suitable

container and then discard. Do not allow fluid to contact paintwork.

6. Reconnect wheel brake lines to master cylinder and tighten to specified torque.

BRAKE PIPE TO MASTER CYLINDER

FLARE NUT TORQUE SPECIFICATION 8 - 11 Nm

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 19

Drain brake calipers as follows:

7. Raise veh icle and plac e on safet y sta nds. Refer to Section 0A GENERAL INFORM AT ION in the MY2003 VY

and V2 Series Service Information for the locations of jacking and support points.

8. Mark position of wheels relative to hub and remove wheels.

9. Loosen the left hand front caliper bleed screw (bold arrow, in Figure 5A - 18).

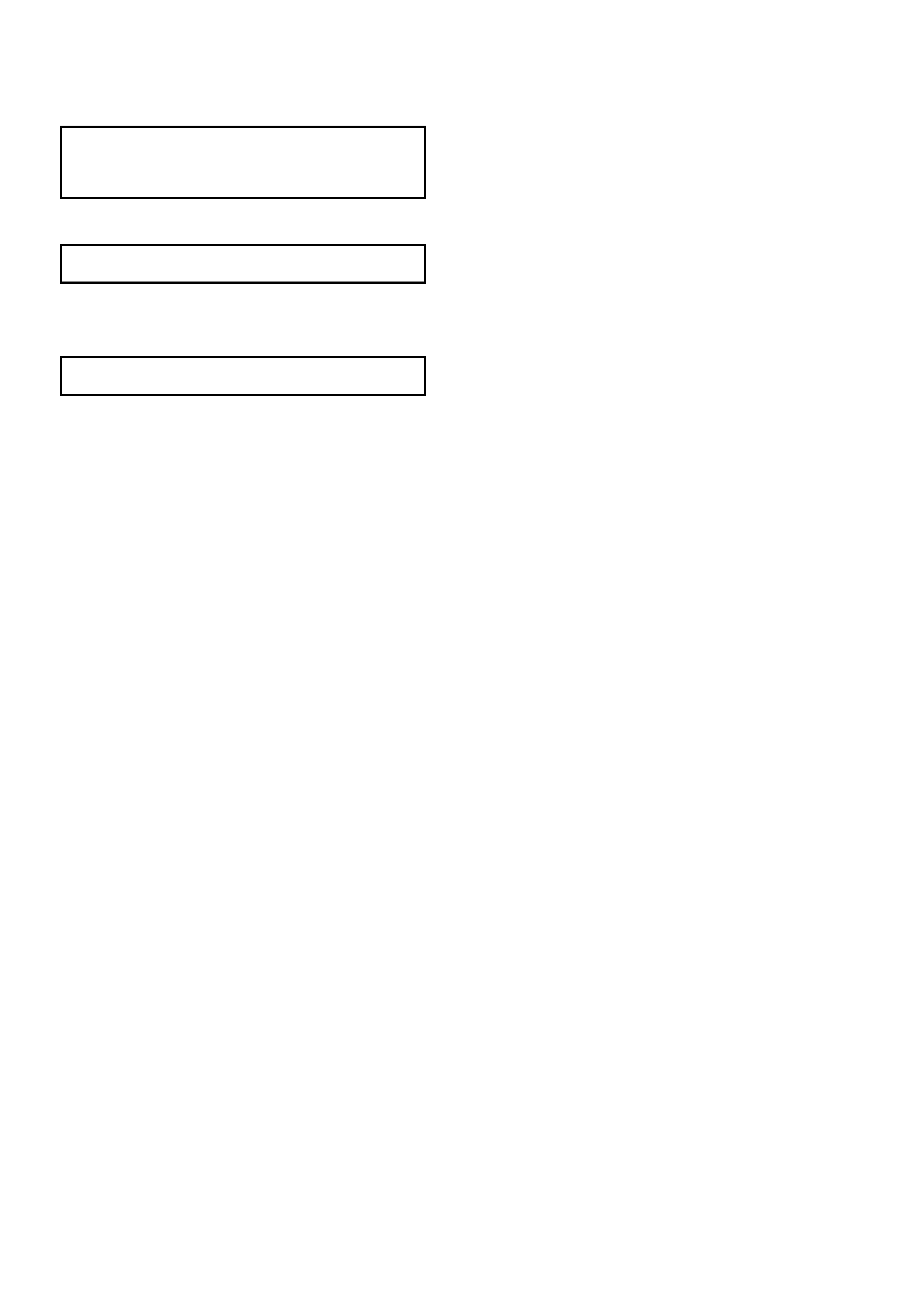

10. Remove front left hand caliper anchor plate

retaining bolts.

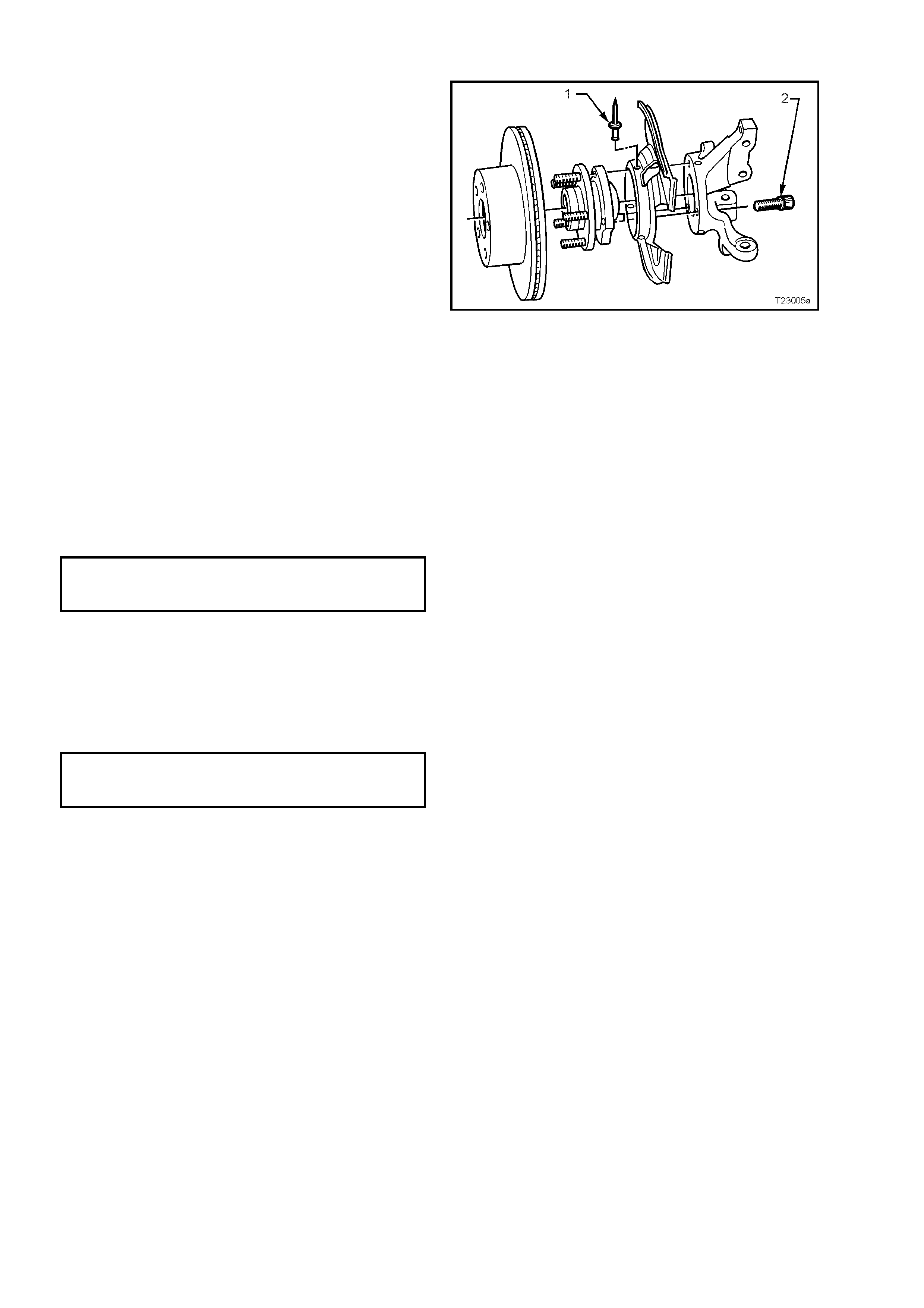

Figure 5A - 20

11. Hold caliper upside down and remove bleed screw to drain contents of caliper into suitable receptacle.

12. Hand tighten bleed screw and reinstall caliper assembly.

13. Tighten caliper anchor plate retaining bolts to specified torque.

(!

!!

!) FRONT BRAKE CALIPER

ANCHOR PLATE BOLT

TORQUE SPECIFICATION 80 - 90 Nm, then

40° - 50° turn angle

14. Repeat steps 8 to 13 for the rem aining cali per assem blies and tighten the r ear brak e caliper anc hor plate b olts

to the correct torque specification.

REAR BRAKE CALIPER ANCHOR

BOLT TORQUE SPECIFICATION 70 - 100 Nm

15. Bleed brake system, refer to 2.4 BRAKE SYSTEM BLEED in this Section.

16. Reinstall road wheel in original position and lower vehicle.

17. Tighten road wheel nuts to the specified torque.

ROAD WHEEL ATT ACHING

NUT TORQUE SPECIFICATION 100 - 125 Nm

2.6 BRAKE PAD WEAR, CHECK

FRONT OR REAR

NOTE: The procedure and minimum thickness specification is common to both f ront and rear brak e pads, despite

the fact that only the front brake caliper procedure is provided.

1. Raise the vehicle and support on safety stands. Refer to Section 0A GENERAL INFORMATION in the

MY2003 VY and V2 Series Service Information for the locations of jacking and support points.

2. Remove rear wheel covers (steel wheels) or wheel nut decorative caps (alloy wheels).

3. Mark position of road wheels relative to hub, remove road wheel attaching nuts, then the road wheels.

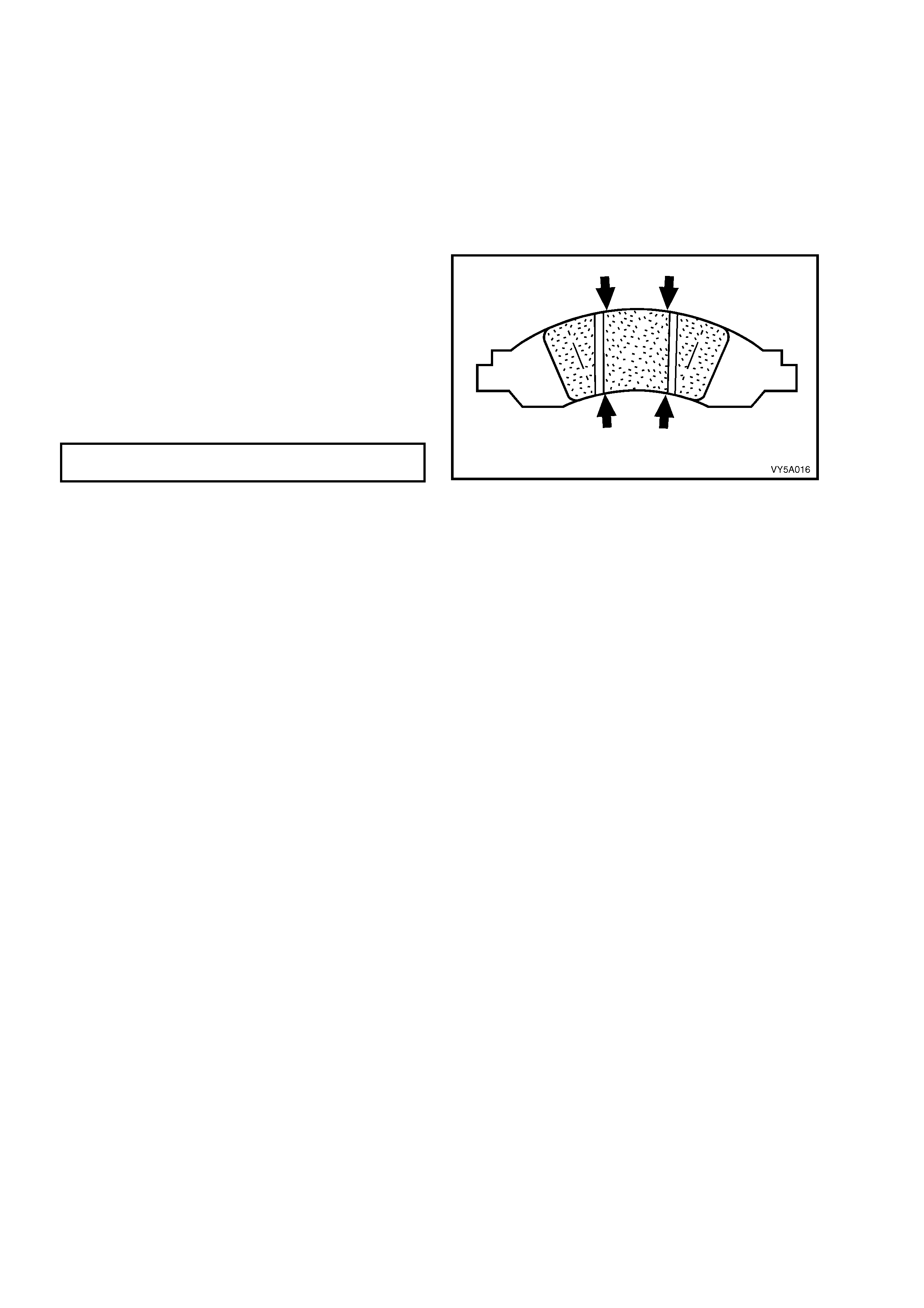

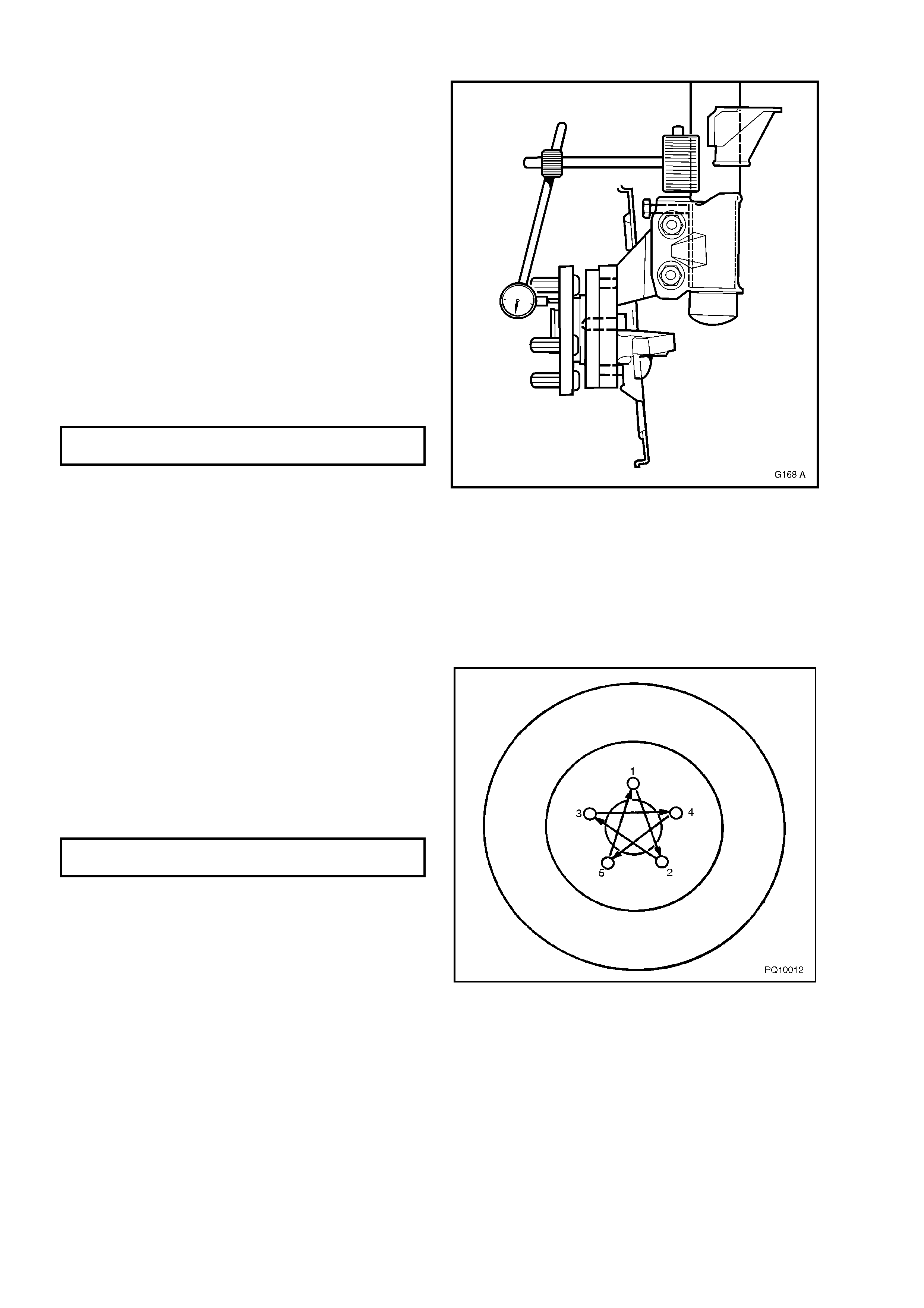

4. Remove the pads to be checked, from the

caliper ensuring that the original pad positions

are noted. Refer to 2.7 BRAKE PADS,

REPLACE, in this Section.

5. Using vernier calipers, check the brake [pad

thickness in the four locations shown. The

minimum lining thickness should be no less

that the thickness specified. Also, pad wear

should be even – if not, then the cause must

be established and corrected.

BRAKE PAD MINIMUM LINING

THICKNESS BEFORE REPLACEMENT 2 mm

6. If not being replaced, reinstall the brake pads

in the same locations, prior to removal. Refer

to 2.7 BRAKE PADS, REPLACE, in this

Section, for the required procedures for this

operation.

7. Reinstall wheel nuts but do not fully tighten at

this time.

Figure 5A - 21

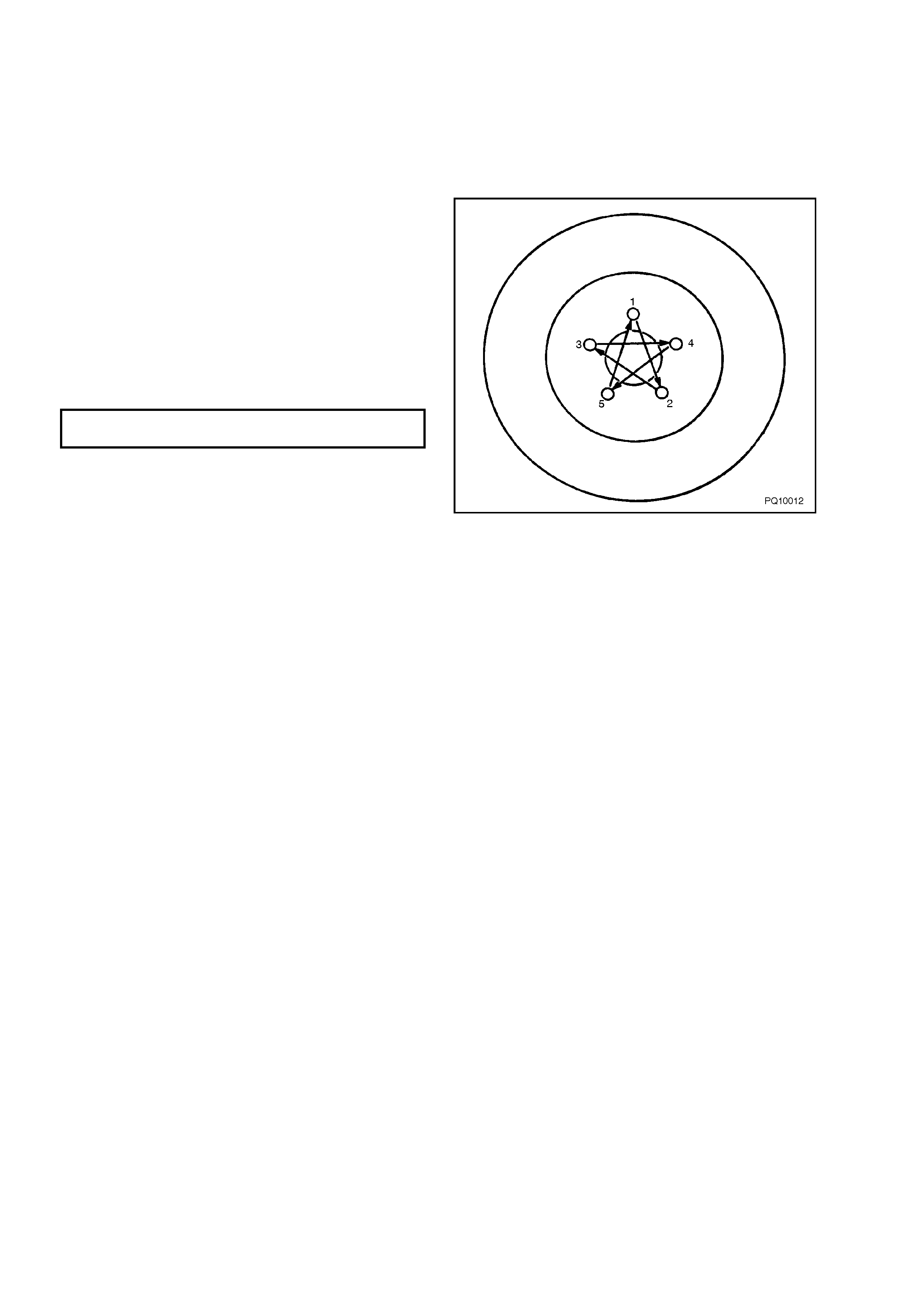

8. Lower the vehicle to the ground and tighten the wheel nuts to the specified torque, working in a star pattern,

refer to 2.1 SERVICE NOTES AND CAUTIONS, in this Section.

9. Reinstall wheel covers (steel wheels) or wheel nut decorative caps (alloy wheels).

10. Road test vehicle to check for correct brake operation.

2.7 BR AKE PADS, REPLACE

LT Section No. – 04-750 and 04-825

NOTE: The following fasteners have micro-

encapsulated sealant applied and should be

replaced (#

##

#) on reassembly:

# Brake caliper guide pin bolt

BR AKE PAD REMOV AL

NOTE: T his proc edure ref ers to f ront brak e pads. An y dif ferenc es relatin g to rear brak e pad repl acem ent are noted

in square brackets.

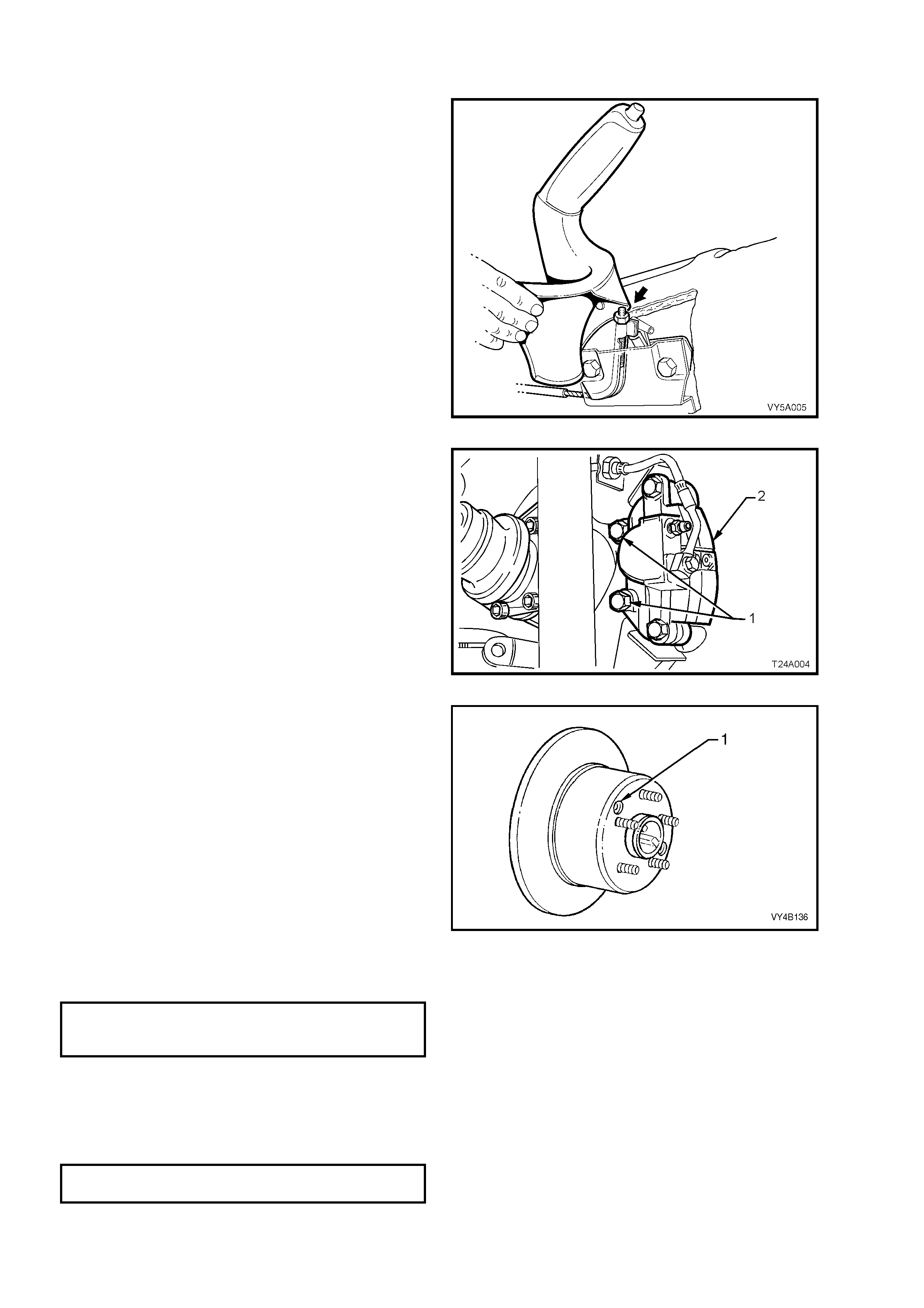

1. Remove m aster c ylinder re servoir cap. L oosen fr ont left (1) [or rear (2)] wheel brak e line connect ion at m aster

cylinder, allowing fluid to bleed into a container until master cylinder reservoir is approximately 1/2 full.

Re tighten line connection and install master cylinder cap.

NOTE 1: Do not completely remove the brake line or empty the reservoir or it will be necessary to bleed the braking

system.

NOTE 2: DO NOT ATTEMPT TO RE-USE the removed fluid.

NOTE 3: Removal of fluid from the reservoir is needed to stop reservoir overflow when caliper piston is pushed

back in its bore during pad replacement.

NOTE 4: Brake fluid will damage paint-work.

NOTE 5: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 22

2. Raise fr ont (or rear) of vehi cle and place on s afety stands. Ref er to Section 0A GENERAL INFORM ATION in

the MY2003 VY and V2 Series Service Information for the necessary procedures.

3. Mark relationship of wheel to hub. Remove front (or rear) wheels.

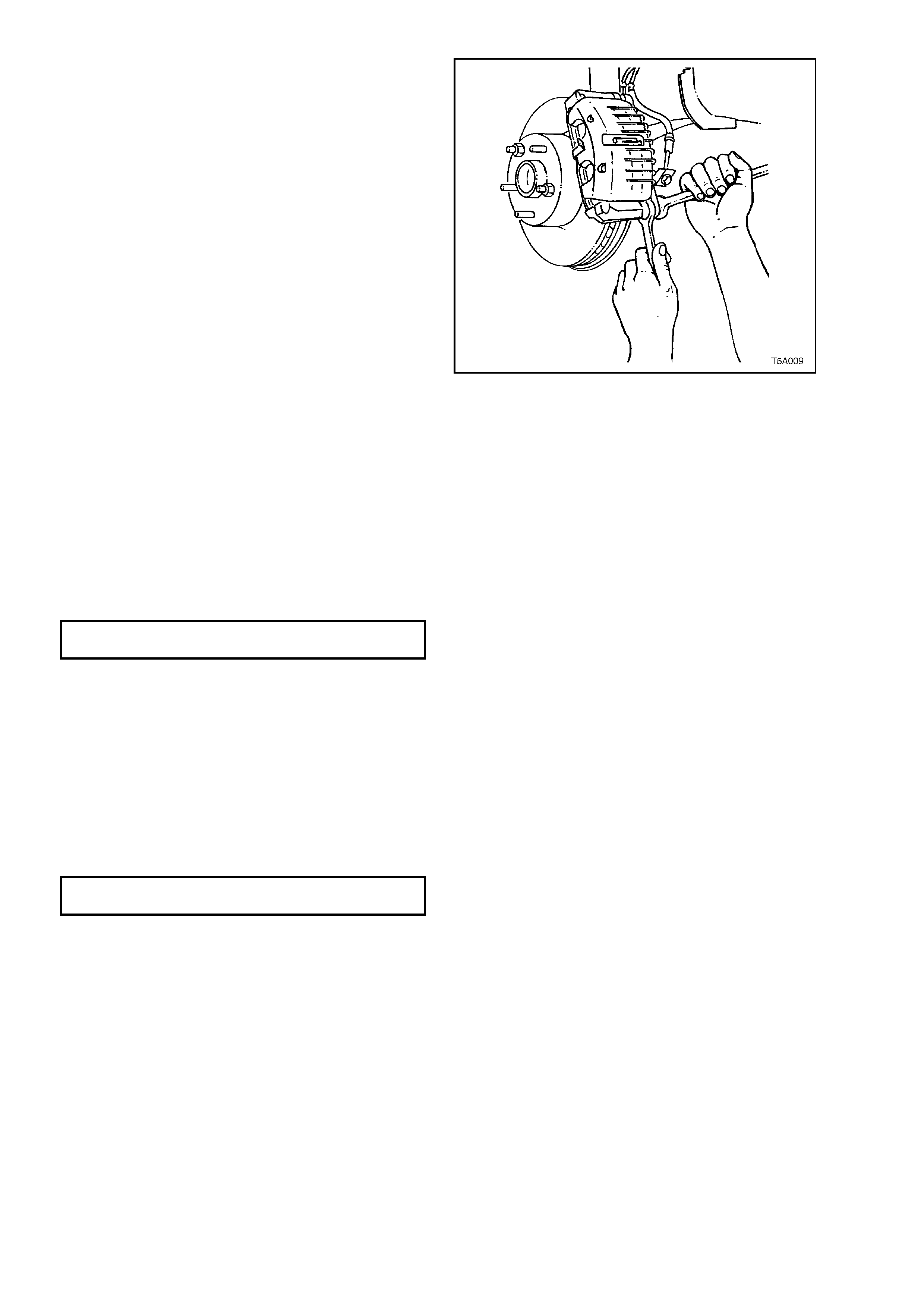

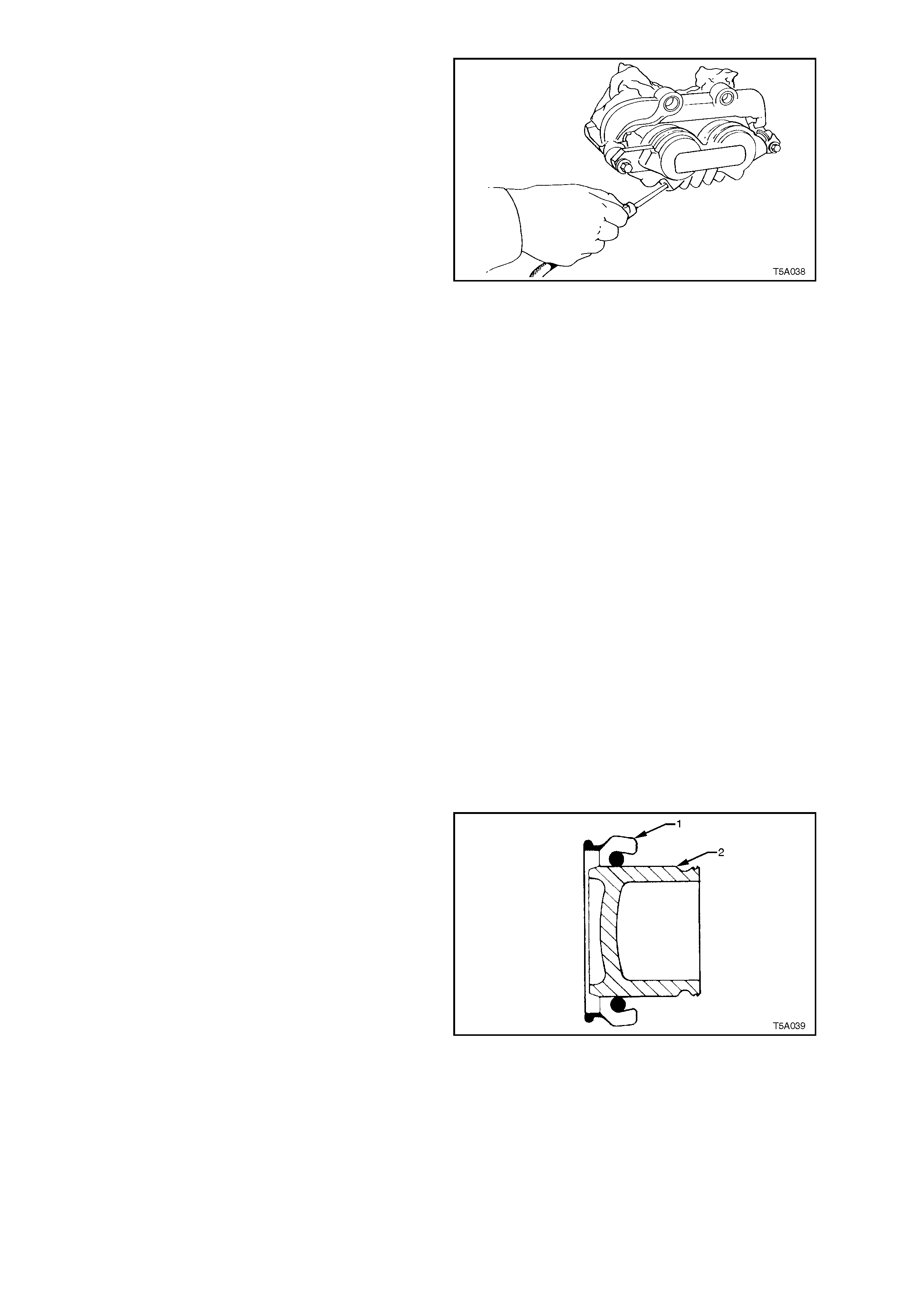

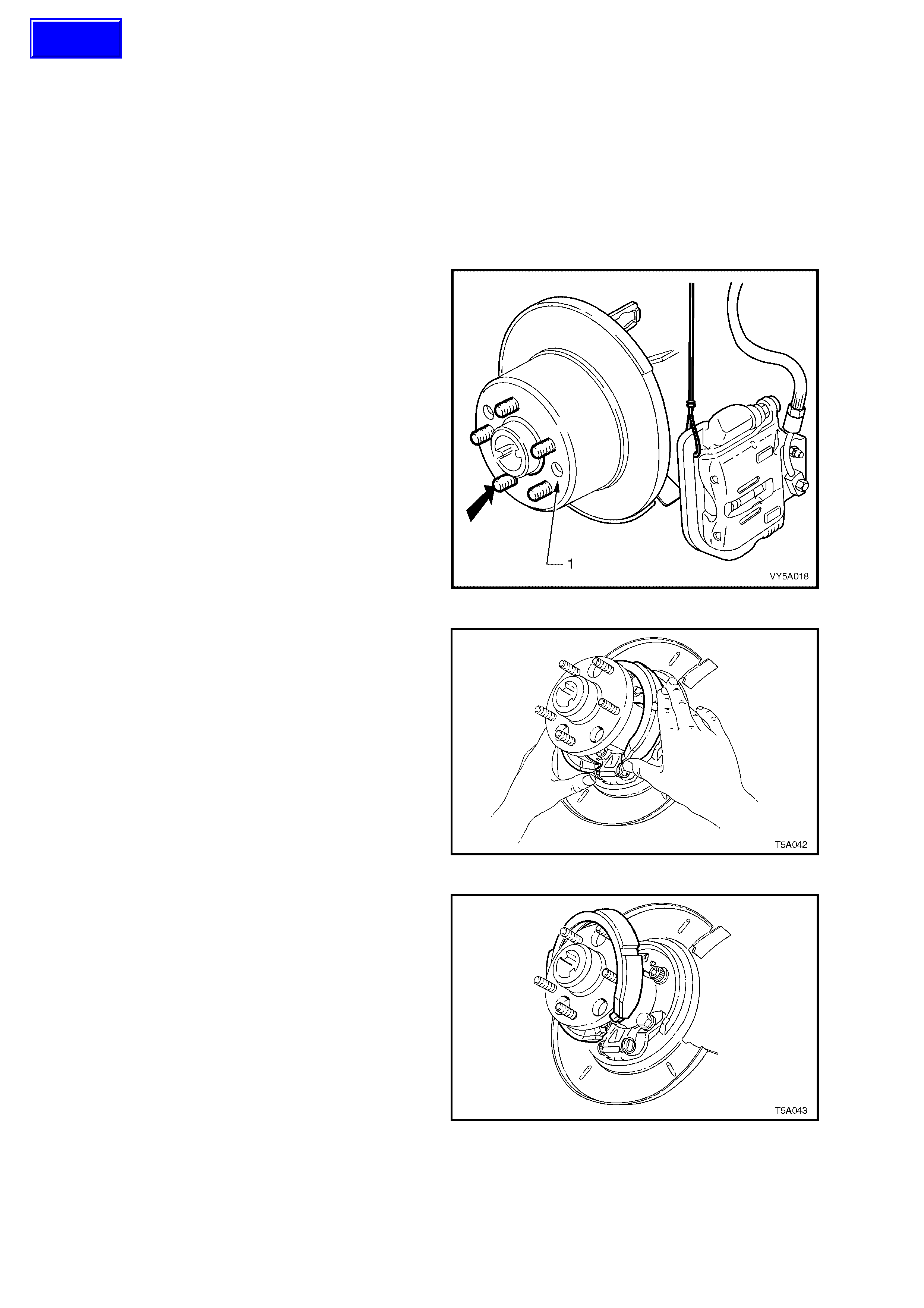

4. Using G-clamps as shown, tighten until the caliper pistons bottom in each bore.

NOTE 1: Ensure that one end of the G-clamp rests on (or is adjacent to) the brake hose attaching bolt head, and

the other against the outer pad.

NOTE 2: View A is for the front brake caliper, while View B is for the rear.

Figure 5A - 23

5. Us ing a s uitab le si ze ope n end sp anner to hol d

the lower guide pin, remove and discard the

guide pin bolt.

NOTE: Old bolts must not be re-used as they are

vital safety components which have a micro-

encapsulated adhesive on the bolt thread.

6. Swing caliper assembly up from the anchor

plate and disc and support caliper with a wire

hook.

7. Remove worn pads from anchor plate.

8. Inspect condition of brake disc.

9. Check guide pins for free movement in anchor

plate. If there is restriction of movement,

replace guide pins and/or guide pin boots.

Refer to 3.3 BRAKE CALIPER in this Section.

10. Clean an y dirt f rom both t he piston f ace, which

contacts the inner pad, and the caliper head

area which contacts the outer pad.

11. Install new brake pads as follows:

Figure 5A - 24

FRONT BRAKE PAD INSTALLATION

1. Thoroughly clean both piston contact faces, using a suitable solvent such as Prepsol, if required.

2. Peel the backing paper from the inner pad and install it to the anchor plate, against the brake disc.

NOTE: Do not handle the exposed, sticky surface of the pad, particularly in the piston contact areas.

3. Install the outer pad to the caliper, noting that a leg of the steel spring should sit on top of the inner pad.

4. Reinstall the brake caliper housing, ensuring that the outer spring clip engages with the middle finger of the

caliper housing.

5. Install and tighten a new guide pin, self locking bolt to the correct torque specification.

(#

##

#) GUIDE PIN BOLT

TORQUE SPECIFICATION 30 - 34 Nm

NOTE 1: Use a suitable open end spanner to prevent the guide pin from rotating when tightening the guide pin bolt.

NOTE 2: Do not wed ge a n yth ing bet ween the guid e p i n hex a nd t he c a lip er as it c ould c aus e inc orr ec t a lignm ent of

the pin which would then restrict the free sliding of the caliper relative to the anchor plate.

6. Fill master cylinder to correct level with fresh, specified brake fluid.

7. Depress an d hold the br ake peda l down in the applied pos ition for at least 5 s econds, to ens ure that the inner

pads stick to the pistons.

8. Refill master cylinder if necessary.

9. Reinstall wheels, aligning marks made prior to removal and lower vehicle to the ground.

10. Tighten road whee l att ac hi ng nuts to th e s pec if ied torque, work ing i n a star patte r n, as detai le d in 2.1 SERVICE

NOTES AND CAUTIONS, in this Section.

ROAD WHEEL ATT ACHING

NUT TORQUE SPECIFICATION 100 - 125 Nm

11. Reins t al l wheel caps (steel whee ls) or wheel nut dec or ati ve ca ps (al loy wheels) .

REAR BRAKE PAD INSTALLATION

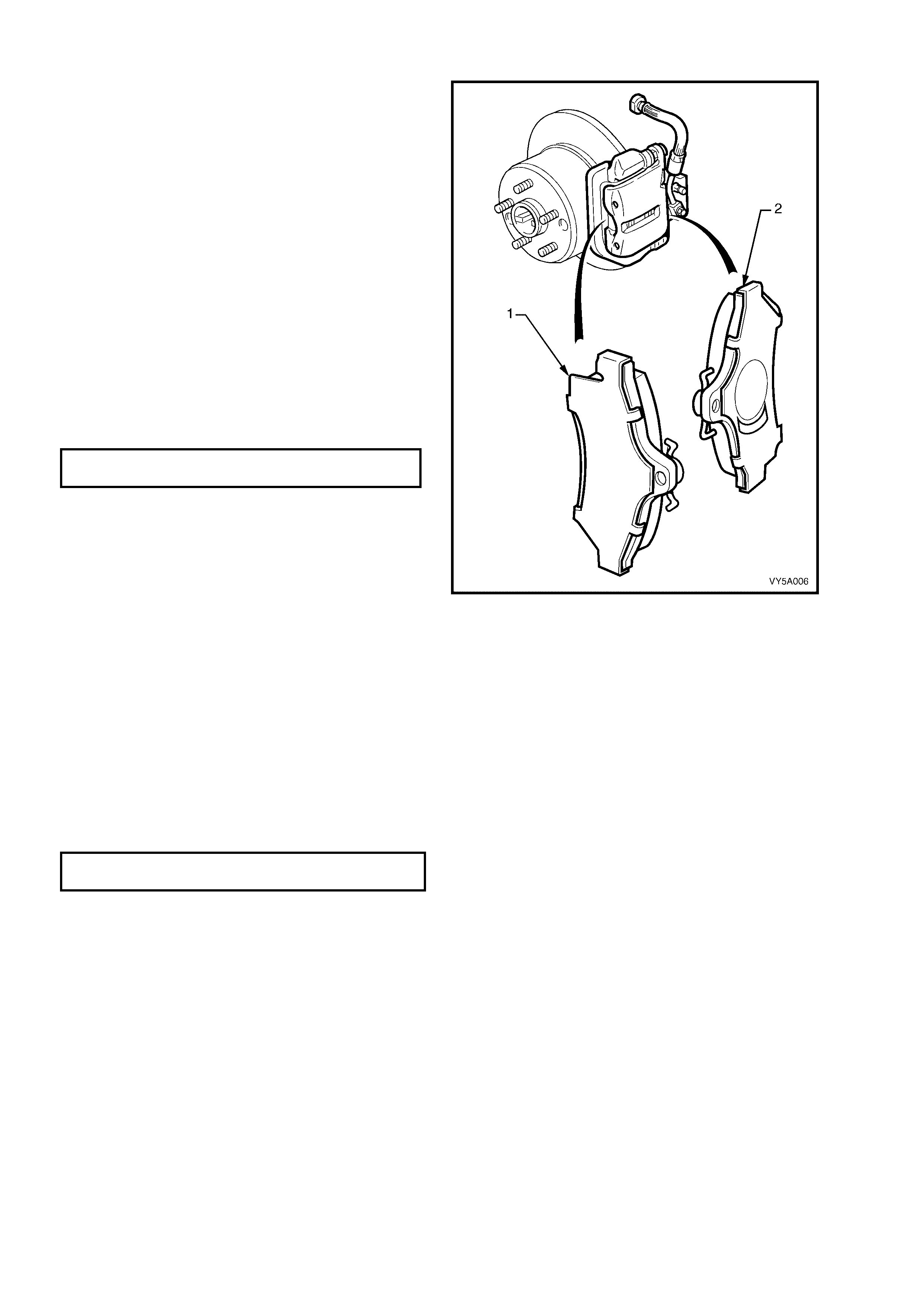

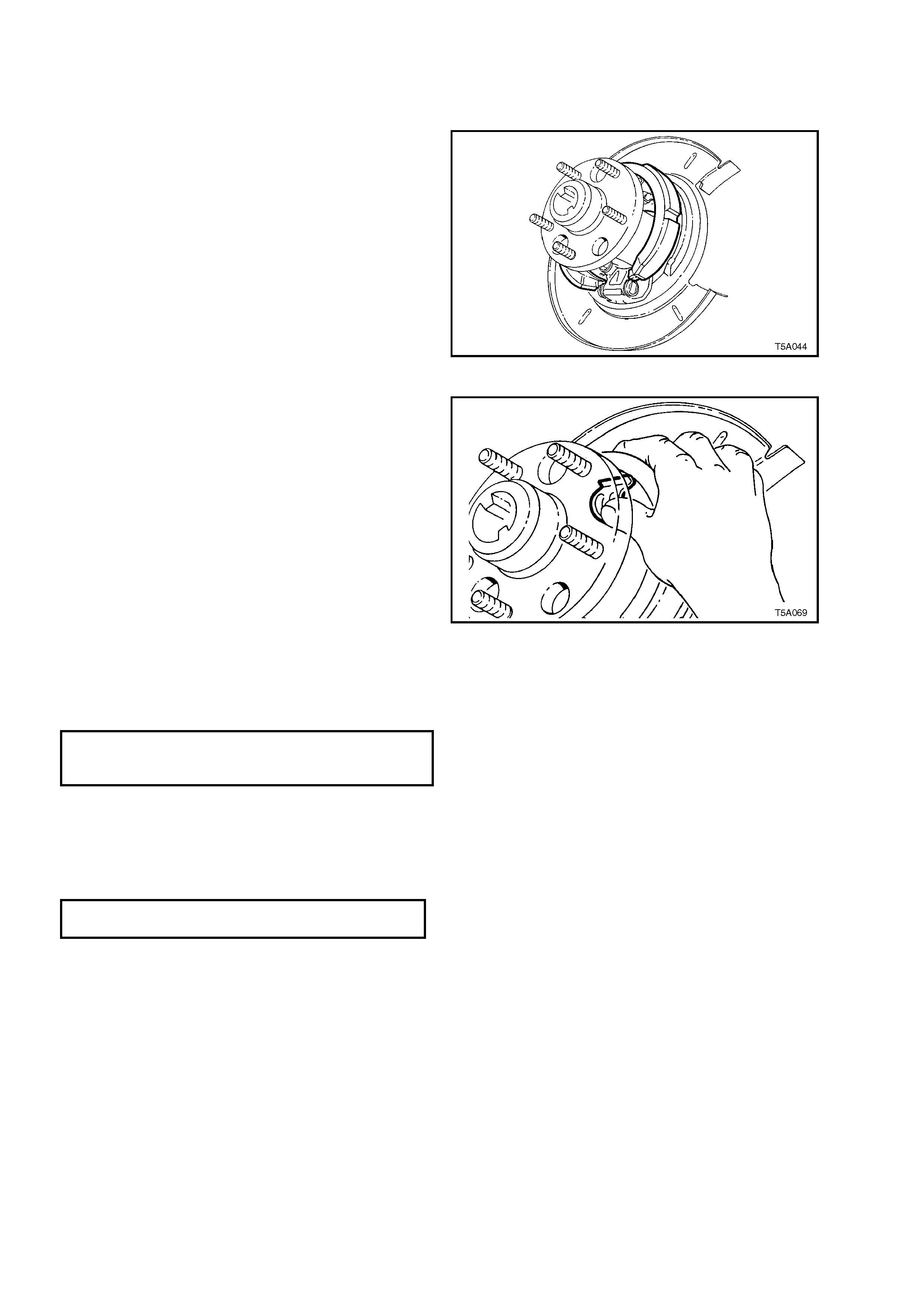

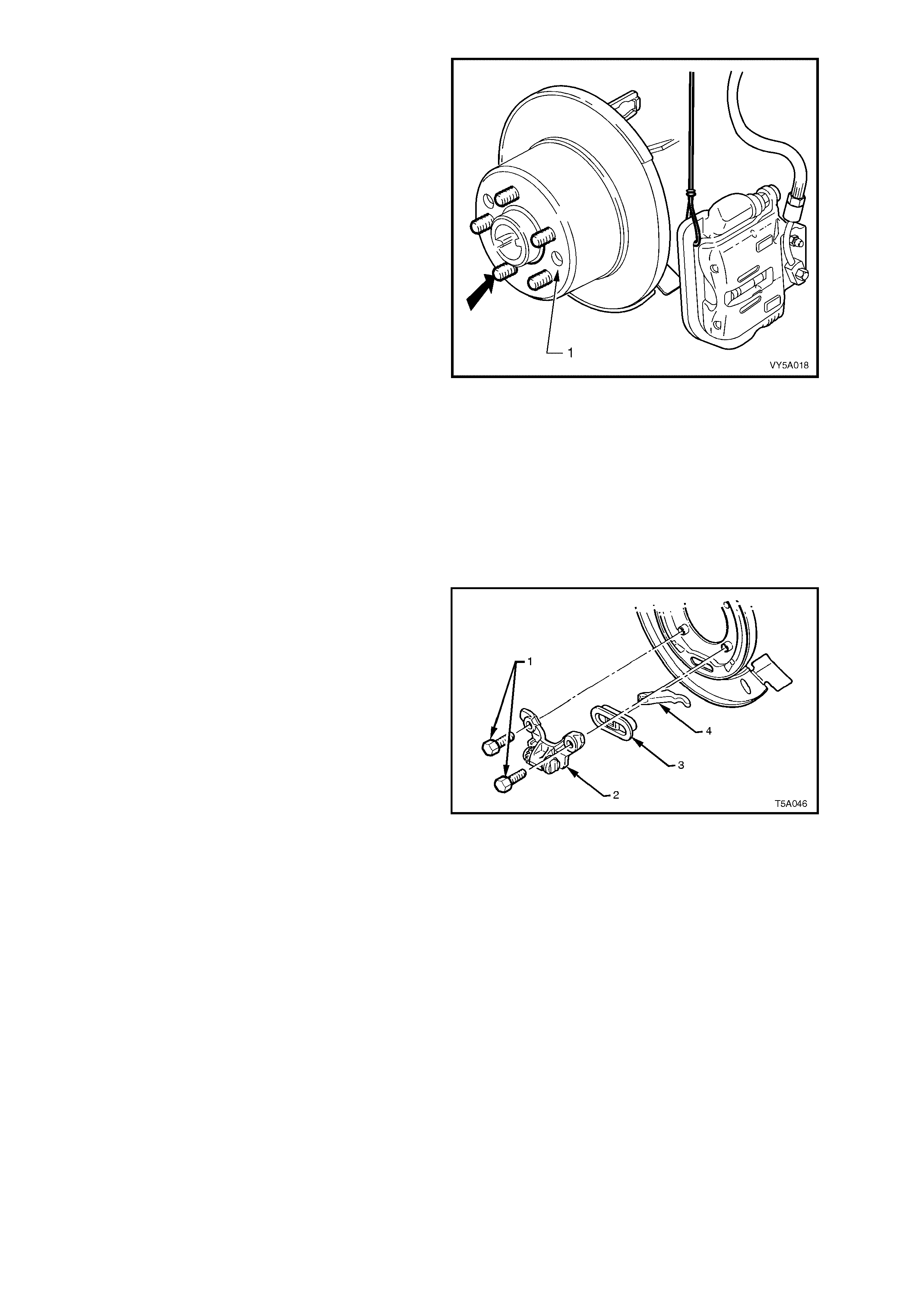

IMPORTANT: For noise damping effectiveness, it

is critical that the brake pad and shim assemblies

are installed in the correct locations. For example:

a. The outer pad (1) (which is retained by the

fingers of the brake caliper housing), has a full

shim.

b. The inner pad (2) has a shim that has an

asymmetrical cut-out above the caliper piston

and mus t be cor rectl y installed to the c aliper b y

having the cut-out on the lower half of the pad

when installed in the caliper (in-car position).

The brake pads illustrated, should only be fitted

to the left hand side, rear brake caliper, in the

attitude, as shown.

1. Reinstall caliper housing over brake pads.

Ensure spring clip is located correctly in the top

of the caliper body.

2. Install new guide pin, self locking bolt. Tighten

to the specified torque.

(#

##

#) GUIDE PIN BOLT

TORQUE SPECIFICATION 30 - 34 Nm

NOTE 1: Use a suitable open end spanner to

prevent t he guide p in from rotating when tig htening

the guide pin bolt.

NOTE 2: Do not wedge anything between the

guide pin hex and the caliper as it could cause

incorrect alignment of the pin which would then

restrict the free sliding of the caliper relative to the

anchor plate.

3. Fill master cylinder to correct level with fresh,

specified brake fluid.

4. Depress brake pedal several times to bring pad

assemblies into position against disc.

5. Refill master cylinder if necessary.

6. Reinstall wheels, aligning marks made prior to

removal and lower vehicle to the ground.

Figure 5A - 25

7. Tighten road wheel attaching nuts to the specified torque, working in a star pattern (refer to 2.1 SERVICE

NOTES AND CAUTIONS, in this Section.

ROAD WHEEL ATT ACHING

NUT TORQUE SPECIFICATION 100 - 125 Nm

8. Reinstal l whee l caps (stee l whee ls ) or wheel nut dec orative caps (alloy wheels).

BRAKE PAD BEDDING-IN PROCEDURE

Whenever brake pads are replaced, they should be burnished, by the following bedding-in procedure:

1. Perform a minimum of 10 moderate (0.3 to 0.4 g deceleration) brake applications from 70 km/h down to 40

km/h every 500 metres.

NOTE 1: A panic stop would be classif ied as being a 0.9 g deceler ation br aking effor t, so a moder ate deceler ation

rate of 0.4 g would be one that required approximately half the brake pedal effort needed for a panic stop.

NOTE 2: Do not perform this procedure at less than 500 metre intervals, as the excessive heat build-up, may

adversely affect the frictional characteristics of the new brake pad material.

2.8 BRAKE PEDAL ASSEMBLY

LT Section No. – 04-600

REMOVE

CAUTION: Disable the SRS (Air Bag). Refer to Section 12M, OCCUPANT PROTECTION SYSTEM.

NOTE: For vehicles with manual transmission, it is necessary to remove the clutch pedal assembly prior to

removing the brake pedal assembly. Ref er to Section 7 A1, 3.7 CLUT CH PEDAL ASSEMBLY in the MY2003 VY

and V2 Series Service Information for details.

1. As required, first remove the following components:

a. Driver side instrument panel lower trim plate assembly, refer to Section 1A3, 3.1 INSTRUMENT PANEL

LOWER TRIM PLATE A SSEMBLY.

b. Instrument panel lower trim panel assembly, refer to Section 1A3, 3.4 INSTRUMENT PANEL LOWER

TRIM PANEL ASSEMBLY.

c. Instrument panel lower trim panel retainer, refer to Section 1A3, 3.5 LOWE R TRIM PANEL RETAINER.

2. For left-hand drive vehicles, disconnect the left hand side ventilation ducting. Refer to Section 2B - HVAC

CLIMATE CONTROL (MANUAL AC) – REMOVAL AND INSTALLATION

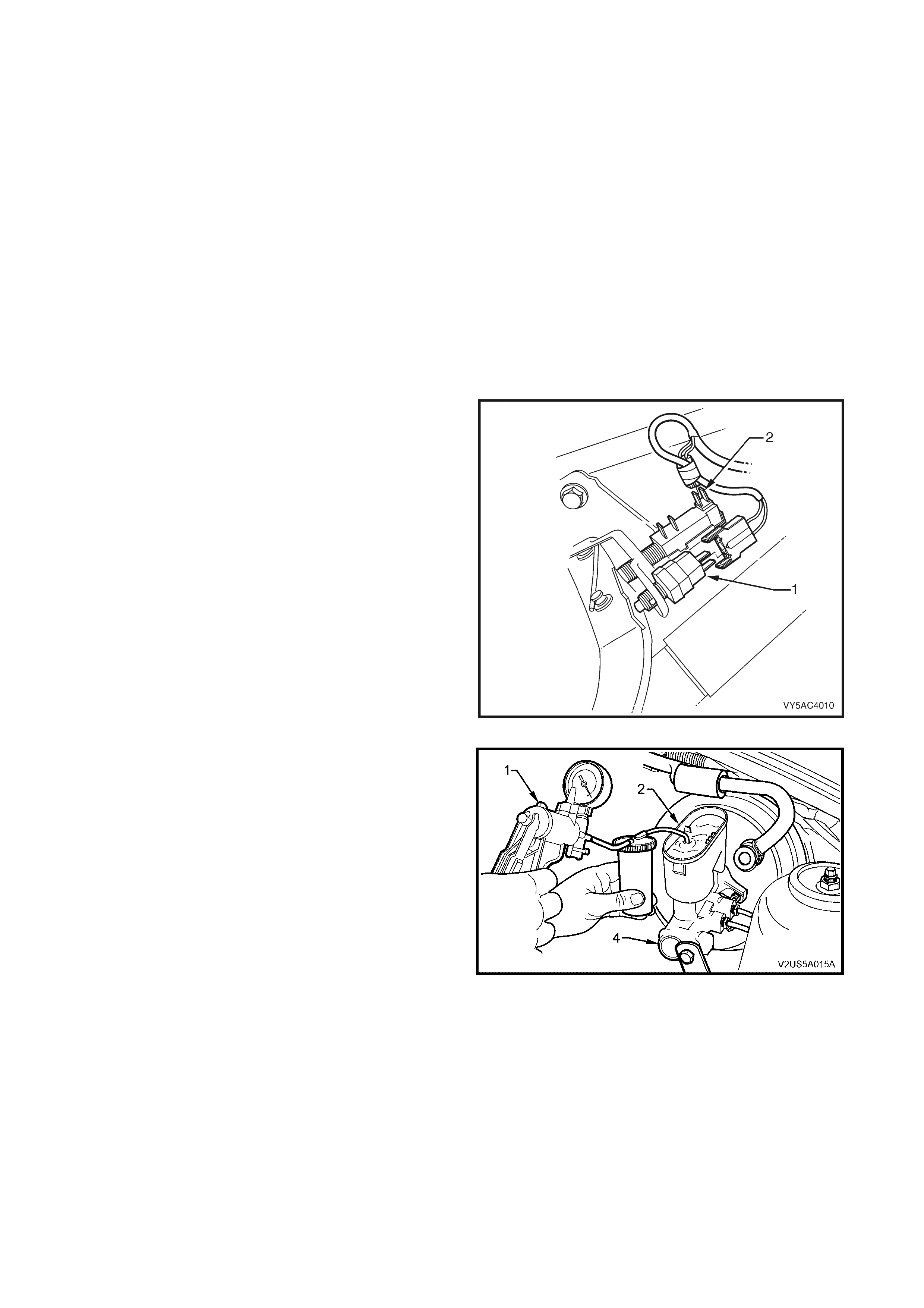

3. Disconnect t he wiring h arness connec tors from the

stop lamp switch (1) and the cruise control switch

(2).

NOTE: Refer to Section 12E, CRUISE CONTROL for

further information on the cruise control switch.

4. Thoroughly clean the master cylinder, especially

around the brake line connections.

Figure 5A - 26

5. Remove the m as ter c ylinder r eservoir cap. Using a

hand vacuum pum p (1), special tool J 23738- A or a

commercially available hand vacuum pump or

syringe, siphon as much brake fluid from the

master cylinder reservoir (2) as possible.

NOTE: Brak e fluid will c aus e dam age to the pa int work

if it comes into contact with it. In the event that this

happens, wash the brake fluid off with water.

Figure 5A - 27

6. Disconnect the brak e lines (2) f rom the m aster cylinde r (1) and allo w an y residu al brak e f luid from the m aster

cylinder t o drain int o a cont ainer. P lug the ope nings in both the m aster c ylinder and th e pipes to pr event f luid

loss and dirt ingress. Refer to Figure 5A - 28.

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 28

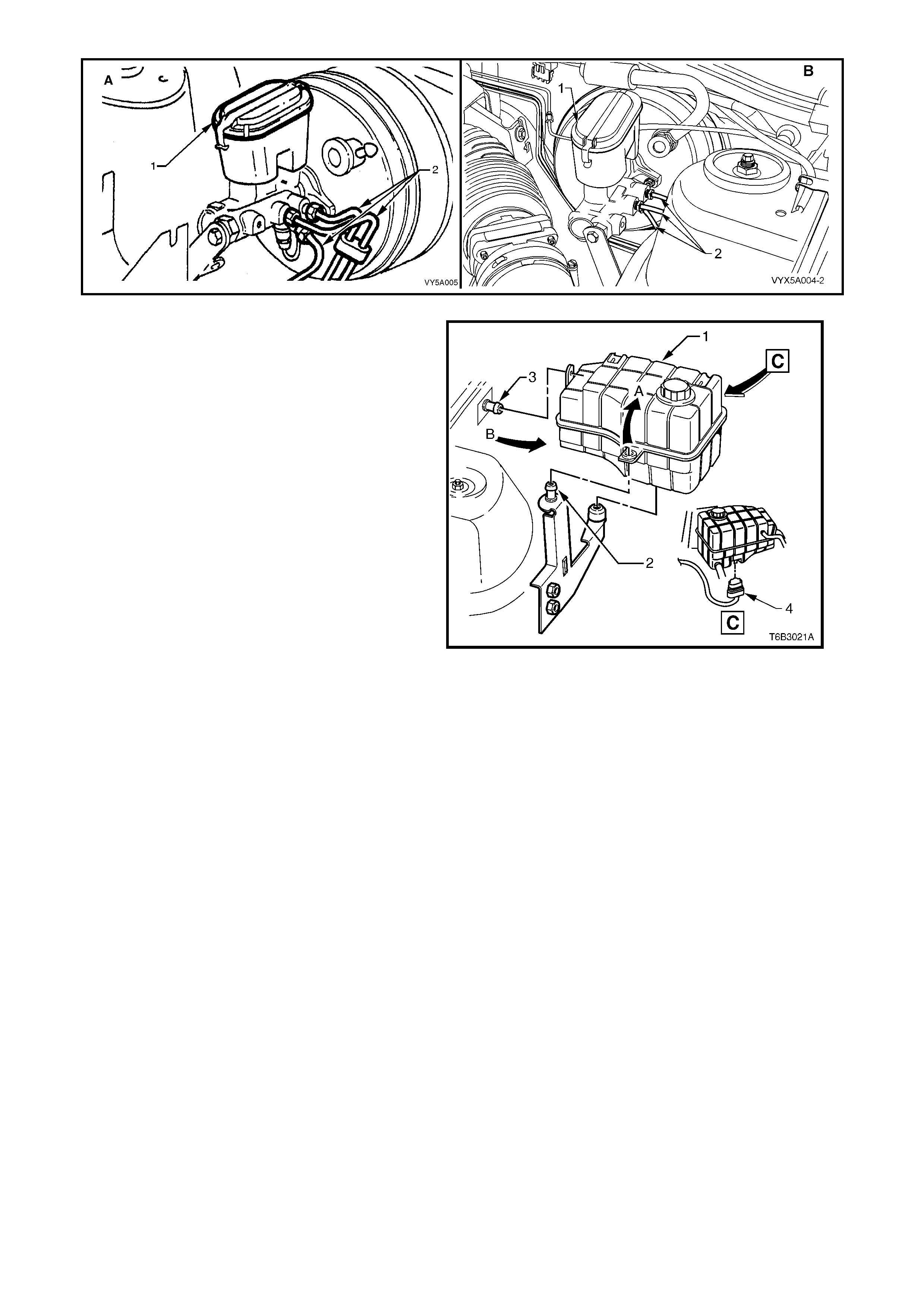

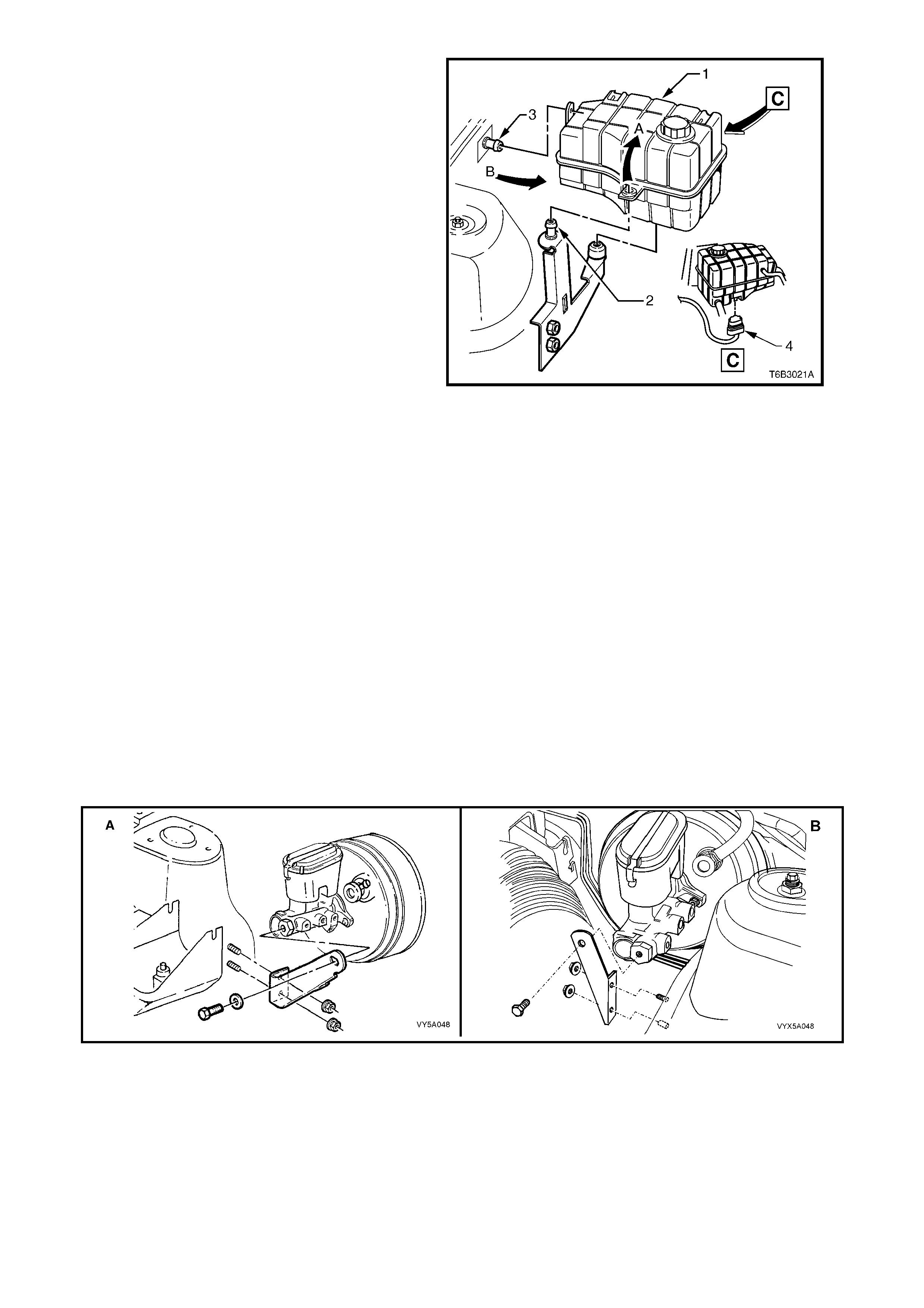

IMPORTANT: The engine surge tank may be hot.

Allow the coolant to cool before performing this

procedure.

7. For lef t-han d drive veh ic les fitted with th e GEN

III V8 engine, disengage the coolant surge

tank from its anchor points by:

A Grasping the surge tank (1) firmly with

both hands and pivoti ng in the direction of

arrow A to dislodge the surge tank from

the rear anchor po int (2).

B Pulling the surge tank inboard (arrow B)

toward the engine to dislodge the inner

fender skirt anchor point (3). Refer to

2.10 Coolant Recovery Surge Tank in

Section 6B3, ENGINE COOLING – GEN

III V8 ENGINE in the MY2003 VY and V2

Series Service Information for further

information.

8. For lef t-han d drive veh ic les fitted with th e GEN

III V8 engine, disconnect the harness

connector (4) from the coolant level sensor

and set the surge tank to one side.

NOTE: It is not necessary to remove the surge

tank from the vehicle. Leave all hoses and screw-

on-cap intact.

9. To provide access to the brake master

cylinder support bracket on left-hand drive

vehicles fitted with the GEN III V8 engine, it is

necessary to remove the Powertrain Control

Module. Refer to 2.1 Powertrain Control

Module (PCM) in Section 6C3-3, SERVICE

OPERATIONS – GEN III V8 ENGINE in the

MY2003 VY and V2 Series Service

Information.

Figure 5A - 29

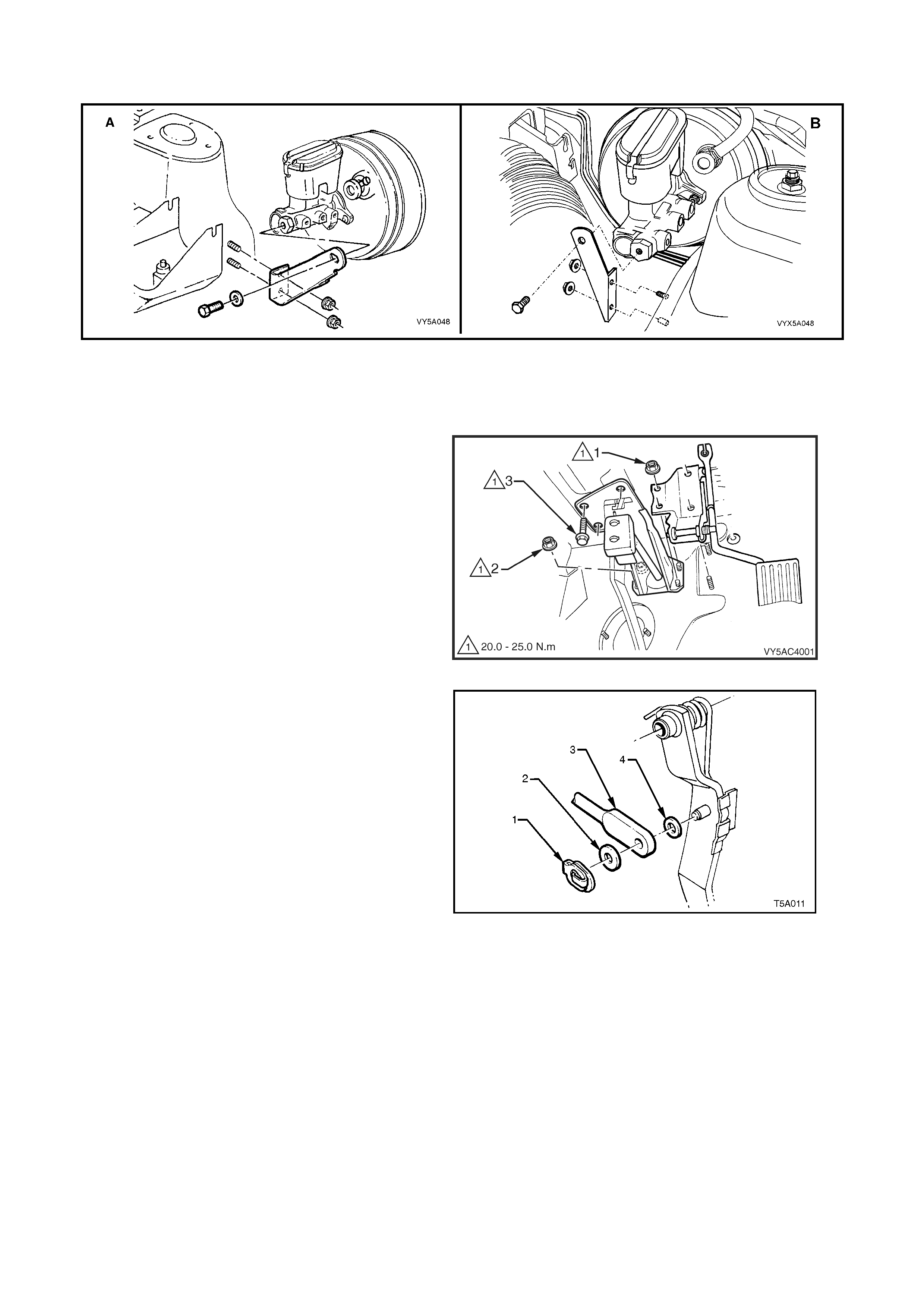

10. Remove the bracket securing the master cylinder to the adjacent strut tower. Refer to Figure 5A - 30.

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 30

11. Disconnect the accelerator pedal cable from the accelerator pedal. Refer to Section:

• Section 6C3- 3 SERVICE OPER ATION S for vehicles fitted with the GEN III V8 engine.

• Section 6C1- 3 SERVICE OPERATION S for vehicles fitted with the V6 and V6 Supercharged engine.

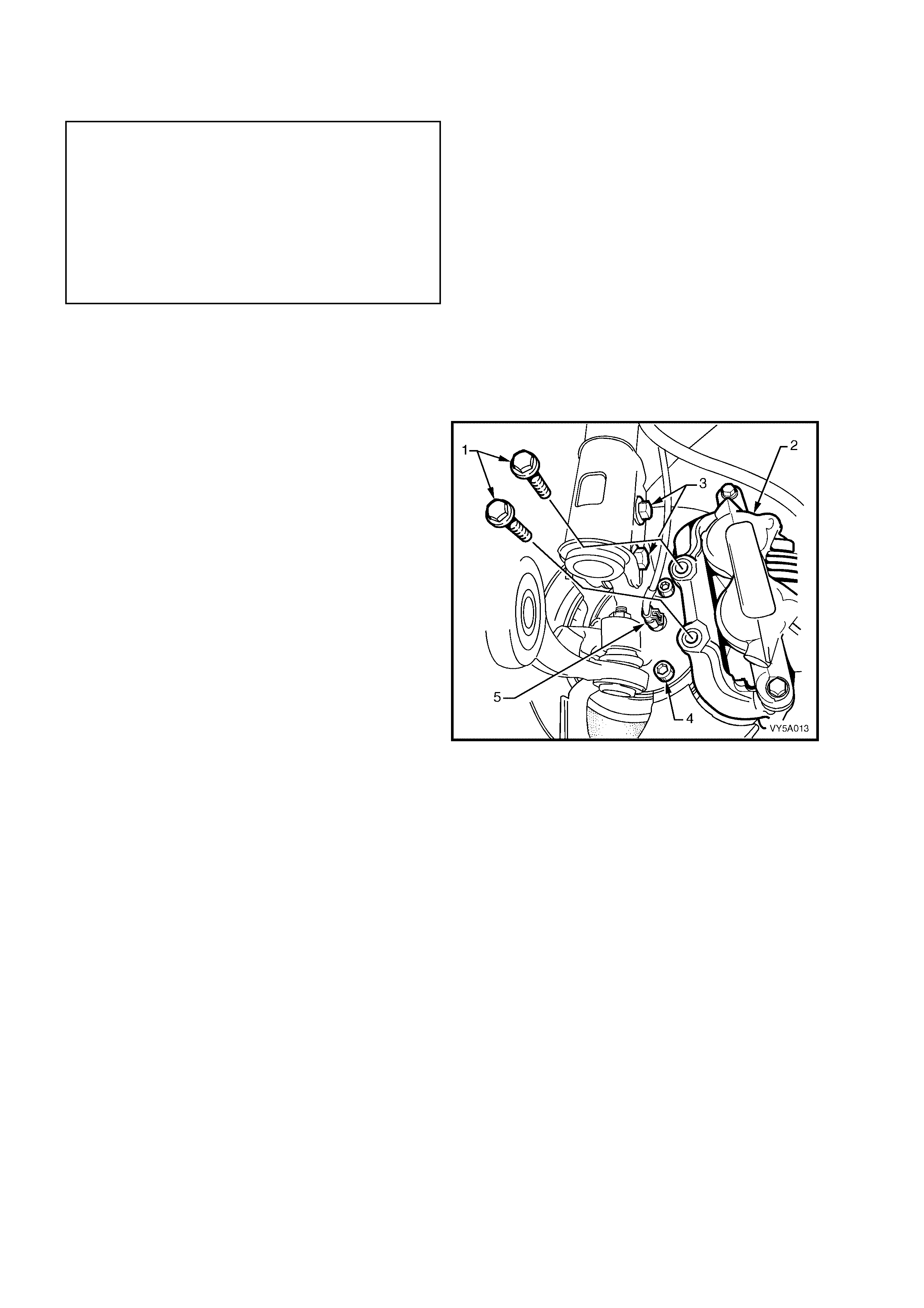

12. Remove the nut (1), four places, securing the

accelerator pedal assembly to the dash panel.

Remove the accelerator pedal assembly.

13. Remove the remaining two nuts (2) securing

the brake booster to the dash panel.

Figure 5A - 31

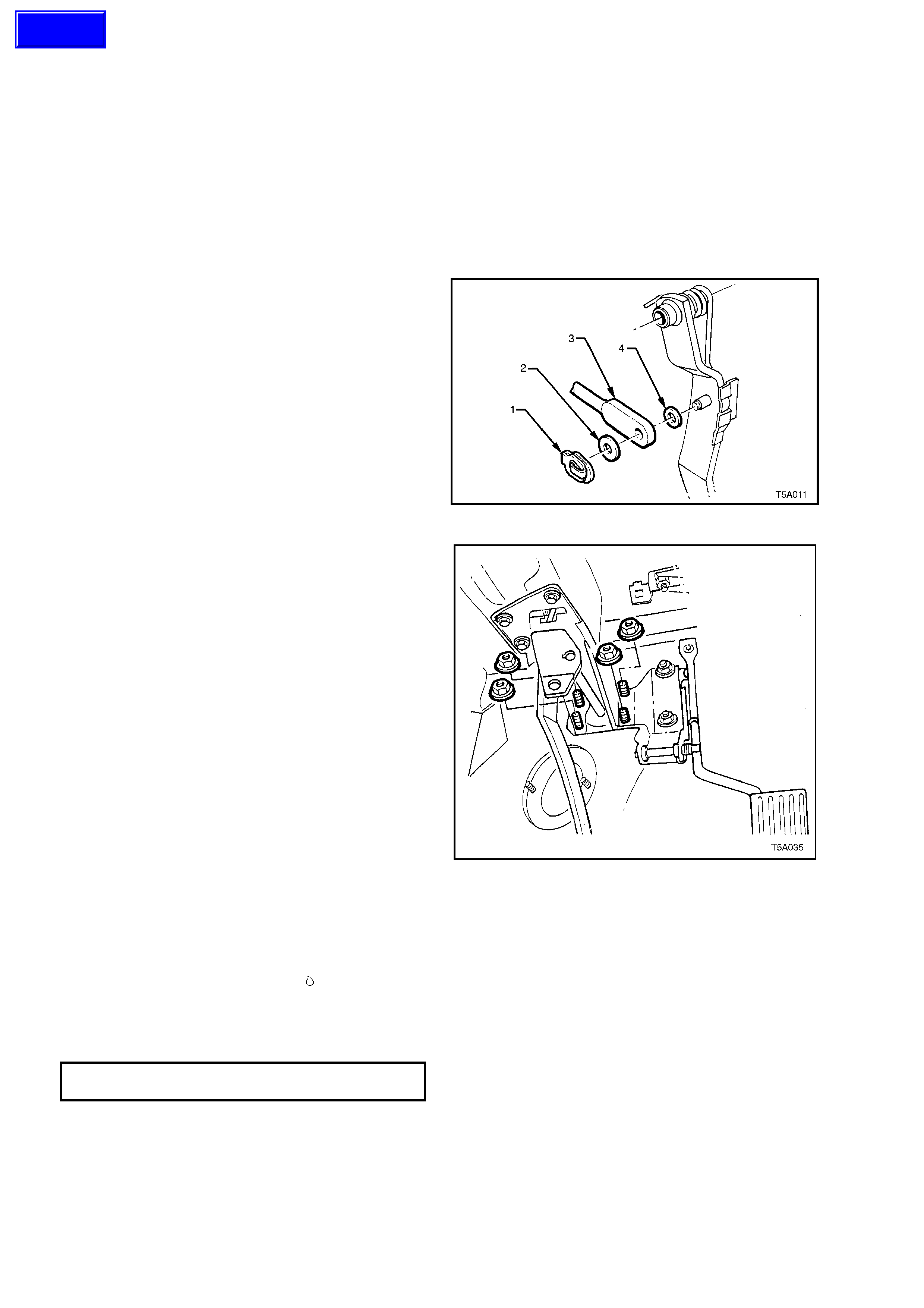

14. Remove the push rod retaining clip (1), push

rod (3) and washers (2 and 4) from the brake

pedal.

15. Remove the three bolts (3) securing the brake

pedal assembly to the steering column. Refer

to Figure 5A - 31.

16. From the engine compartment, pull the brake

booster forward, allowing the brake pedal

assembly to be lowered, rear end first from

under the instrument panel.

Figure 5A - 32

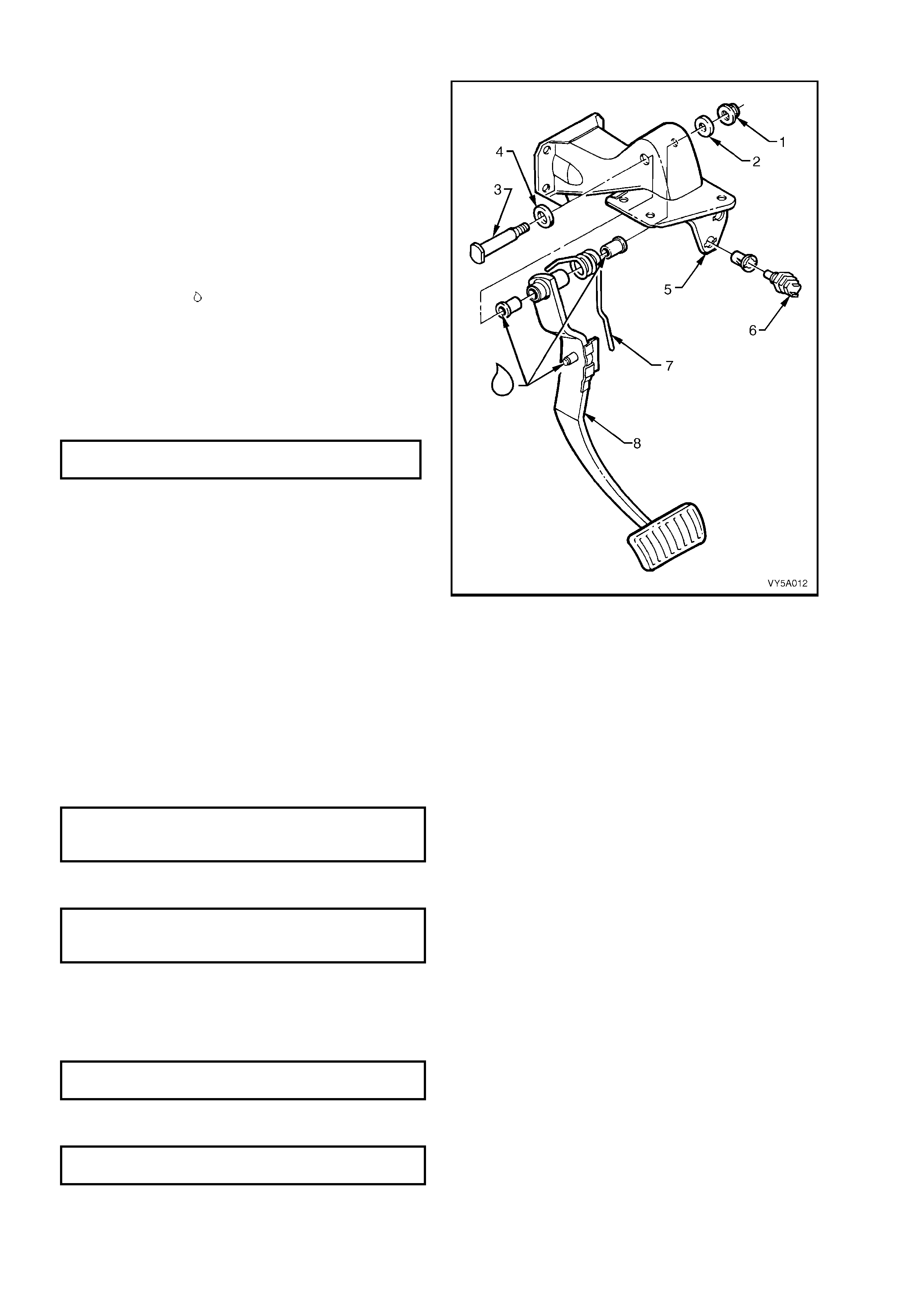

DISASSEMBLE

1. Remove the nut (1) and washer (2) securing

the brake pedal shaft (3) to the brake pedal

support (5).

2. Carefully remove t he s haf t and was her ( 4) f r om

the brake pedal support.

3. W ithdraw the brak e pedal (8) and retur n spring

(7) assembly.

REASSEMBLE

1. Lubricate all bearing surfaces with

Molybdenum Disulphide grease, as indicated

by the symbol .

2. Hold the brake pedal and return spring in

position and insert the brake pedal support

shaft and washer through the brake pedal

support.

3. Reinstall the brake pedal shaft retaining

washer and nut, then tighten to the specified

torque.

PEDAL SUPPORT SHAFT NUT

TORQUE SPECIFICATION 50 - 60 Nm

Figure 5A - 33

REINST ALL

1. Reinstall the brake pedal assembly into the vehicle and install the three bolts securing the brake pedal

assembly to the steering column, refer to Figure 5A - 31. DO NOT tighten the bolts at this time.

2. Push the brake booster rearward to engage the four studs with the brake pedal assembly.

3. Install the push rod (3), washers (2 and 4) and retaining clip (1). Refer to Figure 5A - 32.

4. Install the accelerator pedal assembly, refer to Figure 5A - 31.

5. Install and tighten the four brake pedal assembly to brake booster nuts to the specified torque. Refer to

Figure 5A - 31.

BRAKE PEDAL ASSEMBLY TO

BRAKE BOOSTER NUT

TORQUE SPECIFICATION 20 - 25 Nm

6. Install and tighten the two accelerator pedal assembly to dash panel nuts to the specified torque. Refer to

Figure 5A - 31.

ACCELERATOR PEDAL ASSEMBLY

TO DASH PANEL NUT

TORQUE SPECIFICATION 20 - 25 Nm

7. Reinstall the accelerator cable. Refer to Section:

• Section 6C3- 3 SERVICE OPERATION S for vehicles fitted with the GEN III V8 engine.

• Section 6C1- 3 SERVICE OPERATION S for vehicles fitted with the V6 and V6 Supercharged engine.

8. Tighten the three brake pedal assembly bolts to the specified torque, refer to Figure 5A - 31.

BRAKE PEDAL SUPPORT BOLT

TORQUE SPECIFICATION 20 - 25 Nm

9. Install the m aster c yl inder support brack et, tightening the fasteners to the s pecified torqu e, refer to Figure 5 A -

30.

MASTER CYLINDER BRACKET

NUT TORQUE SPECIFICATION 15 - 20 Nm

10. For lef t-han d dri ve vehicles f itted with the G EN III V8 e ngi ne, re insta ll th e PCM. Refer to 2.1 P o wertrain C ont rol

Module (PCM) in Section 6C3-3, SERVICE OPERATIONS – GEN III V8 ENGINE in the MY2003 VY and V2

Series Service Information.

11. For left-hand drive vehicles fitted with the GEN III V8 engine, reinstall the coolant surge tank. Refer to 2.10

Coolant Recovery Surge Tank in Section 6B3, ENGINE COOLING – GEN III V8 ENGINE in the MY2003 VY

and V2 Series Ser v ice Infor mation.

12. Place a clean container under the brake master cylinder, unplug the brake lines and master cylinder outlet

ports and reinstall the pipes to the master cylinder, refer to Figure 5A - 28.

13. Tighten the brake pipe nuts to their specified torque.

BRAKE PIPE TO MASTER

CYLINDER FLARED NUT

TORQUE SPECIFICATION 8 - 11 Nm

14. Bleed the brake system. Refer to 2.4 BRAKE SYSTEM BLEED.

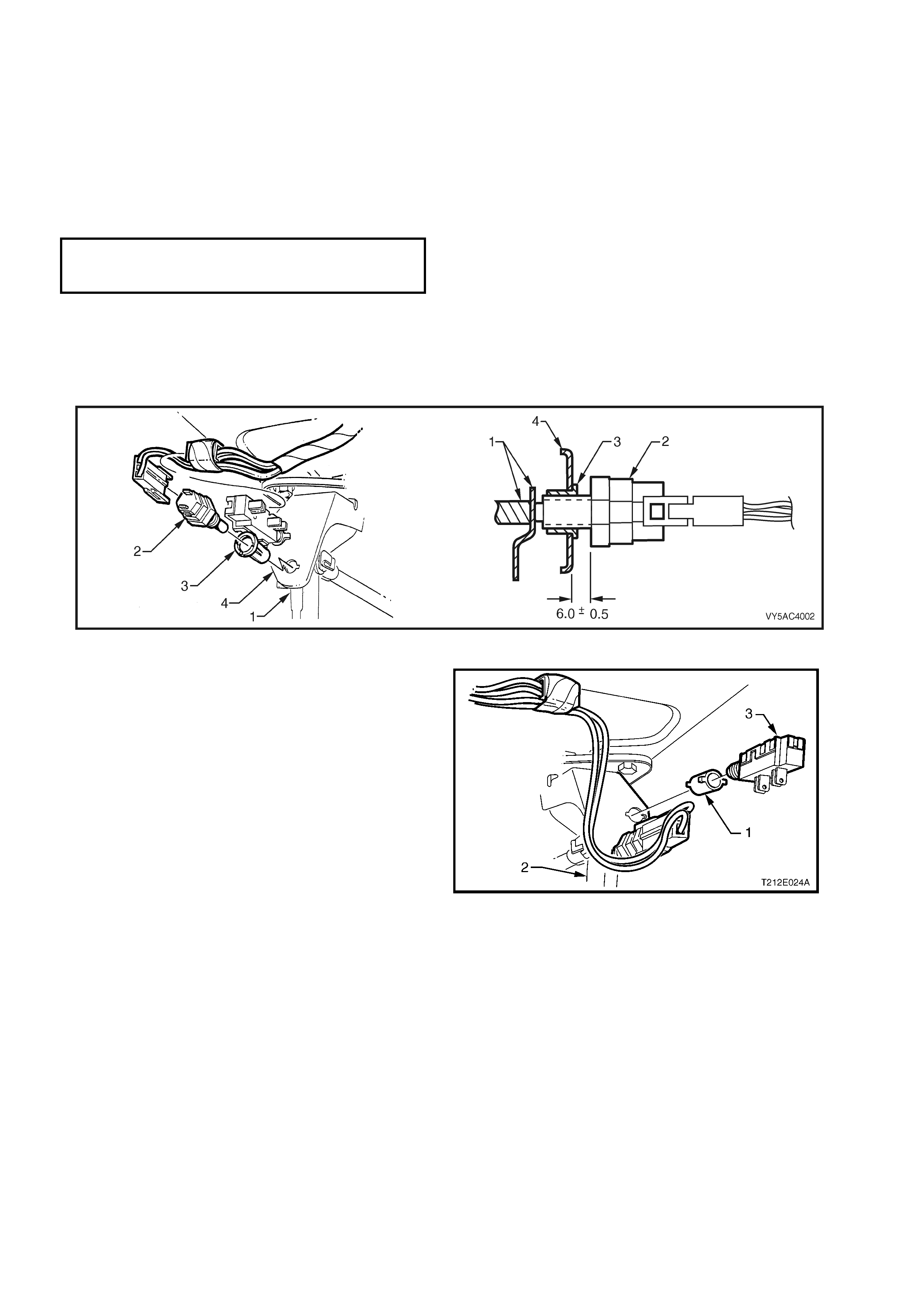

15. Adjust the stop lamp and/or cruise control switches as follows:

Stop Lamp Switch

W ith the pedal (1) held i n the at res t position, pus h or pull the s witch ( 2) through t he metal c lip (3) to ach ieve a

gap of 6 ± 0.5 mm, as shown, between the brake pedal support (4) and switch body. Refer to Figure 5A - 34.

Figure 5A - 34

Cruise Control Switch

Check that the tubular clip (1) is correctly

installed. With the brake pedal (2) held in the

depressed position (brakes applied), push the

cruise contro l s witch (3) for ward u ntil t he s witch

body contacts the tubular clip.

Pull the brake pedal fully up against the brake

pedal stop, until audible click sounds are no

longer heard.

Depress the brake pedal again and repeat the

above procedure until the audible click sounds

can no long er be he ard. At this point, t he switch

will be correctly adjusted.

Figure 5A - 35

16. For left-hand drive vehicles, reinstall the left-hand side ventilation duct.

17. Reinst all the instrum ent panel lower trim panel retainer, lower trim panel and driver side lower trim plate, refer

to Section 1A3, INSTRUMENT PANEL & CONSOLE.

CAUTION: Enable the SRS (Air Bag). Refer to Section 12M, OCCUPANT PROTECTION SYSTEM.

18. Road test the vehicle to check for correct brake operation.

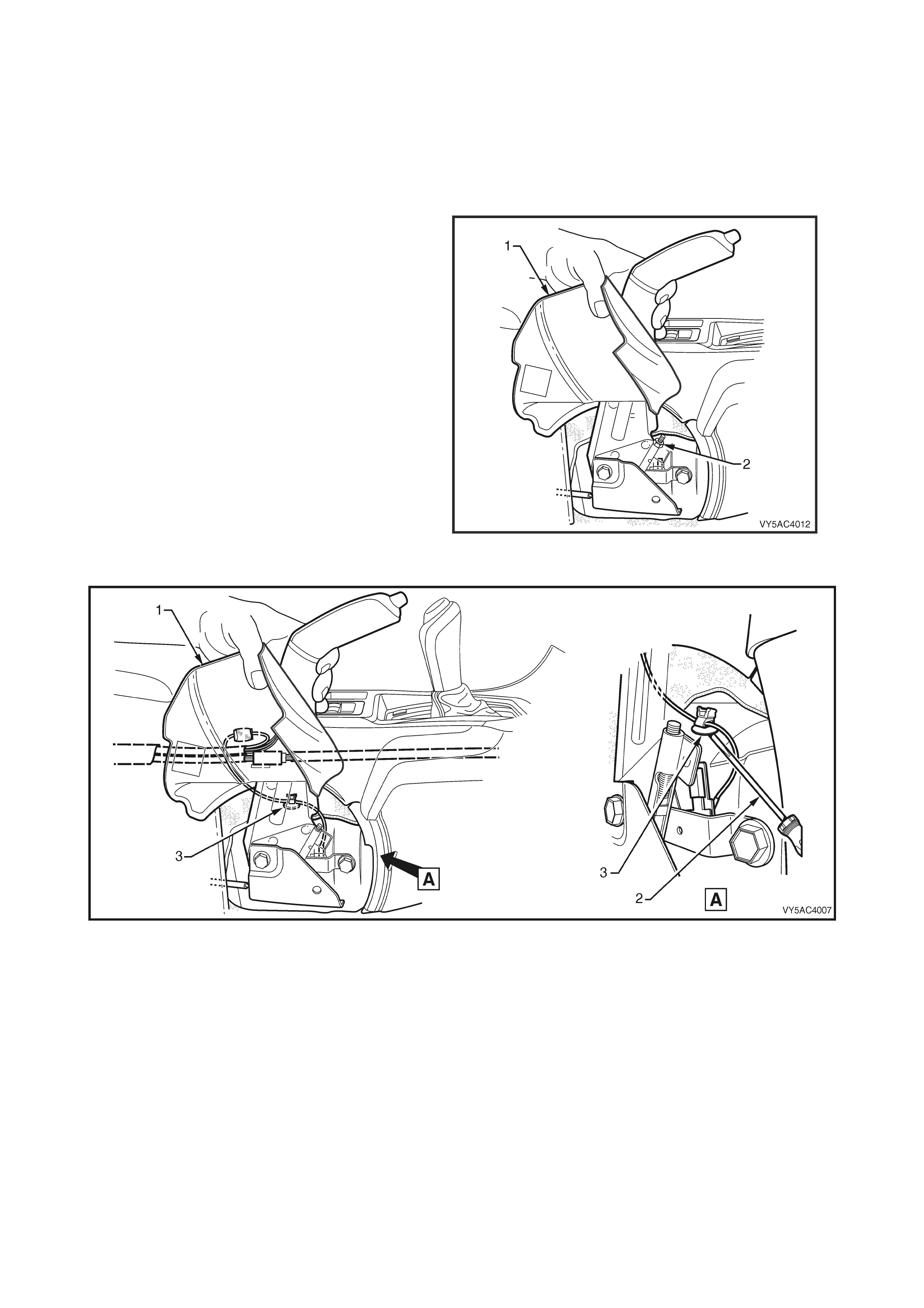

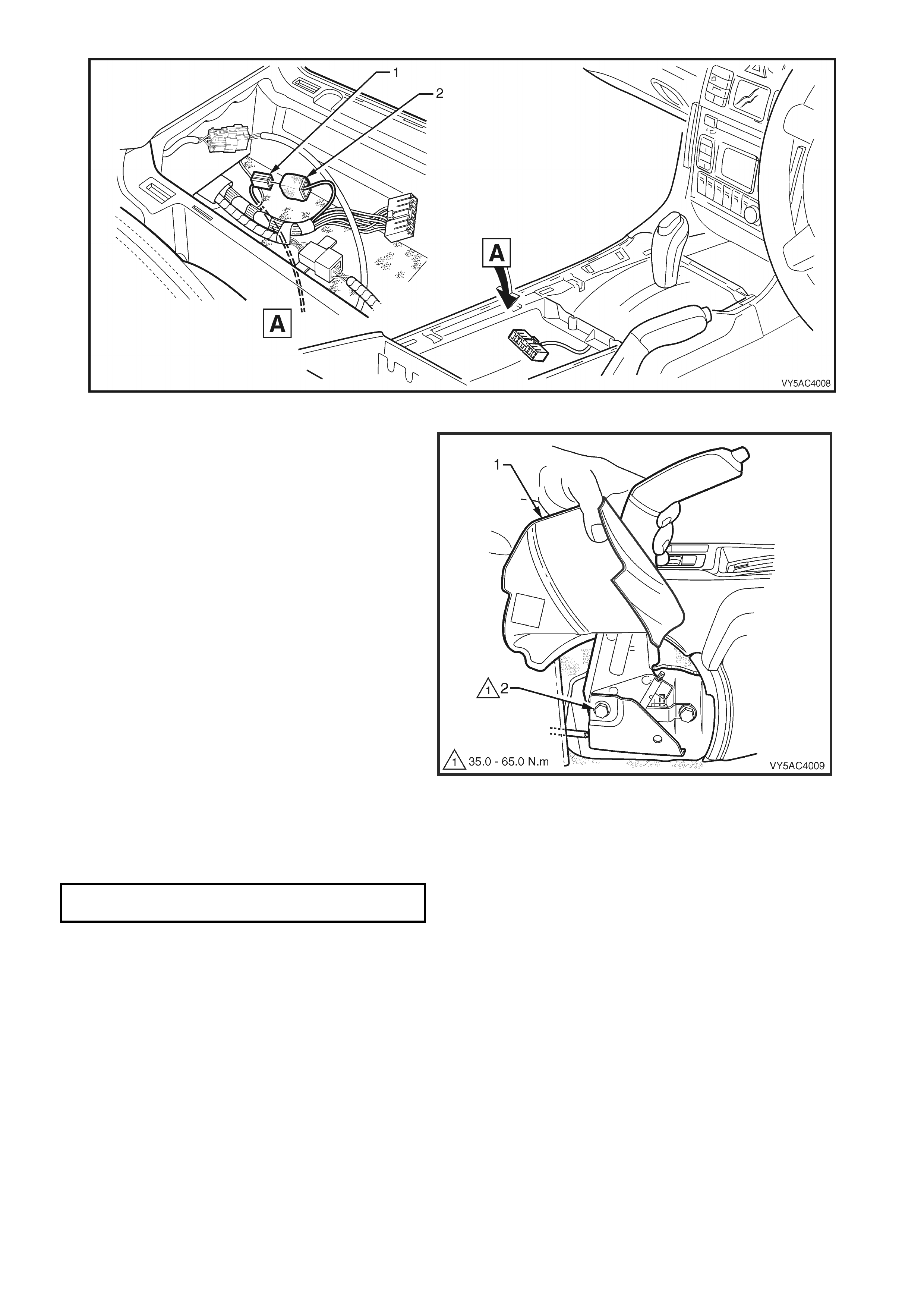

2.9 PARK BRAKE LEVER

LT Section No. – 04-675

REMOVE

1. Remove the right hand front seat. Refer to Section 1A7 SEAT ASSEMBLIES in the MY2003 VY and V2

Series Service Information.

2. Set the park brake in the fully released position.

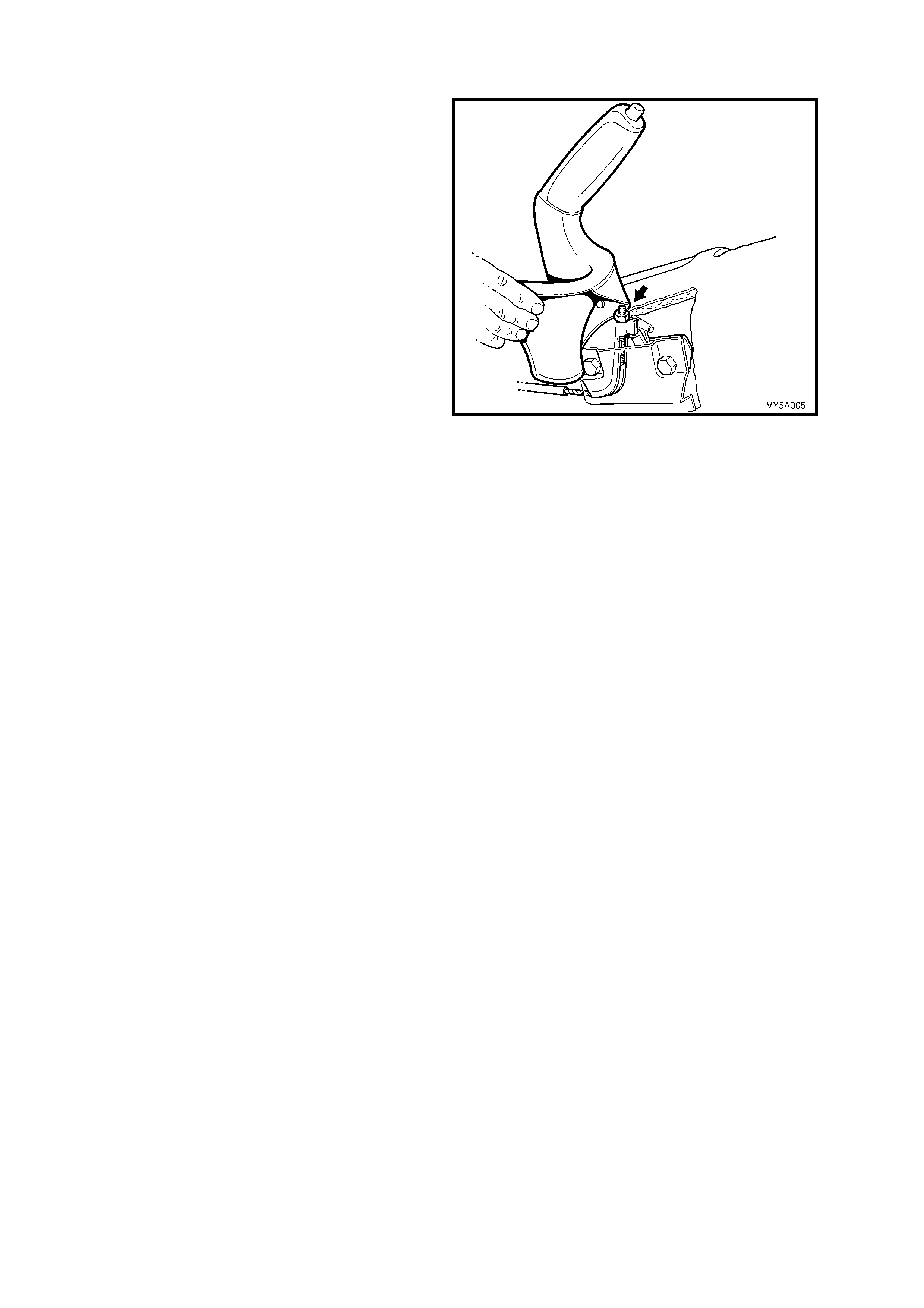

3. Slip the park brake lever boot (1) to one side,

then remove the park brake front cable

adjusting nut (2), using a deep socket.

4. Whilst holding the park brake lever boot (1) to

one side, use a screwdriver (2) to prise the

park brake warning lamp switch harness

retaining clip (3) from the transmission tunnel.

Refer to Figure 5A - 37.

Figure 5A - 36

Figure 5A - 37

5. Remove the floor console cover assembly. Refer to Section 1A3, INSTRUMENT PANEL and CONSOLE.

6. Disconnect the park brake warning lamp switch harness connector (1) from the main vehicle wiring harness

connector (2). Refer to Figure 5A - 38.

Figure 5A - 38

7. Whilst holding the park brake lever boot (1) to

one side, remove the par k brake lever r e tai ni ng

bolt (2), two places.

8. Carefully lift the park brake lever assembly

upwards to free the cable (2).

9. Remove the lever assembly from the vehicle.

Figure 5A - 39

REINST ALL

Installation is the reverse of the removal procedure, noting the following:

1. Tighten the park brake lever bolts to specified torque.

PARK BRAKE LEVER BOLT

TORQUE SPECIFICATION 35 – 65 Nm

2. Reinstal l the thread ed end of the front park brake c able and then inst all the adj usting lock nut. Adjust the park

brake cable. Refer to 2.2 PARK BRAKE CABLE, ADJUST in this Section.

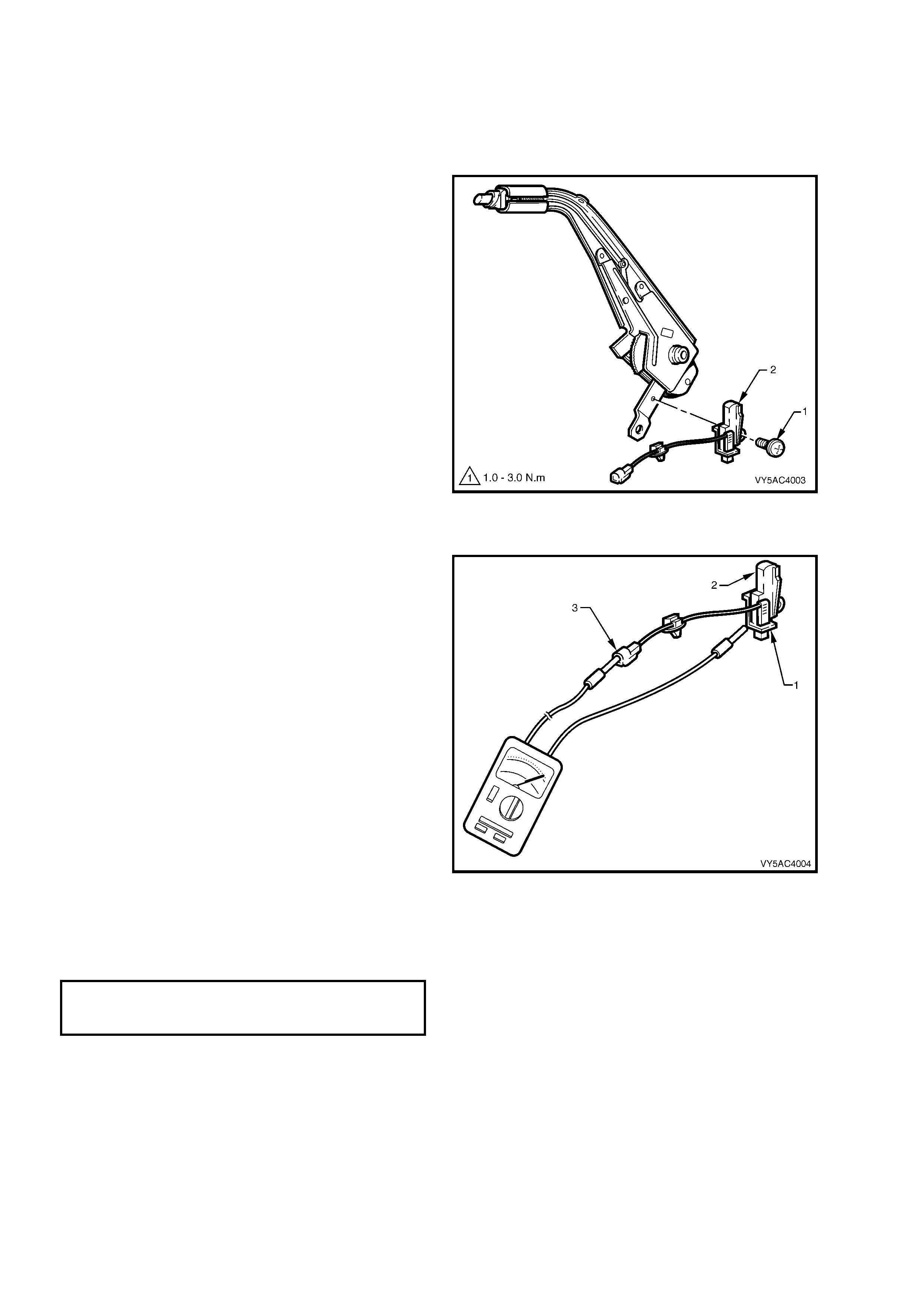

2.10 PARK BRAKE WARNING L AMP SWITCH

LT Section No. – 04-675

REMOVE

1. Remove the park brake lever. Refer to 2 .9 P ARK BR AKE LEVER, REM O VE in this Section.

2. Remove the park brake warning lamp switch

retaining screw (1), and remove the switch (2).

Figure 5A - 40

INSPECT

1. Whilst holding the park brake warning lamp

switch (1), depress and release the plunger (2),

checking that the plunger moves freely.

2. Using a multimeter, check that there is

continuity between the terminal (3) and the

switch body.

3. With the multimeter still connected, check that

there is no continuity when the switch plunger

is depressed.

4. If any of the above tests fail, replace the park

brake warning lamp switch.

Figure 5A - 41

REINST ALL

Installation is the reverse of the removal procedure, noting the following:

1. Tighten the park brake warning lamp switch retaining screw to the specified torque.

PARK BRAKE WARNING LAMP

SWITCH RETAINING SCREW

TORQUE SPECIFICATION 1.0 – 3.0 Nm

NOTE: For further information on the park brake warning lamp operation, refer to Sect ion 12C, INST RUMENTS.

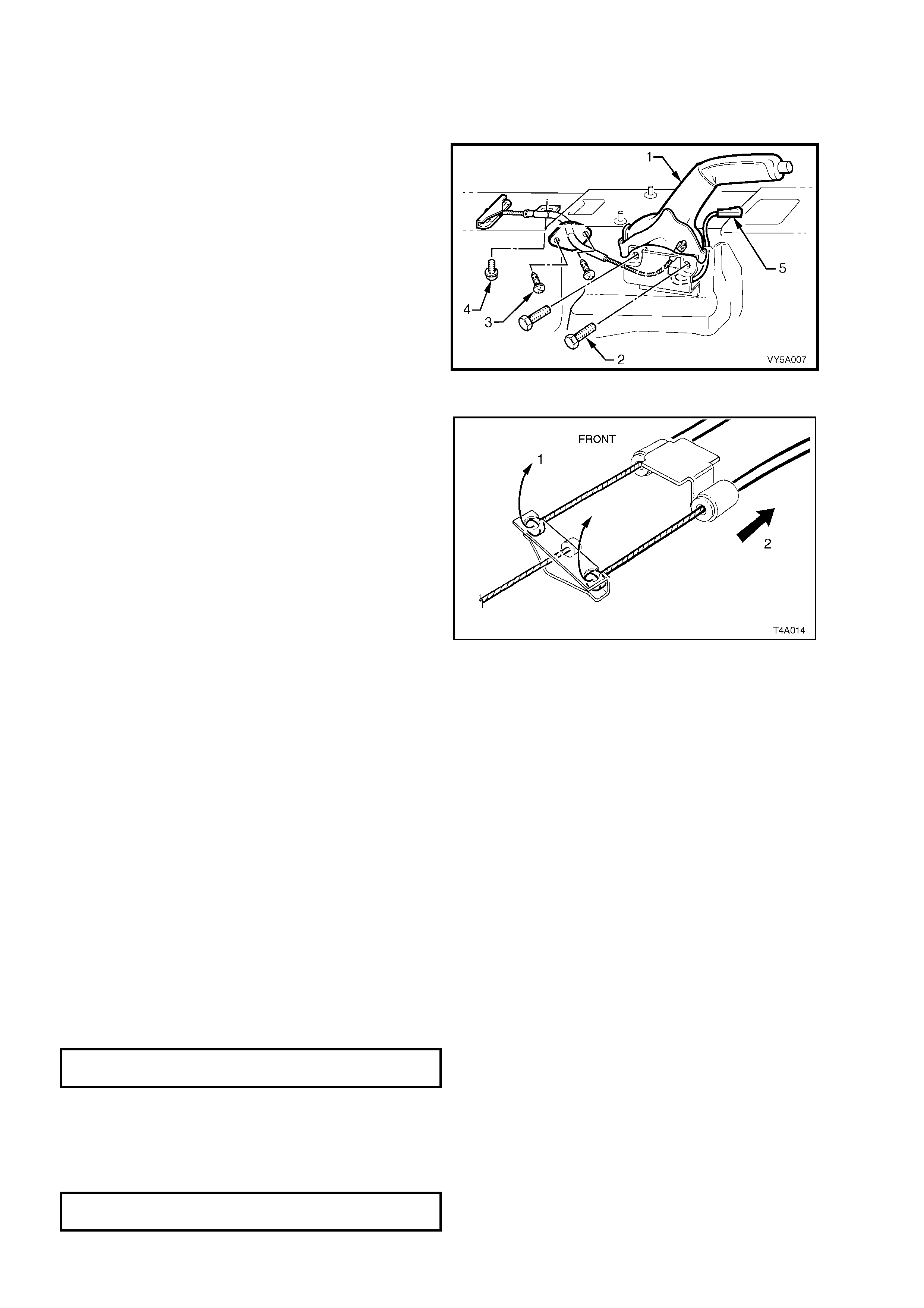

2.11 FRONT P ARK BRAKE CABLE

LT Section No. – 04-675

REMOVE

1. Set park brake in the fully released position.

2. Remove driver’s seat. Refer to Section 1A7

SEAT ASSEMBLIES in the MY2003 VY and

V2 Series Service Information for the

procedure.

3. Remove the park brake lever (1). Refer to

2.9 PARK BRAKE LEVER, in this Section.

4. Remove the centre console and lift the carpet

to gain access to the two front cable

escutcheon screws (3). Refer to Section 1A3

INSTRUMENT PANEL and CONSOLE, in the

MY2003 VY and V2 Series Service

Information, for details.

5. Remove the two screws (3).

Figure 5A - 42

6. Raise vehicle and place safety stands under

each of the rear trailing arms. Refer to

Section 0A, GENERAL INFORMATION, in the

MY2003 VY and V2 Series Service Infor mation

for the recommended support points.

7. Pull each park brake inner rear cable forward

and up (1) to release it from the equaliser

bracket. Pull the outer cables to the rear (2) to

remove the cable from the retaining bracket.

8. Remove the front cable outer cable retaining

bracket bolt (4) from the vehicle underbody,

refer to Figure 5A - 42.

NOTE: Depending on the engine/transmission

fitted to the vehicle, it may be necessary to first

remove the propeller shaf t to enable access to this

bolt. Refer to Section 4C PROPELLER SHAFT

AND UNIVERSAL JOINTS, in the MY2003 V Y an d

V2 Series Service Information for the procedure.

9. Manoeuvre the front cable assembly and

equaliser bracket, through the aperture in the

floor pan, removing the cable assembly from

inside the vehicle.

Figure 5A - 43

REINST ALL

Installation is the reverse to the removal procedure,

apart from the following:

1. Manoeuvr e the front cable and equaliser bracket

assembly, through the hole in the floor pan,

ensuring that the rubber seal is correctly

positioned. Install the two self tapping screws

(3 in Figure 5A - 42), securing the plate to the

floor pan.

2. Reinstall the park brake lever and tighten bolts

(2 in Figure 5A - 42) to the specified torque.

PARK BRAKE LEVER BOLT

TORQUE SPECIFICATION 35 – 65 Nm

3. Reinstal l the park br ake f ront cable adj usting nut

a few threads to secure the cable.

4. Reinstall the outer front cable retaining bracket

bolt to the vehicle underbody, tightening to the

specified torque.

OUTER FRONT CABLE BRACKET

BOLT TORQUE SPECIFICATION 6 - 14 Nm

5. As required, reinstall the propeller shaft. Refer to Section 4C PROPELLER SHAFT AND UNIVERSAL

JOINTS, in the MY2003 VY and V2 Series Service Information for the procedure and the specified torque

specifications.

6. Reinstall the driver’s seat and centre console. Refer to Section 1A7 SEAT ASSEMBLIES and

Section 1A3 INSTRUMENT PANEL and CONSOLE, in t he M Y20 03 V Y a nd V 2 Ser i es S er v ic e I nf ormation f or

the necessary procedures.

7. Reinstall the two rear cables to the equaliser bracket.

8. Adjust the park brake. Refer to 2.2 PARK BRAKE CABLE, ADJUST in this Section.

9. Lower the vehic l e to the ground.

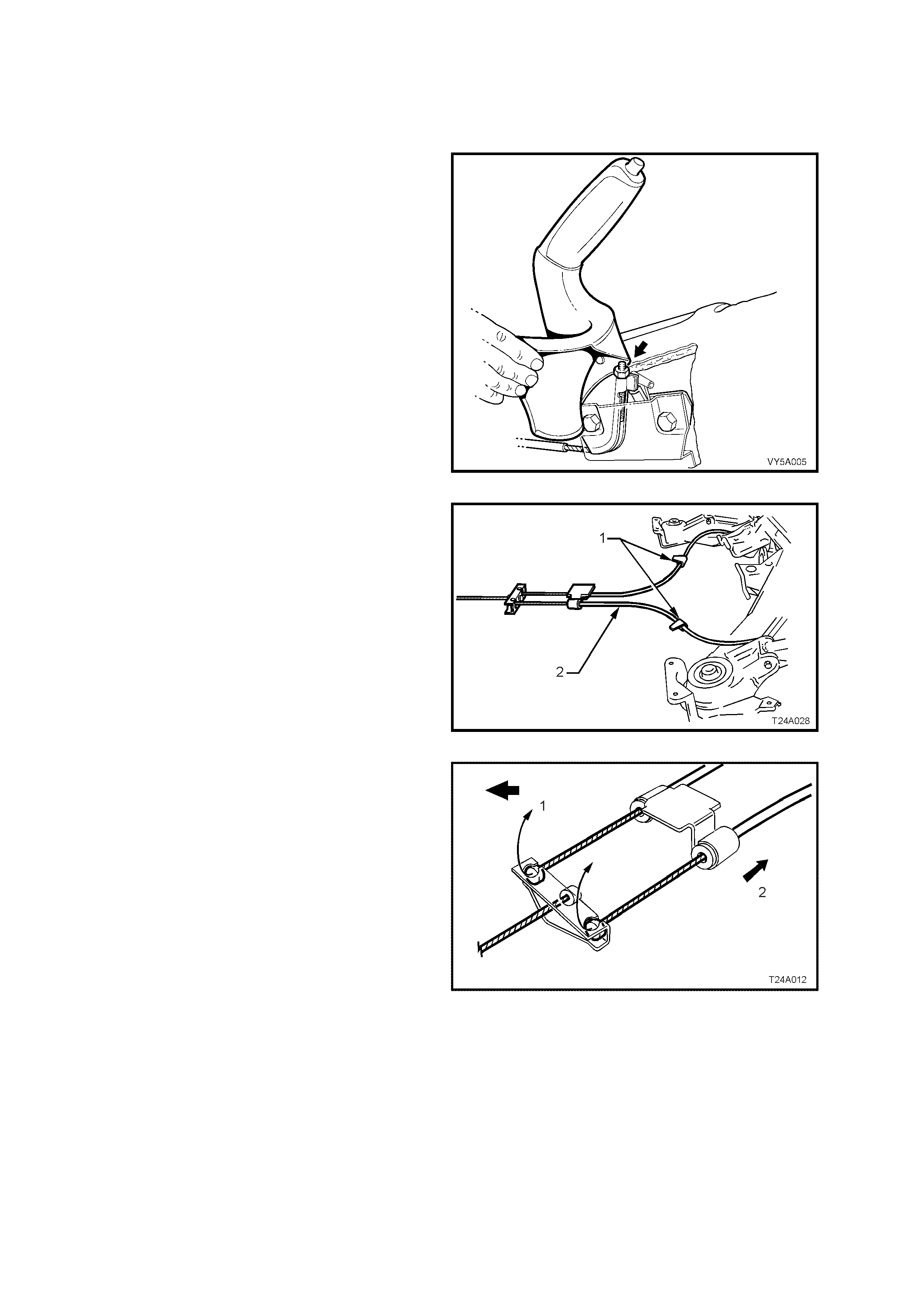

2.12 REAR PARK BRAKE CABLE/S

LT Section No. – 04-675

REMOVE

1. Release park brake.

2. Using a deep socket, loosen the front cable

adjusting nut (arrow) until the nut is almost

removed.

3. Using a floor jack under centre of differential

carrier, jack up and support rear of vehicle on

safety stands under rear trailing arms.

Figure 5A - 44

4. To provide sufficient access, it may be

necessary to remove the propeller shaft from

the vehic le. Refer to Section 4C PROPELLER

SHAFT AND UNIVERSAL JOINTS, in the

MY2003 VY and V2 Series Service Infor mation

for the necessary procedures.

5. Unclip each (or as required) of the cable

gromm ets from the underb ody clip/s (1), to f ree

the cable/s (2).

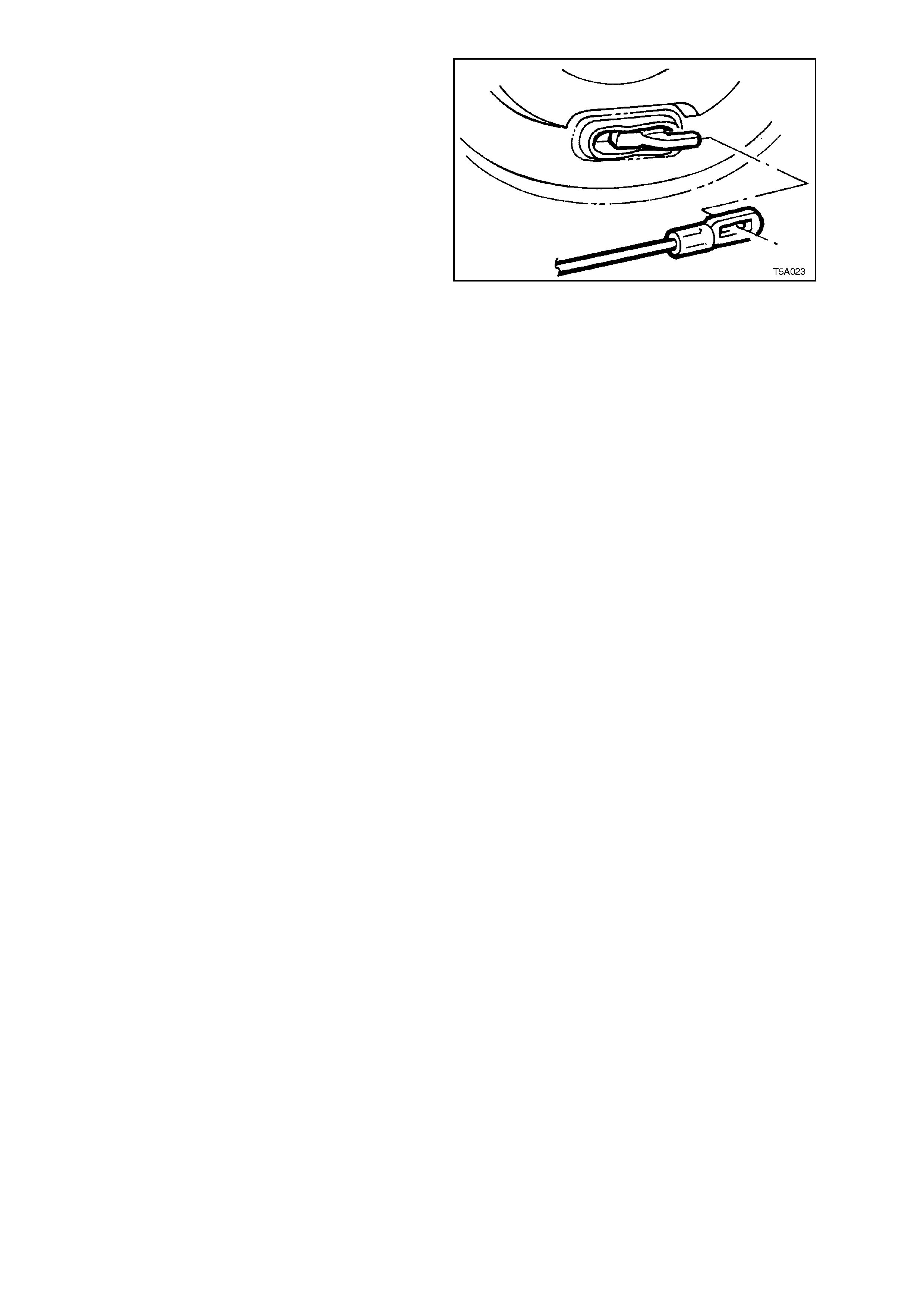

Figure 5A - 45

6. Remove the front of the rear inner cable/s, by

first wrapping rag around the inner cable to

protect it from damage, then use pliers to pull

the ball nipple forward and up (1), to free from

the equaliser bracket.

7. Pull the outer cable rearward (2) to release

from the vehicle underbody bracket.

Figure 5A - 46

8. Disconnect the rear clevis from the rear park

brake actuating lever by gripping with pliers

and pivoting the cable rearwards.

9. Pull outer cable forward, out of trailing arm

retainer/s and remove the cable/s from the

vehicle.

Figure 5A - 47

REINST ALL

Reinstallation of the rear park brake cable/s is the reverse of removal procedure, except for the following points:

1. Install the cable through the trailing arm retainer, then fit the cable clevis to the park brake actuating lever.

2. Wrap rag around the inner cable to protect it from damage, then use pliers to pull the ball end on the inner

cable forward to engage into the equaliser bracket.

3. If removed, reinstall the propeller shaft. Refer to Section 4C PROPELLER SHAFT AND UNIVERSAL JOINTS,

in MY2003 VY and V2 Series Service Information for all details.

4. Adjust park brake cable, refer 2.2 PARK BRAKE CABLE, ADJUST, in this Section.

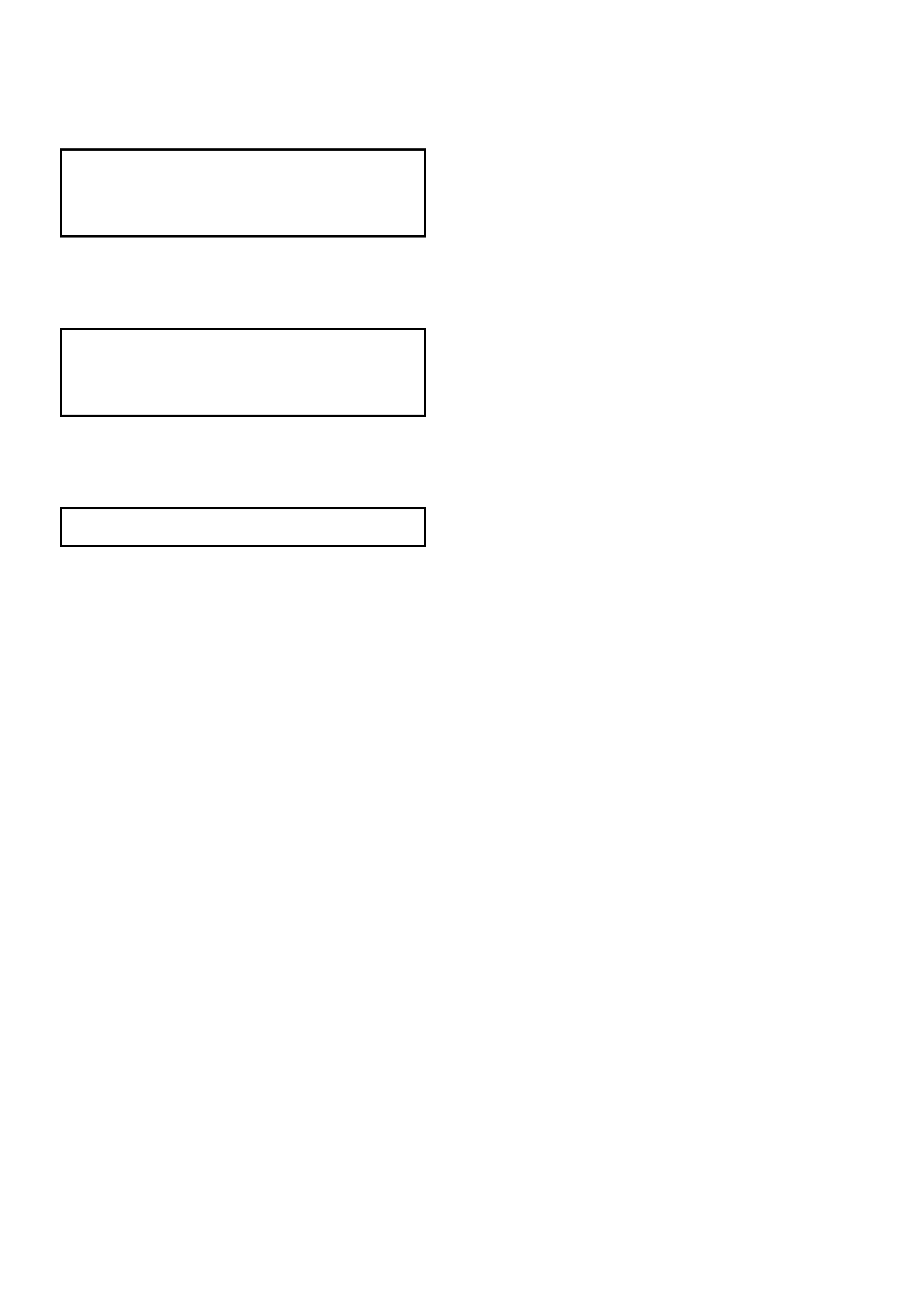

2.13 FRONT BRAKE HOSE

LT Section No. – 04-750

REMOVE

1. Raise fr ont of ve hic le and place o n j ack stands.

Refer to Section 0A, GENERAL

INFORMATION, in the MY2003 VY and V2

Series Service Information for the

recommended support points.

2. Mark position of wheel relative to hub and

remove road wheel.

3. Thoroughly clean connections at each end of

brake hose (1).

4. Disconnect brake pipe (2) from hose (1) and

plug pipe.

5. Remove the screw (3) securing the hose

bracket to the inner skirt panel.

6. Unclip hose and grommet (4) from bracket on

suspension tower.

7. Unbolt and remove the brake hose from the

caliper, refer to Figure 5A - 49.

Figure 5A - 48

REINST ALL

1. Ensure brake hose and c a li per mating surf ac es

are clean and free from burrs.

2. Reconnect brake hose (1) to caliper, using

NEW copper sealing washers (3), then tighten

the banjo bolt (2) to specified torque.

BRAKE HOSE TO CALIPER

TORQUE SPECIFICATION 32 - 37 Nm

3. Clip hose and grommet into suspension strut

bracket.

4. Reinstall the screw to retain the hose bracket

to the inner skirt panel.

5. Remove plug f rom brake pipe an d rec onnect to

hose. Tighten to specified torque.

BRAKE PIPE TO BRAKE HOSE FLARE

NUT TORQUE SPECIFICATION 14 - 17 Nm

6. Check that hose is not twisted.

Figure 5A - 49

7. Bleed brake/s, refer 2.4 BRAKE SYSTEM

BLEED, in this Section.

8. Reinstall road wheel, aligning marks made on

removal and lower vehicle.

9. Tighten road wheel attaching nuts to the

specified torque, tightening in a star pattern,

refer to 2.1 SERVICE NOTES AND

CAUTIONS, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 100 - 125 Nm

2.14 REAR CALIPER BRAKE HOSE

LT Section No. – 04-750

REMOVE

1. Raise the rear of the vehicl e and place o n jack

stands. Refer to Section 0A GENERAL

INFORMATION in the MY2003 VY and V2

Series Service Information, for the procedure.

2. Mark position of wheel relative to hub and

remove road wheel.

3. Thoroughly clean connections at each end of

brake hose (2).

4. While holding the hose (2) with a back-up

spanner, loosen then disconnect brake pipe

from brake hose. Plug the pipe open end.

5. Unclip retainer (1) from hose and withdraw

hose from bracket.

6. Unbolt and remove brake hose from caliper.

Figure 5A - 50

REINST ALL

1. Ensure brake hose and caliper mating surfaces are clean and free of burrs.

2. Rec onnec t brak e hos e to c ali per, ens uring that t he locatin g peg alig ns with the di m ple in the cal iper. Us e NEW

copper sealing washers, then tighten the banjo bolt to specified torque.

BRAKE HOSE TO CALIPER

TORQUE SPECIFICATION 32 - 37 Nm

3. Fit hose correctly into mounting plate bracket and reinstall retainer. Check that hose is not twisted.

4. Remove plug from brake pipe and reconnect to hose. While using a back-up spanner on the brake hose to

prevent twisting, tighten pipe to specified torque.

BRAKE PIPE TO HOSE FLARED

NUT TORQUE SPECIFICATION 14 -17 Nm

5. Bleed brake/s, see 2.4 BRAKE SYSTEM BLEED, in this Section.

6. Reinstall road wheel, aligning marks made on removal and lower vehicle.

7. Tighten road wheel attaching nuts to the specified torque, tightening in a star pattern, refer to 2.1 SERVICE

NOTES AND CAUTIONS, in this Section.

ROAD WHEEL ATTACHING NUT

TORQUE SPECIFICATION 100 - 125 Nm

2.15 REAR BRAKE HOSE

LT Section No. – 04-750

REMOVE

1. Raise rear of vehicle and place on jack stands. Refer to Section 0A GENERAL INFORMATION, in the

MY2003 VY and V2 Series Service Information, for the procedure.

2. Thoroughly clean connections at each end of the rear brake hose to be removed.

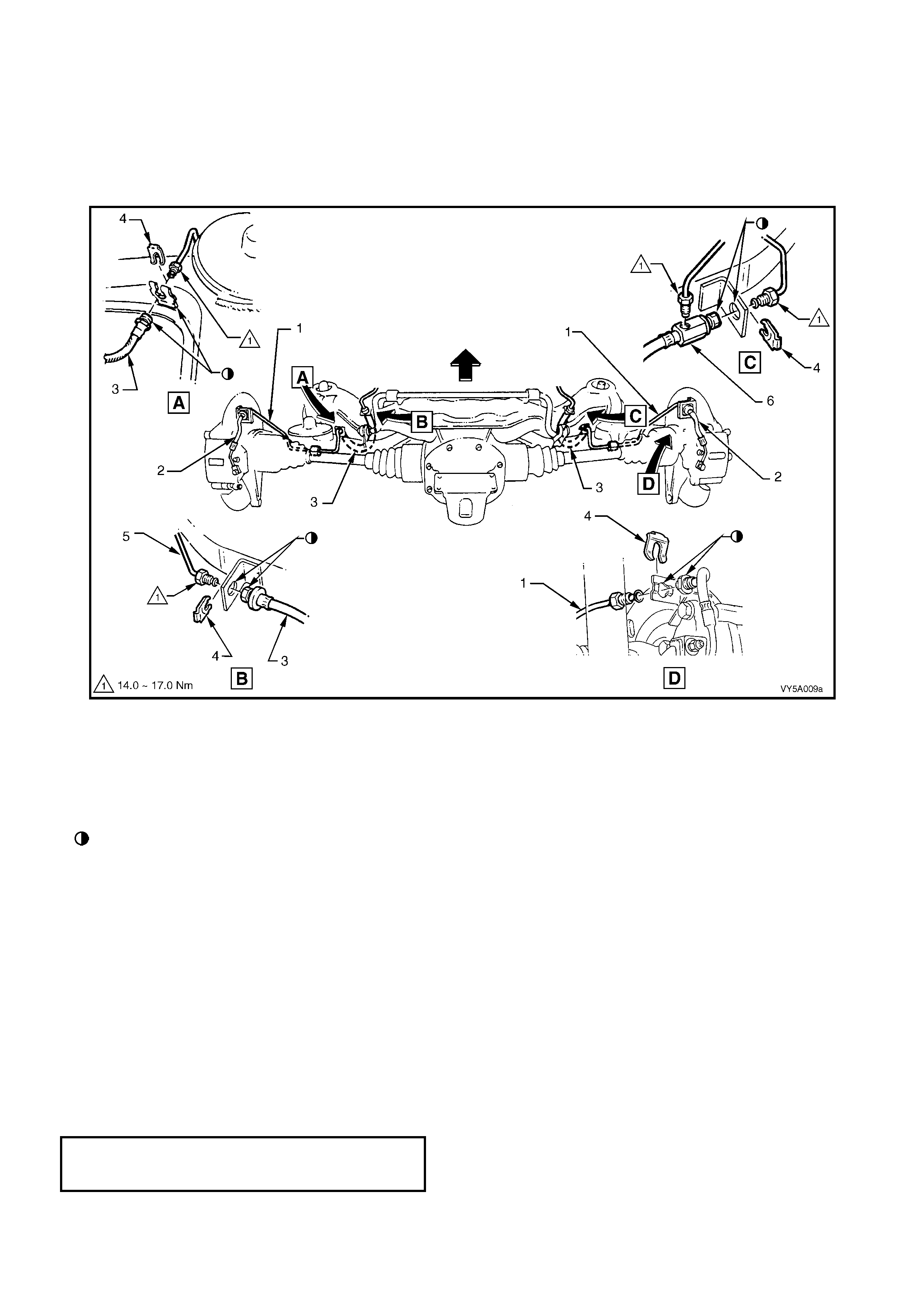

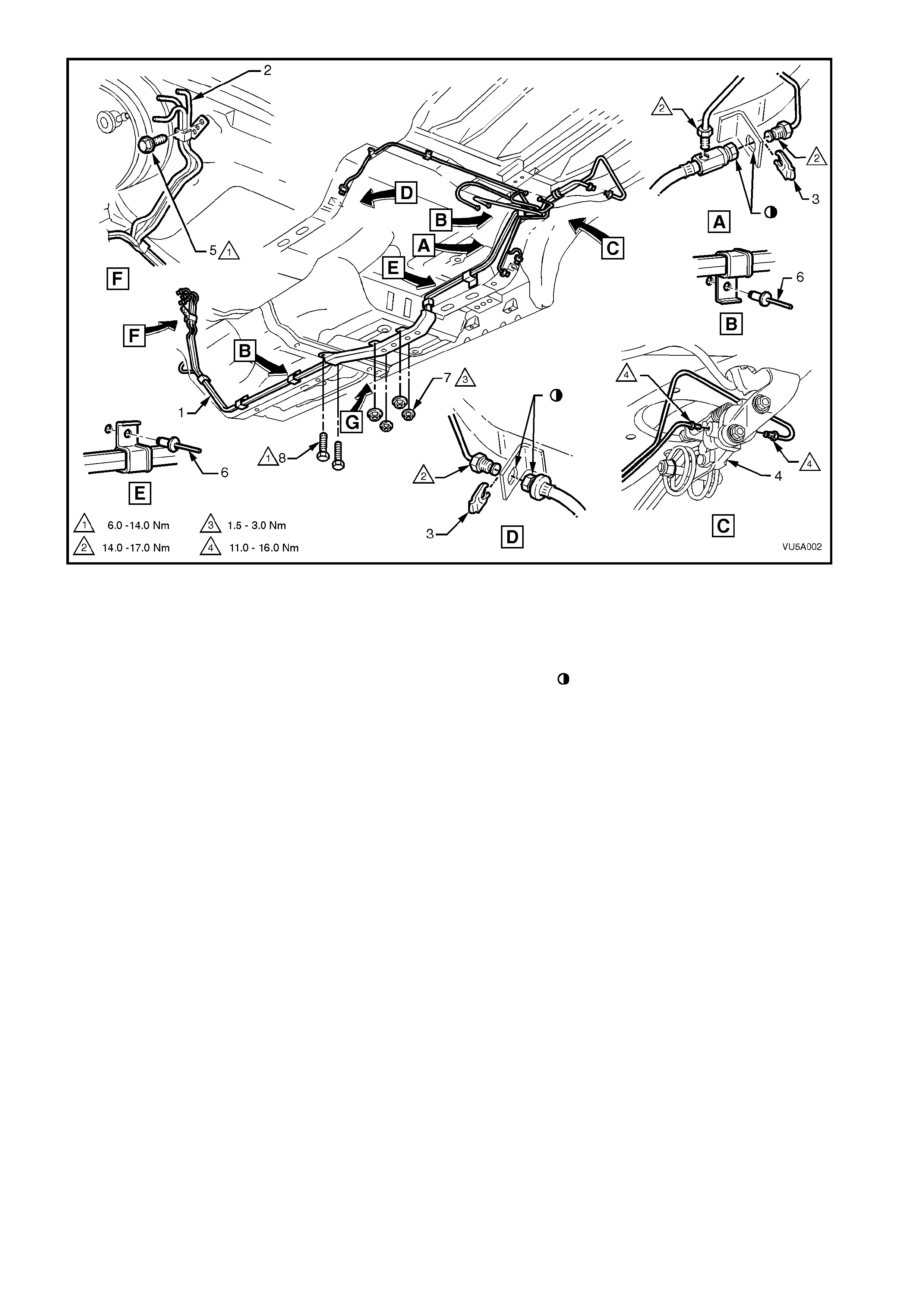

Figure 5A - 51

Legend

VIEW A: LH Shown – RH opposite

VIEW B: With Traction Control – LH shown, RH opposite

Without Traction Control – LH only

VIEW C: Without Traction Control – RH only

VIEW D: RH shown, LH opposite

Align Flats on Brack et and Hose

1. Rear Brake Pipe

2. Rear Brake Hose, Caliper t o Rear Brake Pipe

3. Rear Brake Hose

4. Retaining Clip

5. Brake Hose Connecti on Pipe

6. Junction Block – RH only (Vehicles without Traction Cont rol )

3. Disc onnect brak e pipe (5) fr om brake hos e (3) at trailing ar m brack ets (View B). Plu g open end of br ake pipe/s

to prevent foreign material entry.

4. Dis connect r ear brak e pipe (1) connectio n f rom br ake hose (3), while hol ding the hose with a back -up spann er.

For those v ehicles witho ut ABS/T CS, the RH sid e brak e hose ( View C), a lso has a junction block (6) to provide

for a connection from the master cylinder. Plug all pipe ends to prevent foreign material entry.

5. Unclip retaining clips (4) from the end of each hose end and withdraw hose/s fro m brackets.

NOTE: Refer to Operat ion 2.13 for procedure to remove the rear caliper hose (2).

REINST ALL

1. Ensure brake hose ends and pipe mating surfaces are clean and free of burrs.

2. Fit hose (3) into mounting plate brackets and reinstall retaining clips (4). Check that the hose (3) is not twisted.

3. Remove plugs from brake pipes (1 and 5), then reconnect to hose ends. Tighten all pipe nuts to specified

torque.

BRAKE PIPE FLARE NUT

TO BRAKE HOSE

TORQUE SPECIFICATION 14 - 17 Nm

4. Bleed brake/s, see 2.4 BRAKE SYSTEM BLEED, in this Section.

5. Raise vehicle, remove jack stands, then lower vehicle to the ground.

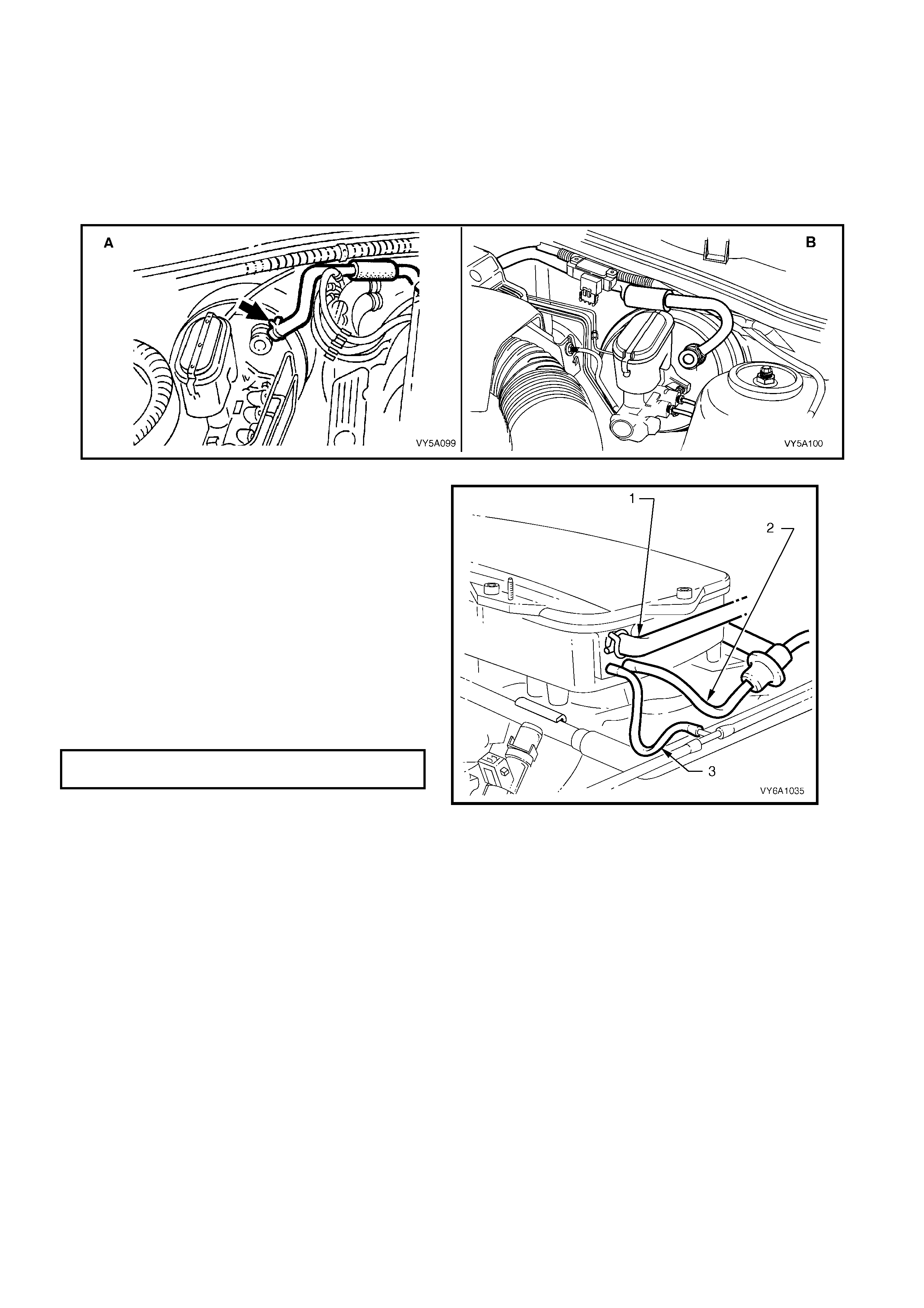

2.16 BRAKE BOOSTER HOSE & VALVE ASSEMBLY – V6 ENGINE

REPLA CE

1. Remove the four decorative nuts securing the engine dress cover, then remove the cover from the engine.

2. Using su itab le pl iers , c ompress the spring h os e c lamp at each end of the br ake booster vacu um hose and sli d e

both clamps back along the hose, refer to Figure 5A - 52 and Figure 5A - 53.

CAUTION: Wear safety glasses to avoid eye injury when working with spring wire hose clamps.

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 52

3. While supporting the vacuum check valve at

the booster end, twist the hose to break the

seal, then remove by twisting back and forth

while maintaining a constant pulling force on

the hose. Repeat for the intake manifold fitting

at the rear of the engine.

4. Reinstallation is the reverse of the removal

process, except that each hose clip must be

reinsta lled over t he hose a nd behind t he nipple

at each end to prevent hose premature

disengagement.

5. Reinstall the engine dress cover and secure

with the four decorative nuts, tightening to the

correct torque specification.

ENGINE DRESS COVER NUT

TORQUE SPECIFICATION 5 Nm

Figure 5A - 53

2.17 BRAKE BOOSTER HOSE & VALVE ASSEMBLY – GEN III V8 ENGINE

REPLA CE

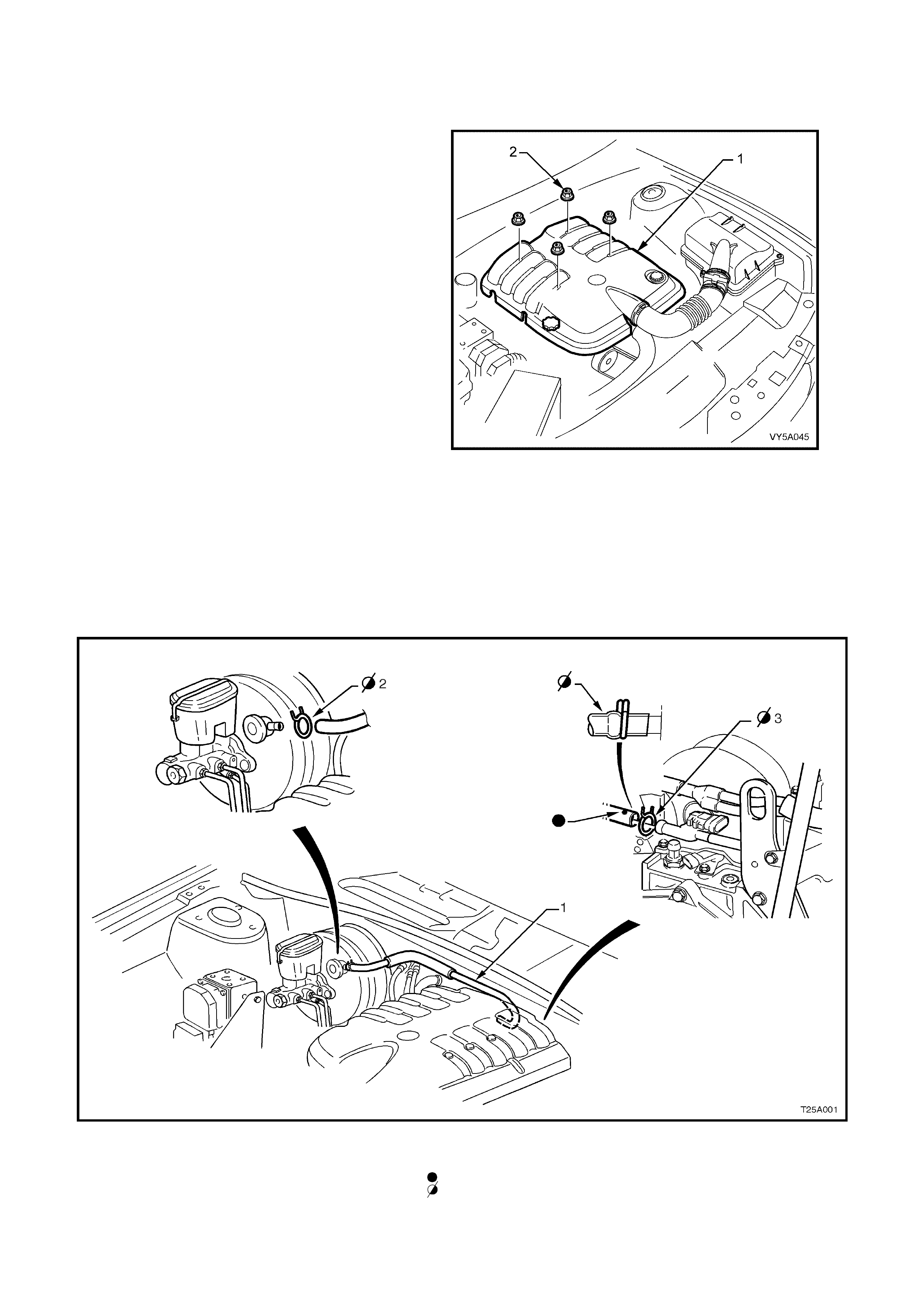

1. Remove the four engine dress cover

decorative nuts (2), then remove the dress

cover (1) from the engine.

Figure 5A - 54

2. Using su itab le pl iers , c ompress the spring h os e c lamp at each end of the br ake booster vacu um hose and sli d e

both clamps back along the hose, refer to Figure 5A - 55 and Figure 5A - 56.

3. W hile suppor ting the vac uum check valve at the boost er end, t wist the h ose to br eak the s eal, then remove by

twisting back and forth while maintaining a constant pulling force on the hose. Repeat for the intake manifold

fitting at the rear of the engine, supporting the fitting during the removal process.

4. Reinstallation is the reverse of the removal process, except that each hose clip must be reinstalled over the

hose and behind the nipple at each end to prevent hose premature disengagement. Also ensure that the b lue

alignment dot on the hose is facing upward

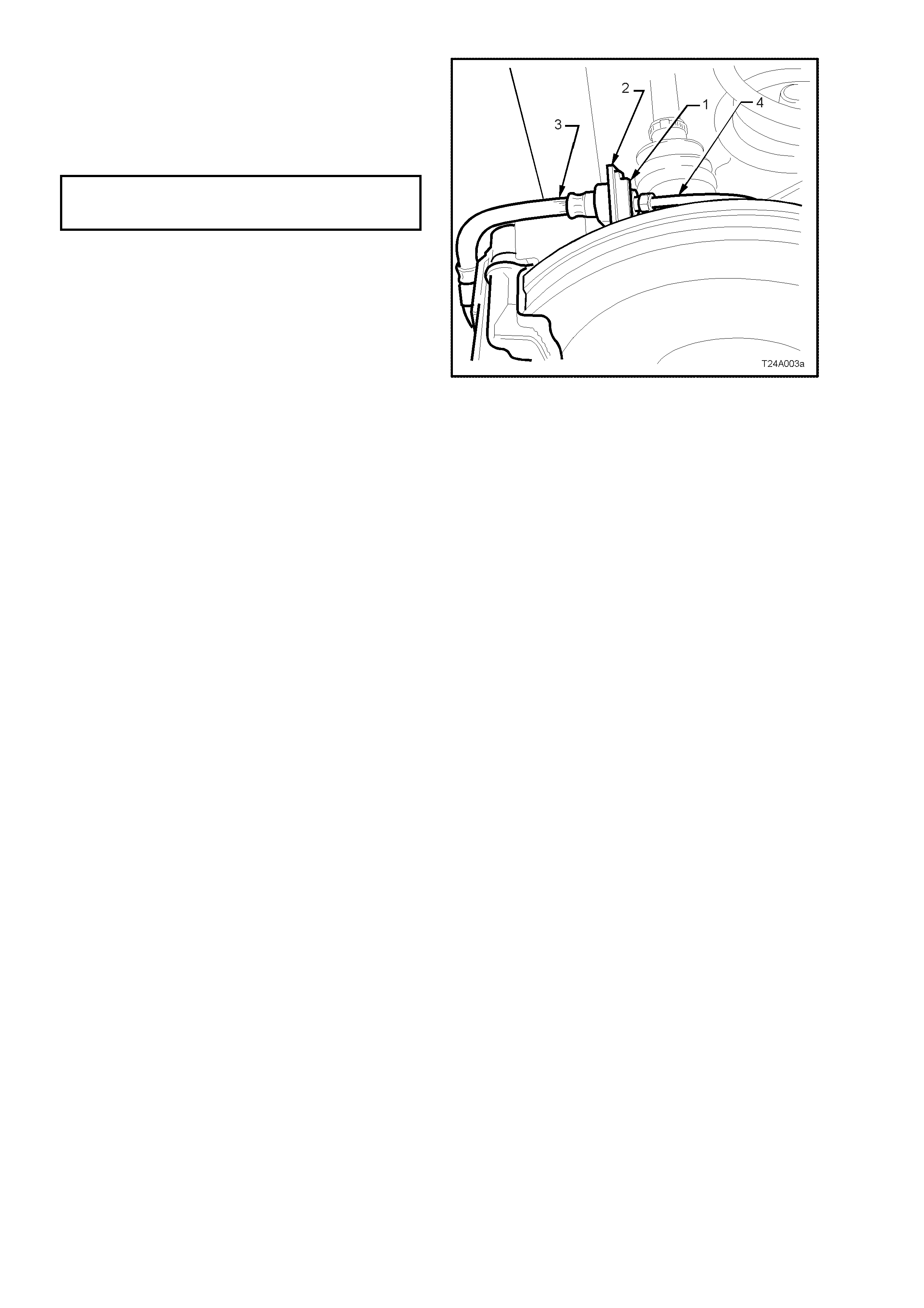

Figure 5A - 55 – Brake Vacuum Booster Hose – RHD with the GEN III V8 Engine

Legend

1. GEN III V8 brake booster vacuum hose.

2. Retaining cli p, brak e boost er end.

3. Retaining cli p, engine m anifol d end.

Blue spot to be on top.

Ens ure hose ends are clamped behind the ri dge on the nipple.

Figure 5A - 56 – Brake Vacuum Booster Hose – LHD with the GEN III V8 Engine

Legend

1. GEN III V8 brake booster vacuum hose.

2. Retaining cli p, brak e boost er end.

3. Retaining cli p, engine m anifol d end.

Blue spot to be on top.

Ens ure hose ends are clamped behind the ri dge on the nipple.

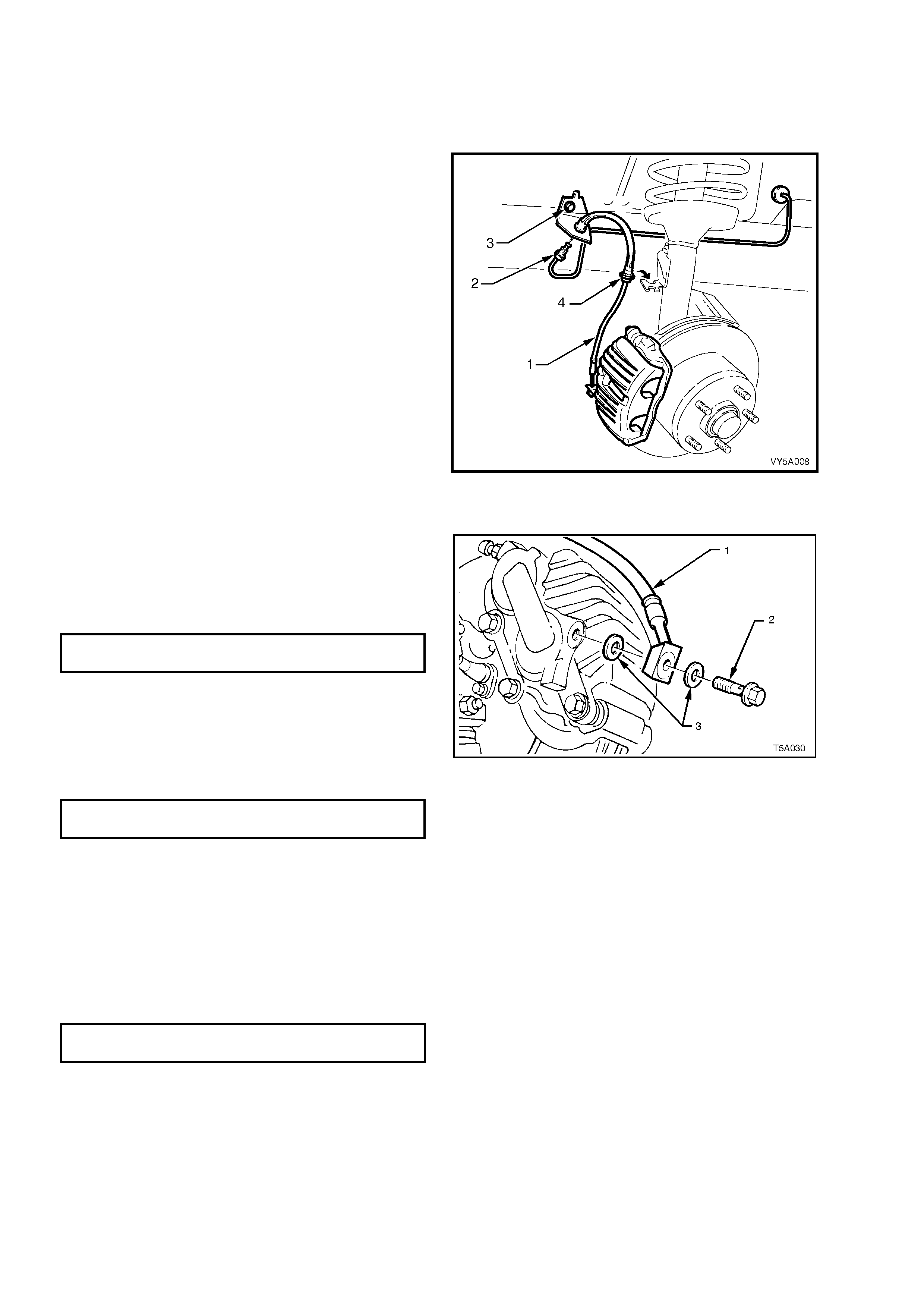

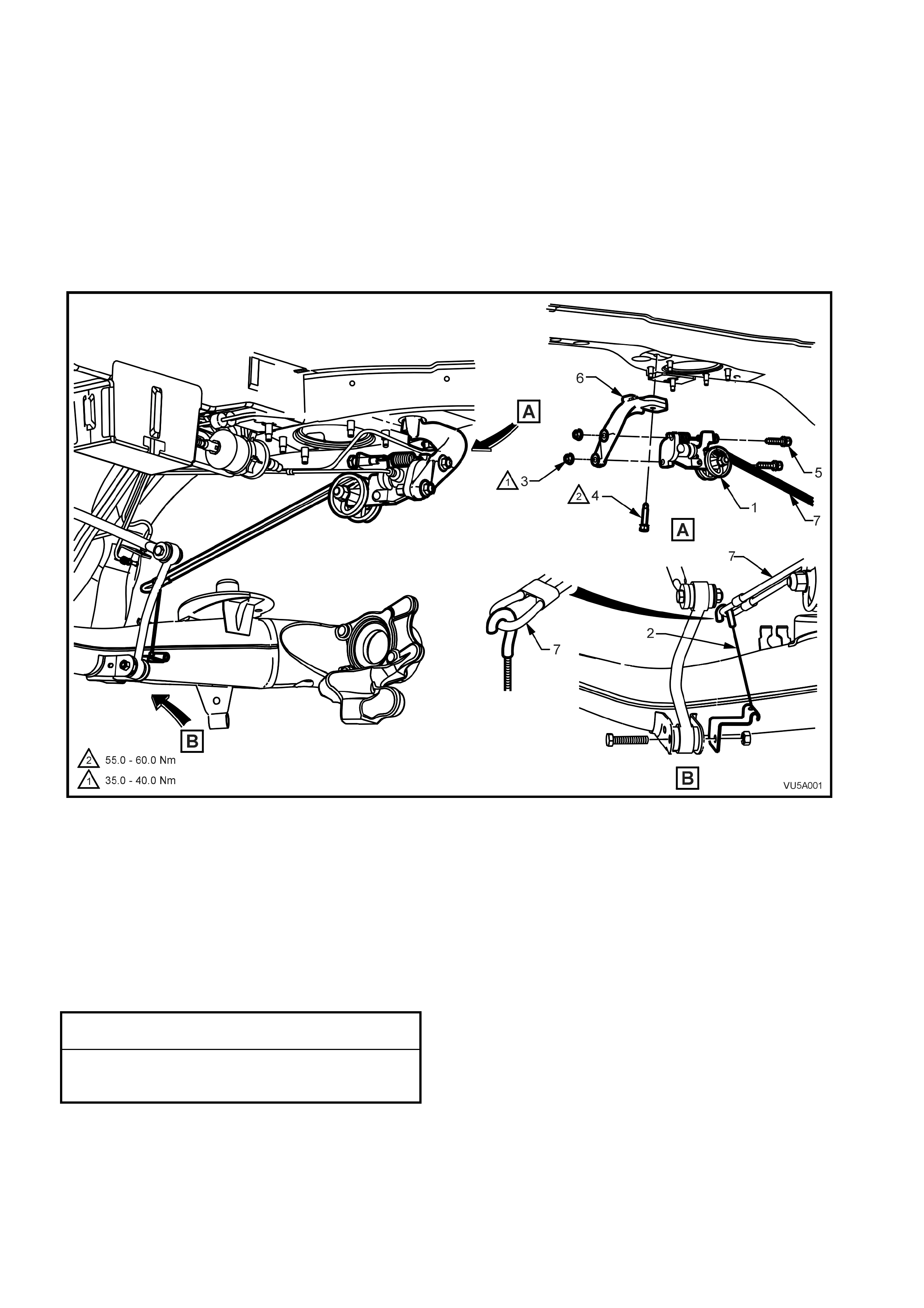

2.18 LOAD SENSING PROPORTIONING VALVE – UTILITY

REMOVE

1. Raise the rear wheels and place the vehicle on suitable safety stands.

2. Dis connec t the brak e li nes f rom the load sens ing pro por tionin g valve. Seal th e openi ngs and li nes with suit able

plugs.

3. Unhook the load sensing proportioning valve connector cable from the load-sensing arm by moving the arm

downward to relieve the tension. Slowly release the arm.

NOTE: The arm may spring up slightly when the hook is released.

4. Support the load sensing proportioning valve, then remove the nuts from the two retaining bolts and remove

the bolts removing the valve assembly.

Figure 5A - 57

Legend

1. Load sensing proporti oni ng val ve

2. Connector cable assembly

3. Nut (2 places)

4. Mounting bracket bolt

5. Bolt (2 places) 6. Mounting bracket

7. Load sensing arm

REINSTALL

The installation procedure is the reverse of the removal procedure, noting the following:

1. Position valve on brack et, then install and secure the two bolts. Tighten the bo lts or nuts to th e correct torque

specification.

LOAD SENSING VALVE MOUNTING

NUT TORQUE SPECIFICATION 35 - 40 Nm

LOAD SENSING VALVE MOUNTING

BRACKET BOLT

TORQUE SPECIFICATION 55 - 60 Nm

2. Ensure all pipes are secured and routed correctly, refer to Figure 5A - 58.

3. Bleed the brake system refer to 2.4 BRAKE SYSTEM BLEED, in this Section.

NOTE 1:The load sensing proportioning valve setting is preset and should not be adjusted.

NOTE 2:The c able hook must be connec ted to the torsion s pring lever in t he correct or ientation, refer to View B in

Figure 5A - 57

Figure 5A - 58

Legend

1. Brake and fuel line harness

2. Fuel feed and return line

3. Brake hose clip

4. Load sensing proporti oni ng val ve

5. Brake pipe clamp to dash panel bolt

6. Rivet (5 plac es)

7. Nut (4 places)

8. Screw (2 places)

Flats aligned on hose and bracket

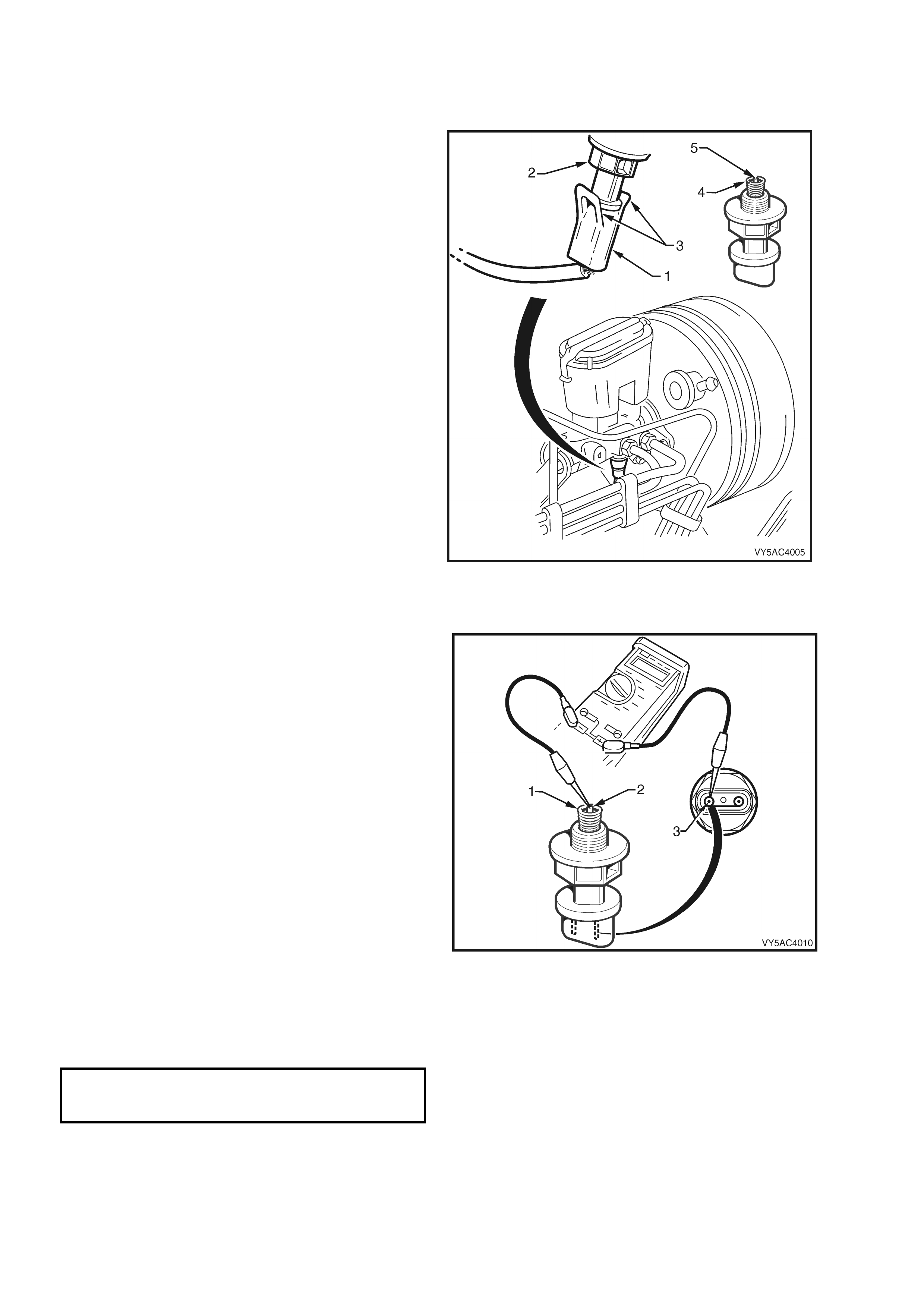

2.19 BRAKE PRESSURE DIFFERENTIAL WARNING SWITCH

REMOVE

1. Dis connec t the brak e pres sure dif fer ential warnin g

switch harness connector (1) from the brake

pressure differential warning switch (2).

NOTE: To disconnect the harness connector, spread

the two locking tangs (3) whilst pulling the connector.

2. Unscrew the brake pressure differential warning

switch from the master cylinder.

NOTE: Ensure the earthing spring (4) is attached to

the plunger switch plunger (5).

Figure 5A - 59

INSPECT

1. Check that the earthing spring (1) is firmly

installed on the switch plunger (2).

NOTE: If necessary, the small end of the spring

may need to be closed down slightly to give the

required attachment.

2. Using a multimeter, check that there is no

continuit y between t he ear thing sprin g and the

switch terminal.

NOTE: Although there are two terminal

connections within the switch assembly, these

terminals are bridged together by a small bridging

wire.

3. With the multimeter still connected, check that

there is continuity when the switch plunger is

depressed.

4. If any of the above tests fail, replace the brake

pressure differential warning switch.

Figure 5A - 60

REINST ALL

1. Reinstall the brake pressure differential switch (1) to the master cylinder. Refer to Figure 5A - 59.

2. Tighten to the brake pressure differential switch to the specified torque – do not over tighten.

BRAKE PRESSURE DIFFERENTIAL

WARNING SWITCH

TORQUE SPECIFICATION 2 Nm

3. Reconnect the brake pressure differential warning switch harness connector to the brake pressure differential

warning switch.

3. MAJOR SERVICE OPERATIONS

3.1 MASTER CYLINDER

LT Section No. – 04-725

REMOVE

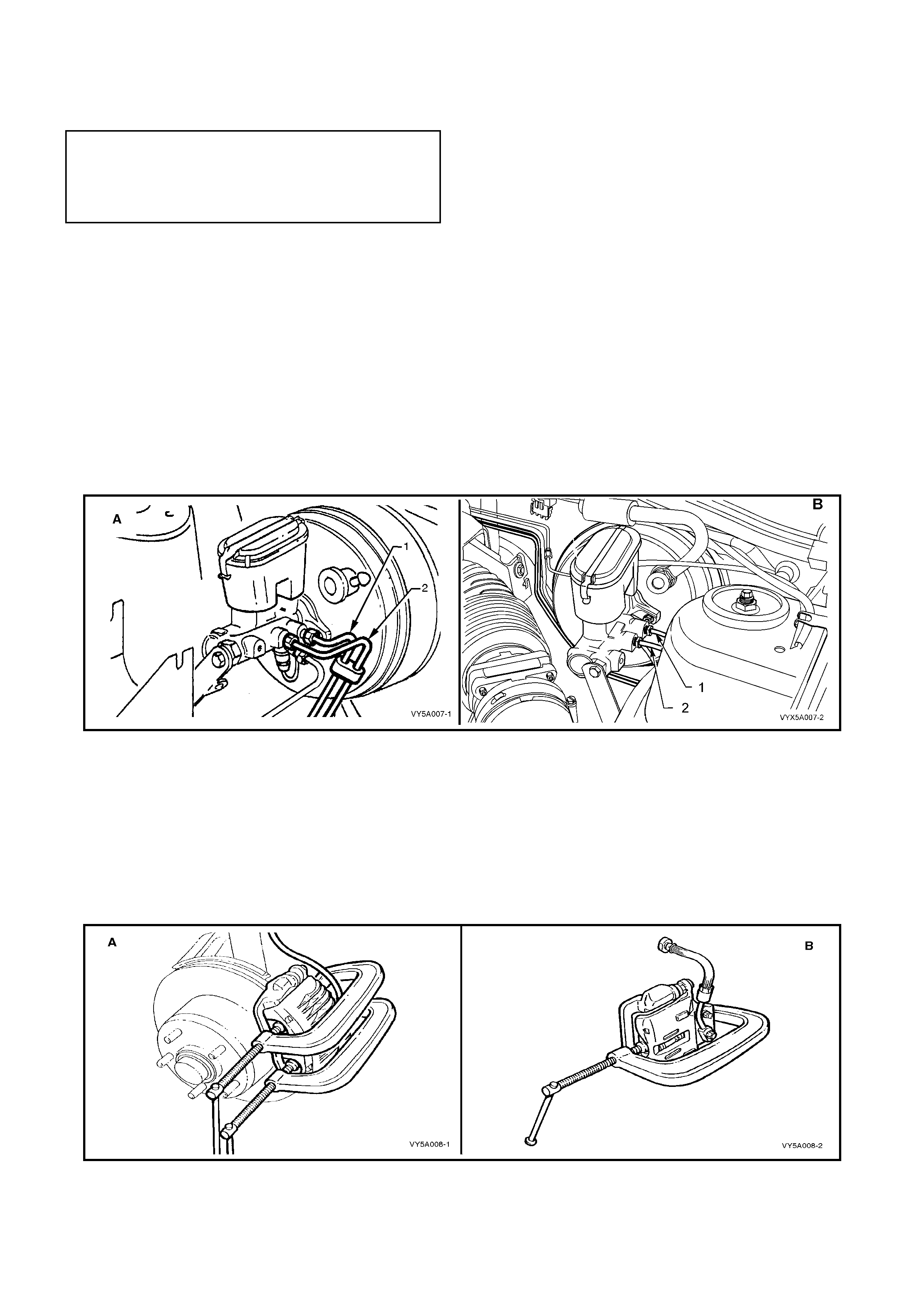

1. Thoroughly clean the master cylinder, especially around the brake line connections.

2. Remove the master cylinder reservoir cap.

Using a hand vacuum pump (1), special tool

J23738-A or a commercially available hand

vacuum pump or syringe, siphon as much

brake fluid from the master cylinder reservoir

(2) as possible.

NOTE: Brake fluid will cause damage to the paint

work if it comes into contact with it. In the event

that this happens, wash the brake fluid off with

water.

Figure 5A - 61

3. Disconnect the electrical connector from the brake pressure differential warning switch.

4. Disconnect the wheel brake lines (2) from the master cylinder (1) and allow any residual brake fluid from the

master cylinder to dr a in int o a c onta in er. Pl ug t he op e nin gs in b oth th e master cylinder and the p ipes to pr ev ent

fluid loss and dirt ingress.

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 62

IMPORTANT: The engine surge tank may be hot.

Allow the coolant to cool before performing this

procedure.

4. For lef t-han d drive veh ic les fitted with th e GEN

III V8 engine, disengage the coolant surge

tank from its anchor points by:

A Grasping the surge tank (1) firmly with

both hands and pivoti ng in the direction of

arrow A to dislodge the surge tank from

the rear anchor po int (2).

B Pull the surge tank inboard (arrow B)

toward the engine to dislodge the inner

fender skirt anchor point (3). Refer to

2.10 Coolant Recovery Surge Tank in

Section 6B3, ENGINE COOLING – GEN

III V8 ENGINE in the MY2003 VY and V2

Series Service Information for further

information.

5. For lef t-han d drive veh ic les fitted with th e GEN

III V8 engine, disconnect the harness

connector (4) from the coolant level sensor

and set the surge tank to one side.

NOTE: It is not necessary to remove the surge

tank from the vehicle. Leave all hoses and screw

on cap intact.

6. To provide access to the brake master

cylinder support bracket on left-hand drive

vehicles fitted with the GEN III V8 engine, it is

necessary to remove the Powertrain Control

Module. Refer to 2.1 Powertrain Control

Module (PCM) in Section 6C3-3, SERVICE

OPERATIONS – GEN III V8 ENGINE in the

MY2003 VY and V2 Series Service

Information.

Figure 5A - 63

7. Remove the bracket securing the master cylinder to the adjacent strut tower.

8. Remove the nuts securing the master cylinder to the brake booster and remove the master cylinder.

IMPORTANT: DO NOT disturb th e brake boos ter push rod, a nd DO NOT depress the brake ped al with the master

cylinder removed or the internal reaction disc in the booster may become dislodged.

NOTE: View A is for RHD vehicles, while View B is for LHD vehicles.

Figure 5A - 64

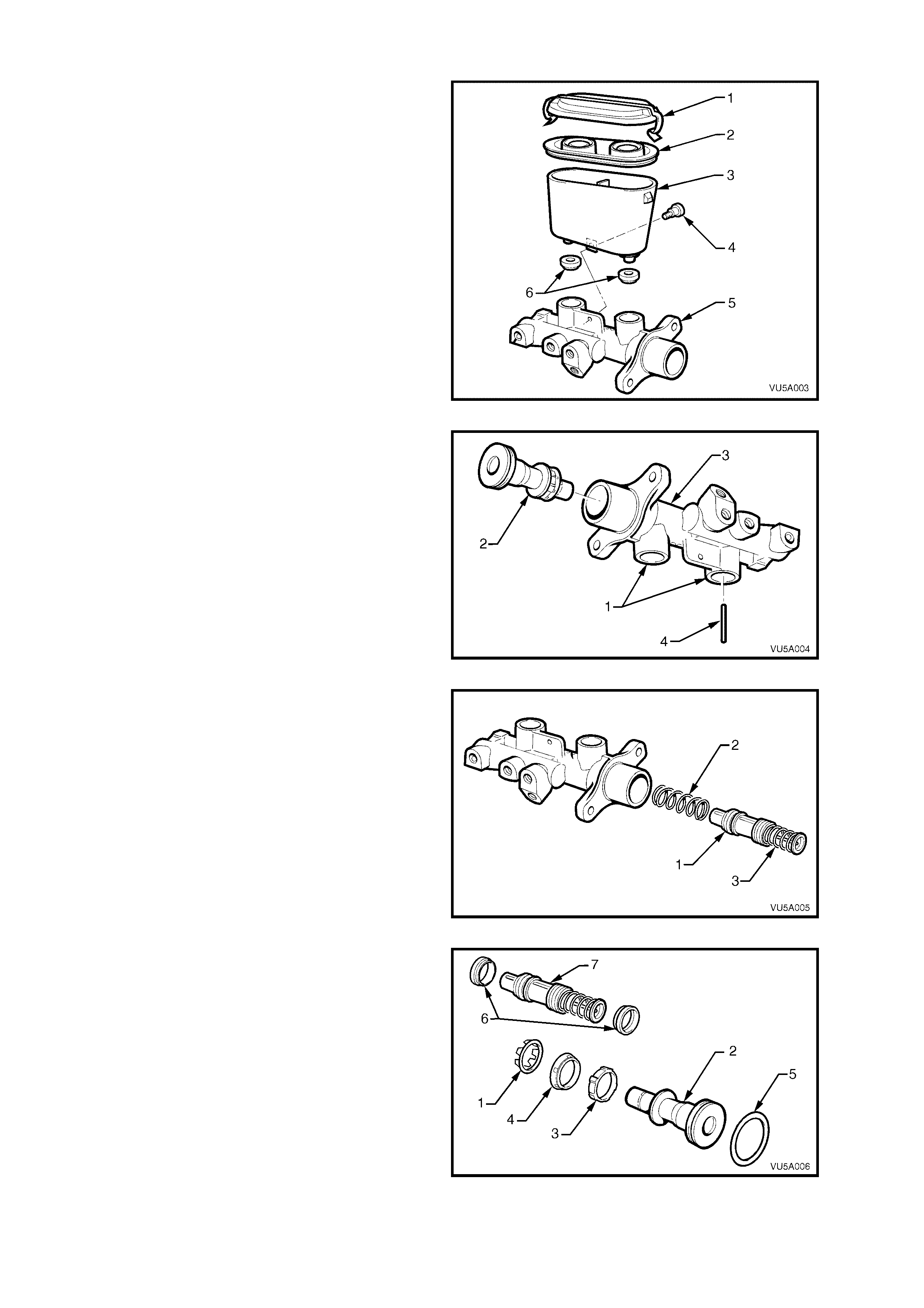

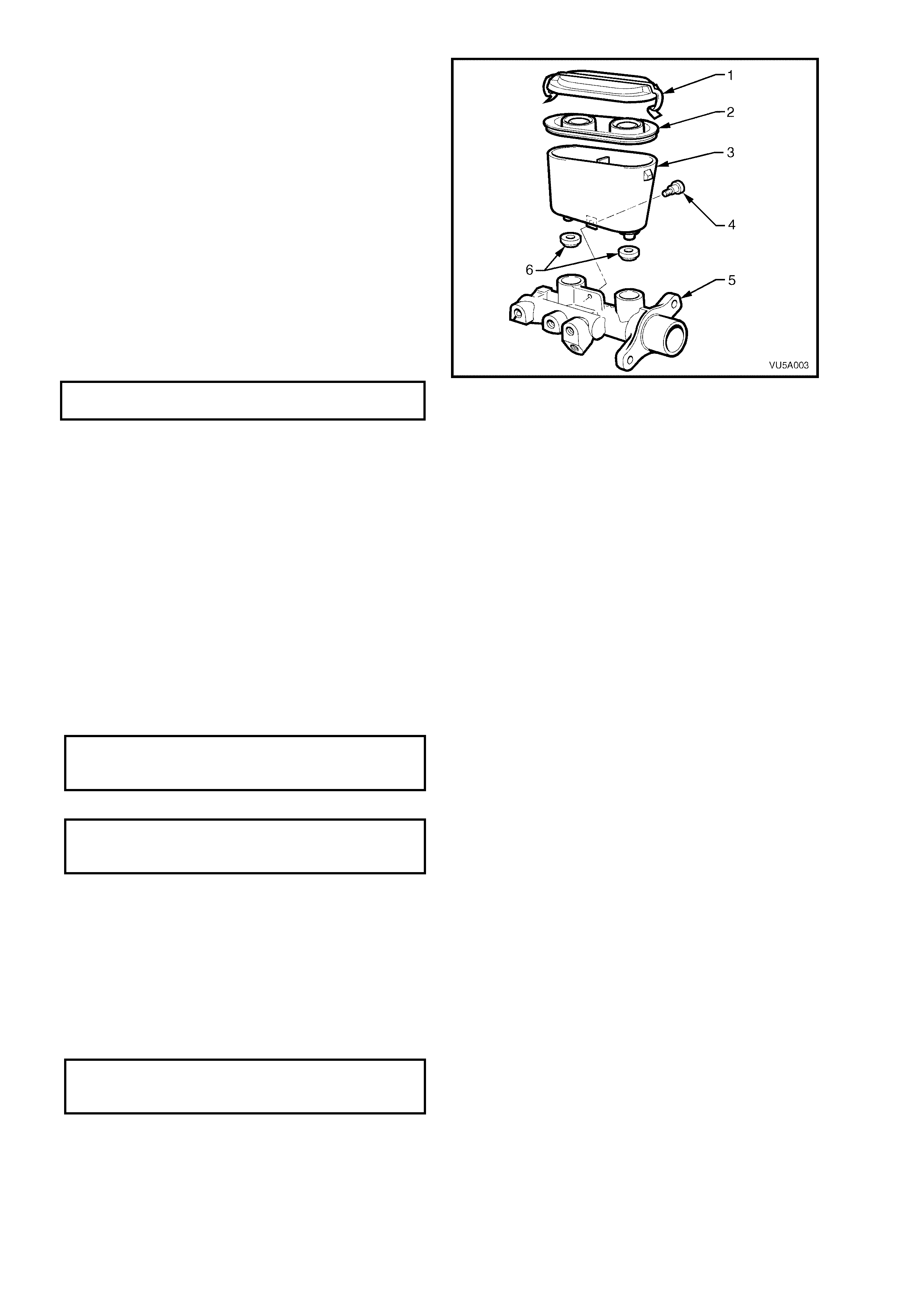

DISASSEMBLE

1. Clean the outside of the master cylinder.

2. Remove reservoir cap (1) and seal (2). Discard

any fluid left in reservoir

3. Unscrew the reservoir to body retaining screw

(4), located at the base of the reservoir.

4. Separate the plastic reservoir (3), by hand,

from the body (5).

5. Remove the two reservoir sealing grommets

(6) from the body (5).

Figure 5A - 65

6. Invert master cylinder body (3) so that the

reservoir ports (1) face downwards. Depress

the primary piston (2) with a wood dowel or

brass r od u nti l t he pis t on b ottoms in th e b ore of

the master cylinder body (3). The secondary

piston stop pin (4) should freely fall out.

7. Carefully remove primary piston (2) from the

main bore of the master cylinder (3).

Figure 5A - 66

8. Remove s ec ond ary piston ( 1) and r eturn s pr ing

(2) by lightly tapping the open end of the

master cylinder b ore squar ely onto a sof t piece

of wood.

NOTE 1: The caged spring (3) of the secondary

piston (1) has been set to a predetermined length.

Do not attempt to adjust or remove the caged

spring (3).

NOTE 2: The centre valve is part of the secondary

piston assembly and is not serviced as a separate

part.

Figure 5A - 67

9. Remove the seal retainer (1) from the primary

piston (2), using a small screwdriver to

caref ull y pry apart the seal retain er legs.

10. Remove the recuperating guide (3) and seal

(4) from the primary piston (2).

11. Remove the O-ring (5) seal from the primary

piston (2), taking EXTREME CARE not to

damage the piston in the process.

12. Remove both seals (6) from the secondary

piston (7), again taking EXTREME CARE not

to damage the piston (7).

Figure 5A - 68

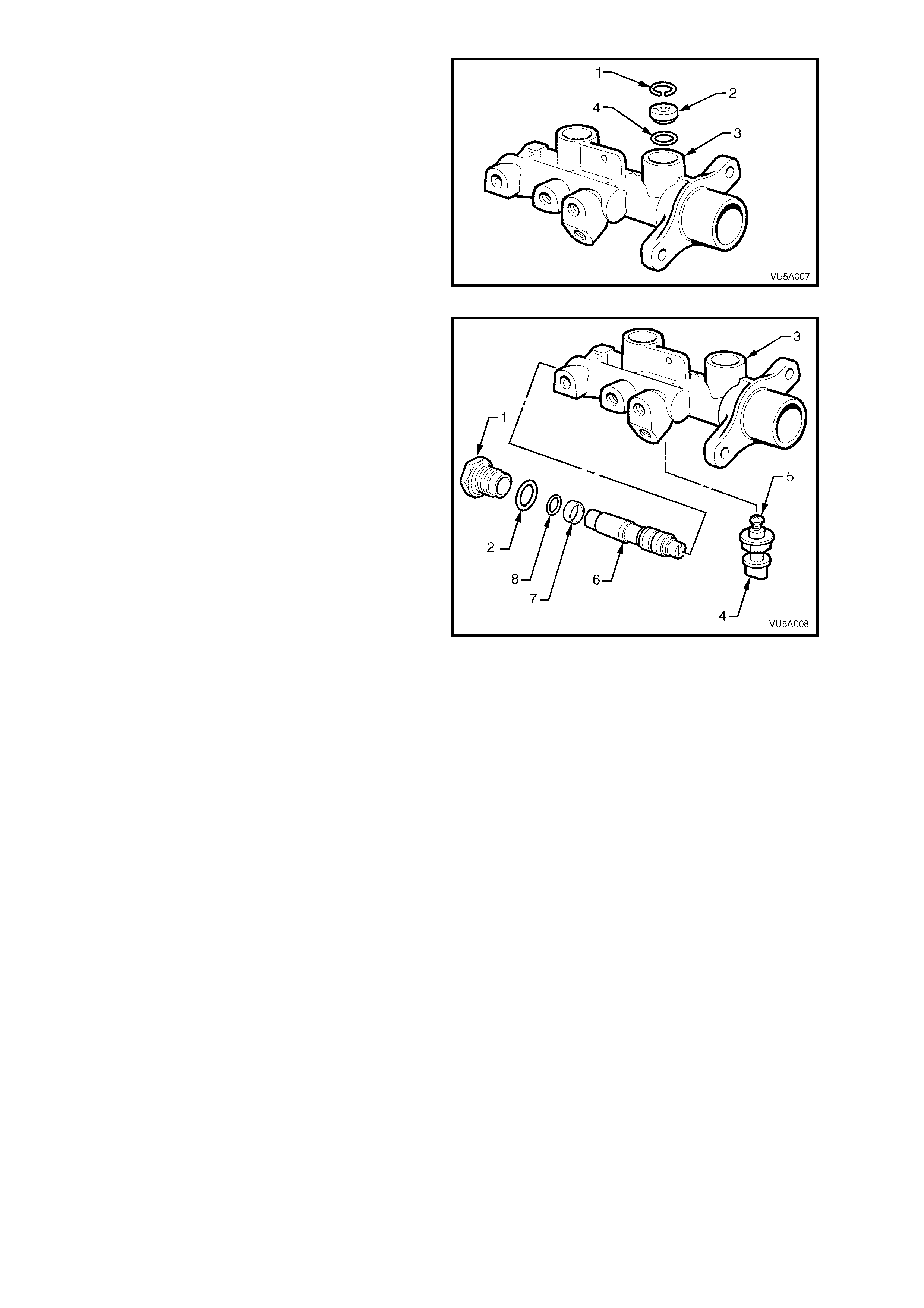

13. Using suitable circlip pliers, remove the circlip

(1) retaining the fast fill valve (2) located in the

primary reservoir port of the master cylinder

(3).

14. Face the master cylinder reservoir ports

downwards to allow the fast fill valve (2) to fall

out. If the valve is stuck, lightly tap the master

cylinder on a piece of wood to assist removal.

15. Remove the valve sealing O-ring (4) from the

bottom of the reservoir port.

Figure 5A - 69

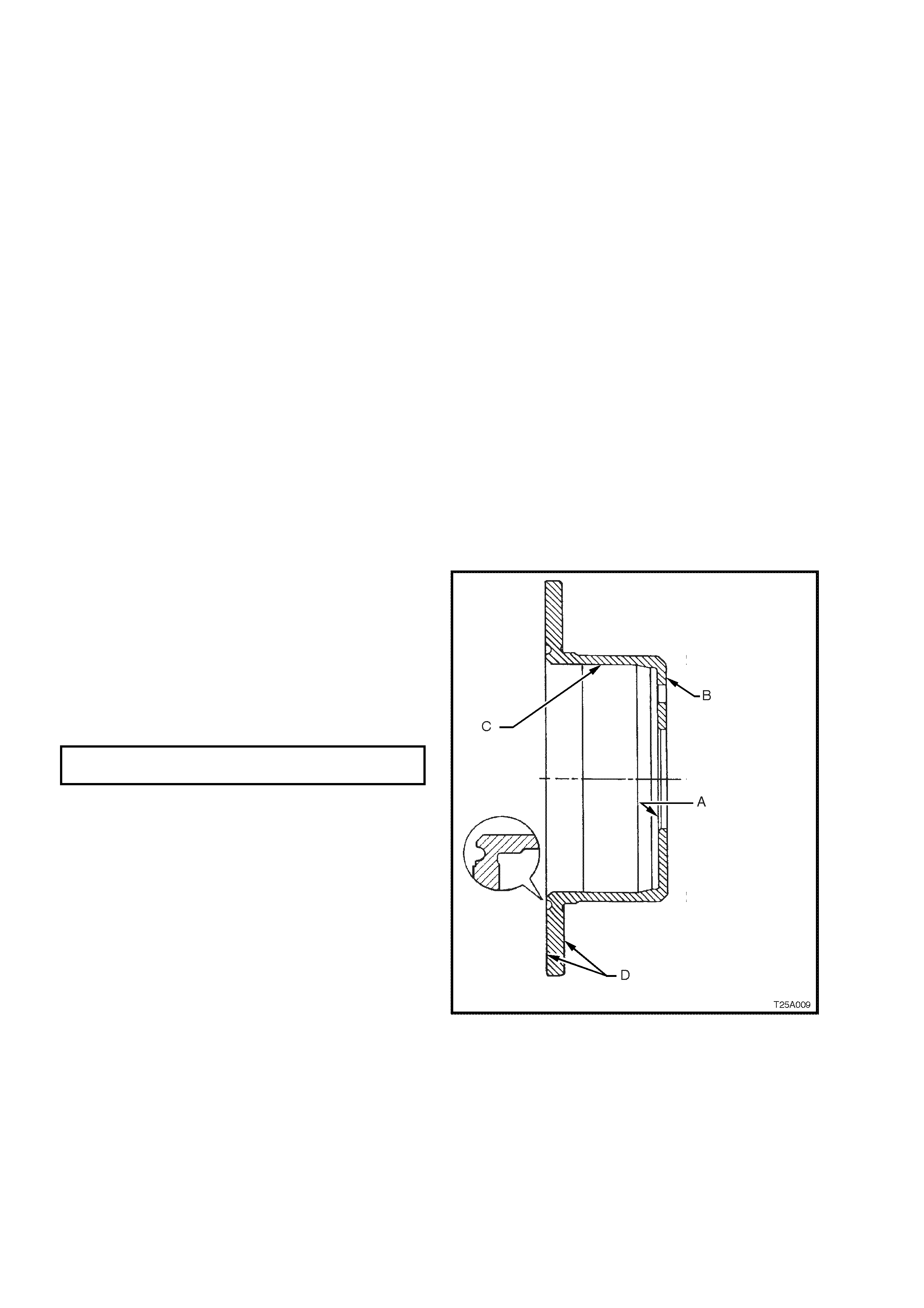

16. Unscrew an d rem ove the e nd plug (1) from the

master cylinder body (3).

17. Remove the brake pressure differential

warning switch (5) from the master cylinder,

ensuring that the electrical earthing spring

remains on the switch plunger.

18. Remove the proportioning valve assembly

(differential spool valve assembly – Utility) (6)

by lightly tapping the end plug end of the

cylinder bore squarely onto a soft piece of

wood to dislodge the proportioning valve

assembly.

IMPORTANT: Do not damage the proportioning

valve assembly by attempting to pull it out of the

bore with pliers .

NOTE: Do not disass emble the propor tioning va lve

assembly as this valve is only serviced as a

complete assembly.

Figure 5A - 70

CLEAN AND INSPECT

NOTE: Ensure work area is clean and free of dust or other contam inants. These can affect the performance of all

the seals in the master cylinder.

1. Wash master cylinder body, reservoir and cap in clean methylated spirits.

2. Wash all internal parts in brake fluid.

3. Check all recesses, openings and passages to ensure they are open and free of foreign matter.

4. Place all parts on a clean surface.

5. Inspect the master cylinder bores for signs of etching, pitting, scoring or rust. If in poor condition, replace the

master cylinder.

IMPORTANT: Do not hone the master cylinder bore.

6. Discard all rubber parts together with the secondary piston assembly (the secondary piston assembly

incorporates; the secondary piston, the centre valve and the caged spring). Only new parts from the genuine

service kit should be used to reassemble the master cylinder.

REASSEMBLE

NOTE 1: Bef ore assembl y, lubricate int ernal parts and m aster cylinder bor es with clean, recom mended brak e fluid

from a sealed container.